Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1477 results about "Catalytic transformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

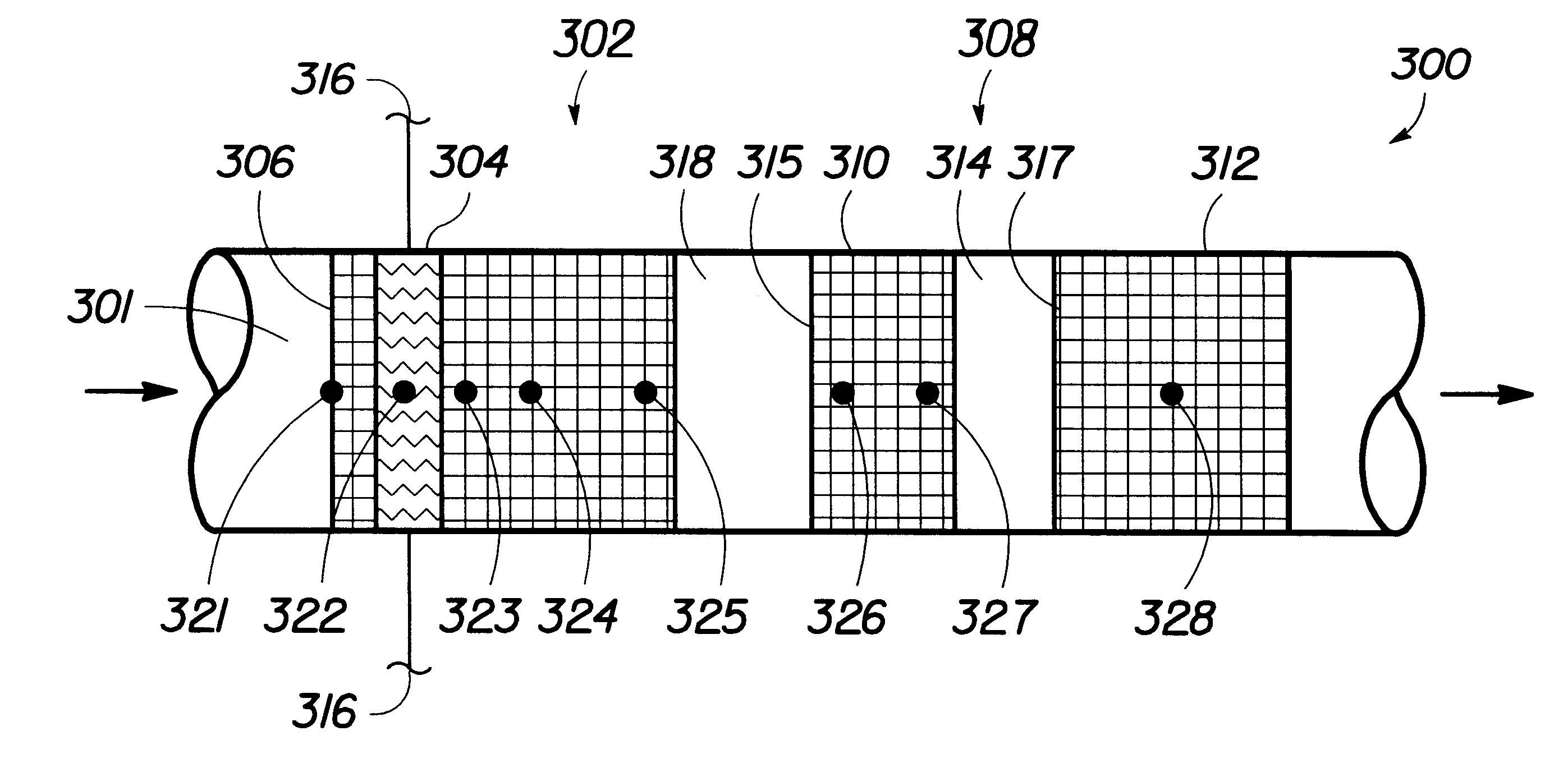

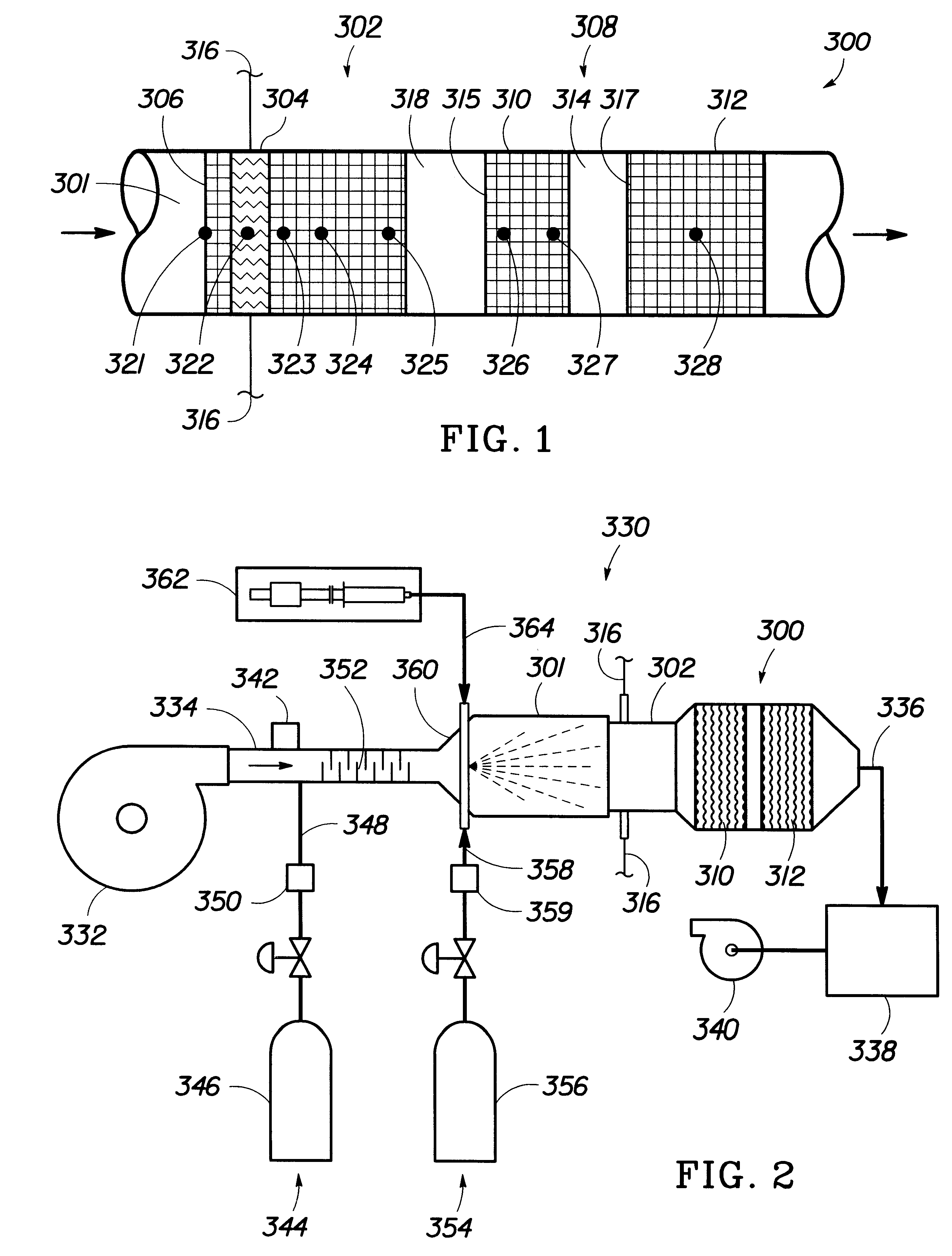

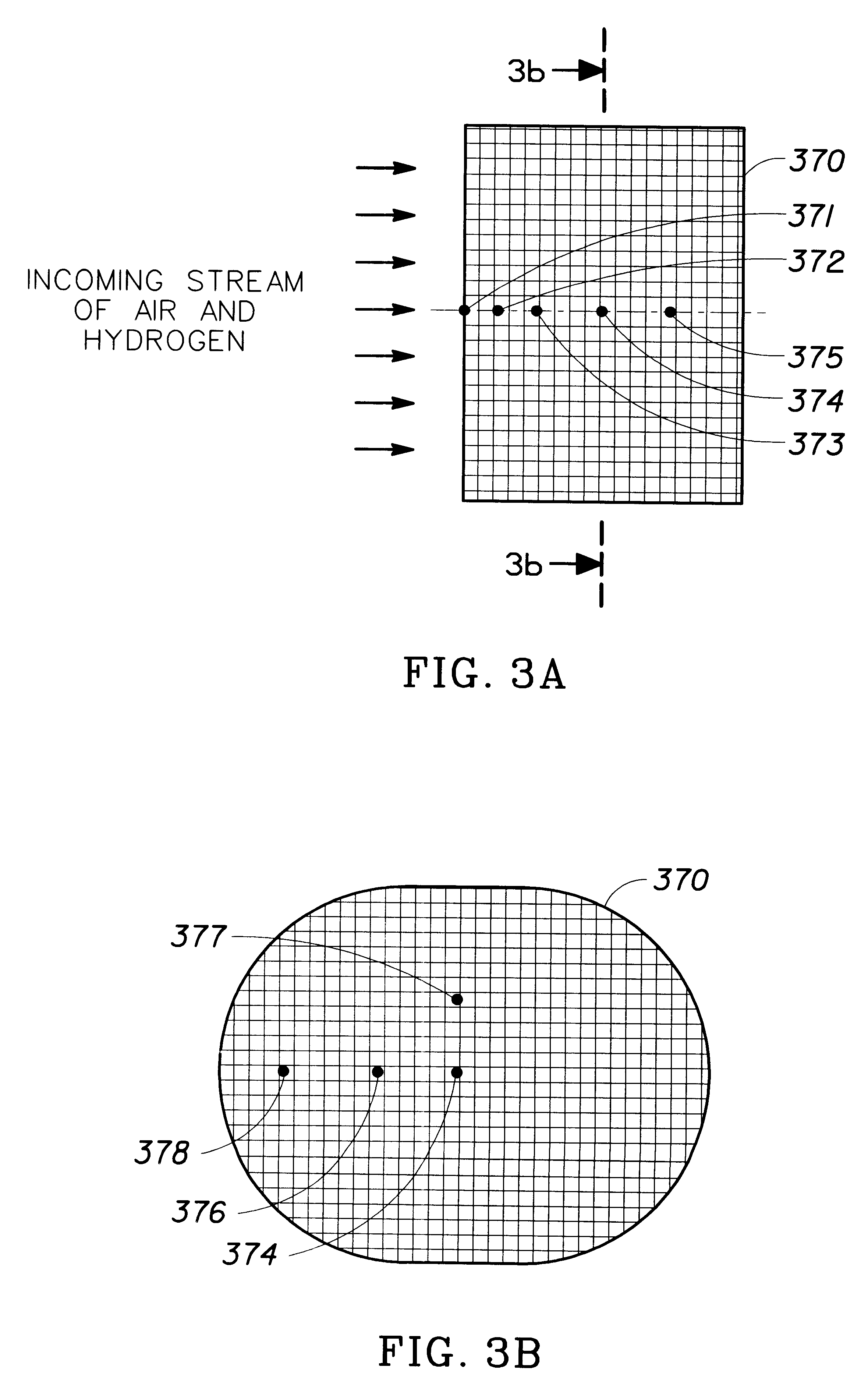

Hybrid catalyst heating system with water removal for enhanced emissions control

The present invention provides a method and apparatus for heating a catalytic converter at least to a light off temperature. In accordance with the invention, the catalytic converter may be heated using a novel monolith construction, electrical heating, catalytic combination of a fuel and oxygen or combinations of these methods. Heating or thermally conditioning a catalyst in accordance with the invention rapidly brings the catalyst up to the light off temperature for the efficient conversion of pollutant gases, such as unacceptable emissions emanating from an internal combustion engine, into water, carbon dioxide and other acceptable emissions. In particular, the invention provides efficient heating of the catalytic converter despite the potential presence of water on the catalyst during startup.

Owner:LYNNTECH POWER SYST

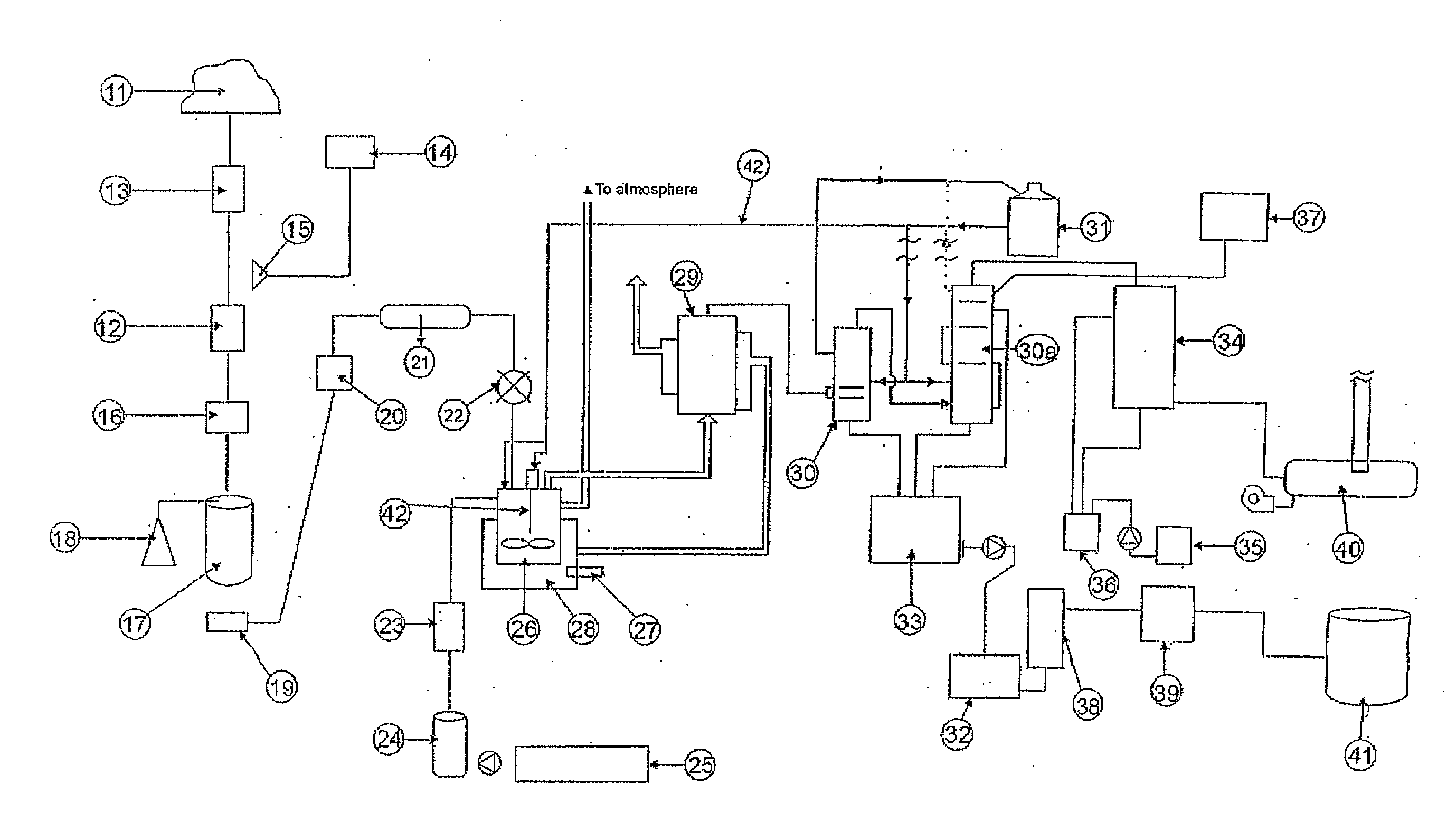

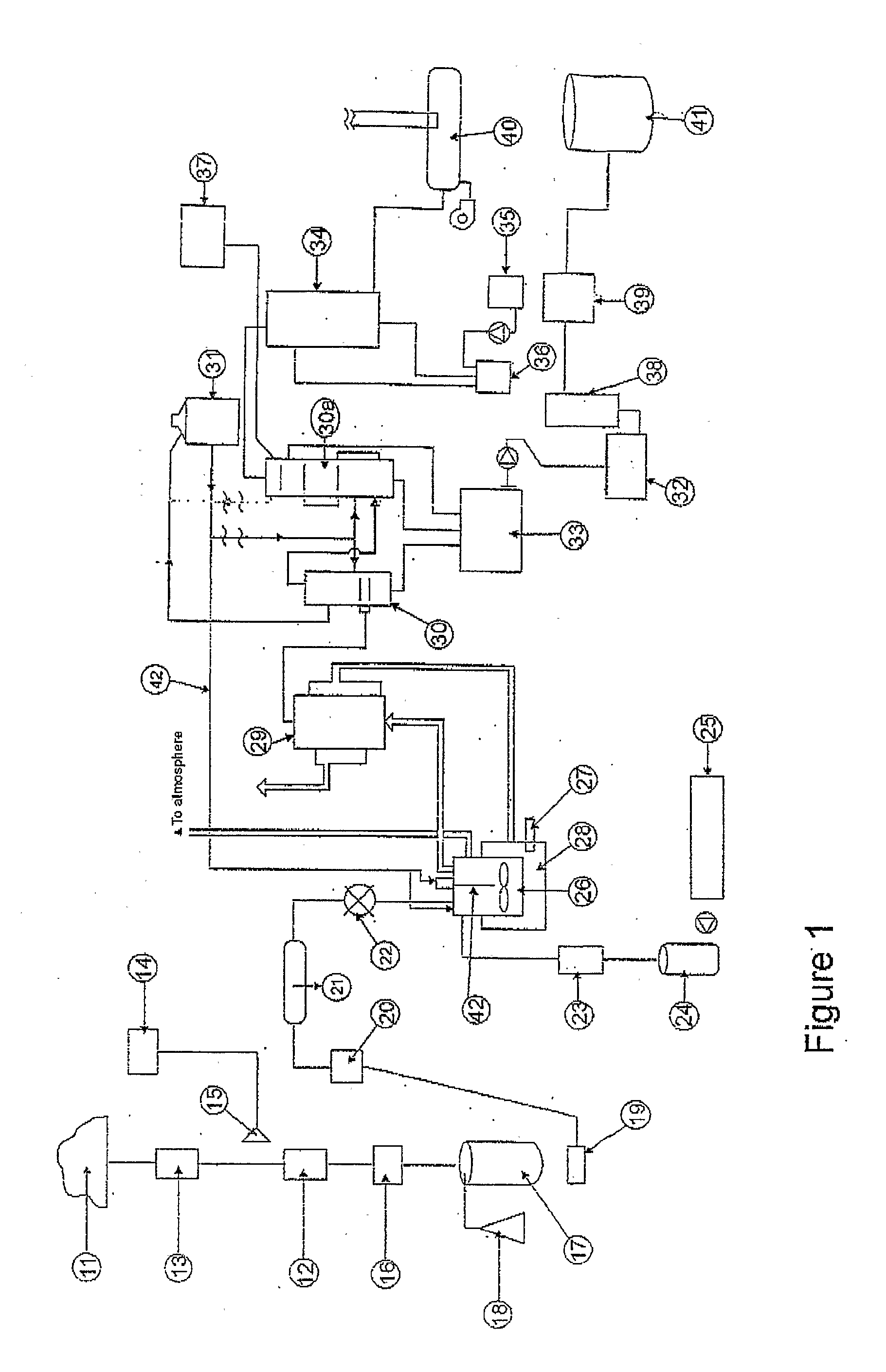

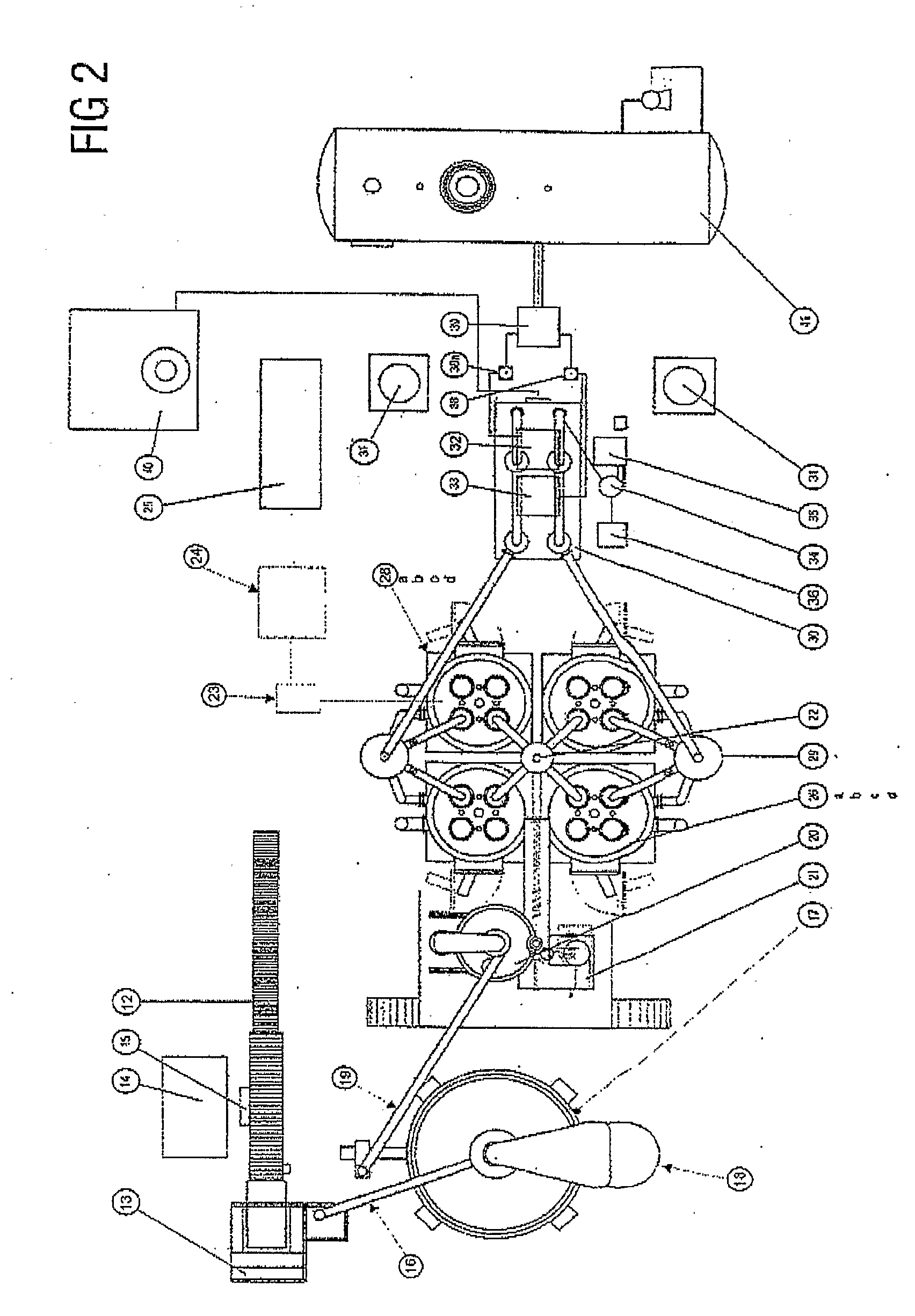

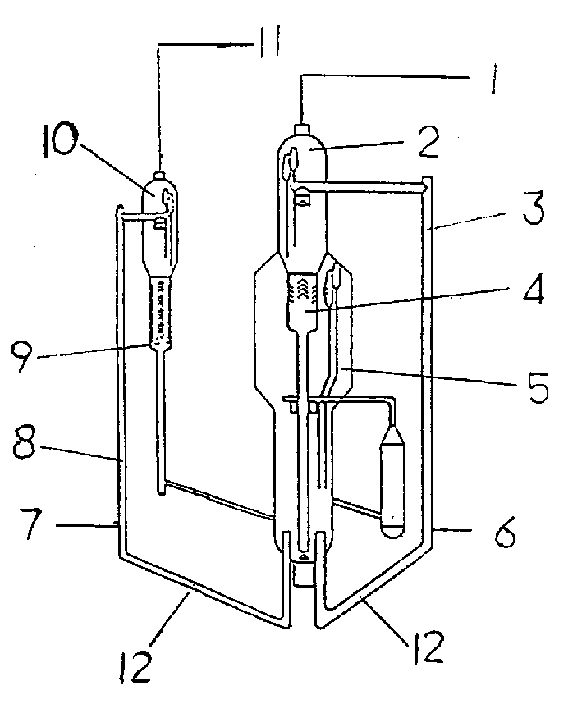

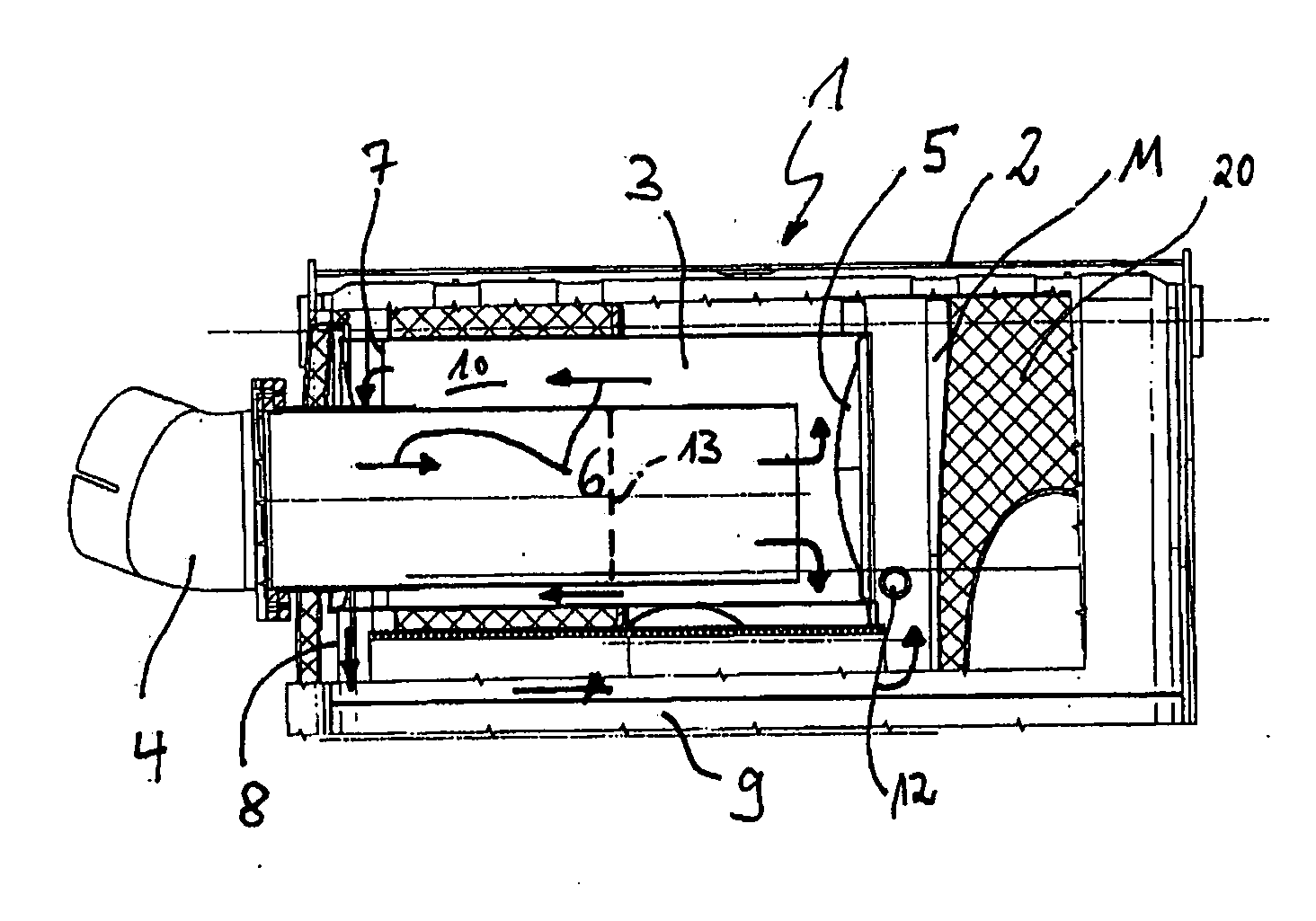

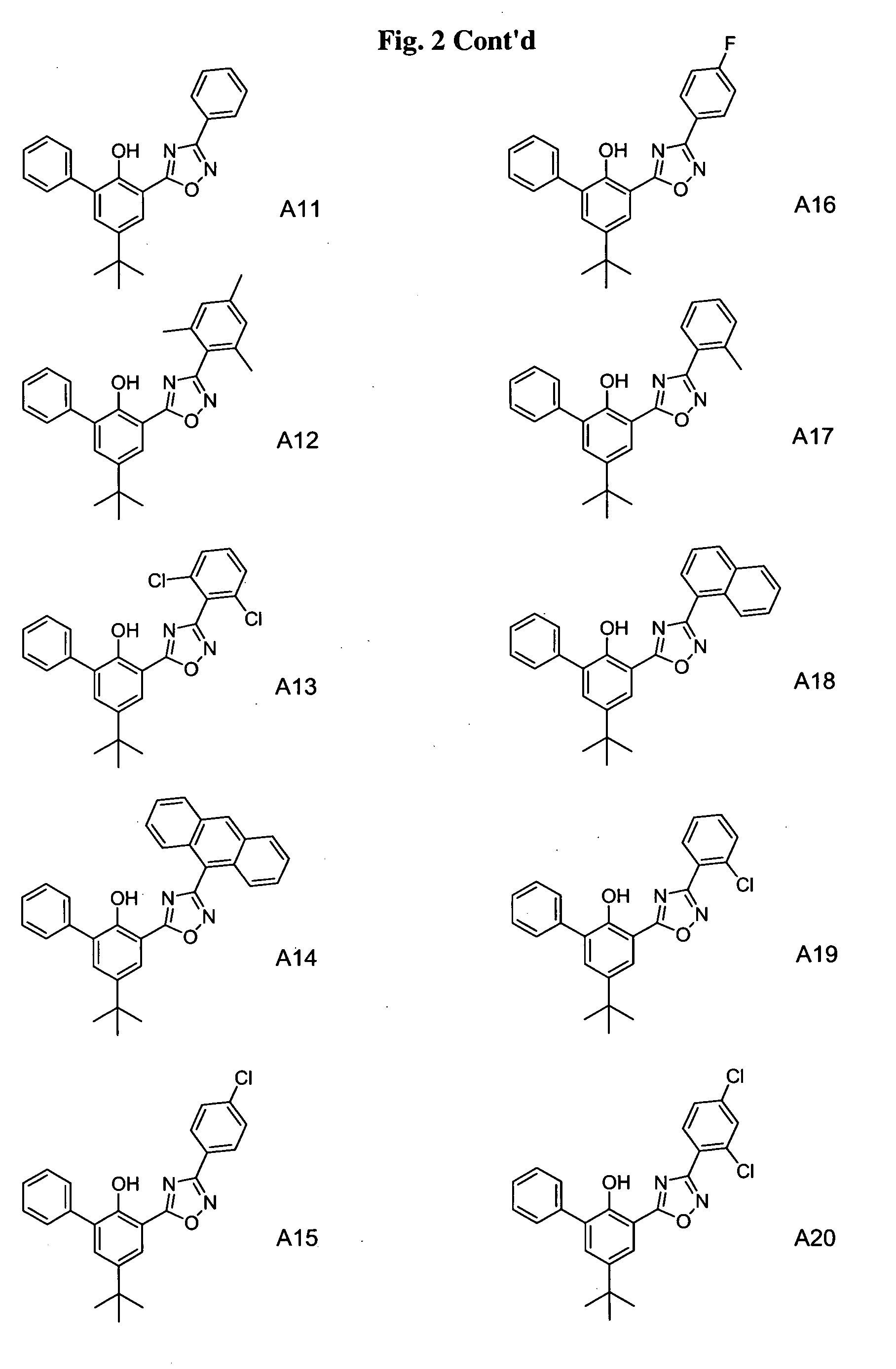

Process and plant for conversion of waste material to liquid fuel

ActiveUS20070179326A1Easy to wasteEasy feedingCatalytic crackingIndirect and direct heating destructive distillationEnvironmental engineeringLiquid fuel

A process and plant for the thermocatalytic conversion of waste materials into reusable fuels and a fuel produced by the process, involving the steps of delivering melted waste material (11) to one or more pyrolysis chambers (26) via heated and valved manifolds (22) and effecting pyrolysis of the waste material into a gascous state in an oxygen purged and pressure controlled environment. Pyrolytic gases are, then transferred to a catalytic converter (29) where the molecular structure of the gaseous material is altered in structure and form, with gases then transferred to one or more condensers (30a) to distil and cool gases in to their respective fractions. After post pyrolysis treatment, fuel fractions thon form a useable fuel. Includes the melting of waste (plastic) material (11) before delivery into any of the pyrolysis chambers (26), making the movement of material into the catalytic tower (29) a semi-continuous operation, directing melted waste material into one or more, but preferably four, pyrolysis chambers (26a, b, c, d), making each chamber capable of independent operation, optionally mechanically removing waste char from the pyrolysis chamber (107) by use of an internet auger (112) or other suitable means.

