Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1894 results about "Catalyst regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst regeneration is a process that renews catalysts, making them reusable after the initial usage. Regenerated catalysts are used in several processes such as reforming, which is a refinery process that converts low octane products into high octane products (reformates).

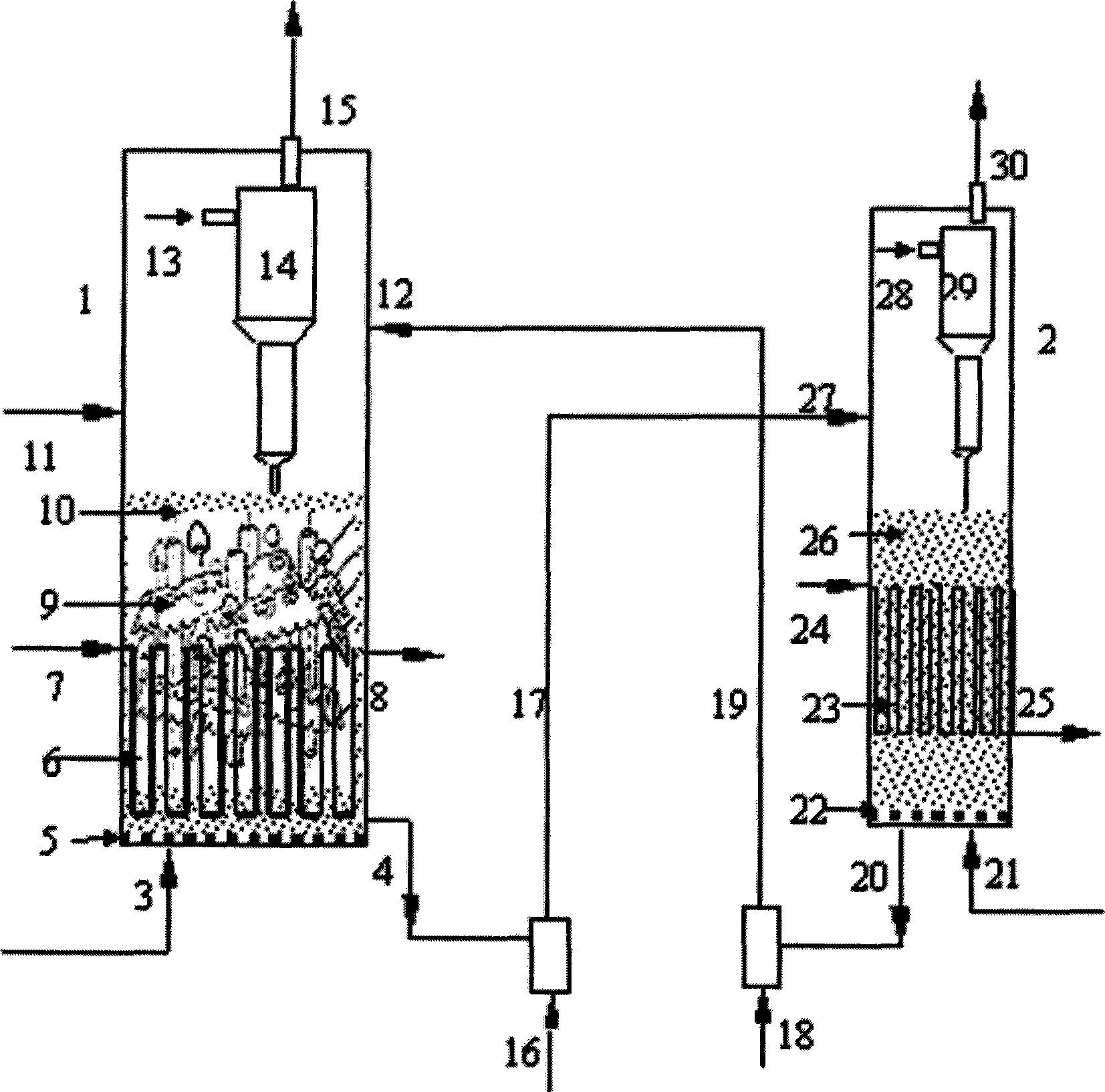

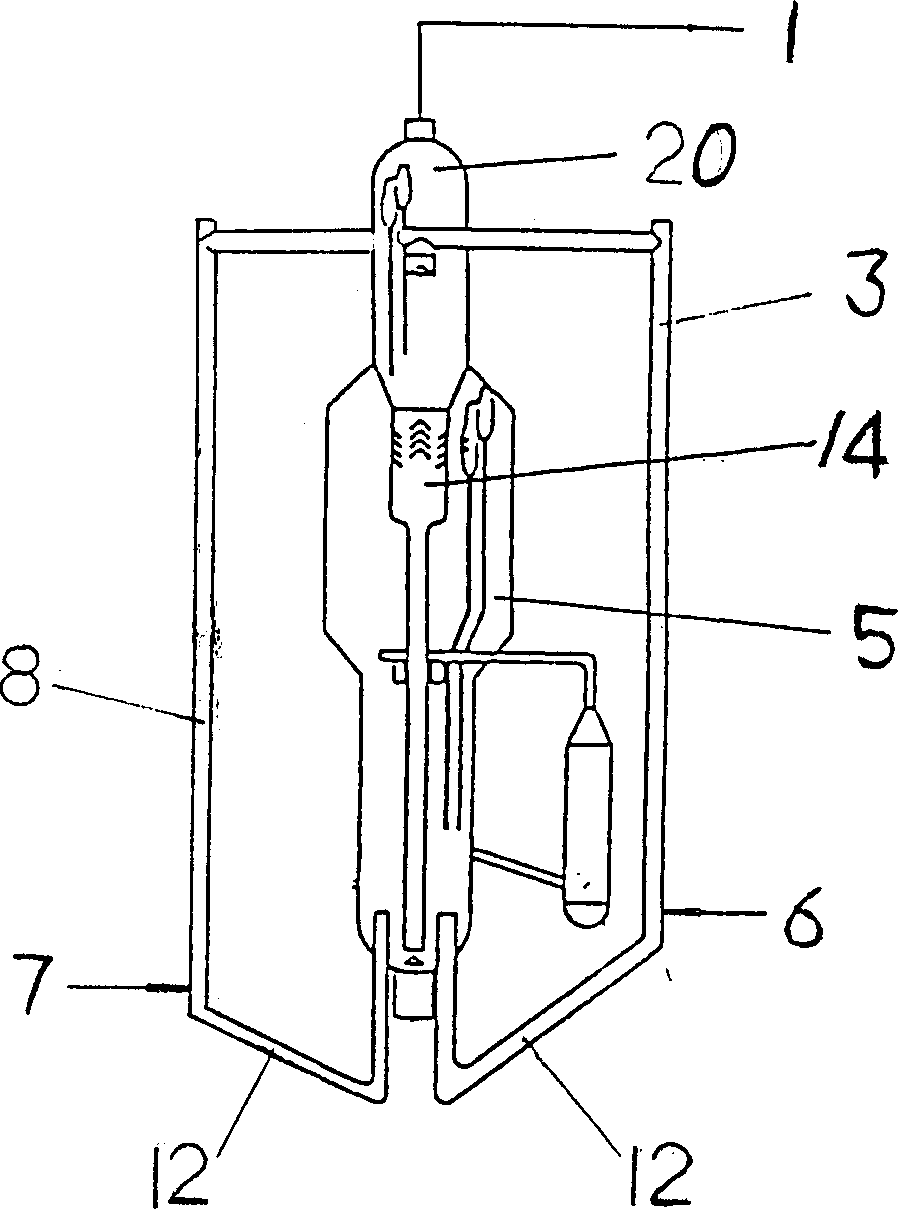

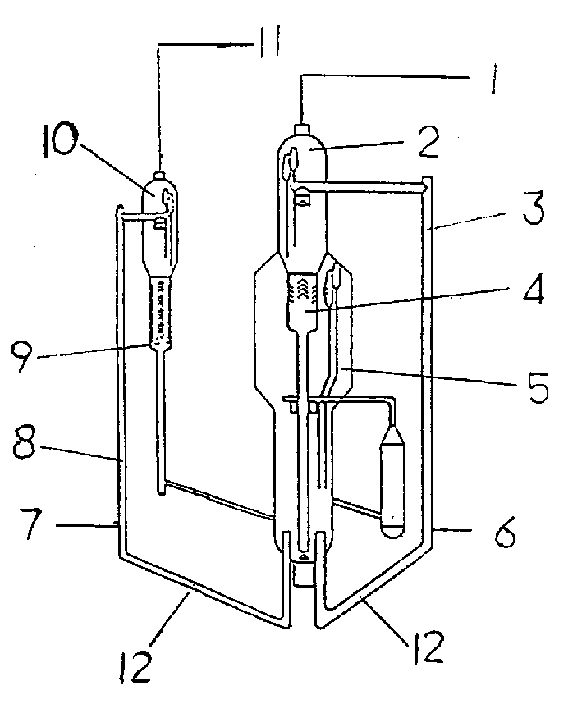

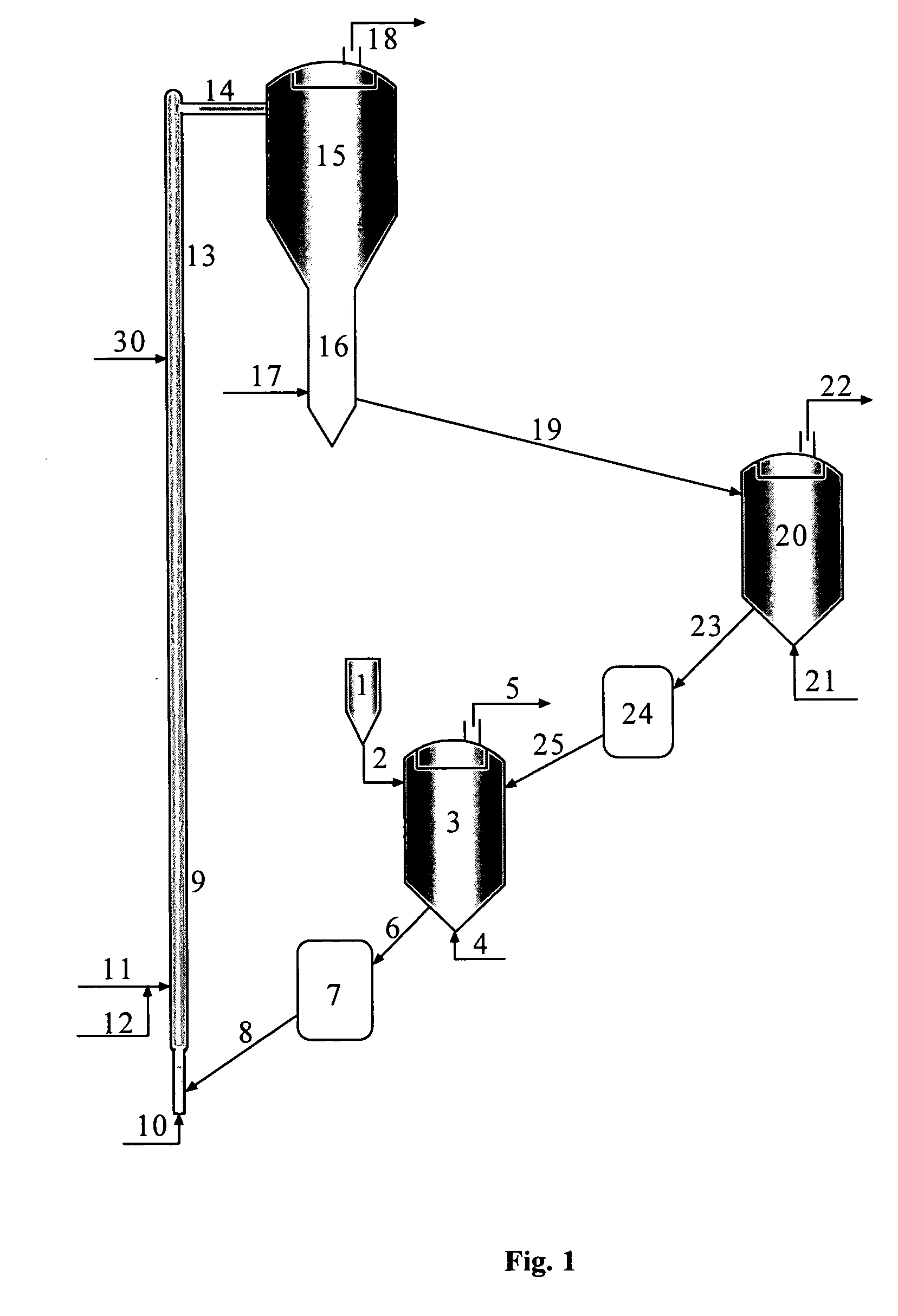

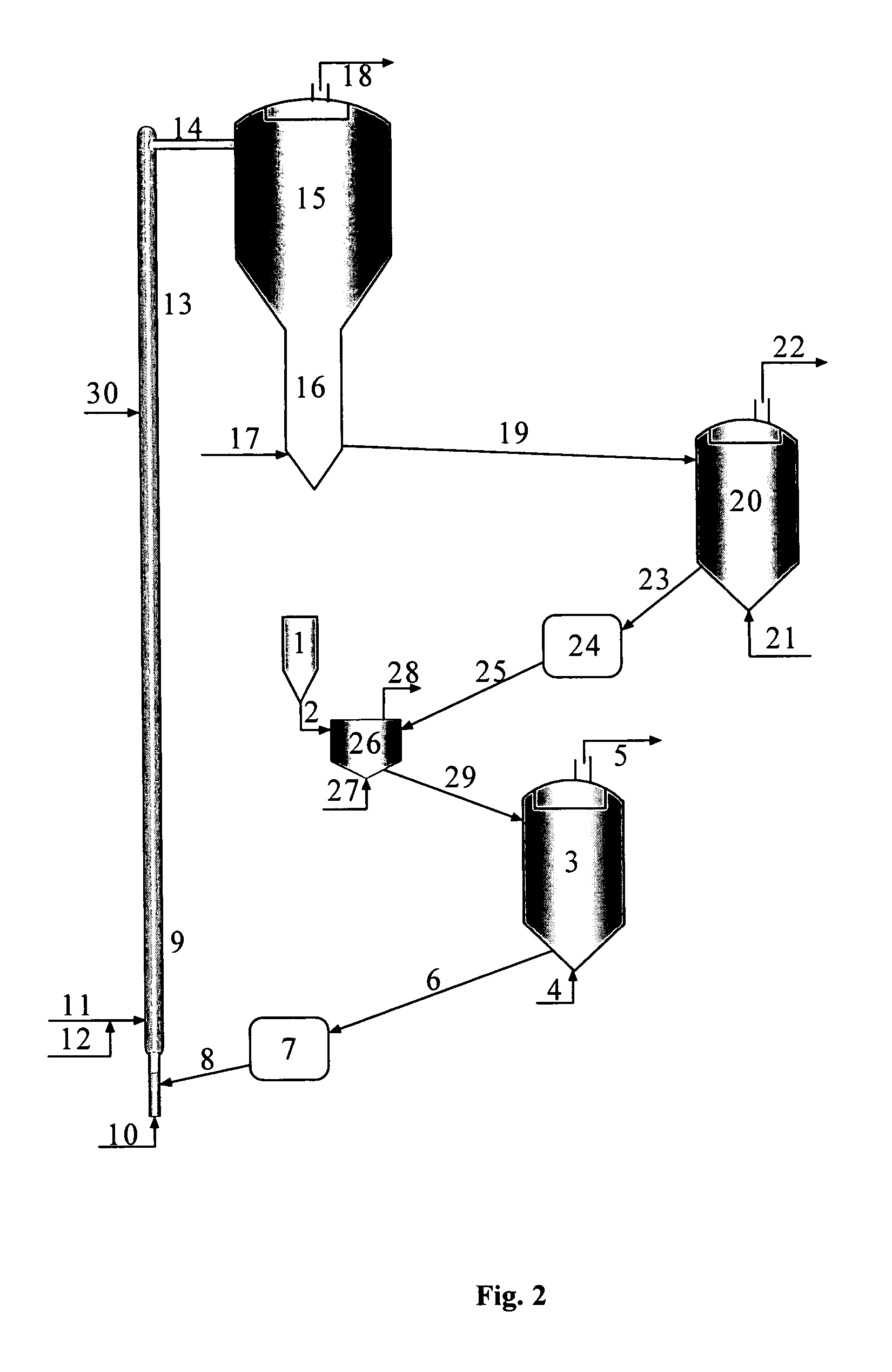

Continuous aromatization and catalyst regeneration device and method thereof

ActiveCN101244969ANo temperature fluctuationsDoes not affect aromatization reactionMolecular sieve catalystsCatalyst regeneration/reactivationFluidized bedAromatization

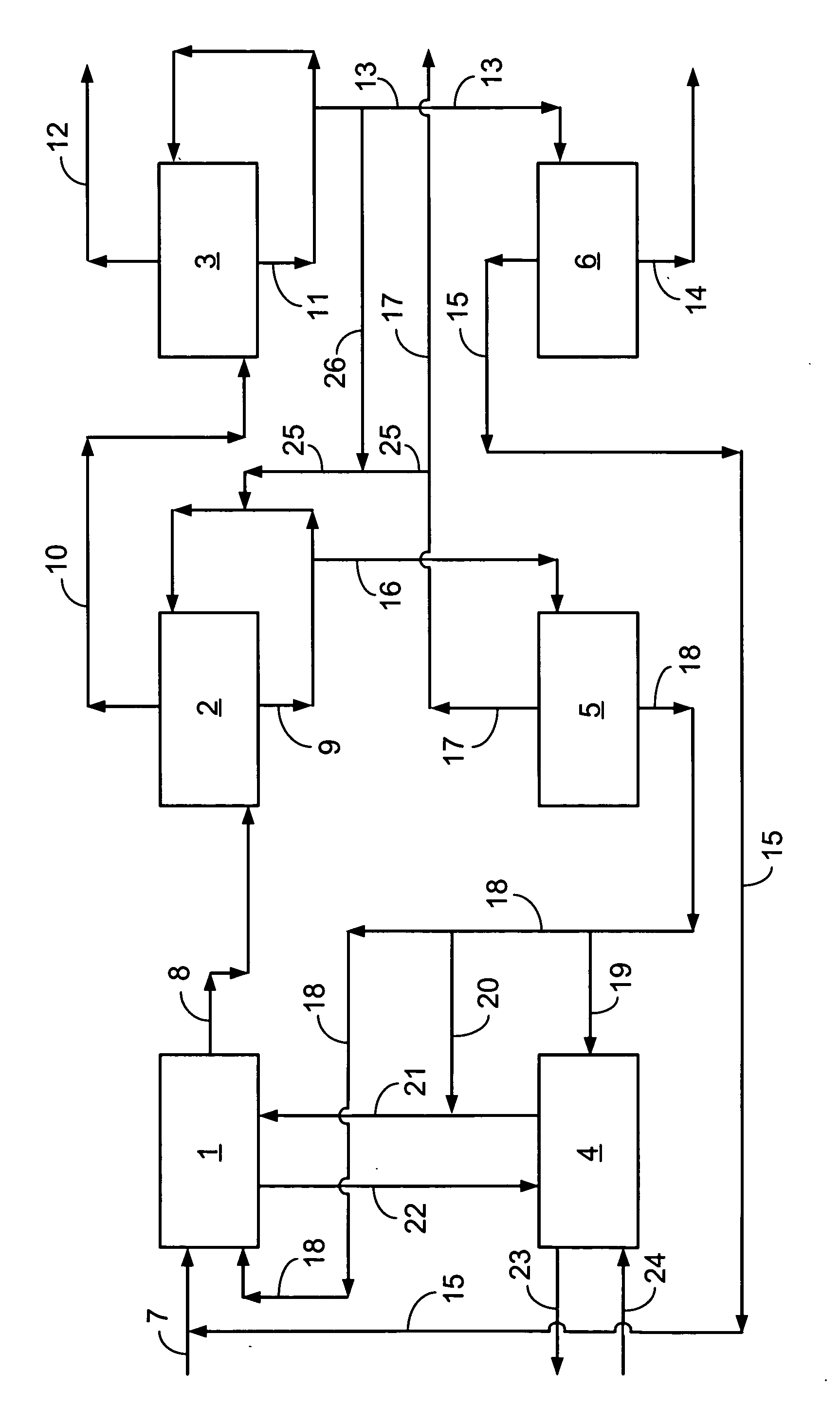

The invention discloses and belongs to the chemical equipment field, which more particularly relates to a C1-C2 hydrocarbon or methanol aromatization and catalyst regeneration fluidized bed device (comprising an aromatization fluidized bed, a catalyst continuous regeneration fluidized bed, a pipeline used for catalyst transportation and a solid transportation device which are arranged between the two fluidized beds), and an aromatization catalyst which is suitable for the fluidized bed operations and the operation methods of aromatization reaction, catalyst regeneration and the device. The device, the catalyst and the method are used for regulating the coking status of the catalyst in an aromatization reactor at any time, thus achieving the aim of transforming the C1-C2 hydrocarbon or the methanol continuously and efficiently and generating aromatics with high selectivity. The C1-C2 hydrocarbon or methanol aromatization and catalyst regeneration fluidized bed device of the invention with adjustable catalyst activity and selectivity can improve the purity and yield of the aromatics, can lead the aromatization reactor operates continuously without stopping at the same time, can improve the strength of aromatics production, and lower the operation cost of the catalyst regeneration when stopping and restarting the whole system.

