Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1353 results about "Ignition timing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In a spark ignition internal combustion engine, Ignition timing refers to the timing, relative to the current piston position and crankshaft angle, of the release of a spark in the combustion chamber near the end of the compression stroke.

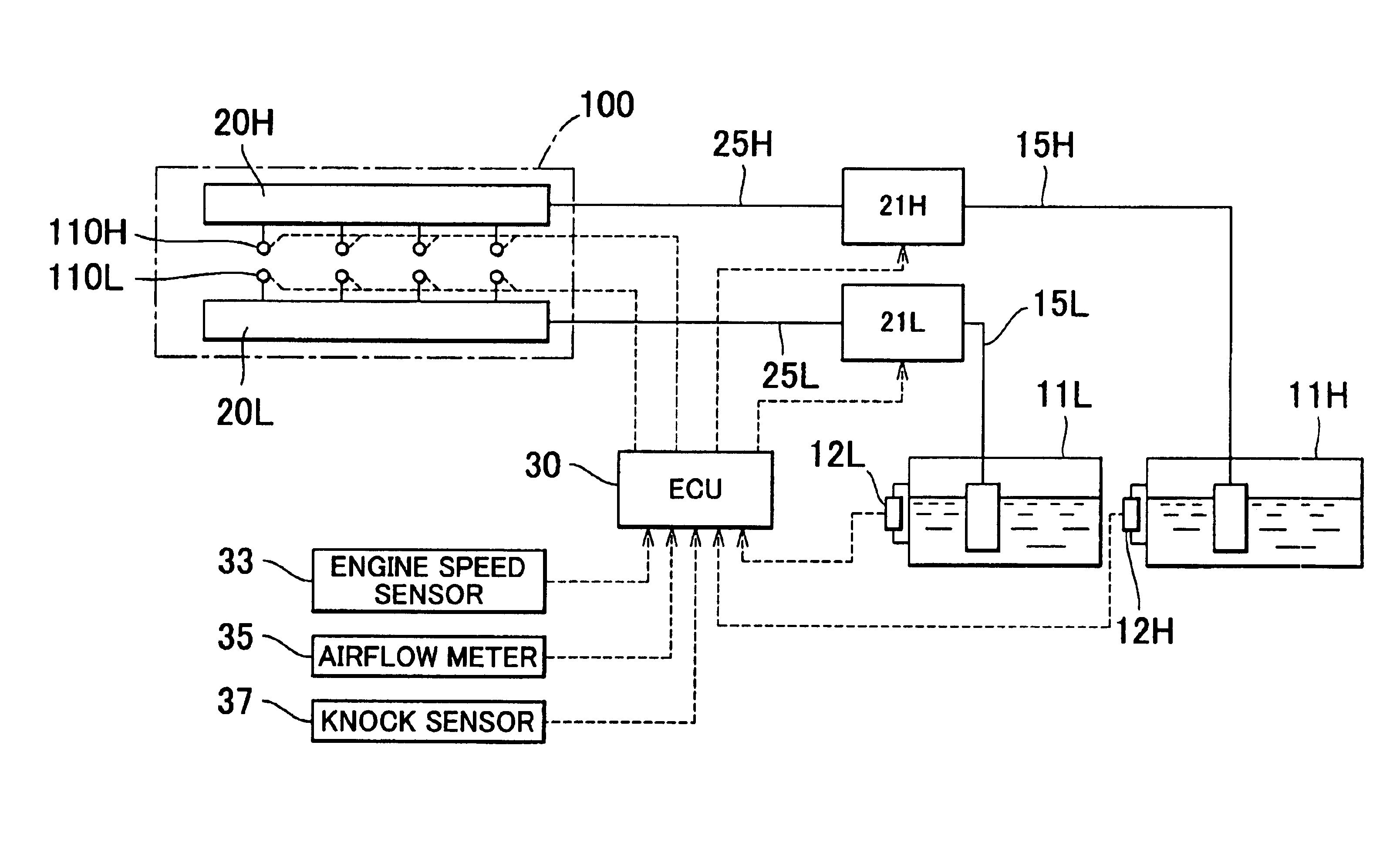

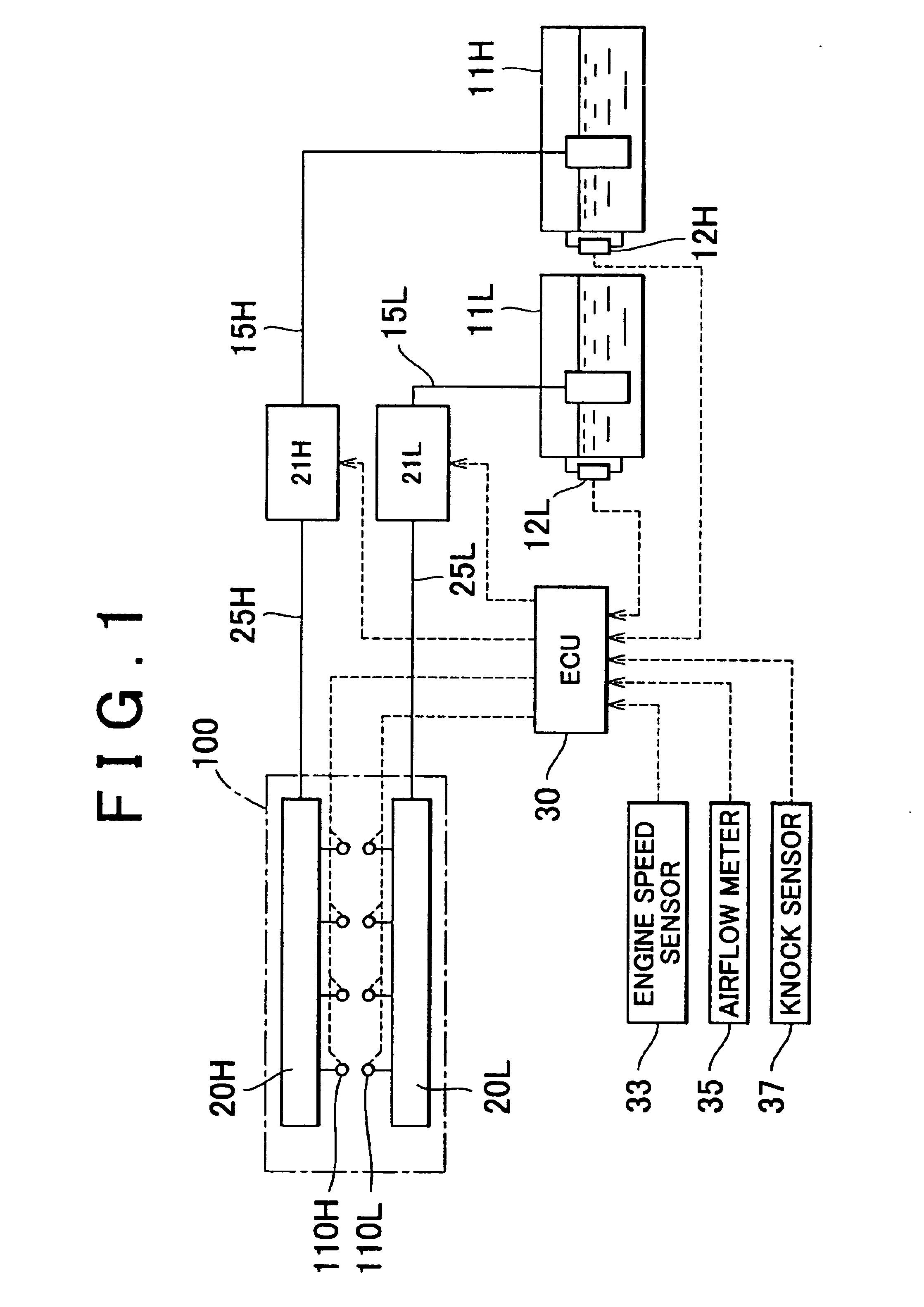

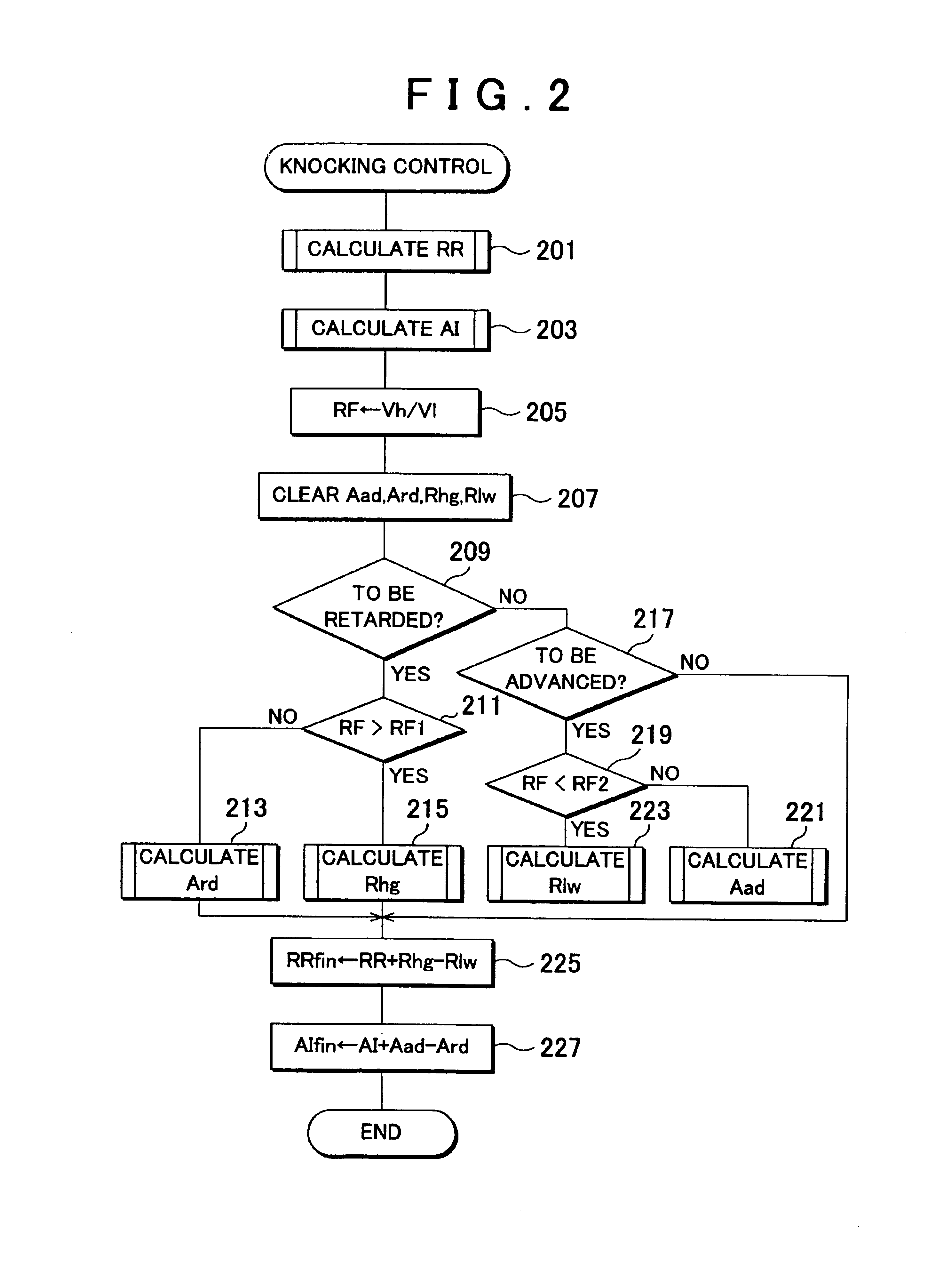

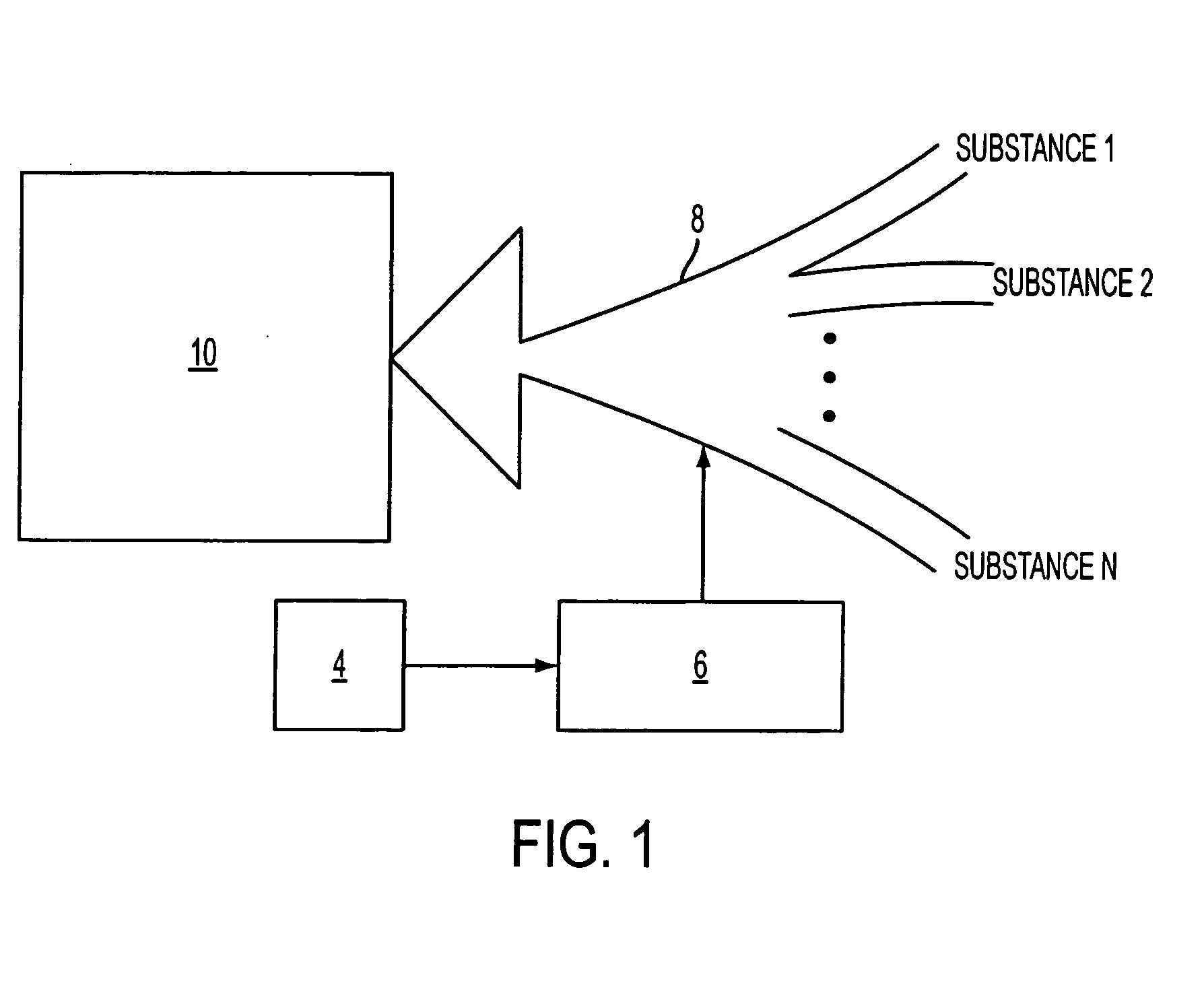

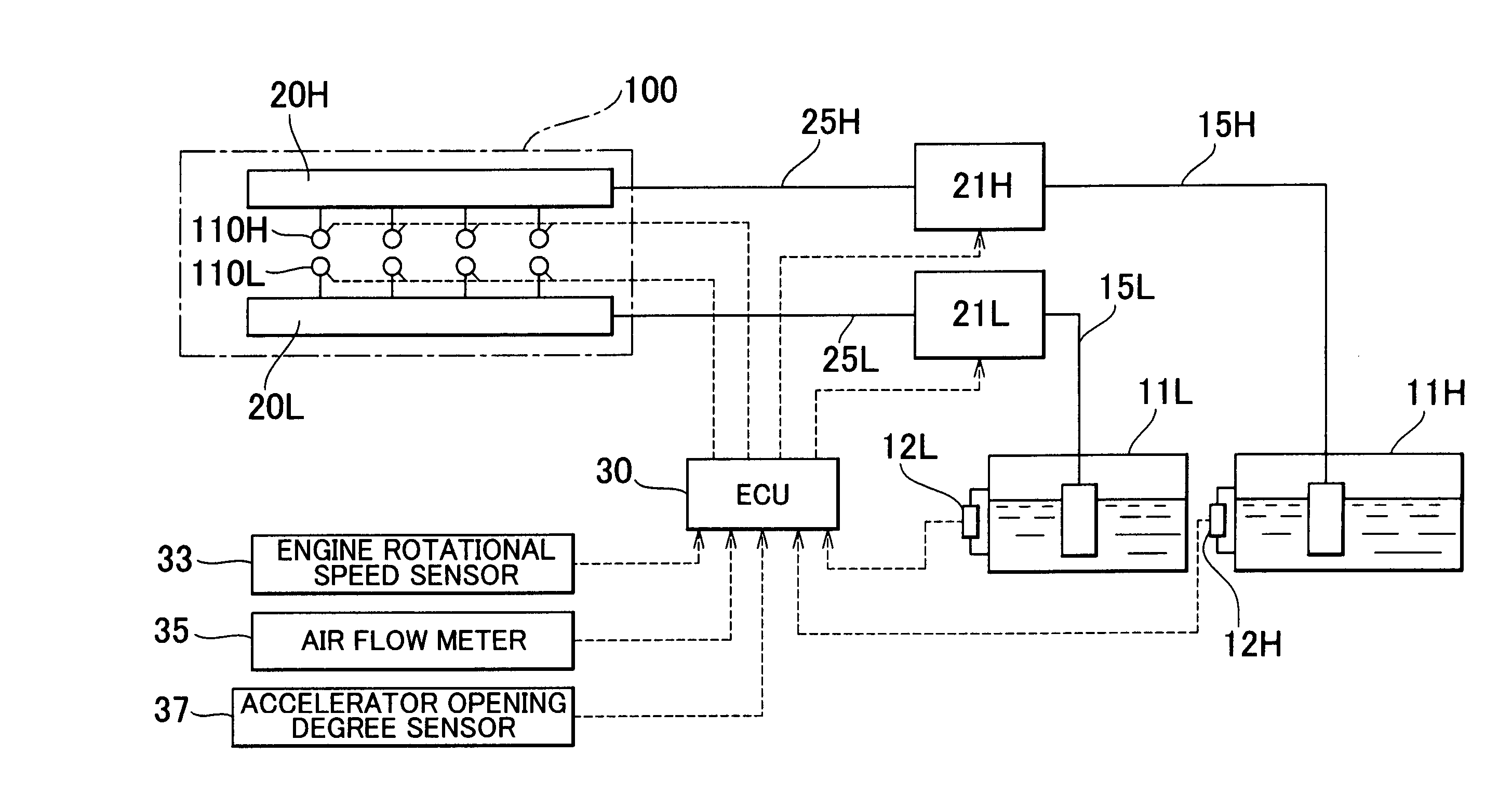

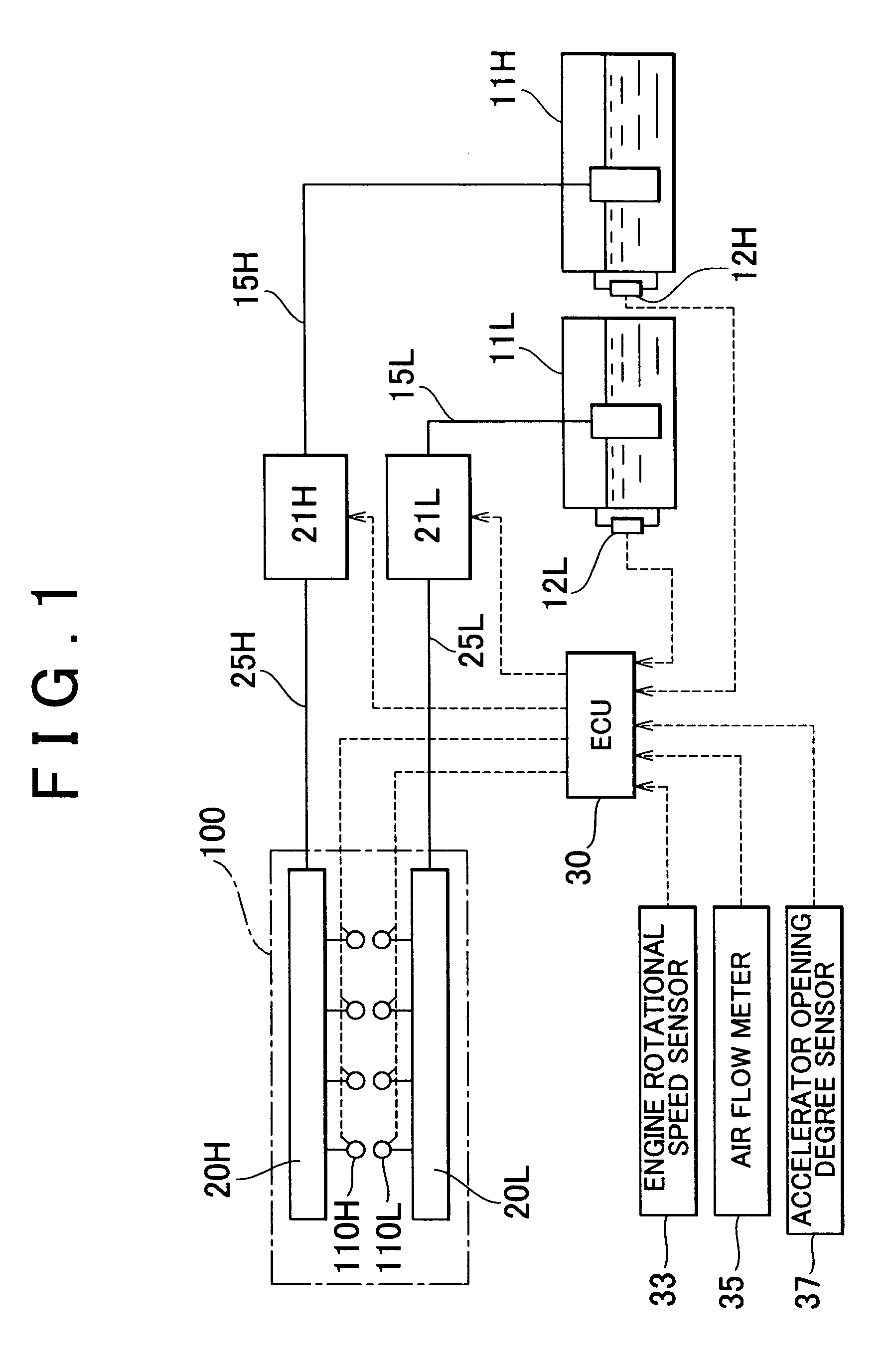

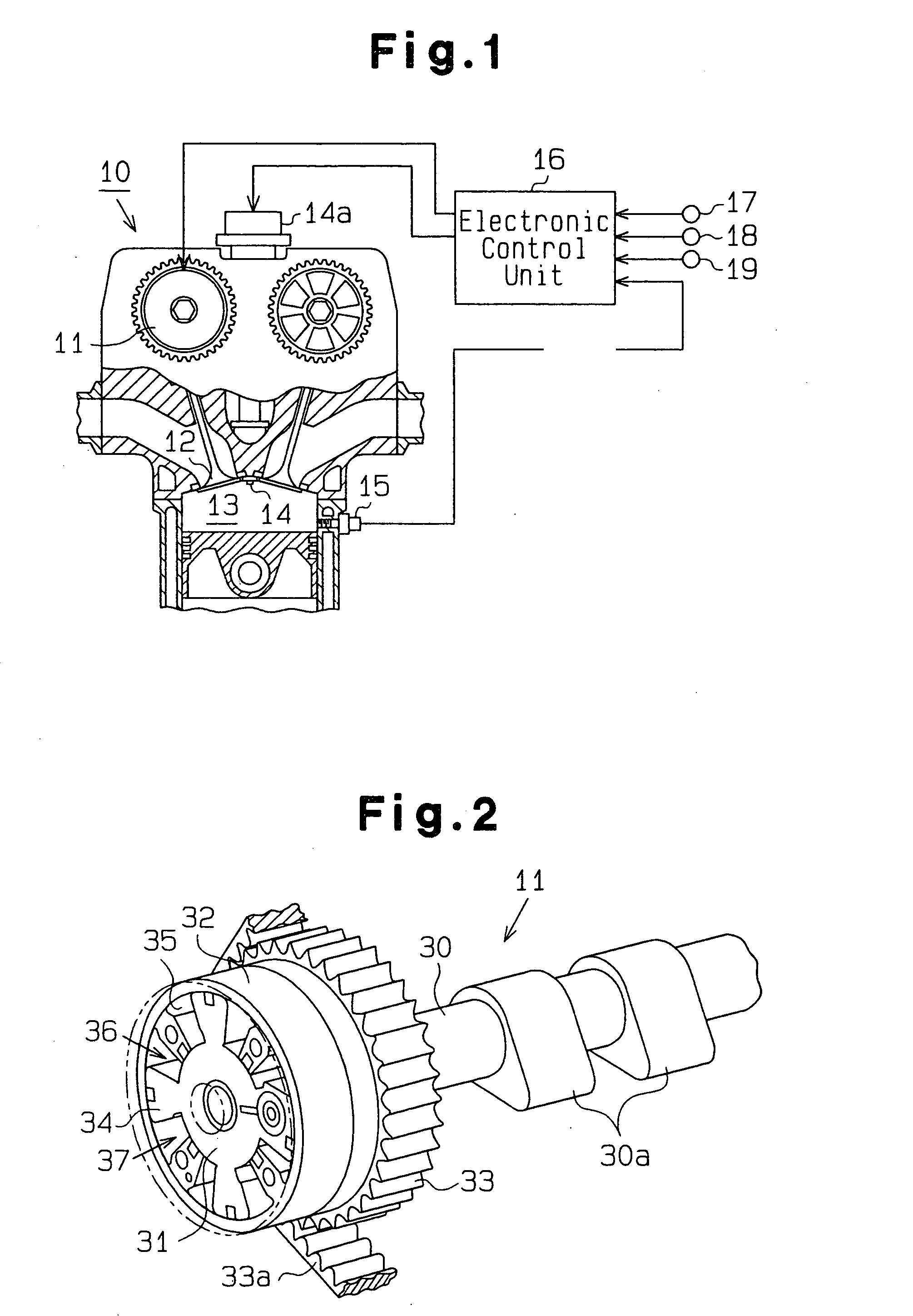

Knocking control system and method for internal combustion engine using multiple fuels

InactiveUS6951202B2Maintain balanceImprove balanceElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

High octane fuel and low octane fuel are supplied into the combustion chamber of an engine from high-octane fuel tank and low octane fuel tank via a high octane fuel injector and a low octane fuel injector. During a knocking control, if the quantity of high and low octane fuels in the respective tanks has been unbalanced, the supply ratio between high octane fuel and low octane fuel is changed 1 to control a knocking occurring in the engine without changing the ignition timing.

Owner:TOYOTA JIDOSHA KK

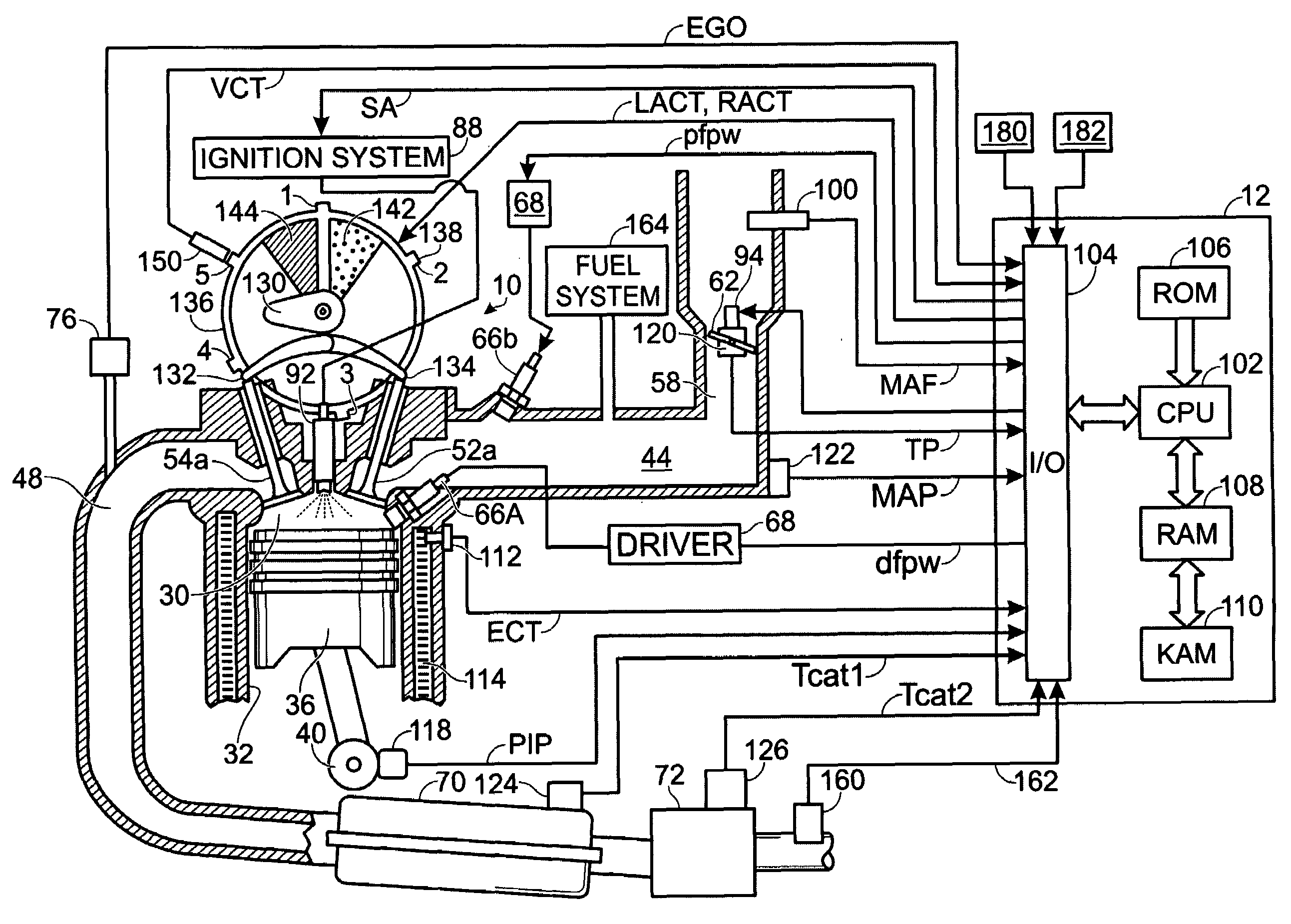

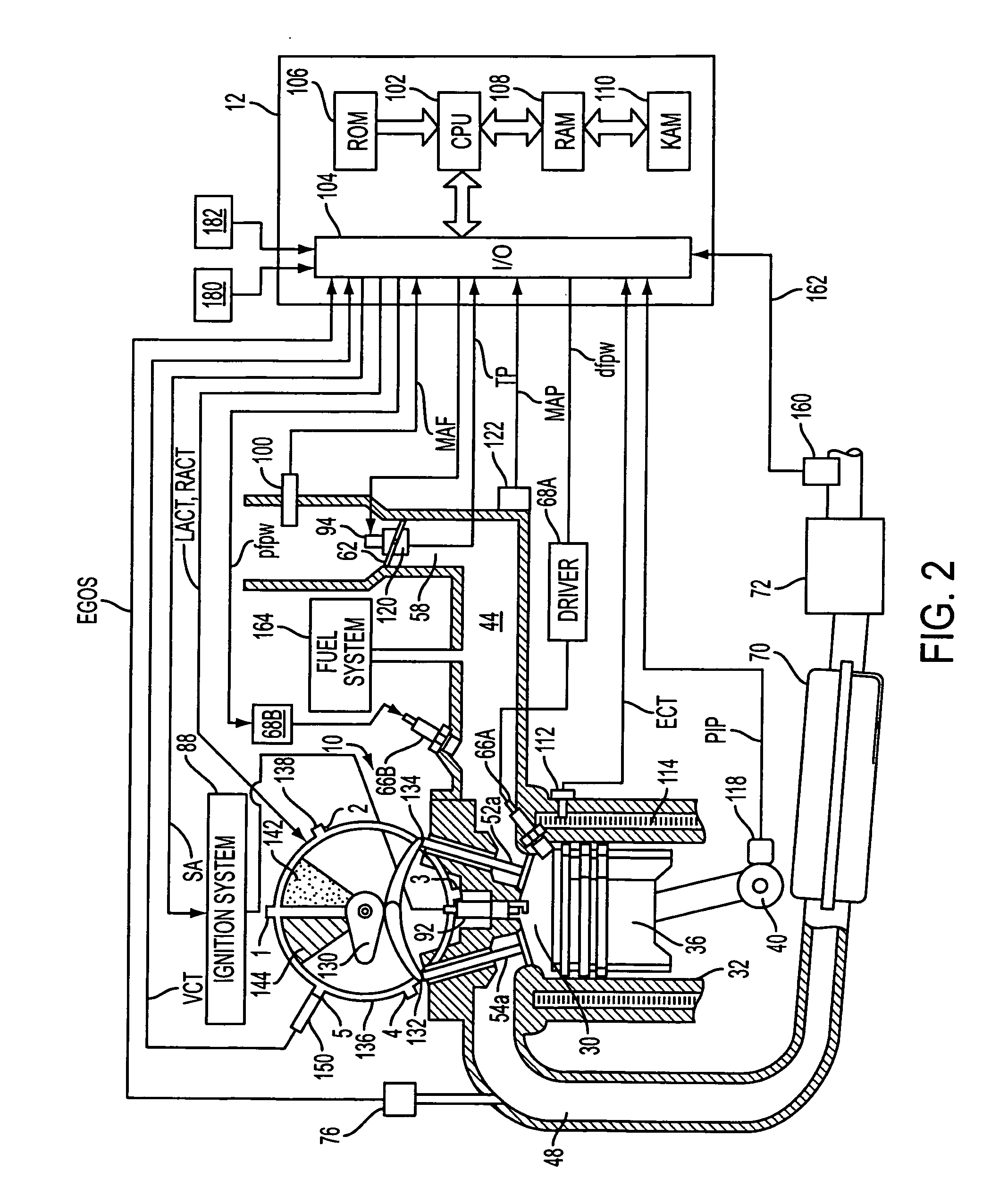

Method for controlling injection timing of an internal combustion engine

InactiveUS7278396B2Reduce mixEmission reductionElectrical controlInternal combustion piston enginesExternal combustion engineIgnition timing

A method to control injection timing for an internal combustion engine having a plurality of injectors in at least a cylinder, the method comprising of injecting a first fuel amount to at least a cylinder of an internal combustion engine from a first injector, injecting a second fuel amount fuel to said cylinder from a second injector, and adjusting the timing between starting or ending injection of said first fuel amount, and starting or ending of said second fuel amount in response to an operating condition of said engine.

