Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3772 results about "Combustion system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combustion system. The combustion system, consisting of the grate system and the furnace, is the technological core of a waste-to-energy plant. We differentiate between conventional combustion system, the combustion system combined with flue gas recirculation and the SYNCOM-process.

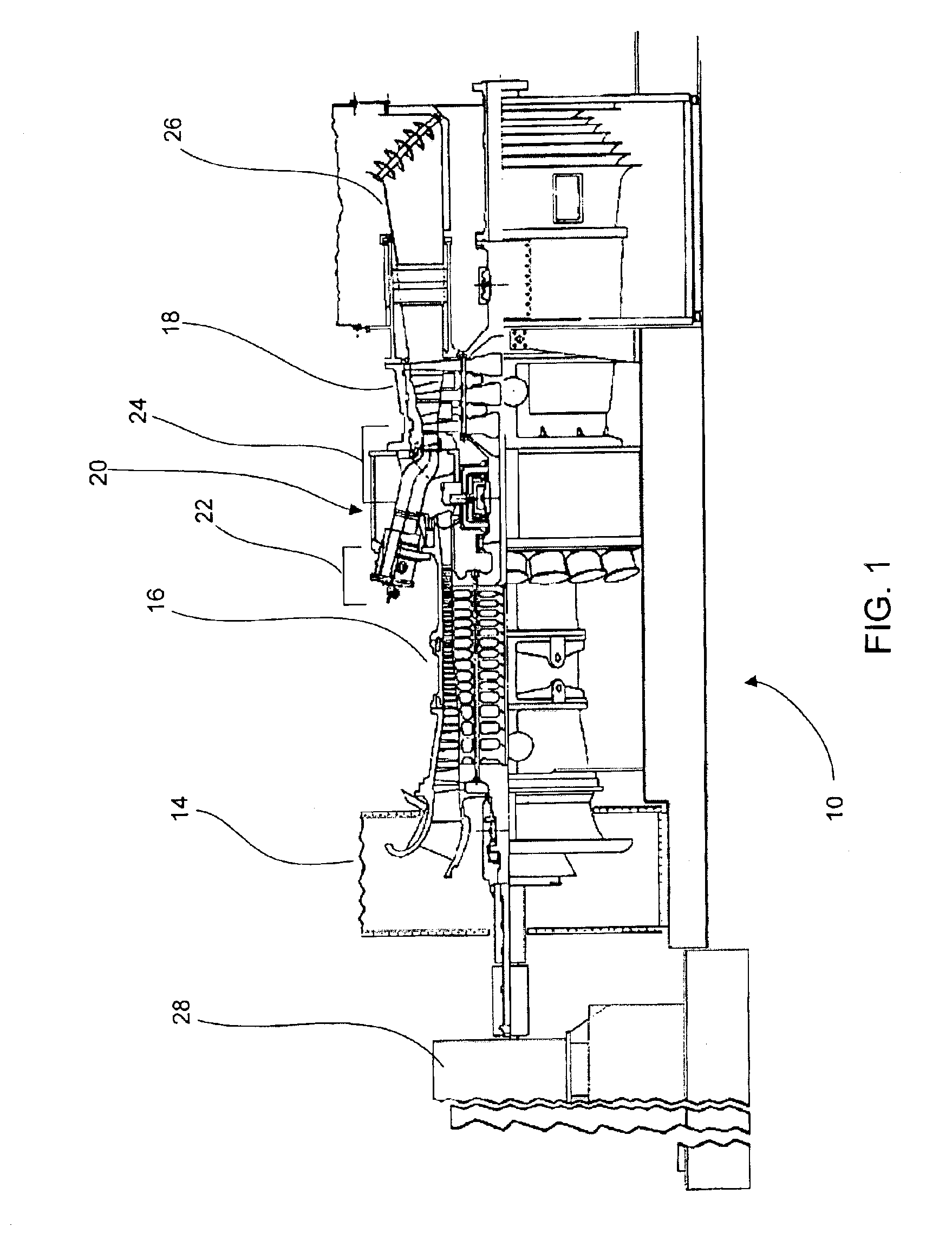

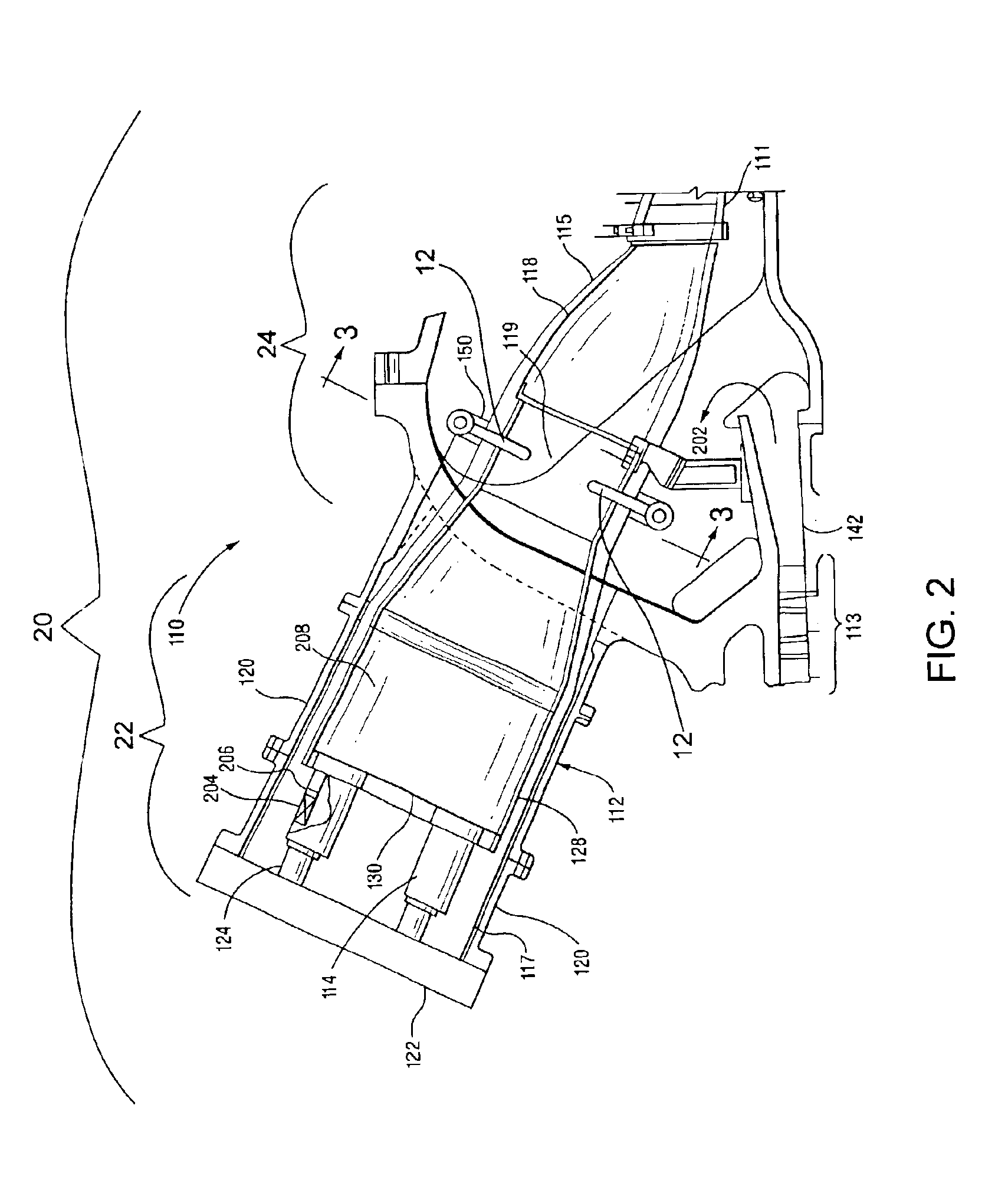

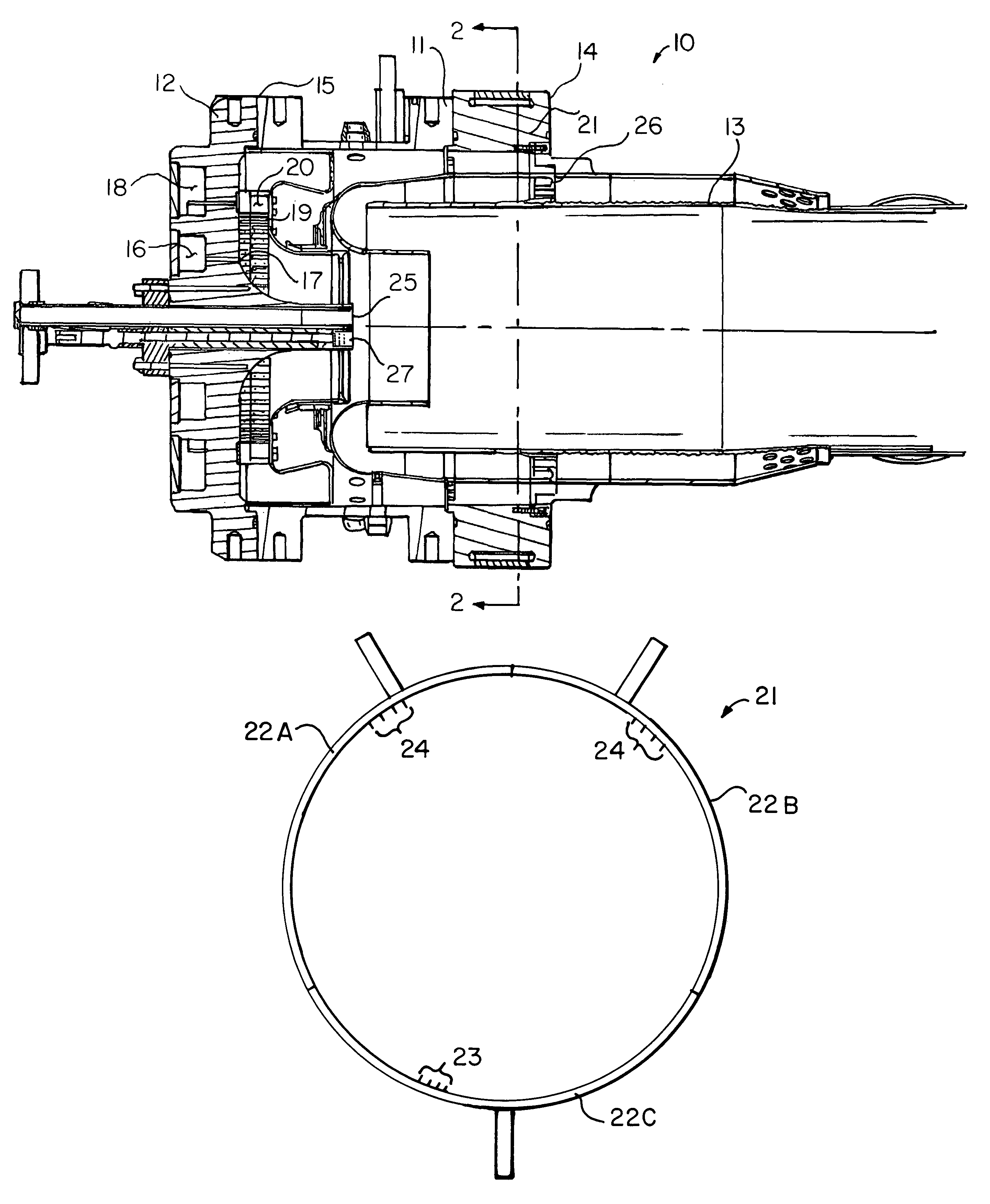

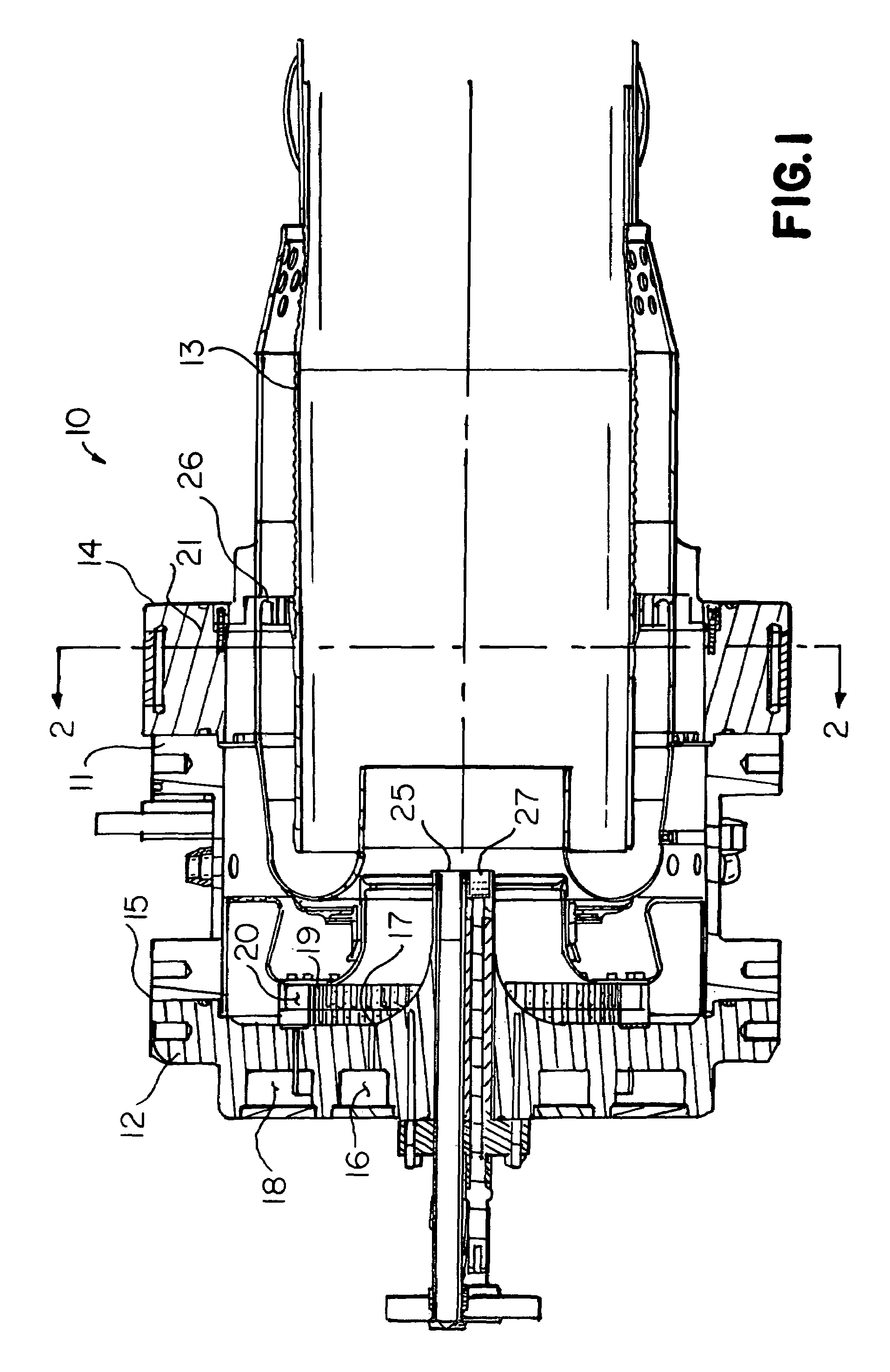

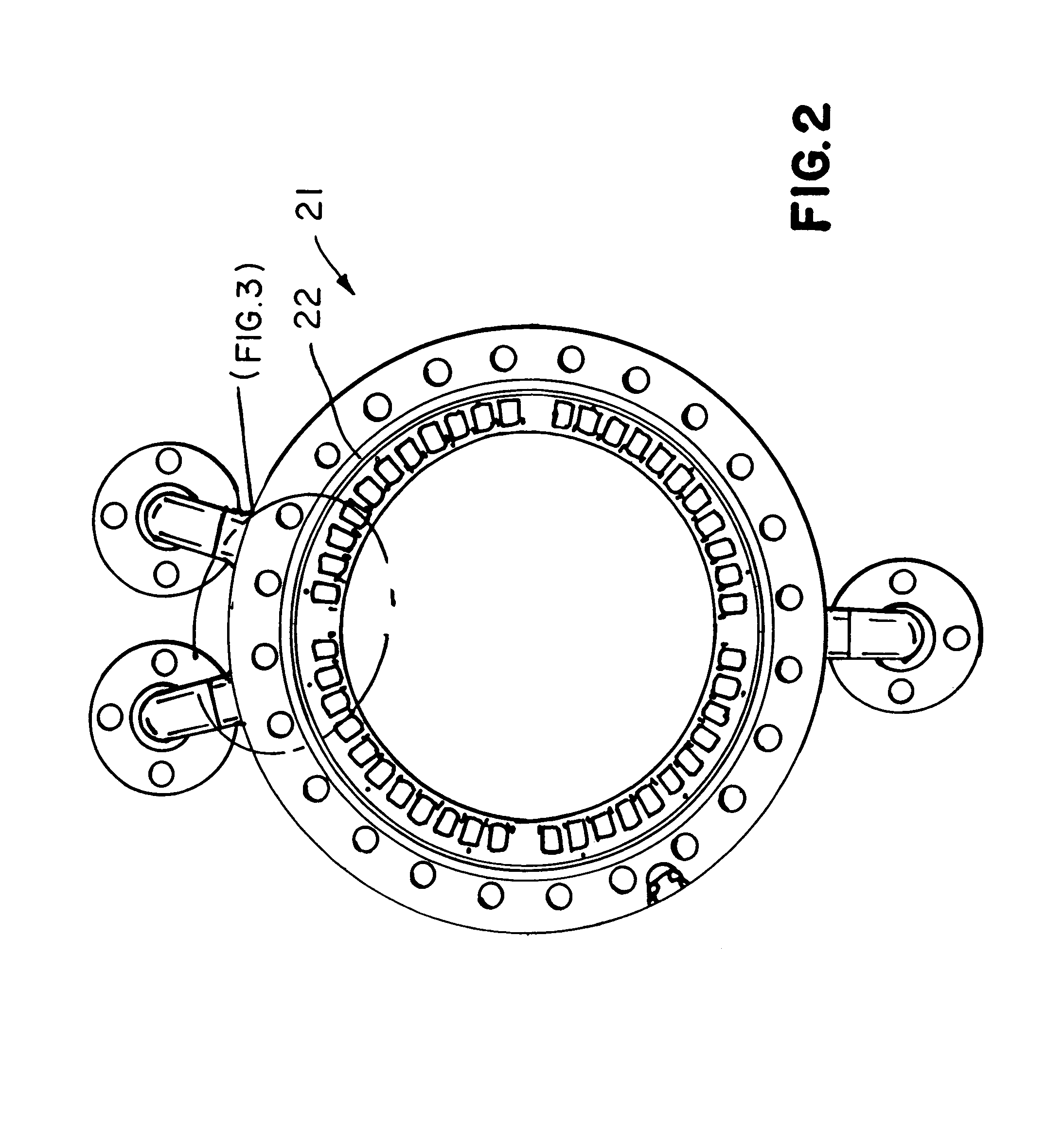

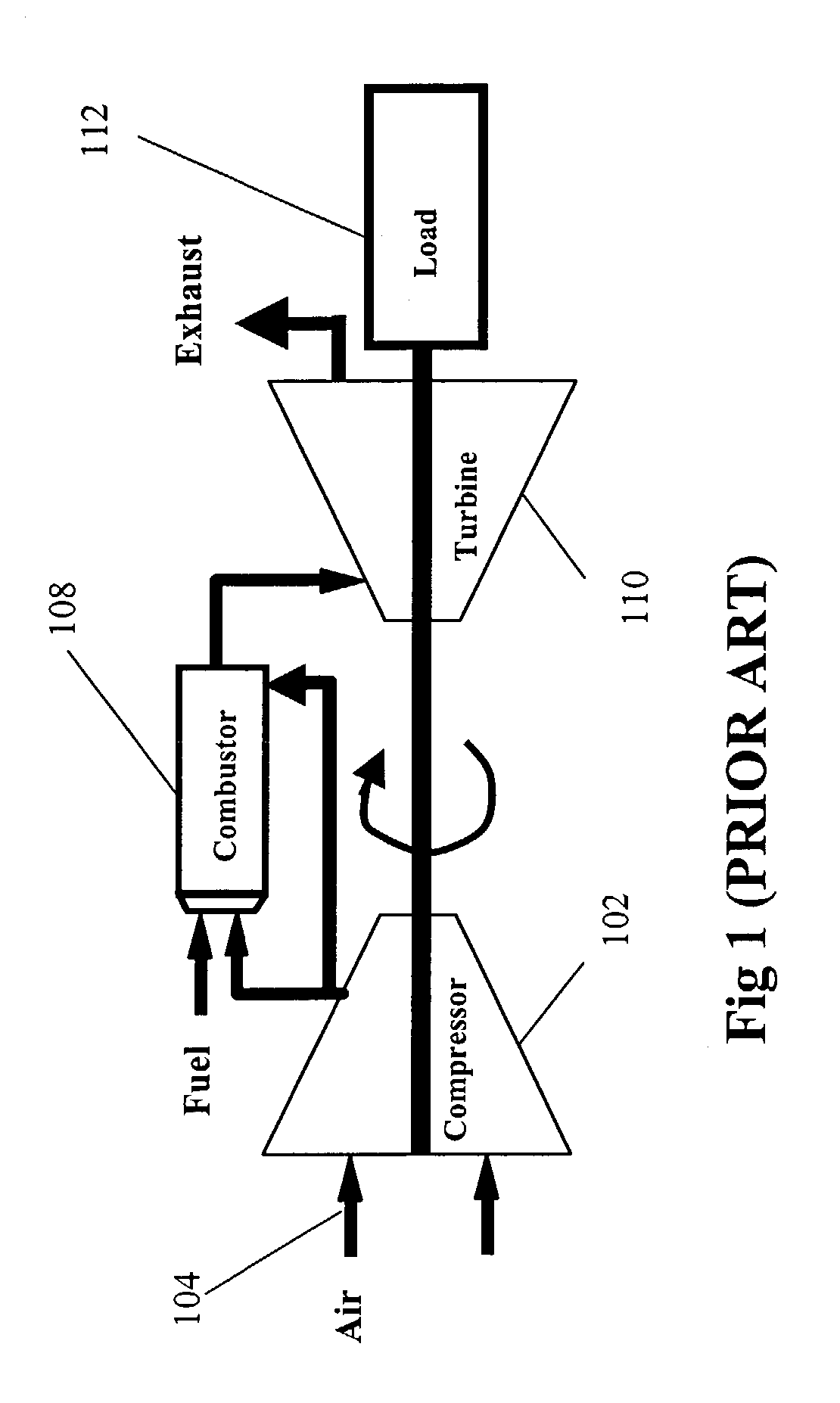

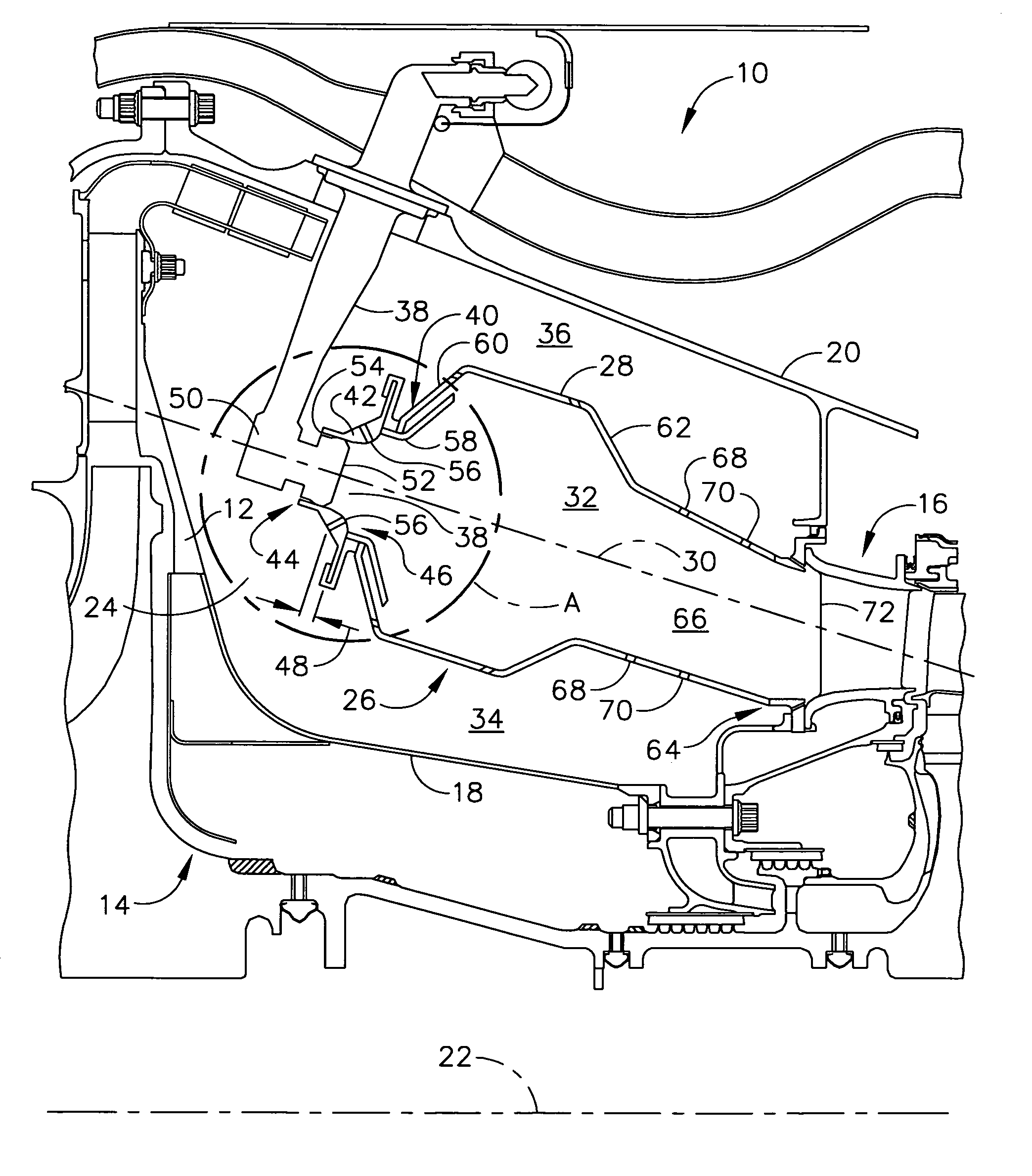

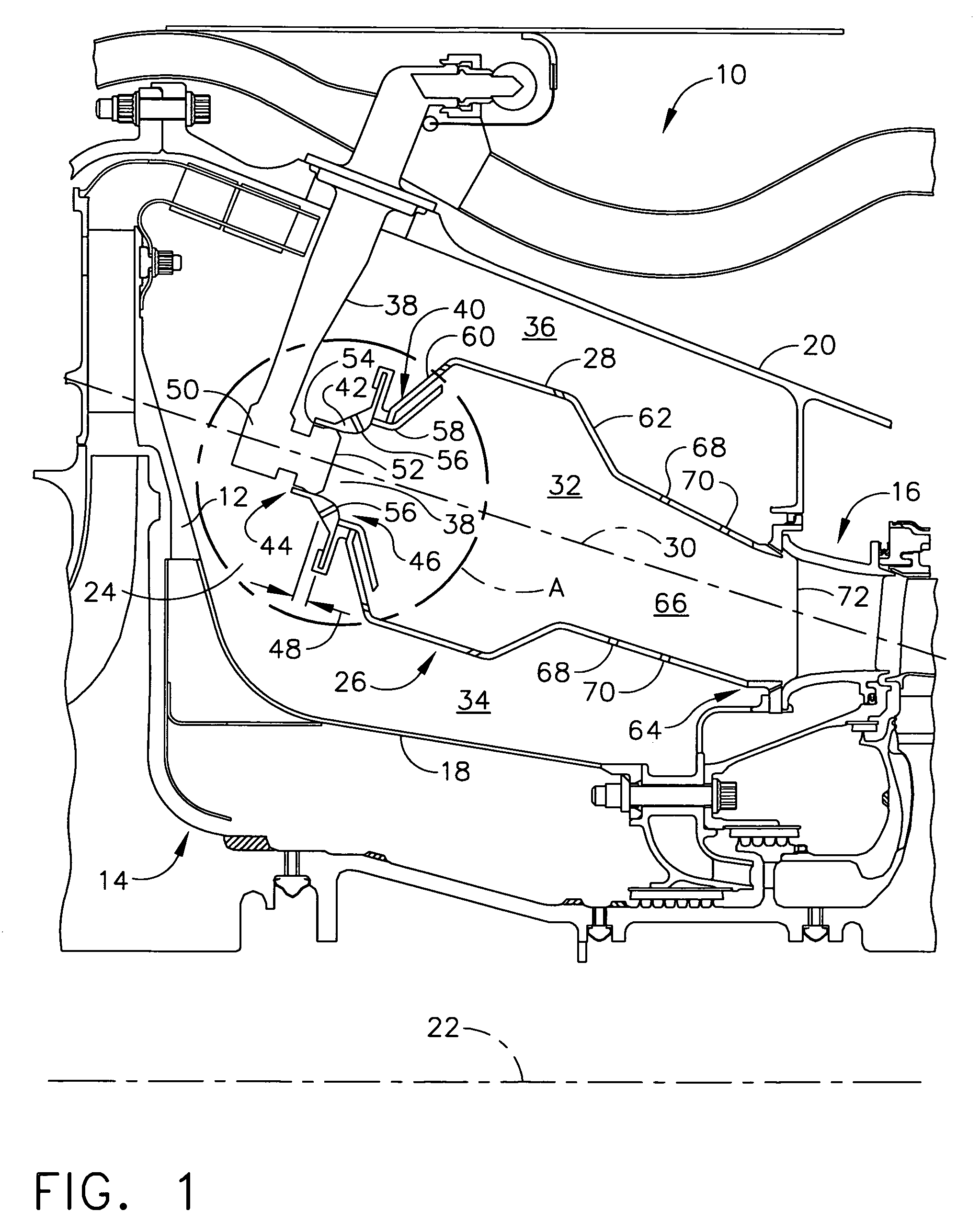

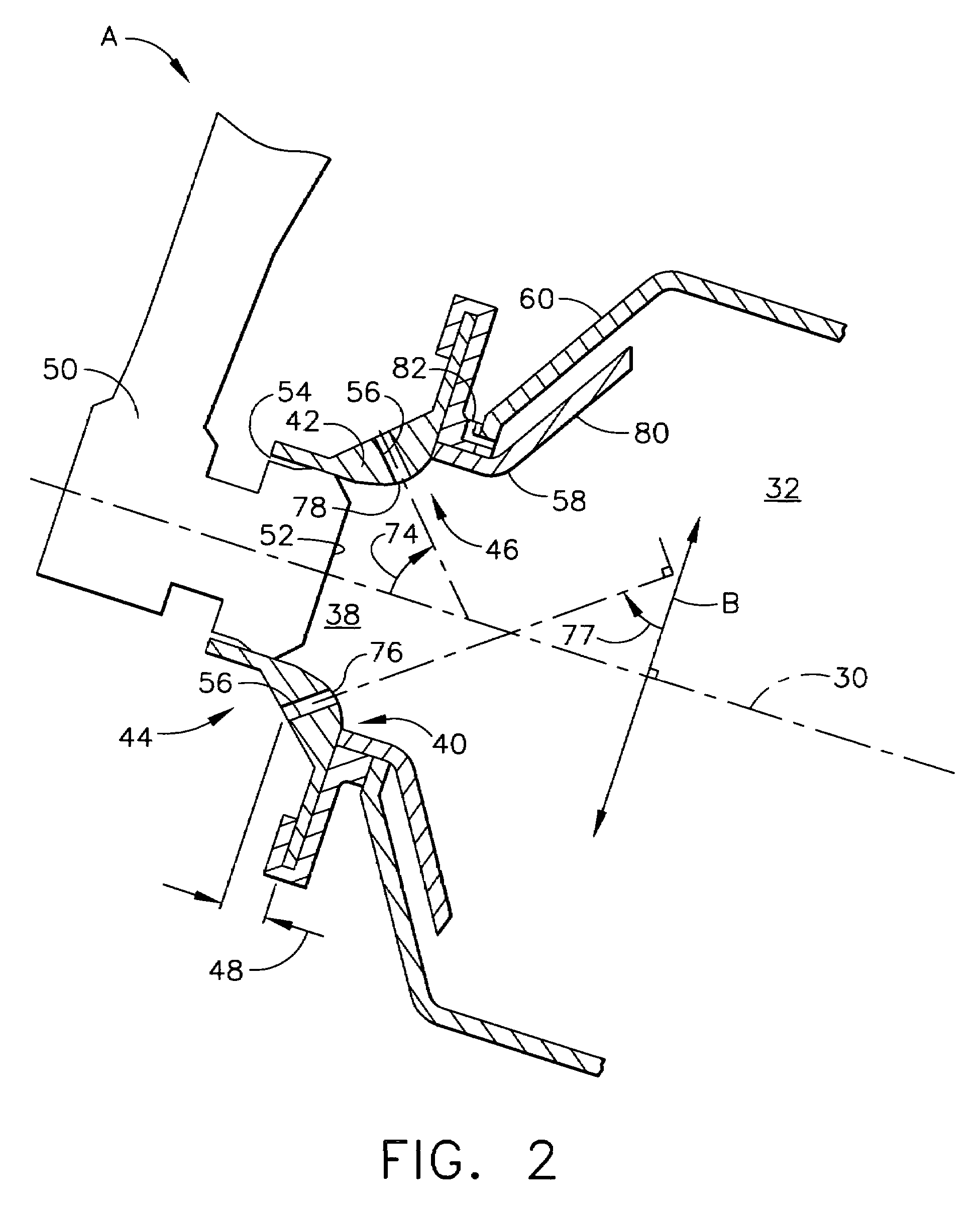

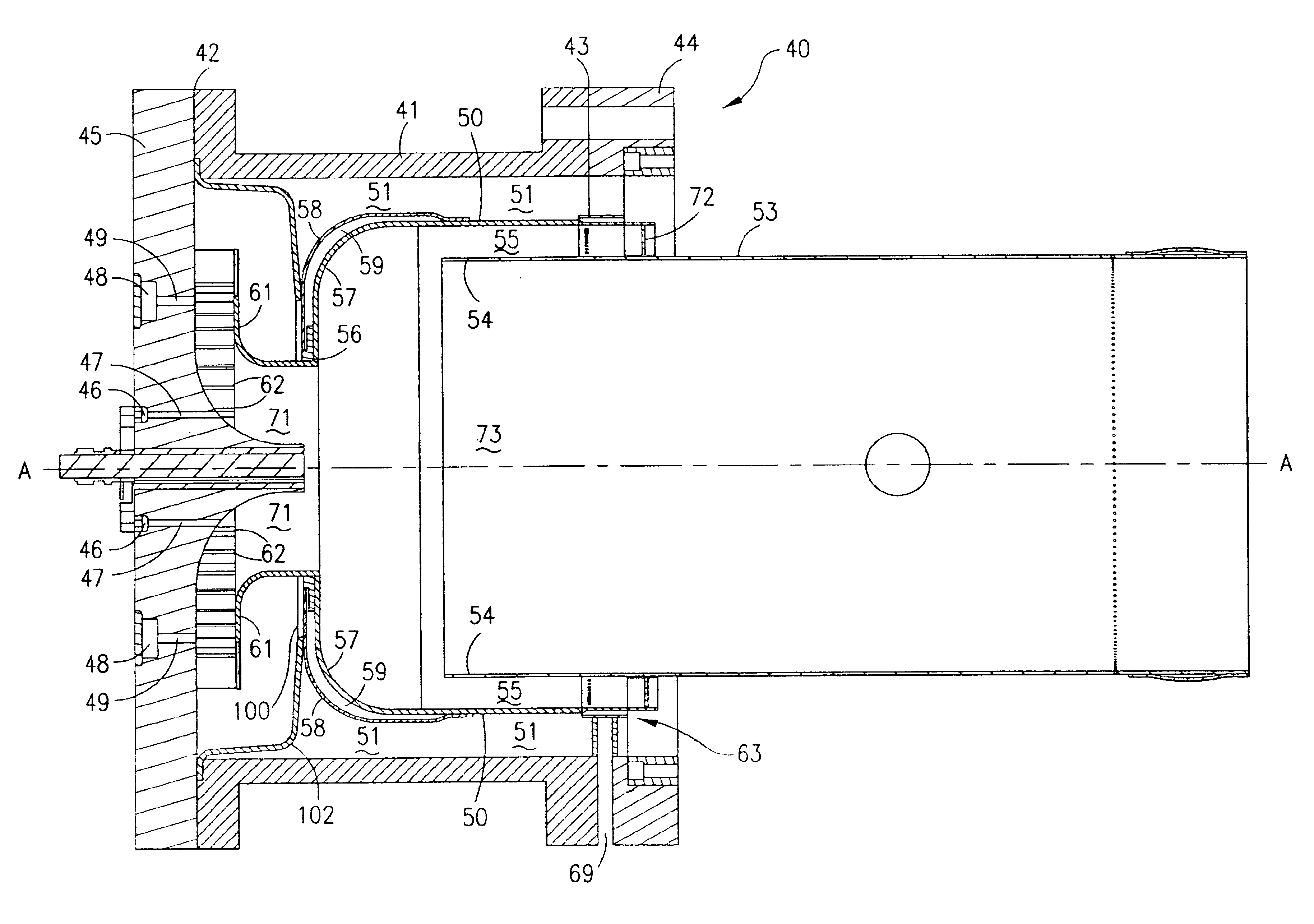

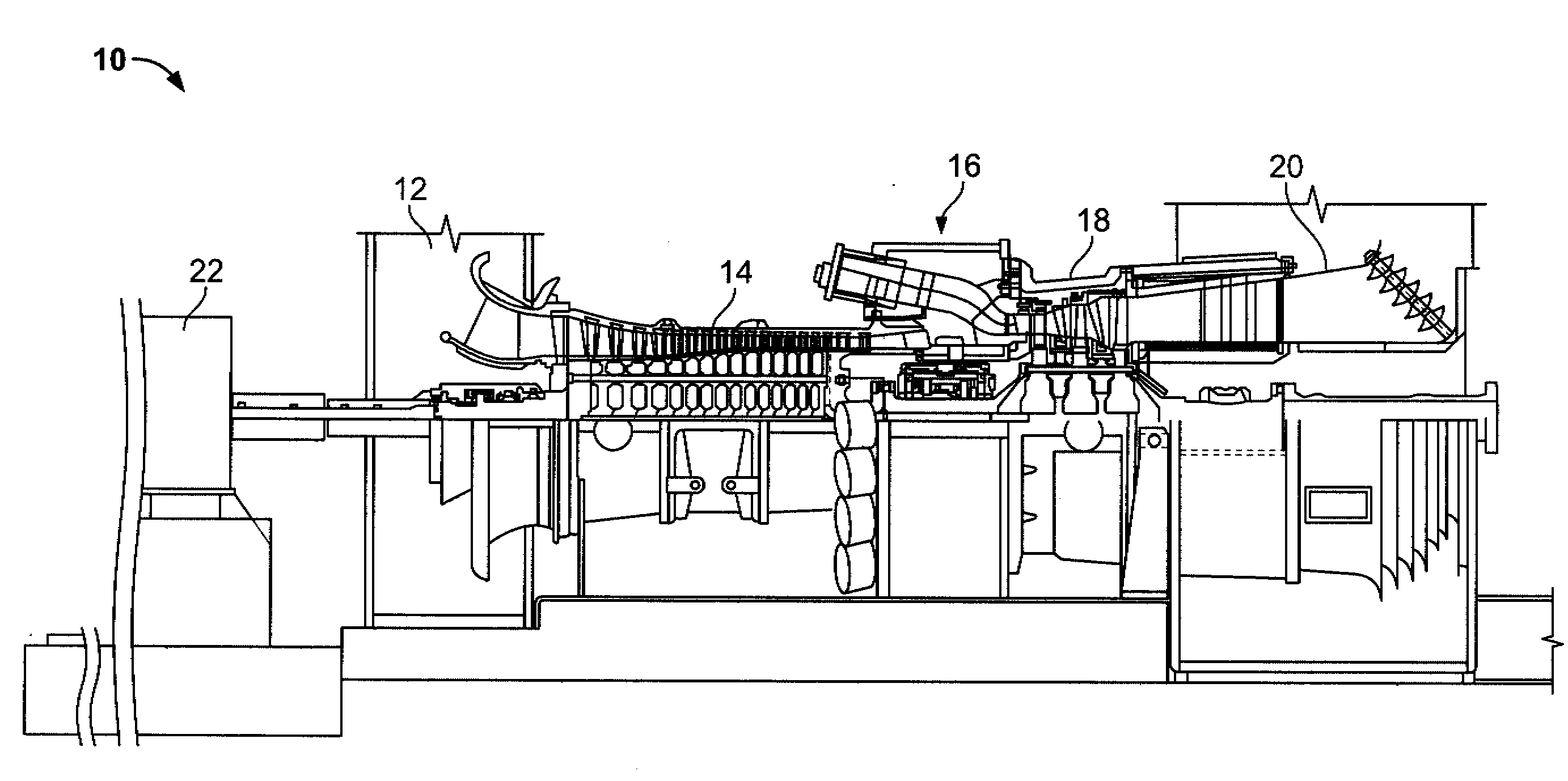

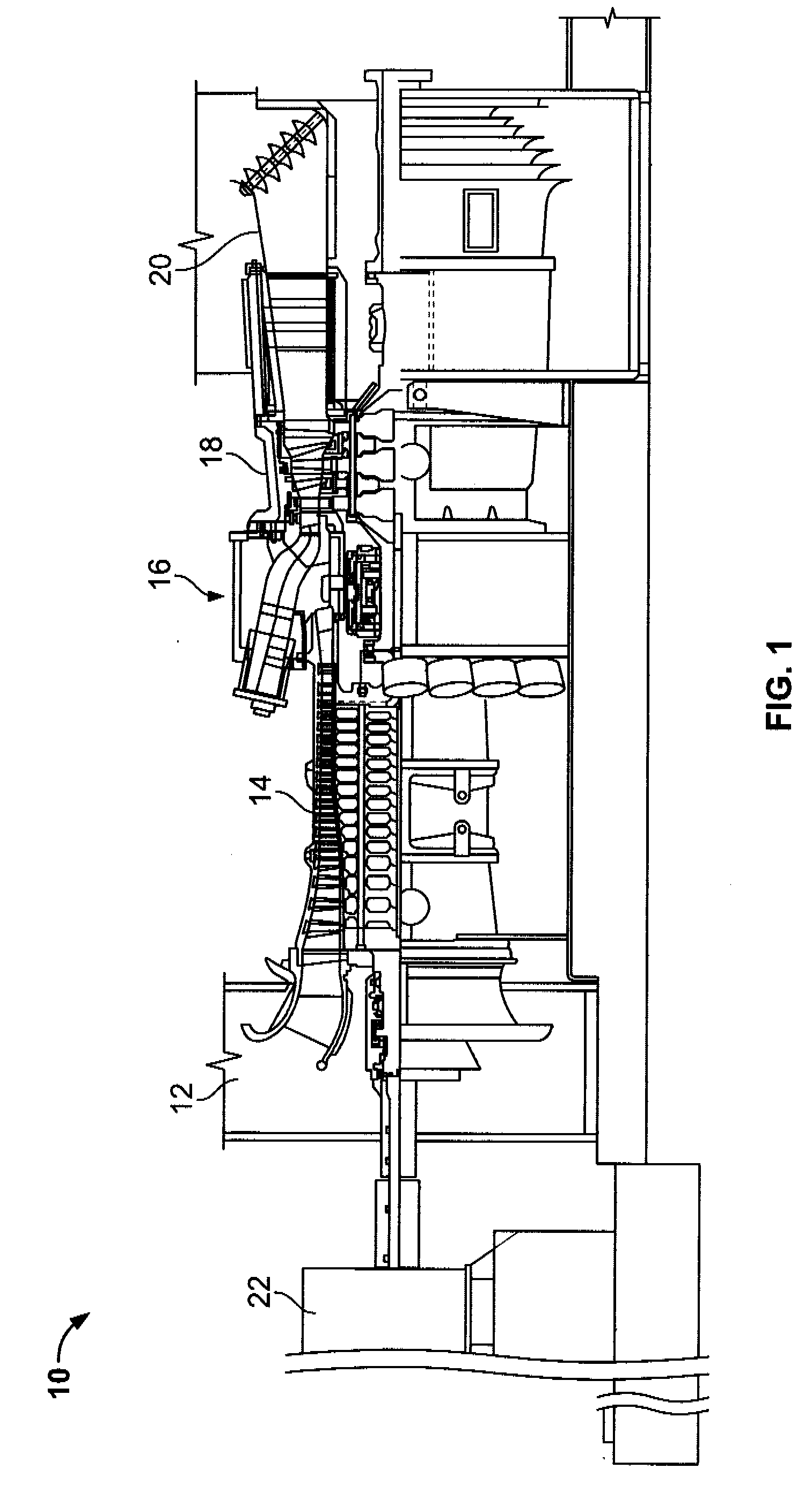

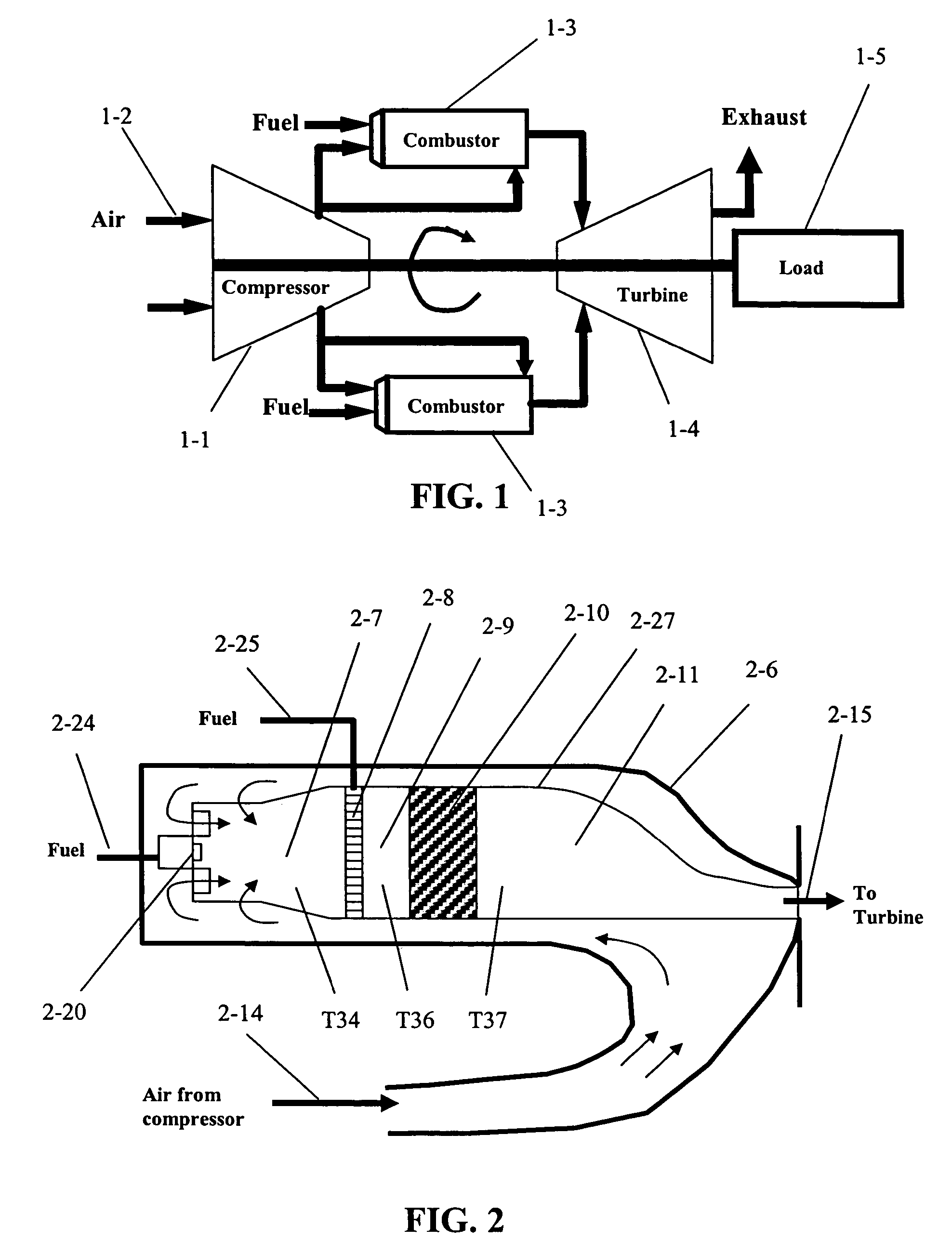

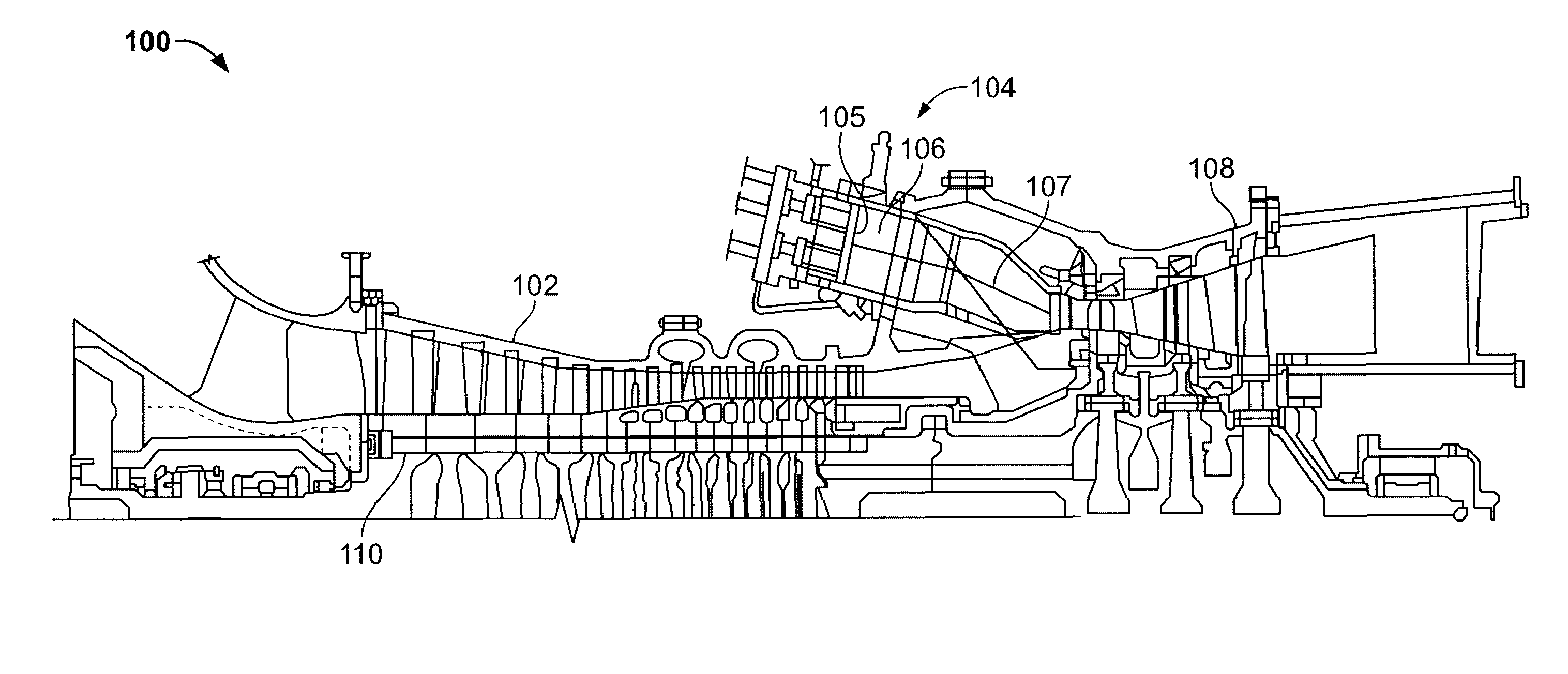

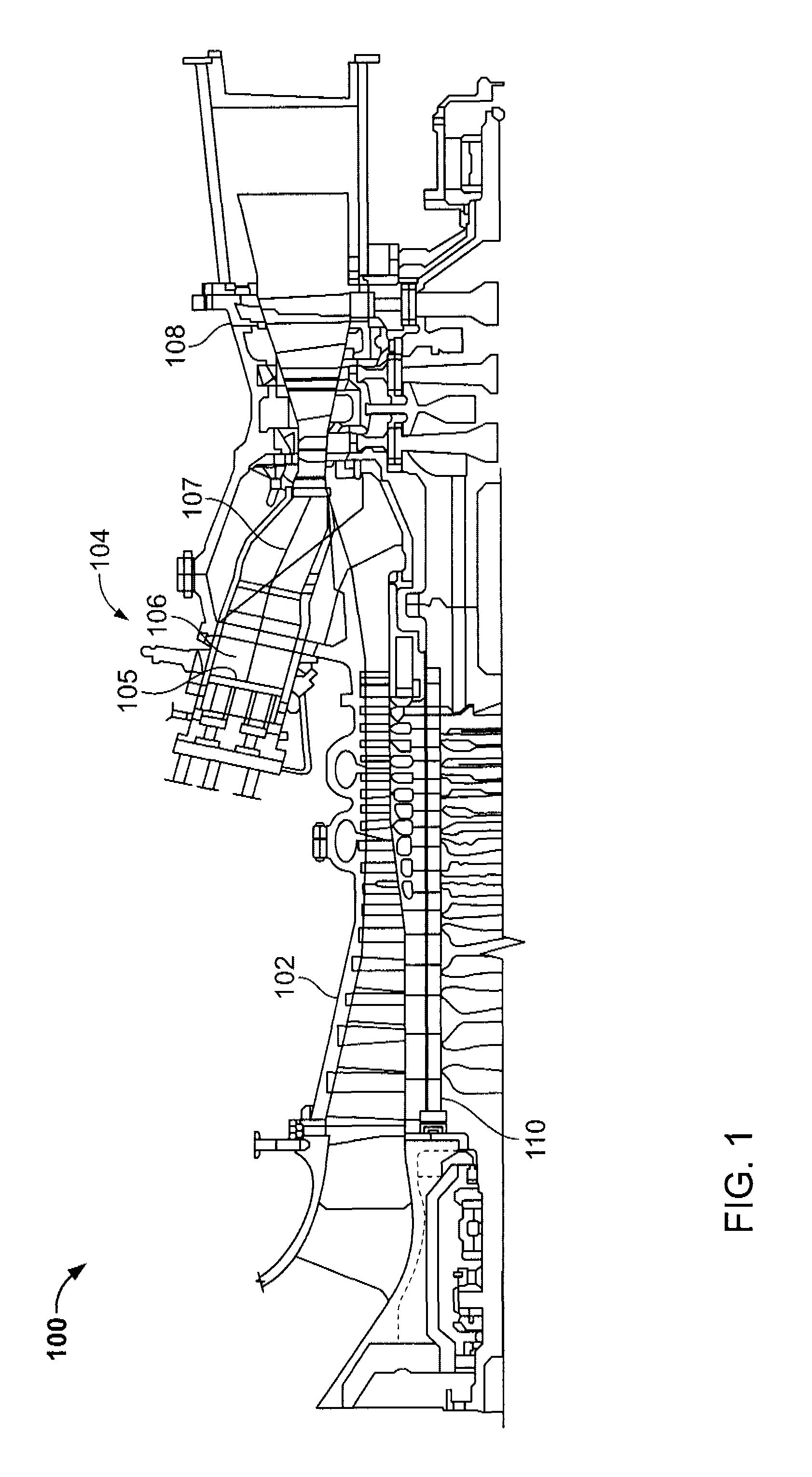

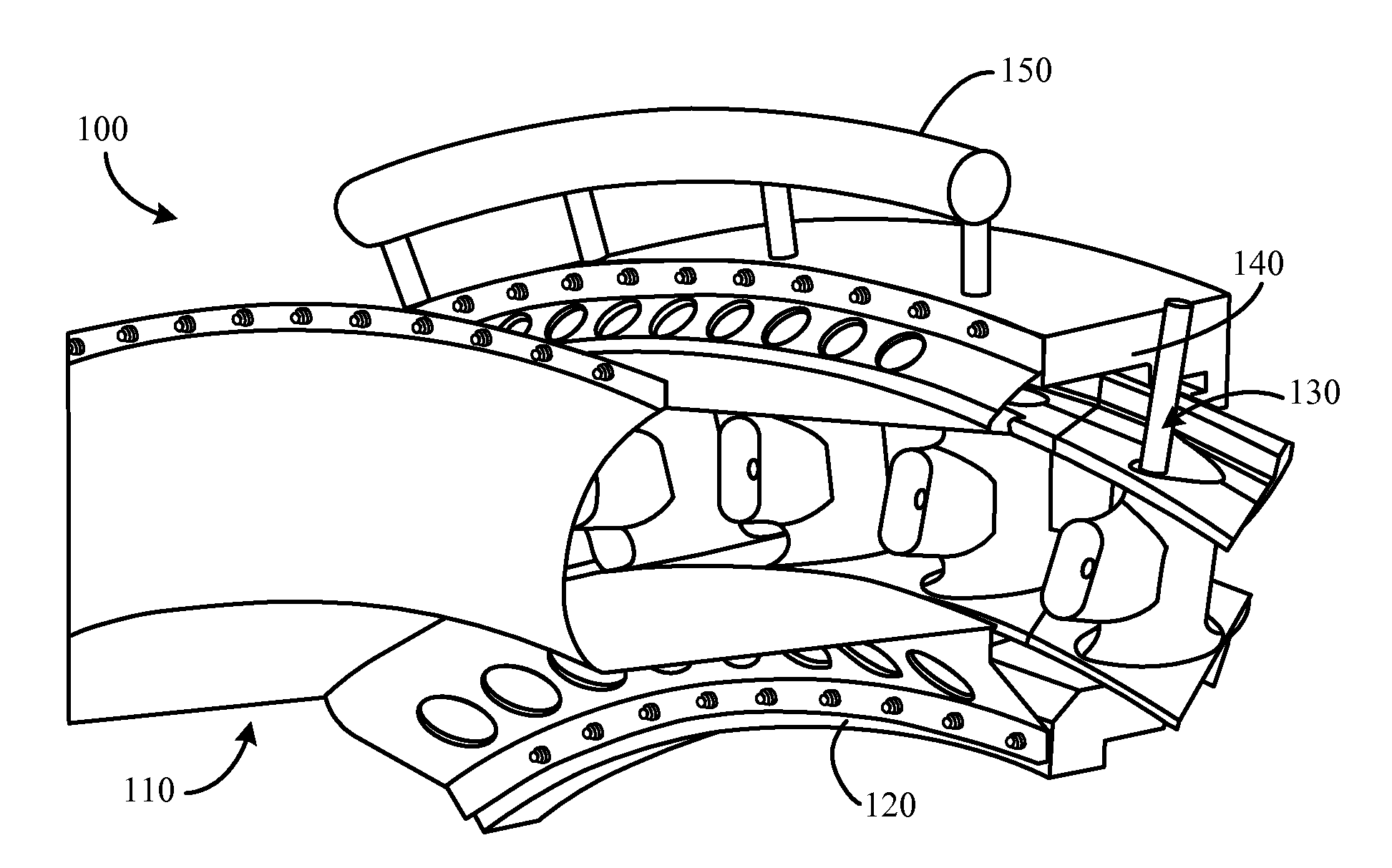

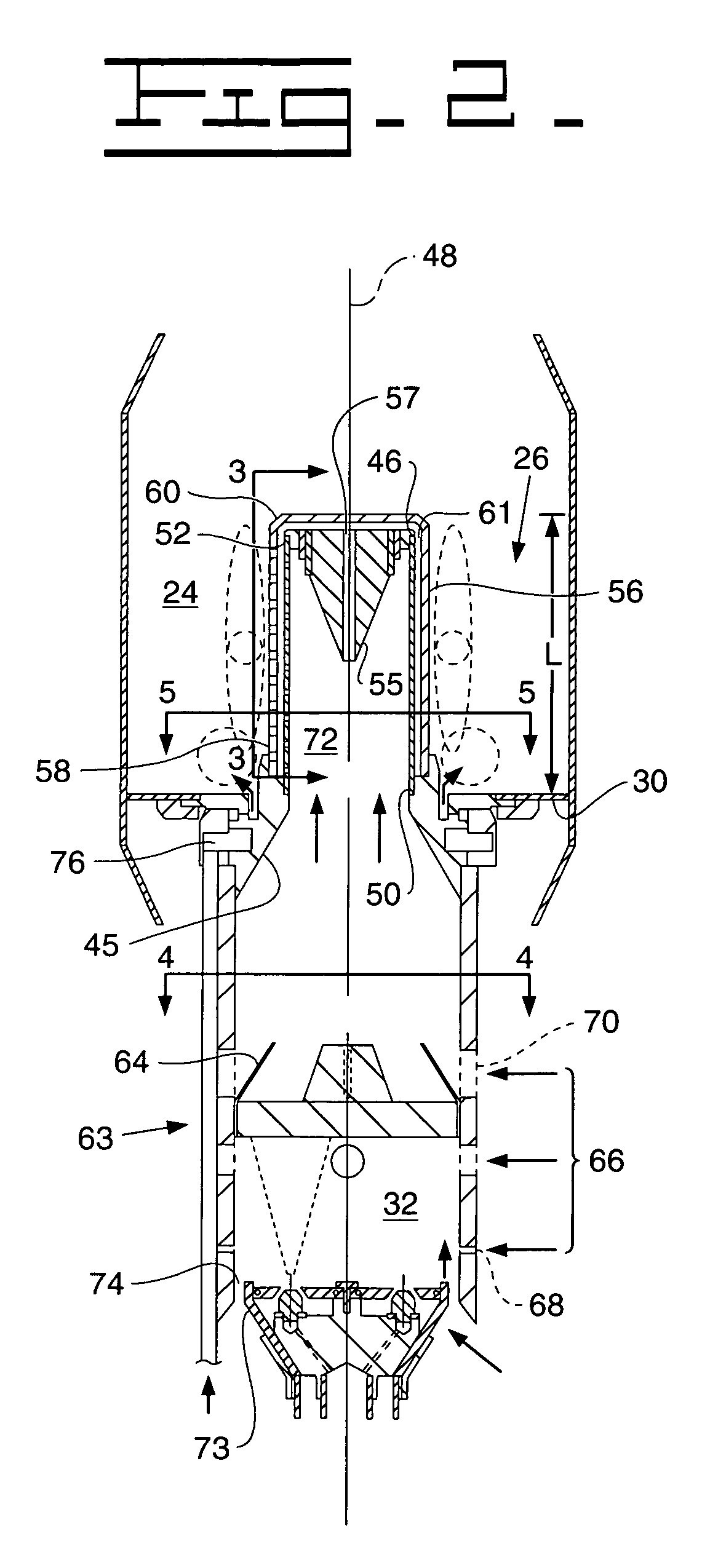

Turbine containing system and an injector therefor

A turbine containing system is disclosed. The system includes an intake section, a compressor section downstream from the intake section, a combustor section having a primary combustion system downstream from the intake section, a secondary combustion system downstream from the primary combustion system, a turbine section, an exhaust section and a load. The secondary combustion system includes an injector for transversely injecting a secondary fuel into a stream of combustion products of the primary combustion system. The injector including a coupling, a wall defining an airfoil shape circumscribing a fuel mixture passage, and at least one exit for communication between said fuel mixture passage and said stream of primary combustion products.

Owner:GENERAL ELECTRIC CO

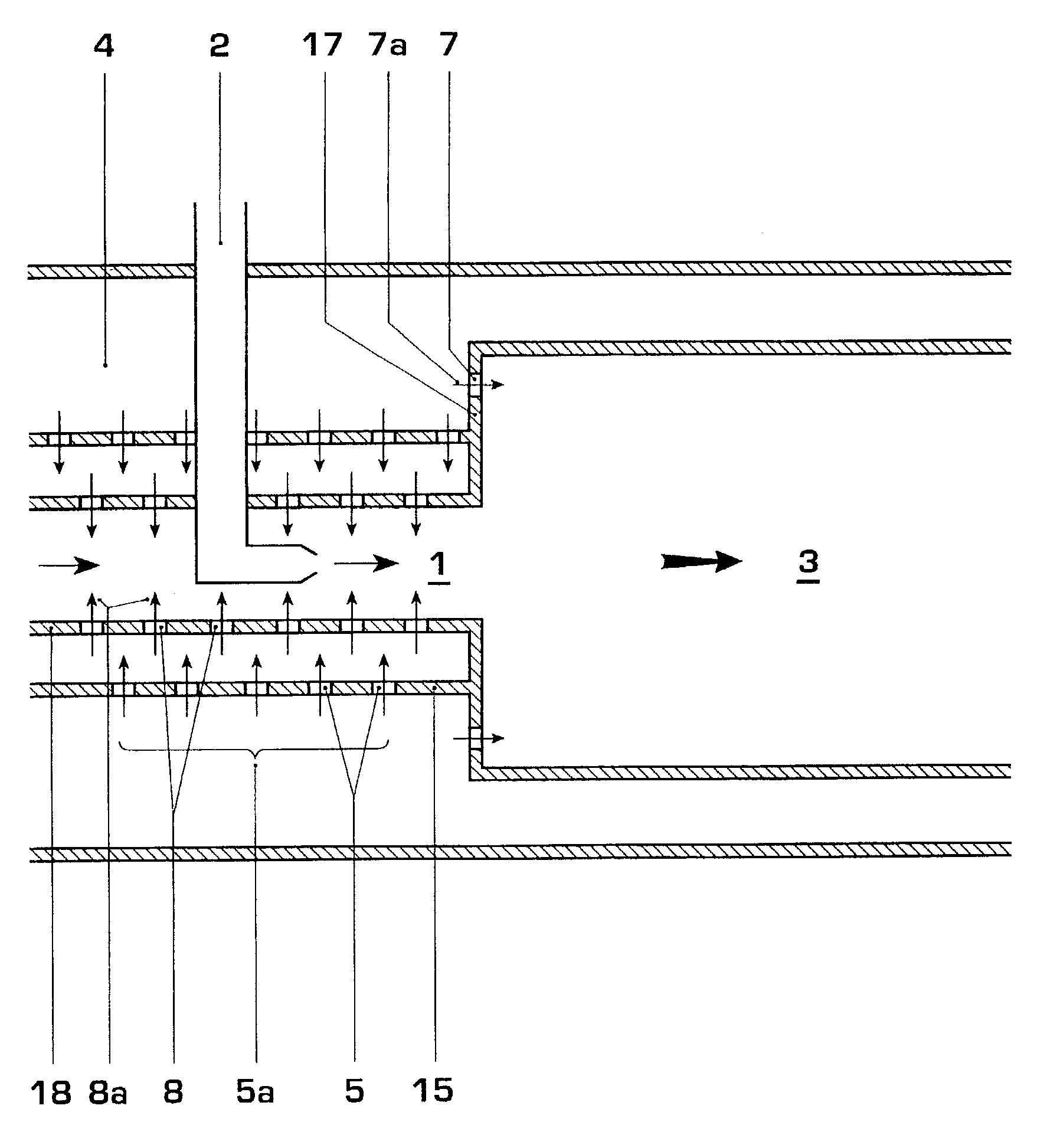

