Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1442 results about "Polymerization reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

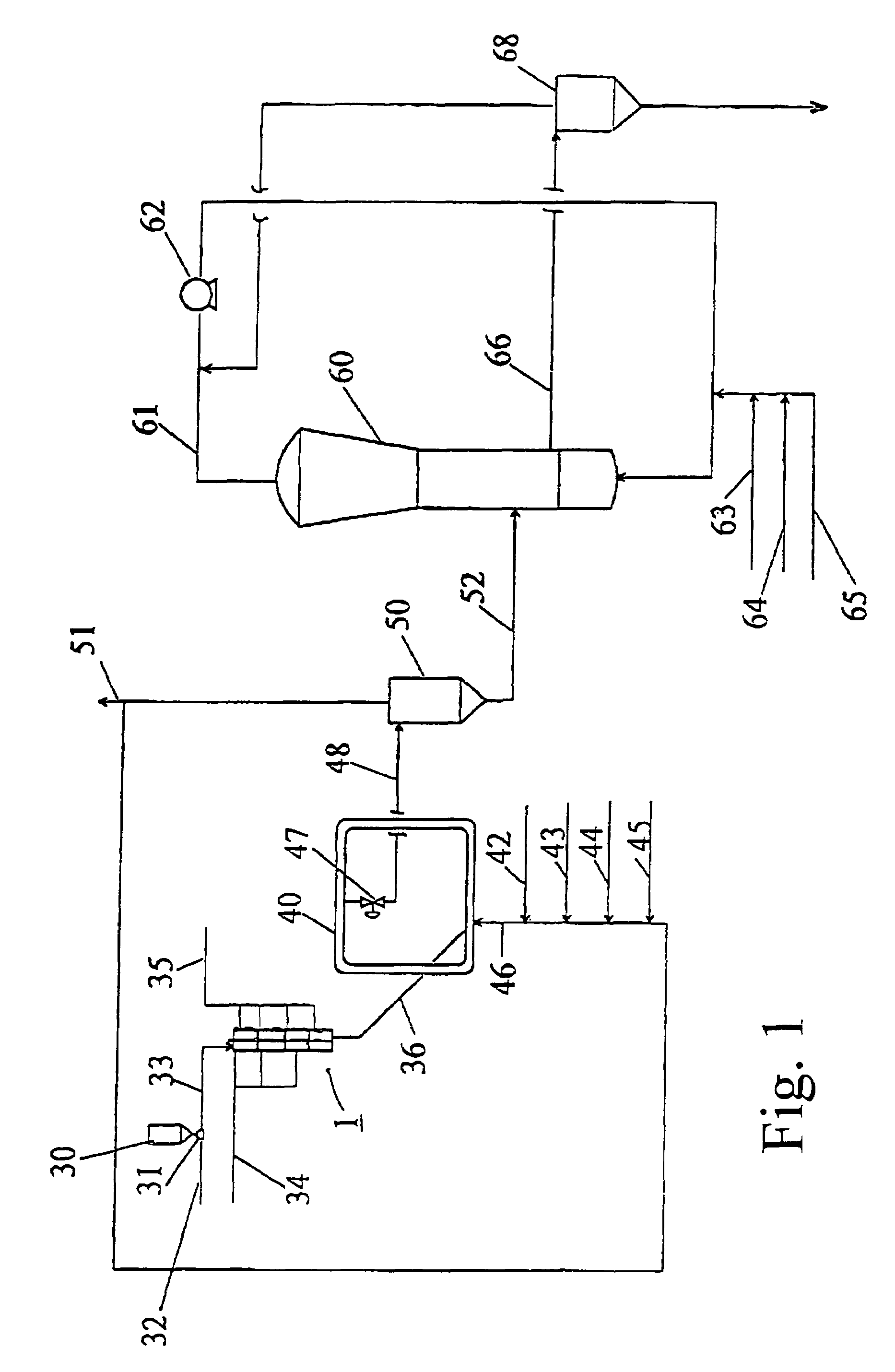

Processes and apparatus for continuous solution polymerization

InactiveUS6881800B2Process control/regulationLiquid-gas reaction as foam/aerosol/bubblesSolution polymerizationProcess plant

