Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

248results about How to "Shorten burn time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

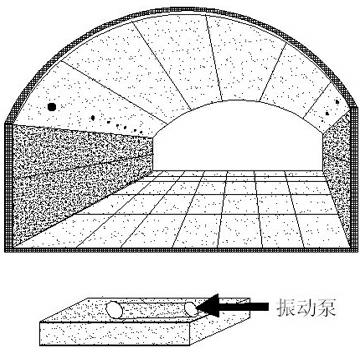

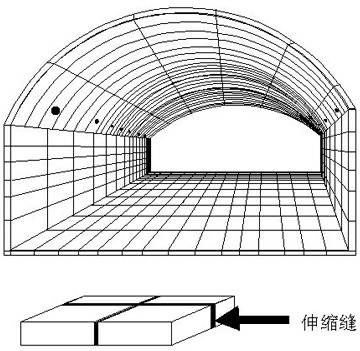

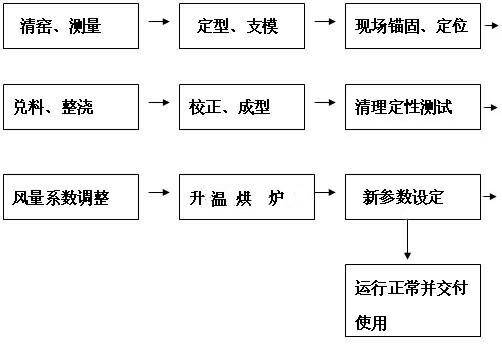

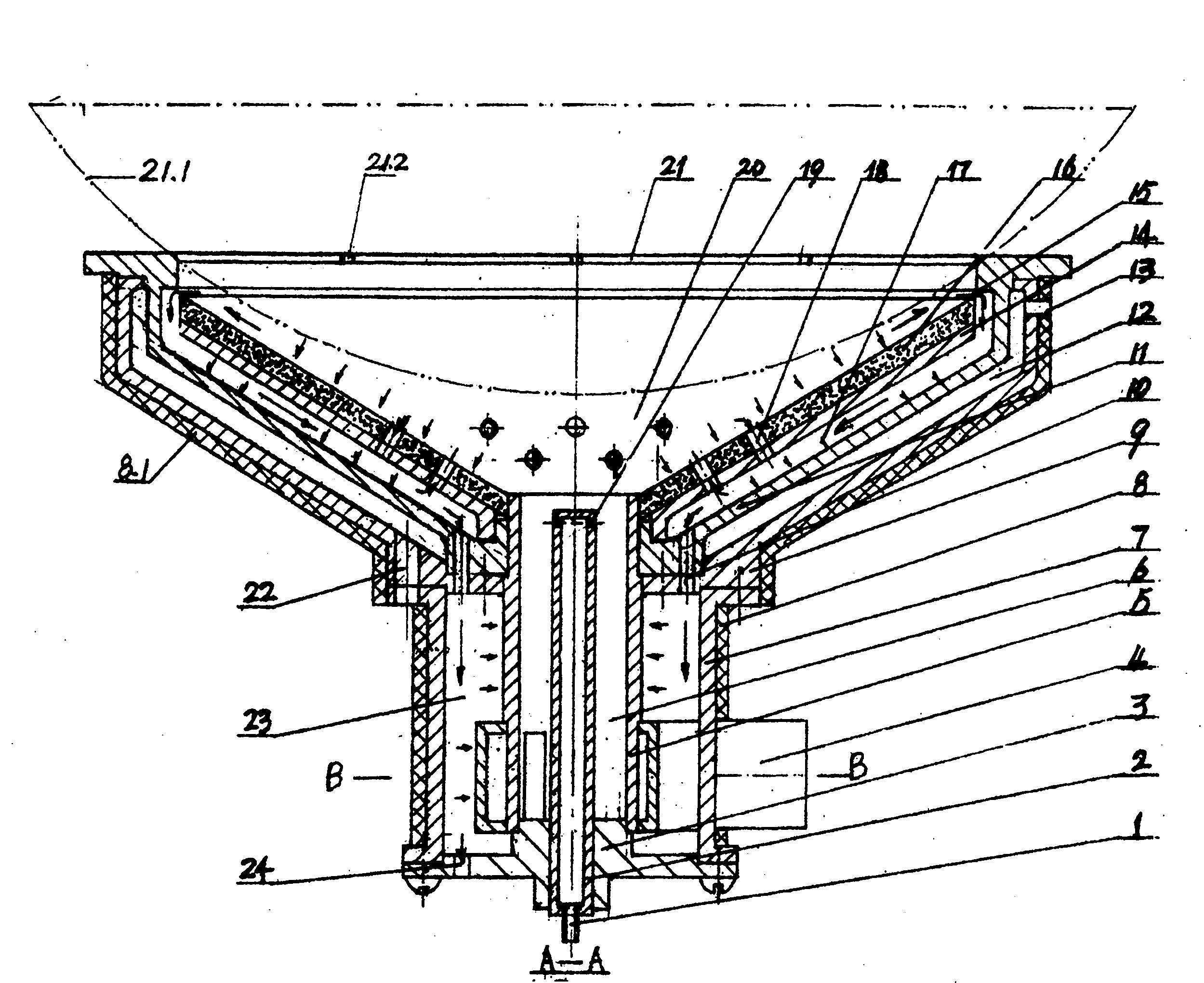

Composite fire-proof material with high refractoriness under load for coke ovens as well as furnace-building process and products thereof

InactiveCN102584294AImprove bindingWaste heat can be recovered for power generationCoke oven brickworkEnergy inputAdhesiveRefractory

The invention discloses a composite fire-proof material with high refractoriness under load for coke ovens. The preparation method of the material comprises the following steps of: evenly mixing and crushing 40%-60% of Al2O3, 15%-30% of SiC micro powder, less than 2% of Fe2O3, 5%-10% of Si micro powder and 1%-3% of cement as an additive; adding 3%-5% of Al(H2PO4)3 as an adhesive and stirring and mixing evenly; and pouring the mixture to a working region in 20-30 minutes. The furnace-building process comprises the following steps of: cleaning a kiln, measuring, molding, positioning and supporting a mould, adding materials, pouring and correcting, cleaning, starting for warming up and testing. The coke ovens newly built by pouring is characterized in that the top of the chamber of the furnace is fan-shaped, the chamber of the furnace is built by on-site seamless overall vibration pouring according to the process above with the furnace-building materials above, afterheat of the furnace can be recycled for power generation and no chemical residues exist. The furnace is short in charring time and higher in coke recovery and can be started and used at any time between the normal temperature and 1550 DEG C.

Owner:GUIYANG DONGJIBOYU REFRACTORY MATERIALS

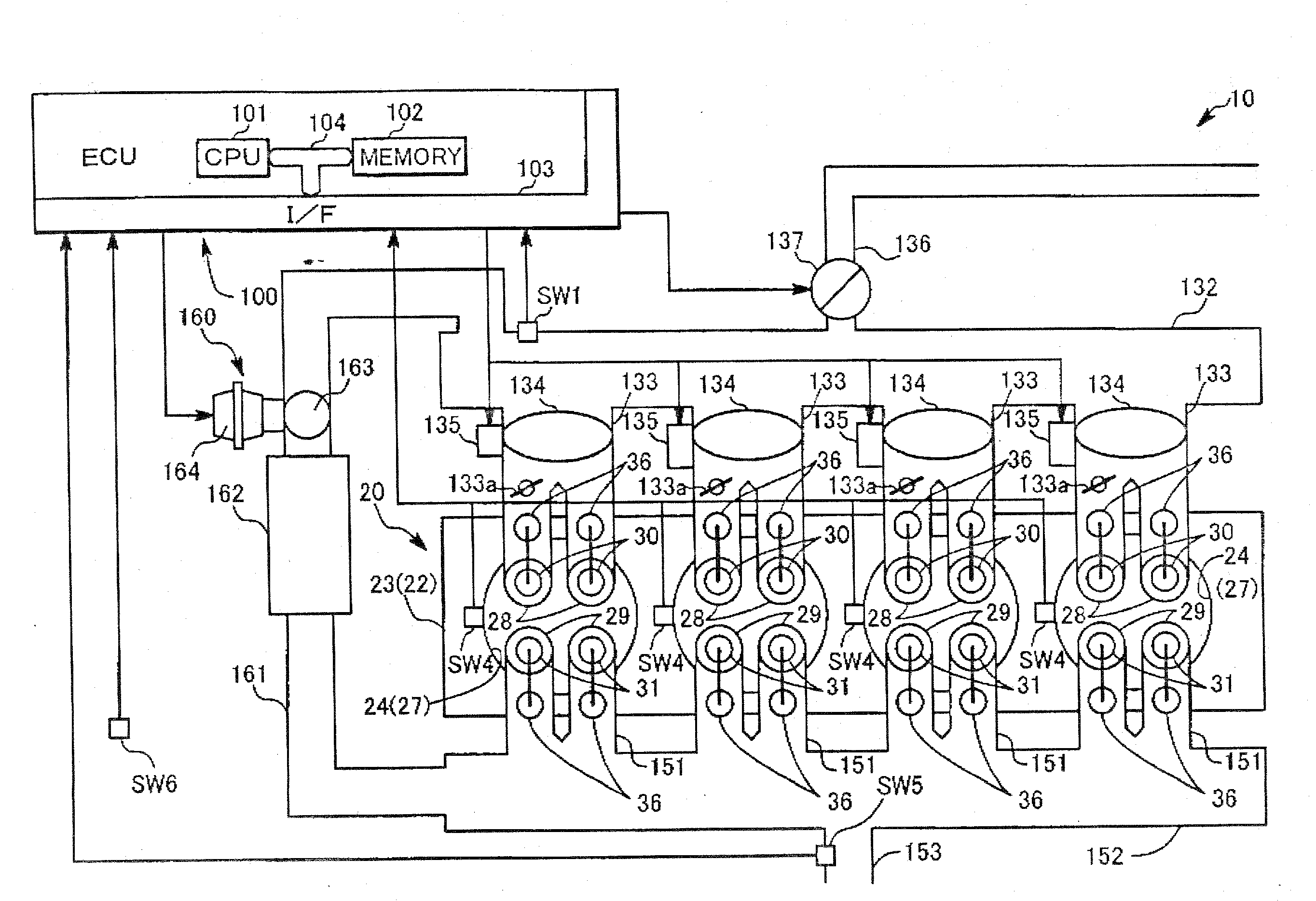

Spark-ignition gasoline engine

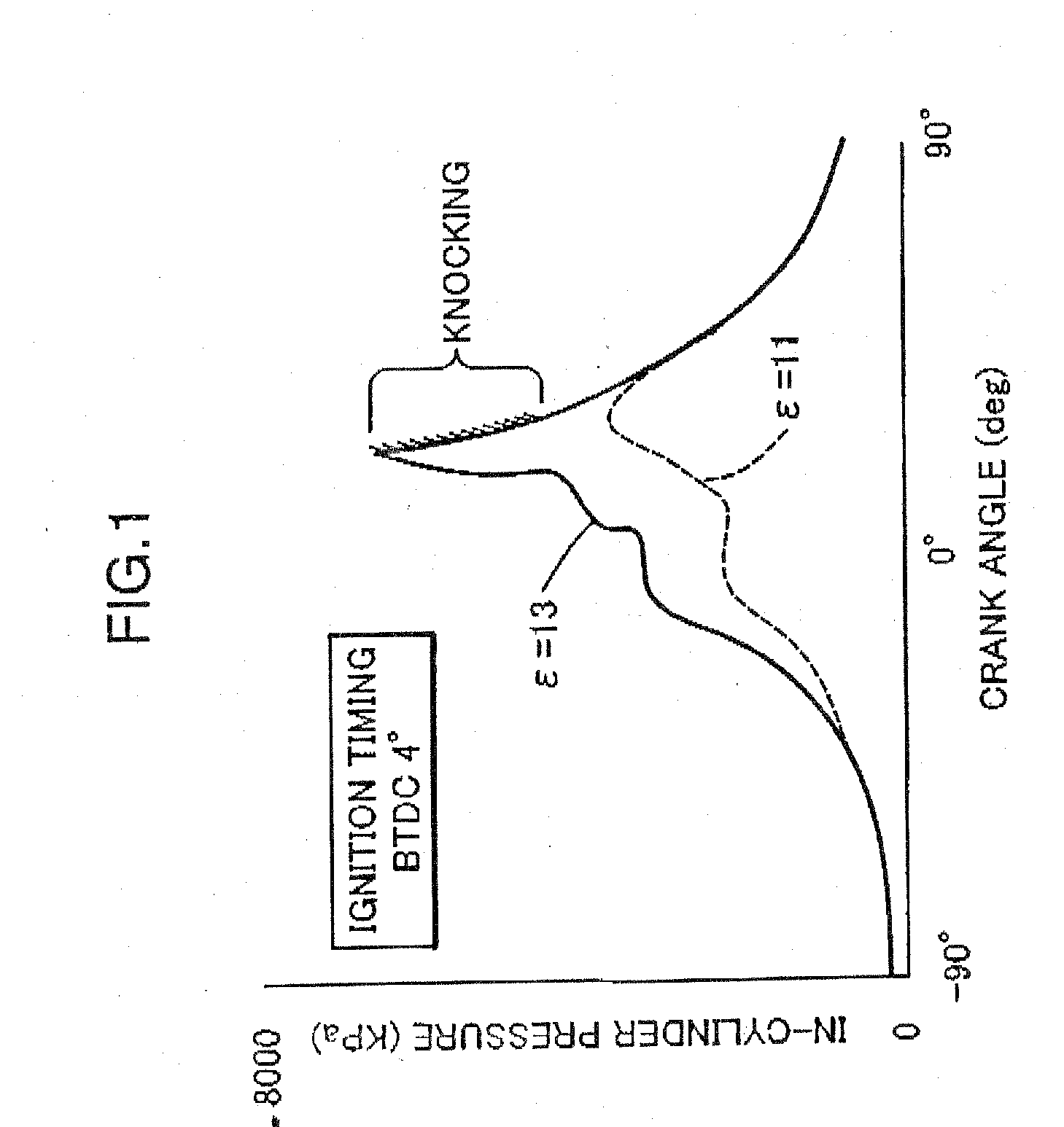

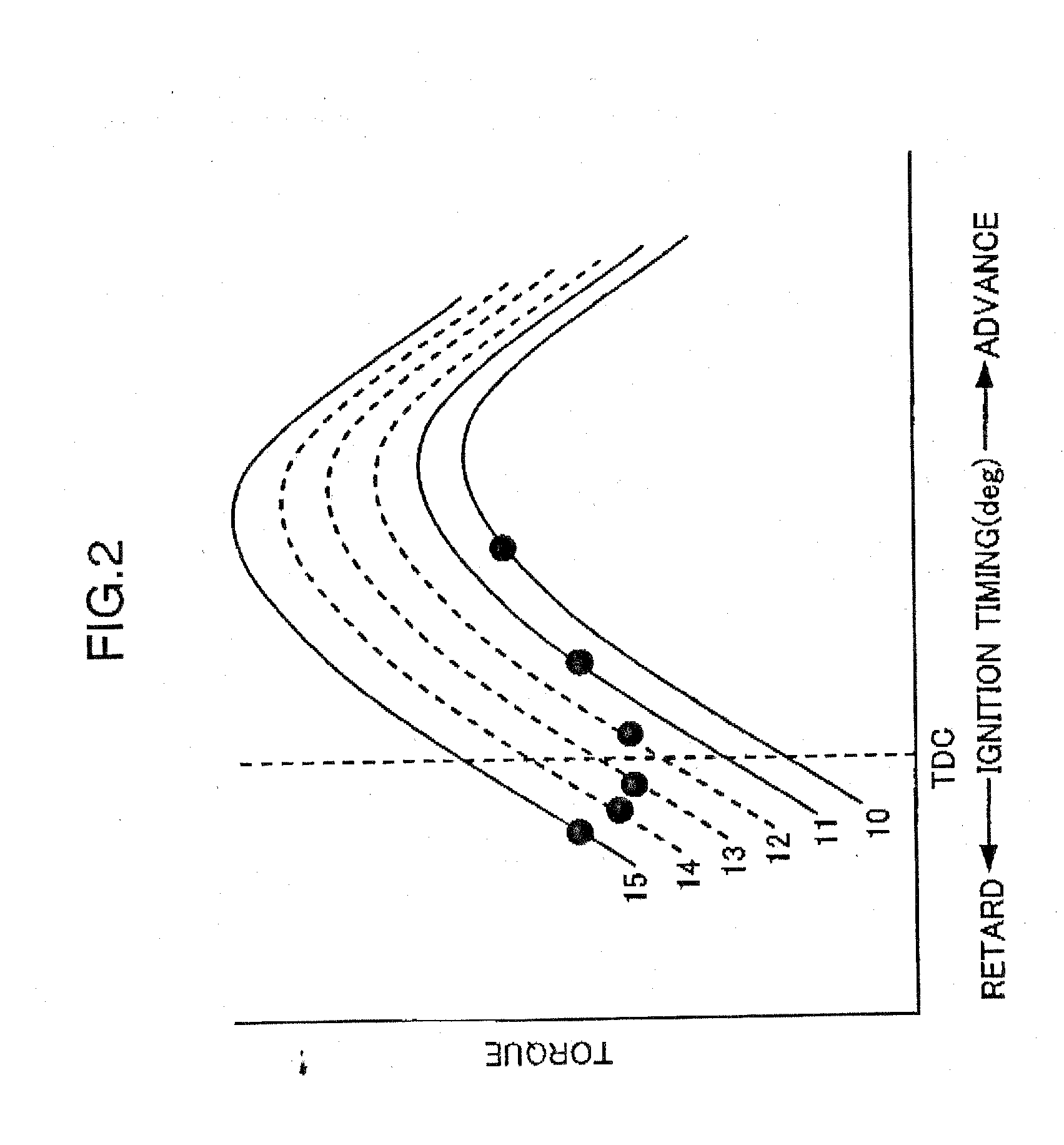

ActiveUS20090159045A1Quantity minimizationReduce consumptionElectrical controlAutomatic controlLow speedExhaust valve

A spark-ignition gasoline engine having at least a spark plug, the engine including an engine body having a geometrical compression ratio set at 14 or more, and an intake valve and an exhaust valve provided, respectively, in intake and exhaust ports connected to each of a plurality of cylinders of the engine body. The intake and exhaust valves are adapted to open and close corresponding respective ones of the intake and exhaust ports. The engine further includes an operation-state detector adapted to detect an operation state of the engine body and a control system adapted, based on detection of the operation-state detector, to perform at least an adjustment control of an ignition timing of the spark plug, the control system being operable, when an engine operation zone is a high-load operation zone including a wide open throttle region within at least a low speed range, to retard the ignition timing to a point within a predetermined stroke range just after a top dead center of a compression stroke.

