Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

329 results about "Catalytic burner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

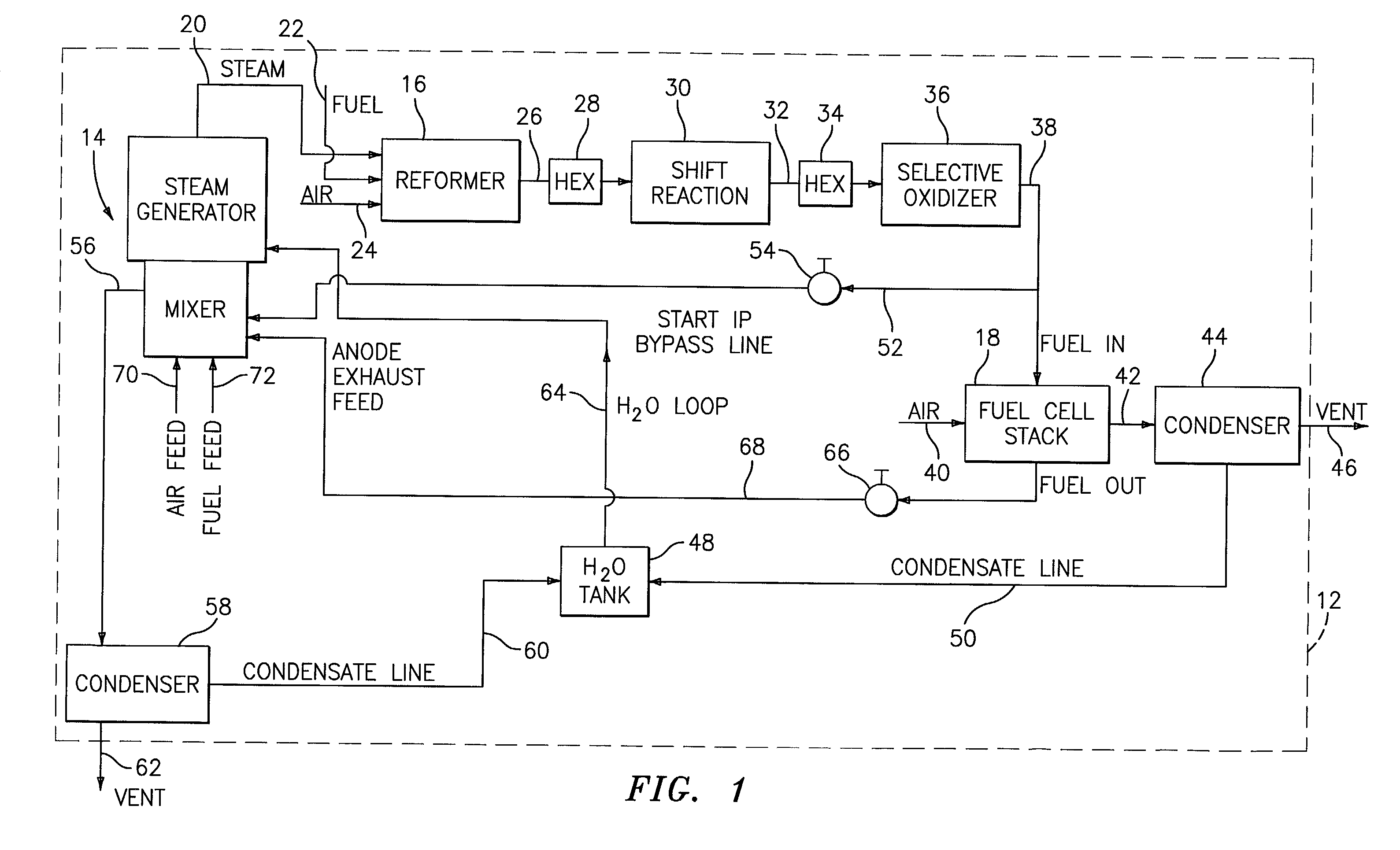

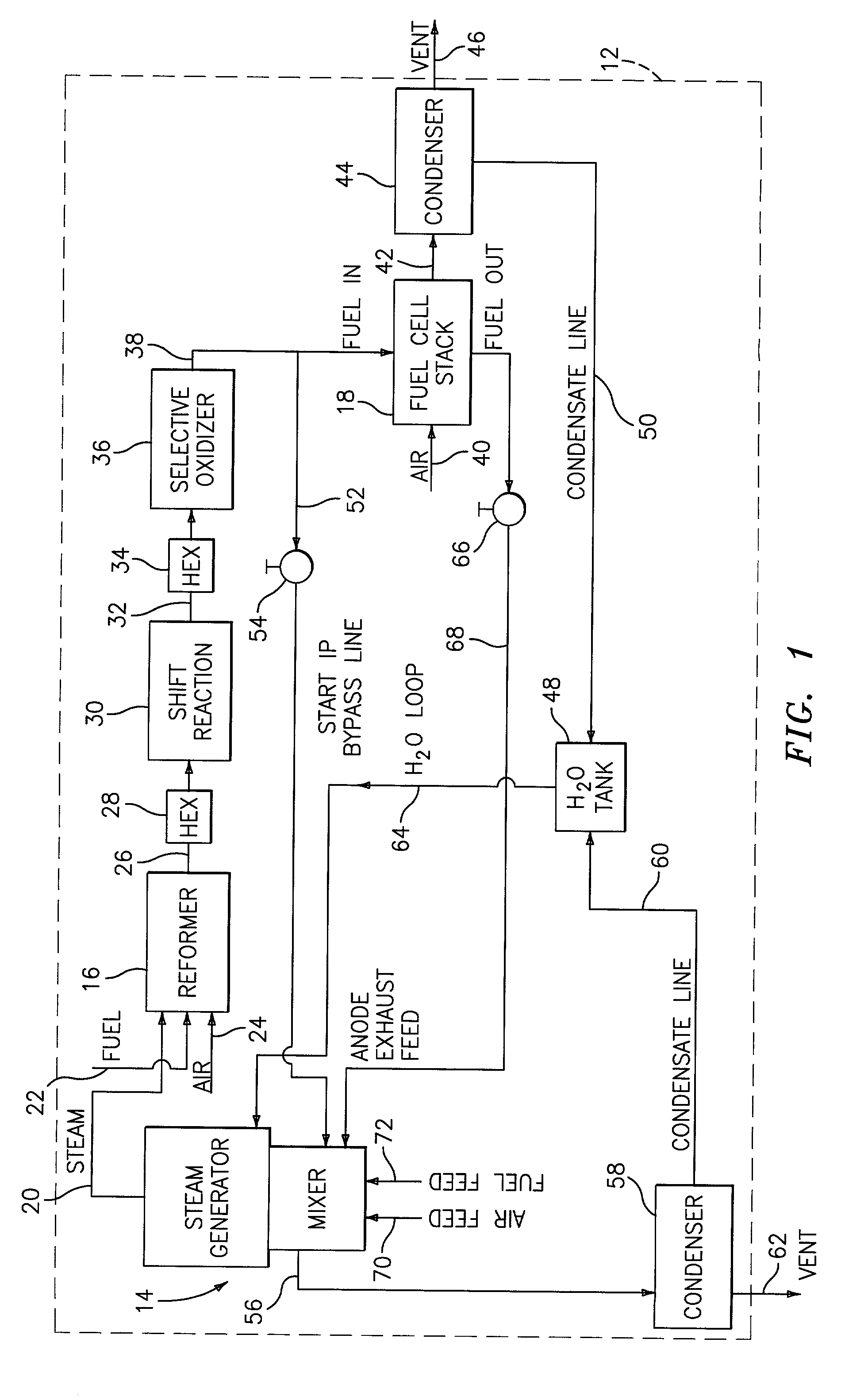

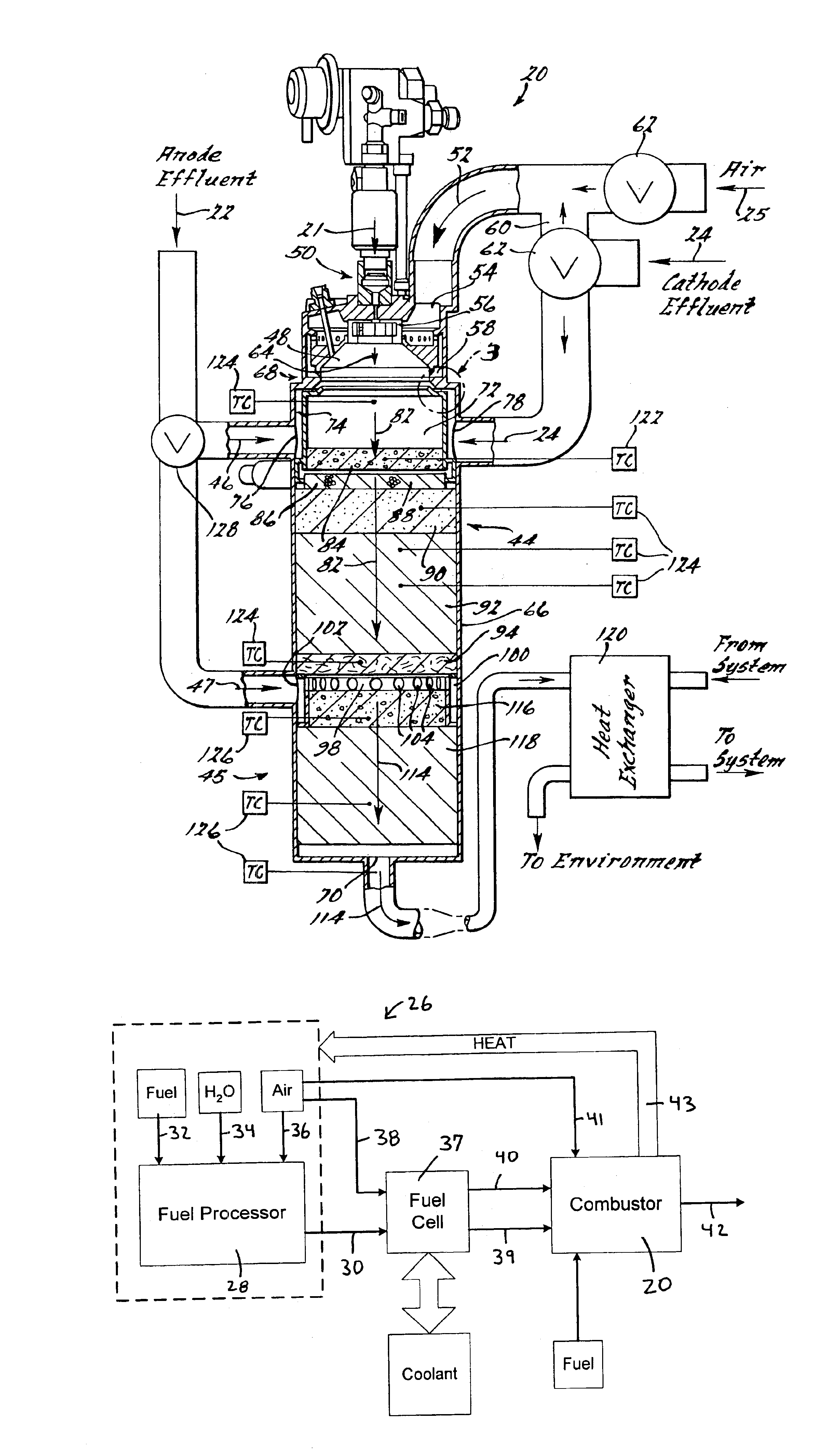

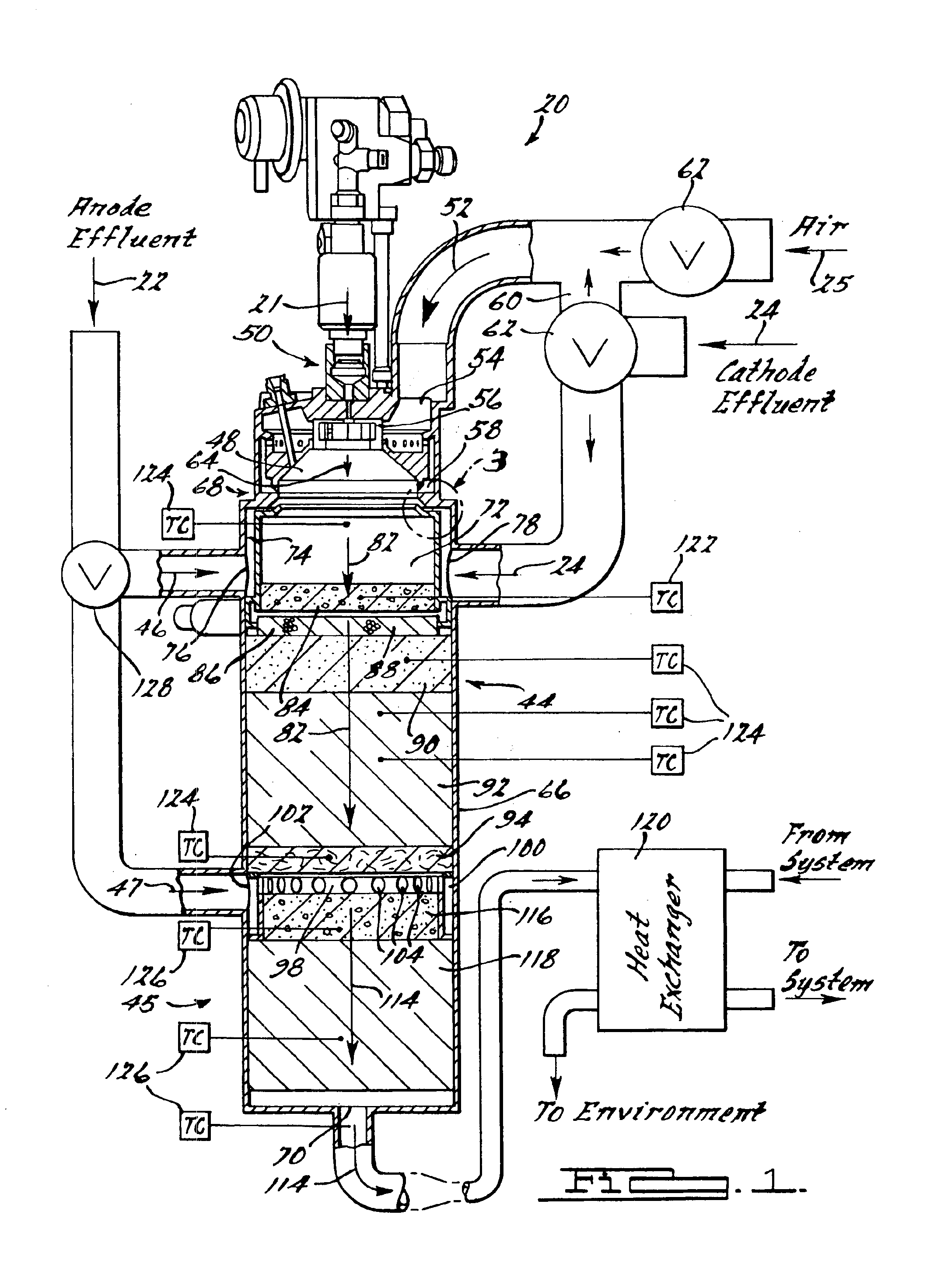

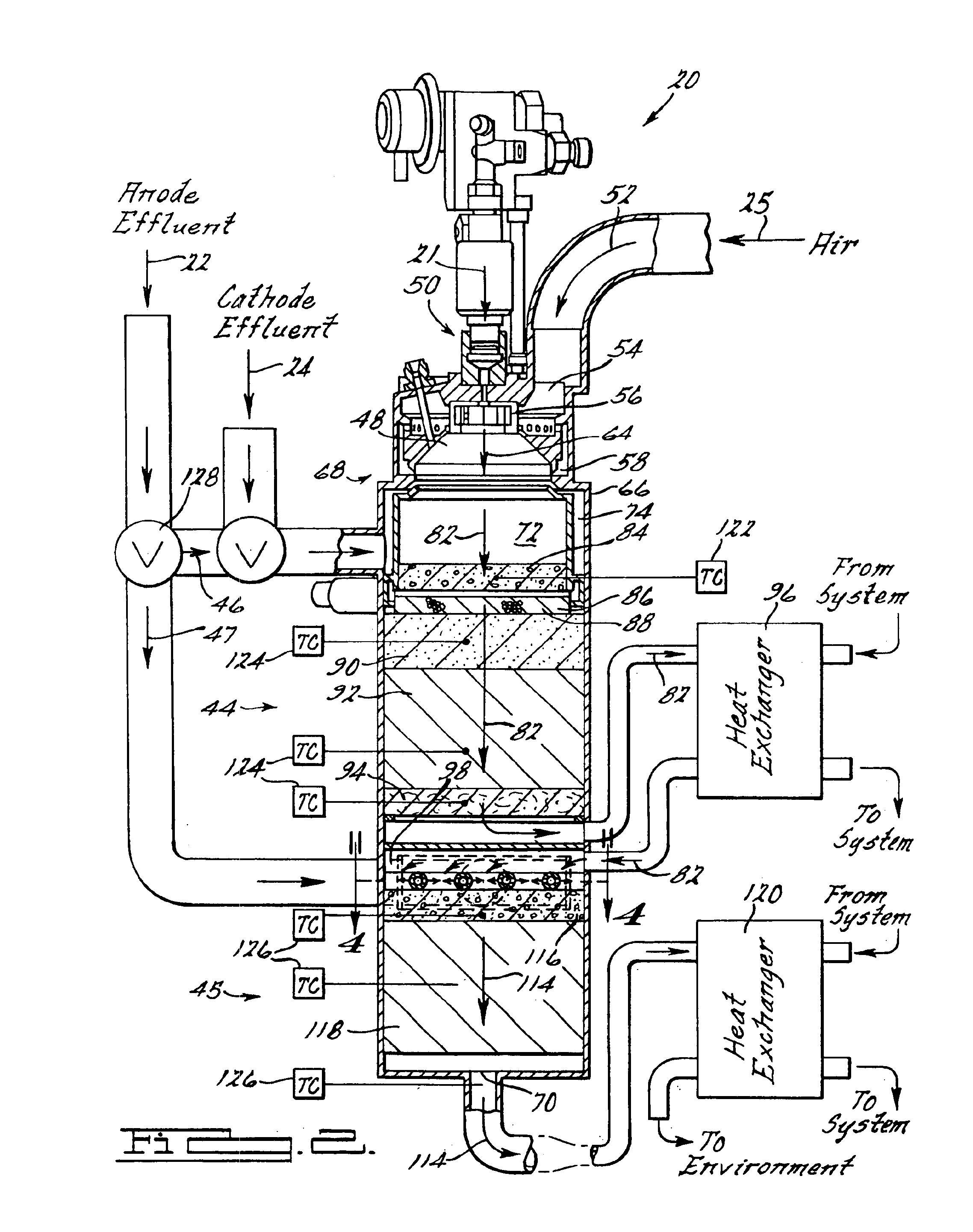

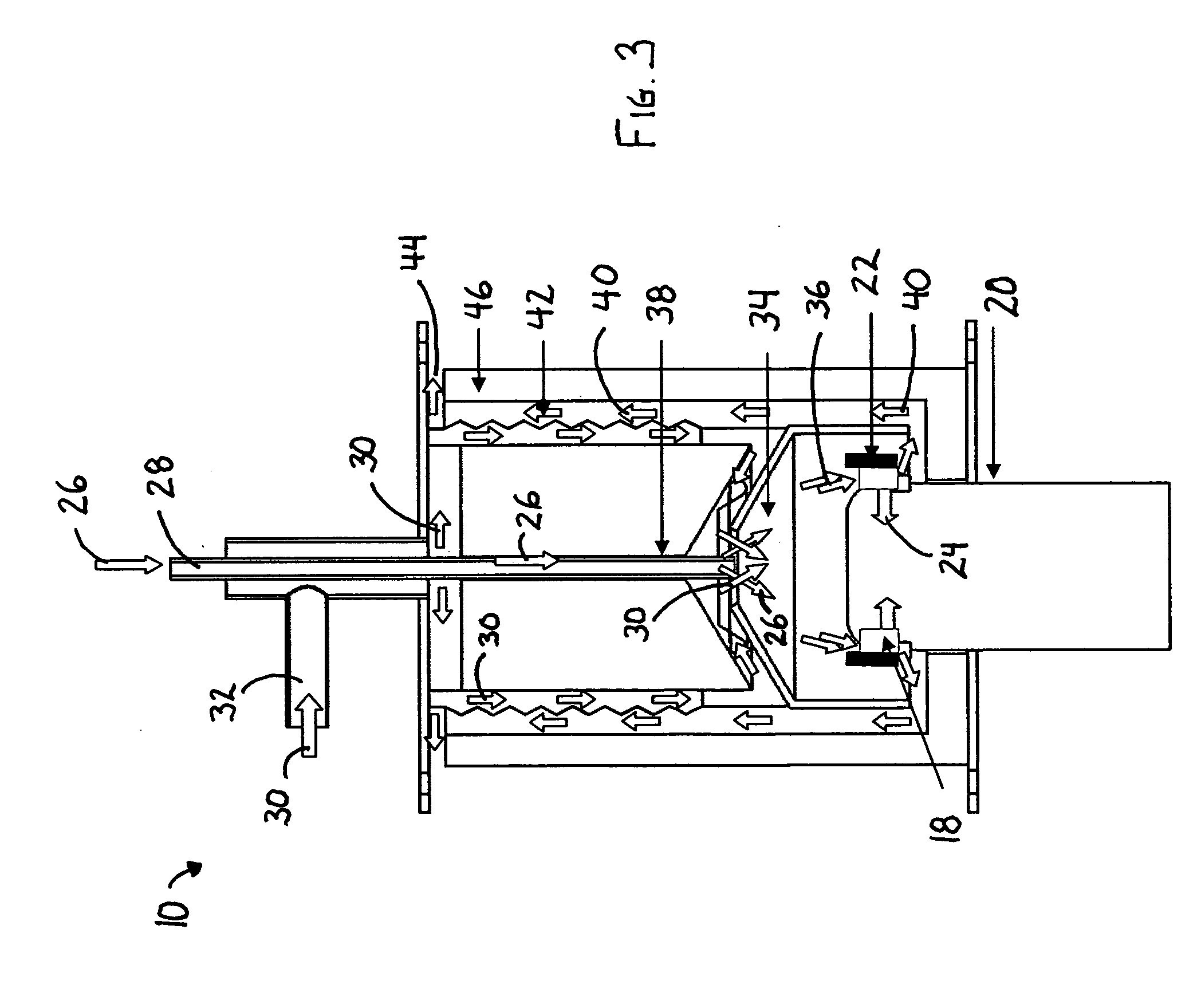

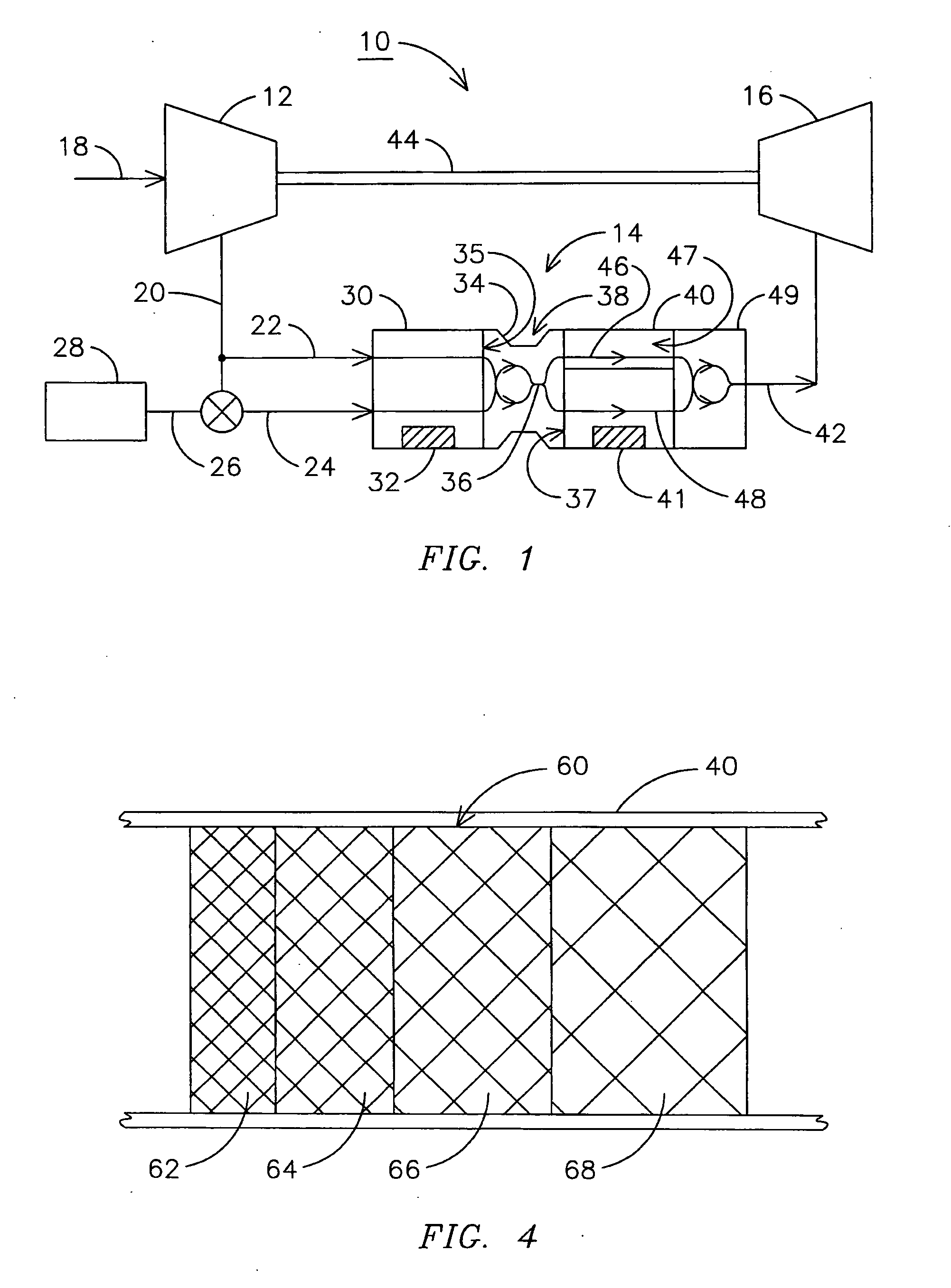

Steam generator for a PEM fuel cell power plant

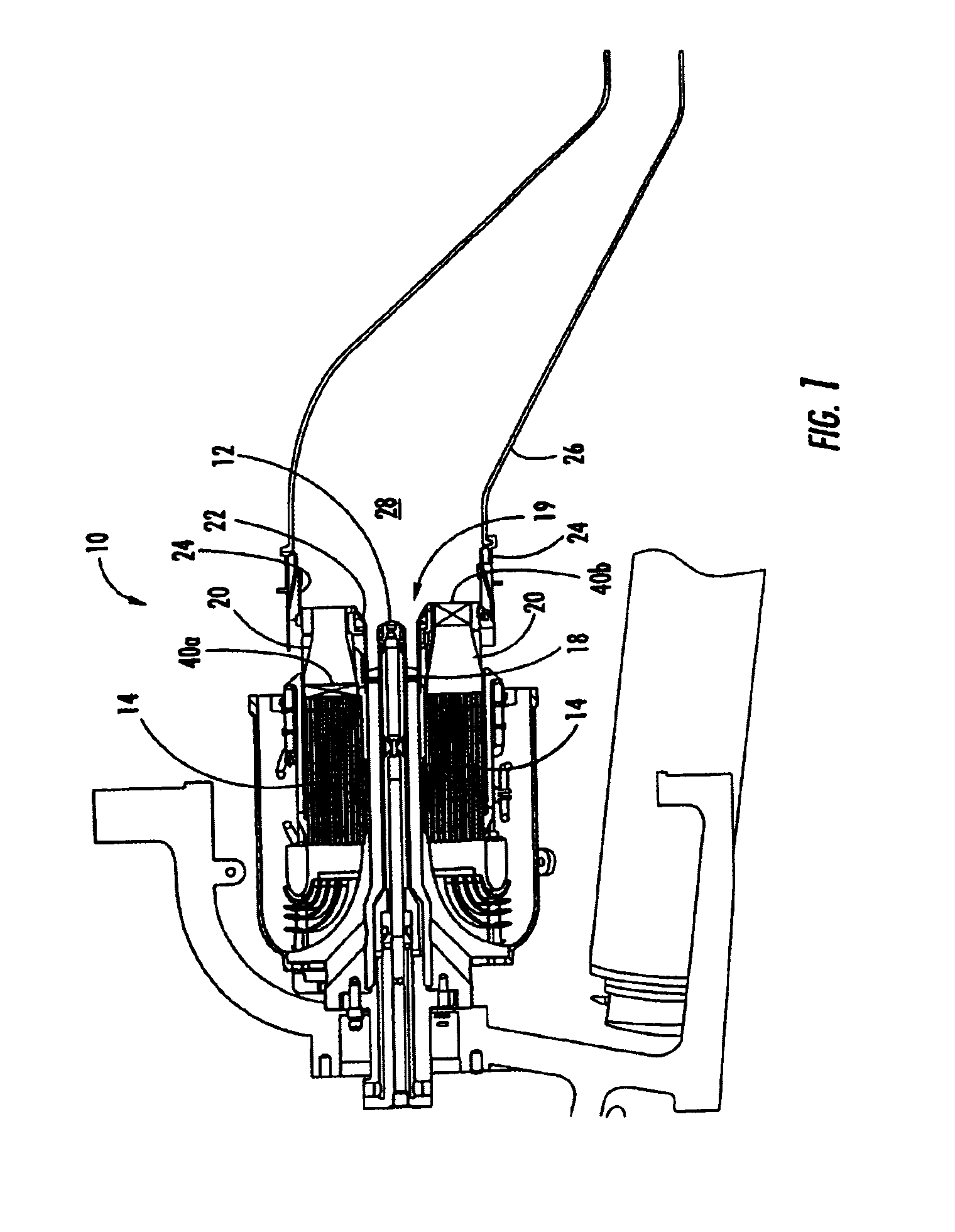

A burner assembly includes a catalyzed burner for combusting an anode exhaust stream from a polymer electrolyte membrane (PEM) fuel cell power plant. The catalysts coated onto the burner can be platinum, rhodium, or mixtures thereof. The burner includes open cells which are formed by a lattice, which cells communicate with each other throughout the entire catalyzed burner. Heat produced by combustion of hydrogen in the anode exhaust stream is used to produce steam for use in a steam reformer in the PEM fuel cell assembly. The catalyzed burner has a high surface area wherein about 70-90% of the volume of the burner is preferably open cells, and the burner has a low pressure drop of about two to three inches water from the anode exhaust stream inlet to the anode exhaust stream outlet . The burner assembly operates at essentially ambient pressure and at a temperature of up to about 1,700° F. (646° C.). The burner assembly can combust anode exhaust during normal operation of the fuel cell assembly. The burner assembly also includes an adjunct burner which can combust gasoline or anode bypass gas (the latter of which is a reformed fuel gas which is tapped off of the fuel cell stack fuel inlet line) during startup of the fuel cell power plant. Once start up of the fuel cell power plant is achieved, the burner assembly will need only combustion of the anode exhaust by the catalytic burner to produce steam for the reformer.

