Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

162results about How to "Improve sag resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High melt strength polypropylene

InactiveUS7365136B2Improve melt strengthHigh viscosityChemical/physical/physico-chemical stationary reactorsPolymer sciencePtru catalyst

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / 10 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

High melt strength polypropylene

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / l0 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

Bi-component polyurethane coating and preparation method thereof

ActiveCN102757722AGuaranteed viscosityGuaranteed mechanical propertiesPolyurea/polyurethane coatingsPlasticizerShock resistance

The invention relates to a bi-component polyurethane coating which is prepared from a component A and a component B in a weight ratio of 1:(1-3), wherein the component A comprises the following materials in parts by weight: 40-80 parts of polylol, 20-50 parts of polyisocyanates, 1-10 parts of plasticizer and 0-5 parts of storage stabilizing agent; and the component B comprises the following materials in parts by weight: 10-40 parts of polylol, 10-40 parts of liquid filler, 5-10 parts of crosslinking agent, 30-60 parts of solid filler, 3-15 parts of plasticizer, 0.1-8 parts of thixotropic agent, 0-5 parts of pigment and 0.2-5 parts of additive. The bi-component polyurethane coating is suitable for water prevention, permeability resistance, corrosion resistance and protection of a horizontal plane, can be thickly coated and constructed (>3mm / turn) on complex parts such as a vertical surface and an incline, does not generate sagging and bubble phenomena in a construction process, is full in color, and has the advantages of excellent mechanical property, shock resistance, water resistance and corrosion resistance.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

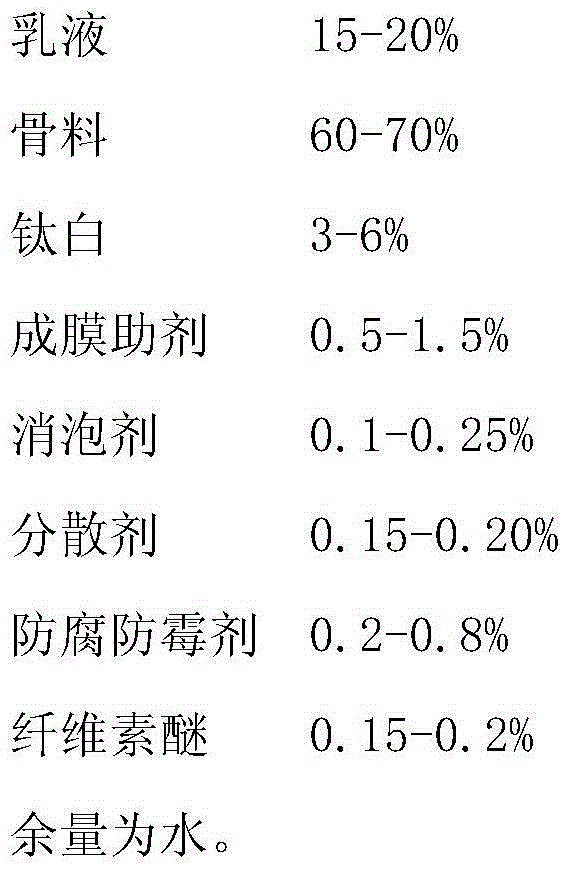

Exterior wall color surface decoration mortar and preparation method thereof

The invention relates to a building material, and in particular relates to an exterior wall color surface decoration mortar and a preparation method thereof. The exterior wall color surface decoration mortar comprises the following raw materials by weight: 20%-30% of white cement, 50%-60% of quartz sand, 0.1%-0.5% of chopped fiber, 10%-20% of heavy calcium carbonate, 0.2%-1% of latex powder, 0.3%-0.5% of cellulose ether, 1%-5% of an inorganic pigment, 0.2%-0.4% of a water repellent, 5%-10% of coal powder ash, 0.1%-0.15% of a defoaming agent, 1%-3% of metakaolin, 0.2%-0.5% of a thixotropic lubricant and 1%-2% of a water reducing agent. The exterior wall color surface decoration mortar has the advantages of crack resistance, weather resistance, good ultraviolet resistance, permanent and uniform color, good whiskering resistance, and the like, can be well combined with various inorganic base layer materials, is good in coating density, and can be widely used in the building fields such as exterior wall decoration and the like.

Owner:KUNSHAN JIANGUO CONCRETE PROD CO LTD

Machine-spraying-type plastering gypsum mortar and preparation technology thereof

ActiveCN104961423ASolve the problems that cannot meet the needs of mechanized constructionReduce dosageBond strengthMaterials science

The invention relates to machine-spraying-type plastering gypsum and a preparation technology thereof and belongs to the technical field of building materials. The machine-spraying-type plastering gypsum is characterized by being prepared from the following raw materials: 200-400 parts of gypsum, 10-60 parts of cement, 520-650 parts of fine aggregate, 80-160 parts of heavy calcium powder, 2-4 parts of redispersible emulsion powder, 2-4 parts of hydroxypropyl methyl cellulose ether, 0.15-0.25 part of an air entraining agent, 5-10 parts of expanded perlite, 0.3-0.8 part of a gypsum retarder and 200-300 parts of water. The machine-spraying-type plastering gypsum is applicable to being directly sprayed to a wall surface by adopting a mortar spraying machine, both time and labour are saved, construction efficiency can be improved, and cost is reduced; bonding performance with the wall surface is good, rebounce is not caused, anti-sagging performance is good, both bonding strength and compressive strength can meet requirements, and cracking of a wall body can be reduced; and usage amount of gypsum is low, and cost can be effectively reduced.

Owner:新疆荣高鸿骏新材料技术有限公司

High melt strength polypropylene

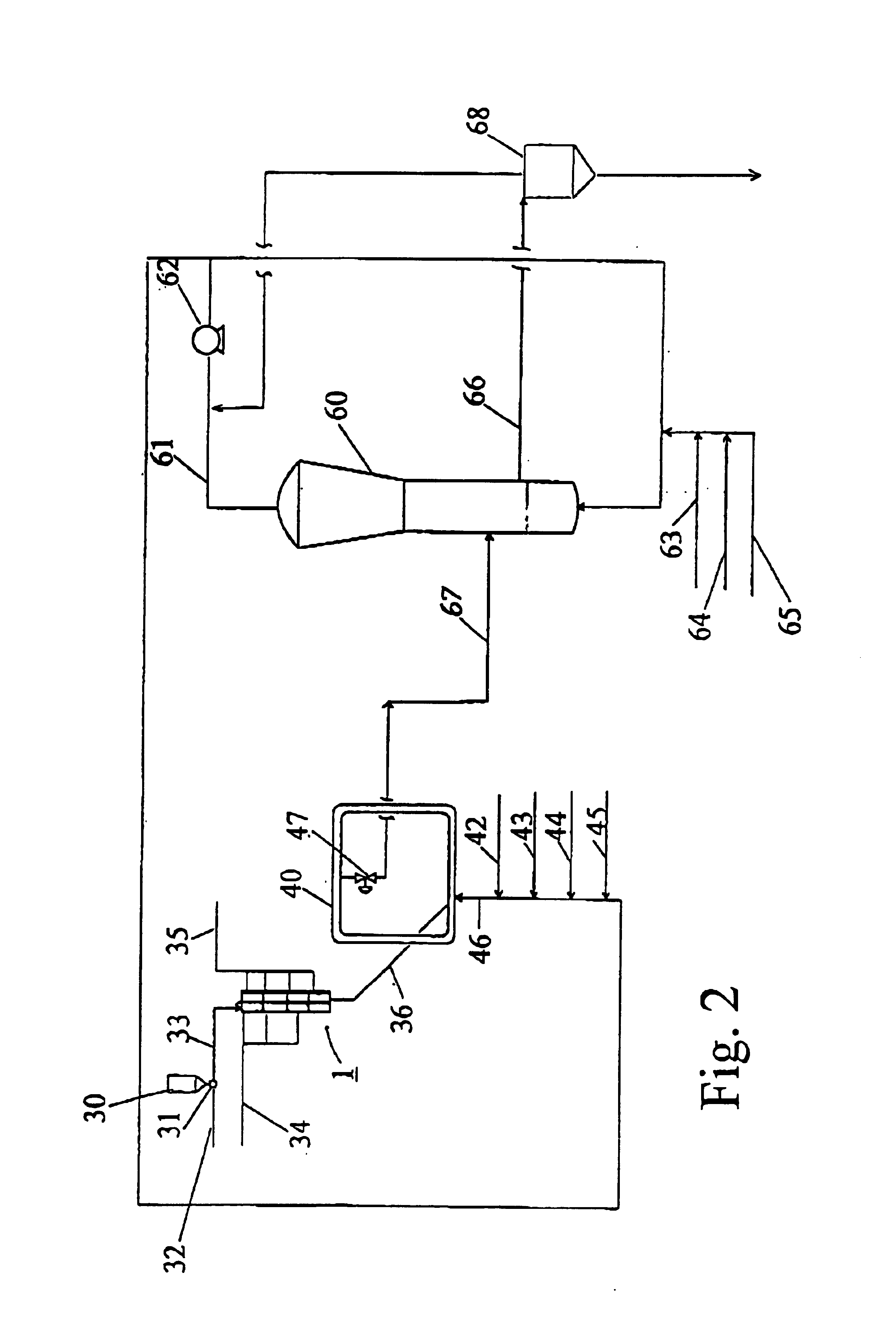

InactiveUS20050159564A1Improve melt strengthHigh viscosityChemical/physical/physico-chemical stationary reactorsPolymer scienceHydrogen

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / 10 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

Special thin anti-crack plastering mortar for autoclaved aerated concrete

The invention discloses a special thin anti-crack plastering mortar for autoclaved aerated concrete and belongs to the technical field of building materials. According to the special thin anti-crack plastering mortar disclosed by the invention, a dry material is added with water by a mass ratio that water to dry material ratio is equal to 1:4, and then stirred for 3-5 minutes to prepare mortar, wherein the dry material consists of the following components in mass by percentage: 20%-35% of cement, 10%-30% of 40-70-mesh quartz sand, 30%-50% of 80-100-mesh quartz sand, 2%-7% of 200-mesh coarse whiting powder, 1.5%-4% of redispersible emulsion powder; 0.15%-0.5% of water-retaining agent; 0.2%-0.7% of wood fiber and 0.11%-0.45% of short fiber. Being prepared by adopting quartz sand of 40-70 meshes or 80-100 meshes, the special thin anti-crack plastering mortar for the autoclaved aerated concrete disclosed by the invention has an excellent anti-crack performance, realizes effective control on contraction percentage of the mortar, causes no cracks during large-area construction, achieves good caking property, and realizes organic combination between the mortar and the surface layer of the autoclaved aerated concrete.

Owner:山东高阳建材有限公司

Dry powder ceramic tile binding agent

The present invention discloses a drying powder ceramic tile , which consists of the following component with the stated molar ratio: 500 pieces of 425# Porland cement, 500 pieces of drying sand to match a grade above 40 items, 2-3 pieces of intension, 1-3 pieces of water-keeping and 3-5 pieces of cement compound; the intension is calcium formate; the water-keeping is methyl cellulose; the cement compound is polyethylene or the subdivided latex powder. Because the cement compound and the water-keeping increase the felting intension during being used so as to make the anti-flow ability and the water-keeping ability for the cement compound enhanced greatly; the decorating effect for the facing brick is much fixed, perfect; the method solves the problem that the decoration is easy to be fallen off; besides, the thickness of the felting sand slurry decreases to 3-4mm from the original 2cm; the device can not only save the material greatly, but also decrease the weight by the over-heavy sand slurry to the building; besides, the device can decrease the labor intension for the worker and make the construction much faster and more high-efficient.