Owner:MAZDA MOTOR CORP

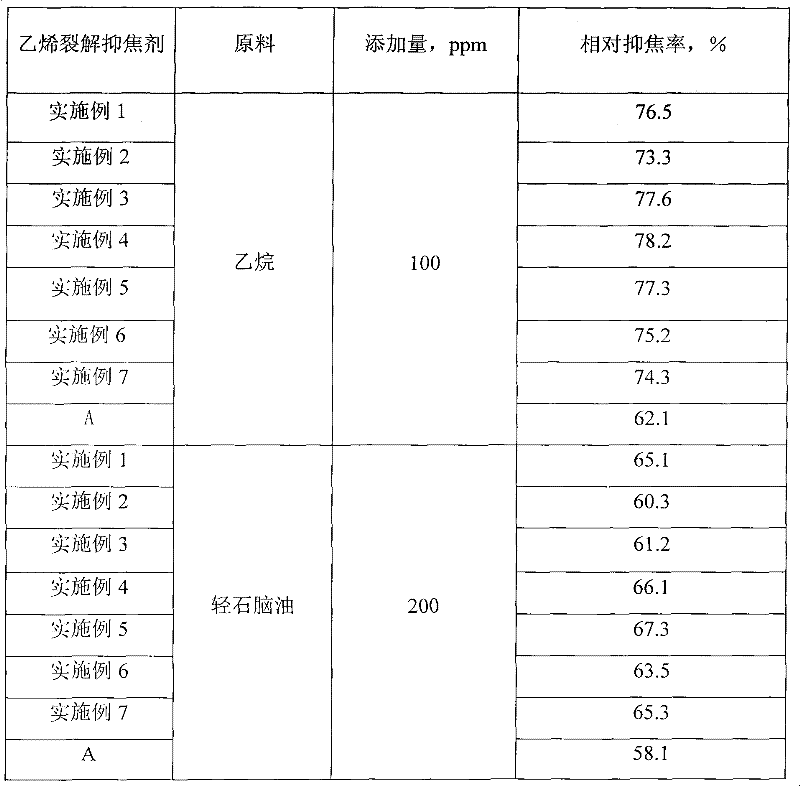

Coke inhibitor for ethylene cracking

ActiveCN101747927AAlleviate cokingGood focus reduction effectThermal non-catalytic crackingPhenyl phosphateSolvent

The invention relates to coke inhibitor for ethylene cracking, which comprises the following component by weight percentage: 20% to 60% of sulfur-containing compound, 5% to 10% of passivator, 1% to 10% of film-forming agent, 5% to 15% of polymerization inhibitor, 1% to 10% of decoking agent and 25% to 45% of solvent, wherein the sulfur-containing compound is particularly dialkyl disulfide, dialkyl sulfide, di-alkylphenol sulfide, diphenyl sulfide, diphenyl disulfide, thiophene or thioxene; and the passivator is particularly triphenyl phosphate, triethyl phosphate, di-octyl-phenyl-phosphate, tributyl phosphate, thiophosphate trilaurate, diethyl-phosphorodi-thioate or triacyl piperidine phosphate, and the passivator is preferably triphenyl phosphate or di-octyl-phenyl-phosphate. The coke inhibitor of the invention for ethylene cracking is capable of effectively relieving the coking condition of an ethylene cracking tube, ensuring the good coke-inhibiting effect, obviously increasing the operation cycle of cracking and reducing the air-decoking time. Therefore, the coke inhibitor of the invention has wide applicable range in the coke inhibition of gaseous light dydrocarbon and naphtha.

Owner:金浦新材料股份有限公司

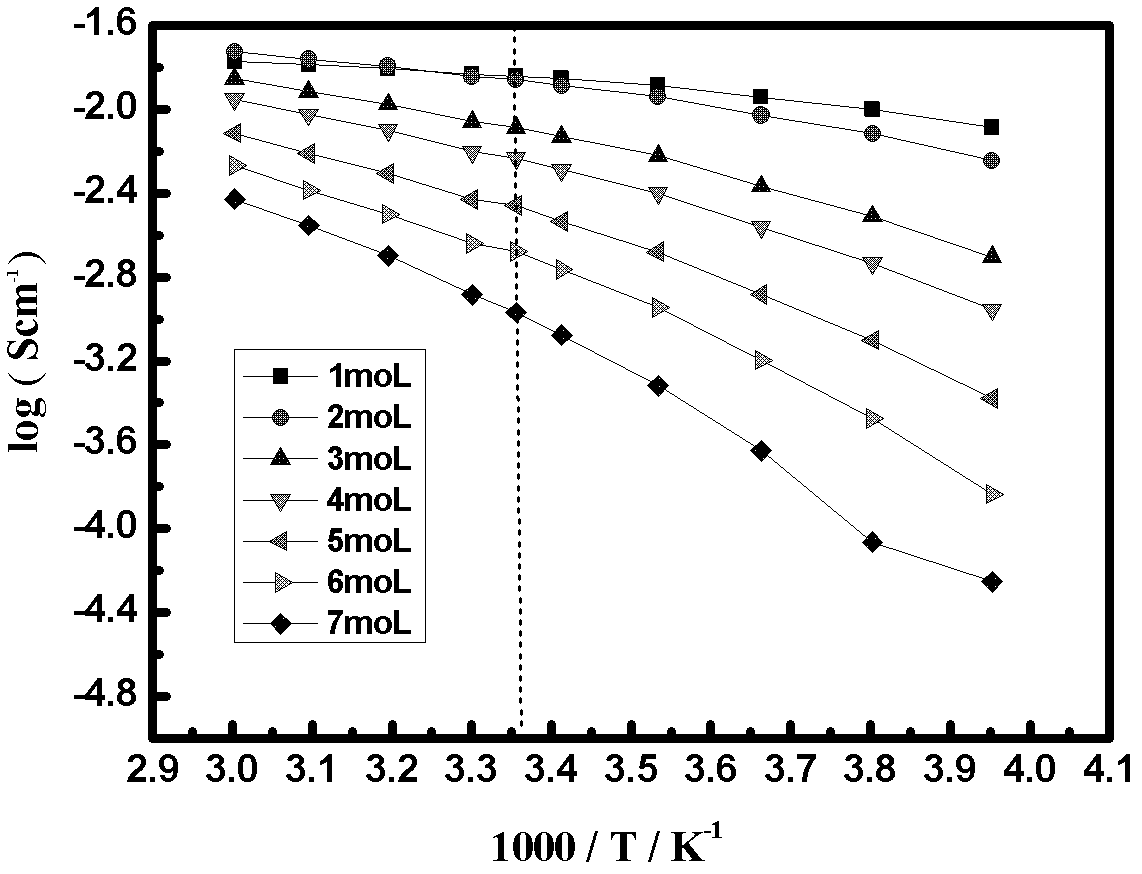

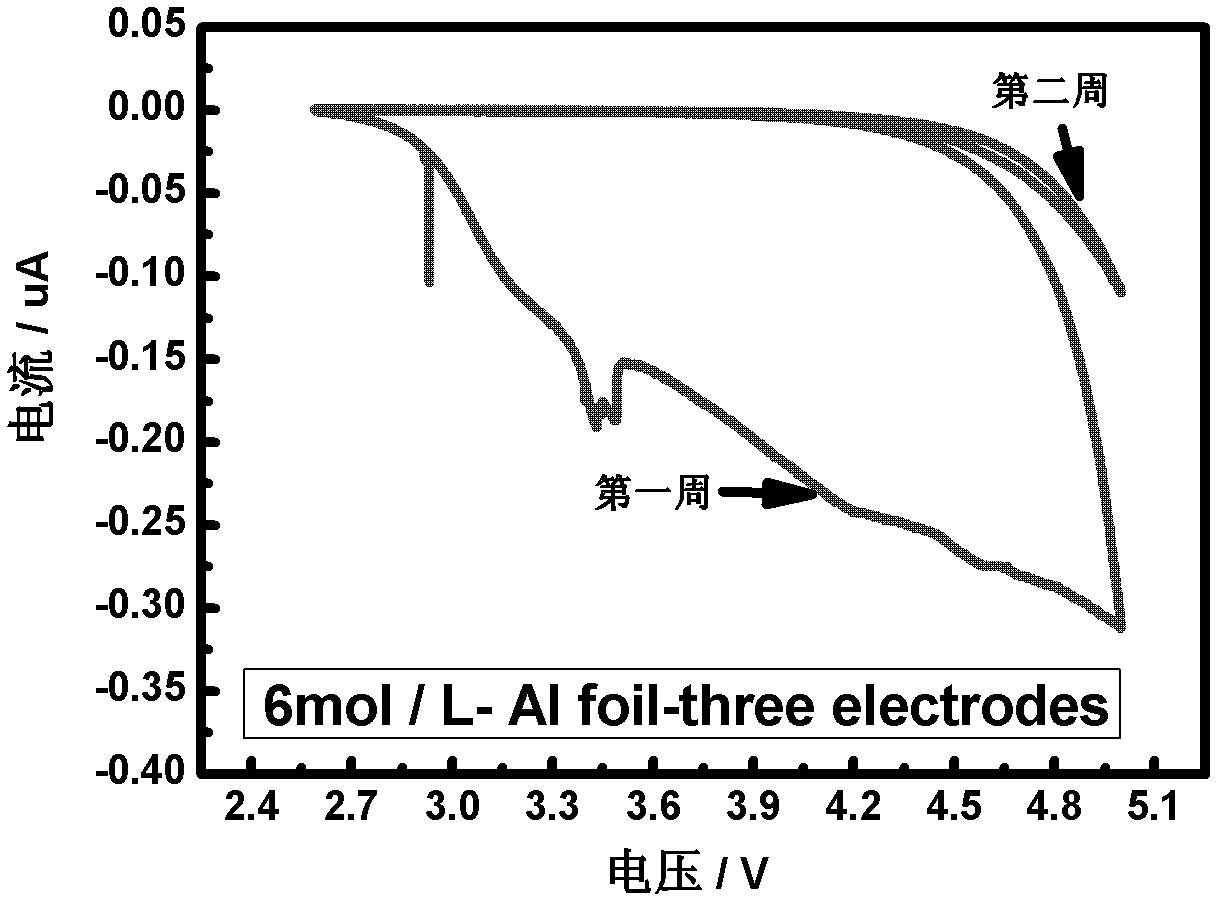

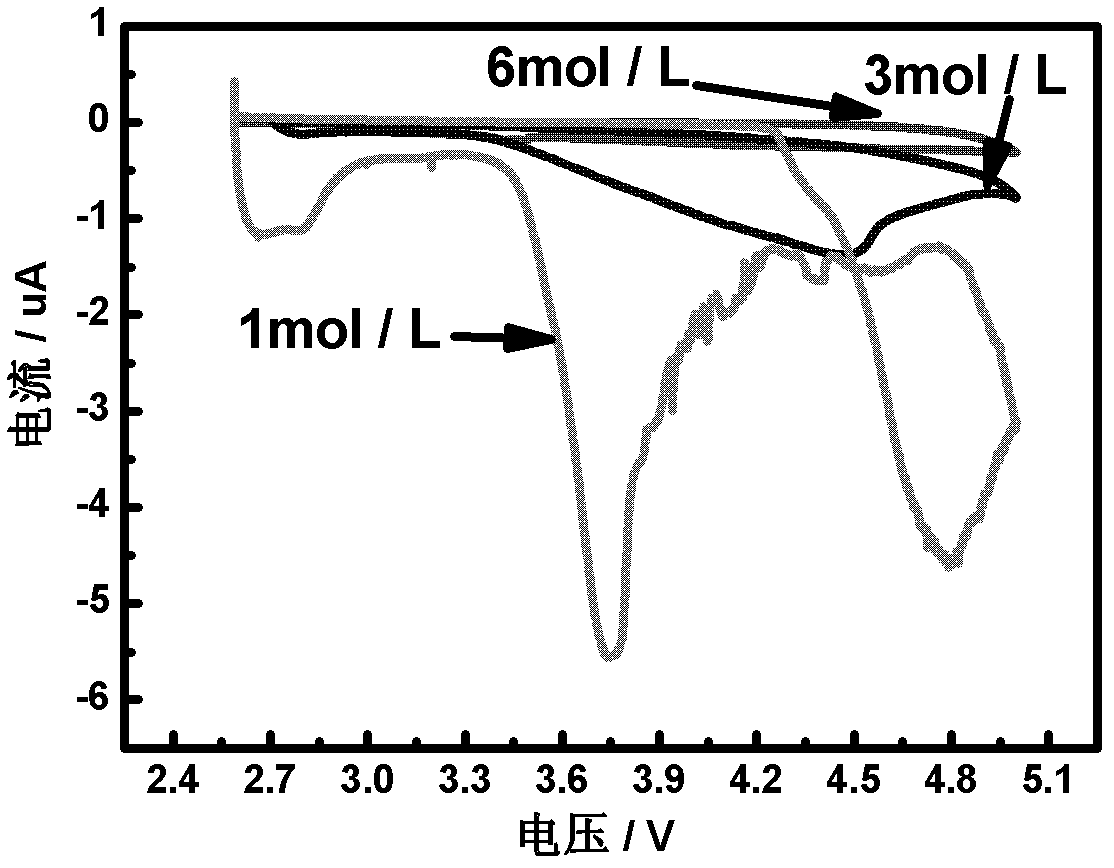

High-salinity non-aqueous electrolyte and use thereof

InactiveCN103219542AImprove thermal stabilityReduce volatilitySecondary cellsElectricityOrganic solvent

The invention discloses a high-salinity non-aqueous electrolyte. The high-salinity non-aqueous electrolyte comprises a lithium salt and a non-aqueous organic solvent, and the concentration of the lithium salt is 2-10mol / L. The invention also discloses a use of the high-salinity non-aqueous electrolyte in a lithium or sodium cell system. The high-salinity non-aqueous electrolyte has the advantages of high thermal stability, low volatility, high safety, electrochemical widow and aluminum foil corrosivity, and lithium or sodium dendrite overcoming.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

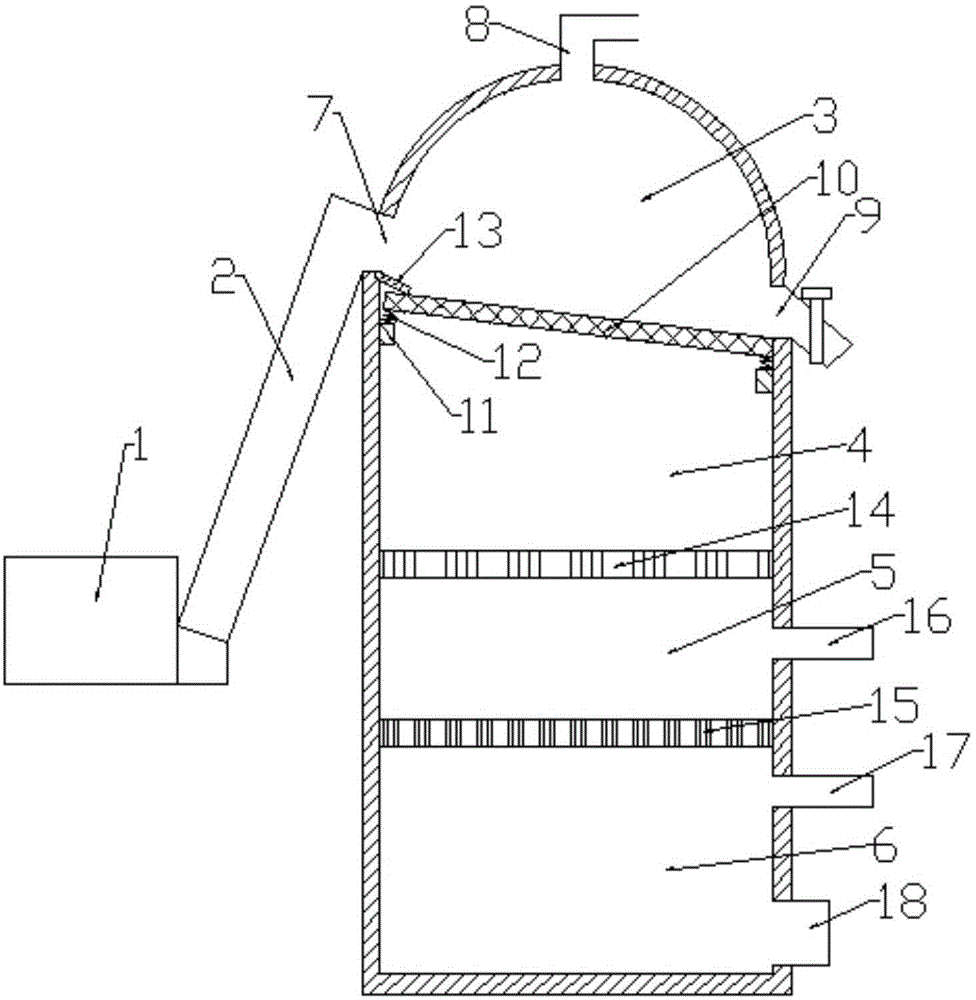

Coal mine waste moving processing device

InactiveCN104832926AReduce volumeReduce processing costsIncinerator apparatusWaste processingEnvironmental resistance

The invention relates to environmental protection equipment, in particular to a coal mine waste moving processing device. A smashing device is connected to a feeding opening of an incinerator through a delivery mechanism. The incinerator comprises a screening chamber, a first combustion chamber, a second combustion chamber and an ash chamber from top to bottom in sequence, the feeding opening is formed in one side of the screening chamber, a discharging opening is formed in the other side of the screening chamber, the top of the screening chamber is provided with a chimney, a screen is installed between the screening chamber and the first combustion chamber in an inclined mode, the higher end of the screen is located at the feeding opening, and the lower end of the screen is located at the discharging opening; a coarse grate is arranged between the first combustion chamber and the second combustion chamber, a fine grate is arranged between the second combustion chamber and the ash chamber, an upwind opening is formed in the second combustion chamber, and a downwind opening is formed in the ash chamber. By means of the coal mine waste moving processing device, the burning efficiency is improved, abundant burning is guaranteed, the device can move along with the change of working areas, the waste can be processed nearby, and the waste processing cost is saved.