Reheat combustion system for a gas turbine

ActiveUS6981358B2Good cooling propertiesDamp pulsationBurnersContinuous combustion chamberCombustion systemCombustion chamber

A reheat combustion system for a gas turbine comprises a mixing tube adapted to be fed by products of a primary combustion zone of the gas turbine and by fuel injected by a lance; a combustion chamber fed by the said mixing tube; and at least one perforated acoustic screen. The or each said acoustic screen is provided inside the mixing tube or the combustion chamber, at a position where it faces, but is spaced from, a perforated wall thereof. In use, the perforated wall experiences impingement cooling as it admits air into the combustion system for onward passage through the perforations of the said acoustic screen, and the acoustic screen damps acoustic pulsations in the mixing tube and combustion chamber.

Owner:ANSALDO ENERGIA IP UK LTD

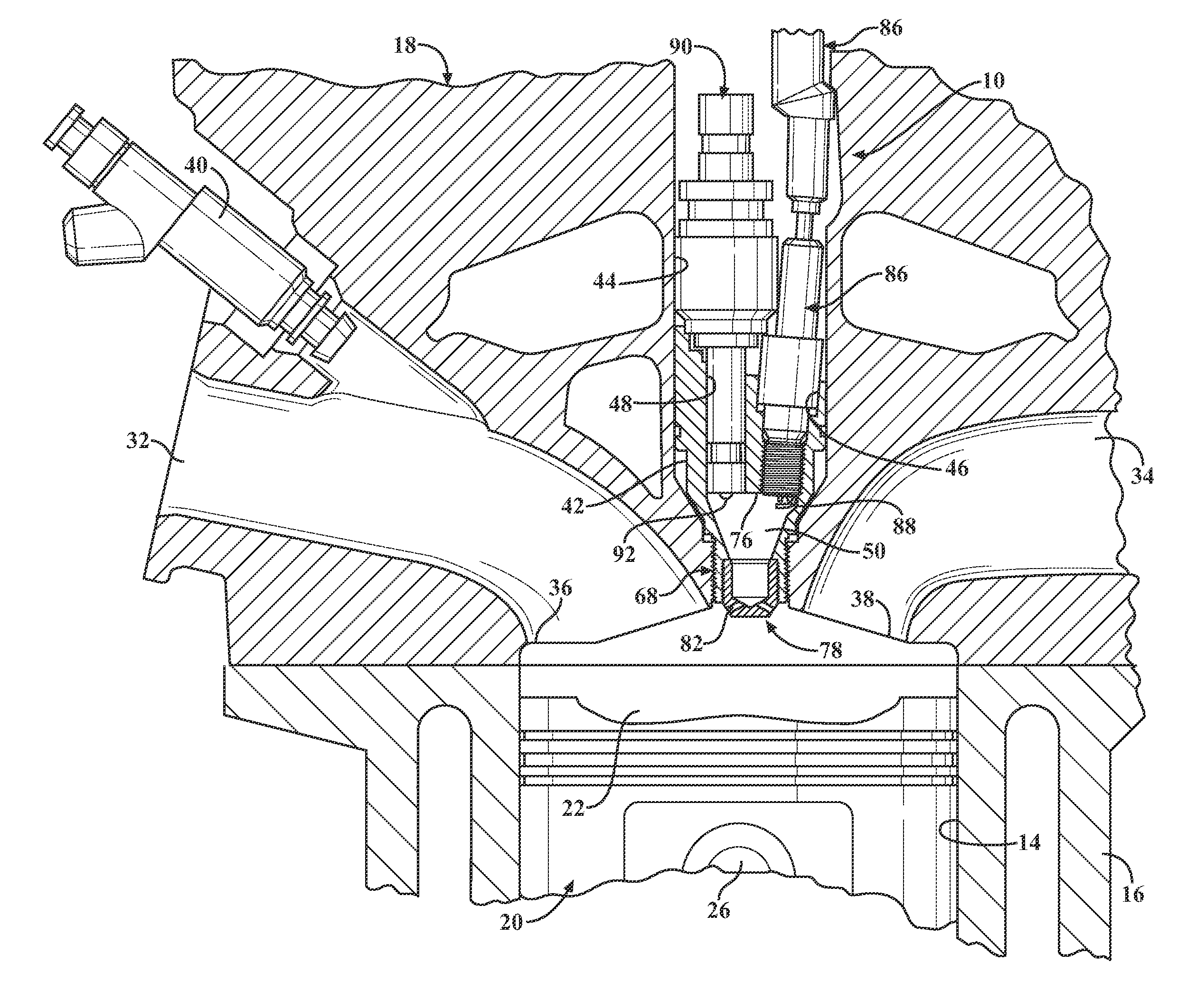

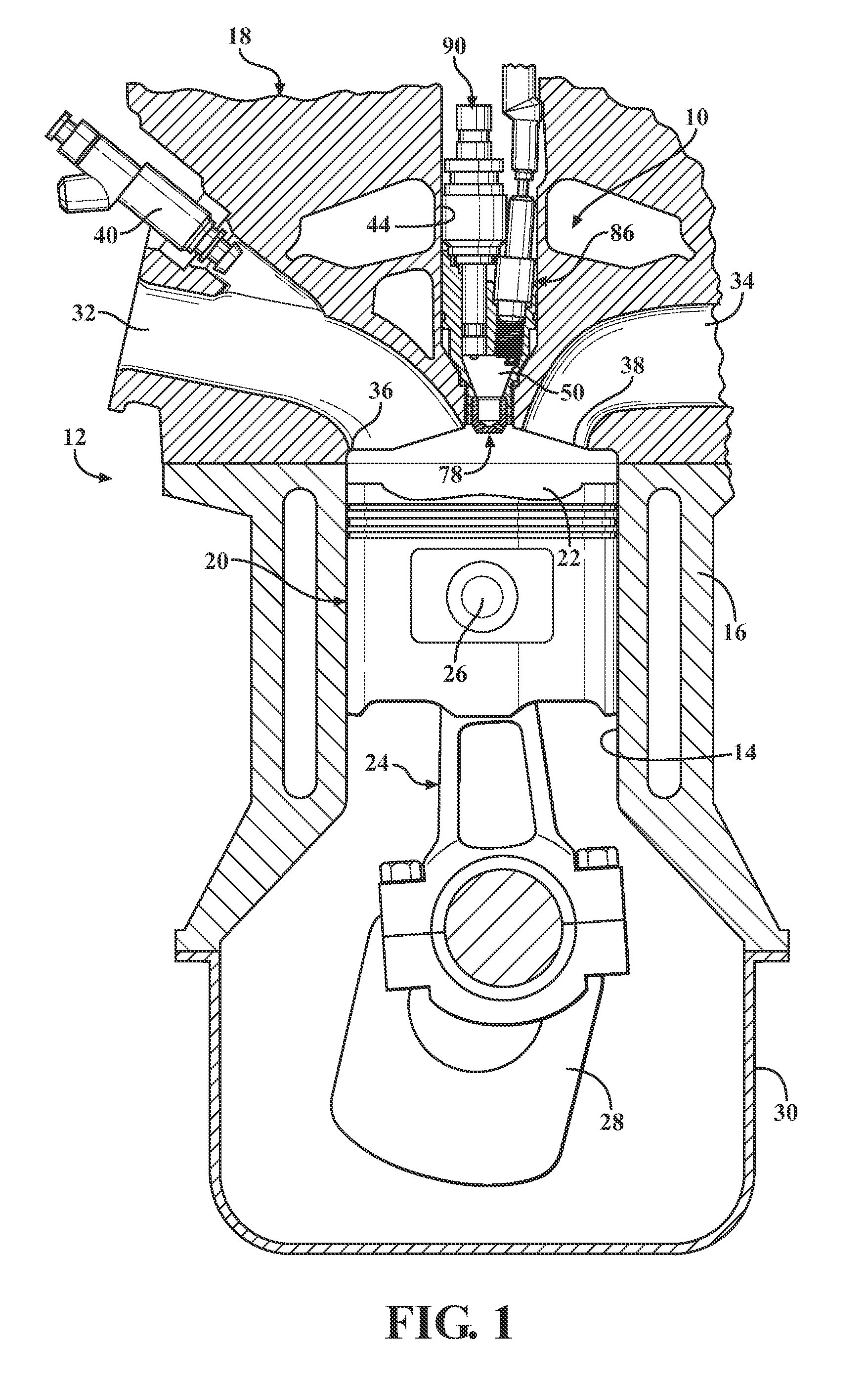

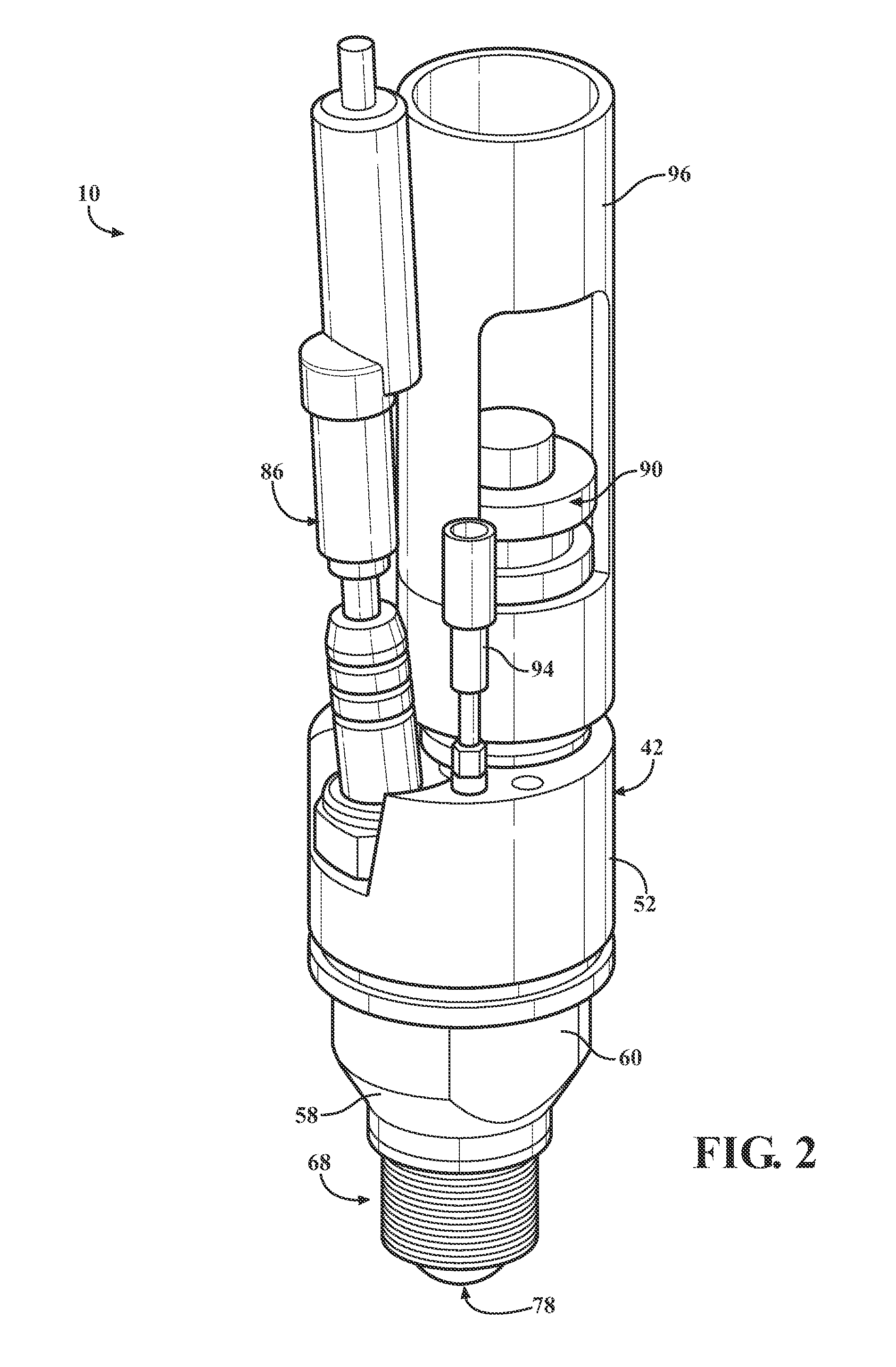

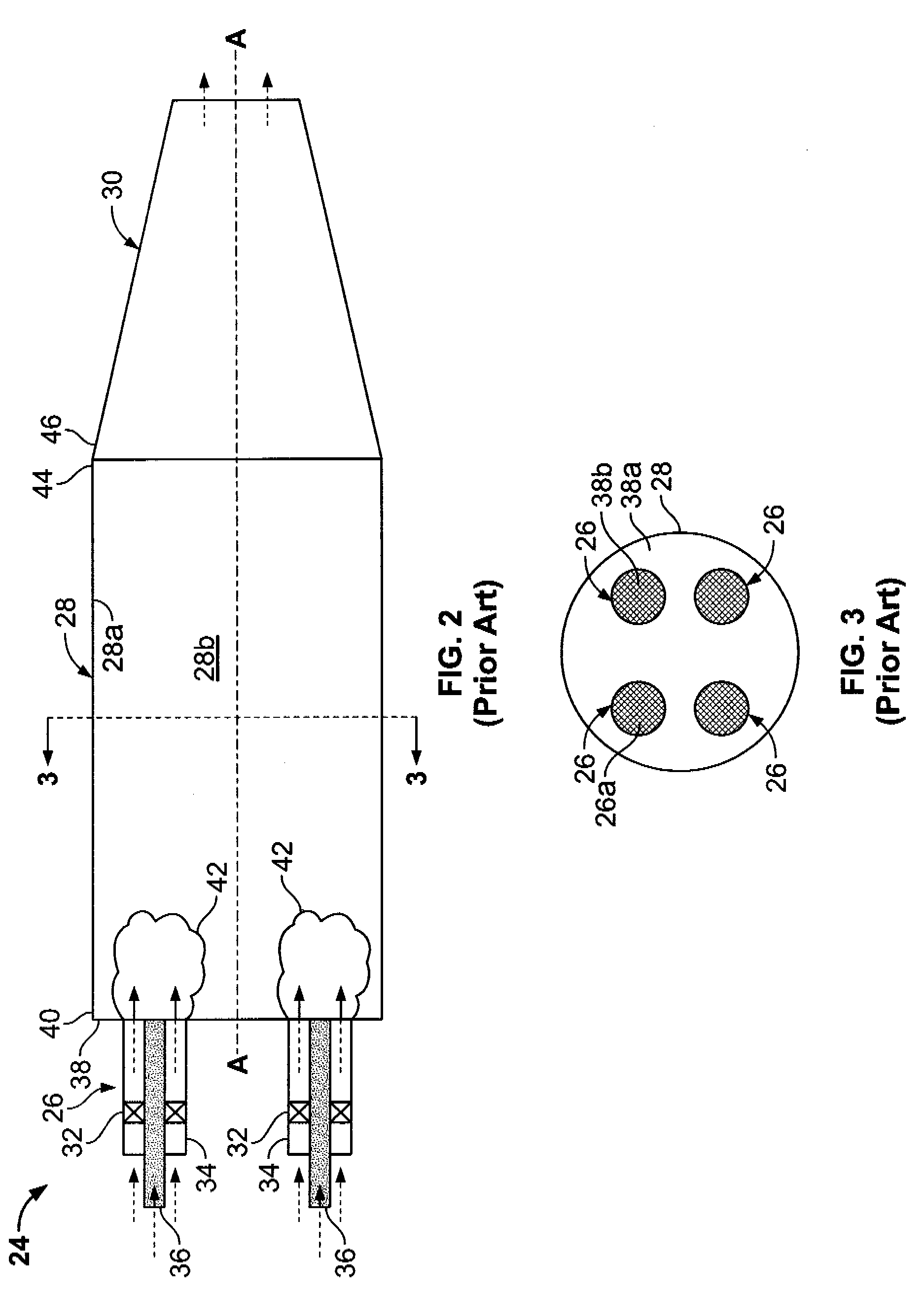

Turbulent jet ignition pre-chamber combustion system for spark ignition engines

ActiveUS20120103302A1Promote flame quenchingHigh-drive cycle (part load) fuel economyElectrical controlInternal combustion piston enginesCombustion systemCombustion chamber

An ignition system for an internal combustion engine having at least one combustion chamber where the ignition system includes a housing, an ignition device, an injector, and a pre-chamber having a nozzle disposed spaced from the proximal portion of the pre-chamber. The igniter portion of the ignition device and the nozzle of the injector are operatively supported in the proximal portion of the pre-chamber and disposed flush therewith. The igniter portion ignites the fuel in pre-chamber such that partially combusted pre-chamber products are forced through orifices in the pre-chamber nozzle and extinguish, but dispersed through the combustion chamber so as to ignite the main fuel charge therein.

