Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1285results about "Boiler cleaning apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

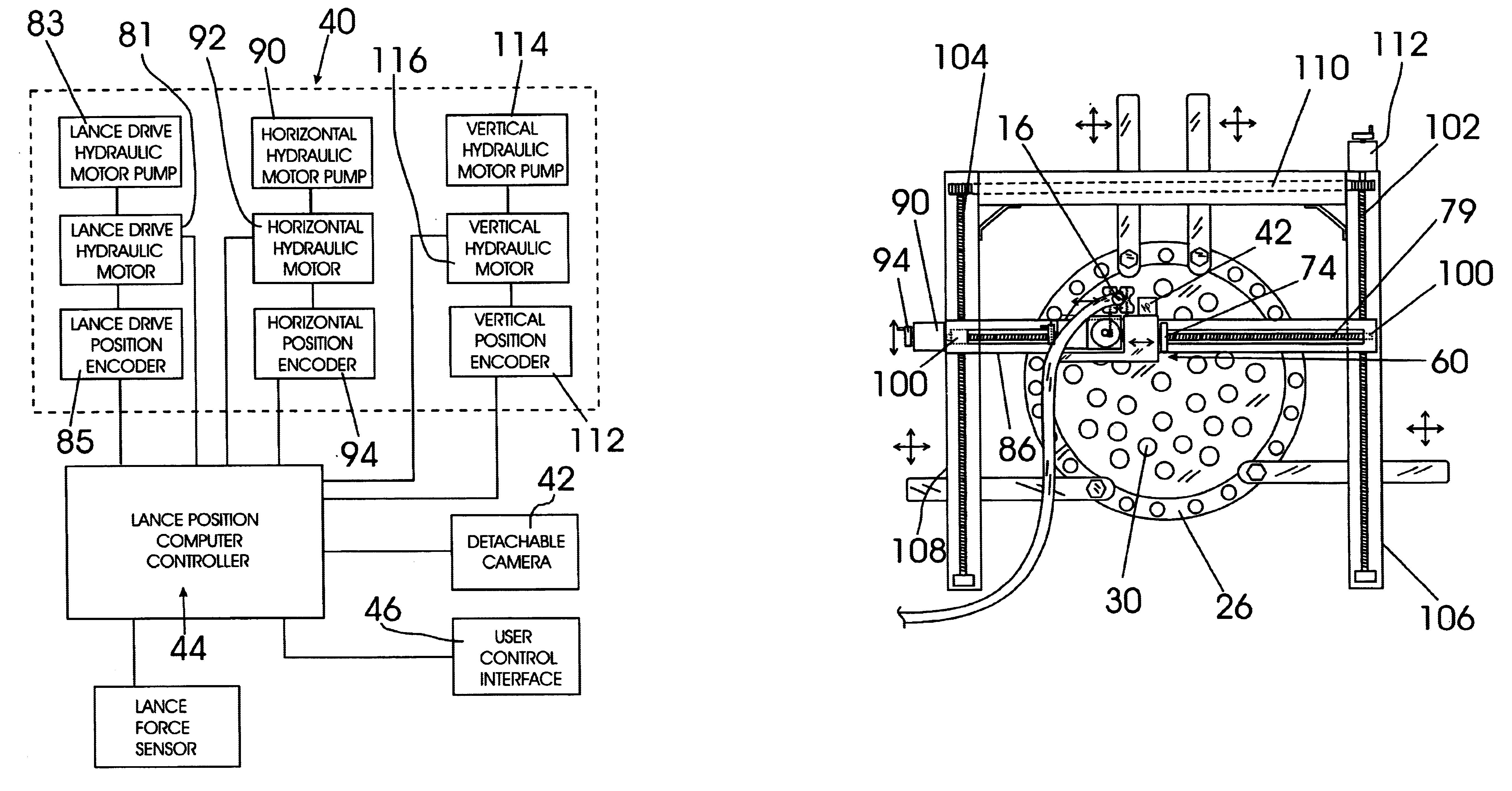

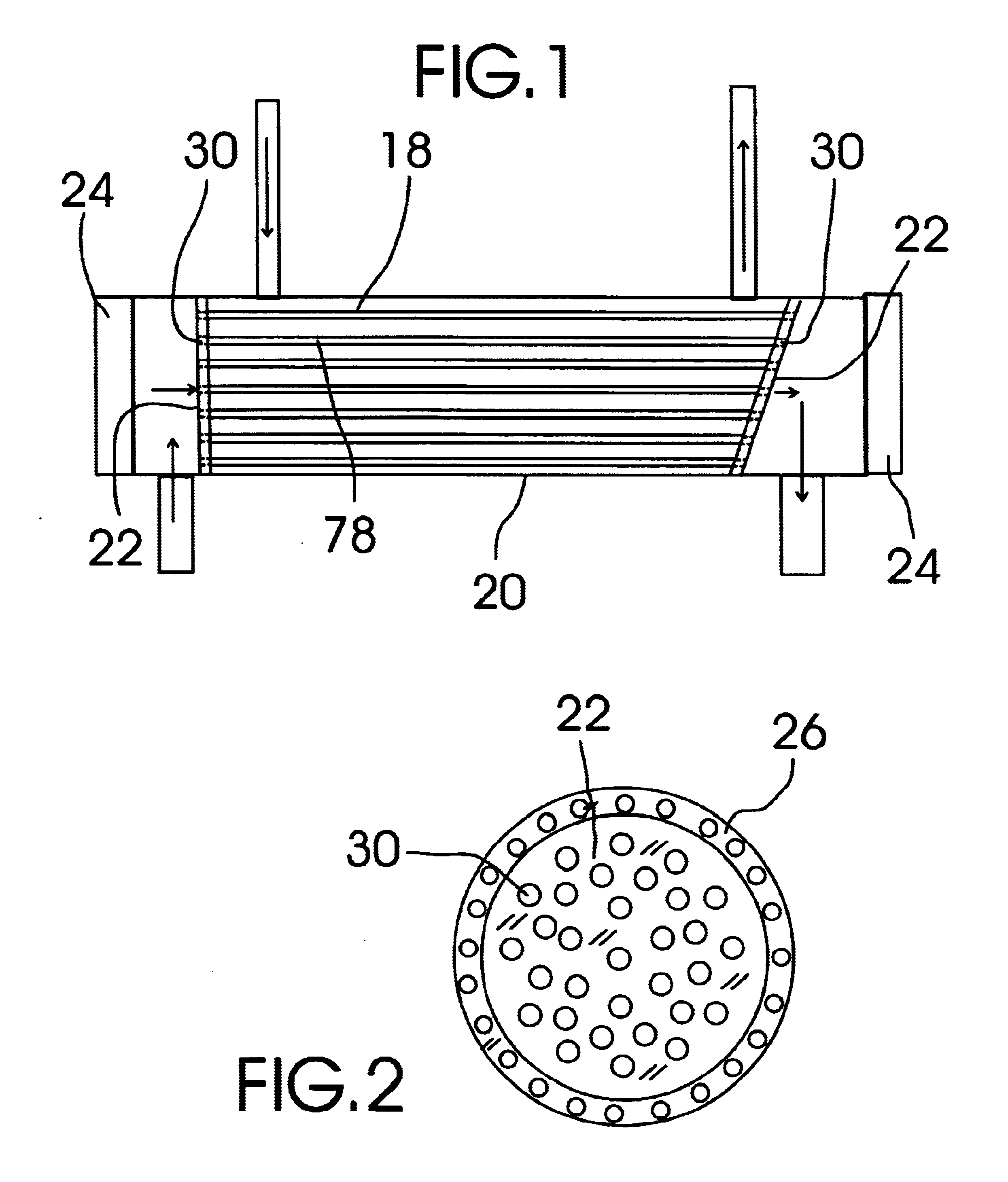

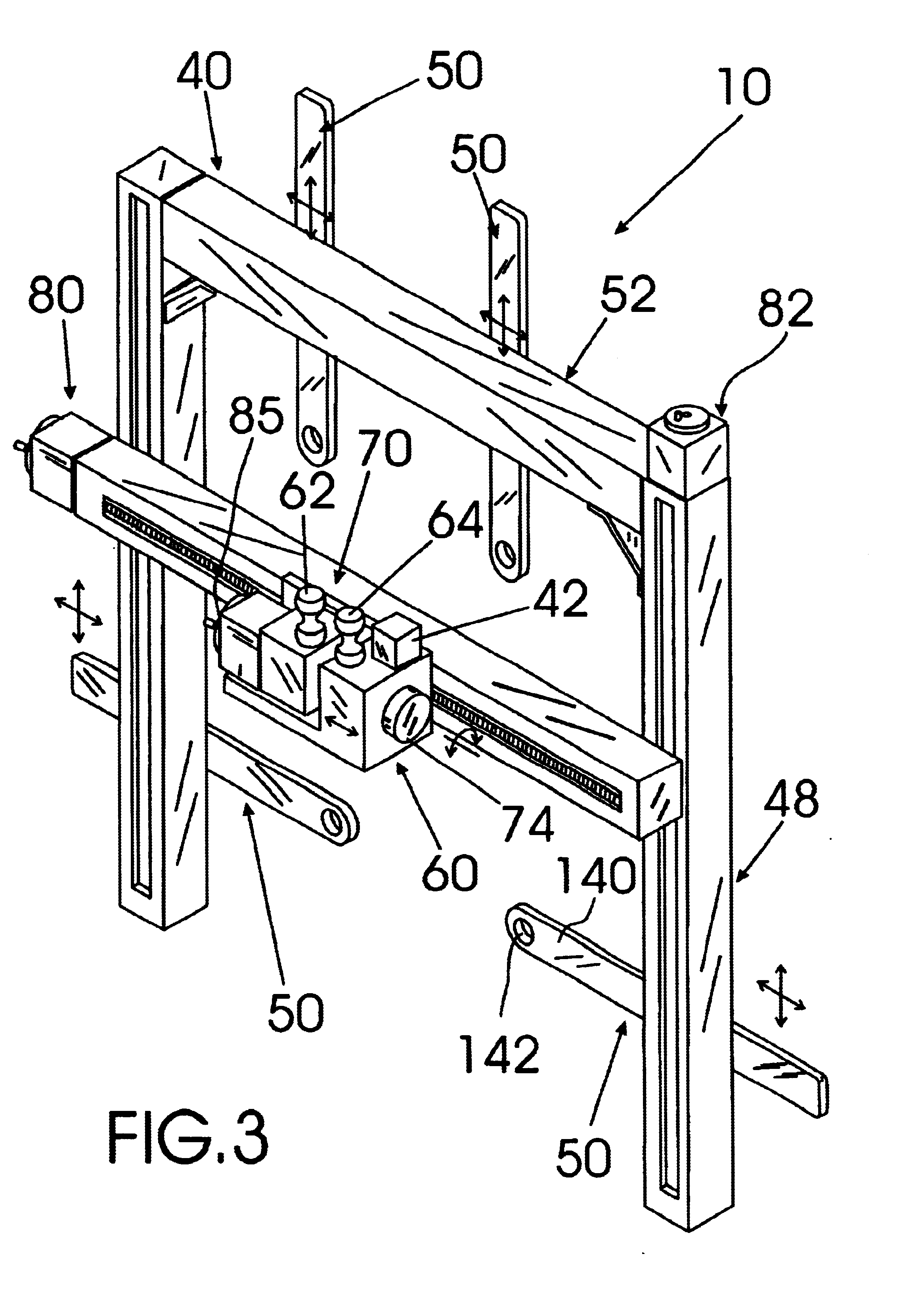

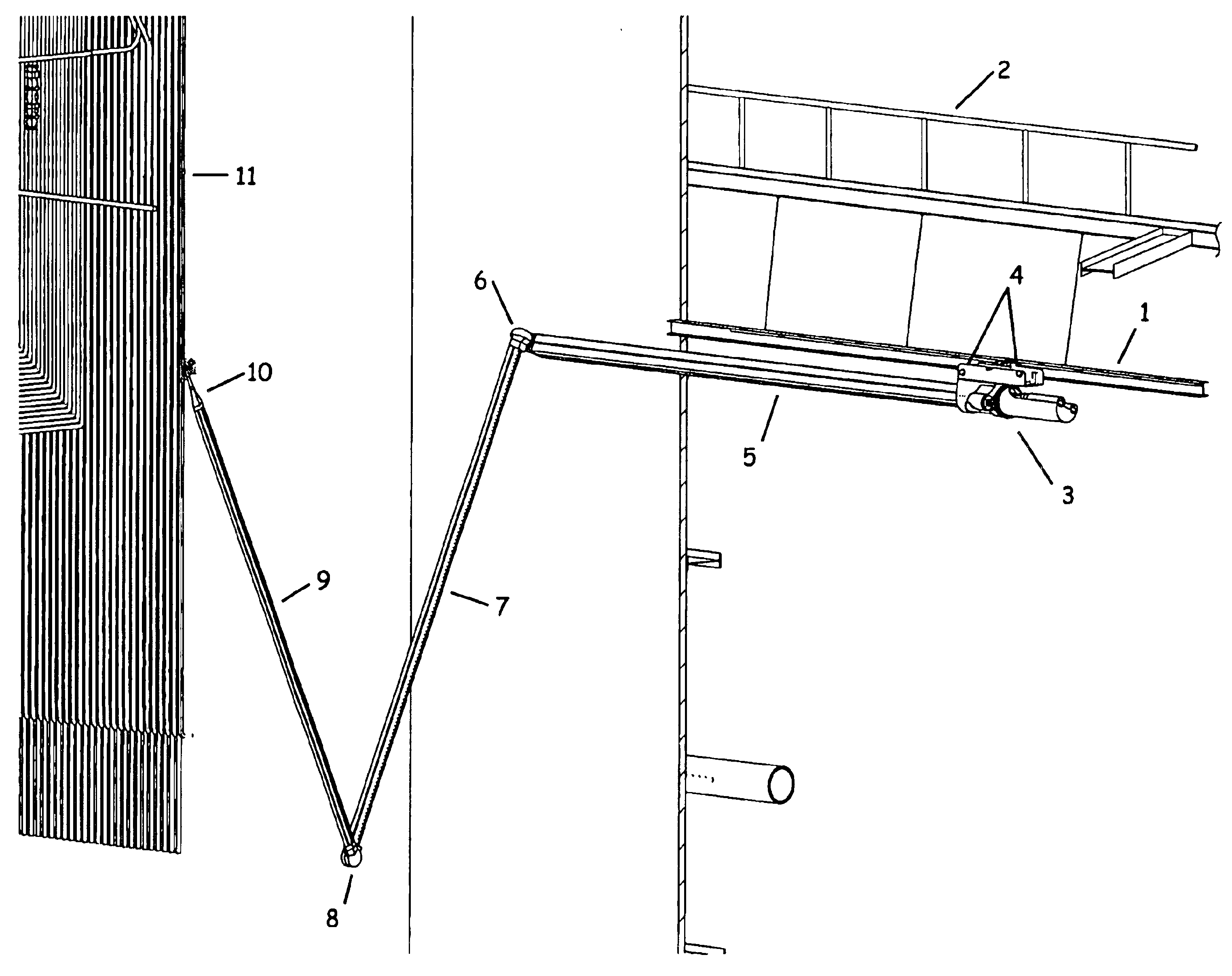

Heat exchanger exchange-tube cleaning lance positioning system

A heat exchanger exchange-tube cleaning lance positioning system that includes a three axis cleaning lance positioning mechanism that is attachable to the end of a heat exchanger and that is controlled by a lance position computer controller that determines the locations of each of the openings of the exchange-tubes of the heat exchanger by analyzing an image signal generated by a camera mounted to the three axis cleaning lance positioning mechanism and then positions a connected exchange tube cleaning lance into and through each of the exchange-tube passageways to clean the exchange-tube passageways automatically.