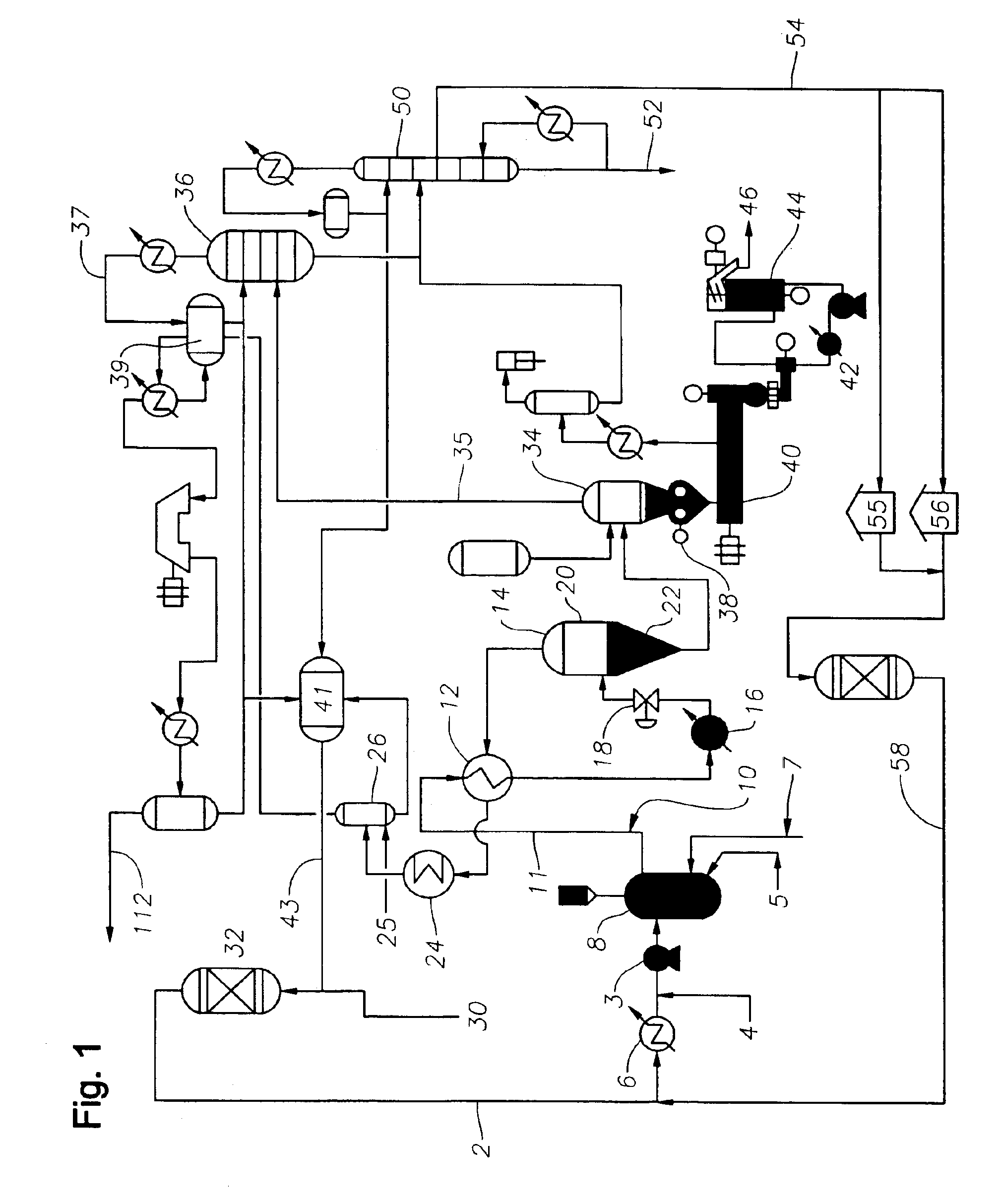

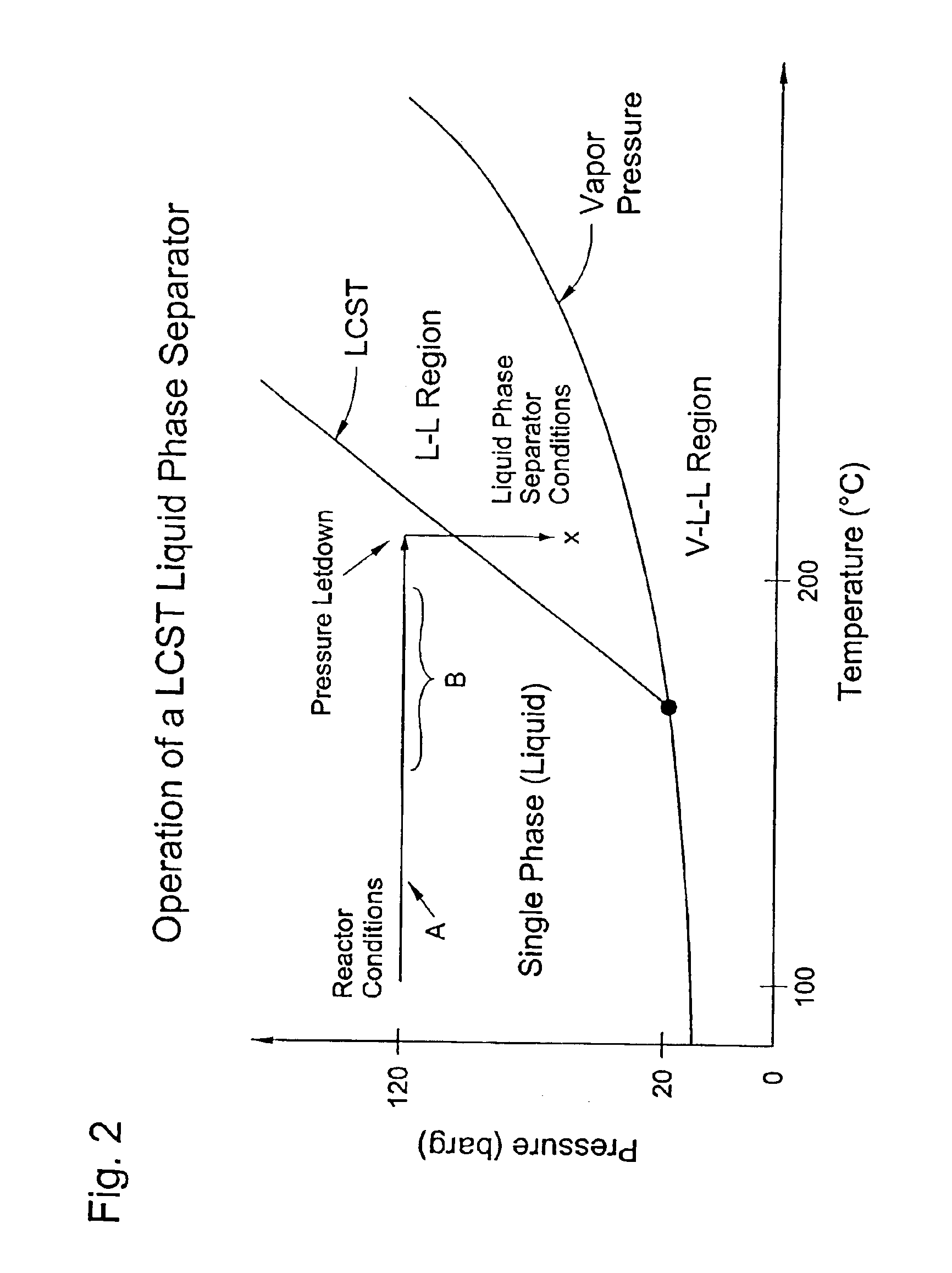

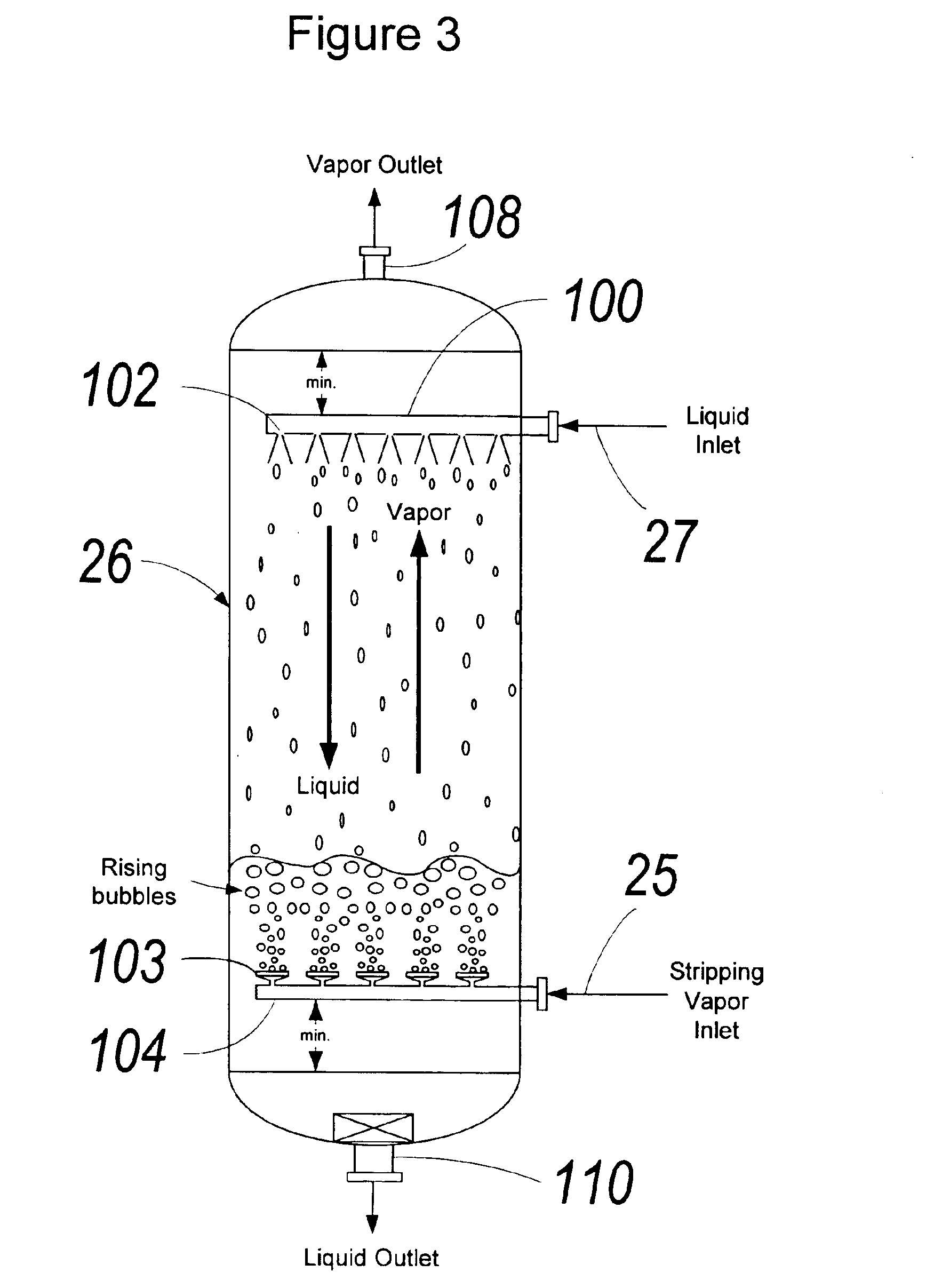

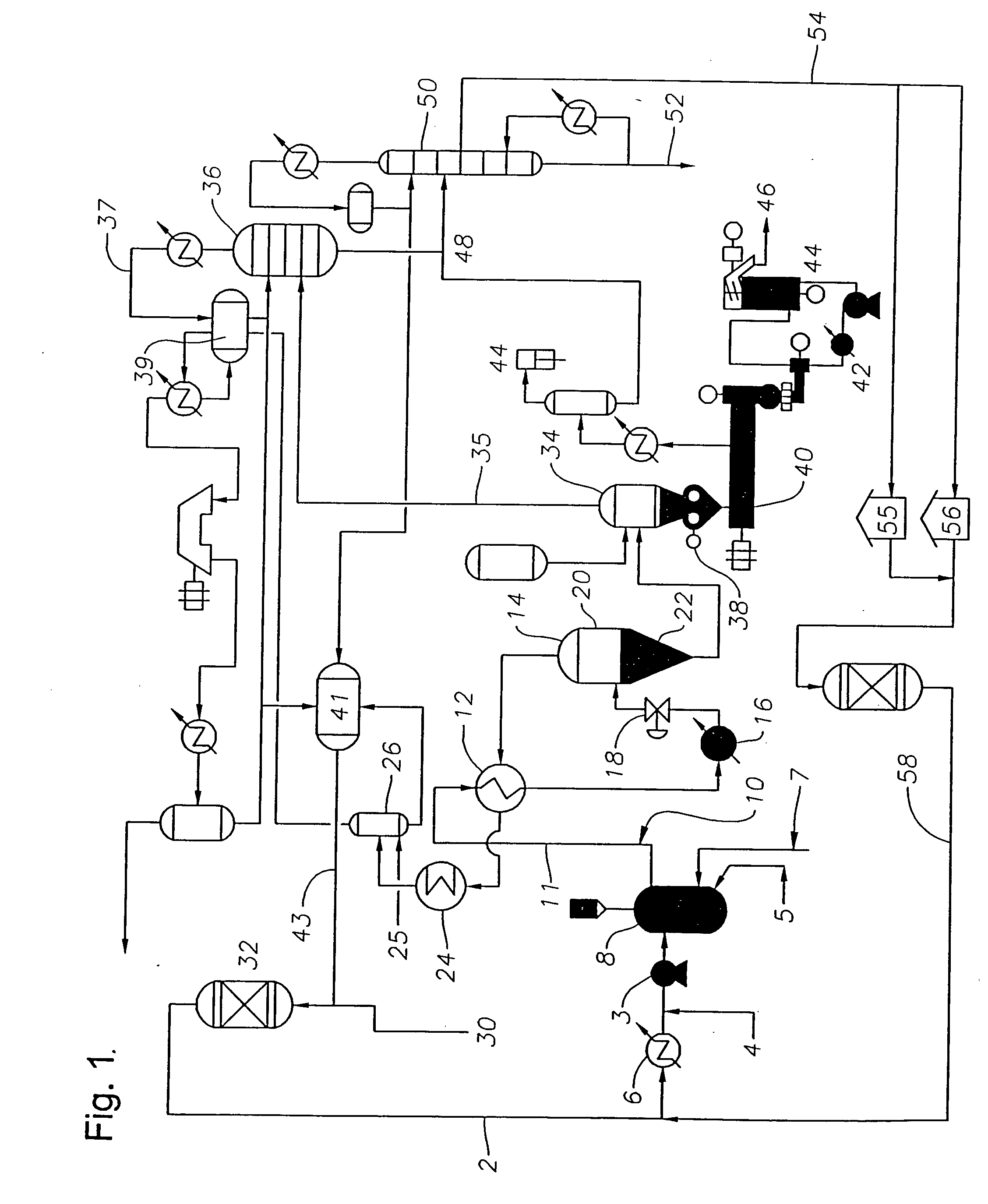

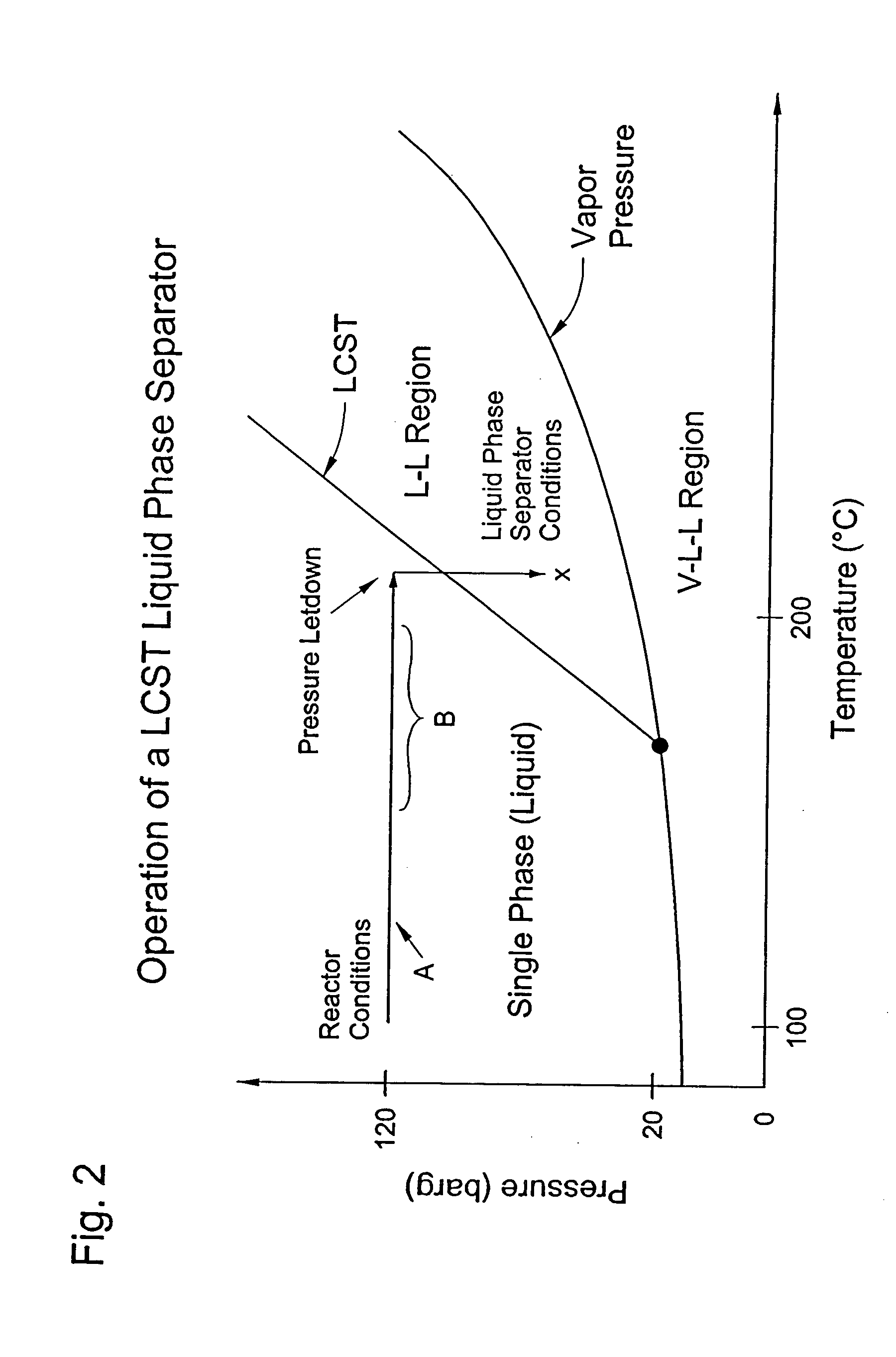

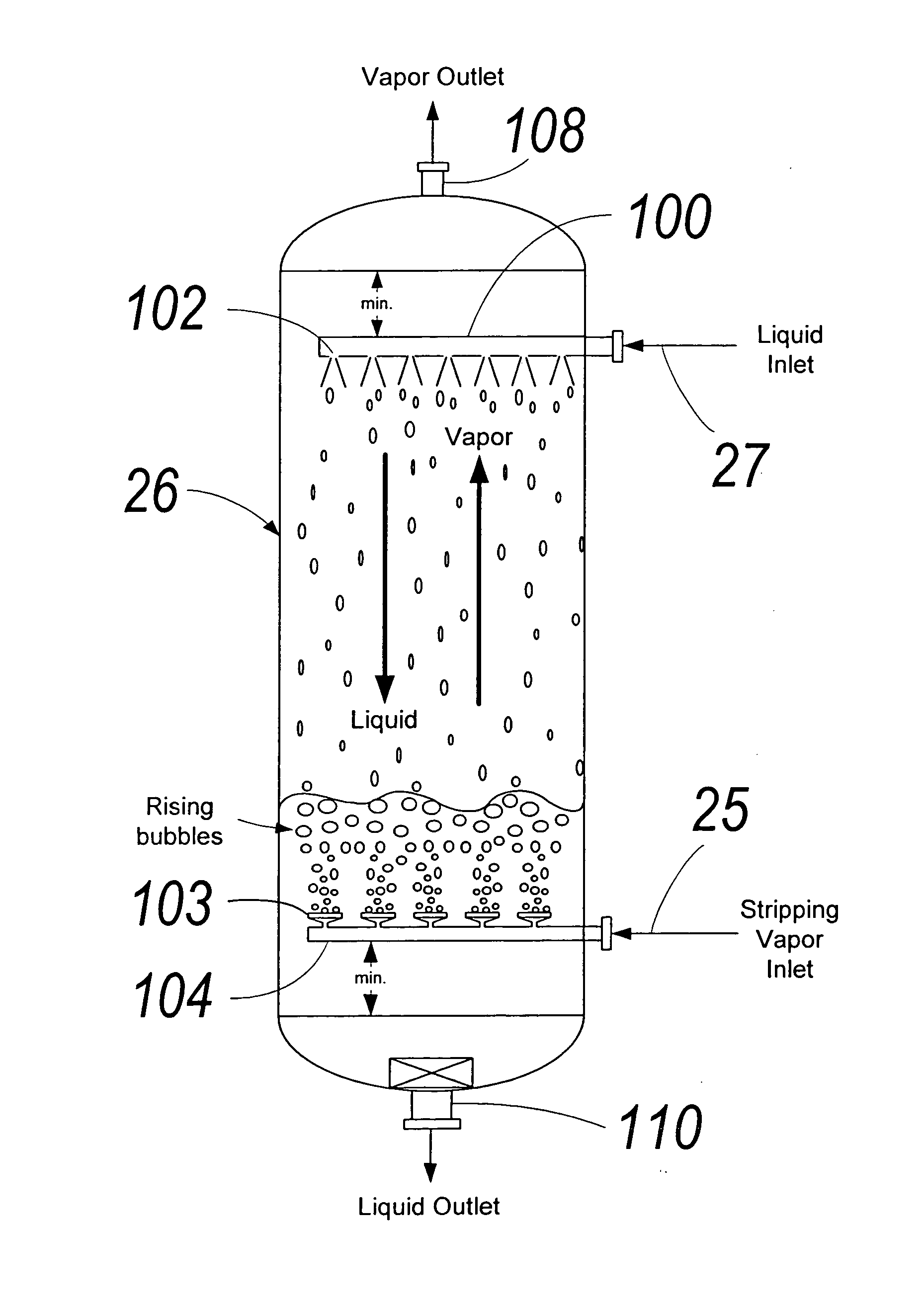

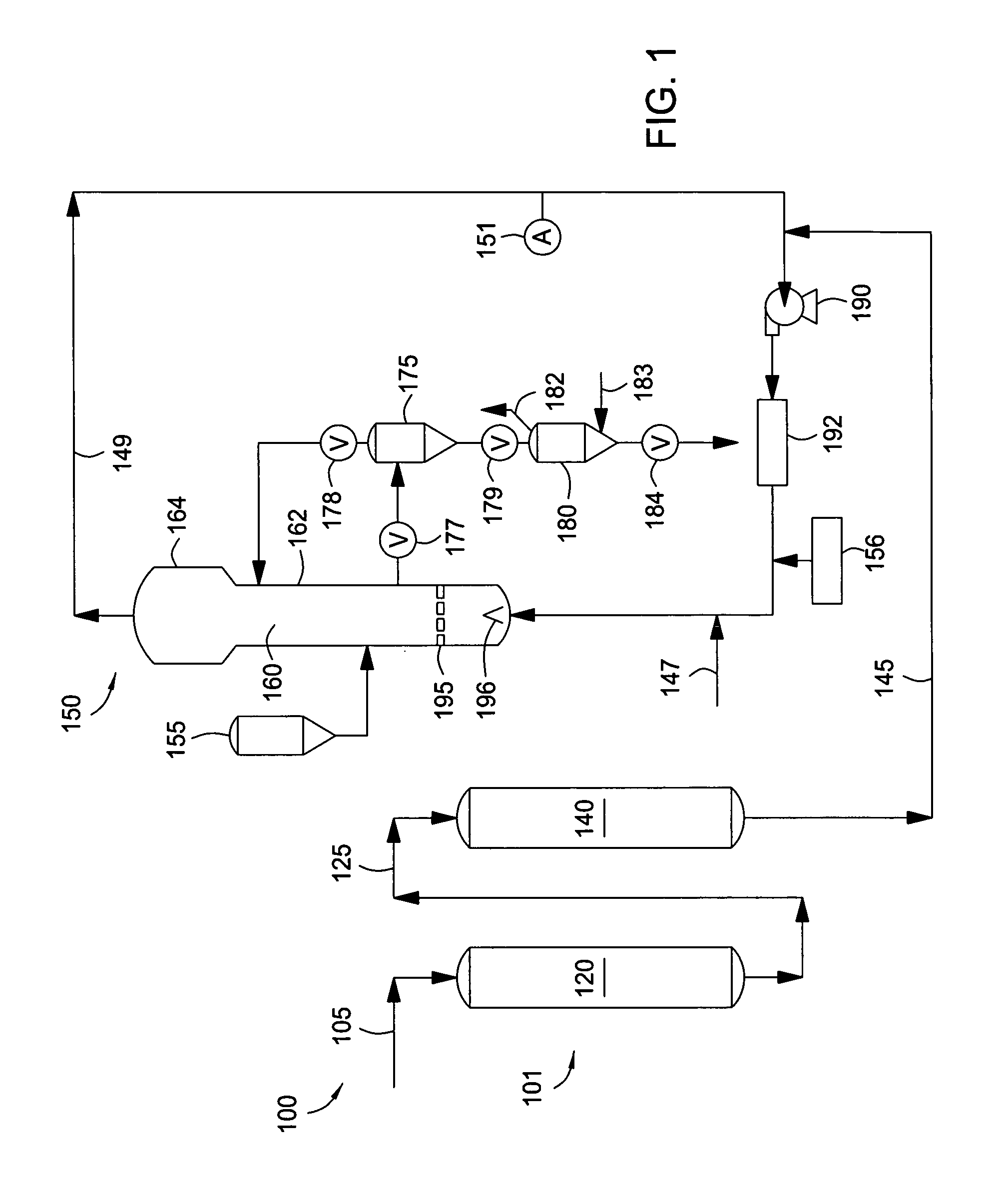

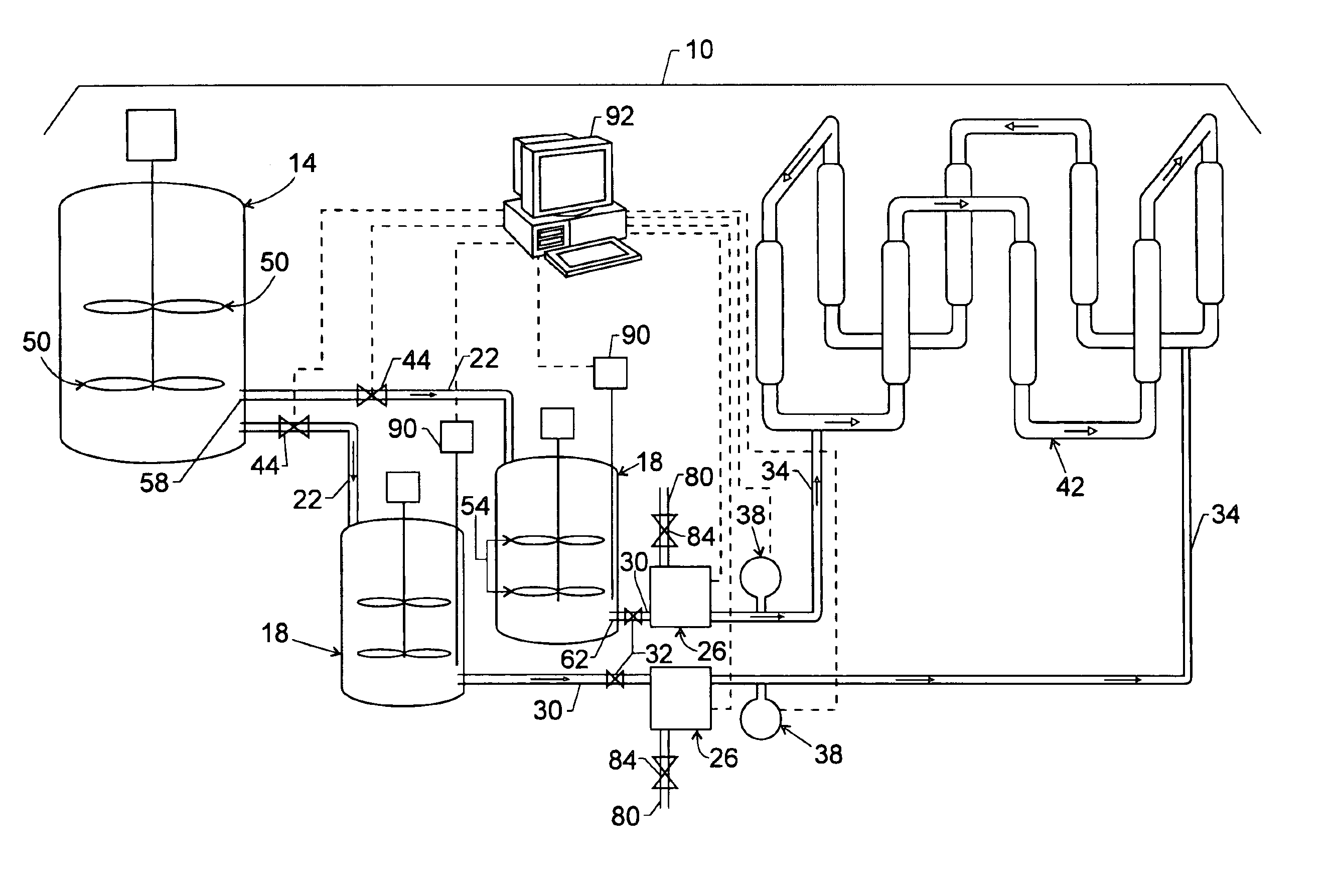

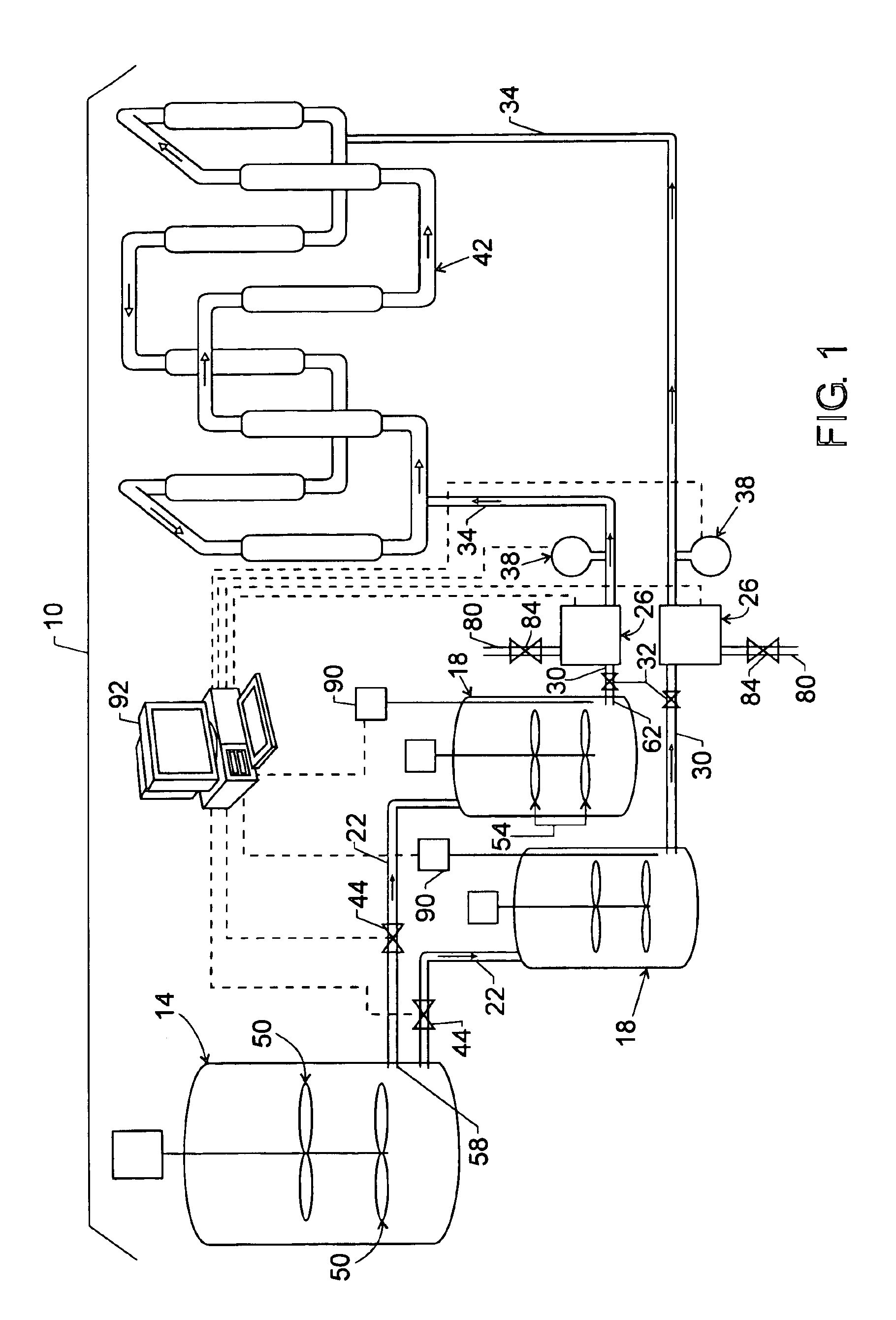

The invention relates to processes and plants for continuous solution polymerization. Such plant and processes include a pressure source, a polymerization reactor, downstream of said pressure source, pressure let-down device, downstream of said polymerization reactor, and a separator, downstream of said pressure let-down device, wherein said pressure source is sufficient to provide pressure to said reaction mixture during operation of said process plant to produce a single-phase liquid reaction mixture in said reactor and a two-phase liquid-liquid reaction mixture in said separator in the absence of an additional pressure source between said reactor and said separator.

Owner:EXXONMOBIL CHEM PAT INC

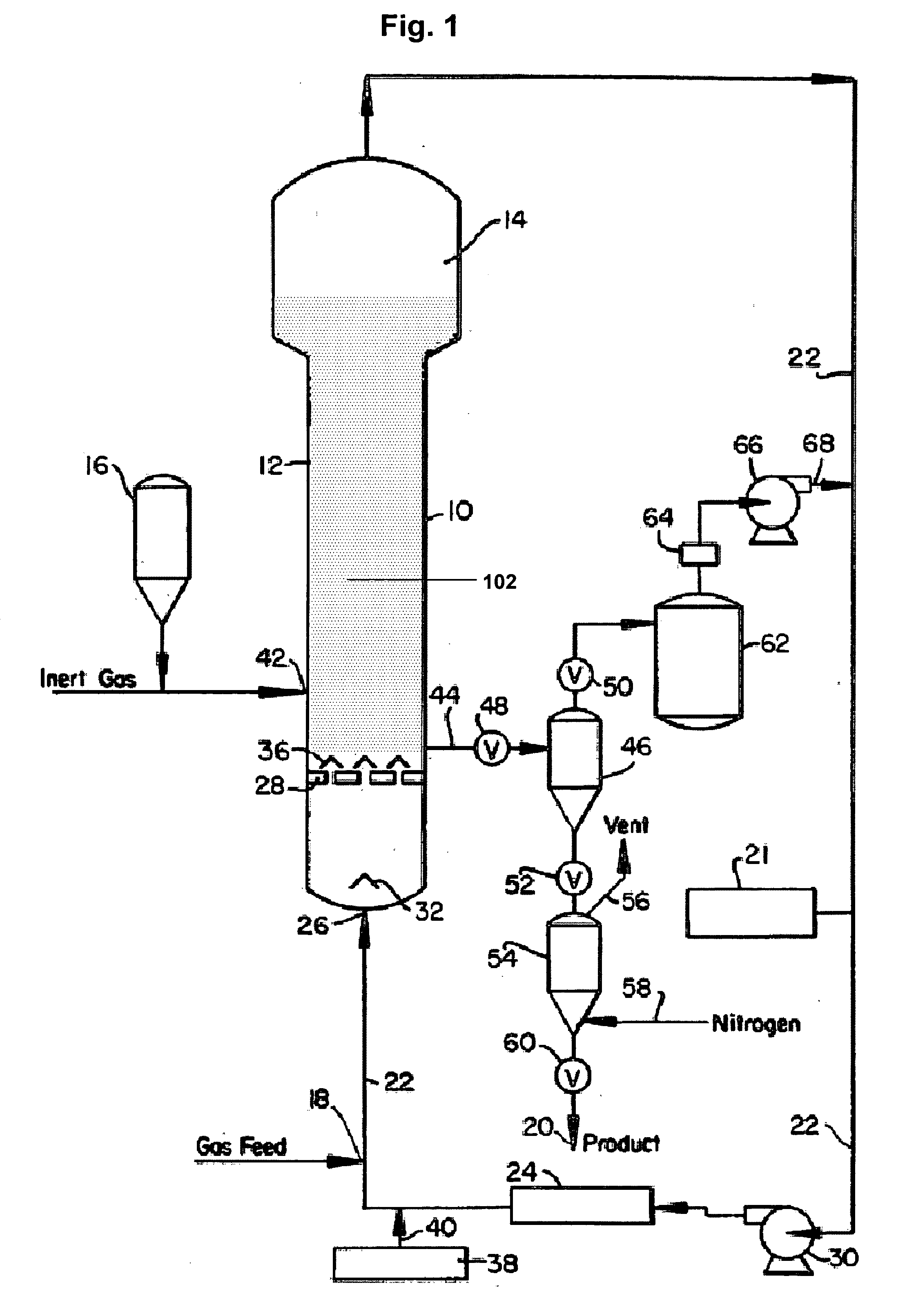

Method for polymerizing olefins in a gas phase reactor using a seedbed during start-up

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

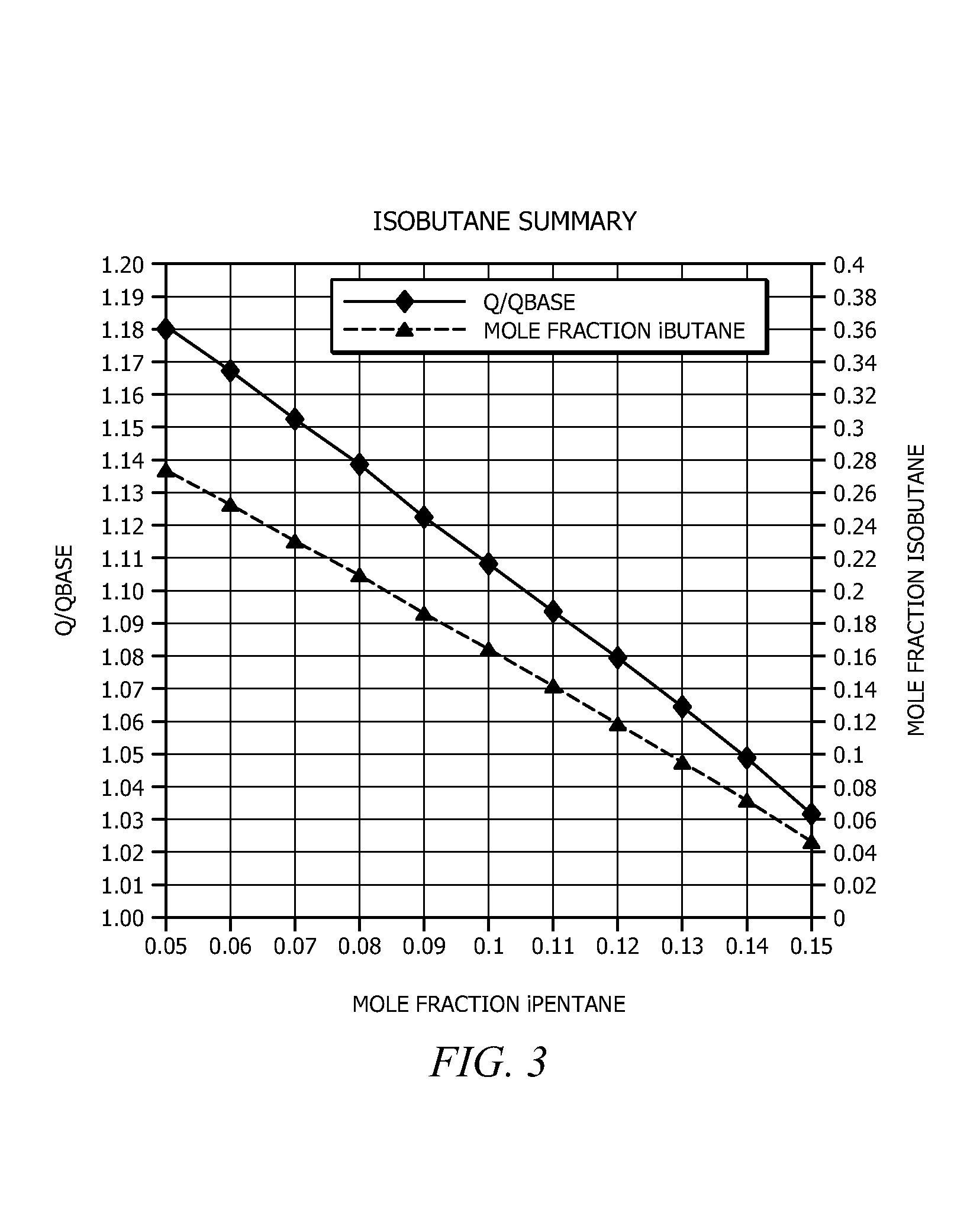

Method for operating a gas phase polymerization reactor

Disclosed herein is a method of operating a polymerization reactor for a polymerization reaction comprising modifying a recycle gas composition to increase the heat capacity of the recycle gas wherein the recycle gas composition is modified by reducing or eliminating the nitrogen concentration in the recycle gas. In an embodiment, the nitrogen concentration is reduced or eliminated by reducing or eliminating one or more nitrogen input sources to the polymerization reactor and replacing the nitrogen with an alternate inert fluid (a gas or liquid that is inert to the catalyst and reactants). The alternate inert fluid has a higher heat capacity and a higher molecular weight than nitrogen. In an embodiment, the nitrogen utilized to convey a catalyst into the polymerization reactor is replaced with an alternate inert fluid. In an embodiment, the alternate inert fluid is ethane, propane, isobutane, or combinations thereof.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

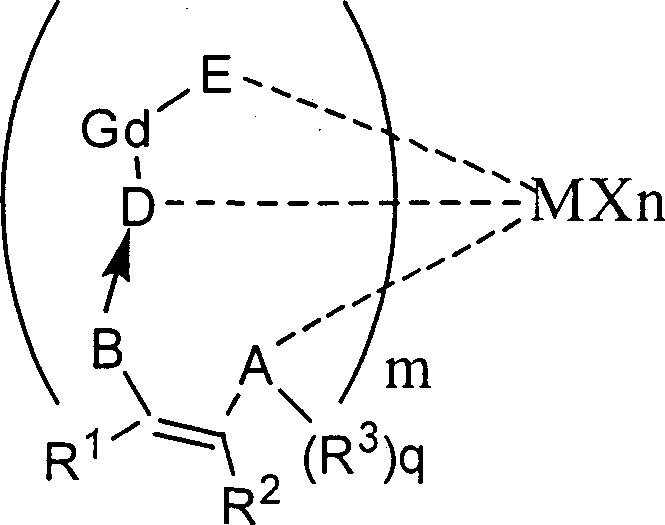

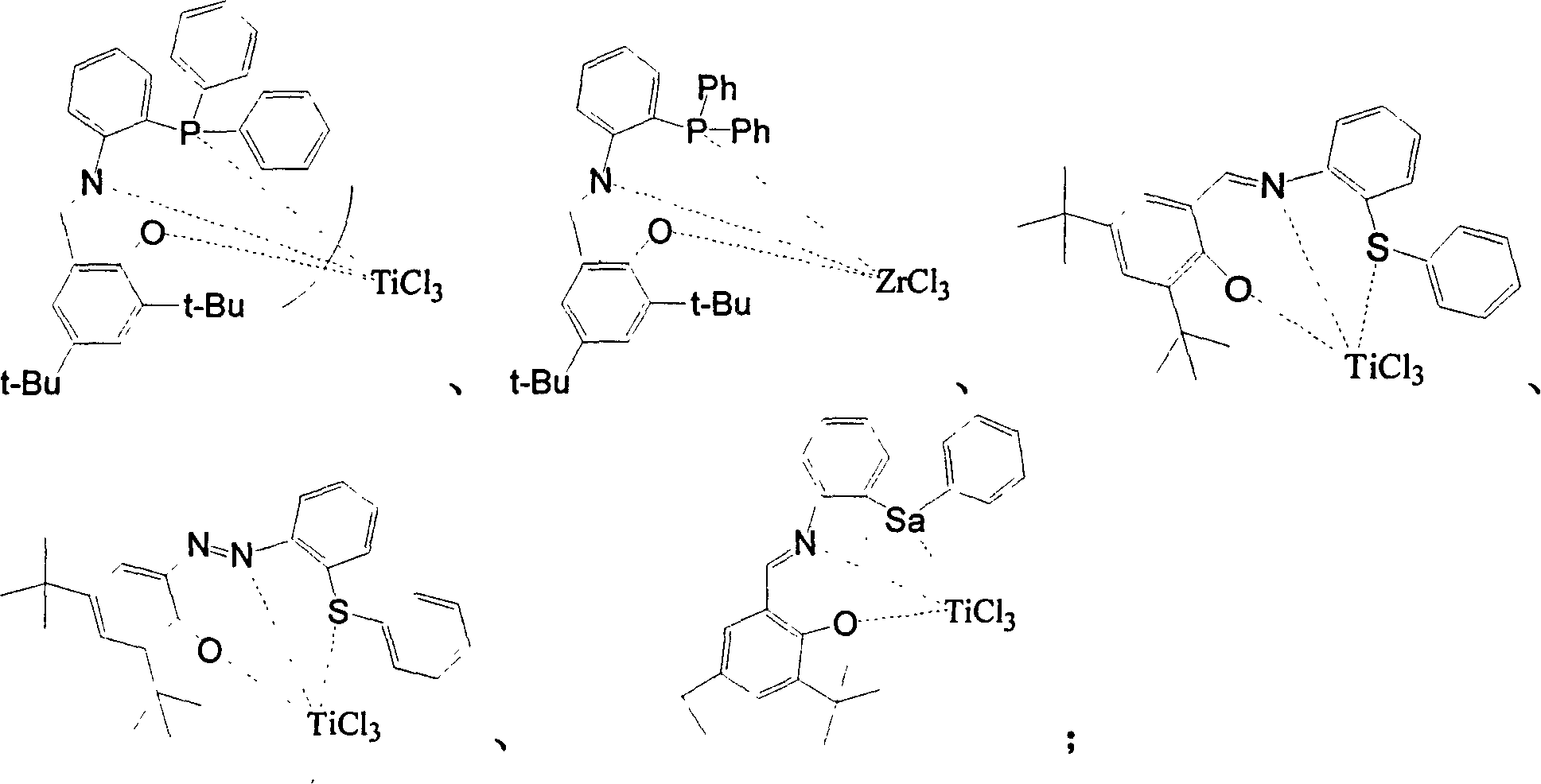

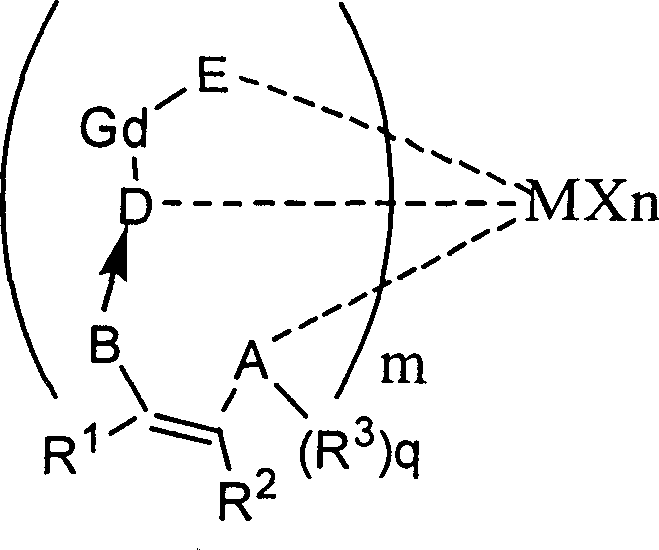

Olefinic polymerization and copolymerization method of supported non-metallocene catalyst

A method of alkene polymerization and copolymarization with f load non- metallocene catalyst: emplying the load non- metallocene catalyst and catalyst promoter forming the catalytic system, introducing polymer monomer or comonomer for alkene polymerization or copolymarization; adding the load non- metallocene catalyst into dissolvent and mixing with catalyst promoter and then transferring the mixture into polymerization reactor, or adding the load non- metallocene catalyst and catalyst promoter into the polymerization reactor in order or simultaneously. The catalyst promoter is chosen from: alkyl aluminium, aluminium oxane, Lewis acid, boralotano, alkyl borane or alkyl borane ammonium salt. The load non- metallocene catalyst is loaded to multiple poral solid by employing methods of solution dipping, equivoluminal dipping or solution dipping-before-equivoluminal dipping to form organic integral of property stable and strong binding force. The invention is characterized by the high alkene polymerization active, high fusion point and good normalization of the produced polymer, and the sastification of the demand of high level product production.