Owner:FORD GLOBAL TECH LLC

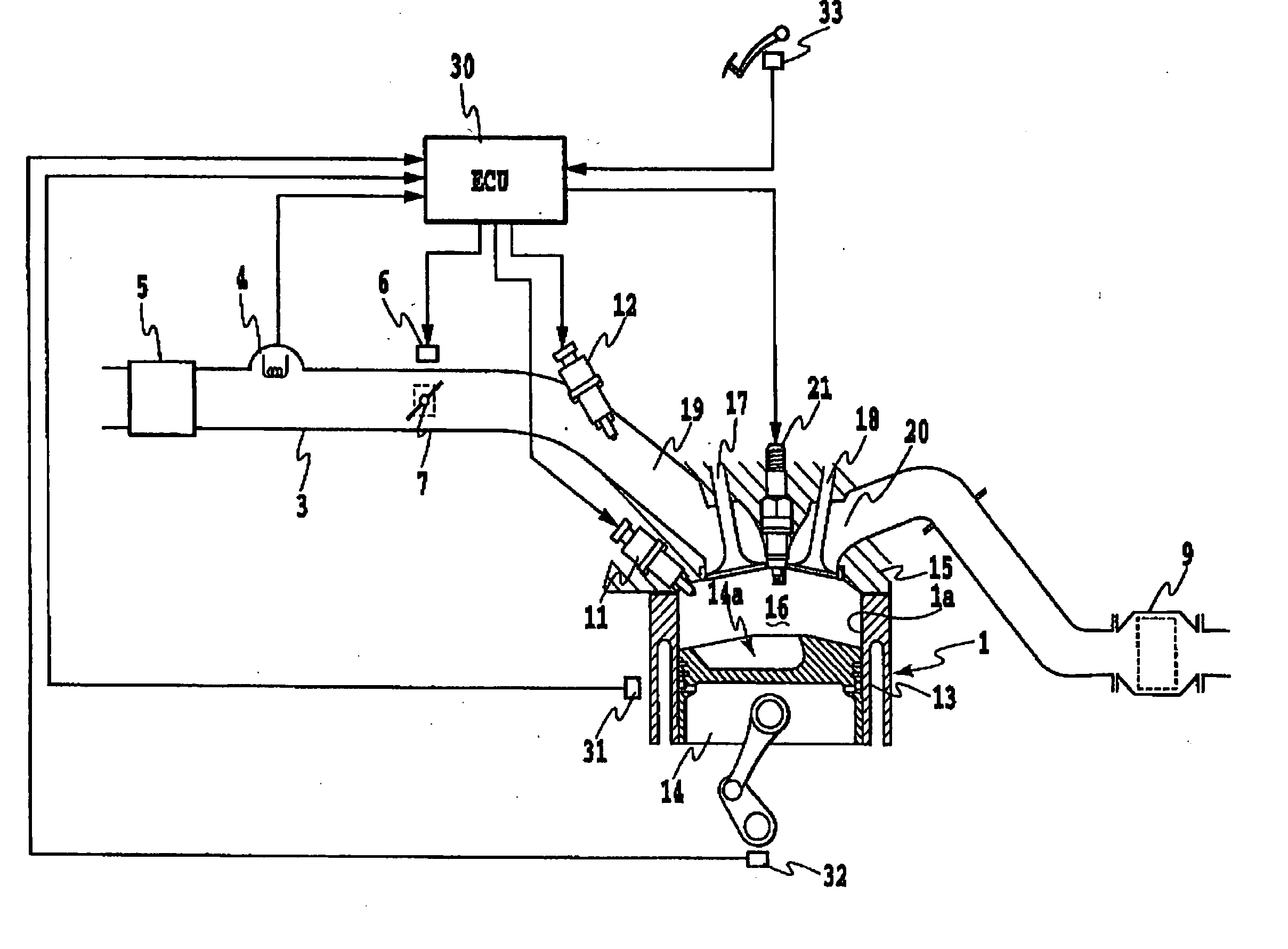

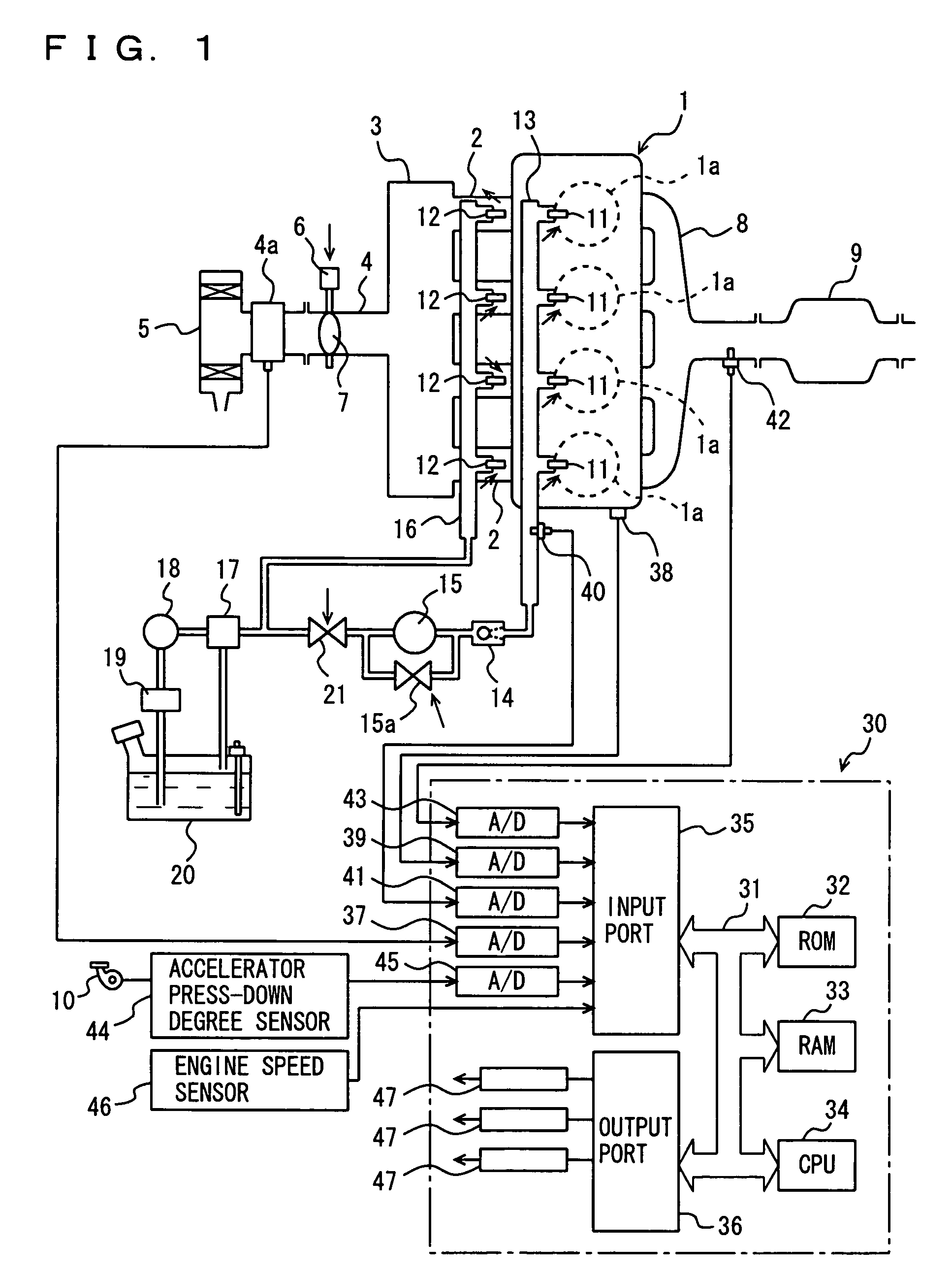

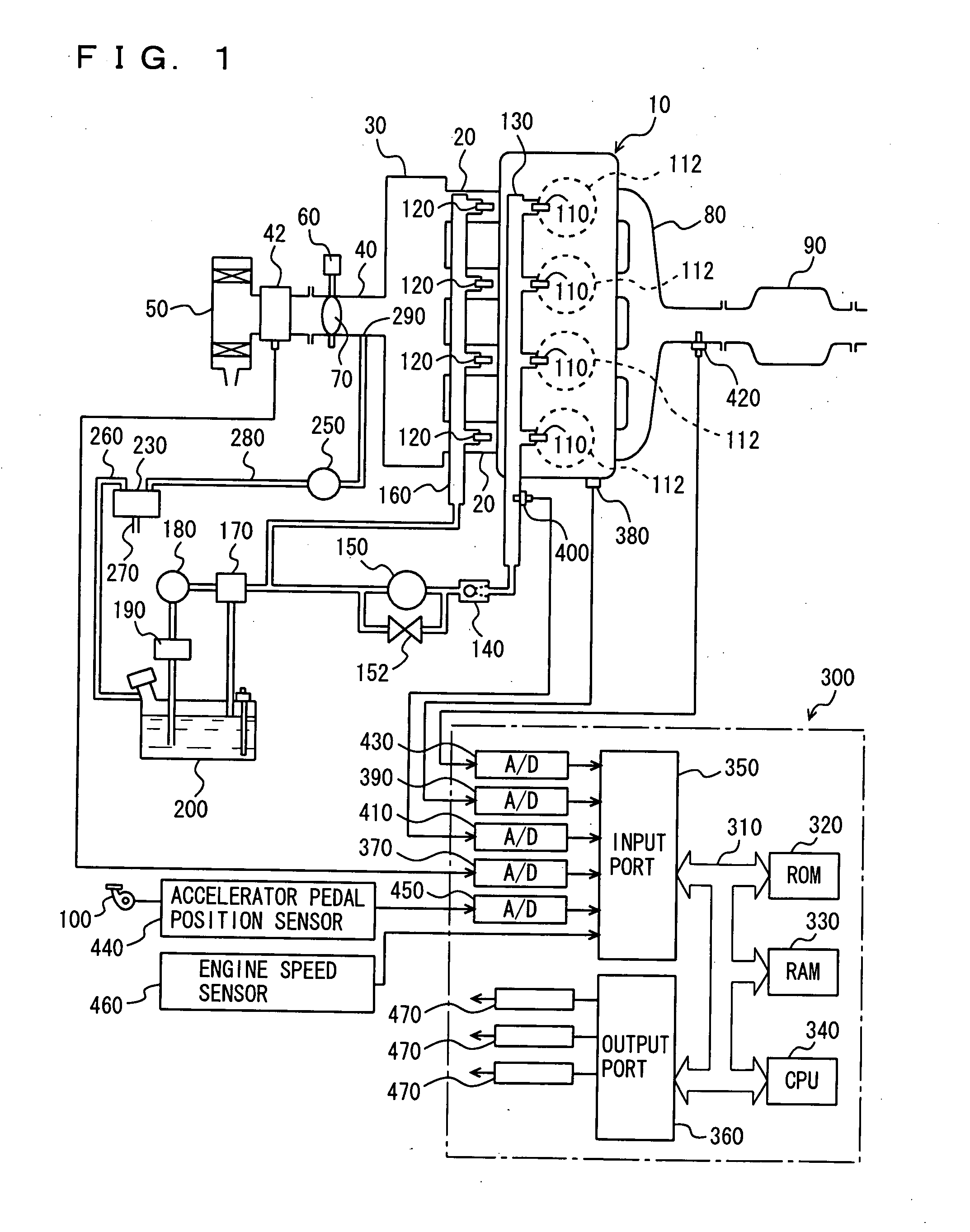

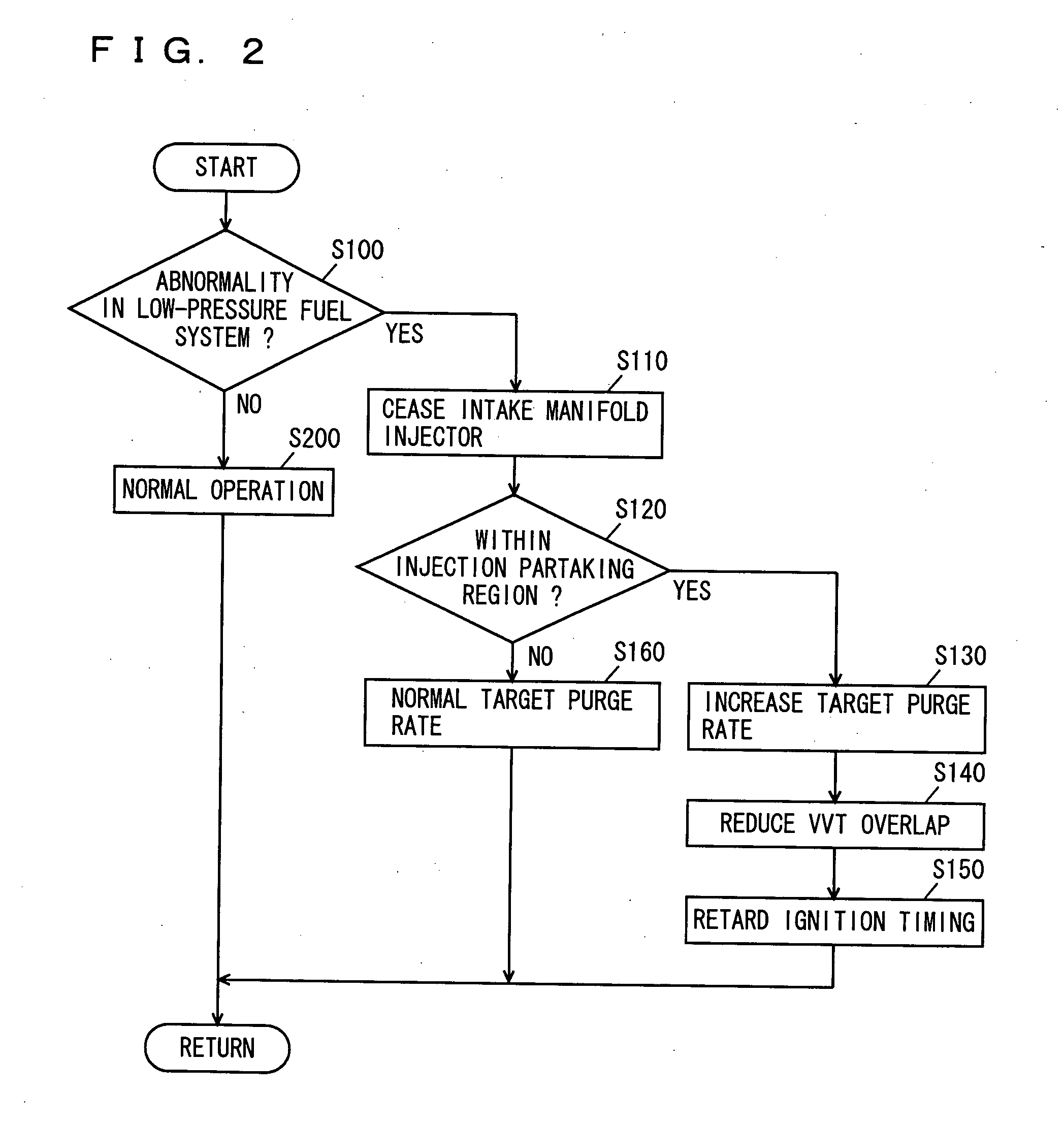

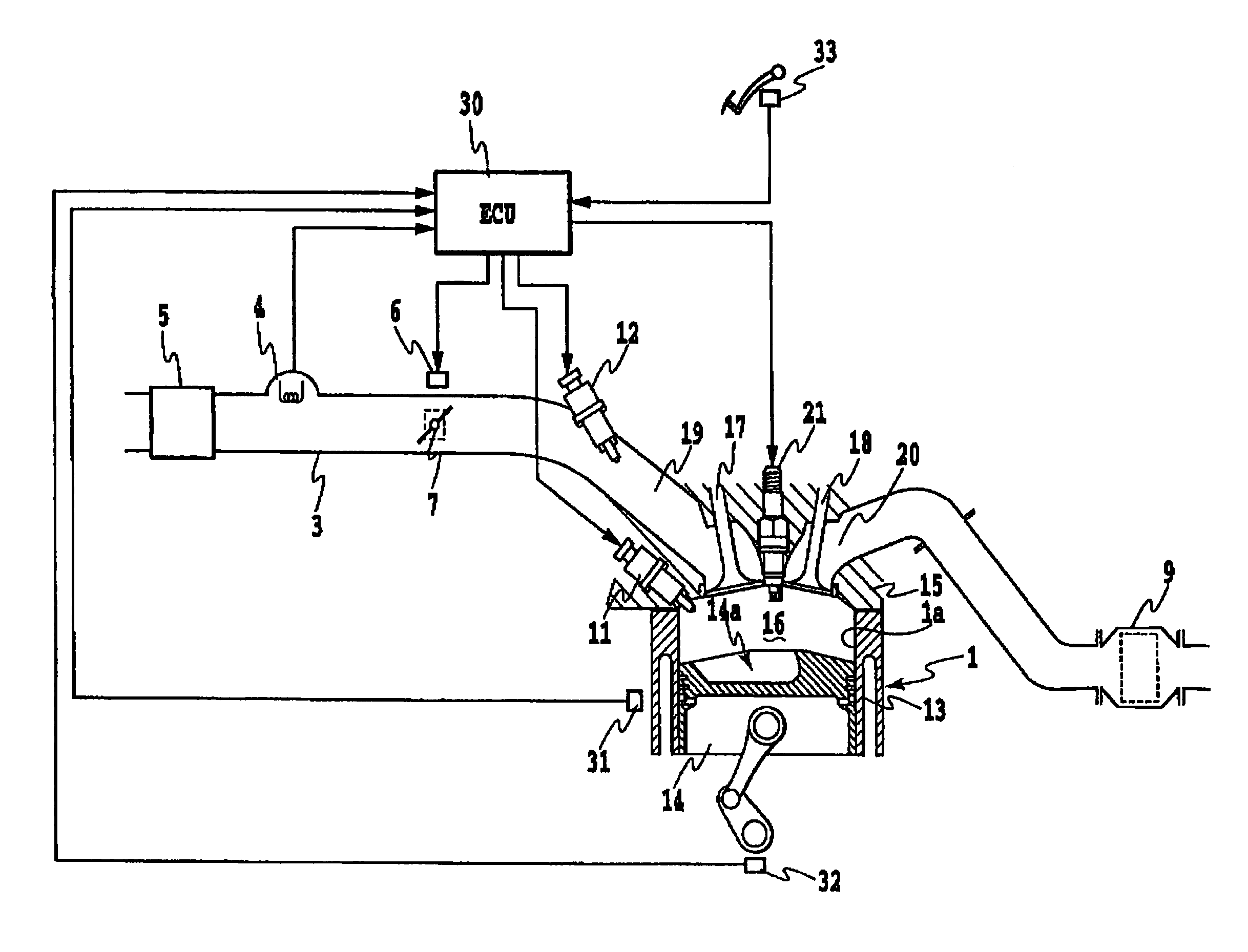

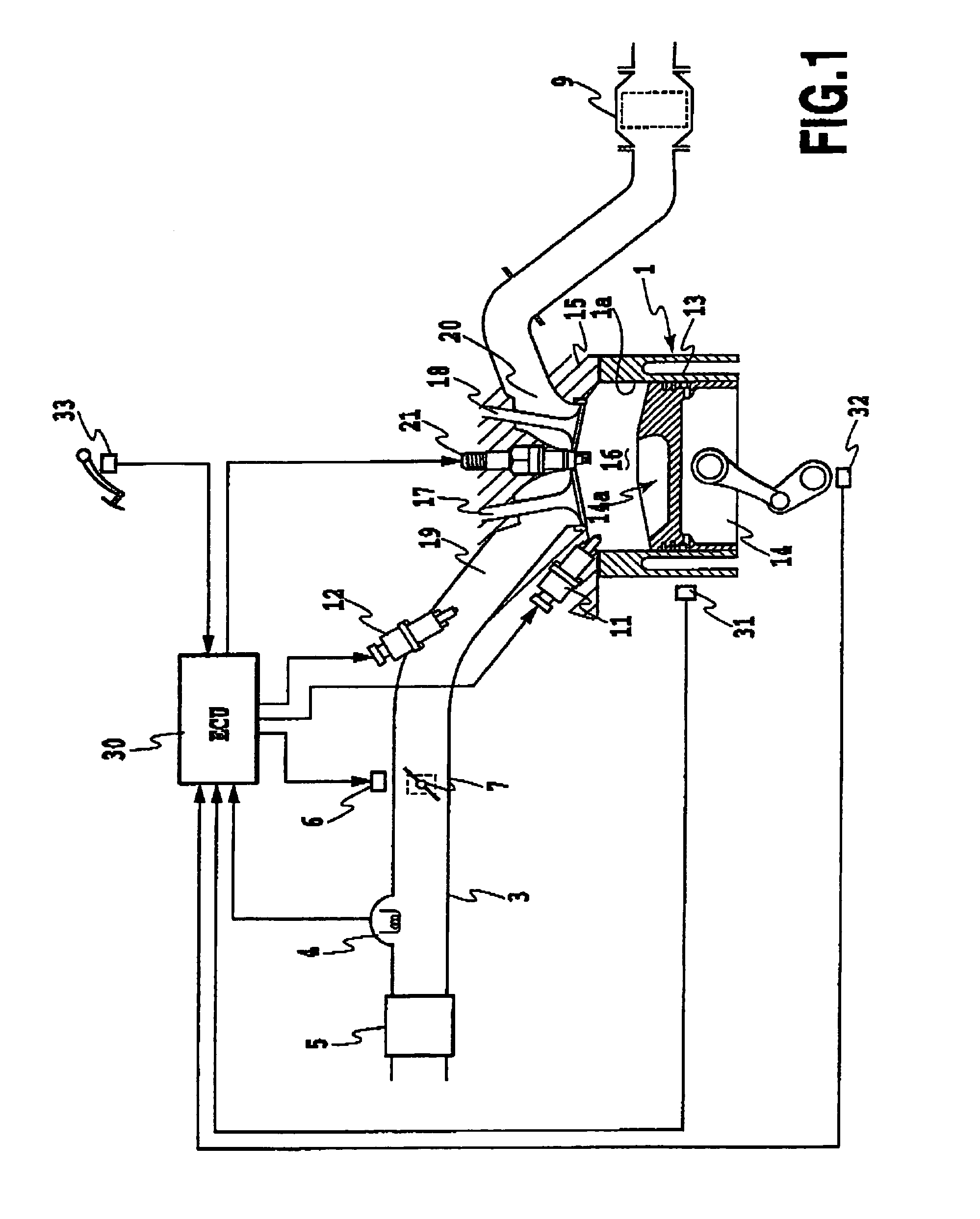

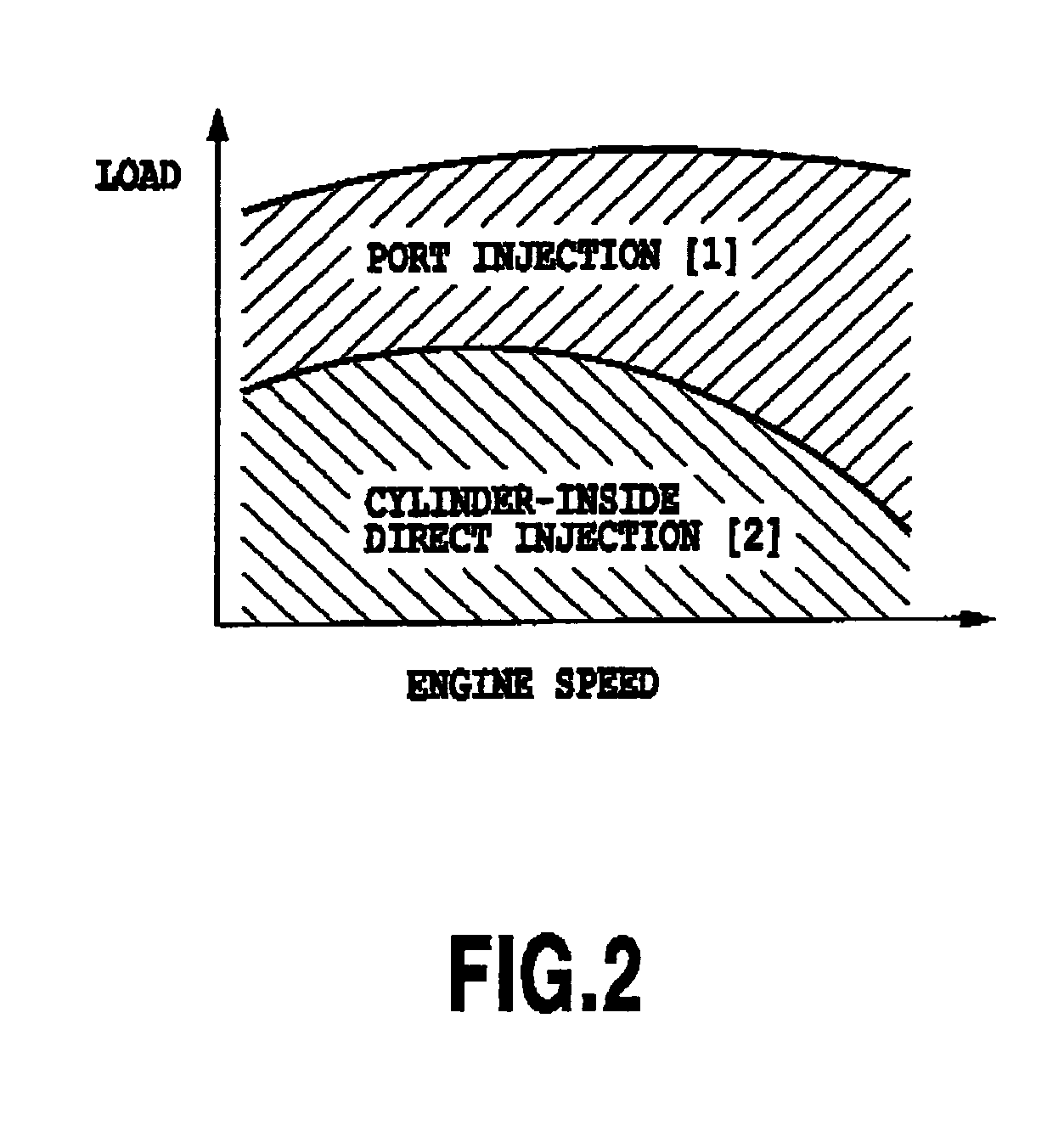

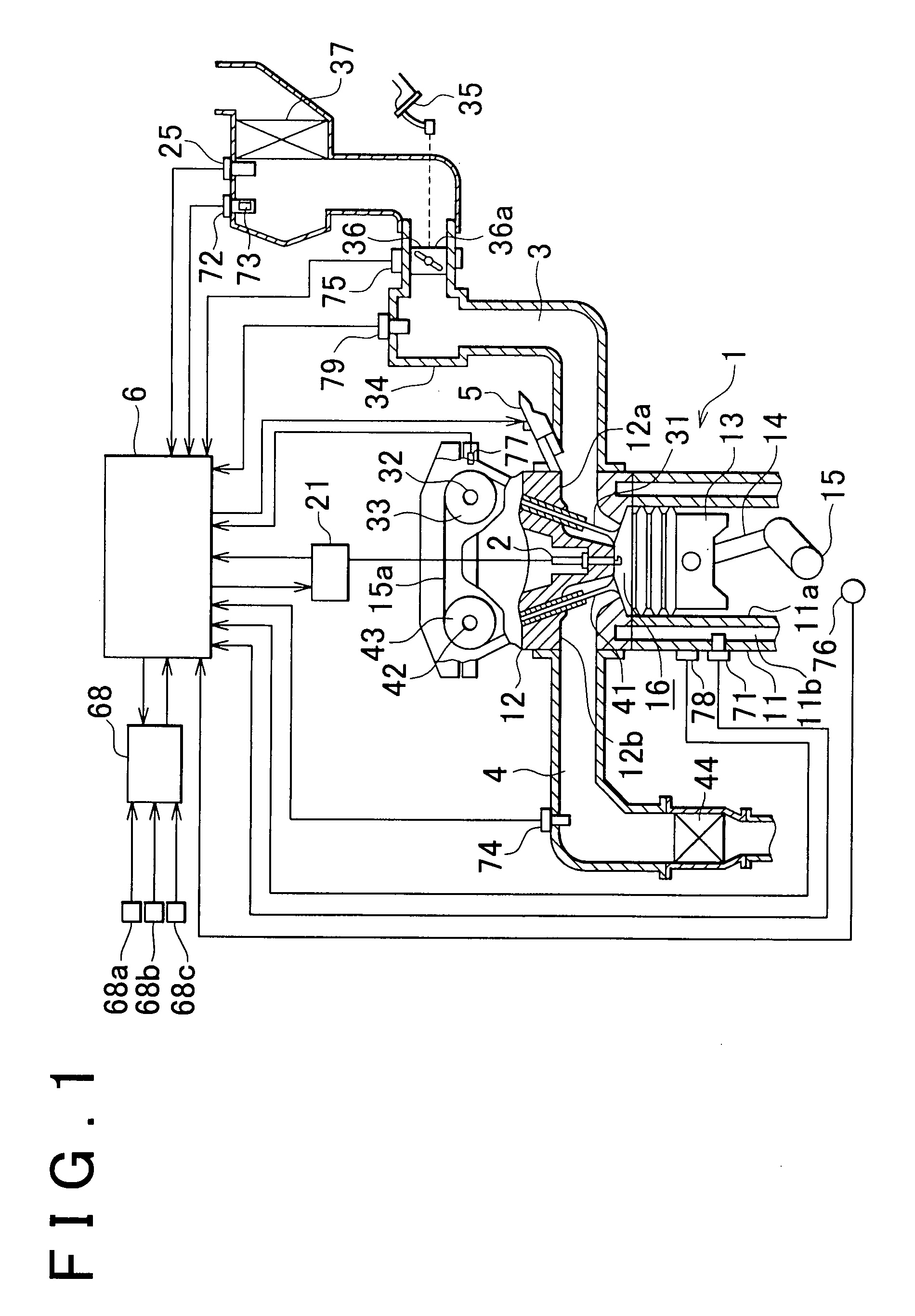

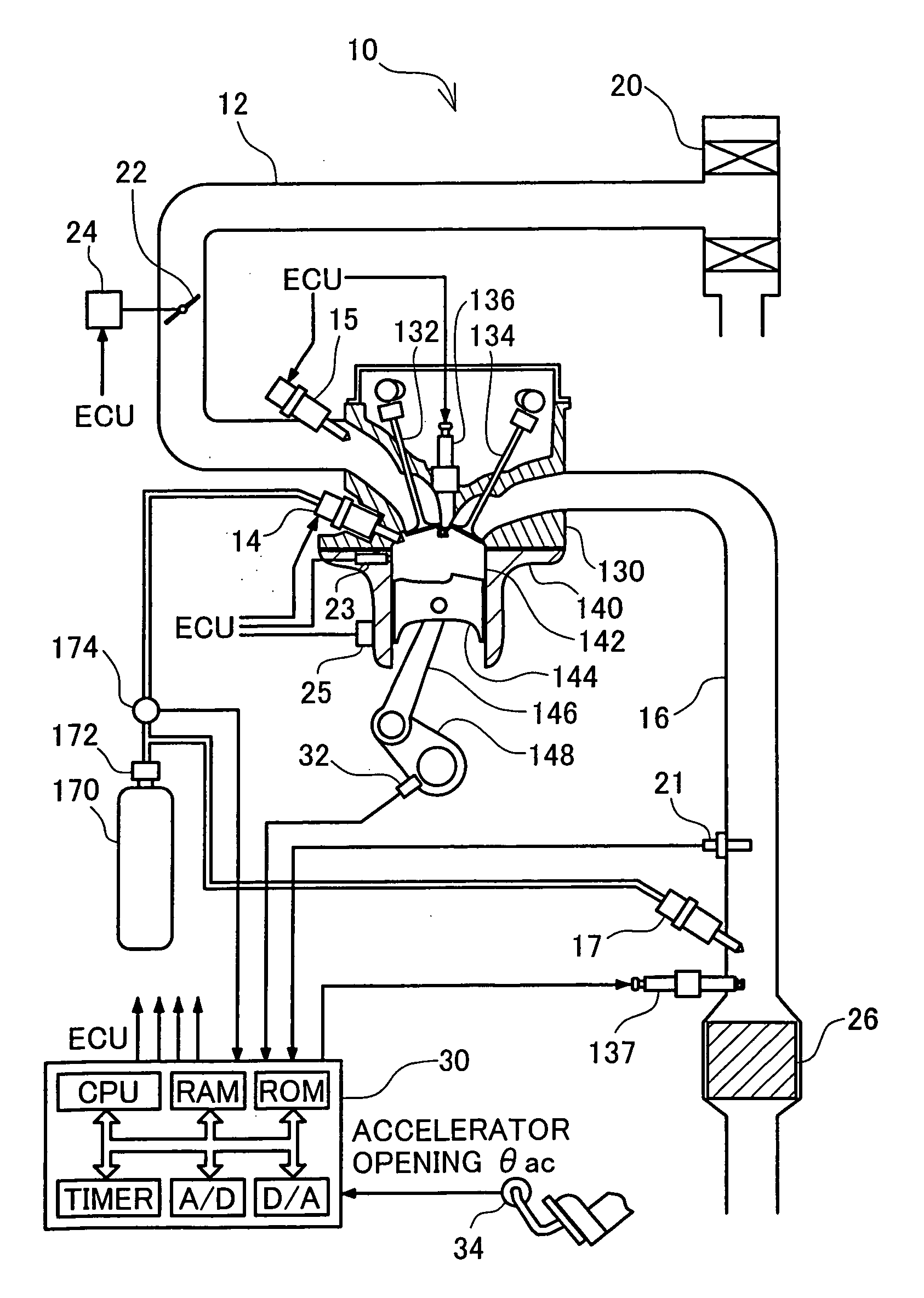

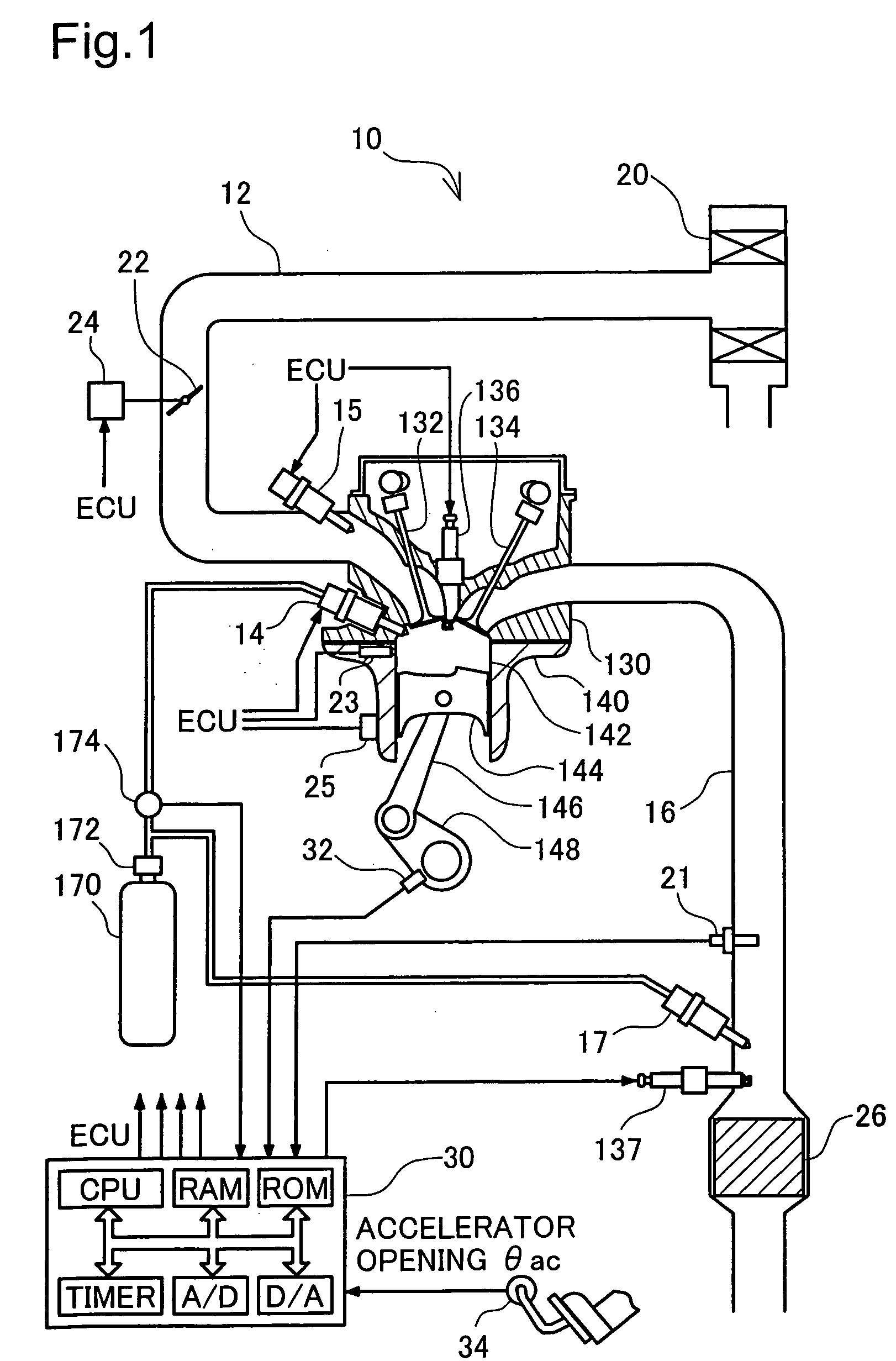

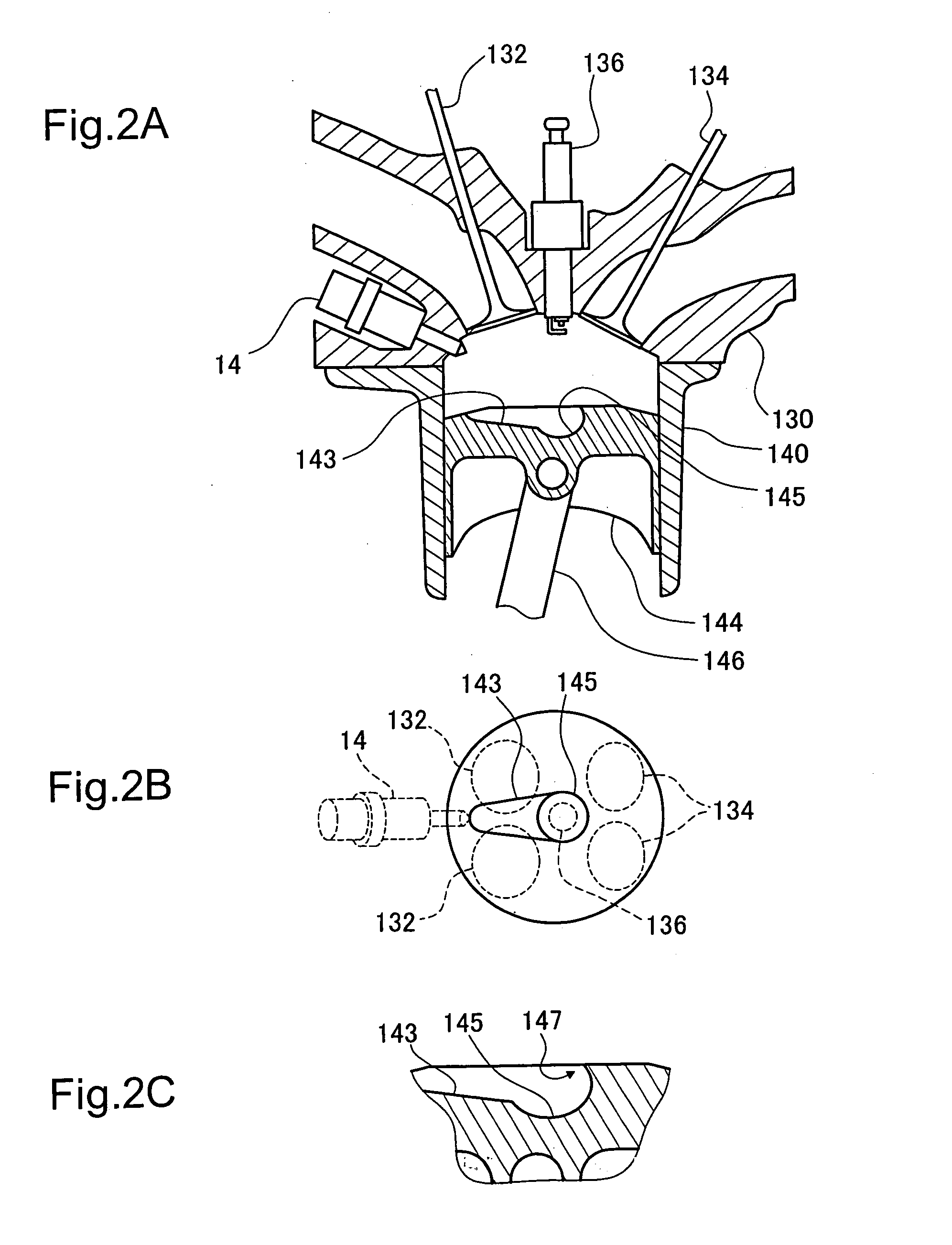

Control system for internal combustion engine

InactiveUS20050172931A1Suppresses torque fluctuationsRapid torque fluctuation is preventedElectrical controlInternal combustion piston enginesControl systemEngineering

In an internal combustion engine equipped with an injector for oylinder-inside injection to inject fuel into a cylinder and an injector for intake port injection to inject fuel into an intake port, both the injectors being switched for use depending upon operating conditions, wherein when an operating condition range using either one of the first or the second injector is switched to an operating condition range using the other one thereof, the amount of fuel to be injected by the either one of the first or the second injector is gradually decreased and the amount of fuel to be injected by the other one is gradually increased over a predetermined period during the switching. Further, at the time of the switching, at least one of ignition timing and throttle opening angle is gradually varied.

Owner:TOYOTA JIDOSHA KK

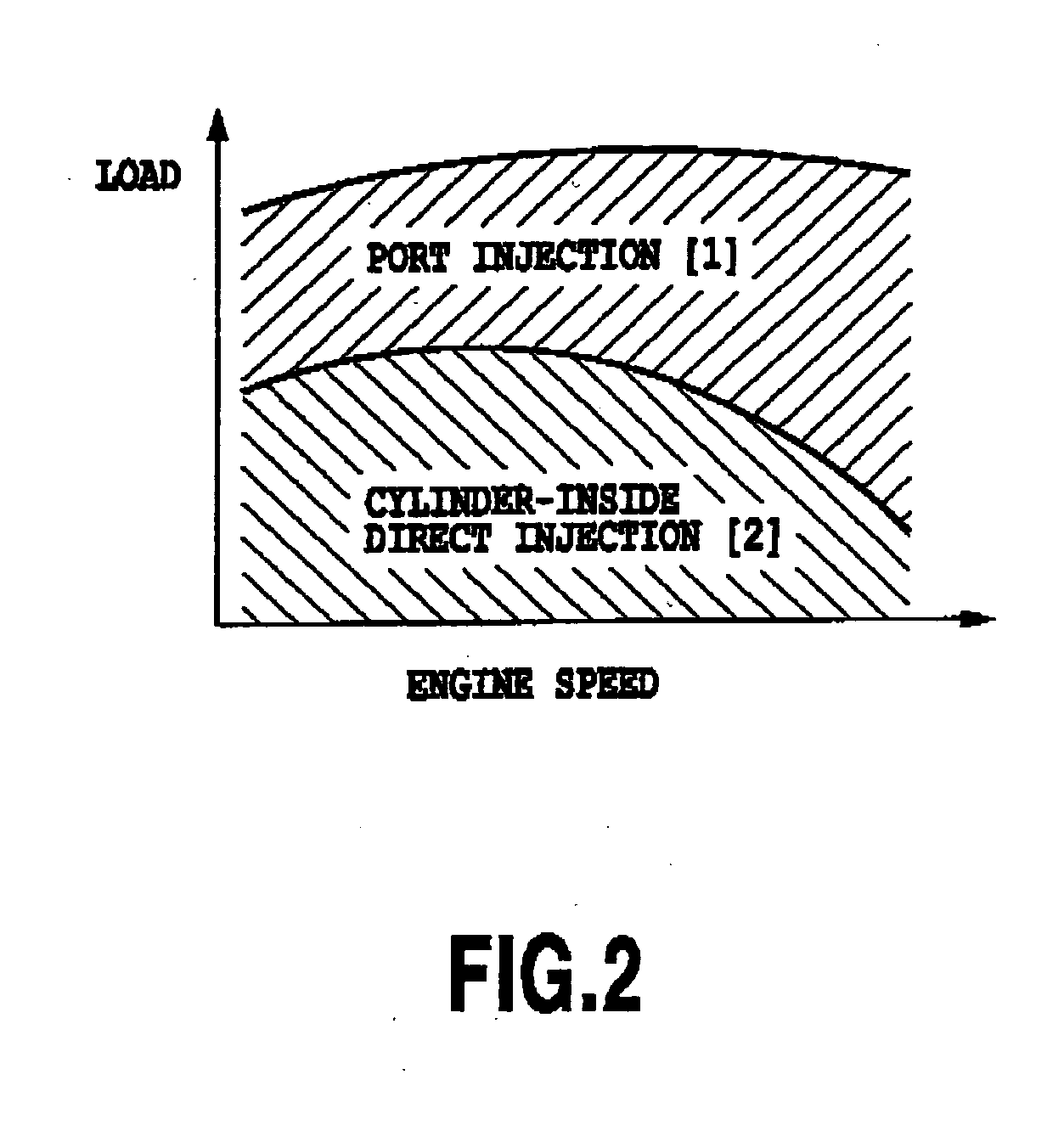

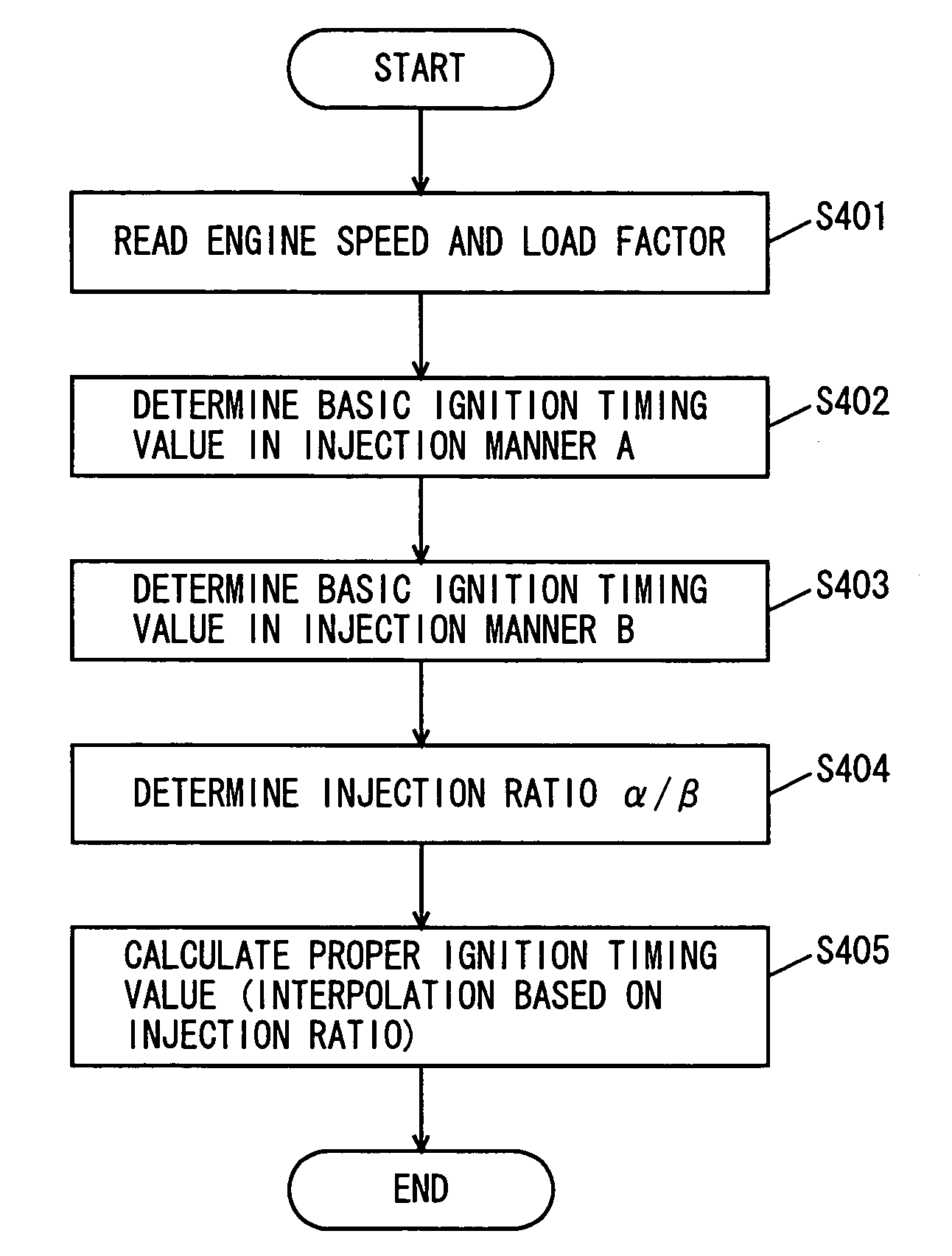

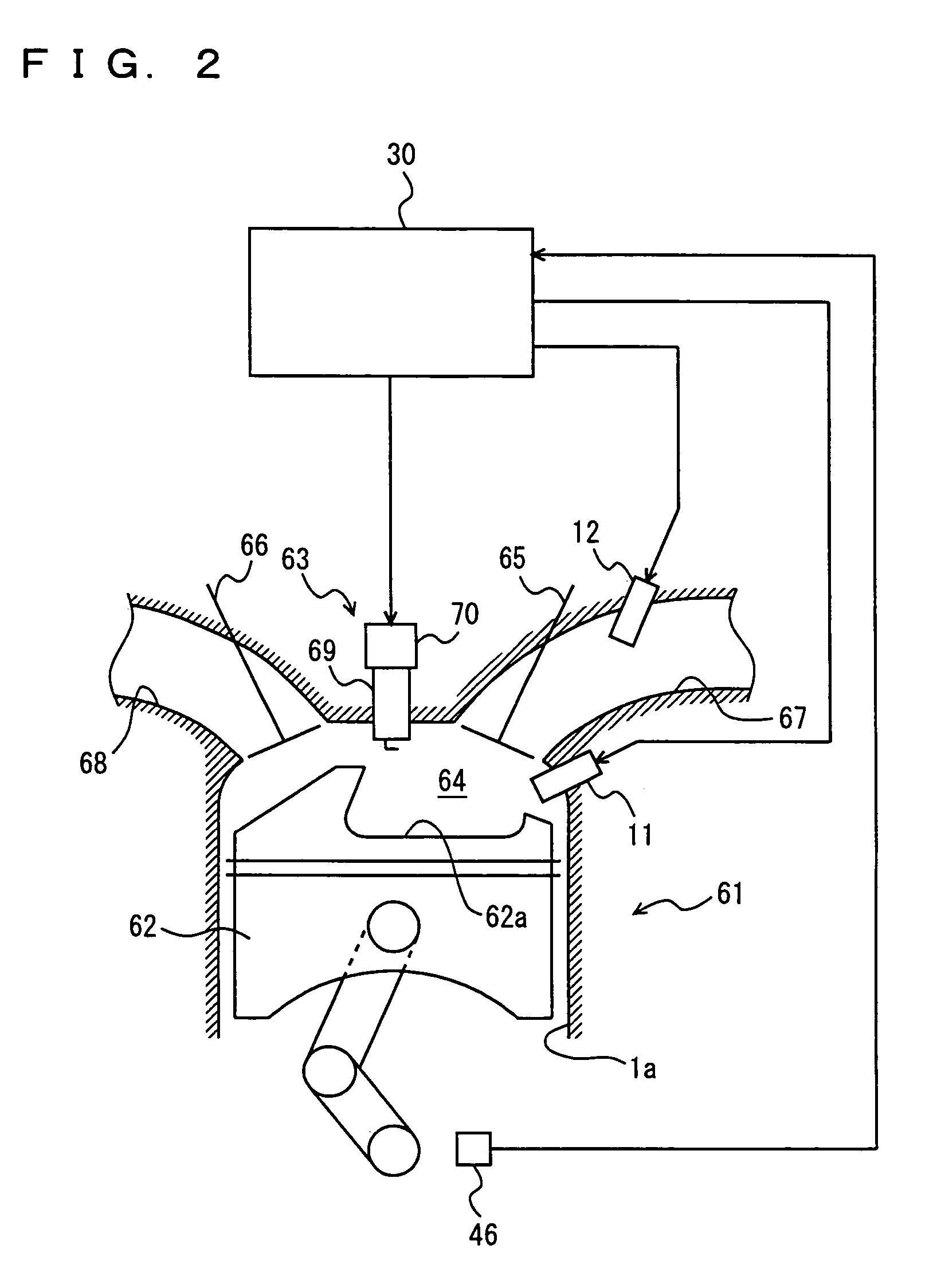

Ignition timing control apparatus for internal combustion engine

For an internal combustion engine including an in-cylinder injector and an intake port injector, proper ignition timing setting means is provided for setting a proper ignition timing according to the fuel injection ratio between injection from the in-cylinder injector and injection from the intake port injector. When a change is made in the fuel injection ratio, the proper ignition timing setting means selects one of a proper ignition timing value before the change and a proper ignition timing value after the change that is on the retard side and sets the ignition timing at the selected proper ignition timing value in at least a predetermined period of time after the change.