Owner:山东润东建材有限公司

Preparation method for graphene rare earth aluminum alloy high-conductive material

ActiveCN107099708AReduce the degree of reunionLow densityConductive materialMetal/alloy conductorsRare earthConductive materials

The invention discloses a preparation method for a graphene rare earth aluminum alloy high-conductive material. The method comprises the following steps: adding aluminum scrap, silicon calcium alloy, copper aluminum alloy, zinc aluminum alloy, magnesium ingot, rare earth aluminum alloy and graphene into a smelting furnace for smelting; performing ladle analysis, thereby acquiring an aluminum alloy solution; casting and rolling the aluminum alloy solution, thereby acquiring aluminum alloy; performing homogenization treatment on the aluminum alloy; performing ageing treatment, thereby acquiring the graphene rare earth aluminum alloy high-conductive material. According to the preparation method for the graphene rare earth aluminum alloy high-conductive material, provided by the invention, the technical parameters are reasonably set, the graphene structure is optimized and the overall performance of the aluminum alloy is effectively improved, so that the acquired graphene rare earth aluminum alloy high-conductive material has excellent electric conductivity, heat resistance, arc altitude resistance and mechanical properties.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

High-sinking-resistance transparent primer and preparation method thereof

The invention relates to a high-sinking-resistance transparent primer and a preparation method thereof. The high-sinking-resistance transparent primer is particularly suitable for application on a wood substrate and especially suitable for application on a substrate with deeper wood-grain guide tubes. The primer is prepared from a main paint, a curing agent and a diluter in a mass ratio of 1:0.5:(0.3-1):0.5:0.7. The main paint is prepared from the following raw materials in parts by mass: 55-70 parts of small-oil-length alkyd resin, 5-15 parts of castor oil modified alkyd resin, 3-10 parts of zinc stearate, 0-30 parts of talcum powder, 0.5-1 part of anti-settling agent, 0.3-1 part of defoamer, 0.2-0.5 part of leveling agent, 0.1-0.5 part of wetting and dispersing agent, 0.1-0.3 part of drier and 5-15 parts of environment-friendly mixed solvent. The primer can be well combined with the substrate after being applied, and has excellent properties in the aspect of wood grain / guide tube filling. After the primer is placed for a long time, the paint film of the finish paint can not shrink, and can not generate the phenomenon of sinking.

Owner:SKSHU PAINT

Vehicular glass adhesive and method of adhering said glass

The invention is an adhesive composition comprising: a) an isocyanate functional polyether base prepolymers having a z molecular weight average (Mz) of about 10,000 to about 80,000 g / mole; a carbon black having an average oil absorption number of at least about 80 to at most about 400 cubic centimeters of dibutyl phthalate per 100 grams of the carbon black; (c) reactive silicon in an amount from about 0.001% to about 10% by weight of the adhesive composition; and (d) one or more catalysts for the reaction of isocyanate with hydroxyl groups. The adhesive compositions of the invention surprisingly may have improved sag performance (i.e., decreased sag) when heated, while also making them more easily pumped.

Owner:DOW GLOBAL TECH LLC

Vehicular glass adhesive and method of adhering said glass

ActiveUS20110265932A1Molecular weightEasy pumpabilityCovering/liningsNon-macromolecular adhesive additivesAdhesiveGram

The invention is an adhesive composition comprising: a) an isocyanate functional polyether base prepolymers having a z molecular weight average (Mz) of about 10,000 to about 80,000 g / mole; a carbon black having an average oil absorption number of at least about 80 to at most about 400 cubic centimeters of dibutyl phthalate per 100 grams of the carbon black; (c) reactive silicon in an amount from about 0.001% to about 10% by weight of the adhesive composition; and (d) one or more catalysts for the reaction of isocyanate with hydroxyl groups. The adhesive compositions of the invention surprisingly may have improved sag performance (i.e., decreased sag) when heated, while also making them more easily pumped.

Owner:DOW GLOBAL TECH LLC

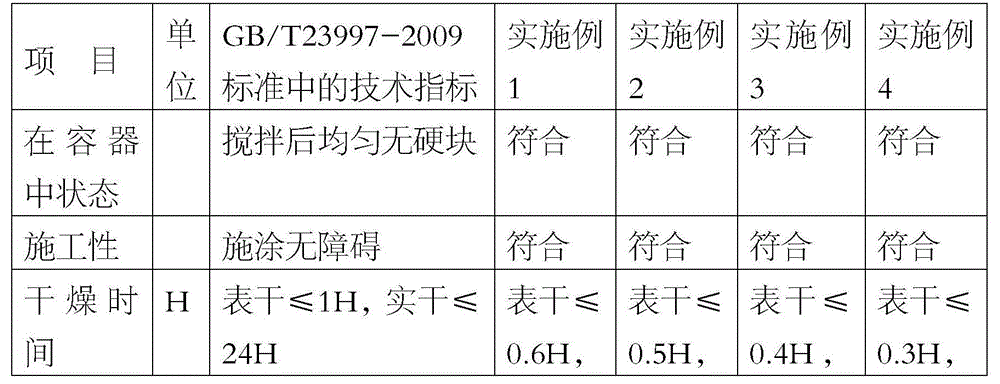

Quick-dry solvent-free anti-sagging polyurethane water-proof paint and preparation method thereof

ActiveCN109321122ALow viscosityImprove thixotropyPolyurea/polyurethane coatingsPlasticizerSolvent free

Owner:JIANGSU CANLON BUILDING MATERIALS

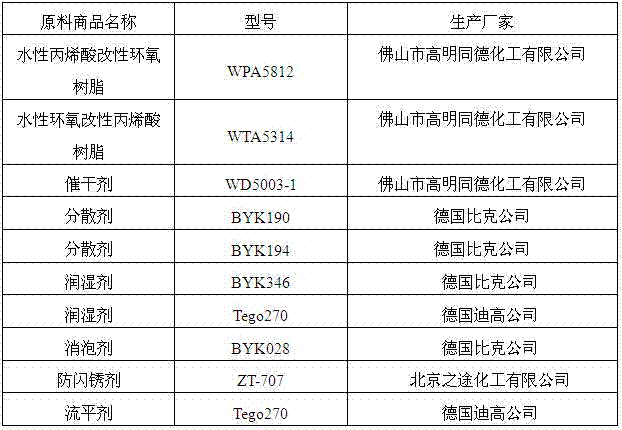

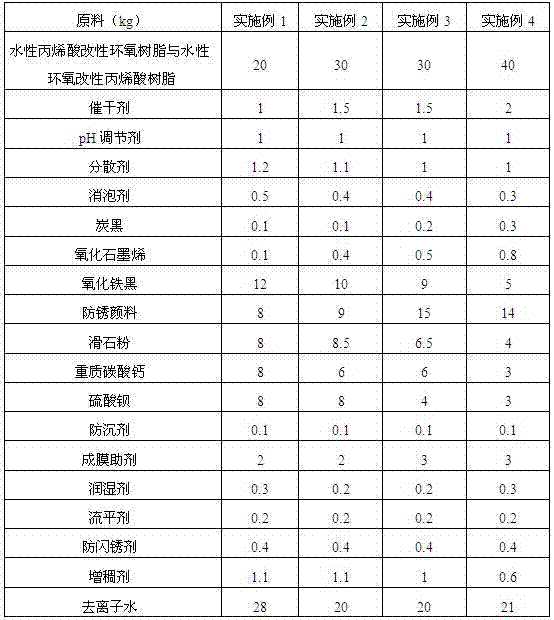

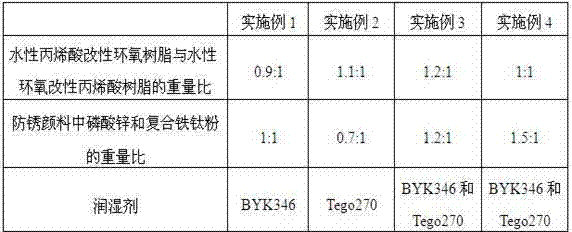

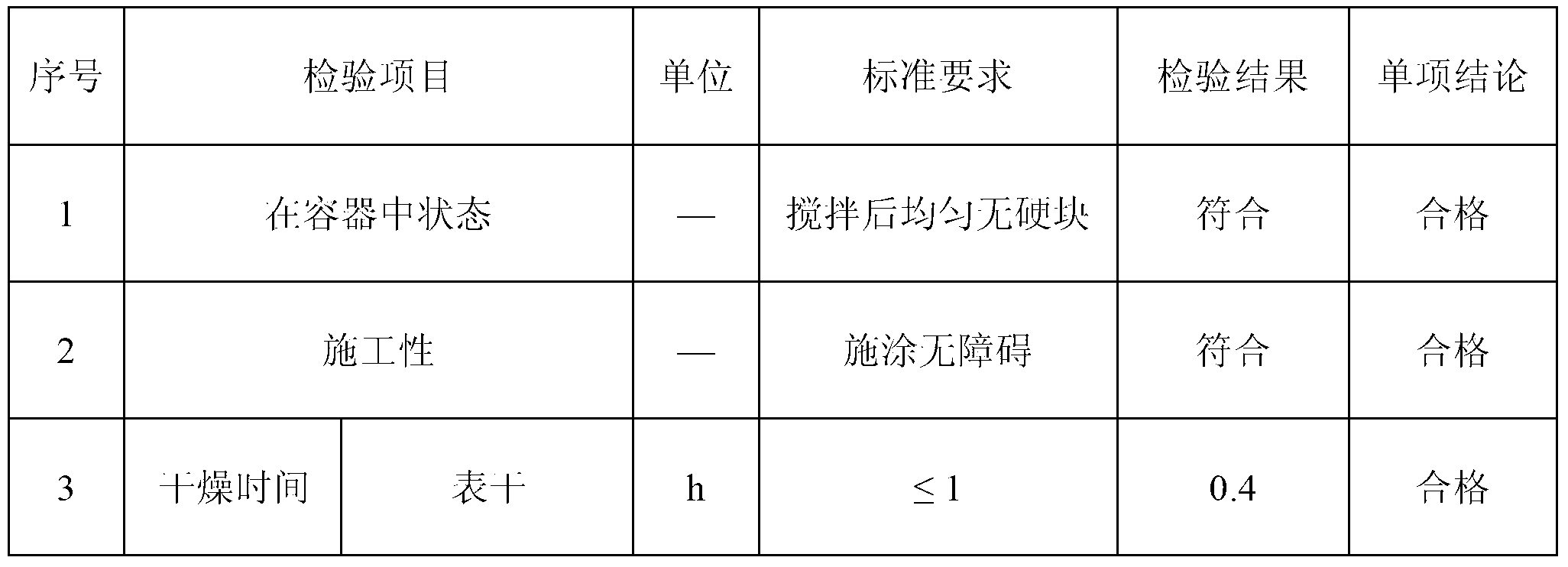

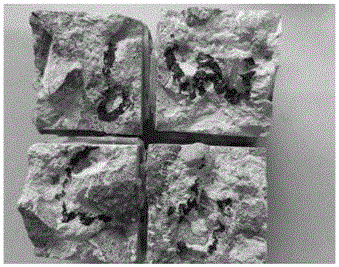

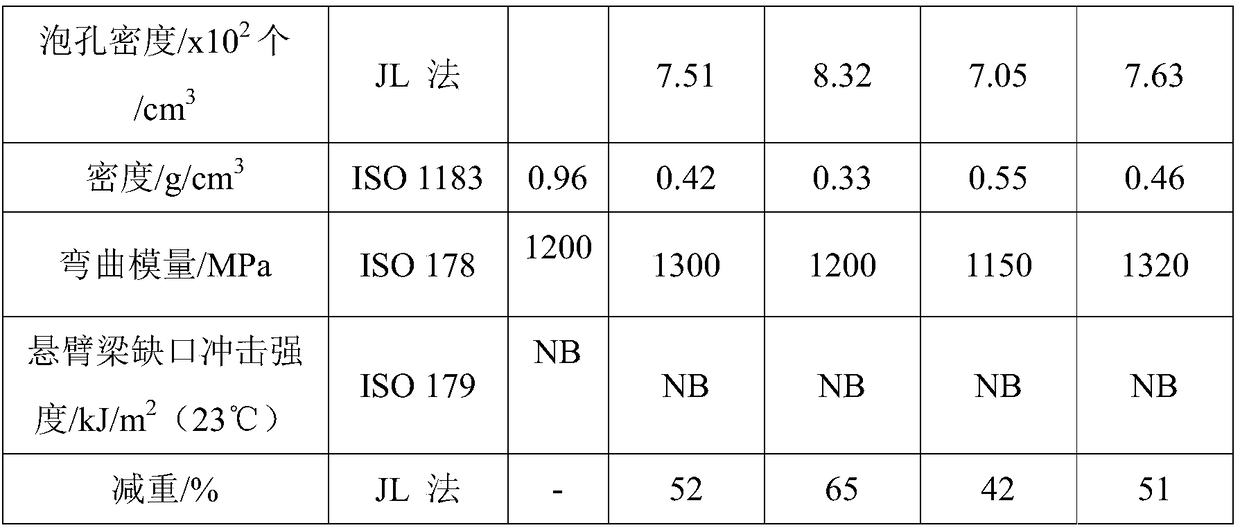

Dip-coating water-based paint for transmission shaft and preparation method thereof

