Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

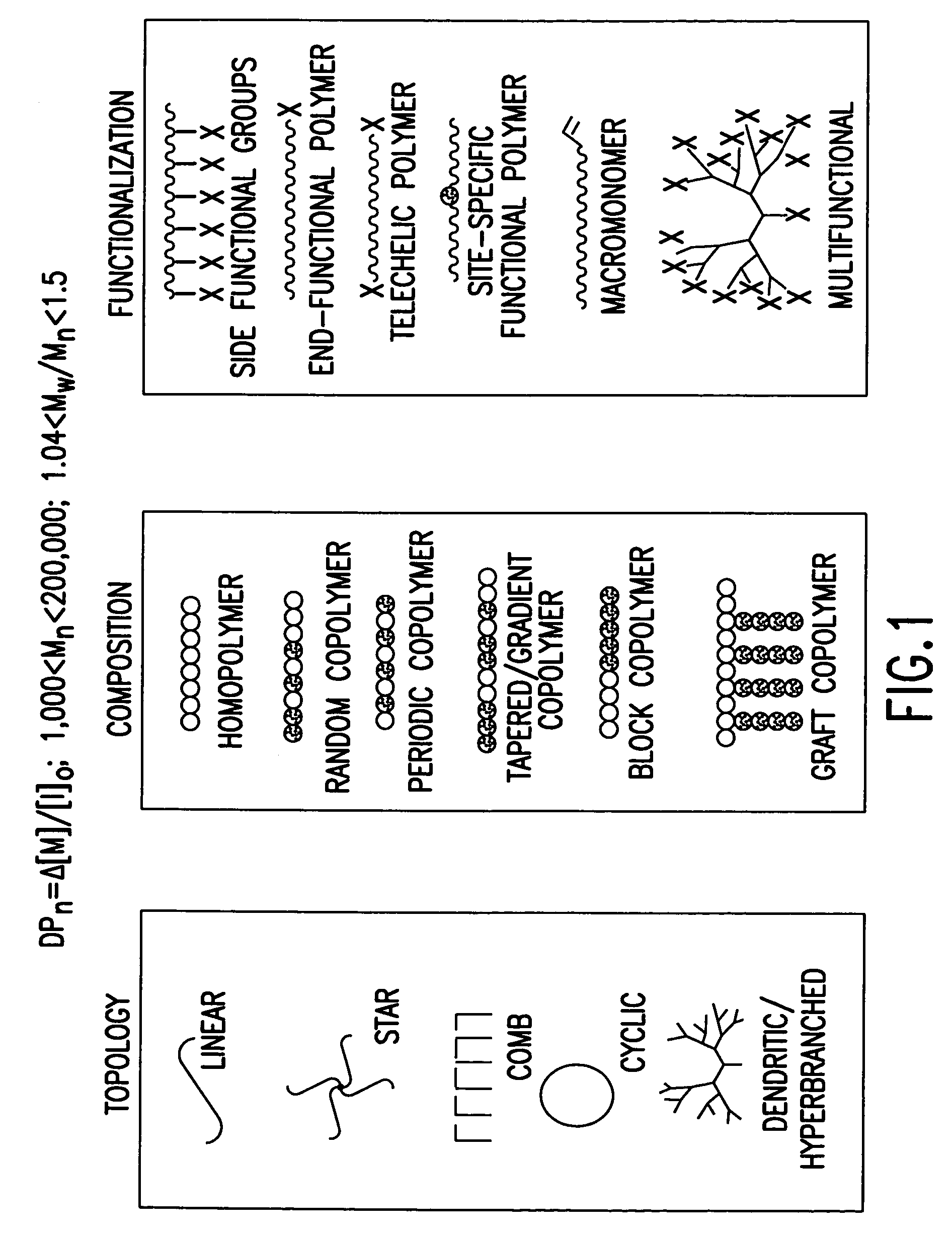

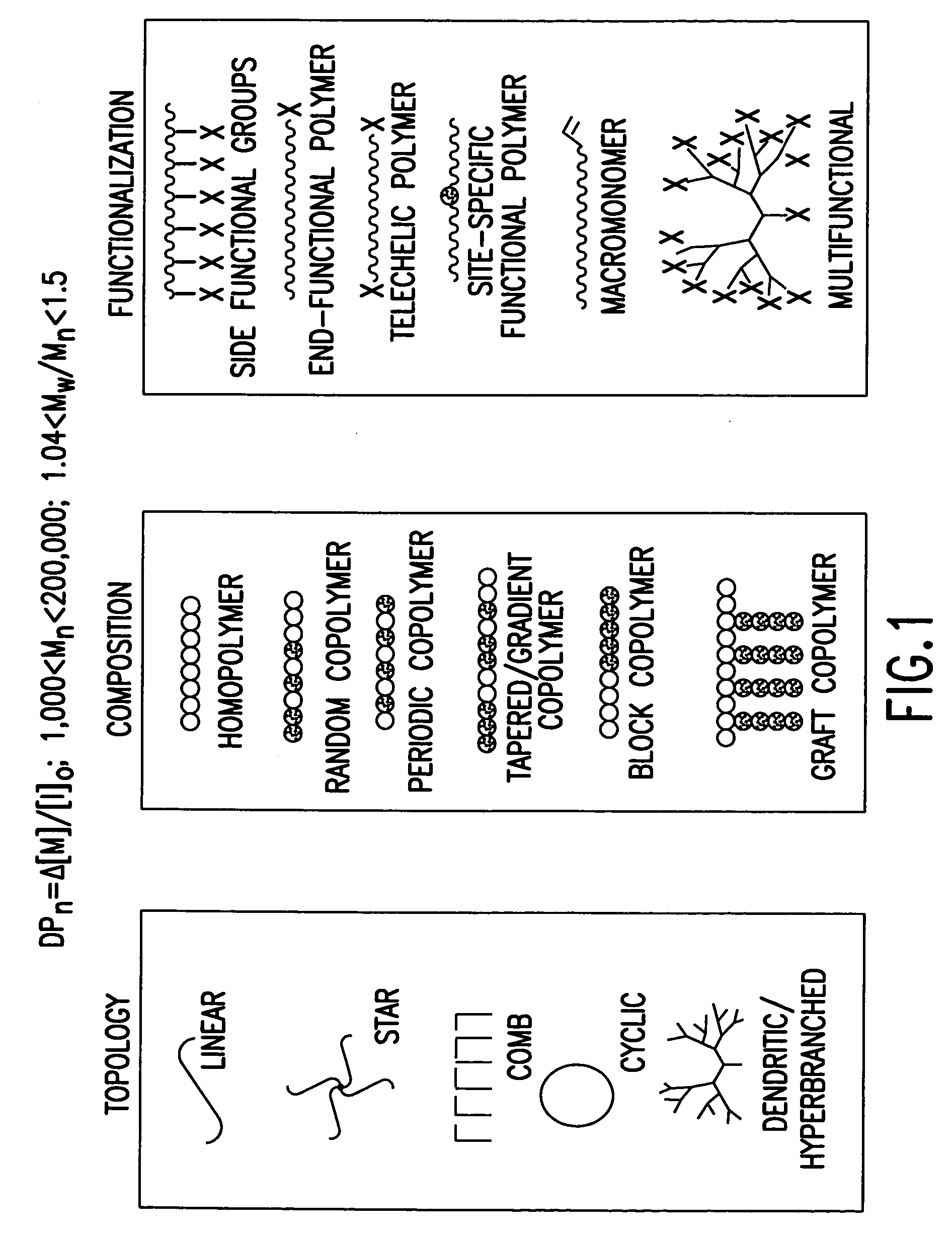

Processes based on atom (or group) transfer radical polymerization and novel (co)polymers having useful structures and properties

InactiveUS6887962B2Increase in the rate of side reactionsReduce rateWater solubleRadical polymerization

