Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4879results about How to "High melting point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organometallic complex, organic EL element and organic EL display

InactiveUS20050244673A1Improve efficiencyExcellent lifetimeGroup 8/9/10/18 element organic compoundsSolid-state devicesRheniumNitrogen

An organic EL element includes an organometallic complex including a rhenium atom; one ligand which has a coordinated nitrogen atom and a coordinated oxygen atom, each coordinated with the rhenium atom, and has at least one π conjugation part; and the other ligand coordinated with the rhenium atom in such a way that the ligand saturates the coordination number of the rhenium atom and the charge of the whole organometallic complex is neutral.

Owner:FUJIFILM HLDG CORP +1

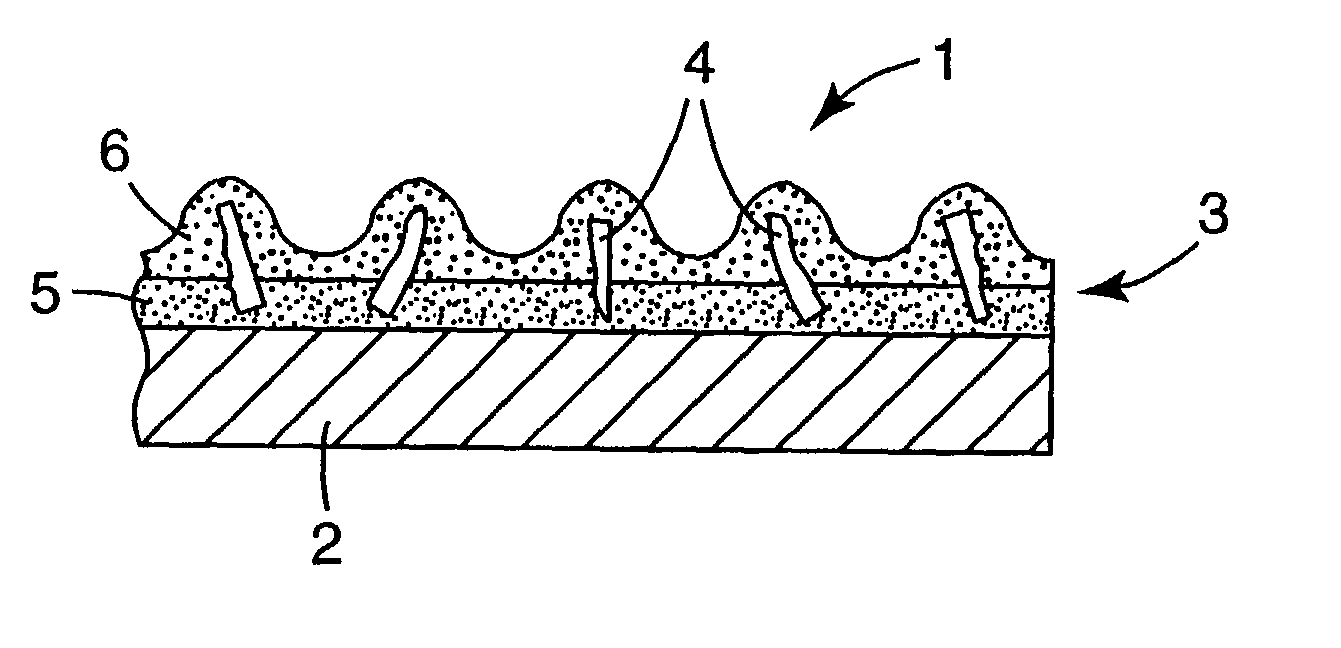

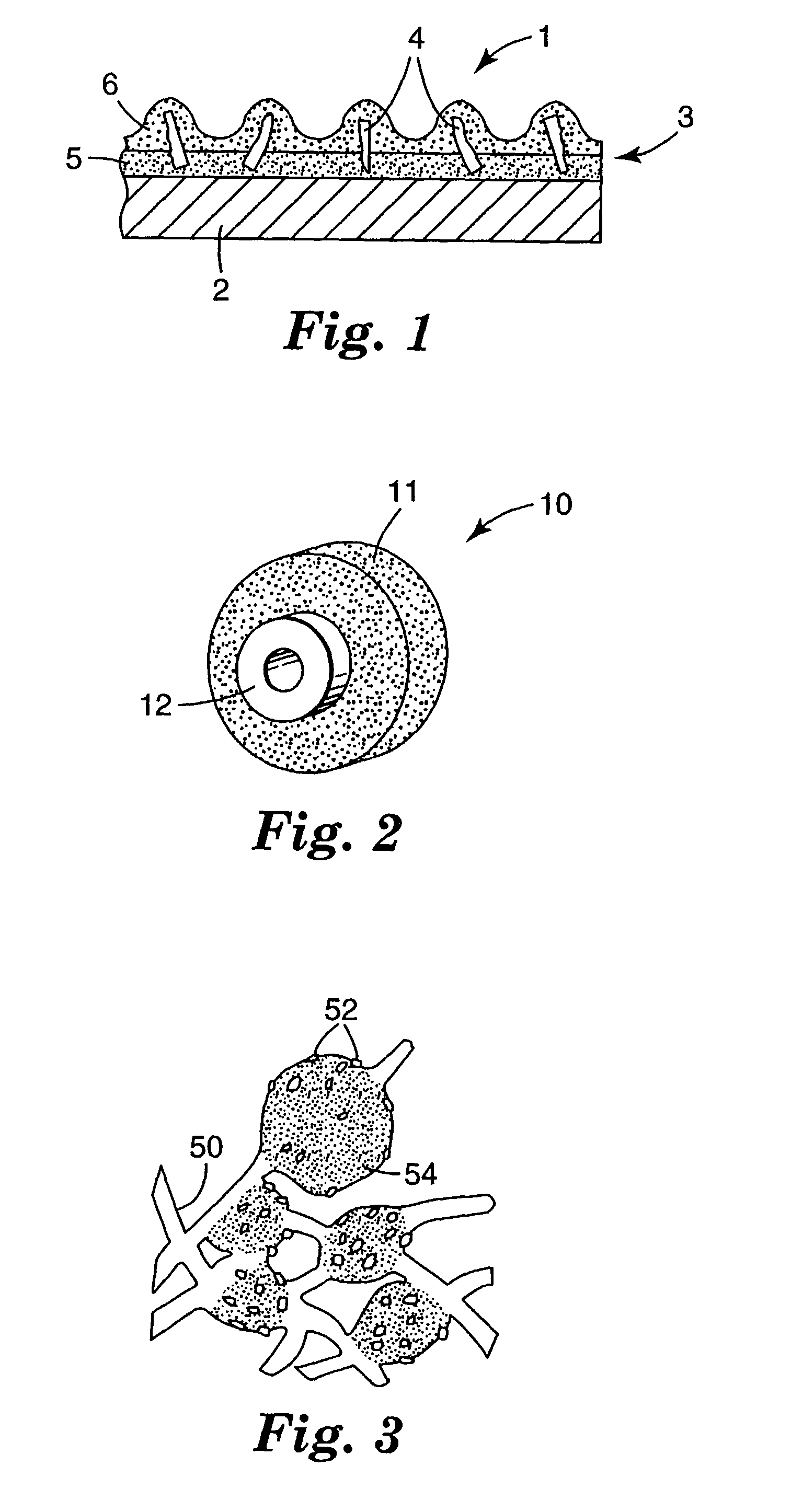

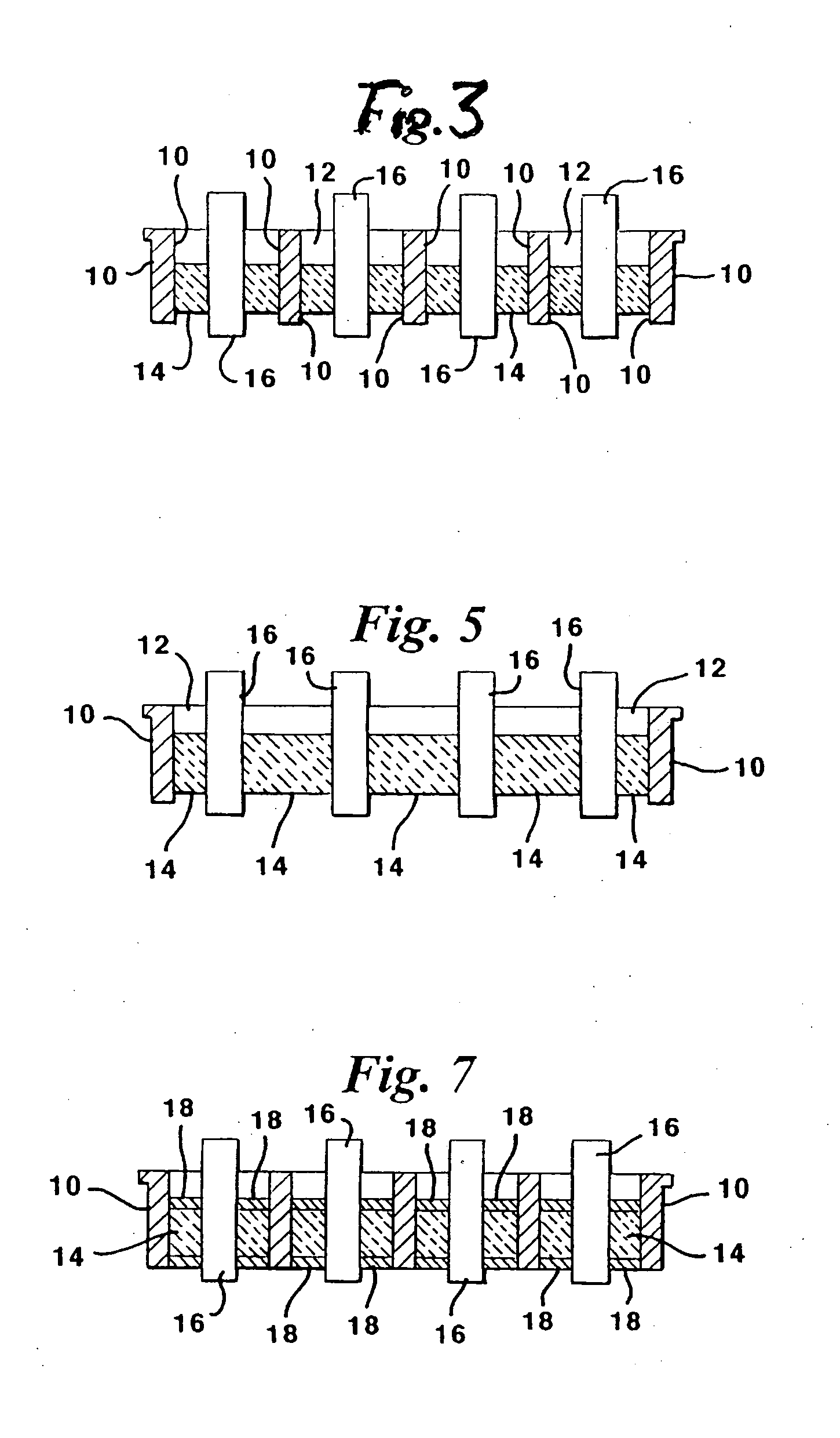

Methods and systems for the manufacture of layered three-dimensional forms

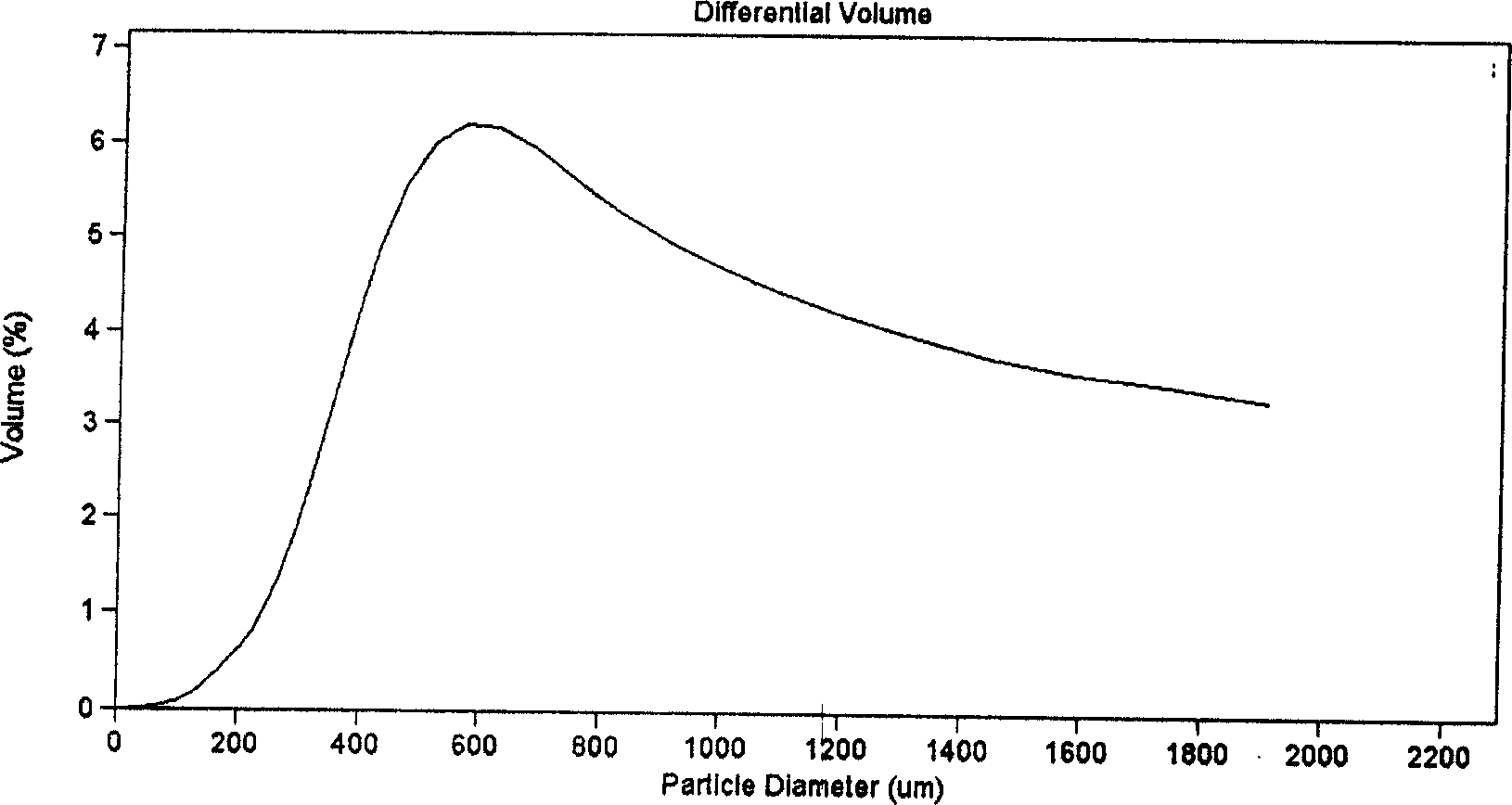

ActiveUS20050017394A1Lower potentialEasy to controlConfectionerySweetmeatsParticulatesBiological activation

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

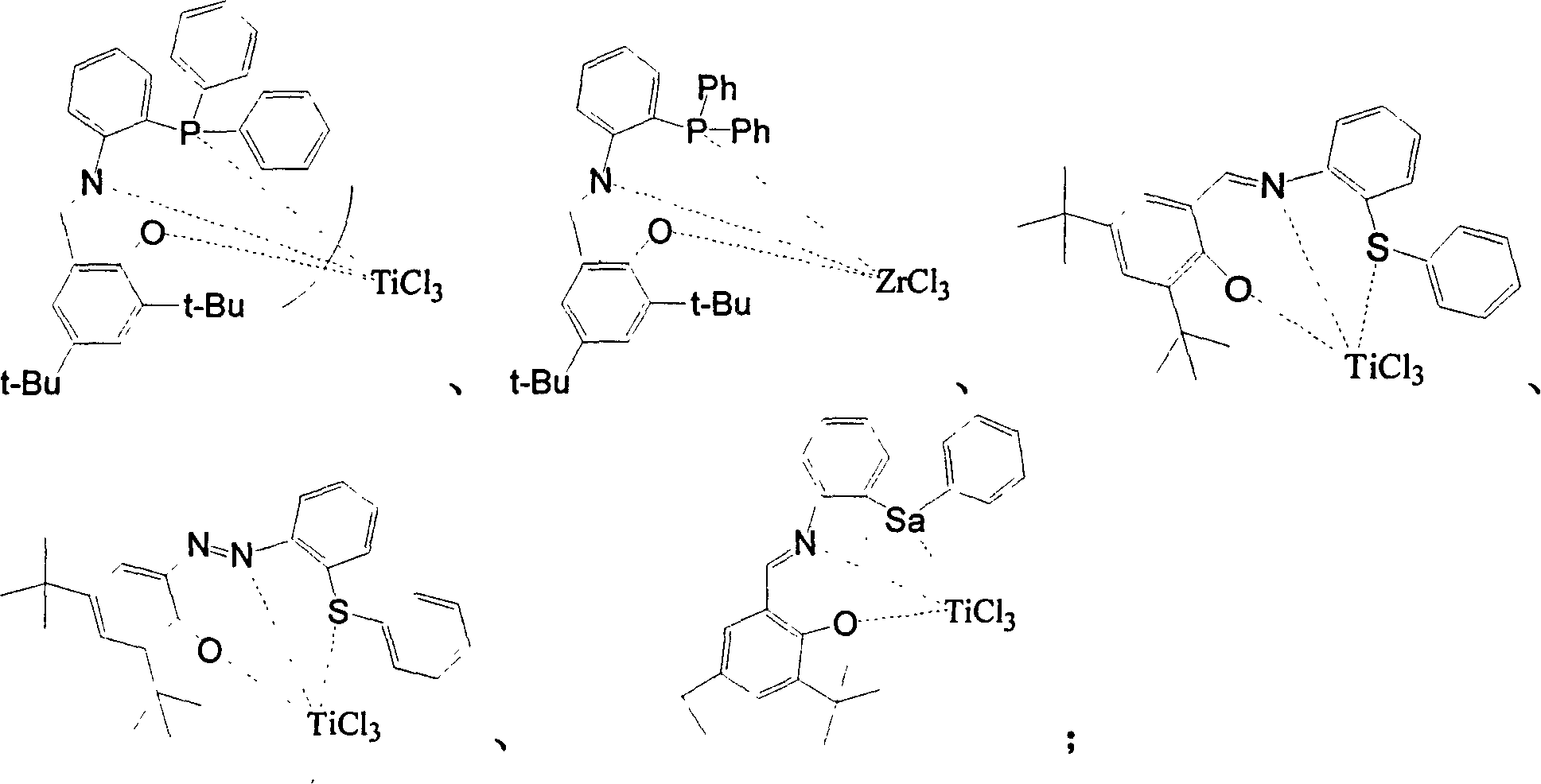

Loaded method of Non-metallocene catalyst loaded by composite carrier and polymerizing application

ActiveCN1539856AGood particle shapeHigh non-metallocene olefin polymerization catalyst contentChemical treatmentAluminoxane

A process for carrying the non-metallocene catalyst by composite carrier includes such steps as thermally activating silica gel, reacting on the solution of magnesium chloride in tetrahydrofuran-alcohol solution to obtain composite carrier, reacting on chemical treating agent to obtain modified composite carrier and carrying non-metallocene catalyst by solution method or dipping method. Said catalyst can be used for the homopolymerization or copolymerization of C2-C10 olefin, styrene, or ethylene.

Owner:SINOPEC YANGZI PETROCHEM +1

Precursor compositions for the deposition of electrically conductive features

InactiveUS6951666B2Reduce settlementGood dispersionRadiation applicationsConductive materialElectrically conductiveCopper metal

A precursor composition for the deposition and formation of an electrical feature such as a conductive feature. The precursor composition advantageously has a viscosity of at least about 1000 centipoise and can be deposited by screen printing. The precursor composition also has a low conversion temperature, enabling the deposition and conversion to an electrical feature on low temperature substrates. A particularly preferred precursor composition includes silver and / or copper metal for the formation of highly conductive features.

Owner:CABOT CORP

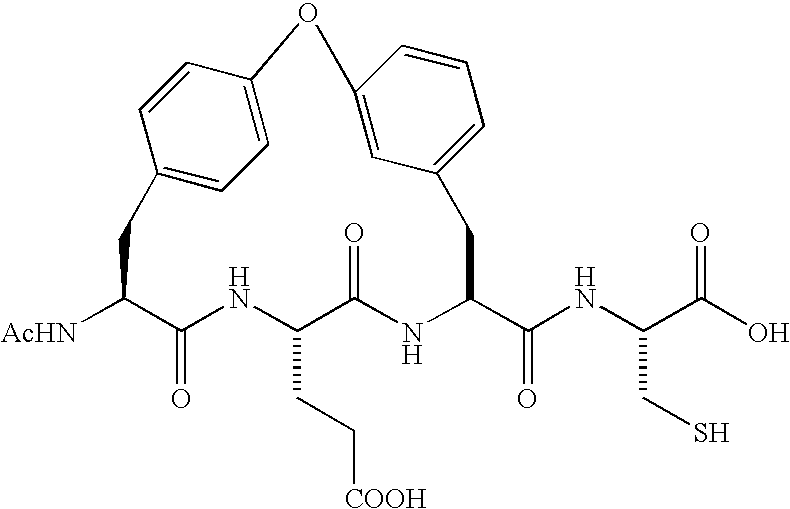

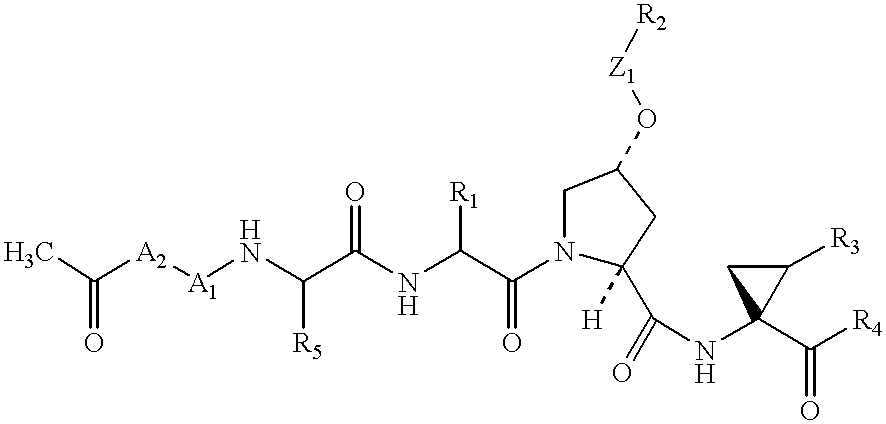

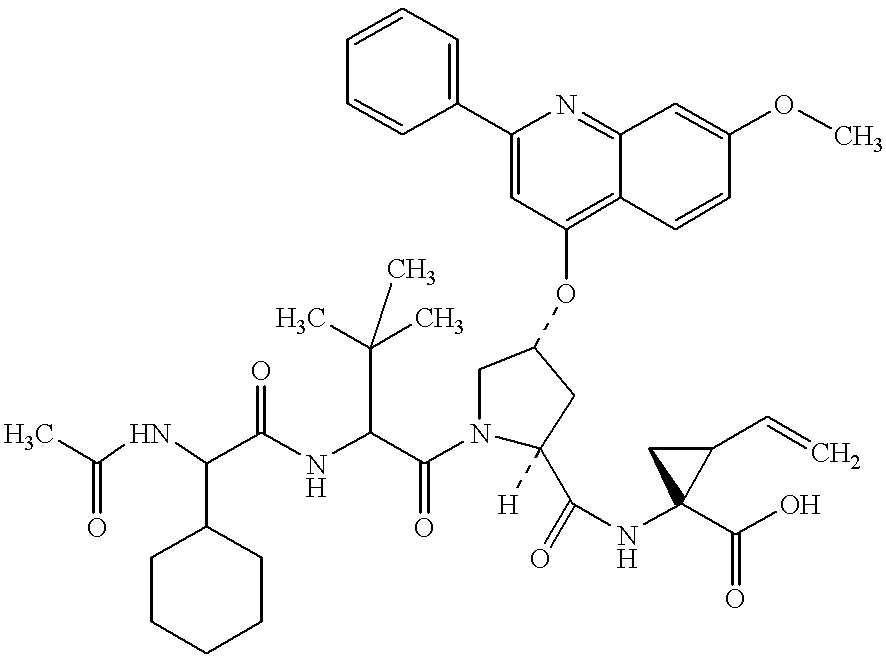

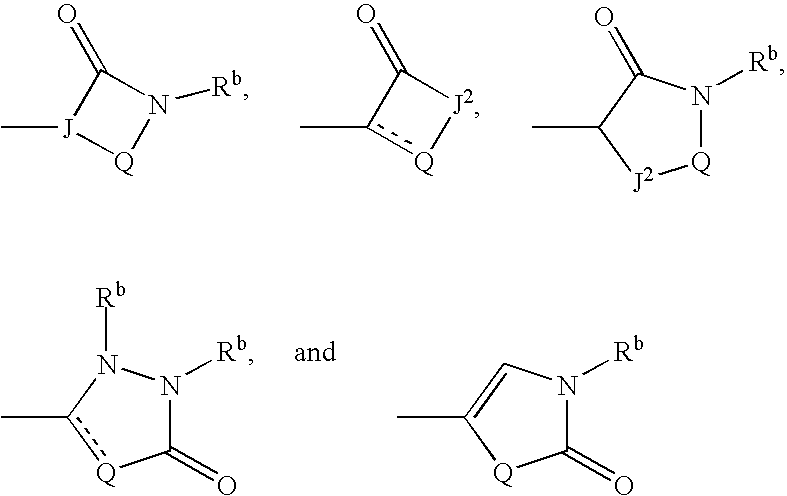

Imidazolidinones as NS3-serine protease inhibitors of hepatitis C virus

InactiveUS6838475B2Reduce frictionReduce wearBiocideOrganic active ingredientsSerine Protease InhibitorsHepacivirus

The present invention discloses novel imidazolidinones which have HCV protease inhibitory activity as well as methods for preparing such compounds. In another embodiment, the invention discloses pharmaceutical compositions comprising such imidazolidinones as well as methods of using them to treat disorders associated with the HCV protease.

Owner:SCHERING CORP

Olefinic polymerization and copolymerization method of supported non-metallocene catalyst

A method of alkene polymerization and copolymarization with f load non- metallocene catalyst: emplying the load non- metallocene catalyst and catalyst promoter forming the catalytic system, introducing polymer monomer or comonomer for alkene polymerization or copolymarization; adding the load non- metallocene catalyst into dissolvent and mixing with catalyst promoter and then transferring the mixture into polymerization reactor, or adding the load non- metallocene catalyst and catalyst promoter into the polymerization reactor in order or simultaneously. The catalyst promoter is chosen from: alkyl aluminium, aluminium oxane, Lewis acid, boralotano, alkyl borane or alkyl borane ammonium salt. The load non- metallocene catalyst is loaded to multiple poral solid by employing methods of solution dipping, equivoluminal dipping or solution dipping-before-equivoluminal dipping to form organic integral of property stable and strong binding force. The invention is characterized by the high alkene polymerization active, high fusion point and good normalization of the produced polymer, and the sastification of the demand of high level product production.