Owner:BALZER BRENT A

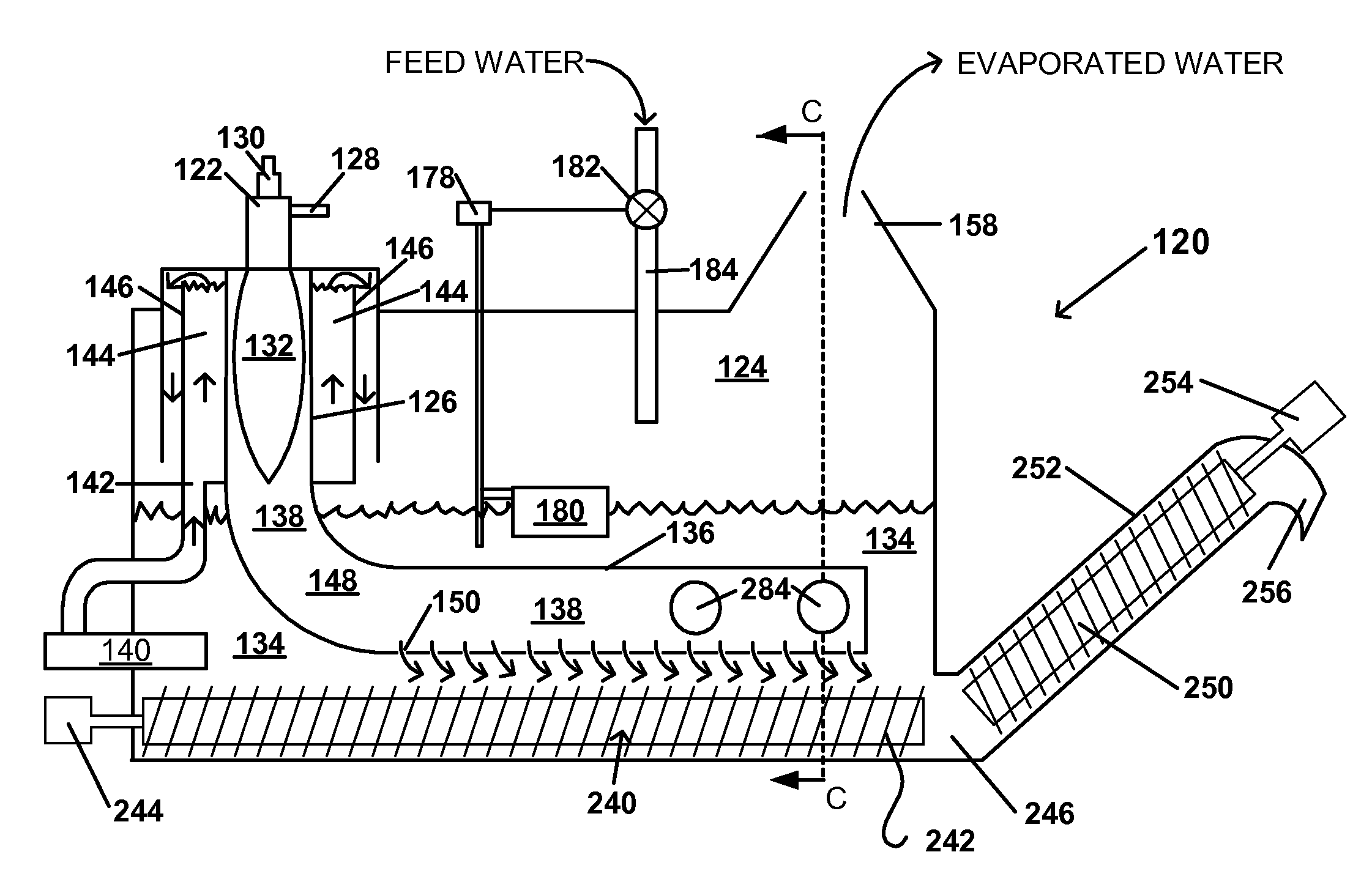

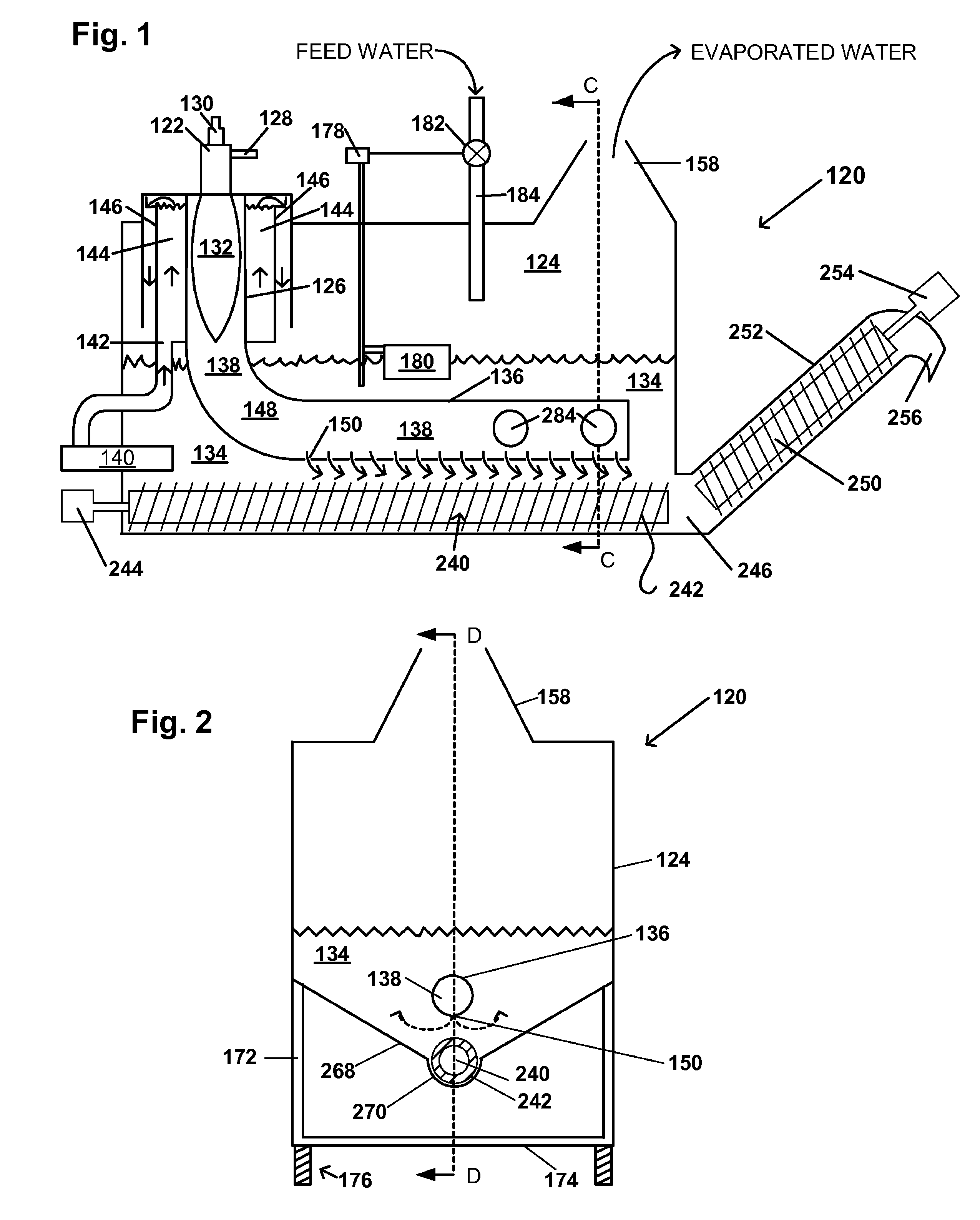

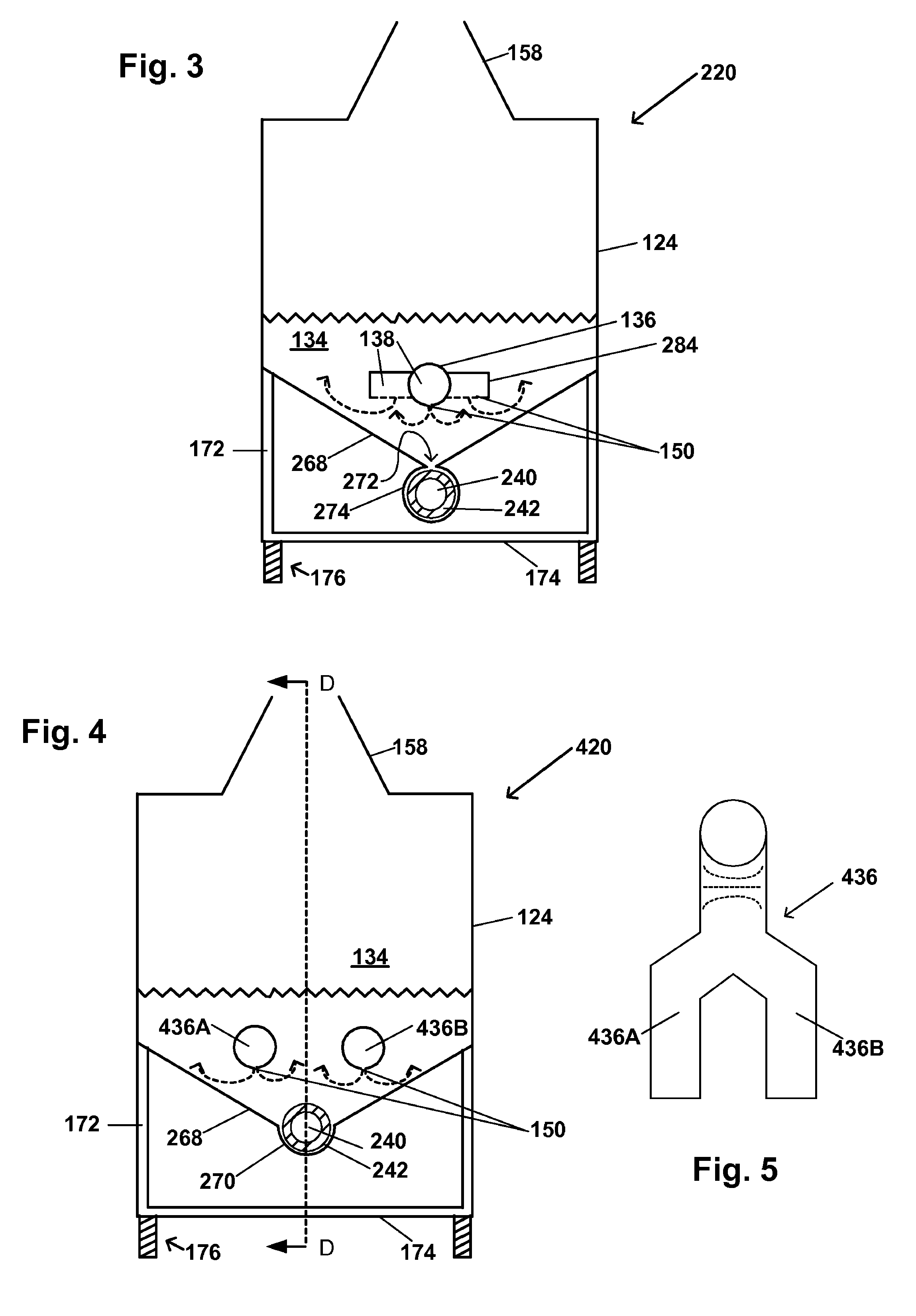

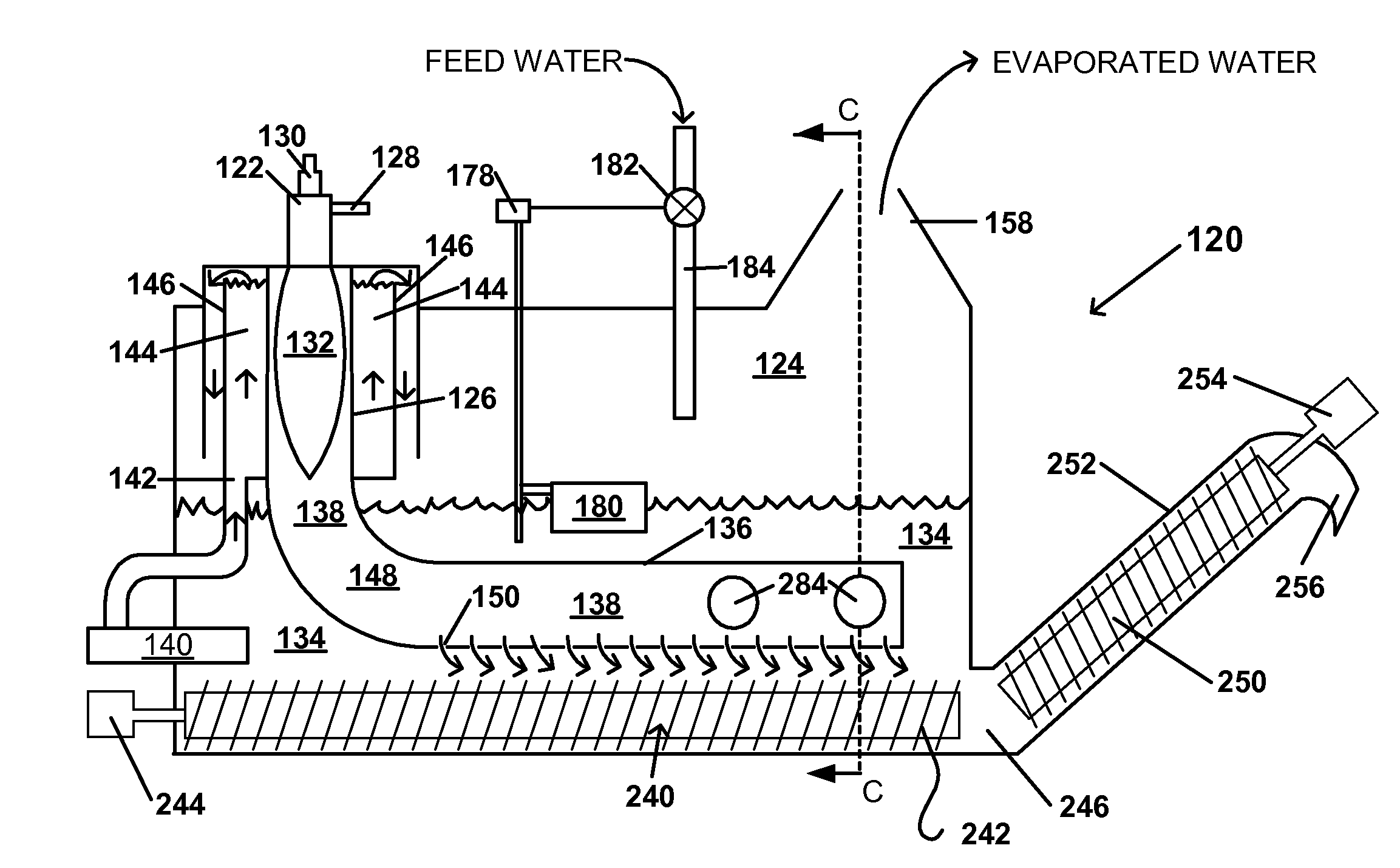

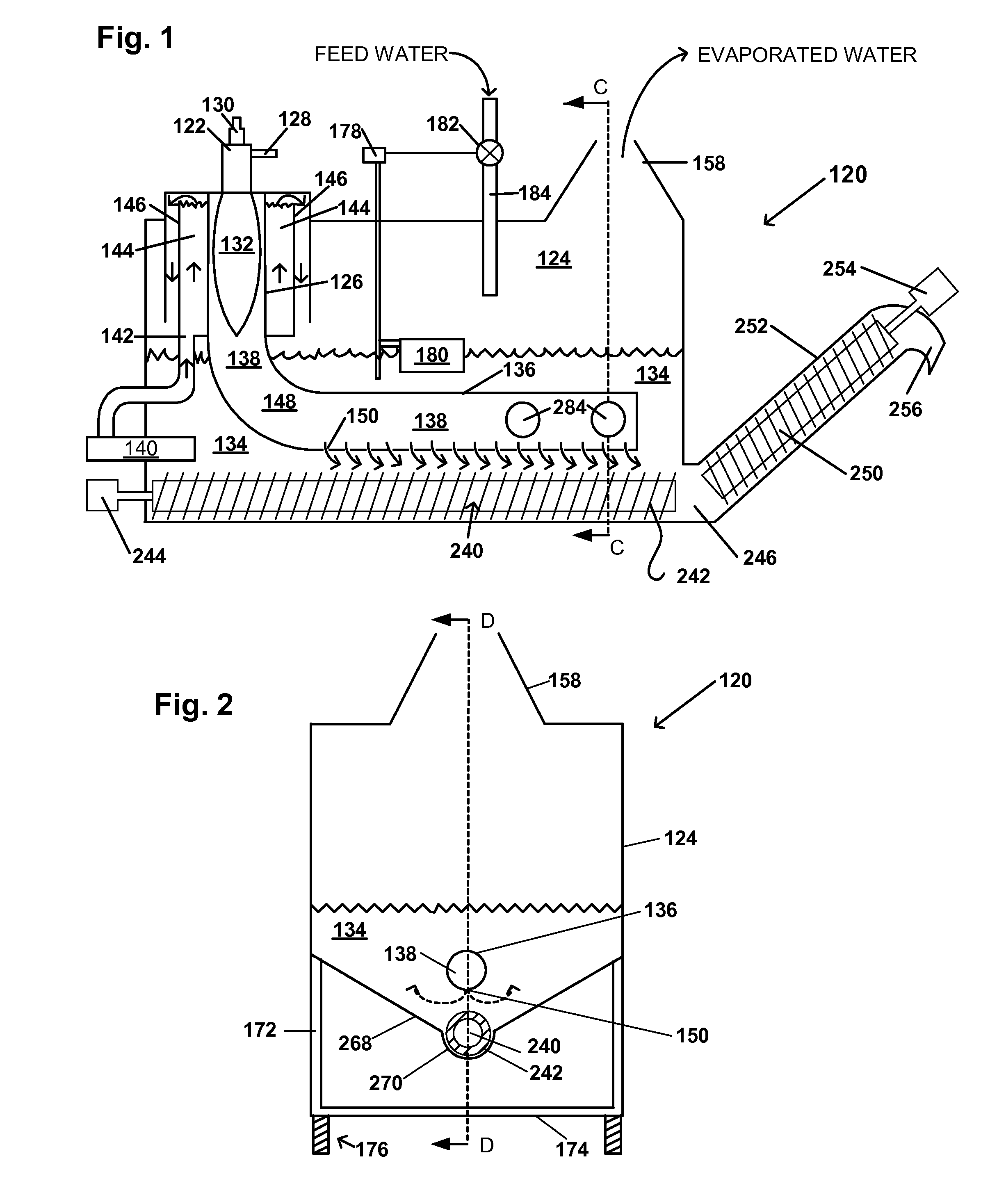

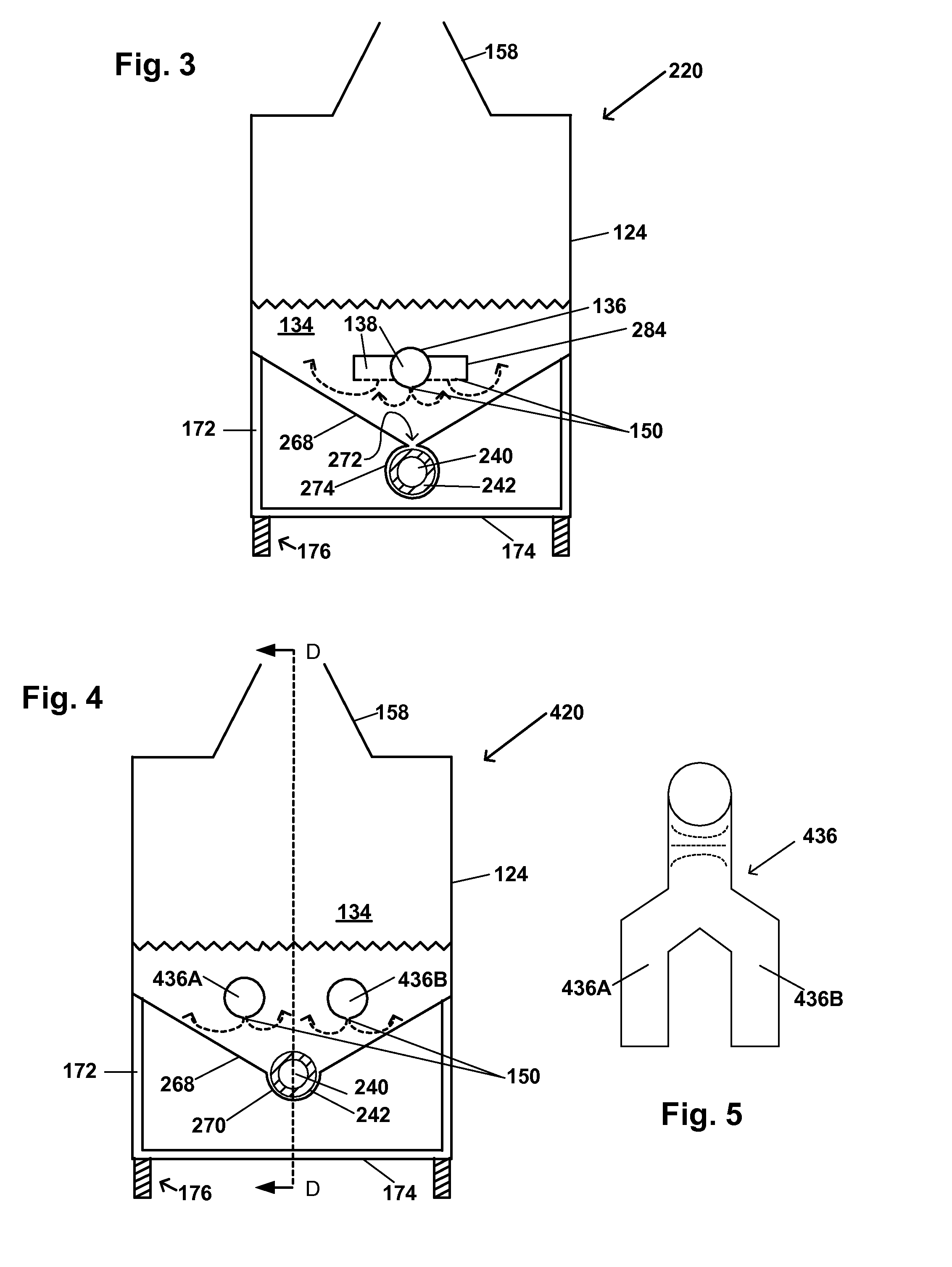

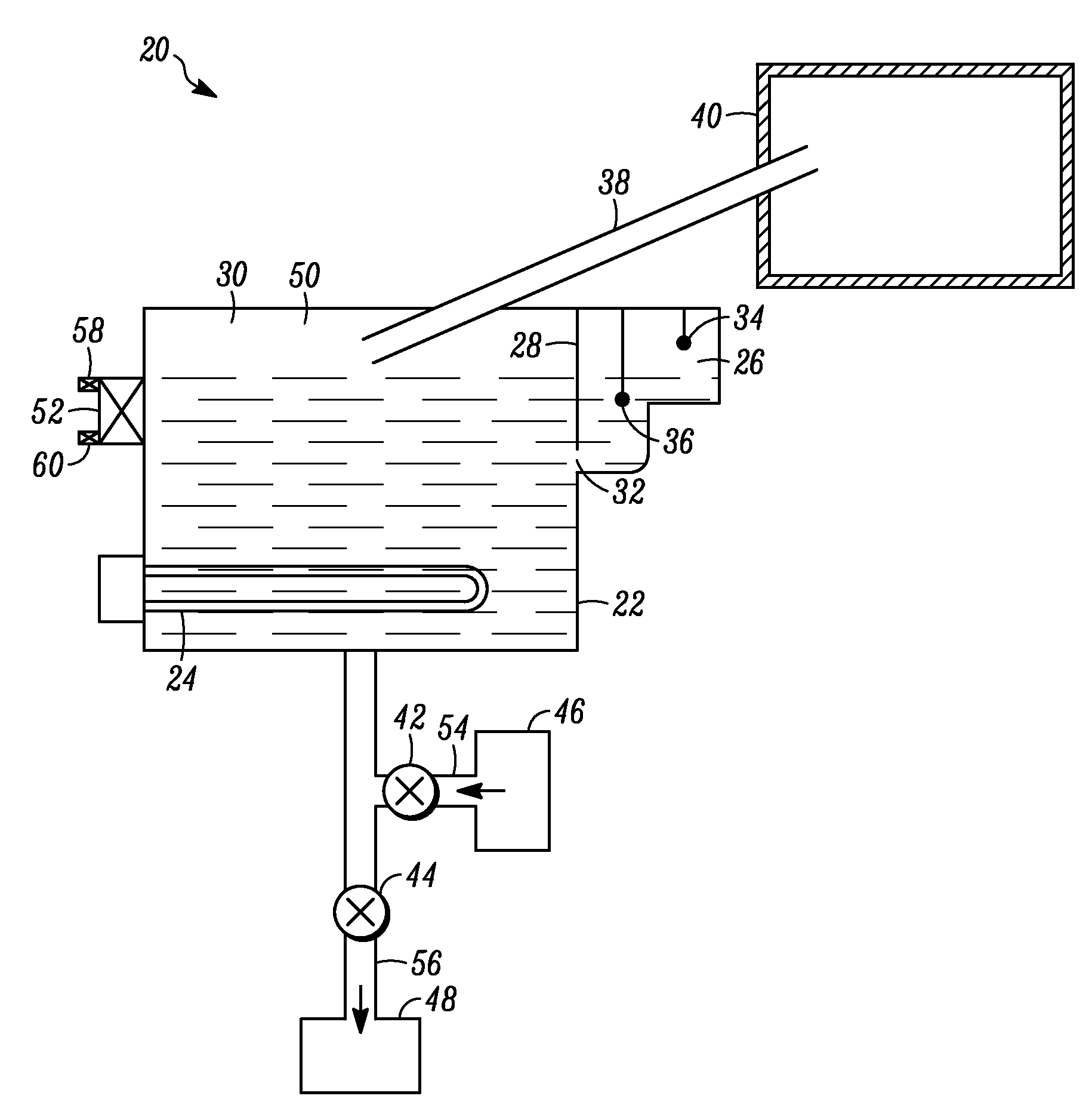

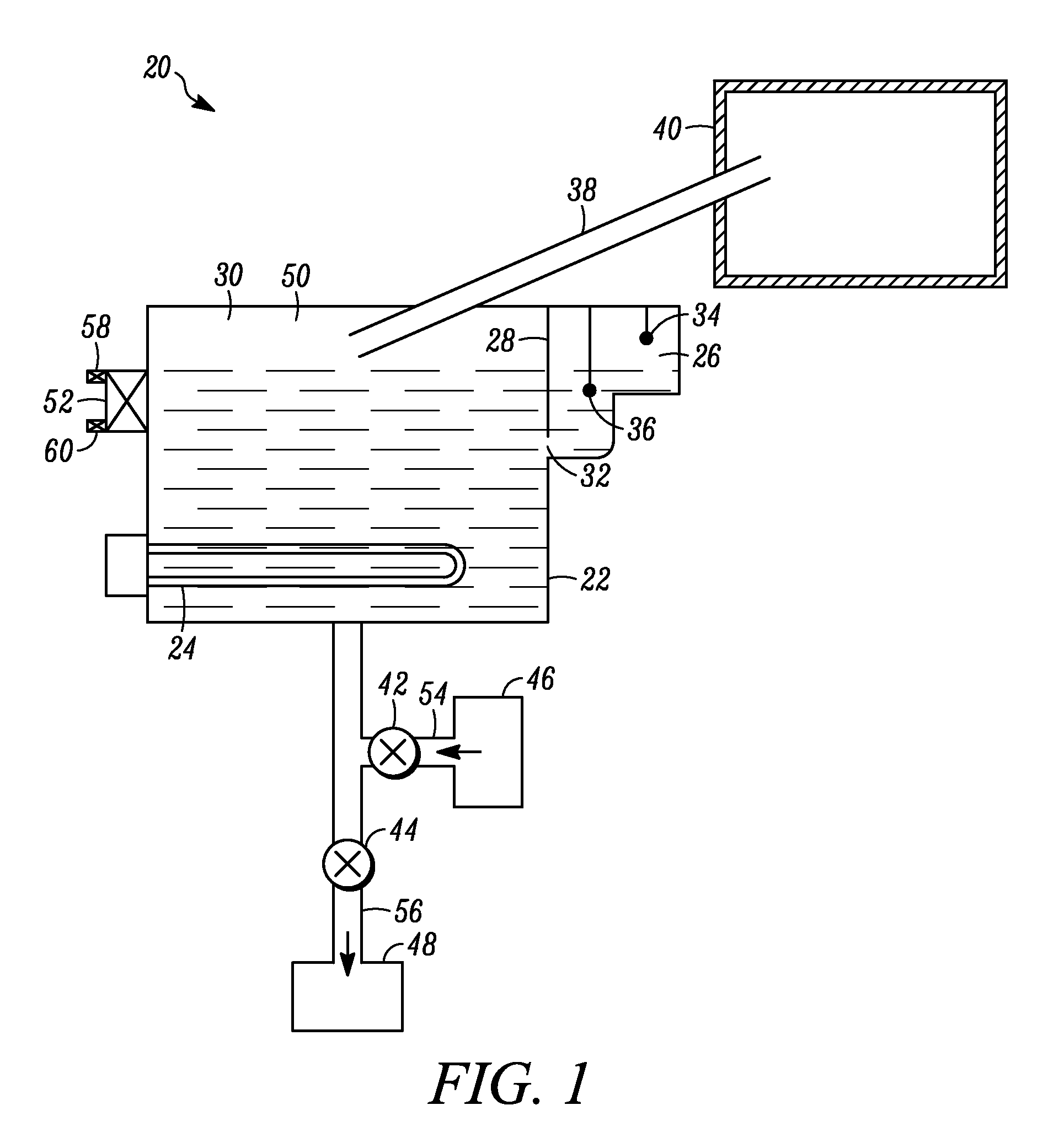

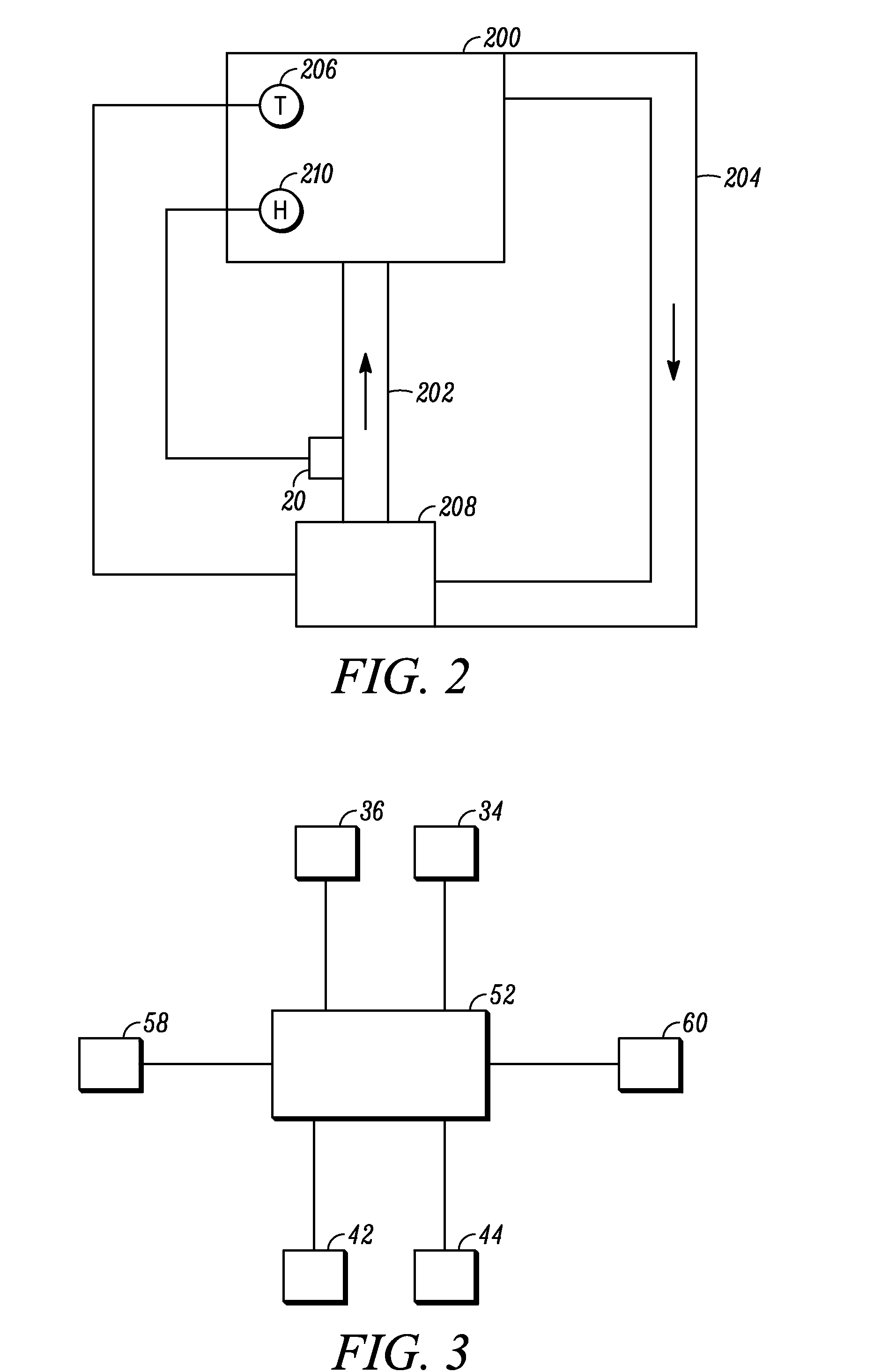

Submerged combustion disposal of produced water

InactiveUS7845314B2Easy to handleEasy disposalBoiler cleaning apparatusSedimentation separationCombustion systemCombustion chamber

The present invention relates to a method of disposing of produced water and to a produced water disposal apparatus including a container for receiving and holding produced water; and a burner having a combustion chamber, wherein at least a portion of the combustion chamber is submerged in the water and the submerged portion of the combustion chamber comprises a sparger tube through which combustion gases emerge into, mix with and agitate the water. The present invention further relates to a mechanism for removing debris from the produced water disposal apparatus. In one embodiment, heat is supplied from an externally operated combustion system, rather than the submerged combustion. In one embodiment, the apparatus provides a concentrator, in which a solute can be removed and recovered from an aqueous medium containing the solute.

Owner:TDU LLC

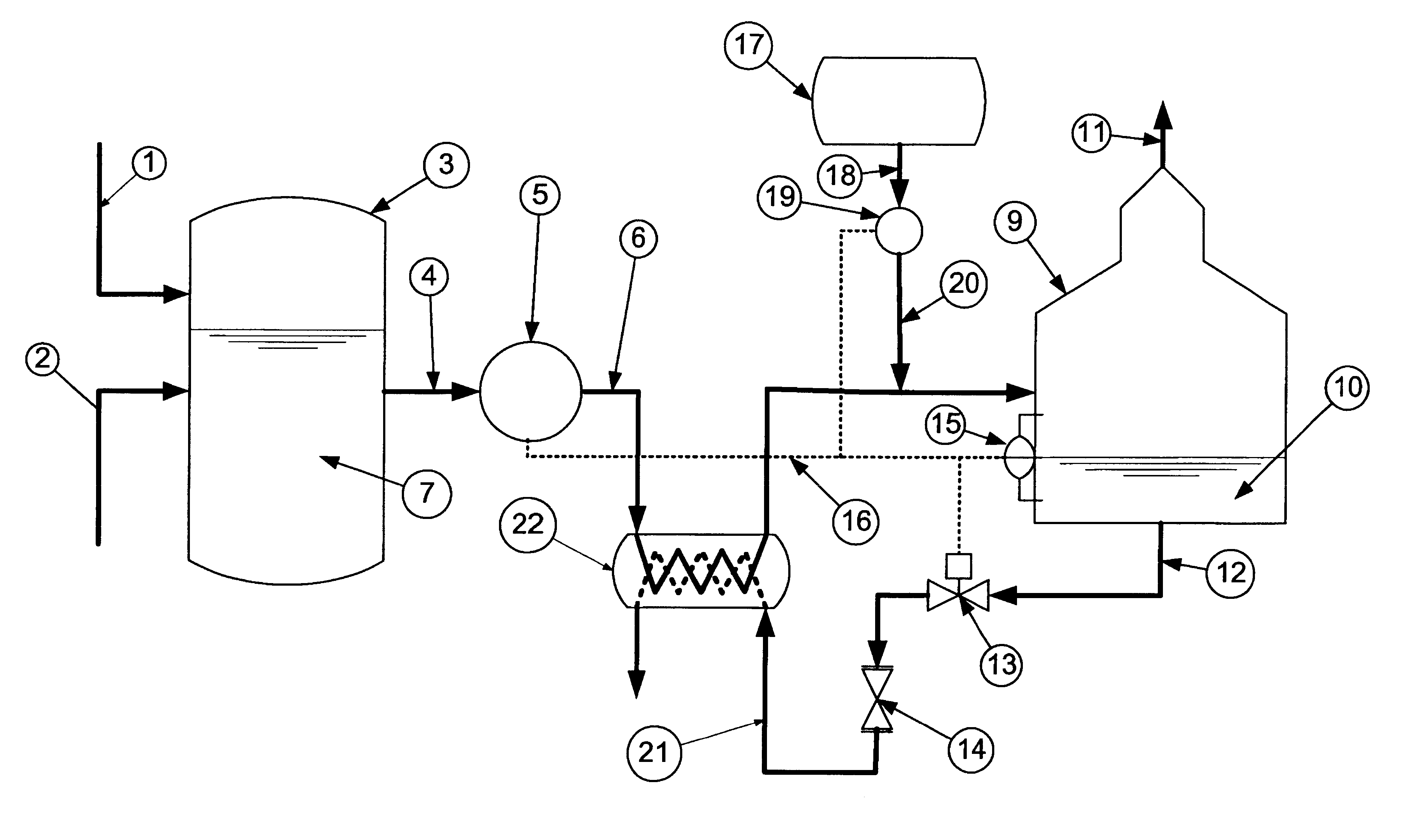

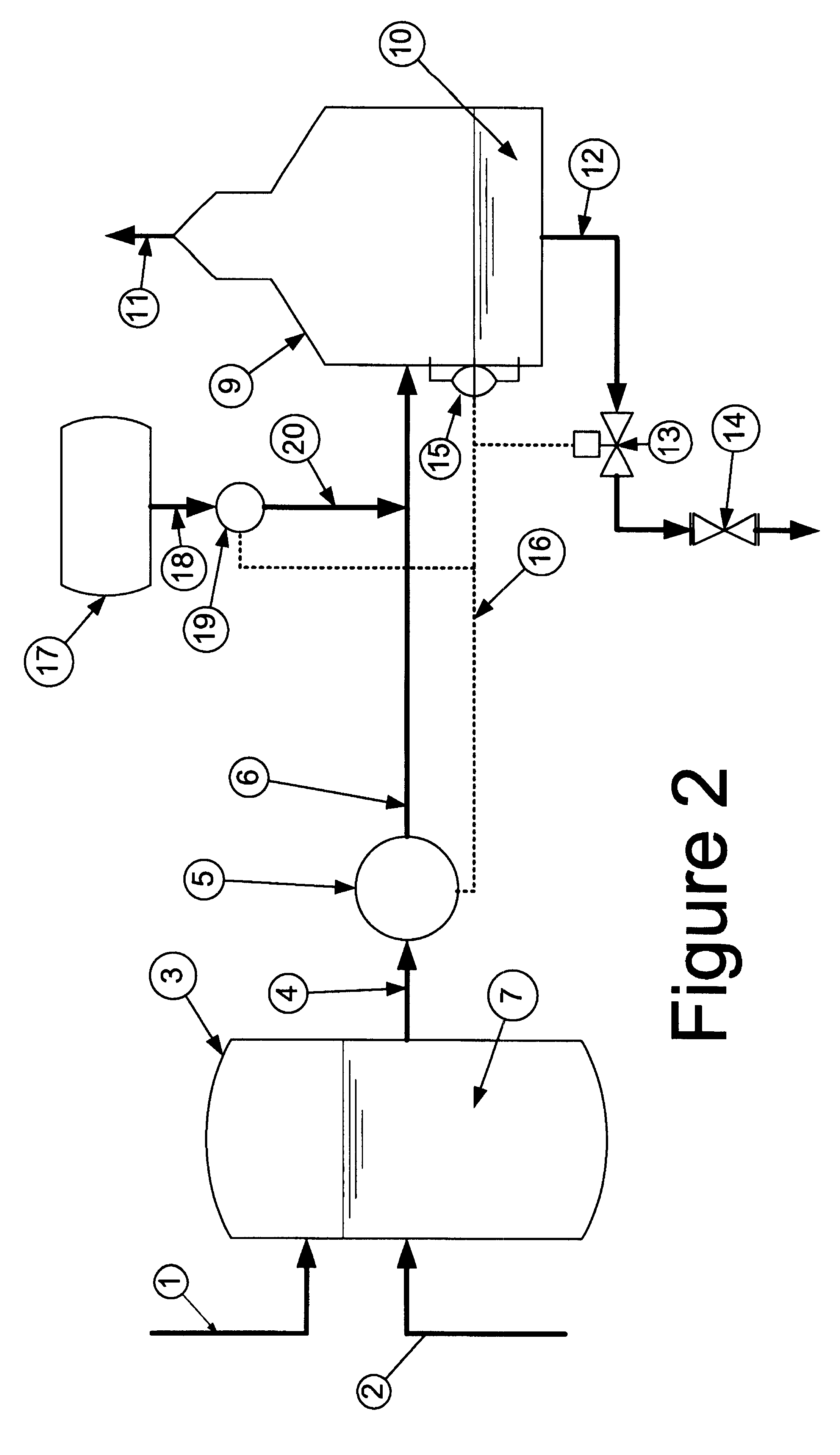

Boiler water blowdown control system

InactiveUS6655322B1Constant flowThe process is simple and accurateBoiler cleaning apparatusMachines/enginesControl systemEngineering

The present invention relates to a method for automatically maintaining the concentration of scale forming minerals in boiler water for boiler systems utilizing bimodal feedwater pumps that deliver a substantially constant feedwater flow to the boiler drum when activated. According to the present invention, the feedwater supply pump and blowdown rate control valve are synchronized to remove boiler water at a predetermined rate when the feedwater pump is activated. The present invention thereby provides a simplified and less expensive method for controlling the concentration of dissolved solids in boiler water despite variations in the steam loads and / or other boiler operation parameters.

Owner:CHEMTREAT

Acid-cleaning inhibiter for cleaning boiler and use method thereof

ActiveCN101634030ASlow down the dissolution rateIncrease activation energyBoiler cleaning apparatusThioureaPhosphoric acid

The invention discloses an acid-cleaning inhibiter for cleaning a boiler and a use method thereof. The acid-cleaning inhibiter comprises the following components by weight percent: 2.0%-10.0% of acid liquor, 0.08-0.25% of urotropine, 0.04-0.15% of dimethylbenzene thiourea or thiourea, 0.01-0.05% of thiocyanate, 0.03-0.12% of dodecyl-cetyl phenmethyl chloride or bromide, 0.05-0.12% of a surface active agent and the balance of water. Acids suitable for the acid-cleaning inhibiter include hydrochloric acid, citric acid, sulphuric acid, hydrofluoric