Owner:HEBEI UNIV OF ENG

Method for extracting lead-zinc oxide by utilizing zincilate volatilization kiln

ActiveCN102399995ALess experience factorImprove evaporation efficiencyProcess efficiency improvementCombustionSlag

The invention belongs to a method for extracting lead-zinc oxide through oxygen enriched combustion by utilizing zincilate volatilization kiln. The process comprises the steps such as burdening, oxygen preparation, oxygen pressure storage, gas mixing, concentration adjusting, air supply and the like, wherein in the burdening link, the mass ratio of leaching slag to coal is 1:(35-45) and the mixture comprises 12-16wt% of carbon; in the volatilization process, slaked lime accounting for 5-10wt% of the mixture is added; in the gas mixing link, oxygen with the volume concentration of more than 90% and the oxygen supply pressure of 0.4-0.5Mpa is introduced, oxygen is mixed in a gas mixing tank at the head of the kiln, and the volume concentration of the mixed gas is controlled to be 25-45%; and in the volatilization link, lead-zinc oxide smoke is controlled to be volatilized and output at the temperature of 200-1350 DEG C. According to the invention, the carbon combustion condition of the volatilization kiln can be improved, the fuel consumption can be greatly reduced, the concentration of the oxygen in the volatilization kiln can be reasonably promoted, the carbon combustion efficiency can be improved, energy conservation can be achieved, the cost is lowered, and the metal volatilization ratio can be improved.

Owner:YUNNAN XIANGYUNFEILONG RESOURCES RECYCLING TECH CO LTD

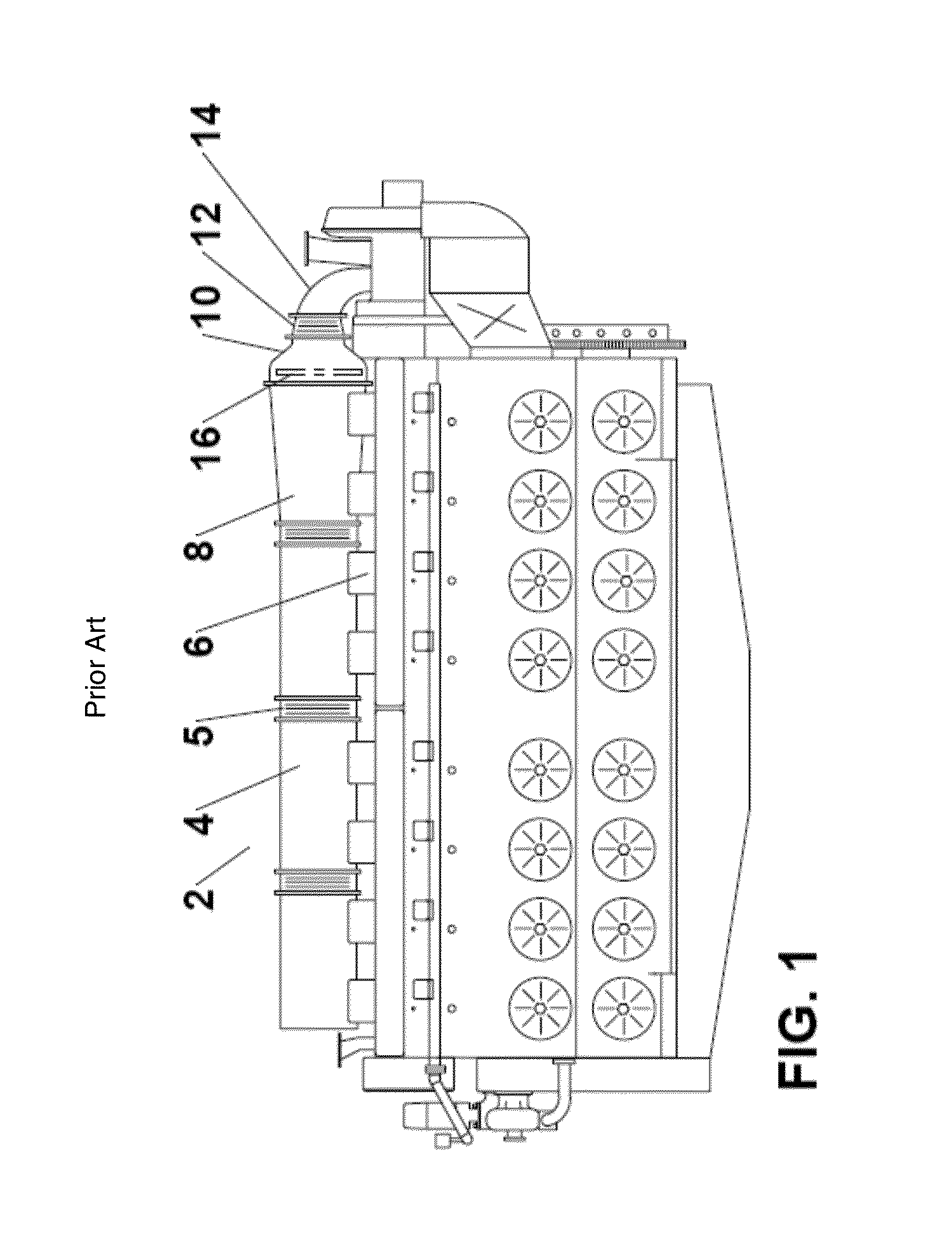

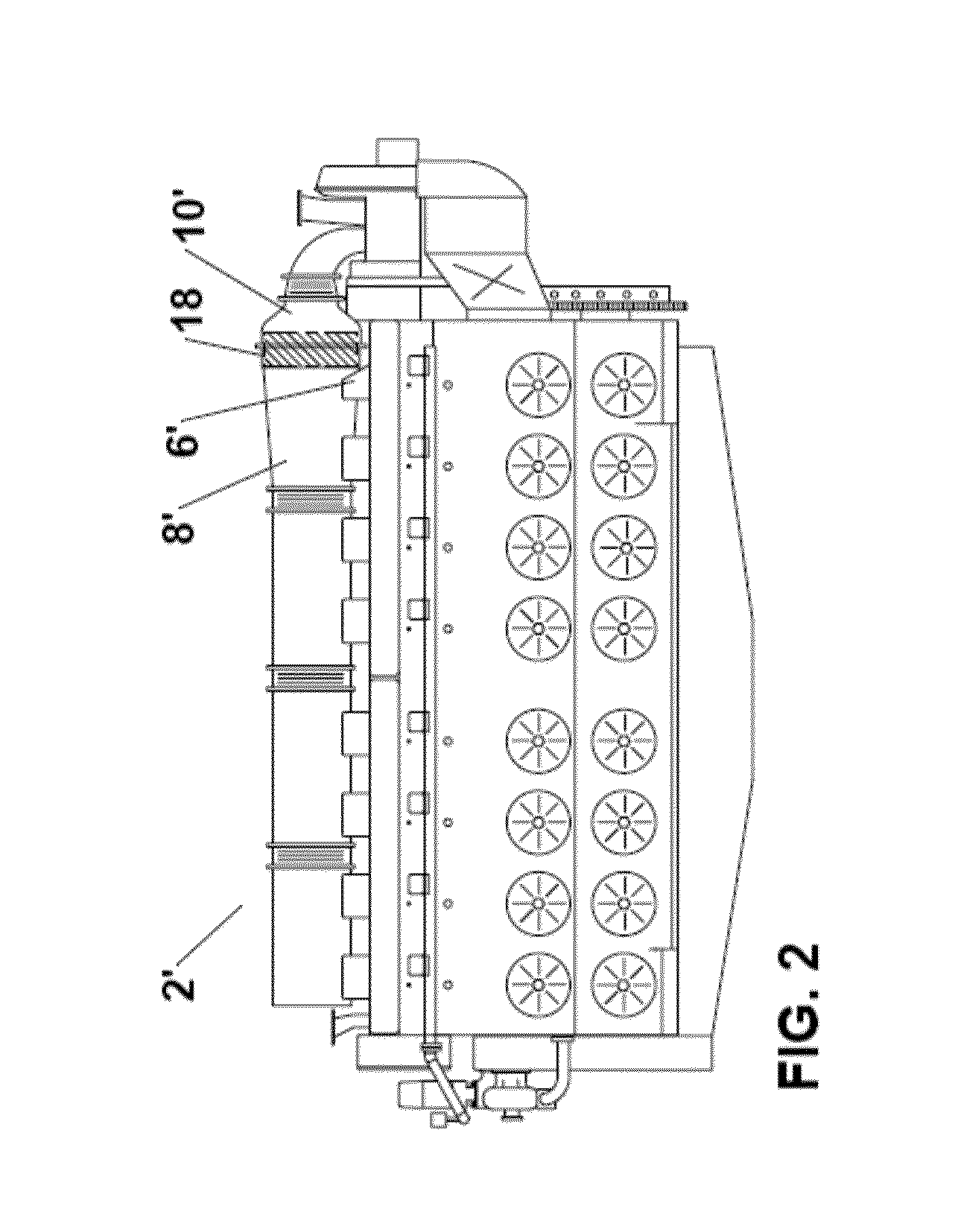

Efficiency and emissions improvements for natural gas conversions of emd 2-cycle medium speed engines

InactiveUS20160003117A1Avoid excessive distanceReduce the impactLiquid coolingInternal combustion piston enginesCylinder headEngineering

A prechamber assembly includes a cylinder head including a coolant cavity, a prechamber body located within the cylinder head, the prechamber body including a nozzle, and an annular sleeve radially surrounding a portion of the prechamber body. The sleeve includes a plurality of coolant inlet holes. A portion of the prechamber body is radially spaced from the sleeve to form a coolant sleeve annulus extending along a length of the prechamber body above the coolant inlet holes. The coolant cavity and the coolant sleeve annulus are in fluid communication through the plurality of coolant inlet holes.

Owner:RAIL PROPULSION SYSTEMS LLC

Spark-ignition gasoline engine

ActiveUS7484498B2Quantity minimizationReduce consumptionValve arrangementsElectrical controlLow speedTop dead center

Owner:MAZDA MOTOR CORP

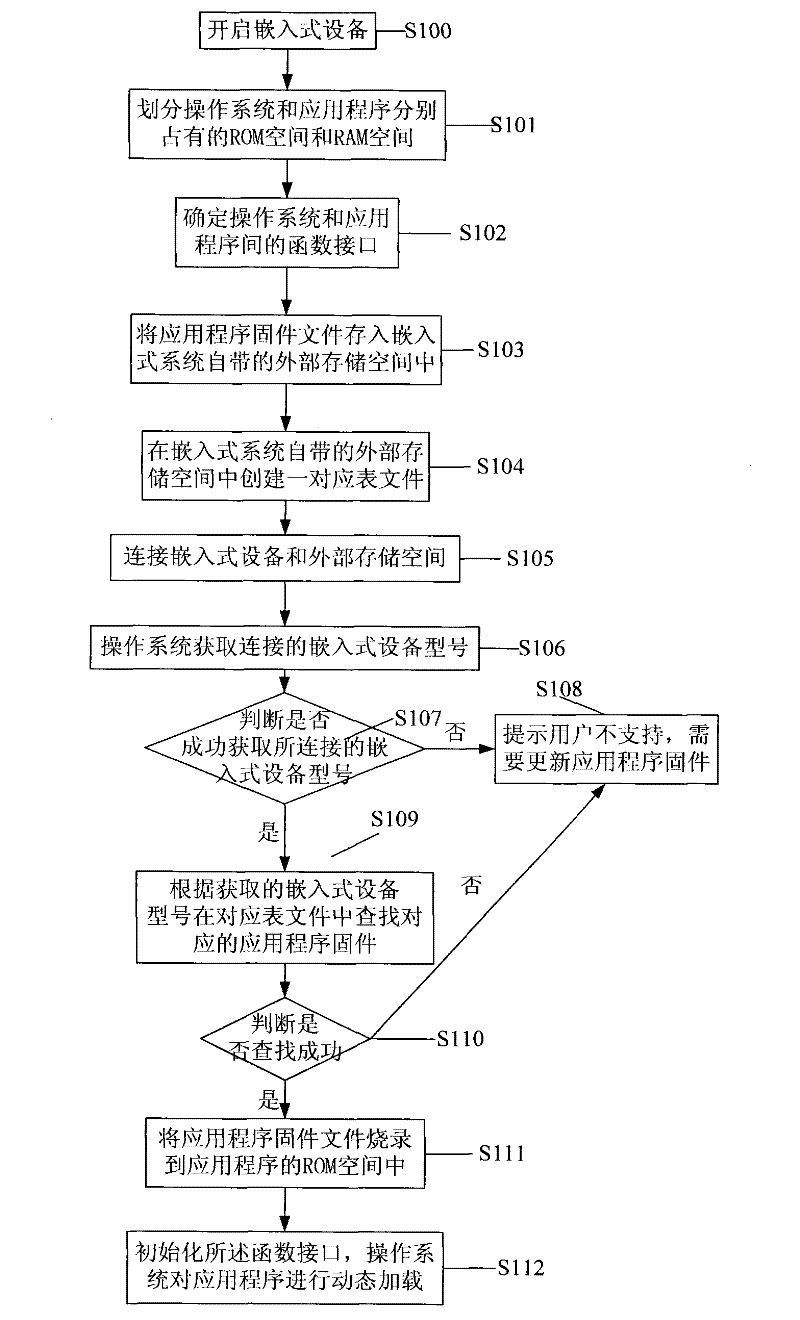

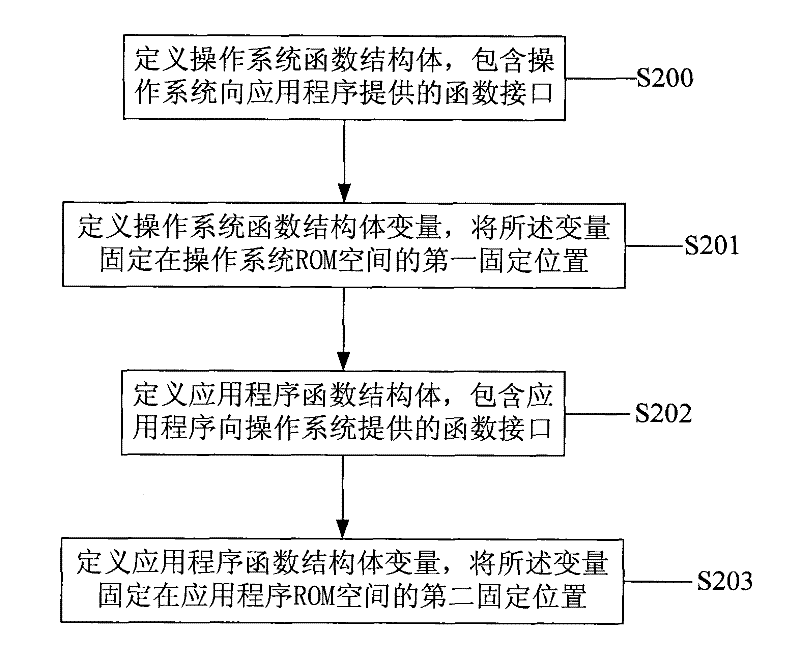

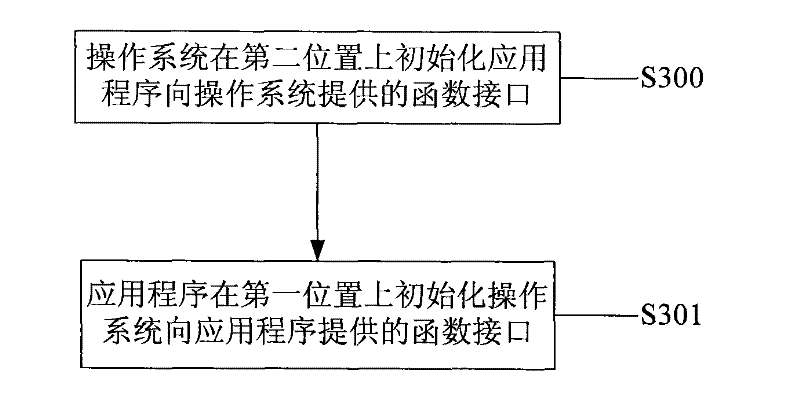

Method for dynamically loading application program of embedded system

InactiveCN102541579AReduce demandReduce R&D costsProgram loading/initiatingExternal storageOperational system

The invention discloses a method for dynamically loading an application program of an embedded system, which comprises the following steps: S1, starting an embedded device and dividing an ROM (read only memory) space and an RAM (random access memory) space respectively occupied by the operating system and the application program; S2, determining the function interface between the operating system and the application program; S3, storing a firmware document of the application program in a built-in external storage space of the embedded device, and connecting the embedded device; S4, burning firmware document of the application program to the ROM space of the application program; and S5, initializing the function interface, wherein the operating system loads the application program dynamically. The method of the invention stores the firmware document of the application program in the own external storage space of the embedded device and dynamically loads the function interface between the operating system and the application program so that the ROM space of a chip is low in demand, and the research and development cost is reduced. In addition, the burning time is shortened and the debugging speed is improved.

