Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5409 results about "Chemical resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The chemical resistance of a material or surface can be determined in compliance with ISO 2812 Paints and varnishes – Determination of resistance to liquids – Part 1: Immersion in liquids other than water (ISO 2812-1:2007); German Version EN ISO 2812-1:2007 or Part 4: Spotting methods (ISO 2812-4:2007); German Version EN ISO 2812-4:2007. With these methods, a material or surface is exposed to the relevant chemical for a longer, defined period of time and the relevant area then inspected microscopically. Possible changes which could occur include...

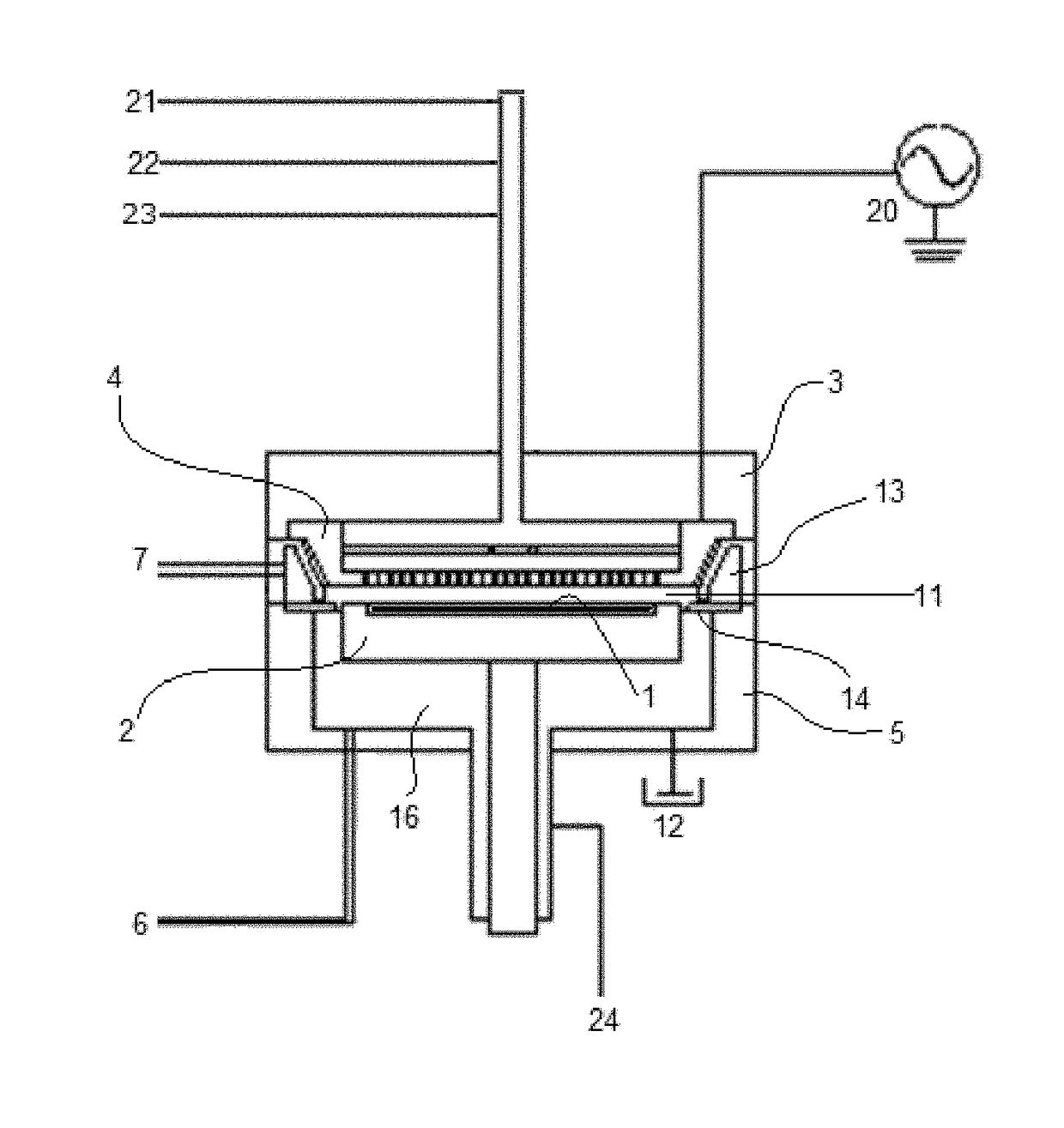

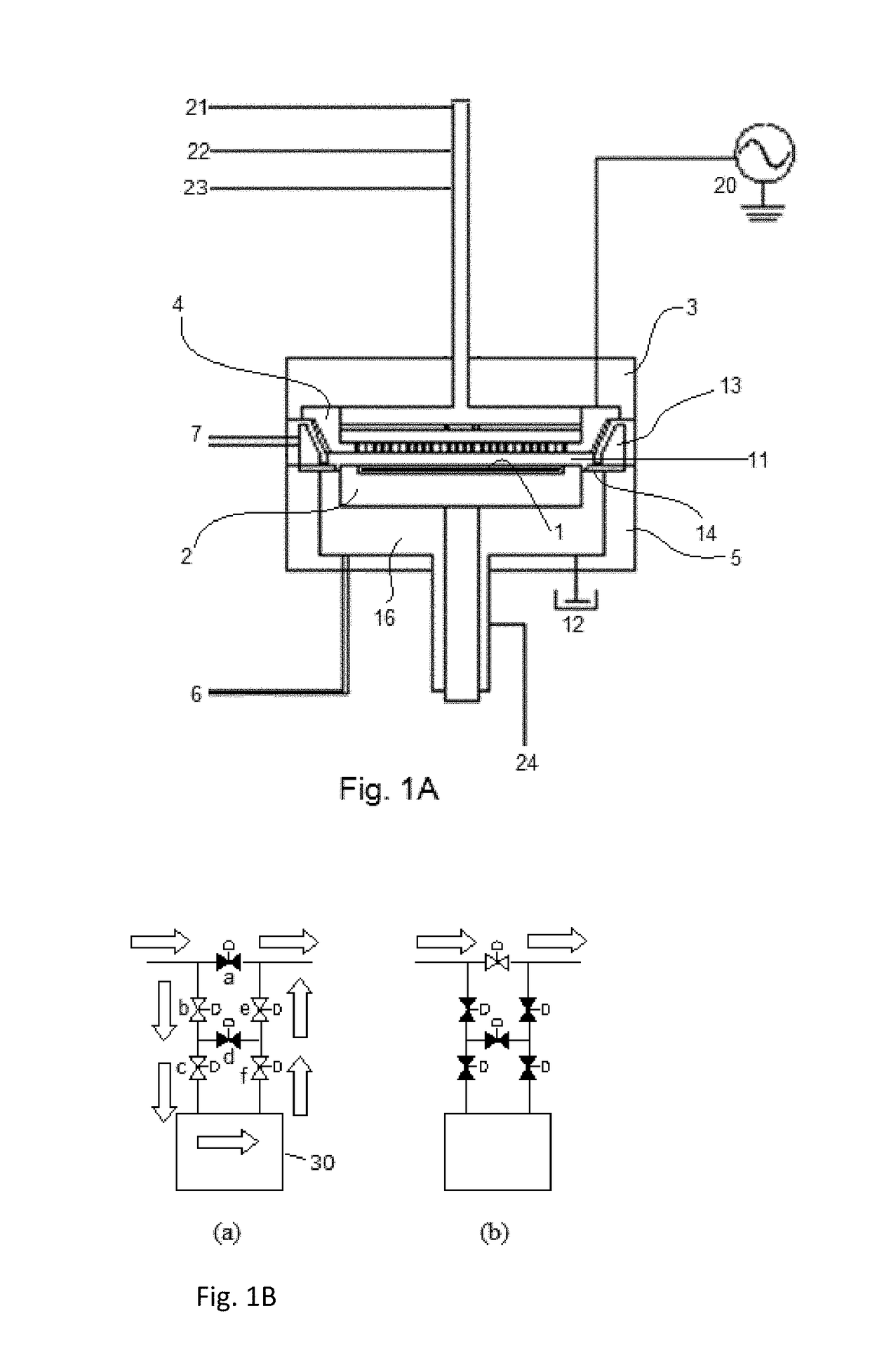

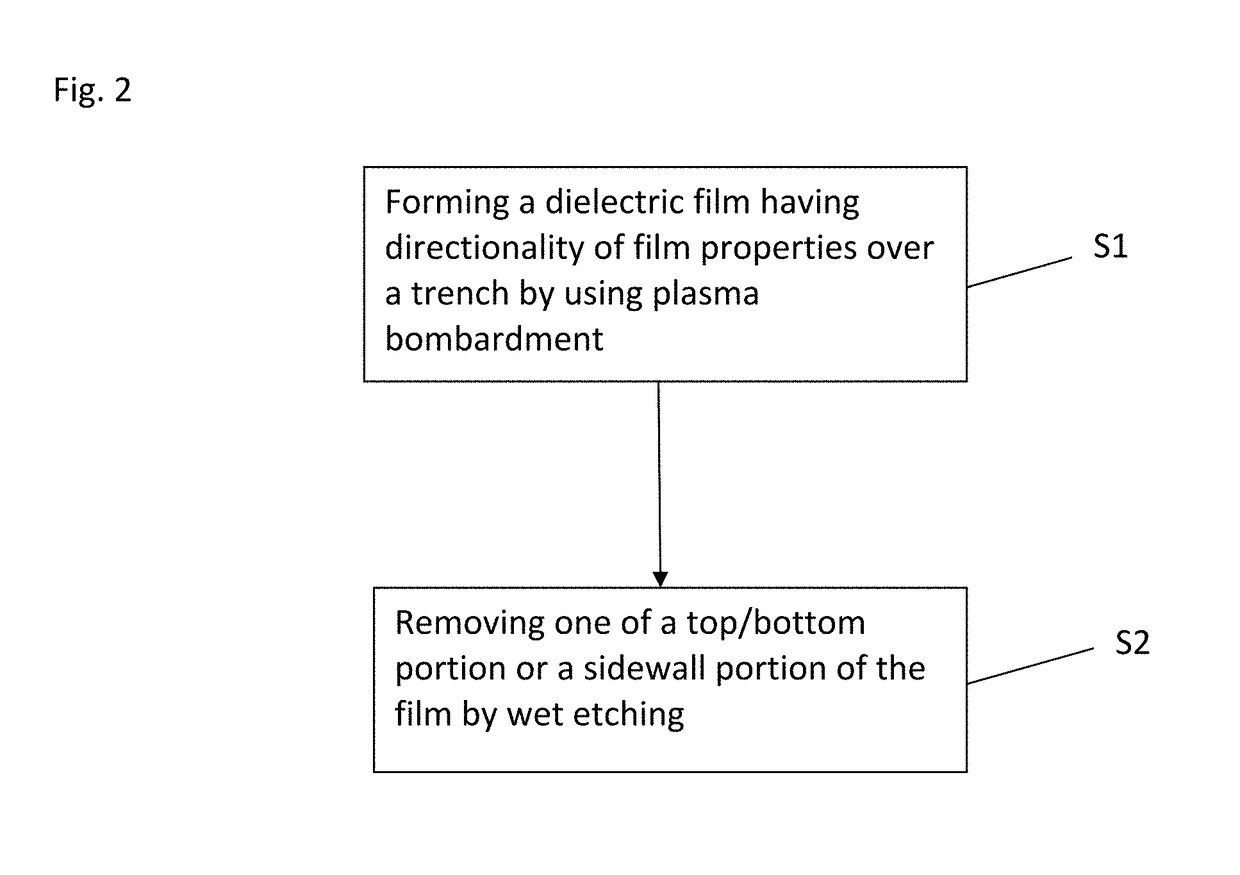