Owner:FUTURE ENERGY INVESTMENTS PTY LTD

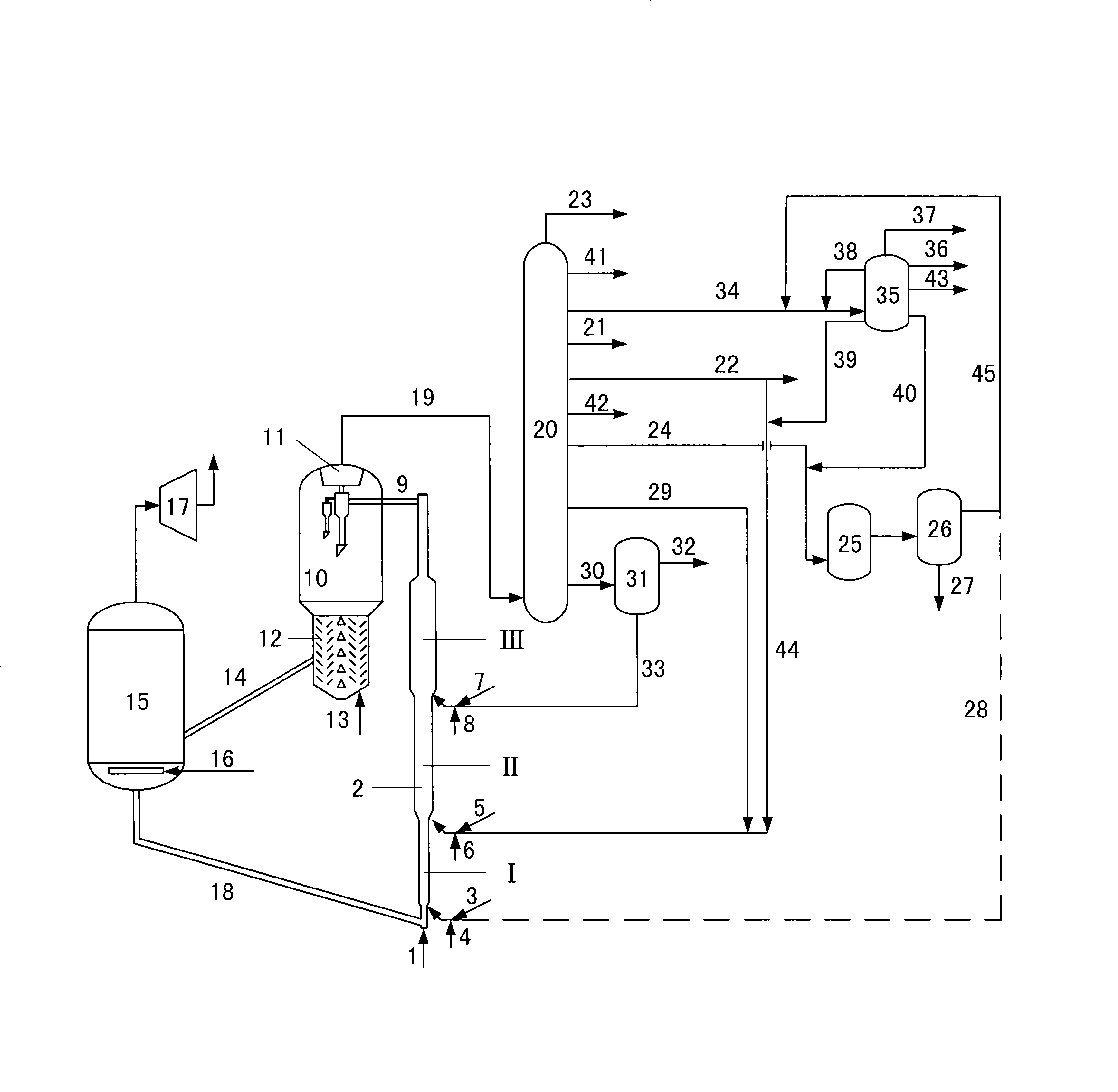

Catalytic conversion method of ethylene, propylene and aromatic hydrocarbon preparation

The invention discloses a catalytic conversion method for preparing ethylene, propylene and aromatic hydrocarbon. Hydrocarbon raw material with different cracking performances is contacted with a catalytic cracking catalyst, and cracking reaction is carried out in a fluidized bed reactor under the conditions that the temperature is 550 DEG C to 800 DEG C, the weight hourly space velocity is 0.1-800h<-1>, the reaction pressure is 0.10MPa to 1.0MPa, the weight ratio of the catalytic cracking catalyst and the raw material is 10-150, and the weight ratio of steam and the raw material is 0.15-1.0.Then a spent catalyst and reaction oil gas are separated, the spent catalyst returns to the reactor after regeneration, and the target products comprising low carbon olefin and the aromatic hydrocarbon are obtained by separating the reaction oil gas, wherein, fraction with the temperature to be 160 DEG C to 260 DEG C returns for catalytic cracking as circulating material, and the ethylene and the propylene are further obtained by cracking of ethane, propane, butane, and the steam entered. Low carbon olefin such as ethylene, propylene, and the like, is produced from heavy feedstock to the utmost extent in the method, and the yield of the ethylene and the propylene is over 20% by weight, in addition, the aromatic hydrocarbon such as toluene, xylene, and the like, are produced in an integrated way.

Owner:CHINA PETROLEUM & CHEM CORP +1

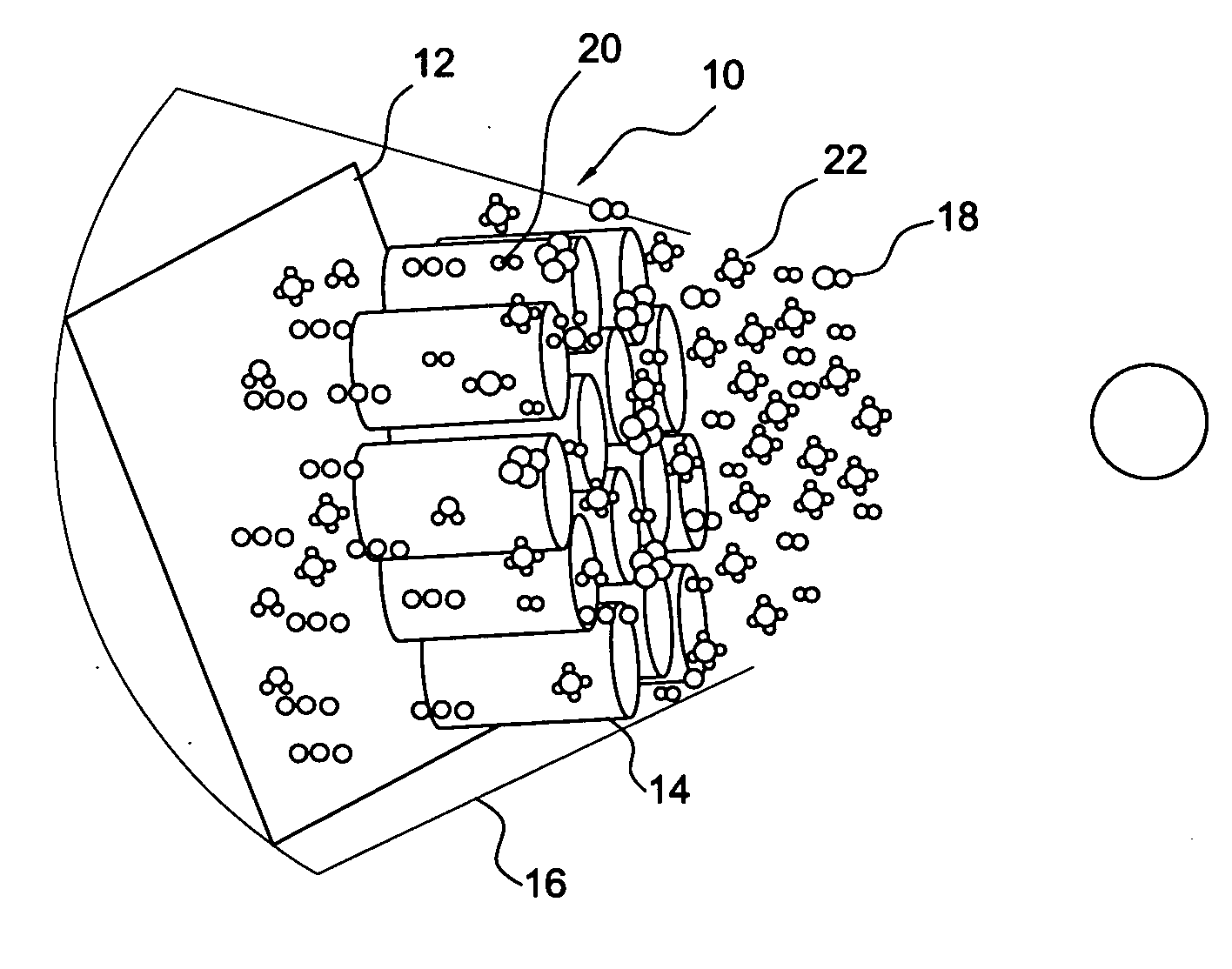

Titania nanotube arrays, methods of manufacture, and photocatalytic conversion of carbon dioxide using same

InactiveUS20100213046A1Improve photocatalytic activityImprove efficiencyCatalyst activation/preparationLiquid hydrocarbon mixture productionTio2 nanotubeWater vapor

Nitrogen-doped titania nanotubes exhibiting catalytic activity on exposure to any one or more of ultraviolet, visible, and / or infrared radiation, or combinations thereof are disclosed. The nanotube arrays may be co-doped with one or more nonmetals and may further include co-catalyst nanoparticles. Also, methods are disclosed for use of nitrogen-doped titania nanotubes in catalytic conversion of carbon dioxide alone or in admixture with hydrogen-containing gases such as water vapor and / or other reactants as may be present or desirable into products such as hydrocarbons and hydrocarbon-containing products, hydrogen and hydrogen-containing products, carbon monoxide and other carbon-containing products, or combinations thereof.

Owner:PENN STATE RES FOUND

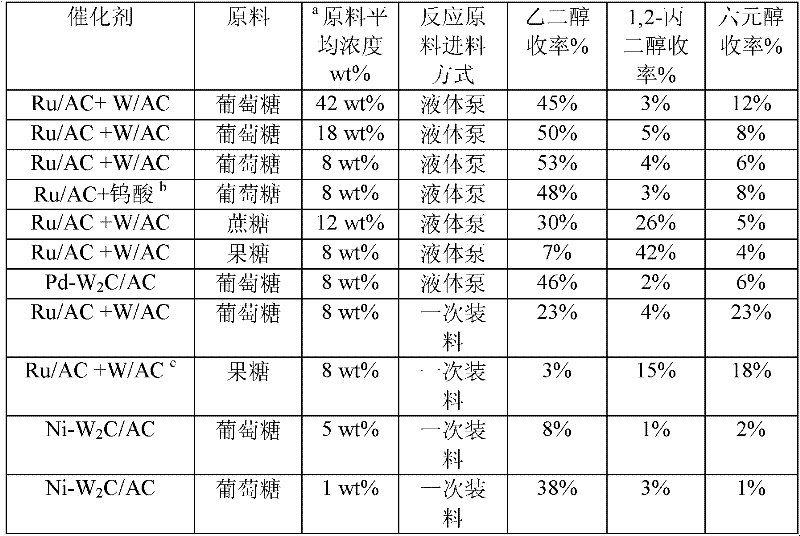

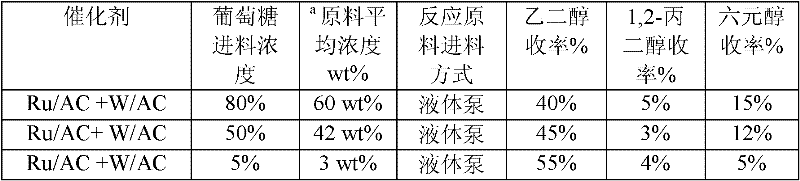

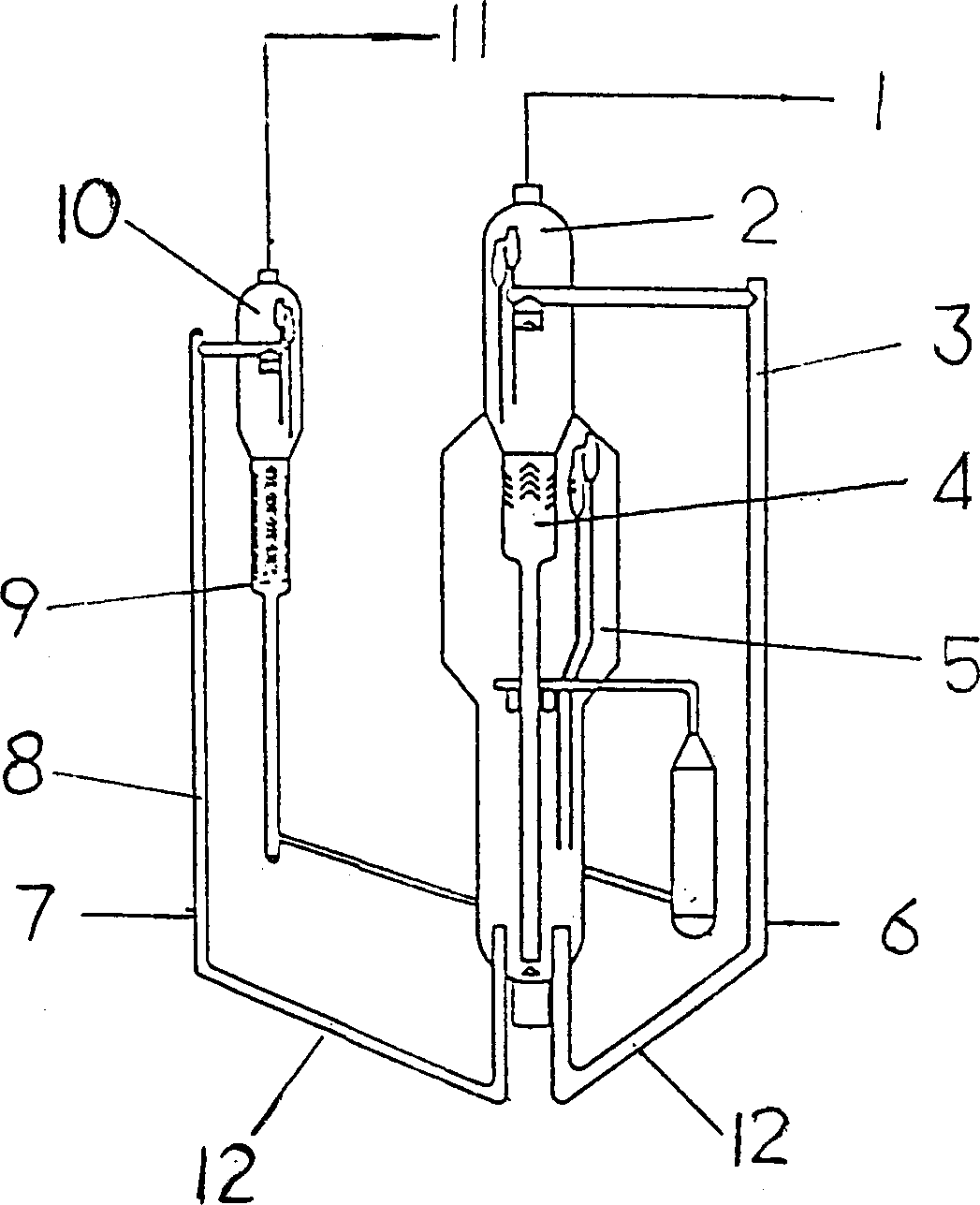

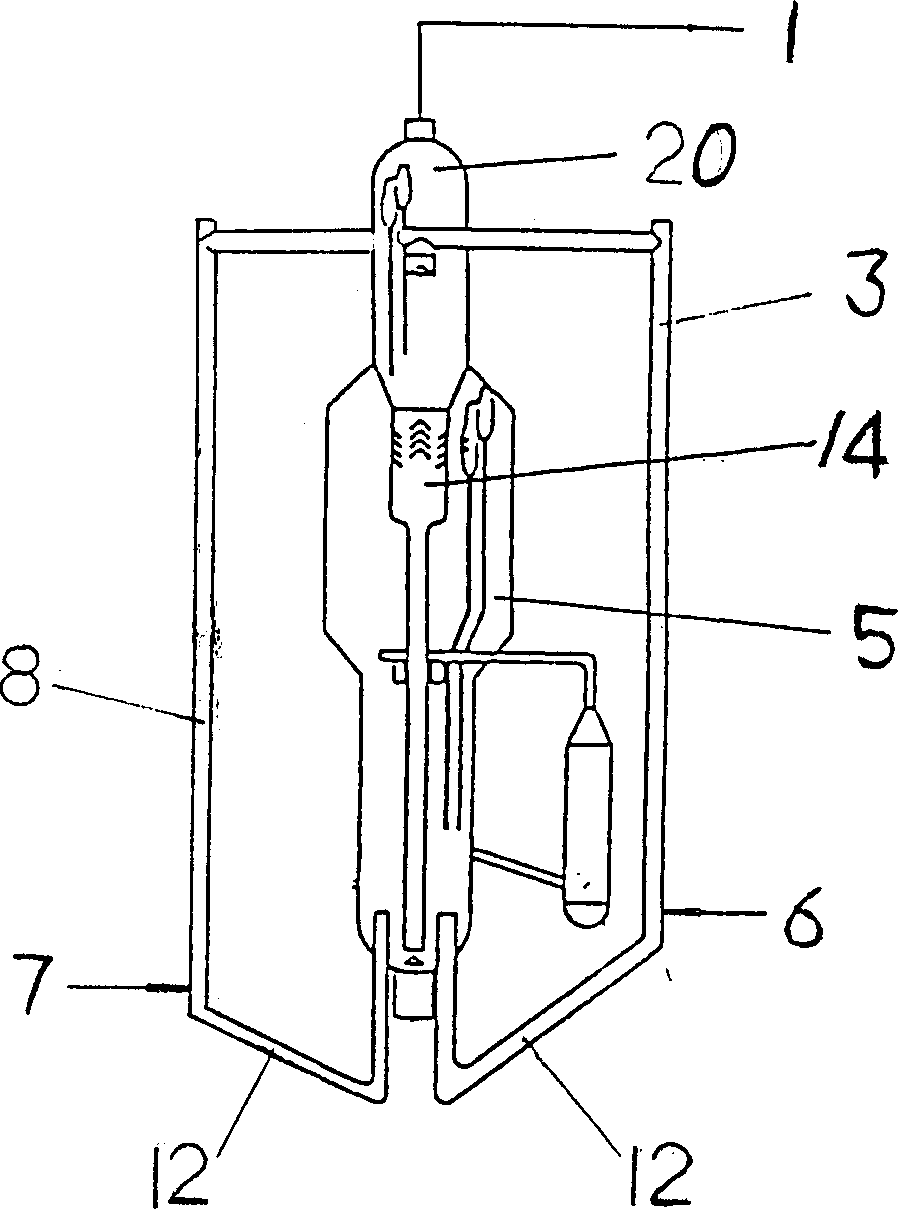

Method for preparing ethylene glycol and 1,2-propylene glycol by using saccharide solution

ActiveCN102675045AIncrease concentrationReduce distillation energy consumptionOrganic compound preparationHydroxy compound preparationHydrogen pressurePolyethylene glycol

The invention provides a method for preparing ethylene glycol and 1,2-propylene glycol by using a high-concentration saccharide solution. Reaction raw materials comprise cane sugar, glucose, fructose, fructosan, xylose, soluble lower polyxylose and soluble starch. According to the method, high-concentration saccharide is used as a reaction raw material, and a high-pressure pump feeding mode is used in a reaction process which is performed in a high-pressure reaction kettle; iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium and platinum which serve as transition metal in eighth, ninth and tenth groups are used as hydrogenation active ingredients; the hydrogenation active ingredients form a composite catalyst together with metal tungsten, tungsten carbide, tungsten nitride, tungsten phosphide, tungsten oxide, tungsten sulfide, tungsten chloride, tungsten hydroxide, tungsten bronze, tungstic acid, tungstate, metatungstic acid, metatungstate, paratungstic acid, paratungstate, peroxotungstic acid, peroxotungstate and tungsten-containing heteropolyacid which serve as catalytic active ingredients; and the high-concentration saccharide solution can be efficiently prepared into the ethylene glycol and the propylene glycol at high selectivity and high yield in a one-step catalytic conversion process under the hydrothermal condition that the temperature is 120 to 300 DEG C and the hydrogen pressure is 1 to 13MPa. By the method, the problem of coking of the high-concentration saccharide in the catalytic conversion process can be effectively solved, and high-concentration ethylene glycol and propylene glycol can be prepared by the high-concentration saccharide.

