Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

508results about "Steam generation using pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

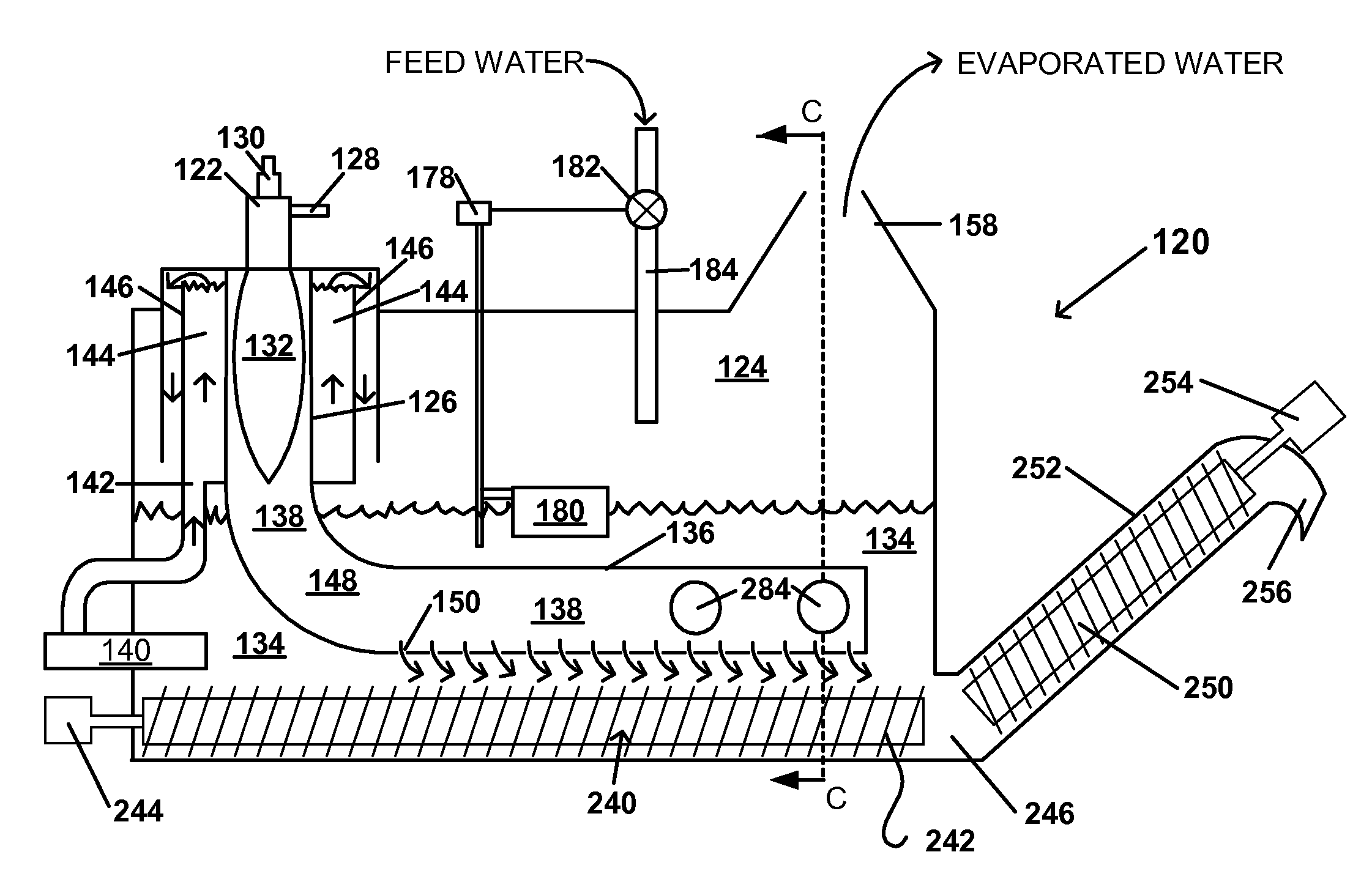

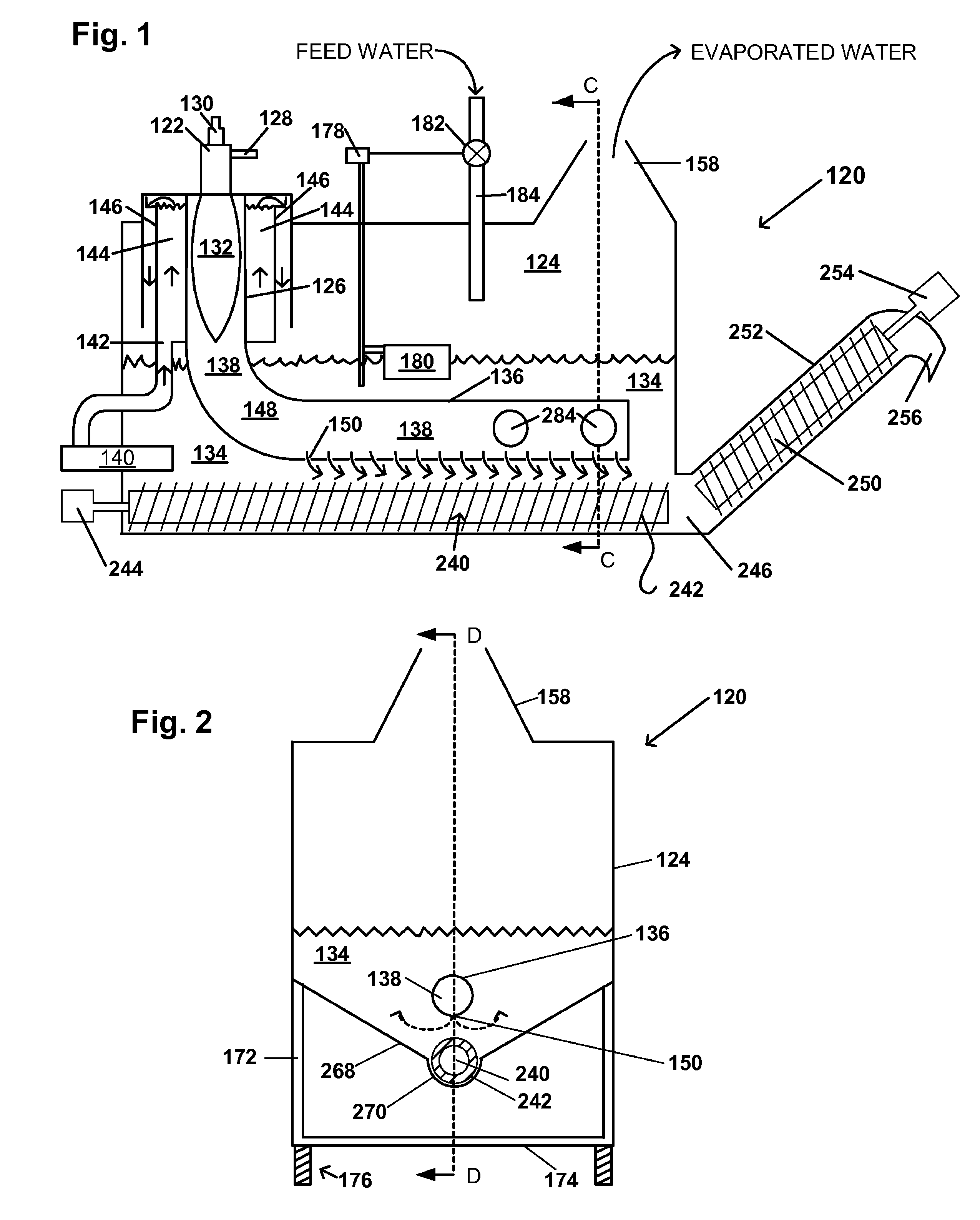

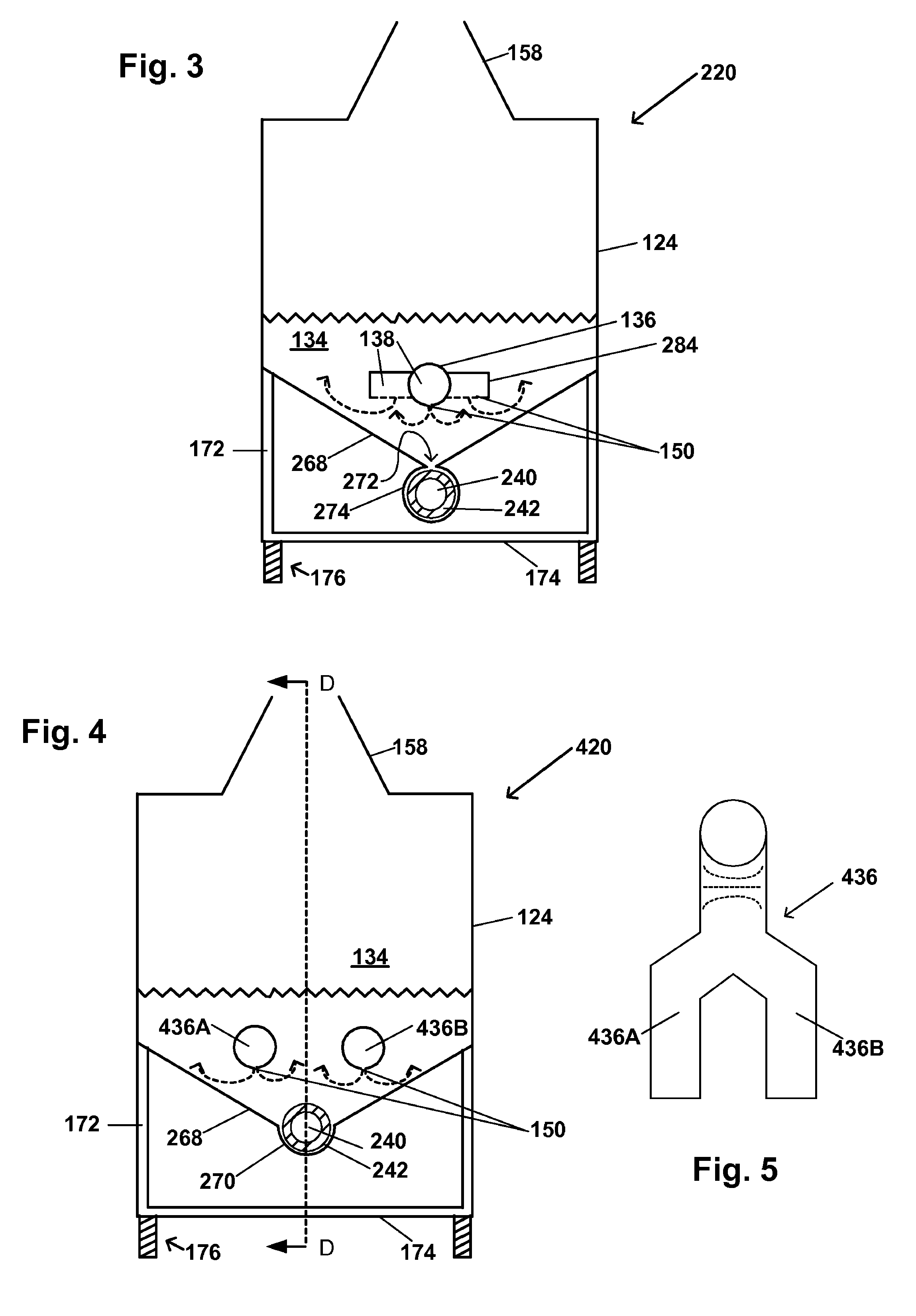

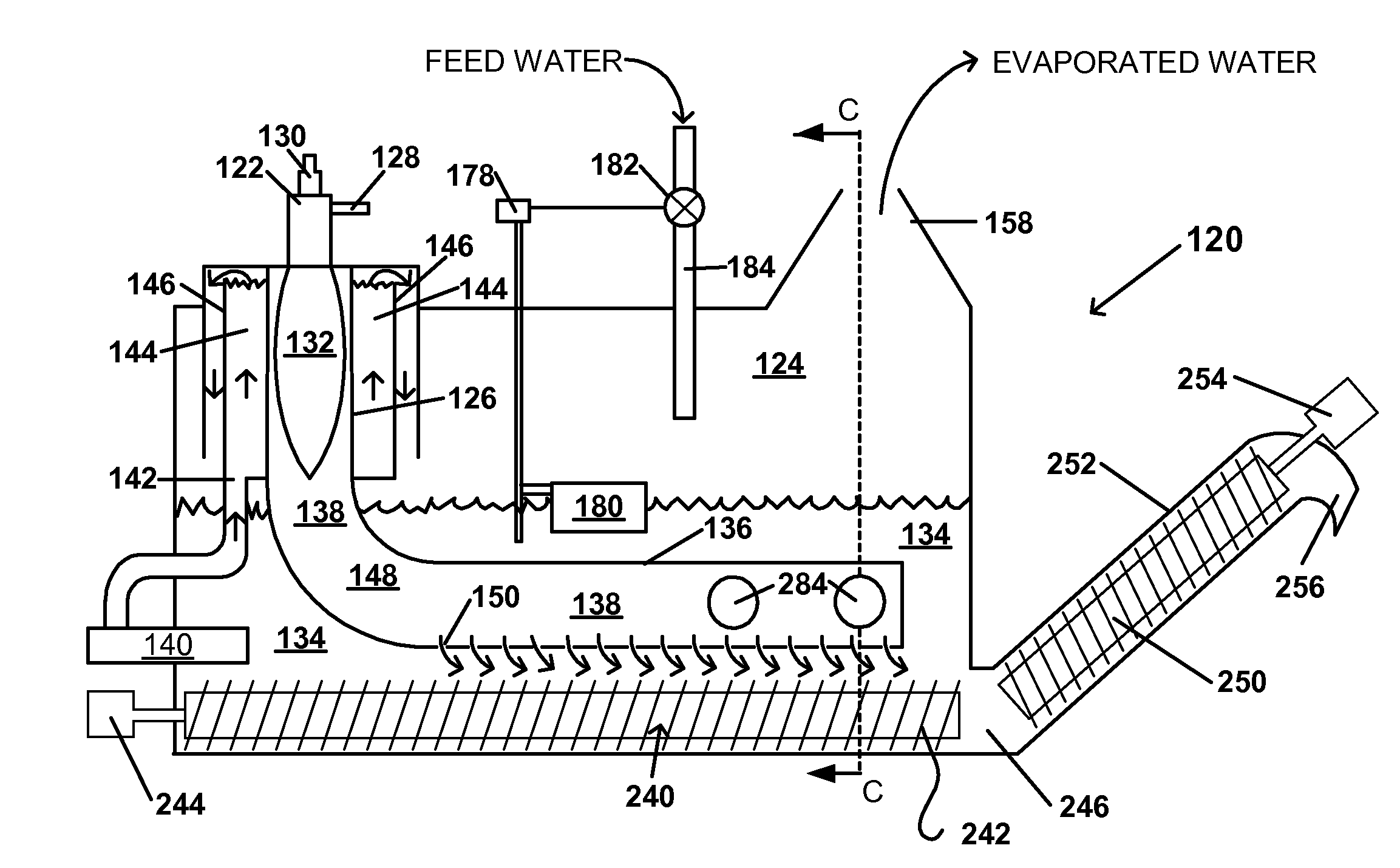

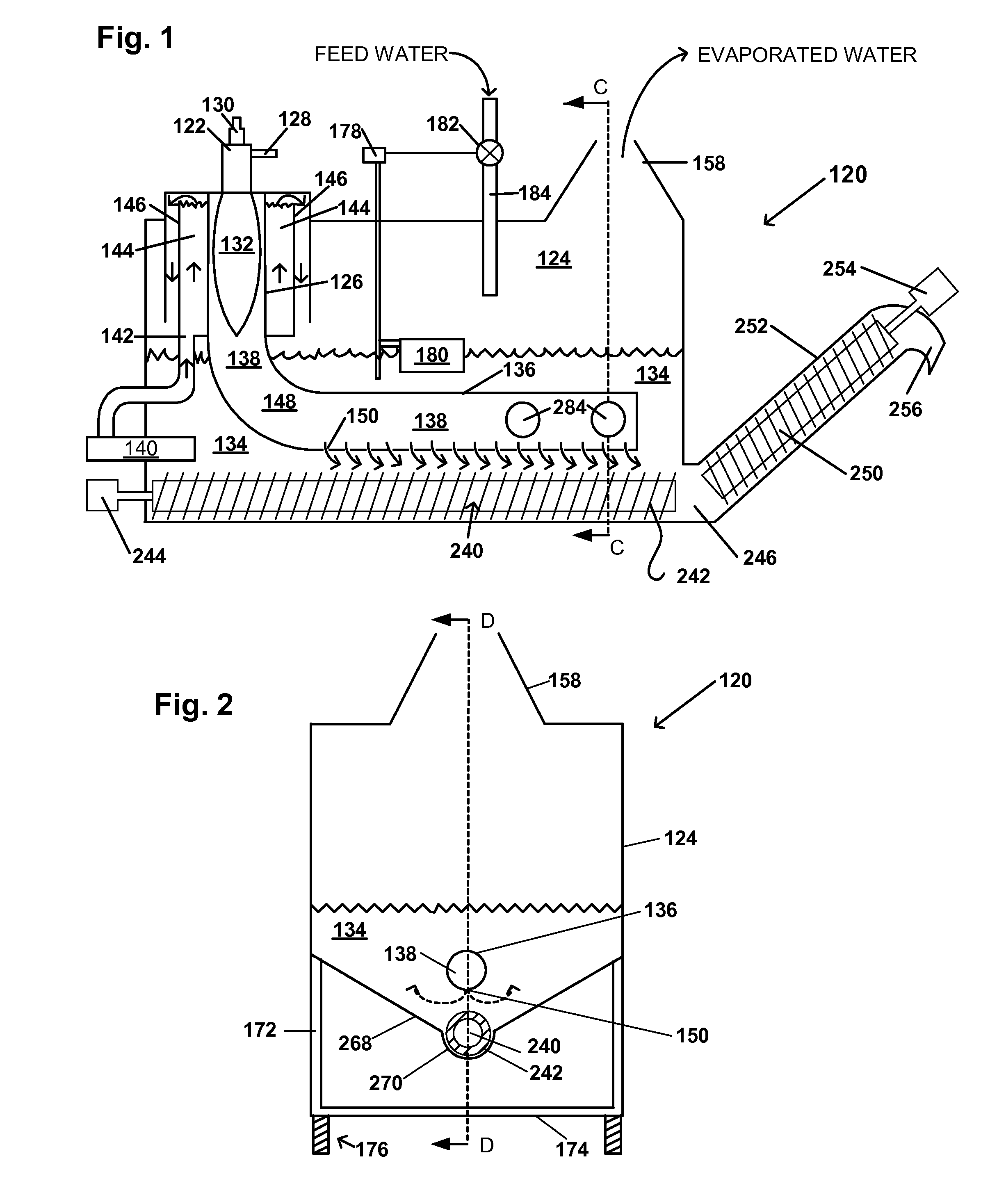

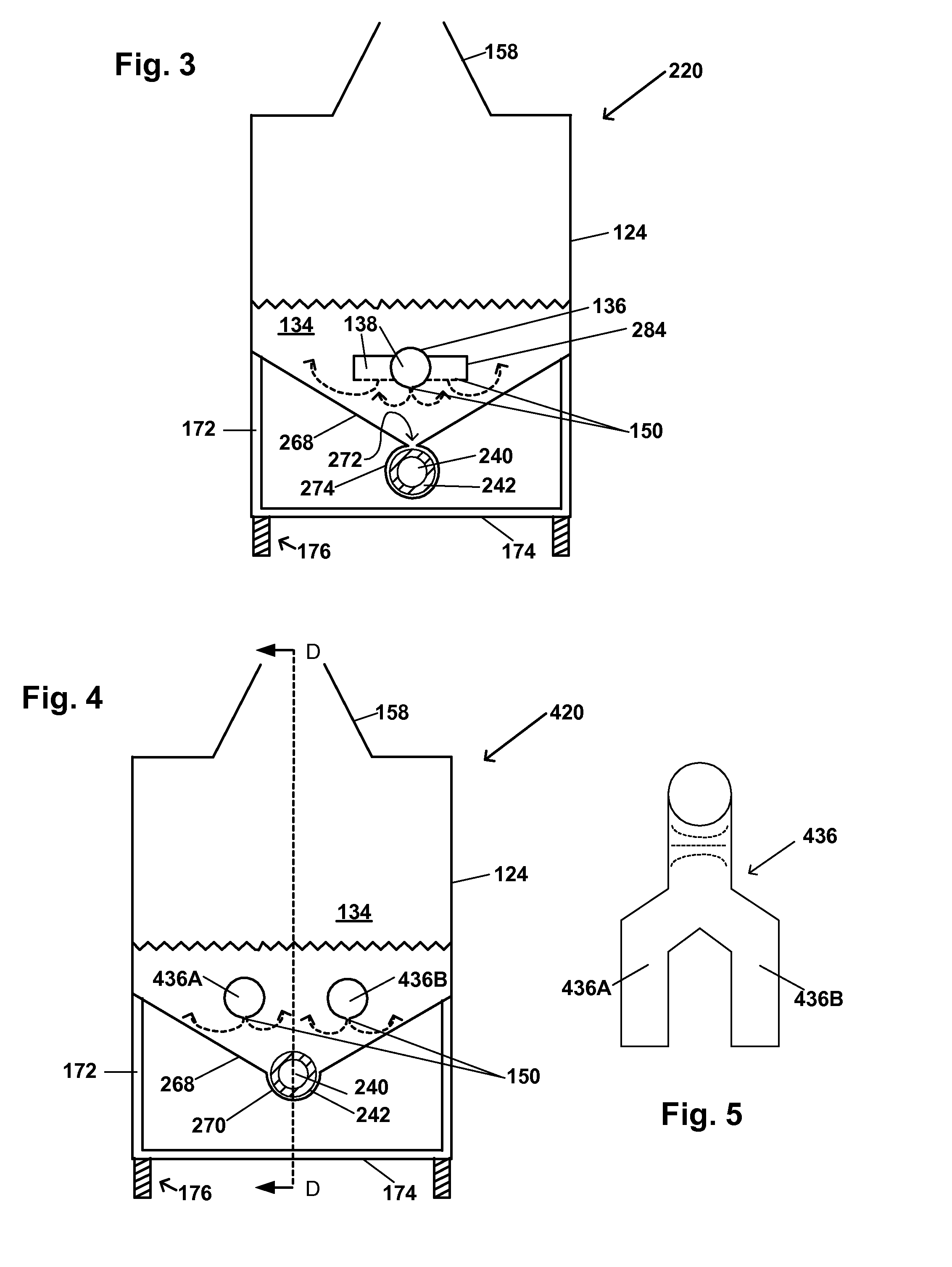

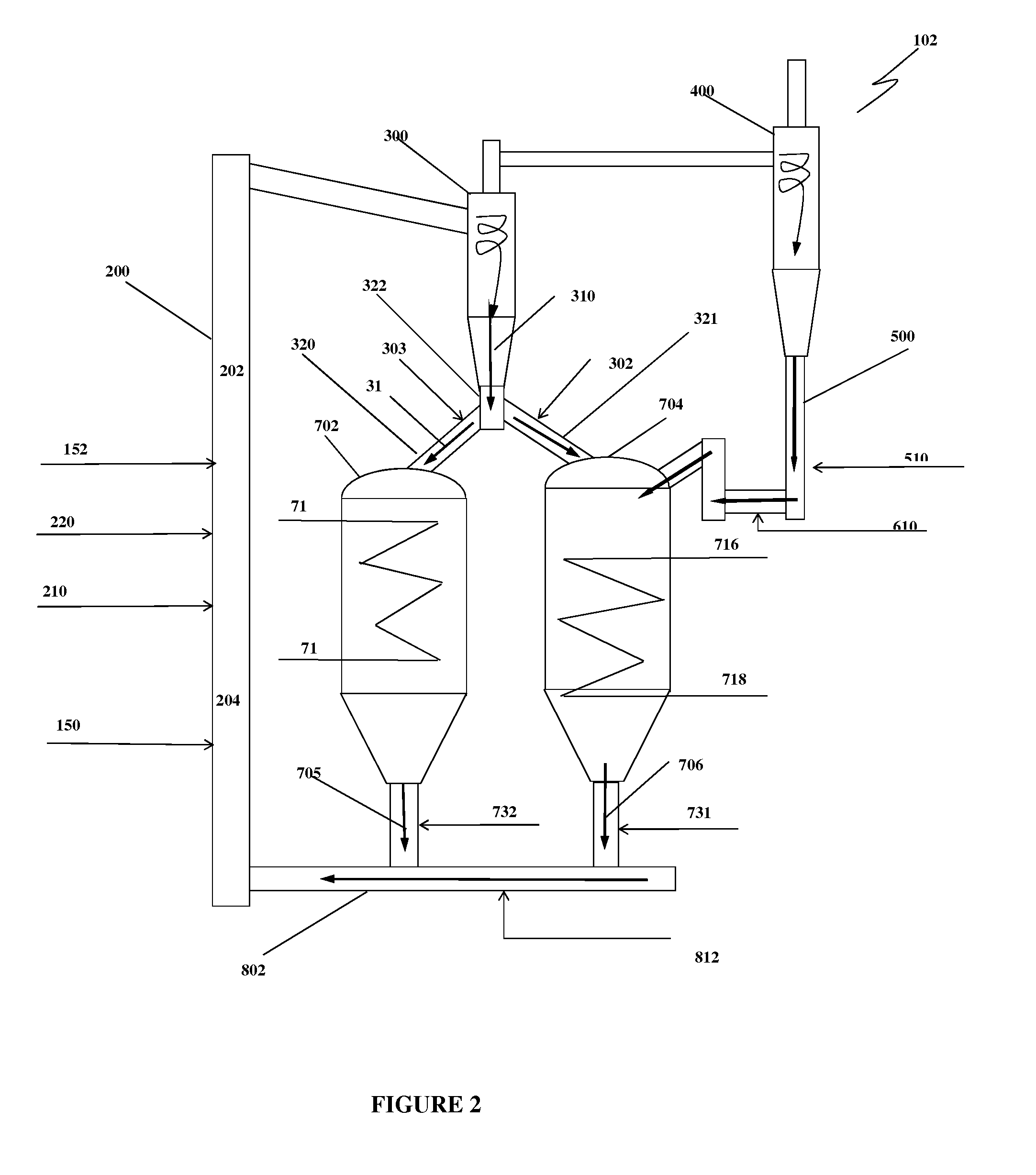

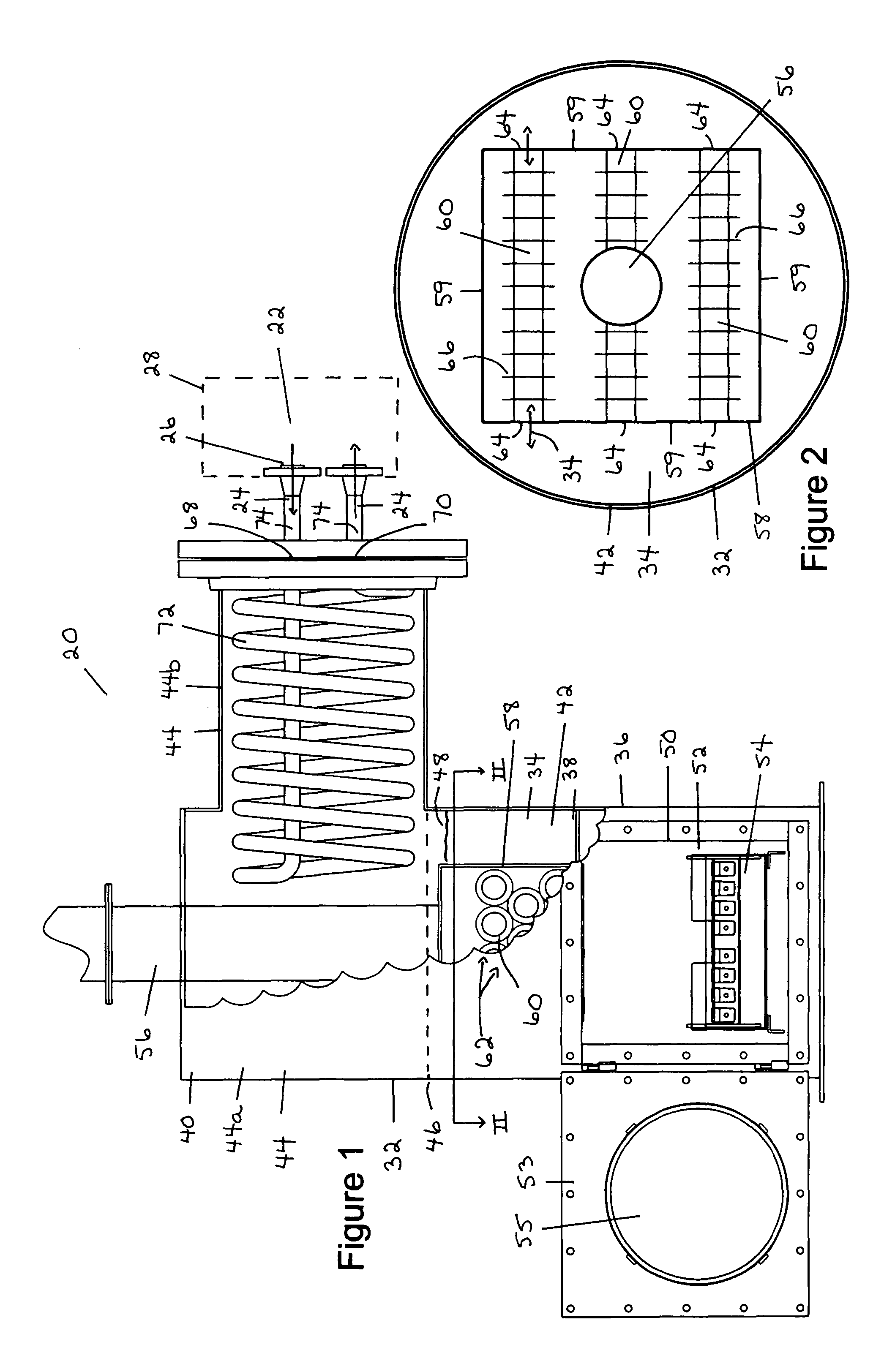

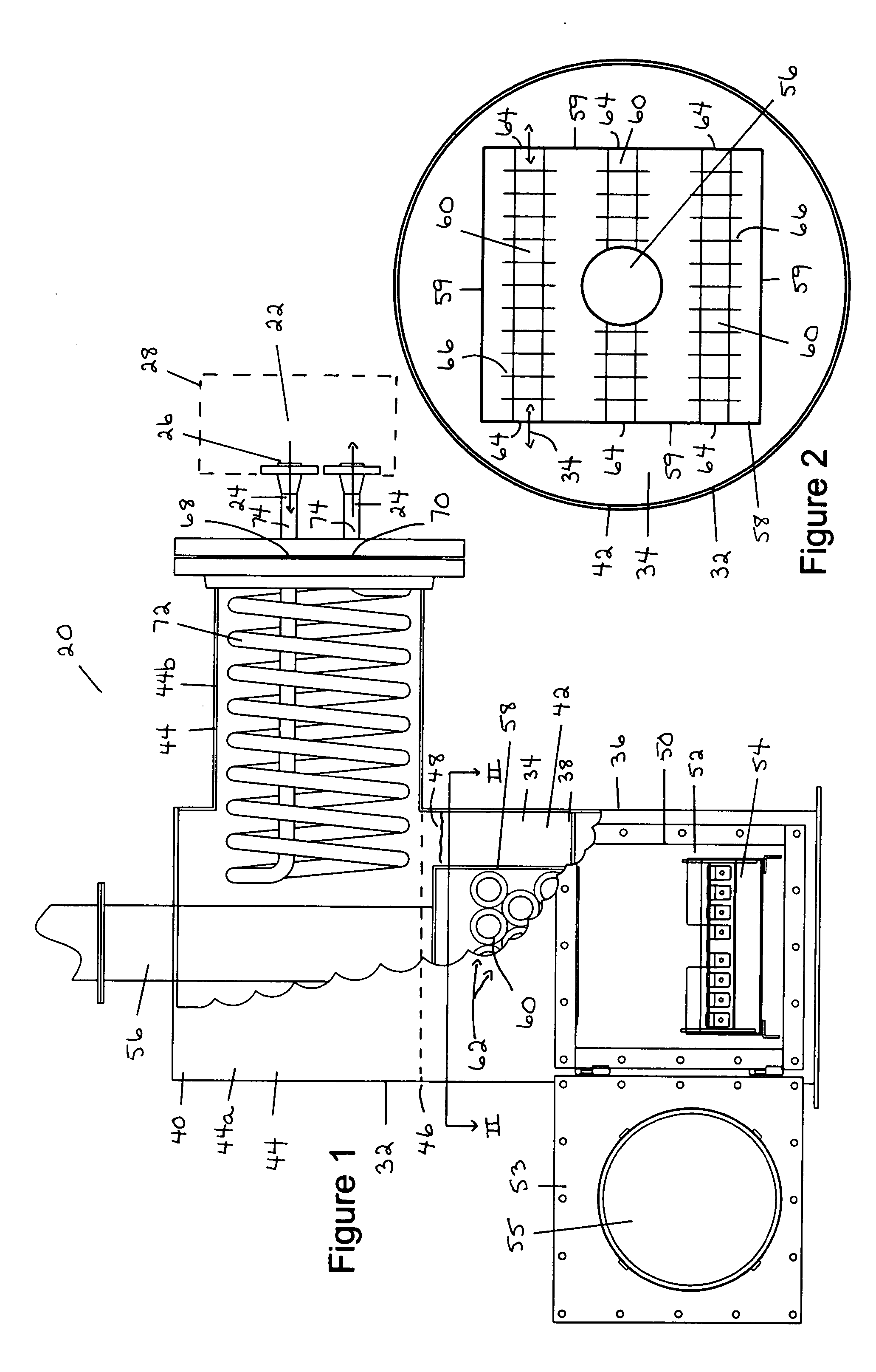

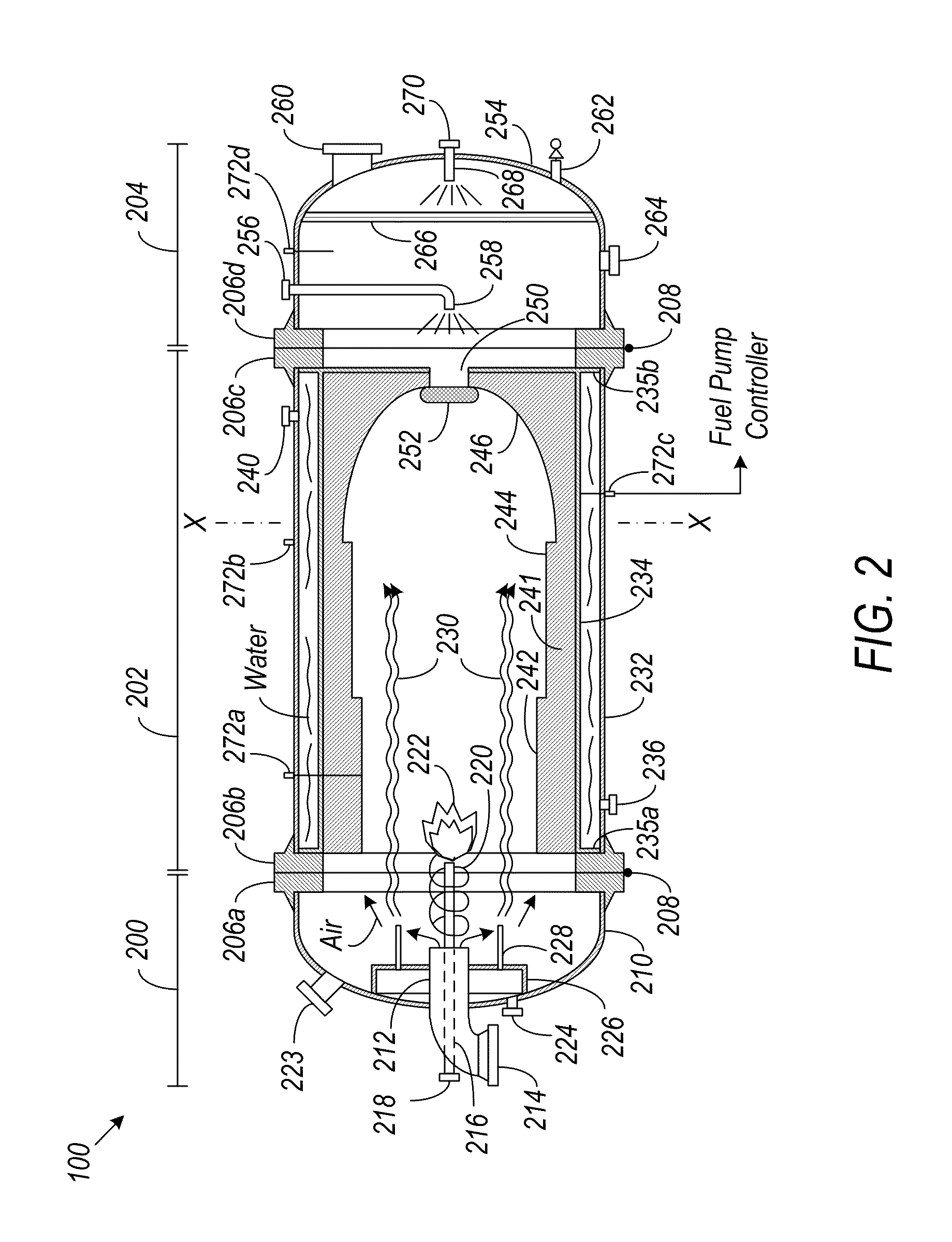

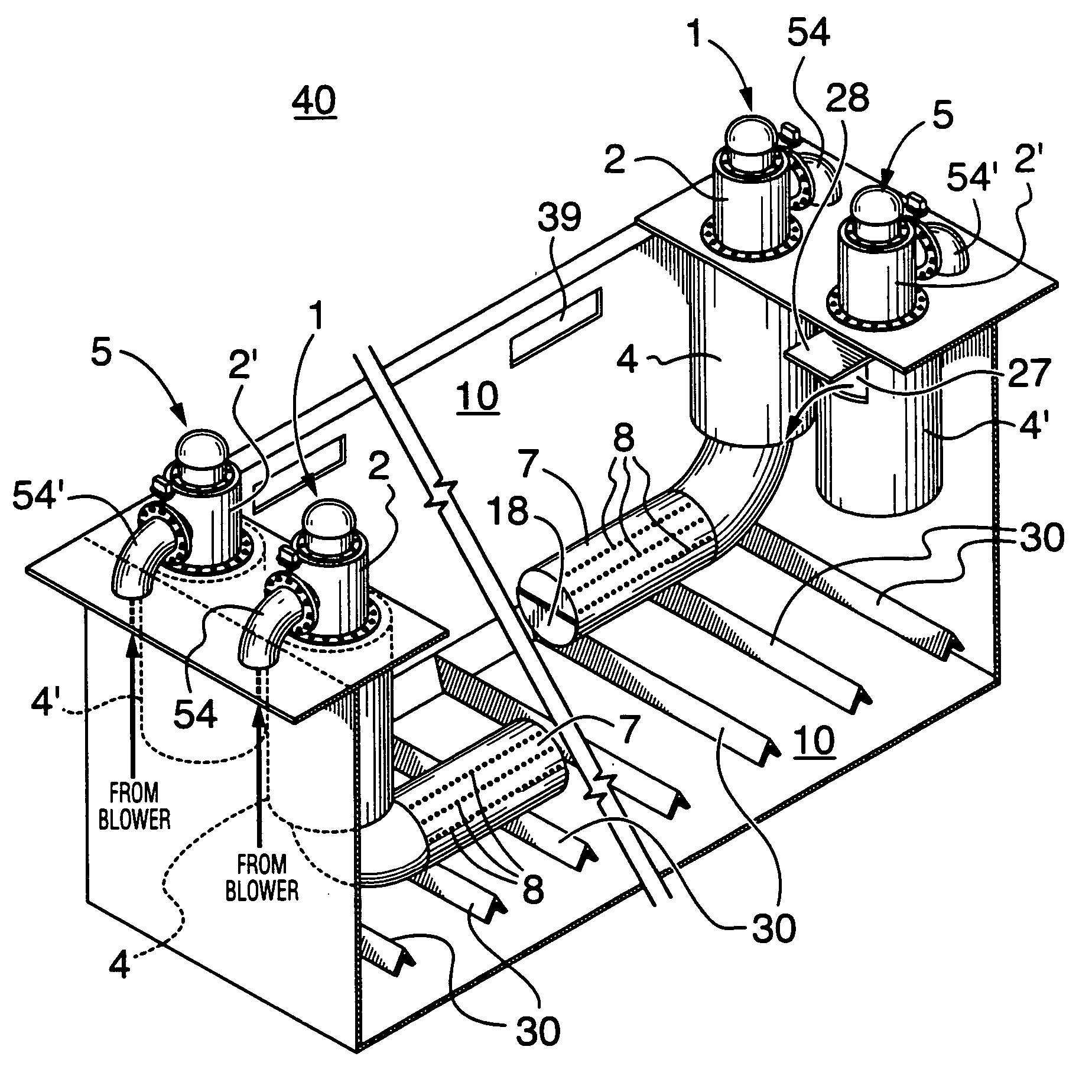

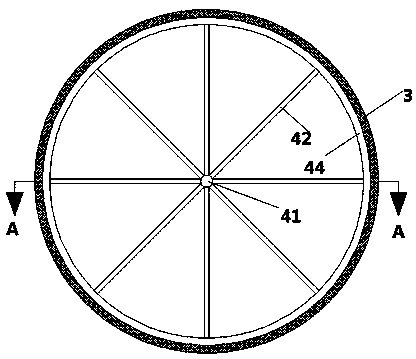

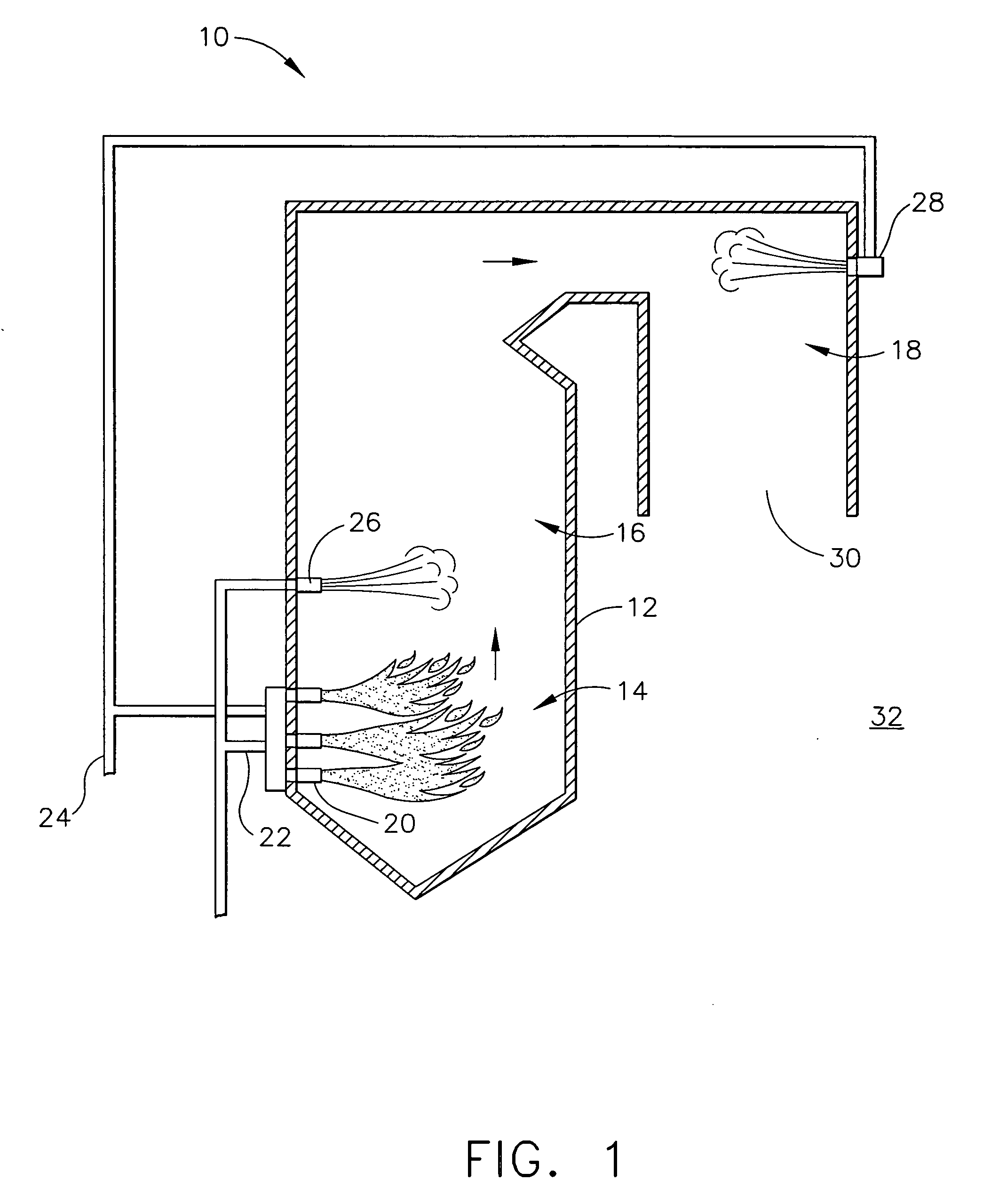

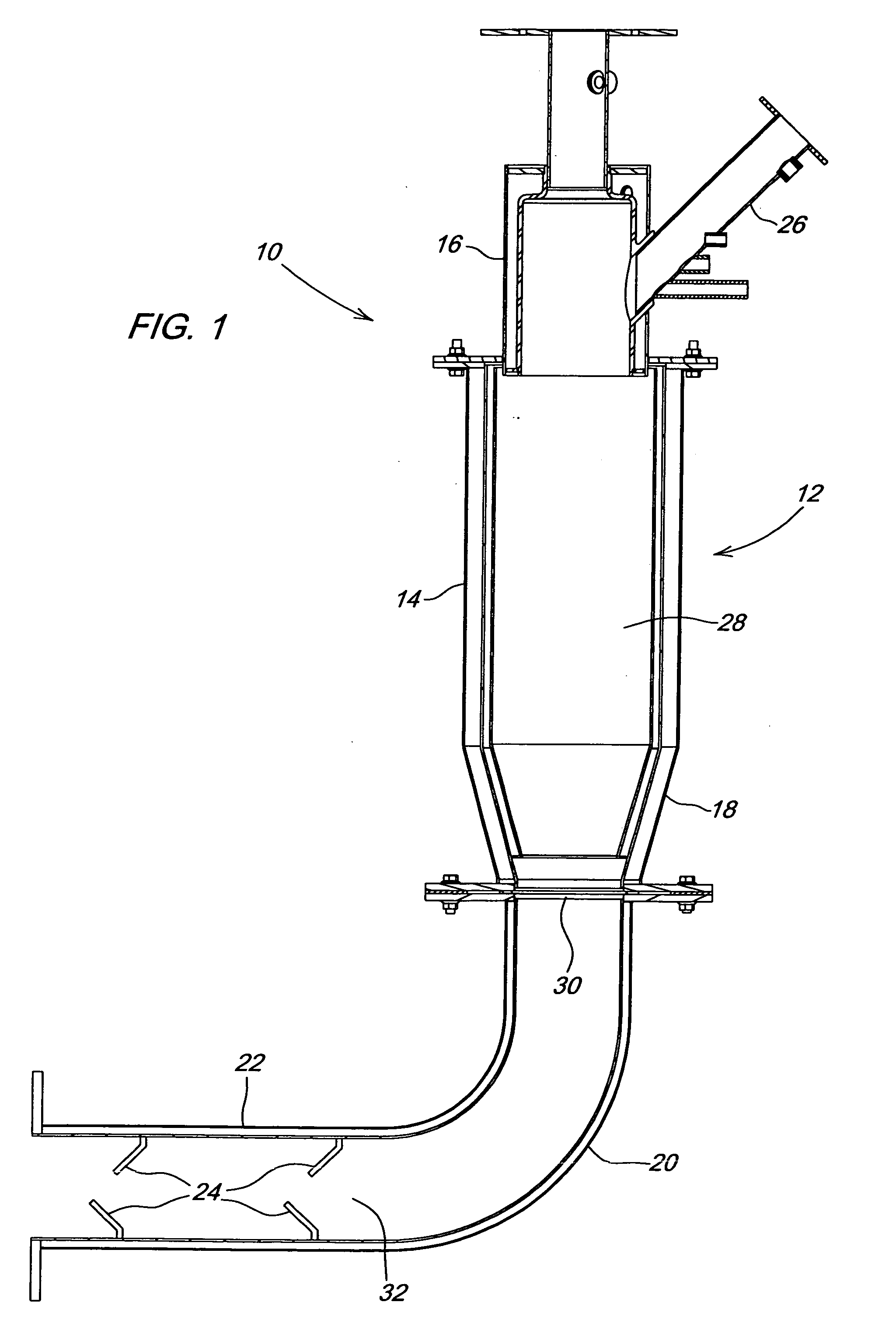

Submerged combustion disposal of produced water

InactiveUS7845314B2Easy to handleEasy disposalBoiler cleaning apparatusSedimentation separationCombustion systemCombustion chamber

The present invention relates to a method of disposing of produced water and to a produced water disposal apparatus including a container for receiving and holding produced water; and a burner having a combustion chamber, wherein at least a portion of the combustion chamber is submerged in the water and the submerged portion of the combustion chamber comprises a sparger tube through which combustion gases emerge into, mix with and agitate the water. The present invention further relates to a mechanism for removing debris from the produced water disposal apparatus. In one embodiment, heat is supplied from an externally operated combustion system, rather than the submerged combustion. In one embodiment, the apparatus provides a concentrator, in which a solute can be removed and recovered from an aqueous medium containing the solute.