Owner:沈阳新邮通信设备有限公司

Preparation method of flame-retardant and waterproof aqueous polyurethane coating and adhesive

ActiveCN104109457AReduced maximum smoke densityDensity time extensionFireproof paintsNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a preparation method of a flame-retardant and waterproof aqueous polyurethane coating and adhesive. The method comprises the following steps: mixing 1,4-di(dimethyl hydroxysilyl) benzene with isophorone diisocyanate in the presence of modified fullerene A, adding a synergist and 2-butoxyl-N-(2-diethylaminoethyl)-4-quinoline formamide hydrochloride and reacting for 1 to 5 hours at 70 DEG C to 80 DEG C so as to obtain a polyurethane prepolymer A; adding a chain extender and a solvent into the prepolymer A, reacting for 3 to 4 hours at 60 DEG C to 80 DEG C, then adding triethylamine and carrying out a neutral reaction for 30 to 60 minutes; then adding a modified manganese hypophosphate solution, coconut oil monoethanolamide and sulfaquinoxaline and reacting for 1 hour at 70 DEG C; and adding water and sodium dodecyl sulfate and emulsifying for 60 minutes, thereby obtaining the flame-retardant and waterproof aqueous polyurethane coating and adhesive. The prepared flame-retardant and waterproof aqueous polyurethane coating and adhesive is environment-friendly and low in cost, and can be widely applied to walls, furniture and metalware surfaces as well as can serve as an adhesive for plastics, glass, papermaking and textiles.

Owner:上海汉司实业有限公司

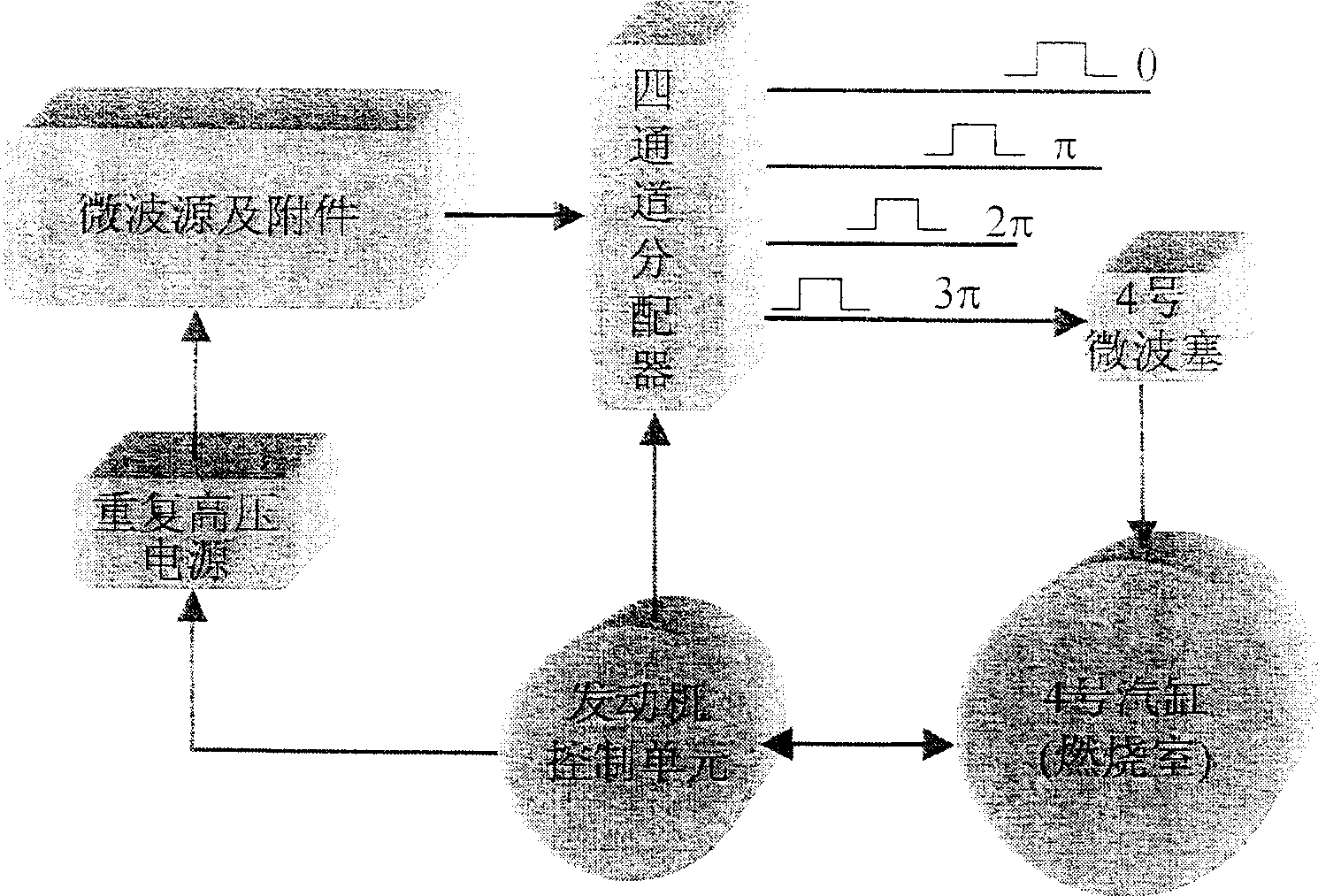

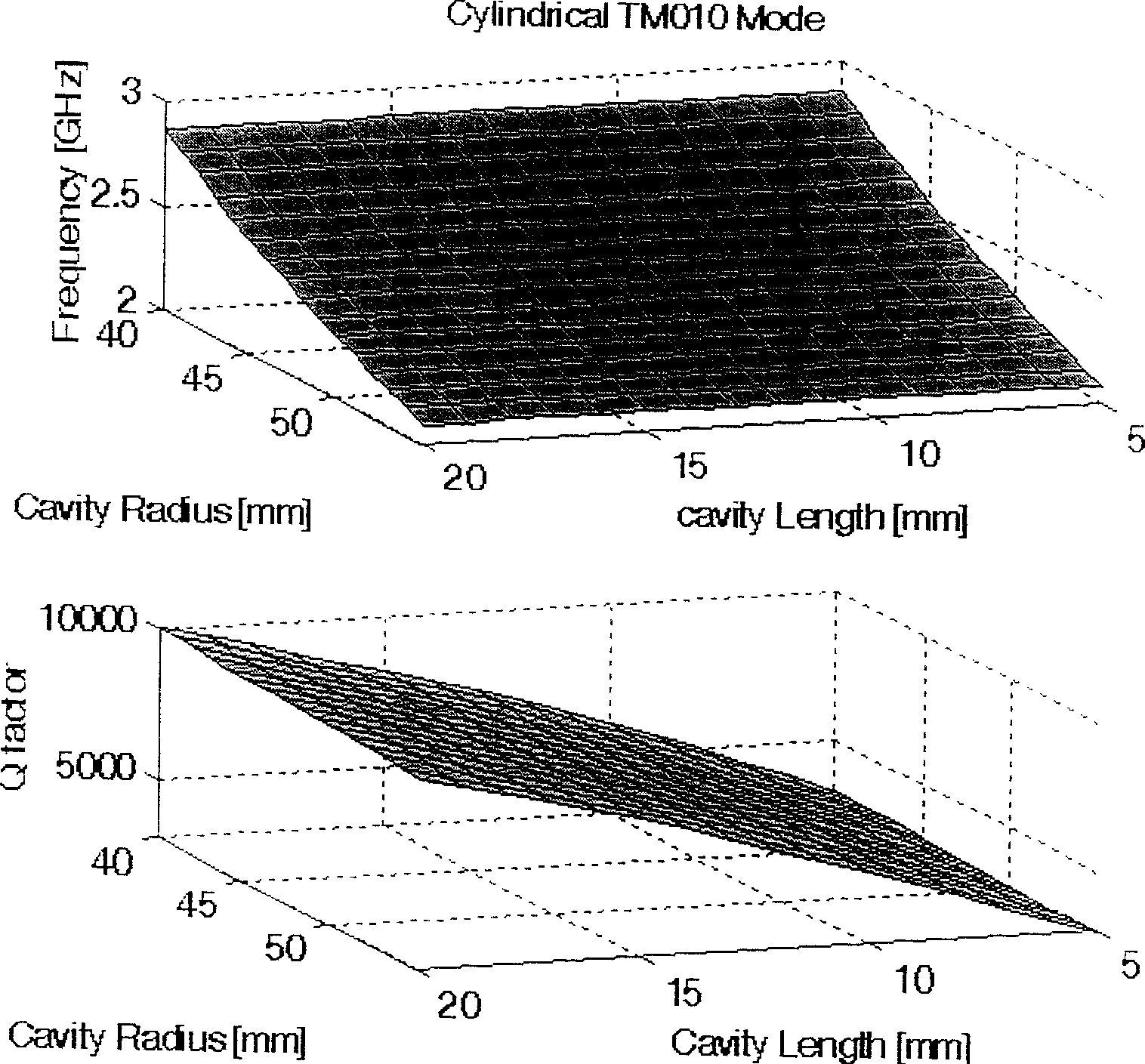

Microwave ignition system for improving combustion efficiency of internal combustion engine

InactiveCN1693699ABurn completelyIdeal to ignite purposeMachines/enginesEngine ignitionCombustion chamberMicrowave

The invention discloses a technology that can improve the burning efficiency of internal fire engine and decrease tail gas release. It couples microwave energy that has a certain frequency into the cylinder of the engine, and fires the oil-gas mixed gas in the cylinder at a seemly moment. The frequency of the microwave is equal to the electromagnetic eigenfrequency that can cause resonance and couple the microwave into the cylinder. After firing, the left microwave acts with the plasma caused by the burning of the cylinder. Thus, the fast entire burning and more absolutely burning of the oil-gas mixture and decreasing the release of end gas would be achieved.

Owner:王刚毅

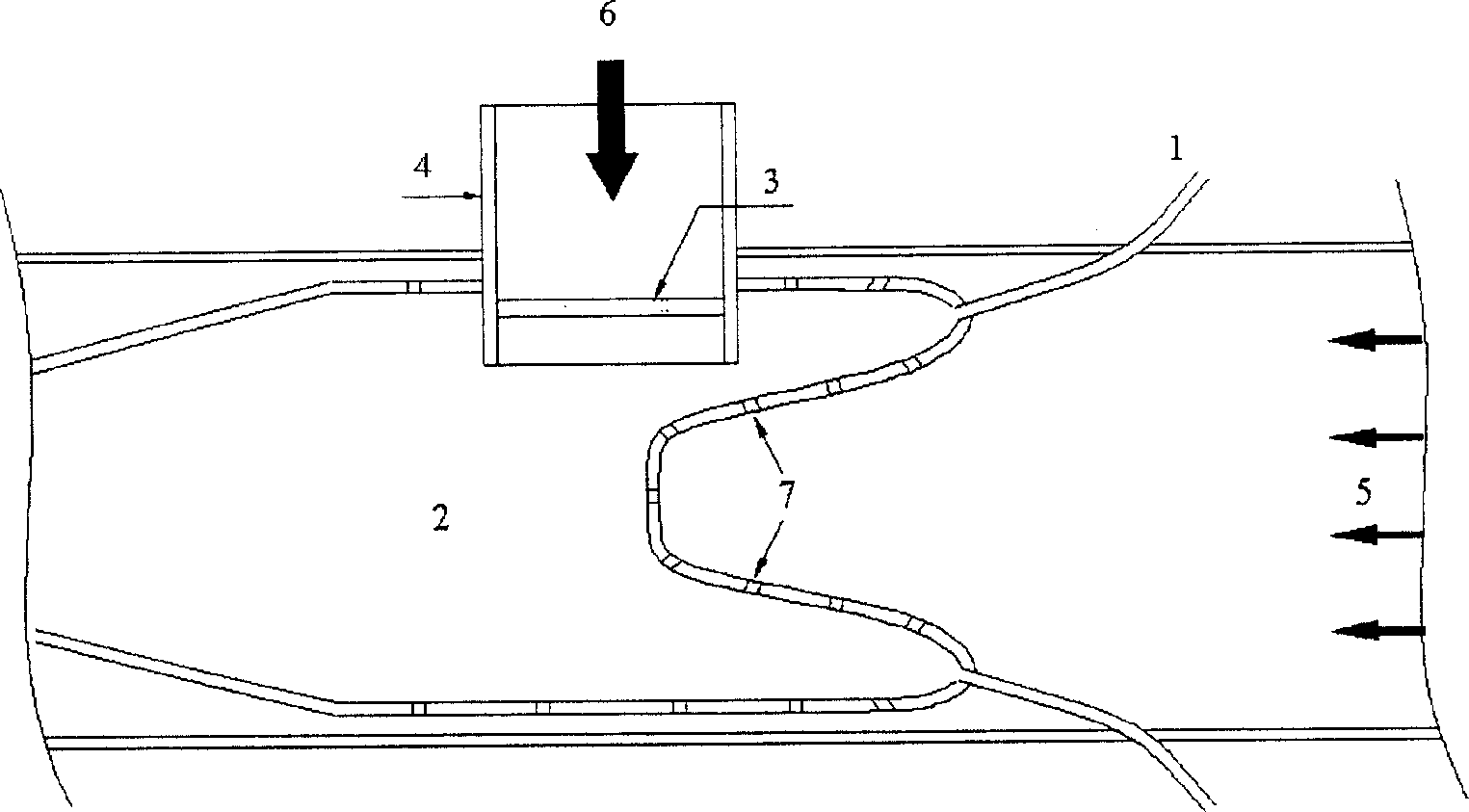

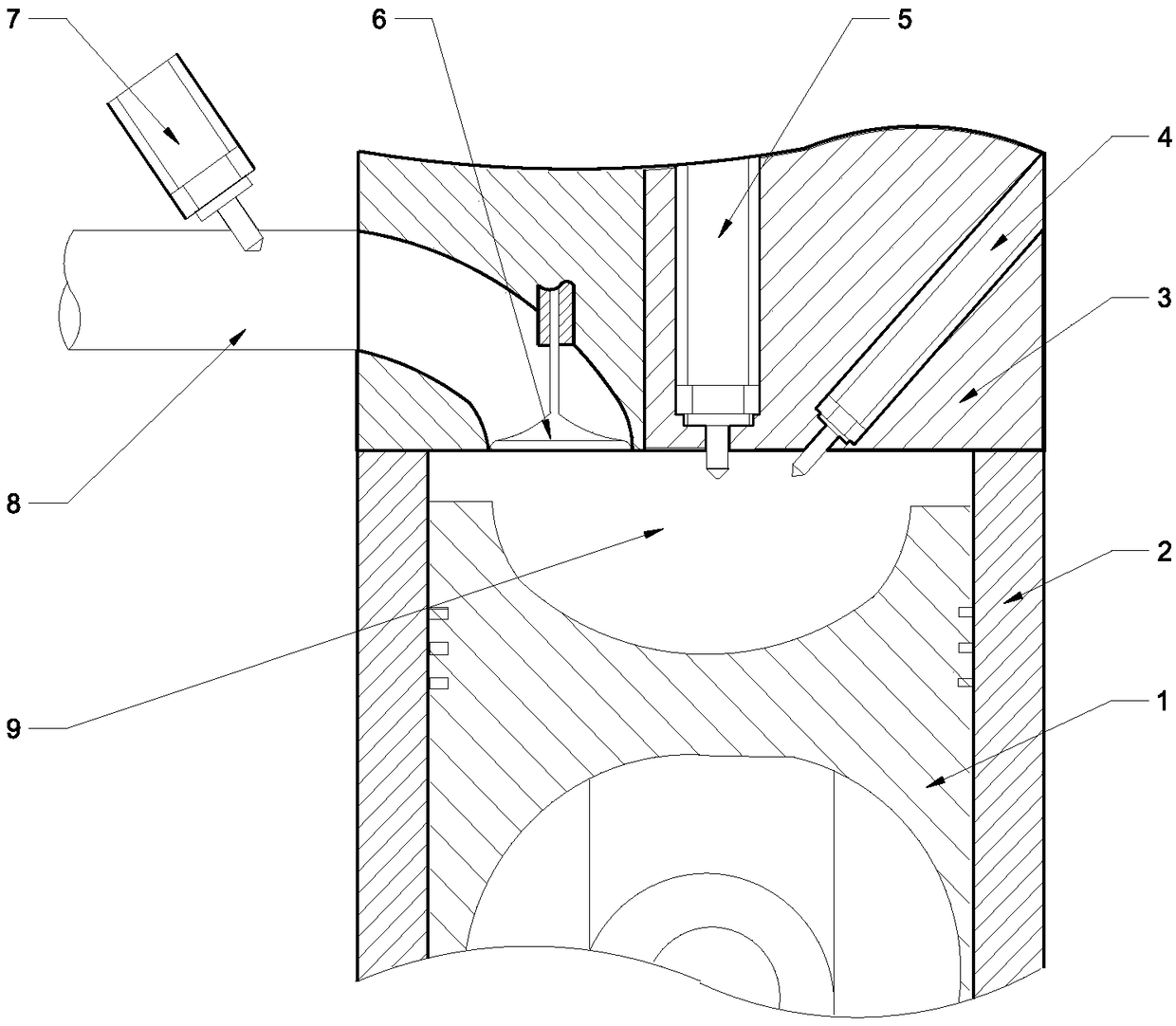

Dual-fuel engine adopting main and auxiliary oil injectors and manifolds for multiple times of spraying, and combustion organization method of dual-fuel engine