Owner:TSINGHUA UNIV

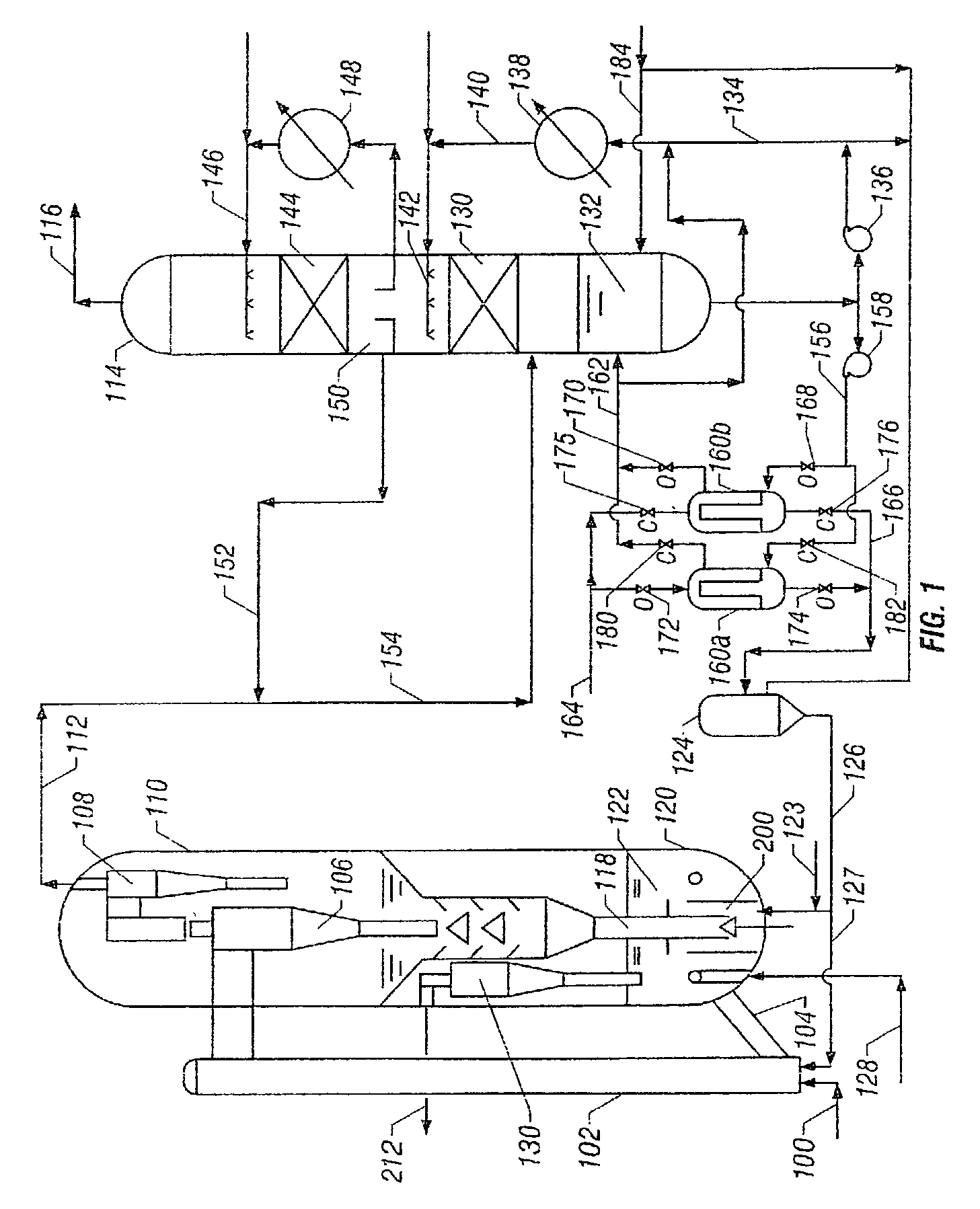

Method and apparatus for making a middle distillate product and lower olefins from a hydrocarbon feedstock

ActiveUS20060178546A1Yield maximizationCatalytic crackingCatalytic naphtha reformingPetroleum productGasoline

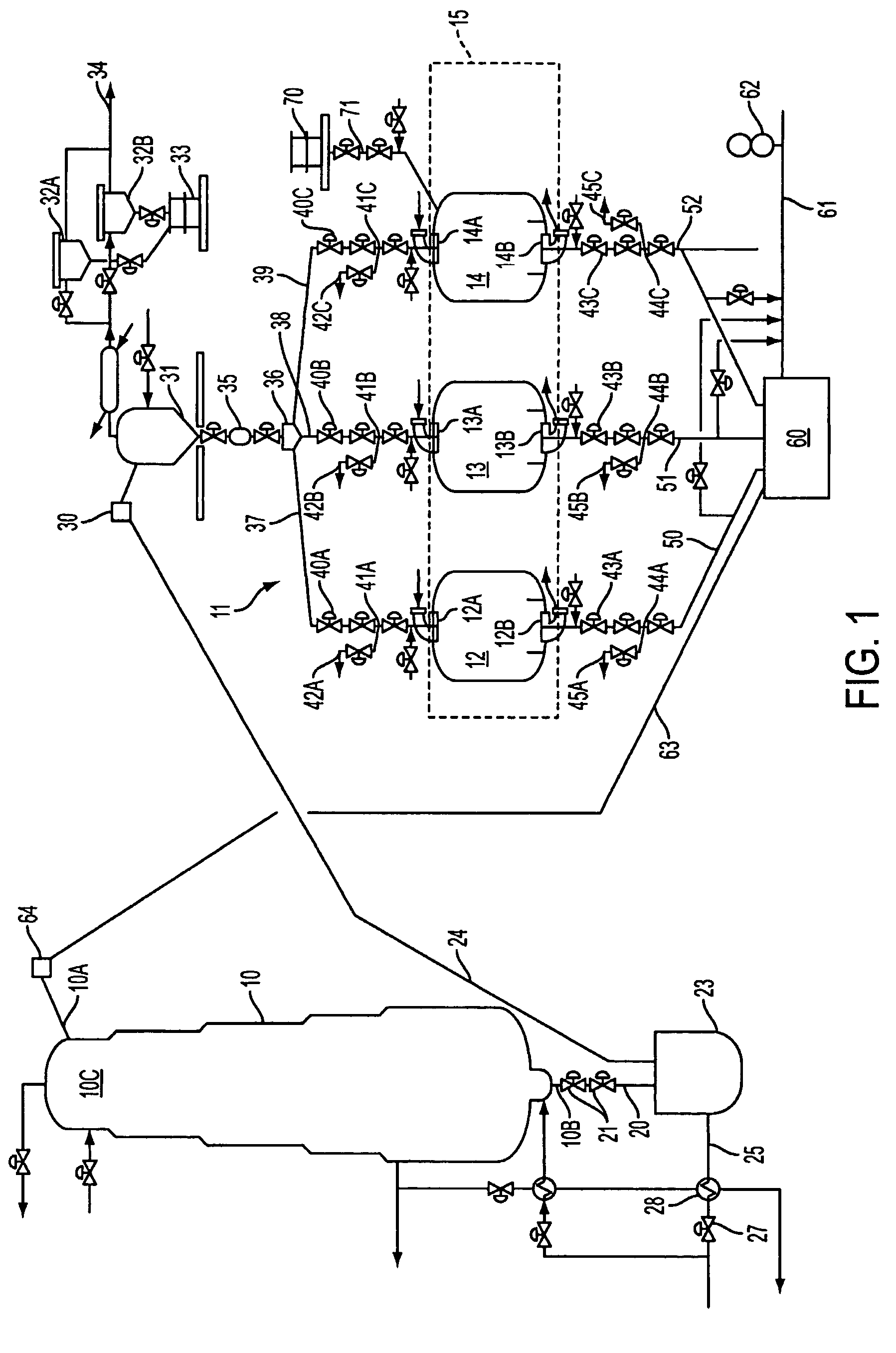

Disclosed is a process for making middle distillate and lower olefins. The process includes catalytically cracking a gas oil feedstock within a riser reactor zone by contacting under suitable catalytic cracking conditions within the riser reactor zone the gas oil feedstock with a middle distillate selective cracking catalyst that comprises amorphous silica alumina and a zeolite to yield a cracked gas oil product and a spent cracking catalyst. The spent cracking catalyst is regenerated to yield a regenerated cracking catalyst. Within an intermediate cracking reactor such as a dense bed reactor zone and under suitable high severity cracking conditions a gasoline feedstock is contacted with the regenerated cracking catalyst to yield a cracked gasoline product and a used regenerated cracking catalyst. The used regenerated cracking catalyst is utilized as the middle distillate selective catalyst.

Owner:SHELL USA INC

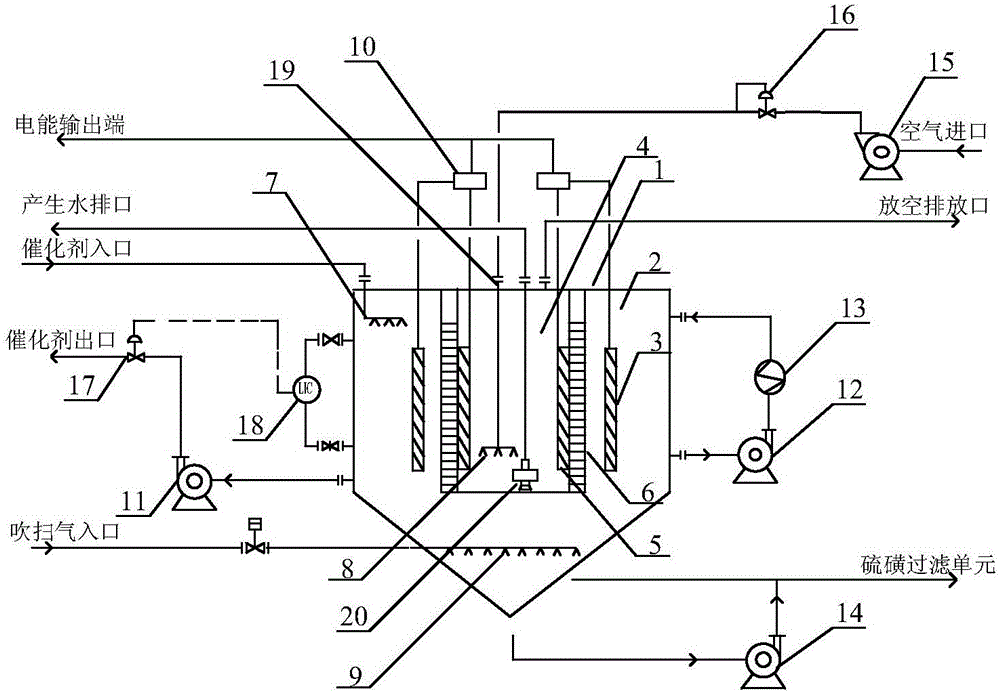

High-efficiency compound regenerative electrical energy device

InactiveCN105958098AIncreased oxidation regeneration rateReduce degradation lossRegenerative fuel cellsFuel cellsCirculator pump

The invention provides a high-efficiency compound regenerative electrical energy device. The device comprises a reactor, an anode chamber, an anode plate, a cathode chamber, a cathode plate, a proton exchange membrane module, a liquid distributor, a gas distributor, a purge distributor, a battery load, an output pump, a circulating pump, a heating / cooling device, a slurry pump, an air blower, a purge gas stop valve, a flow control valve, a magnetic flap liquidometer, a self-operated pressure-regulating valve, and an immersed pump. The gas distributor is disposed at the bottom of the cathode chamber, and the circulating pump is disposed in the middle of the reactor barrel. The air blower communicates with the gas distributor by the self-operated pressure-regulating valve, and the immersed pump is disposed at the bottom of the cathode chamber. The device uses the coupling mode of fuel cell and catalyst reactivation by means of the arrangement of air cathode fuel cell, is beneficial to improve the oxidation regeneration rate of the catalyst, and realizes the rapid regeneration of the complex catalyst.

Owner:JEREH TIANJIN PETROLEUM ENG & TECH

Regeneration fluid for SCR denitration catalyst

InactiveCN101574671AHigh activityEasy to cleanDispersed particle separationCatalyst regeneration/reactivationAdditive ingredientAmmonium paratungstate

The invention discloses a regeneration fluid for an SCR denitration catalyst, which comprises the following components: 0.001 to 1 weight percent of penetration enhancer JFC, 0.001 to 1 weight percent of surfactant OP-10, 0 to 1 weight percent of peregal, 0.6 to 4 weight percent of ammonium metavanadate, 5.5 to 12.5 weight percent of ammonium paratungstate, 0 to 6.5 weight percent of ammonium paramolybdate, and the balance of deionized water and acid. The regeneration fluid has the advantages that the regeneration fluid can also supplement active ingredients during the washing, and the activity recovery of the catalyst after the regeneration is up to between 90 and 105 percent; a nonionic surfactant is added into the regeneration fluid, so that the regeneration fluid improves the cleaning capability on the catalyst and cannot cause the damage to a catalyst carrier and other effective ingredients; and the regenerated catalyst fully can continue to be normally used, and the service life can reach more than 95 percent of that of a new catalyst.