Owner:TOYOTA JIDOSHA KK

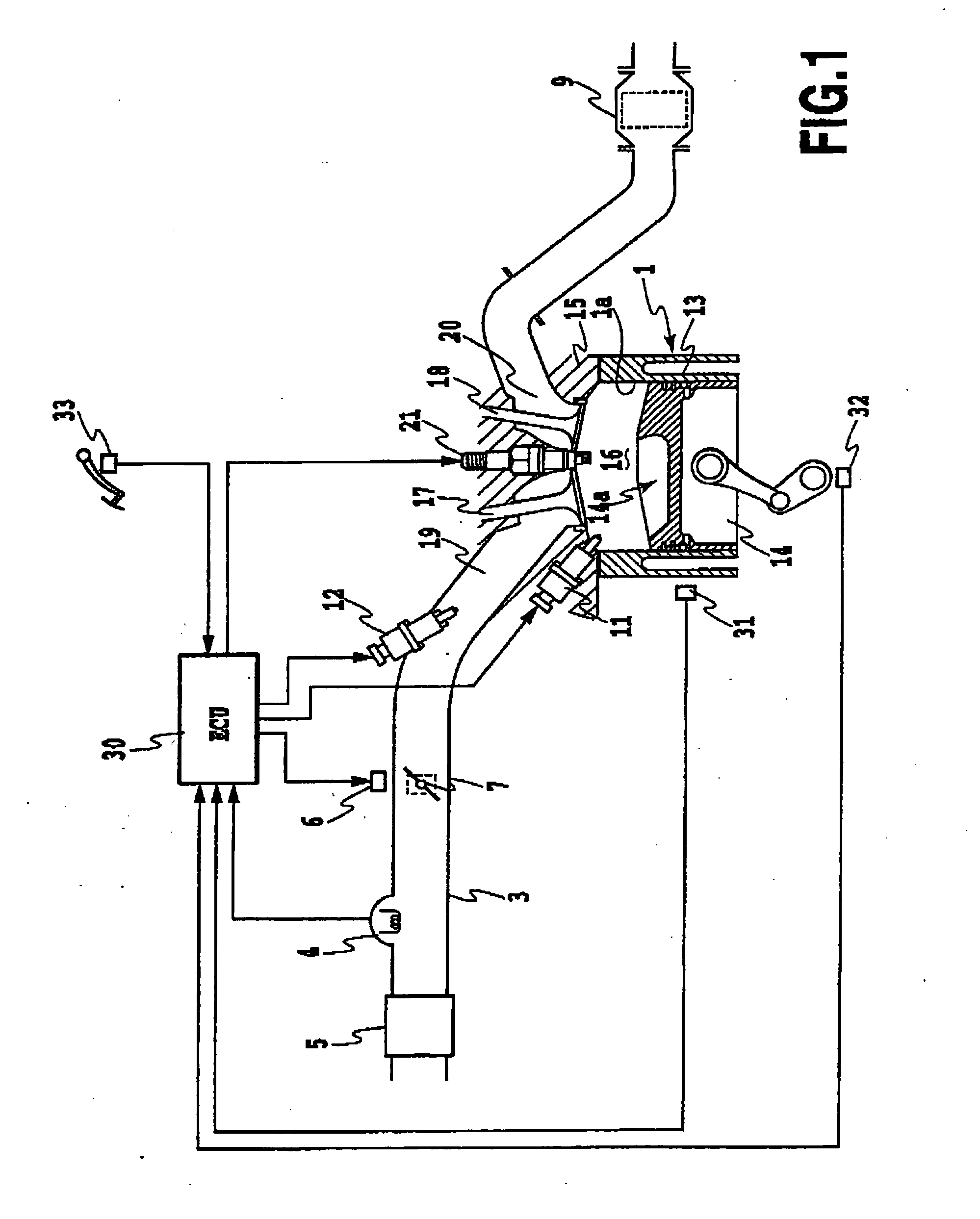

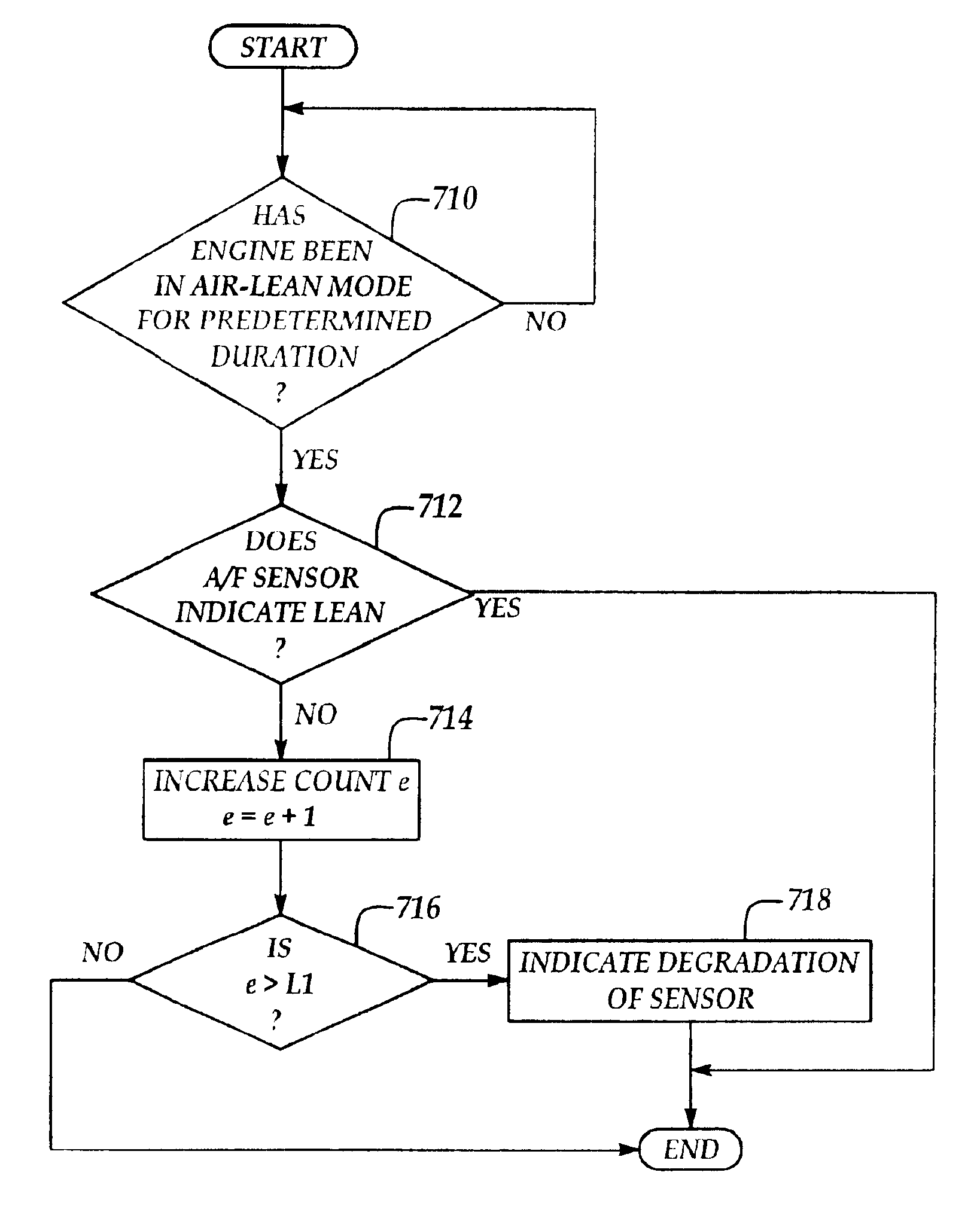

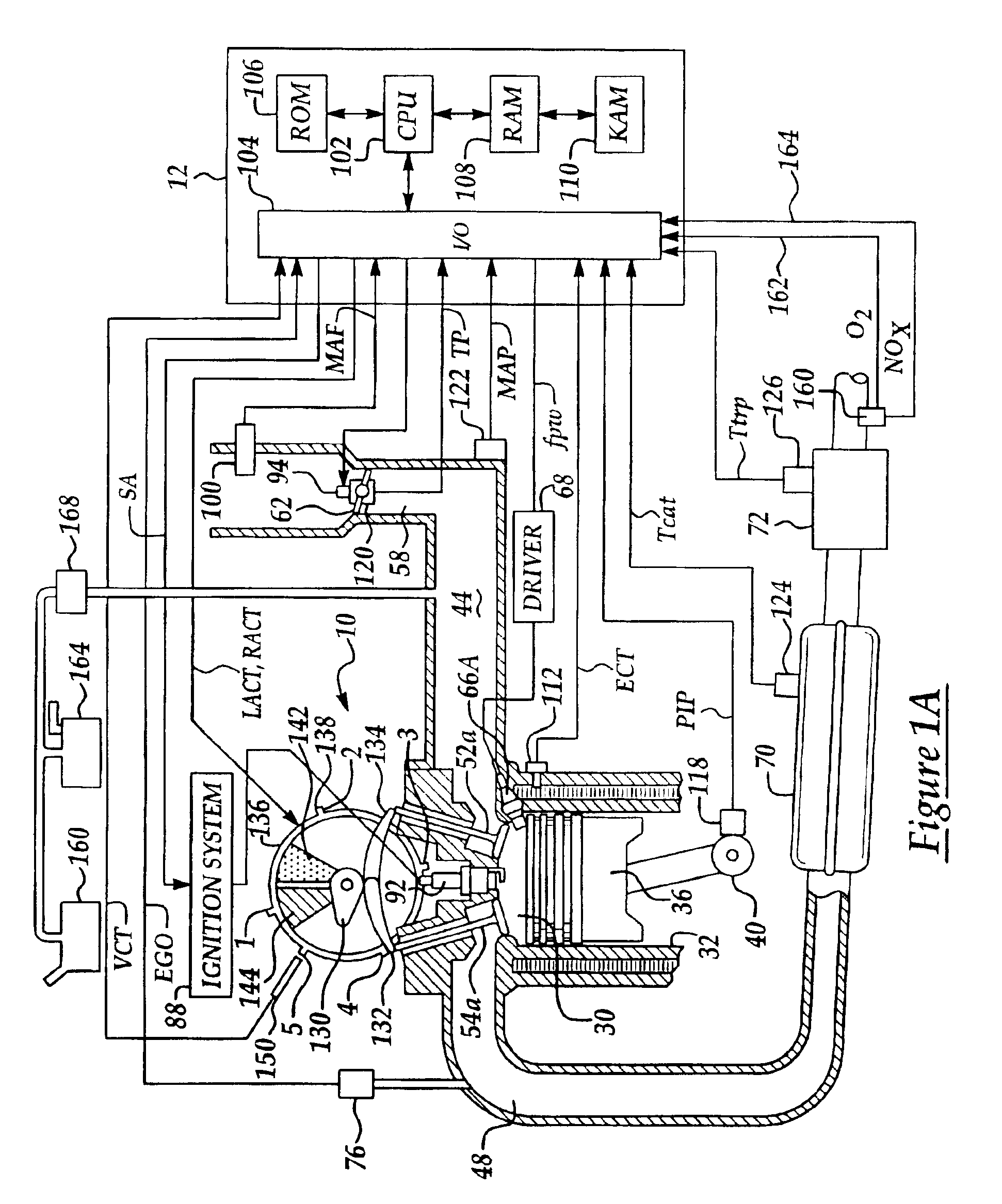

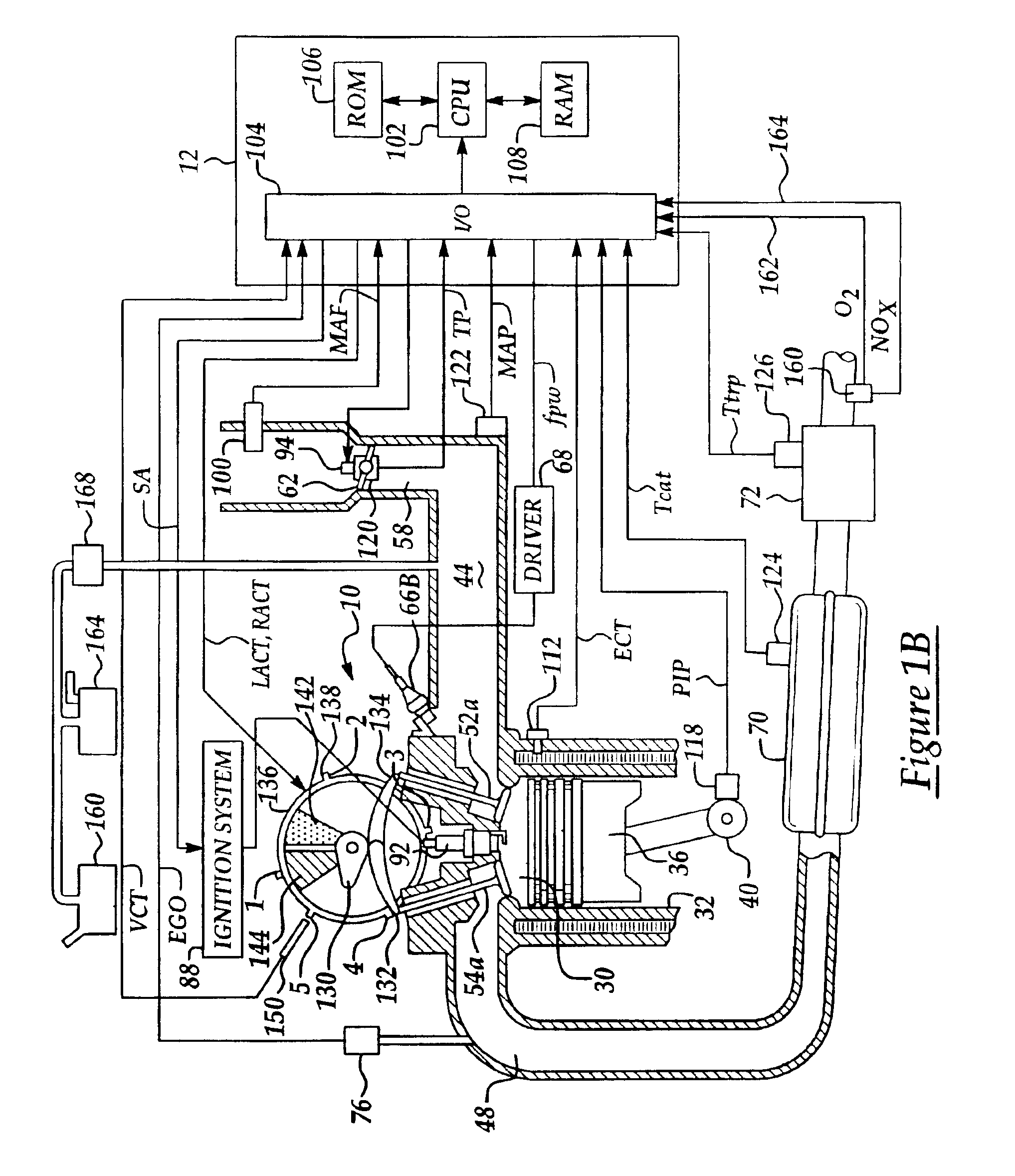

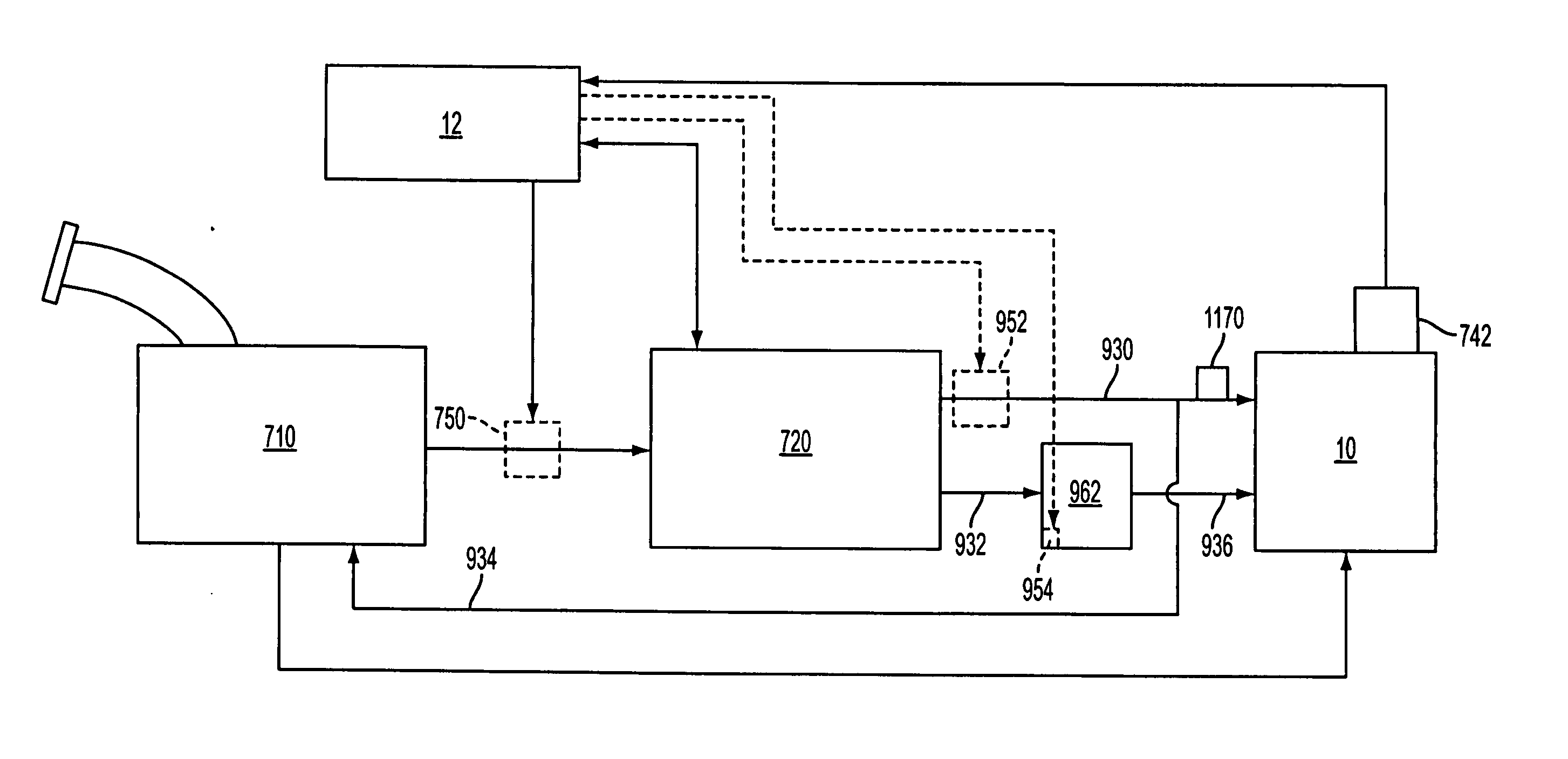

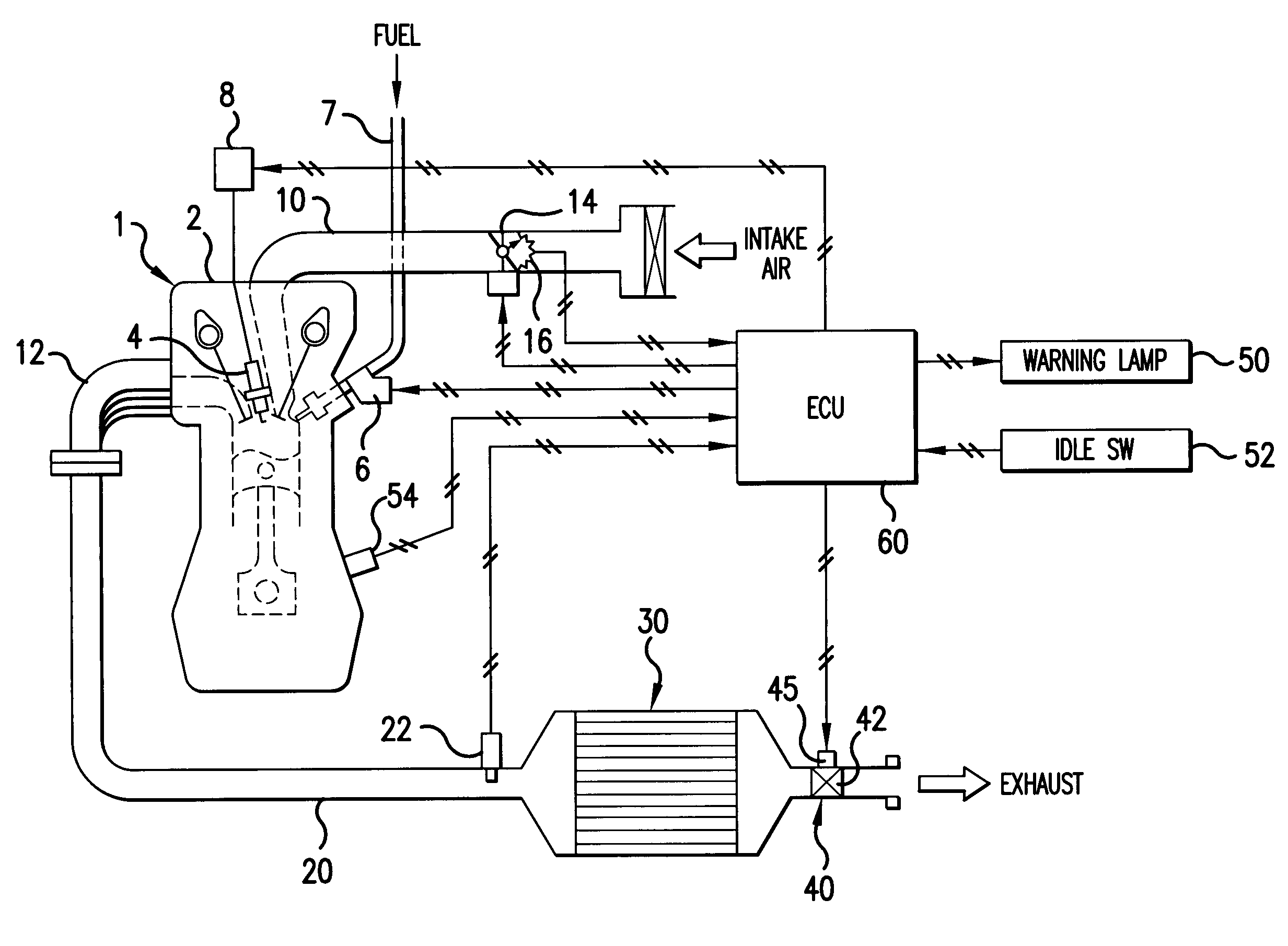

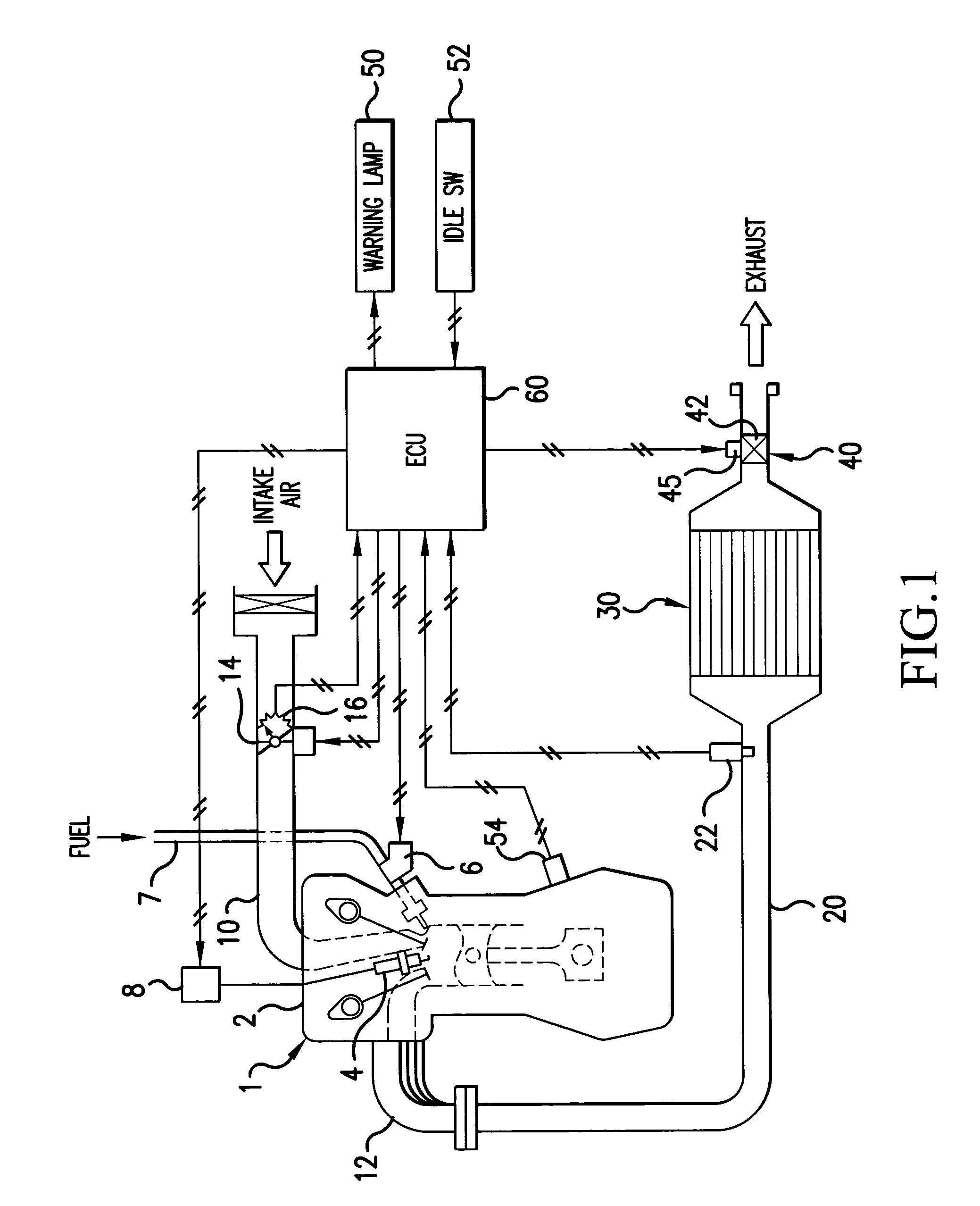

Method for air-fuel ratio sensor diagnosis

InactiveUS6736121B2Avoid false indicationsLow heat generationElectrical controlExhaust apparatusTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, such as after an engine cold start, the method operates an engine with a first group of cylinders having a first ignition timing, and a second group of cylinders having a second ignition timing more retarded than the first group. In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also can change to combusting all cylinders at substantially the same ignition timing under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

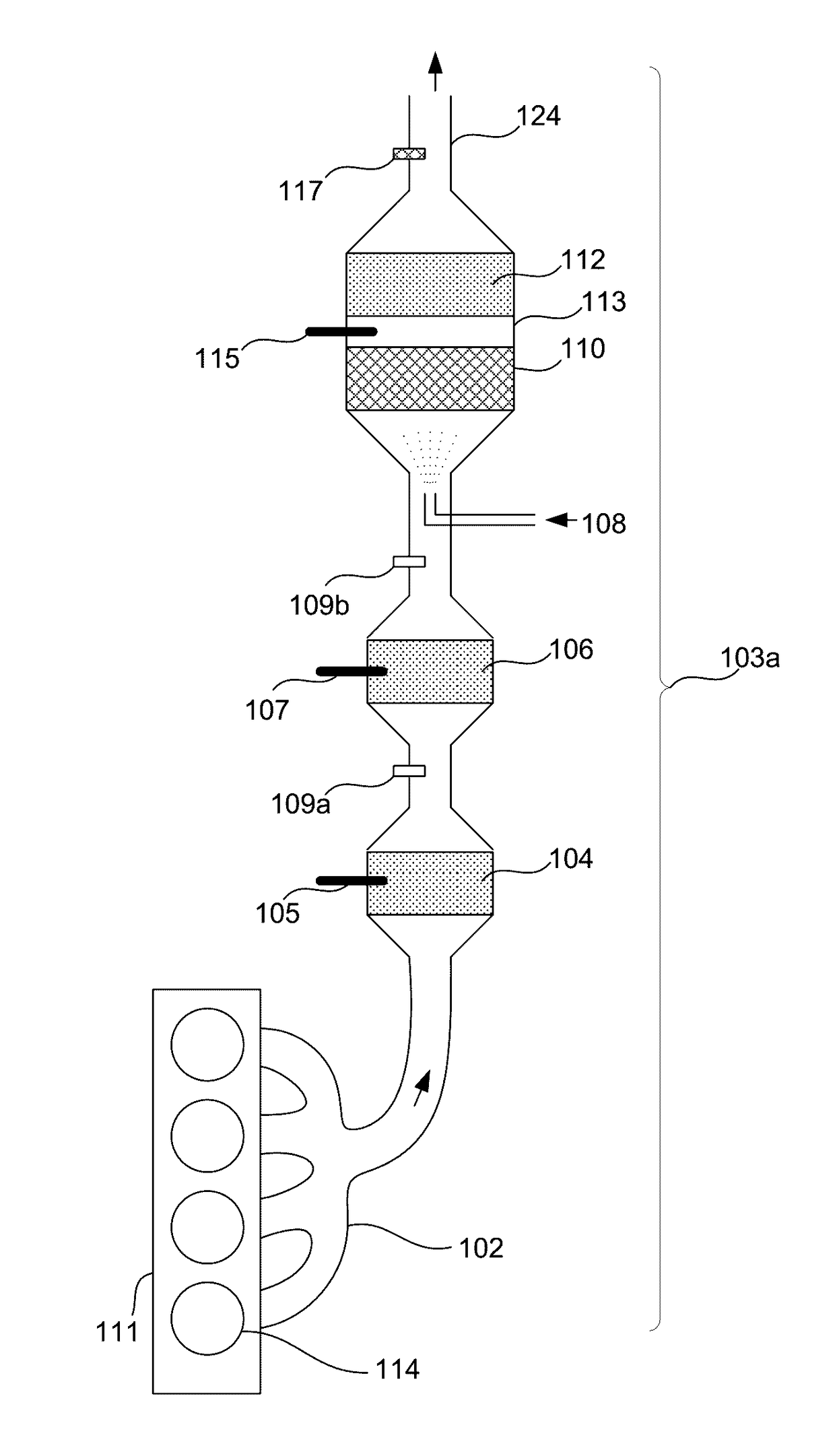

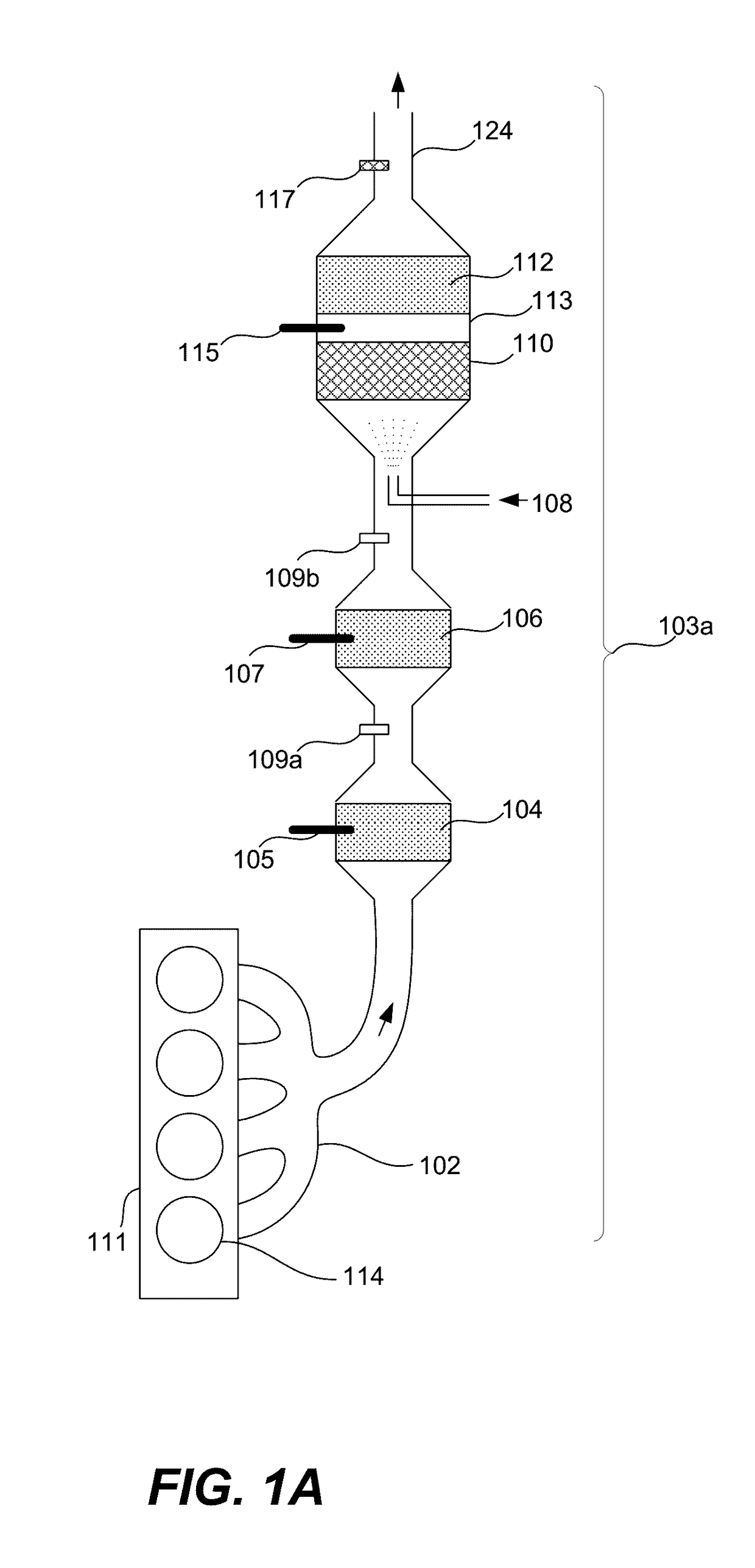

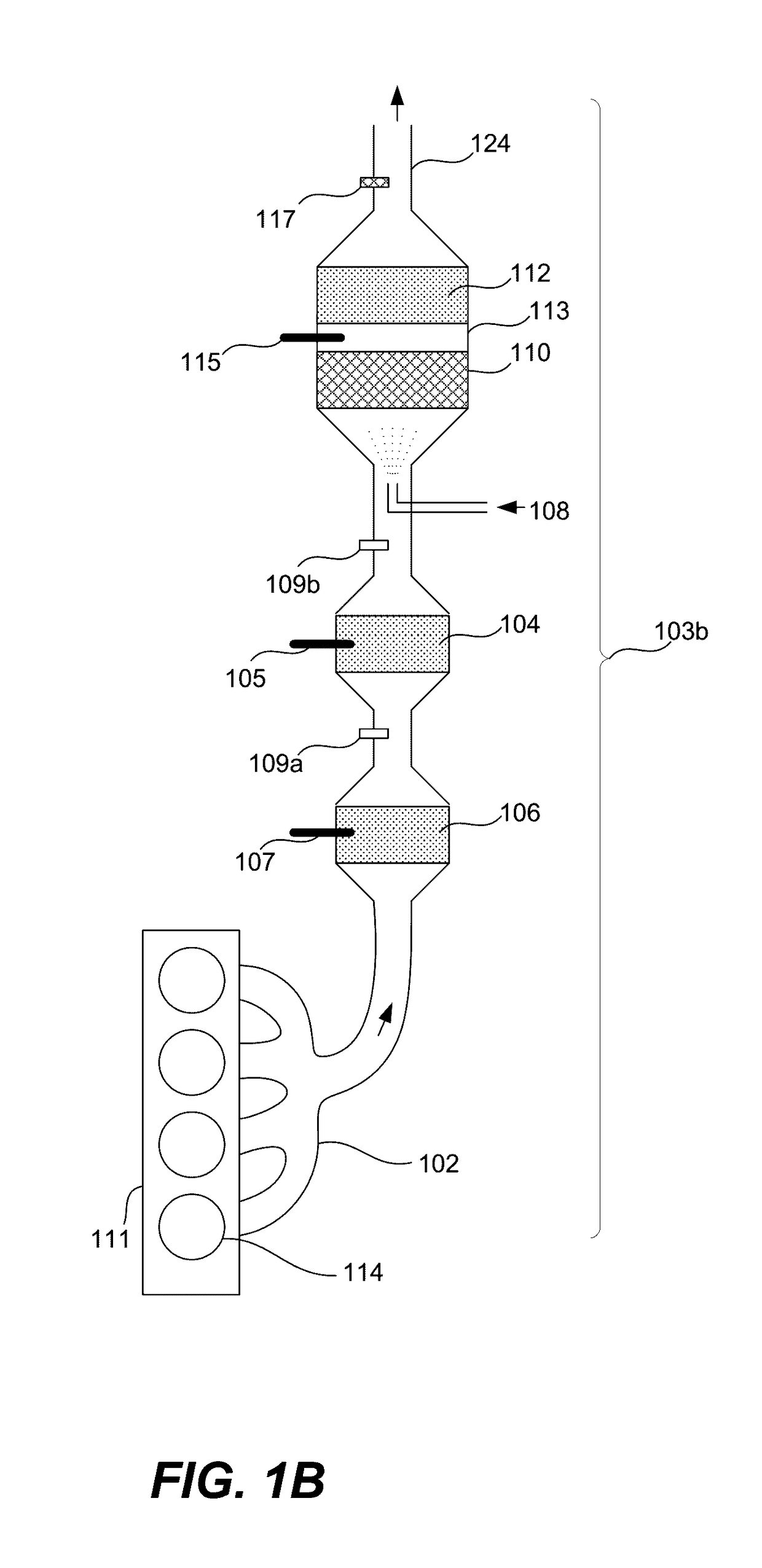

Control for knock suppression fluid separator in a motor vehicle

ActiveUS20070215069A1Low costImprove charge cooling effectElectrical controlNon-fuel substance addition to fuelIgnition timingControl system

A system for an engine of a vehicle, comprising of a cylinder located in the engine, a delivery system configured to deliver fuel and a fluid to at least an engine cylinder while the vehicle is traveling, said fluid comprising alcohol and / or water, and a control system for varying an amount of said fuel and fluid delivered to the cylinder in different ratios as a condition varies, said controller further varying a spark timing of a spark in said cylinder as an amount of alcohol and / or water in said fluid varies.

Owner:FORD GLOBAL TECH LLC

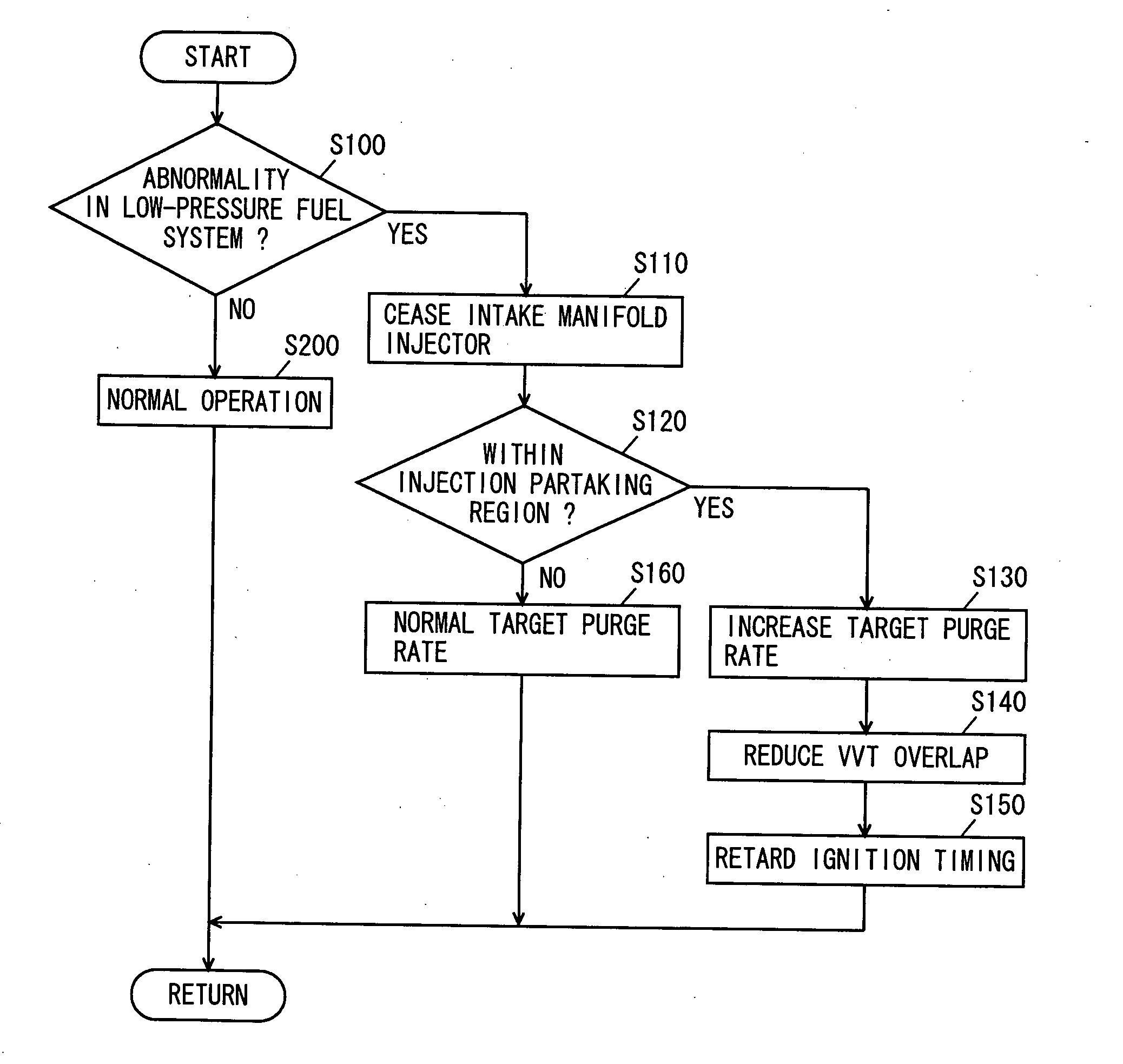

Control apparatus for internal combustion engine

InactiveUS20060090732A1Increasing purge rateVariation can be suppressedValve arrangementsElectrical controlIgnition timingInlet manifold

An engine ECU executes a program including the steps of: determining presence of abnormality in a low-pressure fuel system; ceasing an intake manifold injector when determination is made of abnormality in the low-pressure fuel system; increasing the target purge rate when the engine operation state attains an injection partaking state between an in-cylinder injector and an intake manifold injector; reducing the VVT overlap; and retarding the ignition timing.

Owner:TOYOTA JIDOSHA KK

Control system for internal combustion engine

InactiveUS6978762B2Suppresses torque fluctuationsRapid torque fluctuation is preventedElectrical controlInternal combustion piston enginesExternal combustion engineControl system

In an internal combustion engine equipped with an injector for cylinder-inside injection to inject fuel into a cylinder and an injector for intake port injection to inject fuel into an intake port, both the injectors being switched for use depending upon operating conditions, wherein when an operating condition range using either one of the first or the second injector is switched to an operating condition range using the other one thereof, the amount of fuel to be injected by the either one of the first or the second injector is gradually decreased and the amount of fuel to be injected by the other one is gradually increased over a predetermined period during the switching. Further, at the time of the switching, at least one of ignition timing and throttle opening angle is gradually varied.

