Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172results about How to "Small compression set" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

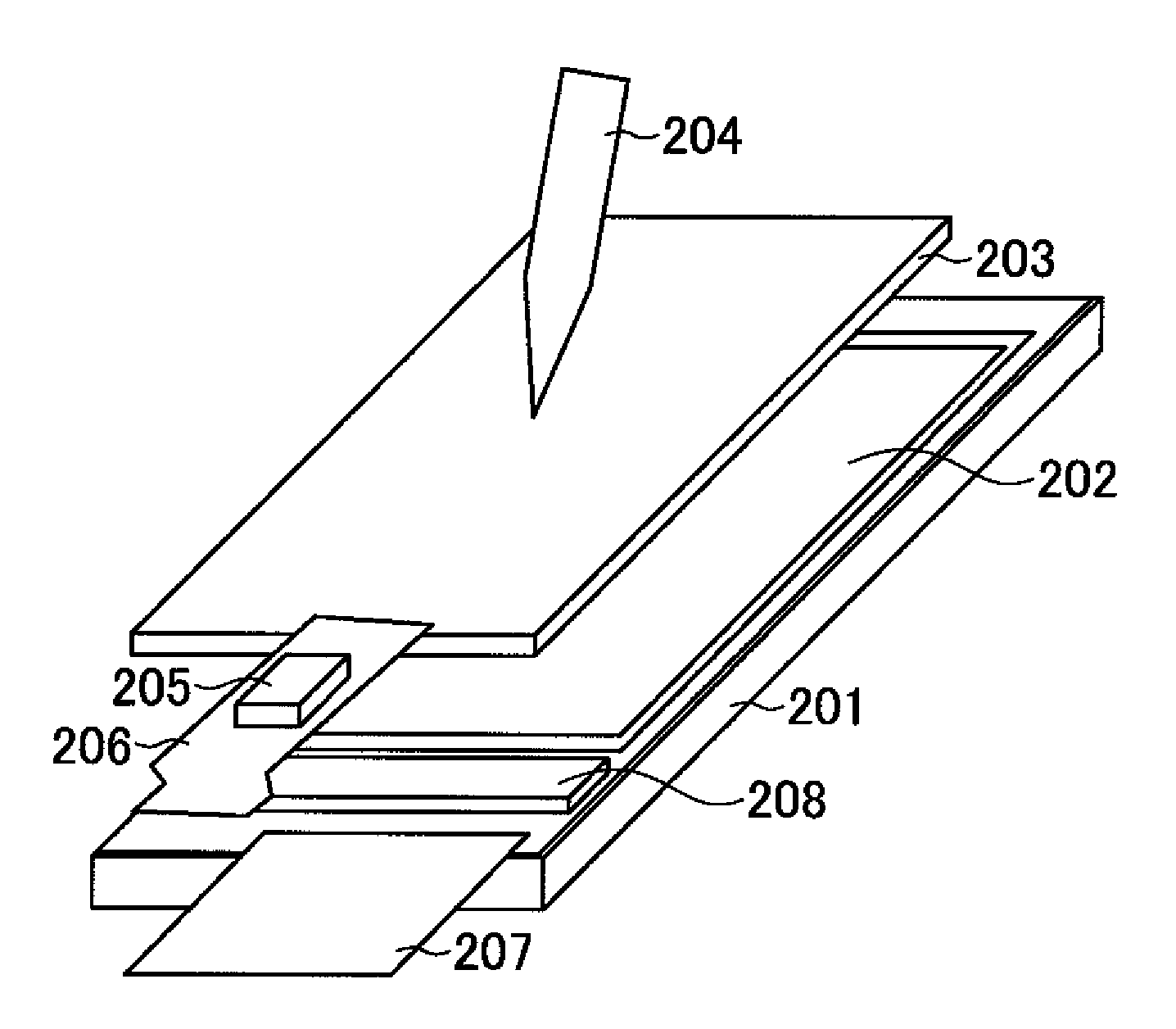

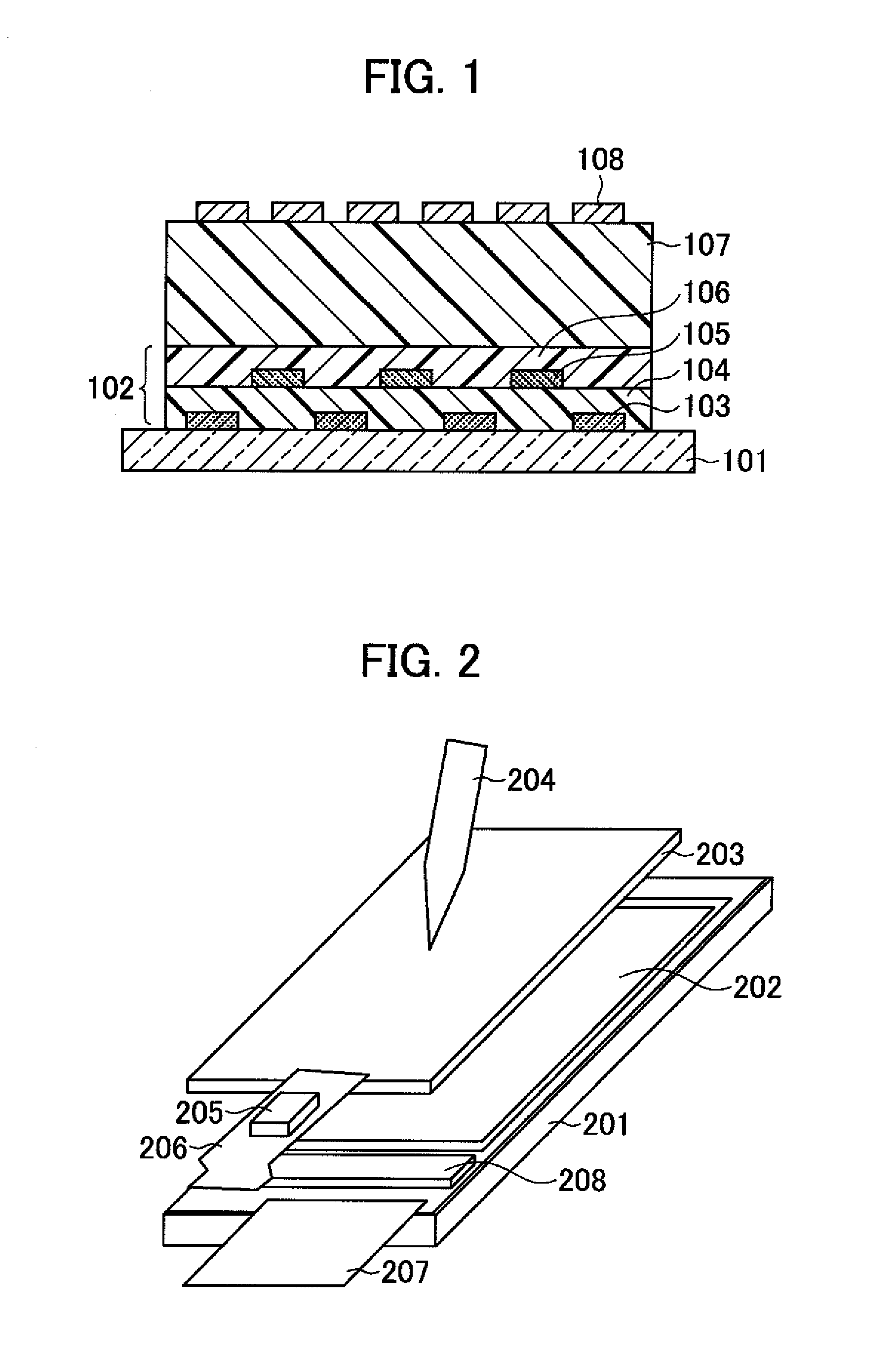

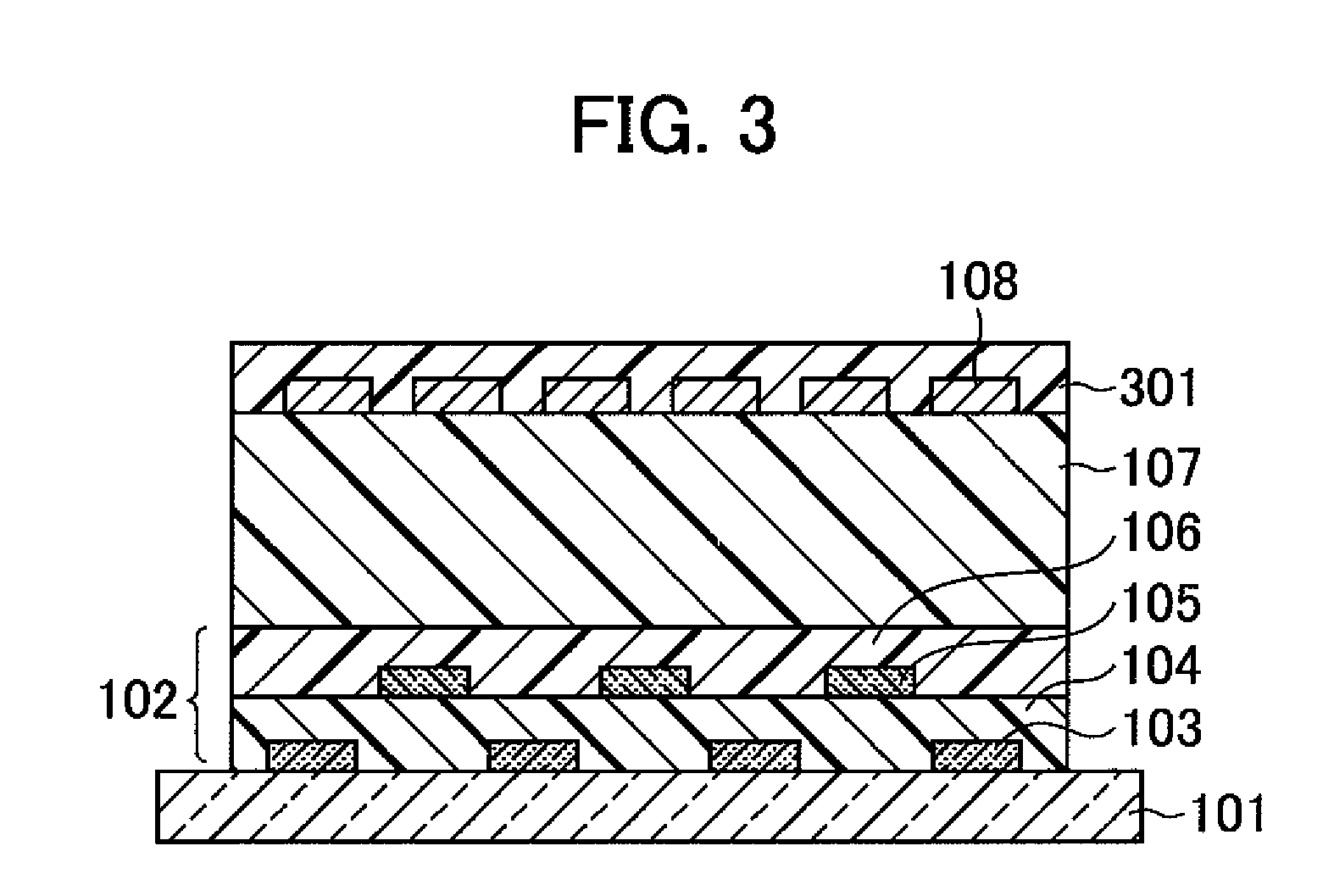

Capacitive coupling type touch panel

InactiveUS20100108409A1Lower the volumeDifficult to maintain load deforming characteristicTransmission systemsInput/output processes for data processingCapacitanceCapacitive coupling

A capacitive coupling type touch panel includes an XY-coordinate electrode configured to detect an XY-position coordinate. The XY-coordinate electrode is provided on a transparent substrate and detects a position inputted by capacitive coupling. The capacitive coupling type touch panel also includes an electrode provided at a position so as to be isolated from and opposed to the XY-coordinate electrode.

Owner:JAPAN DISPLAY INC +1

Blend of fluorubber and silastic, and preparation thereof

InactiveCN101412835ASmall compression setThe preparation method is simple and feasibleTemperature resistancePolymer blend

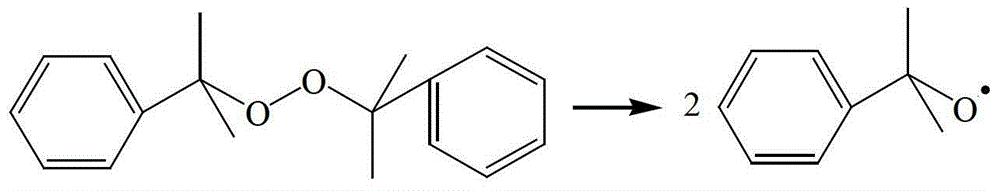

The invention relates to a blend of fluorine rubber and silicone rubber, as well as a preparation method thereof. The composition in weight percentage of the blend of fluorine rubber and silicone rubber is as follows: 12 to 50 percent of fluorine rubber, 12 to 50 percent of silicone rubber, 2.5 to 10 percent of compatibilizer, 2.5 to 10 percent of acid-acceptor, 12 to 35 percent of reinforcing filler, 0.5 to 7 percent of constitution controller, 0.5 to 3 percent of vulcanizing agent and 0.5 to 4 percent of crosslinking additive. The blend of fluorine rubber and silicone rubber is prepared by a mechanical blending method and is vulcanized by use of peroxides. Vulcanized rubber has good mechanical properties, heat resistance, low-temperature resistance, oil resistance and low-compression permanent deformation performance, and can be used for producing and manufacturing high-performance rubber tubes, adhesive tapes, sealing elements, rubber linings and the like needed in automobile, mechanical, chemical, aerospace and other industries.