Owner:COUNTRY JIANGSU CATALYST REGENERATION TECH

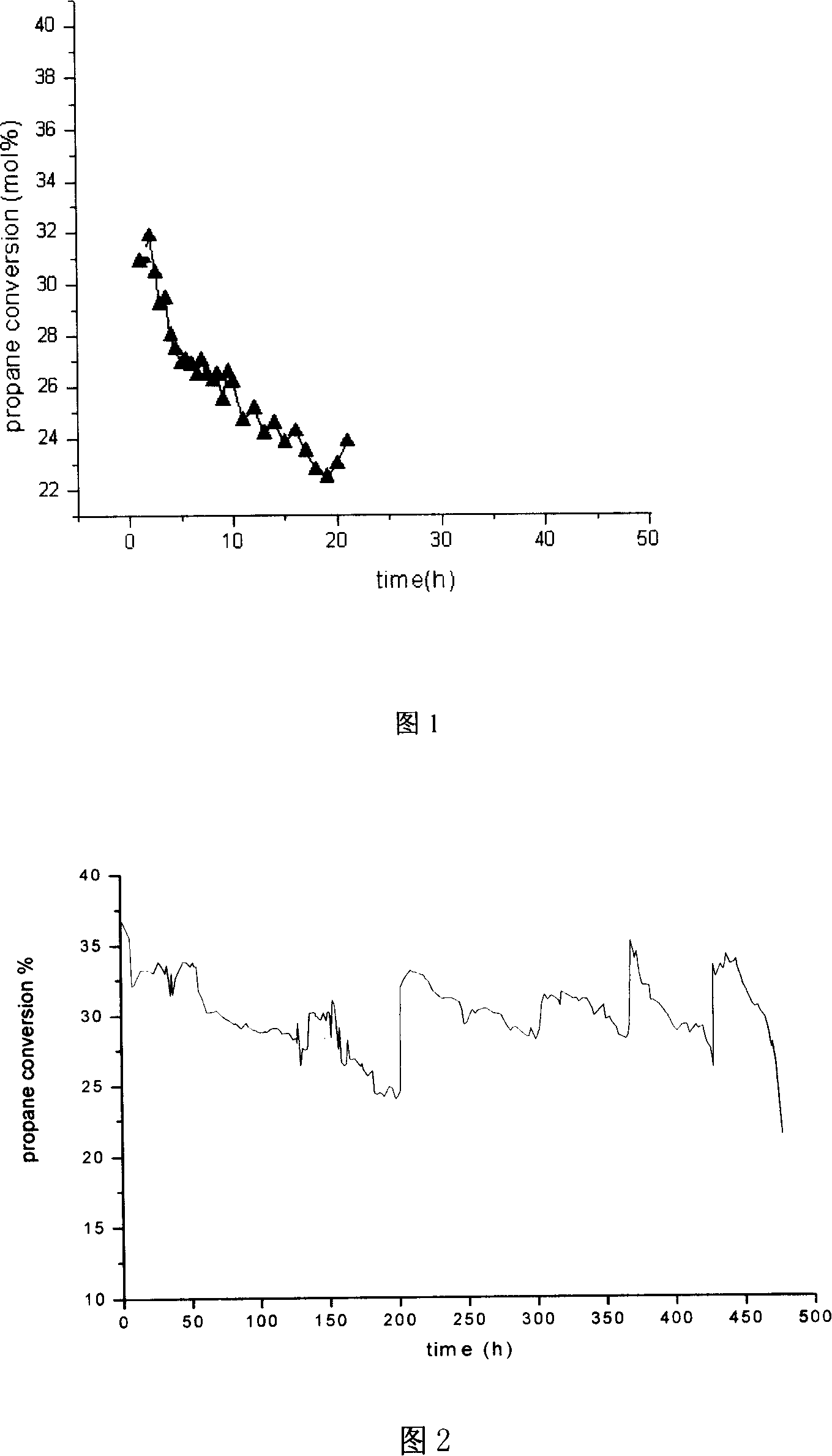

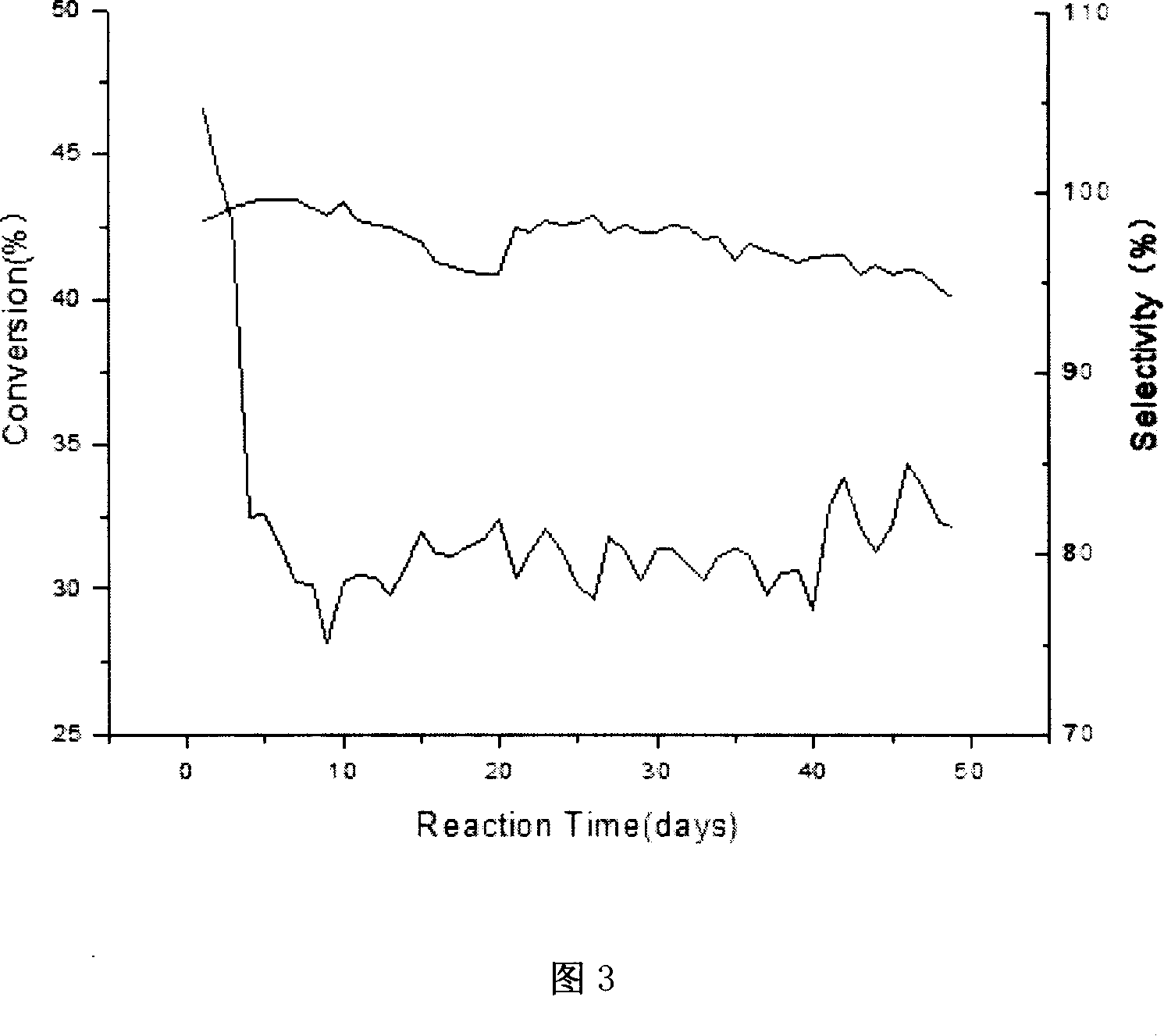

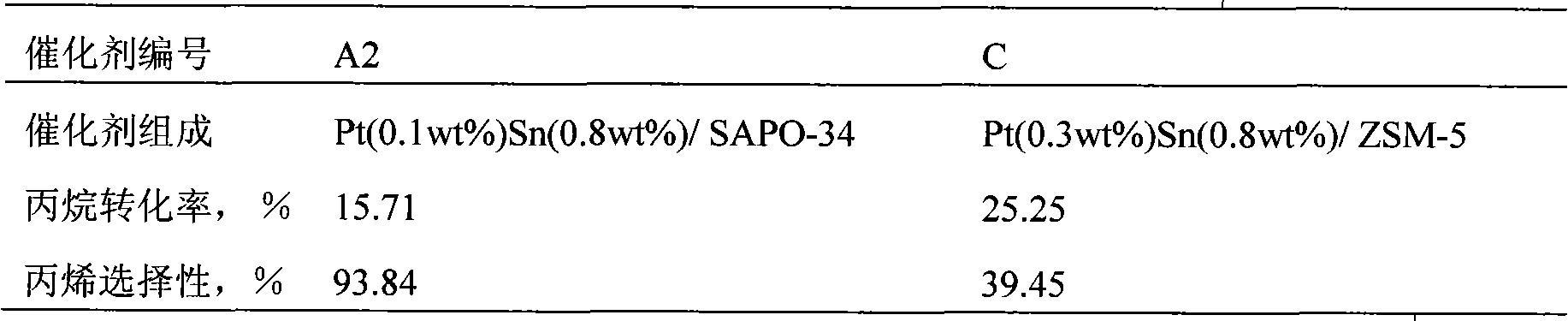

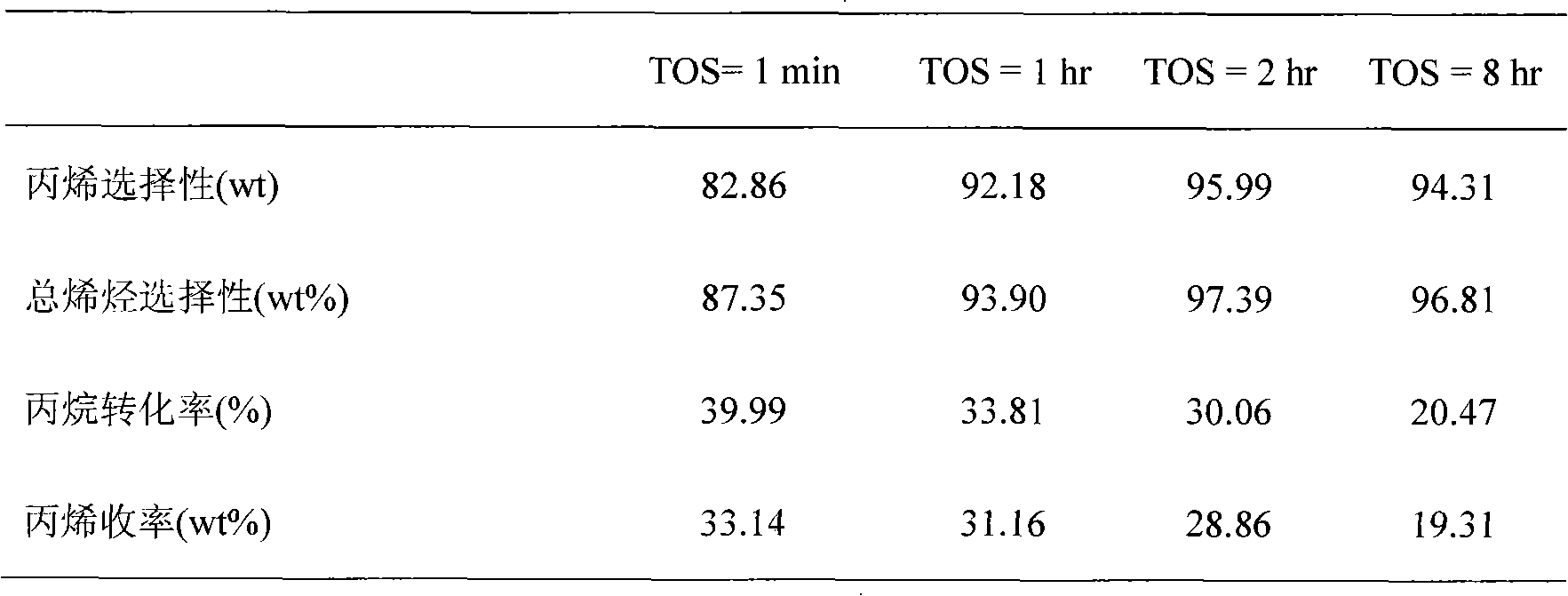

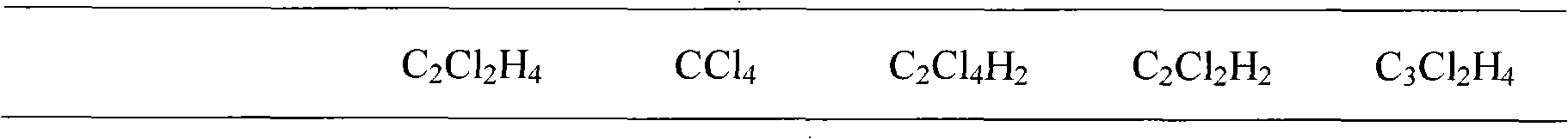

Catalyzer used for low carbon alkane catalytic dehydrogenation and method of manufacturing propylene by paraffin hydrocarbons catalytic dehydrogenation with the same as catalyzer

InactiveCN101108362AReactiveMitigation of heightened demandMolecular sieve catalystsHydrocarbonsAlkaneReaction temperature

The invention relates to a catalyst used for catalyzing and dehydrogenation of low-carbon alkane and the method of producing propylene by alkane catalyzing and dehydrogenation with the catalyst. The former catalyst used for catalyzing and dehydrogenation of low-carbon alkane, each molecule of the hydrocarbon has about 2 to 8 carbon atom, which is characterized in that: the catalyst makes a molecular sieve the carrier, the Pt family metal is loaded on the carrier as the active component, makes the IVA family metal element and alkalinity metal element as additional agent and high temperature standing inorganic oxide as connection agent; when the catalyst is used in producing propylene by alkane catalyzing and dehydrogenation, the reaction temperature is 500 to 700 DEG C., the pressure is 0 to 0.2Mpa, the quality air speed is 2 to 5h to 1, the regenerating temperature of the catalyst is 500 to 700 DEG C., the air speed is 100 to 1000h to 1, the pressure is 0 to 1.0MPa. With adopting the invention, the reaction of producing propylene by alkane catalyzing and dehydrogenation is good, the average transforming rate is 30 per cent, the selectivity above 95 per cent can keep for 50 days.

Owner:SINOPEC JINLING PETROCHEMICAL CO LTD

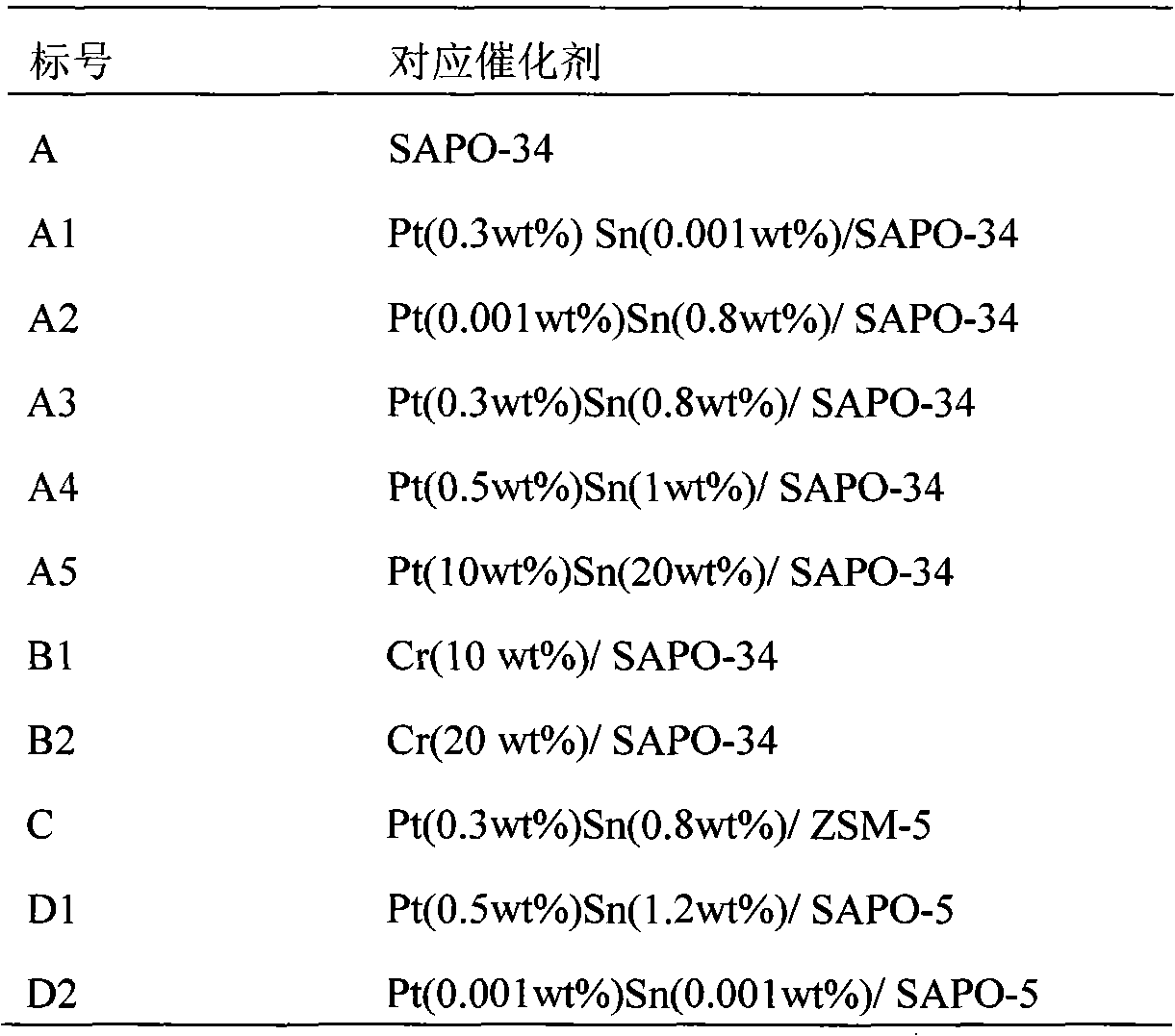

Catalyst for preparing olefin by dehydrogenating low-carbon alkane, and preparation method and application thereof

InactiveCN101623633AHigh selectivitySuitable for acidityCatalyst activation/preparationHydrocarbonsAlkaneMolecular sieve

The invention relates to a catalyst for preparing olefin by dehydrogenating low-carbon alkane, and a preparation method and an application thereof, which belong to the technical field of the preparation of basic organic chemical raw materials. The catalyst is prepared by a dipping method of using an aluminium silicophosphate molecular sieve as a carrier, VIII group or VIB group elements as active constituents and IVA group elements as an auxiliary agent. In the process for preparing olefin by dehydrogenating low-carbon alkane, the catalyst is firstly reduced by hydrogen gas, then participates in a reaction, and is finally regenerated. Compared with the existing catalyst for preparing olefin by dehydrogenating low-carbon alkane, the catalyst has a pore shape selecting function and moderate acidity, thereby the selectivity of the low-carbon alkane can reach more than 90 percent in the process for preparing olefin by dehydrogenating low-carbon alkane. The preparation method of the catalyst is simple; the regeneration process flow of the reaction has a large choice, a fixed bed, a fluidized bed or a moving bed can be used as a reactor, and the catalyst can be regenerated in the reactor or outside the reactor.