Owner:TOYOTA JIDOSHA KK

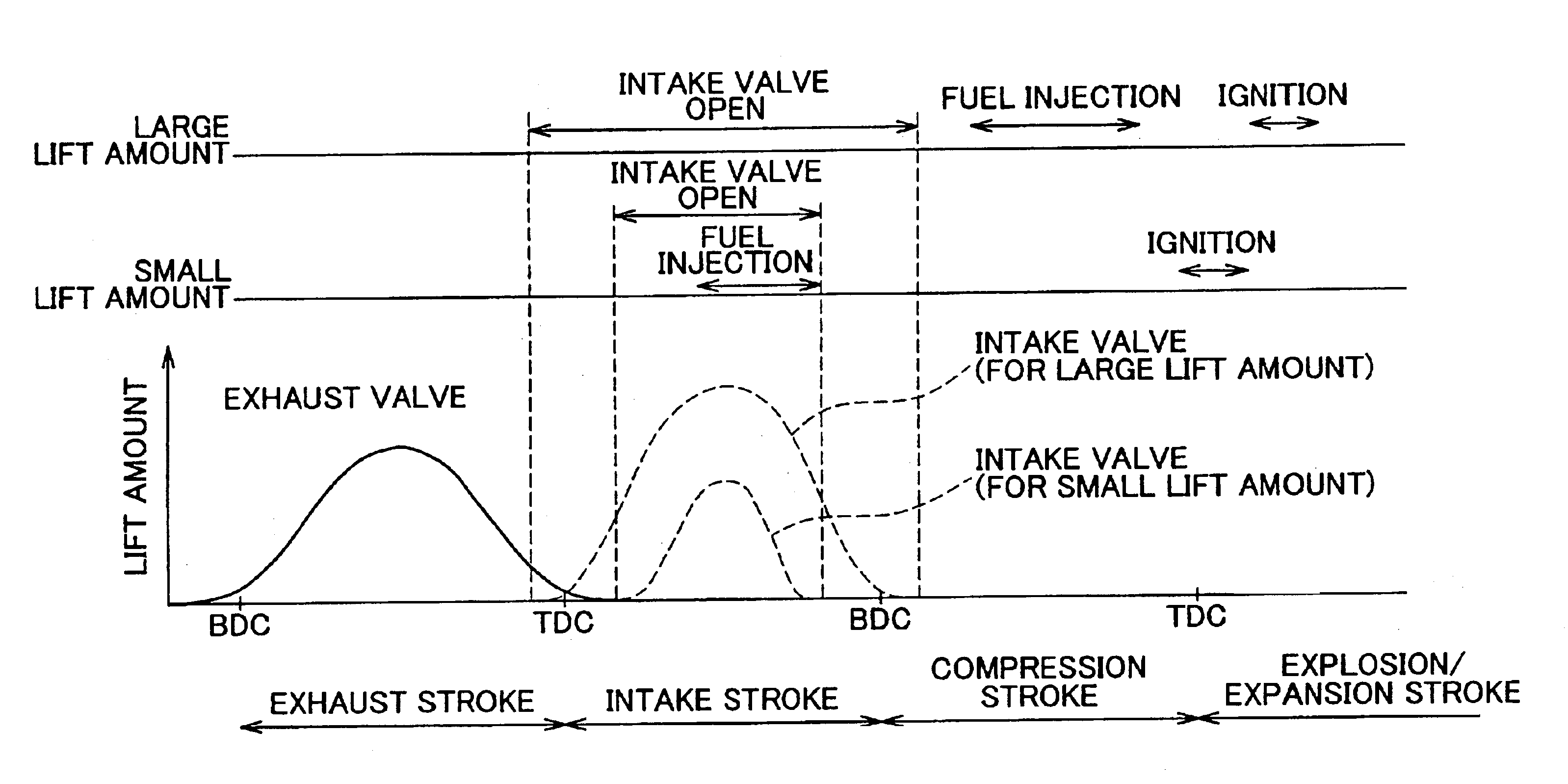

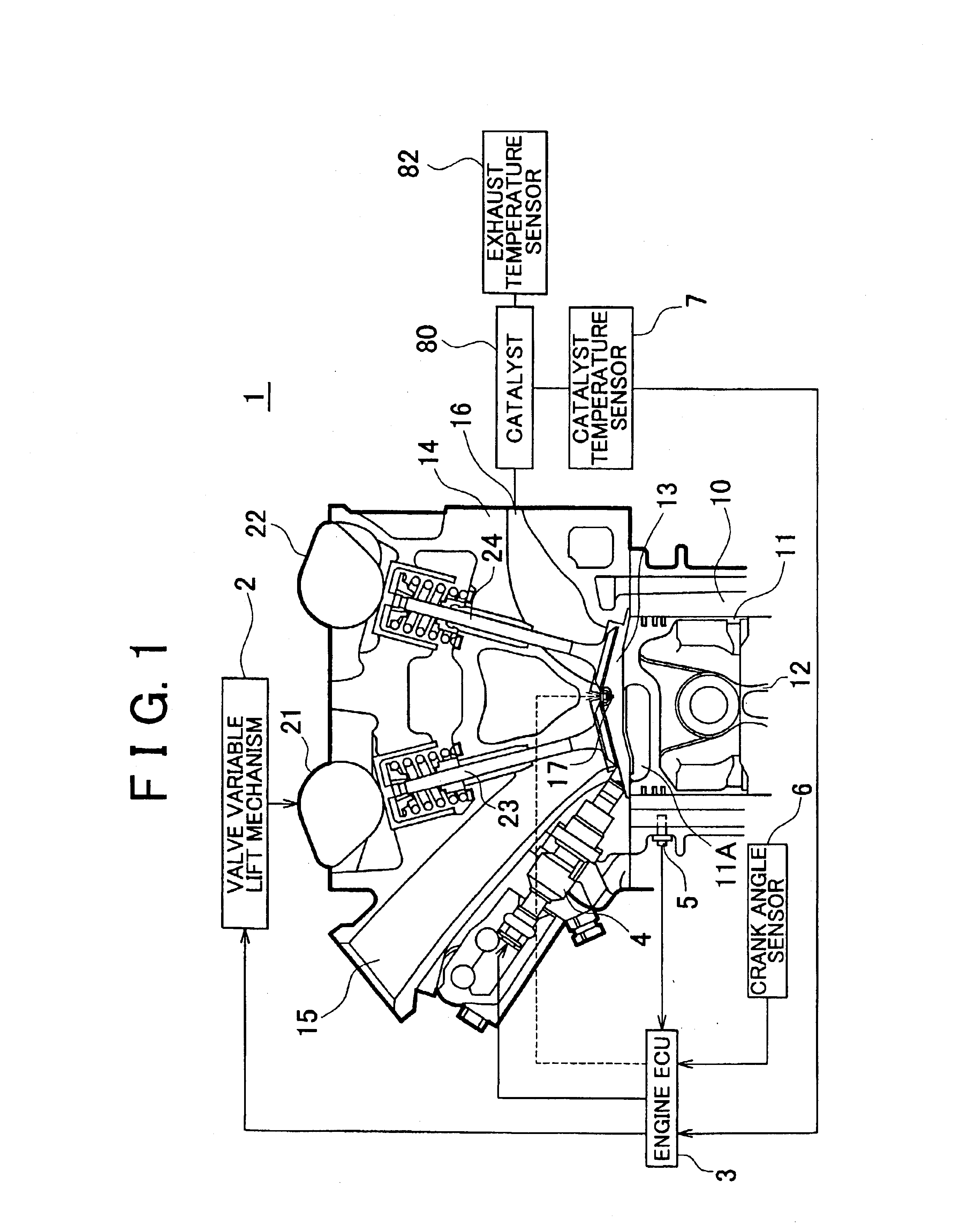

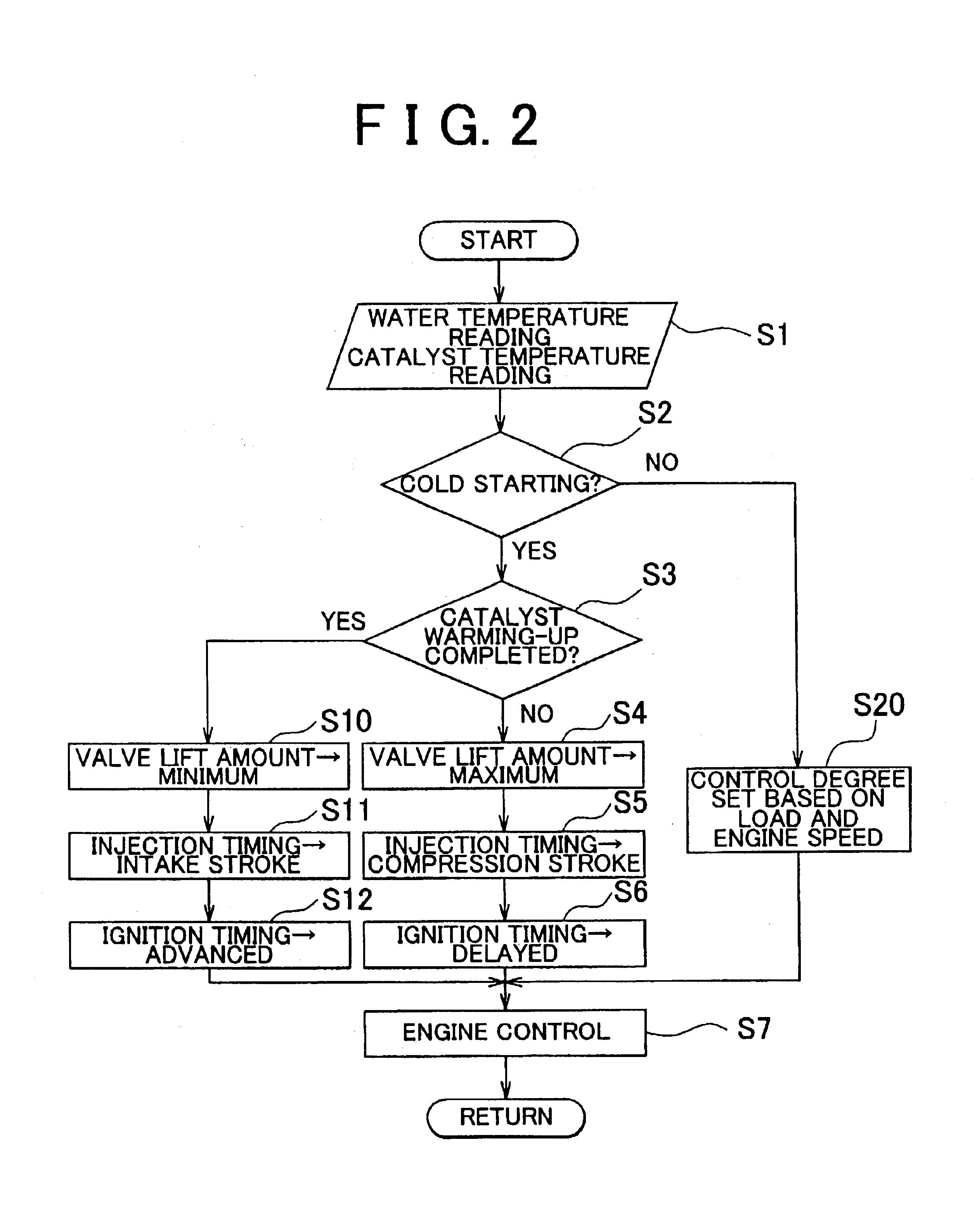

In-cylinder injection type spark-ignition internal combustion engine and control method thereof

InactiveUS6837040B2Improve fuel efficiencyValve arrangementsElectrical controlInlet valveIgnition timing

An in-cylinder injection type spark-ignition internal combustion engine and a control method thereof realize a stabilized stratified-charge combustion by setting a large lift amount to an intake valve when the engine is cold-started and by executing a compression stroke injection. At this time, warming-up capability of a catalyst is improved by delaying an ignition timing.

Owner:TOYOTA JIDOSHA KK

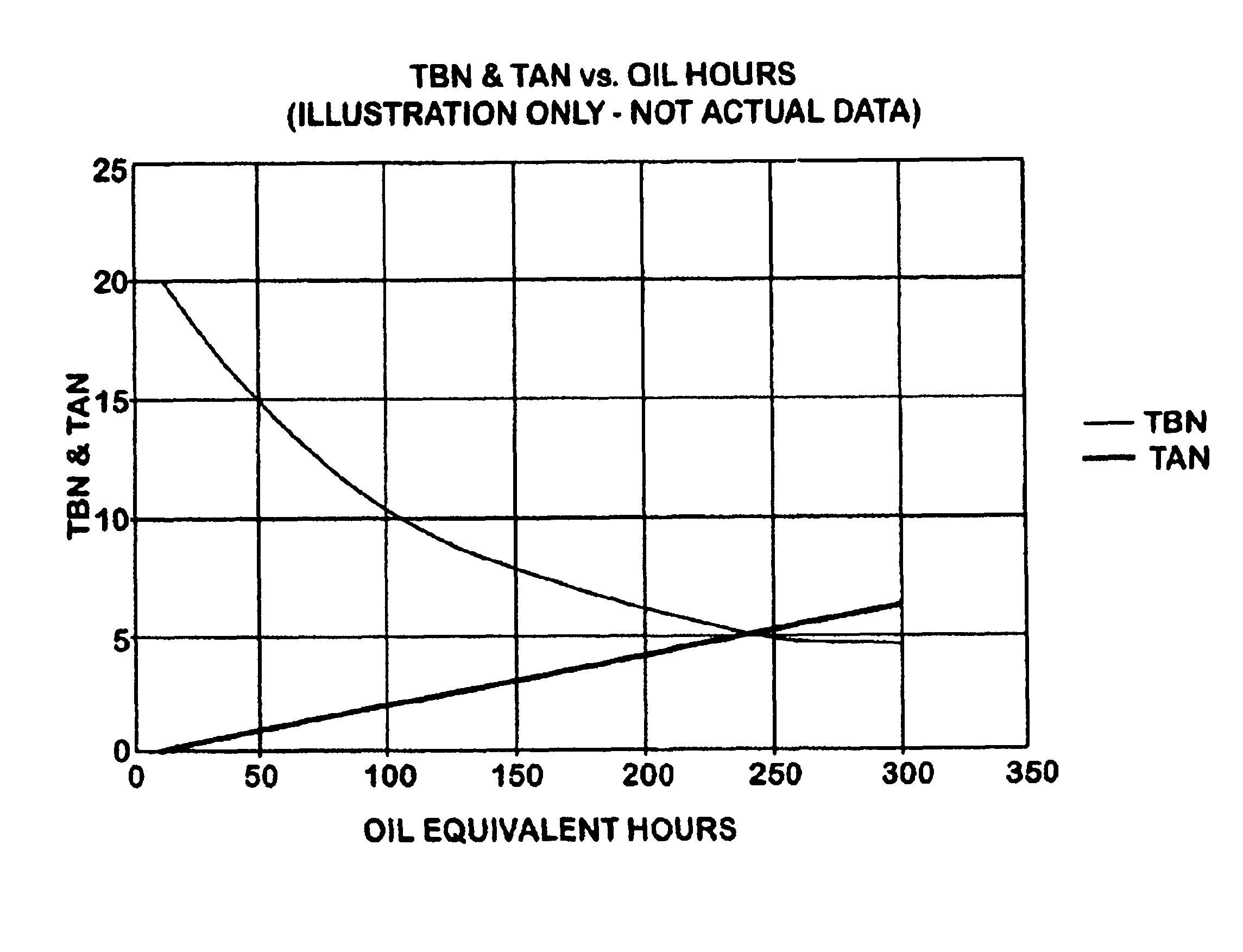

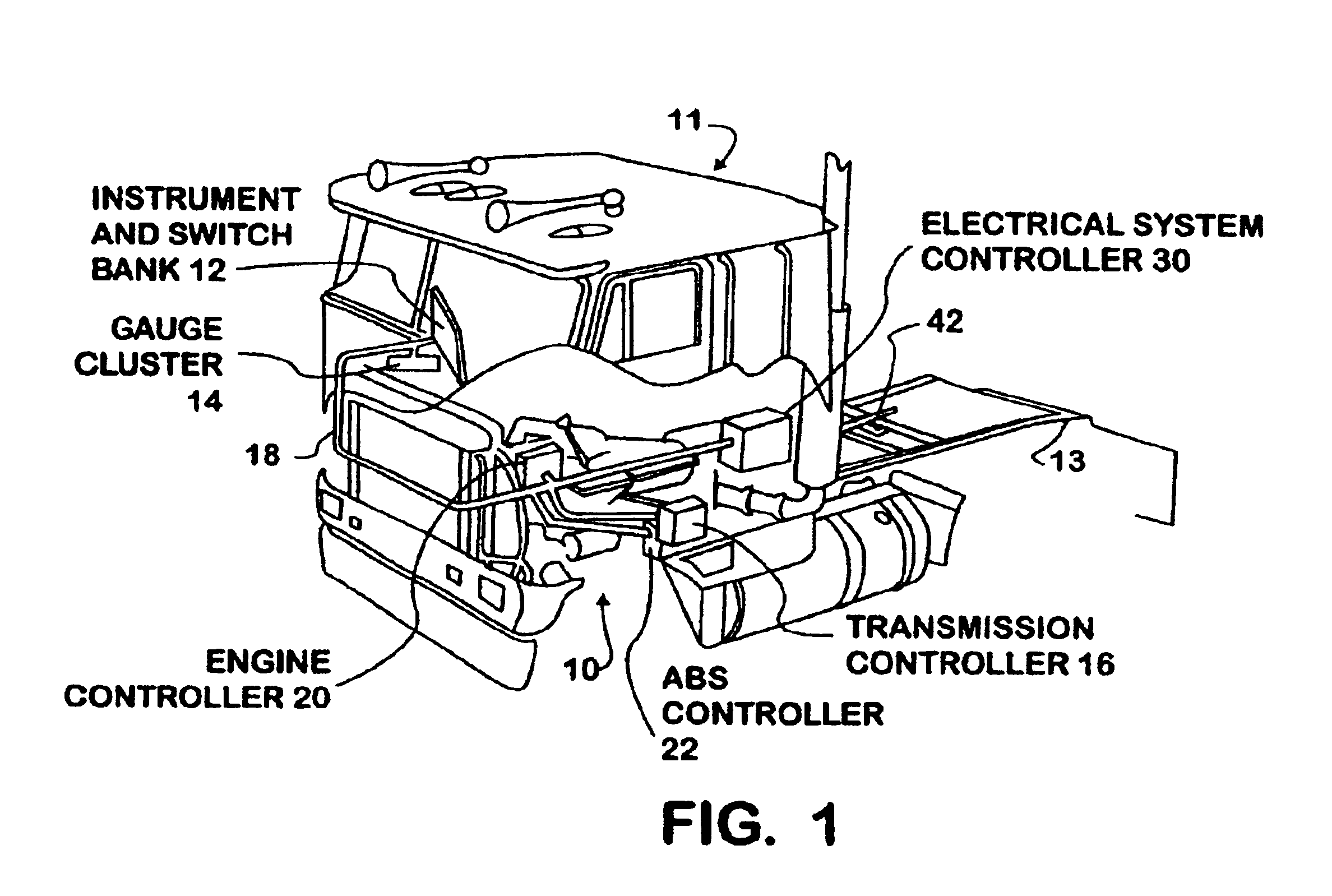

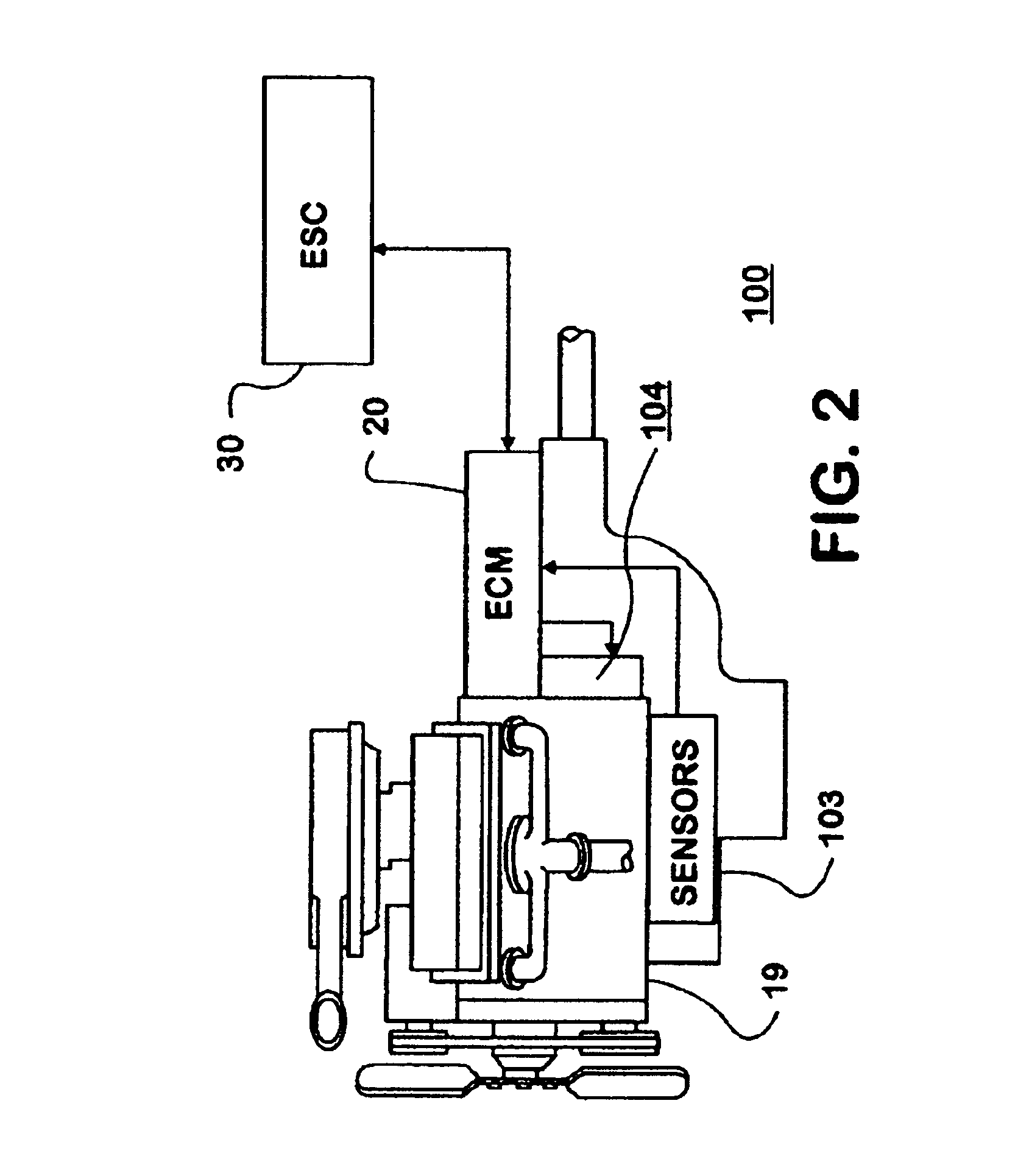

Method of estimating engine lubricant condition

A motor vehicle having an internal combustion engine and a lubricating oil circulation system provides estimates of the distance remaining before an oil change becomes imperative. An indirect estimate of the depletion of various additives and the deterioration of oil operating characteristics is based on engine operating variables including oil temperature, ignition timing and engine load. The limit of depletion of total base number is dynamic, since it is set against total acid number and the two figures are independently calculated.

Owner:INT TRUCK INTPROP LLC

Method for split ignition timing for idle speed control of an engine

InactiveUS20030221664A1High load conditionMore ignition timingAnalogue computers for vehiclesElectrical controlTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, such as after an engine cold start, the method operates an engine with a first group of cylinders having a first ignition timing, and a second group of cylinders having a second ignition timing more retarded than the first group. In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also can change to combusting all cylinders at substantially the same ignition timing under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

Approach for Facilitating Engine Mode Transitions

ActiveUS20080066713A1Increasing negative overlapElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

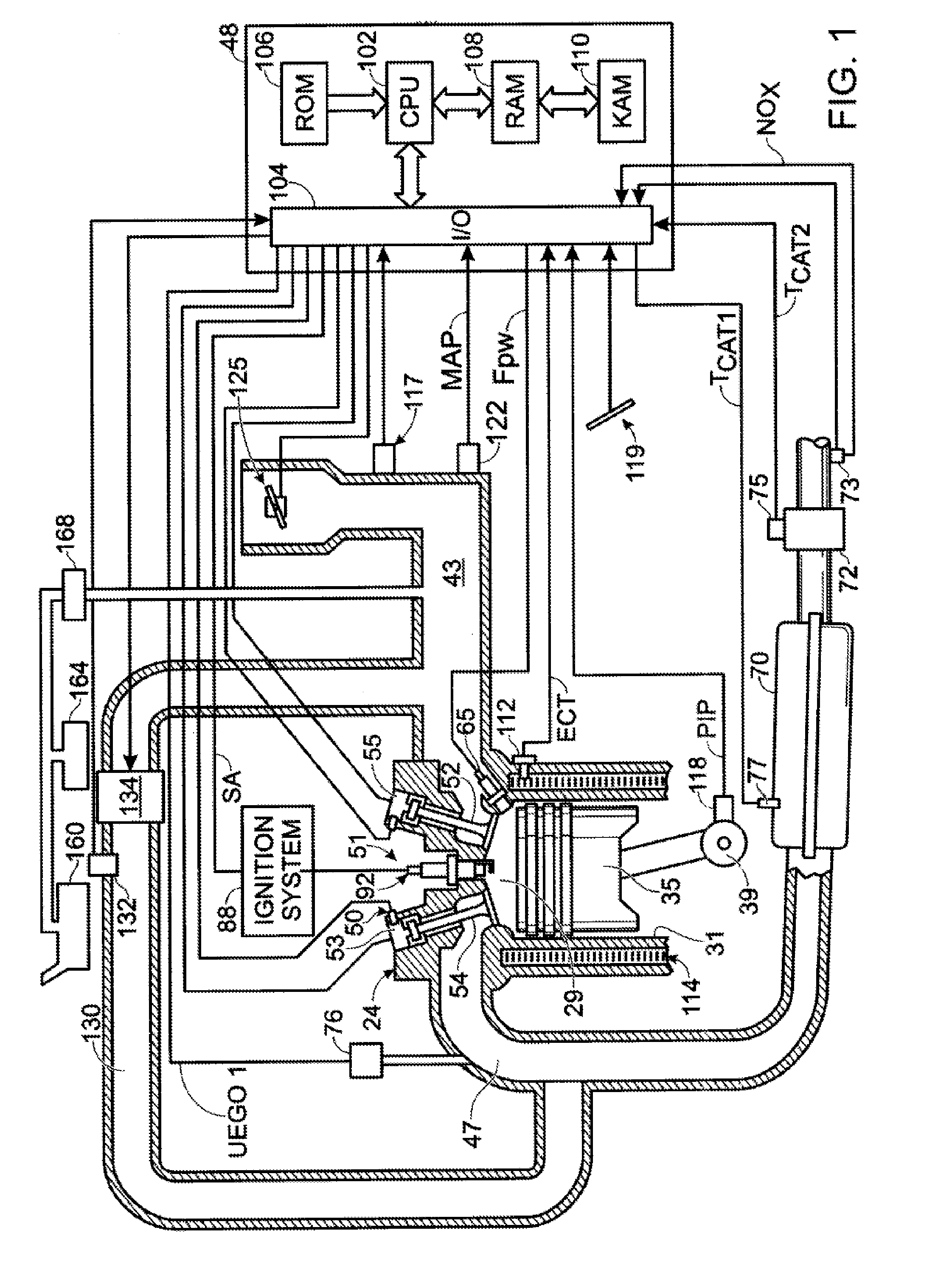

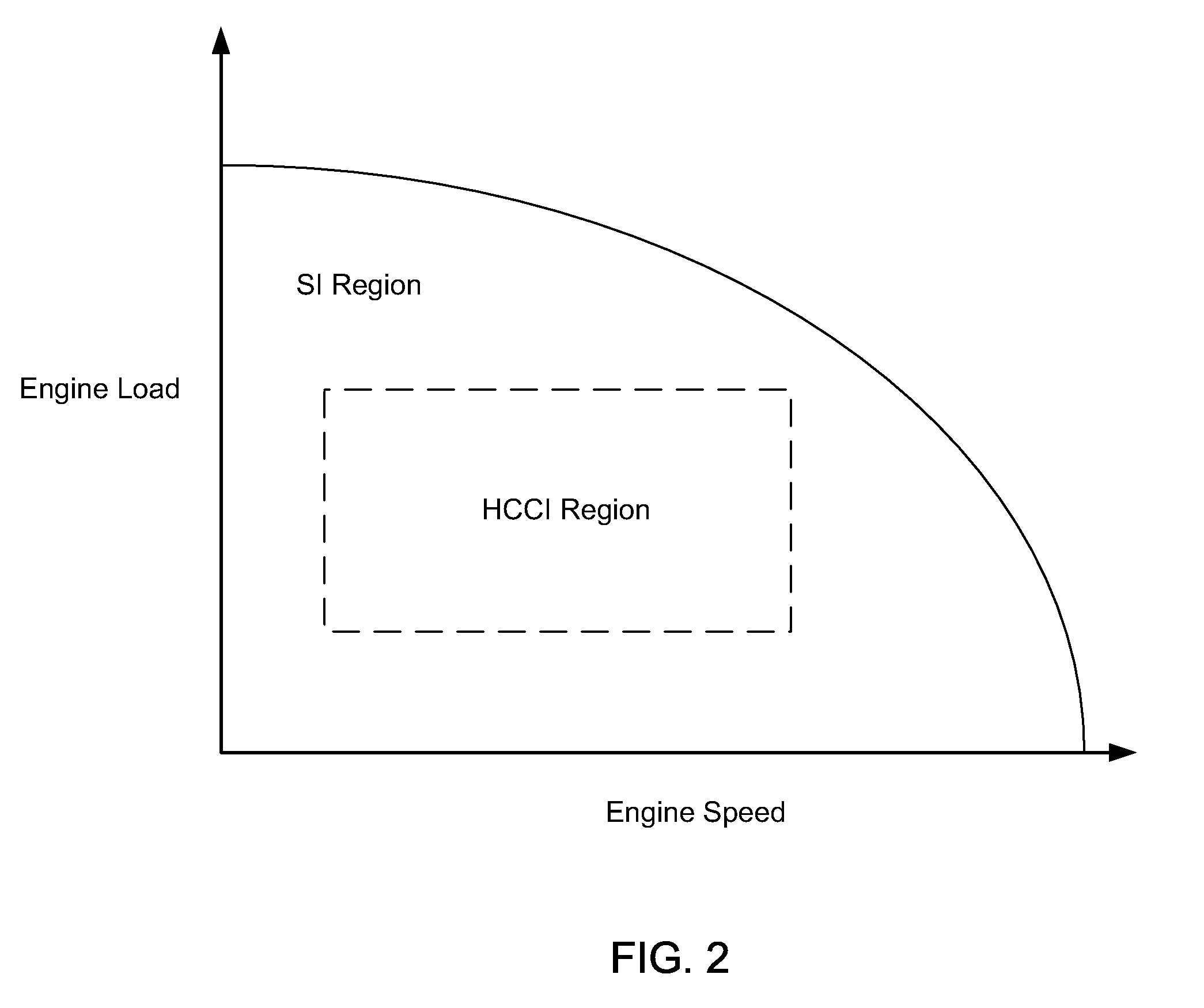

A method of transitioning a cylinder of an engine from a spark ignition mode to a homogeneous charge compression ignition mode, the cylinder having at least one electrically actuated intake valve and at least one exhaust valve, the method comprising of before a transition, operating the cylinder with at least some overlap between an opening event of the intake valve and an opening event of the exhaust valve in the spark ignition mode; in response to a transition request, operating the cylinder with at least some negative overlap between an opening event of the intake valve and an opening event of the exhaust valve, retarding the intake valve opening and closing timing by different amounts and retarding ignition timing; and further increasing negative overlap and performing the homogeneous charge compression ignition mode.

Owner:FORD GLOBAL TECH LLC

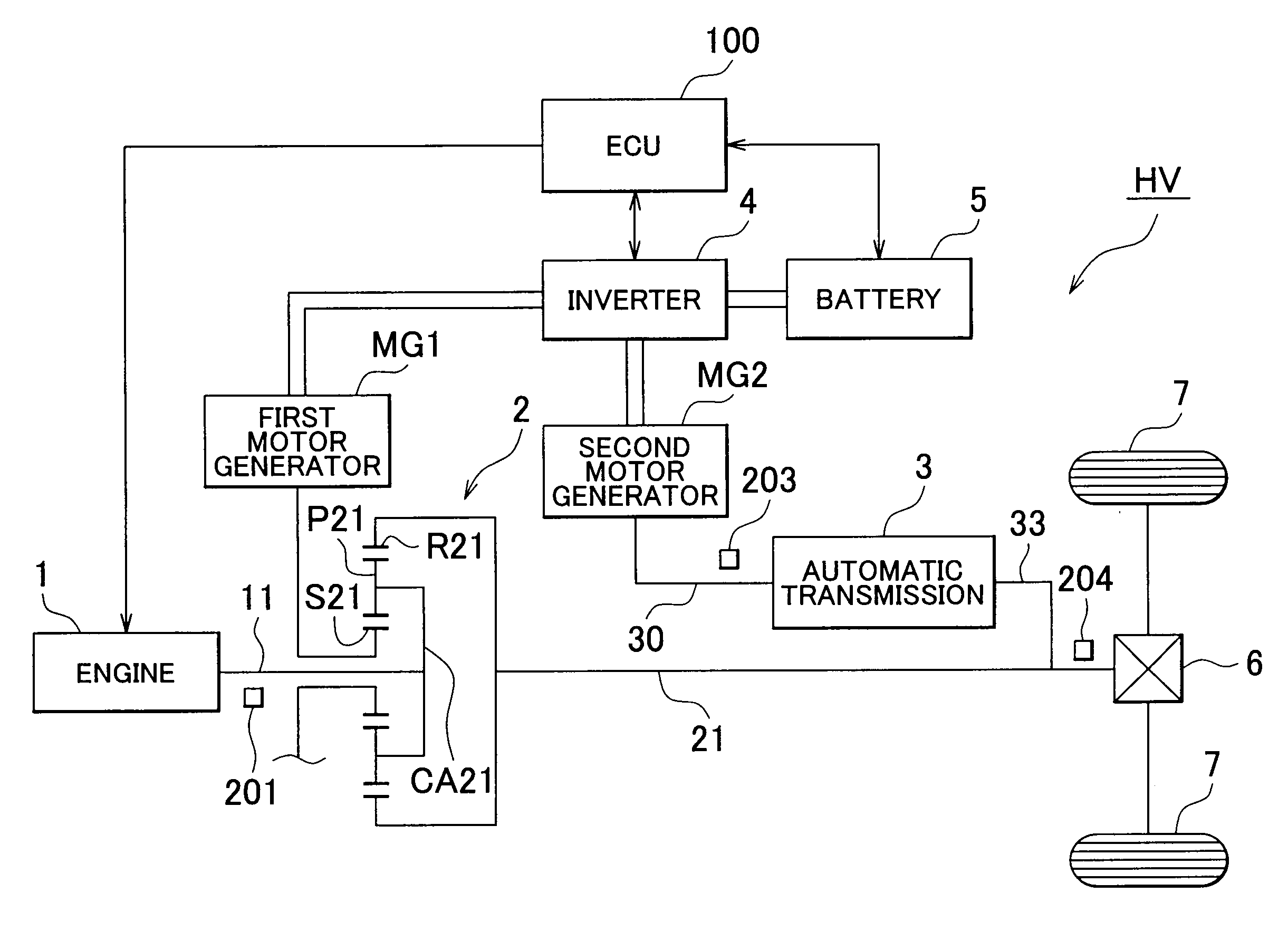

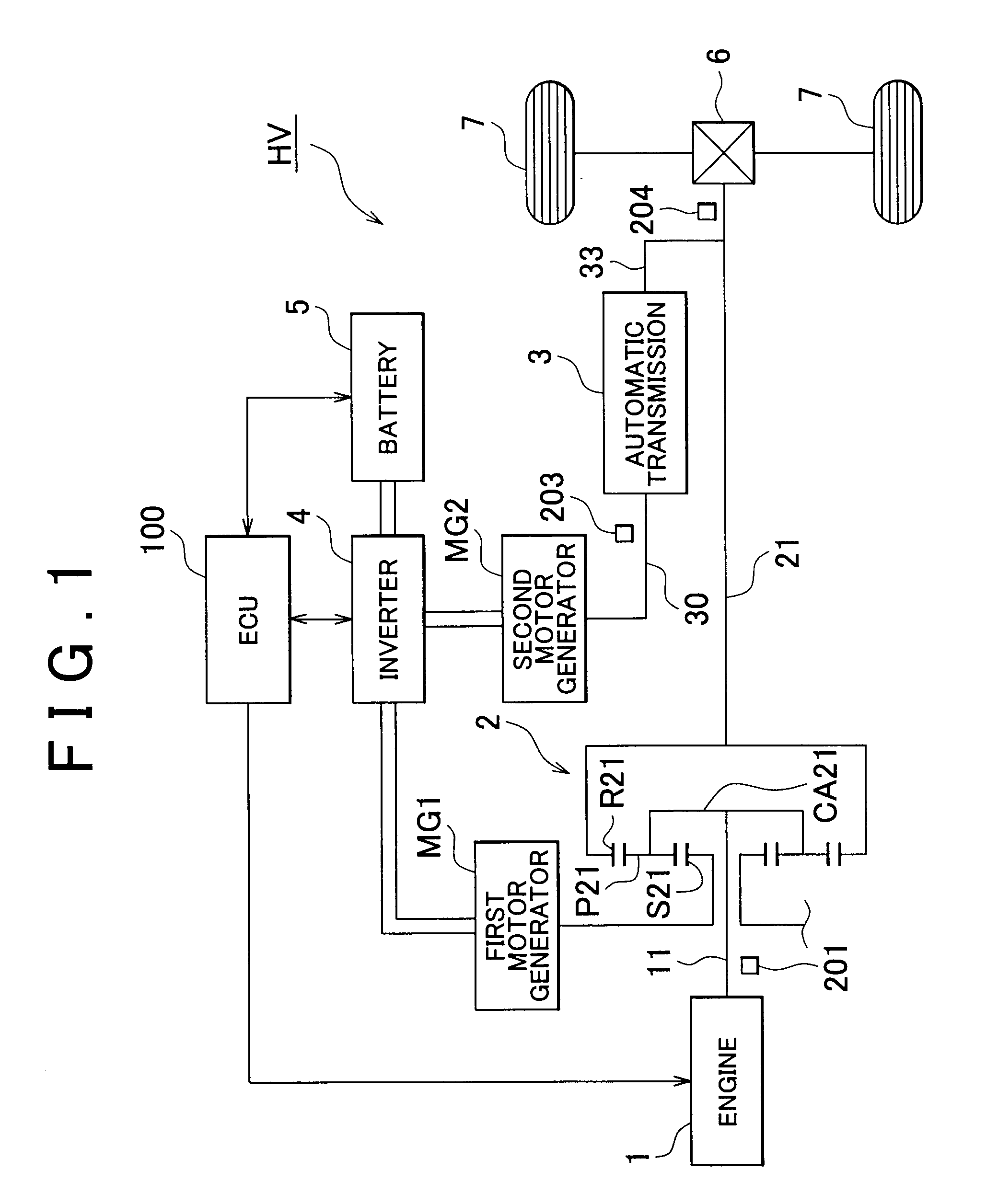

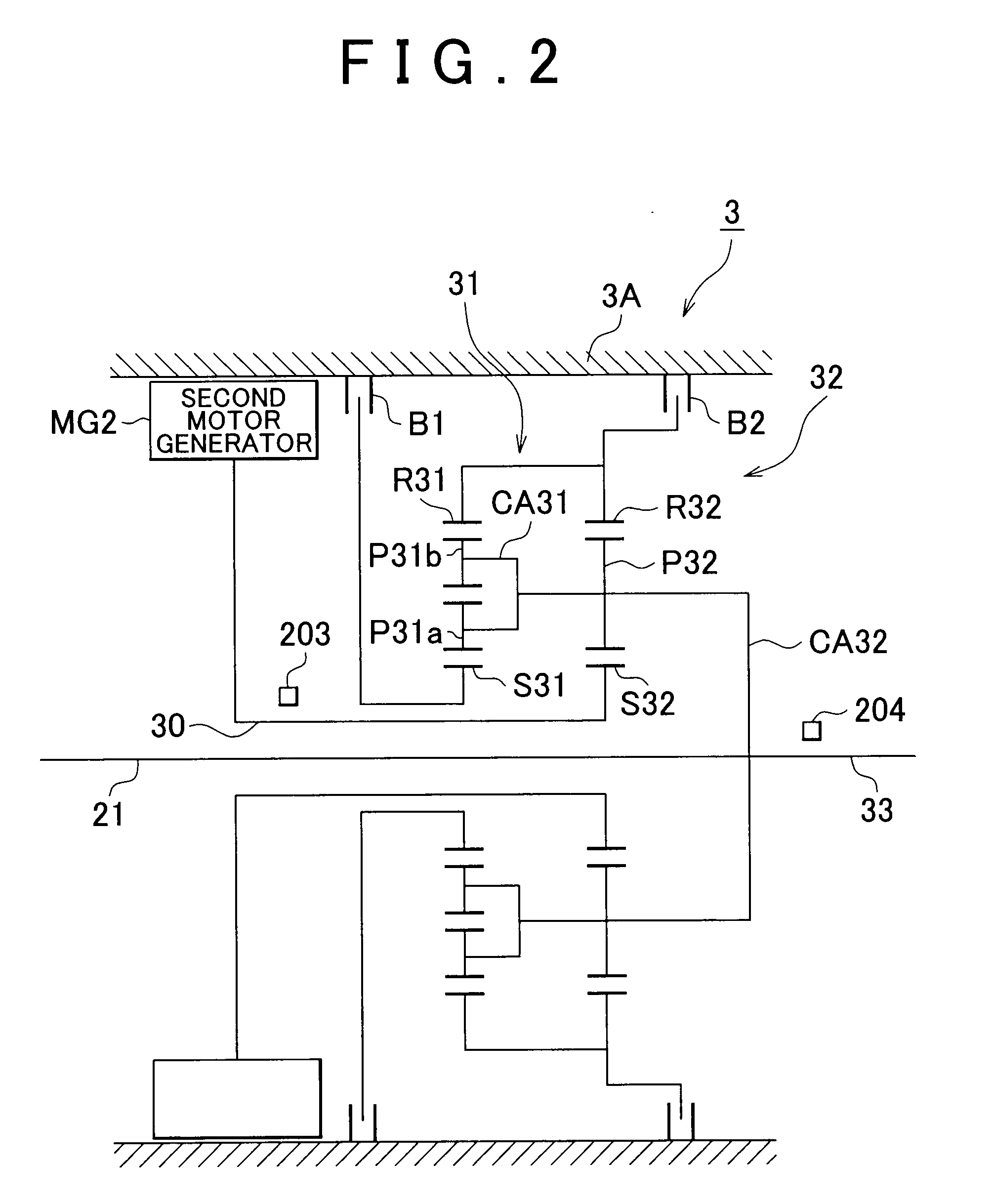

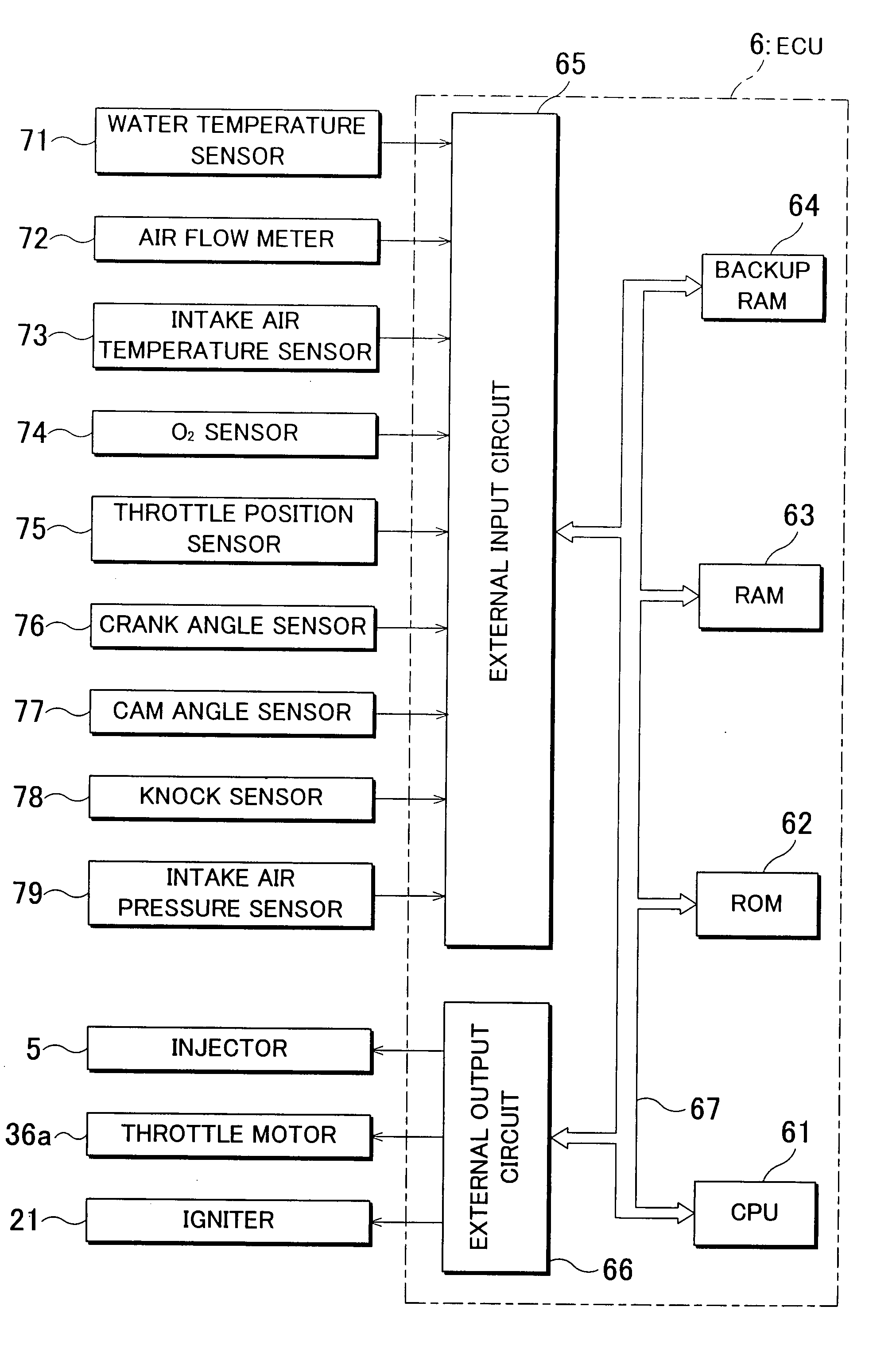

Control device and control method for vehicle

InactiveUS20090227409A1Reduce torqueSuppresses the increase in rotational speedHybrid vehiclesElectrical controlAutomatic transmissionEngineering

During downshifting, a control for restricting an output of an engine to constantly maintain electric power balance between a first electric motor and a second electric motor or a control for suppressing a rate of increase in engine rotational speed by a control on the engine, such as ignition timing retardation control or fuel injection amount reduction control, is executed to thereby allow torque of the second electric motor to be reduced during downshifting. In addition, the engine rotational speed is decreased before downshifting, and, after the engine rotational speed is decreased to a rotational speed at which a protection control is not activated, an automatic transmission downshifts. With the above control, it is possible to suppress an increase in rotational speed of the second electric motor during downshifting. Thus, shift shock may be suppressed, and the friction material of the frictional engagement element may be protected.