Owner:TDU LLC

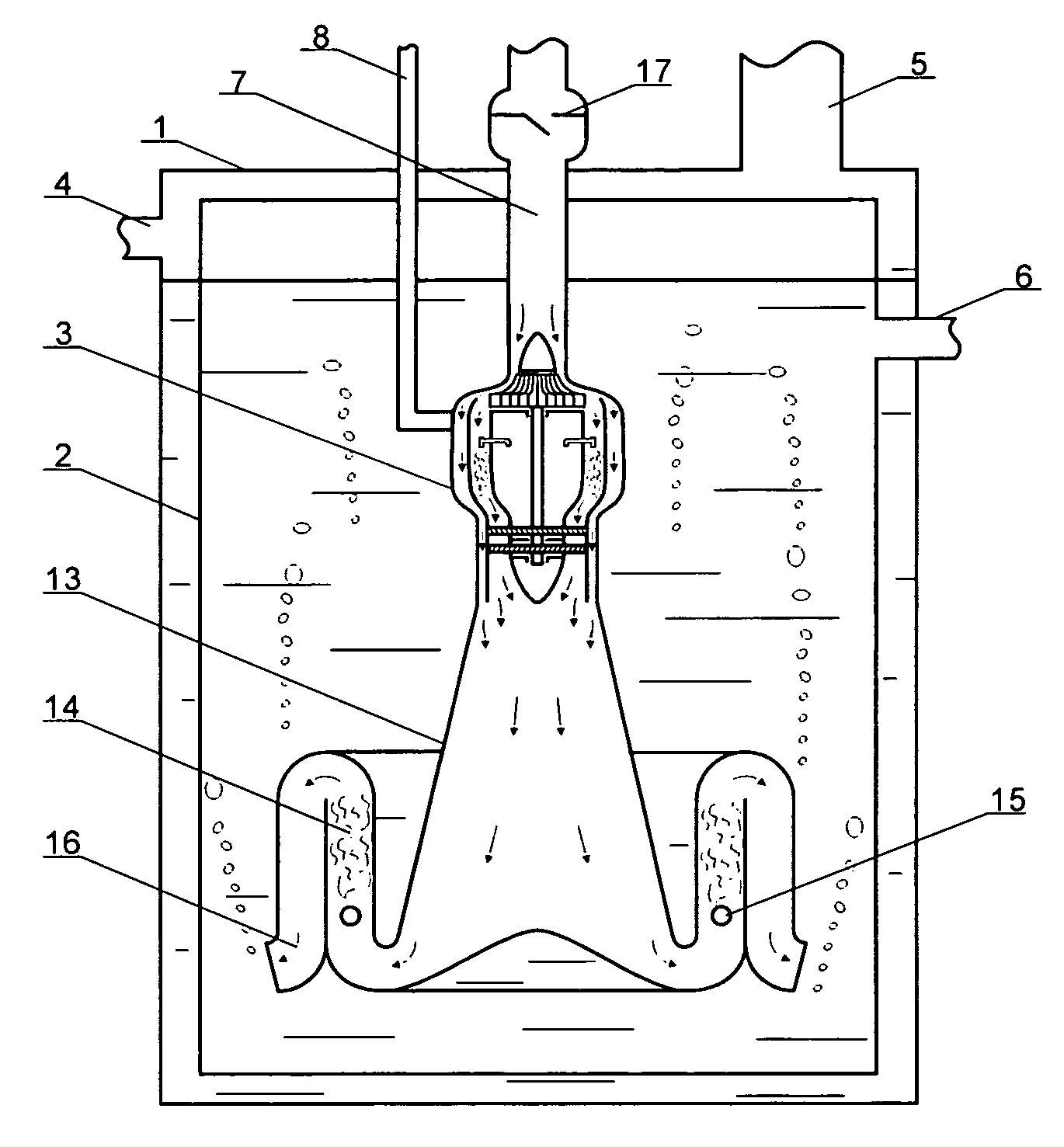

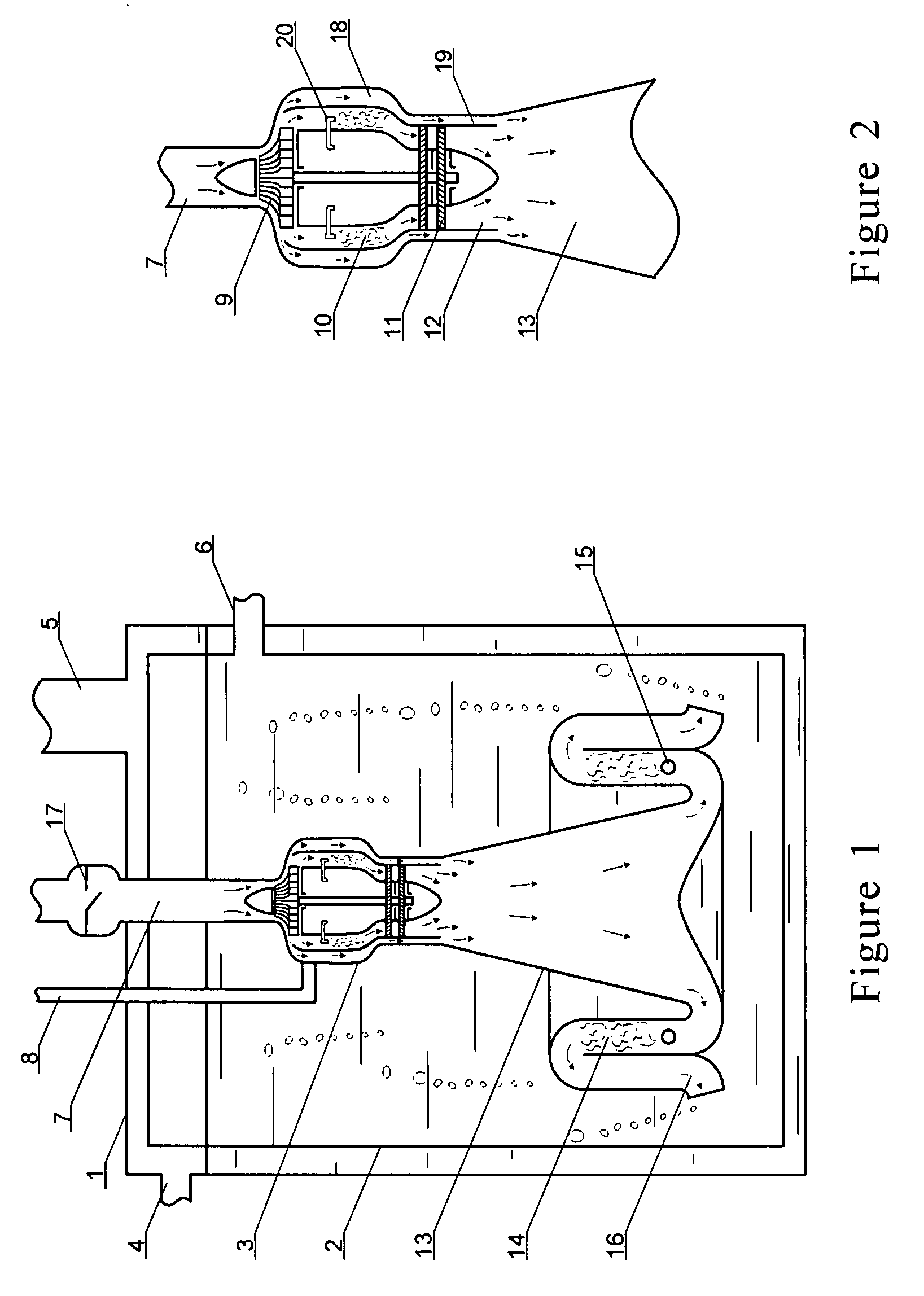

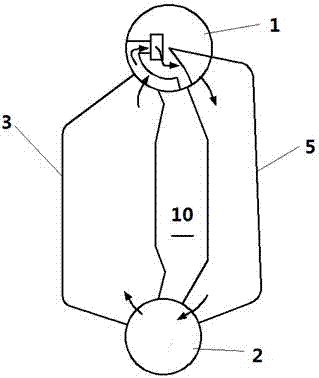

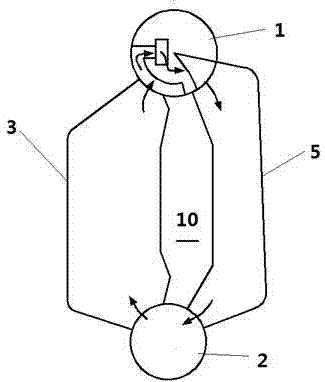

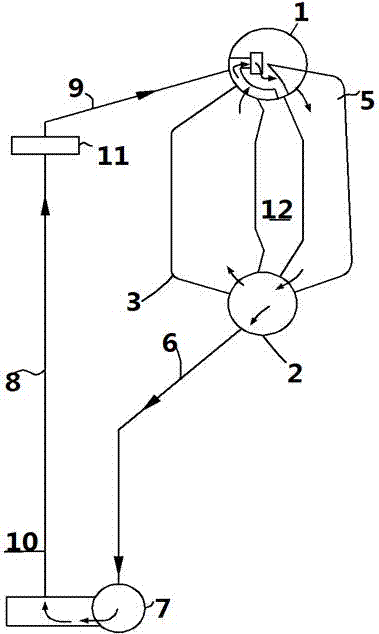

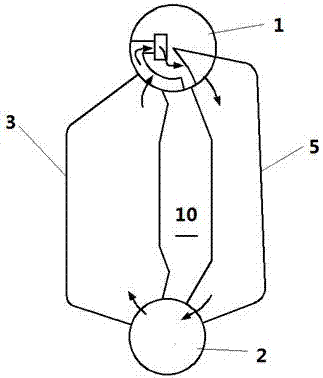

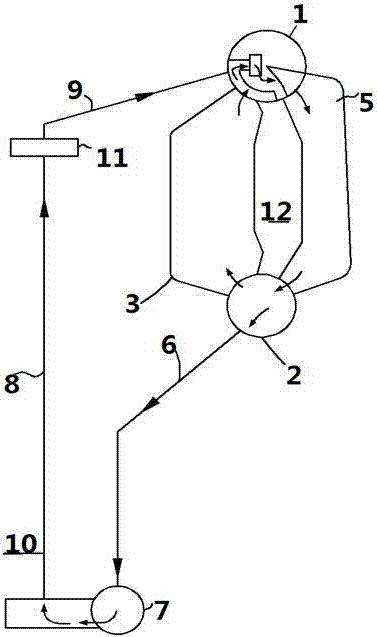

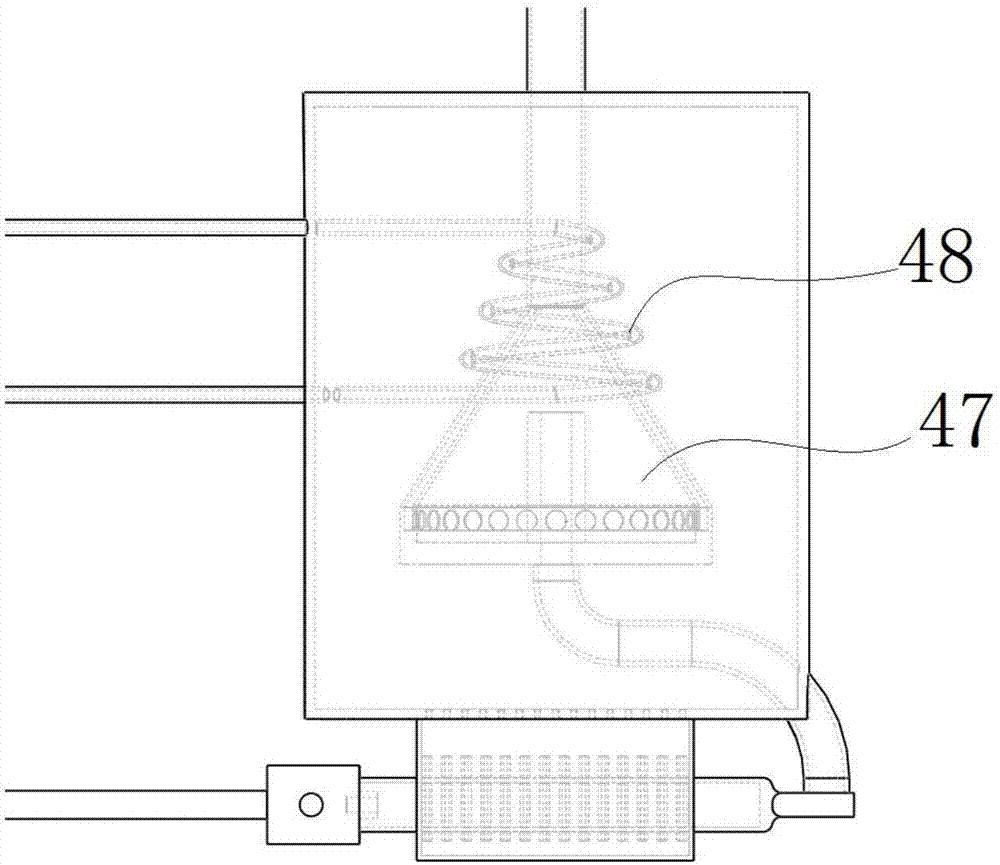

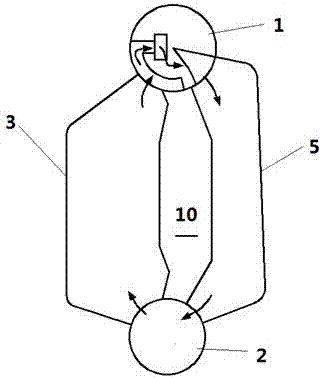

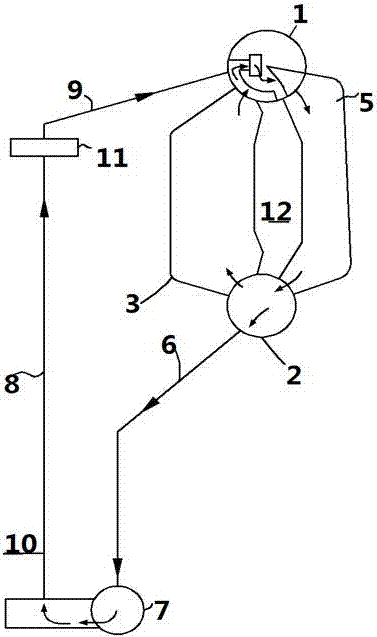

Method and device of turbine submerged combustion boiler

InactiveUS20080035078A1Improve energy efficiencySteam generation using pressureGas turbine plantsComing outHigh energy

The invention is about a submerged combustion method and the device; in details, it is a submerged combustion method and the device utilizing turbine heat engine principle. In the invention, turbine power combustion means is used and substituted conventional submerged combustion system that must equip air blowing means. The high temperature gases generated from the combustion within the turbine power combustion means will do works on turbine, which will drive the air compressor means of the turbine power combustion means to induce air for combustion, and will drive the second-time complete combustion of high temperature gases and the complement fuel, and then the gases will come out from water bottom against tank water pressure and carry out heat interchange with tank water. The turbine submerged combustion boiler device of the invention need not equip air blowing means additionally which would consume energy. So it has high energy efficiency and a simple system structure. And it has features of high heat interchange rate, stable long term heat efficiency, environmental protection, etc.

Owner:LI WEICHENG

Submerged combustion disposal of produced water

InactiveUS20080110417A1Easy to handleEasy disposalBoiler cleaning apparatusSedimentation separationCombustion systemCombustion chamber

The present invention relates to a method of disposing of produced water and to a produced water disposal apparatus including a container for receiving and holding produced water; and a burner having a combustion chamber, wherein at least a portion of the combustion chamber is submerged in the water and the submerged portion of the combustion chamber comprises a sparger tube through which combustion gases emerge into, mix with and agitate the water. The present invention further relates to a mechanism for removing debris from the produced water disposal apparatus. In one embodiment, heat is supplied from an externally operated combustion system, rather than the submerged combustion. In one embodiment, the apparatus provides a concentrator, in which a solute can be removed and recovered from an aqueous medium containing the solute.