Owner:YANGZI PETROCHEM

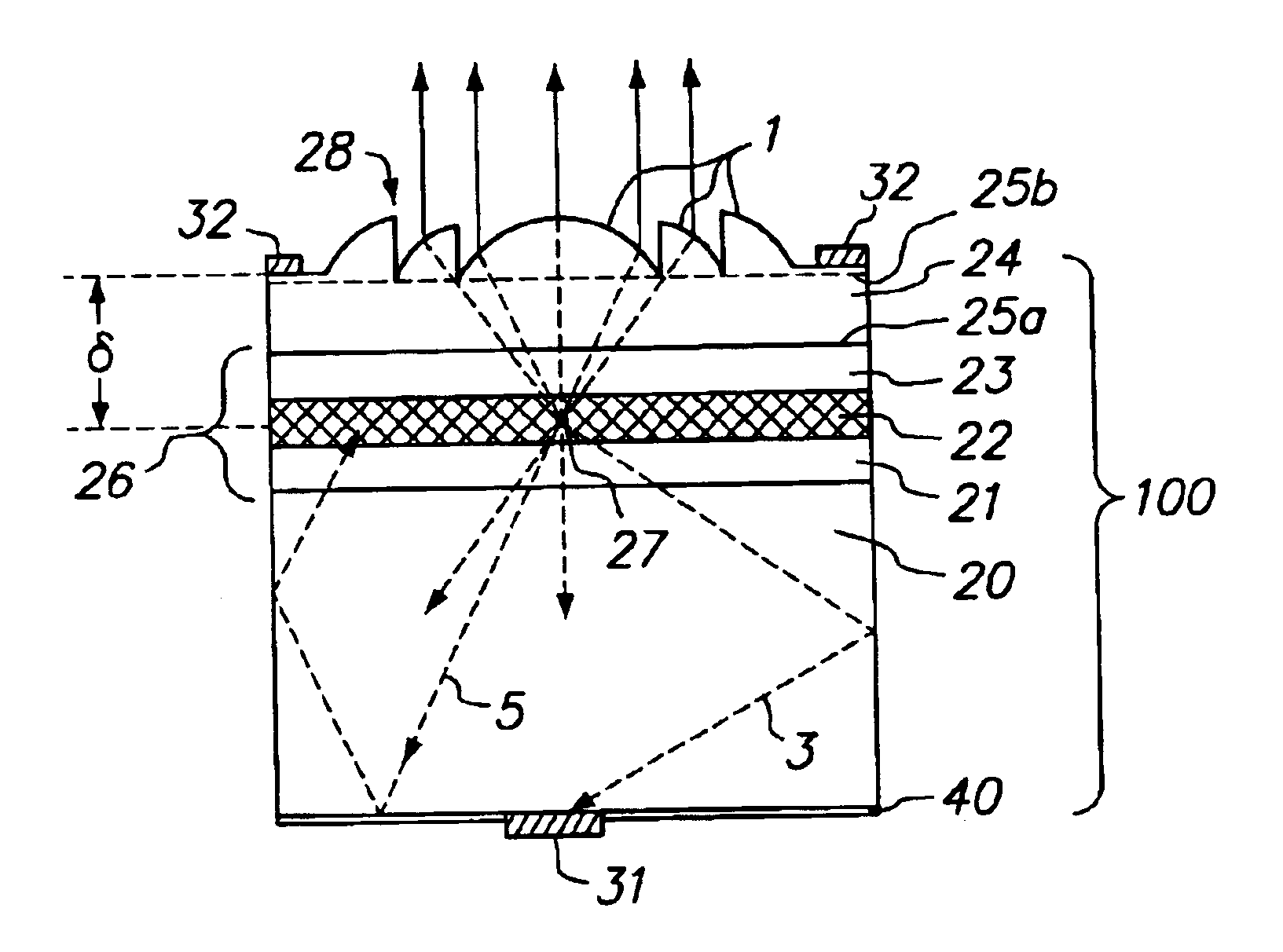

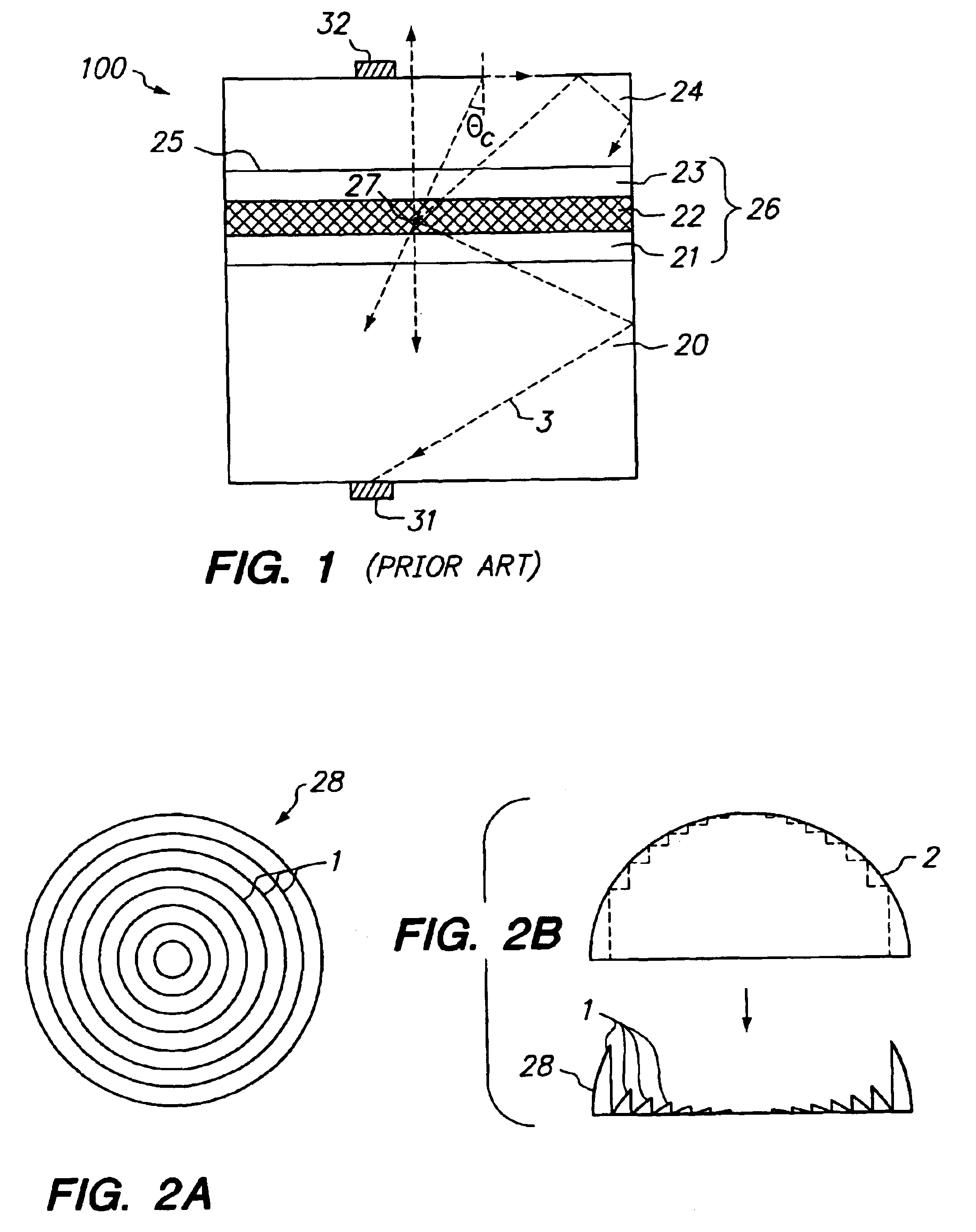

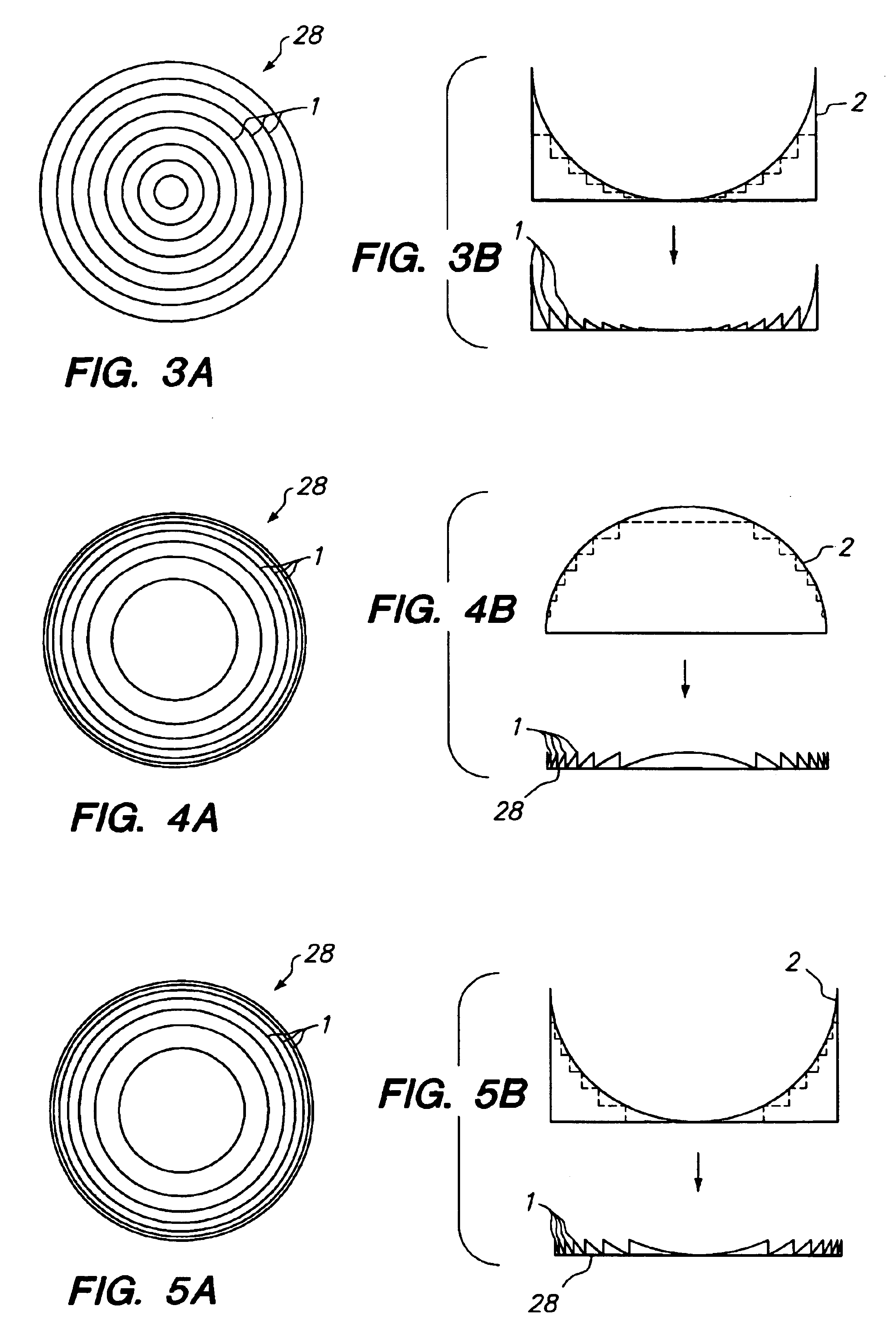

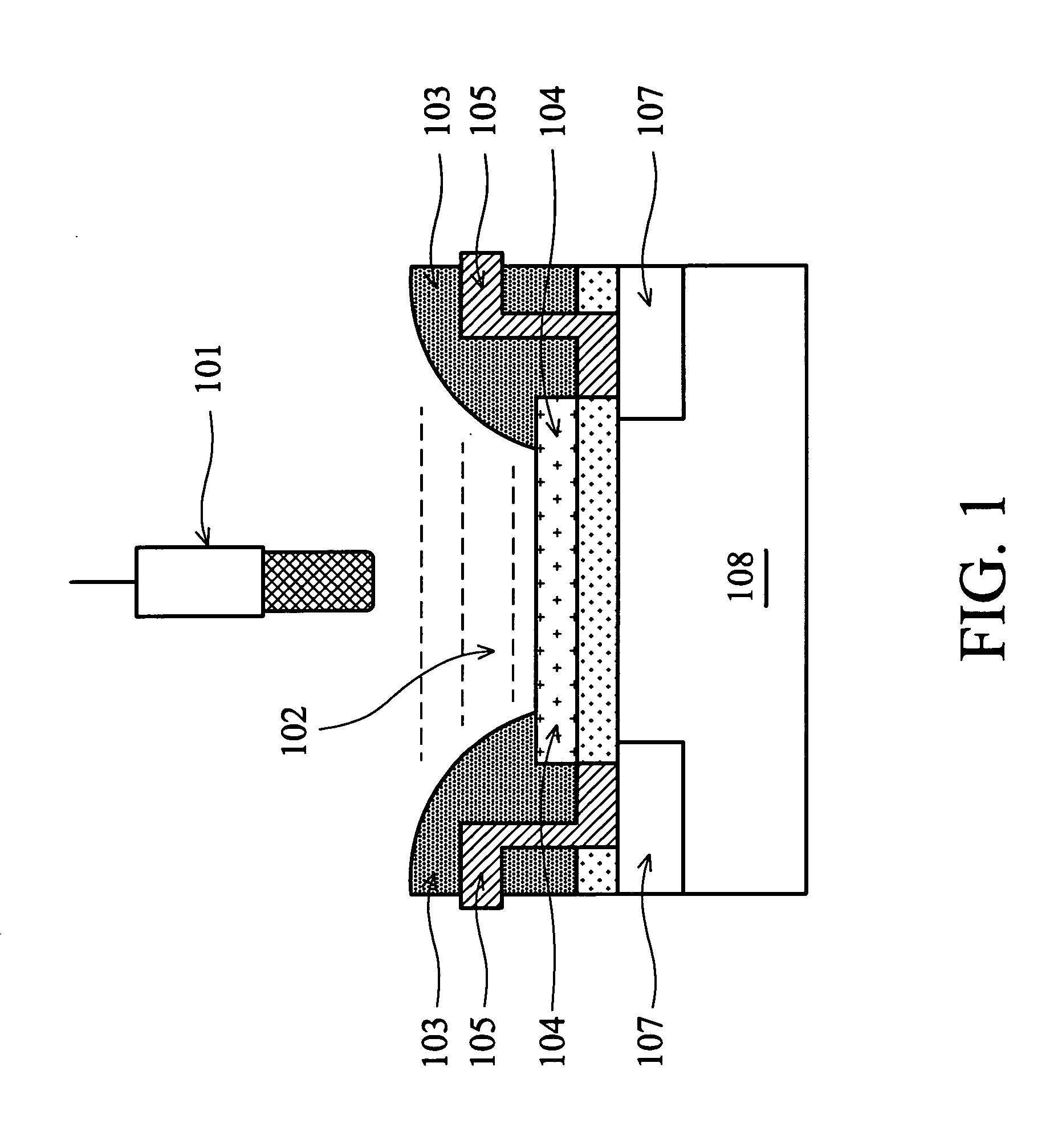

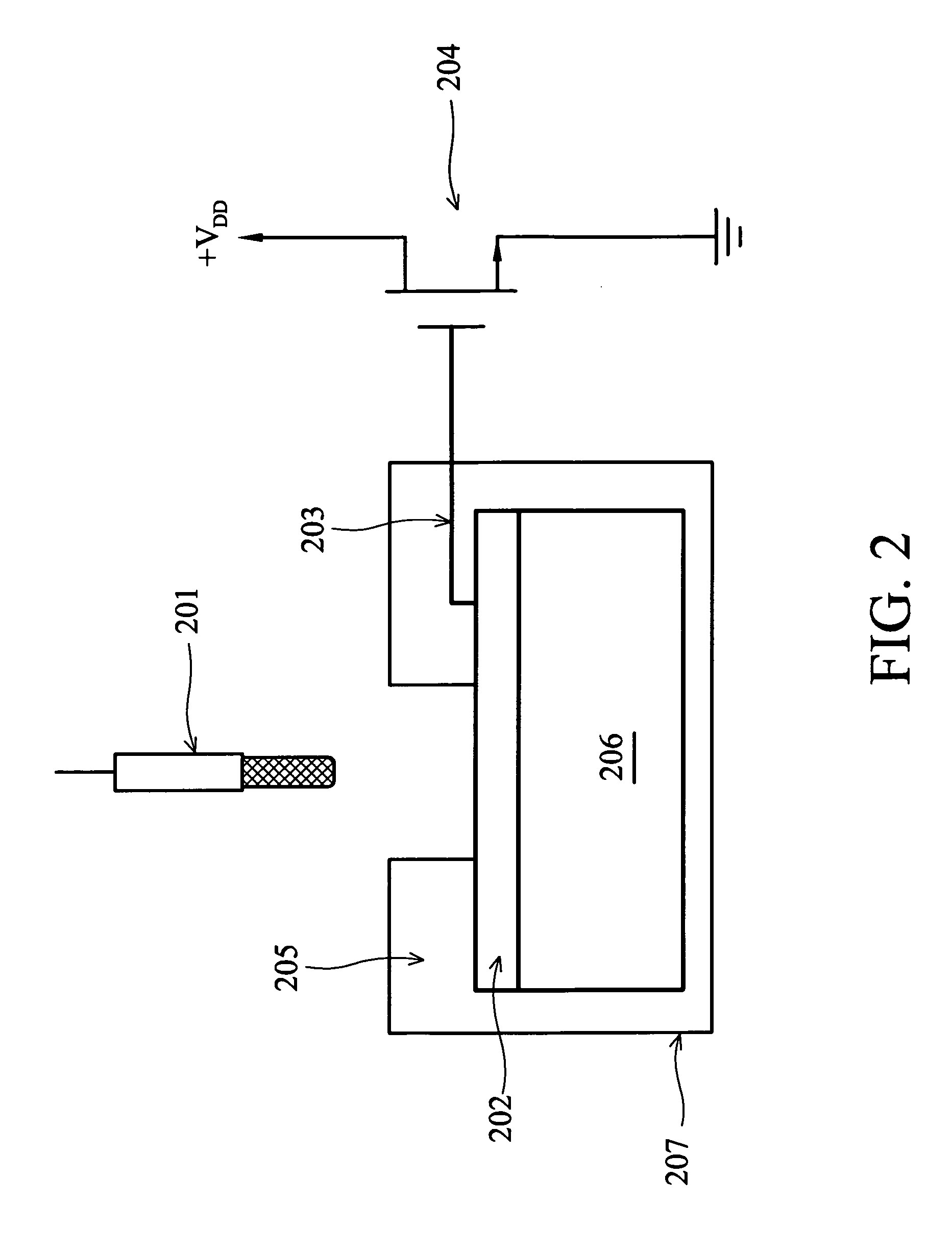

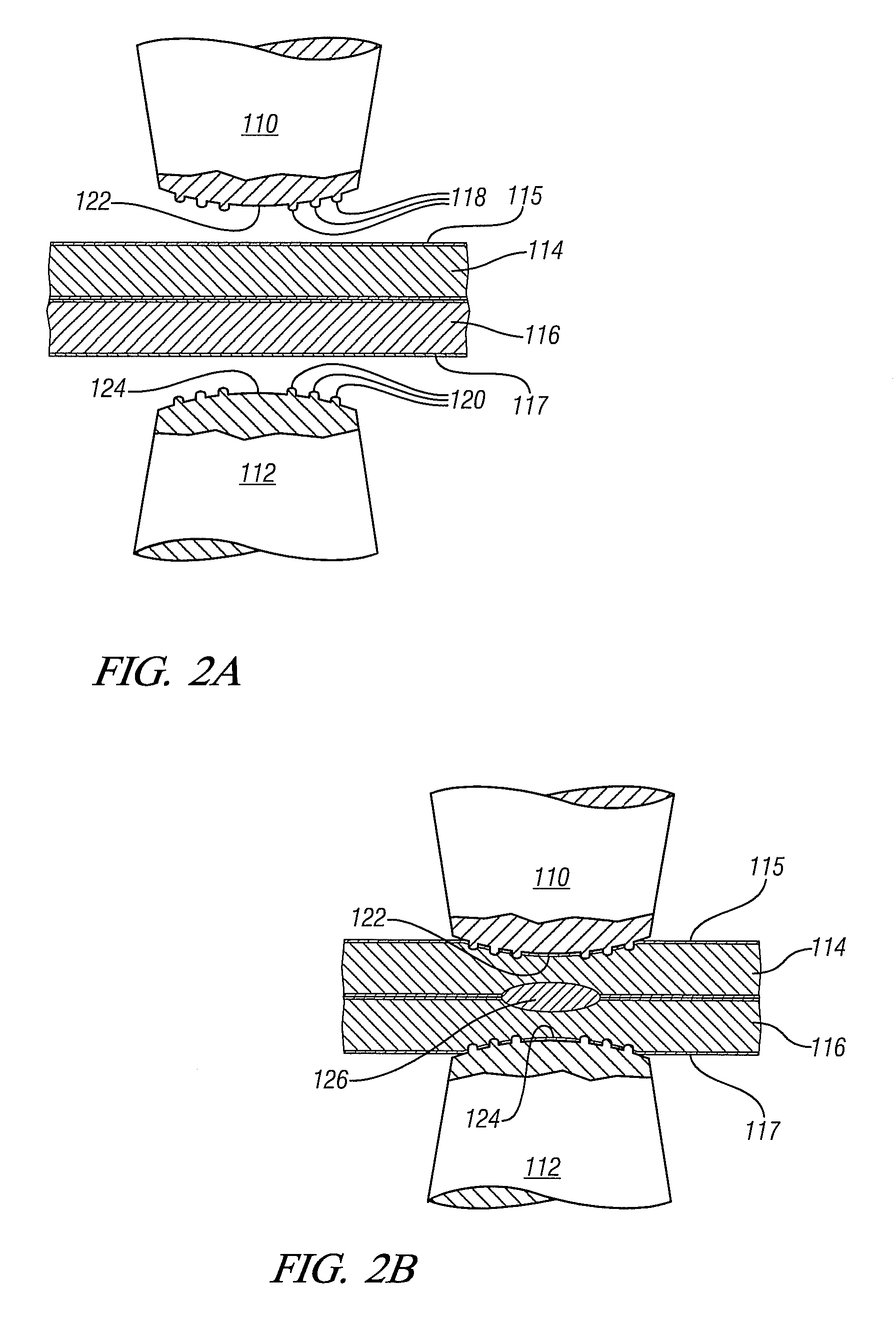

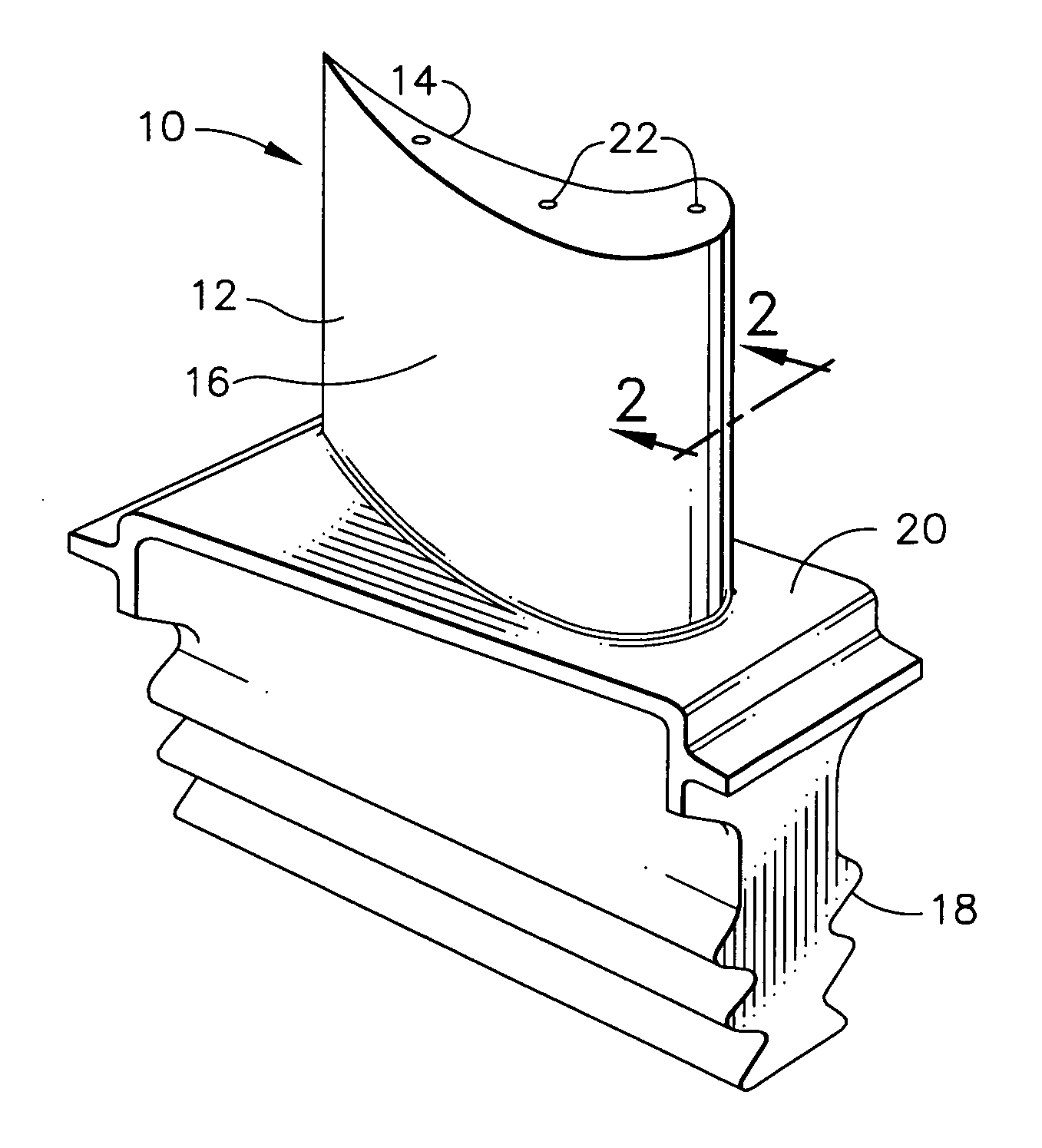

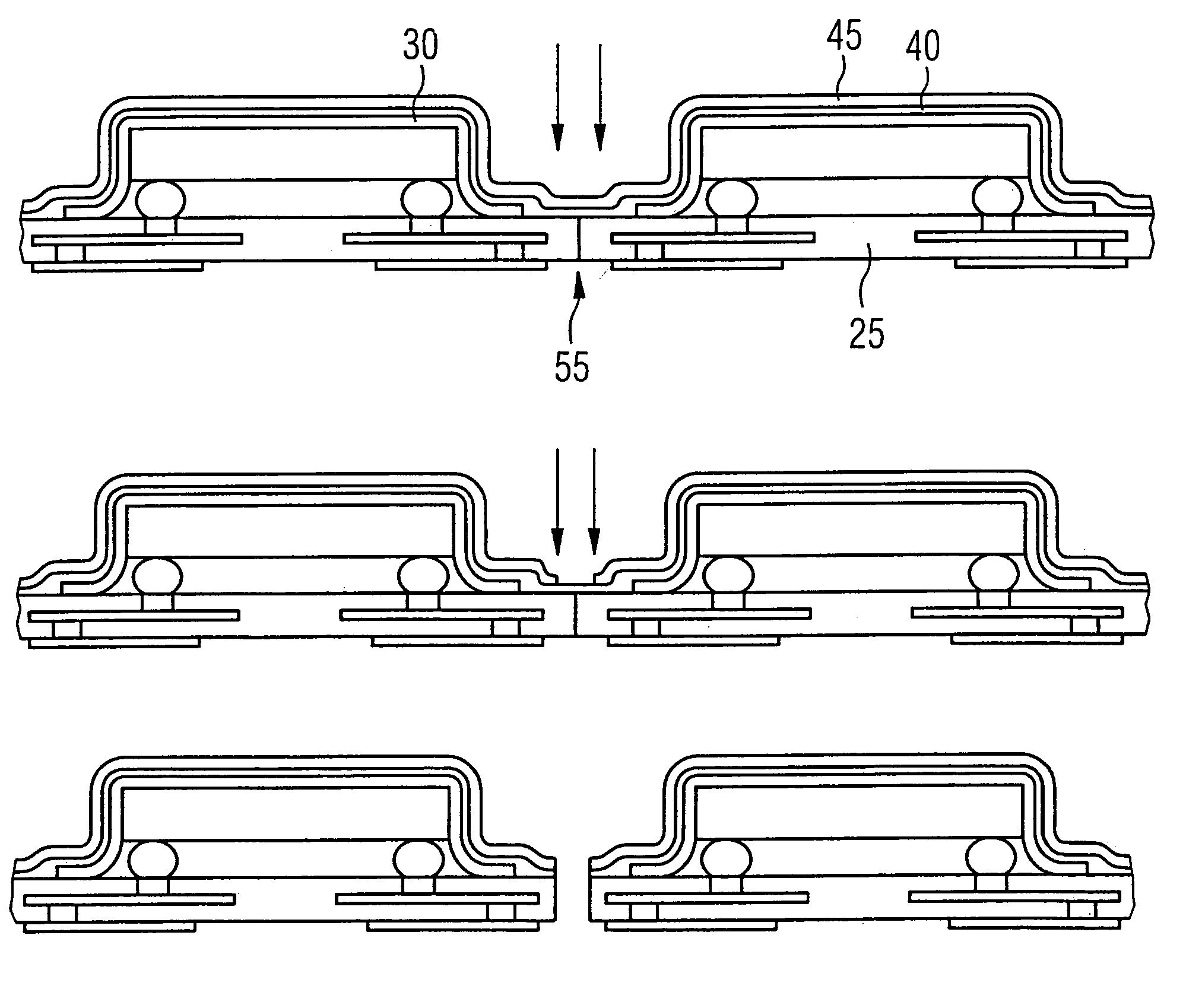

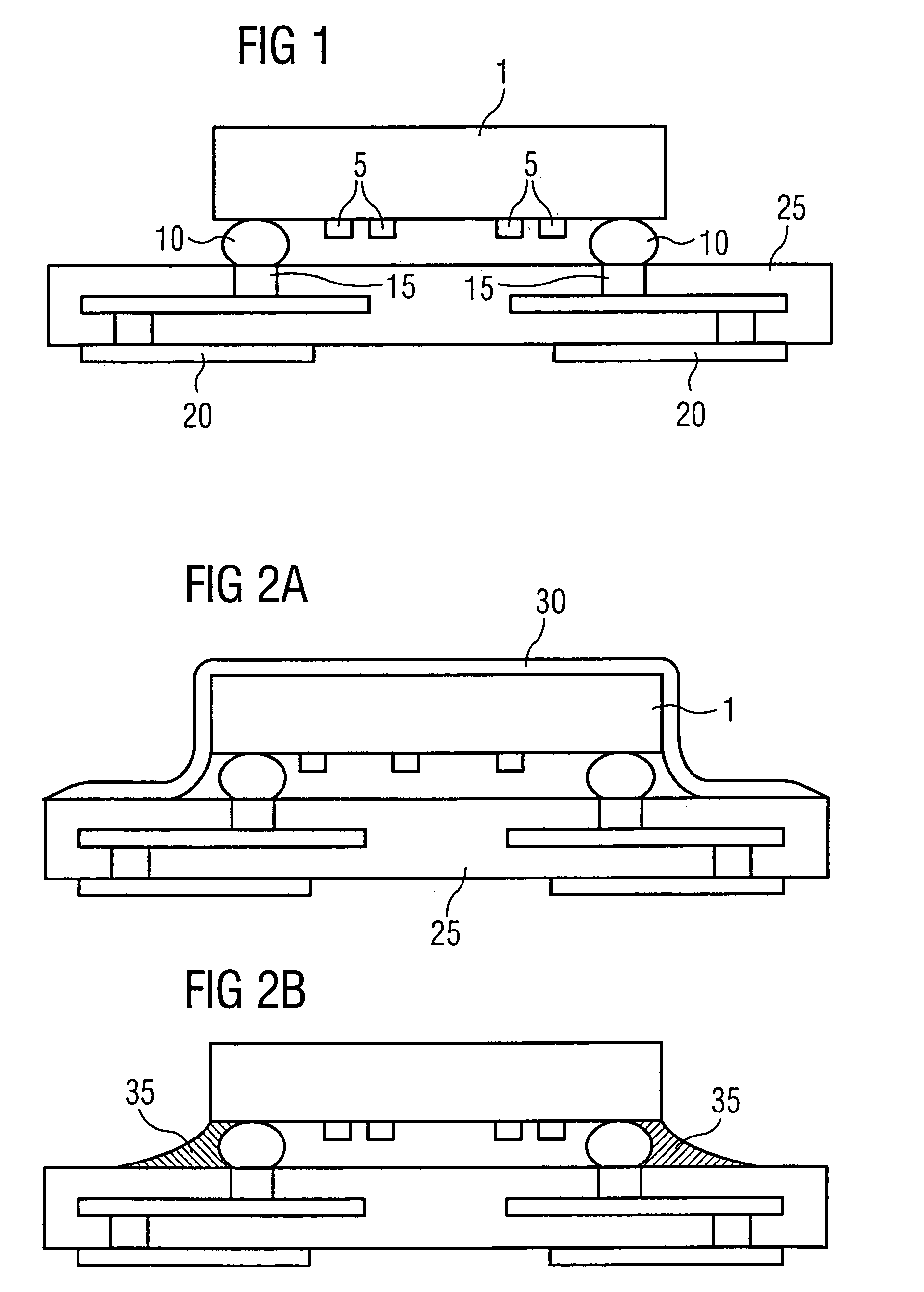

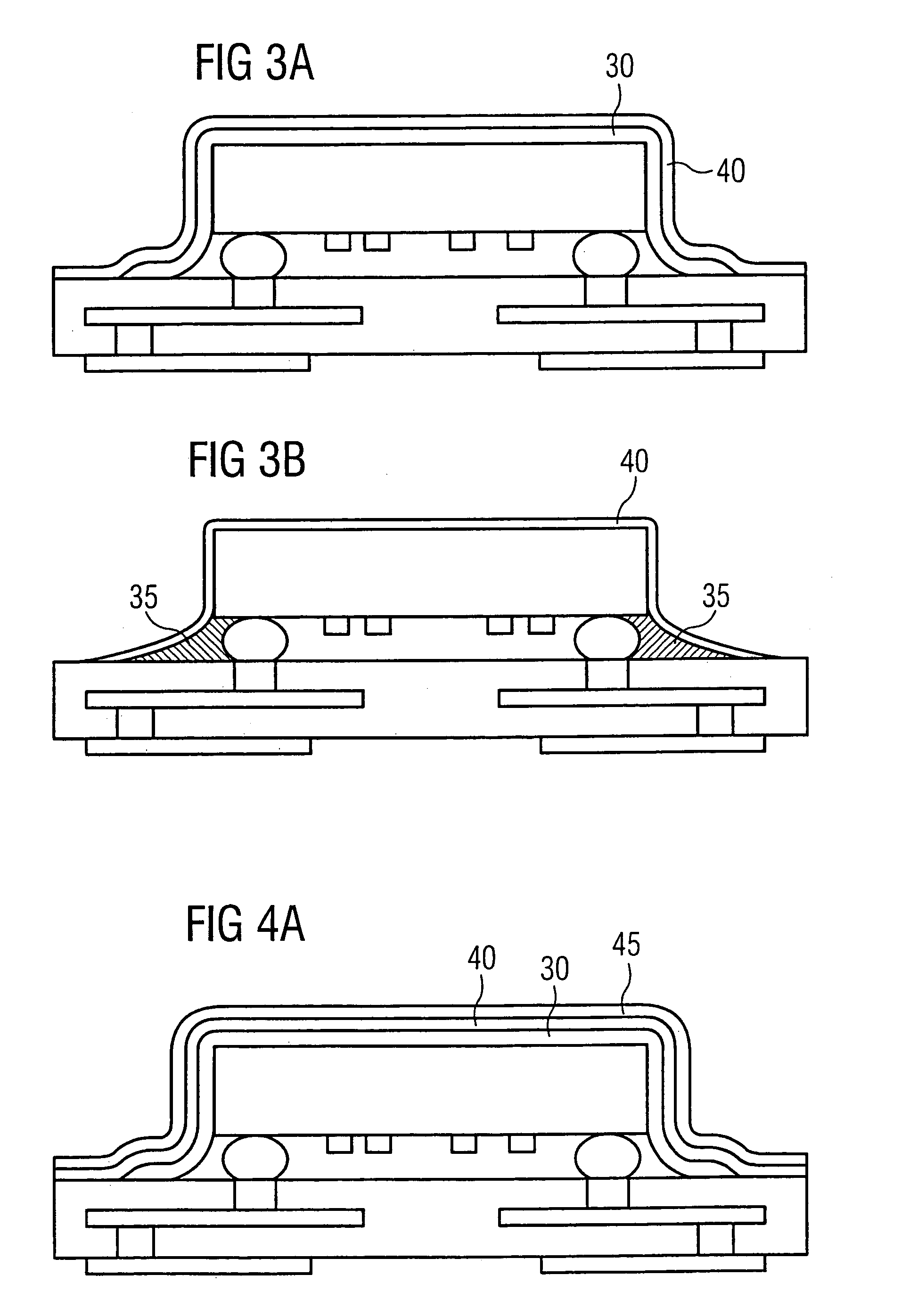

Forming an optical element on the surface of a light emitting device for improved light extraction

InactiveUS6987613B2Easy to integrateMaximize production efficiencyDiffraction gratingsSemiconductor devicesWafer bondingAlternative methods

Provided is a light emitting device including a Fresnel lens and / or a holographic diffuser formed on a surface of a semiconductor light emitter for improved light extraction, and a method for forming such light emitting device. Also provided is a light emitting device including an optical element stamped on a surface for improved light extraction and the stamping method used to form such device. An optical element formed on the surface of a semiconductor light emitter reduces reflective loss and loss due to total internal reflection, thereby improving light extraction efficiency. A Fresnel lens or a holographic diffuser may be formed on a surface by wet chemical etching or dry etching techniques, such as plasma etching, reactive ion etching, and chemically-assisted ion beam etching, optionally in conjunction with a lithographic technique. In addition, a Fresnel lens or a holographic diffuser may be milled, scribed, or ablated into the surface. Stamping, an alternative method for forming an optical element, can also be used to form a Fresnel lens or a holographic diffuser on the surface of a semiconductor light emitter. Stamping includes pressing a stamping block against the surface of a light emitting diode. The stamping block has a shape and pattern that are the inverse of the desired optical element. Optionally, stamping can be done before, after, or concurrently with wafer-bonding. Alternatively, a material can be stamped and later bonded to the semiconductor light emitter.

Owner:LUMILEDS

Abrasive particles, and methods of making and using the same

InactiveUS20030110707A1Facilitates formation and homogeneityOxide formationGlass drawing apparatusGlass forming apparatusAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