Owner:TOYOTA JIDOSHA KK

Automatic internal combustion engine stop device, internal combustion engine provided with the same and automatic internal combustion engine stop method

ActiveUS20070199533A1Short timeGrowth inhibitionPower operated startersElectrical controlStops deviceEngineering

In an automatic stop device that automatically stops the operation of an internal combustion engine after a predetermined automatic stop condition is satisfied, a load acting on the engine is removed when the automatic stop condition is satisfied. When the automatic stop condition is satisfied, the between the magnitude of the load on the internal combustion engine before and after of the automatic stop condition is satisfied is determined, and an ignition timing retard amount of an ignition plug is decided such that the retard amount is increased as the difference becomes greater. The ignition timing is retarded by the retard amount substantially at the same moment as the load removing operation before the automatic stop control is initiated.

Owner:TOYOTA JIDOSHA KK +1

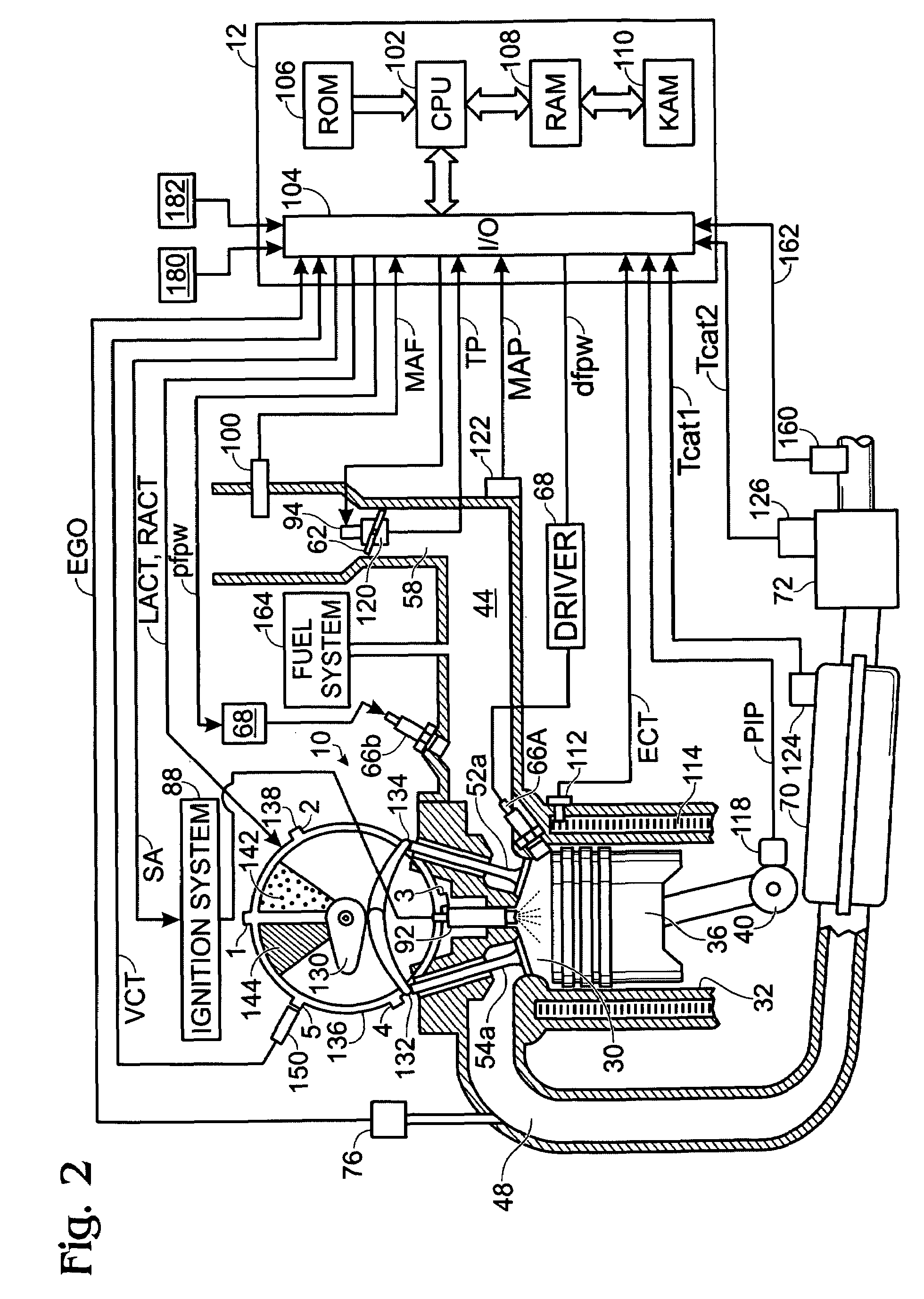

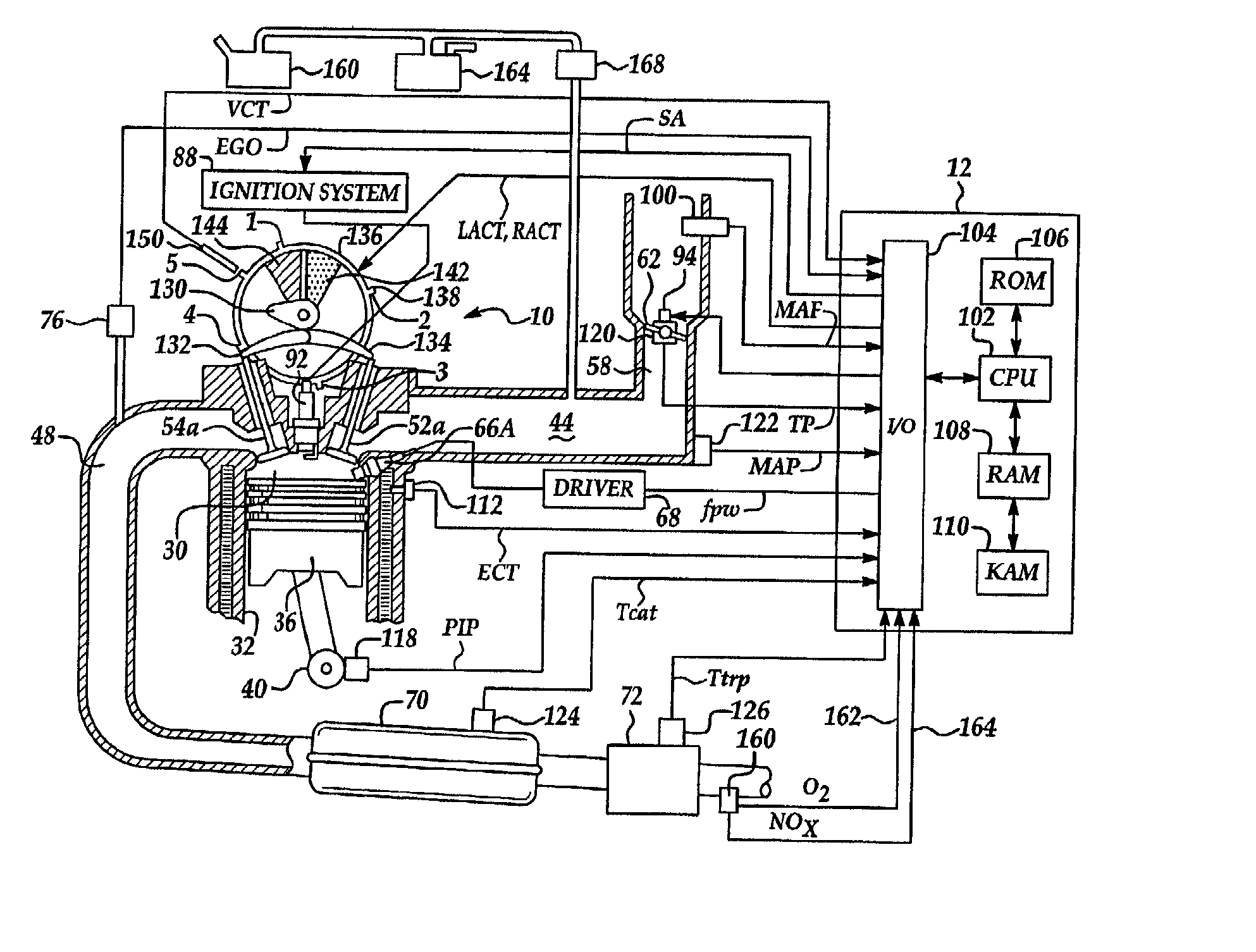

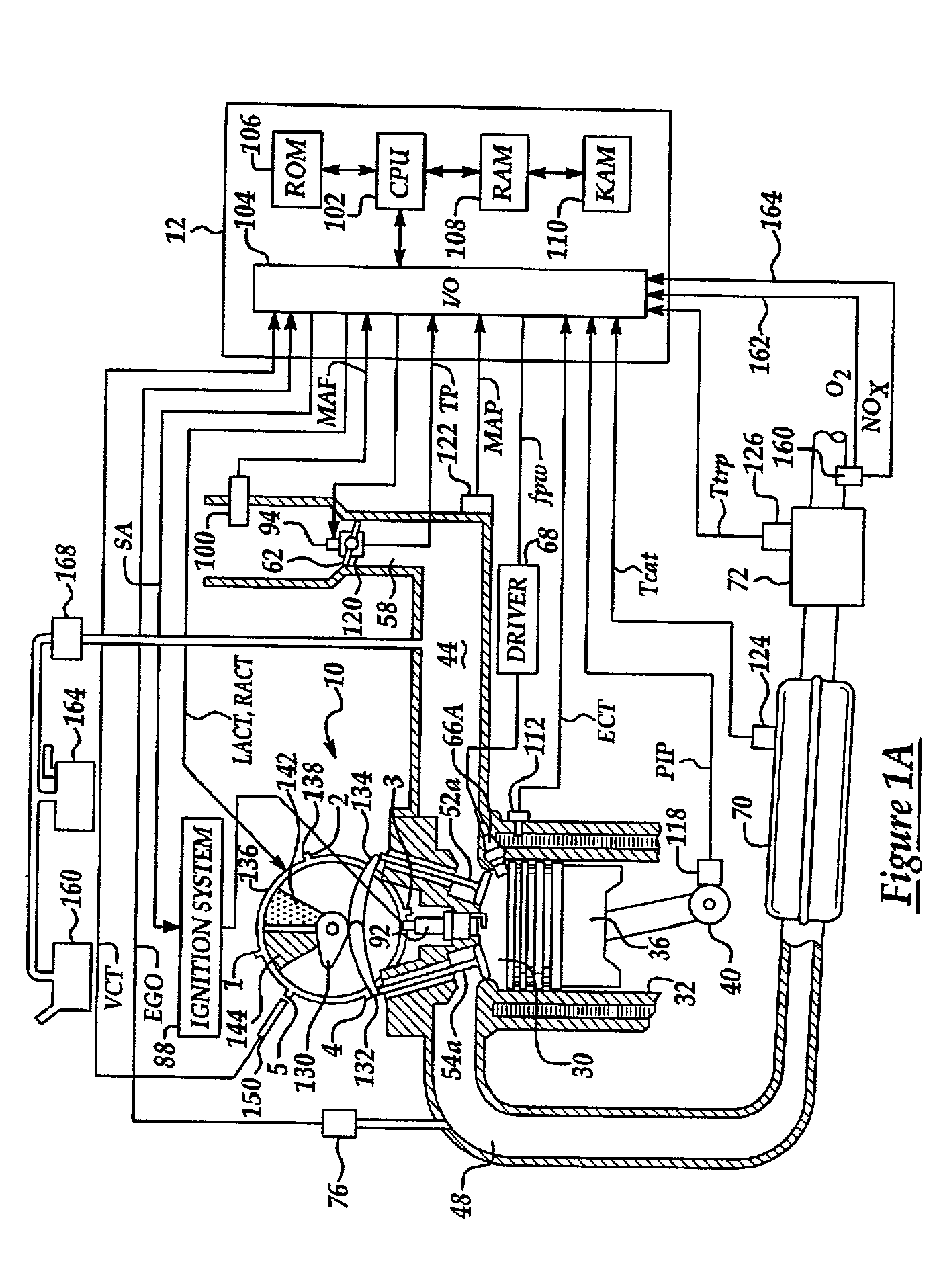

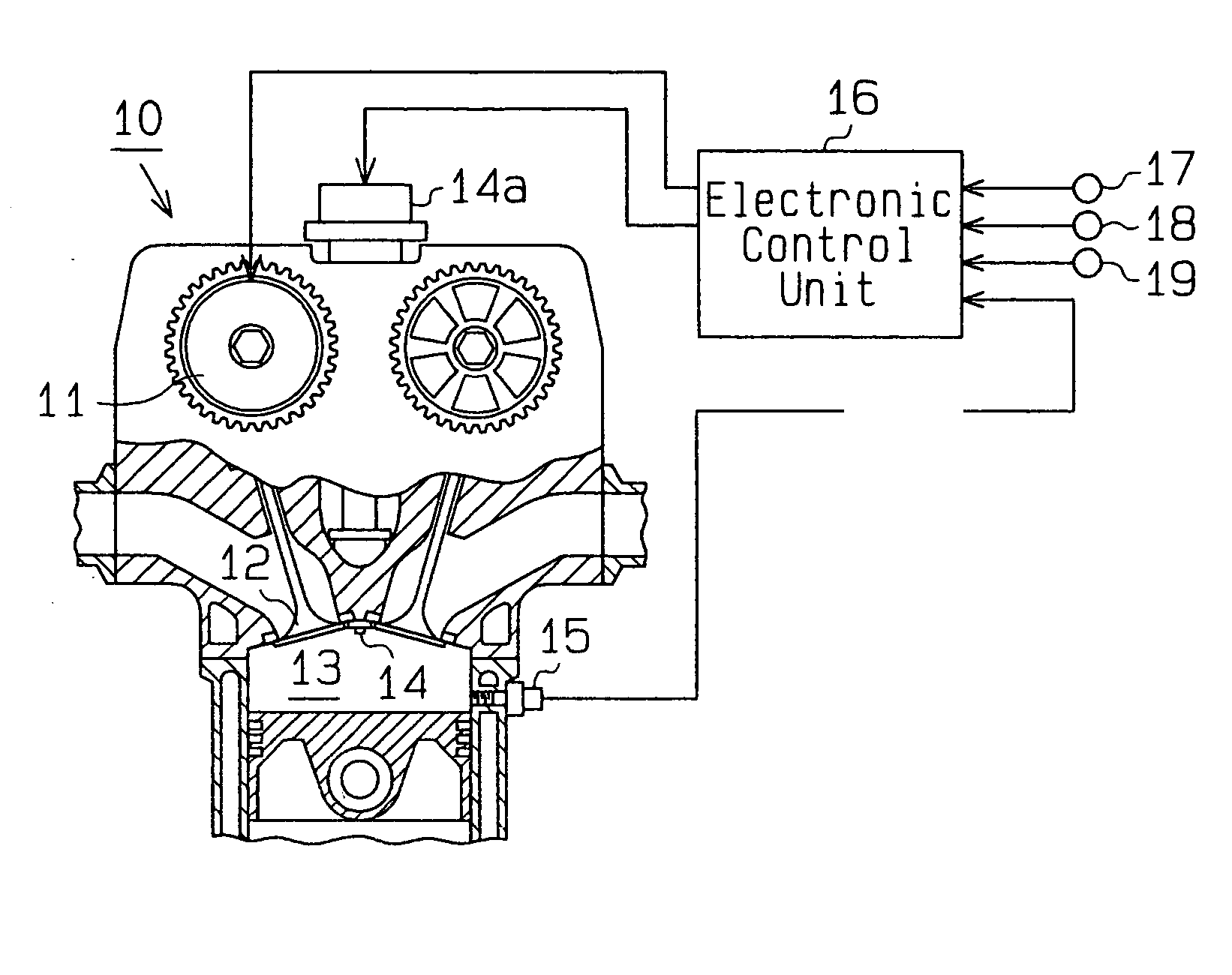

Engine timing control with intake air pressure sensor

InactiveUS6804997B1Reduce in quantityRobust implementationElectrical controlEngine testingExternal combustion engineInlet valve

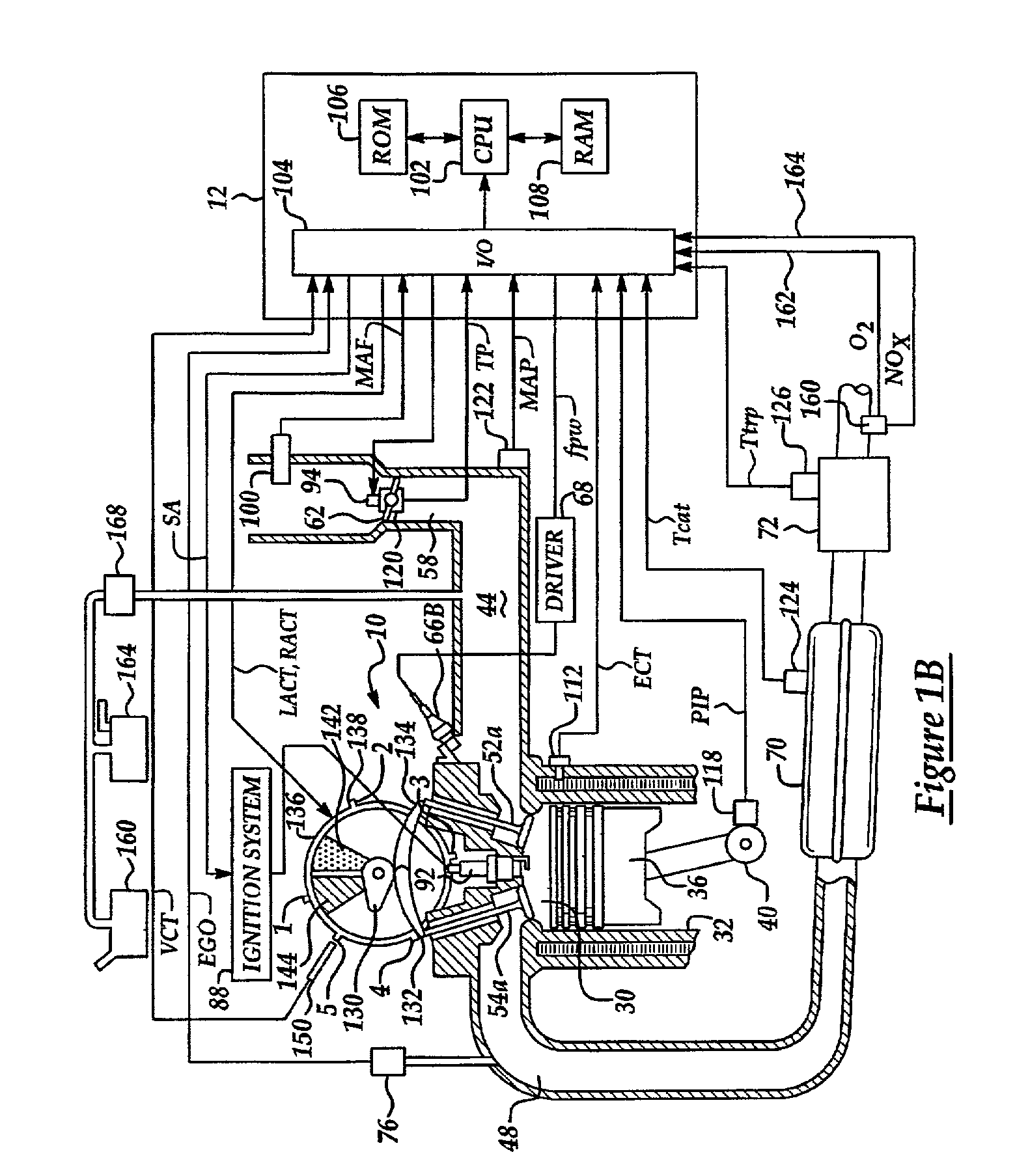

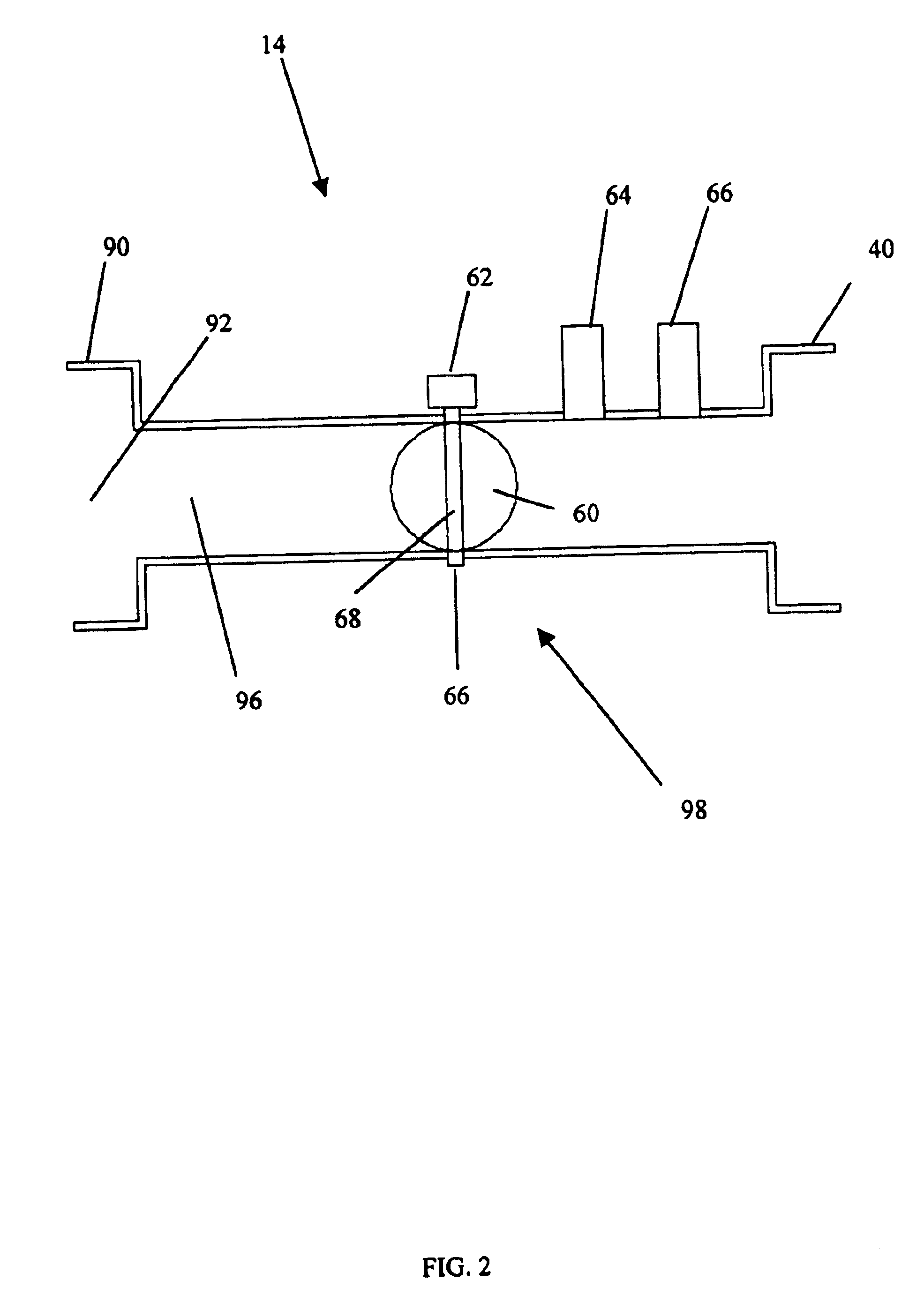

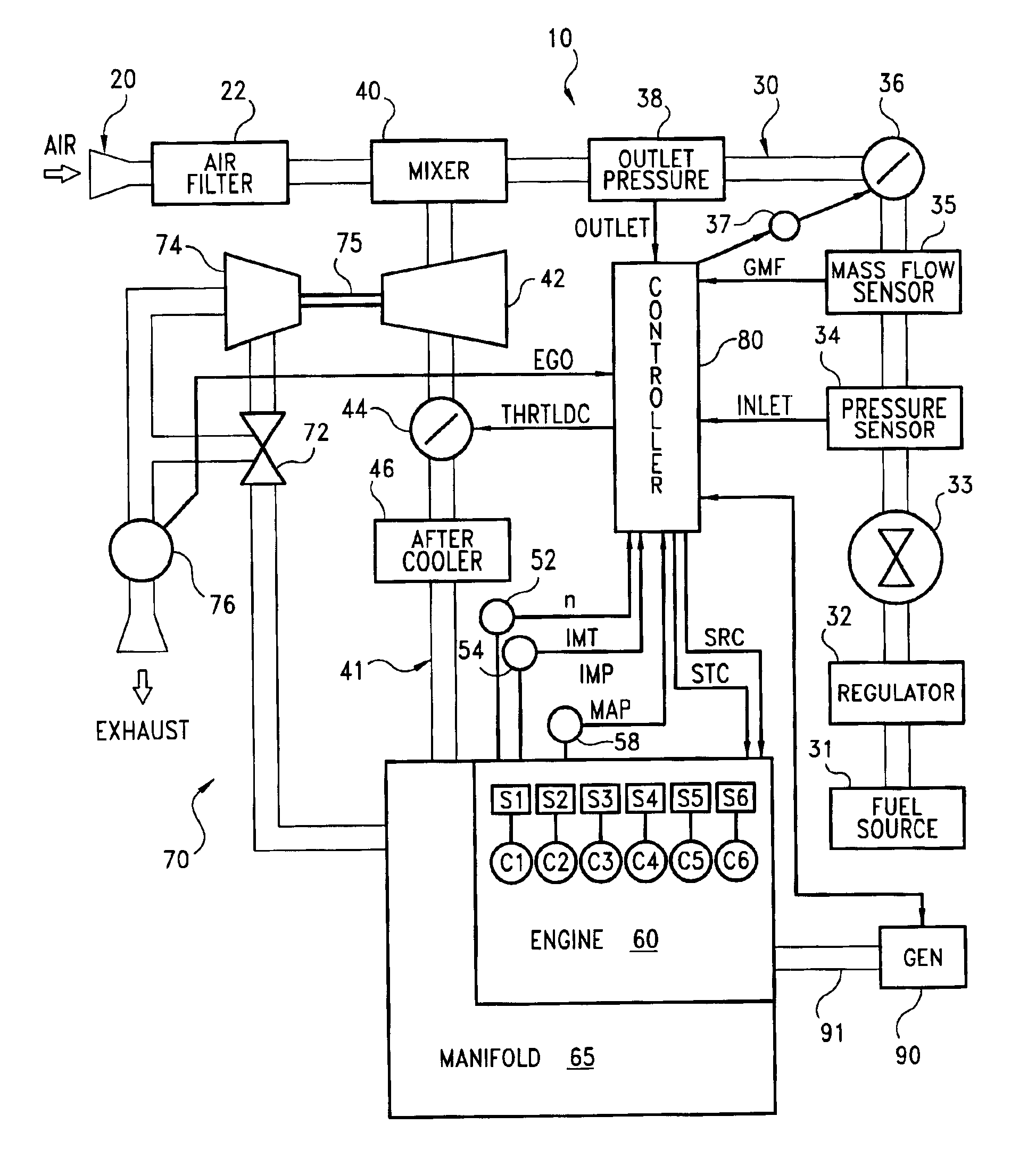

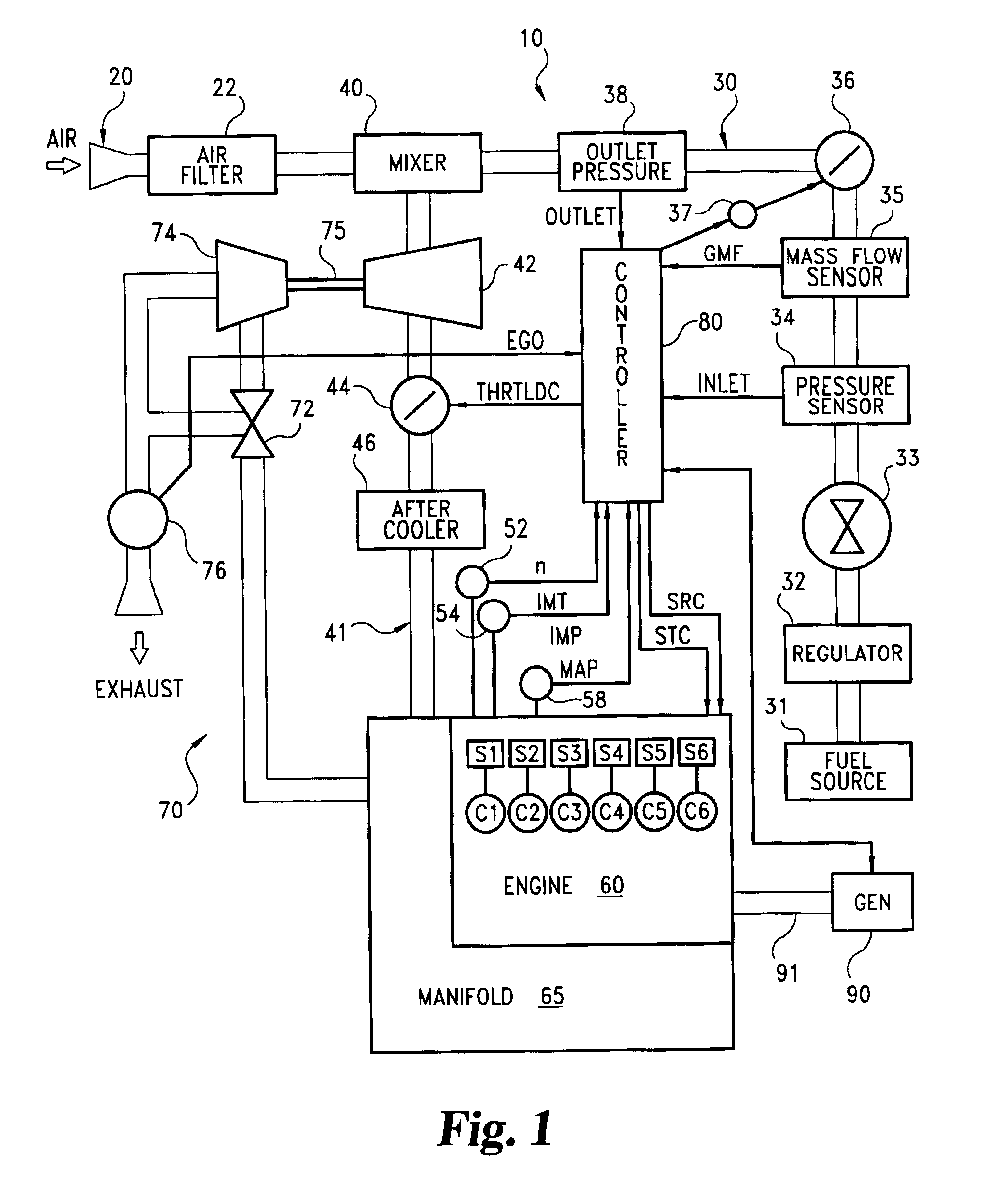

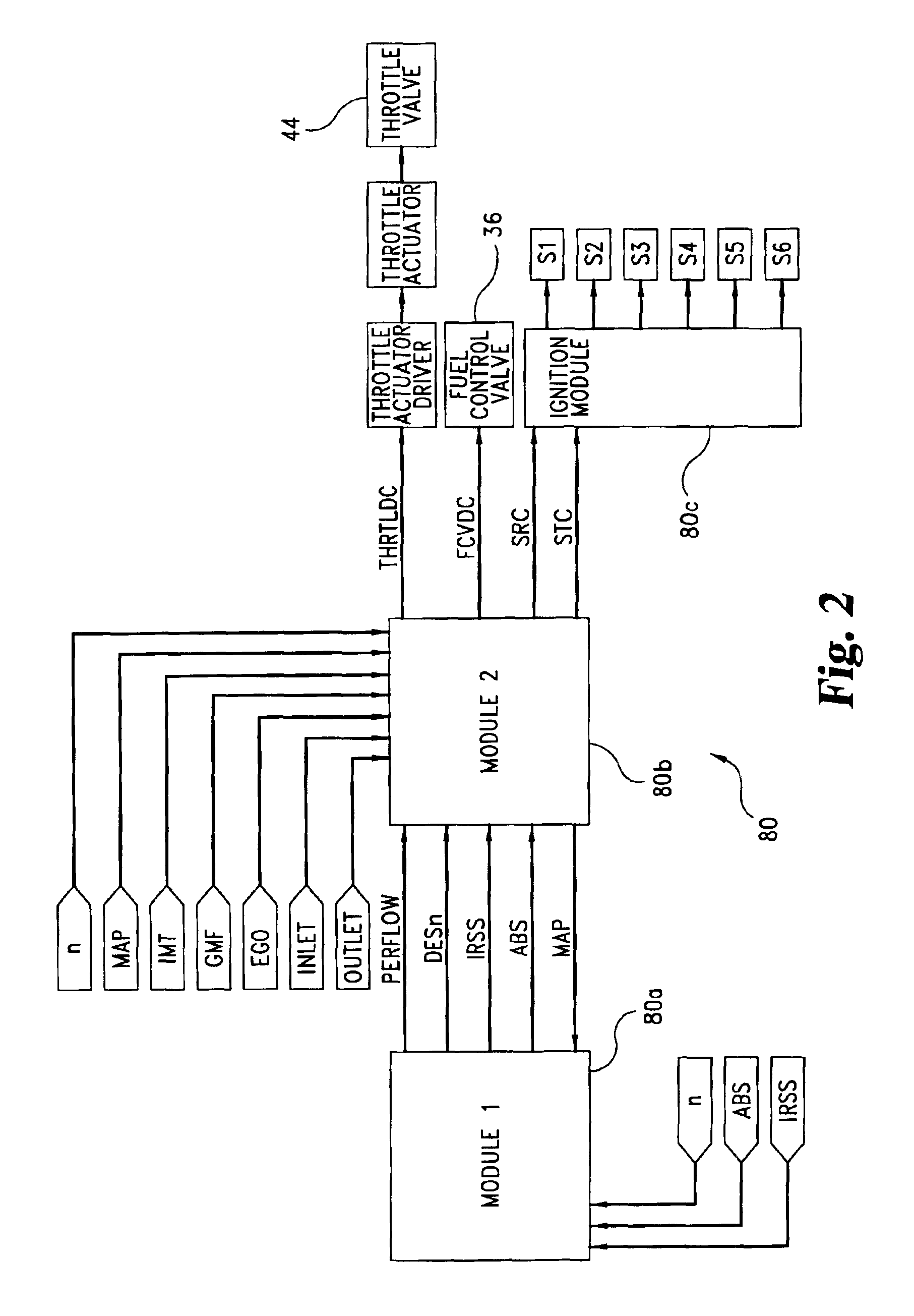

An engine control apparatus is disclosed for determining crankshaft position and engine phase of an internal combustion engine (10) through monitoring intake air pressure fluctuations (120). The opening of the intake valve (44) is mechanically linked to the crankshaft position of an engine. When the intake valve (44) opens it creates air pressure fluctuations in the air induction system (14) of the engine (10). The control apparatus is configured to determine intake air pressure fluctuations indicative of an intake air event (100 to 110) and thus a particular crankshaft position, and their corresponding period of the engine cycle. The controller then uses this information to determine crankshaft speed and position for the purpose of fuel injection and ignition timing of the internal combustion engine. Engine phase is also determined on four-stroke engines. The engine may also include a crankshaft position sensor in combination with monitoring intake air pressure fluctuations to increase resolution in determination of crankshaft position.

Owner:ELECTROJET TECH INC

System for regulating speed of an internal combustion engine

InactiveUS6876097B2Increase speedElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

An internal combustion engine system is disclosed that improves regulation of engine speed relative to a speed setpoint. The system controls ignition timing, throttle plate actuation, fuel valve actuation or a combination thereof in accordance with maintaining a setpoint speed. The system also includes a transient air flow estimation for further improving setpoint speed accuracy.

Owner:CUMMINS INC

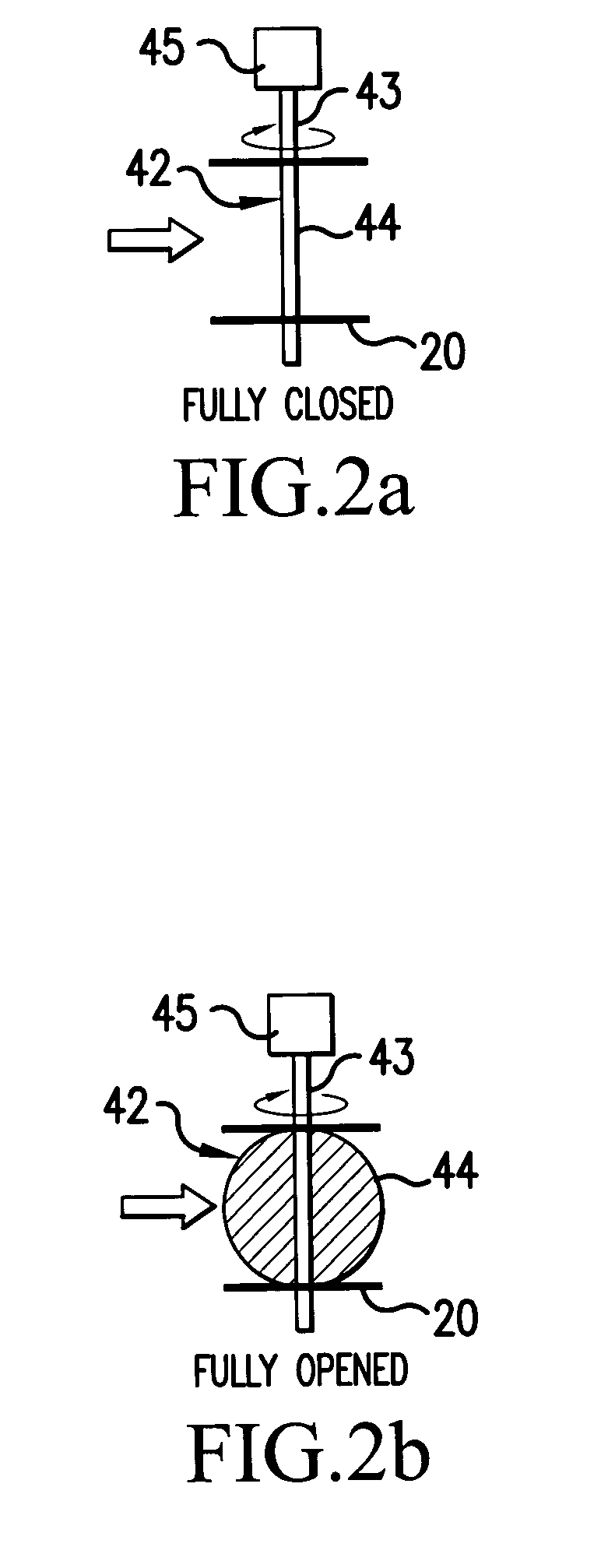

Exhaust emission control apparatus for internal combustion engine

InactiveUS6968677B2Reliable detectionReduce the presence of hazardous substancesAnalogue computers for vehiclesElectrical controlAir volumeExternal combustion engine

There is provided an exhaust emission control apparatus for an internal combustion engine, which includes a failure diagnostic device that fixes three parameters selected from the group consisting of the engine speed detected by an engine speed detecting device, the fuel quantity controlled by a fuel quantity control device, the ignition timing controlled by an ignition timing control device, and the intake air volume controlled by an intake air control device at respective predetermined values, and finds values of the remaining one parameter, and compares the values of the remaining one parameter with each other to determine whether an exhaust flow control apparatus has failed or not.