InactiveCN106867368AWith cleanQuick-drying at room temperatureAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses dip-coating water-based paint for a transmission shaft and a preparation method thereof and relates to the technical field of metal water-based paint. The dip-coating water-based paint is prepared from the following raw materials in parts by weight: 20 to 40 parts of waterborne acrylic modified epoxy resin and epoxy modified acrylic resin, 0.3 to 3 parts of a drier, 0.4 to 1.5 parts of a pH (Potential of Hydrogen) regulator, 0.6 to 1.5 parts of a dispersant, 0.3 to 0.5 part of a de-foaming agent, 0.05 to 3 parts of carbon black, 0.01 to 1 part of graphene oxide, 4 to 12 parts of iron oxide black, 2 to 20 parts of antirust pigment, 3 to 8 parts of talcum powder, 0.5 to 8 parts of heavy calcium carbonate, 3 to 8 parts of barium sulfate, 0.05 to 0.15 part of an anti-sedimentation agent, 2 to 3 parts of a film forming auxiliary agent, 0.1 to 0.5 part of a wetting agent, 0.1 to 0.5 part of a leveling agent, 0.1 to 0.5 part of a flash-rust resisting agent, 0.1 to 1.2 parts of a thickener and 10 to 28 parts of water. The water-based paint has the advantages of easiness of improving a film thickness, high rigidity, good wear-resisting and corrosion-preventing effects, capability of being rapidly dried at room temperature and extremely low VOC (Volatile Organic Compounds) content.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

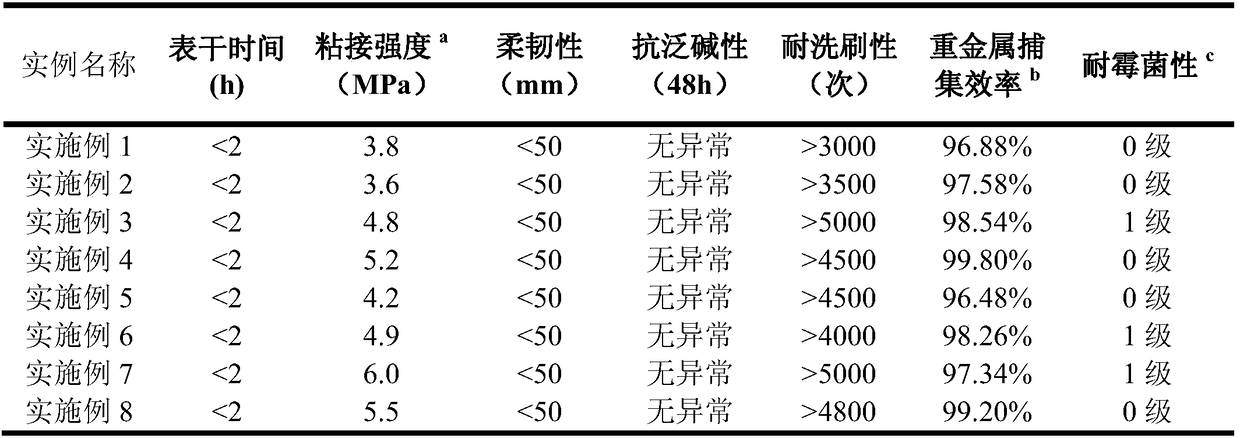

Geopolymer-based mold-proof antibacterial interior wall coating and preparation method thereof

InactiveCN108892978AReduce pollutionGood and long-lasting inhibitory effectAntifouling/underwater paintsPaints with biocidesWater basedBond strength

The invention discloses a geopolymer-based mold-proof antibacterial interior wall coating which is composed of a solid phase S and a liquid phase L, wherein the solid phase S comprises the following components in parts by weight: 10-90 parts of a gel binder, 5-85 parts of pigments and fillers, 0.1-5 parts of a film-forming agent, 0.5-10 parts of an anti-cracking additive and 0.4-5 parts of an anti-settling agent; and the liquid phase L comprises the following components in parts by weight: 5-90 parts of an alkali activator, 0.5-6 parts of a rheological modifier, 0.2-3 parts of an antifoaming agent and 2-90 parts of water. The invention further discloses a preparation method of the geopolymer-based mold-proof antibacterial interior wall coating. The geopolymer-based mold-proof antibacterialinterior wall coating disclosed by the invention realizes the zero-VOC (Volatile Organic Compound) advantage and high-efficiency mold-proof antibacterial functions of the novel water-based inorganicinterior wall coating, and has the advantages of being high in bonding strength with the base plane, excellent in scrubbing resistance, excellent in water resistance and penetration resistance, low inprice and the like, and the mold-proof antibacterial functions have long-term properties.

