Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155 results about "Hydrogen purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen purity or hydrogen quality is a term to describe the lack of impurities in hydrogen as a fuel gas. The purity requirement varies with the application, for example a H₂ ICE can tolerate low hydrogen purity where a hydrogen fuel cell requires high hydrogen purity to prevent catalyst poisoning.

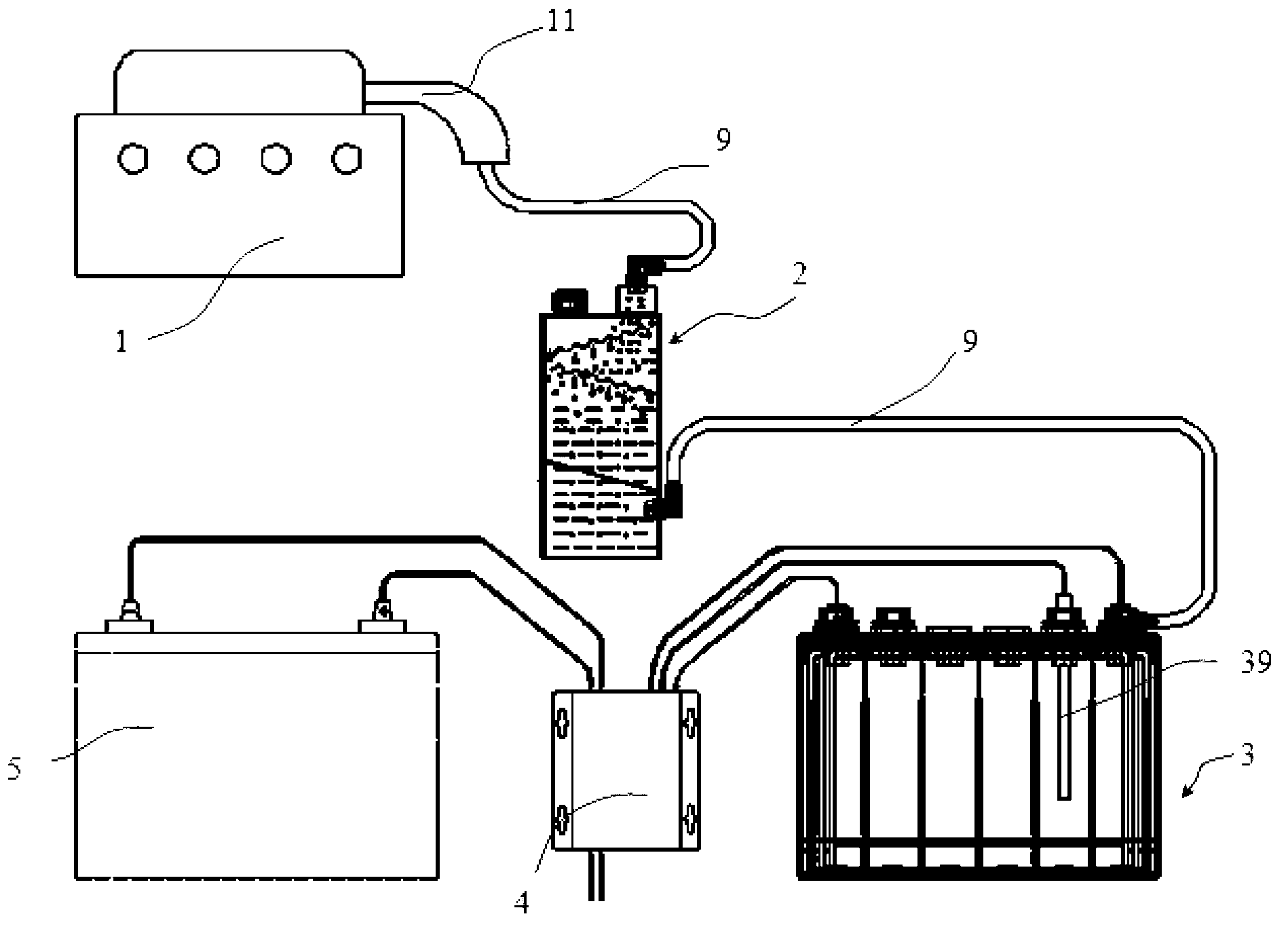

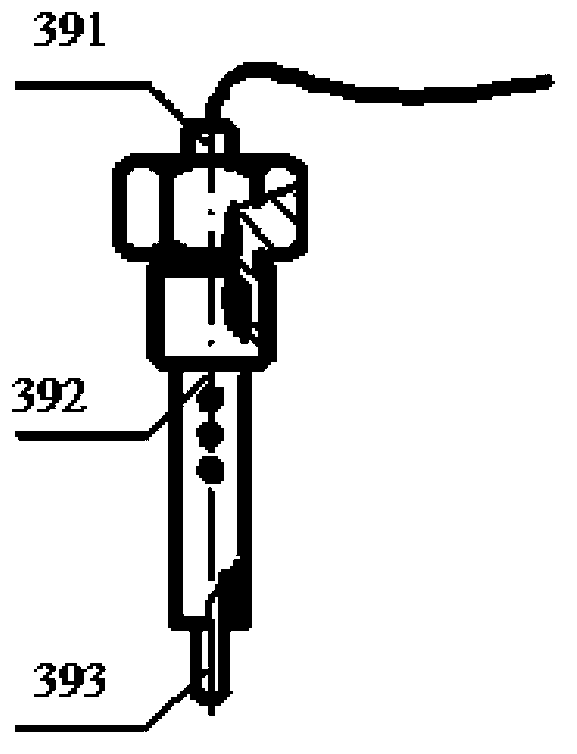

Oxy-hydrogen hybrid power device

ActiveCN103233830APrevent flashbackIncrease powerElectrolysis componentsInternal combustion piston enginesHydrogen purityElectricity

The invention relates to a power device for an automobile or a diesel engine, in particular to an oxy-hydrogen hybrid power device. The oxy-hydrogen hybrid power device comprises an engine provided with an oxy-hydrogen inlet branch tube, a container provided with an oxy-hydrogen inlet and an oxy-hydrogen outlet, filtrate contained in the container, a filter immersed into the filtrate and composed of an air-permeable plate, a water-splitting box composed of a positive electrolysis electrode, a negative electrolysis electrode and electrolyte contained in an electrolytic bath, an automatic controller electrically connected with the positive electrolysis electrode and the negative electrolysis electrode, and a vehicle-mounted storage battery electrically connected with the automatic controller. The oxy-hydrogen inlet is located under the liquid level of the filtrate, and the oxy-hydrogen outlet is located above the liquid level of the filtrate and is communicated with the oxy-hydrogen inlet branch tube. The water-splitting box is used for producing hydrogen and oxygen and is communicated with the oxy-hydrogen inlet. The automatic controller is used for controlling flows of produced hydrogen and oxygen. The oxy-hydrogen hybrid power device saves fuel oil, is environmental-friendly and can ensure the oxy-hydrogen purity and prevent an oxy-hydrogen tempering phenomenon.

