Ethylene propylene diene monomer-based sealing part and preparation method thereof

A technology of EPDM rubber and seals, which is applied in the field of EPDM rubber-based seals and its preparation, can solve the problems of poor gas barrier performance, large compression deformation, insulation and gas permeability that cannot meet the sealing performance, Leak-proof performance and other issues, to achieve the effect of excellent insulation performance, small deformation, low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

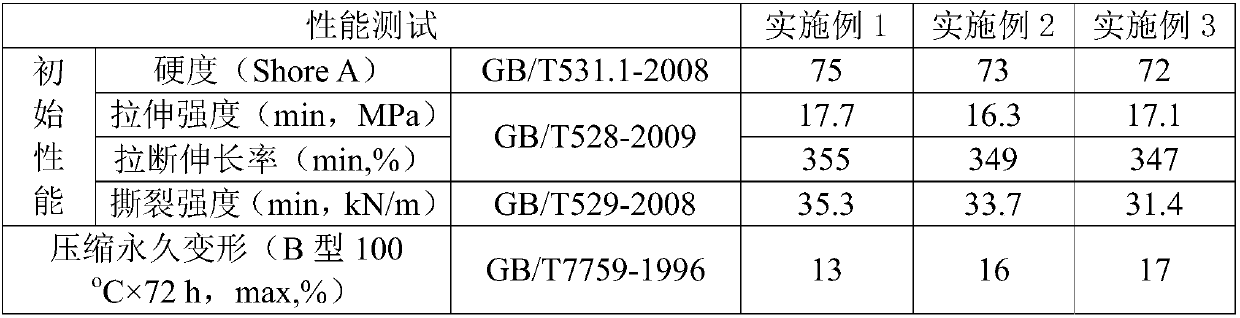

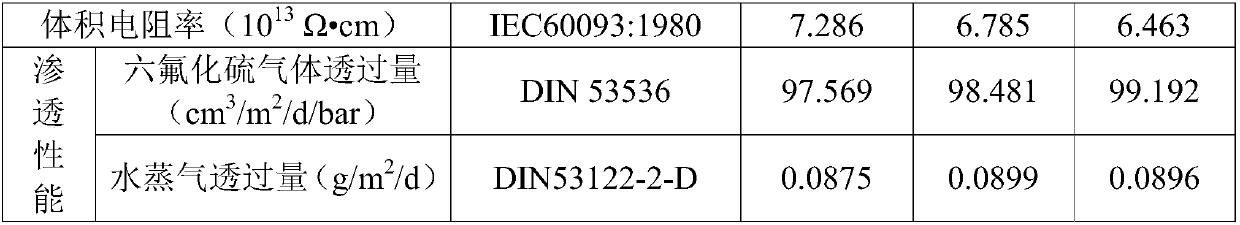

[0026] An EPDM rubber-based seal, comprising the following components expressed in parts by weight: 100 parts of EPDM, 0.5 parts of stearic acid, 6 parts of zinc oxide, 1 part of anti-aging agent MB, 1 part of anti-aging agent RD, white 50 parts of carbon black, 30 parts of inorganic filler, 1 part of carbon black, 1.5 parts of dispersant, 3 parts of polyethylene glycol, 3 parts of silane coupling agent, 2.5 parts of triallyl isocyanurate, 3.5 parts of vulcanizing agent .