Owner:浙江航通舟新材料科技股份有限公司

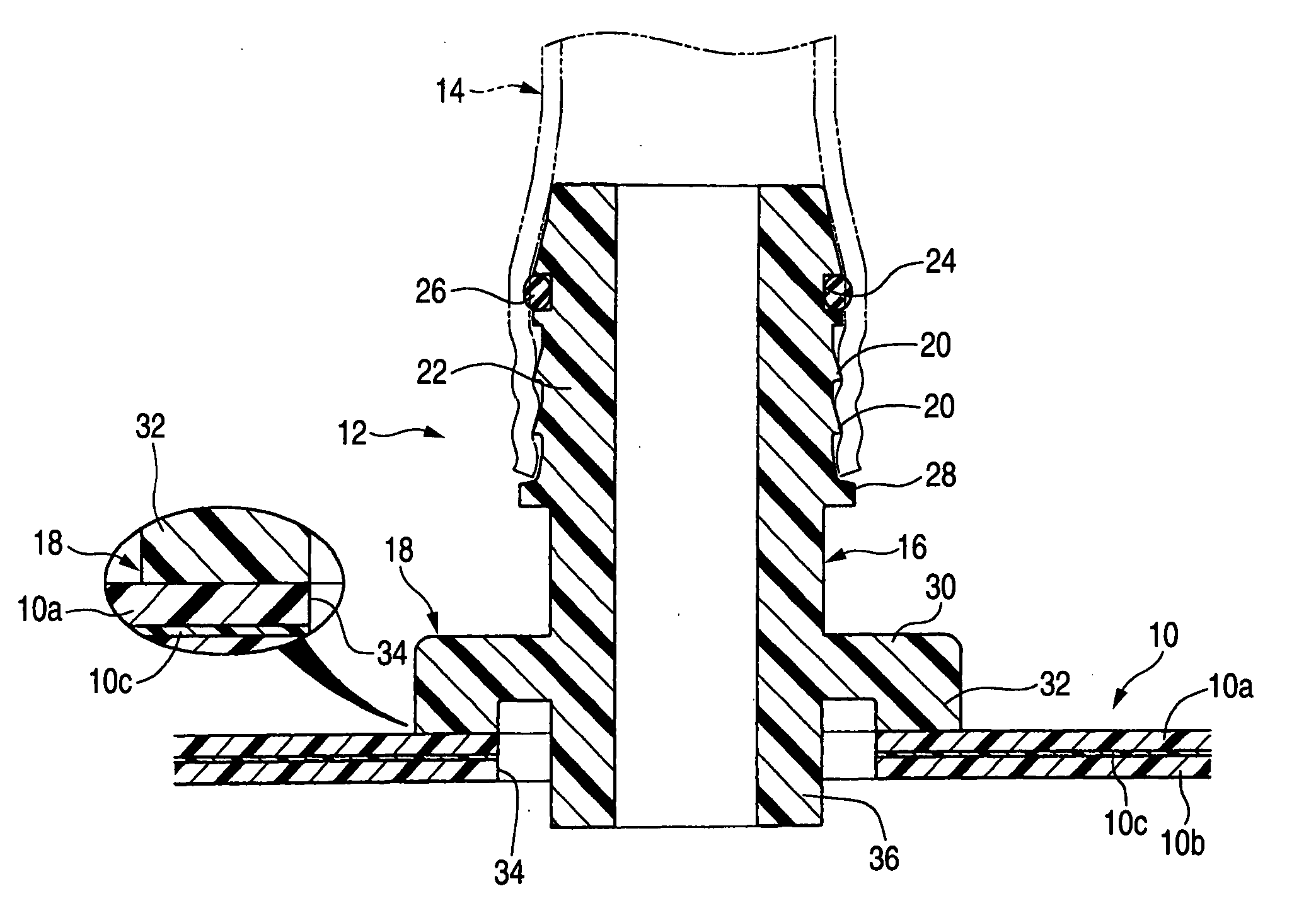

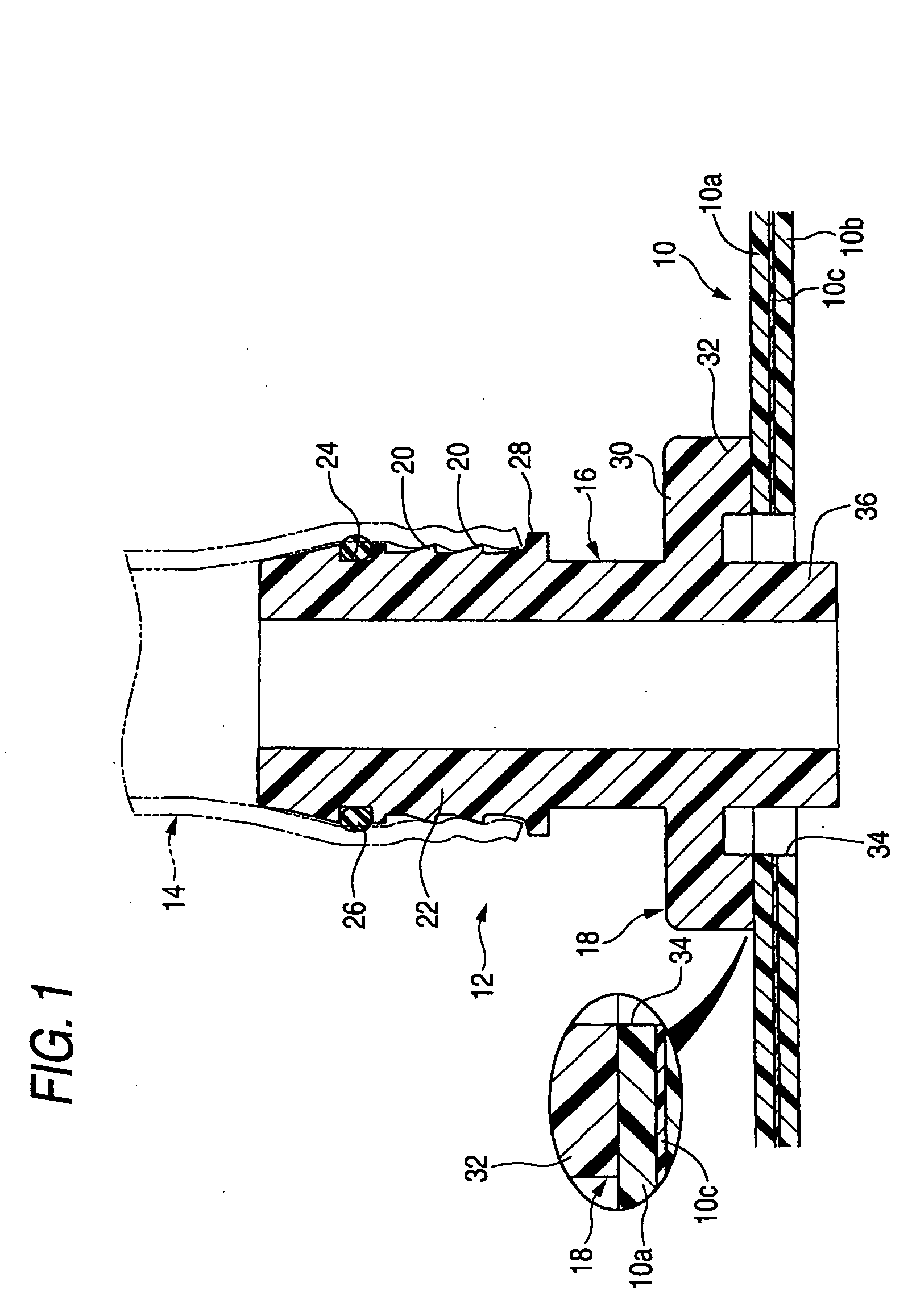

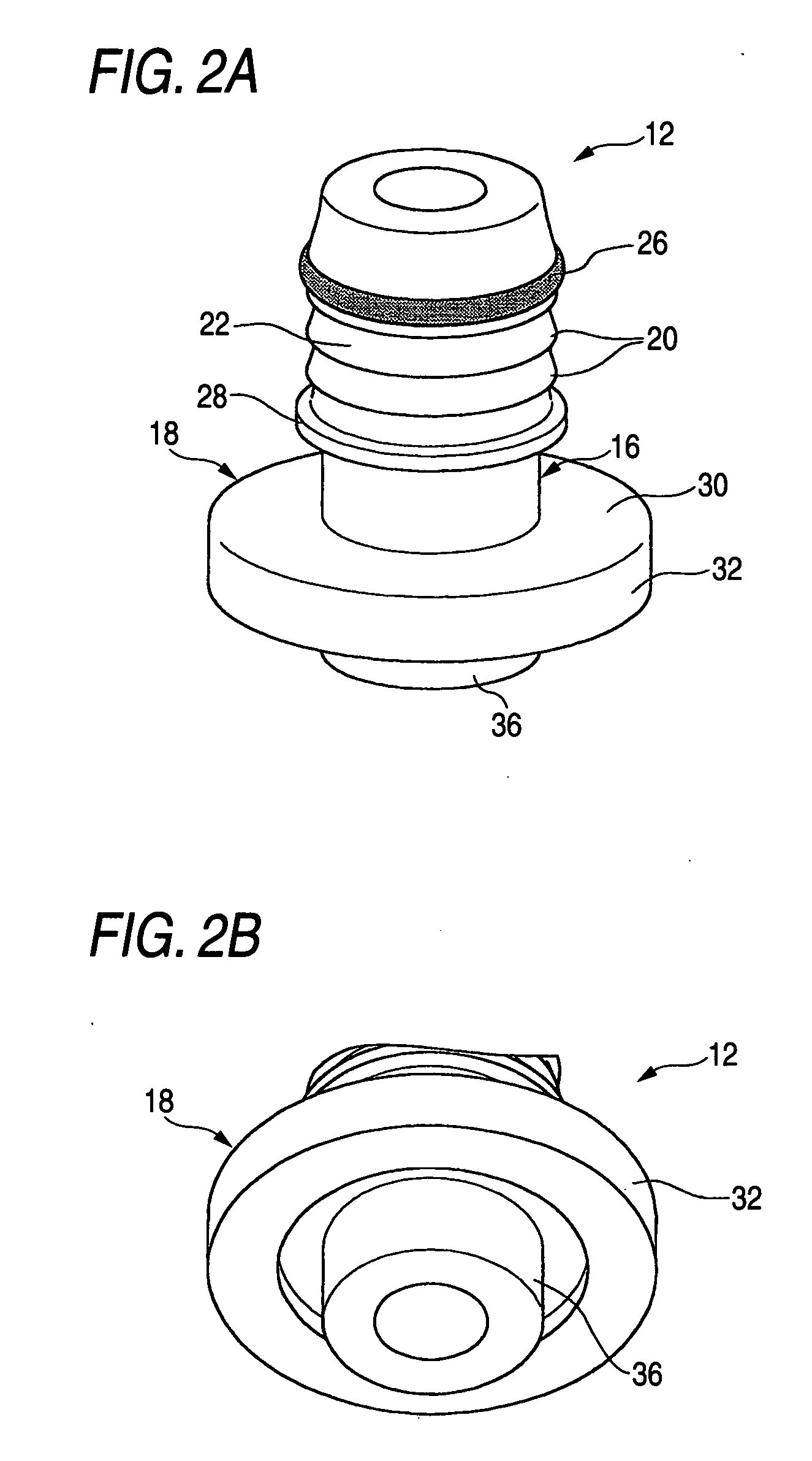

Welding joint of fuel tank

InactiveUS20060088375A1Improve welding effectEasily fusion-weldedBranching pipesHose connectionsFuel tankEngineering

A welding joint has a cylindrical portion being a connection portion and an annular fusion-welded portion disposed at a base end part of the cylindrical portion, the fusion-welded portion being configured to be thermal fusion welded to a resin-made fuel tank. At least parts of the fusion-welded portion and the cylindrical portion are integrally molded by employing a resinous alloy material in which a modified high-density polyethylene obtained by introducing a functional group of high affinity to a hydroxyl group of ethylene-vinylalcohol copolymer is alloyed with the ethylene-vinylalcohol copolymer singly or together with high-density polyethylene.

Owner:SUMITOMO RIKO CO LTD

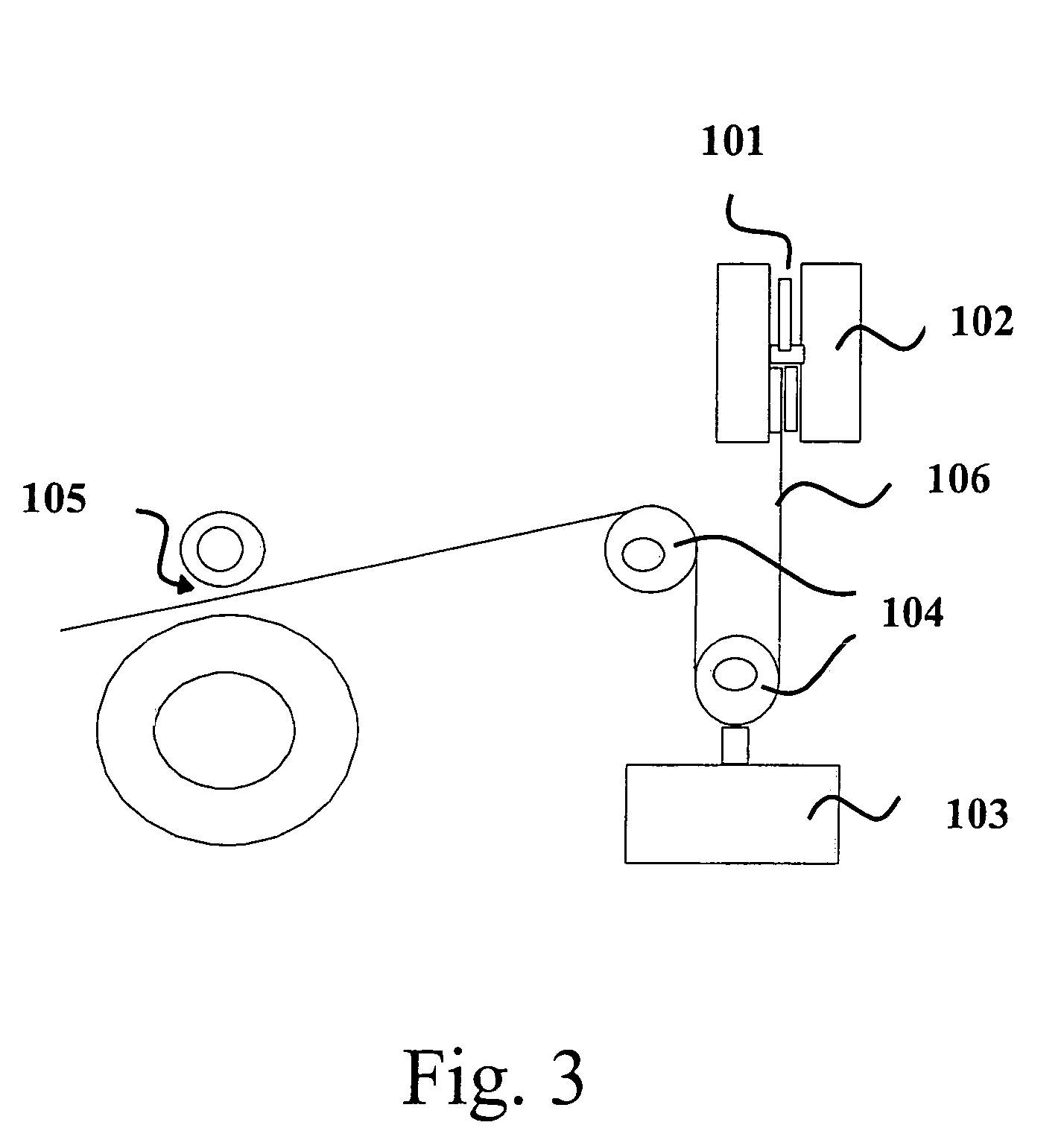

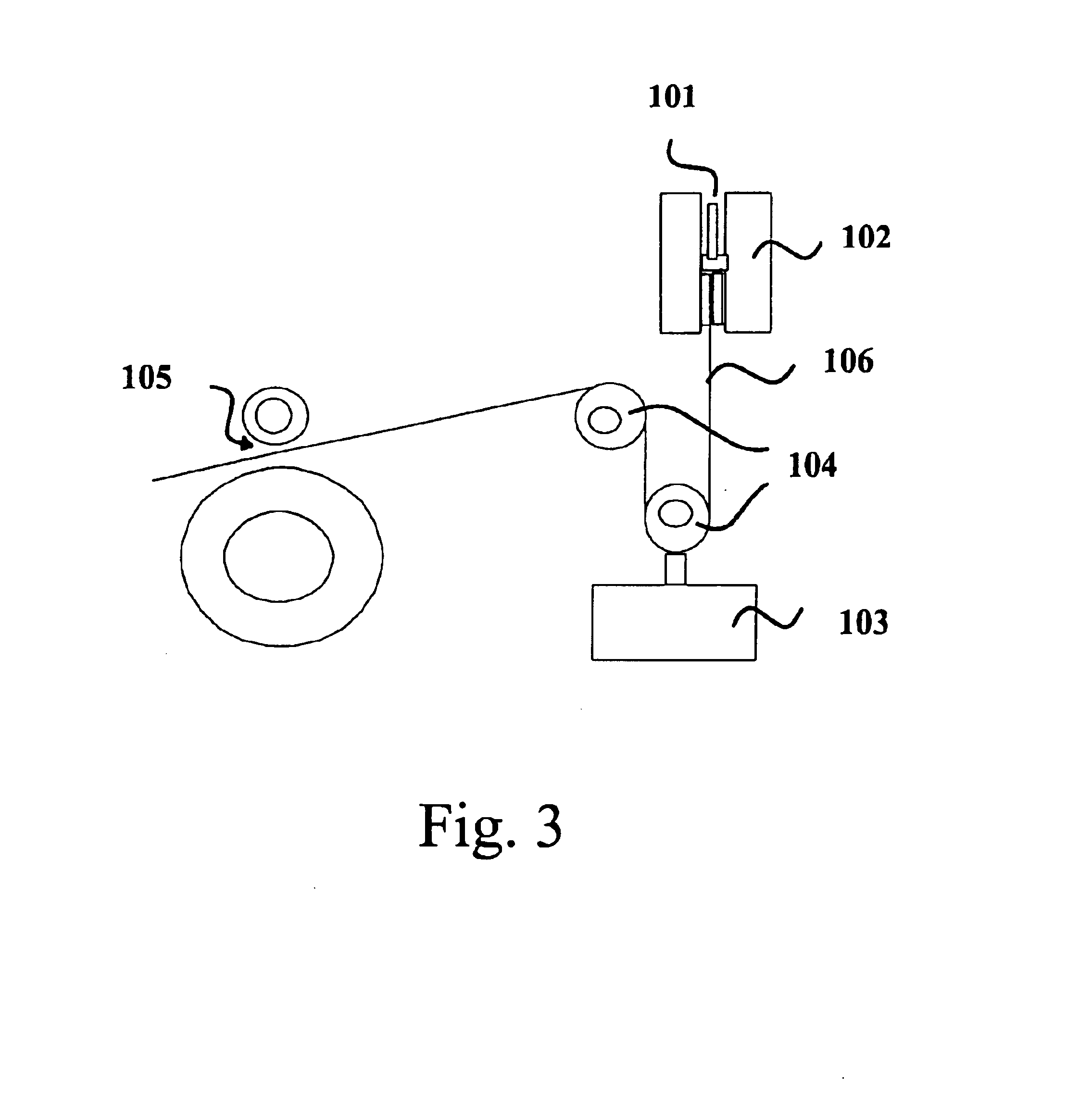

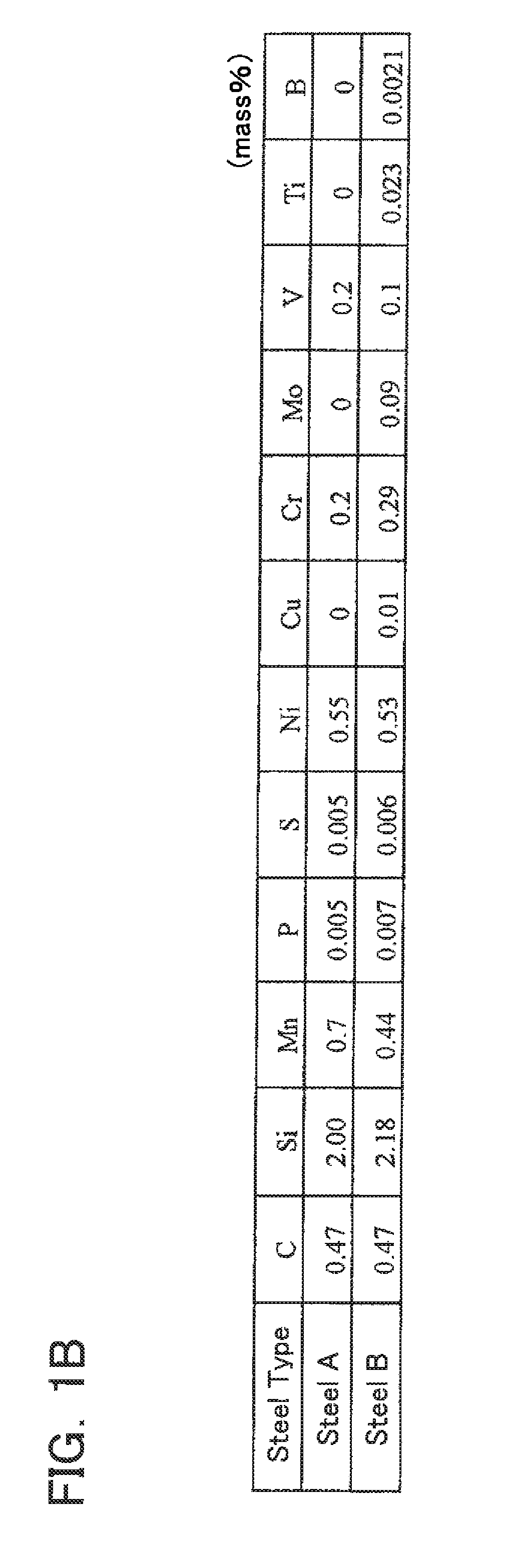

Coil spring for automobile suspension and method of manufacturing the same

ActiveUS20110074079A1Improve sag resistanceIncreased durabilityFurnace typesBurnishing machinesCoil springEngineering