acid, aminosulfonic acid and phosphoric acid, which are suitable for boiler steel, mild steel, alloy steel and steam steel. The inhibition effect of the invention is over 98% with less toxicity under the boiler chemical cleaning condition, the value of LD50 (orally taken by mice) is 5.74 g / kg. The invention can be stored for 2 years, resistant Fe<3+> ion is 800 mg / kg in the acid cleaning. The preparation method has simple steps, easily obtained raw materials and convention operation.

Owner:湖南省湘电试验研究院有限公司 +2

Submerged combustion disposal of produced water

InactiveUS20080110417A1Easy to handleEasy disposalBoiler cleaning apparatusSedimentation separationCombustion systemCombustion chamber

The present invention relates to a method of disposing of produced water and to a produced water disposal apparatus including a container for receiving and holding produced water; and a burner having a combustion chamber, wherein at least a portion of the combustion chamber is submerged in the water and the submerged portion of the combustion chamber comprises a sparger tube through which combustion gases emerge into, mix with and agitate the water. The present invention further relates to a mechanism for removing debris from the produced water disposal apparatus. In one embodiment, heat is supplied from an externally operated combustion system, rather than the submerged combustion. In one embodiment, the apparatus provides a concentrator, in which a solute can be removed and recovered from an aqueous medium containing the solute.

Owner:TDU LLC

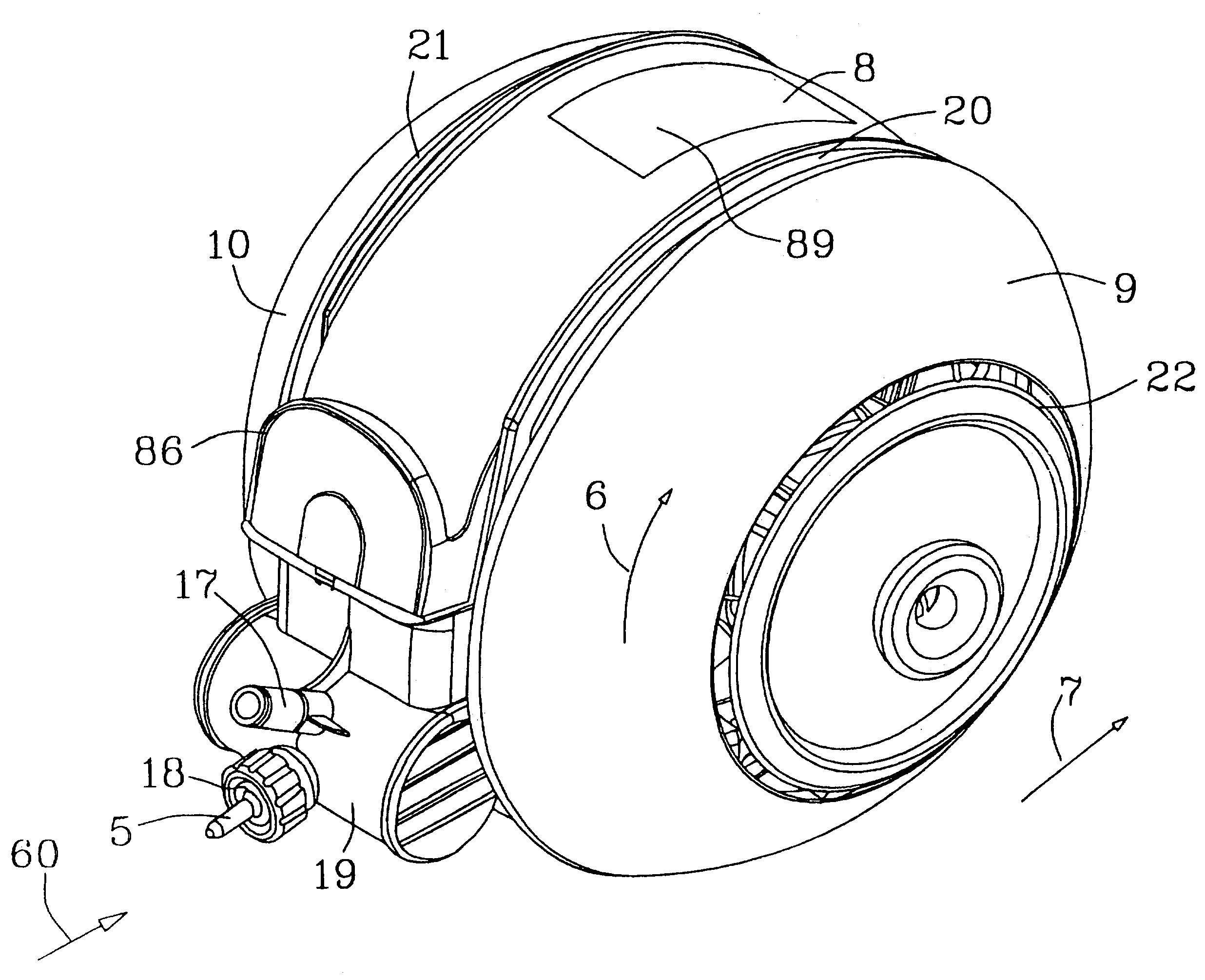

Pool cleaner

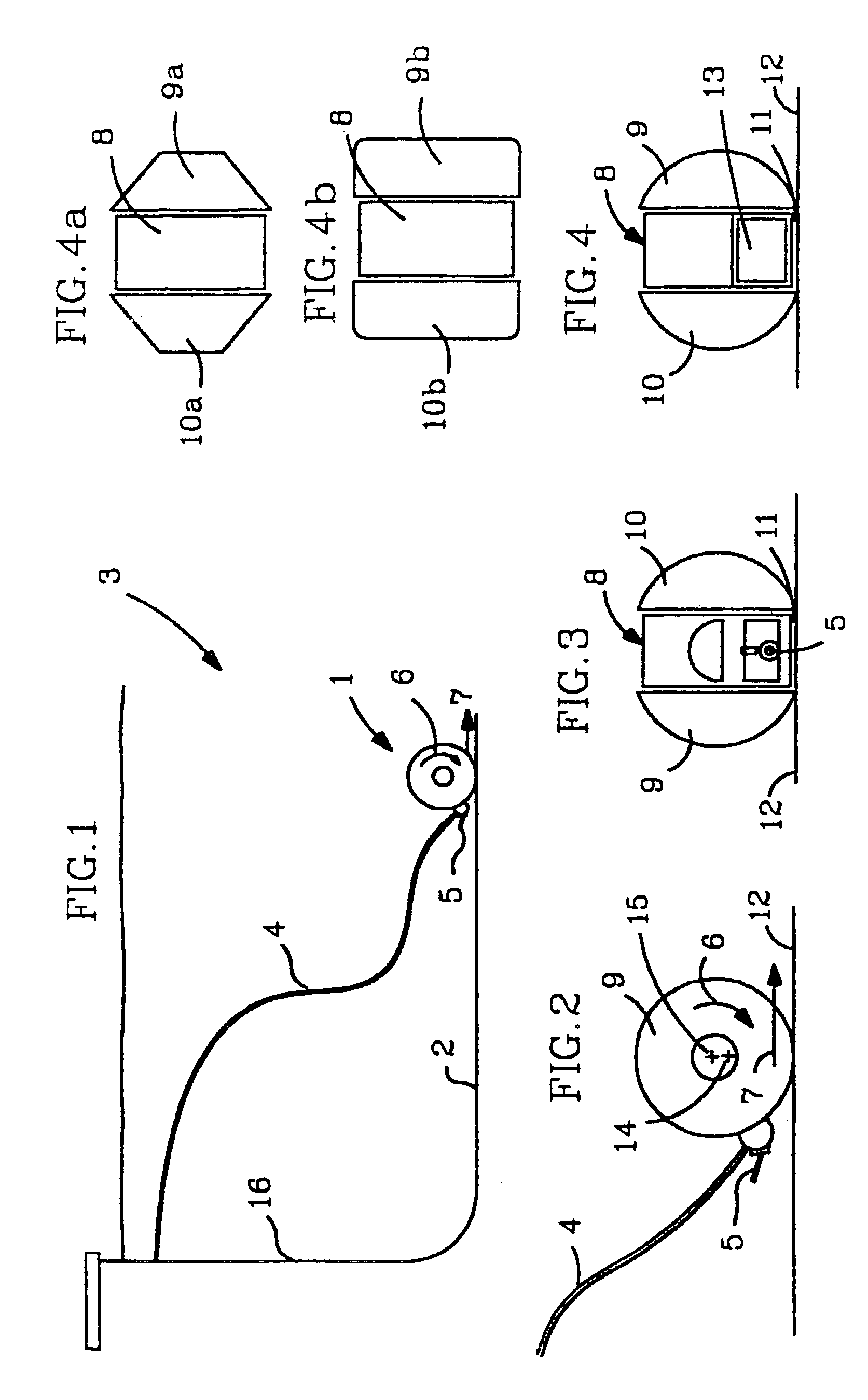

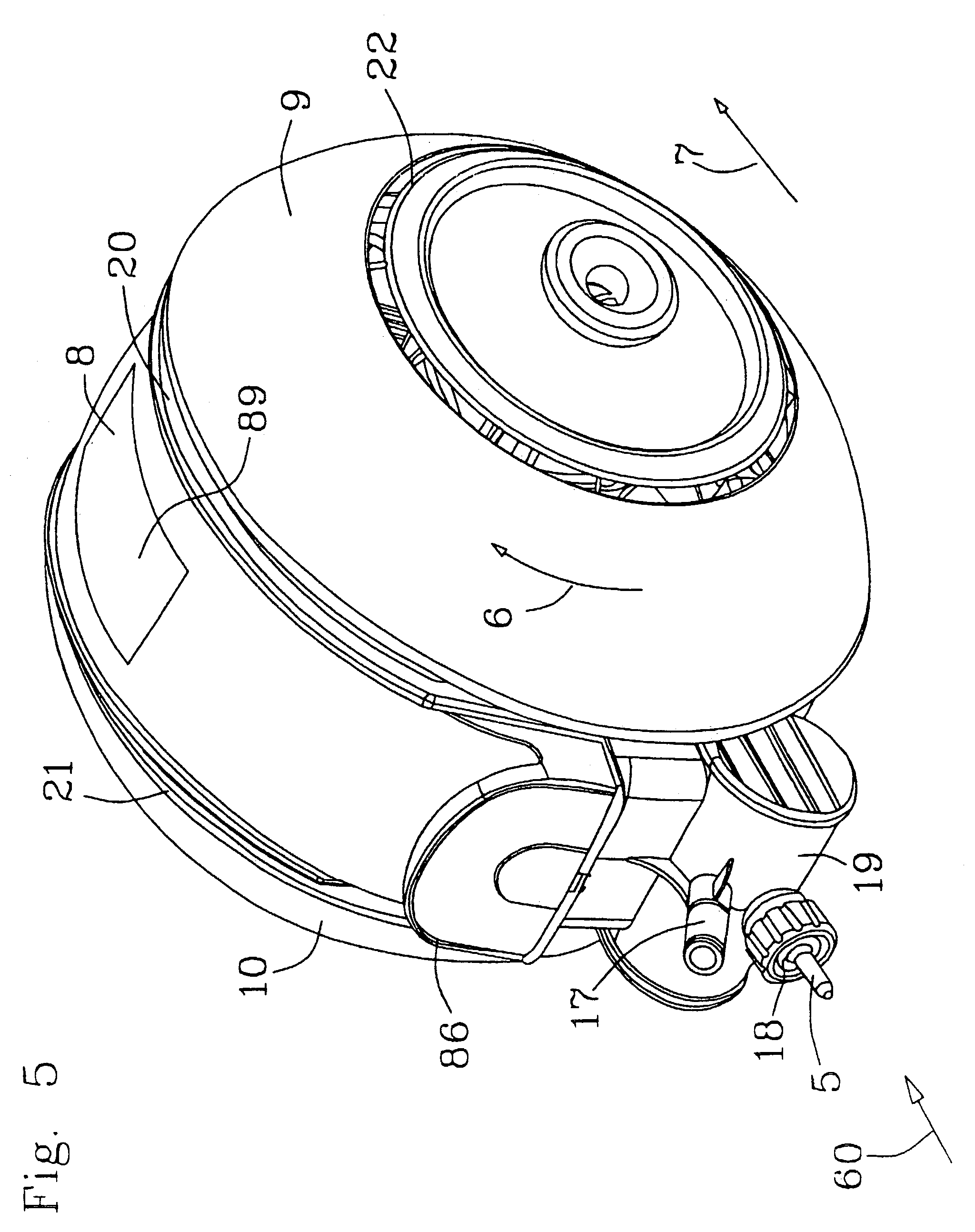

InactiveUS7039980B2Less stable device under waterTolerableBoiler cleaning apparatusWater/sewage treatmentWater flowMechanical engineering

A push side pool cleaner (1) has a spheroidal overall shape, within this shape two outer segments (9, 10) serve as wheels and a central zone (8) carries a suction passage (33) and a debris collector (32) also located entirely within the overall shape. The wheels are driven directly by water jets (44, 45) without any gears or other transmission. A flow splitter is provided in the cleaner (1) to divide push side water flow between the jets (44, 45) which drive the wheels and jets (43) which provide impulsion to the suction passage (33).

Owner:ZODIAC POOL SYST LLC

Machine for cleaning the interior of a water storage tank

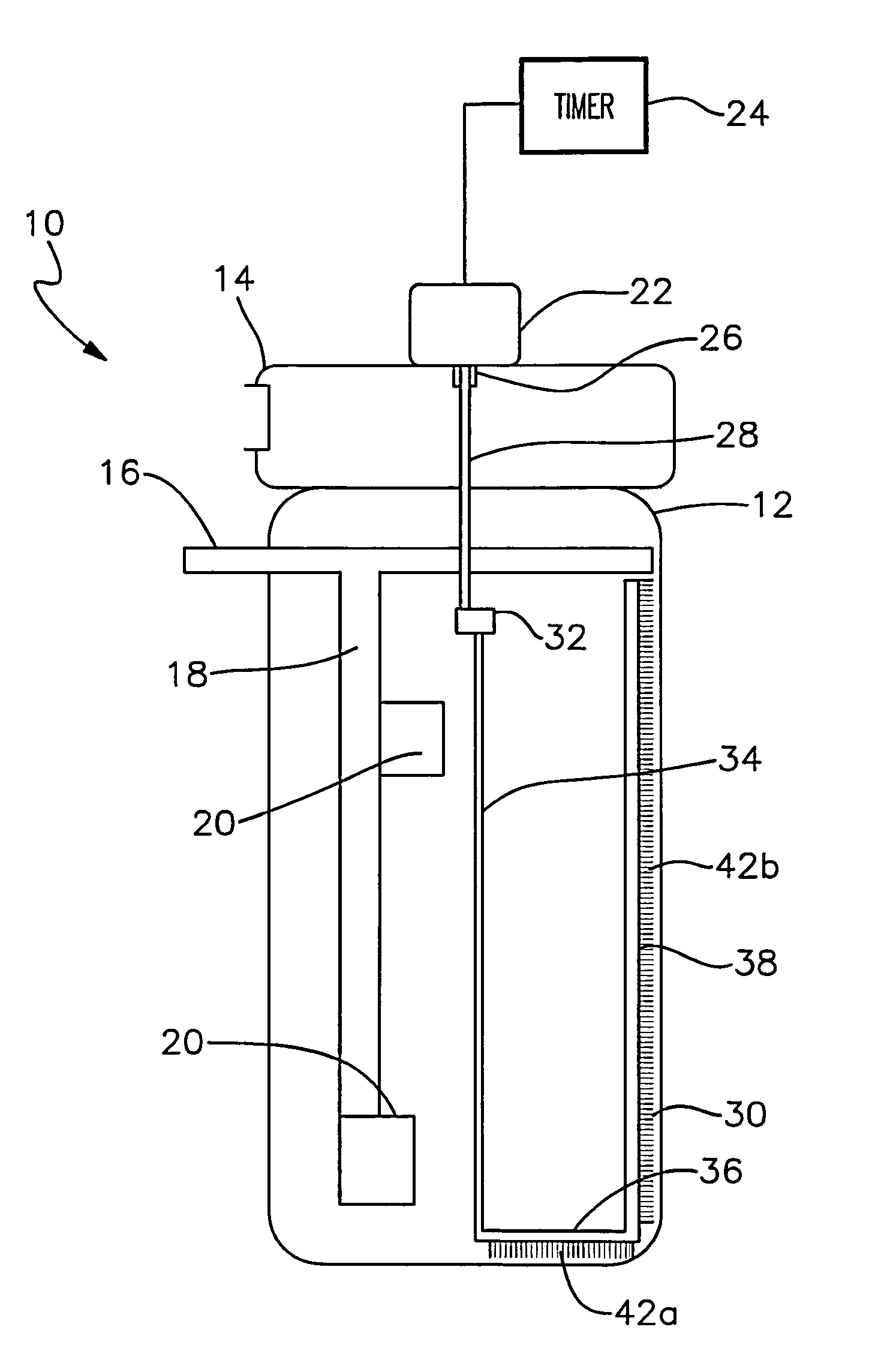

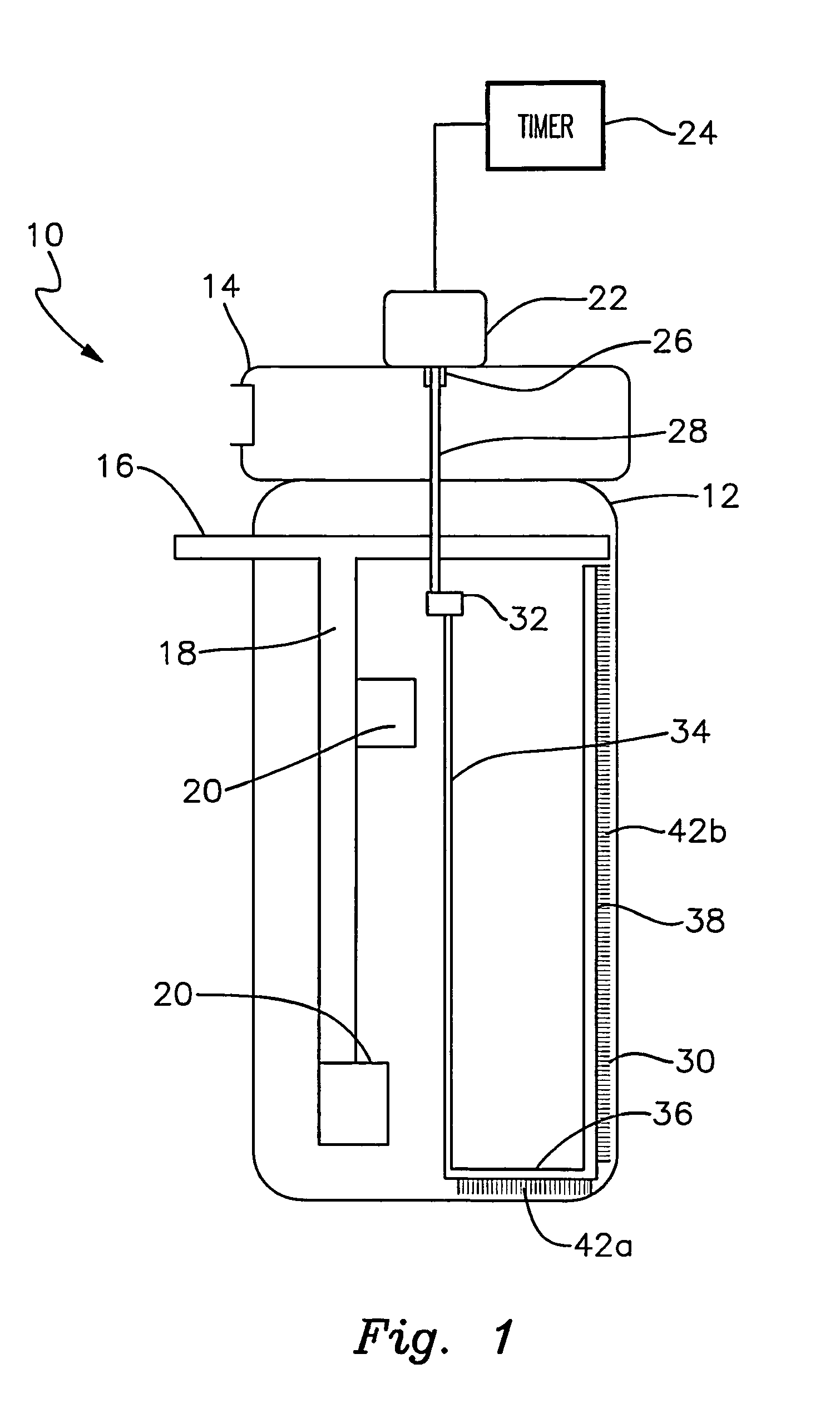

ActiveUS8806697B1Quick and convenient and effective mannerEasy and fastHollow article cleaningBrushesDrive shaftWater storage tank

A machine for automatically cleaning the interior surface of a water storage tank includes a motor for mounting on a cover of the tank. A drive shaft is operably connected to the motor and extends through a channel in the cover of the tank. A scrubbing assembly is connected to the drive shaft. The motor operates the drive shaft to turn the scrubbing assembly within the tank such that brushes of the scrubbing assembly engage and clean the interior surfaces of the tank.