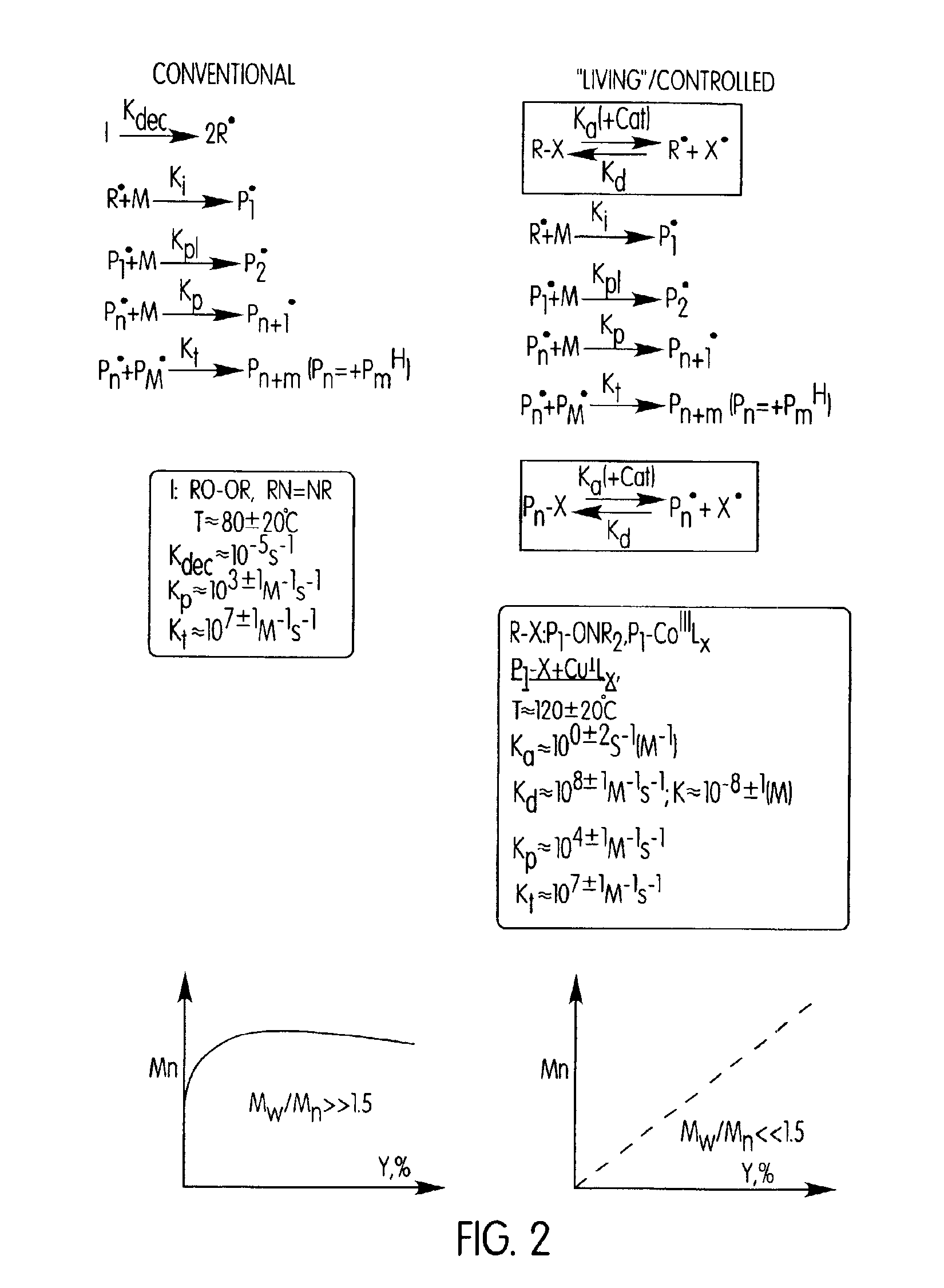

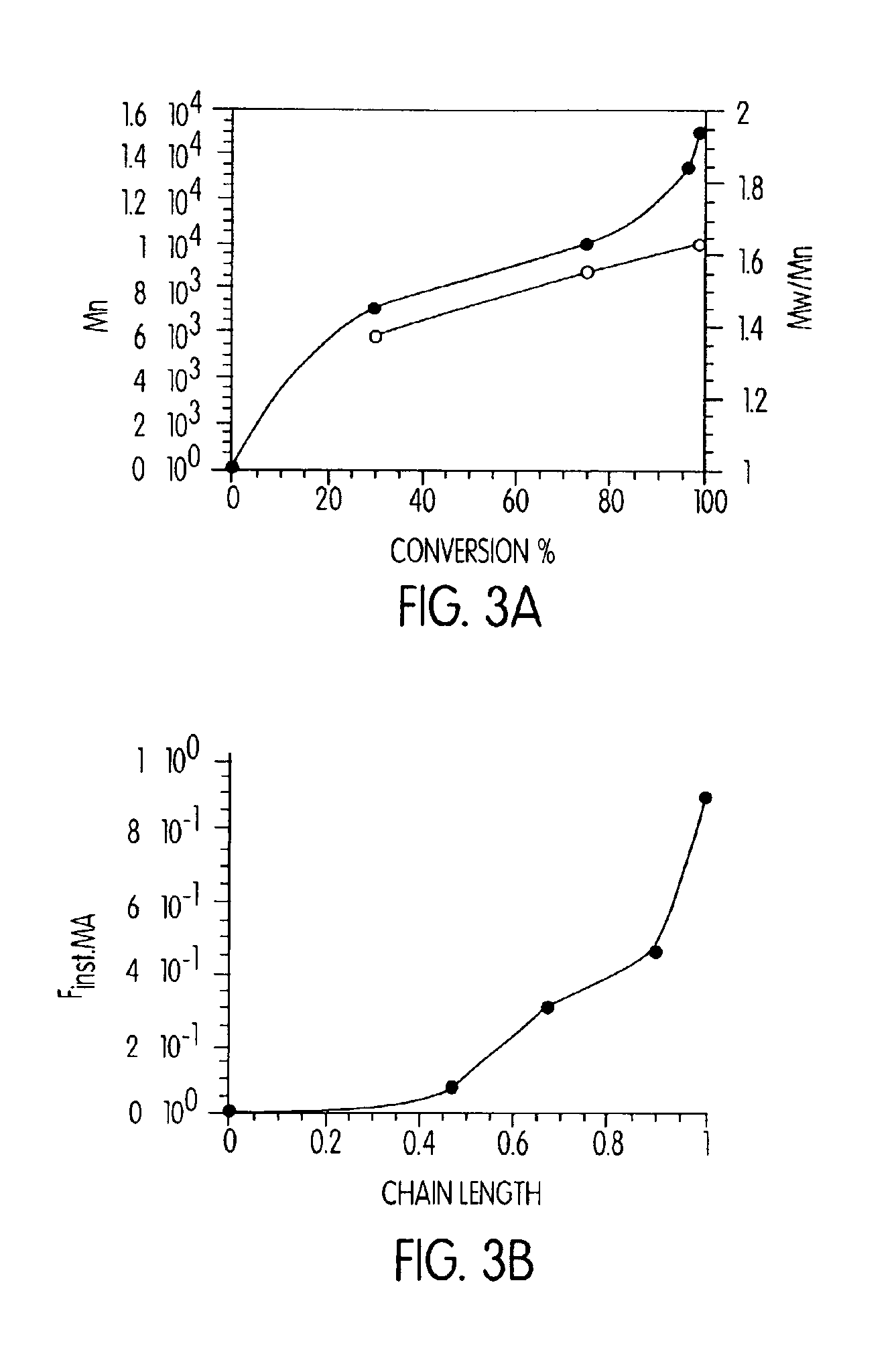

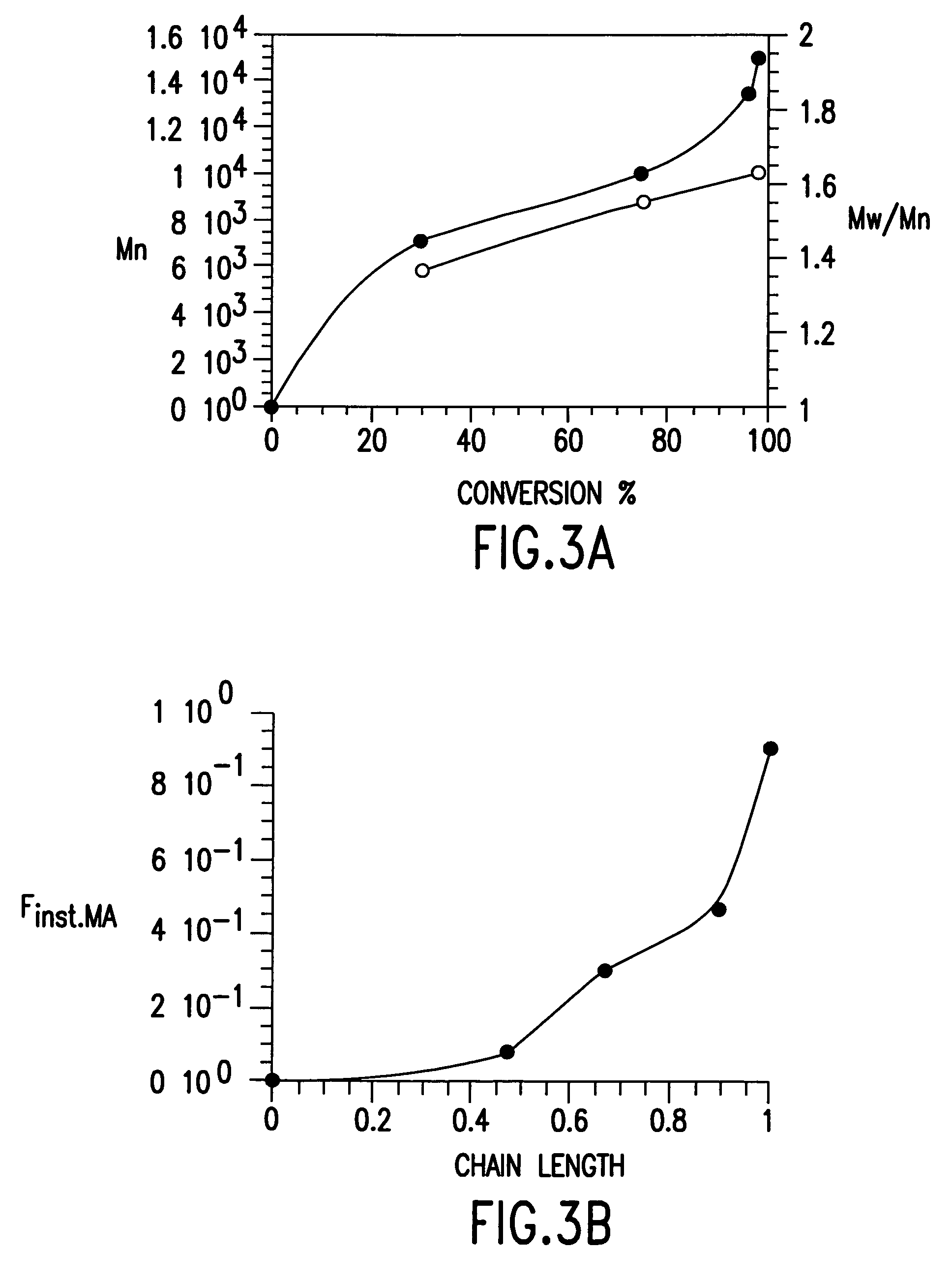

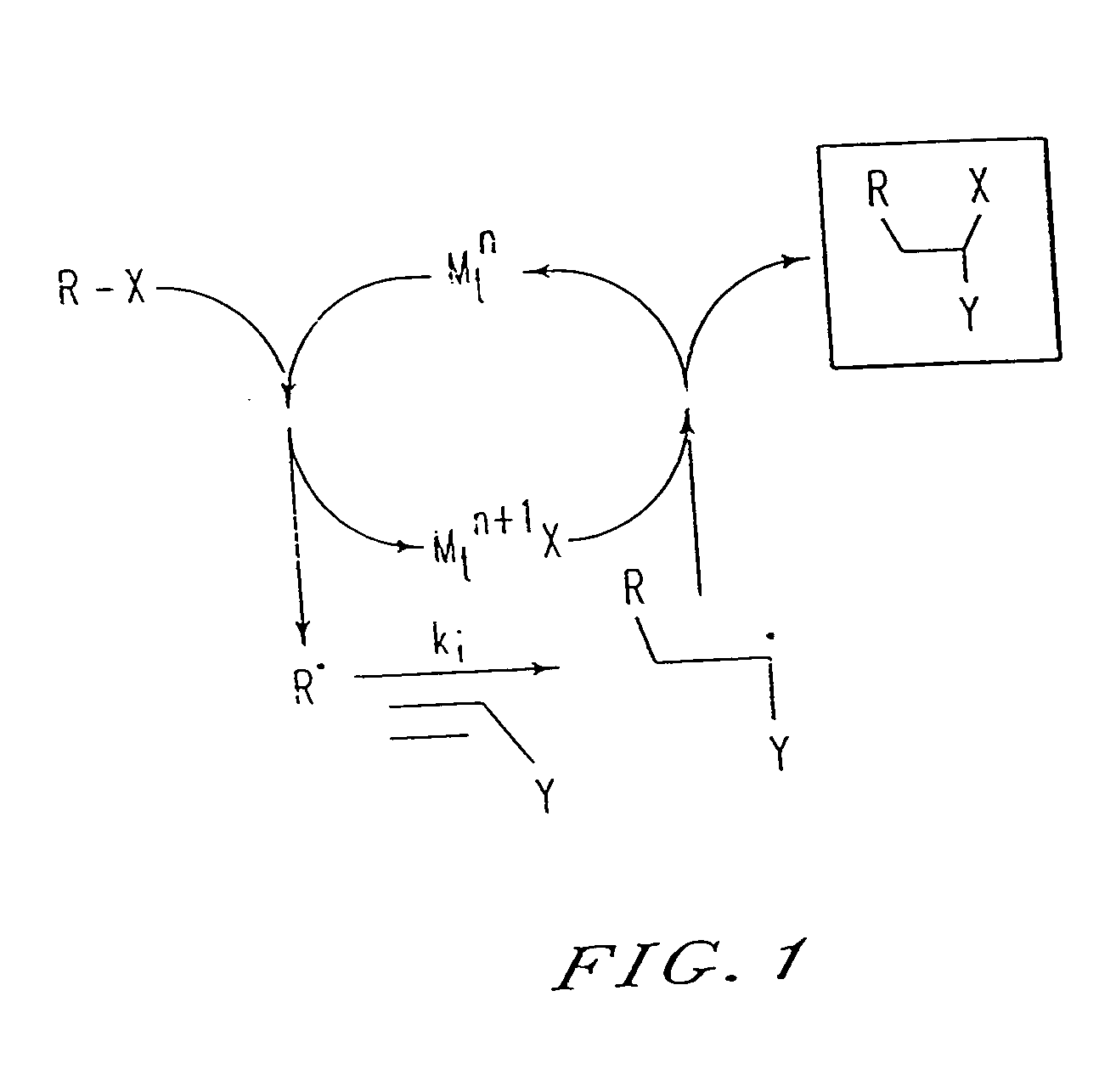

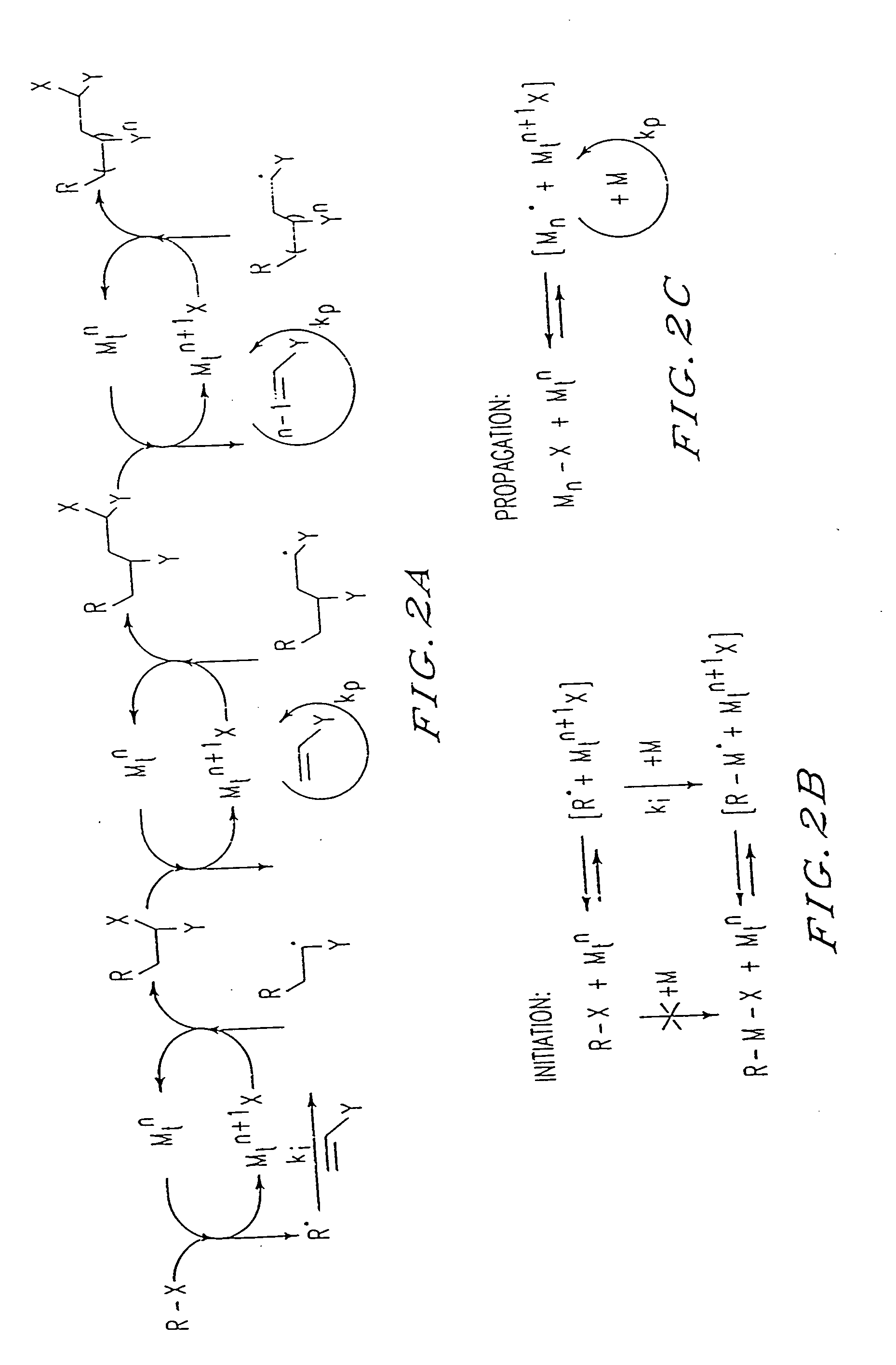

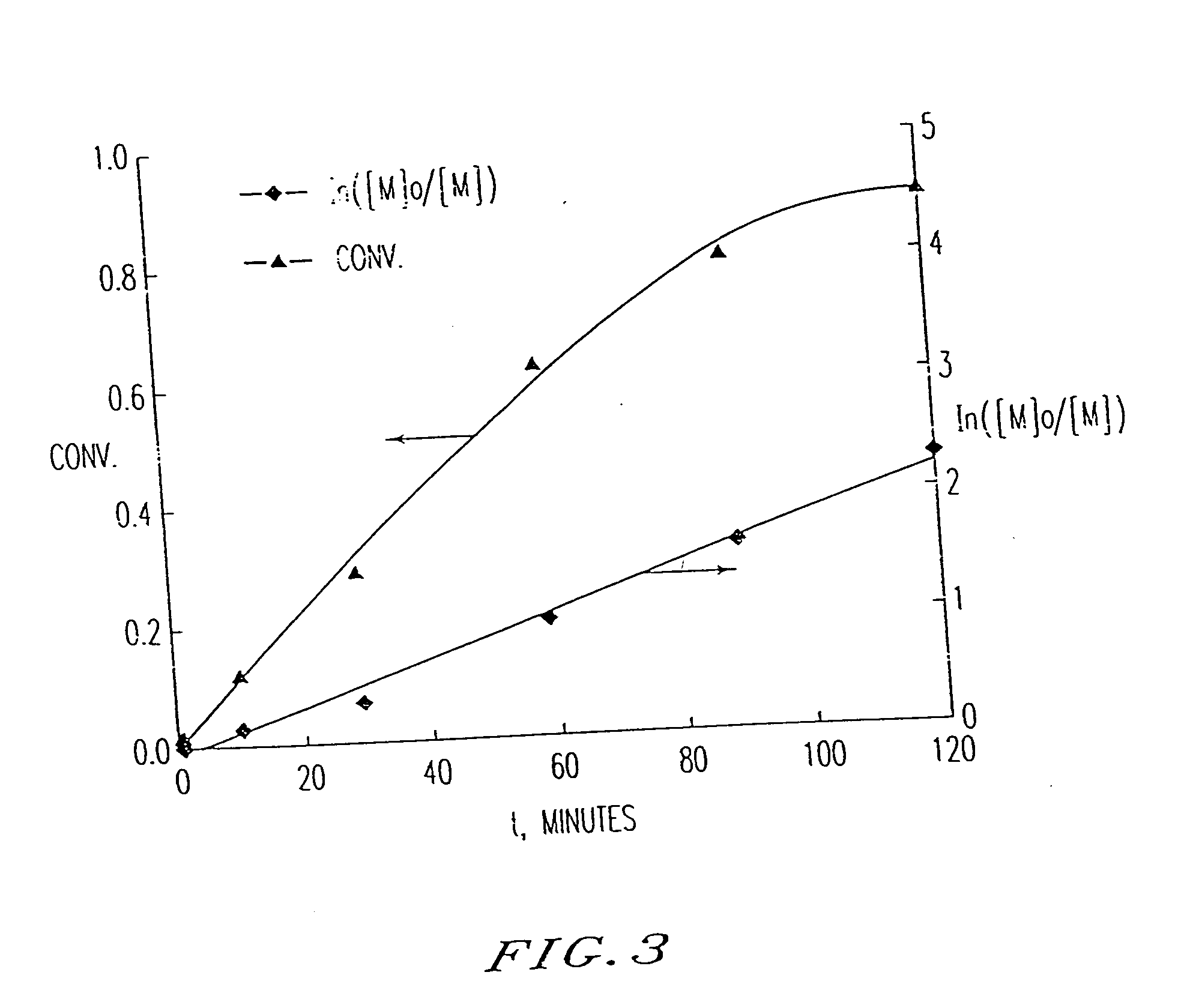

Improved processes for atom (or group) transfer radical polymerization (ATRP) and novel polymers have been developed and are described. In certain embodiments, novel copolymers comprising a least one polymeric branch or polymeric block with a predominantly alternating monomer sequence are described. Novel copolymers comprising a least one polymeric branch or polymeric block with a gradient monomer structure are described. Additionally, novel copolymers comprising a least one polymeric branch or polymeric block with a predominantly periodic monomer sequence are also described. Novel copolymers having a water soluble backbone and at least two hydrophobic polymeric branches grafted to the water soluble backbone are also described.

Owner:CARNEGIE MELLON UNIV

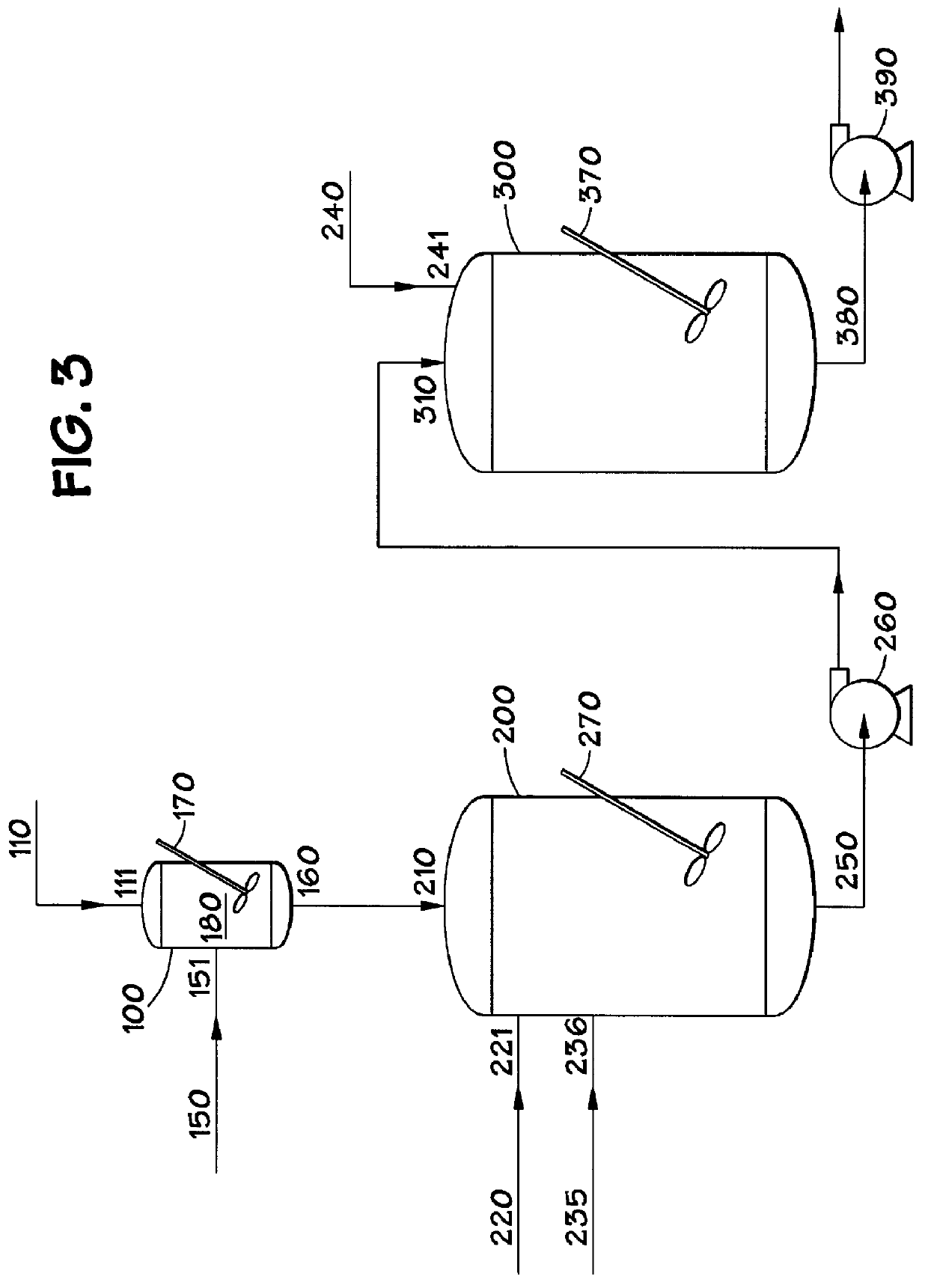

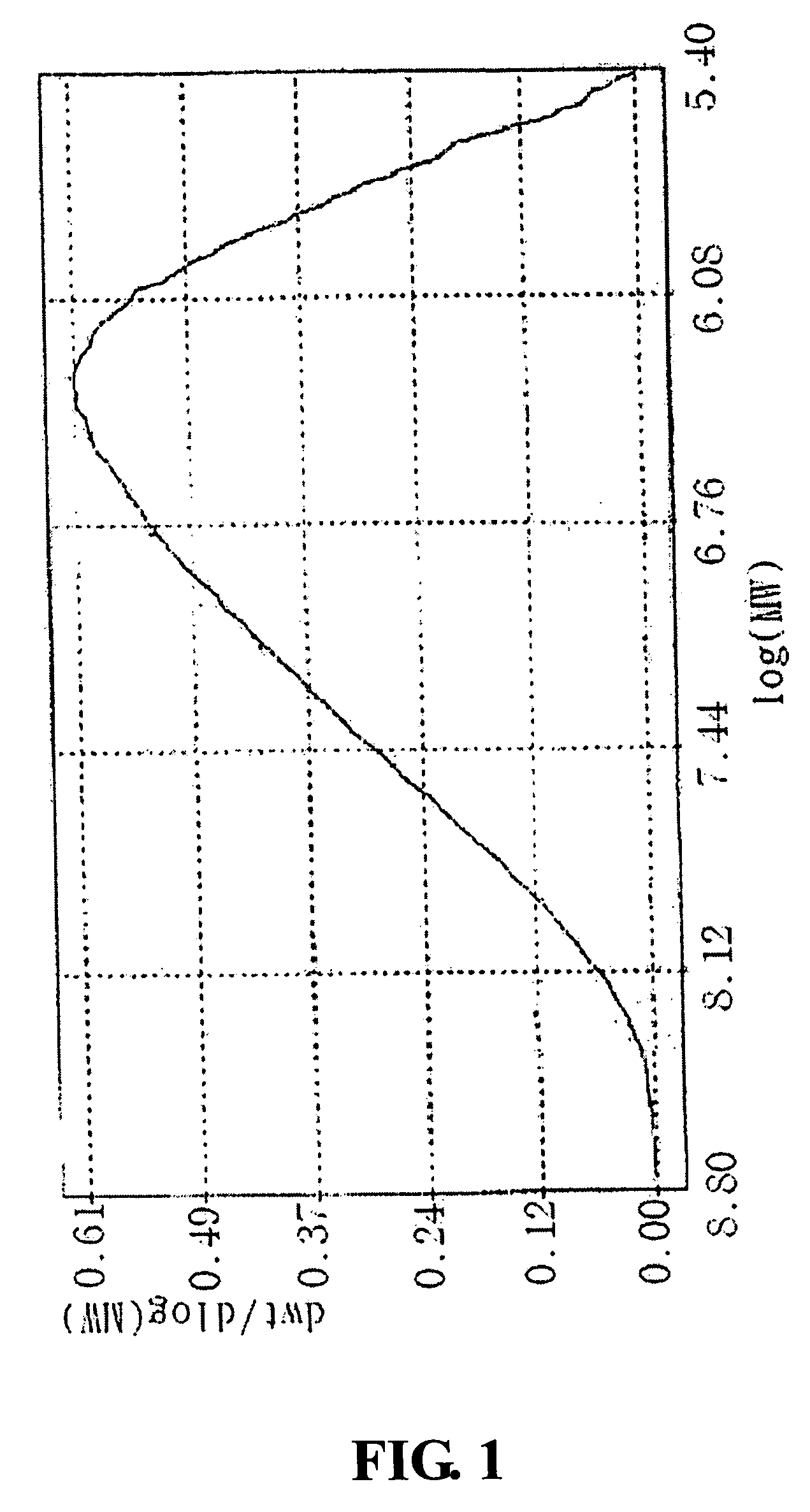

Methods for forming amorphous ultra-high molecular weight polyalphaolefin drag reducing agents