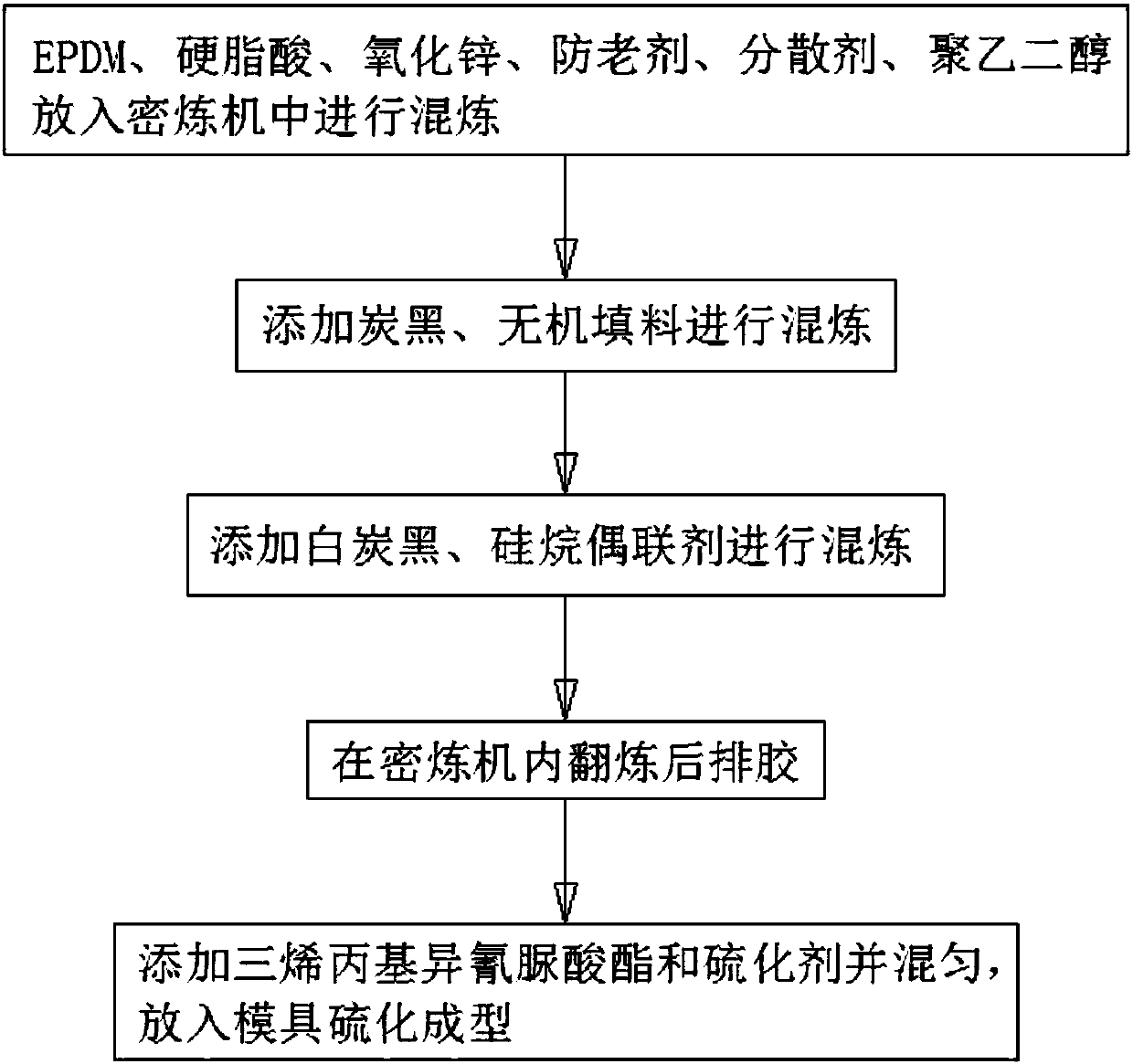

[0027] The preparation method of above-mentioned EPDM rubber-based seal is as follows figure 1 As shown, it specifically includes the following steps:

[0028] In the first step, put EPDM, stearic acid, zinc oxide, anti-aging agent, dispersant, and polyethylene glycol into an internal mixer for mixing. The mixing time is 2 minutes, and the temperature is controlled at 60°C.

[0029] In the second step, the carbon black, the inorganic filler and the mixed rubber in the first step above are mixed, the mixin...

Embodiment 2

[0036] A EPDM rubber-based seal, comprising the following components expressed in parts by weight: 100 parts of EPDM, 0.3 parts of stearic acid, 3 parts of zinc oxide, 0.5 parts of anti-aging agent MB, 0.5 parts of anti-aging agent RD, white 40 parts of carbon black, 20 parts of inorganic filler, 0.5 parts of carbon black, 1 part of dispersant, 2 parts of polyethylene glycol, 2 parts of silane coupling agent, 2 parts of triallyl isocyanurate, 2 parts of vulcanizing agent .

[0037] The preparation method of above-mentioned EPDM rubber-based seal is as follows figure 1 As shown, it specifically includes the following steps:

[0038] Step 1: Put EPDM, stearic acid, zinc oxide, anti-aging agent, dispersant, and polyethylene glycol into an internal mixer for mixing. The mixing time is 2.5 minutes, and the temperature is controlled at 65°C.

[0039] In the second step, the carbon black, the inorganic filler and the mixed rubber in the first step above are mixed, the mixing time i...

Embodiment 3

[0046]A EPDM rubber-based seal, comprising the following components expressed in parts by weight: 100 parts of EPDM, 1 part of stearic acid, 8 parts of zinc oxide, 2 parts of anti-aging agent MB, 2 parts of anti-aging agent RD, white 60 parts of carbon black, 40 parts of inorganic filler, 2 parts of carbon black, 3 parts of dispersant, 4 parts of polyethylene glycol, 5 parts of silane coupling agent, 4 parts of triallyl isocyanurate, 5 parts of vulcanizing agent .

[0047] The preparation method of above-mentioned EPDM rubber-based seal is as follows figure 1 As shown, it specifically includes the following steps:

[0048] In the first step, put EPDM, stearic acid, zinc oxide, anti-aging agent, dispersant, and polyethylene glycol into an internal mixer for mixing. The mixing time is 3 minutes, and the temperature is controlled at 70°C.

[0049] In the second step, the carbon black, the inorganic filler and the mixed rubber in the first step above are mixed, and the mixing ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com