Owner:BALLARD POWER SYSTEMS

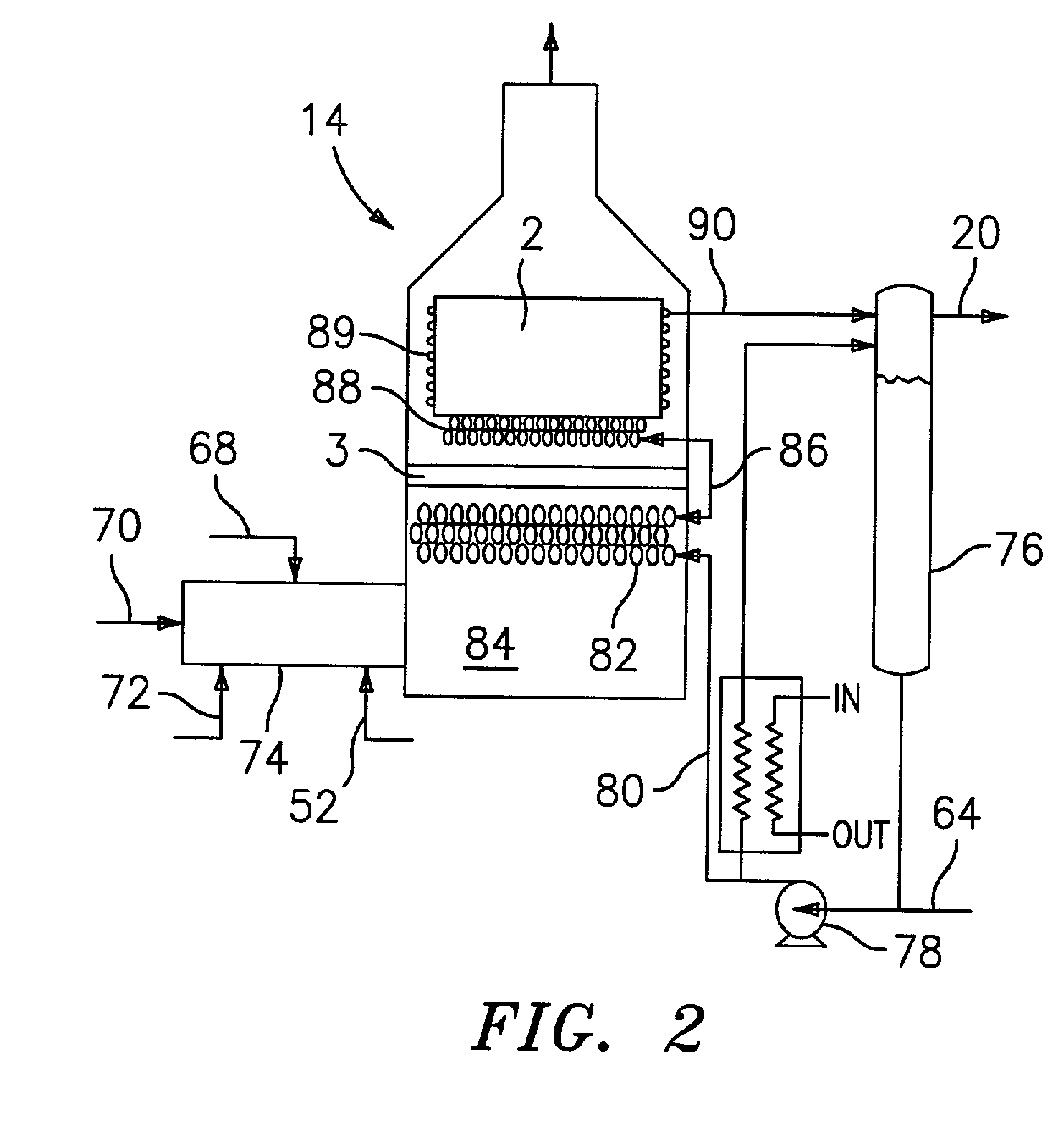

Fuel-air premixing system for a catalytic combustor

InactiveUS7093445B2Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustion systemHybrid system

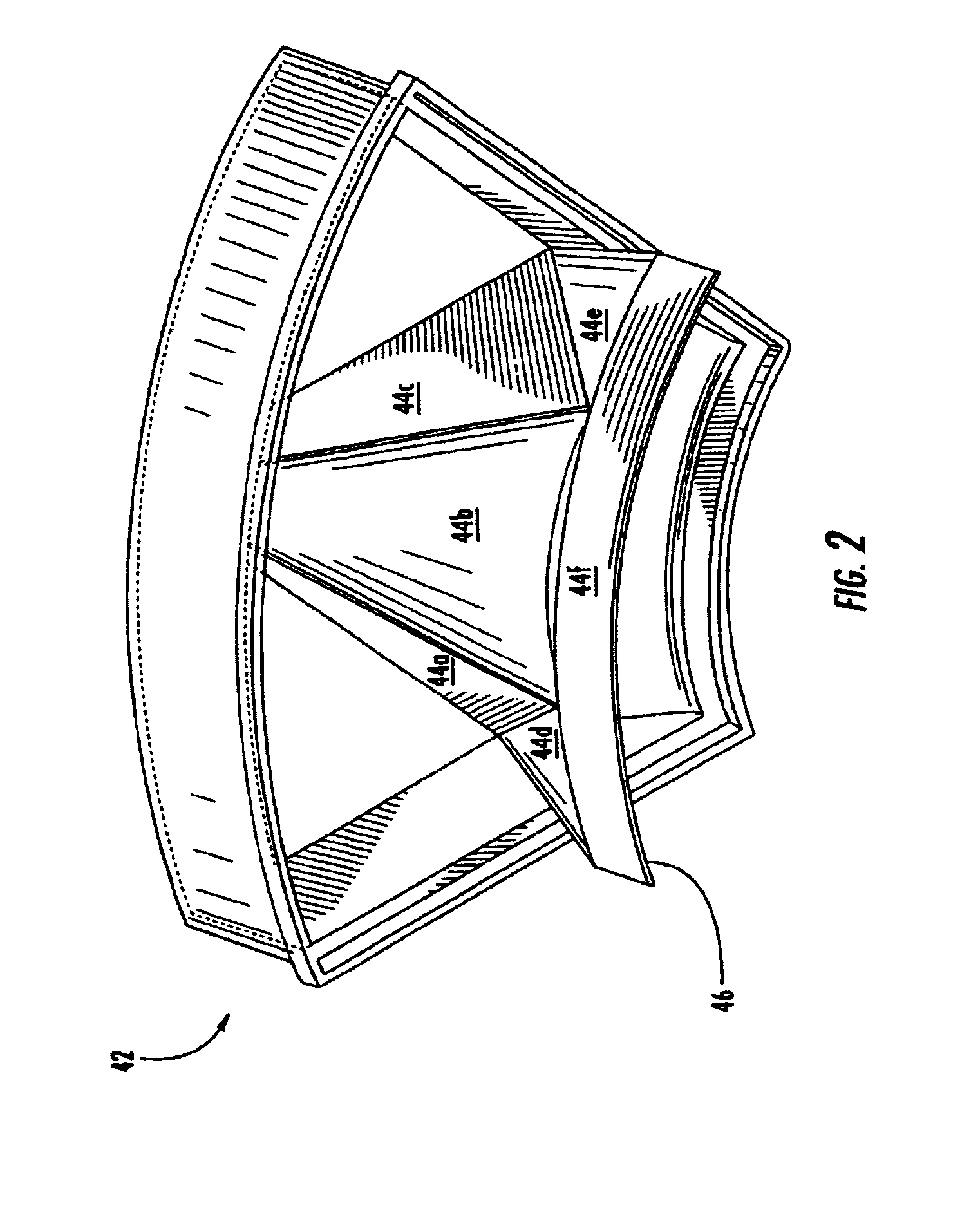

Disclosed is a unique fuel and air premixing system for a gas turbine catalytic combustion system. The mixer utilizes a multi-channel counter-rotating swirler with aerodynamically shaped fuel pegs located upstream of the swirler. The premixing system provides the downstream catalyst with a fuel-air mixture sufficiently uniform for proper catalyst operation and wide operating limits. Features have been incorporated in the system to make it resistant to flameholding.

Owner:KAWASAKI HEAVY IND LTD

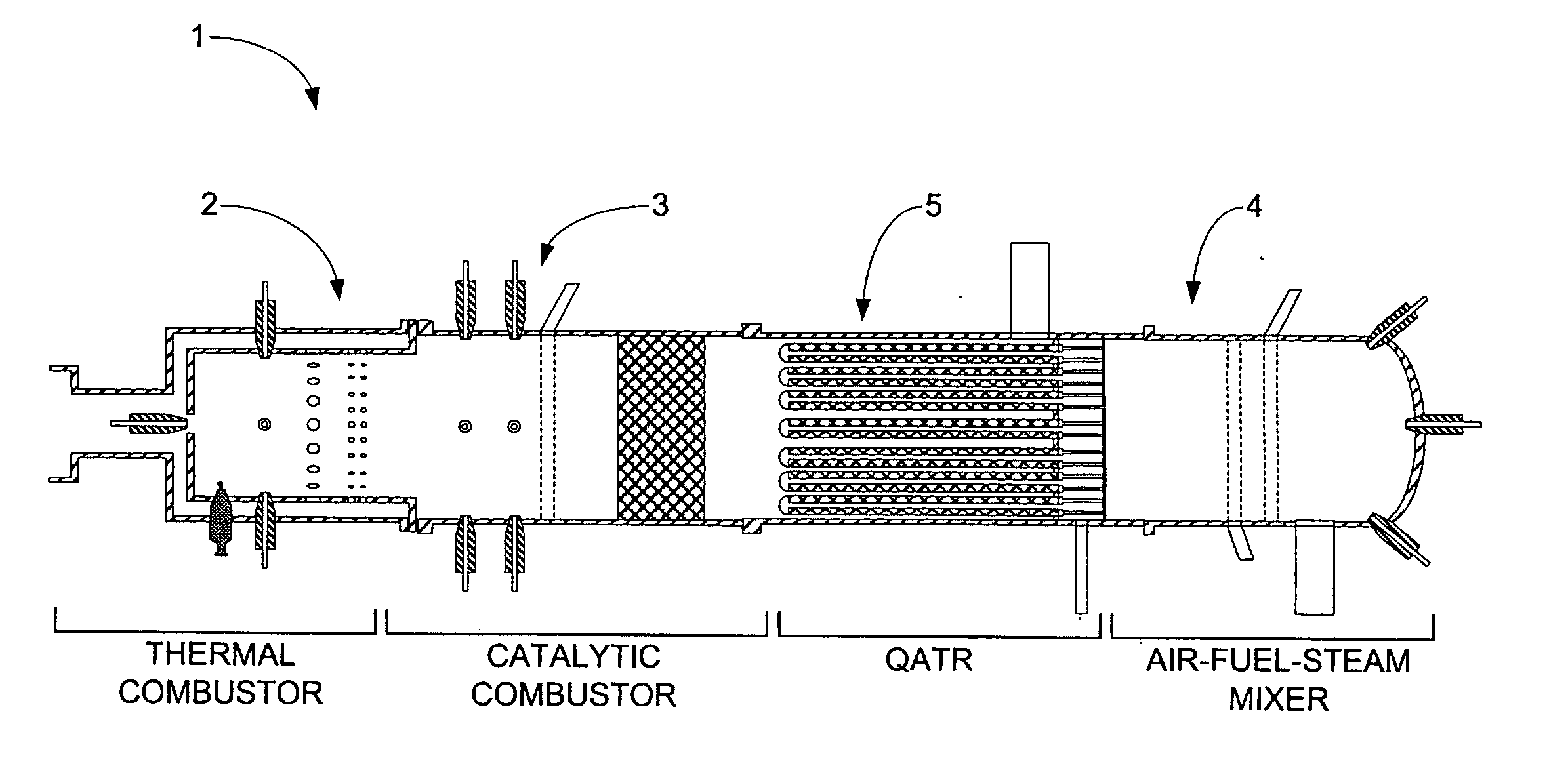

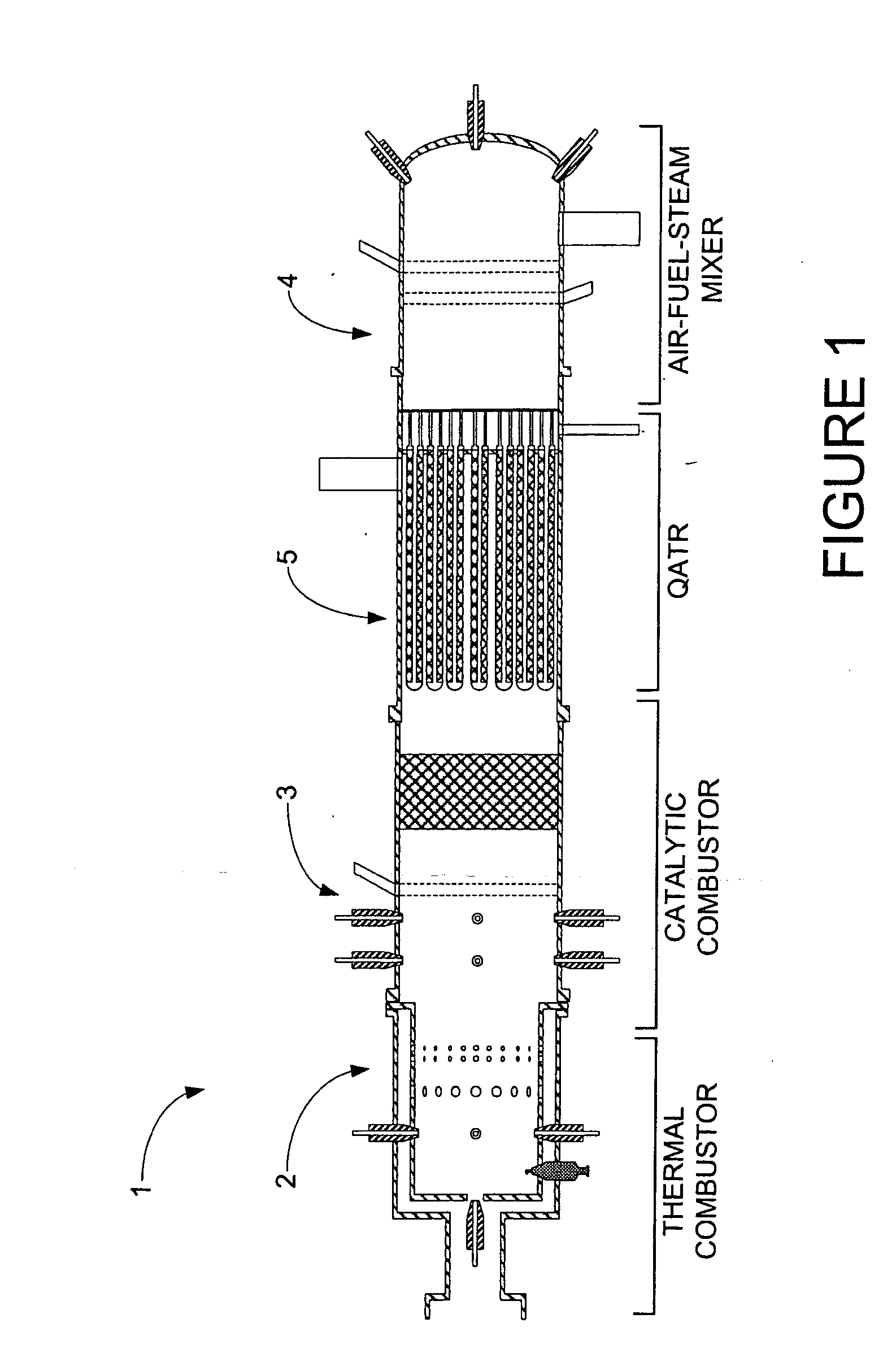

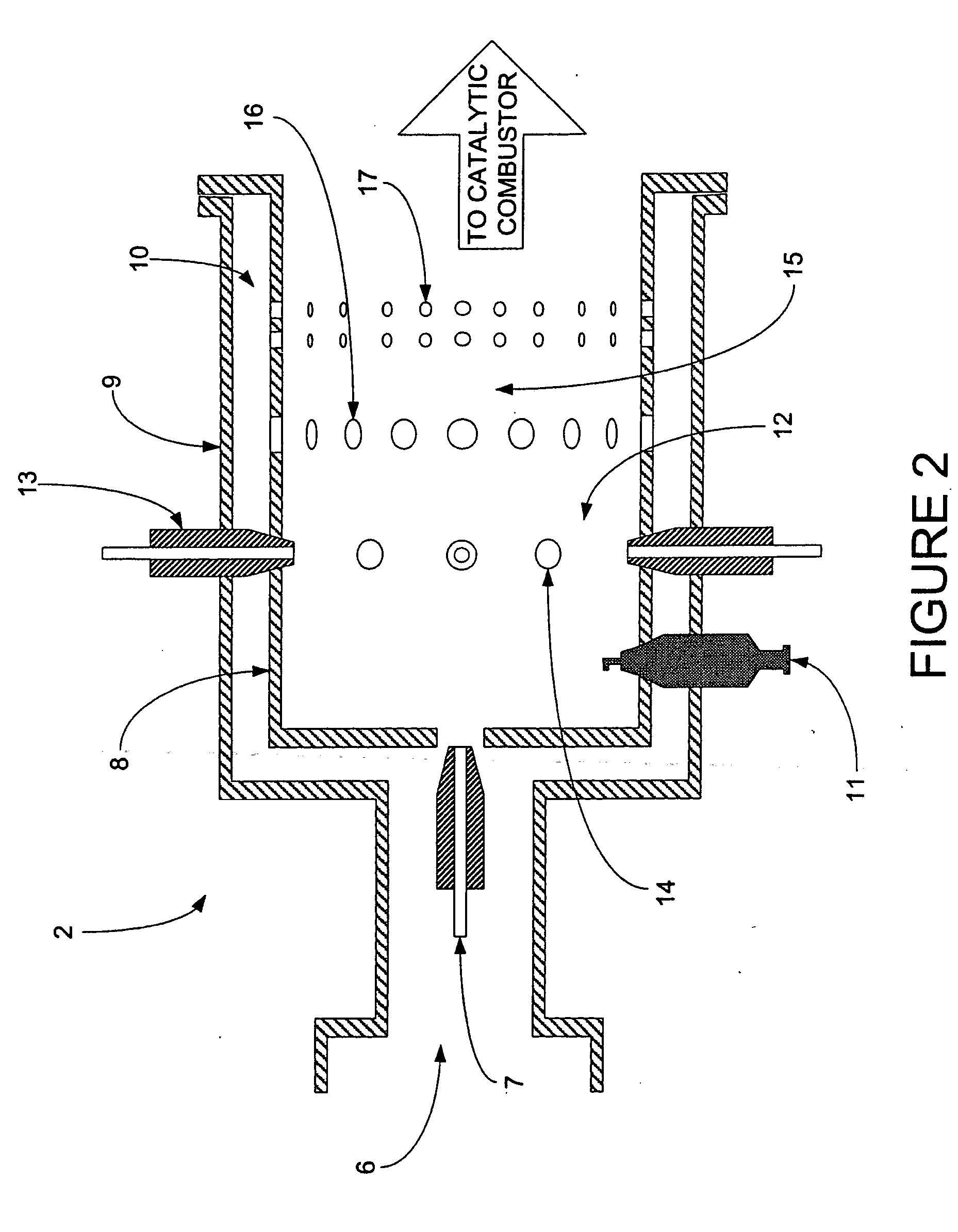

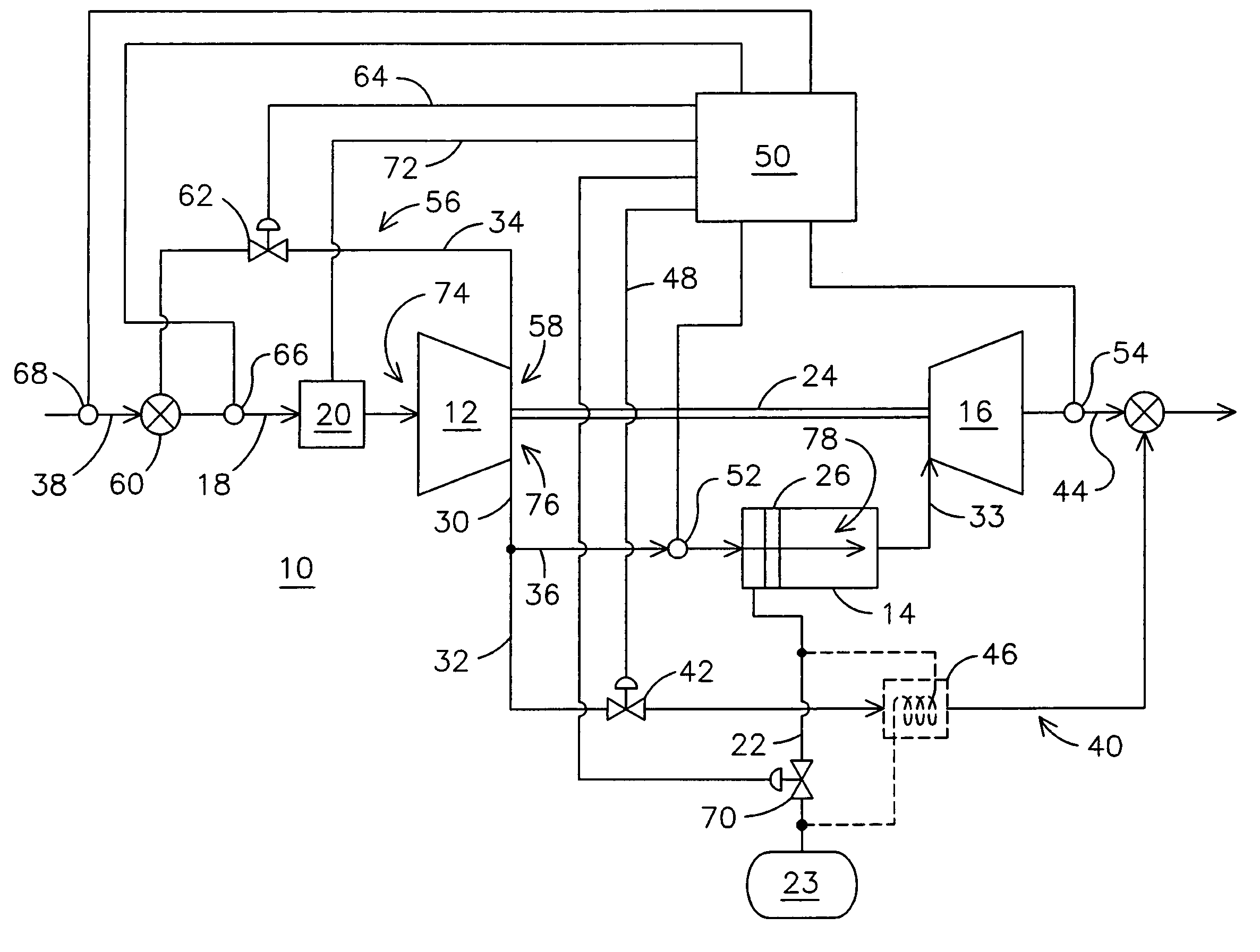

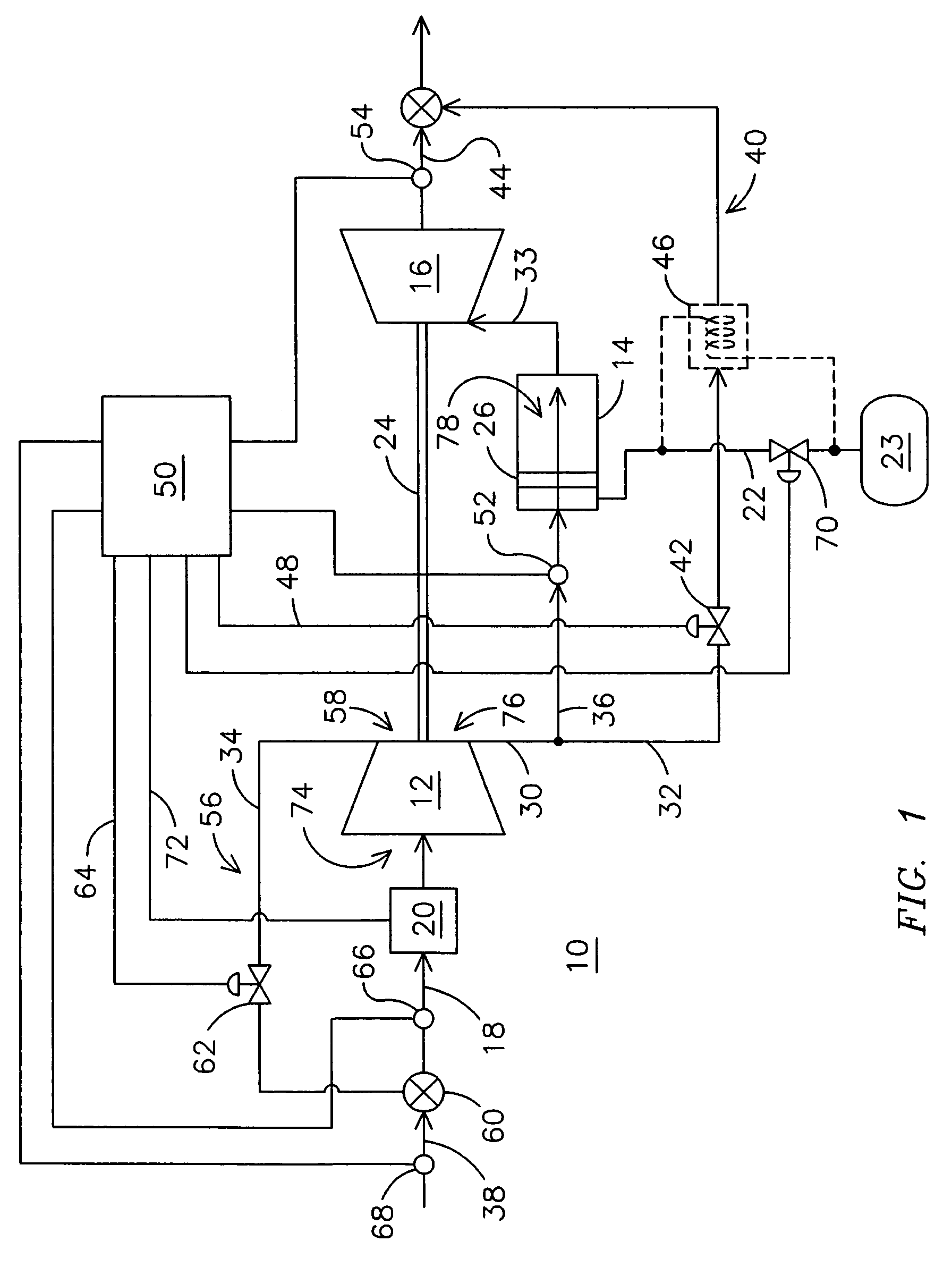

Integrated fuel processor subsystem with quasi-autothermal reforming

InactiveUS20050188615A1Provide flexibilitySufficient flexibilityReciprocating combination enginesExhaust apparatusSteam reformingFuel treatment

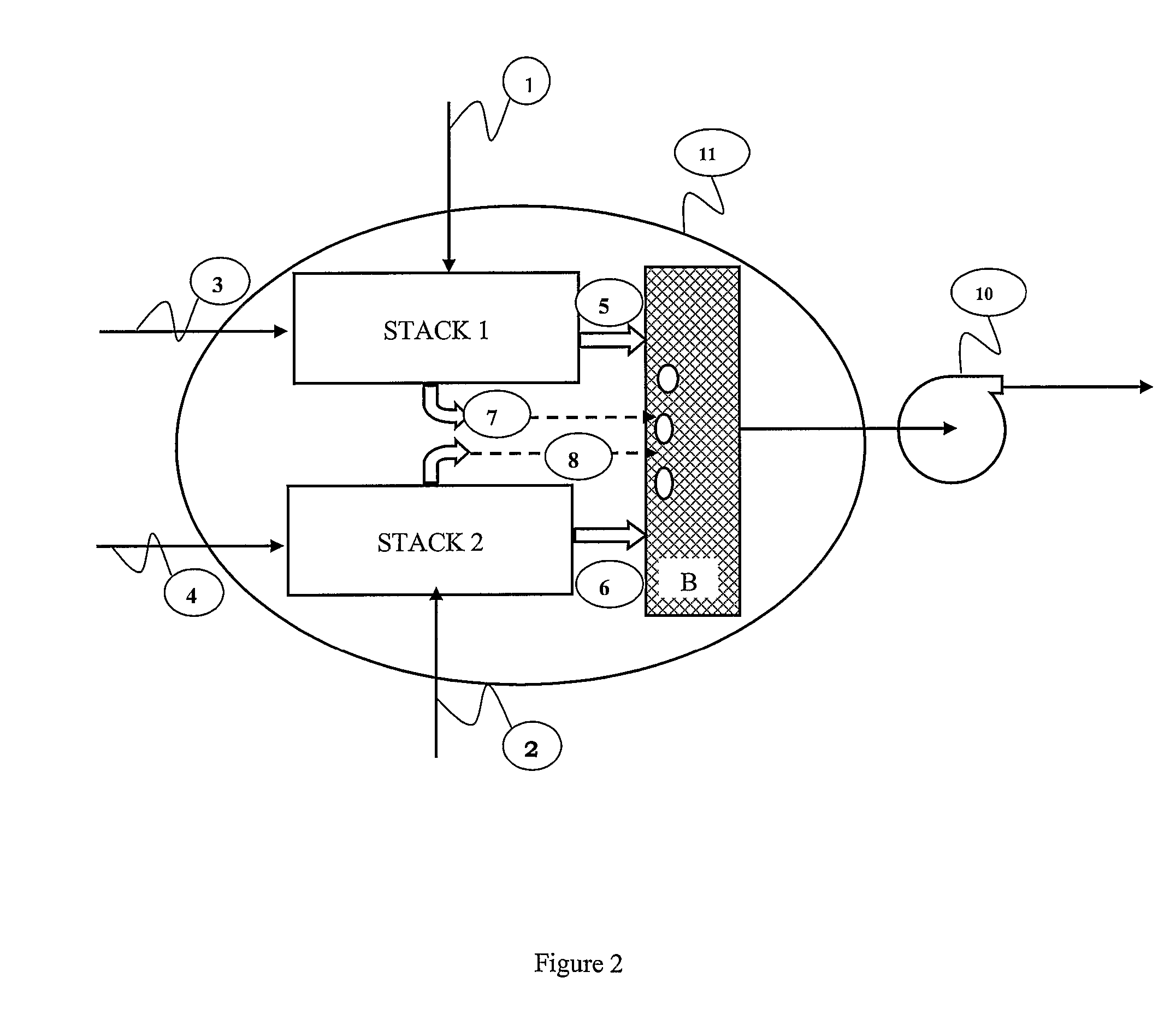

The present invention includes an integrated fuel processor subsystem incorporating a thermal combustor, a catalytic combustor, a quasi-autothermal reactor (QATR) and a air-fuel-steam (AFS) mixer to provide a range of operating modes exhibiting performance between that of a pure steam reformer and a pure autothermal reformer to increase the flexibility of the fuel processor to handle transient system demands such as cold starts, suppress emissions and carbon formation and improve efficiency.