InactiveUS6015779AReduce frictional energy lossHigh molecular weightOther chemical processesLiquid organic insulatorsHalohydrocarbonAlpha-olefin

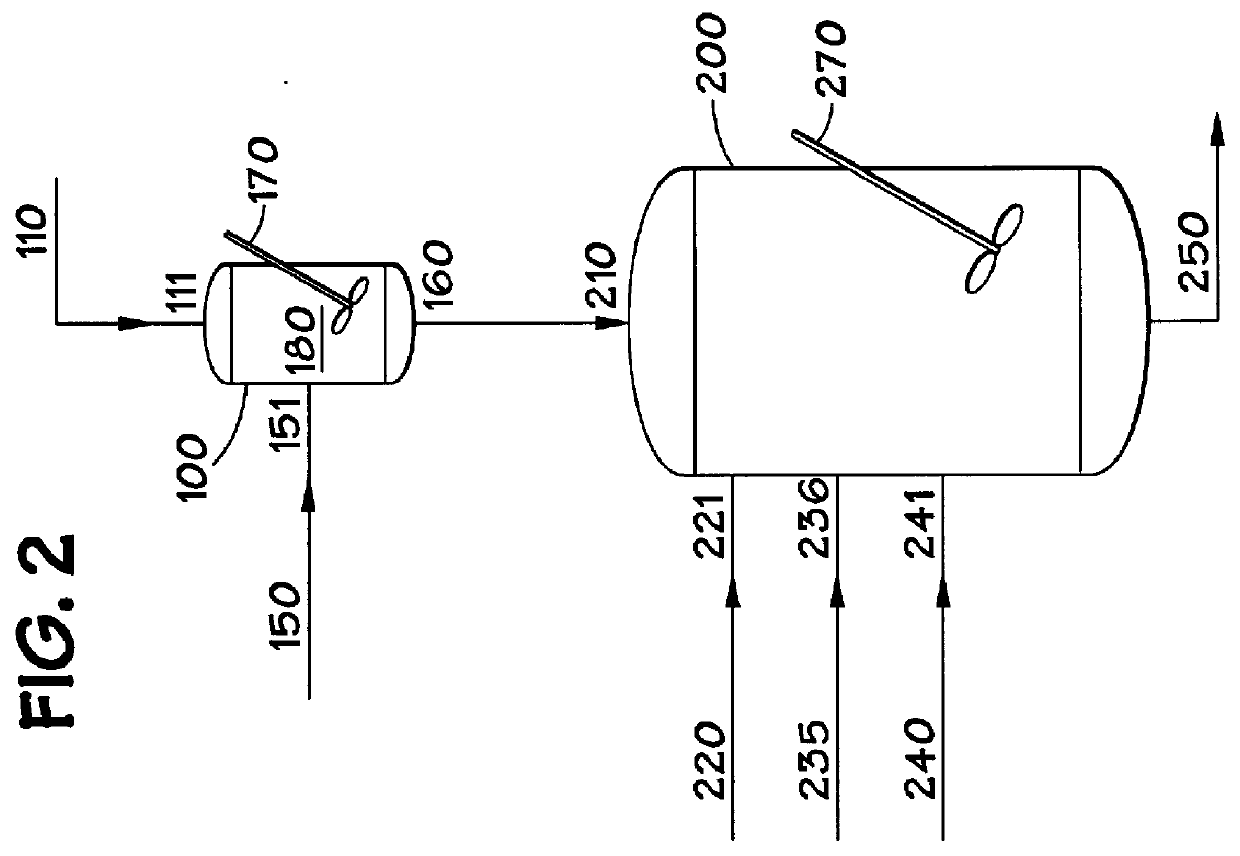

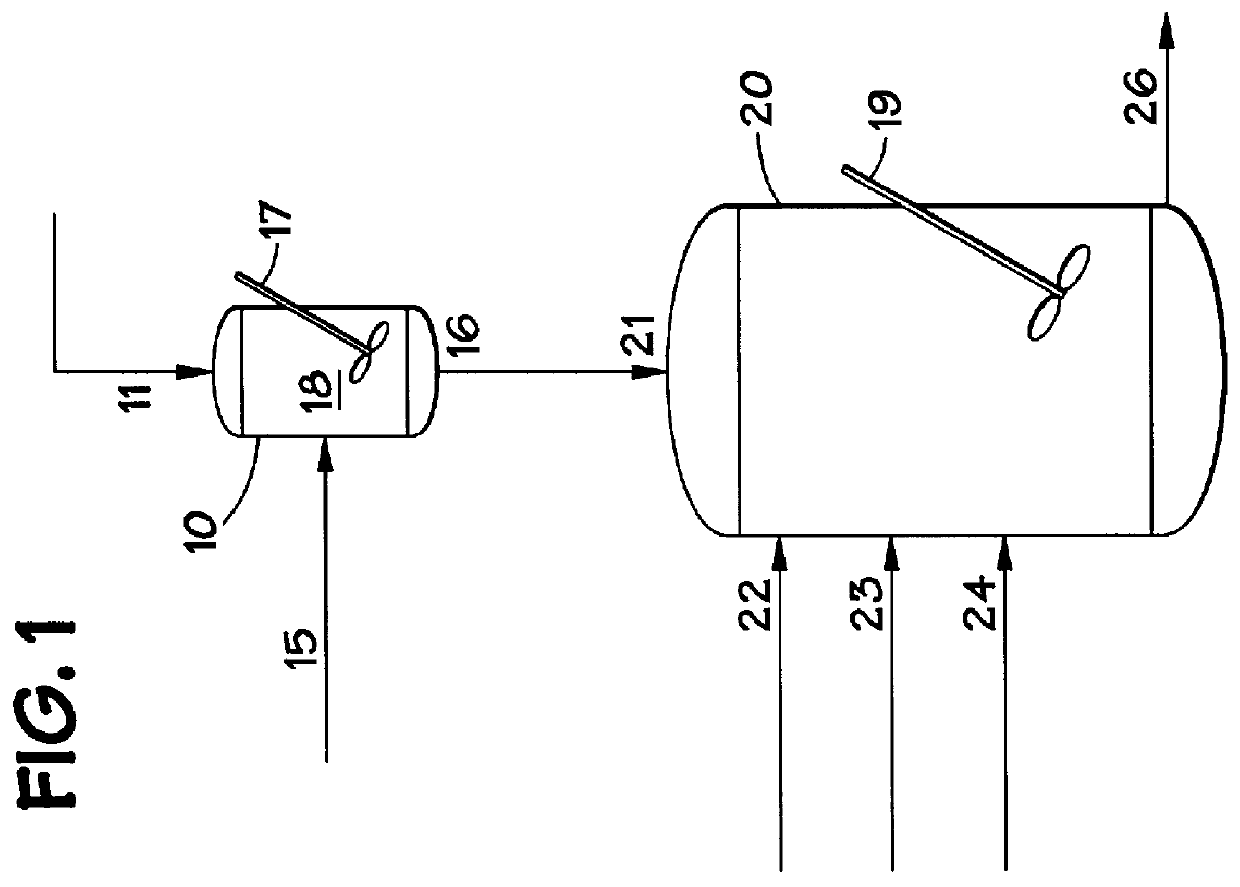

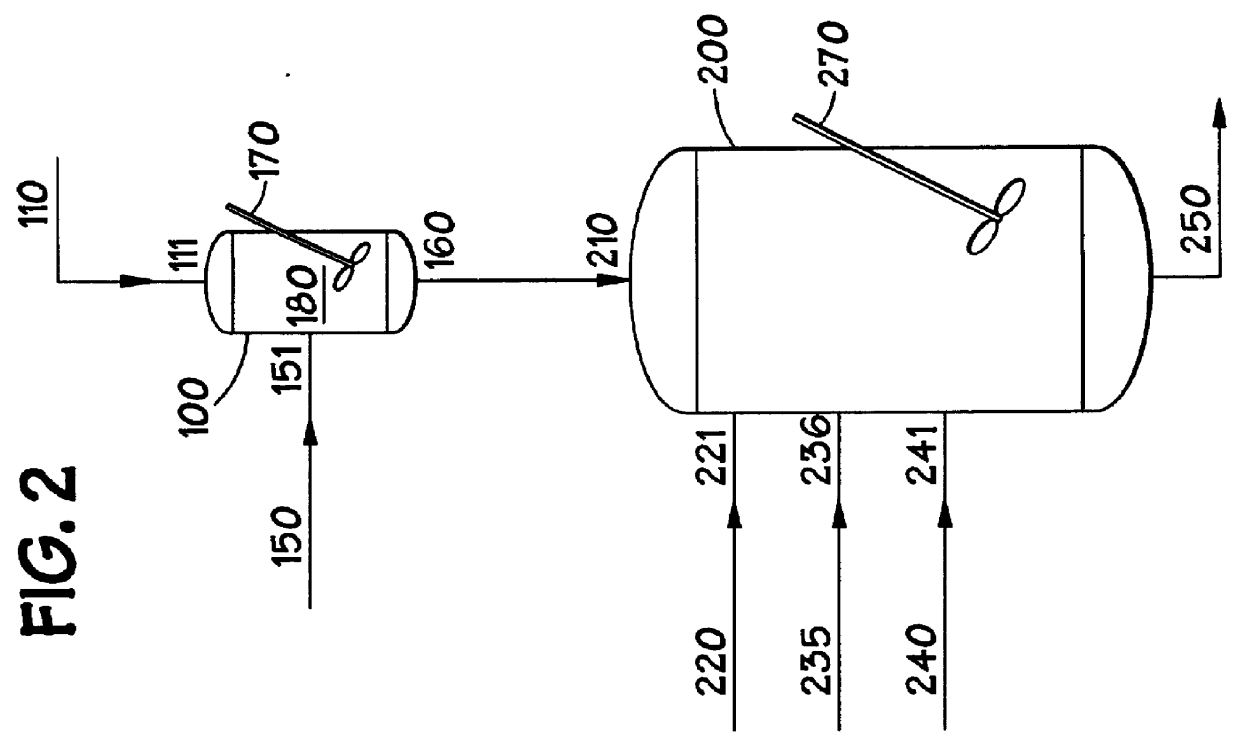

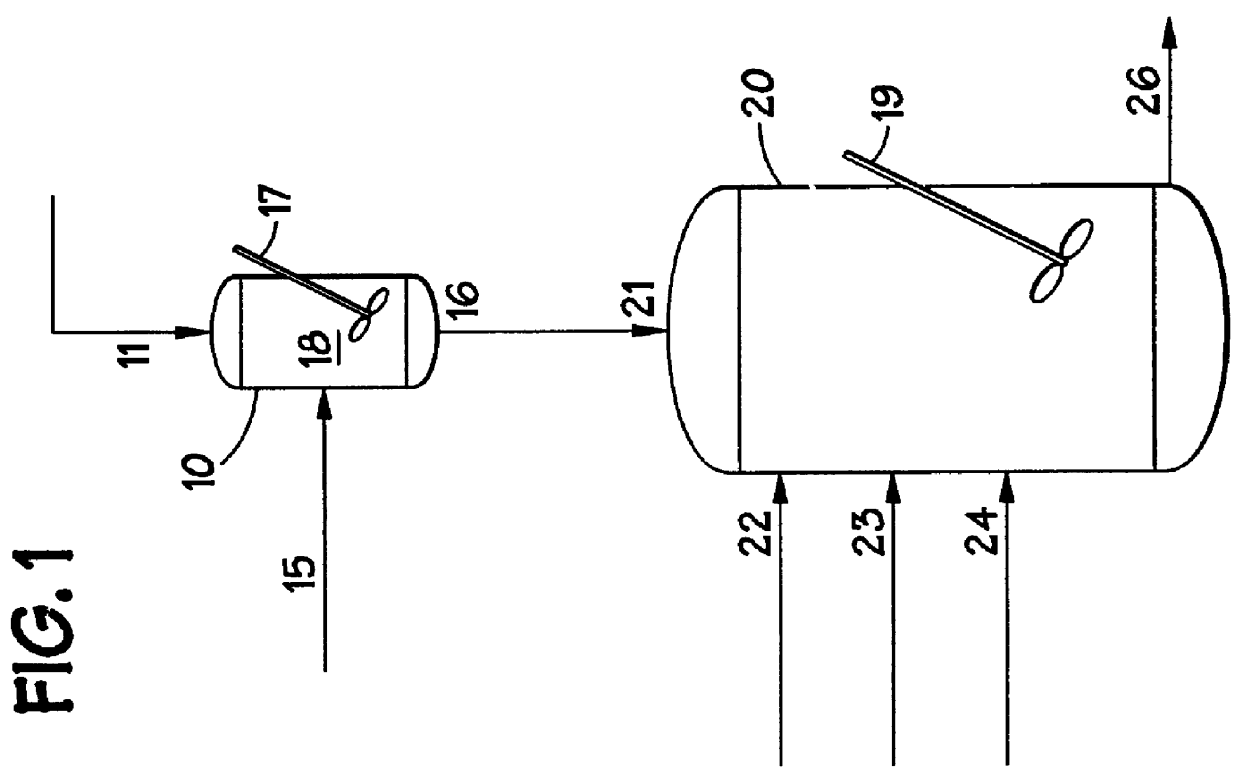

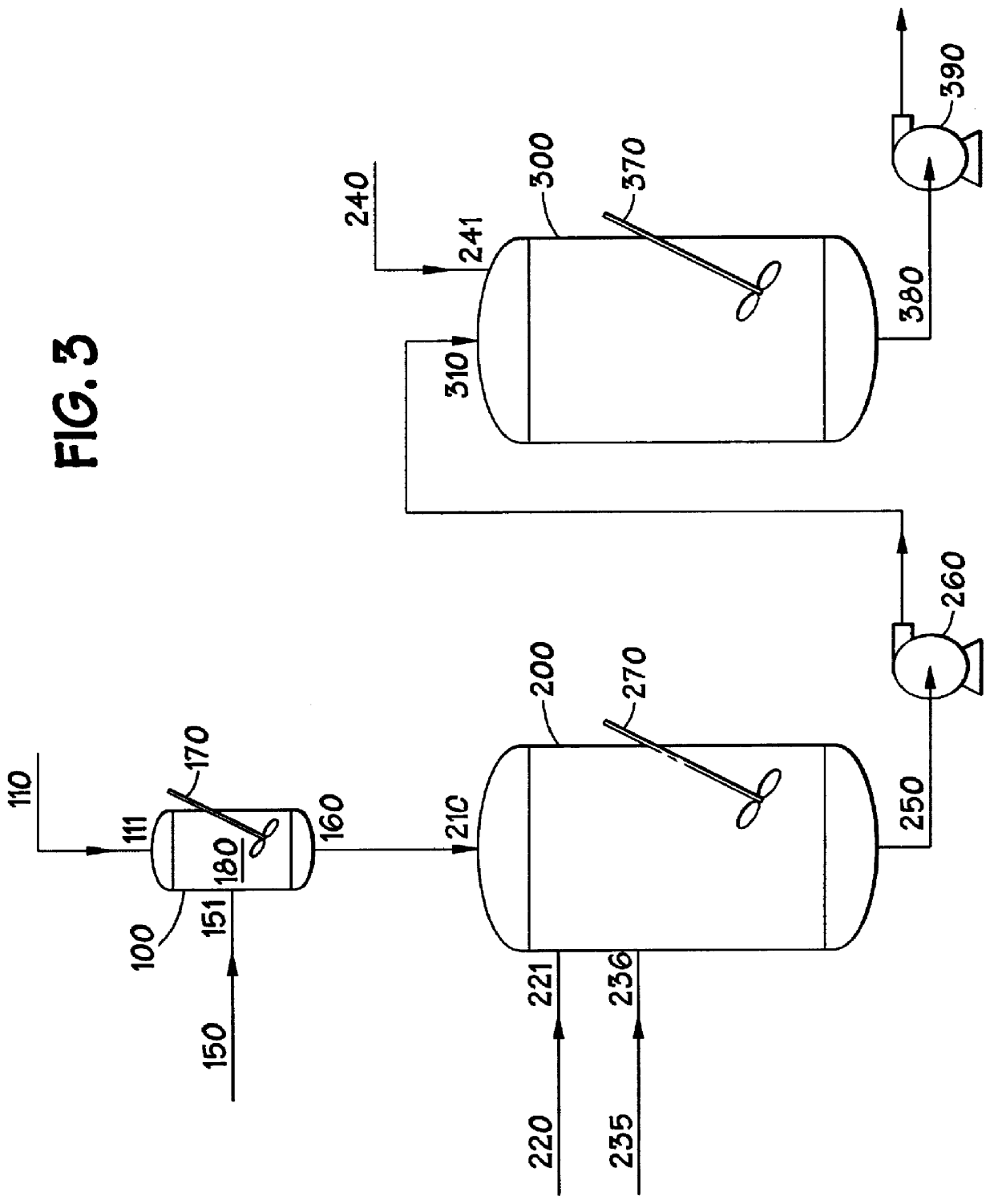

A composition including polyalphaolefins that function as drag reducing agents and a process for the preparation of polyalphaolefins that function as drag reducing agents are disclosed. The process includes contacting alpha olefin monomers with a catalyst system, which includes a catalyst and an activator (co-catalyst) in a reactant mixture. The catalyst is a transition metal catalyst, preferably titanium trichloride, and the co-catalyst may include an alkylaluminoxane, alone or in combination, with a dialkylaluminum halide or a halohydrocarbon. The polymerization of the alpha olefin monomers produces a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of at least 10 dL / g. The addition of the alkylaluminoxane during the polymerization process provides for a non-crystalline, ultra-high molecular weight polyalphaolefin and a more uniform molecular weight distribution of the resulting polyalphaolefin, thereby creating a drag reducing agent superior to known drag reducing agents. A process for forming a drag reducing agent comprising a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of about at least 10 dL / g and a process for reducing drag in a conduit are also disclosed.