Owner:中科柏易金(郑州)新能源科技有限责任公司

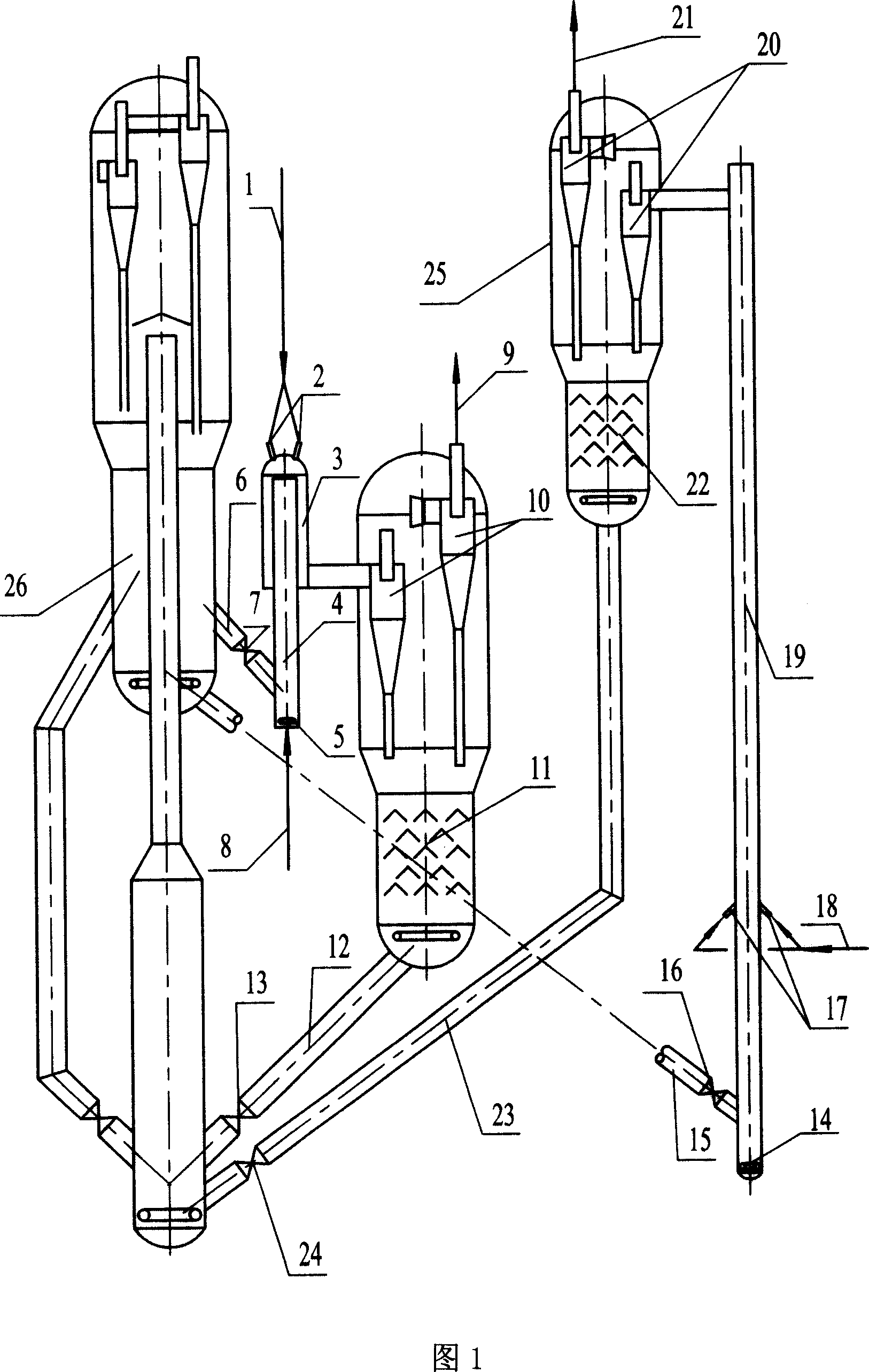

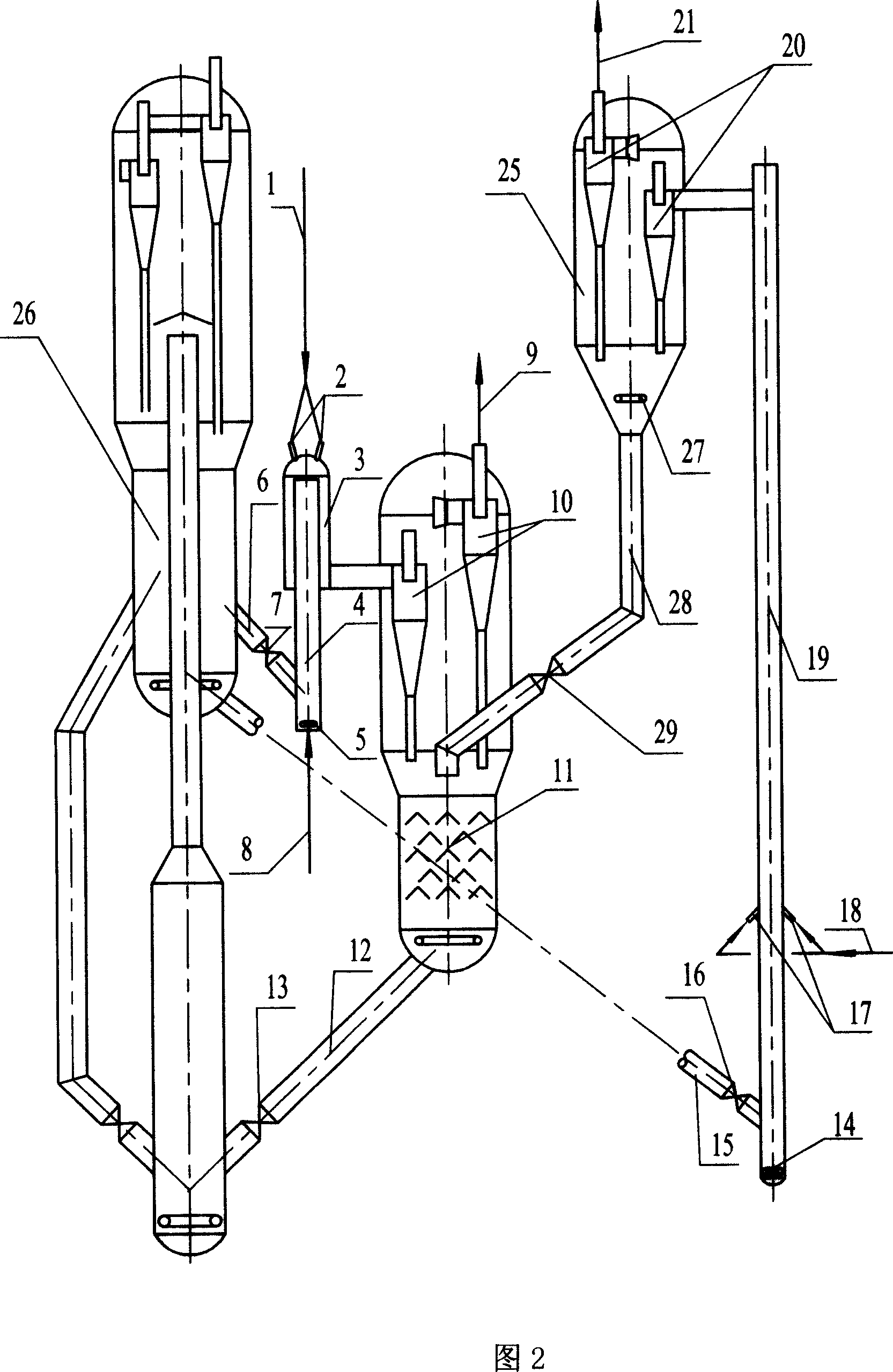

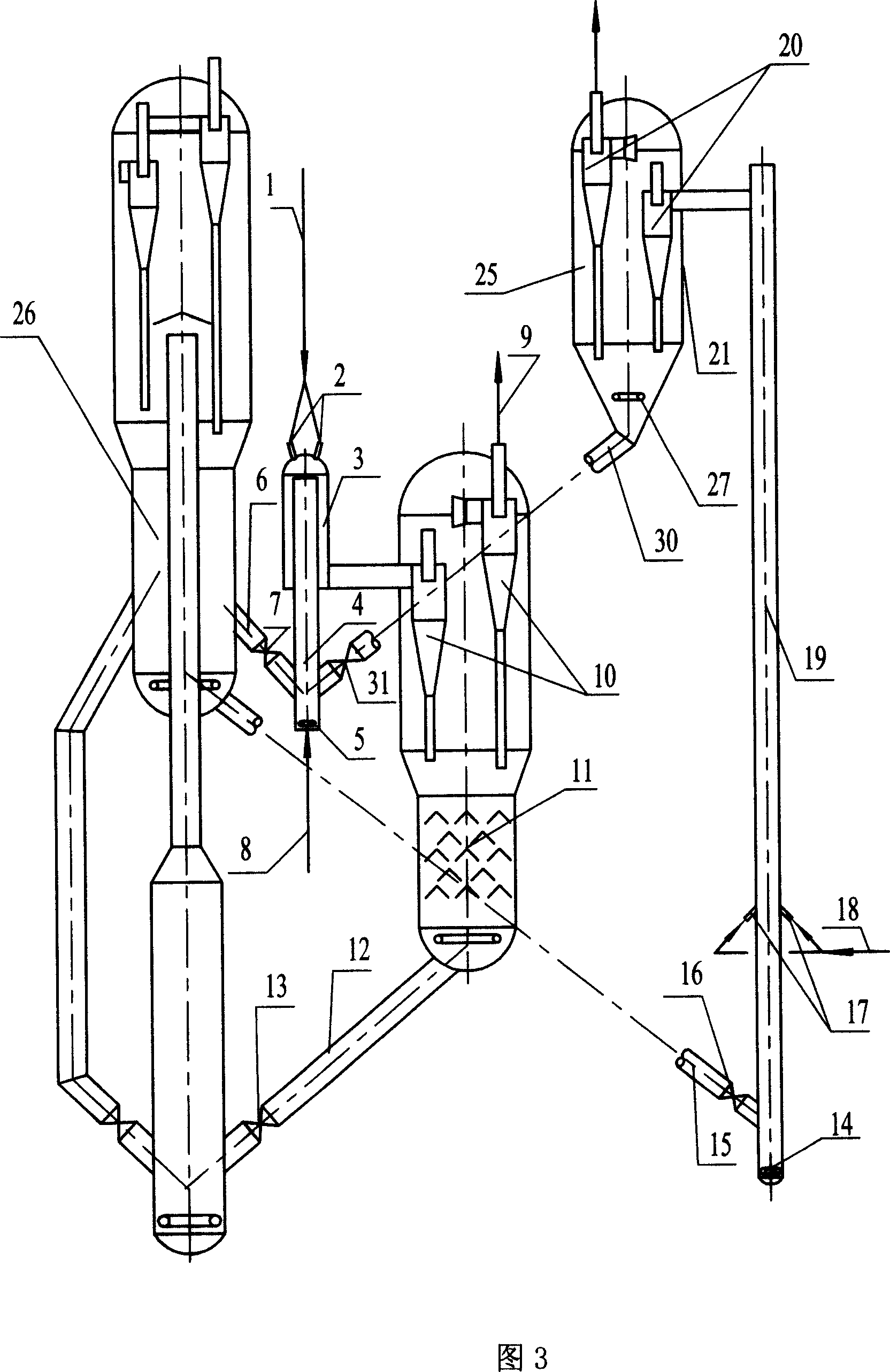

Catalytic conversion method and apparatus for upgrading poor gasoline

InactiveCN1401740AReduce olefin contentReduce sulfur contentTreatment with plural serial stages onlyCatalytic transformationFuel oil

A catalytic converting process for upgrading poor-quality gasoline with high olefine content incldues a conventional catalytic cracking step for heavy oil and a catalytic converting step for upgrading said gasoline. It is characterized by in that two steps a common catalyst regenerator and a same catalyst are used. It can decrease olefine content by 15-50 vol% and S content by 5-30% and increase RON by 0.2-2 units.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

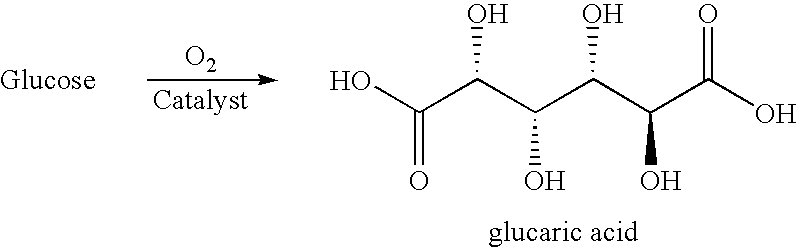

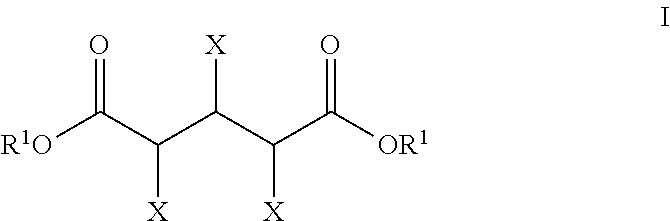

Oxidation Catalysts

Disclosed are catalysts comprised of platinum and gold. The catalysts are generally useful for the selective oxidation of compositions comprised of a primary alcohol group and at least one secondary alcohol group wherein at least the primary alcohol group is converted to a carboxyl group. More particularly, the catalysts are supported catalysts including particles comprising gold and particles comprising platinum, wherein the molar ratio of platinum to gold is in the range of about 100:1 to about 1:4, the platinum is essentially present as Pt(0) and the platinum-containing particles are of a size in the range of about 2 to about 50 nm. Also disclosed are methods for the oxidative chemocatalytic conversion of carbohydrates to carboxylic acids or derivatives thereof. Additionally, methods are disclosed for the selective oxidation of glucose to glucaric acid or derivatives thereof using catalysts comprising platinum and gold. Further, methods are disclosed for the production of such catalysts.

Owner:ARCHER DANIELS MIDLAND CO

Catalytic converter for cleaning exhaust gas

InactiveUS6881384B1High catalytic activityEffectively its catalytic activityCombination devicesInternal combustion piston enginesCeriumCe element

A catalytic converter for cleaning exhaust gas includes a heat-resistant support, and a catalytic coating formed on the heat-resistant support. The catalytic coating contains zirconium complex oxide on which Pt and Rh are coexistently carried, and cerium complex oxide on which Pt and Rh are coexistently carried. The Pt- and Rh-carrying zirconium complex oxide and the Pt- and Rh-carrying cerium complex oxide are contained in a same layer of the catalytic coating.

Owner:DAIHATSU MOTOR CO LTD

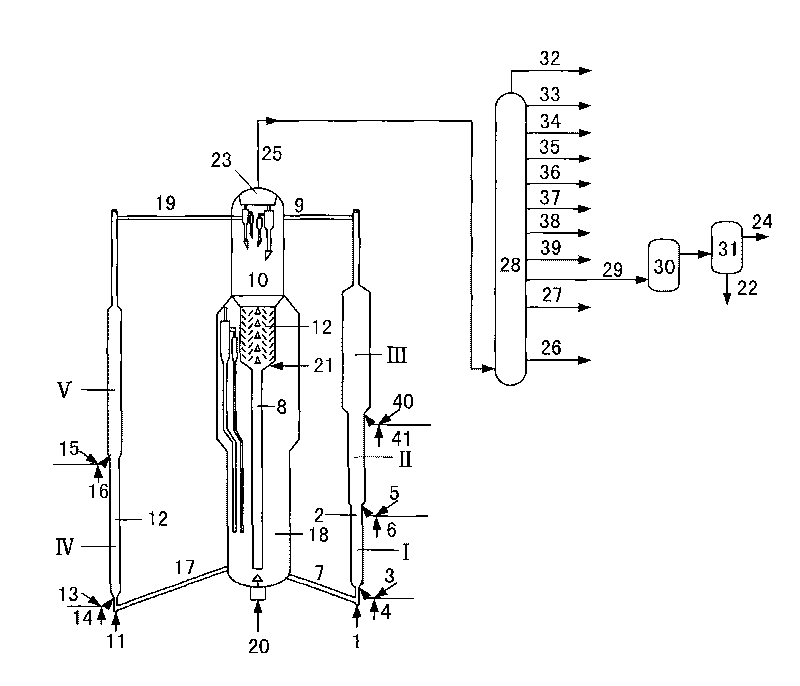

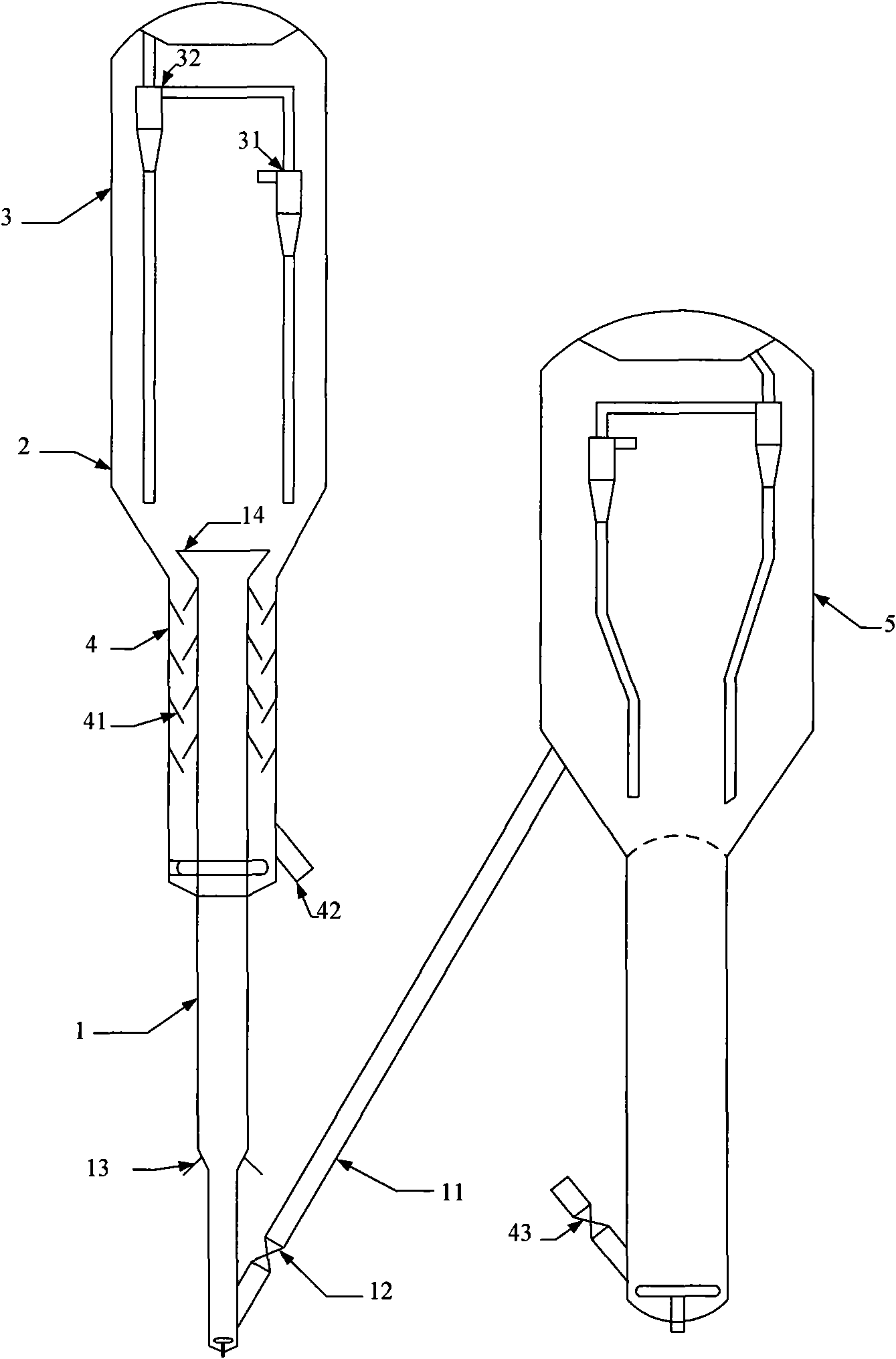

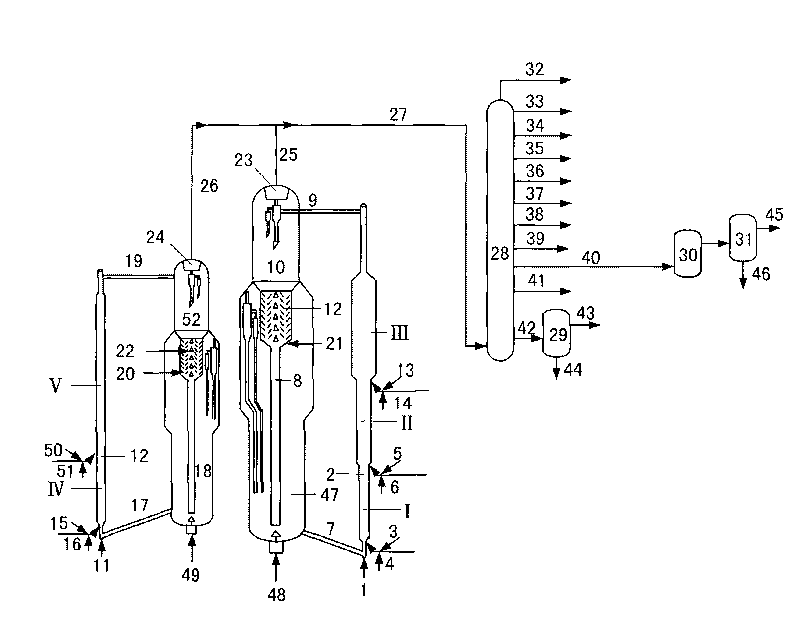

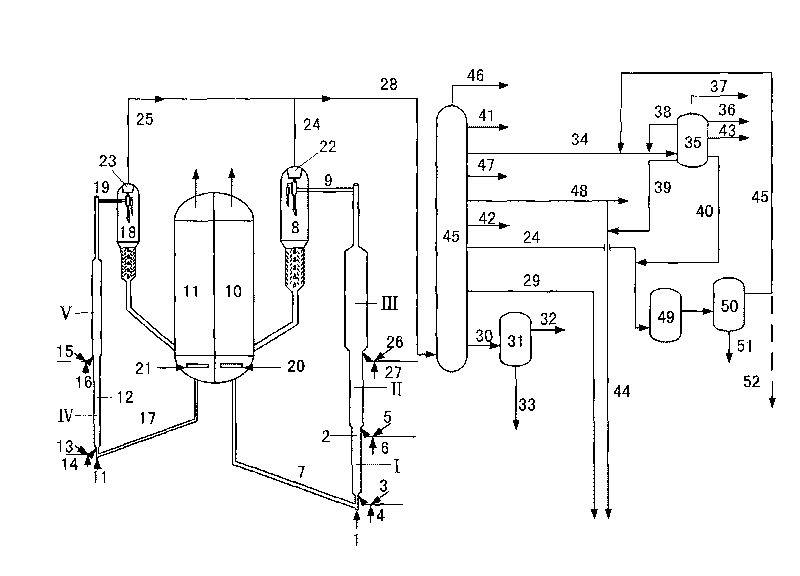

Catalytic conversion method for preparing lower olefins and aromatics

The invention relates to a catalytic conversion method for preparing lower olefins and aromatics. Raw oil with different cracking performances enters different reaction zones of a first riser reactor to contact with a catalytic cracking catalyst for cracking reaction to separate a spent catalyst from reaction oil gas, wherein the reaction oil gas is separated to obtain a product containing lower olefins, gasoline, distillates with distillation range of 180-250 DEG C and catalytic wax oil, wherein the gasoline is extracted by light aromatics to obtain light aromatics and gasoline raffinate; the raw materials are cracked to be sent into a second riser reactor to contract with a hot regenerated catalyst for catalytic conversion; and the spent catalysts of the two riser reactors are burned and regenerated in the same one regenerator and then returns to the two riser reactors. The method uses heavy raw materials to furthest produce the lower olefins, such as propylene, ethylene, and the like, particularly the propylene, the production rate can exceed 40 wt%, and at the same time the method can coproduce the aromatics, such as toluene, xylene, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

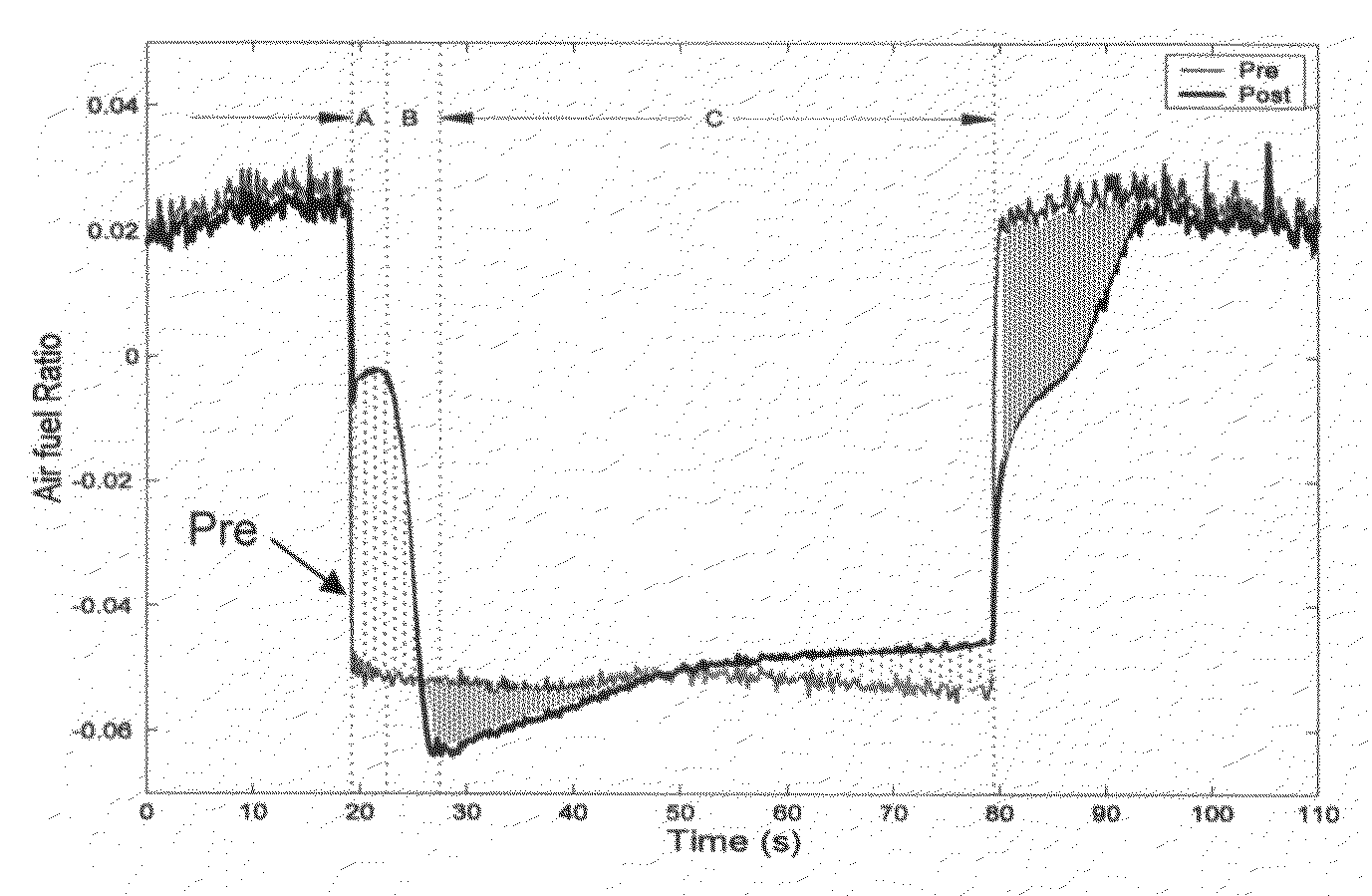

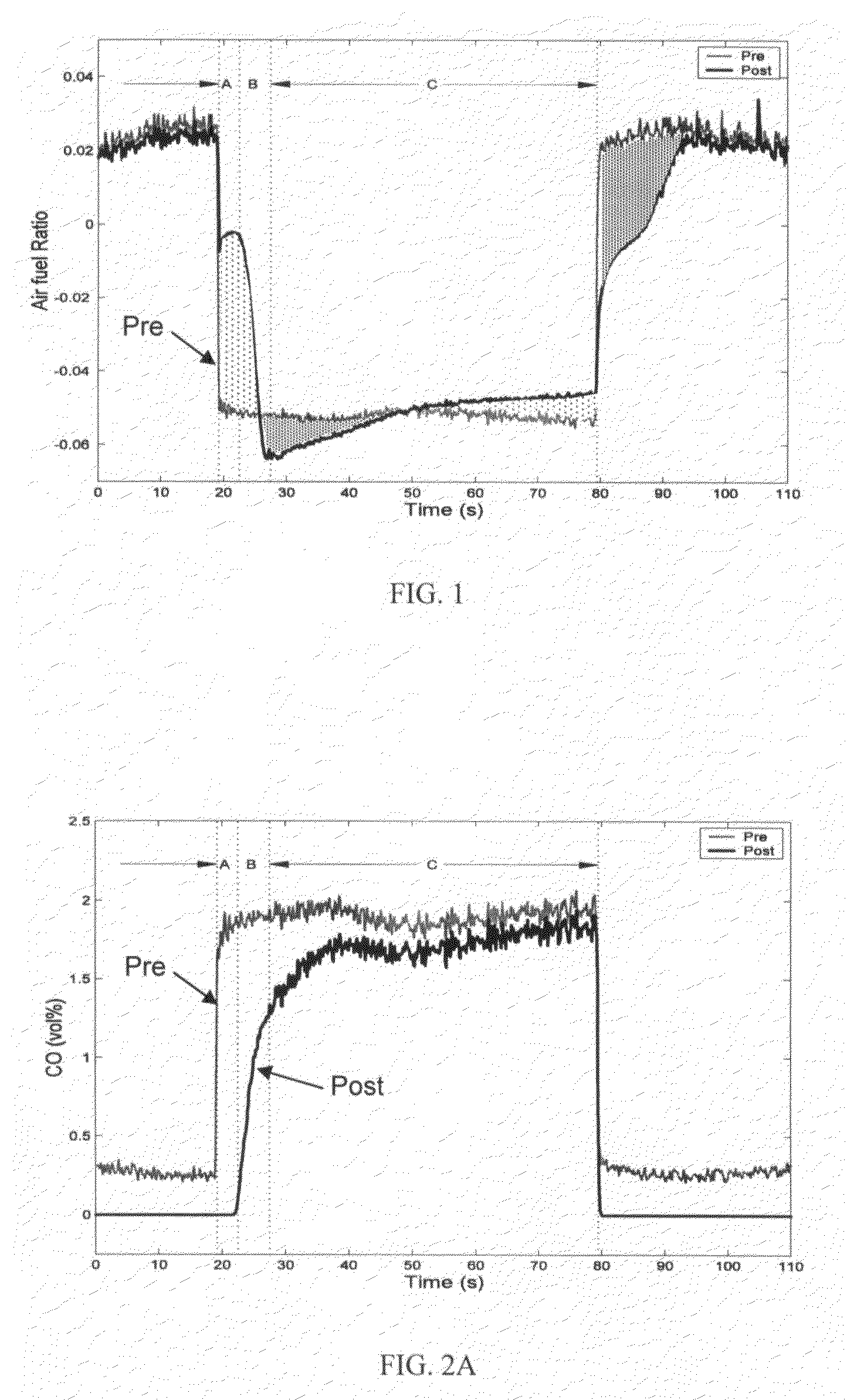

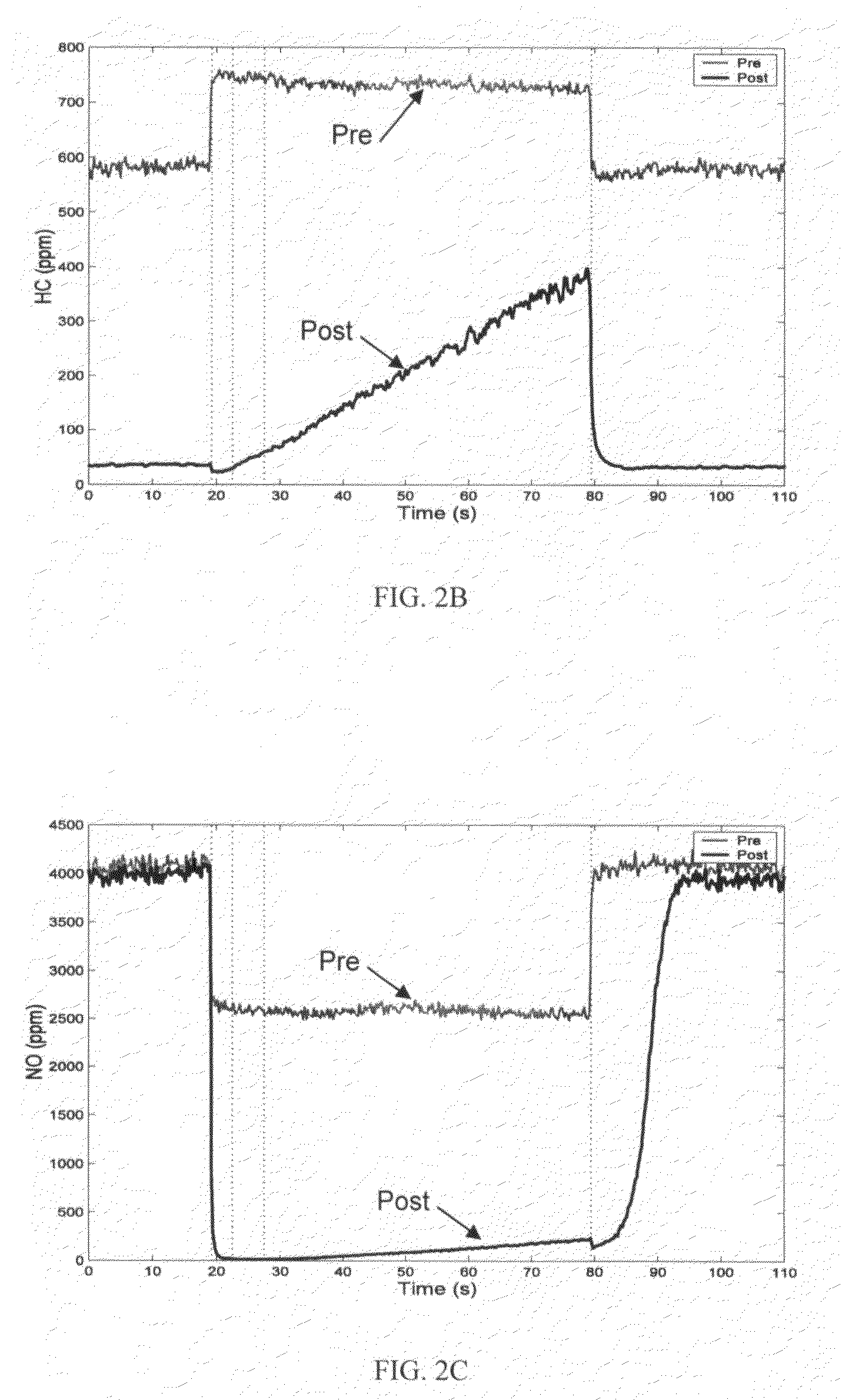

Method of on-board diagnostic catalyst monitoring

InactiveUS20070234708A1Direct relationshipInternal combustion piston enginesExhaust apparatusHydrogenNitrogen dioxide

A method of on-board diagnostic (OBD) catalyst monitoring. Vehicle OBD exhaust systems often include a catalyst, a pre-catalyst exhaust gas oxygen sensor, and a post-catalyst exhaust gas oxygen sensor. A method is provided of monitoring the catalyst which includes the steps of measuring hydrogen or nitrogen dioxide generation by the catalyst, and correlating changes in hydrogen or nitrogen dioxide generation to changes in catalytic conversion efficiency. Because OBD legislation defines catalyst deterioration or malfunction in terms of hydrocarbon or nitrogen oxide emission levels, the method uses hydrogen or nitrogen dioxide generation as a metric for OBD monitoring of the catalyst and offers the advantage of a more direct relationship to catalyst health than conventional methods.