Owner:MITSUBISHI MOTORS CORP

Spark-ignition gasoline engine

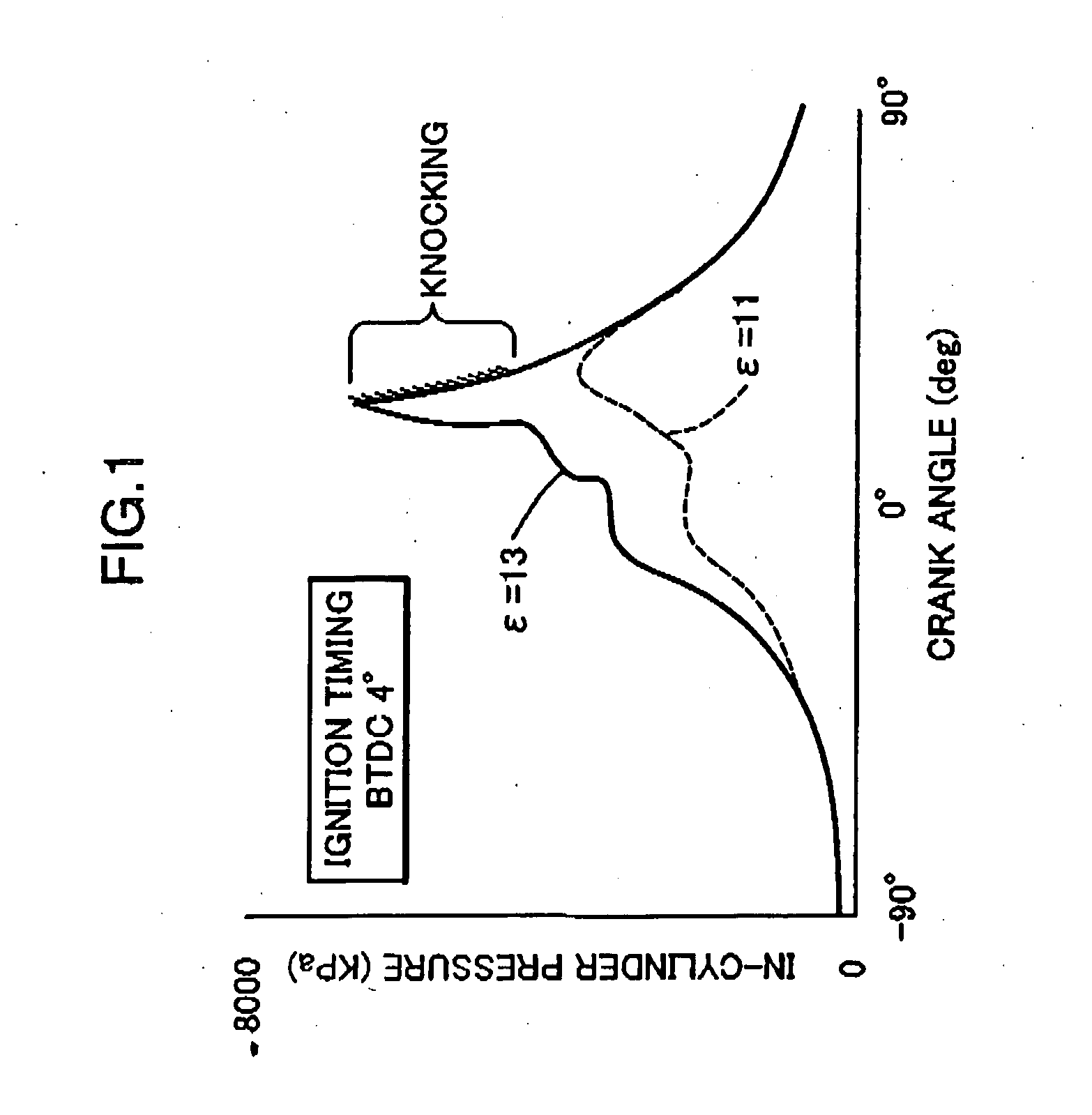

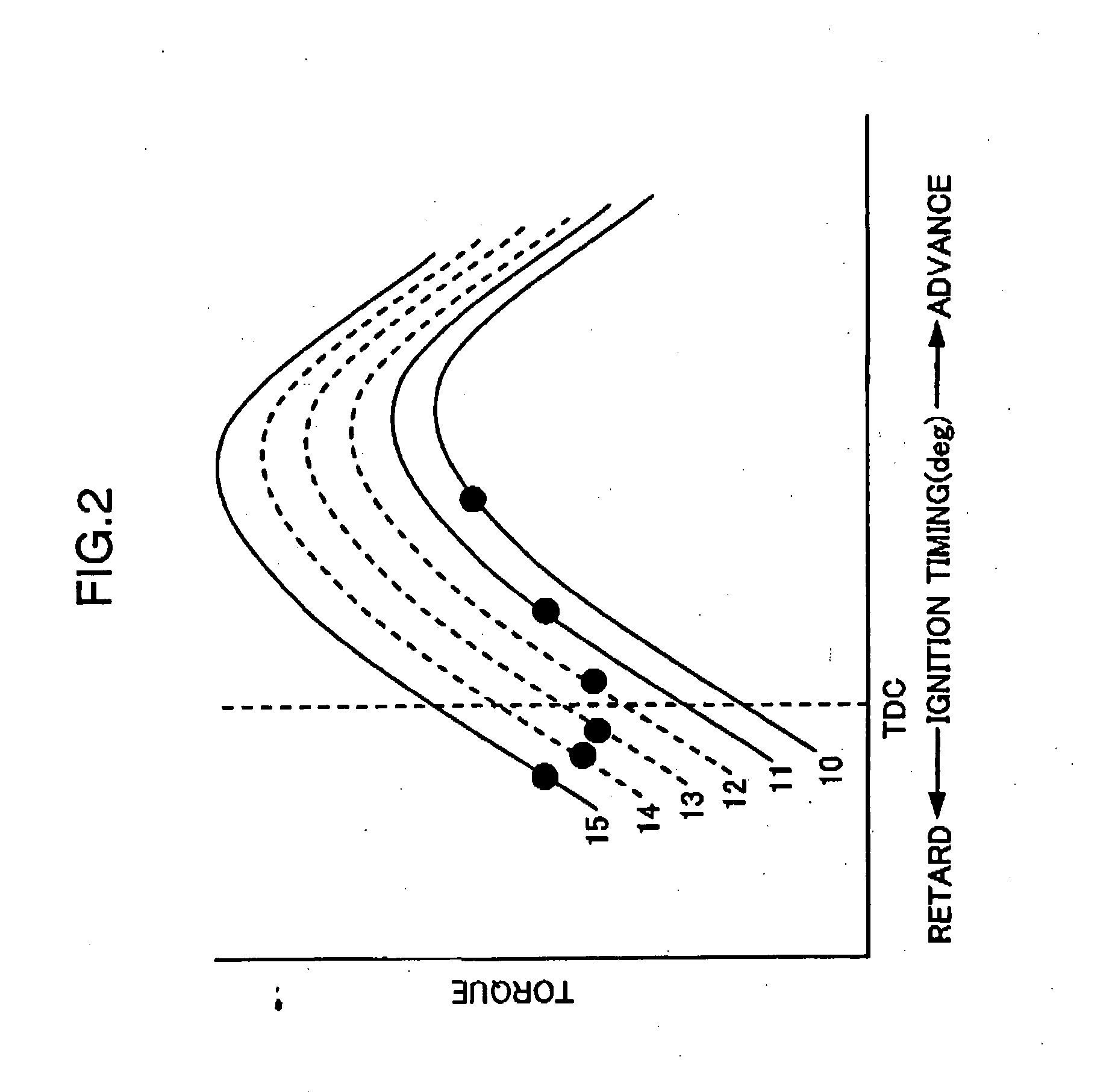

ActiveUS20070227503A1Improve fuel economyShorten burn timeElectrical controlInternal combustion piston enginesLow speedTop dead center

Disclosed is a spark-ignition gasoline engine, which comprises control means operable, when an engine operation zone is a high-load operation zone including a WOT region within at least a low speed range, to adjust a closing timing of an intake valve in such a manner as to maintain an effective compression ratio at 13 or more, and retard an ignition timing to a point within a predetermined stroke range just after a top dead center of a compression stroke, wherein the effective compression ratio is calculated based on an intake-valve closing timing defined by a valve lift amount of 1 mm. The present invention can provide a spark-ignition gasoline engine having both a low-cost performance and a high engine-power performance even in a high-load operation zone (particularly WOT region) in a low speed range.

Owner:MAZDA MOTOR CORP

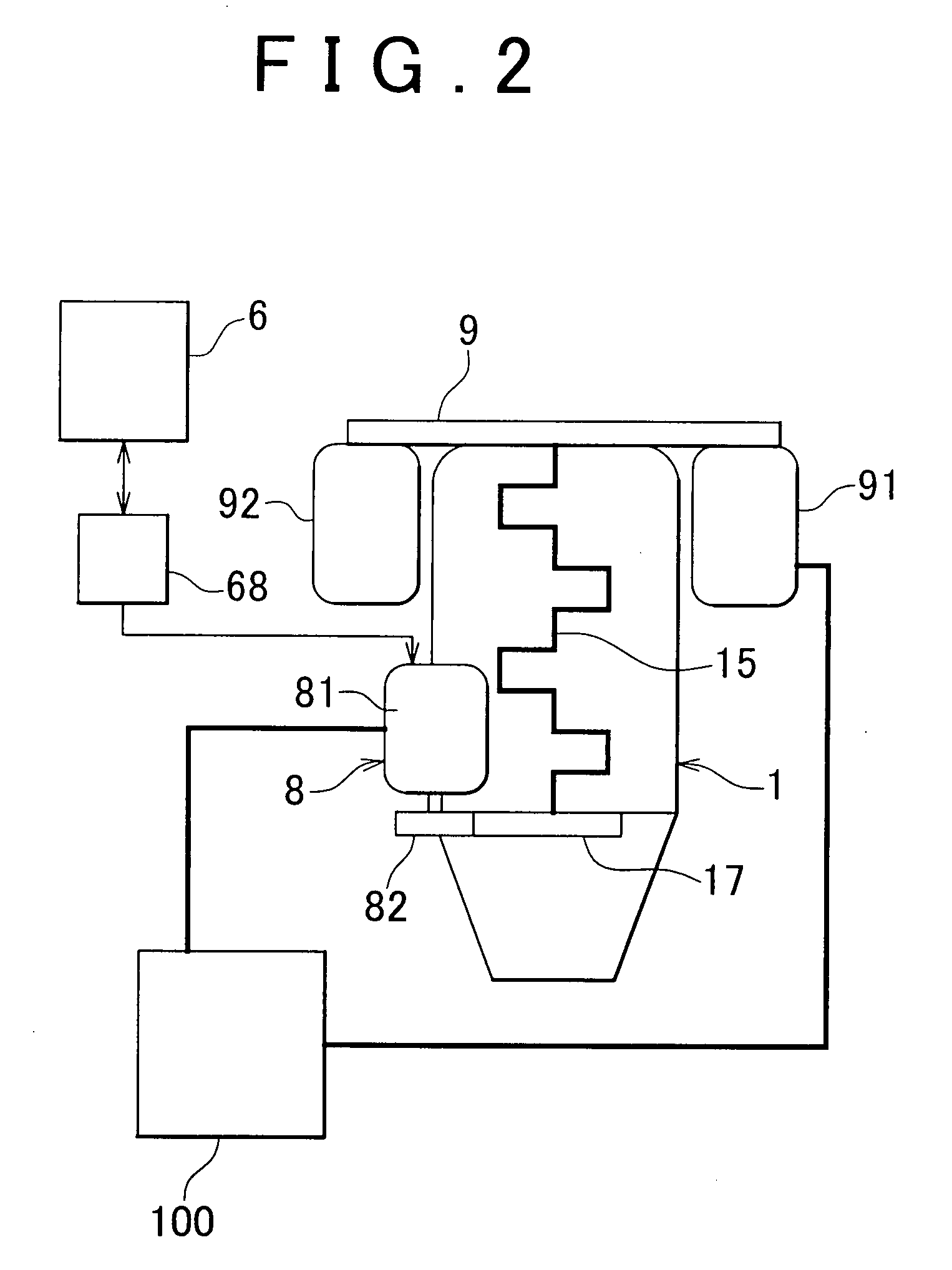

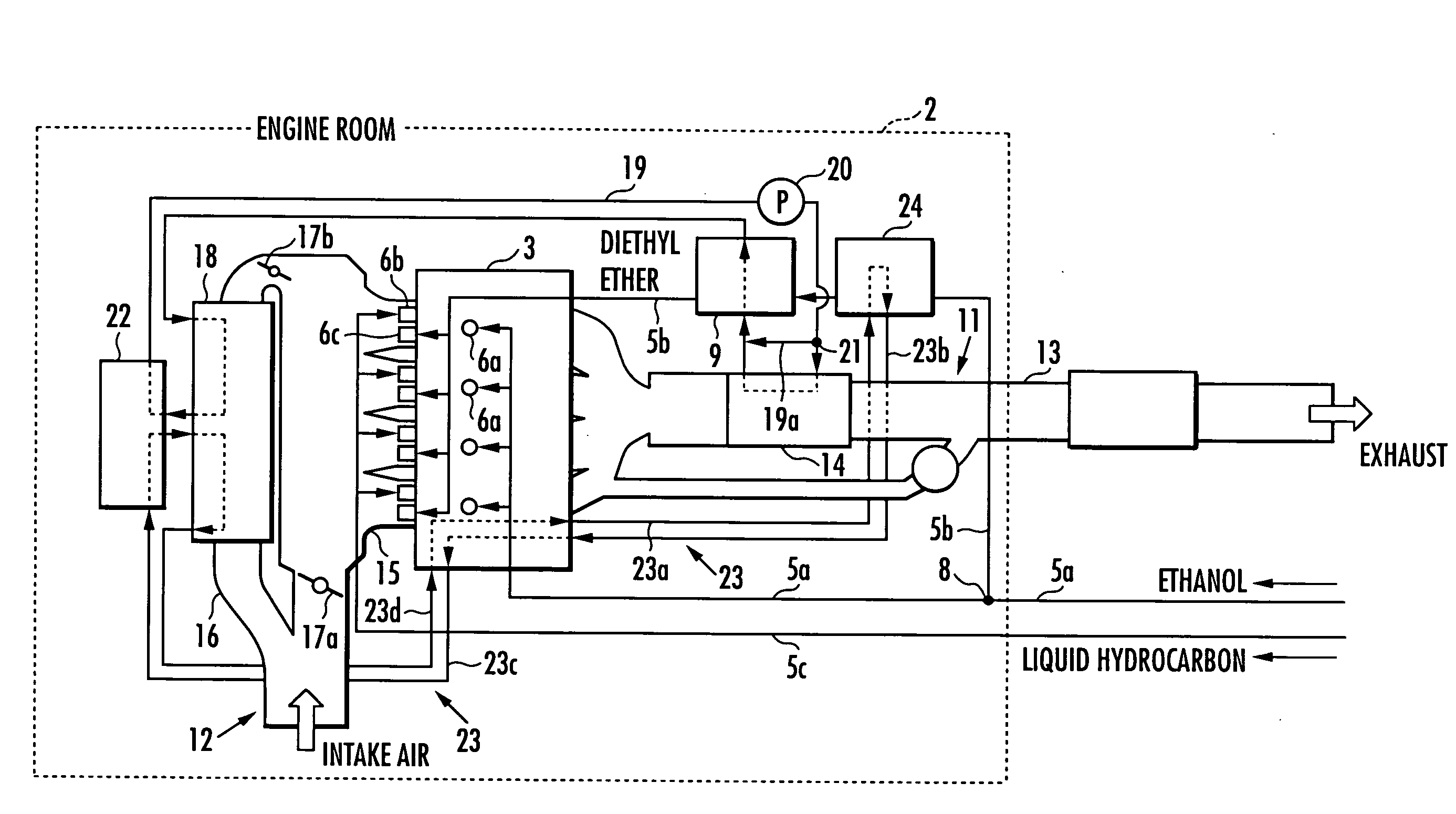

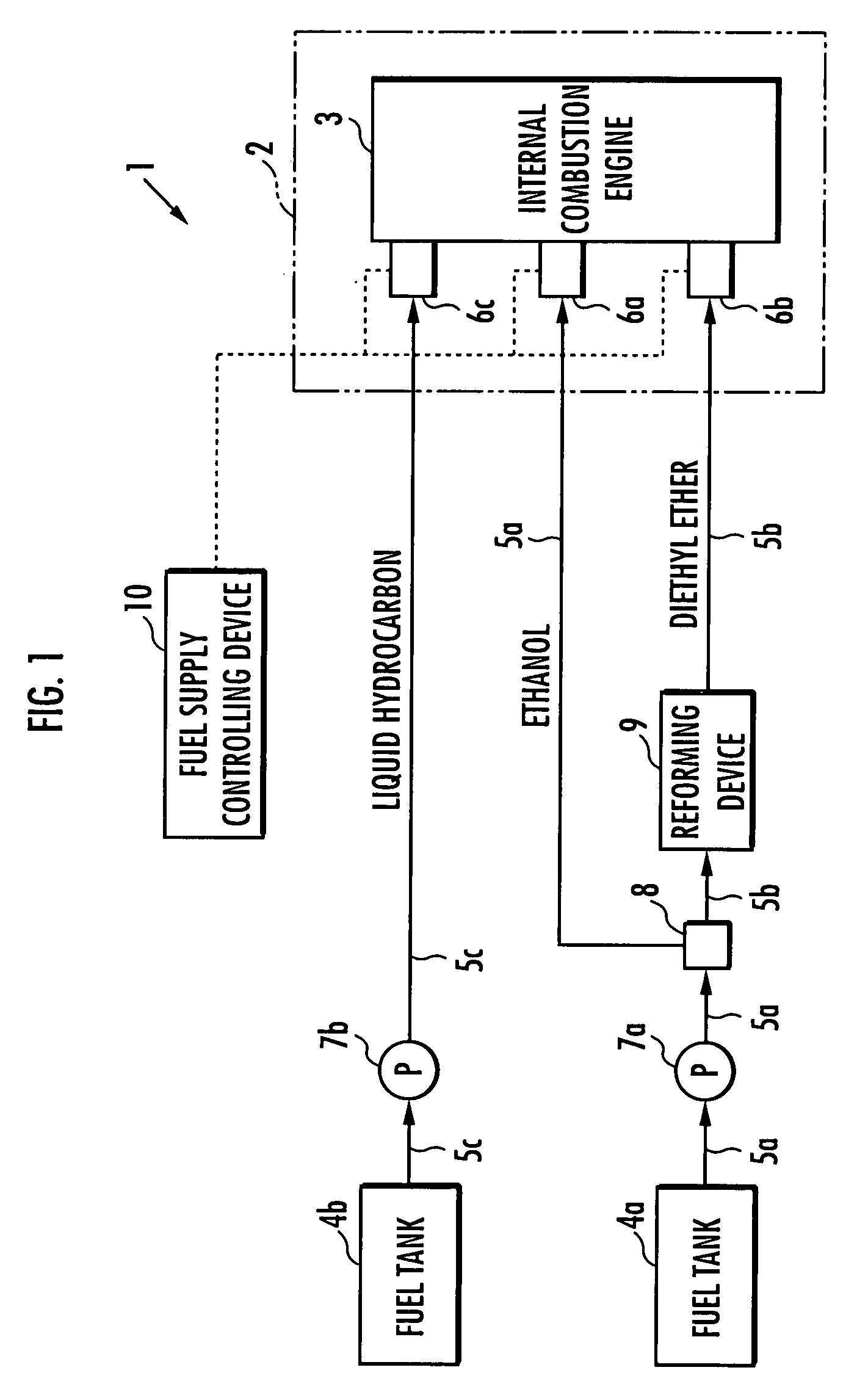

Internal combustion engine system

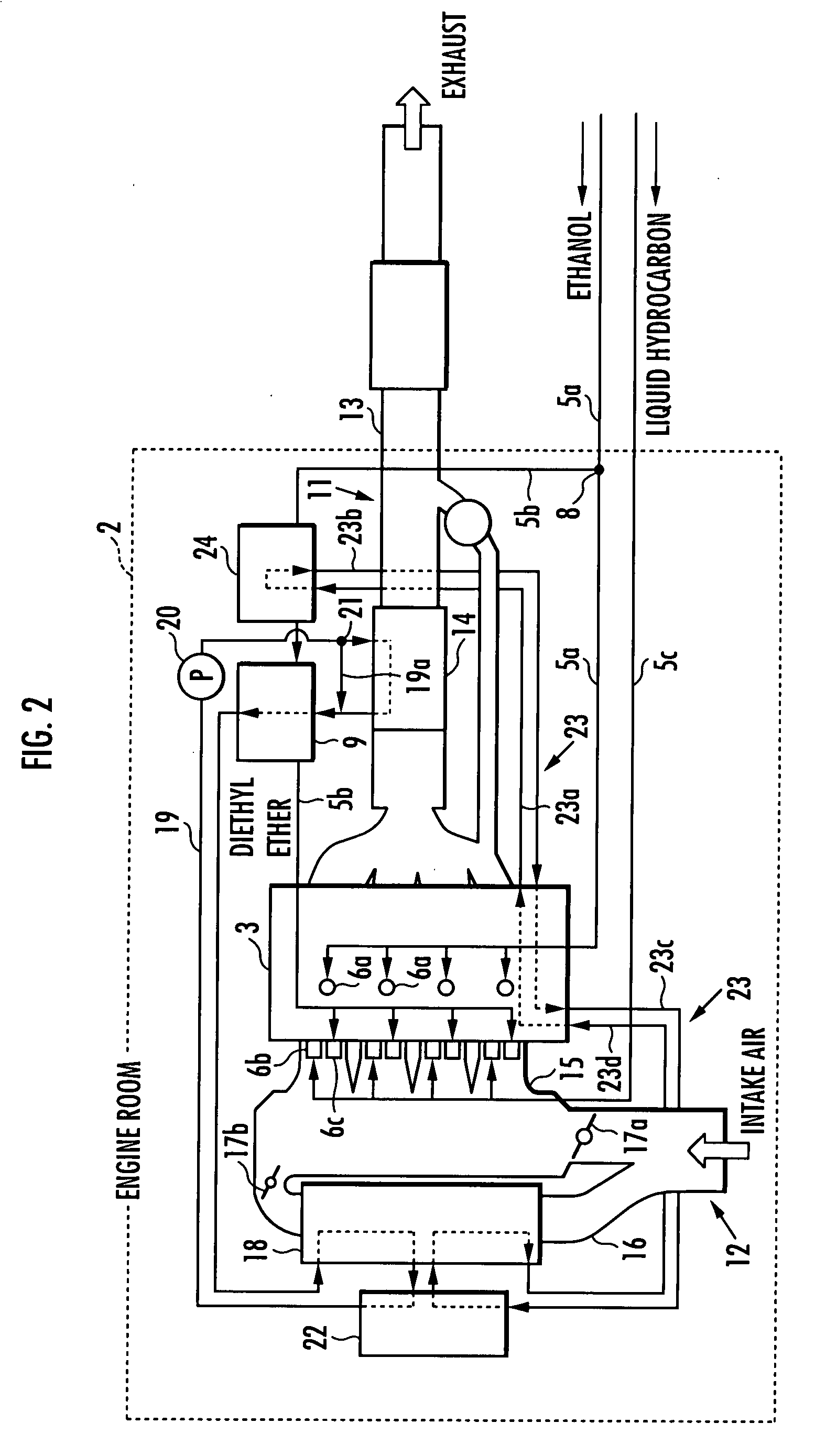

InactiveUS20080098985A1Accurate timingElectrical controlNon-fuel substance addition to fuelHomogeneous charge compression ignitionNaphtha

The present invention provides an internal combustion engine system that can precisely control ignition timing on homogeneous charge compression ignition. The internal combustion engine system includes a fuel tank 4a containing ethanol, a fuel tank 4b containing at least one of gasoline and GTL naphtha, a reforming device 9 for reforming ethanol to obtain diethyl ether, a heat exchange device 14 for heating a heating medium, an ethanol heater 9b for heating ethanol with the heating medium, and a fuel supply controlling device 10 for controlling a mixture ratio of the fuel. The internal combustion engine system further includes an intake air heater 18 for heating intake air with the heating medium. The internal combustion engine system further comprises an adiabatic storage container 29 for storing the heating medium during a halt of an internal combustion engine 3. The internal combustion engine system further comprises a flow controlling device 27 for flowing the heating medium to the adiabatic storage container 29 only when a temperature detected by a thermal detector 30a is higher than a temperature detected by a thermal detector 30b during an operation of the internal combustion engine 3. The internal combustion engine system further comprises a fuel tank 42 containing a mixed fuel, and a separating device 43 for separating the mixed fuel into an ethanol-water mixture, gasoline and GTL naphtha by adding water to the mixed fuel.

Owner:HONDA MOTOR CO LTD

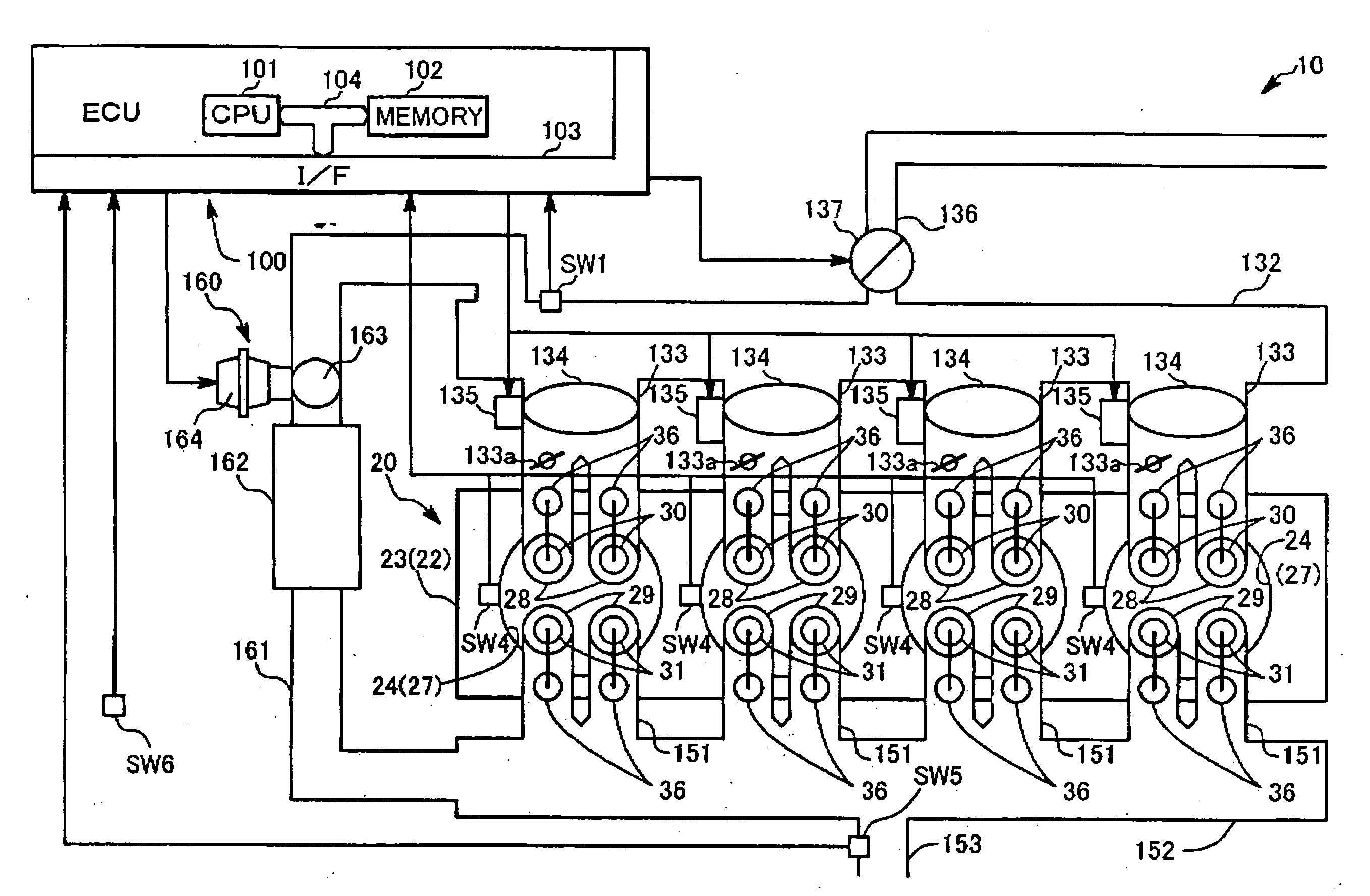

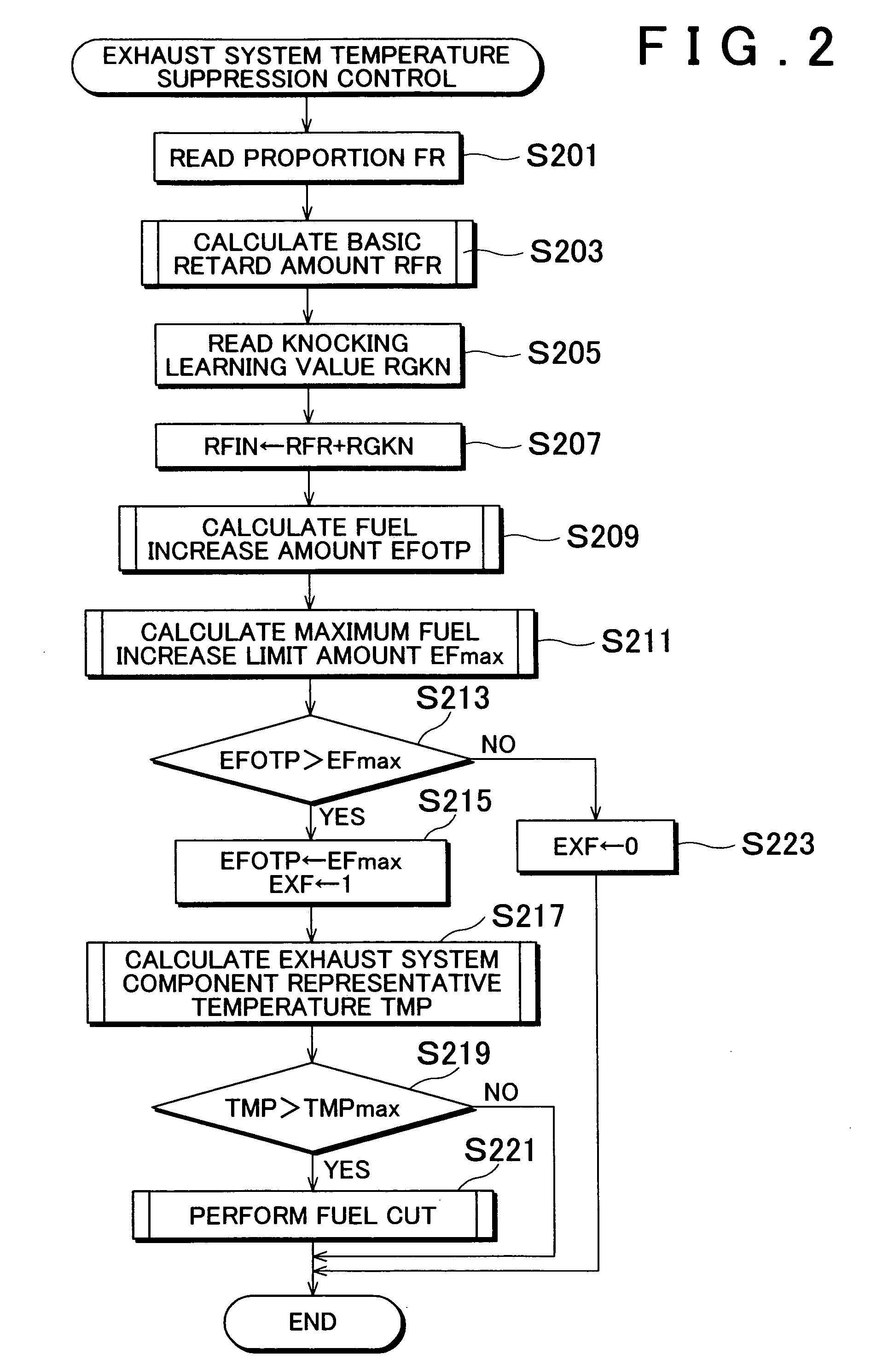

Control apparatus and control method for internal combustion engine

InactiveUS7047940B2Reduces the possibility of) an excessive increase in an exhaust system temperaturePrevent over-boostingElectrical controlInternal combustion piston enginesExternal combustion engineIgnition timing

A control apparatus stops supply of a fuel to an engine (a) when a value of a parameter relating to a misfire of the engine satisfies a misfire condition that is set based on an octane value of the fuel, or (b) when it is determined that a misfire may occur if an increased amount of the fuel is supplied to the engine in the case where ignition timing of the engine is retarded based on an octane value of the fuel, and the amount of the fuel is increased according to a retard amount of the ignition timing.

Owner:TOYOTA JIDOSHA KK

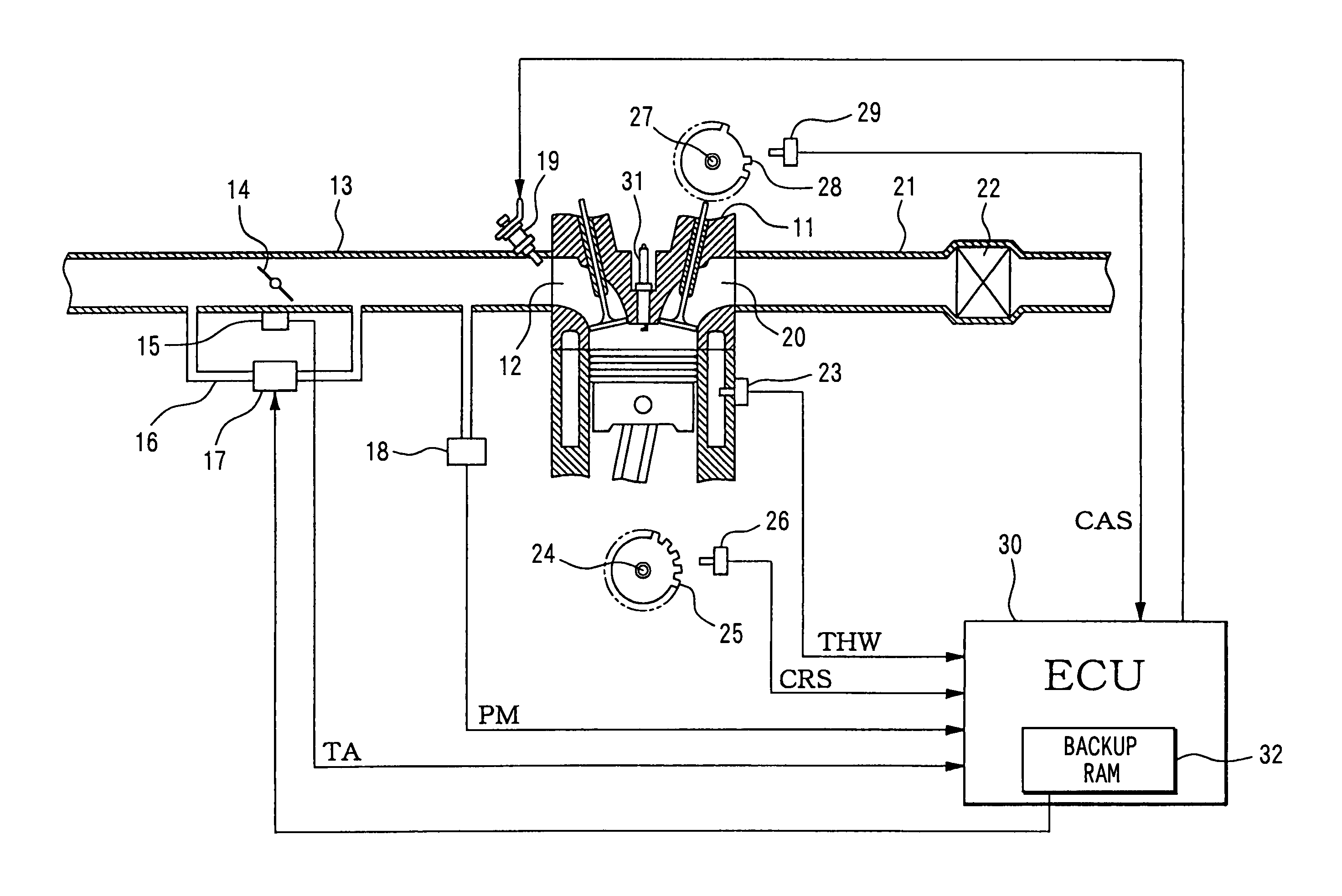

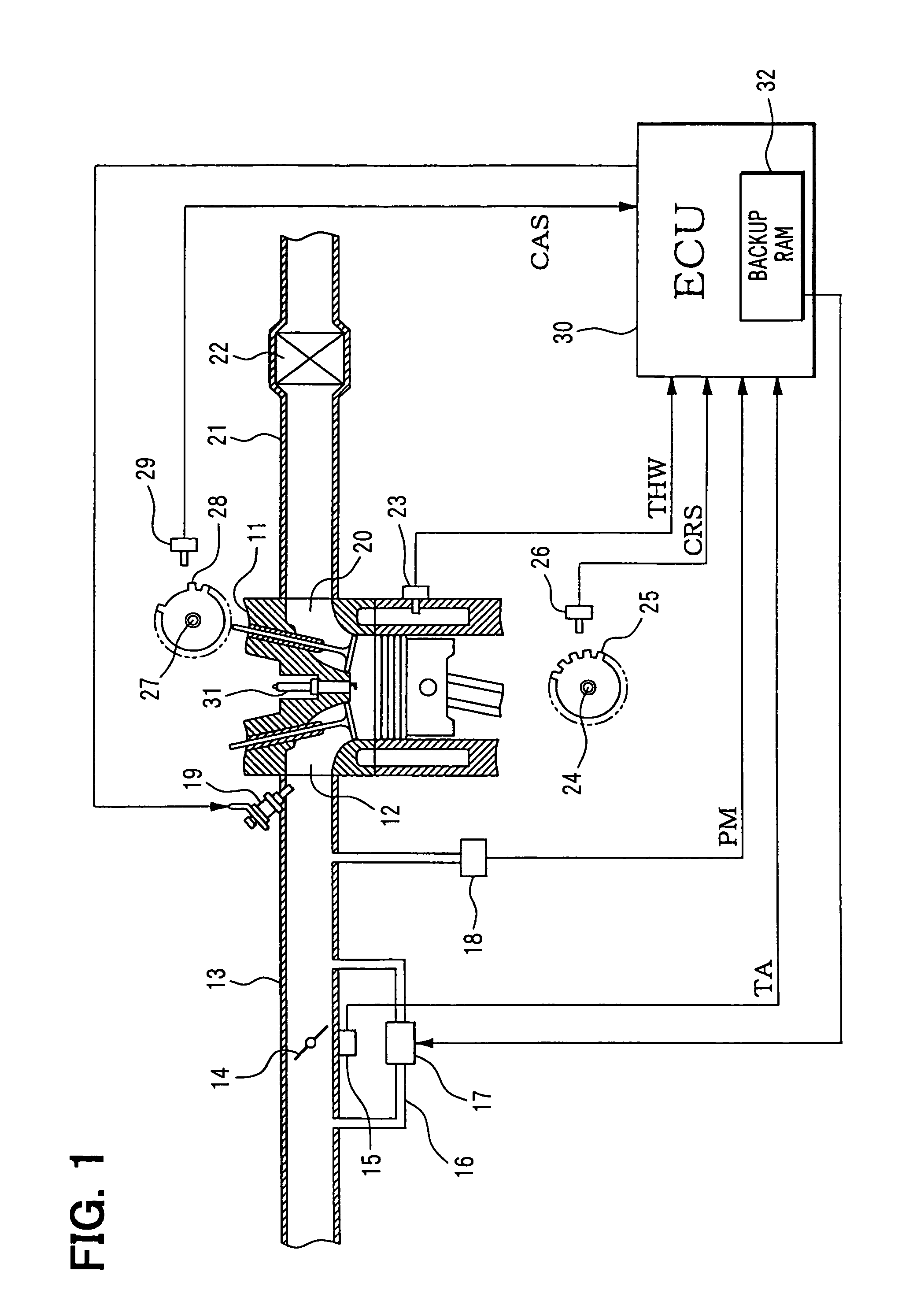

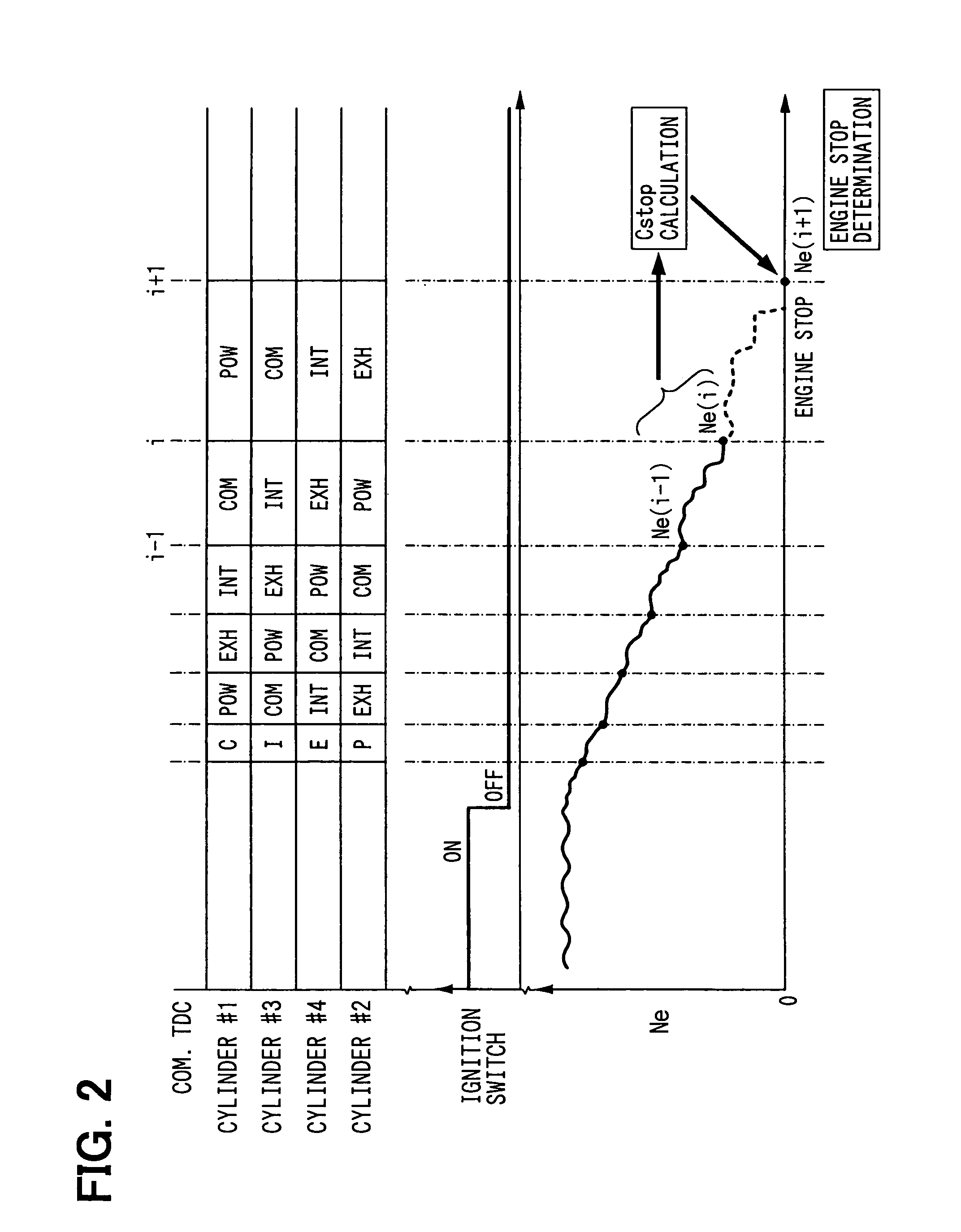

Engine controller for starting and stopping engine

InactiveUS7066128B2Low costQuick stopAnalogue computers for vehiclesElectrical controlIdle speedIgnition timing

During a shut-down period of an engine based on an idle stop control, a computer estimates a power stroke cylinder and a compression stroke cylinder when the engine is stopped. A fuel is injected into the power stroke cylinder and the compression stroke cylinder in an intake stroke just before the engine is stopped. An air-fuel mixture is hold in each cylinder with the engine stopped. When an auto start is required while the engine is stopped, a spark ignition is performed in the power stroke cylinder to start cranking of the engine by combustion energy. At nest ignition timing, a spark ignition is performed in the compression stroke cylinder to start the engine without an aid of a starter.