Owner:SOUTH CHINA UNIV OF TECH

Oilfield ultrahigh-pressure acid-resistant rubber seal material and preparation method thereof

ActiveCN103396591AOvercome leaksOvercoming extrusion edge tearing phenomenonOther chemical processesPolymer scienceAntioxidant

An oilfield ultrahigh-pressure acid-resistant rubber seal material comprises, by weight, 85-65 parts of hydrogenated butadiene-acrylonitrile rubber, 15-35 parts of butadiene-acrylonitrile rubber, 5-7 parts of zinc oxide, 1-4 parts of stearic acid, 1-2 parts of an antioxidant, 50-65 parts of nanometer carbon black, 15-25 parts of white carbon black, 5-10 parts of a phenolic resin, 5-10 parts of a softener, 3-6 parts of a peroxide vulcanizing agent, 6-8 parts of a vulcanizing aid, 1-3 parts of sulfur, and 2-4 parts of a promoter, wherein the sum of the weight parts of the hydrogenated butadiene-acrylonitrile rubber and the butadiene-acrylonitrile rubber is 100. A seal ring made through adopting the rubber seal material can satisfy the seal of oilfield high-pressure acid-resistant liquid (hydrochloric acid or hydrofluoric acid) pipelines, and overcomes the leakage and torn edge extrusion phenomena of seal members under a high hydraulic pressure.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

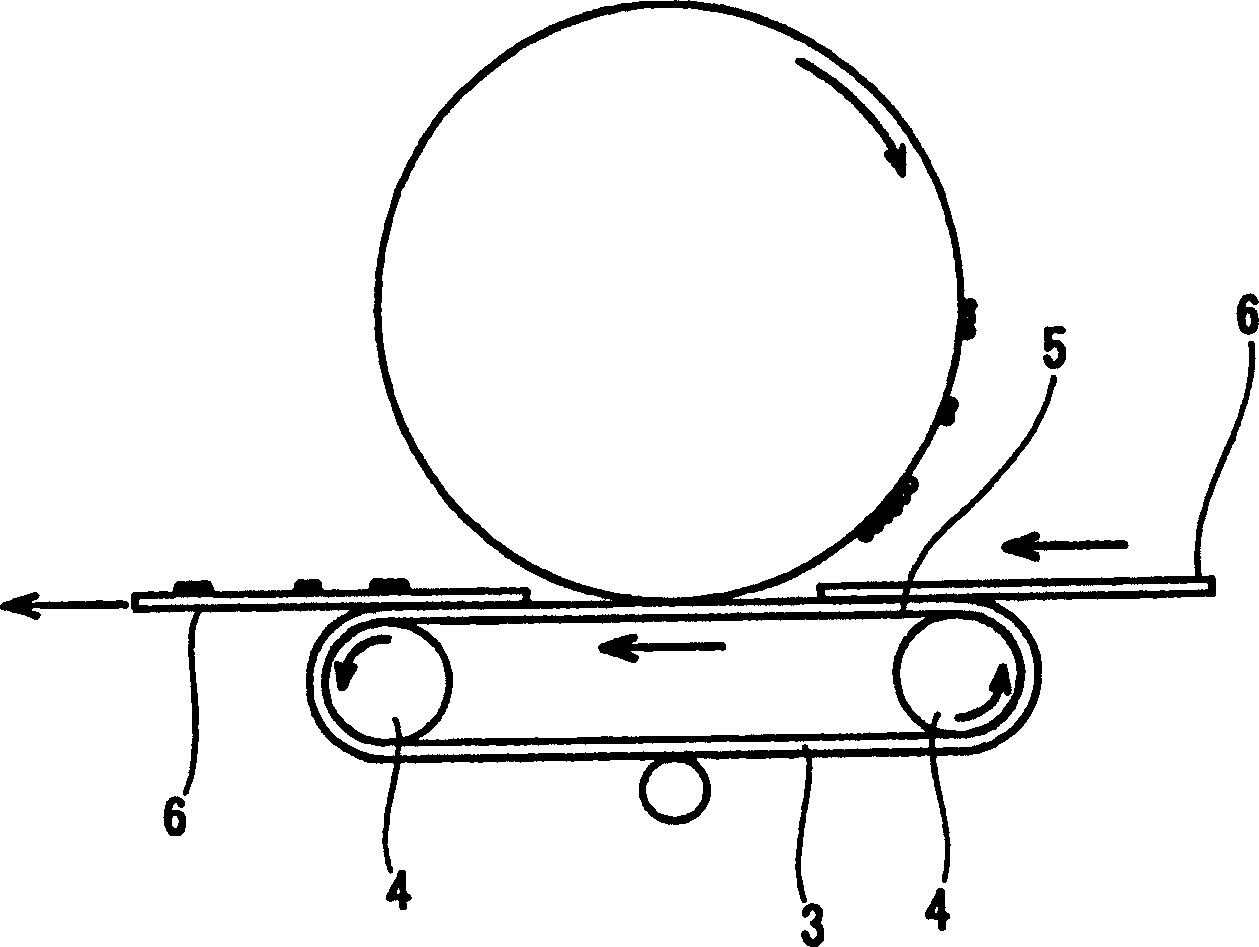

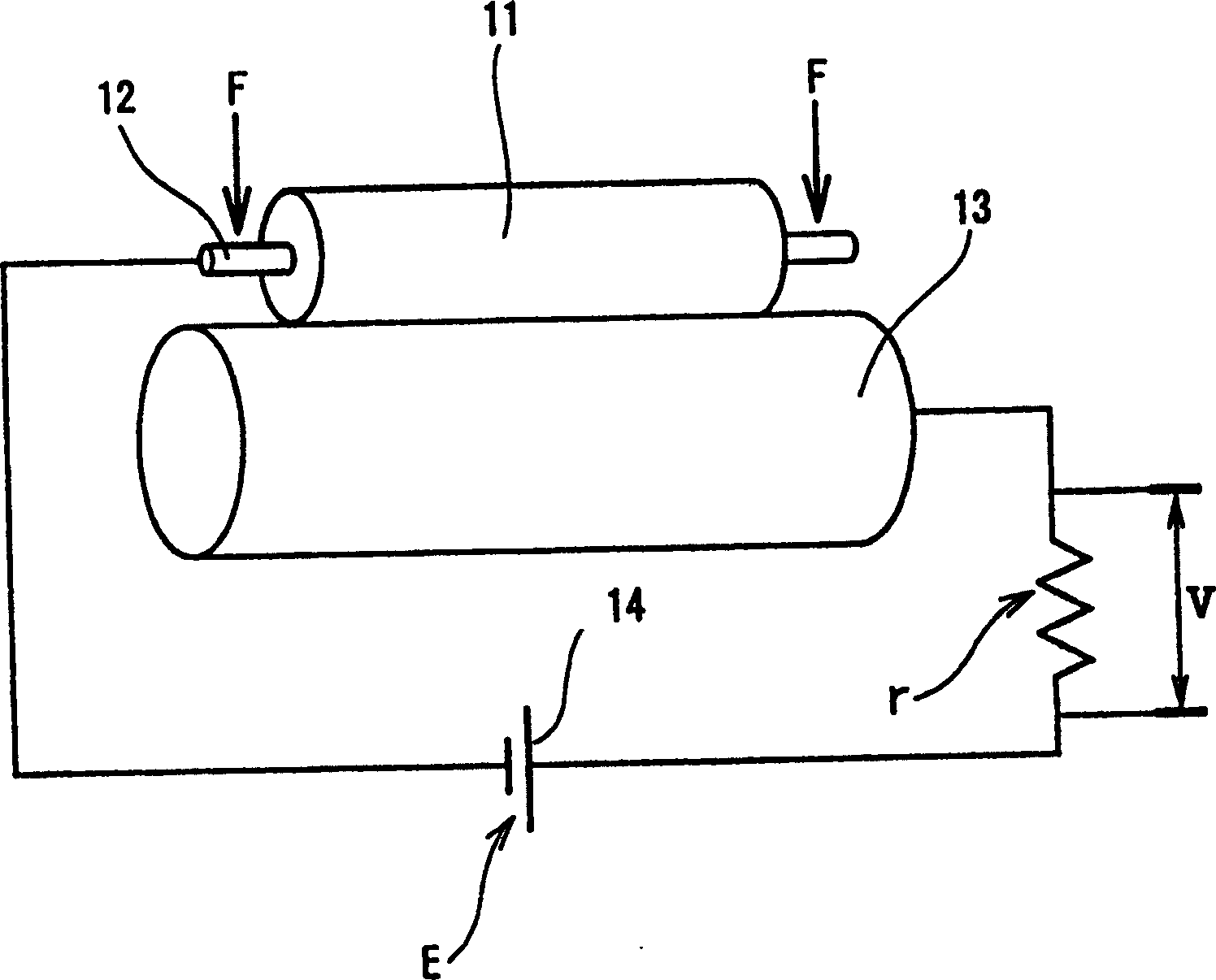

Conductive elastomer composition and method of producing same

ActiveUS7141183B2Improve conductivityEasy to operateSynthetic resin layered productsConductive materialElastomerThermoplastic elastomer

A conductive elastomer composition having rubber-like elasticity and flexibility and thermoplastic-resin-like moldability and realizing a high conductivity. The conductive elastomer composition includes a thermoplastic elastomer composition (A) containing a compound (A1) composed of a thermoplastic resin and / or a thermoplastic elastomer and a compound (A2), composed of a crosslinkable rubber and / or a crosslinkable thermoplastic elastomer, dispersed in the compound (A1) by dynamically crosslinking the compound (A2); and an ionic-conductive agent (B), containing a metal salt and a polyether-containing block copolymer resin, dispersed in the thermoplastic elastomer composition (A). The conductive elastomer composition may contain carbon black (C).

Owner:SUMITOMO RUBBER IND LTD

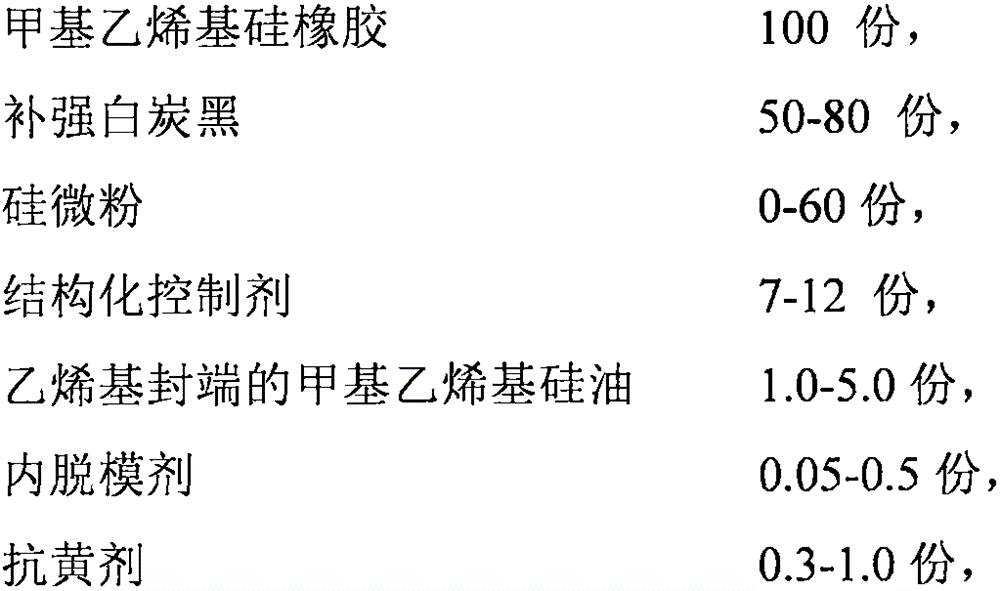

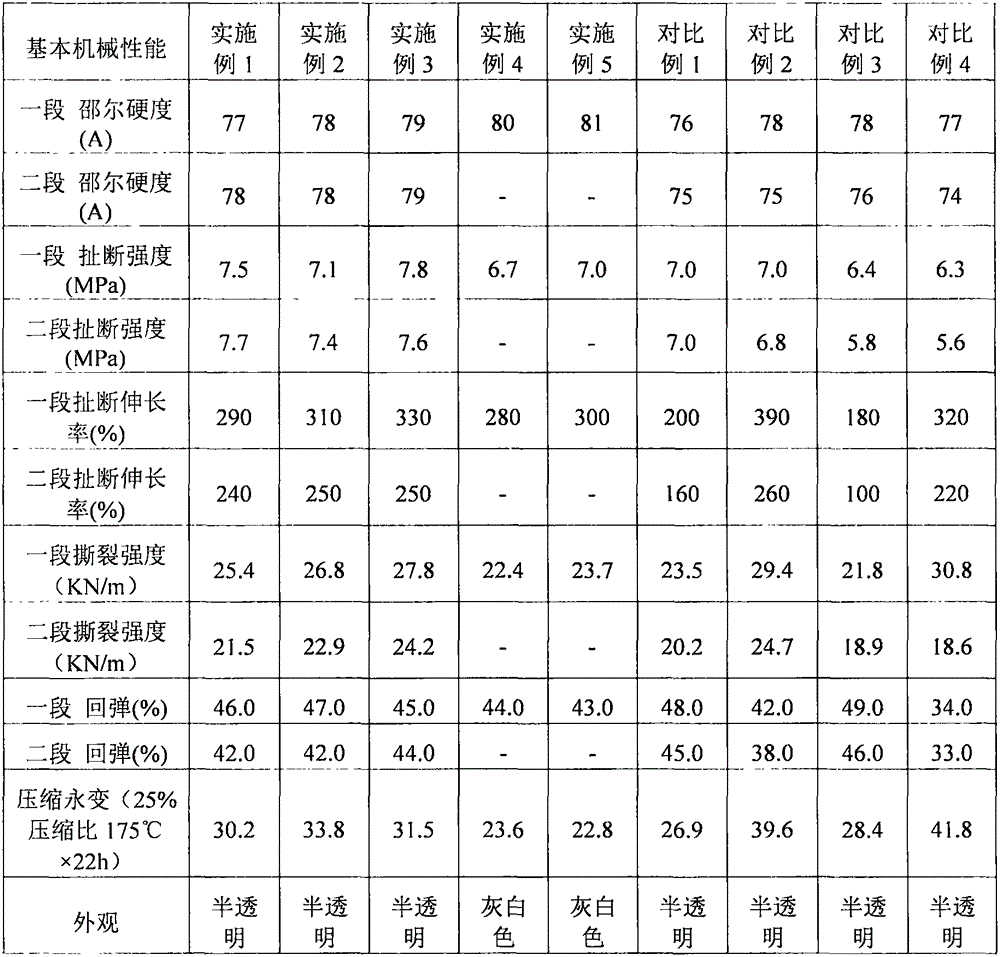

High-hardness extruded silicone rubber composition and preparation method thereof