Security paper

InactiveUS6159585AAvoid the needLow compositionNon-fibrous pulp additionNatural cellulose pulp/paperOrganic solventChemical separation

A security paper indicates exposure to a solvent by a solvent resistant color signal. A metal mordant dye first co-reactant and a mordant dye second co-reactant form an organic solvent-insoluble colored reaction product when the paper is washed with an organic solvent. The metal mordant dye first co-reactant and a mordant dye second co-reactant are chemically isolated from each other so as to prevent the coordinate covalent bond from forming until the paper is washed with an organic solvent. The chemical isolation can be effected by encapsulation or other physical separation of the co-reactants. The organic solvent-insoluble colored reaction product, once formed, remains entrapped in the web when the paper is washed with an organic solvent. The chemical isolation prevents the organic solvent-insoluble colored reaction product from forming upon the application of pressure alone to the paper.

Owner:DOMTAR +1

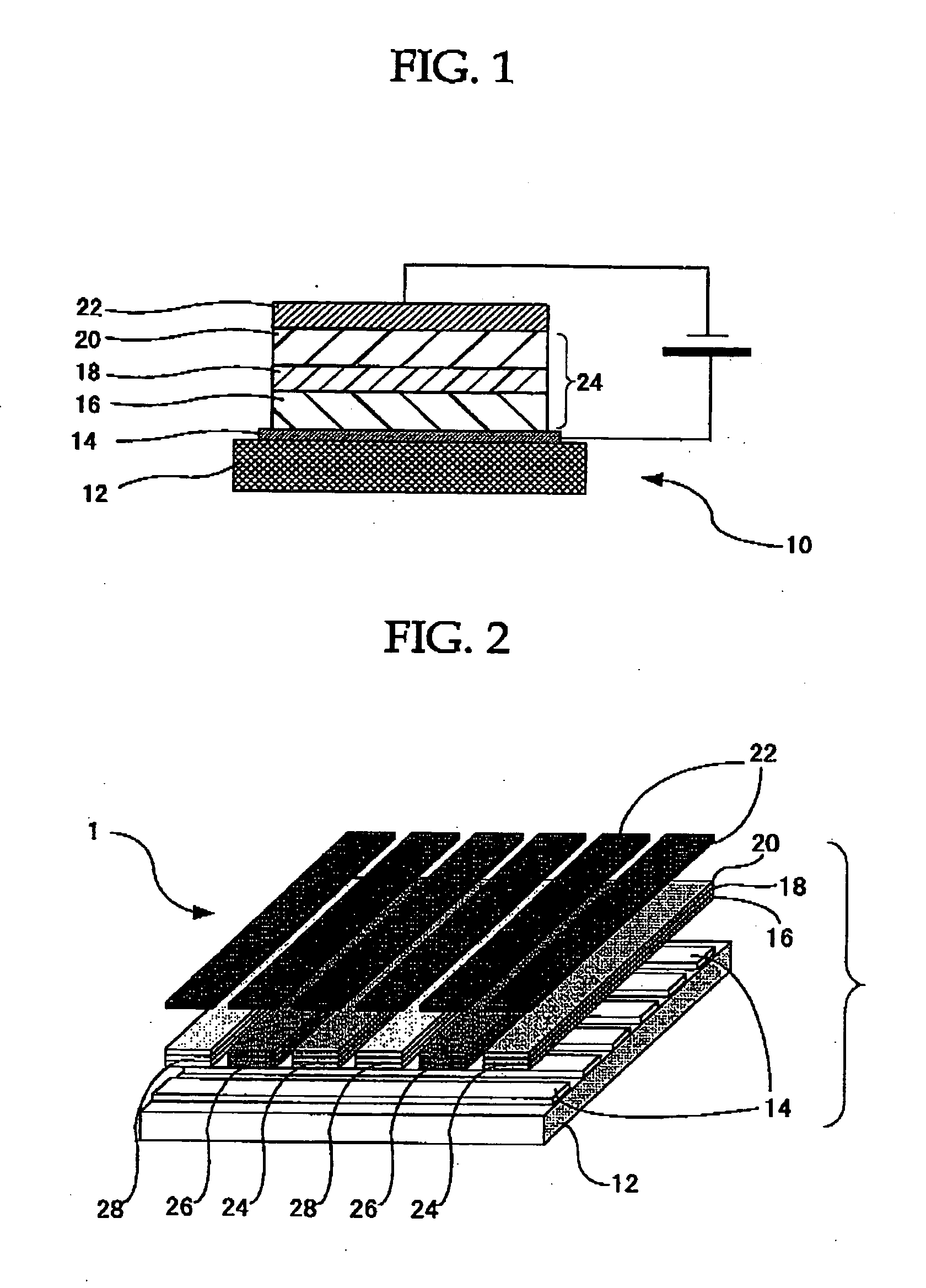

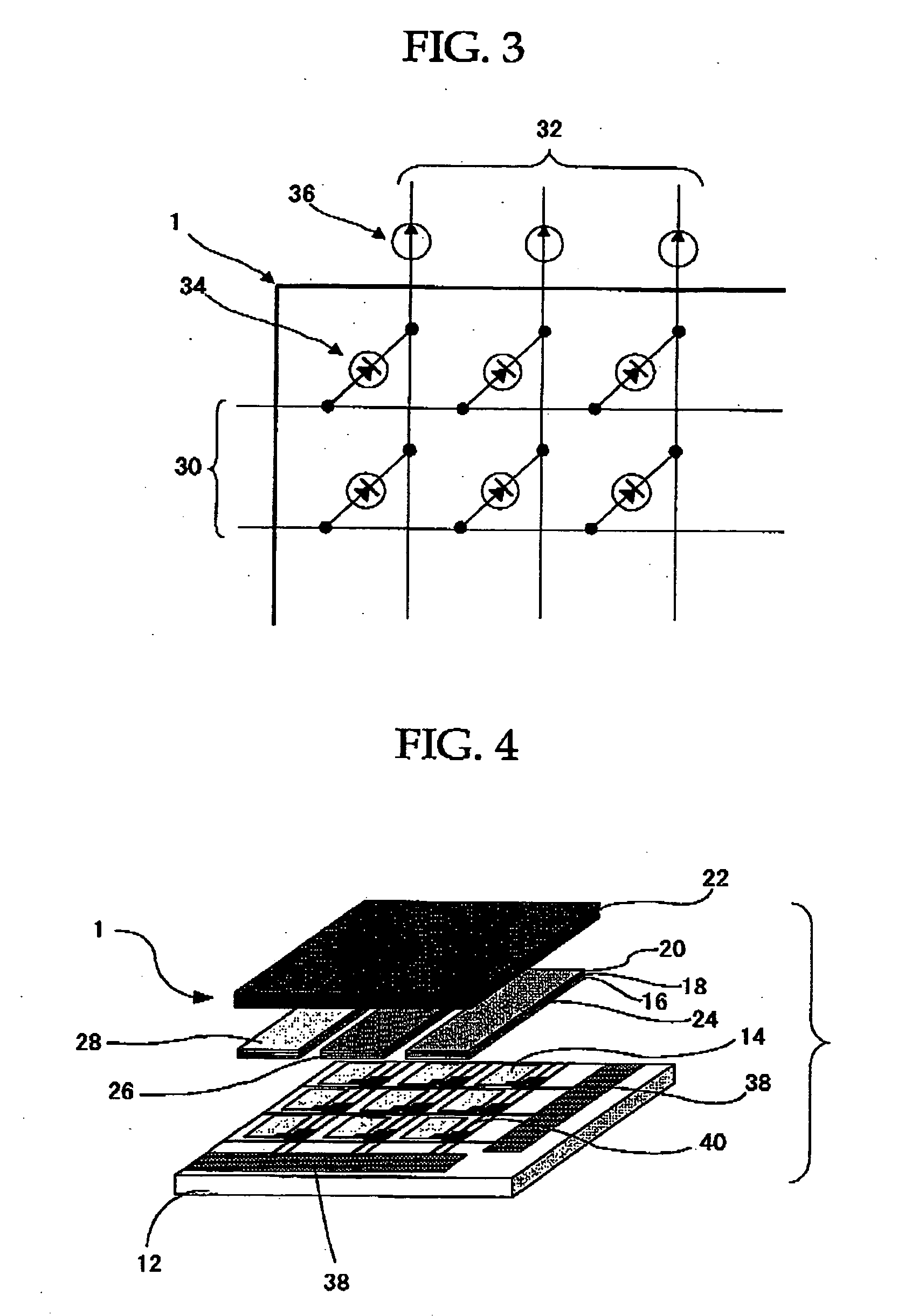

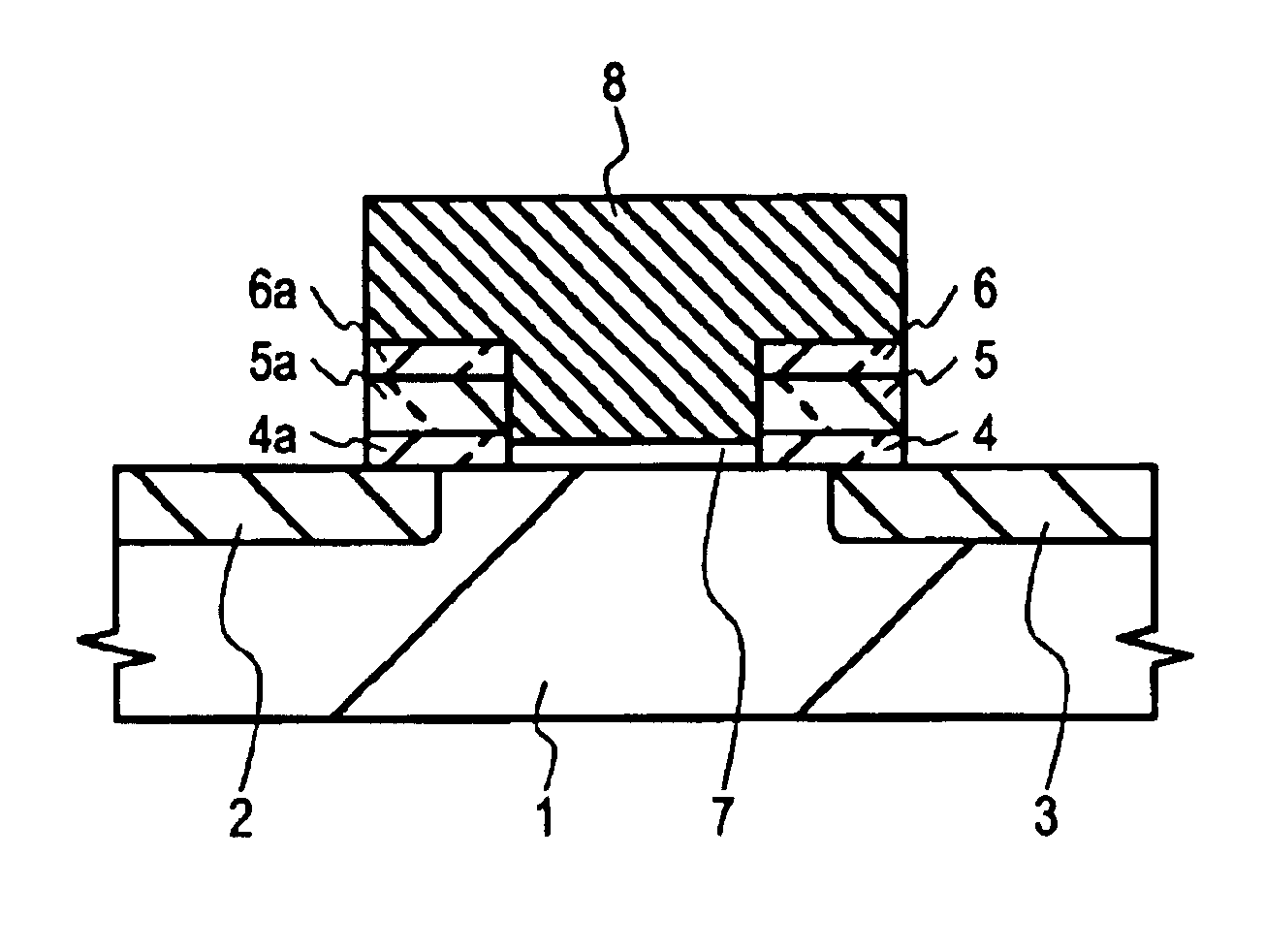

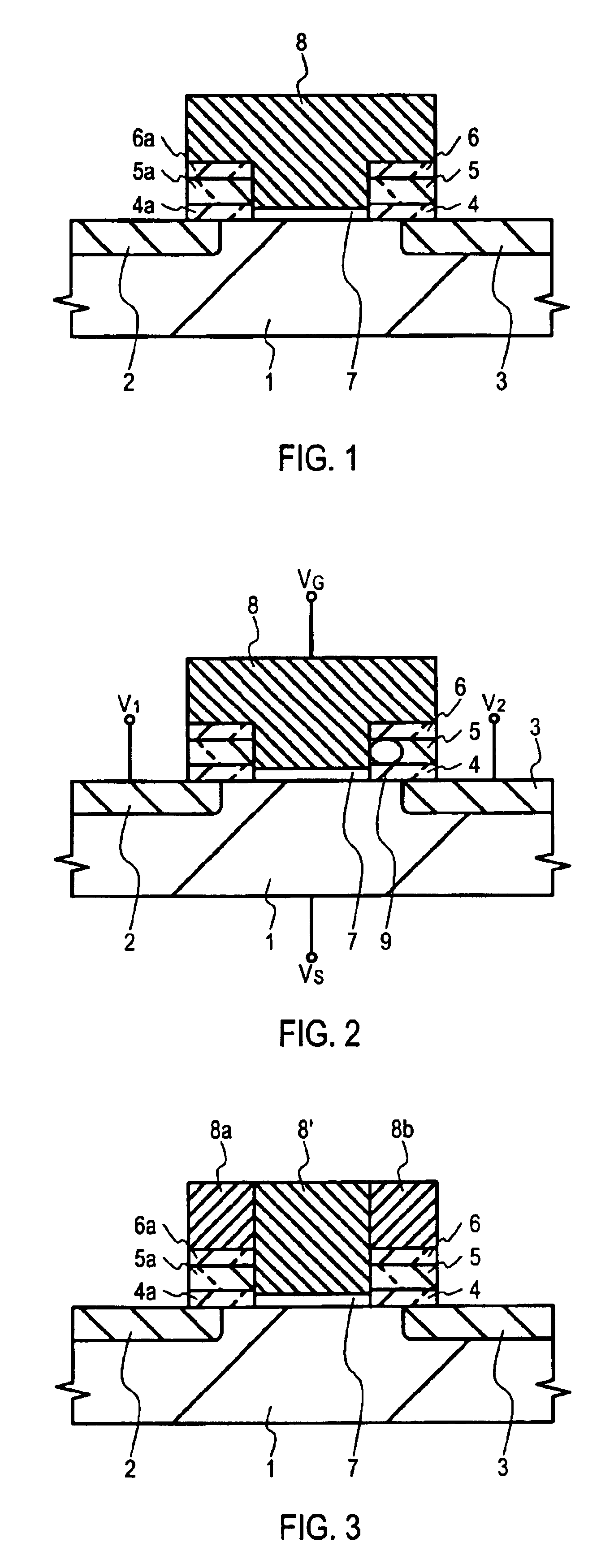

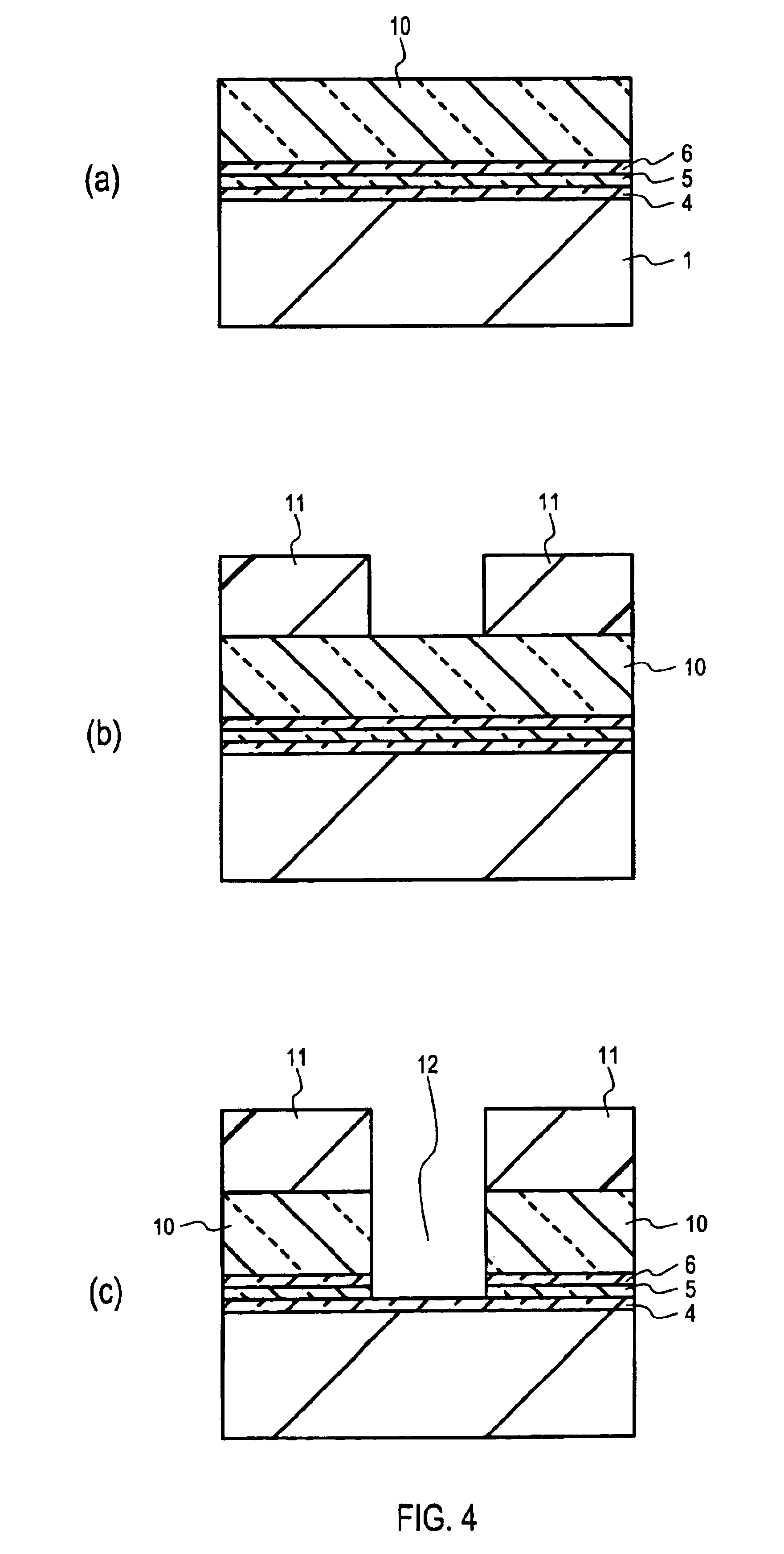

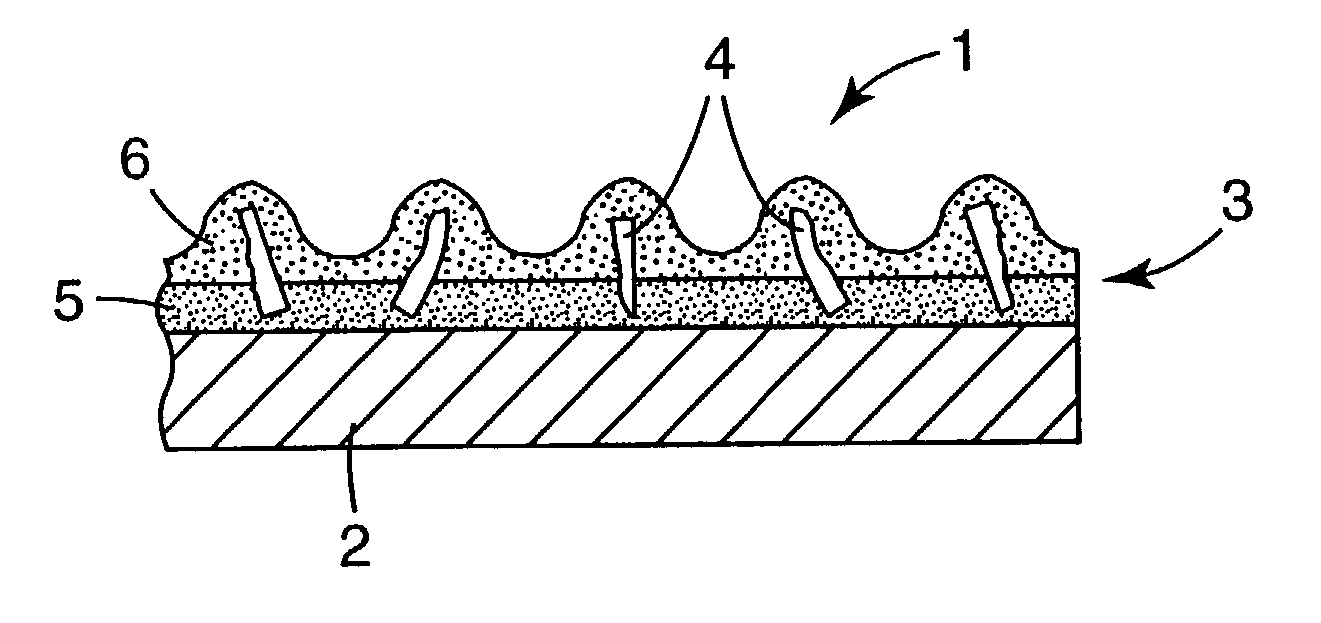

Nonvolatile semiconductor memory device, manufacturing method thereof, and operating method thereof

Nonvolatile memory elements are disclosed which can have increased capacity, reduced operating voltage and / or faster operating speeds. According to one embodiment, a nonvolatile memory element can include a first diffusion layer (2) and a second diffusion layer (3) formed in a main surface of a substrate (1). A laminate film can be formed near a first diffusion layer (2) and / or a second diffusion layers (3) that includes a first insulating film (4a or 4), a second insulating film (5a or 5), and a third insulating film (6a or 6). A gate insulating film (7) can be formed a channel region and gate electrode (8) can be formed to cover gate insulating film (7) and the laminate film(s) that has a T-shape. A gate electrode (8) can have end portions that sandwich a first insulating film (4a or 4), a second insulating film (5a or 5), and a third insulating film (6a or 6) with a first diffusion layer (2) and / or second diffusion layer (3).