Owner:DENSO CORP

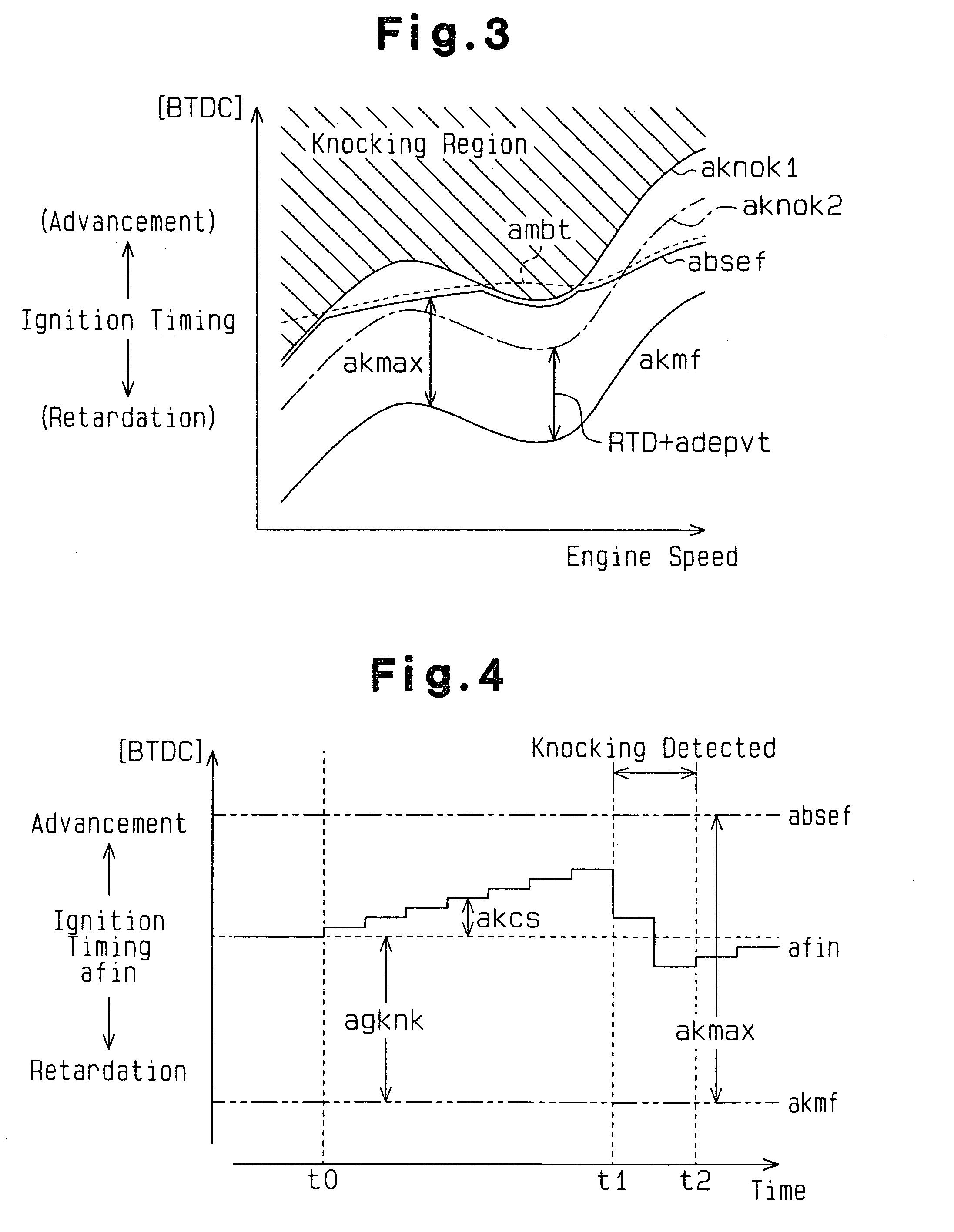

Control apparatus for internal combustion engine

ActiveUS20050005908A1Efficient solutionValve arrangementsElectrical controlVariable valve timingIgnition timing

Based on results of a knock control for adjusting ignition timing in accordance with the occurrence of knocking, an electronic control unit computes deposit required ignition timing akgrg, which is ignition timing determined by taking adhesion of deposits in an internal combustion engine into consideration. Based on the deposit required ignition timing akgrg, the electronic control unit reduces a vvt allowable variable range of a target VVT advancement amount, which is a control target value of a variable valve timing mechanism. The electronic control unit corrects a required ignition timing based on the actual VVT advancement amount vt, which is chanted according to the reduction of the allowable variable range of the target VVT advancement amount. As a result, problems resulting from the adhesion of deposits are effectively avoided.

Owner:TOYOTA JIDOSHA KK

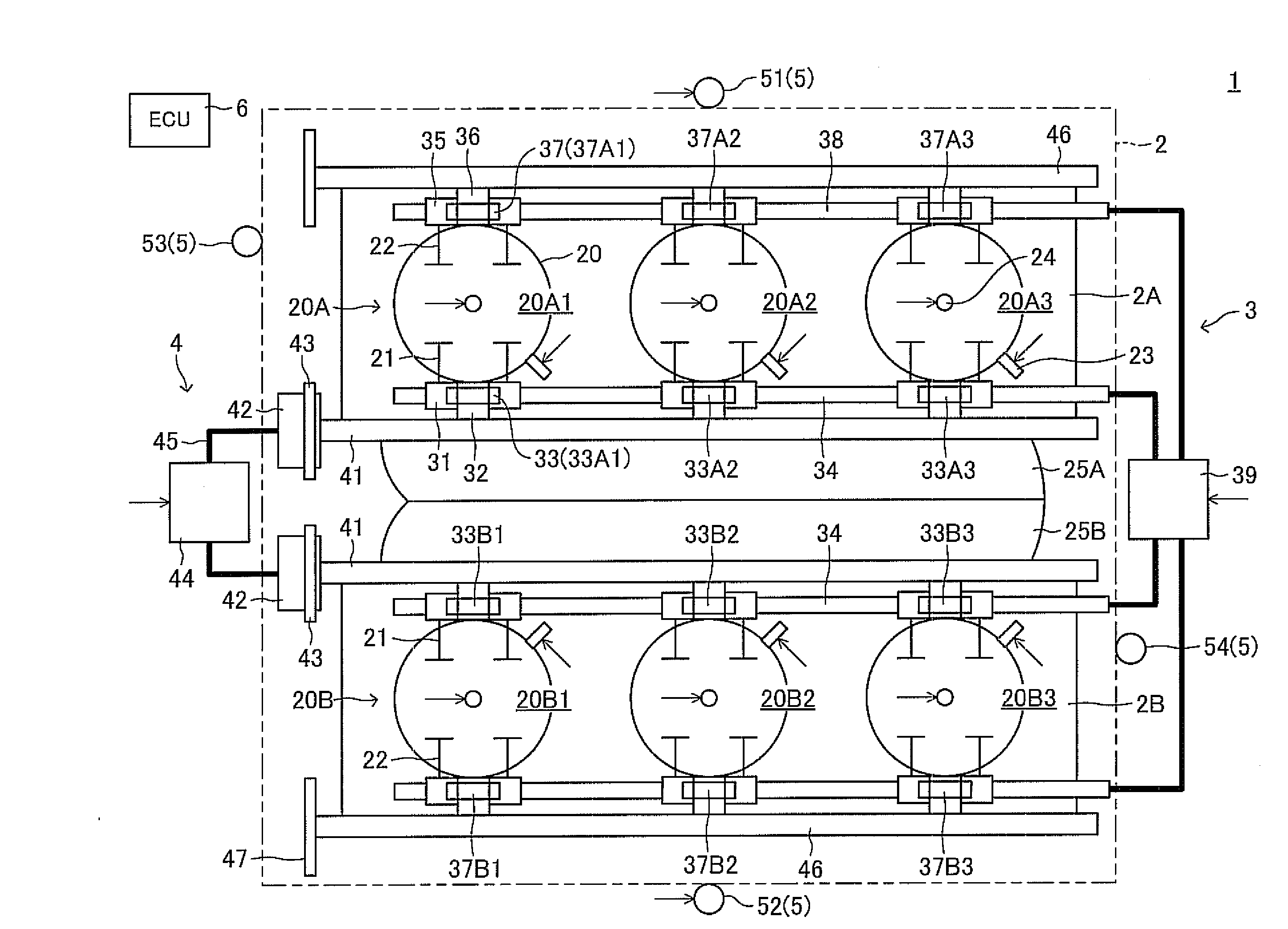

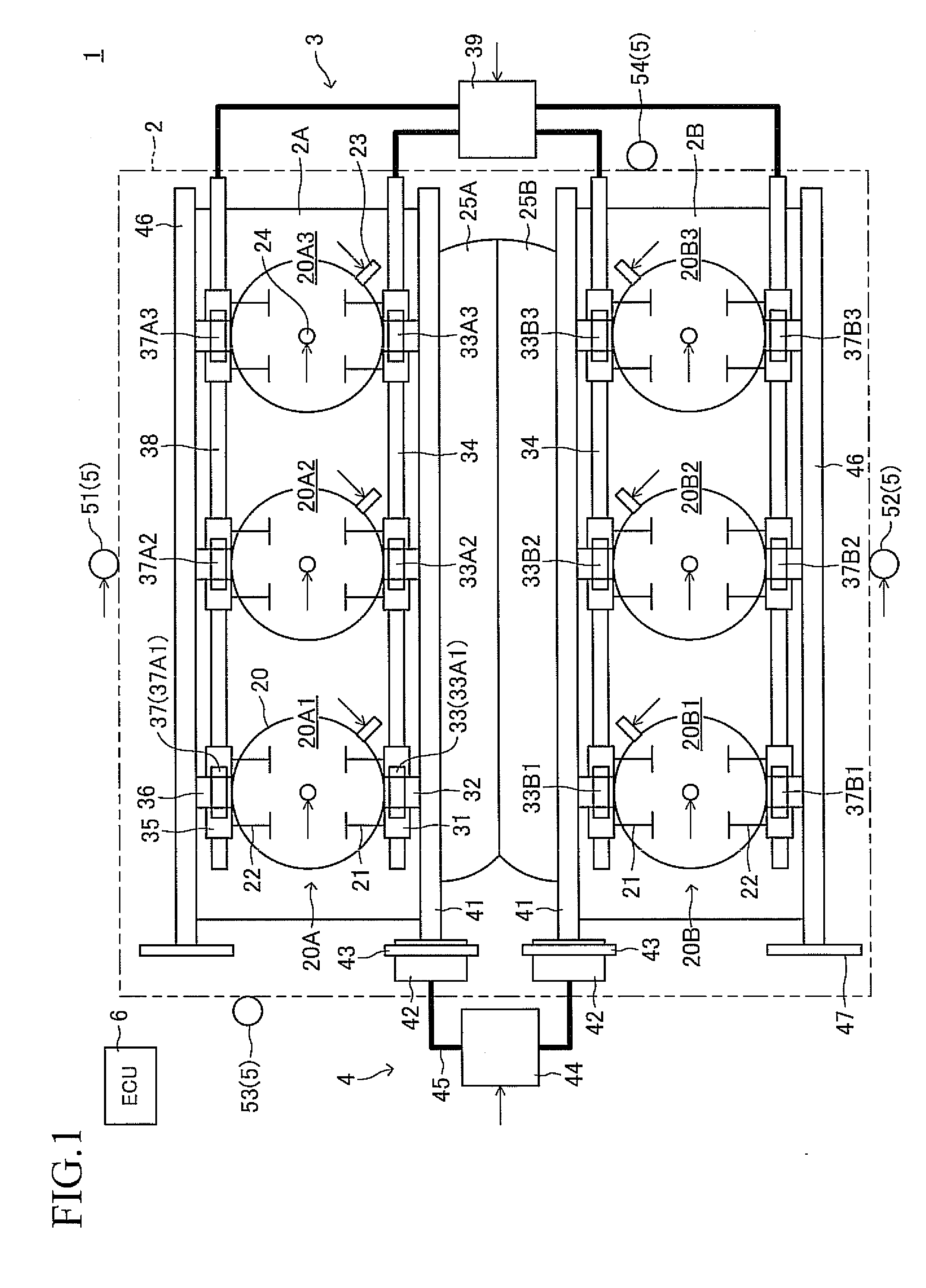

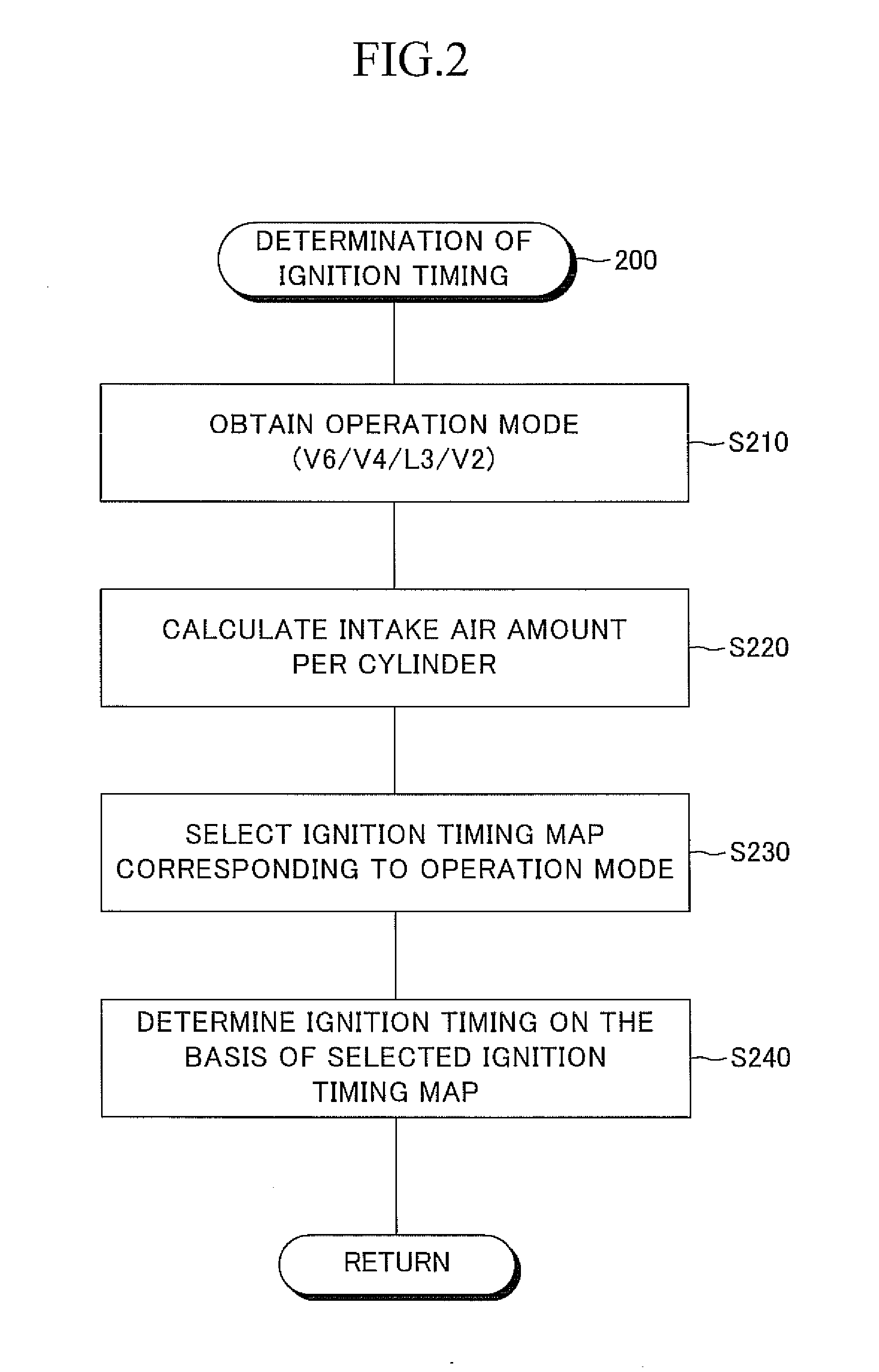

Multi-cylinder engine

InactiveUS20090248278A1Analogue computers for vehiclesElectrical controlInternal pressureEngineering

A multi-cylinder engine is configured to be able to perform a selected cylinder operation in which combustion is stopped in some cylinders. The multi-cylinder engine includes an ignition-timing adjustment section. This ignition-timing adjustment section retards ignition timing of each operating cylinder when the number of operating cylinders is small or when the engine operates in a selected cylinder operation mode in which explosion occurs at irregular intervals. In such a case, the peak of cylinder internal pressure is lowered by ignition timing retard. Thus, vibration and noise can be suppressed effectively.

Owner:TOYOTA JIDOSHA KK

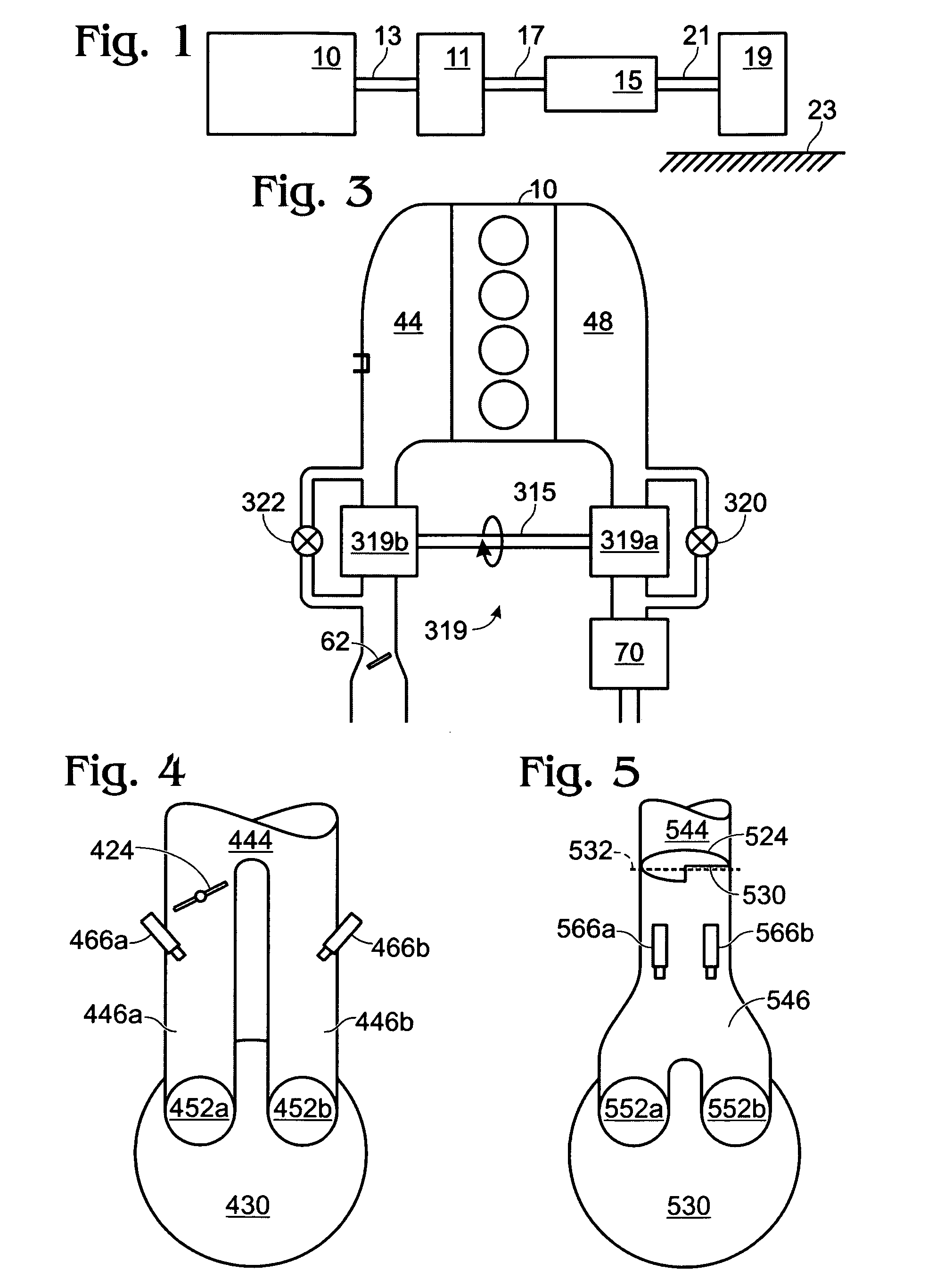

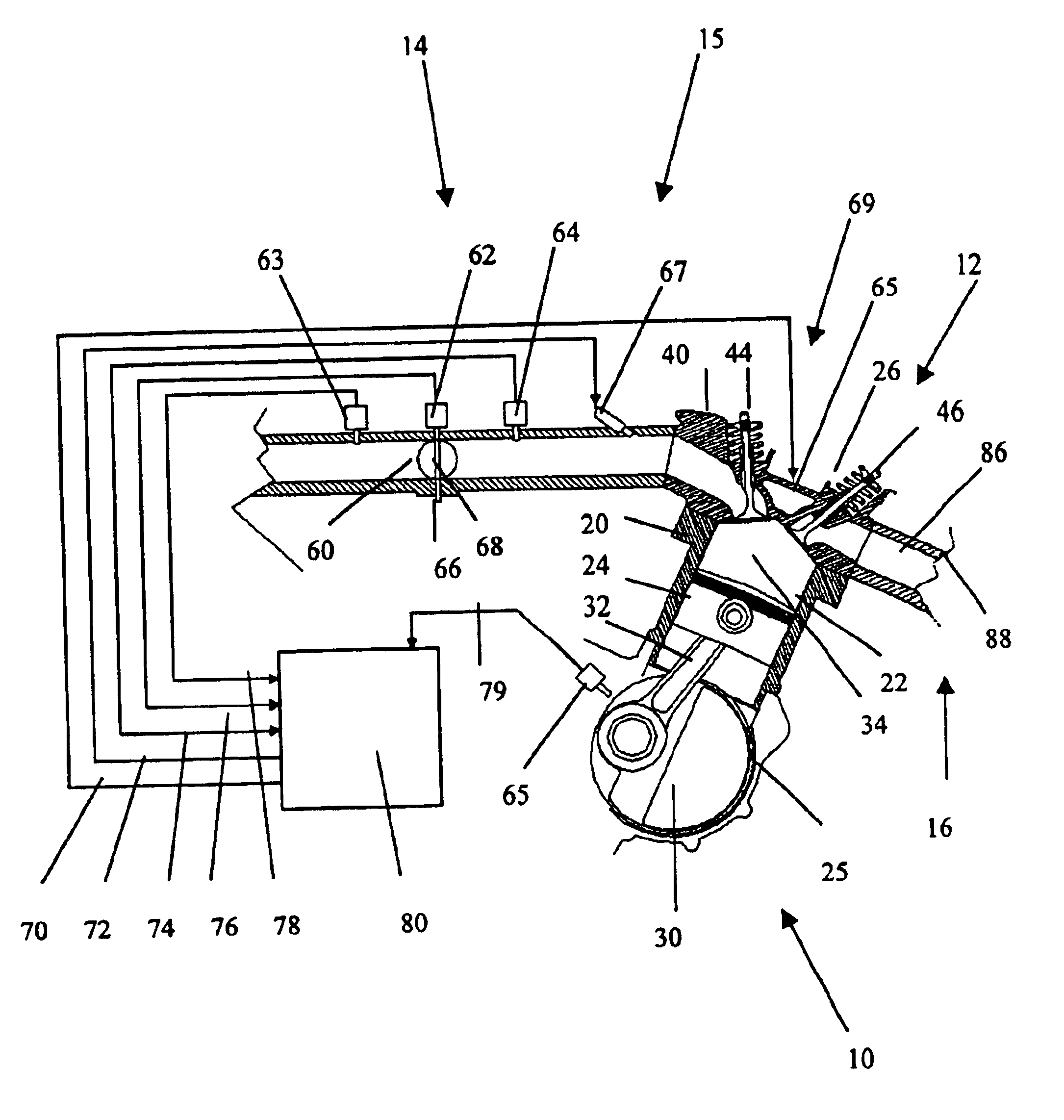

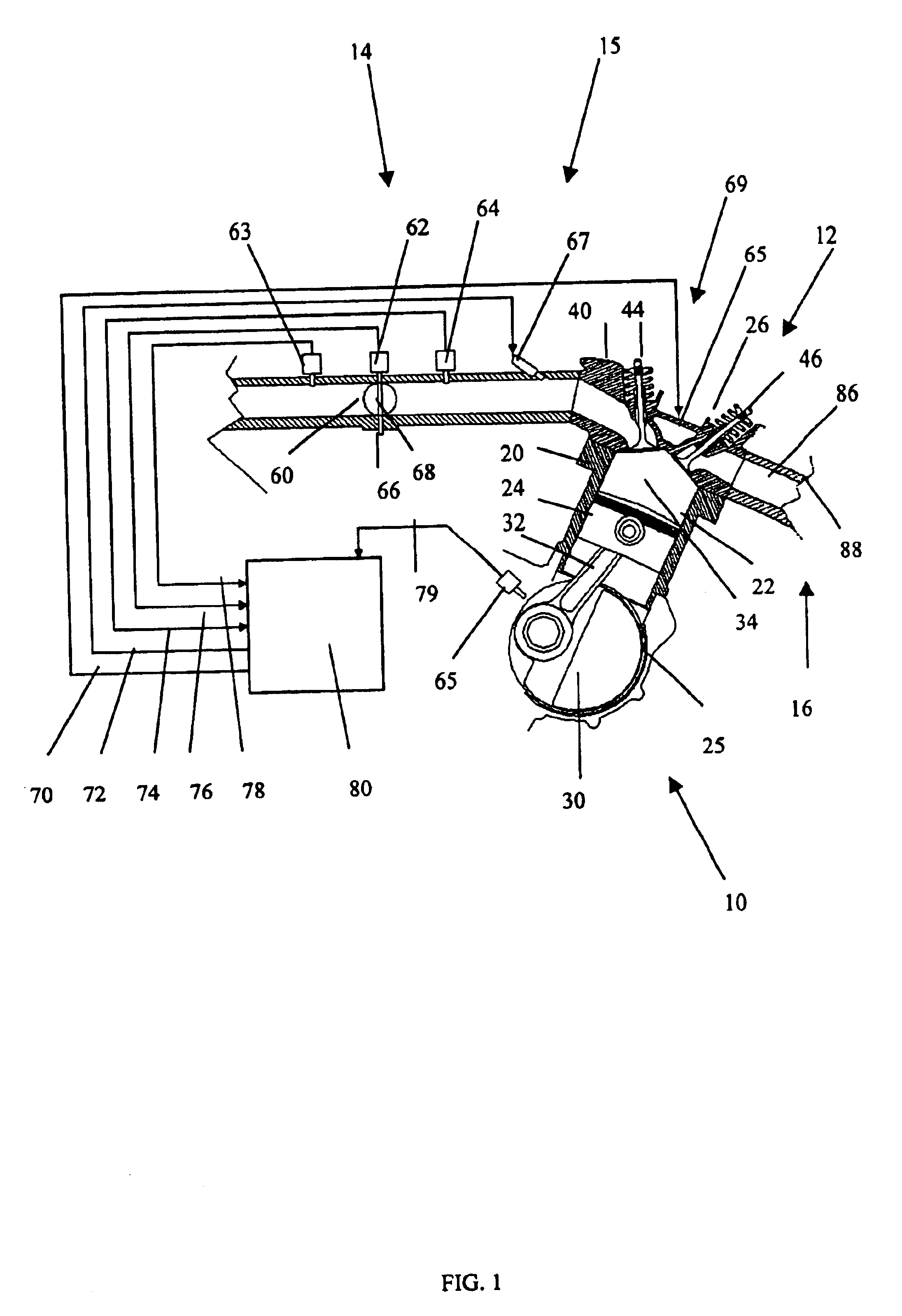

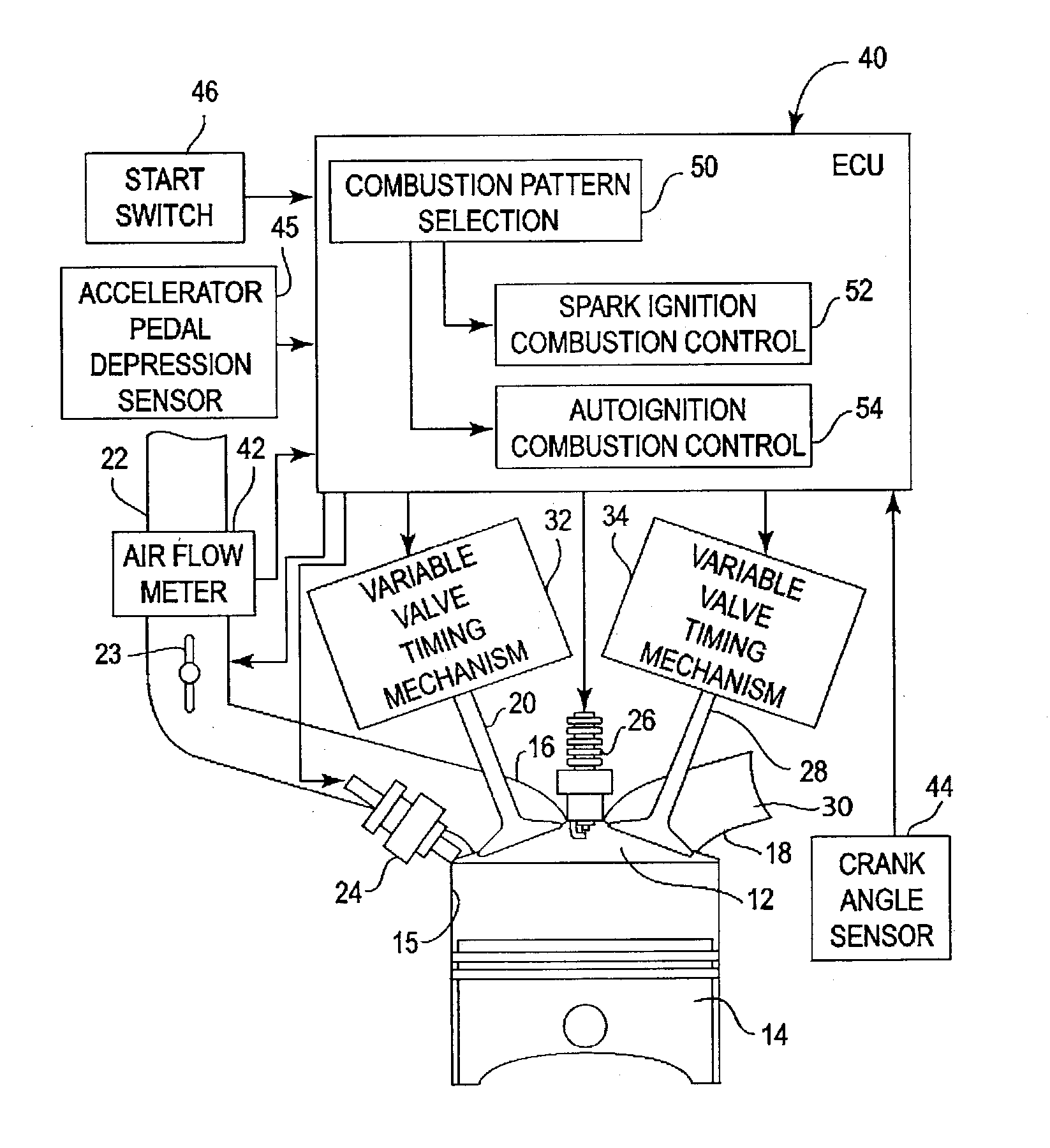

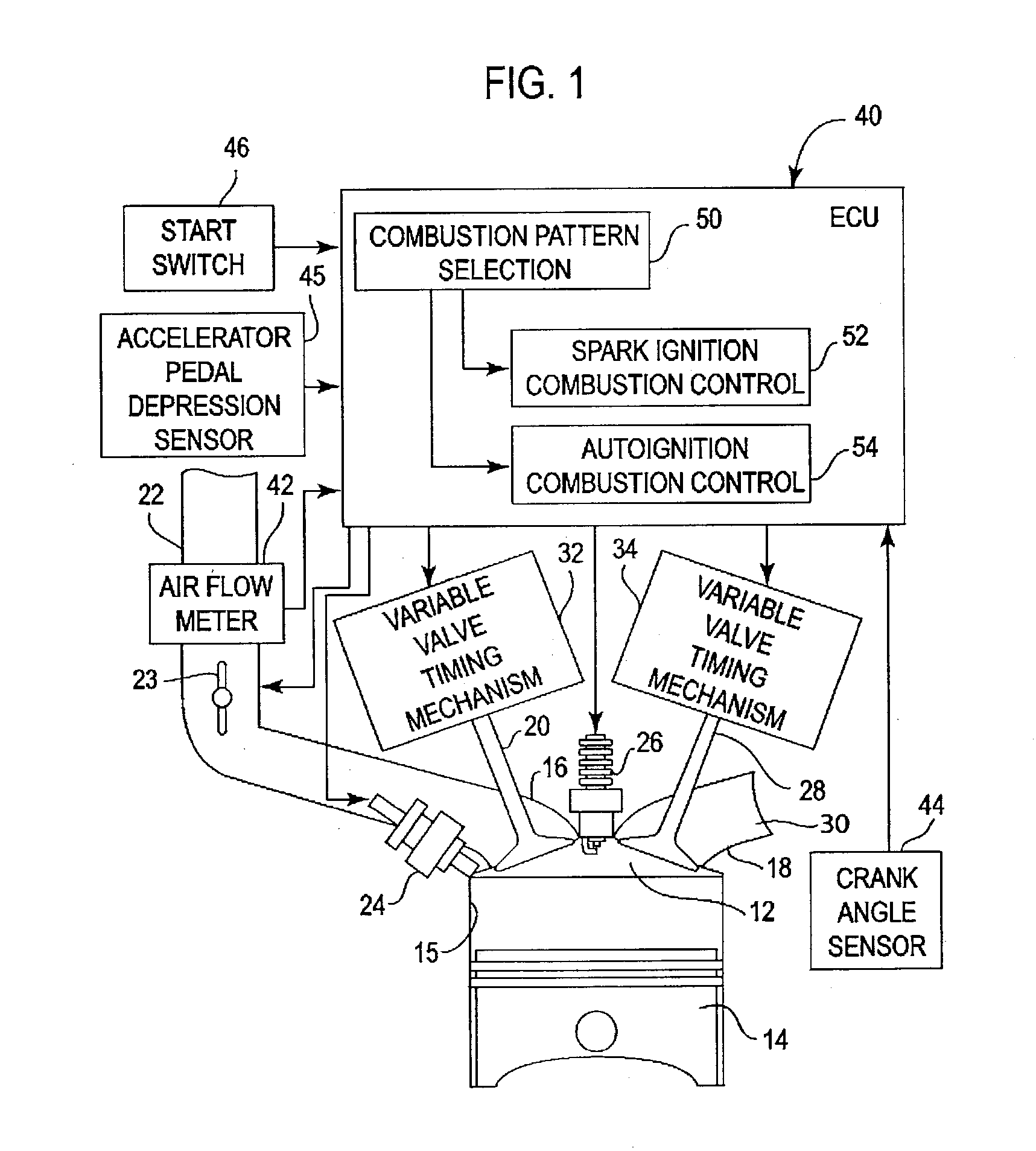

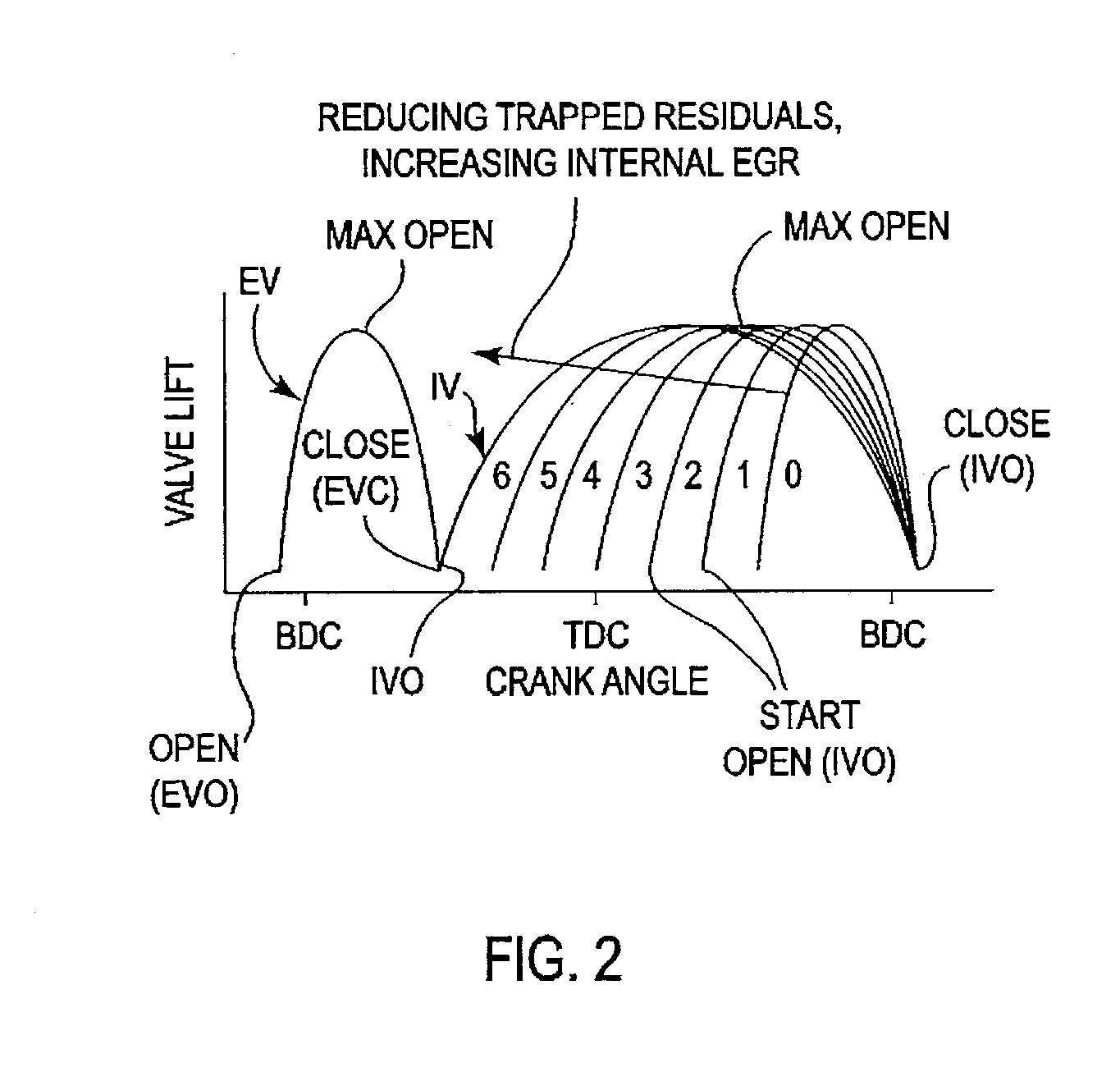

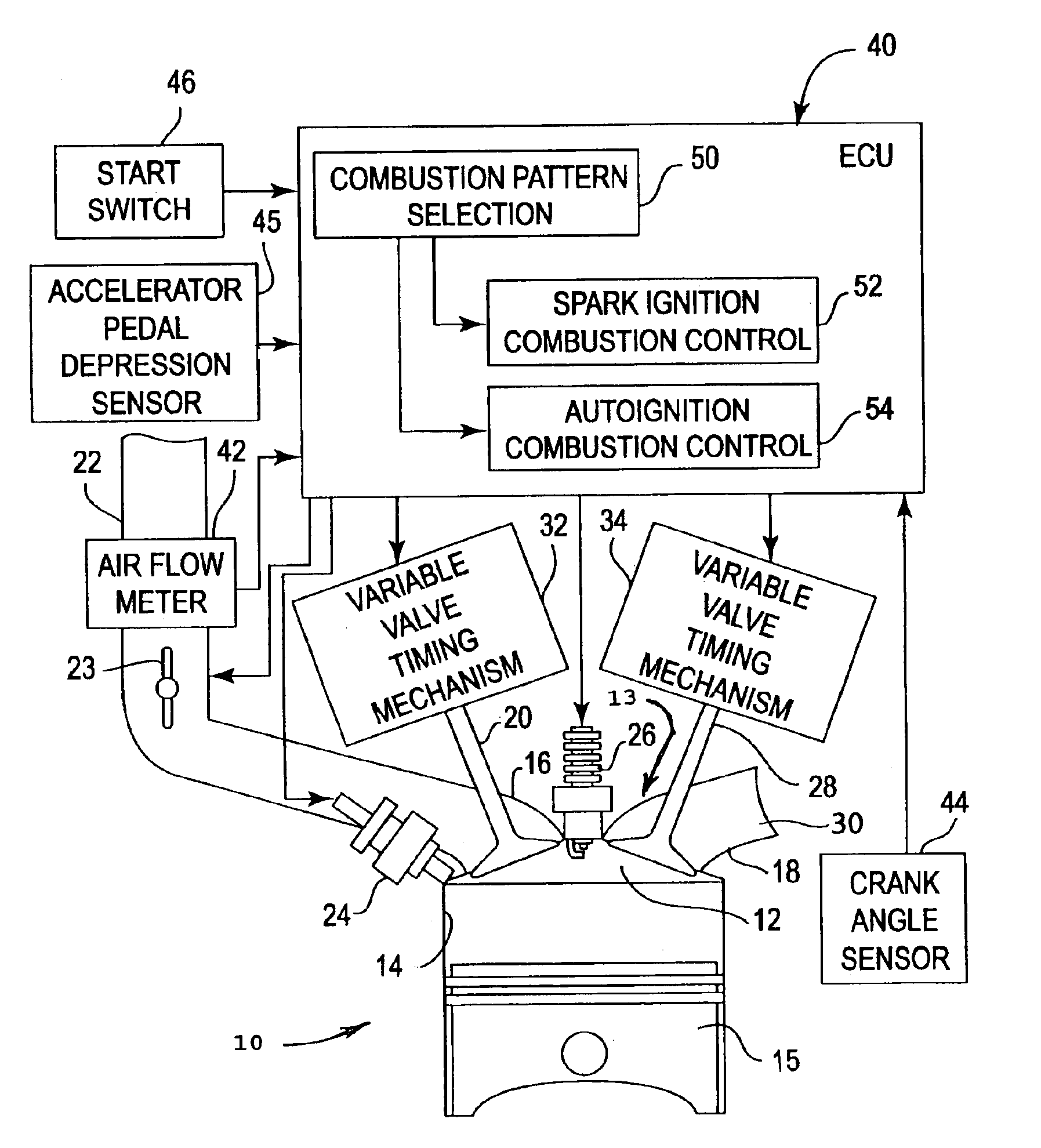

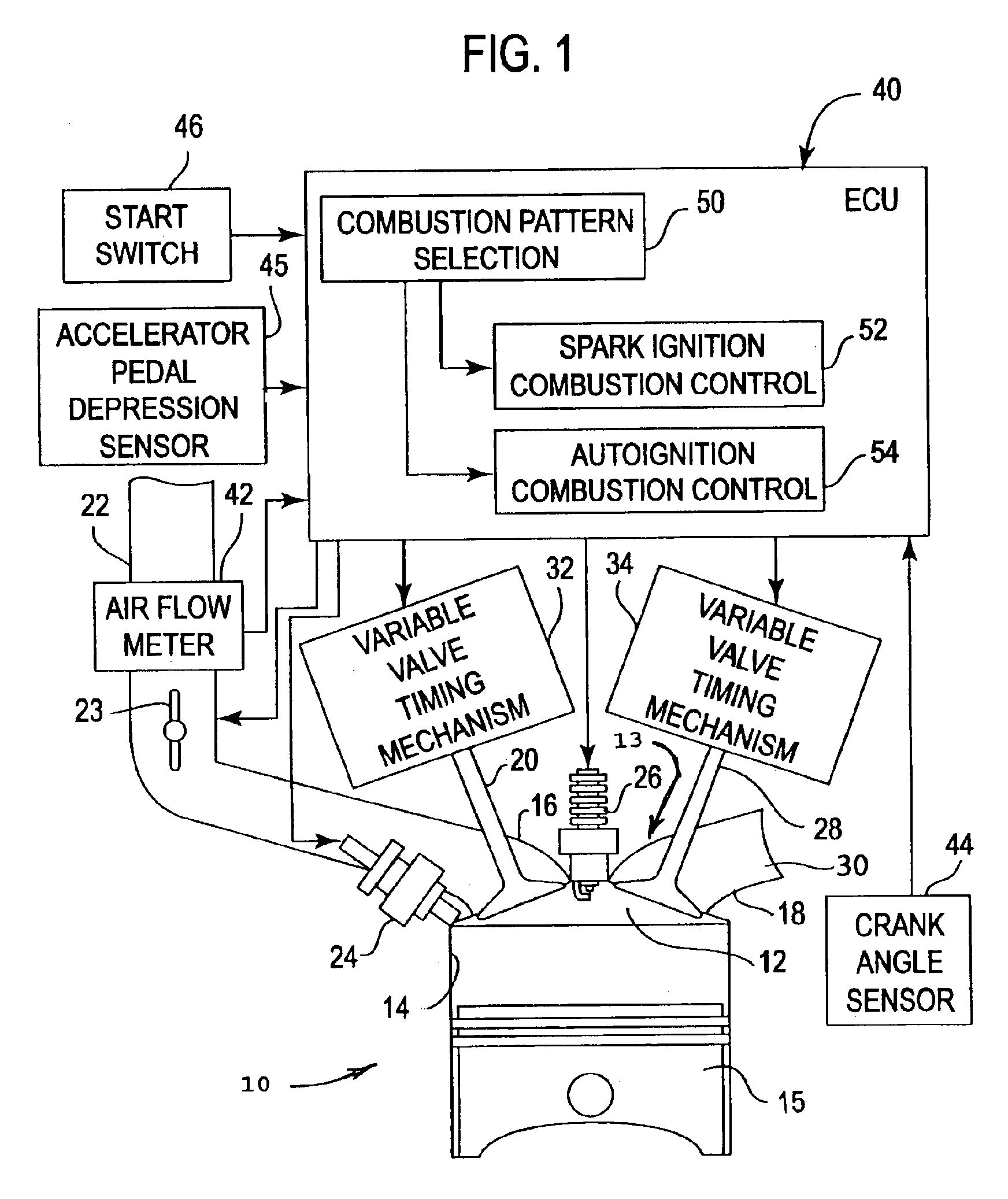

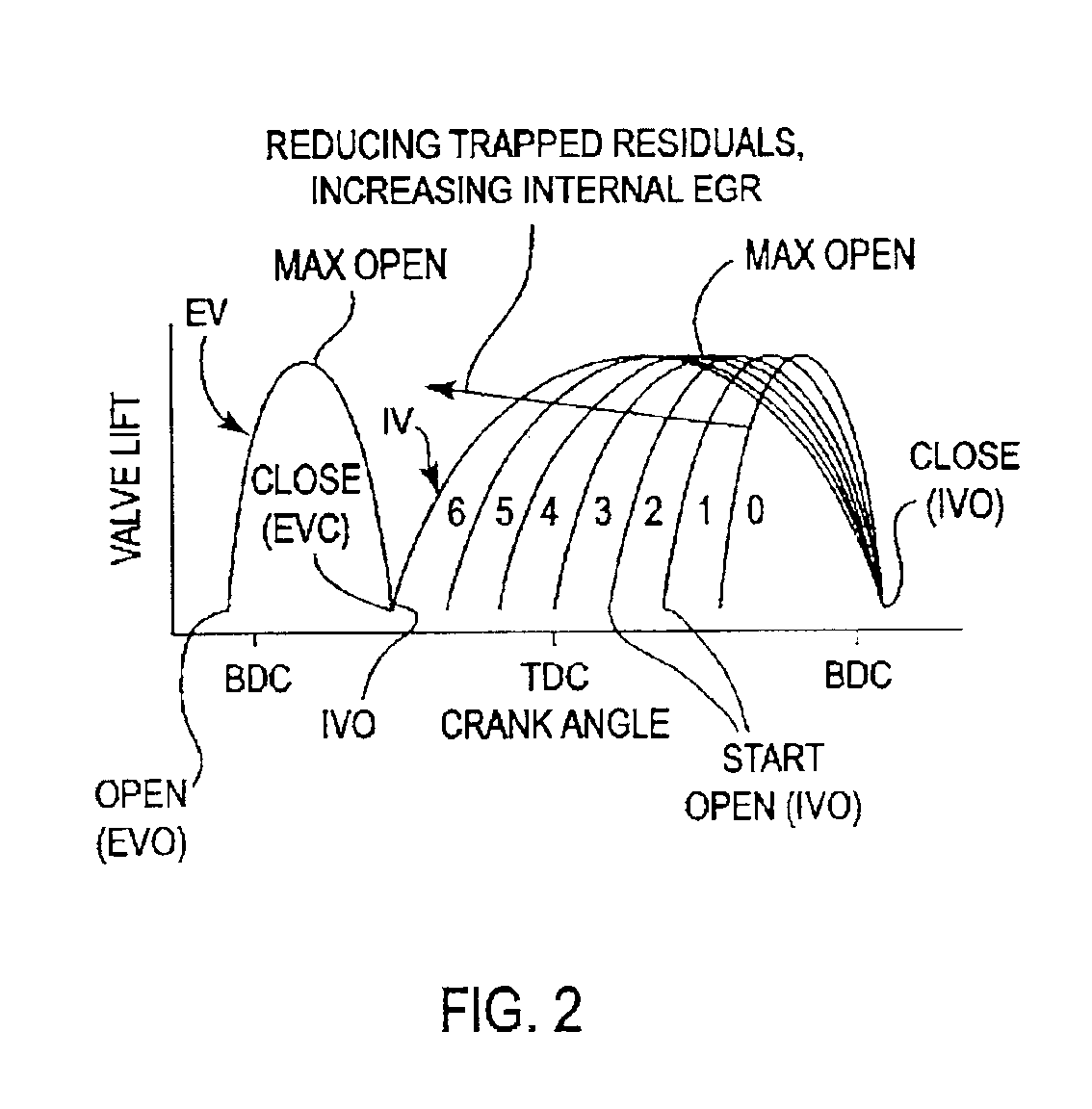

Control of autoignition timing in a hcci engine

ActiveUS20040134449A1Reduces and minimizesCompensation effectElectrical controlInternal combustion piston enginesCombustion chamberExhaust valve