Owner:JONES JAMES PEYTON +1

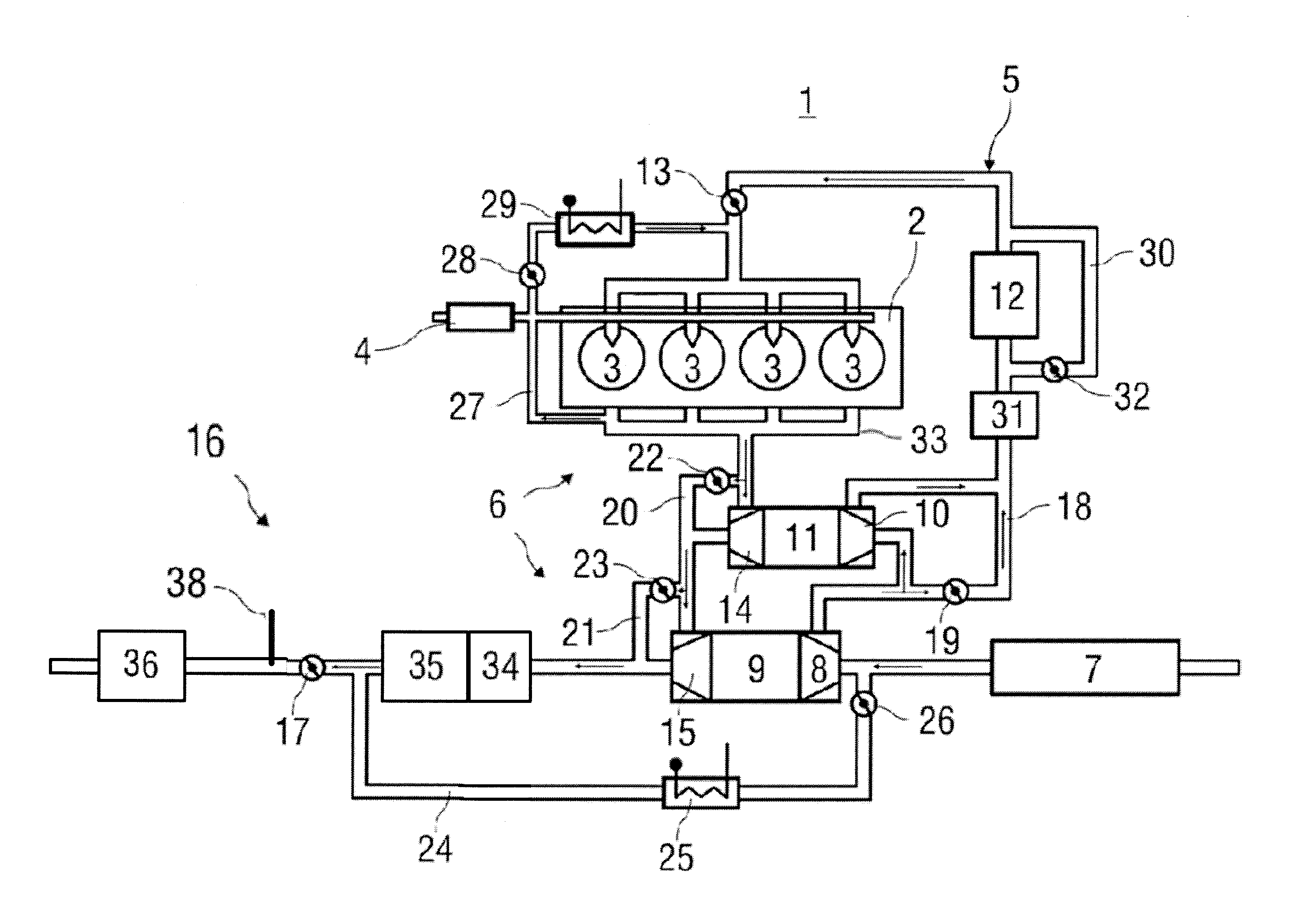

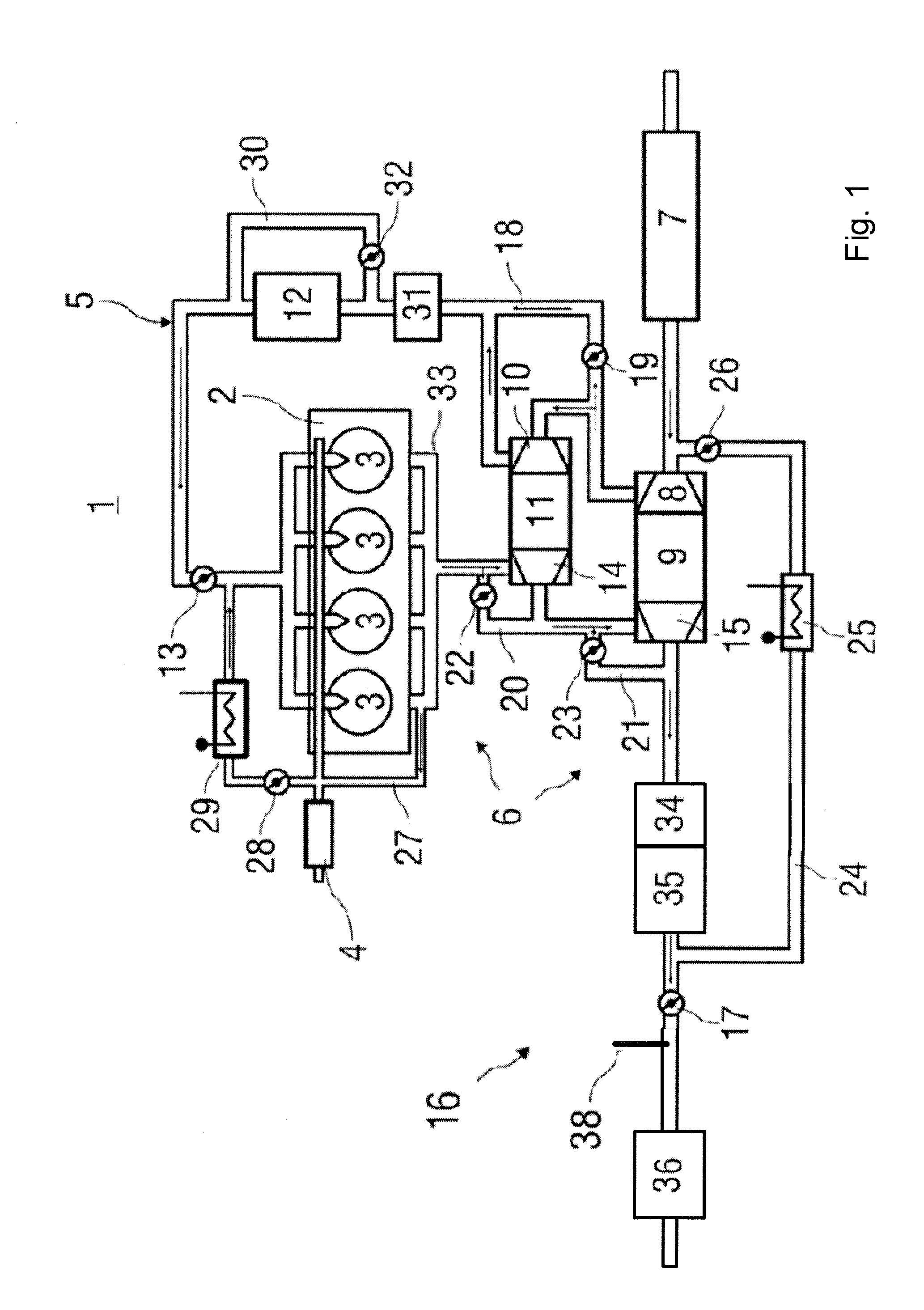

Exhaust gas post treatment system

ActiveUS20080041052A1Emission reductionReduce selection requirementsInternal combustion piston enginesExhaust apparatusParticulatesNitric oxide gas

An exhaust gas post treatment system for nitrogen oxide and particle reduction of internal combustion engines operated with excess air. An oxidation catalytic converter is disposed in the exhaust gas stream of the engine for converting at least a portion of the nitric oxide in the exhaust gas into nitrogen dioxide. The first particle separator or filter is disposed in the exhaust gas stream downstream of the oxidation catalytic converter for converting carbon particles accumulated in the separator or filter into carbon monoxide, carbon dioxide, nitrogen and nitric oxide with the aid of nitrogen dioxide contained in the exhaust gas. A partial exhaust gas stream is branched off from the exhaust gas stream upstream of the first separator or filter. A metering device adds reduction agent to the partial exhaust gas stream in the form of ammonia or a material that releases ammonia downstream of the supply location due to hot exhaust gas. A second particle separator or filter is disposed in the partial exhaust gas stream downstream of the supply location. The partial exhaust gas stream returns to the exhaust gas stream downstream of both particle separators or filters. An SCR catalytic converter is disposed downstream of the return location for reducing nitrogen oxides in the exhaust gas to nitrogen and water vapor with the aid of ammonia or released ammonia by way of selective catalytic reduction.

Owner:MAN NUTZFAHRZEUGE AG

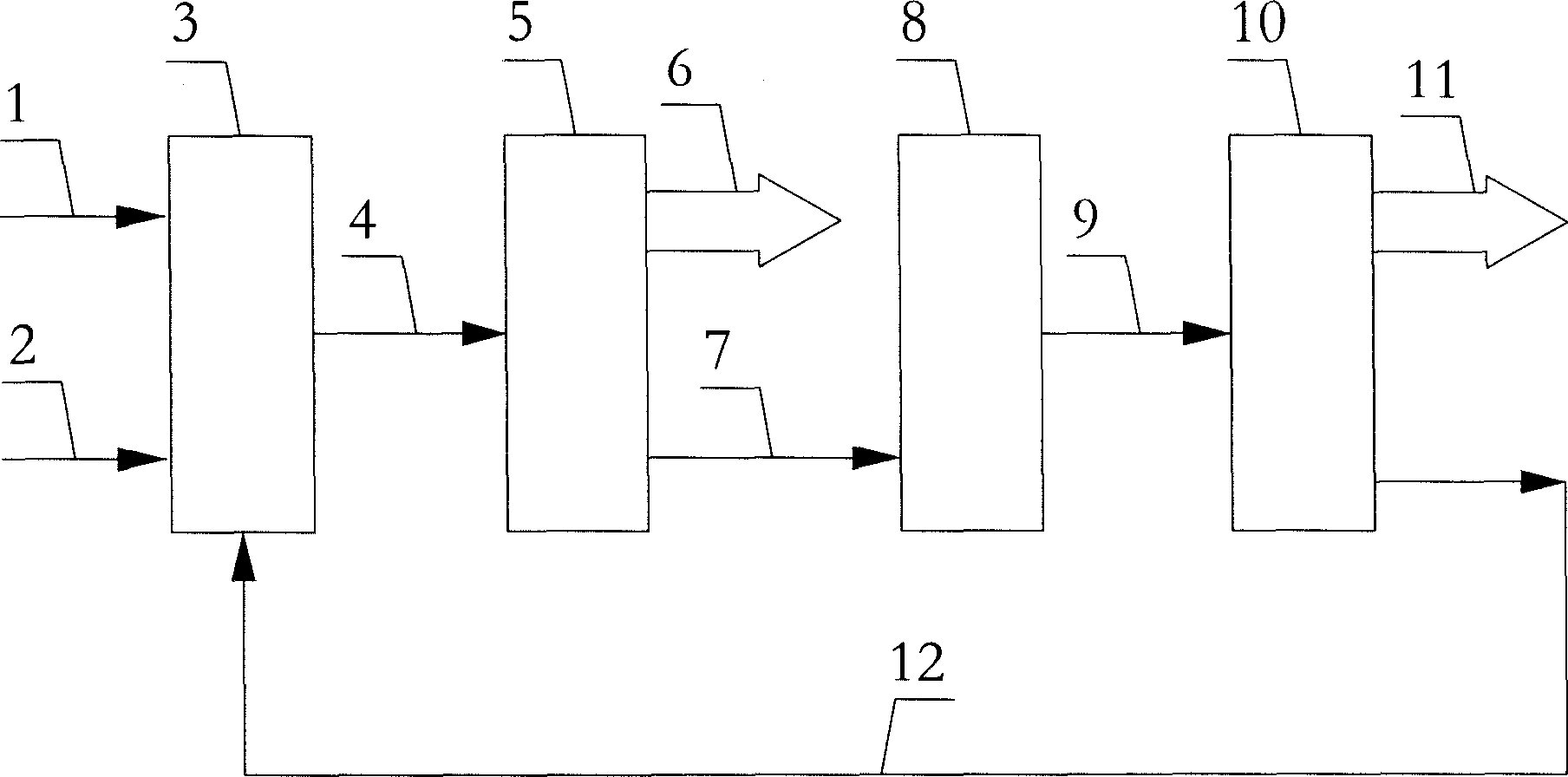

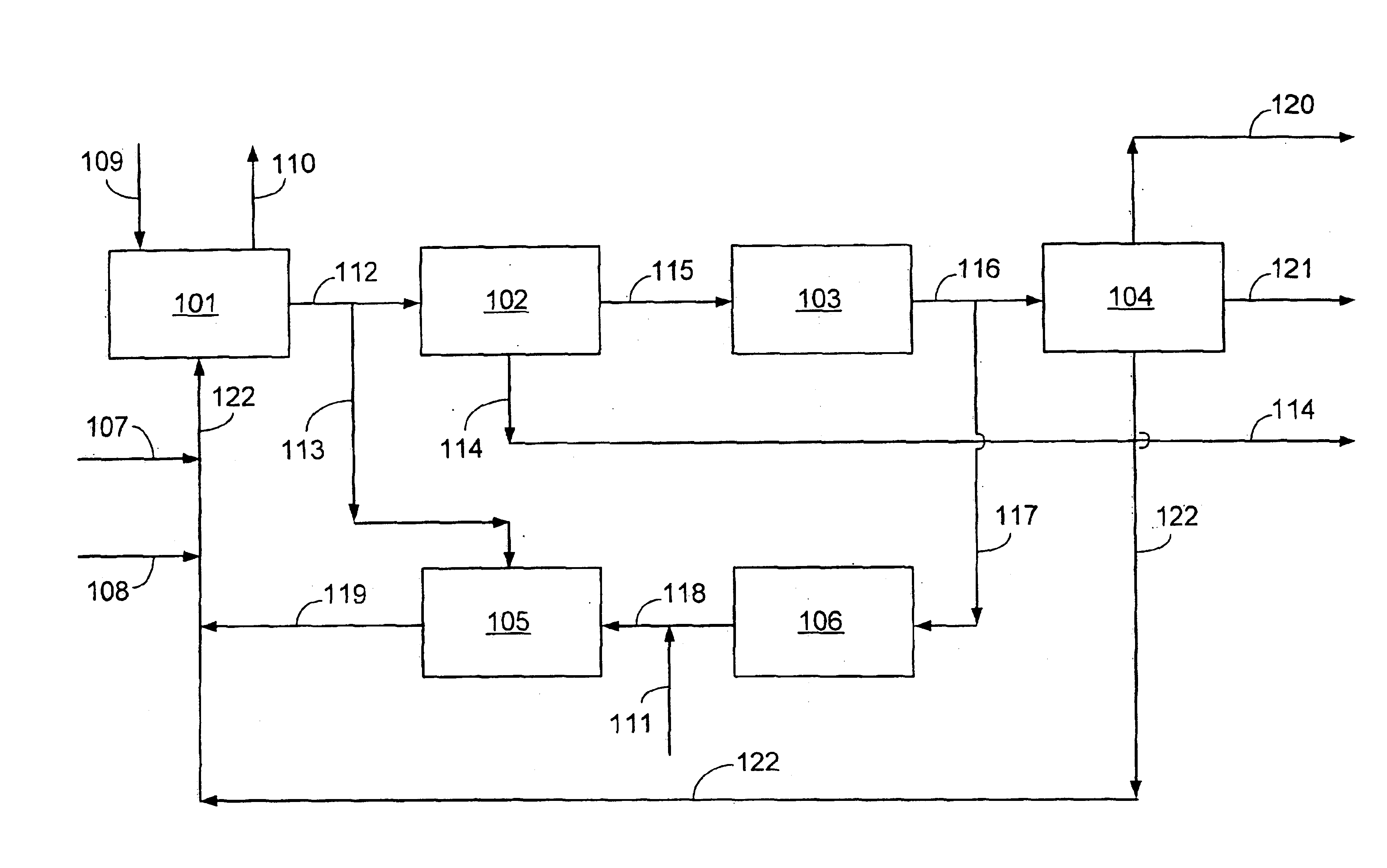

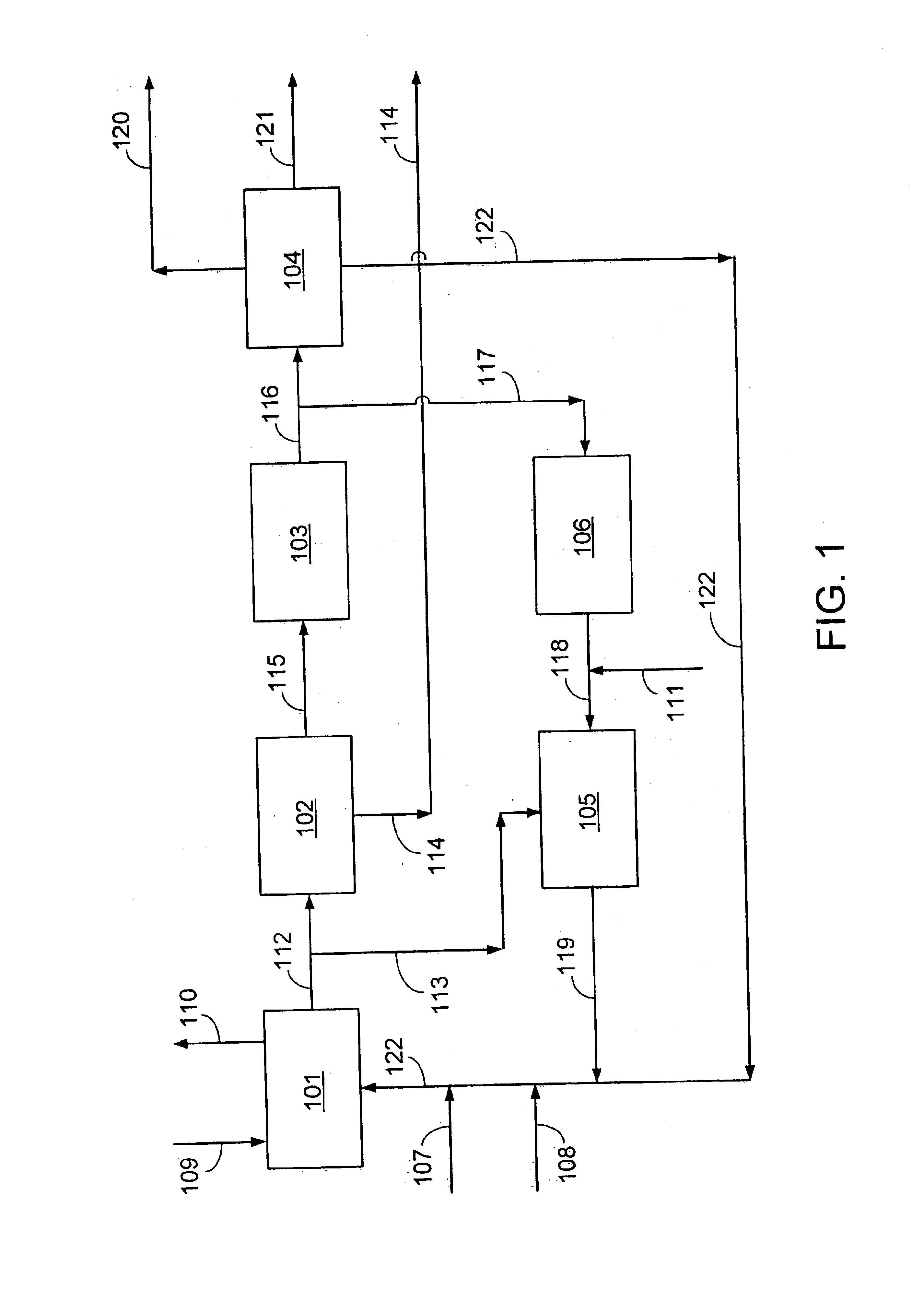

Hydrocarbon catalytic conversion method for producing propylene and light aromatic hydrocarbon

ActiveCN102206509AImprove utilization efficiencyImprove conversion rateTreatment with plural parallel stages onlyLiquid hydrocarbon mixture productionCatalytic transformationPtru catalyst

A method for producing propylene and light aromatic hydrocarbon comprises the steps of contacting heavy hydrocarbons and / or grease with a cracking catalyst containing modified beta zeolite in a first reactor for catalytic cracking reaction, contacting C4 hydrocarbon fraction and / or light gasoline fraction with the cracking catalyst containing modified beta zeolite in a second reactor for catalytic cracking reaction, and then leading the reaction products into a third reactor for reaction. The hydrocarbon-gasoline conversion method provided by the invention has the advantages of higher propylene yield and light aromatic hydrocarbon yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

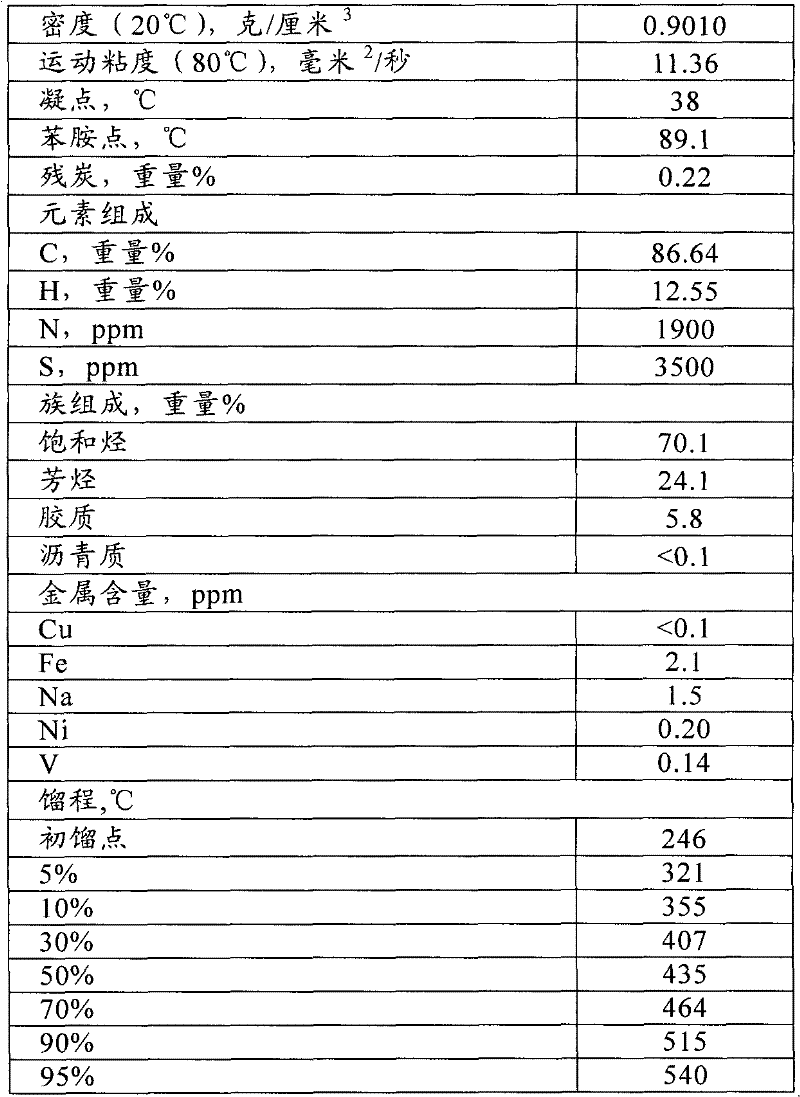

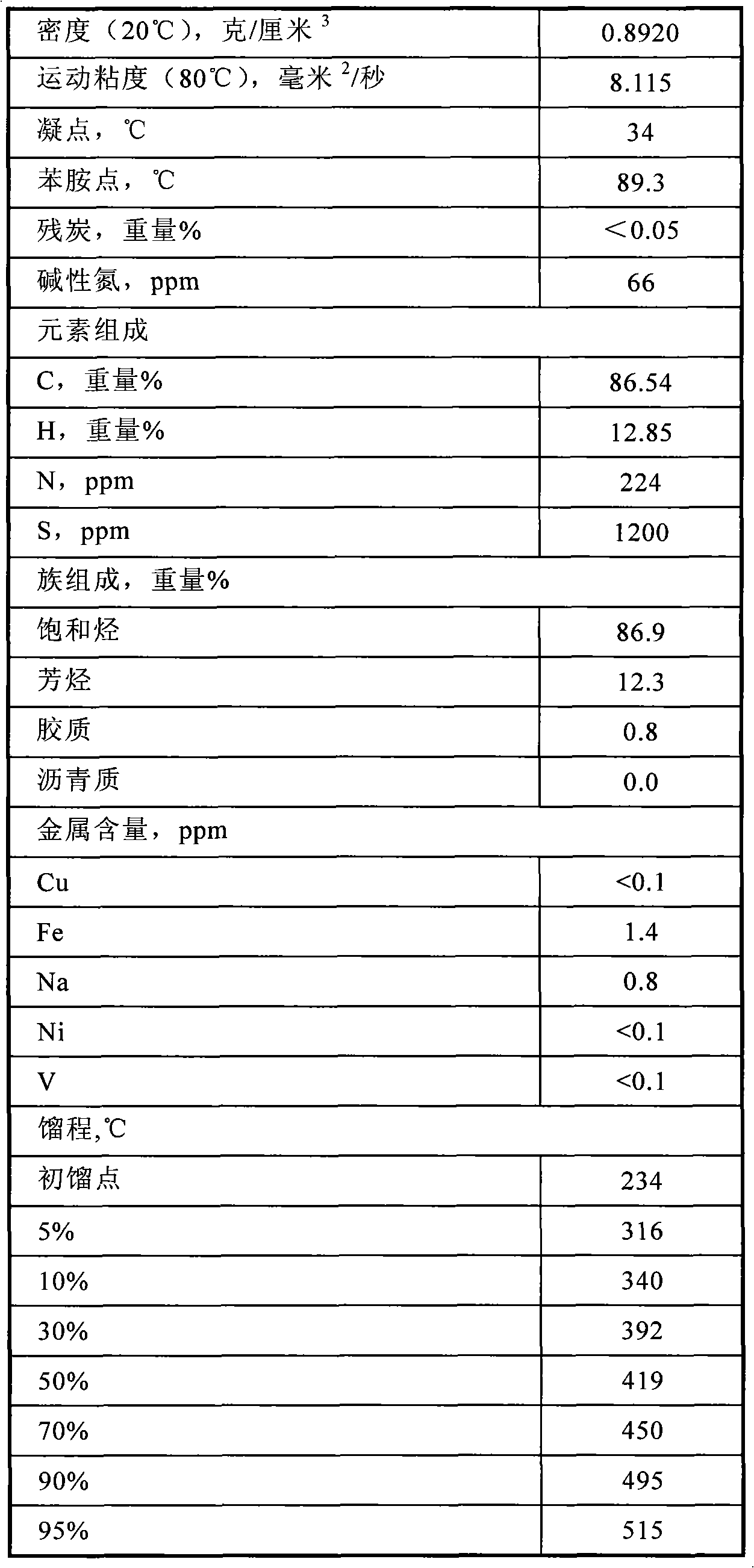

Shale oil producing process

The present invention relates to shale oil processing procedure, which includes the steps of hydrogenating shale oil to obtain hydrogenated shale oil; separating into heavy hydrogenated shale oil and light product; catalytically converting the heavy hydrogenated shale oil to obtain dry gas, liquefied gas, gasoline, diesel oil and catalytic heavy oil; and returning the diesel oil to the hydrogenating step. The shale oil processing procedure has the advantages of high light product yield and high product quality.