Owner:RENESAS ELECTRONICS CORP

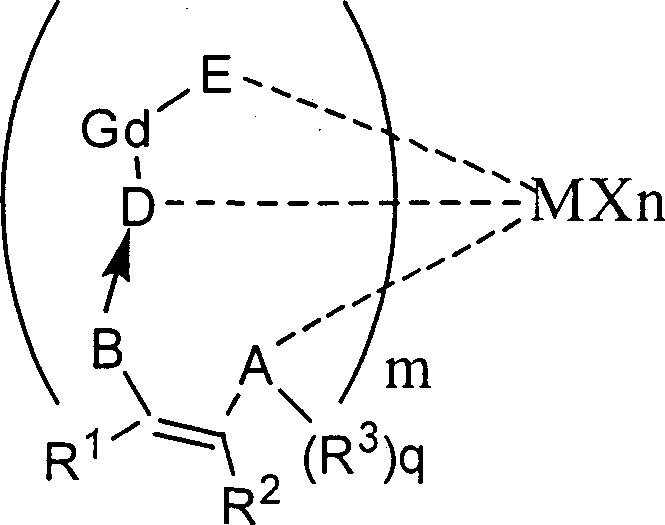

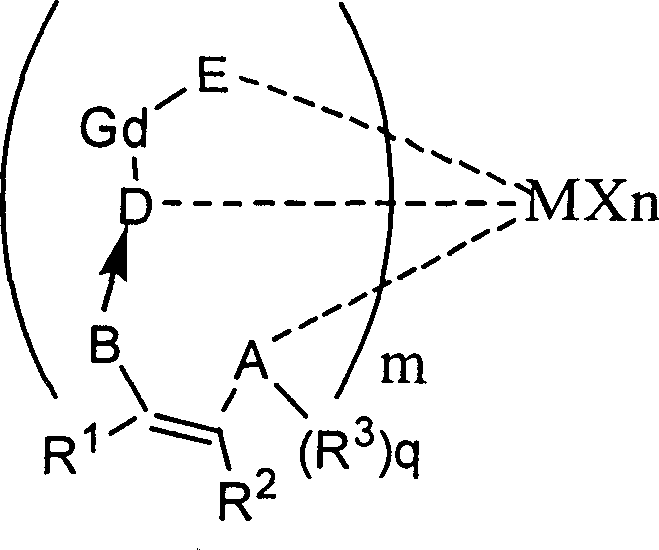

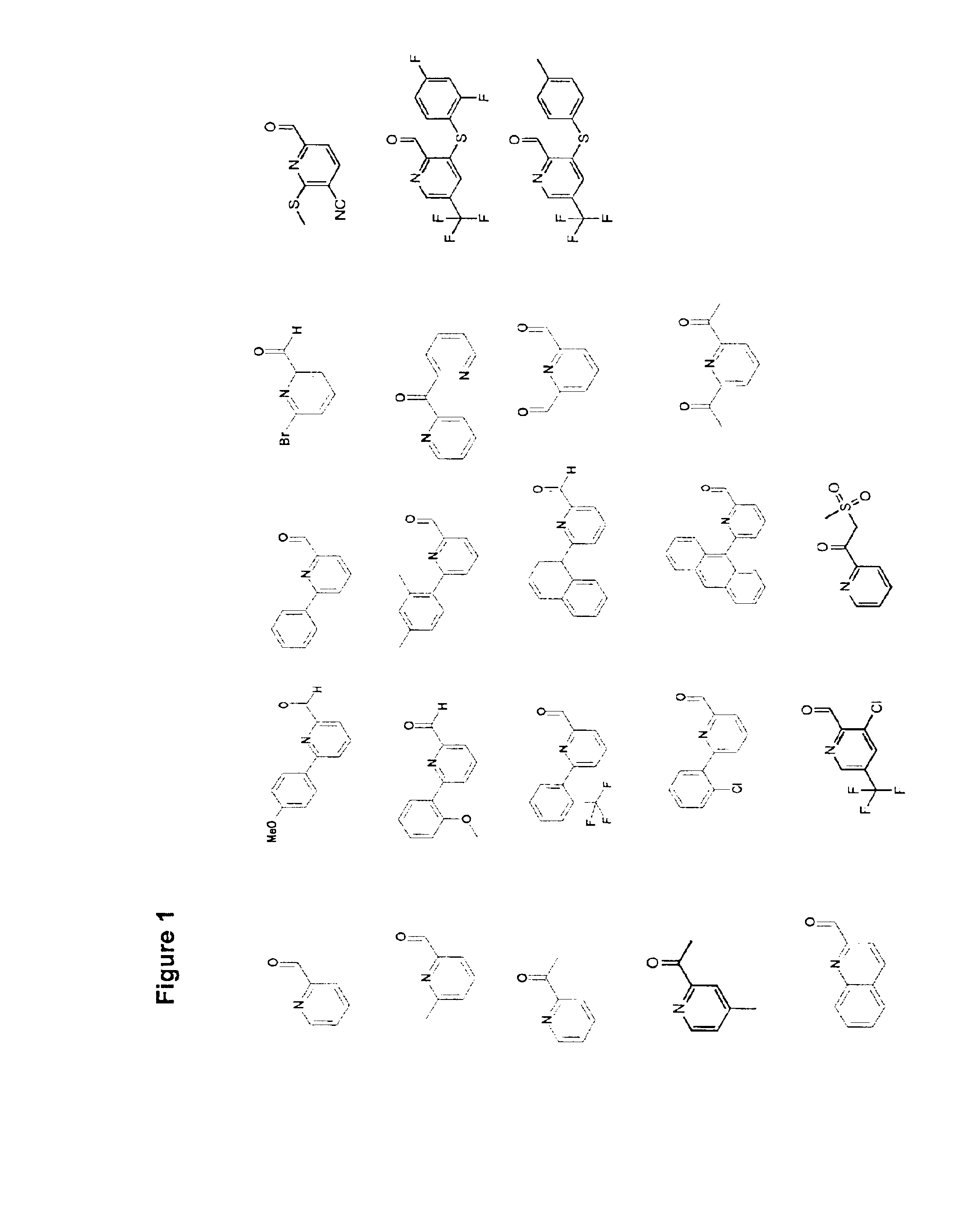

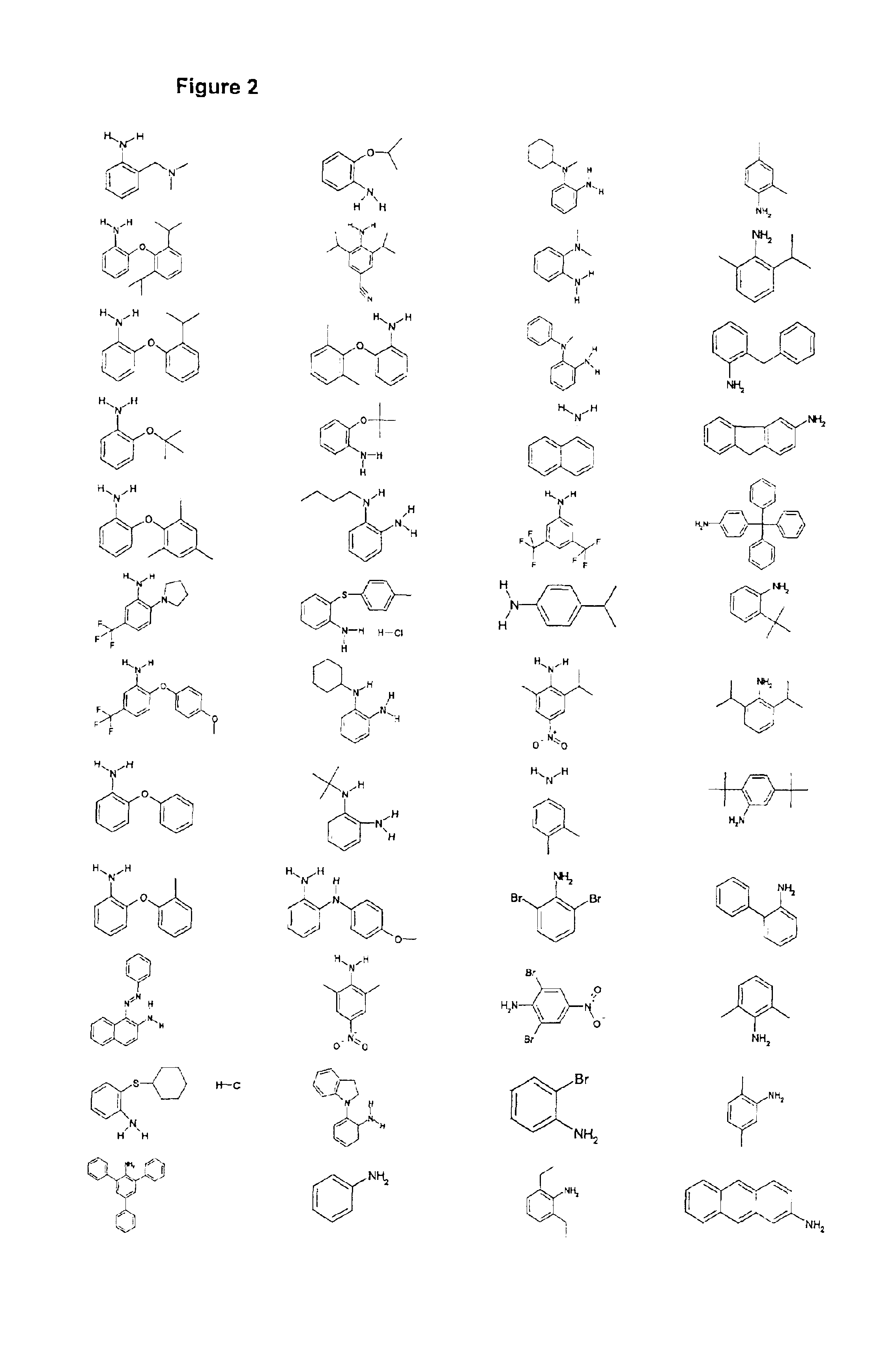

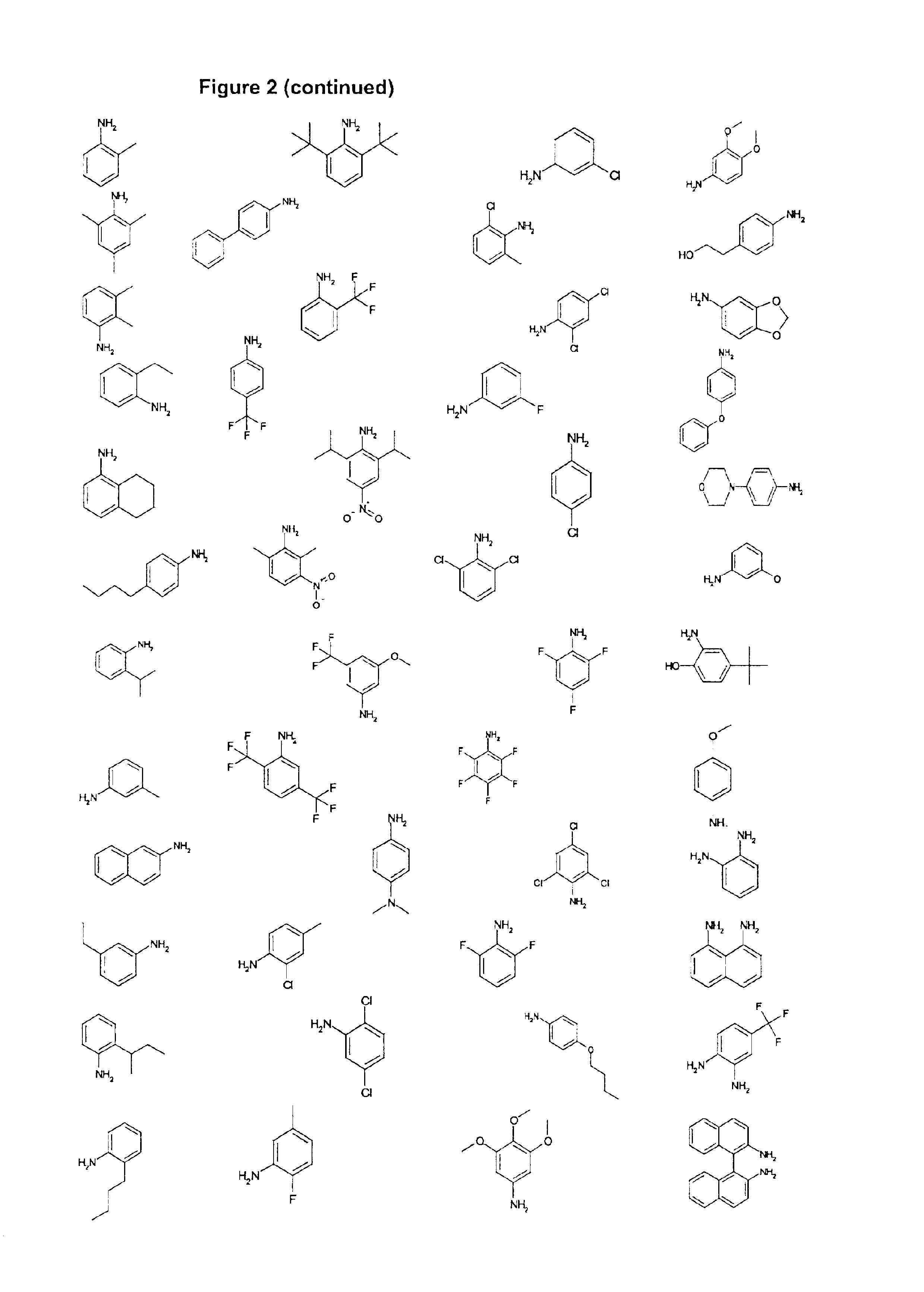

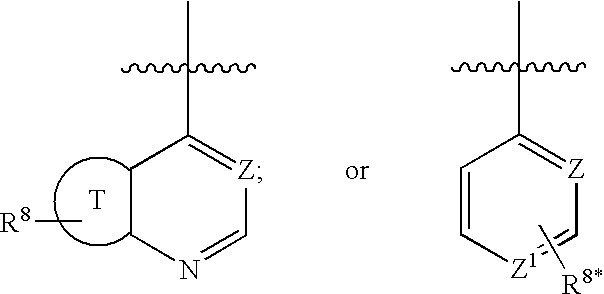

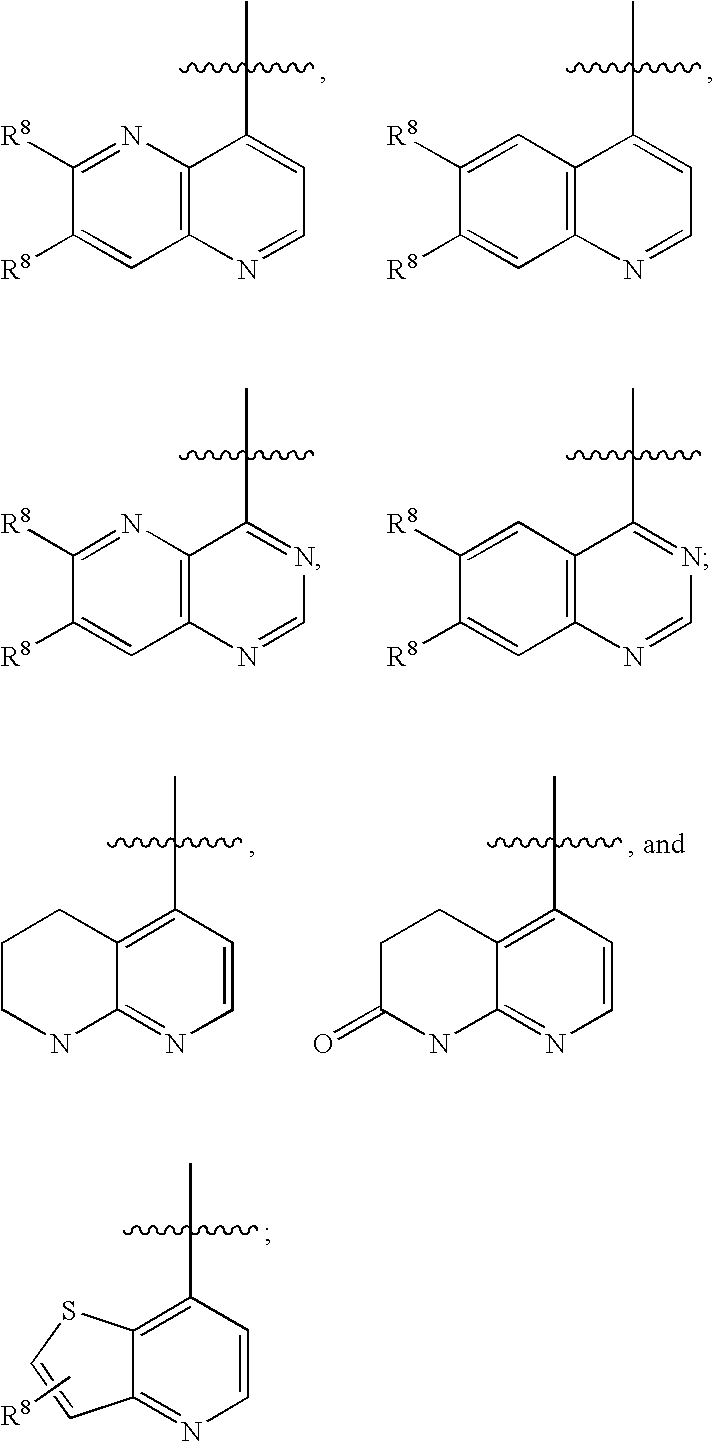

Substituted pyridyl amine complexes, and catalysts

InactiveUS6900321B2Improve catalytic performanceIncrease temperatureSilicon organic compoundsMacromolecular libraries1-OcteneHafnium

New ligands, compositions, metal-ligand complexes and arrays with pyridylamine ligands are disclosed that catalyze the polymerization of monomers into polymers. Certain of these catalysts with hafnium metal centers have high performance characteristics, including higher comonomer incorporation into ethylene / olefin copolymers, where such olefins are for example, 1-octene, isobutylene or styrene. Certain of the catalysts are particularly effective at polymerizing propylene to high molecular weight isotactic polypropylene in a solution process at a variety of polymerization conditions.

Owner:FREESLATE

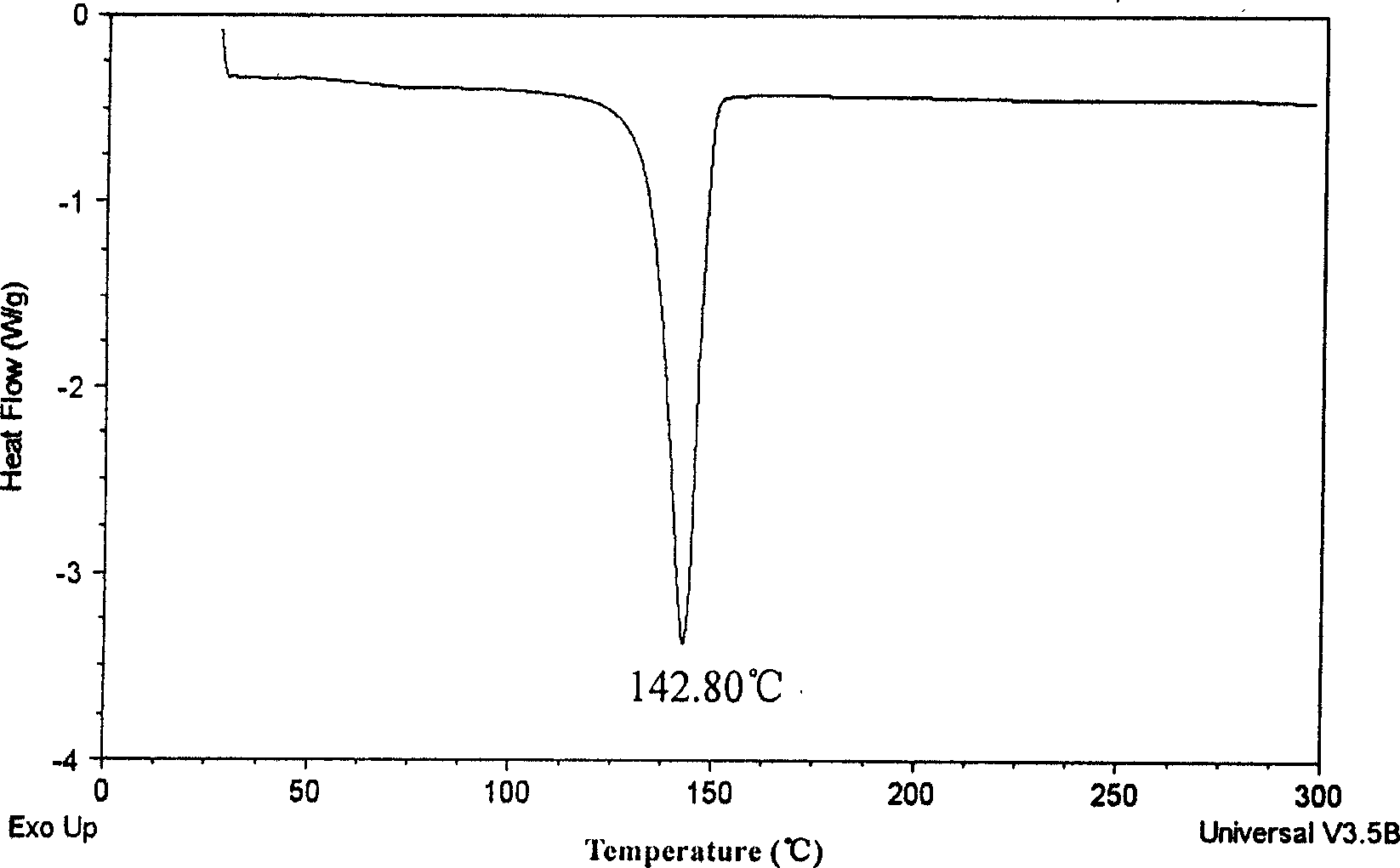

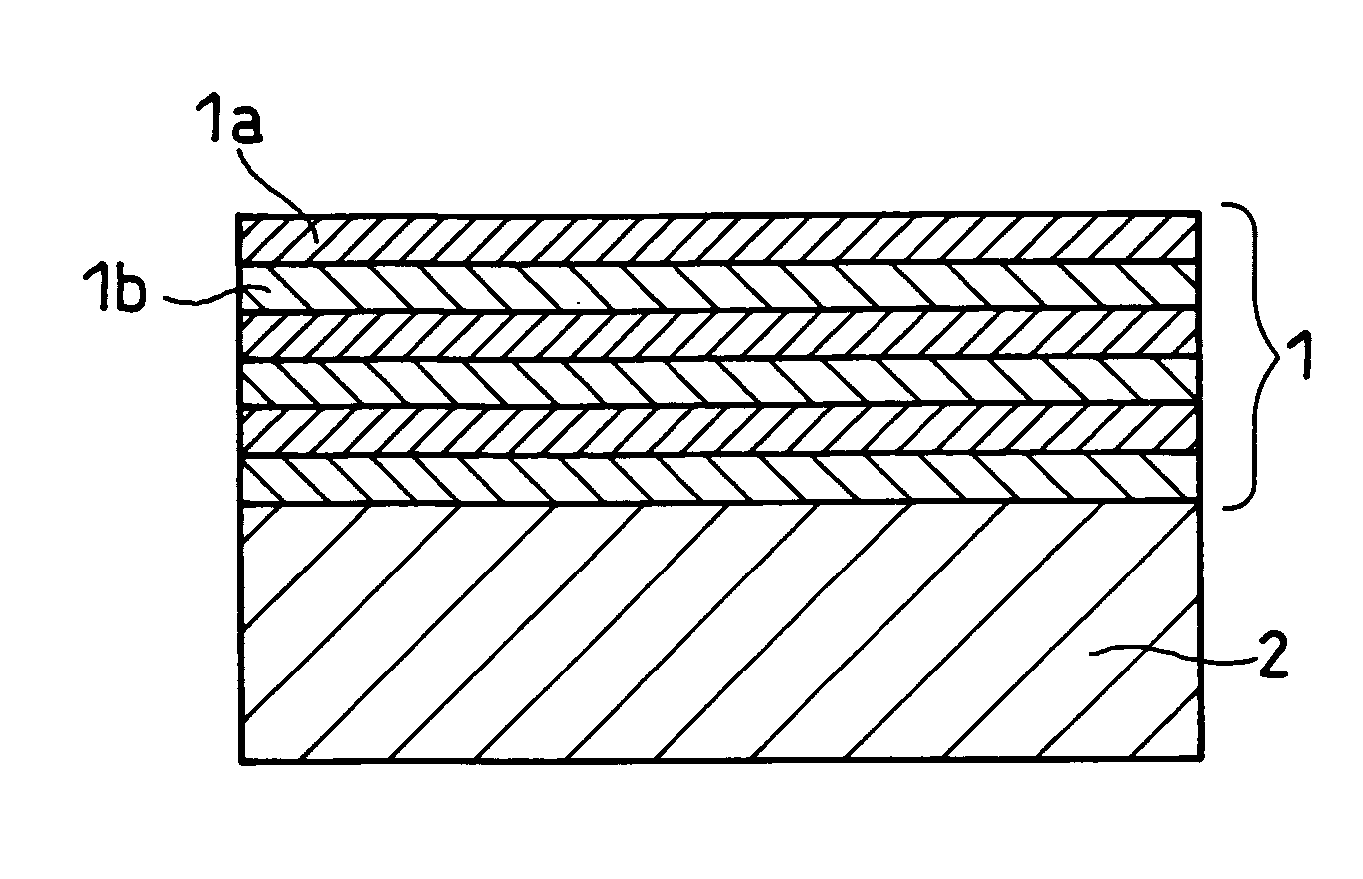

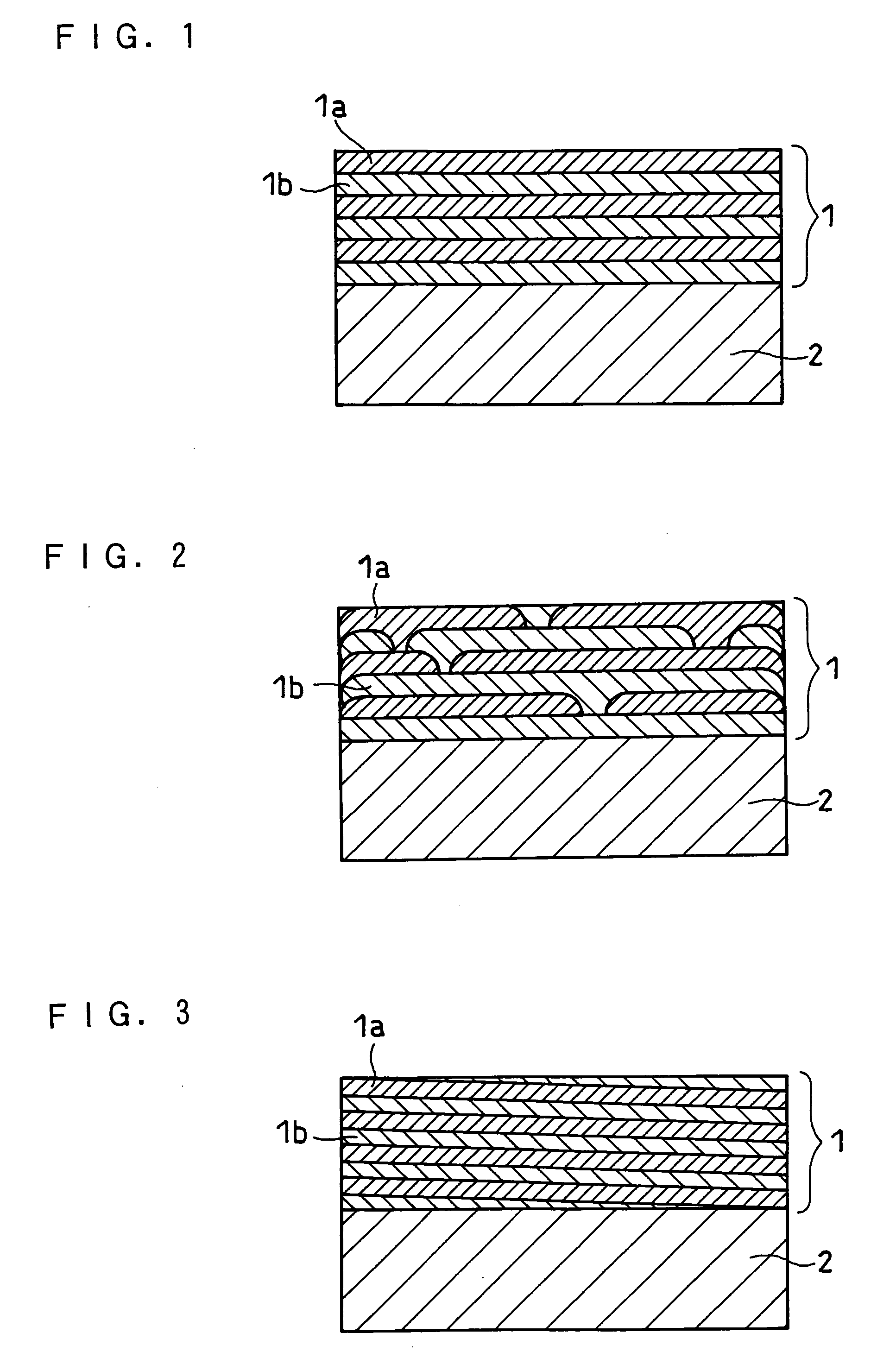

Liquid crystal polymer film, laminate, method of making them and multi-layered parts-mounted circuit board

InactiveUS6274242B1With balanceImprove thermal conductivityLiquid crystal compositionsLamination ancillary operationsThermal deformationPolymer chemistry

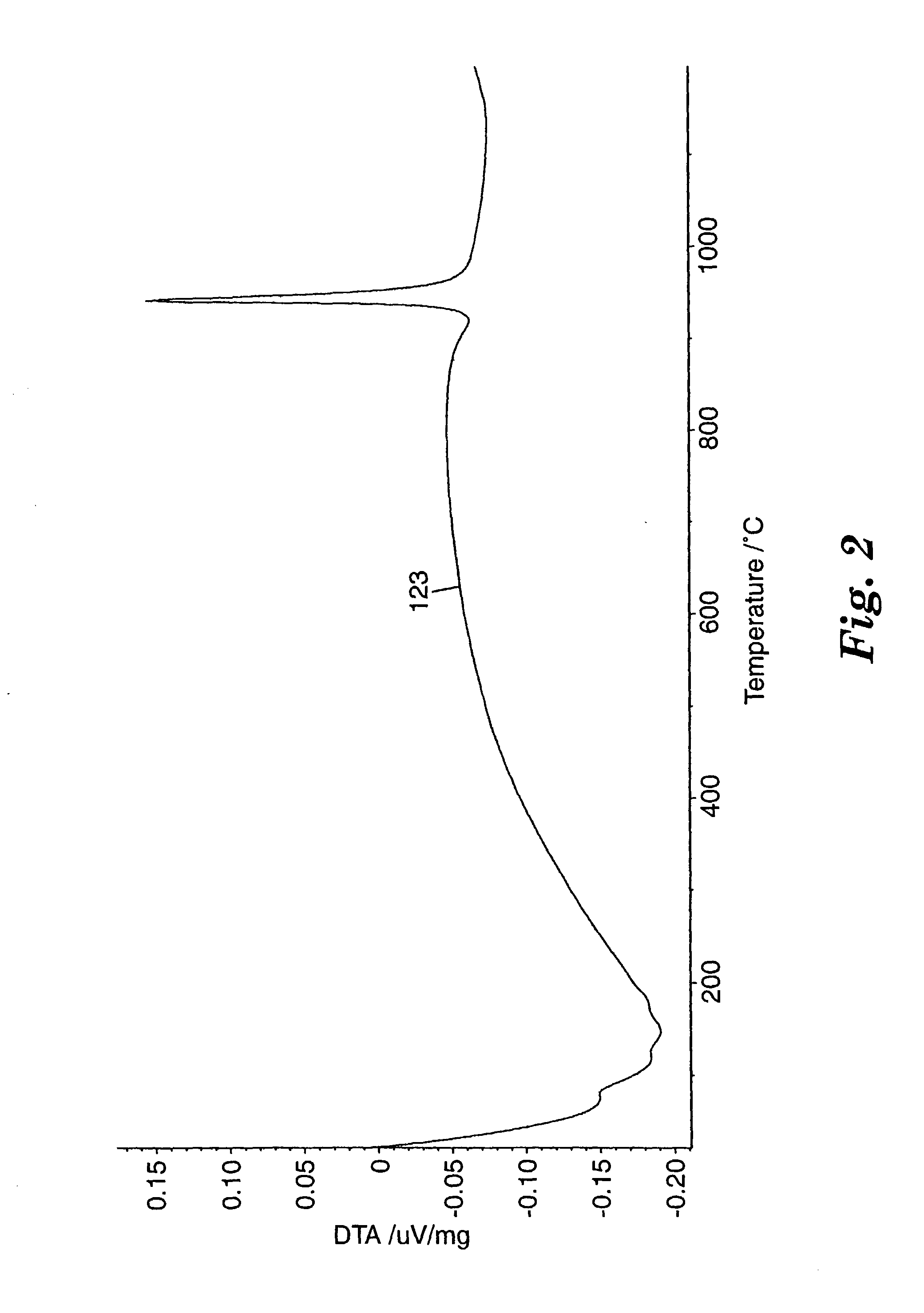

A polymer film capable of forming an optically anisotropic melt phase is, after having been laminated on a base material capable of supporting the shape of the film during heat treatment, is heat-treated at a temperature of from the thermal deformation temperature Tdef of the film to a temperature lower by alpha (alpha=10 to 35° C.) than the melting point Tm of the film until the fusion peak temperature TA of the film attains a temperature which is higher by beta (beta=5 to 30° C.) than the melting point Tm of the film before the heat treatment and is subsequently heat-treated at a temperature of from a temperature not lower than the melting point Tm of the film to a temperature lower than the fuision peak temperature TA for a length of time over which the TA increases by gamma (gamma=5 to 20° C.), and thereafter the base material is removed to produce the film.