ActiveCN109441626AImprove performanceGuaranteed ignition stabilityElectrical controlInternal combustion piston enginesBurning tissueTop dead center

The invention belongs to the technical field of combustion of internal combustion engines, and particularly relates to a dual-fuel engine adopting main and auxiliary oil injectors and manifolds for multiple times of spraying, and a combustion organization method of the dual-fuel engine. The dual-fuel engine comprises a piston, an air cylinder sleeve, an air cylinder cover, the main oil injector, the auxiliary oil injector, a manifold low-pressure gas jetting device and the like; the main oil injector is mounted at the center of the air cylinder cover, and the diesel injection ratio during thelow load can be controlled by changing the oil spraying pulse width of the main oil injector; the auxiliary oil injector is obliquely mounted on the air cylinder cover, diesel micro-jet is conducted during the middle and high load, and natural gas is ignited after diesel nearby a top dead center is self-ignited; and a manifold low-pressure gas jetting valve is mounted on the gas inlet manifold ofeach cylinder, during the middle and high load, the number of times of jetting and the timing of the low-pressure gas jetting valves are controlled, and thus reasonable mixed gas concentration distribution is formed in the cylinders. According to the dual-fuel engine, ignition stability under different working conditions is ensured through diesel ignition, and different oil and gas jetting strategies are adopted under the different working conditions, so that reasonable oil and gas distribution is achieved in the cylinders to achieve the good combustion effect, and thus the economical efficiency and emission performance of the engine are improved.

Owner:HARBIN ENG UNIV

Machine-made charcoal and preparation method thereof

The invention discloses machine-made charcoal. The machine-made charcoal is prepared from the following components in parts by weight: 40-50 parts of Chinese herbal medicine residues, 2-5 parts of a combustion improver, 35-52 parts of biomass waste and 6-10 parts of a binder, wherein the Chinese herbal medicine residues consist of 60-65 parts of wormwood, 10-15 parts of lavender platycodon grandiflorum, 4-6 parts of dried tangerine or orange peel, 2-4 parts of lotus leaves, and 10-24 parts of momordica grosvenori and a branch-leaf mixture thereof. The machine-made charcoal disclosed by the invention takes waste Chinese herbal medicine residues as raw materials, so that the waste is changed into things of value; the properties of the residual medicines are utilized, so that the machine-made charcoal not only has no irritant small, but also has fresh scent; more importantly, the machine-made charcoal has a health effect and a certain action on cough, sphagitis and bronchial asthma, and does not cause a dryness-heat feeling.

Owner:FUJIAN ZHONGMEI CHEM ENVIRONMENTAL PROTECTION TECH CO LTD

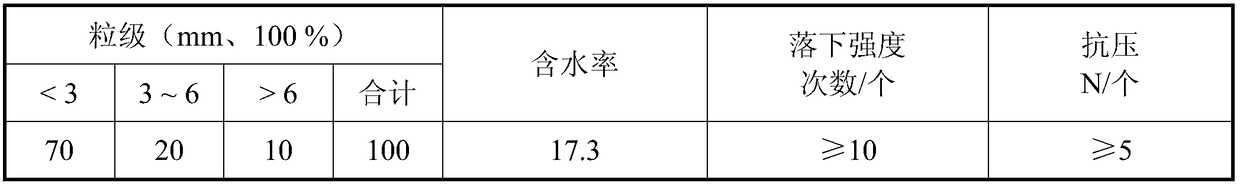

Garbage incineration fly ash high-temperature melting innocuous treatment process

ActiveCN109404916AShorten and simplify the balling processRealize nearby processingIncinerator apparatusBiomass carbonSlag

The invention relates to a garbage incineration fly ash high-temperature melting innocuous treatment process. The garbage incineration fly ash high-temperature melting innocuous treatment process comprises the steps that (1) garbage fly ash and glass powder are mixed to prepare fly ash ball cores; (2) fly ash composite pellets are obtained by adding slag to coat the surfaces of the ball cores; (3)the fly ash composite pellets are mixed with biomass carbon to obtain mixtures; and (4) the mixtures are directly accessed into an incineration device of an existing garbage incineration plant for high-temperature incineration, flue gas generated by incineration is purified by flue gas purification equipment of the garbage incineration plant, and incineration residue is subjected to residue treatment. According to the garbage incineration fly ash high-temperature melting innocuous treatment process, only the garbage fly ash and the glass powder are adopted to prepare the ball cores, the ballcores are coated with slag substances, and the obtained composite pellets are mixed with biomass carbon particles to form the mixtures, so that the ball forming process of the garbage fly ash is shortened and simplified, solid melting of heavy metals in the fly ash is facilitated, glass melts are formed, and leaching toxicity requirements are met; and meanwhile, the required equipment is less, andthe process is matched with the existing garbage incineration plant for implementation, so that nearby treatment of the garbage fly ash can be realized.

Owner:CHONGQING ANGRUIYUE SCI & TECH +1

Method for preparing flame retardant aqueous polyurethane coating and adhesive

InactiveCN104861851APromote expansionGood dispersionFireproof paintsPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention discloses a method for preparing flame retardant aqueous polyurethane coating and adhesive. Polytetrahydrofuran ether glycol and isocyanate are mixed in a 500ml four-opening flask where a stirrer, a thermometer and a condenser pipe are arranged, reaction is performed for 2.5 hours at the temperature of 75 DEG C under the condition of existing of catalyzer dibutyl tin dilaurate to obtain a polyurethane prepolymer A, pyridoxal phosphate and inrumescent flame retardants are added into the polyurethane prepolymer A, reaction is performed for 2.5 hours at the temperature of 85 DEG C, triethylamine is added for neutralization reaction for 90 minutes, water is added for emulsification, ethylenediamine tetramethylenephosphonic acid, dipotassium ethylene diamine tetraacetate and bis(4-carboxyphenyl)phenyl-phosphine oxide are added, reaction temperature is 85 DEG C, the reaction time is one hour, and a system potential of hydrogen (pH) is adjusted to 7-8 to form the flame retardant aqueous polyurethane coating and adhesive. The polyurethane material is high in flame retardant property, environmental friendly, low in price and capable of meeting low cost requirements of market.