Owner:DAVILA JR GILBERTO

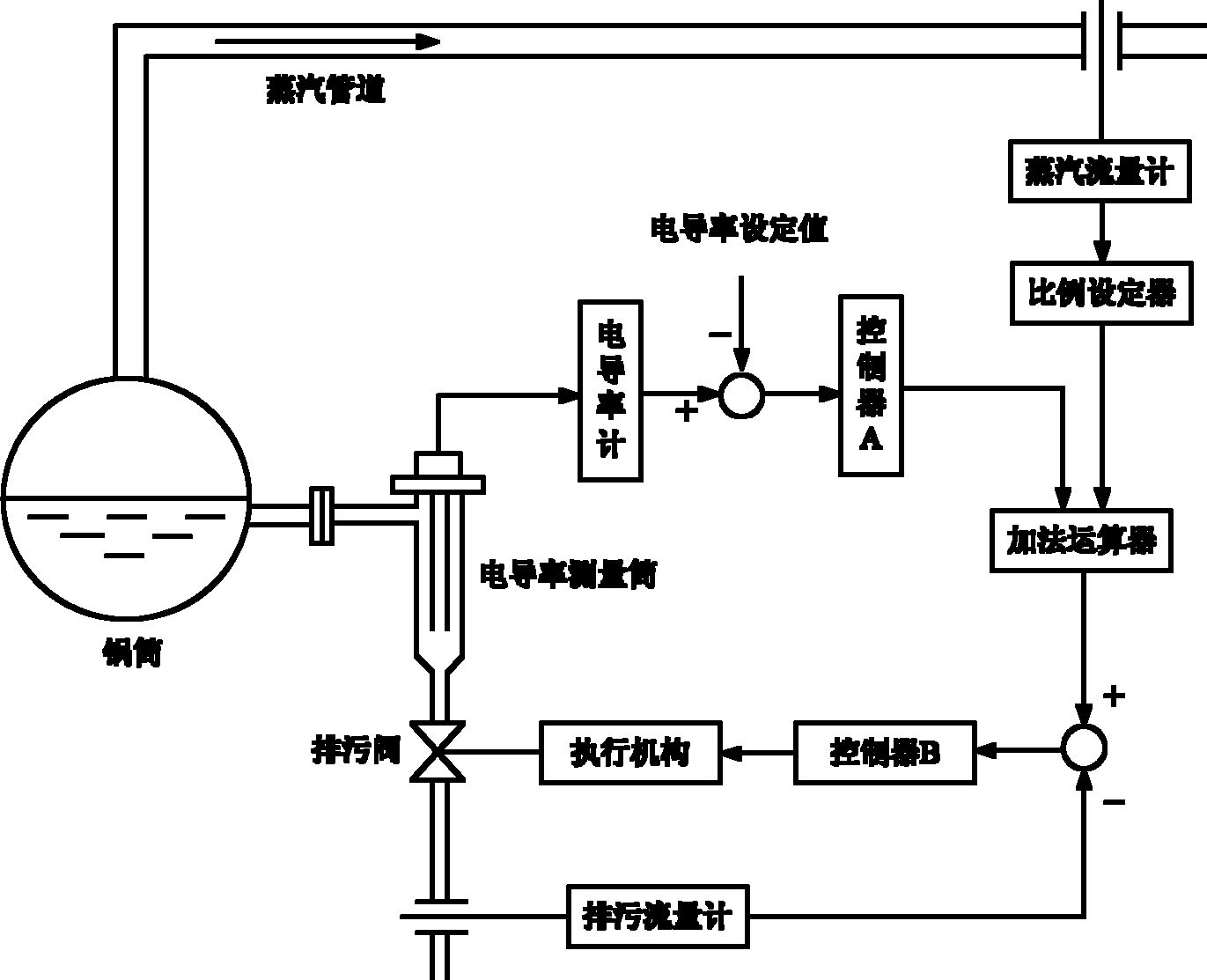

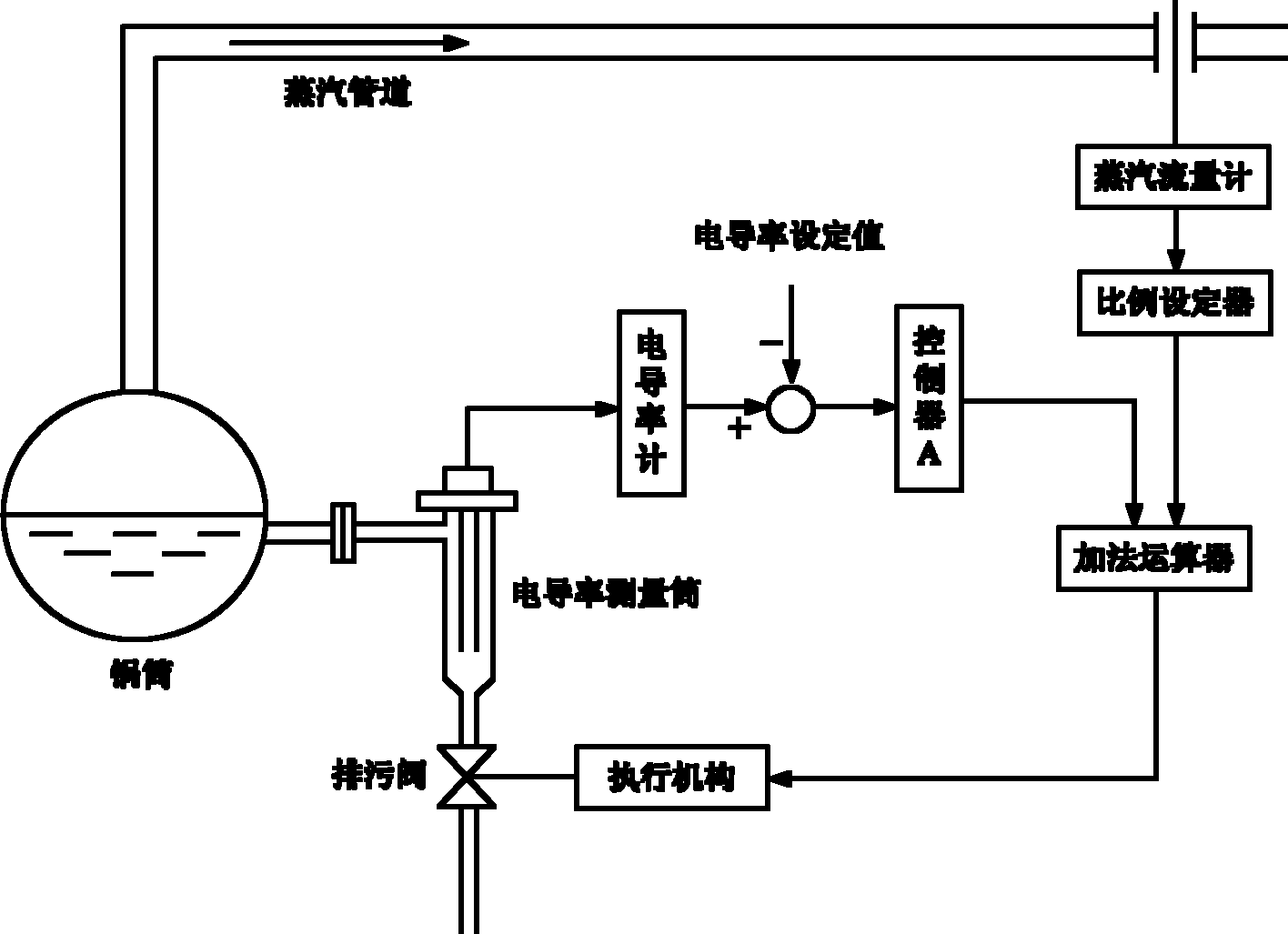

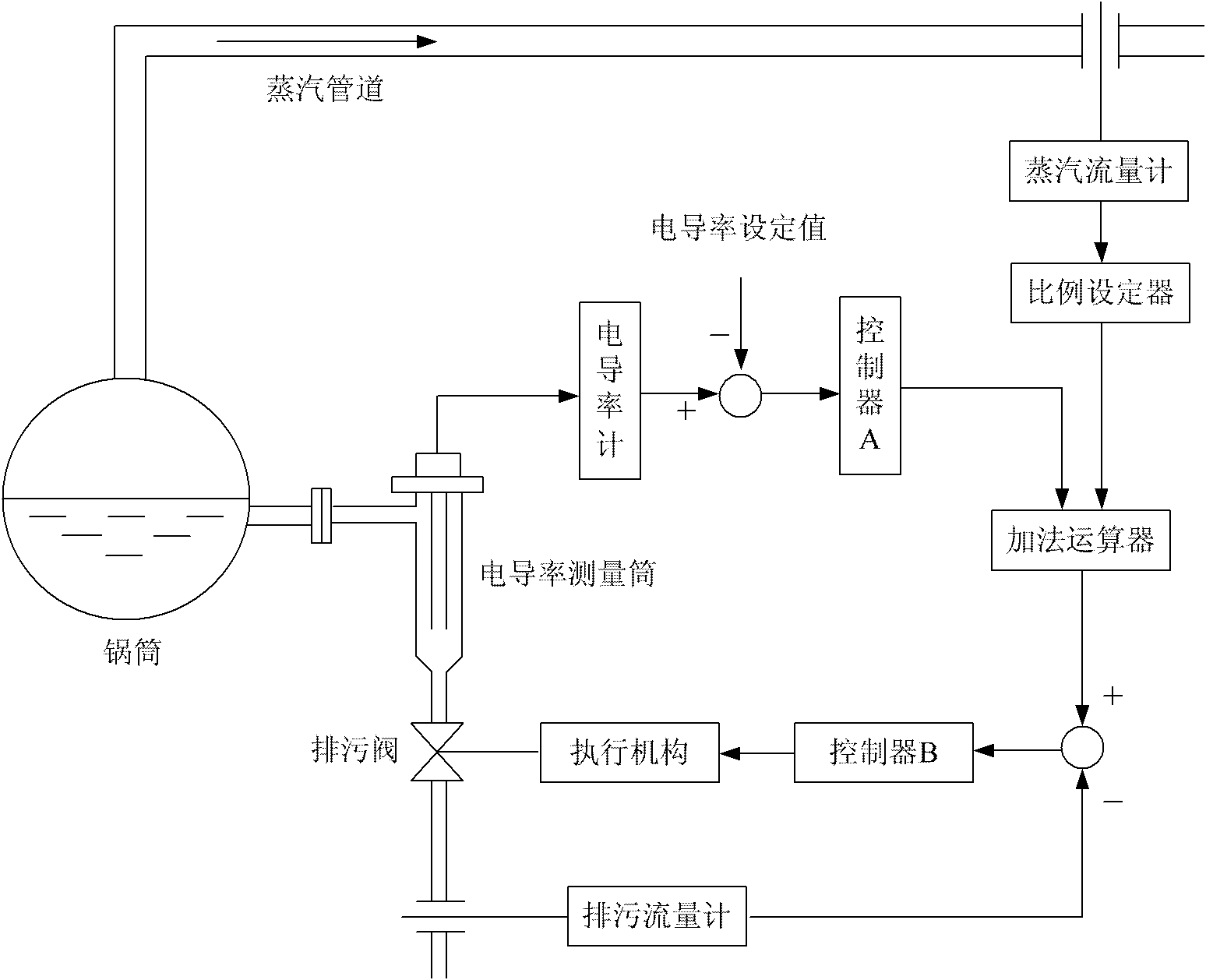

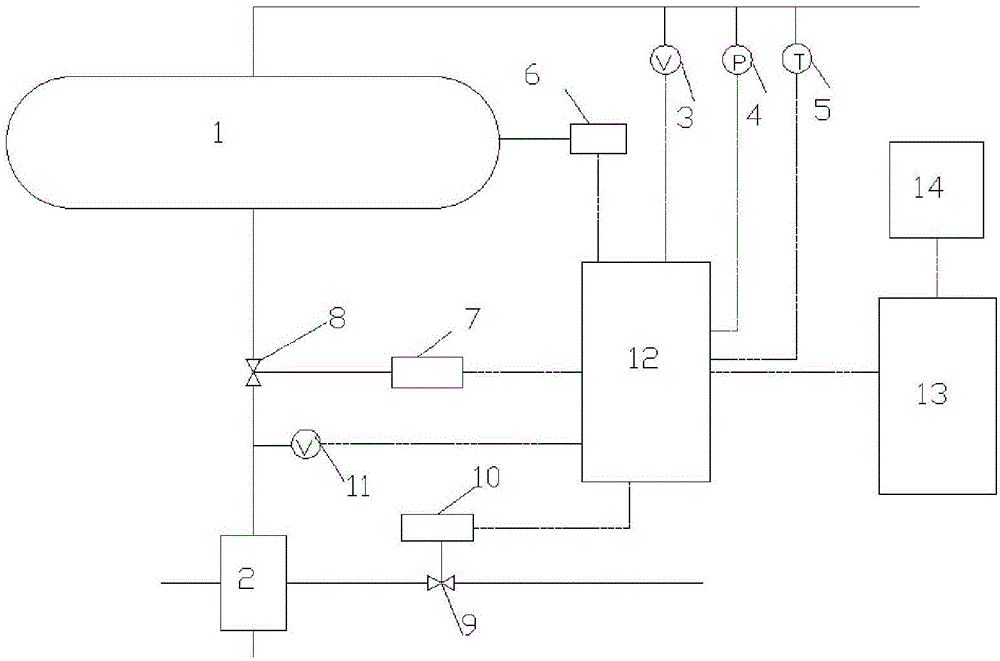

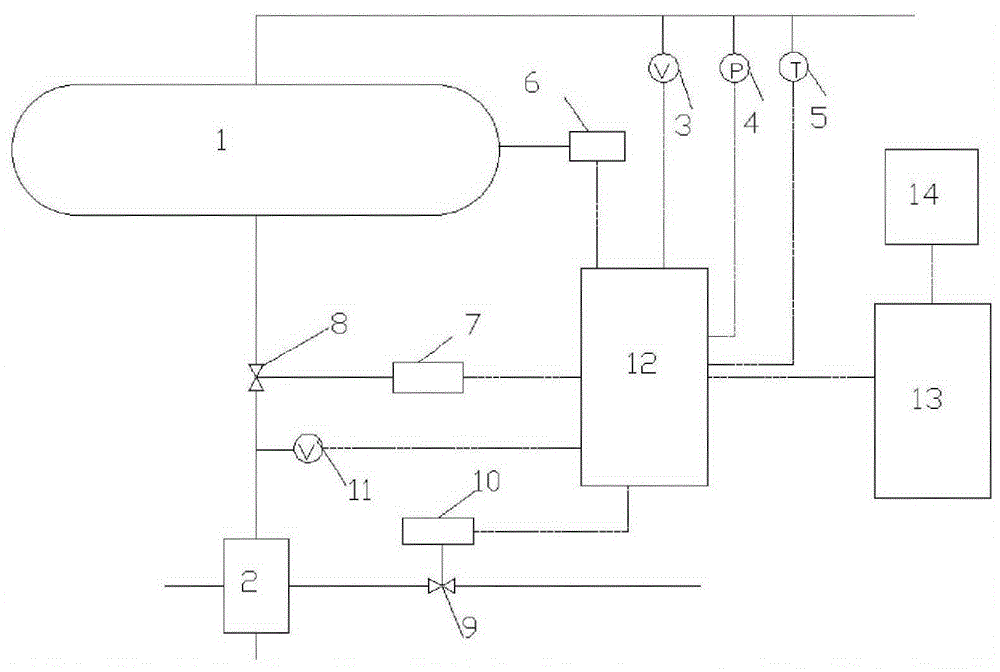

Optimal energy-saving method for controlling surface pollutant discharge of steam boiler

The invention discloses an optimal energy-saving method for controlling the surface pollutant discharge of a steam boiler. The method comprises the steps of firstly controlling the flow of pollutant discharge according to the steam flow proportionally, and continuously diluting water in the steam boiler as required; on this basis, configuring a conductivity close loop control circuit to prevent the influences, such as water supply salinity fluctuation, flow rate measurement error, boiler bottom periodic pollutant discharge and the like, and coupling the both by an addition logic unit so as to form a feedforward-feedback complex control system. The invention can prevent various interferences, stably keep the salinity of the water in the steam boiler above the desired level, and realize the optimal energy-saving and emission-reducing effects by the least pollutant discharge amount.

Owner:西安交大思源科技股份有限公司 +2

Method and apparatus for commissioning power plants

ActiveUS20080236616A1Reduce fuel consumptionReduce water consumptionLiquid degasificationDrying solid materials without heatPower stationEngineering

An apparatus and method for commissioning steam turbine generator power plants to advance the cleanliness of the complete steam cycle by the conditioned discharge of steam to the plant surface condenser.

Owner:BEST ENERGY SERVICES INC

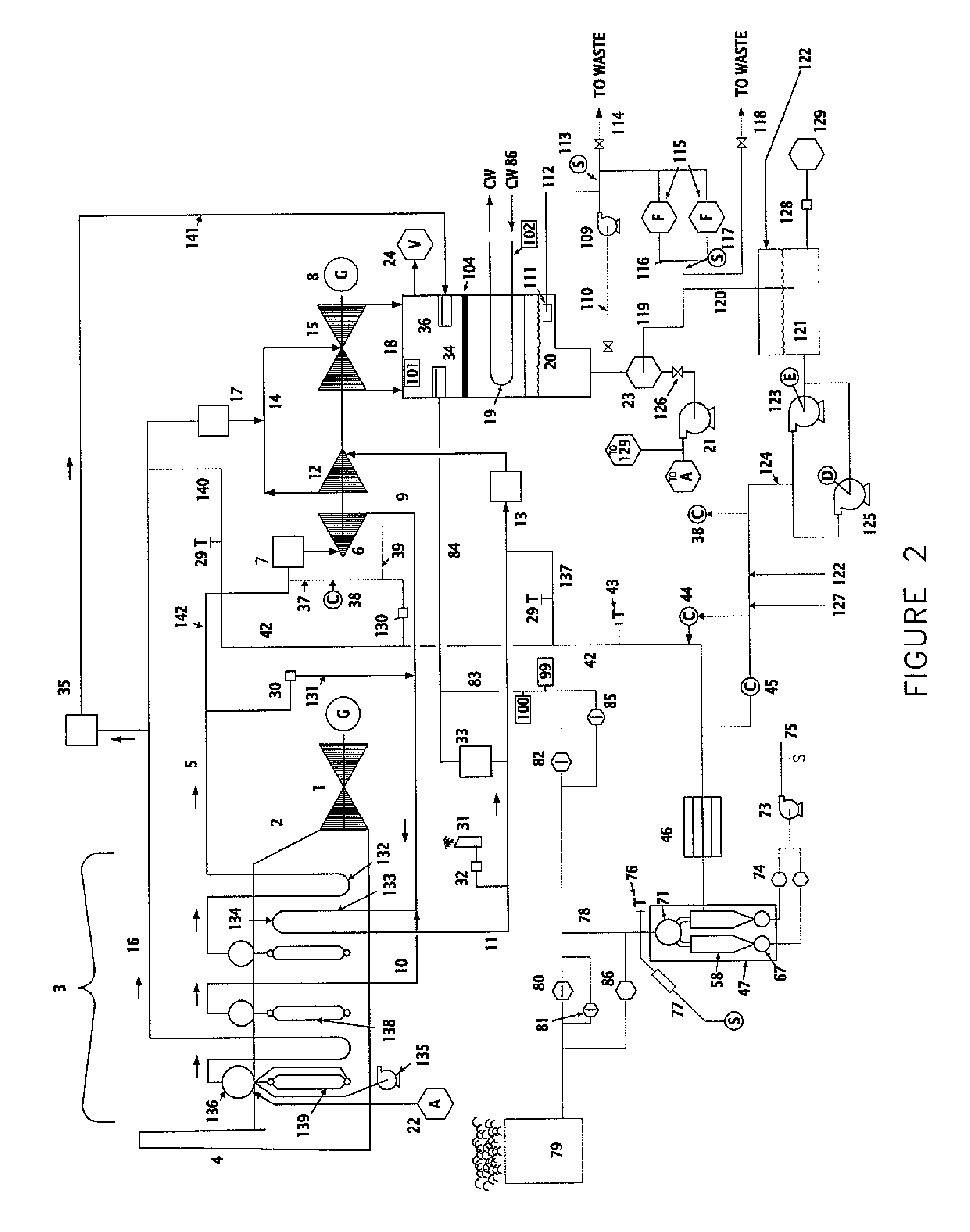

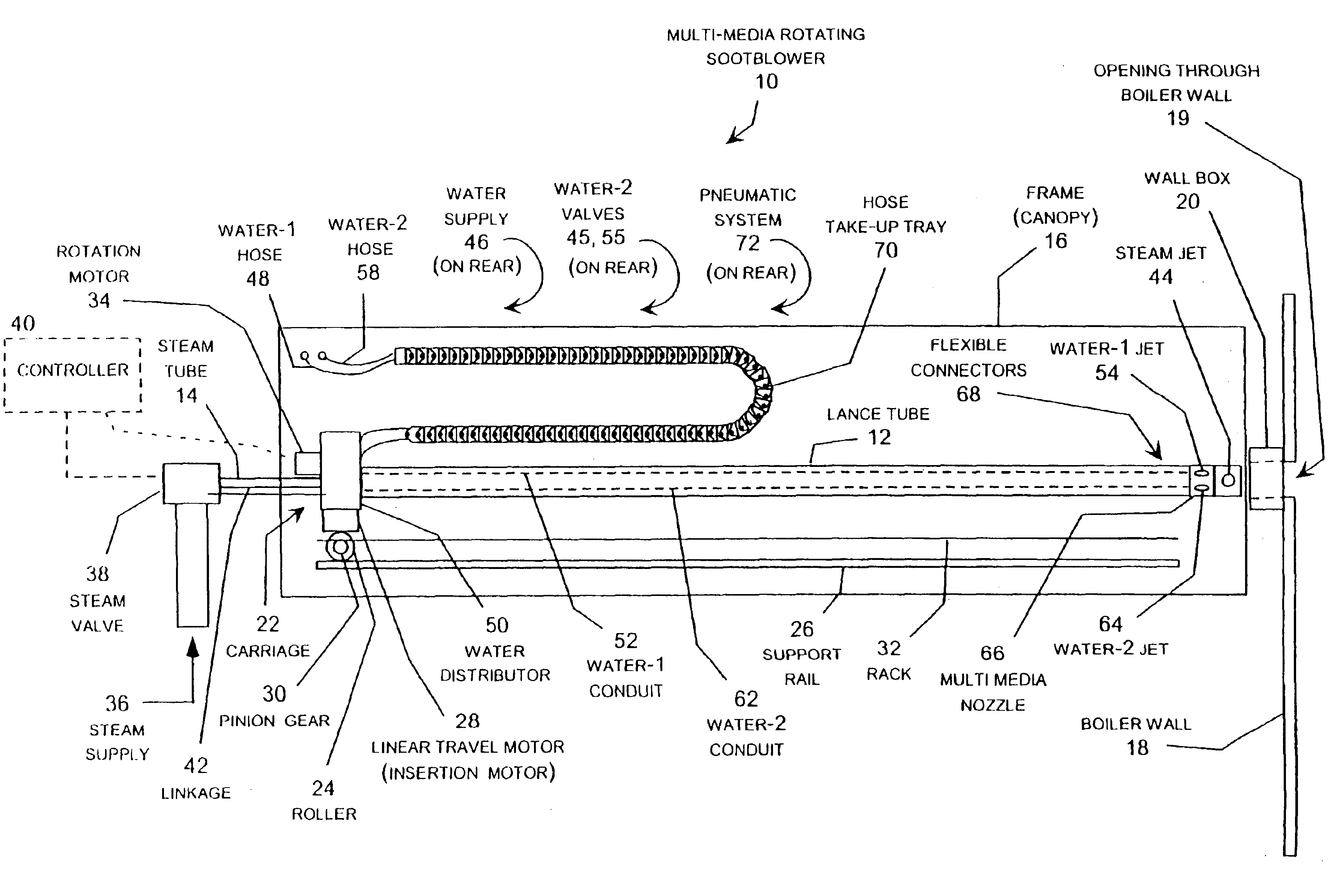

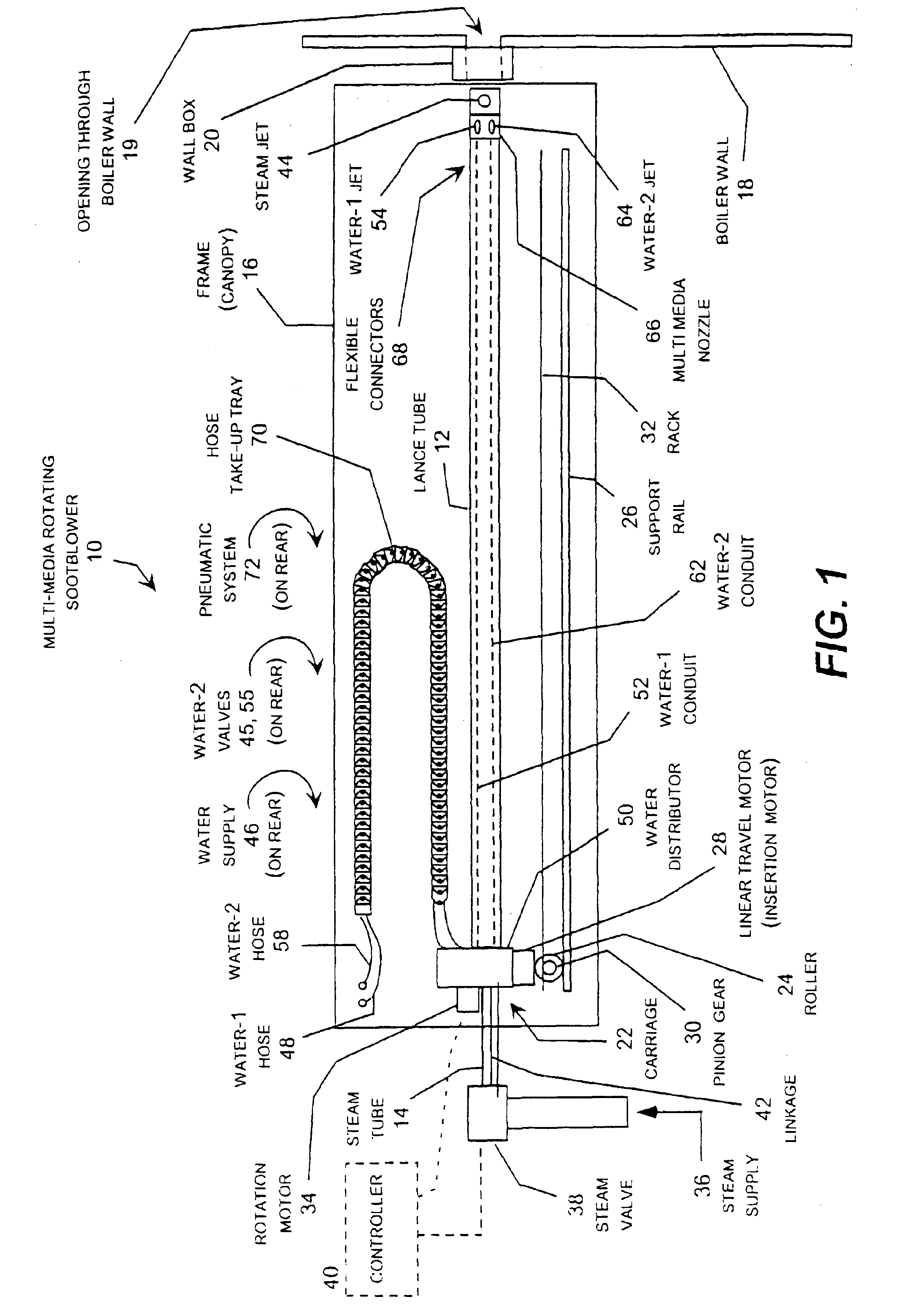

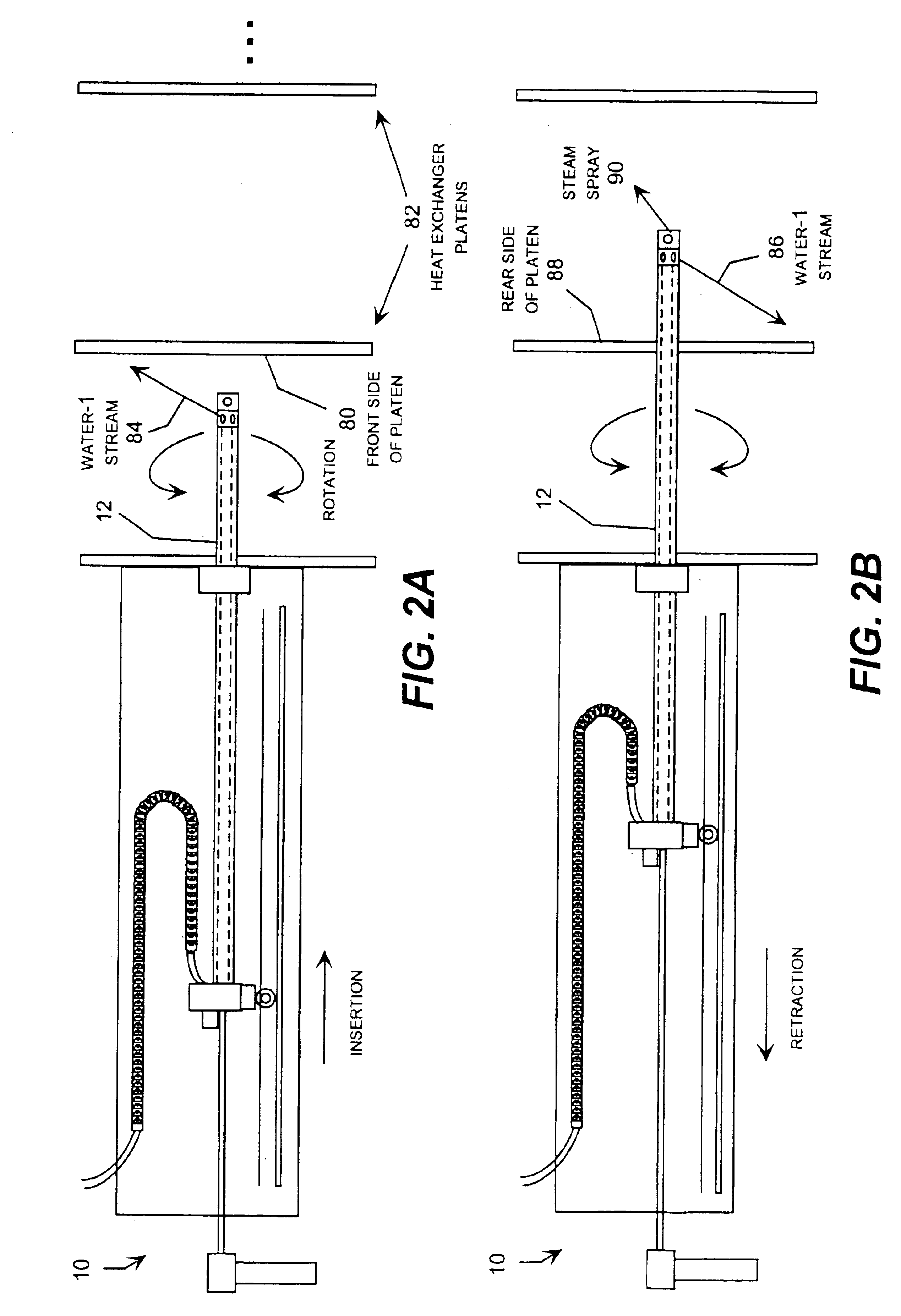

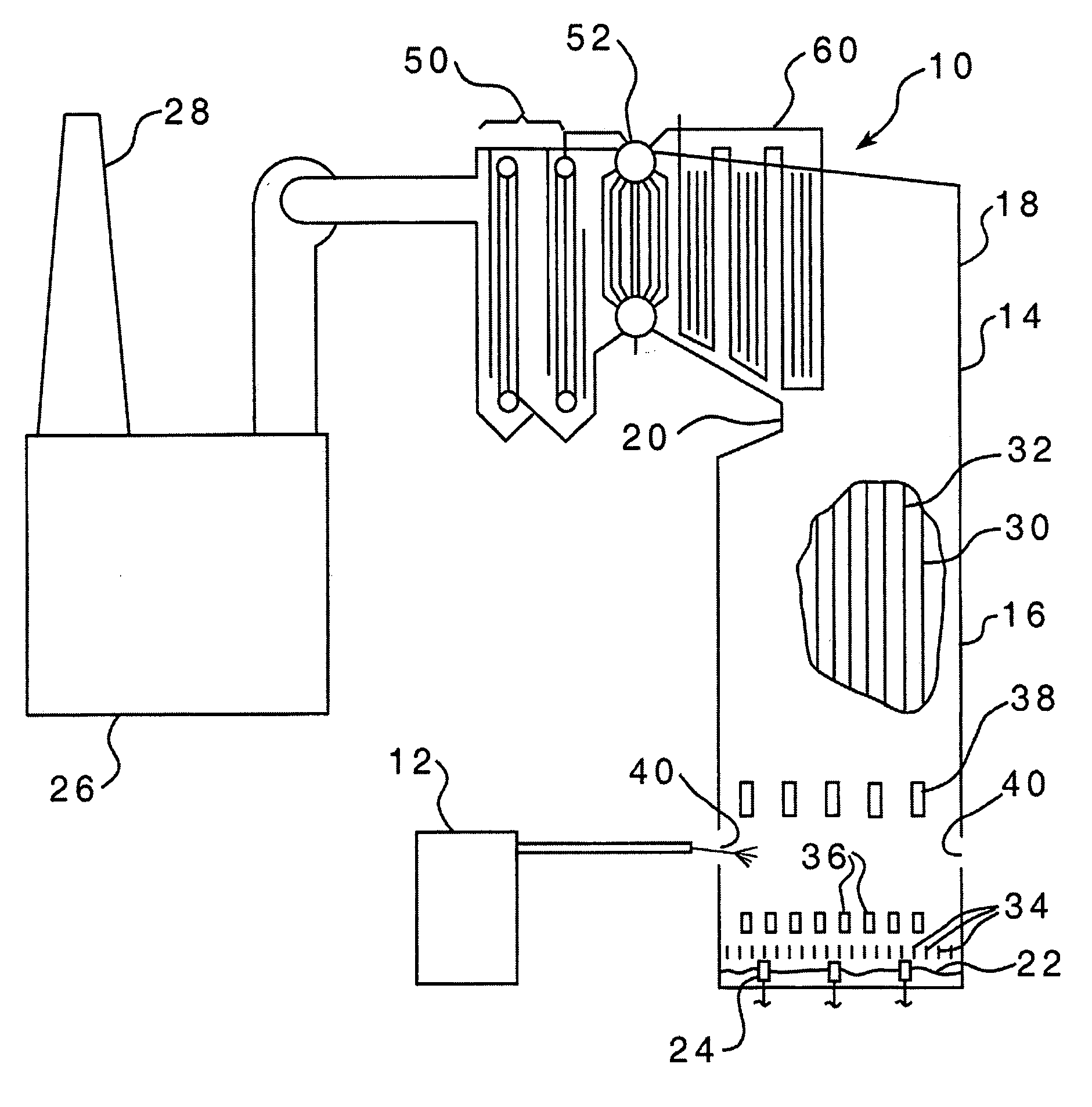

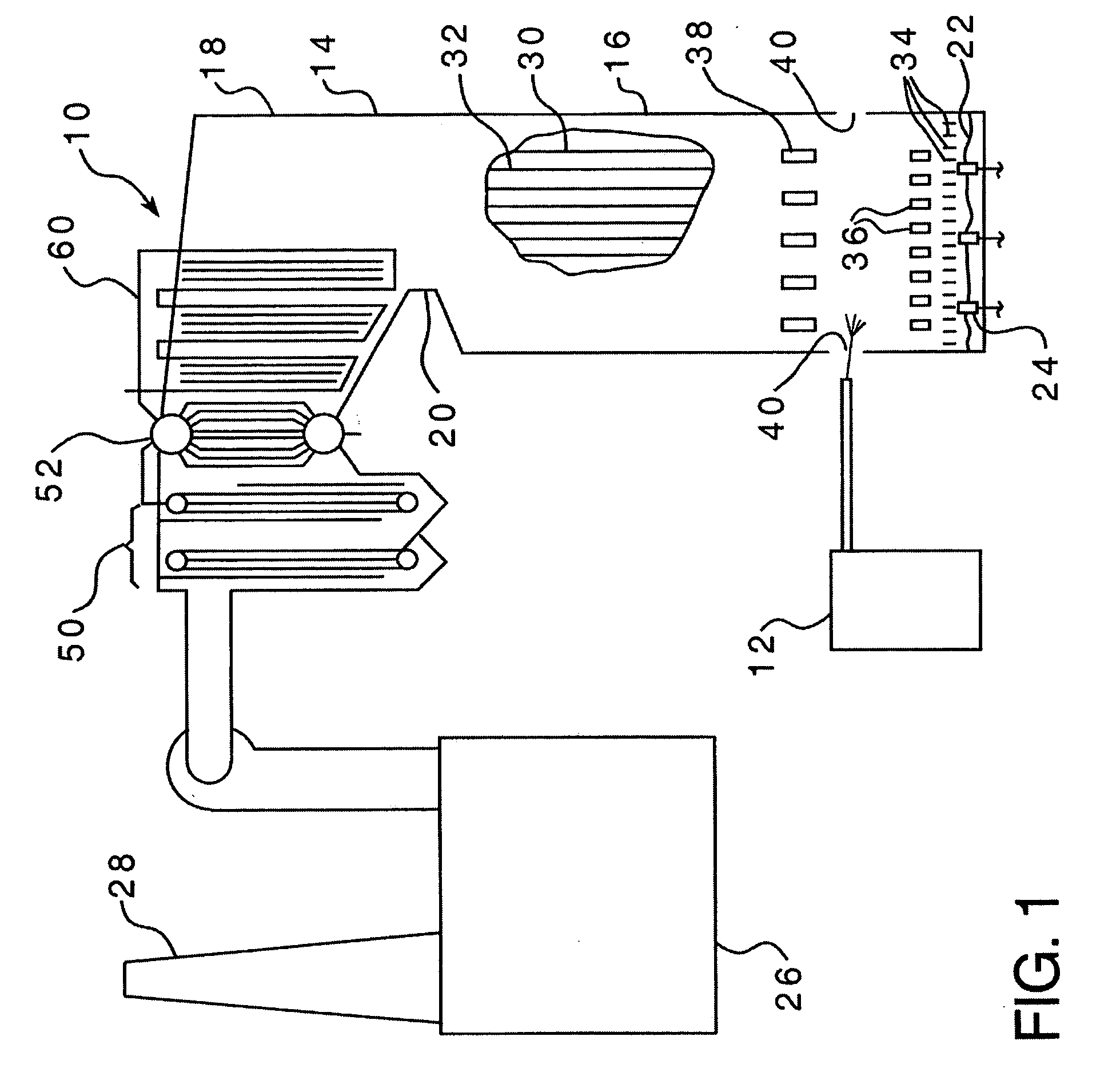

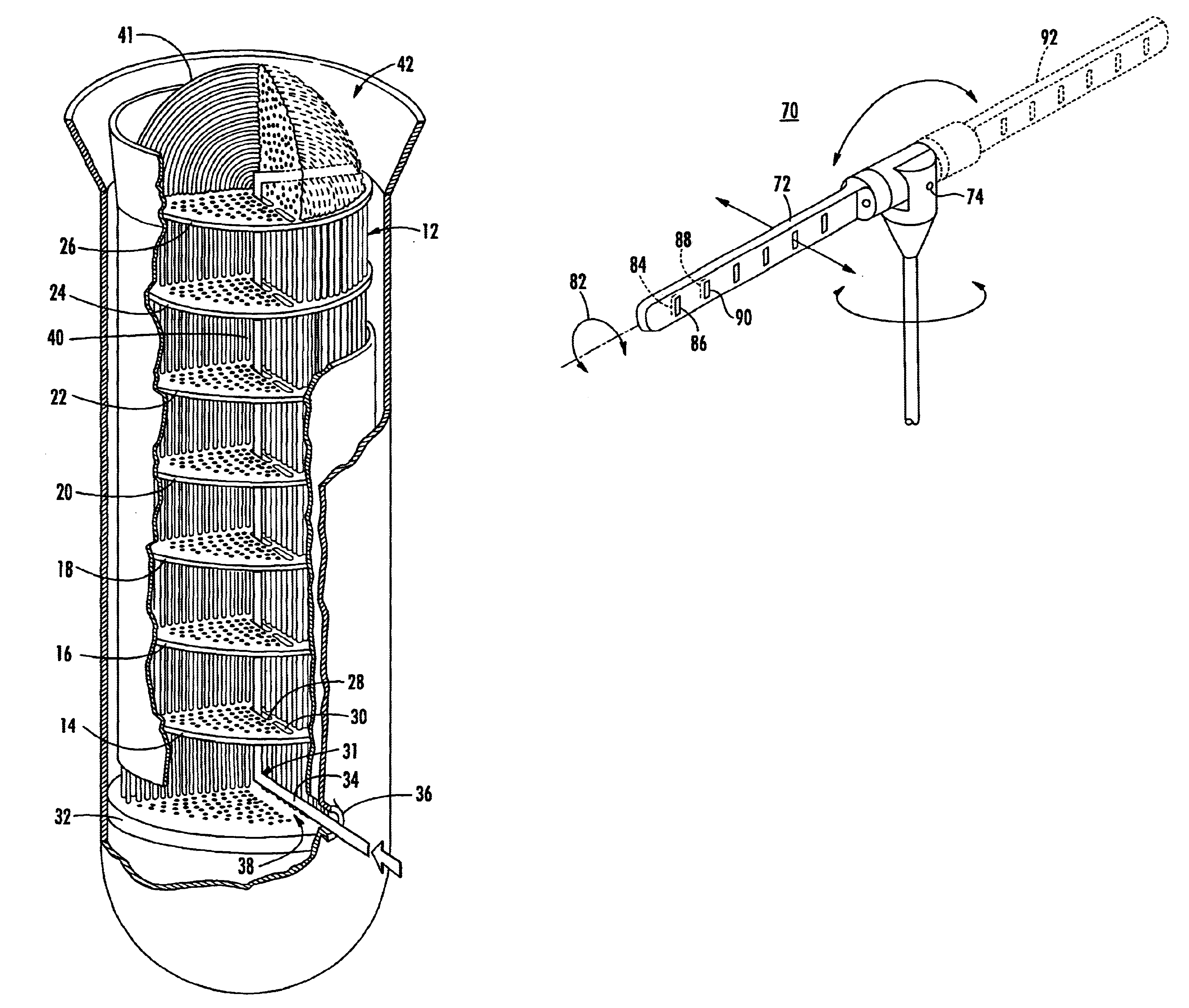

Multi-media rotating sootblower and automatic industrial boiler cleaning system

ActiveUS6892679B2Avoiding unnecessary thermal stressUnnecessary thermal stressMechanical cleaningPressure cleaningRegimenControl system

A multi-media rotating sootblower that includes multiple rotating and individually controlled cleaning fluid applicators, such a set of steam nozzles and two sets of water nozzles, and an automatic boiler cleaning system using these sootblowers. The boiler superheater typically includes a system of these sootblowers to clean a number of large platens that are arranged in rows. The boiler may also include additional boiler cleaning equipment, including water cannons to clean the furnace, and conventional steam sootblowers to clean other heat exchangers of the boiler. A number of sensors, including heat transfer gauges that measure the heat transfer at the furnace wall, strain gauges that measure the weight of slag deposits on platens, and boiler cameras are used to monitor slag accumulations within the boiler. A control system uses this sensor data to automatically operate the boiler cleaning system to implement an automatic boiler cleaning regimen.