Owner:SHANGHAI WONENG ENVIRONMENTAL PROTECTION TECH

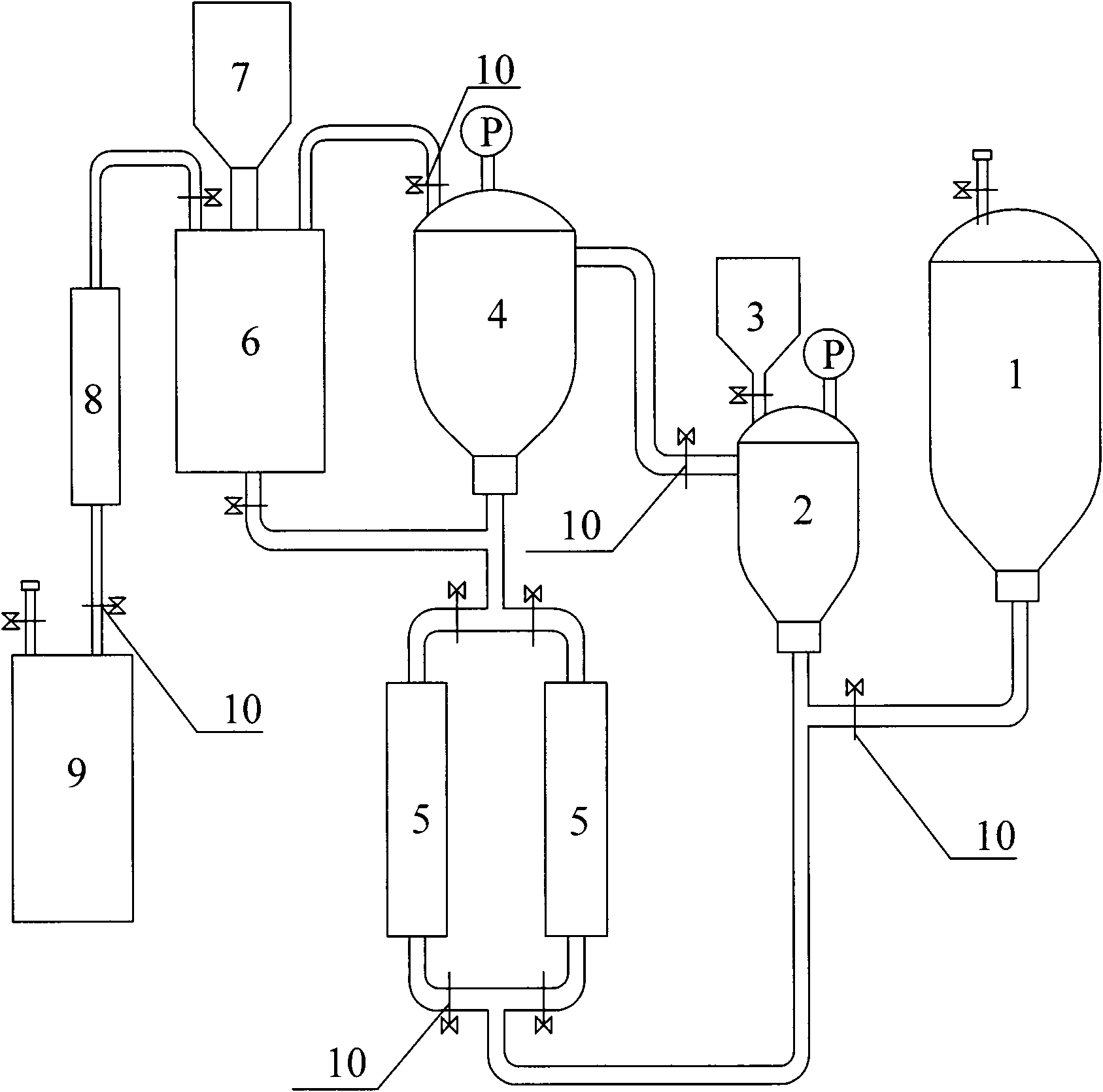

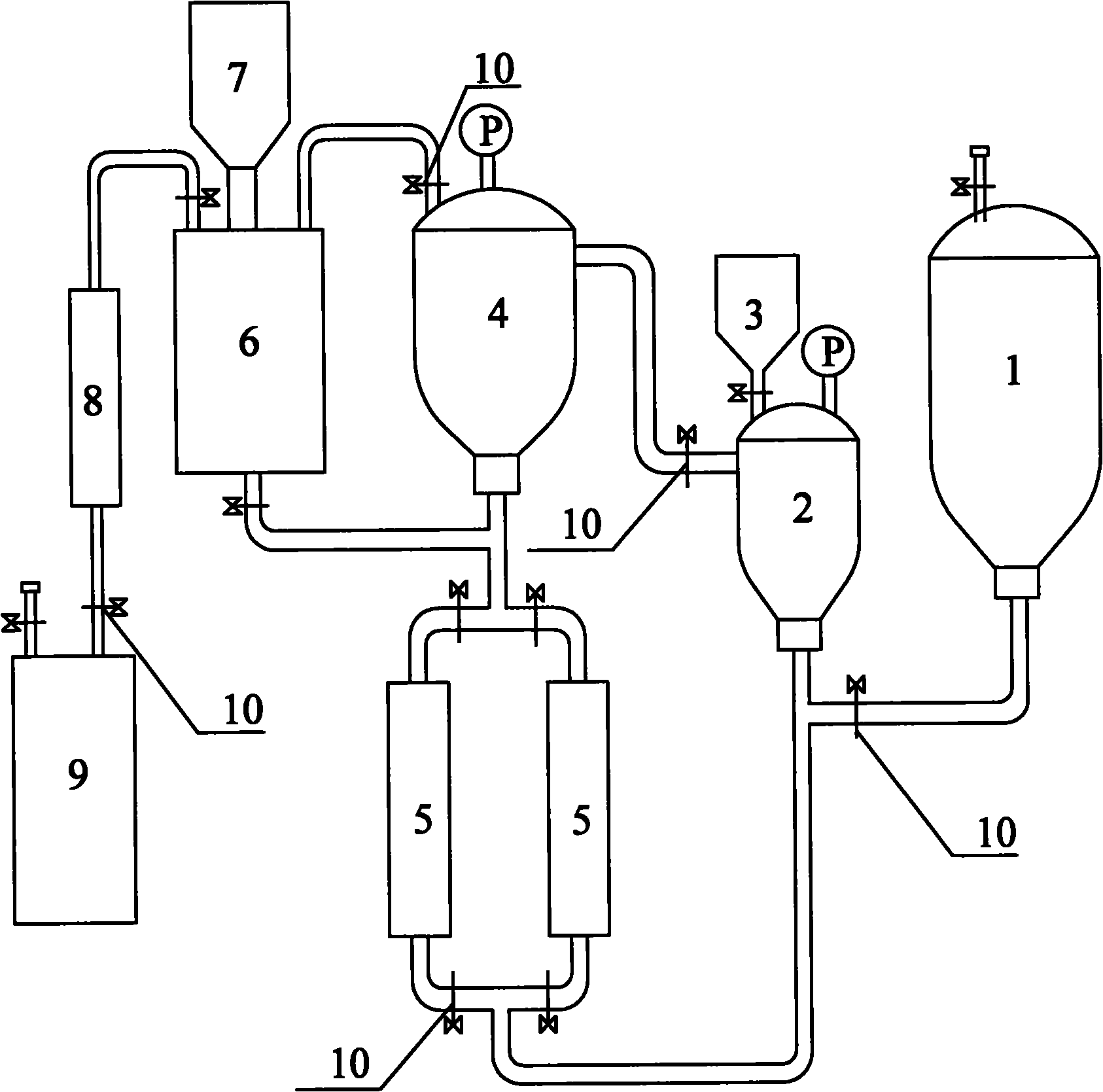

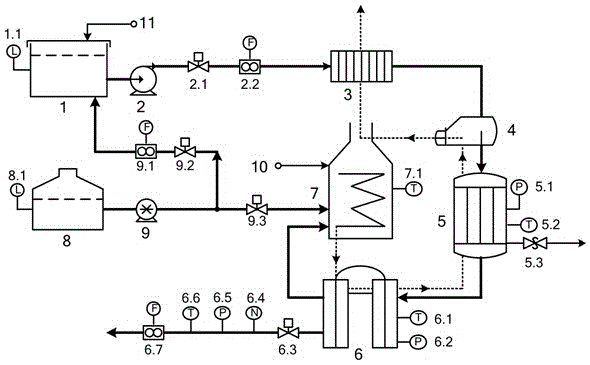

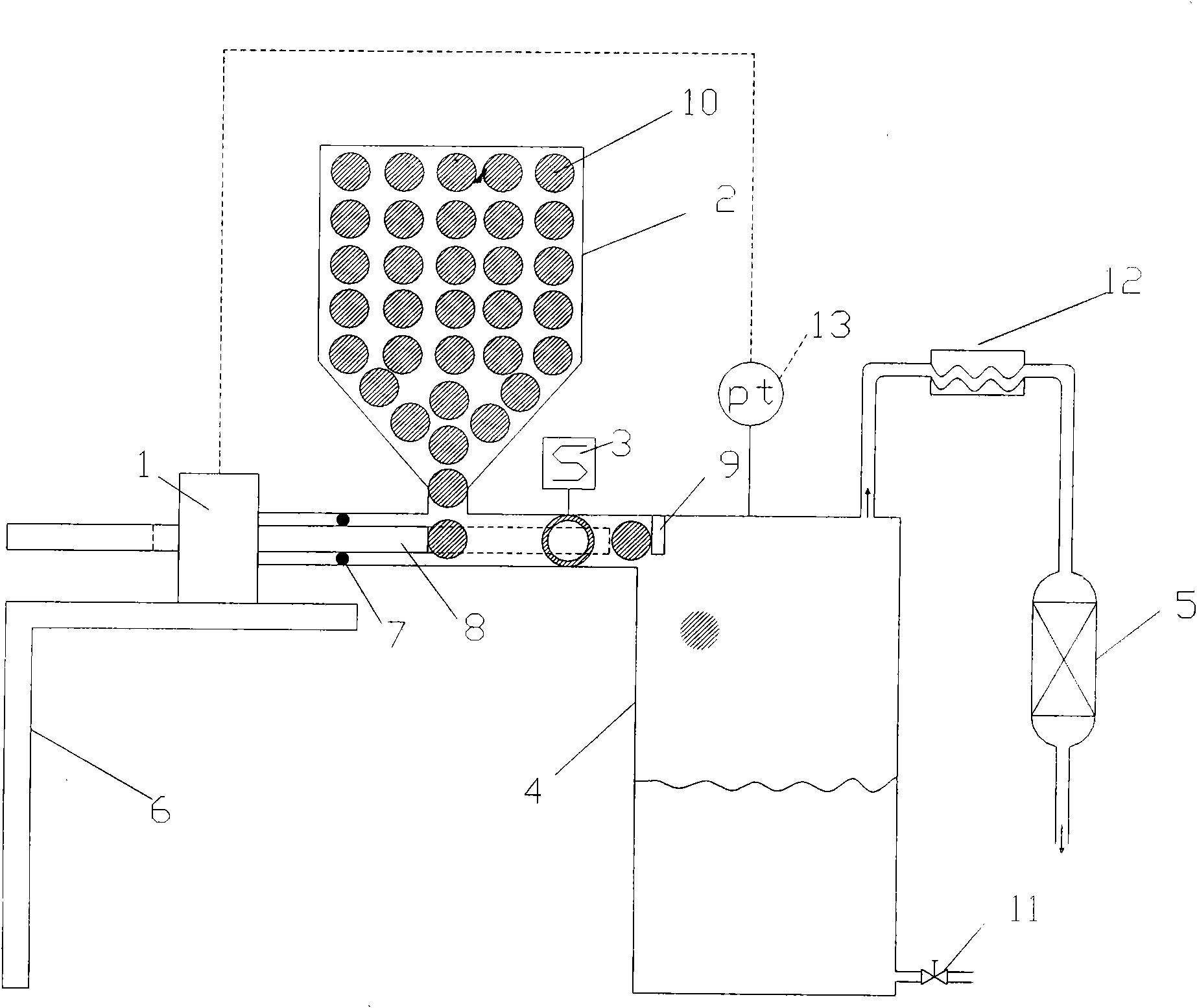

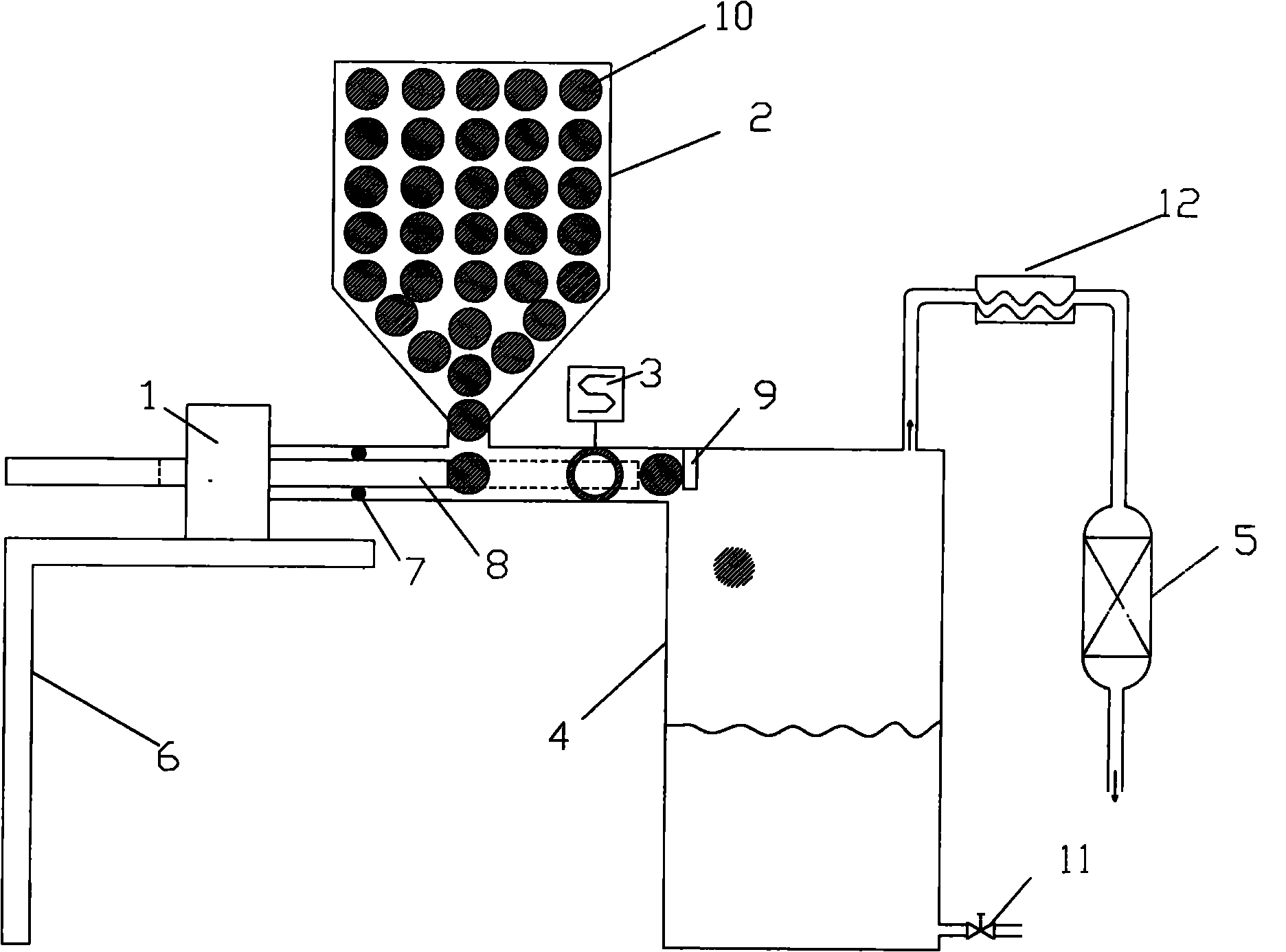

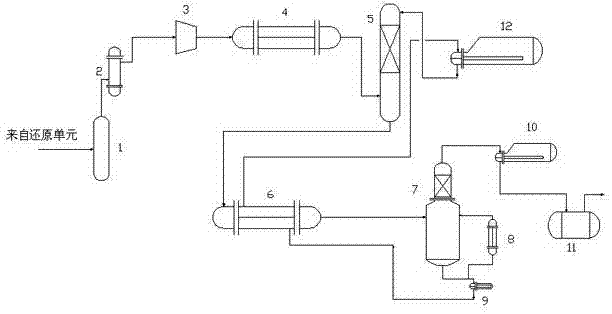

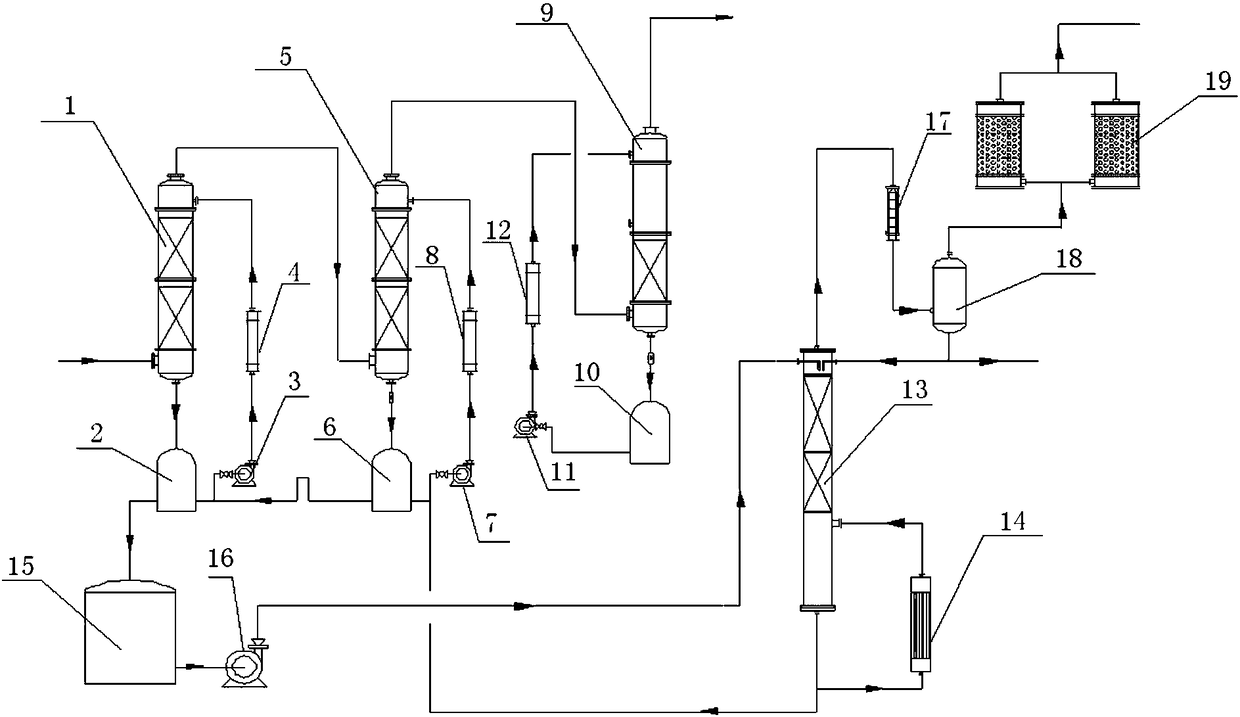

System for continuously generating hydrogen from molten aluminum

ActiveCN101962171ATo achieve an organic combinationHydrogen productionHydrogen purityVapor–liquid separator

The invention discloses a system for continuously generating hydrogen from molten aluminum, which comprises an alkaline liquor tank, wherein the liquid outlet of the alkaline liquor tank is connected with the liquid inlet of a reaction kettle and the liquid outlet of a filter through a three-way pipe; the outlet of the reaction kettle is connected with the inlet of a gas-liquid separator through a pipe; the air outlet of the gas-liquid separator is connected with the air inlet of a gas washing device through a pipe; the liquid outlet of the gas-liquid separator is connected with the liquor outlet of the gas washing device and the liquid inlet of the filter through a three-way pipe; the air outlet of the gas washing device is connected with the air inlet of a drying device through a pipe; the air outlet of the drying device is connected with a gas buffer tank through a pipe; each connecting pipe has a control valve; the gas washing device is provided with a water barrel; and the reaction kettle is provided with a feeding hopper. The system has the characteristics of low cost, high hydrogen generation speed, high hydrogen purity, continuous hydrogen production, no external power supply and the like and is suitable for generating hydrogen on site.

Owner:TSINGHUA UNIV

Fiber optic hydrogen purity sensor and system

InactiveUS20110228275A1Material analysis by observing effect on chemical indicatorTransmissivity measurementsHydrogen purityFiber

A hydrogen purity sensing system includes a light source which provides an optical signal through a fiber optic cable. A hydrogen purity sensor is provided in the system which comprises a multilayered nanostructural film of high refractive index and low refractive index materials for receiving the optical signal. The system further includes a photodetector for receiving a reflected optical signal from the hydrogen purity sensor and a processing circuitry coupled to the photodetector for analyzing the reflected optical signal.

Owner:GENERAL ELECTRIC CO

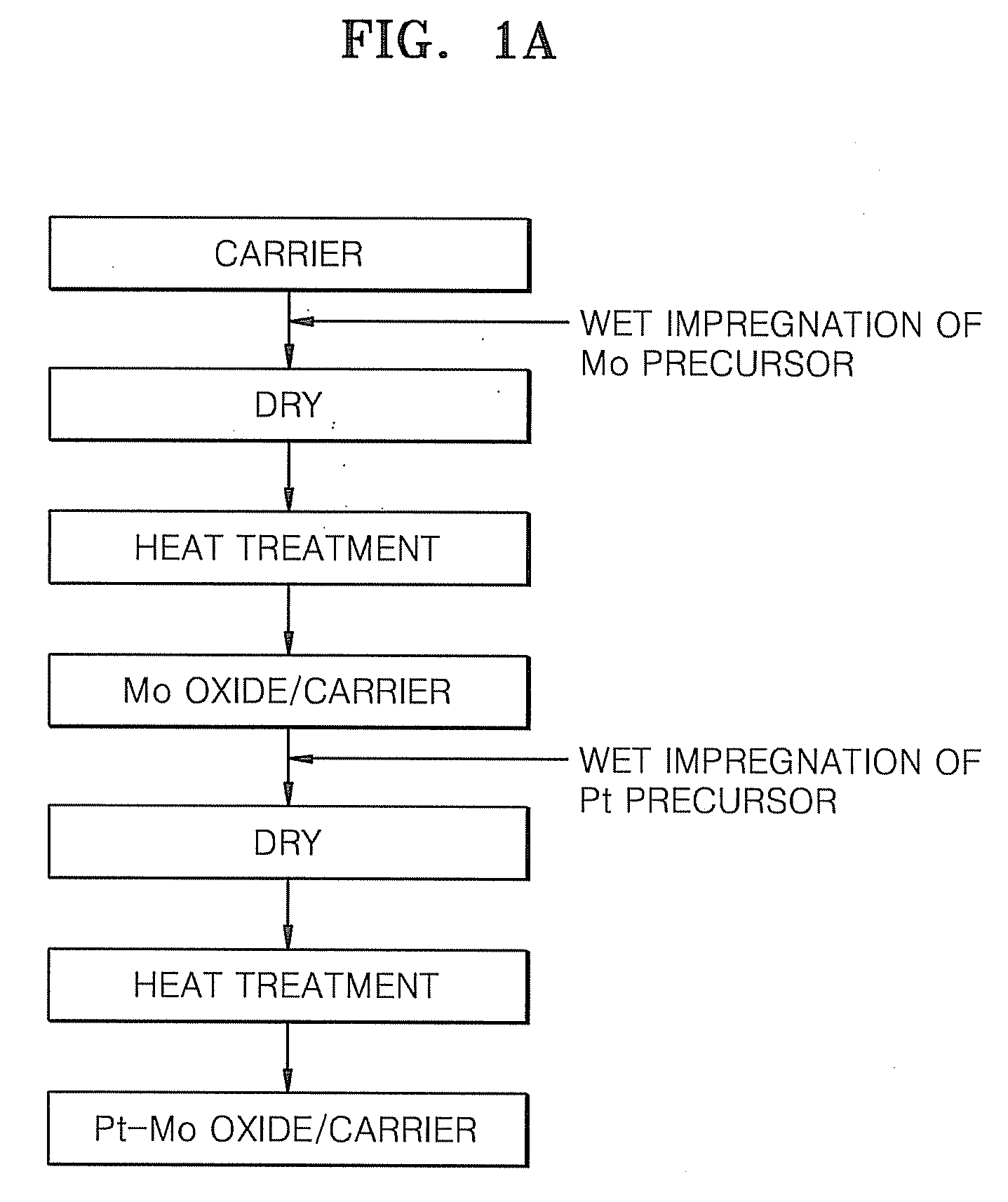

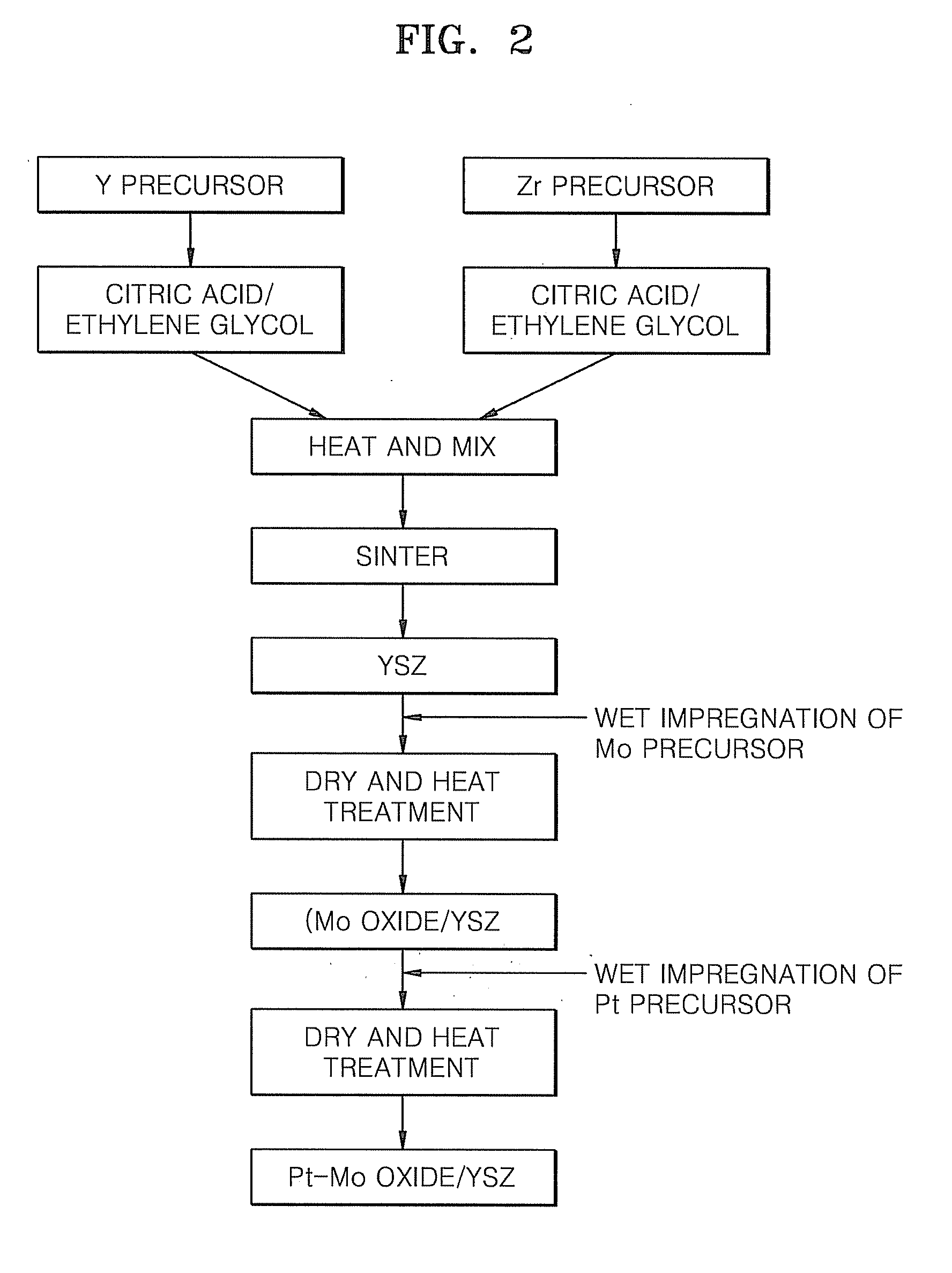

Catalyst for fuel reforming and method of producing hydrogen using the same

InactiveUS20080219918A1Improved reforming reactivityHigh purity hydrogenCatalyst activation/preparationHydrogen productionHydrogen purityHydrogen

A catalyst for fuel reforming including a metal catalyst that includes at least one active component A selected from the group consisting of Pt, Pd, Ir, Rh and Ru; and an active component B that is at least one metal selected from the group consisting of Mo, V, W, Cr, Re, Co, Ce and Fe, oxides thereof, alloys thereof, or mixtures thereof, and a carrier impregnated with the metal catalyst, and a method of producing hydrogen by performing a fuel reforming reaction using the catalyst for fuel reforming. The catalyst for fuel reforming has excellent catalytic activity at a low temperature and improved hydrogen purity. Therefore, when the catalyst for fuel reforming is used, high-purity hydrogen, which can be used as a fuel of a fuel cell, can be produced with high purity.