Owner:YANGZI PETROCHEM

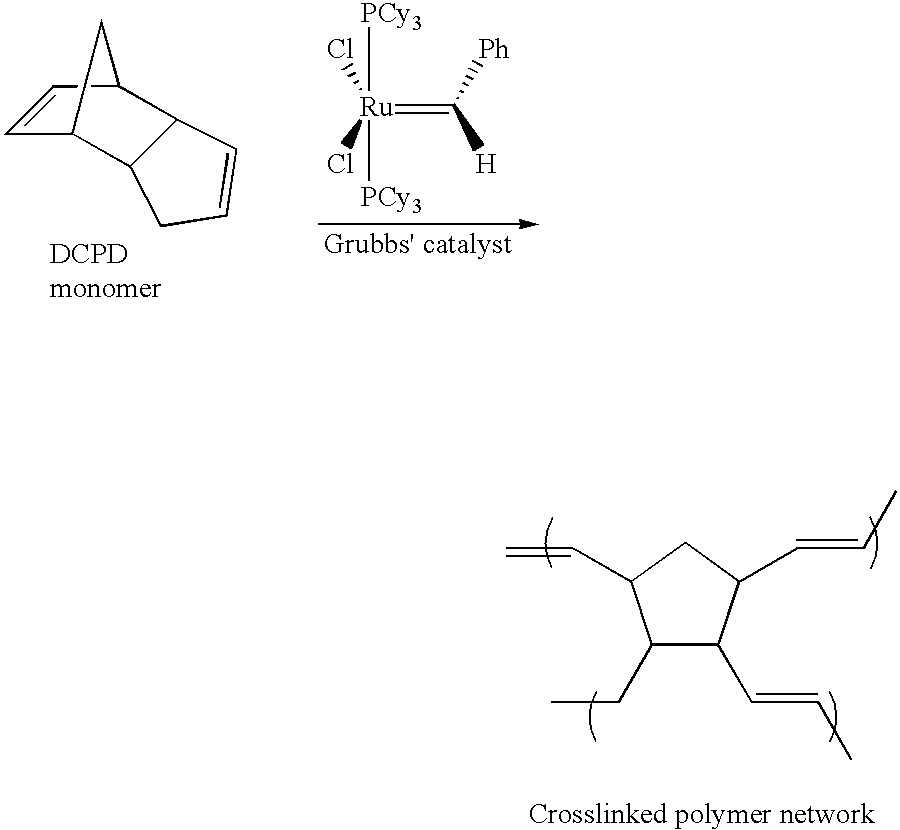

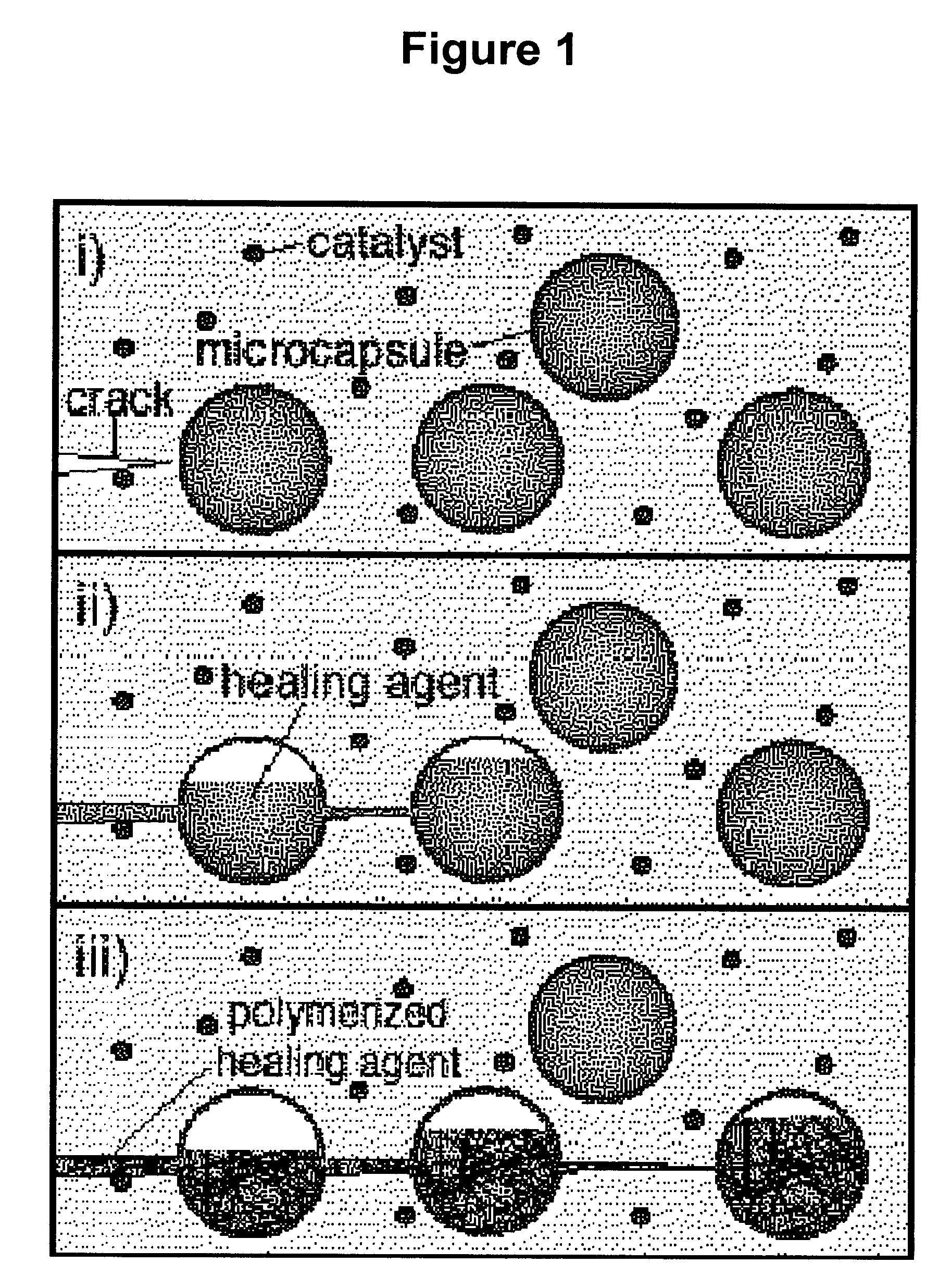

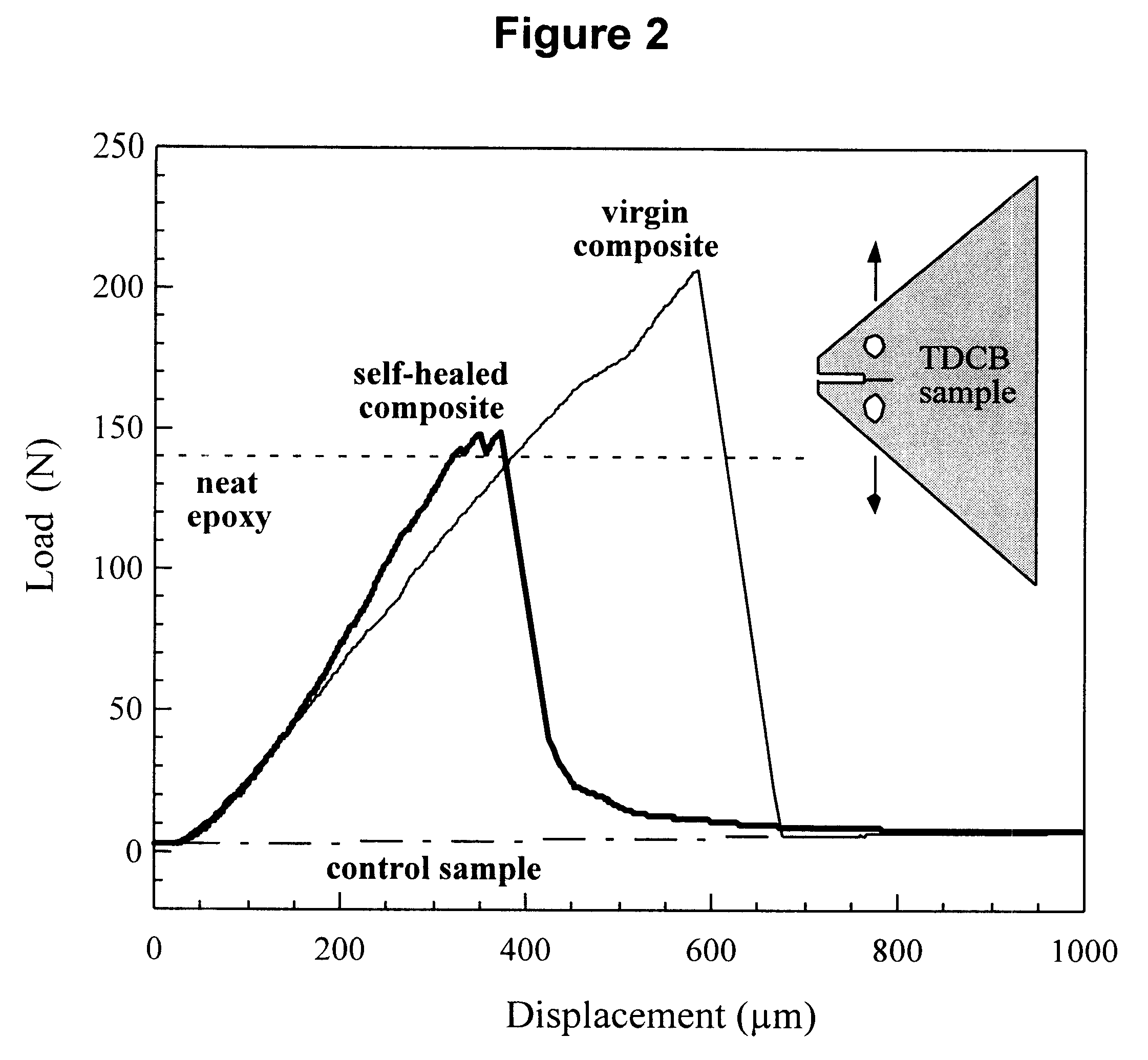

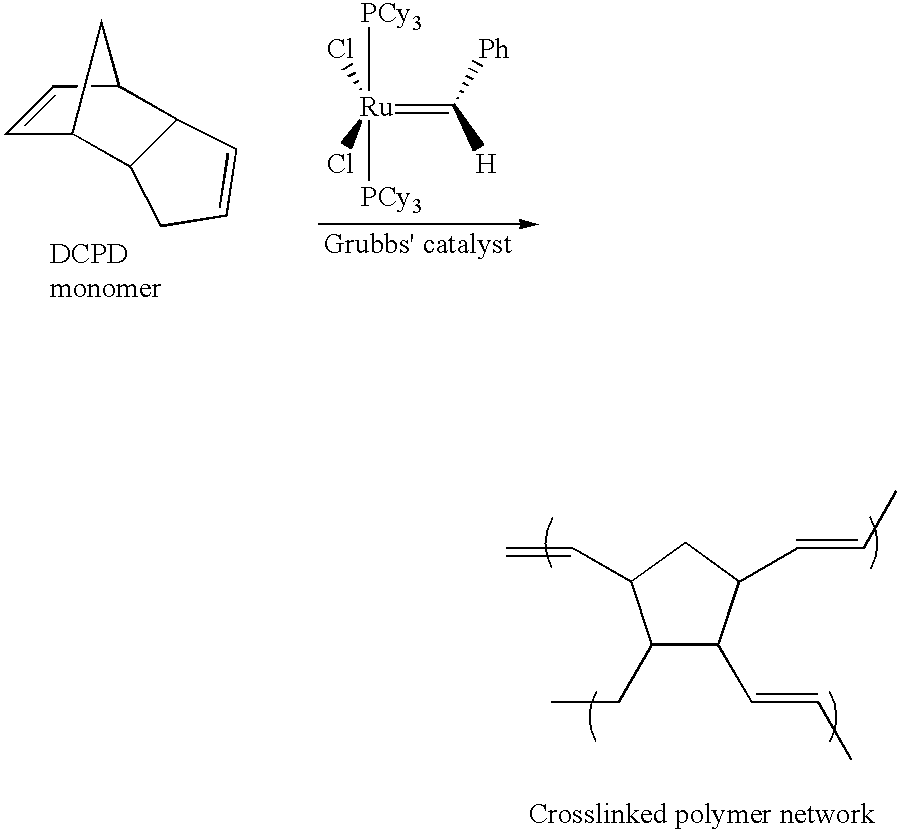

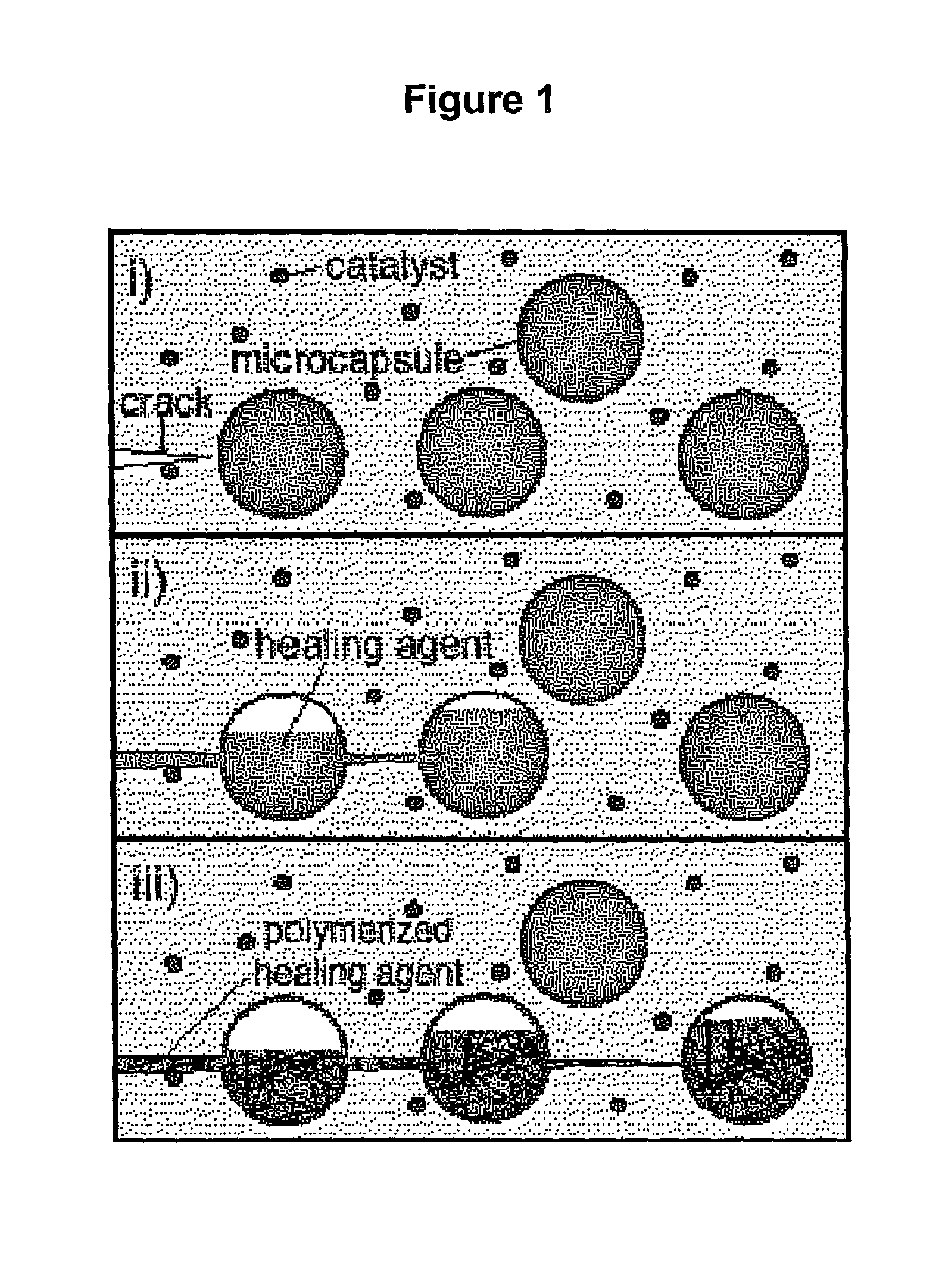

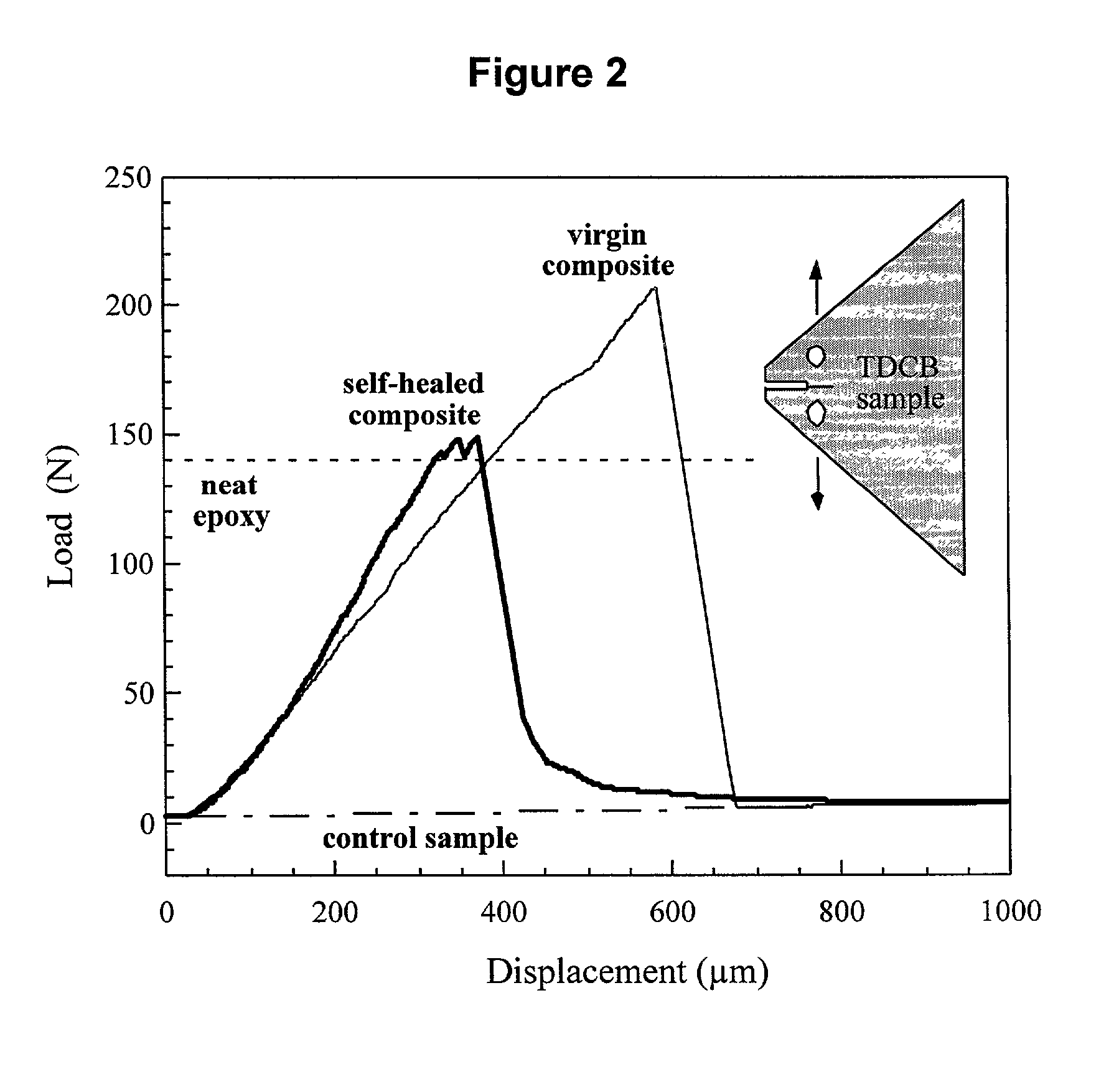

Multifunctional autonomically healing composite material

InactiveUS6518330B2Improve adhesionSynthetic resin layered productsCellulosic plastic layered productsSelf-healingPolymer

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

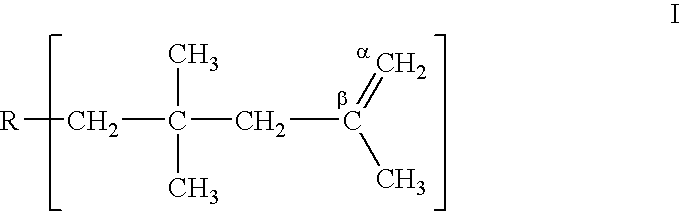

High melt strength polypropylene

InactiveUS7365136B2Improve melt strengthHigh viscosityChemical/physical/physico-chemical stationary reactorsPolymer sciencePtru catalyst

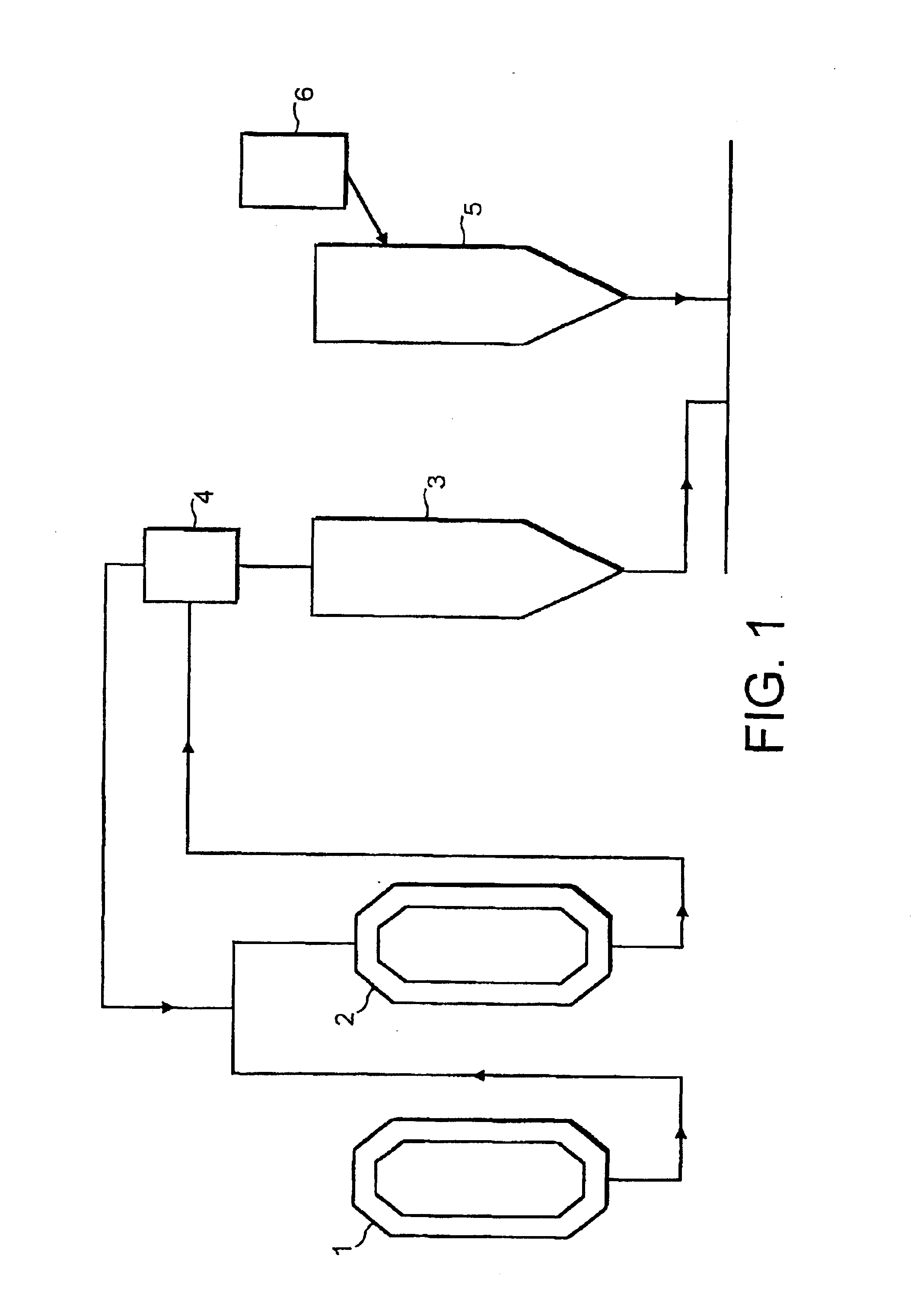

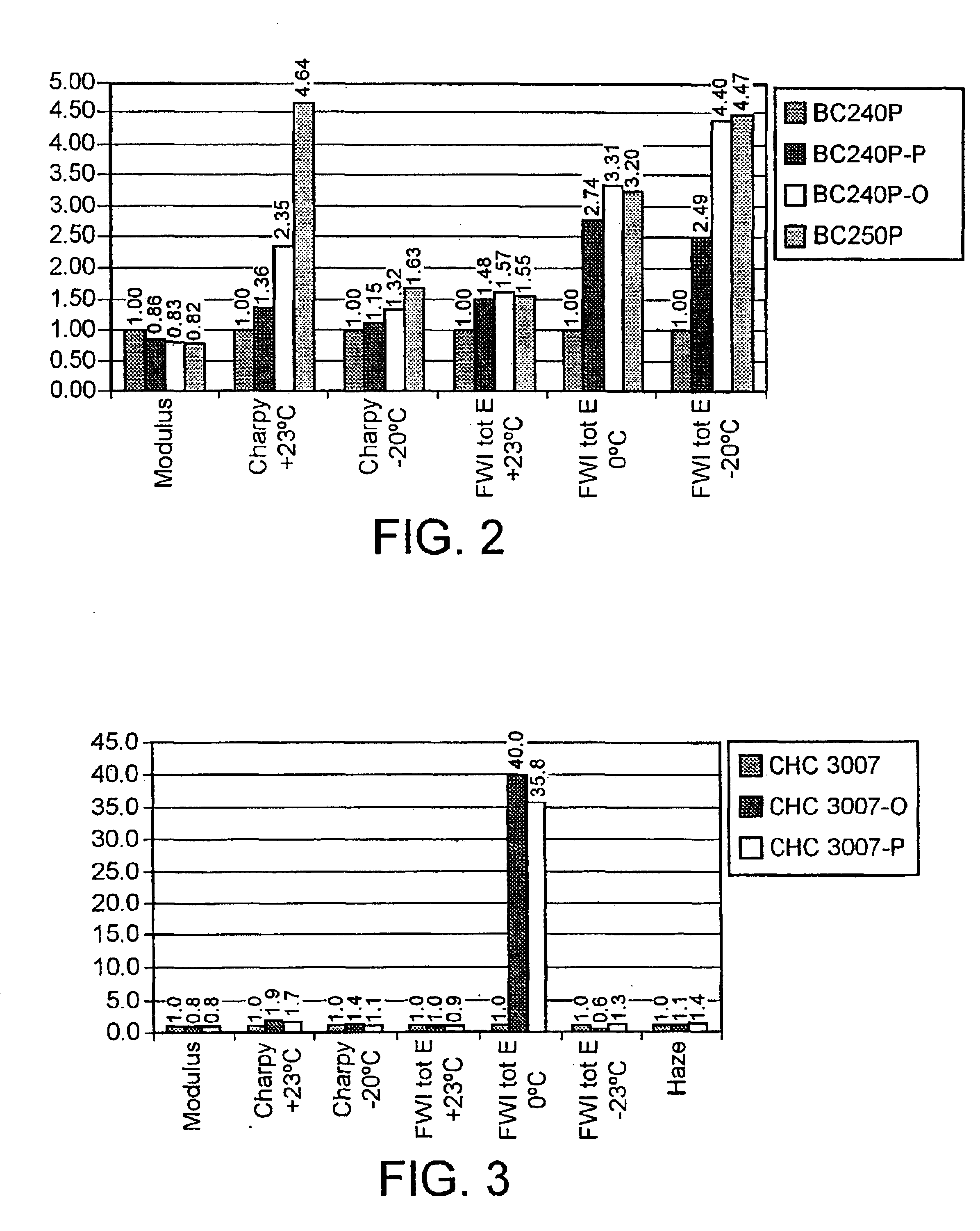

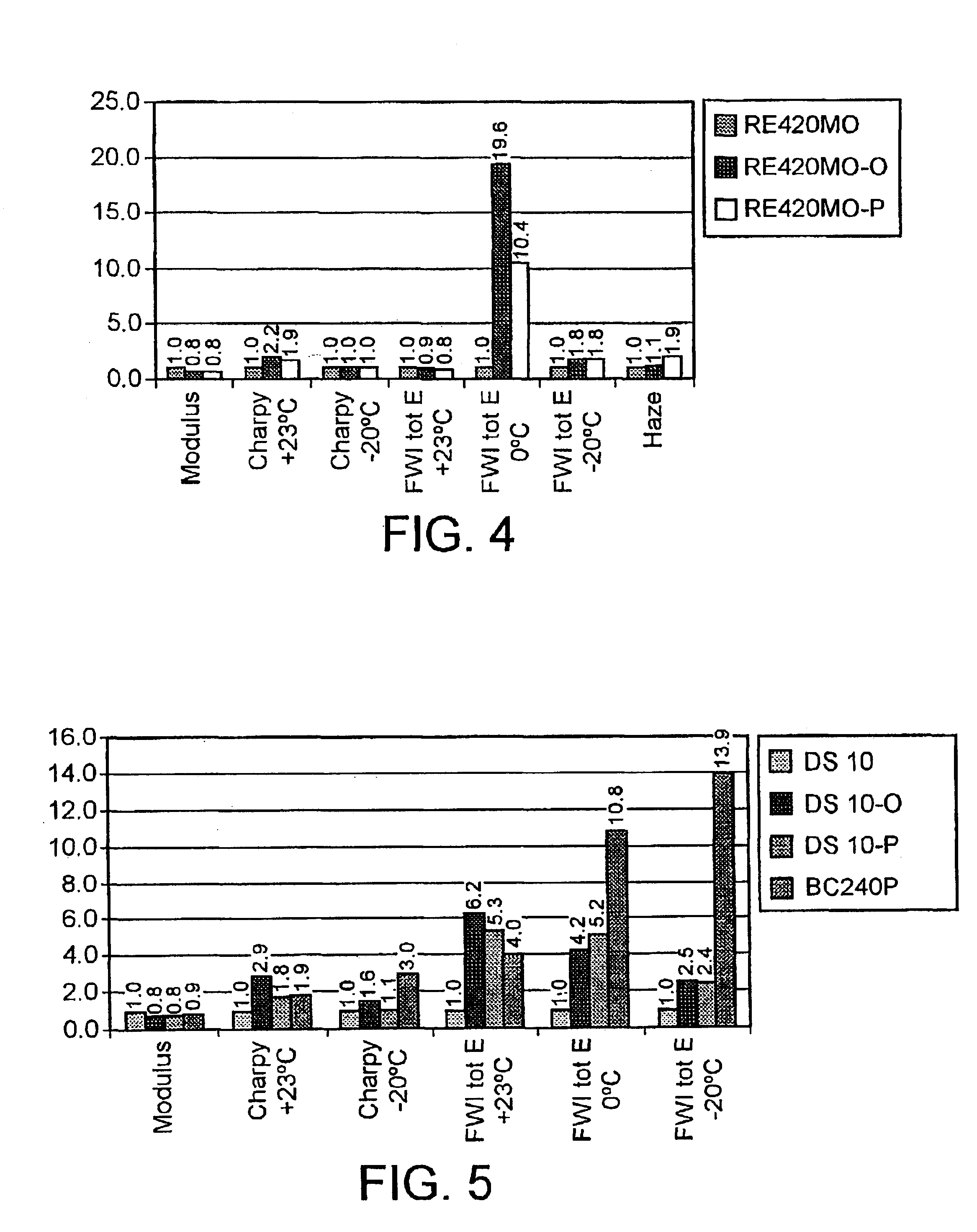

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / 10 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

High melt strength polypropylene

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / l0 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

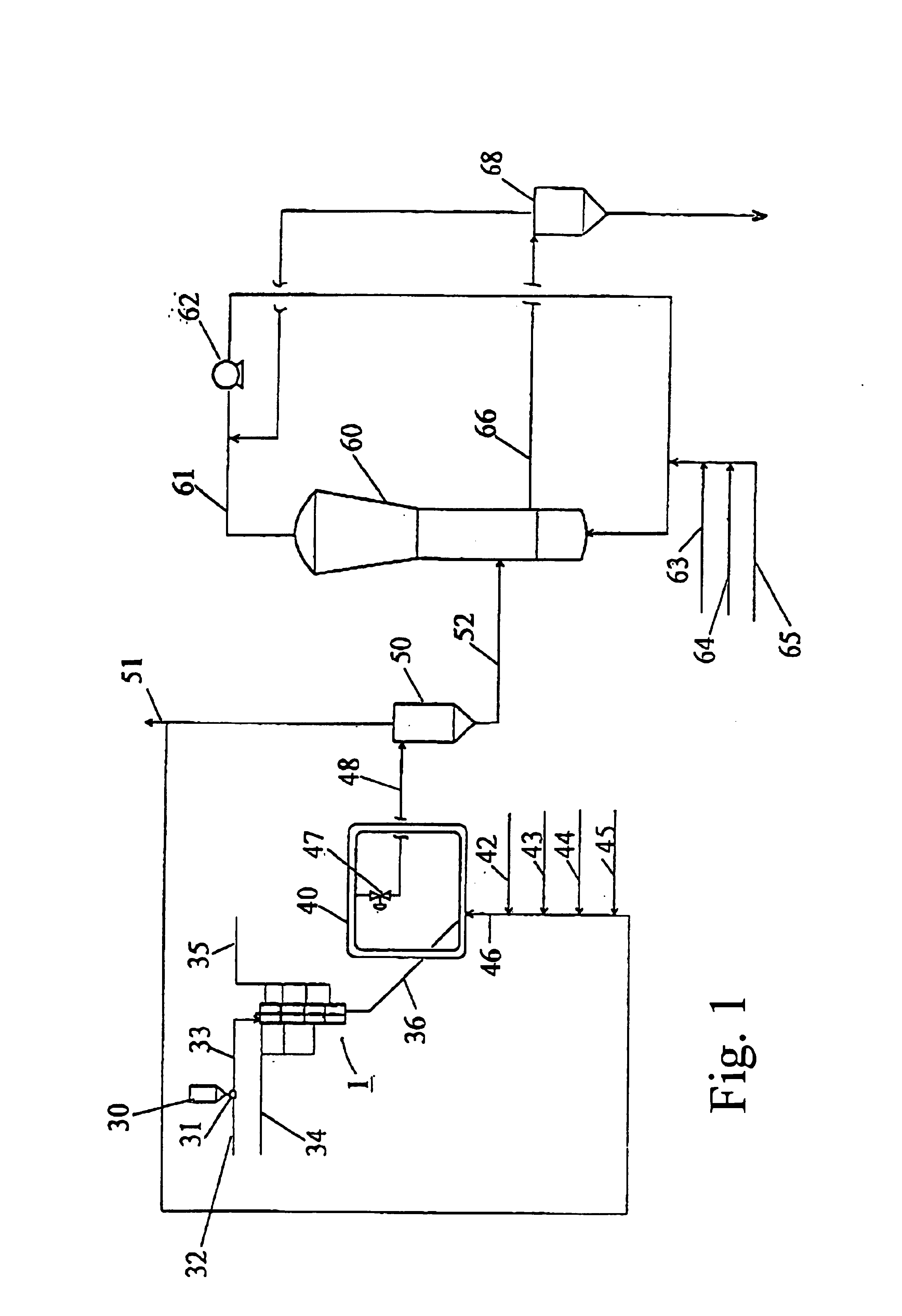

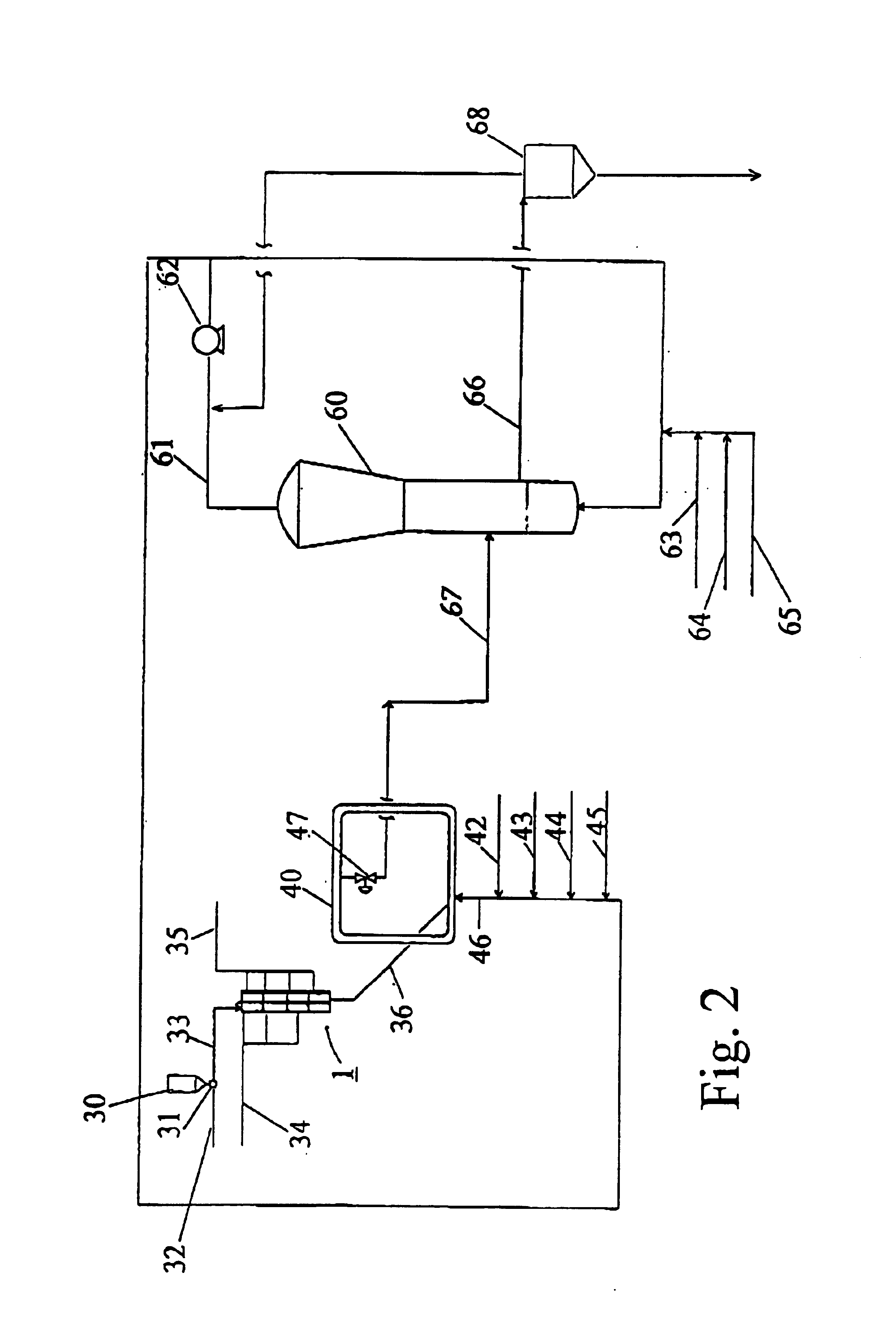

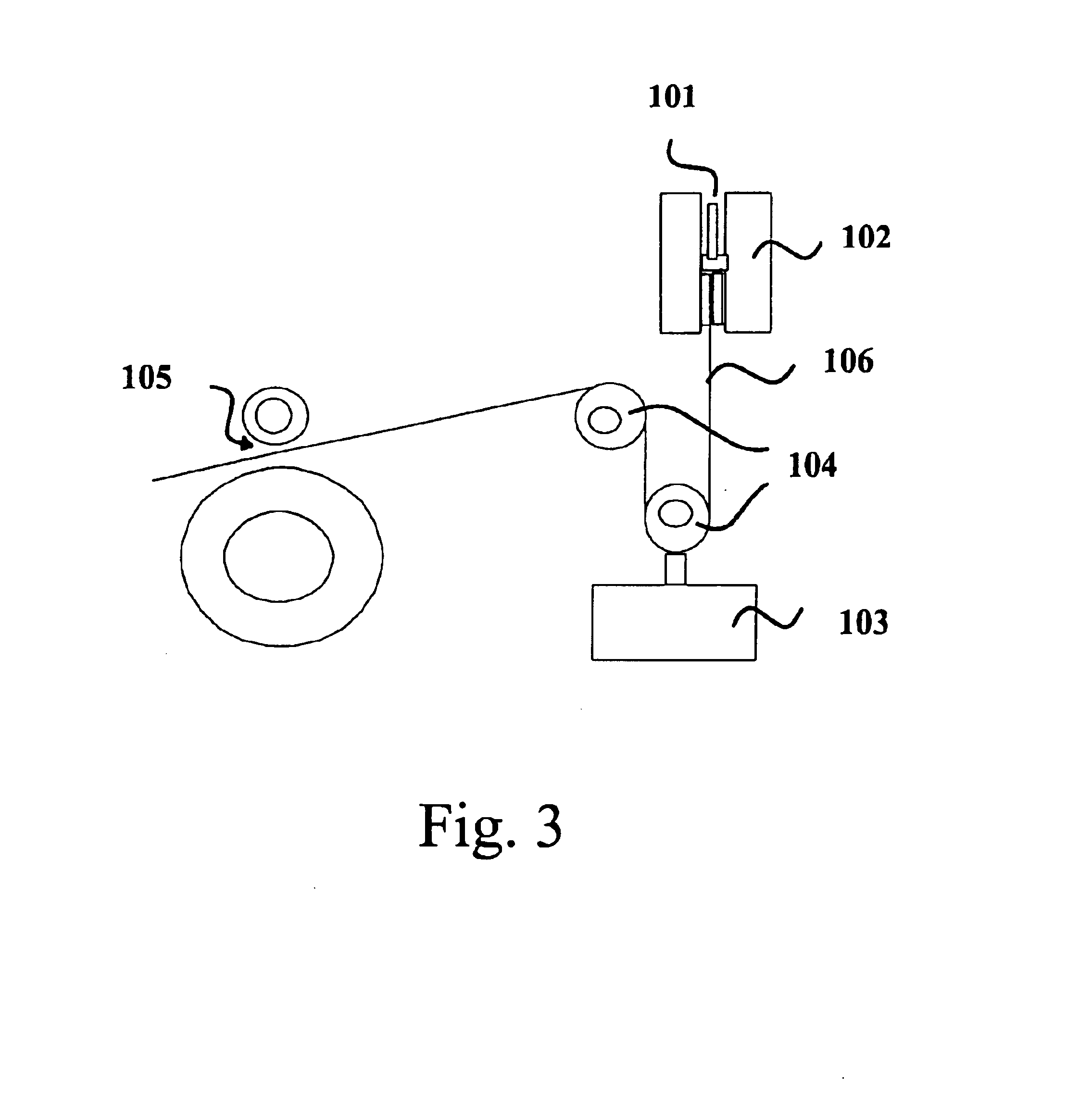

Processes and apparatus for continuous solution polymerization

InactiveUS20040024146A1Suppress further polymerizationProcess control/regulationLiquid-gas reaction as foam/aerosol/bubblesSolution polymerizationProcess plant

The invention relates to processes and plants for continuous solution polymerization. Such plant and processes include a pressure source, a polymerization reactor, downstream of said pressure source, pressure let-down device, downstream of said polymerization reactor, and a separator, downstream of said pressure let-down device, wherein said pressure source is sufficient to provide pressure to said reaction mixture during operation of said process plant to produce a single-phase liquid reaction mixture in said reactor and a two-phase liquid-liquid reaction mixture in said separator in the absence of an additional pressure source between said reactor and said separator.