Owner:CLYDE IND

Intelligent measurement and control boiler system dynamically calculating water loss according to drum water level

InactiveCN105135406AKeep abreast of the operation status in timeAvoid wastingBoiler indication operationsBoiler cleaning apparatusData connectionEngineering

The invention provides a boiler system. A monitoring diagnosis controller calculates water loss of a boiler by calculating the ratio of the sum of the steam mass, the change mass of drum water and the sewage discharge mass to the mass of water input into the boiler. The monitoring diagnosis controller is in data connection with a cloud server, so that monitored data are transmitted to a cloud server; the cloud server is connected with a client side, and the client side can obtain the monitored data by means of the cloud server. By means of the client side, the operation condition of water loss of the boiler can be mastered in time, and by means of the client side, the situation that due to water loss of the boiler, a large amount of heat is wasted can be avoided in time.

Owner:SHANDONG UNIV OF TECH

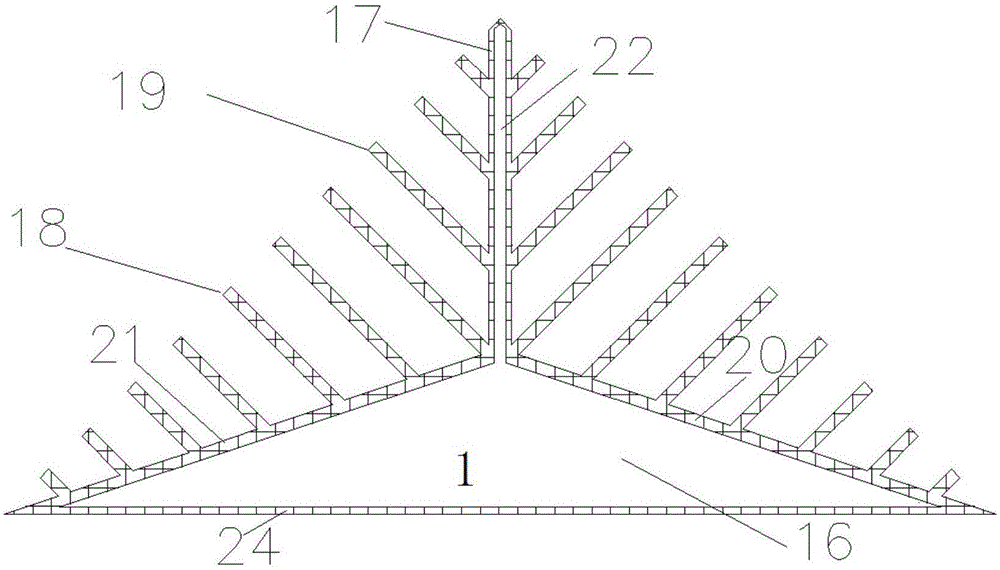

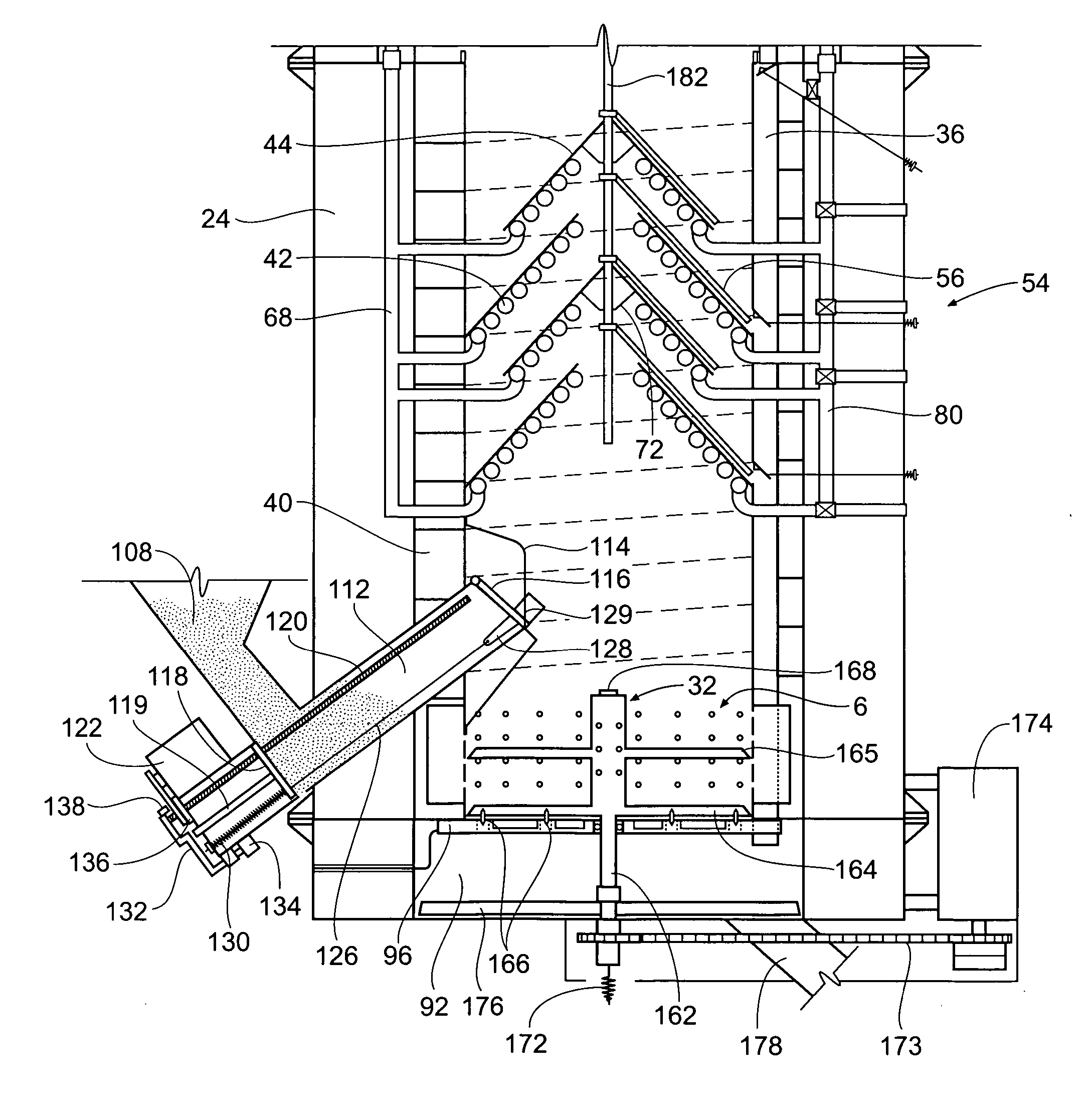

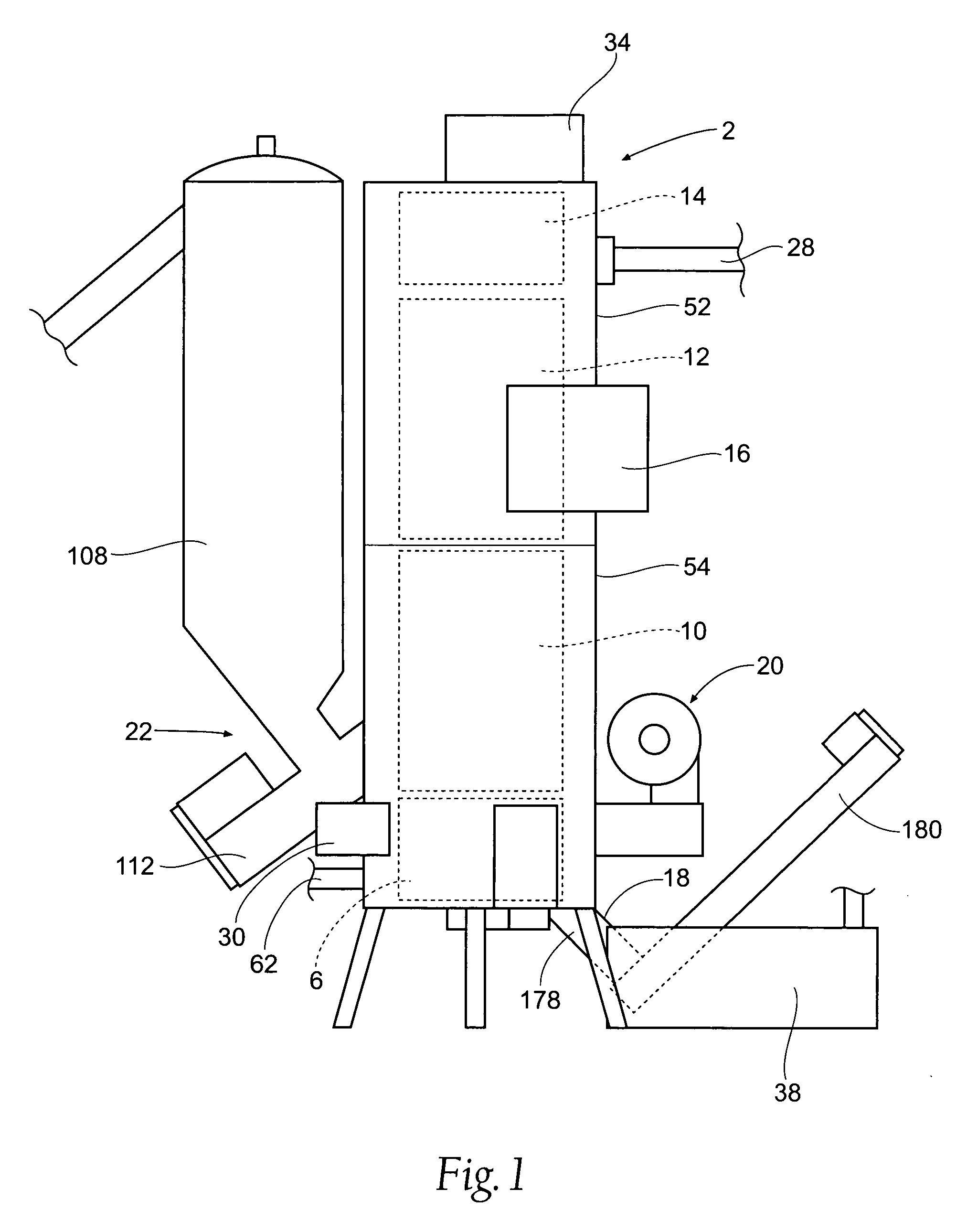

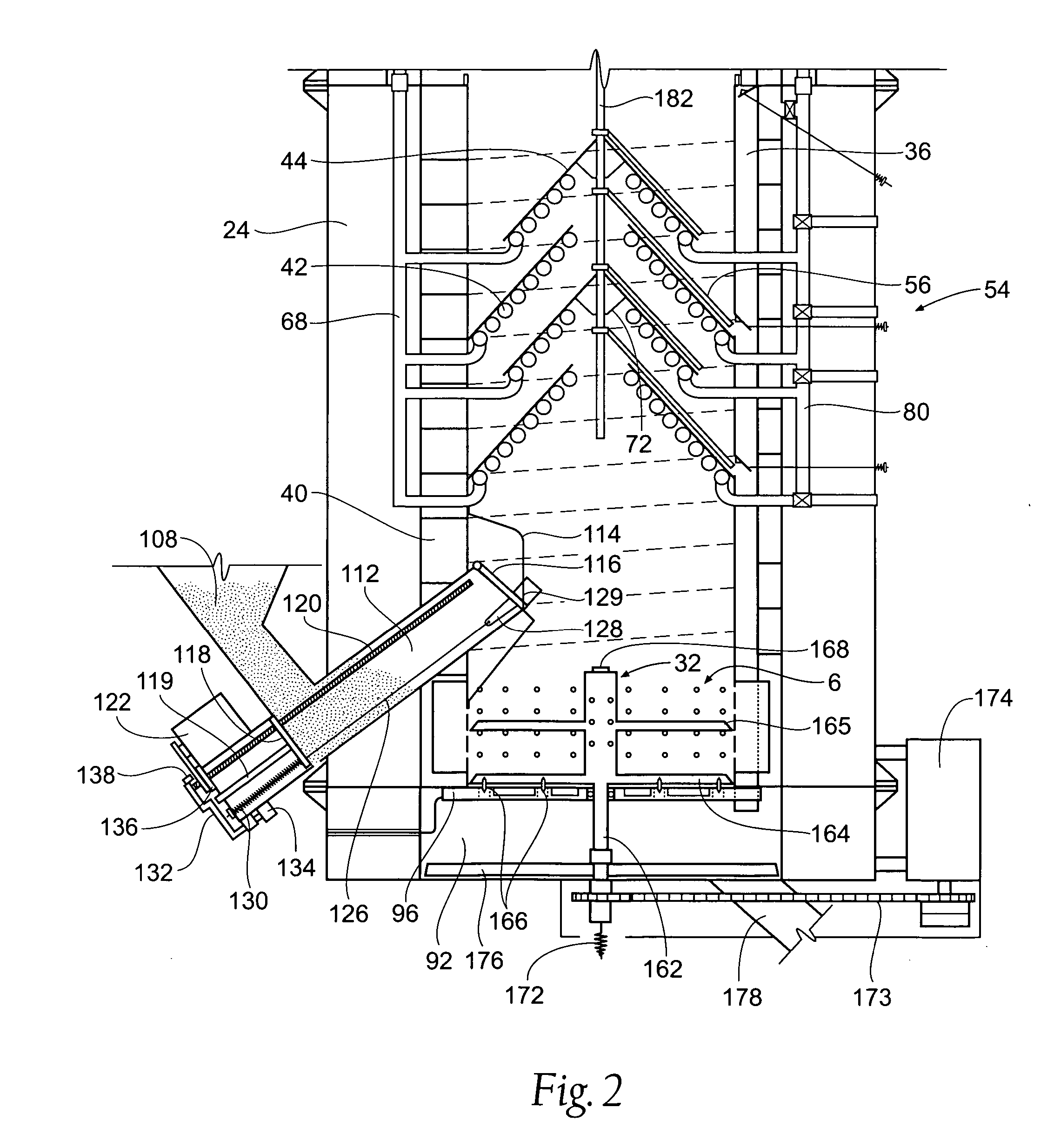

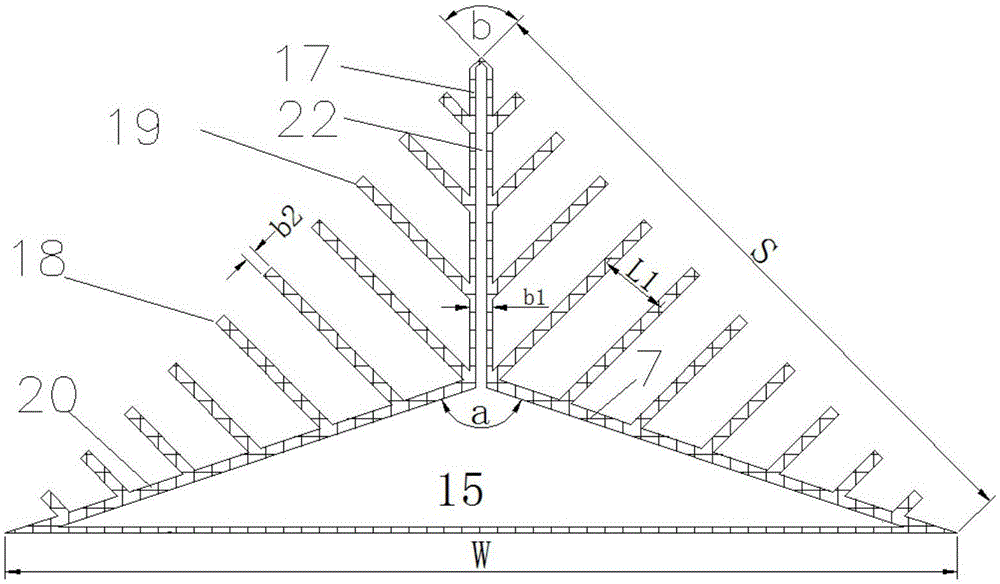

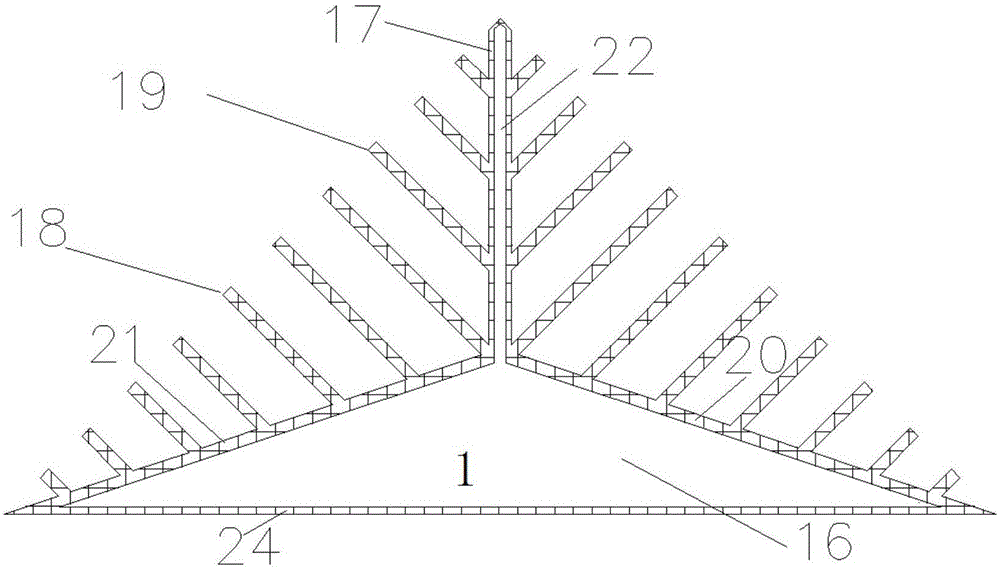

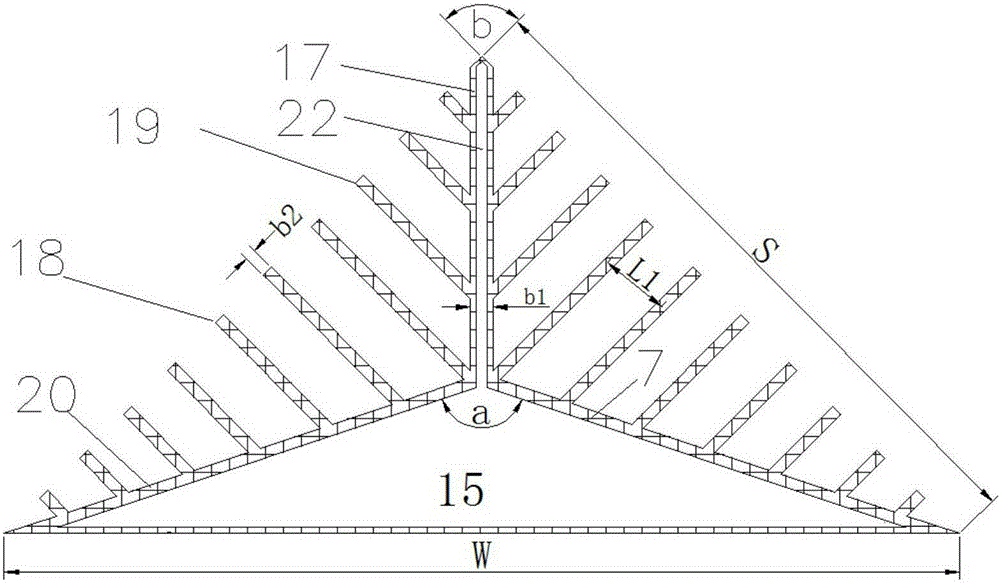

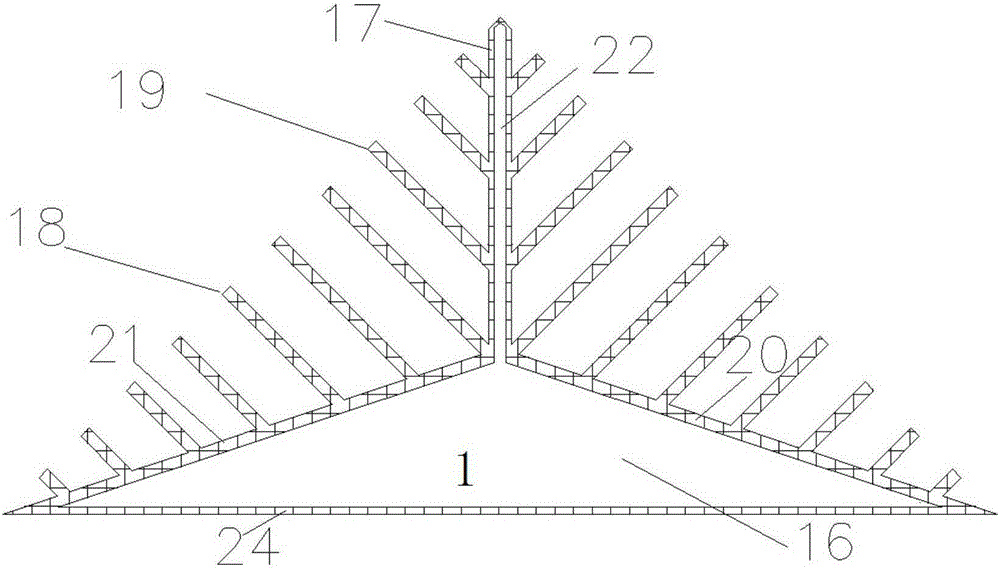

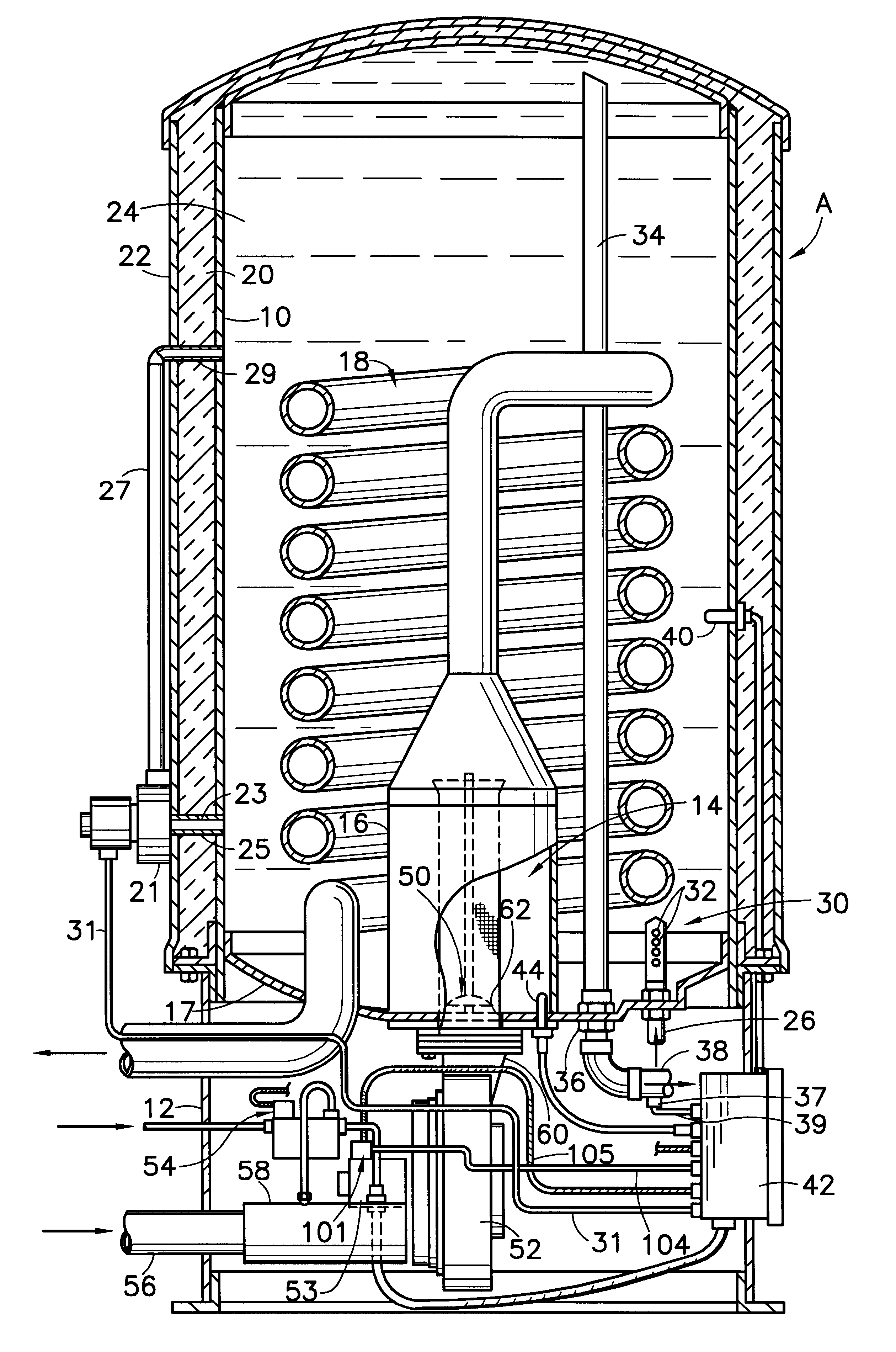

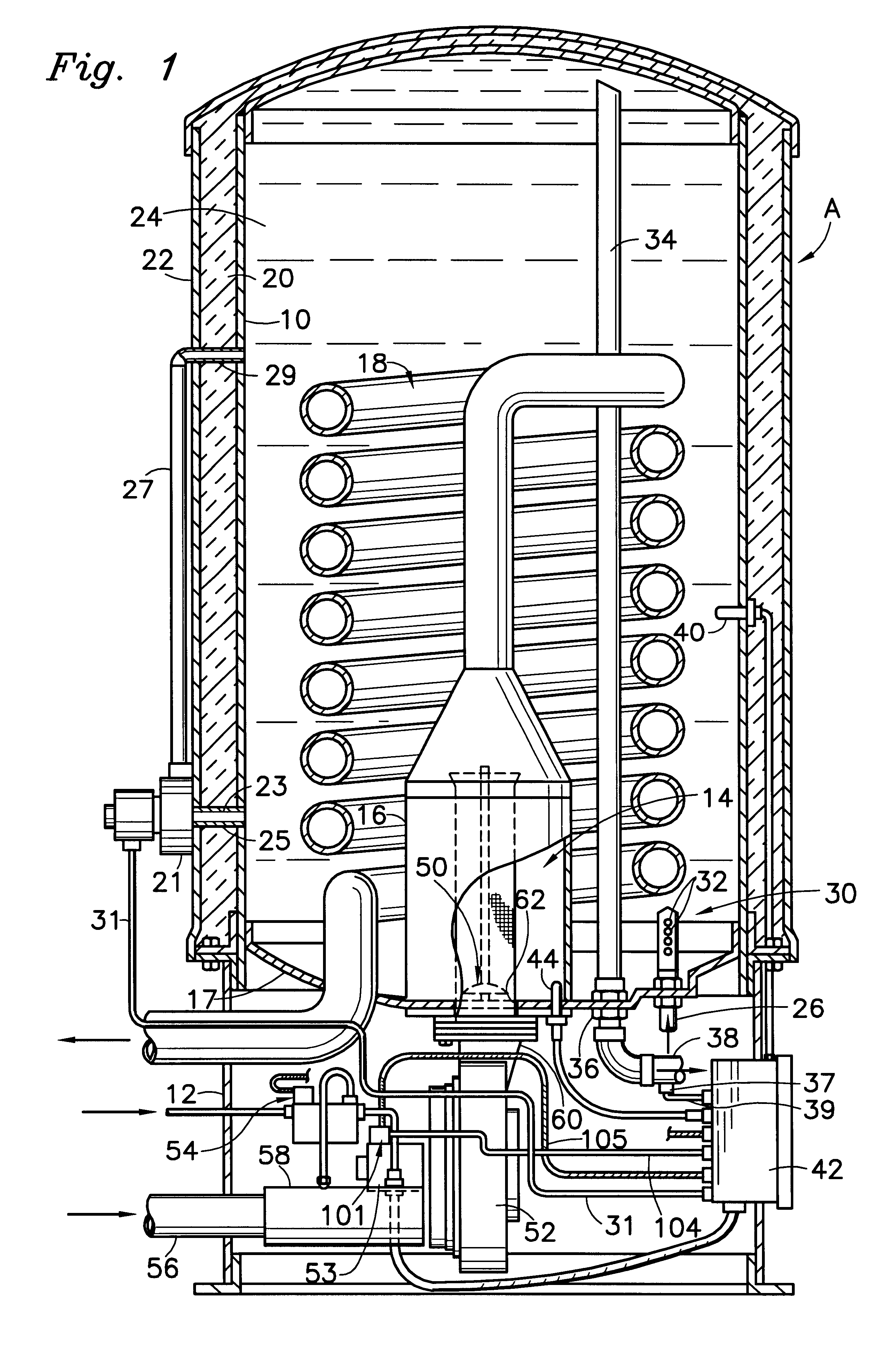

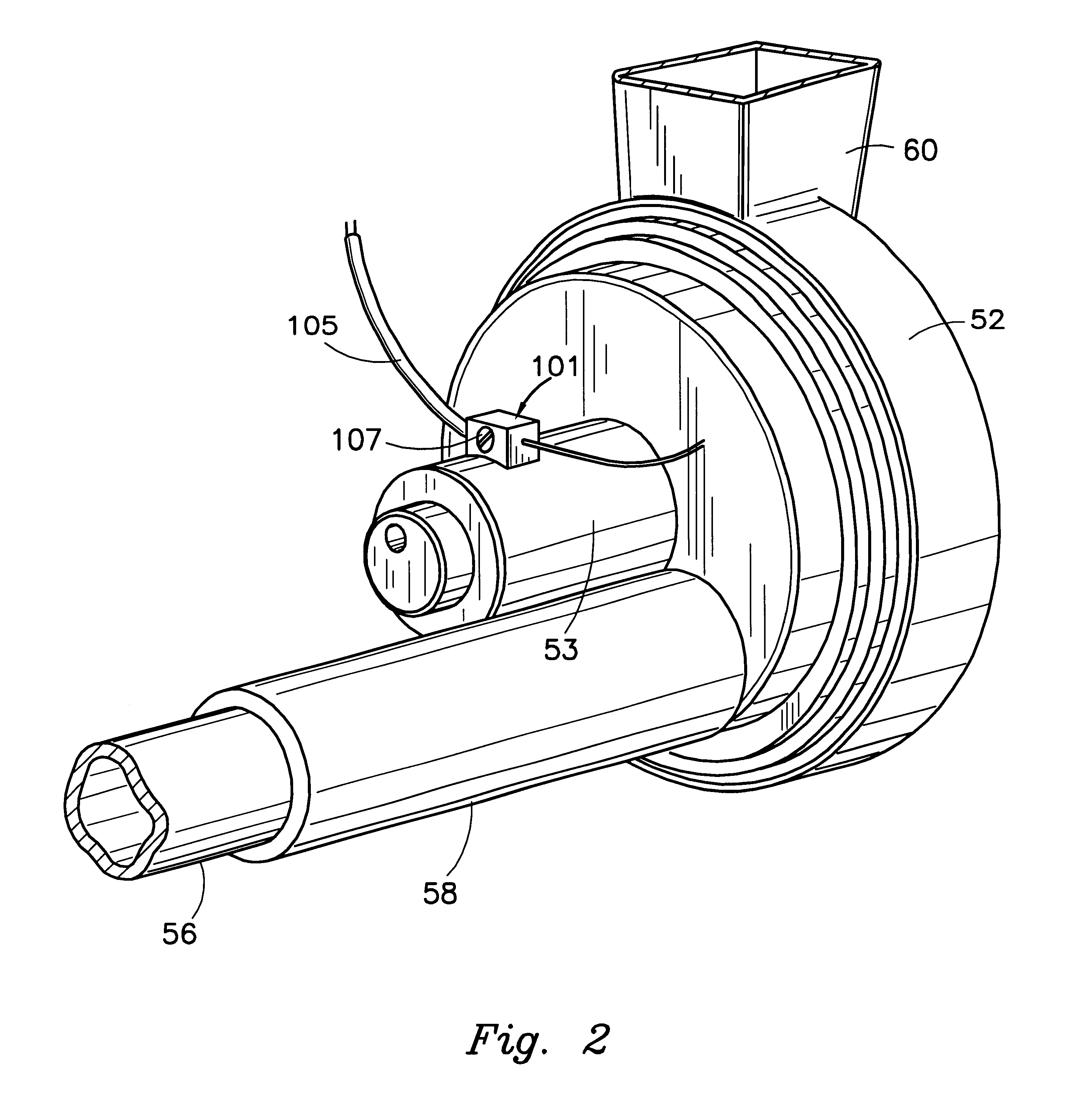

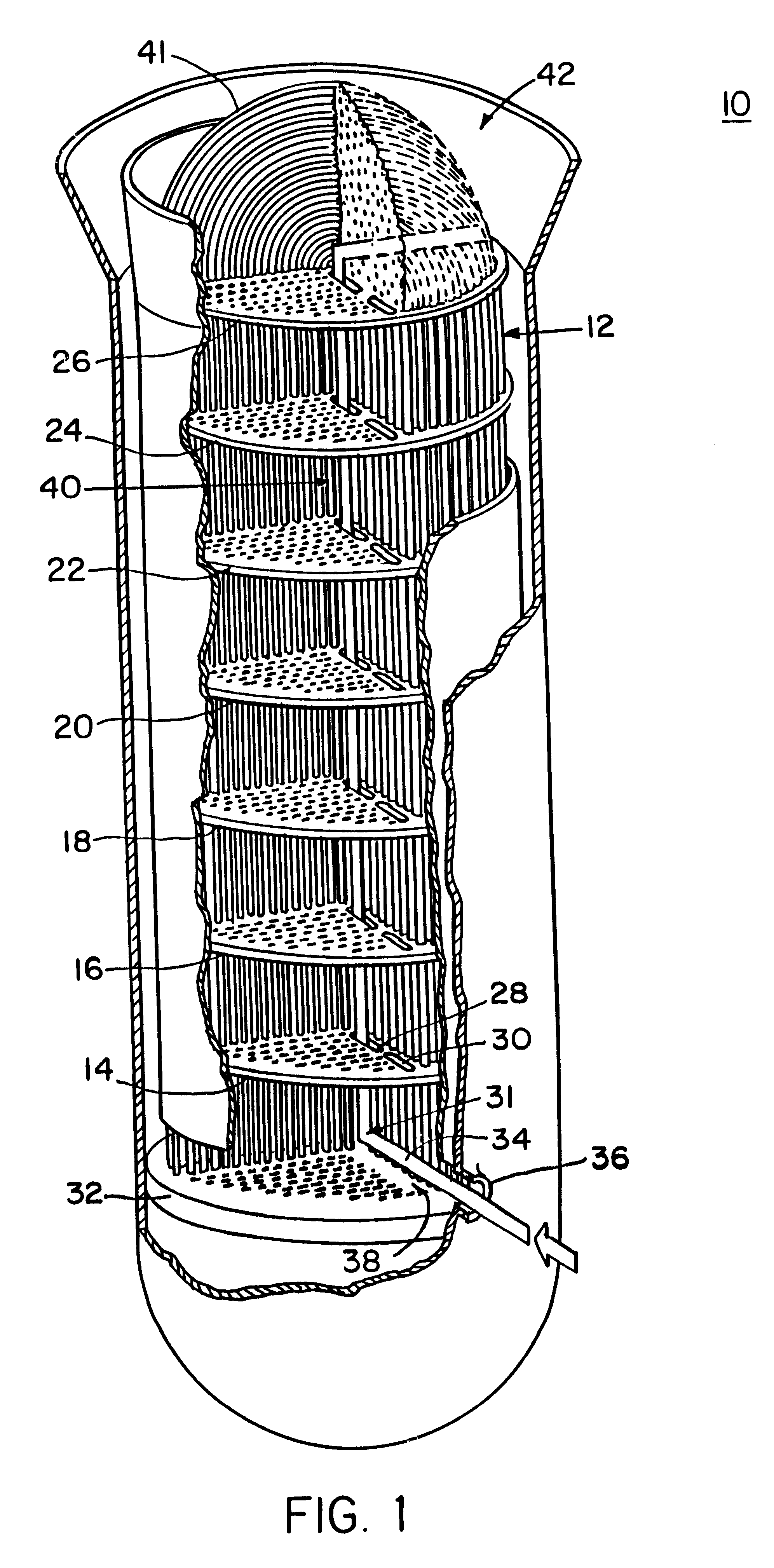

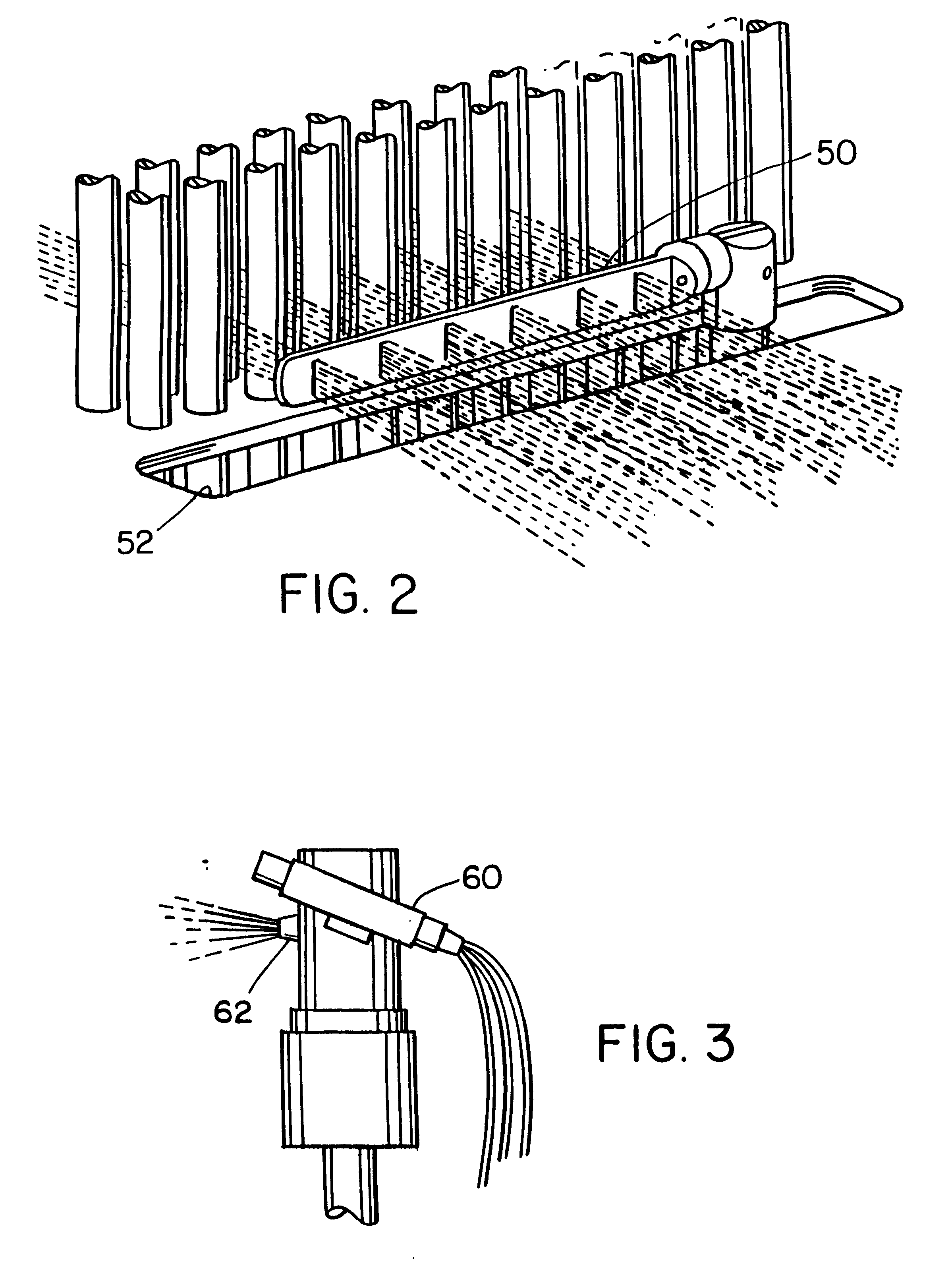

Granular biomass burning heating system

InactiveUS20070137538A1Improve unit efficiencyReduce lag timeAir supply regulationStirring devicesInformation controlProcess engineering

A granular biomass burning furnace for use with any appropriate granular biomass, such as grains, cherry pits, etc. The furnace includes a three stage heat exchanger, a fuel injector, a fuel stirrer, an ash ejector, a wash down system, a three stage air inducer, a fuel igniter, and supporting components. The unit includes a computer controller which controls all aspects of the operation of the unit based on information from sensors located throughout the unit. The unit includes a smart logic thermal controller to adjust the output heat of the unit via a variable speed air inducer. The three stage heat exchanger system includes a spiral water jacket surrounding the burn pot, a plurality of heat exchanger baffles in the unit, and a fine finned heat exchanger at the top of the unit. The air inducer provides air to the burn pot from three directions to promote complete combustion.

Owner:STERR KEVIN K

Method of determining individual sootblower effectiveness

ActiveUS20060065291A1Hollow article cleaningBoiler cleaning apparatusBoiler furnaceProcess engineering

A method of cleaning a heat transfer element within a boiler furnace is provided. The method includes the steps of allowing a furnace to operate and deposit ash on a heat transfer element, determining an efficiency rate for at least one cleaning element, and managing the cleaning element based on the efficiency rate.

Owner:INT PAPER CO

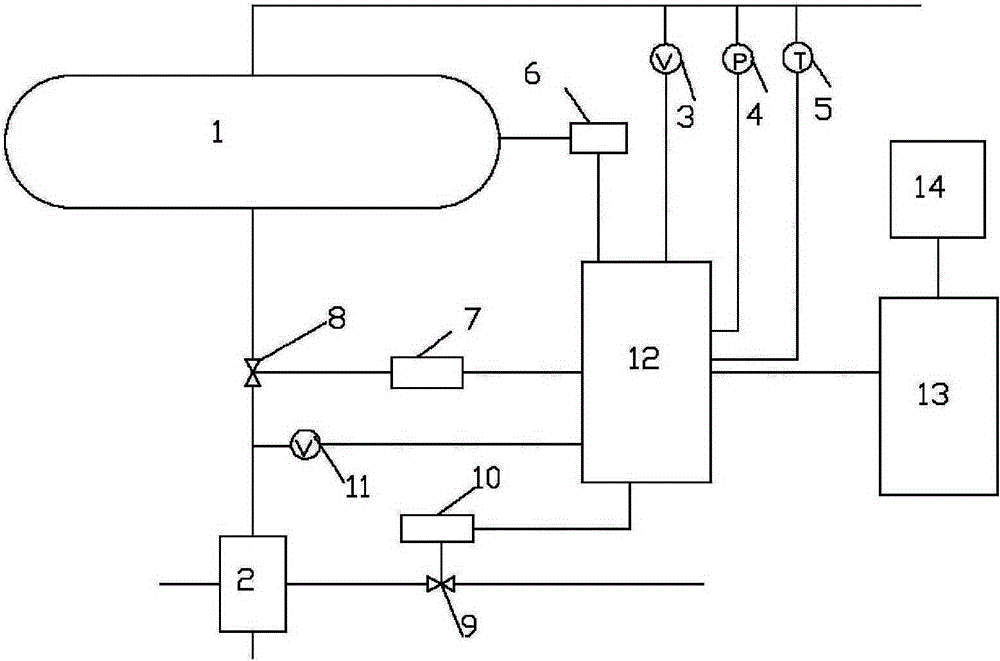

Cloud measurement and control boiler waste heat system for intelligently controlling output temperature

InactiveCN105114935AKeep the temperature constantSimple structureBoiler cleaning apparatusBoiler controlEngineeringCLOUD experiment

The invention provides a boiler waste heat system. A boiler comprises a blowdown valve and a blowdown waste-heat heat exchanger cold source valve. The cold source valve is correspondingly changed according to change of the blowdown valve. By the adoption of the system, it can be guaranteed that the cold source temperature output by a waste-heat heat exchanger is kept constant.

Owner:SHANDONG UNIV OF TECH

Cloud-computing-based boiler blow-off system conducting control according to blow-off water quality

InactiveCN105222119AKeep abreast of the operation status in timeAvoid wastingBoiler indication operationsBoiler cleaning apparatusData connectionThermal energy

The invention provides a boiler system. A water quality analyzer is arranged on a blow-off pipeline and used for measuring the quality of water in the blow-off pipeline. The water quality analyzer is in data connection with a monitoring and diagnosis controller so as to receive measured data and control the opening degree of a blow-off valve according to the measured data. If some measured index exceeds the upper limit of the data, the monitoring and diagnosis controller automatically increases the opening degree of the blow-off valve through a valve adjusting device. If some measured index is lower than the upper limit of the data, the monitoring and diagnosis controller automatically decreases the opening degree of the blow-off valve through the valve adjusting device. The monitoring and diagnosis controller is in data connection with a cloud server so as to transmit monitoring data to the cloud server. The cloud server is connected with a client-side. The client-side can acquire the monitoring data through the cloud server. The client-side can know the blow-off operation condition of a boiler through the client-side in time. Blow-off parameters can be adjusted through the client-side in time, and therefore a large amount of thermal energy waste caused by failures of a boiler blow-off system can be prevented.

Owner:SHANDONG UNIV OF TECH

Methods and compositions for on-line gas turbine cleaning

InactiveUS20040016445A1Inorganic/elemental detergent compounding agentsDetergent mixture composition preparationCombustion chamberAromatic solvents

Methods and compositions for on-line cleaning of internal surfaces of selected sections of a hydrocarbon fuel burning gas turbine and associated heat recovery equipment, during operation. Cleaning solutions containing graphite and / or molybdenum-based particles and oil soluble corrosion inhibitors, aromatic solvents, and surfactants are selectively introduced directly into the combustion chamber (combustor) of the gas turbine, into the fuel stream, water washing system, or the combustion air system (hot gas path). The cleaning process dislodges unwanted ash deposit buildup and, thereby restores the gas turbine to rated power. When introduced into the compressor section, the particles impinge on the metal surfaces, cleaning them prior to entering the hot gas section where the process may be repeated. They may also be carried through the exhaust to additionally clean attendant heat recovery equipment, if present.

Owner:LIQUID MINERALS GRP LTD

Control of detonative cleaning apparatus

A shockwave cleaning apparatus cleans one or more surfaces within a vessel. A sensor senses one or more thermodynamic properties associated with the vessel. A control system is coupled to an initiator and a fuel / oxidizer source to control the firing of the apparatus responsive to input from the sensor.

Owner:SHOCKSYST

Detection of deposits in steam humidifiers

A humidifier configured to determine when the humidifier requires cleaning. The humidifier includes a tank for containing water, a heater for heating the water in the tank to generate steam, and one or more water level sensors for detecting the level of water in the tank, including detecting water at first level and a second level, where the first level is lower than the second level. The humidifier further includes a drain valve for draining water from the tank and a controller. The controller is configured to open the drain valve to drain water from the tank, measure a time interval required for the water to drain from the second level to the first level, and compare the time interval against a threshold value. If the time interval exceeds the threshold value, then the controller is configured to provide an indication to clean the humidifier. Methods are also disclosed.

Owner:ADEMCO INC

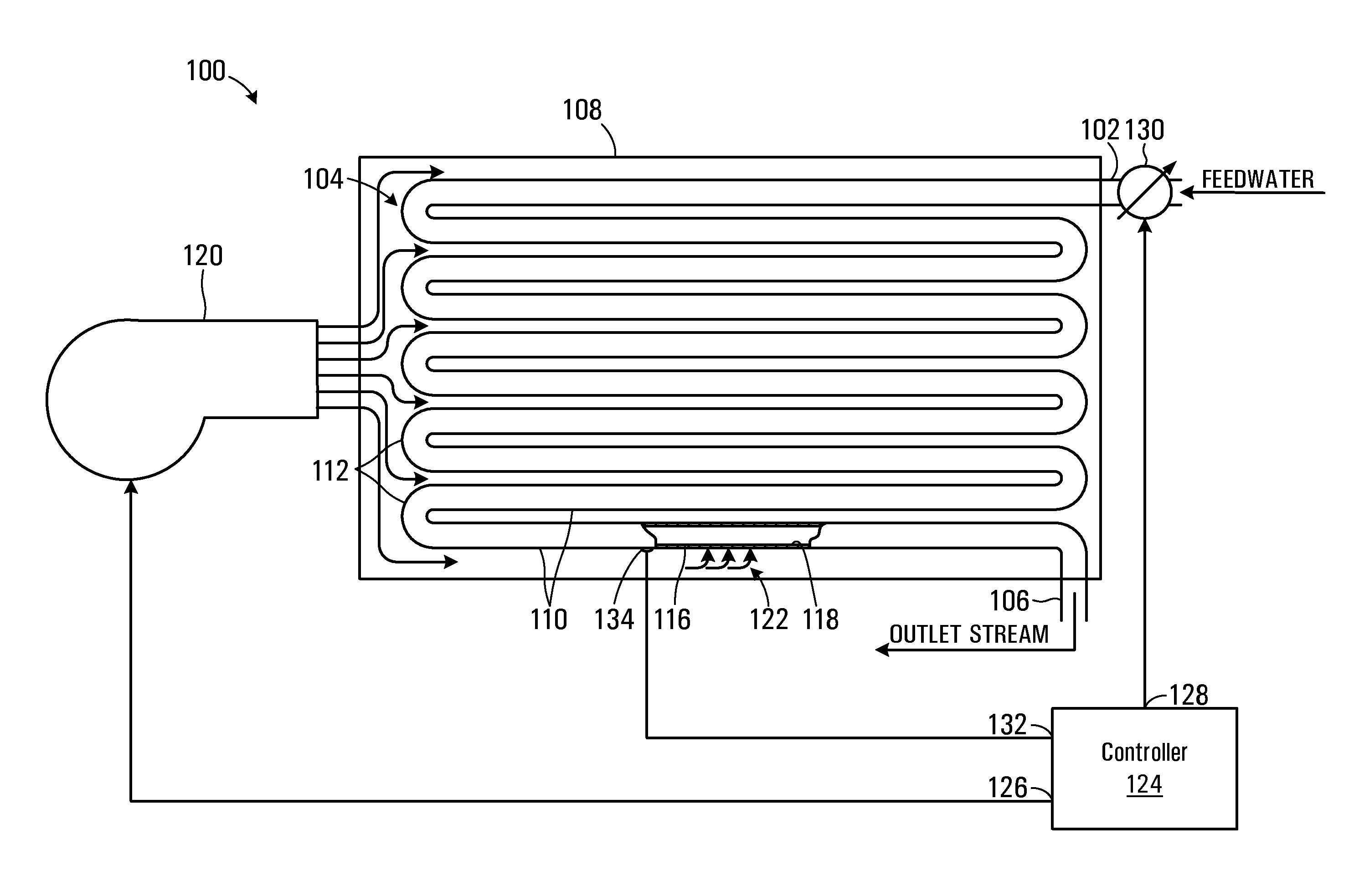

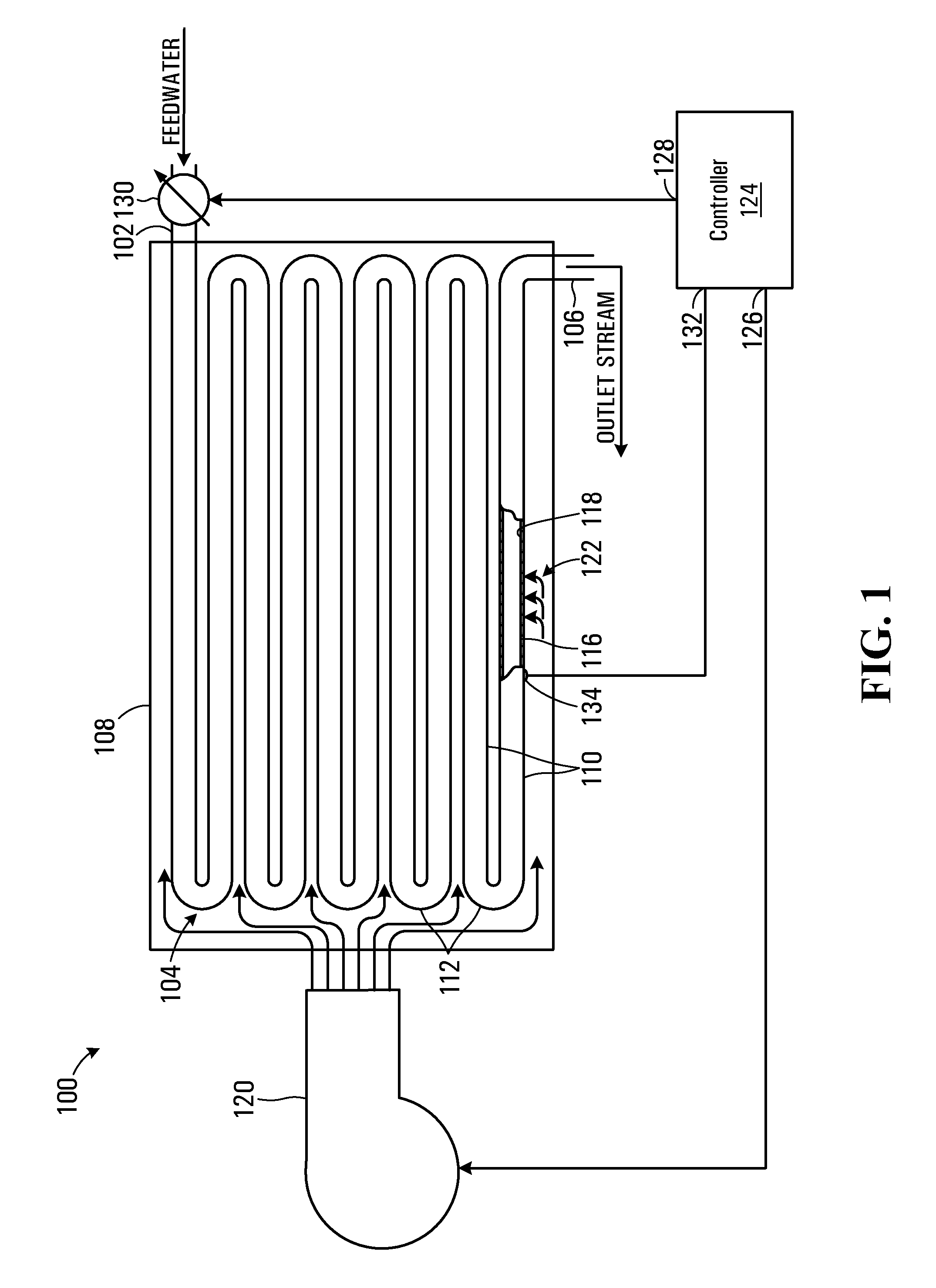

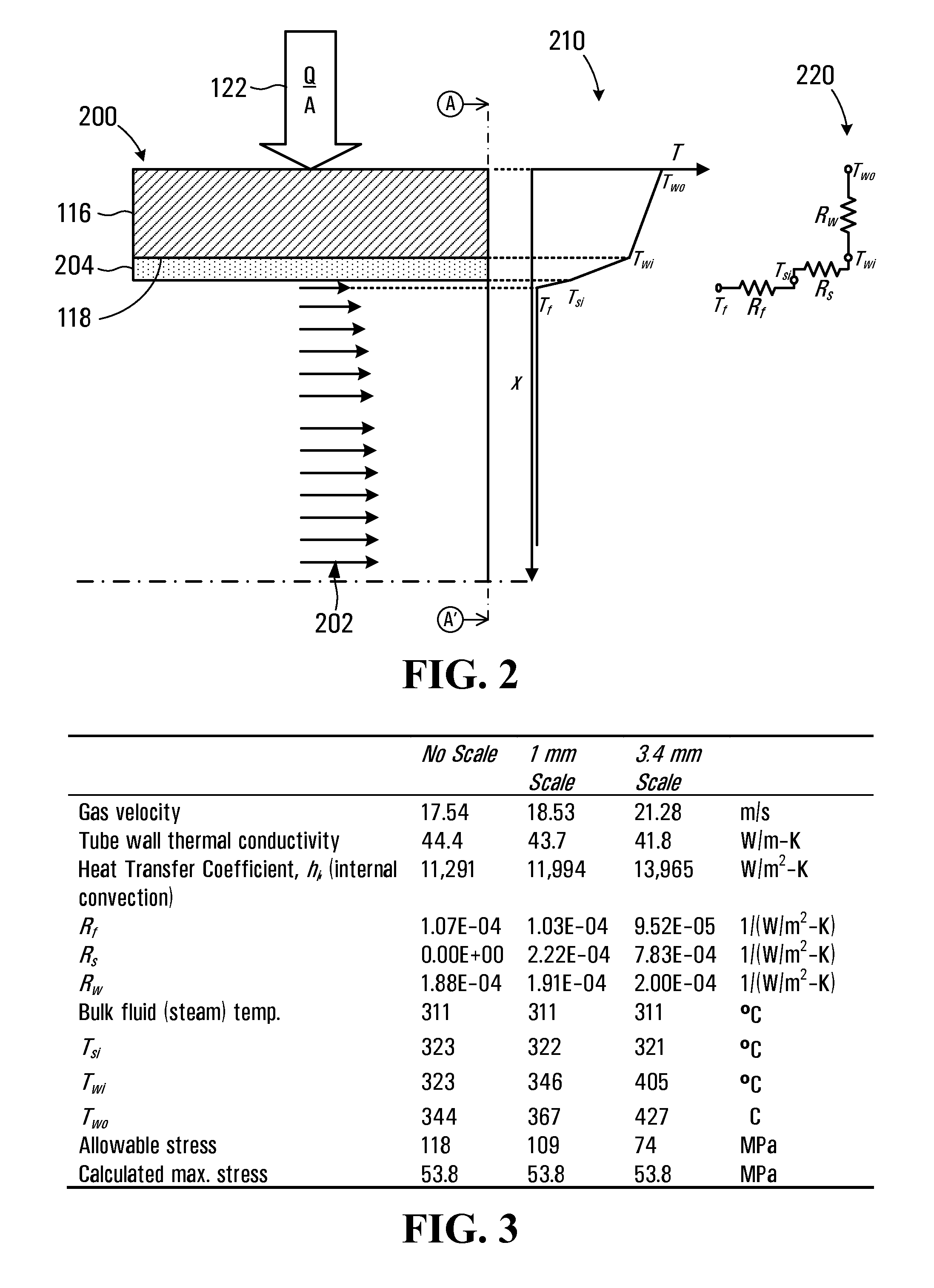

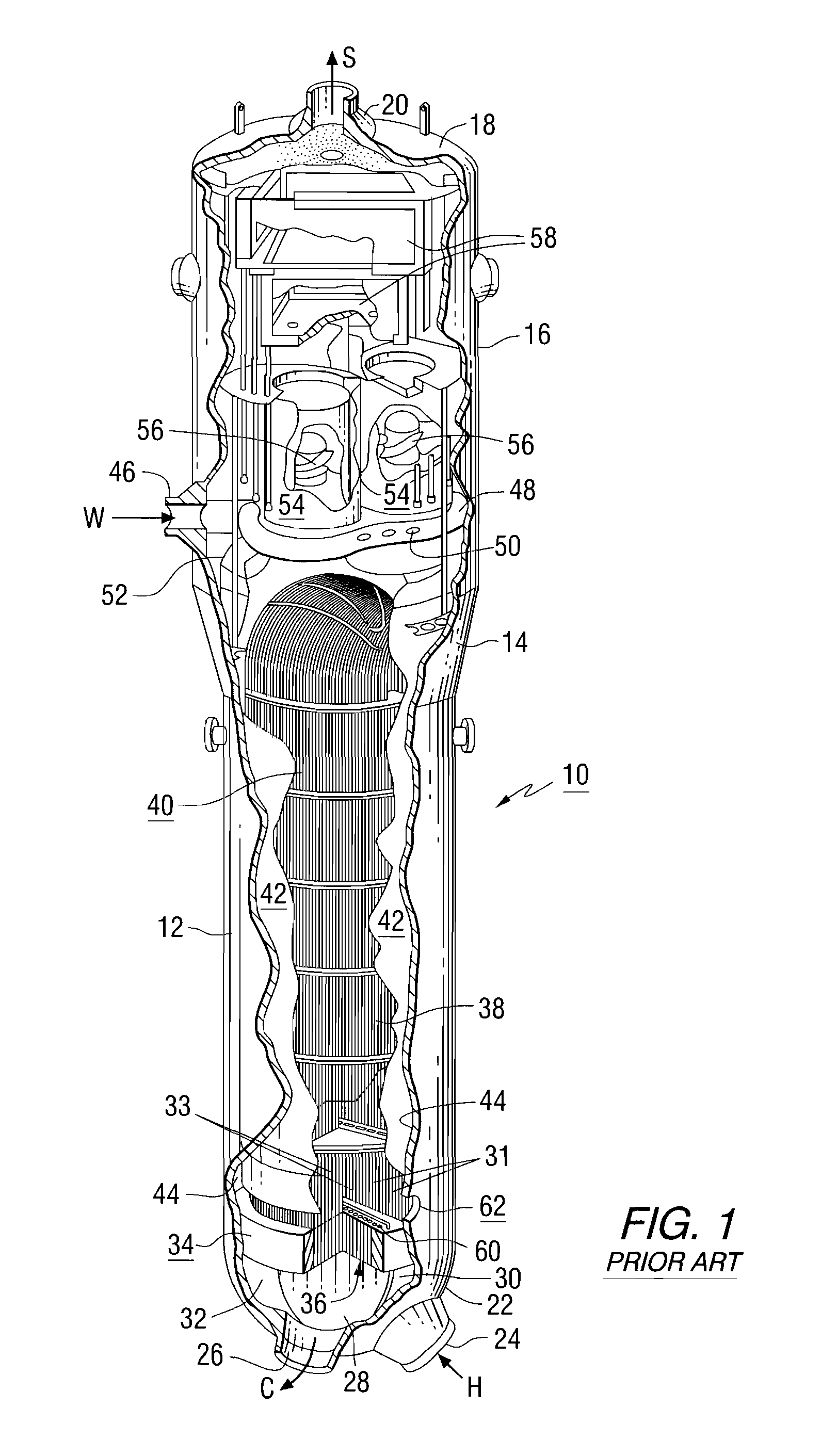

Steam generator and method for generating steam

ActiveUS20130161009A1Improve cooling effectReduce problem sizeBoiler water tubesBoiler cleaning apparatusHeat fluxEvaporation

A method for generating steam from a feedwater inlet stream including impurities is disclosed. The method involves receiving the feedwater inlet stream at an inlet of a steam generator and causing the feedwater stream to flow through a tubing circuit to an outlet of the tubing circuit, the tubing circuit having a substantially un-rifled bore defined by a metal wall. The method also involves delivering a heat flux to the feedwater stream through the metal wall of the tubing circuit to generate steam by causing evaporation of feedwater within the tubing circuit, and controlling at least one of a flow rate of the feedwater stream and the heat flux to cause generation of an outlet stream at the outlet includes a steam portion and liquid phase portion, the steam portion being greater than about 80% of the outlet stream by mass. The steam portion provides sufficient cooling of the metal wall to maintain a wall temperature at less than a threshold temperature.