Owner:KURARAY CO LTD

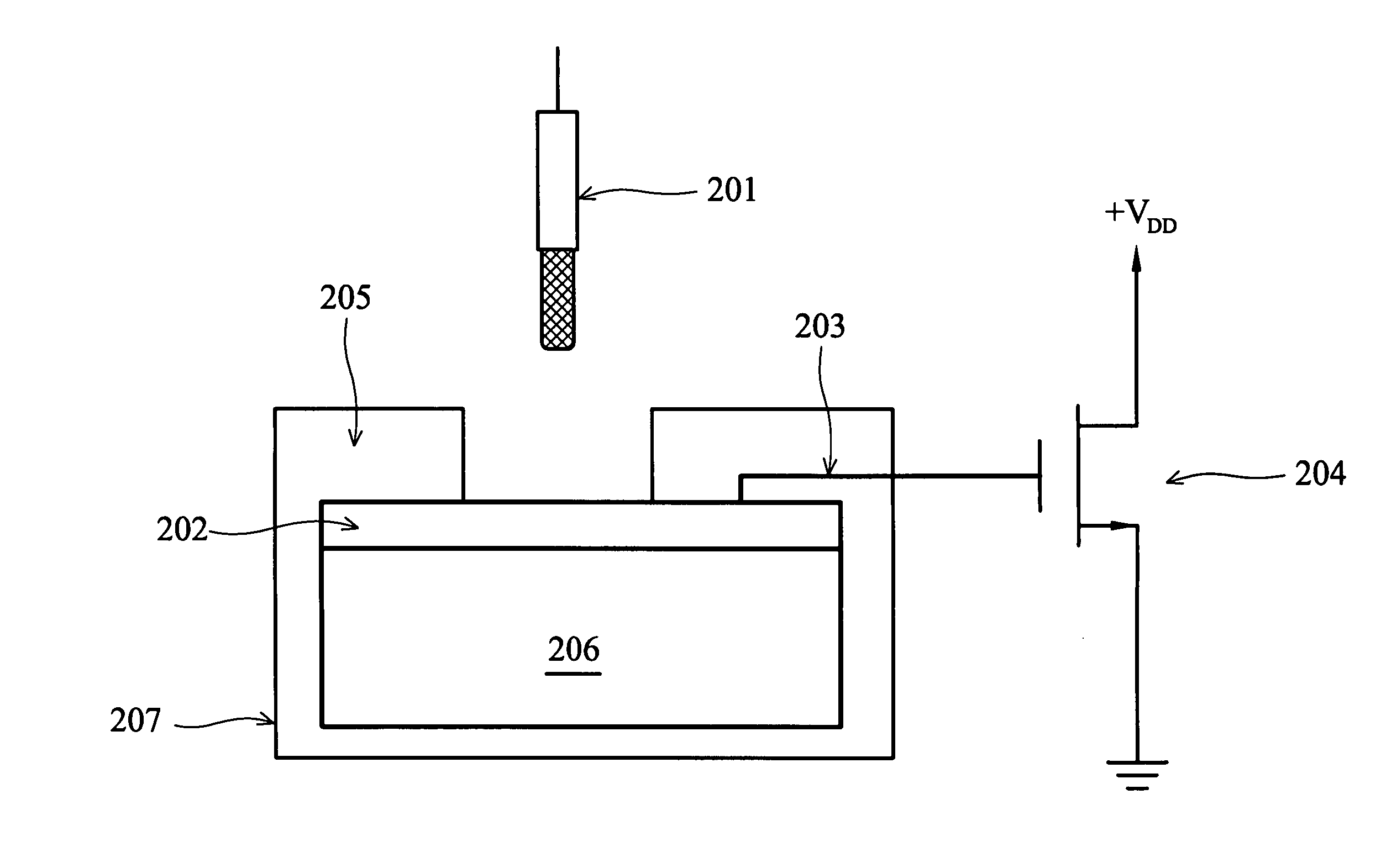

Preparation of a PH sensor, the prepared PH sensor, system comprising the same and measurement using the system

InactiveUS20070095663A1Reduce sheet resistanceImprove conductivityMaterial electrochemical variablesSputteringTitanium nitride

Preparation of a pH sensor, the prepared pH sensor, system comprising the same, and measurement using the system. The pH sensor is an extended gate field effect transistor (EGFET) structure. The preparation includes the steps of providing an extended gate ion sensitive field effect transistor comprising an extended gate region, forming a titanium nitride film on the extended gate region by RF sputtering deposition to obtain a pH sensor.

Owner:NATIONAL YUNLIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

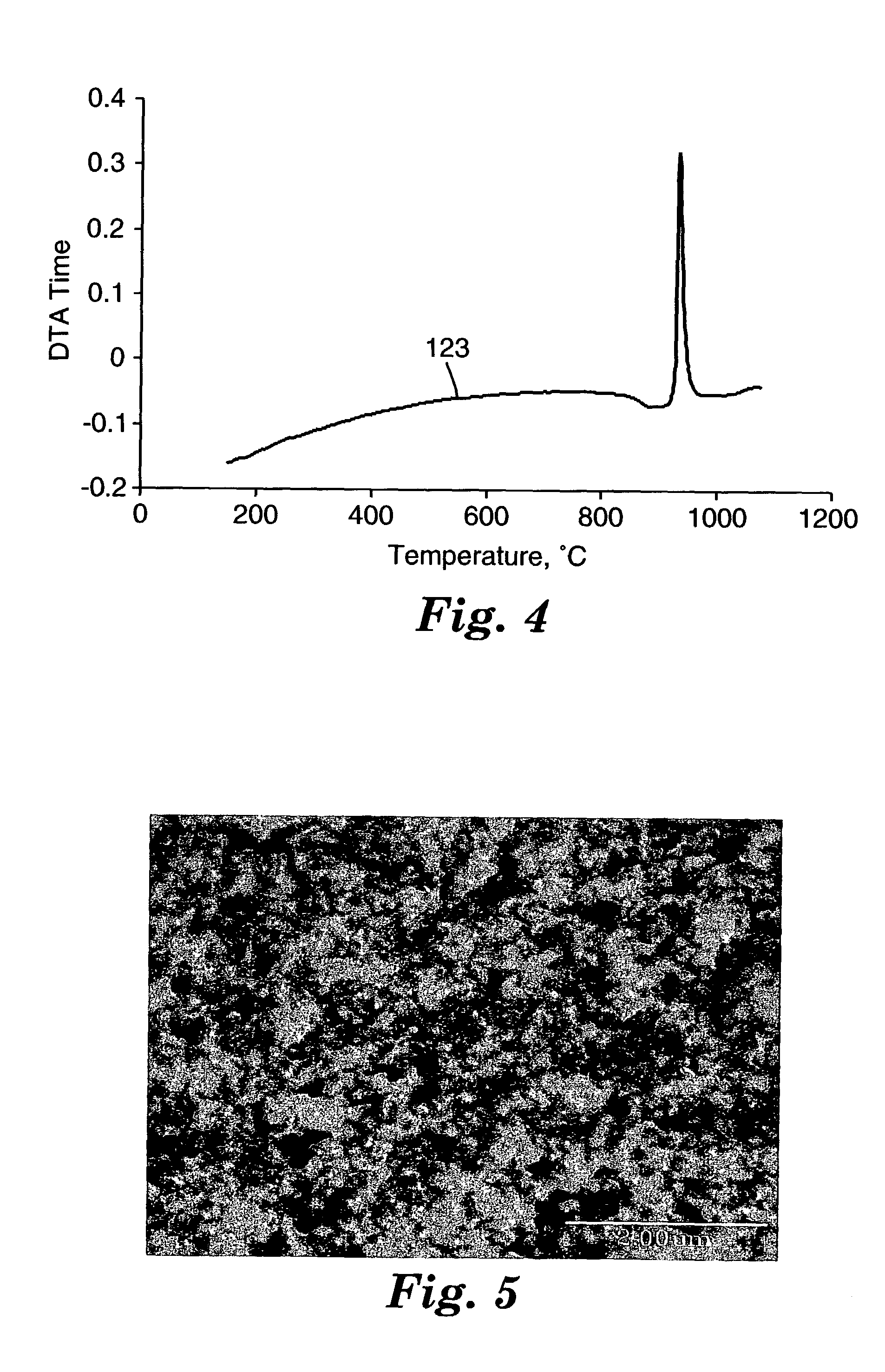

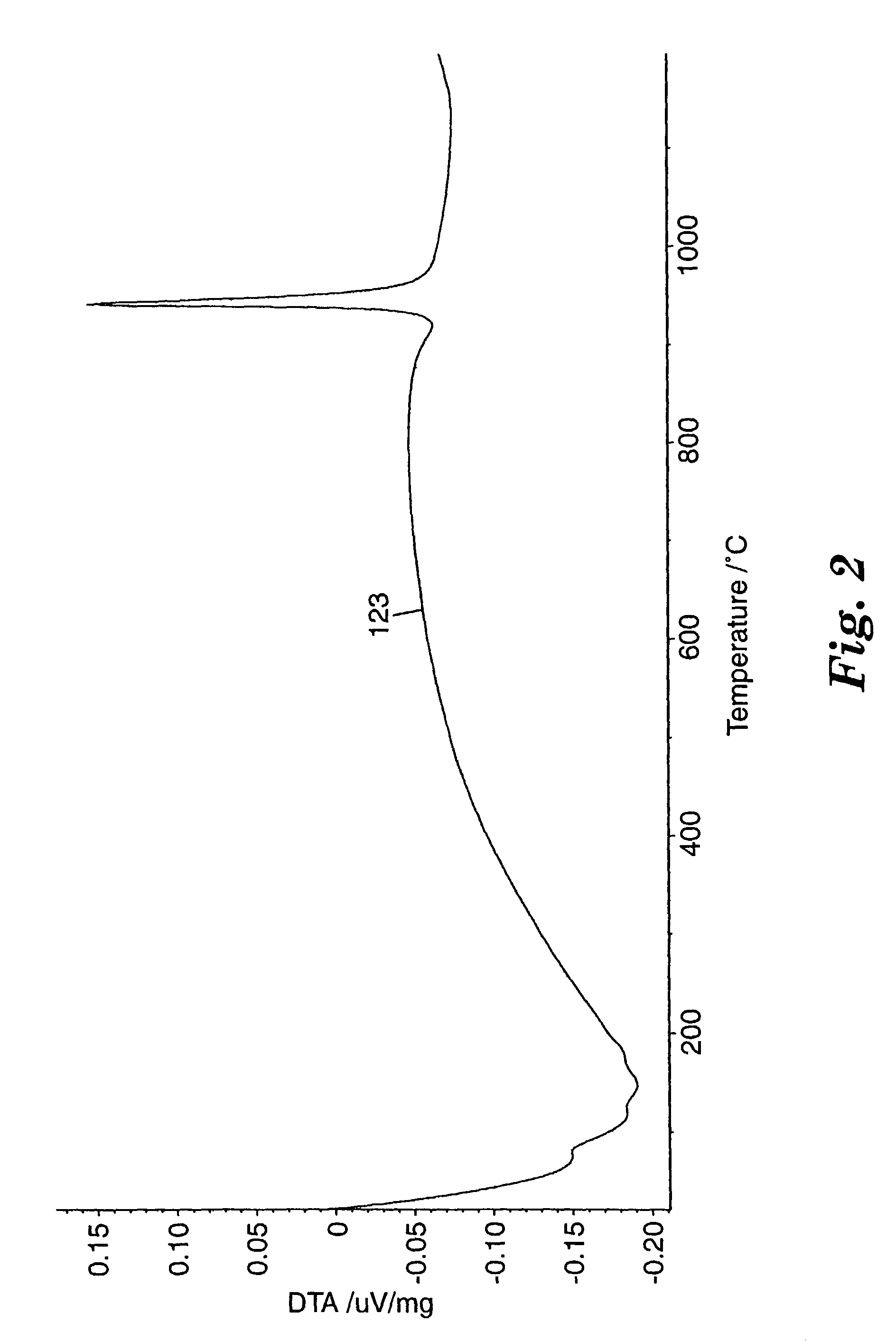

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS7507268B2Facilitates formation and homogeneityEliminates and minimizes heat transferPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3—Y2O3—ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

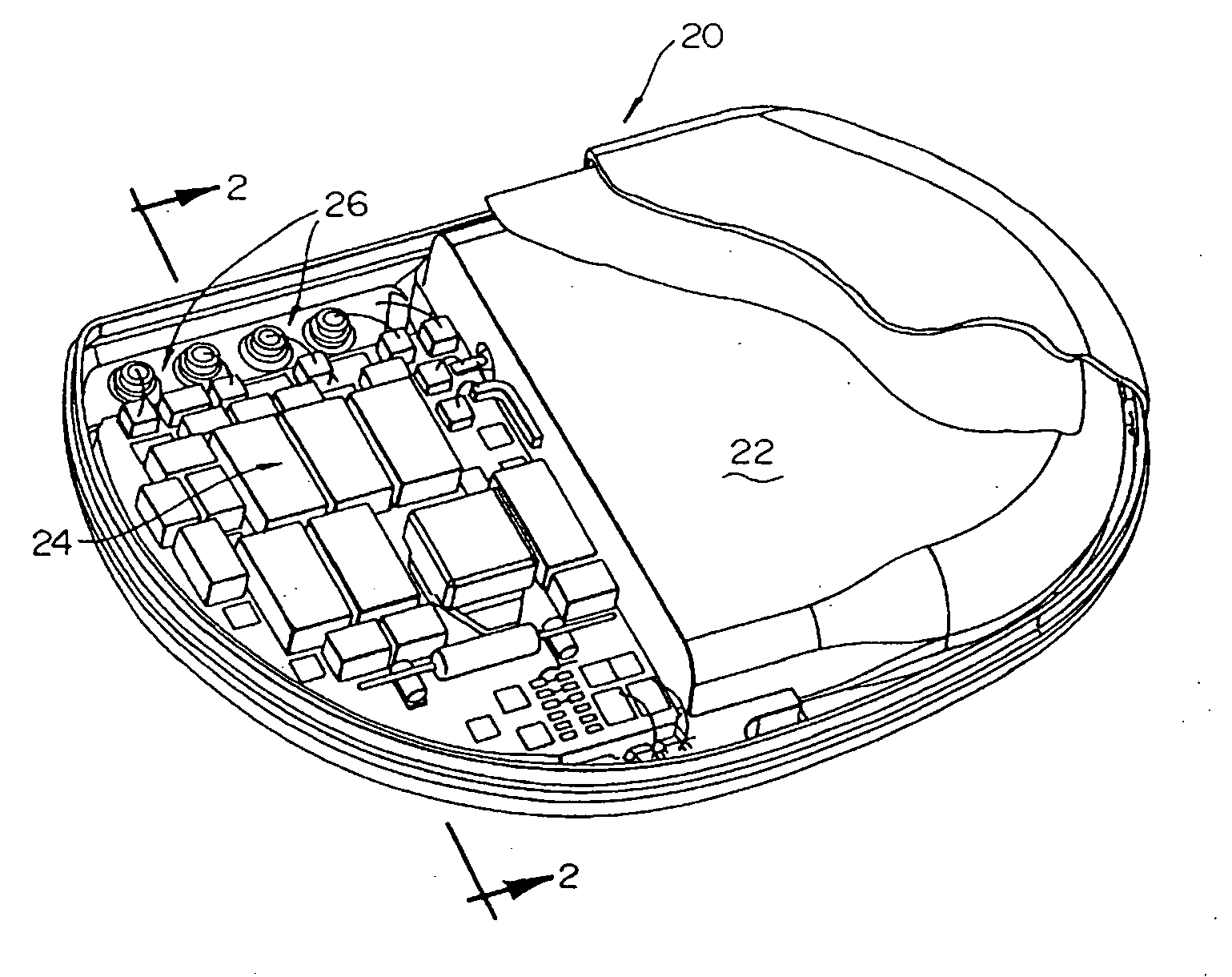

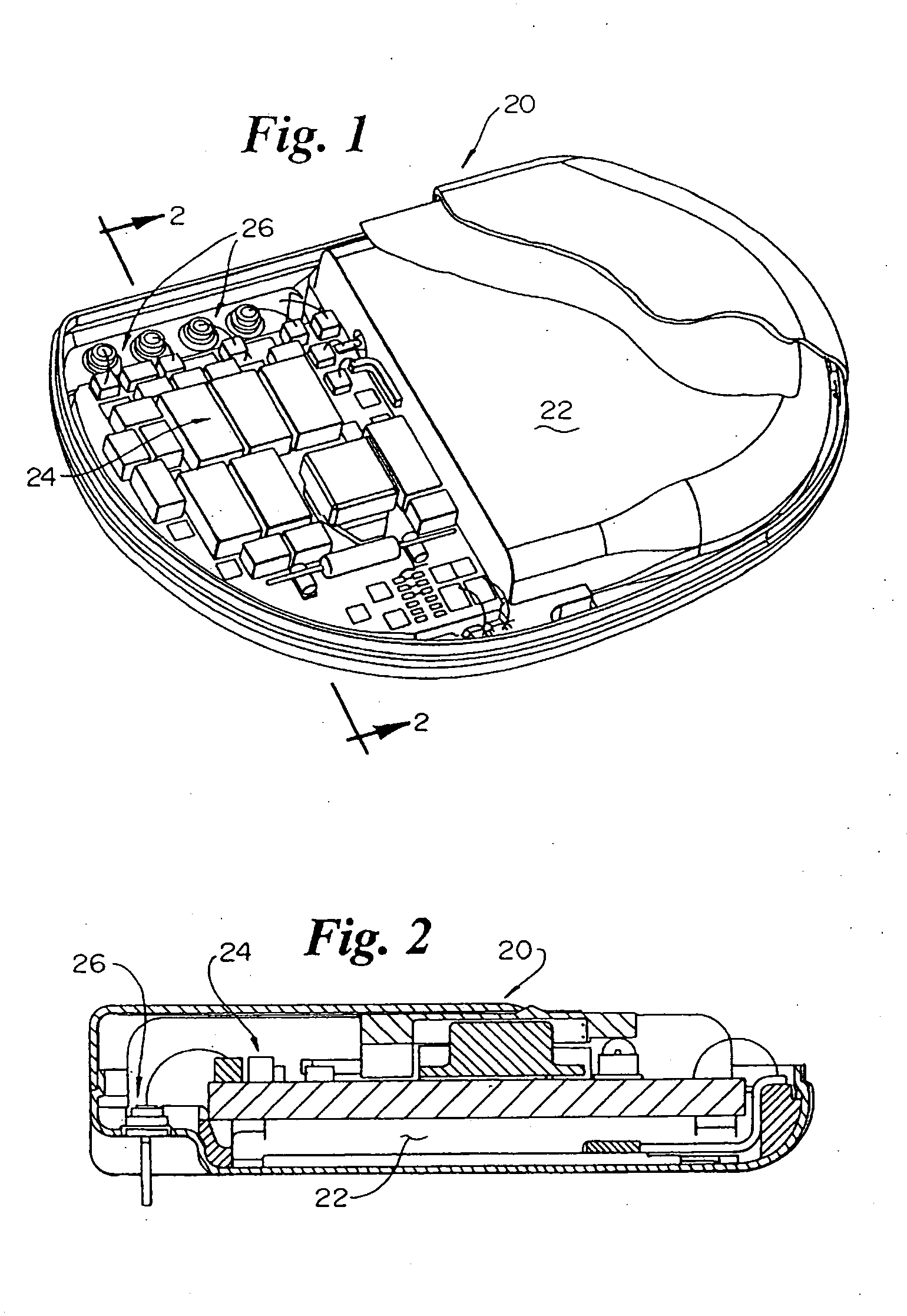

Glass-to-metal feedthrough seals having improved durability particularly under AC or DC bias

A hermetic implantable medical device (IMD) is provided with a single or multi-pin arrangement including selected glass to metal seals for a feedthrough including a ceramic disk member coupled to the sealing glass surface in potential contact with body fluids. By judicious selection of component materials (ferrule, seal insulator and pin) provides for either compression or match seals for electrical feedthroughs (having a single or multi-pin array) provide corrosion resistance and biocompatibility required in IMDs. The resultant feedthrough configuration accommodates one pin within a single ferrule or at least two pins in a single ferrule having a pin surrounded by insulator material (e.g., alumina ceramic, zirconia ceramic, zirconia silicate ceramic, mullite, each having higher melting points than the sealing glass distributed around the pin within the ferrule, or feldspar porcelain materials or alumino-silicate glasses having a lower melting point than the sealing glass) distributed around the pin within the ferrule.