Owner:EXXONMOBIL CHEM PAT INC

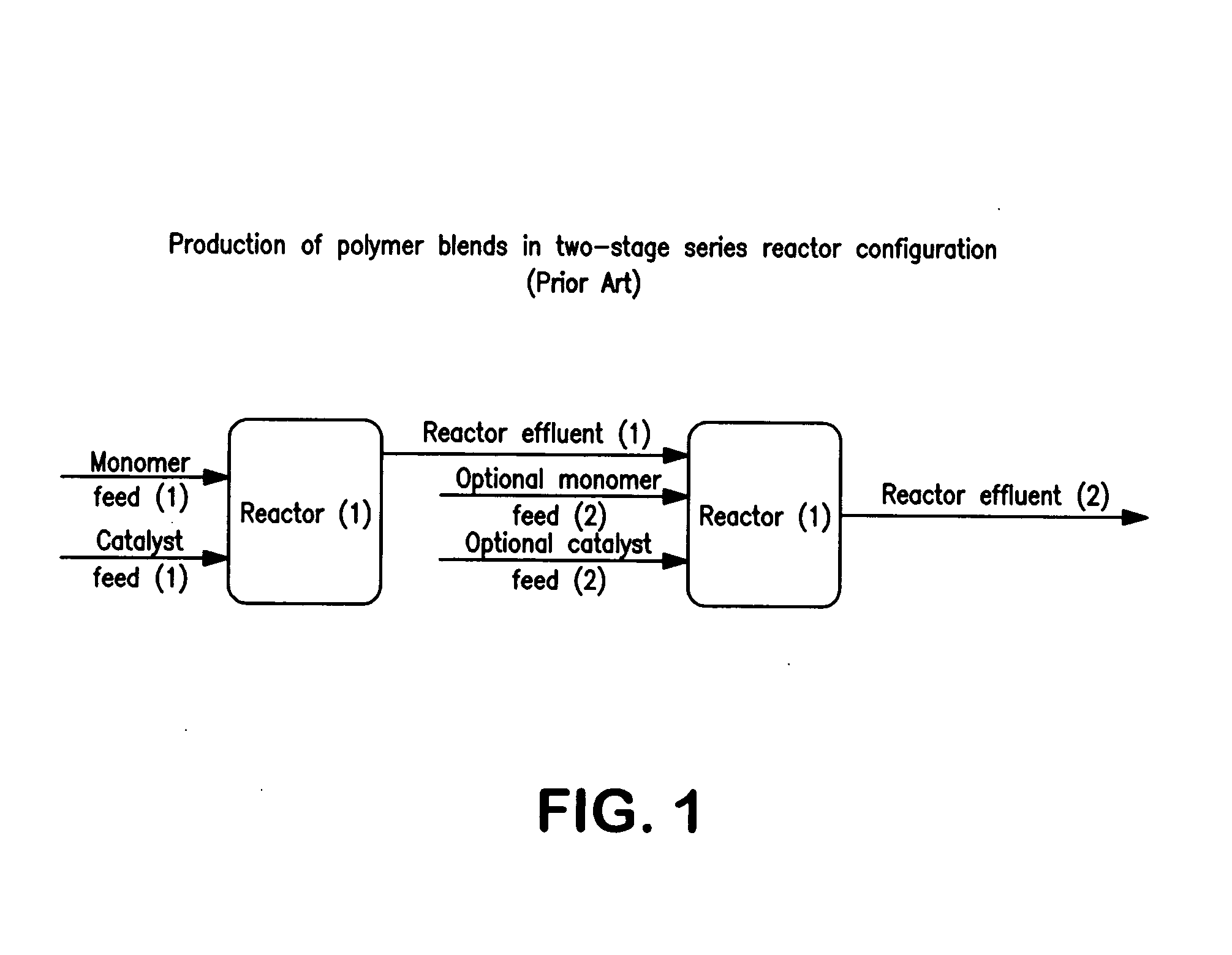

Process for producing propylene based polymer compositions

A process for the production of a propylene based polymer, the process comprising the following steps: (a) a first polymerization stage comprising homopolymerizing propylene or copolymerizing propylene and at least one alpha-olefin in the presence of an alpha-olefin polymerization catalyst whereby to produce a polypropylene component; (b) a second polymerization stage comprising copolymerizing ethylene and at least one alpha-olefin in the presence of an alpha-olefin polymerization catalyst whereby to produce an ethylene / alpha-olefin copolymer component; and (c) blending the polymer components produced in steps (a) and (b) whereby to produce a polymer blend, wherein the first and second polymerization stages are effected in separate polymerization reactors connected in parallel. Also provided are polymer compositions comprising: (i) 30 to 97% by weight, based on the total weight of the polymer composition, of a propylene based polymer; and (ii) 3 to 70% by weight, preferably 5 to 20% by weight, based on the total weight of the polymer composition, of an ethylene copolymer plastomer (e.g., an ethylene-propylene plastomer) containing at least 60% by weight ethylene.

Owner:BOREALIS TECH OY

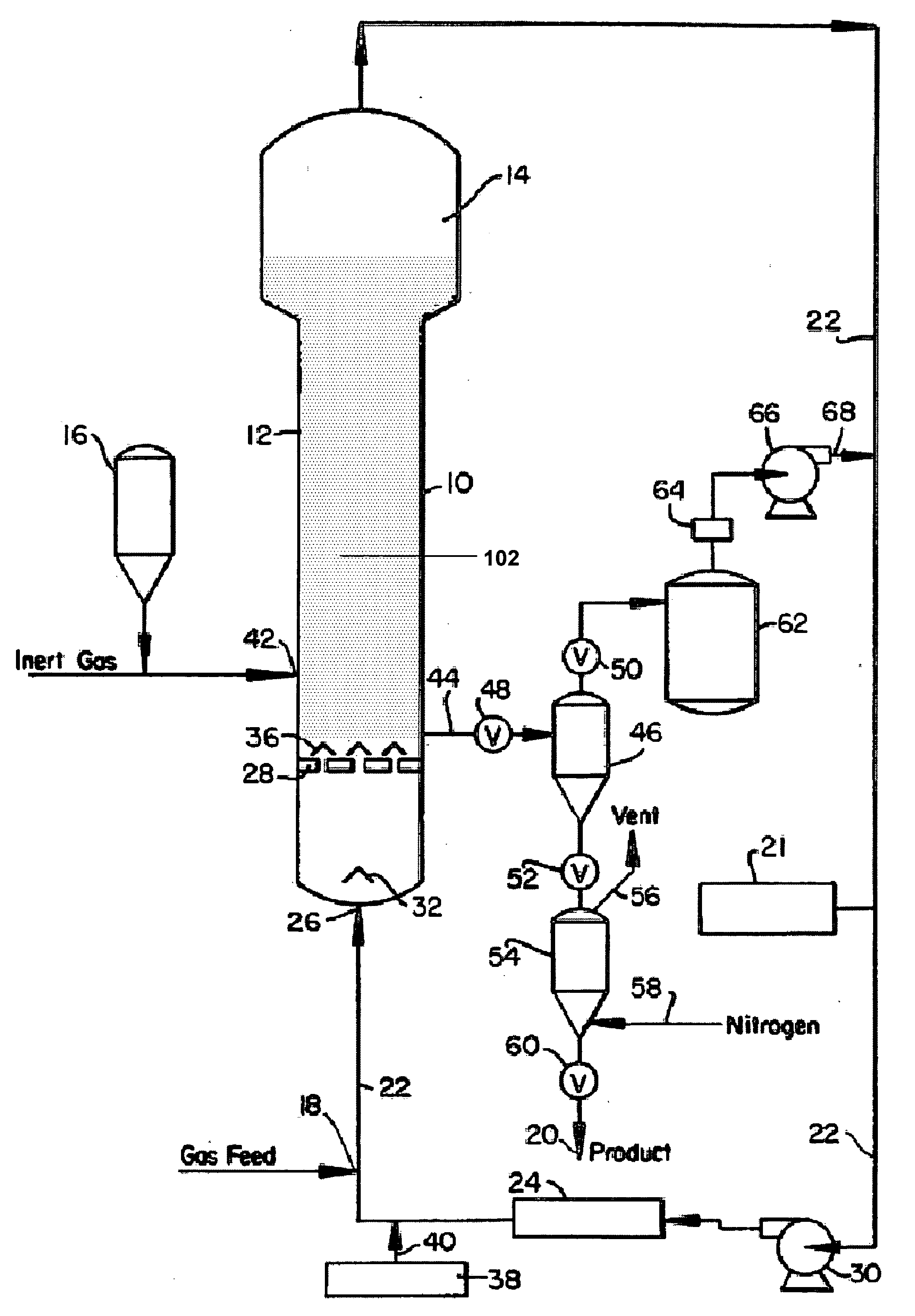

Condensing mode operation of gas-phase polymerization reactor

A continuous gas fluidized bed polymerization process for the production of a polymer from a monomer including continuously passing a gaseous stream comprising the monomer through a fluidized bed reactor in the presence of a catalyst under reactive conditions; withdrawing a polymeric product and a stream comprising unreacted monomer gases; cooling said stream comprising unreacted monomer gases to form a mixture comprising a gas phase and a liquid phase and reintroducing said mixture into said reactor with sufficient additional monomer to replace that monomer polymerized and withdrawn as the product, wherein said liquid phase is vaporized, and wherein the stream comprises an induced condensing agent selected from the group consisting of alkanes, cycloalkanes, and mixtures thereof, the induced condensing agent having a normal boiling point less than 25° C.

Owner:UNIVATION TECH LLC

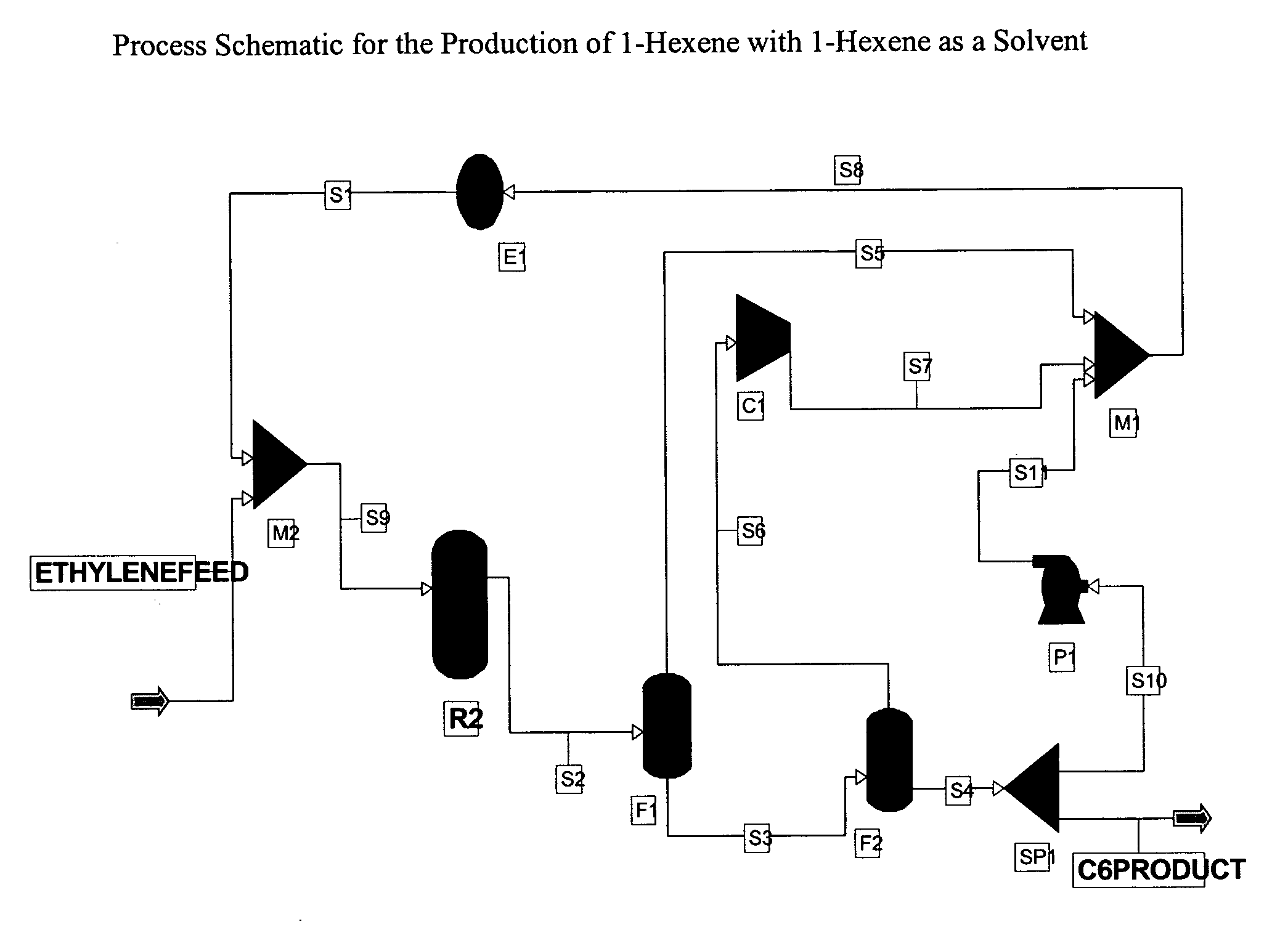

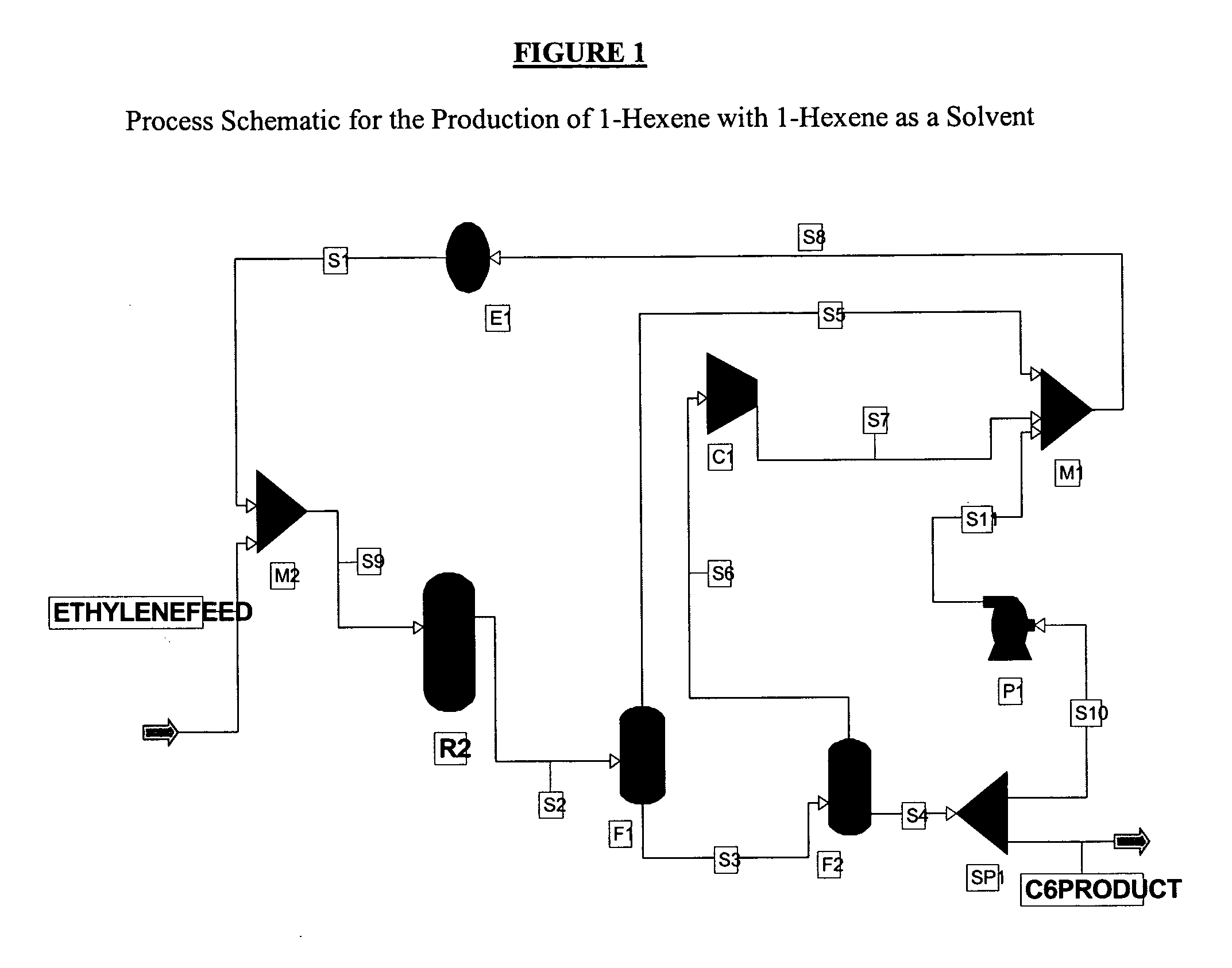

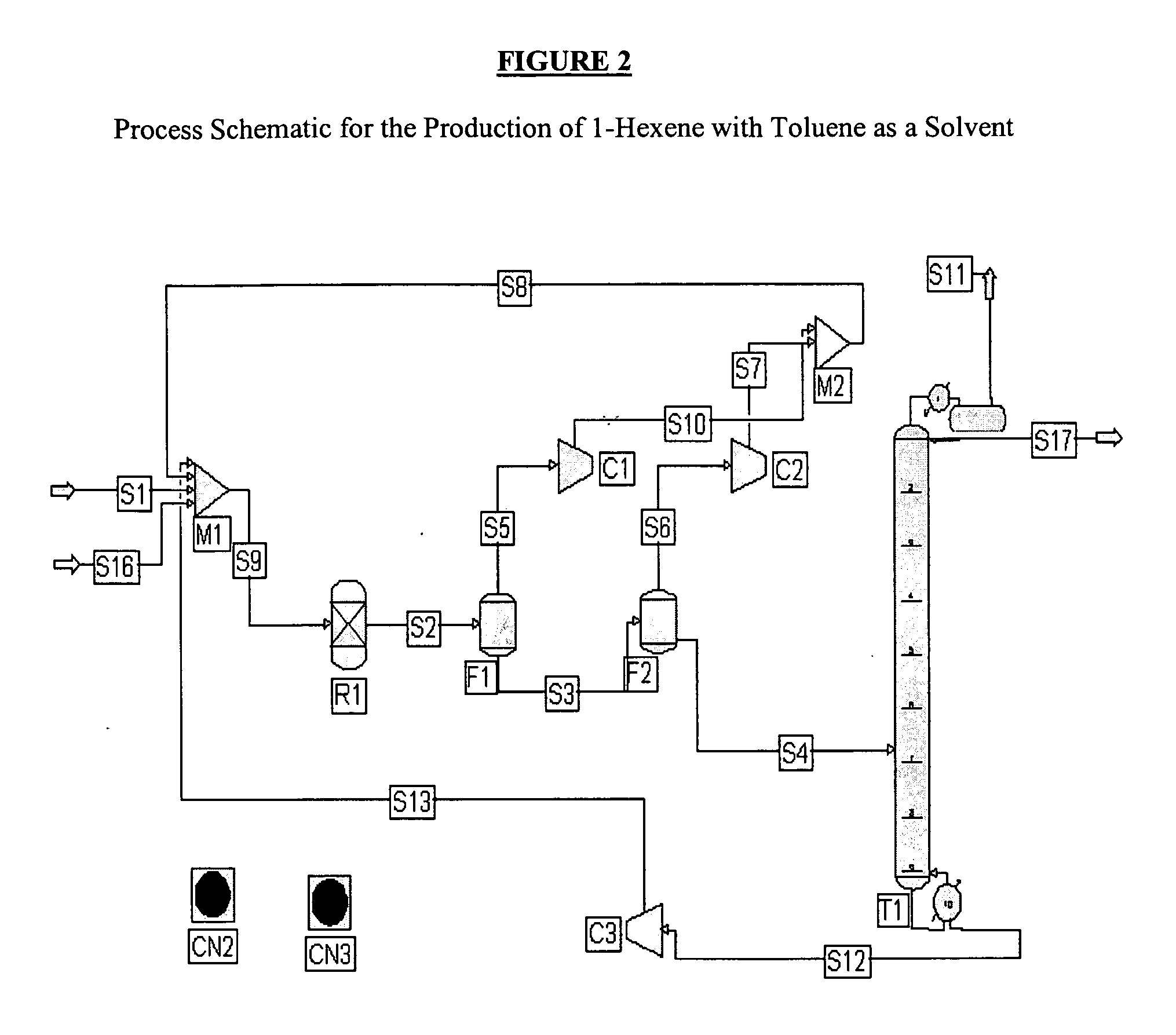

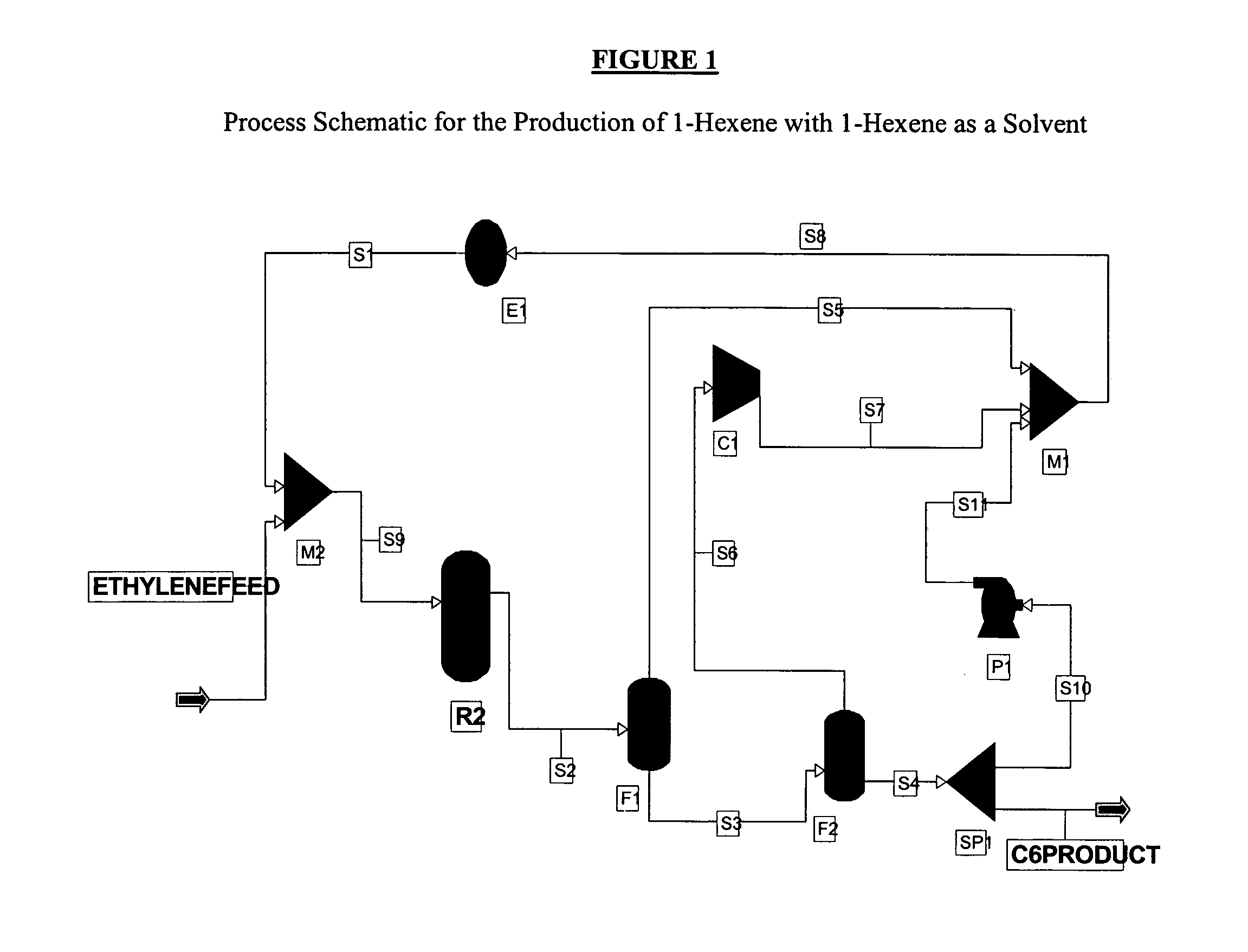

Process for generating alpha olefin comonomers

ActiveUS20070185362A1High selectivityHigh activityHydrocarbons from unsaturated hydrocarbon additionCatalystsPolymer scienceDiluent

The present invention relates to a method for preparing olefin comonomers from ethylene. The comonomer generated can be used in a subsequent process, such as a polyethylene polymerization reactor. The comonomer generated can be transported, optionally without isolation or storage, to a polyethylene polymerization reactor. One method includes the steps of: feeding ethylene and a catalyst in a solvent / diluent to one or more comonomer synthesis reactors; reacting the ethylene and the catalyst under reaction conditions sufficient to produce an effluent comprising a desired comonomer; forming a gas stream comprising unreacted ethylene, and a liquid / bottoms stream comprising the comonomer, optionally by passing the effluent to one or more downstream gas / liquid phase separators; and purifying at least a portion of said liquid / bottoms stream by removing at least one of solid polymer, catalyst, and undesirable olefins therefrom.

Owner:EXXONMOBIL CHEM PAT INC

Feed purification at ambient temperature

ActiveUS6987152B1Hydrocarbons from unsaturated hydrocarbon additionHydrocarbonsOxygenOlefin polymerization

A method for olefin polymerization is provided. A feed stream comprising more than 0.1 ppm by volume of oxygen and 0.3 ppm by volume of water is passed through a first packed bed to selectively remove at least a portion of the oxygen. The feed stream is then passed through a second packed bed to selectively remove at least a portion of the water, providing a purified feed stream comprising less than 0.1 ppm by volume of oxygen and 0.3 ppm by volume of water. Both the first and second packed beds operate at a temperature of from about 0° C. to about 50° C. The purified feed stream is then passed to a polymerization reactor.