Owner:MPOWER SPECIALTY CHEM

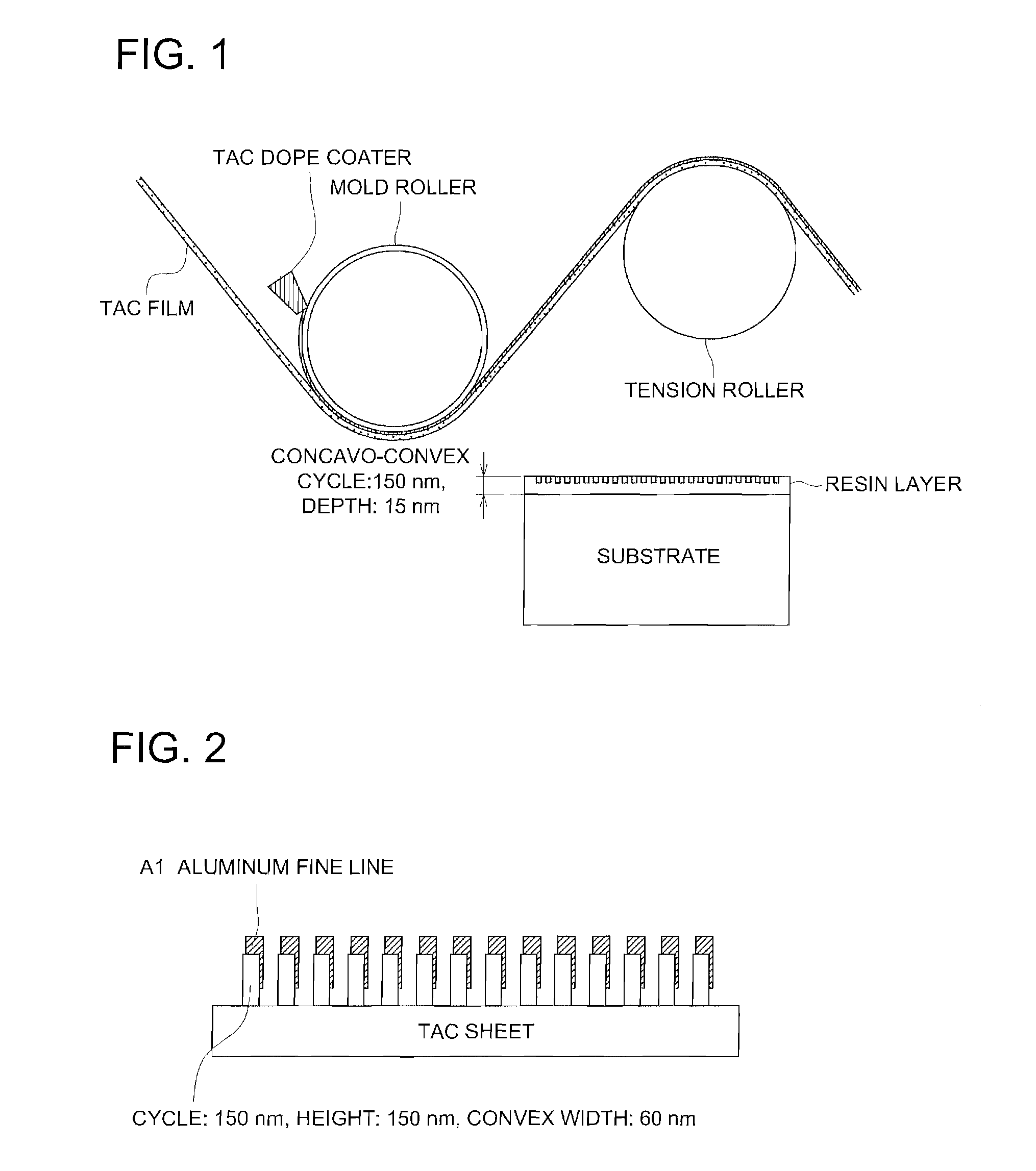

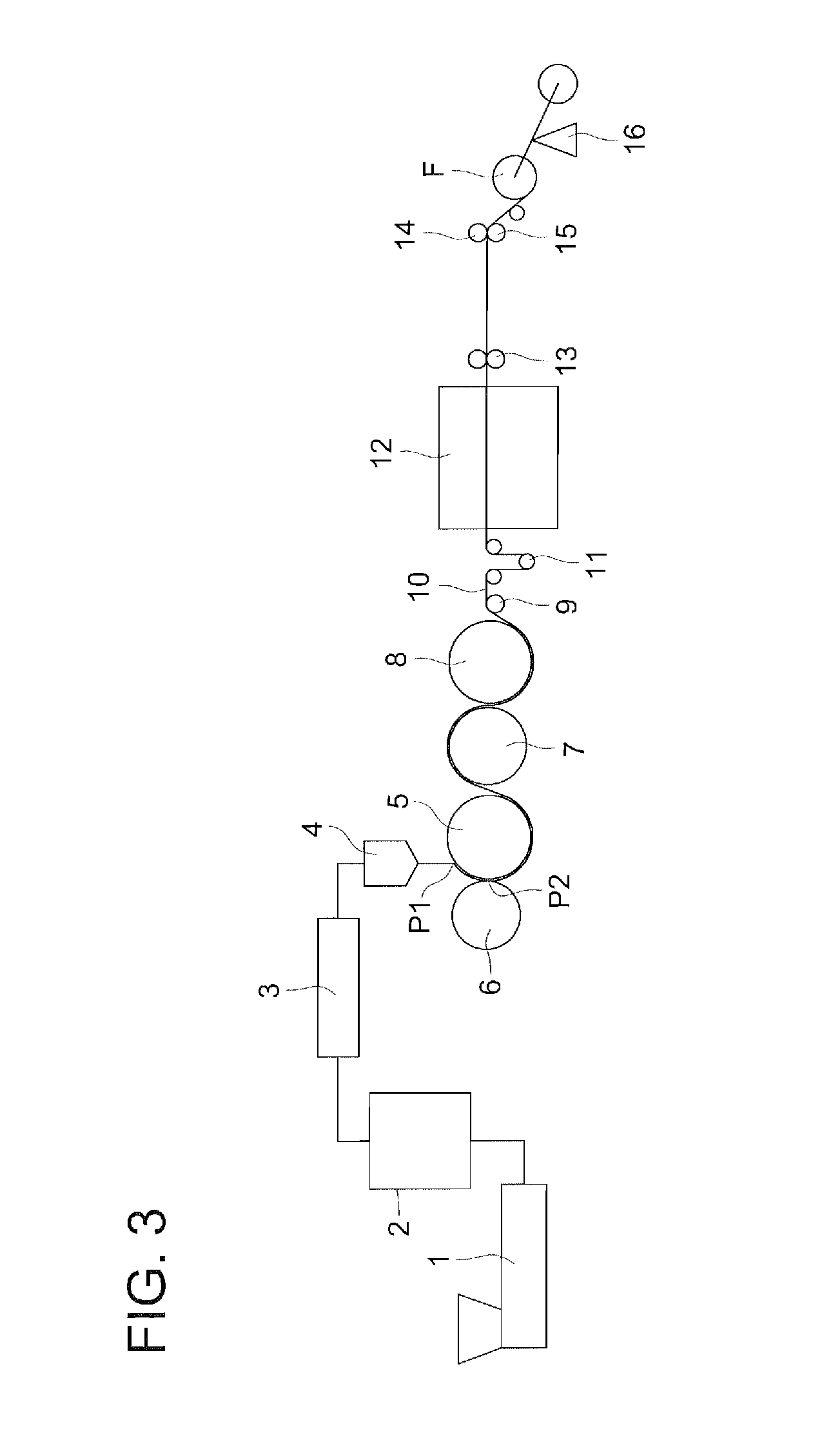

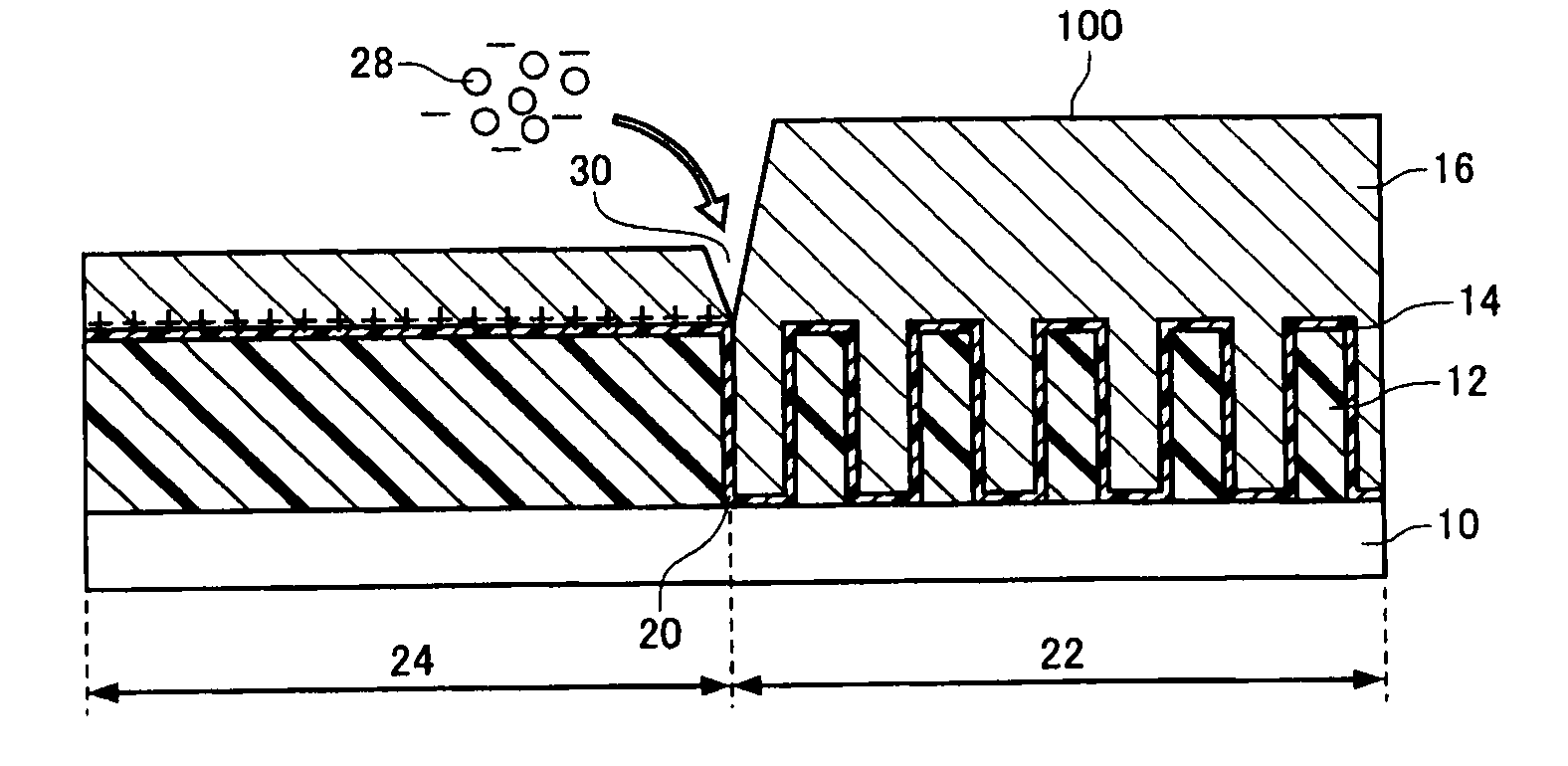

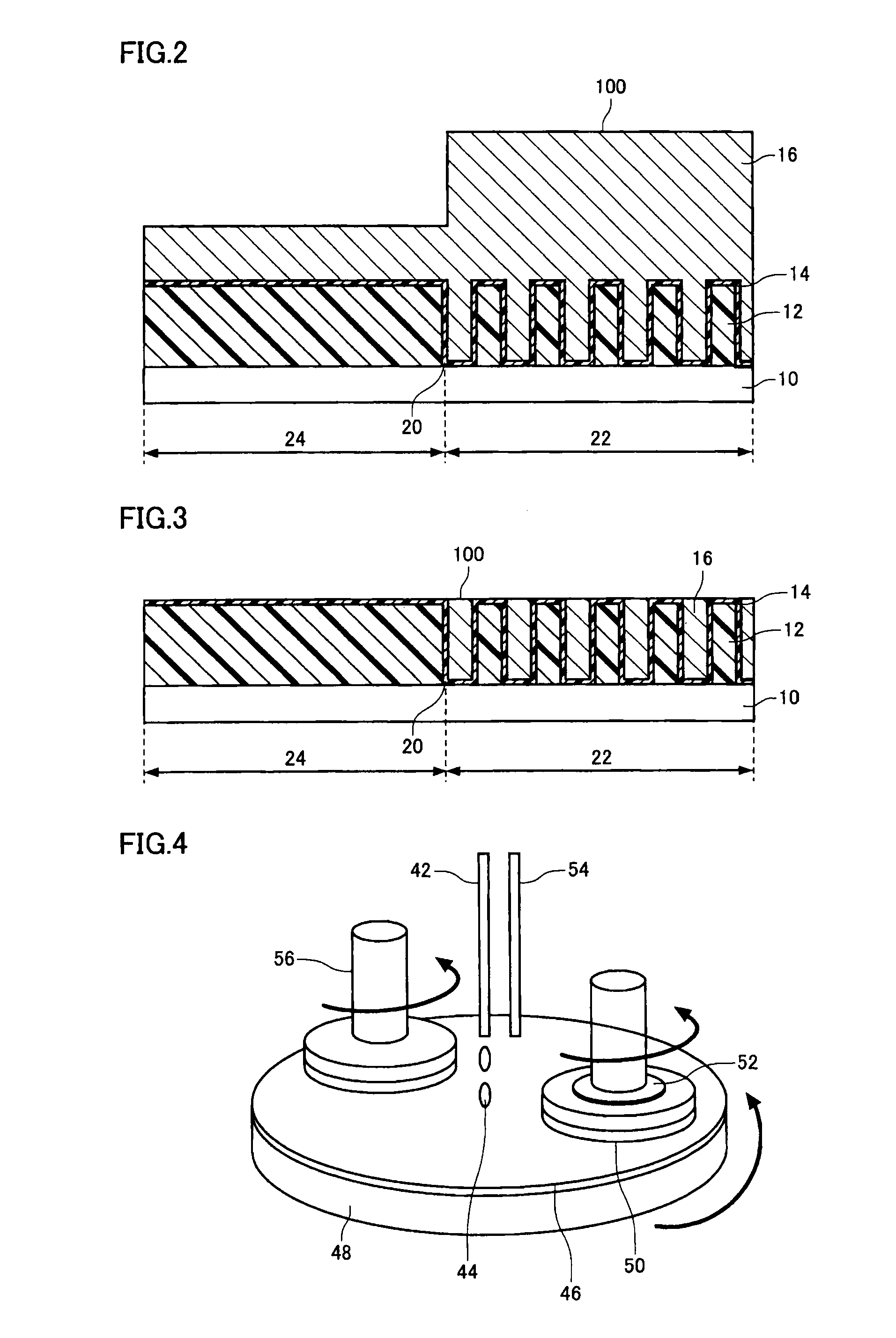

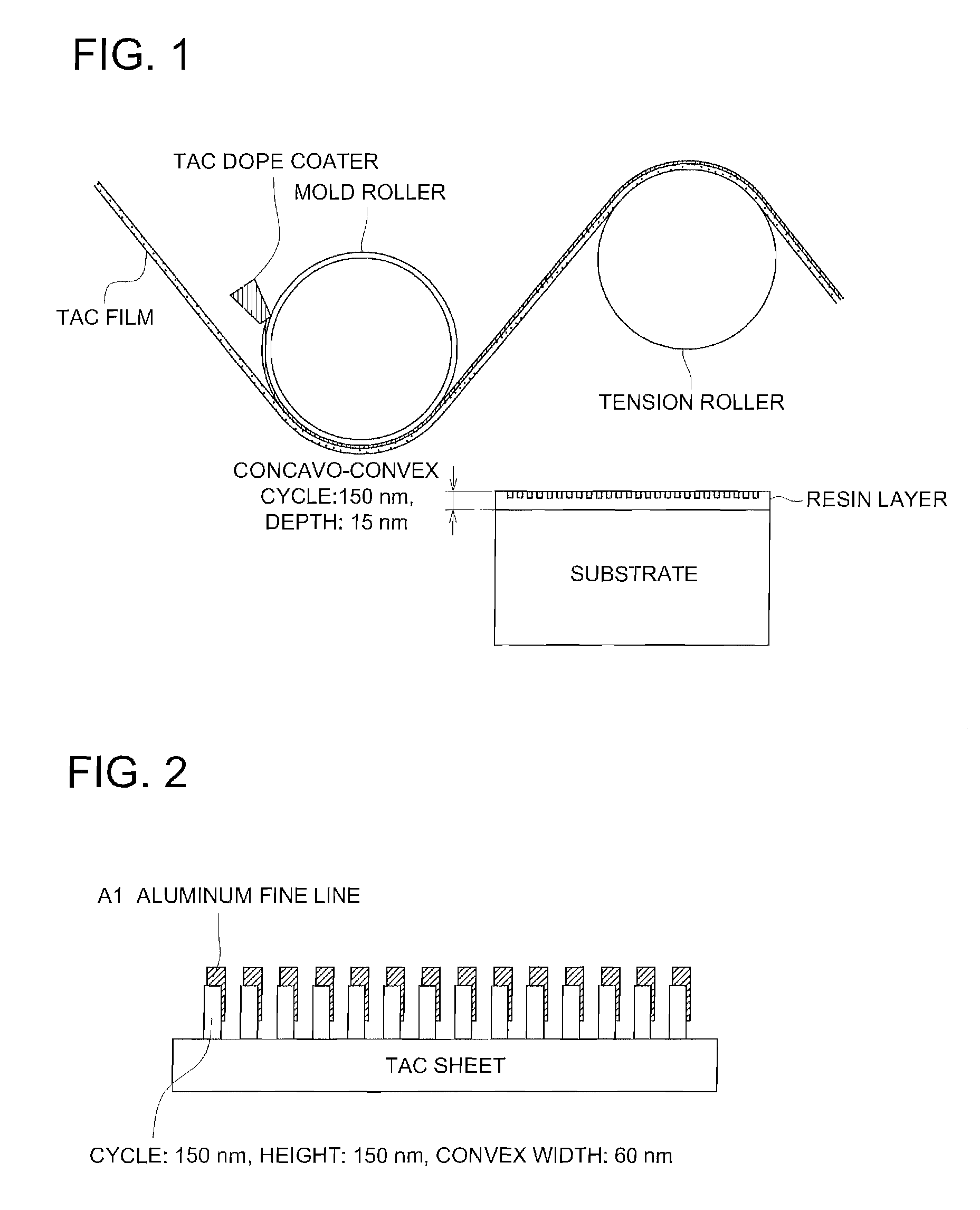

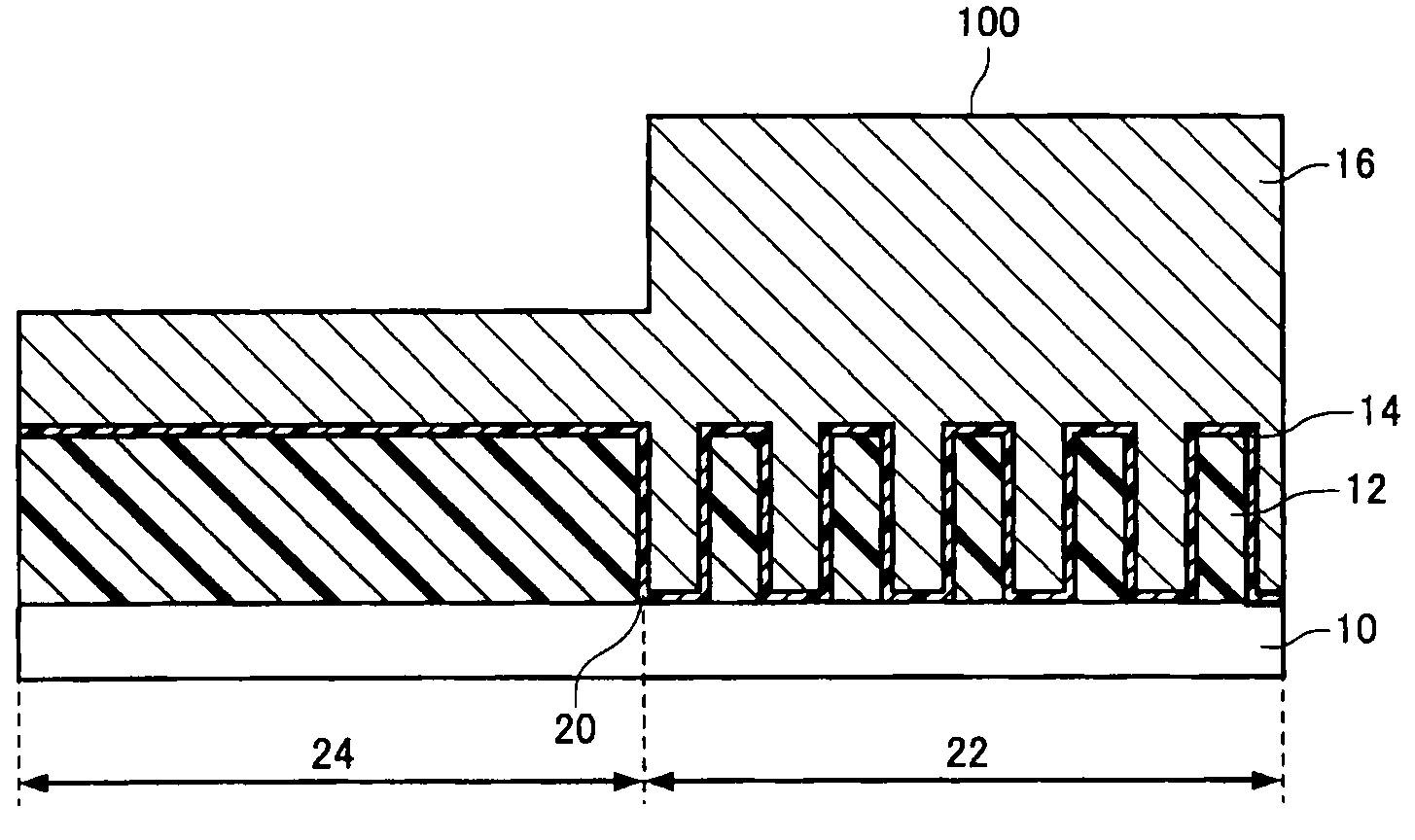

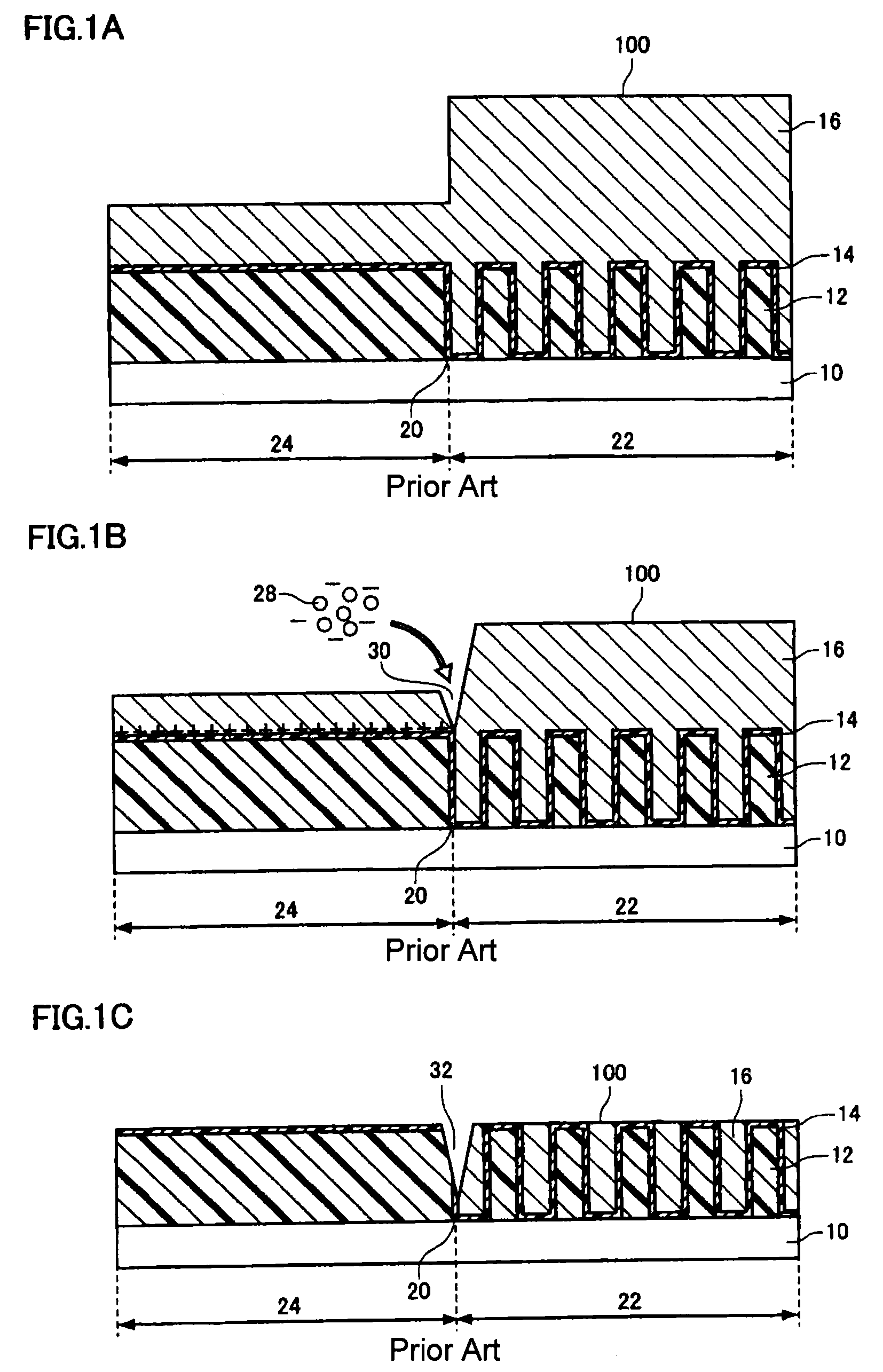

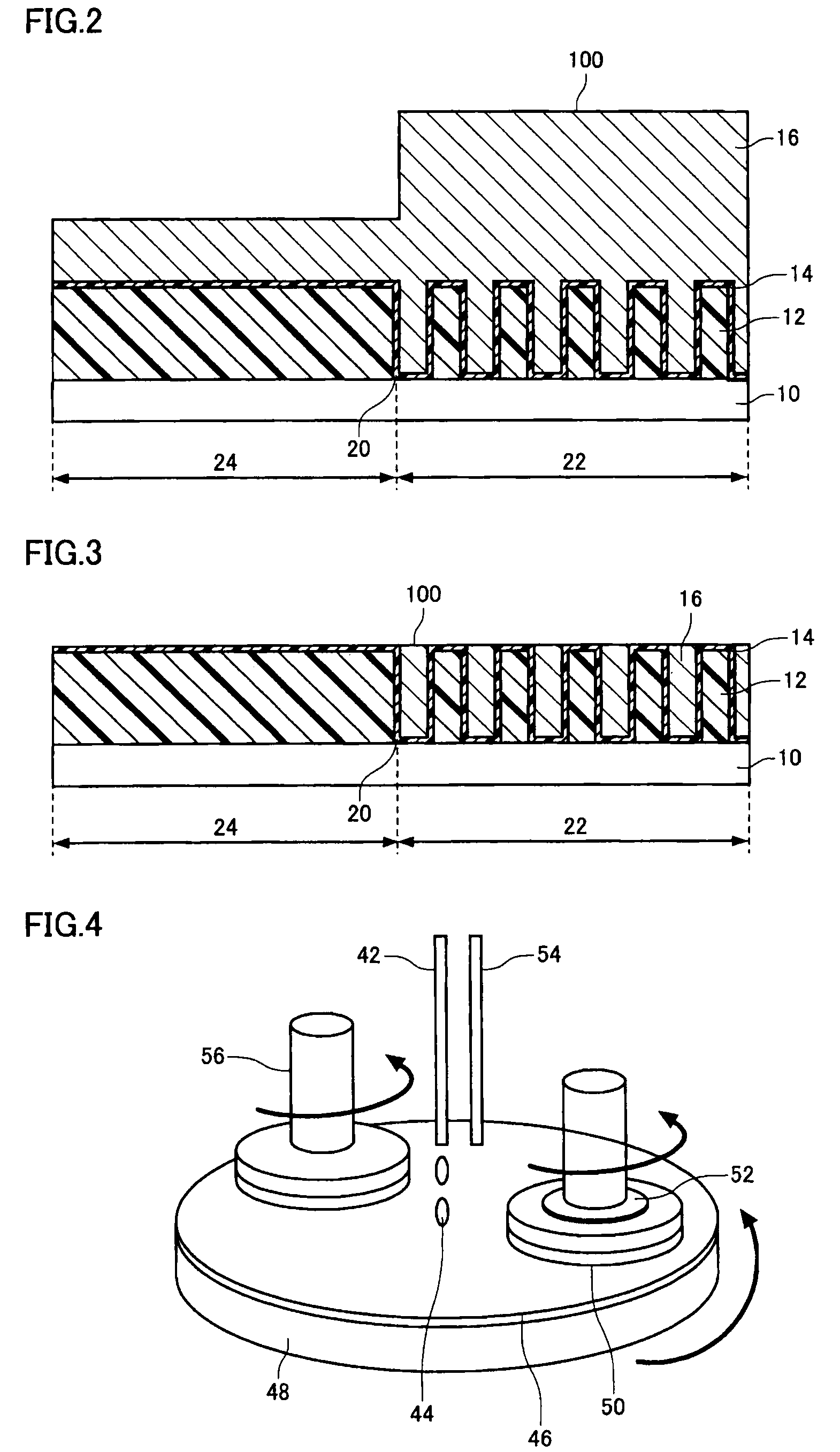

Method for manufacturing an optical film having a convexoconcave structure, optical film, wire grid polarizer and retardation film

InactiveUS20070252293A1High productivity and uniformityHigh productivityDiffusing elementsOptical articlesSolventChemistry

A manufacturing method of an optical film provided with a convexoconcave structure, comprises the steps of: coating a resin solution including a first resin solved by a solvent onto an endless or roll-like mold provided with a convexoconcave structure, and forming a resin solution layer on the mold; laminating a film substrate onto the resin solution layer to make a laminated film before the solvent in the resin solution layer is completely dried, the film substrate including a second resin, which is capable of absorving the solution or is soluble by the solvent; and peeling the laminated film from the mold before the solvent in the laminated film is completely dried.

Owner:KONICA MINOLTA OPTO

Processes based on atom (or group) transfer radical polymerization and novel (co)polymers having useful structures and properties

Improved processes for atom (or group) transfer radical polymerization (ATRP) and novel polymers have been developed and are described. In certain embodiments, novel copolymers comprising a least one polymeric branch or polymeric block with a predominantly alternating monomer sequence are described. Novel copolymers comprising a least one polymeric branch or polymeric block with a gradient monomer structure are described. Additionally, novel copolymers comprising a least one polymeric branch or polymeric block with a predominantly periodic monomer sequence are also described. Novel copolymers having a water soluble backbone and at least two hydrophobic polymeric branches grafted to the water soluble backbone are also described.

Owner:CARNEGIE MELLON UNIV

Noel (co) polymers and a novel polymerization process based on atom (or group) transfer radical polymerization

InactiveUS20050090632A1Increase in the rate of side reactionsReduce rateCoatingsGraft polymer adhesivesElastomerMeth-

A new polymerization process (atom transfer radical polymerization, or ATRP) based on a redox reaction between a transition metal (e.g., Cu(I) / Cu(II), provides “living” or controlled radical polymerization of styrene, (meth)acrylates, and other radically polymerizable monomers. Using various simple organic halides as model halogen atom transfer precursors (initiators) and transition metal complexes as a model halogen atom transfer promoters (catalysts), a “living” radical polymerization affords (co)polymers having the predetermined number average molecular weight by Δ[M] / [I]0 (up to Mn>105) and a surprisingly narrow molecular weight distribution (Mw / Mn), as low as 1.15. The participation of free radical intermediates in ATRP is supported by end-group analysis and stereochemistry of the polymerization. In addition, polymers with various topologies (e.g., block, random, star, end-functional and in-chain functional copolymers [for example, of styrene and methyl (meth)acrylate]) have been synthesized using the present process. The polymeric products encompassed by the present invention can be widely used as plastics, elastomers, adhesives, emulsifiers, thermoplastic elastomers, etc.

Owner:CARNEGIE MELLON UNIV

Energy ray-curable elastomer composition

InactiveUS20120157564A1Easy to optimizeHigh elongationEngine sealsCarrier constructional parts dispositionChemistryCompression set

An energy ray-curable elastomer composition, which comprises an energy ray-curable compound (A) having a (meth)acryloyl group, a polythiol compound (B) having 2 to 6 mercapto groups per molecule, and a polyfunctional (meth)acrylate (C), characterized in that the ratio of the number of (meth)acryloyl functional groups in component (A) to the number of mercapto functional groups in component (B) is 100:0.1-100:5n (wherein n represents the number of mercapto groups per molecule of the polythiol compound), and component (C) is used at a ratio of 1-8 parts by mass per 100 parts by mass of component (A). Thus, an energy ray-curable elastomer composition, which can achieve both high breaking elongation and good processability and shows good compression set, can be provided.