Owner:MAHLE POWERTRAIN

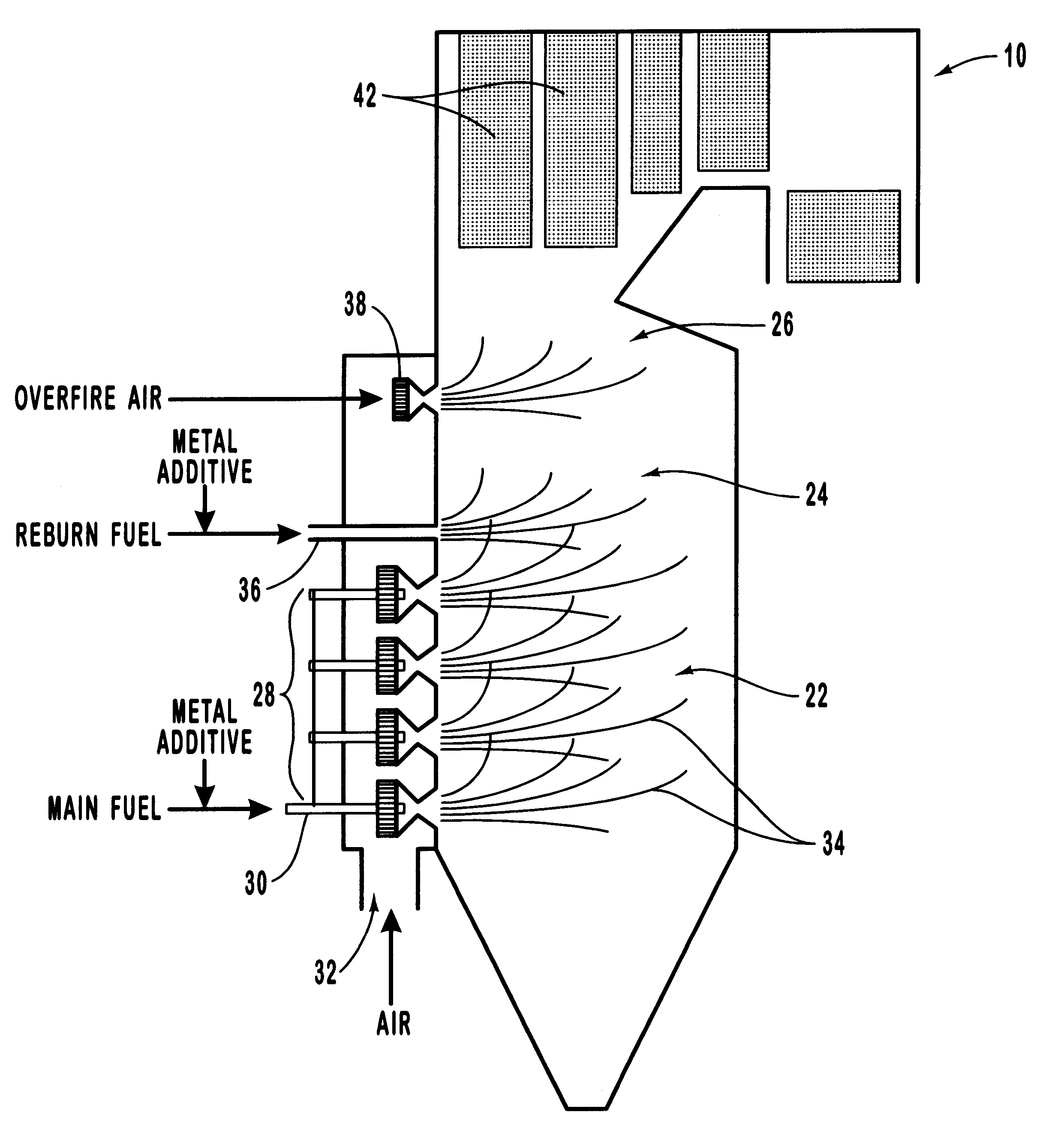

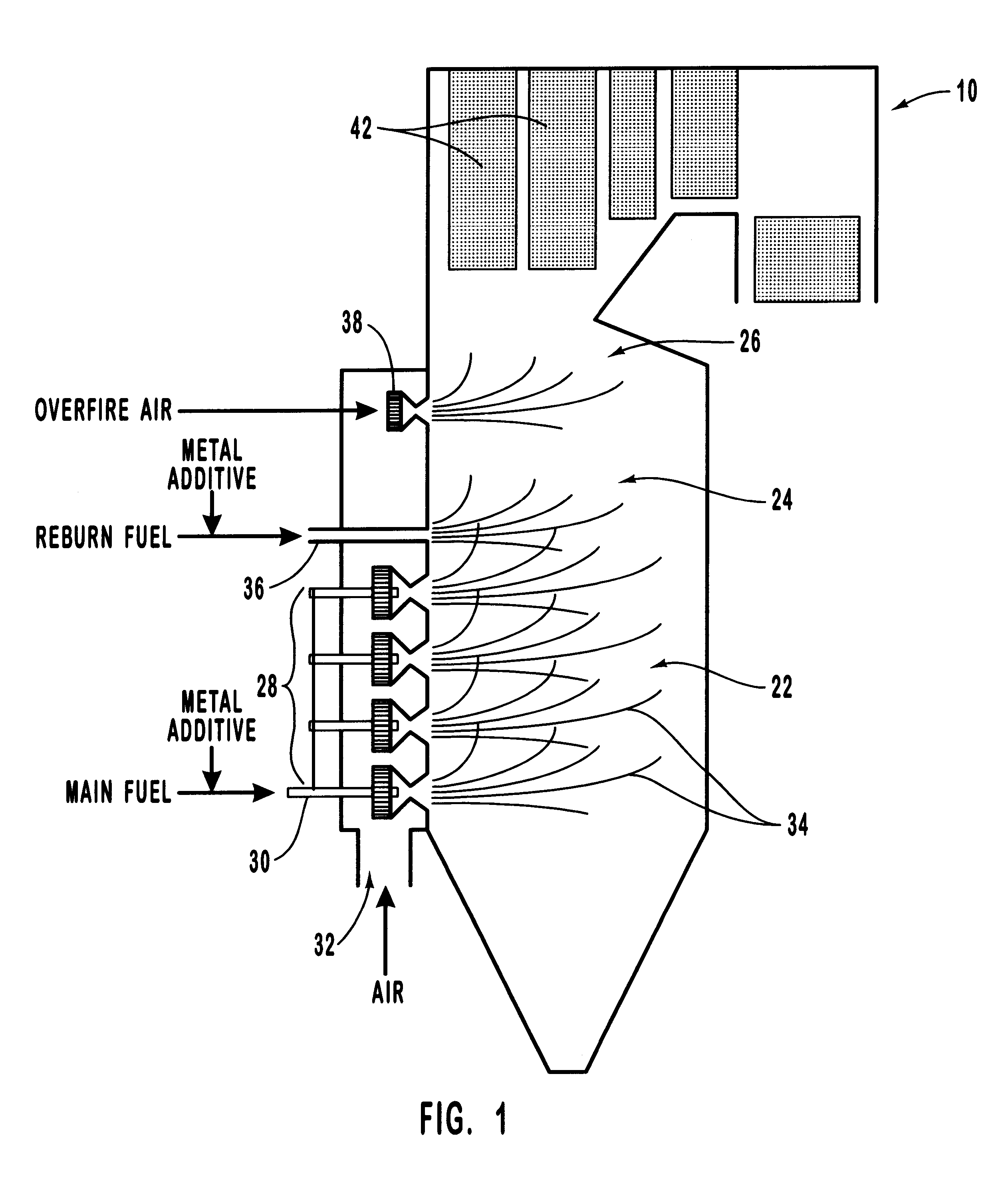

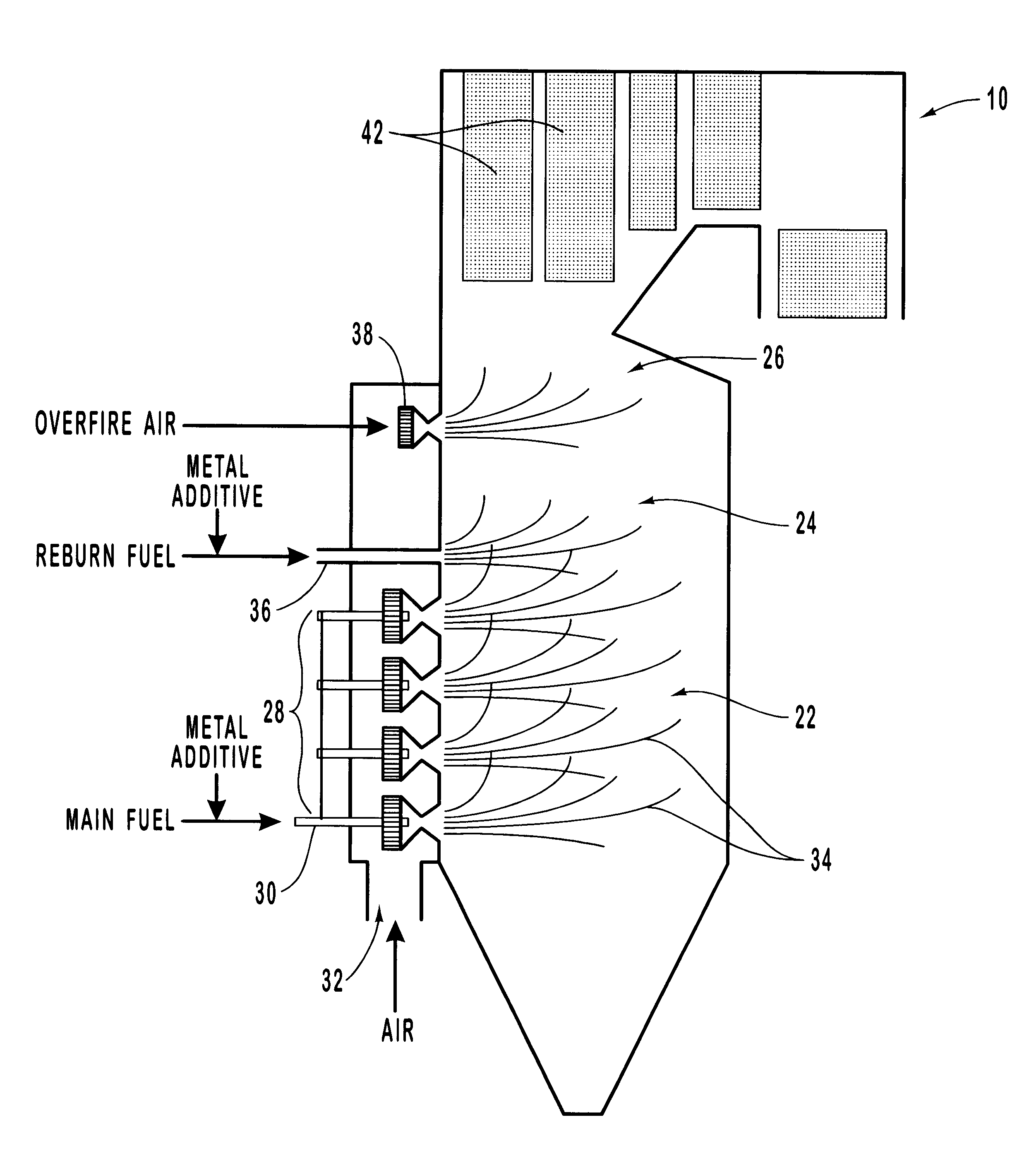

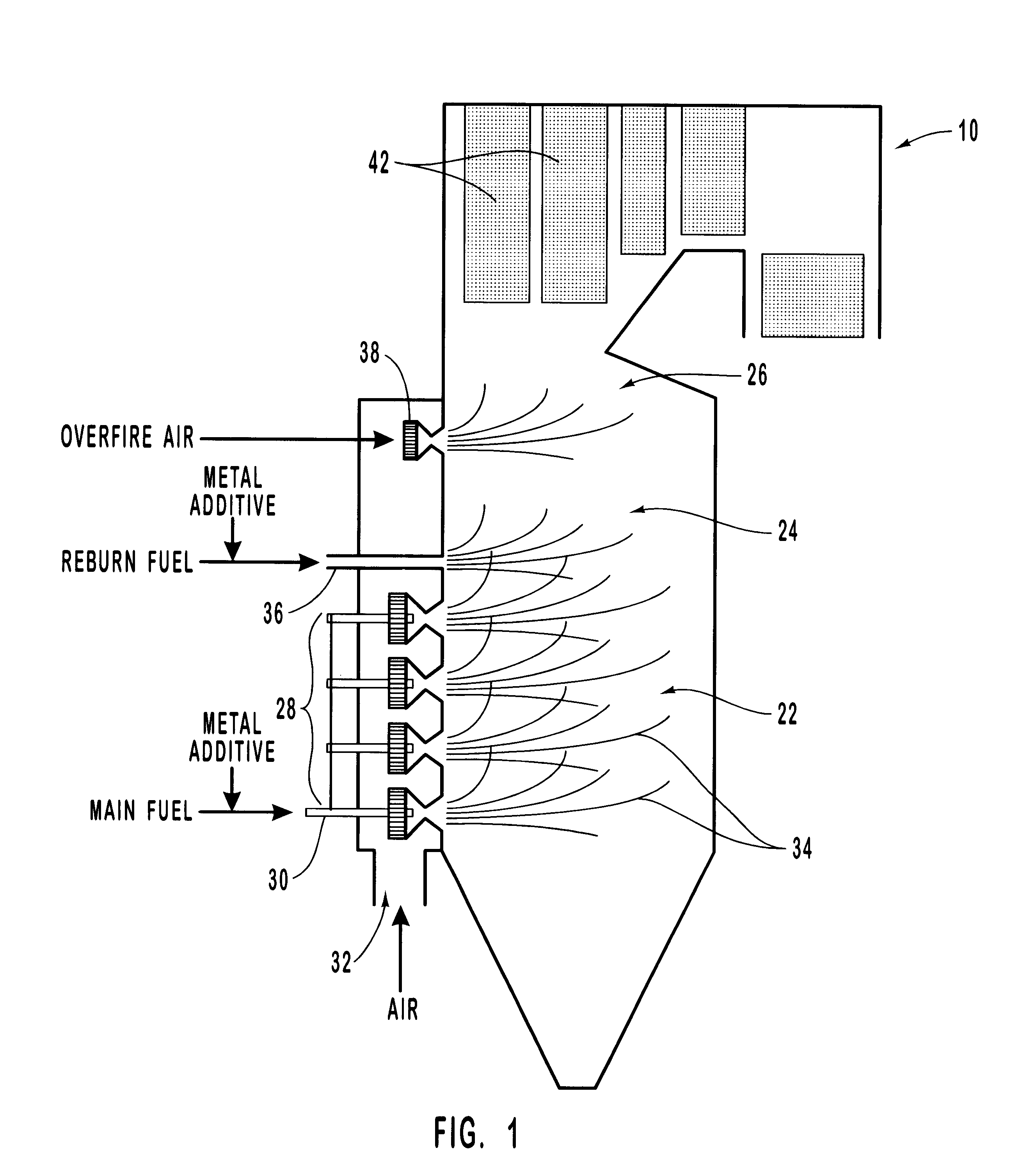

Method for reducing NOX in combustion flue gas using metal-containing additives

InactiveUS6206685B1Improved control deviceSure easyDispersed particle separationSolid fuel combustionAtmospheric airNitric oxide

Various methods for decreasing the amount of nitrogen oxides released to the atmosphere as a component of combustion gas mixtures are provided. The methods specifically provide for the removal of nitric oxide and nitrogen dioxide (NOx) from gas mixtures emitted from stationary combustion systems. In particular, methods for improving efficiency of nitrogen oxide reduction from combustion systems include injecting metal-containing compounds into the main combustion zone and / or the reburning zone of a combustion system. The metal containing compounds react with active combustion species, and these reactions change radical concentrations and significantly improve NOx conversion to molecular nitrogen. The metal-containing additives can be injected with the main fuel, in the main combustion zone, with secondary or reburning fuel addition, or at several locations in the main combustion zone and reburning zone. Optionally, nitrogenous reducing agents and / or overfire air can be injected downstream to further increase NOx reduction.

Owner:GE ENERGY & ENVIRONMENTAL RES

Method of operating a combustion system for increased turndown capability

ActiveUS7137256B1Emission reductionStable combustionContinuous combustion chamberGas turbine plantsCombustion systemLow load

A method of operating a gas turbine engine combustion system at lower load conditions while maintaining required emissions levels is disclosed. The present invention includes multiple embodiments of axial, radial, and circumferential fuel staging within a can-type combustor having alternate ignition techniques of spark ignition or torch ignition.