Owner:UNIVATION TECH LLC

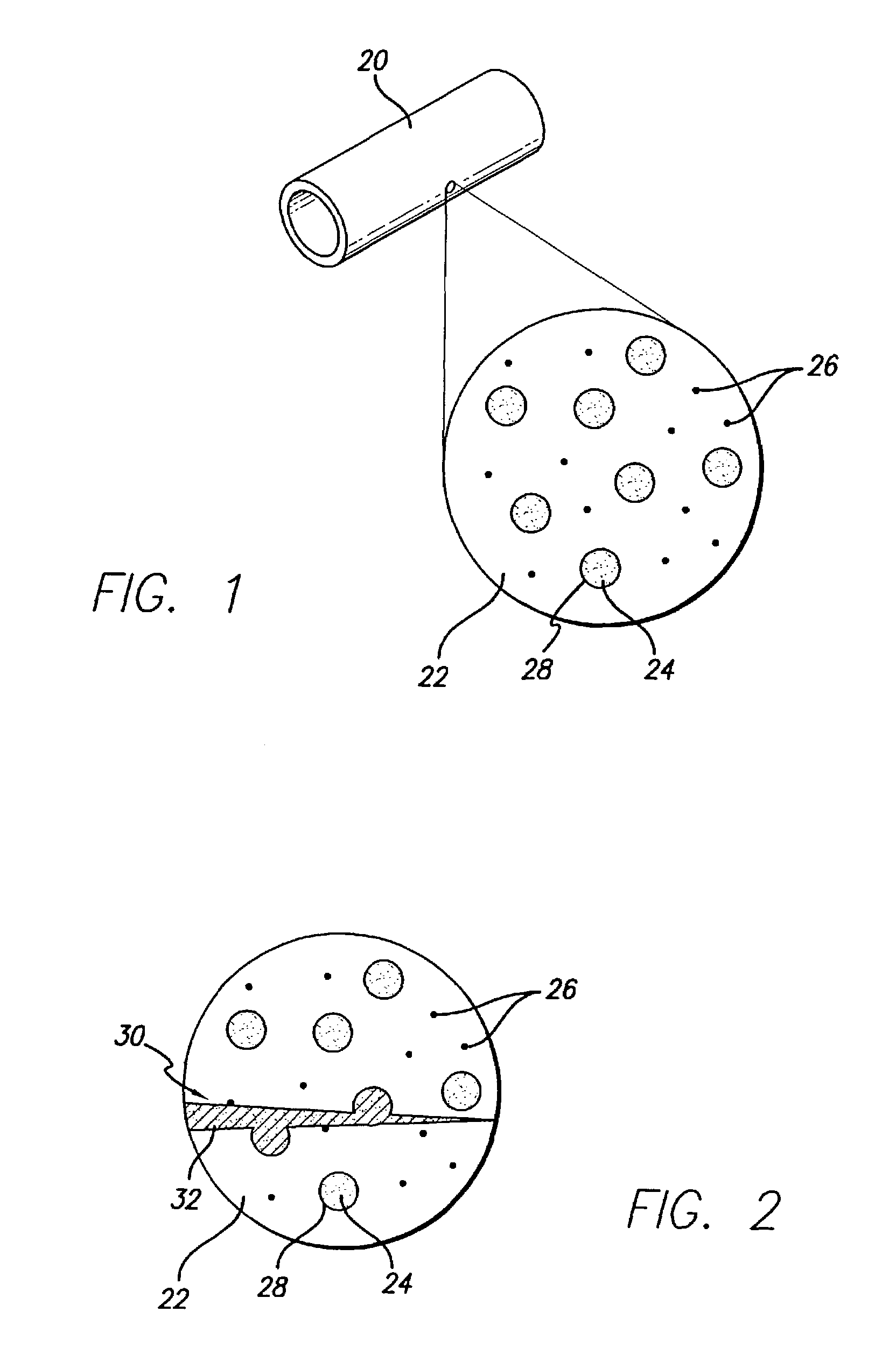

Multifunctional autonomically healing composite material

InactiveUS20020111434A1Improve adhesionSynthetic resin layered productsCellulosic plastic layered productsSelf-healingMaterials science

A composite material, contains a polymer, a polymerizer, a corresponding catalyst for the polymerizer, and a plurality of capsules. The polymerizer is in the capsules. The composite material is self-healing.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

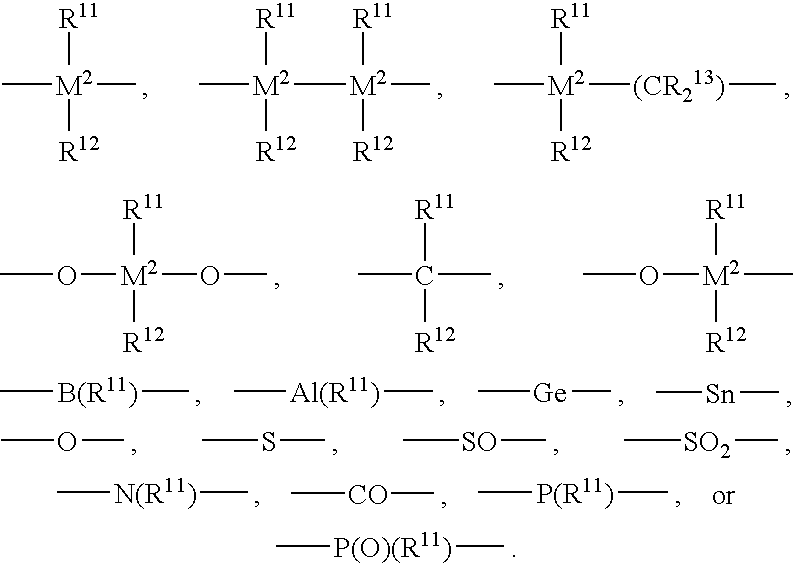

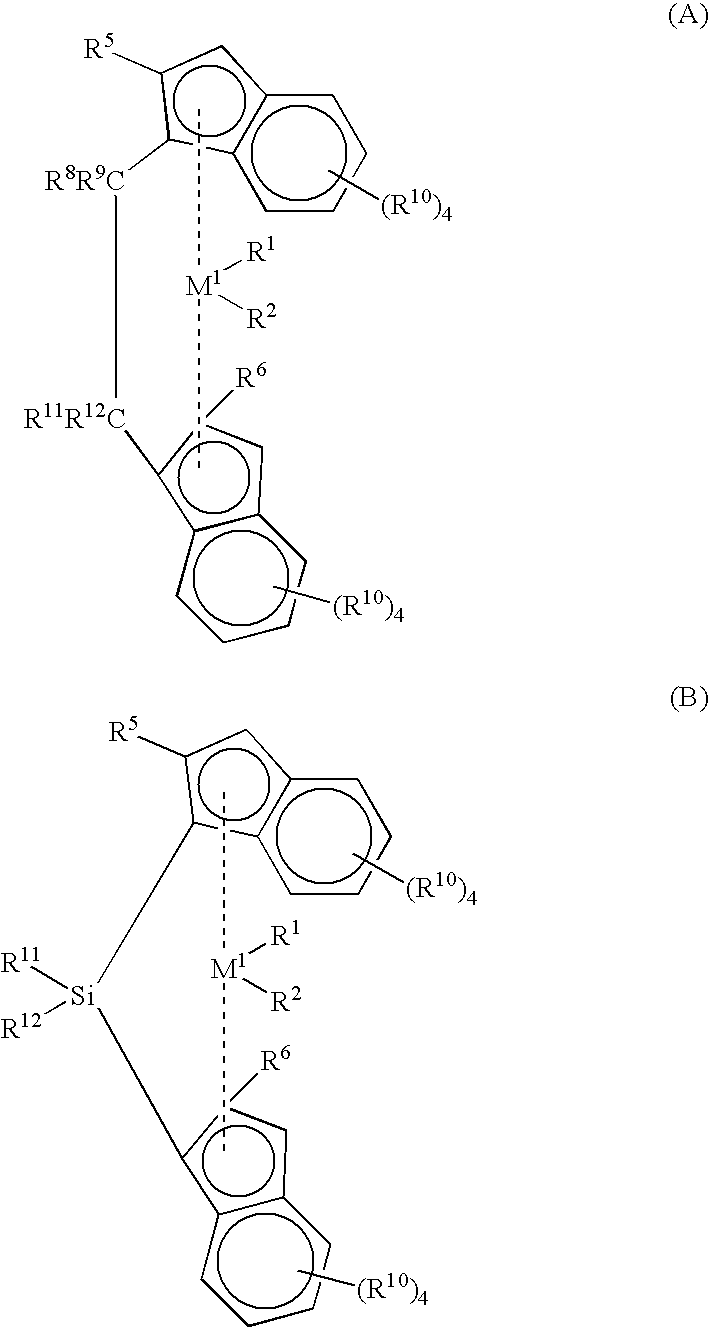

Polymerization process with mixed catalyst compositions

InactiveUS7192902B2Selectively activateEffectively tailor-makeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationEmulsion polymerizationOlefin polymerization

The application describes a mixed olefin polymerization catalyst composition comprising a support, a reaction product of at least one first organometallic compound and a first activator capable of rendering the first organometallic compound active for insertion polymerization, and at least one second organometallic compound, the activator incapable of rendering the second organometallic compound active for polymerization of the monomers. The mixed catalyst composition can be used to prepare a first polymer component in a first polymerization reactor stage and then, when an effective activator is added for the second organometallic compound, the catalyst composition can be used to prepare a second polymer composition that is homogeneously blended with the first polymer component.

Owner:EXXONMOBIL CHEM PAT INC

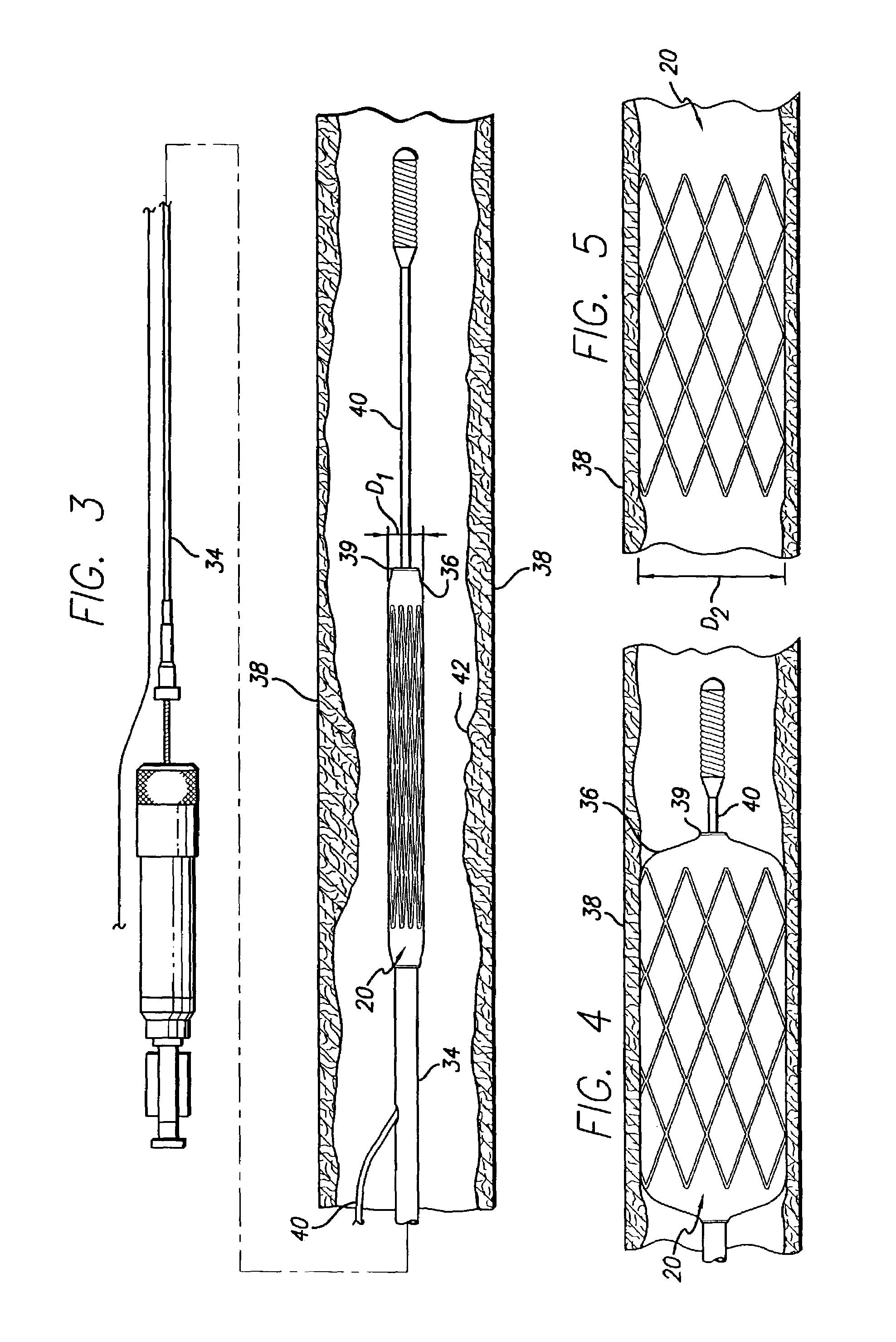

Medical device made from self-stiffening composite

InactiveUS6994723B1Effective expansionImprove radial strengthStentsBlood vesselsUltimate tensile strengthMedical device

Medical devices are made from a self-stiffening composite including a base material, a polymerizer and a corresponding activator for the polymerizer. The medical devices have an initial configuration in which the polymerizer and activator are separated from each other and an activated configuration in which the polymerizer and activator are brought into contact with each other. Polymerization is triggered when the polymerizer and activator are contacted together, forming a polymer that stiffens the medical device. The medical device may thus be flexible in the initial configuration so it can be easily advanced through tortuous passageways during delivery to a body lumen and further have sufficient radial strength in the activated configuration to hold open the body lumen after implantation.

Owner:ABBOTT CARDIOVASCULAR

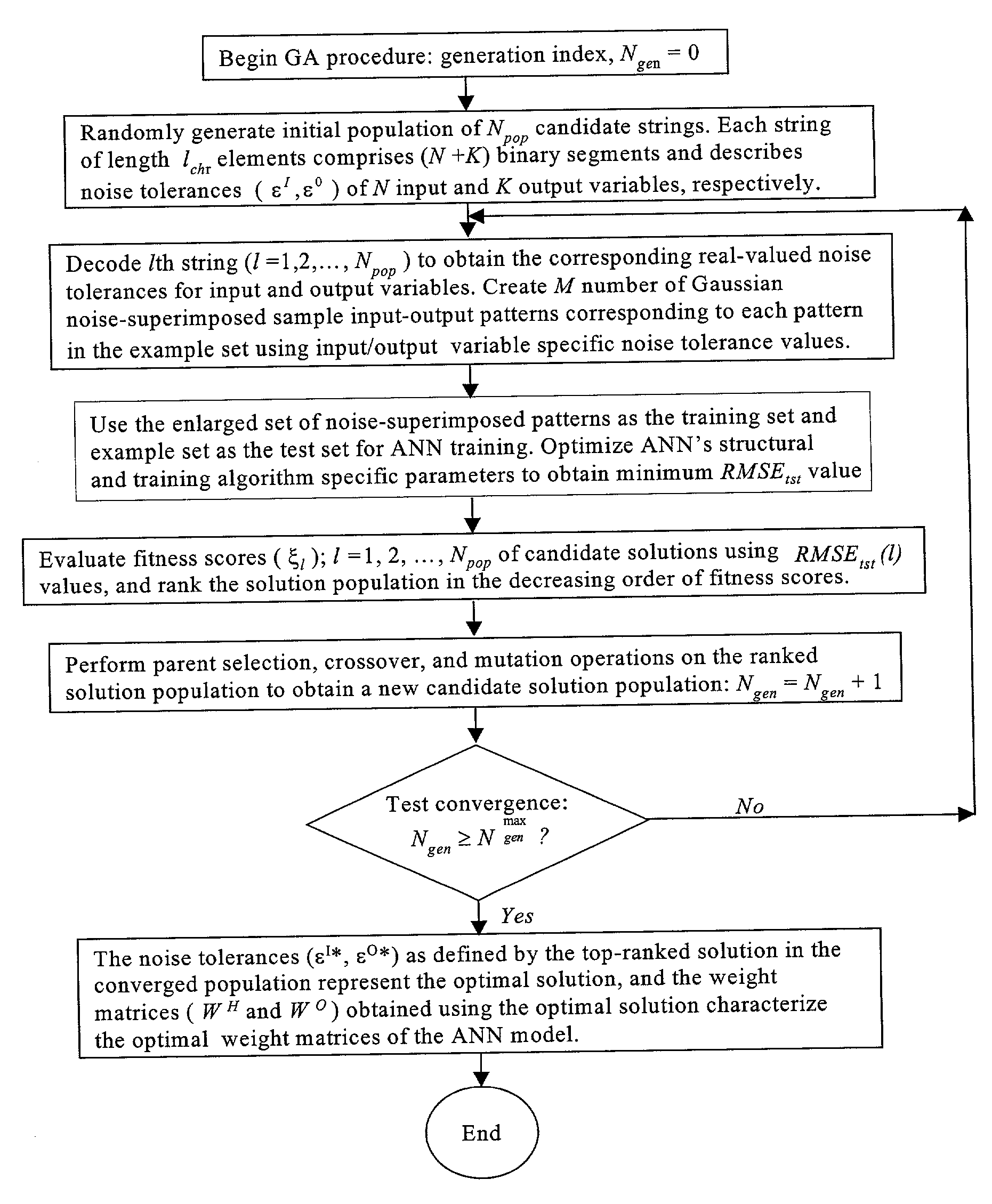

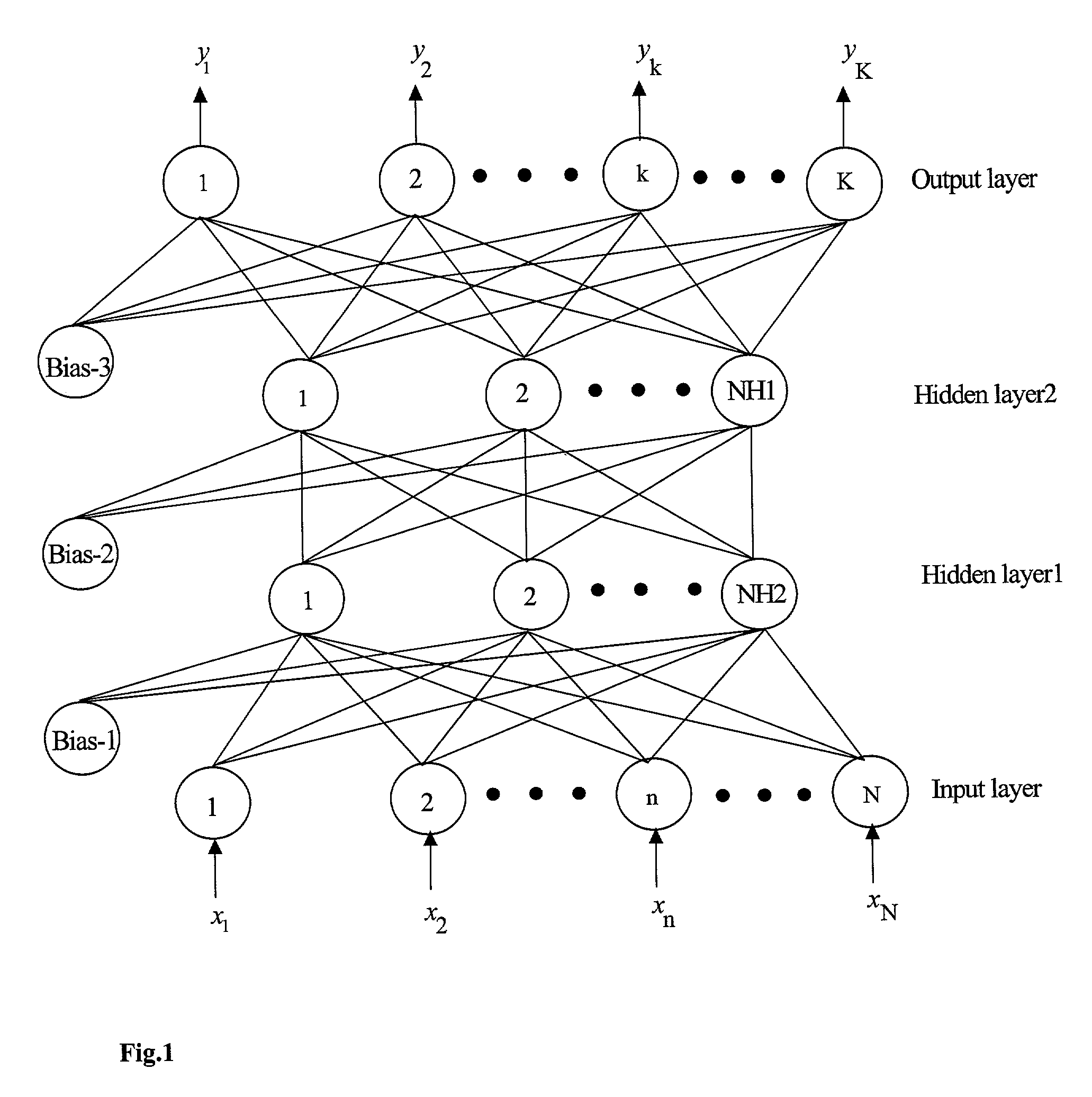

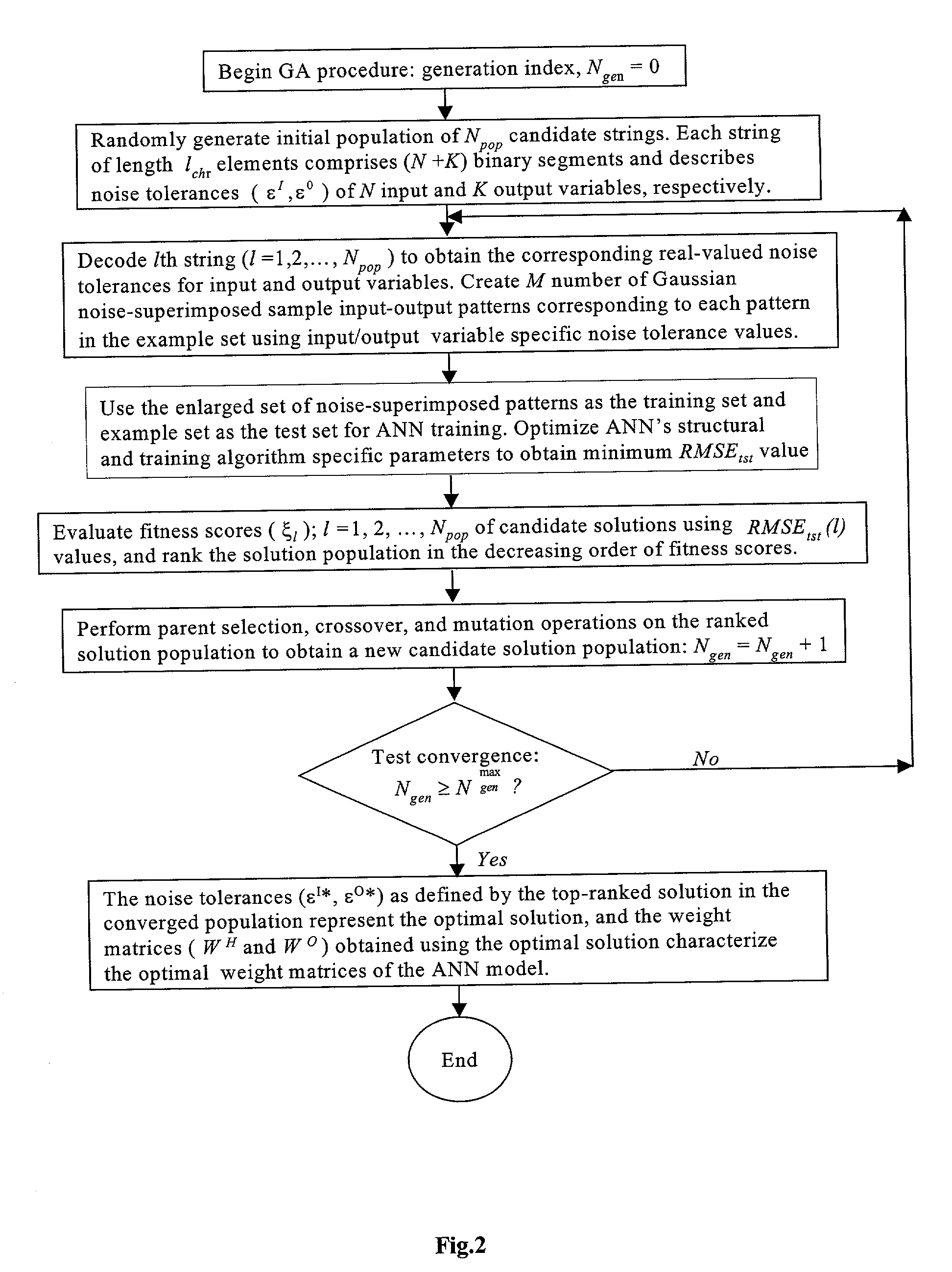

Performance of artificial neural network models in the presence of instrumental noise and measurement errors

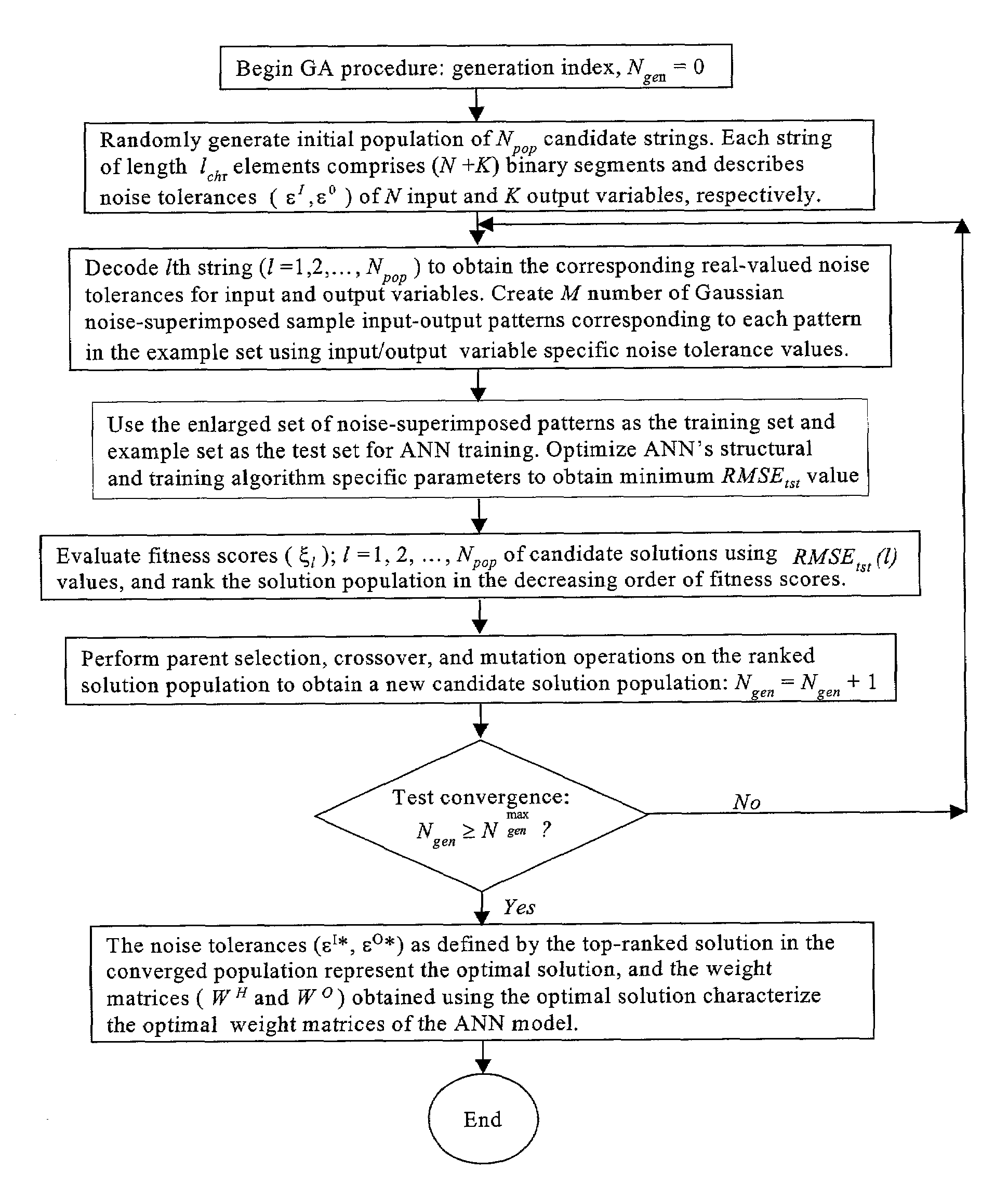

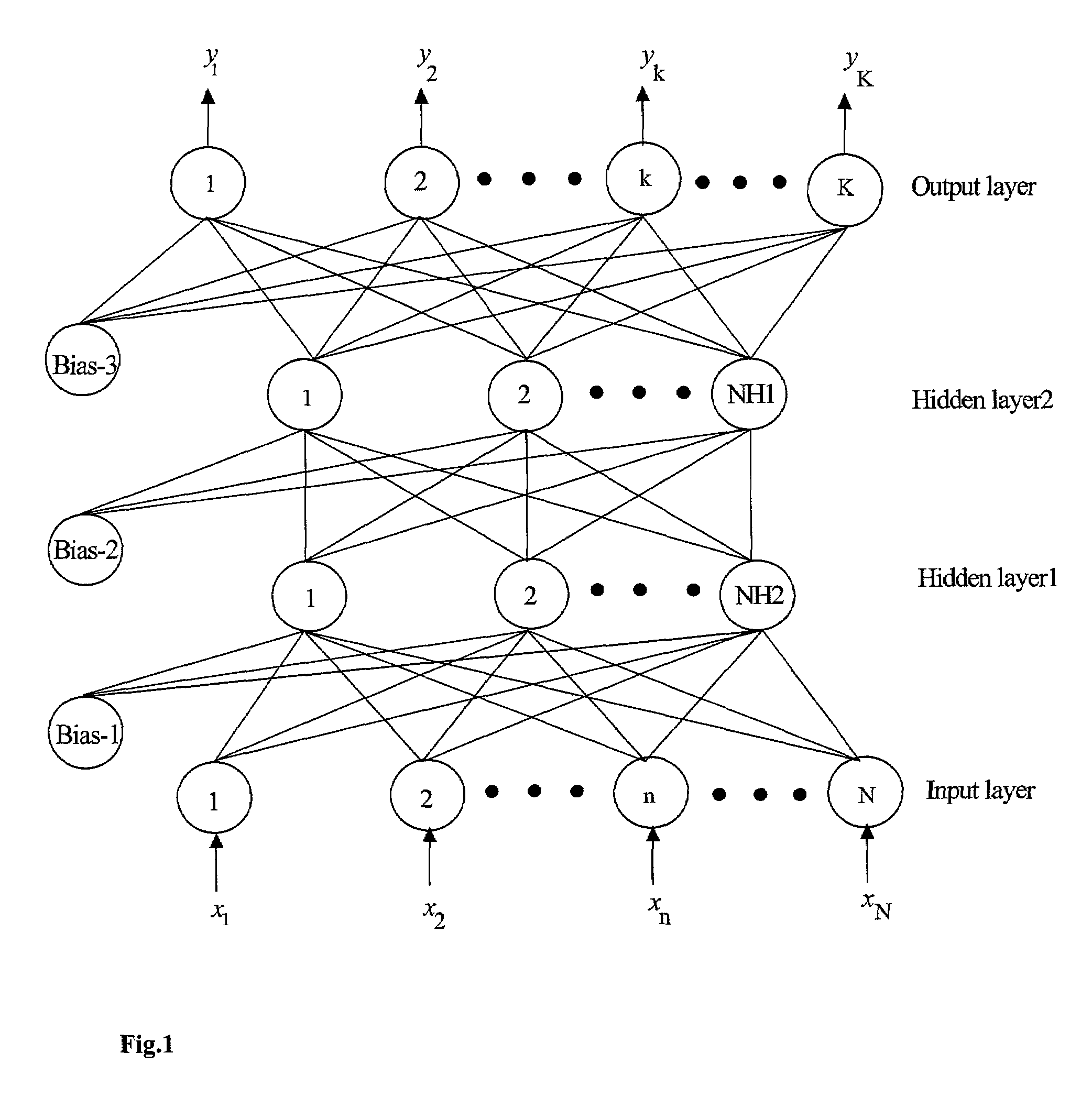

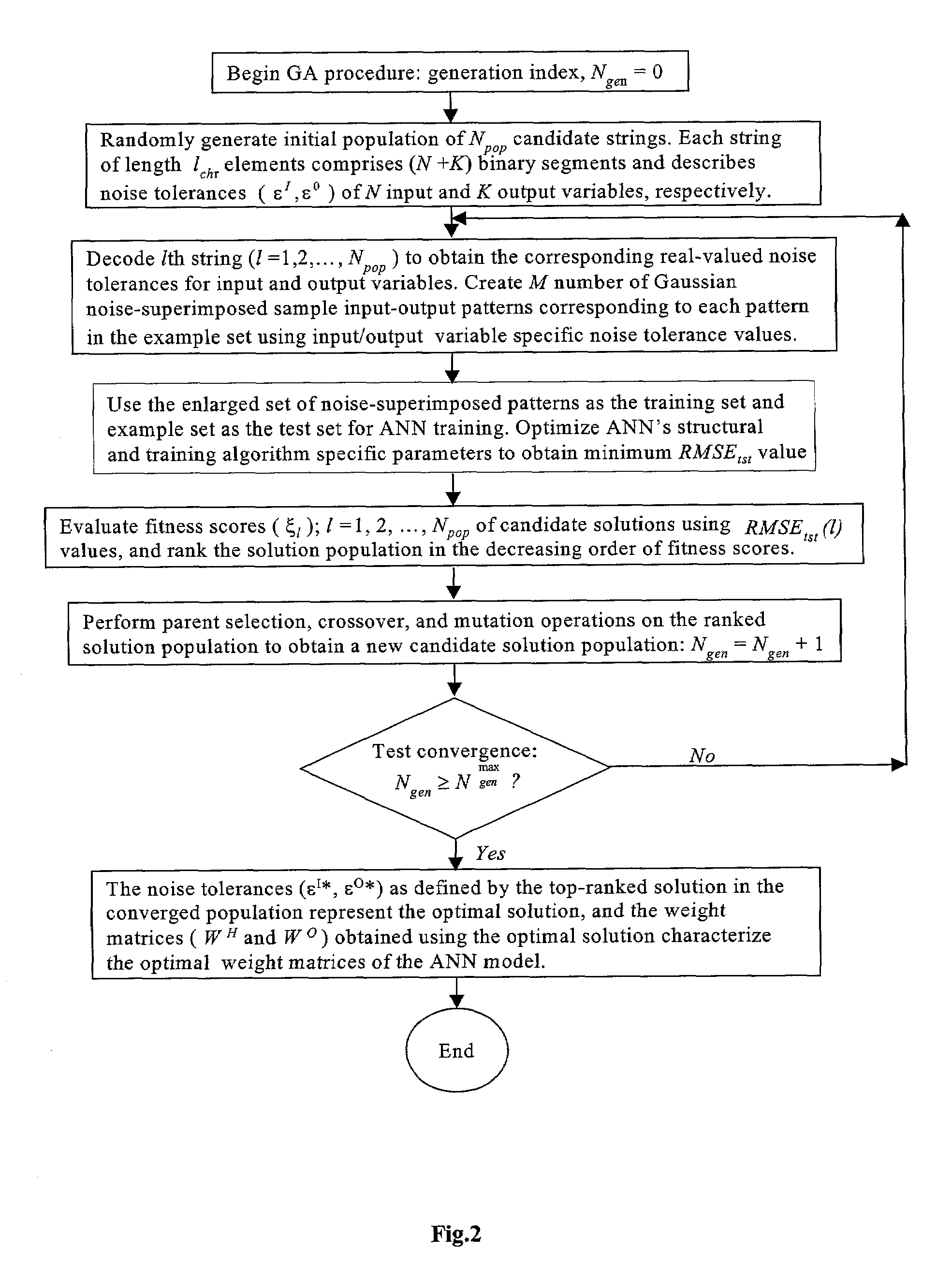

ActiveUS20030191728A1Improve accuracy performanceImprove generalization performanceGenetic modelsDigital computer detailsObservational errorData set

A method is described for improving the prediction accuracy and generalization performance of artificial neural network models in presence of input-output example data containing instrumental noise and / or measurement errors, the presence of noise and / or errors in the input-output example data used for training the network models create difficulties in learning accurately the nonlinear relationships existing between the inputs and the outputs, to effectively learn the noisy relationships, the methodology envisages creation of a large-sized noise-superimposed sample input-output dataset using computer simulations, here, a specific amount of Gaussian noise is added to each input / output variable in the example set and the enlarged sample data set created thereby is used as the training set for constructing the artificial neural network model, the amount of noise to be added is specific to an input / output variable and its optimal value is determined using a stochastic search and optimization technique, namely, genetic algorithms, the network trained on the noise-superimposed enlarged training set shows significant improvements in its prediction accuracy and generalization performance, the invented methodology is illustrated by its successful application to the example data comprising instrumental errors and / or measurement noise from an industrial polymerization reactor and a continuous stirred tank reactor (CSTR).