Owner:FCCL PARTNERSHIP

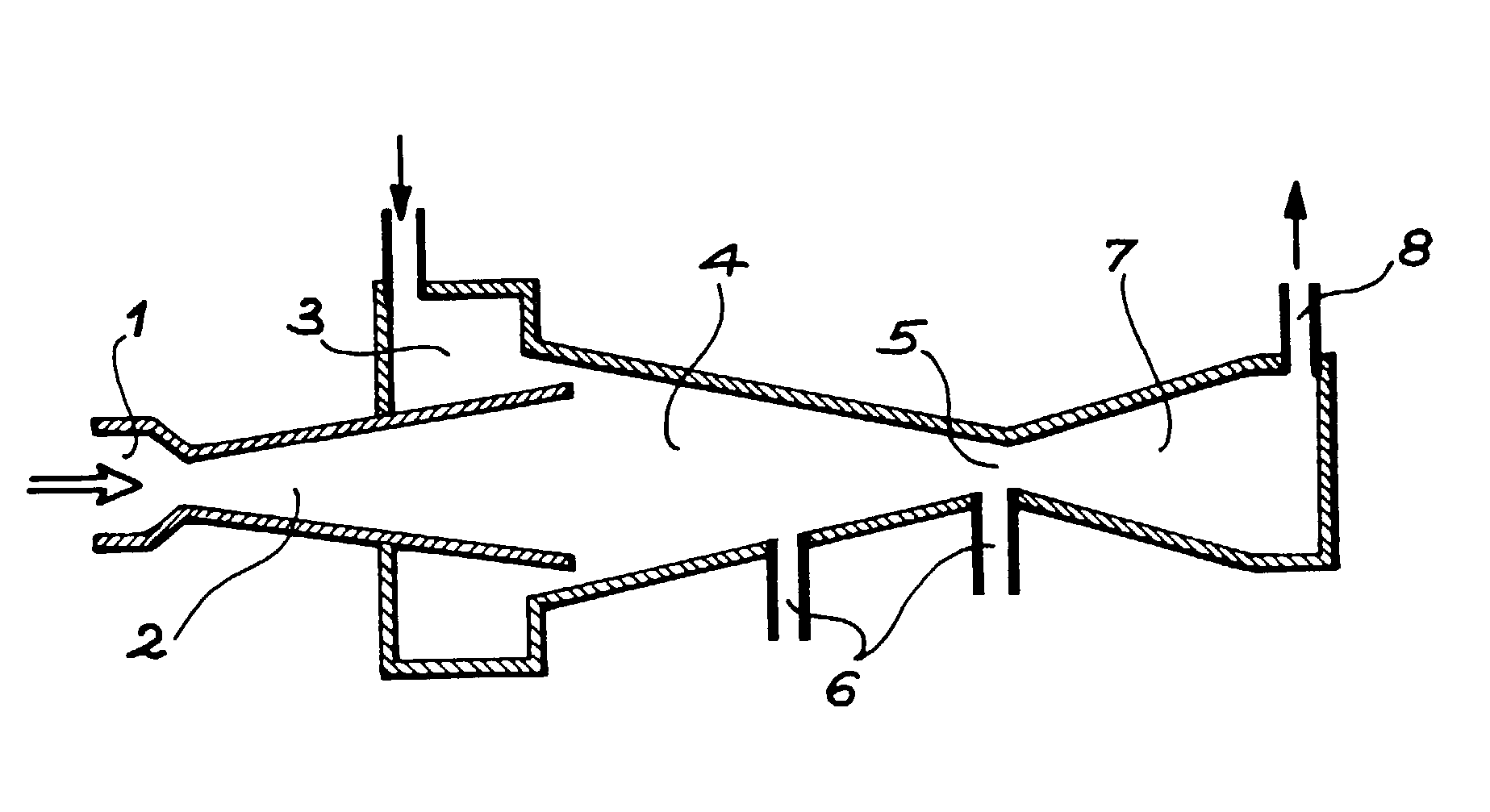

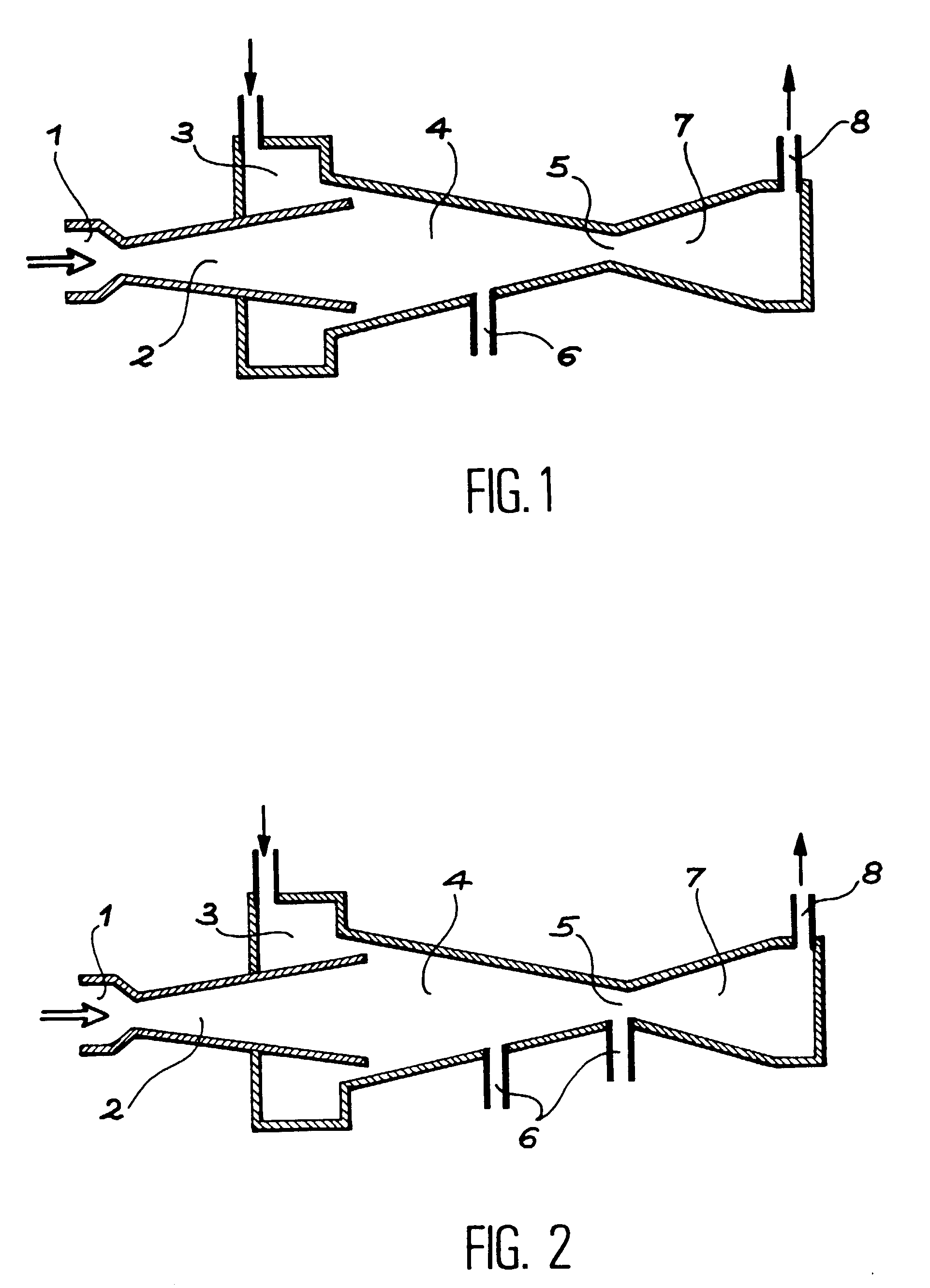

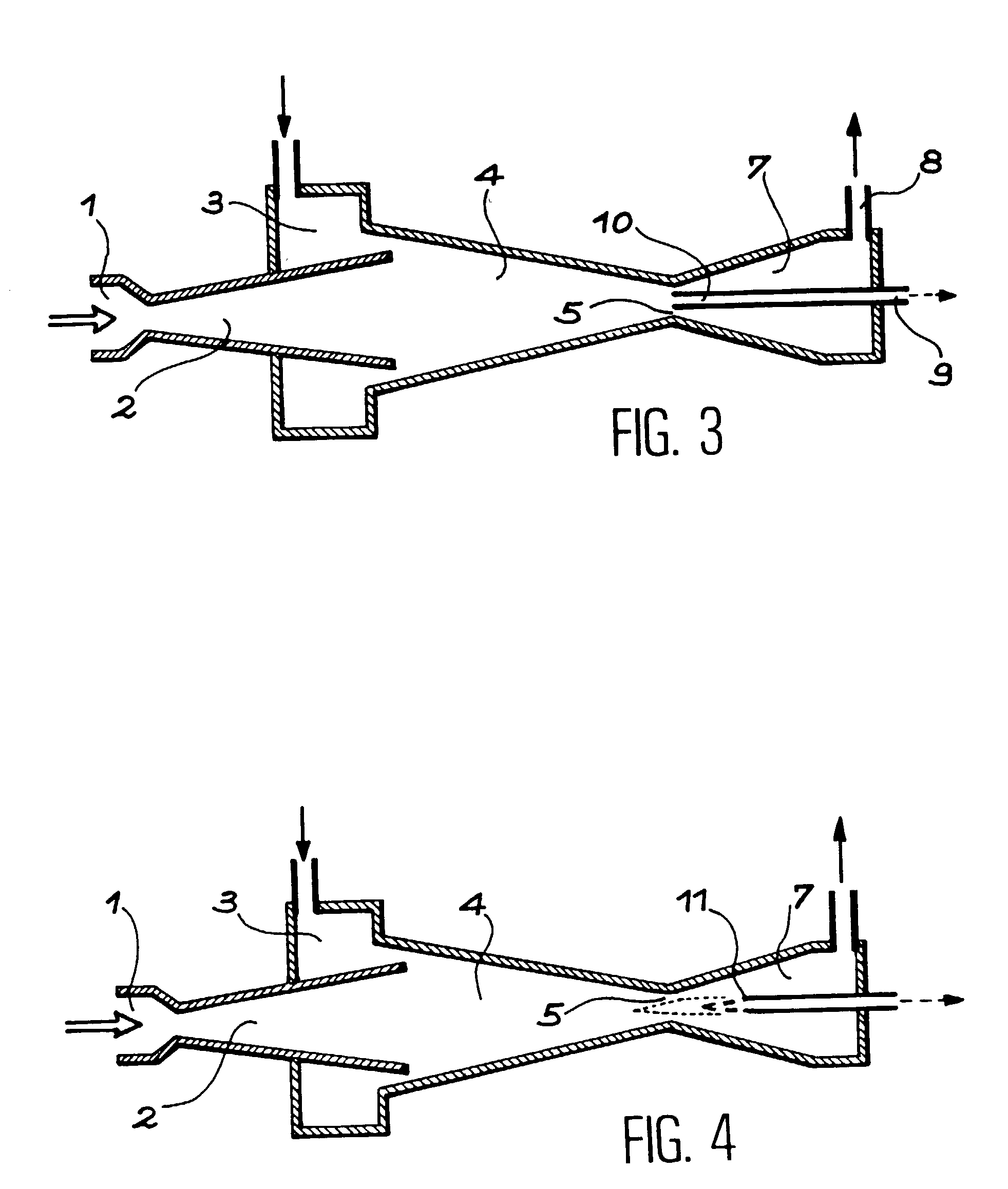

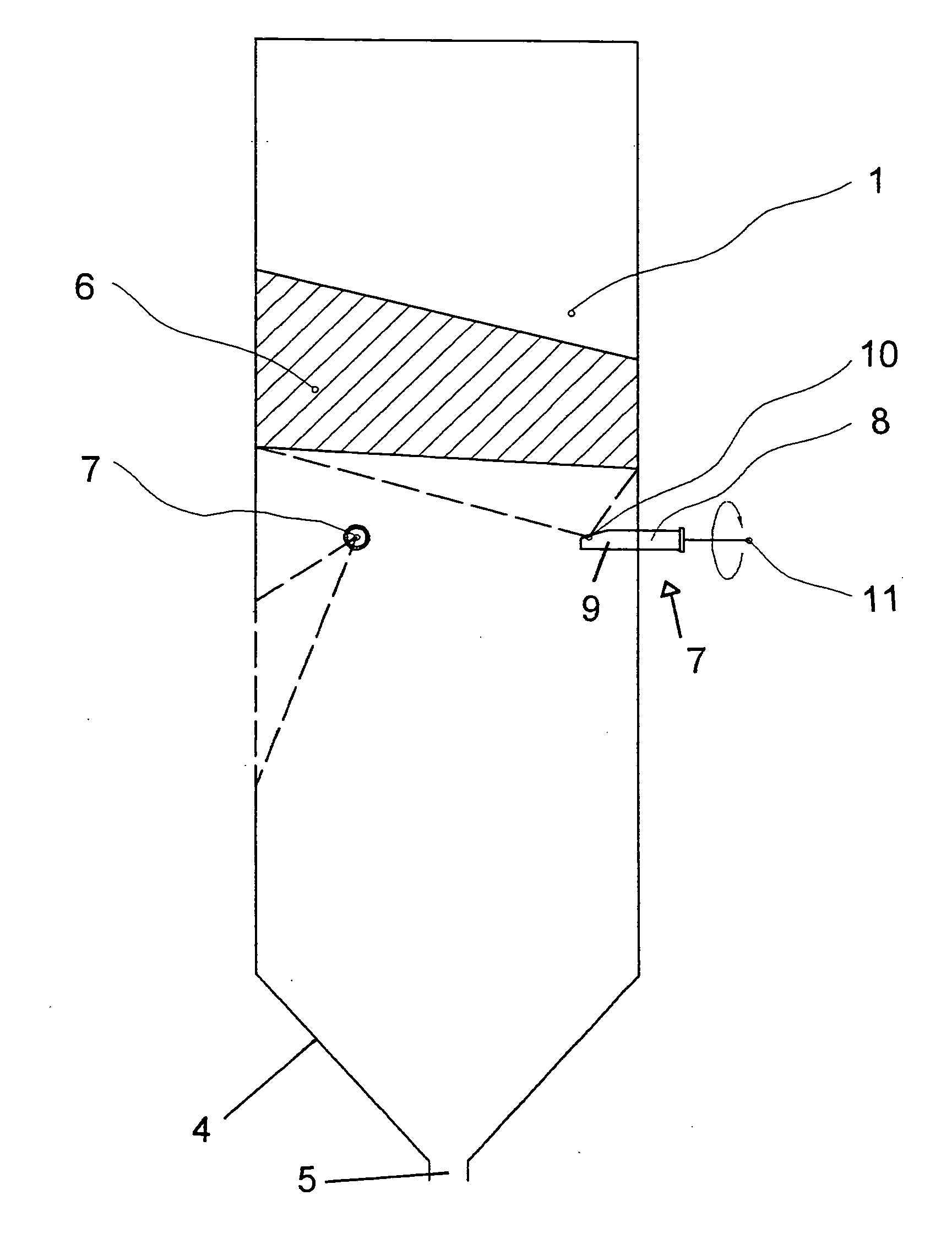

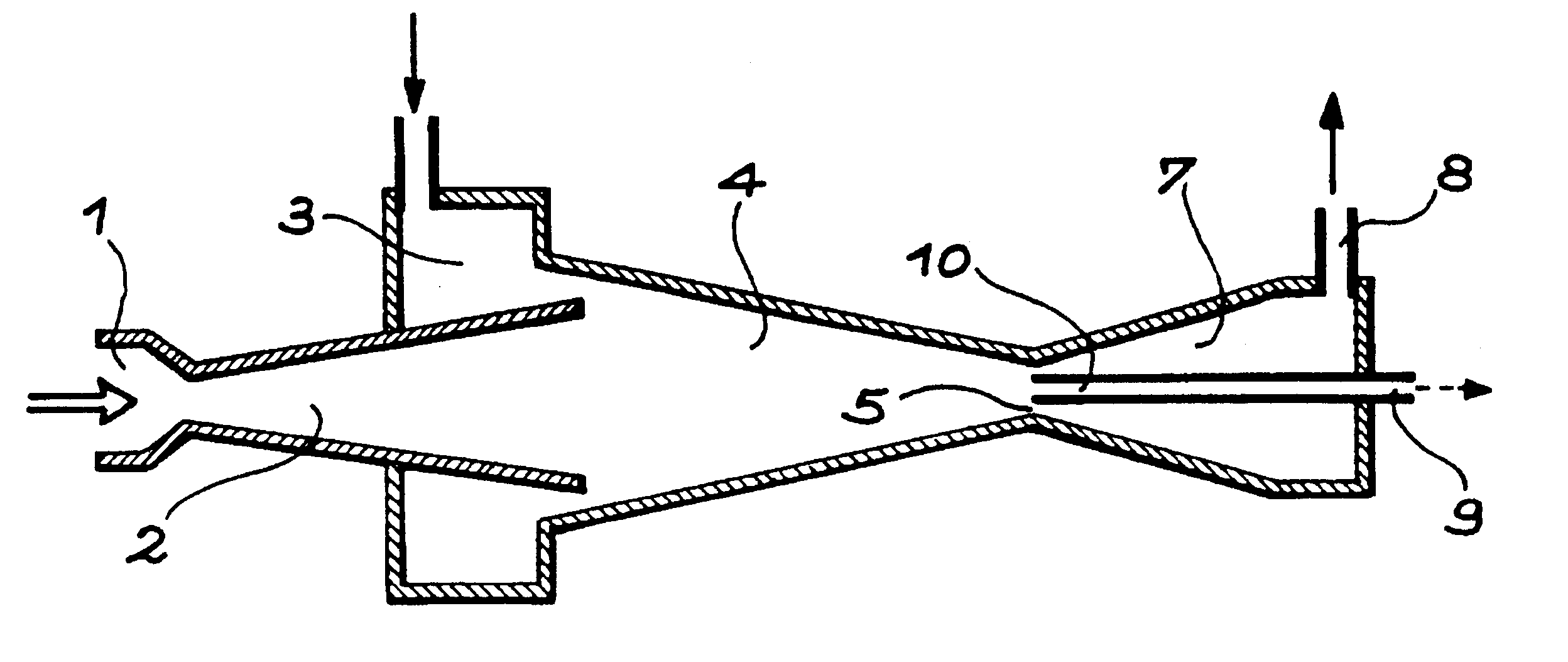

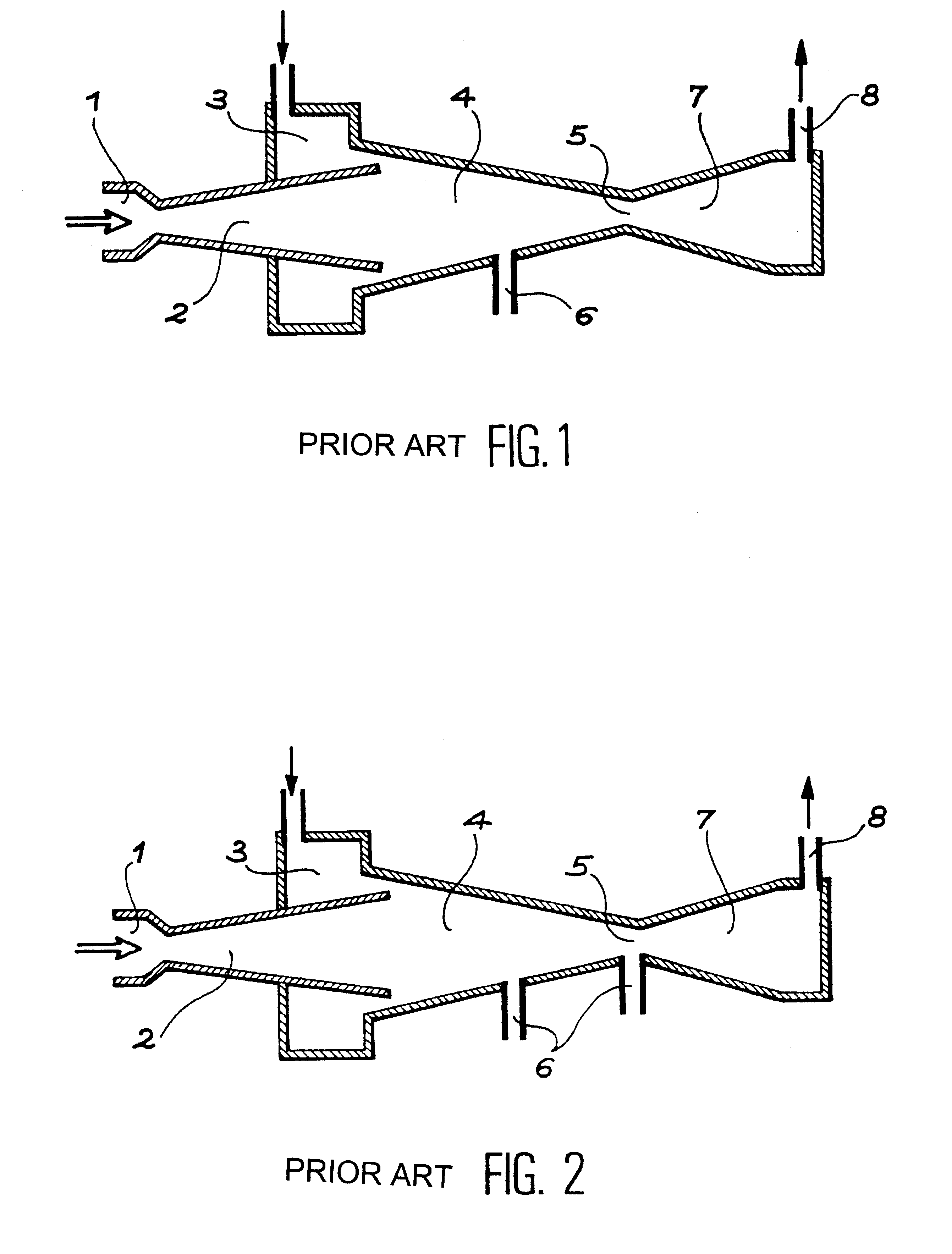

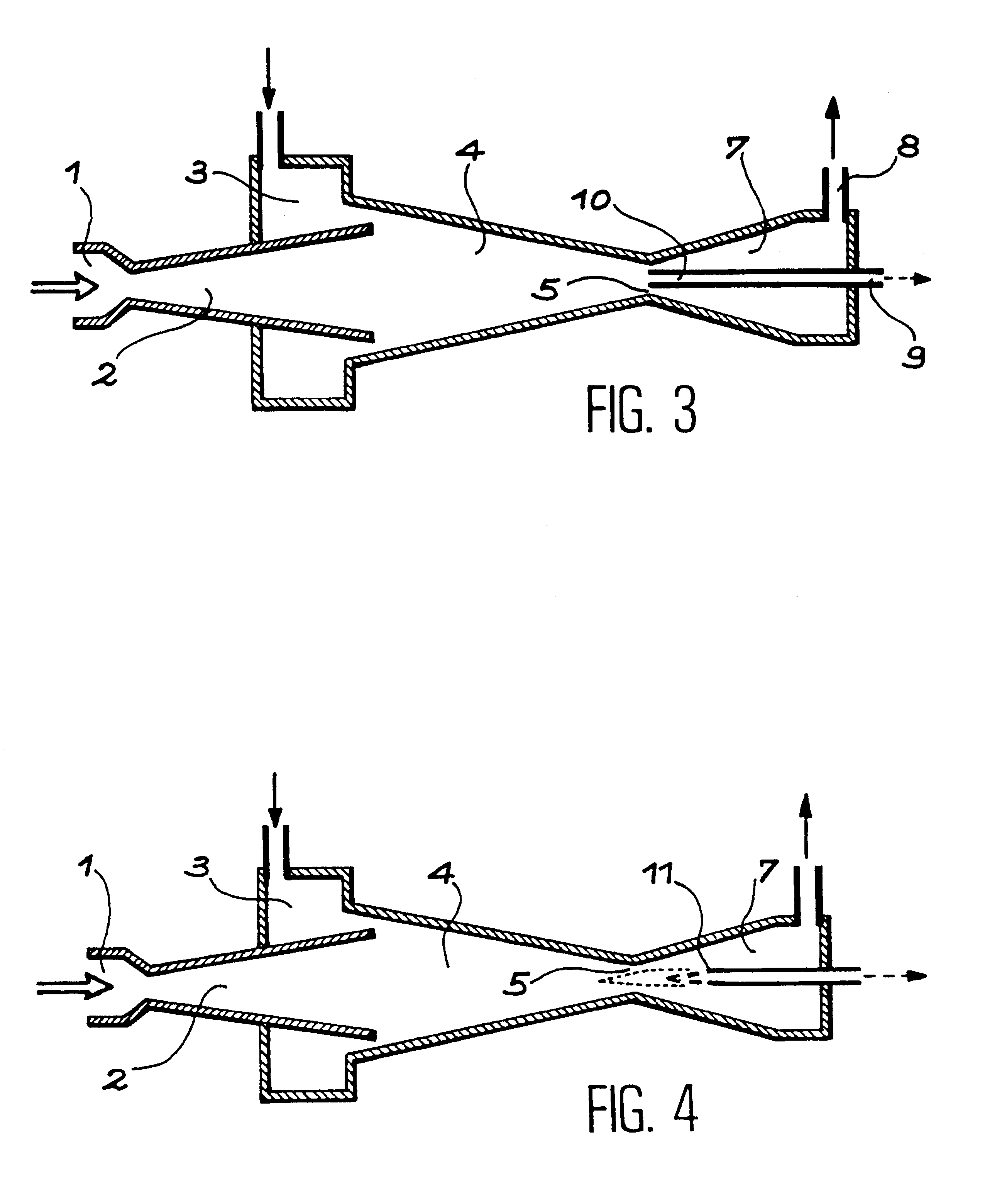

High pressure steam water injector comprising an axial drain

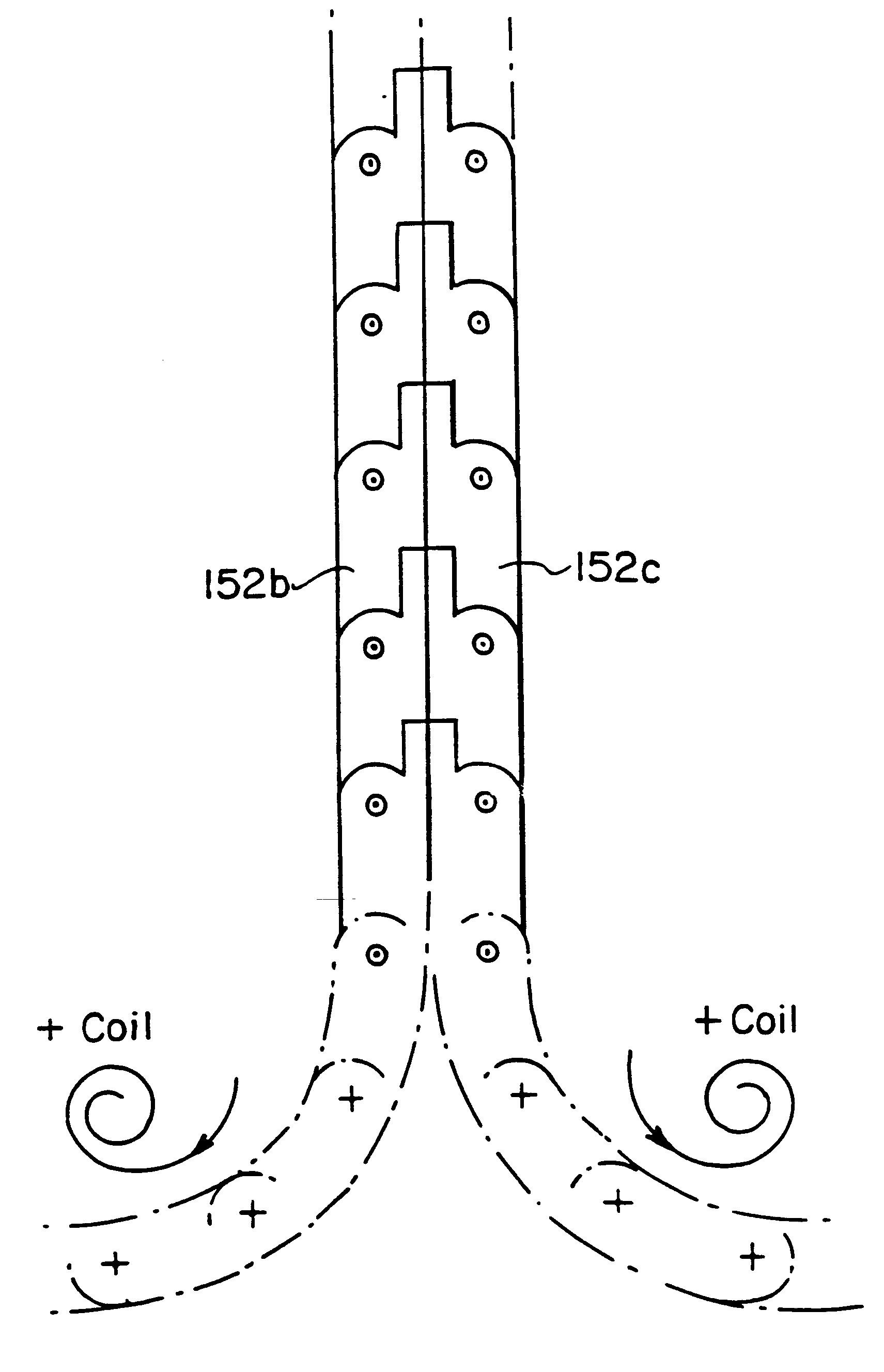

InactiveUS20020162518A1Increase the maximum pressureLow sectionFlow mixersWater circulationNuclear reactorHigh pressure

The steam injector is characteristic in its high pressure and improved start-up. It uses an axial drain (10) positioned in the centre of the neck (5) downstream from the mixing chamber (4) and inserted in the diffuser (7) for the purpose of narrowing the section of the neck (5) and evacuating a large part of the steam which has not been condensed. The axial drain (10) may be mounted so that it is axially mobile. Application to the water supply for steam generators in pressurized water nuclear reactors.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

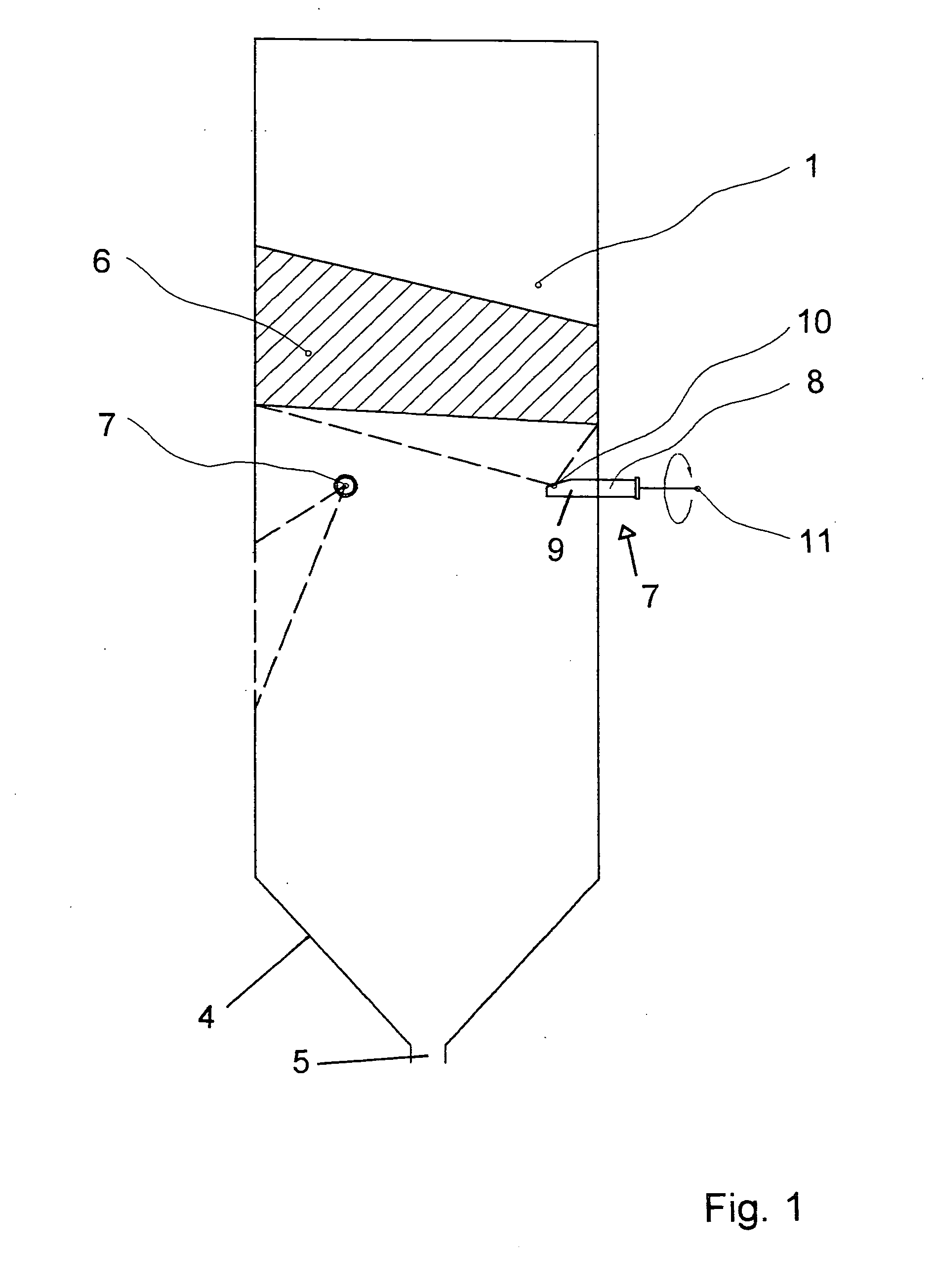

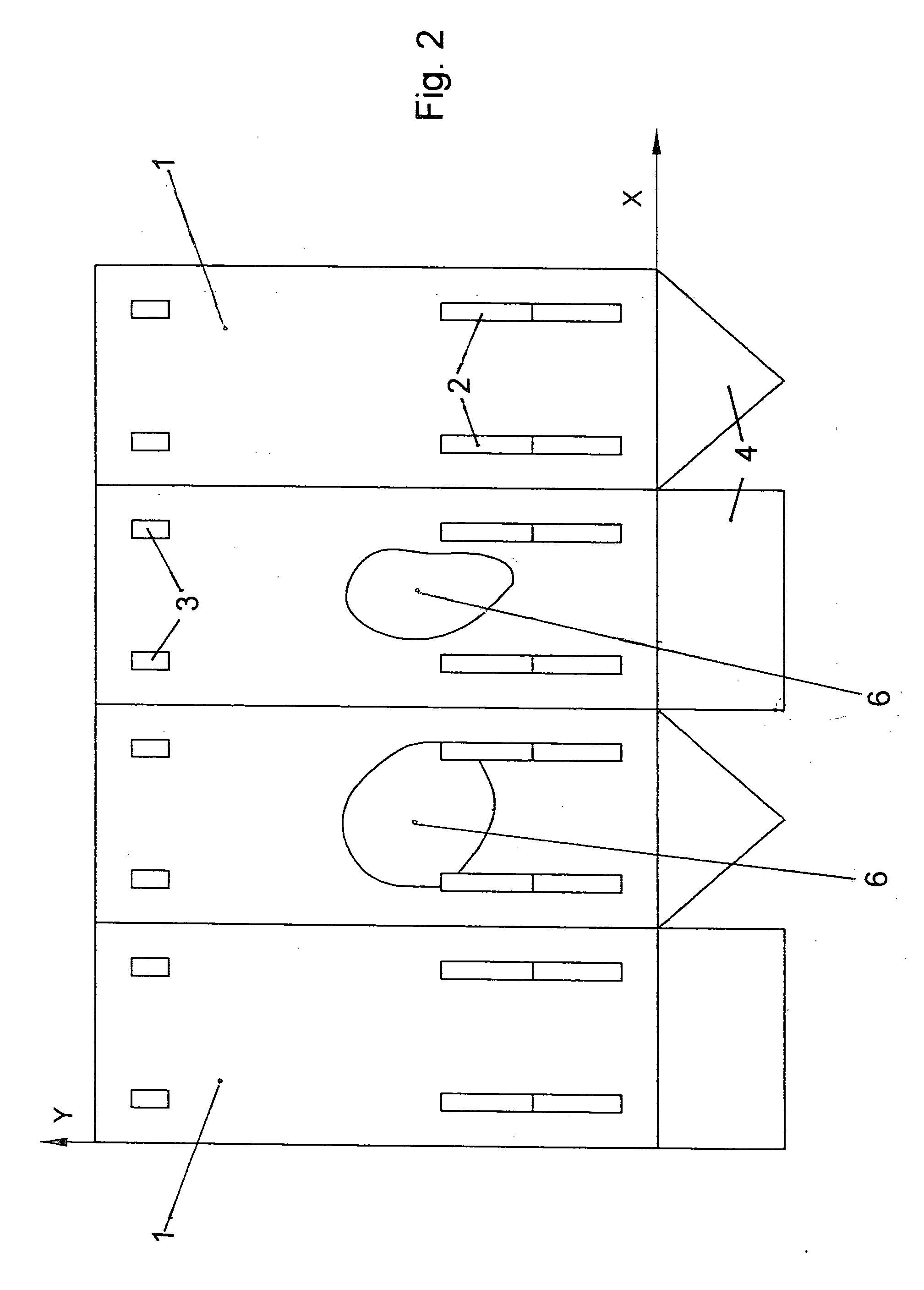

Method and apparatus for monitoring the formation of deposits in furnaces

InactiveUS20080298426A1Simpler and universally usableIncrease temperatureThermometer detailsRadiation pyrometryFlue gasSolid particle

Method and apparatus for monitoring formation of deposits of solid particles from flue gas onto furnace walls formed of welded-together tubes through which cooling medium flows. For the entire surface of the walls, the exact surface temperature is detected with infrared cameras, offset by 90° relative to one another, via a thermal image obtained of a surface development of the furnace. This exact surface temperature is compared with the temperature of the cooling medium from measurement locations. Individual images from the cameras are composed to form an overall development of the inner surface of the furnace walls. The coordinates of the deposits on the walls are determined from the overall development, and the thickness of the deposits is determined from the temperature comparison.

Owner:DIPL ING INGO RADUNZ

High pressure steam water injector comprising an axial drain

InactiveUS6595163B2Increase the maximum pressureLow sectionFlow mixersWater circulationNuclear reactorHigh pressure

The steam injector is characteristic in its high pressure and improved start-up. It uses an axial drain (10) positioned in the centre of the neck (5) downstream from the mixing chamber (4) and inserted in the diffuser (7) for the purpose of narrowing the section of the neck (5) and evacuating a large part of the steam which has not been condensed. The axial drain (10) may be mounted so that it is axially mobile.Application to the water supply for steam generators in pressurized water nuclear reactors.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

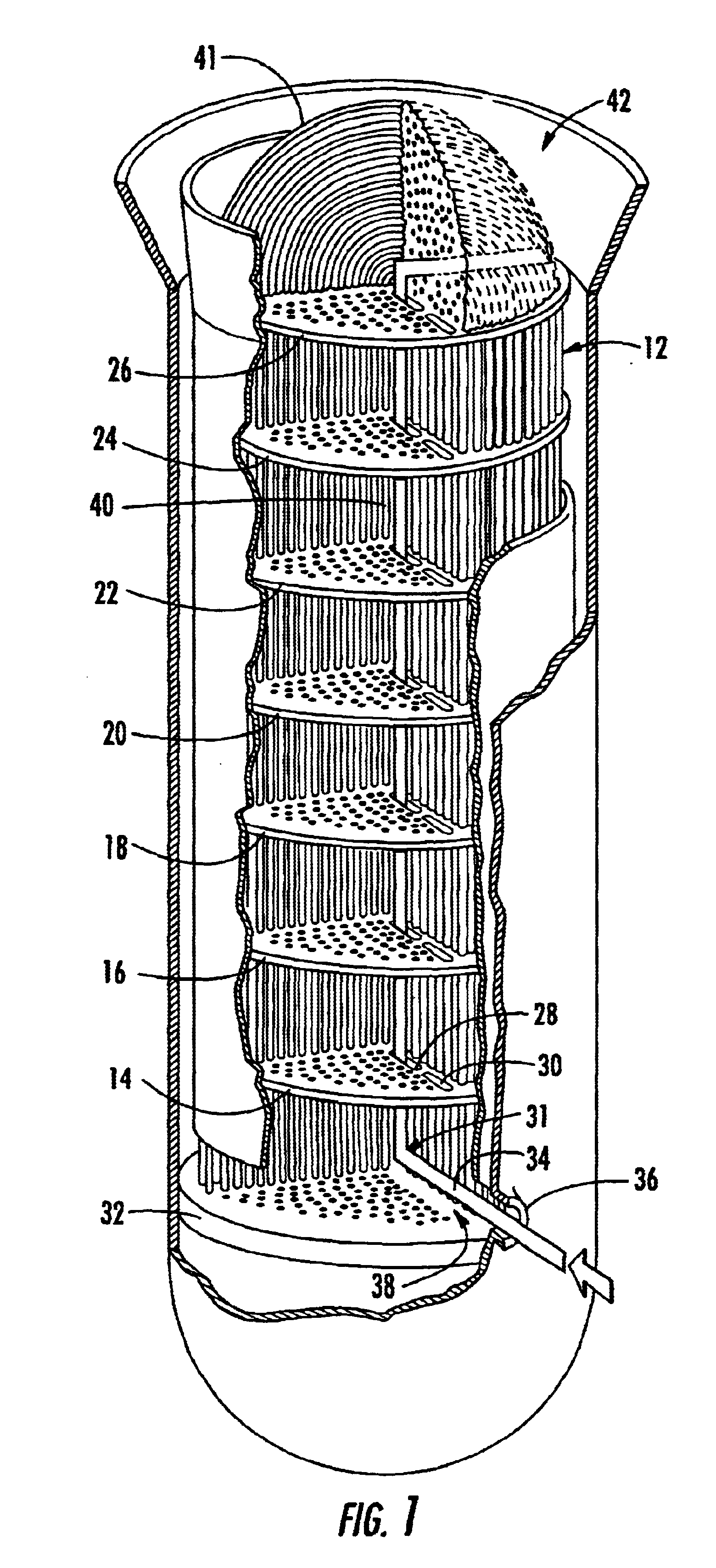

Upper bundle steam generator cleaning system and method

InactiveUS6672257B1Eliminate needOvercome disadvantagesBoiler cleaning apparatusMachines/enginesEngineeringThermodynamics

An upper bundle steam generator cleaning, inspection, and repair system including a deployment support device receivable within the steam generator to raise a cleaning device, an inspection device, and / or a tool up to the upper bundles of the steam generator.