Owner:FLARION TECH +1

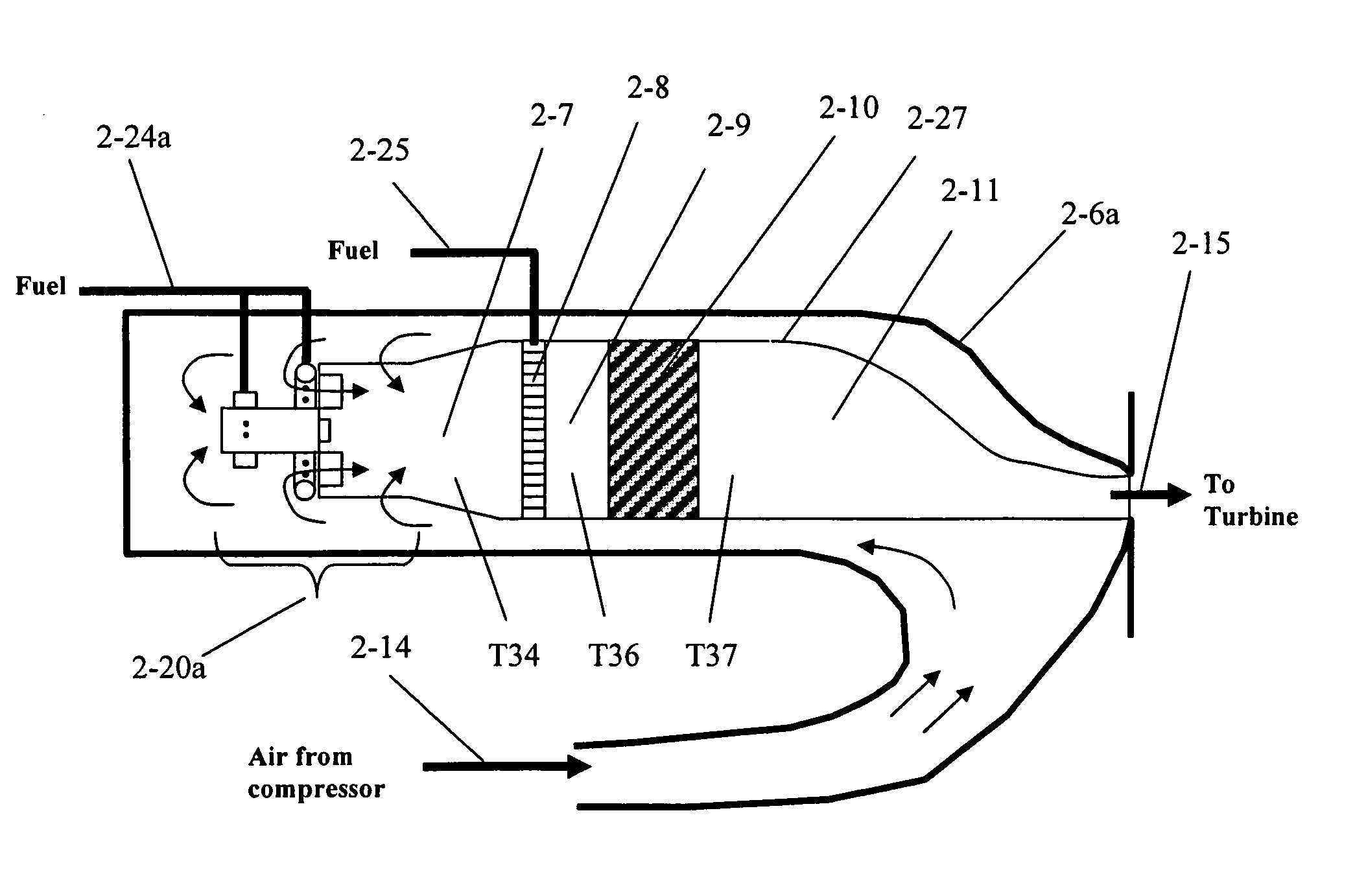

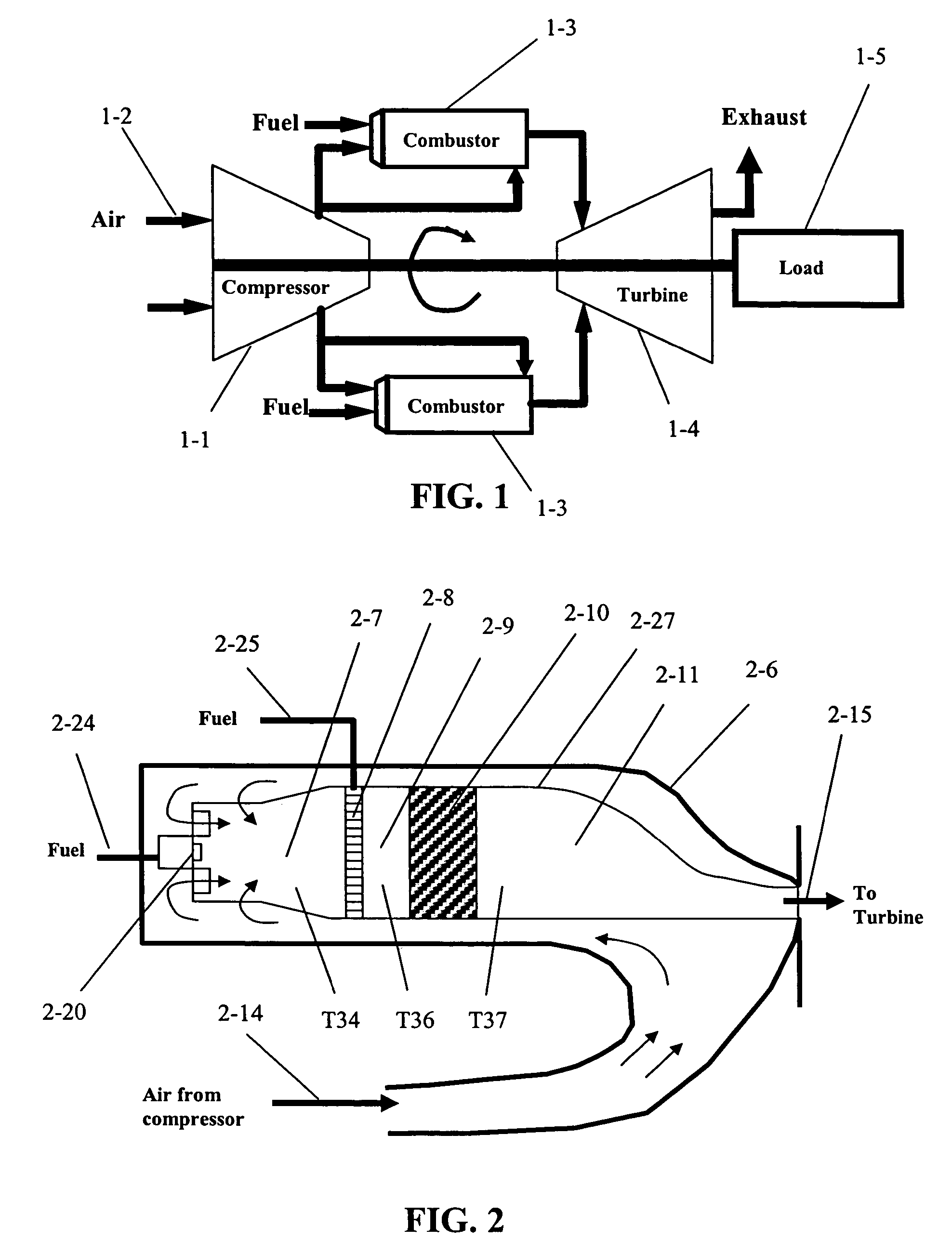

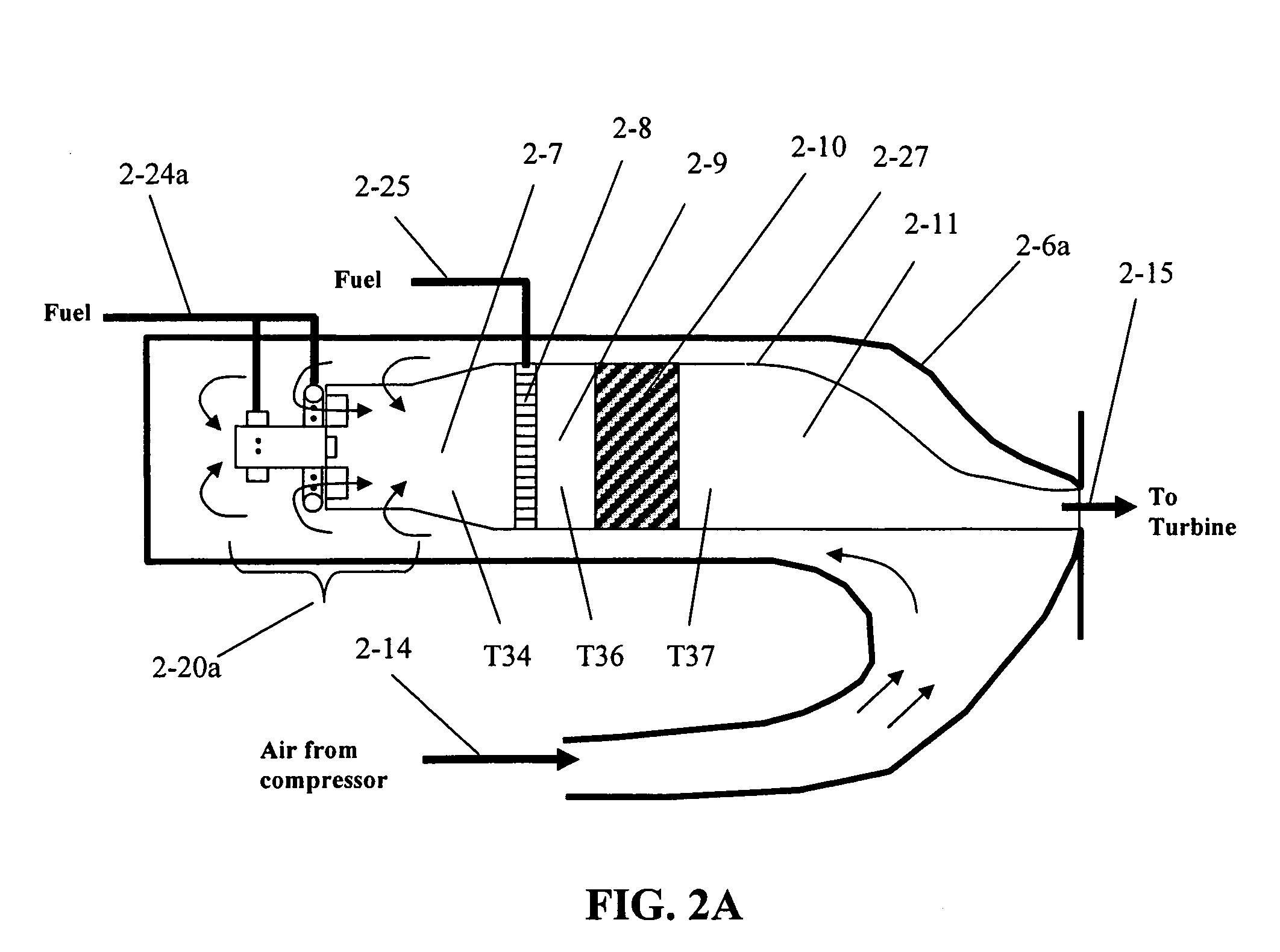

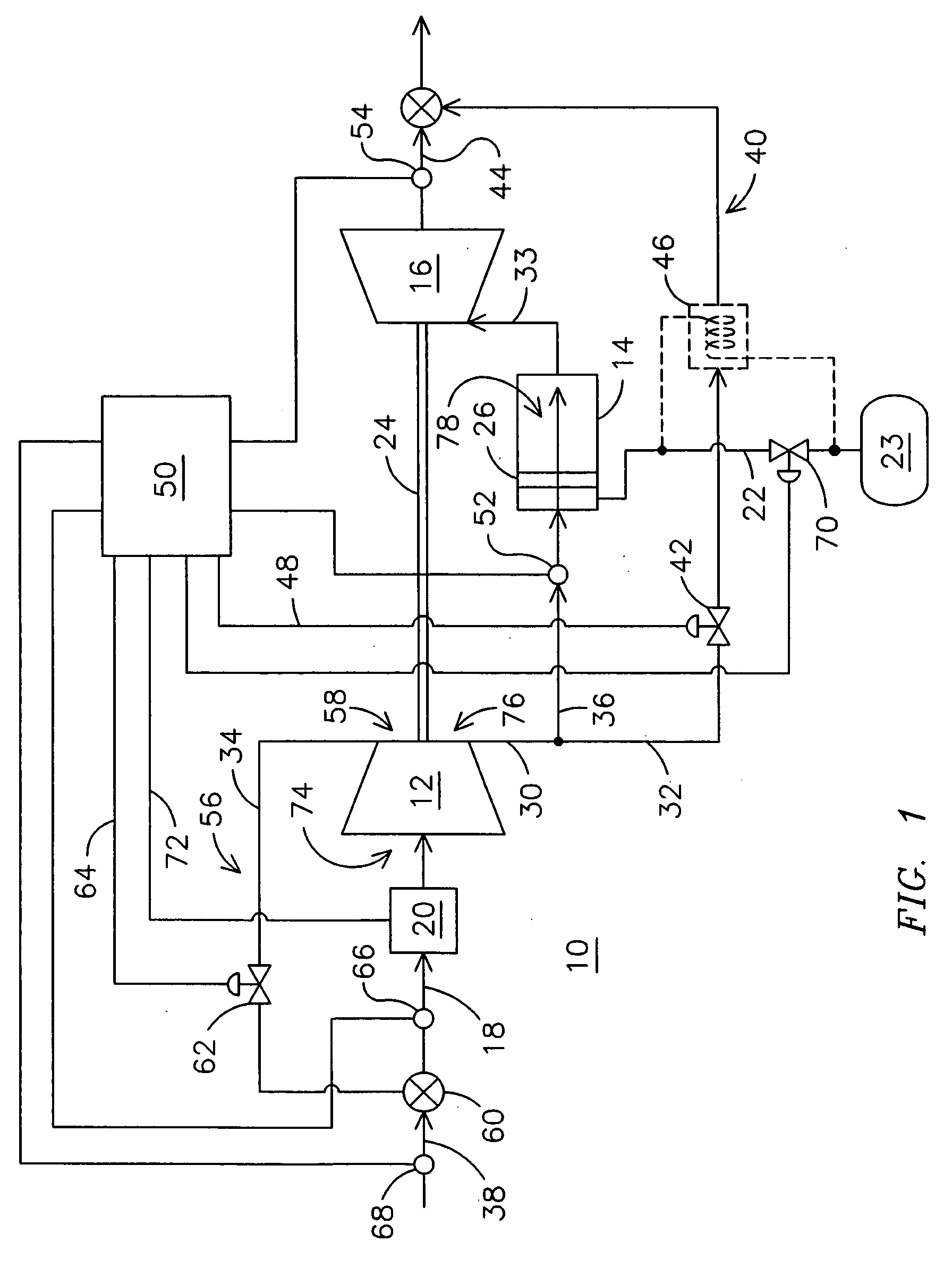

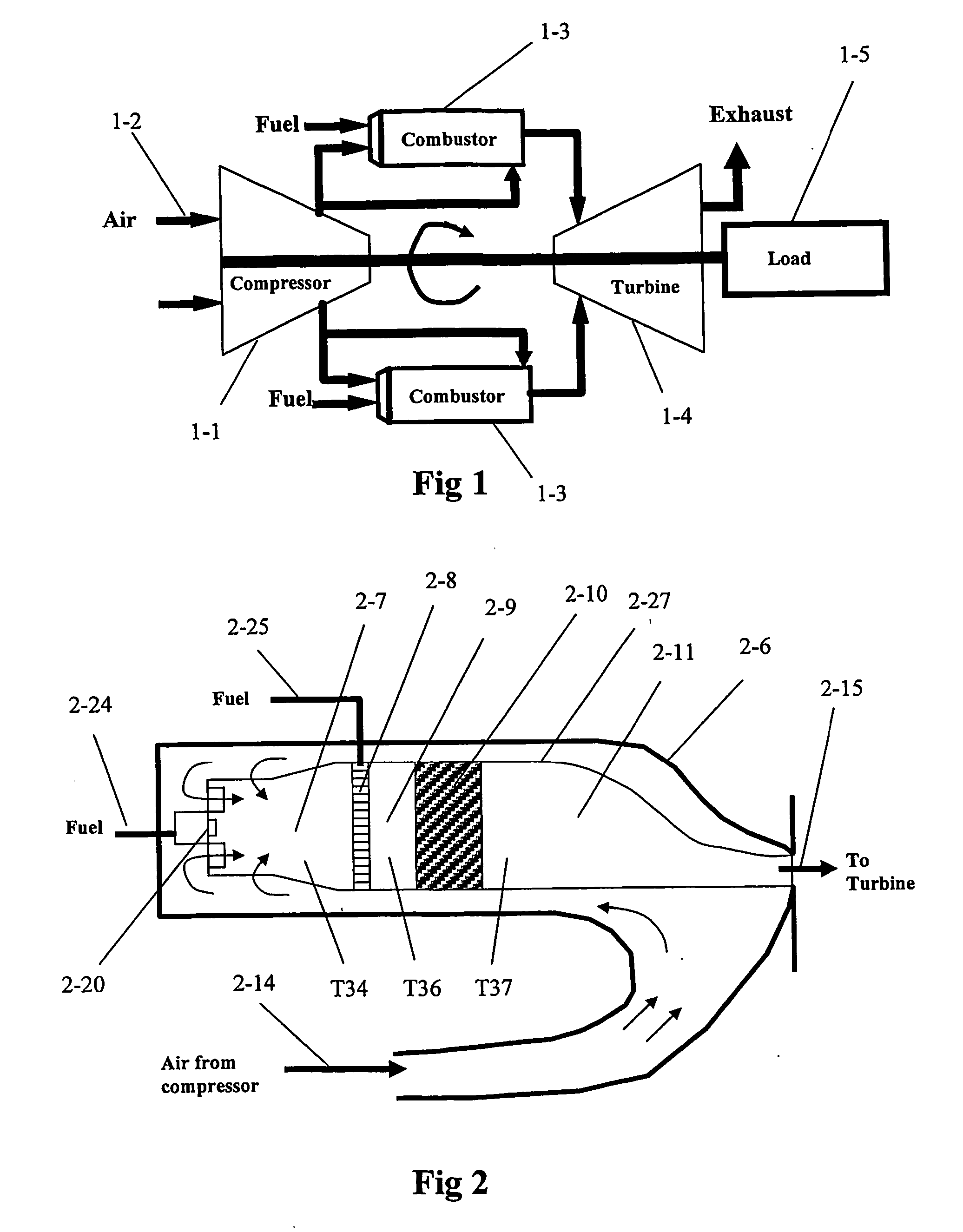

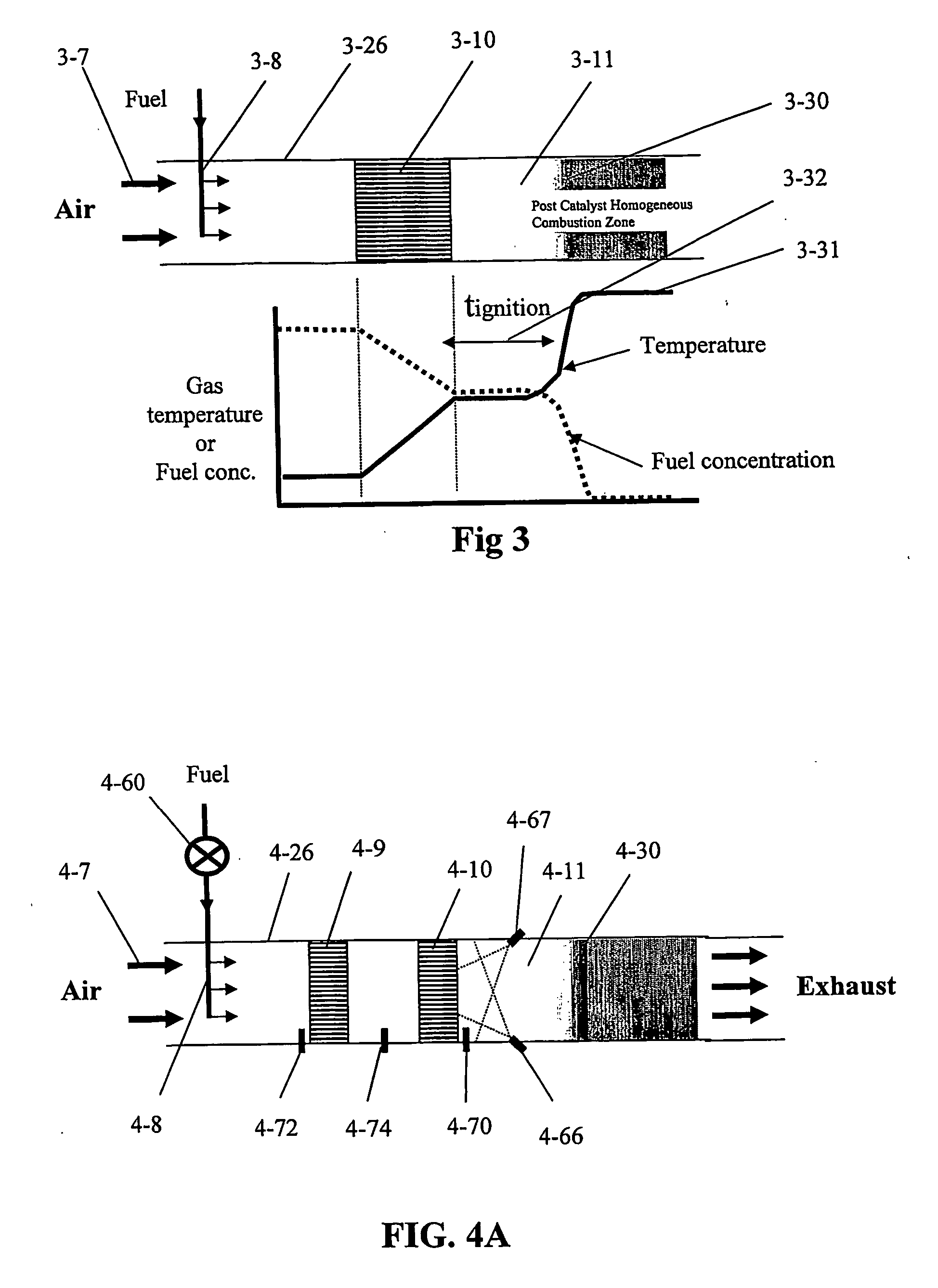

Dynamic control system and method for multi-combustor catalytic gas turbine engine

InactiveUS7152409B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemControl system

According to one aspect, a method of controlling a multi-combustor catalytic combustion system is provided for determining a characteristic of a fuel-air mixture downstream of a preburner associated with a catalytic combustor and adjusting the fuel flow to the preburner based on the characteristic. The characteristic may include, for example, a measurement of the preburner or catalyst outlet temperature or a determination of the position of the homogeneous combustion wave in the burnout zone of the combustor.

Owner:KAWASAKI HEAVY IND LTD

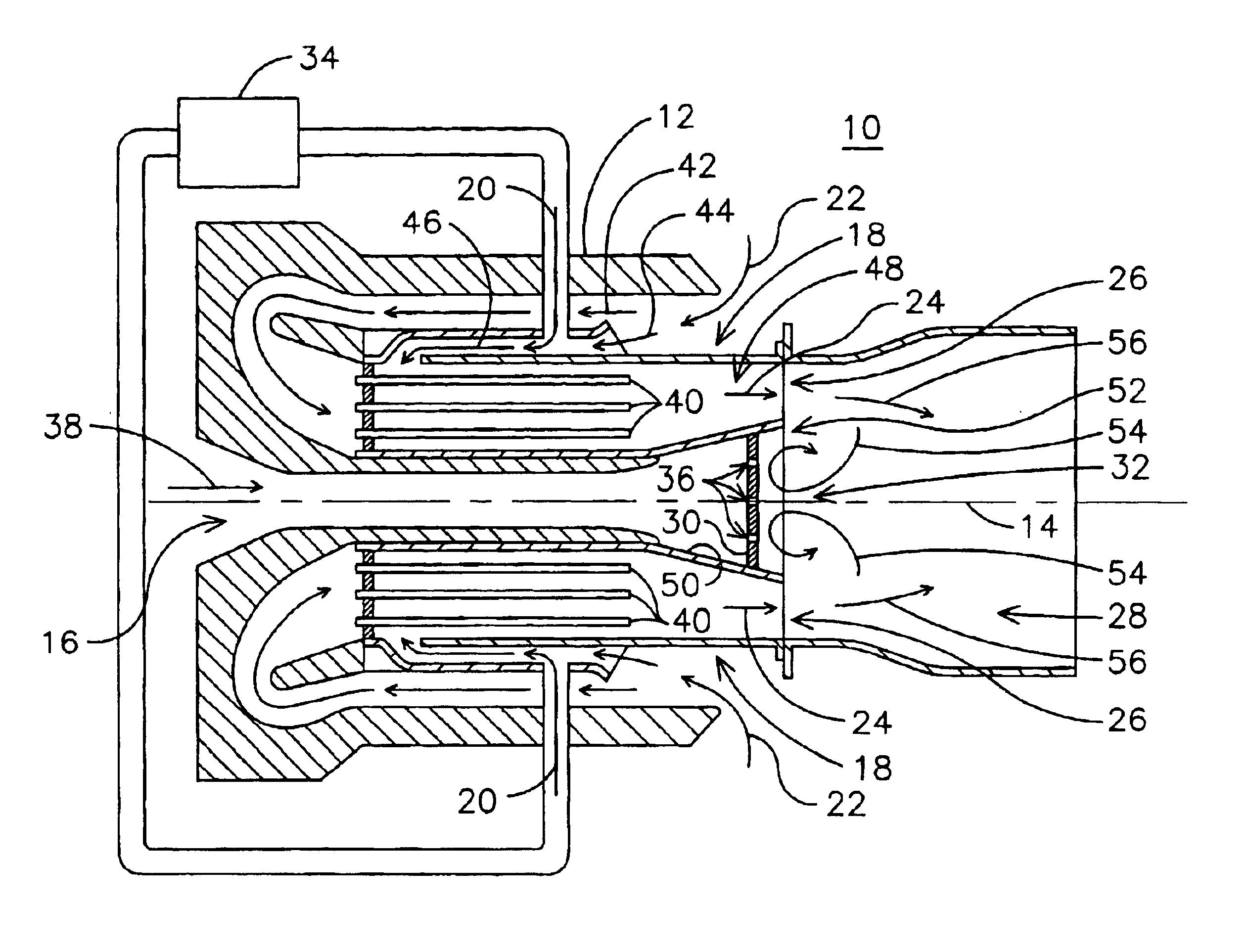

Pilotless catalytic combustor

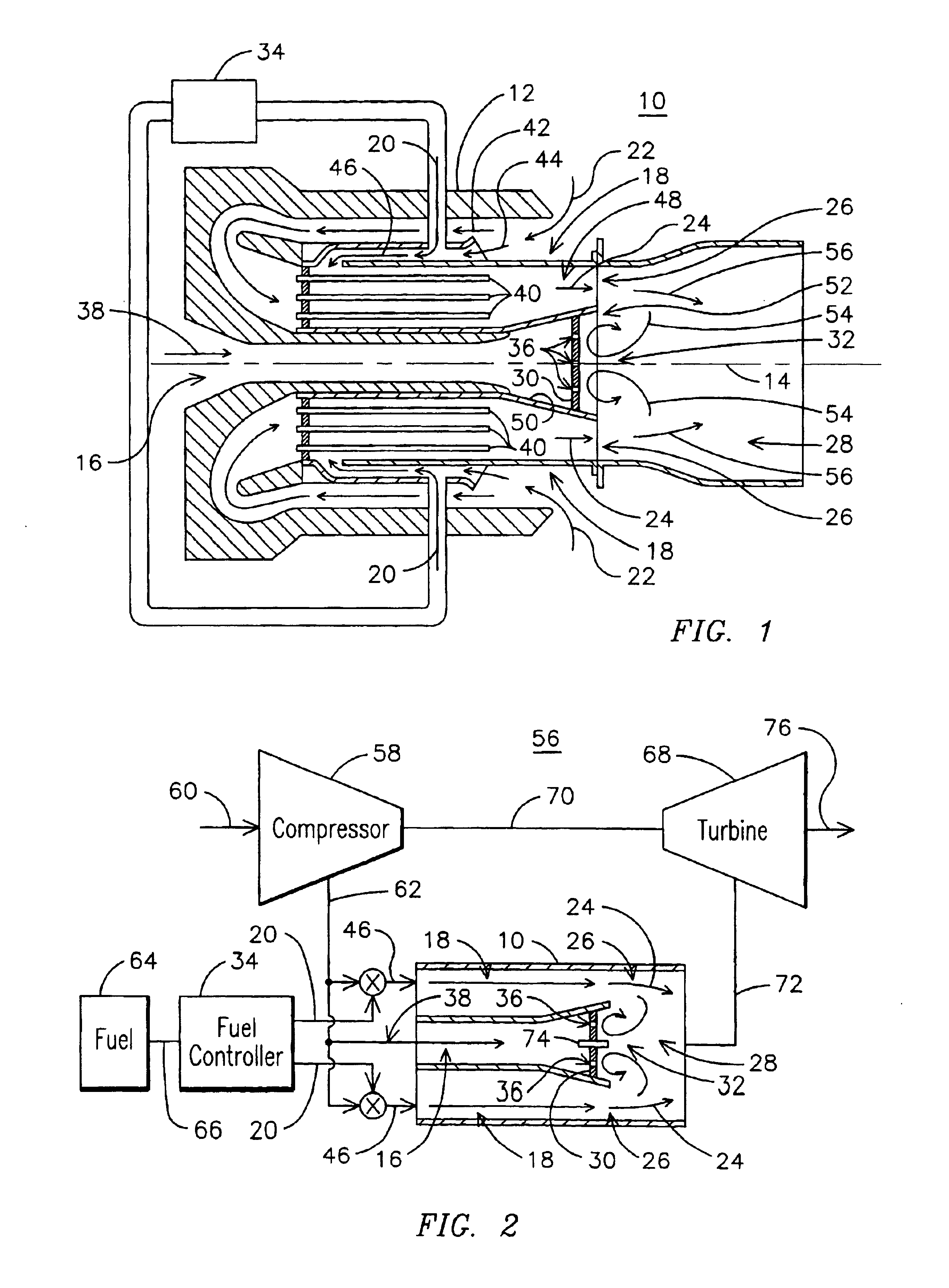

A pilotless catalytic combustor (10) including a basket (12) having a central axis (14) and a central core region (16) disposed along a portion of the central axis. Catalytic combustion modules (18) are circumferentially disposed about the central axis radially outward of the central core region for receiving a fuel flow (20) and a first portion of an oxidizer flow (22), and discharge a partially oxidized fuel / oxidizer mixture (24) at respective exit ends (26). A base plate (30) is positioned in the central core region upstream of the exit ends of the catalytic combustion modules, the baseplate defining a recirculation zone (32) near the respective exit ends for stabilizing oxidation in the burnout zone. A method of staged fueling for a pilotless catalytic combustor includes providing fuel to at least one of the modules during start up and progressively providing fuel to other modules as a load on the turbine engine is increased.