The invention provides high-hardness extruded silicone rubber composition. The silicone rubber takes methyl vinyl siloxane with the average molecular weight of 0.55-0.75 million and the average vinyl molar content of 0.4-0.55% as rubber master batch, and reinforced white carbon black, silica powder, a structurized control agent, vinyl-terminated methyl vinyl silicone oil, an internal releasing agent, an anti-yellowing agent, magnesium oxide and cerium oxide are added. The prepared silicone rubber has high hardness, high resilience, relatively high elongation and high tear resistance after high temperature vulcanization and can be applicable to silicone products such as an industrial rubber-covered roller, a pressing wheel, a sealing ring and a sealing element.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

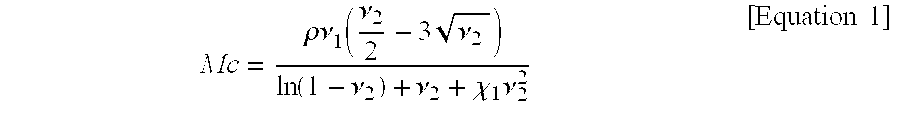

Low rigidity, low compression permanent deformation cold tolerant butadiene nitrile rubber compositions

The invention provides a permanent deformation cold resistance nitrile-butadiene rubber composition with low hardness and low compression, which contains nitrile-butadiene rubber, peroxides and auxiliary crosslinking agents; wherein, the auxiliary crosslinking agents are selected from one or a plurality of 1, 3-(citraconic maleimide methyl) benzene, meta phenylene bis maleimide, triallyl cyanurate and triallyl isocyanurate. The nitrile-butadiene rubber which is prepared by the nitrile-butadiene rubber composition has the advantages that peroxide curing system containing the auxiliary crosslinking agents of the invention can improve the cold resistance and has small compression permanent deformation; at the same time, the tensile strength and the elongation at break are large, and the fatigability is good. The advantages are not possessed by the curing systems that singly use peroxides and the combination of the peroxide sulphur and other auxiliary crosslinking agents.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

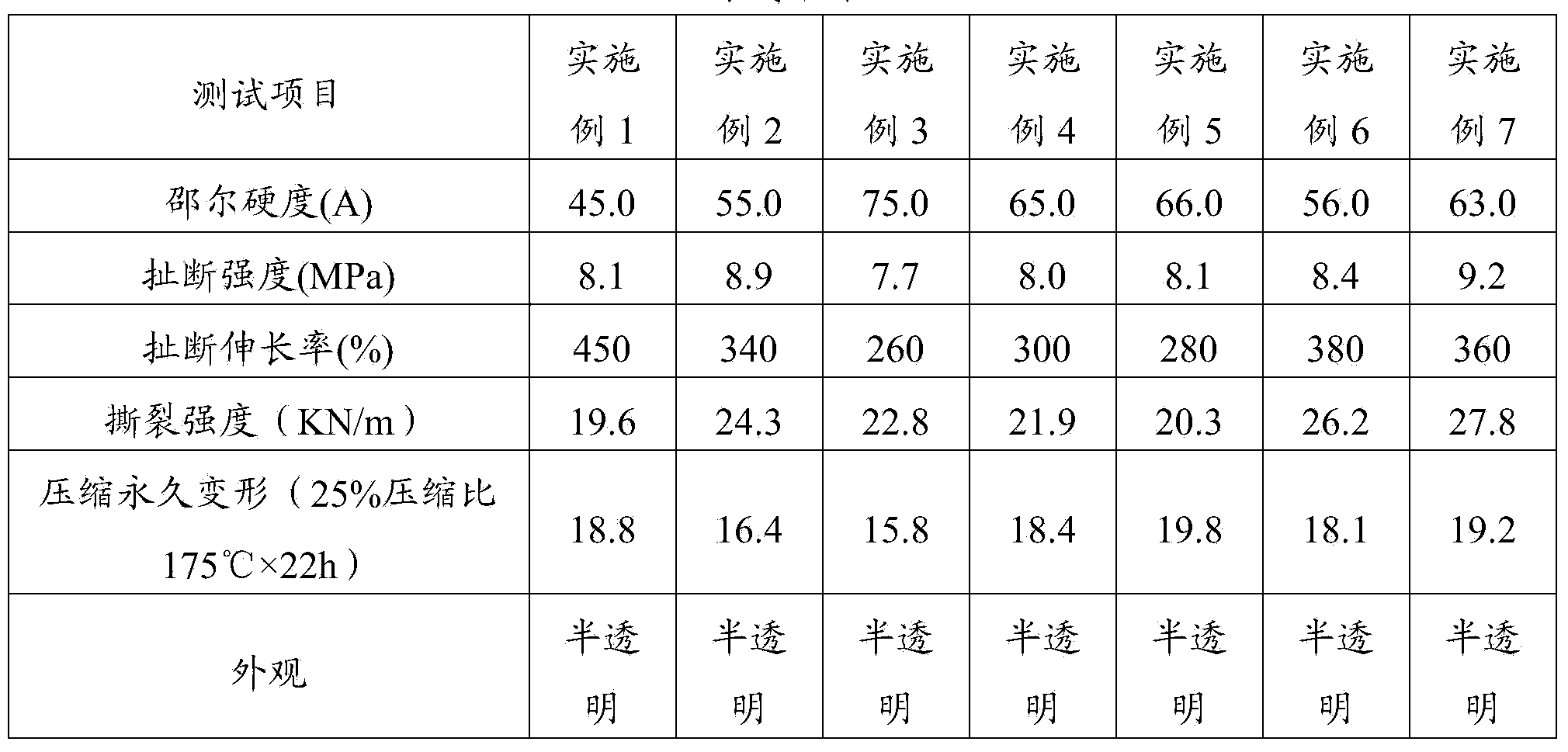

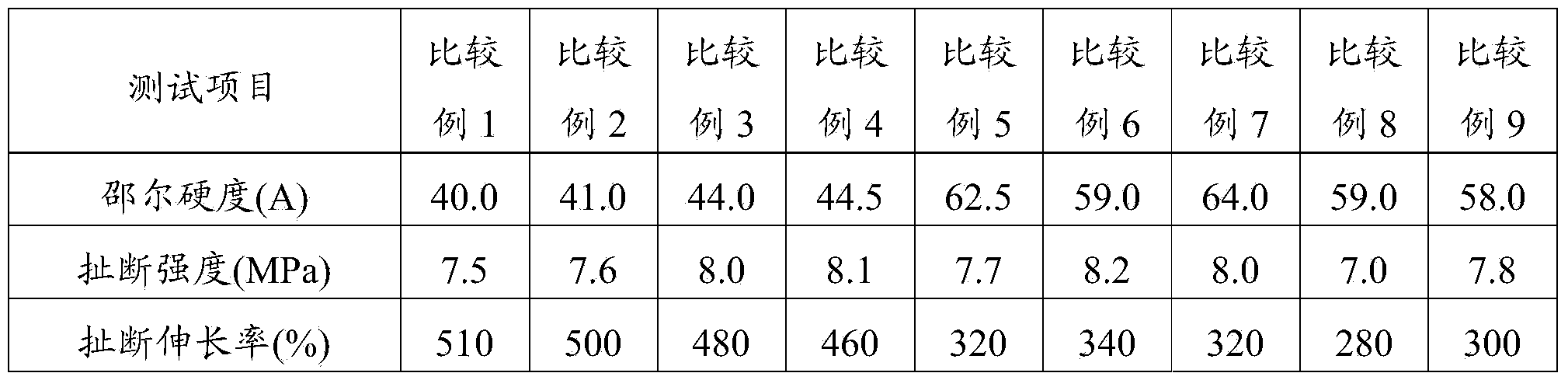

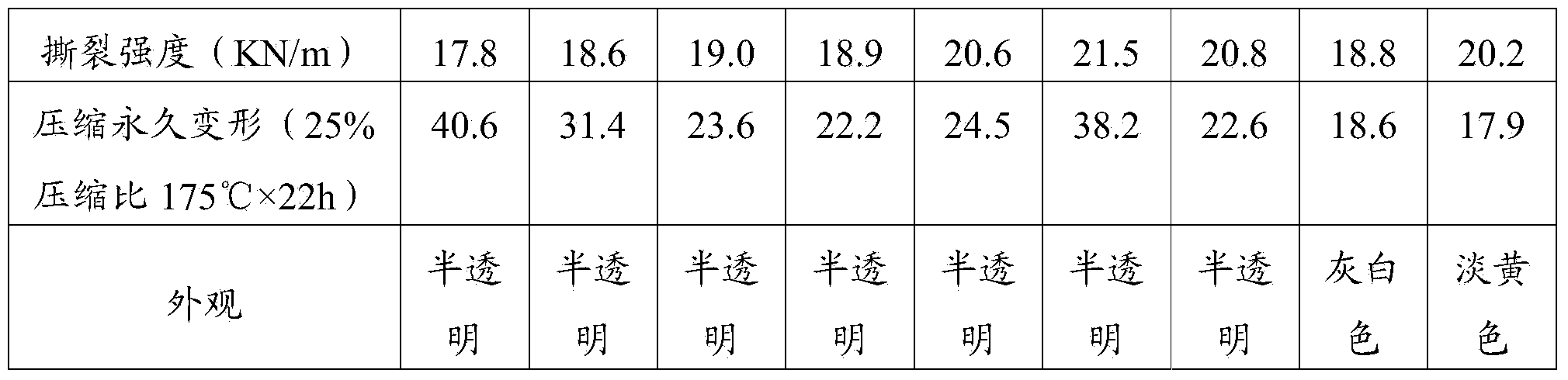

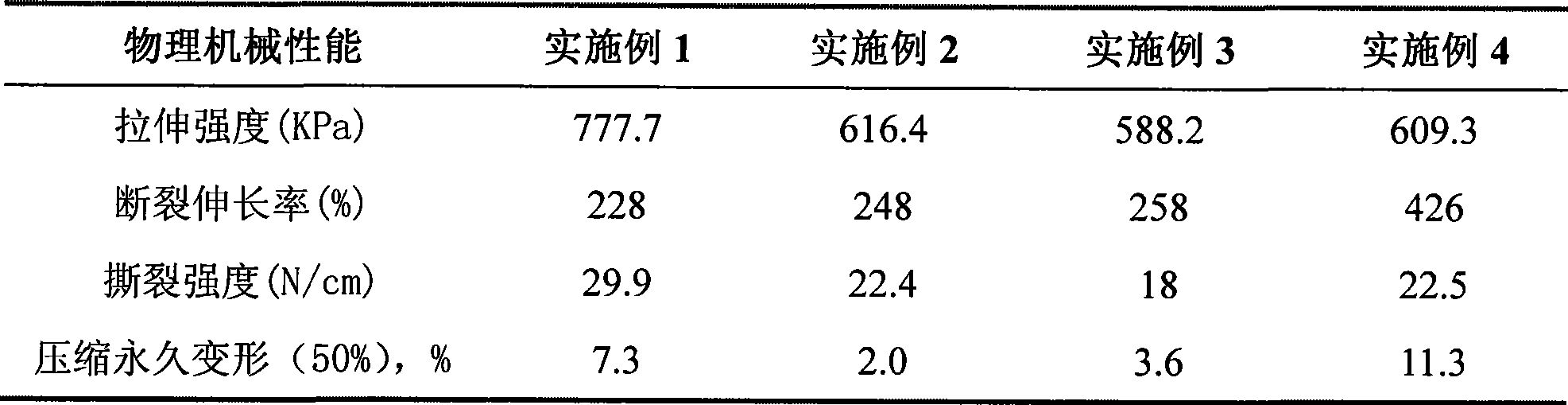

Low-compression permanent deformation silicone rubber composition and preparation method thereof

ActiveCN103709763AGood physical and mechanical propertiesShao and good hardnessPolymer scienceGas phase

The invention provides a low-compression permanent deformation silicone rubber composition. The low-compression permanent deformation silicone rubber composition comprises the following components in parts by weight: 100 parts of methyl vinyl silicone rubber, 20-80 parts of reinforced fillers, 1-15 parts of a structured control agent, 0.2-0.3 part of a compression permanent deformation conditioning agent, 0.05-0.5 part of an internal releasing agent, 0.3-3 parts of a vulcanizing agent and 0.1-1.5 parts of a vulcanizing auxiliary agent, wherein the mol content of vinyl of the methyl vinyl silicone rubber is 0.09%-0.50%; the reinforced fillers comprise 70wt%-100wt% of precipitation-method white carbon black and 0wt%-30wt% of gas-phase-method white carbon black; the compression permanent deformation conditioning agent is a silicon-based compound containing the vinyl. The low-compression permanent deformation silicone rubber composition provided by the invention has low compression permanent deformation and has high physical and mechanical properties and a semitransparent appearance.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

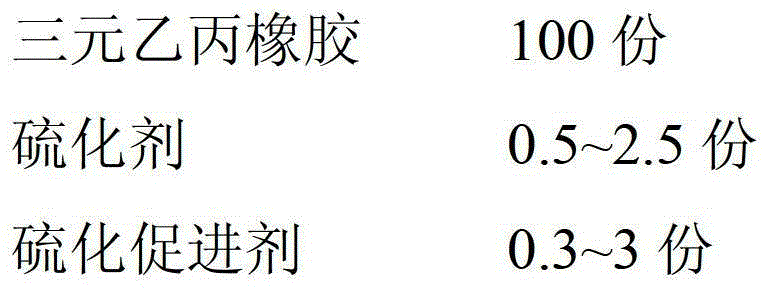

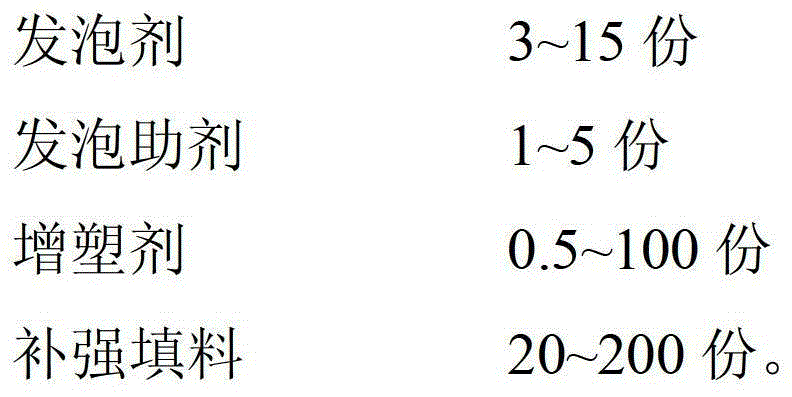

Environment-friendly sulfur-free foaming material as well as preparation method and application of environment-friendly sulfur-free foaming material

InactiveCN103333416AMeet environmental protection requirementsImprove performanceMaterials preparationFoaming agent

The invention belongs to the technical field of foaming material preparation and discloses an environment-friendly sulfur-free foaming material as well as a preparation method and application of the environment-friendly sulfur-free foaming material. The environment-friendly sulfur-free foaming material comprises the following ingredients in parts by weight: 100 parts of ethylene propylene diene rubber, 0.5 to 2.5 parts of vulcanizing agents, 0.3 to 3 parts of vulcanization accelerators, 3 to 15 parts of foaming agents, 1 to 5 parts of foaming auxiliary agents, 0.5 to 100 parts of plasticizers and 20 to 200 parts of reinforcement fillings. The environment-friendly sulfur-free foaming material adopts environment-friendly raw materials and conforms to the environment protection requirement of China; and the vulcanizing agents are used, the materials can form single C-C crosslink bonds, the foaming material with excellent performance is obtained through preparation, excellent heat resistance and ageing resistant performance are realized, the compression permanent deformation is little (12 percent), and the elongation at break (246 percent) is equivalent to that of a sulfur vulcanizing system foaming material.

