Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

786results about "Boiler water tubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

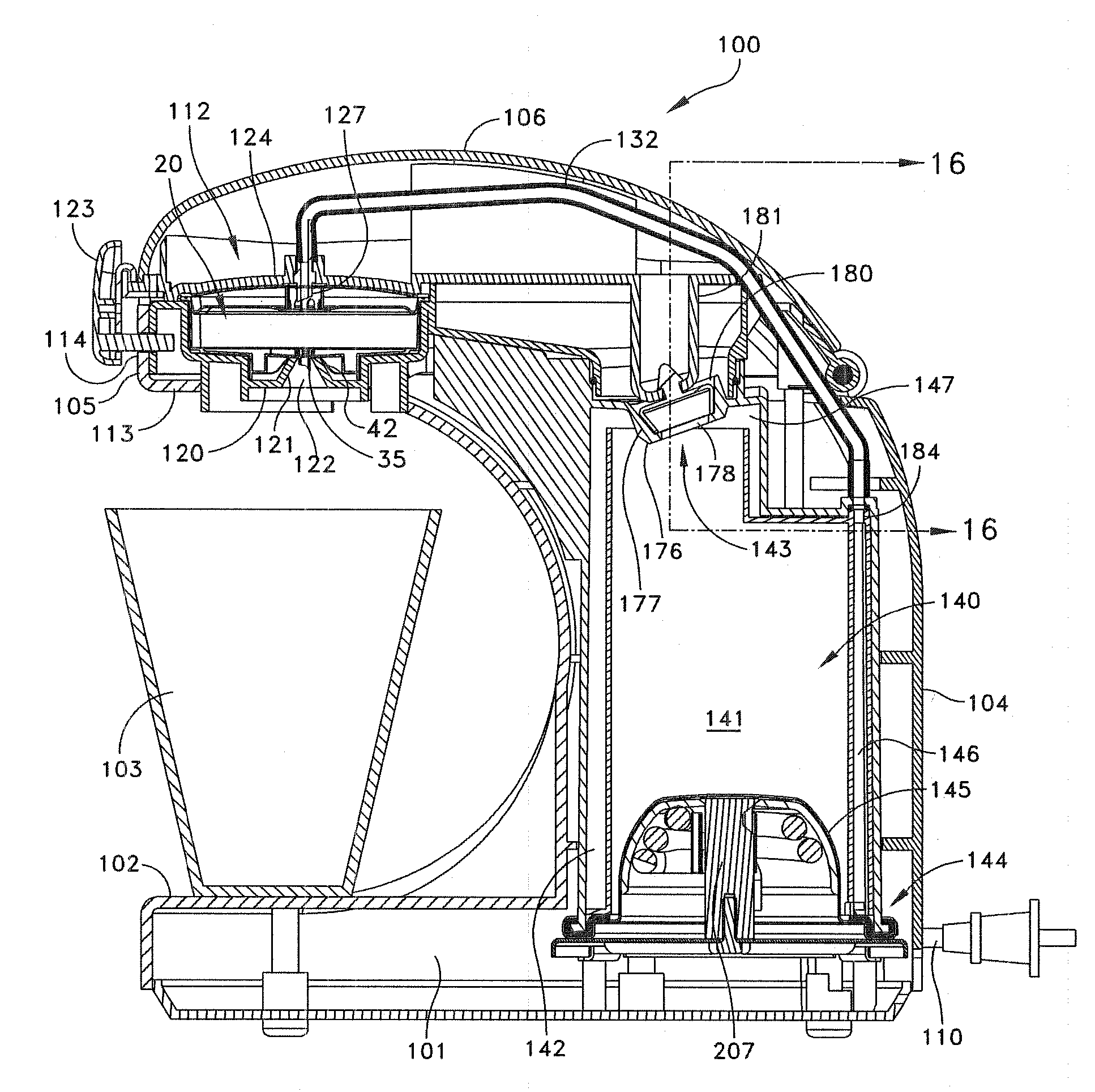

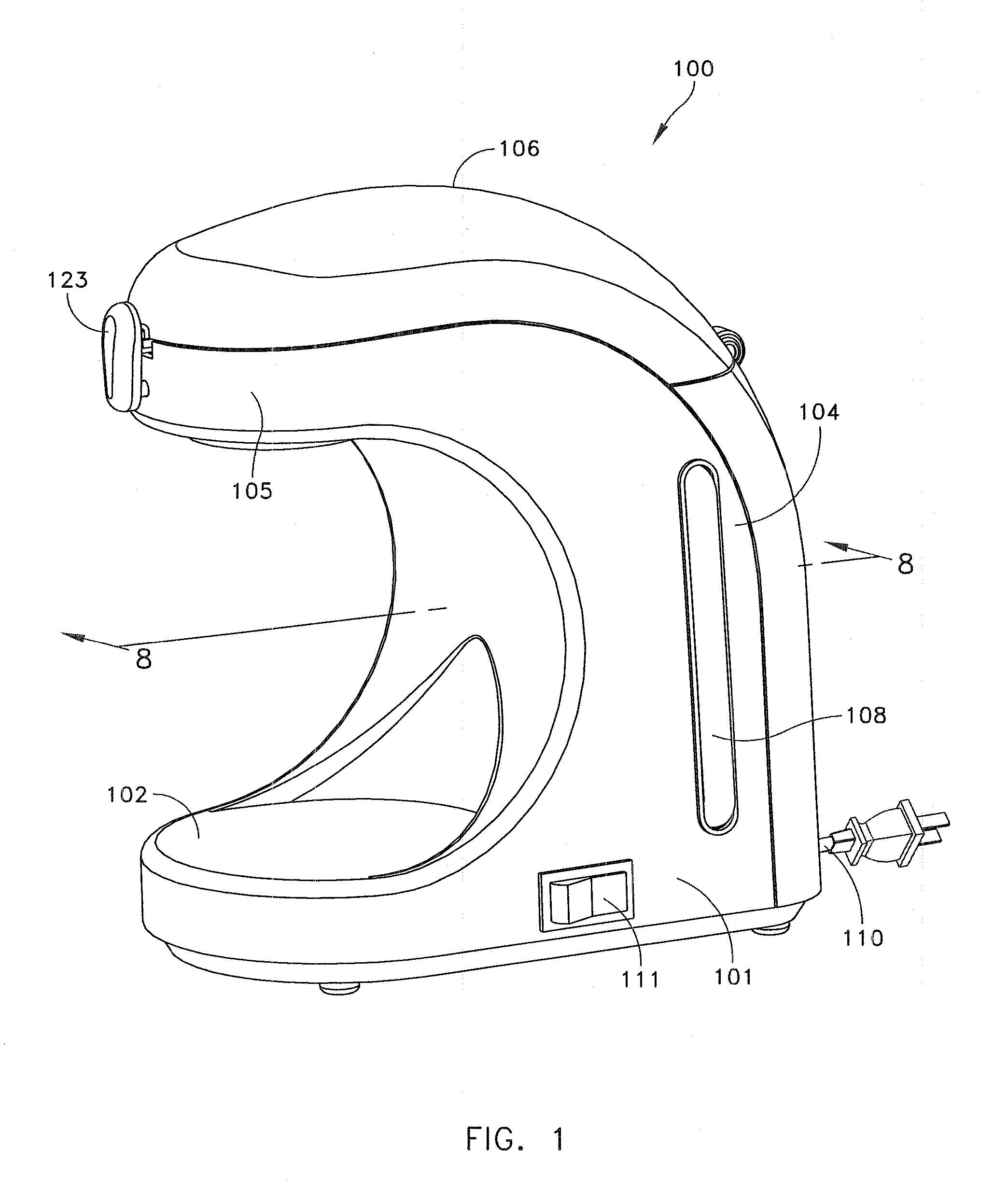

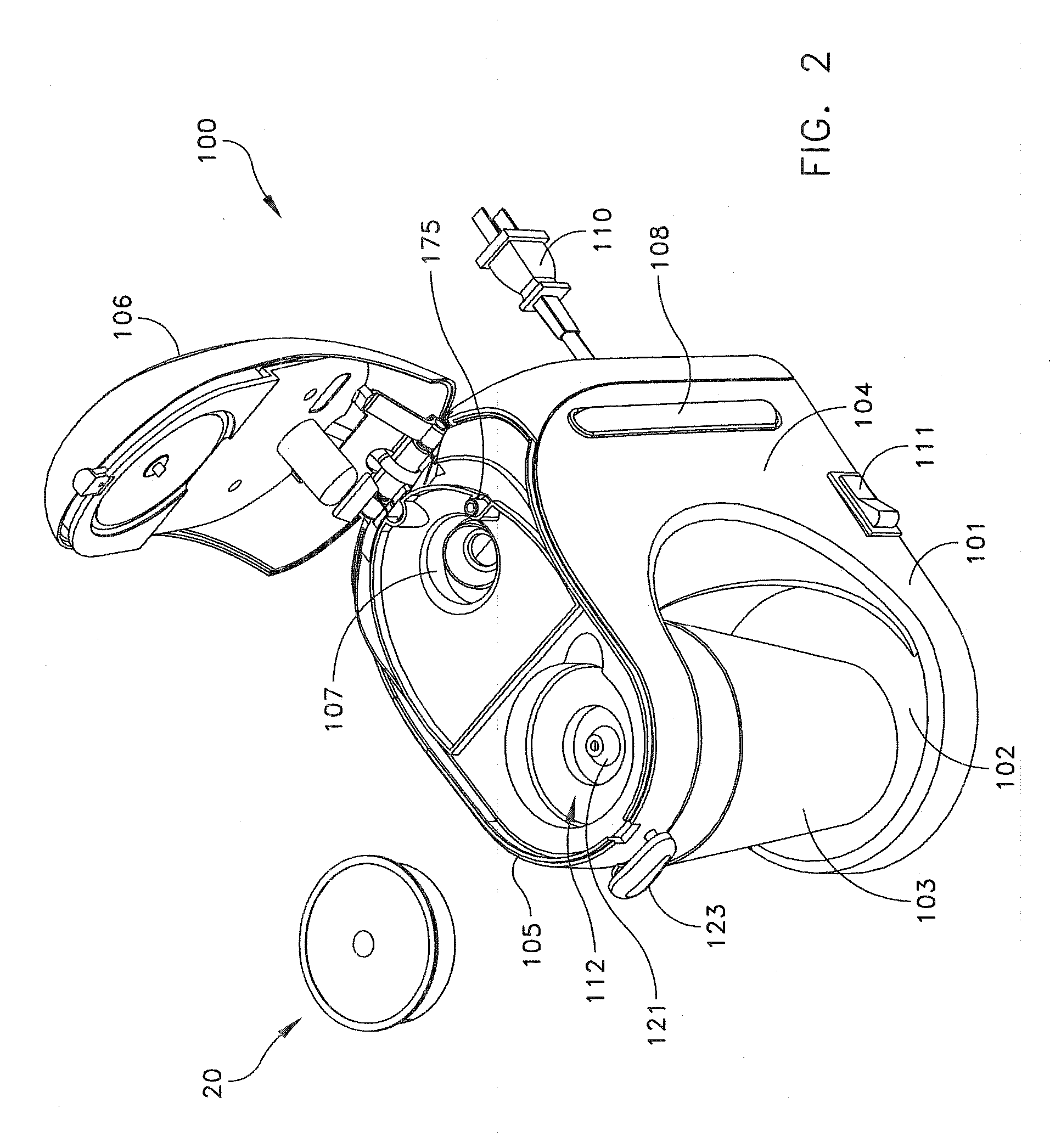

Hot beverage brewing apparatus

ActiveUS20090007792A1Easy to controlCompact and reliable and inexpensive to manufactureSteam generation heating methodsBoiler flue tubes/fire tubesProcess engineeringHot liquids

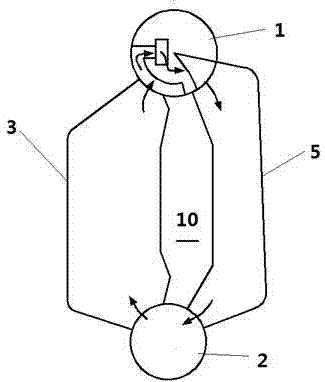

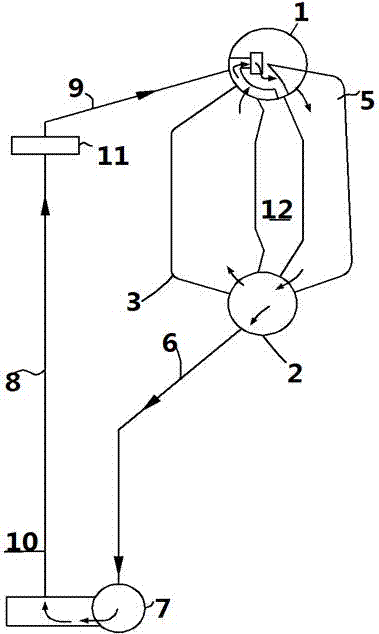

A hot beverage brewing apparatus. A pressurized hot liquid delivery system provides liquid under pressure within a range of acceptable brewing temperatures without any mechanical pump. Water is apportioned into sealable tank volumes, one of which is heated to boil the liquid and produce steam under pressure. The pressurized steam displaces the liquid from the tank volumes in proportion and at a temperature that is within the acceptable brewing range. The hot liquid under pressure is directed to a capsule receiving station to infuse a material in a capsule. The capsule dispenses the brewed beverage without contacting the brewing apparatus.

Owner:SOLABEV

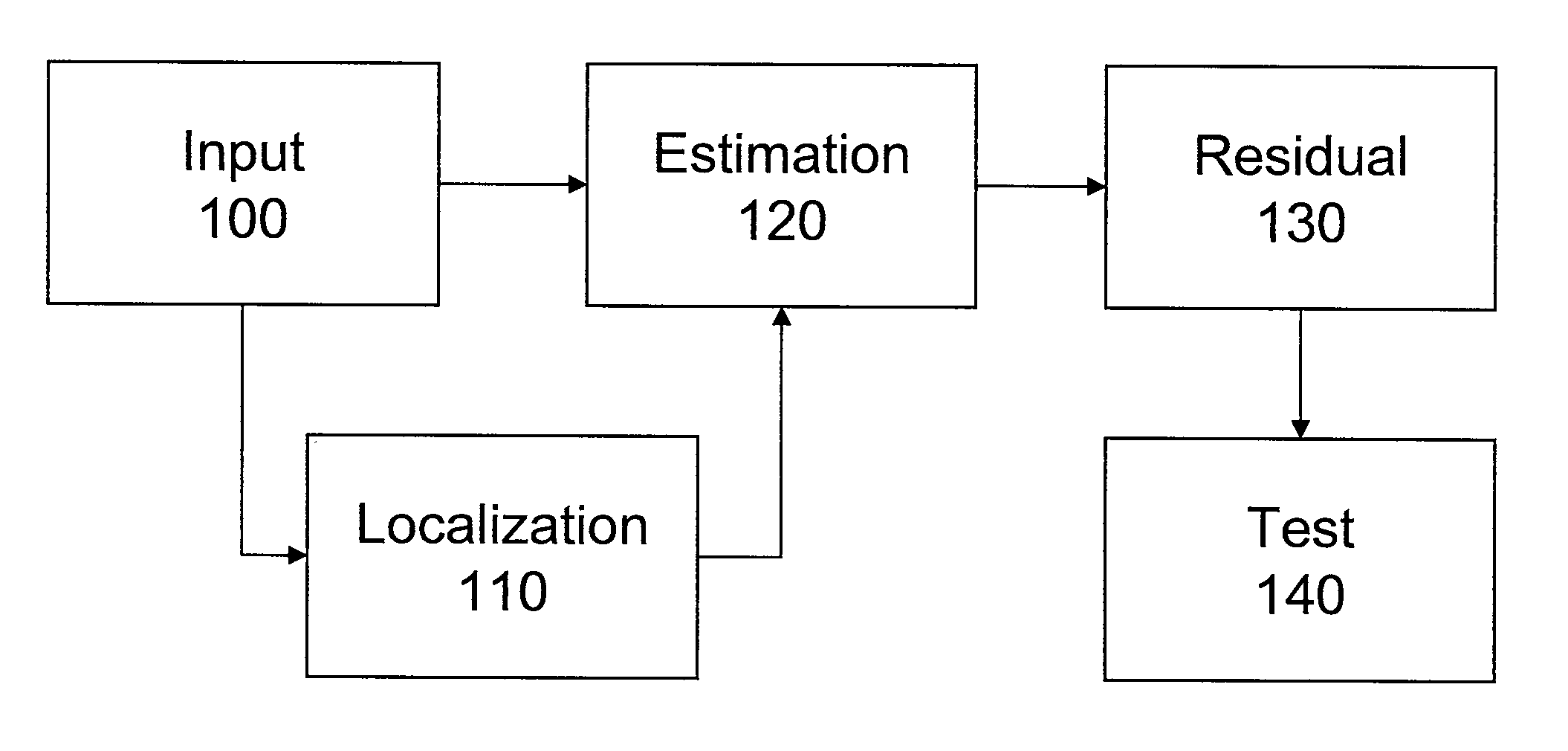

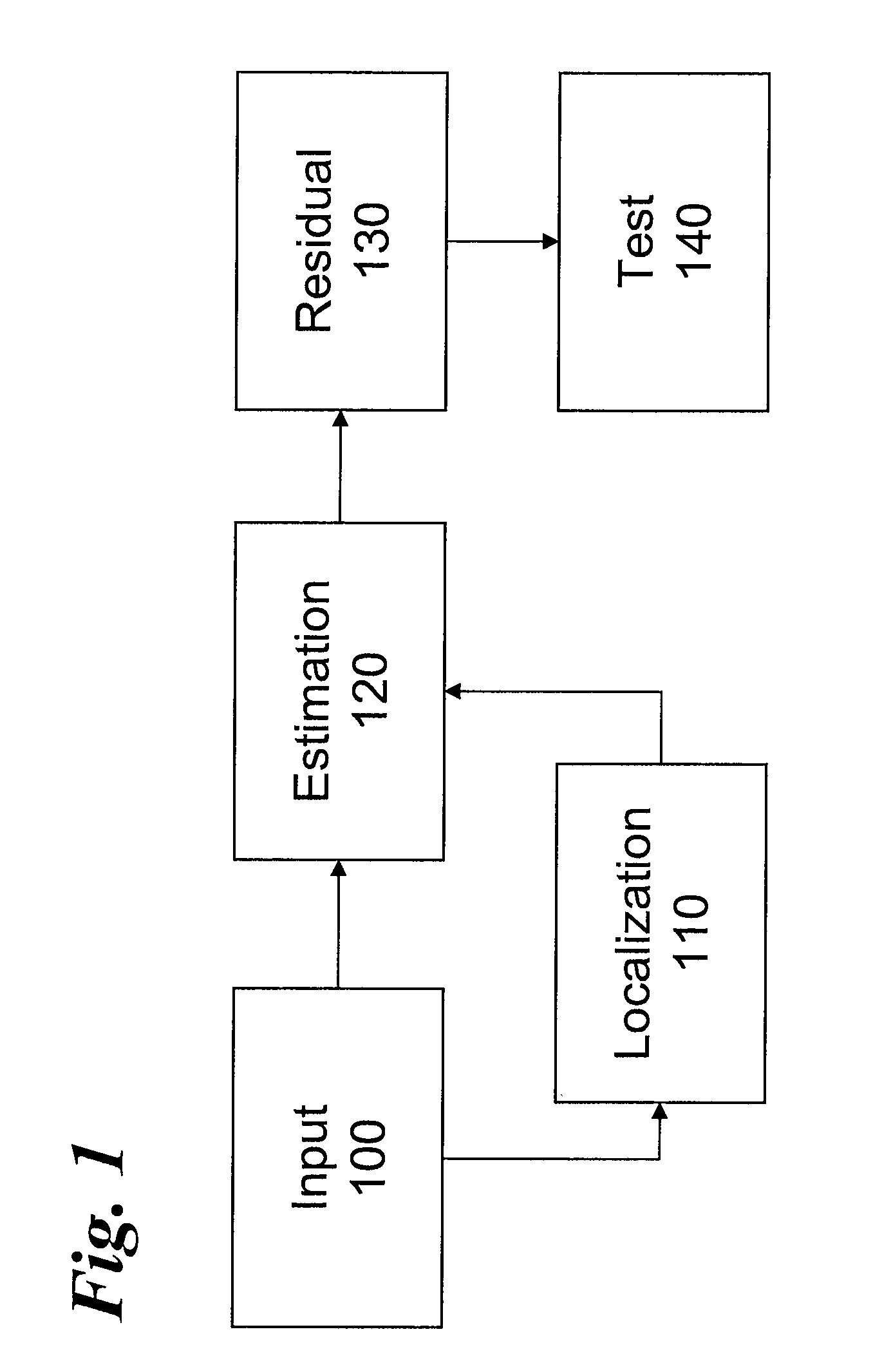

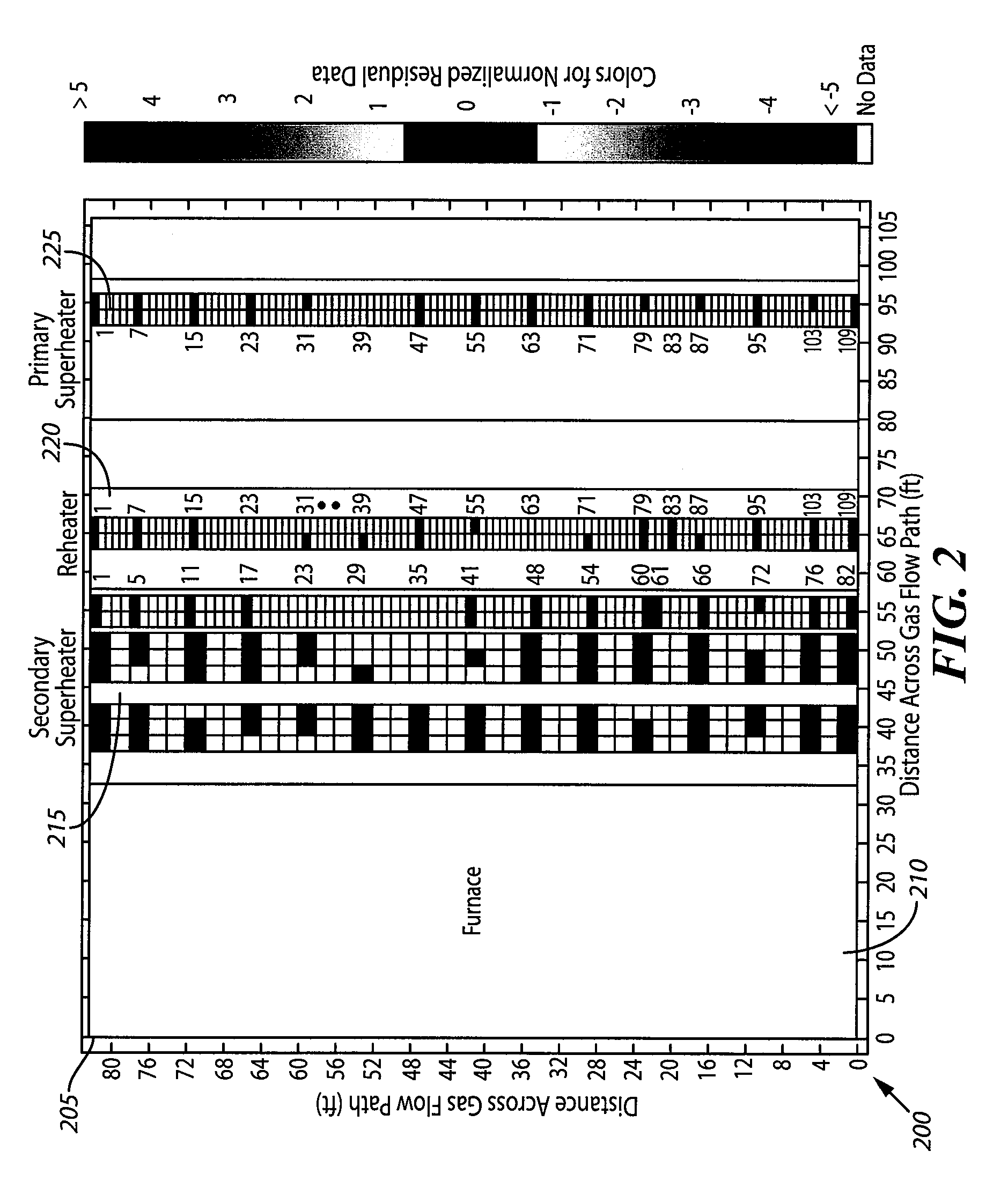

Kernel-based method for detecting boiler tube leaks

ActiveUS8275577B2Accurate accountingBoiler water tubesSafety devices for heat exchange apparatusMonitoring systemData source