Owner:SIEMENS ENERGY INC

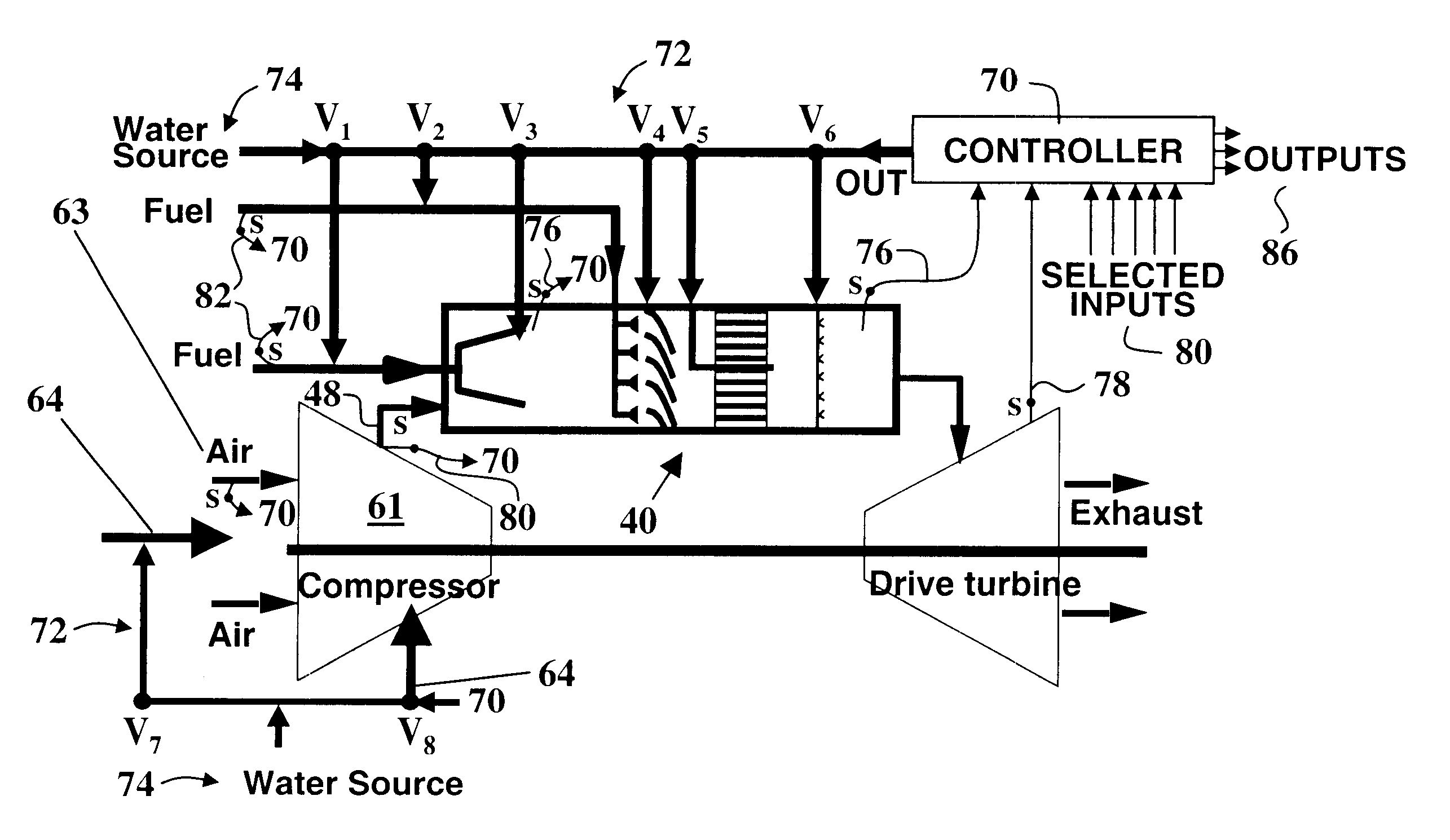

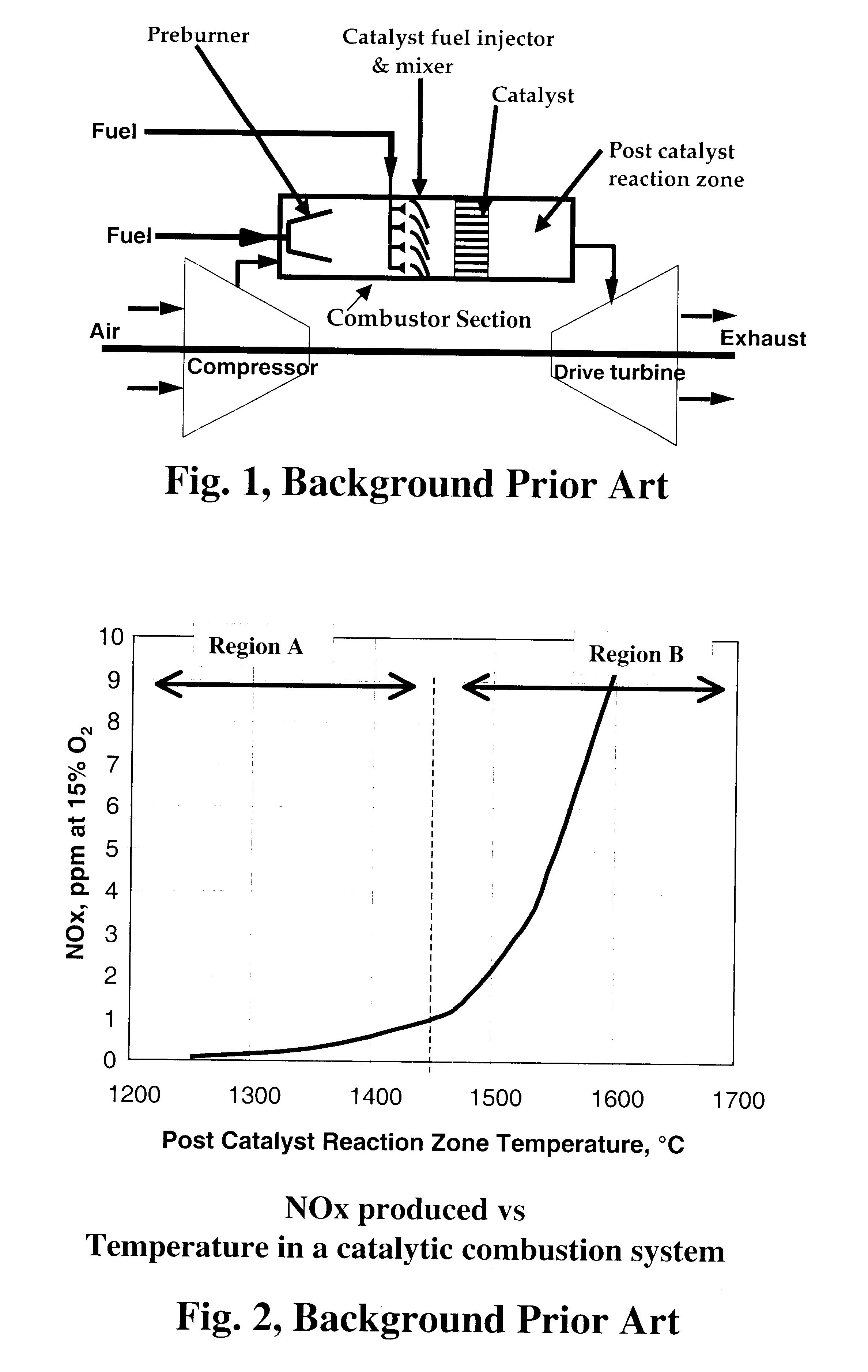

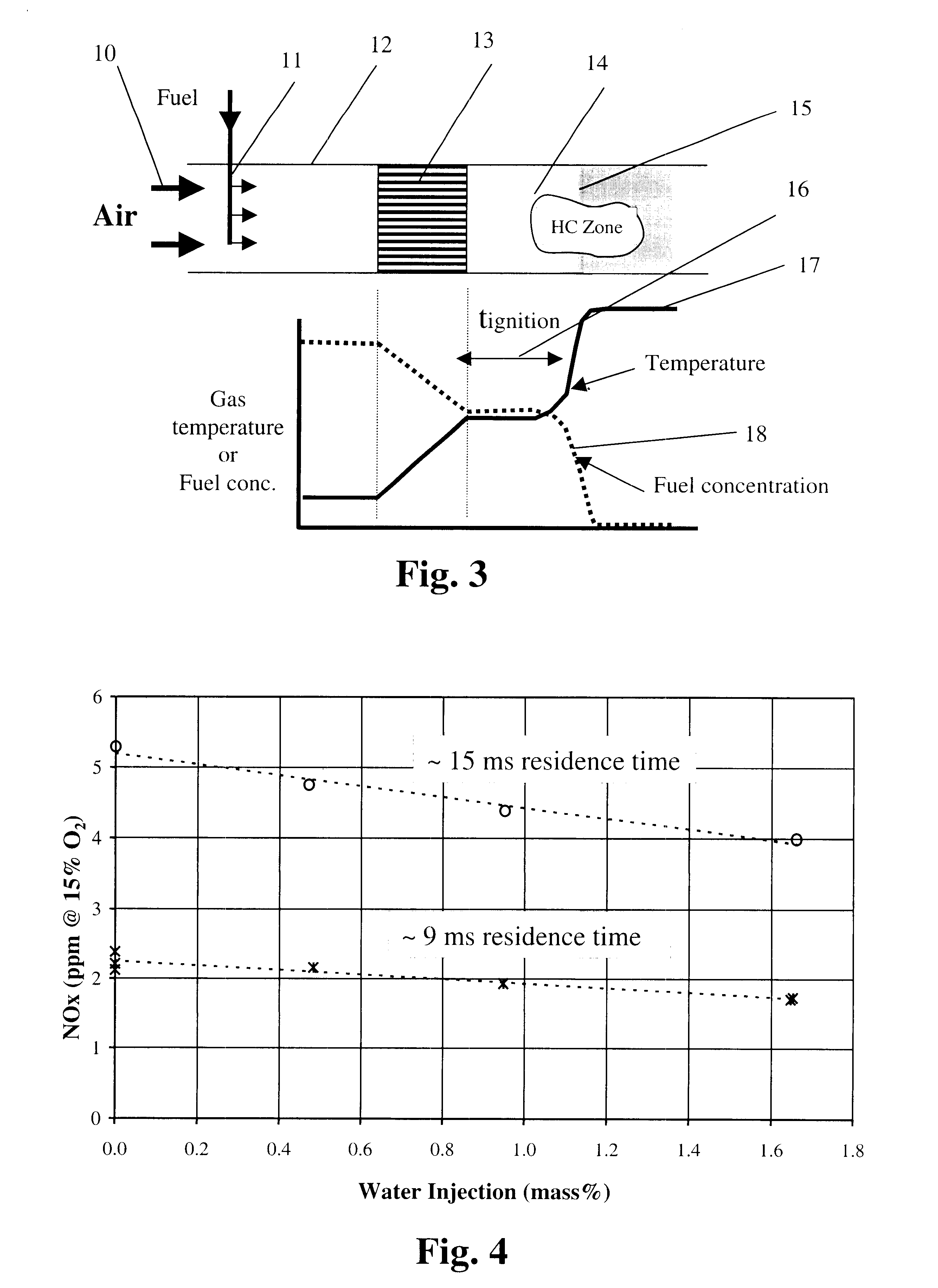

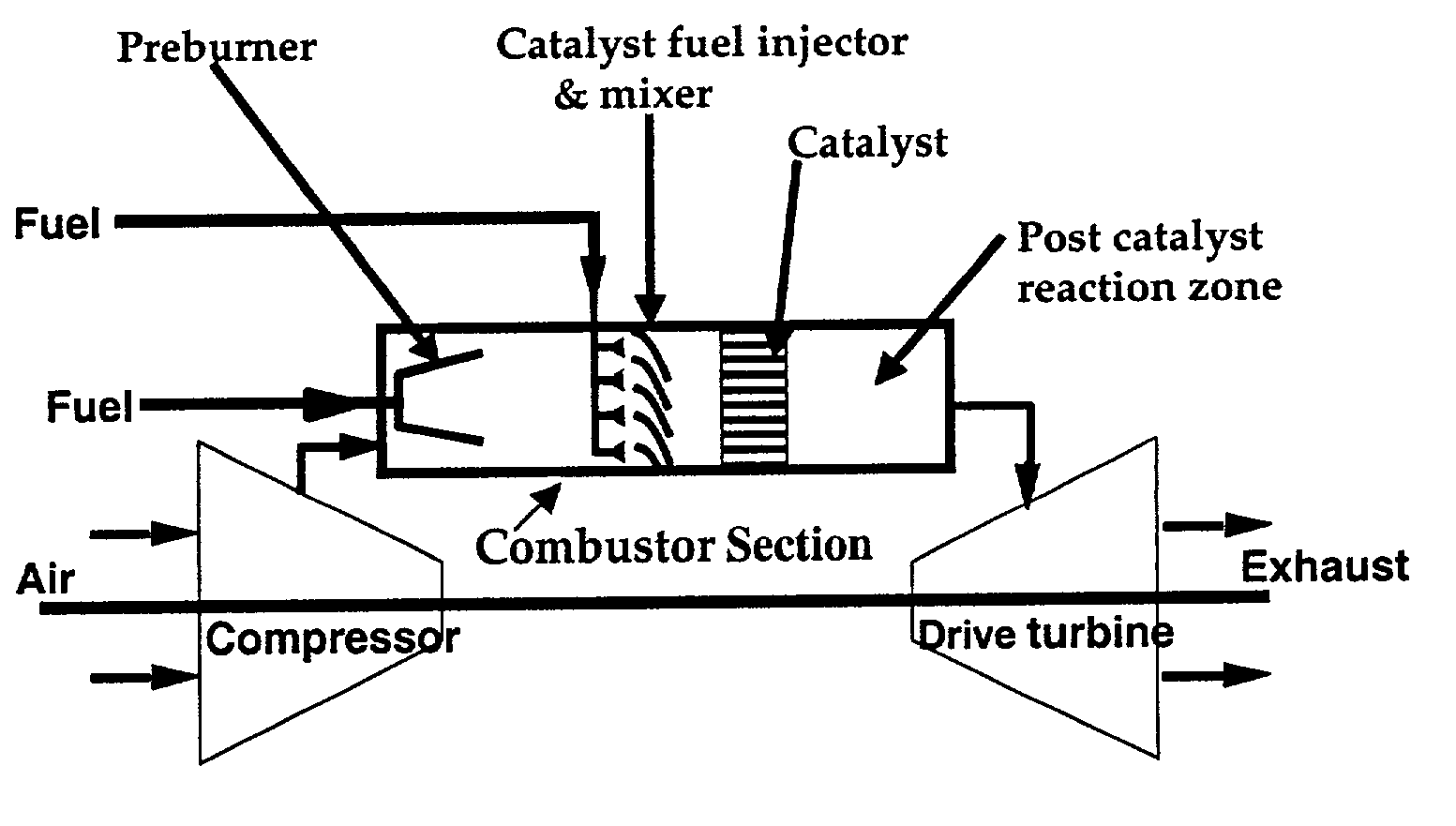

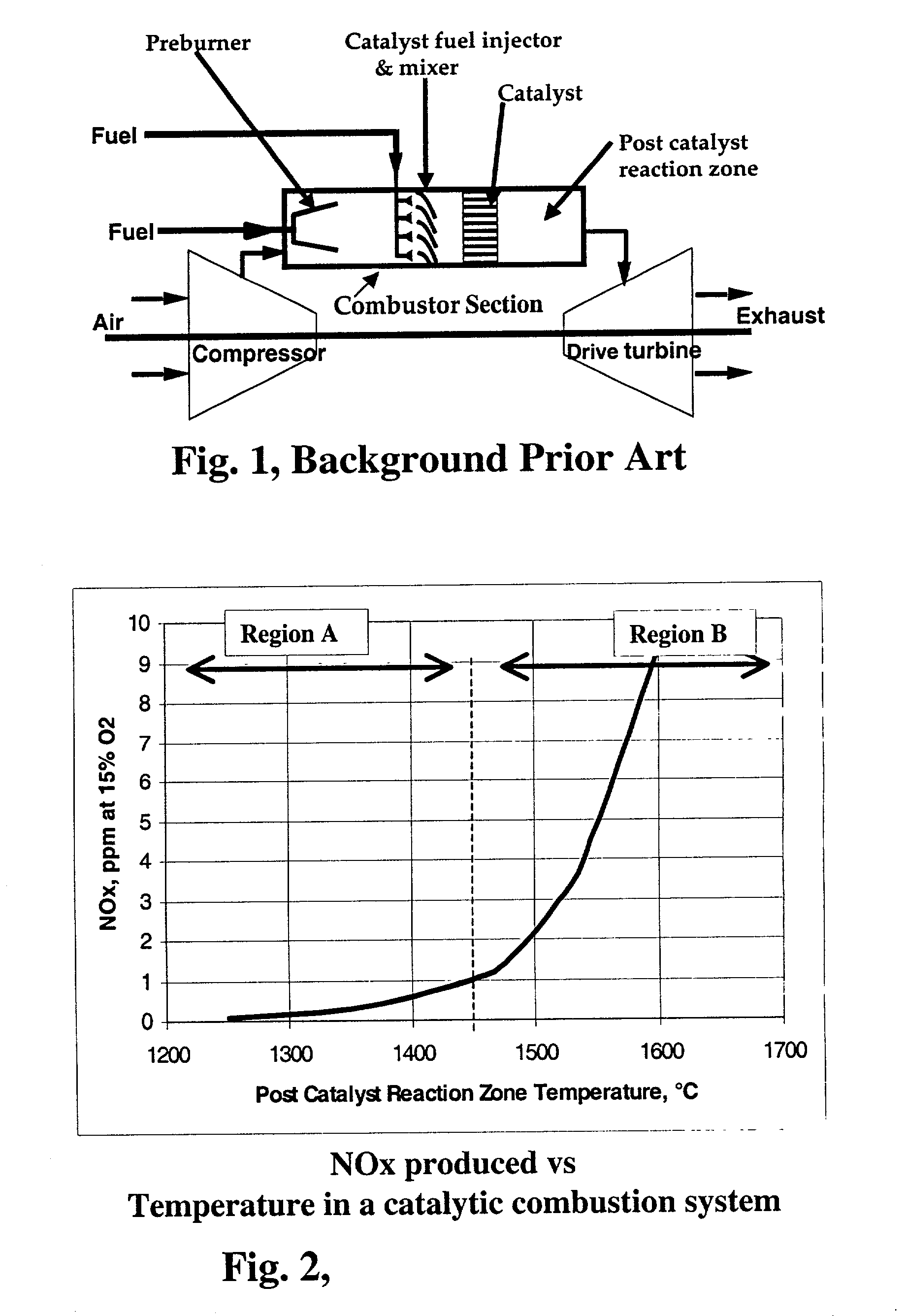

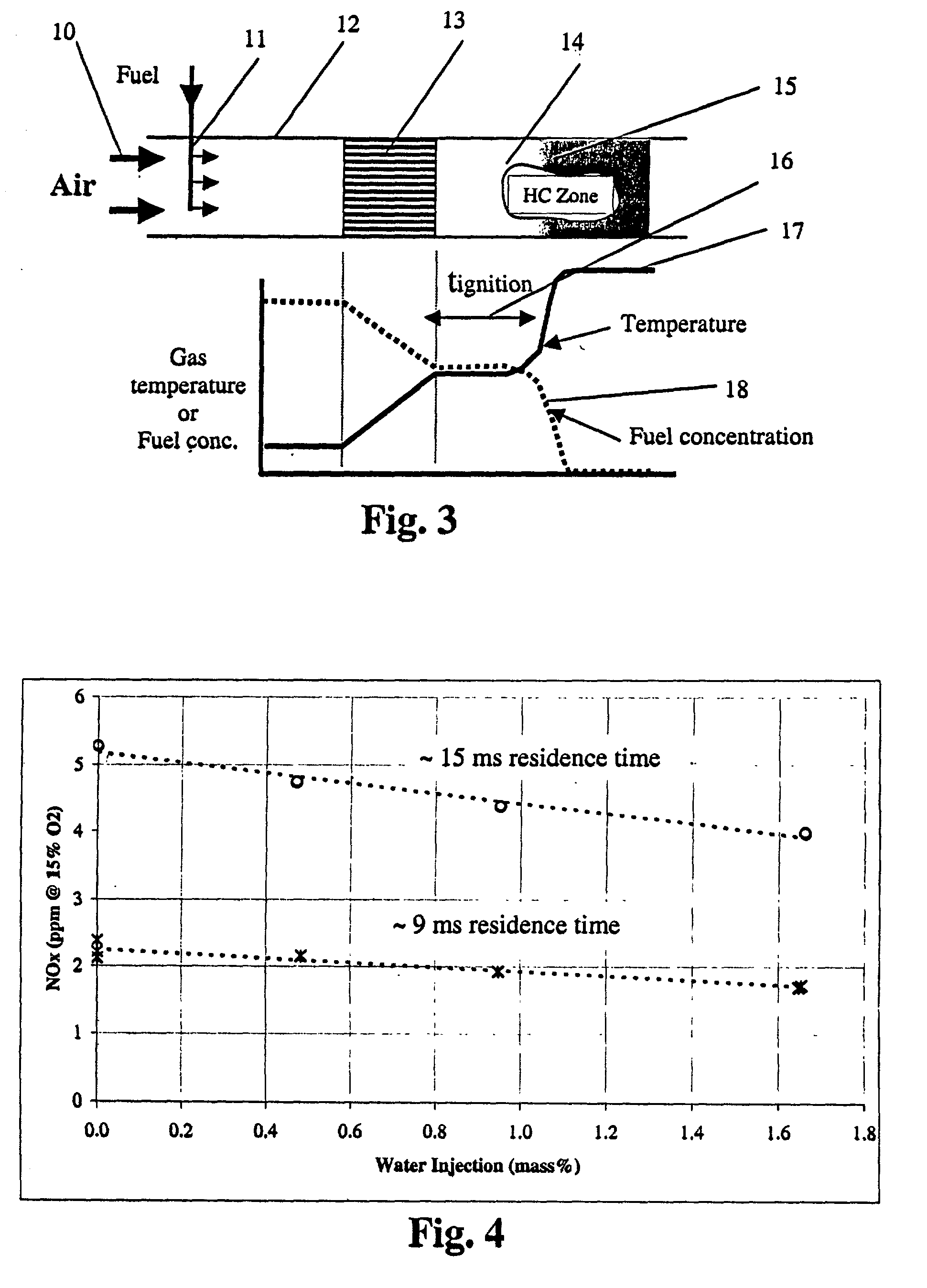

Process and apparatus for control of NOx in catalytic combustion systems

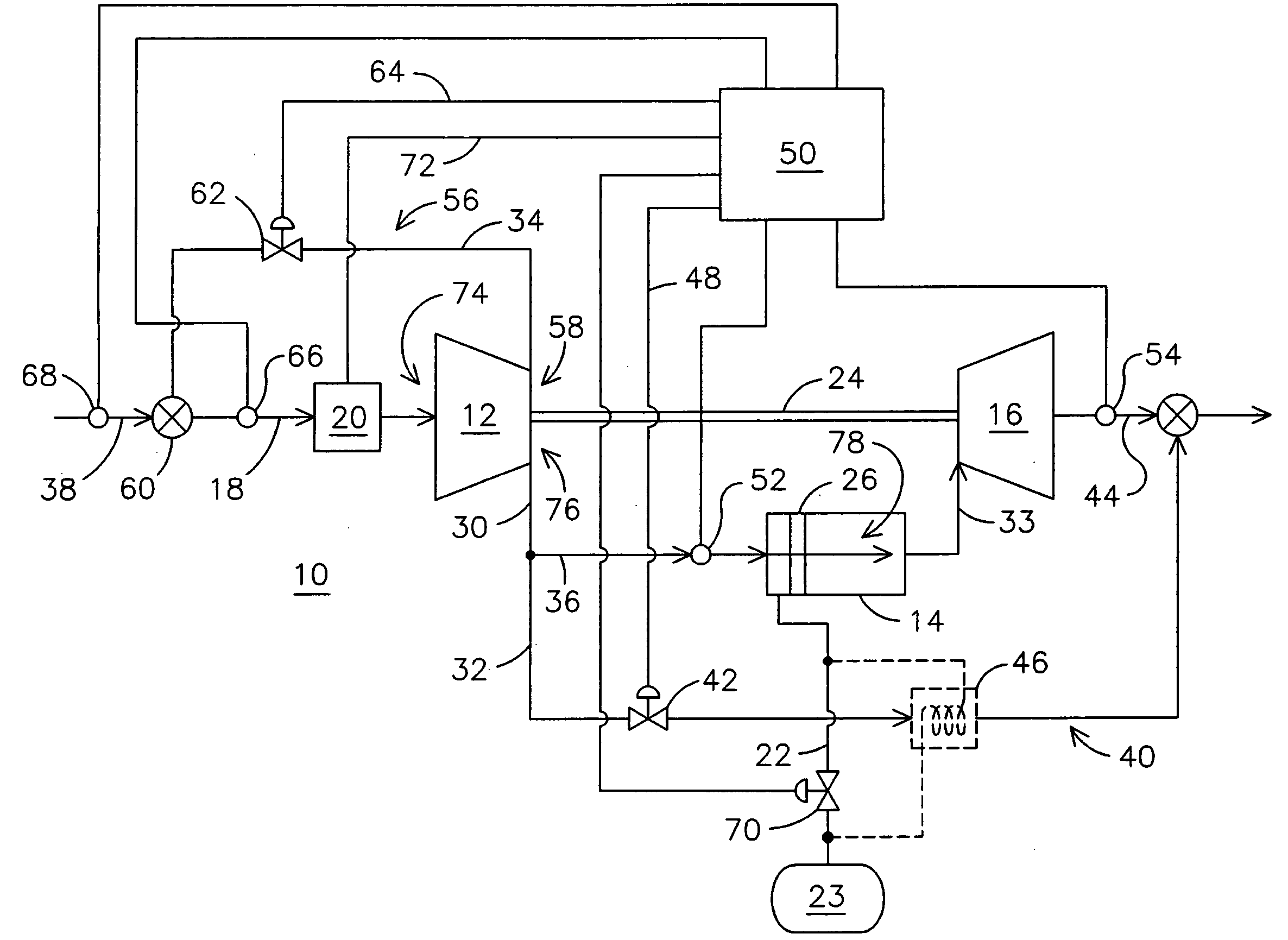

InactiveUS6595003B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemLiquid water

Methods and apparatus for control of NOx in catalytic combustion systems, and more particularly to control of thermal or / and prompt NOx produced during combustion of liquid or gaseous fuels in the combustor sections of catalytic combustor-type gas turbines, by controlled injection of water in liquid or vapor form at selected locations, orientations, amounts, rates, temperatures, phases, forms and manners in the compressor and combustor sections of gas turbines. The ratio of thermal NOx ppm reduction to water addition, in weight %, is on the order of 4-20, with % NOx reduction on the order of up to about 50-80% and NOx of below 2 ppm. Liquid water, steam or superheated steam can be used to reduce NOx in combustion systems operating at reaction zone temperatures above 900° C., preferably 1400° C. to 1700° C. The amount of water added is sufficient to provide a concentration of water in the range of from about 0.1% to about 20% by weight of the total air and fuel mixture flowing into the post catalyst reaction zone. Water is introduced simultaneously or sequentially in a plurality of locations, at selected rates, amounts, temperatures, forms, and purity, preferably in accord with a suitable control algorithm.

Owner:KAWASAKI HEAVY IND LTD

Procedure for starting up a fuel cell system having an anode exhaust recycle loop

InactiveUS20060093879A1Fuel flow rate can be increasedIncrease removalFuel cell heat exchangeSolid electrolyte fuel cellsEngineeringDissolution

A procedure for starting up a fuel cell system that is disconnected from its primary load and that has air in both its cathode and anode flow fields includes a) connecting an auxiliary resistive load across the cell to reduce the cell voltage; b) initiating a recirculation of the anode flow field exhaust through a recycle loop and providing a limited flow of hydrogen fuel into that recirculating exhaust; c) catalytically reacting the added fuel with oxygen present in the recirculating gases until substantially no oxygen remains within the recycle loop; disconnecting the auxiliary load; and then d) providing normal operating flow rates of fuel and air into respective anode and cathode flow fields and connecting the primary load across the cell. The catalytic reaction may take place on the anode or within a catalytic burner disposed within the recycle loop. The procedure allows start-up of the fuel cell system without the use of an inert gas purge while minimizing dissolution of the catalyst and corrosion of the catalyst support during the start-up process.

Owner:AUDI AG

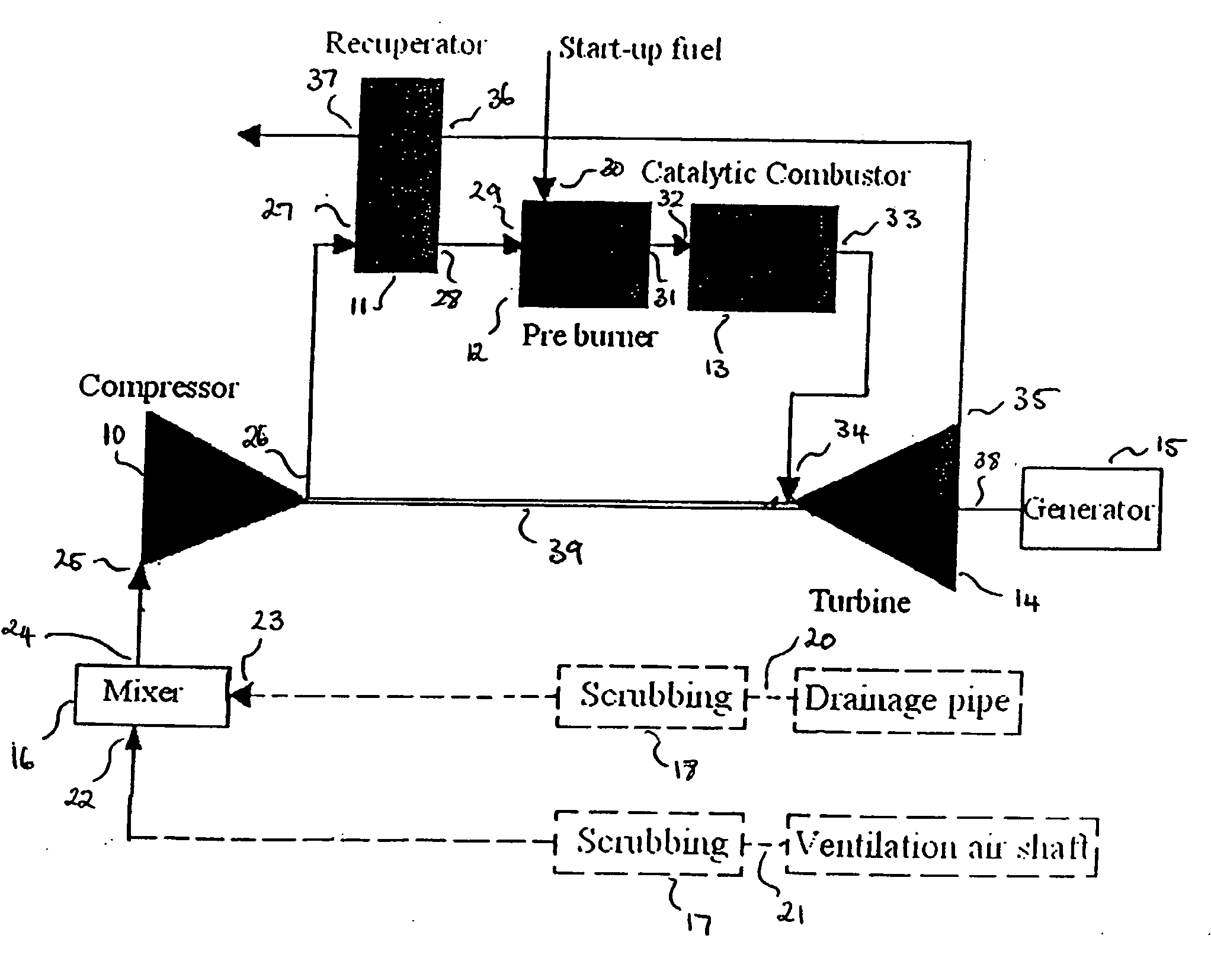

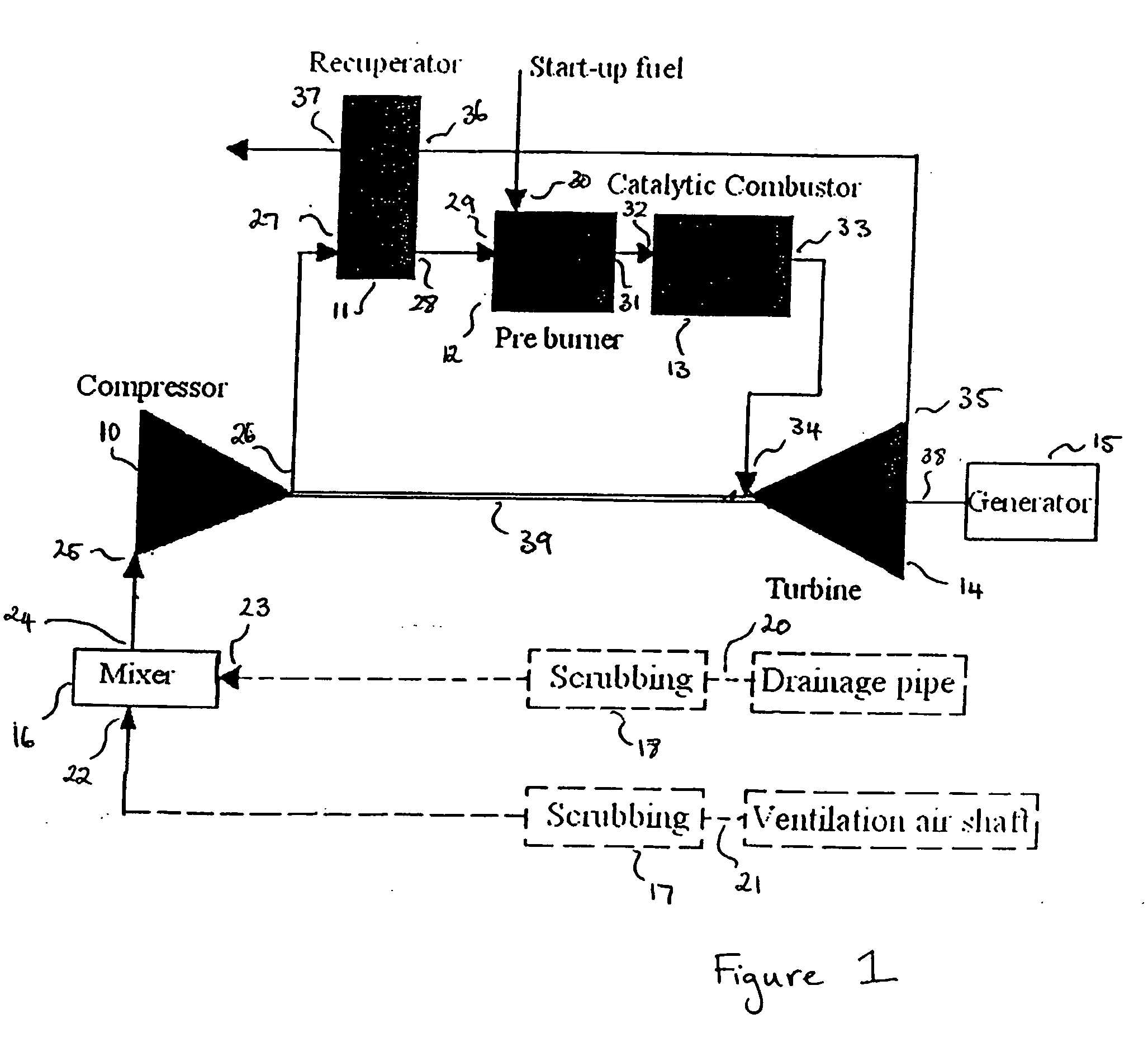

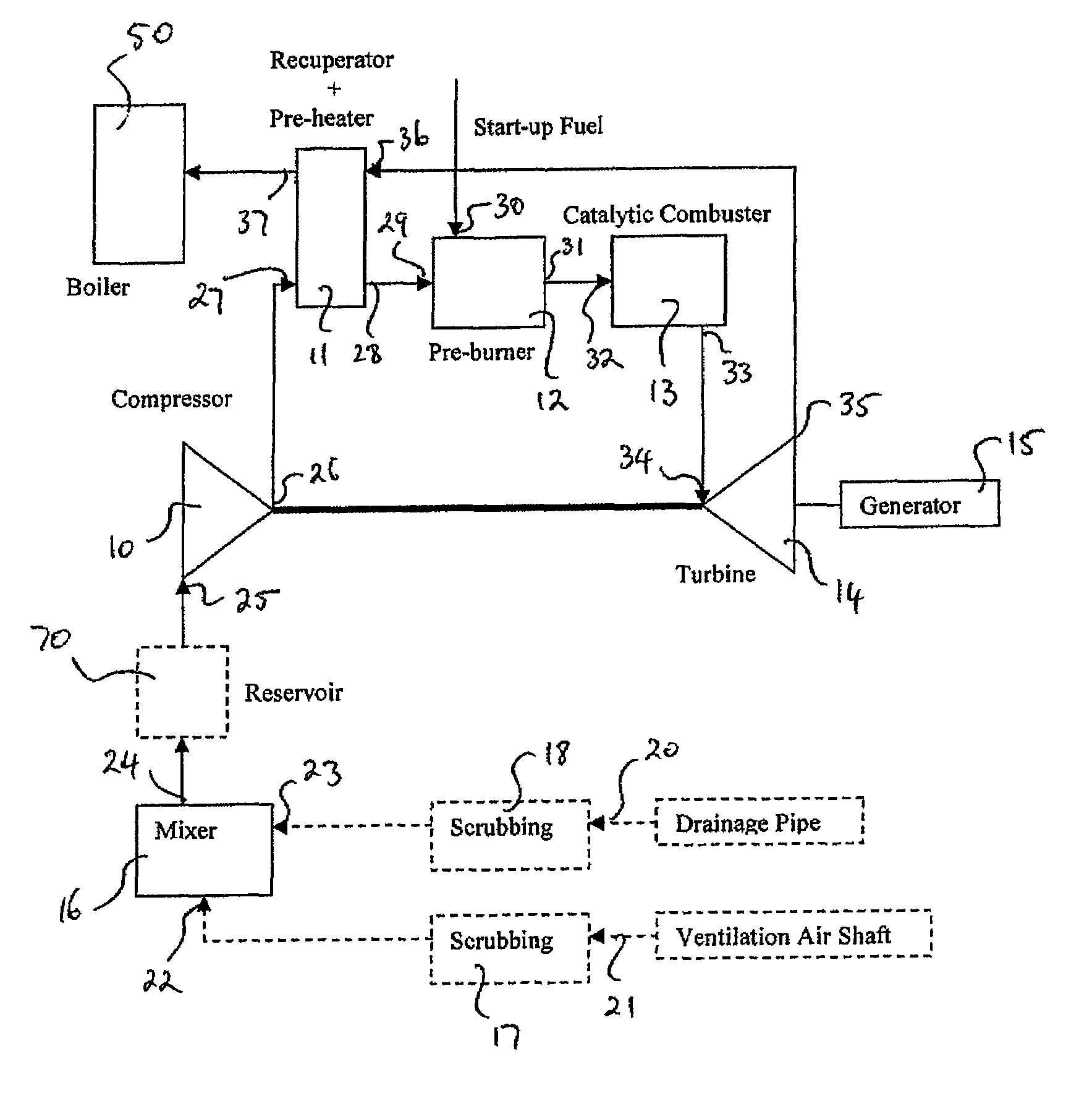

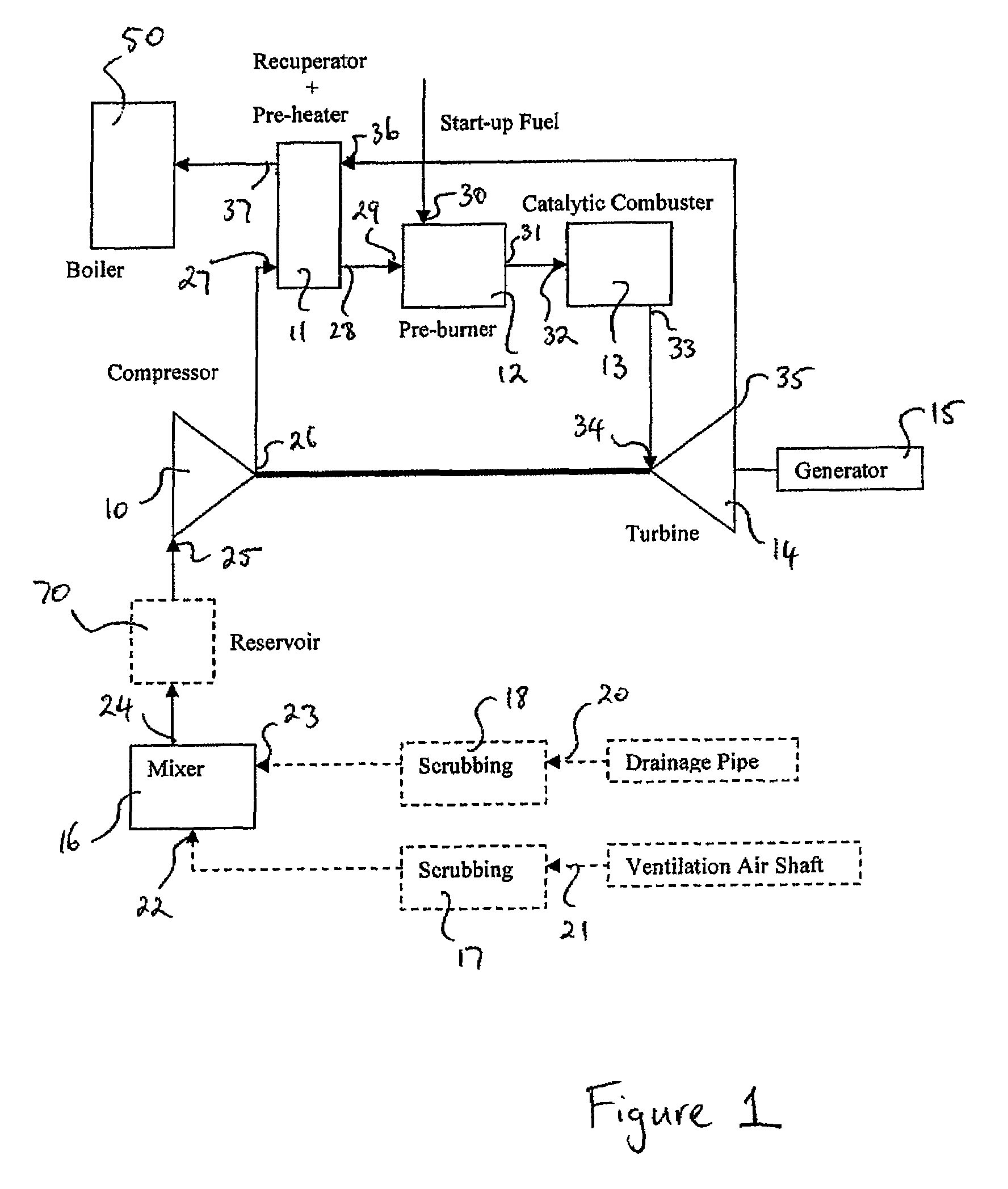

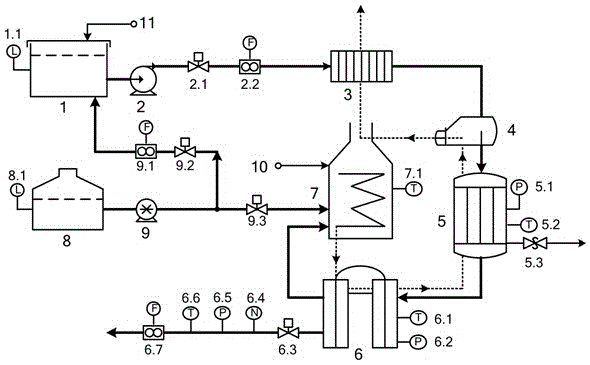

System for catalytic combustion

ActiveUS20060150635A1High activityLarge specific surface areaContinuous combustion chamberTurbine/propulsion engine ignitionEnvironmental engineeringTurbine