Owner:BRIDGESTONE CORP

Aqueous dispersion for chemical mechanical polishing and chemical mechanical polishing method for semiconductor device

InactiveUS20090221213A1High viscosityReducing fangEdge grinding machinesPigmenting treatmentCompound (substance)Water soluble

A chemical mechanical polishing aqueous dispersion of the invention includes (A) a first water-soluble polymer having a weight average molecular weight of 500,000 to 2,000,000 and including a heterocyclic ring in its molecule, (B) a second water-soluble polymer or its salt having a weight average molecular weight of 1000 to 10,000 and including one group selected from a carboxyl group and a sulfonic group, (C) an oxidizing agent, and (D) abrasive grains, and has a pH of 7 to 12.

Owner:JSR CORPORATIOON

Vehicular glass adhesive and method of adhering said glass

The invention is an adhesive composition comprising: a) an isocyanate functional polyether base prepolymers having a z molecular weight average (Mz) of about 10,000 to about 80,000 g / mole; a carbon black having an average oil absorption number of at least about 80 to at most about 400 cubic centimeters of dibutyl phthalate per 100 grams of the carbon black; (c) reactive silicon in an amount from about 0.001% to about 10% by weight of the adhesive composition; and (d) one or more catalysts for the reaction of isocyanate with hydroxyl groups. The adhesive compositions of the invention surprisingly may have improved sag performance (i.e., decreased sag) when heated, while also making them more easily pumped.

Owner:DOW GLOBAL TECH LLC

Vehicular glass adhesive and method of adhering said glass

ActiveUS20110265932A1Molecular weightEasy pumpabilityCovering/liningsNon-macromolecular adhesive additivesAdhesiveGram

The invention is an adhesive composition comprising: a) an isocyanate functional polyether base prepolymers having a z molecular weight average (Mz) of about 10,000 to about 80,000 g / mole; a carbon black having an average oil absorption number of at least about 80 to at most about 400 cubic centimeters of dibutyl phthalate per 100 grams of the carbon black; (c) reactive silicon in an amount from about 0.001% to about 10% by weight of the adhesive composition; and (d) one or more catalysts for the reaction of isocyanate with hydroxyl groups. The adhesive compositions of the invention surprisingly may have improved sag performance (i.e., decreased sag) when heated, while also making them more easily pumped.

Owner:DOW GLOBAL TECH LLC

Methods for forming amorphous ultra-high molecular weight polyalphaolefin drag reducing agents using a halohydrocarbon

InactiveUS6162773AGood drag reduction effectInherent viscosityOther chemical processesLiquid organic insulatorsHalohydrocarbonAluminoxane

A composition including polyalphaolefins that function as drag reducing agents and a process for the preparation of polyalphaolefins that function as drag reducing agents are disclosed. The process includes contacting alpha olefin monomers with a catalyst system, which includes a catalyst and an activator (co-catalyst) in a reactant mixture. The catalyst is a transition metal catalyst, preferably titanium trichloride, and the co-catalyst may include an alkylaluminoxane, alone or in combination, with a dialkylaluminum halide or a halohydrocarbon. The polymerization of the alpha olefin monomers produces a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of at least 10 dL / g. The addition of the alkylaluminoxane during the polymerization process provides for a non-crystalline, ultra-high molecular weight polyalphaolefin and a more uniform molecular weight distribution of the resulting polyalphaolefin, thereby creating a drag reducing agent superior to known drag reducing agents. A process for forming a drag reducing agent comprising a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of about at least 10 dL / g and a process for reducing drag in a conduit are also disclosed.