Owner:TSINGHUA UNIV

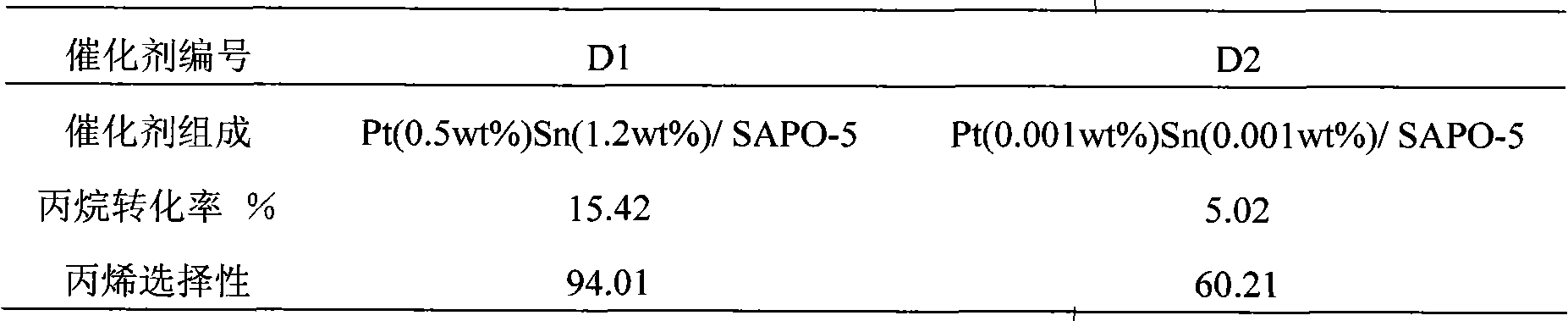

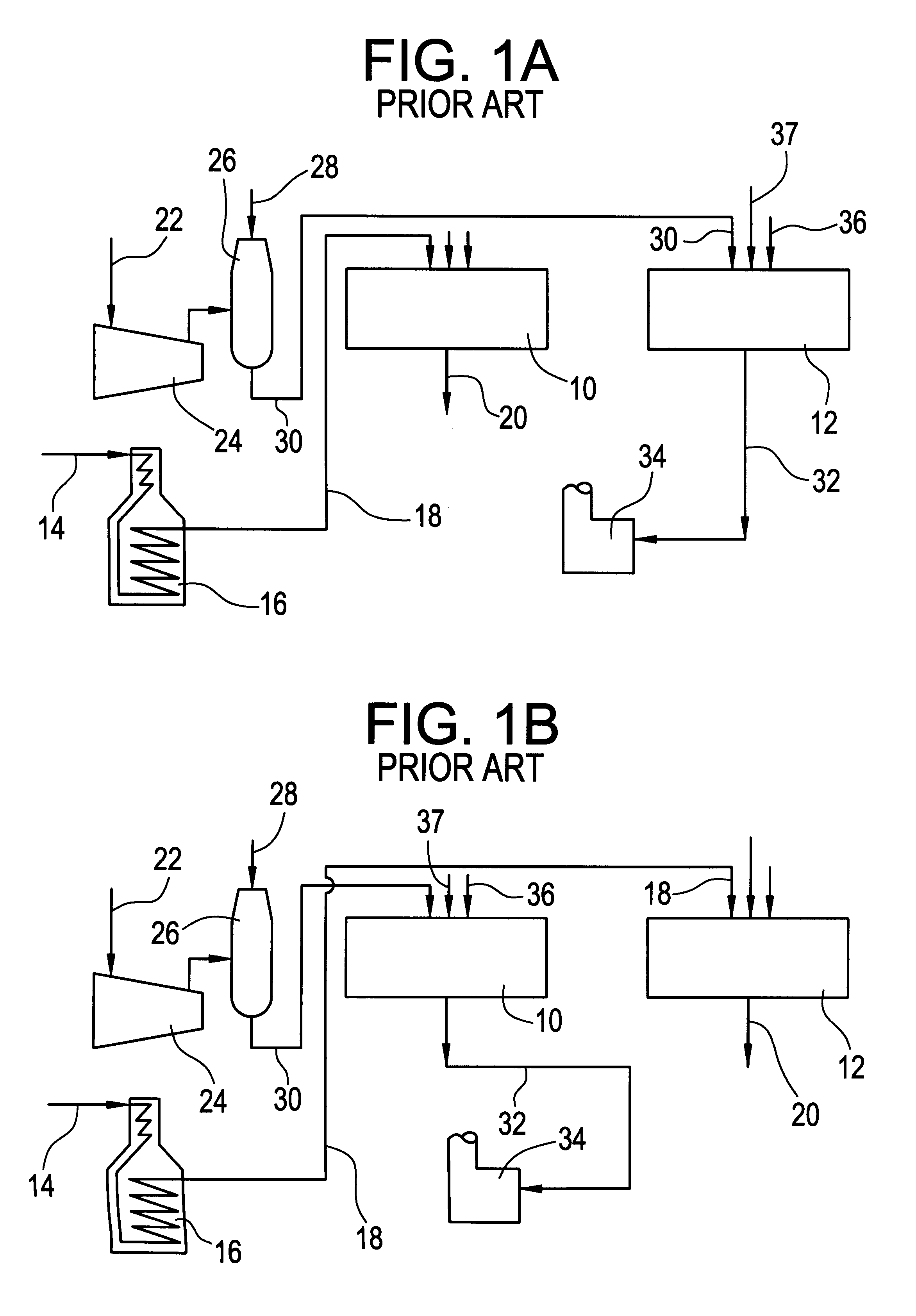

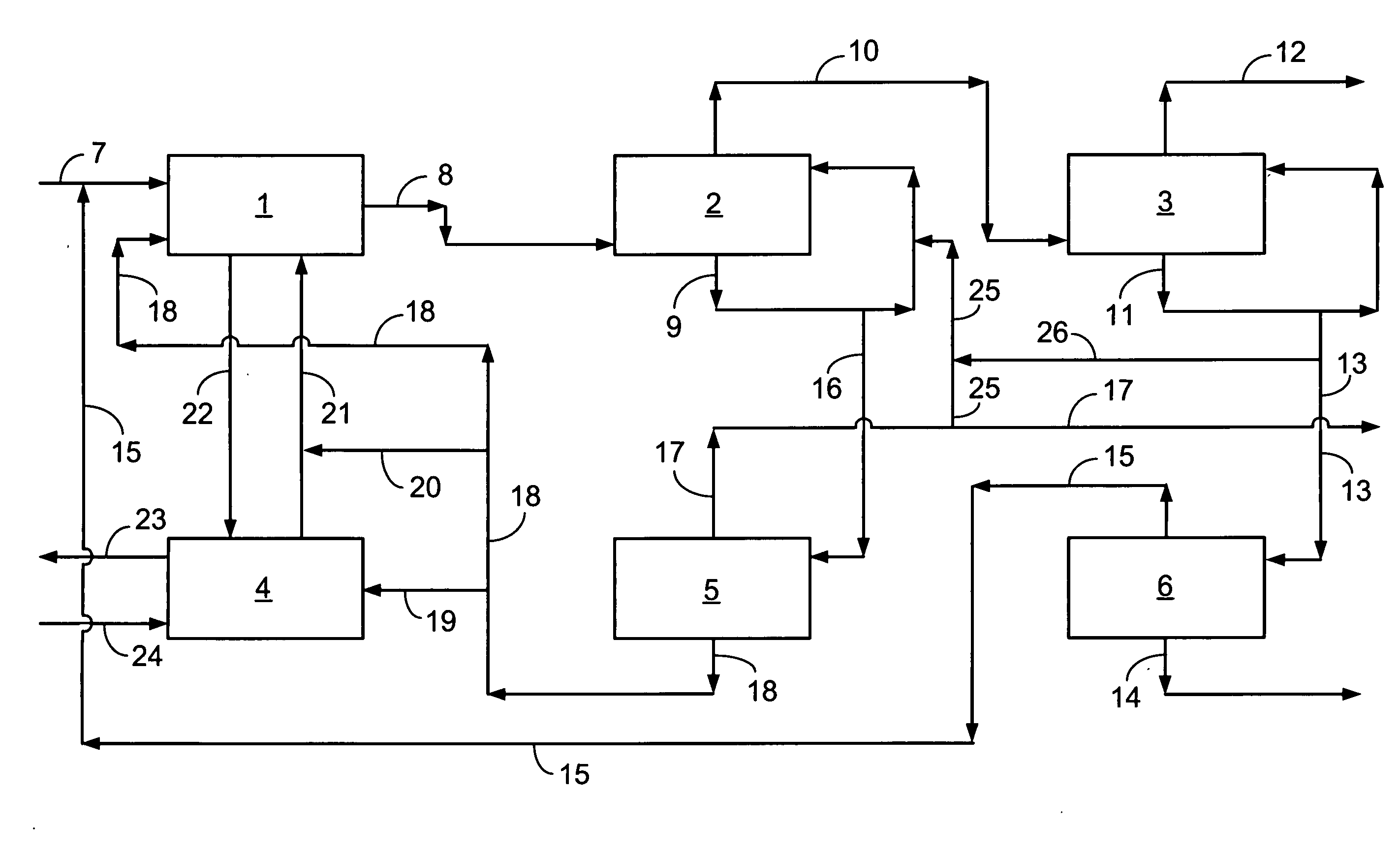

Process for the regeneration of a catalyst plant and apparatus for performing the process

InactiveUS6946419B2Reduce consumptionCost savingCombination devicesMolecular sieve catalystsFlueGas turbines

A gas stream containing e.g. molecular hydrogen is used for the regeneration of a catalyst for NOx and SO2 removal from the flue gas of a gas turbine. In order to reduce the consumption of regeneration gas, the gas inlet is located between the SCOSOx catalyst (2) and the SCONOx catalyst (3). The regeneration gas leaves the catalyst chamber upstream of the SCOSOx catalyst and is recycled. For the regeneration of the SCONOx catalyst and to keep SO2 containing gas from entering the SCONOx catalyst, a second regeneration gas inlet is located downstream of the SCONOx catalyst. The regeneration gas entering the catalyst chamber through this port passes the SCONOx (3) and the SCOSOx catalyst (2). The direction of the flow in the SCONOx catalyst can also be reversed. In another example, regeneration gas outlets are located both upstream of the SCOSOx and downstream of the SCONOx catalyst. But, only the regeneration gas from the SCONOx catalyst is recycled.

Owner:ANSALDO ENERGIA IP UK LTD

Catalytic conversion method and apparatus for upgrading poor gasoline

InactiveCN1401740AReduce olefin contentReduce sulfur contentTreatment with plural serial stages onlyCatalytic transformationFuel oil

A catalytic converting process for upgrading poor-quality gasoline with high olefine content incldues a conventional catalytic cracking step for heavy oil and a catalytic converting step for upgrading said gasoline. It is characterized by in that two steps a common catalyst regenerator and a same catalyst are used. It can decrease olefine content by 15-50 vol% and S content by 5-30% and increase RON by 0.2-2 units.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Method for removing oxysulfide and/or nitrogen oxide from flue gas and hydrocarbon oil cracking method

ActiveCN101209391ANot easy to saturateMany timesCatalytic crackingDispersed particle separationFlue gasSorbent

The invention discloses a method for desorbing oxysulphide and / or oxynitride in the regenerated fume of a catalytic cracking catalyst, and the method comprises that the fume is kept in contact with a sorbent, wherein, the sorbent is a catalytic cracking catalyst. The method for desorbing oxysulphide and / or oxynitride in the regenerated fume of the catalytic cracking catalyst which is provided by the invention adopts the catalytic cracking catalyst to replace existing specialized sorbents, thus fully achieving effects of desorbing oxysulphide and oxynitride at the same time, and as the catalytic cracking catalyst is not easy to reach saturation, the catalytic cracking catalyst can be regenerated for a plurality of times when taken as the sorbent; furthermore, after being taken as the sorbent, the catalyst can still be used in a catalytic cracking process, and the activity and reactivity of the catalyst which is taken as the catalytic cracking catalyst are not affected.

Owner:CHINA PETROLEUM & CHEM CORP +1

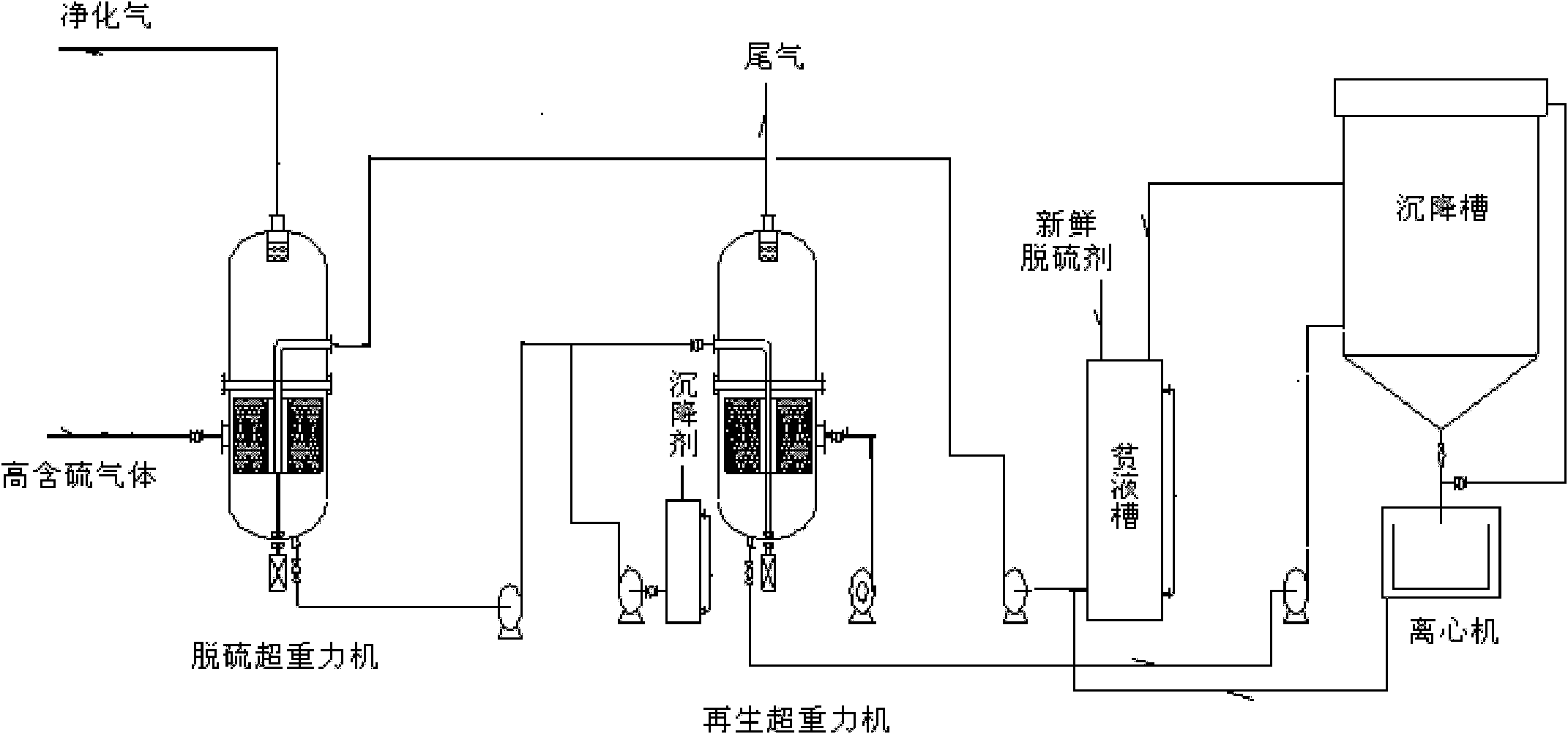

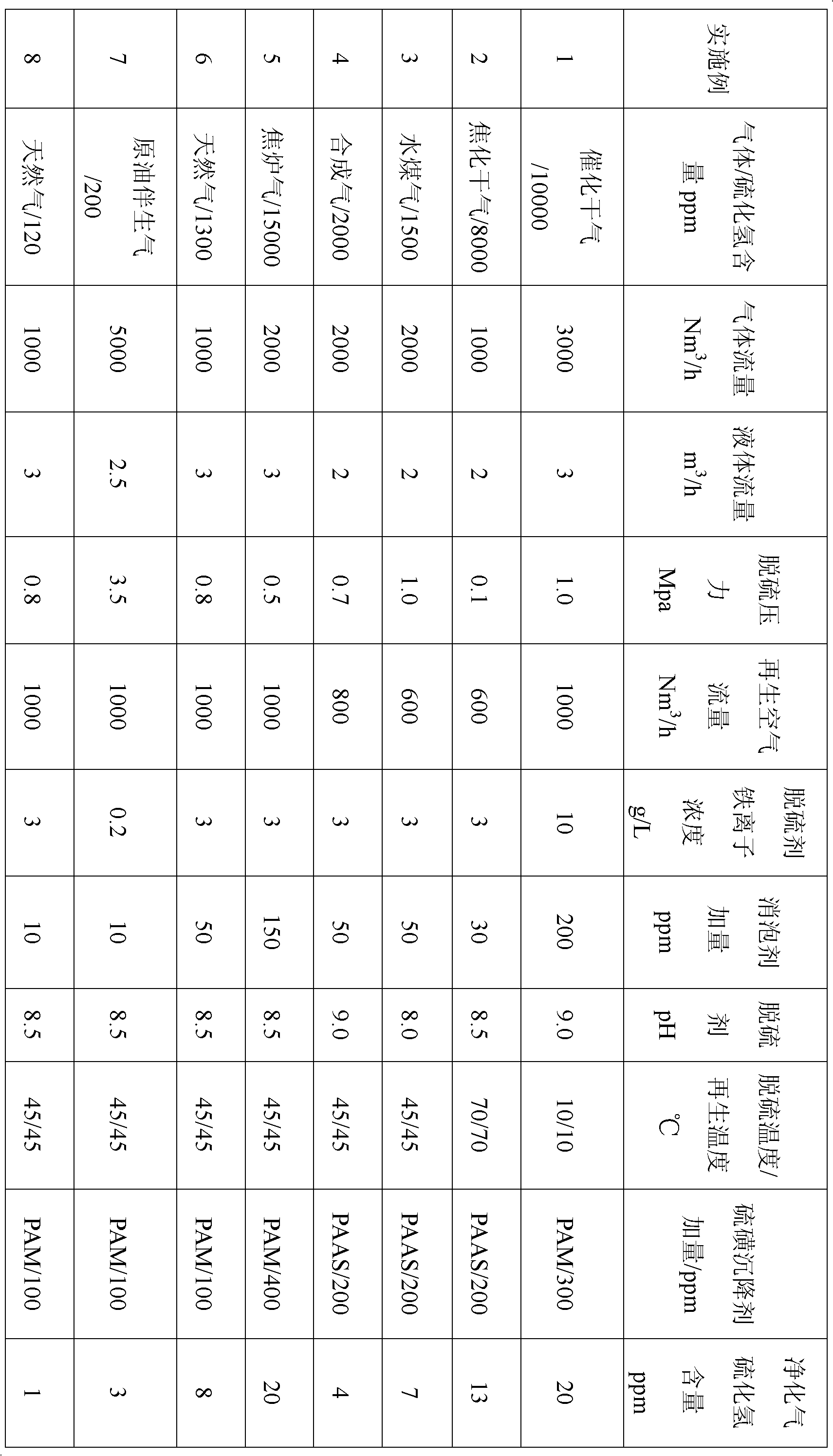

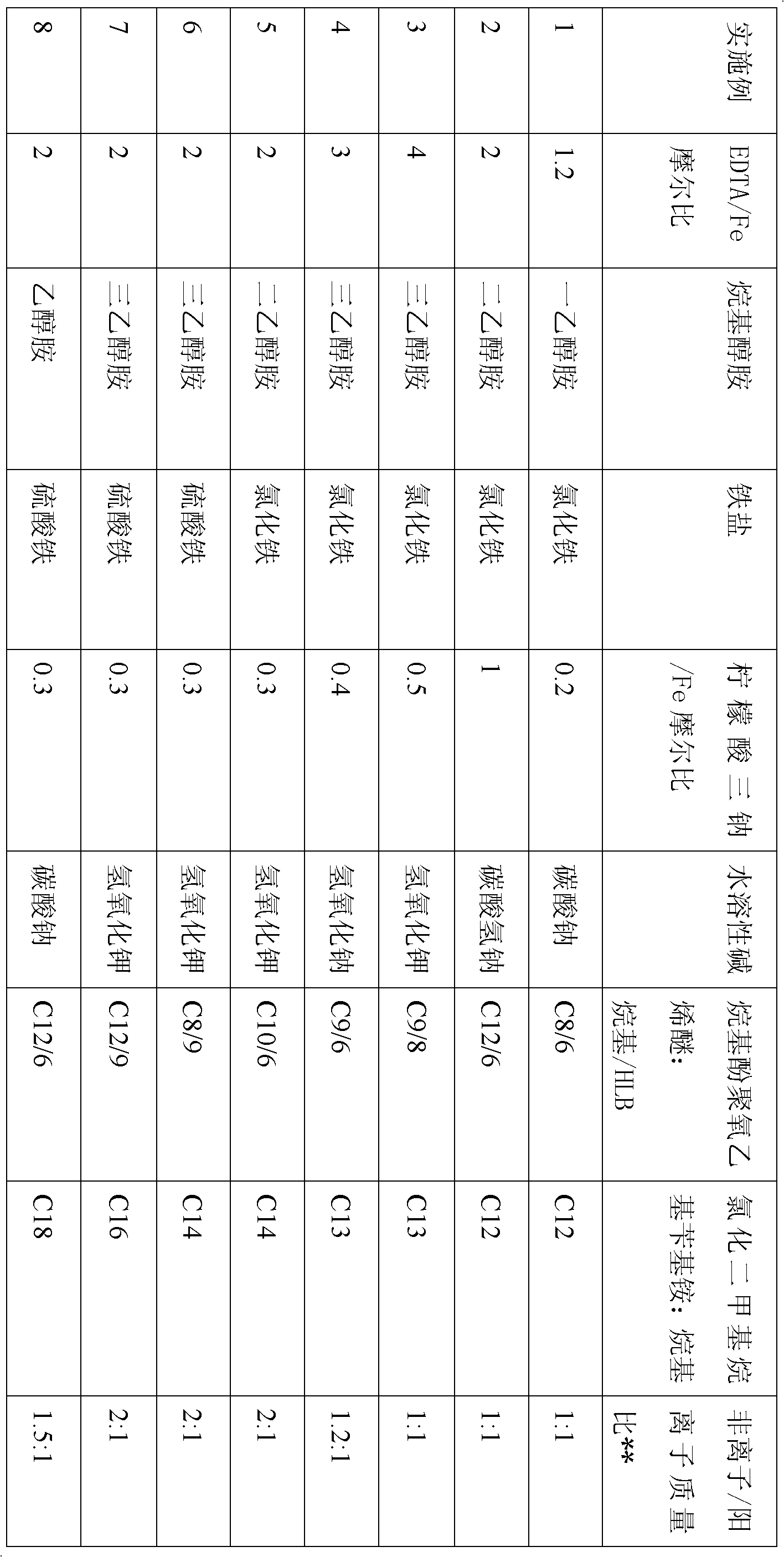

Method for removing hydrogen sulfide in gas phase through oxidization under high gravity field

InactiveCN102151476AShort regeneration timeSmall sizeDispersed particle separationGas phaseDefoaming Agents

The invention discloses a method for removing hydrogen sulfide in a gas phase through oxidization under a high gravity field, which comprises the steps of: enabling a desulfurizing agent to be in a countercurrent or cross current contact with a hydrogen sulfide containing gas in a desulfurizing high gravity machine; and then adding the desulfurizing agent rich in sulphur in a sulphur sedimentation agent and then enabling the desulfurizing agent added with the sulphur sedimentation agent to be in a countercurrent or cross current contact with air in a regeneration high gravity machine, whereinthe desulfurizing agent is a mixed solution consisting of complex iron, aqueous alkali, a sulphur modifying agent and a defoaming agent, and in the mixed solution, the concentration of iron ions is 0.1-10g / L, pH is 8.0-9.2, the concentration of the sulphur modifying agent is 10-200ppm, and the concentration of the defoaming agent is 5-50ppm. The high gravity machine is used for replacing the traditional low-transfer-efficiency reactor, and a high gravity rotary packed bed reactor is adopted during hydrogen sulfide oxidization and catalyst regeneration, thus process transfer efficiency is greatly strengthened, and time of oxidization desulfurization and regeneration of a desulfurizing agent is shortened; in addition, the sedimentation agent is adopted in a sulphur sedimentation stage and acts together with the sulphr modifying agent, thus the sulphur sedimentation time is also greatly shortened.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD +1

SCR (selective catalytic reduction) flue gas denitration catalyst regeneration method

InactiveCN102658215AEasy to cleanEfficient regenerationDispersed particle separationCatalyst regeneration/reactivationFlue gasActive component

The invention relates to a catalyst regeneration method, and especially relates to an SCR flue gas denitration catalyst regeneration method. The method concretely comprises the following steps: purging a catalyst to be regenerated; putting the catalyst into a cleaning pool, cleaning with a cleaning solution, and drying; dipping the cleaned catalyst into an activity supplement solution to carry out activity supplement, and drying; and roasting and cooling the dried catalyst to obtain a generated denitration catalyst. The method of the invention has the following beneficial effects: catalyst carriers are not destroyed during cleaning; the catalyst can be cleaned, active substances can be supplemented, and active components of the regenerated catalyst are environmentally-friendly, so the regenerated catalyst does not generate pollution in the use process; and the denitration activity of the regenerated catalyst reaches above 90%. The method is very important for regeneration and reuse of dead toxic vanadium-titanium catalysts, and use promotion of self-developed novel environmentally-friendly and cheap titanium-based denitration catalysts.