Owner:TDU LLC

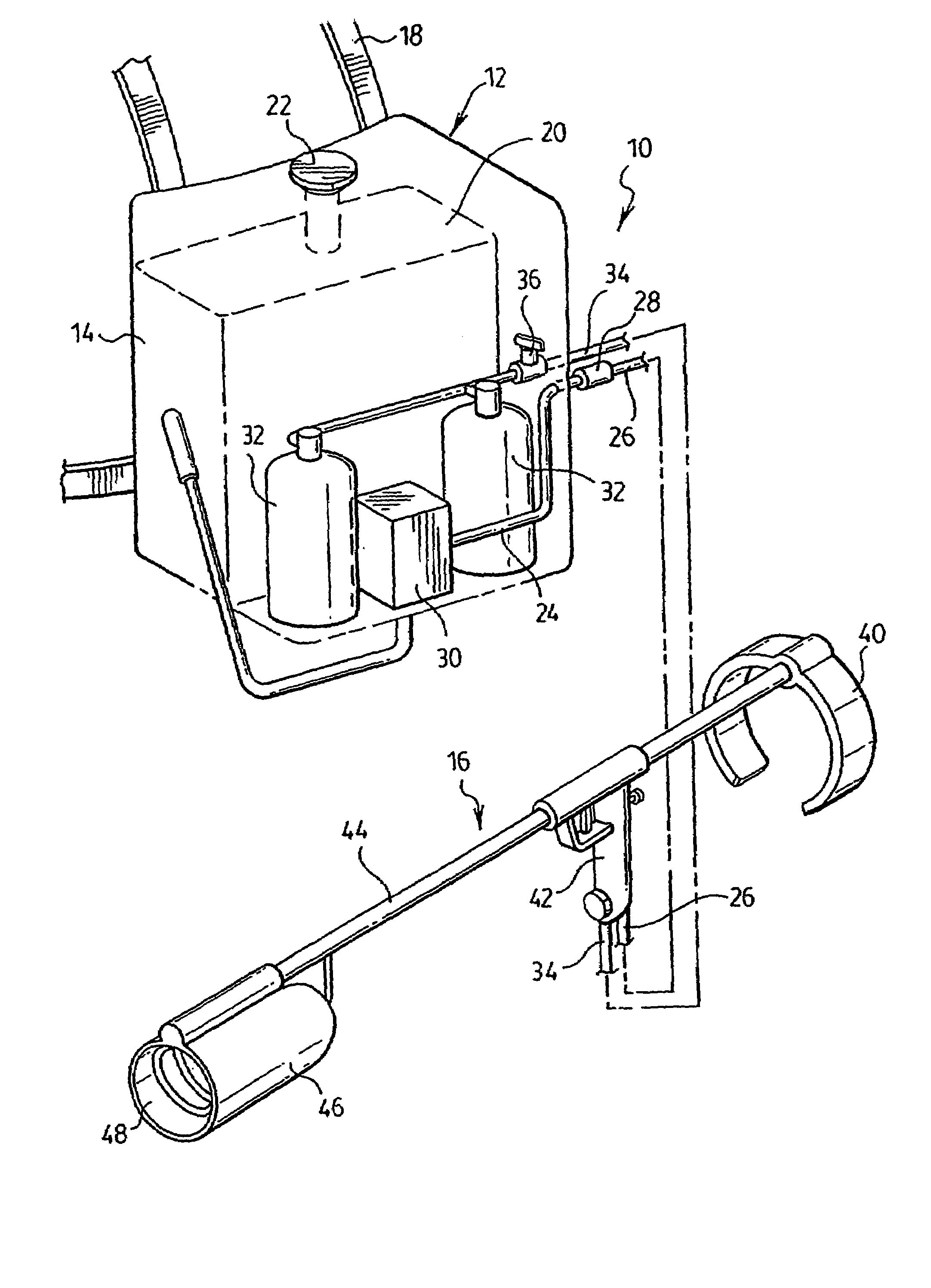

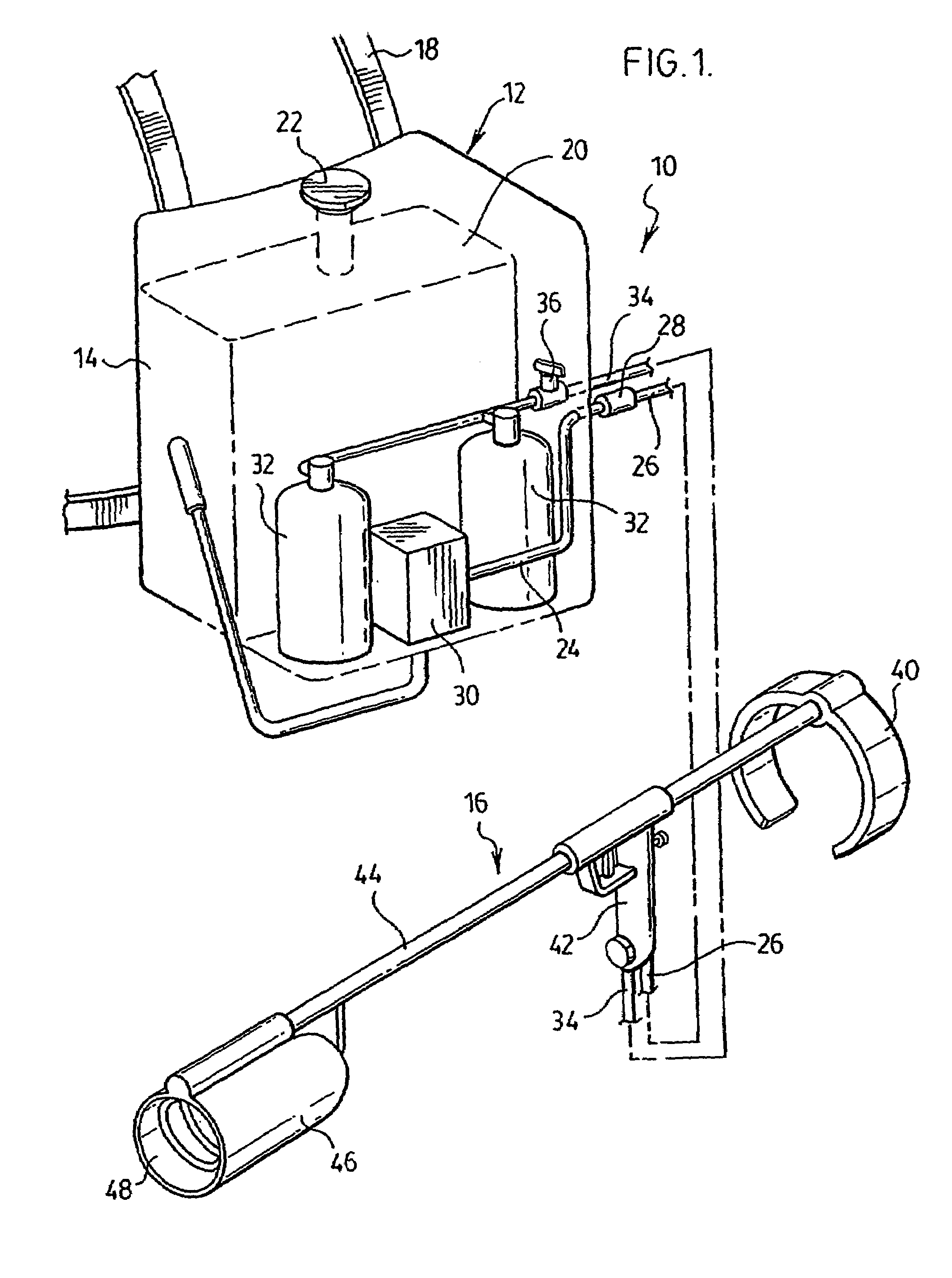

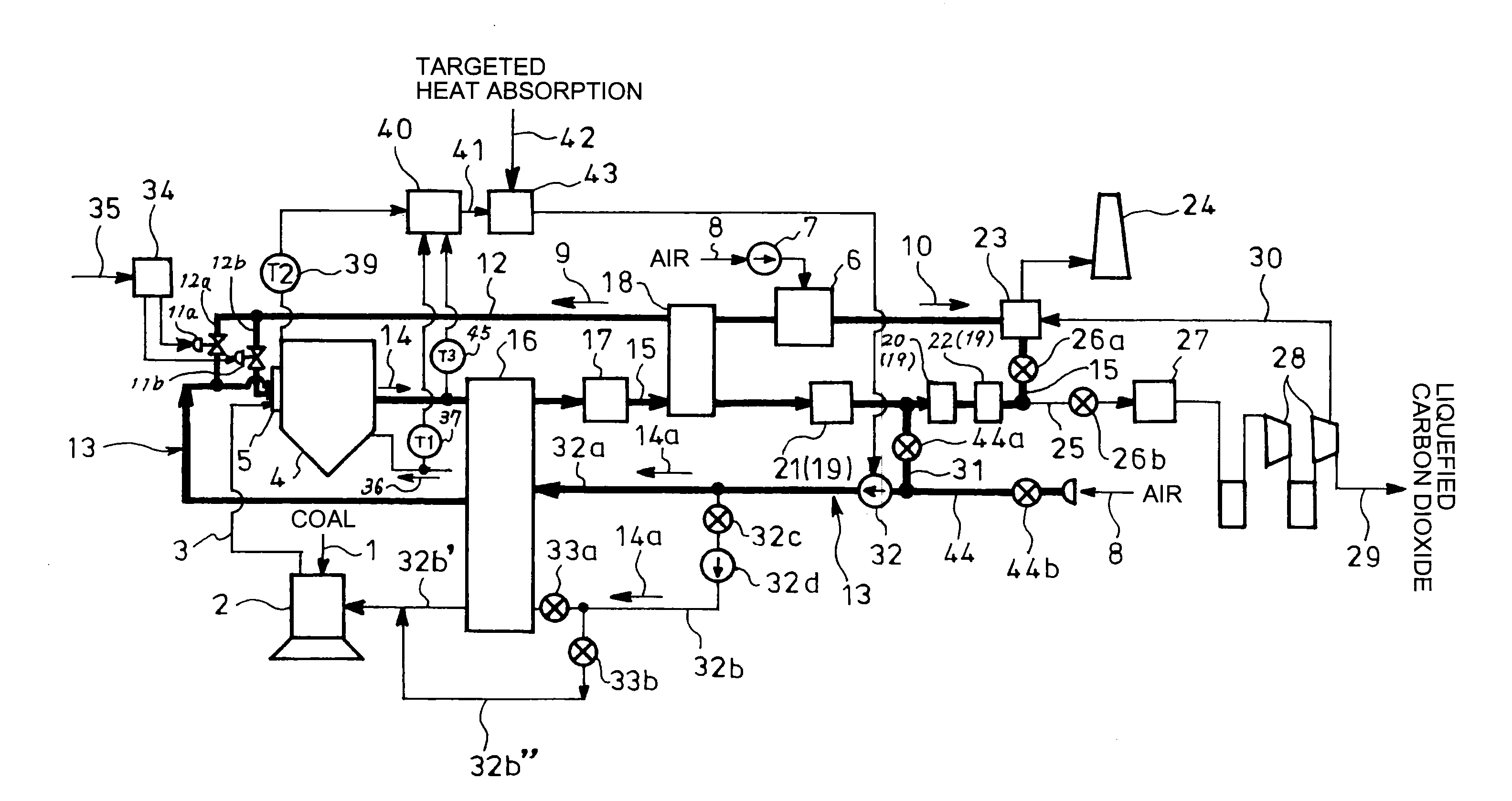

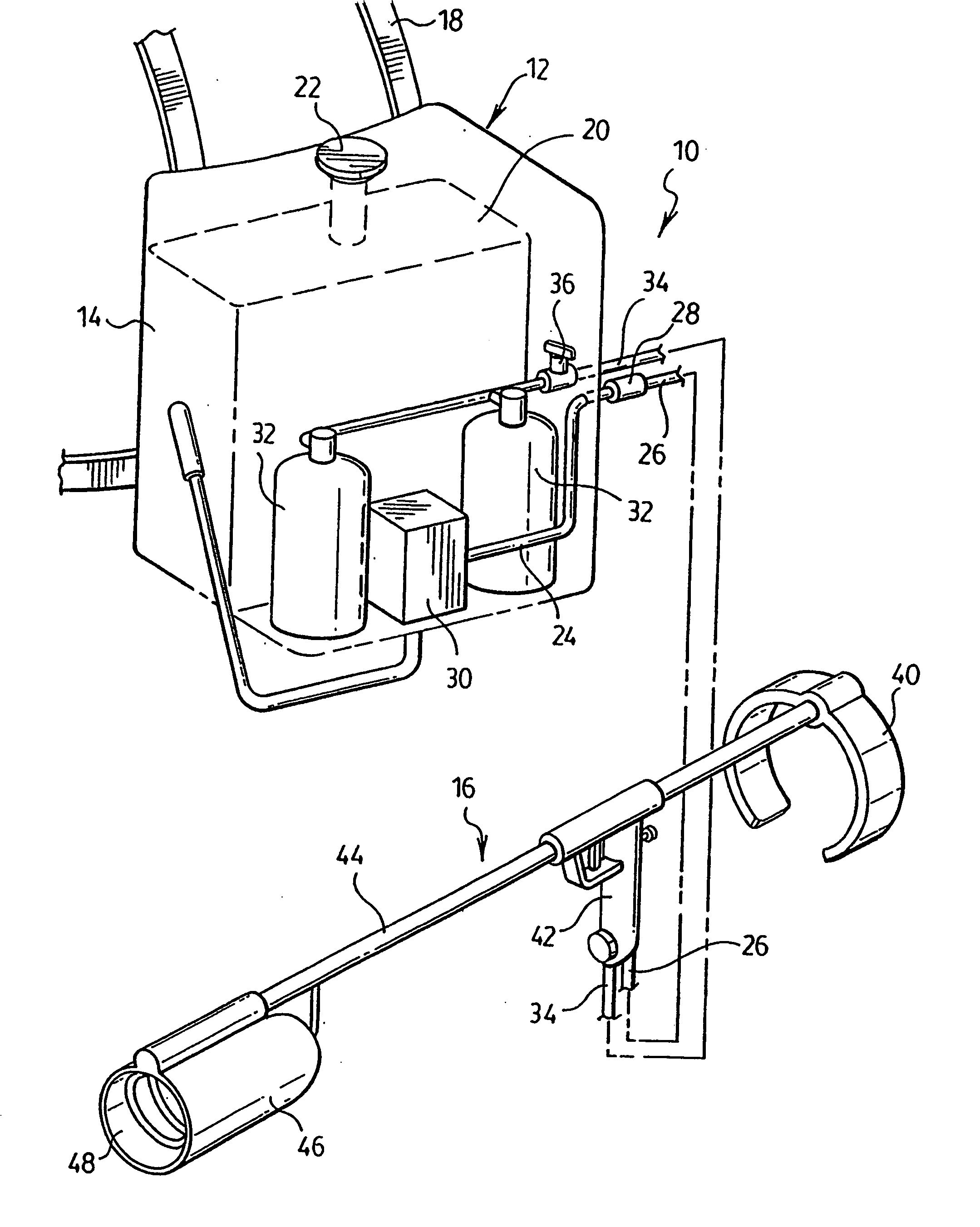

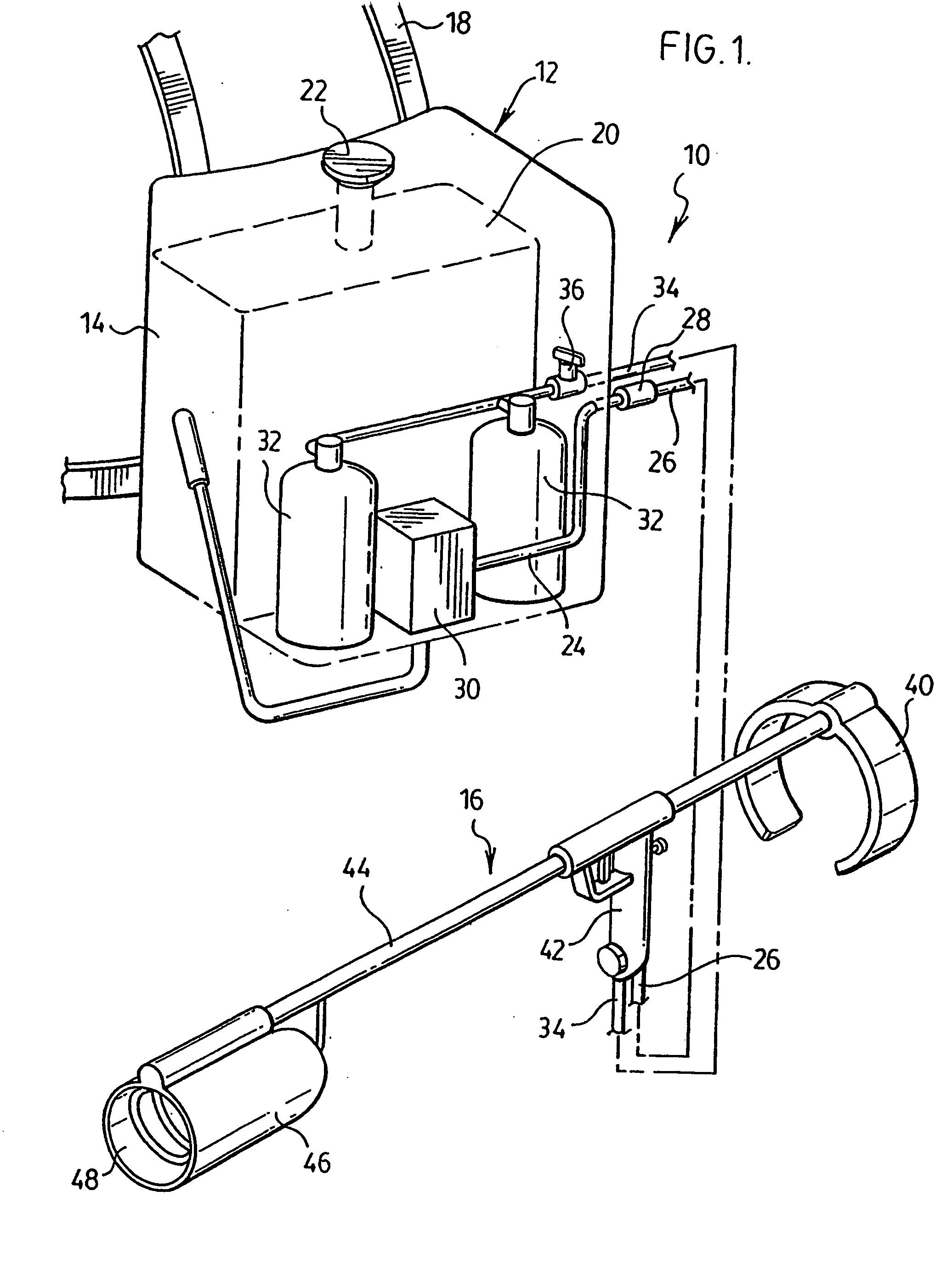

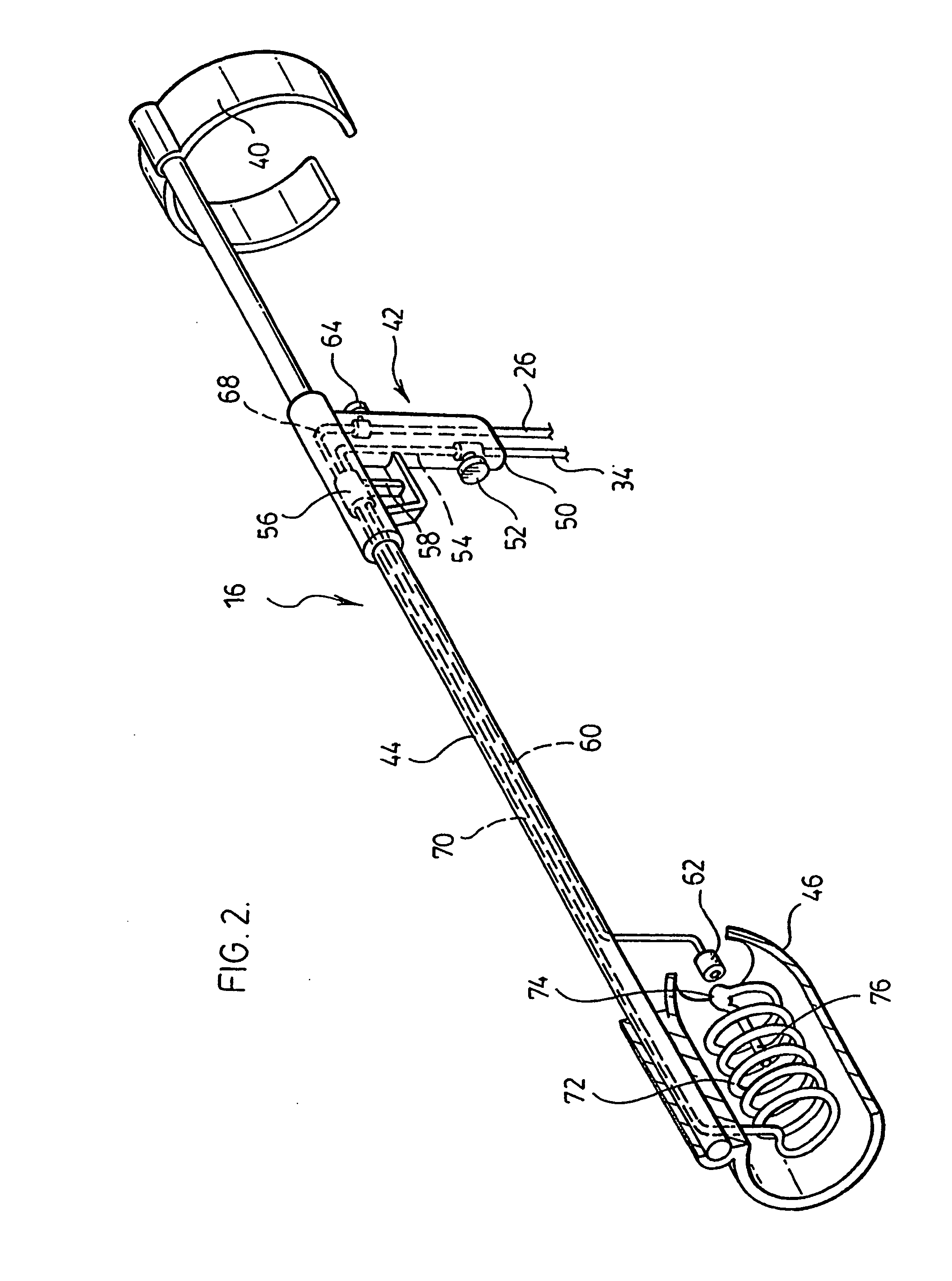

Portable steam and heat generator

The present invention is directed to an apparatus for directing steam, hot water or hot water vapor and hot air onto a target area, the apparatus comprising a water container and a fuel container connected and supplying water and fuel to an applicator wand with an applicator head which generates steam and heat for application adjacent to the target area of application to the unwanted vegetation. Steam is generated immediately adjacent to the target area within the applicator head and combined with surplus heat from the steam generation process to produce heated steam and water vapor for application to the target area. In a preferred embodiment of the invention, the applicator wand is hand held, the applicator head having an inlet, an outlet and a body therebetween, the water and fuel being supplied to a steam generator and burner within the body of the applicator head which generates steam and hot air adjacent to the target area for application through the outlet to the target area.

Owner:GREENSTEAM

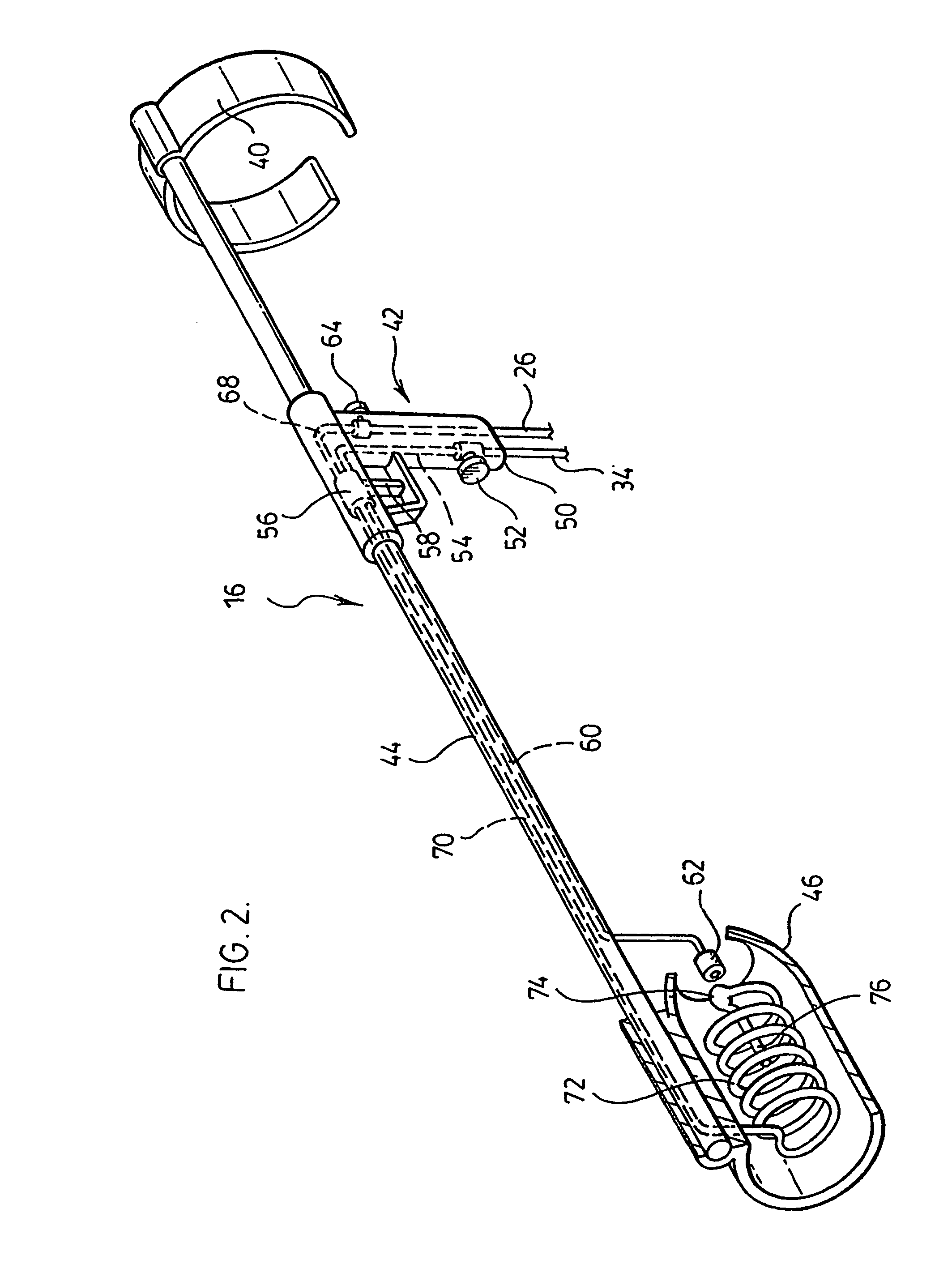

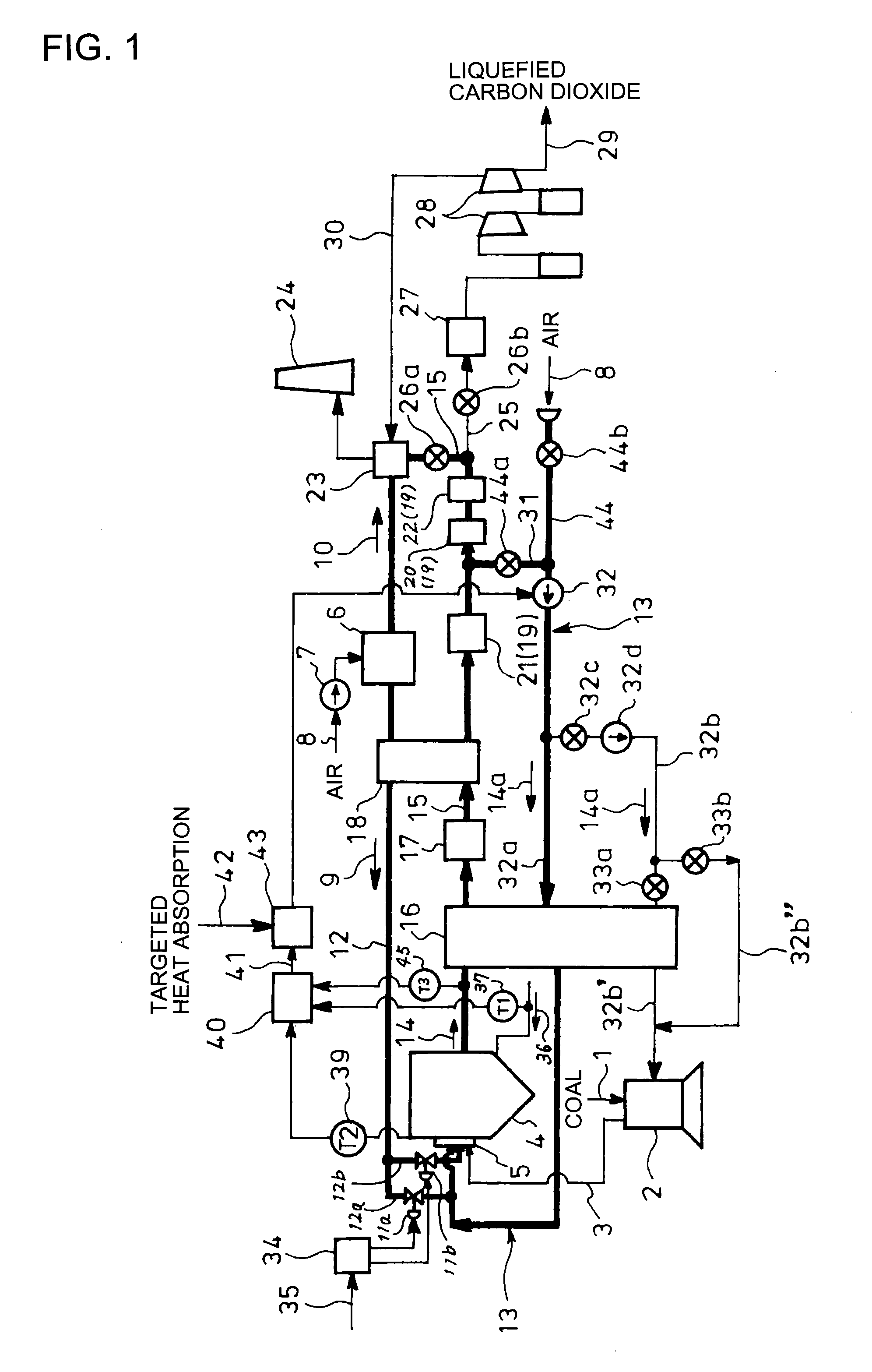

Method and apparatus for controlling combustion in oxygen fired boiler

ActiveUS20090272300A1Great advantageGood effectMechanical apparatusFluegas recirculationCombustionEngineering

Provided are a method and an apparatus for controlling combustion in an oxygen fired boiler which are easily applicable to an existing air fired boiler for easy and stable control of the combustion.Oxygen with a setting amount in accordance with a boiler load demand 35 is supplied to a boiler body 4. Heat absorption amount of the boiler is measured from inlet temperature of feedwater supplied to the boiler body 4 and outlet temperature of steam. Recirculation flow rate of combustion exhaust gas 14a is controlled such that heat absorption amount 41 of the boiler body 4 becomes equal to a targeted heat absorption amount 42 to thereby control oxygen concentration in all gas guided to the boiler body 4.