Owner:MPOWER SPECIALTY CHEM

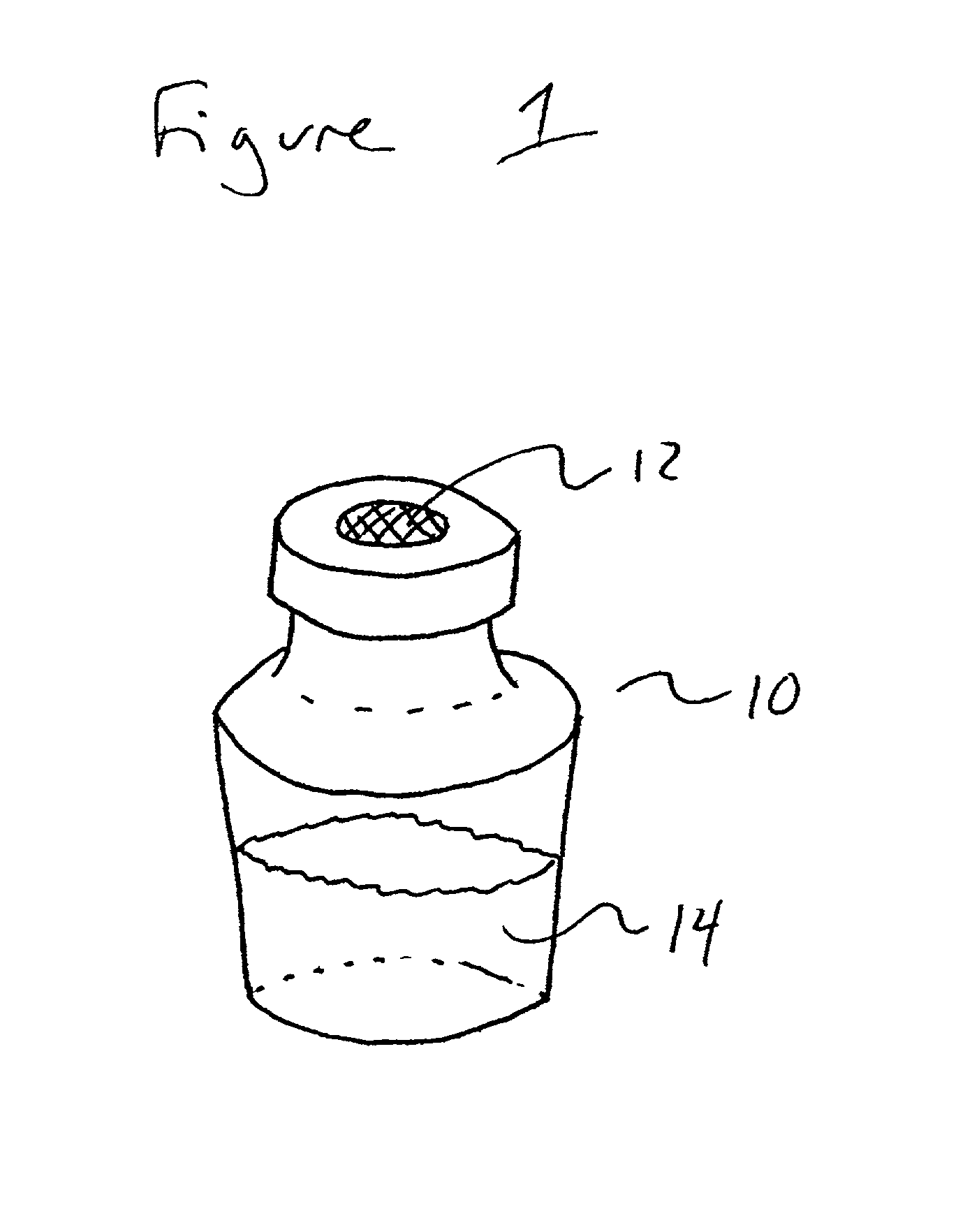

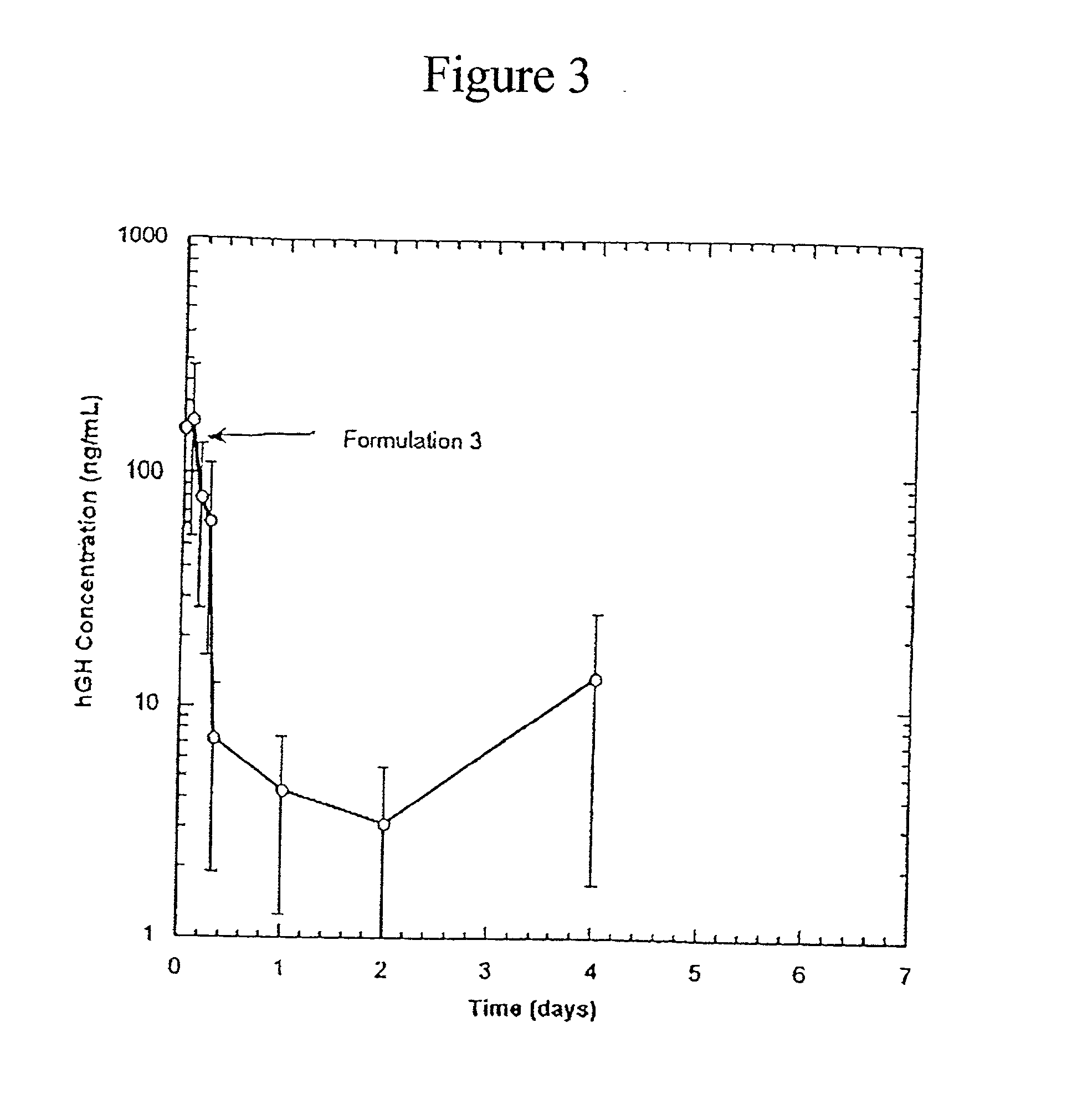

Erodible polymers for injection

InactiveUS20020173552A1Easy to packReduce molecular weightPharmaceutical non-active ingredientsEmulsion deliveryHypodermic needleBioerodible polymers

A composition for administration of a beneficial agent, contains a solvent mixture including a hydrophobic solvent and a hydrophilic solvent; a bioerodible polymer; and a beneficial agent. The polymer and the beneficial agent are dissolved. The composition has a low viscosity, allowing for easy injection through standard hypodermic needles.

Owner:GENENTECH INC

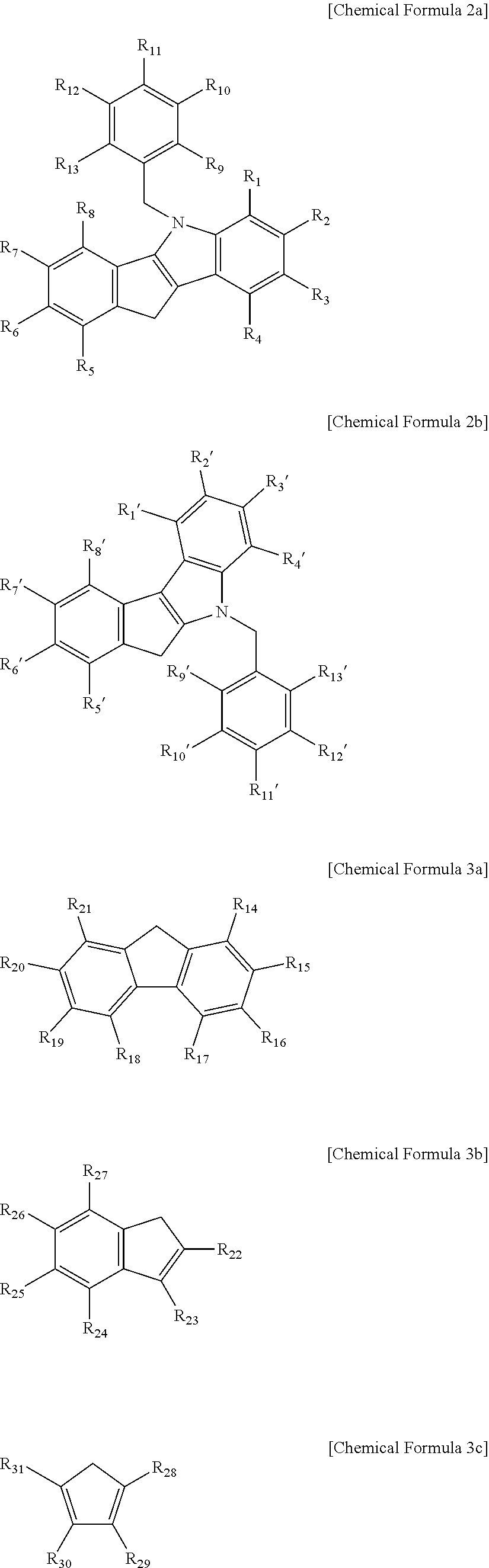

Metallocene compound, catalyst composition including the same, and method of preparing polyolefin using the same

ActiveUS20170107307A1High activityHigh molecular weightSilicon organic compoundsOrganic chemistry methodsPolymer sciencePolyolefin

Provided are a novel metallocene compound, a catalyst composition including the same, and a method of preparing a polyolefin using the same. The metallocene compound according to the present invention and the catalyst composition including the same may be used for the preparation of a polyolefin, may have excellent polymerization ability, and may produce a polyolefin having an ultra-high molecular weight. In particular, when the metallocene compound according to the present invention is employed, an olefin-based polymer having an ultra-high molecular weight may be polymerized because the metallocene compound shows high polymerization activity even when it is supported on a support.

Owner:LG CHEM LTD

Synthetic rubber with narrow molecular weight distribution, a process for its preparation and a method of use

ActiveUS20070142621A1Small polydispersity indexSolution value is not highSpecial tyresMechanical vibrations separationPolymer scienceInjection moulding

A novel process is used to prepare synthetic rubbers (B) which feature very narrow molecular weight distribution and a correspondingly low value for the polydispersity index. The preparation process encompasses the treatment of a synthetic rubber with ultrasound, where the resultant synthetic rubber (B) has a lower weight-average molecular weight (Mw) than the synthetic rubber (A) used. The resultant synthetic rubbers (B) have excellent suitability for processing via extruder processes or injection-moulding processes.

Owner:ARLANXEO DEUT GMBH

Method for manufacturing an optical film having a convexoconcave structure

InactiveUS7854864B2Low moisture permeabilityReduce capacityDiffusing elementsPolarising elementsSolventChemistry

A manufacturing method of an optical film provided with a convexoconcave structure, comprises the steps of: coating a resin solution including a first resin solved by a solvent onto an endless or roll-like mold provided with a convexoconcave structure, and forming a resin solution layer on the mold; laminating a film substrate onto the resin solution layer to make a laminated film before the solvent in the resin solution layer is completely dried, the film substrate including a second resin, which is capable of absorbing the solvent or is soluble by the solvent; and peeling the laminated film from the mold before the solvent in the laminated film is completely dried.

Owner:KONICA MINOLTA OPTO

Cosmetic

ActiveUS20080188569A1Good moisturizing effectReduce the amount requiredBiocideCosmetic preparationsIsostearic acidAlcohol

The present invention relates to cosmetics comprising a hydroxyl compound obtained by the reaction of a di- or higher-valent alcohol with a monovalent carboxylic acid and dimer acid, characterized in that the hydroxyl compound is obtained by reacting diglycerin with isostearic acid, and then reacting the obtained ester compound with dimer acid, wherein a molar ratio among diglycerin, isostearic acid and dimer acid is in the range of 1.0:1.4 to 1.6:0.5 to 0.8. The present invention provides cosmetics comprising the hydroxyl compounds having a high hydroxyl value.

Owner:KOKYU ALCOHOL KOGYO

Processes based on atom (or group) transfer radical polymerization and novel (co)polymers having useful structures and properties

Owner:CARNEGIE MELLON UNIV

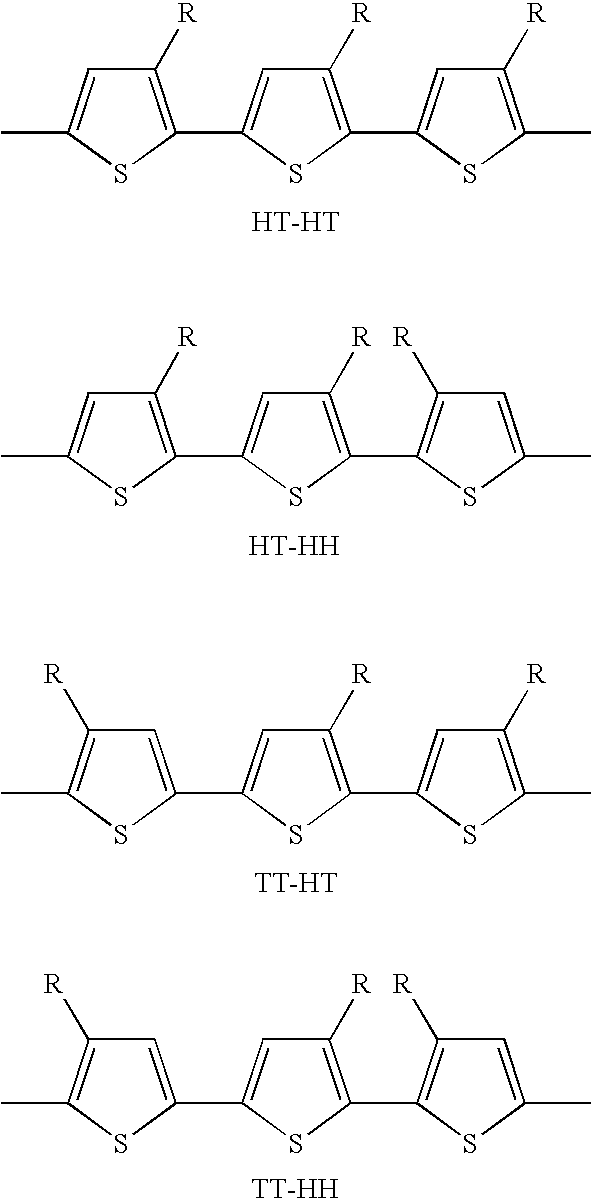

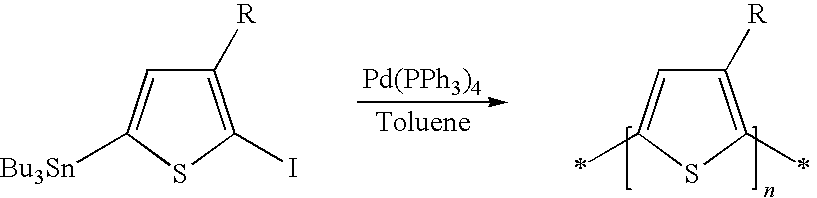

Process of preparing regioregular polymers

InactiveUS20100084614A1Speed up the processGood control over molecular weightFinal product manufactureConductive materialField effectField-effect transistor

The invention relates to a process of preparing regioregular polymers, in particular head-to-tail (HT) poly-(3-substituted) thiophenes or selenophenes with high regioregularity and defined molecular weight, to novel polymers prepared by this process, to the use of the novel polymers as semiconductors or charge transport materials in optical, electrooptical or electronic devices including field effect transistors (FETs), electroluminescent, photovoltaic and sensor devices, and to FETs and other semiconducting components or materials comprising the novel polymers.