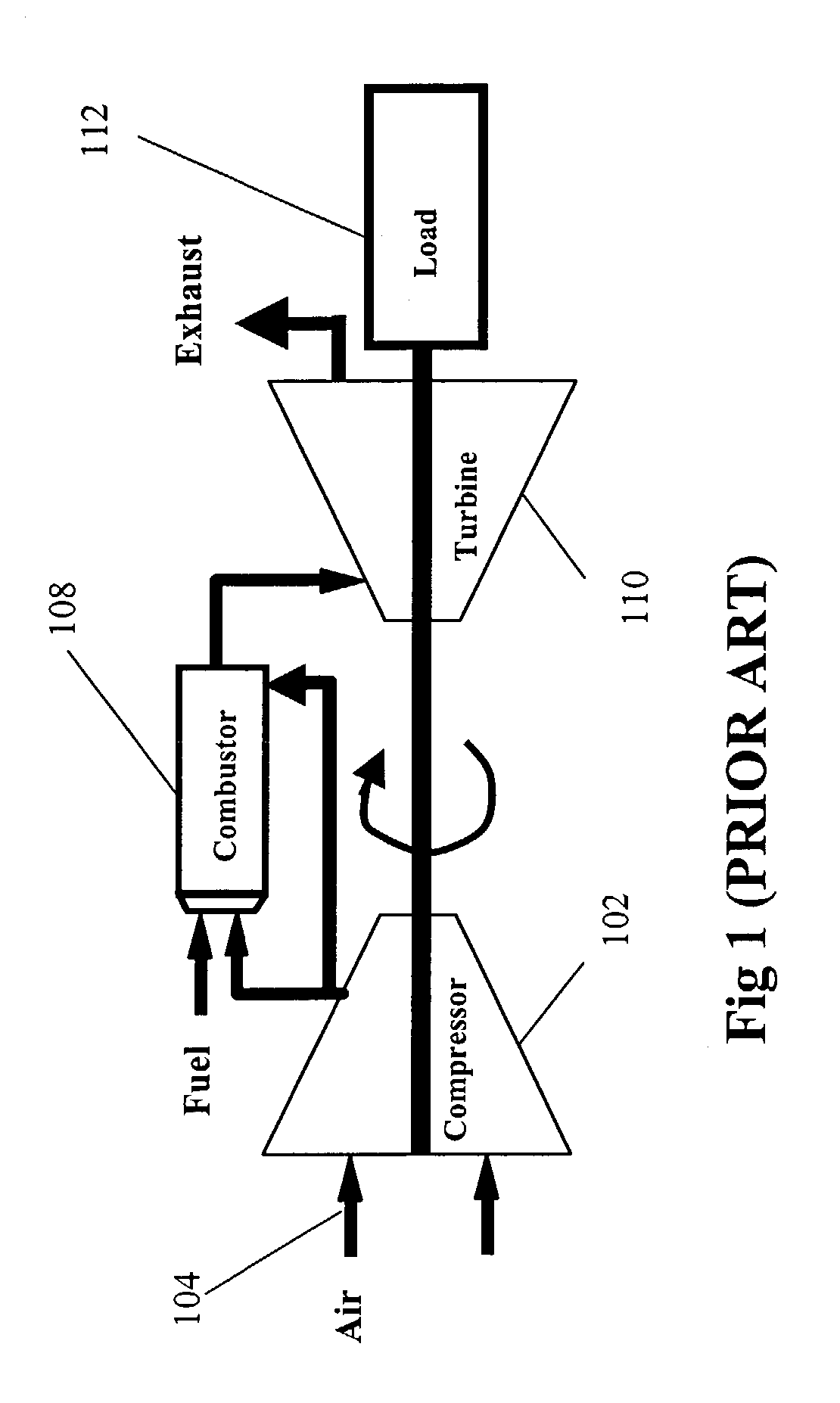

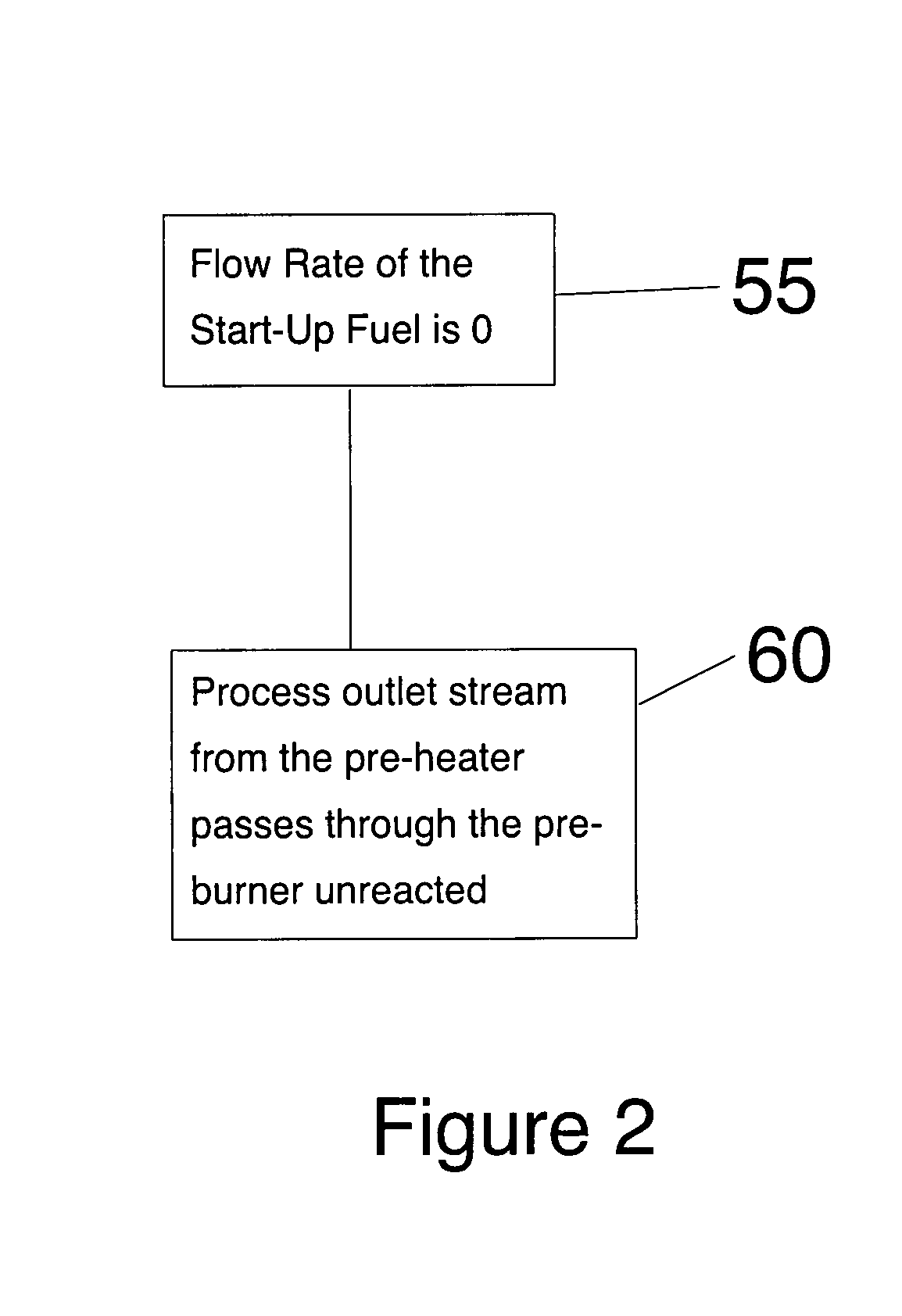

A system comprising a compressor (10) having an inlet stream (25) and an outlet stream (26), a pre-heater (12) having a process inlet stream (29) and a process outlet stream (31), a catalytic combustor (13) having an inlet stream (32) and an outlet stream (33) and containing an catalyst, and a turbine (14) having an inlet stream (34) and an outlet stream (35), wherein, the outlet stream (26) of the compressor(10) is connected to the process inlet stream (29) of the pre-heater (12), the process outlet stream (31) of the pre-heater (12) is connected to the inlet stream (32) of the catalytic combustor (13). The outlet stream (33) of the catalytic combustor (13) is connected to the inlet stream (34) of the turbine (14). During operation of the system, the inlet stream (25) of the compressor (10) has a substantially constant and low concentration of fuel.

Owner:COMMONWEALTH SCI & IND RES ORG

System for catalytic combustion

InactiveUS7430869B2High activityLarge specific surface areaContinuous combustion chamberTurbine/propulsion engine ignitionEnvironmental engineeringTurbine

A system comprising a compressor (10) having an inlet stream (25) and an outlet stream (26), a pre-heater (12) having a process inlet stream (29) and a process outlet stream (31), a catalytic combustor (13) having an inlet stream (32) and an outlet stream (33) and containing an catalyst, and a turbine (14) having an inlet stream (34) and an outlet stream (35), wherein, the outlet stream (26) of the compressor(10) is connected to the process inlet stream (29) of the pre-heater (12), the process outlet stream (31) of the pre-heater (12) is connected to the inlet stream (32) of the catalytic combustor (13). The outlet stream (33) of the catalytic combustor (13) is connected to the inlet stream (34) of the turbine (14). During operation of the system, the inlet stream (25) of the compressor (10) has a substantially constant and low concentration of fuel.

Owner:COMMONWEALTH SCI & IND RES ORG

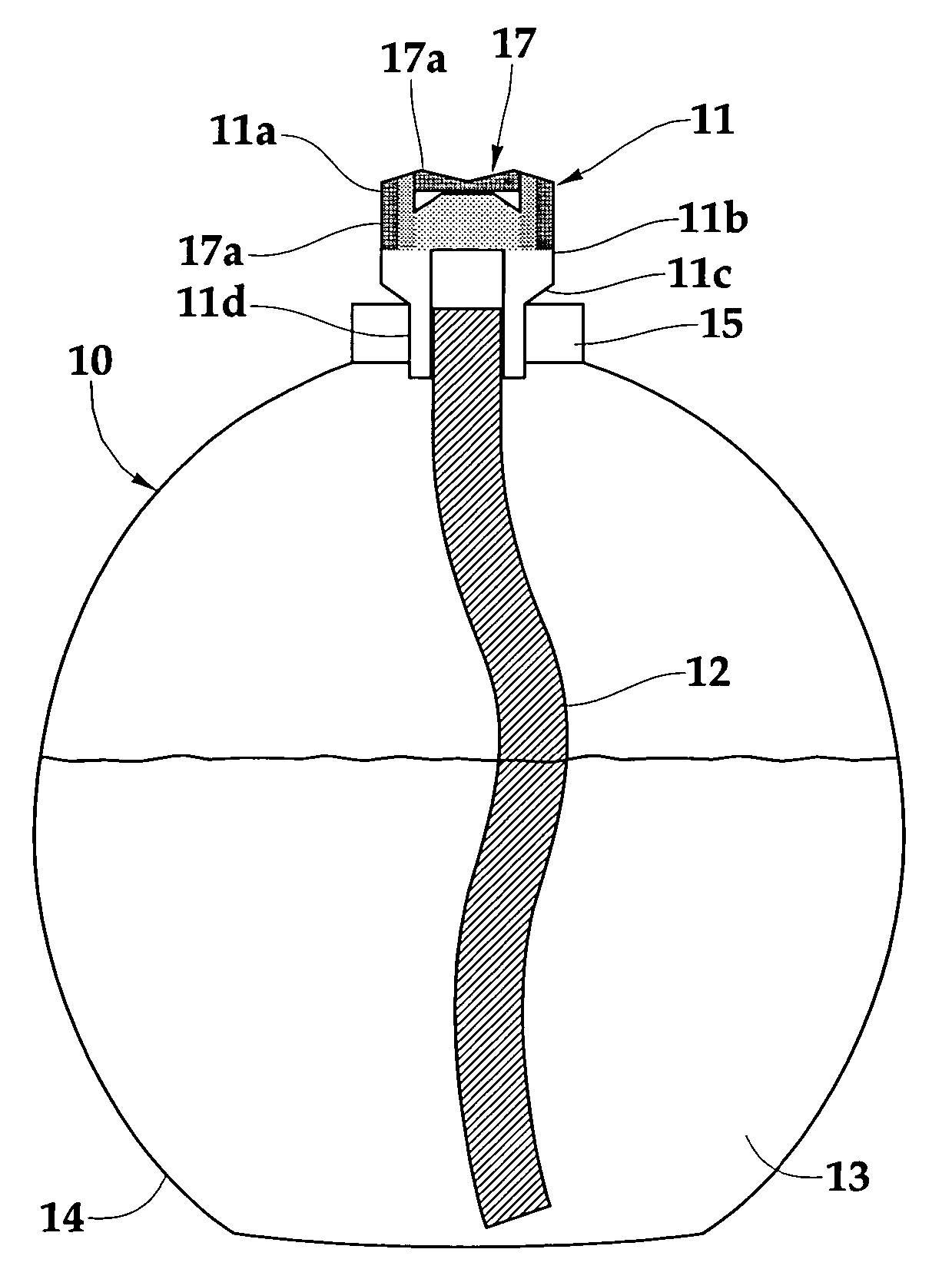

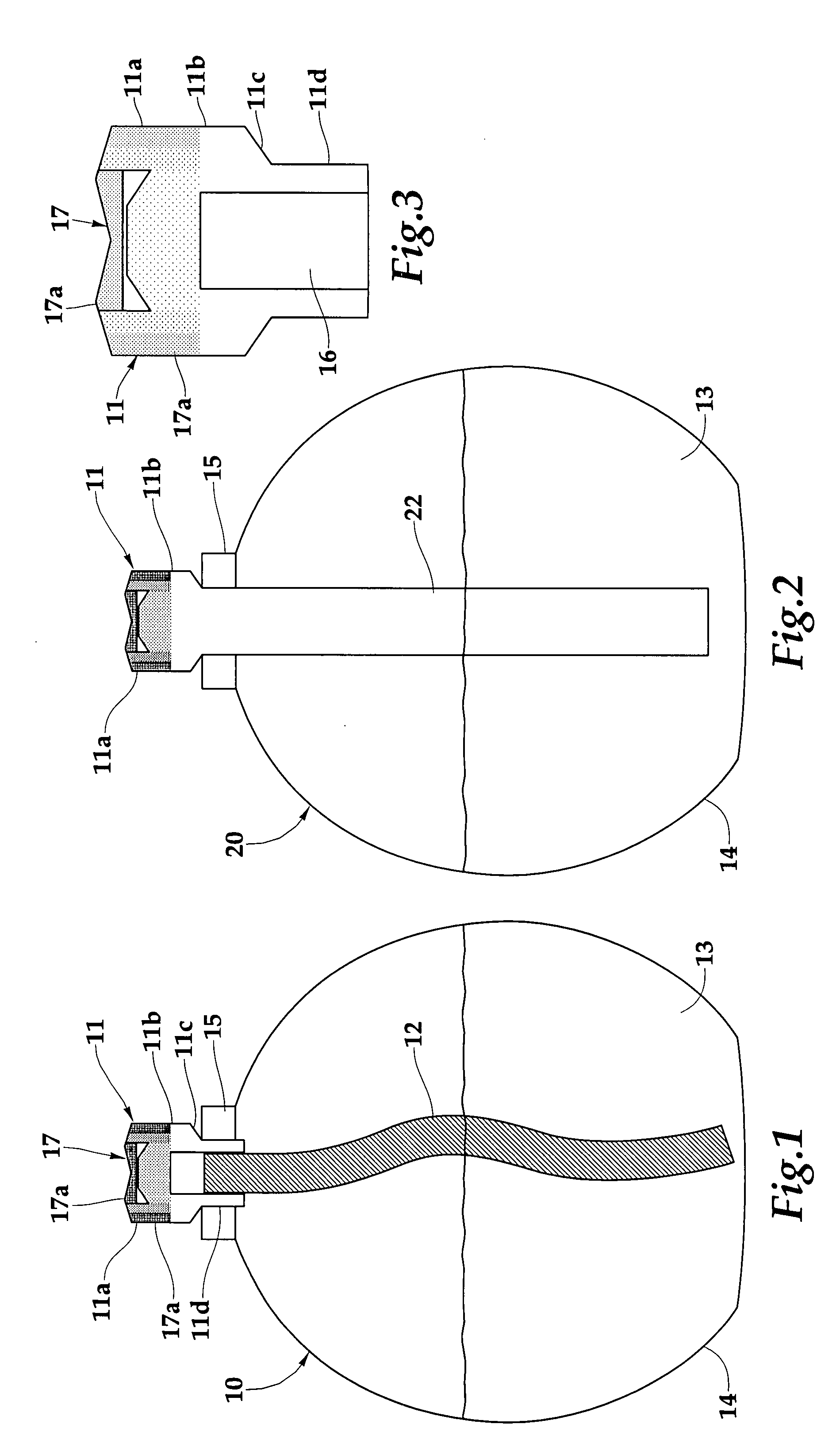

Low vapor pressure fuels for use in catalytic burners

Low vapor pressure compound-based fuels are provided. These fuels are useful in catalytic burner systems that can be used to disperse fragrances, insecticides, insect repellants (e.g., citronella), aromatherapy compounds, medicinal compounds, deodorizing compounds, disinfectant compositions, fungicides and herbicides.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Catalytic combustion system and method

InactiveUS7096671B2Emission reductionShorten flame lengthContinuous combustion chamberTurbine/propulsion fuel supply systemsNitrogenNitrogen oxide

Aspects according to the invention relate to a catalytic combustor system for a turbine engine and an associated method. Catalytic combustors are used in connection with turbine engines because they can minimize the formation of oxides of nitrogen during combustion. Despite this emissions advantage, catalytic combustion systems can increase the level of CO in the turbine exhaust. According to aspects of the invention, vortex formation devices includes vortex generators, swirlers and mixers can be placed downstream of each catalytic module surrounding the pilot nozzle so as to form one or more vortices in the otherwise substantially laminar flow exiting the modules. The vortices can create a suction so that a portion of the flow exiting the pilot nozzles is mixed with the flow exiting the catalyst modules. The introduction of the higher temperature pilot flow can accelerate the catalytic reaction time, promoting burnout of the CO formed during combustion.

Owner:SIEMENS ENERGY INC

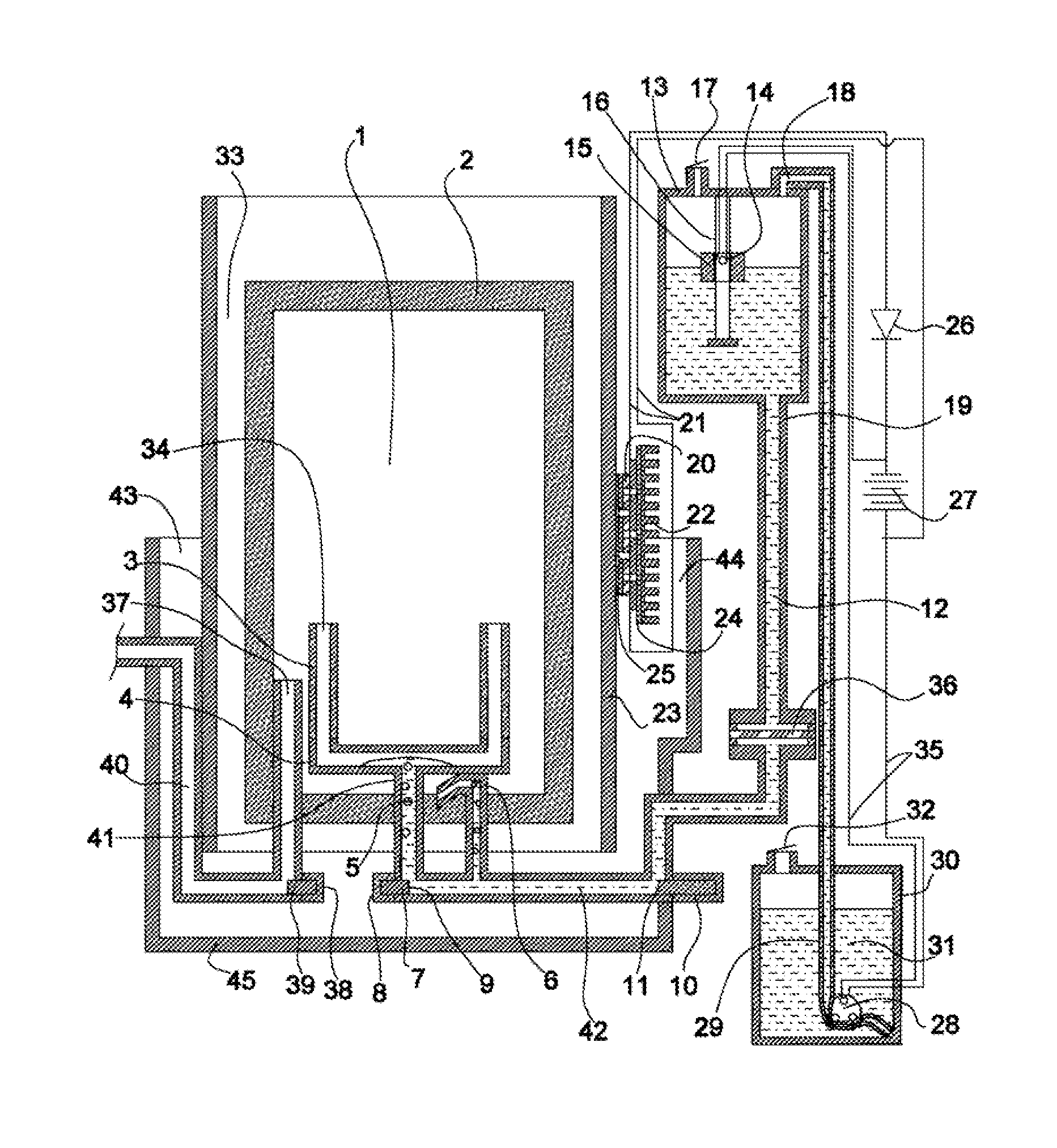

Deferential Presssure Control Method for Molten Carbonates Fuel Cell Power Plants

InactiveUS20070224467A1Low efficiencyWithout riskFuel cells groupingFuel cell auxillariesFuel cellsPower station

A molten carbonate fuel cell System in which the fuel cell stack(s) is (are) enclosed within a containment vessel and in which a burner exhaust is used to control the system operating pressure is described. Moreover, highly reliable, simple and low-cost differential pressure control method never affected by service interruption or troubles in control valves or other components is disclosed. Excluding differential control valves and reducing the cost by guiding the anode, cathode and vessel exhaust gases to the inlet of a catalytic burner forward the containment vessel and mixed therein so that the pressure of these gases are equal to each other, this fuel cell system guarantees dynamic pressure balancing between the vessel and reactants to prevent leakage of the reactants from the fuel cell stack and avoid an excessive differential pressure between the fuel cell and the vessel and between the anode and the cathode.

Owner:ANSALDO FUEL CELLS SPA

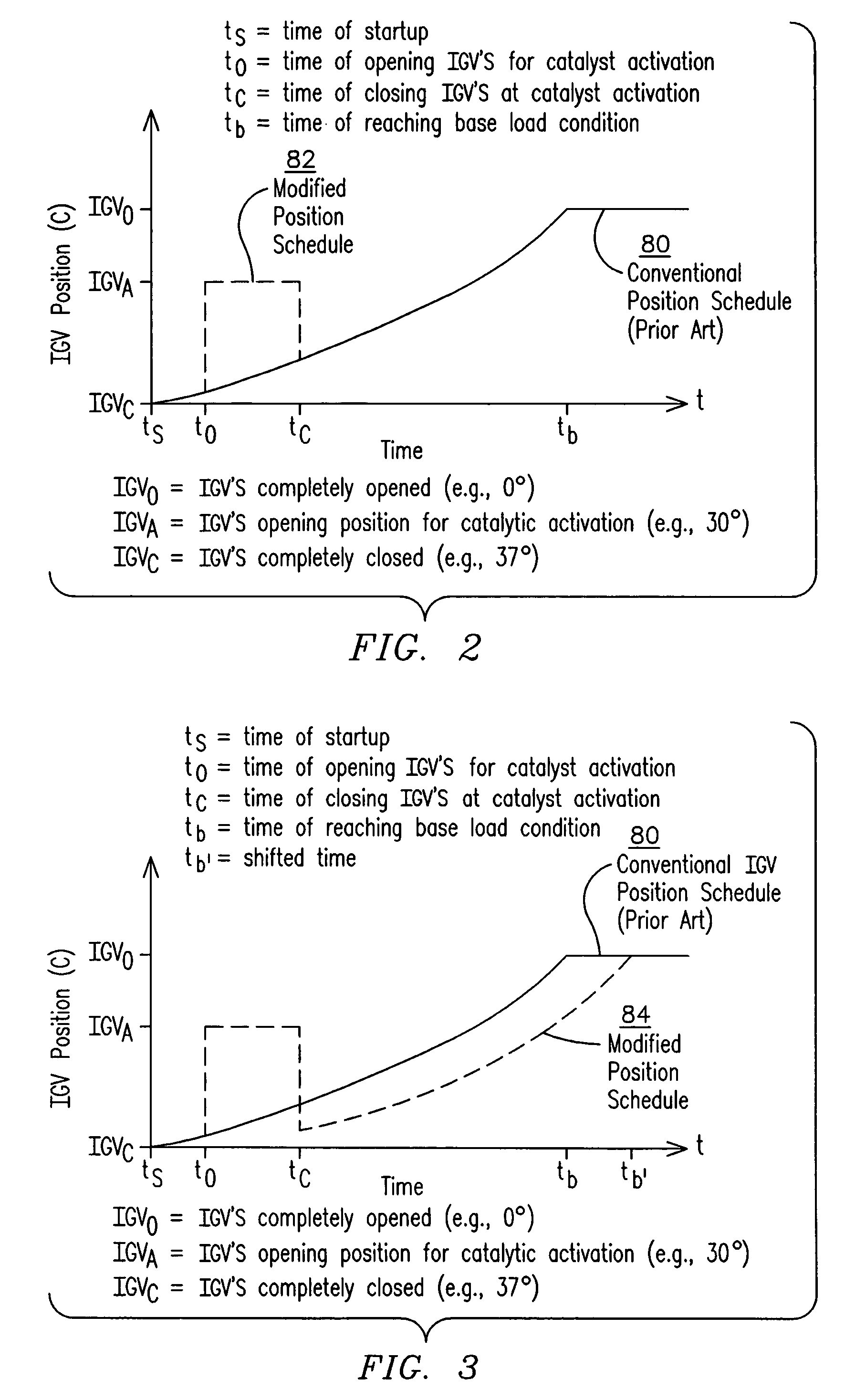

Control of gas turbine for catalyst activation

InactiveUS20050150231A1Turbine/propulsion fuel supply systemsContinuous combustion chamberEngineeringBiological activation

A catalytic gas turbine includes a compressor, a catalytic combustor, a turbine, and a flow path conducting a bypass portion of the compressed air around the combustor and turbine. A method of operating the catalytic gas turbine to activate a catalyst in the catalytic combustor includes opening an inlet guide vane upstream of the compressor to a position to produce an increased volume of compressed air. The increased volume exceeds a volume of compressed air needed to support combustion. A bypass portion of the compressed air is extracted and directed around the combustor and turbine. The method may also include extracting a recirculation portion of the compressed air and directing the recirculation portion into the inlet of the compressor.

Owner:SIEMENS ENERGY INC

Process and apparatus for control of NOx in catalytic combustion systems

InactiveUS20020056276A1Minimize energy consumptionImprove processing efficiencyContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion systemCombustion chamber

Methods and apparatus for control of NOX in catalytic combustion systems, and more particularly to control of thermal or / and prompt NOX produced during combustion of liquid or gaseous fuels in the combustor sections of catalytic combustor-type gas turbines, by controlled injection of water in liquid or vapor form at selected locations, orientations, amounts, rates, temperatures, phases, forms and manners in the compressor and combustor sections of gas turbines. The ratio of thermal NOX ppm reduction to water addition, in weight %, is on the order of 4-20, with % NOX reduction on the order of up to about 50-80% and NOX of below 2 ppm. Liquid water, steam or superheated steam can be used to reduce NOX in combustion systems operating at reaction zone temperatures above 900° C., preferably 1400° C. to 1700° C. The amount of water added is sufficient to provide a concentration of water in the range of from about 0.1% to about 20% by weight of the total air and fuel mixture flowing into the post catalyst reaction zone. Water is introduced simultaneously or sequentially in a plurality of locations, at selected rates, amounts, temperatures, forms, and purity, preferably in accord with a suitable control algorithm.

Owner:KAWASAKI HEAVY IND LTD

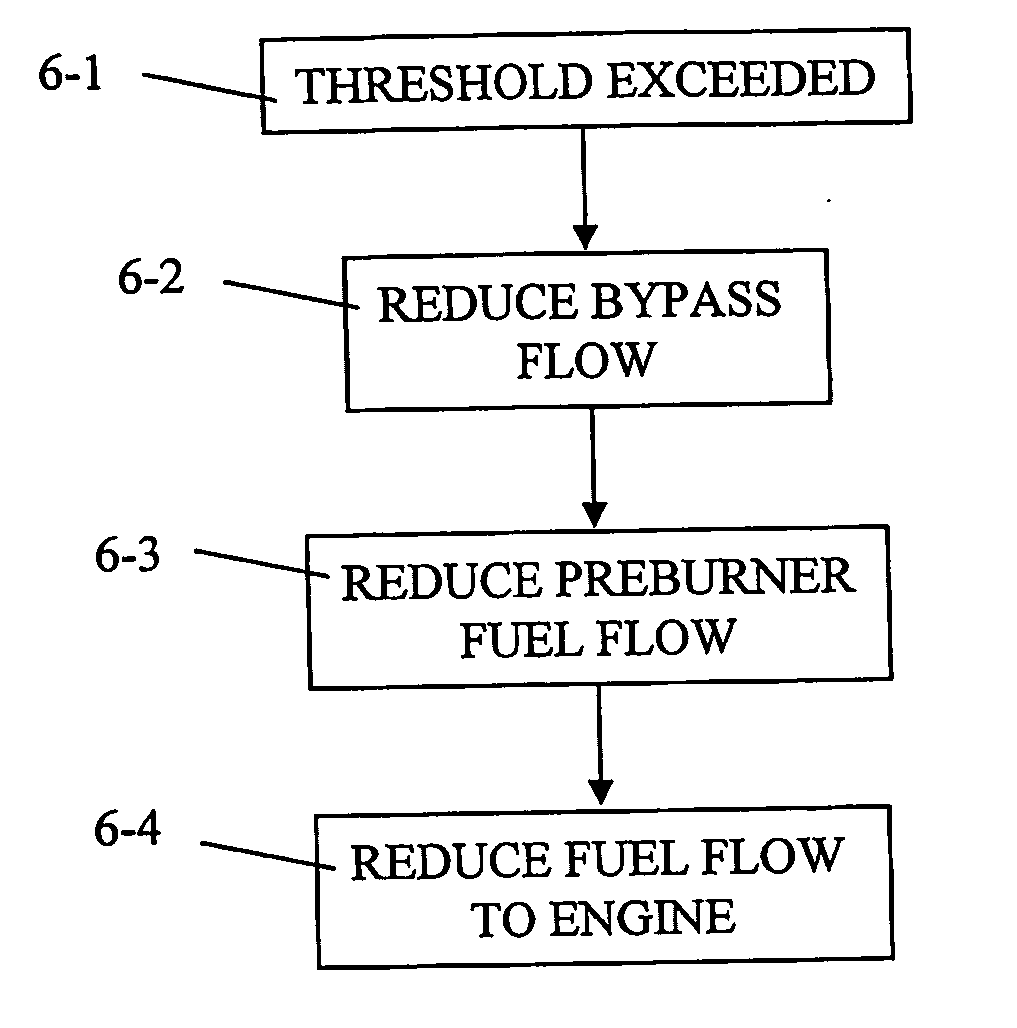

Catalyst module overheating detection and methods of response

InactiveUS20070028625A1Continuous combustion chamberTurbine/propulsion fuel supply systemsResponse methodEngineering

According to one aspect, a method of detecting catalyst module overheating in a catalytic combustion system is provided. In one example, the method includes detecting one or more signals from at least one probe adapted to obtain values associated with at least one of the outlet gas temperature of a catalyst module and the outlet face temperature of the catalyst module included in a catalytic combustor. The one or more signals are compared with a preselected value associated with catalyst overheating. The detected temperature may be detected over time to determine a rate of change in the temperature. The temperature may be detected with a UV sensor directed to the catalyst outlet face.