Owner:NANJING UNIV OF TECH

Process for producing lower olefins by using multiple reaction zones

ActiveUS20070038010A1Easy to processStable periodTreatment with plural serial cracking stages onlyCatalytic crackingReaction temperatureReaction zone

The present invention provides a process for producing lower olefins by catalytic cracking a feedstock comprising an olefins-enriched mixture containing C4 or higher olefins and optionally an organic oxygenate compound. The technical problem mainly addressed in the present invention is to overcome the defects presented in the prior art including low yield and selectivity of lower olefins as the target products, and short regeneration period of catalyst. The present process, which is carried out under the conditions of catalytic cracking olefins and adopts as a feedstock an olefins-enriched mixture containing one or more C4 or higher olefins and optionally an organic oxygenate compound, comprises the steps of: a) letting the feedstock firstly enter a first reaction zone to contact with a first crystalline aluminosilicate catalyst having a SiO2 / Al2O3 molar ratio of at least 10, to thereby produce a first reaction effluent containing lower olefins; b) letting the first reaction effluent enter in turn at least one second reaction zone to contact with a second crystalline aluminosilicate catalyst having a SiO2 / Al2O3 molar ratio of at least 10, to thereby produce a second reaction effluent containing lower olefins; and c) separating lower olefins from the second reaction effluent; wherein the reaction temperatures in the first and second reaction zones are controlled. The present process, which desirably solves the above technical problem, can be used in industrial production of lower olefins.

Owner:CHINA PETROCHEMICAL CORP +1

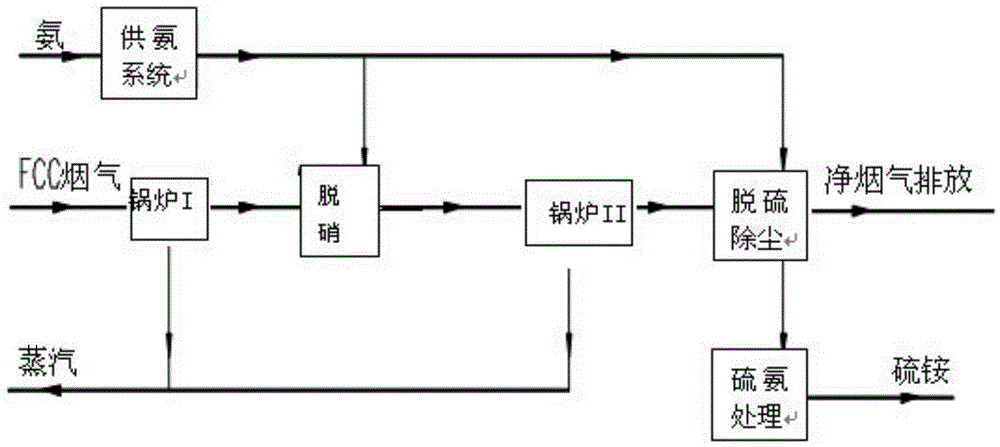

Ammonia desulfurization and denitrification dedusting method and device utilizing catalytic cracking regeneration flue gas

ActiveCN104941423ALess investmentLow running costUsing liquid separation agentEnergy inputNitric oxidePetroleum

The invention relates to an ammonia desulfurization and denitrification dedusting method and device utilizing catalytic cracking regeneration flue gas, comprising the following steps: enabling high-temperature catalyst regeneration flue gas coming from a catalytic cracking unit and containing catalyst dust to firstly enter a waste heat boiler I, reducing the temperature of the flue gas to 280-430 DEG C, wherein the heat of the flue gas is externally supplied by steam produced by the waste heat boiler I; enabling flue gas at temperature of 280-430 DEG C to enter a denitrification device for denitrification and enter a waste heat boiler II through an outlet flue after sufficiently reacting on the surface of a denitrification catalyst in a denitrification reactor; removing sulfur dioxide, nitric oxide and byproduct ammonium sulfate by taking ammonia as a reactant, and removing catalyst dust in the regeneration flue gas to achieve clean gas up-to-standard release; the three waste free release purifying method can be applied to catalytic cracking catalyst regeneration flue gas treatment in oil refining.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Catalyst for manufacturing olefin by low-carbon alkane dehydrogenation and application thereof

ActiveCN101773850AHigh selectivityHigh activityMolecular sieve catalystsHydrocarbonsAlkaneRare-earth element

The invention discloses a catalyst for manufacturing olefin by low-carbon alkane dehydrogenation and application thereof, belonging to the technical field of preparation of basic organic chemical materials. The catalyst takes silicoaluminophosphate molecular sieve and alumina mixture as carriers, VIII group or IVA group elements as active components and alkaline-earth metal or rare-earth elements as auxiliary agents for the process of olefin preparation by ethane, propane, butane or pentane dehydrogenation. In the process of olefin preparation by low-carbon alkane dehydrogenation, catalyst is firstly reduced by hydrogen and then reacts, and finally the catalyst is in charcoaling regeneration and chlorination update; and reaction regeneration process flow has big choice, the reactor can adopt a fixed bed, a moving bed, a fluidized bed or a double-particle fluidized bed, and catalyst regeneration can be carried out in a device or out of the device. Compared with the existing catalyst for manufacturing olefin by low-carbon alkane dehydrogenation, the catalyst provided by the invention ensures that low-carbon alkane selectivity is above 95% in the olefin preparing process by low-carbon alkane dehydrogenation under high conversion rate.

Owner:TSINGHUA UNIV

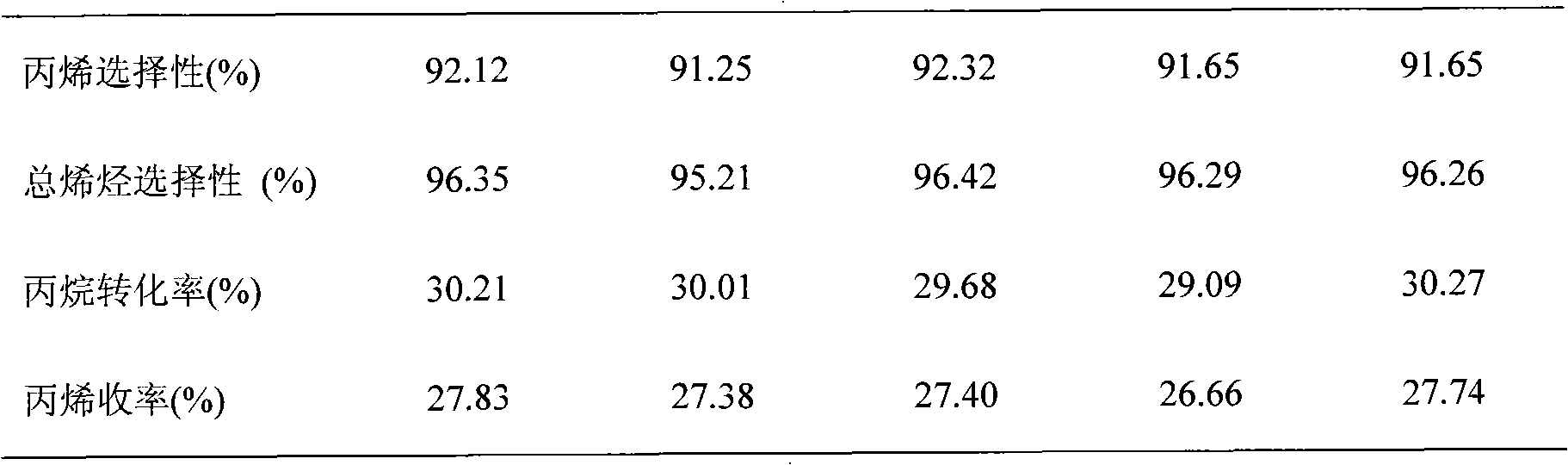

Low temperature Claus sulfur recovery process and device therefor

InactiveCN101519192AAchieve regenerationImprove conversion rateEnergy inputSulfur preparation/purificationReaction temperatureOxygen

Owner:CHENGDU SEPMEM SCI & TECH

Process for cracking hydrocarbon oils

ActiveUS20050279670A1Improve abilitiesImprove not only the desulfurizing ability but also the conversion of the hydrocarbon oilsThermal non-catalytic crackingCatalytic crackingChemistryCatalyst regeneration

This invention relates to a process for cracking hydrocarbon oils. Said process comprises contacting a hydrocarbon oil with a catalyst that has contacted with an atmosphere containing a reducing gas, separating cracked products and the catalyst, regenerating the catalyst, contacting the regenerated catalyst with said atmosphere containing a reducing gas, wherein said catalyst is a cracking catalyst containing a metal component, or a catalyst mixture of a cracking catalyst containing a metal component and a cracking catalyst free of metal component, contacting said catalyst with the atmosphere containing a reducing gas at a temperature of 100 to 900° C. for at least 1 second, wherein the amount of the atmosphere containing a reducing gas is not less than 0.03 cubic meters of reducing gas per ton of the cracking catalyst containing a metal component per minute, at a pressure of 0.1-0.5 MPa in the reduction reactor. The process has higher ability of desulfurizing and cracking heavy oils.

Owner:CHINA PETROCHEMICAL CORP +1

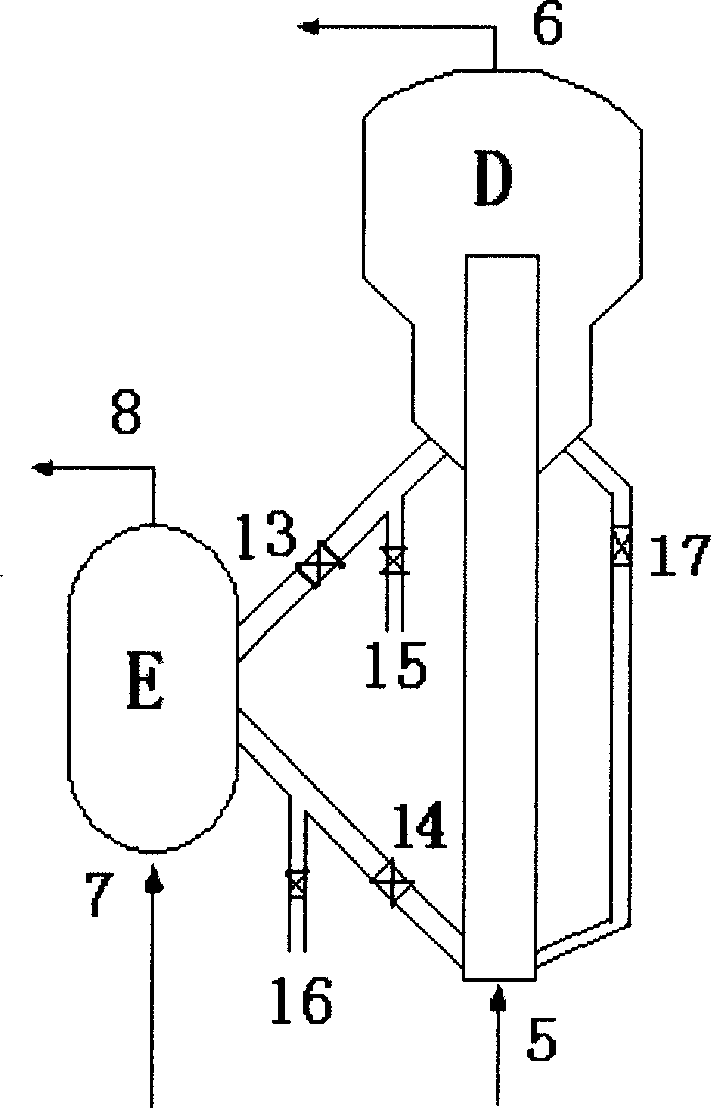

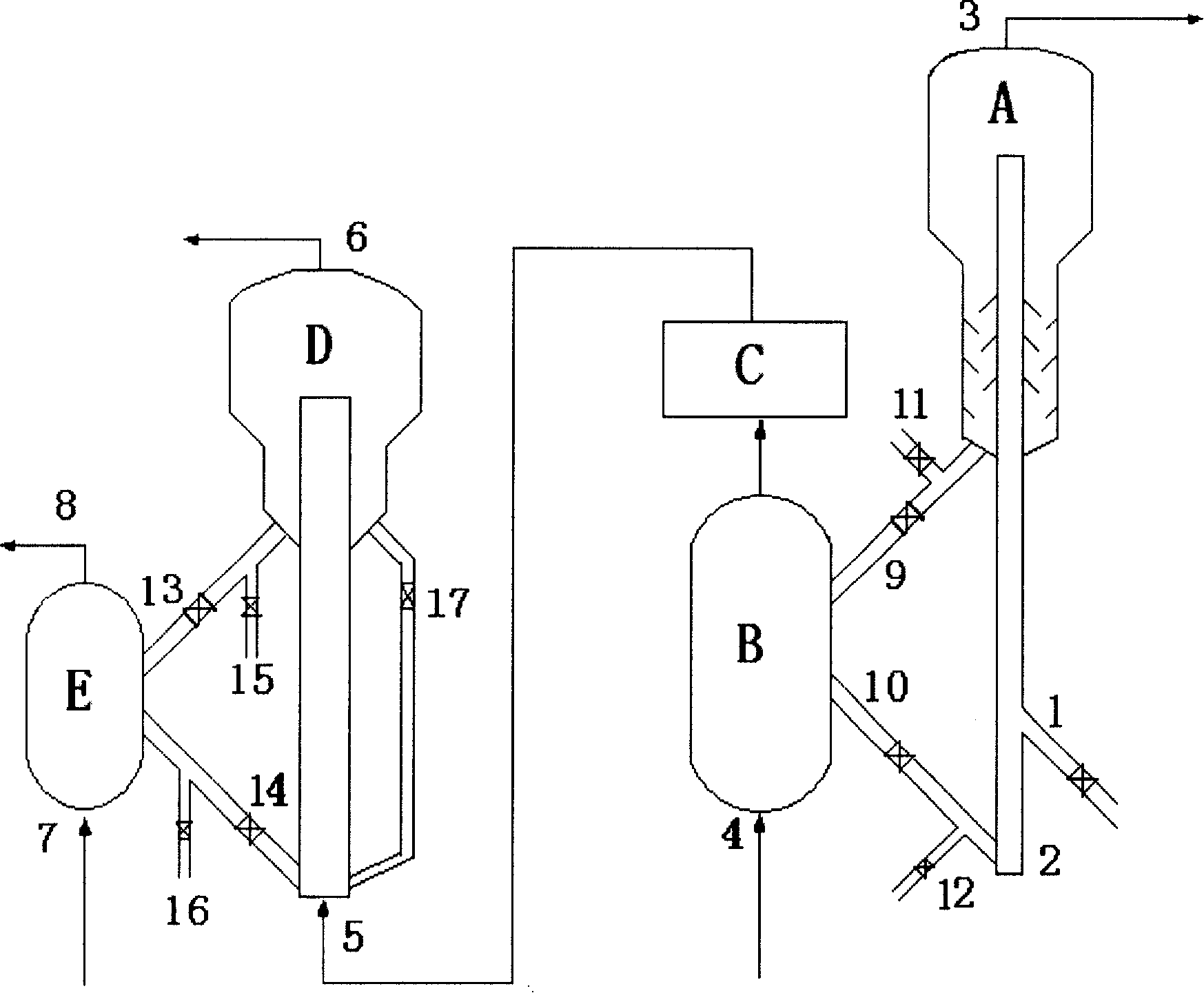

Catalyst for alkane dehydrogenation and device

ActiveCN102451677AHigh catalytic activityHigh selectivityHydrocarbonsChemical recyclingAlkaneAlkali metal oxide

The invention provides a catalyst for alkane dehydrogenation as well as a continuous reaction regeneration device and method using the catalyst for catalytic dehydrogenation. The catalyst comprises four ingredients, the ingredient A is oxides of one kind of element or several kinds of elements from Ti, Nb, Ta, Mo, W, Re, In or Ga, the ingredient B is one kind or several kinds of materials in MgO, P2O5, ZrO2, Al2O3 or SiO2, the ingredient C is oxides of one kind of material or several kinds of materials from Zn, Cd and Sn, and the ingredient D is one kind of material or a mixture of several kinds of materials from alkali oxides or alkaline earth metal oxides. The catalyst does not contain noble metal such as Pt and the like, does not contain toxic ingredients such as Cr and the like and cannot pollute the environment. The activity of the catalyst is high, the selectivity of olefin generated by alkane dehydrogenation is high, the stability of the catalyst is good, the mechanical intensity is high, the continuous reaction regeneration device is used for alkane dehydrogenation, the reaction and the catalyst regeneration are continuously carried out, the efficiency is high, and the safety is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

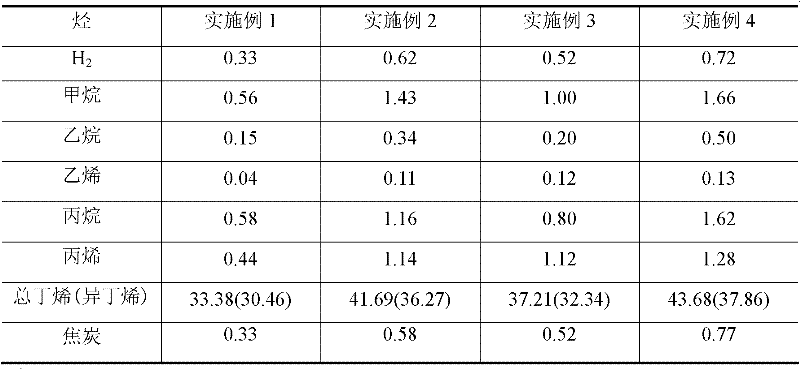

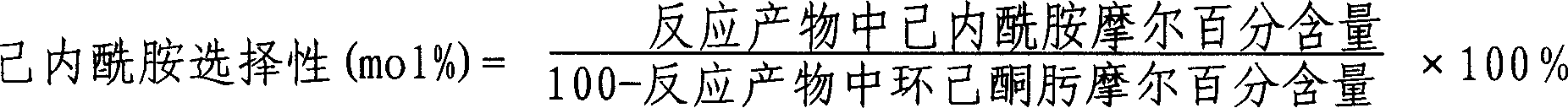

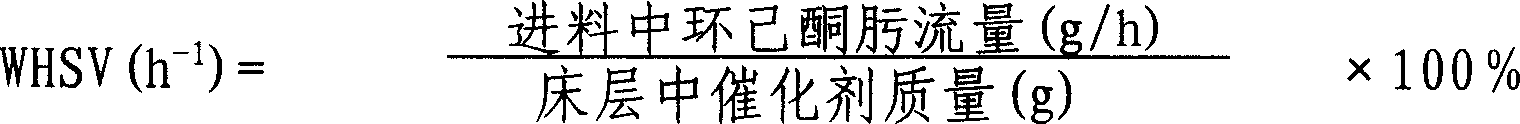

Method for preparing catalyst of containing MFI structured molecular sieve

ActiveCN1600428APromote regenerationImprove conversion rateLactams preparationMolecular sieve catalystsBeckmann rearrangementMolecular sieve

A MFI-molecular sieve catalyst for preparing caprolactam from cyclohexanone oxime by gas-phase Beckmann rearrangement is prepared through proportionally mixing MFI-molecular sieve with alkaline silica gel, shaping, drying and calcining. It has high conversion rate and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