A manufacturing method of a coil spring for an automobile suspension includes forming a material into a coil shape; performing a heat treatment step on the material; performing a warm shot peening step on the material, and performing a hot setting step on the material. By performing the warm shot peening step prior to the hot setting step, a stronger compressive residual stress is imparted in a direction along which a large tensile stress acts during actual use of the coil spring, thereby improving sag resistance and durability of the coil spring. A coil spring is also manufactured according to this method.

Owner:CHUO SPRING

Preparation method of environment-friendly dry powder pointing agent

InactiveCN101774793AImprove adhesionIncreased durabilitySolid waste managementBrickResource utilization

The invention relates to a preparation method of an environment-friendly dry powder pointing agent taking slag powder as main raw materials, belonging to the technical field of building material preparation processes. The environment-friendly dry powder pointing agent comprises the raw materials in percentage by weight: 55-75 percent of slag powder, 2-10 percent of cement, 10-30 percent of calcite powder, 2-5 percent of re-dispersible emulsoid powder and 0.05-0.3 percent of thickening agent. The environment-friendly dry powder pointing agent has good caking property, good durability and high antiseepage grade, is not in contact with a tapestry brick, generates no cracks, and can effectively inhibit saltpetering. The invention widens a new approach for the resource utilization of the slag powder and has better social efficiency and economic benefit.

Owner:SHANGHAI UNIV +2

Texture paint and preparation method thereof

InactiveCN103602267ADoes not affect water whitening resistanceIncrease artistic senseCoatingsCelluloseEmulsion

Provided texture paint is aqueous texture paint employing macromolecular synthetic resin emulsion and additives. By employing a strong-thixotropy alkali-swelling type thickener and cellulose ether for cooperative use, the texture paint is reasonable in thixotropy and relatively good in thickening property, storage property and construction property, and has no influence on water whitening resistance of the emulsion. After a high-viscosity auxiliary agent with water-retaining property replaces part of cellulose ether, the texture paint is high in viscosity, good in water-retaining property, no sand falls off during construction, the opening time is long, the scraping and the levelling are facilitated, and the use amount of the paint is substantially reduced. The addition of a thixotropy lubricant helps to improve the lubrication viscosity-reducing property, reduce construction resistance, improve sagging resistance, improve construction performances, prevent knife-adhering phenomenon from generating and prolong construction time.