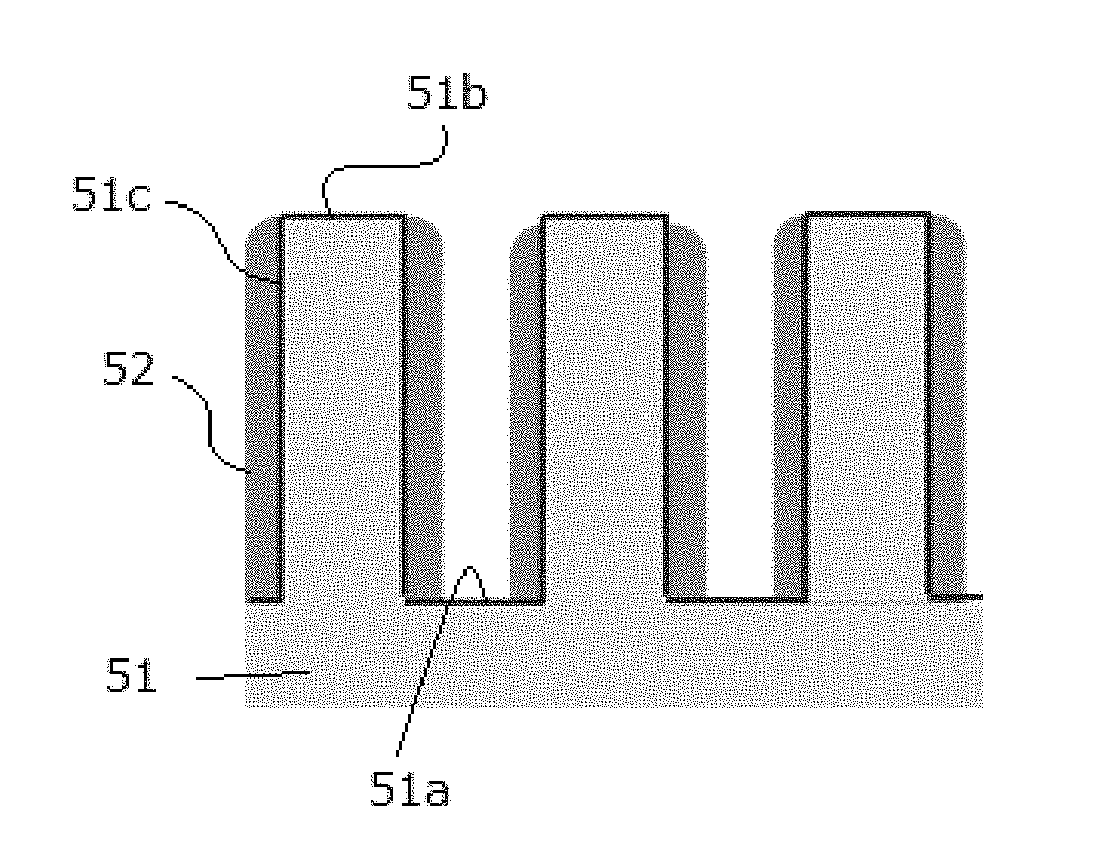

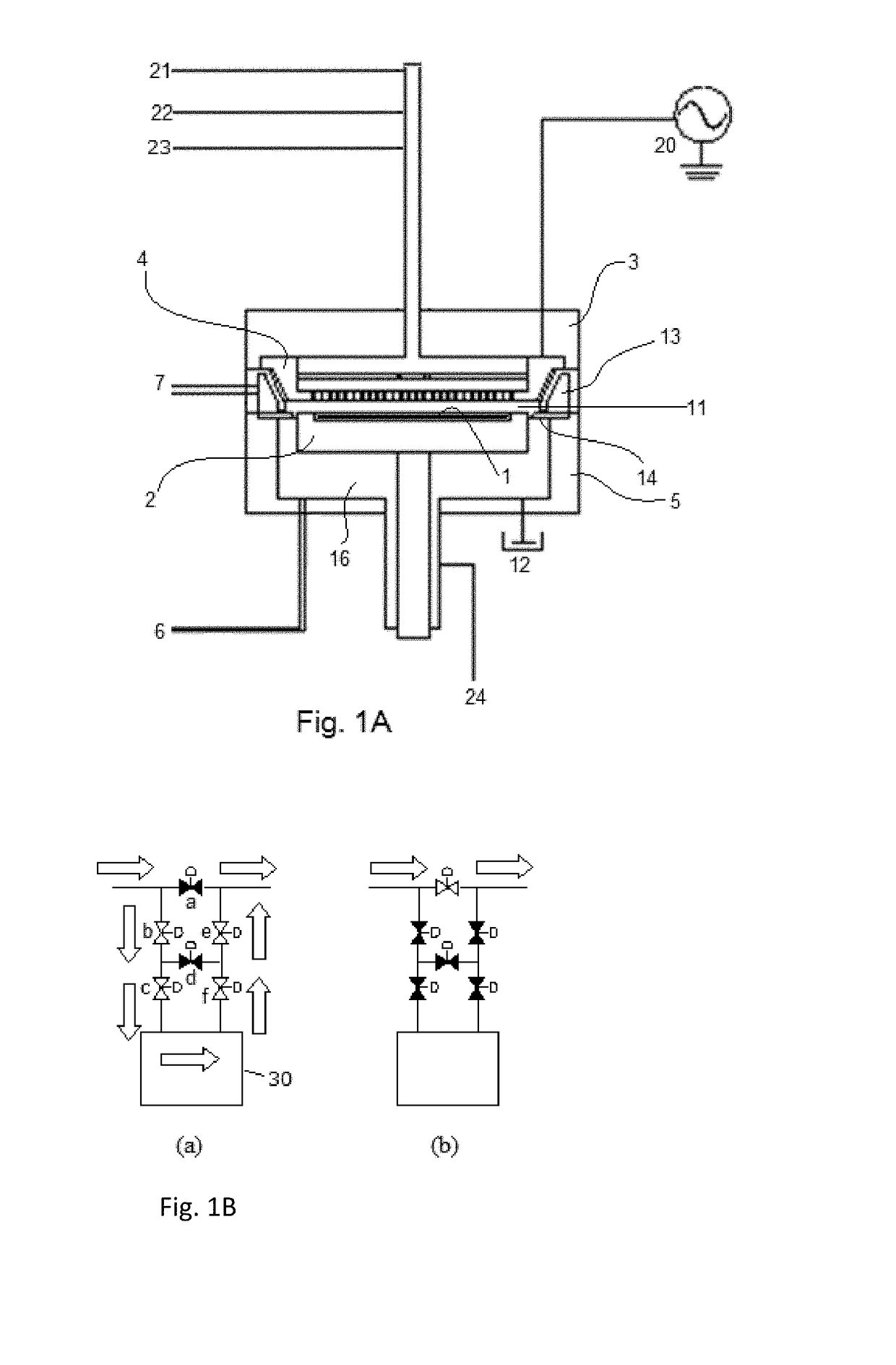

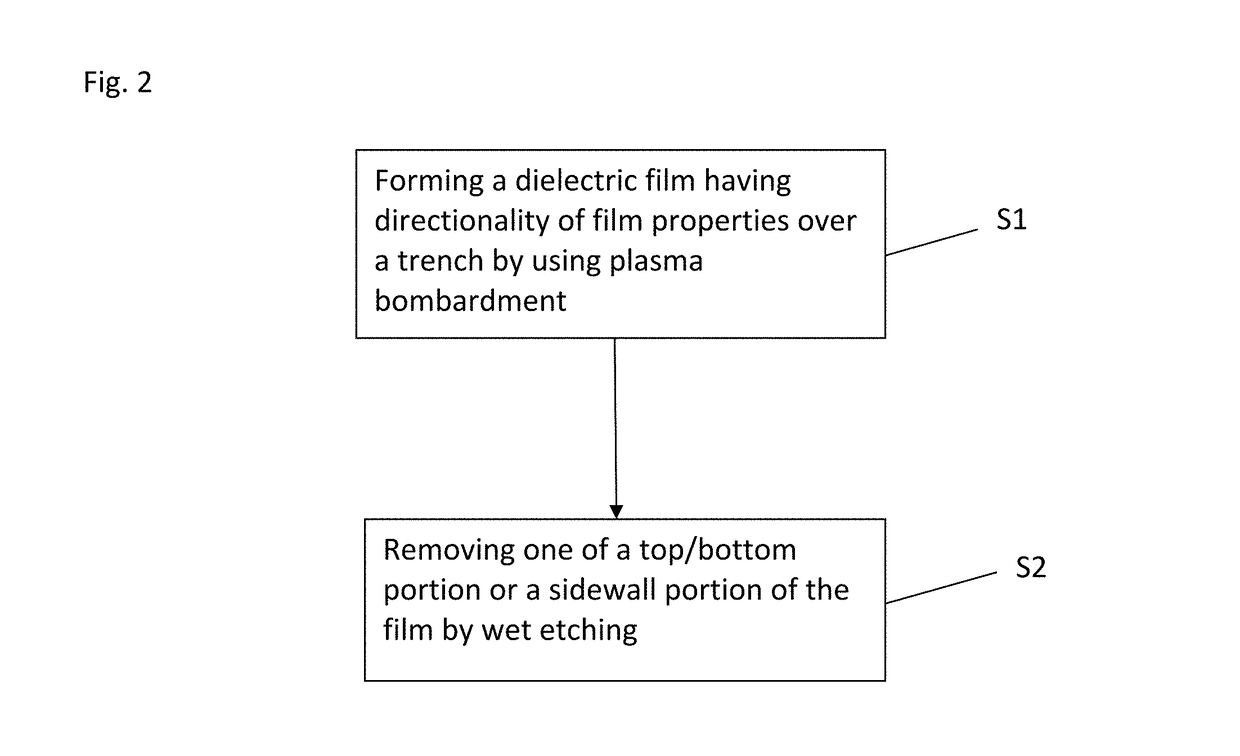

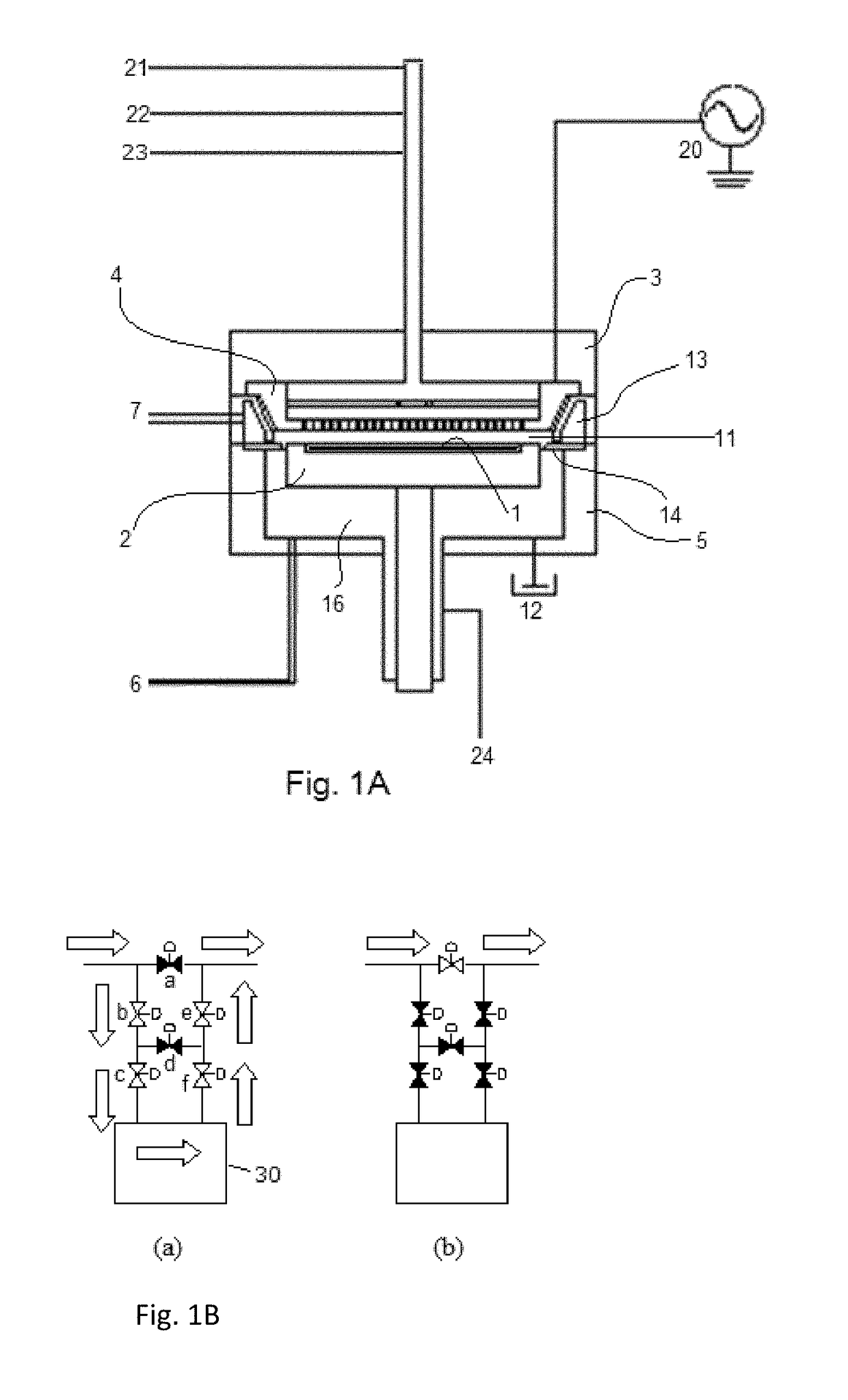

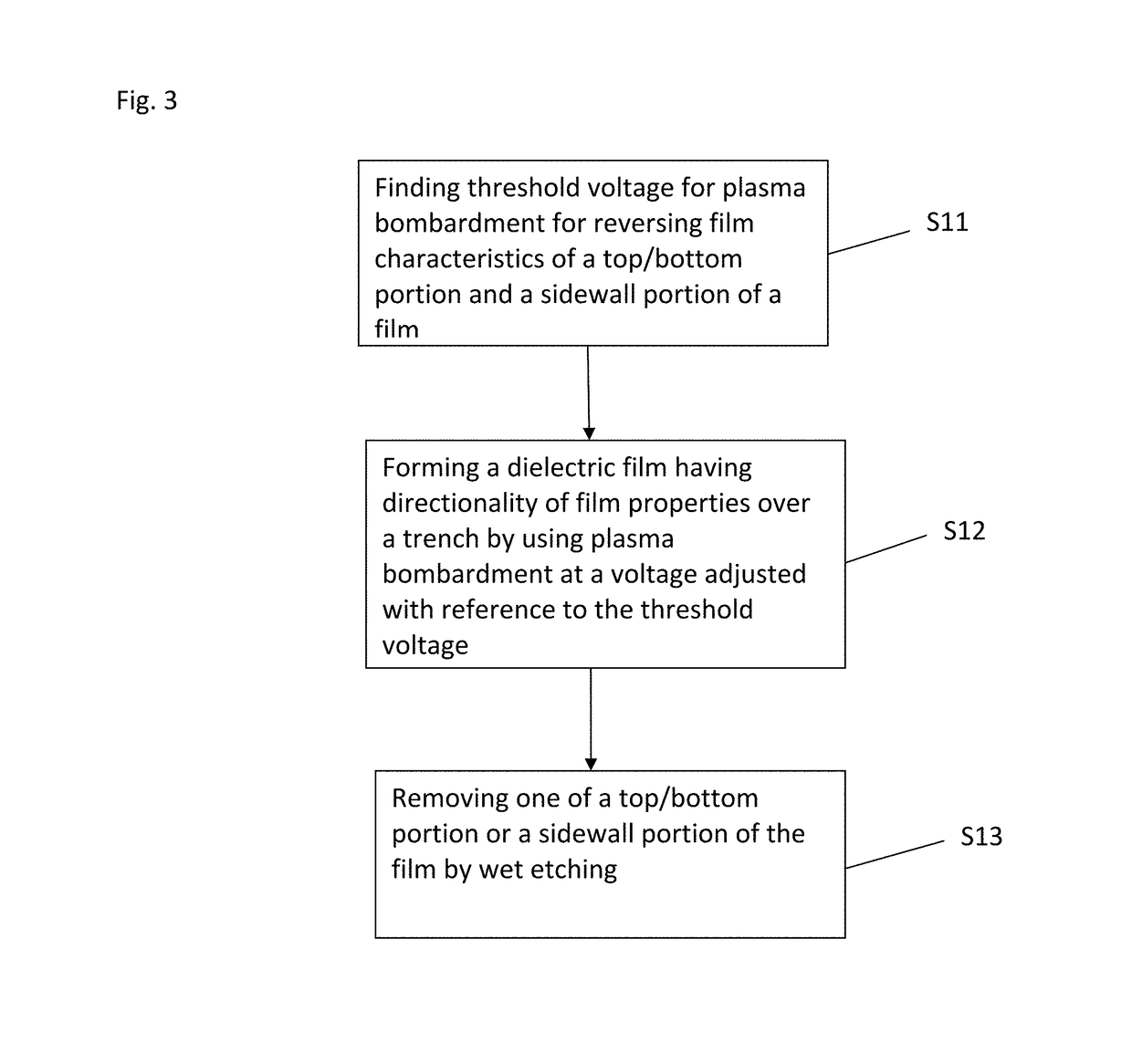