Owner:GUANGZHOU JUNYIHUI AUTOMOBILE TECH

Energy ray-curable elastomer composition

InactiveUS20120157564A1Easy to optimizeHigh elongationEngine sealsCarrier constructional parts dispositionChemistryCompression set

An energy ray-curable elastomer composition, which comprises an energy ray-curable compound (A) having a (meth)acryloyl group, a polythiol compound (B) having 2 to 6 mercapto groups per molecule, and a polyfunctional (meth)acrylate (C), characterized in that the ratio of the number of (meth)acryloyl functional groups in component (A) to the number of mercapto functional groups in component (B) is 100:0.1-100:5n (wherein n represents the number of mercapto groups per molecule of the polythiol compound), and component (C) is used at a ratio of 1-8 parts by mass per 100 parts by mass of component (A). Thus, an energy ray-curable elastomer composition, which can achieve both high breaking elongation and good processability and shows good compression set, can be provided.

Owner:BRIDGESTONE CORP

Ethylene propylene rubber with high temperature resistance and low compression deformation

The invention discloses ethylene propylene rubber with high temperature resistance and low compression deformation, which is prepared from the following raw materials in mass part: 30-80 parts of ethylene propylene rubber, 70-20 parts of ethylene propylene terpolymer rubber, 1-3 parts of anti-aging agent, 2.5-5 parts of phenolic resin, 5-8 parts of zinc oxide, 2.5-5 parts of white carbon black, 50-80 parts of carbon black N550, 45-90 parts of carbon black N774, 10-20 parts of paraffin oil, 1-3 parts of Rhine wax, 1-2 parts of polyethylene glycol, 0.5-1 part of stearic acid, 2-4 parts of cross-linking agent, 2 parts of cross-linking addictive and 0.2-0.5 part of accelerating agent. According to the invention, the ethylene propylene rubber and the ethylene propylene terpolymer rubber are used in combination, and co-vulcanization is performed to the ethylene propylene rubber and the ethylene propylene terpolymer rubber by means of adjusting a vulcanization system, so that the requirement for high temperature resistance can be met and the rubber can obtain lower compression permanent deformation; and moreover, the highest use temperature of the ethylene propylene rubber vulcanized by the vulcanization system can achieve 150 DEG C, can resist the temperature of 175 DEG C in short-time or intermittent use, and has good heat resistance, chemical stability and lower compression deformation.

Owner:SHANDONG MEICHEN ECOLOGY & ENVIRONMENT CO LTD

Duprene rubber foamed sheet and preparation method thereof

ActiveCN101392076AImprove flame retardant performanceHigh tensile strengthPolymer sciencePropanoic acid

The invention relates to a neoprene foaming board and a preparation method thereof. The neoprene foaming board is prepared by the following materials according to weight parts: 100 portions of neoprene, 15 portions to 200 portions of kaolin or calcium carbonate, 15 portions to 45 portions of carbon black, 10 portions to 20 portions of a vulcanizing agent, 0 portion to 2 portions of an accelerant, 5 portions to 15 portions of a vesicant, 0 portion to 5 portions of urea resin, 1 portion to 4 portions of olefin, 0 portion to 3 portions of dilauryl thiodipropionate, 0 portion to 2 portions of 2, 2'-methylene-bis(4-methyl-6- tert-butylphenol), 0 portion to 1 portion of nickel dibutyldithiocarbamate, 0 portion to 2 portions of stearic acid, 8 portions to 30 portions of black factice, 0 portion to 4 portions of vaseline, 10 portions to 20 portions of naphthenoid oil, 20 portions to 40 portions of perfume oil, and 1 portion to 4 portions of a dispersant. The preparation method thereof includes the steps of first-time mixing of a pressurizing milling machine, first-time mixing of a mixing mill, second-time mixing of the pressurizing milling machine, second-time mixing of the mixing mill, extrusion of an extruder, first-time foaming vulcanization, second-time foaming vulcanization, cooling and the like. The neoprene foaming board and the preparation method have the advantages of good flame resistance, high tensile strength, high extensibility, good performance of tear resistance, small compression set, good abrasion resistance and skidproof effect, good effect of shock absorption and the like.

Owner:常州美利晟高分子科技有限公司

Conductive elastomer composition and its mfg. method

InactiveCN1475865ALower volume resistivityReduce hardnessConductive materialOrganic conductorsElastomerThermoplastic elastomer

A conductive elastomer composition having rubber-like elasticity and flexibility and thermoplastic-resin-like moldability and realizing a high conductivity. The conductive elastomer composition includes a thermoplastic elastomer composition (A) containing a compound (A1) composed of a thermoplastic resin and / or a thermoplastic elastomer and a compound (A2), composed of a crosslinkable rubber and / or a crosslinkable thermoplastic elastomer, dispersed in the compound (A1) by dynamically crosslinking the compound (A2); and an ionic-conductive agent (B), containing a metal salt and a polyether-containing block copolymer resin, dispersed in the thermoplastic elastomer composition (A). The conductive elastomer composition may contain carbon black (C).

Owner:SUMITOMO RUBBER IND LTD

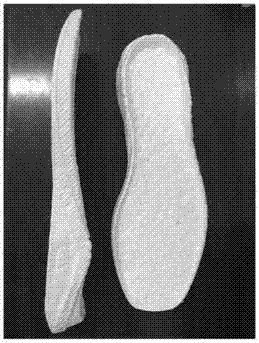

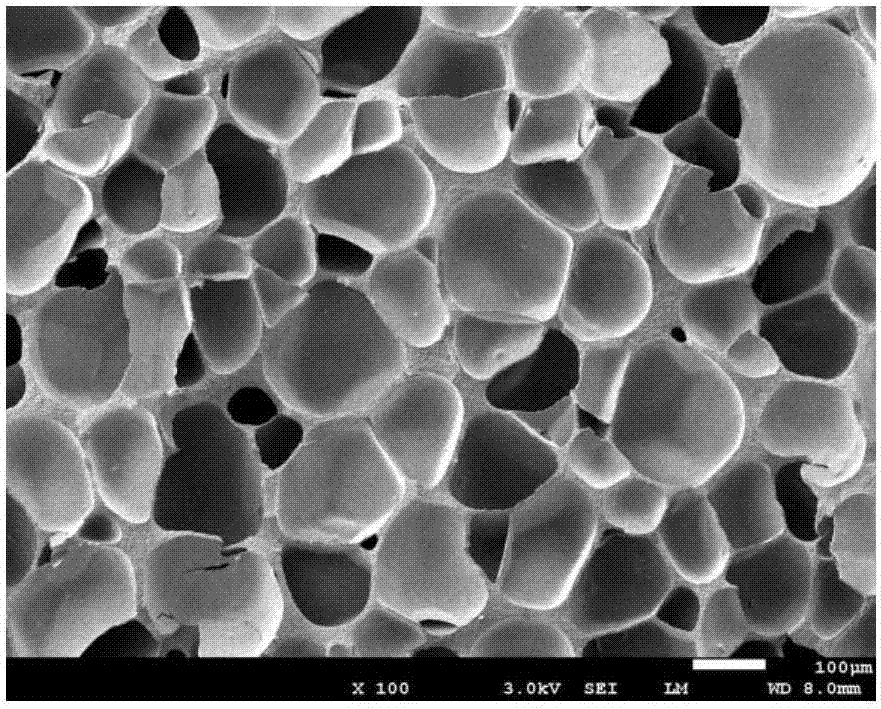

Environment-friendly EVA (ethylene vinyl acetate copolymer) insole

The invention provides a preparation method of environment-friendly EVA (ethylene vinyl acetate copolymer) foamed beads and insole. The highly-elastic foamed beads are prepared from EVA particles, EVA and POE (polyolefin elastomer) blended particles, EVA and SEBS (styrene-ethylene-butylene-styrene) blended particles or EVA, POE and SEBS blended particles as raw materials with an irradiation crosslinking technology and an intermittent supercritical nitrogen foaming technology, then the highly-elastic foamed beads are subjected to hot pressing molding with steam, and the foamed middle sole is prepared. Compared with an existing traditional chemically foamed sole, the crosslinked elastomer foam material formed through supercritical nitrogen foaming is more complete and full in foam structure, has better elasticity and is free of harmful residues.

Owner:FUJIAN XINGXUN NEW MATERIALS TECH CO LTD

Cold-resisting oil-resisting modified fluorine rubber cable sheath material

The invention discloses a cold-resisting oil-resisting modified fluorine rubber cable sheath material which comprises the following components in parts by weight: 50-70 parts of fluorine rubber, 15-30 parts of silica rubber, 15-20 parts of fluorine silica rubber, 10-25 parts of pre-swelled organic clay, 15-25 parts of white carbon black, 5-13 parts of ternary nylon, 1-2.5 parts of stearic acid, 3-10 parts of active magnesium oxide, 3-9 parts of rare earth complex, 5-12 parts of calcium hydroxide, 0.5-1.8 parts of polyethylene glycol, 1-5 parts of epoxy octyl stearate, 1-2.5 parts of epoxy triglyceride fatty acid, 4-8 parts of a bisphenol vulcanizing agent, 1-3 parts of an accelerant, 0.5-2 parts of an anti-aging agent MB and 0.8-1.5 parts of an anti-aging agent 4010NA. The cold-resisting oil-resisting modified fluorine rubber cable sheath material disclosed by the invention is excellent in cold resistance and oil resistance and is good in comprehensive property and long in service life when used for manufacturing a cable sheath.

Owner:安徽华峰电缆集团有限公司

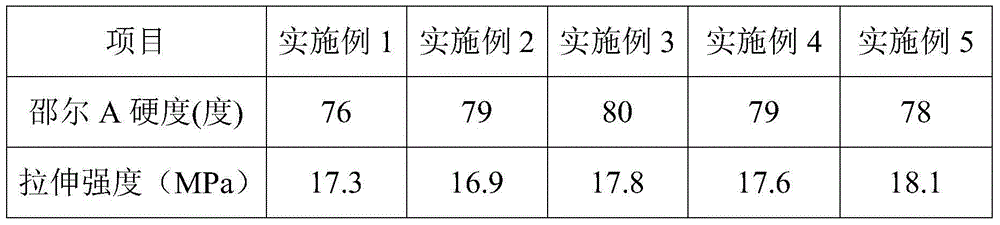

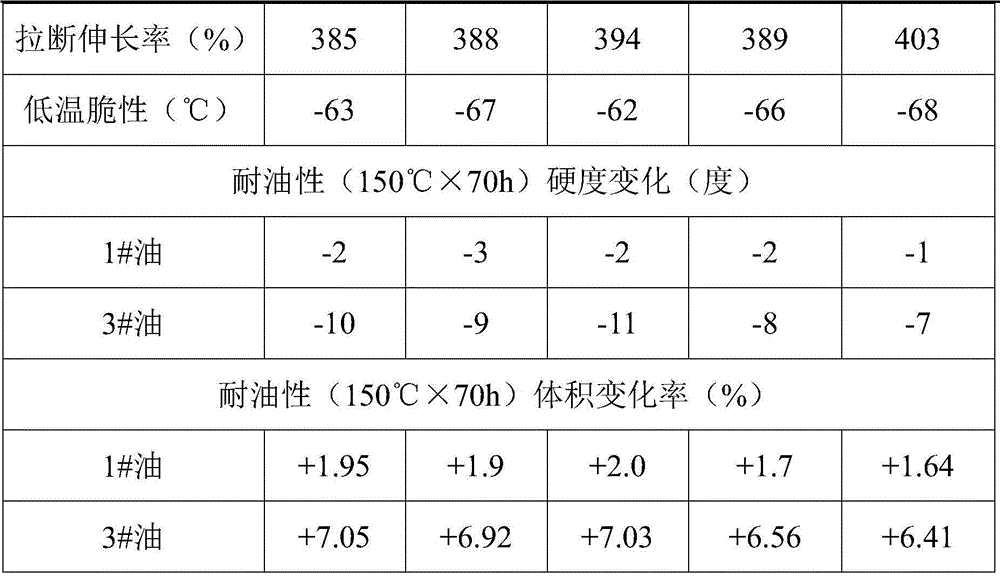

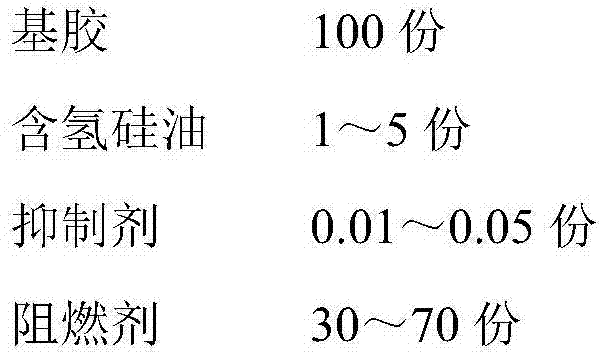

Two-component addition type high-fire-retardant silica gel with low compression deformation and preparation method thereof

The invention discloses two-component addition type high-fire-retardant silica gel with low compression deformation. The two-component addition type high-fire-retardant silica gel with low compression deformation is formed by mixing a component A with a component B in a mass ratio of 1:1, wherein the component A is composed of the following components in parts by mass: 100 parts of base gum, 0.01-0.05 part of a platinum catalyst and 30-70 parts of a fire retardant; and the component B is composed of the following components in parts by mass: 100 parts of base gum, 1-5 parts of hydrogen-containing silicone oil, 0.01-0.05 part of an inhibiting agent and 30-70 parts of a fire retardant. The invention also discloses a preparation method of the two-component addition type high-fire-retardant silica gel with low compression deformation. The prepared two-component addition type high-fire-retardant silica gel with low compression deformation has the advantages that the fire-retardant grade of the silica gel reaches up to 94V-0 by adding the fire retardant, good physical properties are realized, a compression deformation value is less than 12%, the strength is high, the adhesive property is good, and the storage property is good, so that the two-component addition type high-fire-retardant silica gel with low compression deformation has an industrial value. The preparation method of the two-component addition type high-fire-retardant silica gel with low compression deformation is simple and practicable and is low in cost, thus being applicable to mass production.