Owner:SAMSUNG SDI CO LTD

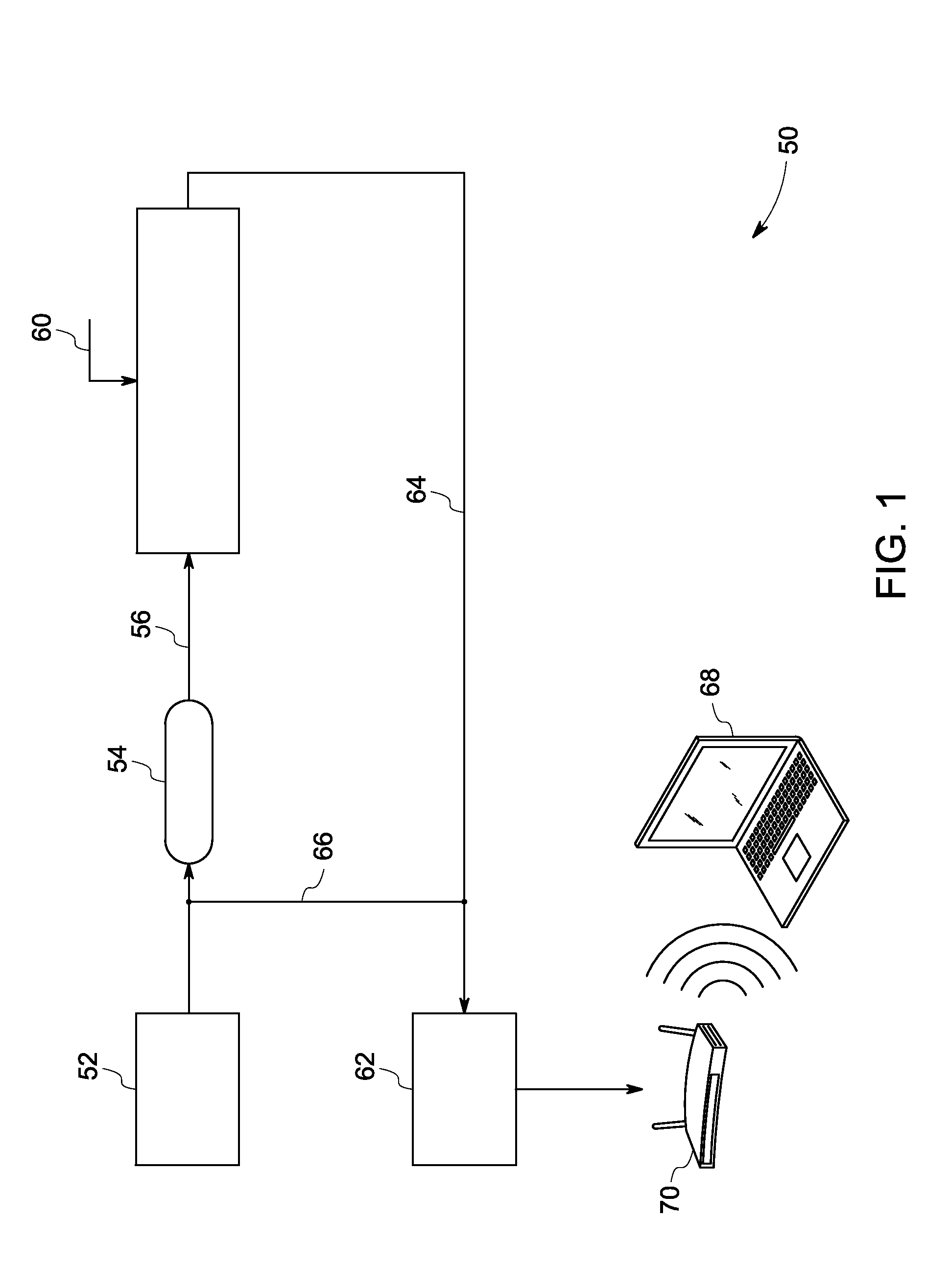

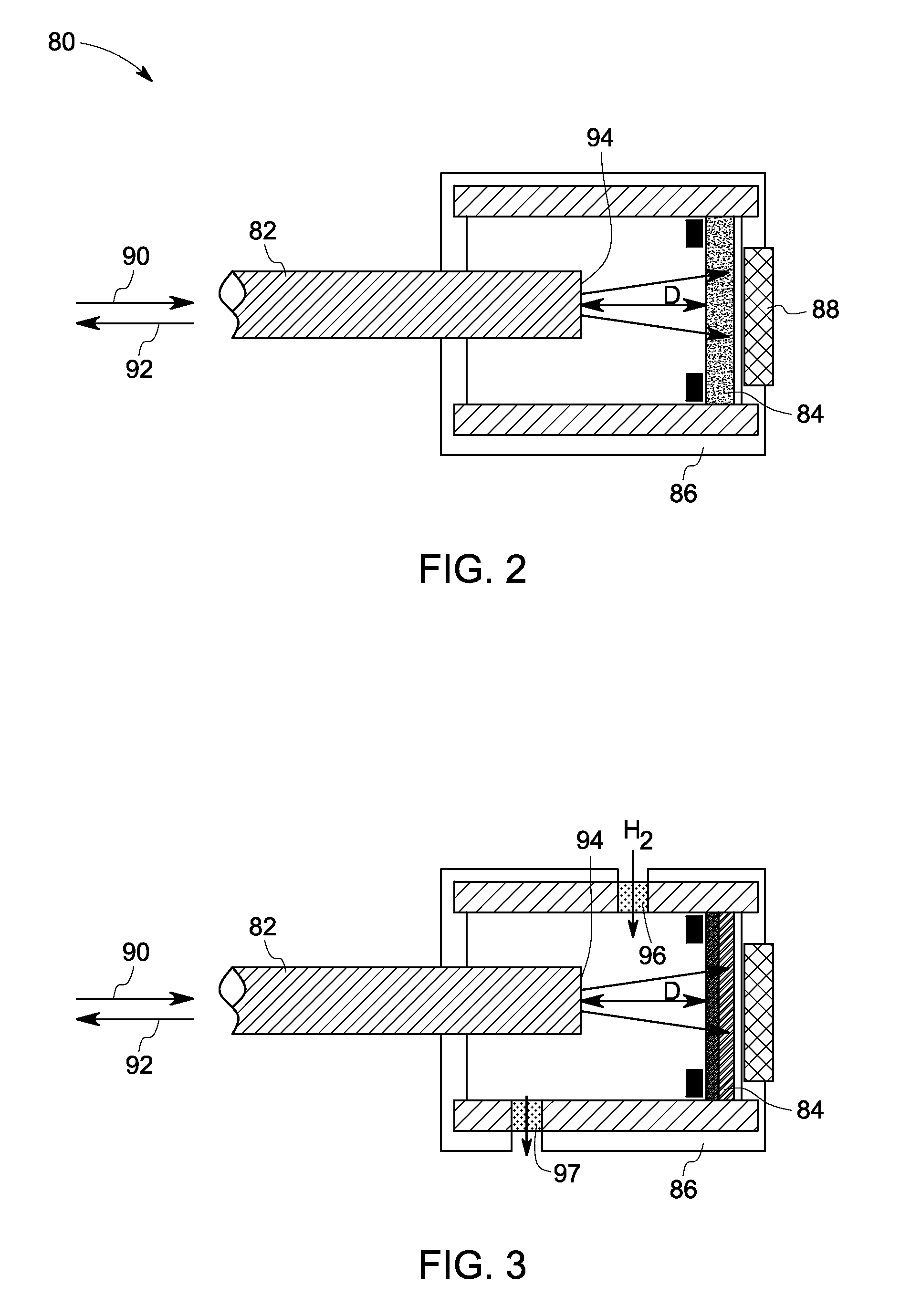

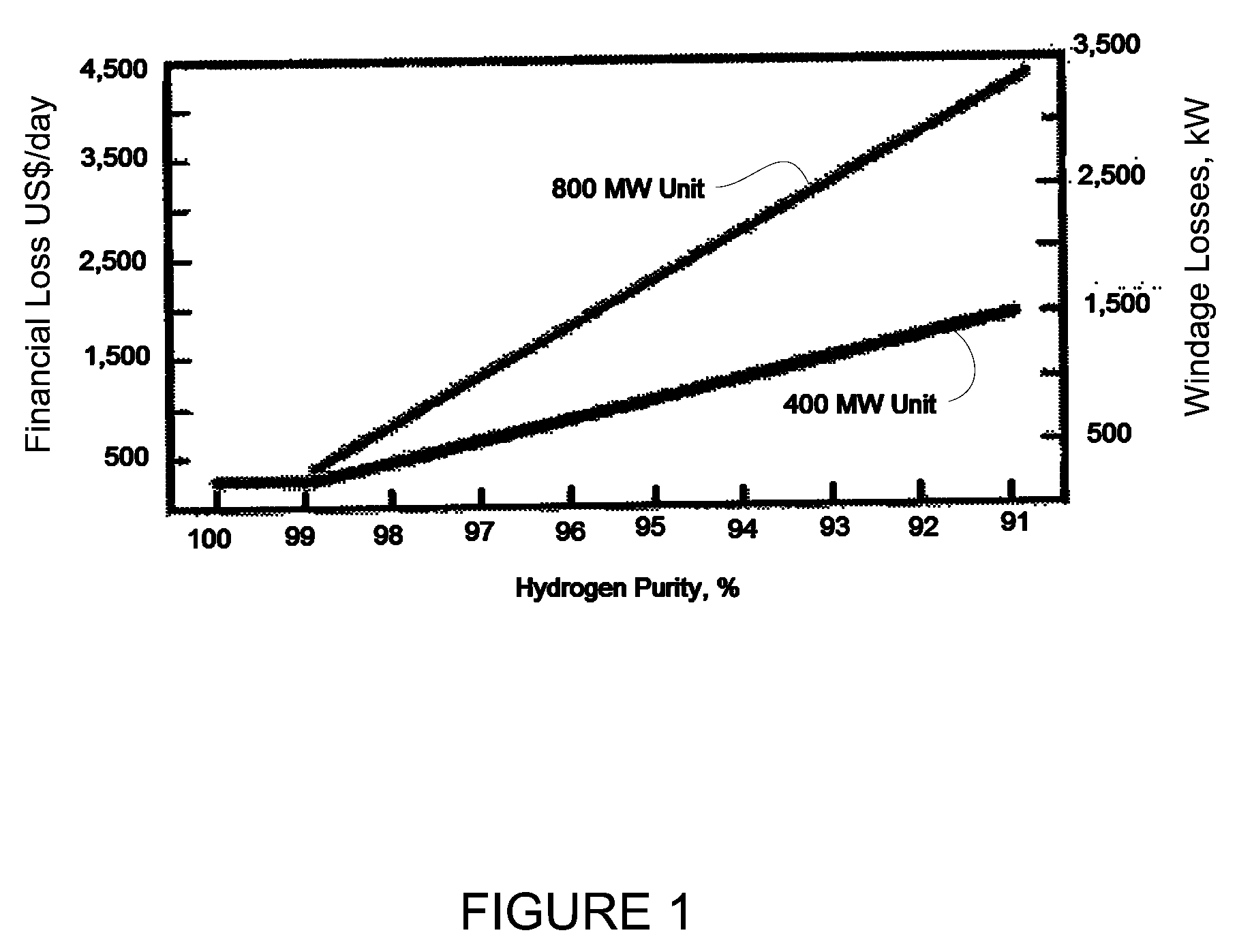

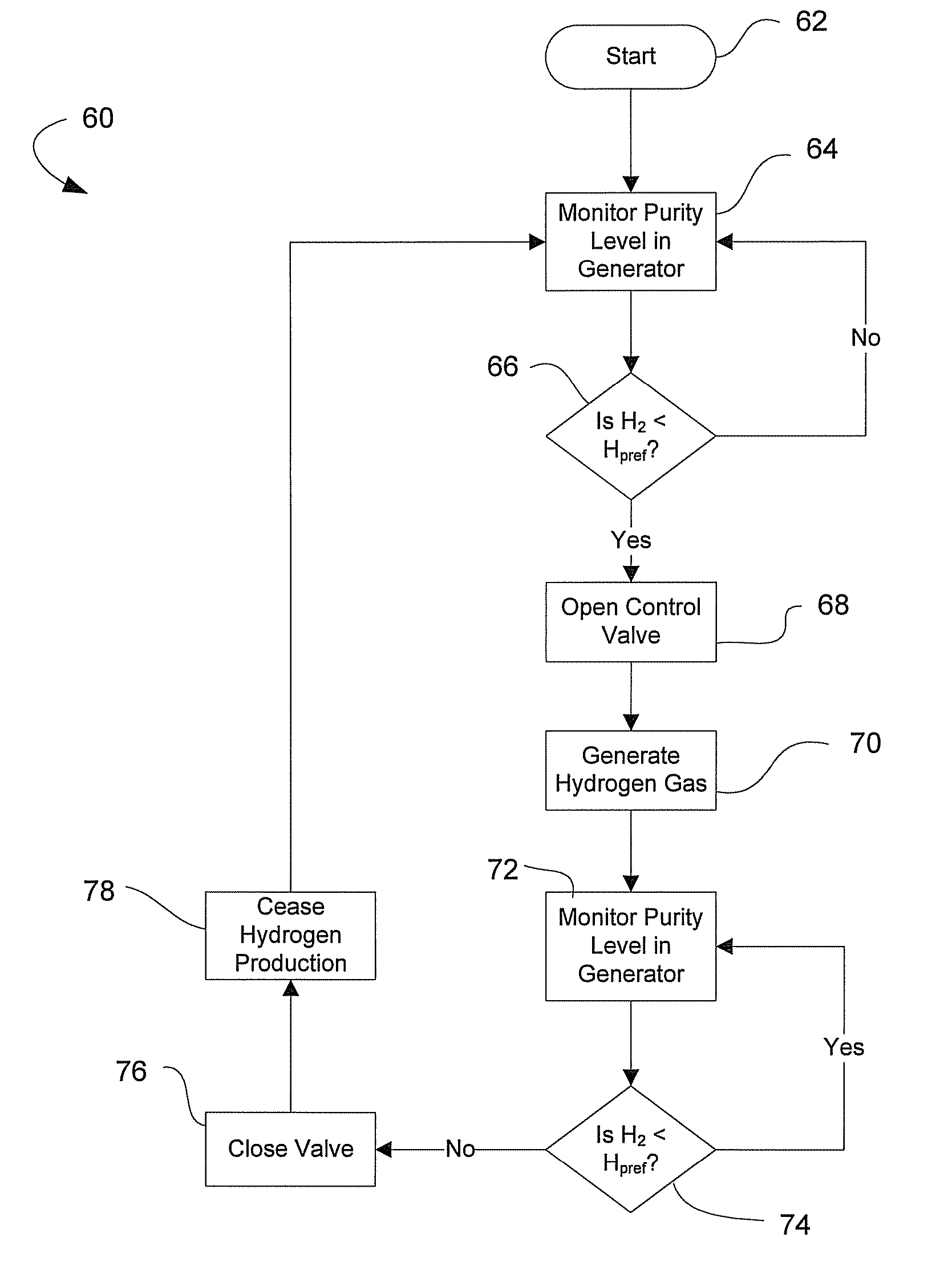

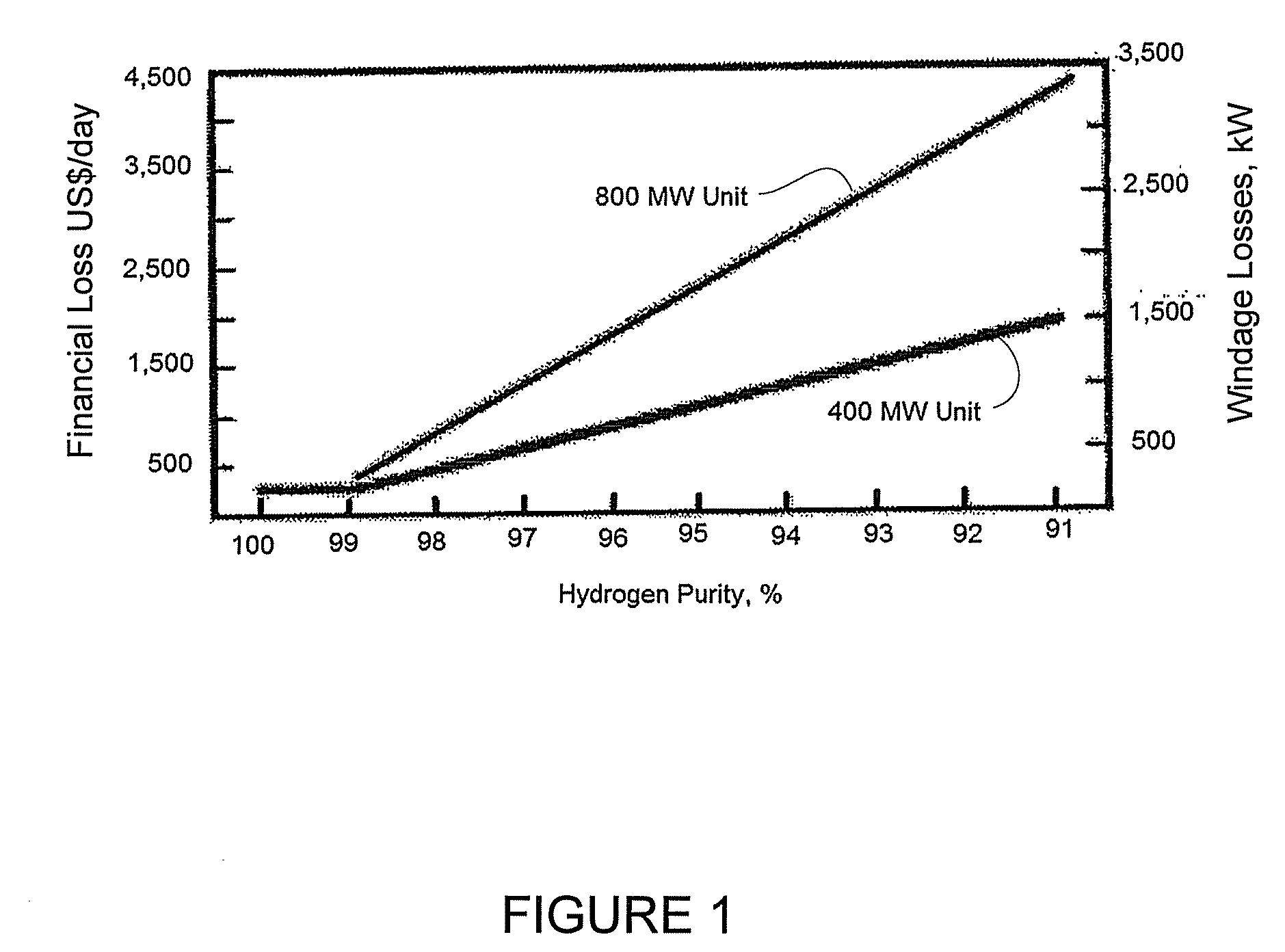

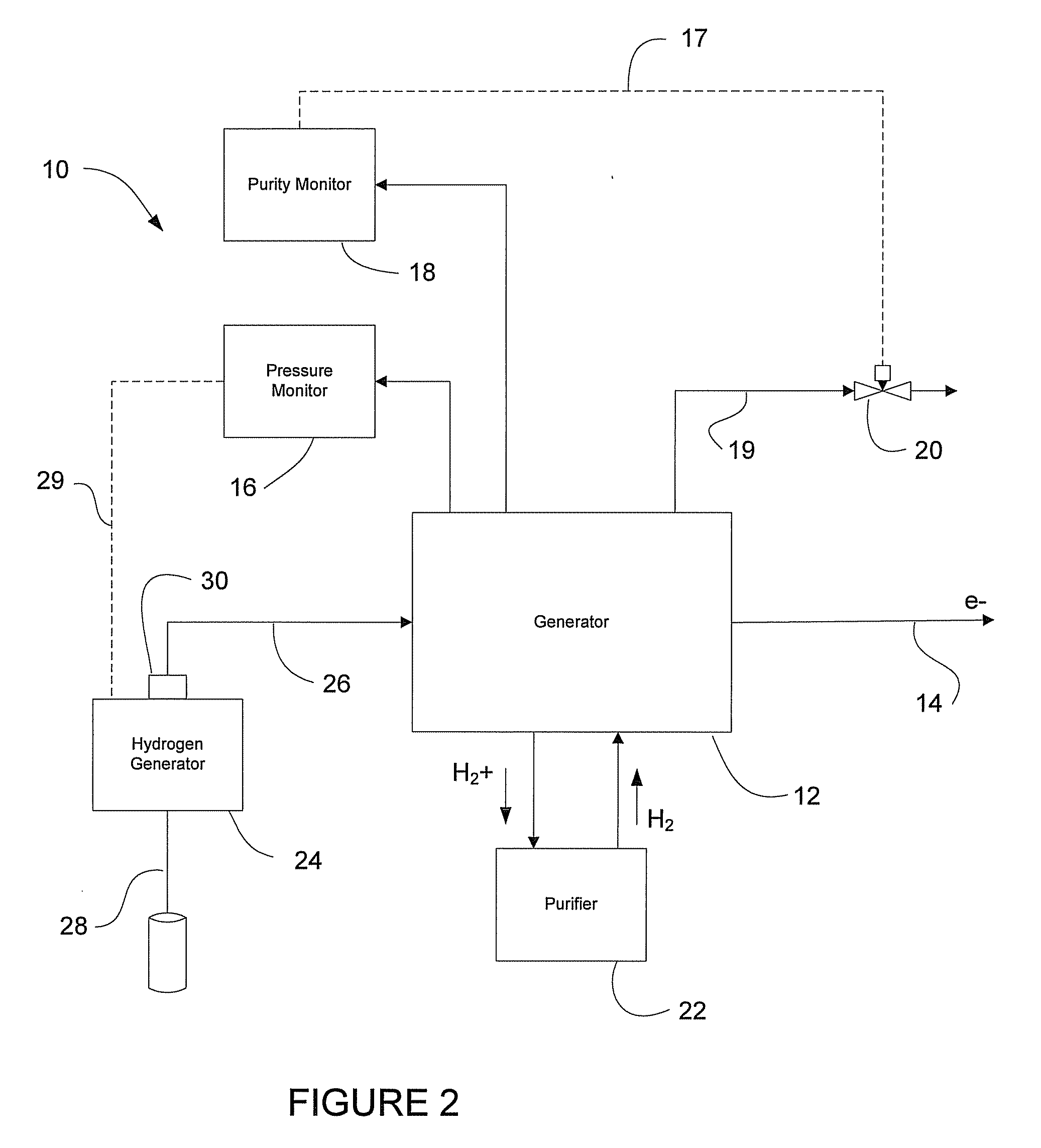

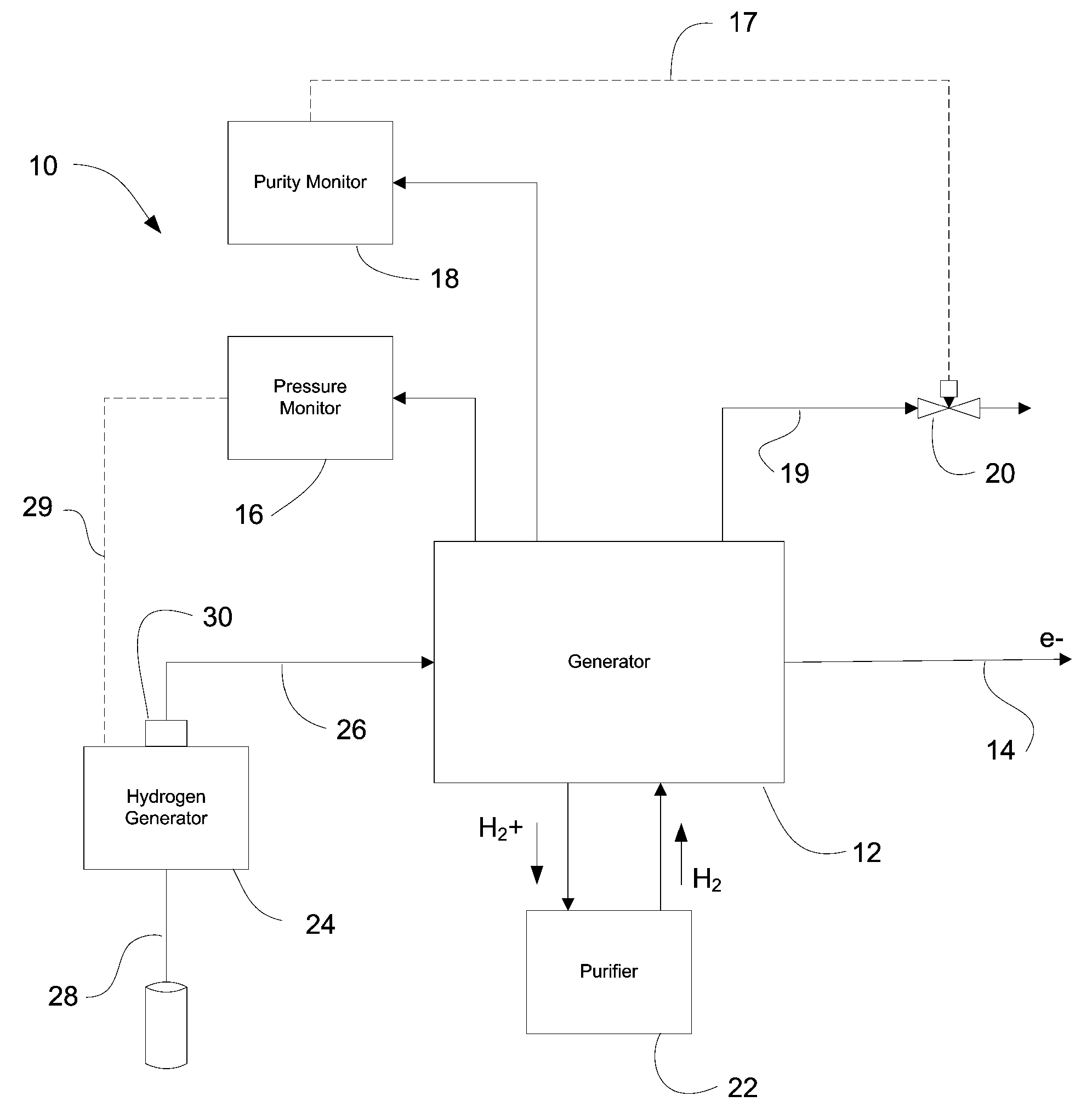

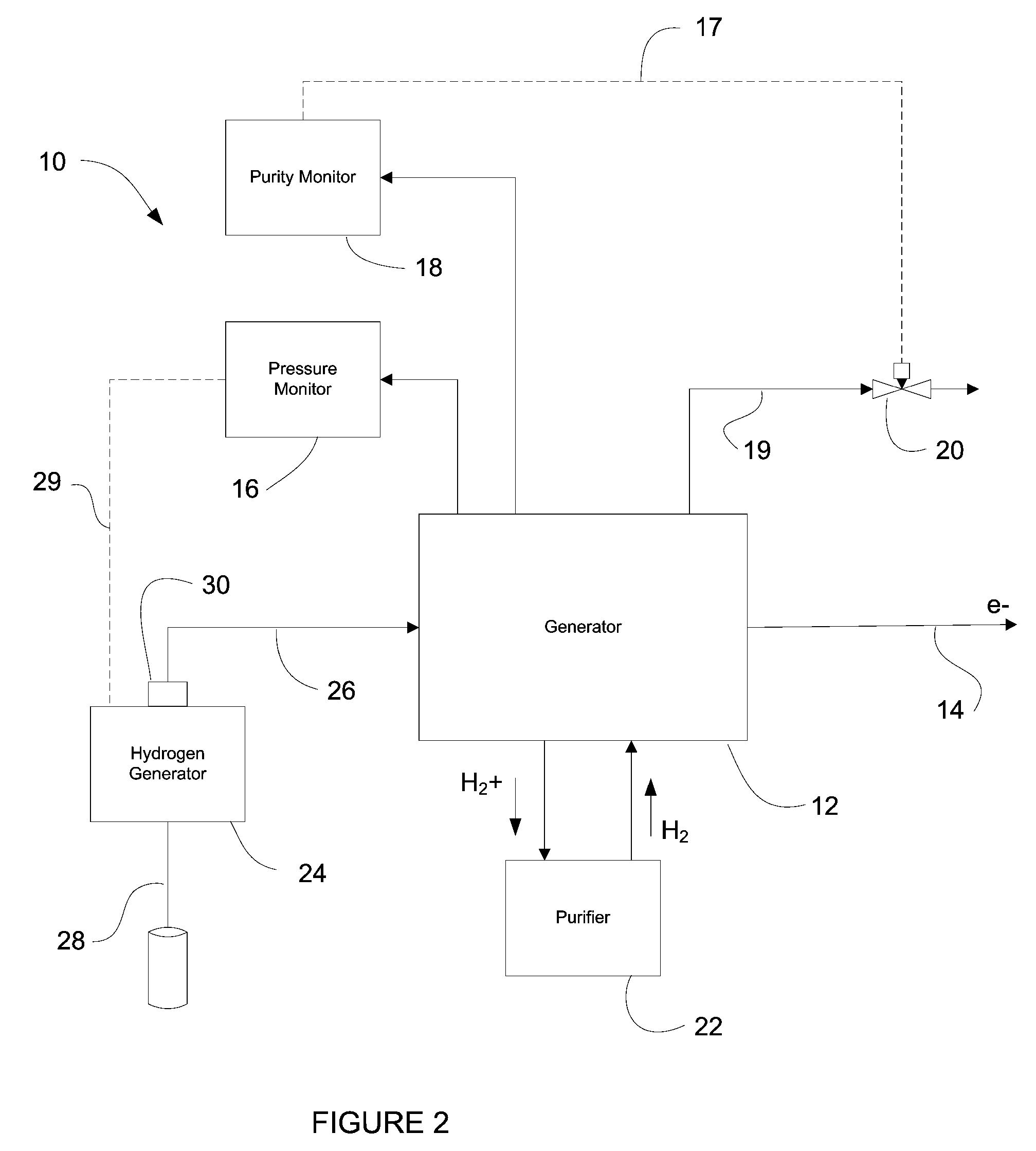

System for Maintaining Hydrogen Purity in Electrical Generators and Method Thereof

A method and apparatus is provided for an a system for maintaining hydrogen purity in an electrical power generator. The purity system includes: a generator, a hydrogen generator configured to provide hydrogen gas to the generator, a purity monitor for detecting the level of hydrogen purity in the generator and providing a signal when the purity drops below a predetermined threshold. The system automatically compensates for gas loss or contamination to maintain the desired level of efficiency in the electrical generator.

Owner:PROTON ENERGY SYST

Online high-purity hydrogen preparation system for fuel cell and control method of online high-purity hydrogen preparation system

ActiveCN105152133AReduce energy consumptionLower requirementHydrogenSolid electrolyte fuel cellsHydrogen purityOxygen

The invention discloses an online high-purity hydrogen preparation system for a fuel cell. The online high-purity hydrogen preparation system comprises a methyl alcohol box as well as a raw material box and a catalytic burner which are connected with the methyl alcohol box through a methyl alcohol metering pump, wherein a fuel cell discharge water inlet is formed in the raw material box, an oxygen inlet is formed in the catalytic burner, an ethanol water metering pump and a heat exchanger are sequentially connected onto the raw material box, a vaporizer is connected onto the heat exchanger, a reforming reactor is connected onto the vaporizer, a palladium film purifier is connected onto the reforming reactor, and the palladium film purifier is connected with the catalytic burner; the invention further discloses a control method of the system. According to the system provided by the invention, online hydrogen supplying is performed through a manner of using a methanol water reforming reaction to produce hydrogen, the yield of pure hydrogen is controlled through adjusting the flow of an ethanol water mixture; the method has the characteristics of high hydrogen storage density, high hydrogen purity, low energy consumption, compact structure, simpleness and convenience in start-stop controlling, easiness in implementing modular design and the like.