Owner:MEDTRONIC INC

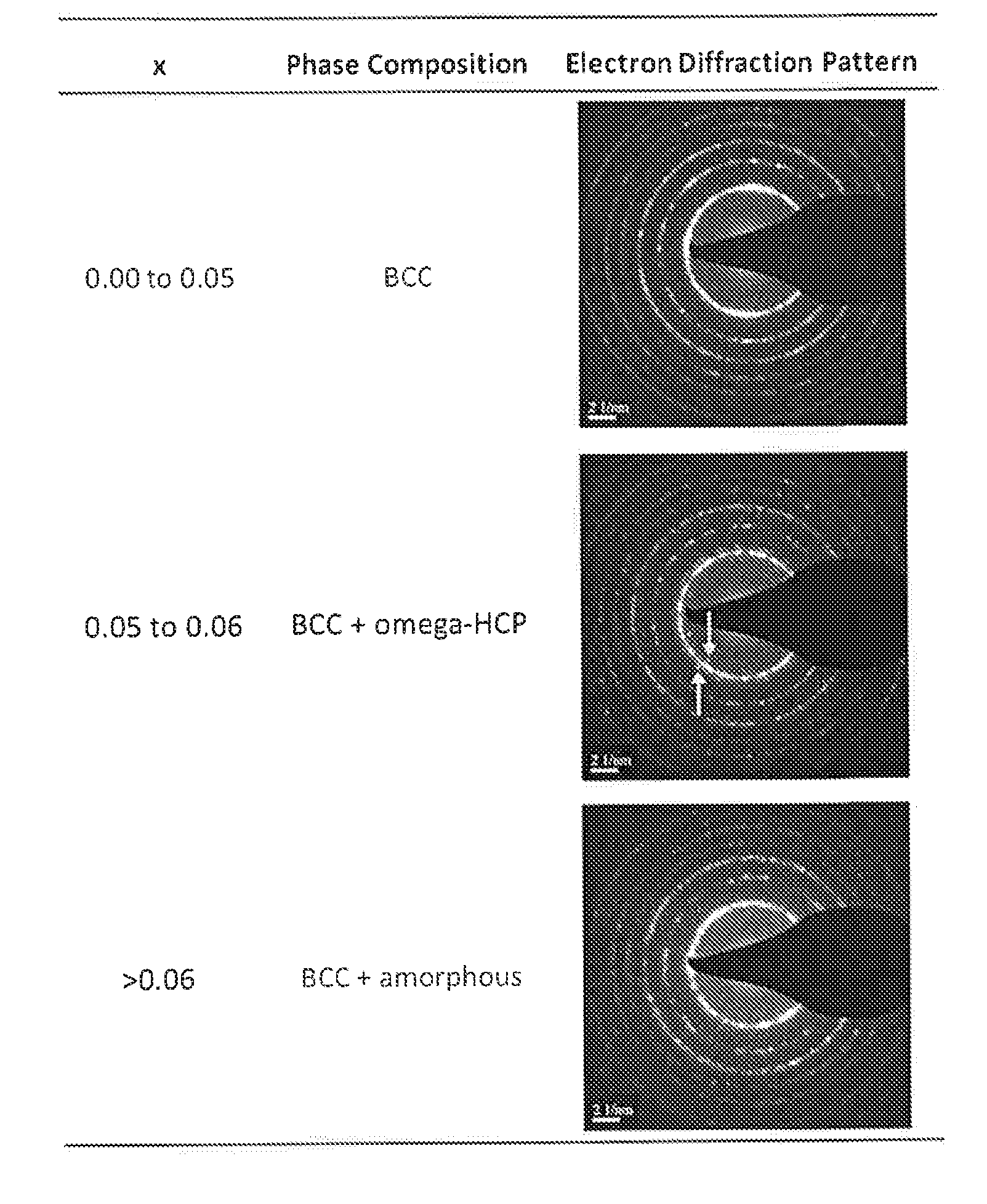

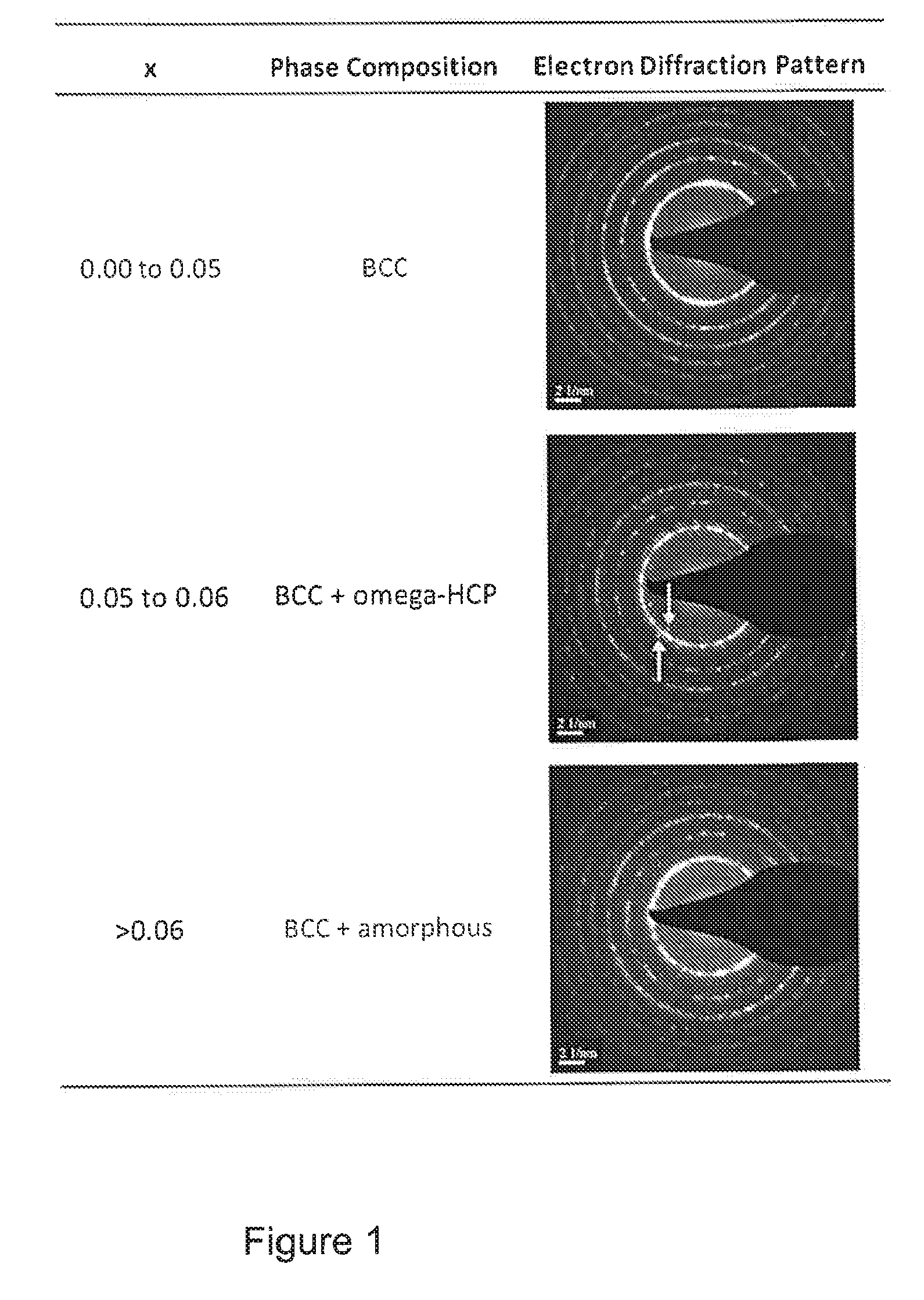

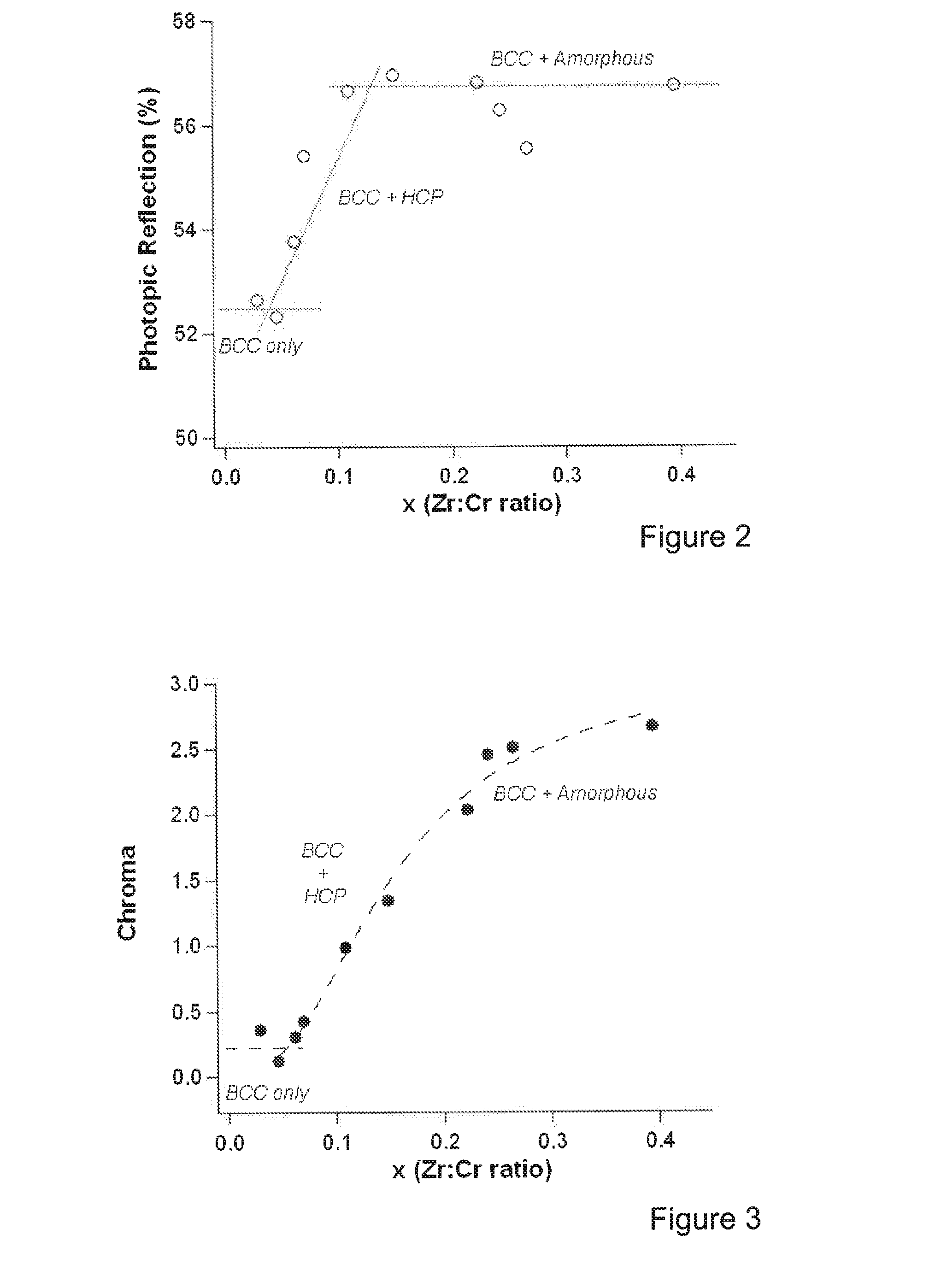

Chromium-based reflective coating

ActiveUS9181616B2High melting pointStable crystal structureMirrorsLighting and heating apparatusDopantPolymer substrate

A chromium-based reflective coating for a polymeric substrate, wherein the coating has a thickness of 200 nm or less and is an alloy of chromium and a dopant material, the dopant material being selected from the hexagonally close-packed transition metals, the alloy having a crystal structure of a primary body-centered cubic phase in coexistence with a secondary omega hexagonally close-packed phase.

Owner:SMR PATENTS S A R L +1

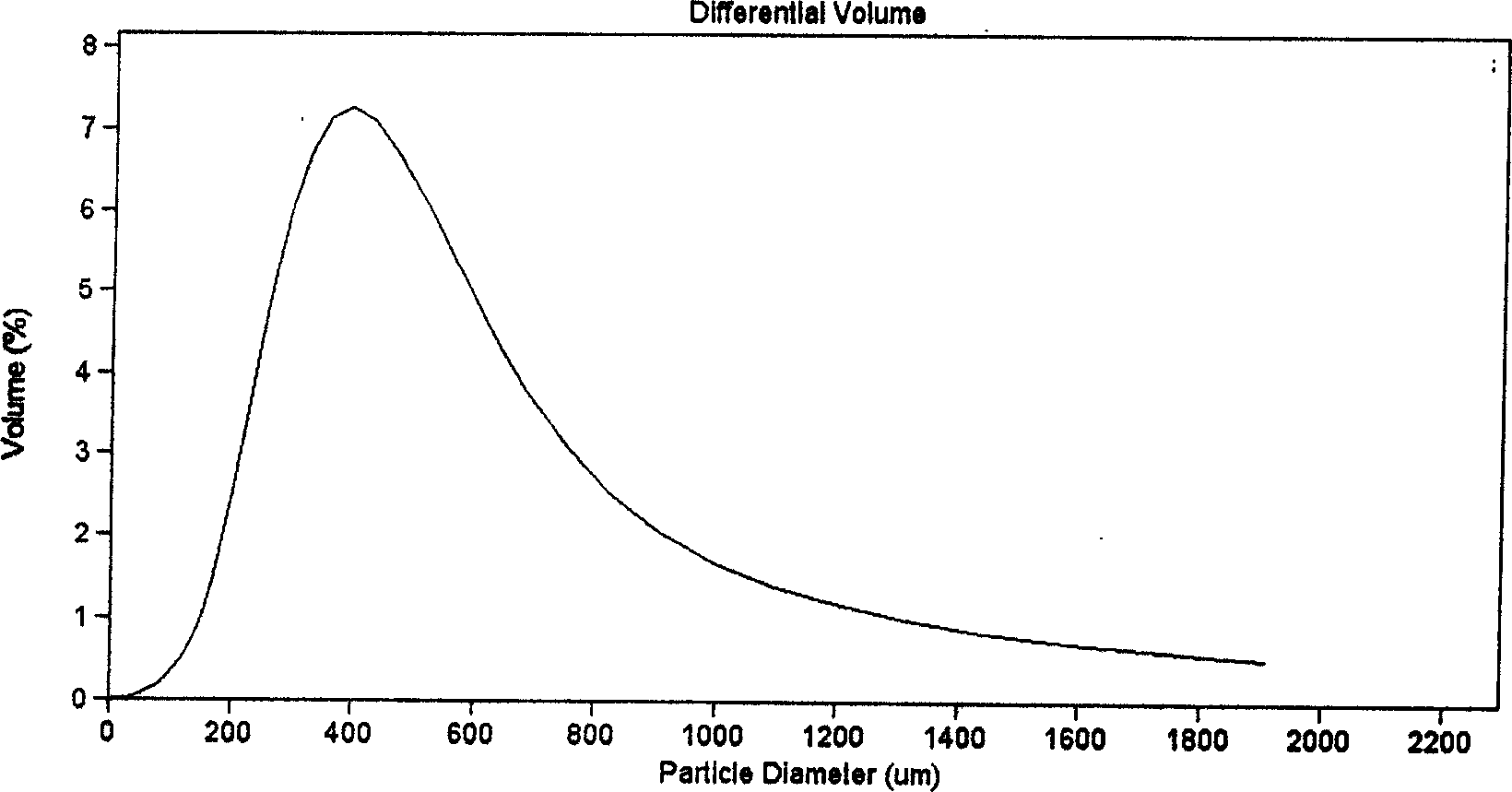

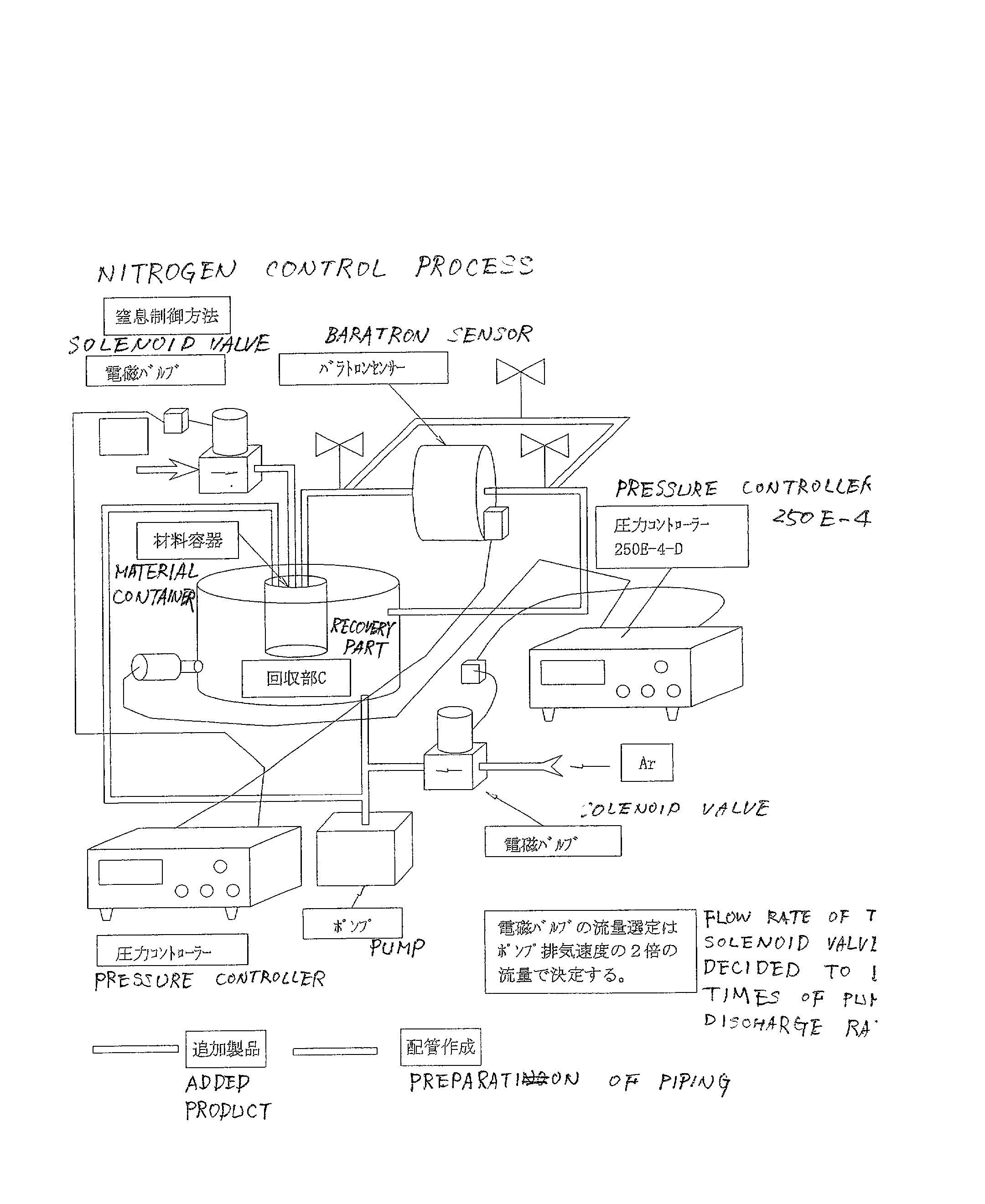

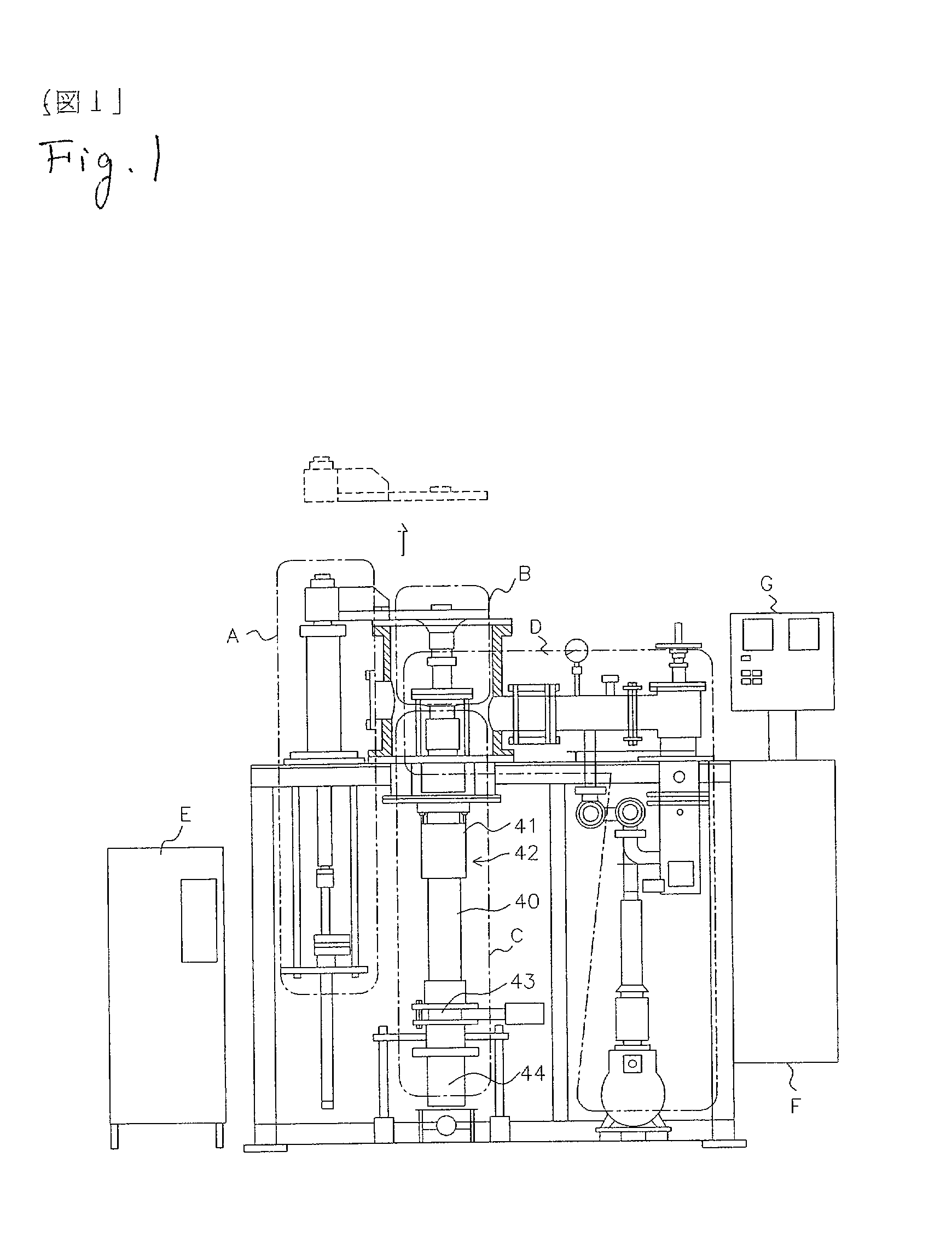

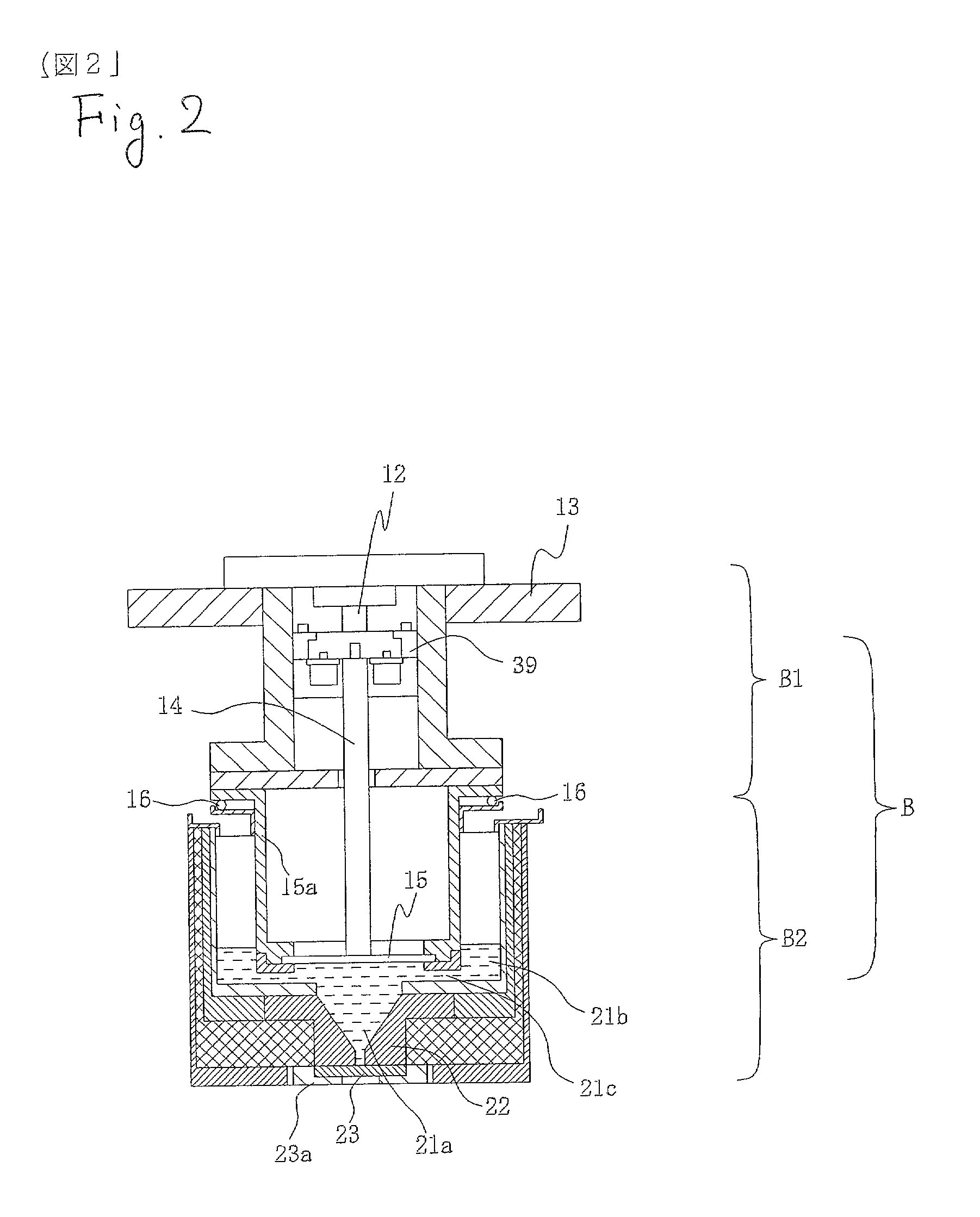

Production apparatus of monodisperse particle and production process of monodisperse particle and monodisperse particle produced by the process

InactiveUS20020089100A1Highly multi-purpose monodisperse particle industrially and cheaplyEasy to controlTransportation and packagingMetal-working apparatusMetallurgySlurry

It is the object to provide a production process of monodisperse particle in which monodisperse particle with uniform particle size (particle diameter) can be stably mass-produced, and monodisperse particle produced by this process, and its production apparatus. The supply pipe diameter deltaf is set to be greater than the orifice diameter deltao and the internal and external pressure of the slurry retention part b is controlled, and this allows to facilitate supply of the slurry through the supply pipe (21c), and continuously and efficiently supply the slurry, and then to produce monodisperse particle with uniform particle size (particle diameter).

Owner:KAWASAKI CORP KK

Substituted amide derivatives and methods of use

ActiveUS20080312232A1Appropriate consistencyHigh melting pointBiocideSenses disorderPharmaceutical medicinePerylene derivatives

Selected compounds are effective for prophylaxis and treatment of diseases, such as HGF mediated diseases. The invention encompasses novel compounds, analogs, prodrugs and pharmaceutically acceptable salts thereof, pharmaceutical compositions and methods for prophylaxis and treatment of diseases and other maladies or conditions involving, cancer and the like. The subject invention also relates to processes for making such compounds as well as to intermediates useful in such processes.