Owner:SMARTSIGNAL CORP

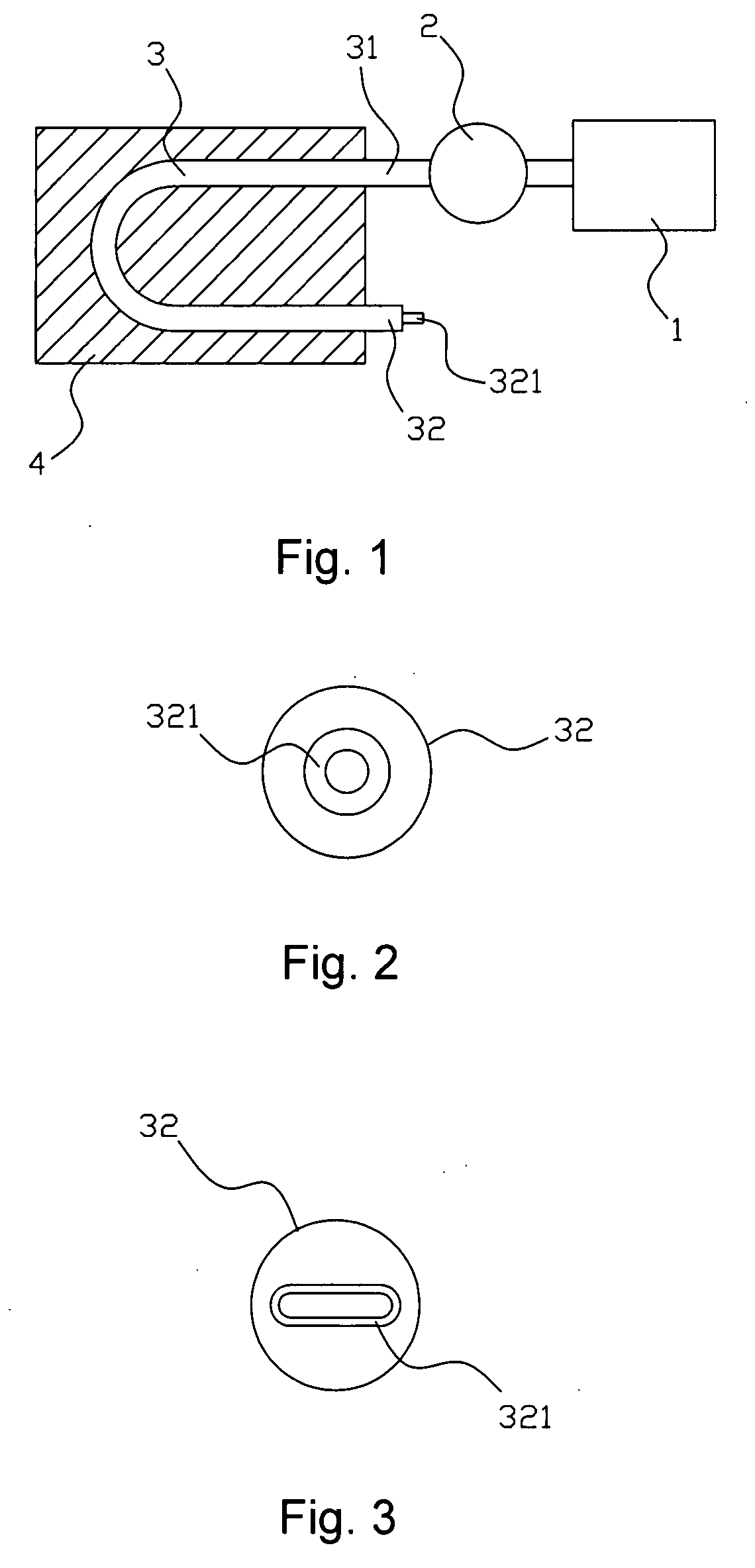

Method and device for forming steam for household appliance

InactiveUS20080115740A1Overcomes drawbackBoiler water tubesWater-tube boilersWater contactEngineering

Owner:YOU TUMING

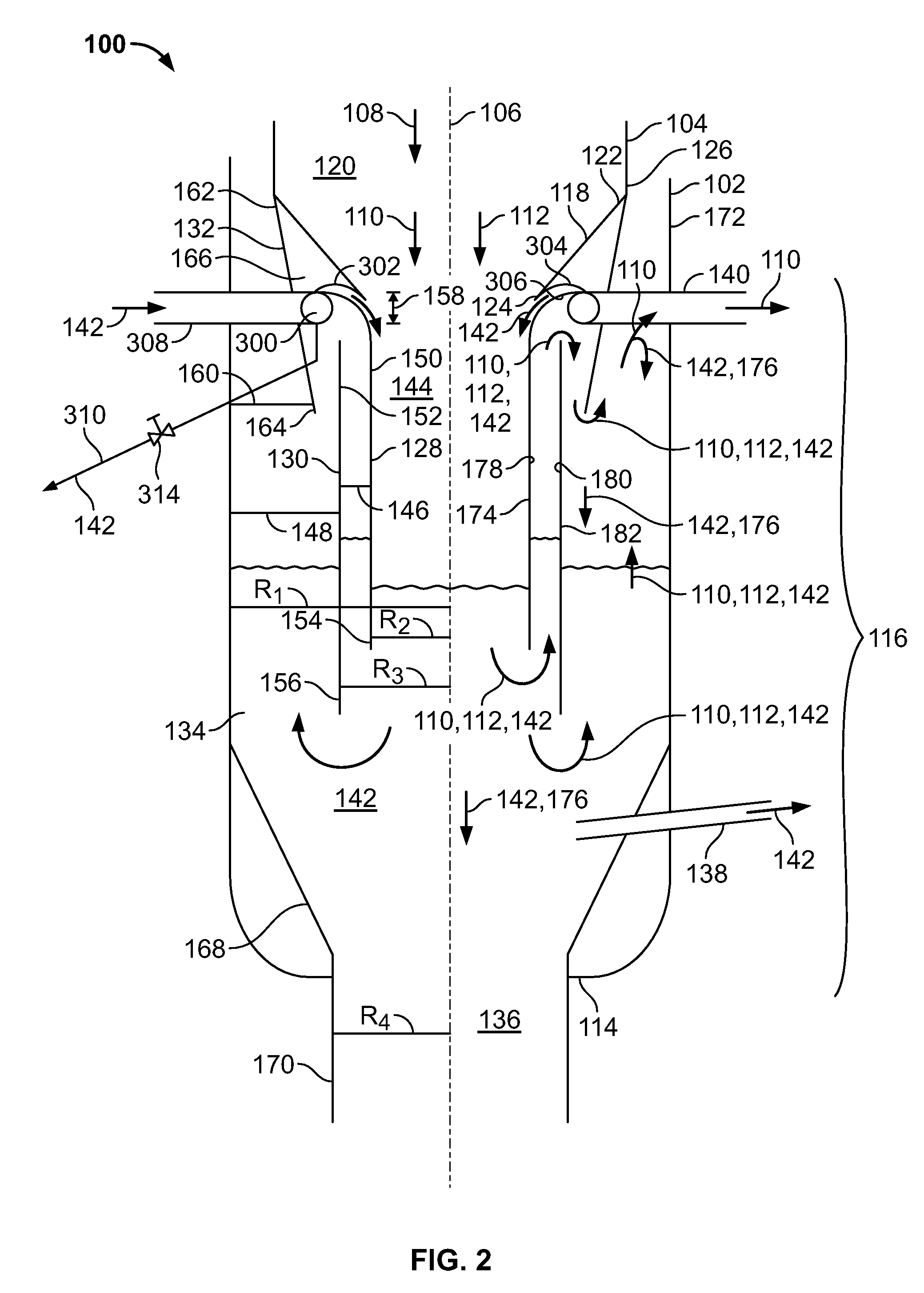

Methods and apparatus for cooling syngas within a gasifier system

A method for operating a syngas cooler is provided. The method includes channeling a flow of syngas into an annular cooling chamber having a longitudinal axis, injecting a cooling fluid into a manifold such that the cooling fluid is channeled substantially circumferentially about the annular cooling chamber, and discharging the cooling fluid from the manifold such that the cooling fluid contacts a surface of the cooling chamber at a predetermined angle relative to the axis of the cooling chamber.

Owner:AIR PROD & CHEM INC

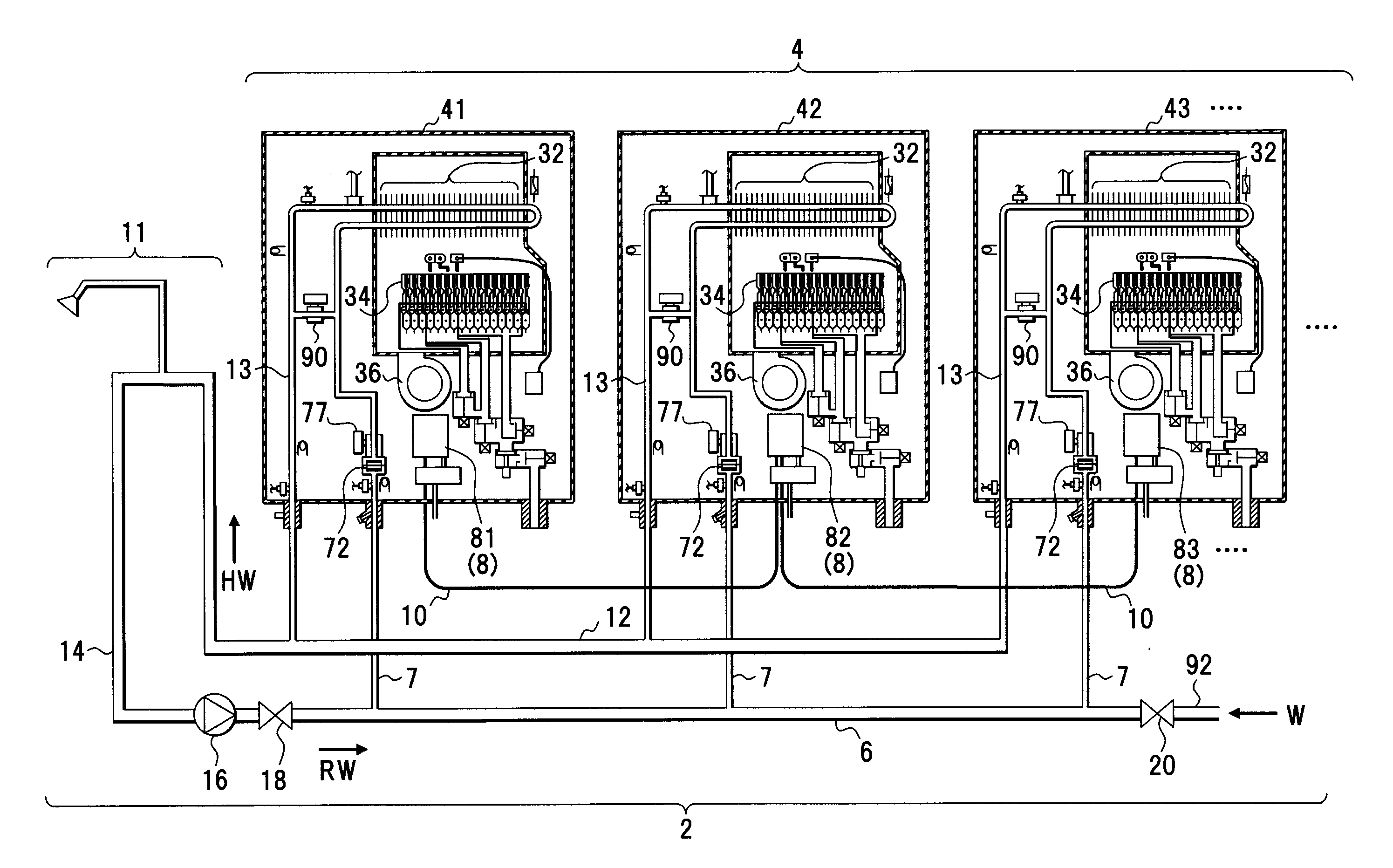

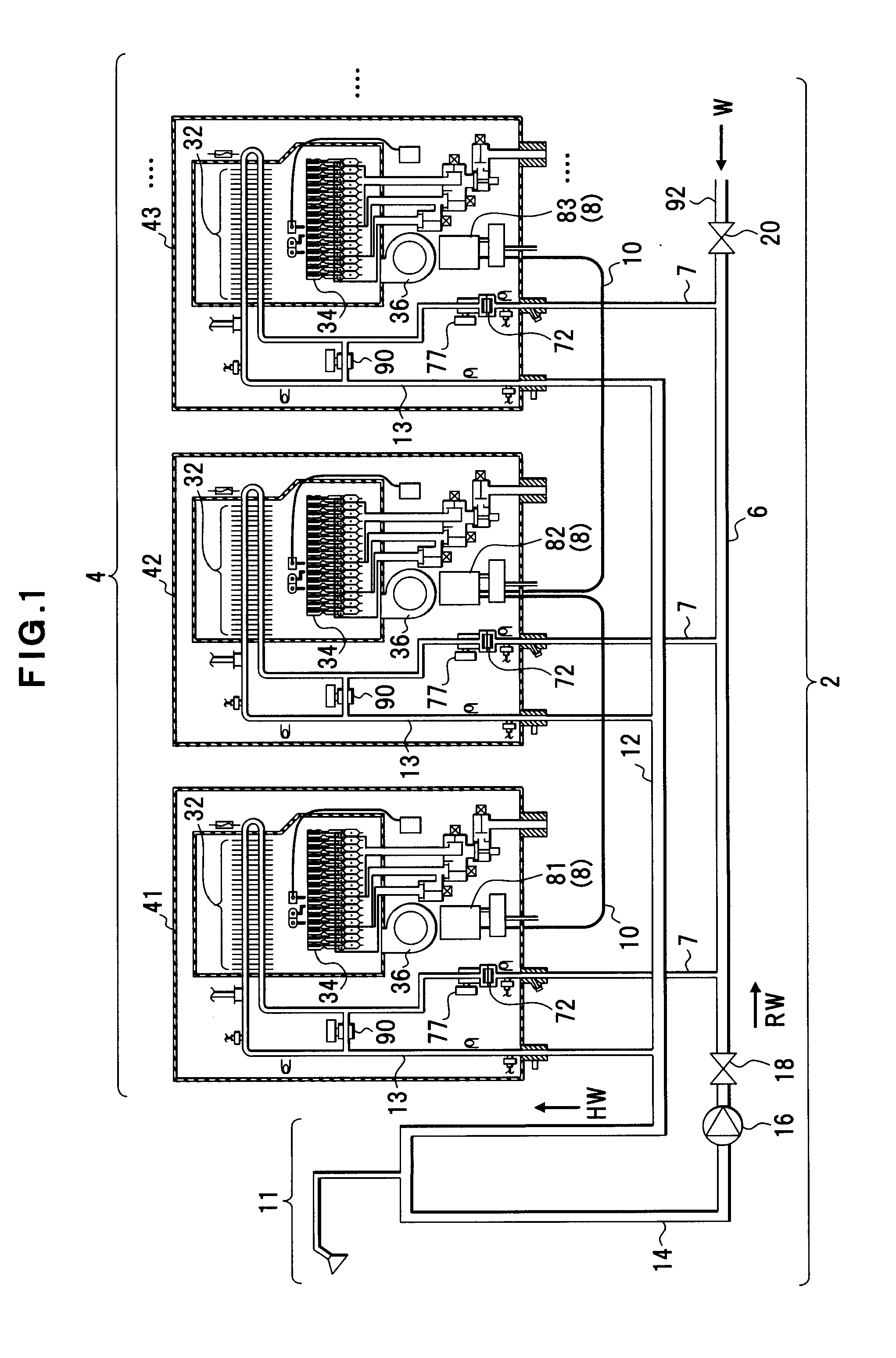

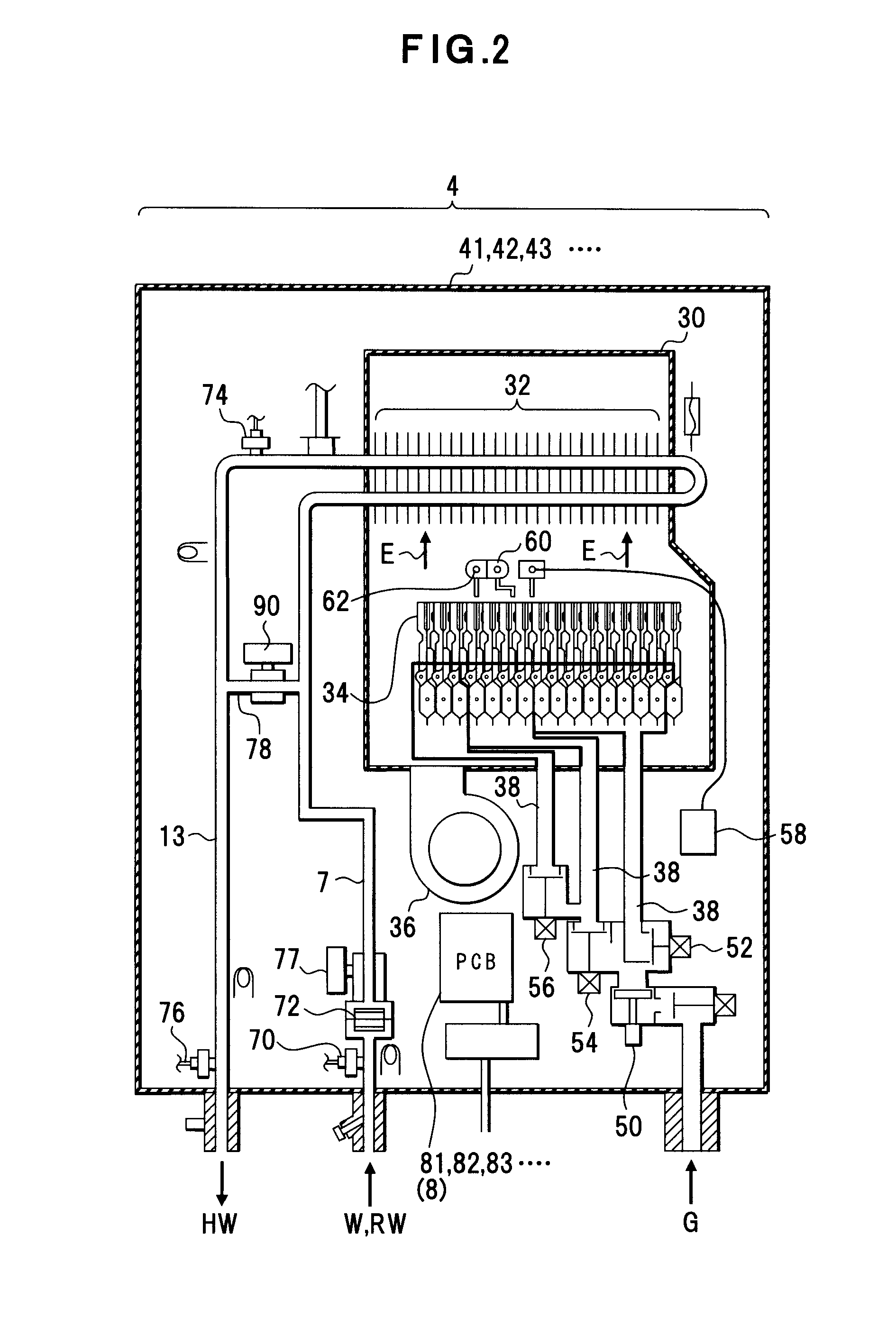

Hot water supply system, water heater and hot water supply control method

ActiveUS20120138149A1Improve convenienceBoiler water tubesSpeed sensing governorsEnvironmental engineeringThermal water

A hot water supply system including a water heater that includes a storage unit storing at least device information of another water heater, and performs hot water supply control by which the water heater cooperates with the other water heater, these water heaters being able to supply hot water according to a hot water supply request; one or a plurality of the other water heater that is connected to the water heater in parallel, and supplies hot water according to the hot water supply control by the water heater; communication connection means that communicably connects the water heater and the other water heater; water supply means that supplies water to the water heater and the other water heater; and hot water supply means that supplies hot water heated by the water heater and the other water heater to a hot water supply destination.