Owner:武汉氢能与燃料电池产业技术研究院有限公司

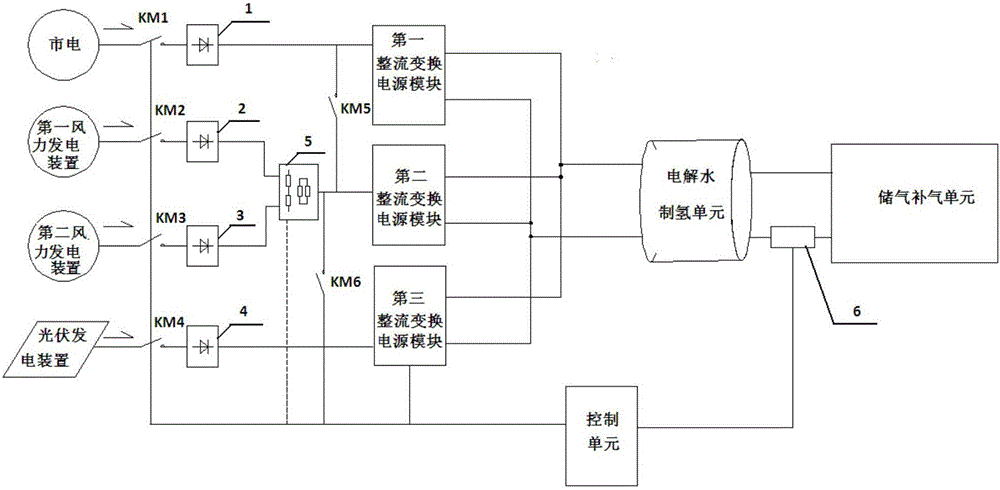

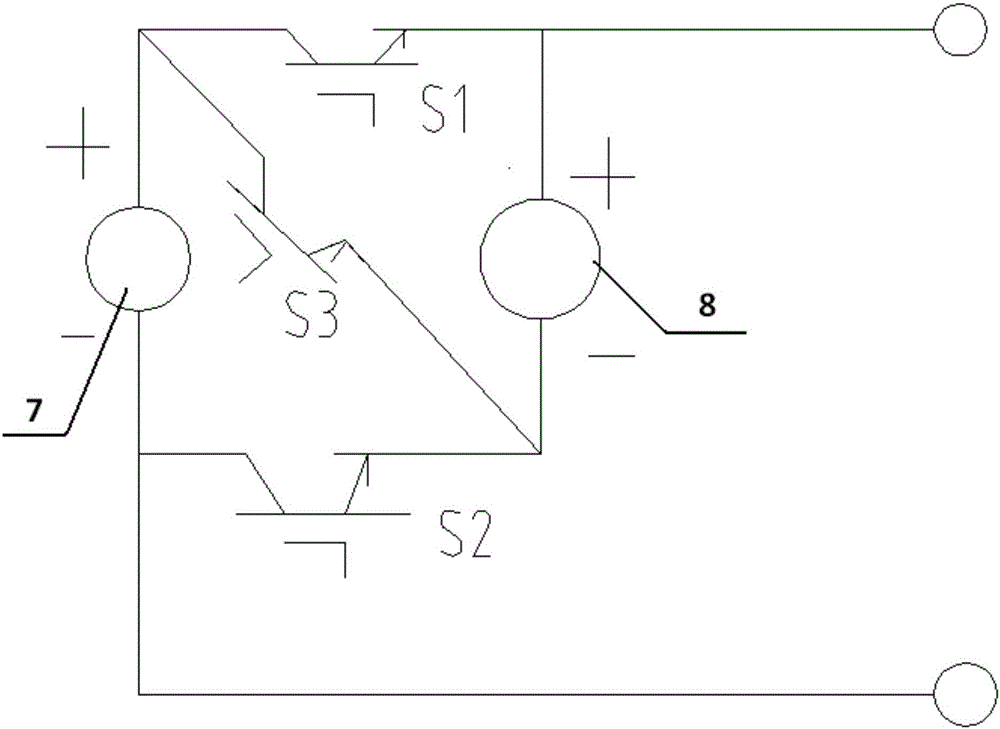

Coupling hydrogen production system and control method thereof

ActiveCN106119883ASolving the Hydrogen Purity ConundrumImprove general performanceCellsEnergy inputHydrogen purityElectricity

The invention provides a coupling hydrogen production system and a control method thereof and belongs to the technical field of new energy. The system comprises a control unit and further comprises an electricity generation unit, an energy management unit, a hydrogen production unit and a gas storage and supplement unit which are all connected with the control unit and connected with one another in sequence. The control unit detects and analyzes all working parameters of the electricity generation unit and the hydrogen production unit and controls actions of the energy management unit and the gas storage and supplement unit. Hydrogen produced by the hydrogen production unit enters into the gas storage and supplement unit to be stored, and the control unit controls the gas storage and supplement unit to supplement the hydrogen production unit with hydrogen if necessary. The control method involves three operation modes, that is, electricity is supplied only by a wind power generation device and a photovoltaic power generation device, electricity is independently supplied by a mains supply, and electricity is supplied by the mains supply, the wind power generation device and the photovoltaic power generation device simultaneously. The problem of the hydrogen purity of commercial hydrogen production equipment under the condition of a fluctuant intermittent power supply with a wide power range can be solved through the coupling hydrogen production system and the control method thereof, cost is low, safety is high, and stability is high.

Owner:TONGJI UNIV

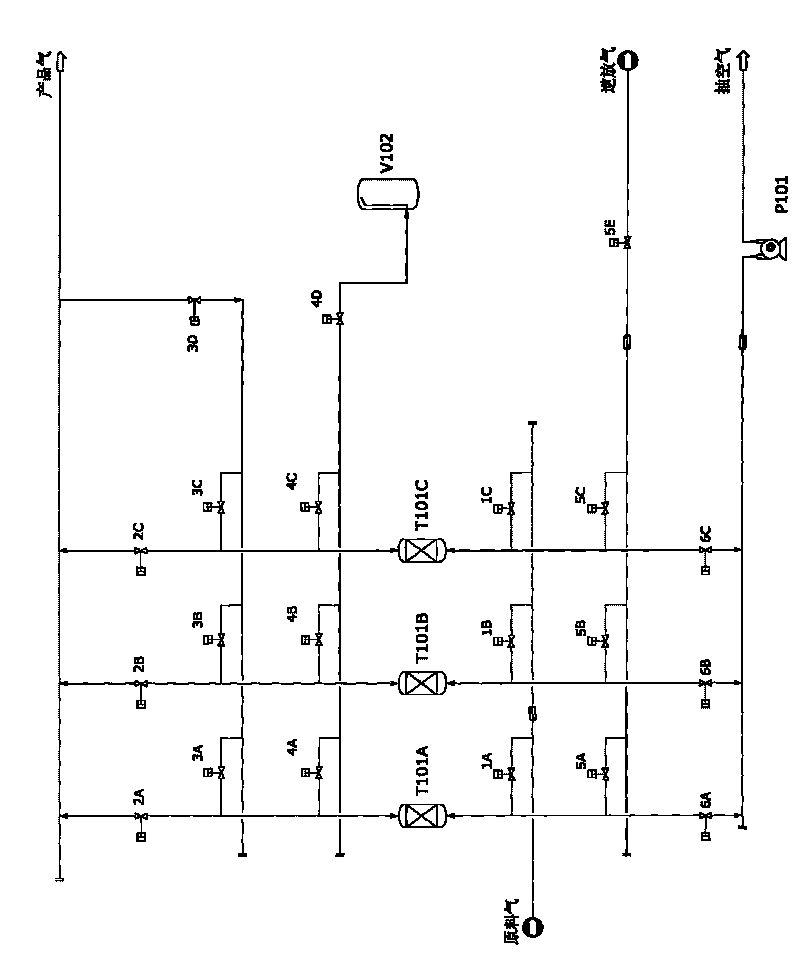

Method for recovering hydrogen from tail gas containing chlorsilane

InactiveCN101732945ASatisfied with recyclingEfficient separation and recoveryHydrogen separation using solid contactDispersed particle separationHydrogen purityDesorption

The invention discloses a method for recovering hydrogen from tail gas containing chlorsilane. The method comprises the following steps of: by a pressure-swing absorption method, performing pressure-swing absorption process for absorption and desorption on raw gas respectively through each absorption tower in a pressure-swing absorption system consisting of at least three absorption towers to obtain purified hydrogen, and performing circulatory operation in each absorption tower respectively according to the conventional pressure-swing absorption process. Absorption agents filled in the absorption towers comprise alumina, silica gel, active carbon and molecular sieves. The method can effectively separate and recover pure hydrogen from gases containing hydrogen, chlorine hydride, chlorsilane and the like, the recovery yield of hydrogen is high, the content of impurities of chlorine hydride, chlorsilane and the like remained in the product is low, the hydrogen purity is high, and simultaneously the components of chlorine hydride, chlorsilane and the like in the product can be separated and recovered. The equipment cost is low, the process is simple, and the energy consumption is low.