Owner:ANSALDO ENERGIA SWITZERLAND AG

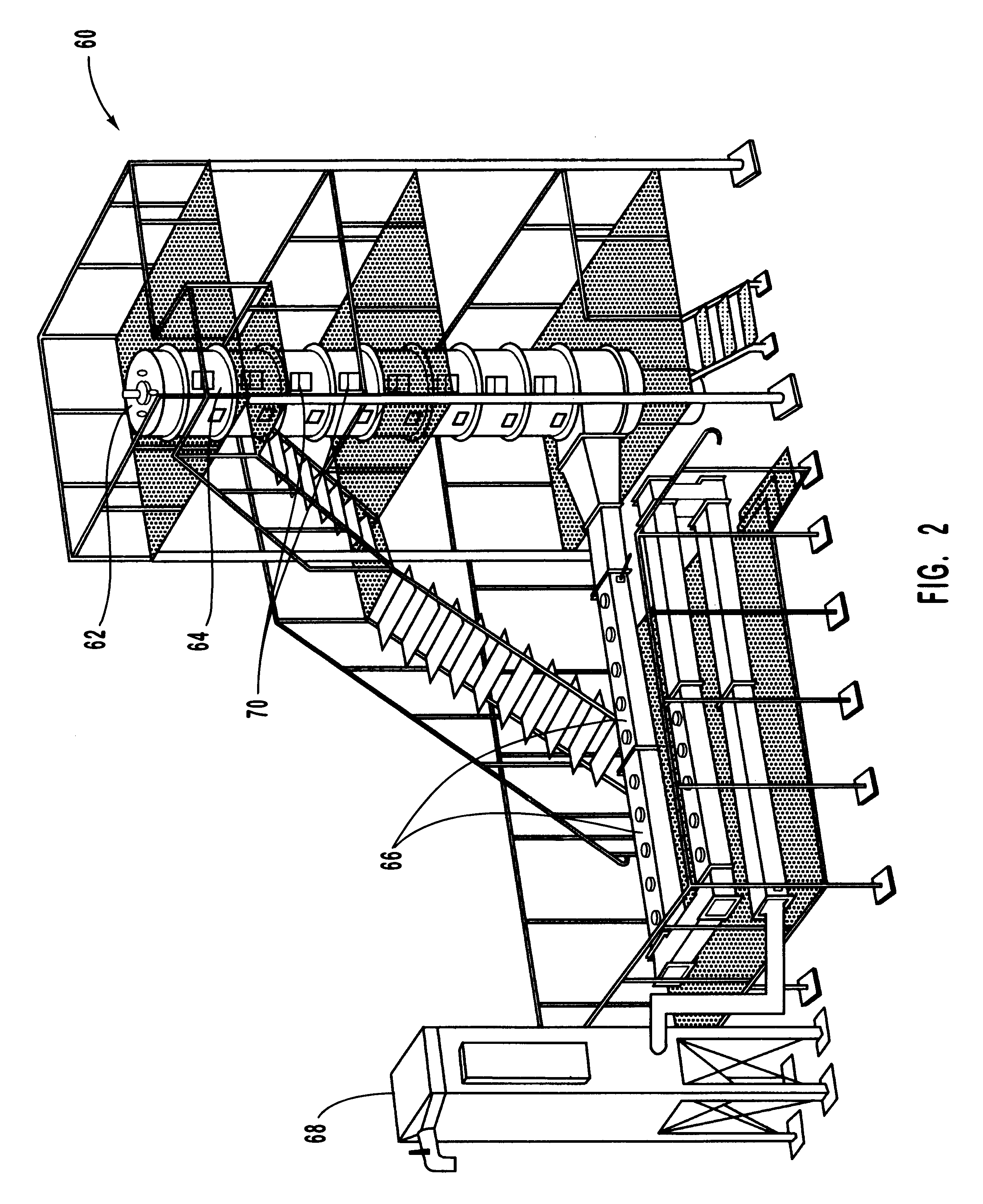

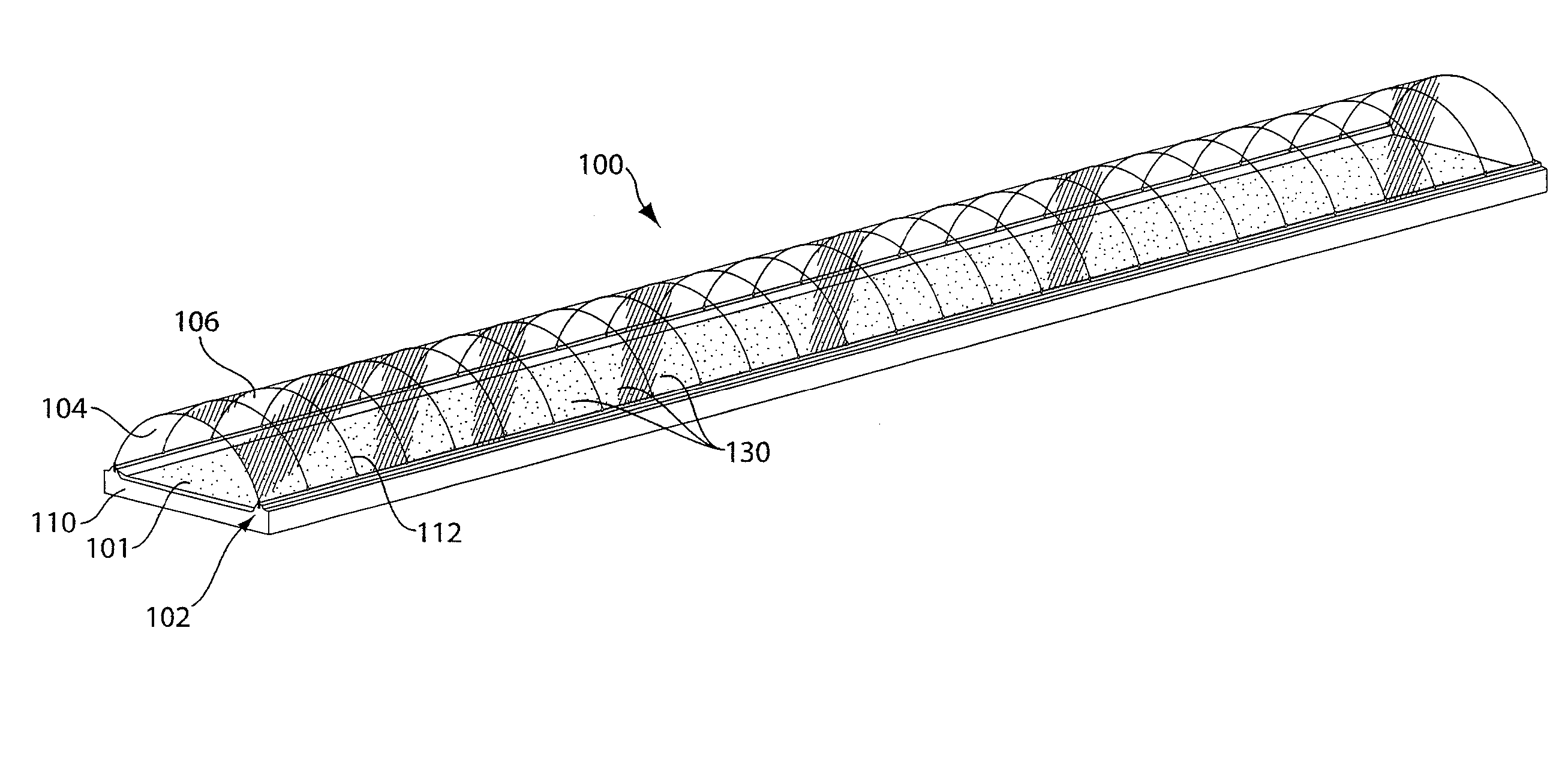

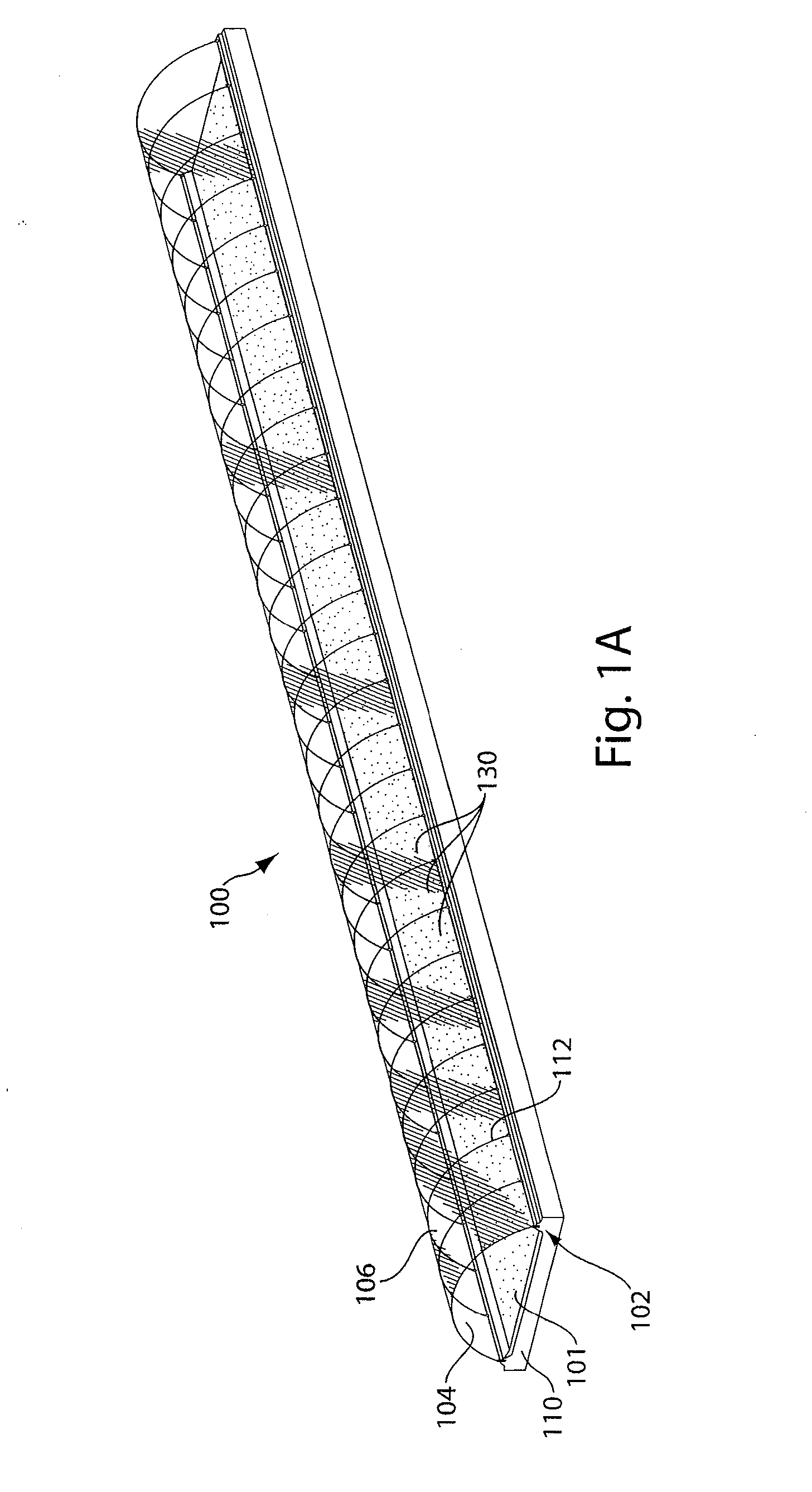

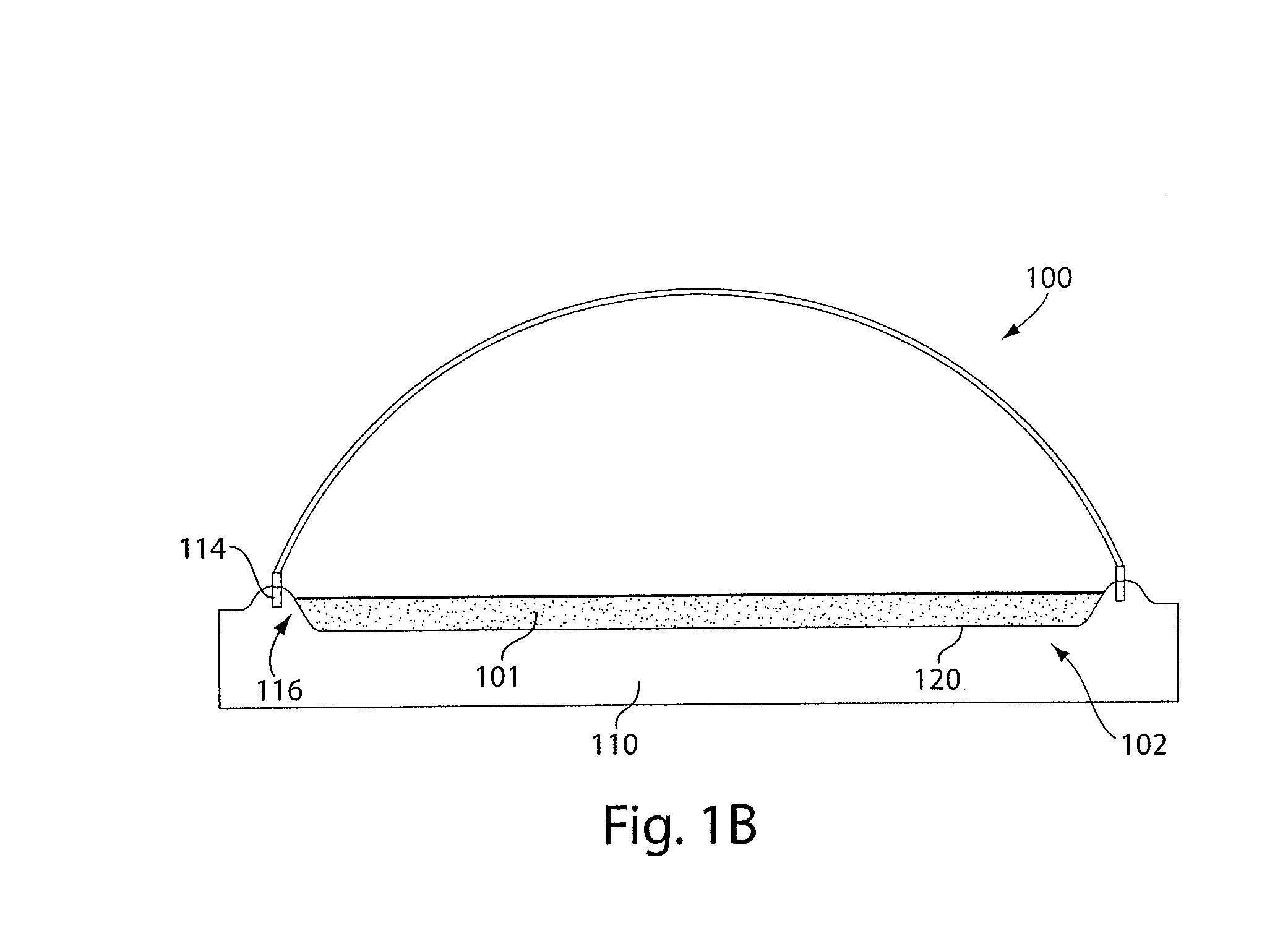

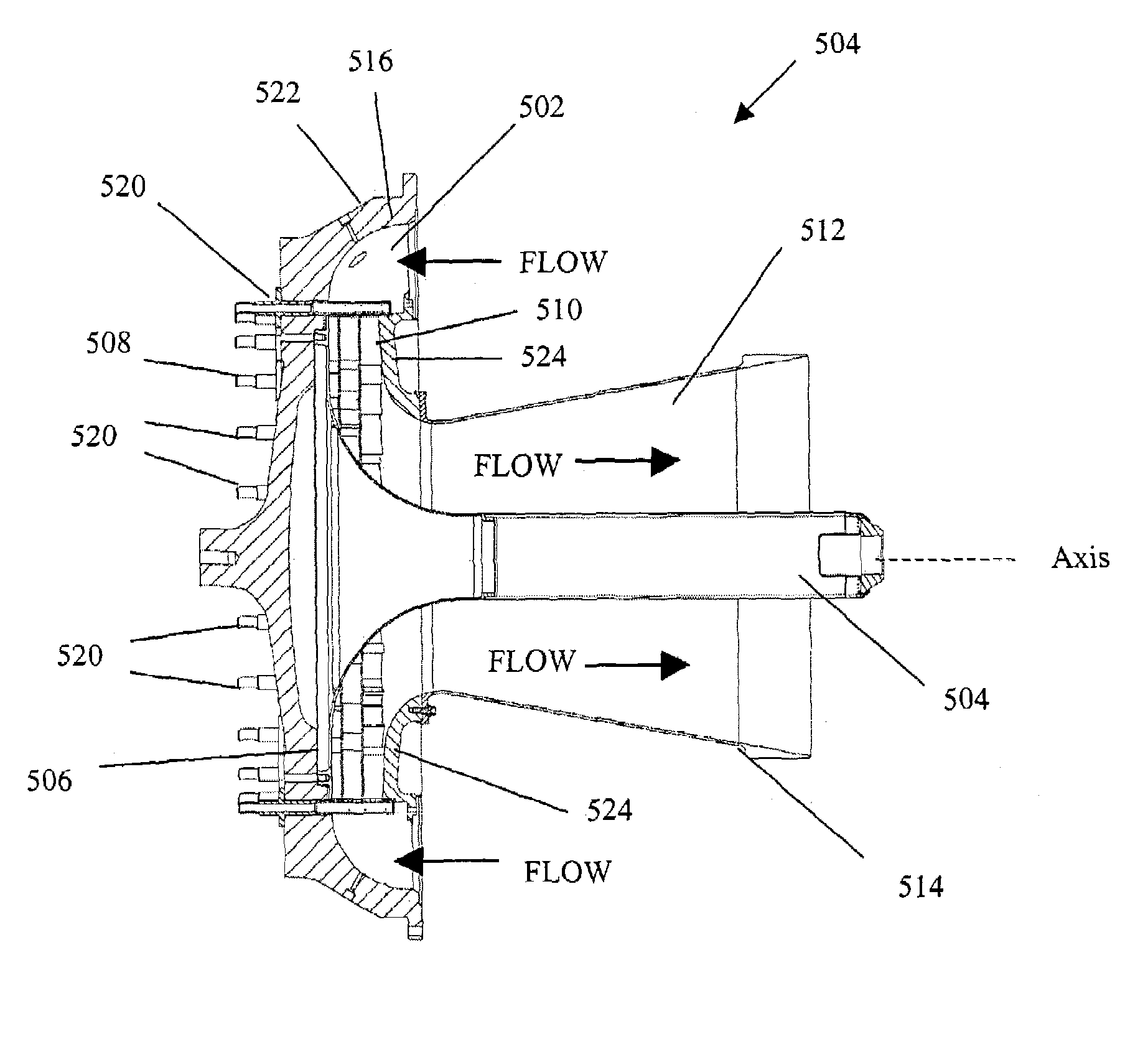

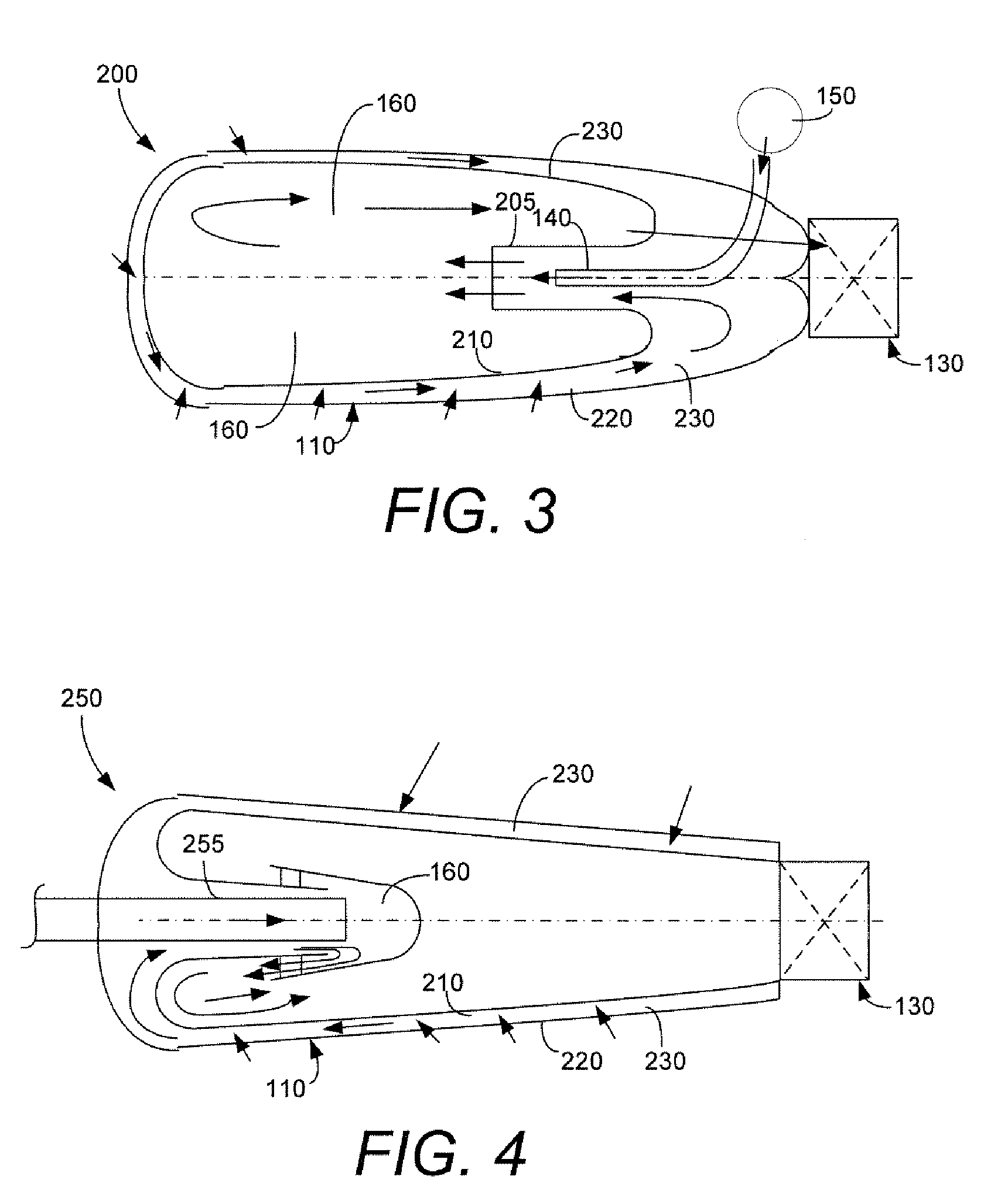

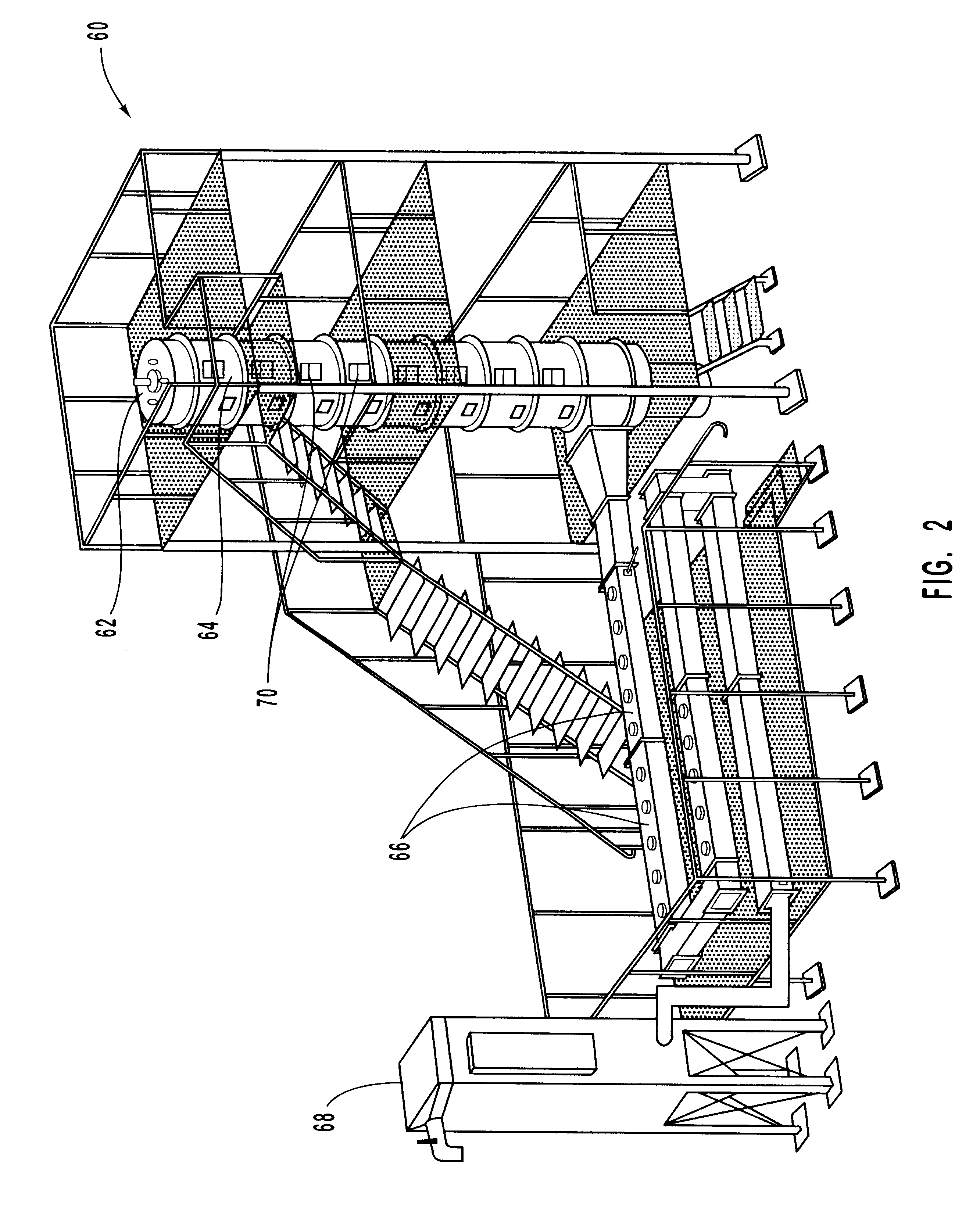

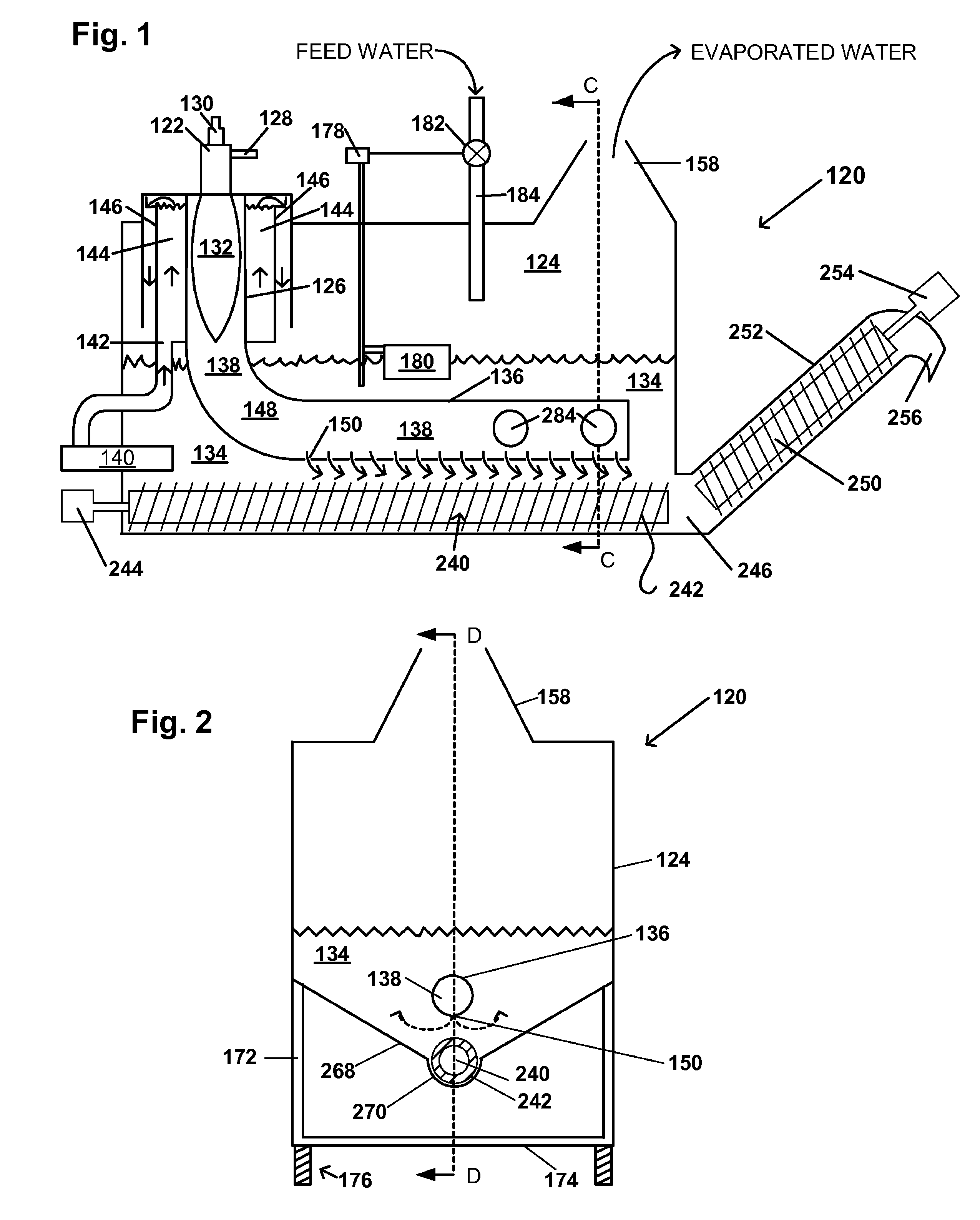

Photobioreactor systems and methods for treating CO2-enriched gas and producing biomass

InactiveUS20080178739A1Facilitate evaporative coolingSupport growthBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumStream flow

Certain embodiments and aspects of the present invention relate to a photobioreactor including covered photobioreactor units through which a liquid medium stream and a gas stream flow. The liquid medium comprises at least one species of phototrophic organism therein. Certain methods of using the photobioreactor system as part of fuel generation system and / or a gas-treatment process or system at least partially remove certain undesirable pollutants from a gas stream. In certain embodiments, a portion of the liquid medium is diverted from a photobioreactor unit and reintroduced upstream of the diversion position. In certain embodiments, the disclosed photobioreactor system, methods of using such systems, and / or gas treatment apparatus and methods provided herein can be used as part of an integrated combustion method and system, wherein photosynthetic organisms used within the photobioreactor are harvested from the photobioreactor, processed, and used as a fuel source for a combustion system such as an electric power plant.

Owner:THE TRON GRP

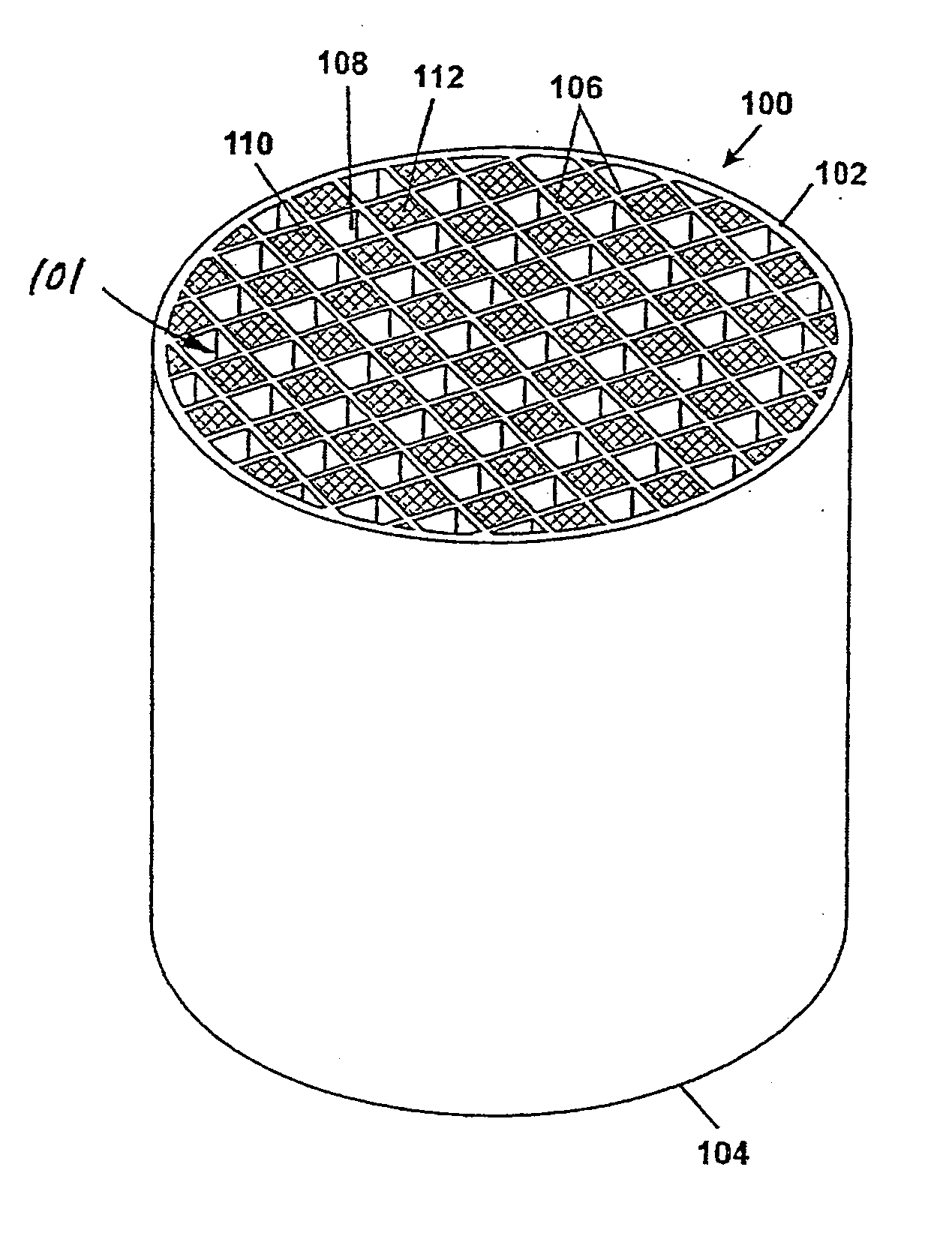

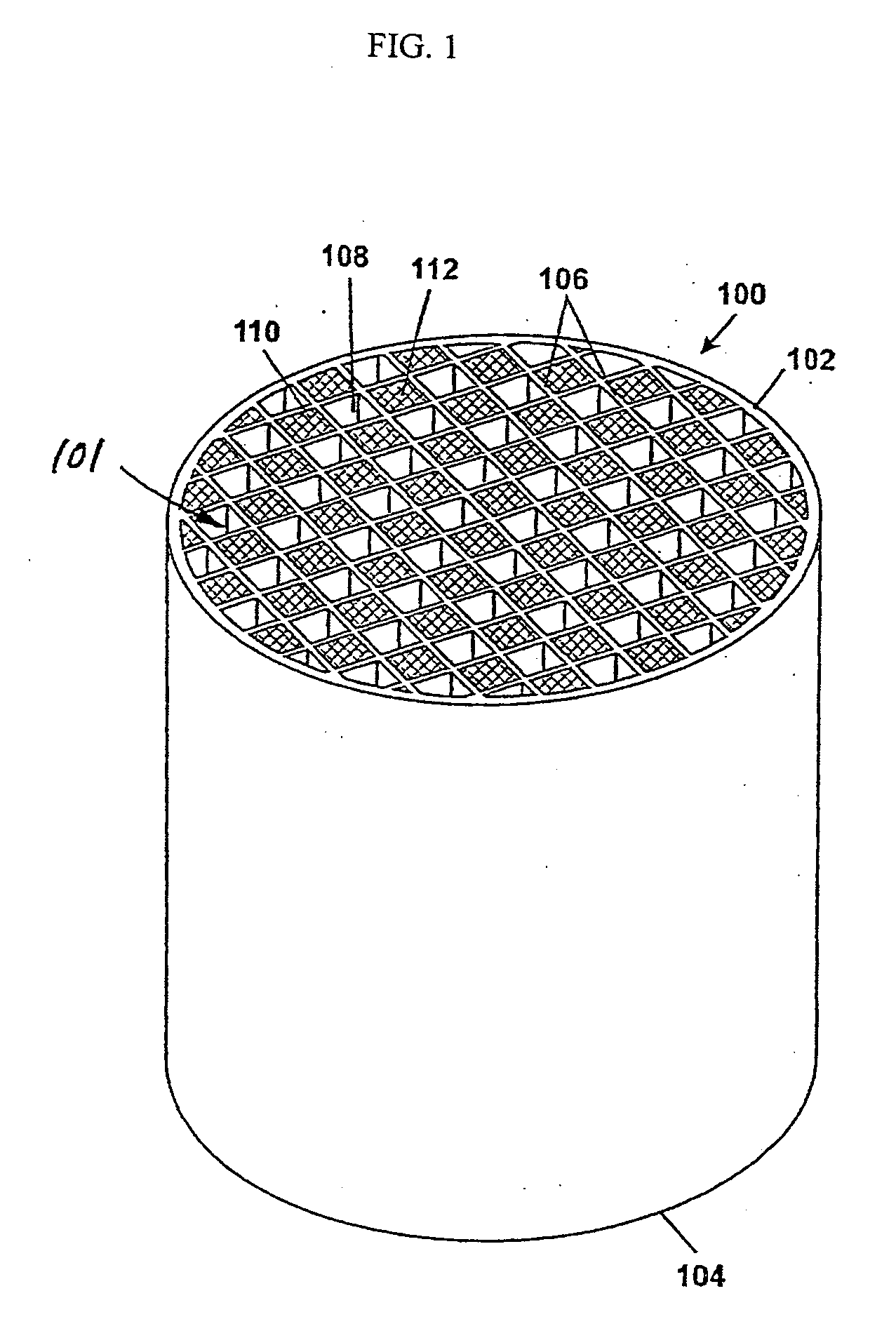

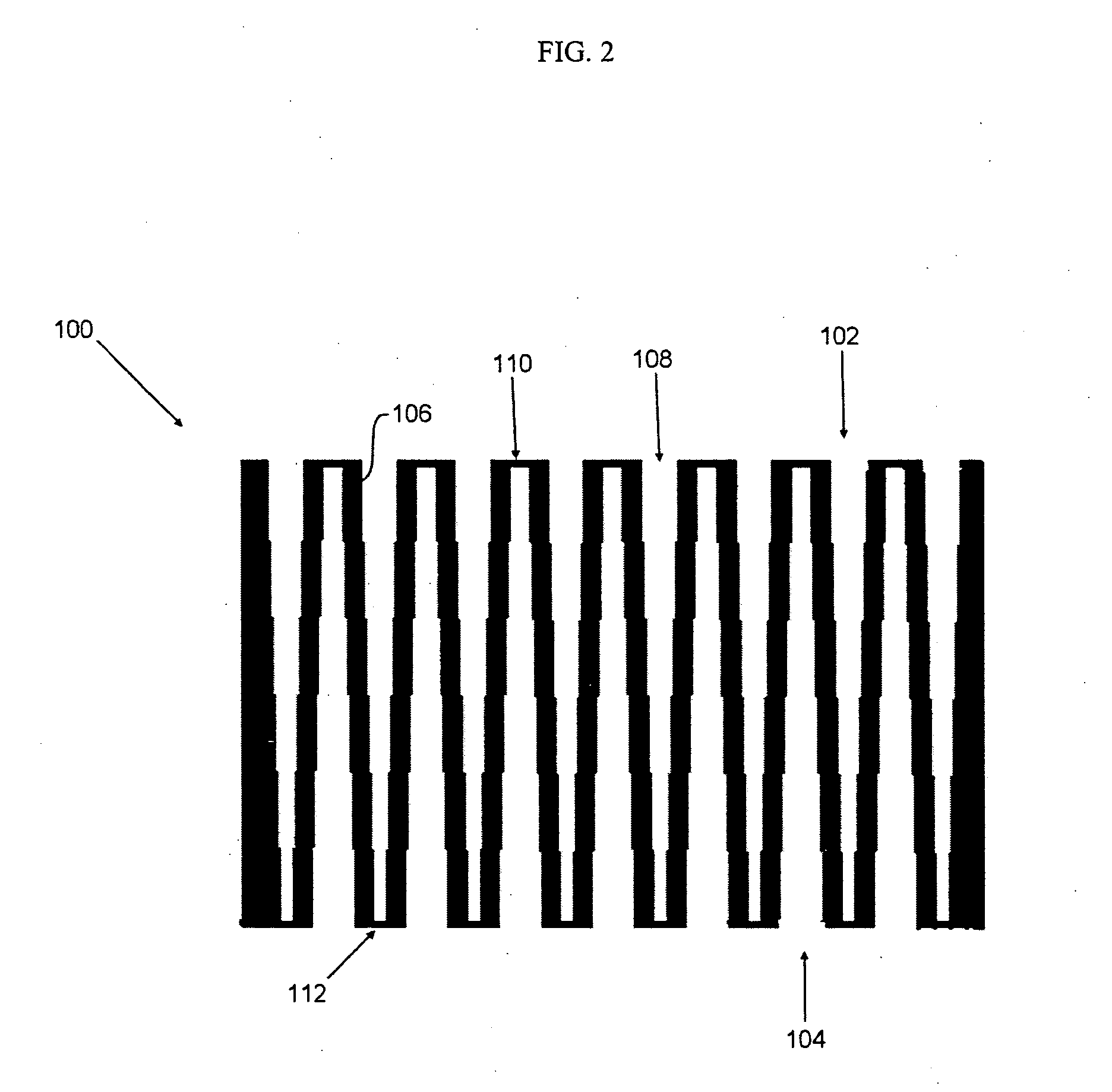

Activated carbon honeycomb catalyst beds and methods for the use thereof

InactiveUS20070261557A1Simple designLow costGas treatmentCarbon compoundsActivated carbonCombustion system

Disclosed herein, without limitation, are activated carbon honeycomb catalyst beds and systems for removing mercury and other toxic metals from a process stream, i.e, from flue gas of a coal combustion system. The activated carbon honeycomb can for example remove greater than 90% mercury from flue gas with a simple design and without adding material to the flue gas. Also disclosed herein, and without limitation, are methods for manufacturing and using the disclosed honeycomb catalyst beds and systems.

Owner:CORNING INC

Fuel-air premixing system for a catalytic combustor

InactiveUS7093445B2Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustion systemHybrid system

Disclosed is a unique fuel and air premixing system for a gas turbine catalytic combustion system. The mixer utilizes a multi-channel counter-rotating swirler with aerodynamically shaped fuel pegs located upstream of the swirler. The premixing system provides the downstream catalyst with a fuel-air mixture sufficiently uniform for proper catalyst operation and wide operating limits. Features have been incorporated in the system to make it resistant to flameholding.

Owner:KAWASAKI HEAVY IND LTD

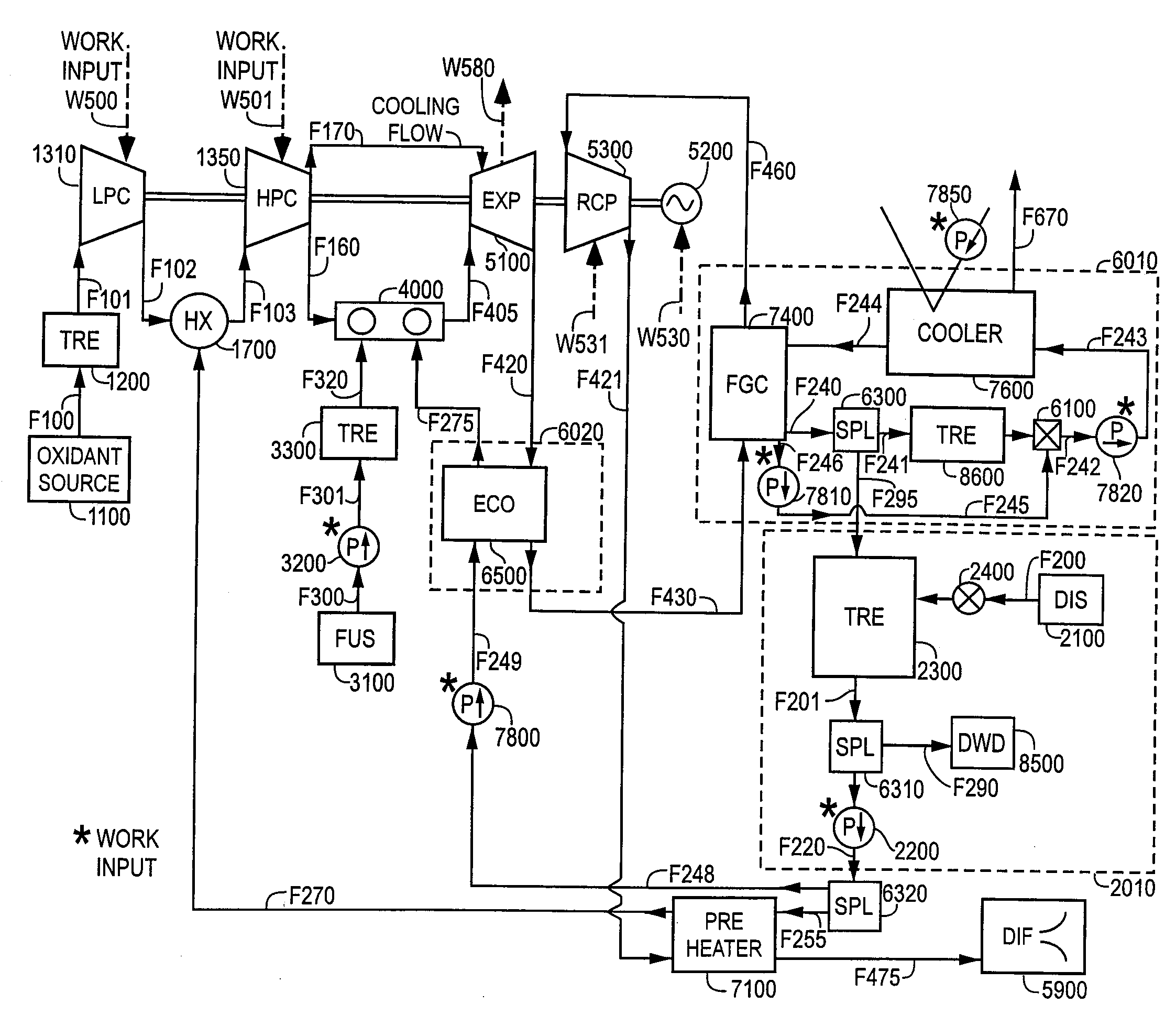

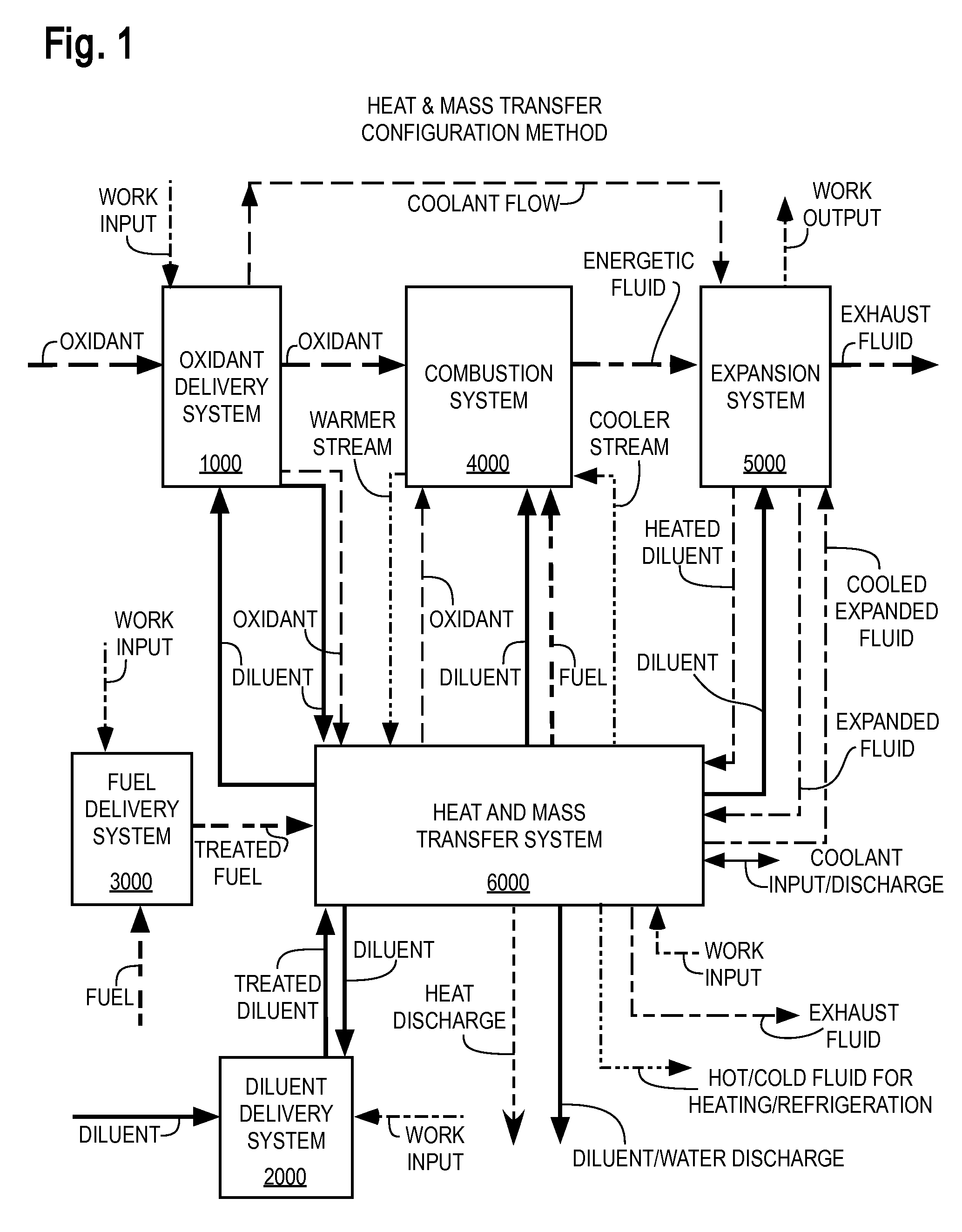

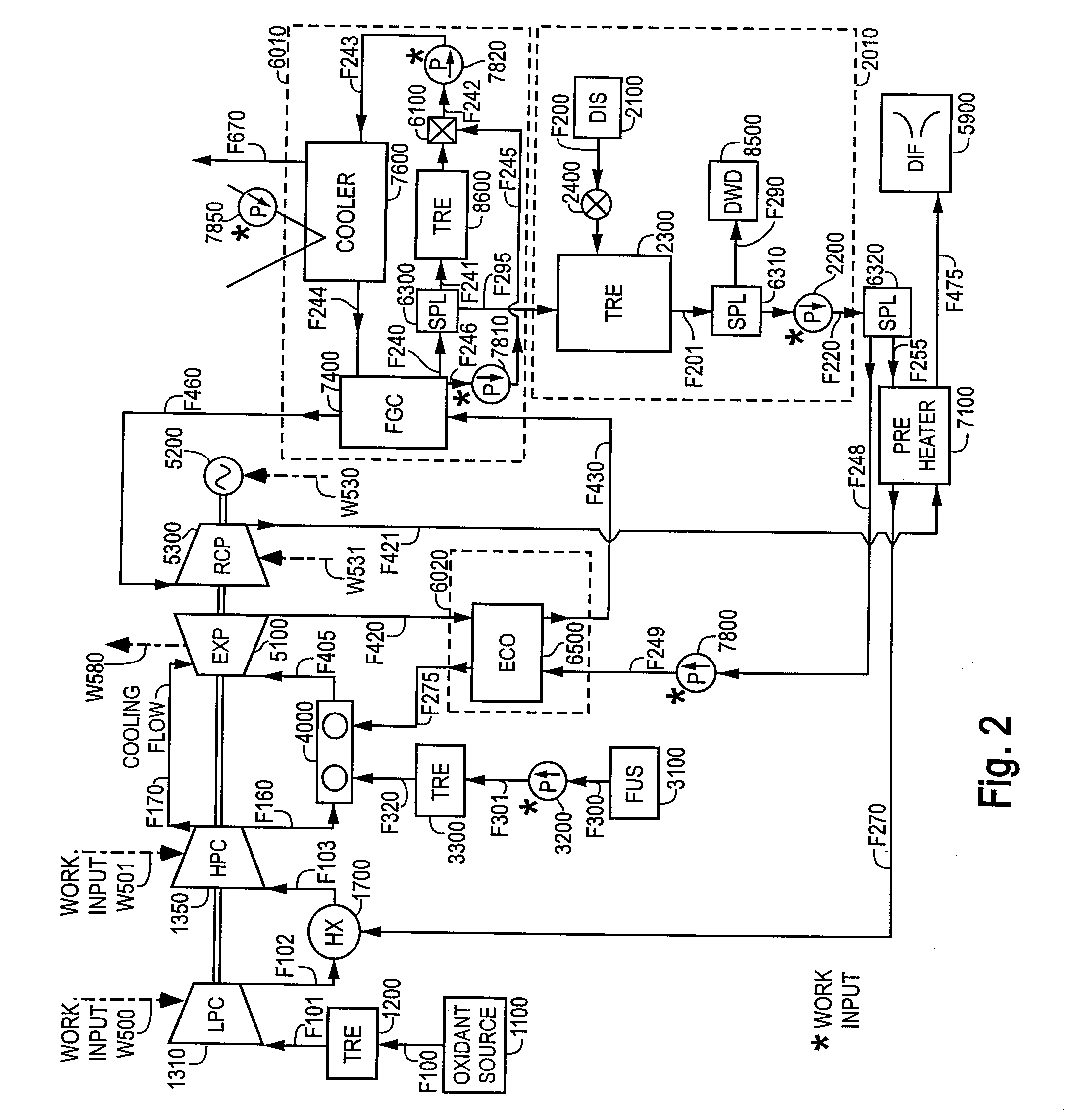

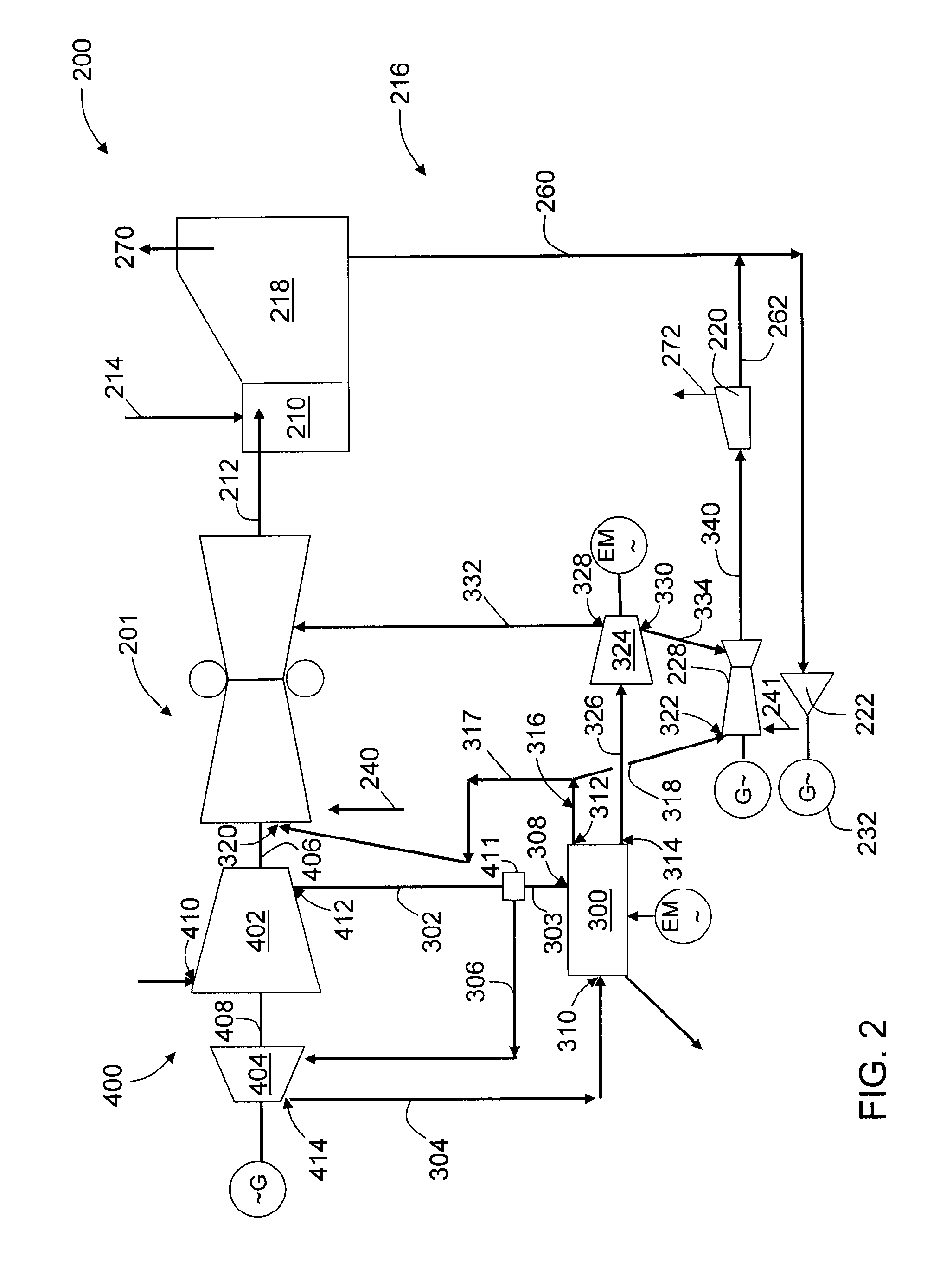

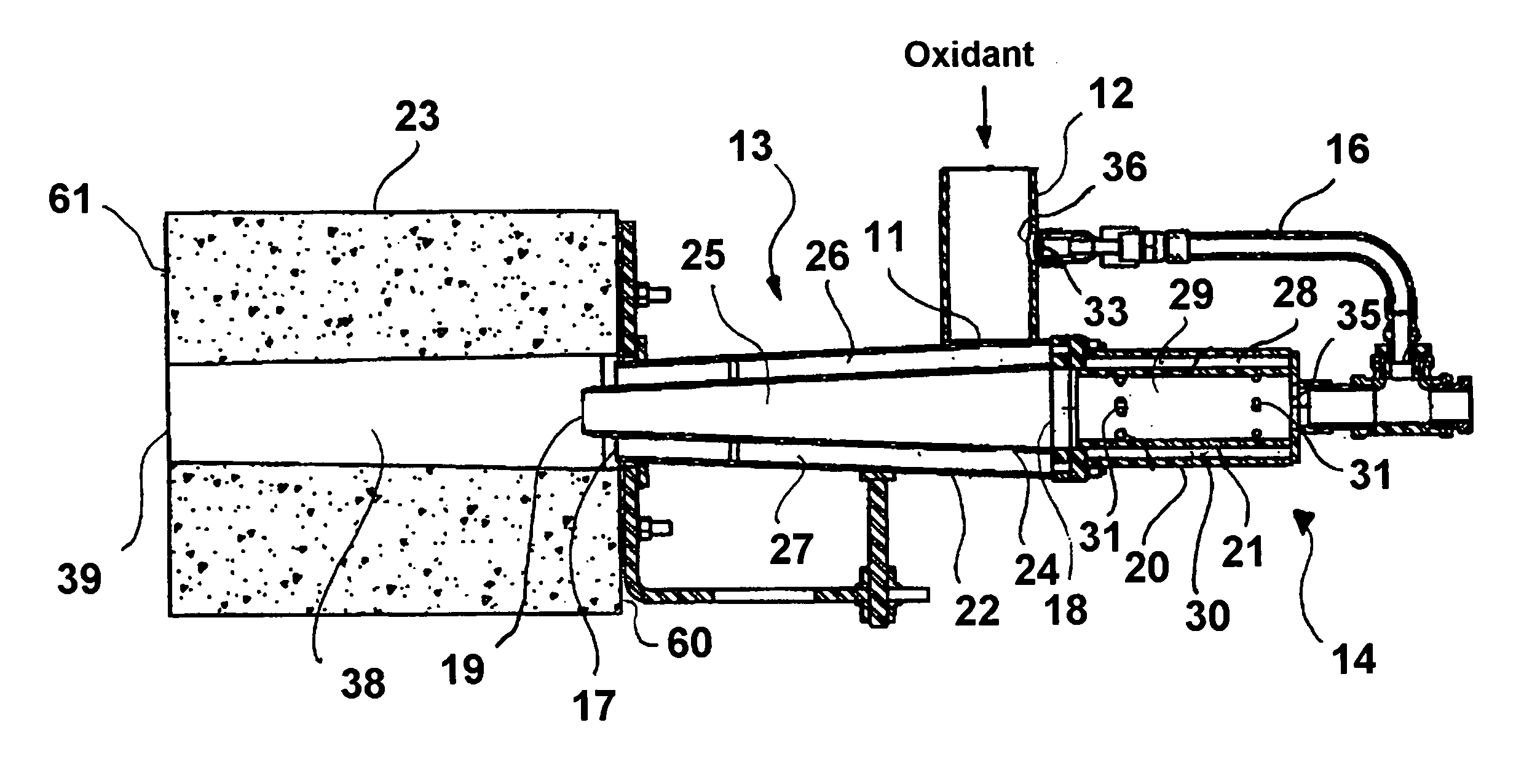

Thermodynamic cycles using thermal diluent

ActiveUS20090071166A1Low costEmission reductionSpace heating and ventilationSulfur compoundsCombustion systemCombustion

A thermodynamic system that produces mechanical, electrical power, and / or fluid streams for heating or cooling. The cycle contains a combustion system that produces an energetic fluid by combustion of a fuel with an oxidant. A thermal diluent may be used in the cycle to improve performance, including but not limited to power, efficiency, economics, emissions, dynamic and off-peak load performance, and / or turbine inlet temperature (TIT) regulation and cooling heated components. The cycle preferably includes a heat recovery system and a condenser or other means to recover and recycle heat and the thermal diluent from the energetic fluid to improve the cycle thermodynamic efficiency and reduce energy conversion costs. The cycle may also include controls for temperatures, pressures, and flow rates throughout the cycle, and controls power output, efficiency, and energetic fluid composition.