Owner:PURPOSE CO LTD

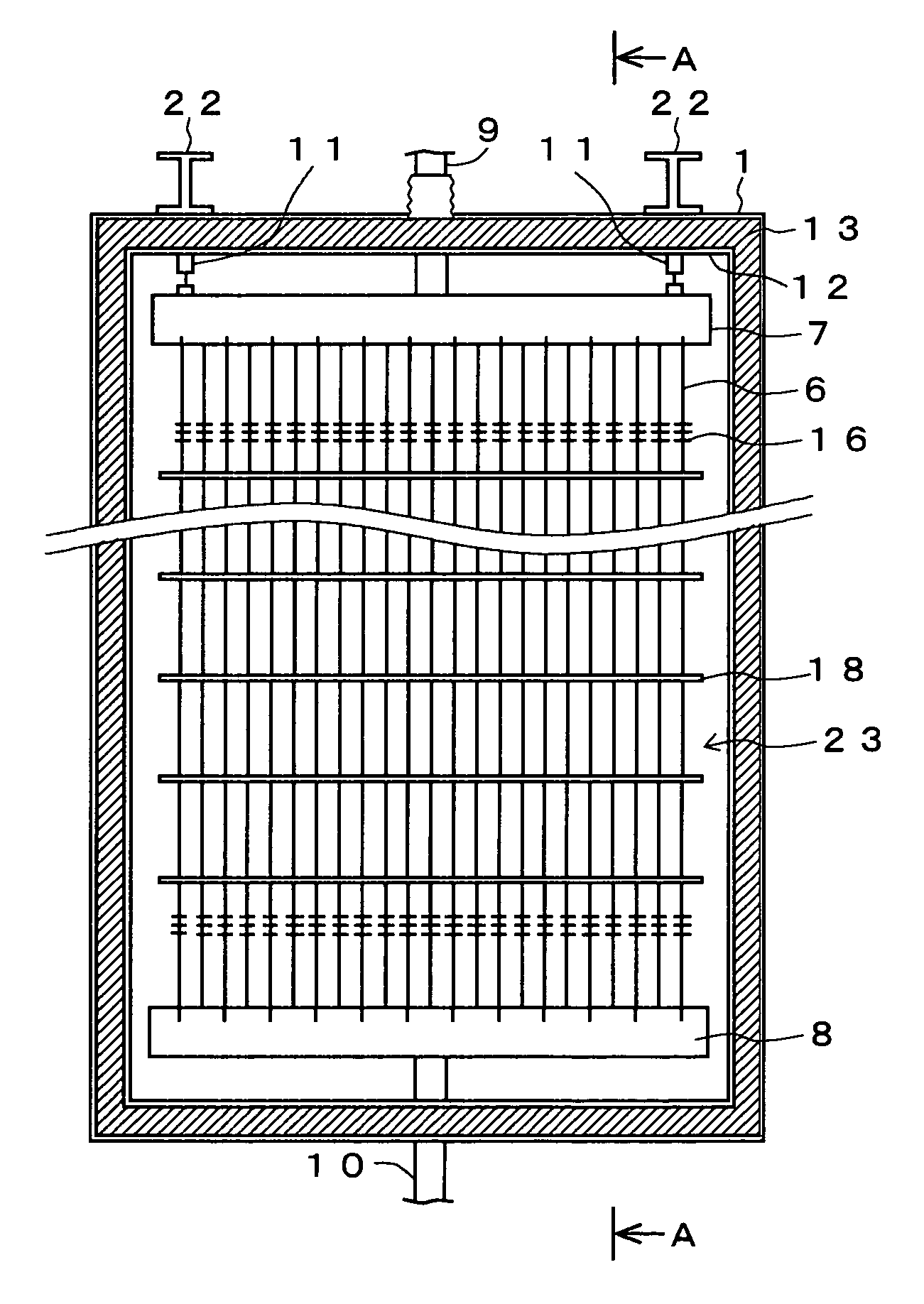

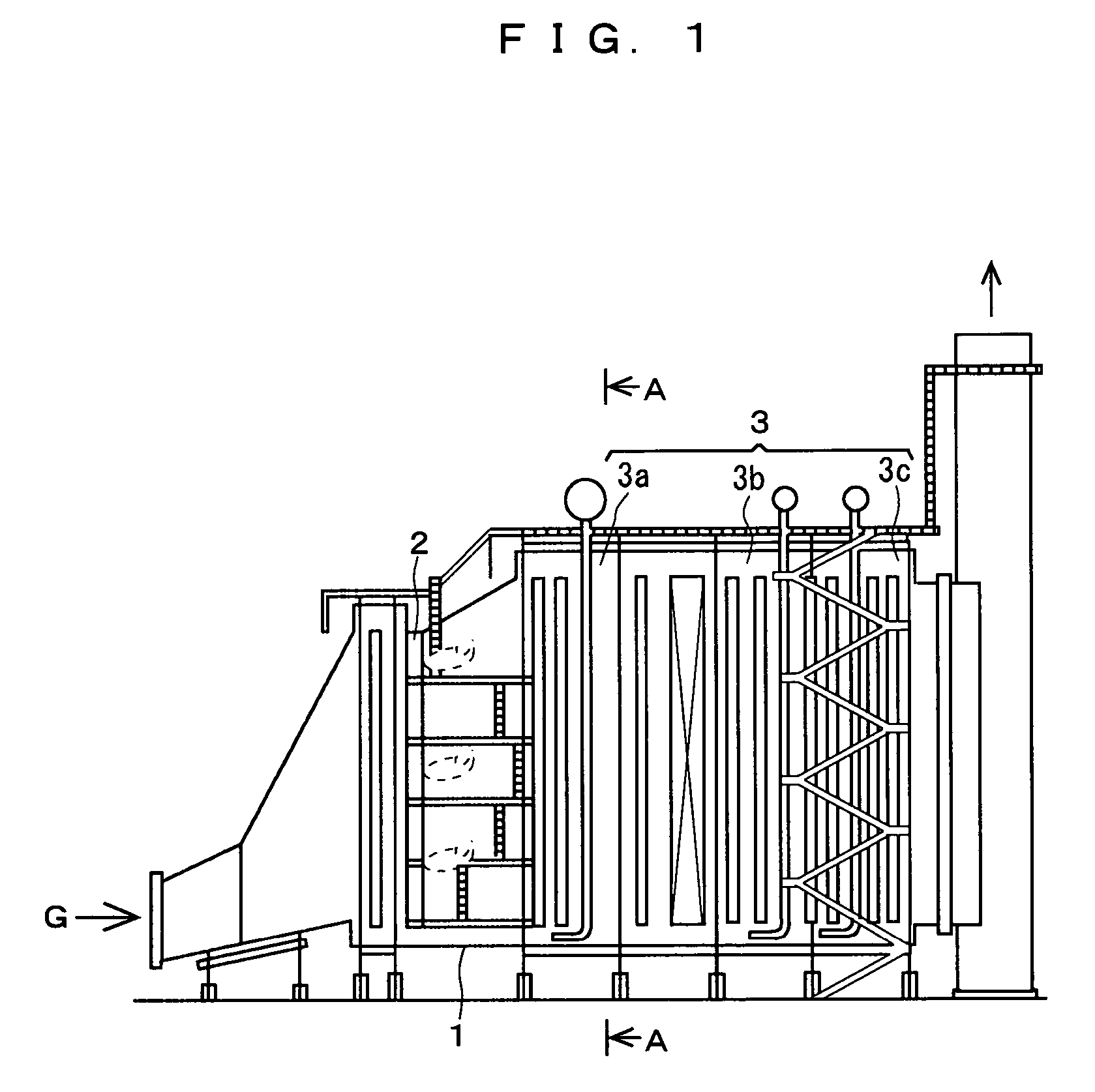

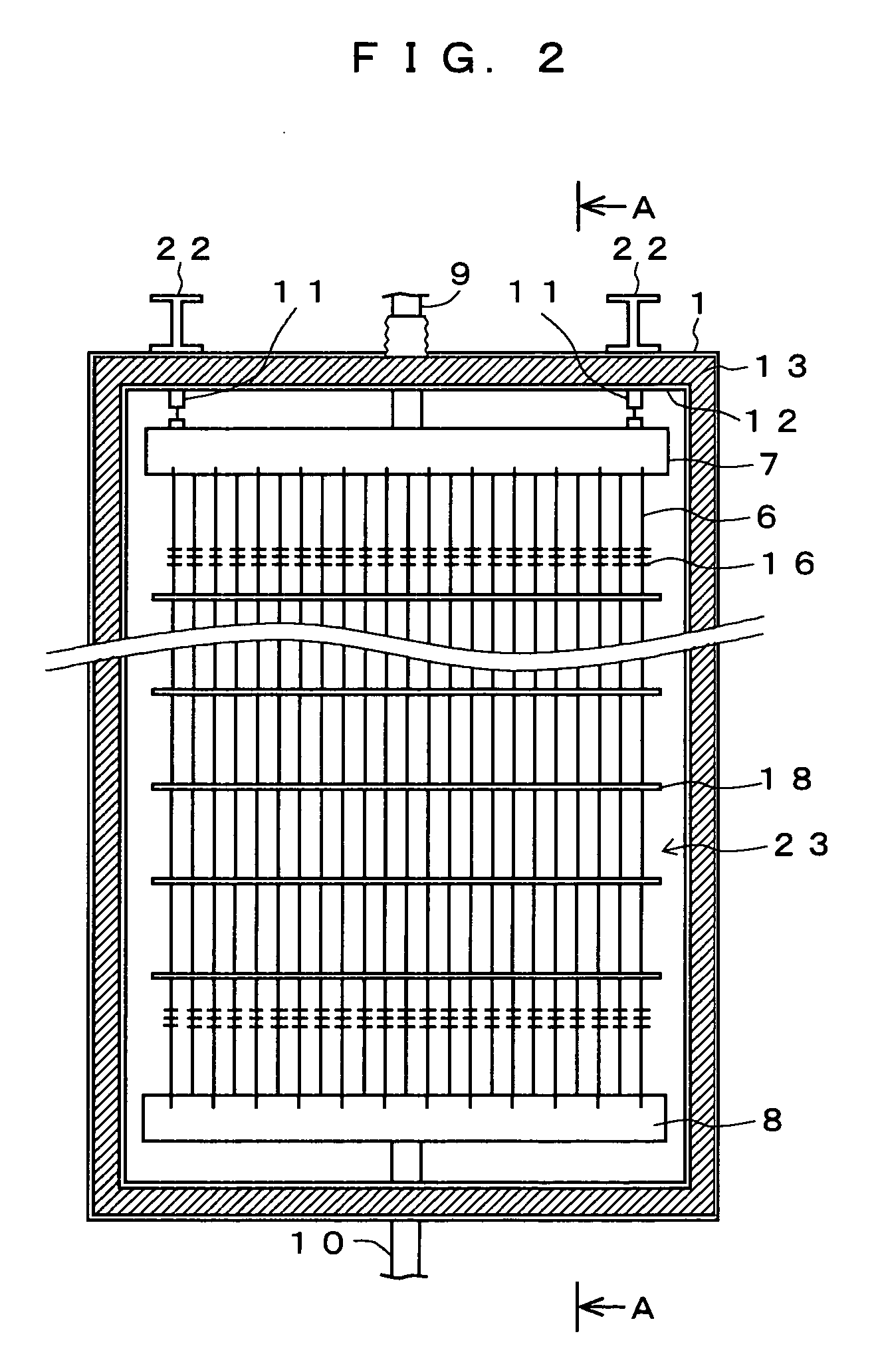

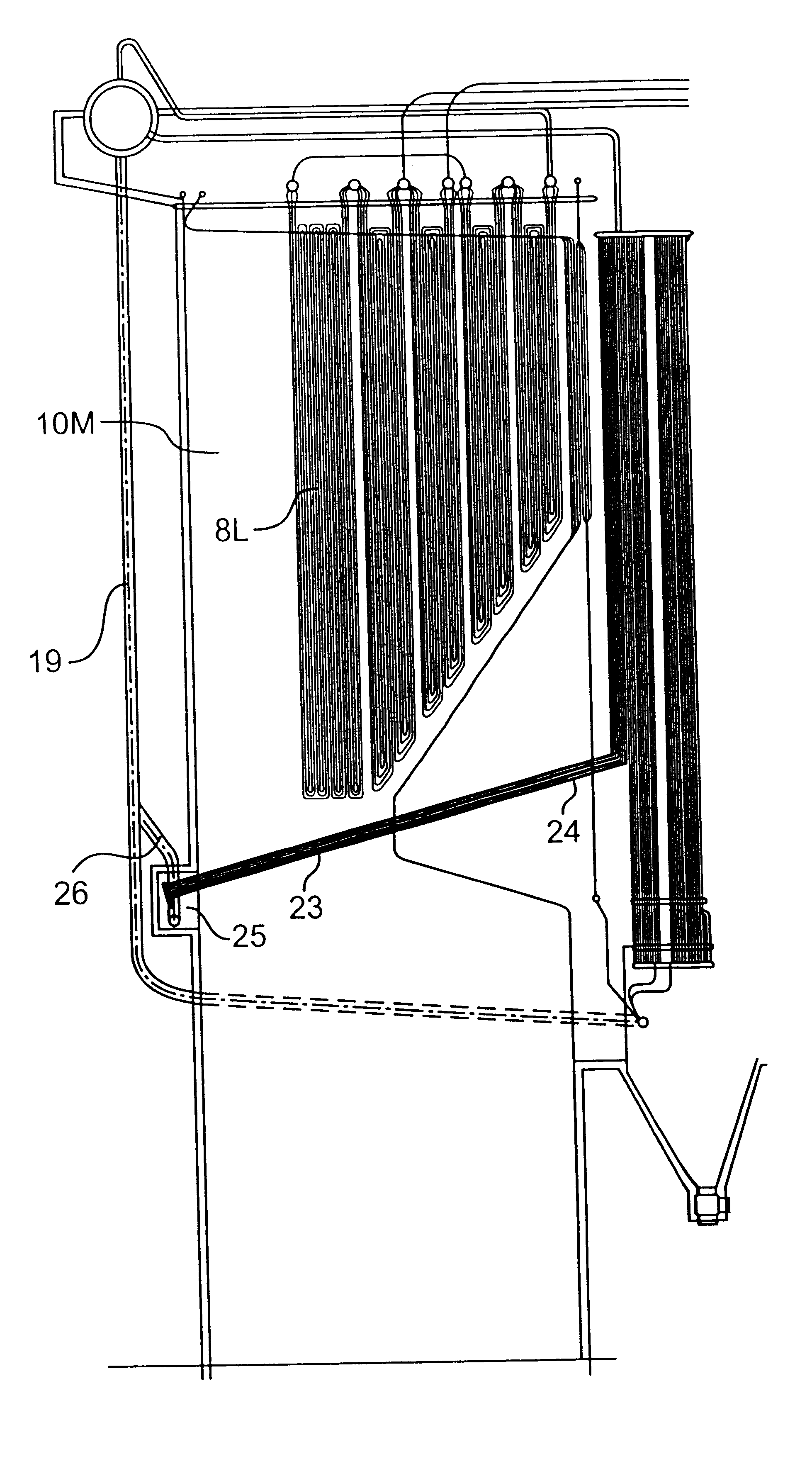

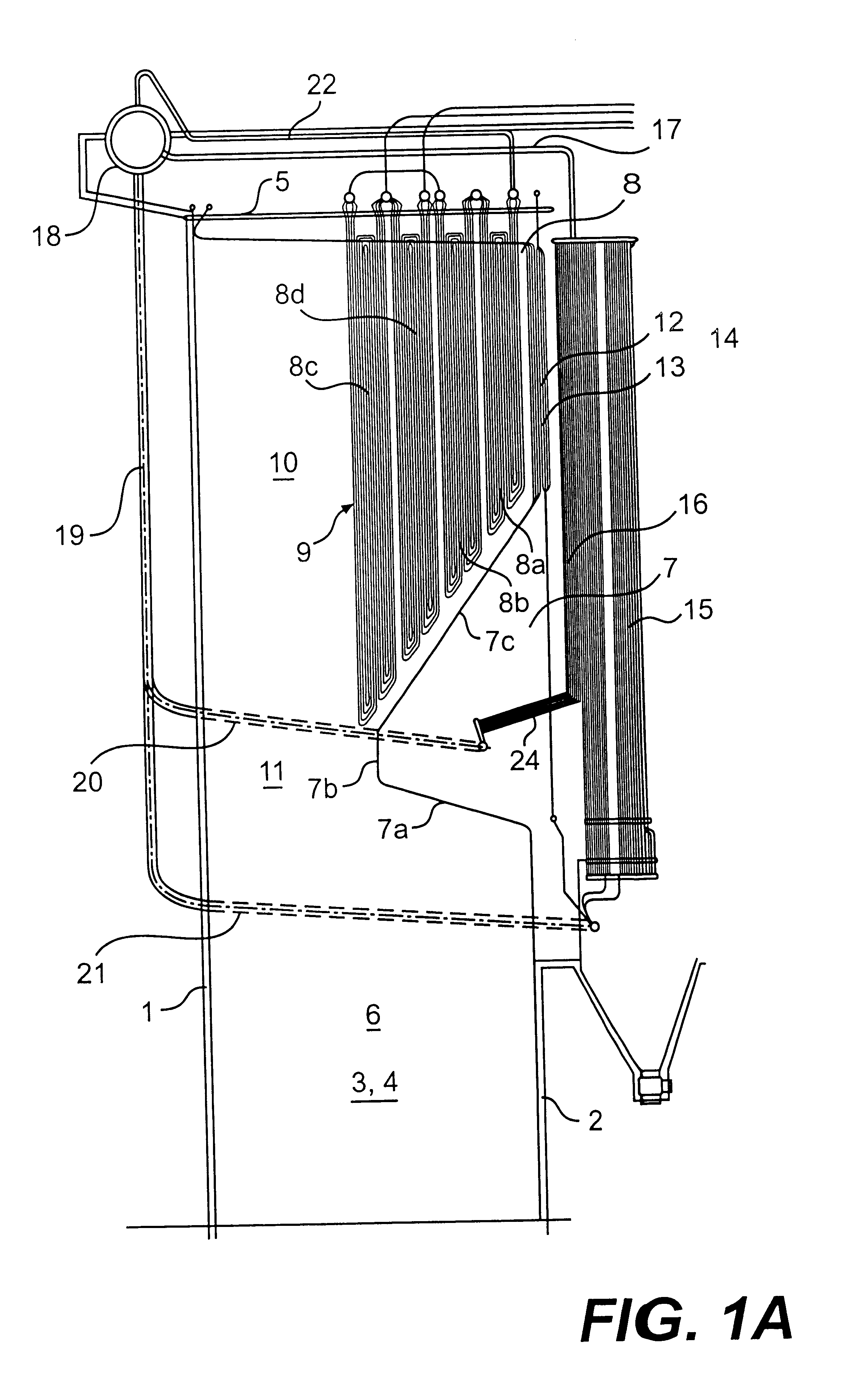

Heat exchanger tube panel module, and method of constructing exhaust heat recovery boiler using the same

InactiveUS20070119388A1Easy to installShort timeBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesEngineeringRecovery boiler

A necessary size and number of modules each obtained by housing a member including heat exchanger tube panels each comprising a heat exchanger tube bundle and headers for the heat exchanger tube bundle, an upper casing of an exhaust heat recovery boiler (HRSG), provided above the heat exchanger tube panels, heat insulators, and heat exchanger tube panel support beams provided on the upper surface of the upper casing into a transportation frame, are prepared according to design specifications of the HRSG, and side casings and a bottom casing except for the ceiling part casing are constructed in advance at a construction site of the HRSG, and the modules are suspended from above between adjacent support beams of the ceiling part to dispose the heat exchanger tube panel support beams of the modules at the set heights of the ceiling part support beams, and the support beams and the ceiling part support beams are connected and fixed via connecting steel plates, whereby the respective modules are transported to the HRSG construction site and can be easily constructed.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Flow stabilizer steam boiler

ActiveCN107143838AReduce vibrationImprove heat transfer performanceBoiler water tubesSteam generation using pressureNoise levelHeat transmission

The invention provides a steam boiler. The steam boiler comprises an upper boiler barrel, a lower boiler barrel, rising pipes and falling pipes, wherein the rising pipes and the falling pipes are connected between the upper boiler barrel and the lower boiler barrel. The rising pipes are internally provided with flow stabilizers, and the multiple flow stabilizers are arranged in the same rising pipe; and the lengths of the flow stabilizers are constantly increased in the fluid flowing direction of the rising pipes. According to the flow stabilizer steam boiler of a novel structure, through length changing of the flow stabilizers, when steam-liquid two phase flowing exists in the rising pipes, heat transmission is reinforced; and meanwhile, vibration of the rising pipes is weakened, and the noise level is reduced.

Owner:咸阳新兴分布式能源有限公司

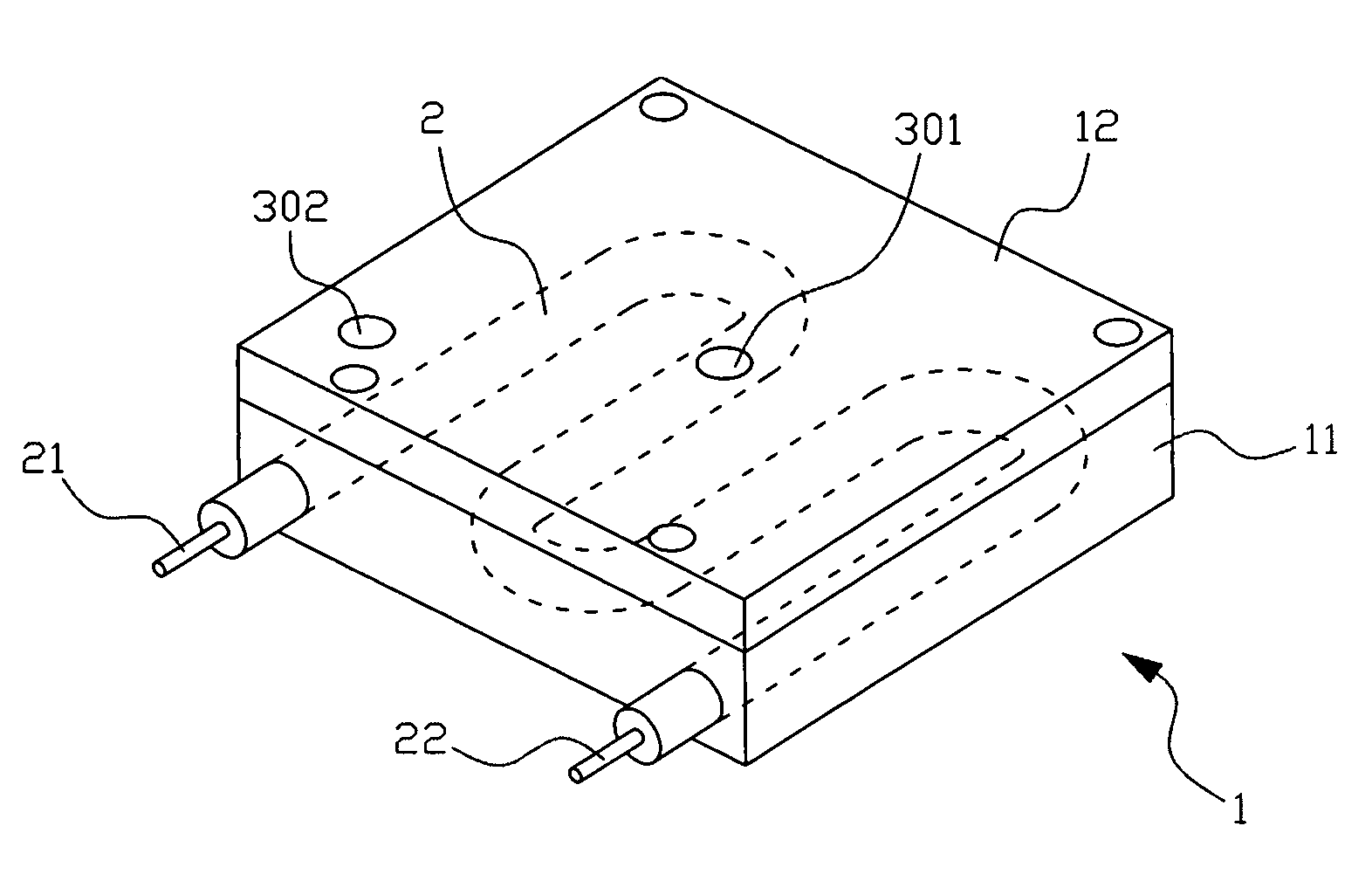

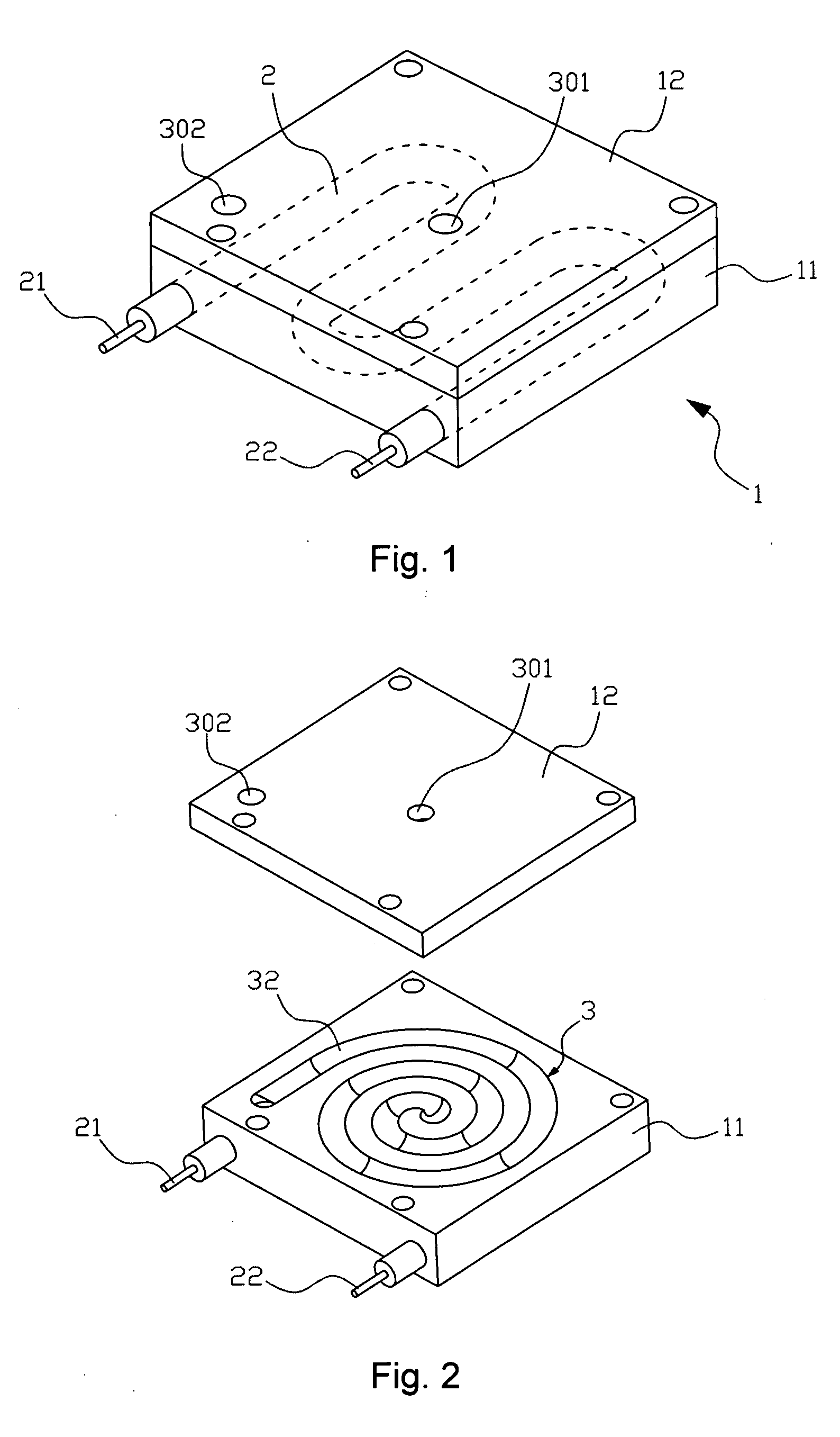

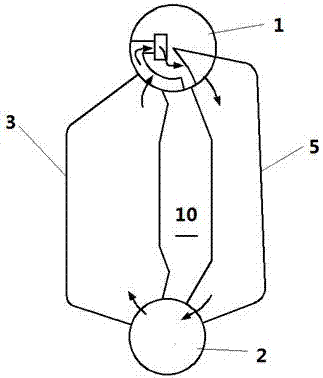

Instantaneous steam boiler

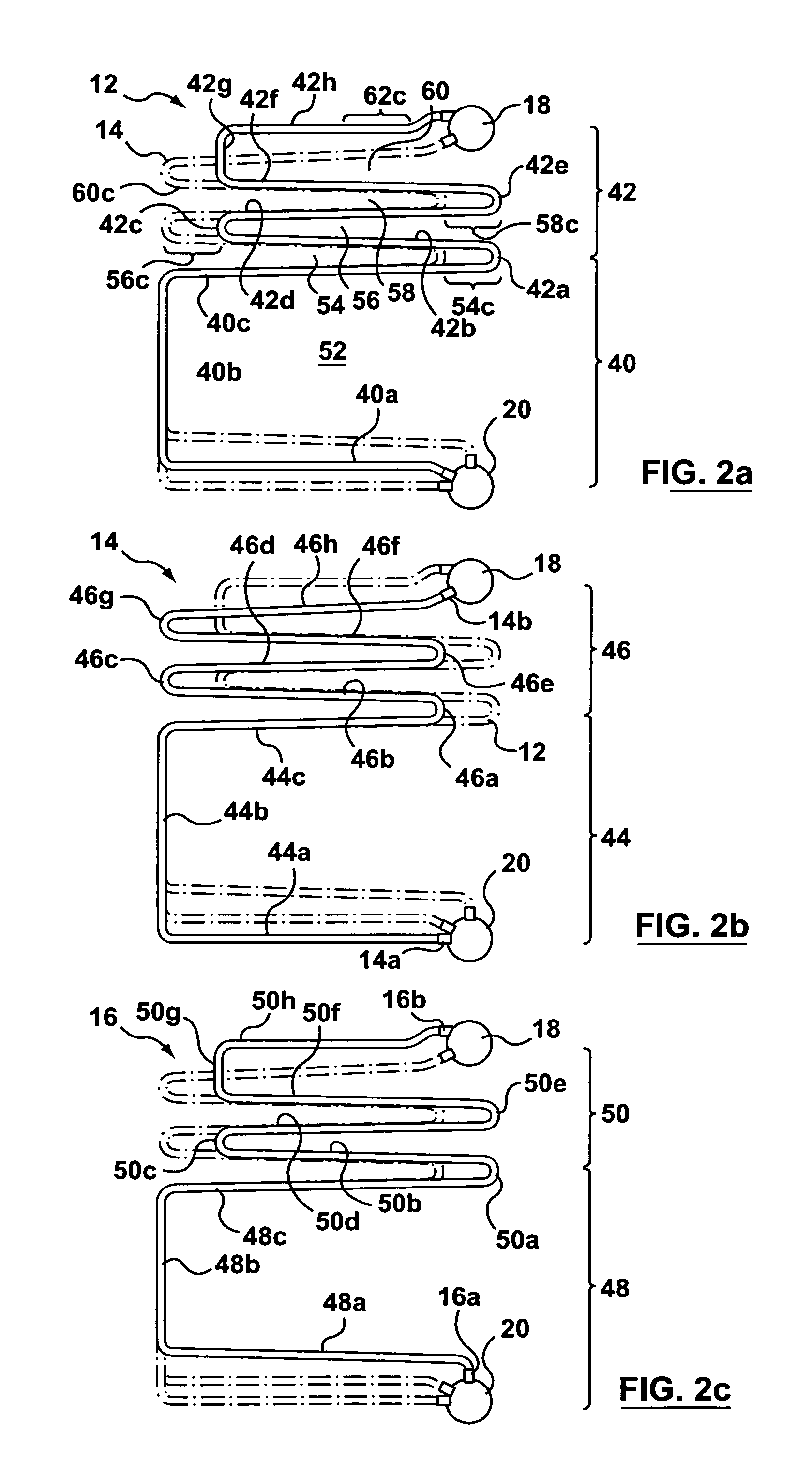

InactiveUS7813628B2Shorten the lengthSuppress formationBoiler water tubesWater-tube boilersVaporizationEngineering

The present invention relates to an instantaneous steam boiler generating steam in a steam cleaner, a steam-vacuum cleaner, a steam iron, etc. The instantaneous steam boiler includes a U-shaped heater and a separate flow tube arranged in parallel and contact with said heater. The flow tube may be arranged orthogonally or at a 180 degree opposite direction and may include a circular or square-shaped end with rounded edges, thereby increasing the heating / vaporization efficiency of the device.