Owner:CHENGDU SEPMEM SCI & TECH

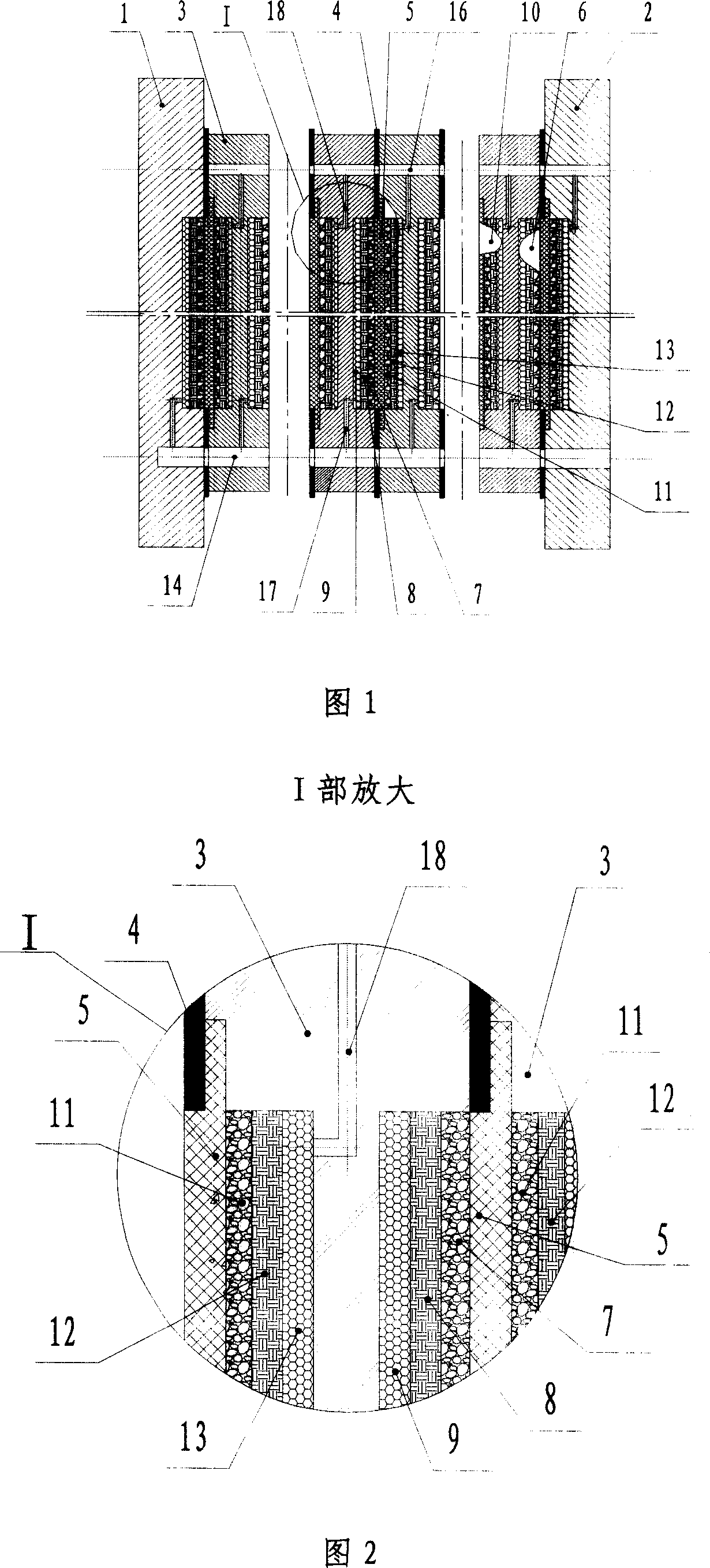

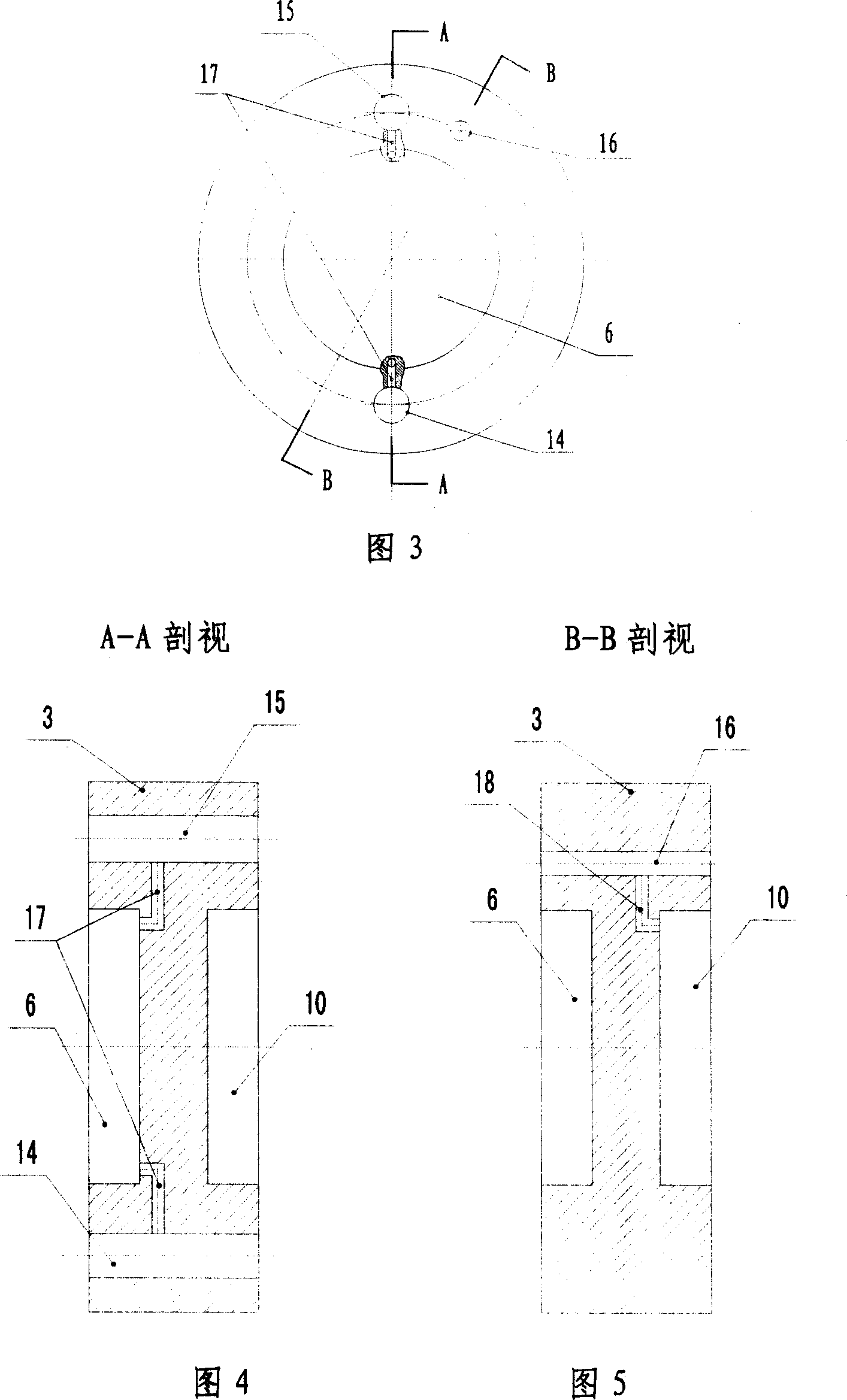

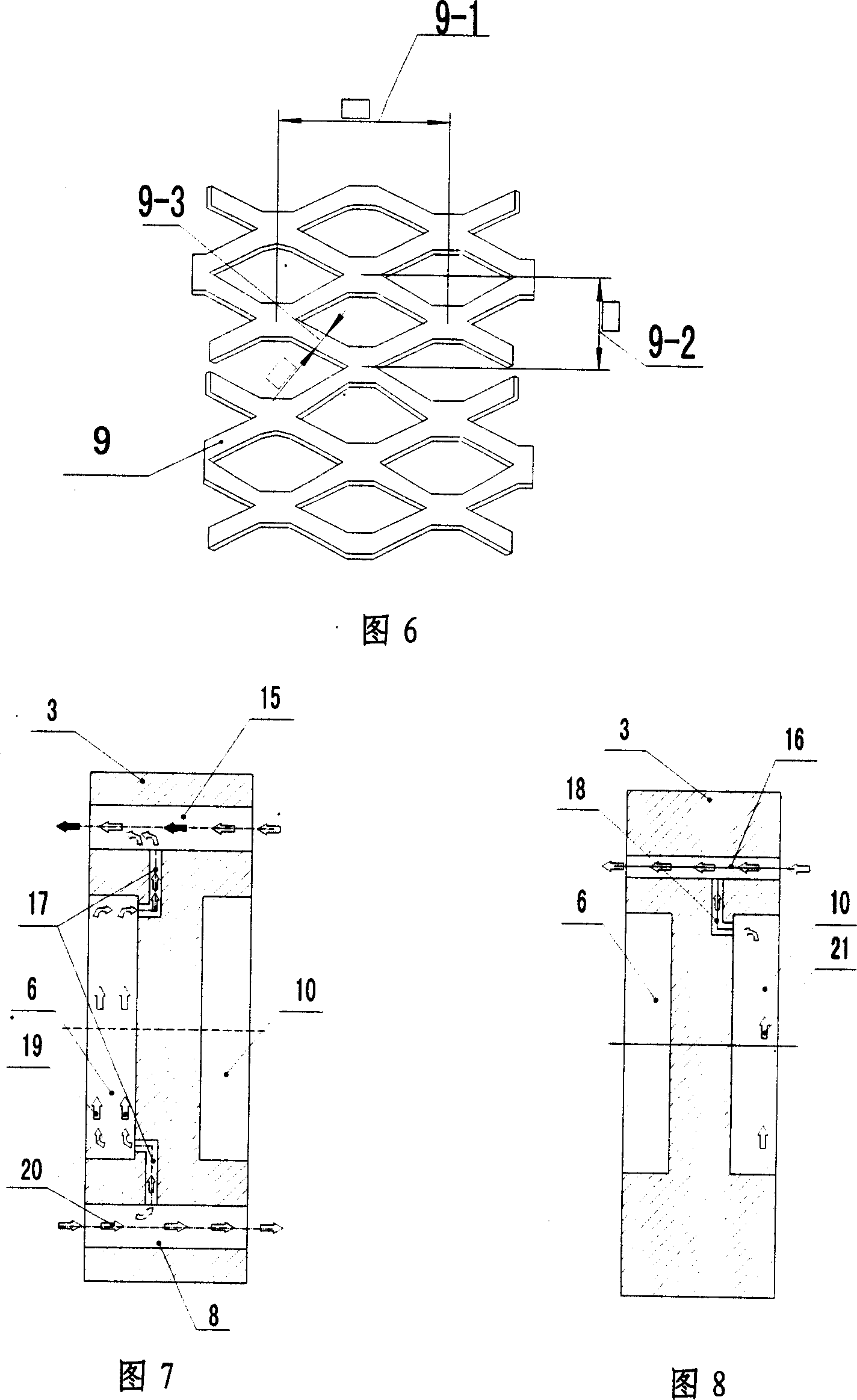

Filter-press type water electrolyzer

The invention belongs to an electrolysis device for producing hydrogen, in particular to a filter-pressing water electrolyser tank applied in the industry of hydrogen production with water electrolysis. Flexible metal or a netty main anode 7 knitted with metal wire, a netty auxiliary anode 8 and an anode support component 9 which is provided with a vented mesh to allow the passing of liquid and the function of elastic expansion are arranged in the anode room 6 of anode half groove 1 and bipolar unit groove 3; and flexible metal or a netty main cathode 11 knitted with metal wire, a netty auxiliary cathode 12 and an cathode support component 13 which has a vented mesh to allow the passing of liquid and the function of elastic expansion are arranged in the cathode room 10 of anode half groove 2 and bipolar unit groove 3; and the main anode 7 and the main cathode 11 are mounted in a film-type pole distance. The invention has a simple structure, convenient manufacture and maintenance, high hydrogen purity, small size and light weight; the voltage in the unit groove is 1.9 to 2.2v, the current efficiency is above 99 percent, the consumption of direct current is 4.5 to 5.0KW.h / Nm3H2 and the purity of hydrogen is 99.99 to 99.999 percent.

Owner:李士宏

Separation method for removing styrene from ethylbenzene-dehydrogenation tail gas and recovering hydrogen

ActiveCN103908868AReduce the possibility of self-aggregationSafe and stable operationHydrogen separationDispersed particle separationHydrogen purityDehydrogenation

The invention relates to a separation method for removing small amount of styrene from ethylbenzene-dehydrogenation tail gas and recovering hydrogen and belongs to the field of petrochemical industry. The separation method comprises the following steps: adopting a dehydrogenizing material (ethylbenzene) as an absorbent, carrying out circular absorption on tail gas to reduce the content of the styrene to 30-50ppm; and recovering the ethylbenzene by compression and condensation to reduce the content of the styrene to 5-10ppm and meet the requirement for safe and stable operation of the hydrogen separation and purification section. After deep removal of the styrene, three different separation schemes are adopted for purifying hydrogen so as to meet different requirements of hydrogen purity and recovery rate; by variable-pressure absorption for purification, the concentration of hydrogen is more than 98%, the recovery rate is 80-85%, and the power consumption is 0.21kWh / Nm<3>; by hydrogen-membrane separation for purification, the concentration is more than 95%, the recovery rate is 90-95% and the power consumption is 0.7kWh / Nm<3>; and by coupling of variable-pressure absorption and hydrogen-membrane separation for purification, the concentration of the hydrogen is more than 98%, the recovery rate is 94-97%, simultaneously high purity and high yield are realized and the power consumption is 0.25kWh / Nm<3>.

Owner:DALIAN UNIV OF TECH

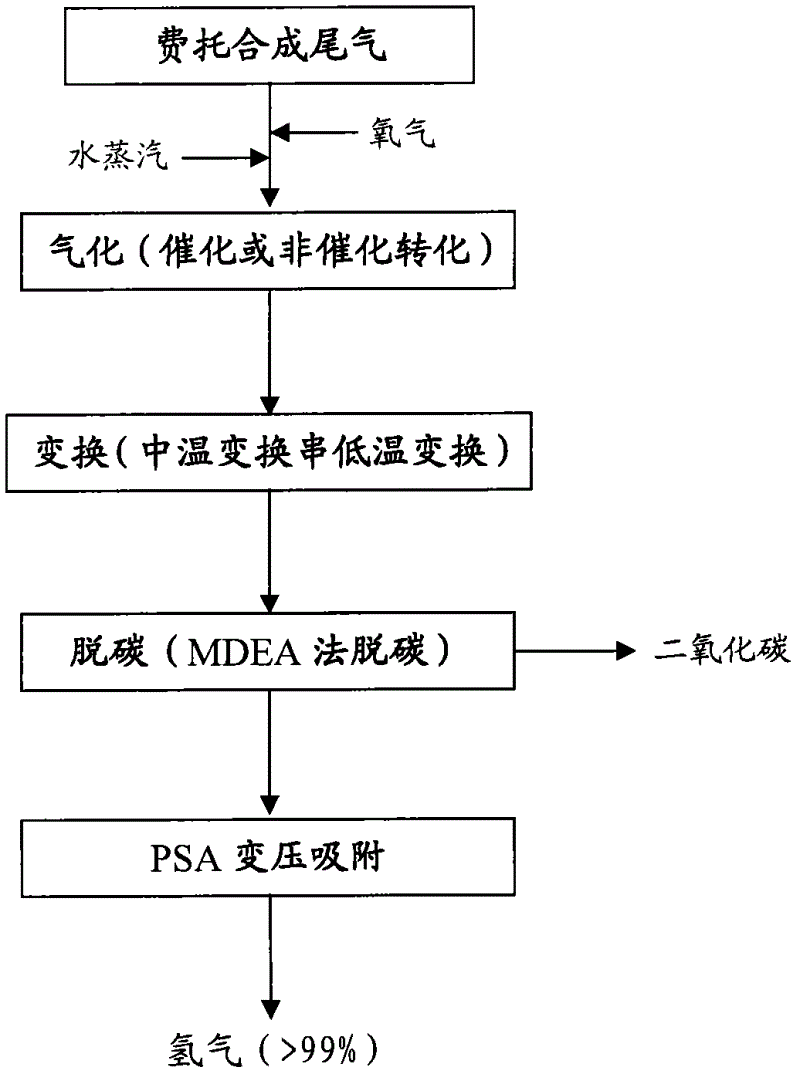

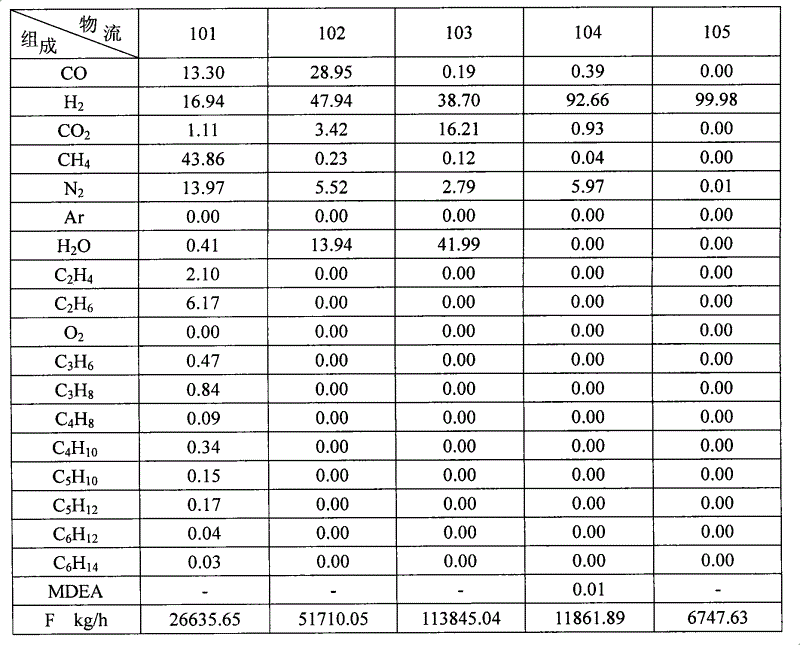

Method for processing Fischer-Tropsch synthesis tail gas

ActiveCN102614764AIncrease profitReduce investmentDispersed particle separationAir quality improvementHydrogen purityPartial oxidation

The invention provides a method for preparing hydrogen with high purity by using Fischer-Tropsch synthesis tail gas, the method comprises four steps of light hydrocarbon partial oxidation, transformation, decarburization and pressure swing adsorption, and hydrogen with purity of more than 99% can be obtained. The invention has the advantages of simple process, high process integration degree, high produced hydrogen purity, and the method of the invention can be used for recovering and utilizing Fischer-Tropsch synthesis tail gas during the process of transforming carbonaceous resources of coal, natural gas, biomass and the like into liquid fuels.

Owner:SYNEFUELS CHINA

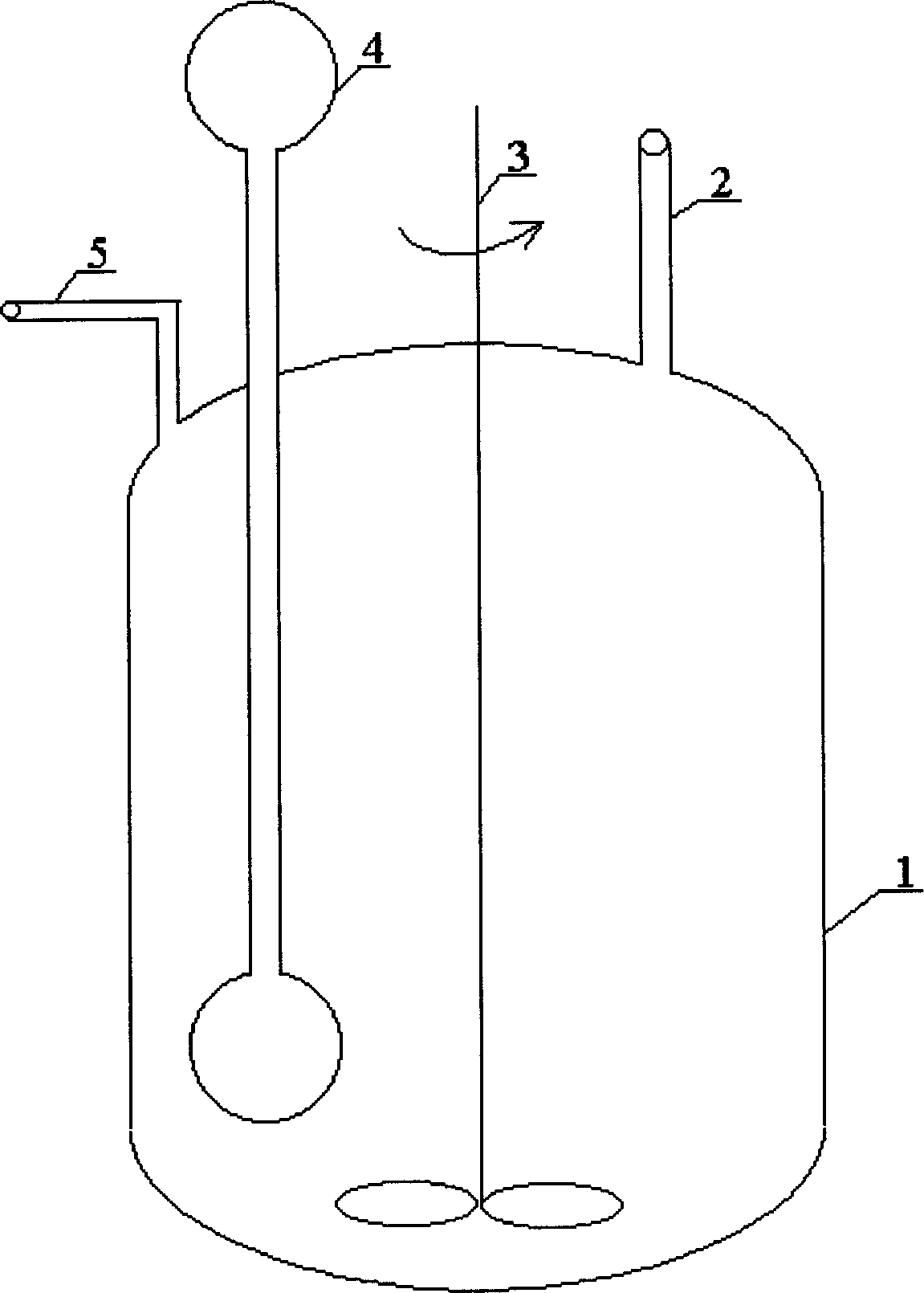

Sodium borohydride catalytic hydrolysis process and reactor of generating hydrogen

The present invention belongs to hydrogen generating technology. Water solution of sodium borohydride in 5-40 wt% concentration and water solution of sodium hydroxide in 0.1-20 wt% concentration andmade to react inside a reactor in the presence of catalyst to produce hydrogen with the heat produced in reaction being removed timely. The present invention features that the catalyst is non-crystalline composite metal alloy produced with composite metal ions in the hydrolysis of sodium borohydride. The reactor consists of casing, stirrer, feeding pipe and gas exhaust port and features its double-chamber steam-liquid circular flow heat exchanger comprising an evaporating chamber inside the reactor casing, a condensating chamber outside the casing and communicating tube in between. The present invention has the advantages of fast removal of reaction heat, use safety, high hydrogen purity, and circular use and no deactivation of catalyst.

Owner:TIANJIN UNIV

Device for preparing hydrogen through hydrolysis

InactiveCN101786603ASimple structureFast hydrogen productionHydrogen productionHydrogen purityHydrogen

The invention relates to a device for preparing hydrogen through hydrolysis and belongs to the technical field of hydrogen preparation. The device comprises a storage tank, a reactor, a condenser and a drier and is characterized in that the storage tank is used for storing solid reactant and connected to a driving mechanism; the driving mechanism is communicated with a hydrolysis reactor provided with a hydrogen outlet; and the hydrogen outlet is provided with a pipeline sequentially communicated with the condenser and the drier. The device of the invention has the advantages of simple structure, rapid hydrogen preparation, controllable rate, high hydrogen purity, low pollution level, low manufacturing cost, high safety and reliability, good controllability wide applicable range, convenient popularization and application and the like.

Owner:天津海蓝德能源技术发展有限公司

Supported type nickel catalyst for producing hydrogen via decomposition of ammonia and preparation method

InactiveCN101352686APromote resource utilizationLess investmentHydrogenMetal/metal-oxides/metal-hydroxide catalystsHydrogen purityCatalytic reforming

The invention relates to a catalyst applied to catalyst hydrogen generation and a method of the catalyst hydrogen generation. The catalyst comprises industrial catalyst YWC-95 and CaO. The catalyst is used in steam catalytic reforming reaction of the catalyst hydrogen generation, the technical process of the catalyst hydrogen generation is shortened, hydrogen purity and production rate are improved and no secondary pollutant is generated in the production process.