Owner:ELECTRIC POWER DEVELOPMENT COMPANY +1

Pipeline heater

ActiveUS7066730B2Extended stayImprove heat transfer performanceOther heat production devicesSteam generation using pressureEngineeringResidence time

A pipeline heater comprising a plurality of flameless catalytic IR emitters positioned about a section of pipe in a substantially diamond-shaped configuration, the diameter of the pipe section being greater than the diameters of the heater inlet and outlet manifolds in order to increase the residence time of the fluid within the heater. The pipeline heater may comprise a single or multiple passes of the pipe section therethrough, each pass having a plurality of catalytic emitters positioned thereabout in a substantially diamond-shaped configuration.

Owner:CATALYTIC INDAL GROUP

Flow stabilizer steam boiler

ActiveCN107143838AReduce vibrationImprove heat transfer performanceBoiler water tubesSteam generation using pressureNoise levelHeat transmission

The invention provides a steam boiler. The steam boiler comprises an upper boiler barrel, a lower boiler barrel, rising pipes and falling pipes, wherein the rising pipes and the falling pipes are connected between the upper boiler barrel and the lower boiler barrel. The rising pipes are internally provided with flow stabilizers, and the multiple flow stabilizers are arranged in the same rising pipe; and the lengths of the flow stabilizers are constantly increased in the fluid flowing direction of the rising pipes. According to the flow stabilizer steam boiler of a novel structure, through length changing of the flow stabilizers, when steam-liquid two phase flowing exists in the rising pipes, heat transmission is reinforced; and meanwhile, vibration of the rising pipes is weakened, and the noise level is reduced.

Owner:咸阳新兴分布式能源有限公司

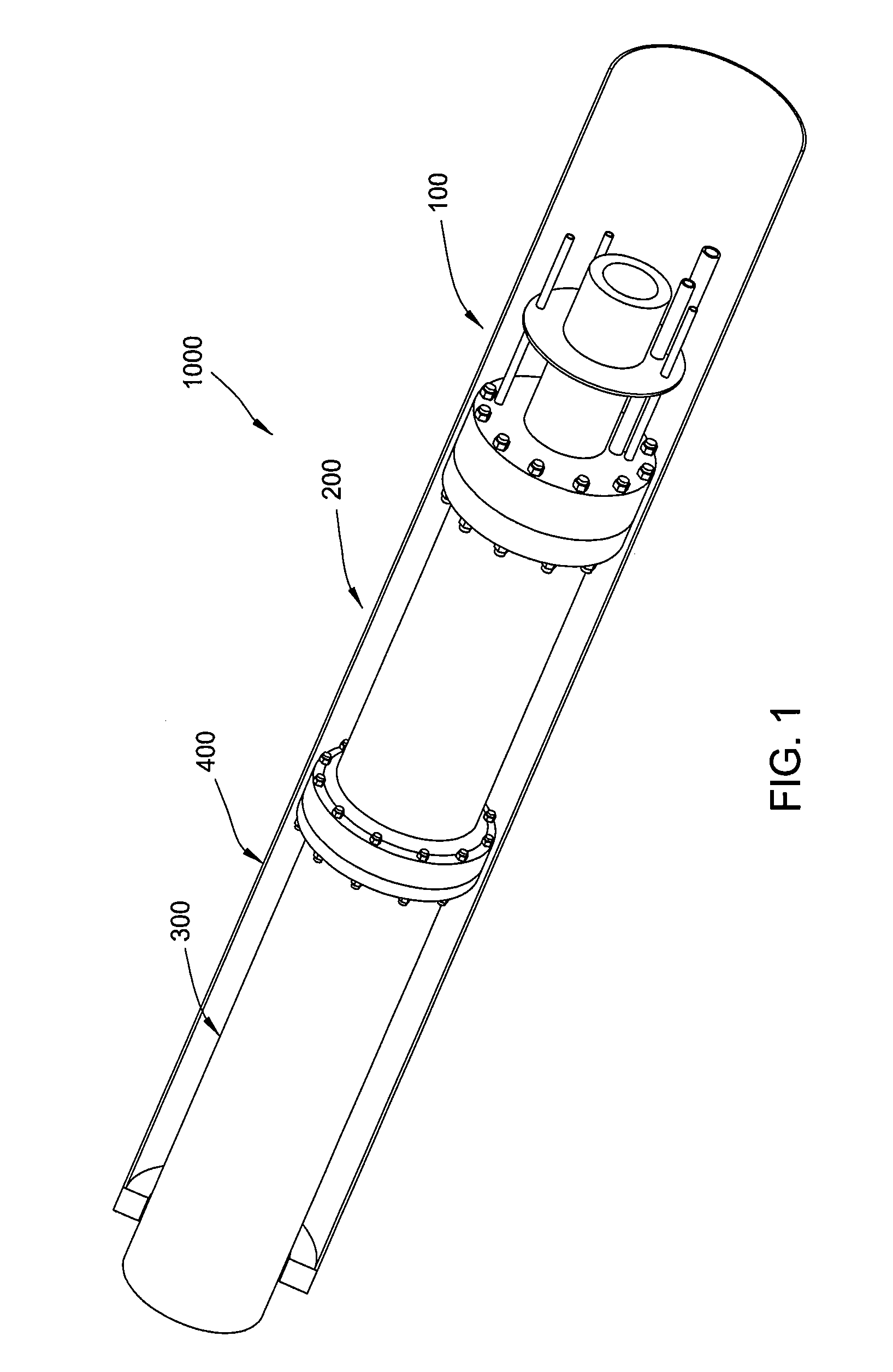

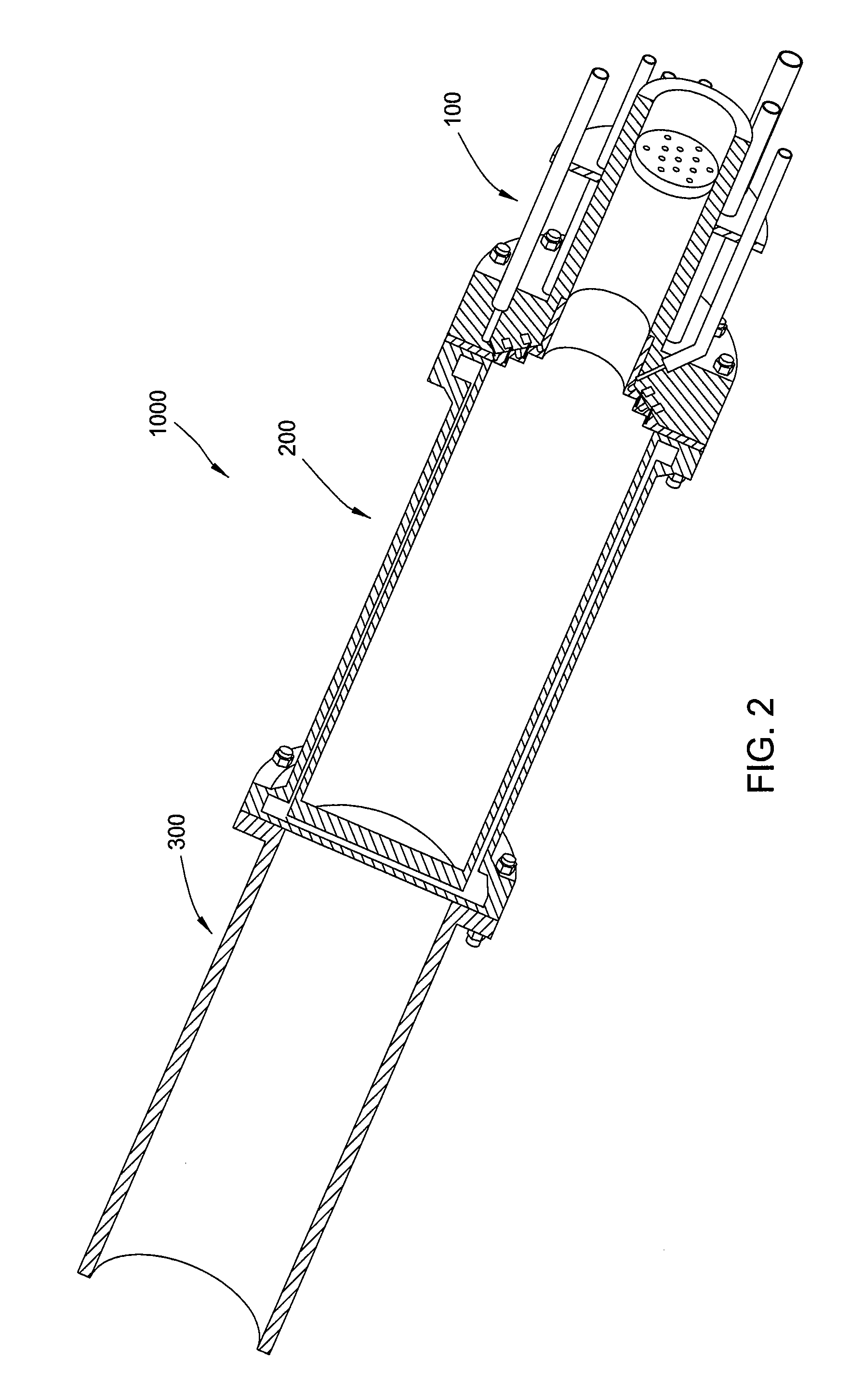

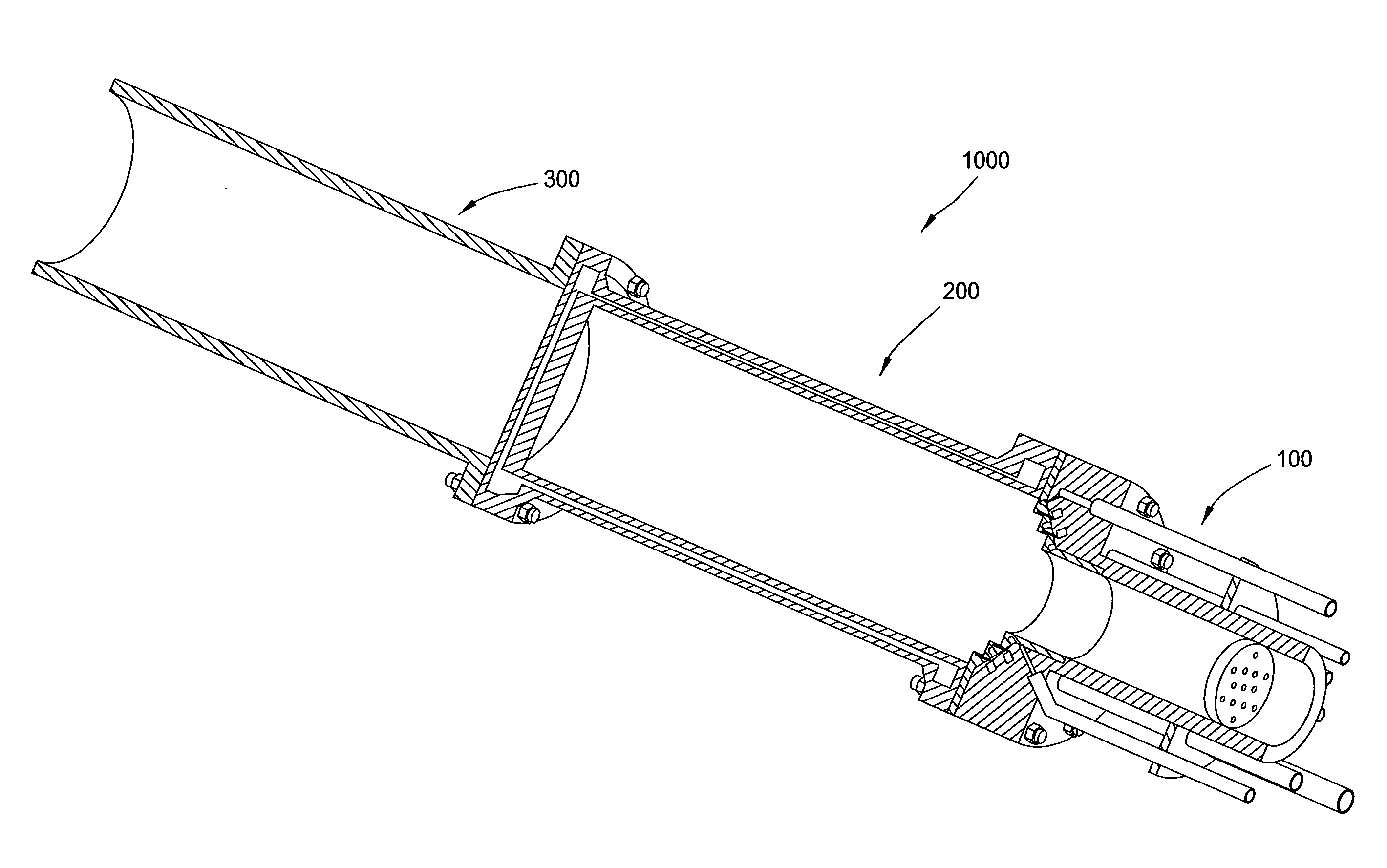

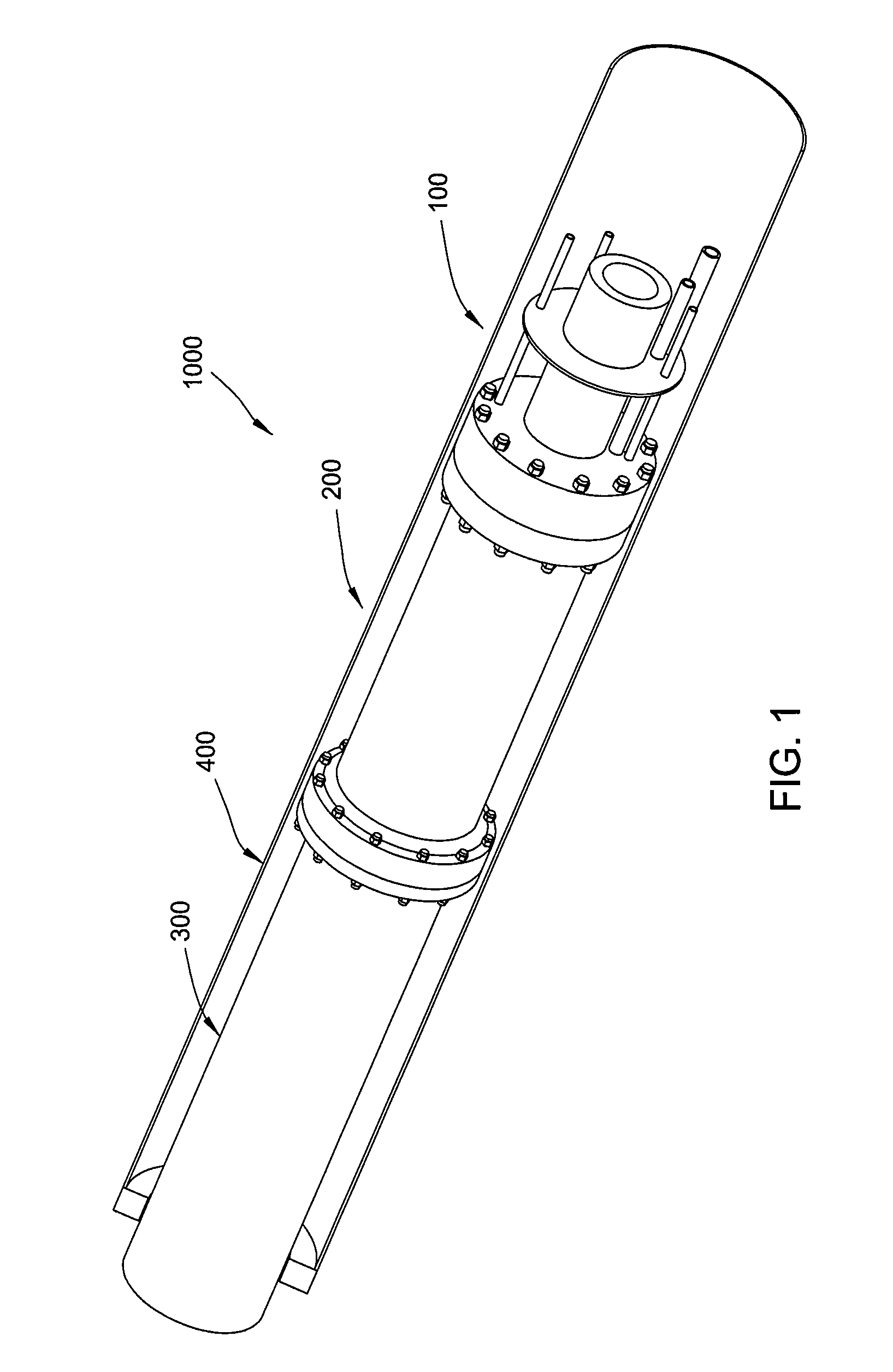

Downhole steam generator and method of use

A downhole steam generation system may include a burner head assembly, a liner assembly, a vaporization sleeve, and a support sleeve. The burner head assembly may include a sudden expansion region with one or more injectors. The liner assembly may include a water-cooled body having one or more water injection arrangements. The system may be optimized to assist in the recovery of hydrocarbons from different types of reservoirs. A method of recovering hydrocarbons may include supplying one or more fluids to the system, combusting a fuel and an oxidant to generate a combustion product, injecting a fluid into the combustion product to generate an exhaust gas, injecting the exhaust gas into a reservoir, and recovering hydrocarbons from the reservoir.

Owner:WORLD ENERGY SYST

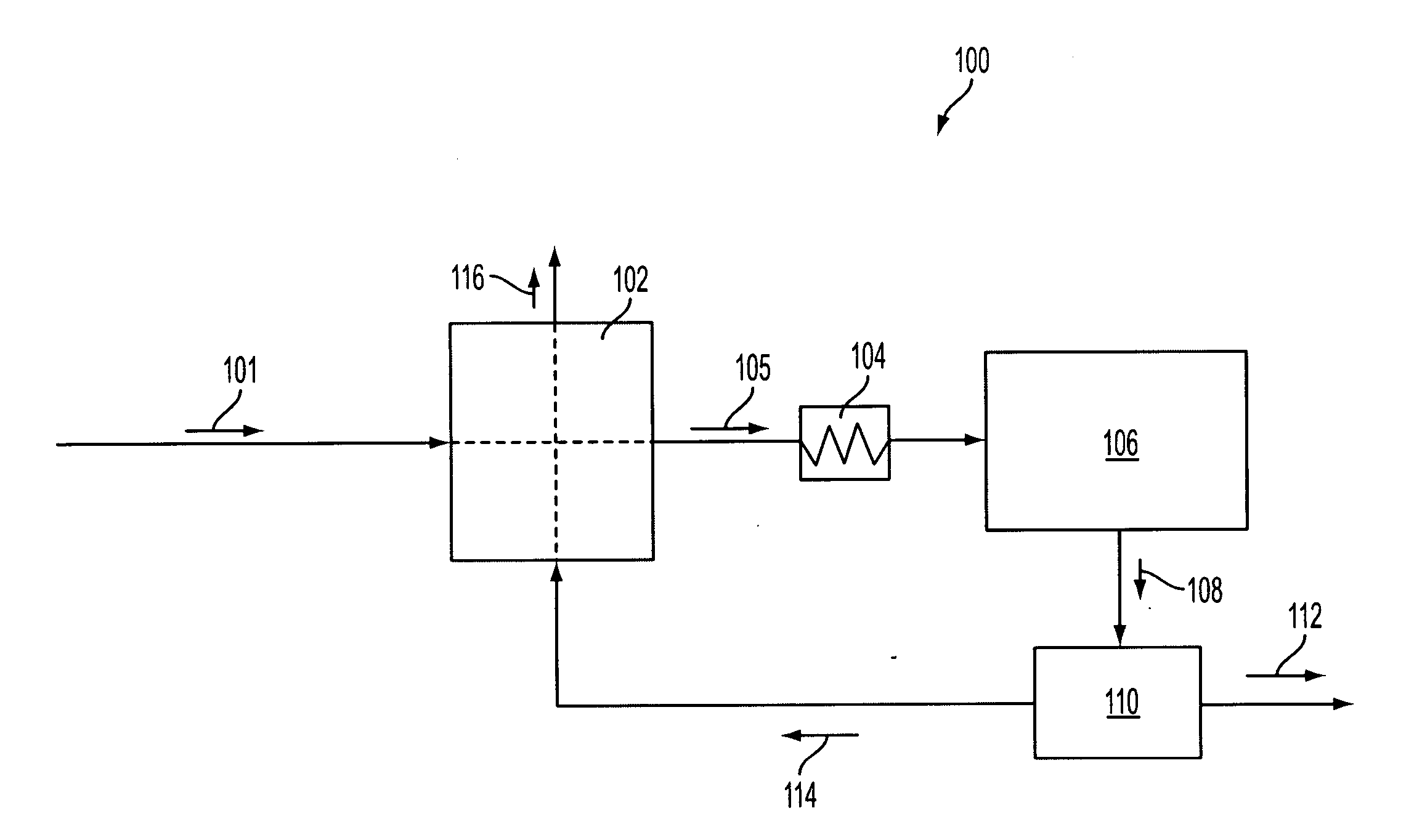

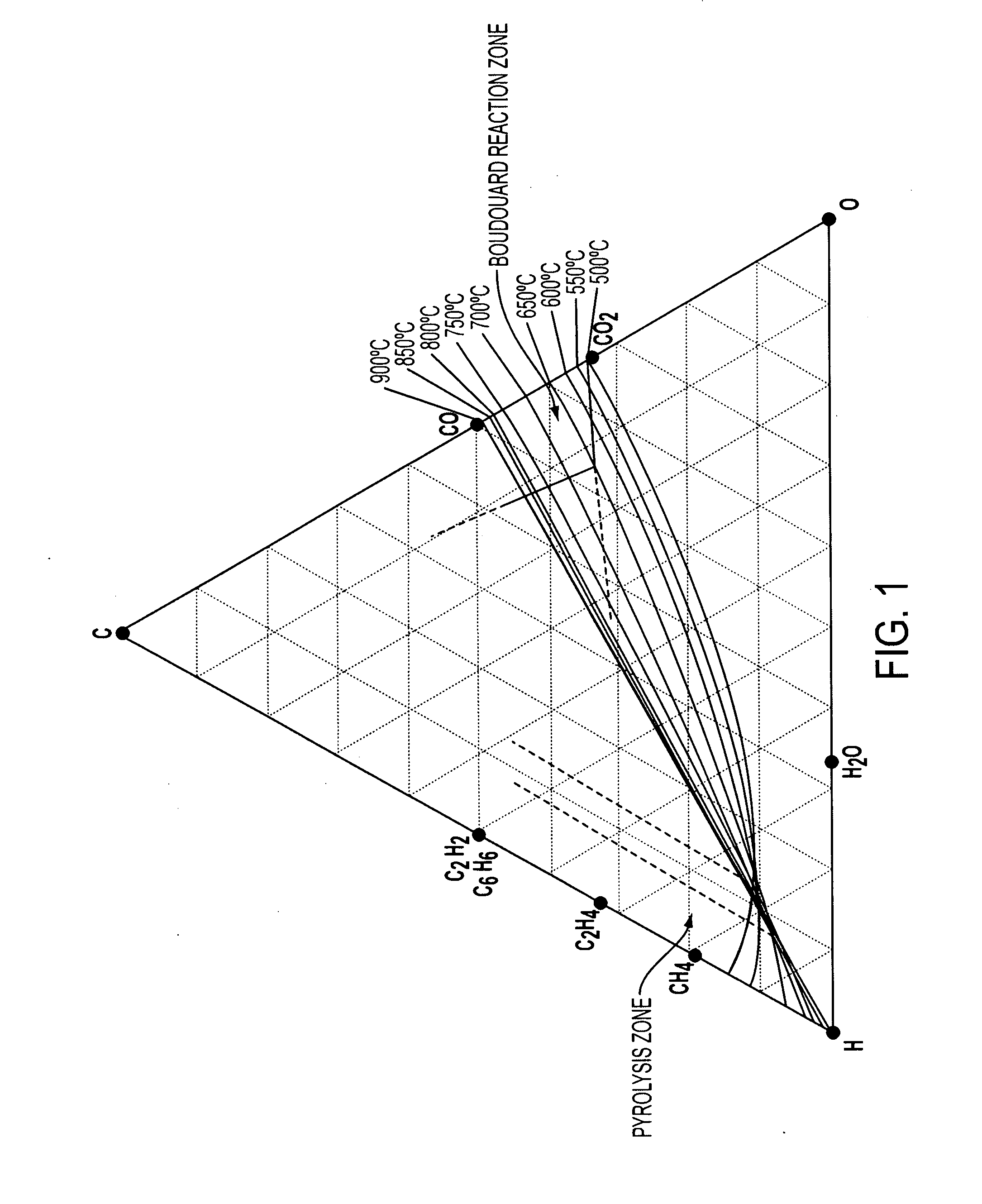

Methods and systems for thermal energy recovery from production of solid carbon materials by reducing carbon oxides

A method of thermal energy recovery from production of at least one solid carbon material comprises reacting at least one carbon oxide material and at least one gaseous reducing material at a temperature of greater than or equal to about 400° C., at a pressure greater than or equal to about 1×105 pascal, and in the presence of at least one catalyst material to produce at least one solid carbon material and a gaseous effluent stream comprising water vapor. Thermal energy is extracted from the gaseous effluent stream comprising water vapor. Other methods of generating recoverable thermal energy are disclosed, as is a solid carbon production system having thermal energy recovery.