Owner:JIANGSU TIANCHEN NEW MATERIALS

Ethylenic copolymer, composition containing the copolymer and use thereof

ActiveUS8329848B2High vinyl-group contentGood cross-linking effectDomestic footwearFootwearAlpha-olefinCompression set

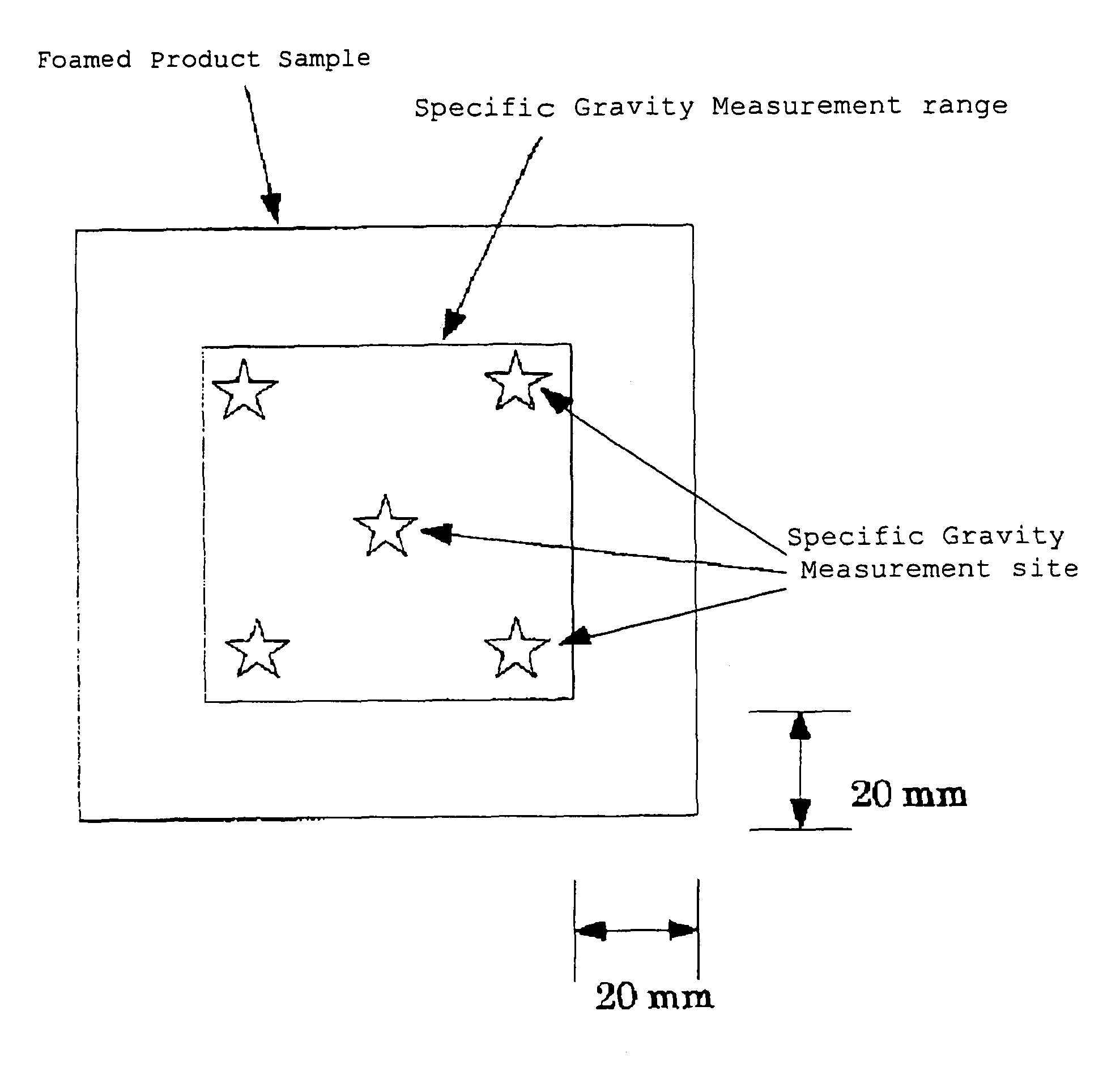

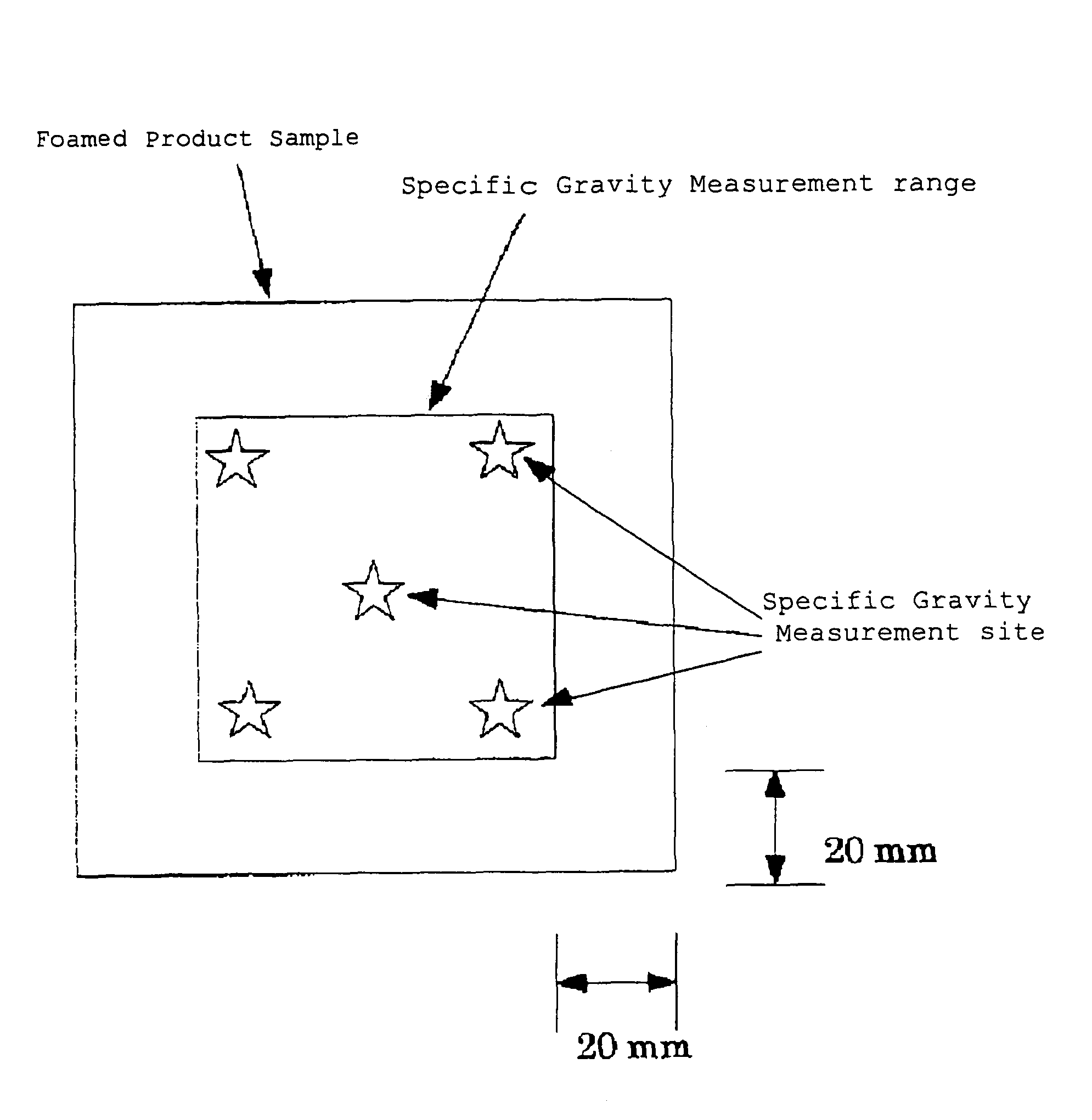

An object of the present invention is to provide a novel ethylene-α-olefin copolymer excellent in crosslinking properties; a foamed molded article having a low specific gravity and a low compression set (CS) and a composition capable of producing the foamed molded article, footwear parts composed of a foamed molded article; an ethylenic copolymer composition excellent in balance between weather resistance and mechanical strength, and an electric wire coating material and an electric wire sheath using the ethylenic copolymer composition; and a thermoplastic elastomer capable of producing a molded article excellent in balance between mechanical strength and toughness. The ethylenic copolymer (A) of the present invention is a copolymer composed of only ethylene and an α-olefin having 3 to 20 carbon atoms, and is characterized in that vinyl-group content (a) per 1000 carbon atoms as measured by infrared absorption spectroscopy, MFR10 / MFR2.16 (b), and the specific gravity (c) are within a specific range.

Owner:MITSUI CHEM INC

Sponge tire sponge rubber material containing butyl reclaimed rubber

The invention discloses sponge tire sponge rubber material containing butyl reclaimed rubber. The sponge tire sponge rubber material comprises the following ingredients in parts by weight: 30-100 parts of natural rubber (NR), 20-50 parts of butadiene styrene rubber (SBR), 50-100 parts of butyl reclaimed rubber, 10-25 parts of an active agent, 2-6 parts of an age resister, 20-26 parts of a reinforcing agent, 30-60 parts of a plasticizer, 1.5-4.5 parts of a vulcanizing agent, 0.5-1.5 parts of an accelerating agent and 1-10 parts of a foaming agent, and the material is prepared by using a normal process with a refining machine. The sponge rubber material has relatively good heat-resisting and aging-resisting properties and high-temperature compression permanent deformation resistance, stabbing resistance and cutting resistance, and the service life of a sponge tire is further prolonged under the condition that the comprehensive property is met.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