Owner:JIANGMEN CRYSTONE PAINT

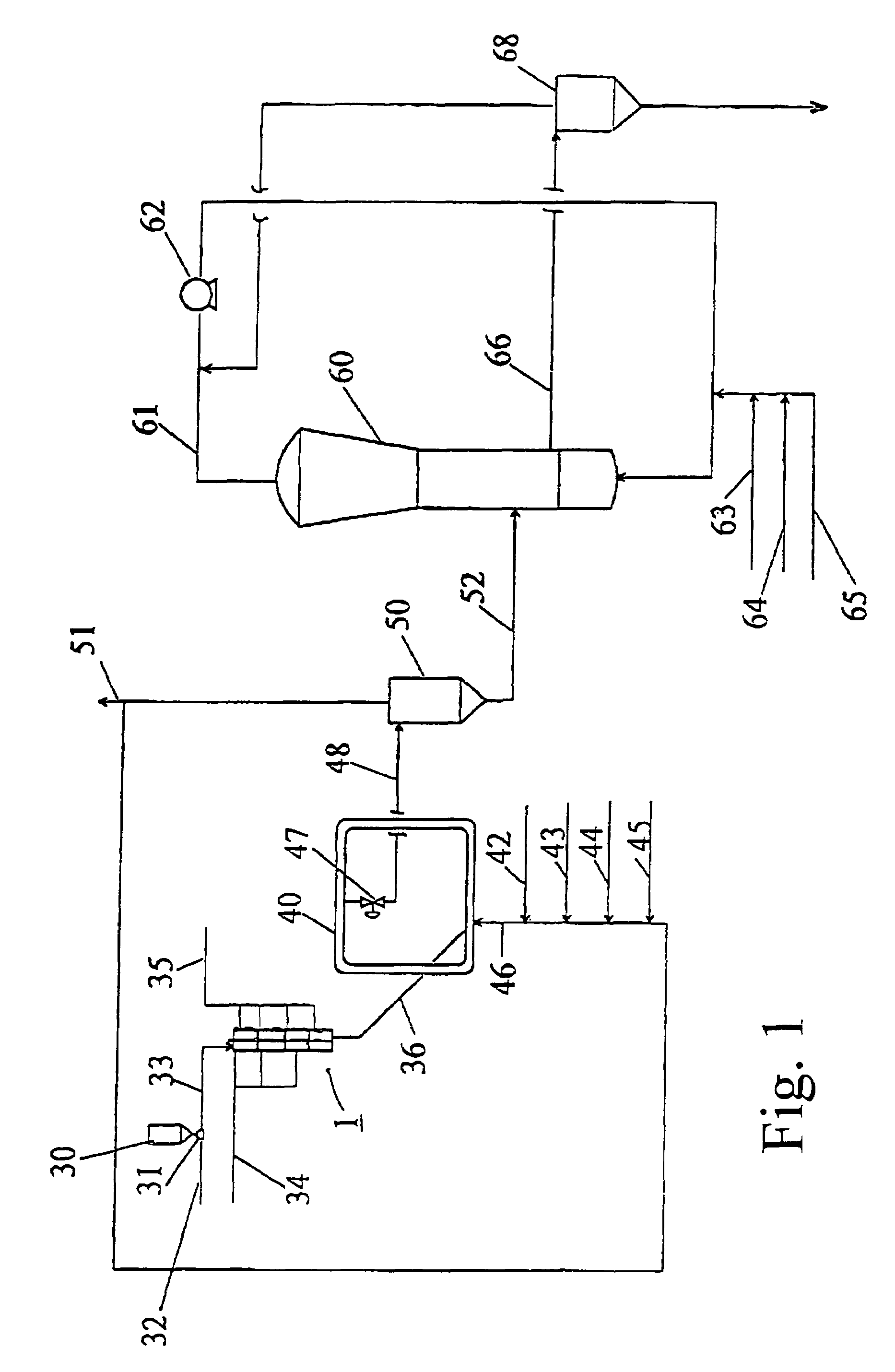

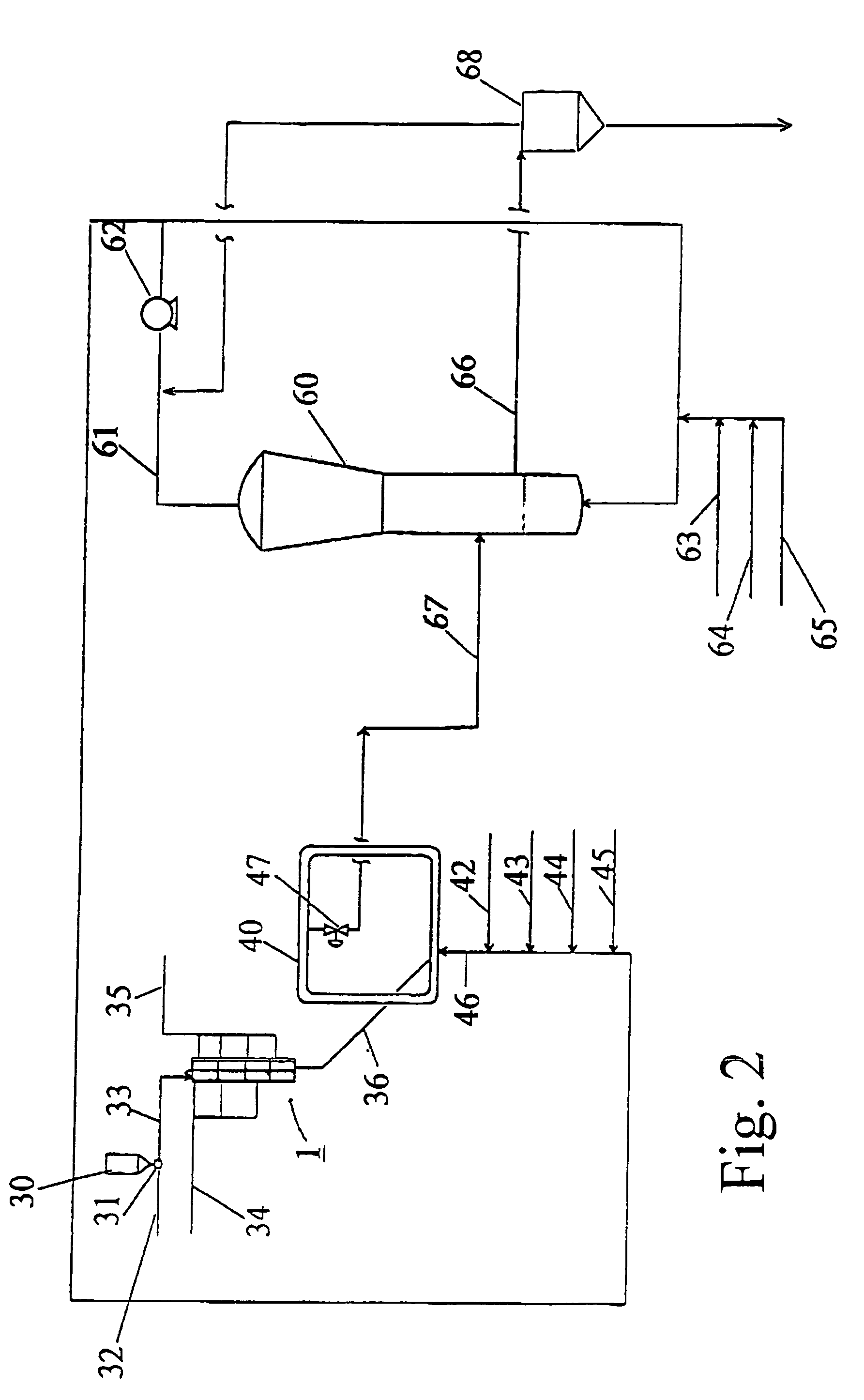

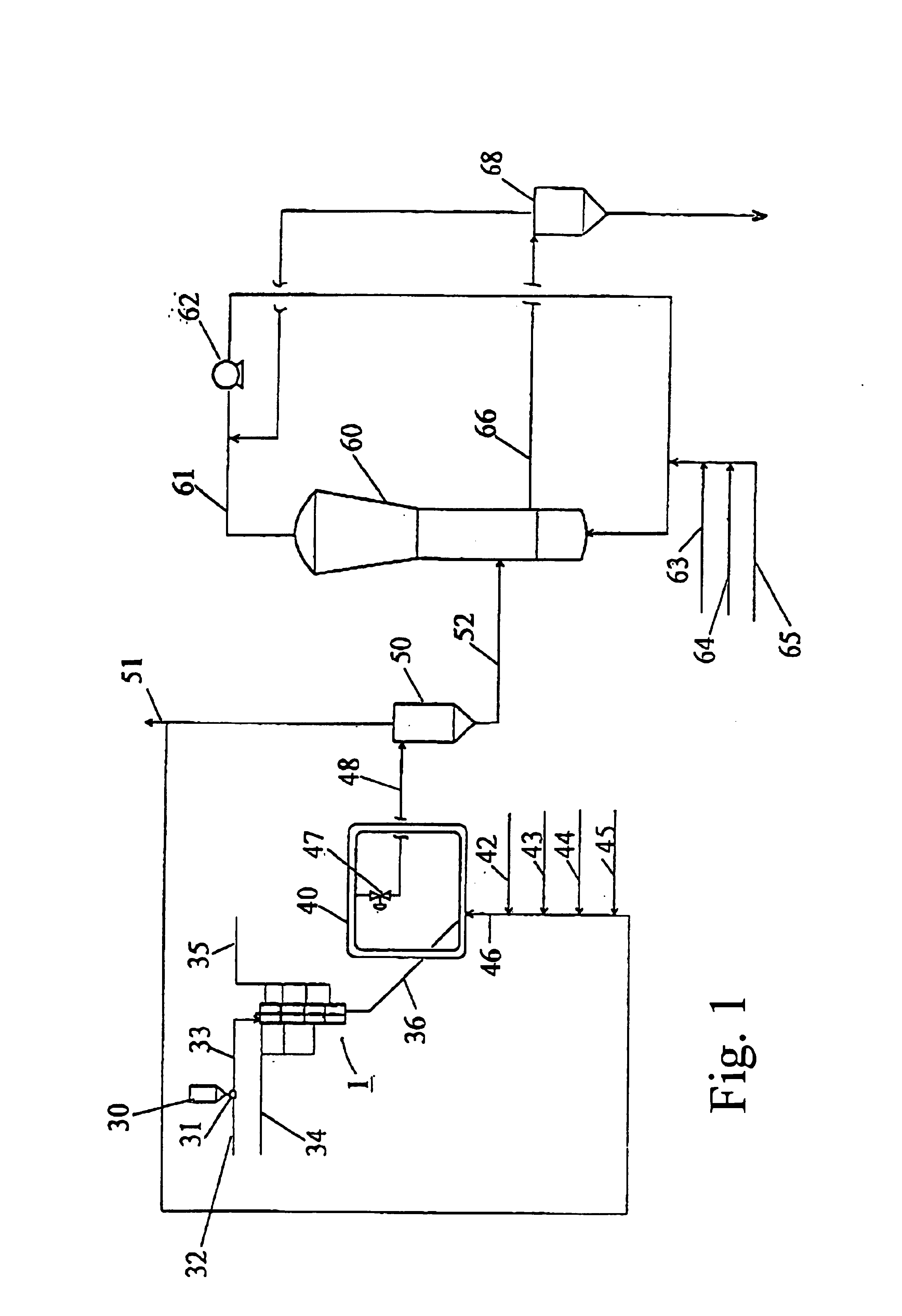

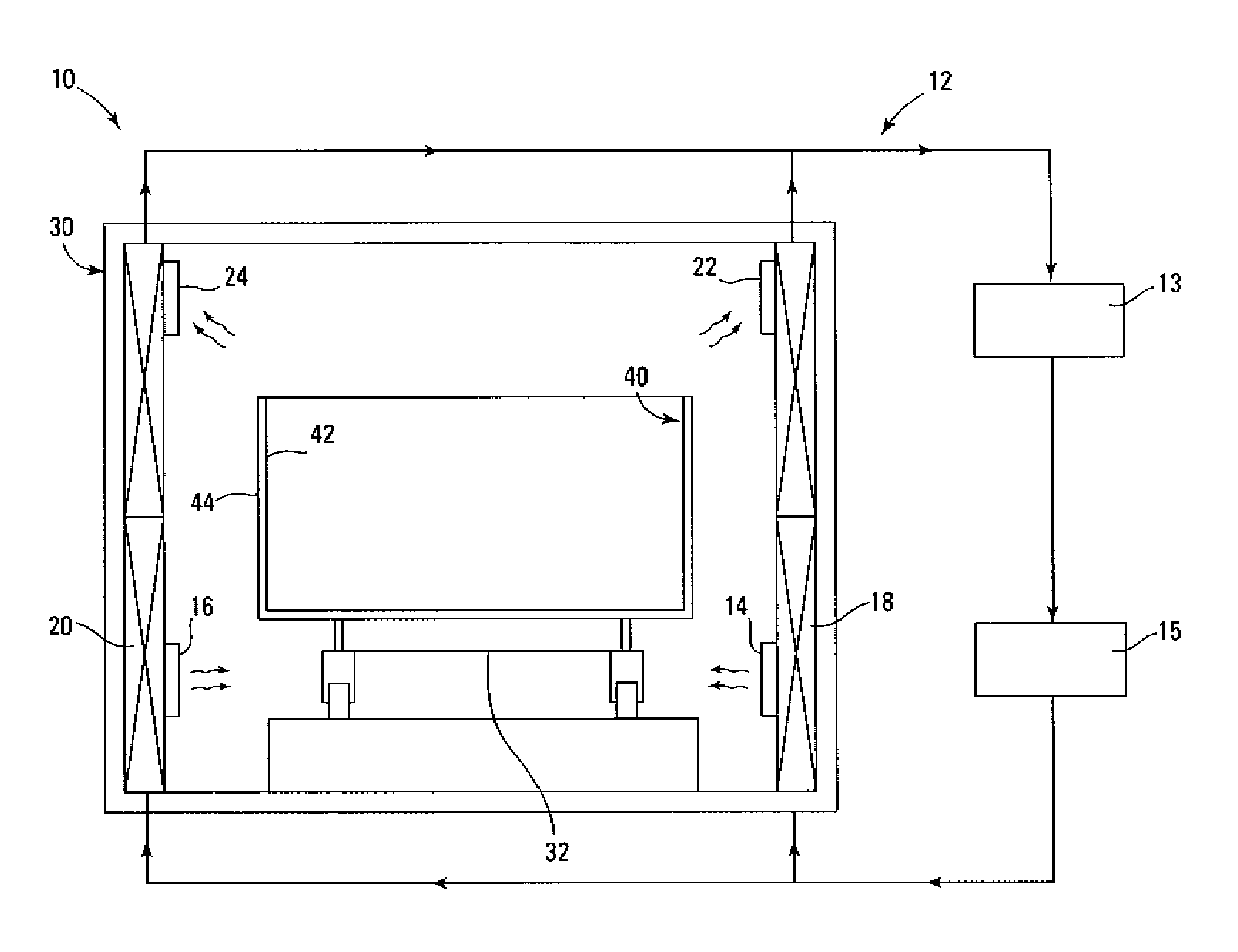

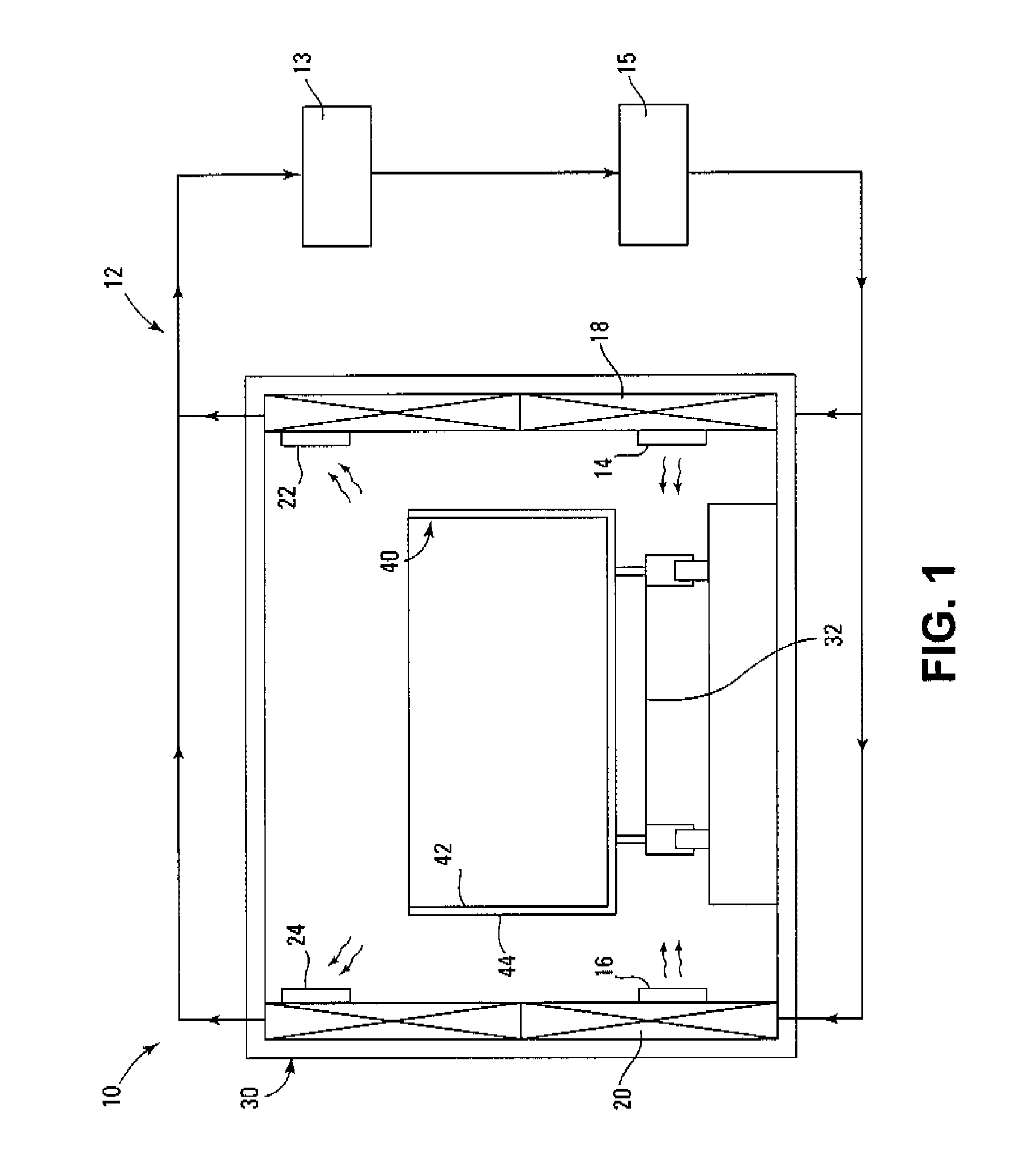

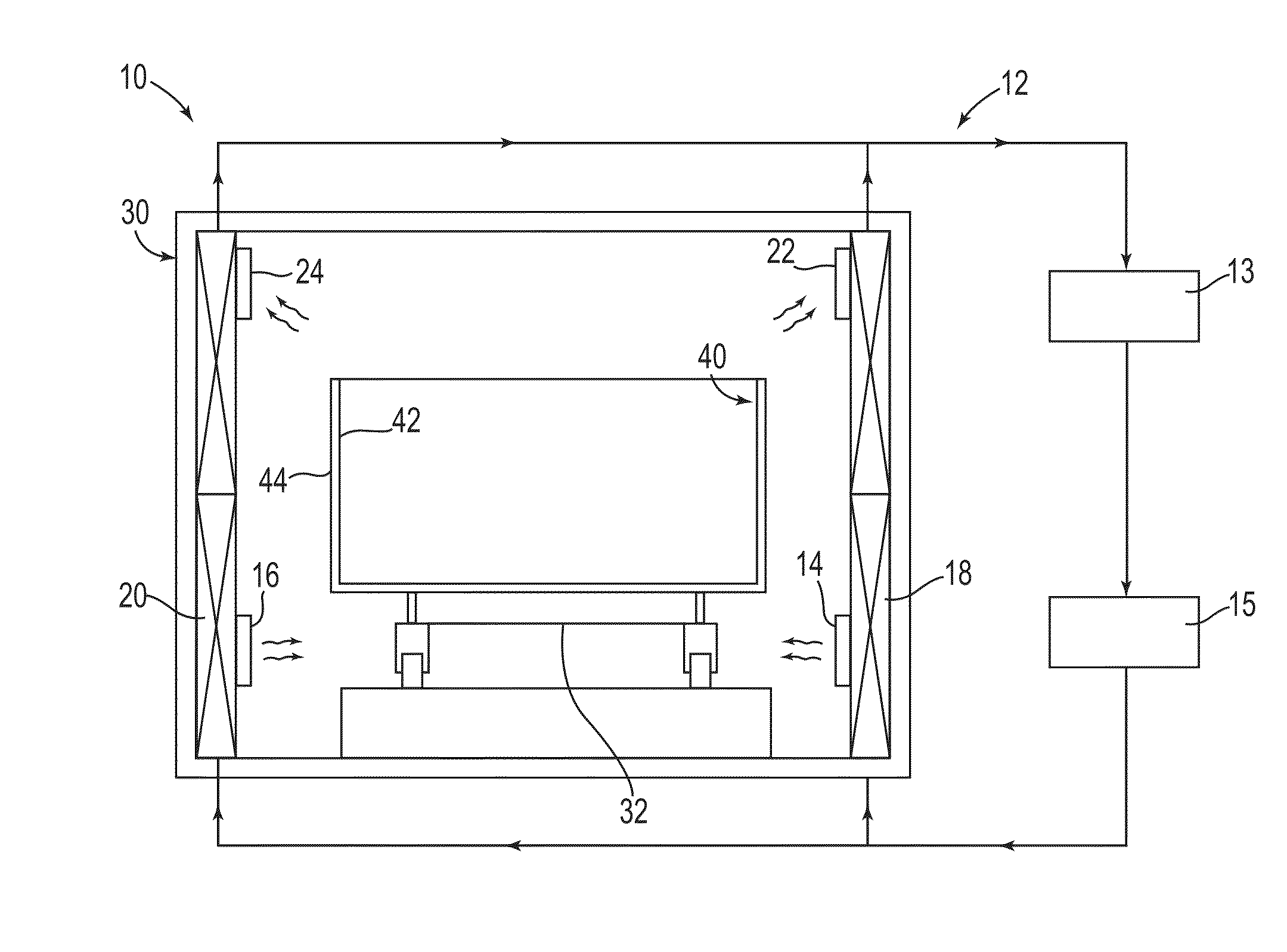

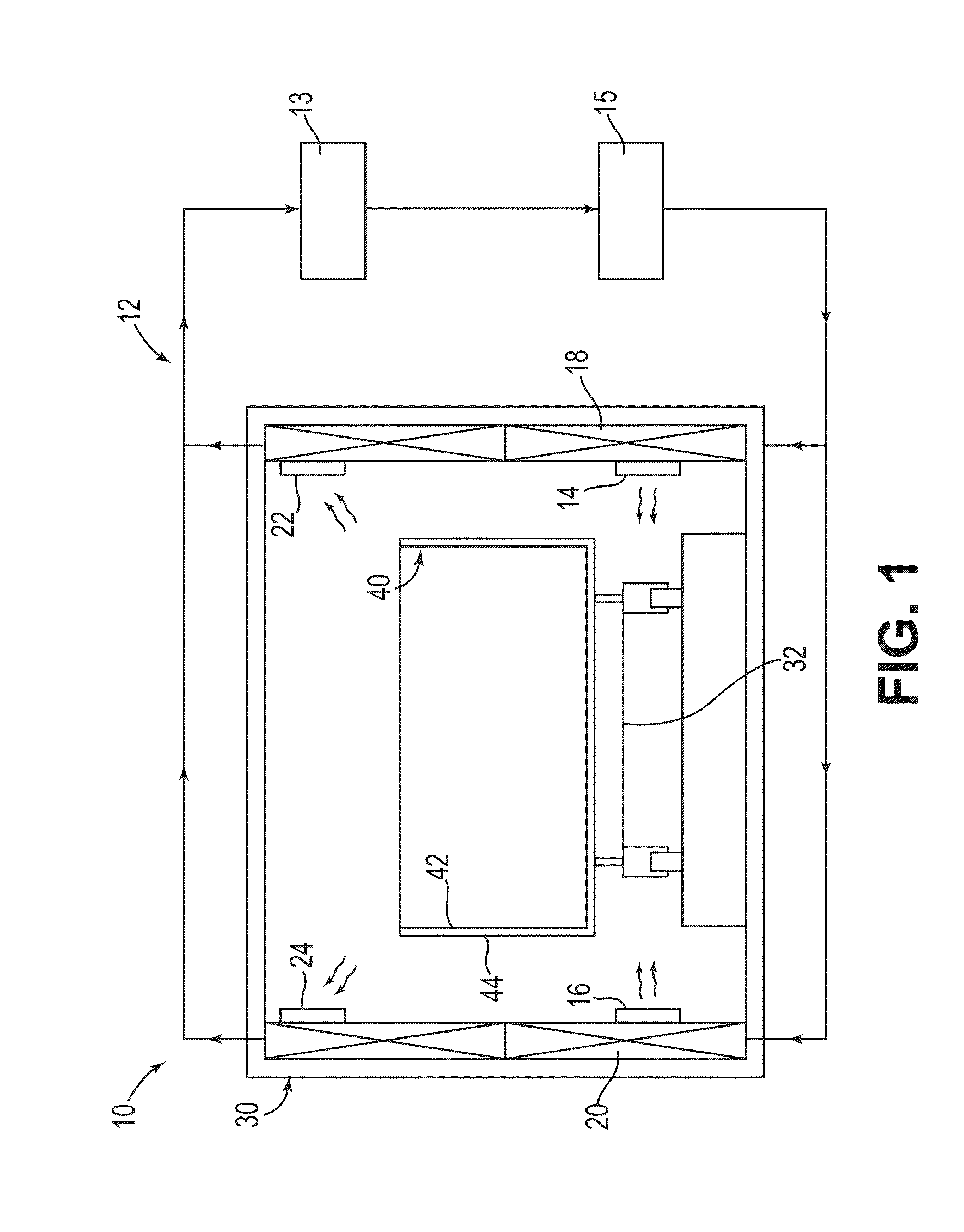

Water-based coating compositions and systems with improved sag resistance and related methods

InactiveUS20130105473A1High viscosityExtended drying timeSpraying apparatusDrying gas arrangementsWater basedCoating system

The present invention provides a water-based coating and / or coating system that can be used to form sag resistant wet layers or coatings on a wide range of substrates. The coating system is particularly effective for protecting metal-containing substrates, such as intermodal cargo containers, against corrosion. As an overview, the present invention provides water-based compositions suitable to form primer coats on substrates. Desirably, the primer incorporates a high level of one or more CAS agents for excellent sag resistance while drying in a broad range of relative humidity environments. Alternatively, modifications can be made to control temperature and humidity during spray application and drying as a way to increase sag resistance of the coating.

Owner:VALSPAR SOURCING INC

Anti-sinking PU extra-clear primer and preparation method thereof

ActiveCN103305113AGood anti-sag performanceHigh transparencyPolyurea/polyurethane coatingsMethyl carbonateSlurry

The invention provides an anti-sinking PU extra-clear primer which is prepared by mixing an anti-sinking PU polyurethane primer, a PU anti-sinking curing agent and a PU anti-sinking diluent, wherein the anti-sinking PU polyurethane primer is prepared from soybean oil alkyd resin, a dispersant, an antifoaming agent, anti-settling slurry, pigment and filler, nitrocotton liquid, a leveling agent, a dryer and the like in addition with an environment-friendly solvent; the PU anti-sinking curing agent is prepared from n-butyl acetate, isocyanate tripolymer and isocyanate heteropolymer; and the PU anti-sinking diluent is prepared from the solvents such as n-butyl acetate, propylene glycol monomethyl ether acetate, dimethyl carbonate and the like. The anti-sinking PU polyurethane primer, the PU anti-sinking curing agent and the PU anti-sinking diluent are sufficiently and uniformly mixed to prepare the anti-sinking PU extra-clear primer which has excellent anti-sinking property and extra high transparency and is easy to polish; and the shortcomings of slow drying, poor anti-sinking property, common adhesion, low transparency, common polishing property and the like of the commercially available products are overcome.

Owner:广东花王涂料有限公司

Low-temperature repairing material for high-speed rail base concrete in severe cold region and application of low-temperature repairing material