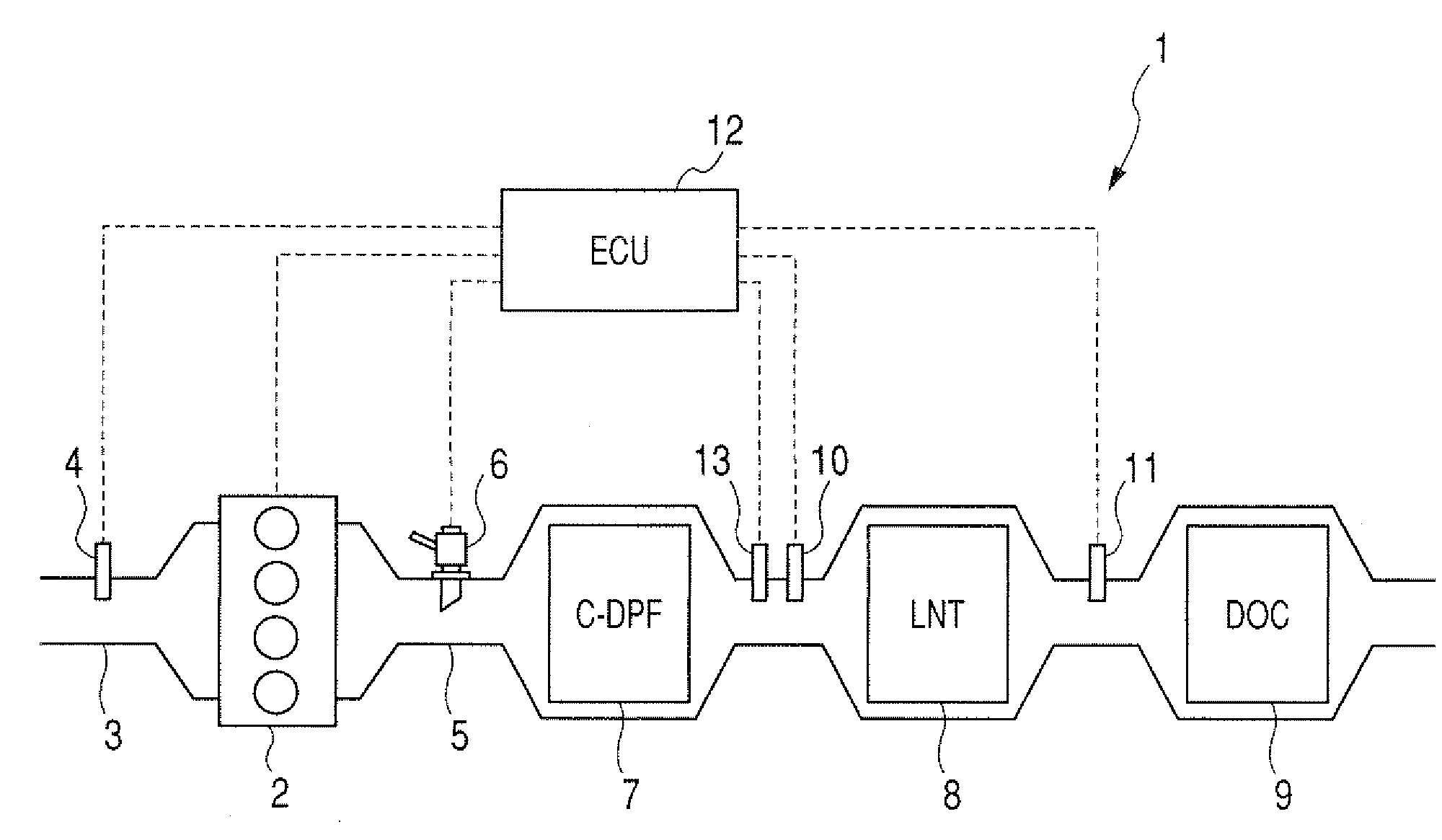

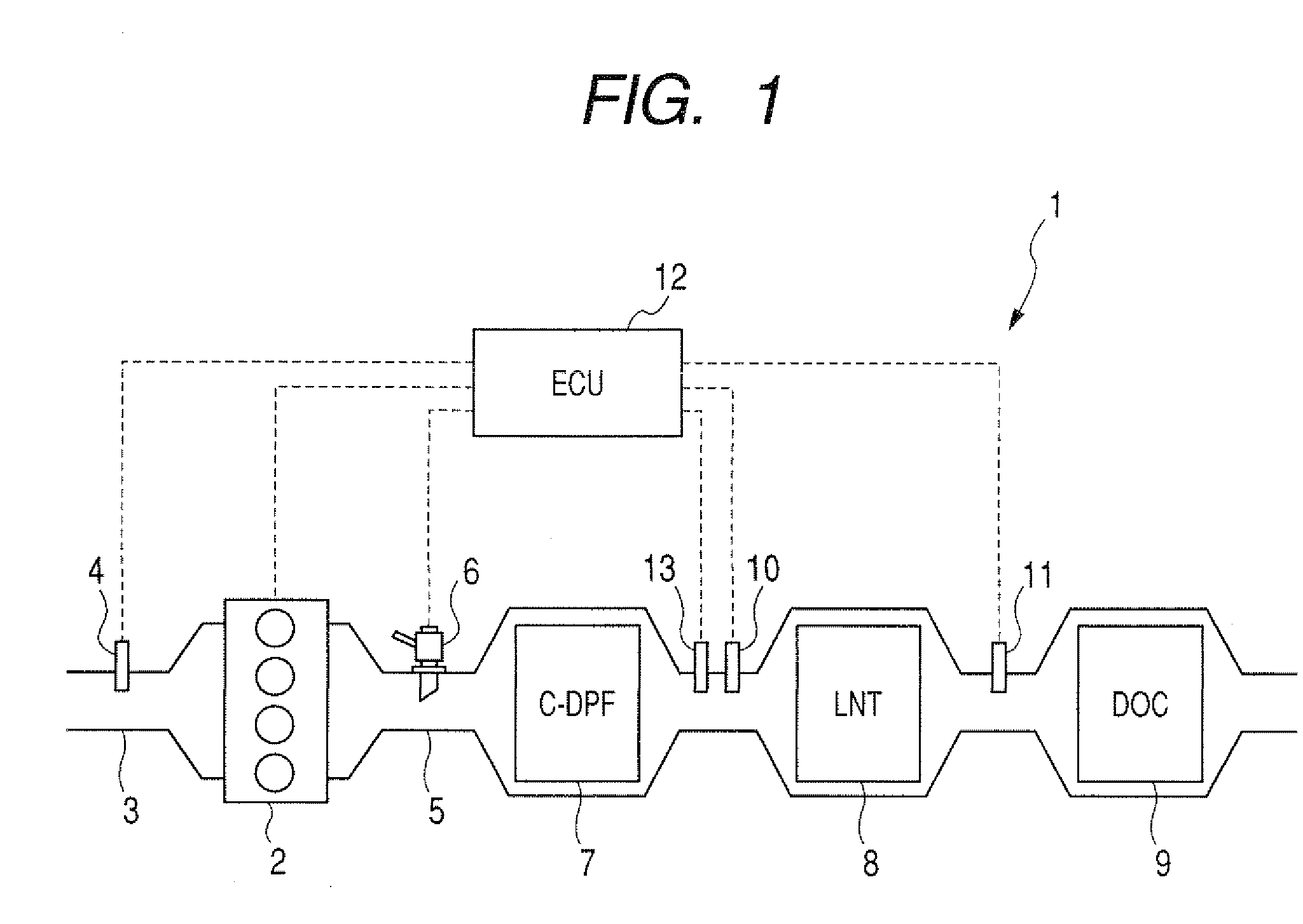

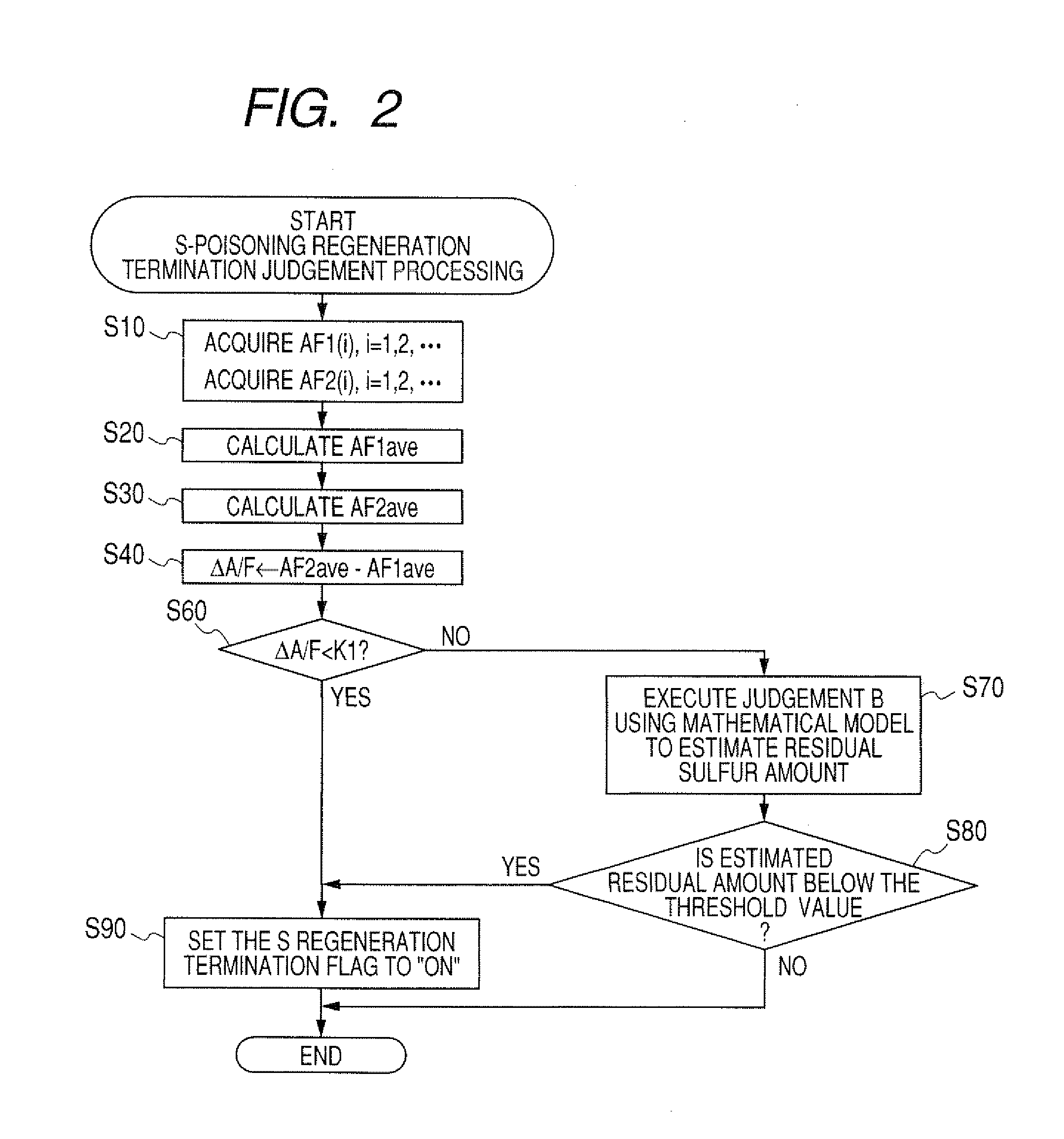

ENGINE EXHAUST GAS PURIFICATION APPARATUS ENABLING ACCURATE JUDGEMENT OF APPROPRIATE TIME FOR TERMINATING NOx CATALYST REGENERATION PROCEDURE

ActiveUS20090049824A1Accurate judgmentIncreased deoxidation of sulfur oxidesInternal combustion piston enginesExhaust apparatusSulfurExhaust fumes

In an engine exhaust gas purification apparatus incorporating a LNT (lean NOx trap), during a NOx catalyst regeneration procedure for deoxidizing and removing accumulated sulfur from the LNT by producing a fuel-rich atmosphere in the exhaust system, the point at which to terminate the regeneration procedure is judged based on a difference between values of A / F ratio measured by sensors located respectively upstream and downstream from the LNT, with the regeneration being terminated when the difference falls below a predetermined threshold value.