Owner:EAST CHINA UNIV OF SCI & TECH

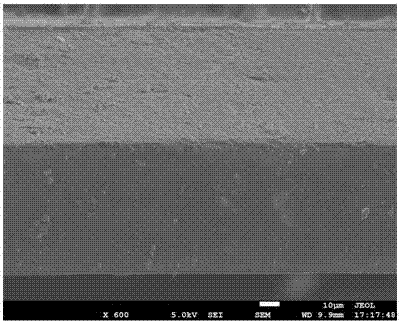

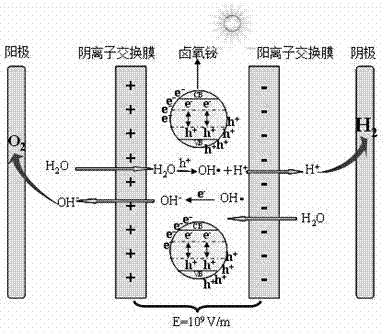

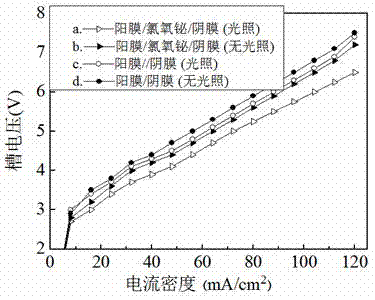

Preparation of photoelectric catalytic membrane for preparing hydrogen by decomposing water

ActiveCN104117391AEasy reunionHigh hydrogen quantum efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsDiaphragmsHydrogen purityPtru catalyst

The invention relates to the preparation of a photoelectric catalytic membrane for preparing hydrogen by decomposing water. The preparation method comprises the steps of mixing sodium cellulose acetate or sodium carboxymethyl cellulose with polyvinylpyrrolidone; heating by distilled water, and stirring for dissolving; spreading the product on a flat glass plate, and drying to form a membrane; crosslinking by heavy metal ions; soaking in solution containing anion groups, and drying at the room temperature to obtain a thin membrane; evenly dispersing oxyhalide bismuth catalyst in absolute ethyl alcohol under ultrasonic oscillation, pouring the mixed solution onto the surface of the thin membrane, and drying by air; mixing chitosan and polyvinylpyrrolidone, and dispersing the mixture; heating by acetic acid water solution, and stirring for dissolving; feeding an aldehyde crosslinking agent for crosslinking, and then pouring the product onto the oxyhalide bismuth thin membrane to obtain the photoelectric catalytic membrane. The photoelectric catalytic membrane is used for preparing the hydrogen by decomposing water, and is capable of effectively separating photoproduction electron holes; the hydrogen production quantum efficiency reaches up to 90-96%, the hydrogen purity reaches up to 99-99.9%, and 15-40% of energy consumption can be saved, so that a new way is provided for preparing hydrogen by decomposing water through photoelectrocatalysis.

Owner:TAIYUAN UNIV OF TECH

System for monitoring the health of electrical generators and method thereof

ActiveUS20070244601A1Noise figure or signal-to-noise ratio measurementVolume/mass flow measurementHydrogen purityHydrogen

A method and apparatus is provided for a system for maintaining hydrogen purity in an electrical power generator where the system monitors the health of the electrical generating system by calculating the time remaining until preventative maintenance is required based on hydrogen usage. The system also monitors the health of the system by detecting the occurrence of major leaks within the electrical power generator and adapting the operation of the system to maintain a desired operating environment.

Owner:PROTON ENERGY SYST

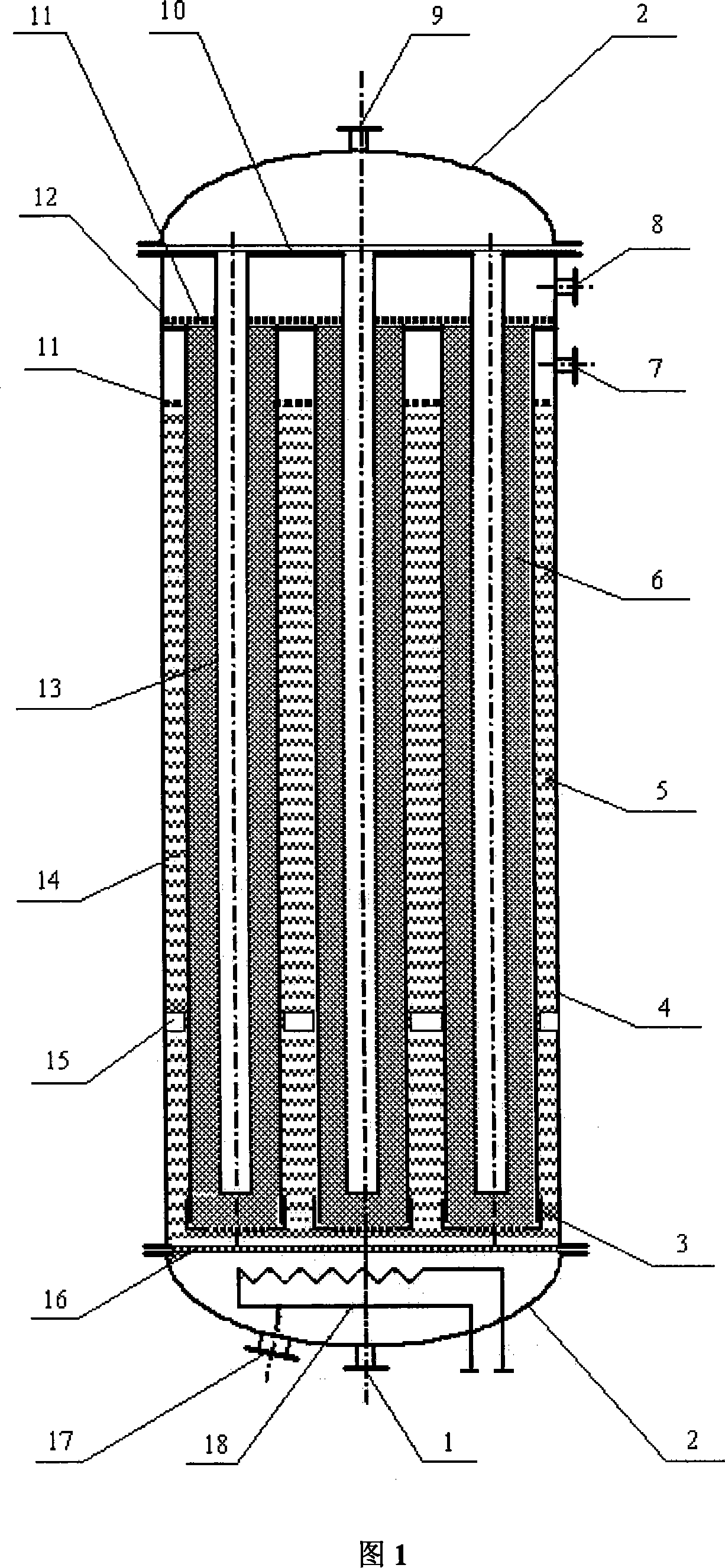

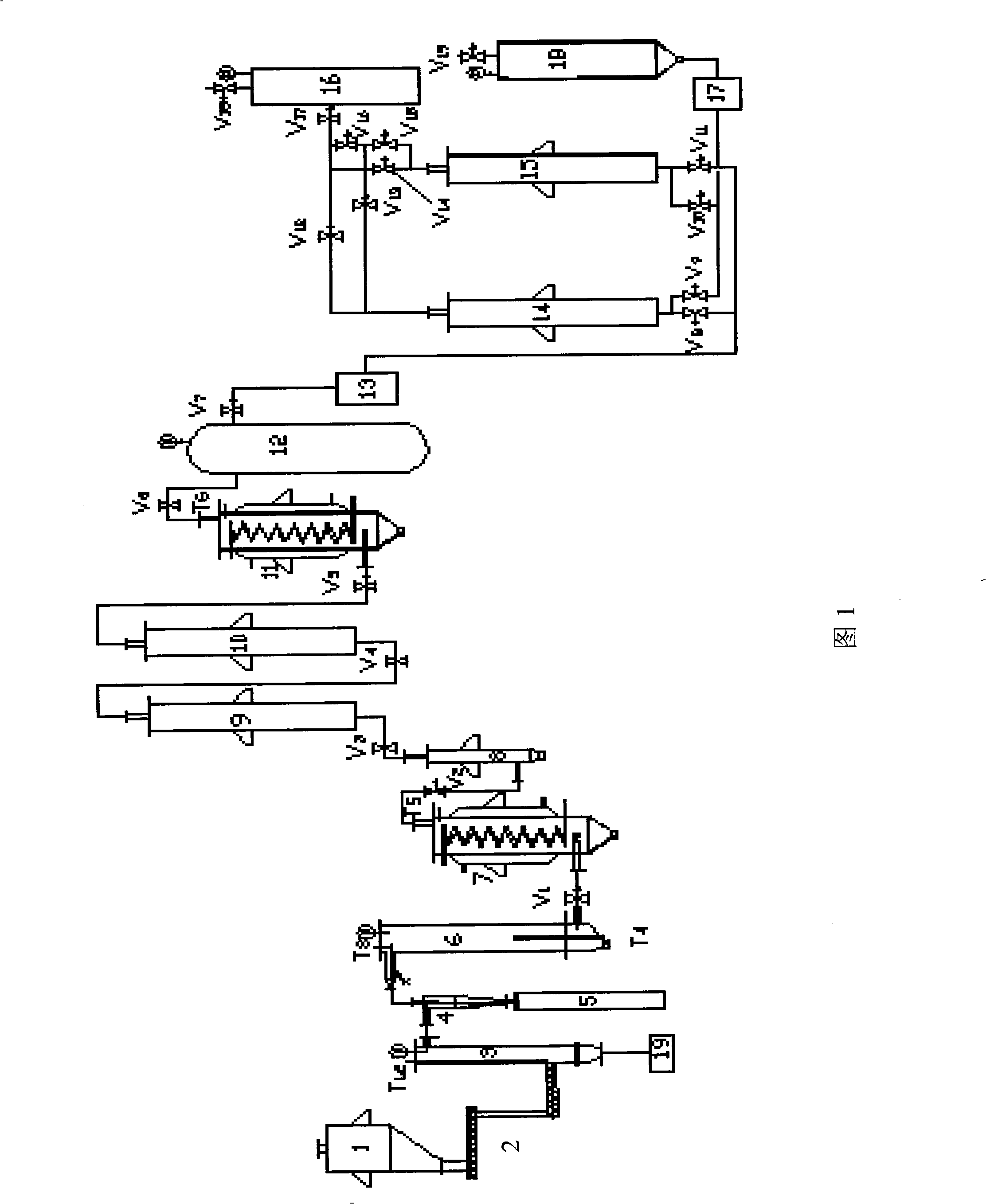

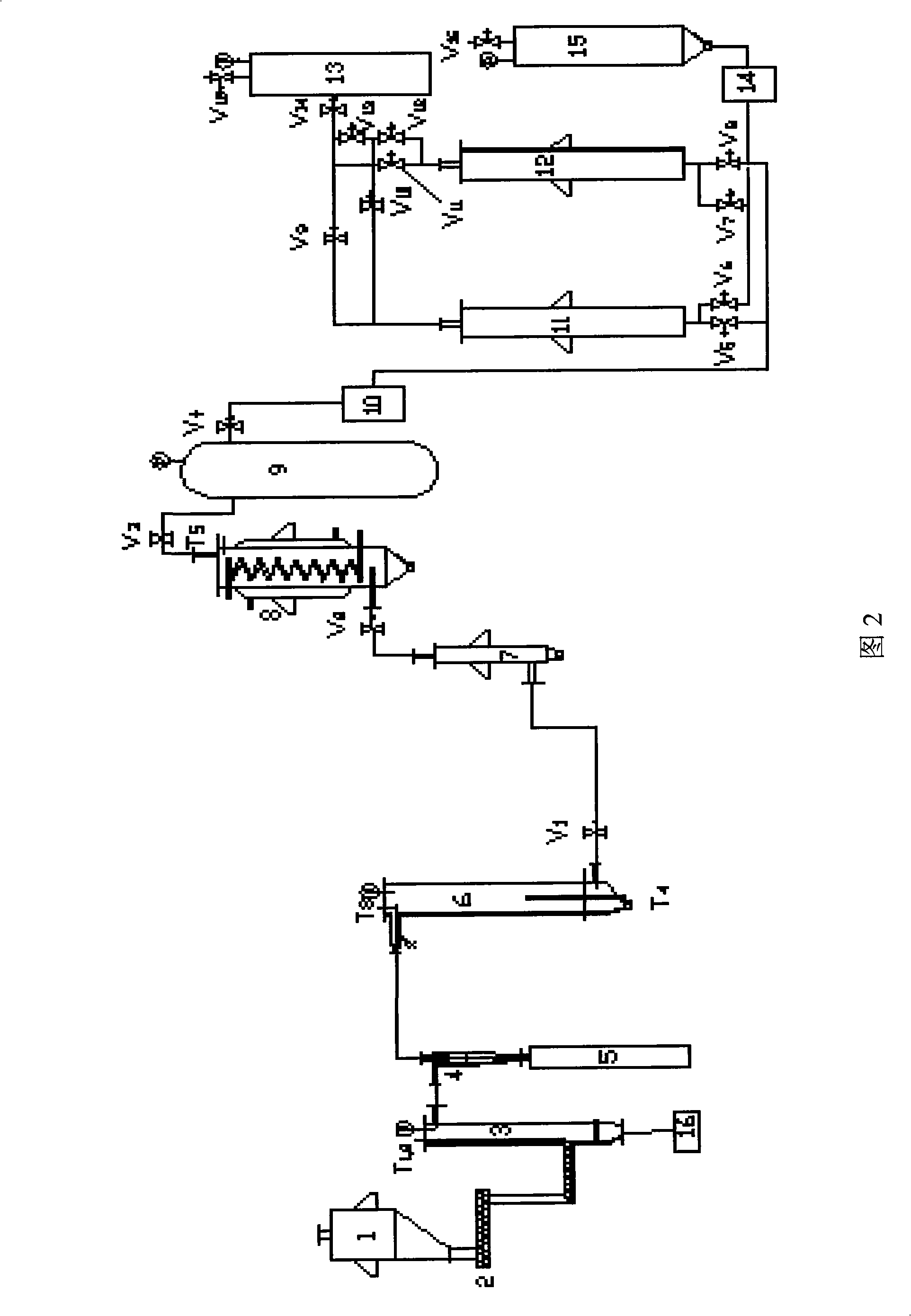

Integrated device for preparing hydrogen by the recapitalization of dimethyl ether aqueous vapor and method

InactiveCN101177240AHigh purityImprove conversion rateHydrogenBulk chemical productionHydrogen puritySteam reforming

The invention discloses an integrated dimethyl ether steam reforming hydrogen-production device and a method, belonging to the hydrogen-production equipment and the method. The invention utilizes a dual-jacketed membrane reactor to realize the coupling of an exothermic reaction and an endothermic reaction and the coupling of a catalytic reaction and a product separation. The invention is characterized in that the central tube of the double cannula is a hydrogen permeation membrane made of palladium silver alloy for in-situ separation of H2, the product of the reaction system; two reforming catalysts are filled in a jacket of the double cannula and the dimethyl ether steam reforming hydrogen production is carried out in the jacket of the tube side; a combustion supporting catalyst is filledin the shell side out of the double cannula to supply heat for the dimethyl ether steam reforming reaction. The invention has the advantages of greatly promoting the steam reforming reaction rate ofthe dimethyl ether, the heat utilization rate and the product purity. The invention obtains high purity hydrogen at lower reaction temperature and pressure, in which the conversion of dimethyl ether canreach 80%, the hydrogen recovery rate 85%, the hydrogen production rate 0.05 to 0.6 m<3> / h, the hydrogen purity 99.5% and the thermal efficiency of the system is above 80%.

Owner:TSINGHUA UNIV

Method for preparing hydrogen from biomass

InactiveCN101348234APromote resource utilizationNo secondary pollutionHydrogenCatalytic reformingHydrogen purity

The invention discloses a method for preparing hydrogen gases by taking biomass as a material. The method comprises the following steps that: the biomass materials are subjected to fast thermal cracking, and directly subjected to vapor catalytic reforming. The method is characterized in that the fast thermal cracking temperature is lower and between 350 and 600 DEG C. The preparation method of the invention has the advantages of low energy consumption, low requirement on equipment, high hydrogen purity and yield and no secondary pollution in the production process; moreover, the preparation method facilitates the emission reduction of greenhouse gases.