The invention belongs to the technical field of construction materials, and particularly relates to a low-temperature repairing material for a high-speed rail base concrete in a severe cold region and application of the concrete low-temperature repairing material. The low-temperature repairing material comprises the following components: 425 ordinary Portland cement, 425 sulphoaluminate cement, 725 sulphoaluminate cement, a waterproof admixture, rubber powder, an aggregate, a water reducer, a construction improver, a water-retaining agent, an early strength agent, a nano multifunctional water repellent agent, and PP (polypropylene) fiber. The low-temperature repairing material for the high-speed rail base concrete in the severe cold region, provided by the invention, has a repairing construction time meeting a skylight time requirement of a high-speed rail, has compression strength after completion of hydration matching with that of the base concrete, is high in tensile bond strength with the base concrete, is slightly expanded and strong in anti-freezing circulation capability at -40 DEG C, can avoid secondary detachment, and well meets requirements on the low-temperature repairing material for the high-speed rail base concrete in the severe cold region.

Owner:郑州筑邦建材有限公司 +1

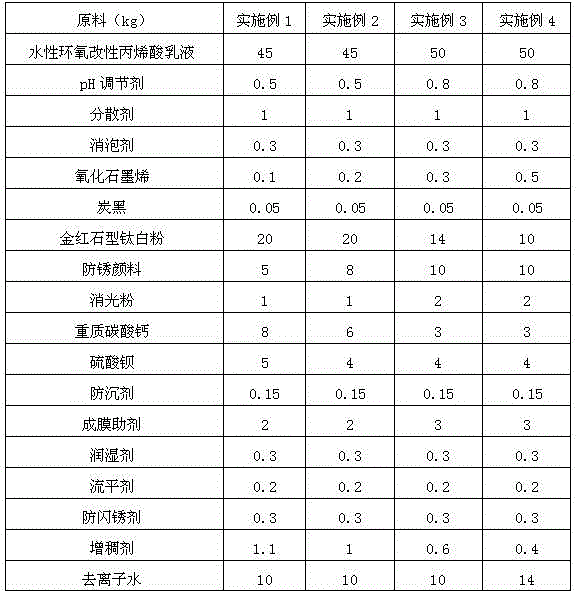

Acrylic water-based paint for motor shells and preparation method thereof

The invention discloses an acrylic water-based paint for motor shells and a preparation method thereof, relating to the technical field of metal water-based paints. The acrylic water-based paint for motor shells comprises the following raw materials in parts by weight: 45-50 parts of acrylic modified resin, 0.4-0.8 part of pH regulator, 0.6-1.5 part of dispersing agent, 0.3-0.5 part of defoaming agent, 0.01-0.5 part of graphene oxide, 0.05-3 parts of carbon black, 10-20 parts of rutile titanium white, 2-10 parts of antirust pigment, 0.5-4 parts of matting powder, 0.5-8 parts of ground calcium carbonate, 3-8 parts of barium sulfate, 0.05-0.15 part of anti-settling agent, 2-3 parts of film forming aid, 0.1-0.5 part of wetting agent, 0.1-0.5 part of leveling agent, 0.1-0.5 part of flash-rust inhibitor, 0.1-1.2 parts of thickener and 6-16 parts of deionized water. The water-based paint has the advantages of favorable antirust effect, quick air-drying, high adhesive force and high hardness; and by using water as the diluter, the water-based paint satisfies the environmental requirements, and is harmless to the human body.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

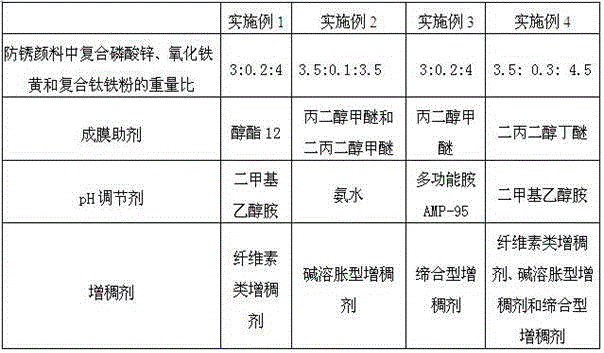

Aluminum fin alloy and method of making the same

ActiveUS20130156634A1High cooling rateLow cooling rateConductive materialHeat exchange apparatusHigh intensityHeat exchanger

The present invention relates to an aluminum alloy product for use as a finstock material within brazed heat exchangers and, more particularly, to a finstock material having high strength and conductivity after brazing. The invention is an aluminum alloy finstock comprising the following composition in weight %:Fe 0.8-1.25;Si 0.8-1.25;Mn0.70-1.50;Cu0.05-0.50;Znup to 2.5;other elements less than or equal to 0.05 each and less than or equal to 0.15 in total; and balance aluminum.The invention also relates to a method of making the finstock material.