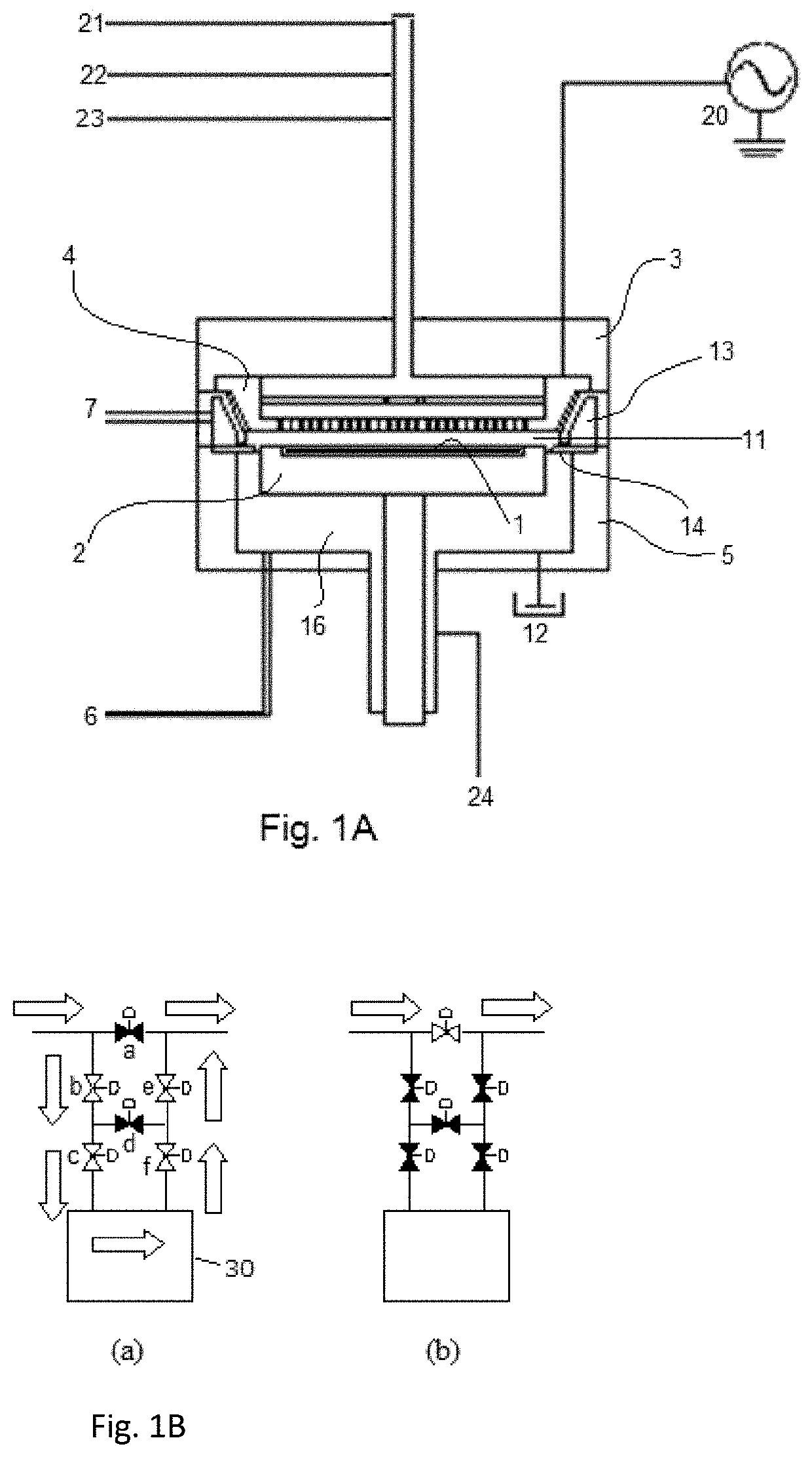

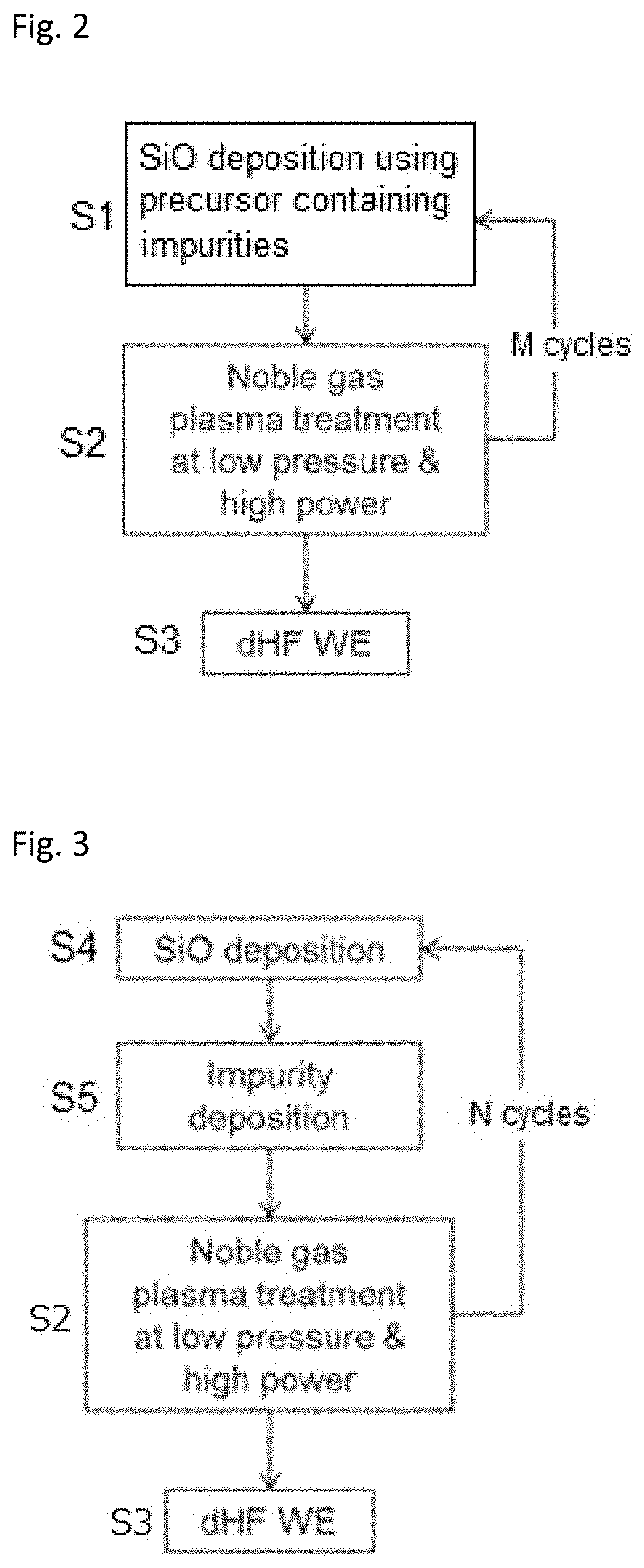

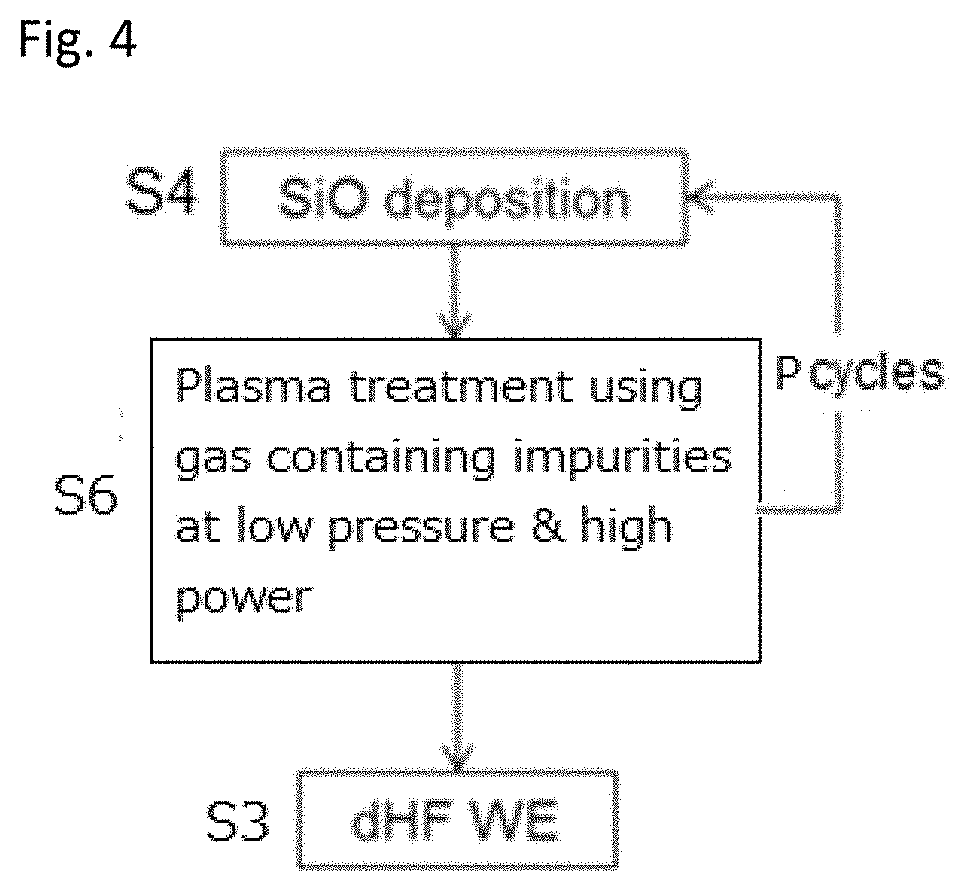

Method for forming silicon nitride film selectively on sidewalls or flat surfaces of trenches