Owner:VAST HLDG LLC

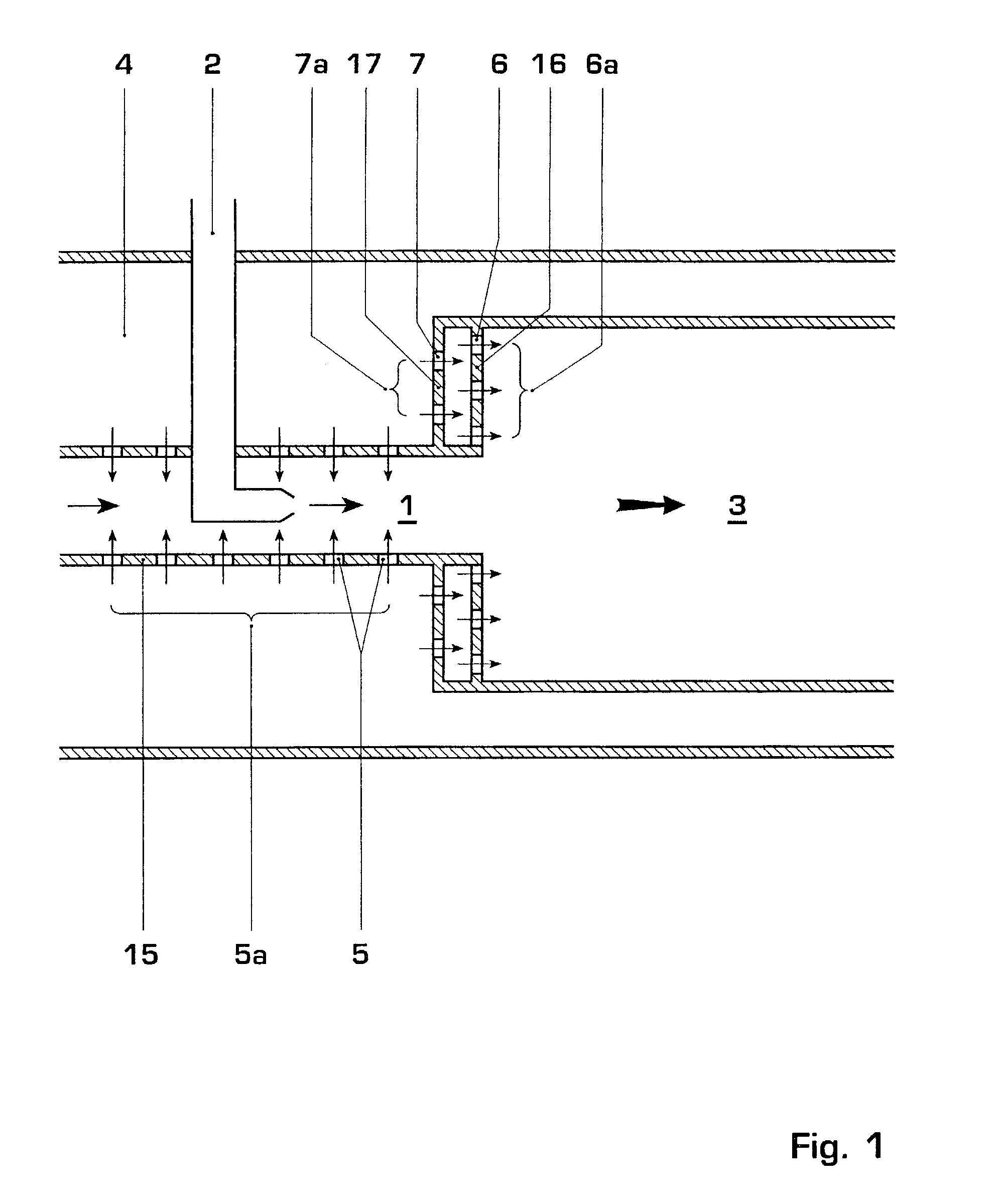

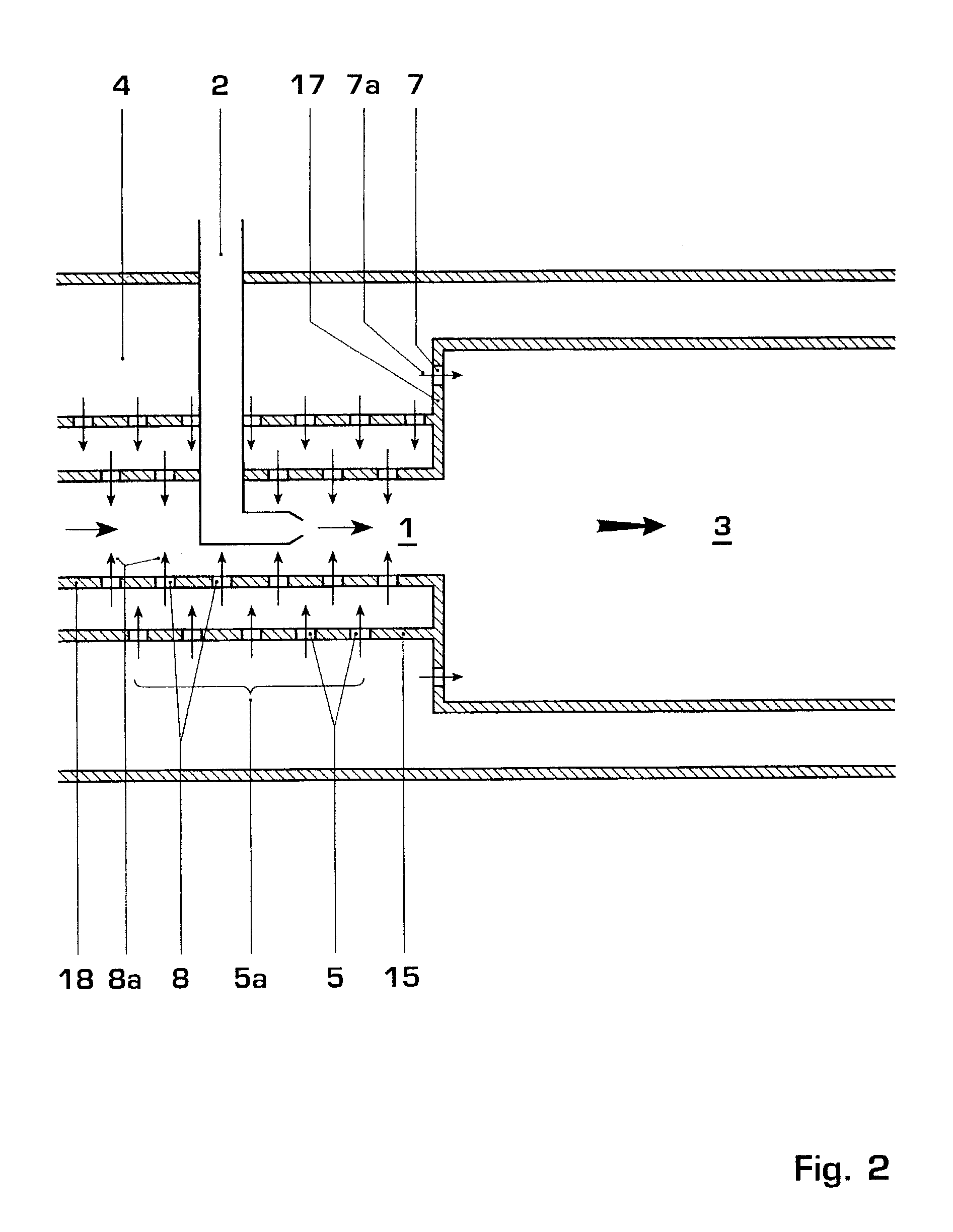

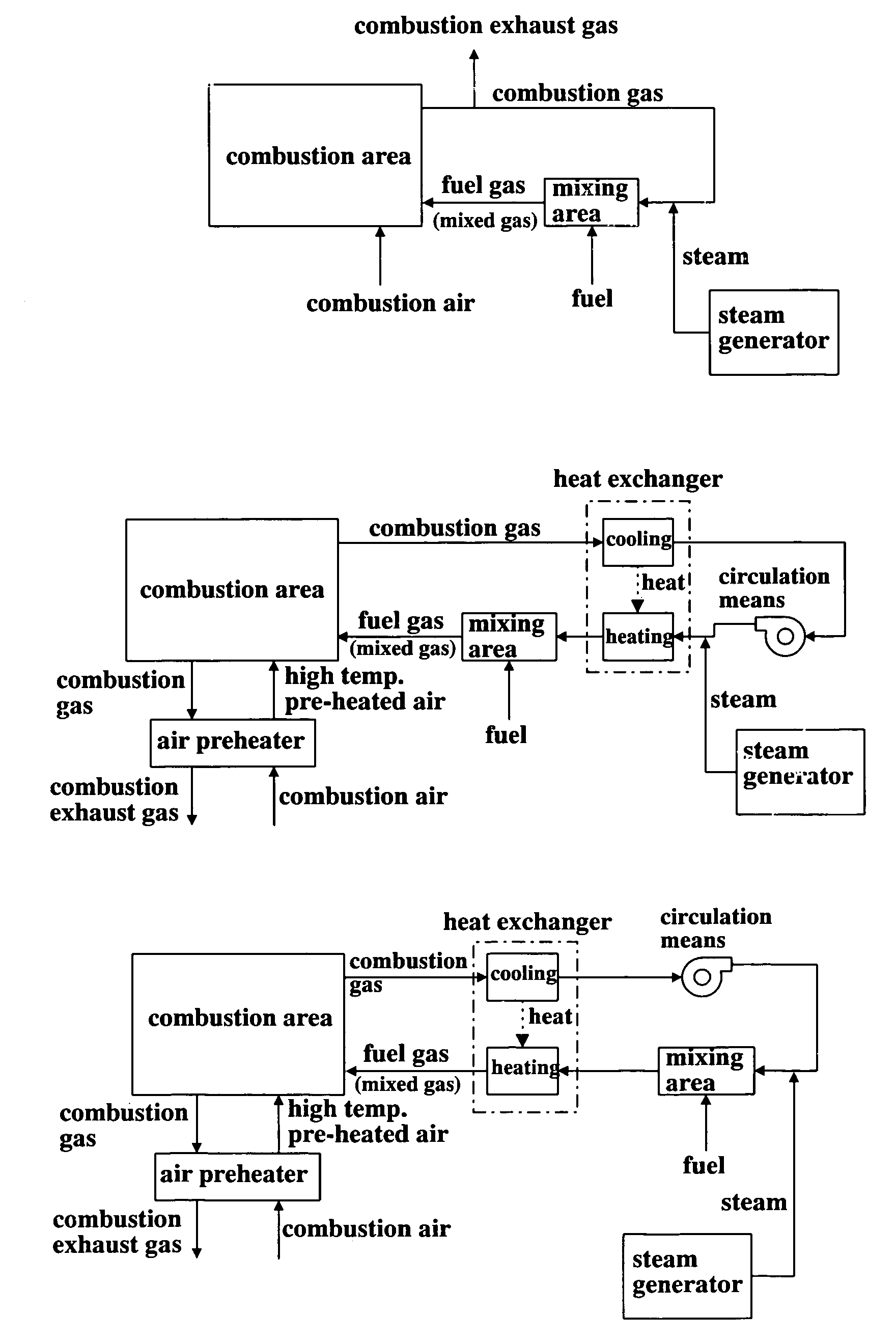

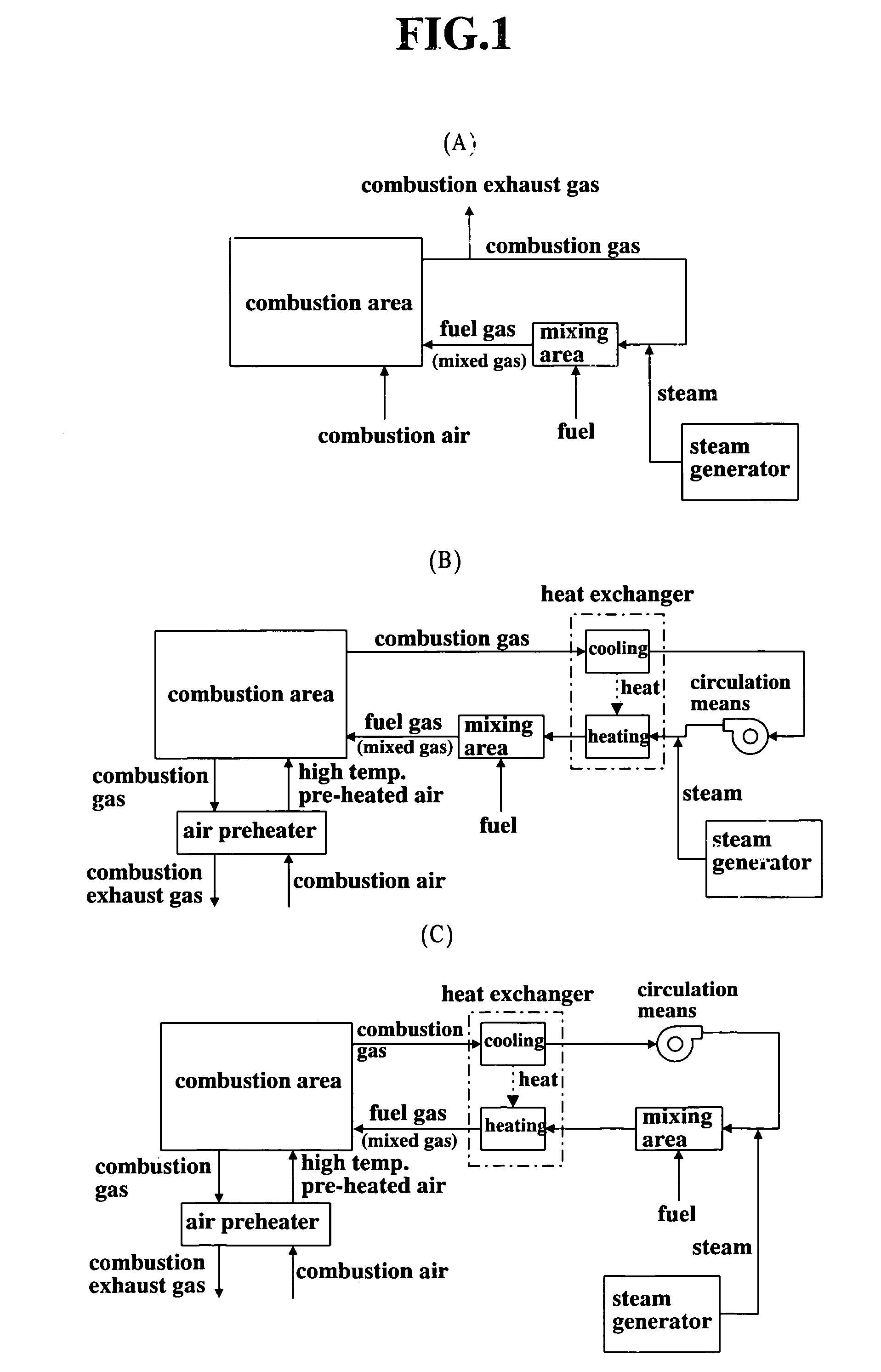

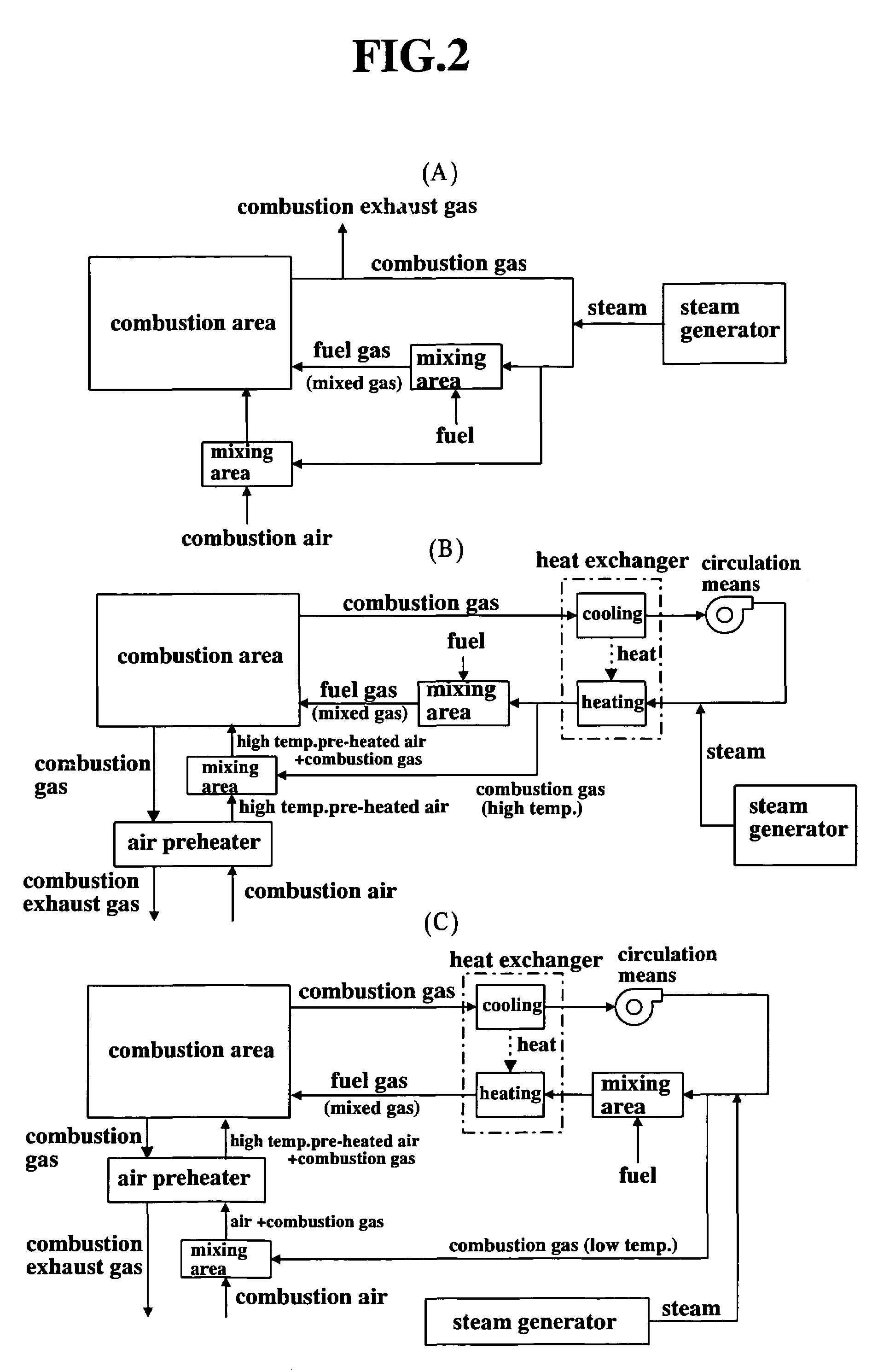

Device and method for feeding fuel

InactiveUS7104784B1Control of combustionReduced flexibilityGaseous fuel pretreatmentCombustion using multiple fuelsCombustion systemProduct gas

The present invention provides a fuel feeding apparatus and method for improving the controllability of mixing process and mixing ratio of fuel and combustion air, and a combustion system and method for effecting new combustion properties. The fuel feeding apparatus of the combustion system has fuel feeding means, combustion gas extraction means, steam supply means, mixing means and fuel gas introduction means. The combustion gas extraction means extracts combustion gas of a combustion area therefrom. The mixing means mixes the fuel of fuel feeding means with at least one of combustion gas extracted from the furnace and steam of a steam generator. The fuel gas introduction means introduces a mixed fluid of combustion gas, steam and fuel to the combustion area as a fuel gas, and allows the fuel gas to be mixed with the combustion air. A step of mixing the fuel with the combustion gas after extracted from the furnace and a step of mixing the fuel gas with the combustion air are stepwisely carried out, so that the controllability of mixing process and ratio of the air and fuel is improved. Such a control of fuel gas flow enables control of characteristics of flame and production of flame with new properties in the combustion area.

Owner:NFK HLDG

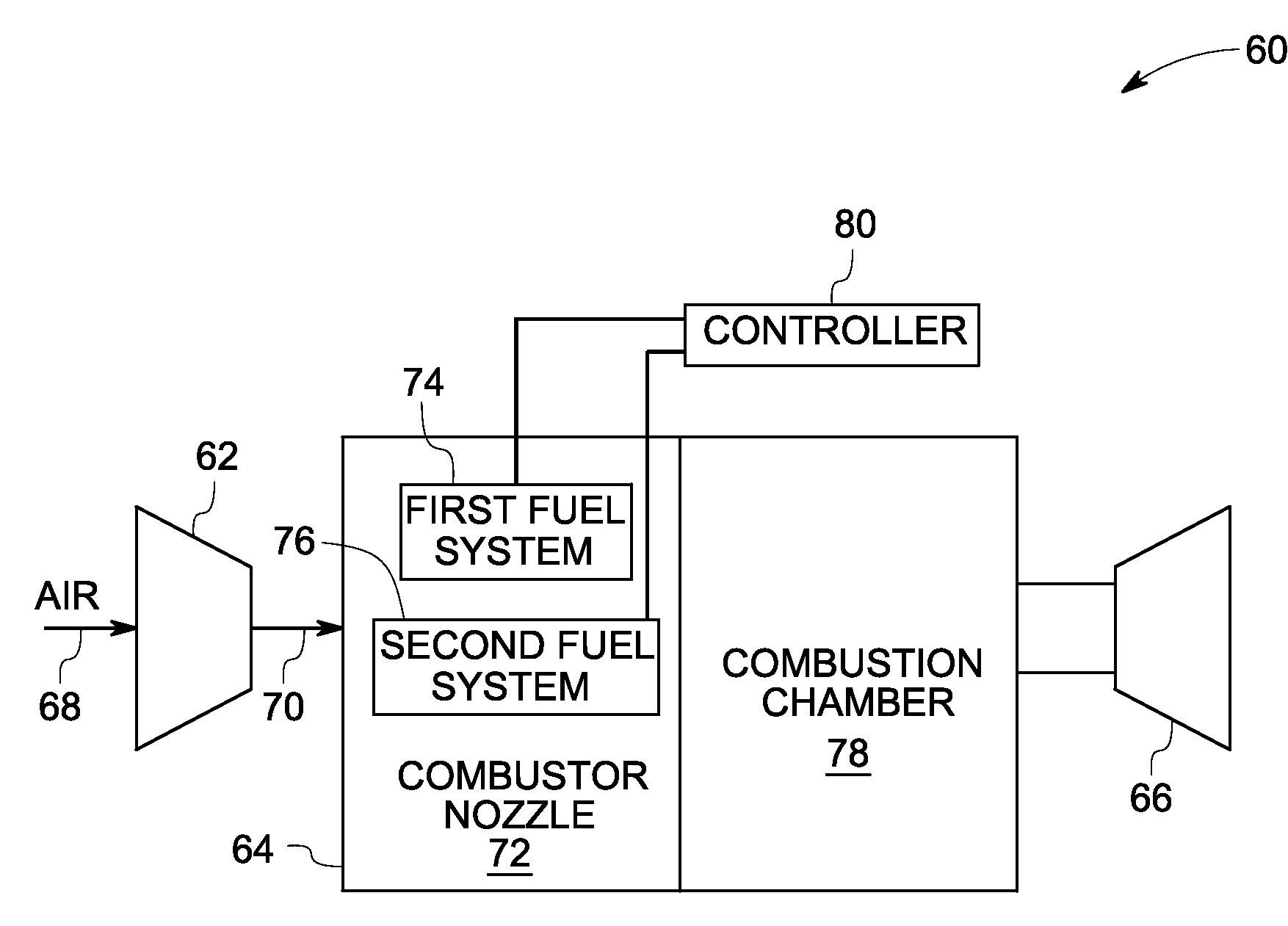

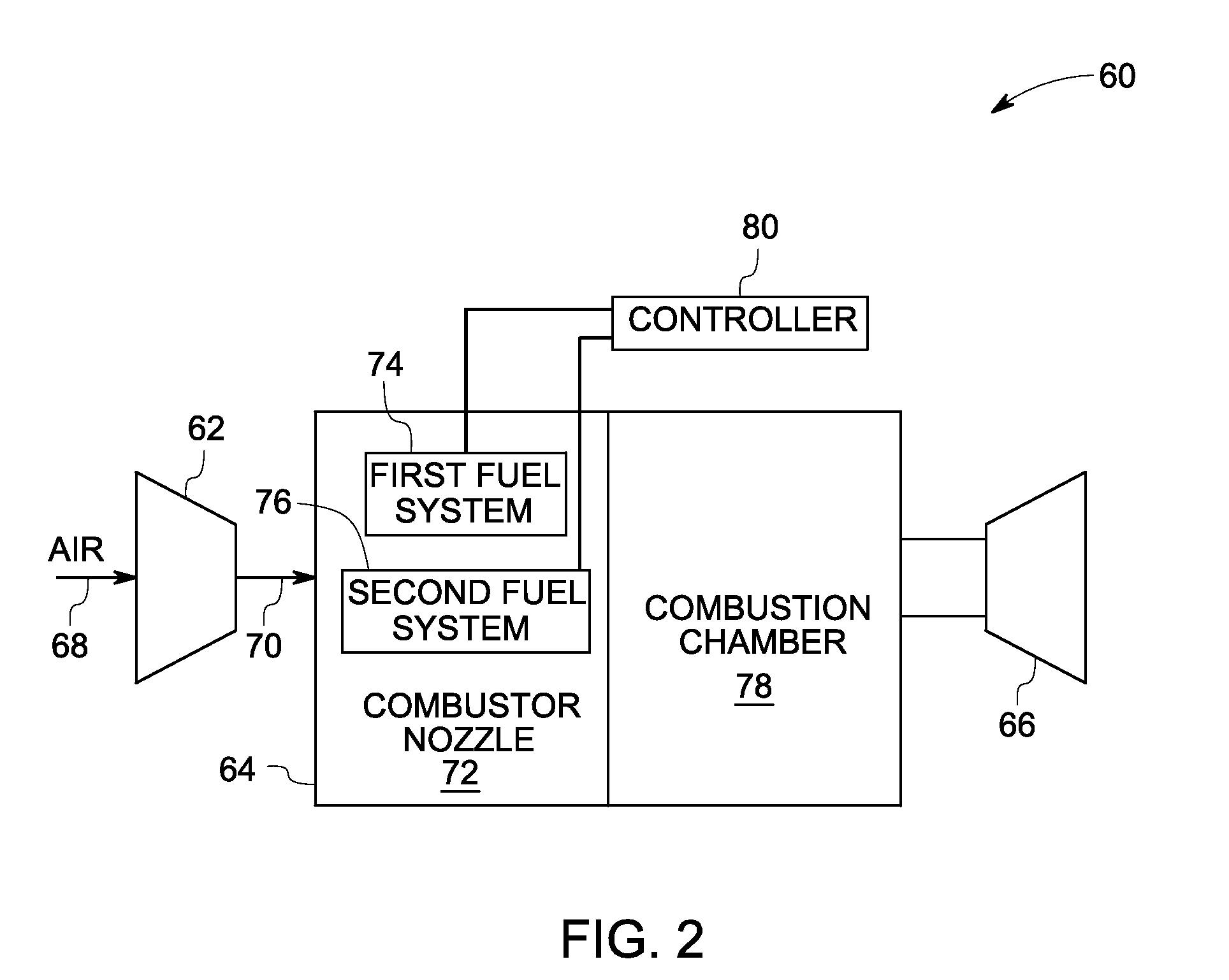

Combustor nozzle for a fuel-flexible combustion system

A combustor nozzle is provided. The combustor nozzle includes a first fuel system configured to introduce a syngas fuel into a combustion chamber to enable lean premixed combustion within the combustion chamber and a second fuel system configured to introduce the syngas fuel, or a hydrocarbon fuel, or diluents, or combinations thereof into the combustion chamber to enable diffusion combustion within the combustion chamber.

Owner:NUOVO PIGNONE TECH SRL

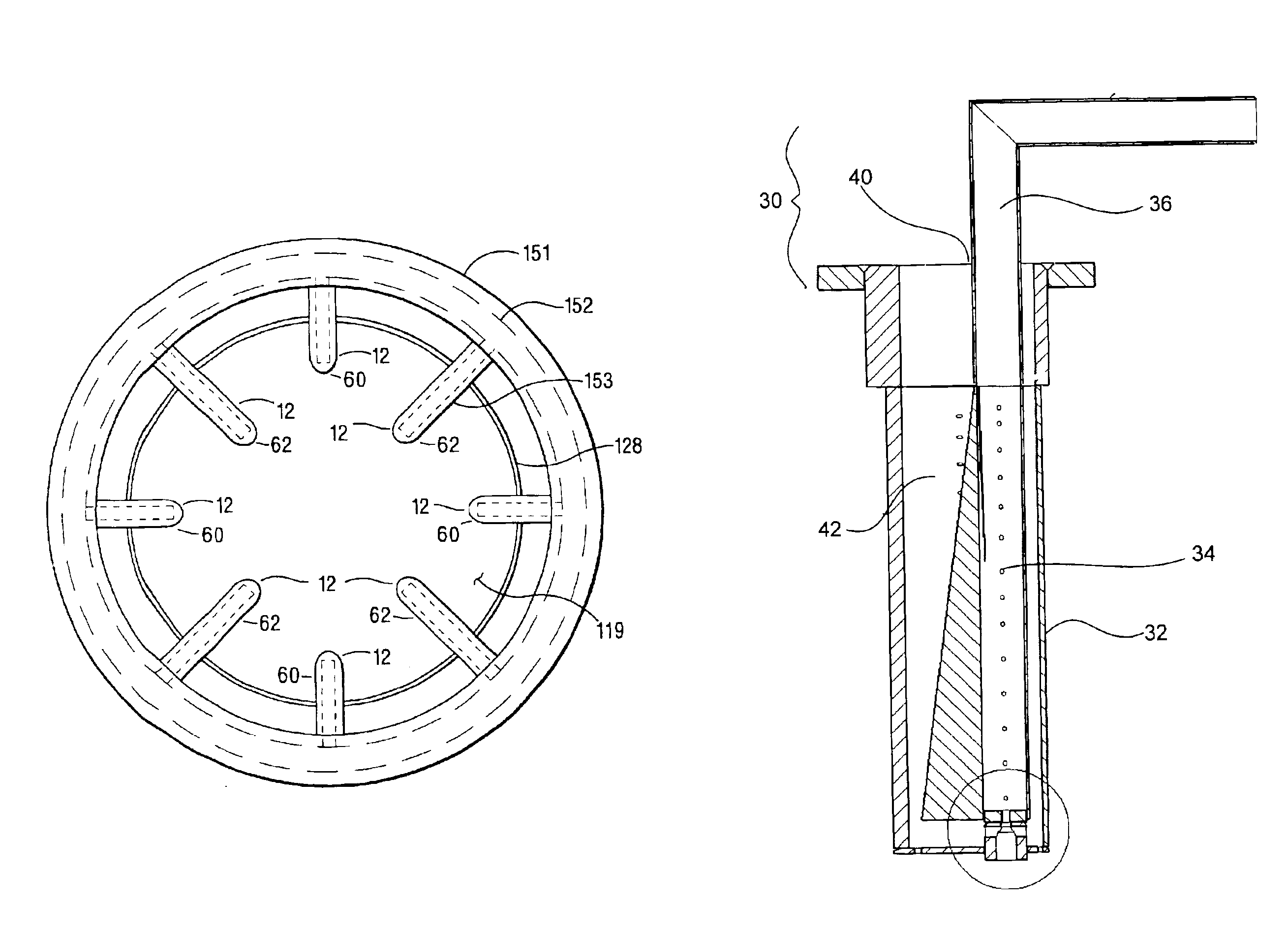

Rich quick mix combustion system

ActiveUS7185497B2Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustion systemEngineering

A premix chamber for a combustor of a gas turbine engine comprises a cylindrical chamber having a premix chamber wall, the cylindrical chamber having a chamber inlet end longitudinally separated from a chamber outlet end along a central axis, a chamber inlet plate in communication with the premix chamber wall at the chamber inlet end, the chamber inlet plate having a fuel nozzle inlet hole disposed through the chamber inlet plate, the chamber inlet plate further comprising a plurality of swirler passages disposed through the chamber inlet plate, and the chamber outlet end being open. A method of producing turbine gas is also disclosed.