Owner:SEERSTONE

Portable steam and heat generator

The present invention is directed to an apparatus for directing steam, hot water or hot water vapor and hot air onto a target area, the apparatus comprising a water container and a fuel container connected and supplying water and fuel to an applicator wand with an applicator head which generates steam and heat for application adjacent to the target area of application to the unwanted vegetation. Steam is generated immediately adjacent to the target area within the applicator head and combined with surplus heat from the steam generation process to produce heated steam and water vapor for application to the target area. In a preferred embodiment of the invention, the applicator wand is hand held, the applicator head having an inlet, an outlet and a body therebetween, the water and fuel being supplied to a steam generator and burner within the body of the applicator head which generates steam and hot air adjacent to the target area for application through the outlet to the target area.

Owner:GREENSTEAM

Damping steam boiler

ActiveCN107143837AReduce vibrationImprove heat transfer performanceBoiler water tubesSteam generation using pressureHeat transmissionNoise level

The invention provides a damping steam boiler. The damping steam boiler comprises an upper boiler barrel, a lower boiler barrel, rising pipes and falling pipes, wherein the rising pipes and the falling pipes are connected between the upper boiler barrel and the lower boiler barrel. The rising pipes are internally provided with flow stabilizers, and the multiple flow stabilizers are arranged in the same rising pipe; and the space between every two adjacent flow stabilizers is constantly reduced in the fluid flowing direction of the rising pipes. According to the damping steam boiler, through gap changing of the flow stabilizers, when steam-liquid two phase flowing exists in the rising pipes, heat transmission is reinforced; and meanwhile, vibration of the rising pipes is weakened, and the noise level is reduced.

Owner:连云港虹洋热电有限公司

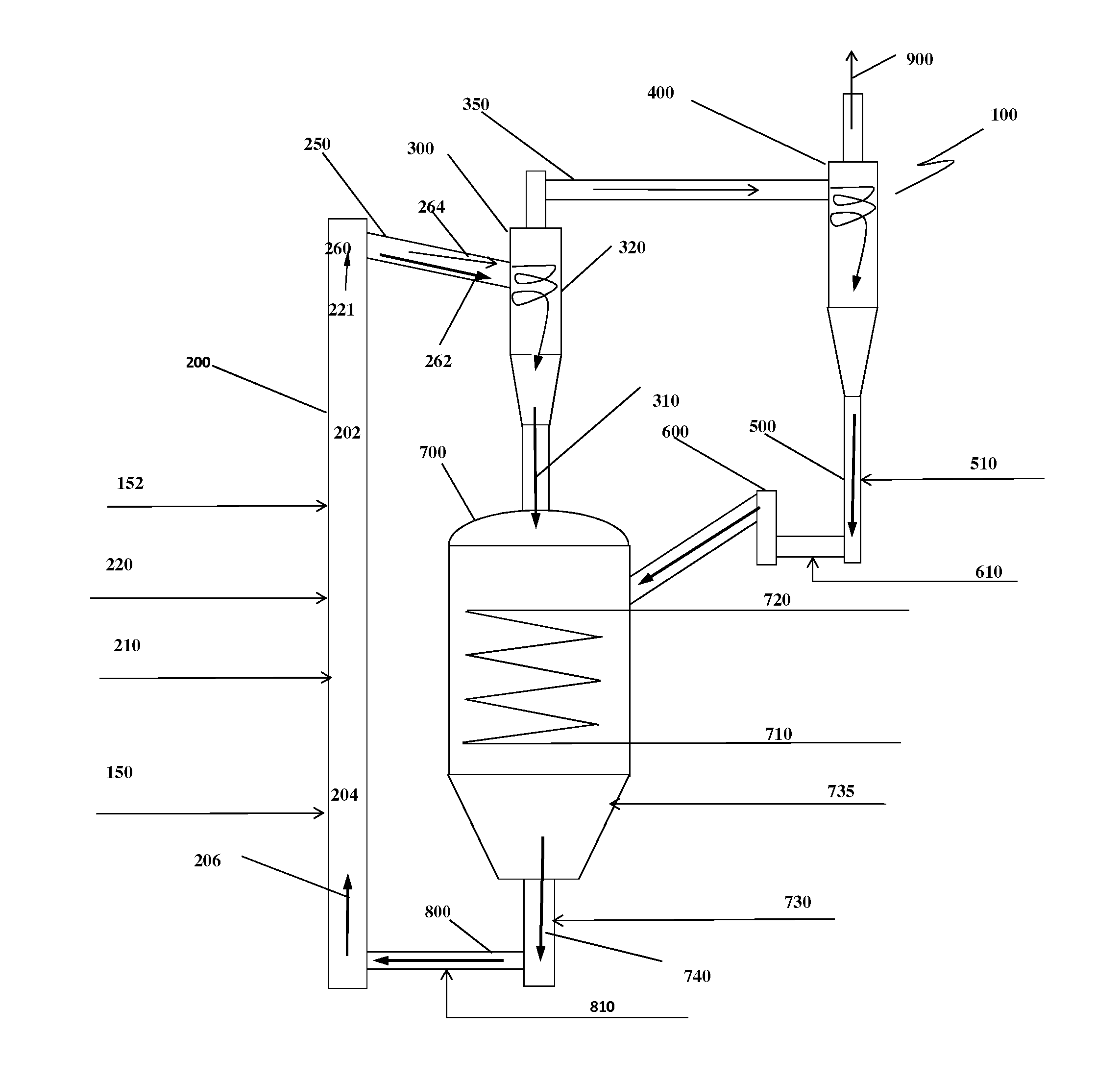

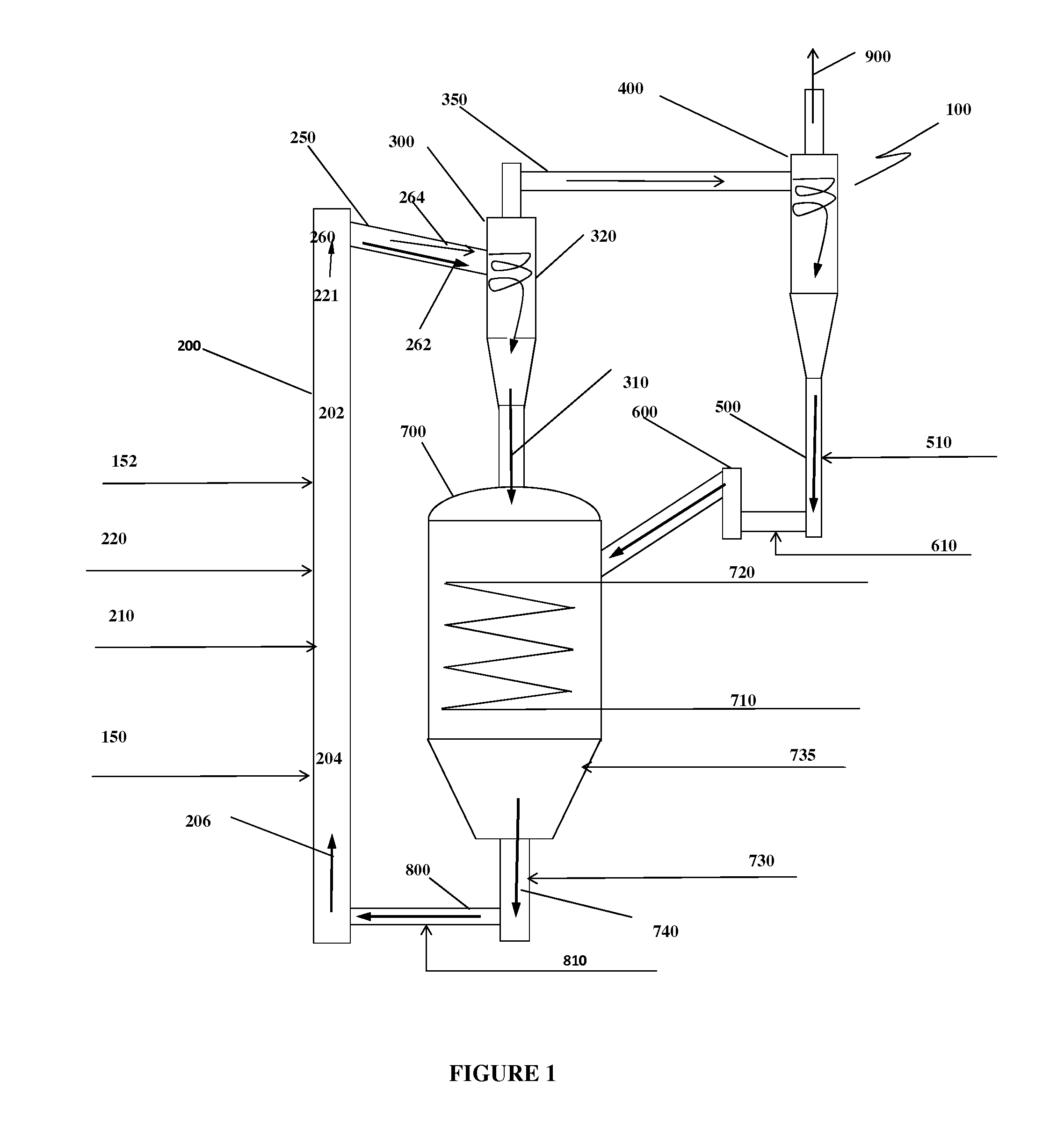

Oxycombustion In Transport Oxy-Combustor

ActiveUS20130055936A1Efficient removalReduce operating costsFluidized bed combustionSteam generation using pressureFlue gasMoisture condensation

A pressurized transport oxy-combustor with different configurations is disclosed. Substantially pure oxygen is fed to the transport oxy-combustor under pressure to combust fossil fuels, generating steam for power generation. The end product is the flue gas containing substantially pure CO2 after moisture condensation. The low excess oxygen necessary to achieve complete combustion in the combustor is scavenged by adding another fuel so that substantially all oxygen fed to the combustor is completely consumed. The capability to operate the transport oxy-combustor as a circulating fluidized bed combustor at very high solids circulation rates makes it unnecessary to use recycled CO2 or flue gas as a means to moderate and control the combustion temperature. The temperature in the combustor is effectively controlled by relatively cooler circulating solids that enter the combustion zone. A small amount of CO2 is recycled for aeration and to convey solids fuel to the combustor.

Owner:THE SOUTHERN CO

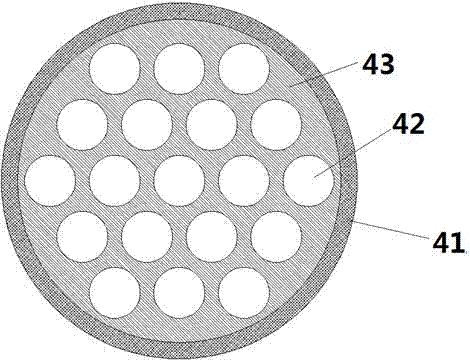

Steam boiler with through hole diameters being changeable

ActiveCN107062187AReduce vibrationReduce noise levelBoiler water tubesSteam generation using pressureNoise levelEngineering

The invention provides a steam boiler. The steam boiler comprises an upper boiler barrel, a lower boiler barrel, ascending pipes and descending pipes, wherein the ascending pipes and the descending pipes are arranged between the upper boiler barrel and the lower boiler barrel; the ascending pipes are internally provided with flow stabilizing devices, the same ascending pipe is internally provided with a plurality of the flow stabilizing devices, and the diameters of through holes of the flow stabilizing devices are smaller and smaller in the fluid flowing direction of the ascending pipes. The steam boiler is provided with the flow stabilizing devices of novel structures, and through the change of the diameters of the through holes, when gas-liquid two-phase flowing exists in the ascending pipes, heat transfer is strengthened; and meanwhile, vibration of the ascending pipes is weakened, and the noise level is lowered.

Owner:王芸芸

Steam heating system and method thereof

ActiveCN107965750AImprove energy efficiencyReduce jet dragSteam generation using pressureWater heatersCombustionWater flow

The invention discloses a steam heating system. The steam heating system comprises a steam heating box, a condensing pipe, a hot-smoke tower, a smoke guide pipe and a combustion furnace body, whereina smoke exhaust end of the combustion furnace body is in conduction connection with a smoke inlet end of the hot-smoke tower through the smoke guide pipe, and a smoke outlet end of the hot-smoke toweris in conduction with the outside through a smoke exhaust pipe; the steam heating box is of a negative pressure box body structure in the shape of an airtight column; the condensing pipe and the hot-smoke tower are arranged in a steam cavity of the steam heating box; the condensing pipe is spirally arranged above the hot-smoke tower in a helical shape; and condensed water flowing off from the condensing pipe just drips onto the hot-smoke tower. A hot-smoke pipe in an inverted state and in the shape of a hollow top is adopted, and the waste heat of smoke is adequately utilized for re-vaporizing water dripping after being condensed, so that the energy utilization rate of the smoke is increased.

Owner:临沂兴源热力有限公司

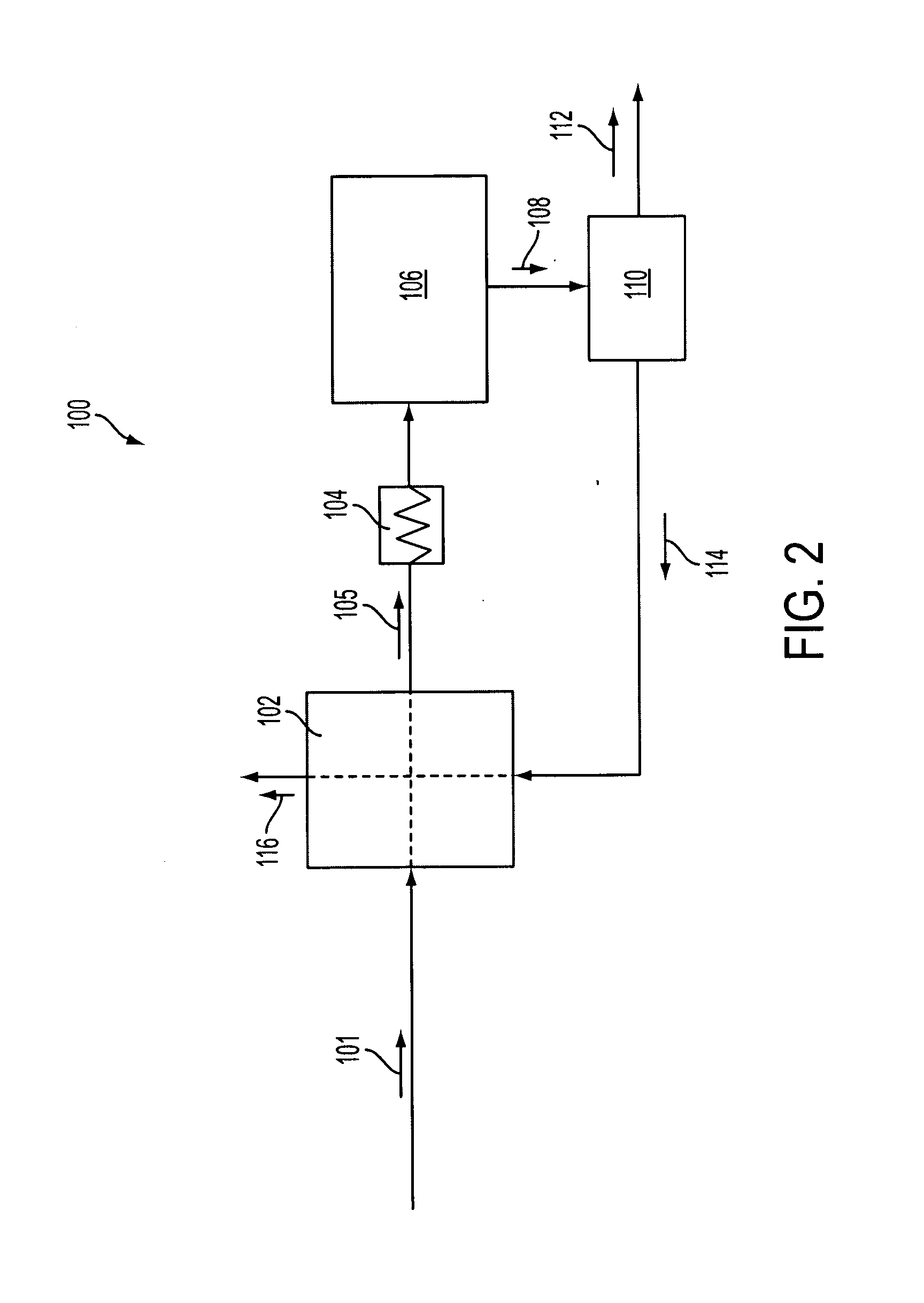

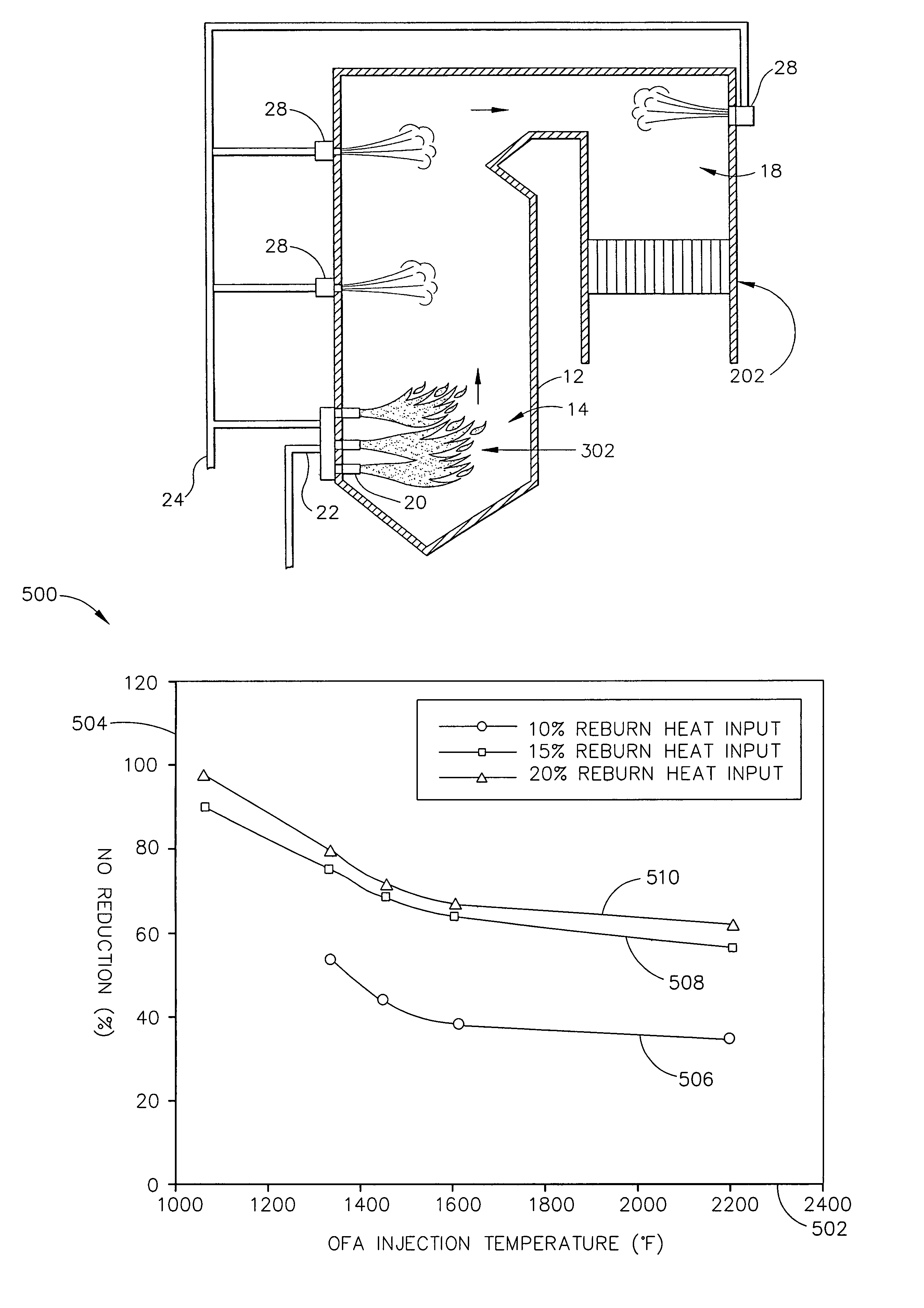

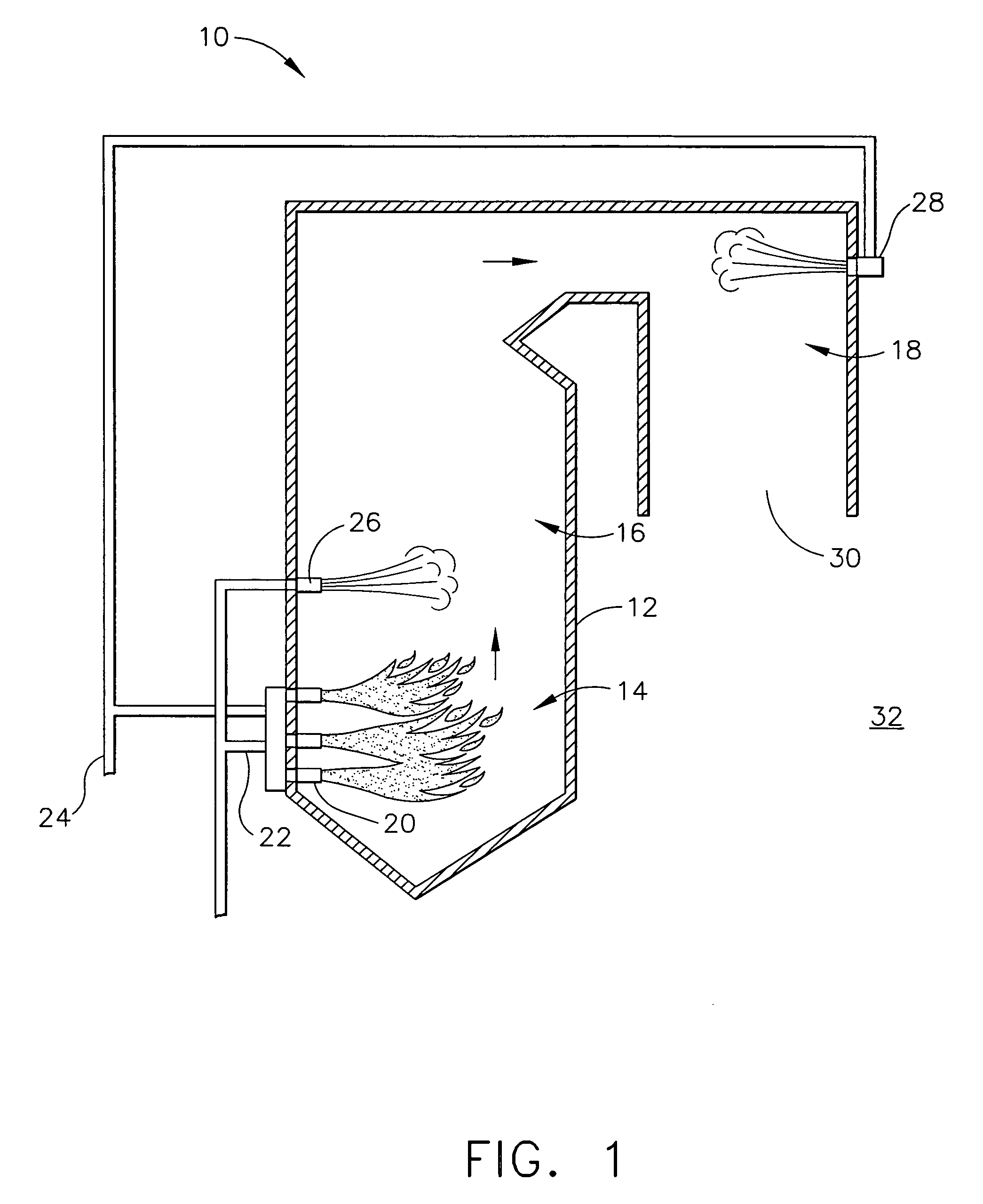

Methods and systems for operating combustion systems

ActiveUS7168947B2Reducing nitrogen oxideReduce the concentration of nitrogen oxidesStaged combustionFurnace typesCombustion systemCombustion

Methods and systems for reducing nitrogen oxides in combustion flue gas is provided. The method includes combusting a fuel in a main combustion zone such that a flow of combustion flue gas is generated wherein the combustion flue gas includes at least one nitrogen oxide species, establishing a fuel-rich zone, forming a plurality of reduced N-containing species in the fuel rich zone, injecting over-fire air into the combustion flue gas downstream of fuel rich zone, and controlling process parameters to provide conditions for the reduced N-containing species to react with the nitrogen oxides in the OFA zone to produce elemental nitrogen such that a concentration of nitrogen oxides is reduced.