Owner:HAAN

Steam generator and method for generating steam

ActiveUS20130161009A1Improve cooling effectReduce problem sizeBoiler water tubesBoiler cleaning apparatusHeat fluxEvaporation

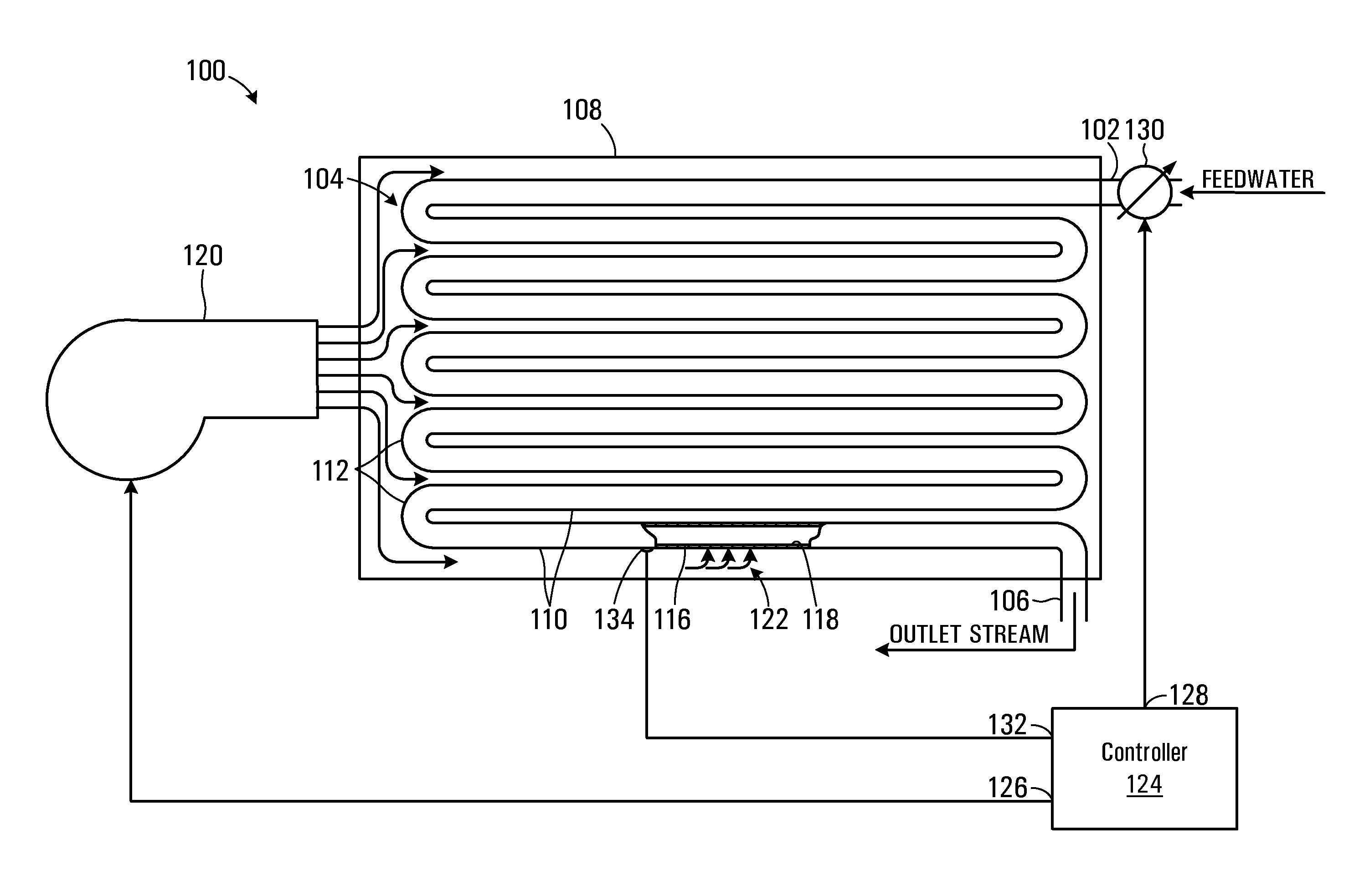

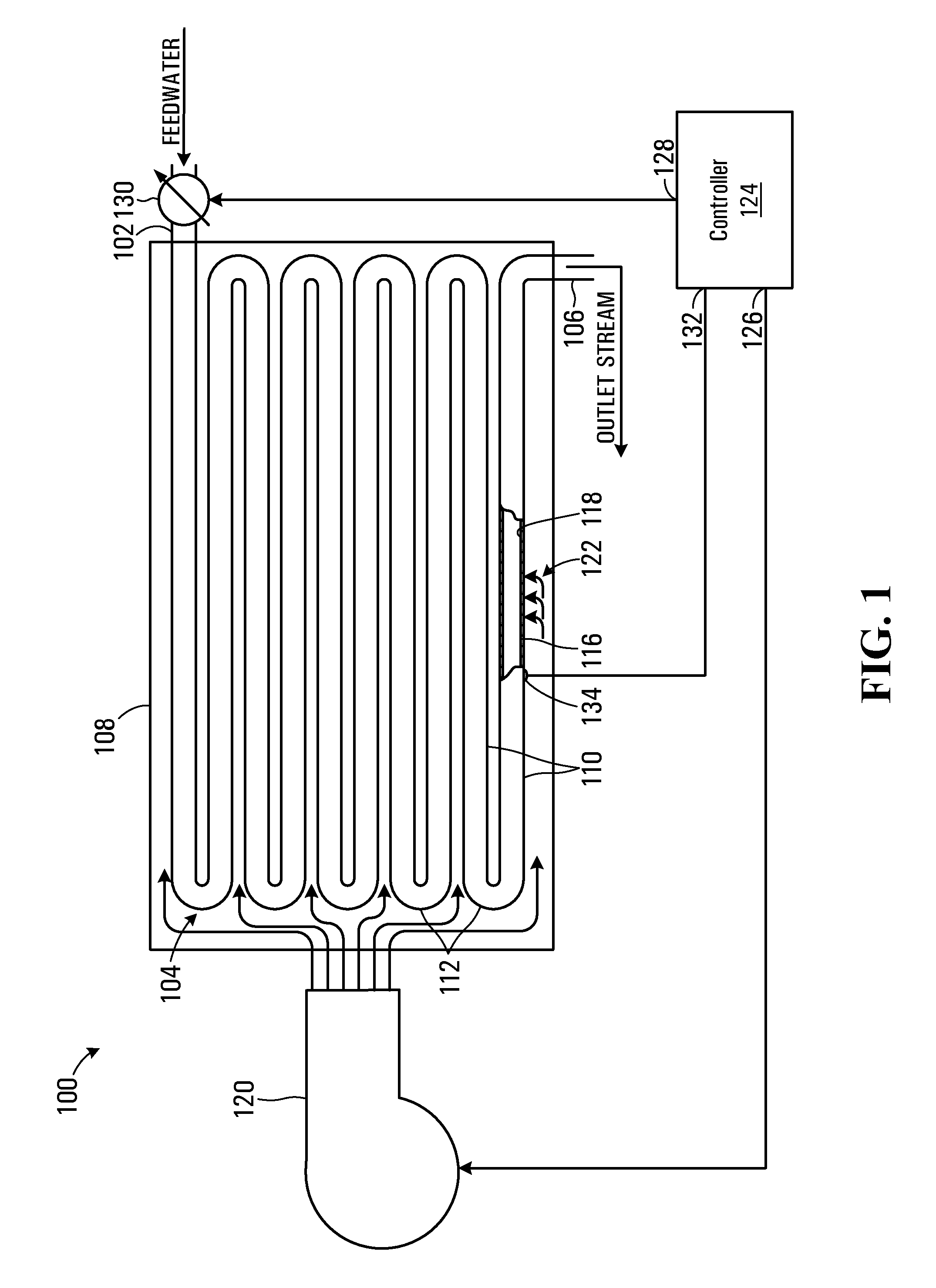

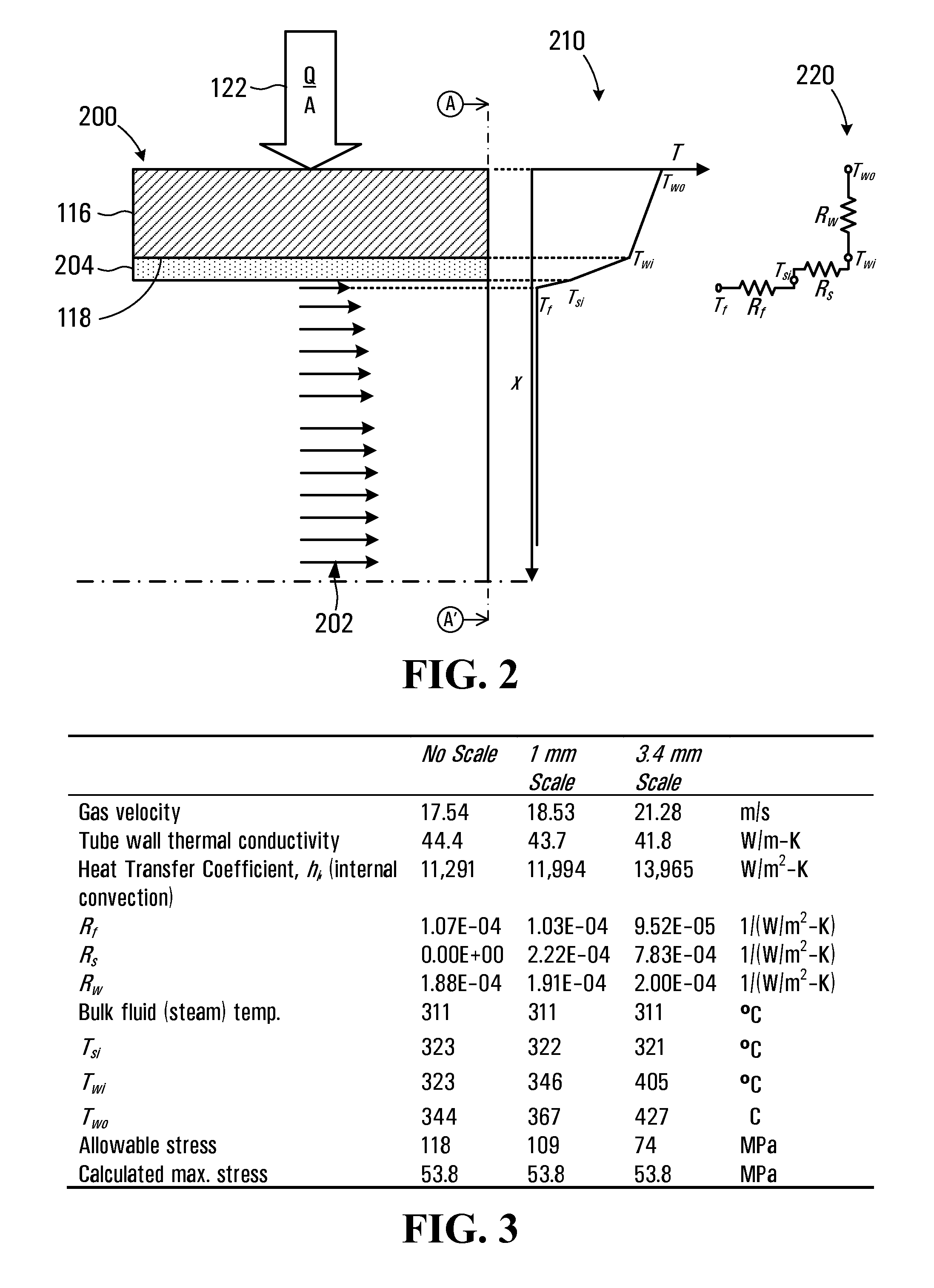

A method for generating steam from a feedwater inlet stream including impurities is disclosed. The method involves receiving the feedwater inlet stream at an inlet of a steam generator and causing the feedwater stream to flow through a tubing circuit to an outlet of the tubing circuit, the tubing circuit having a substantially un-rifled bore defined by a metal wall. The method also involves delivering a heat flux to the feedwater stream through the metal wall of the tubing circuit to generate steam by causing evaporation of feedwater within the tubing circuit, and controlling at least one of a flow rate of the feedwater stream and the heat flux to cause generation of an outlet stream at the outlet includes a steam portion and liquid phase portion, the steam portion being greater than about 80% of the outlet stream by mass. The steam portion provides sufficient cooling of the metal wall to maintain a wall temperature at less than a threshold temperature.

Owner:FCCL PARTNERSHIP

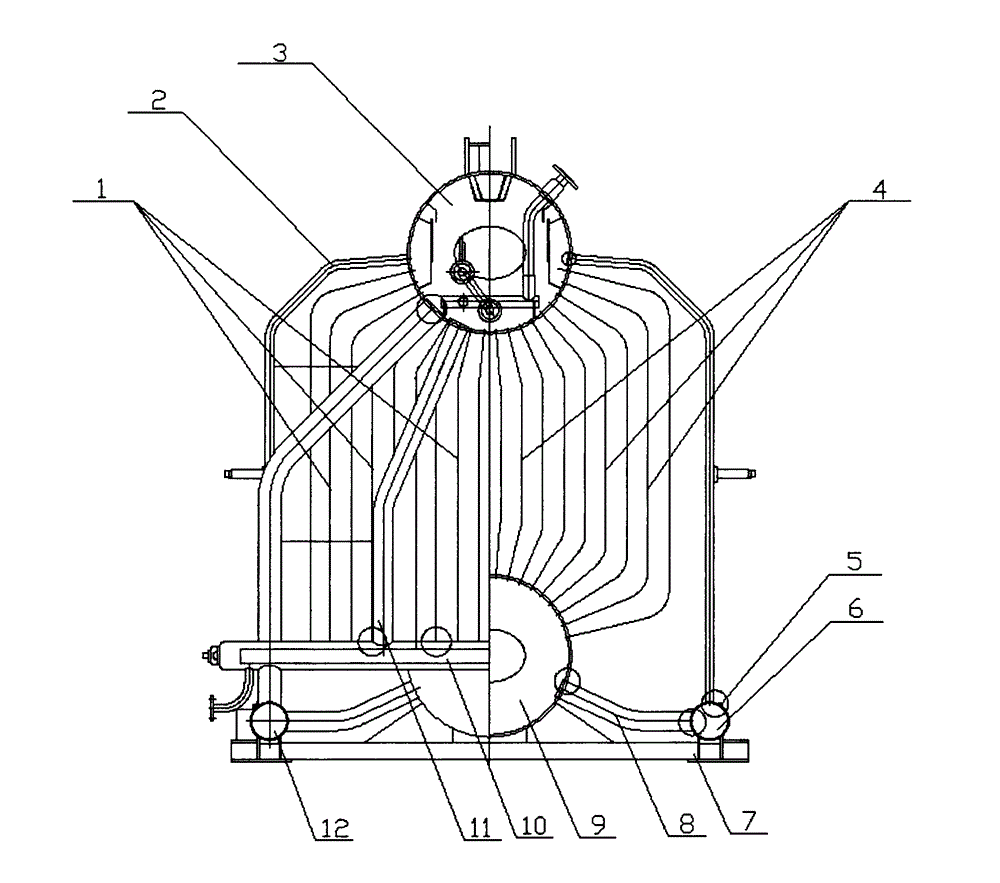

Biomass boiler

InactiveCN102913889ALess heat storageReduce lossesBoiler water tubesWater-tube boilersRefractoryPulp and paper industry

The invention relates to a biomass boiler. The biomass boiler comprises a base plate, an upper boiler, two lower boilers and a controller, wherein the two lower boilers are arranged end to end and connected with each other through a pipeline. The novel structure of the biomass boiler causes less heat accumulation of a furnace wall, so that construction for a thick furnace wall can be avoided when the biomass boiler is arranged, a refractory material can be saved or used fewer, the cost can be reduced, the arrangement cost can be reduced, and the arrangement complexity can be reduced. Therefore, the biomass boiler is simple in structure and convenient in use, can reduce the arrangement and complexity of a water-tube boiler can be effectively reduced, the boiler heat is prevented from losing, and the heat efficiency of the water-tube boiler can be improved.

Owner:青岛华泰锅炉热电设备有限公司

Method for upgrading a boiler

InactiveUS6178924B1Increase capacityImprove efficiencyFluidized bed combustionPulp liquors combustionEngineeringSuperheater

A method for upgrading a boiler is provided. When operating at a first capacity, the boiler is used such that an open space is kept in radiation communication with a firebox. The open space is also kept as empty. A first set of water circulation tubes are connected to the boiler cylinder in connection with the ascending tubes. When the boiler is operated at a second capacity, which is higher than the first capacity, at least one additional part is arranged in the open space to expand the basic super heater arrangement. Additionally, or alternatively at the second capacity, a second set of water circulation tubes may be connected to the boiler cylinder in connection with the ascending tubes. The second set of water circulation tube has a capacity exceeding that of the first set of water circulation tubes.

Owner:KVAERNER POWER OY

Method and device for forming steam

InactiveUS20080047172A1Simple structureLow costBoiler water tubesMixing methodsThermodynamicsProcess engineering

A method and device for forming steam with high pressure and a cleaner or iron comprising the device are provided.

Owner:YOU TUMING

Steam boiler

InactiveCN106949449ASpeed up the flowHas the effect of reducing vibration and noiseBoiler water tubesWater-tube boilersNoise levelEngineering

The invention provides a steam boiler. The steam boiler comprises an upper boiler barrel, a lower boiler barrel, and an ascending pipe and a descending pipe which are connected between the upper boiler barrel and the lower boiler barrel, wherein a current stabilizer is arranged in the ascending pipe, and comprises a core and a shell, the core is arranged in the shell, the shell is fixedly connected with the inner wall of the ascending pipe, the core is an integrated structural member extending in the length direction of the shell, and a plurality of through holes are formed in the structural member. According to the steam boiler with a current stabilizer, adopting a novel structure, provided by the invention, when steam-liquid two-phase flow exists in the ascending pipe, the heat transfer is strengthened, besides, the vibration of the ascending pipe is weakened, and the noise level is reduced.

Owner:ZHONGBEI UNIV

Method and device for forming steam for household appliance

Owner:YOU TUMING

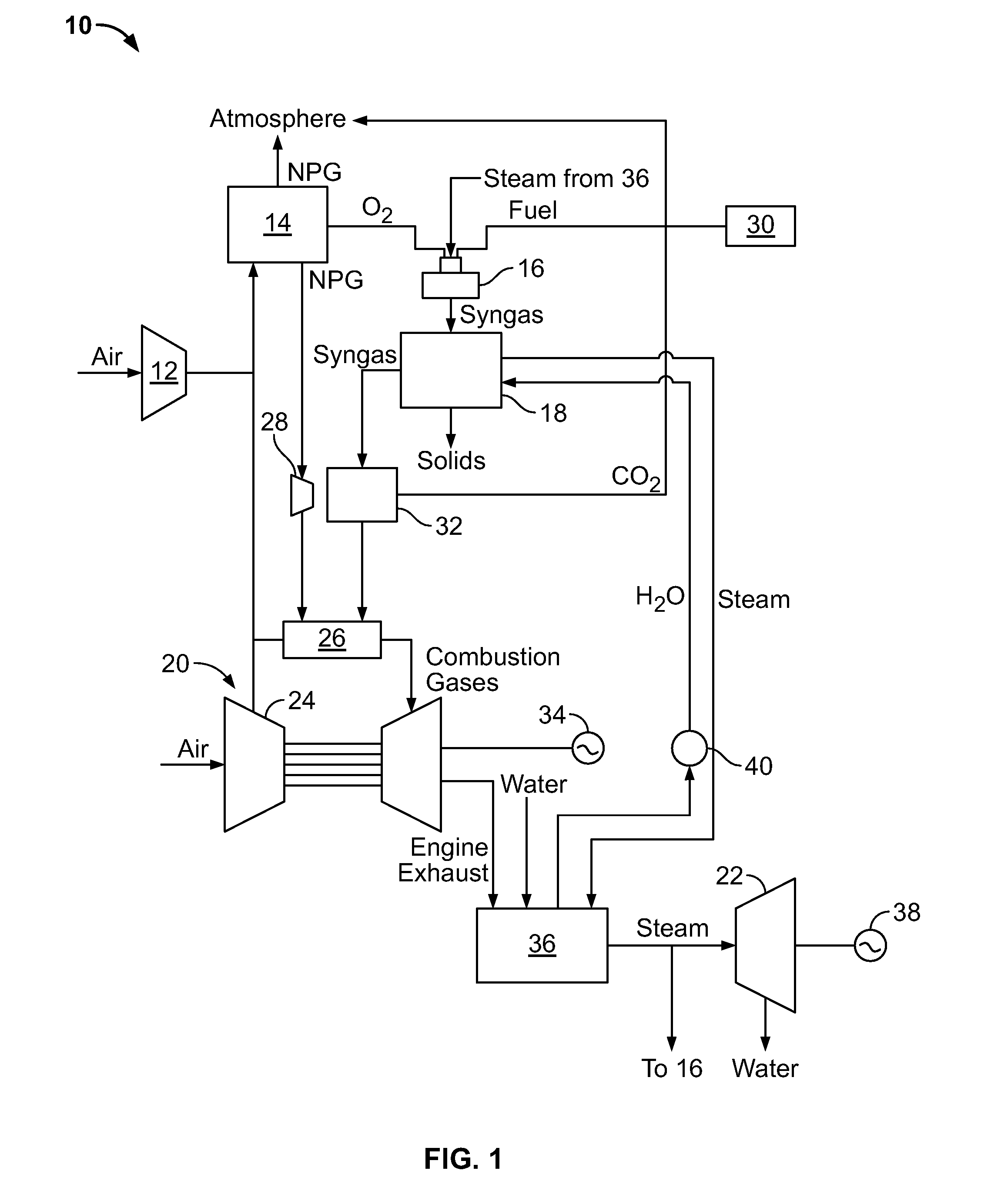

Hybrid Combustor for Fuel Processing Applications

InactiveUS20080141675A1Improved fuel processing efficiencyStart fastTurbine/propulsion fuel supply systemsBoiler water tubesProcess engineeringStart up

The present invention discloses a hybrid combustor, such as an anode tailgas oxidizer (ATO), for fuel processing applications which combines both flame and catalytic type burners. The hybrid combustor of the present invention combines the advantages of both flame and catalytic type burners. The flame burner component of the hybrid combustor is used during start-up for the preheating of the catalytic burner component. As soon as the catalytic burner bed is preheated or lit off, the flame burner will be shut off. Optionally, the hybrid combustor may also include an integrated heat recovery unit located downstream of the catalytic burner for steam generation and for the preheating of the feed for a reformer, such as an autothermal reformer.

Owner:TEXACO INC

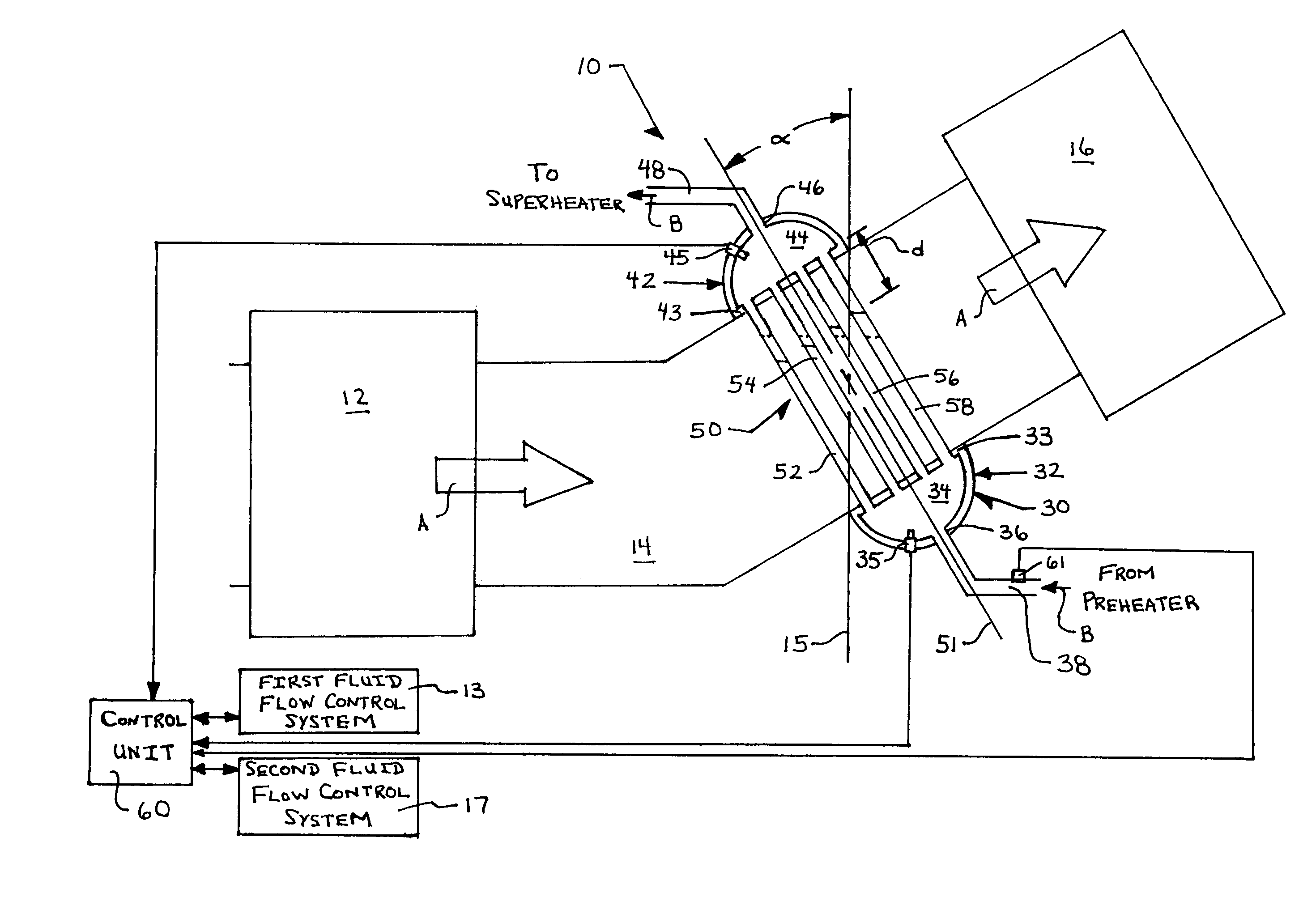

Boiler system and method of controlling a boiler system

InactiveUS7017529B1Provide goodIncreasing sensible heat contentBoiler water tubesWater-tube boilersEngineeringThermocouple

A boiler system including a first manifold, a second manifold provided at an elevation above the first manifold, and a heat exchanger conduit fluidly connecting the first and second manifolds. The conduit is provided within a first fluid flow, and the heat exchanger conduit receives a second fluid. A thermocouple is provided within the second manifold to measure a temperature of the second fluid within the second manifold. A control unit is provided to maintain a level of liquid phase of the second fluid such that liquid phase of the second fluid does not enter the second manifold based on the temperature measured by the thermocouple. The boiler system can be provided with first and second conduits, where the second conduit is provided within the first fluid flow downstream of the first conduit, and where the first and second conduits are inclined with respect to a vertical axis.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Tube assembly for a boiler

InactiveUS7137360B1Improve boiler efficiencyGood coefficientBoiler water tubesEnergy industryFlue gasEngineering

A boiler is described comprising a housing with a flue gas inlet for receiving a hot gas flame and an outlet for venting a hot gas produced by the hot gas flame, and a tube assembly mounted within the housing. The tube assembly comprises a lower manifold for receiving a liquid, an upper manifold for receiving a heated version of the liquid; and, a plurality of tubes disposed between the lower and upper manifolds. Each tube is shaped to provide a hot gas pathway that travels in a parallel fashion along at least a lower portion of the longitudinal extent of each tube in the tube assembly to the outlet, whereby the liquid introduced into the lower manifold travels in the plurality of tubes and receives heat from the hot gas along the extent of the hot gas pathway.