Owner:AMGEN INC

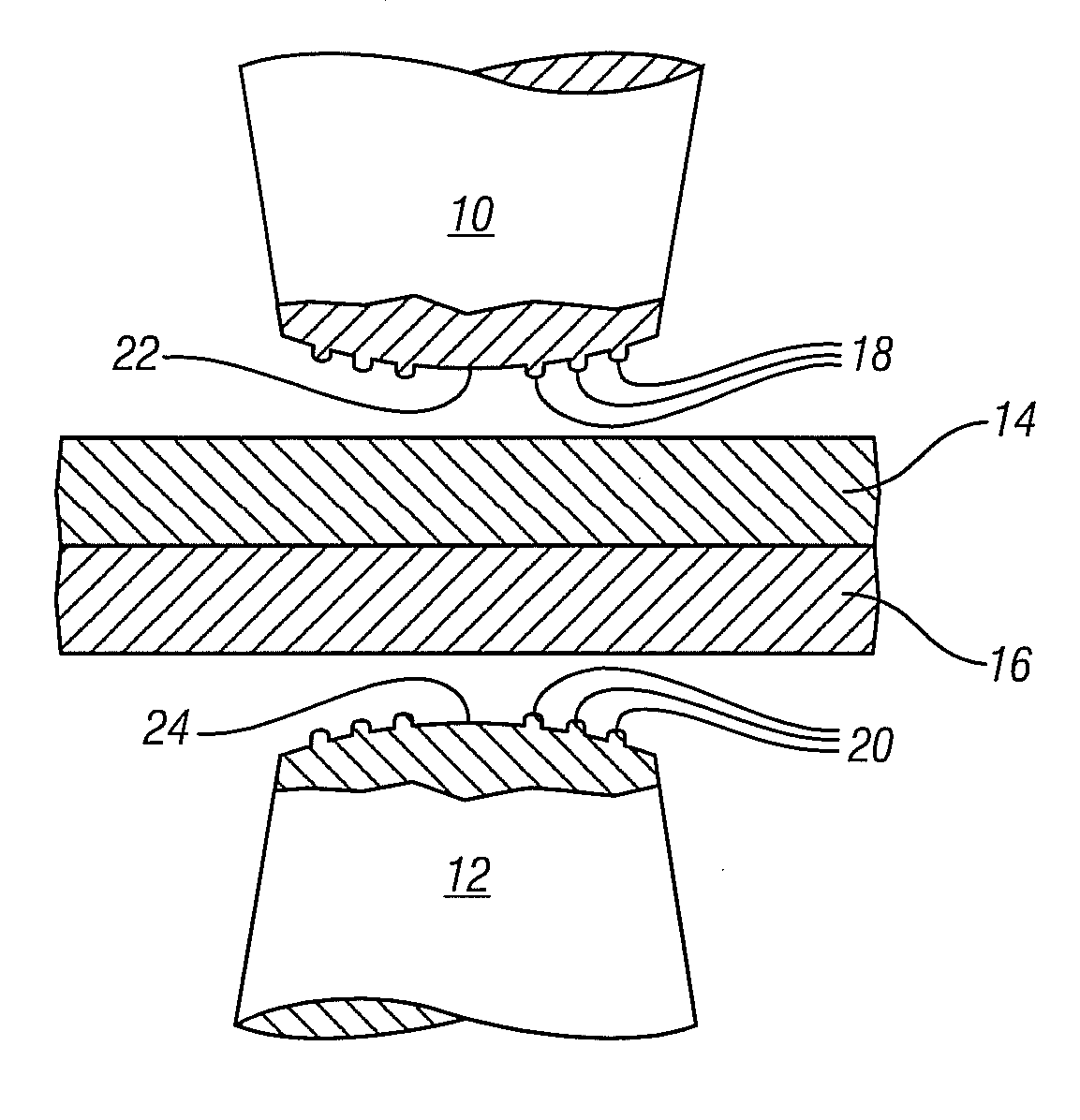

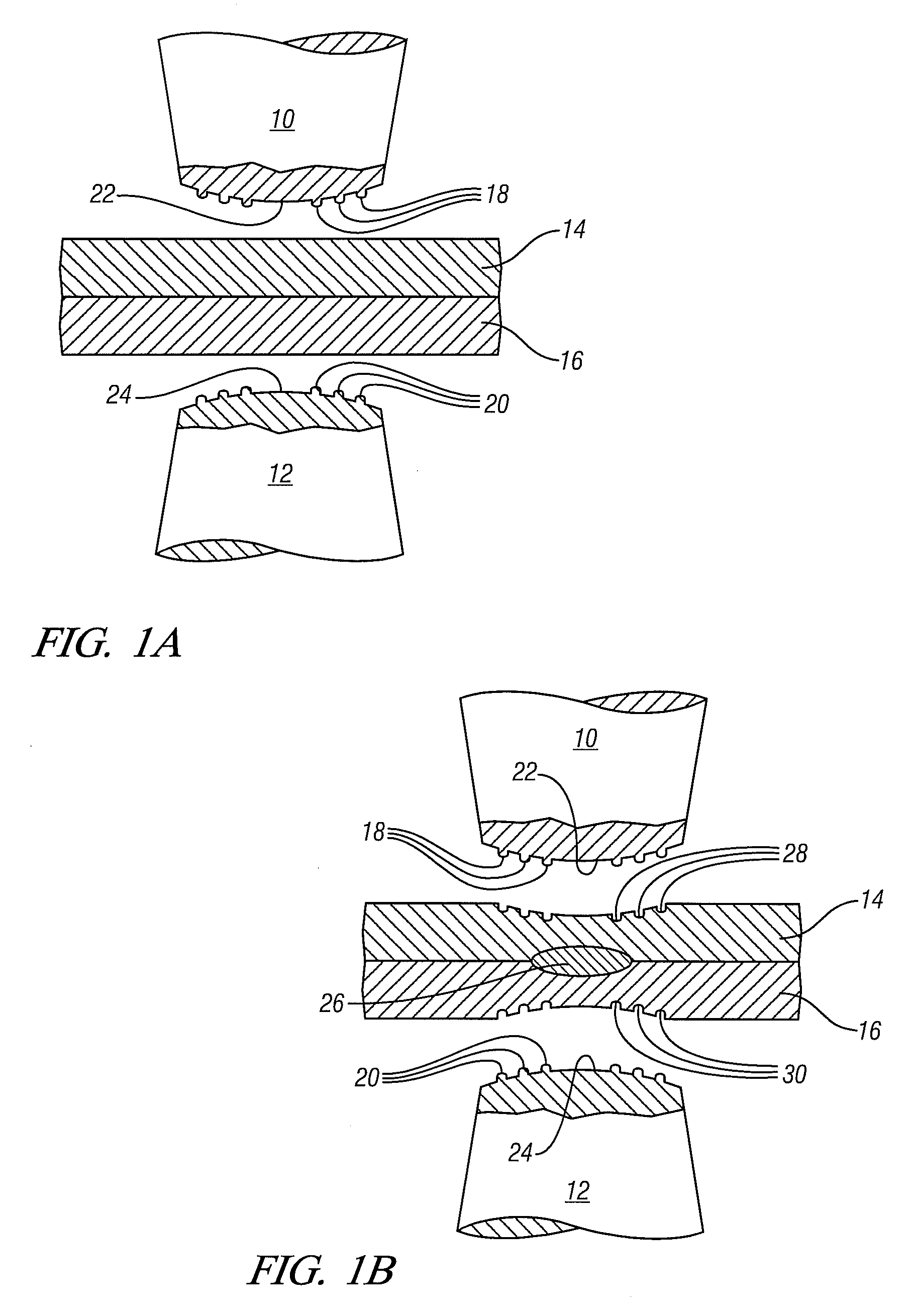

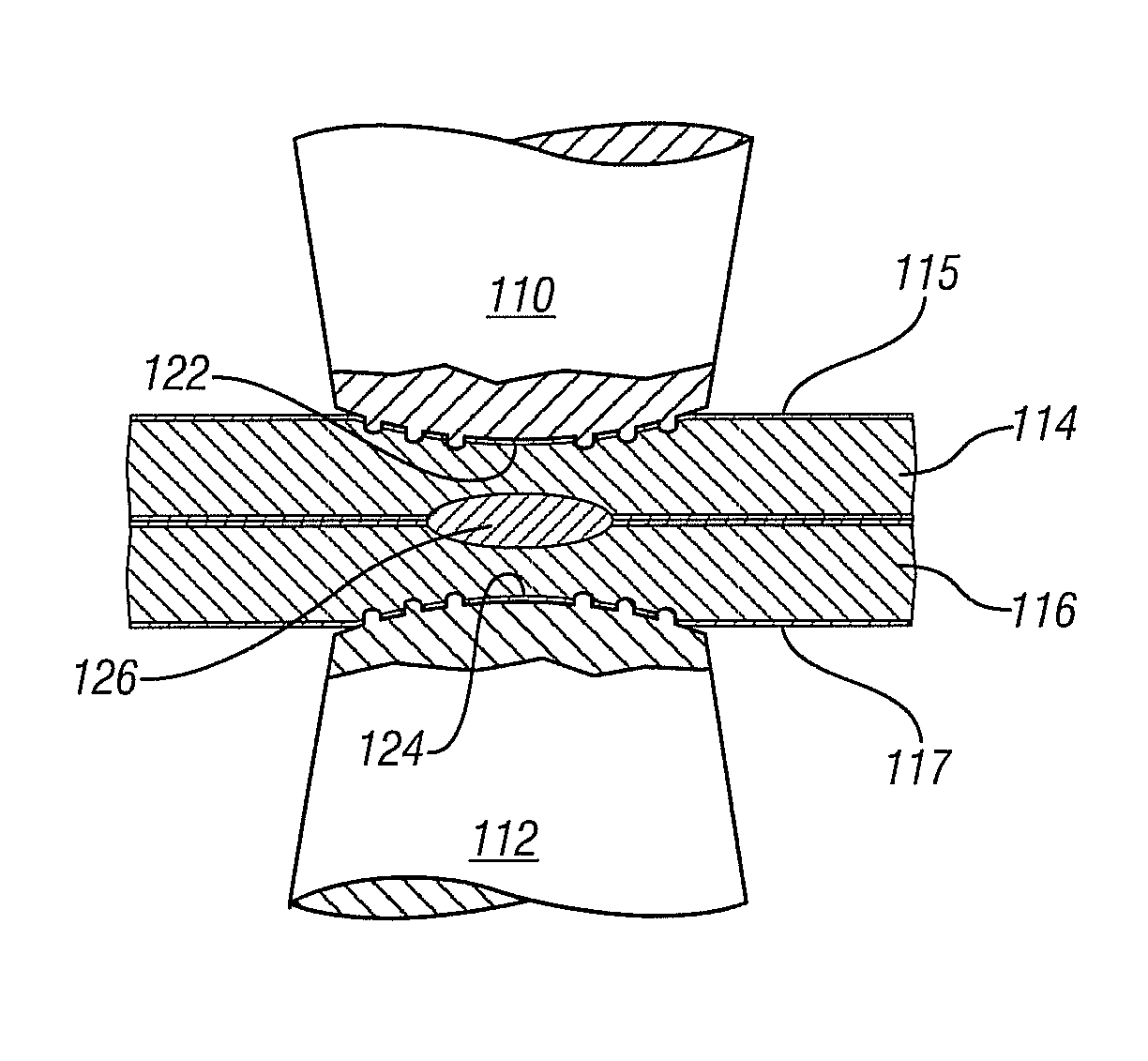

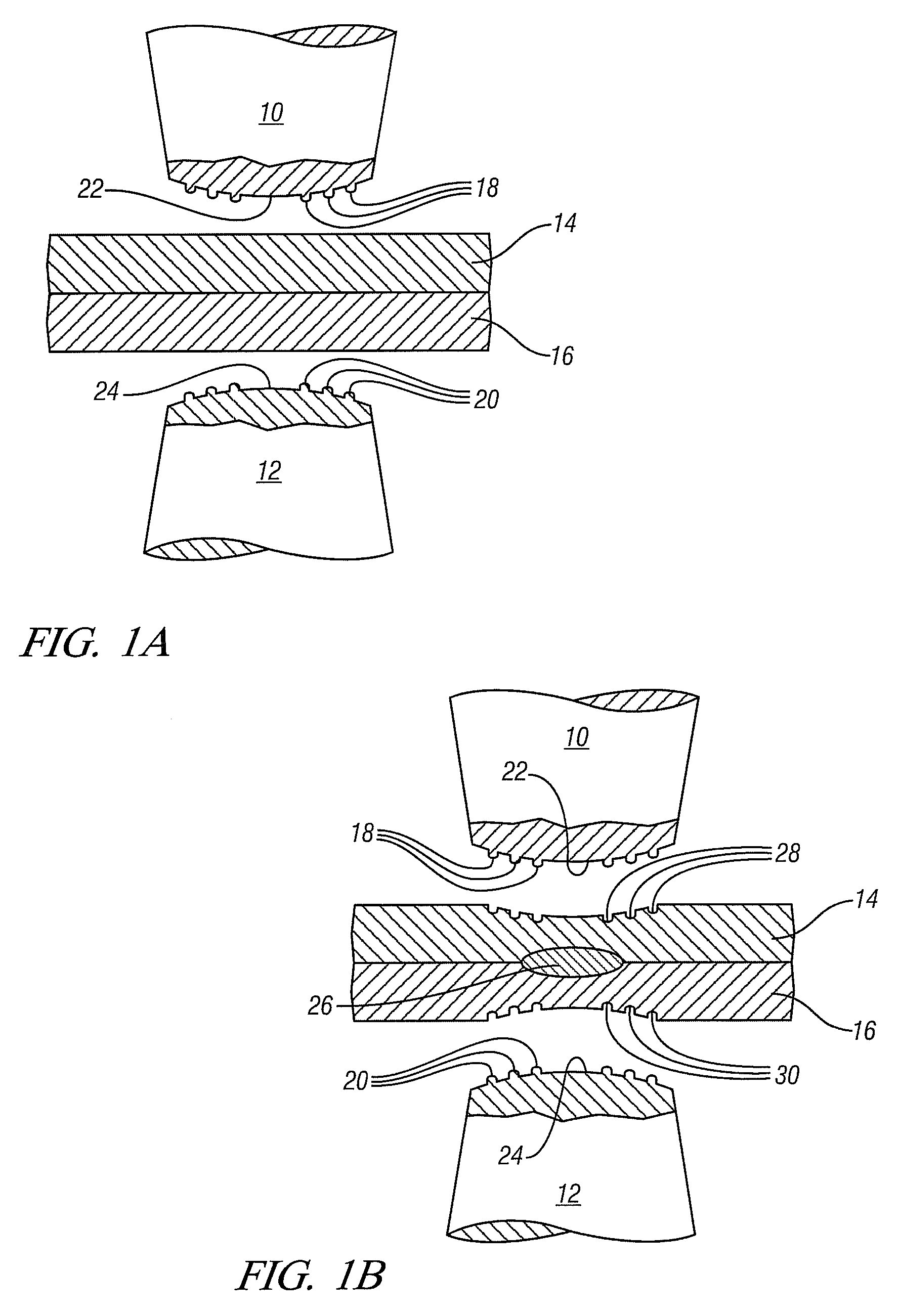

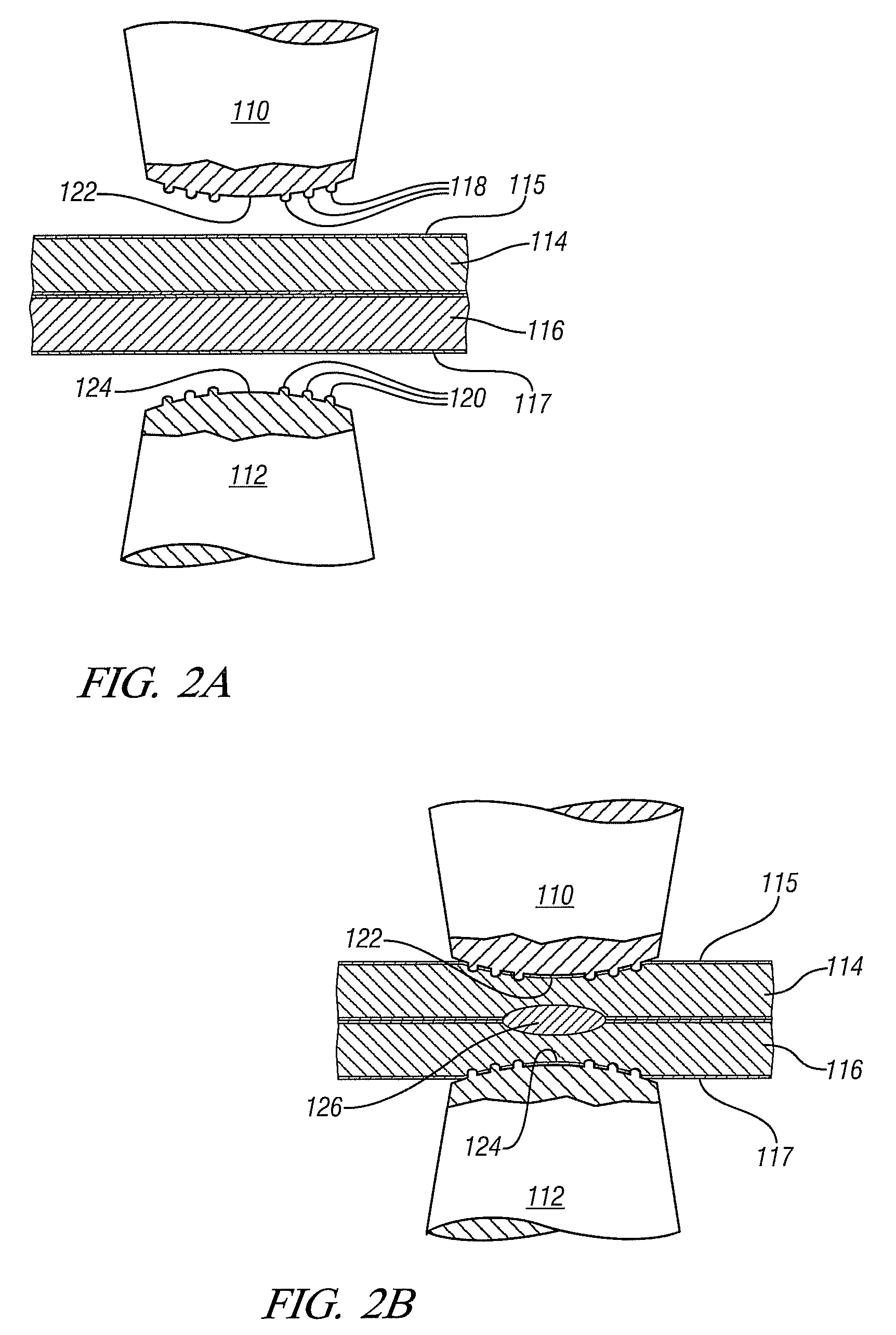

Weld electrode for attractive weld appearance

ActiveUS20090255908A1High thermal and electrical resistivityHigh melting pointPressure electrodesSheet steelSpot welding

Weld faces of electrodes for resistance spot welding are formed with a suitable area of protrusions and / or intrusions. The size, shape, and elevation or depths of the protrusions or intrusions are determined for the formation of suitable spot welds in and between metal workpieces such as aluminum or steel panels for vehicle bodies. The protrusions or intrusions are also conceived and used to form an image on at least a visible surface of the welded article to produce an attractive appearance on the surface of the welded sheet.

Owner:GM GLOBAL TECH OPERATIONS LLC

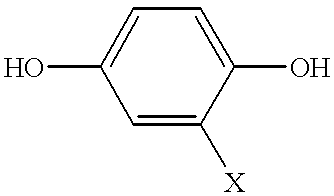

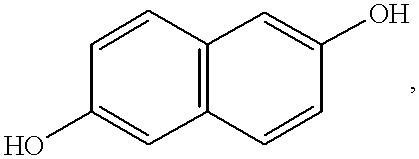

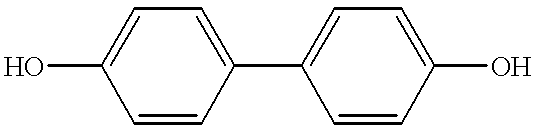

Carbon and/or silicon bridged binuclear metallocene catalyst for styrene polymerization

InactiveUS6010974AHigh catalytic activityHigh Molecular Weight DistributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationArylSilylene

An alkylene and / or silylene bridged binuclear metallocene catalyst for styrene polymerization is represented by the following formula (I): where M1 and M2 are the same or different transition metal of Group IVb of the Periodic Table; Cp1 and Cp2 are the same or different cyclopentadienyl; alkyl, alkoxy, silyl or halogen substituted cyclopentadienyl; indenyl; alkyl, alkoxy, silyl or halogen substituted indenyl; fluorenyl; or alkyl, alkoxy, silyl or halogen substituted fluorenyl, which is capable of pi -electron, eta 5-bonding with M1 or M2; each of E1, E2 and E3, independently of one another, is a carbon atom or a silicon atom; m, p and q are integers of 0 to 15 and m+p+q> / =1; each of R1, R2, R3, R4, R5 and R6, independently of one another, is a hydrogen, an alkyl, an aryl, an alkoxy or a halogen; X is a hydrogen, an alkyl, an alkoxy or a halogen; and n is 3. M1 and M2 may also be in cardin form by mixture of (I) with a compound which abstructs an X gray from each metal atom and substitution then with non-coordinating anions.

Owner:CHEIL IND INC

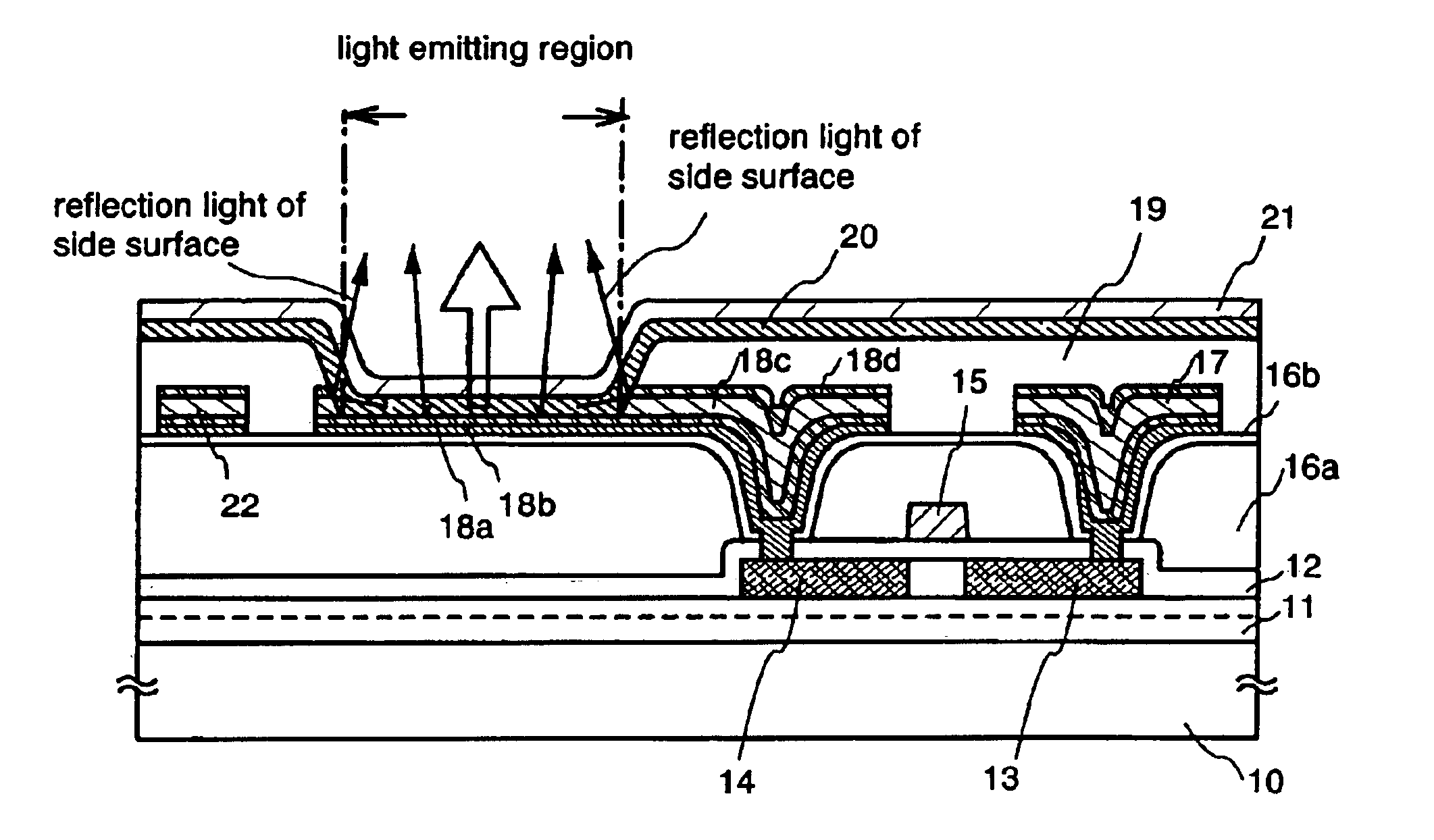

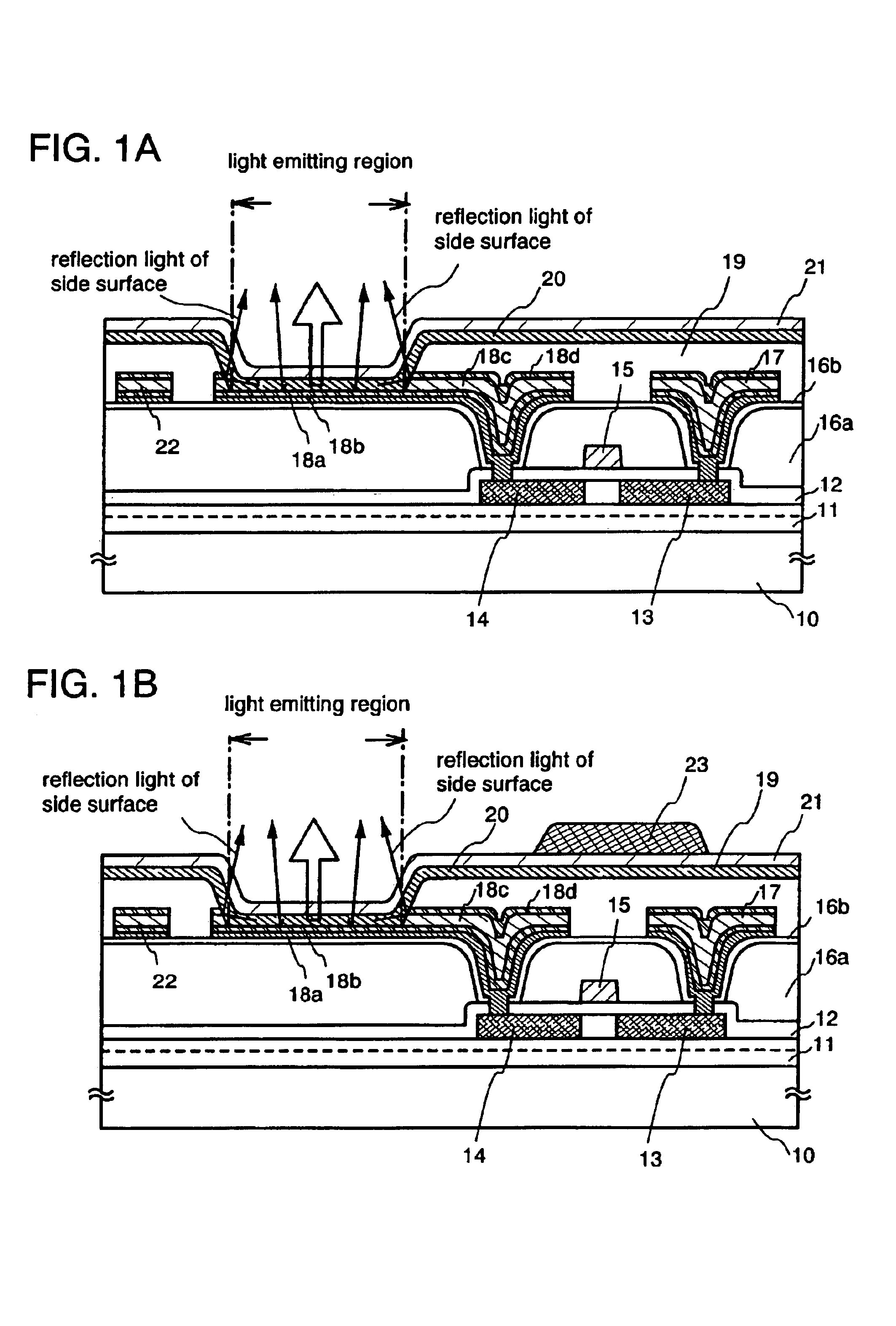

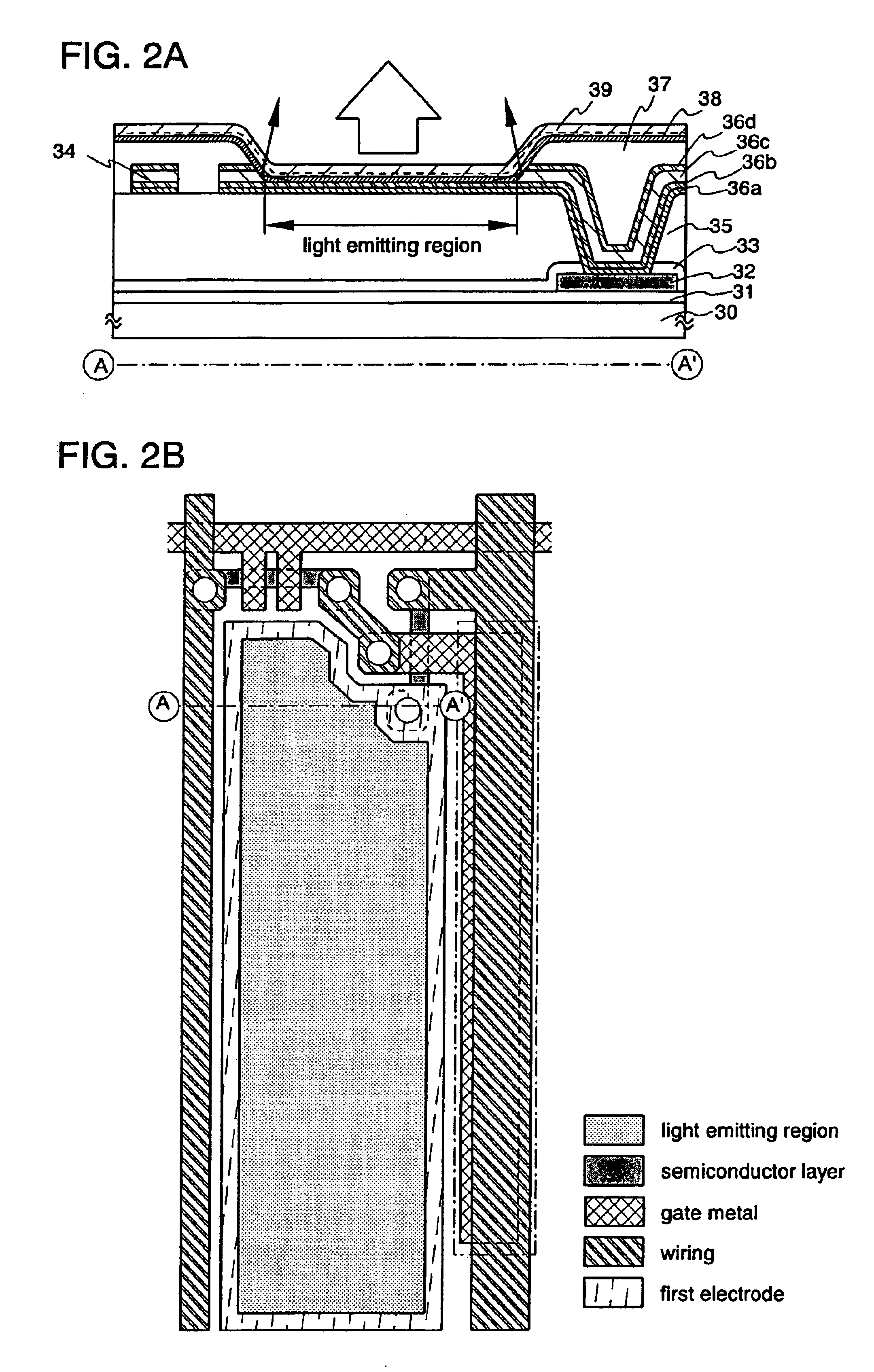

Light-emitting apparatus

InactiveUS6958490B2Reduce defectsImprove reliabilityDischarge tube luminescnet screensSemiconductor/solid-state device detailsEngineeringLight emitting device

A light-emitting device, which has a structure that improves an opening ratio and light extraction efficiency, can solve a problem of an etching residue occurred during forming the device itself, and reduce deterioration due to poor coverage and short-circuiting to improve greatly the reliability, and a method for manufacturing the light-emitting device. In the light-emitting device having a structure that improves light extraction efficiency, a material used for forming a first electrode is Ti / TiN / Al (or Al—Ti) / Ti (or TiN).