Owner:HONEYWELL INT INC

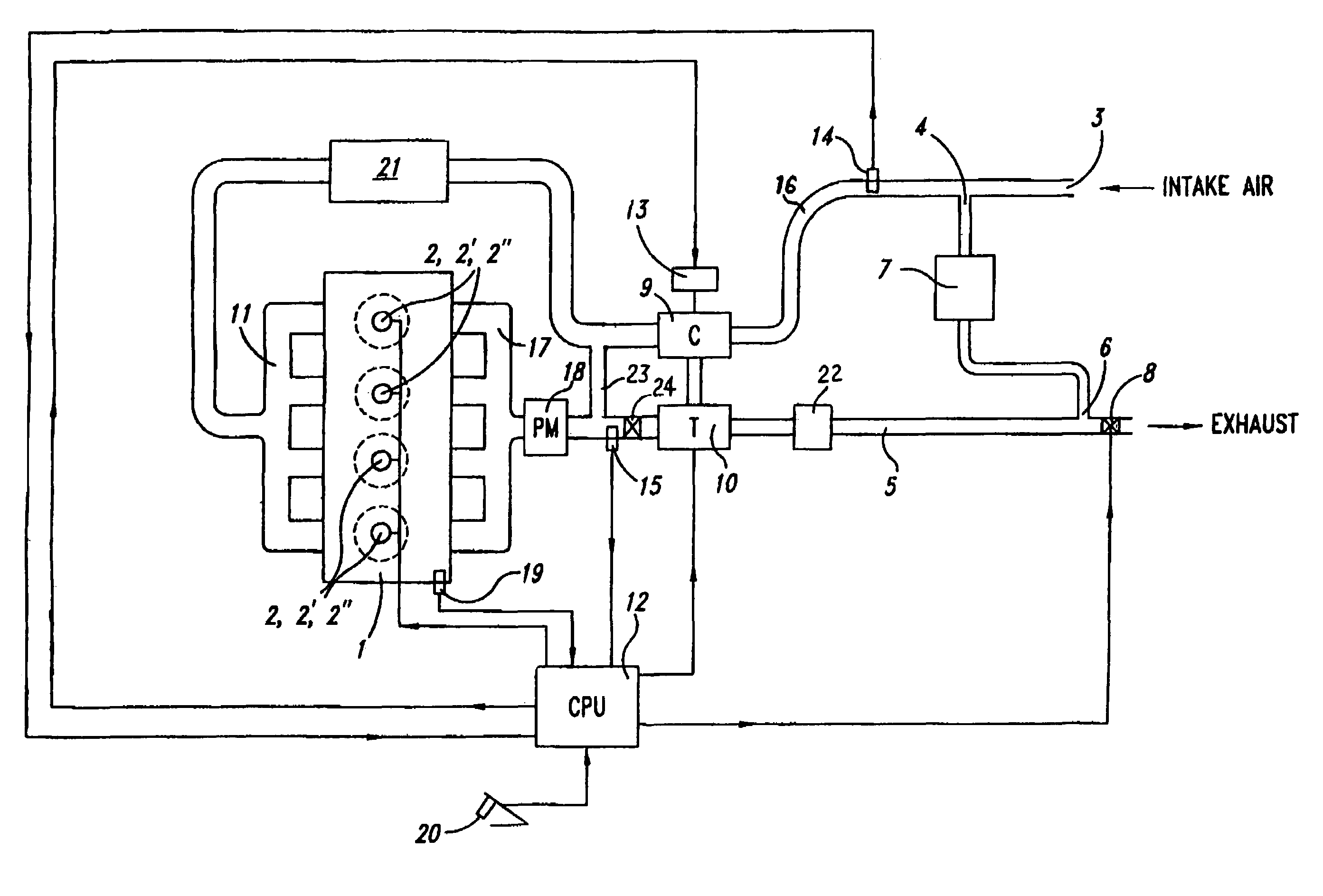

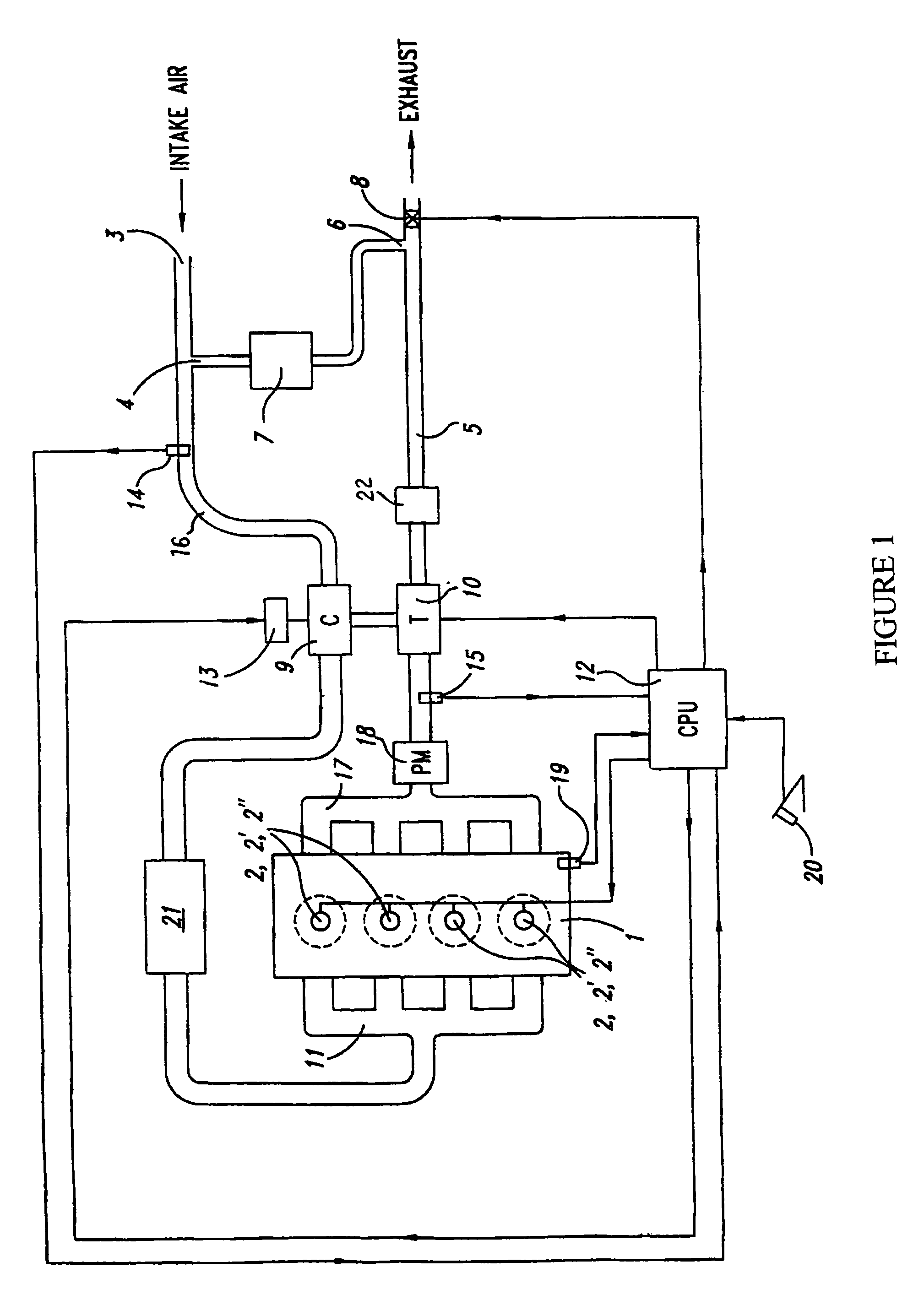

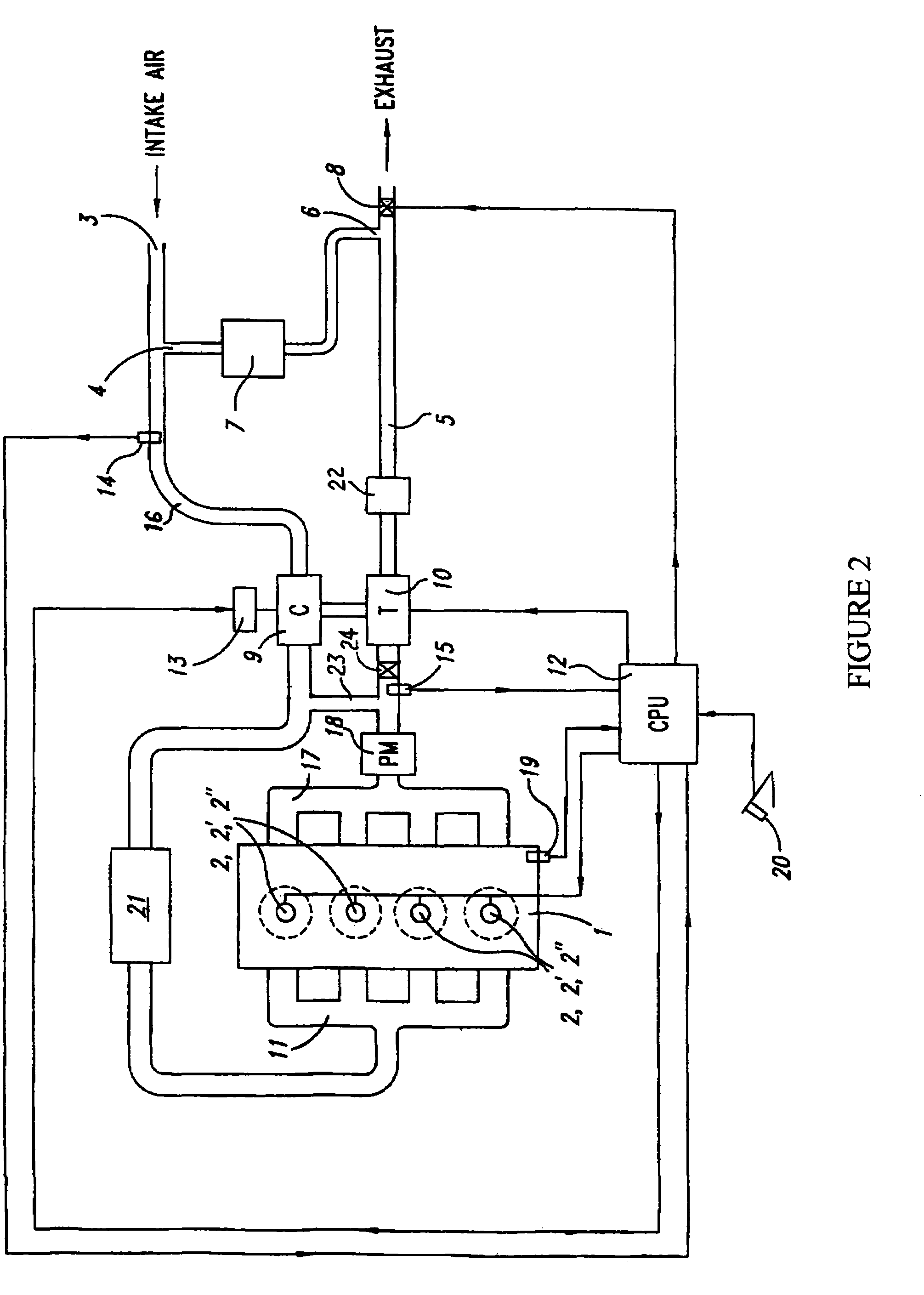

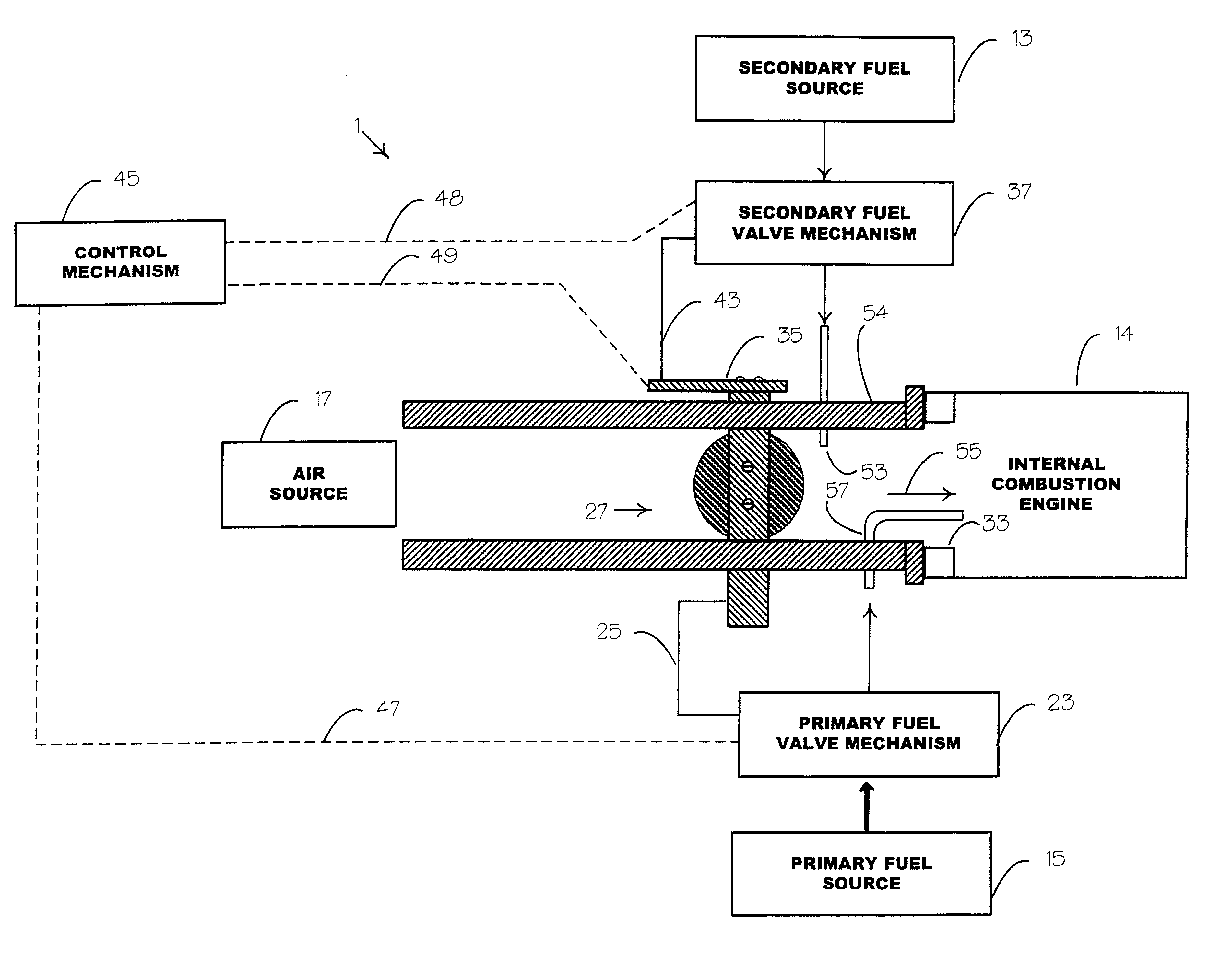

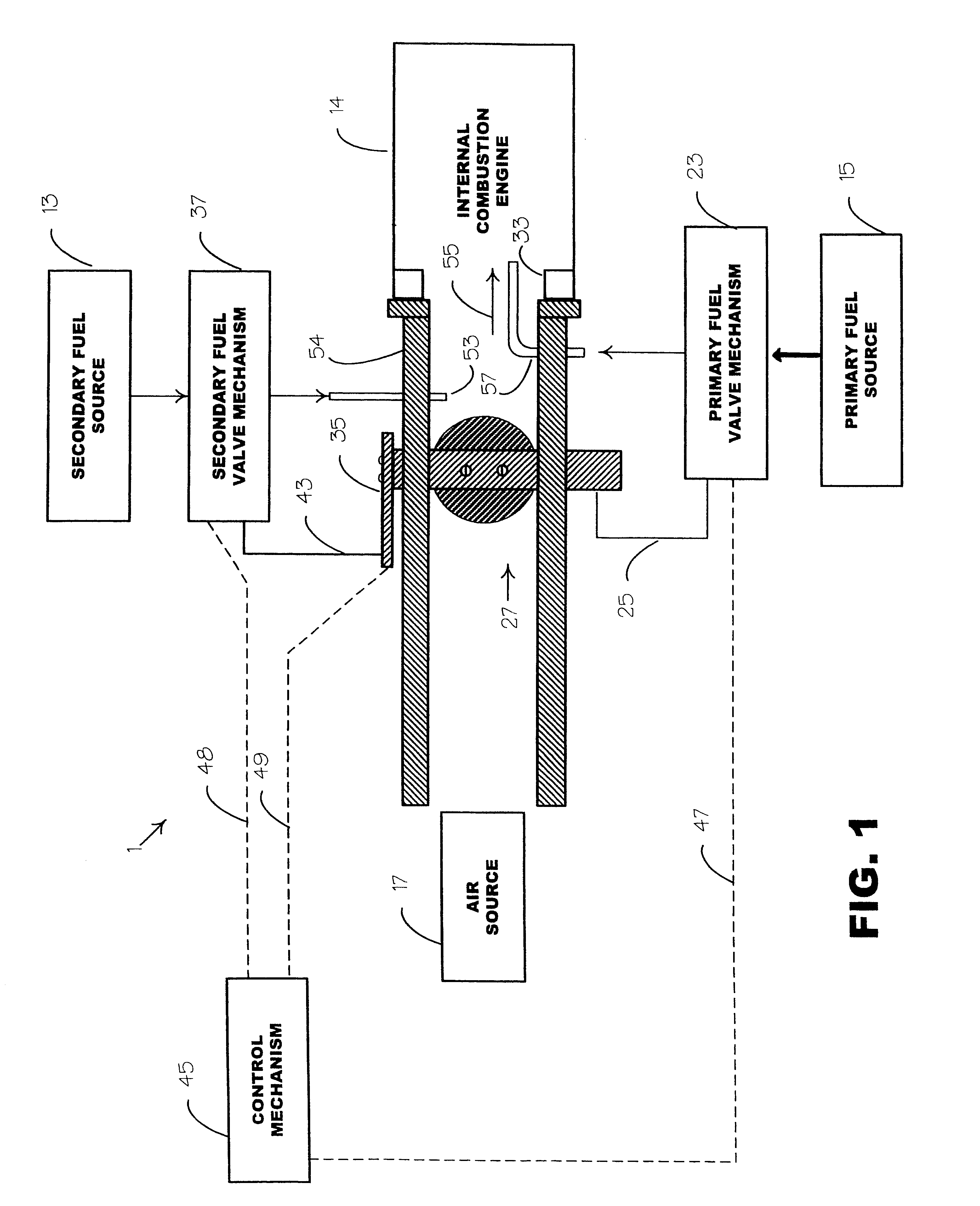

Control methods for low emission internal combustion system

InactiveUS7681394B2Cost-effectiveMaintaining NOx emissionsElectrical controlNon-fuel substance addition to fuelCombustion systemEngineering

Owner:US EPA OFFICE OF GENERAL COUNSEL UNITED STATES OF AMERICA THE

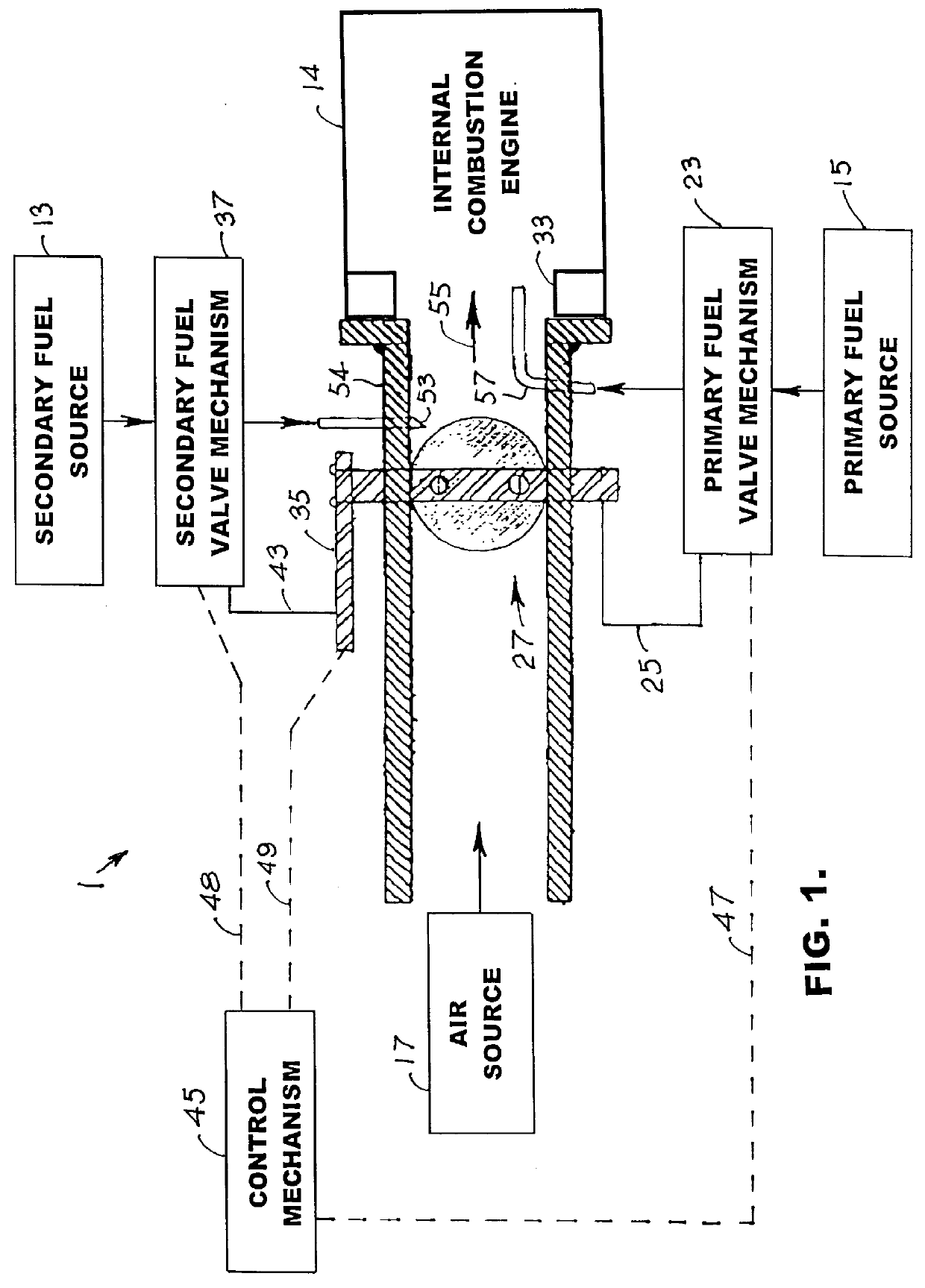

Internal combustion system using acetylene fuel

InactiveUS6076487AInternal combustion piston enginesNon-fuel substance addition to fuelCarbon chainInternal combustion engine

An environmentally clean dual fuel for an internal combustion engine, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C20 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel. The dual fuel, internal combustion system, which generally utilizes a two-stage process for start-up and operation and can be operated with air- or liquid-cooling, is environmentally clean with hydrocarbon, CO, NOx, and SOx emissions substantially eliminated.

Owner:GOTEC

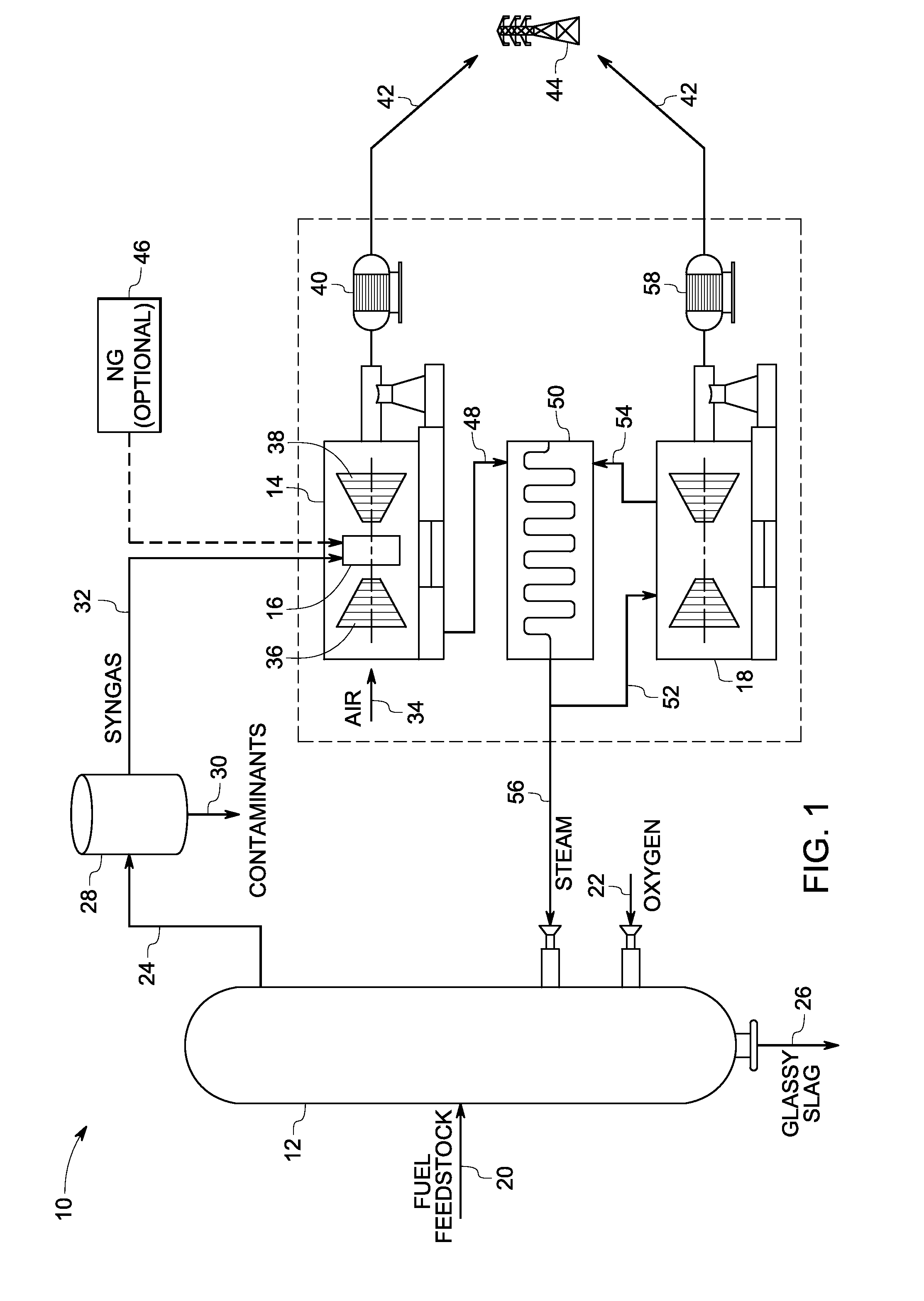

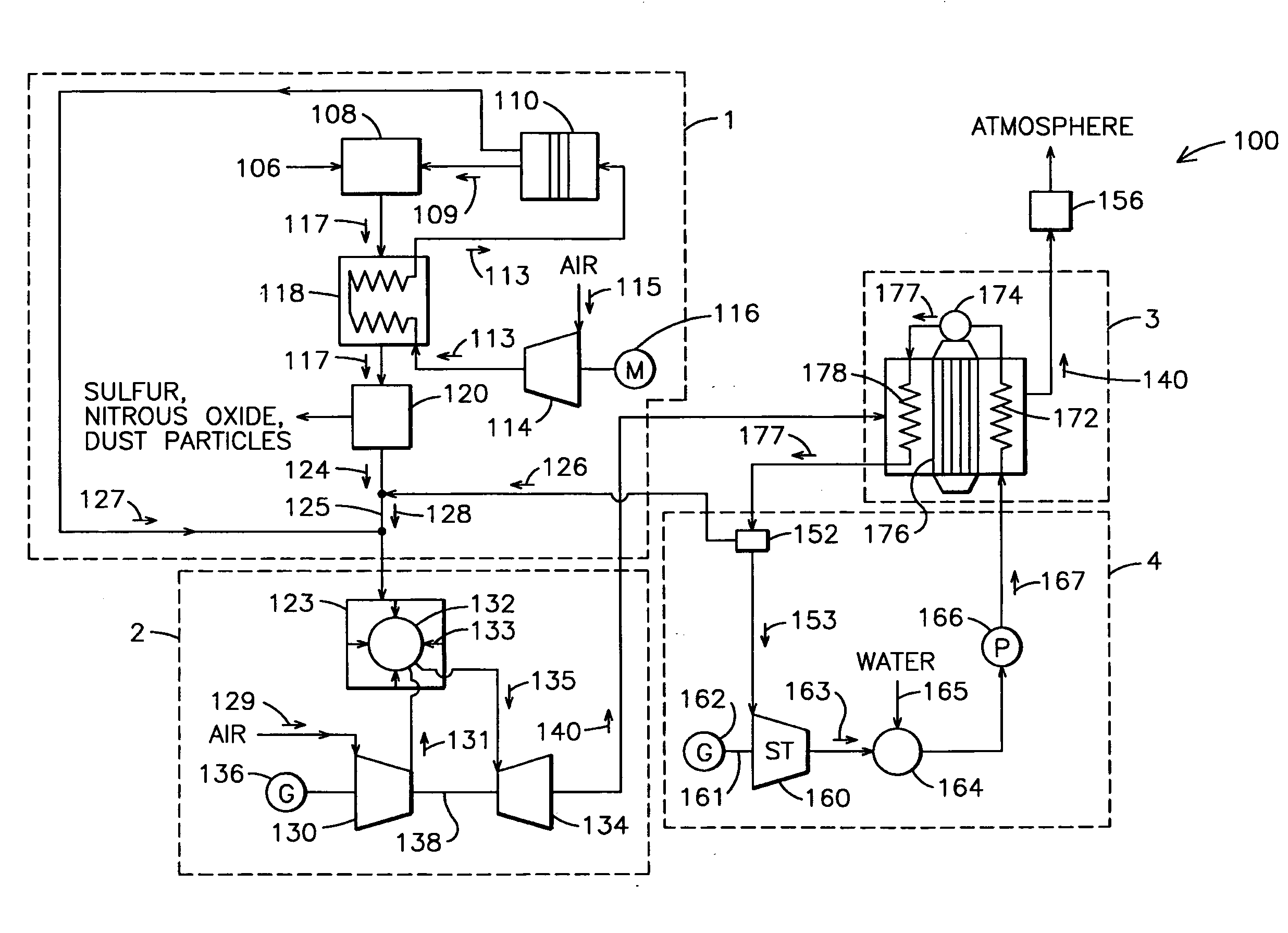

System and method for oxygen separation in an integrated gasification combined cycle system

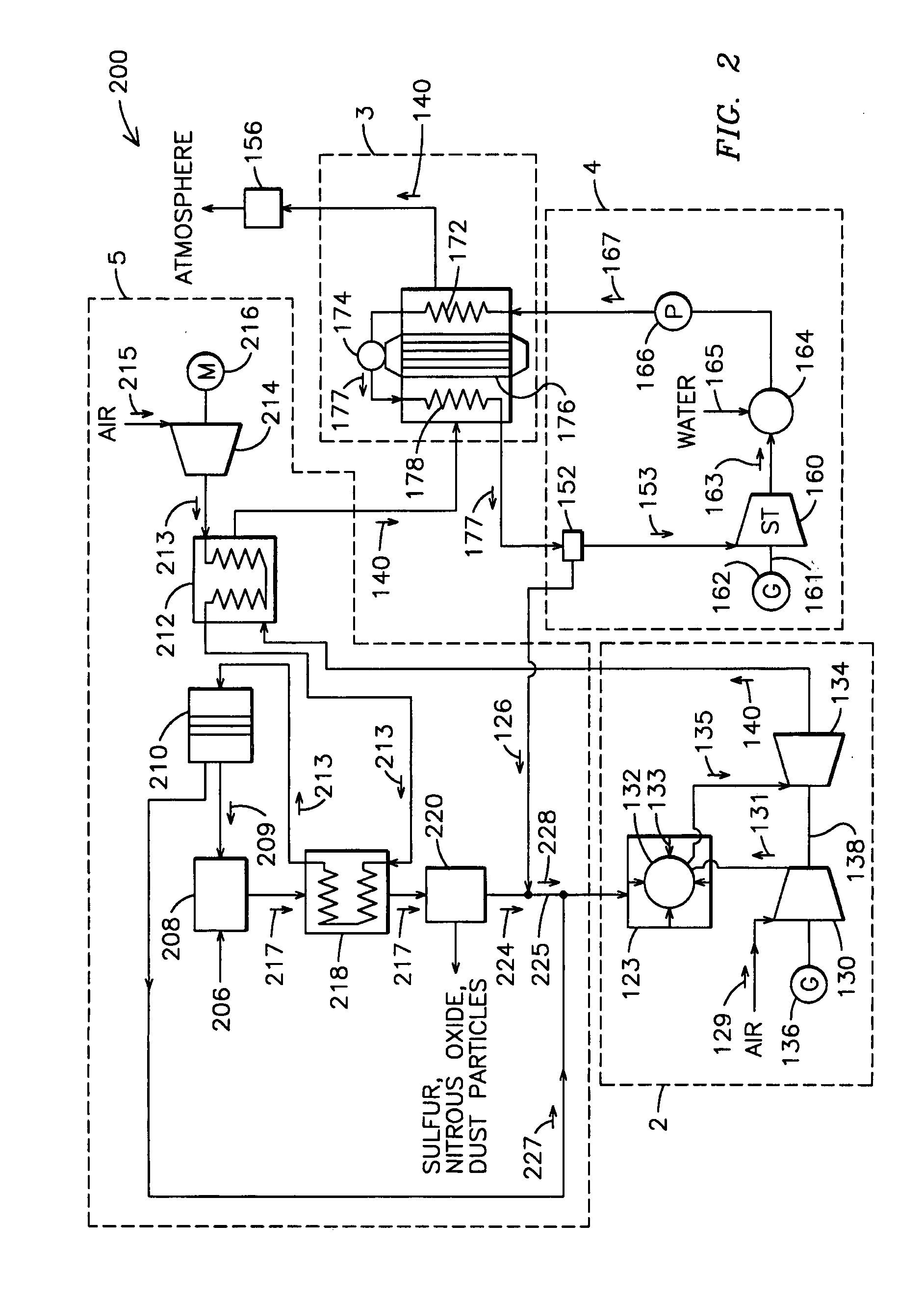

An integrated gasification combined cycle power generation system (100). In one embodiment, shown in FIG. 1, a gasifier (108) is configured to generate synthetic gas (117) from a carbonaceous material (106) and an oxygen supply (109) with a cleaning stage (120) positioned to receive synthetic gas (117) from the gasifier (108) and remove impurities therefrom. A gas turbine combustion system (2) including a turbine (123) is configured to receive fuel (128) from the gasifier (108) and a first air supply (131) from a first air compressor (130). A steam turbine system (4) is configured to generate power with heat recovered from exhaust (140) generated by the gas turbine system (2) and an ion transport membrane air separation unit (110) includes a second air compressor (114) for generating a second air supply (113). A first heat exchanger (118) is configured to cool the synthetic gas (117) prior to removal of impurities in the cleaning stage (120) by flowing the second air supply (113) through the first heat exchanger (118) so that the second air supply (113) receives heat from the synthetic gas (117).

Owner:SIEMENS ENERGY INC

Flamesheet combustor

InactiveUS6935116B2Well mixedEmission reductionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemCombustion chamber

A gas turbine combustion system having reduced emissions and improved flame stability at multiple load conditions is disclosed. The improved combustion system accomplishes this through complete premixing, a plurality of fuel injector locations, combustor geometry, and precise three dimensional staging between fuel injectors. Axial, radial, and circumferential fuel staging is utilized including fuel injection proximate air swirlers. Furthermore, strong recirculation zones are established proximate the introduction of fuel and air premixture from different stages to the combustion zone. The combination of the strong recirculation zones, efficient premixing, and staged fuel flow thereby provide the opportunity to produce low emissions combustion at various load conditions.

Owner:H2 IP UK LTD

METHODS AND SYSTEMS TO FACILITATE REDUCING NOx EMISSIONS IN COMBUSTION SYSTEMS

A method for assembling a gas turbine combustor system is provided. The method includes providing a combustion liner including a center axis, an outer wall, a first end, and a second end. The outer wall is orientated substantially parallel to the center axis. The method also includes coupling a transition piece to the liner second end. The transition piece includes an outer wall. The method further includes coupling a plurality of lean-direct injectors along at least one of the liner outer wall and the transition piece outer wall such that the injectors are spaced axially apart along the wall.

Owner:GENERAL ELECTRIC CO

Internal combustion system adapted for use of a dual fuel composition including acetylene

InactiveUS6575147B2Easy to operateImprove performanceNon-fuel substance addition to fuelInternal combustion piston enginesCarbon chainMineral spirit

An internal combustion engine adapted to use an environmentally clean multi-fuel composition, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C12 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate, ethyl malate, butyl malate, and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel.

Owner:GOTEC INC

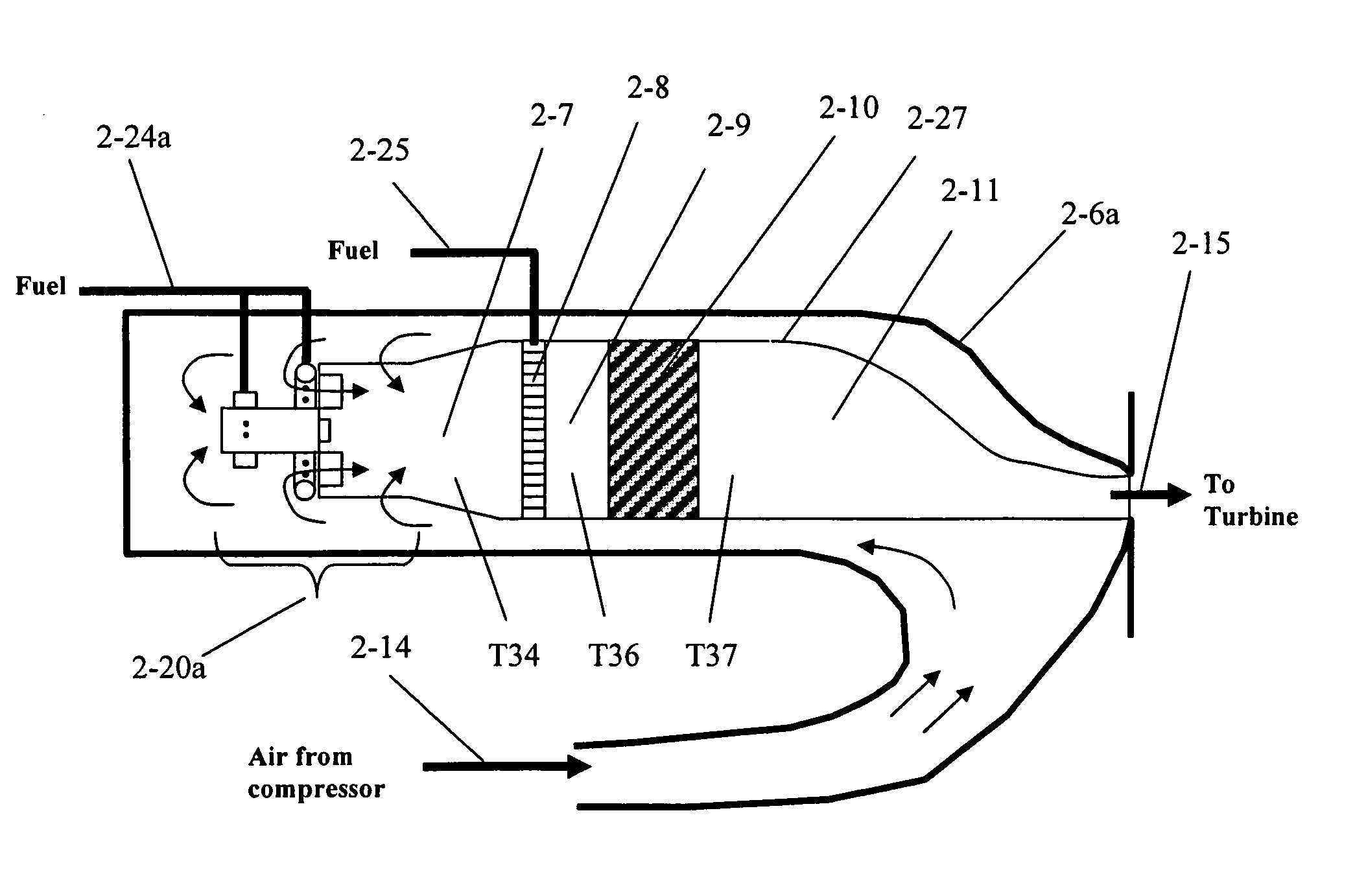

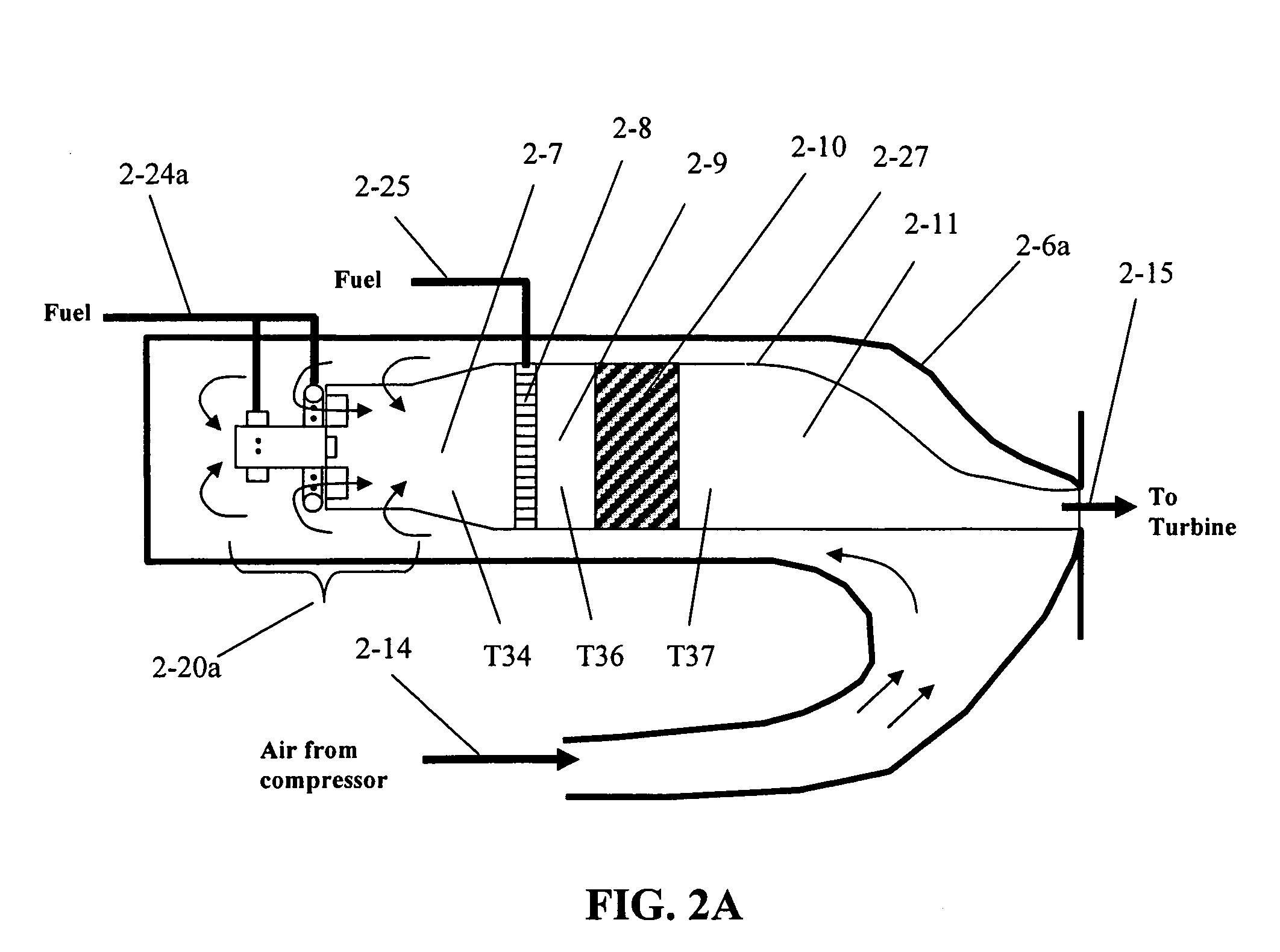

Dynamic control system and method for multi-combustor catalytic gas turbine engine

InactiveUS7152409B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemControl system

According to one aspect, a method of controlling a multi-combustor catalytic combustion system is provided for determining a characteristic of a fuel-air mixture downstream of a preburner associated with a catalytic combustor and adjusting the fuel flow to the preburner based on the characteristic. The characteristic may include, for example, a measurement of the preburner or catalyst outlet temperature or a determination of the position of the homogeneous combustion wave in the burnout zone of the combustor.