Owner:COUNCIL OF SCI & IND RES

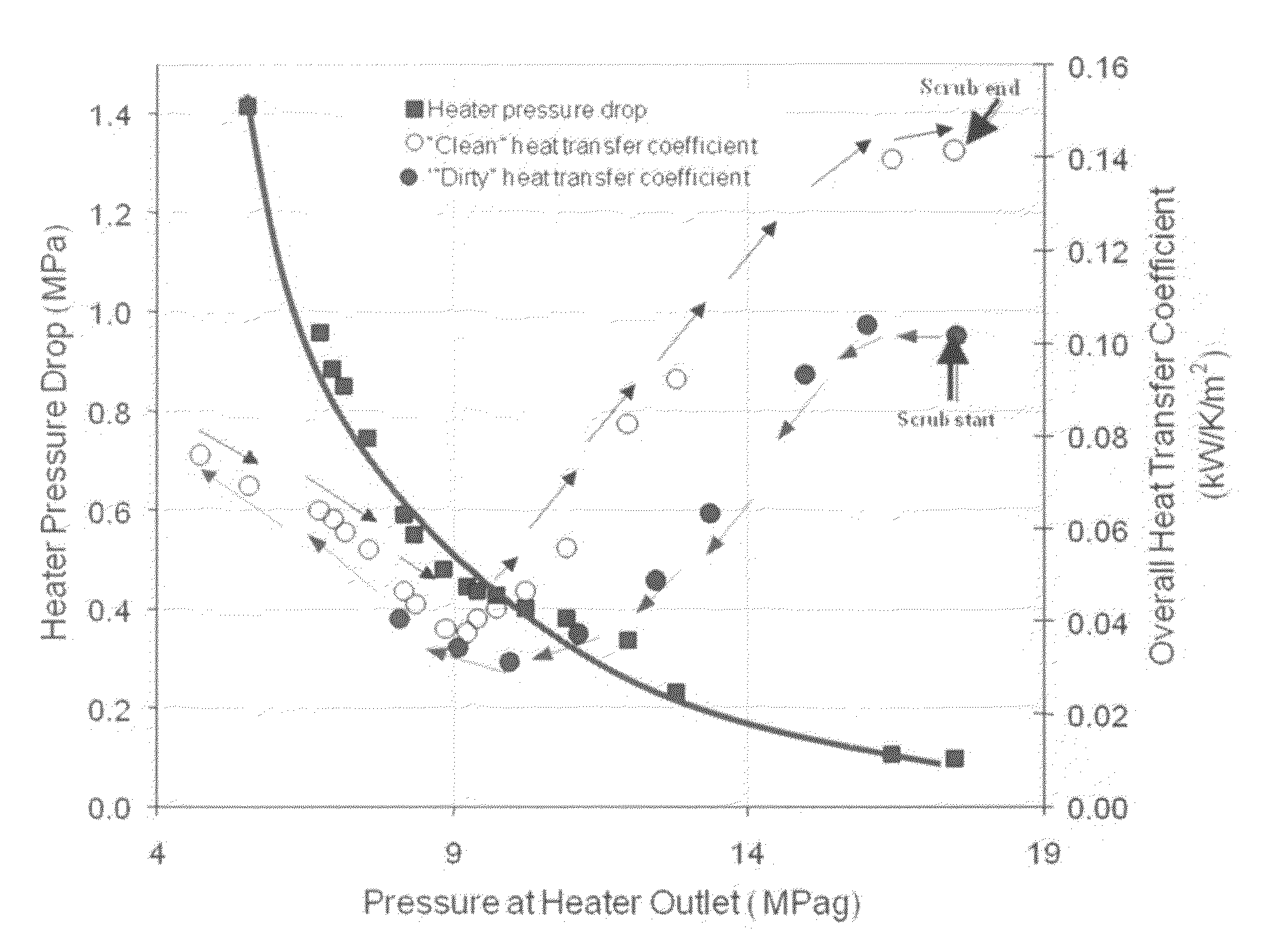

High temperature process for solution polymerization

ActiveUS7650930B2Avoid accumulationIncrease forceHollow article cleaningVapor condensationPlate heat exchangerEmulsion polymerization

A process for the solution polymerization of olefins with improved on-stream time is provided. The solution polymerization process of the current invention comprises a method for the on-line removal of foulant material from one or more heat exchangers downstream of a polymerization reactor. Removal of foulant material is accomplished by deliberately applying a positive pressure differential across a heat exchanger. In the process of the current invention, reactor shut down is not required for the purpose of cleaning foulant material from a heat exchanger.

Owner:NOVA CHEM (INT) SA

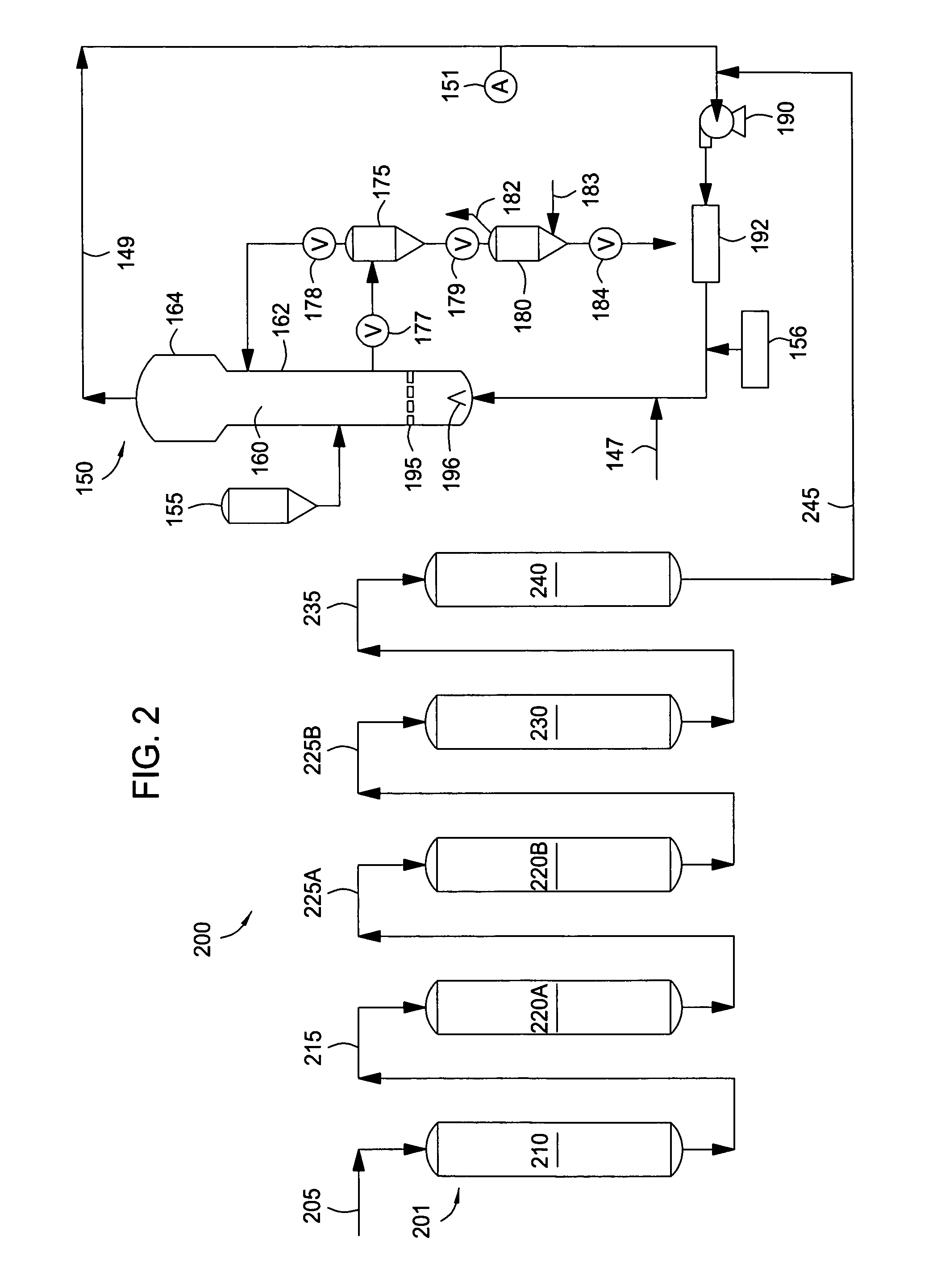

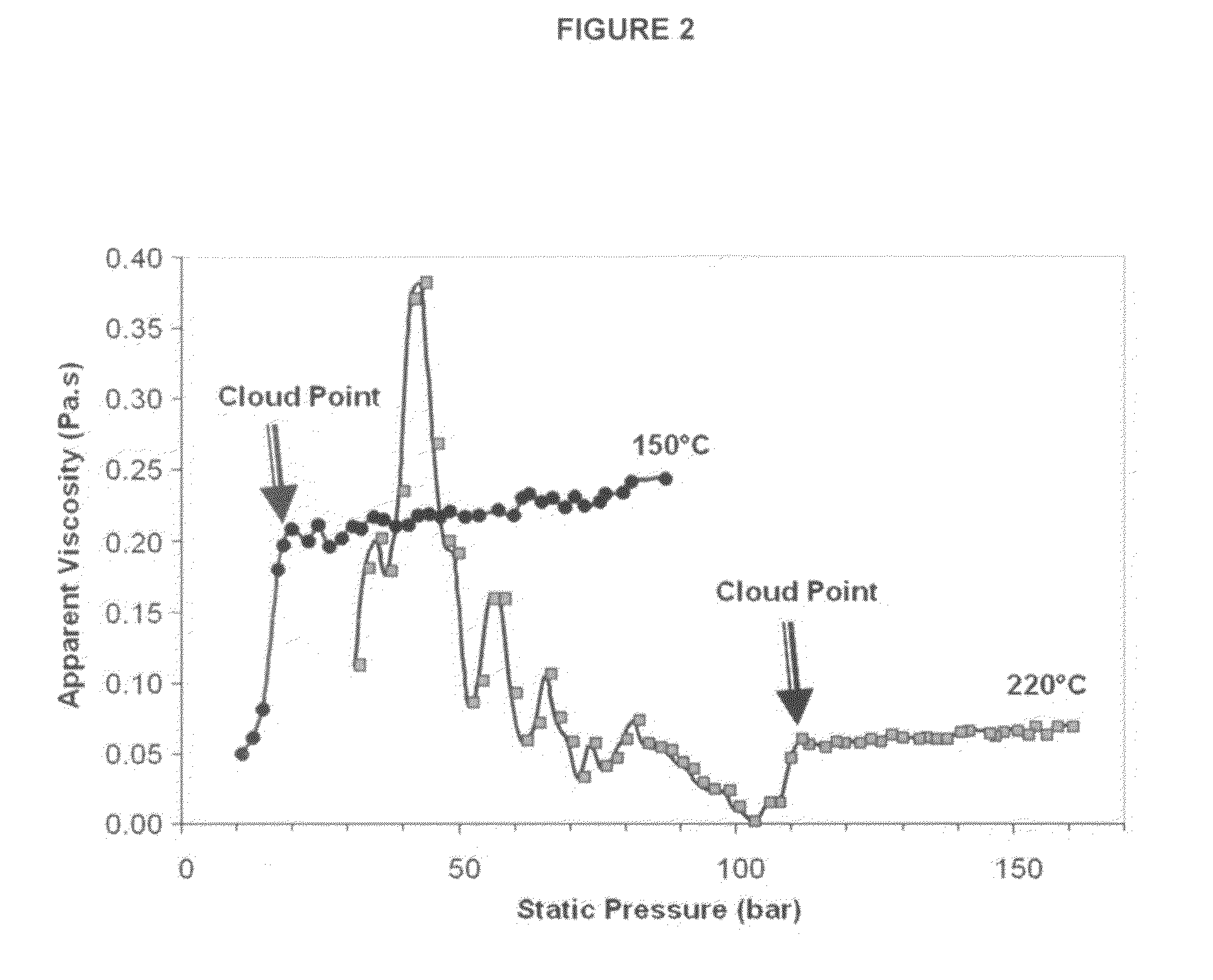

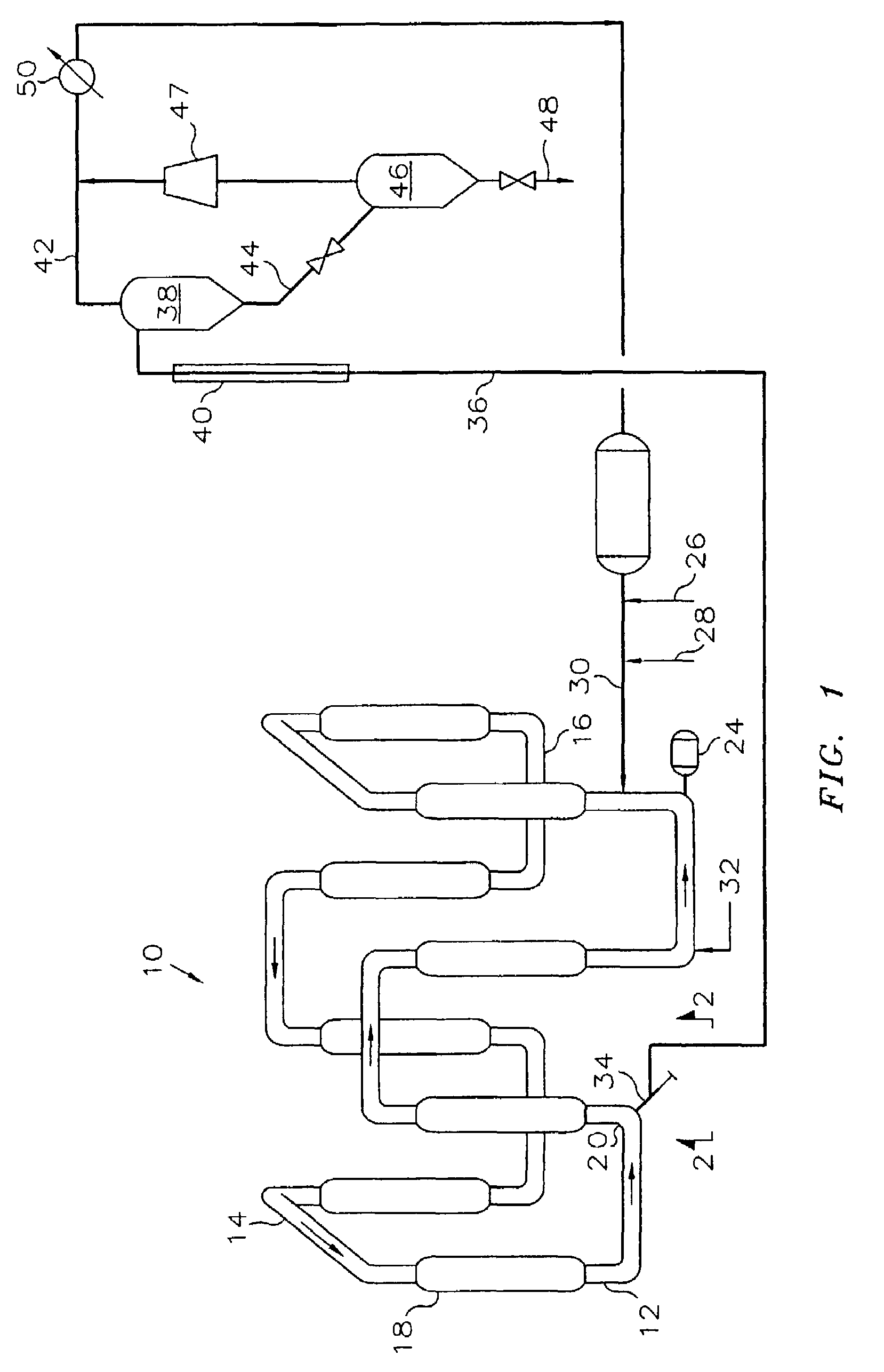

Process for fluid phase in-line blending of polymers

ActiveUS20080234443A1Maintain temperatureSpecial tyresChemical/physical/physico-chemical stationary reactorsScavengerSolvent

A process for fluid phase in-line blending of polymers. The process includes providing two or more reactor trains configured in parallel and a separator for product blending and product-feed separation; contacting in at least one of the parallel reactor trains olefin monomers having three or more carbon atoms, catalyst systems, optional comonomers, optional scavengers, and optional inert diluents or inert solvents, at a temperature above the solid-fluid phase transition temperature of the polymerization system and a pressure no lower than 10 MPa below the cloud point pressure of the polymerization system and less than 1500 MPa; forming a reactor effluent including a homogeneous fluid phase polymer-monomer mixture in each parallel reactor train; combining the reactor effluent from each parallel reactor; passing the combined reactor effluent through the separator; maintaining the temperature and pressure within the separator above the solid-fluid phase transition point but below the cloud point pressure and temperature to form a fluid-fluid two-phase system including a polymer-rich blend phase and a monomer-rich phase; and separating the monomer-rich phase from the polymer-rich blend phase. The separated monomer-rich phase is recycled to the polymerization reactor bank. The polymer-rich blend phase is conveyed to a downstream finishing stage for further monomer stripping, drying and / or pelletizing to form a polymer product blend.

Owner:EXXONMOBIL CHEM PAT INC

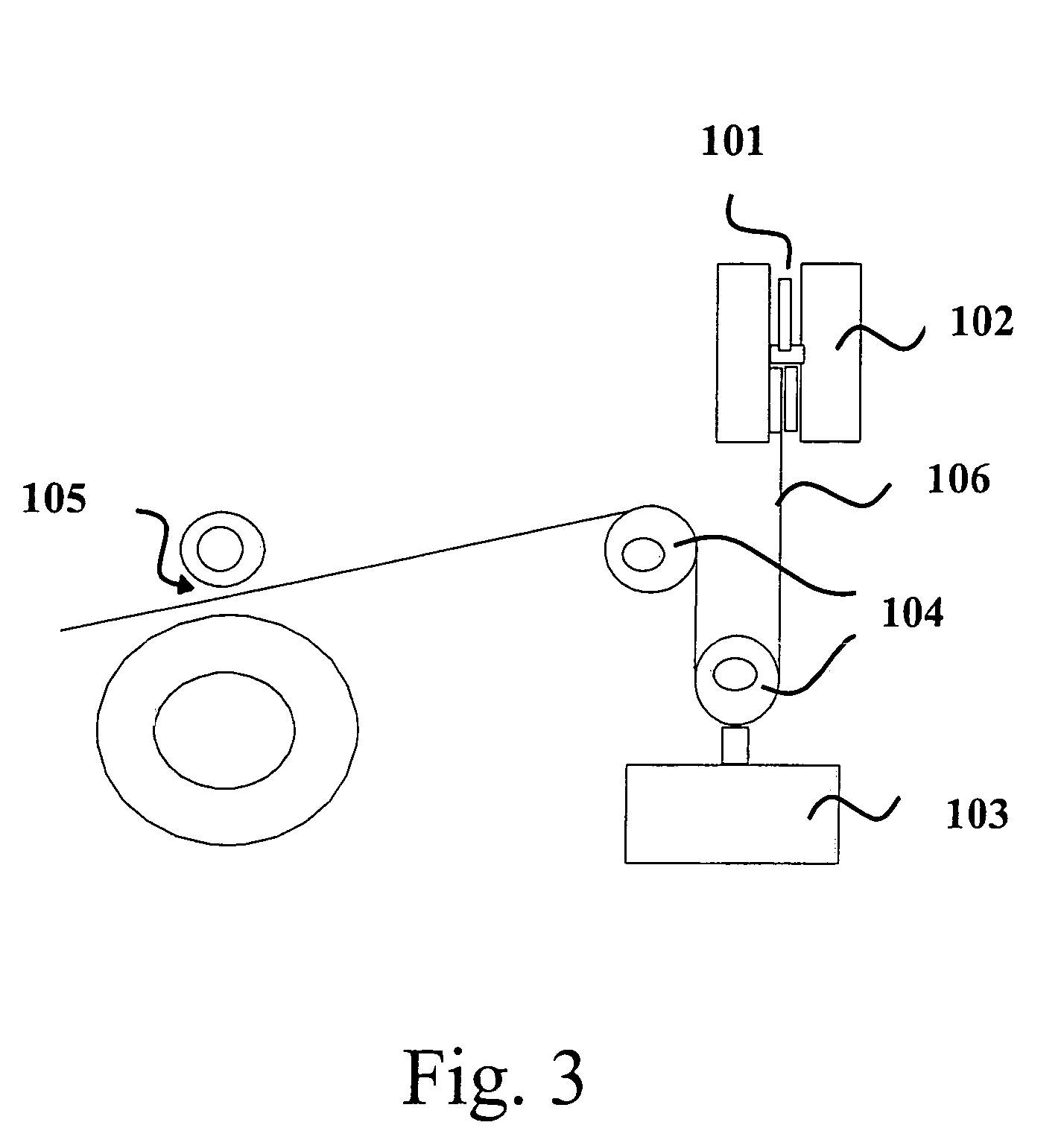

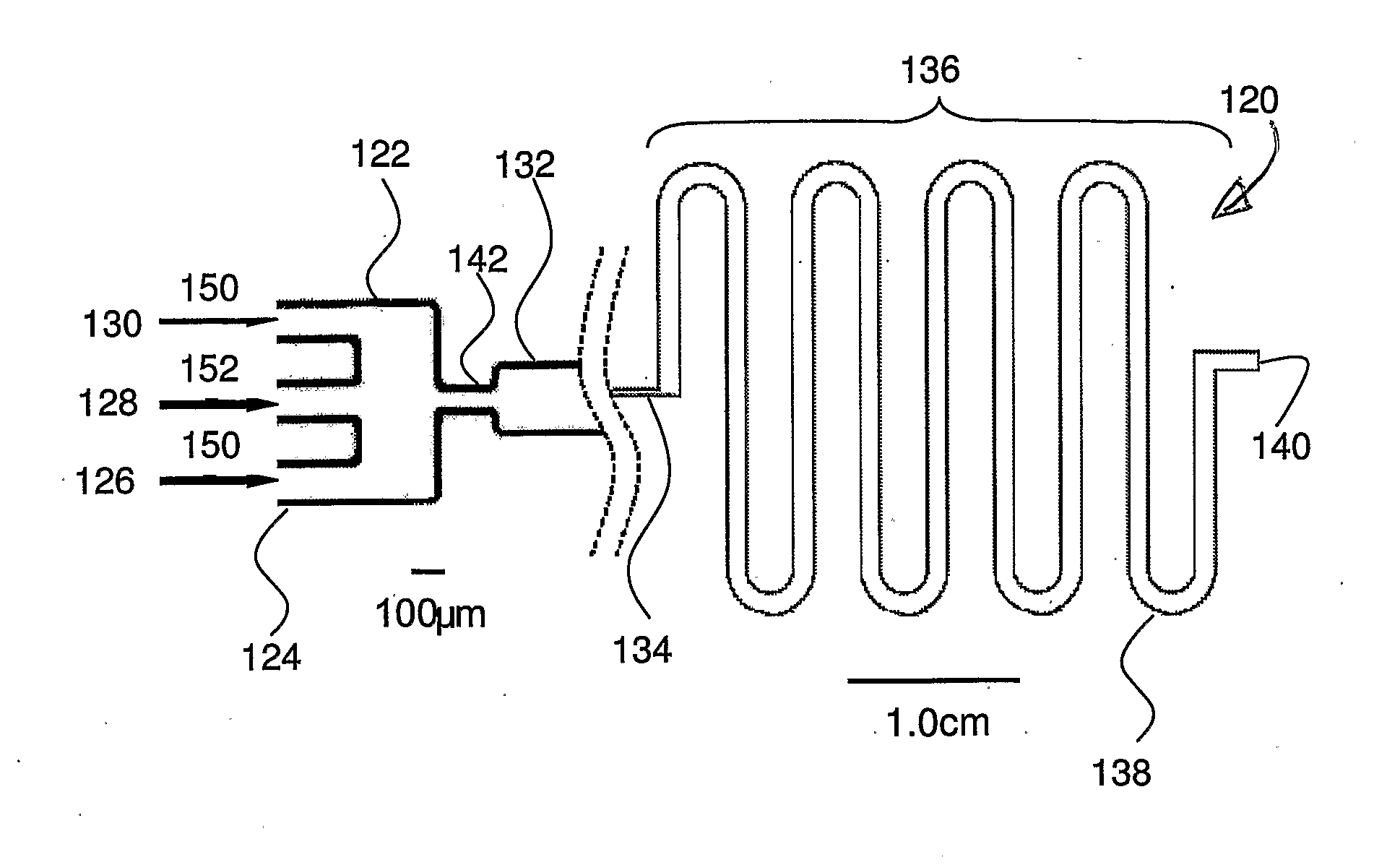

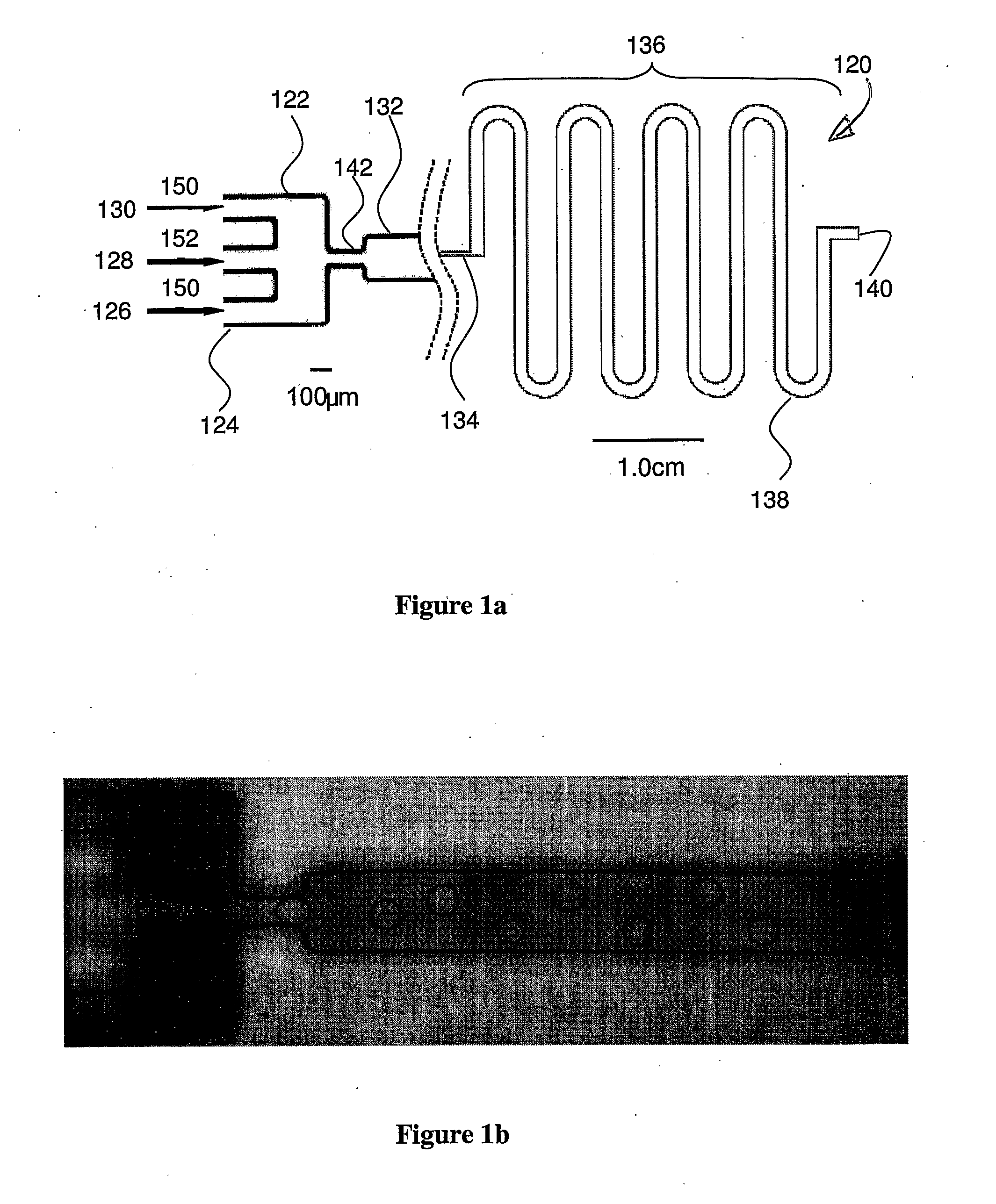

Method of Producing Polymeric Particles With Selected Size, Shape, Morphology and Composition

ActiveUS20110129941A1Long enough residence timeMaterial nanotechnologyFlow mixersControl flowChemical physics

The present invention provides a method and apparatus for producing polymeric particles with pre-designed size, shape, morphology and composition, and more particularly the present invention uses a microfluidic polymerization reactor for producing same. The present invention disclosed herein provides a process for producing polymer particles with pre-selected shapes. The method includes injecting a first fluid comprising a polymerizable constituent with a controlled flow rate into a microfluidic channel and injecting a second fluid with a controlled flow rate into the microfluidic channel in which the second fluid mixes with the first fluid, the second fluid being immiscible with the first fluid so that the first fluid forms into droplets in the microfluidic channel. The microfluidic channel has pre-selected dimensions to give droplets of pre-selected size, morphology and shape. The microfluidic channel is sufficiently long so that the droplets have a sufficiently long residence time in the channel so that they polymerize or otherwise harden into droplets of pre-selected size and shape.