Owner:PRIME BOILERS

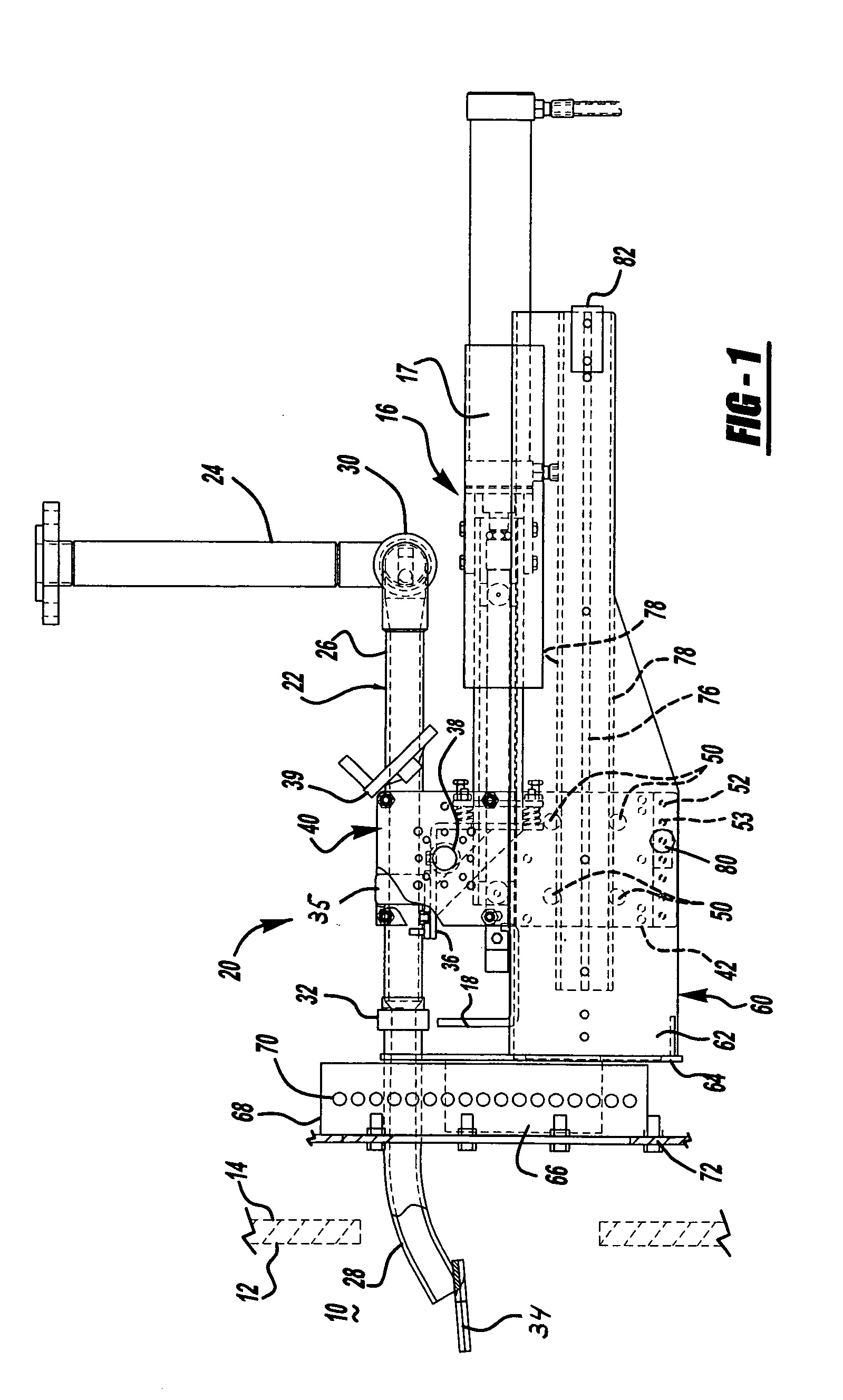

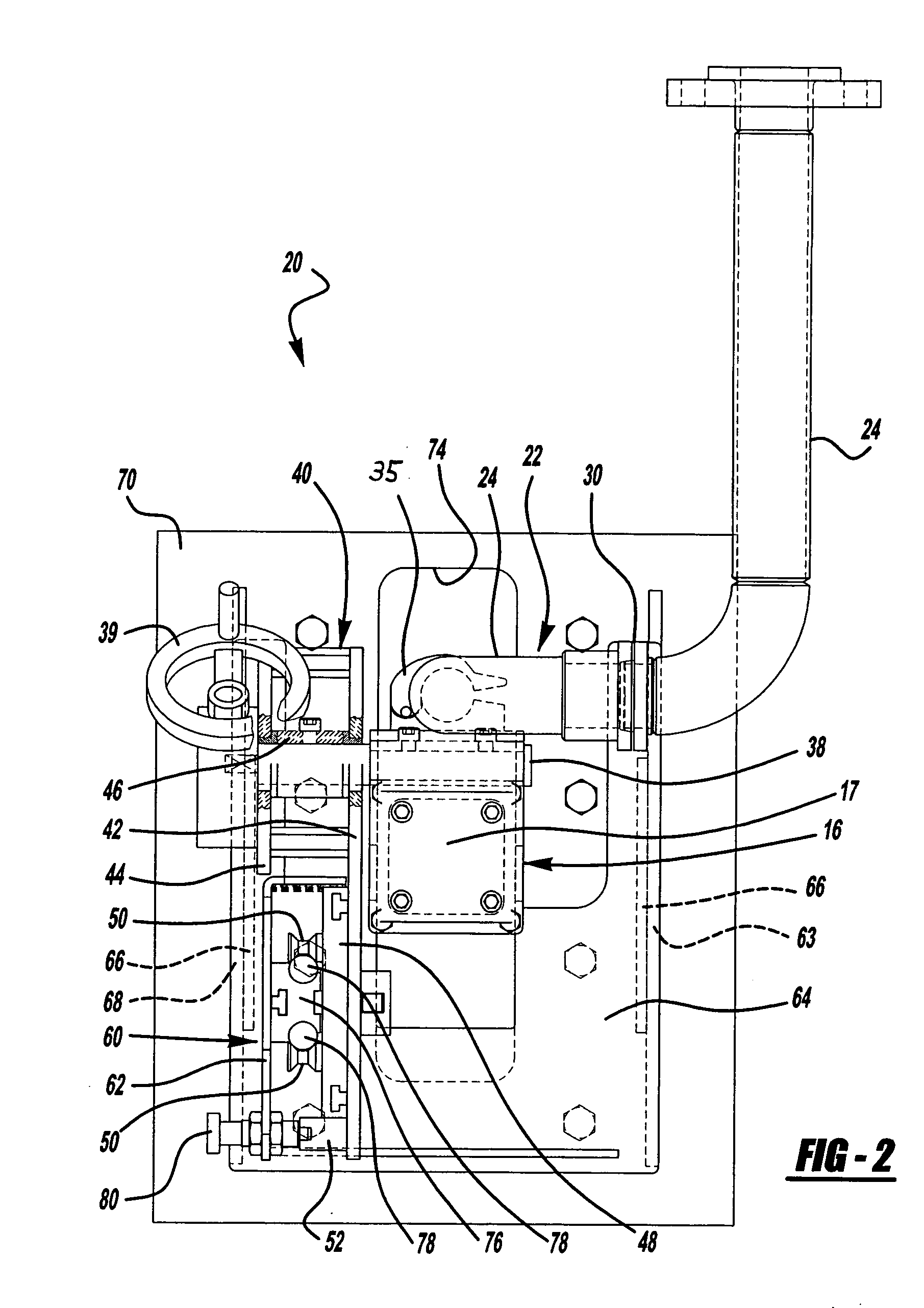

Retractable liquor gun holder for a recovery furnace

A liquor gun holder for a recovery furnace includes a rail assembly, a carriage assembly moveably mounted onto the rail assembly such that the carriage assembly is moveable longitudinally along the rail assembly, a pivot pin supported by a bearing and extending laterally from the carriage assembly, and a cleaning assembly pivotally mounted onto the pivot pin such that the cleaning assembly is rotatable about a horizontal axis extending longitudinally through the pivot pin and is positioned laterally from the carriage assembly and the rail assembly, the cleaning assembly including a clamp adapted to secure a liquor gun thereon such that the liquor gun is rotatable with the cleaning assembly and is positioned laterally from the carriage assembly.

Owner:DIAMOND POWER INT

High efficiency, glass-lined, combination space and hot water heater

InactiveUS6334411B1Improve efficiencyOvercome disadvantagesBoiler water tubesSpeed sensing governorsWater sourceCoupling

A combination space and hot water heater is comprised of an inner tank having an outer casing spaced therebout with insulation being interposed between the casing and the inner tank. The inner tank has a glass-lined inner surface and a heater is provided within the inner tank for heating a same volume of water within the inner tank. An anode is provided within the inner tank. A closed water circulating circuit is connected to the inner tank for circulating hot water from the tank through heat exchange means connected in the closed water circulating circuit. Preferably, but not exclusively, the heat exchange devices are radiators. The inner tank contains a predetermined same volume of recirculating water wherein minimal deposits are accumulated in the inner tank by not admitting fresh water thereby substantially preventing the build-up of deposits on heat exchange elements within the tank and the formation of harmful bacteria in radiators and corrosion and further wherein a high constant efficiency is achieved and the life expectancy of the hot water heater is substantially prolonged. At least one heat exchange coil is disposed in the inner tank and immersed in the water contained therein. The heat exchange coil is connected at one end to an outlet coupling to which a domestic hot water line is connected. An opposed end of the heat exchange coil is connected to an inlet coupling. The inlet coupling is connected to a pressurized water supply.

Owner:MICLAU S R I

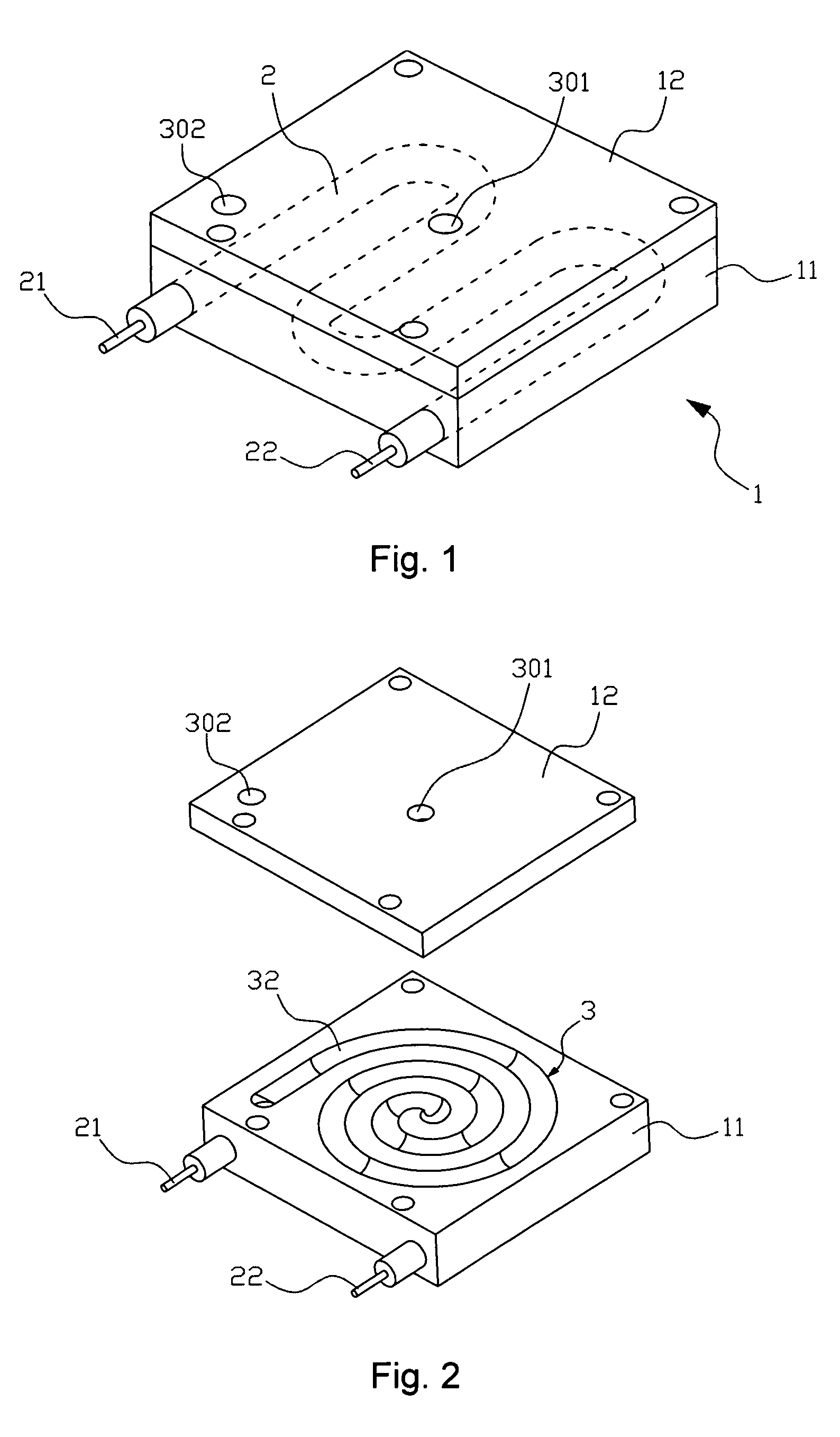

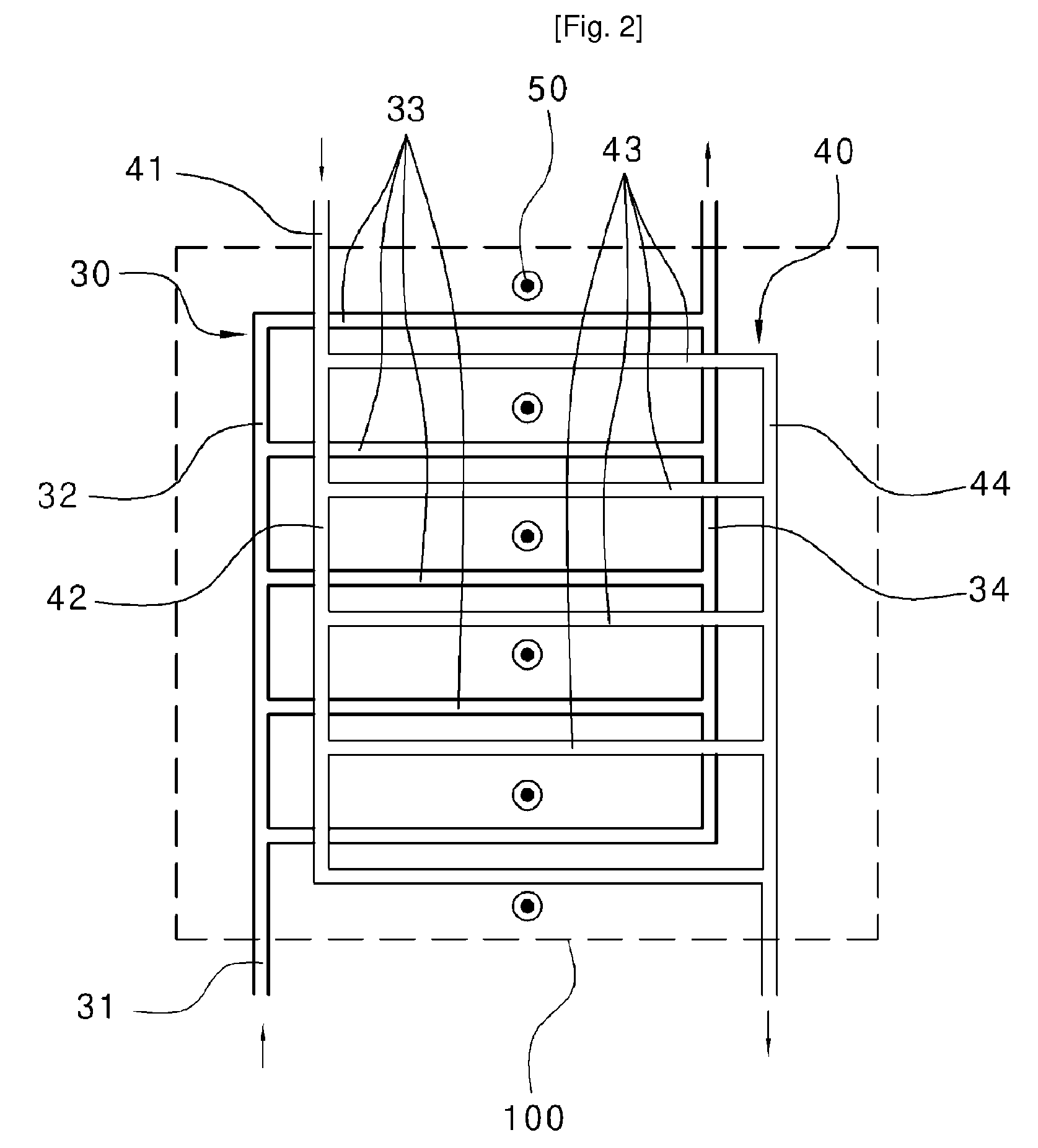

Heat Exchanger of Condensing Boiler for Heating and Hot-Water Supply

ActiveUS20090133861A1Simple structureLower the volumeMechanical apparatusBoiler water tubesEngineeringLatent heat

Disclosed is a heat exchanger for a condensing boiler supplying both heating water and hot water, which can use a double pipe as a sensible heat exchanger, instead of the use of an indirect heat exchanger. The heat exchanger includes: a sensible heat exchanger; and a latent heat exchanger made by connecting a plurality of unit heat exchangers to define exhaust gas pathway, each unit heat exchanger being manufactured in such a manner that three plates having a convexo-concave shape are stacked on one another to define a heating water pathway and a hot water pathway to be adjacent to each other in order to increase a heat transfer area.