Owner:黄玉豹 +4

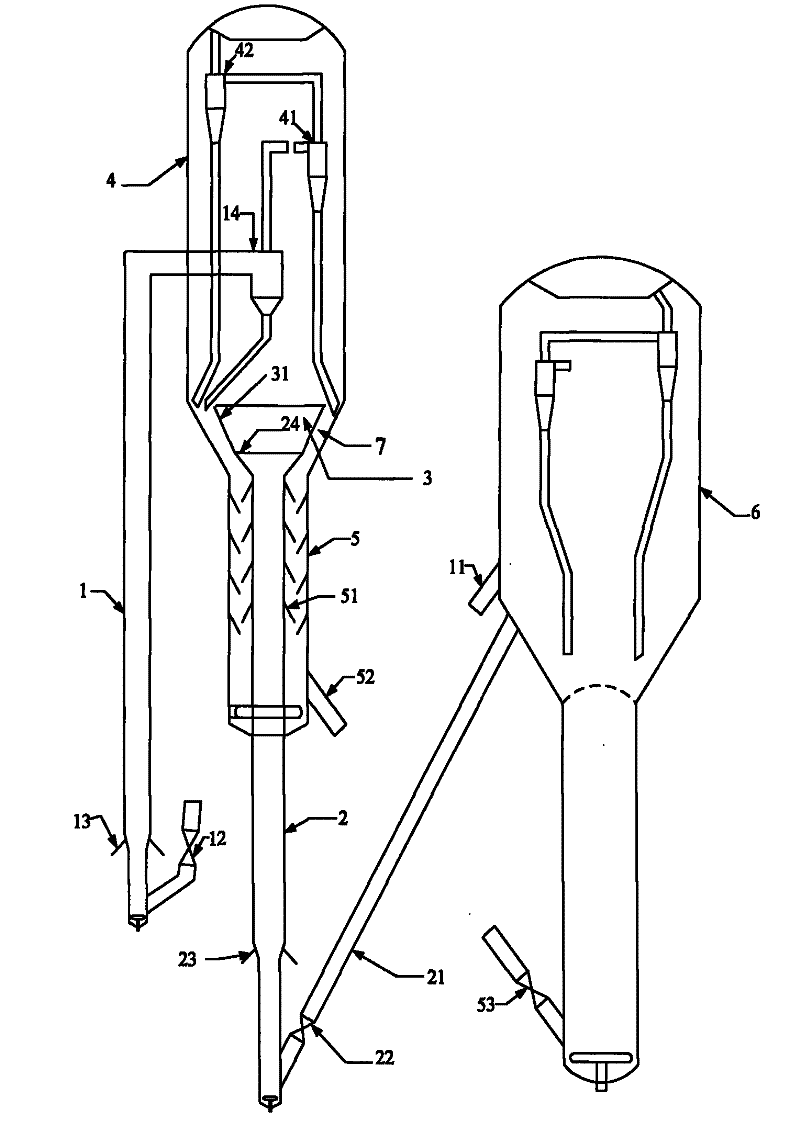

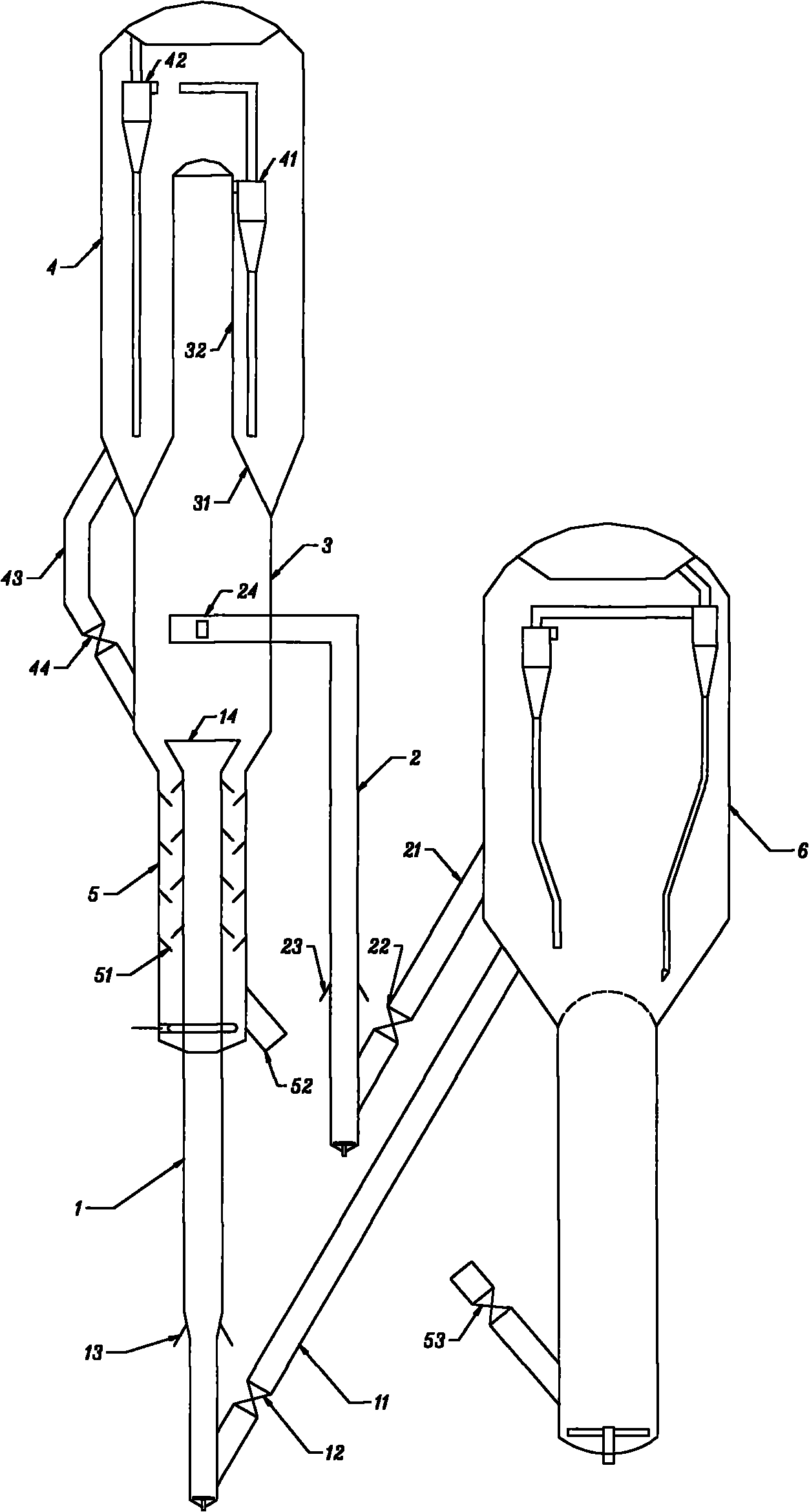

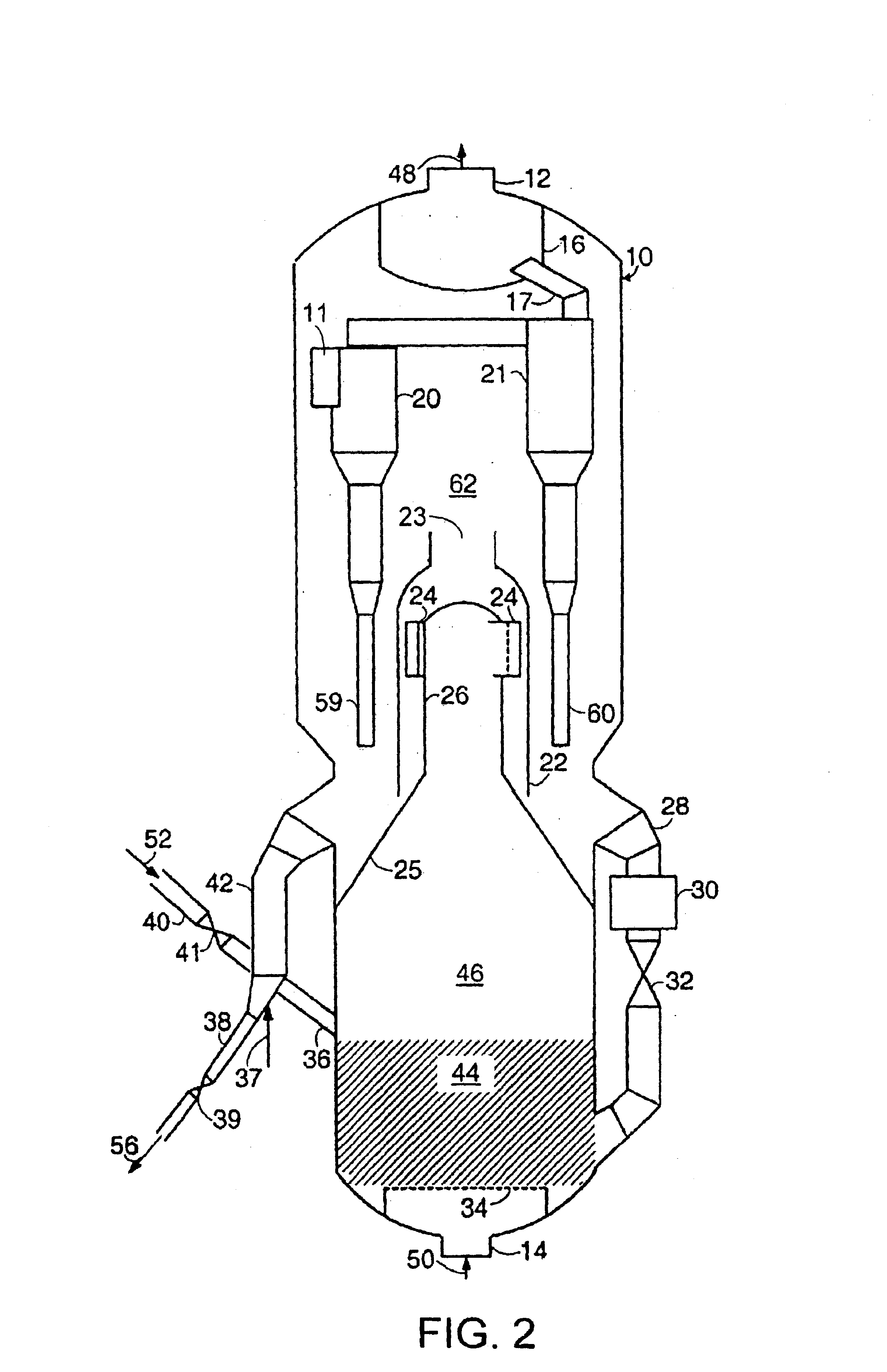

Combined catforming of high-production low carbon alkene

ActiveCN101045667AReduce backmixingHigh selectivityChemical recyclingBulk chemical productionCarbon depositAlkene

A combined catalytic converting process for preparing low-carbon olefin with high output includes such steps as contacting between heavy oil as raw material, regenerated catalyst and carbon deposited catalyst in flow-down tube reactor, cracking reaction, separating the cracked product from the catalyst to be regenerated, separating low-carbon olefin from cracked product, contacting between rest of said product and regenerated catalyst in flow-up tube reactor, reaction, separating oil gas from catalyst, separating low-carbon olefin from oil gas, and regenerating the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

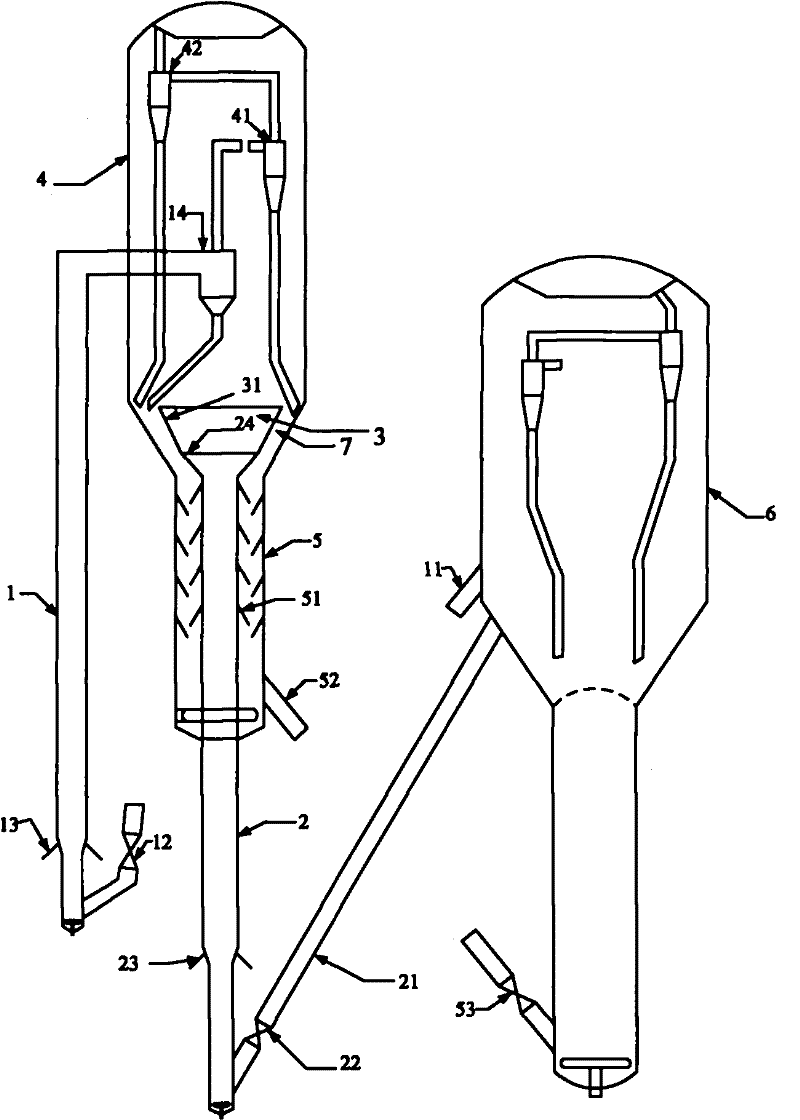

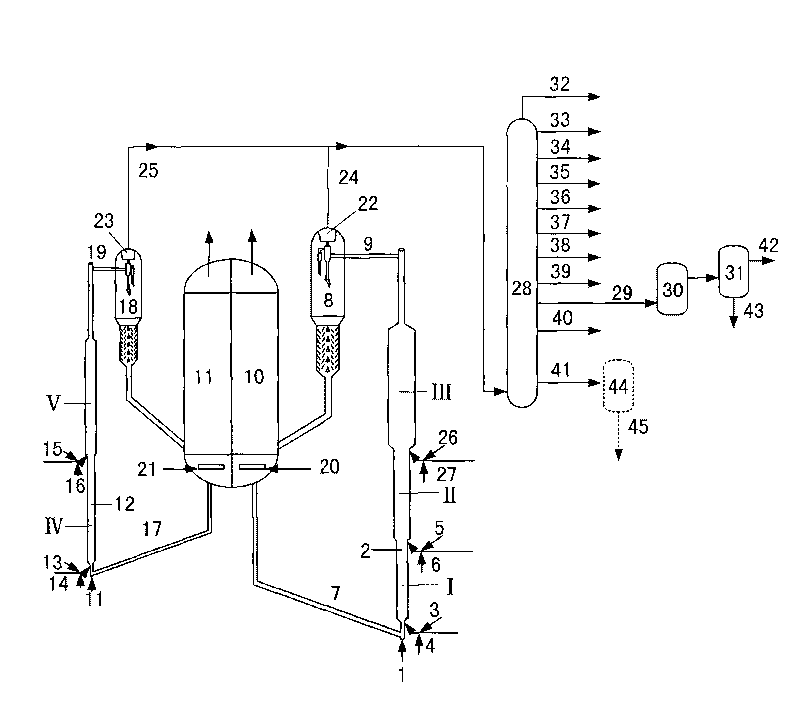

Method for catalytic conversion production of propylene and light aromatics

ActiveCN102337154AIncreased processing flexibilityImprove conversion rateTreatment with hydrotreatment processesChemical recyclingCatalytic transformationPtru catalyst

The invention provides a method for catalytic conversion production of propylene and light aromatics, which is characterized in that a hydrocarbon raw material and a catalytic cracking catalyst are contacted in a composite reactor for reacting under the catalytic cracking condition, the reaction products and the to-be-regenerated catalyst are separated, the separated to-be-regenerated catalyst is circularly used through stripping and performing coke burn-off regeneration, the separated reaction products is fractionated to obtain low carbon olefin, gasoline containing light aromatics and the like, and separated to obtain the light aromatics further; the composite reactor comprises a riser reactor and a fluidized bed reactor, an outlet of the riser reactor is communicated with a lower part of the fluidized bed reactor, a stripper is positioned at the lower part of the fluidized bed reactor, an upper part of the stripper is communicated with the bottom of the fluidized bed reactor, and the outlet of the fluidized bed reactor is communicated with the inlet of a gas solid separation device in a settler though a conveying pathway, a catalyst outlet of the settler is communicated with the lower part of the fluidized bed reactor. According to the invention, propylene and light aromatics enable high yield by using the method.

Owner:CHINA PETROLEUM & CHEM CORP +1

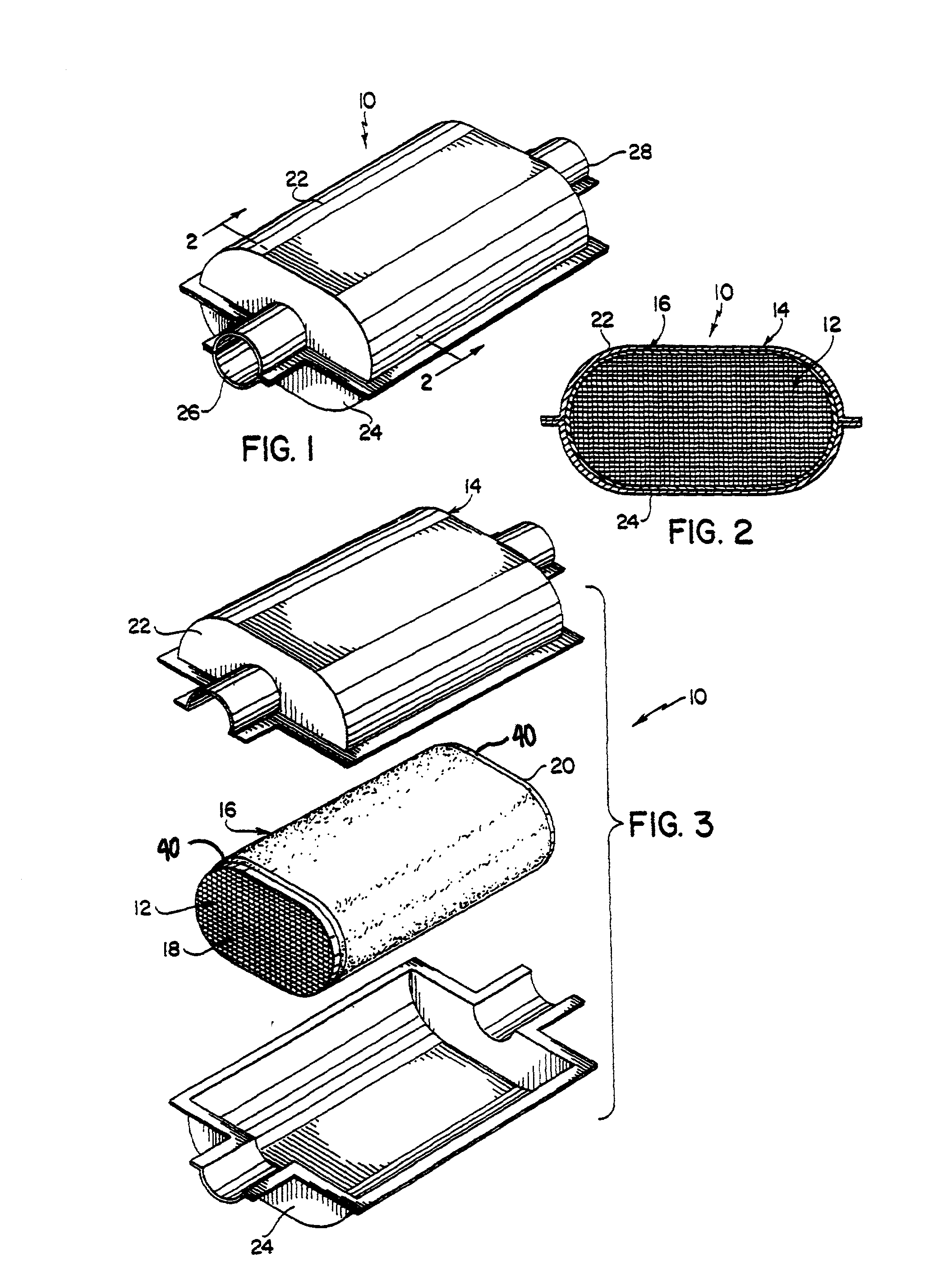

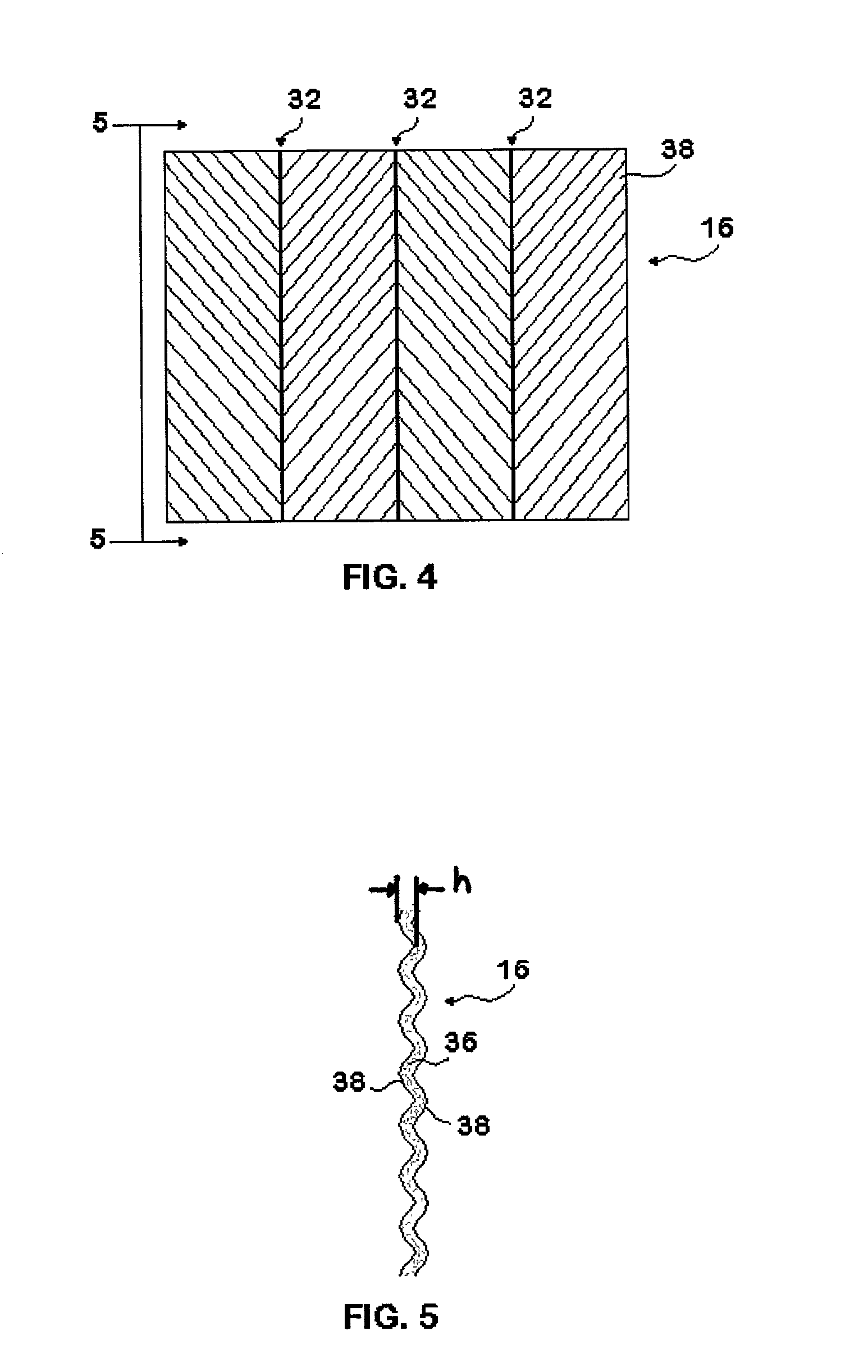

Catalytic monolith support system with improved thermal resistance and mechanical properties

InactiveUS20030129101A1Effective supportEffective insulationCombination devicesSilencing apparatusCatalytic transformationSupporting system

The instant invention provides a new high temperature catalytic monolith support system which can be effectively utilized for sealing between the catalytic monolith and the housing of a catalytic converter, as well as physically cushioning the catalytic monolith within the housing. The support system preferably is made form wire mesh and a non-intumescent thermoresistant paper, in which the wire mesh and thermoresistant paper are integral and crimped together to produce a multi-herringbone configuration, providing multiple perpendicular barriers that prevent the gas-flow from bypassing the monolith.