Owner:DENSO CORP

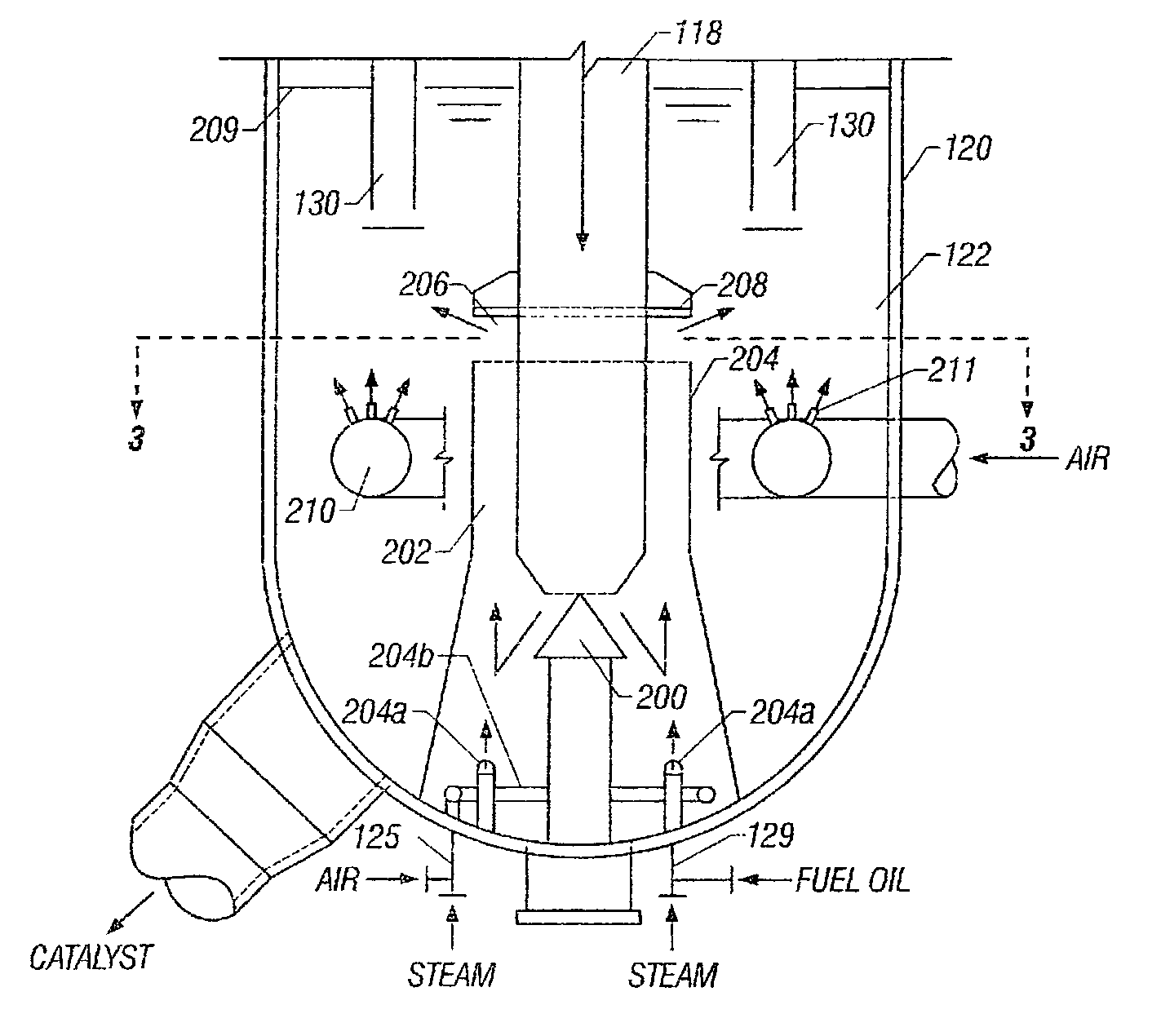

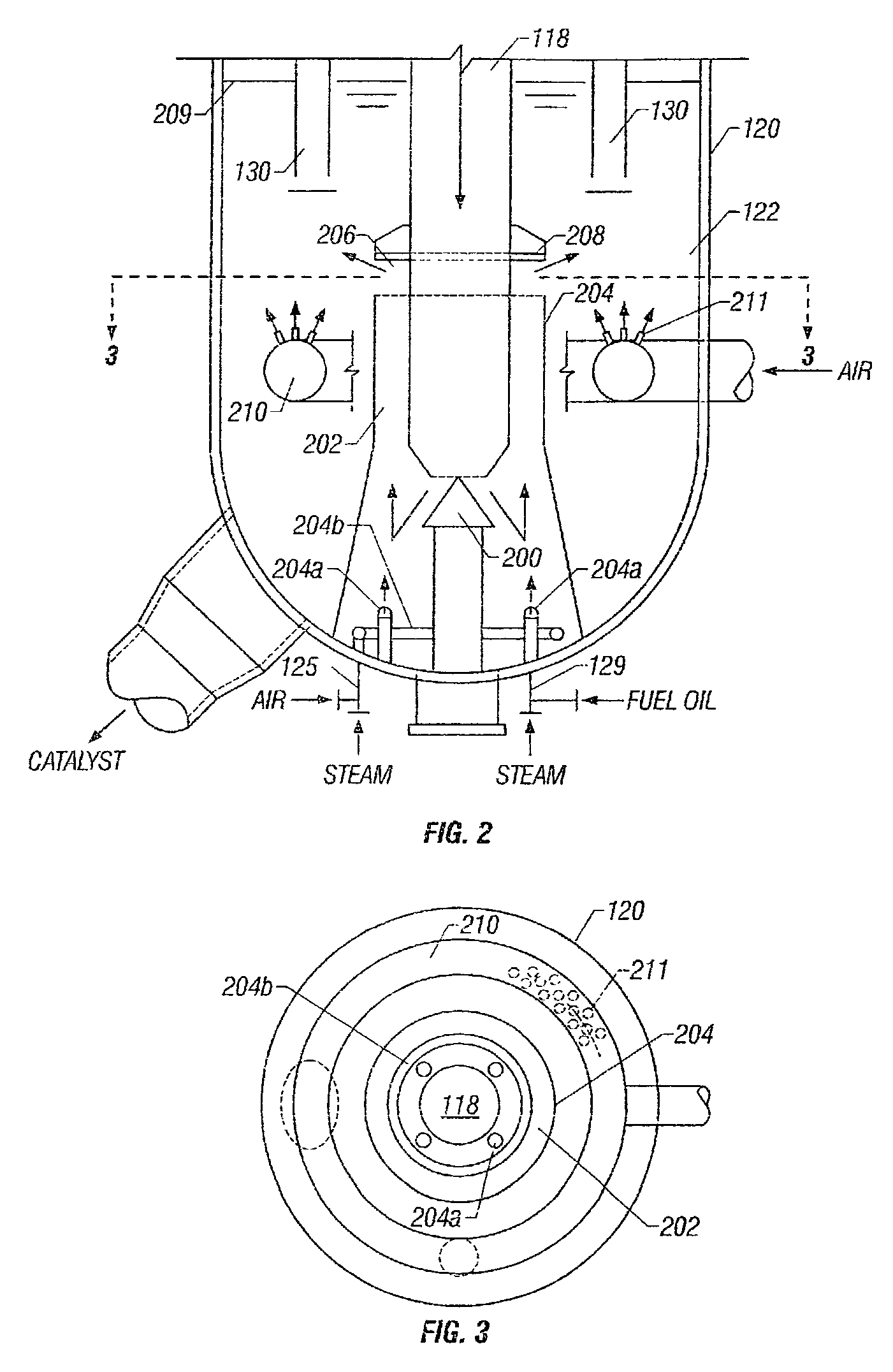

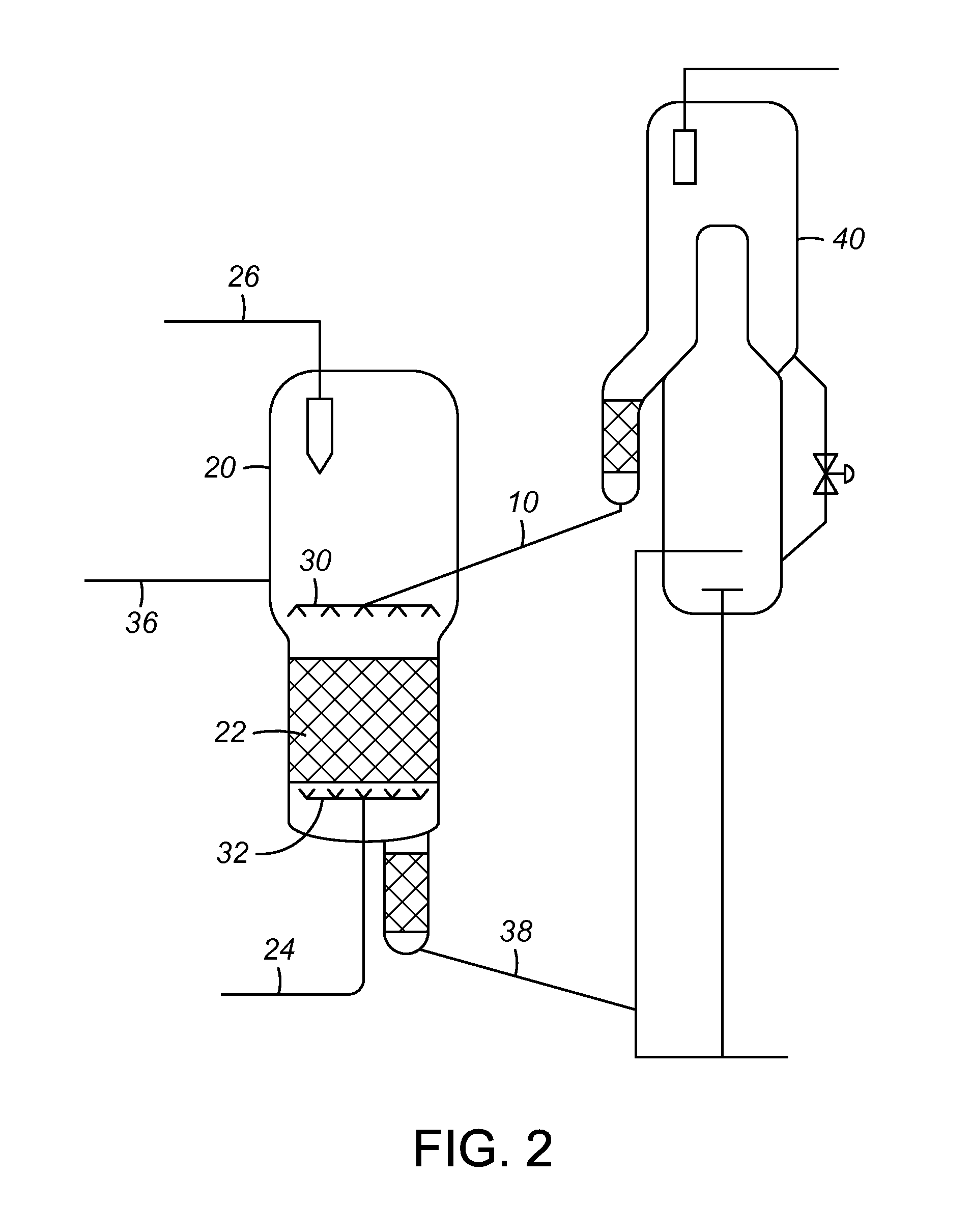

Catalyst regenerator with a centerwell

ActiveUS7153479B2Eliminate catalyst lossThermal non-catalytic crackingCatalytic crackingCombustionProcess engineering

A catalyst regenerator for regenerating spent light FCC catalyst and heating the catalyst to supply heat to an FCC reactor. The regenerator has discharge outlets for catalyst and off gas and a valve for introducing spent catalyst through a central stand pipe portion. The regenerator houses a dense phase catalyst bed. A centerwell receives a lower end of the standpipe portion and defines an annulus therebetween. The spent catalyst is introduced through the standpipe portion into the annulus. A fuel distributor introduces fuel into the centerwell for mixing with the catalyst in the annulus. A fluidization distributor introduces fluidization gas into the centerwell for fluidizing the catalyst in the annulus. A radial slot in the centerwell introduces the catalyst and fuel mixture from the annulus below the upper surface of the dense phase bed. An air distributor located below the radial slot introduces combustion air into the dense phase bed.

Owner:KELLOGG BROWN & ROOT LLC

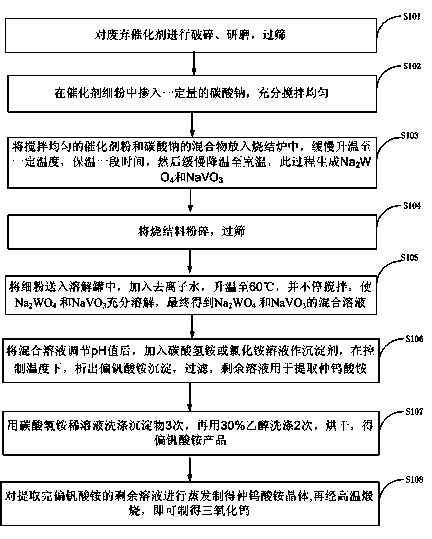

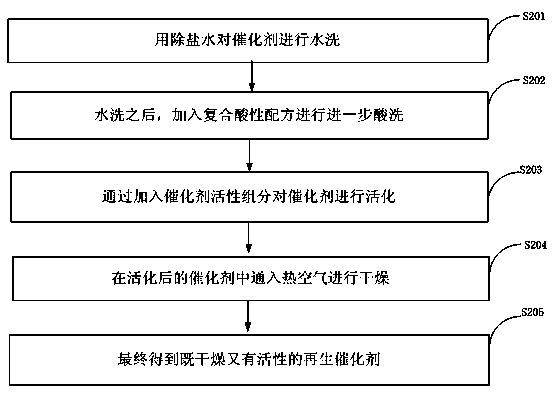

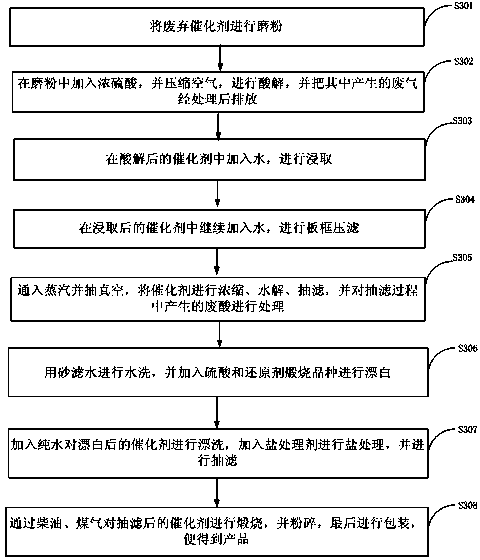

Method for regeneration and resource utilization of waste honeycombed denitrification catalyst

InactiveCN103508491ALow costRestore activityTungsten oxides/hydroxidesDispersed particle separationResource utilizationAmmonium paratungstate

The invention discloses a method for regeneration and resource utilization of a waste honeycombed denitrification catalyst. The method comprises the following steps of: crushing, grinding and sieving the waste catalyst; loading a mixture of the powdered catalyst and sodium carbonate into a sintering furnace to produce Na2WO4 and NaVO3, dissolving completely, adjusting the pH value to separate ammonium metavanadate precipitates, filtering, applying the remaining liquid to ammonium paratungstate extraction, washing the precipitates and oven-drying to obtain ammonium metavanadate, and making ammonium paratungstate crystals and tungsten trioxide. The regeneration method of the SCR catalyst comprises the following steps of: performing water-washing, pickling, activation and drying on the catalyst. The method for producing titanium pigment from the waste catalyst as raw material comprises the following steps of: performing pulverization, acidolysis and extraction on the waste catalyst, performing plate-frame pressure filtration; performing concentration, hydrolysis and suction-filtration on the catalyst, washing and blanching with sand leaching water, calcining, grinding and packaging. The method disclosed by the invention can effectively restore the activity of a deactivated catalyst and prolong the service life of the deactivated catalyst, which not only reduce the operating cost of a thermal power plant but also save the valuable rare earth resources.

Owner:YIXING YIGANG ENVIRONMENTAL PROTECTION ENG & MATERIALS

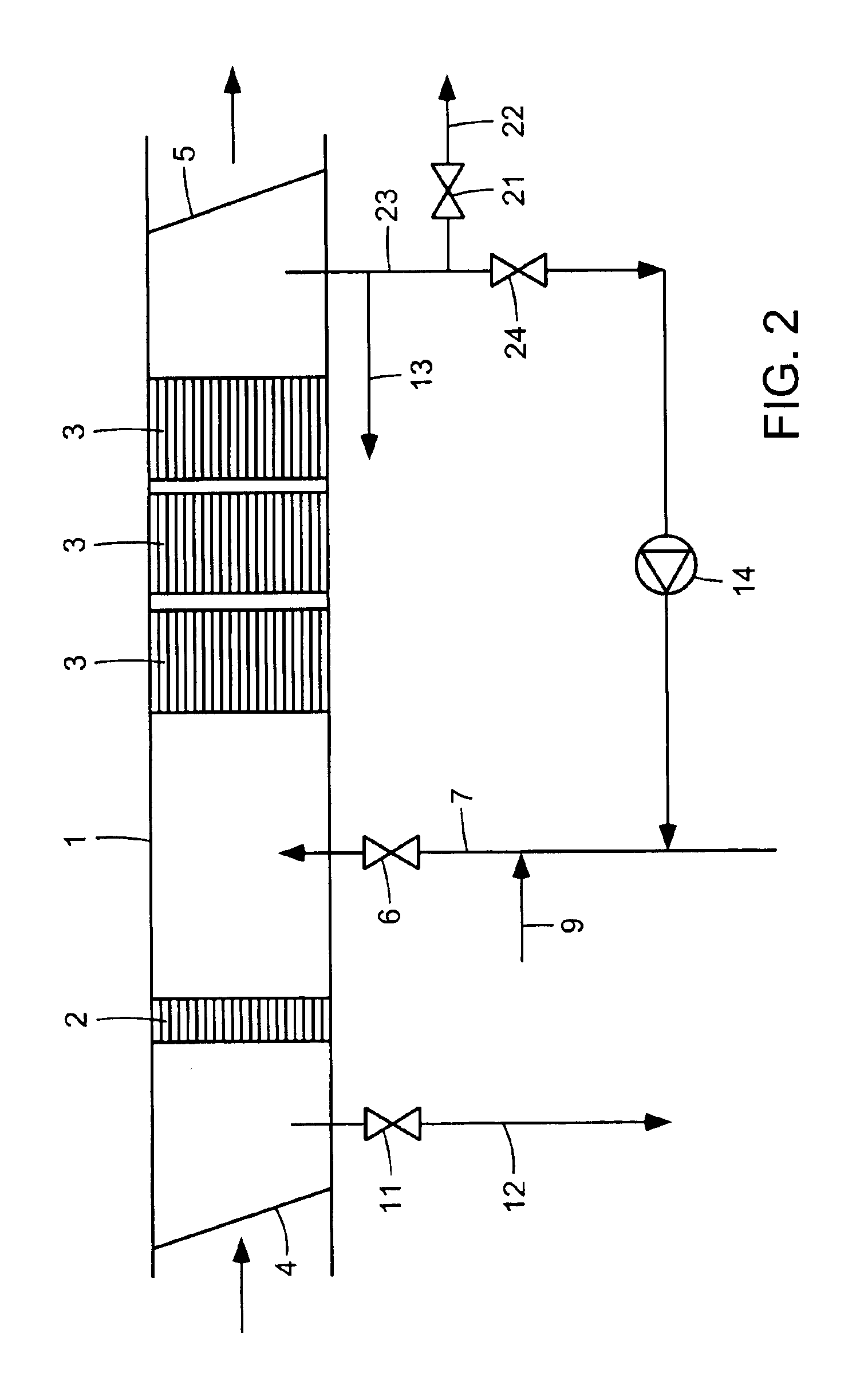

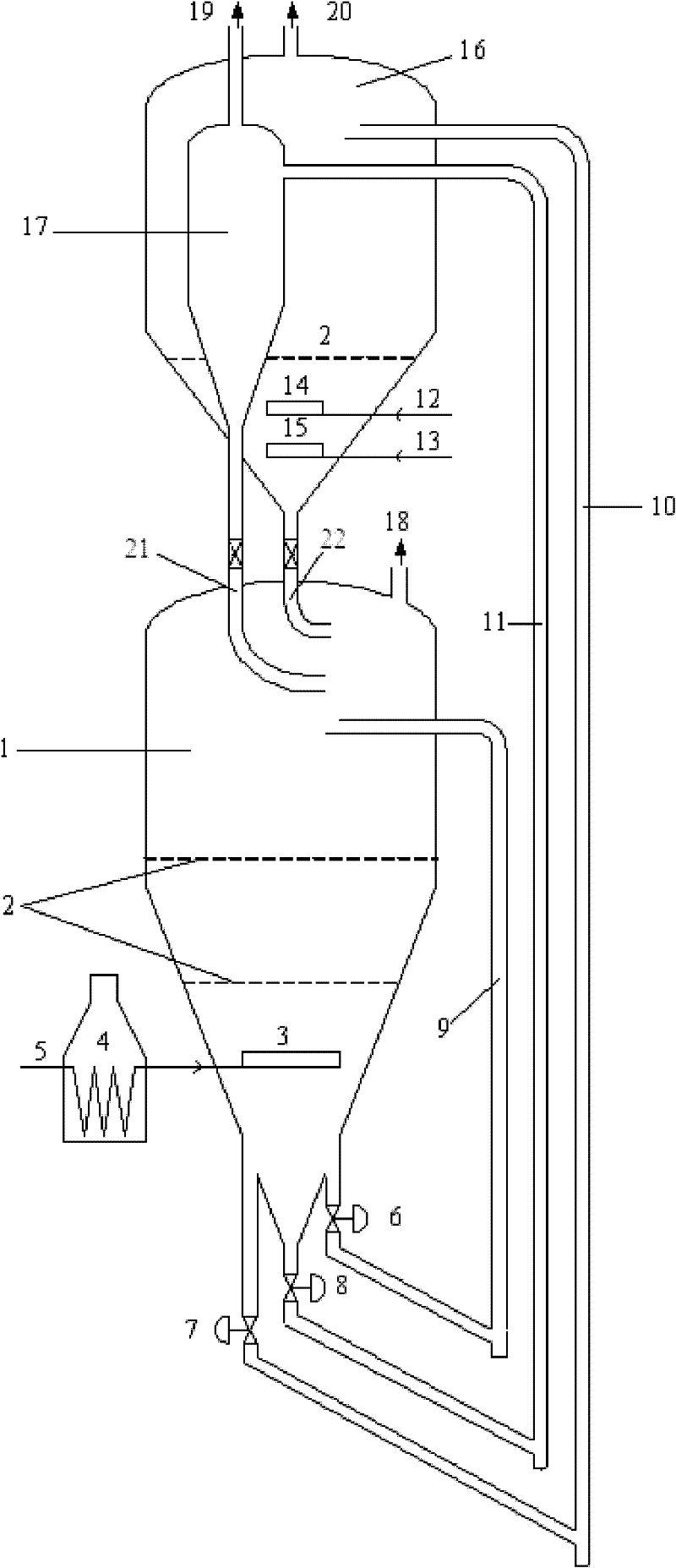

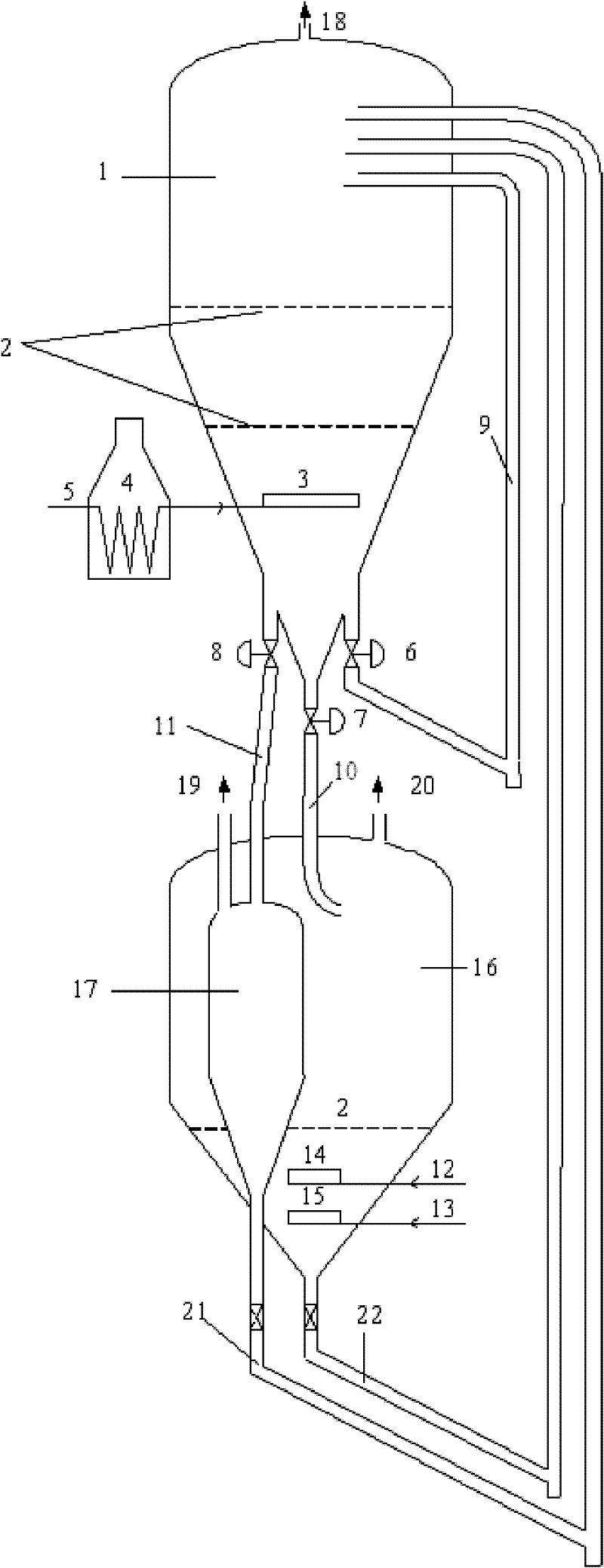

Counter-Current Fluidized Bed Reactor for the Dehydrogenation of Olefins

ActiveUS20140142362A1Large caliberHydrocarbonsBed hydrotreatment processes apparatusFluidized bedDehydrogenation

A process and apparatus for the dehydrogenation of paraffins is presented. The process utilizes a reactor that includes a slower flow of catalyst through the reactor, with a counter current flow of gas through the catalyst bed. The catalyst is regenerated and distributed over the top of the catalyst bed, and travels through the bed with the aid of reactor internals to limit backmixing of the catalyst.