Owner:FOSTER-MILLER

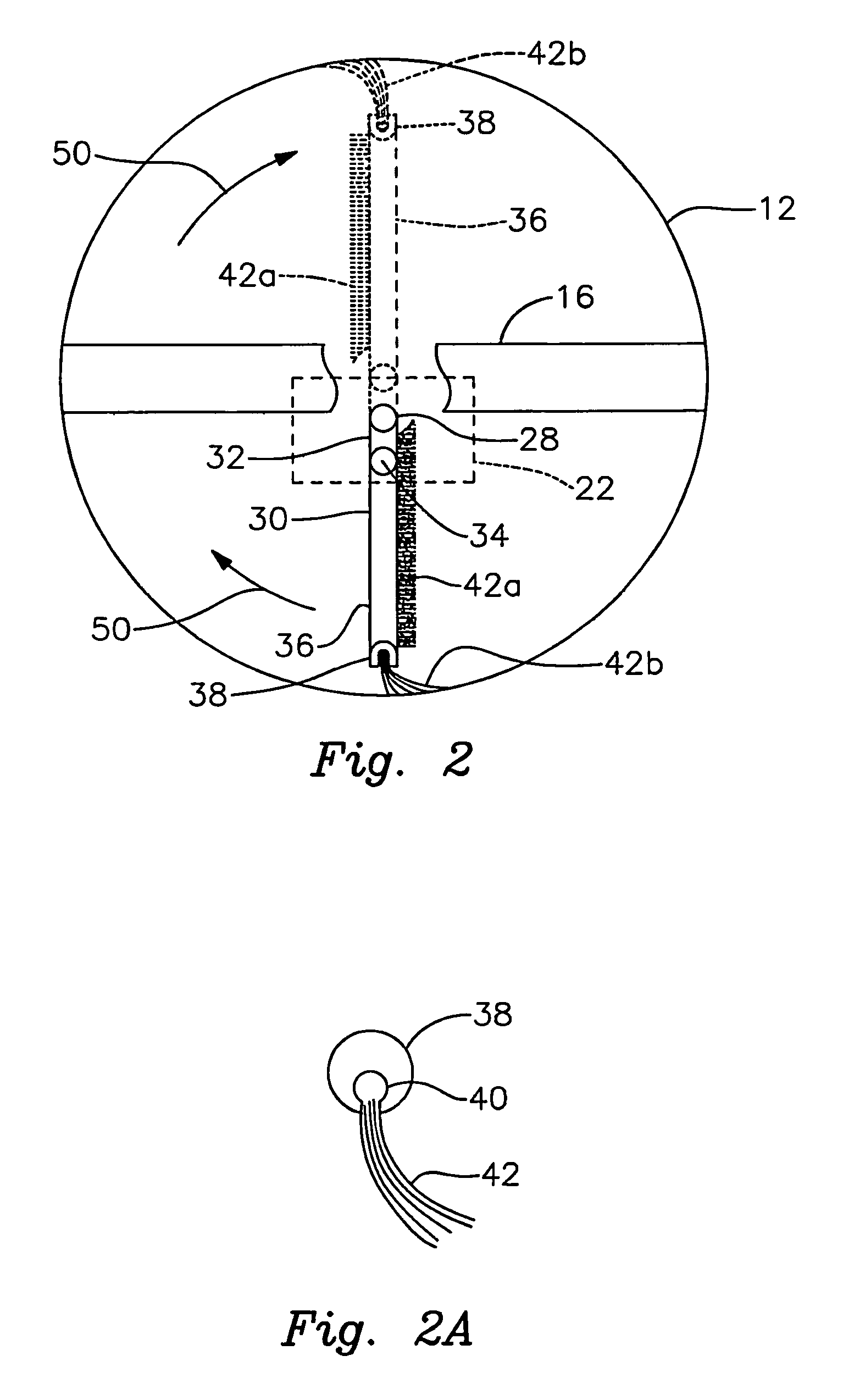

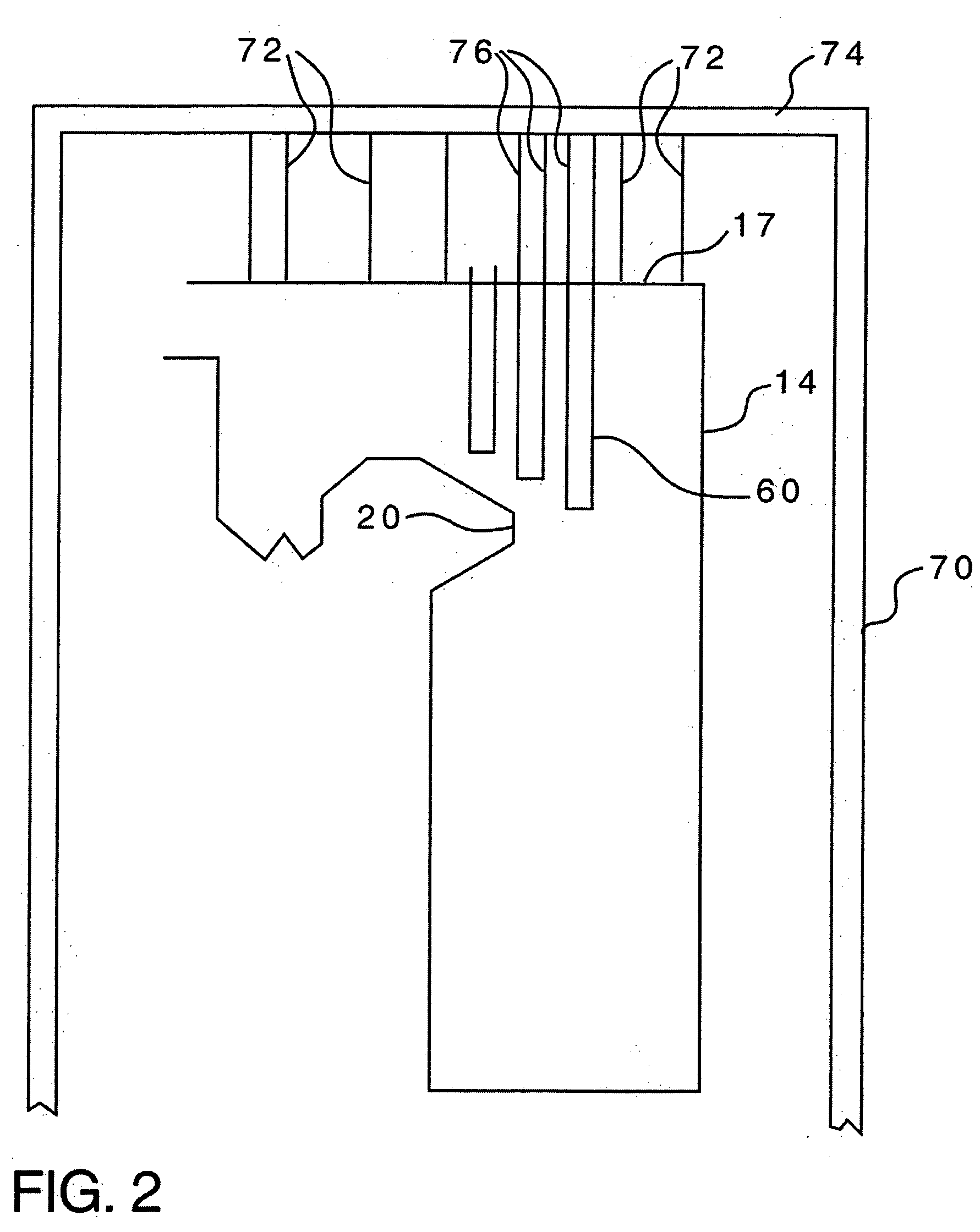

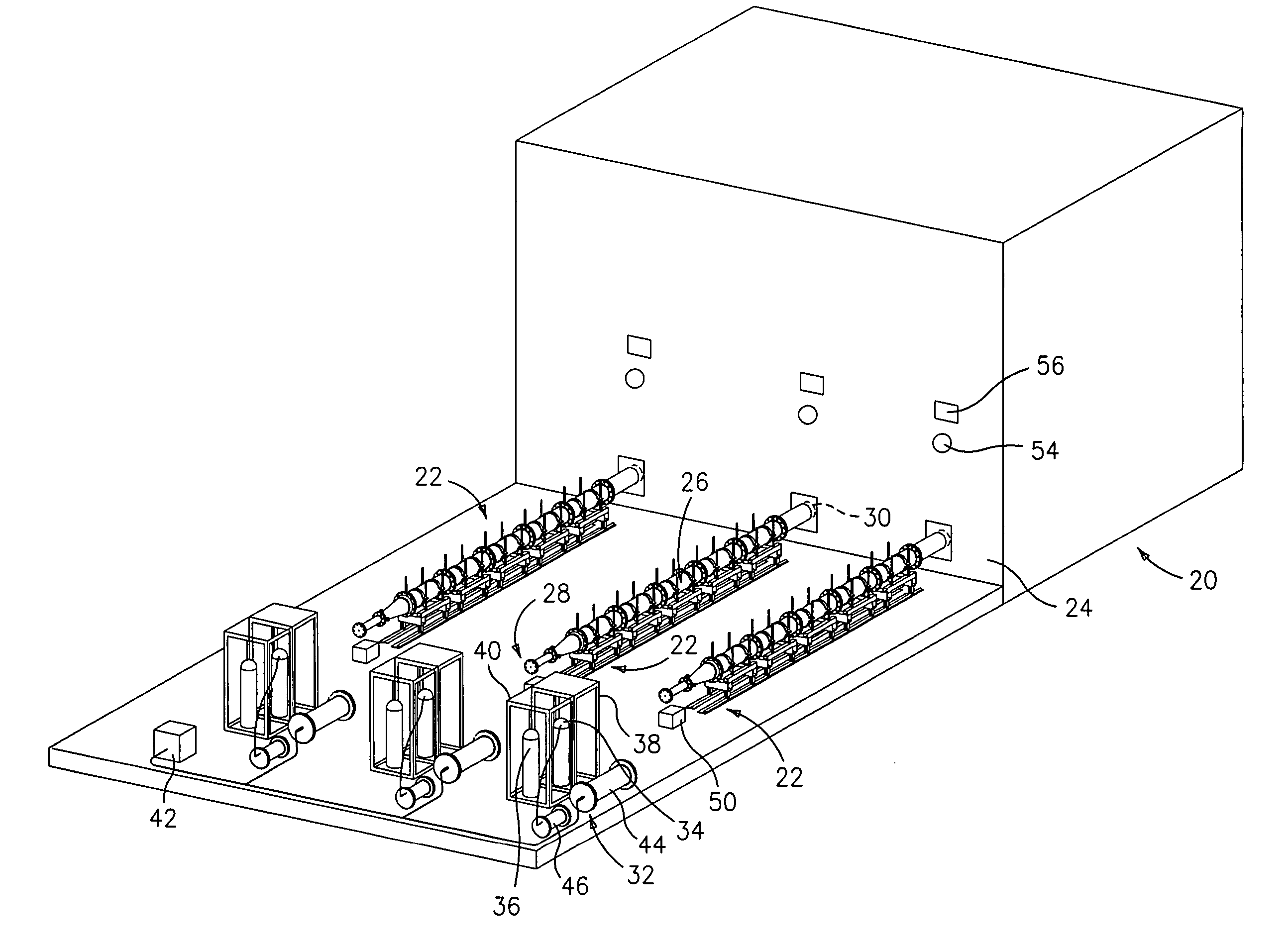

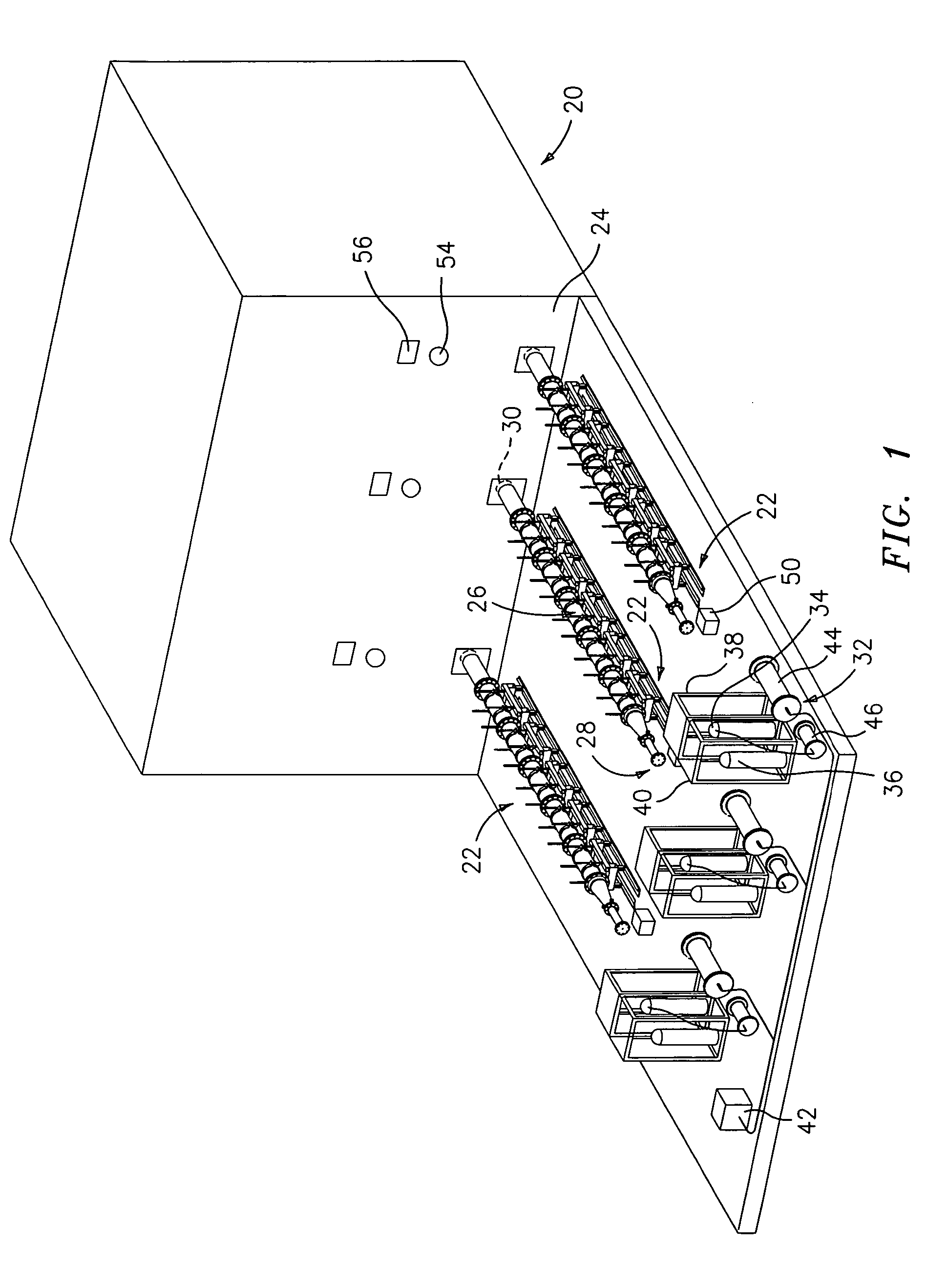

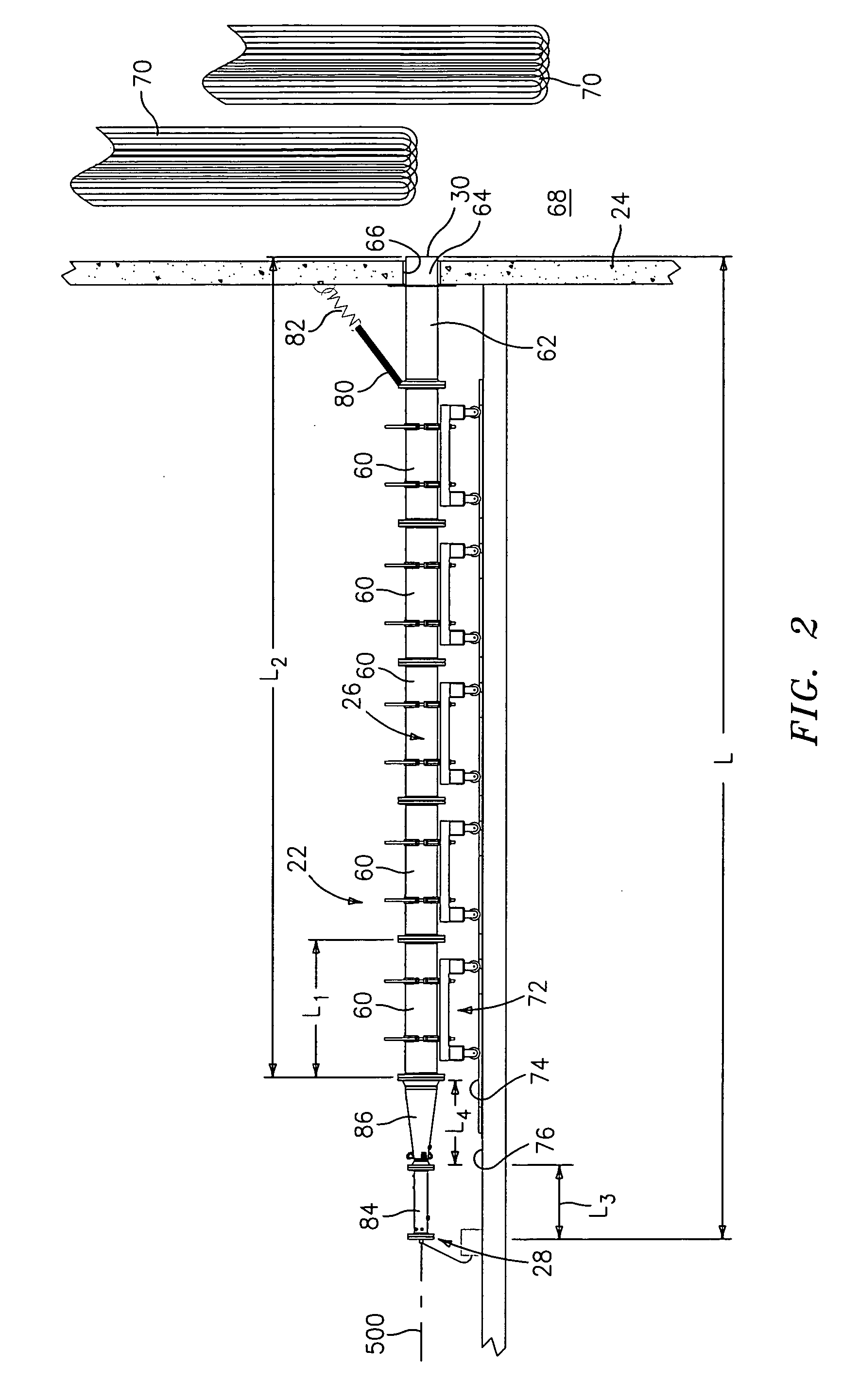

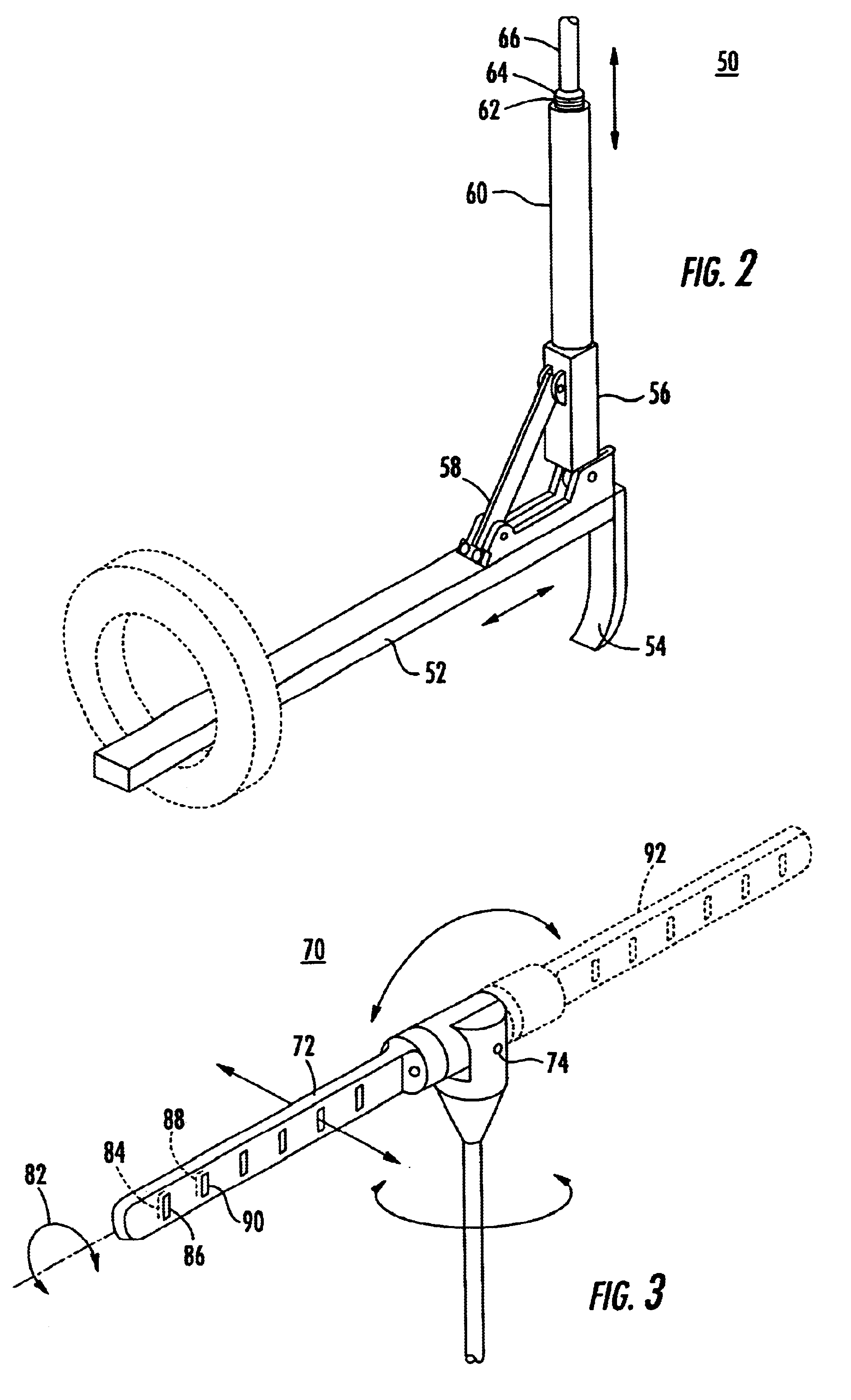

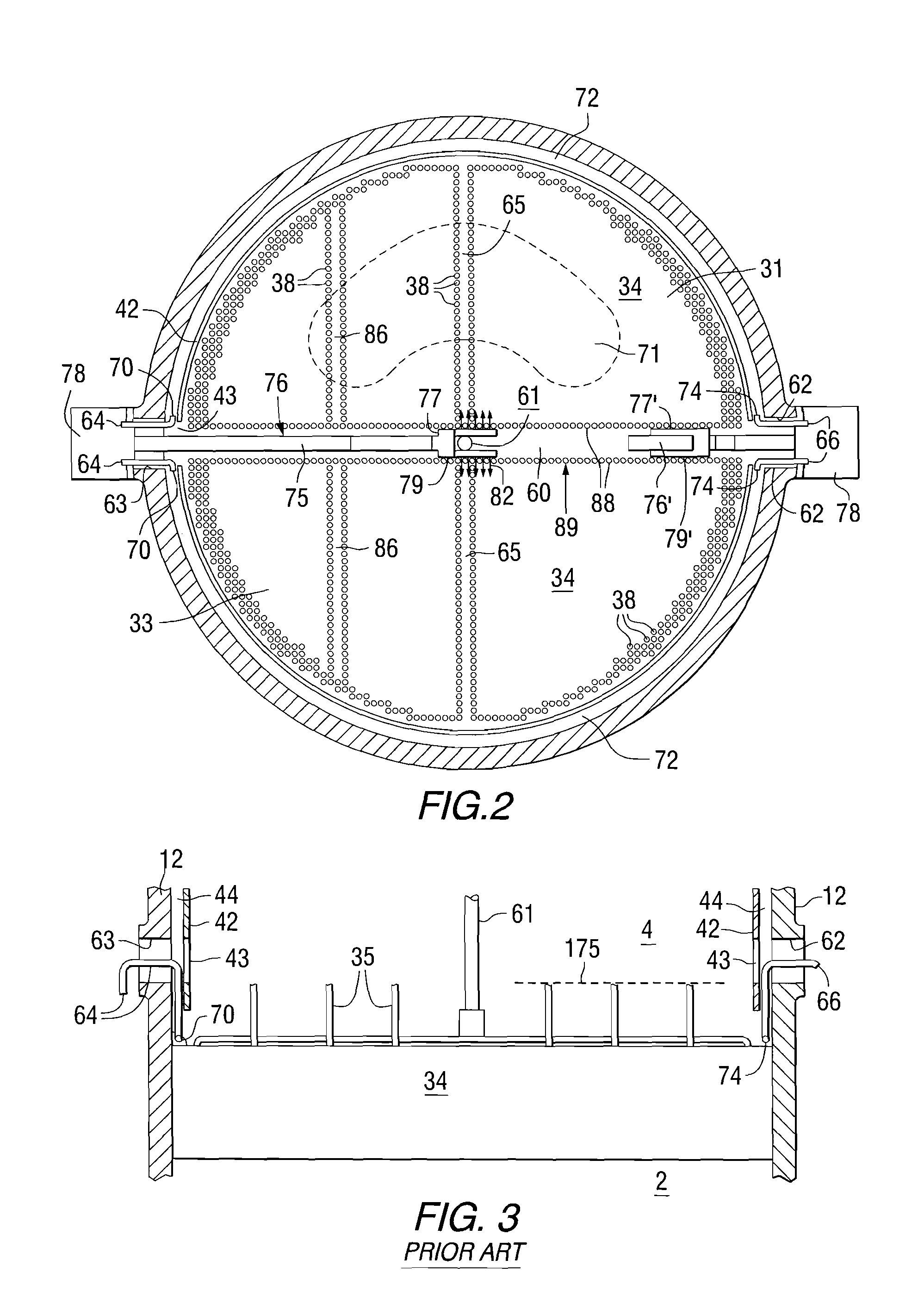

Steam generator dual head sludge lance and process lancing system

A method of cleaning sludge from the tube sheet (34) of a nuclear steam generator (10) includes introducing a moveable sludge lance (76) said moveable sludge lance having duel lance heads (77) through handholes (62) in the side of the generator and into a central tube lane (60) having a central stay rod (61) and sludge lancing with high pressure fluid through the row 1 tubes (85) in the tube lane, where the distance (200) between the dual lance heads (77) is wide enough to allow the dual lance heads to extend beyond the central stay rod (61).

Owner:WESTINGHOUSE ELECTRIC CORP

Water heater with reduced localized overheating

InactiveUSRE37240E1Reduce the effect of temperatureWater heating stoves/rangesBoiler cleaning apparatusWater cyclingEnvironmental engineering

A water and / or space heater is provided in which water is circulated to prevent the localized overheating or vaporization thereof.

Owner:FLEET CAPITAL CORPORATION

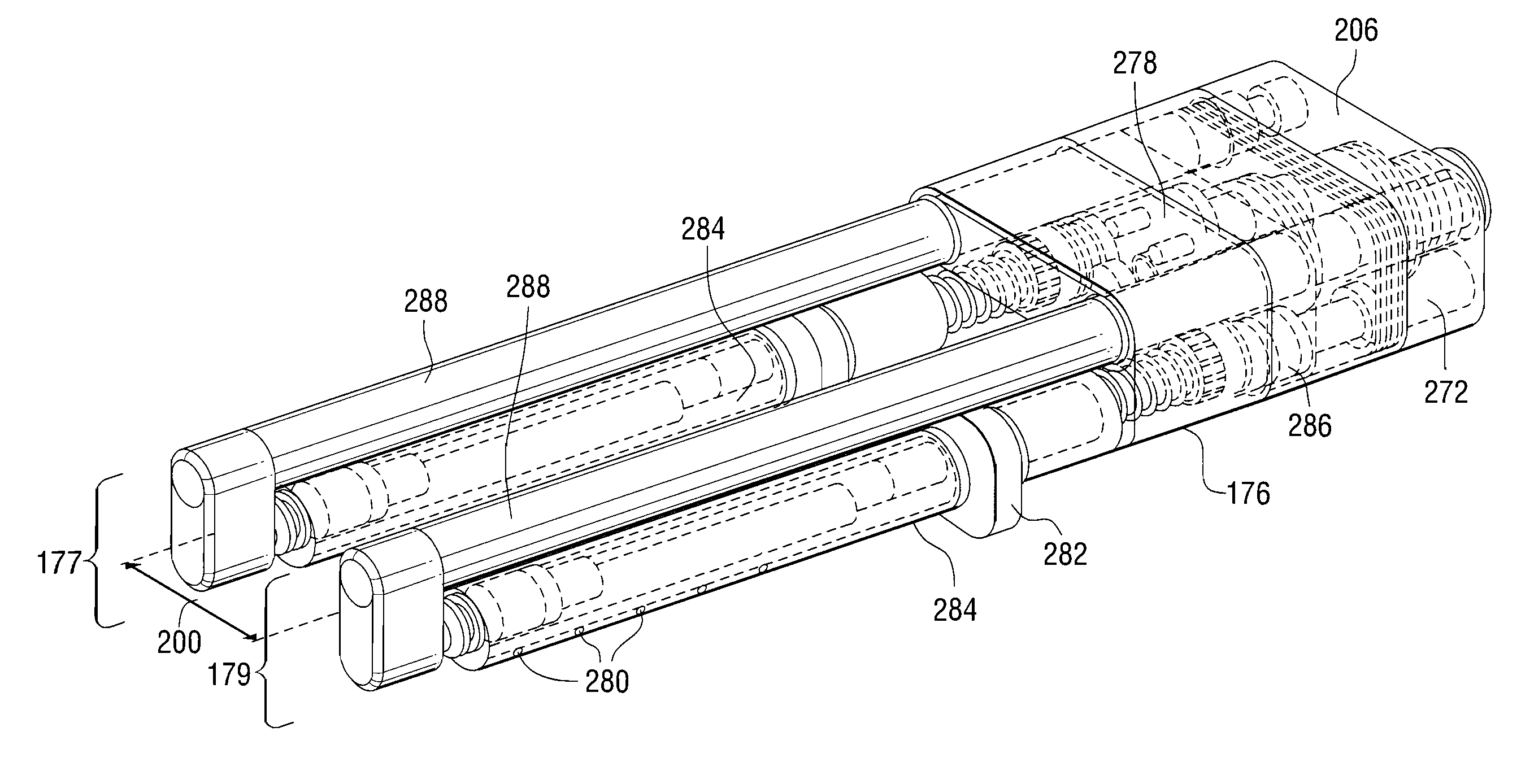

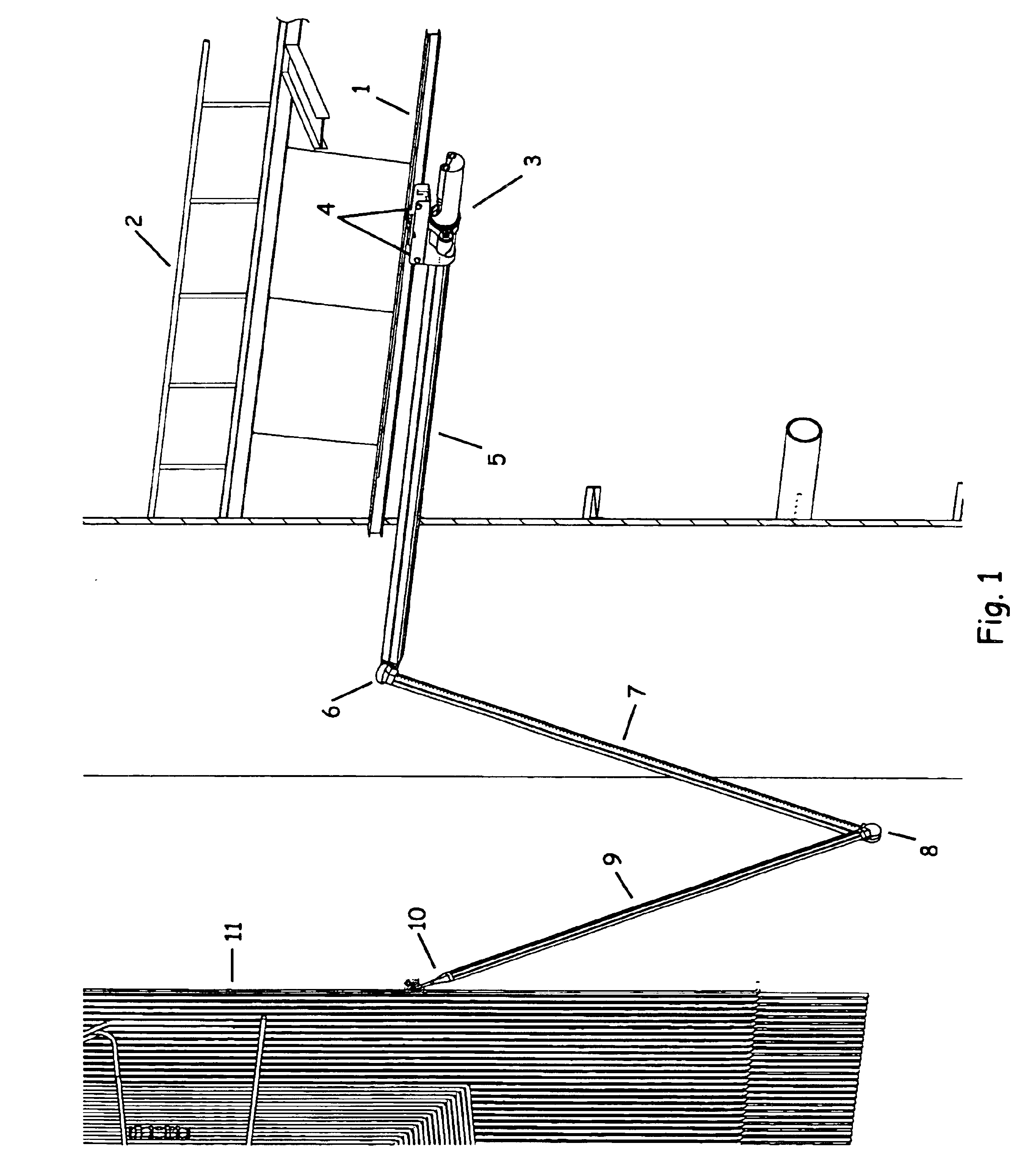

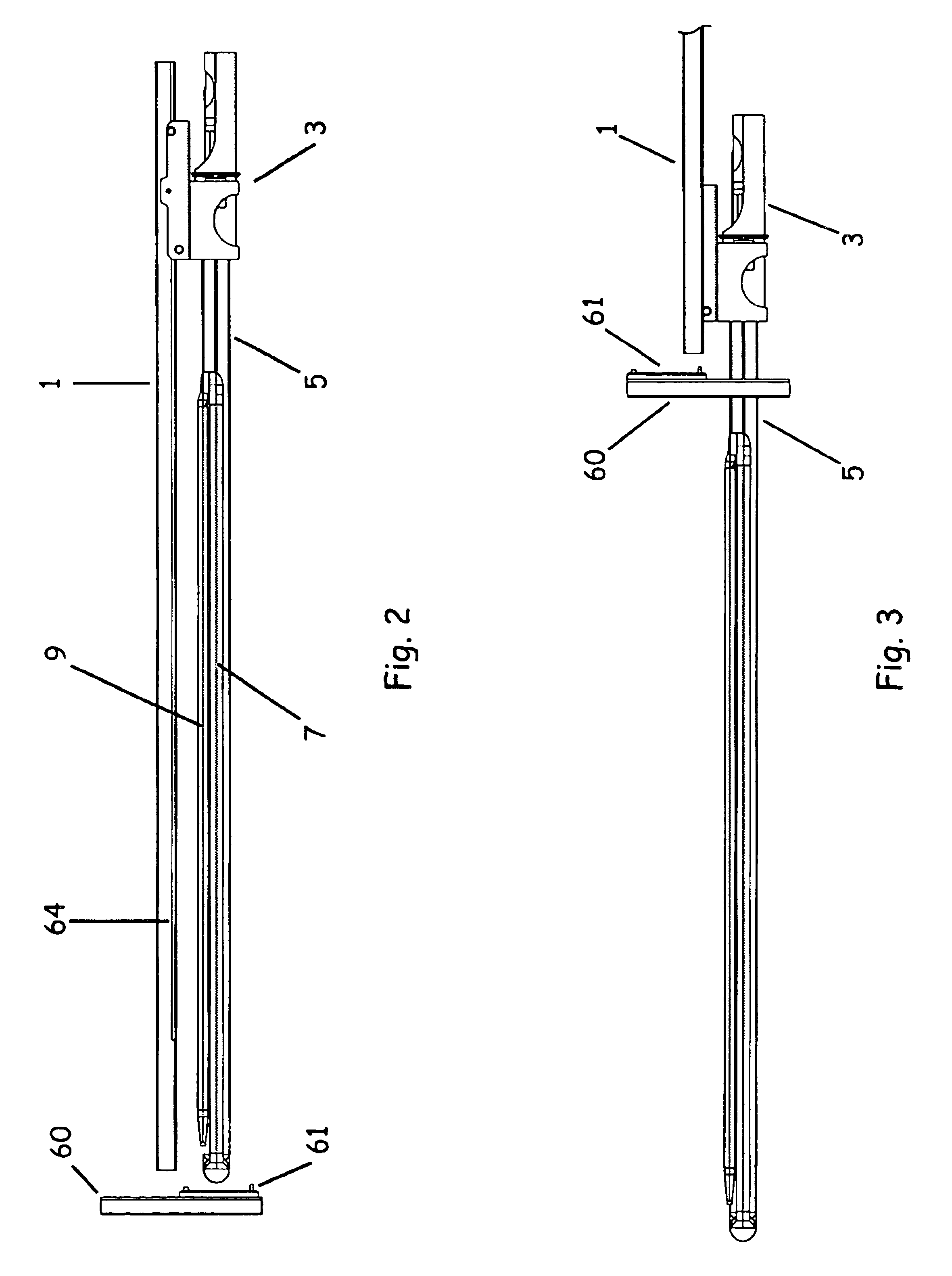

Deployment system for an upper bundle steam generator cleaning/inspection device

InactiveUS6543392B1Overcome disadvantagesEliminate needElectrostatic cleaningBoiler cleaning apparatusEngineering

A deployment system for an upper bundle steam generator cleaning / inspection device, the deployment system including an elongated body feedable through an access in a steam generator shell proximate the tube sheet of the steam generator, the elongated body flexible in one configuration to bend into a position for extension up through flow slots in support plates of the interior of the steam generator, and rigid in another configuration for positioning and supporting cleaning / inspection devices up through the steam generator proximate the upper tube bundles of the steam generator; and a drive device for driving the elongated body up through the support plates and for retracting the elongated body back down through the support plates.

Owner:FOSTER-MILLER

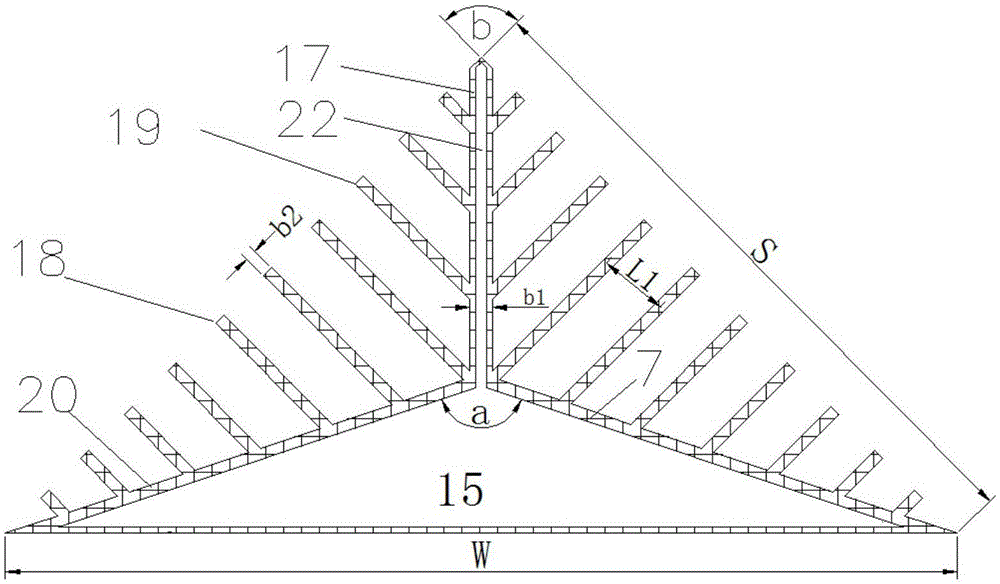

Method and apparatuses to remove slag

ActiveUS7204208B2Eliminate tube damageEliminate erosionMechanical cleaningPressure cleaningFiberCarbon fibers

A robotic apparatus for the cleaning and maintenance of coal fired boilers, which is designed to operate in the high temperature environment of the combustion gasses to effectively clean and remove slag deposits of the boiler heat transfer surfaces by use of a precision directed, low pressure, low flow rate water stream. The robotic cleaning apparatus is comprised of lightweight carbon fiber structural elements, attached to the exterior of the boiler, and cooled by annular pressurized water sheaths impingent on a thin metal skin covering the lightweight structural elements. Multiple articulated joints allow for complete access to the heat transfer surfaces of the boiler. A variety of payloads can be delivered to specific points within the boiler, including imaging systems, cutting, and welding apparatuses. A mathematical state space control matrix allows for optimal positioning and feedback control of motions.