Owner:ACS IND INC

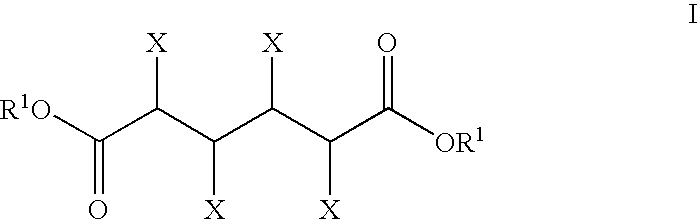

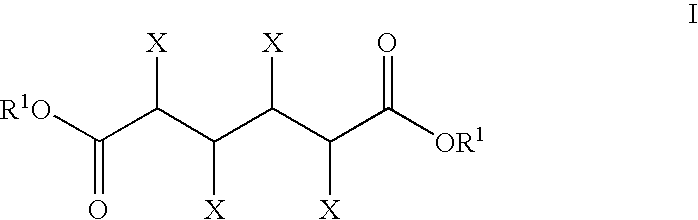

Production of Adipic Acid and Derivatives from Carbohydrate-Containing Materials

ActiveUS20100317823A1Increase costLow costCarboxylic acid nitrile preparationOrganic chemistry methodsCatalytic transformationCatalytic oxidation

The present invention generally relates to processes for the chemocatalytic conversion of a glucose source to an adipic acid product. The present invention includes processes for the conversion of glucose to an adipic acid product via glucaric acid or derivatives thereof. The present invention also includes processes comprising catalytic oxidation of glucose to glucaric acid or derivative thereof and processes comprising the catalytic hydrodeoxygenation of glucaric acid or derivatives thereof to an adipic acid product. The present invention also includes products produced from adipic acid product and processes for the production thereof from such adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

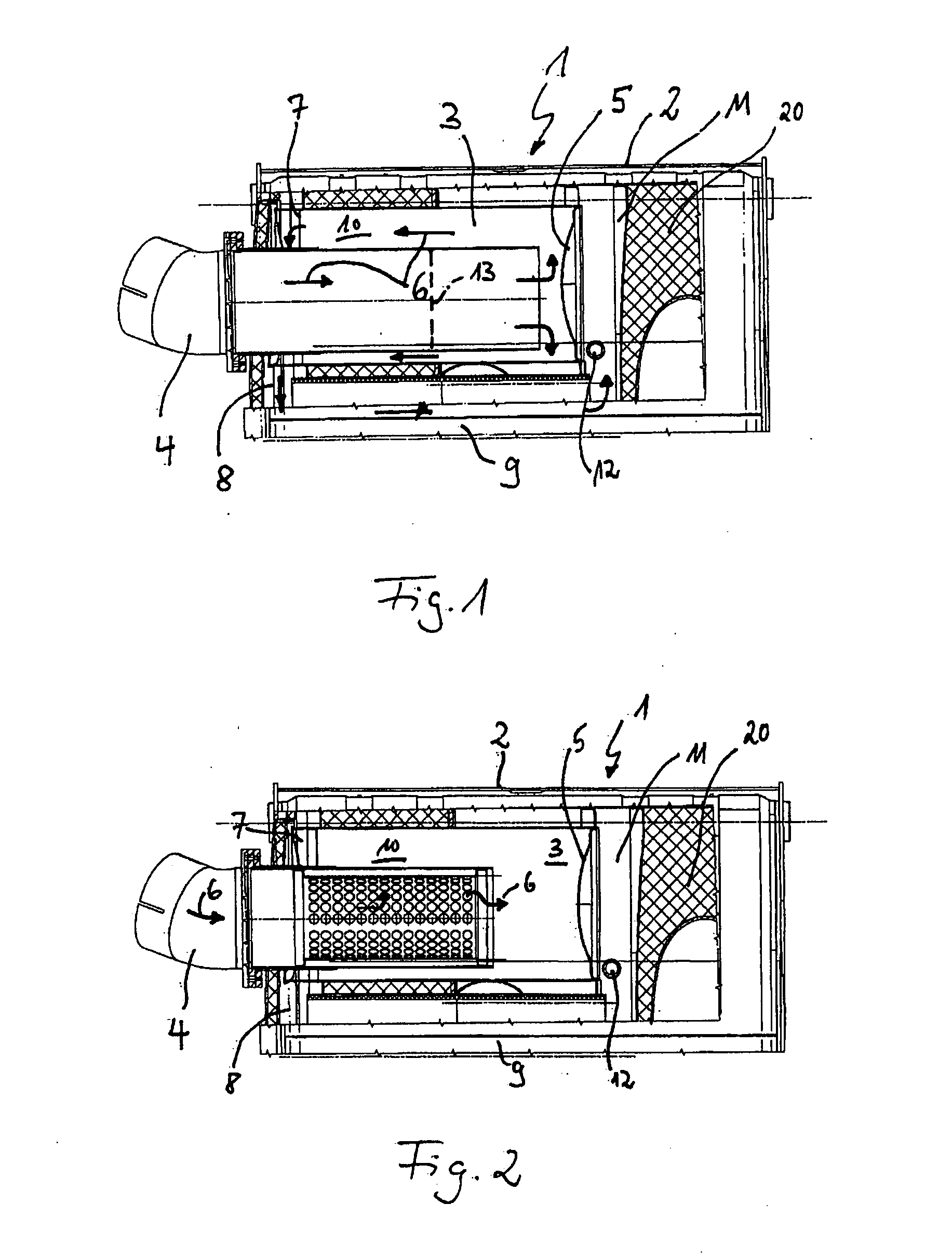

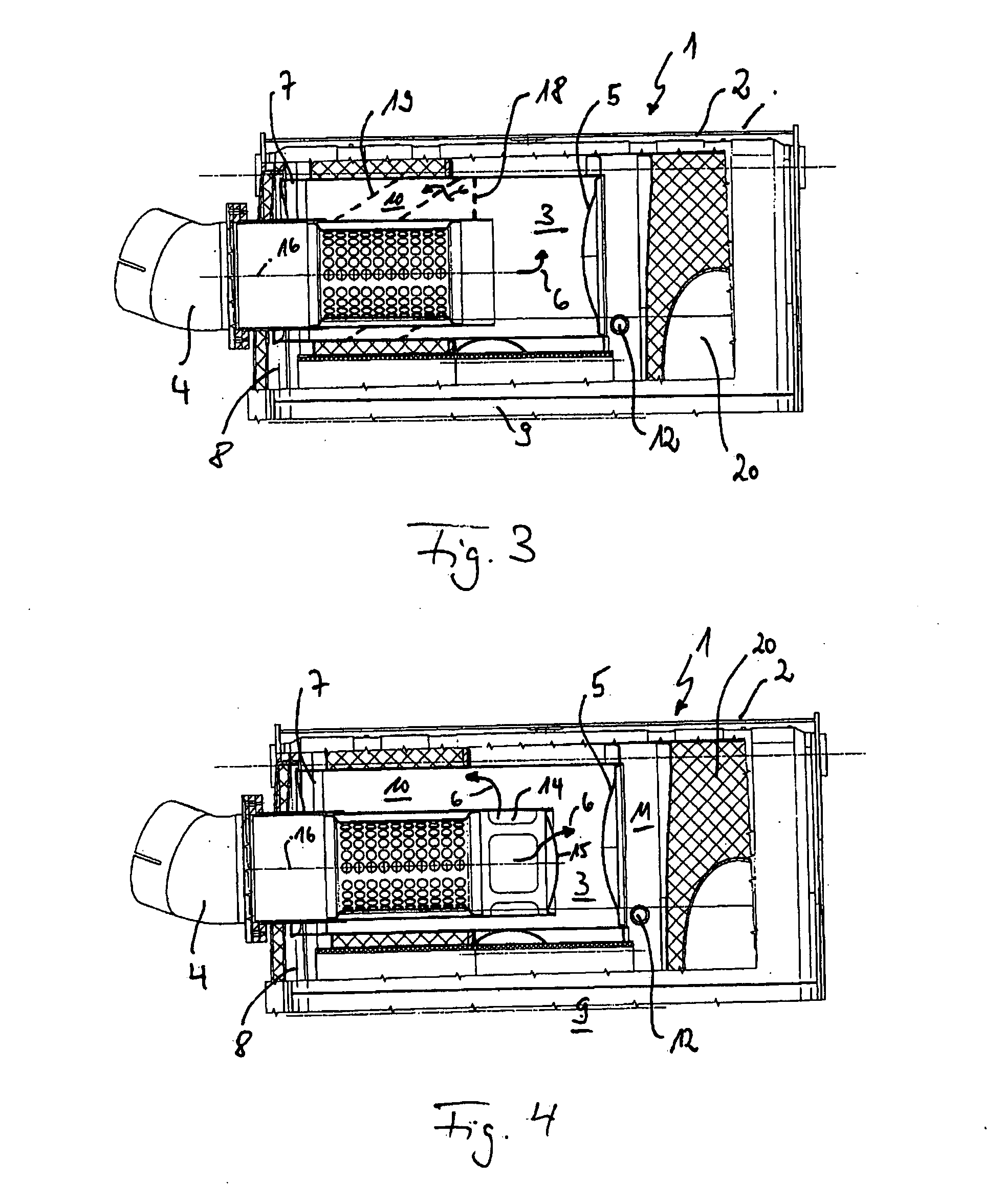

Exhaust gas aftertreatment device for an internal combustion engine

ActiveUS20070289294A1Good and thorough mixingWell and thorough mixingInternal combustion piston enginesSilencing apparatusExhaust fumesAfter treatment

The invention relates to an exhaust gas after-treatment device for an internal combustion engine, including a housing into which an exhaust pipe that opens into a mixing chamber penetrates. The mixing chamber is shaped as a pot and reverses a direction of flow of the incoming exhaust gas whereby it returns the exhaust gas radially outside of the exhaust pipe. An open end of the pot-shaped mixing chamber opens into a collecting space which is designed so that it supplies the exhaust gas to at least one downstream SCR catalytic converter.

Owner:PUREM GMBH

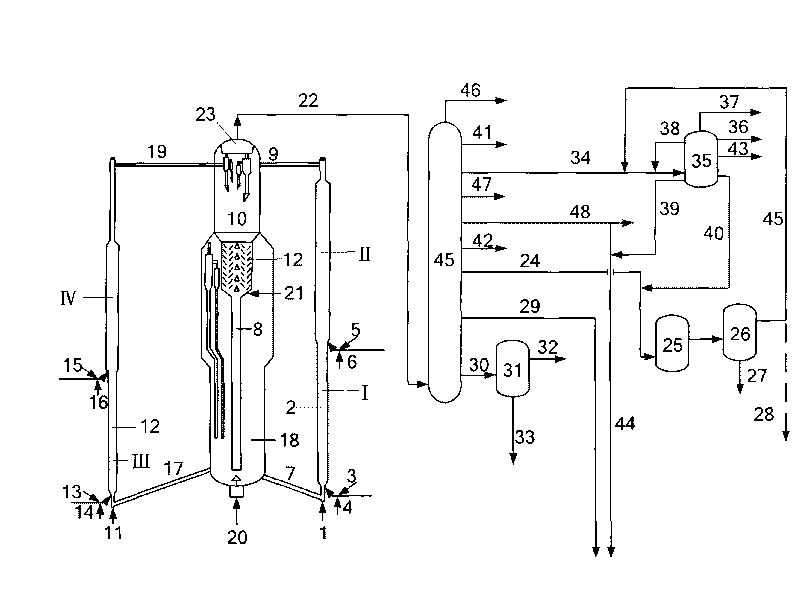

Catalytic conversion method for preparing lower olefins and aromatics

The invention relates to a catalytic conversion method for preparing lower olefins and aromatics. Raw oil with different cracking performances enters different reaction zones of a first riser reactor to contact with a catalytic cracking catalyst for cracking reaction to separate a spent catalyst from reaction oil gas, wherein the spent catalyst after stripping enters a first regenerator and returns to a first riser after scorching regeneration, the reaction oil gas is separated to obtain a product containing lower olefins, gasoline, distillates with distillation range of 180-250 DEG C and catalytic wax oil, wherein the gasoline is extracted by light aromatics to obtain light aromatics and gasoline raffinate; the raw materials are cracked to be sent into a second riser reactor to contract with a hot regenerated catalyst for catalytic conversion; and the spent catalyst is burned and regenerated in a second regenerator and then returns to a second riser reactor. The method uses heavy rawmaterials to furthest produce the lower olefins, such as propylene, ethylene, and the like, particularly the propylene, the production rate can exceed 40 wt%, and at the same time the method can coproduce the aromatics, such as toluene, xylene, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Start-up of a methanol-to-olefin process

InactiveUS6872867B1Low costAvoid expensesMolecular sieve catalystCatalystsMotor driveThermal compression

A catalytic conversion process using a fluidized conversion zone, which requires a minimum superficial gas velocity to function properly, and a motor-driven, capacity-limited product compressor zone is started up using a thermal compressor by establishing two start-up gas recirculation circuits, one using the product compression zone running at high pressure to recirculate about 40 to 60 vol-% of the effluent gas stream from the conversion zone and the other running at low pressure and carrying the remaining portion of the effluent gas stream from the fluidized conversion zone where the high pressure circuit supplies motive gas to the thermal compression zone and the low pressure circuit supplies suction gas to the thermal compressor and the resulting compressed discharge gas enables the catalytic process to start up without the use of a dedicated motor-driven start-up compressor.

Owner:UOP LLC

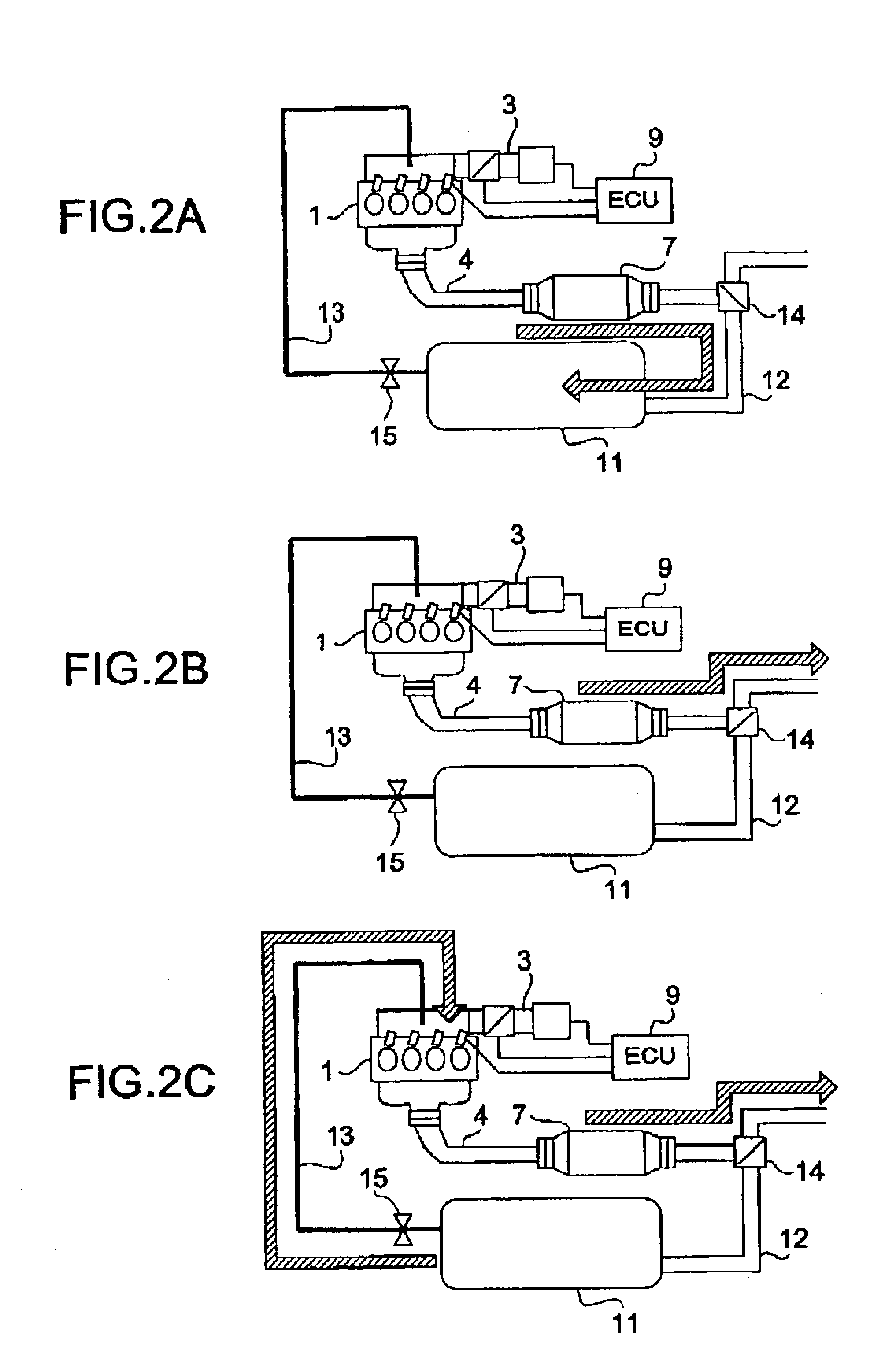

Exhaust gas purifying method, exhaust gas purifying apparatus, and exhaust gas collecting apparatus of internal combustion engine

InactiveUS6901743B2Avoid dischargeSuitable for useNon-fuel substance addition to fuelInternal combustion piston enginesExhaust fumesEnvironmental engineering

An exhaust gas collecting apparatus, of an internal combustion engine including a collection vessel that can hold exhaust gas, an exhaust gas taking-out passage through which exhaust gas is introduced from an exhaust passage to the collection vessel, an exhaust gas introduction passage through which the exhaust gas is introduced from the collection vessel to the exhaust passage at a position upstream from the catalytic converter, a first valve that is switchable between a position where the introduction of the exhaust gas from the exhaust passage to the exhaust gas taking-out passage is permitted and a position where the introduction of the exhaust gas is prevented, and a second valve that is switchable between a position where the introduction of the exhaust gas through the exhaust gas introduction passage is permitted and a position where the introduction of the exhaust gas is prevented.

Owner:TOYOTA JIDOSHA KK

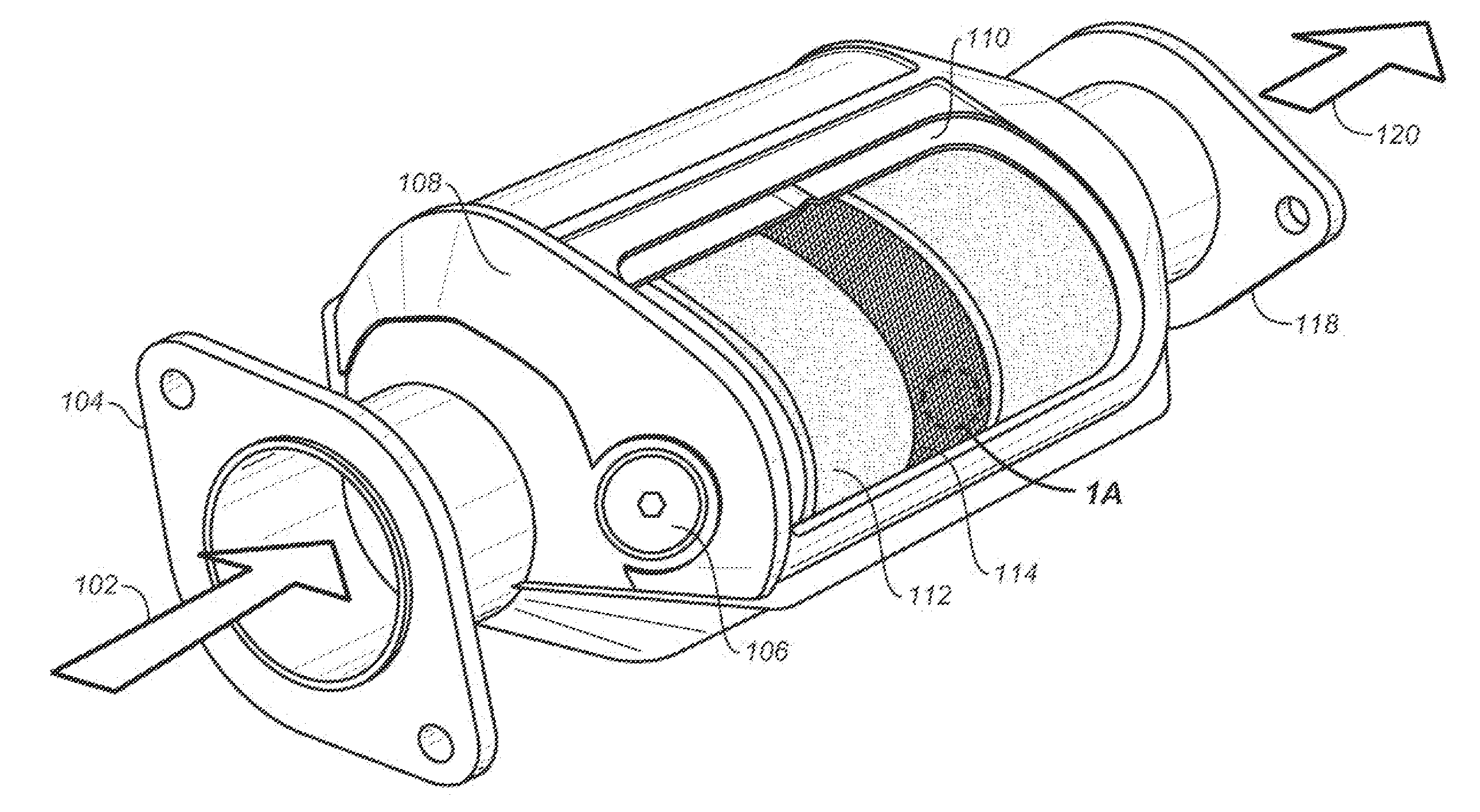

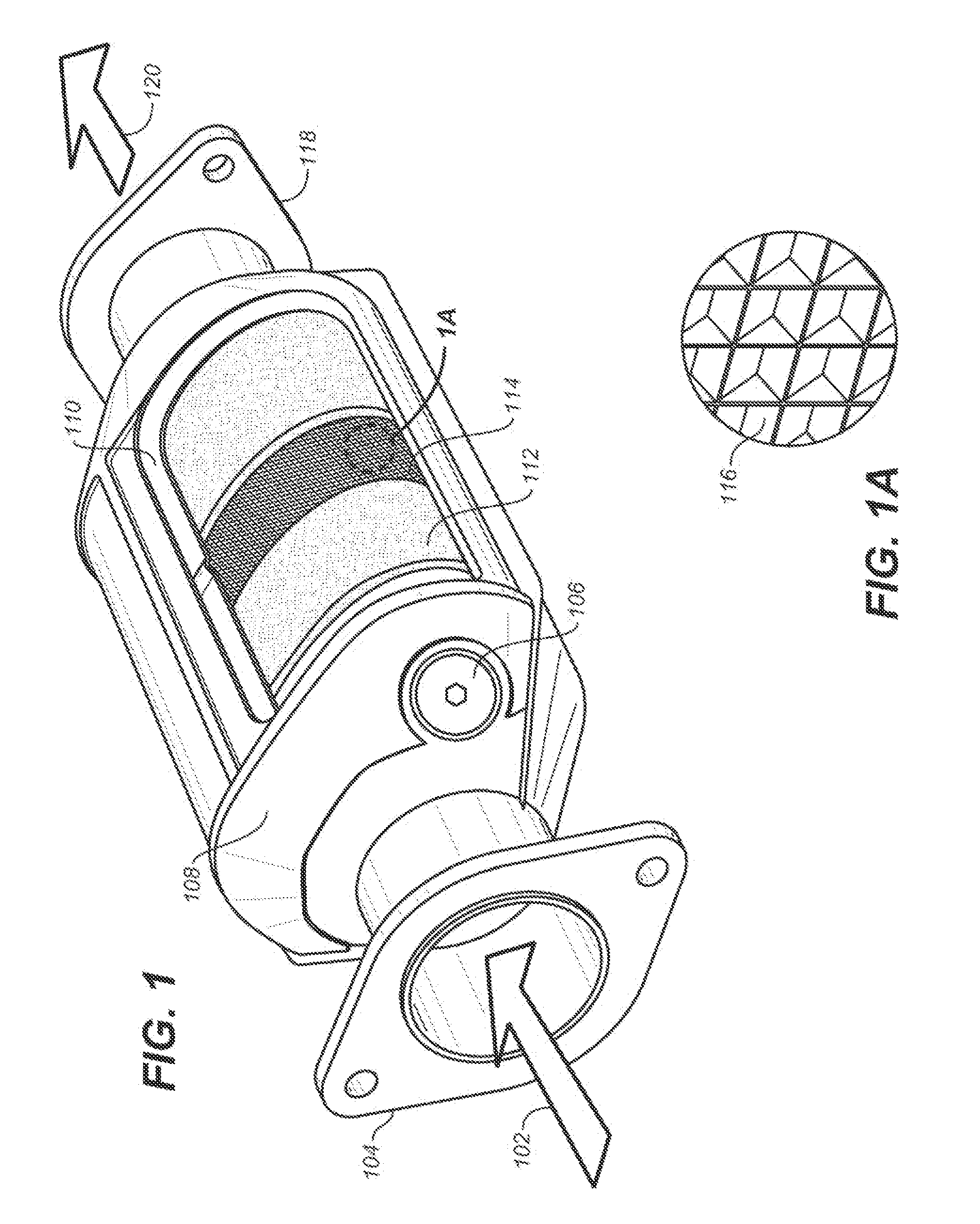

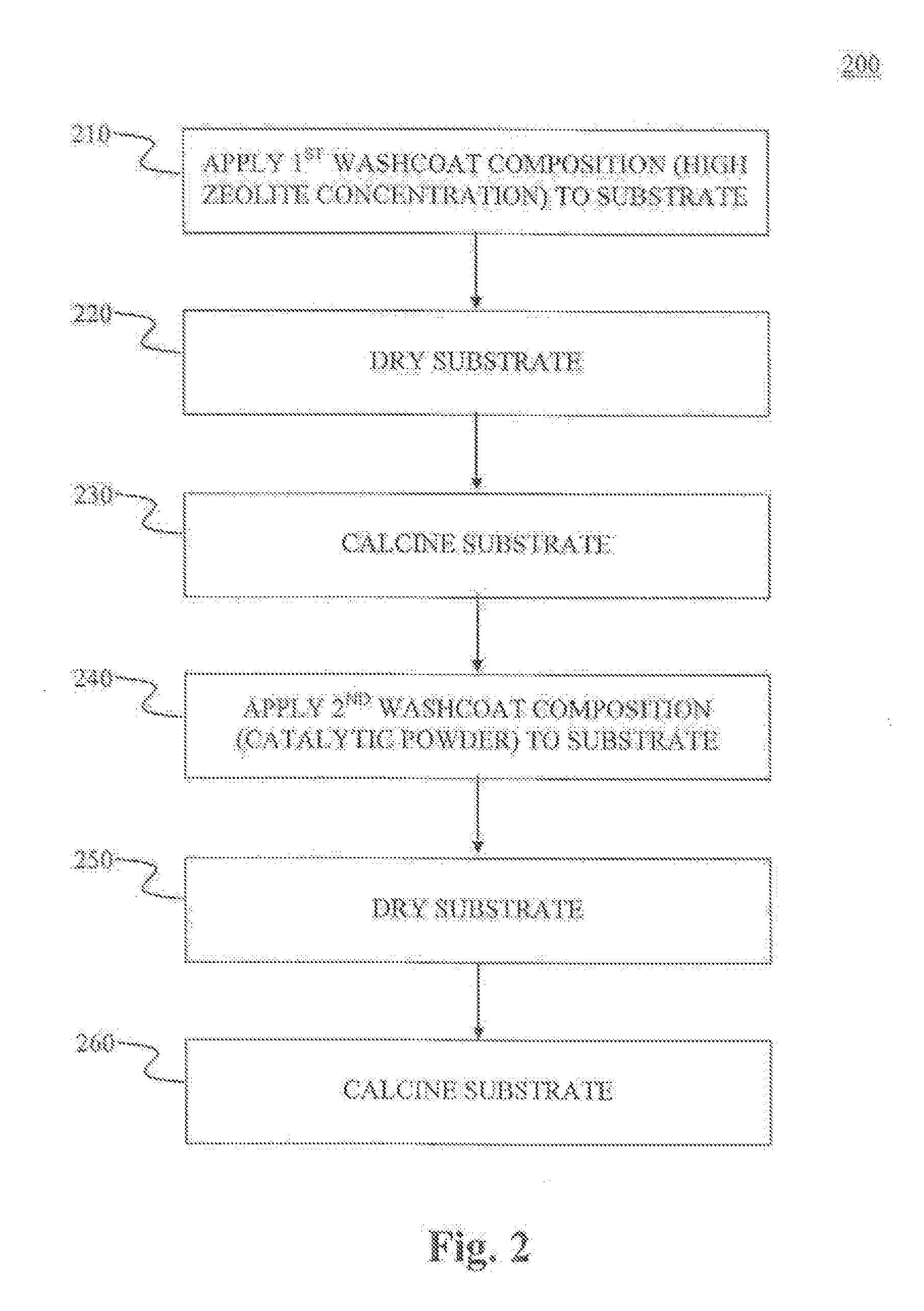

Coated substrates for use in catalysis and catalytic converters and methods of coating substrates with washcoat compositions

InactiveUS20140243187A1Improve performanceEmission reductionGas treatmentMolecular sieve catalystsCatalytic transformationConverters

Owner:SDC MATERIALS +1

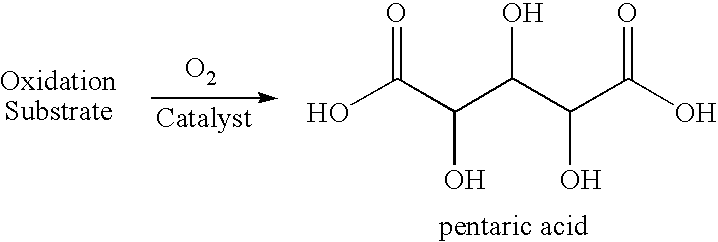

Production of glutaric acid and derivatives from carbohydrate-containing materials

ActiveUS8785683B2Low costCarboxylic acid nitrile preparationOrganic compound preparationGlutaric acidHydrodeoxygenation

The present invention generally relates to processes for the chemocatalytic conversion of a pentose source to a glutaric acid product. The present invention includes processes for the conversion of pentose to a glutaric acid product via pentaric acid or derivatives thereof. The present invention also includes processes comprising the catalytic oxidation of pentose to pentaric acid and catalytic hydrodeoxygenation of pentaric acid or derivatives thereof to a glutaric acid product.