Owner:KAWASAKI HEAVY IND LTD

Method and system to facilitate combined cycle working fluid modification and combustion thereof

InactiveUS20090193809A1Emission reductionEasy dischargeGas turbine plantsCombined combustion mitigationCombustion systemCombustion chamber

A method of assembling a combustion system includes providing a gas turbine engine that includes a gas turbine section coupled downstream from a combustion chamber and coupling a source of oxygen to the gas turbine engine such that a stream of oxygen discharged from the source facilitates displacing nitrogen in the working fluid of the gas turbine engine and facilitates decreasing emissions generated within the gas turbine engine.

Owner:GENERAL ELECTRIC CO

Reverse-flow gas turbine combustion system

InactiveUS7966822B2Turbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionCombustion systemTurbine

A gas turbine combustion system for burning air and fuel into exhaust gases. The gas turbine combustion system may include a combustor, a turbine nozzle integral with the combustor for providing the air to the combustor, and a fuel injector for providing the fuel to the combustor. The turbine nozzle and the fuel injector are positioned within the combustor such that a mixture of the air and the fuel flows in a first direction and the exhaust gases flow in a second direction.

Owner:GENERAL ELECTRIC CO

Methods for reducing NOx in combustion flue gas using metal-containing additives

InactiveUS6471506B1Simple and inexpensive methodReduce penetrationDispersed particle separationIncinerator apparatusAtmospheric airMolecular nitrogen

Various methods for decreasing the amount of nitrogen oxides released to the atmosphere as a component of combustion gas mixtures are provided. The methods specifically provide for the removal of nitric oxide and nitrogen dioxide (NOx) from gas mixtures emitted from stationary combustion systems. In particular, methods for improving efficiency of nitrogen oxide reduction from combustion systems include injecting metal-containing compounds into the main combustion zone and / or the reburning zone of a combustion system. The metal containing compounds react with active combustion species, and these reactions change radical concentrations and significantly improve NOx conversion to molecular nitrogen. The metal-containing additives can be injected with the main fuel, in the main combustion zone, with secondary or reburning fuel addition, or at several locations in the main combustion zone and reburning zone. Optionally, nitrogenous reducing agents and / or overfire air can be injected downstream to further increase NOx reduction.

Owner:GE ENERGY & ENVIRONMENTAL RES

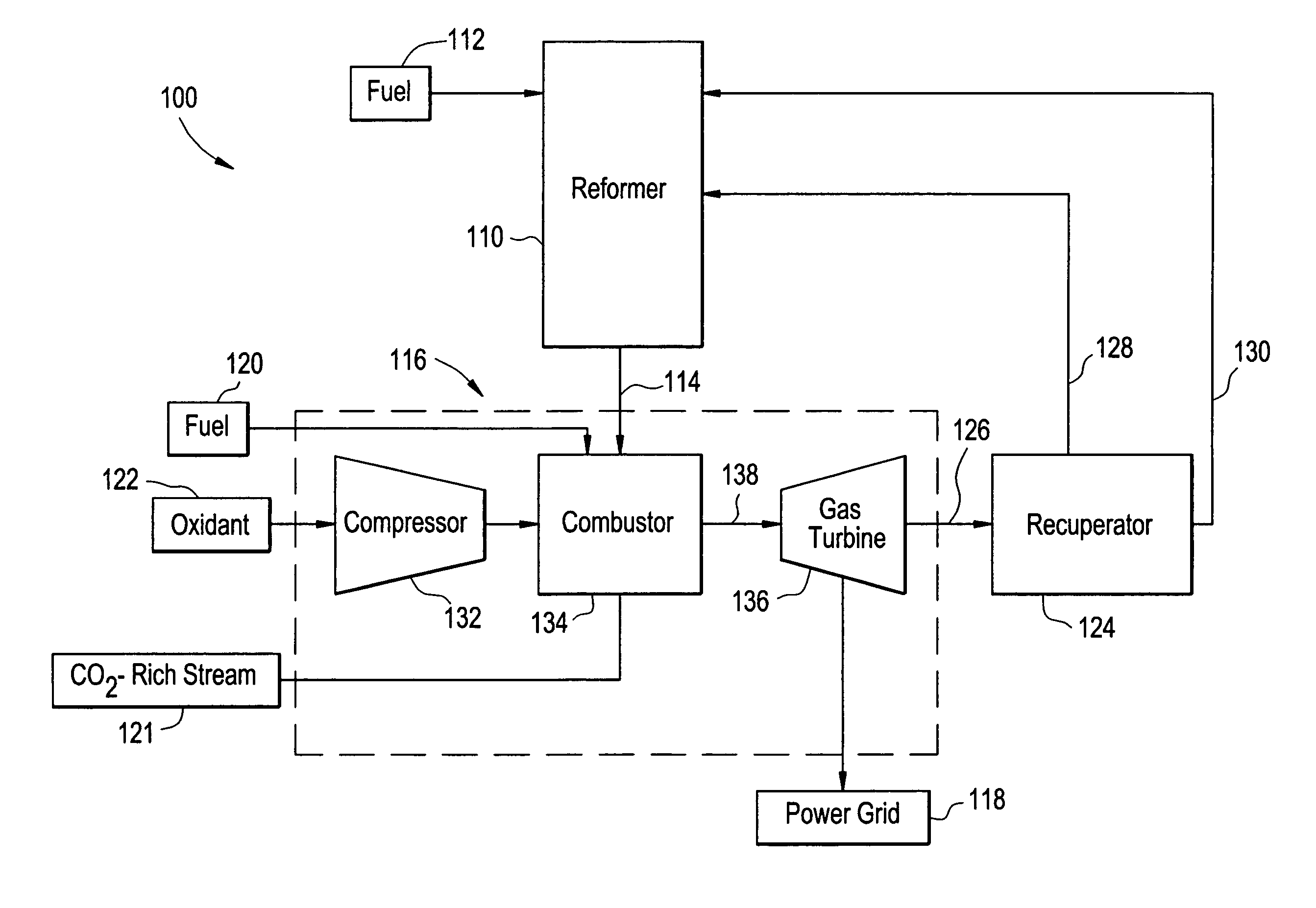

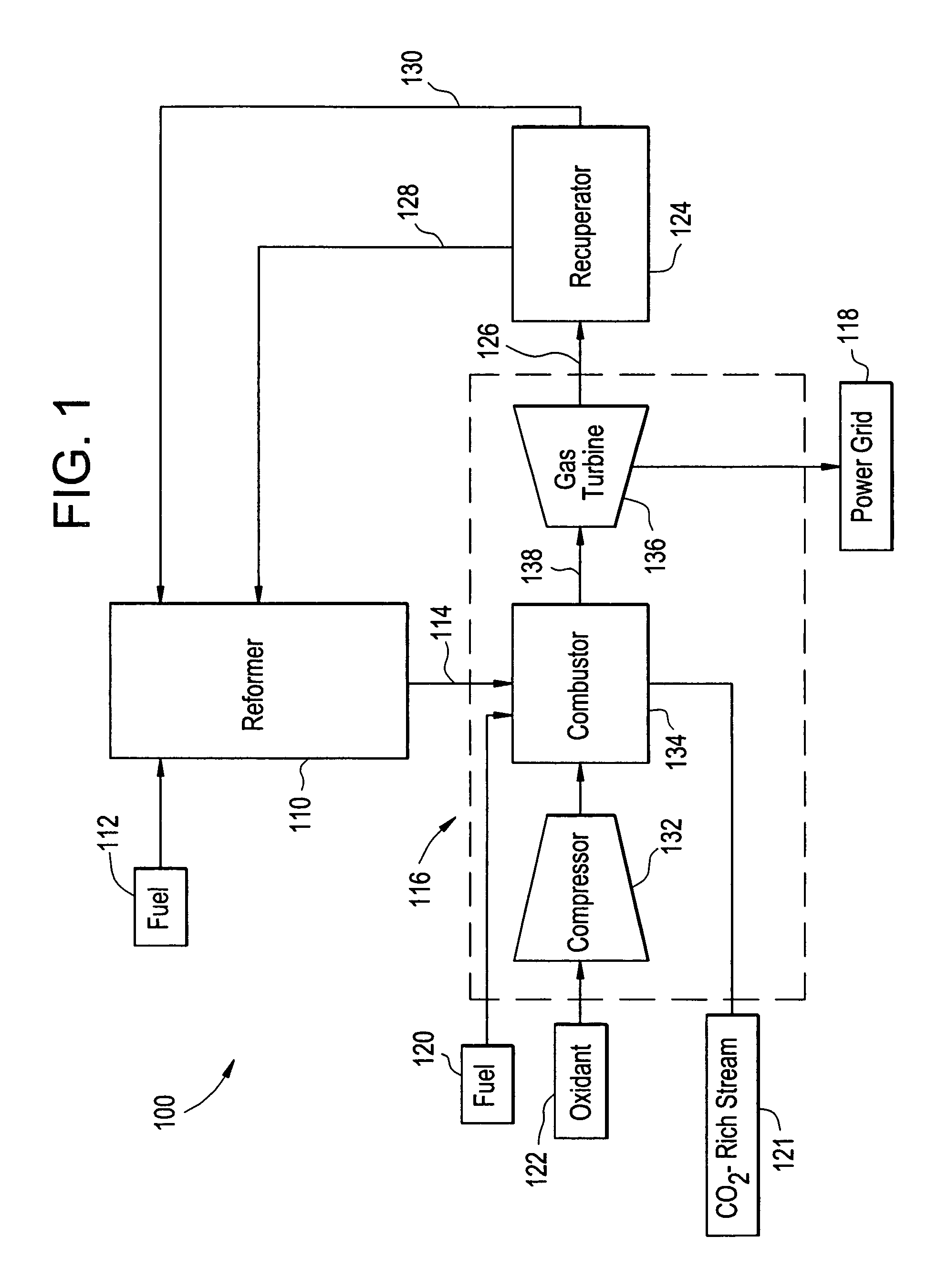

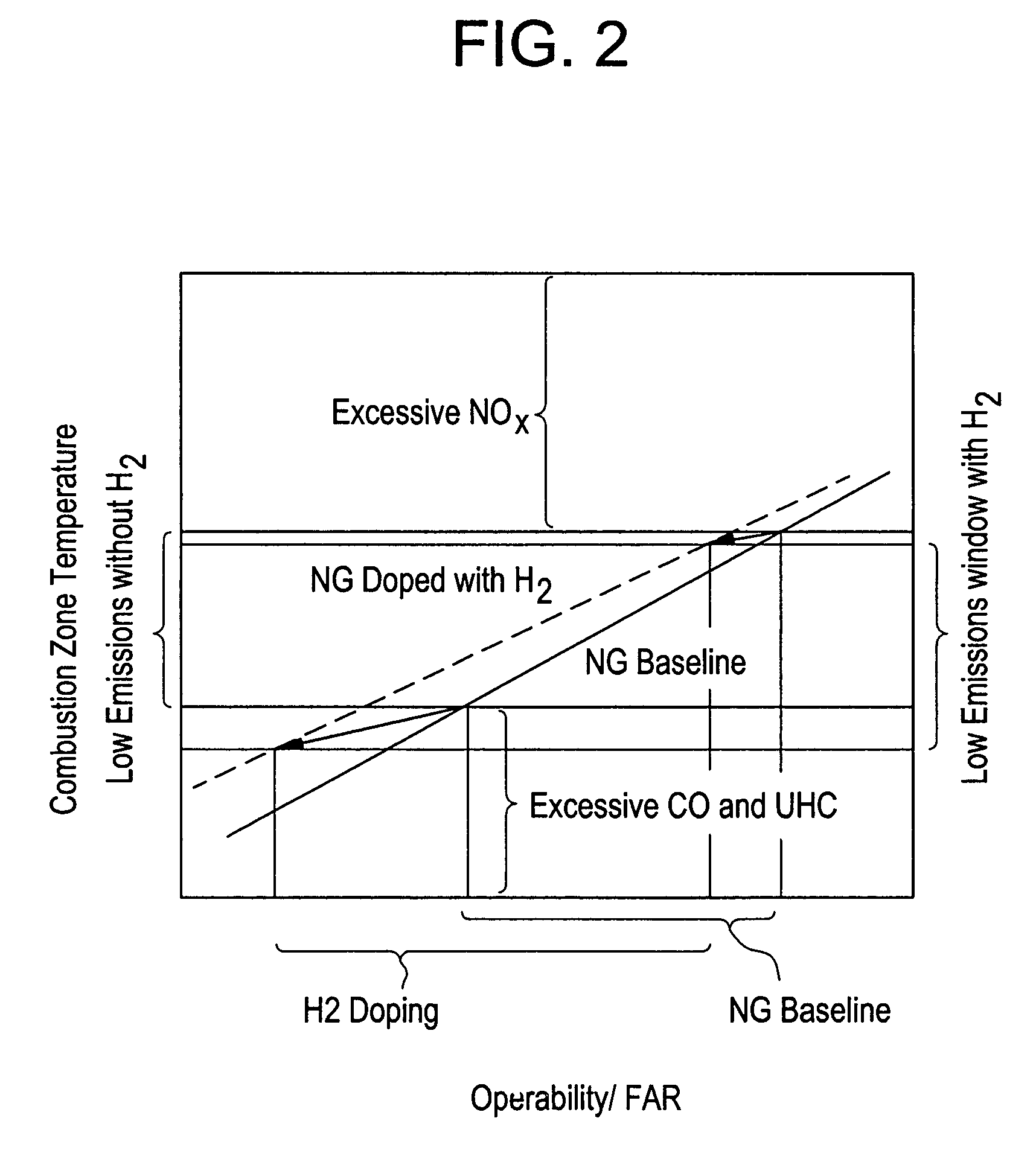

Systems and processes for reducing NOx emissions

A system for reducing NOx emissions, includes a reformer configured to receive a fuel and produce a hydrogen-enriched stream, a combustion system configured to burn the hydrogen enriched-stream and produce electricity and an exhaust stream, and a recuperator configured to recover heat from the exhaust stream, wherein the recovered heat is recycled back to the reformer.

Owner:GENERAL ELECTRIC CO

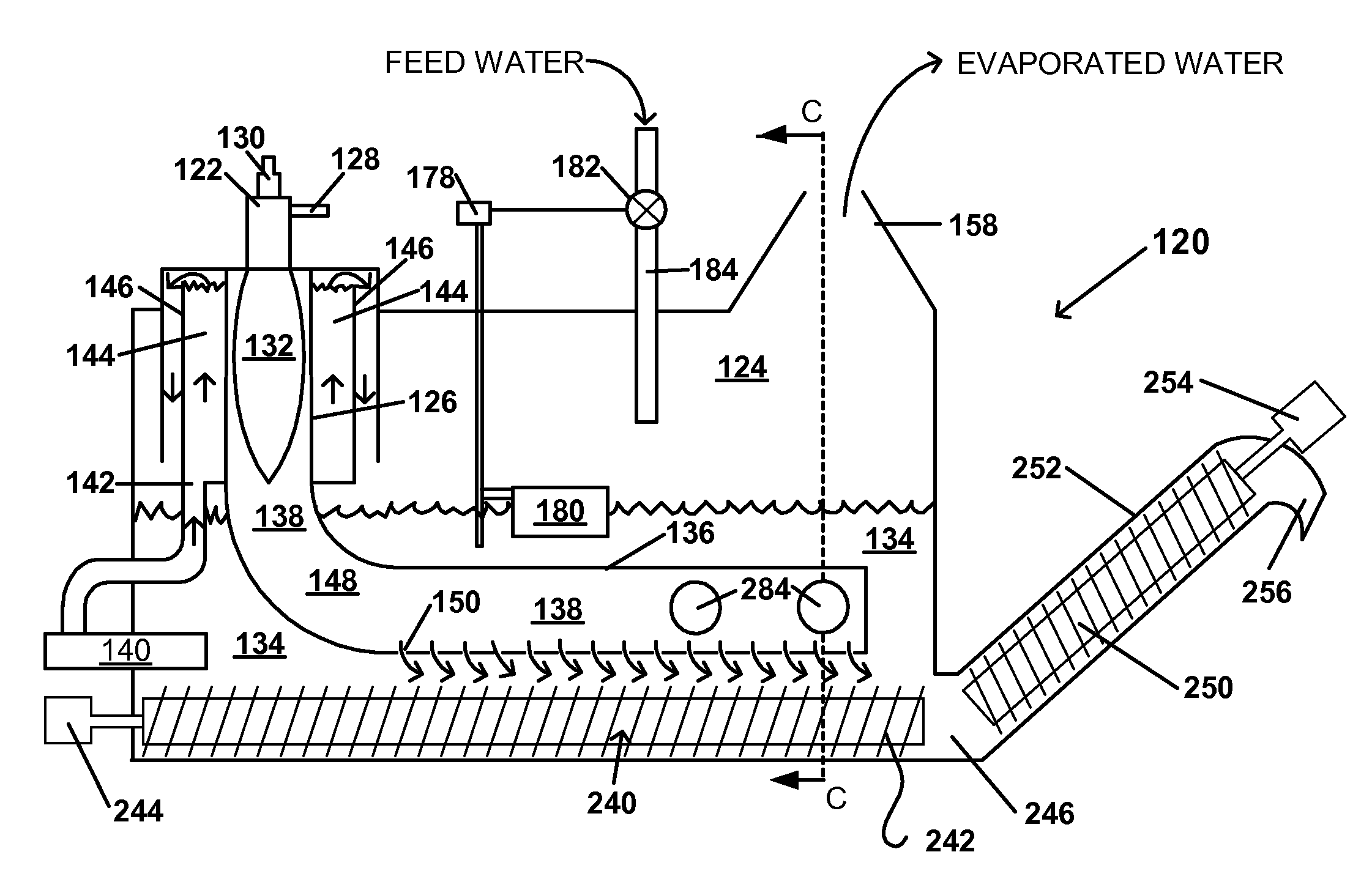

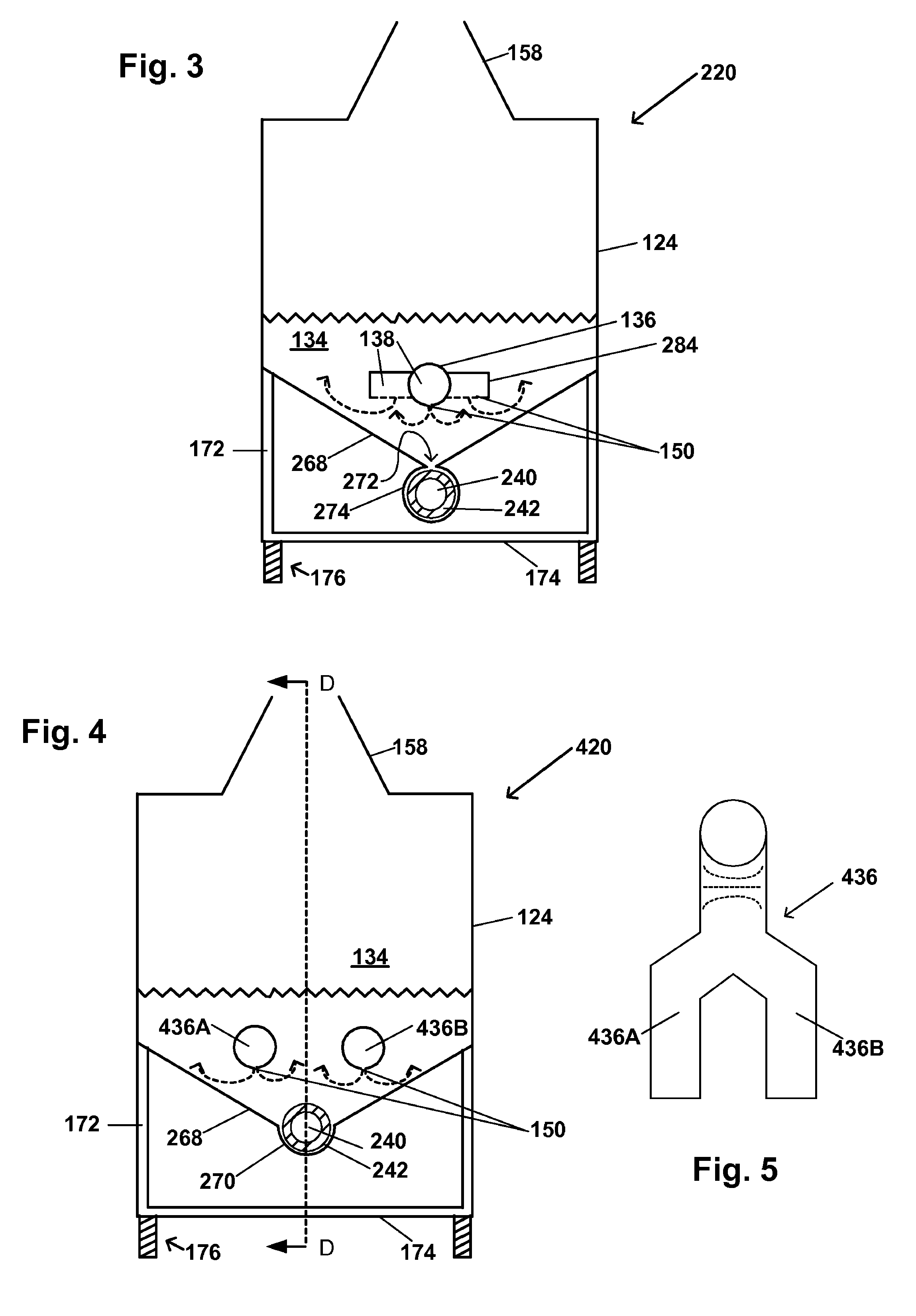

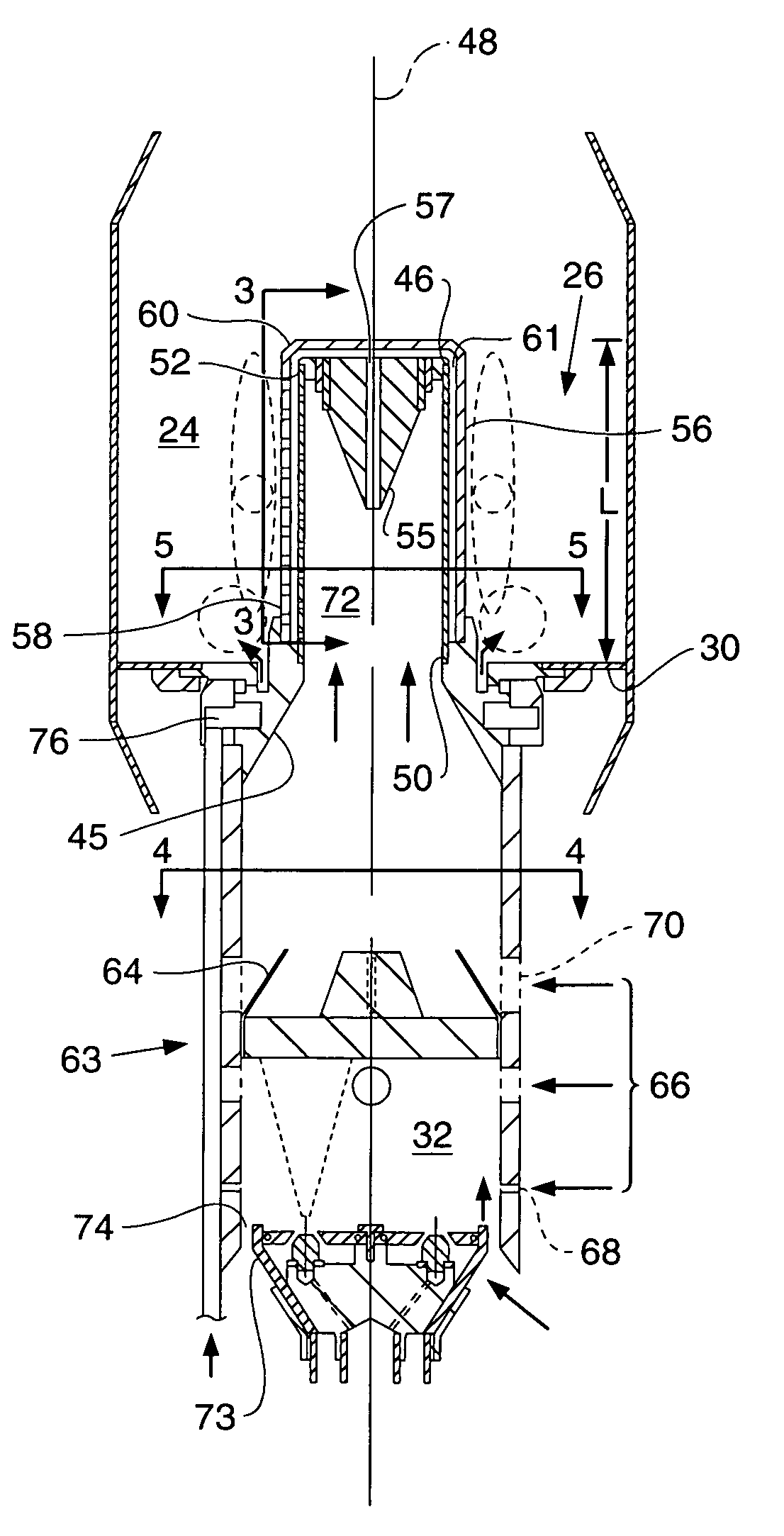

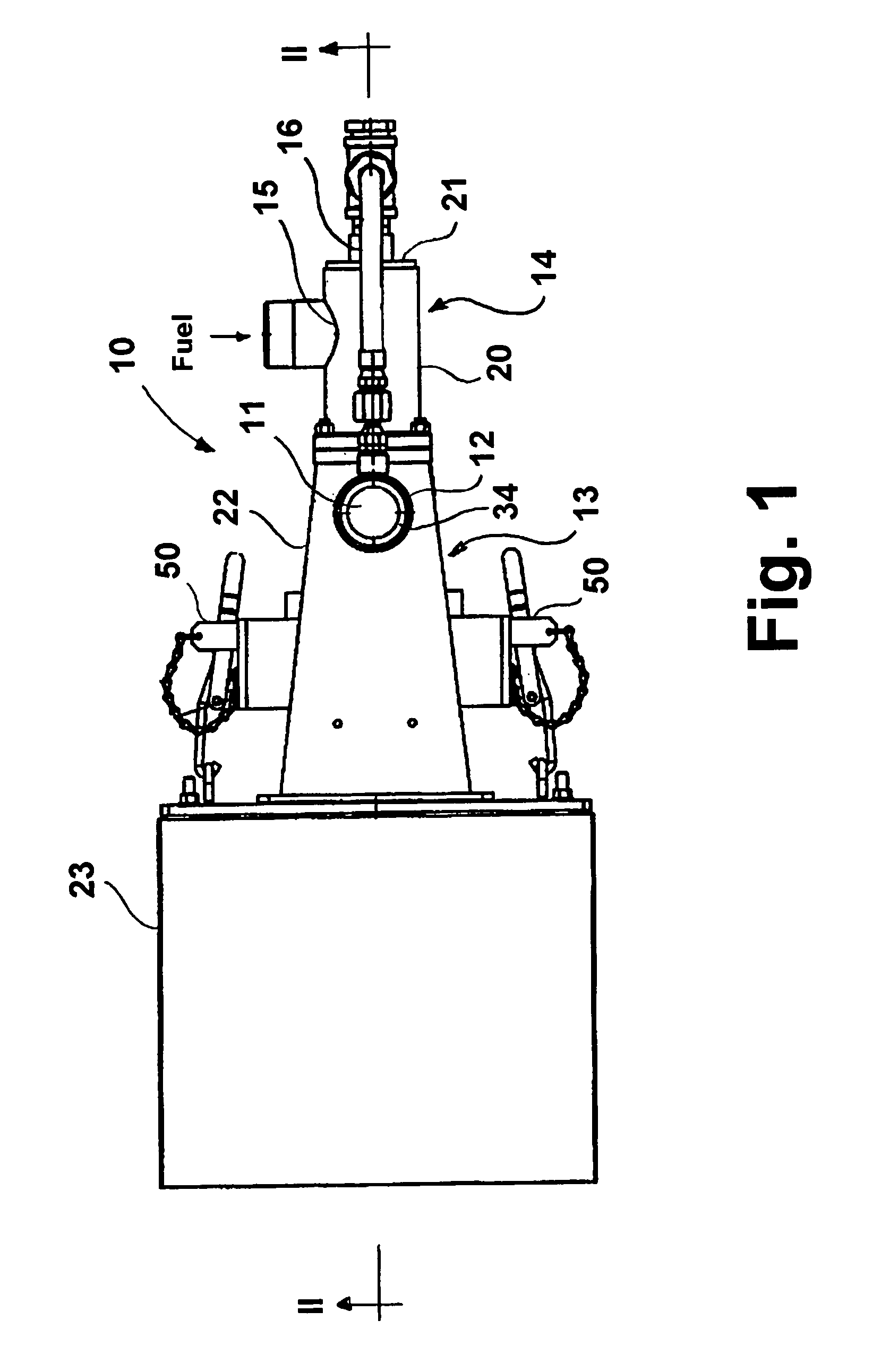

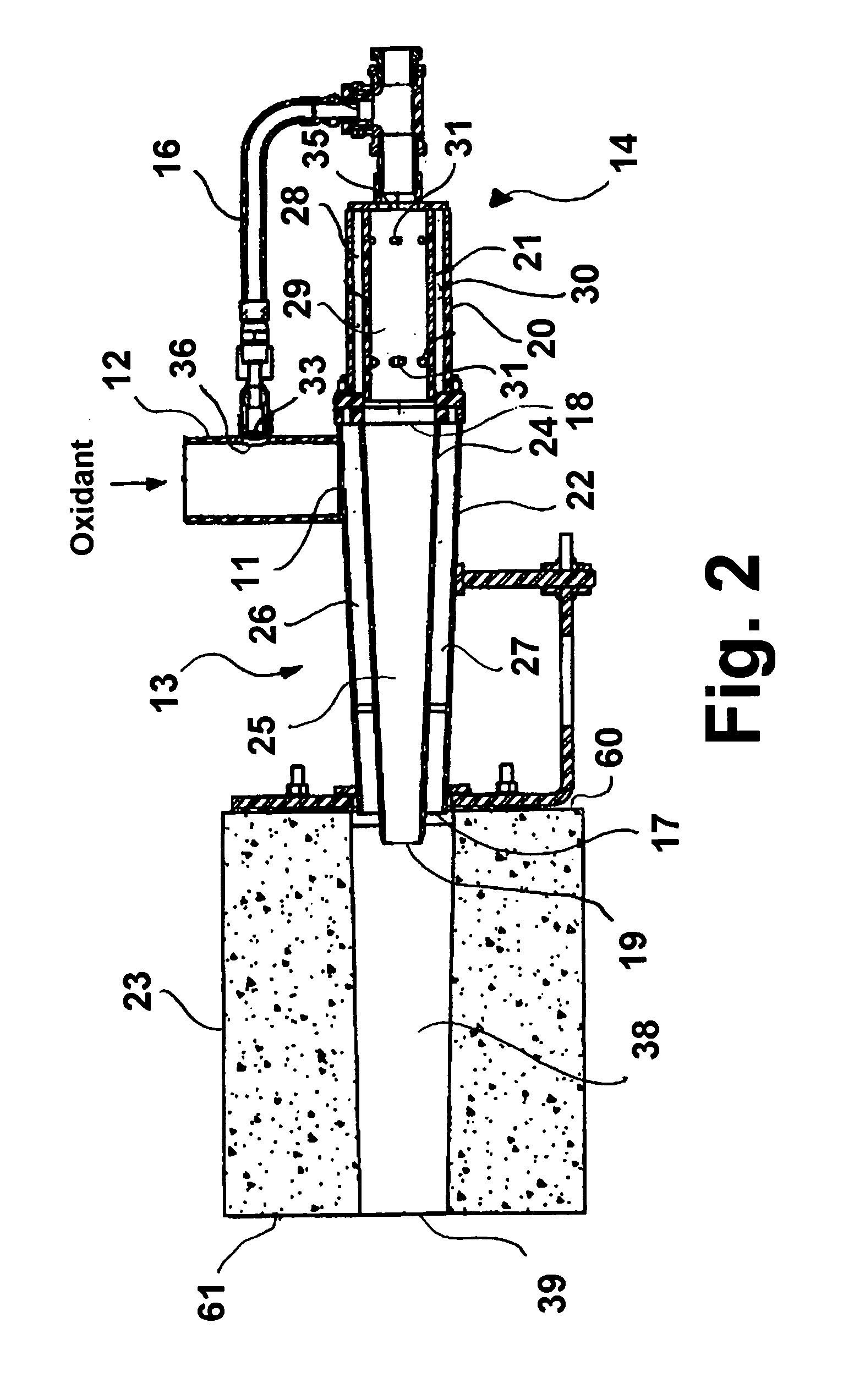

Submerged combustion disposal of produced water

InactiveUS7845314B2Easy to handleEasy disposalBoiler cleaning apparatusSedimentation separationCombustion systemCombustion chamber

The present invention relates to a method of disposing of produced water and to a produced water disposal apparatus including a container for receiving and holding produced water; and a burner having a combustion chamber, wherein at least a portion of the combustion chamber is submerged in the water and the submerged portion of the combustion chamber comprises a sparger tube through which combustion gases emerge into, mix with and agitate the water. The present invention further relates to a mechanism for removing debris from the produced water disposal apparatus. In one embodiment, heat is supplied from an externally operated combustion system, rather than the submerged combustion. In one embodiment, the apparatus provides a concentrator, in which a solute can be removed and recovered from an aqueous medium containing the solute.