Owner:KAWASAKI HEAVY IND LTD

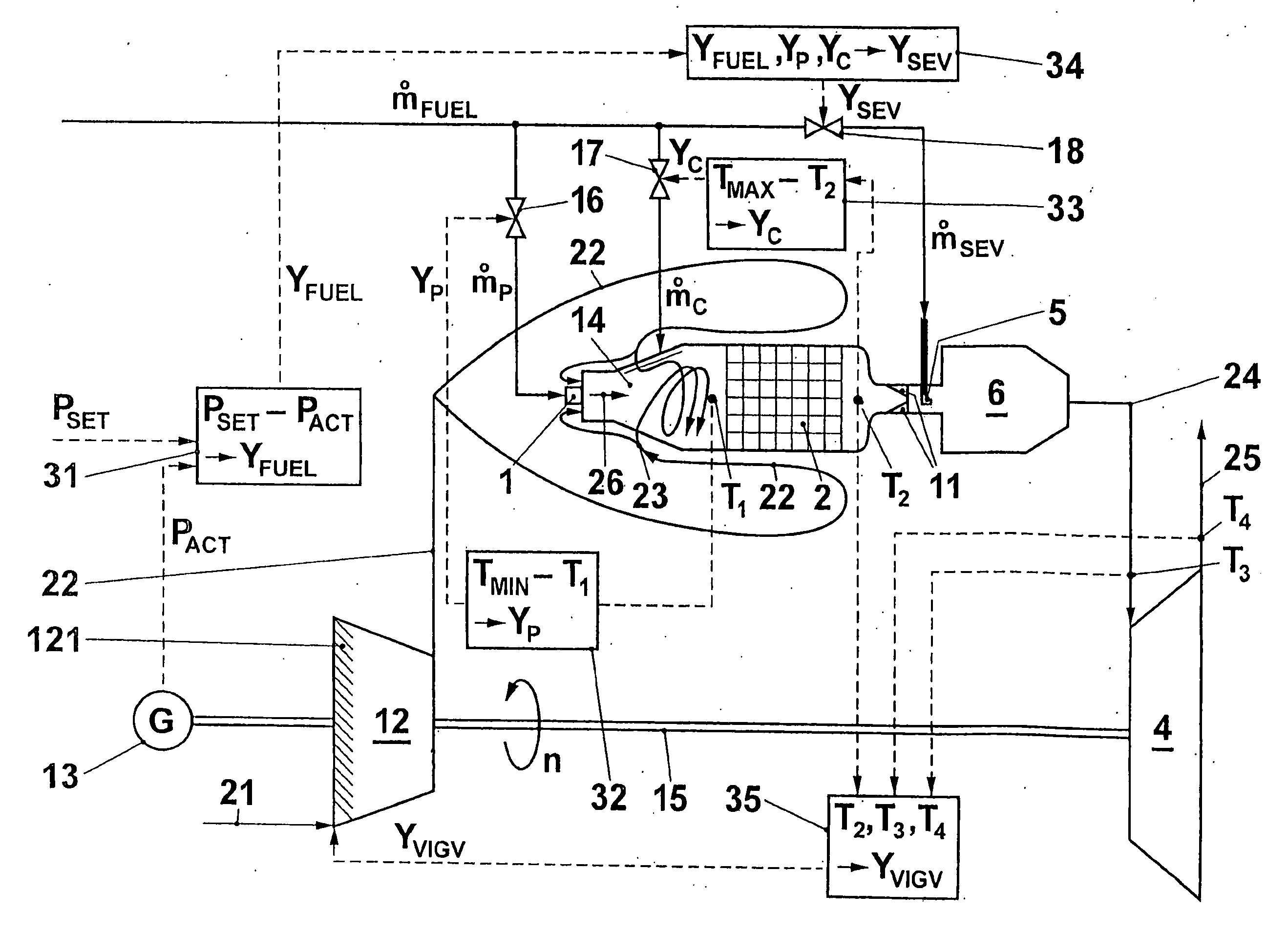

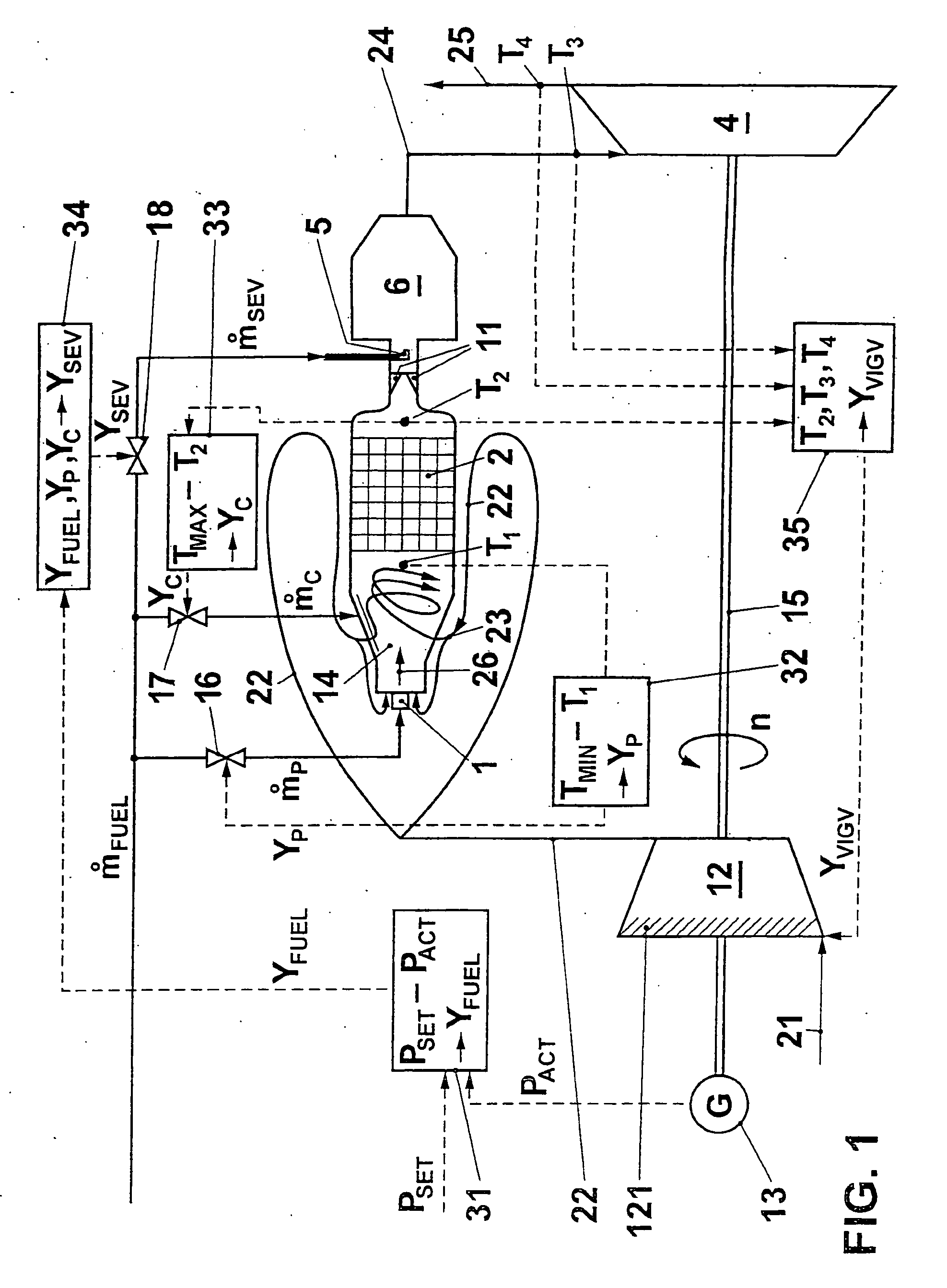

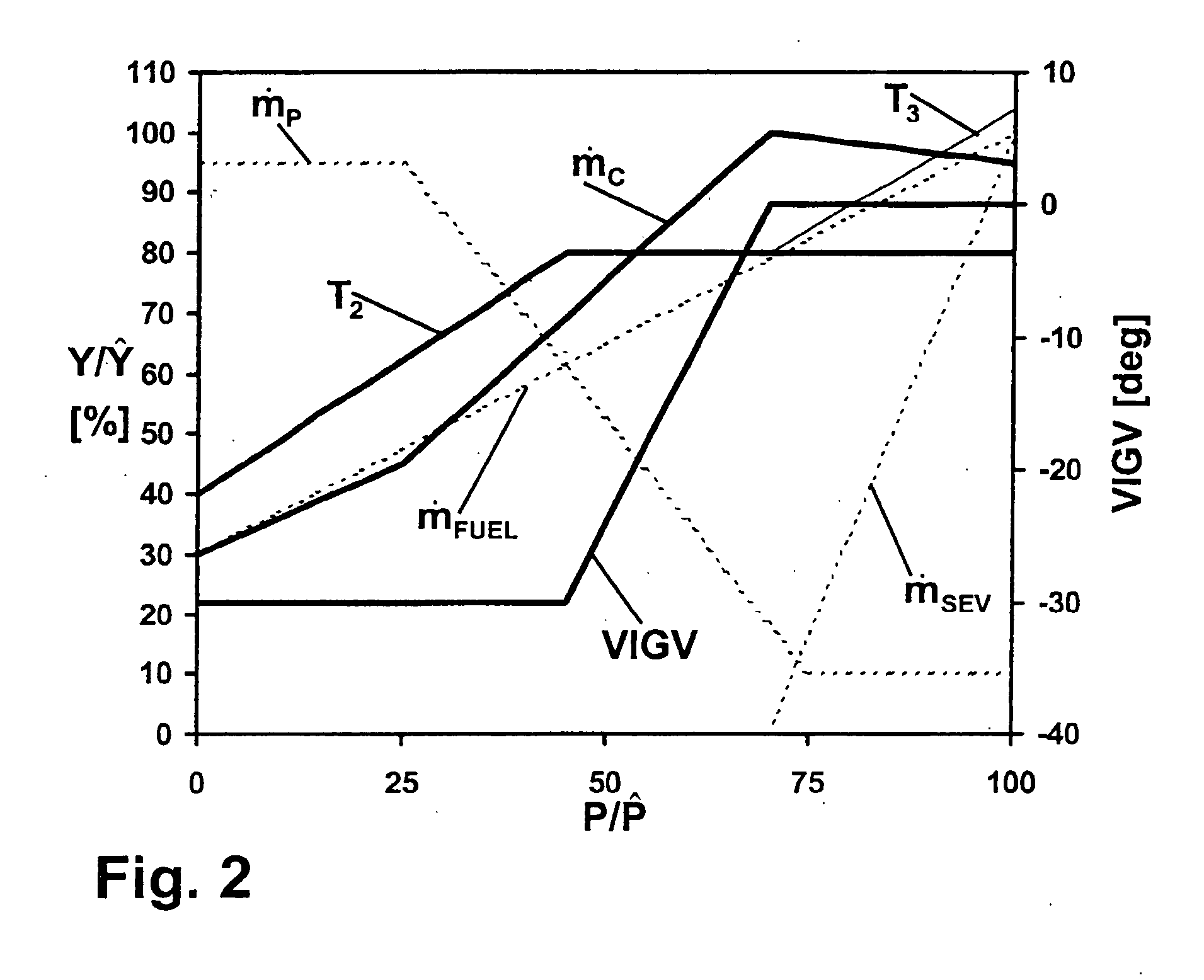

Method for operating a gas turbo group

InactiveUS20040216462A1Speed up the flowReduce cooling powerContinuous combustion chamberTurbine/propulsion engine ignitionCombustion chamberProcess engineering

A gas turbo group has a combustion chamber comprising a catalytic burner stage (2), a preburner stage (1) located upstream from the catalytic burner stage, as well as a non-catalytic burner stage (11, 5, 6) located downstream from the catalytic burner stage. The preburner stage serves to always maintain a temperature (T1) at the inlet into the catalytic stage that corresponds at least to a minimum temperature (TMIN) necessary for operating the catalytic burner stage. According to the invention, the gas turbo group is operated so that the burner stage located downstream from the catalytic combustion chamber is taken into operation only when the temperature (T2) at the outlet from the catalytic stage has reached an upper limit in the presence of a maximum combustion air mass flow.

Owner:ALSTOM TECH LTD

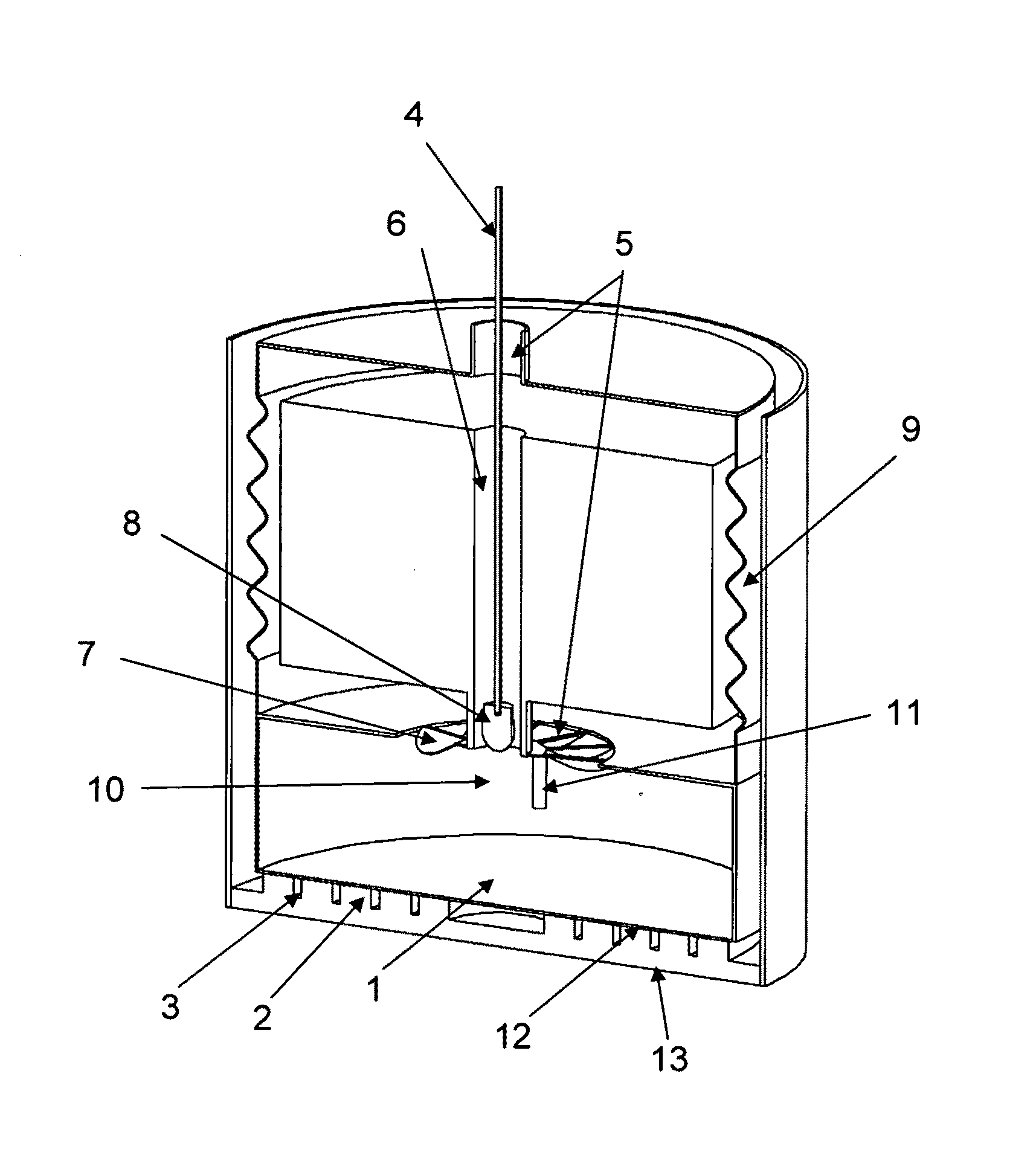

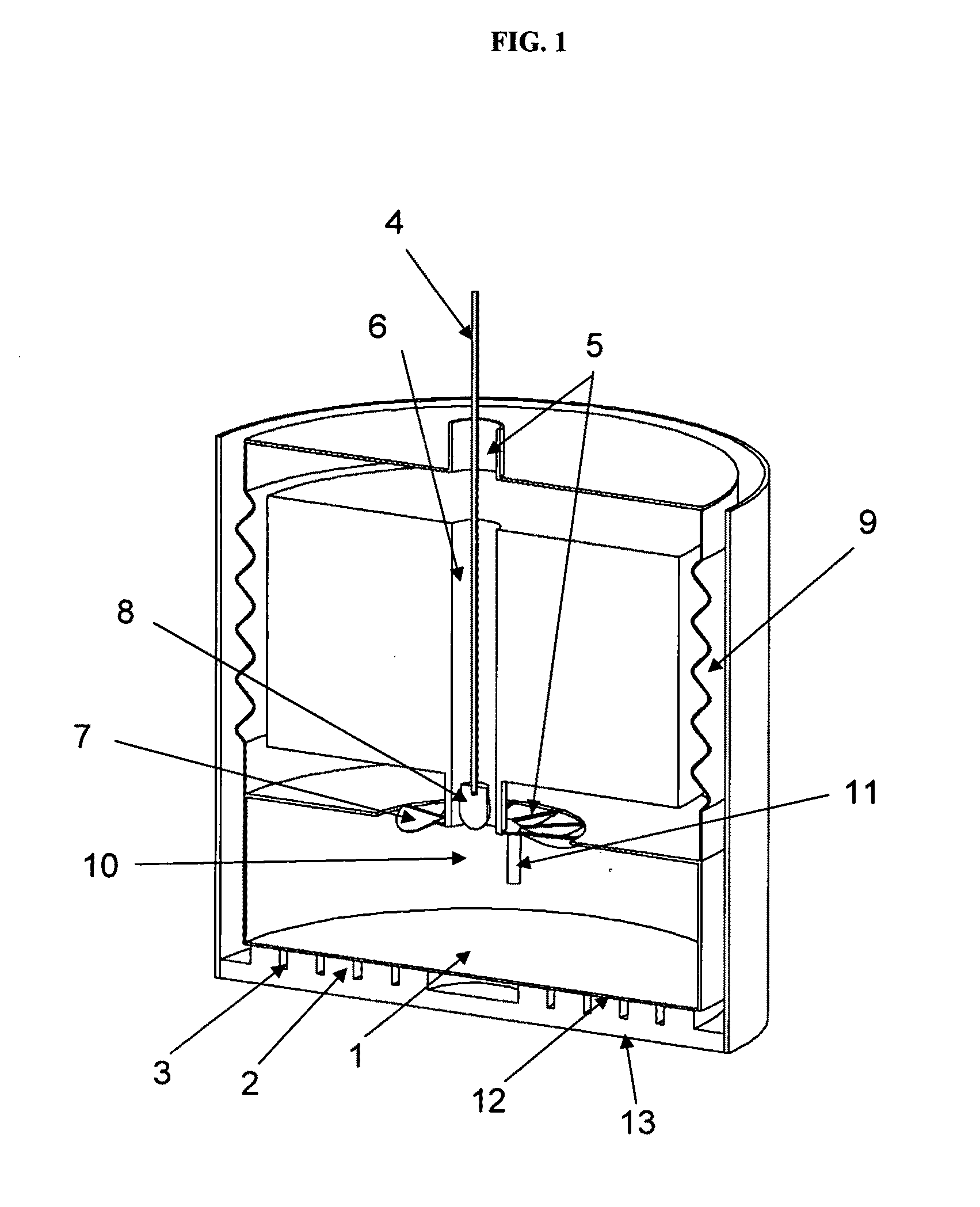

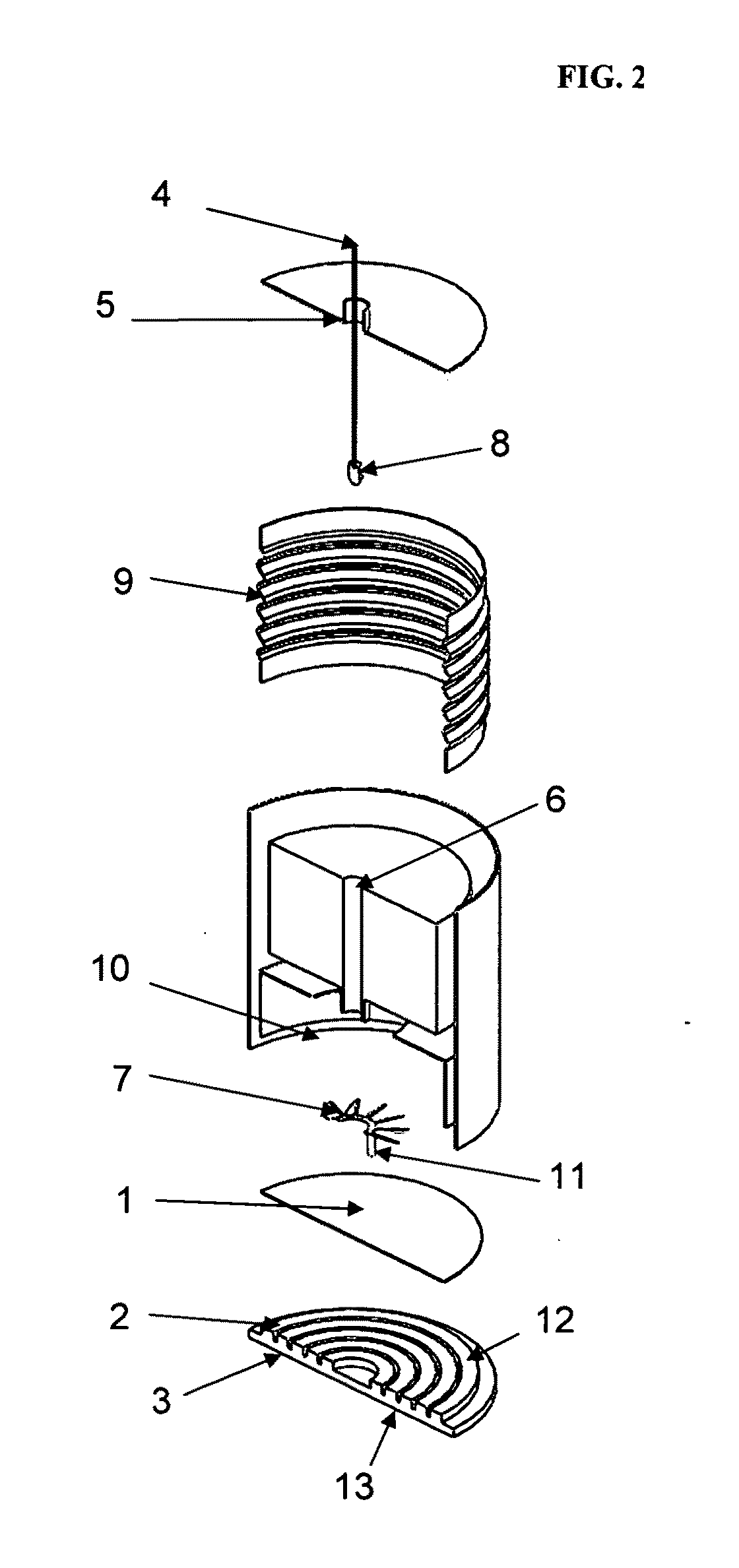

Catalytic burner apparatus for stirling engine

ActiveUS20110146264A1Furnace componentsCombustion using catalytic materialHeat fluxExternal combustion engine

The invention provides an apparatus for generating heat and transferring the heat to a heater head of an external combustion engine, preferably, a Stirling engine. Fuel and air are introduced into a combustion chamber and mixed to form an air / fuel mixture. The air / fuel mixture is combusted over a combustion catalyst positioned in physical contact with a heat spreader, which itself is positioned in physical contact with a heat acceptor surface. The heat acceptor surface is secured in thermal communication with the heater head. Depending upon the design of the heater head, heat flux from the heat acceptor surface into the heater head may occur radially or non-radially.

Owner:PRECISION COMBUSTION

Multiple port catalytic combustion device and method of operating same

A catalytic combustor contains multiple sections for catalytically combusting an anode effluent. The anode effluent is divided into a plurality of portions with each portion routed to a different section or stage of the combustor. The proportioning of the anode effluent allows the combustor to be operated so that the flows combusted do not autoignite and various heat loads placed on the different stages of the combustor can be met. Additionally, the proportioning of the anode effluent allows the temperature within the various components of the combustor to be controlled so that a useful life of the combustor can be increased.