Owner:段宝荣

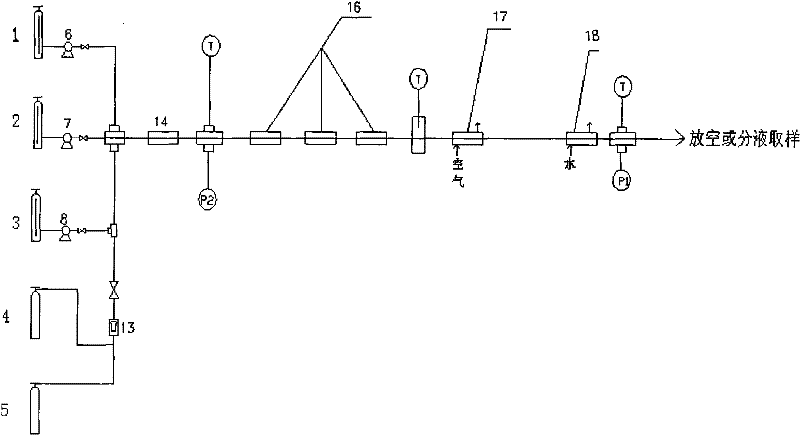

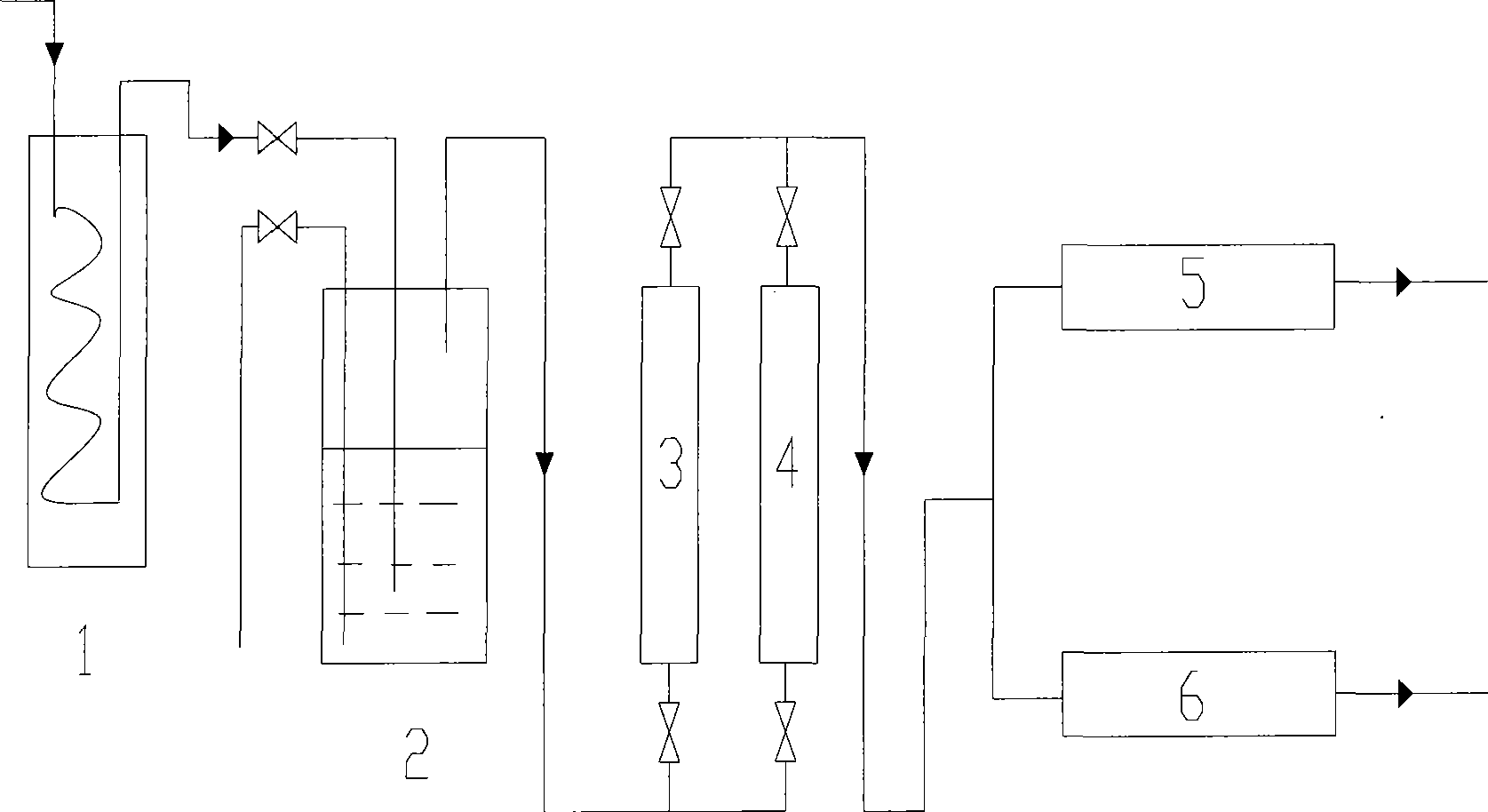

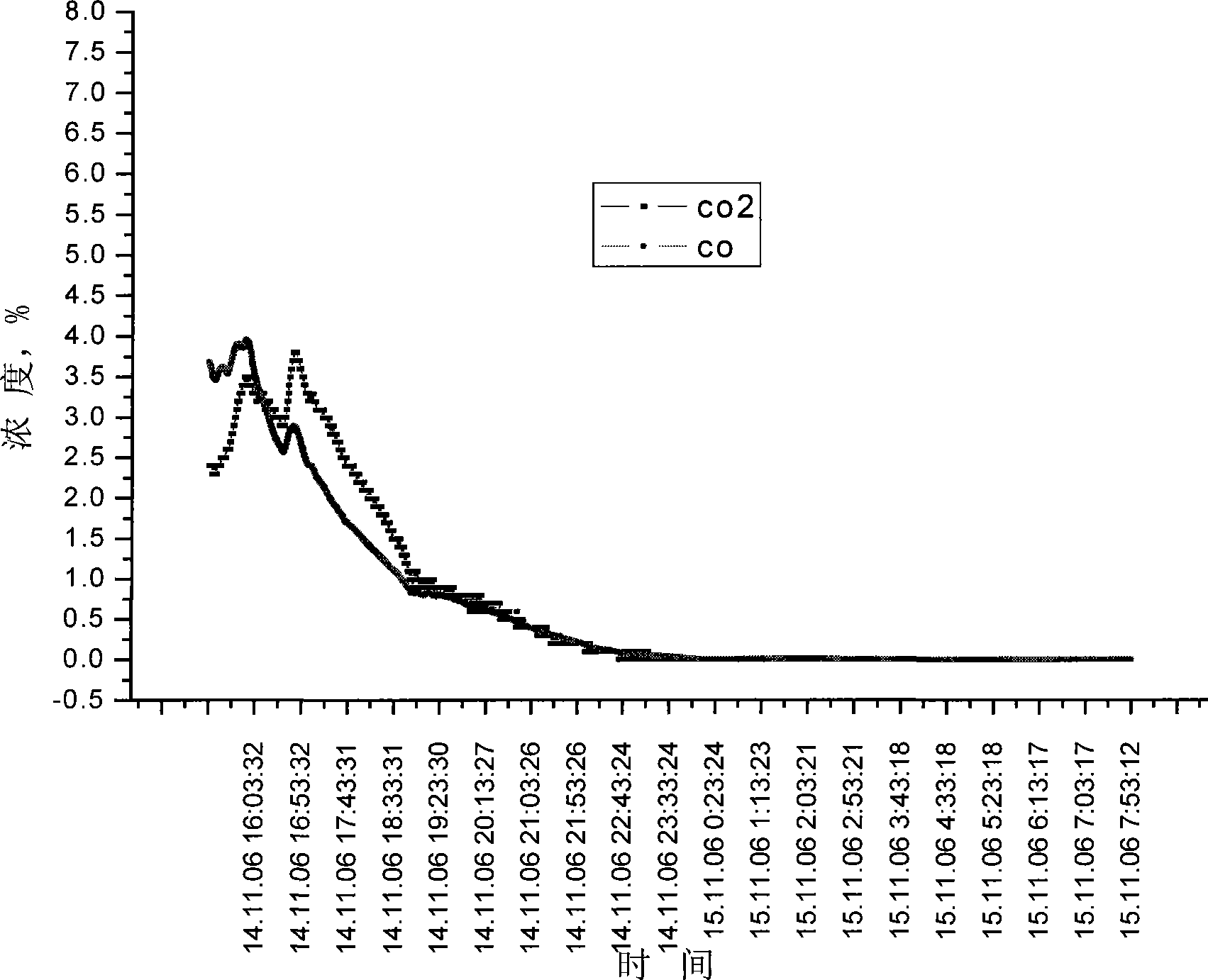

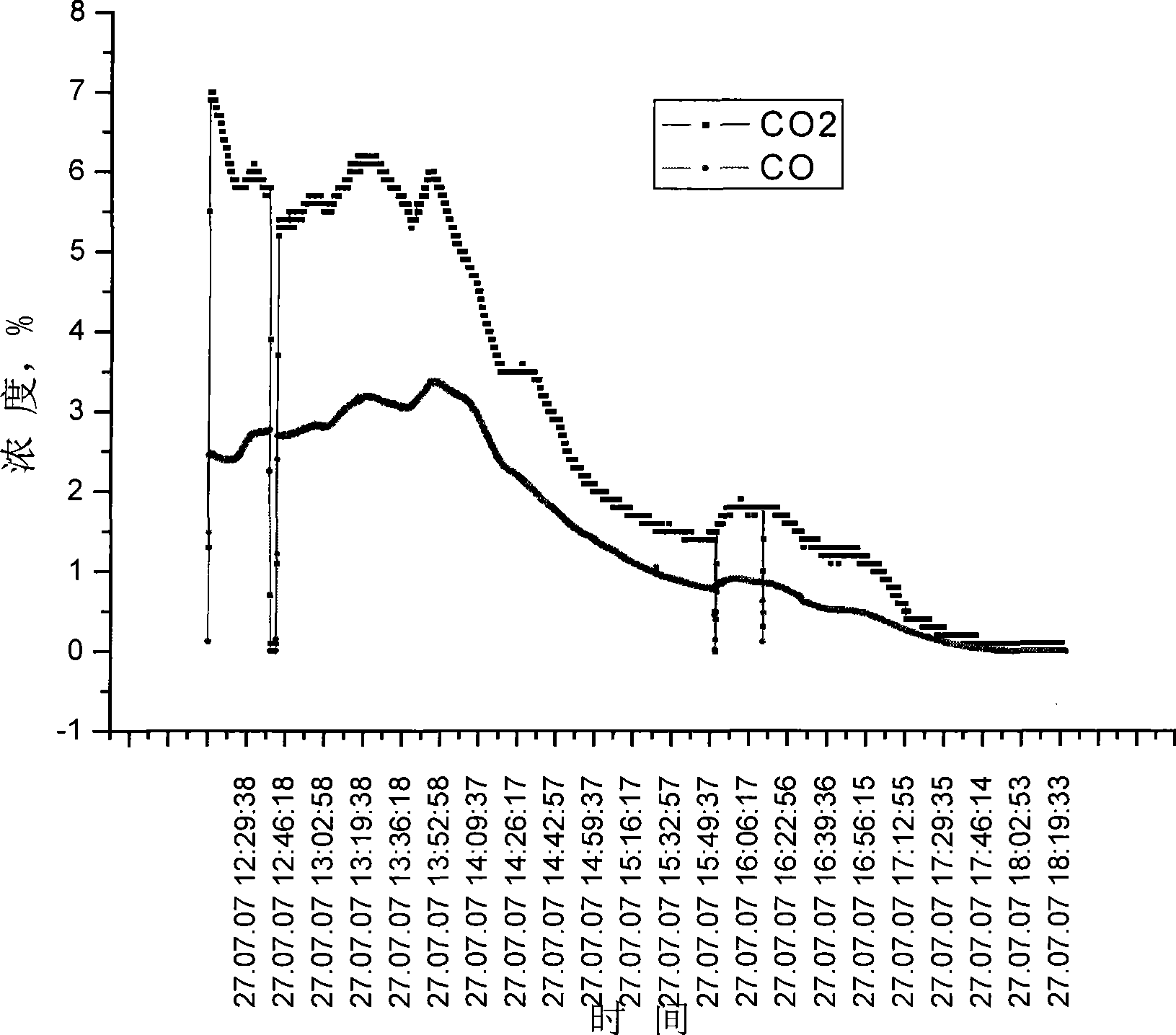

Control method for accelerating on-line coke burning for industrial pyrolysis furnace

InactiveCN101423453AAccelerated scorching rateShorten burn timeHydrocarbon by hydrocarbon crackingProcess engineeringOxygen

The invention relates to a method for on-line control of coke burning of an industrial pyrolysis furnace. The method is to perform on-line coke burning in a furnace tube of a radiant section of an ethylene pyrolysis furnace, adopts the concentration amount of carbon dioxide and oxygen to control vapor, air, the outlet temperature of the furnace tube and the coke-burning time, can monitor the coke-burning process of the pyrolysis furnace, can also be used for coke-burning improvement, reduce the coke-burning time of the pyrolysis furnace, and improve the on-line production time of the industrial pyrolysis furnace, thereby improving the annual yield of the industrial pyrolysis furnace.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for flame-retardant waterborne polyurethane coating and adhesive

ActiveCN104830220AImprove bindingReduced maximum smoke densityFireproof paintsAdhesive processesPolymer sciencePtru catalyst

The invention discloses a preparation method for a flame-retardant waterborne polyurethane coating and adhesive. The preparation method comprises the following steps: mixing polytetramethylene ether glycol with isocyanate in a four-neck flask equipped with a stirring blade, a thermometer and a condenser tube and having a volume of 500 ml and carrying out a reaction at a temperature of 85 DEG C for 2.5 h in the presence of 0.26 g of a catalyst dibutyltin dilaurate so as to obtain a polyurethane perpolymer A; and adding a chain extender and an intumescent flame retardant D into the polyurethane perpolymer A, carrying out a reaction at a temperature of 85 DEG C for 2.5 h, carrying out addition of triethylamine and neutralization for 60 min, carrying out addition of water and emulsification for 1 h, then adding a fire retardant E, carrying out a reaction at a temperature of 75 DEG C for 1 h and adjusting the pH value of a system to be 7 to 8 so as to form the flame-retardant waterborne polyurethane coating and adhesive. The obtained polyurethane materials have the advantages of high flame resistance, environment friendliness and low price and can meet the need of the market for low cost.

Owner:GUANGZHOU WEIDISHI AUTOMOBILE ARTICLE CO LTD

Flame-retardant and high temperature-resistant polyimide compound and preparation method thereof

InactiveCN106519663AImprove flame retardant performanceMeet material requirementsPolyesterHigh humidity

The invention discloses a flame-retardant and high temperature-resistant polyimide compound and a preparation method thereof. The compound comprises, by weight, 40-70 parts of polyimide, 0.1-30 parts of polyol, 0-10 parts of an anti-impact modifier, 0-60 parts of a filler, 5-20 parts of a flame retardant, and 0.2-1 part of a heat stabilizer. The polyol and the polyimide are blended and modified, so the high temperature ageing resistance and the flame retardation performance are effectively improved; and the carbon formation ability of the polyimide is improved, so the burning time is shortened, and the flame retardation performance of the polyimide is improved. The use amount of the flame retardant is effectively reduced, so influences of the flame retardant on the the high temperature ageing resistance of the polyamide are reduced. The anti-impact modifier regulates the anti-impact strength of alloy and plays a great role in enhancement of the compatibility of polyester and polyamide. The compound is suitable for being applied to high-temperature and high-humidity application environment of precise electronic and electric parts and automobile engine compartments and the most advanced fields of aerospace.

Owner:SHANGHAI KINGFA SCI & TECH +2

Preparation method of waterborne polyurethane coating and adhesive modified by graphene and rare earth

InactiveCN104789102AReduced maximum smoke densityDensity time extensionFireproof paintsNon-macromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a preparation method of waterborne polyurethane coating and adhesive which are modified by graphene and rare earth. The preparation method of the waterborne polyurethane coating and adhesive which are modified by graphene and rare earth comprises the following steps: in presence of a dibutyltin dilaurate catalyst, mixing a ytterbium phosphorus flame retardant with hexamethylene diisocyanate, carrying out reaction for 2-3 hours at the temperature of 70-90 DEG C, adding sodium glucoheptonate, and carrying out reaction for 30 minutes at the temperature of 70-90 DEG C, so that a polyurethane prepolymer is obtained; adding a hydrophilic chain extender and butanone into the polyurethane prepolymer, carrying out reaction for 1-3 hours at the temperature of 70-80 DEG C, adding triethylamine for carrying out reaction for 30-60 minutes, and adding water for emulsifying, so that hydrophilic polyurethane is formed; adding a graphene dispersion liquid and phospholipid into the hydrophilic polyurethane, and shearing and stirring for 60-90 minutes under the condition that pH value is 7, so that the waterborne polyurethane coating and adhesive which are modified by graphene and rare earth are obtained, and fire resistance and mechanical properties of the obtained polyurethane coating and adhesive are greatly improved.

Owner:段宝荣

Prepration method of nanometer material capable of improving fire resistance of waterborne polyurethane coating and adhesive

ActiveCN104449325AReduced maximum smoke densityDensity time extensionFireproof paintsNon-macromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a prepration method of a nanometer material capable of improving fire resistance of a waterborne polyurethane coating and an adhesive. The method comprises the following steps: mixing polytetrahydrofuran glycol with isophorone diisocyanate, reacting in the presence of a Pd / Fe3O4-CNT catalyst, so as to obtain a polyurethane prepolymer A; adding dimethylolpropionic acid to the polyurethane prepolymer A, and reacting; adding triethylamine and carrying out neutral reaction; adding water and emulsifying, so as to form polyurethane B; adding a nanometer material emulsion C to the polyurethane B; and shearing and stirring under the condition that pH is 7, so as to obtain the prepared waterborne polyurethane coating and adhesive. The polyurethane material is environment-friendly and low in price, and can meet the low-cost requirements of the market.