Owner:GENERAL ELECTRIC CO

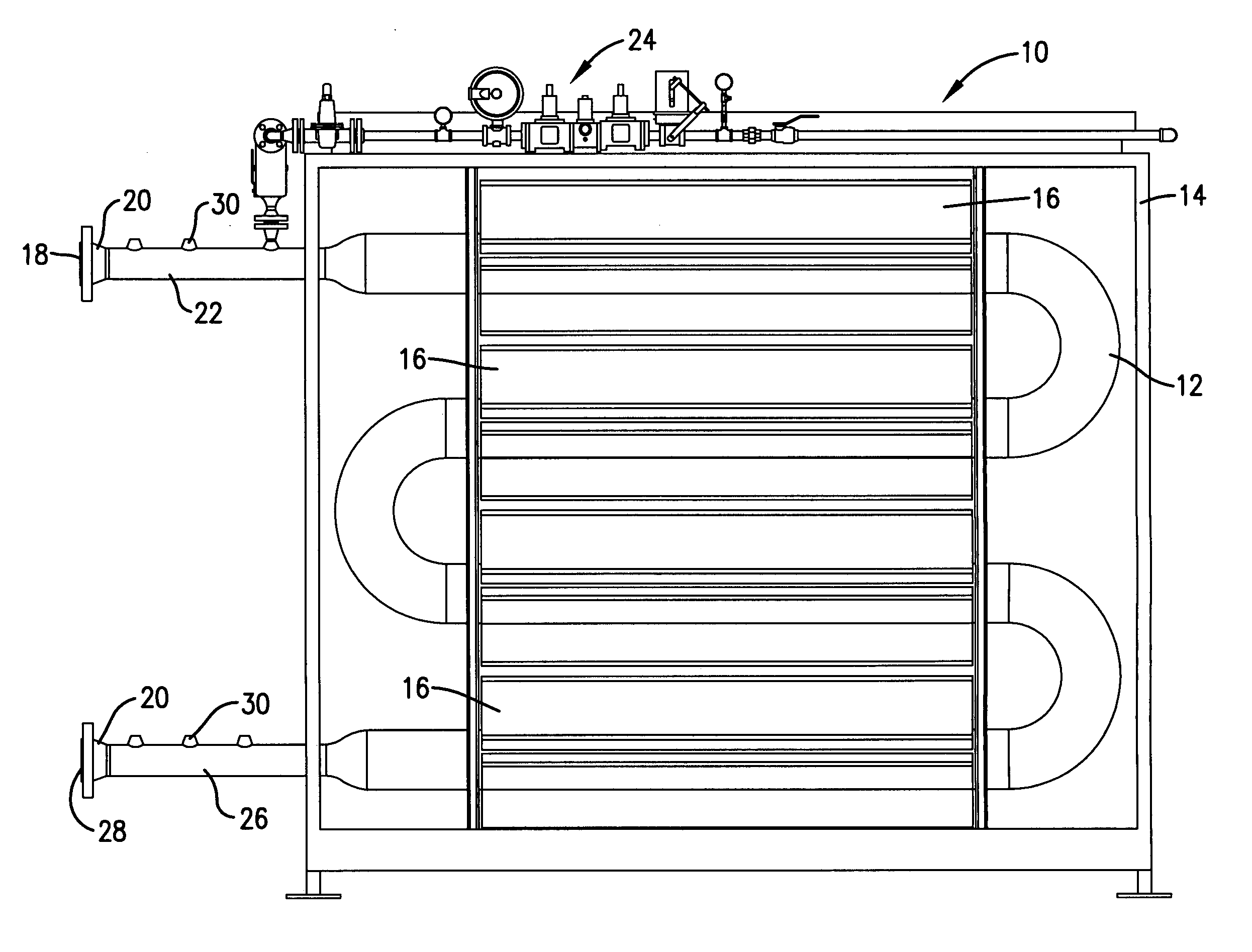

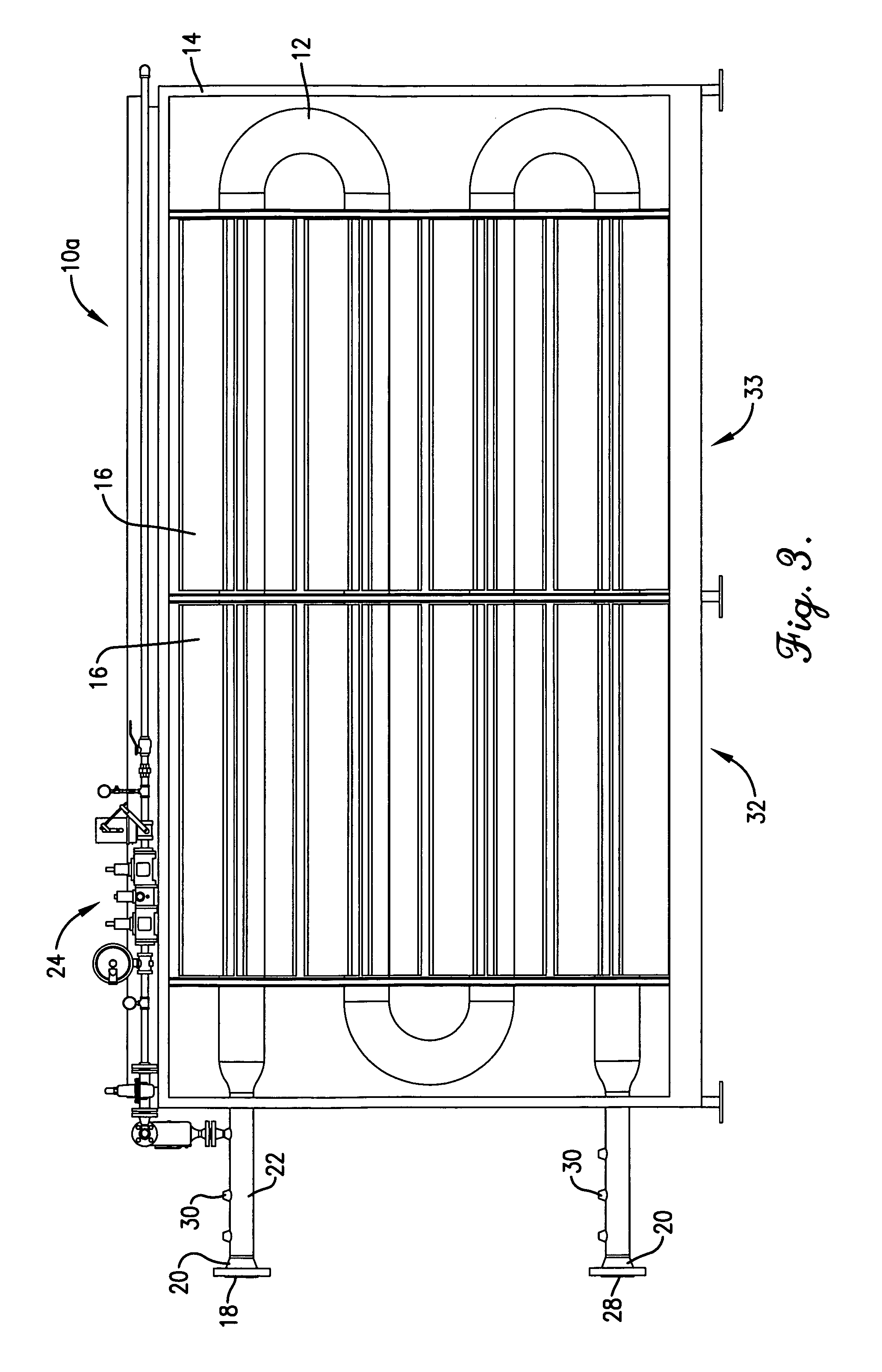

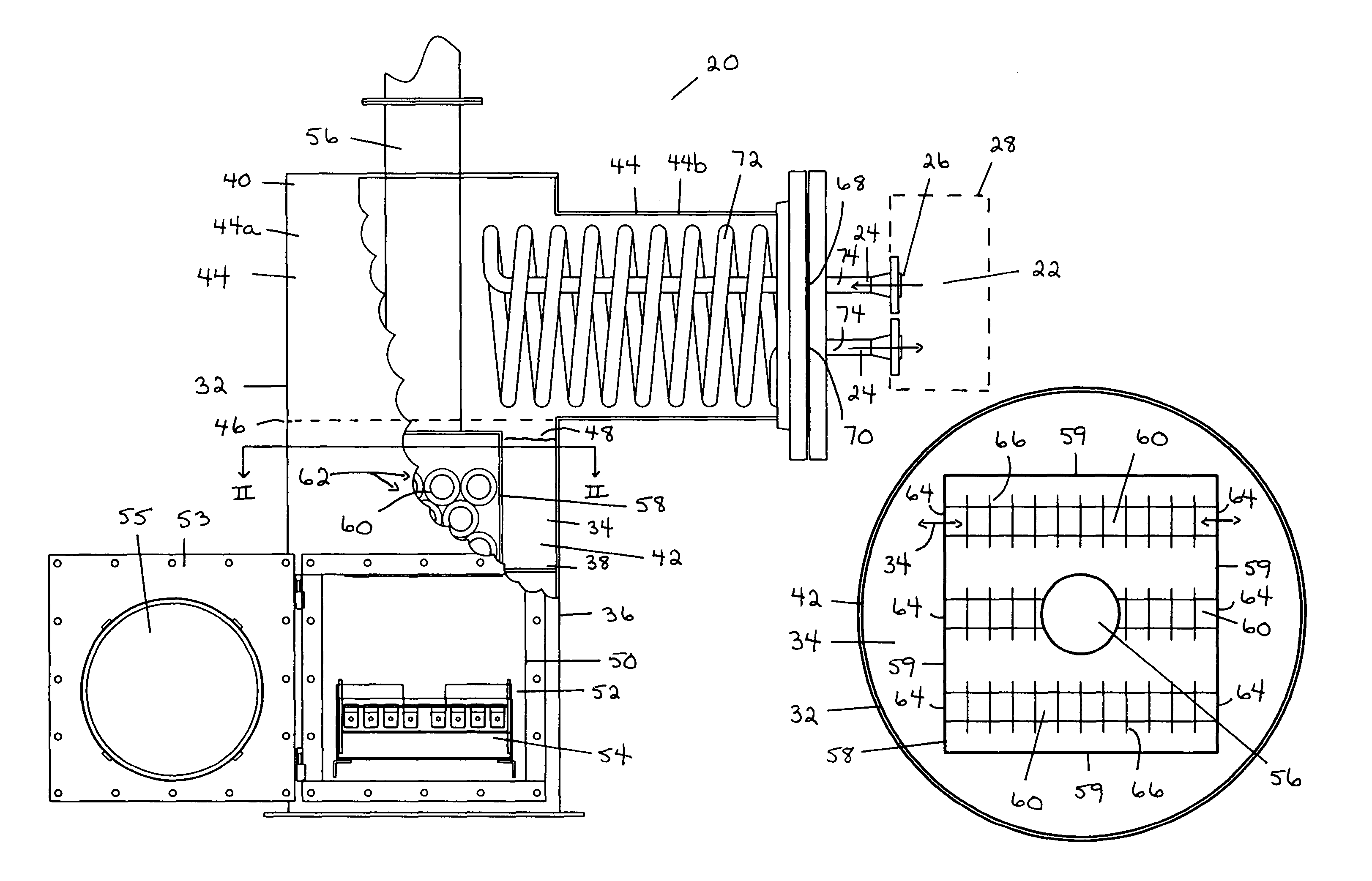

Heat exchange apparatus

ActiveUS7841305B2Improve heat transfer effectSteam generation using pressureSubmerged flame steam boilersEngineeringPressure reduction

A heat exchange apparatus for use in transferring heat to a heat sink. Preferably, the heat sink is comprised of a natural gas supply line at a pressure reduction station. Alternately, the heat sink is comprised of a storage tank. The apparatus is comprised of a heat exchange vessel, adapted to contain an amount of a heat exchange fluid, and a heat source. The heat exchange vessel includes a sump section at a lower end thereof, and a heat transfer section for transferring heat to the heat sink. The heat exchange vessel further includes a single communication junction between the sump section and the heat transfer section which provides fluid communication therebetween. The heat source is associated with the sump section and adapted to add heat to the heat exchange fluid in order to cause the heat exchange fluid to evaporate in the heat exchange vessel.

Owner:TECVALCO LTD

Heat exchange apparatus

ActiveUS20070000453A1Improve heat transfer effectSteam generation using pressureSubmerged flame steam boilersEngineeringPressure reduction

A heat exchange apparatus for use in transferring heat to a heat sink. Preferably, the heat sink is comprised of a natural gas supply line at a pressure reduction station. Alternately, the heat sink is comprised of a storage tank. The apparatus is comprised of a heat exchange vessel, adapted to contain an amount of a heat exchange fluid, and a heat source. The heat exchange vessel includes a sump section at a lower end thereof, and a heat transfer section for transferring heat to the heat sink. The heat exchange vessel further includes a single communication junction between the sump section and the heat transfer section which provides fluid communication therebetween. The heat source is associated with the sump section and adapted to add heat to the heat exchange fluid in order to cause the heat exchange fluid to evaporate in the heat exchange vessel.

Owner:TECVALCO LTD

Zero emission steam generation process

InactiveUS20120160187A1Eliminate requirementsImprove thermal efficiencySteam generation using pressureSubmerged flame steam boilersWater requirementProduced water

This invention provides a new process to generate steam directly from untreated water produced simultaneously with thermally recovered crude oil, and to inject the steam and combustion products into a hydrocarbon reservoir to recover hydrocarbons and to sequester a portion of the carbon dioxide produced during the creation of steam. The invention removes the ongoing additional water requirements for thermal oil recovery and the need for surface treating of produced water for re-use, yielding improved process efficiencies, reduced environmental impact, and improved economic value.

Owner:PAXTON CORP +2

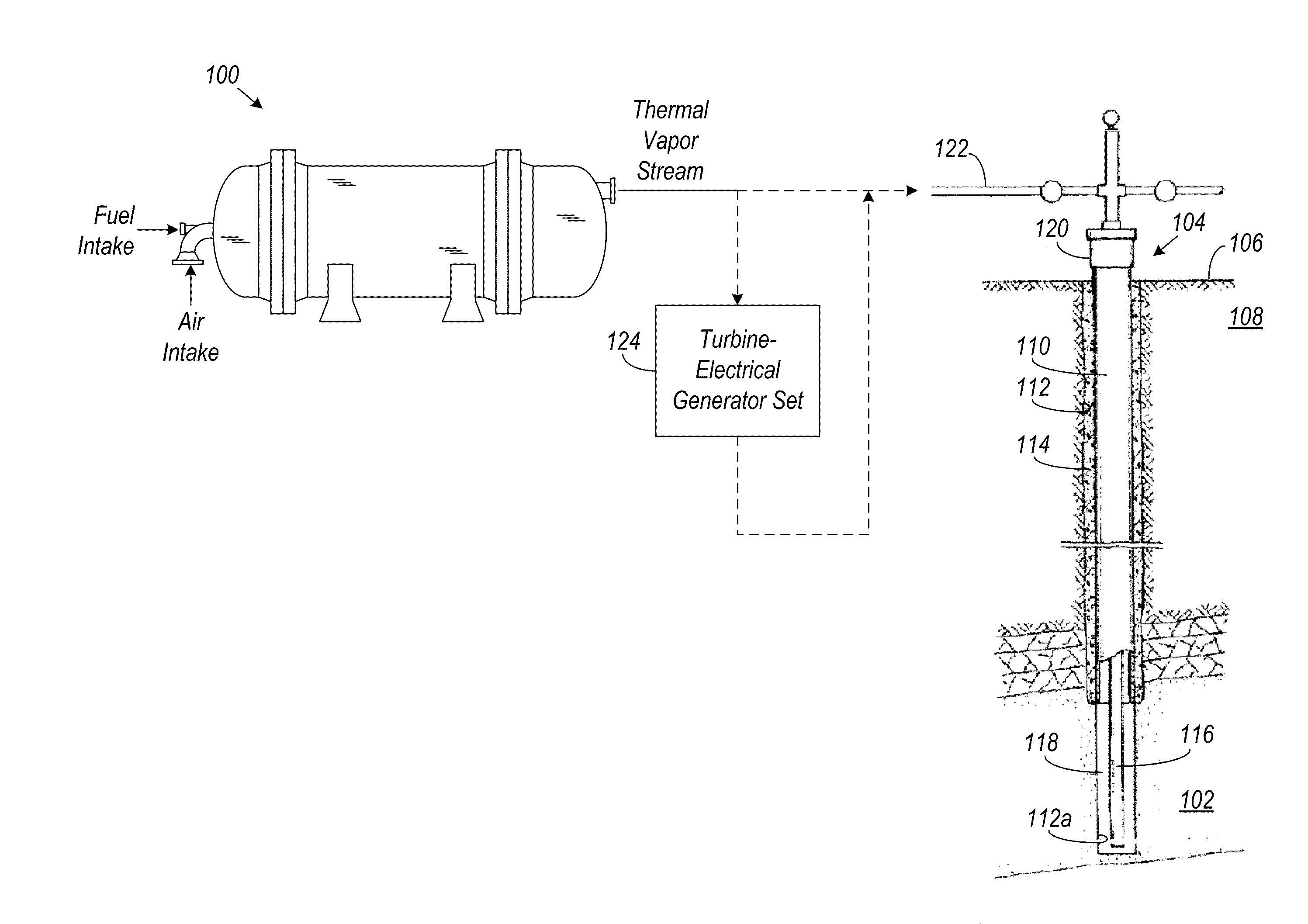

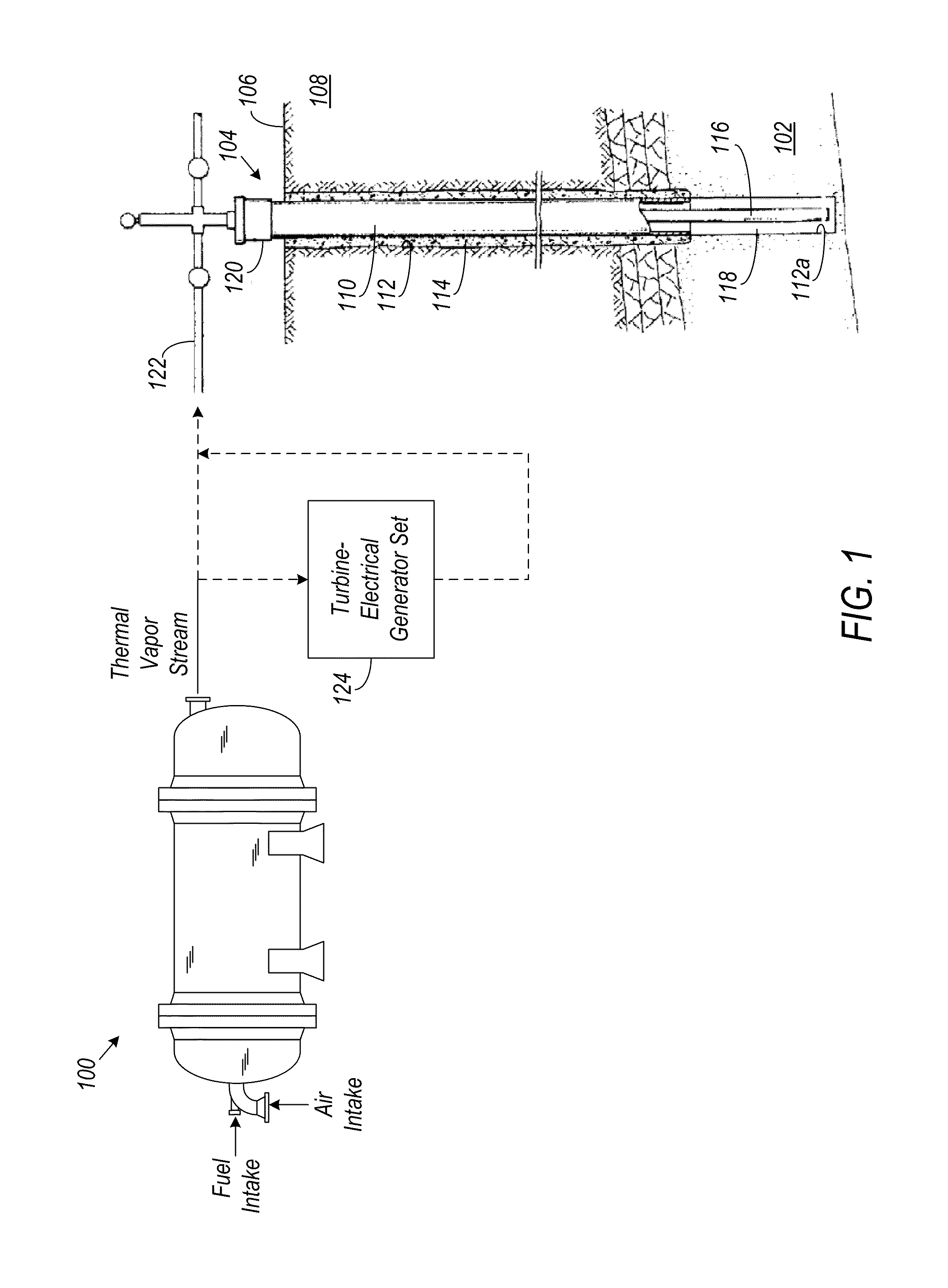

Thermal vapor stream apparatus and method

InactiveUS20110036095A1Easy injectionPromote recoverySteam generation using pressureGas turbine plantsEngineeringHigh pressure

A low emission and environmentally friendly apparatus and method is used to generate a high pressure stream of thermal vapor. The thermal vapor stream may be injected into a subterranean formation for recovery of highly viscous petroleum or used to turn a steam turbine for driving an electrical generator. In one implementation, the high pressure stream of thermal vapor is generated by burning a high temperature fuel, including any short or long chain hydrocarbon products from methane to coal, in an enclosed vessel to produce combustion gases. Various techniques may be used to improve heat distribution and lower the temperature of the combustion gases. Water may be used to quench the combustion gases and produce the superheated steam or vapor. The water may be introduced onto the combustion gases by spraying, weeping, dripping, and the like.

Owner:EOR TECH HLDG INC

Air-independent internal oxidation

A chemical-looping combustion system is provided in which an oxygen carrier, for example a metallic oxide or peroxide, is used for fuel combustion and produces carbon dioxide and water as by-products. The system delivers steam and CO2 at for direct utilization by steam cycle power generation equipment and heat exchangers. After fuel combustion, the oxygen-poor carrier is regenerated by exposure to air in a second, sequestered reactor. Choice of oxygen-carrier material and conditions allows for the fuel oxidizer reactor to run at temperatures greater than the running temperature of the regenerator reactor.