Owner:EAST CHINA UNIV OF SCI & TECH

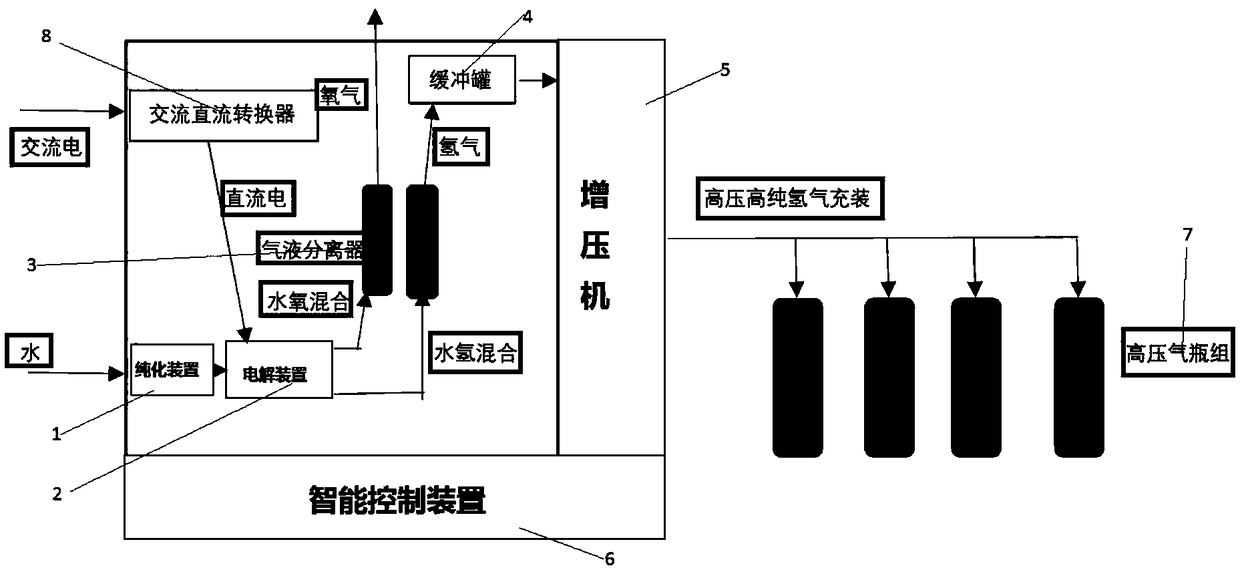

High-pressure high-purity hydrogen manufacturing and adding all-in-one machine

PendingCN108692185AControl gas productionControl rateCellsVessel mounting detailsHydrogen purityElectrolysis

The invention relates to a high-pressure high-purity hydrogen manufacturing and adding all-in-one machine which comprises a purification device, an electrolyzer, a gas-liquid separating device, a buffering device, a pressurization device and an intelligent control device, wherein the purification device is connected with the electrolyzer and is then connected with the gas-liquid separating device;the gas-liquid separating device is connected with the buffering device; the buffering device is connected with the pressurization device; the intelligent control device is connected with the electrolyzer and the pressurization device through a power line or a signal line; the purification device is connected with a water source; and the back of the pressurization device is connected with a hydrogen filling device. The high-pressure high-purity hydrogen manufacturing and adding all-in-one machine can automatically output high-pressure hydrogen with set pressure and is high in hydrogen manufacturing safety and manufactured hydrogen purity.

Owner:浙江氢航科技有限公司

Method for promoting purity of chlorine hydride recycled by reduction unit of polysilicon tail gas separating system

InactiveCN102389687AHigh purityFully resolvedChlorine/hydrogen-chlorideDispersed particle separationHydrogen purityPhysical chemistry

The invention provides a method for promoting purity of chlorine hydride recycled by a reduction unit of a polysilicon tail gas separating system. Low-concentration chlorine hydride which is recycled by the reduction unit of the polysilicon tail gas separating system is directly sent to a hydrogenating unit of the system; technological parameters of the hydrogenating unit are optimized; the problem of low purity of the chlorine hydride recycled by the reduction unit of a polysilicon tail gas dry-method separating system is solved technically; in an absorption tower, the chlorine hydride gas in a gas mixture is completely absorbed by low-temperature chlorosilane liquid, thereby forming enriched liquid; and in a dissolving tower, the chlorine hydride gas in the chlorosilane can be completely dissolved from the enriched liquid, thereby efficiently promoting the purity of the recycled chlorine hydride. The purity of the chlorine hydride is increased to 85% from original 60%.

Owner:SICHUAN RENESOLA SILICON MATERIAL

System for maintaining hydrogen purity in electrical generators and method thereof

A method and apparatus is provided for an a system for maintaining hydrogen purity in an electrical power generator. The purity system includes: a generator, a hydrogen generator configured to provide hydrogen gas to the generator, a purity monitor for detecting the level of hydrogen purity in the generator and providing a signal when the purity drops below a predetermined threshold. The system automatically compensates for gas loss or contamination to maintain the desired level of efficiency in the electrical generator.

Owner:PROTON ENERGY SYST

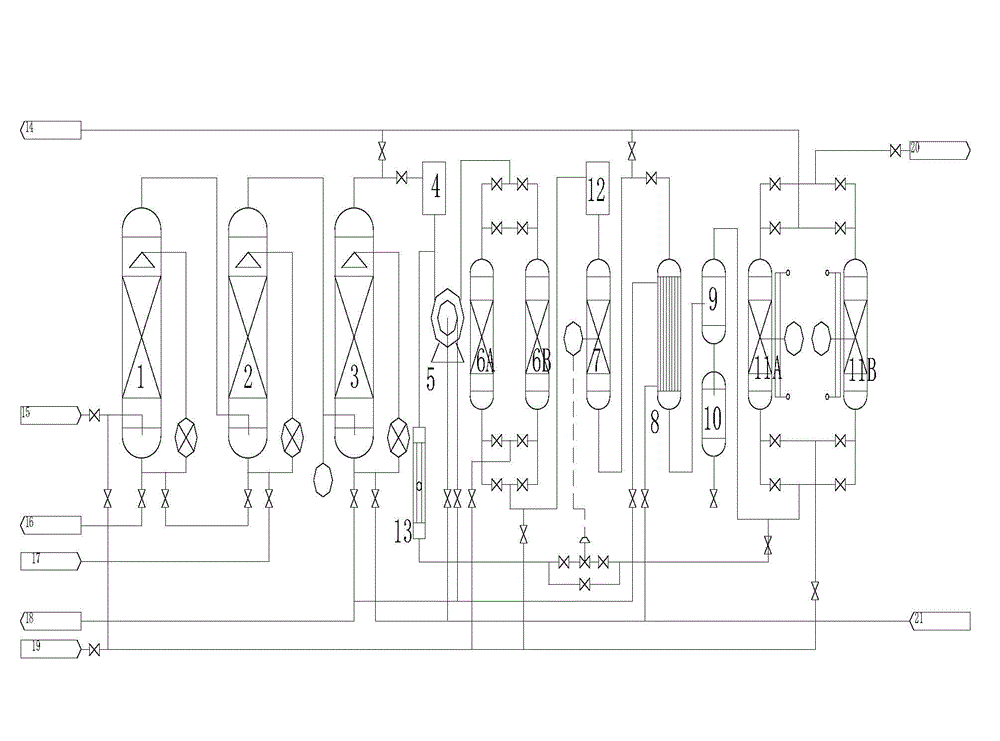

Method and device for jointly separating hydrogen through pressure swing adsorption and unpowered membrane separation

InactiveCN103112823AHigh yieldHigh purityHydrogen separation using solid contactHydrogen purityPressure rise

The invention discloses a method for jointly separating hydrogen through pressure swing adsorption and unpowered membrane separation. The method comprises a one-stage pressure swing adsorption, a two-stage pressure swing adsorption and a regeneration step, wherein the regeneration step specifically comprises the following steps that: reverse release is carried out after uniform pressure drop of a one-stage pressure swing adsorption tower, the reverse release is carried out after the uniform pressure drop of a two-stage pressure swing adsorption tower, the one-stage pressure swing adsorption tower is subjected to the first washing by the reverse gas release of the two-stage pressure swing adsorption tower, uniform pressure rise of the two-stage pressure swing adsorption tower is carried out, then the two-stage pressure swing adsorption tower is subjected to high-pressure washing by using hydrogen, and at the same time, the high-pressure washing gas is introduced in a membrane separation device, permeate gas with high hydrogen content is recycled, un-permeate gas is used for carrying out the second washing on the one-stage pressure swing adsorption tower, and the one-stage pressure swing adsorption tower is subjected to the uniform pressure rise after the washing is accomplished. The invention further discloses a device for jointly separating hydrogen through pressure swing adsorption and unpowered membrane separation. The method and device have the advantages of high yield, high hydrogen purity, low cost investment and low energy consumption.

Owner:SICHUAN TECHAIRS

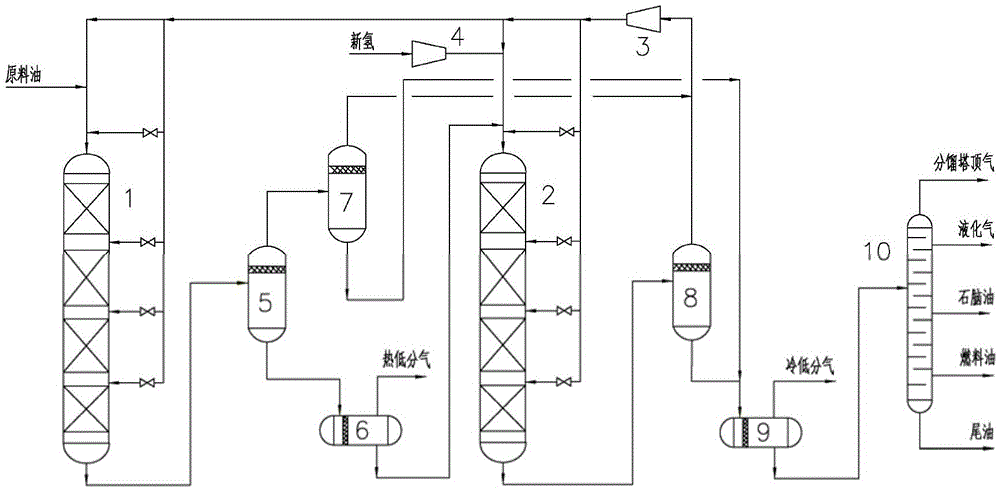

Anthracene oil hydrogenation method

ActiveCN105462610AAdd depthIncrease liquid collectionTreatment with hydrotreatment processesAnthraceneHydrogen purity

The invention discloses an anthracene oil hydrogenation method. According to the method, anthracene oil is diluted with hot low-pressure segregator oil, and then the diluted oil and inlet hydrogen are mixed to undergo hydrofining so as to obtain a hydrofining product; the hydrofining product is separated to obtain refined hot low-pressure segregator oil; part of the refined hot low-pressure segregator oil and inlet hydrogen are mixed, and new hydrogen is supplemented to carry out hydrocracking so as to obtain a hydrocracking product; the hydrocracking product is separated to obtain cracked cold high-pressure segregator oil; the cracked cold high-pressure segregator oil and refined cold high-pressure segregator oil are mixed and separation is then carried out to obtain cold low-pressure segregator oil; and the cold low-pressure segregator oil undergoes fractionation so as to obtain a product. by the method of introducing inlet hydrogen in the hydrofining stage and supplementing new hydrogen in the hydrocracking stage, the hydrogen circulatory system and new hydrogen joint point are adjusted, hydrogen purity and hydrogen partial pressure in the hydrogen circulatory system are guaranteed, hydrofining and hydrocracking depth is enhanced, liquid yield of the product is raised, and tail oil quantity is reduced. The method has advantages of simple technological flow, high conversion rate and stable plant operation.

Owner:HUADIAN HEAVY IND CO LTD

Method and system for jointly treating refinery gas by adopting membrane separation and pressure swing adsorption

ActiveCN104495752AHigh recovery rateSolve the problem of insufficient processing capacityHydrogen separation using solid contactHydrogen purityHigh pressure hydrogen

The invention provides a method and a system for jointly treating a refinery gas by adopting membrane separation and pressure swing adsorption. According to the method, multiple refinery gases are sorted as reforming hydrogen, a low-pressure hydrogen-poor gas, a low-pressure hydrogen-rich gas, a high-pressure hydrogen-poor gas and a high-pressure hydrogen-rich gas according to different requirements of a membrane separation device and a pressure swing adsorption device on the composition and pressure of a feed gas; hydrogen is recovered from the reforming hydrogen through the membrane separation device or the pressure swing adsorption device; the low-pressure hydrogen-poor gas and the high-pressure hydrogen-poor gas are purified through the membrane separation device and then hydrogen is recovered through the pressure swing adsorption device; and hydrogen is recovered from the high-pressure hydrogen-rich gas and the low-pressure hydrogen-rich gas through the pressure swing adsorption device. The invention also provides a system for the method. The method and system which are provided by the invention have the characteristics of high hydrogen purity and high recovery rate, are suitable for the yield increase of an old device and high in operating flexibility and can achieve the recovered hydrogen purity more than 99vol / % and the recovery rate more than 95%.

Owner:PETROCHINA CO LTD +1

Solar hydrogen making process

InactiveCN1966776ALess investmentNo resource consumptionCellsEnergy inputHydrogen purityElectrolysis

The invention belongs to the technique of producing hydrogen with solar energy. The invention mainly contains parabolic mirror plane heat collecting plate, turbine (generator), accumulator, water electrolyzer. The water is heated to boiling point, vapor pushes the aerorbiculus generator, electric energy is stored in the electric bottle which supply electric to the water electrolyzer, heating the water to 80DEG C and adding industrial grade hydrogen peroxide 0.03-0.05wt%, electrolyzing water to separate hydrogen. The invention has the advantages of simple equipment structure, simple installation, low cost, good technology, high hydrogen purity, and easy production.

Owner:刘志平

Startup presulfurization method of hydrogenation catalyst

ActiveCN103059913AConvenience and Economic PathwayEmission reductionHydrocarbon oil crackingHydrogen purityHydrogen

The invention discloses a startup presulfurization method of a hydrogenation catalyst. The method consists of: collecting the sulfur-containing effluent gas of a refinery plant, first conducting light hydrocarbon absorption to remove the light hydrocarbon with a high content of C1-C4, and enhancing the hydrogen purity and hydrogen sulfide concentration; then mixing the effluent gas with a circulating gas in a high pressure separator, and passing the gas generated in the high pressure separator through a circulating hydrogen desulfurization tower; and adjusting the operations on the desulfurization tower to control the concentration of hydrogen sulfide in circulating hydrogen, thus finishing sulfurization of the hydrogenation catalyst. The method provided in the invention can, on the one hand, cancel the consumption of a sulfurization agent, and on the other hand can perform optimization treatment on the sulfur-containing effluent gas, so that a more convenient and economical approach can be found for governance of sulfur-containing exhaust gases from refinery plants while startup sulfurization of hydrogenation equipment is completed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Phenol adsorption enhanced reforming hydrogen production method

ActiveCN108328574AHigh purityHigh activityHydrogenHeterogenous catalyst chemical elementsHydrogen purityPhenol adsorption

The invention discloses a phenol adsorption enhanced reforming hydrogen production method. According to the method, a Ni-Ca-Al-O dual-functional catalyst with the catalysis and CO2 adsorption functions is filled in a fixed bed reactor; under the condition of using inert gas as carrier gas, a phenol solution with the concentration being 0.0399 to 0.1594g / ml is introduced at the weight hourly spacevelocity of 0.432 to 2.592h<-1>; the reaction temperature is 400 to 700 DEG C; after the CO2 adsorption saturation, catalyst regeneration is performed for 0.1 to 3h at 500 to 1000 DEG C in the inert atmosphere. The hydrogen purity obtained by the method can reach 98 percent or higher; the phenol conversion rate reaches 99 percent or higher; the catalysis and adsorption stability is high.

Owner:SOUTH CHINA UNIV OF TECH

Device and method for separating hydrogen chloride from tail gas of fumed silica production

InactiveCN108926982AIncrease added valueHigh purityGas treatmentChlorine/hydrogen-chloride purificationExhaust gasHydrogen chloride

The invention discloses a device and method for separating hydrogen chloride from tail gas of fumed silica production. The device comprises a concentrated acid absorption tower, a dilute acid absorption tower, an alkali absorption tower and a hydrochloric acid analysis tower. An absorption and analysis cycle system is constituted by the concentrated acid absorption tower, the dilute acid absorption tower and the hydrochloric acid analysis tower in the device; hydrogen chloride gas in fumed silica is separated out through the absorption and analysis cycle system. The device and method have thefollowing beneficial effects that all hydrogen chloride in the fumed silica tail gas can be separated and recovered without production of hydrochloric acid with low added value; high-concentration hydrochloric acid with the mass percentage concentration of 37%-40% can be produced; and the recovered hydrogen chloride has high purity and the volume content can reach 99.9%.

Owner:XINTE ENERGY

Method for recycling hydrogen in ethylbenzene dehydrogenation waste gas

InactiveCN104677053AReduce the possibility of self-aggregationEfficient removalSolidificationLiquefactionHydrogen purityVapor–liquid separator

The invention relates to a method for recycling hydrogen in ethylbenzene dehydrogenation waste gas and belongs to the field of petrochemical engineering. By the method, styrene and water vapor in the ethylbenzene dehydrogenation waste gas are effectively removed by a deep freezer, an absorbing tower and a gas-liquid separator, possibility of auto-agglutination of styrene is greatly reduced, service life of catalyst of a pressure swing adsorption device is prolonged, and accordingly, hydrogen purity is up to 98%, and recovery rate of the hydrogen is up to 80-90%.

Owner:NORTH HUAJIN CHEM IND GRP

Device and method used for recycling hydrogen from chlor-alkali industry vented tail gas and preparing high purity hydrogen

The invention provides a device and a method used for recycling hydrogen from chlor-alkali industry vented tail gas and preparing high purity hydrogen. The method comprises following steps: two times of alkaline washing, one time of water washing, adsorption deep dechlorination, water ring compressor pressurizing, catalytic deoxidation, water cooling, terminal purification, oxygen dilution with countercurrent flow hydrogen, and explosion precaution. Production hydrogen purity of the method is as high as 99.9 to 99.999999%, and recovery rate is as high as 98%. Chlorine content and oxygen content in residual impurities can be as low as 1*10<-8> respectively, and flexible adjustment can be realized based on product purity requirements. The method is especially suitable to separate and recycle hydrogen from vented tail gas in chlor-alkali production, and possesses excellent economic benefits and environmental protection benefits.

Owner:DALIAN ZHONGDING CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com