Owner:成都富安纳新材料科技有限公司

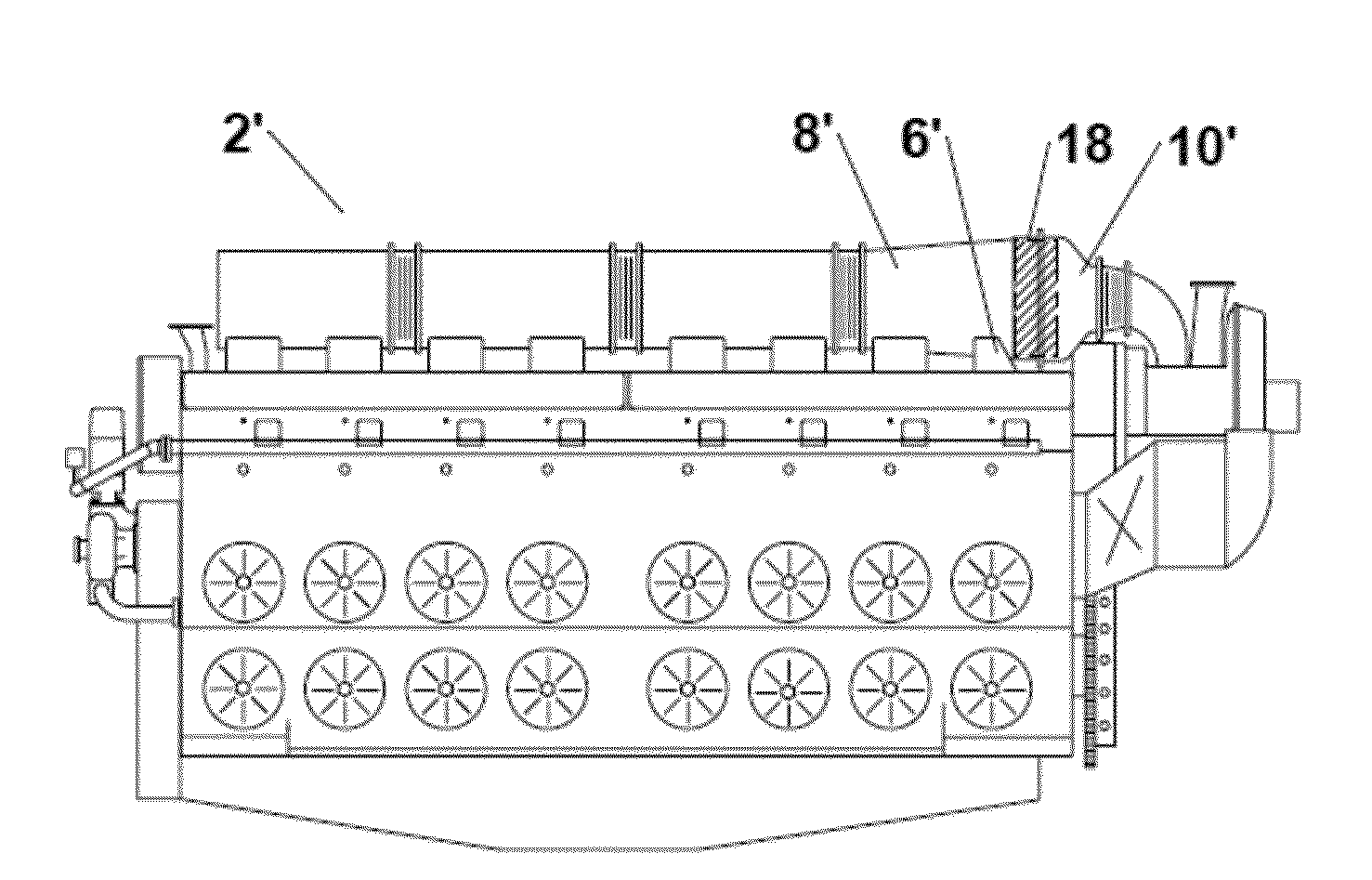

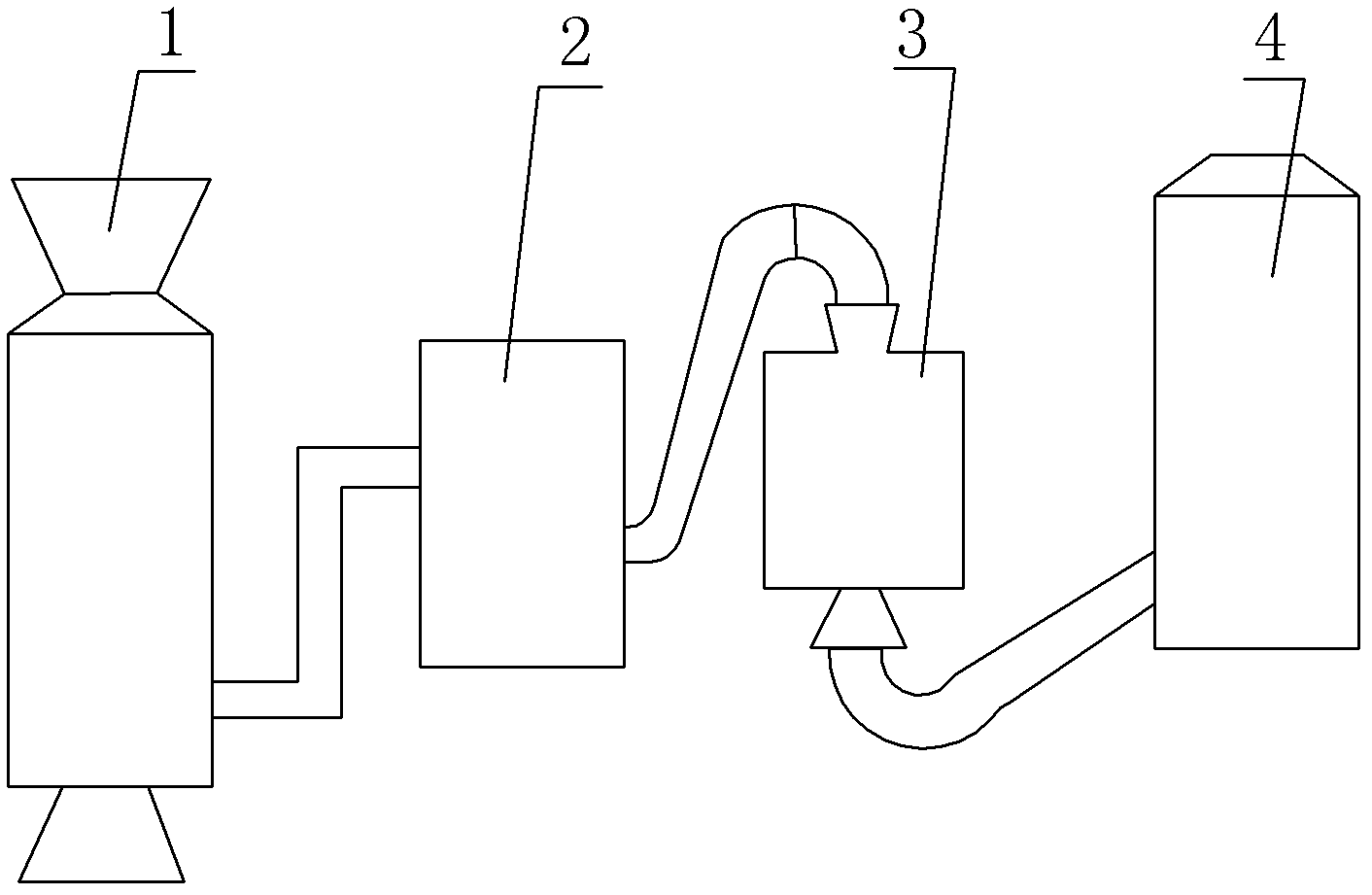

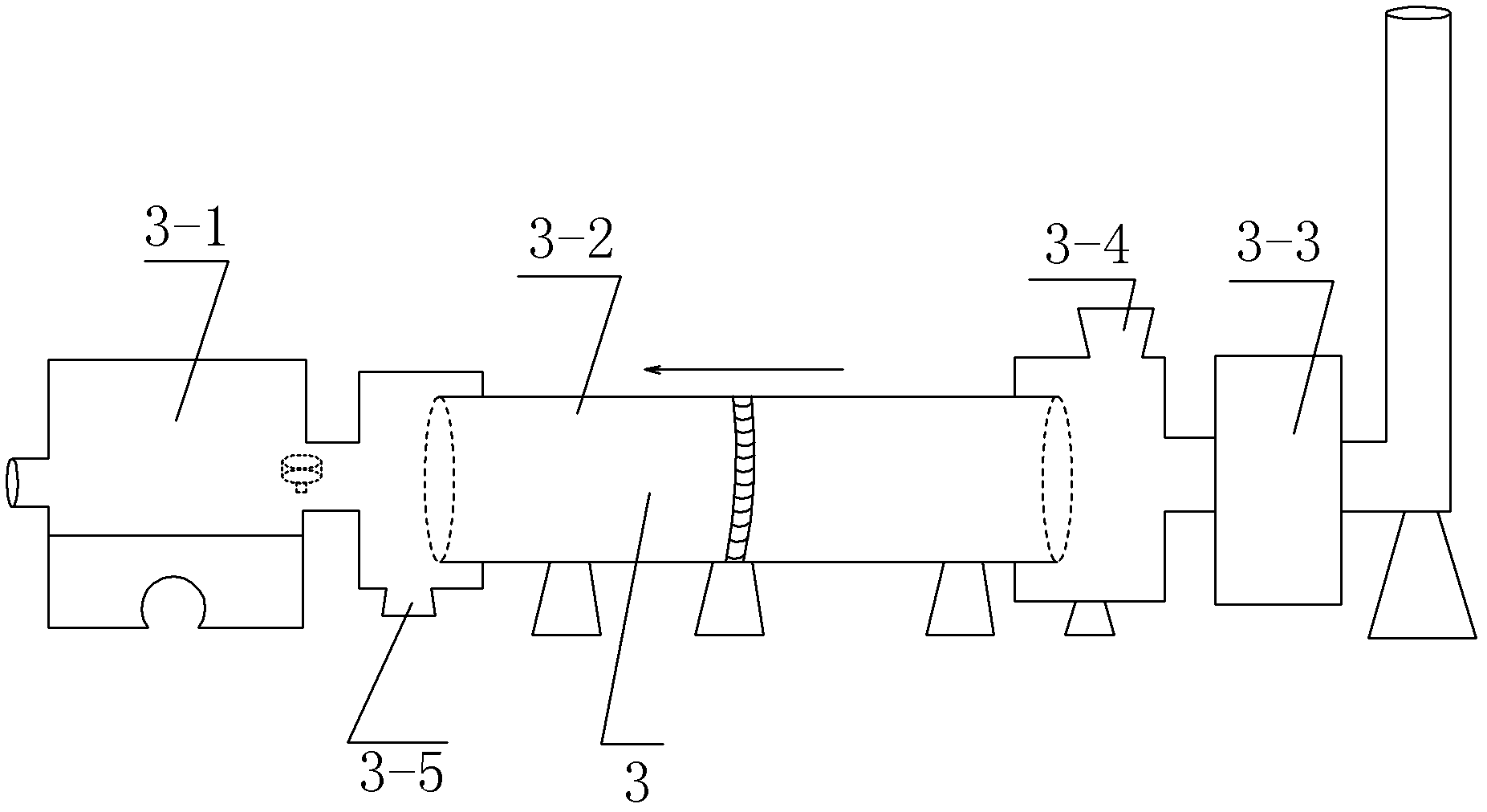

Refuse incineration power generation process and refuse incineration power generation equipment

InactiveCN102563659AImprove power generation efficiencyShorten burn timeIncinerator apparatusCombined combustion mitigationGeneration processCombustion

The invention discloses a refuse incineration power generation process, which includes the steps: 1 conveying refuse into a screening machine and screening out incombustible hard materials in refuse; 2 conveying the screened refuse into a crusher for crushing; 3 conveying the crushed refuse into a dryer for drying and leading the water content of the dried refuse to be lower than 15%; and 4 directly conveying the dried refuse into a thermal power incinerator for incineration power generation. The invention further discloses refuse incineration power generation equipment, which comprises the screening machine, the crusher, the dryer and the thermal power incinerator which are sequentially connected. The water content of the dried refuse is lower than 15%, the dried refuse can be directly used for a thermal plant for power generation without adding any combustion improvers, the dried refuse can combust in a short time to generate heat, power generation efficiency is high, and the combustion time of the dried refuse is about three times shorter than that of conventional refuse added with combustion improvers.

Owner:唐伟民

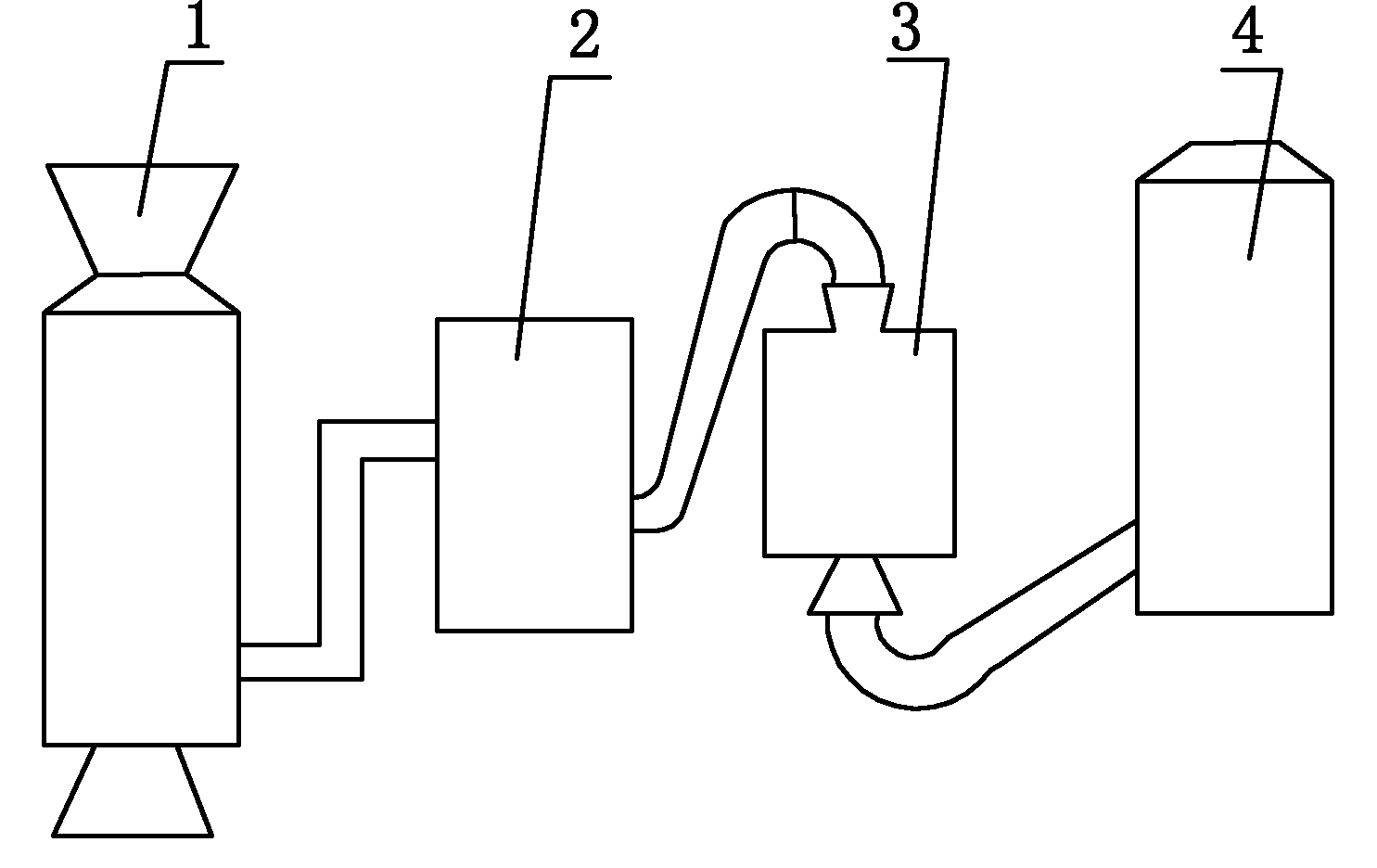

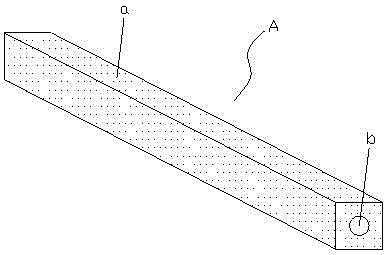

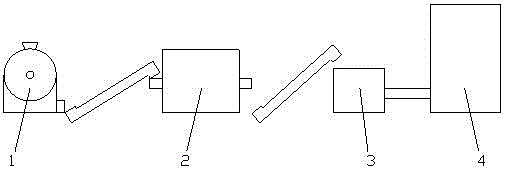

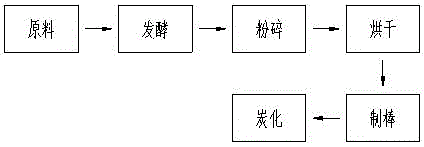

Machine-made bamboo charcoal rod as well as manufacturing equipment and process thereof

The invention relates to a machine-made bamboo charcoal rod which comprises a rod body, wherein a through hole which penetrates through the whole length of the rod body is arranged at the middle part of the rod body, and the rod body is made by processing leftover of a bamboo product after fermentation. The invention also relates to manufacturing equipment of the machine-made bamboo charcoal rod, comprising a grinder for grinding the fermented leftover of the bamboo product, wherein the grinder is connected with a dryer used for drying the ground leftover of the bamboo product, the dryer is connected with a rod making machine for manufacturing a semi-finished charcoal rod from the dried leftover of the bamboo product, and the rod making machine is connected with a carbonization furnace for smouldering the semi-finished charcoal rod at high temperature to form the bamboo charcoal rod. The invention also relates to a corresponding producing process of the machine-made bamboo charcoal rod. The machine-made bamboo charcoal rod has the advantages of high rigidity, no easy breaking, high carbon content, high heat productivity, long burning time, low ash content and the like.

Owner:FUJIAN ZHUJIANV IND & TRADE

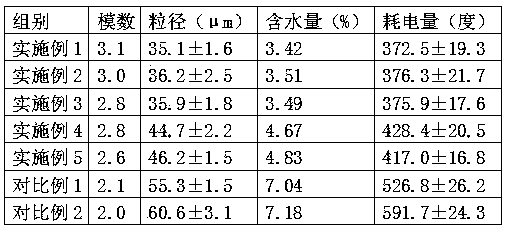

Processing technology for white carbon black with low water content

ActiveCN103803559ARigorous and perfect processEasy to operateSilicaSoluble glassPulp and paper industry

The invention discloses a processing technology for white carbon black with the low water content. The processing technology provided by the invention has the advantages that rice hull ash is utilized as a raw material, soluble glass is obtained through the rice hull ash subjected to alkali lye treatment, and a white carbon black finished product is obtained through acidification sedimentation and three-section drying. The processing technology provided by the invention has the advantages that the technology steps are rigorous, technology parameters are definite, the white carbon black is subjected to three-section drying treatment, the content of water of the white carbon black is low, the particle size distribution is uniform, particles are small, energy is recycled, and the white carbon black processing technology is environmentally-friendly and efficient.

Owner:QUECHEN SILICON CHEM

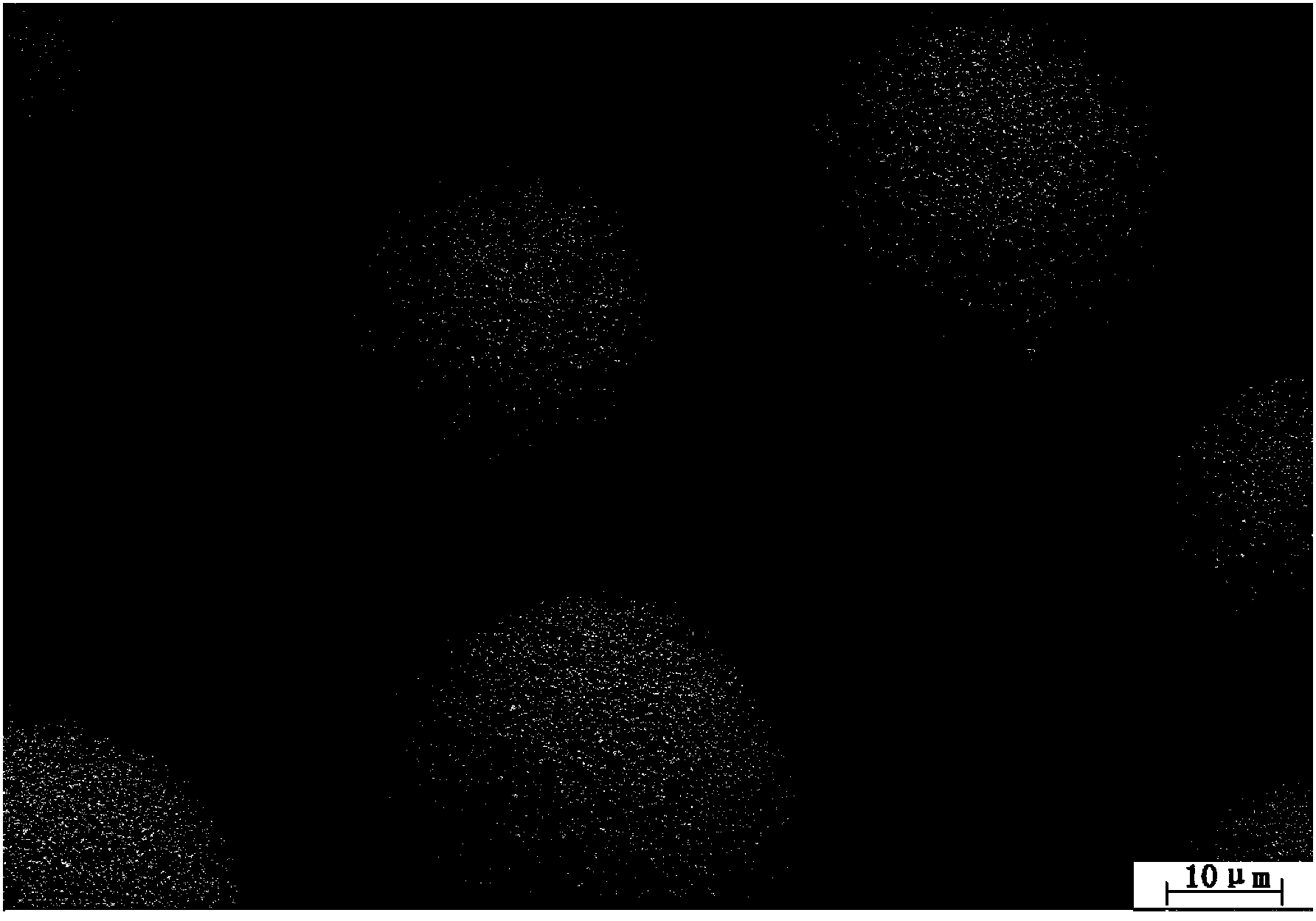

Plasma-etching-resistant granulated yttrium oxide for hot spraying and preparation method thereof

The invention belongs to the technical field of hot spraying, and particularly relates to plasma-etching-resistant granulated yttrium oxide for hot spraying and a preparation method thereof. The preparation method of the plasma-etching-resistant granulated yttrium oxide for hot spraying comprises the following steps: preparing nano or ultrafine yttrium oxide powder and deionized water or an organic solution into a paste, performing depolymerization and reduction, adding surface activity activator into the paste for preparation, and performing hot expansion balling and high-temperature densification treatment to obtain the granulated yttrium oxide for hot spraying. According to the invention, the surface activity activator is added into the paste before hot expansion balling, so that the prepared granulated yttrium oxide for hot spraying is favorable in spherical degree, and the high-spherical-degree favorable-flowability high-density granulated yttrium oxide for hot spraying can be obtained without later spheroidization, thereby achieving favorable flowability during hot spraying, ensuring that the supply of the granulated yttrium oxide for hot spraying is more stable, and providing a guarantee for obtaining a hot spray coating having a uniform thickness.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

Method for large-scale on-site production of biochar from crop straws

InactiveCN103265962AReduce investmentReduce manufacturing costBiofuelsSpecial form destructive distillationEngineeringLow oxygen

The invention discloses a method for large-scale on-site production of biochar from crop straws. The method comprises the following steps of building a soil pyrolysis tank in an open space, stacking air-dried crop straws on the soil pyrolysis tank according to a certain dimension, burning the crop straws under the condition of enough oxygen in a short time, and fast covering the burning area by soil so that the fire is extinguished completely, wherein by heat produced by combustion of a small part of biomass, under the conditions of low oxygen content and thermal resistance caused by soil covering, the rest of the biomass can be fast pyrolyzed into high-quality biochar. The biochar obtained by the method has the advantages of high yield, good charing uniformity, high charing level and low smoke production amount.