Owner:MERCK PATENT GMBH

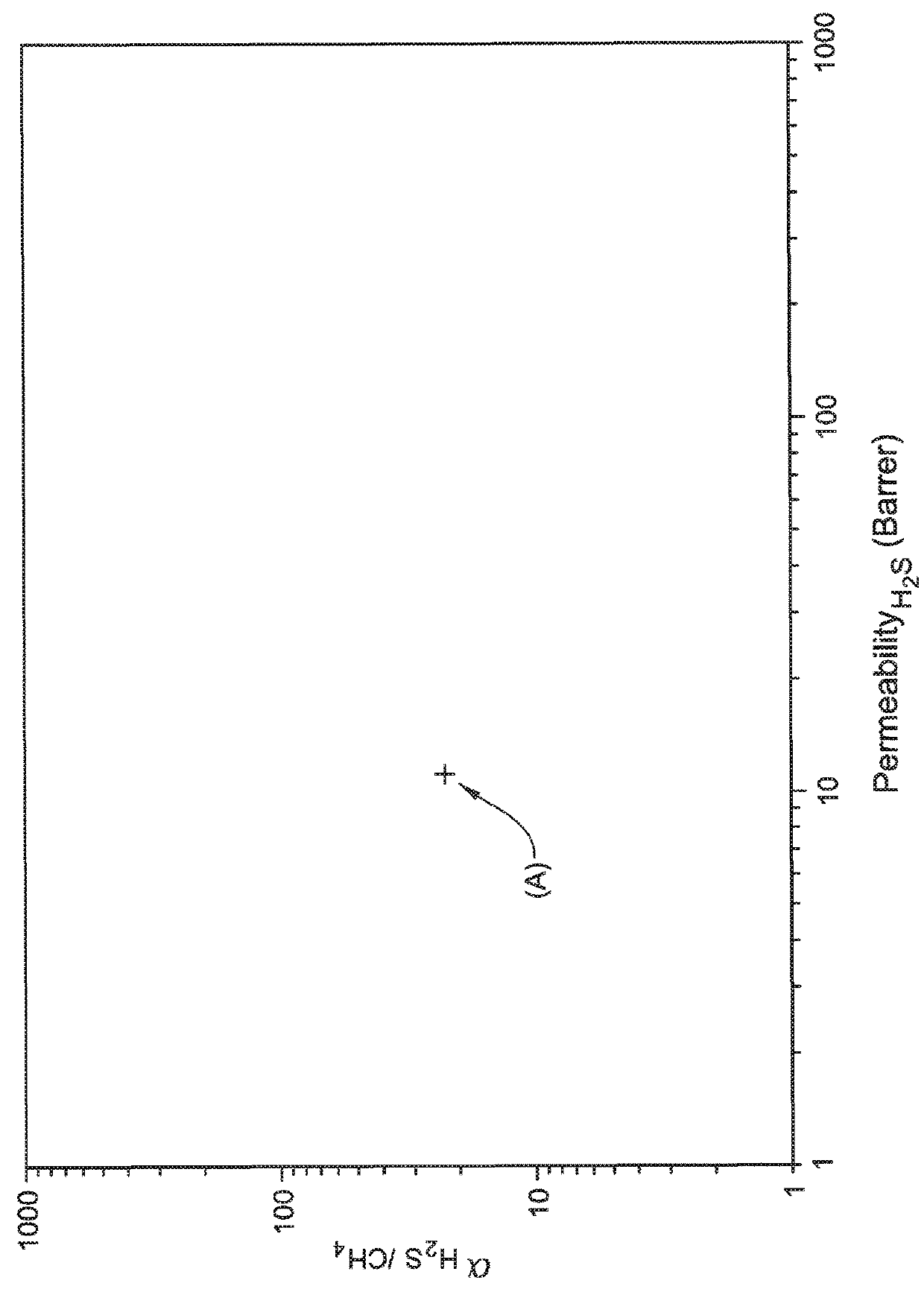

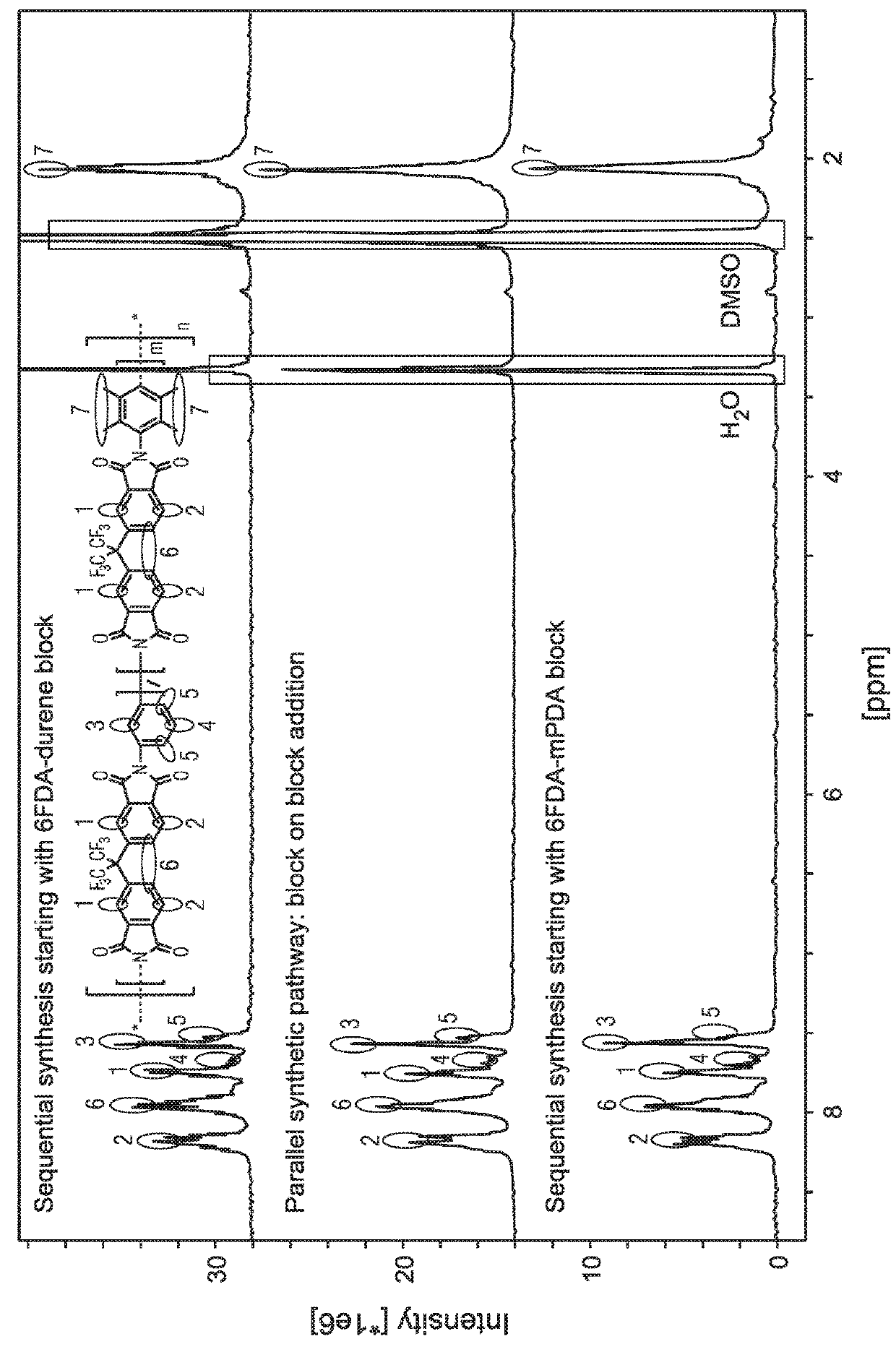

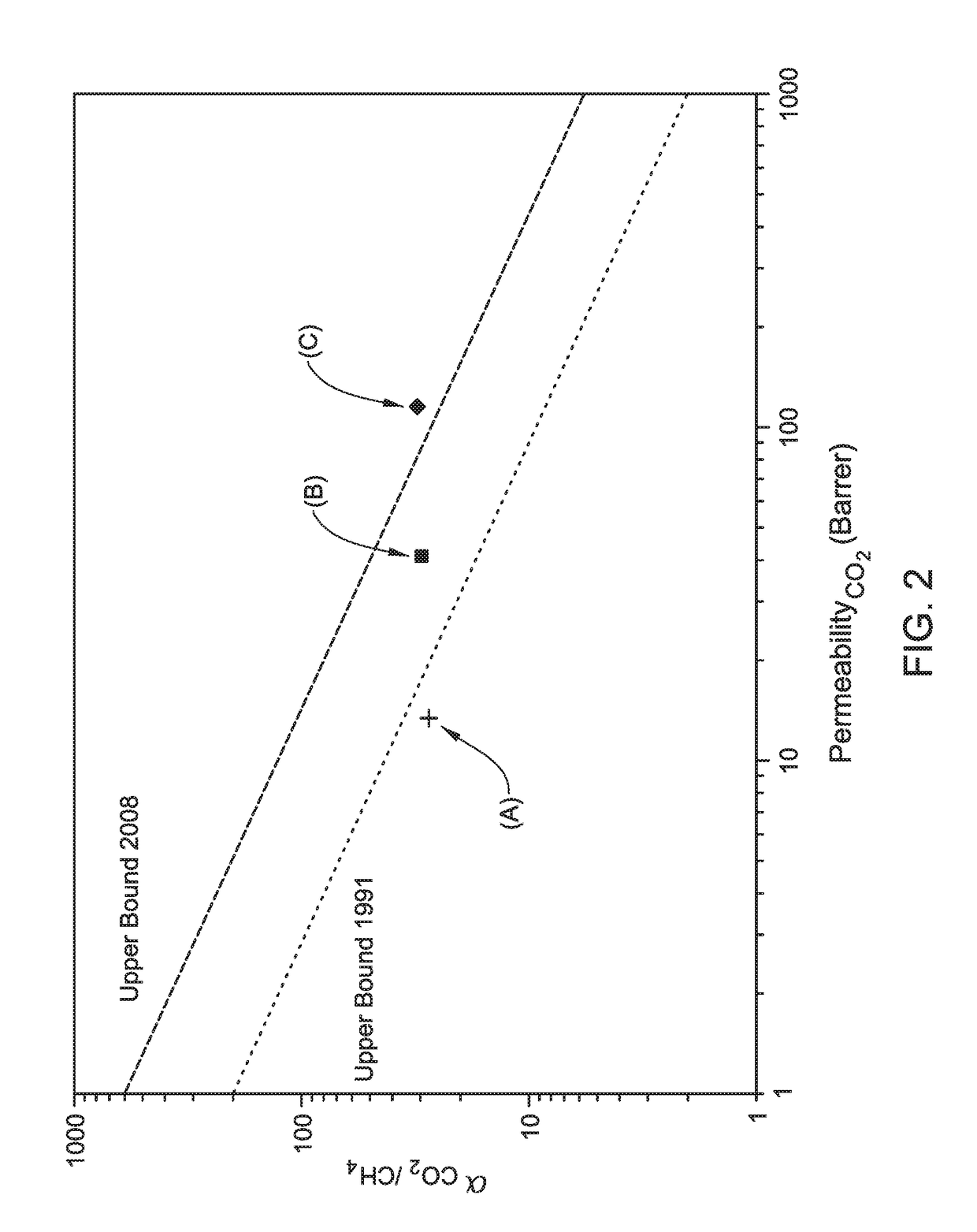

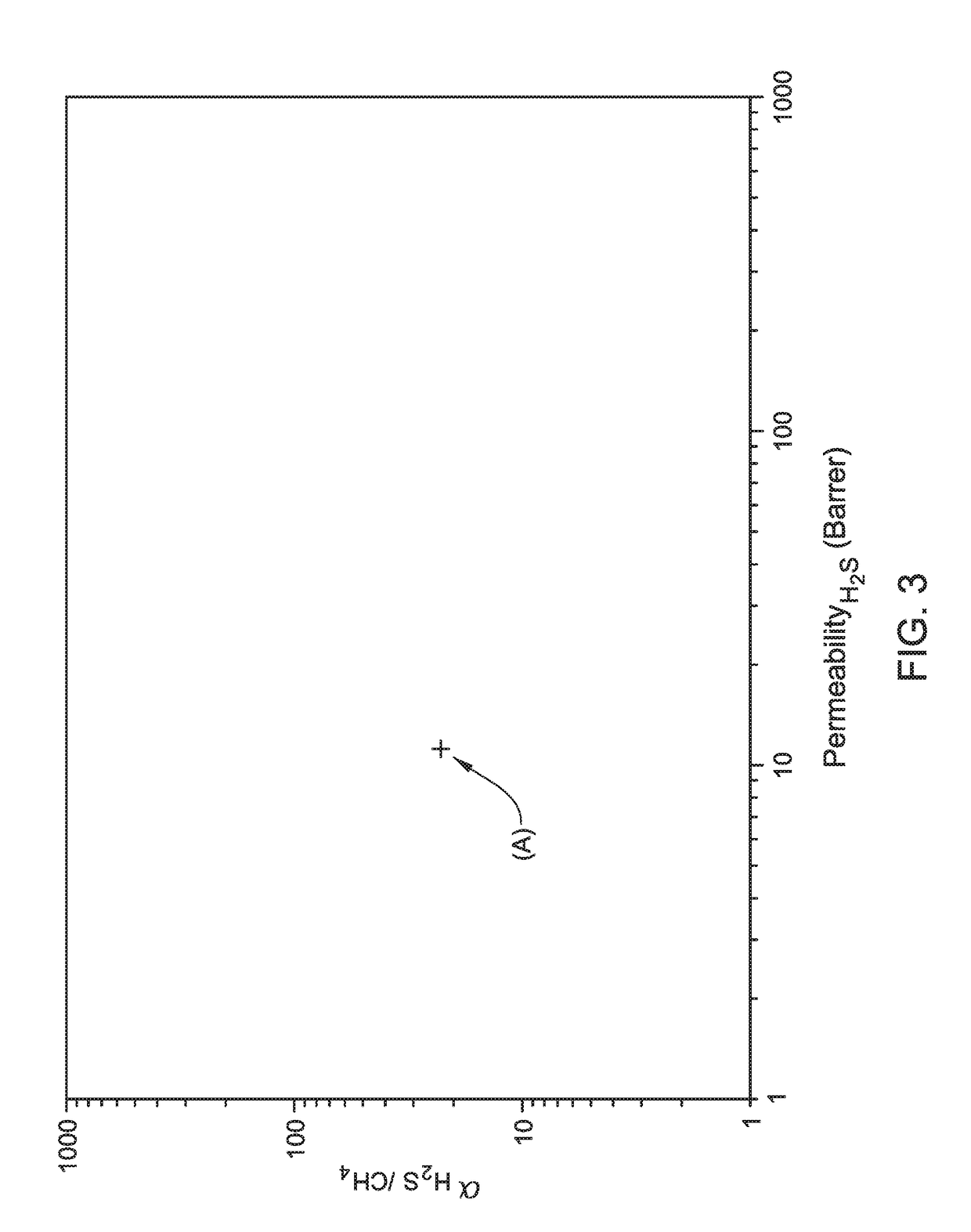

Sour gas feed separations and helium recovery from natural gas using block co-polyimide membranes

Compositions of and methods for separating components of a natural gas stream are disclosed. In one embodiment, the method includes receiving an inlet stream comprising natural gas, the inlet stream having an inlet pressure, and the inlet stream further comprising methane, helium, and an impurity. The method includes allowing the inlet stream to contact a block co-polyimide membrane, the block co-polyimide membrane exhibiting both higher permeability for and higher selectivity for the helium and the impurity than for the methane at the inlet pressure of the inlet stream and separating the methane from the helium and the impurity to create a retentate stream, the retentate stream comprising an increased concentration of methane relative to the inlet stream. The method also includes creating a permeate stream comprising the helium and the impurity at an increased concentration of helium and impurity relative to a concentration of helium and impurity in the inlet stream.

Owner:SAUDI ARABIAN OIL CO

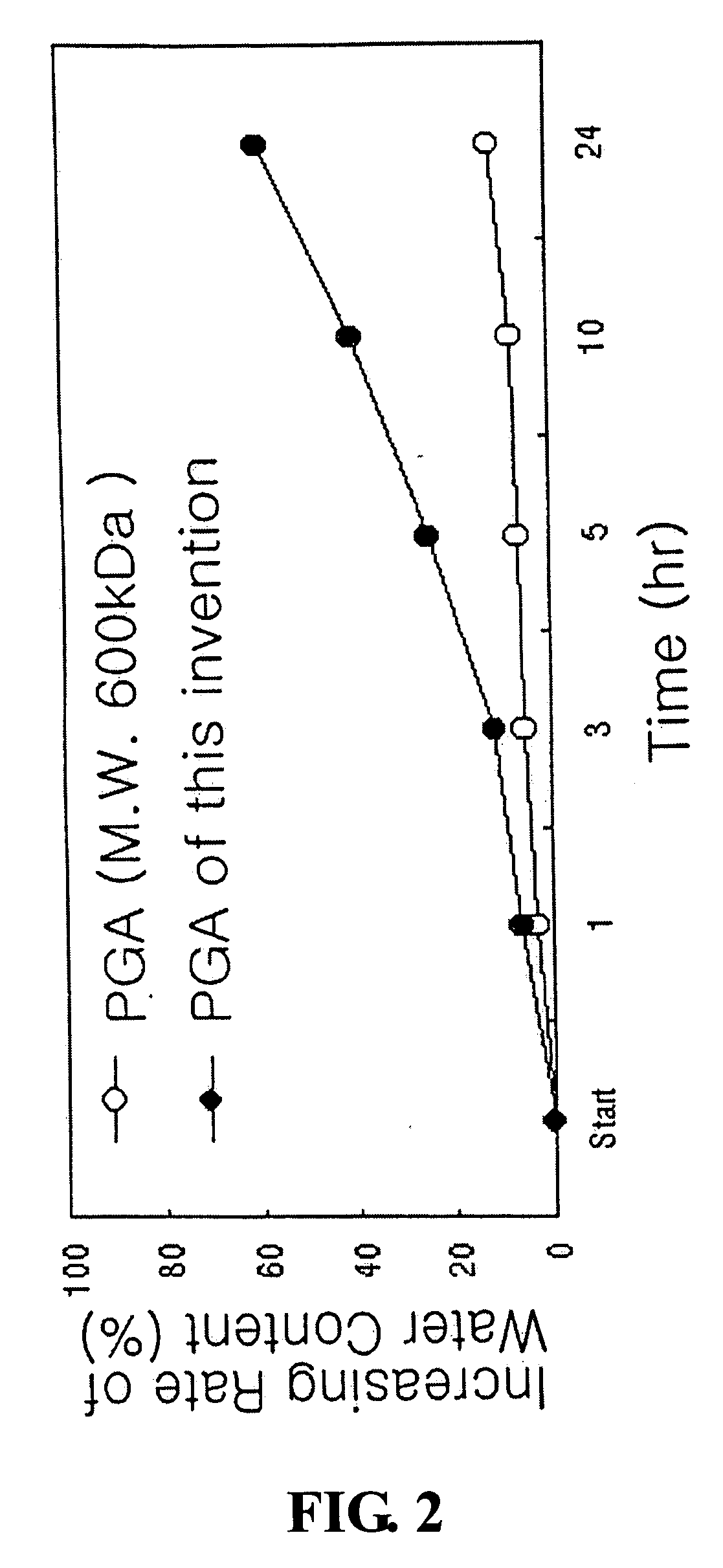

Poly-gamma-glutamate having ultra high molecular weight and method for using the same

InactiveUS20060127447A1Improve propertiesMaintain good propertiesCosmetic preparationsDispersion deliverySolubilityUltrahigh molecular weight

The present invention relates to a poly-gamma-glutamate (PGA) having an ultra-high molecular weight greater than 5,000 kDa. The ultra-high molecular weight PGA according to the present invention has a mean molecular weight greater than 13,000 kDa, and more than 95% of its molecules have a molecular weight ranging from 3,000 to 15,000 kDa. Also, it can be produced by the culturing of Bacillus subtilis var. chungkookjang. The ultra-high molecular weight PGA according to the present invention shows very excellent moisture-absorbing, moisture-retaining, sustained release, mineral solubility, and water-absorbing properties, and thus, can be used as a new and high value-added material in various applications.

Owner:BIOLEADERS CORP +1

Chemical mechanical polishing aqueous dispersion and chemical mechanical polishing method for semiconductor device

InactiveUS8574330B2High affinityReduce copper dishing and copper corrosionEdge grinding machinesPigmenting treatmentWater solubleOxidizing agent

A chemical mechanical polishing aqueous dispersion of the invention includes (A) a first water-soluble polymer having a weight average molecular weight of 500,000 to 2,000,000 and including a heterocyclic ring in its molecule, (B) a second water-soluble polymer or its salt having a weight average molecular weight of 1000 to 10,000 and including one group selected from a carboxyl group and a sulfonic group, (C) an oxidizing agent, and (D) abrasive grains, and has a pH of 7 to 12.

Owner:JSR CORPORATIOON

Sour gas feed separations and helium recovery from natural gas using block co-polyimide membranes

ActiveUS20170189850A1Improve performanceEasy to separateSemi-permeable membranesMembranesPolyimide membraneHelium

Compositions of and methods for separating components of a natural gas stream are disclosed. In one embodiment, the method includes receiving an inlet stream comprising natural gas, the inlet stream having an inlet pressure, and the inlet stream further comprising methane, helium, and an impurity. The method includes allowing the inlet stream to contact a block co-polyimide membrane, the block co-polyimide membrane exhibiting both higher permeability for and higher selectivity for the helium and the impurity than for the methane at the inlet pressure of the inlet stream and separating the methane from the helium and the impurity to create a retentate stream, the retentate stream comprising an increased concentration of methane relative to the inlet stream. The method also includes creating a permeate stream comprising the helium and the impurity at an increased concentration of helium and impurity relative to a concentration of helium and impurity in the inlet stream.

Owner:SAUDI ARABIAN OIL CO

Process for producing phenolic novolak resin

A process for advantageously producing, in a short period of time, a phenolic novolak resin, in which substantially no unreacted aldehyde remains, by using a continuous reactor, while a generation of high order condensation products is prevented. In continuously producing the phenolic novolak resin by reacting at least one of phenols with at least one of aldehydes in the presence of an acidic catalyst by using a continuous reactor which has a long reaction tube: the reaction tube is provided with a heating zone and a temperature control zone; a mixture of raw materials is heated, at the heating zone, to a temperature not less than a temperature, at which a reaction heat is generated; and then the mixture is subjected to a cooling operation at the temperature control zone, while the pressure within the reaction tube is kept to be not lower than a vapor pressure of water.

Owner:ASAHI YUKIZAI KOGYO CO LTD

Starch

InactiveUS20070142325A1Reduce molecular weightEliminate residueOrganic active ingredientsBiocideLipid formationAcid hydrolysis

Production of purified, parenterally administrable starch by washing starch containing more than 85% amylopectin in order to remove surface-localized proteins, lipids and endotoxins, subjecting the starch to a molecular weight reduction by acid hydrolysis, and optionally removing residual water-soluble proteins. Purified starch and microparticles based on such starch.

Owner:PACIRA PHARMA INC

Chemical mechanical polishing aqueous dispersion and chemical mechanical polishing method for semiconductor device

InactiveUS20140011360A1High affinityReduce copper dishing and copper corrosionOther chemical processesSemiconductor/solid-state device manufacturingCompound (substance)Water soluble

A chemical mechanical polishing aqueous dispersion of the invention includes (A) a first water-soluble polymer having a weight average molecular weight of 500,000 to 2,000,000 and including a heterocyclic ring in its molecule, (B) a second water-soluble polymer or its salt having a weight average molecular weight of 1000 to 10,000 and including one group selected from a carboxyl group and a sulfonic group, (C) an oxidizing agent, and (D) abrasive grains, and has a pH of 7 to 12.