Owner:KUMACHEVA EUGENIA +5

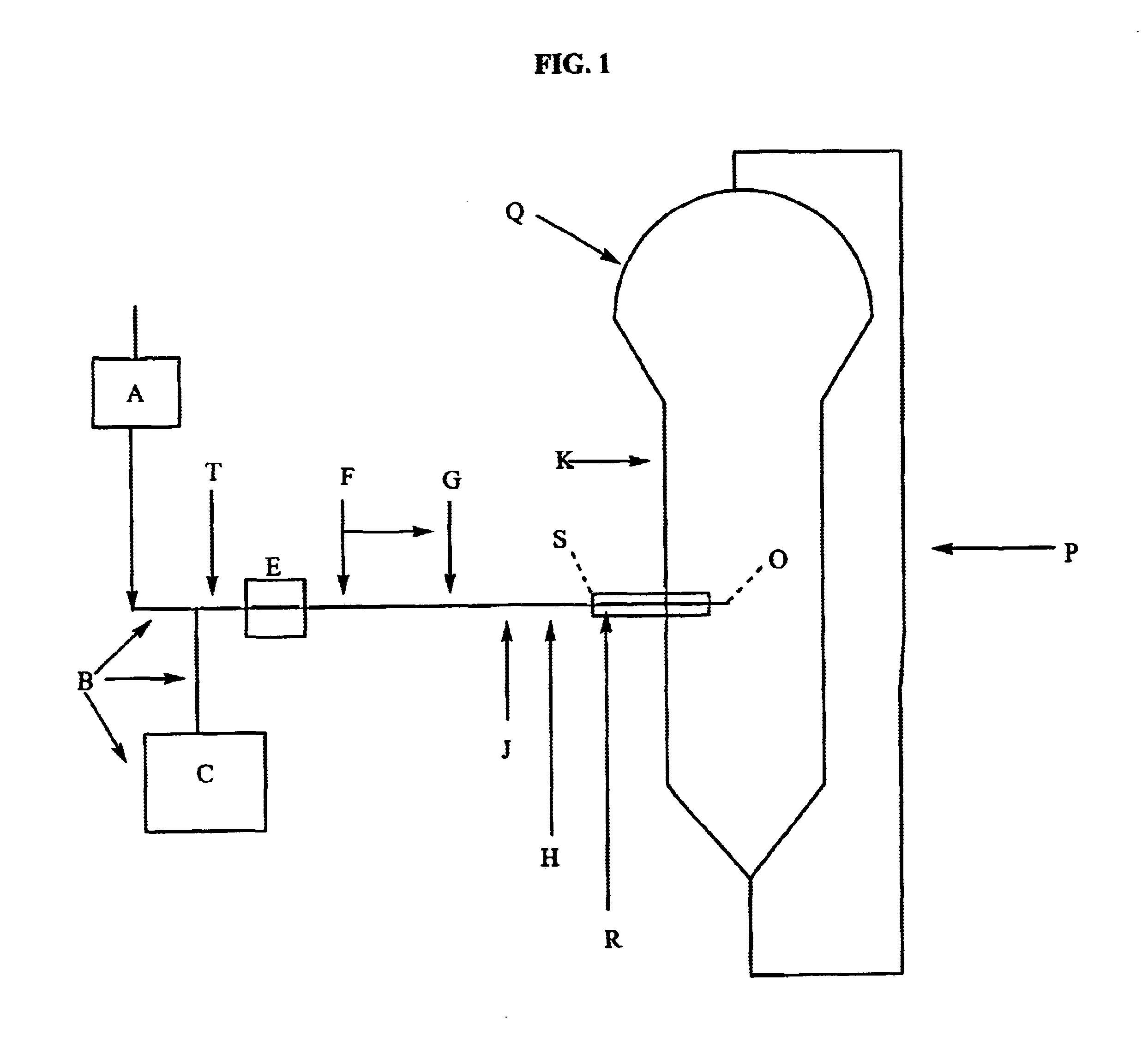

Polymerization process

InactiveUS6956089B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSlurryPolymerization catalysts

Owner:UNIVATION TECH LLC

Process for generating linear apha olefin comonomers

ActiveUS20070185360A1High selectivityHigh activityHydrocarbons from unsaturated hydrocarbon additionCatalystsDiluentAlpha-olefin

The present invention relates to an in-line method for generating comonomer, from monomer, such as ethylene. The comonomer generated is directly transported, without isolation or storage, to a polyethylene polymerization reactor. The in-line method includes the steps of providing an in-line comonomer synthesis reactor and a downstream gas / liquid phase separator prior to the polymerization reactor; feeding ethylene monomer and a catalyst in a solvent and / or diluent to the comonomer synthesis reactor; reacting the ethylene monomer and the catalyst in solvent and / or diluent under reaction conditions to produce an effluent stream including ethylene monomer and comonomer; passing the effluent stream from the comonomer synthesis reactor to the downstream gas / liquid phase separator to separate a gas stream from a bottom stream, wherein the gas stream is a mixture of ethylene monomer and comonomer; and passing the gas stream to the polymerization reactor to provide the necessary comonomer input,

Owner:EXXONMOBIL CHEM PAT INC

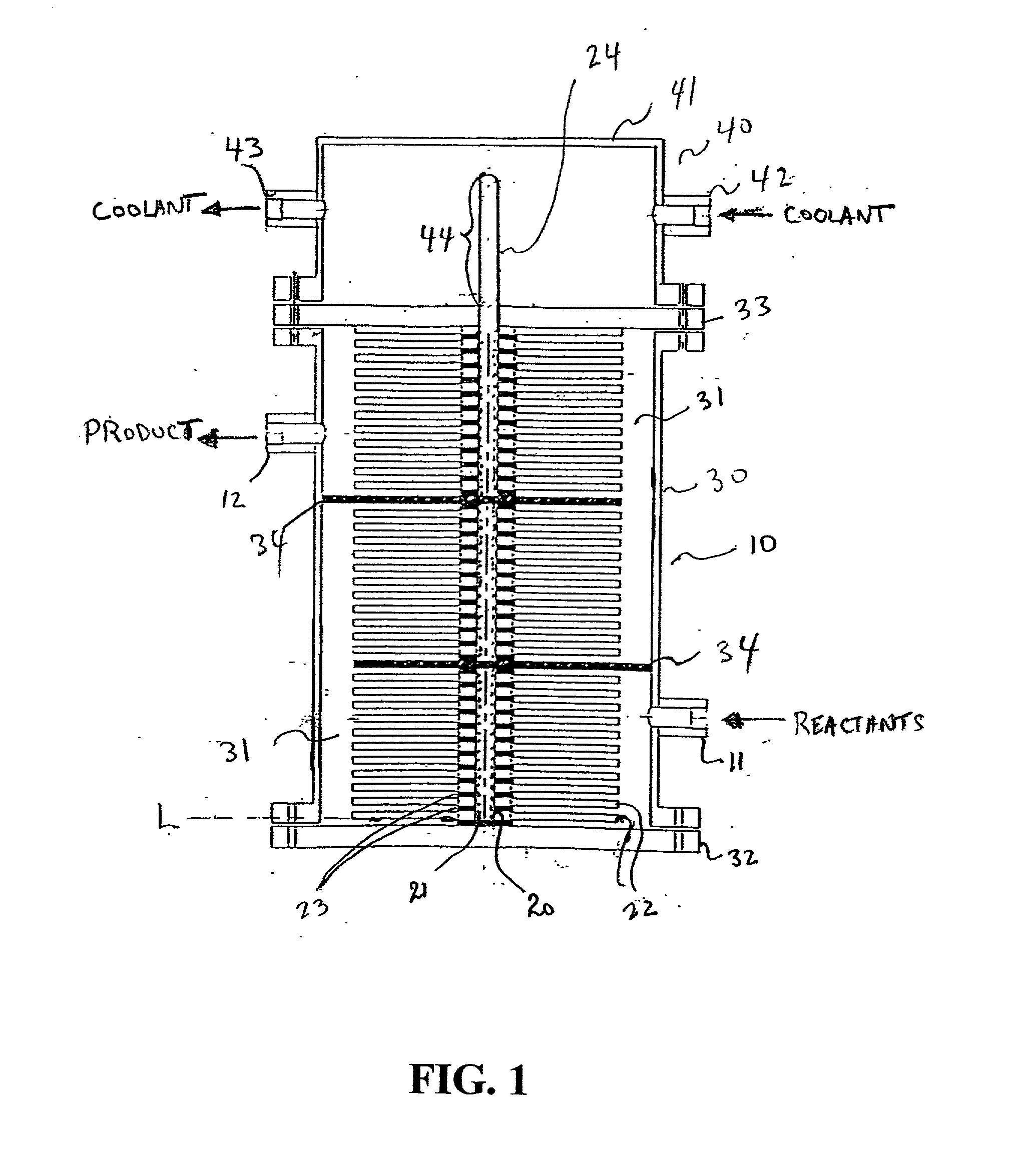

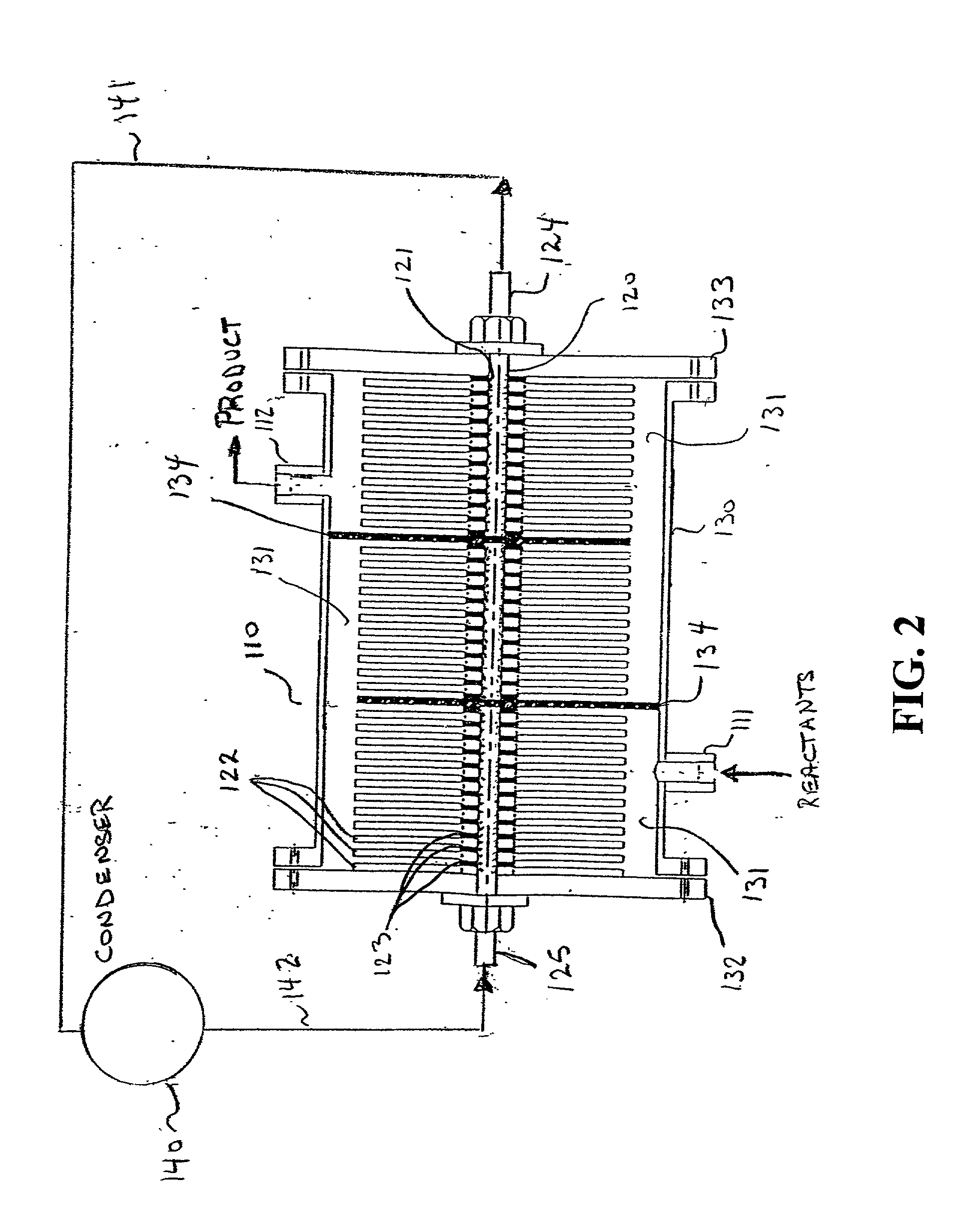

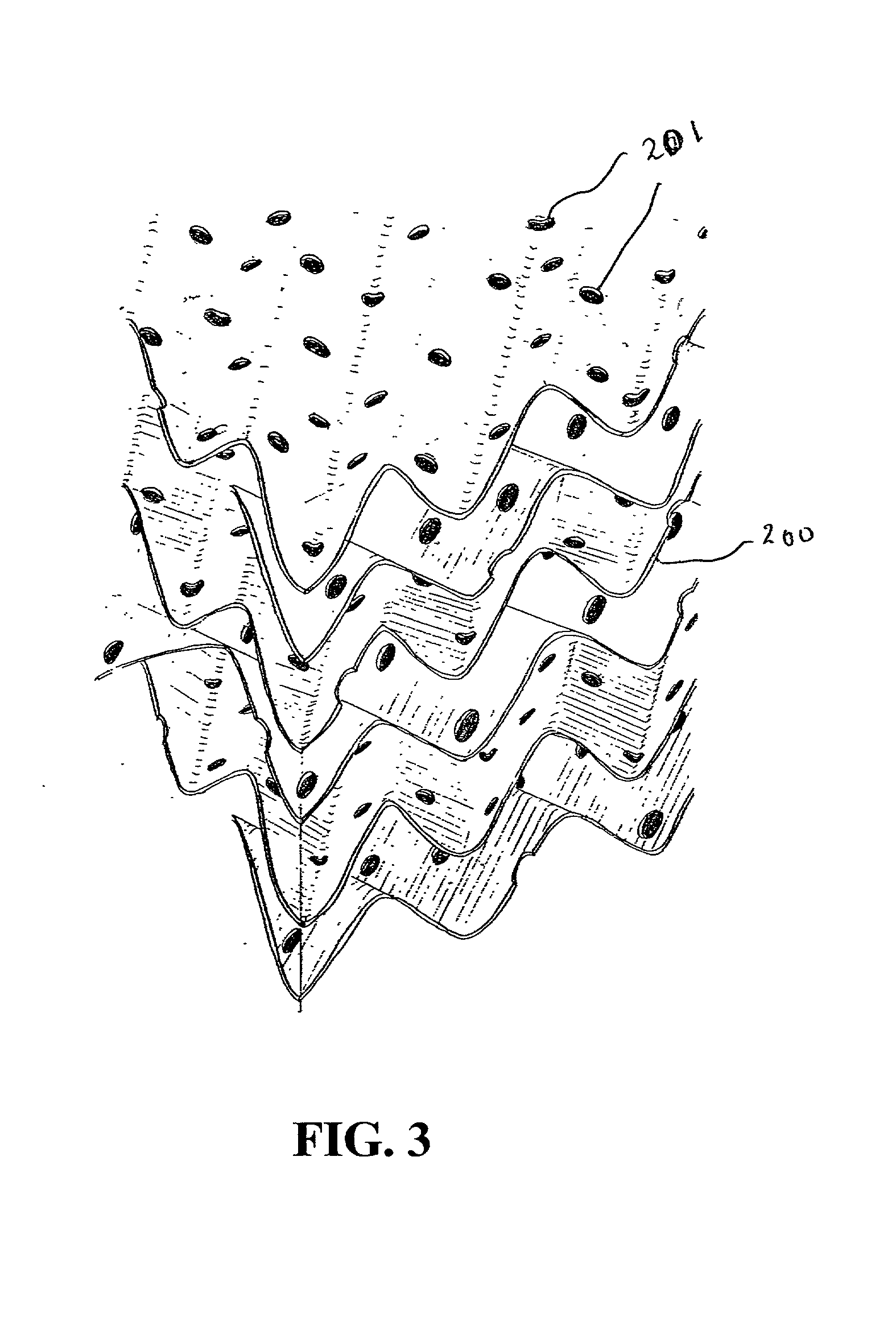

Stratified flow chemical reactor

InactiveUS20030133856A1Maximum effectivenessImprove thermal efficiencyFlow mixersTransportation and packagingReaction rateRates reactions

A polymerization reactor for exothermic liquid phase reactions comprises a reaction zone which is divided into a plurality of channels by thermally conductive heat transfer fins which are conductively mounted on one or more heat pipes for the removal of heat of reaction from reactants and reaction products flowing between the heat transfer fins. The reactor of the invention is capable of maintaining essentially isothermal conditions without the use of complicated and maintenance intensive agitators. The reactor is particularly useful when viscosity of the reactants and / or reaction products is high, when the reaction conducted has a fast reaction rate and when consistent polymer properties are desired.

Owner:SAUDI BASIC IND CORP SA

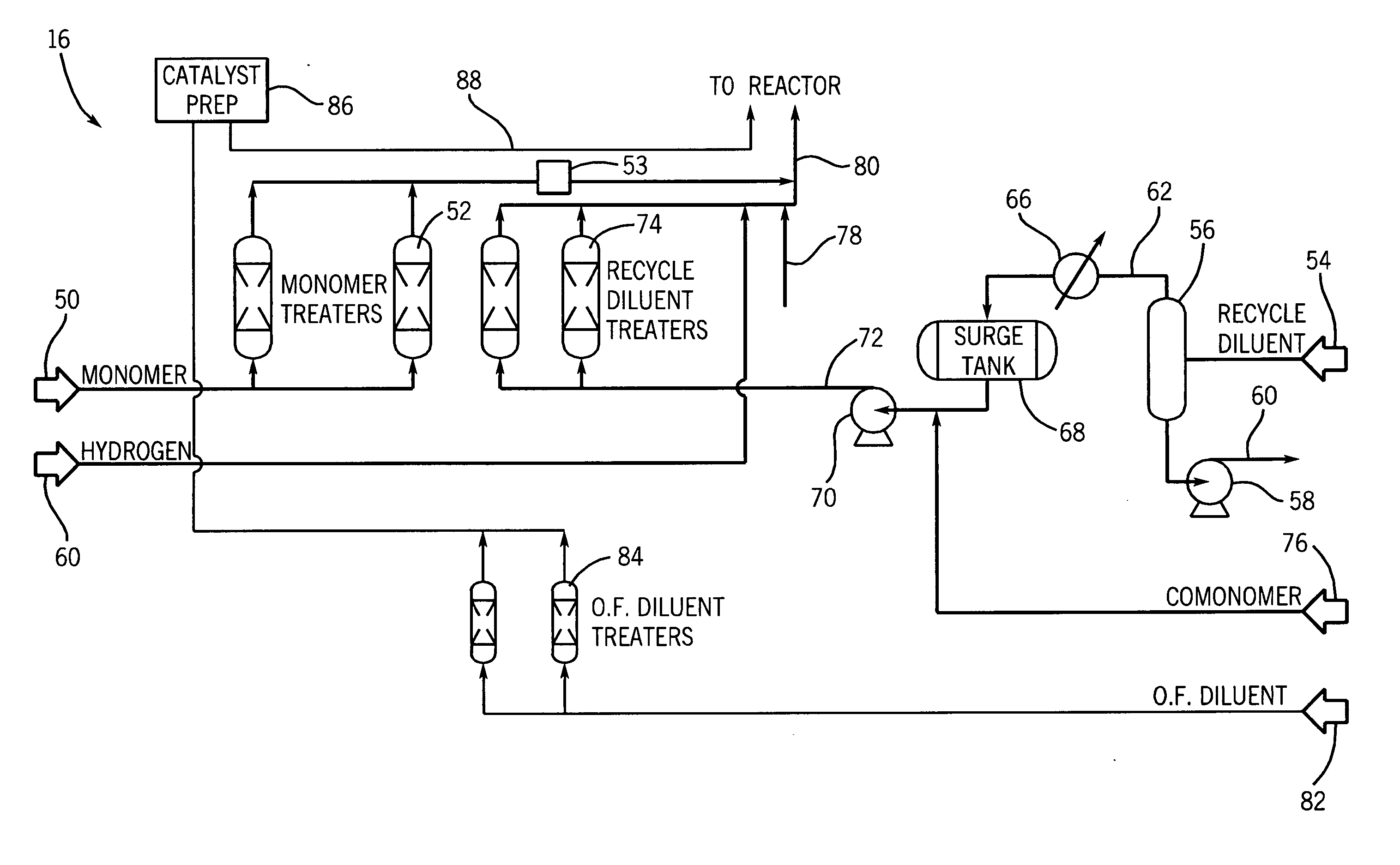

Energy efficient polyolefin process

A manufacturing process for producing polyolefin, having a feed system, a reactor system including at least one polymerization reactor, a diluent / monomer recovery system, a fractionation system, and an extrusion / loadout system having an extruder. The manufacturing process is configured to consume less than 325 kilowatt-hours of electricity per metric ton of polyolefin produced.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

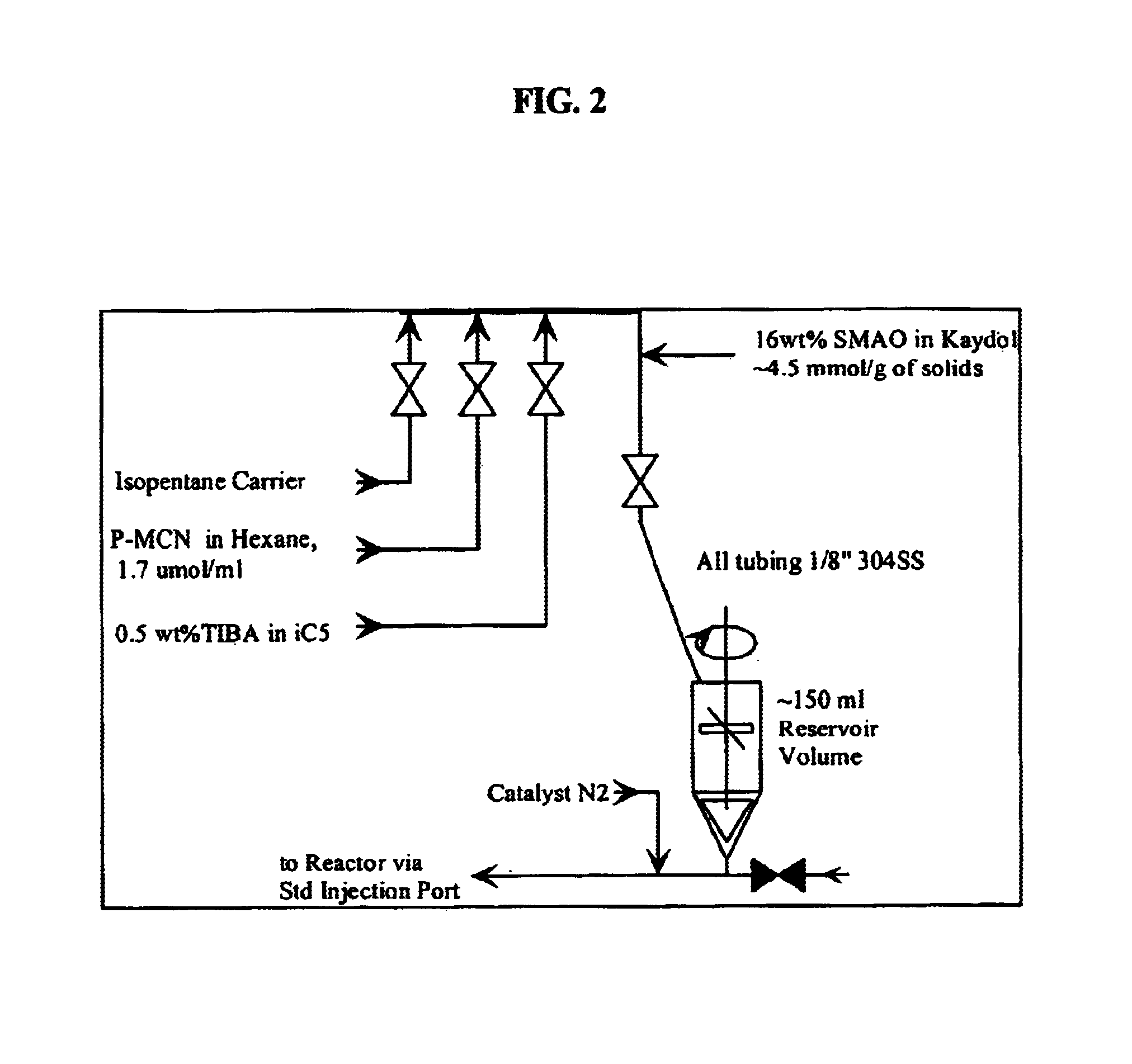

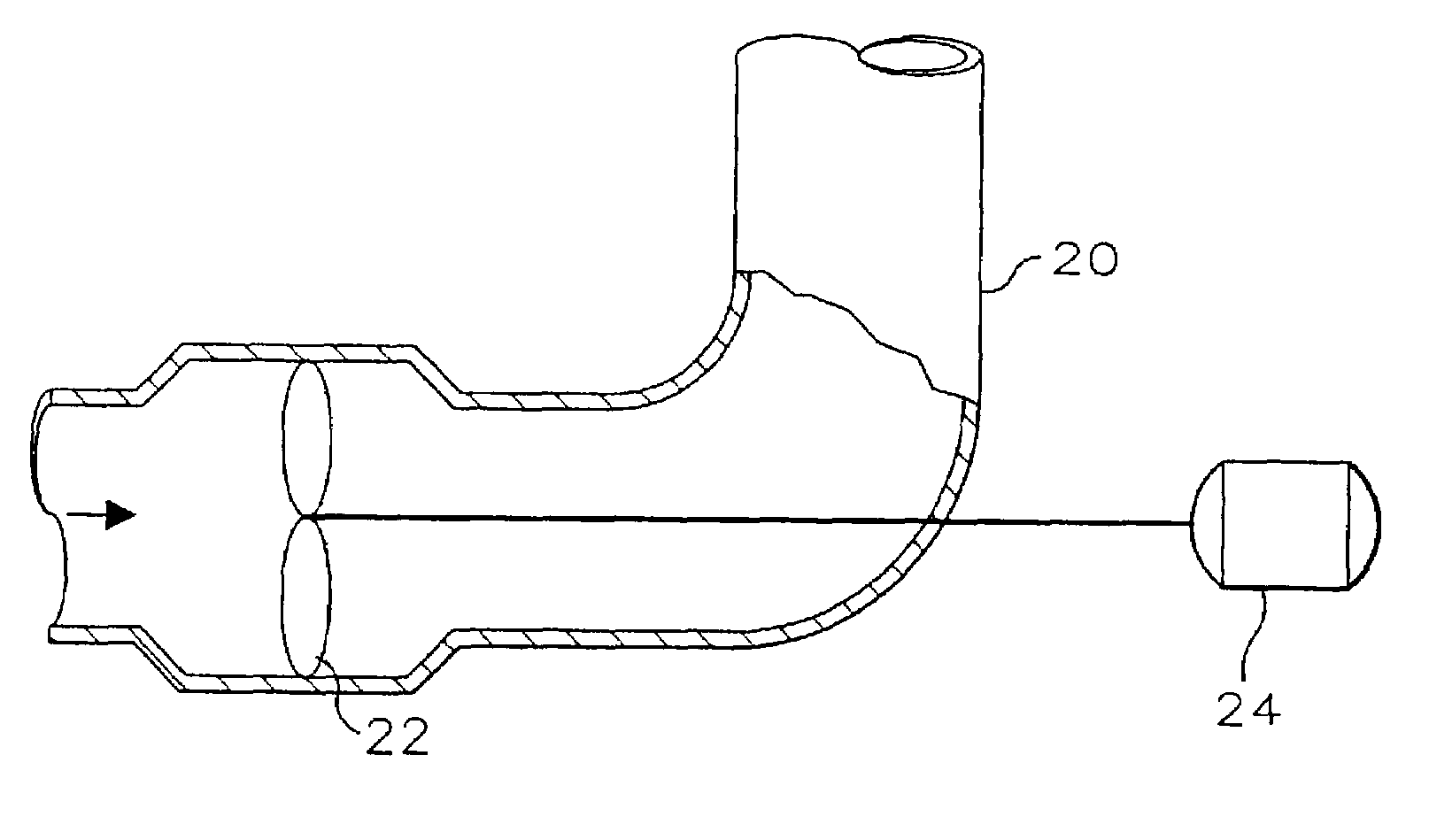

Catalyst slurry feeding assembly for a polymerization reactor

ActiveUS6908971B2Increase heightAvoid necessityChemical/physical/physico-chemical stationary reactorsFlow controlLiquid ratioSlurry

A catalyst slurry for a polymerization reactor can be prepared in a mixing tank and the catalyst slurry fed to one or more storage tanks. The storage tanks can include agitators so that the catalyst slurry is maintained at an essentially homogeneous solids-to-liquid ratio. From the storage tank(s), the catalyst slurry can be pumped to the polymerization reactor along a fluid passage having a flow meter. The flow of the catalyst slurry can be continuous and / or adjusted based on a measured parameter. The catalyst slurry may be continuously and reliability fed to the polymerization reactor.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Performance of artificial neural network models in the presence of instrumental noise and measurement errors

InactiveUS7313550B2Improve accuracyImprove performanceGenetic modelsDigital computer detailsObservational errorData set

A method is described for improving the prediction accuracy and generalization performance of artificial neural network models in presence of input-output example data containing instrumental noise and / or measurement errors, the presence of noise and / or errors in the input-output example data used for training the network models create difficulties in learning accurately the nonlinear relationships existing between the inputs and the outputs, to effectively learn the noisy relationships, the methodology envisages creation of a large-sized noise-superimposed sample input-output dataset using computer simulations, here, a specific amount of Gaussian noise is added to each input / output variable in the example set and the enlarged sample data set created thereby is used as the training set for constructing the artificial neural network model, the amount of noise to be added is specific to an input / output variable and its optimal value is determined using a stochastic search and optimization technique, namely, genetic algorithms, the network trained on the noise-superimposed enlarged training set shows significant improvements in its prediction accuracy and generalization performance, the invented methodology is illustrated by its successful application to the example data comprising instrumental errors and / or measurement noise from an industrial polymerization reactor and a continuous stirred tank reactor (CSTR).