Owner:ZHEJIANG UNIV

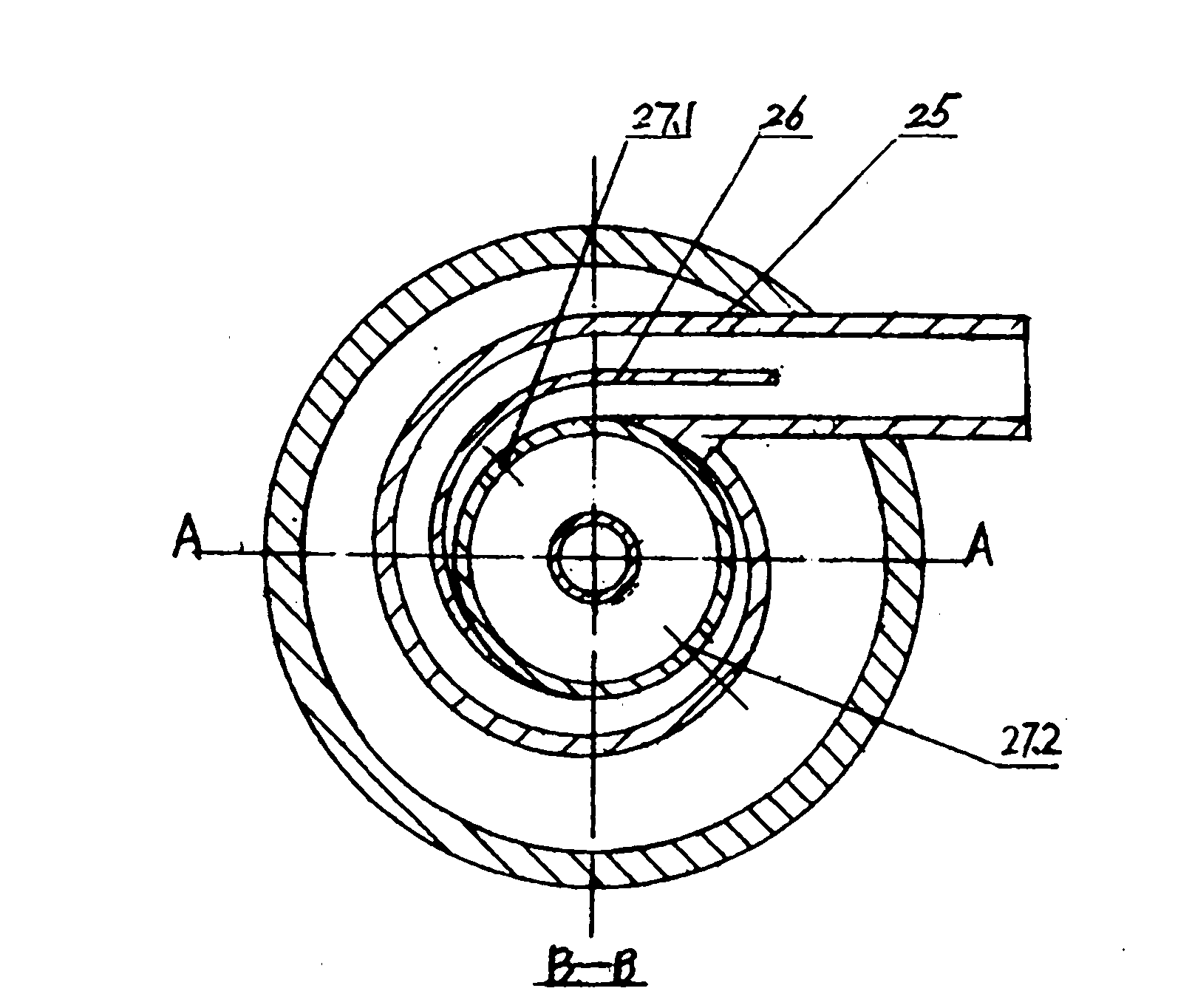

Spiral-flow type fishtail high-efficiency energy-saving burner

ActiveCN103629705AHeating up fastHeat up fastDomestic stoves or rangesStoves/ranges topsAir preheaterEngineering

The invention discloses a spiral-flow type fishtail high-efficiency energy-saving burner. The spiral-flow type fishtail high-efficiency energy-saving burner comprises a burner and a hearth. The burner comprises a spiral-flow type air register, a cylindrical channel, a return pipe, combustion gas holes and an air preheater. The hearth comprises a furnace ring and an expansion cover. The expansion cover is a hollow interlayer and comprises an inner expansion cover, a middle expansion cover and a flue gas chamber between the inner expansion cover and the middle expansion cover. An upper opening of the inner expansion cover and a lower opening of the furnace ring form an annular flue gas shunting opening and the annular flue gas shunting opening is communicated with the flue gas chamber, flue gas holes, the air preheater and a gas outlet hole. The outer wall of the middle expansion cover is provided with a hot water sleeve. The hot water sleeve is provided with a water inlet and a water outlet. A temperature-resistant heat-collection corrosion-resistant sleeve is arranged in the inner expansion cover and the lower periphery of the temperature-resistant heat-collection corrosion-resistant sleeve is provided with a flue gas backflow hole communicated with the flue gas chamber. When the spiral-flow type fishtail high-efficiency energy-saving burner burns, the flame in a fishtail shape radially burns closely to the surface of the inner expansion cover, a pan clings to the furnace ring and is closely heated and high-temperature flue gas goes through the flue gas chamber from the annular flue gas shunting opening and then enters into the air preheater to heat air so that the hearth has a high temperature, foods can be heated fast and work efficiency is high. The spiral-flow type fishtail high-efficiency energy-saving burner is environmentally friendly, saves energy, can supply hot water and can effectively improve a kitchen environment.

Owner:湖北满天星节能环保科技有限公司

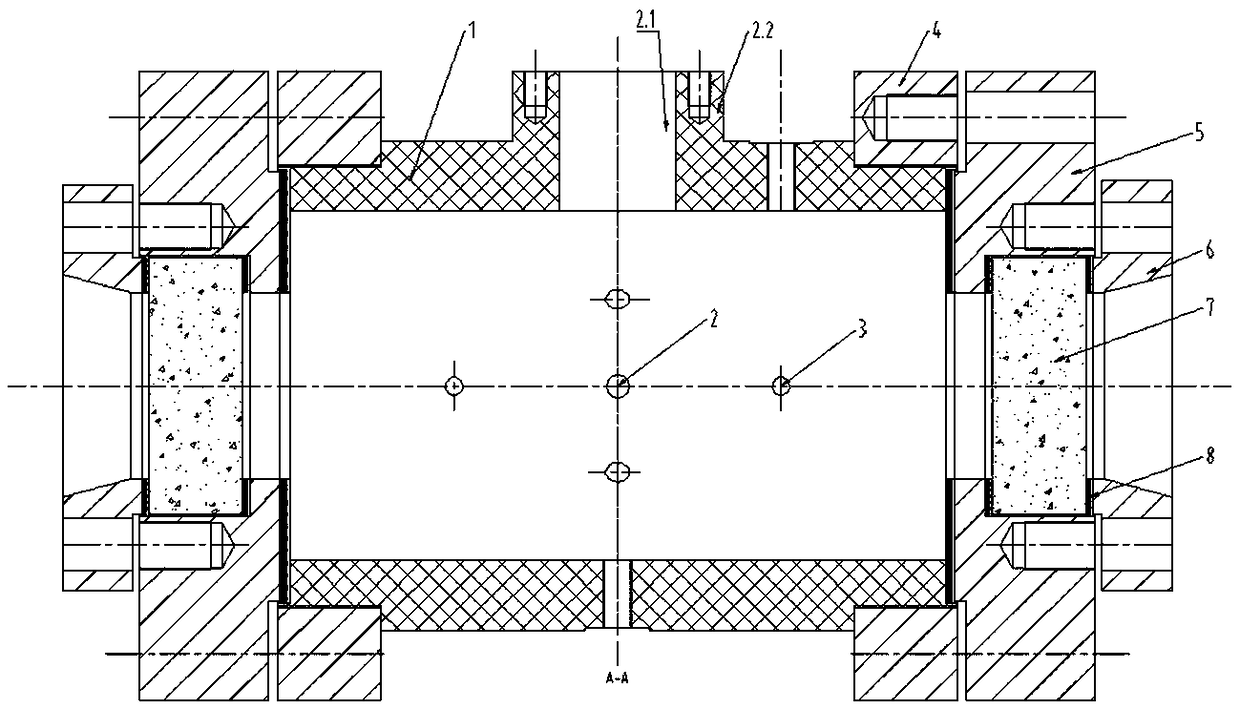

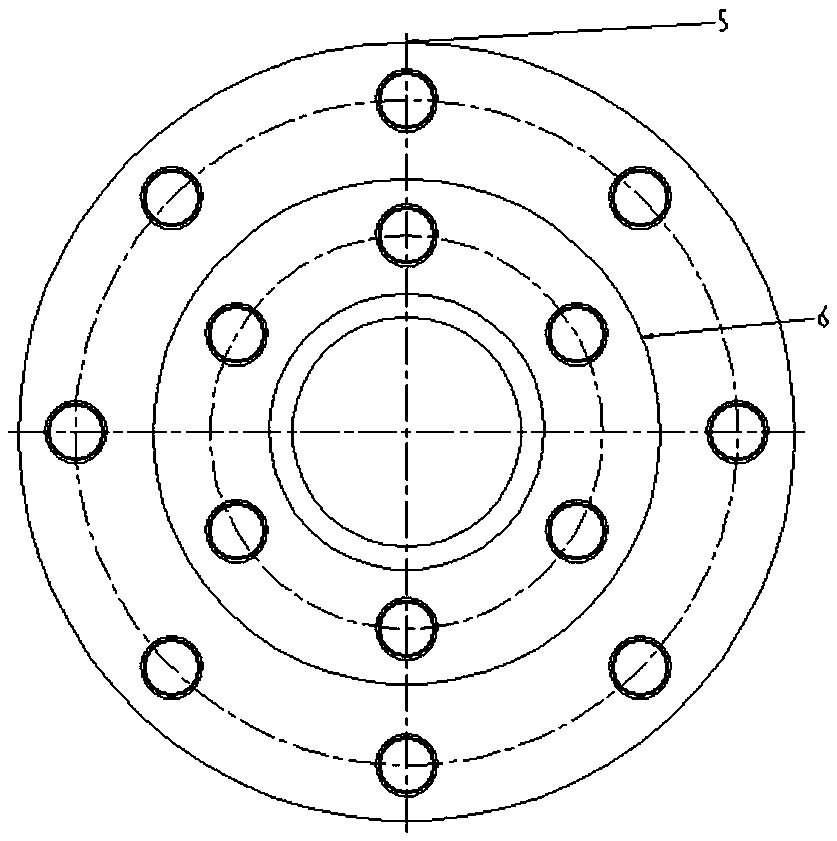

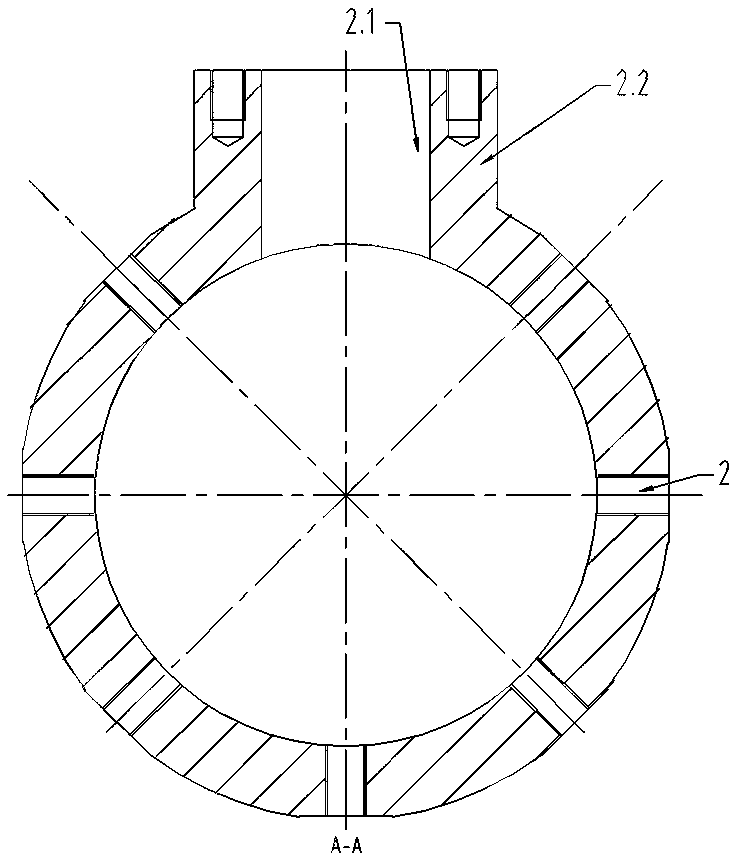

Multi-point ignition multi-functional constant volume combustion device

ActiveCN109164204AIncrease profitRealization of multi-point ignitionChemical analysis using combustionExperimental researchRadial plane

The invention discloses a multi-point ignition multi-functional constant volume combustion device which comprises a horizontal tubular constant volume bomb main body, wherein the radial top of the constant volume bomb main body is coaxially provided with cylindrical bosses and a sleeve mounting hole; two axial ends of the constant volume bomb main body are respectively provided with observation windows; the constant volume bomb main body is further equipped with a set of ignition electronic control system; 7 spark plug holes are evenly distributed in a same radial plane as the sleeve mountinghole; a plurality of accessory mounting holes are formed in an axial cross section of the bomb body; the observation windows at both ends have same structures; each observation window comprises a flange plate, glass bases, quartz glasses and glands which are sequentially connected; and each flange plate is in threaded connection with the constant volume bomb main body. The device provided by the invention mainly has the advantages that experimental studies such as mist spray, premixed laminar flow combustion, multi-point ignition and the like can be performed; the number, energy and positionsof ignition can be changed when multi-point ignition is preformed, and the ignition timing can be controlled; two sets of the observation windows are optimized and designed, and the observation windows can be switched according to the experimental content so as to achieve a best observation effect; and the device is easy to assemble and disassemble integrally and convenient to clean.

Owner:HEFEI UNIV OF TECH

Blast-injecting forced-advancing full pre-mixing energy-saving combustor

The invention provides a blast-injecting forced-advancing full pre-mixing energy-saving combustor which comprises a main cavity, a blast pipe, a fuel gas pipe, a nozzle, a fire distributor and a firing needle, wherein the blast pipe and the fuel gas pipe are connected with the main cavity; the nozzle is connected with the fuel gas pipe; and the fire distributor and the firing needle are arranged at the top of the main cavity. The blast-injecting forced-advancing full pre-mixing energy-saving combustor is characterized in that a screen, a flow fixer and a gas flow mixer are sequentially arranged between the fire distributor and the nozzle in the main cavity; the caliber of the gas outlet end of the flow fixer is smaller than the caliber of a gas inlet end of the flow fixer; the flow mixer is a cylinder of which the diameter corresponds to the internal diameter of the main cavity; and a plurality of gas mixing holes are arranged vertically along the cylinder and the calibers of all gas outlet ends of the gas mixing holes are smaller than the calibers of all gas inlet ends of the gas mixing holes. By adopting the structure, the effects of the high efficiency, the energy conservation and the environment protection are achieved.

Owner:何梅顺

Method for preparing flame-retardant water-based polyurethane coating and adhesive for building

InactiveCN104861852AReduced maximum smoke densityDensity time extensionFireproof paintsNon-macromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a method for preparing a flame-retardant water-based polyurethane coating and adhesive. The method comprises the following steps: mixing PTMG and isocyanate to obtain a polyurethane prepolymer A in the presence of a catalyst (dibutyltin dilaurate); adding an intumescent flame retardant into the polyurethane prepolymer A, then adding triethylamine for neutralization reaction, adding water for emulsification, adding ethylenediamine tetramethylenephosphonic acid and EDTA dipotassium salt, and regulating the system pH to be 7-8 to obtain the flame-retardant water-based polyurethane coating and adhesive. The polyurethane material is high in flame retardant property, environment-friendly and low in price, and can meet the low-cost requirement of the market.

Owner:朱明德

Preparation method of flame-retardant and light-resistant paint

InactiveCN103435743AIncrease the difficulty of outward transmissionImprove flame retardant performanceCoatingsPolymer scienceAcrylate ester

The invention discloses a preparation method of a flame-retardant and light-resistant paint. The method comprises the following steps: adding red phosphorous dispersion to an acrylate monomer and an emulsifier; forming a nuclear layer under the effect of an initiator; adding hydroxyethyl acrylate and home-made light-resistant intumescent flame retardants to the nuclear layer; carrying out chain polymerization; and forming a shell layer so as to obtain the flame-retardant and light-resistant paint. The paint can be applied to industrial corrosion prevention, ships and containers, metal protection, interior and exterior walls of buildings, and leather finishing.

Owner:LIAONING XIN XING ART COLOR TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com