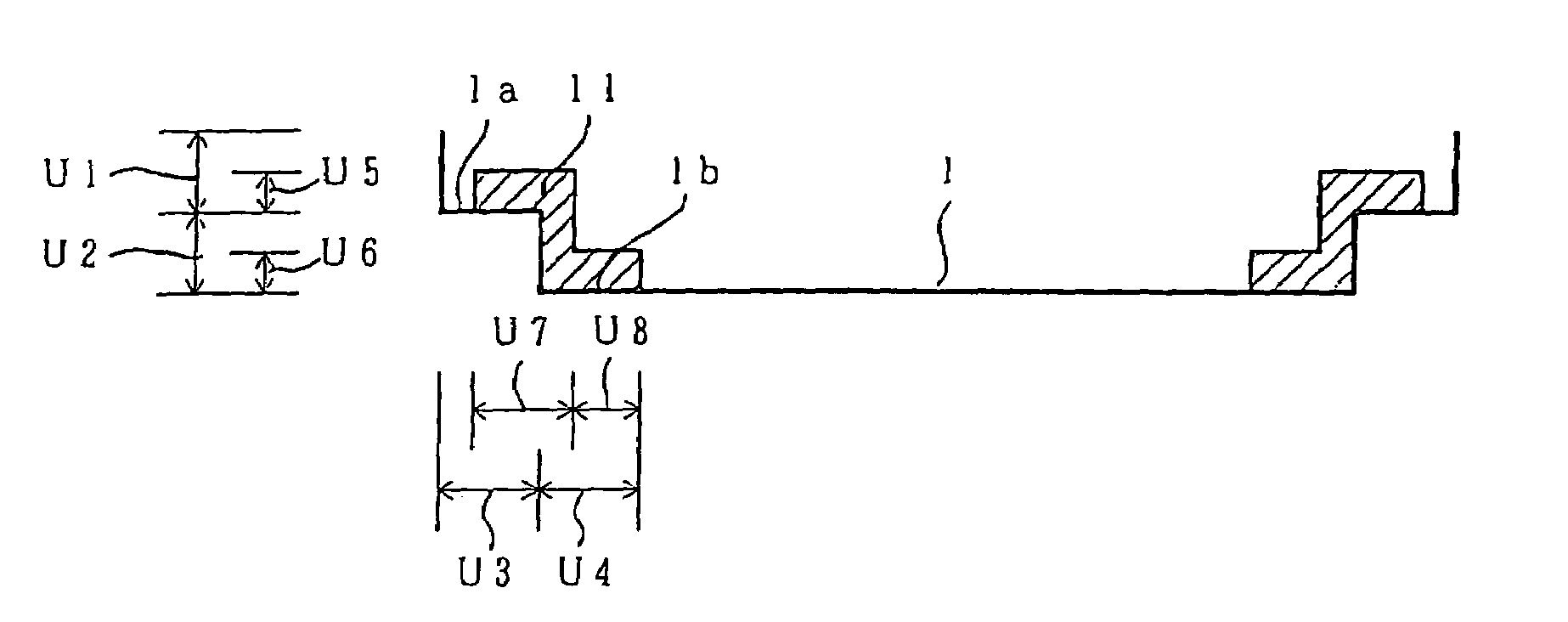

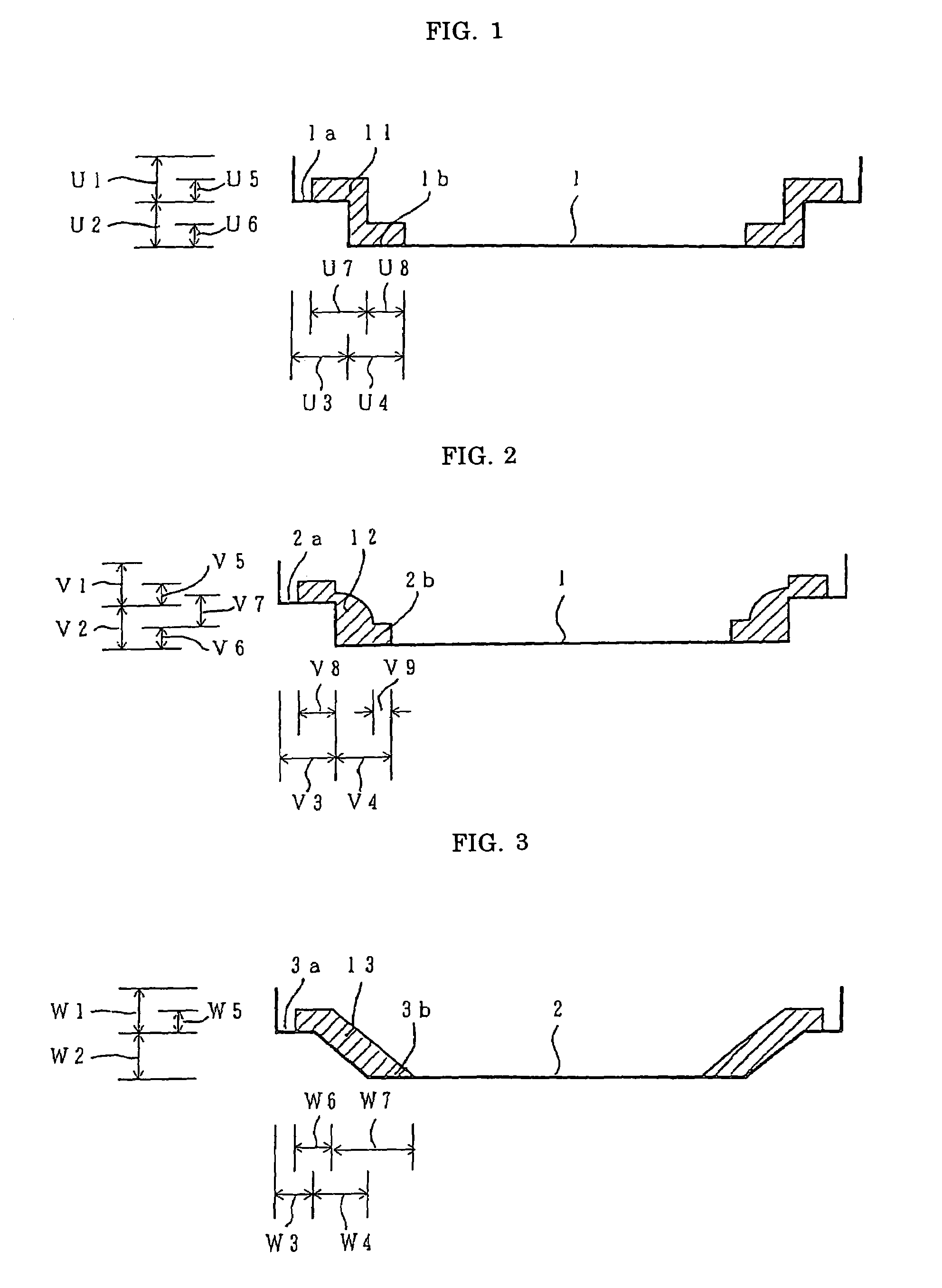

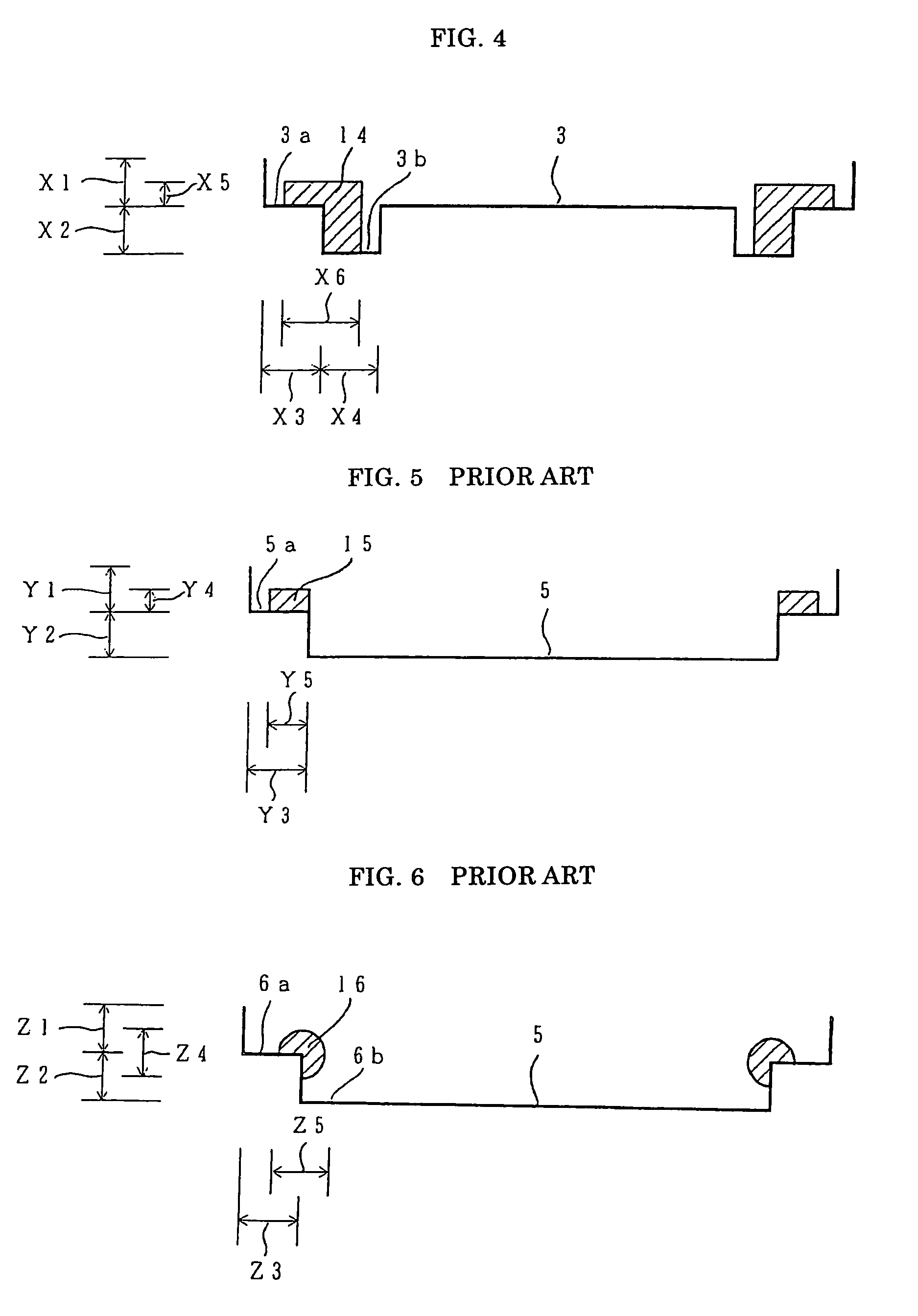

Cover-integrated gasket

InactiveUS7044475B2Improve adhesionIncrease productivityEngine sealsOther chemical processesVitrificationThermoplastic elastomer

A gasket integrated with a cover wherein a gasket material composed of a thermoplastic elastomer composition is integrally fixed to the cover having a shape of multistep contraction over at least two contraction steps, a gasket wherein the cover and the gasket are integrally molded and after molding, are subjected to a heating treatment at a temperature not lower than the temperature at which an adhesive component in materials constituting the gasket initiates crystal fusion or glass transition, or a gasket wherein the cover and the gasket are integrally molded and a covering layer composed of a fluoropolymer is formed on the gasket surface on atmospheric side are proposed. According to the present invention, a gasket integrated with a cover for a hard disc device which gasket is excellent in adhesive property and productivity, and is minimized in permeability and penetration of substances is provided.

Owner:BRIDGESTONE CORP

Low-compression set silicone rubber and preparation method thereof

The invention discloses a silicone rubber technology, and particularly relates to a low-compression set silicone rubber and a preparation method thereof. The low-compression set silicone rubber comprises the following components in parts by weight: 100 parts of methyl vinyl silicone rubber, 30-70 parts of white carbon black, 2-15 parts of a structurized control agent, 0.1-5 parts of a heat-resistant auxiliary agent, 0.2-2 parts of a vulcanizing auxiliary agent, 0.2-1.5 parts of a silane coupling agent and 0.05-1 part of a demoulding agent. After the adoption of the formula and the preparation method, through reasonable cross-linking structure design and addition of the vulcanizing auxiliary agent, the slippage of a molecular chain of a polymer is reduced; through addition of the heat-resistant auxiliary agent, oxidation and degradation of the polymer at high temperature are prevented; moreover, through a multistage heating mixing process, uniform treatment and dispersion of the white carbon black are achieved; the obtained silicone rubber has relatively low compression set and relatively good mechanical properties.

Owner:JIANGSU TIANCHEN NEW MATERIALS

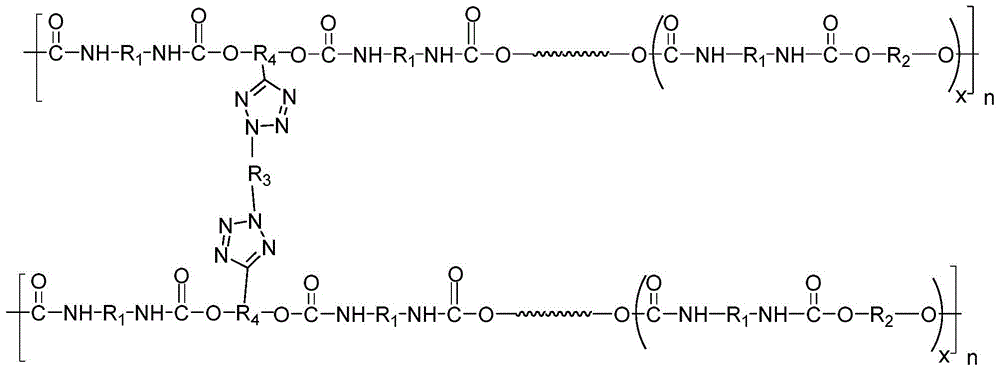

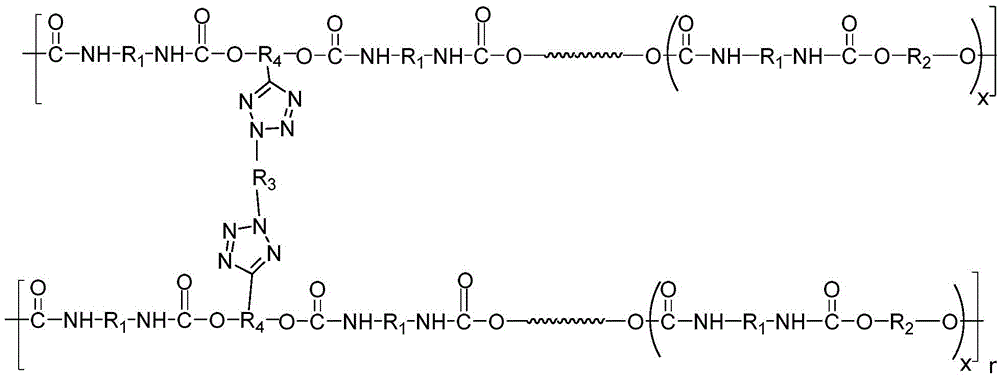

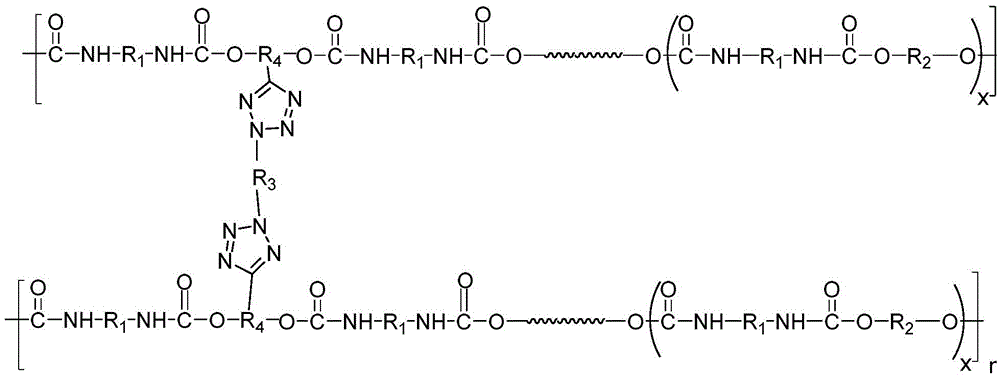

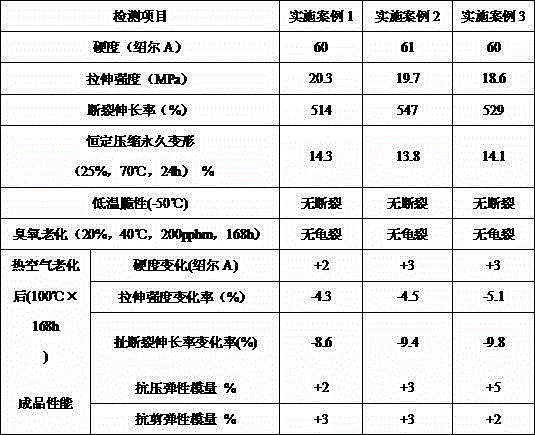

Thermoplastic polyurethane elastomer containing cyano in soft segment and preparation method thereof

The invention relates to a thermoplastic polyurethane elastomer containing cyano in a soft segment and a preparation method thereof. The preparation method comprises the following steps: polymerizing hydroxyl-terminated polybutadiene acrylonitrile, polyester macromolecular dihydric alcohol and / or polyether macromolecular dihydric alcohol, organic diisocyanate and micromolecule dihydric alcohol to obtain a product, namely, a thermoplastic polyurethane elastomer body containing the cyano in the soft segment; and blending the thermoplastic polyurethane elastomer body containing the cyano in the soft segment , a cross-linking agent containing diazido functional groups and a cross-linking catalyst, and performing a cross-linking reaction to obtain the thermoplastic polyurethane elastomer. The performance of a material can be conveniently adjusted by simply adjusting the consumption of the cross-linking agent, the cross-linked thermoplastic polyurethane elastomer has excellent mechanical performance and relatively low compressive permanent deformation, and can better meet the requirements of high-pressure sealing elements, automobile cushions and other parts requiring high mechanical strength and low compressive permanent deformation.