Owner:TDU LLC

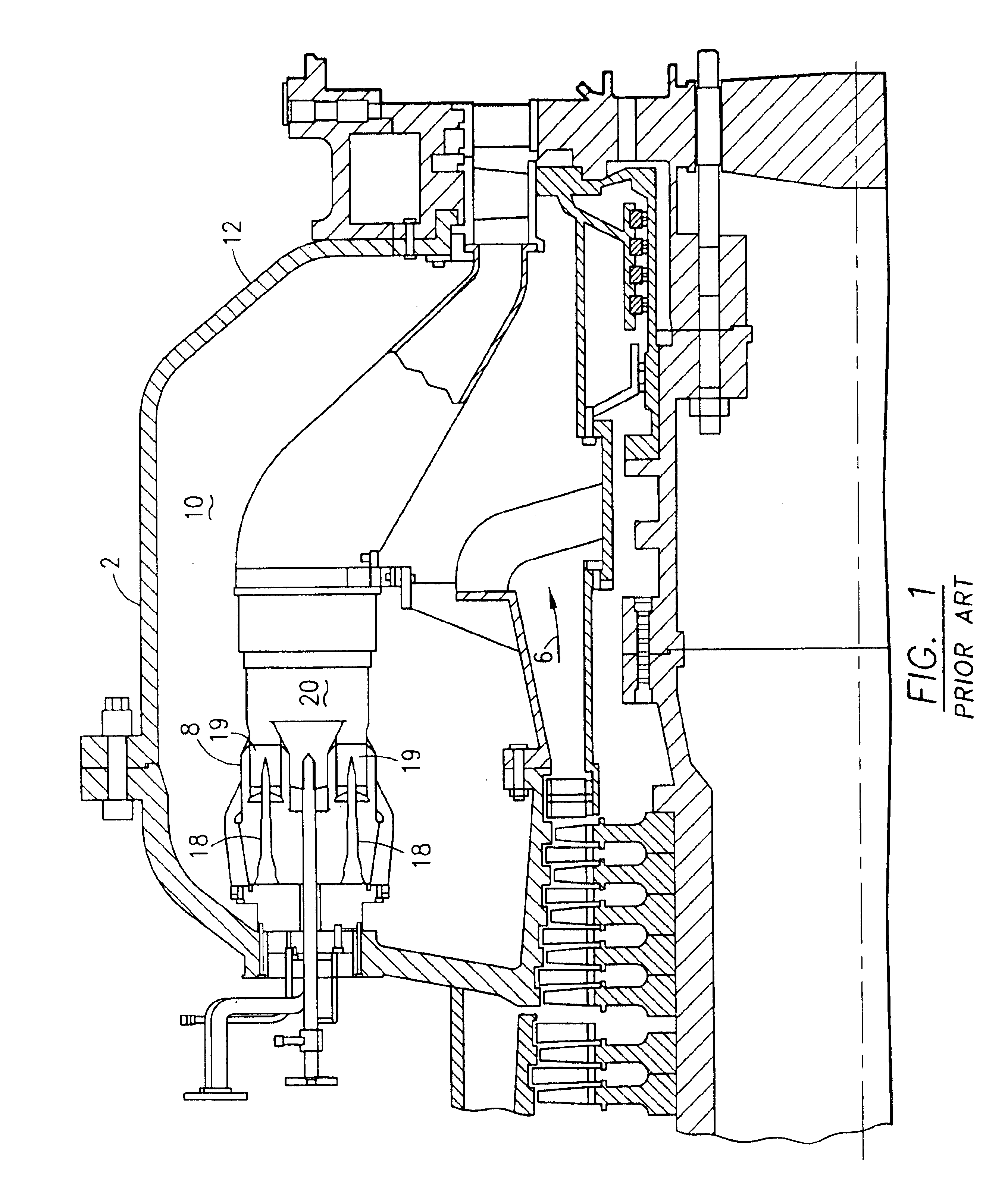

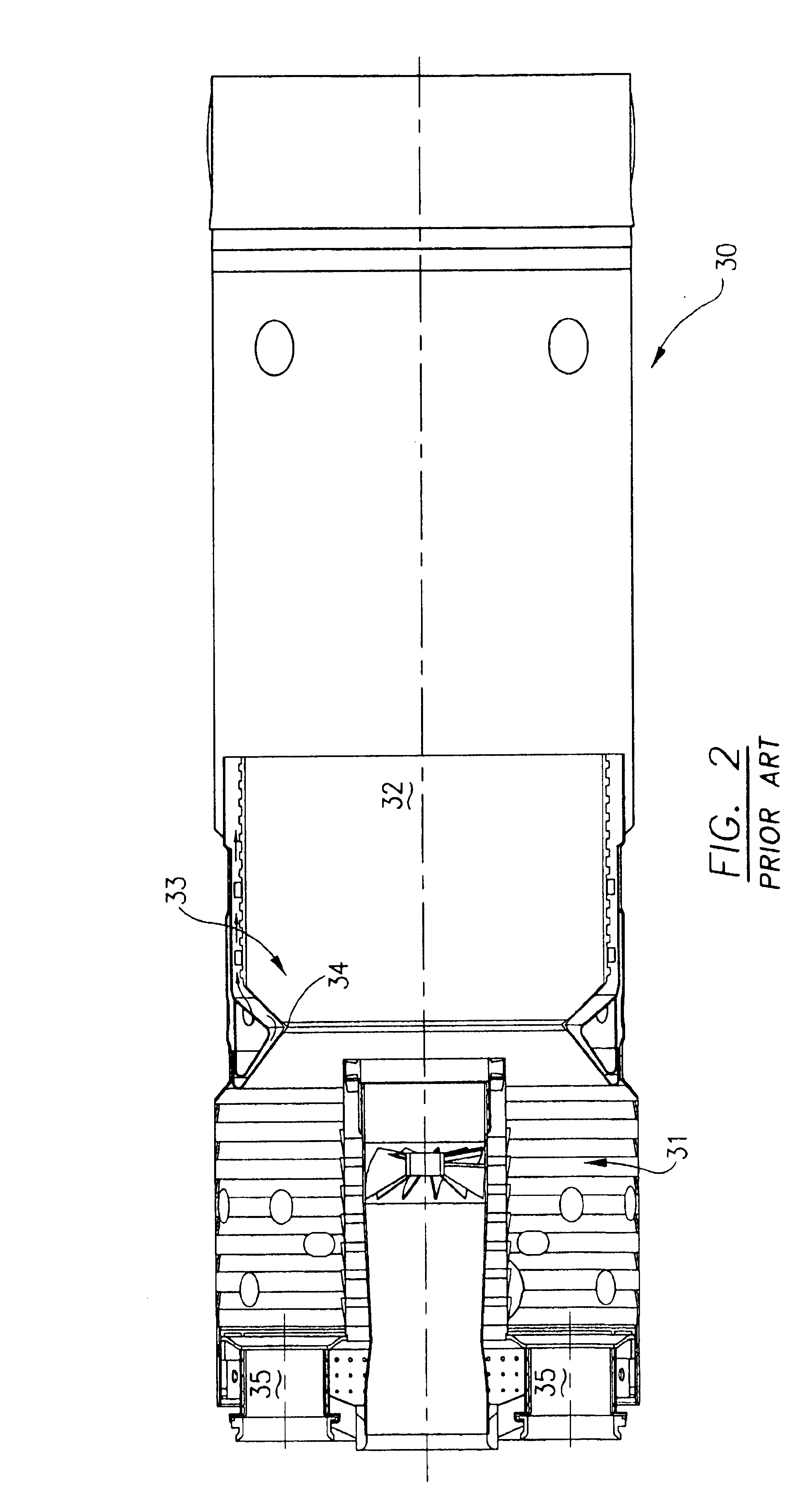

Burner for a gas turbine engine

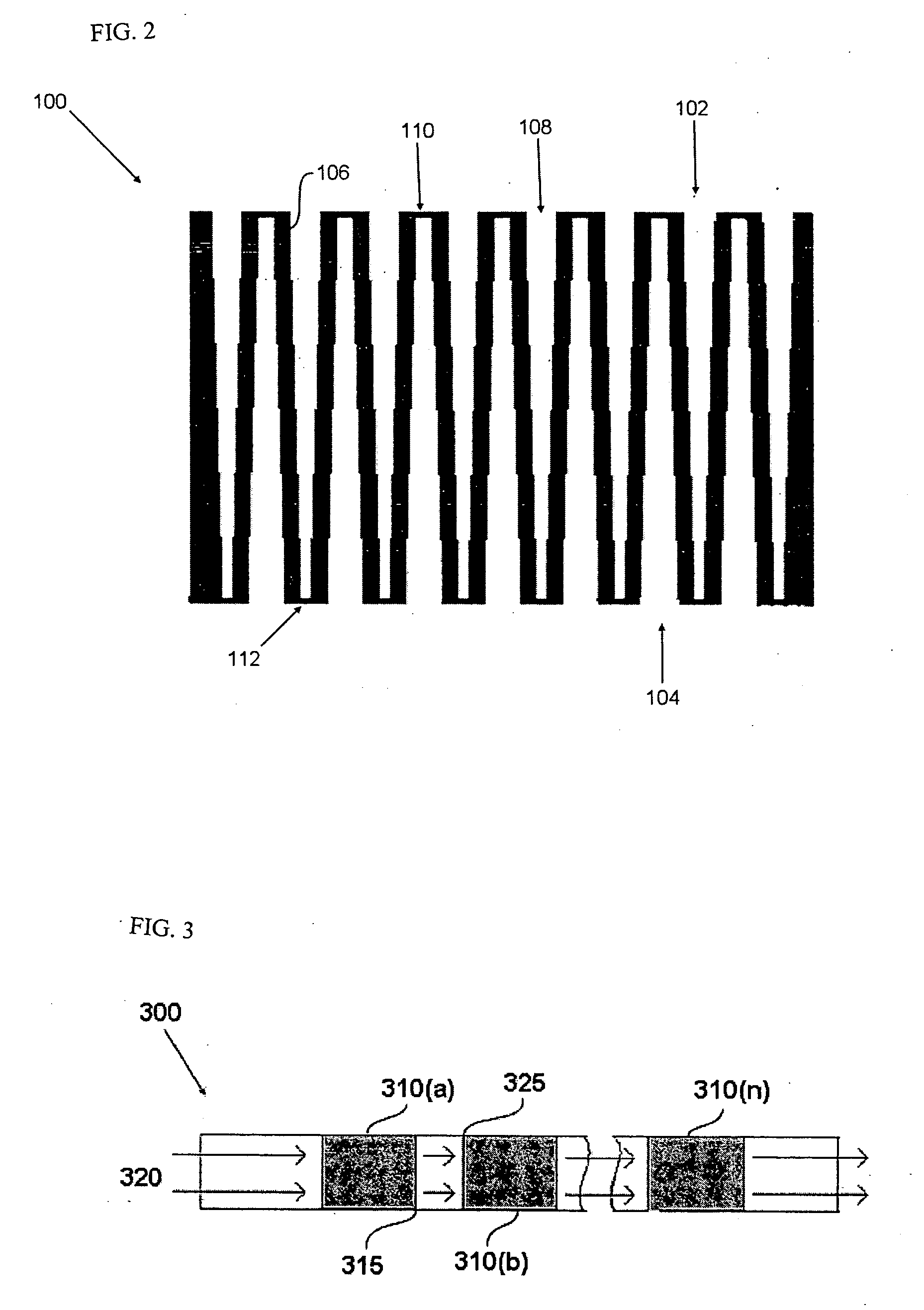

To meet emissions standards, many gas turbine engines use some form of lean, pre-mixed combustion systems. These systems may lead to combustion oscillations or other instabilities. Jet combustion techniques provide a stable alternative lean, pre-mixed combustion system. The present invention presents a jet combustion system that includes a first cylinder having a first array of orifices. A second cylinder is positioned coaxially with the first cylinder. The second cylinder has a second array of orifices offset from the first array of orifices.

Owner:SOLAR TURBINES

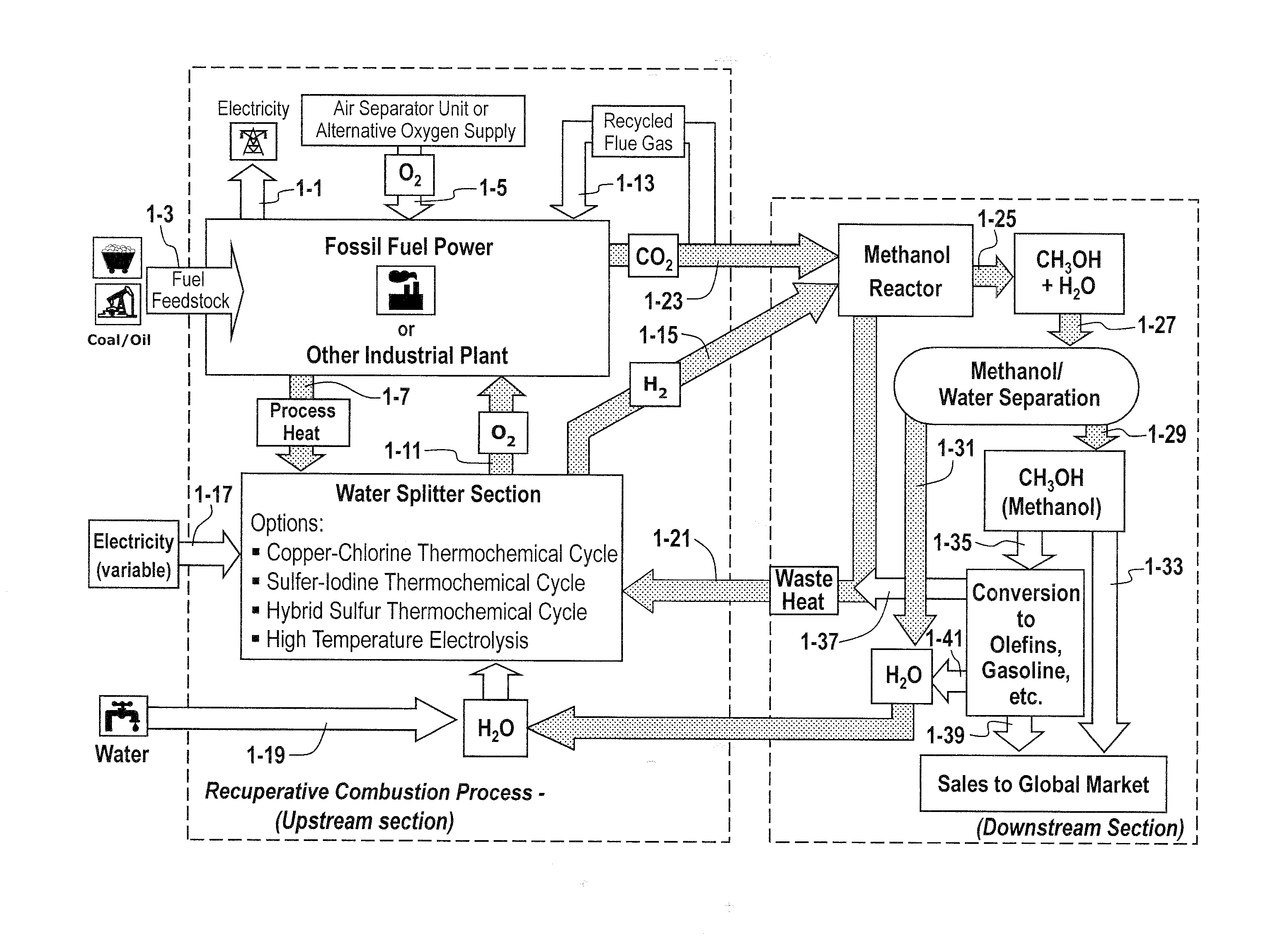

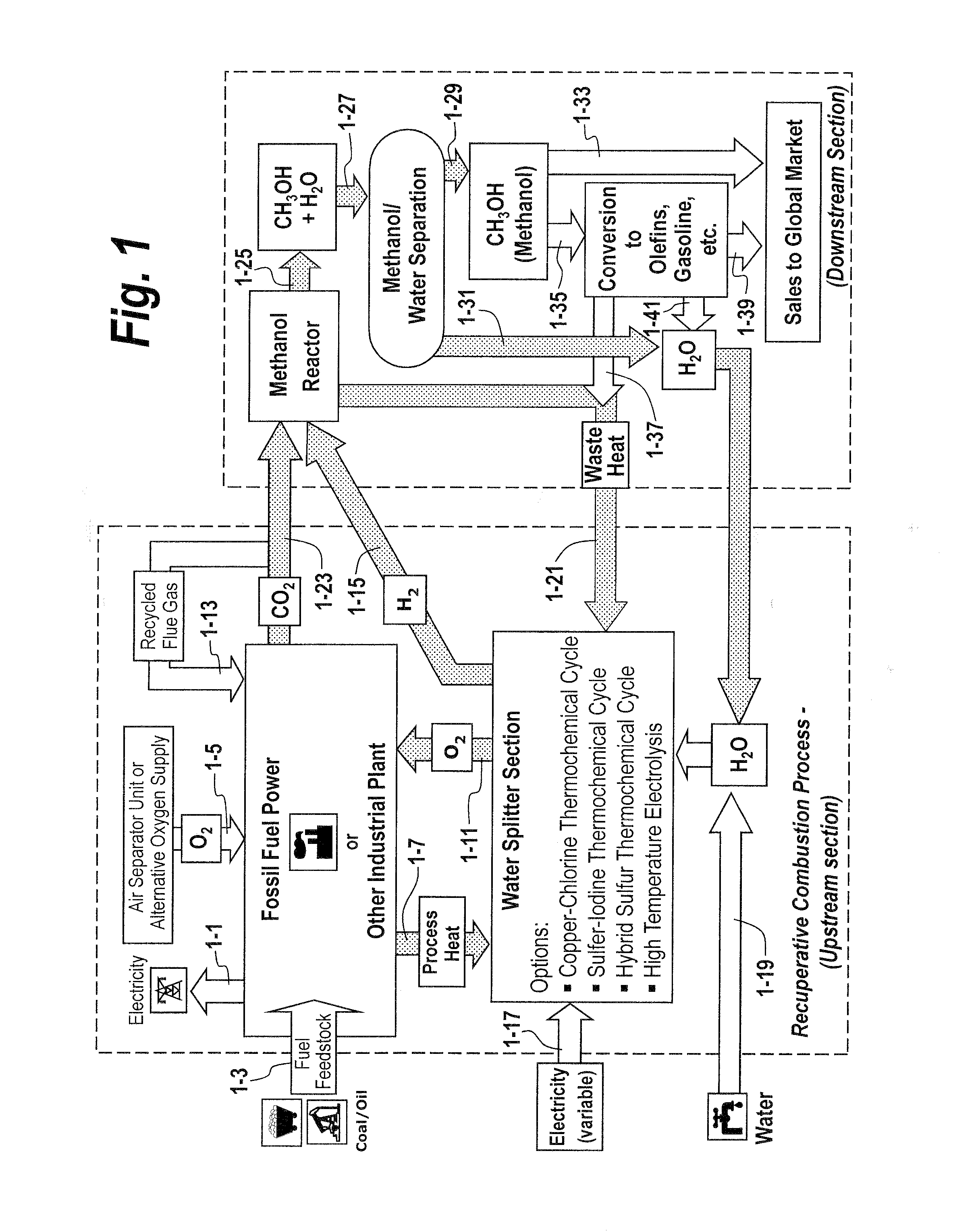

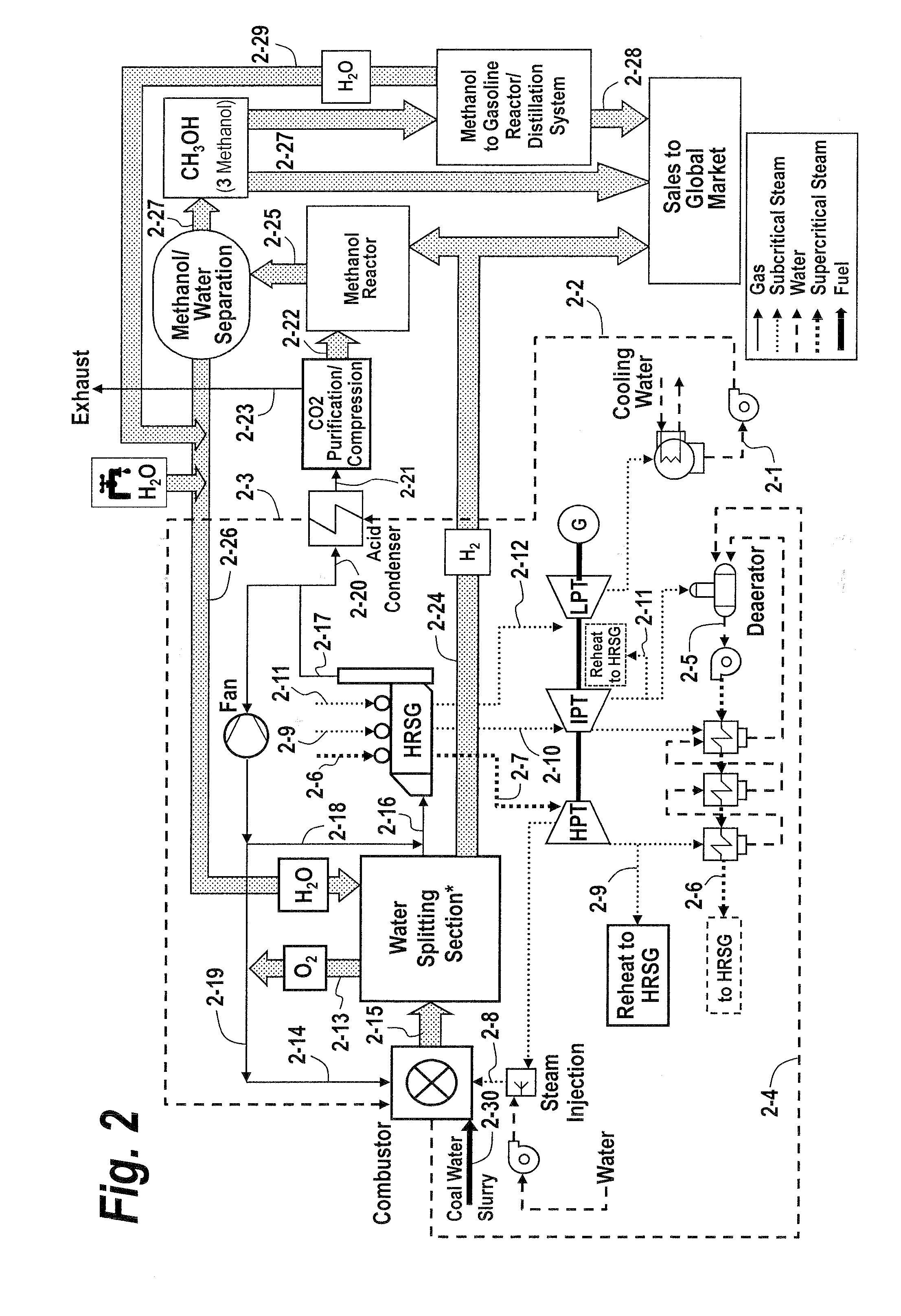

Recuperative combustion system

InactiveUS20110041740A1Reducing and eliminating amount of oxygenSolid fuel combustionIndirect carbon-dioxide mitigationOxygenDimethyl ether

The methods and systems described herein relate to a recuperative combustion system that recuperates energy from fuel combustion that would otherwise be lost. The recuperative combustion system minimizes or eliminates the need for an air separator unit through the use of a clean water splitter section, consisting of a thermochemical cycle or high-temperature electrolysis. Water is split into its component hydrogen and oxygen, primarily with process heat from the combustion process. The oxygen produced by the water splitter provides oxygen necessary for oxy-fuel combustion, thereby reducing or eliminating the need for the power intensive air separator unit and / or external oxygen source, significantly increasing the efficiency of the oxy-fuel combustion cycle. Hydrogen produced by the water splitter may be used for a variety of industrial uses, or combined with carbon dioxide (captured from the flue gases produced by said combustion process) to produce methanol. Methanol can further be refined in a methanol to gasoline reactor to produce dimethyl ether, olefins or high grade gasoline. Described herein are methods and systems that 1) increase oxy-fuel combustion efficiency, 2) produce hydrogen for a suite of industrial / energy uses, and 3) capture carbon dioxide and convert it to high value hydrocarbons.

Owner:REILLY TIMOTHY J

Activated carbon honeycomb catalyst beds and methods for the manufacture of same

InactiveUS20070265161A1Simple designMercury can be removedGas treatmentDispersed particle separationActivated carbonCombustion system

Disclosed herein, without limitation, are activated carbon honeycomb catalyst beds for removing mercury and other toxic metals from flue gas of a coal combustion system. The activated carbon honeycomb can for example removal greater than 90% mercury from flue gas with a simple design and without adding material to the flue gas. Also disclosed herein, and without limitation, are methods for manufacturing the disclosed honeycomb catalyst beds.

Owner:CORNING INC

High-heat transfer low-NOx combustion system

ActiveUS6939130B2Lower NO<sub>xIncrease brightnessCombustion using gaseous and pulverulent fuelBurner safety arrangementsCombustion systemVertical plane

Owner:GAS TECH INST

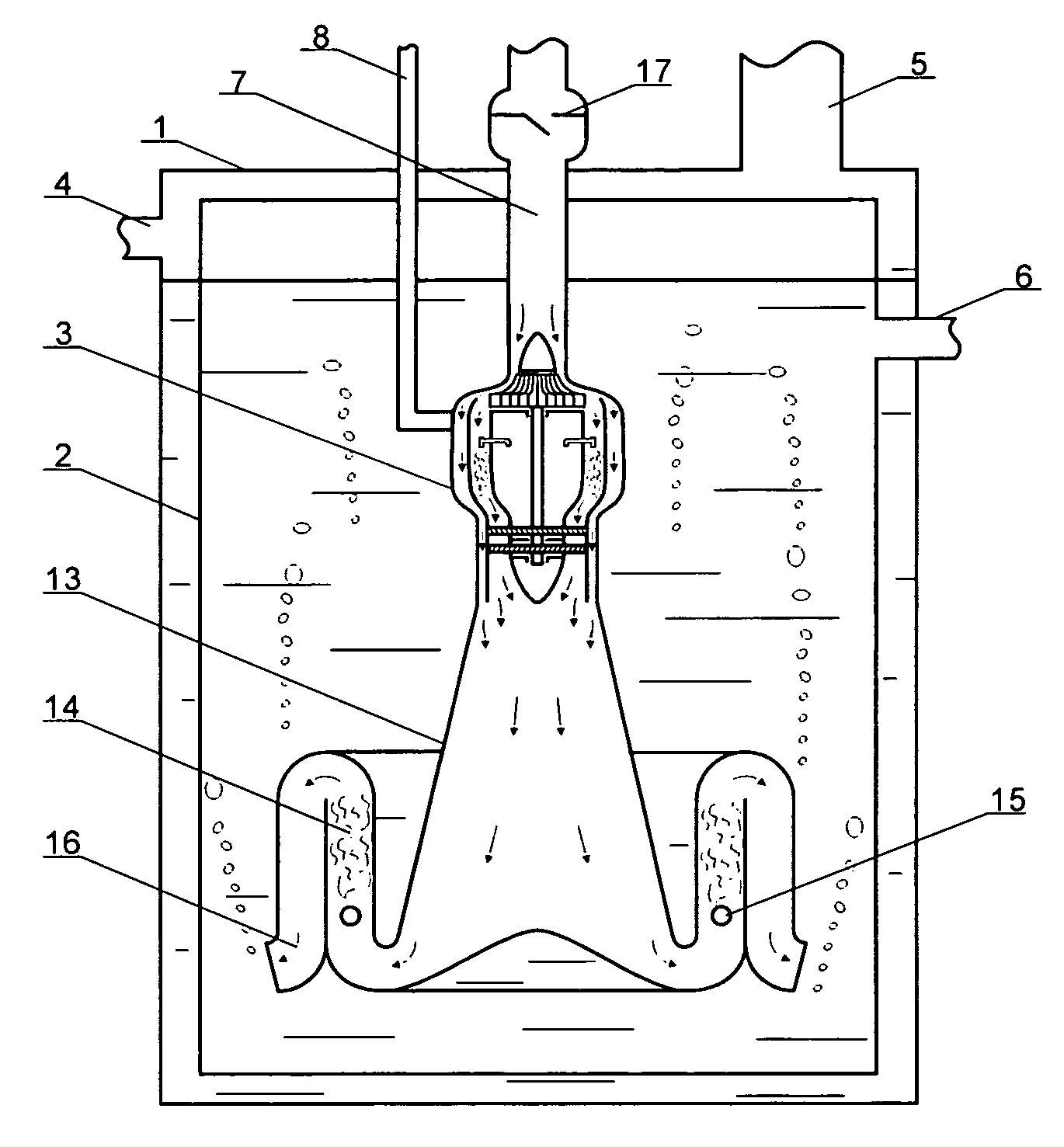

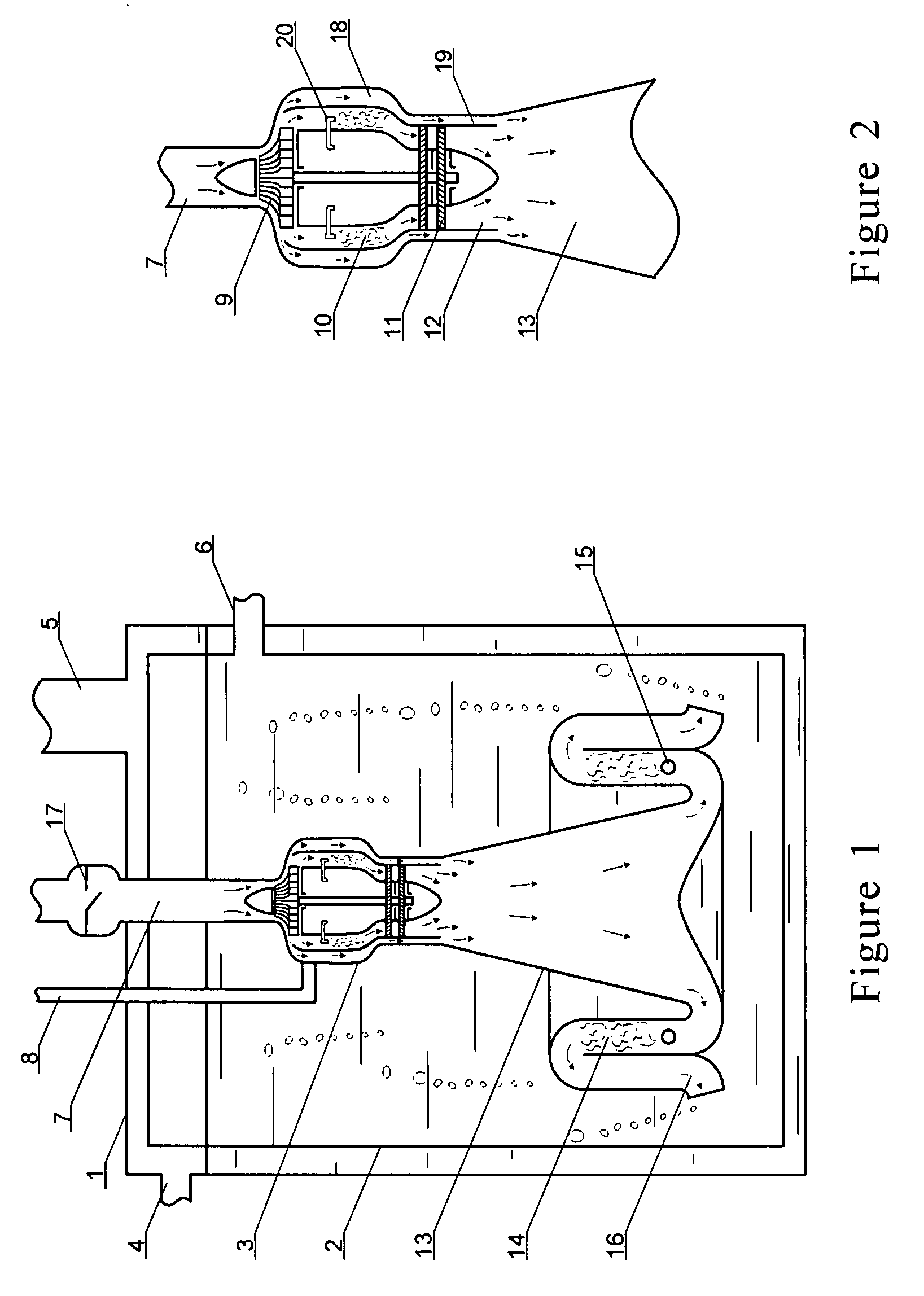

Method and device of turbine submerged combustion boiler

InactiveUS20080035078A1Improve energy efficiencySteam generation using pressureGas turbine plantsComing outHigh energy

The invention is about a submerged combustion method and the device; in details, it is a submerged combustion method and the device utilizing turbine heat engine principle. In the invention, turbine power combustion means is used and substituted conventional submerged combustion system that must equip air blowing means. The high temperature gases generated from the combustion within the turbine power combustion means will do works on turbine, which will drive the air compressor means of the turbine power combustion means to induce air for combustion, and will drive the second-time complete combustion of high temperature gases and the complement fuel, and then the gases will come out from water bottom against tank water pressure and carry out heat interchange with tank water. The turbine submerged combustion boiler device of the invention need not equip air blowing means additionally which would consume energy. So it has high energy efficiency and a simple system structure. And it has features of high heat interchange rate, stable long term heat efficiency, environmental protection, etc.

Owner:LI WEICHENG

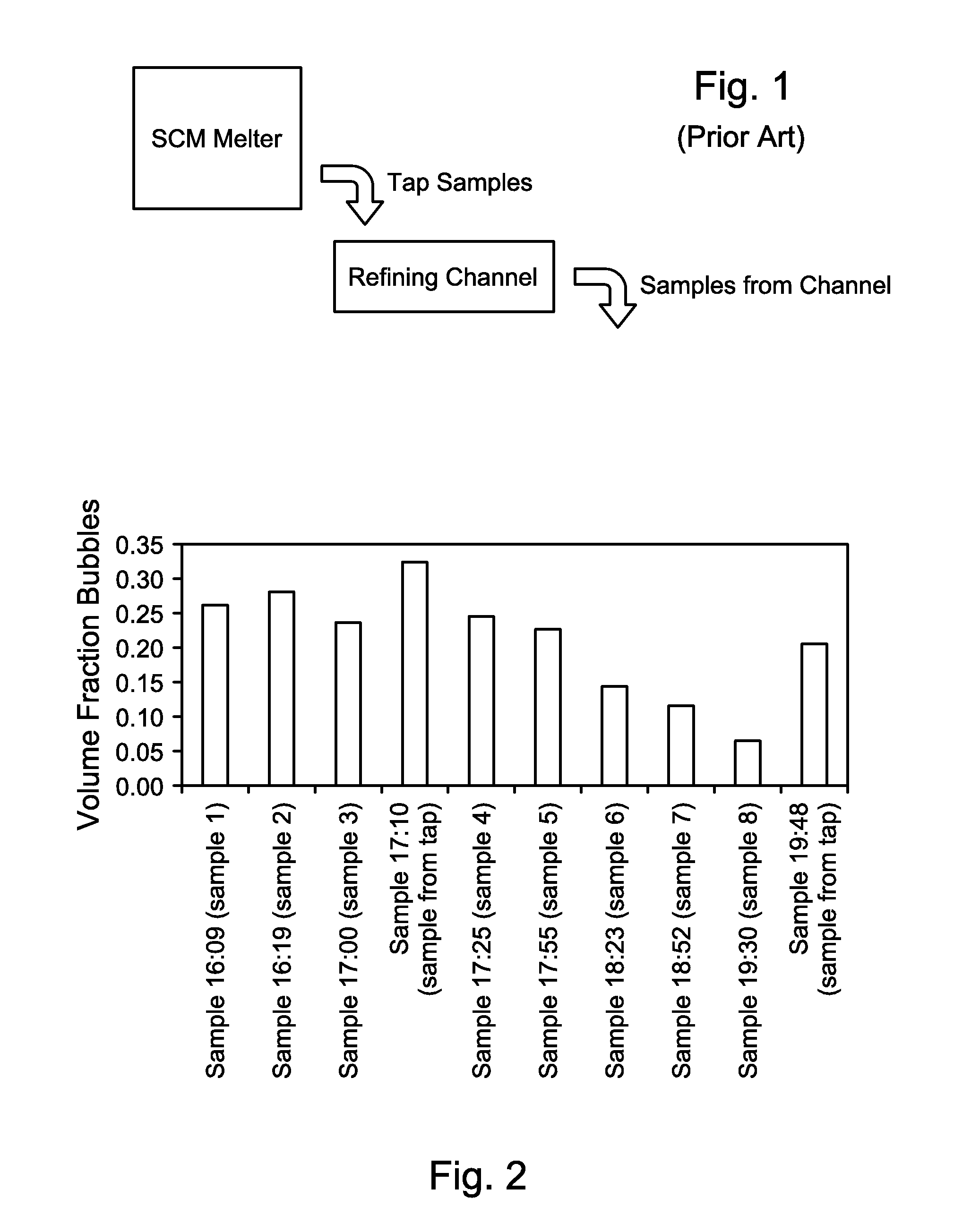

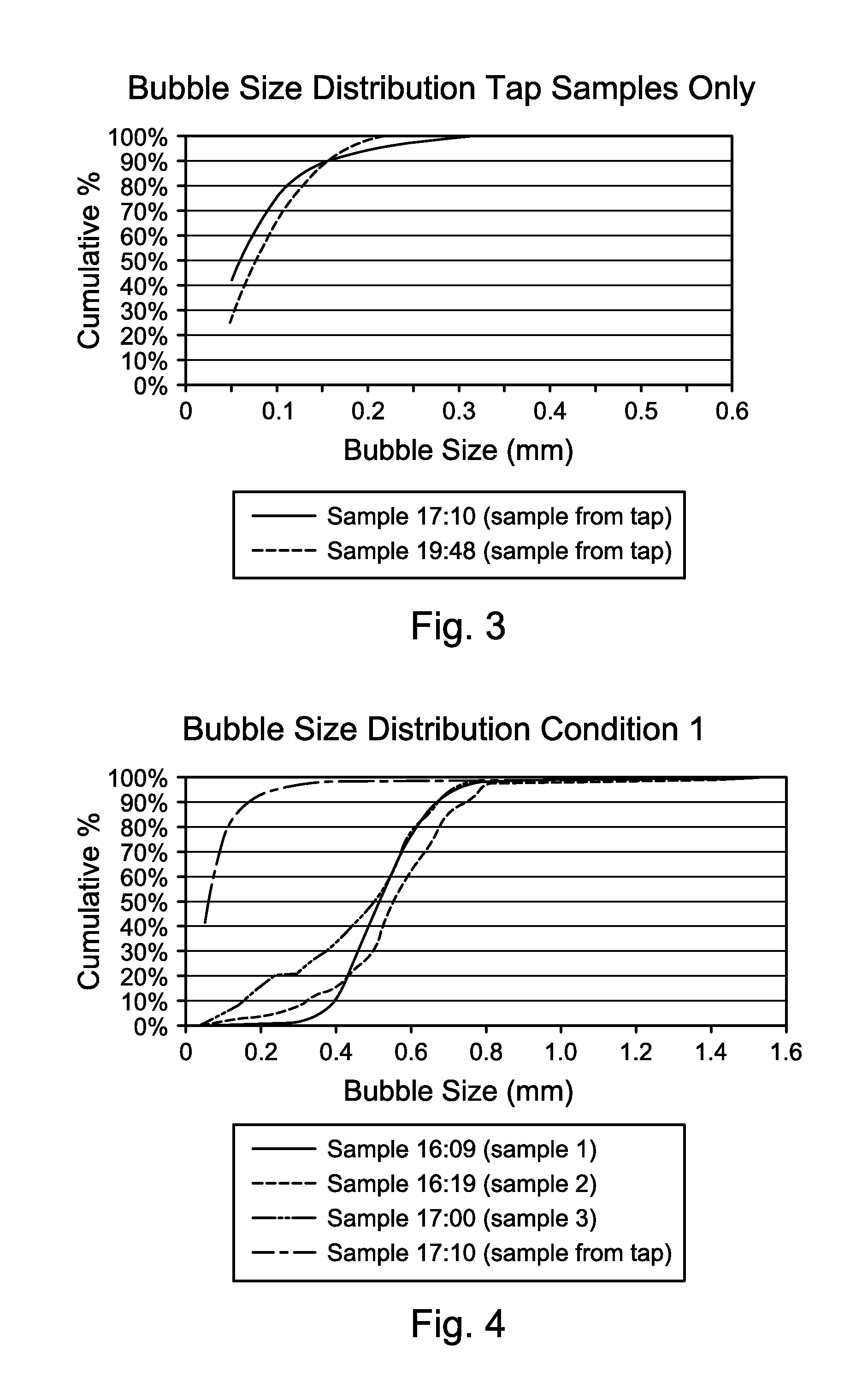

Systems and methods for making foamed glass using submerged combustion

ActiveUS20130086944A1High densityLow densityRibbon machinesGlass furnace apparatusCombustion systemDownstream processing

Submerged combustion systems and methods of use to produce foamed glass. One system includes a submerged combustion melter having an outlet, the melter configured to produce an initial foamy molten glass having a density and comprising bubbles filled primarily with combustion product gases. The initial foamy molten glass is deposited directly onto or into a transport apparatus that transports the initial foamy molten glass to a downstream processing apparatus. An intermediate stage may be included between the melter and the transport apparatus. One intermediate stage is a channel that includes gas injectors. Another intermediate stage is a channel that produces an upper flow of a less dense glass and a relatively more dense glass lower flow. The upper flow may be processed into foamed glass products, while the more dense flow may be processed into dense glass products.

Owner:JOHNS MANVILLE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com