ActiveUS9754779B1Low densityPlasma-enhanced chemical vapor depositionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingChemical resistance

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing either one of but not both of the top / bottom portion and the sidewall portion of the film by wet etching which removes the one of the top / bottom portion and the sidewall portion of the film more predominantly than the other according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

Method for forming silicon nitride film selectively on sidewalls or flat surfaces of trenches

ActiveUS20170243734A1Improve film qualityDecreasing density of filmElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingChemical resistance

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing either one of but not both of the top / bottom portion and the sidewall portion of the film by wet etching which removes the one of the top / bottom portion and the sidewall portion of the film more predominantly than the other according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

Method for forming silicon nitride film selectively on sidewalls of trenches

ActiveUS20190057857A1Low densityPlasma-enhanced chemical vapor depositionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingChemical resistance

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing the sidewall portion of the film by wet etching which removes the sidewall portion of the film more predominantly than the top / bottom portion according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

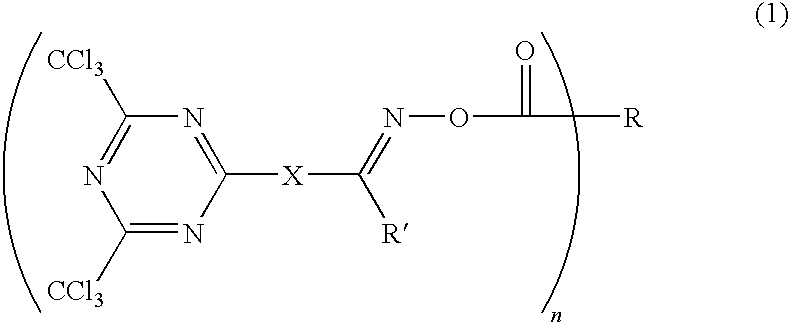

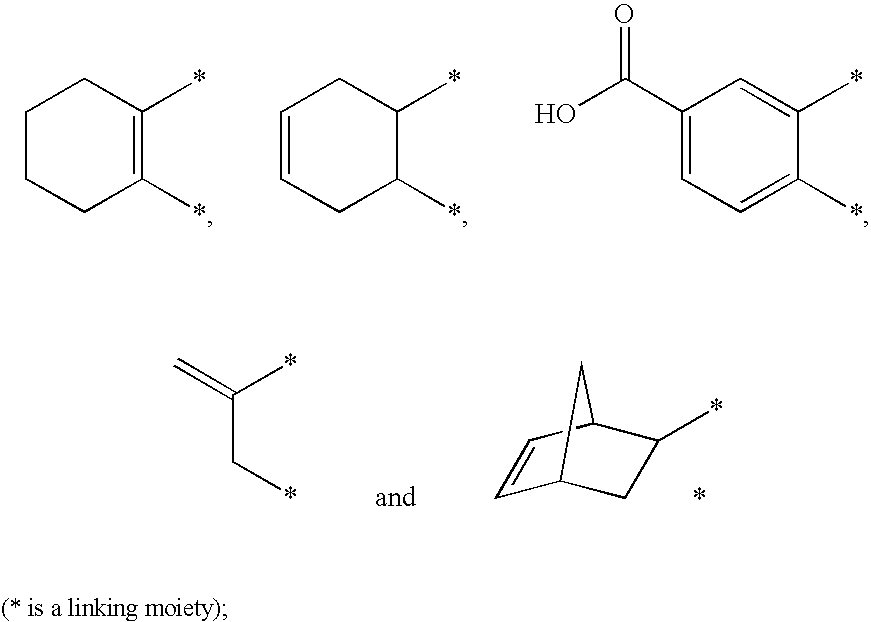

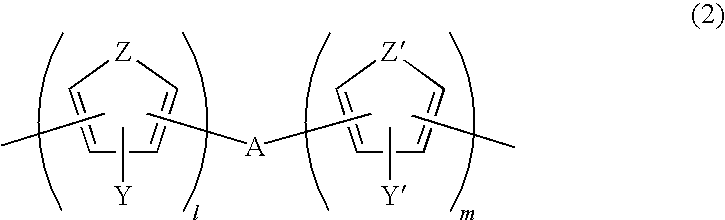

Photosensitive composition comprising triazine-based photoactive compound containing oxime ester

ActiveUS7556910B2Effective absorptionDevelopment durabilityOrganic chemistryPhotosensitive materialsOximePhotochemistry

The present invention relates to a photosensitive composition comprising a triazine-based photoactive compound containing oxime ester. The photosensitive composition according to the present invention has good sensitivity, retention rate, mechanical strength, heat resistance, chemical resistance and developing durability since it contains, as photopolymerization initiator, a compound having an oxime ester group and a triazine group in one molecule and thus effectively absorbs UV radiation. Therefore, the photosensitive composition according to the present invention is advantageous not only in curing of materials for color filters, resin black matrixes, column spacers, overcoats and passivation films of liquid crystal displays, but also in high temperature process characteristics.