Owner:ARCHER DANIELS MIDLAND CO

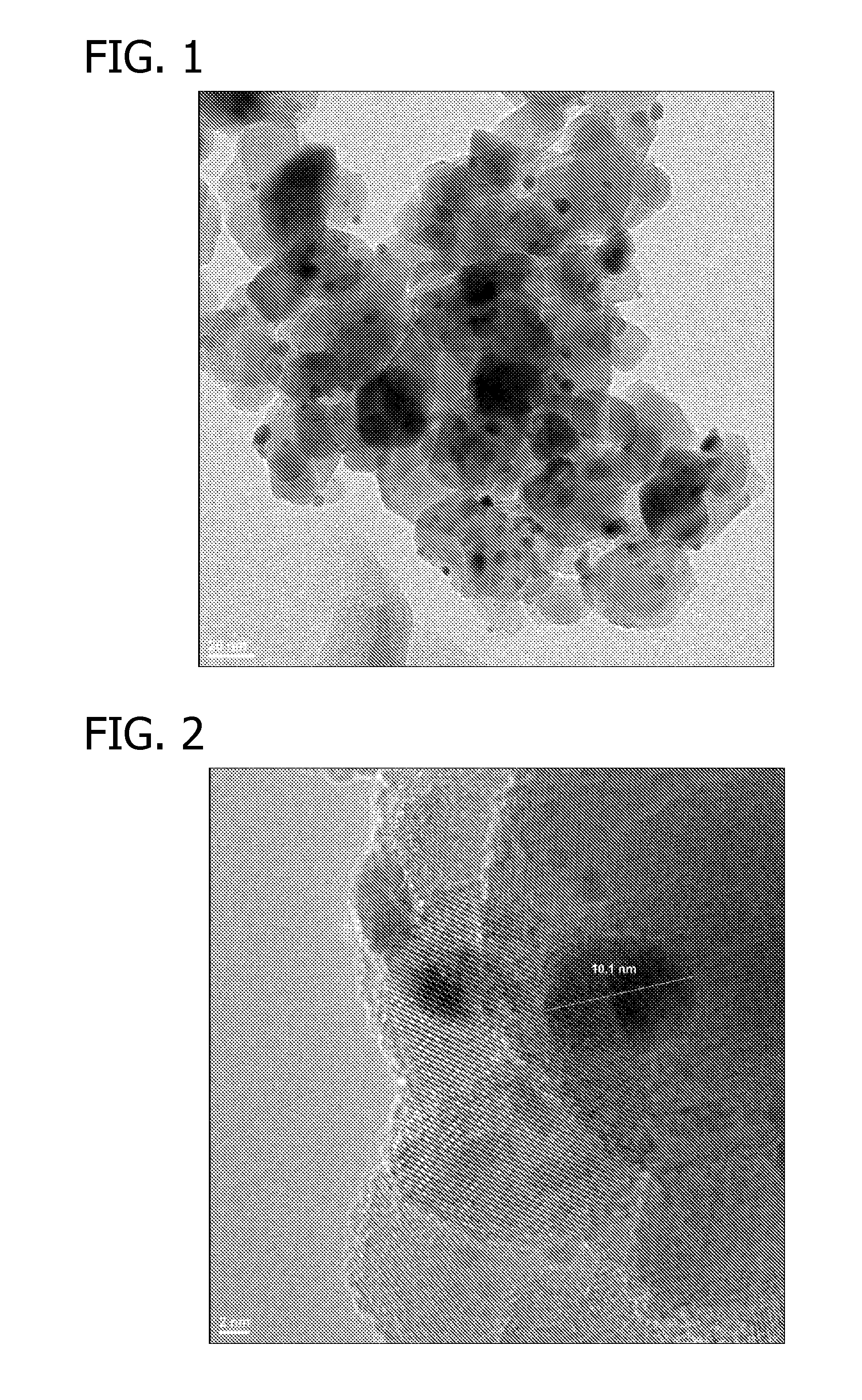

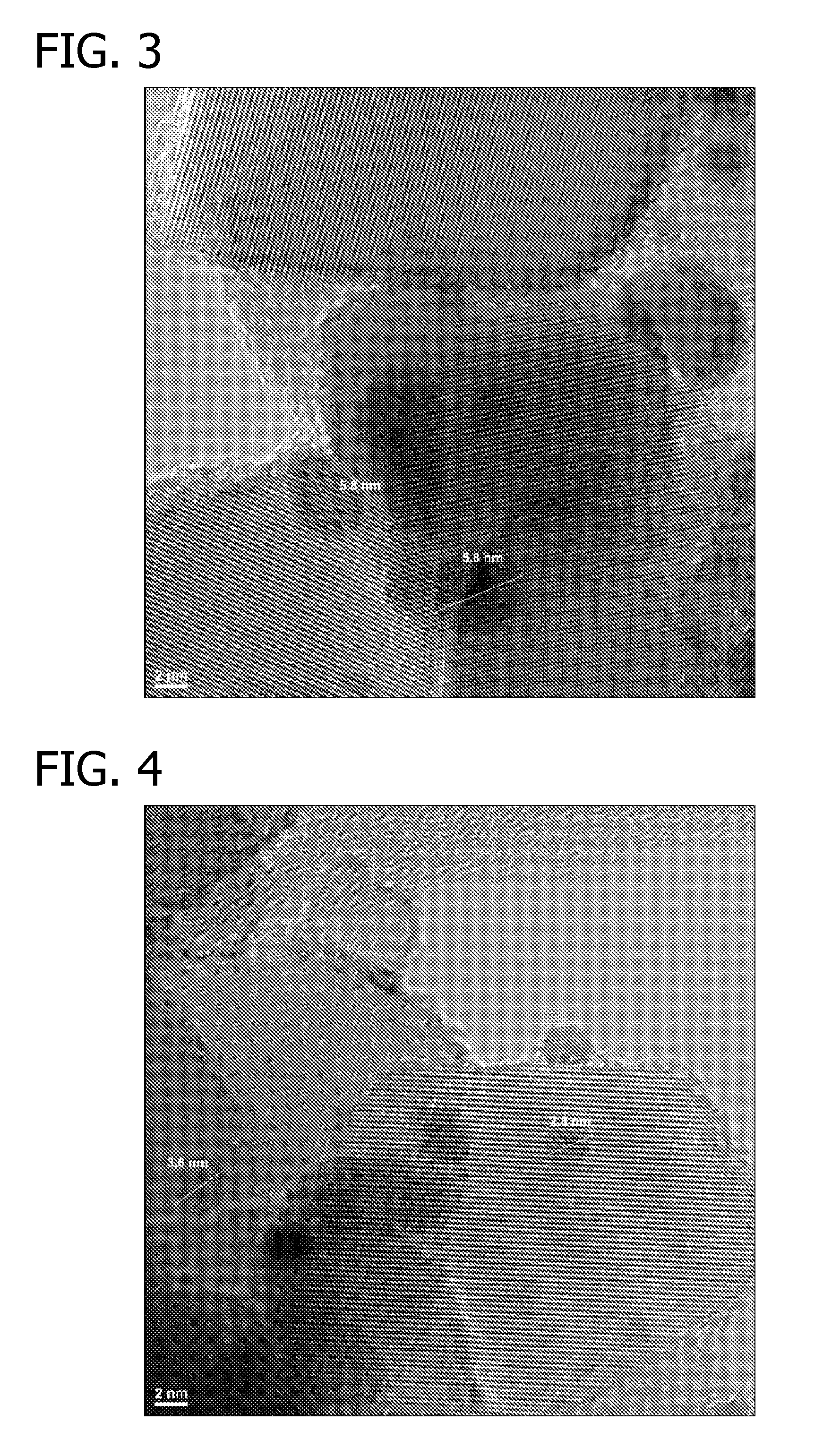

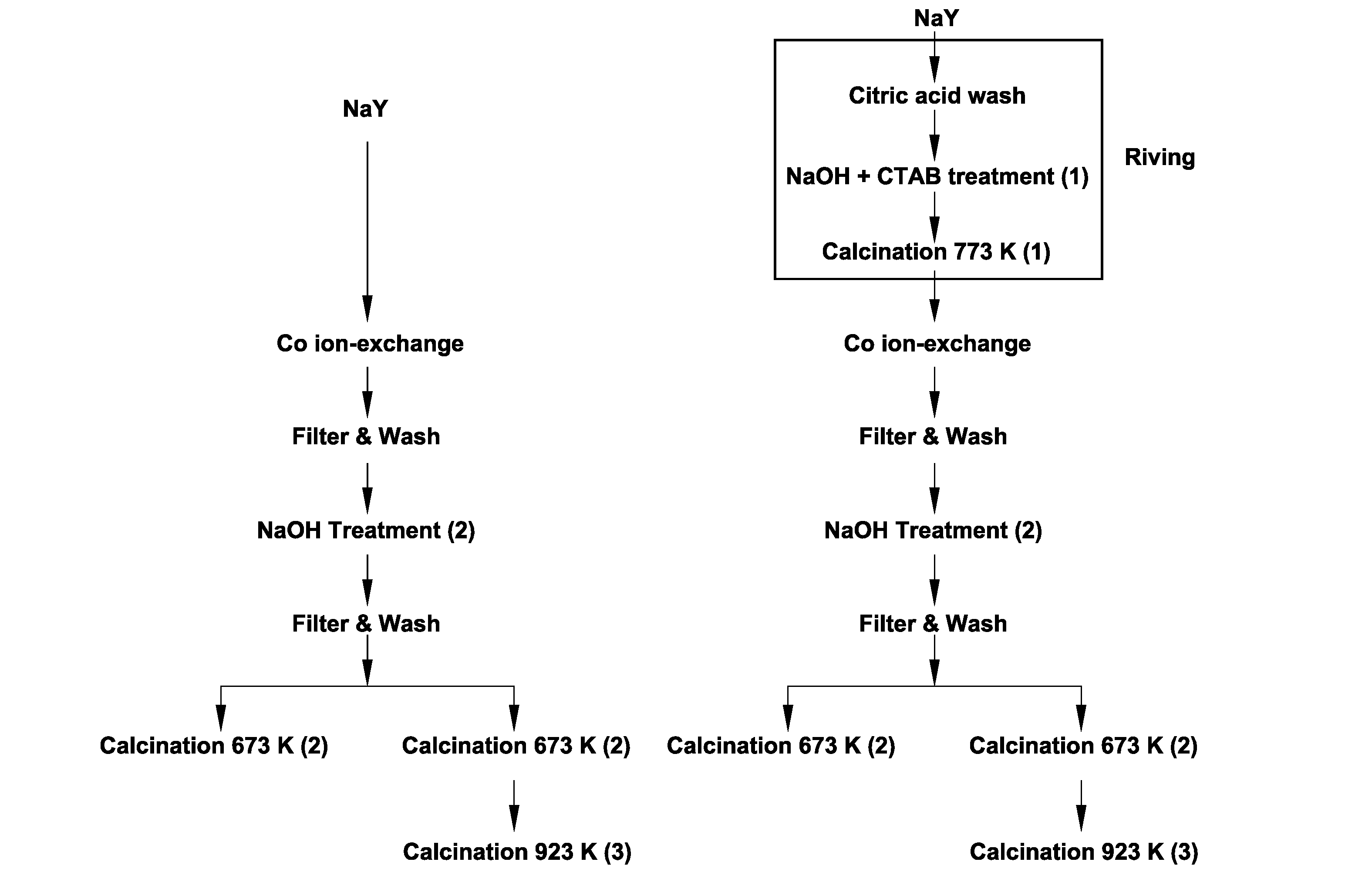

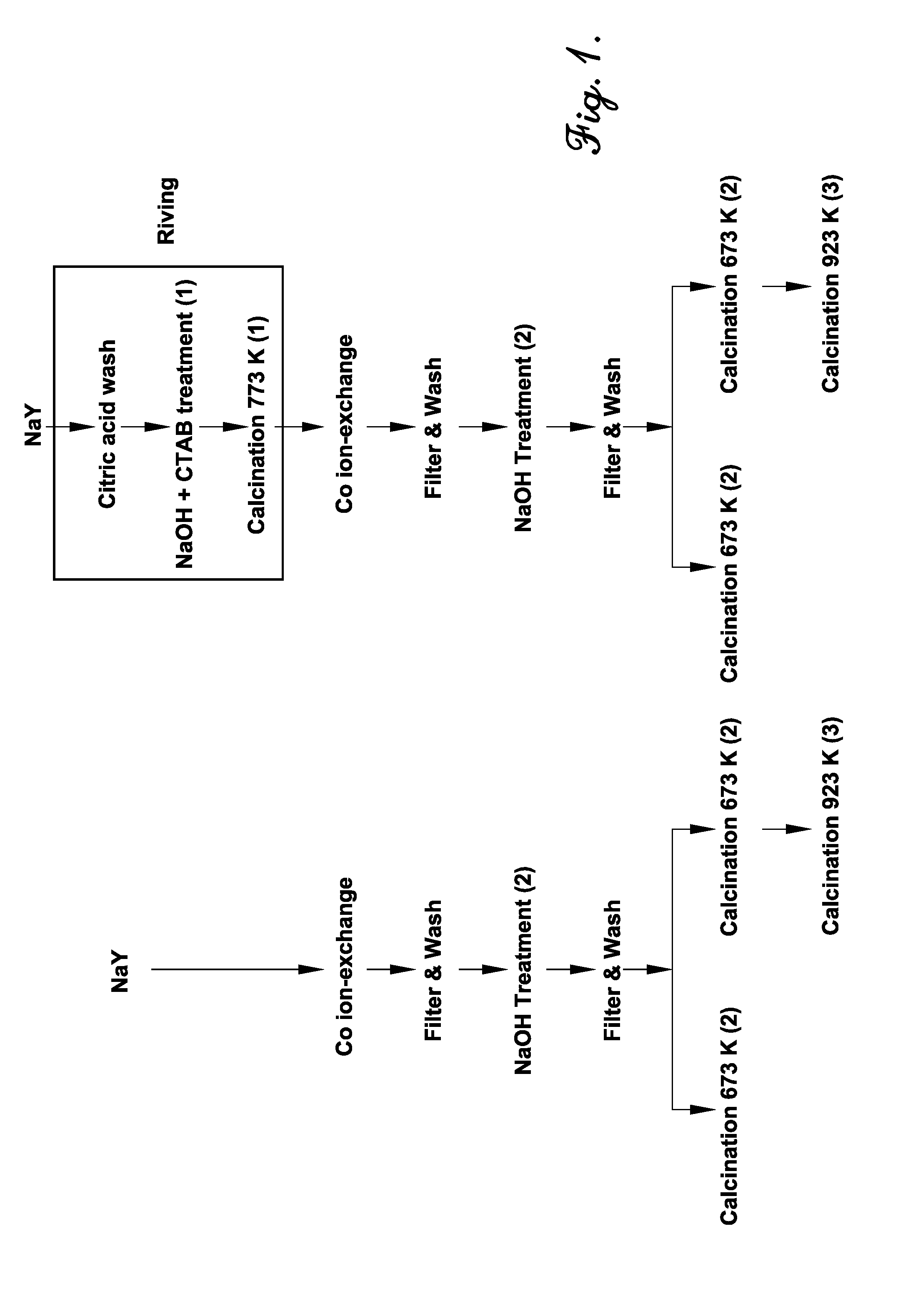

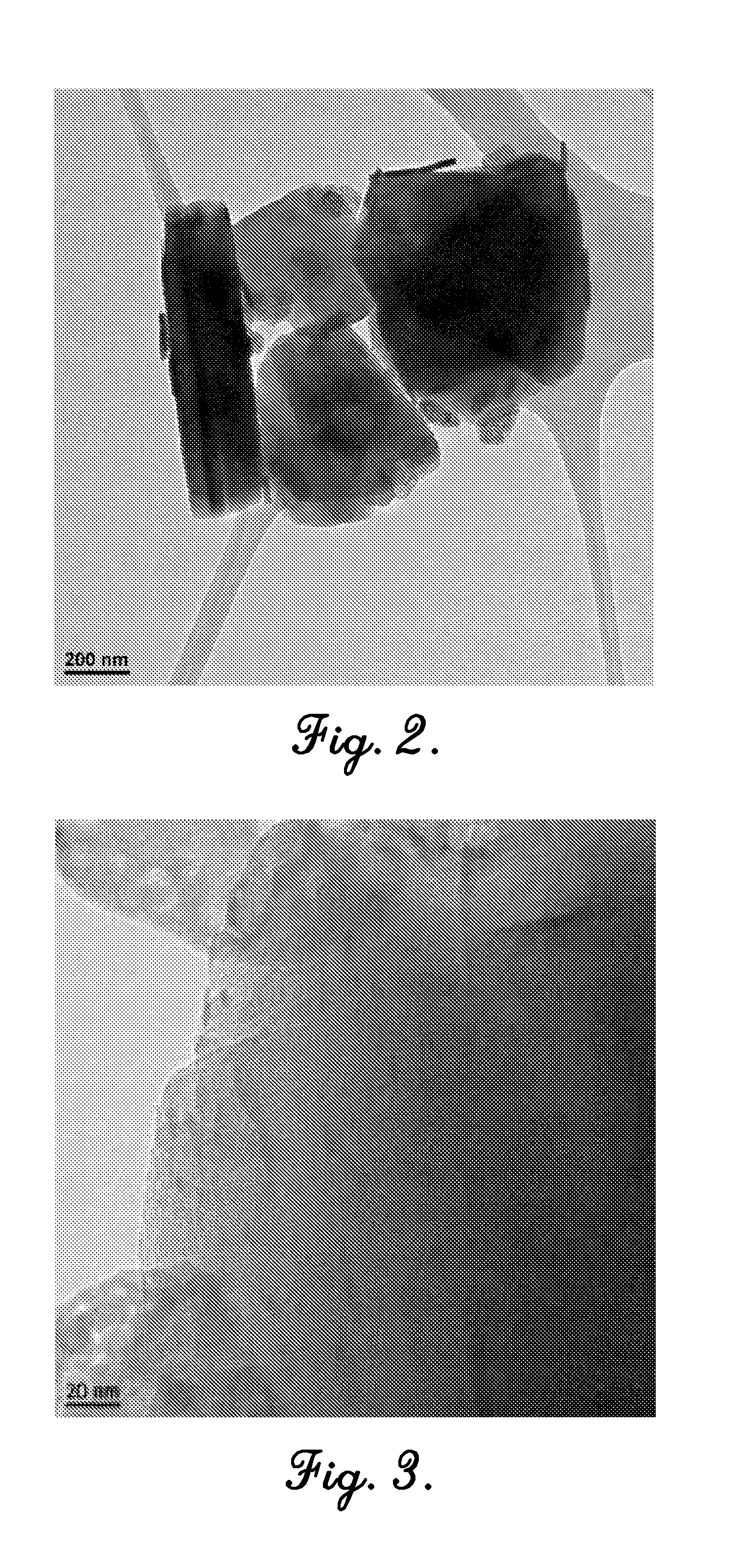

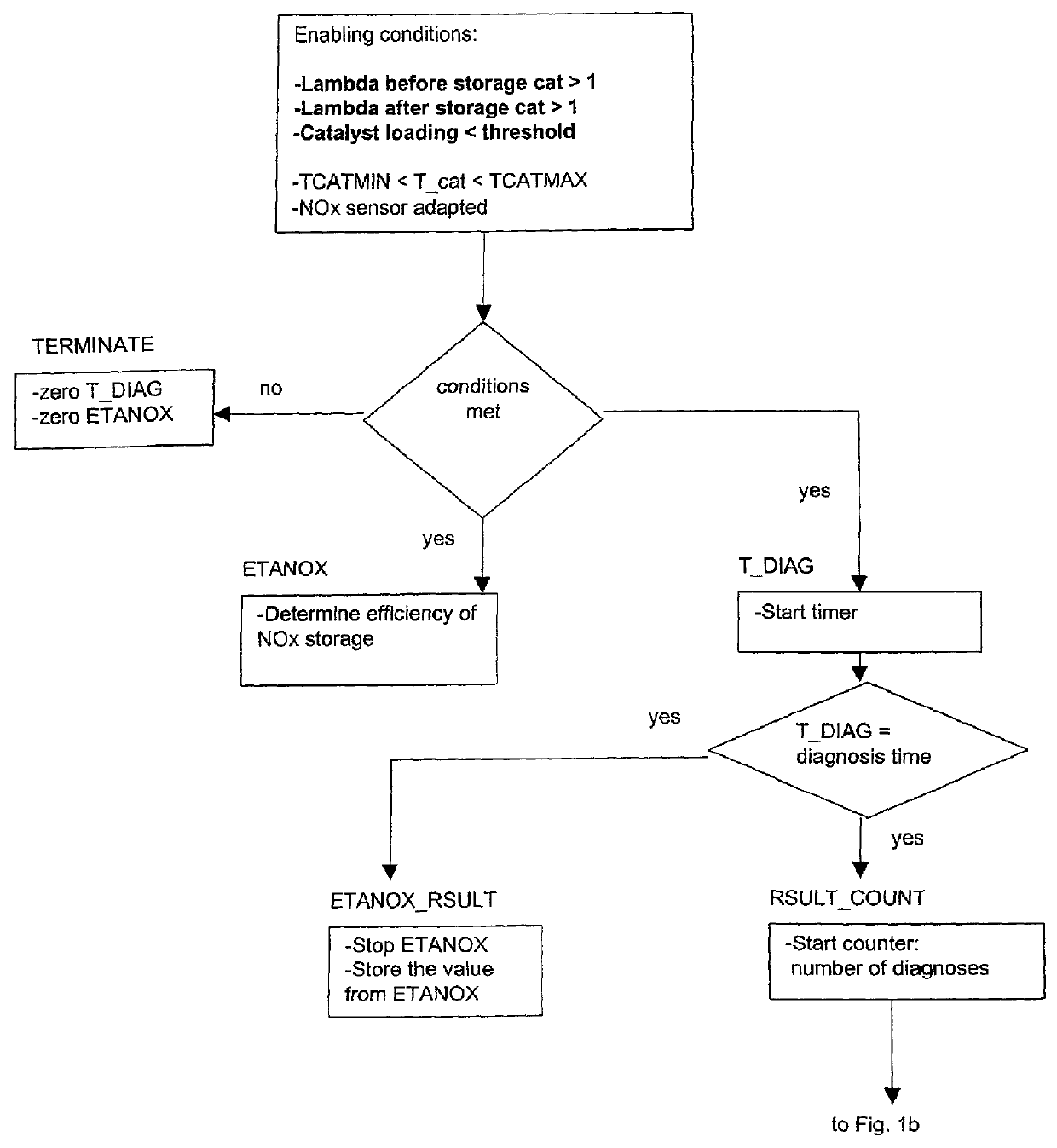

Mesoporous zeolite catalyst supports

Compositions and methods for preparing a catalyst composition containing mesoporous materials are described herein. In particular, various embodiments described herein relate to the preparation of catalytic compositions containing a mesoporous zeolite and one or more catalytic nanoparticles dispersed therein. In various embodiments described herein, such catalyst compositions can be used in various catalytic conversion processes, such as hydrocracking.