Owner:NOVELIS INC

Concrete surface retarder as well as preparation method and application thereof

InactiveCN112079653AImprove adaptabilityImprove high temperature performanceSolid contentPrecast concrete

The invention provides a concrete surface retarder, and belongs to the technical field of concrete. The concrete retarder is prepared from the following components, by mass: 15%-25% of a composite retarder, 0.5%-1% of a thickening agent, 0.1%-1% of a corrosion inhibitor and 0.3%-2% of a preservative, wherein the solid content of the surface retarder is 19-29%. The invention also provides a preparation method of the retarder and application of the retarder in precast concrete components. By adopting a mode of compounding various retarders, the adaptability to cement is improved, and the application range of the surface retarder is widened; the surface retarder disclosed by the invention contains a high-temperature-resistant retarder, is good in high-temperature performance, is suitable forprefabricated parts subjected to natural curing or high-temperature steam curing, and is relatively wide in use temperature range; according to the invention, the types and dosages of the raw materials are optimized, the corrosion of the concrete template is fully considered, and the corrosion inhibitor is added, so that the negative effect of the surface retarder is effectively reduced; the surface retarder disclosed by the invention is low in raw material cost, not easy to volatilize, environment-friendly and suitable for popularization and application.

Owner:福建西建新材料有限公司 +3

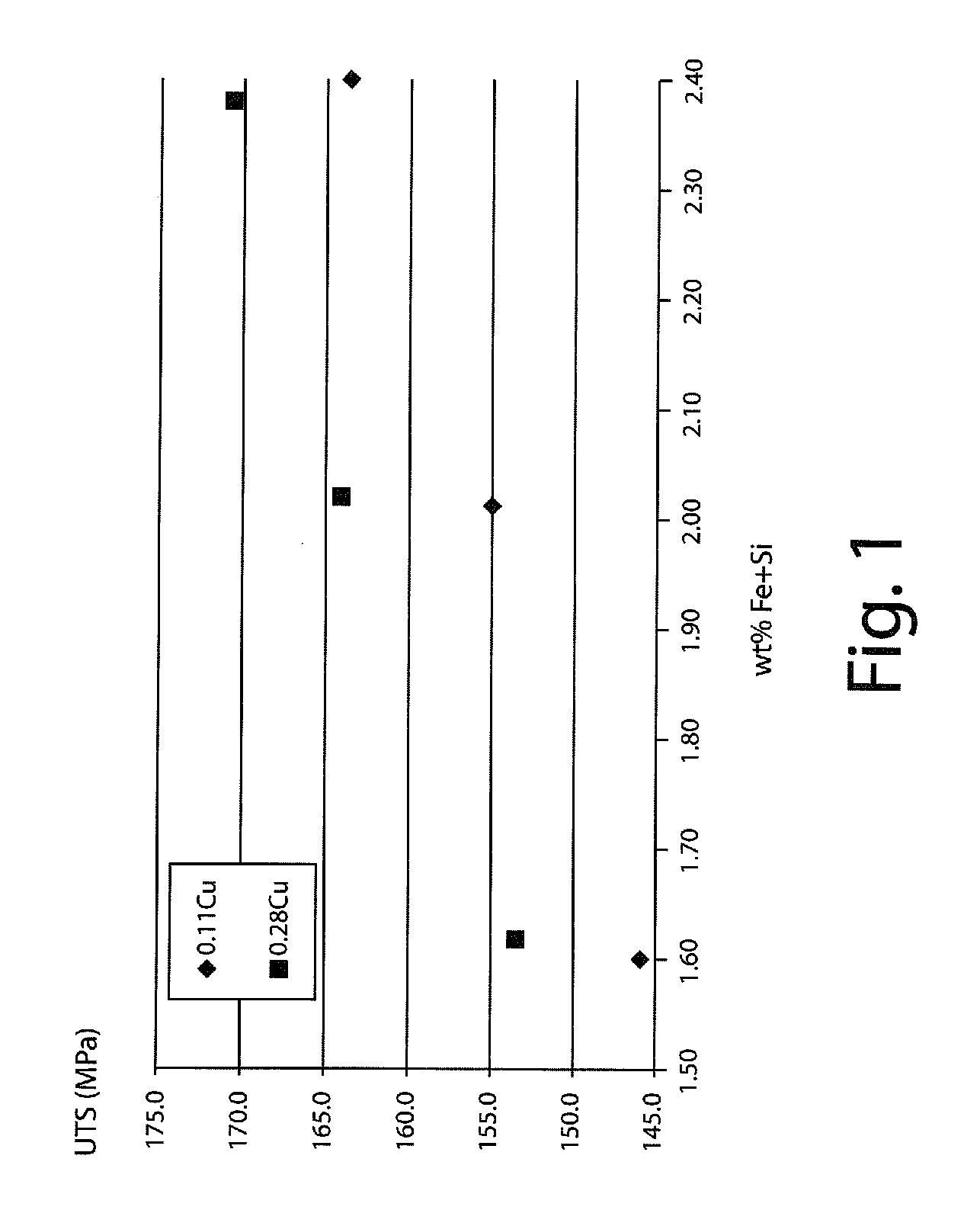

Hollow blow-molded micro-foamed automobile air duct material and preparation method thereof

InactiveCN108892830AImprove appearance qualityGood material strengthTubular articlesPolyesterMaterials science

The invention relates to an automobile air duct and a preparation method, especially to a hollow blow-molded micro-foamed automobile air duct material and a preparation method thereof. The material ofthe invention comprises the following components, by weight: 50-80 parts of polyethylene, 0-15 parts of mineral powder, 1-30 parts of polyester, 0.2-1 part of a tackifier, 0.5-10 parts of a foaming agent, 5-15 parts of a blowing promotor, 0.2-0.5 part of a lubricant, and 0.2-0.5 part of an antioxidant. The invention also discloses the preparation method of the material. The hollow blow-molded micro-foamed automobile air duct has the characteristics of high cell density and good apparent quality. An automobile engine hood product prepared by the material has the characteristics of light weight, good heat insulation effect, good dimensional stability, high yield and the like. Under the condition that the whole weight of the product is reduced by more than 40%, the normal assembly and use ofparts are not affected, and the purpose of lightweight is achieved.

Owner:NANJING JULONG SCI&TECH CO LTD +1

Lightweight panel

A composite board comprising a core and a paper facer sheet adhesively laminated to one face of the core, the core including a mixture of perlite, binder, and cellulose fiber, the core being formed as a water slurry with said perlite, binder and cellulose fiber being uniformly distributed therein, the perlite being in an expanded state such that its particles include internal voids and exhibit a density of about 5 to about 15 pounds per cubic foot and being present in sufficient quantity to occupy in bulk at least 50% of the volume of the core, on a weight basis, the perlite and cellulose fiber combined forming at least 25% of the weight of the core. The paper facer being laminated to the core with a water-based adhesive applied across substantially the full area of the facer, both the compressive strength of the perlite and tensile strength of the cellulose fiber being utilized by operation of the binder such that a relatively high nail-pull capacity in comparison to the weight of the composite board is achieved and sag resistance is imparted to the composite board when it is used for ceiling tile.

Owner:USG INTERIORS INC

Water-based coating compositions and systems with improved sag resistance and related methods

InactiveUS20140324234A1Improve the level ofHigh viscositySpraying apparatusDrying gas arrangementsWater basedComputer module

Owner:SWIMC LLC

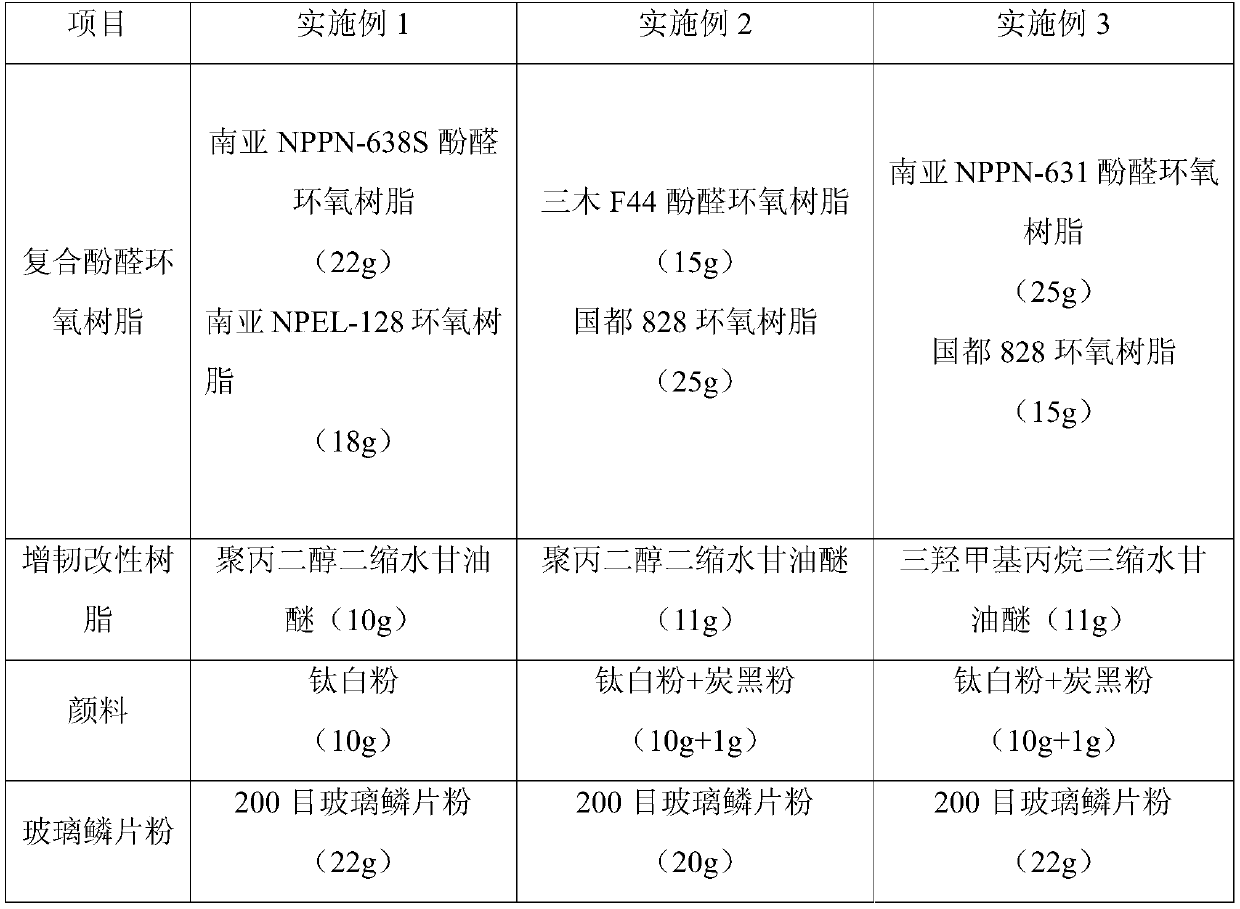

High-solid phenolic aldehyde epoxy glass scale anti-corrosion paint and preparation method thereof

ActiveCN109749585AHigh solid contentGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsOrganic solventSewage

The invention discloses high-solid phenolic aldehyde epoxy glass scale anti-corrosion paint and a preparation method thereof, and belongs to the field of heavy-duty anticorrosion. The anti-corrosion paint comprises a component A and a component B. The component A comprises, by weight, composite phenolic aldehyde epoxy resin, toughened modified resin, pigments, glass scale powder, fillers, rheological additives and solvents. The component B comprises, by weight, amine curing agents and solvents. The paint has the advantages that solid content is high, chemical resistance is excellent, and one-time construction formed film is thick through interaction between components. After a cabin and the inner wall of a tank are coated with the paint, corrosion of chemicals such as acid, alkaline, organic solvent and oily sewage can be effectively resisted, the service lives of the cabin and the tank are prolonged, and maintaining cost is saved.

Owner:NANJING CHANGJIANG PAINT

Novel wall heat-insulating material and preparation process thereof

InactiveCN108129108AIncreased durabilityRealize the insulation effectMethyl cellulosePolyvinyl chloride

The invention discloses a novel wall heat-insulating material and a preparation process thereof. The novel wall heat-insulating material mainly comprises the following components in parts by weight: 22 to 42 parts of cement, 14 to 23 parts of polyvinyl chloride resin powder, 13 to 26 parts of modified plant straw powder, 3 to 10 parts of dispersible latex powder, 2 to 8 parts of hydroxypropyl methyl cellulose, 1.3 to 6.5 parts of glass bead, 0.3 to 2.2 parts of water-reducing agent, 0.5 to 3.8 parts of coagulation accelerator and 0.2 to 1.4 parts of curing agent. The novel wall heat-insulatingmaterial provided by the invention has the advantages of light weight, high strength, high heat-insulating property, low water-absorbing rate, sound absorption, shock prevention and the like; furthermore, the preparation method is simple and suitable for large-scale production and application.

Owner:合肥卓创新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com