Owner:UOP LLC

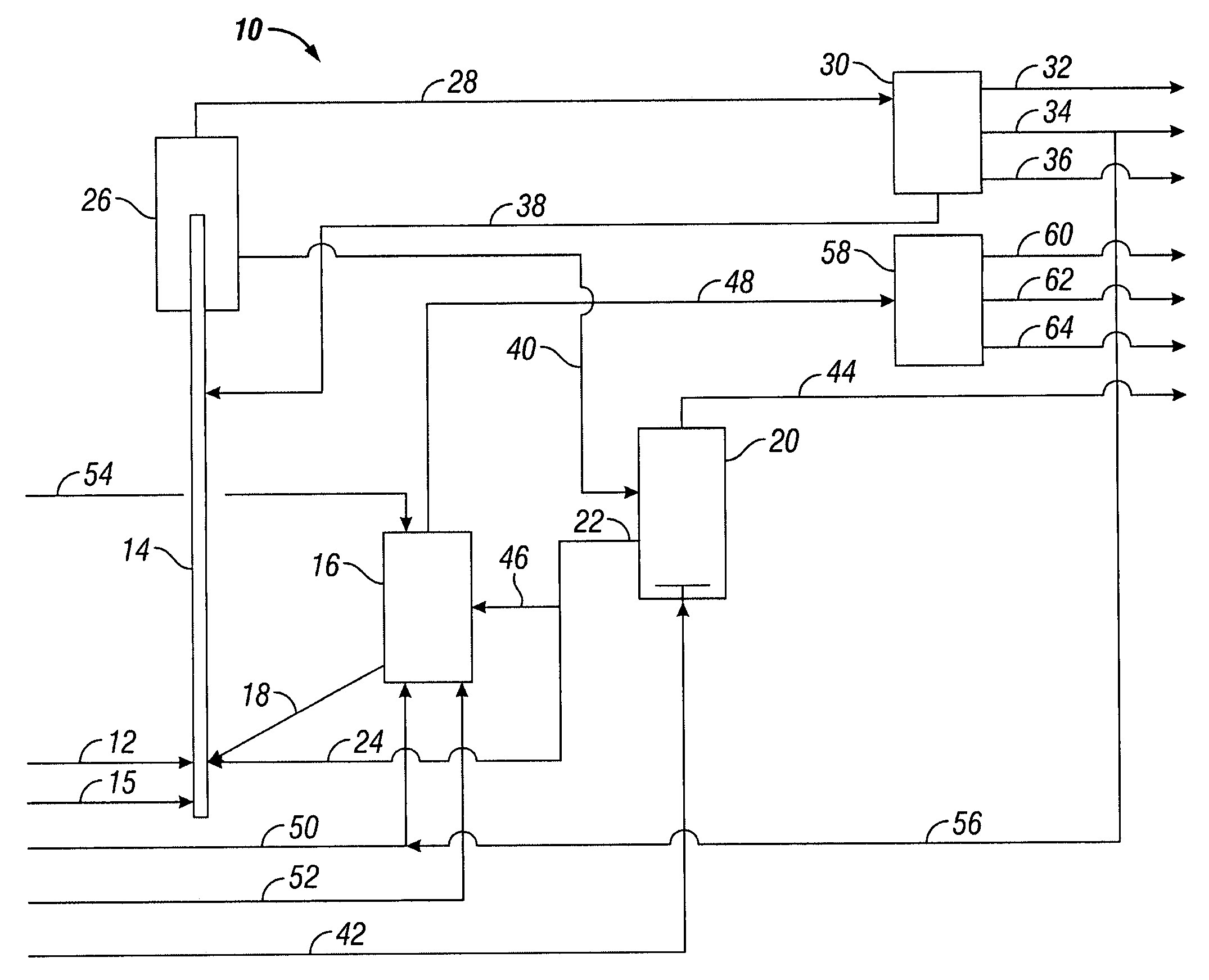

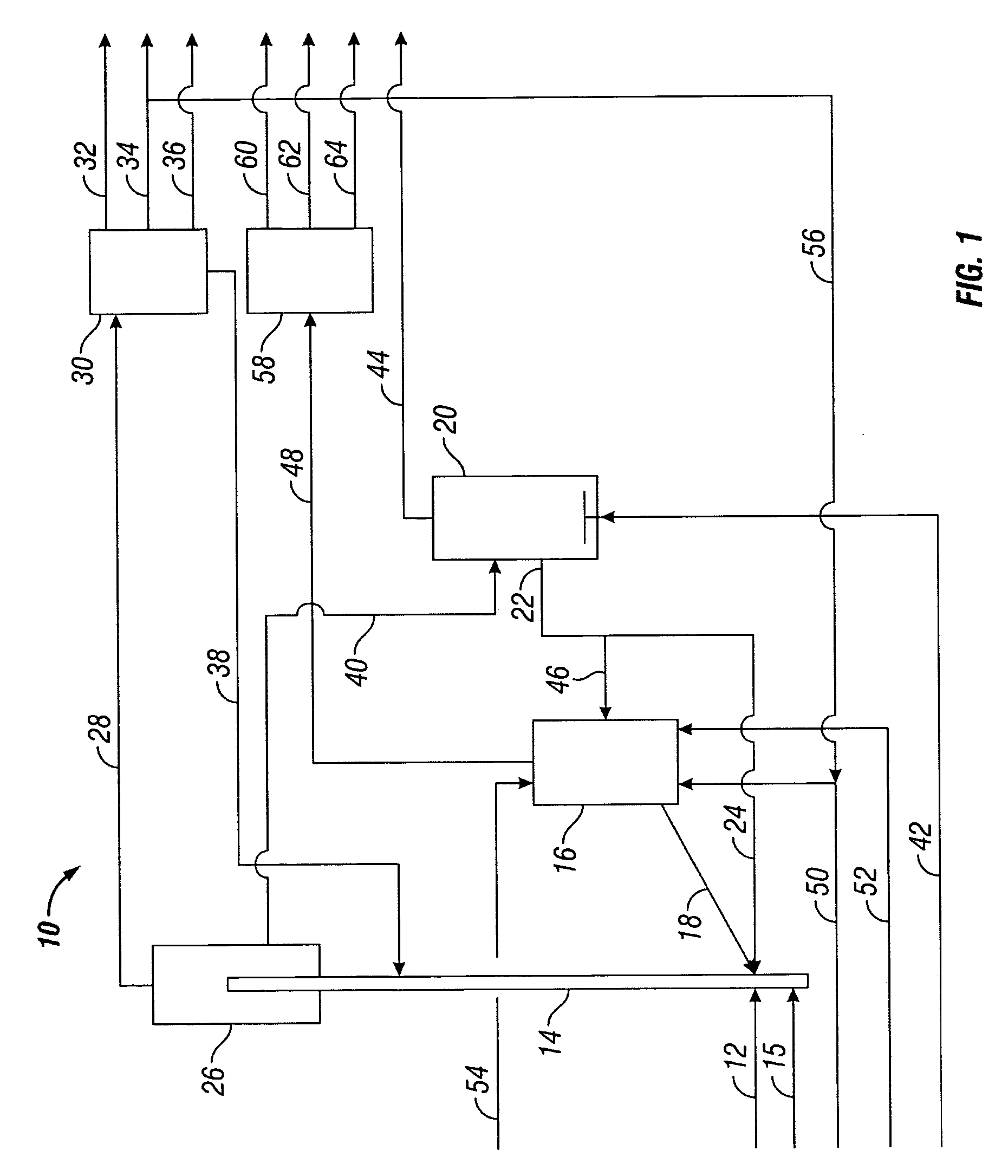

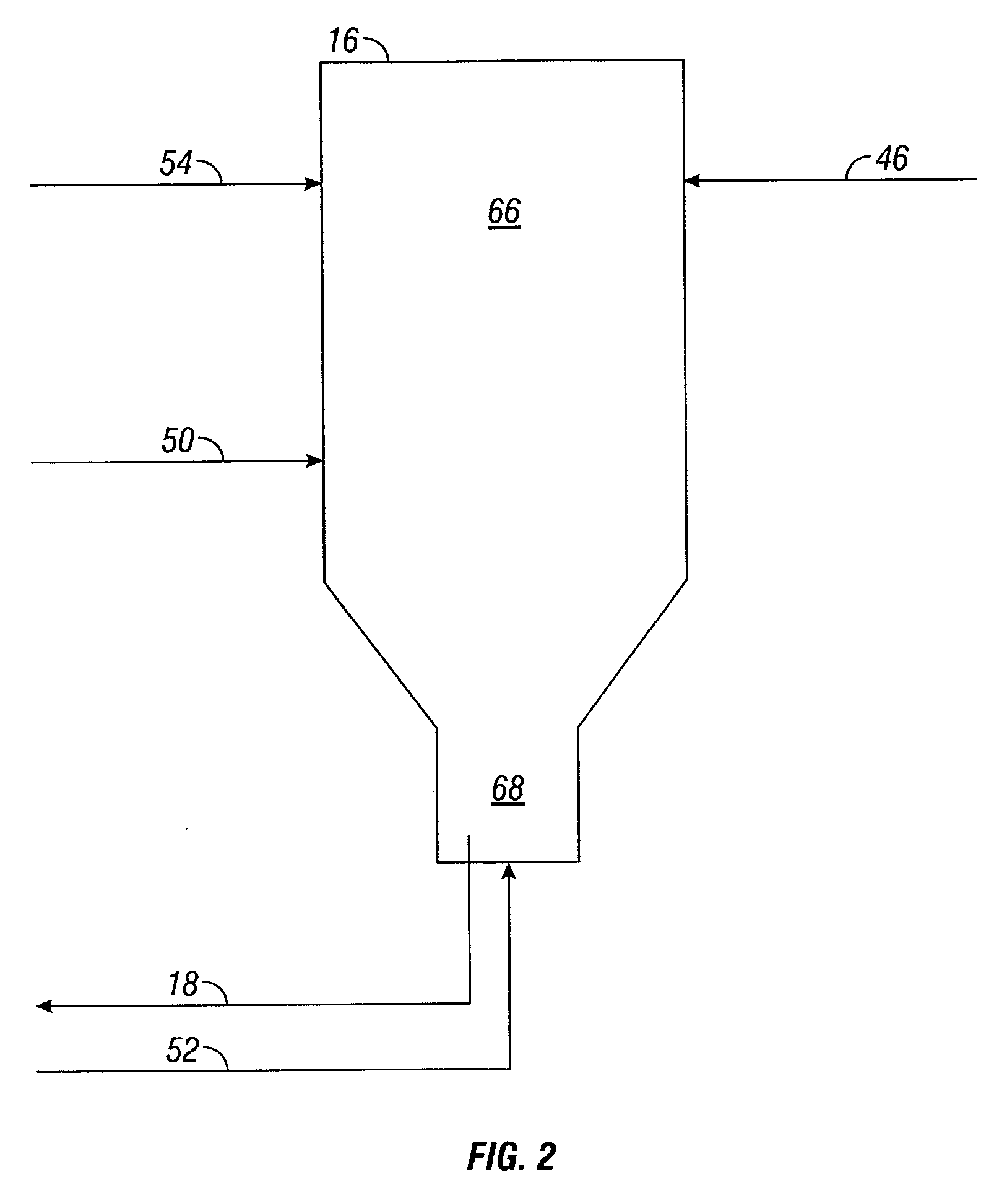

Catalytic hydrocarbon dehydrogenation system with prereaction

InactiveUS6392113B1Improve performanceHydrocarbon by dehydrogenationHydrocarbon by hydrogenationDehydrogenationHydrocarbon

The performance of an endothermic catalytic dehydrogenation process is increased without requiring additional catalyst regeneration and reheat air flow and compression by partially prereacting the preheated hydrocarbon feed and then reheating the partially dehydrogenated effluent from the prereactor to the same hydrocarbon preheat temperature prior to the main catalytic reactor. The preferable source of the heat for reheating is the effluent air from the reheat and regeneration of the catalyst in the main reactor. This same effluent air is used to regenerate the catalyst in the prereactor as needed.

Owner:ABB LUMMUS GLOBAL INC

Catalyst regeneration

A method is disclosed for regenerating regenerating a used catalyst mixture comprising (i) an isomerization catalyst comprising magnesium oxide and (ii) a metathesis catalyst comprising an inorganic carrier and at least one of molybdenum oxide and tungsten oxide. The method comprises (a) decoking the used catalyst mixture in the presence of an oxygen-containing gas to produce a decoked catalyst mixture; and (b) contacting the decoked catalyst mixture with steam at a temperature in the range of 100 to 300° C. to produce a regenerated catalyst mixture.

Owner:LYONDELL CHEM TECH LP

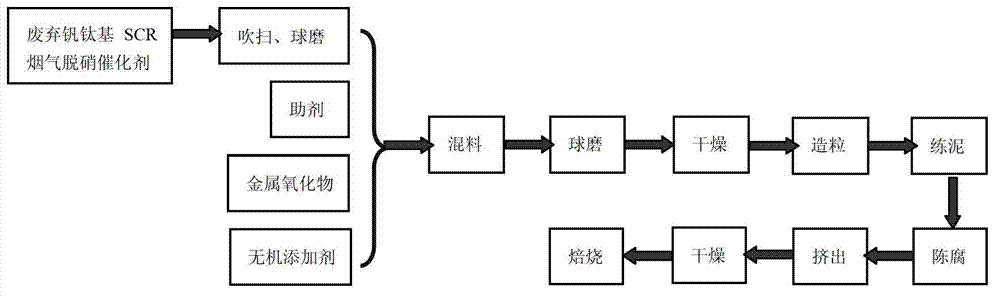

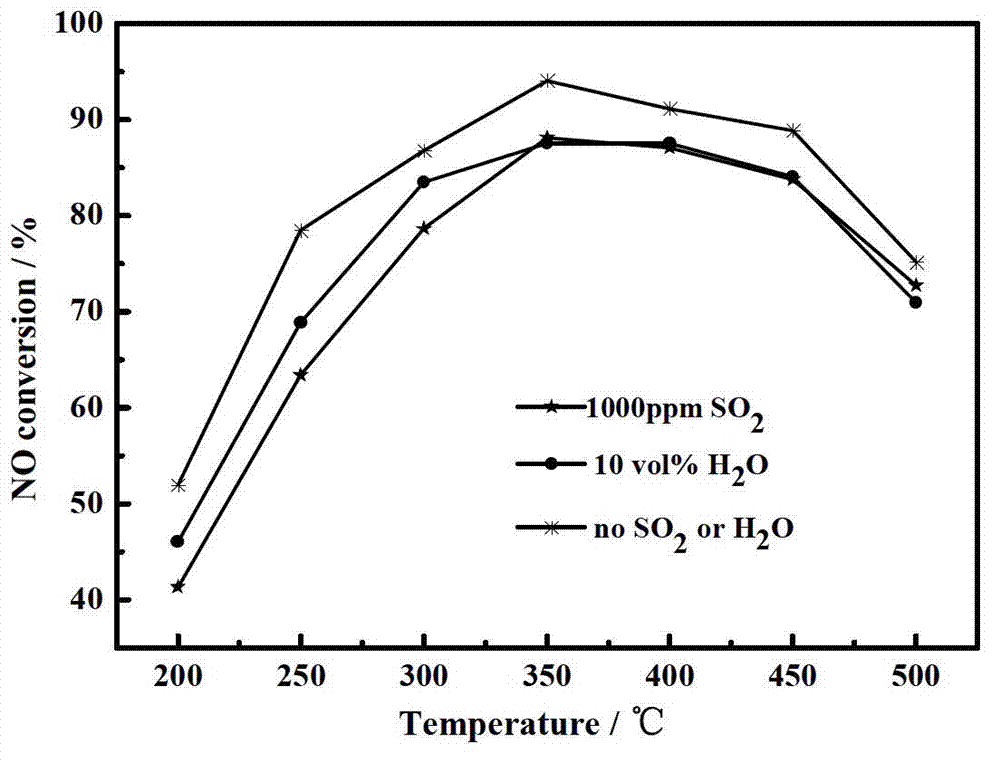

Regeneration method for waste vanadium-titanium-based SCR (Selective Catalytic Reduction) flue gas denitrification catalyst

ActiveCN102962079AIncrease profitReduce governance costsMetal/metal-oxides/metal-hydroxide catalystsBall millWater intoxication

The invention relates to a regeneration method for a waste vanadium-titanium-based SCR (Selective Catalytic Reduction) flue gas denitrification catalyst, comprising the following concrete steps of: (1) purging the waste vanadium-titanium-based SCR flue gas denitrification catalyst and ball-milling the purged waste vanadium-titanium-based SCR flue gas denitrification catalyst to obtain a reclaimed material of the waste vanadium-titanium-based SCR flue gas denitrification catalyst; (2) mixing a metal oxide, an assistant, an inorganic additive and the reclaimed material of the waste vanadium-titanium-based SCR flue gas denitrification catalyst, ball-milling and drying to obtain regenerated SCR flue gas denitrification catalyst powder; (3) adding a proper amount of binder, lubricating agent and water into the regenerated SCR flue gas denitrification catalyst powder to be uniform, then, pelleting, pugging, ageing and carrying out extrusion molding to obtain a regenerated SCR flue gas denitrification catalyst green body; and (4) drying and calcining the green body to obtain a regenerated SCR flue gas denitrification catalyst. The regeneration method provided by the invention is simple in process, low in cost and low in environment pressure. The regenerated SCR flue gas denitrification catalyst is higher in denitrification activity, wider in activity temperature window, better in sulfur and water intoxication resistance and higher in mechanical strength.

Owner:NANJING UNIV OF TECH

Wet scrubbing and recycle of effluent-contaminating catalyst particles in an oxygenate-to-olefin process

ActiveUS20050234281A1Improve economyLower requirementMolecular sieve catalystHydrocarbon purification/separationCycloneCyclonic separation

The economics of a catalytic process using a fluidized conversion zone and a relatively expensive catalyst for converting an oxygenate to light olefins are substantially improved by recovering and recycling effluent contaminating catalyst particles from the product effluent stream withdrawn from the conversion zone which are present despite the use of one or more vapor-solid cyclone separating means to clean up this effluent stream. The contaminating catalyst particles are separated from this product effluent stream using a wet scrubbing zone and an optional dewatering zone to recover a slurry containing the contaminated particles which, quite surprisingly, can be successfully directly recycled to the oxygenate conversion zone or to the associated catalyst regeneration zone without loss of any substantial amount of catalytic activity thereby decreasing the amount of fresh catalyst addition required to make up for this source of catalyst loss.

Owner:UOP LLC

Method and system for regeneration of a catalyst

InactiveUS20070000239A1Gas treatmentInternal combustion piston enginesProcess engineeringSystem parameters

The disclosed embodiments relate to a method and system for regeneration of a catalyst. The system includes an engine that creates an exhaust stream and a fuel supply adapted to supply a fuel stream to the engine. A reactor includes a catalyst and is in fluid communication with the engine to receive the exhaust stream. A sensor senses a system parameter and produces a signal corresponding to the system parameter. A controller receives the signal and directs at least a portion of the exhaust stream or at least a portion of the fuel stream to the catalyst to control a regeneration operation based on a value of the system parameter sensed by the sensor.

Owner:GENERAL ELECTRIC CO

Method for preparing methyl methacrylate from methyl propionate and formaldehyde

ActiveCN102775302AImprove utilization efficiencyImprove efficiencyOrganic compound preparationCarboxylic acid esters preparationFluidized bedEconomic benefits

The invention provides a method for preparing methyl methacrylate from methyl propionate and formaldehyde. According to the method for preparing the methyl methacrylate from the methyl propionate and the formaldehyde, the fluidized bed reactor and the catalyst regenerator are coupled, so that the problem on the rapid deactivation of the catalyst is solved effectively, and the continuous production is realized. The method achieves important economic benefits.

Owner:BEIJING RISUN TECH CO LTD

Method for revamping fixed-bed catalytic reformers

InactiveUS20050274648A1Avoids major expenseQuality improvementCatalytic naphtha reformingBed hydrotreatment processes apparatusCatalytic reformingThermodynamics

A fixed-bed catalytic reformer unit is converted to moving bed reactor / cyclic regenerator operation by re-using the fixed bed reactors of the original unit as regenerator vessels operated in cyclic regeneration mode in a new catalyst regeneration section. A flow connection, suitably a liftpipe, is provided to convey spent catalyst from the spent catalyst outlet of a new moving bed reactor section to the converted regenerator section, together with a flow connection for regenerated catalyst from the regenerator section to the regenerated catalyst inlet of the new moving bed reactor section. A flow control distributor directs spent catalyst sequentially to each of the regenerator vessels to carry out the regeneration with regeneration gas. Each regenerator vessel is cycled through a fill, regeneration, discharge sequence to maintain a continuous flow of catalyst to and from the reactor section.

Owner:EXXON RES & ENG CO

Counter-Current Fluidized Bed Reactor for the Dehydrogenation of Olefins

ActiveUS20140140895A1Limit and even preventCatalystsHydrocarbon preparation catalystsFluidized bedDehydrogenation

A process and apparatus for the dehydrogenation of paraffins is presented. The process utilizes a reactor that includes a slower flow of catalyst through the reactor, with a counter current flow of gas through the catalyst bed. The catalyst is regenerated and distributed over the top of the catalyst bed, and travels through the bed with the aid of reactor internals to limit backmixing of the catalyst.

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com