Owner:KURION INC

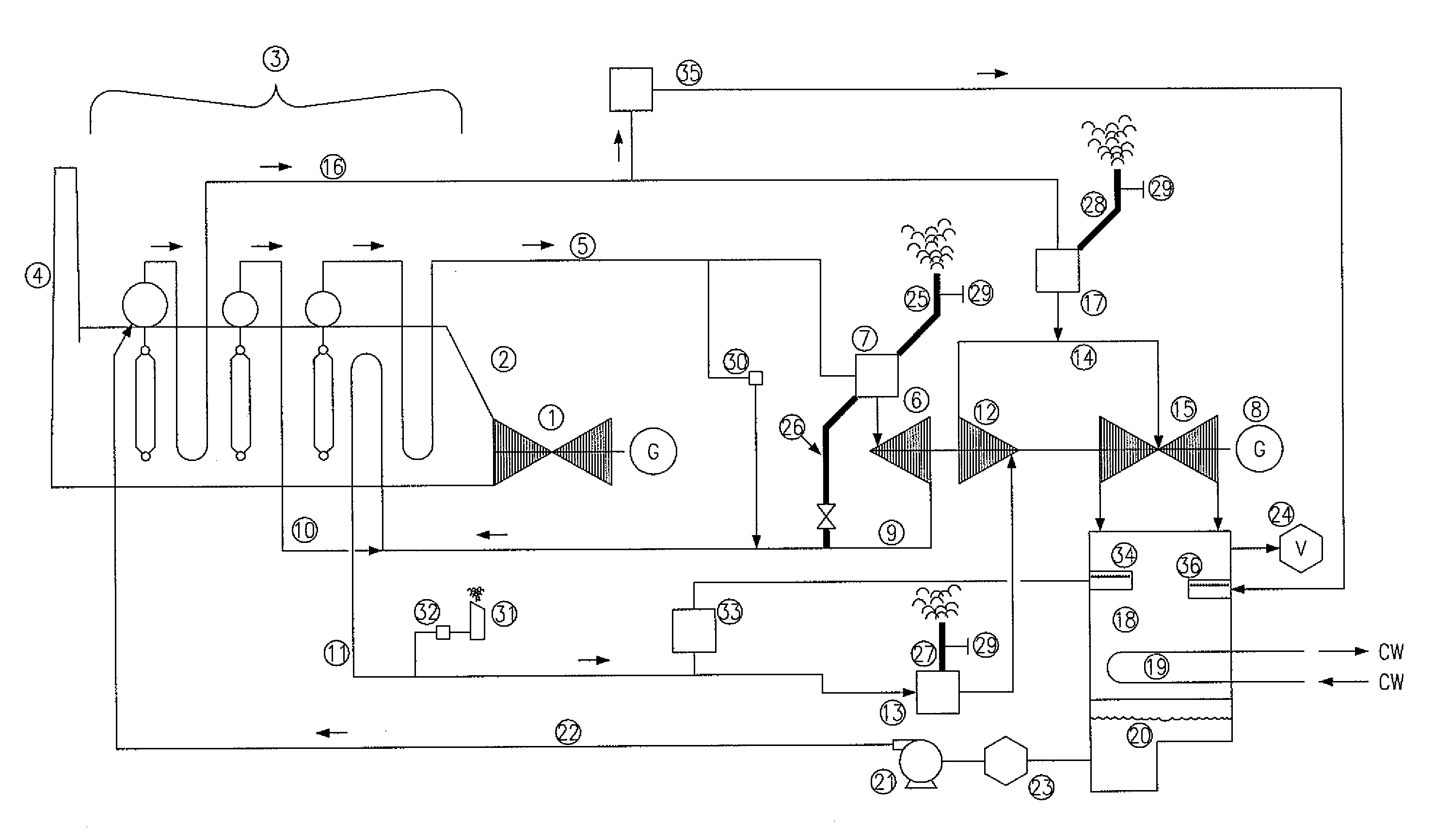

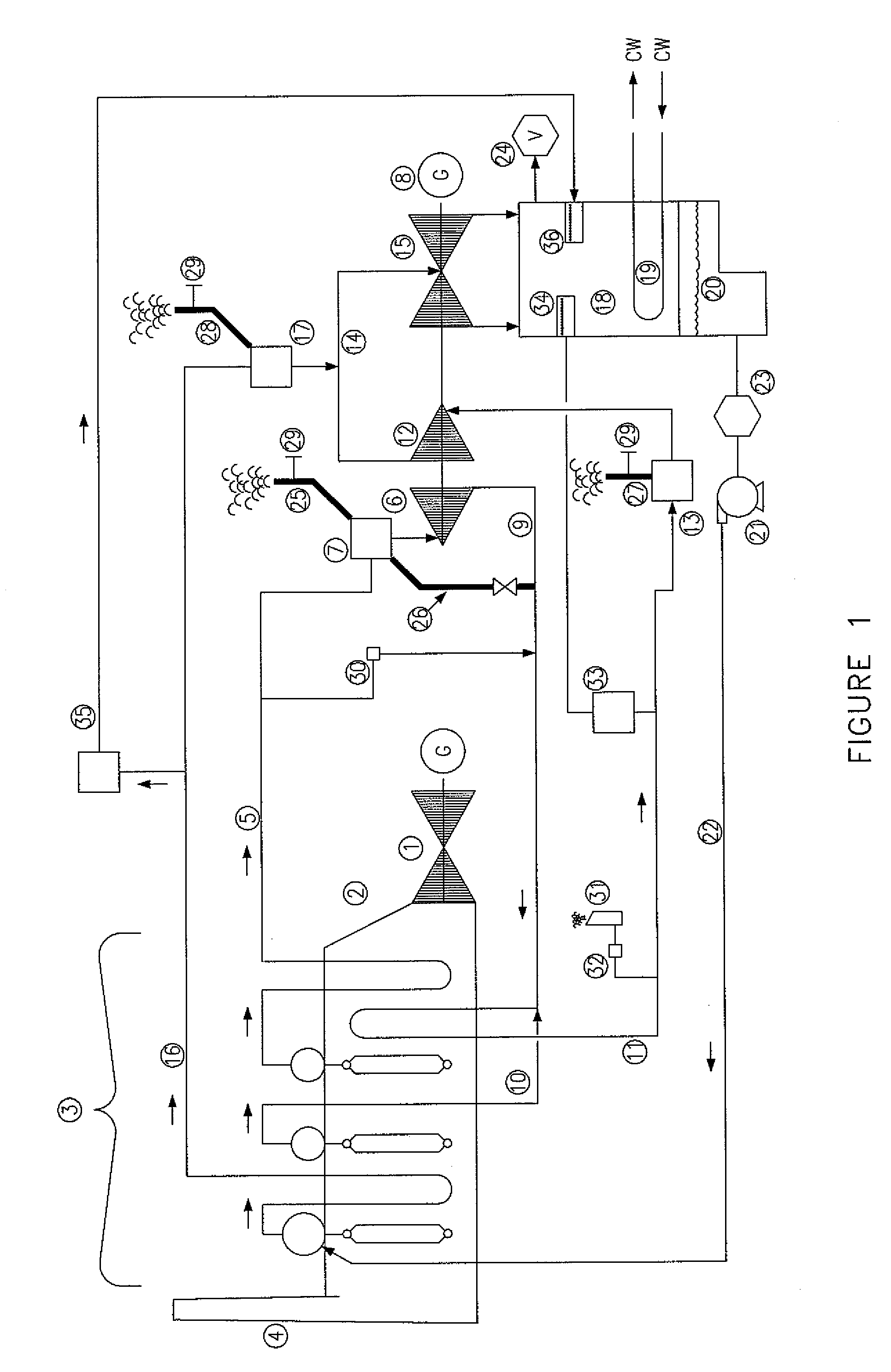

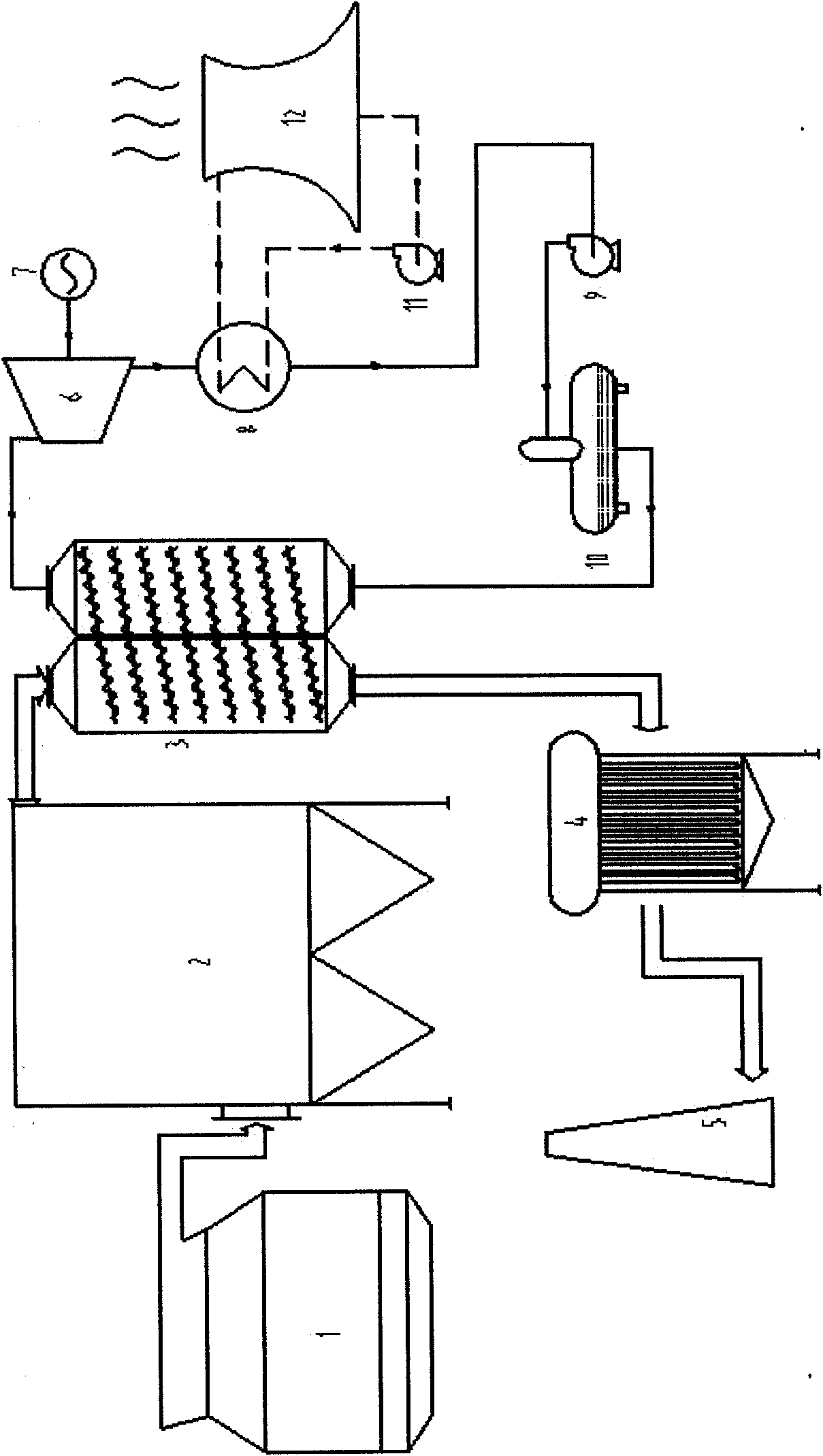

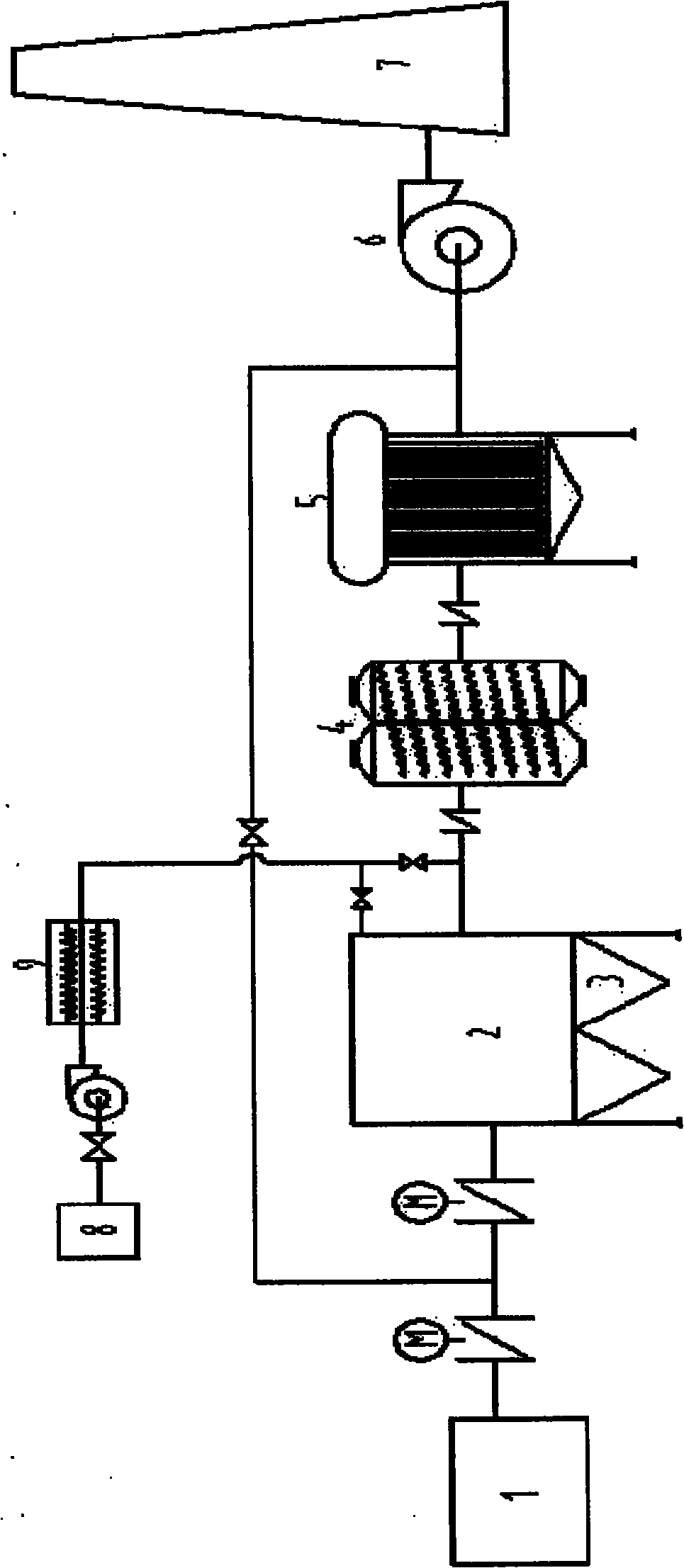

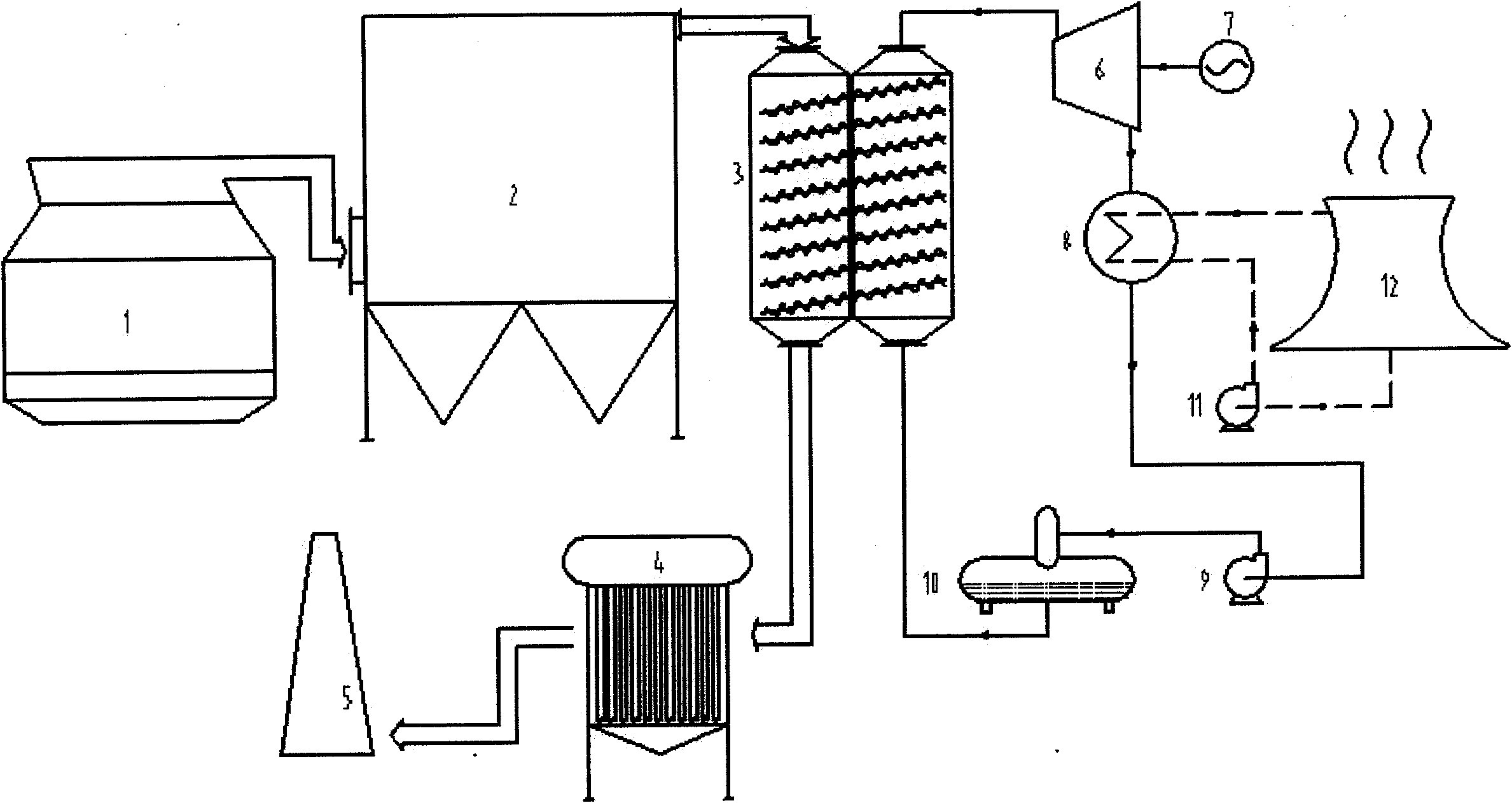

Integrated waste heat generating and heating system and process flow thereof

InactiveCN101852555AAvoid paralysisLow running costValve arrangementsDispersed particle filtrationFiberHeat conducting

The invention discloses a waste heat generating equipment system and a waste heat generating process. The system comprises a ceramic fiber dust collector (2), a rapid heat conducting heat-pipe waste heat boiler (3), a rapid heat conducting heating device (4), a steam replenishing and condensing steam turbine (6), a condenser (8), a condensing water pump (9) and a vacuum deaerator (10), wherein ceramic fiber dust collector (2) is arranged at a waste heat outlet end; the rapid heat conducting heat-pipe waste heat boiler (3) bears a steam preparing device for power generation; the rapid heat conducting heating device (4) is arranged on the smoke inlet of a boiler; medium and high-pressure main steam generated by a rapid heat conducting heat-pipe waste heat boiler is mixed and enters the steam replenishing and condensing steam turbine (6) through a pipeline; low-pressure steam enters the steam replenishing and condensing steam turbine (6) through a steam replenishing pipeline; waste steam on the tail part of the steam turbine enters the condenser (8); condensed water enters the vacuum deaerator (10) through the condensing water pump (9) and a pipeline; water from which oxygen is removed in the deaerator enters the heat-pipe waste heat boiler (3) through a water supply pump of the boiler; and low-temperature smoke discharged from the back end of the boiler is delivered into the rapid heat conducting heating device (4). The waste heat utilization ratio of the integrated system is enhanced by over 60 percent on average, so unit energy consumption of an enterprise is greatly lowered, the problem of unstable running of the system due to dust blocking of the boiler and wearing of a heat exchange tube in a medium and low temperature waste heat generating system is solved and comprehensive generating efficiency is enhanced by over 30 percent.

Owner:童裳慧

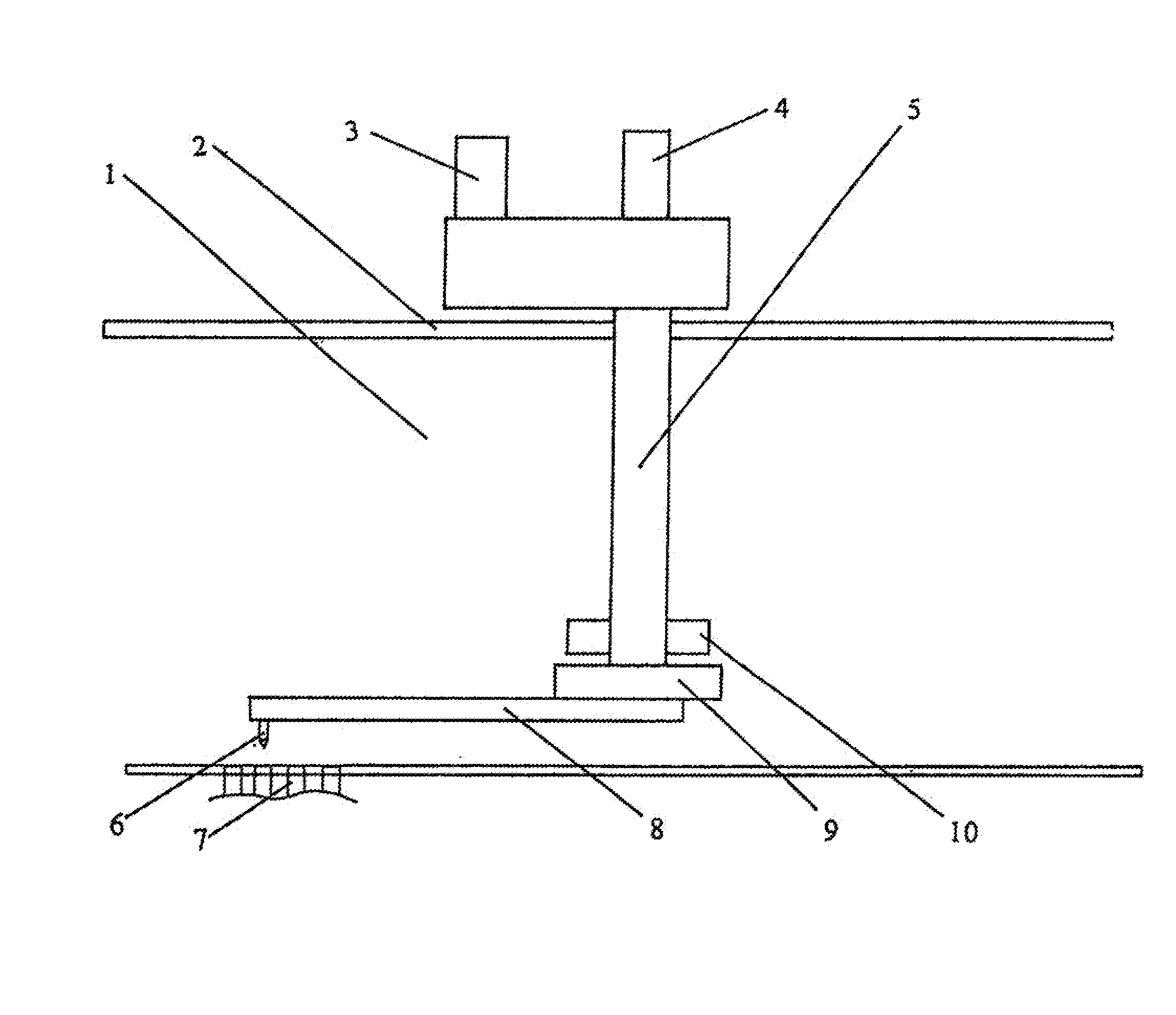

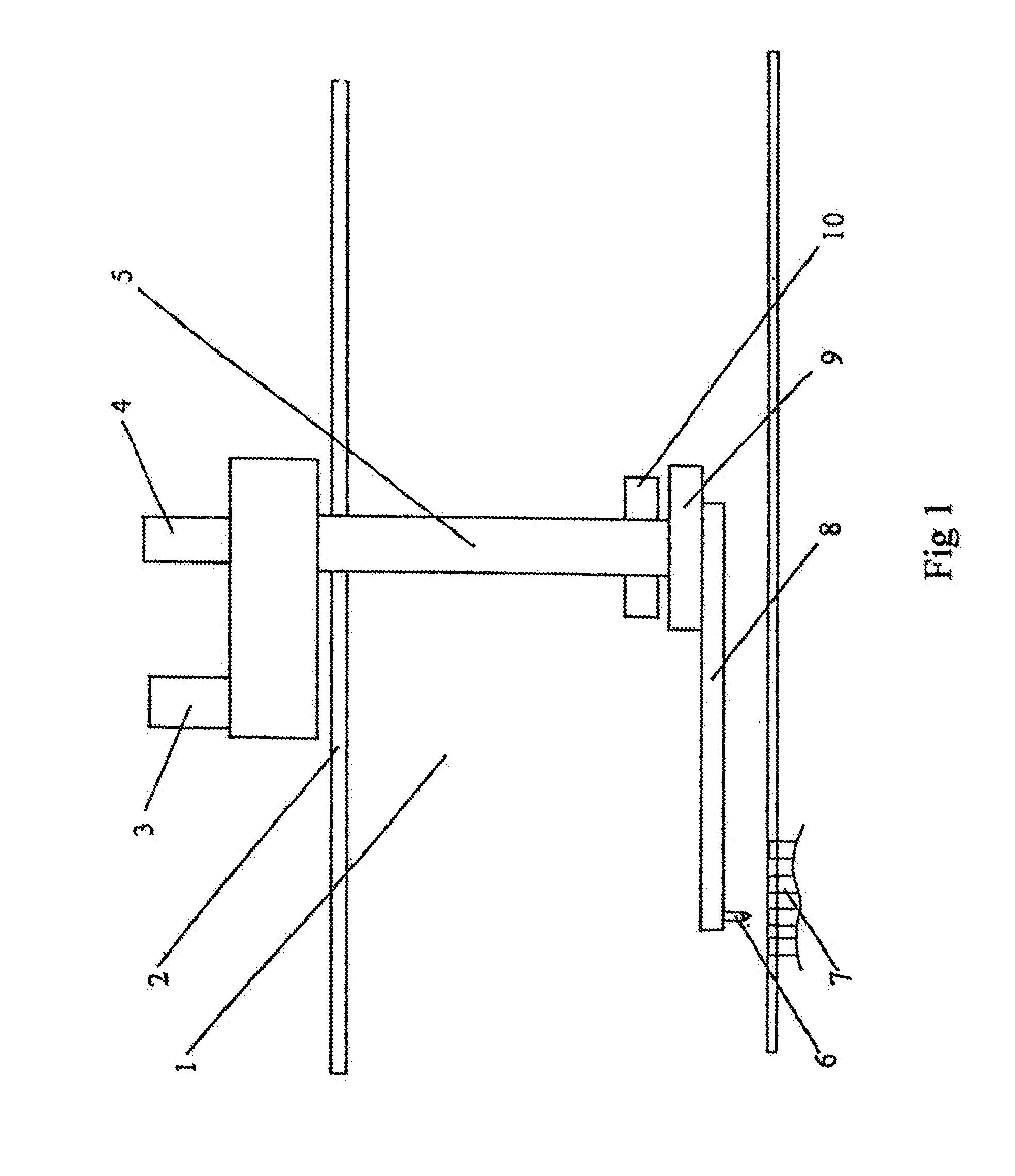

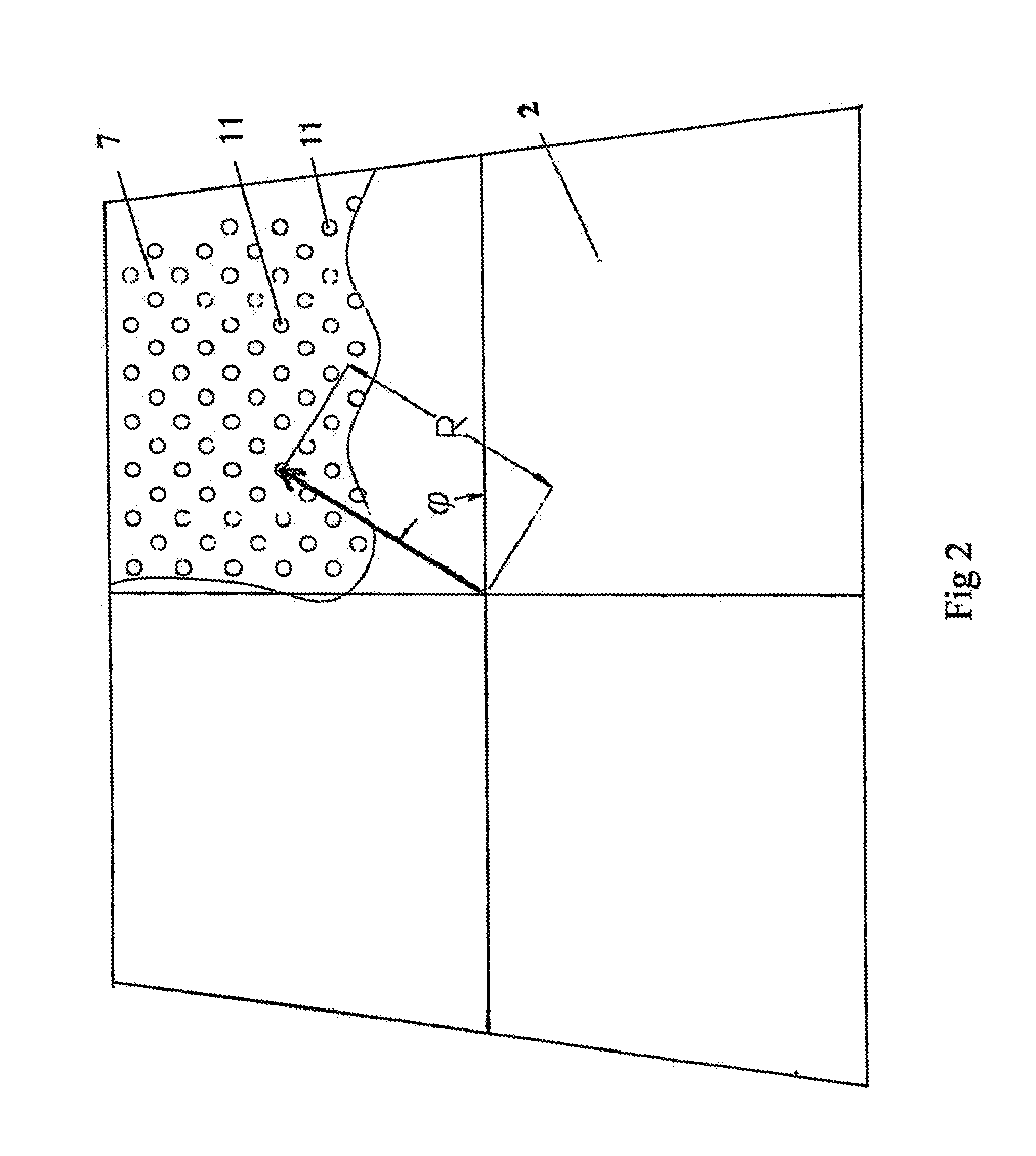

On-Line Automatic Cleaning Device For A Condenser In A Turbine Generator

InactiveUS20080185126A1Improve heat transfer efficiencyReduce coal consumptionHollow article cleaningBoiler cleaning apparatusEngineeringTitanium

A device and method to perform on-line automatic flushing and cleaning for a steam turbine generator condenser, related with technology for flushing and cleaning of equipment during steam turbine generator operation, the apparatus includes: a polar coordinate traveling mechanical system, including one computer program polar coordinate control unit, which will control the servo motors to position the high-pressure water jet on the opening for Copper tube (or Titanium tube); the benefit for the invention is that, the polar coordinate traveling mechanical system move the high-pressure water jet to flush and clean each Copper tube (or Titanium tube) on condenser tube plate, to realize high-pressure water cleaning for each pipe during operation of generator, therefore, the heat exchanging efficient can be increased, further to reduce the consumption of coal for steam turbine generator, and archive the aim to saving coal, and reduction in generating cost.

Owner:JIANG CONGQUAN

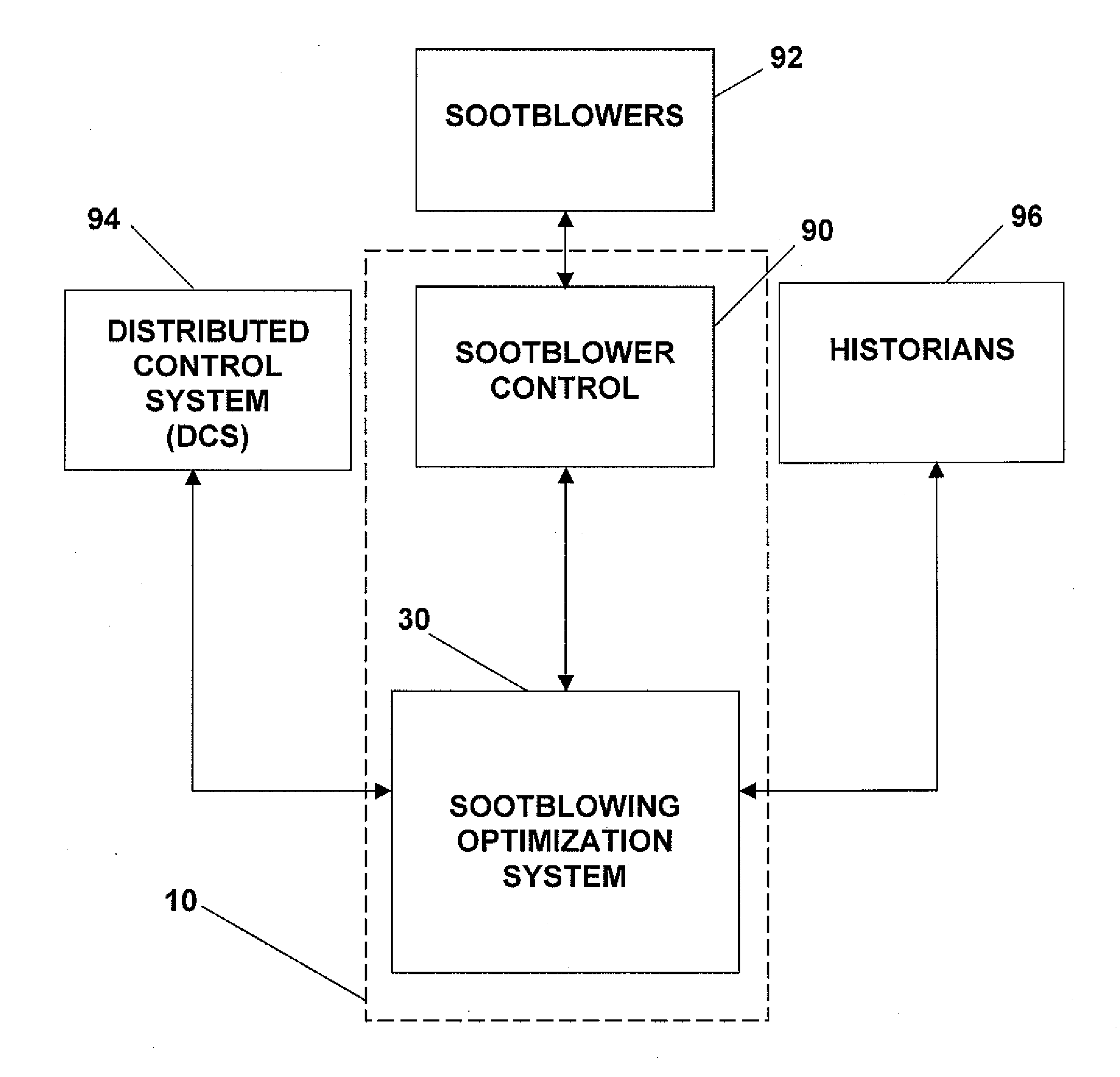

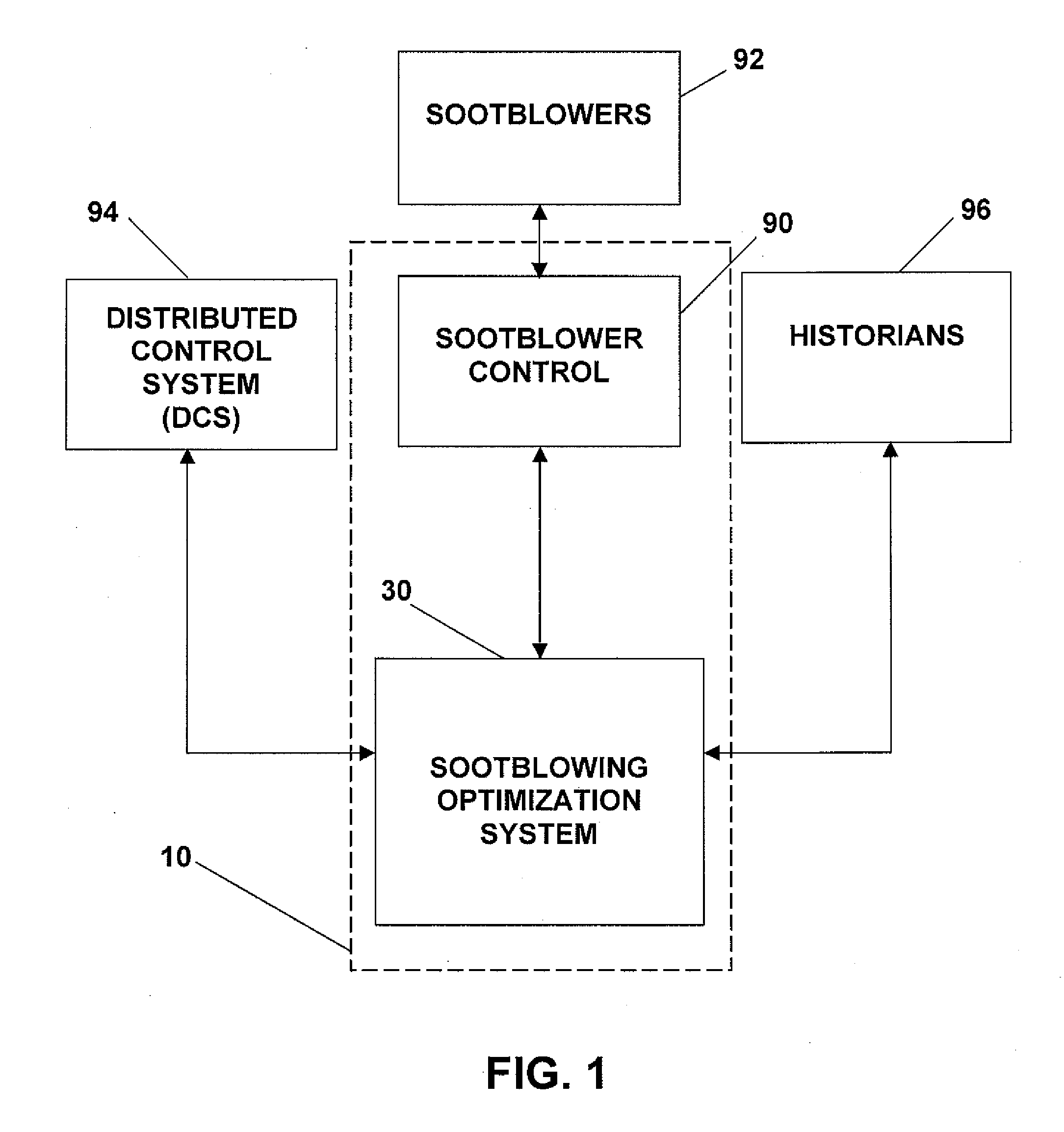

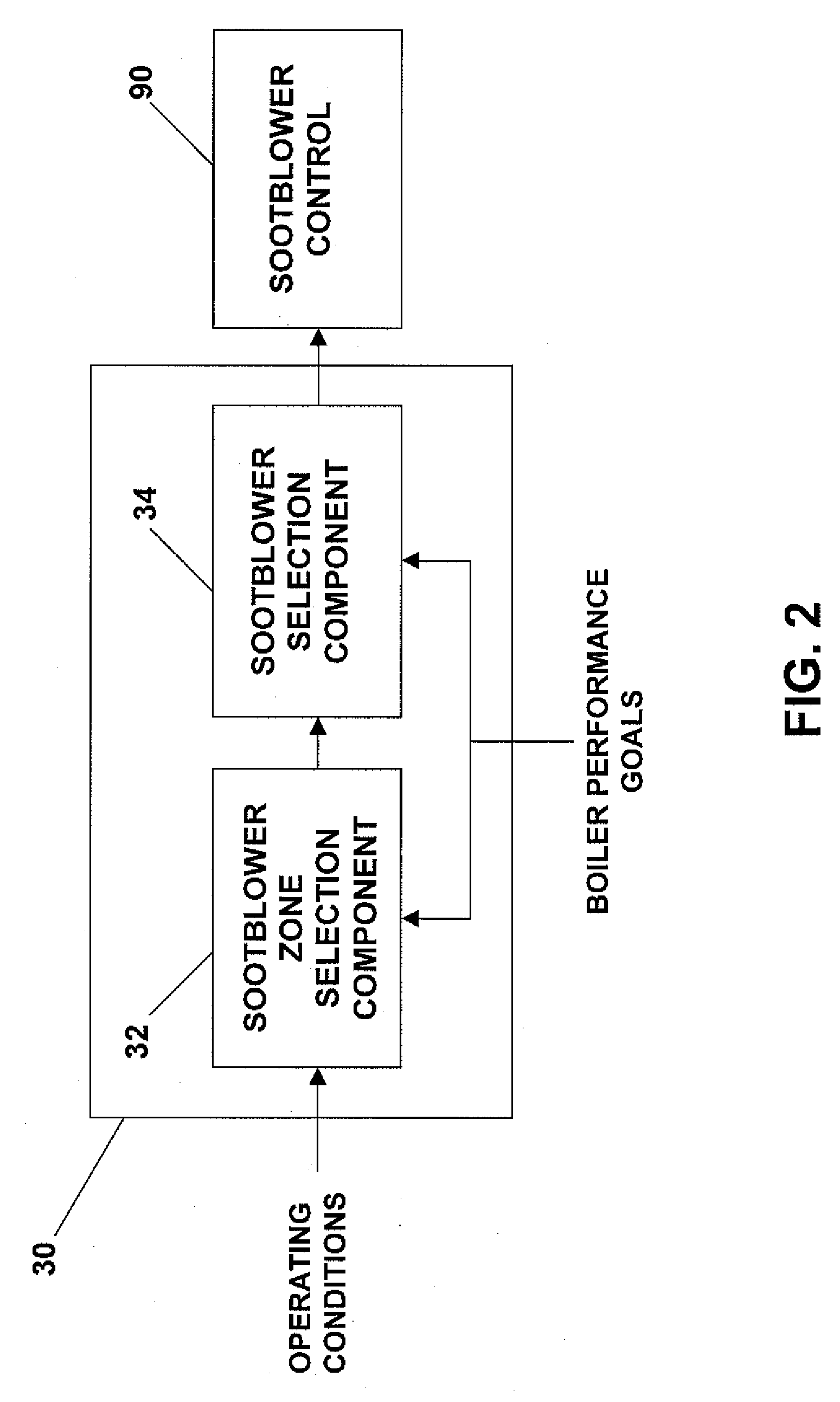

Sootblowing optimization for improved boiler performance

A sootblowing control system that uses predictive models to bridge the gap between sootblower operation and boiler performance goals. The system uses predictive modeling and heuristics (rules) associated with different zones in a boiler to determine an optimal sequence of sootblower operations and achieve boiler performance targets. The system performs the sootblower optimization while observing any operational constraints placed on the sootblowers.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com