Owner:SEMICON ENERGY LAB CO LTD

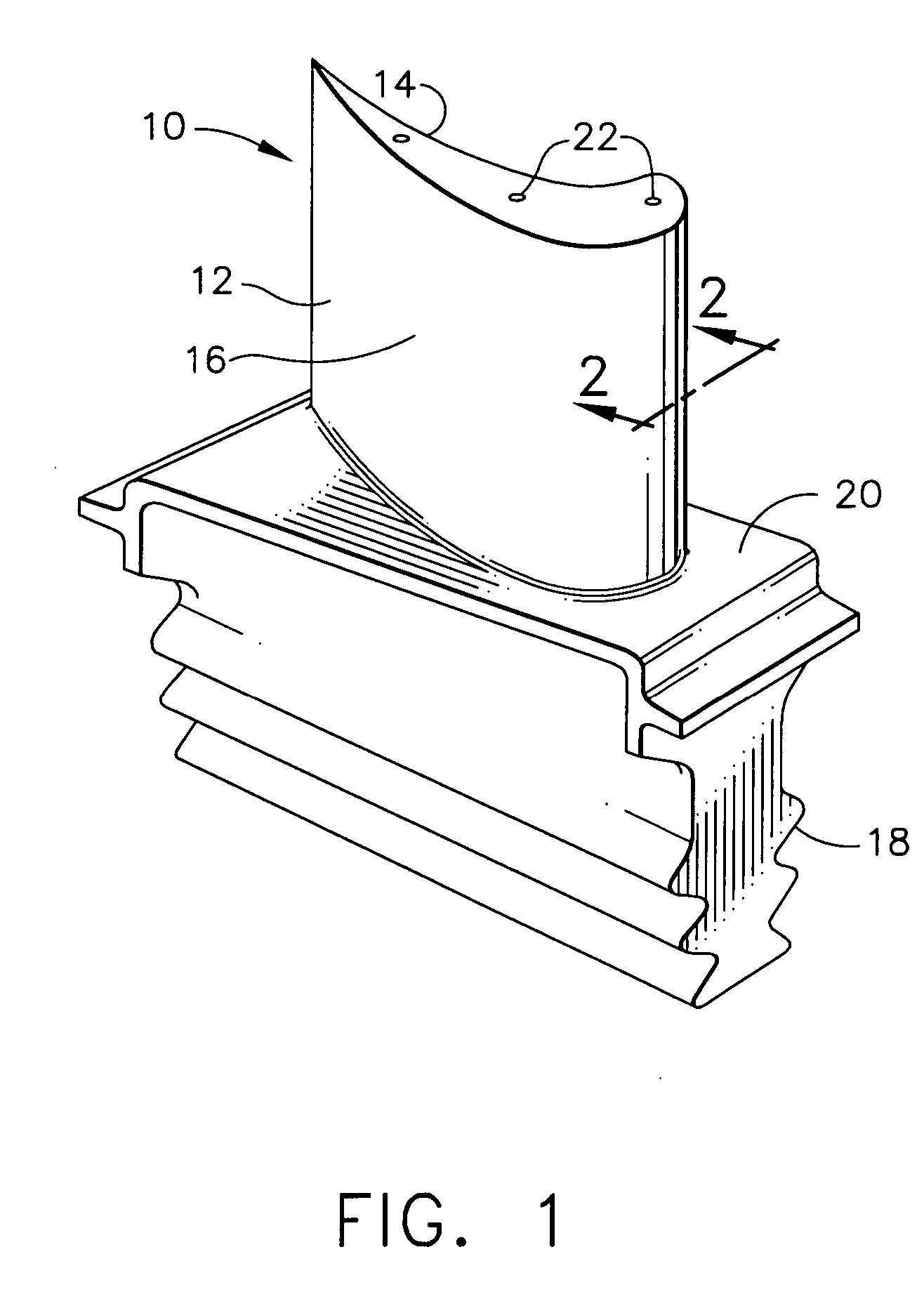

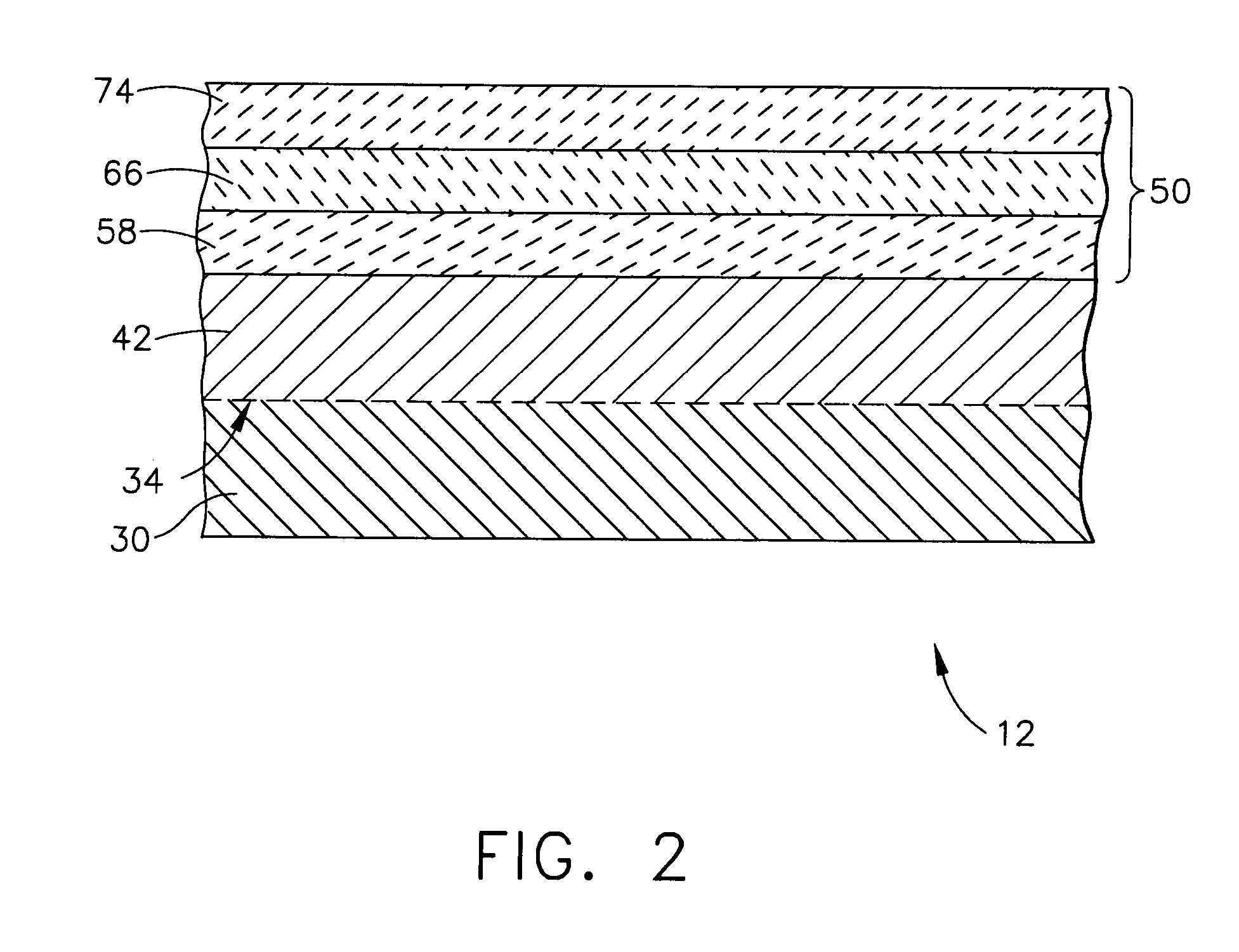

Bond coat for corrosion resistant EBC for silicon-containing substrate and processes for preparing same

ActiveUS20060280952A1Improve adhesionHigh melting pointMolten spray coatingBlade accessoriesBond coatMaterials science

An article comprising a silicon-containing substrate, a silicide-containing bond coat layer overlying the substrate, and an environmental barrier coating (EBC) overlying the bond coat layer, wherein the EBC comprises a corrosion resistant outer layer comprising a corrosion resistant metal silicate. A process is also provided for forming the corrosion resistant outer layer over the silicide-containing bond coat layer.

Owner:GENERAL ELECTRIC CO

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS20030110708A1Facilitates formation and homogeneityOxide formationPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3-Y2O3-ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

Weld electrode for attractive weld appearance

ActiveUS8222560B2High thermal and electrical resistivityHigh melting pointOhmic-resistance electrodesPressure electrodesSpot weldingVisible surface

Weld faces of electrodes for resistance spot welding are formed with a suitable area of protrusions and / or intrusions. The size, shape, and elevation or depths of the protrusions or intrusions are determined for the formation of suitable spot welds in and between metal workpieces such as aluminum or steel panels for vehicle bodies. The protrusions or intrusions are also conceived and used to form an image on at least a visible surface of the welded article to produce an attractive appearance on the surface of the welded sheet.

Owner:GM GLOBAL TECH OPERATIONS LLC

Methods and systems for the manufacture of layered three-dimensional forms

ActiveUS7807077B2Efficiently reclaim and re-useEfficient use ofAdditive manufacturing apparatusFoundry mouldsChemistryComposite material

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

Method of Treating Hair with a Concentrated Conditioner

A method of treating the hair including providing a concentrated hair care composition in an aerosol foam dispenser. The concentrated hair care composition includes one or more silicones, perfume, and less than 10% high melting point fatty compounds. The method also includes dispensing the concentrated hair care composition from the aerosol foam dispenser as a dosage of foam; applying the foam to the hair; and rinsing the foam from the hair. The foam has a density of from about 0.025 g / cm3 to about 0.40 g / cm3 when dispensed from the aerosol foam dispenser.

Owner:THE PROCTER & GAMBLE COMPANY

Negative electrode for lithium ion secondary battery, production method thereof and lithium ion secondary battery comprising the same

ActiveUS20060134518A1Excellent low temperature characteristicHigh melting pointFinal product manufactureNegative electrodesPhysicsHigh rate

A negative electrode for a lithium ion secondary battery including a current collector and an active material layer carried on the current collector, wherein the active material layer includes a first layer and a second layer alternately laminated in a thickness direction of the active material layer, and wherein the first layer includes silicon or silicon and a small amount of oxygen and the second layer includes silicon and a larger amount of oxygen than the first layer. With the use of the negative electrode, it is possible to provide a high capacity lithium ion secondary battery having excellent high rate charge / discharge characteristics and superior cycle characteristics.

Owner:PANASONIC CORP

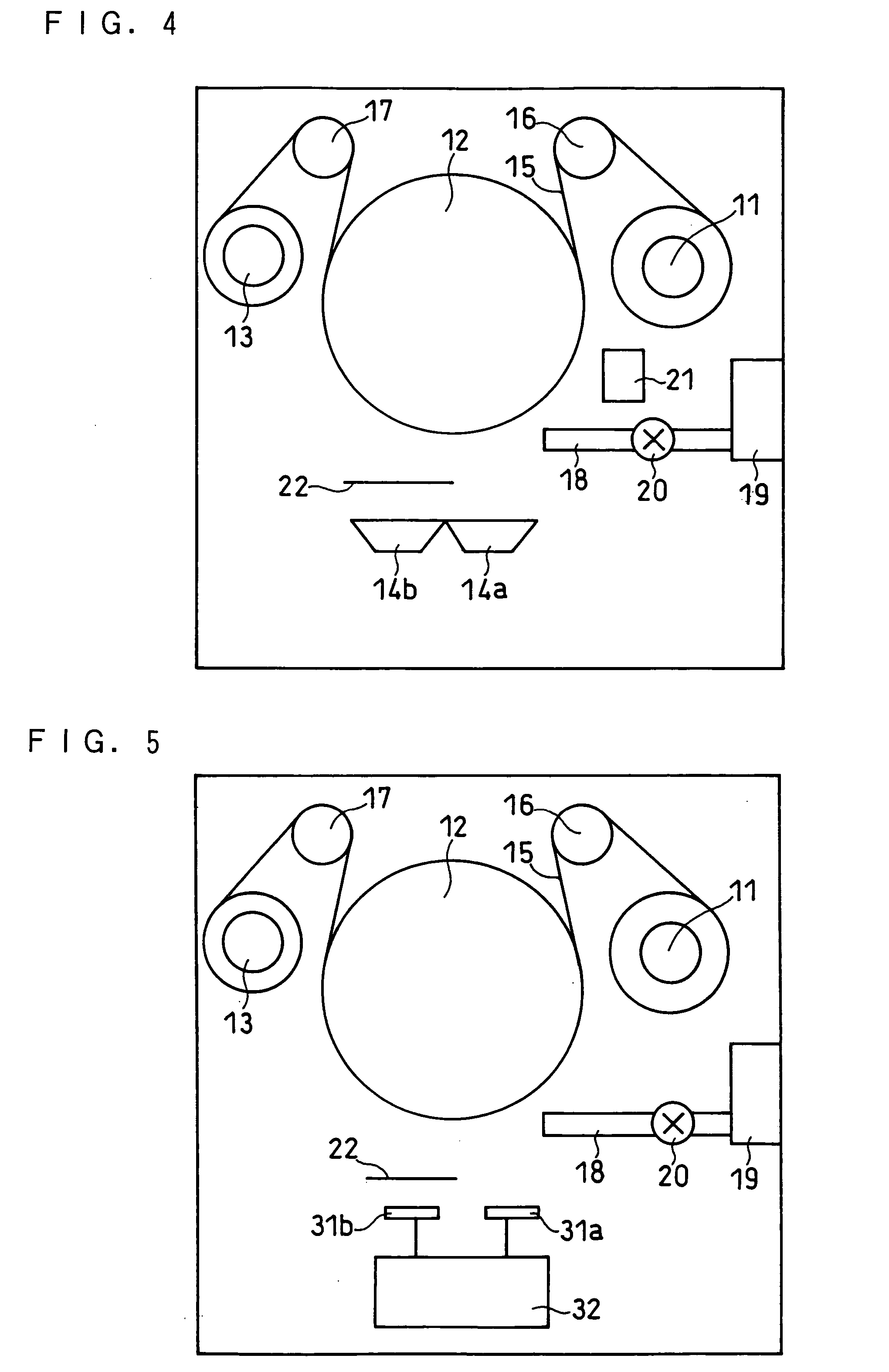

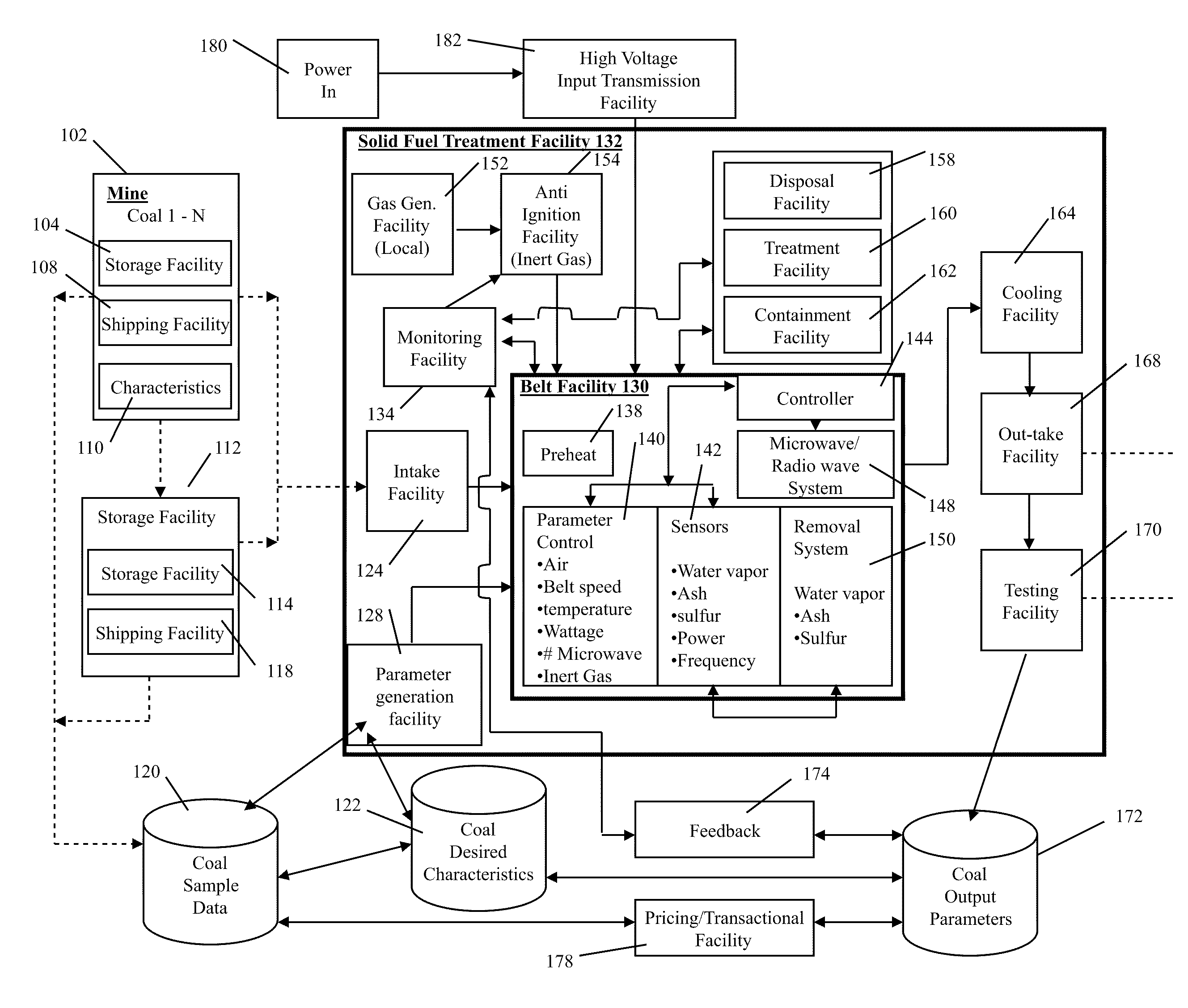

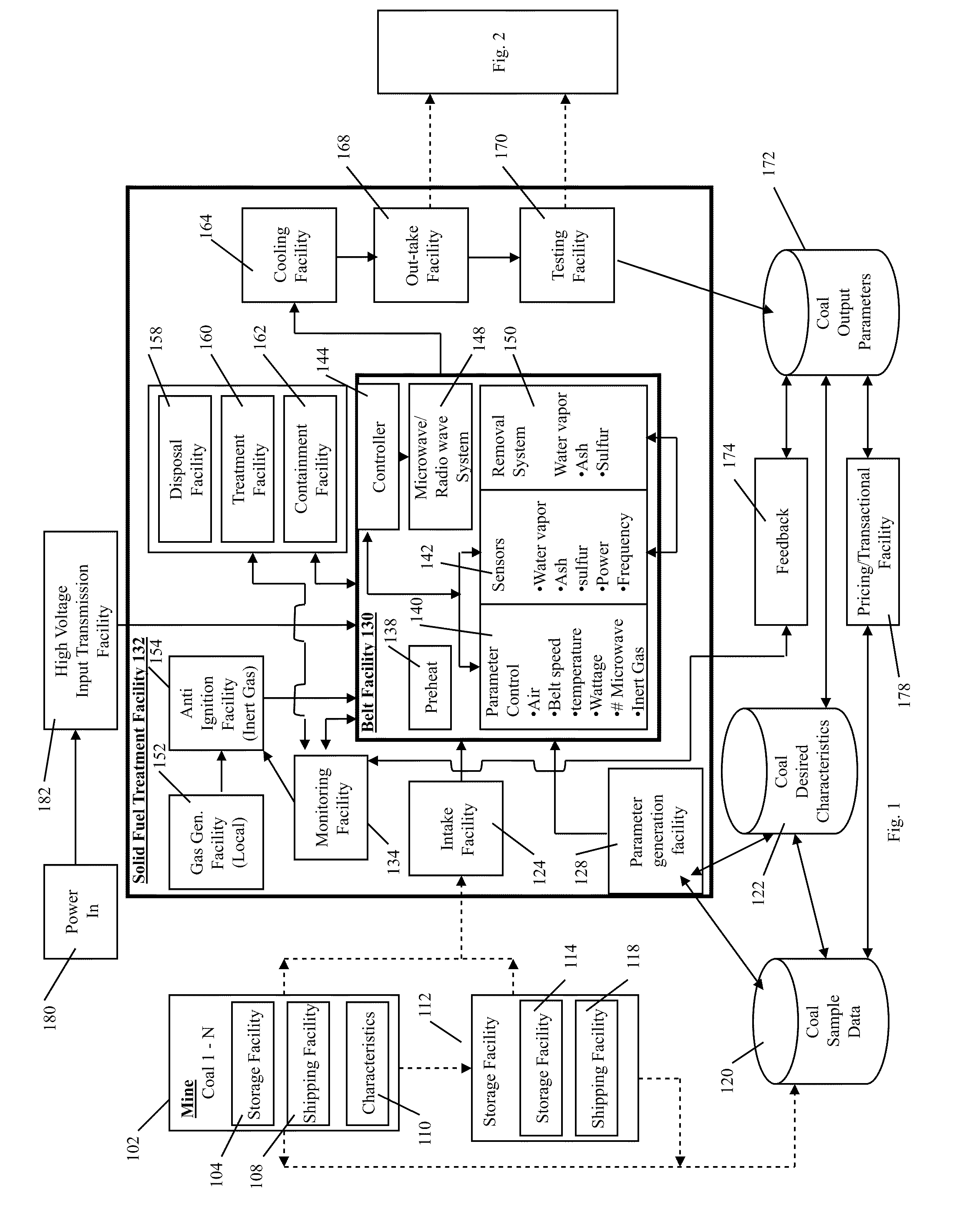

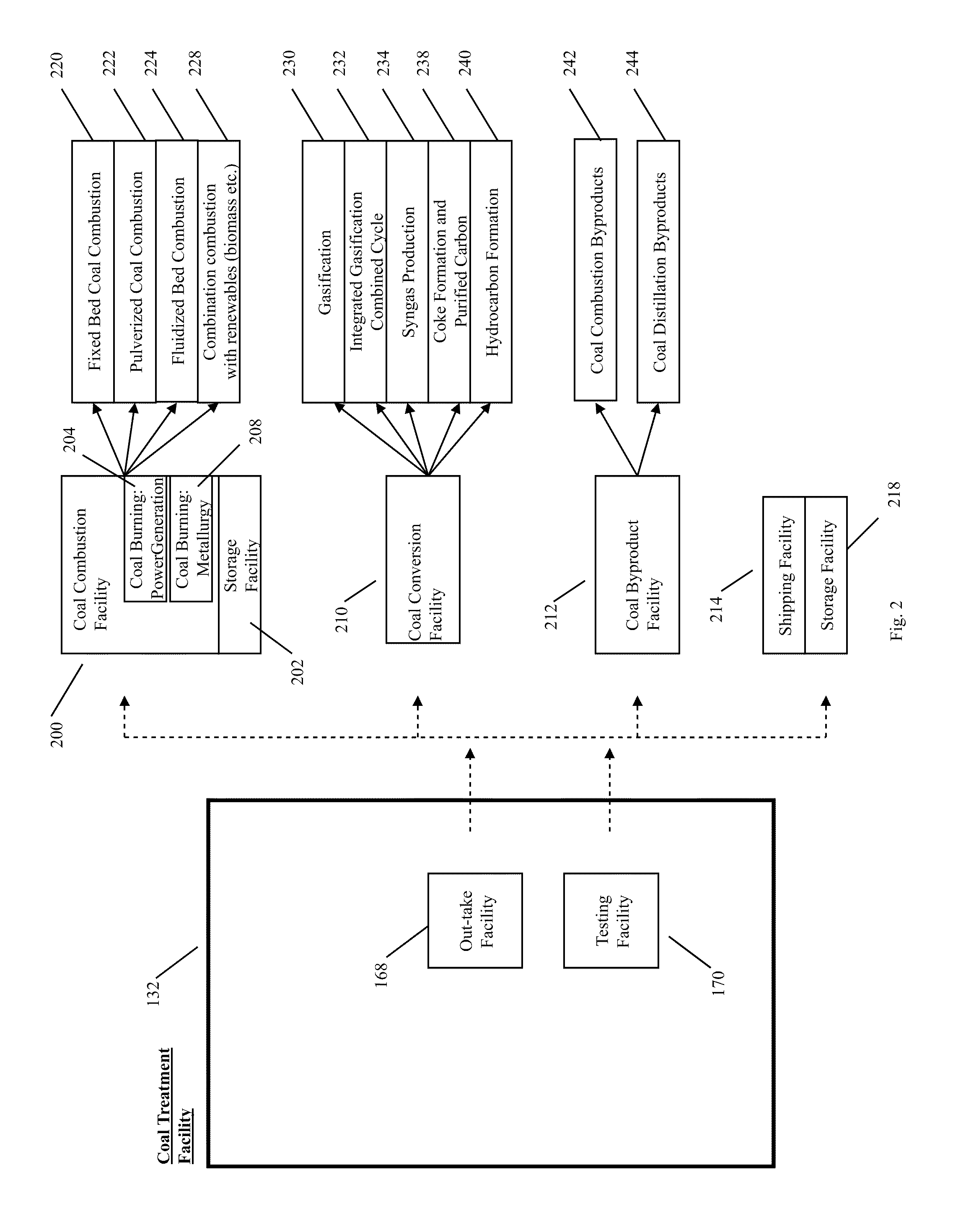

Methods and systems for processing solid fuel

InactiveUS20090272028A1Minimize return lossLow microwave lossBiofuelsSolid fuelsFuel treatmentSolid fuel

In embodiments of the present invention, a method of heat treating a solid fuel briquette may include heating the solid fuel briquette using energy from at least one of a heat furnace or an electromagnetic energy system of a solid fuel treatment facility as the solid fuel briquette is moved through the treatment facility to a specified internal temperature, and sealing the heat-treated solid fuel briquette in a vessel for a duration of time.

Owner:COALTEK INC

Method for the hermetic encapsulation of a component

InactiveUS7259041B2Easy to implementReduce metal consumptionImpedence networksSemiconductor/solid-state device detailsSolvent freeMaterials science

For hermetic encapsulation of a component, which includes a chip with component structures applied on a substrate in a flip-chip construction, a material is applied onto the lower edge of the chip and regions of the substrate abutting the chip, and then a first continuous metal layer is applied on the back side of the chip and on the material, as well as on edge regions of the substrate abutting the material. For hermetic encapsulation, a second sealing metal layer is subsequently applied by a solvent-free process at least on those regions of the first metal layer that cover the material.

Owner:SNAPTRACK

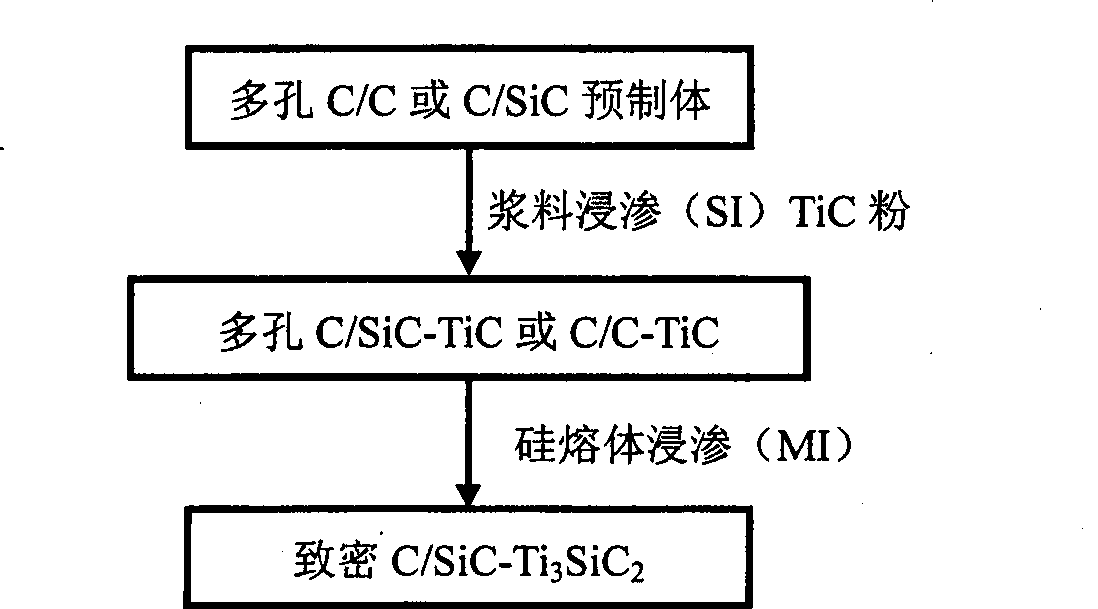

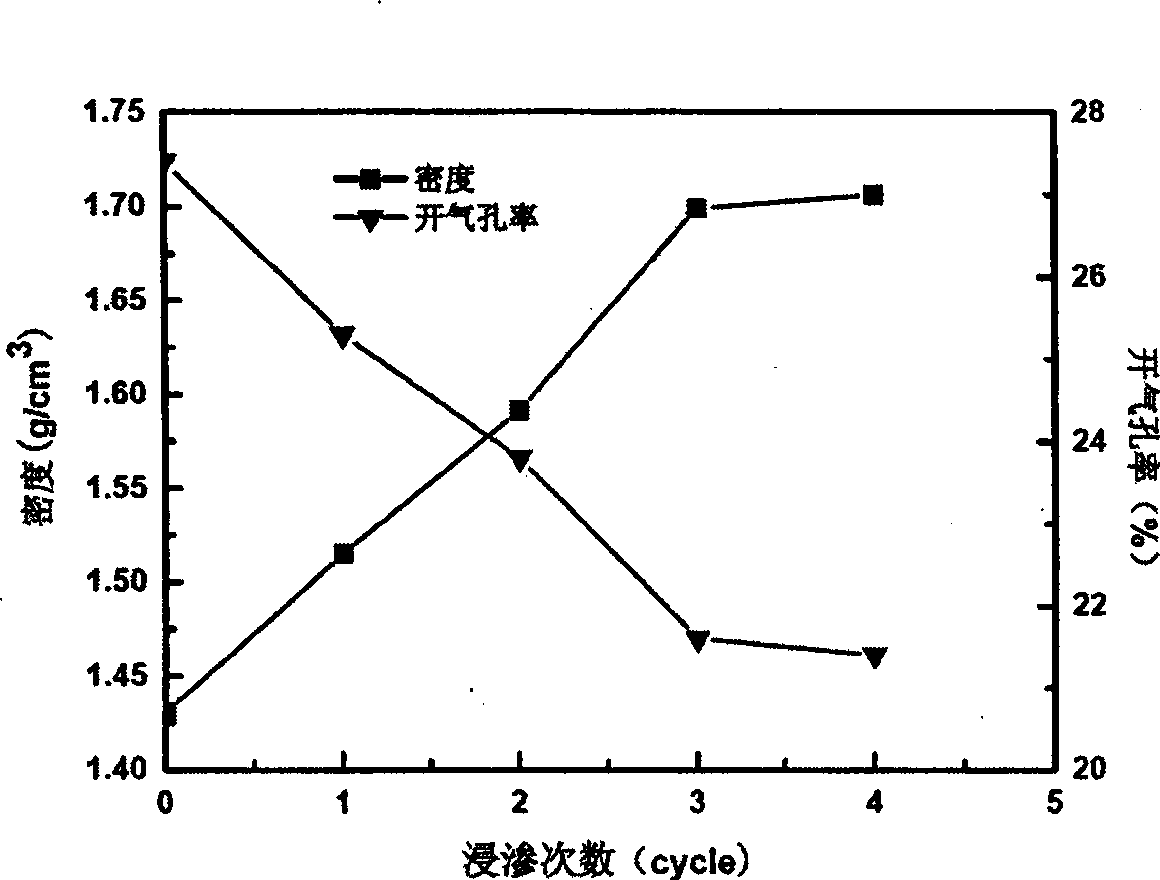

Process for producing composite material of Ti3SiC2 modified C/SiC

The invention discloses a method for preparing Ti3SiC2 modified C / SiC composite material, comprising the following steps: firstly, carrying out ultrasonic cleaning and drying on the pre-prepared body to be modified; compounding the size with distilled water, cellulose sodium carboxy methyl and TiC powder; then carrying out vacuum infiltration combined with pressure infiltration on the pre-prepared body and refrigeration and drying in vacuum; coating industrial silicon powder on the surface of the pre-prepared body; calcining the pre-prepared body in a vacuum furnace to lead the silicon to fuse to penetrate into the pre-prepared body; and cooling the pre-prepared body gradually to room temperature after full reaction in the vacuum furnace. As SI method is adopted to lead C / C or C / SiC composite material to be firstly internally filled with TiC granules, then MI method is adopted to penetrate silicon fusant, and TiC reacts with Si to generate Ti3SiC2 and SiC, the content of residue Si in the composite material is reduced, and the Ti3SiC2 phase in-situ generated in the C / SiC composite material causes the use temperature of the modified C / SiC composite material to rise from 1420 DEG C in the prior art to 1500-2300 DEG C and the fracture toughness property to rise from 8MPa.m in the prior art to 9-16 MPa.m.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com