Owner:SHANGHAI YITAN NEW MATERIAL CO LTD

Rubber material for weather-resistant and aging-resistant plate type rubber support

The invention belongs to the technical field of rubber materials, particularly a rubber material for weather-resistant and aging-resistant plate type rubber support. The rubber material comprises the following components: rubber type chlorinated polyethylene (CM), natural rubber, zinc oxide, stearic acid, magnesium oxide, an antiaging agent, paraffin, carbon black, modified nano attapulgite, a plasticizer, an organic peroxide vulcanizing agent, sulfur and an accelerant. The rubber material for weather-resistant and aging-resistant plate type rubber support can be prepared by virtue of the steps: plastifying, mixing, vulcanizing and the like, wherein the rubber material has the characteristics of being high in mechanical strength, strong in weather resistance, heat aging resistant, ozone aging resistant and the like.

Owner:HENGSHUI ZHONGTIEJIAN ENG RUBBER

Fluororubber compound and preparation method thereof

ActiveCN107778734AImprove low temperature performanceBoth high and low temperatureHexafluoropropyleneFluoride

The invention relates to the field of rubber, in particular to a fluororubber compound. The fluororubber compound is prepared from the following raw material components in parts by weight: 100 parts of raw fluororubber, 15 to 30 parts of carbon black filler, 10 to 20 parts of modified silica filler and 2.3 to 4 parts of vulcanizing agent, wherein the fluororubber is a mixture of ternary raw rubberand binary raw rubber; the ternary raw rubber is vinylidene fluoride-hexafluoropropylene-tetrafluoroethylene or vinylidene fluoride-hexafluoropropylene-tetrafluoroethylene-csm; the binary raw rubberis vinylidene fluoride-hexafluoropropylene or vinylidene fluoride-hexafluoropropylene-csm. The compound has wider temperature tolerant range and good tolerance to novel fuel or additive, and can be widely applied to sealing products for automobiles, spaceflight, chemical machines and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Process for production of thermoplatic elastomer composition

InactiveUS7169849B2Good flexibilityGood rubber elasticityFilm/foil adhesivesElastomerPolymer science

A process for production of a thermoplastic elastomer composition by melt-kneading a mixture in one step to thereby conduct dynamic crosslinking, wherein the mixture comprises a hydrogenated block copolymer (a1) which is prepared by hydrogenating a block copolymer comprising a vinyl aromatic polymer block (A1) and a conjugated diene polymer block (B1) and has number-average molecular weight of 200000 or above and, if necessary, a non-hydrogenated block copolymer (a2) comprising a vinyl aromatic polymer block (A2) and a conjugated diene polymer block (B2), and contains a non-aromatic rubber softening agent (b), a peroxide-crosslinkable olefin resin (c) having a density of 0.94 g / cm3 or above, a peroxide-decomposable olefin resin (d), an organic peroxide (e), and a crosslinking aid (f), the amount of (b) being 50 to 250 parts by mass per 100 parts by mass of the sum of (a1) +(a2), the amount of (c) being 2.5 to 50 parts by mass per 100 parts by mass of (a); and the amount of (d) being 0.5 to 10 times that of (c) by mass.

Owner:KURARAY CO LTD

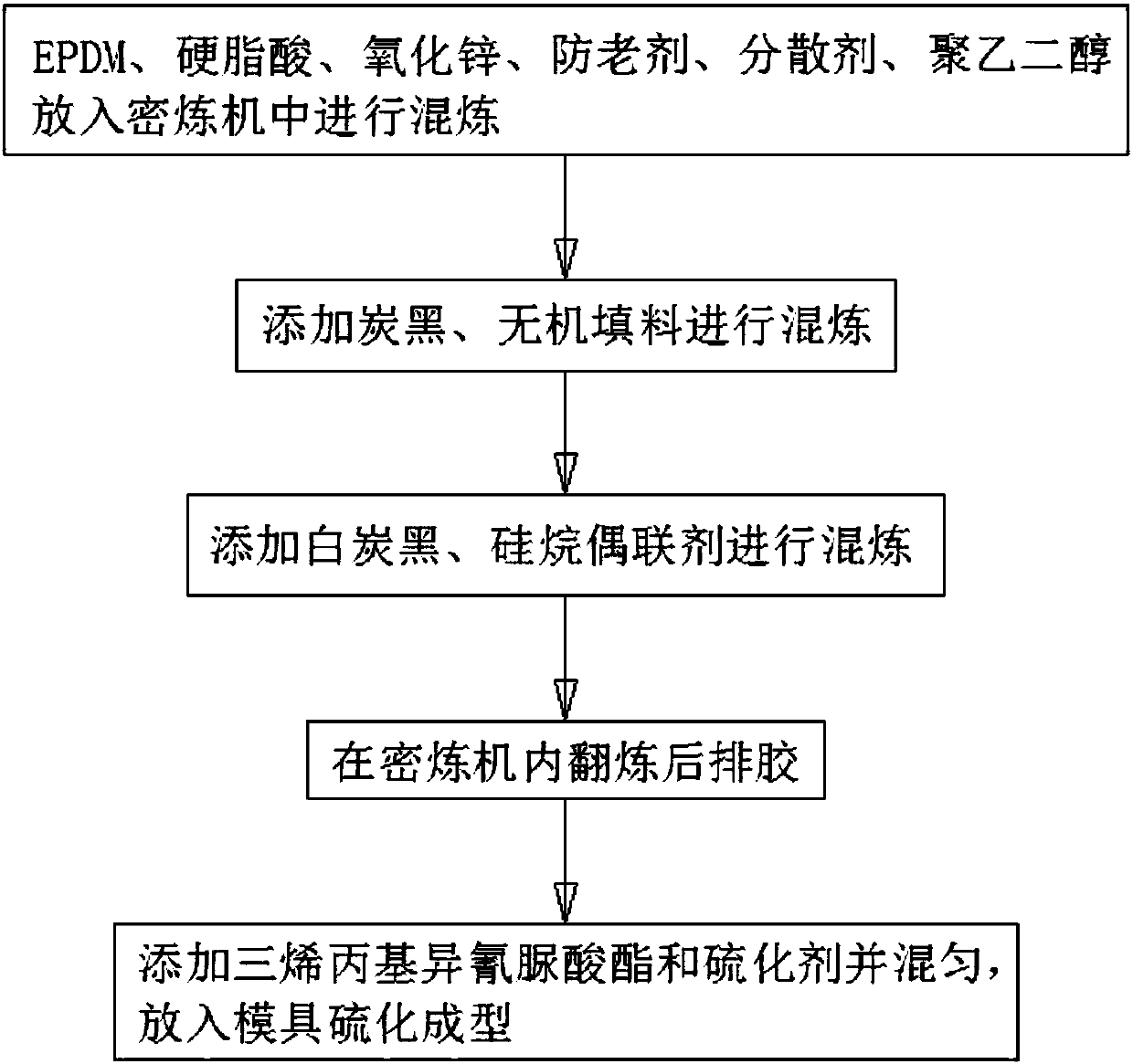

Ethylene propylene diene monomer-based sealing part and preparation method thereof

InactiveCN107674326AIncrease crosslink densityImprove insulation performanceCross-linkRubber material

The invention provides an ethylene propylene diene monomer (EPDM)-based sealing part and a preparation method thereof. The ethylene propylene diene monomer-based sealing part is prepared from the following components in parts by weight: 100 parts of EPDM, 0.3 to 1 part of stearic acid, 3 to 8 parts of zinc oxide, 1 to 4 parts of an anti-ageing agent, 40 to 60 parts of white carbon black, 20 to 40parts of inorganic filling, 0.5 to 2 parts of carbon black, 1 to 3 parts of a dispersant, 2 to 4 parts of polyethylene glycol, 2 to 5 parts of a silane coupling agent, 2 to 4 parts of triallyl isocyanurate and 2 to 5 parts of a vulcanizing agent. According to the ethylene propylene diene monomer-based sealing part provided by the invention, a mass ratio of all the components is strictly controlledso that the cross-linking density of a rubber material is increased and a sealing part product keeps relatively high physical and mechanical performance; meanwhile, the permanent compression deformation is reduced; the ethylene propylene diene monomer-based sealing part has excellent insulating performance and airtight performance and has relatively small deformation under high temperature; the ethylene propylene diene monomer-based sealing part has the prominent advantages of simple preparation method, easiness for operation, low implementation cost and the like.

Owner:CHENGDU SHENGBANG SEALS

Automobile shock absorber bushing

The invention relates to the technical field of automobile shock absorbers, and discloses an automobile shock absorber bushing which comprises the following raw materials by weight: 65-75 parts of natural rubber, 25-35 parts of polynorbornene rubber, 10-25 parts of high abrasion furnace black, 45-55 parts of carbon black N660, 1-4 parts of a promoter, 2-8 parts of zinc oxide, 1-6 parts of paraffin wax, 1-5 parts of an antioxidant, 1-5 parts of a dispersing agent, 3-8 parts of aromatic oil, 1-5 parts of a curing agent, 1-5 parts of a plasticizer and 1-5 parts of a coupling agent. Through simultaneous use of the natural rubber and the polynorbornene rubber, the heat resistance of products is excellent, by simultaneous use of the high abrasion furnace black and the carbon black N660, aging resistance and bending fatigue resistance of the rubber reinforcing system are excellent, the service life is longer, compression permanent deformation is small, rubber tensile strength is high, rebound elasticity is excellent, and the compression permanent deformation is small.

Owner:NINGGUO ZHONGCHEN SEALING PARTS

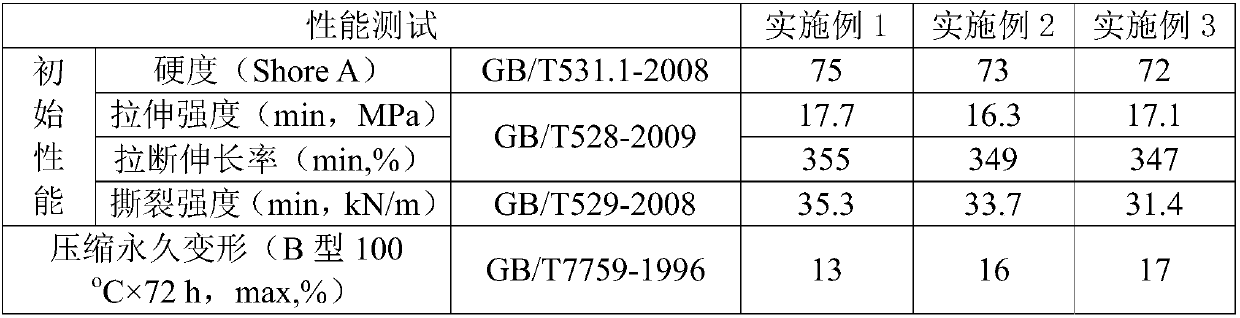

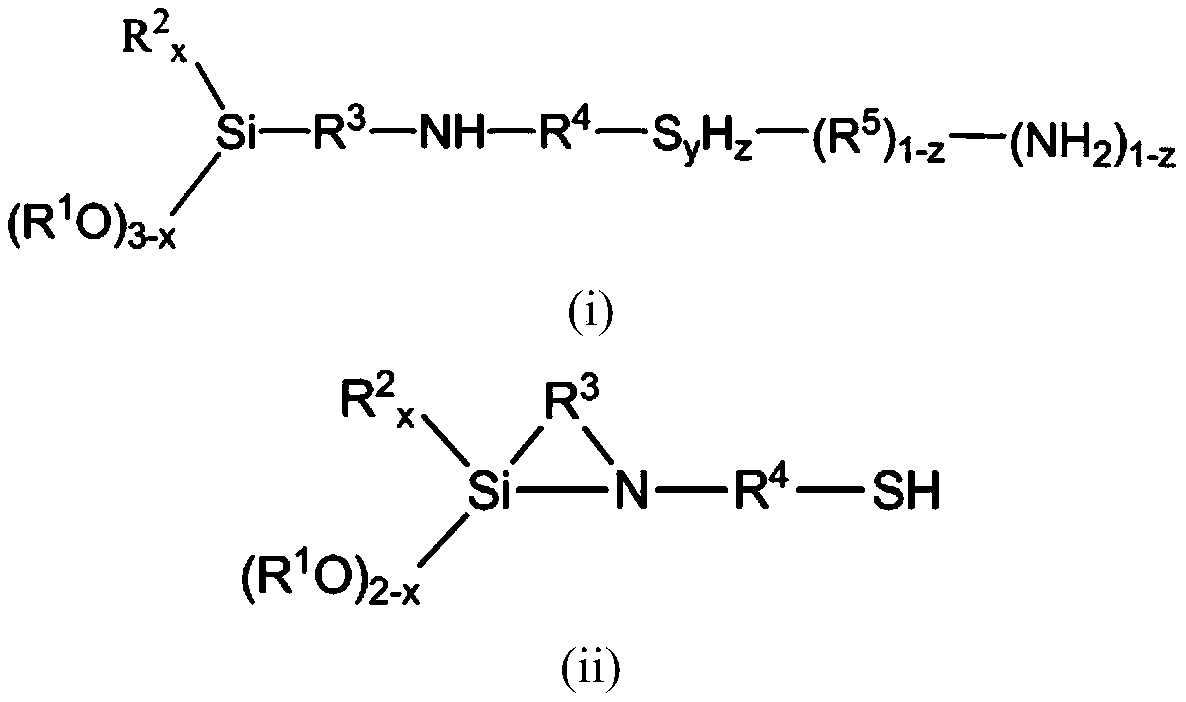

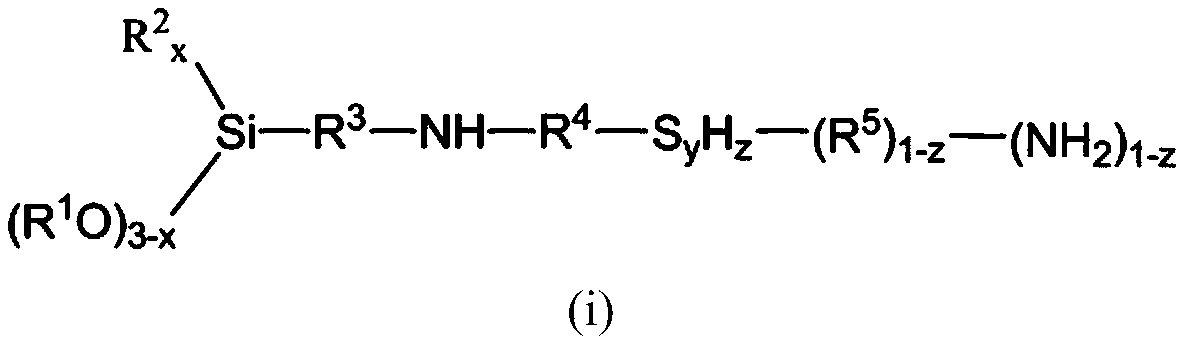

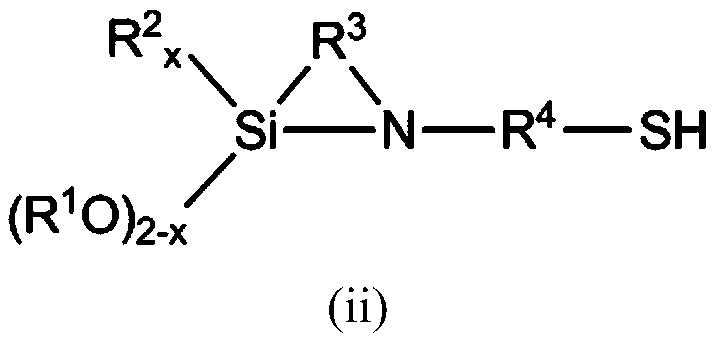

Multi-functional silane coupling agent as well as preparation method and application thereof