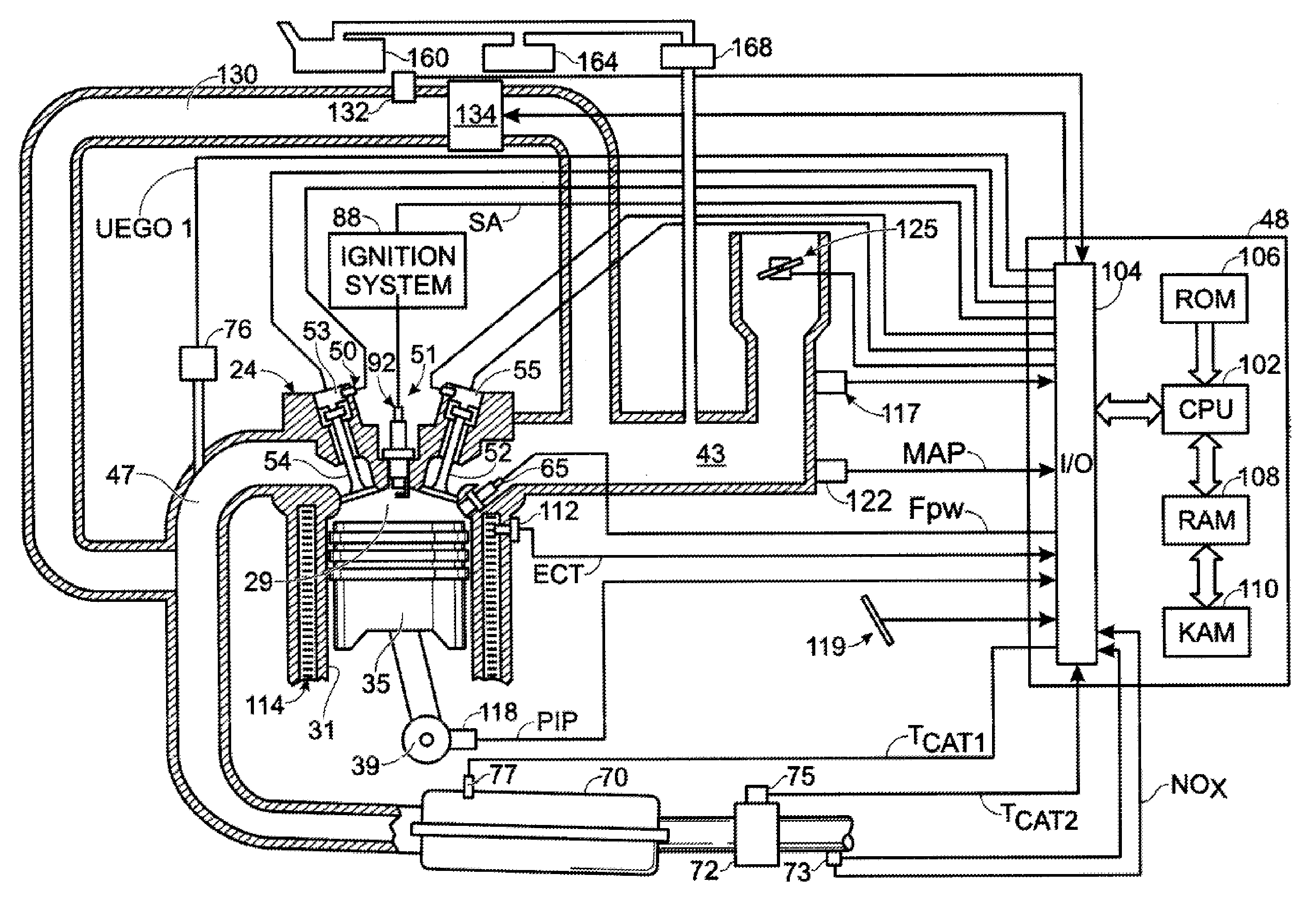

Method and system embody a valve timing strategy to control the autoignition timing of a four stroke internal combustion engine (10) operated in an HCCI mode at different engine operating conditions such as different engine speed and torque. A particular valve timing strategy varies lift timing of the intake valve (20) relative to the exhaust valve (28), or vice versa, and relative to top dead center in response to a change in engine torque, for example, to vary amount of trapped residual burned gas in the combustion chamber (12) flowing to an intake or exhaust port (16,18) and back to the combustion chamber during which the residual gas is cooled. Control of the flow of residual gas between the combustion chamber and intake or exhaust port and thus its temperature by the valve timing strategy, in turn, is used to control the temperature of the fresh air / residual gas / fuel mixture in the combustion chamber (12) and thus autoignition timing in response to a change in engine torque.

Owner:FORD GLOBAL TECH LLC

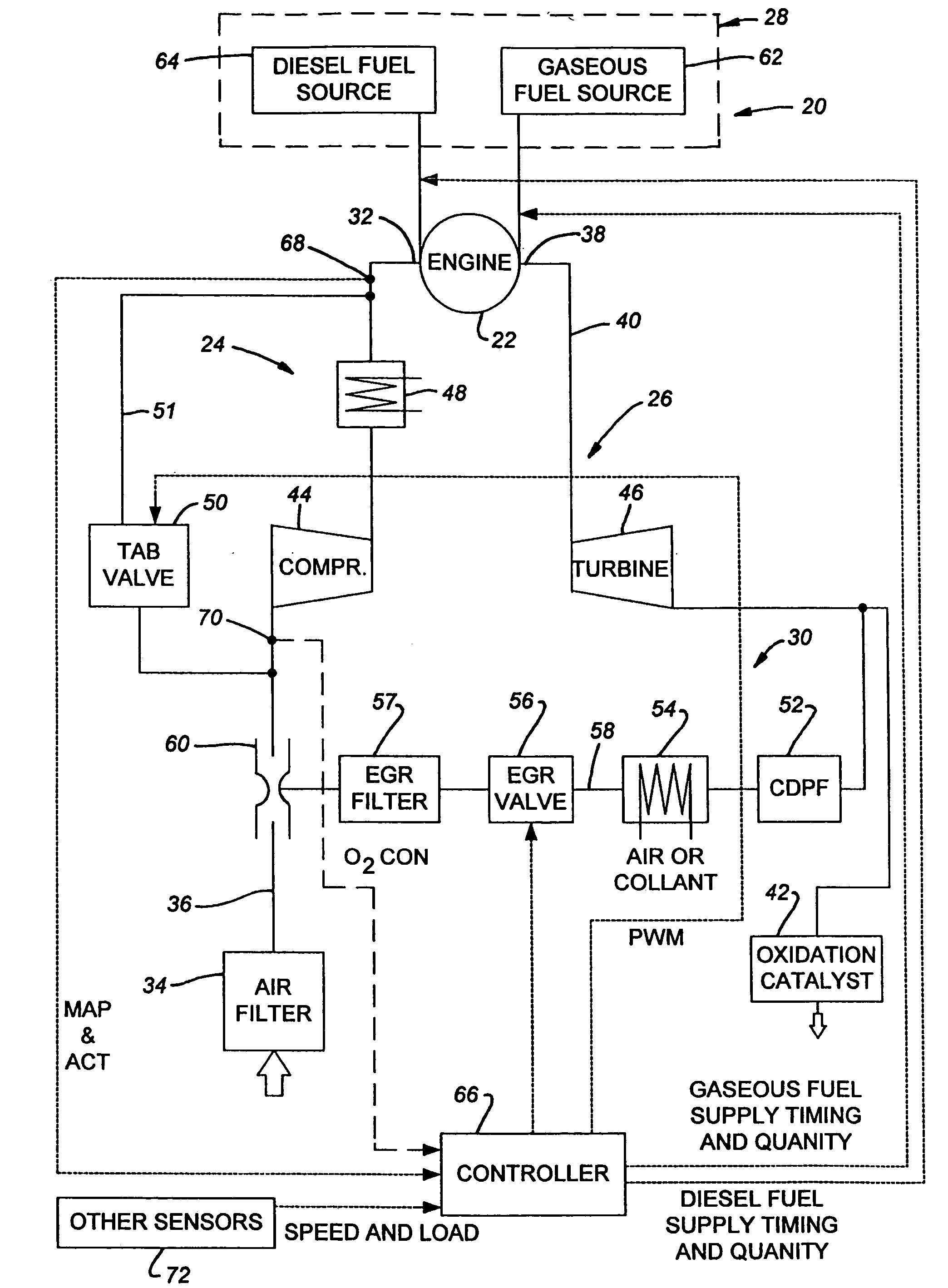

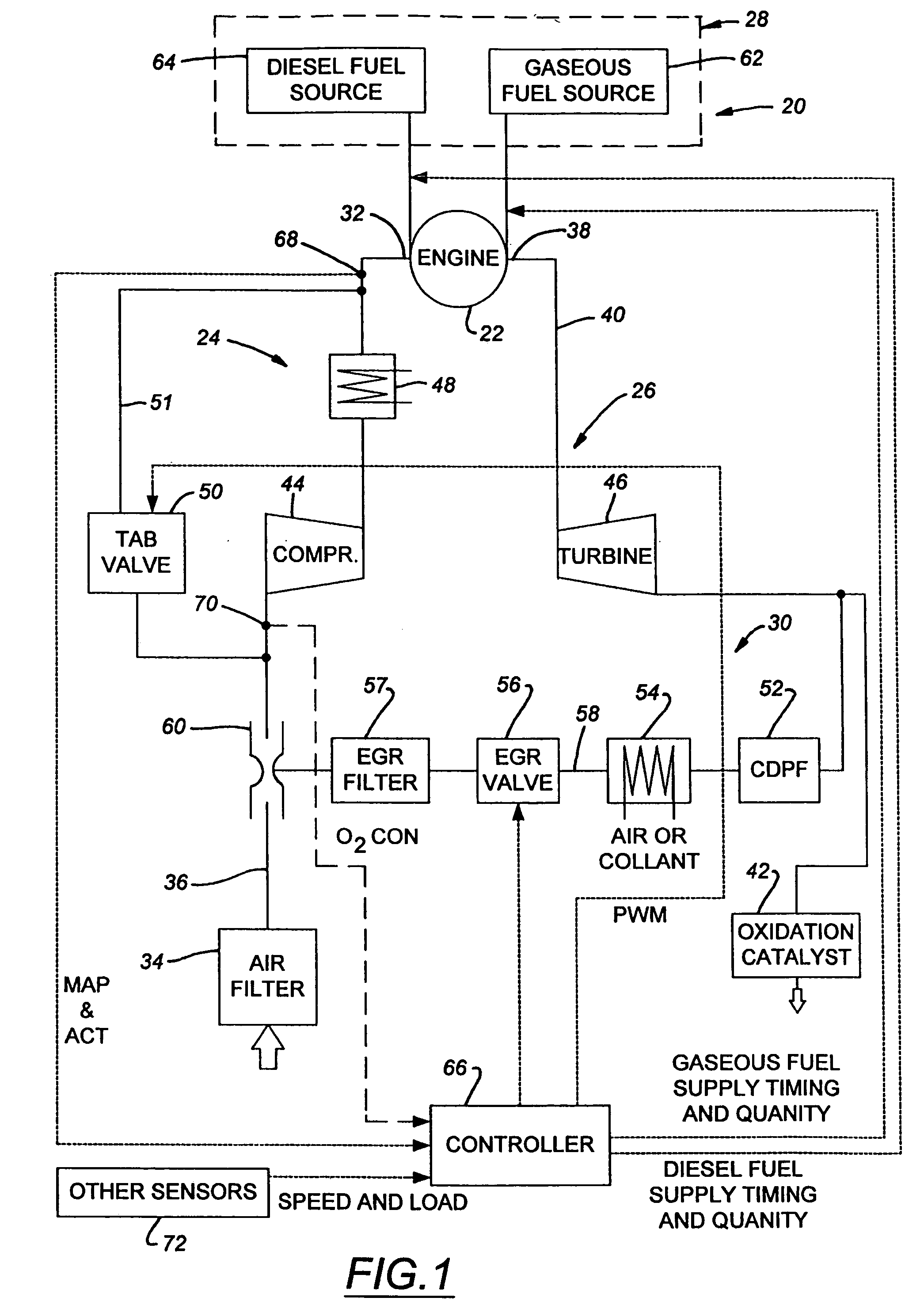

Method and apparatus for controlling transition between operating modes in a multimode engine

InactiveUS7270089B2Non-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberControl system

At least one engine operating parameter other than total fuel energy content is taken into account when transitioning between operating modes in a dual fuel or other multimode engine (20) in order to maintain a smooth transition between modes. The parameter preferably comprises at least one of primary fuel excess air ratio (lambda) and ignition timing and preferably is controlled in addition to total fuel energy content control. Lambda control is especially beneficial because it permits the control system to compensate for the engine's inability to substantially alter the instantaneous air mass in the combustion chamber during the transition period. For instance, during a transition from pilot ignited gaseous fuel mode to diesel mode, the controlled parameter preferably comprises diesel lambda, and the controlling step comprises setting diesel lambda at a relatively high value at the beginning of the transition period and thereafter reducing diesel lambda during the transition period.

Owner:CLEAN AIR POWER

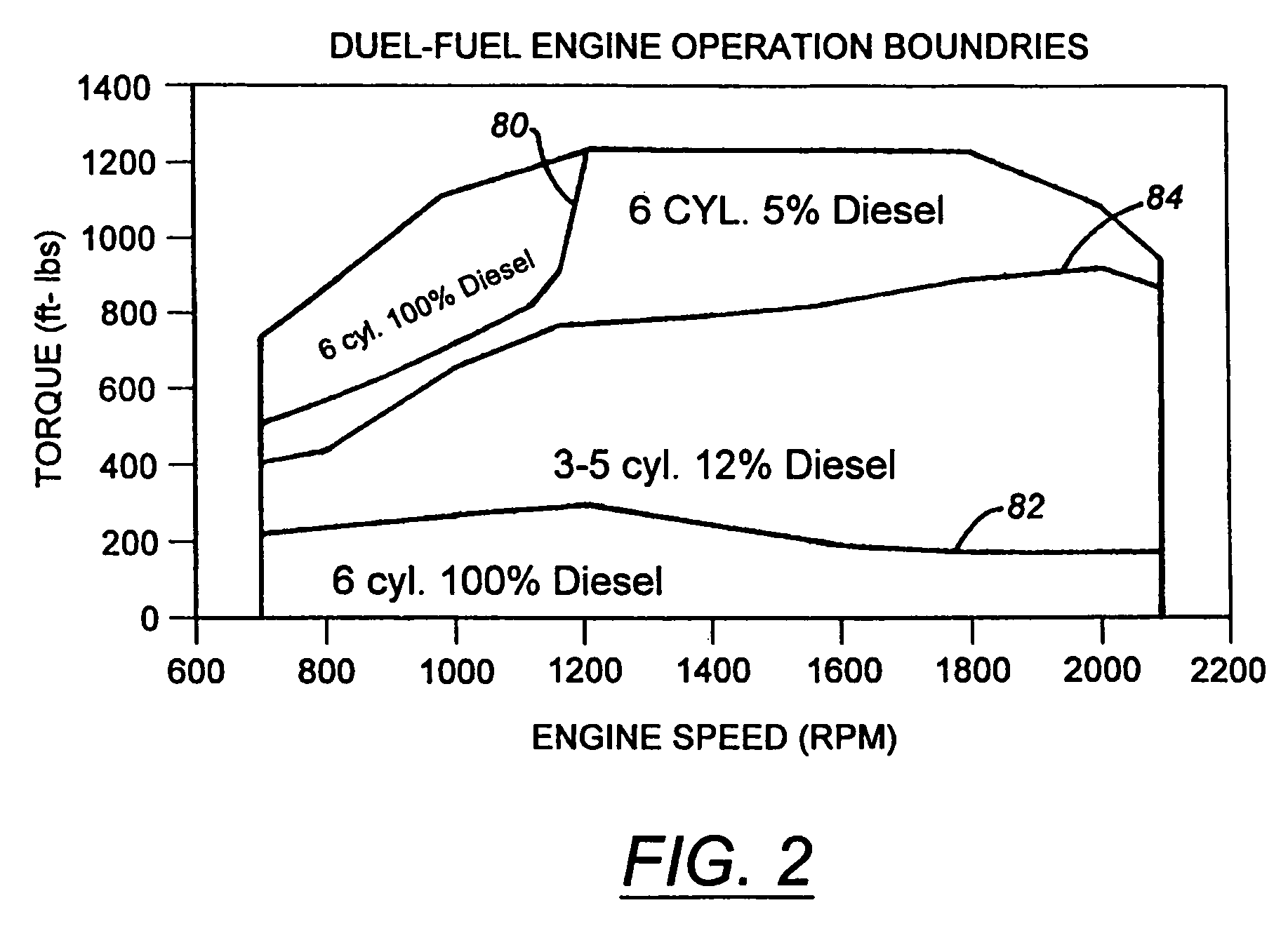

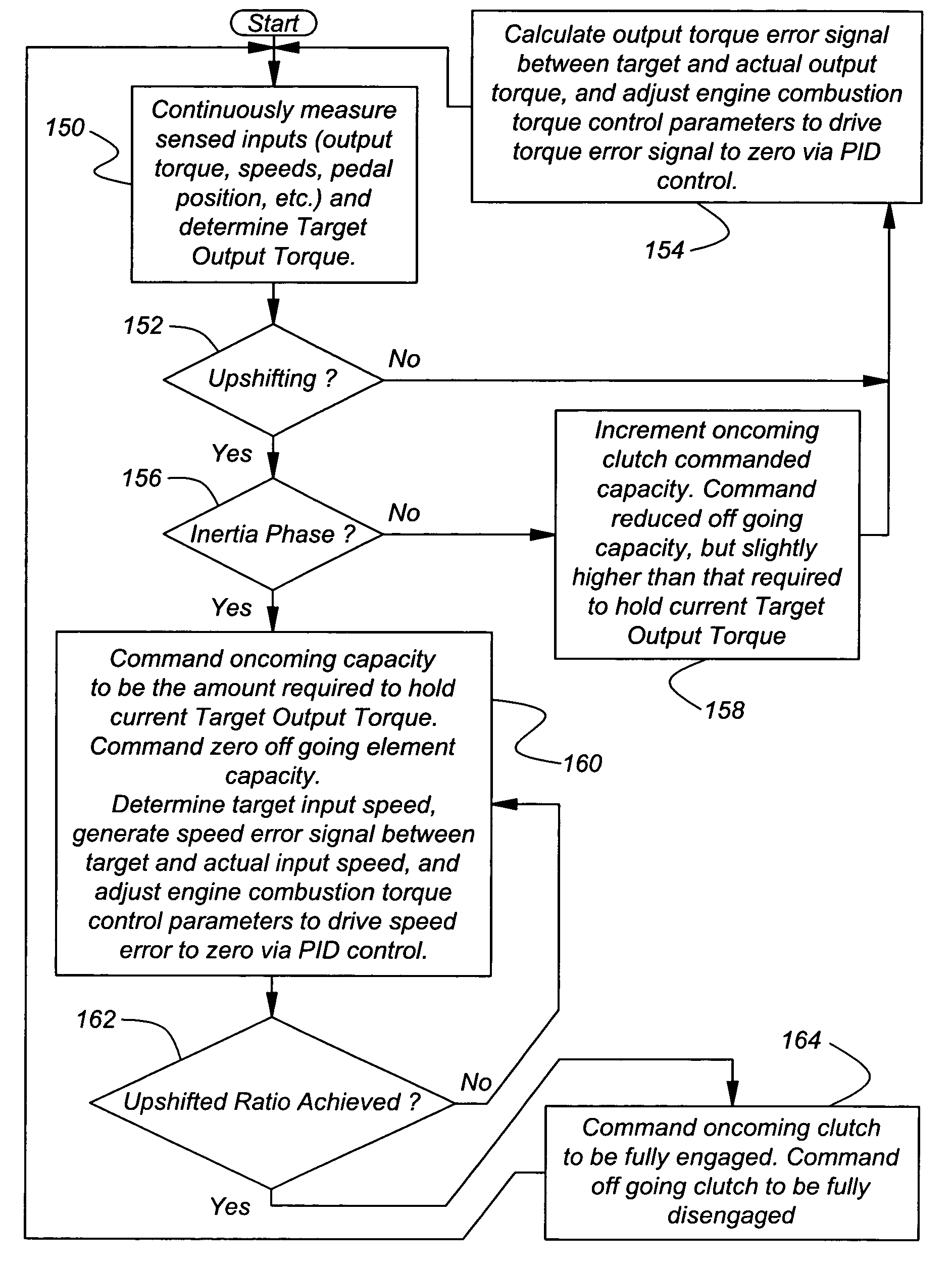

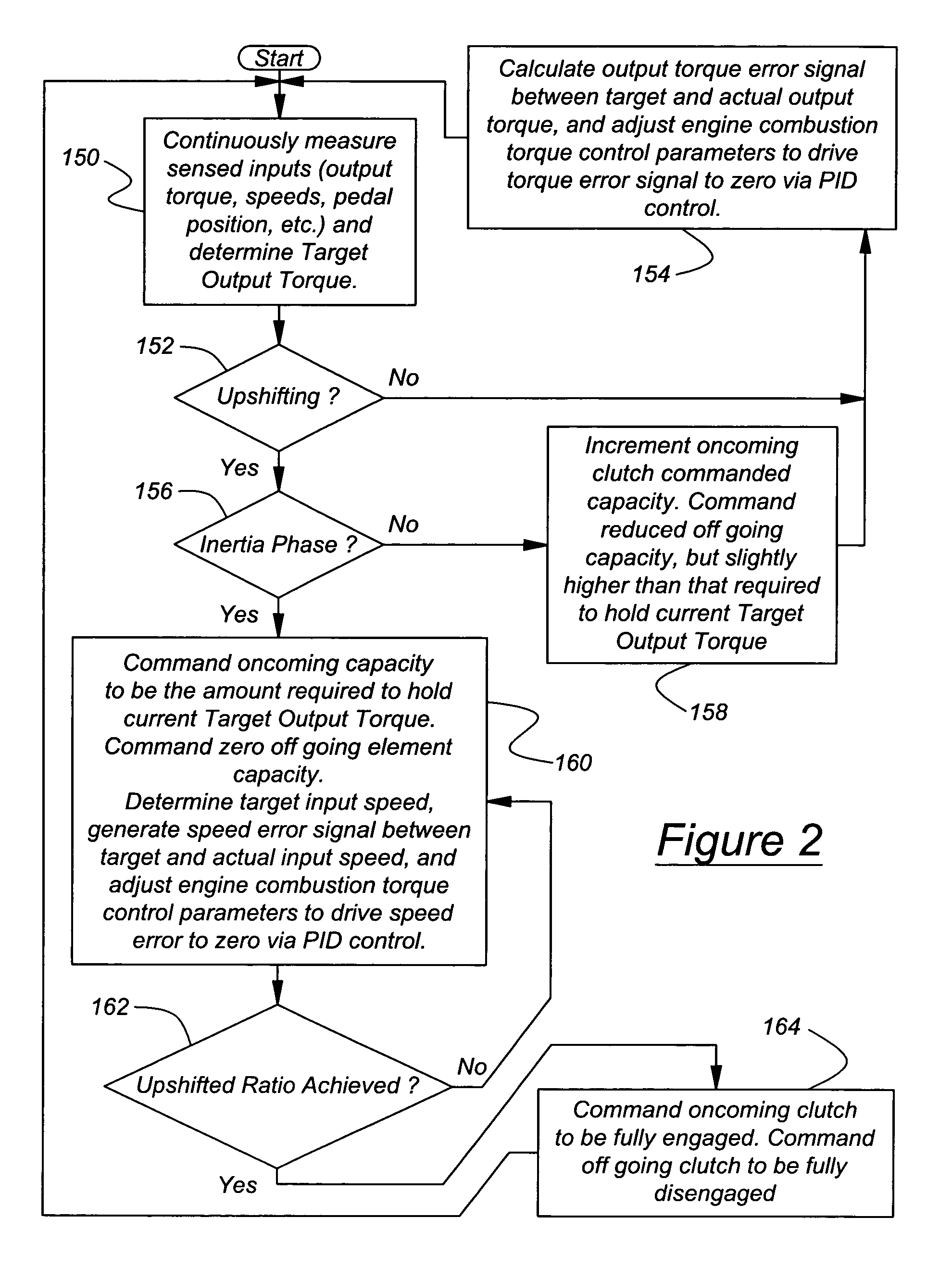

Control of powertrain smoothness using output torque sensing and input torque control

ActiveUS6991584B2Inhibit outputSimplify hydraulic controlsGearing controlConjoint controlElectronic controllerClosed loop

Owner:FORD GLOBAL TECH LLC

Internal combustion engine of compressing and auto-igniting air-fuel mixture and method of controlling such internal combustion engine

ActiveUS20050155344A1Effective controlEffective timeElectrical controlNon-fuel substance addition to fuelCombustion systemCombustion chamber

The technique of the present invention produces a first fuel-air mixture containing a first fuel and the air at a specific ratio, which does not allow for auto ignition of the first fuel-air mixture by simple compression, in a combustion chamber. The technique then injects a second fuel, which has a higher octane value than that of the first fuel, into a partial area of the combustion chamber, so as to produce a second fuel-air mixture. The technique ignites the second fuel-air mixture for combustion, so as to compress and auto-ignite the first fuel-air mixture. The second fuel has the higher octane value, so that a combustion start timing of the second fuel-air mixture is reliably regulated by ignition. Namely the technique positively controls the timing of auto ignition of the first fuel-air mixture. Setting an adequate value to the ignition timing thus effectively prevents the occurrence of knocking in an internal combustion engine that adopts a premix compression ignition combustion system.

Owner:TOYOTA JIDOSHA KK

Lean burn internal combustion engine exhaust gas temperature control

ActiveUS20170130630A1Electrical controlInternal combustion piston enginesTemperature controlExternal combustion engine

A variety of methods and arrangements for controlling the exhaust gas temperature of a lean burn, skip fire controlled internal combustion engine are described. In one aspect, an engine controller includes an aftertreatment system monitor and a firing timing determination unit. The aftertreatment monitor obtains data relating to a temperature of one or more aftertreatment elements, such as a catalytic converter. Based at least partly on this data, the firing timing determination unit generates a firing sequence for operating the engine in a skip fire manner such that the temperature of the aftertreatment element is controlled within its effective operating range.

Owner:TULA TECH INC

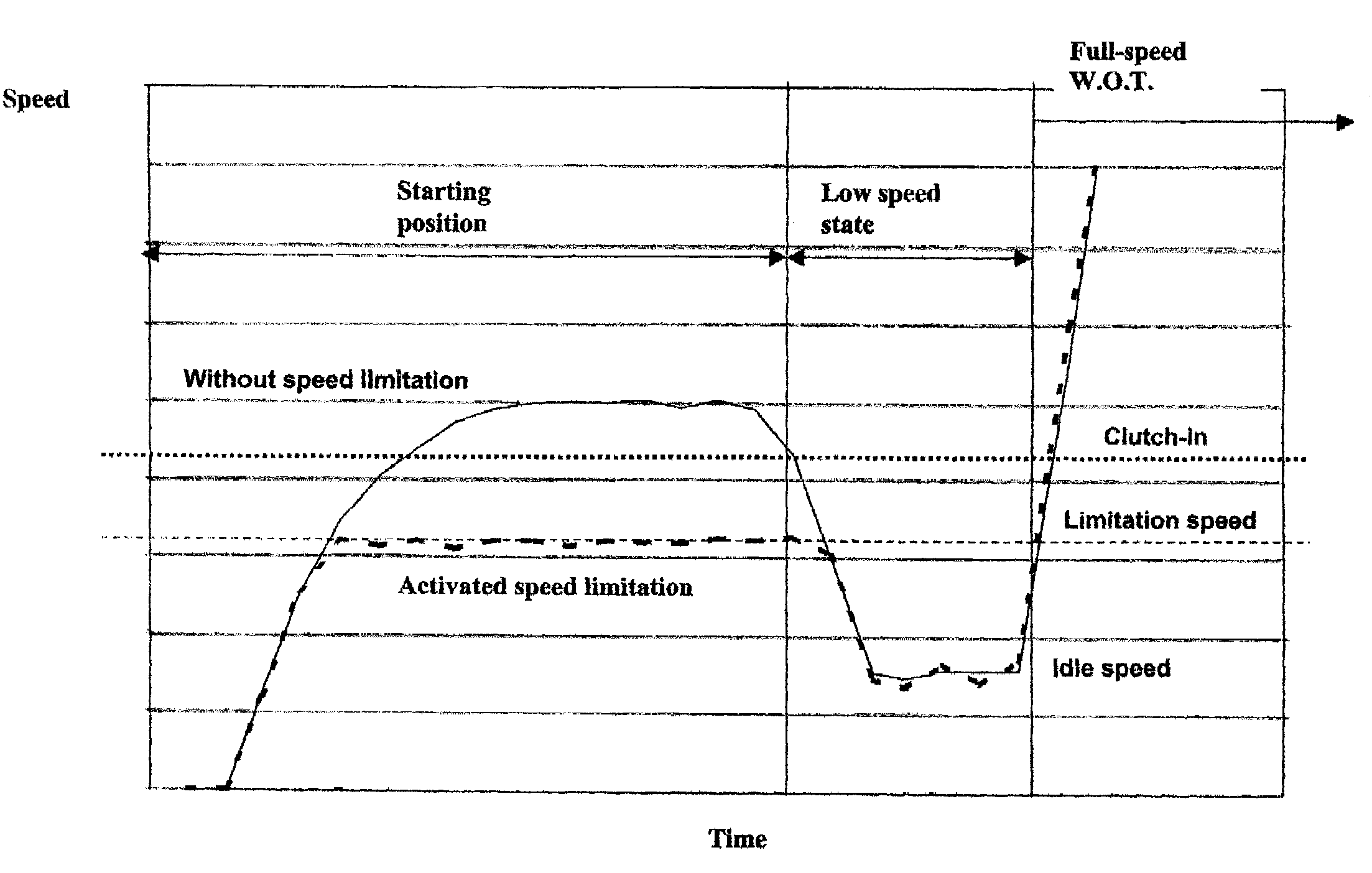

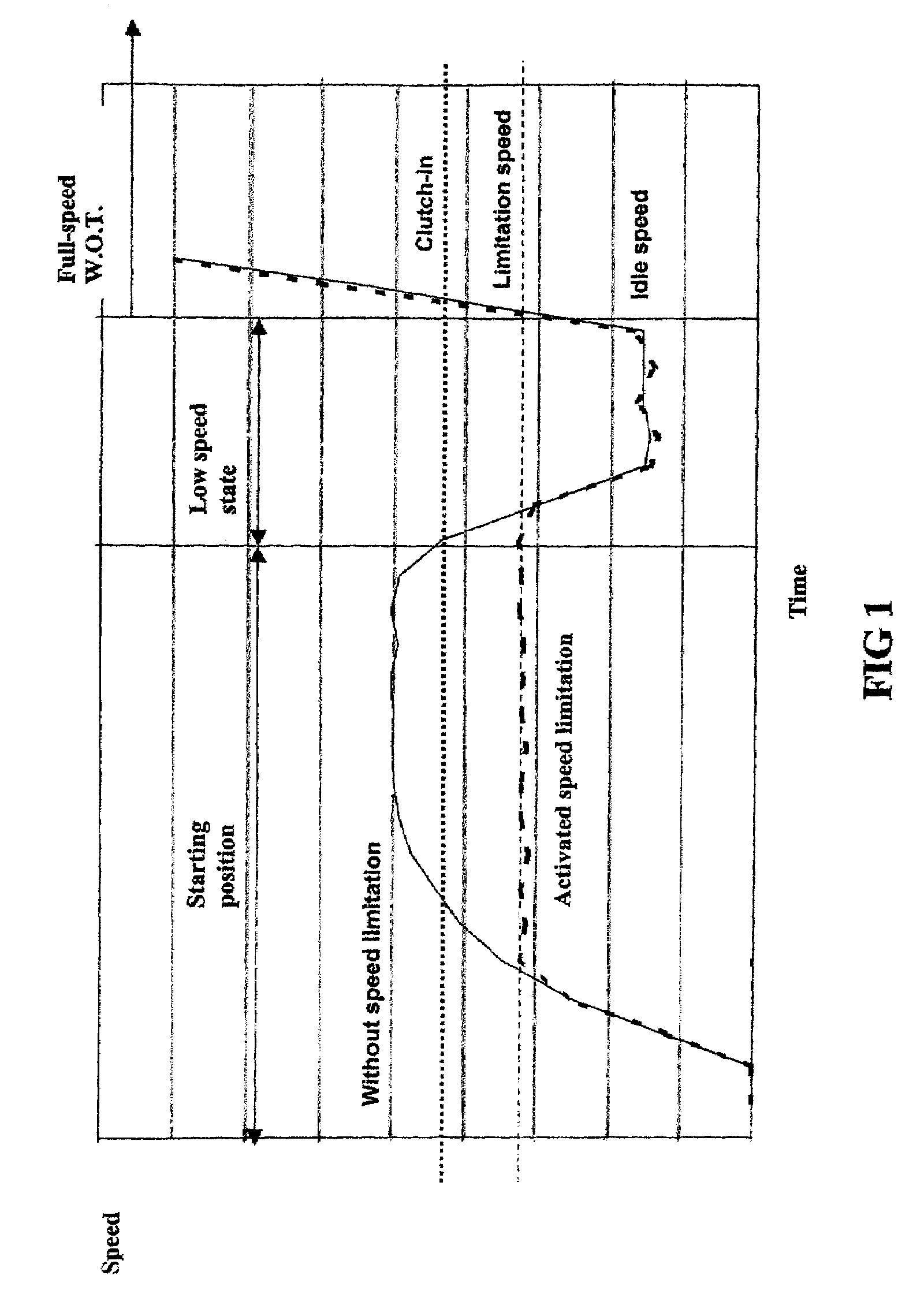

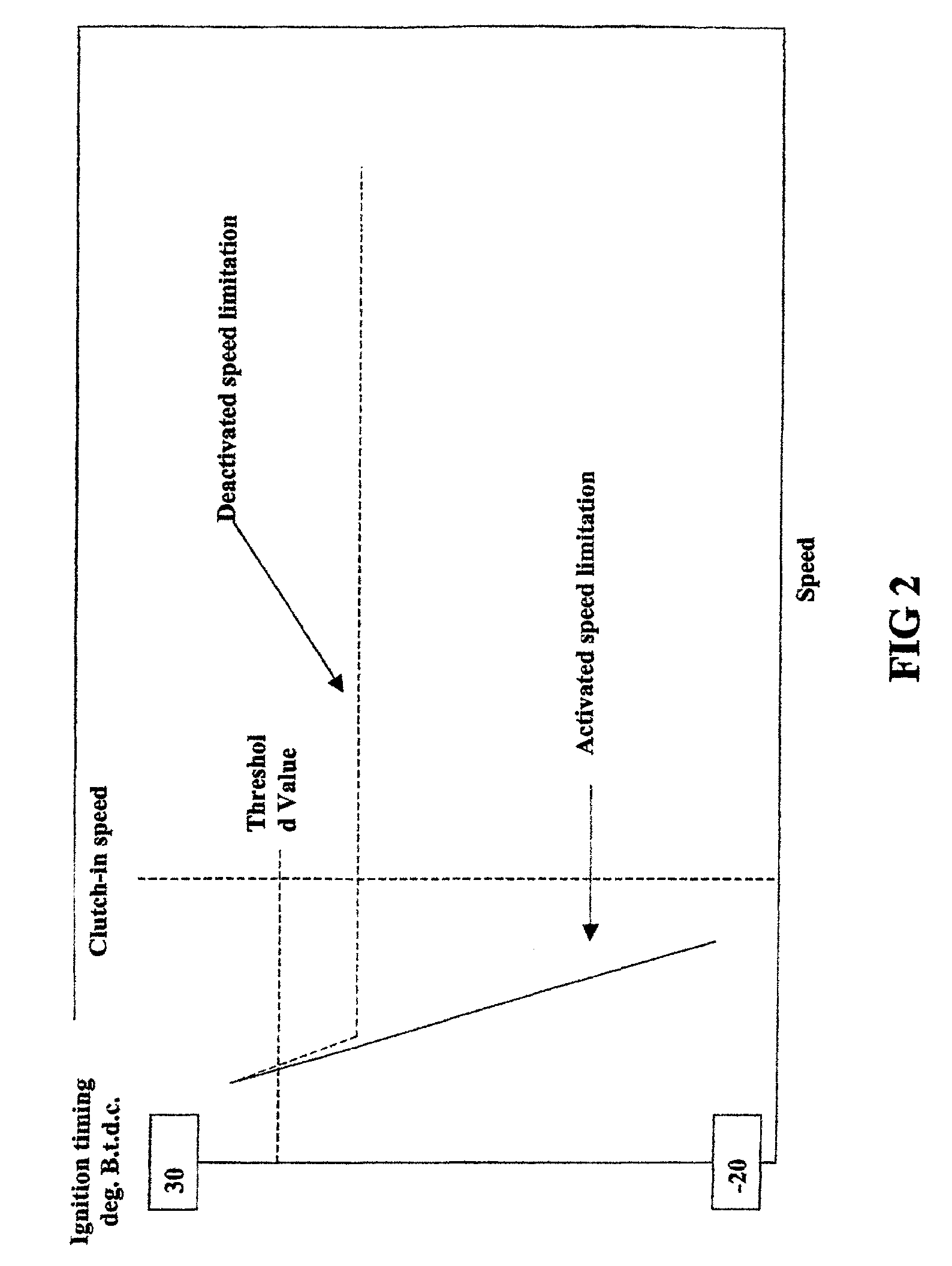

Start safety ignition system

A method for controlling an ignition system of an internal combustion engine having a primary firing pulse generator for charging a capacitor. An electronic switch is included for discharging the capacitor via an ignition coil to generate an ignition voltage. A microcomputer operates the switch to control the ignition timing of the generator. The microcomputer is in communication with a speed sensor that detects the rotational speed of the engine and a speed limitation control that limits the engine speed to a limitation speed below the clutch-in speed of an included centrifugal clutch. The speed limitation control is active or activated when one of either starting the engine or an operating problem of the power tool is detected. The speed limitation control is deactivated when a low speed state of the engine is detected.

Owner:HUSQVARNA AB

Control of autoignition timing in a HCCI engine

InactiveUS7093568B2Reduces and minimizesCompensation effectElectrical controlInternal combustion piston enginesCombustion chamberExhaust valve

Method and system embody a valve timing strategy to control the autoignition timing of a four stroke internal combustion engine (10) operated in an HCCI mode at different engine operating conditions such as different engine speed and torque. A particular valve timing strategy varies lift timing of the intake valve (20) relative to the exhaust valve (28), or vice versa, and relative to top dead center in response to a change in engine torque, for example, to vary amount of trapped residual burned gas in the combustion chamber (12) flowing to an intake or exhaust port (16,18) and back to the combustion chamber during which the residual gas is cooled. Control of the flow of residual gas between the combustion chamber and intake or exhaust port and thus its temperature by the valve timing strategy, in turn, is used to control the temperature of the fresh air / residual gas / fuel mixture in the combustion chamber (12) and thus autoignition timing in response to a change in engine torque.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com