Owner:GENERAL MOTORS COMPANY

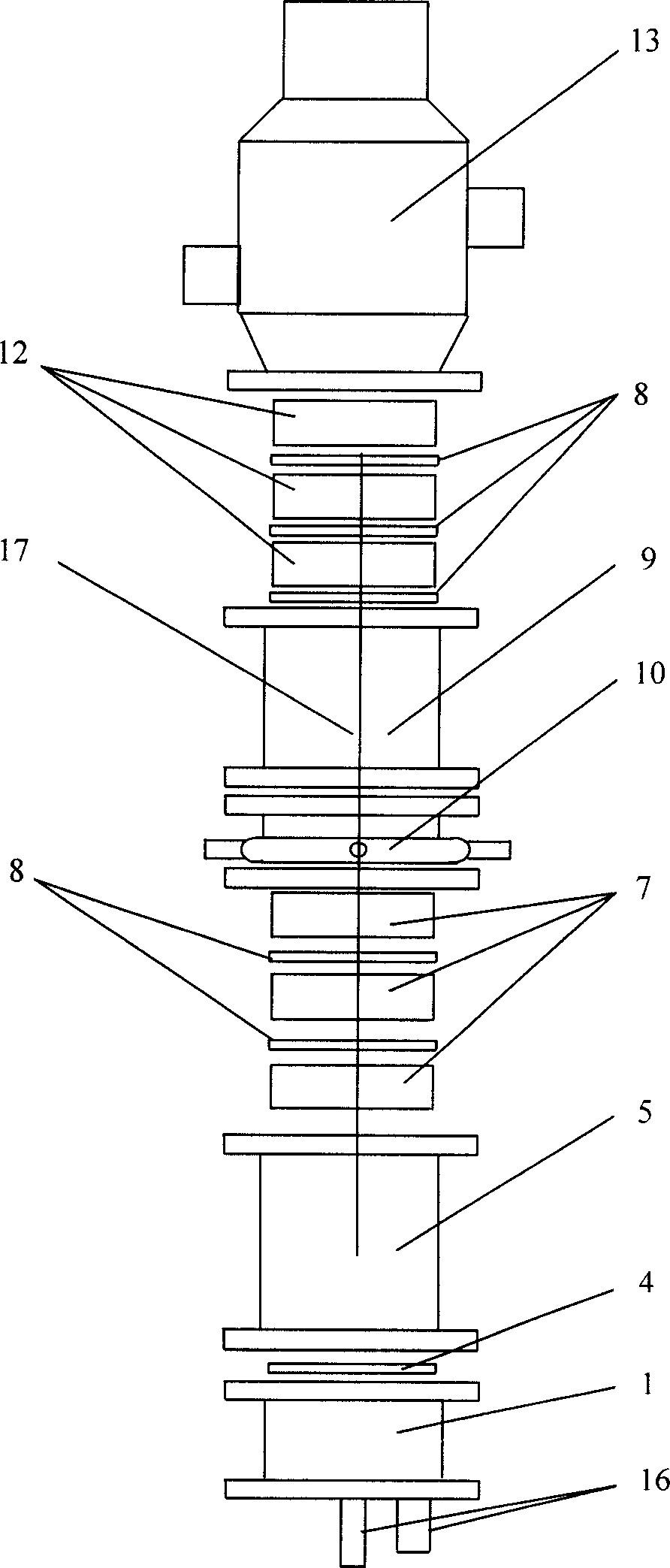

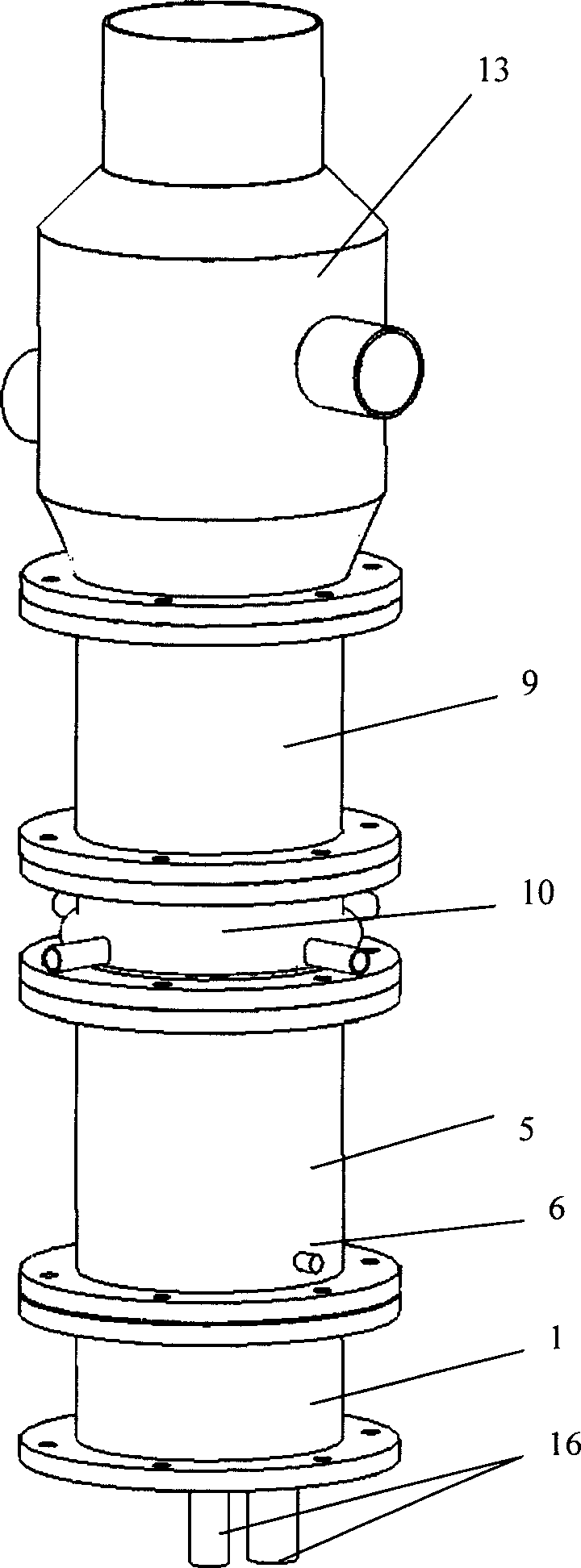

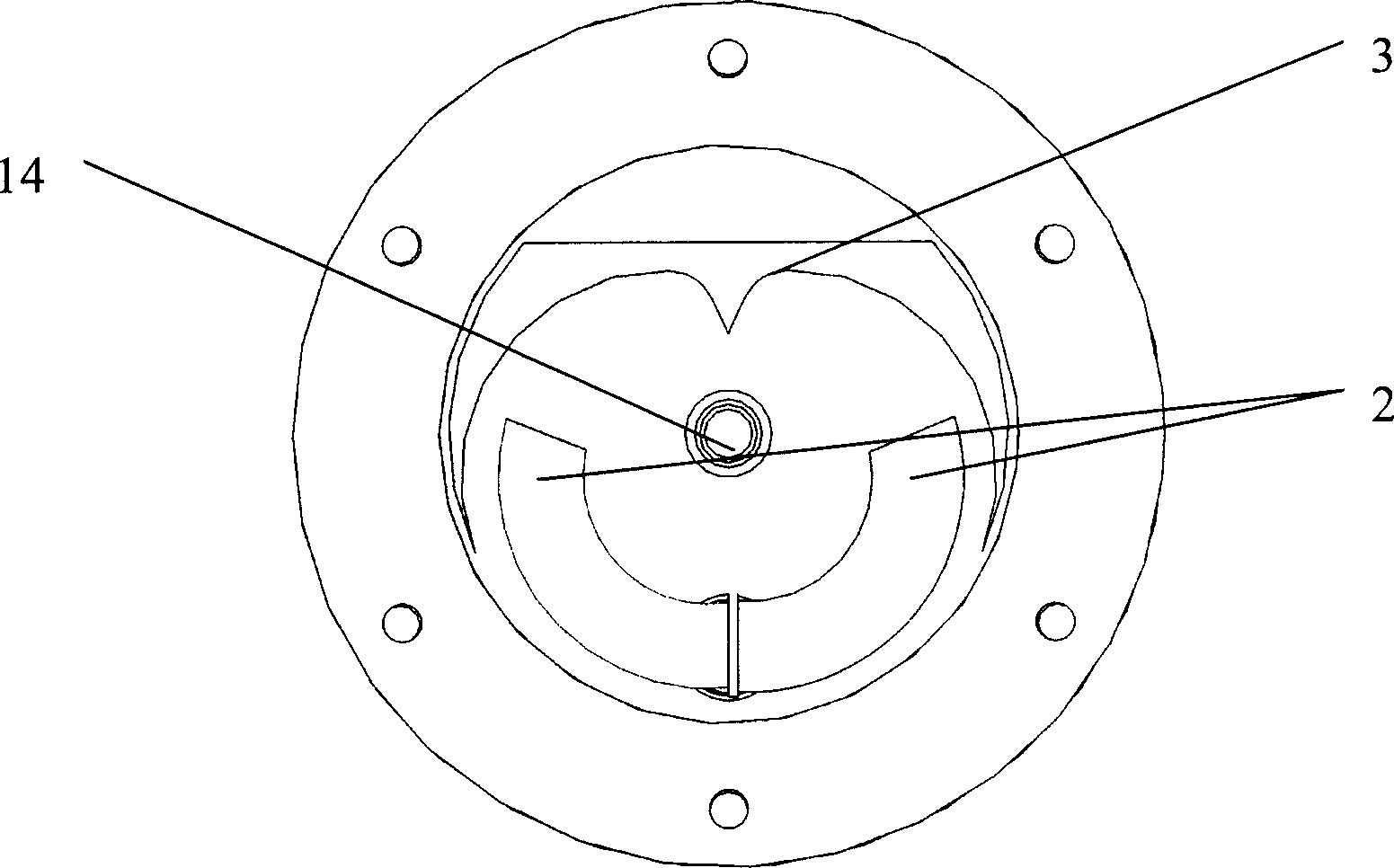

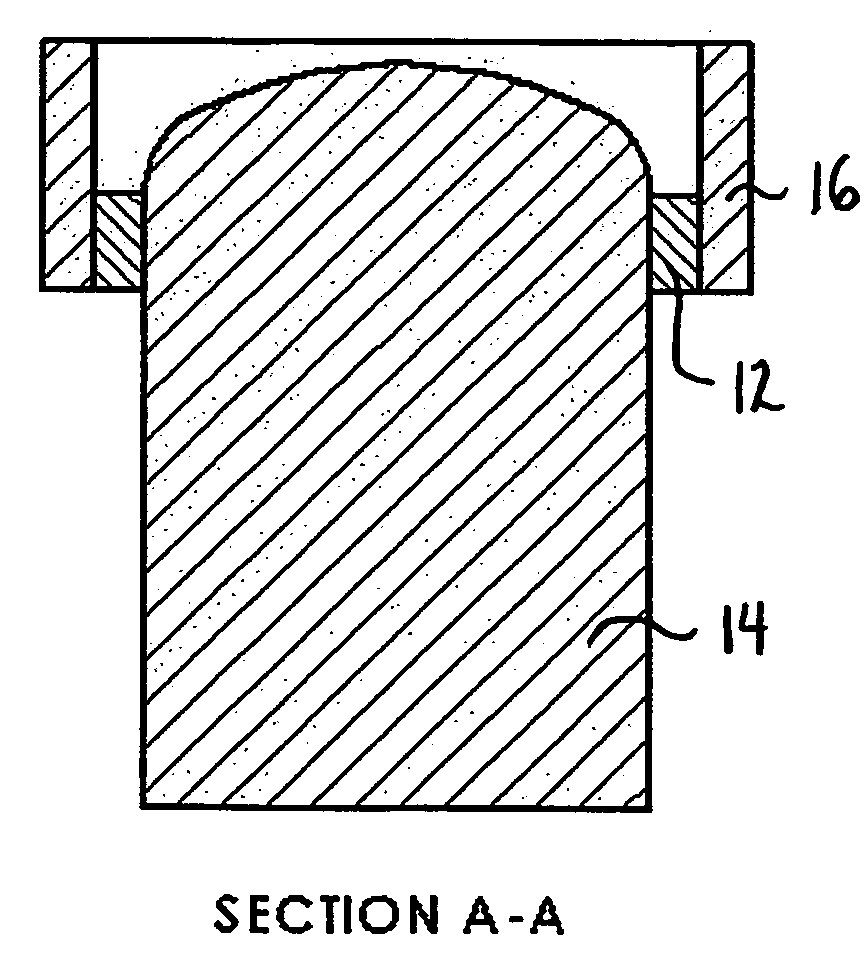

Gas fuel catalytic combustor

The invention relates to a gas fuel catalyst burner, which can be used to heat system. Wherein, the pre-mixing room (1) has a air guide tube (2) and a cyclone guide surface (3) to mix the fuel gas and the air uniformly; the catalyst burning room is formed by two catalyst burning rooms as fuel-rich area and fuel-lack area; the second fuel or air mixing room (10) is arranged between two catalyst burning rooms, which comprises four tangential fuel gas or air nozzles (11) to form the cyclone to mix the secondary fuel gas and air and fuel gas uniformly; and a metallic porous plate (4) is between the pre-mixing room and the first catalyst burning room to avoid backfire. The invention can realize high efficiency and lower discharge.

Owner:BEIJING UNIV OF TECH

Catalytic burner for stirling engine

InactiveUS20090113889A1Simple and efficient and effectiveEffective at generating heatBurnersCatalytic ignitersExternal combustion engineEngineering

The invention provides a method for transferring heat by conduction to the internal heat acceptor of an external combustion engine. Fuel and air are introduced and mixed to form an air / fuel mixture. The air / fuel mixture is directed into a catalytic reactor that is positioned substantially adjacent to the heater head. Heat is transferred via conduction from the catalytic reactor to the heater head and the catalytic reaction products are exhausted.

Owner:PRECISION COMBUSTION

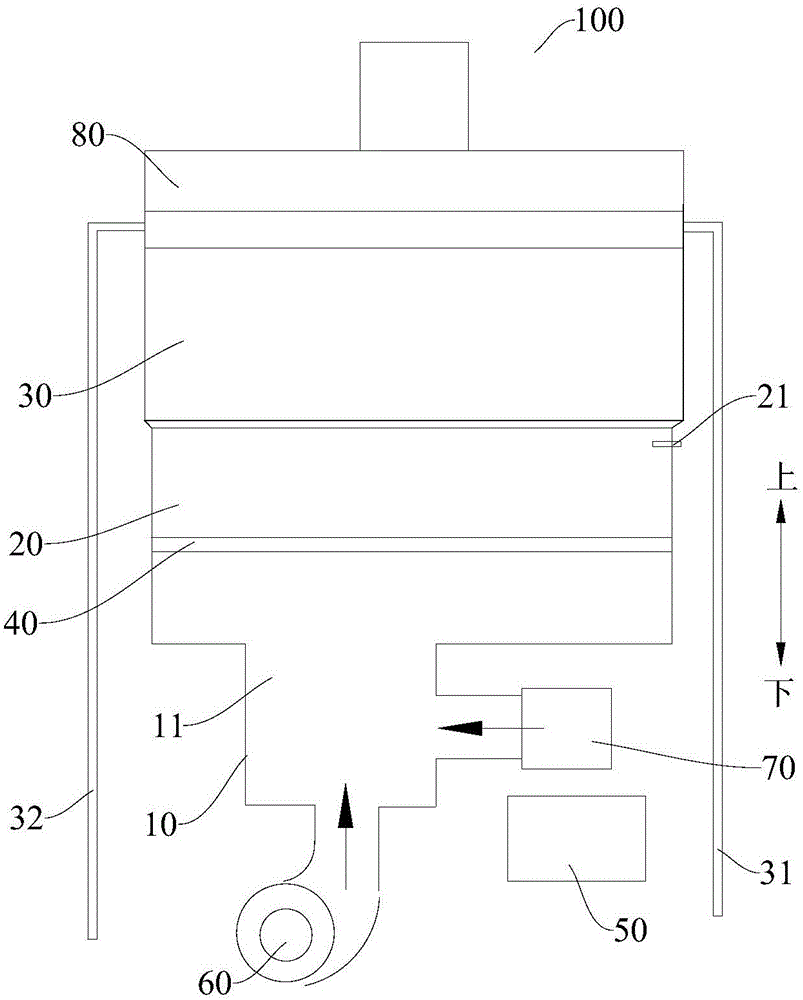

Gas water heater

InactiveCN105841340ASimple structureEasy to assemble and disassembleWater heatersGaseous fuel burnerReaction rateProcess engineering

The invention discloses a gas water heater. The gas water heater comprises a pre-mixing cavity shell, a combustor, a heat exchanger, a pre-heating disc and controller; a mixing cavity is limited in the pre-mixing cavity shell, and the pre-mixing cavity shell is provided with a gas inlet, an air inlet and a mixed gas outlet which are communicated with the mixing cavity; the combustor is communicated with the mixed gas outlet, and a catalyst for catalyzing the combustor to carry out smokeless catalytic combustion is arranged in the combustor; the heat exchanger is connected with the combustor so as to absorb heat generated by combusting of the combustor and is provided with a water inlet and a water outlet; the pre-heating disc is connected with the combustor so as to preheat the combustor; and the controller is connected with the pre-heating disc so as to control heating temperature of the pre-heating disc. According to the gas water heater, the reaction rate of fuel can be improved, the utilization rate of the fuel is improved, generation of harmful gas can be avoided, the fuel can be subject to flameless catalytic combustion in the combustor, generation of the harmful gas is greatly reduced, and use is safe and environment-friendly.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

Control of gas turbine for catalyst activation

InactiveUS7096667B2Continuous combustion chamberTurbine/propulsion fuel supply systemsEngineeringBiological activation

A catalytic gas turbine includes a compressor, a catalytic combustor, a turbine, and a flow path conducting a bypass portion of the compressed air around the combustor and turbine. A method of operating the catalytic gas turbine to activate a catalyst in the catalytic combustor includes opening an inlet guide vane upstream of the compressor to a position to produce an increased volume of compressed air. The increased volume exceeds a volume of compressed air needed to support combustion. A bypass portion of the compressed air is extracted and directed around the combustor and turbine. The method may also include extracting a recirculation portion of the compressed air and directing the recirculation portion into the inlet of the compressor.

Owner:SIEMENS ENERGY INC

Jet Cavity Catalytic Heater

ActiveUS20100192937A1Heat generationReduced advantageCombination devicesExothermal chemical reaction heat productionAlcohol fuelThermopile

The present invention is a method of delivering vaporized alcohol fuel through a thermally conductive porous nozzle to a catalytic burner with a plasma cavity and a surrounding porous catalytic cavity with fuel vapor and air supplied separately and inter diffusing into each other from different routes to the catalyst to achieve an efficient, steady, and complete combustion of the hydrogen bearing fuels. This heating system with passive auto thermostatic behavior, coupled to thermopiles, heat pipes and fluid heating systems may provide useful heat and electricity to applications of floors, roadways, runways, electronics, refrigerators, machinery, automobiles, structures, and fuel cells.

Owner:GHT GLOBAL HEATING TECH

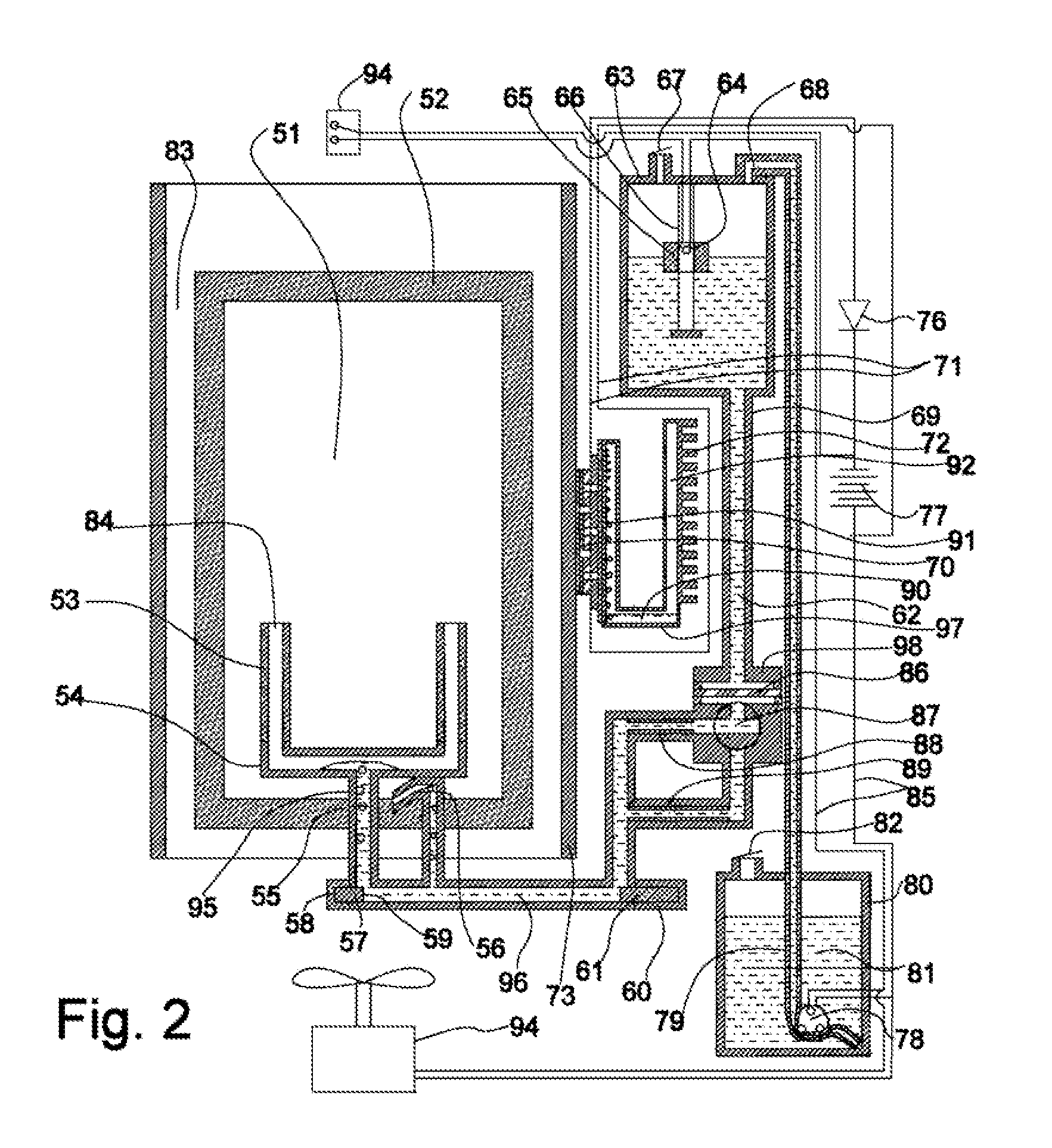

Online high-purity hydrogen preparation system for fuel cell and control method of online high-purity hydrogen preparation system

ActiveCN105152133AReduce energy consumptionLower requirementHydrogenSolid electrolyte fuel cellsHydrogen purityOxygen

The invention discloses an online high-purity hydrogen preparation system for a fuel cell. The online high-purity hydrogen preparation system comprises a methyl alcohol box as well as a raw material box and a catalytic burner which are connected with the methyl alcohol box through a methyl alcohol metering pump, wherein a fuel cell discharge water inlet is formed in the raw material box, an oxygen inlet is formed in the catalytic burner, an ethanol water metering pump and a heat exchanger are sequentially connected onto the raw material box, a vaporizer is connected onto the heat exchanger, a reforming reactor is connected onto the vaporizer, a palladium film purifier is connected onto the reforming reactor, and the palladium film purifier is connected with the catalytic burner; the invention further discloses a control method of the system. According to the system provided by the invention, online hydrogen supplying is performed through a manner of using a methanol water reforming reaction to produce hydrogen, the yield of pure hydrogen is controlled through adjusting the flow of an ethanol water mixture; the method has the characteristics of high hydrogen storage density, high hydrogen purity, low energy consumption, compact structure, simpleness and convenience in start-stop controlling, easiness in implementing modular design and the like.

Owner:武汉氢能与燃料电池产业技术研究院有限公司

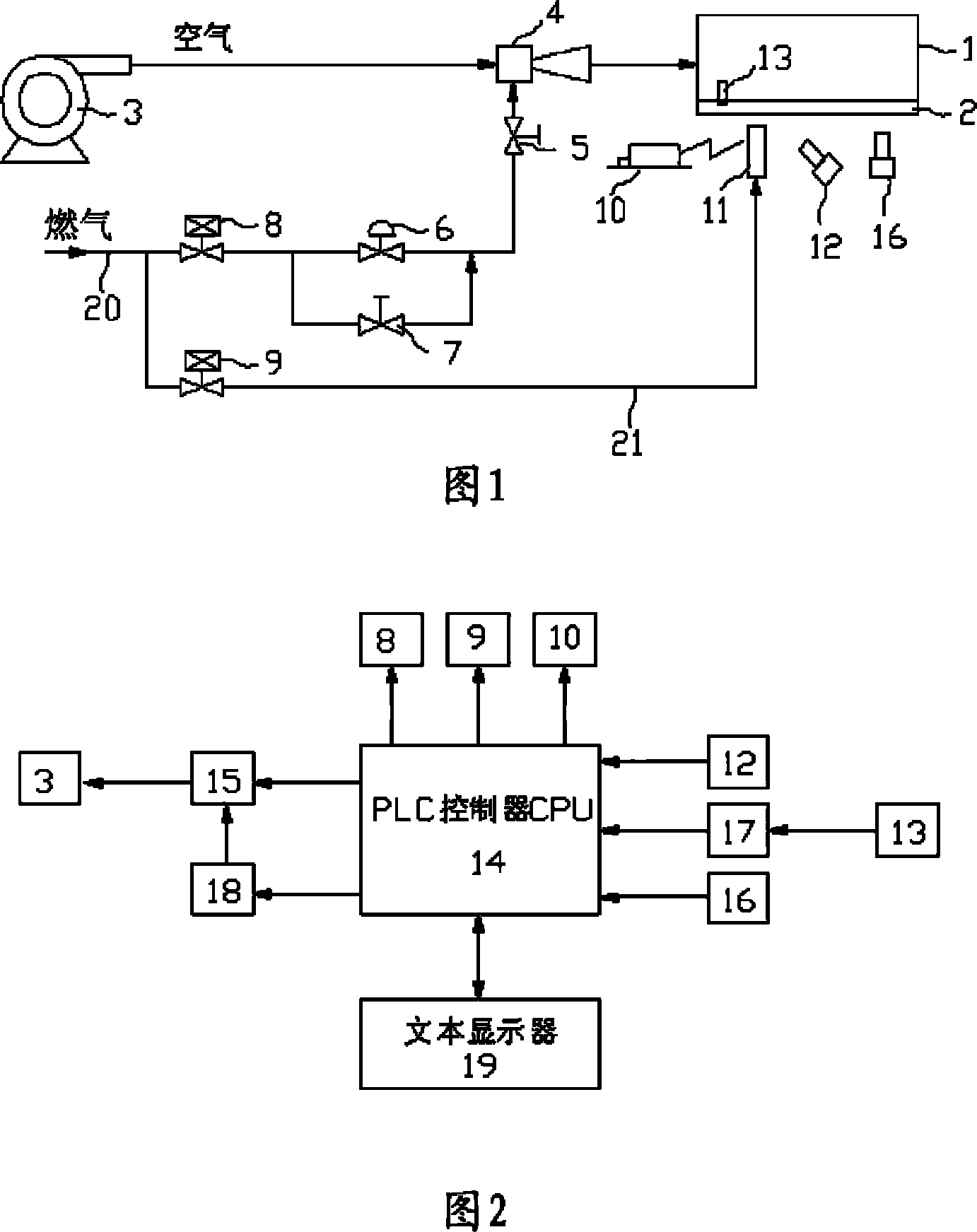

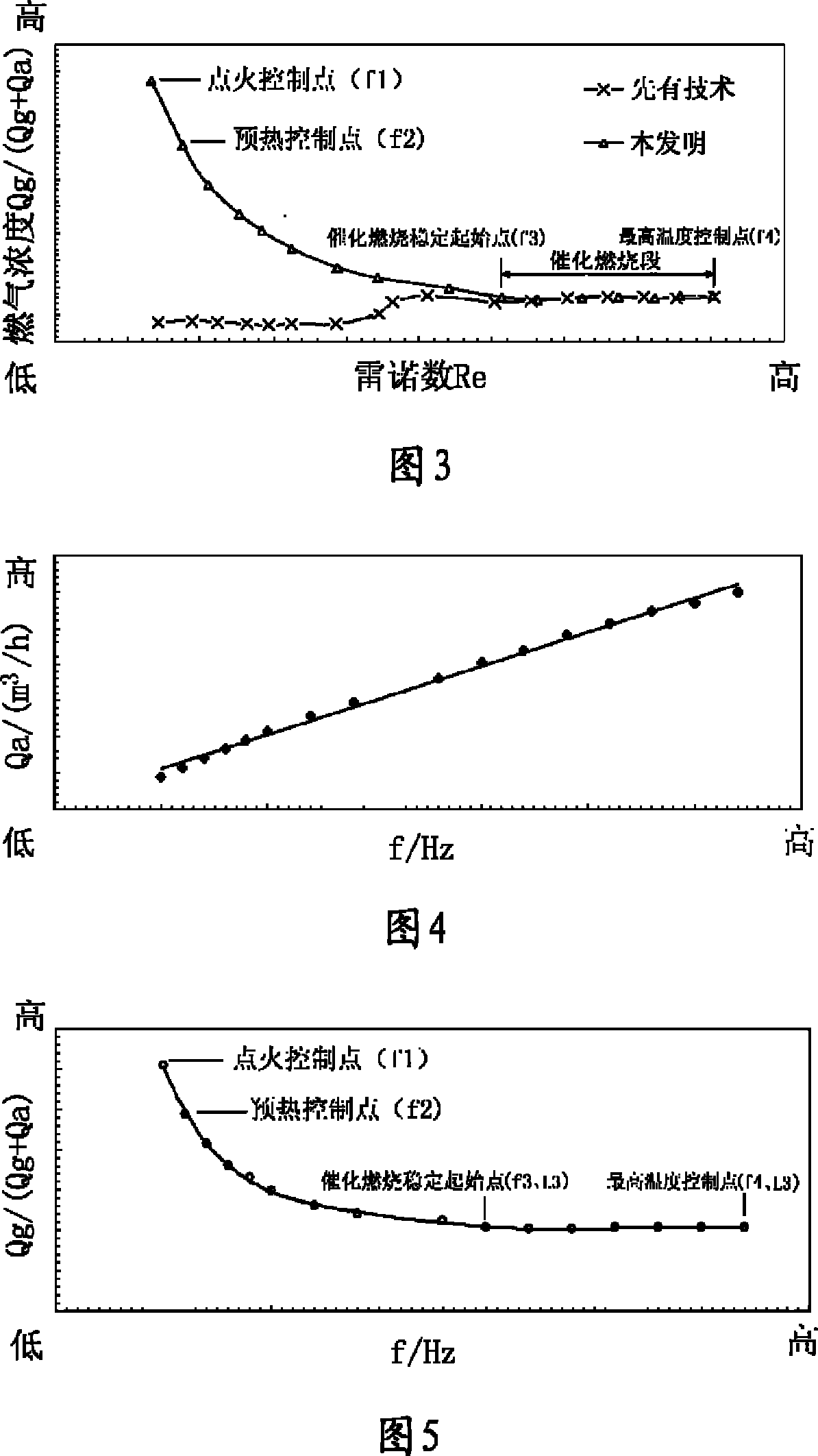

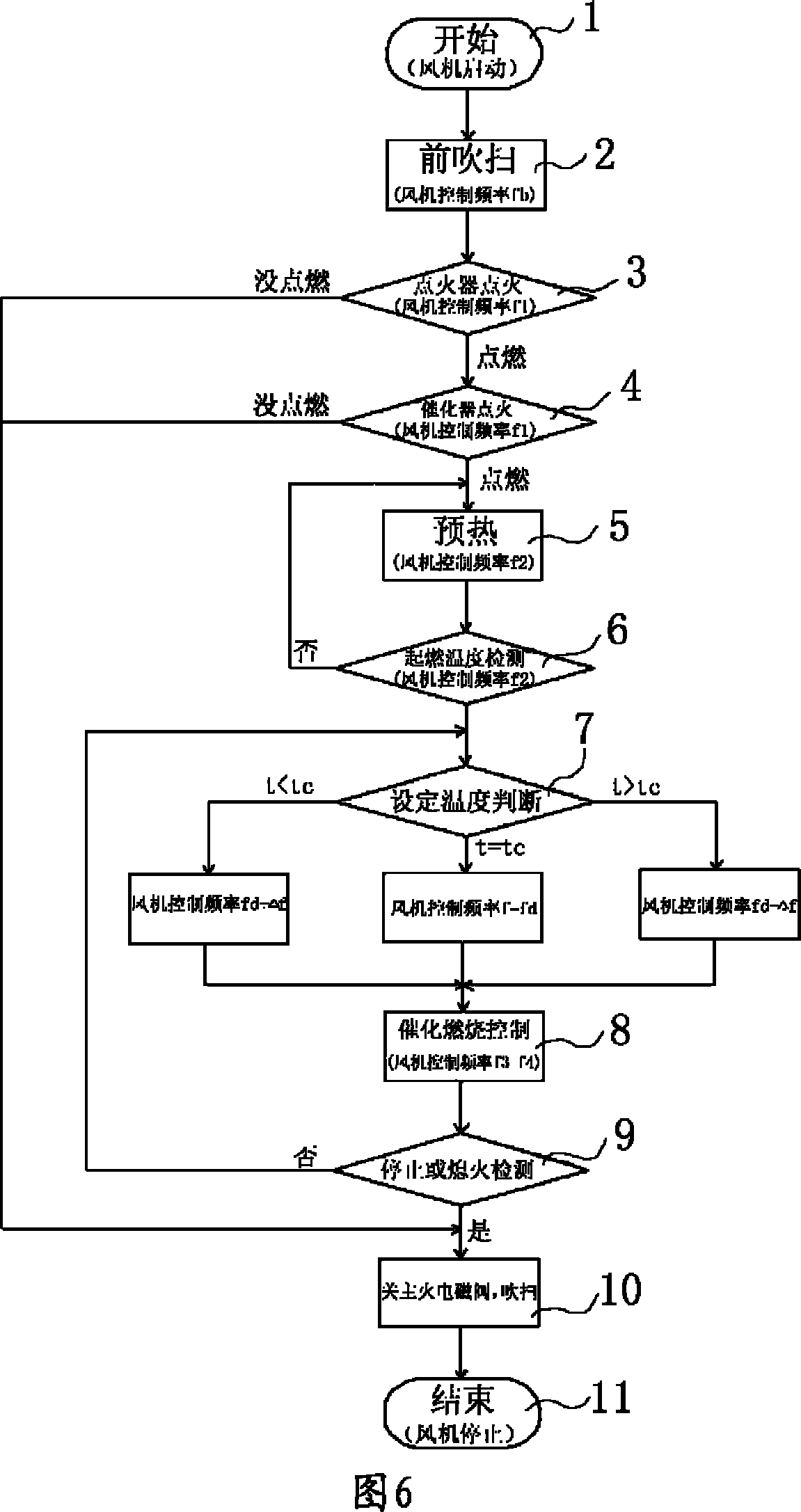

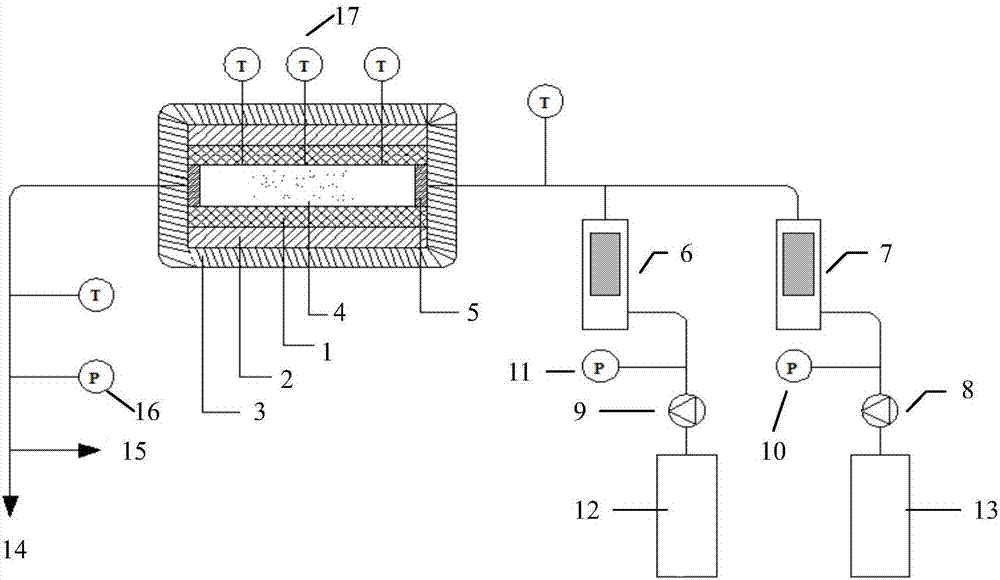

Control system for catalytic combustion

InactiveCN1971135AMeet the special requirements of different mixing concentrationsReduce volumeCombustion using catalytic materialCombustion apparatusAir volumeFluid control

The invention relates to a catalytic combustion control system, comprising fluid pre-mixed control system and PLC controller. The fluid pre-mixed control system comprises a fan connected with venturi-mixed reactor in series. Suction port at the hollow throat of venture-mixed reactor is connected with proportional regular valve and the inlet of proportional regular valve is connected with the outlet of zero-pressure valve. The zero-pressure valve is connected with needle valve in parallel. PLC controller comprises a CPU of PLC controller. By the combination technology of fluid control and PLC automatic control, in the whole fluid pre-mixed system, there is only need to control the inputting frequency of fan so as to control the outputting air quantity by the PLC control parts and different mixed concentration of gas and air demanded in the catalytic combustion process is realized. Automatic control ignition, pre-heat flaming combustion and catalytic combustion can be realized on the catalyst carrier of catalytic combustion directly. It is provided with simplified structure of catalytic combustor, decreased cubage, decreased cost, improved automaticity and control accuracy.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

Carried noble metal complete-combustion catalyst and its prepn

InactiveCN1332035AAchieve combustionLow ignition temperatureCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAlkaneRaw material

The catalyst for the combustion reaction of natural gas and light alkane consists of alkali earth metal 1-60 wt%, noble metal 0.2-5 wt% and alumina 40-99 wt%. The precursors of the components are soluble organic or inorganic salt, and there must not be halogen in the raw material. The catalyst is used in both self-heated combustor and heated combustor and can ignite combustion at 284-350 deg.c. In case of low heat transfer efficiency, it can heat fuel gas fluid spontaneously to carry out complete combustion with less CO and NOx in tail gas. The said catalyst has the advantages of low initiation temperature, wide use range of temperature and space velocity, high stability, long service life, etc. and can be formed in different shape for practical industrial application.

Owner:XIAMEN UNIV

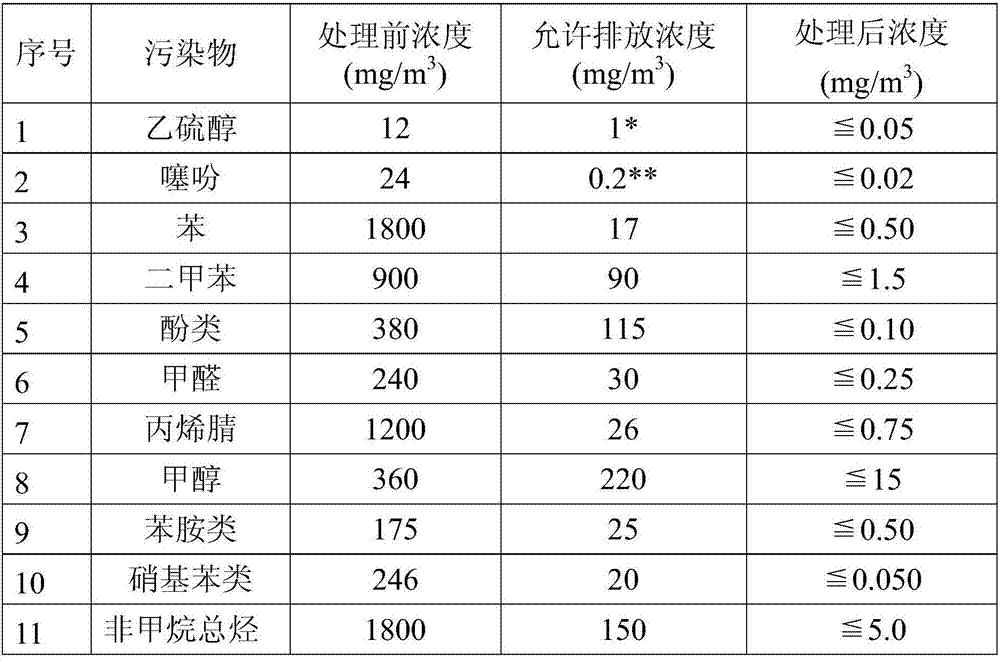

Innocent treatment method for sulfur-bearing VOC

InactiveCN107202333AEasy to handleRealize harmless treatmentIncinerator apparatusChemical LinkageBond energy

The invention belongs to the field of environmental protection and discloses a method for harmless treatment of sulfur-containing VOC. The method is as follows: (1) the catalyst is placed in the combustion furnace of the sulfur-containing VOC combustion treatment device, and the sulfur-containing VOC gas and the combustion-supporting gas are introduced; (2) the mixed sulfur-containing VOC gas and the combustion-supporting gas are placed in the catalytic combustion furnace Carry out catalytic combustion under the effect of the catalyzer, the gas gained after combustion is absorbed by alkaline substance at last; The catalyst described in step (1) is main catalyst, main catalyst and co-catalyst, main catalyst and carrier or main catalyst, co-catalyst and carrier. The method of the present invention is simple and efficient, and the catalyst used can increase the local concentration of sulfur-containing VOC gas and combustion-supporting gas, and can also weaken its chemical bond energy, increase its reactivity, and make the catalytic combustion of sulfur-containing VOC easier to carry out, and the reaction is more efficient. Thoroughly and effectively realize the harmless treatment of sulfur-containing VOC.