Owner:KYUNGDONG NAVIEN

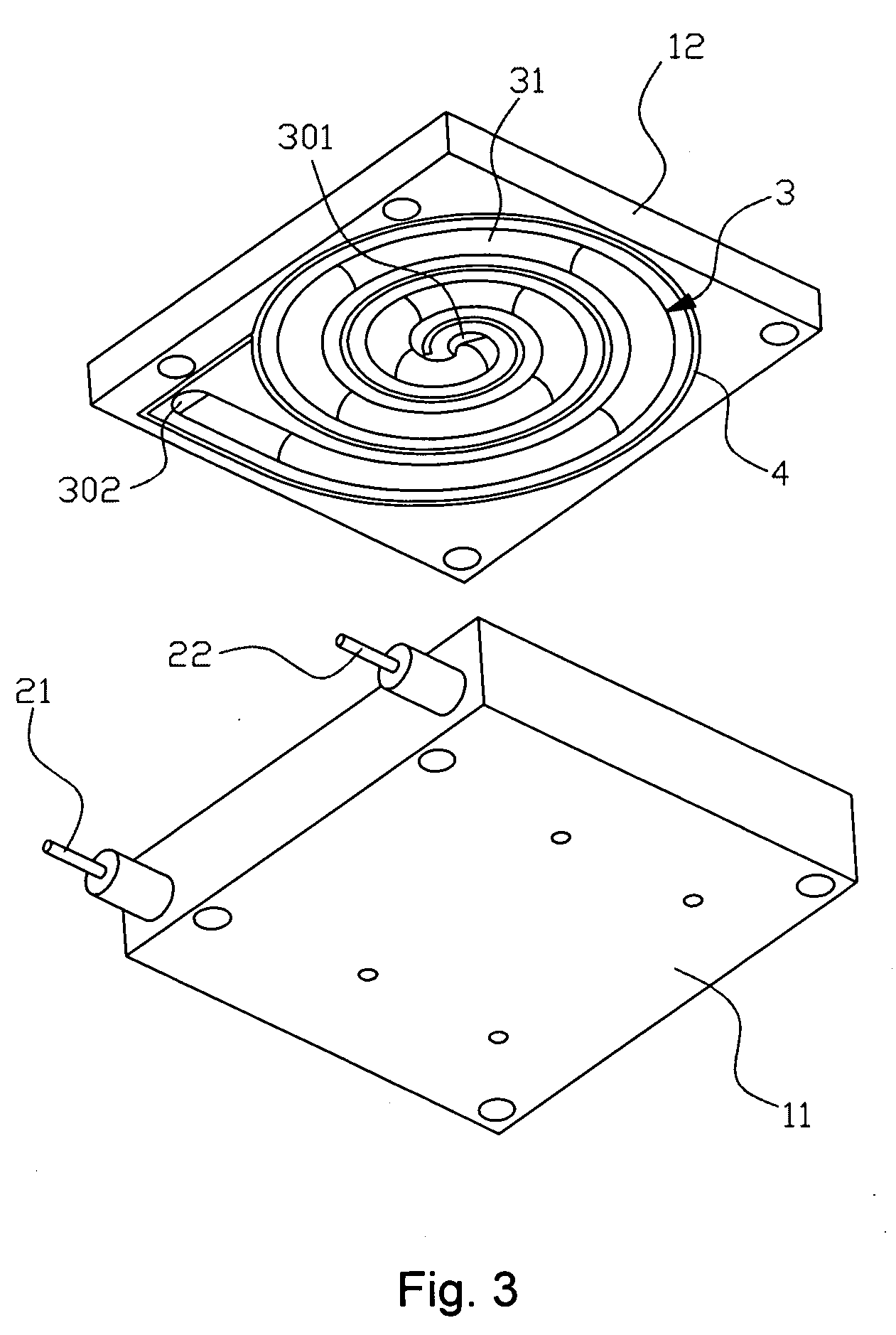

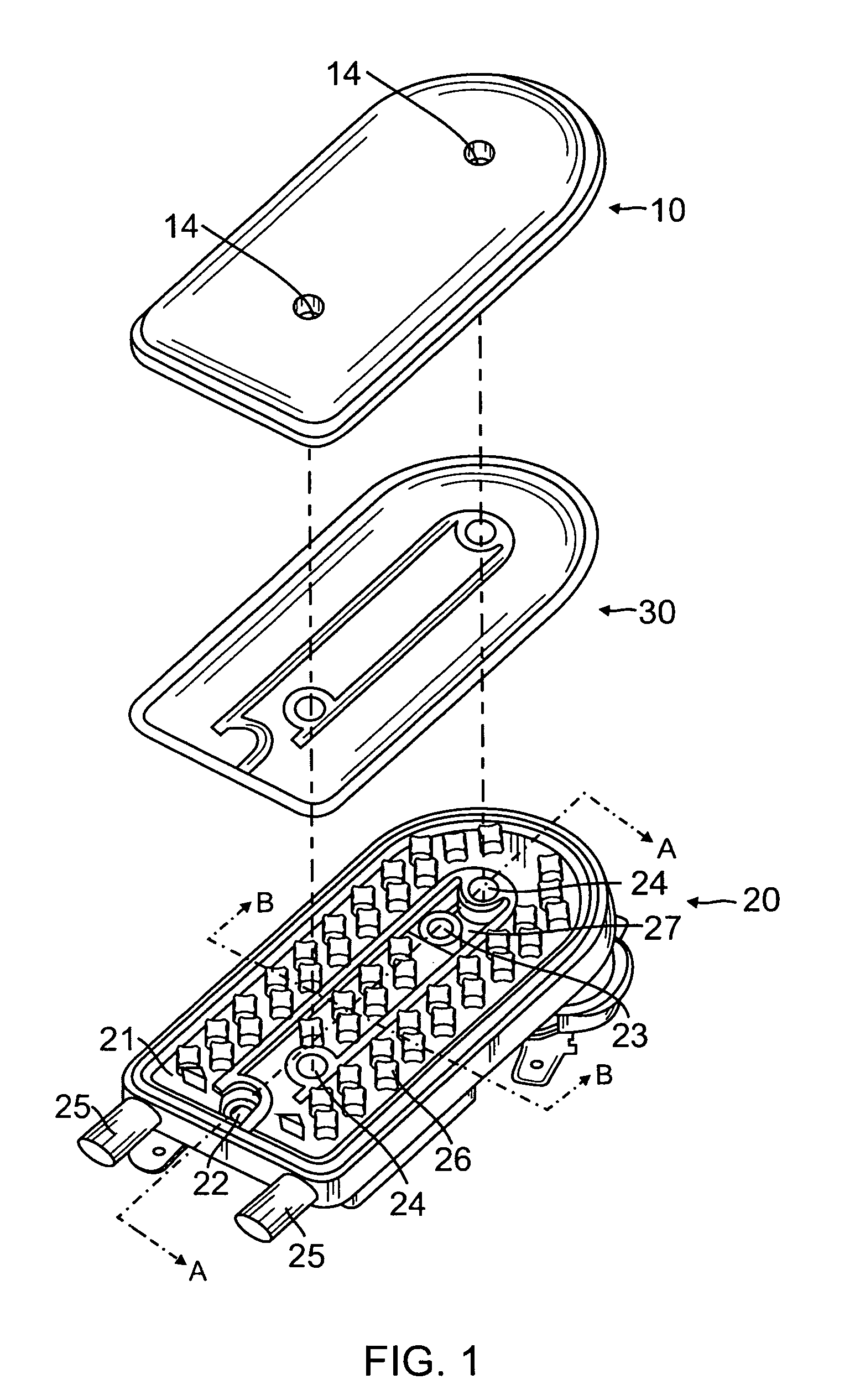

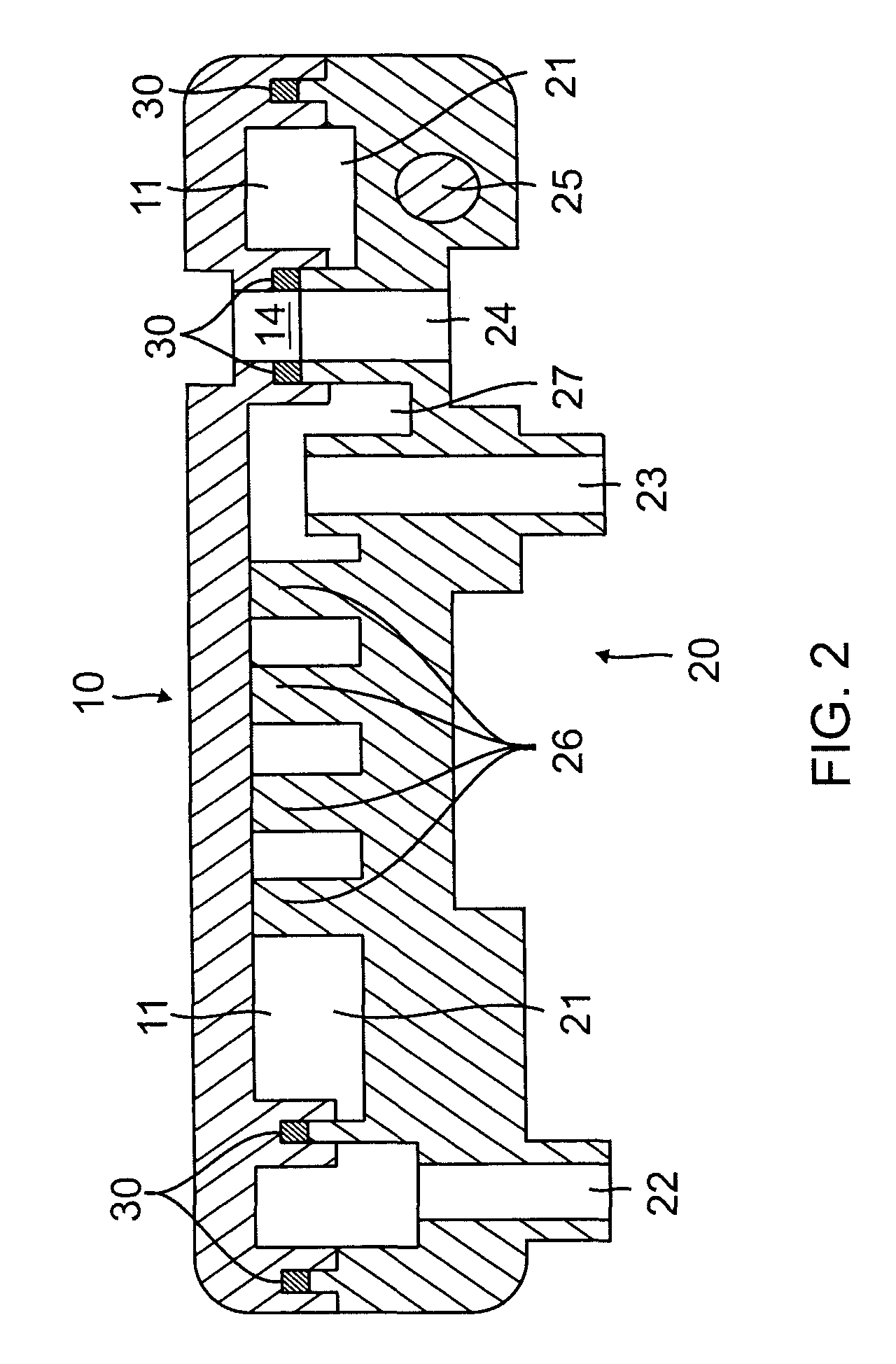

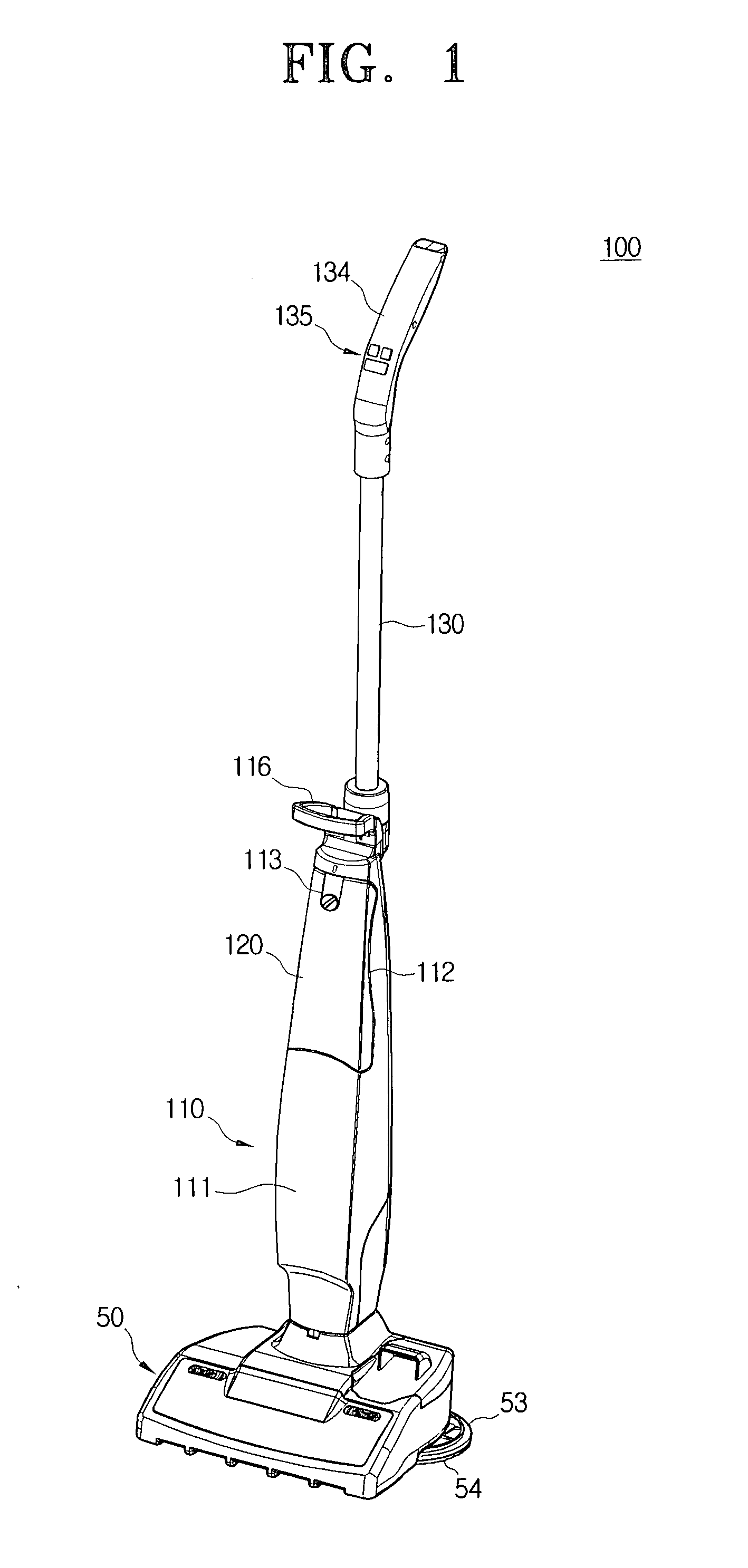

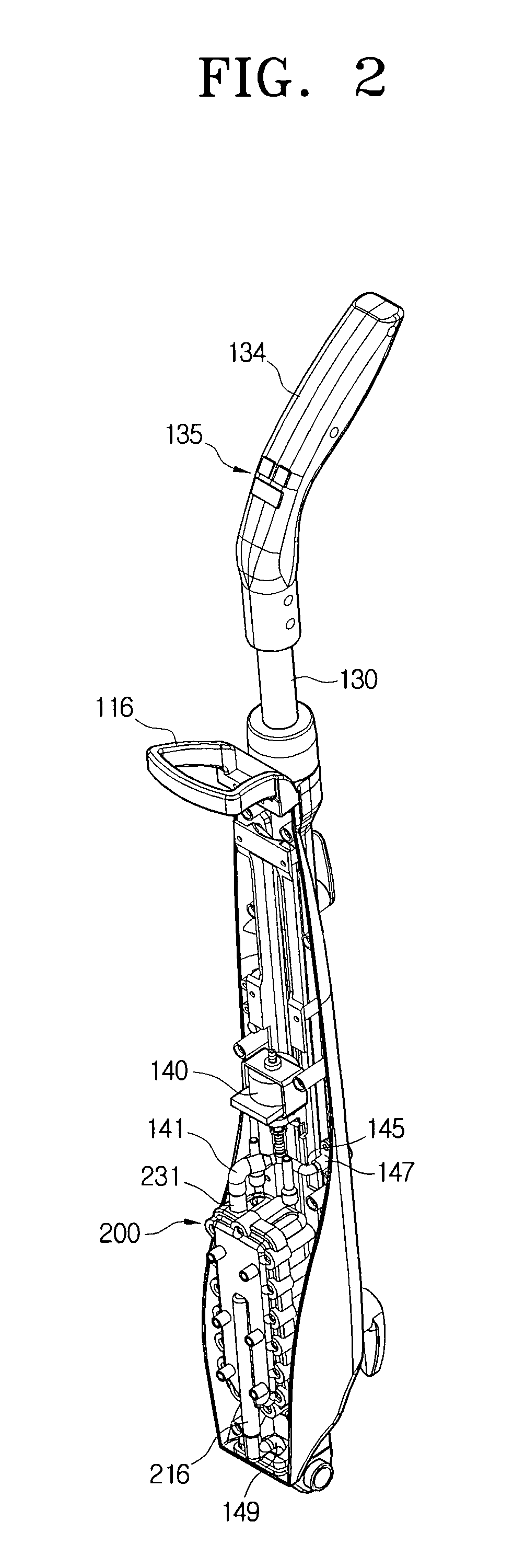

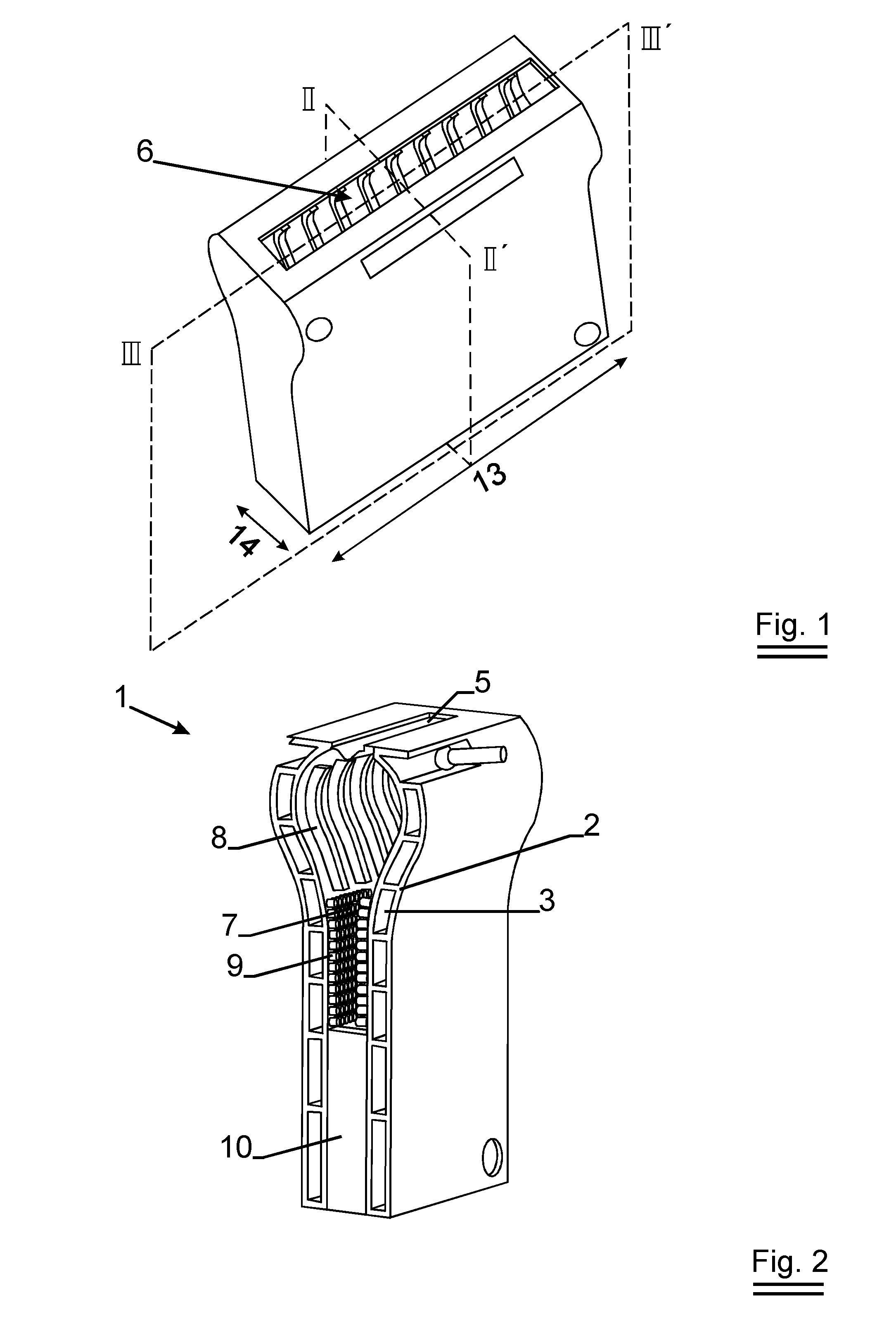

Heating apparatus and cleaner having the same

A heating apparatus and a cleaner having the same are disclosed. The heating apparatus includes a heating casing to receive water from a water container and convert the water into steam, wherein the heating casing comprises a plurality of ribs and each successive rib comprises a space to collect water and convert the water into steam. The cleaner includes a cleaner body in which a water container is detachably mounted, a nozzle assembly rotatably connected to a lower part of the cleaner body and including a nozzle to inject steam, and a heating apparatus that includes a heating casing to receive water from the water container, convert the water into steam, and supply the steam to the nozzle assembly, wherein the heating casing includes a plurality of ribs and each successive rib includes a space to collect water and convert the water into steam.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

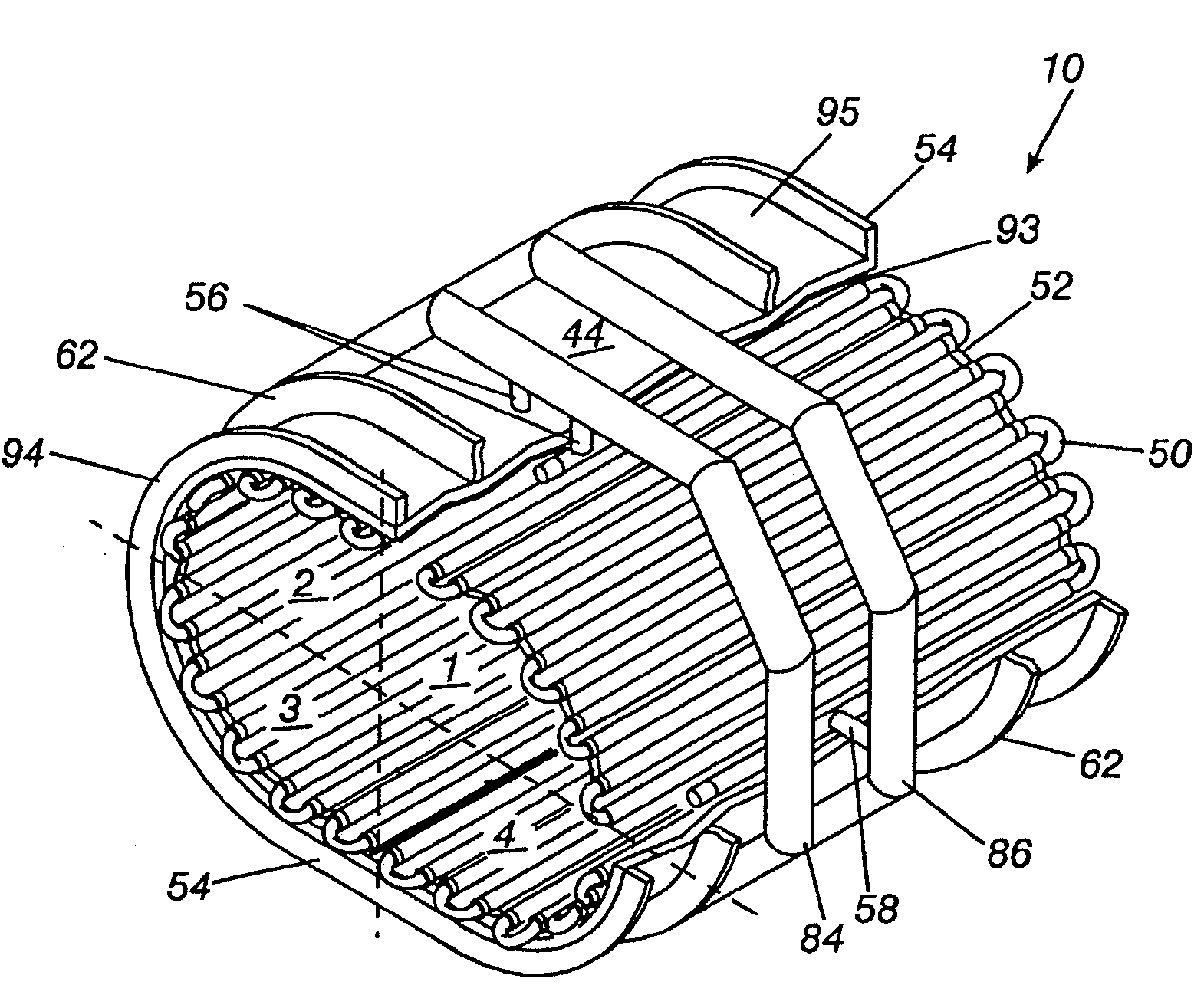

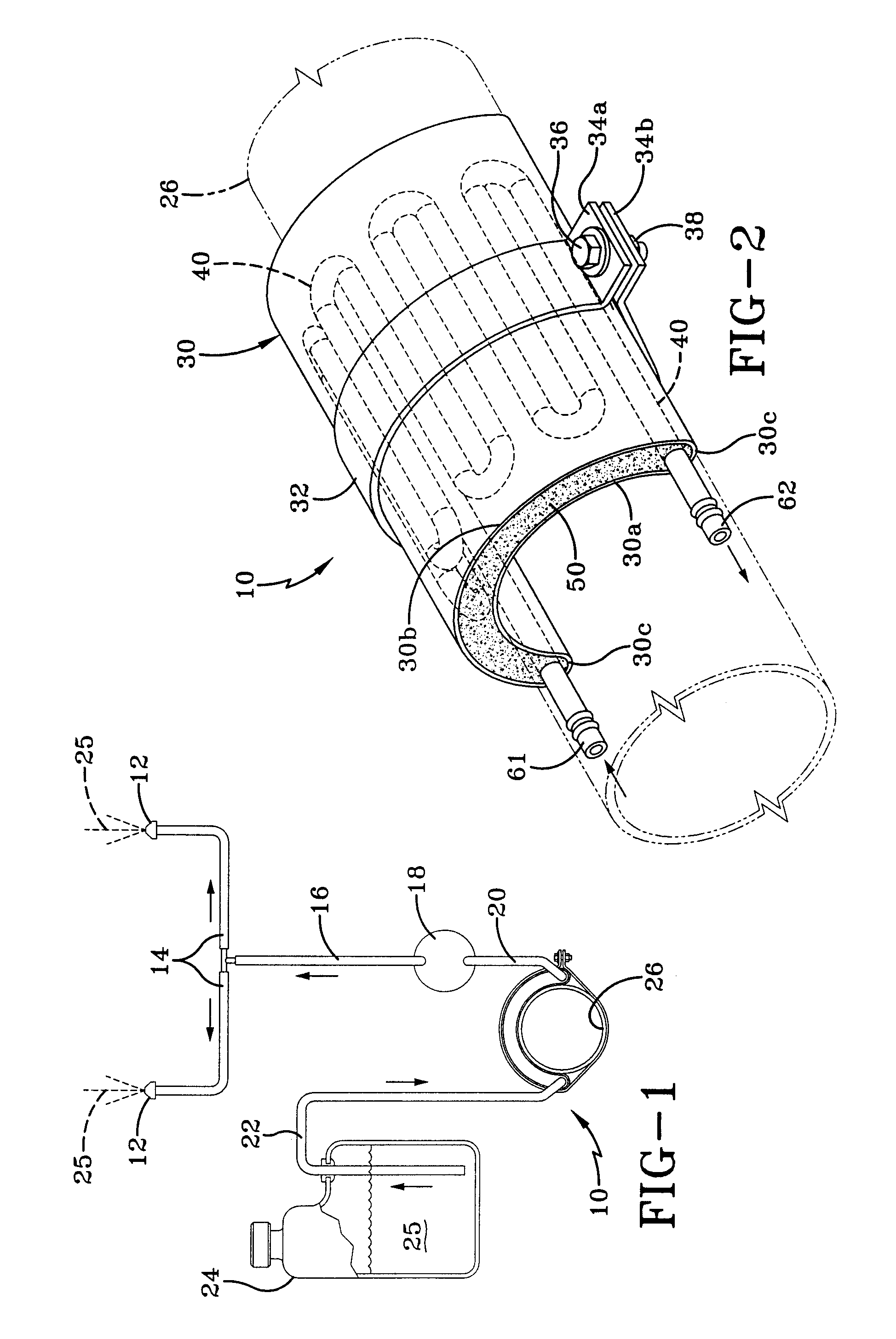

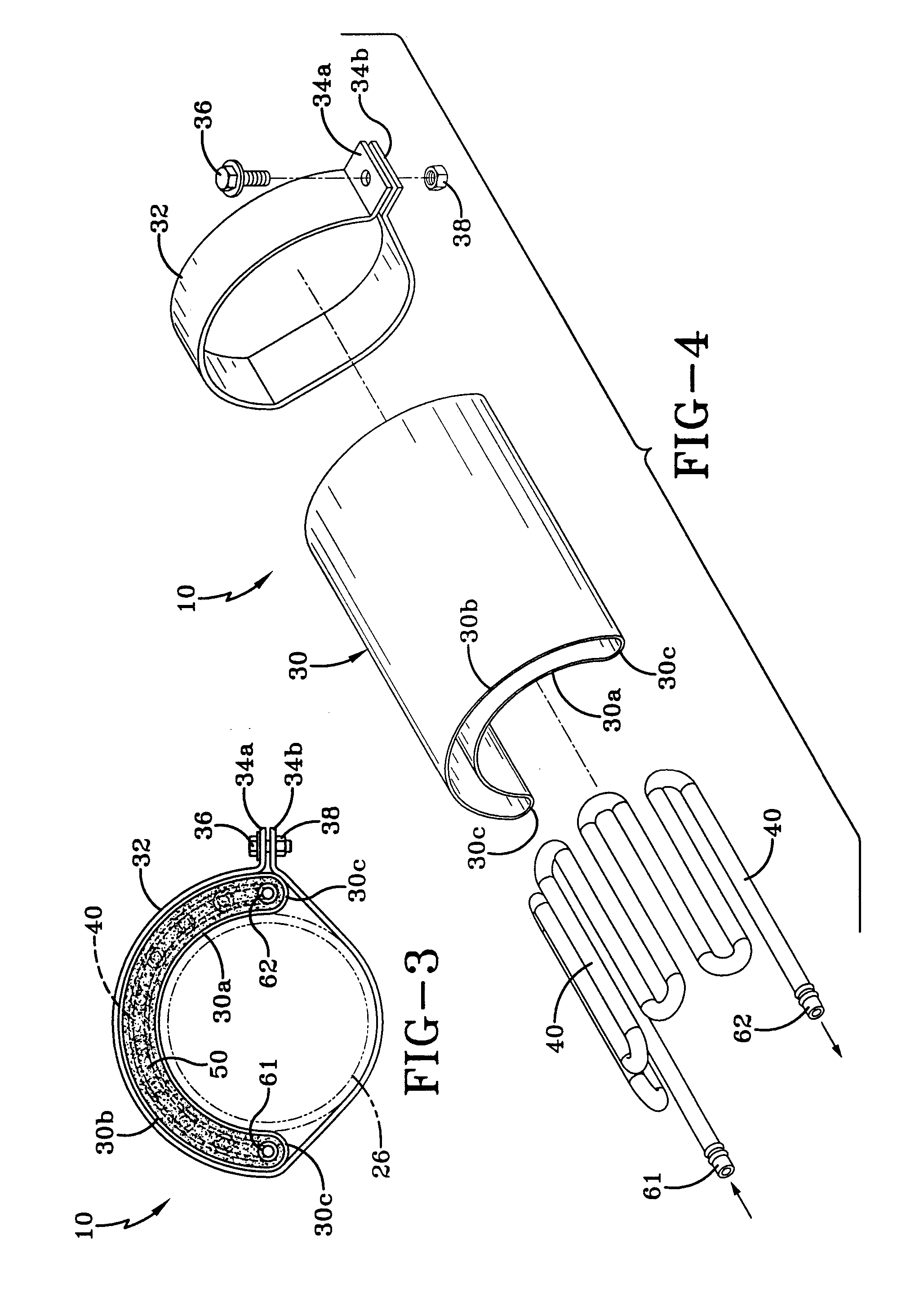

Adjustable heat exchange apparatus and method of use

InactiveUS20080296006A1Low densityLimited operating lifeEnvelopes/bags making machineryBoiler water tubesBiomedical engineering

