Dual-fuel engine adopting main and auxiliary oil injectors and manifolds for multiple times of spraying, and combustion organization method of dual-fuel engine

A dual-fuel engine and multiple injection technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as which combustion mode is not considered, so as to improve misfire and knocking problems and accelerate flame propagation Speed, burn time shortening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

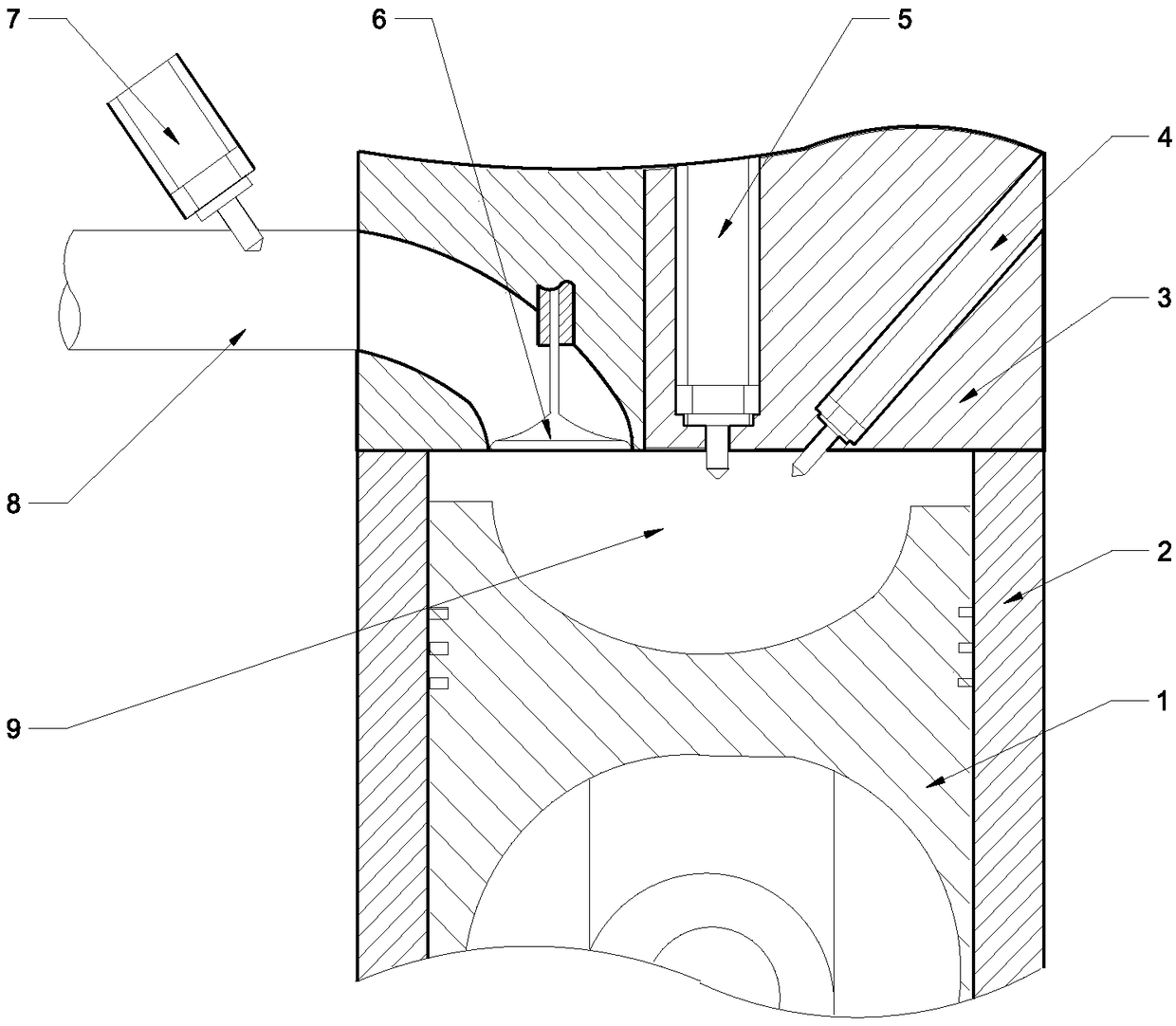

[0032] The present invention will be further described below in conjunction with accompanying drawing:

[0033] as attached figure 1 As shown, it is a specific layout diagram of the dual-fuel engine combustion system in the embodiment of the present invention. The structure of the dual-fuel engine combustion system using main and auxiliary injectors and manifold multiple injections includes: piston 1, cylinder liner 2, cylinder head 3 , auxiliary injector 4, main injector 5, intake valve 6, manifold low-pressure gas injection device 7, intake passage 8, combustion chamber 9. The combustion chamber is composed of the upper surface of the piston, the peripheral wall of the cylinder liner and the lower surface of the cylinder head; the main and auxiliary injectors are installed in the cylinder head, the main injector is located in the center of the cylinder head, and its axis coincides with the axis of the cylinder, and the auxiliary injector is installed on the On the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com