Owner:ZERE ENERGY & BIOFUELS

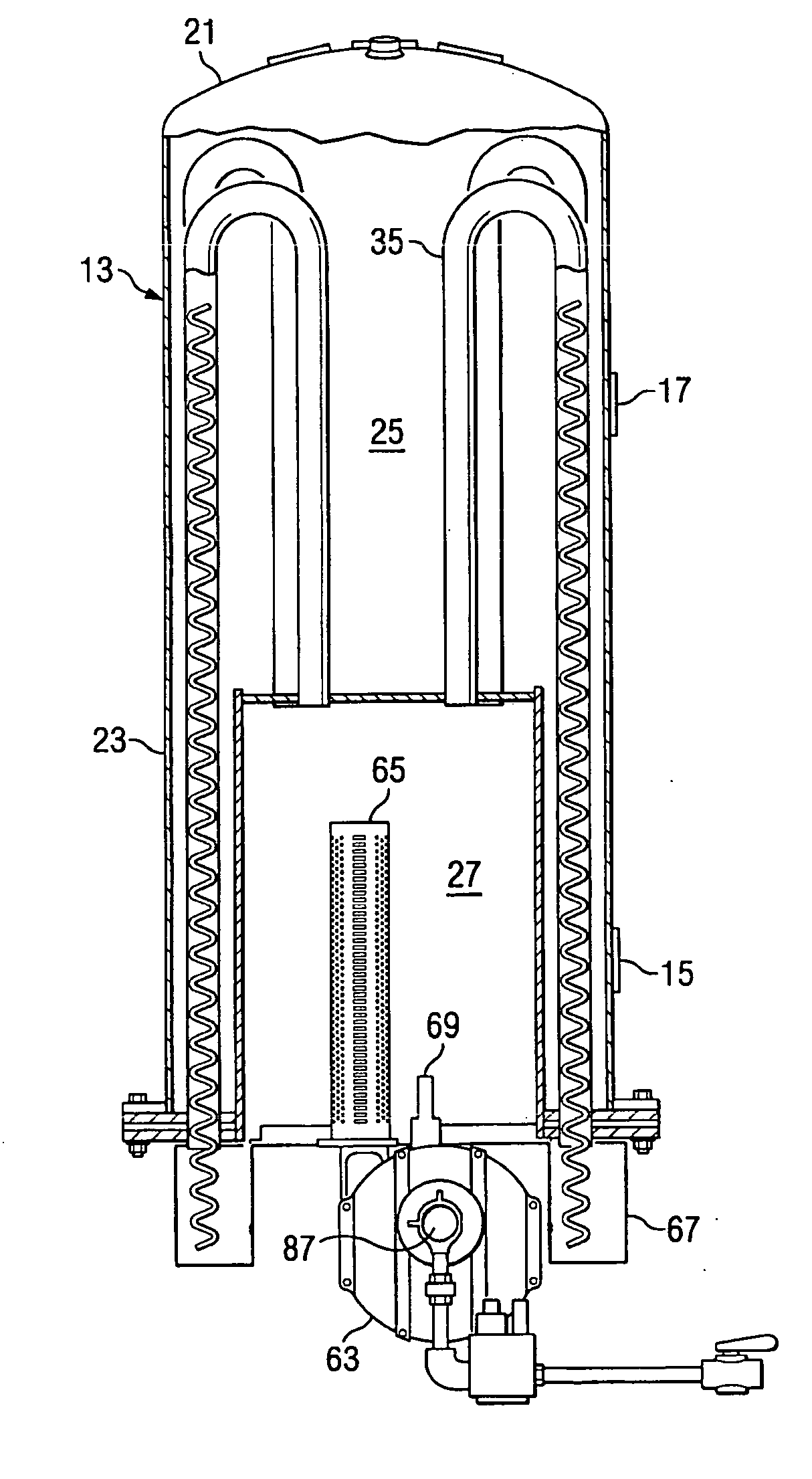

Condensing gas fired water heater

InactiveUS20070125318A1Easy to optimizeImprove heat transfer performanceSteam generation using pressureSubmerged flame steam boilersCombustion chamberCombustor

A water heater is shown having a closed metal tank with an upwardly mounted combustion chamber and burner / blower assembly. Curved fire tubes convey the products of combustion from the chamber to an exterior mounted flue assembly. The closed tank is enclosed by a rotomolded jacket. A support stand with vertically arranged support legs supports the tank in a normally vertical position but also allows the tank to be pivoted to a horizontal position on the support stand for maintenance or repair operations.

Owner:PVI IND +1

Steam generator with current stabilizers

ActiveCN107062186AReduce vibrationImprove heat transfer performanceBoiler water tubesSteam generation using pressureNoise levelEngineering

The invention relates to a steam generator which comprises an upper boiler barrel, a lower boiler barrel, rising pipes and falling pipes, and the rising pipes and the falling pipes are connected between the upper boiler barrel and the lower boiler barrel. Current stabilizers are arranged in the rising pipes, multiple current stabilizers are arranged in one rising pipe, and the lengths of the current stabilizers are gradually increased in the fluid flowing directions of the rising pipes. The steam generator with the current stabilizers of new structures is provided, the lengths of the current stabilizers are changed, when steam-liquid two-phase flow exists in the rising pipe, heat transfer is strengthened, vibration of the rising pipes is weakened, and the noise level is reduced.

Owner:王芸芸

Startup burner assembly for snow melting apparatus and method of snow melting

ActiveUS20060137677A1Improve efficiencyEffective distributionPilot flame ignitersWater heatersCombustion chamberCombustor

A startup burner assembly for use in snow melting applications, and which permits initiation of snow melting without first supplying water as a coolant. The startup burner assembly comprises a fuel burner having adjustable combustion output and a nozzle to facilitate the emergence of products of combustion, and a combustion chamber having a first portion in substantially air-tight communication with the fuel burner and enclosing the nozzle and a second portion shaped and dimensioned for disposition into a snow melting receptacle or pit. The combustion chamber has a plurality of discharge holes formed at least on the second portion thereof to permit the egress of products of combustion from the fuel burner into the tank or pit, and thereby permit agitation and melting of snow loaded therein, The startup burner assembly also includes an air cooling assembly for supplying air to cool at least the first portion of the combustion chamber.

Owner:TRECAN COMBUSTION

Steam boiler

ActiveCN108332179ASpeed up the flowStable flowSteam generation using pressureSteam boilersEngineeringHeat transfer

The invention provides a steam boiler which comprises an upper boiler barrel, a lower boiler barrel, ascending pipes and descending pipes; the ascending pipes and the descending pipes are connected between the upper boiler barrel and the lower boiler barrel; flow stabilization devices are arranged in the ascending pipes; each flow stabilization device comprises a core body and a shell; the core bodies are arranged in the shells; the shells are connected with and fixed to the inner walls of the ascending pipes; each core body comprises a plurality of radial rods extending from the center of thecore body to the radial directions; a plurality of fins extending from the radial rod down are arranged on each radial rod; the fins are provided with sharp parts; and the sharp parts face downwards.With the adoption of the novel structure steam boiler with the flow stabilization devices, when gas-liquid two-phase flowing exists in the ascending pipes, heat transfer is improved, vibration of theascending pipes is weakened, and the level of noise is lowered.

Owner:罗定市佳得利食品有限公司

Downhole steam generator and method of use

A downhole steam generation system may include a burner head assembly, a liner assembly, a vaporization sleeve, and a support sleeve. The burner head assembly may include a sudden expansion region with one or more injectors. The liner assembly may include a water-cooled body having one or more water injection arrangements. The system may be optimized to assist in the recovery of hydrocarbons from different types of reservoirs. A method of recovering hydrocarbons may include supplying one or more fluids to the system, combusting a fuel and an oxidant to generate a combustion product, injecting a fluid into the combustion product to generate an exhaust gas, injecting the exhaust gas into a reservoir, and recovering hydrocarbons from the reservoir.

Owner:WORLD ENERGY SYST

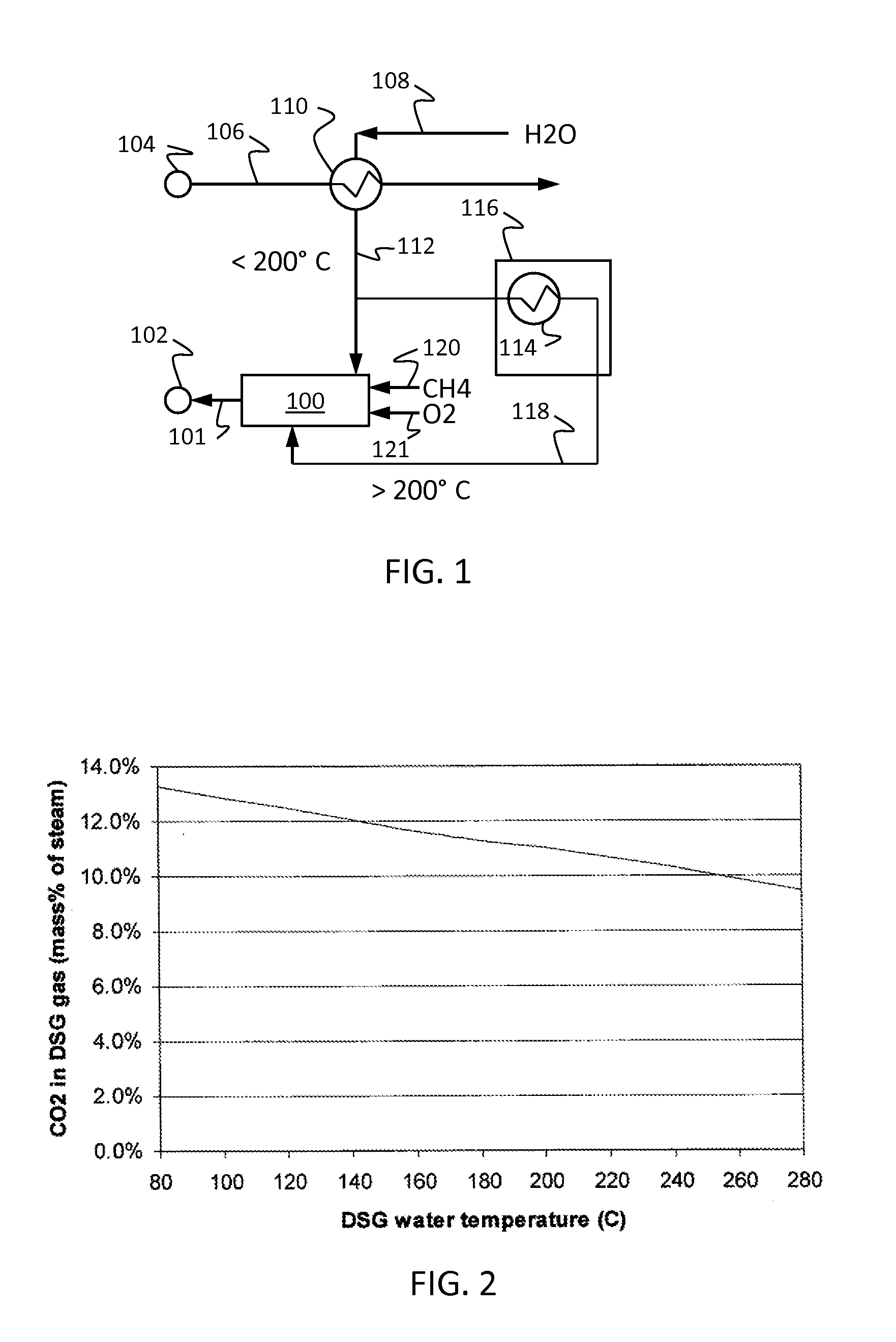

Direct steam generation co2 output control

InactiveUS20140060825A1Steam generation using pressureCombustion processEngineeringIncrease temperature

Methods and systems generate steam and carbon dioxide mixtures suitable for injection to assist in recovering hydrocarbons from oil sands based on concentration of the carbon dioxide in the mixtures as influenced by temperature of water introduced into a direct steam generator. Increasing temperature of the water to above 200° C. before introduction into the direct steam generator may utilize heat from an electrical power generation unit. Enthalpy of this preheated water impacts amount of fuel needed to burn in the direct steam generator and hence the concentration of the carbon dioxide, which may be below 11% by mass percent of the steam.

Owner:CONOCOPHILLIPS CO

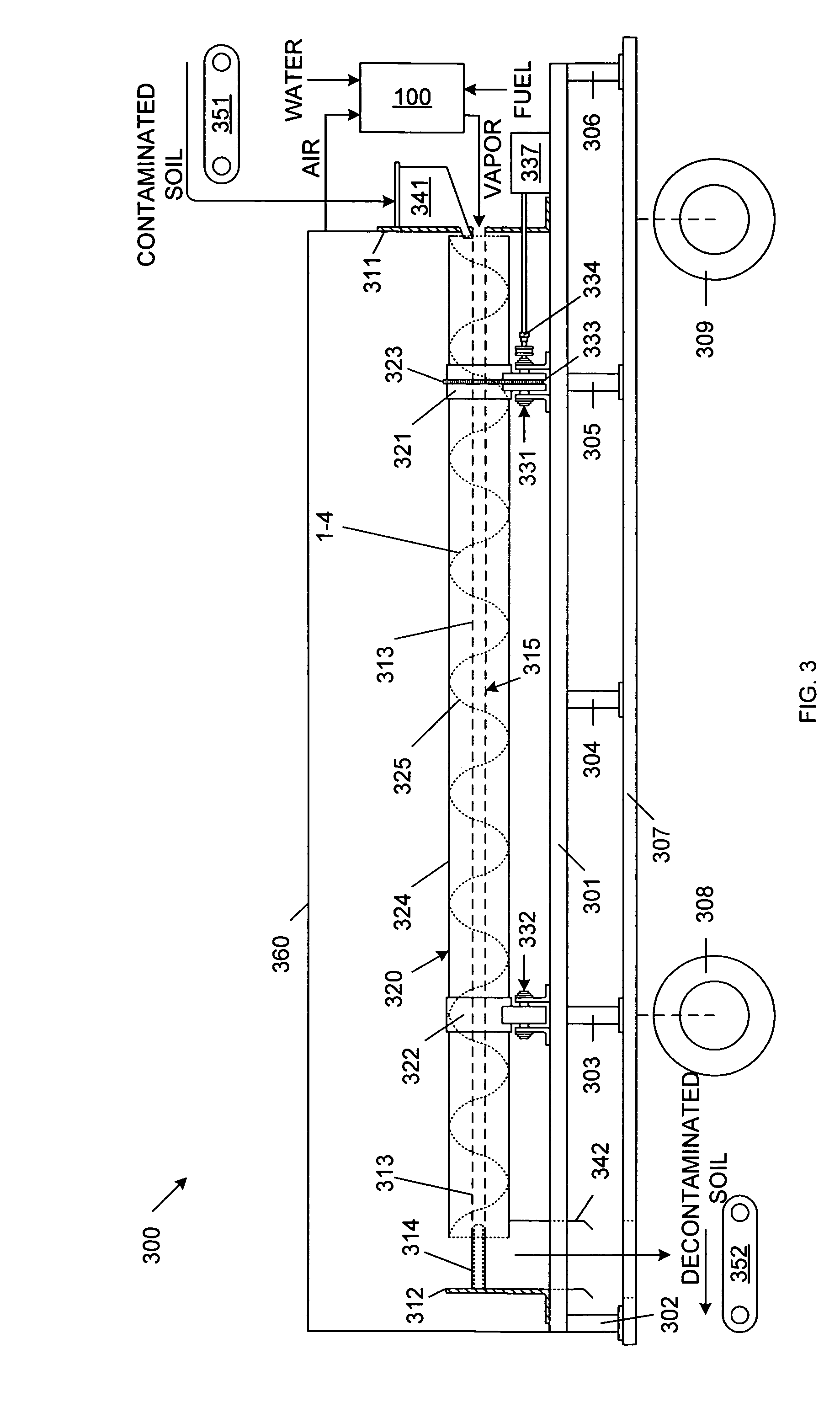

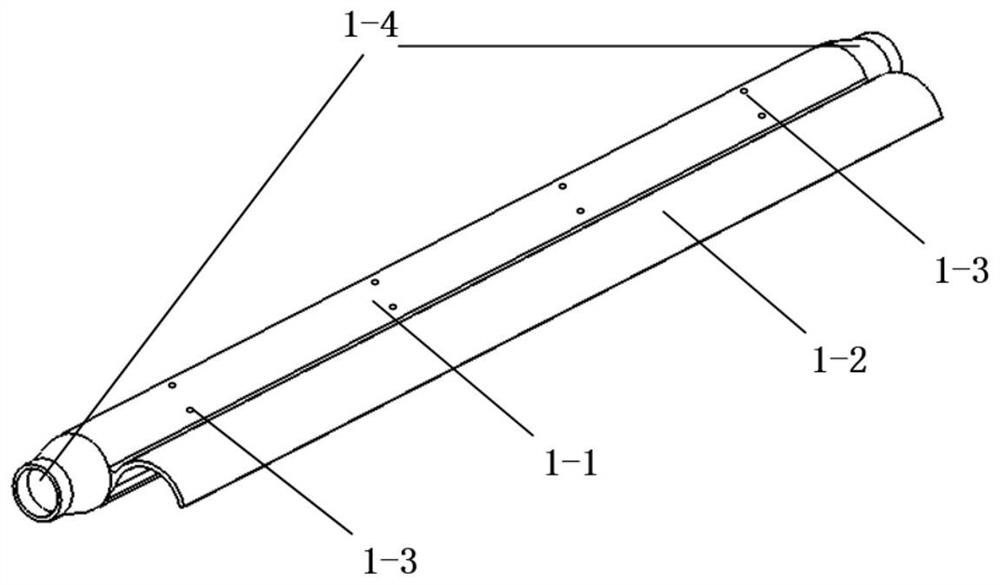

Environmental clean-up system

InactiveUS20050080312A1Improve efficiencyEfficient systemBoiler water tubesContaminated soil reclamationCombustion chamberWater vapor

An efficient high-temperature water vapor generator is used to de-contaminate soil. The vapor generator includes a combustion chamber and a surrounding structure, wherein a cavity is located therebetween. Water is routed through the cavity and into the combustion chamber, where water vapor and heat are generated in the presence of fuel, ignition and air. The generated heat pre-heats the water in the cavity, thereby creating an efficient system. The water vapor is forced into a vapor tube (which has openings for emitting the vapor), thereby heating the vapor tube to temperatures of 800° F. or greater. A soil tube having lifting paddles located therein surrounds the vapor tube. Contaminated soil enters one end of the soil tube. The soil tube is rotated, thereby moving the contaminated soil into contact with the vapor tube (decontaminating the soil). The lifting paddles move the soil toward the second end of the rotating soil tube.

Owner:JAVAHERIAN MEHRDAD

Methods and systems for operating low NOx combustion systems

ActiveUS20060008757A1Reducing nitrogen oxideReduce the concentration of nitrogen oxidesStaged combustionFurnace typesCombustion systemCombustion

Methods and systems for reducing nitrogen oxides in combustion flue gas is provided. The method includes combusting a fuel in a main combustion zone such that a flow of combustion flue gas is generated wherein the combustion flue gas includes at least one nitrogen oxide species, establishing a fuel-rich zone, forming a plurality of reduced N-containing species in the fuel rich zone, injecting over-fire air into the combustion flue gas downstream of fuel rich zone, and controlling process parameters to provide conditions for the reduced N-containing species to react with the nitrogen oxides in the OFA zone to produce elemental nitrogen such that a concentration of nitrogen oxides is reduced.

Owner:GENERAL ELECTRIC CO

Combined gap type gas steam boiler

ActiveCN113091031AReduce consumptionReduce water volumeBoiler water tubesSteam generation using pressureThermodynamicsCombustor

The invention discloses a combined gap type gas steam boiler. The combined gap type gas steam boiler comprises heat exchange pipes, an upper header, a lower header, a smoke shell, a combustor, a condenser, a chimney and a controller; the multiple heat exchange pipes form a vertically-arranged annular pipe row; a space defined by the annular pipe row is a hearth; the adjacent heat exchange pipes are combined to form axial gap channels evenly distributed along the circumference; the width of each axial gap channel ranges from 0.1 to 4mm, a laminar flow strengthening effect is formed, a center high-temperature area is eliminated, and only the 50 to 300 mm process is needed when the smoke temperature is reduced to 300 DEG C or below; and meanwhile, the smoke resistance is smaller than 1000Pa, heat loads of all the heat exchange pipes are evenly distributed, the scaling risk is reduced, and the boiler ton steel steaming consumption, the water volume and the draught fan power consumption are reduced. The combined gap type condenser is suitable for a heat conduction oil boiler, the combined gap type coil condenser is suitable for a coil steam generator, the laminar flow strengthening design is introduced into the two traditional boiler types, and the application of laminar flow strengthening is further expanded.

Owner:XI AN JIAOTONG UNIV +1

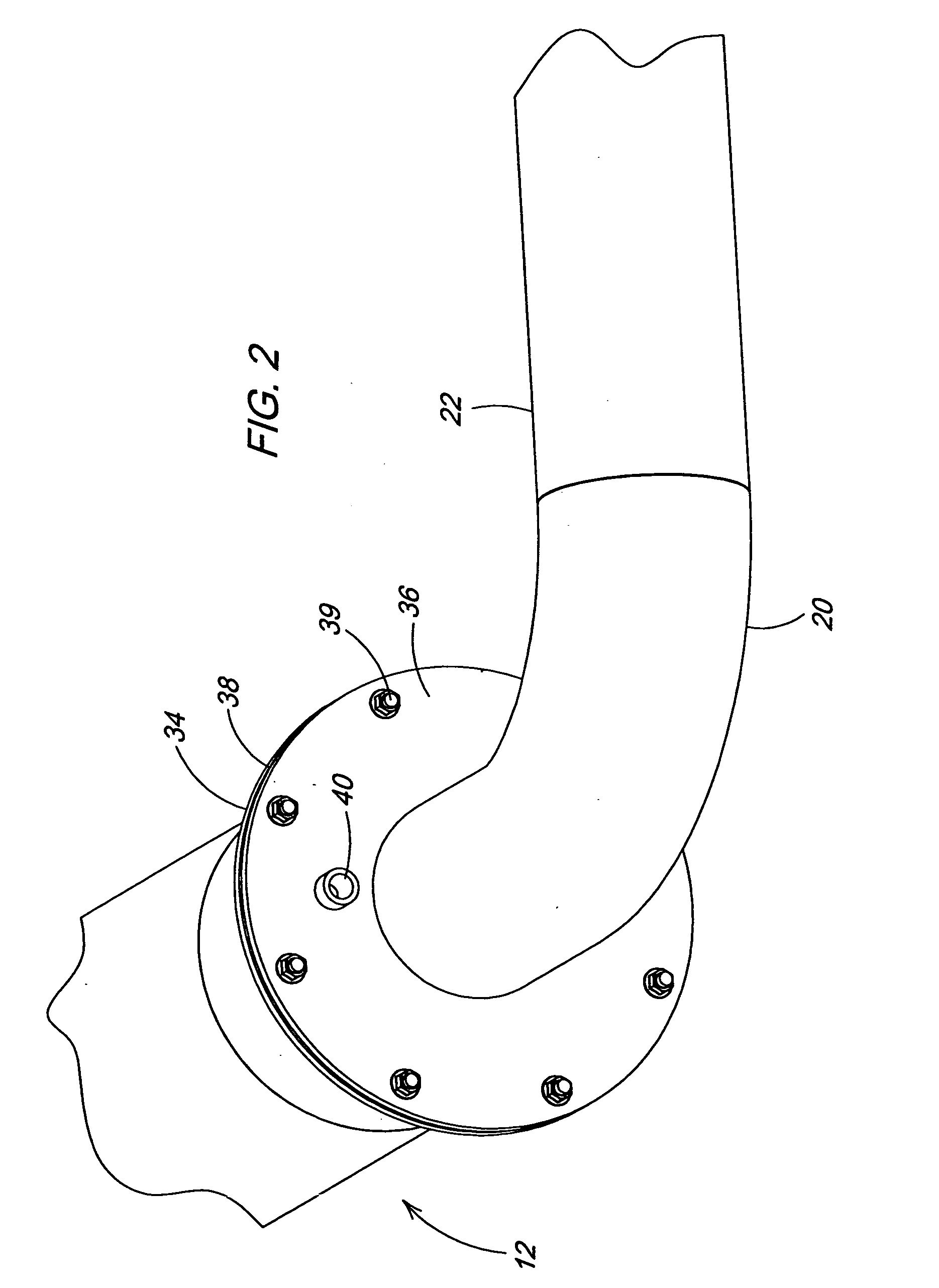

Combustion chamber design with water injection for direct-fired steam generator and for being cooled by the water

InactiveUS20060000427A1Eliminate needSuperheating controlSteam generation using pressureCombustion chamberInjection port

A direct-fired steam generator body defines a combustion chamber and having an exhaust outlet. A mixing chamber is provided for receiving the exhaust gases from the combustion chamber. A flange joint between an elbow forming part of the mixing chamber and the end of the steam generator body defining the exhaust outlet is designed so as to be cooled by process water coupled to the joint by an injection port provided in one of the flanges.

Owner:DEERE & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com