Owner:AMERIFAB INC

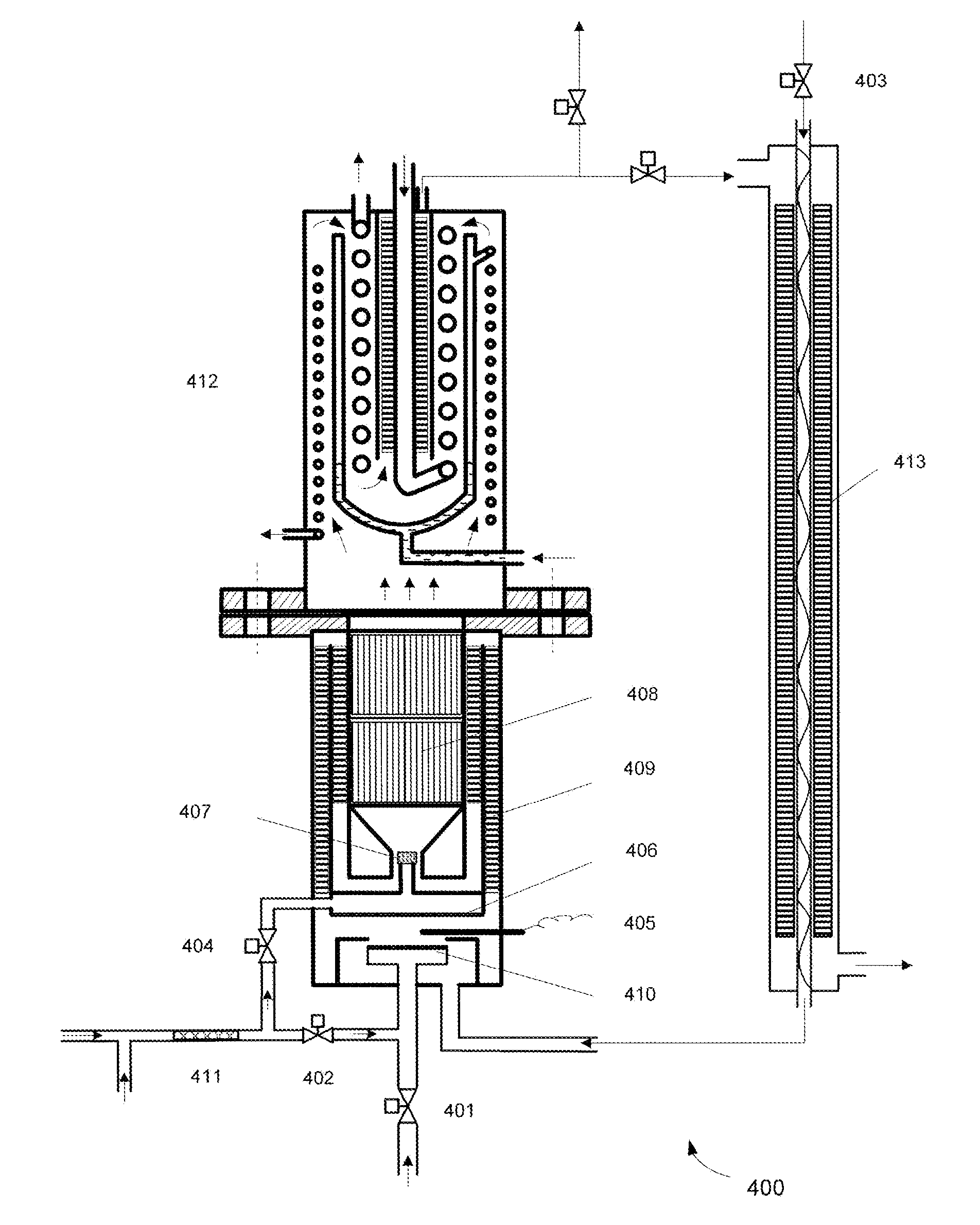

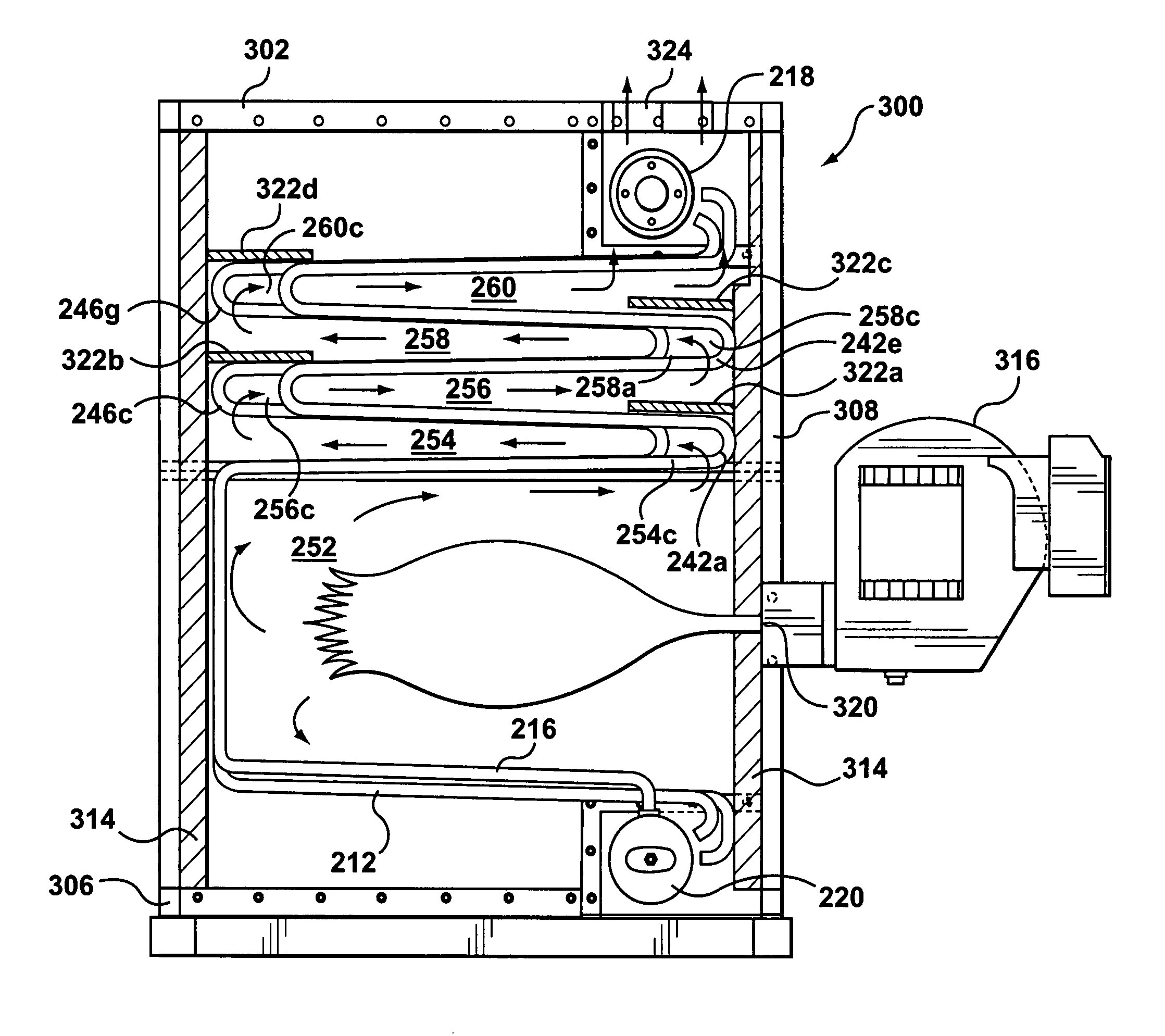

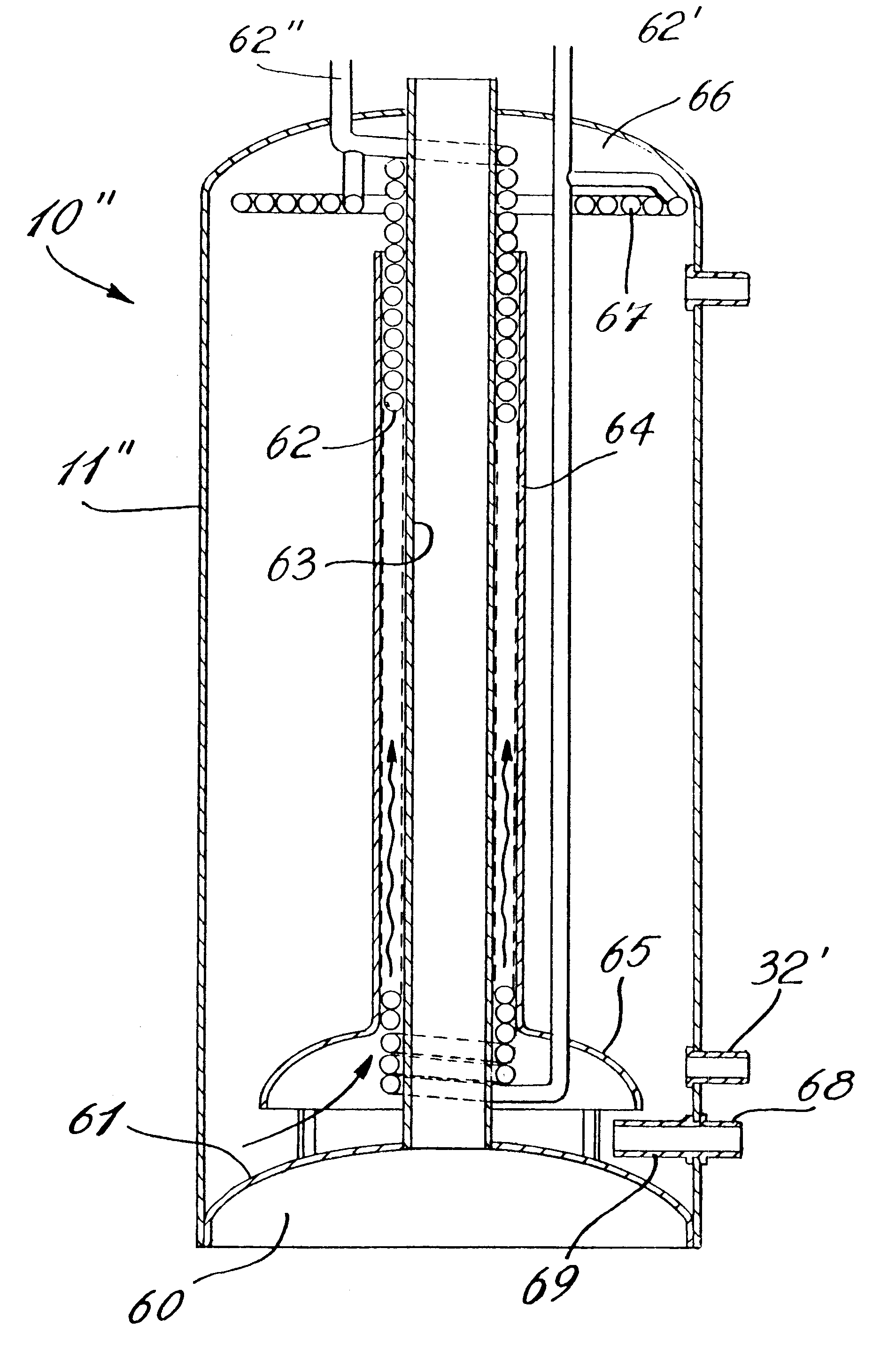

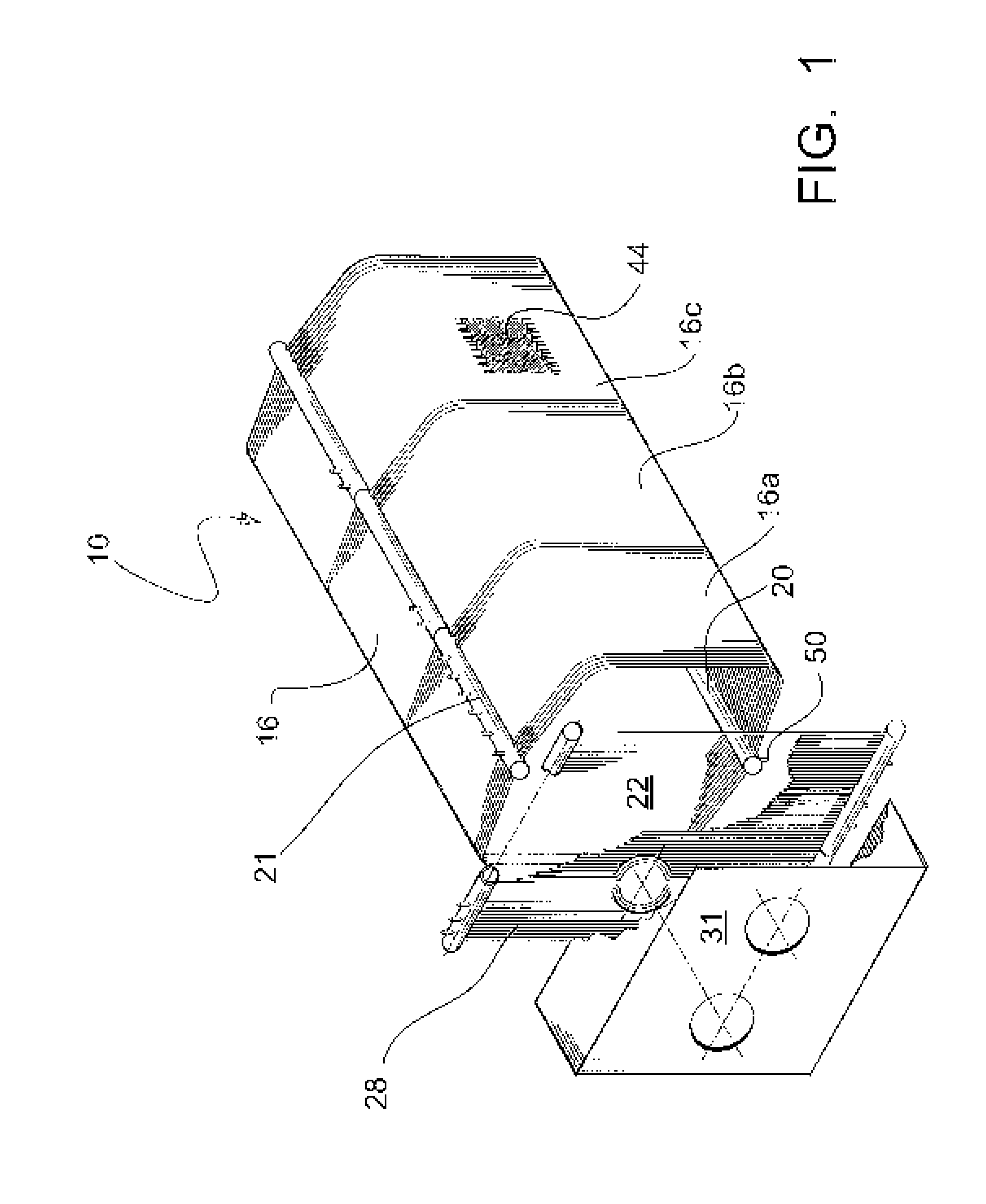

Natural Circulation Industrial Boiler for Steam Assisted Gravity Drainage (SAGD) Process

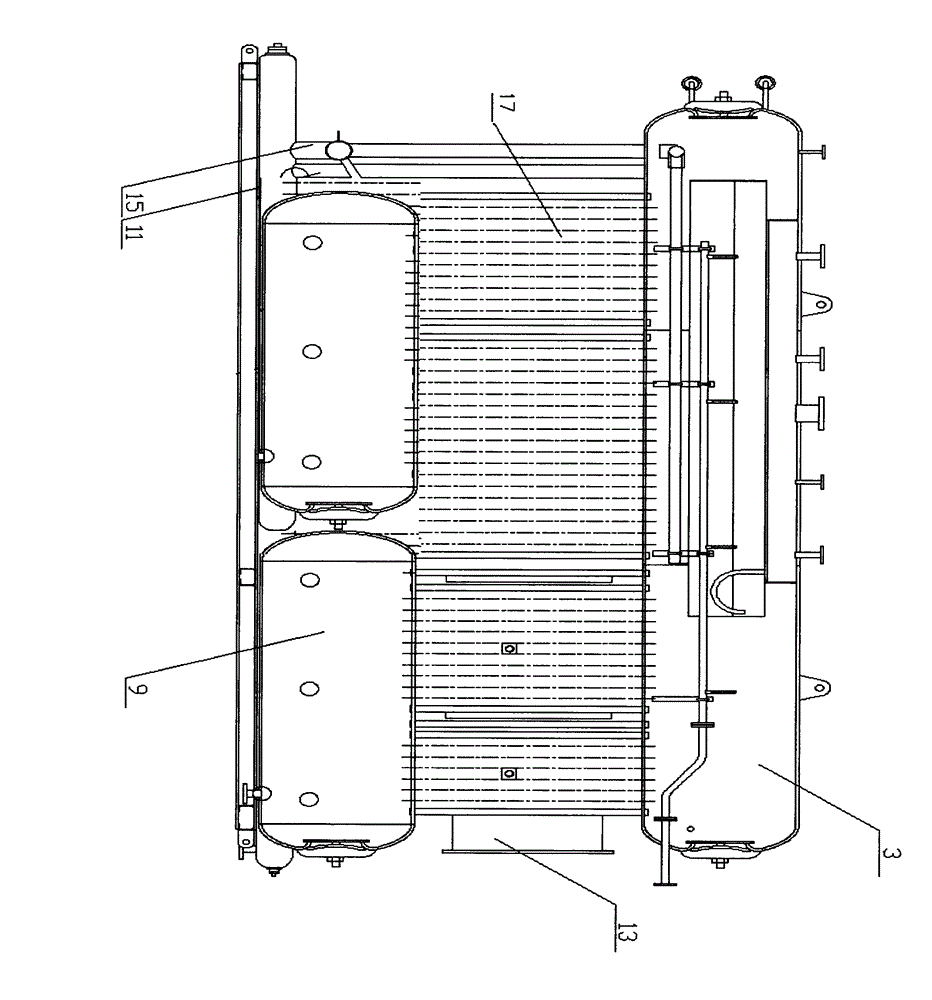

A gravity feed, natural circulation boiler for an SAGD process using low quality feedwater for carbonatious material recovery, has a large diameter steam drum with downcomers. A furnace of the boiler has individually replaceable membrane wall modules, each with upper and lower headers and membrane roof, wall and floor parts connected to the drum and defining a fire box having an inlet end and an outlet end. The furnace includes a membrane front wall connected to the drum with a windbox upstream of the front wall. Burners at the inlet end of the firebox heat the firebox and riser pipes are connected between the steam drum and the upper header for supplying steam to the steam drum when the firebox in heated, the downcomer pipes being connected to the lower header for supplying water from the stream drum under gravity feed so that each module defines a single circuit. Furnace outlet screen bank and subsequent generating banks each with upper and lower headers and associated feeder and riser tubes complete the boiler.

Owner:BABCOCK & WILCOX CANADA LIMITED

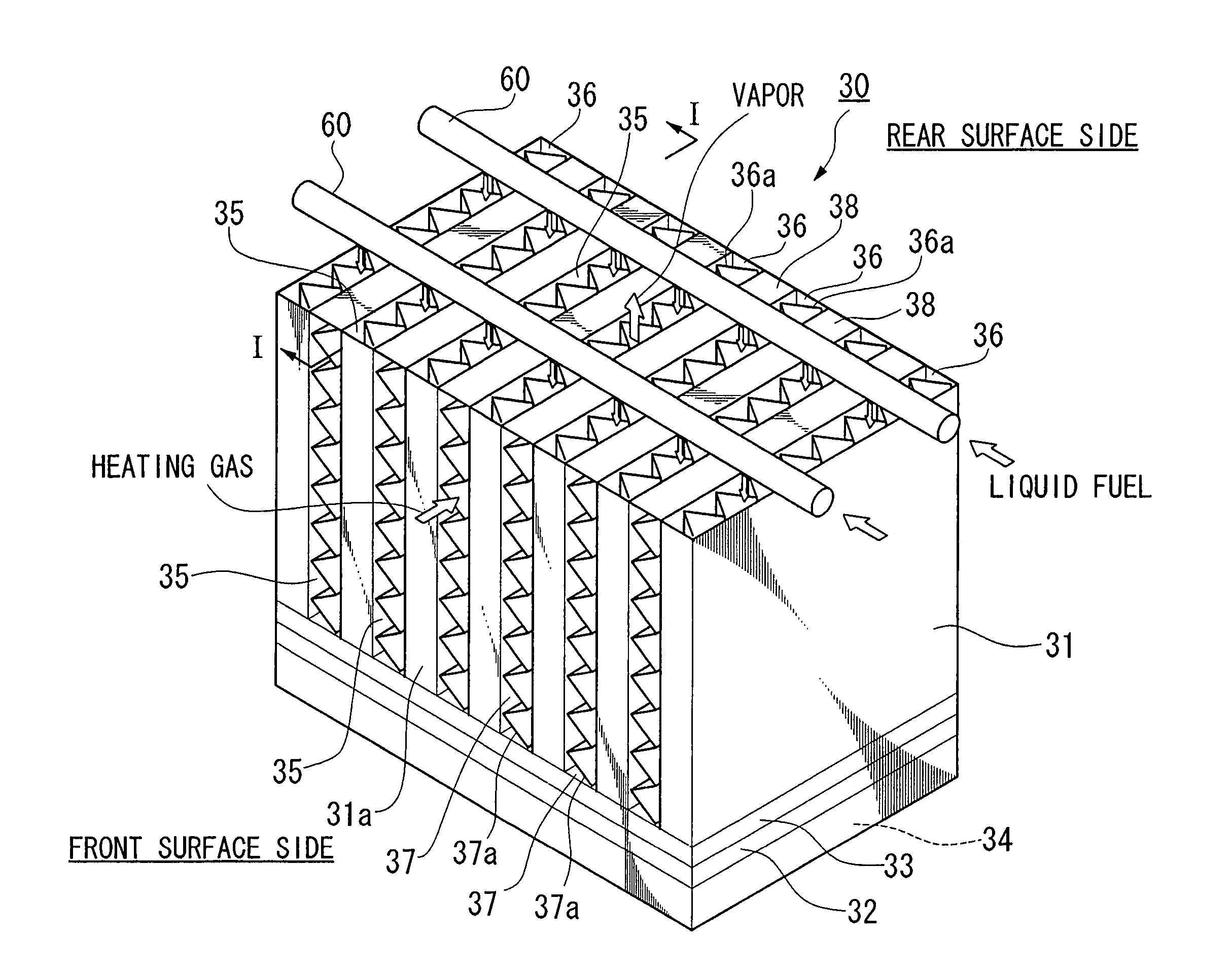

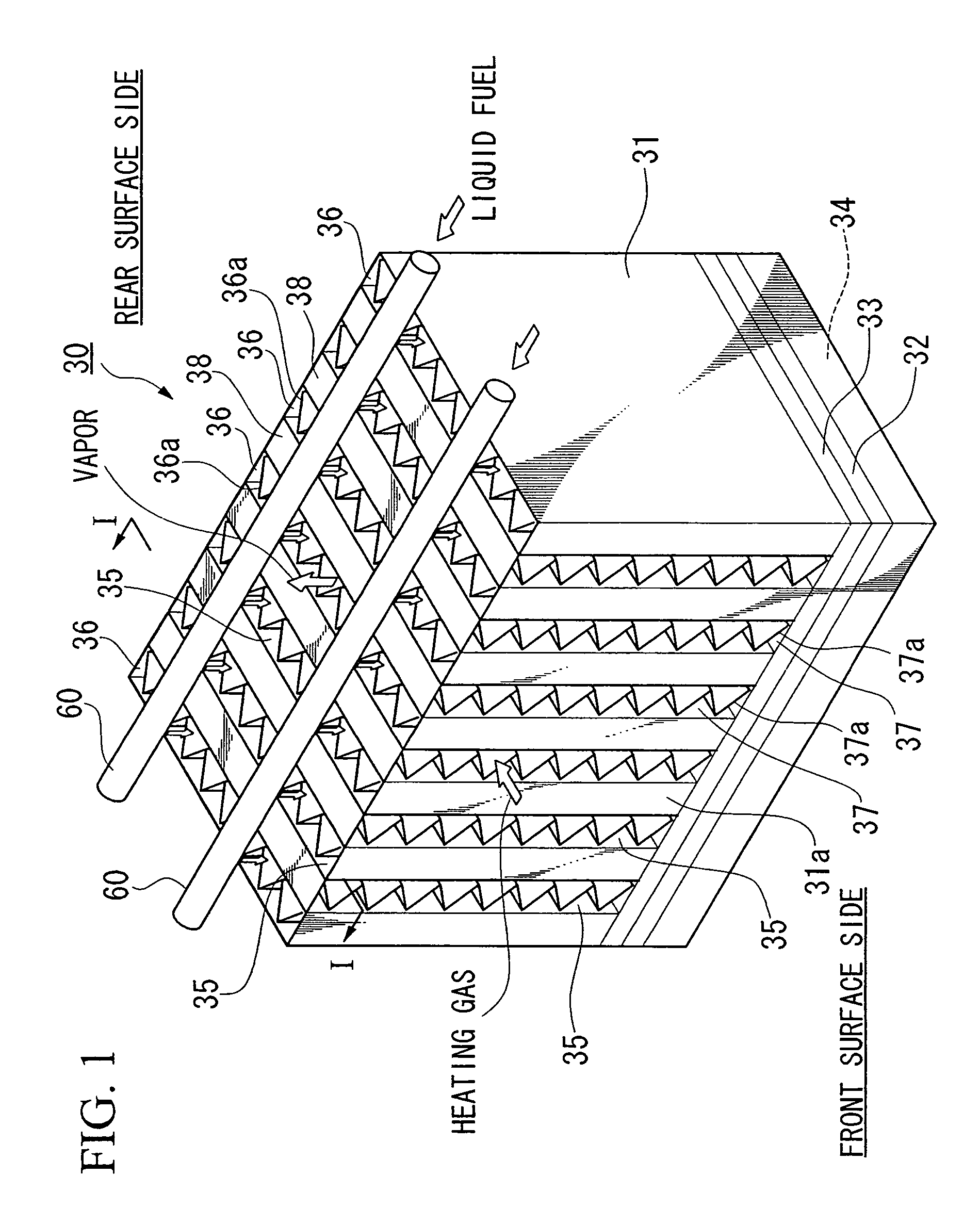

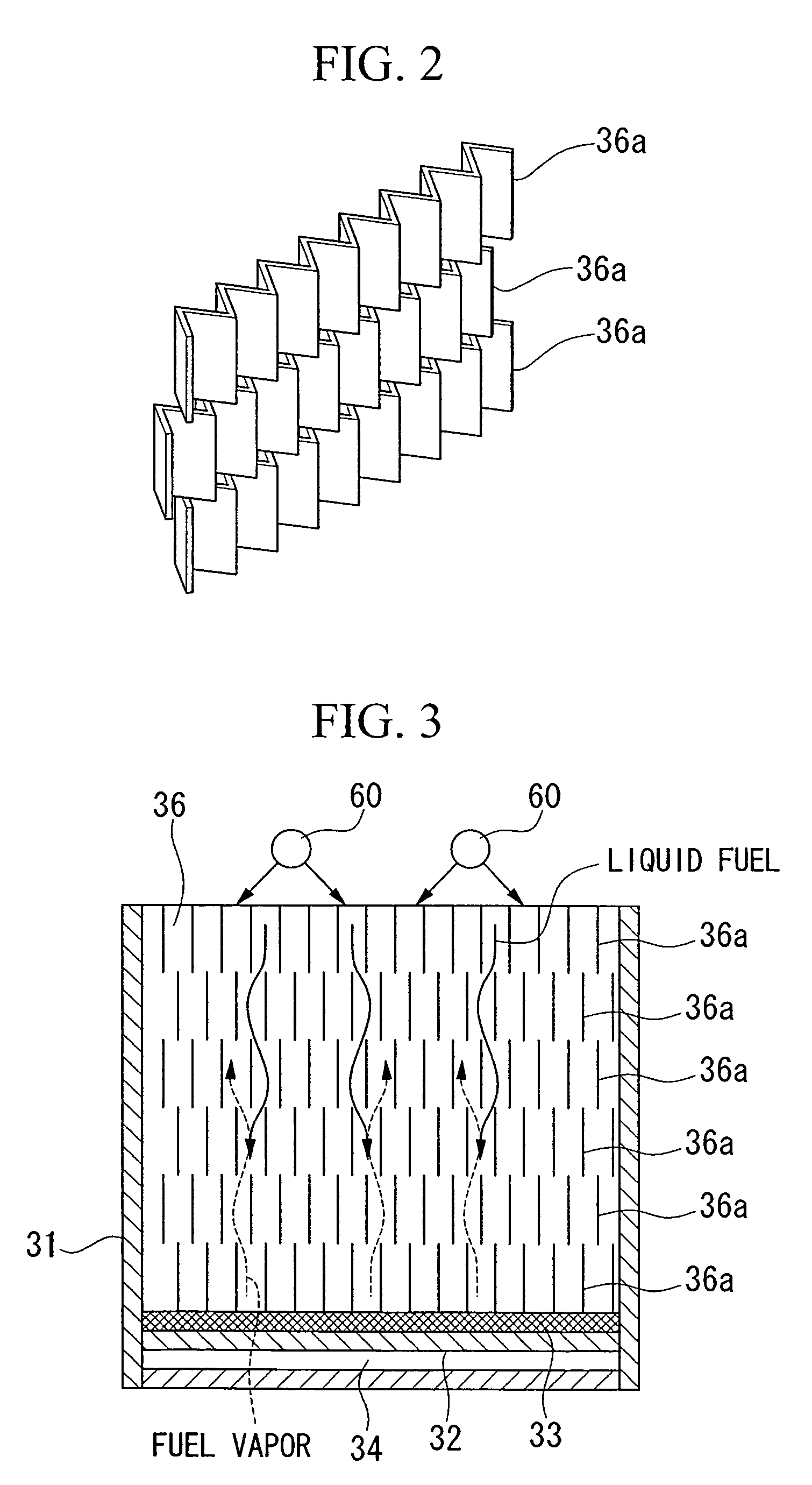

Vaporizer that vaporizes a liquid to generate vapor

InactiveUS7490580B2Efficient use ofImprove responseLiquid fuel feeder/distributionBoiler water tubesLiquid fuelVaporization

A vaporizer generates vapor by vaporizing a liquid. In particular, a vaporizer generates fuel vapor that is used for reforming fuel by vaporizing a liquid fuel that contains a hydrocarbon. This vaporizer includes a heating gas direct movement flow path along which a heating gas flows by moving directly in a horizontal direction; vaporization flow paths that are positioned such that they can exchange heat with the heating gas direct movement flow path, and that vaporizes liquid fuel; a fuel supply pipe that supplies the liquid fuel to the vaporization flow paths; and a vapor flow path that is positioned in an upstream portion on the heating gas direct movement flow path from the vaporization flow paths and that heat fuel vapor that is discharged from the vaporization flow paths. Fuel vapor that is generated on the vaporization flow paths circulates upwards in the direction of gravity along the vaporization flow paths, and subsequently is discharged from a top portion of the vaporization flow paths and is introduced into the vapor flow path. The fuel vapor then circulates in the direction of gravity along the vapor flow path.