Owner:JSR CORPORATIOON

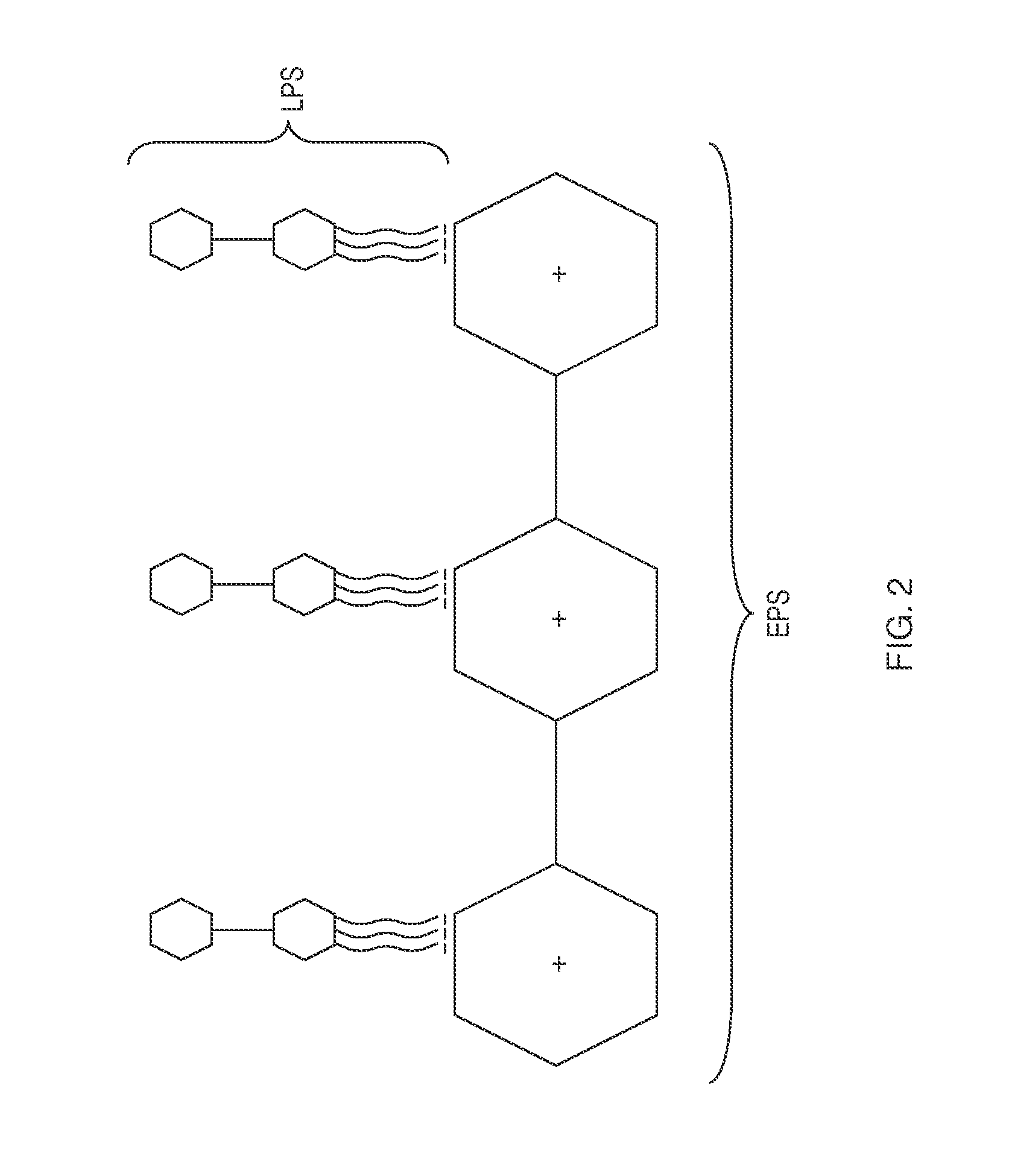

Polysaccharide composition and methods of isolation of the emulsion stabilizing cationic polyelectrolytic polysaccharide

InactiveUS20110206772A1Reduce surface tensionHigh molecular weightPowder deliveryBiocideEmulsionChemistry

The present invention relates to purification and use of a novel emulsion stabilizing polysaccharide. In particular, a polyelectrolyte exopolysaccharide with high molecular weight comprising a high molecular weight polymer with a tri-saccharide repeating unit is disclosed. In one aspect of the invention, methods are directed to isolating and purifying a high molecular weight exopolysaccharide (EPS) from a cell supernatant. In another aspect, methods are disclosed for isolating a lipopolysaccharide (LPS) and a high molecular weight Acinetobacter polyelectrolyte exopolysaccharide (APE) from Acinetobacter bacteria. Compositions are also directed to lipid nanoparticles comprising a therapeutic agent encapsulated by a high molecular weight polysaccharide and nanoparticles comprising a therapeutic agent bound to a cationic polysaccharide cross-linked with a polyanion.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

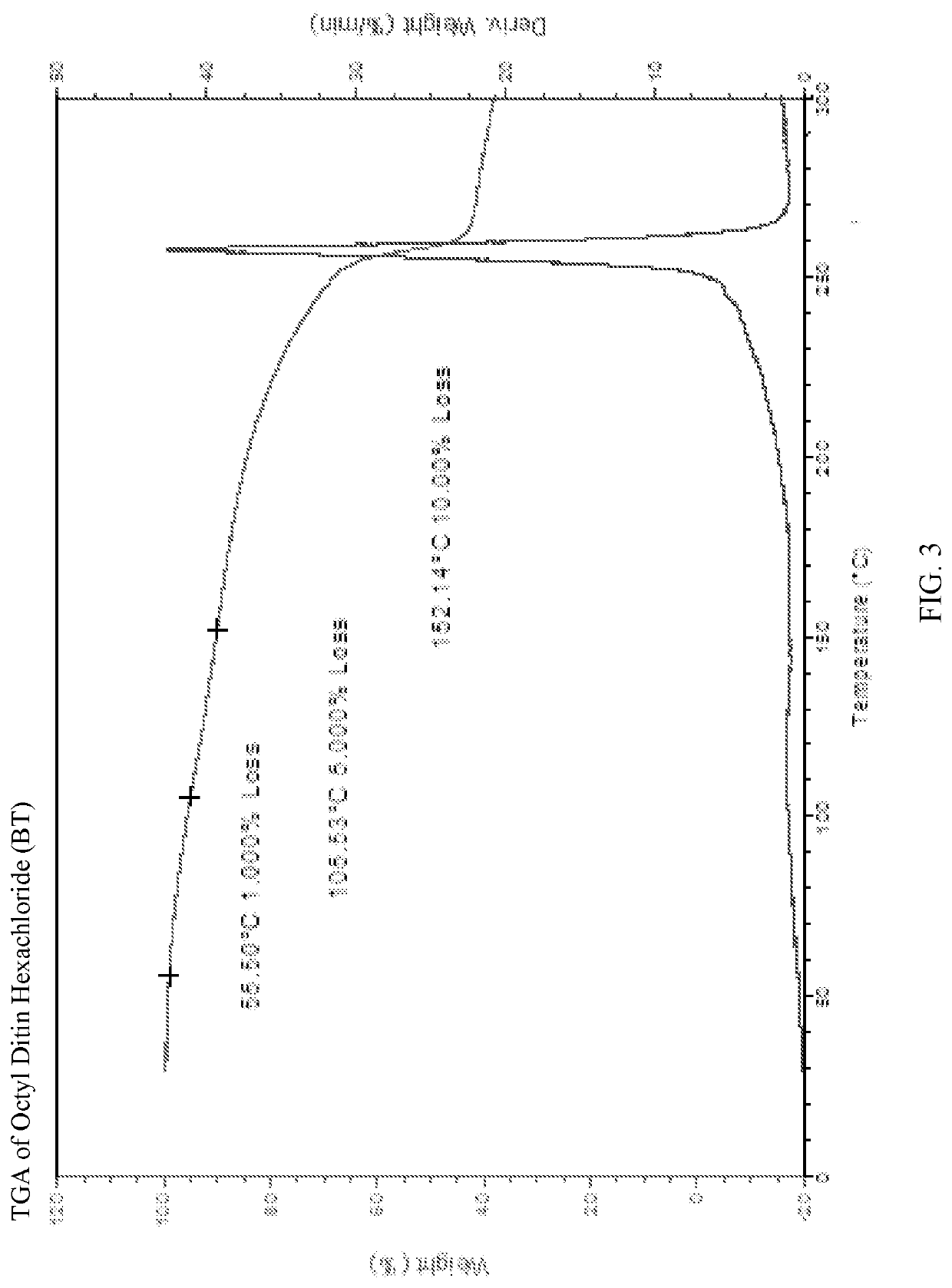

Alkyl-bridged tin-based thermal stabilizers for halogenated resins and synthesis and uses therof

The present invention relates to stabilizer composition for halogen-containing polymer. It has recently been found that tin-based thermal stabilizers with a bridging alkyl group between two tin centers are effective stabilizers while having effectively double the molecular weight of the corresponding non-alkyl bridged stabilizer. It is expected that ongoing experimentation will confirm that the alkyl bridged stabilizers have much lower volatility which leads to greater retention of the stabilizer in the finished article.

Owner:PMC ORGANOMETALLIX INC

Starch

InactiveUS20020065411A1Reduce molecular weightEliminate surface-localized proteinsBiocideOrganic active ingredientsLipid formationAcid hydrolysis

Owner:PACIRA PHARMA INC

Metallocene compound, catalyst composition including the same, and method of preparing polyolefin using the same

ActiveUS9994652B2High activityHigh molecular weightSilicon organic compoundsOrganic chemistry methodsPolyolefinPolymer science

Provided are a novel metallocene compound, a catalyst composition including the same, and a method of preparing a polyolefin using the same. The metallocene compound according to the present invention and the catalyst composition including the same may be used for the preparation of a polyolefin, may have excellent polymerization ability, and may produce a polyolefin having an ultra-high molecular weight. In particular, when the metallocene compound according to the present invention is employed, an olefin-based polymer having an ultra-high molecular weight may be polymerized because the metallocene compound shows high polymerization activity even when it is supported on a support.

Owner:LG CHEM LTD

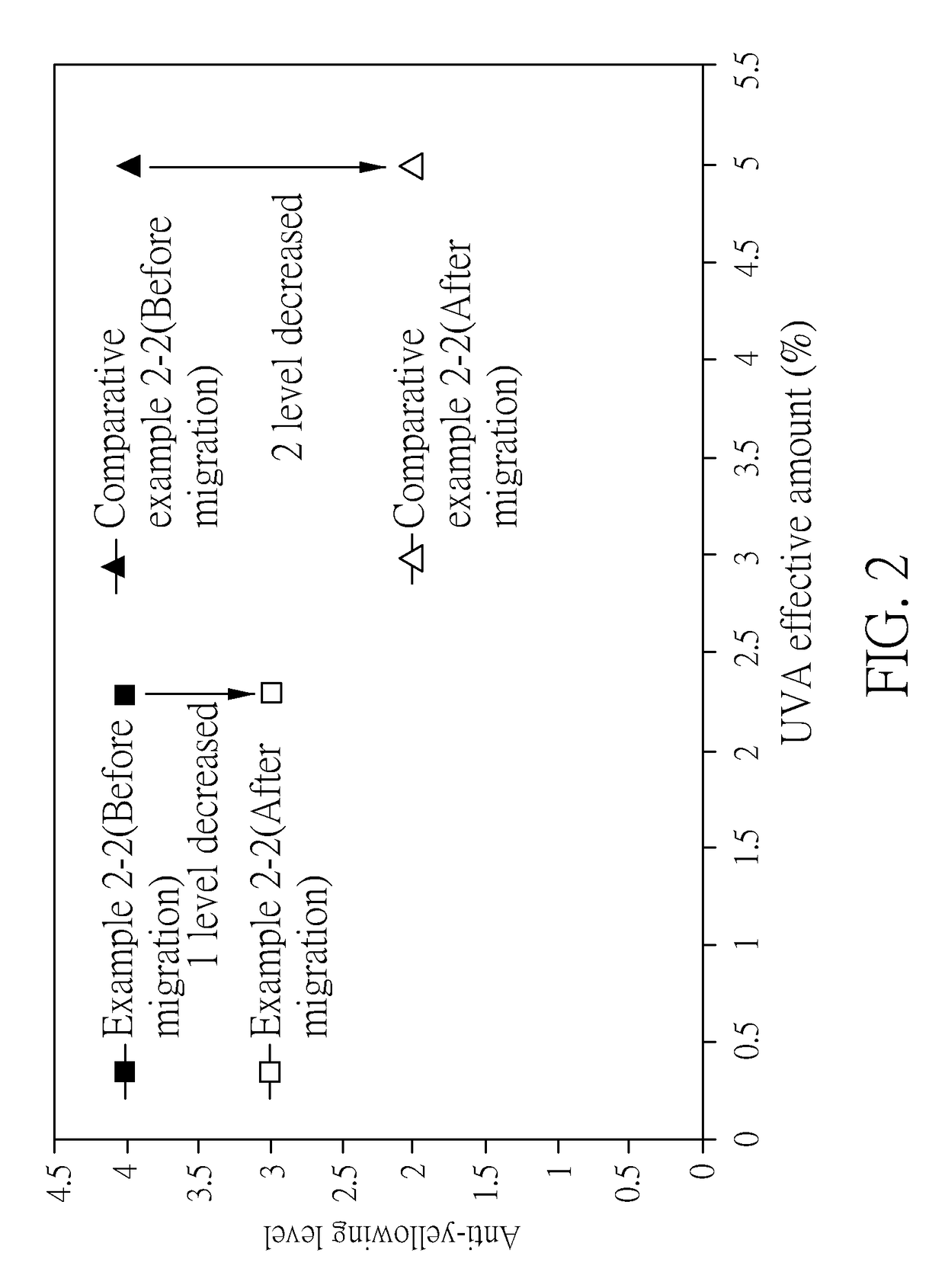

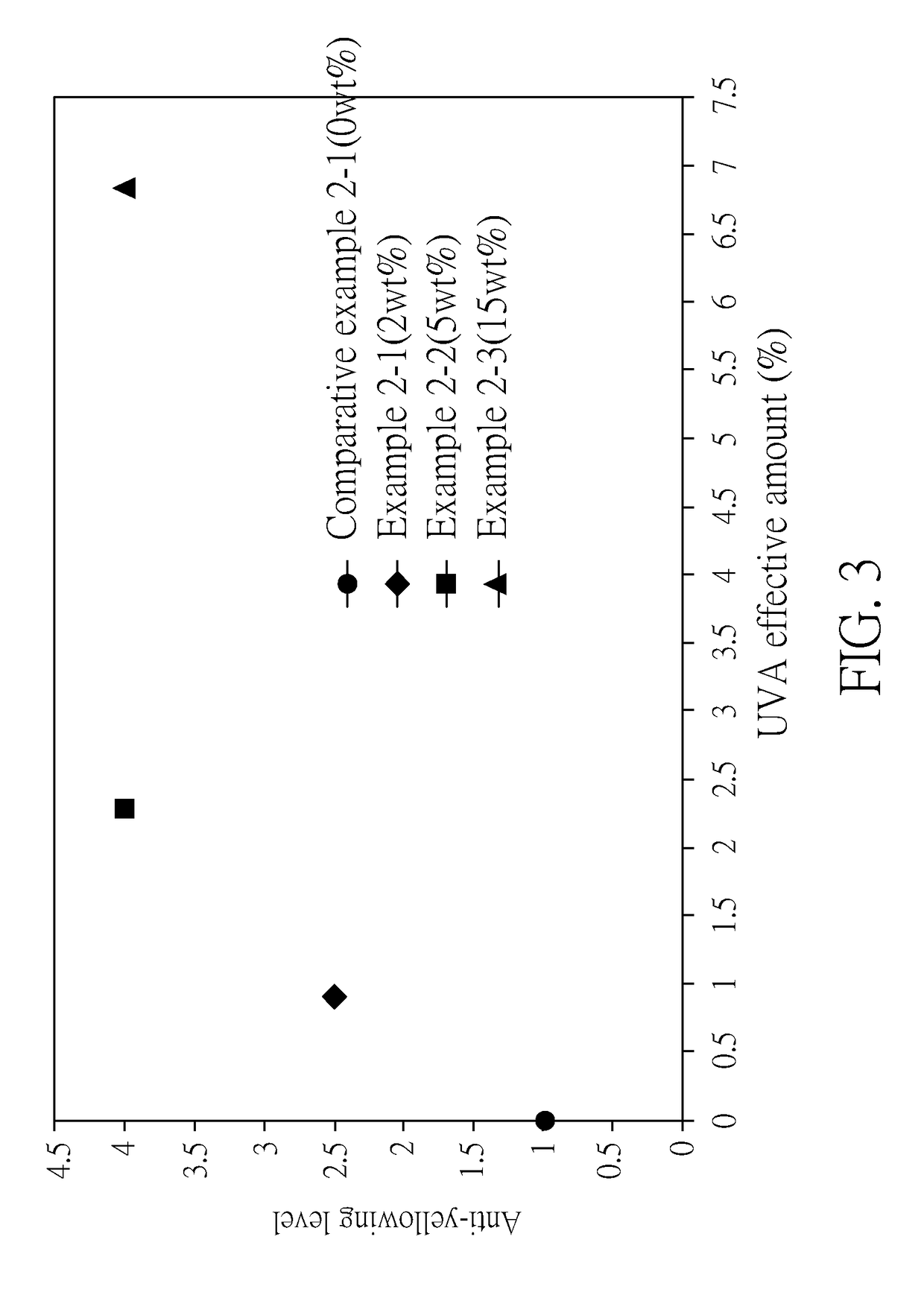

Use of polymerizable ultraviolet absorber in polyurethane and composition for preparing polyurethane comprising the same

A use of a polymerizable ultraviolet absorber is disclosed, which is applied to a polyurethane preparation. The polymerizable ultraviolet absorber is obtained by reacting an UV absorber having a reactive hydrogen group with a polyisocyanate having three —NCO groups. In addition, a composition for forming polyurethane comprising the aforementioned polymerizable ultraviolet absorber is also disclosed.

Owner:EVERLIGHT CHEMICAL INDUSTRIAL CORPORATION

Method To Produce Polymer Matrix Composites

InactiveUS20200023598A1Molecular weightExemption stepsDomestic sealsNon-macromolecular adhesive additivesPolymer scienceOligomer

This patent describes a new, simple, and low-cost method to produce aromatic thermosetting copolyester (ATSP) based polymer matrix composites. For this method, the ATSP based composites are directly produced from the blended mixtures of the ATSP oligomer powders with the composite fillers through a high temperature and high pressure curing process. In addition, the fully cured ATSP composite laminates can be bonded together to form thicker multi-material composites. The characterization showed that these ATSP based composites are fully condensed, they have excellent tribological performance (low friction and low wear rate), and they have excellent thermal stability, indicating utility in high performance bearing applications, structural materials, and as an ablative composite material.

Owner:ATSP INNOVATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com