ActiveCN109749129AHigh tensile strengthHigh elongation at breakGroup 4/14 element organic compoundsTetraReinforced rubber

The invention relates to a multi-functional silane coupling agent. The molecular structure of the silane coupling agent simultaneously contains an amino group, an alkoxysilyl group and a sulfur-containing functional group; the amino functional group comprises one or more of an amino group, a secondary amino group and a tertiary amino group; the sulfur-containing functional group comprises one or several of sulfydryl, a mono-sulfide bond, a dis-ulfide bond, a tri-sulfide bond and a tetra-sulfide bond. The multi-functional silane coupling agent provided by the invention contains the amino group,the alkoxysilyl group and the sulfur-containing functional group and can simultaneously modify carbon black, white carbon black and rubber, fully realize the effect of carbon black and / or white carbon black mixed filling and reinforcing rubber, effectively improve the tensile strength, the elongation at break and the constant tensile stress of the rubber, significantly reduce the permanen compression deformation and significantly improve the heat generation performance.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

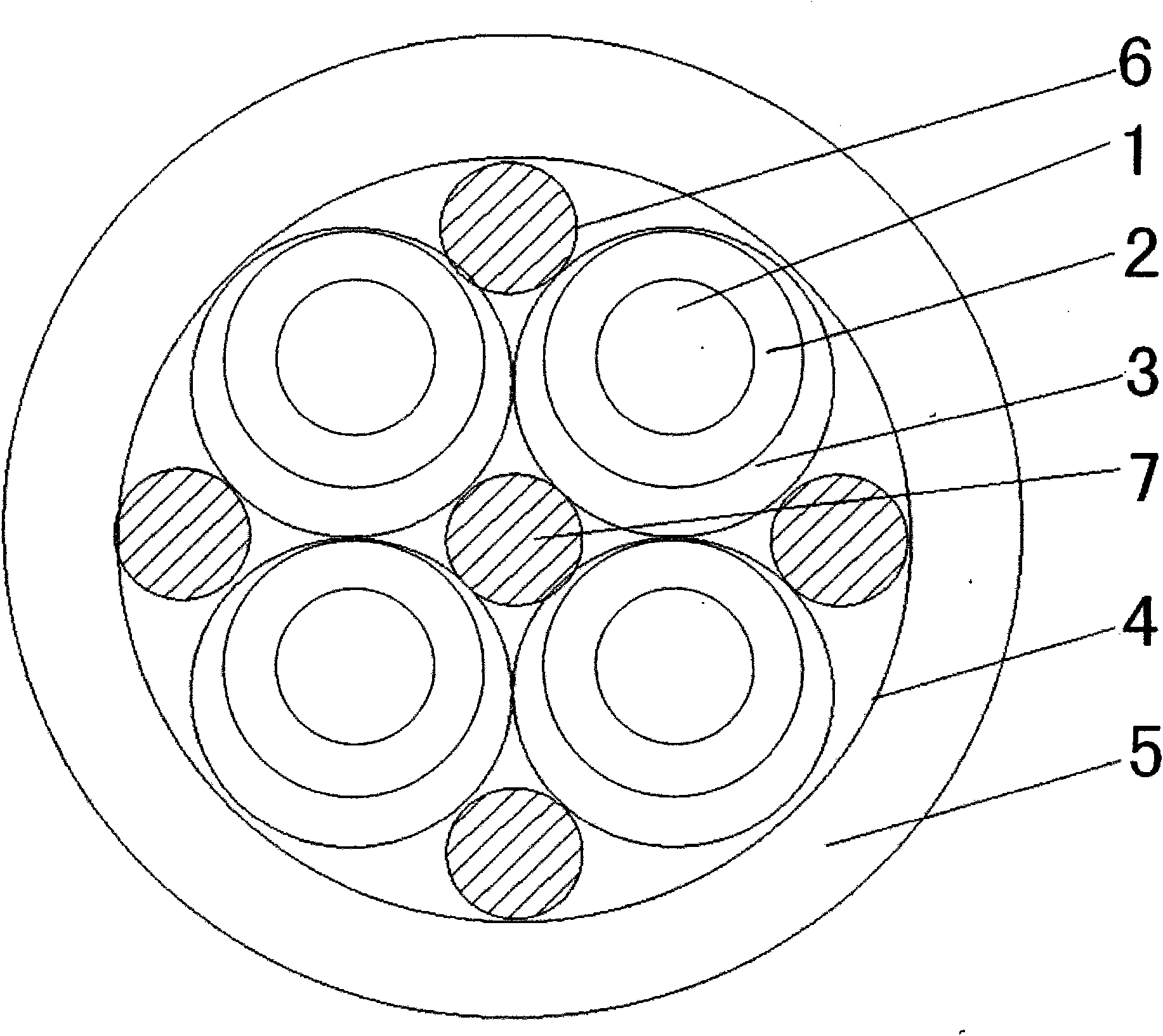

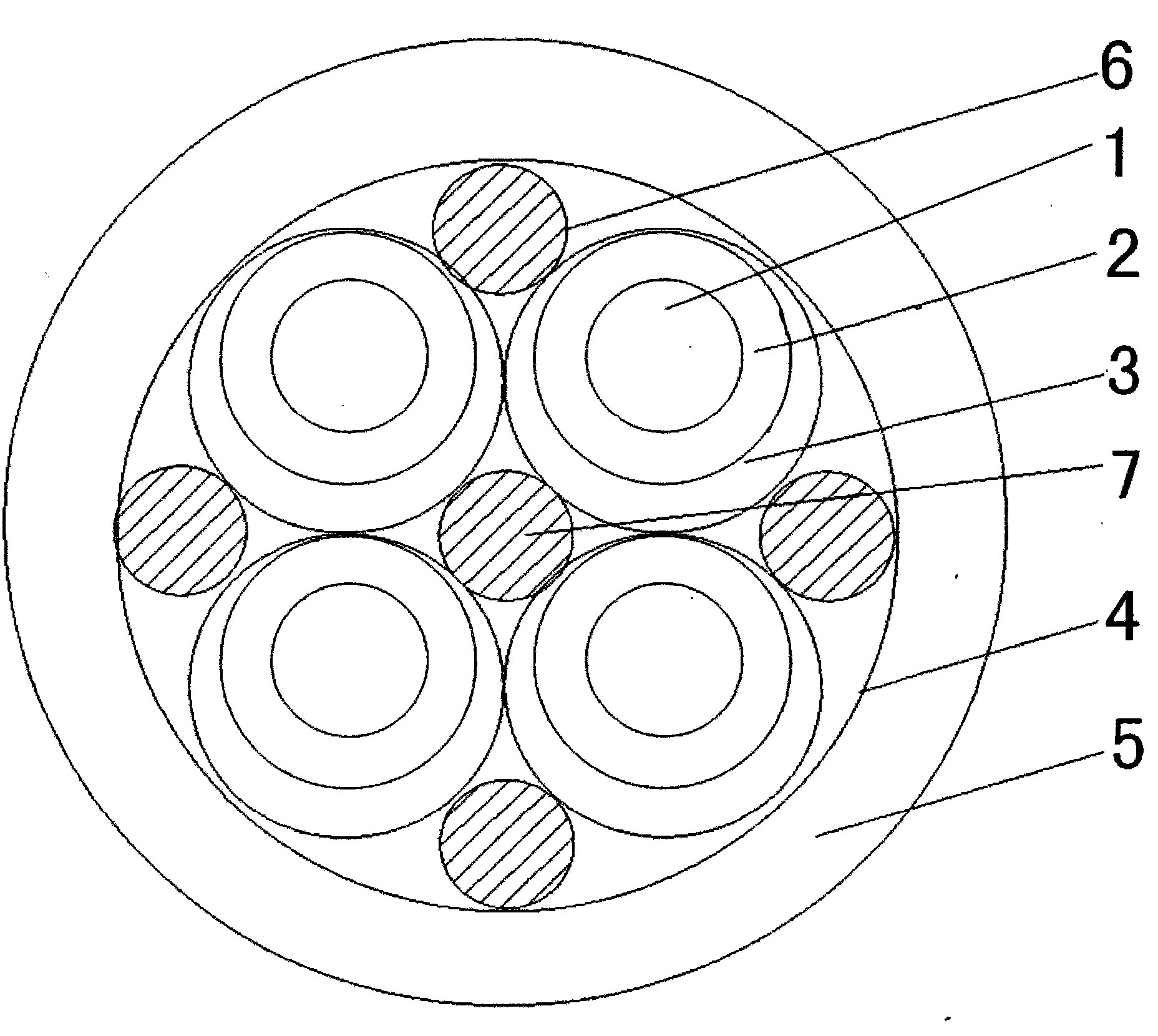

Silicone rubber insulating fire-resisting flexible cable

InactiveCN101847461AImprove insulation performanceImprove stabilityFlexible cablesFlexible conductorsFire retardantMetal

The invention aims to provide a silicone rubber insulating fire-resisting flexible cable and can effectively solve the problems that a control cable in the prior art has a high halogen content, is inflammable, generates toxic gas after combustion, and the like. The invention relates to a silicone rubber insulating cladding high temperature resisting flexible cable which comprises an inner core and a cable outer layer clad outside the inner core, wherein the inside of the inner core comprises a conductor wire core, an insulating layer and a fire-resisting layer from inside to outside in sequence; the inside of the cable outer layer comprises a fire-retardant tape and a cladding layer from inside to outside in sequence; and a flame-retardant filler is arranged in a gap between the cable outer layer and the inner core. The invention can realize fire resistance of the cable mainly by cladding mica on the surface of a silicone rubber insulated wire core, and can achieve the effects of fire resistance and flame retardant by using filling materials, tapes, cladding materials and metal materials which are not inflammable or have flame-retardant performance.

Owner:上海索谷电缆集团有限公司

High-flame retardation solar energy cell organosilicon pouring sealant and preparation method thereof

InactiveCN107384305AHigh transparencyGood flexibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkAcrylic resin

The invention relates to a high-flame retardation solar energy cell organosilicon pouring sealant and a preparation method thereof. The high-flame retardation solar energy cell organosilicon pouring sealant comprises the following raw materials in parts by weight: 40 parts of methyl phenyl vinyl silicone rubber, 20 parts of room-temperature sulfured phenylene silicone rubber, 20 parts of addition-type heat vulcanized nitrile silicone rubber, 20 parts of phosphate silicone oil, 20 parts of polyoxypropylene glycerol ether silicone oil, 10 parts of mercapto silicone oil, 5 parts of low-molecular hydroxy silicone oil, 5 parts of hydrogen-containing silicone oil with hydrogen containing amount accounting for 0.5% of mass content, 10 parts of an ethene-vinyl acetate copolymer, 10 parts of otcamethylcyclotetrasiloxane-modified acrylic resin, 7 parts of hydrogenated castor oil, 1-3 parts of an adhesion agent, 1-3 parts of a strengthening agent, 0.1-0.4 parts of a catalyst, 1-3 parts of a silicon nitrogen cross-linking agent, 0.5-2.5 parts of an inhibitor, and 1-2 parts of a flame-retardation filling material.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

High-strength anti-aging ethylene propylene diene monomer rubber pipe

The invention discloses a high-strength anti-aging ethylene propylene diene monomer rubber pipe, wherein a used ethylene propylene diene monomer material includes the raw materials in parts by weight: 100 parts of ethylene propylene diene monomer, 15-25 parts of polypropylene, 15-25 parts of an ethylene-octene block copolymer, 0.2-1 part of zinc oxide, 0.3-1.5 parts of stearic acid, 0.5-1.5 parts of bromo-octyl-phenolic curing resin, 0.2-1 part of benzoyl peroxide, 0.05-0.3 part of zinc methacrylate, 15-25 parts of modified nano silica, 5-10 parts of attapulgite, 5-10 parts of nano carbon fiber, 2-5 parts of nylon, 0.5-1.2 parts of an anti-aging agent MC, 0.2-1 part of an anti-aging agent 4020, 2-5 parts of zinc nitrilotiracetate, 0.2-0.9 part of an accelerator, 3-10 parts of a plasticizer, and 1.5-3 parts of a silane coupling agent. The high-strength anti-aging ethylene propylene diene monomer rubber pipe provided by the invention has high strength and good heat resistance and aging resistance.

Owner:安徽都邦电器有限公司

Preparation method of silicon-rubber composite molding material

InactiveCN107815121AReliable mechanical strengthGood electrical performanceVulcanizationAluminium hydroxide

The invention relates to the field of silicon-rubber composite materials, and particularly relates to a preparation method of a silicon-rubber composite molding material. The method adopts methylvinylsilicon rubber, fumed silica, precipitated silica, hydroxyl silicone oil, silane coupling agent surface treatment type active aluminium hydroxide, titanate coupling agent surface treatment type aluminium hydroxide, zinc stearate, iron oxide red, cerium oxide and 2,5-dimethyl-2,5-dihexane as raw materials to prepare the silicon-rubber composite molding material with reliable mechanical strength, excellent electrical performance, good hydrophobicity and flame retardance and better outdoor-aging resistance. The silicon-rubber composite molding material is designed for a hot die-pressing vulcanization molding production process, can be applied in production and manufacture of electrical-equipment insulation sleeves and products in related fields, and also can be applied to sealing products and damping and shock-absorbing products for hot die-pressing vulcanization molding.

Owner:董绍光

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com