Owner:HONDA MOTOR CO LTD

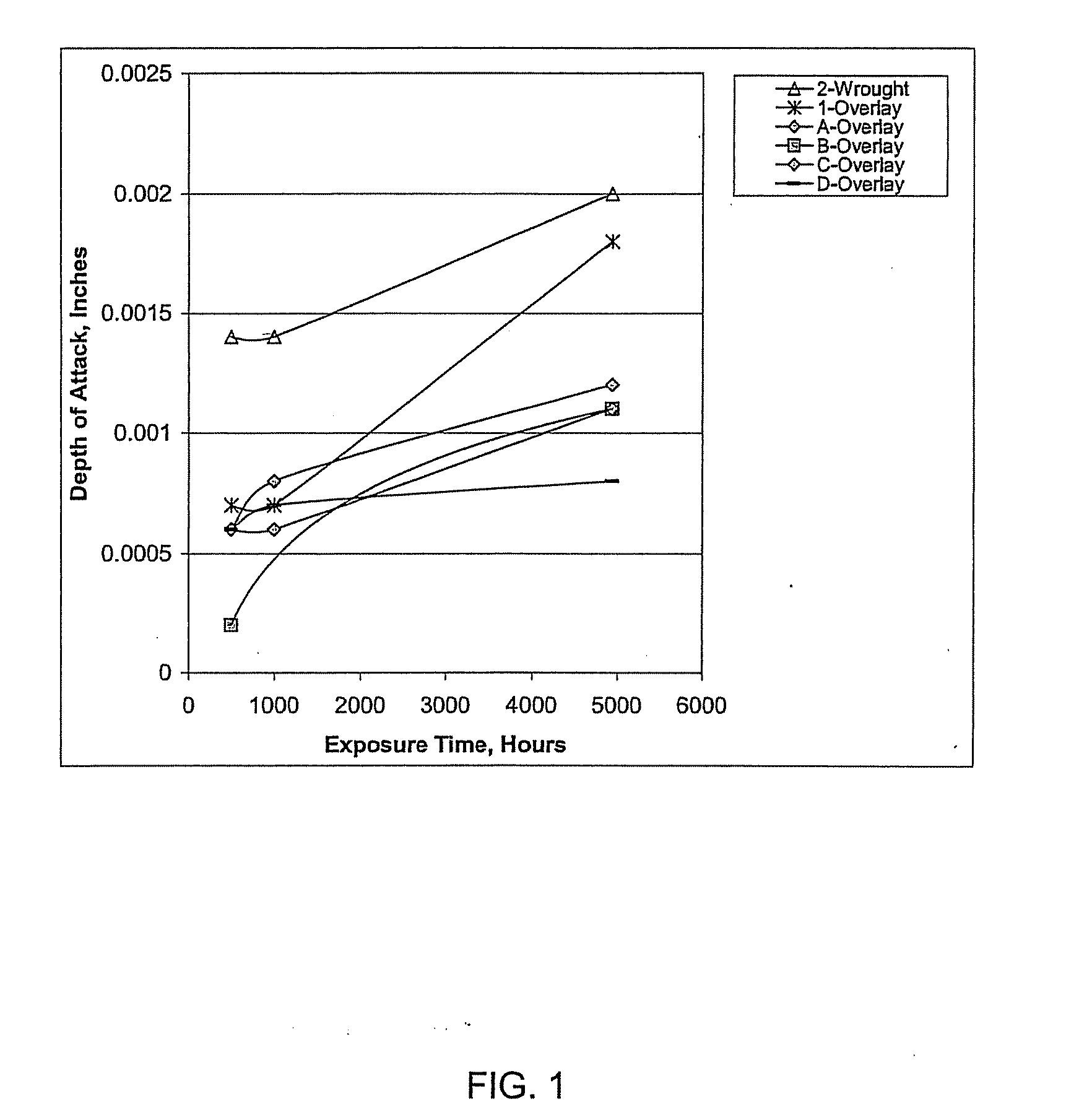

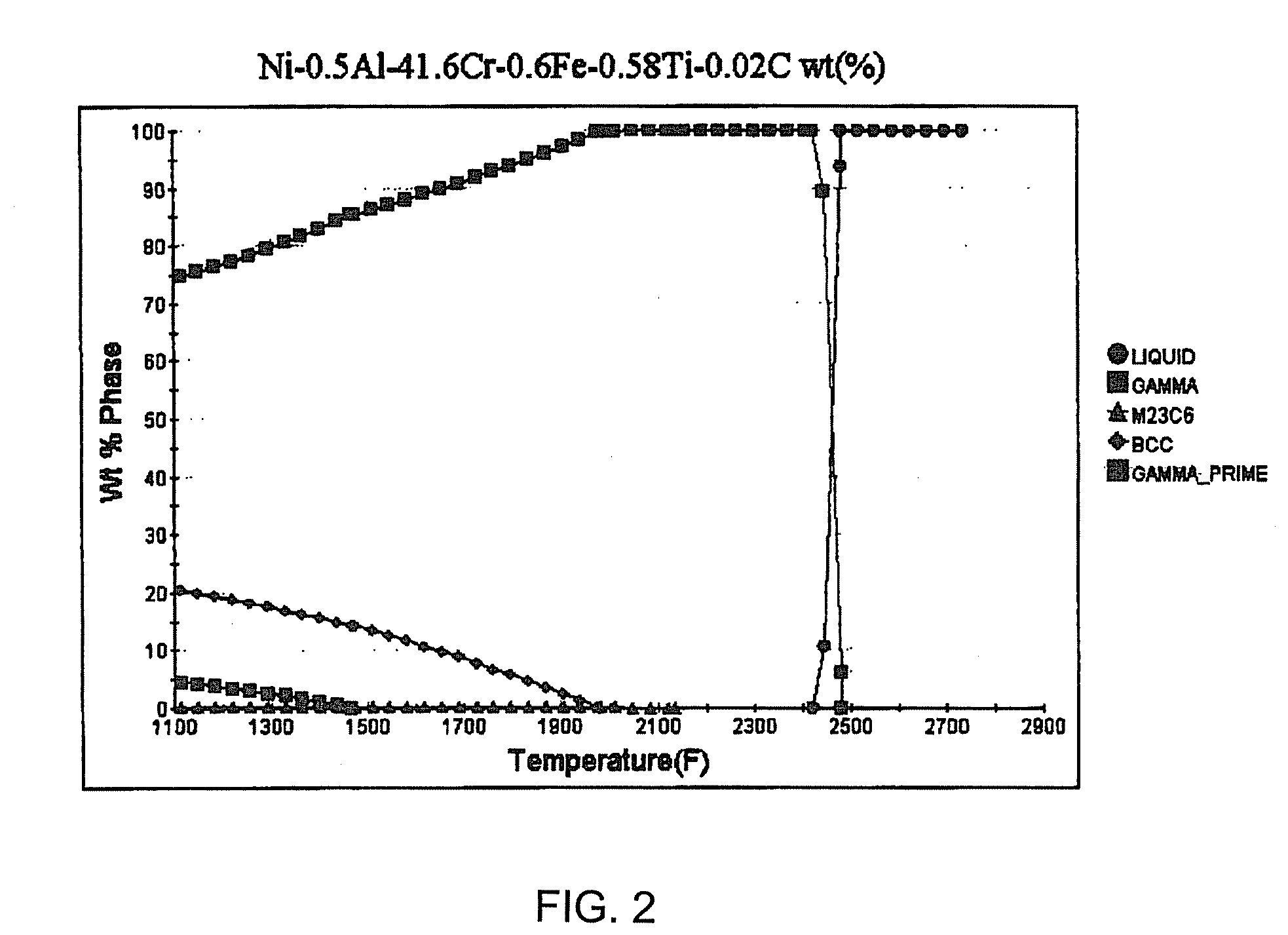

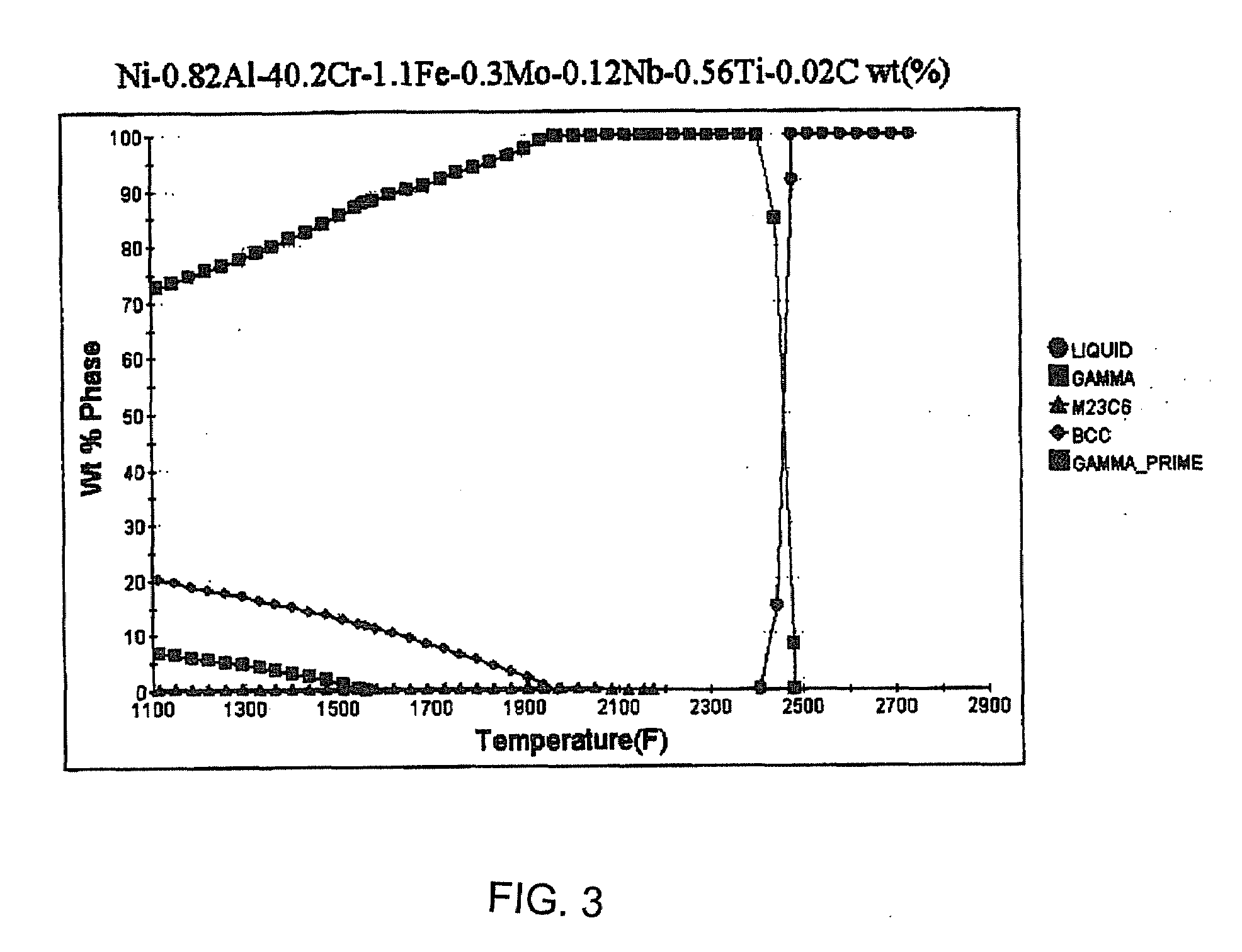

Filler Metal Composition and Method for Overlaying Low NOx Power Boiler Tubes

ActiveUS20080241580A1Solve the lack of corrosion resistanceEnvelopes/bags making machineryElectric discharge heatingAlloyOxygen

An alloy for use as a welding overlay for boiler tubes in a low NOx coal-fired boiler comprising in % by weight: 36 to 43% Cr, 0.2 to 5.0% Fe, 0-2.0% Nb, 0-1% Mo, 0.3 to 1% Ti, 0.5 to 2% Al, 0.005 to 0.05% C, 0.005 to 0.020% (Mg+Ca), 0-1% Mn, 0-0.5% Si, less than 0.01% S, balance substantially Ni and trace additions and impurities. The alloy provides exceptional coal ash corrosion resistance in low partial pressures of oxygen. The alloy also increases in hardness and in thermal conductivity at service temperature over time. The increased hardness improves erosion resistance of the tubes while the increased thermal conductivity improves the thermal efficiency of the boiler and its power generation capabilities.

Owner:HUNTINGTON ALLOYS CORP (US)

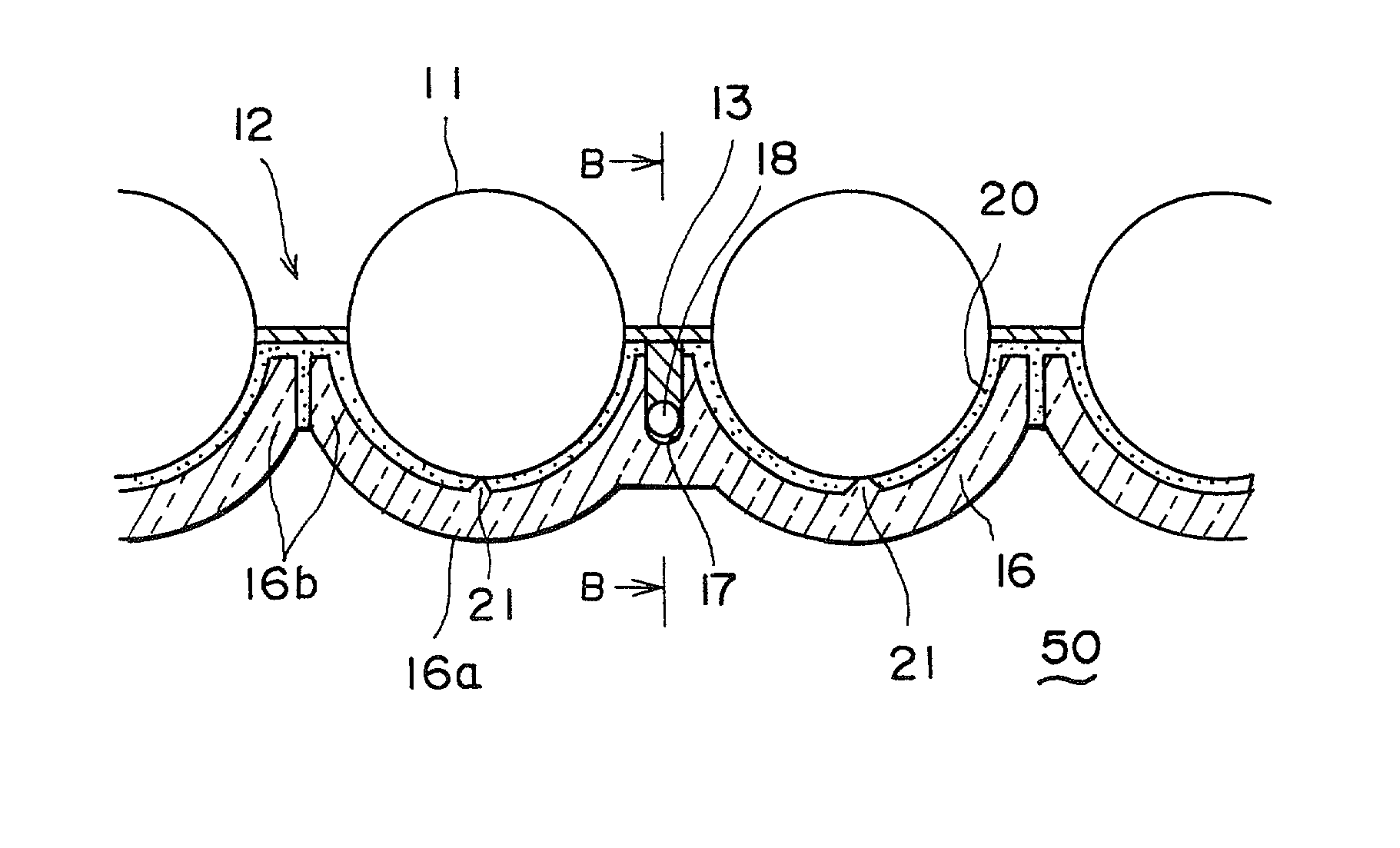

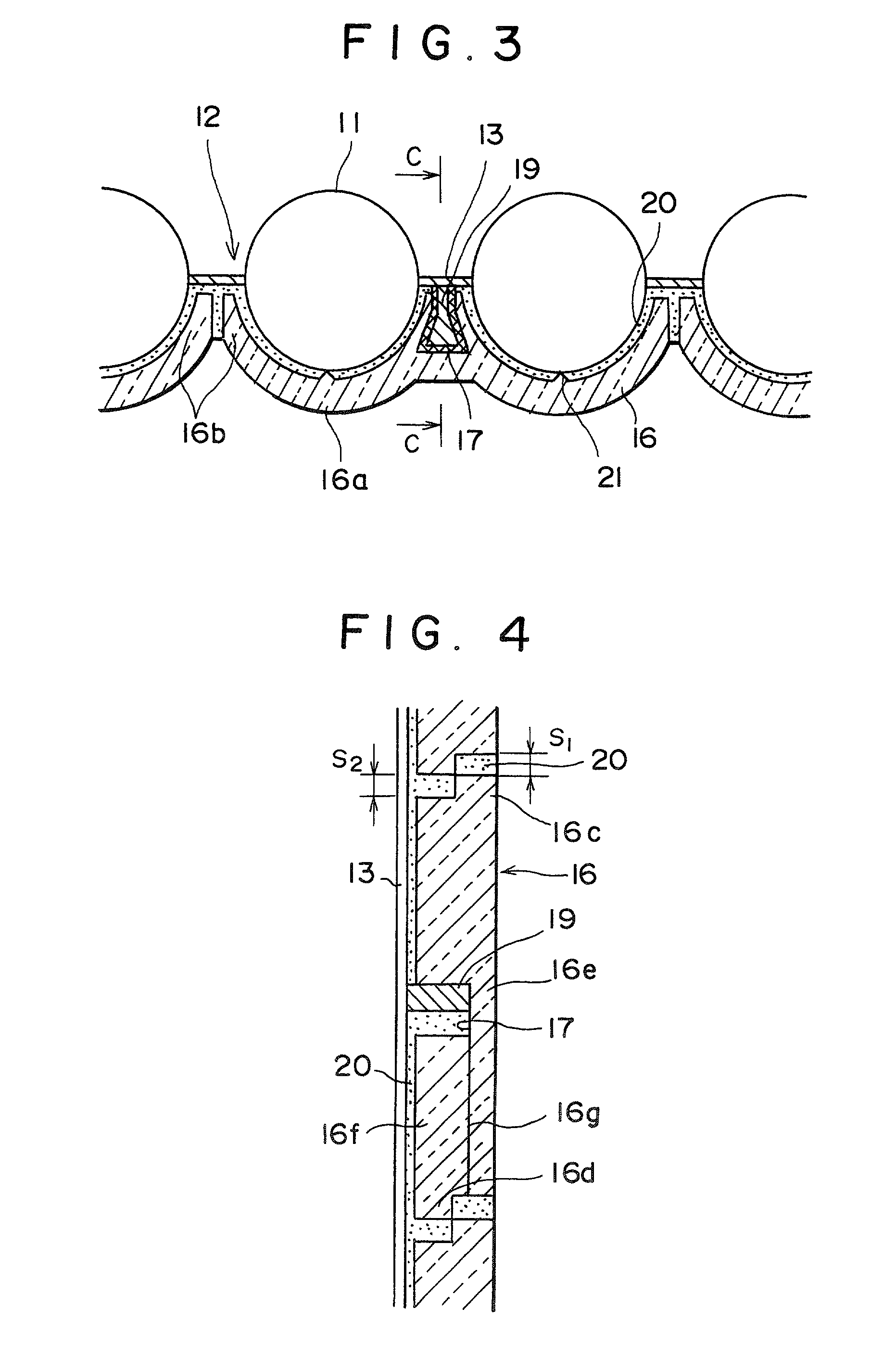

Heat-resistant assembly for protecting boiler tubes and method of assembling same

InactiveUS20020077767A1Thermometer detailsBoiler supporting/setting arrangementsEngineeringMechanical engineering

This invention concerns a heat-resistant assembly having a heat-resistant block conformed to the contours of boiler tubes and the surface of their connecting rib. The heat-resistant assembly has an arm which protrudes from the surface of the rib toward the heat-resistant block and which has a catch on the end. The block has an indentation in which the catch on the arm engages. The block can be hung on or removed from the tube assembly by means of the arms and indentations. The heat-resistant assembly is further distinguished by the fact that a space is created between the end of the arm and the indentation of the block. A fusible substance, which will melt when the temperature of the arm exceeds a given value, is placed in the space. The heat-resistant assembly is further distinguished by the fact that an indentation is formed in the block in which a heat-resistant sleeve is adhered to engage the arm. This arrangement makes it possible to manufacture the heat-resistant block using press molding.

Owner:MITSUBISHI HEAVY IND LTD

Damping steam boiler

ActiveCN107143837AReduce vibrationImprove heat transfer performanceBoiler water tubesSteam generation using pressureHeat transmissionNoise level

The invention provides a damping steam boiler. The damping steam boiler comprises an upper boiler barrel, a lower boiler barrel, rising pipes and falling pipes, wherein the rising pipes and the falling pipes are connected between the upper boiler barrel and the lower boiler barrel. The rising pipes are internally provided with flow stabilizers, and the multiple flow stabilizers are arranged in the same rising pipe; and the space between every two adjacent flow stabilizers is constantly reduced in the fluid flowing direction of the rising pipes. According to the damping steam boiler, through gap changing of the flow stabilizers, when steam-liquid two phase flowing exists in the rising pipes, heat transmission is reinforced; and meanwhile, vibration of the rising pipes is weakened, and the noise level is reduced.

Owner:连云港虹洋热电有限公司

Windshield liquid wash heater

InactiveUS20050235979A1Low costHeating fastDomestic stoves or rangesBoiler water tubesExhaust pipeThin walled

For inclusion on the line between the liquid wash supply and the discharge jets of a vehicle windshield liquid wash pumping system, a liquid wash heater secured on an engine manifold or exhaust pipe, comprising a housing with a thin-walled, relatively small diameter, non-linear liquid wash tube contained therein.

Owner:WHITTAKER THOMAS H

Metallic porous body incorporated by casting into a heat exchanger

InactiveUS20100242863A1Reduce weightIncrease productionBoiler water tubesMetal-working apparatusCombustorFlue gas

The present invention relates to a co-cast heat exchanger element intended for a central heating boiler, which heat exchanger element is made from substantially aluminum, the heat exchanger element being provided with walls which enclose a water carrying channel, and with at least one wall which encloses at least one flue gas draft to which a burner can be connected, at least one wall which encloses the at least one flue gas draft being water-cooled in that it also forms a boundary of the water-carrying channel, while one of the water-cooled walls is provided with heat exchanging surface enlarging pins and / or fins which extend in the respective flue gas draft and is also provided with other heat exchanging surface enlarging metallic porous structures.

Owner:BEKAERT COMBUSTION TECH

Low thermal expansion Ni-base superalloy

InactiveUS7160400B2Reduce bloatBoiler water tubesMetal/metal-oxides/metal-hydroxide catalystsThermal expansionSuperalloy

A low thermal expansion Ni-base superalloy contains, by weight % (hereinafter the same as long as not particularly defined) C: 0.15% or less; Si: 1% or less; Mn: 1% or less; Cr: 5 to 20%; at least one of Mo, W and Re of Mo+½(W+Re) of 17 (exclusive) to 25%; Al: 0.2 to 2%; Ti: 0.5 to 4.5%; Fe of 10% or less; at least one of B: 0.02% and Zr: 0.2% or less; a remainder of Ni and inevitable impurities; wherein the atomic % of Al+Ti is 2.5 to 7.0.

Owner:DAIDO STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com