Owner:SOUTH CHINA UNIV OF TECH

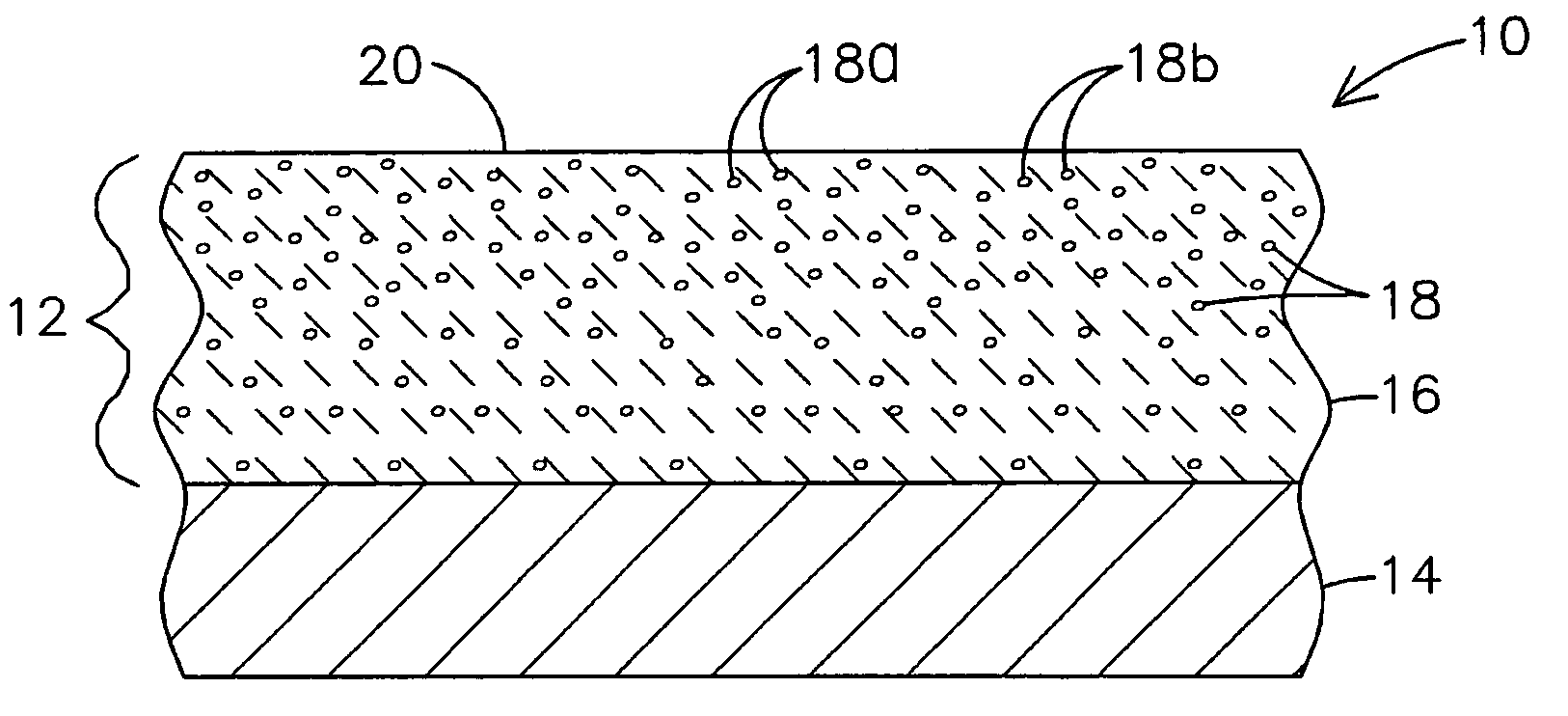

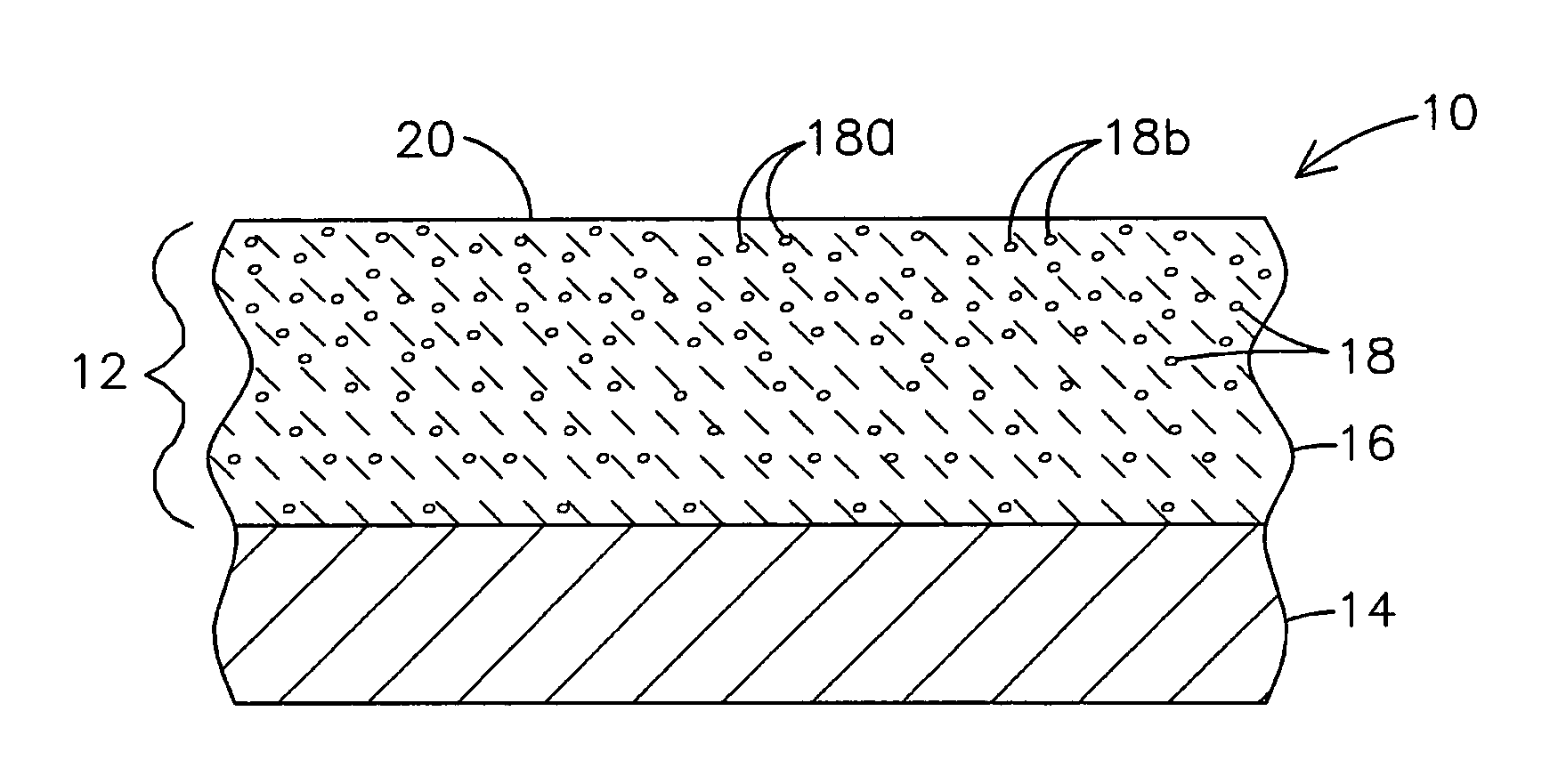

Ceramic wash-coat for catalyst support

InactiveUS8242045B2Heterogenous catalyst chemical elementsCatalyst activation/preparationThermal expansionSolid solution

A wash-coat (16) for use as a support for an active catalyst species (18) and a catalytic combustor component (10) incorporating such wash-coat. The wash-coat is a solid solution of alumina or alumina-based material (Al2O3-0-3 wt % La2O3) and a further oxide exhibiting a coefficient of thermal expansion that is lower than that exhibited by alumina. The further oxide may be silicon dioxide (2-30 wt % SiO2), zirconia silicate (2-30 wt % ZrSiO4), neodymium oxide (0-4 wt %), titania (Al2O3-3-40% TiO2) or alumina-based magnesium aluminate spinel (Al2O3-25 wt % MgO) in various embodiments. The active catalyst species may be palladium and a second metal in a concentration of 10-50% of the concentration of the palladium.

Owner:SIEMENS ENERGY INC

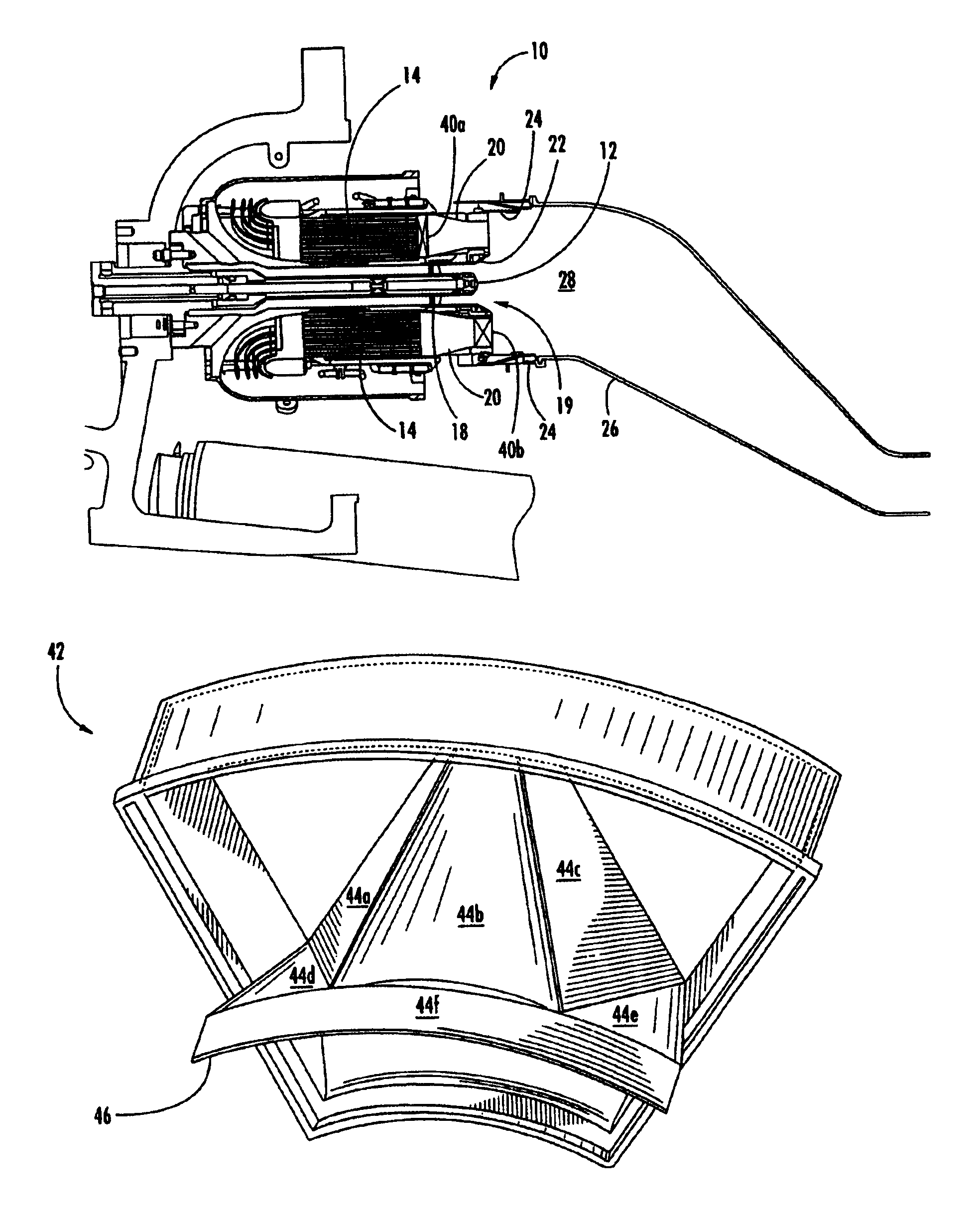

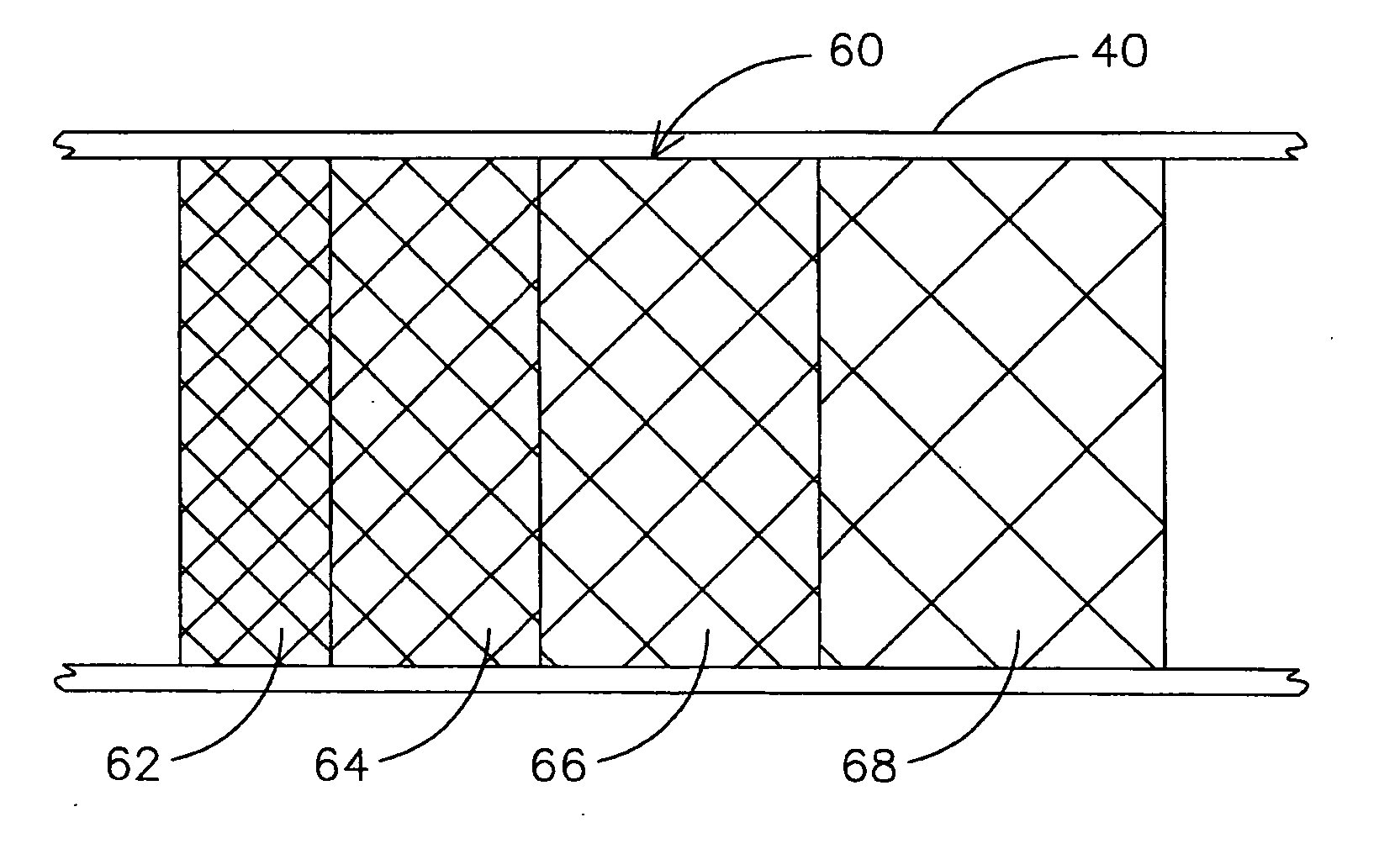

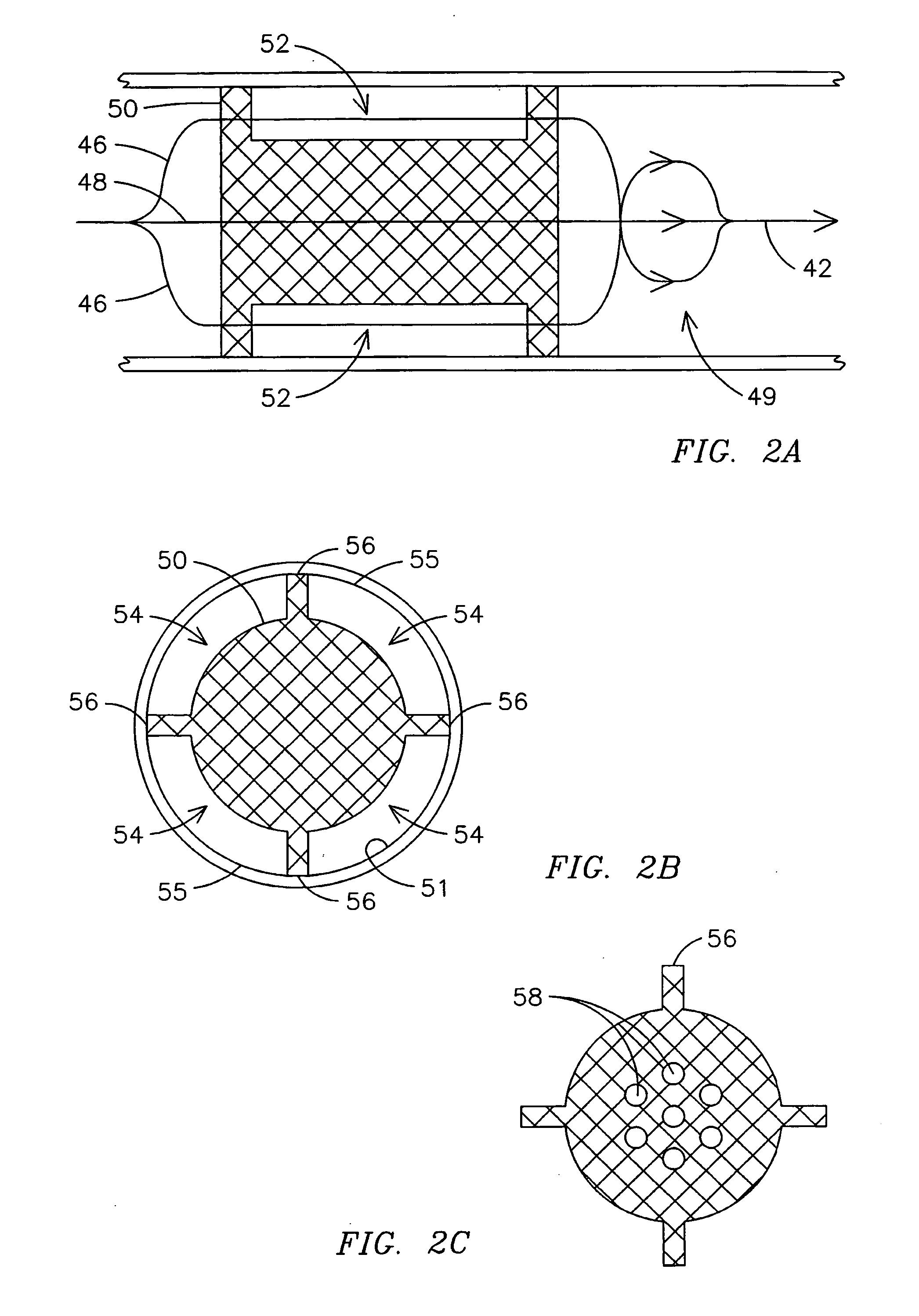

Two stage catalytic combustor

InactiveUS20050201906A1Combination devicesContinuous combustion chamberPartial oxidationReticulated foam

A catalytic combustor (14) includes a first catalytic stage (30), a second catalytic stage (40), and an oxidation completion stage (49). The first catalytic stage receives an oxidizer (e.g., 20) and a fuel (26) and discharges a partially oxidized fuel / oxidizer mixture (36). The second catalytic stage receives the partially oxidized fuel / oxidizer mixture and further oxidizes the mixture. The second catalytic stage may include a passageway (47) for conducting a bypass portion (46) of the mixture past a catalyst (e.g., 41) disposed therein. The second catalytic stage may have an outlet temperature elevated sufficiently to complete oxidation of the mixture without using a separate ignition source. The oxidation completion stage is disposed downstream of the second catalytic stage and may recombine the bypass portion with a catalyst exposed portion (48) of the mixture and complete oxidation of the mixture. The second catalytic stage may also include a reticulated foam support (50), a honeycomb support, a tube support or a plate support.

Owner:SIEMENS ENERGY INC

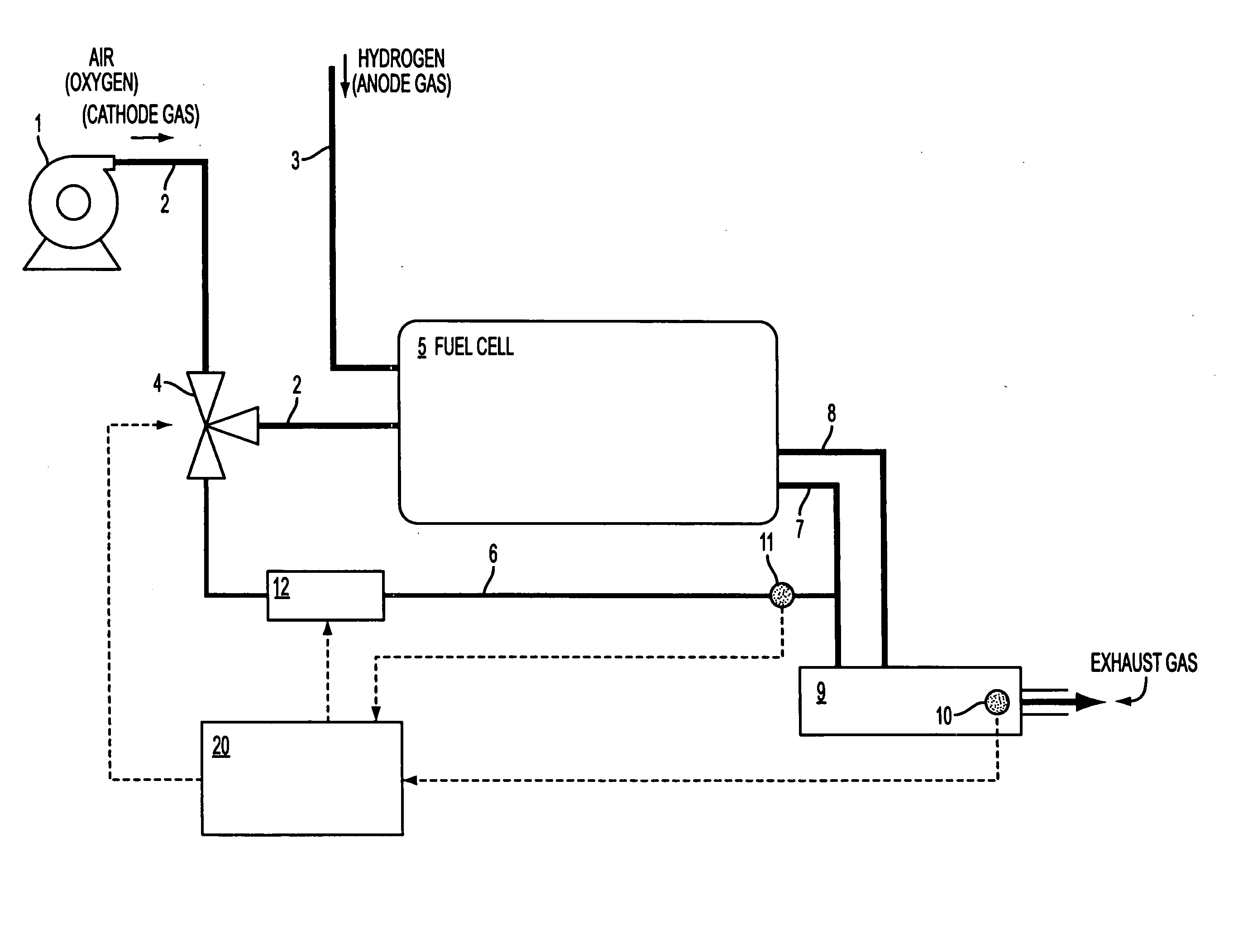

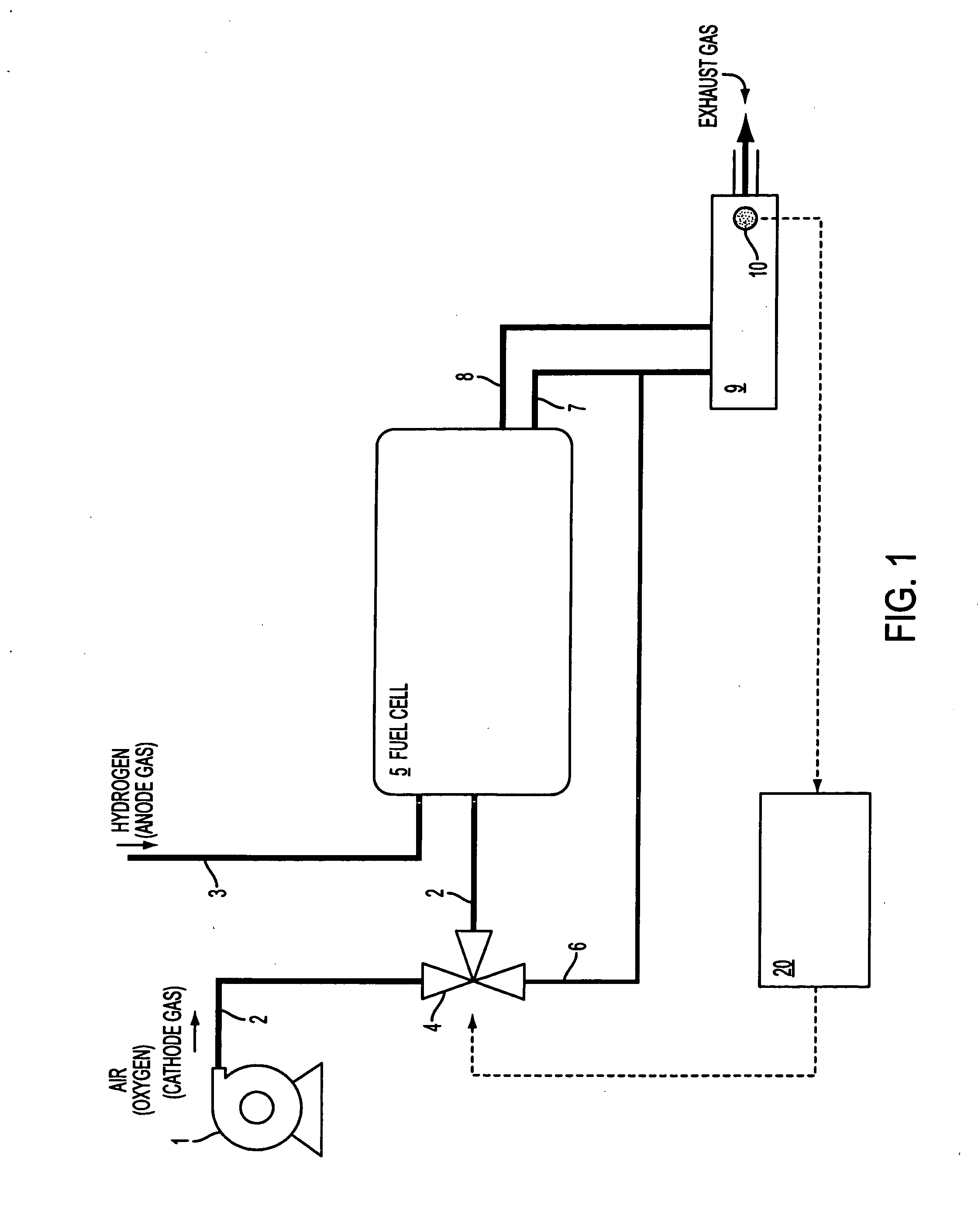

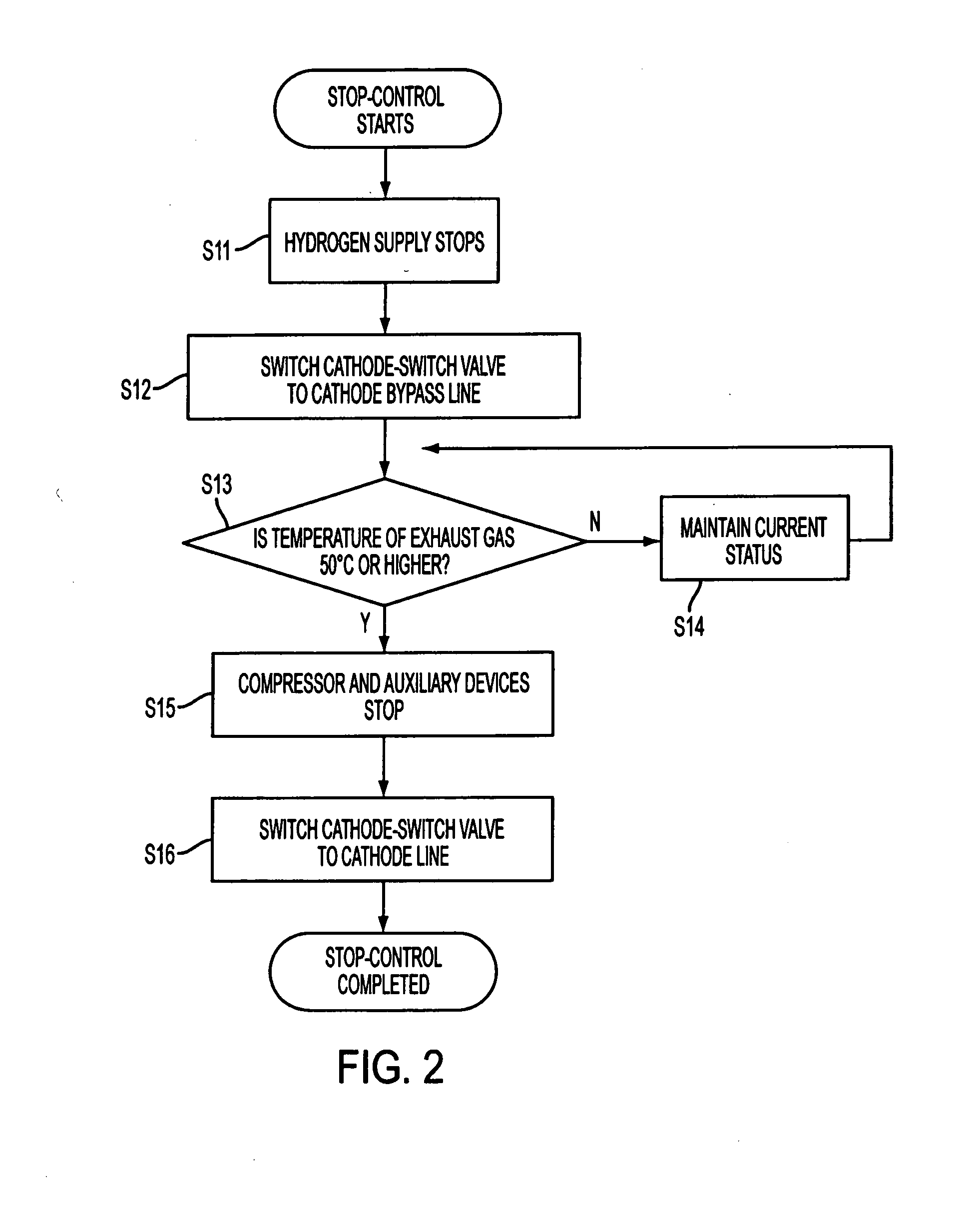

Fuel cell system

InactiveUS20050136302A1Simple compositionFuel cell auxillariesSolid electrolyte fuel cellsElectrochemical responseFuel cells

A fuel cell generates electric power by the electrochemical reaction of hydrogen and the oxygen in air. After the hydrogen discharged without being consumed by an anode is burned in a burner, it is discharged out of a fuel cell system. Therefore, the fuel cell system has a cathode switch valve in the middle of the cathode line, and when the fuel cell system stops, non-saturated air of a compressor bypasses the fuel cell, and supplies the air to the catalytic burner. Although the cathode exhaust gas of saturated water vapor is circulating to the catalytic burner at the time of regular operation of the fuel cell, the non-saturated air which bypasses the fuel cell and is supplied can replace the inside of the catalytic burner with dry air. Therefore, the amount of water vapor in the catalytic burner is decreased at the time of a stop, and the catalyst is quickly activated at the time of re-starting.

Owner:NISSAN MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com