Owner:WR GRACE & CO CONN

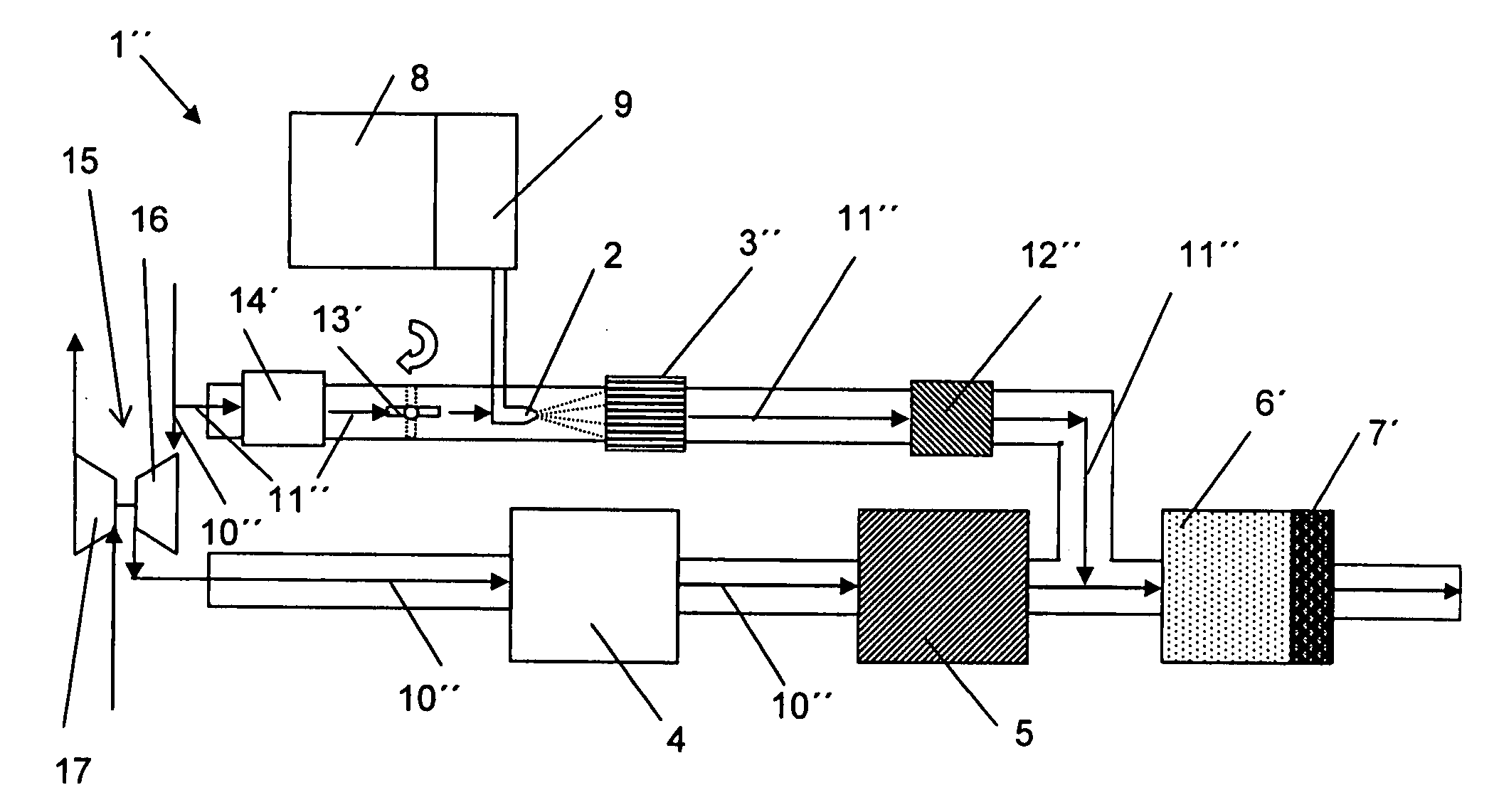

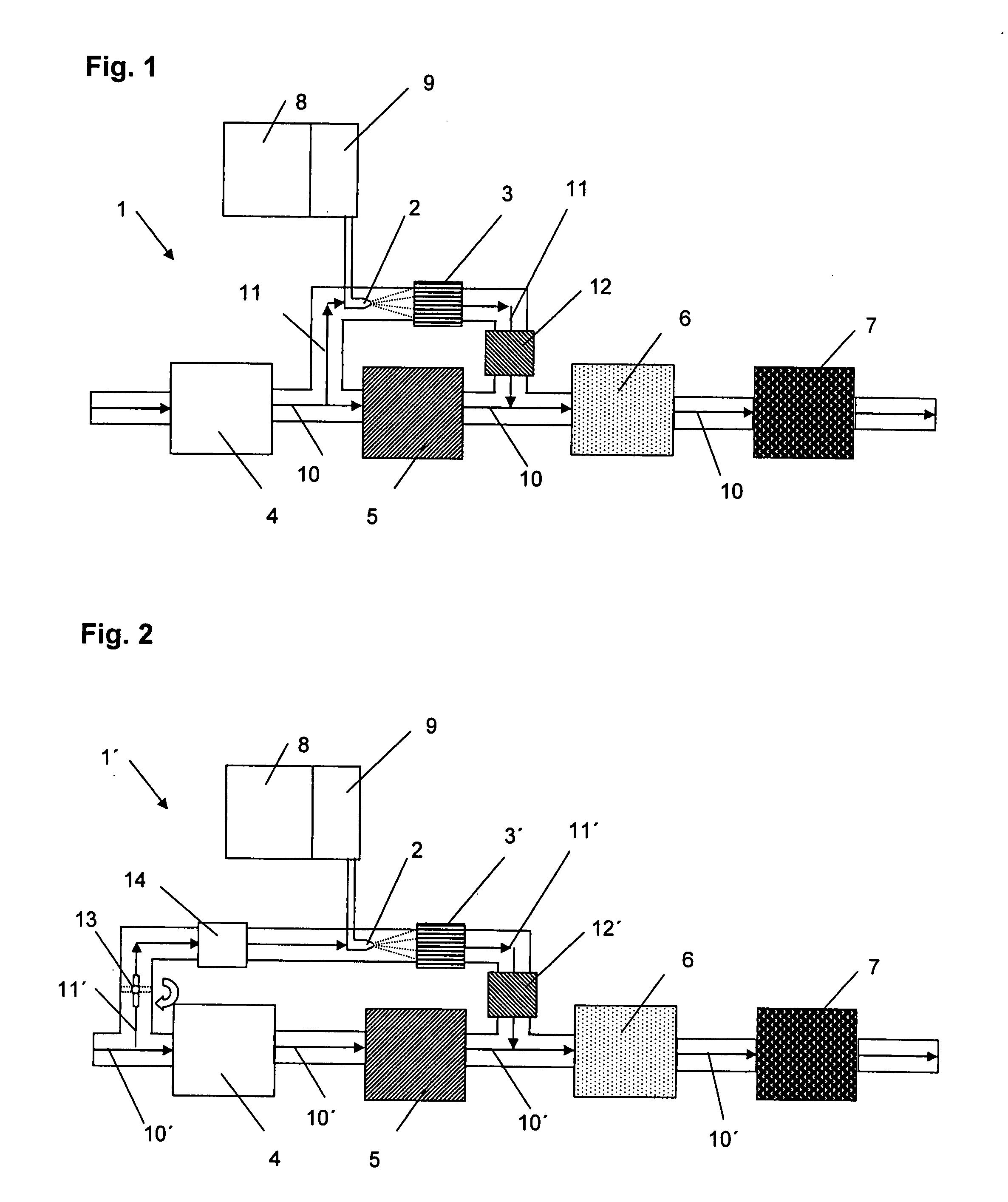

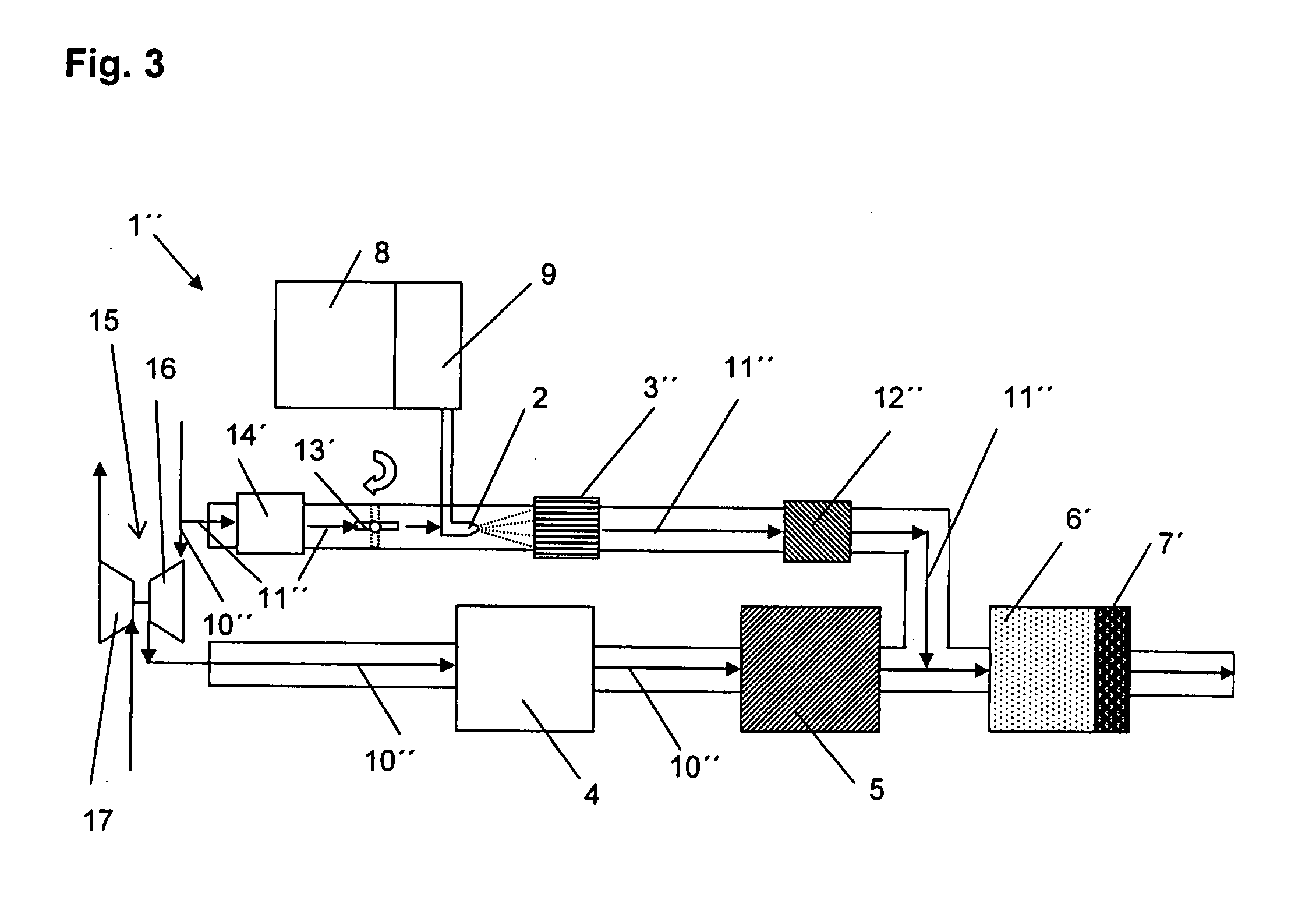

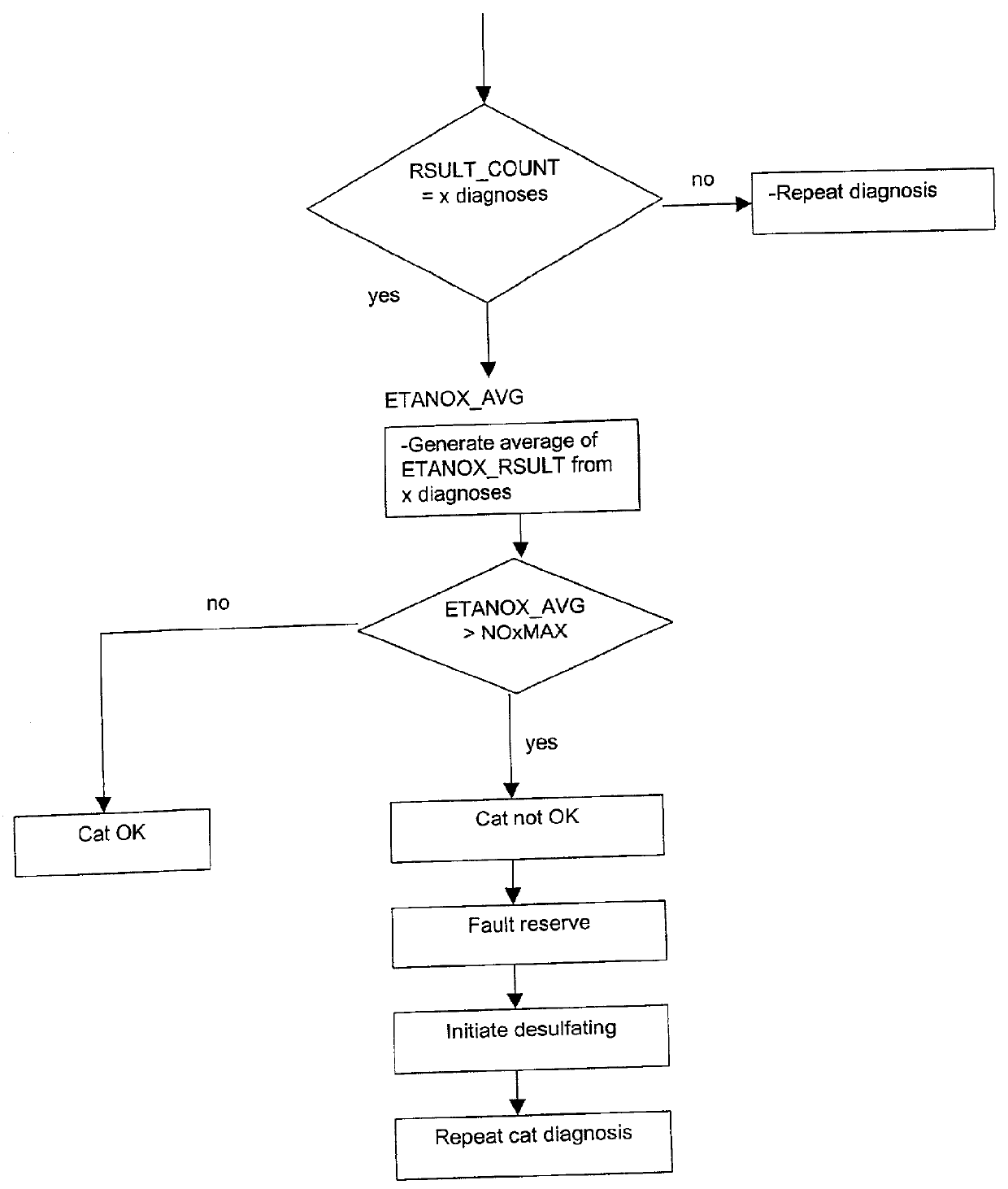

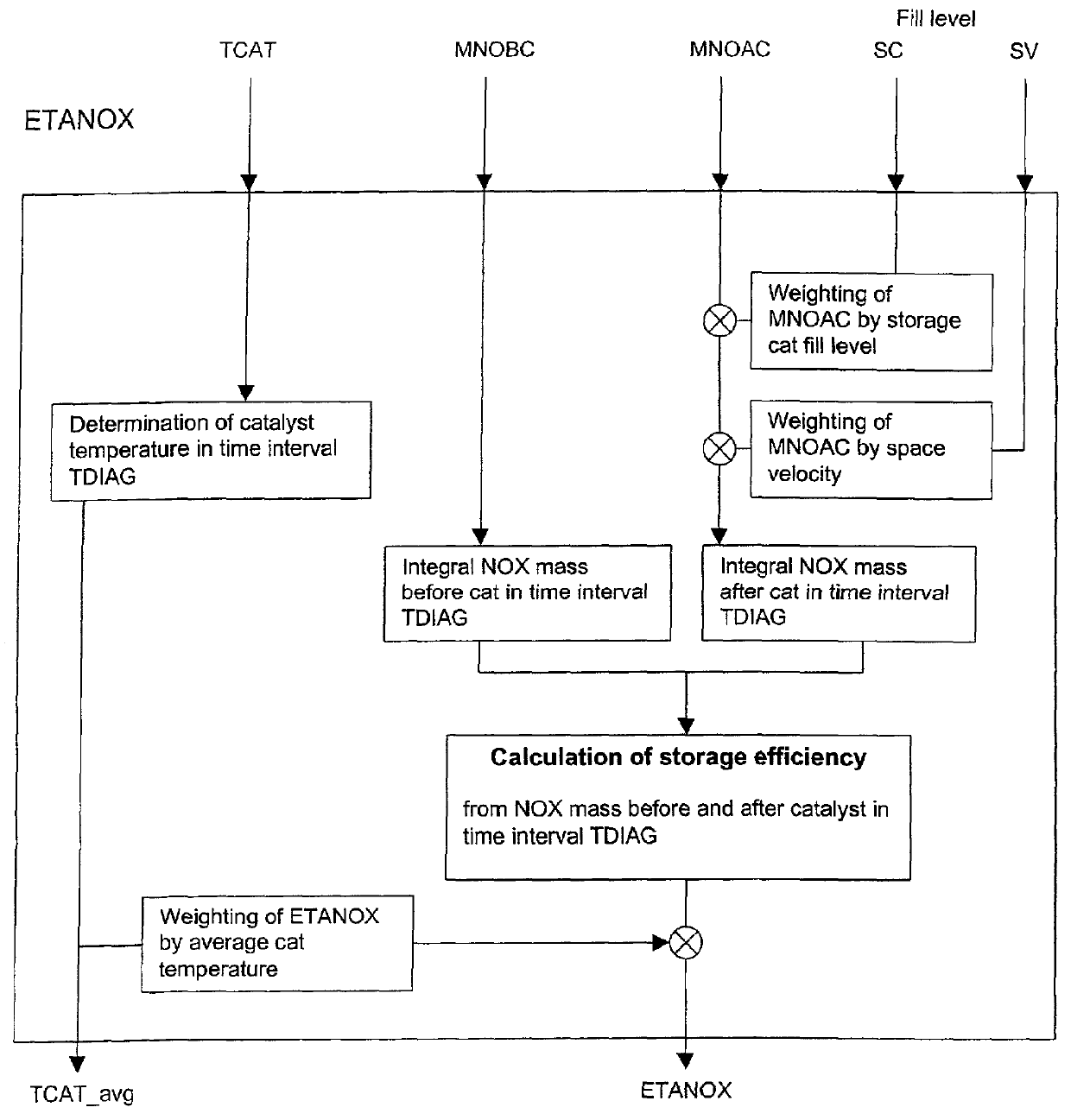

Apparatus and method for monitoring NOx storage catalytic converters

InactiveUS20010054282A1Electrical controlInternal combustion piston enginesCatalytic transformationConverters

A method and apparatus is provided for monitoring the operation of a NOx storage catalytic converter in the exhaust stream of an internal combustion engine. The NOx content of the gas stream upstream and downstream of the catalytic converter is measured and used to determine storage efficiency. This is compared to a threshold value, and if the threshold value is not met a regeneration process is performed. The storage value is measured after regeneration to determine if the catalytic converter is faulty.

Owner:VOLKSWAGEN AG

Washcoats and coated substrates for catalytic converters and methods of making and using same

ActiveUS20150093312A1Low ignition temperatureImprove performanceNitrogen compoundsInternal combustion piston enginesTreatment systemDiesel fuel

Disclosed are, inter alia, methods of forming coated substrates for use in catalytic converters, as well as washcoat compositions and methods suitable for using in preparation of the coated substrates, and the coated substrates formed thereby, which in some cases use iron-exchanged zeolite particles that provide enhanced performance such as lower light-off temperatures and lower pollutant levels in exhaust gases. The catalytic material is prepared by a plasma-based method, yielding catalytic material with a lower tendency to migrate on support at high temperatures, and thus less prone to catalyst aging after prolonged use. Also disclosed are catalytic converters using the coated substrates, which have favorable properties as compared to catalytic converters using catalysts deposited on substrates using solution chemistry. Also disclosed are exhaust treatment systems, and vehicles, such as diesel vehicles, particularly light-duty diesel vehicles, using catalytic converters and exhaust treatment systems using the coated substrates.

Owner:UMICORE AG & CO KG +1

Hydrocarbons catalytic conversion method

ActiveCN101134913AHigh yieldHigh selectivityCatalytic crackingMolecular sieve catalystsCatalytic transformationGasoline

The catalytic hydrocarbon converting process for preparing low carbon olefin cracks hydrocarbon material catalytically to obtain C2-C4 olefin, gasoline, diesel oil, heavy oil and other low molecular saturated hydrocarbons. The catalyst therefor contains zeolite mixture in 1-60 wt%, heat resistant inorganic oxide in 5-99 wt% and clay in 0-70 wt%. The zeolite mixture contains phosphorus and transition metal M modified beta- zeolite in 1-75 wt% and other kinds of zeolite, and the phosphorus and transition metal M modified beta- zeolite has the anhydrous chemical expression of (0-0.3)Na2O.(0.5-10)Al2O3.(1.3-10)P2O5.(0.7-15)MxOy.(64-97)SiO2, where, M is one or several selected from Fe, Co, Ni, Cu, Mn, Zn and Sn, x is the atom number of M and y is atom number of O in the oxide of M. The process of the present invention has high hydrocarbon converting capacity, and high low carbon olefin yield, especially high propene yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

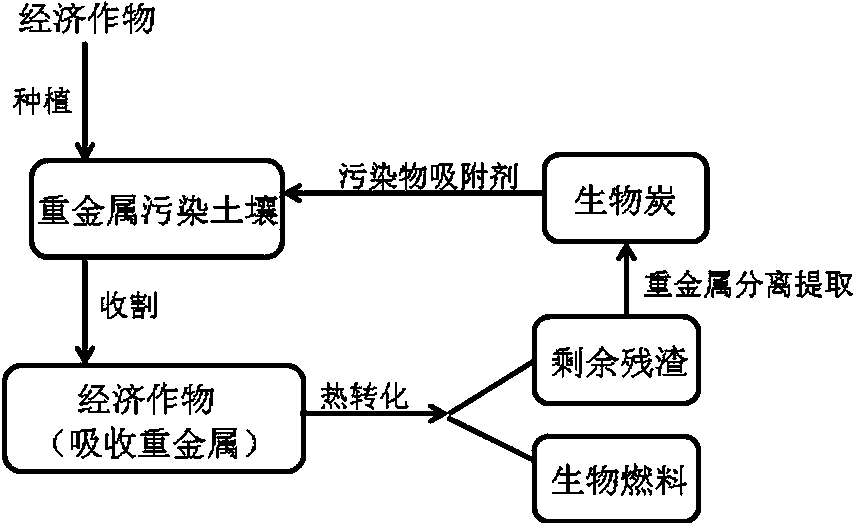

Method for using plants to control and restore soil and to generate biological fuel

ActiveCN103394505ALow costReach cascade utilizationBiofuelsContaminated soil reclamationCelluloseEcological environment

The invention provides a method for using plants to control and restore soil and to generate a biological fuel. The method comprises: planting fast-growing economic crops abundant in cellulose and lignin in polluted metal mine soil, wherein the crops are capable of absorbing and gathering heavy metals in the soil in the rapid growth process; after harvesting, moving away the economic crops, employing technologies such as thermochemistry, catalytic transformation and the like to transfer the economic crops into a biological ethanol fuel; at the same time extracting the heavy metals absorbed and gathered by the crops for separate treatment; and performing pyrolysis and charring on the residual solid residue to form biological charcoal for recycling in the mine soil and absorption of heavy metals and organic pollutants in the soil so as to gradually make the polluted soil restored and improved. The method of the invention helps to substantially reduce soil restoration cost, and reaches the purposes of cascade utilization, cyclic utilization and ecological environment protection.

Owner:ZHONGKE DINGSHI ENVIRONMENTAL ENG CO LTD

Operating Method for a Motor Vehicle Diesel Engine Having an Exhaust Emission Control System

InactiveUS20140041367A1Reduced operating requirementsLow pollutant emissionElectrical controlInternal combustion piston enginesControl systemDiesel engine

An operating method is provided for a motor vehicle diesel engine having an exhaust emission control system that includes a three-way catalytic converter and an SCR catalytic converter situated one behind the other in the flow direction of the exhaust gas. The diesel engine is operated, at least intermittently, with an air-fuel ratio of approximately λ=1.0 in a first operating range in which the SCR catalytic converter falls below a predefinable minimum temperature and with excess air that is typical for normal diesel engine operation in a second operating range in which the SCR catalytic converter exceeds the predefinable minimum temperature. An output signal of an exhaust gas sensor situated downstream from the three-way catalytic converter and which is correlated with a NOx concentration of the exhaust gas is used to set the air-fuel ratio in the first operating range.

Owner:DAIMLER AG

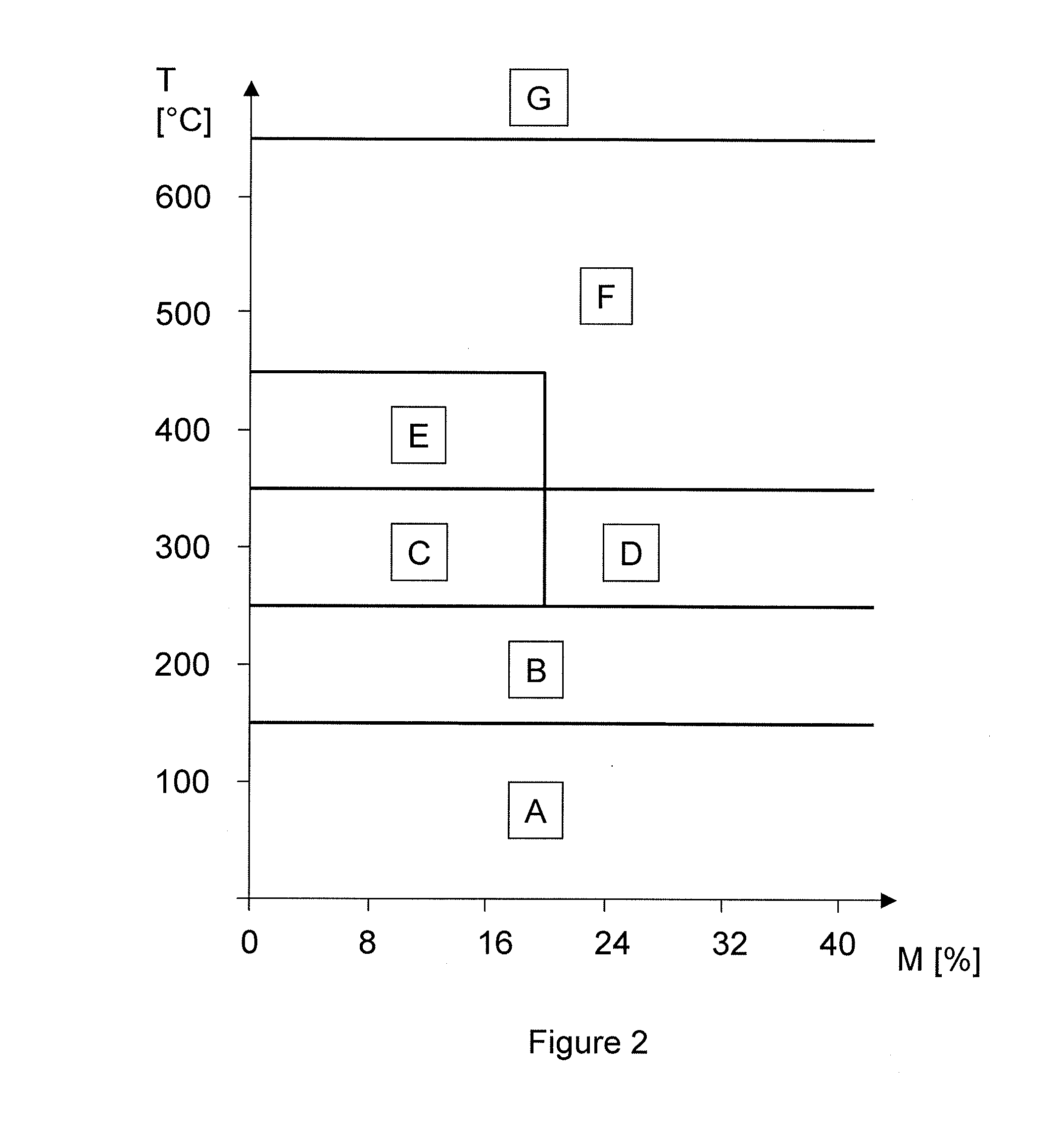

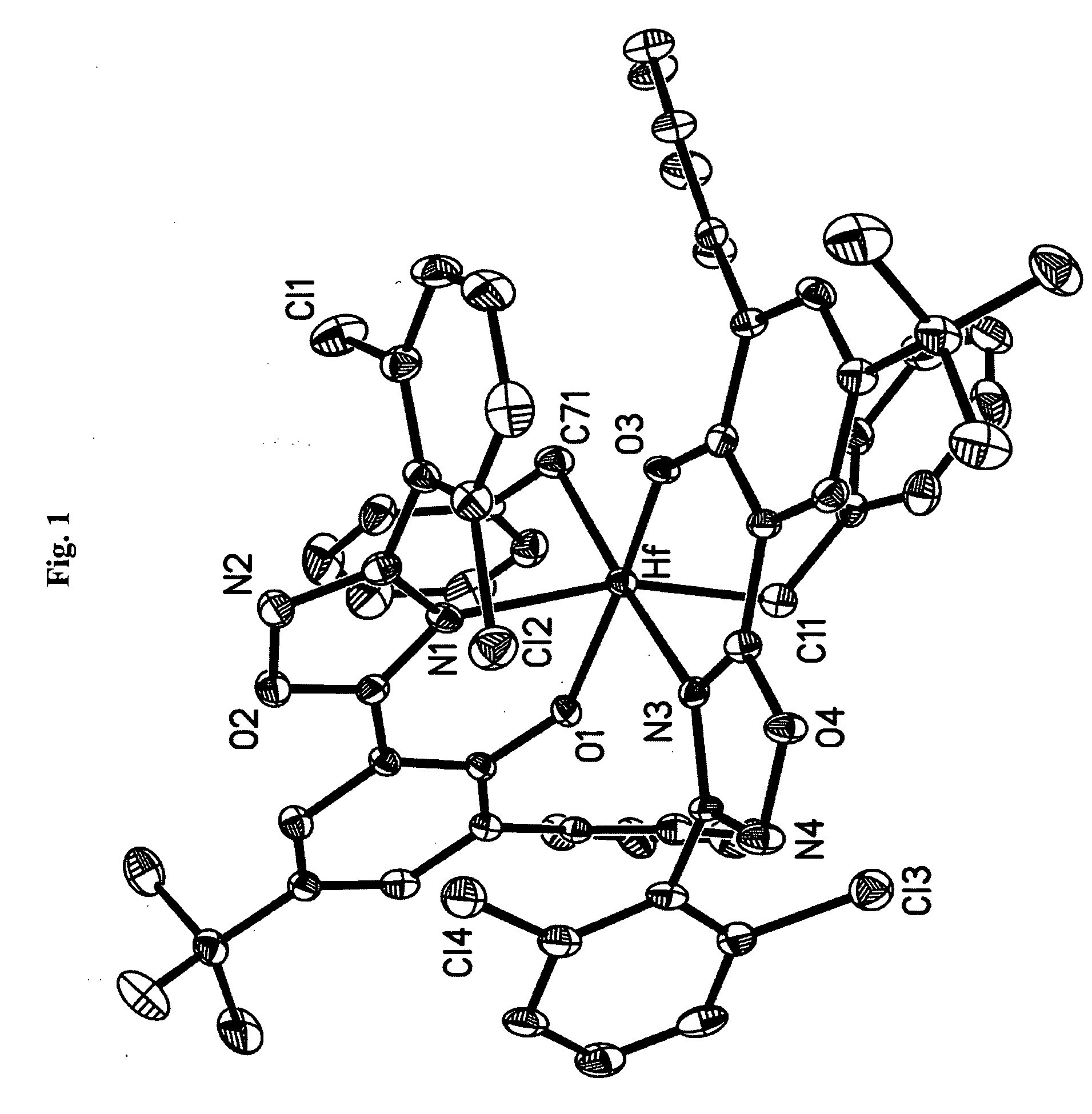

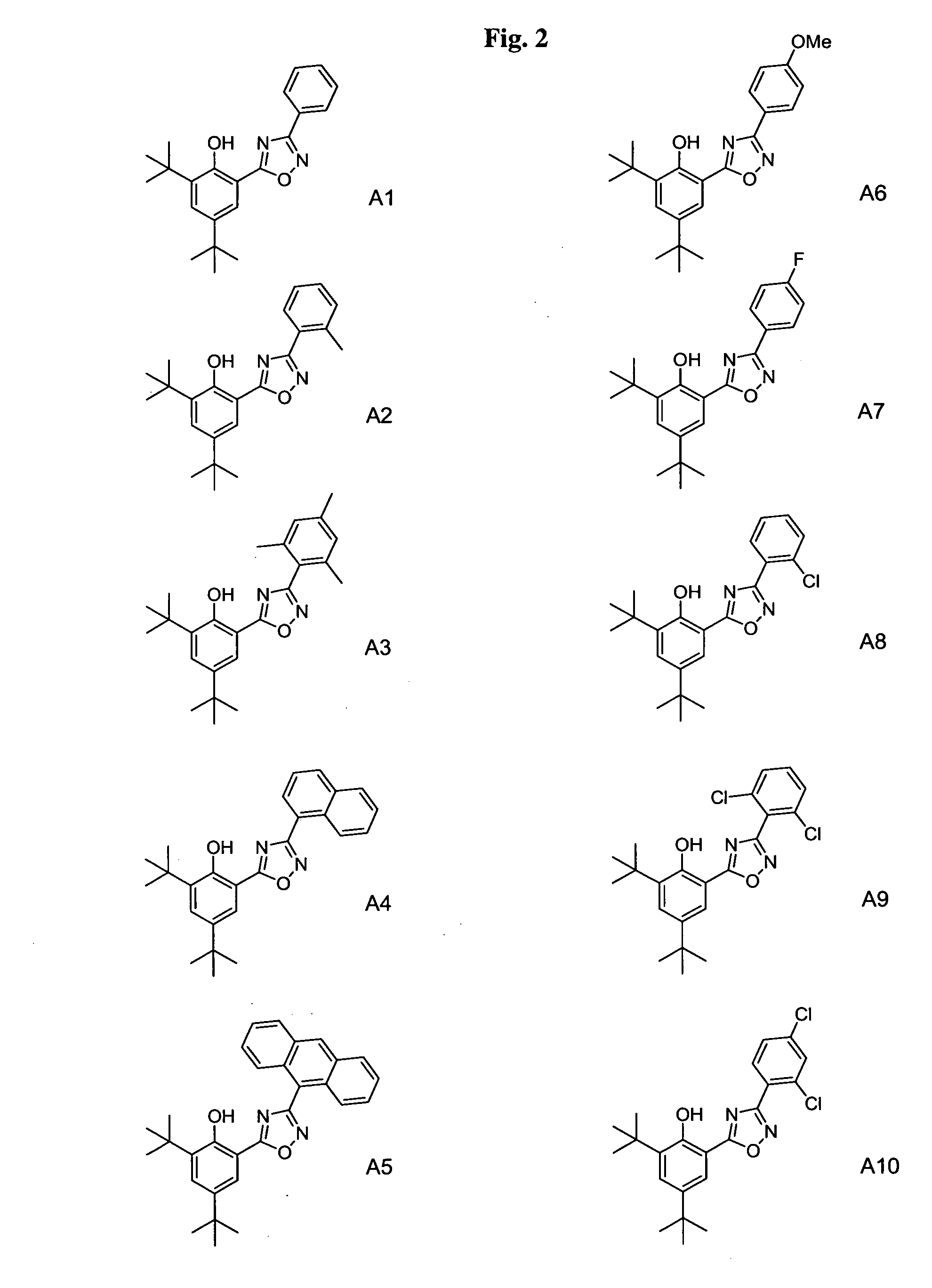

Phenol-heterocyclic ligands, metal complexes, and their uses as catalysts

InactiveUS20060135713A1High activityHigh melting pointGroup 4/14 organic compounds without C-metal linkagesGroup 8/9/10/18 element organic compounds1-OctenePHENOL LIQUID

Ligands, compositions, and metal-ligand complexes that incorporate phenol-heterocyclic compounds are disclosed that are useful in the catalysis of transformations such as the polymerization of monomers into polymers. The catalysts have high performance characteristics, including high comonomer incorporation into ethylene / olefin copolymers, where such olefins are for example, 1-octene, propylene or styrene. The catalysts particularly polymerize styrene to form polystyrene.

Owner:FREESLATE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com