Owner:COUNCIL OF SCI & IND RES

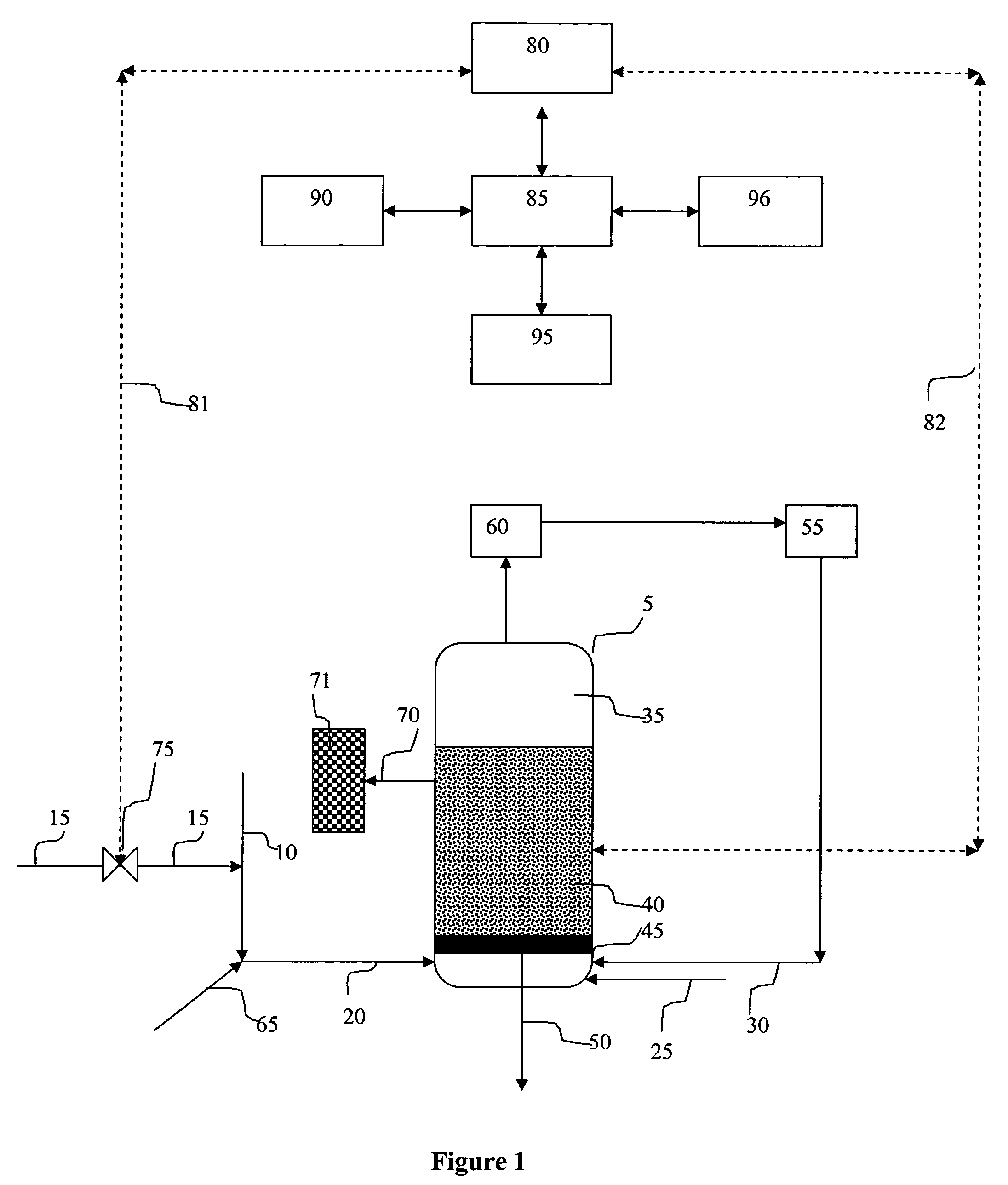

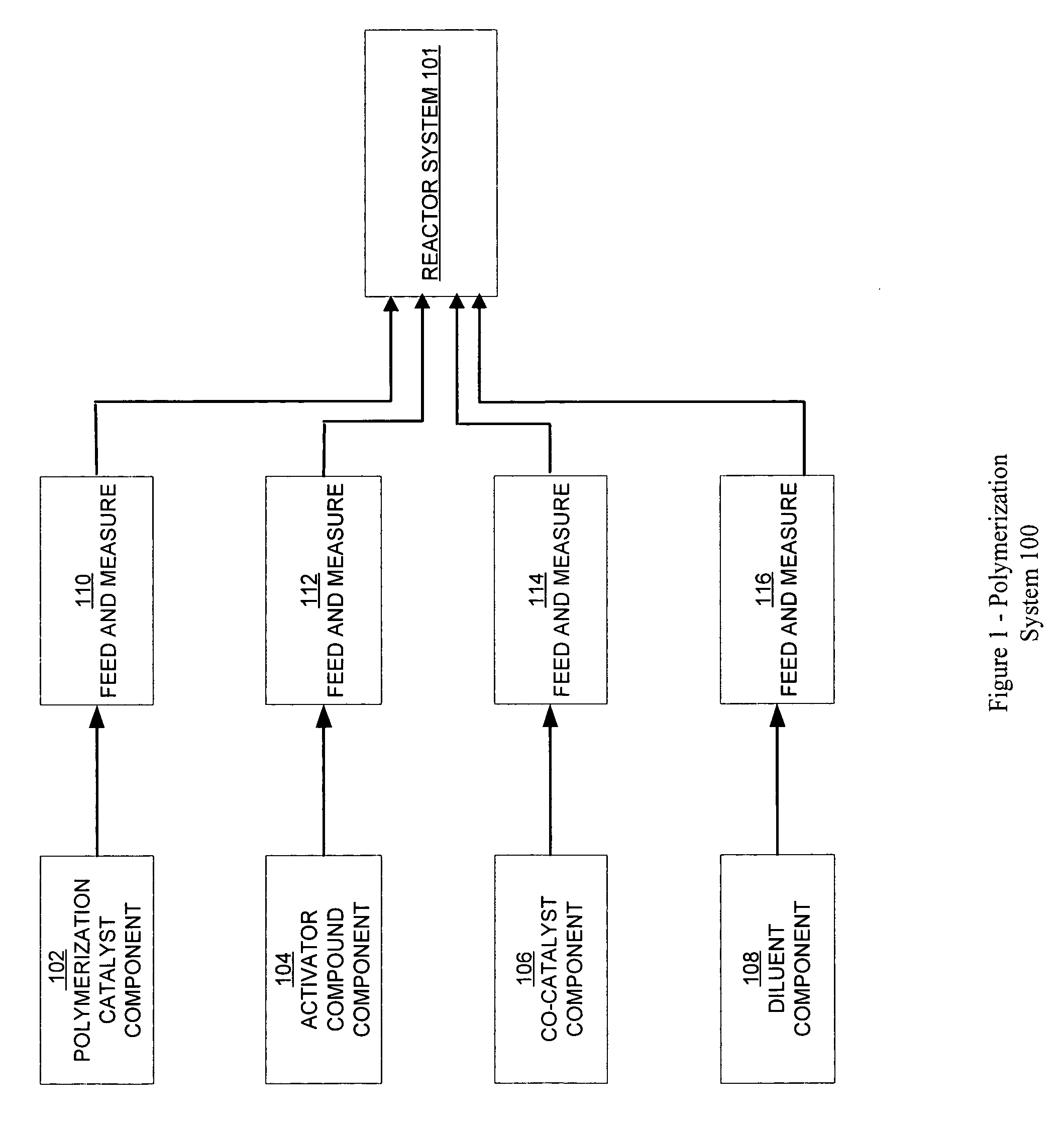

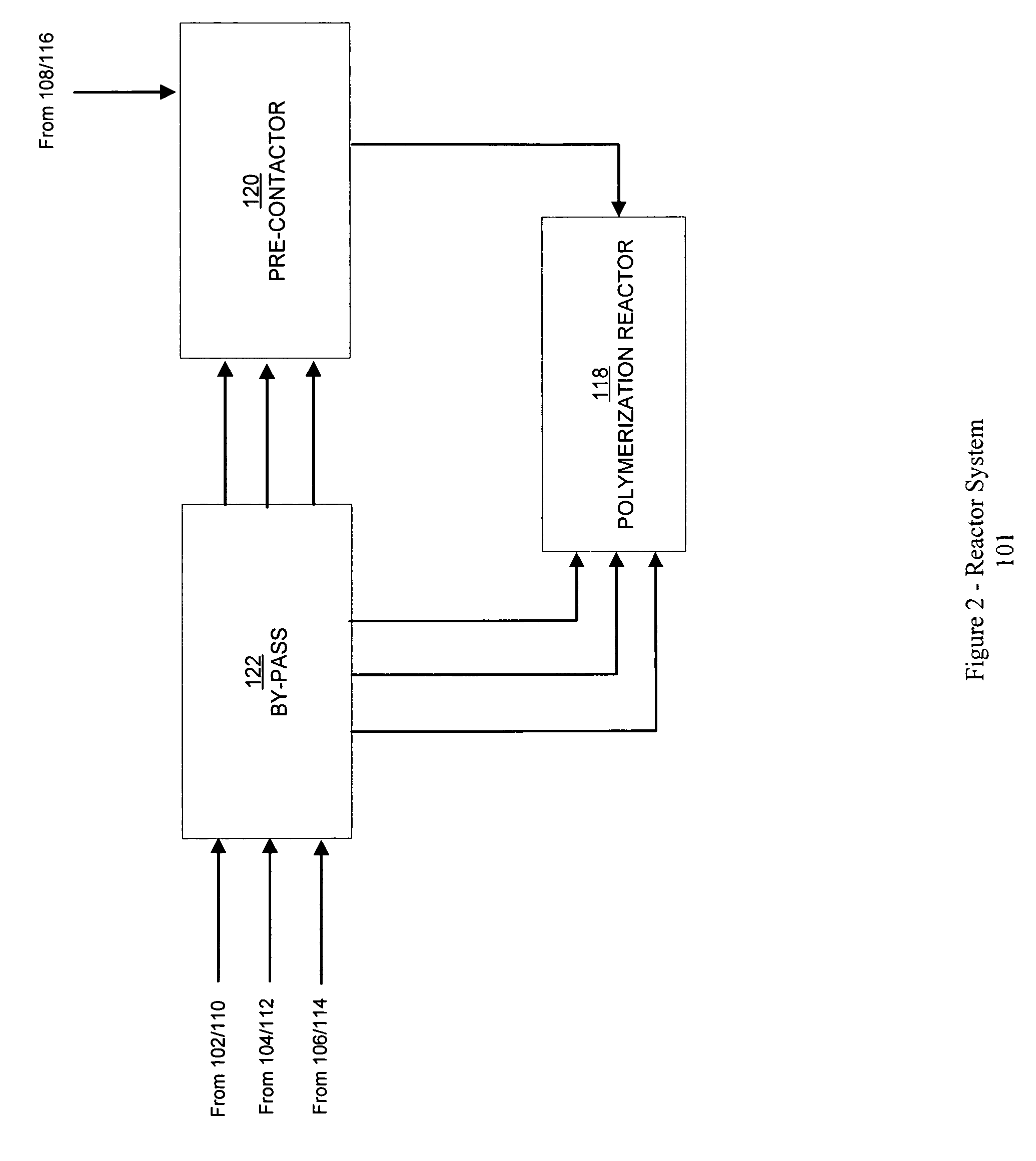

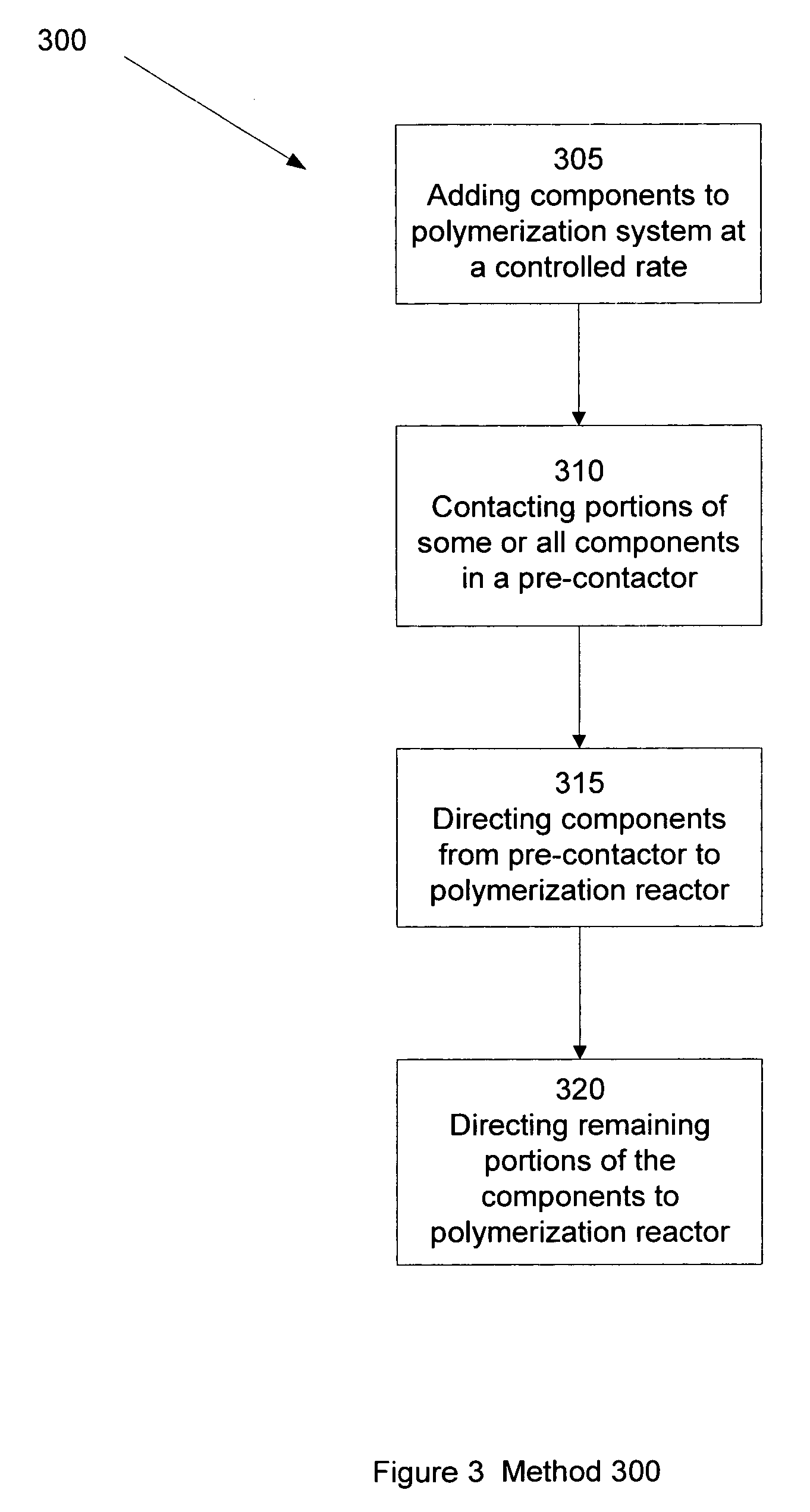

Multiple component feed methods and systems

Multiple components are selected, conveyed, and measured in a polymerization system. A control system adjusts the system variables to the desired values. Portions of the components can be fed to a pre-contactor before introduction into the polymerization reactor. The catalyst component concentrations and residence times are tightly controlled in the pre-contactor to affect product properties. The pre-contactor can be a single or multiple combinations of a CSTR or plug flow pre-contactors.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

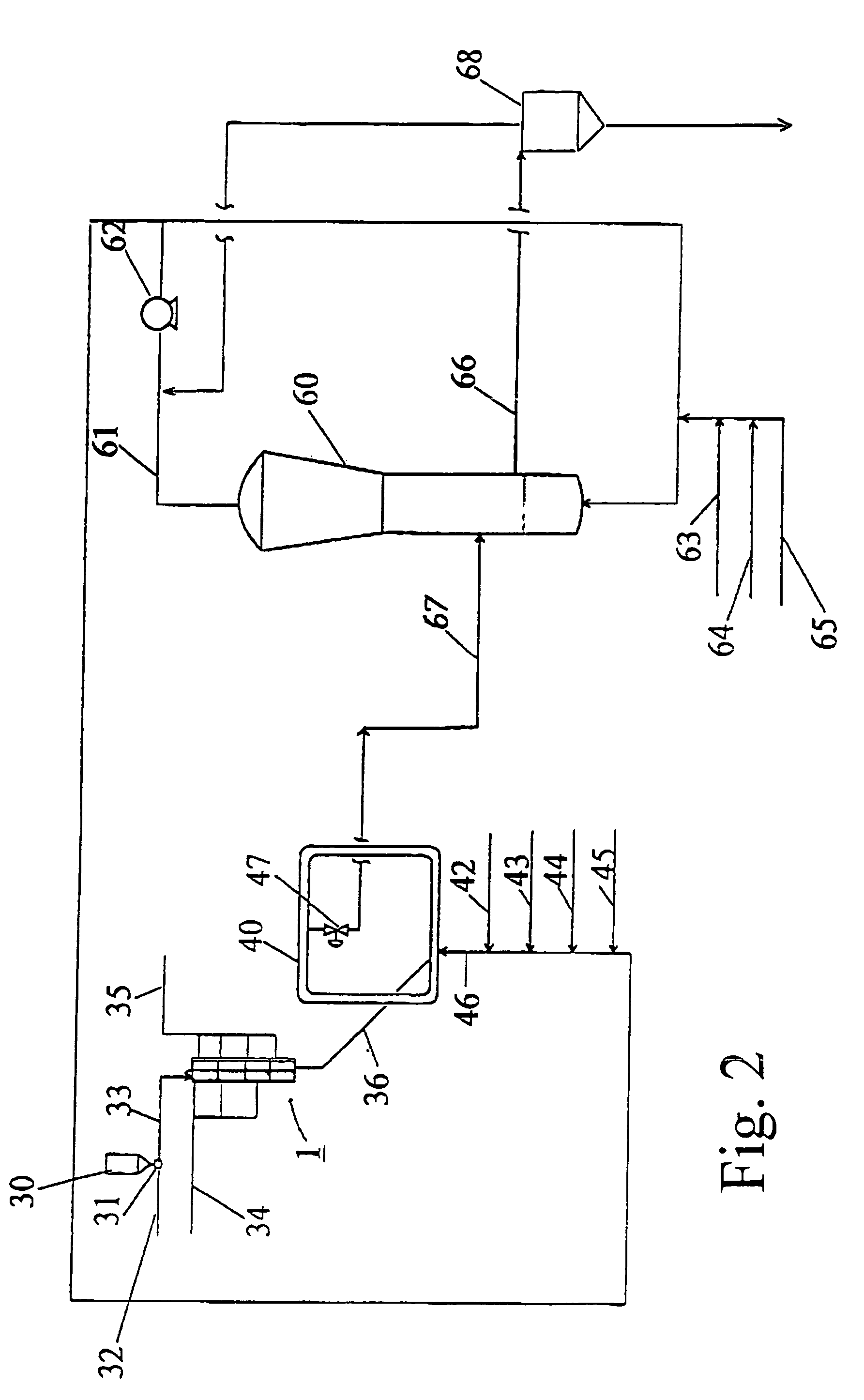

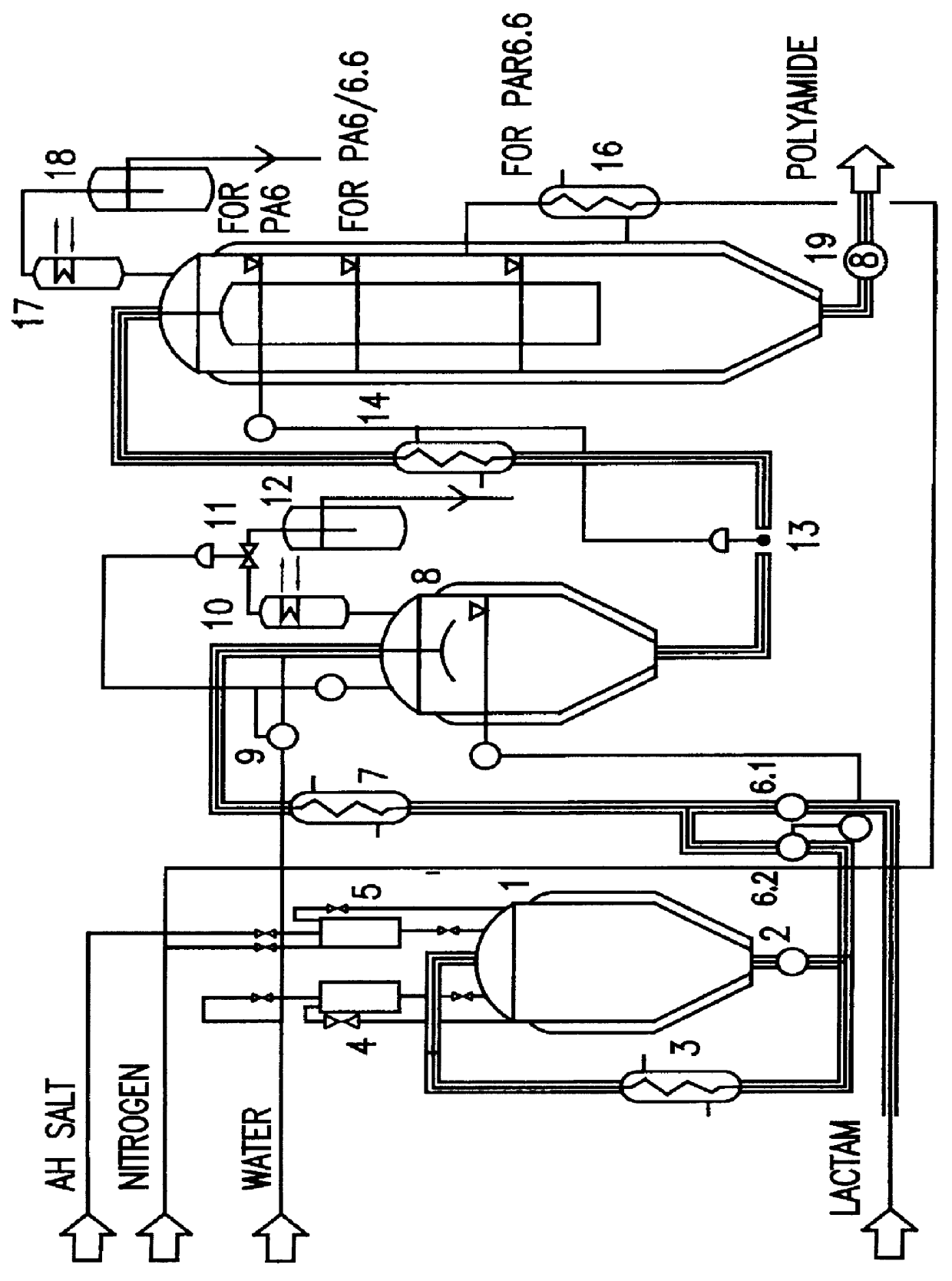

Process and device for the standardized continuous production of polyamides

InactiveUS6136947AHigh viscosityOvercome disadvantagesChemical recyclingHexamethyldiamineHexamethylenediamine

PCT No. PCT / EP96 / 05514 Sec. 371 Date Nov. 13, 1998 Sec. 102(e) Date Nov. 13, 1998 PCT Filed Dec. 10, 1996 PCT Pub. No. WO90 / 21758 PCT Pub. Date Jun. 19, 1997A process and device for the standardised continuous production of polyamide 6, polyamide 6.6 and / or copolyamides from e-caprolactam and / or adipic acidic hexamethylenediamine or adipic acid and hexamethylenediamine uses a combination of known specific processes to design a polymerisation reactor in which product with sufficiently high quality can be produced with the most efficient possible use of the energy applied and in such a way that the initial substances can be used alternately in the individual processing stages: pre-heating of the initial products using a common heat exchanger to 190-300 DEG C.; polymerisation of the initial products in a pressure stage with or without elimination of water and product recycling at 150-280 DEG C. and a pressure of <20 bar, dewatering of the polymer melt in a one to five turn coil under slow pressure reduction; and final condensation of the melt in at least one common vertical reactor at temperatures of between 210 and 285 DEG C.

Owner:POLYMER ENG

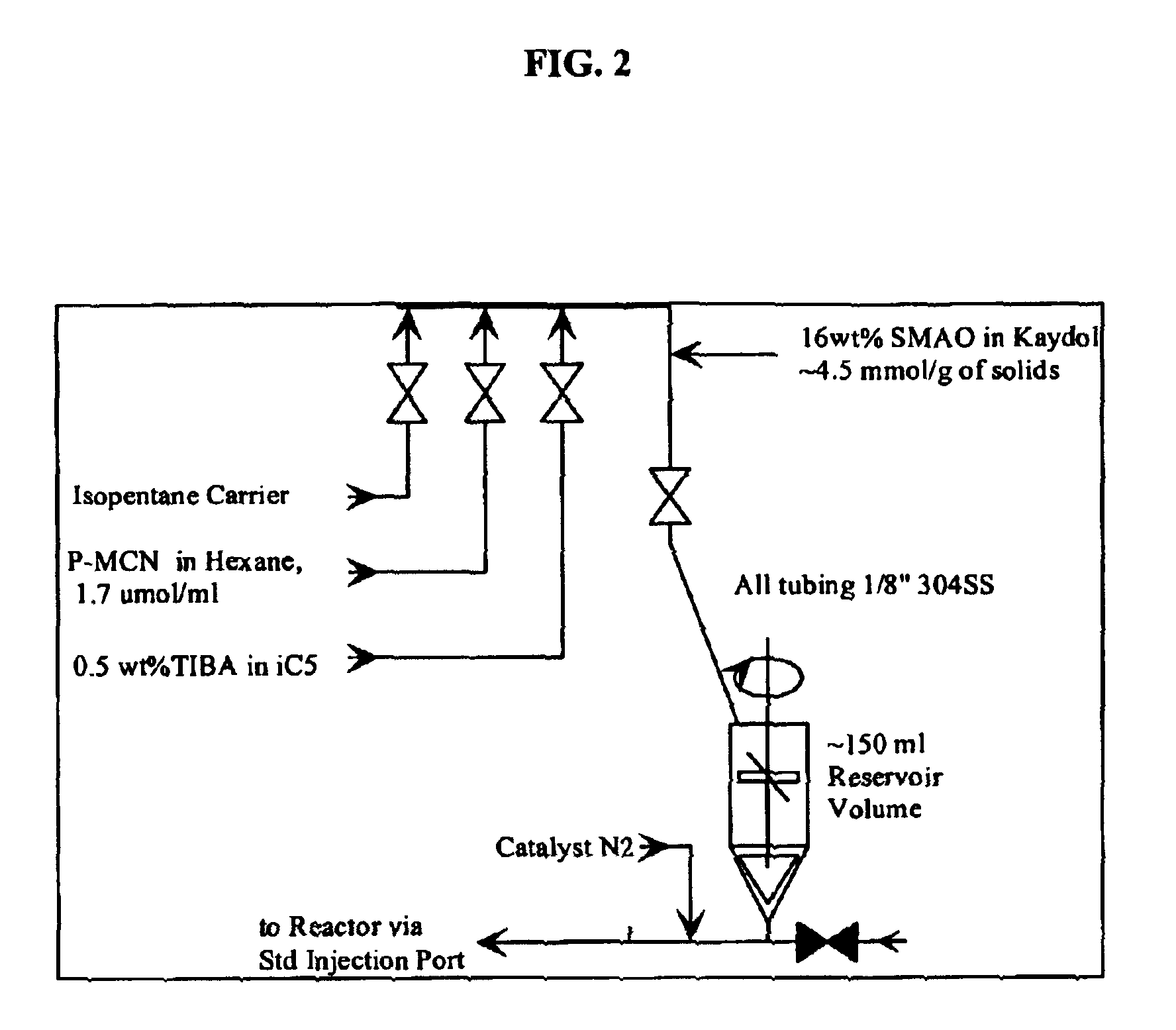

Polymerization process

InactiveUS6846886B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSlurryPolymerization catalysts

The invention provides for polymerization catalyst compositions, and for methods for introducing the catalyst compositions into a polymerization reactor. More particularly, the method combines a catalyst component containing slurry and a catalyst component containing solution to form the completed catalyst composition for introduction into the polymerization reactor. The invention is also directed to methods of preparing the catalyst component slurry, the catalyst component solution and the catalyst compositions, to methods of controlling the properties of polymer products utilizing the catalyst compositions, and to polymers produced therefrom.

Owner:UNIVATION TECH LLC

Slurry polymerization reactor having large length/diameter ratio

InactiveUS7033545B2Synthetic resin layered productsChemical/physical/physico-chemical stationary reactorsDiluentDiameter ratio

A polymerization loop reactor including a loop reaction zone, a continuous takeoff, and a fluid slurry disposed in the reaction zone. A generally cylindrical wall defines the loop reaction zone. The length of the loop reaction zone and the nominal outside diameter of the generally cylindrical wall define a length / diameter ratio greater than 250. The reactor can be charged with a fluid slurry including an olefin monomer reactant, solid olefin polymer particles, and a liquid diluent. The concentration of the solid olefin polymer particles in the slurry can be greater than 40 weight percent based on the weight of polymer particles and the weight of liquid diluent. Also disclosed is a polymerization process carried out by polymerizing, in the loop reaction zone of a reactor as defined above, at least one olefin monomer in a liquid diluent to produce a fluid slurry as defined above.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Method for deactivating and recovering boron trifluoride when producing polyisobutenes

InactiveUS6939943B2Speed up the processCatalyst regeneration/reactivationAlcoholCationic polymerization

The invention relates to a method for deactivating and recovering boron trifluoride when producing polyisobutenes by means of cationic polymerization of isobutene or hydrocarbon streams containing isobutene in the liquid phase in the presence of boron trifluoride or in the form of a boron trifluoride catalyst complex. The catalyst complex is separated, essentially in the liquid phase, from the reactor discharge. The method comprises the following steps: a) removing from the polymerization reactor at −60 to 020 C., methanol, ethanol or a mixture of methanol and ethanol in such a quantity that an alcohol phase rich in boron trifluoride is formed; b) separating the alcohol phase according to (a) and, (c) optionally recycling the boron trifluoride of the alcohol phase obtained from (b) to the method in a suitable manner.

Owner:BASF AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com