Owner:LG CHEM LTD

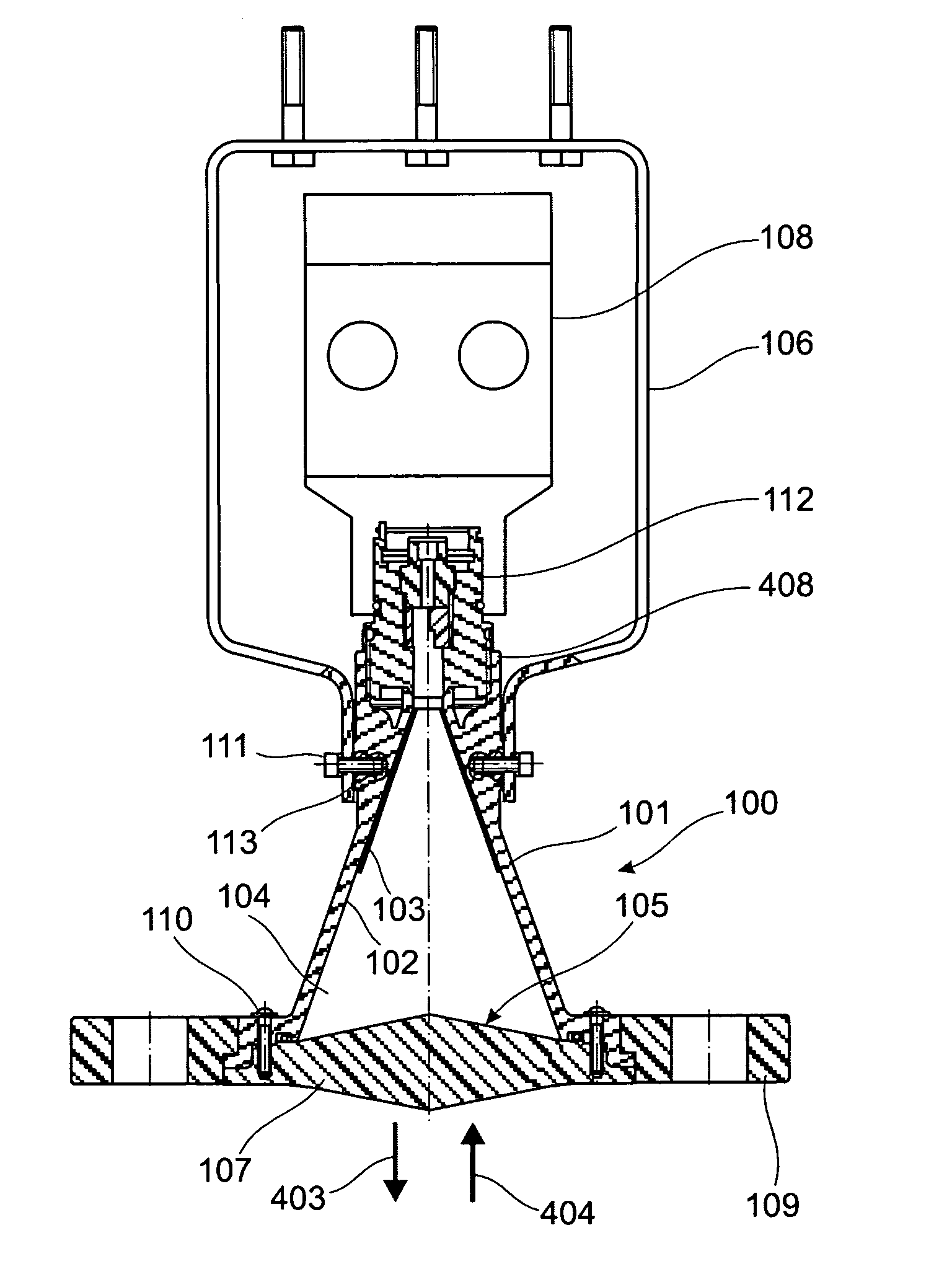

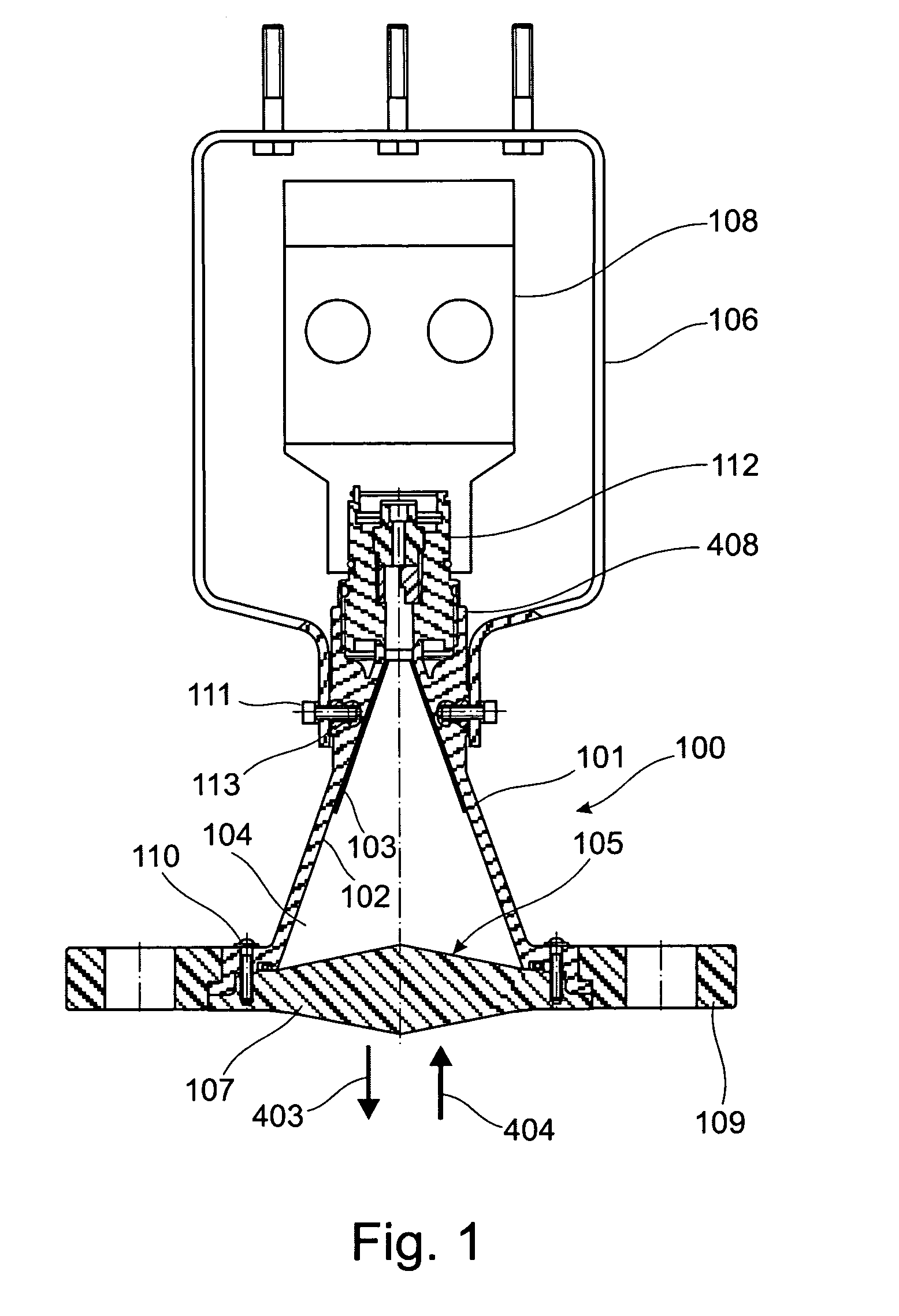

Metallised plastic antenna funnel for a fill level radar

A metalized plastic antenna includes a plastic antenna body with metallization on the inside. In this arrangement metallization is used for conducting electromagnetic waves. Furthermore, metallization may be implemented as a protective coating so that chemical resistance of the plastic antenna may be ensured even in the case of corrosive environmental conditions.

Owner:VEGA GRIESHABER GMBH & CO

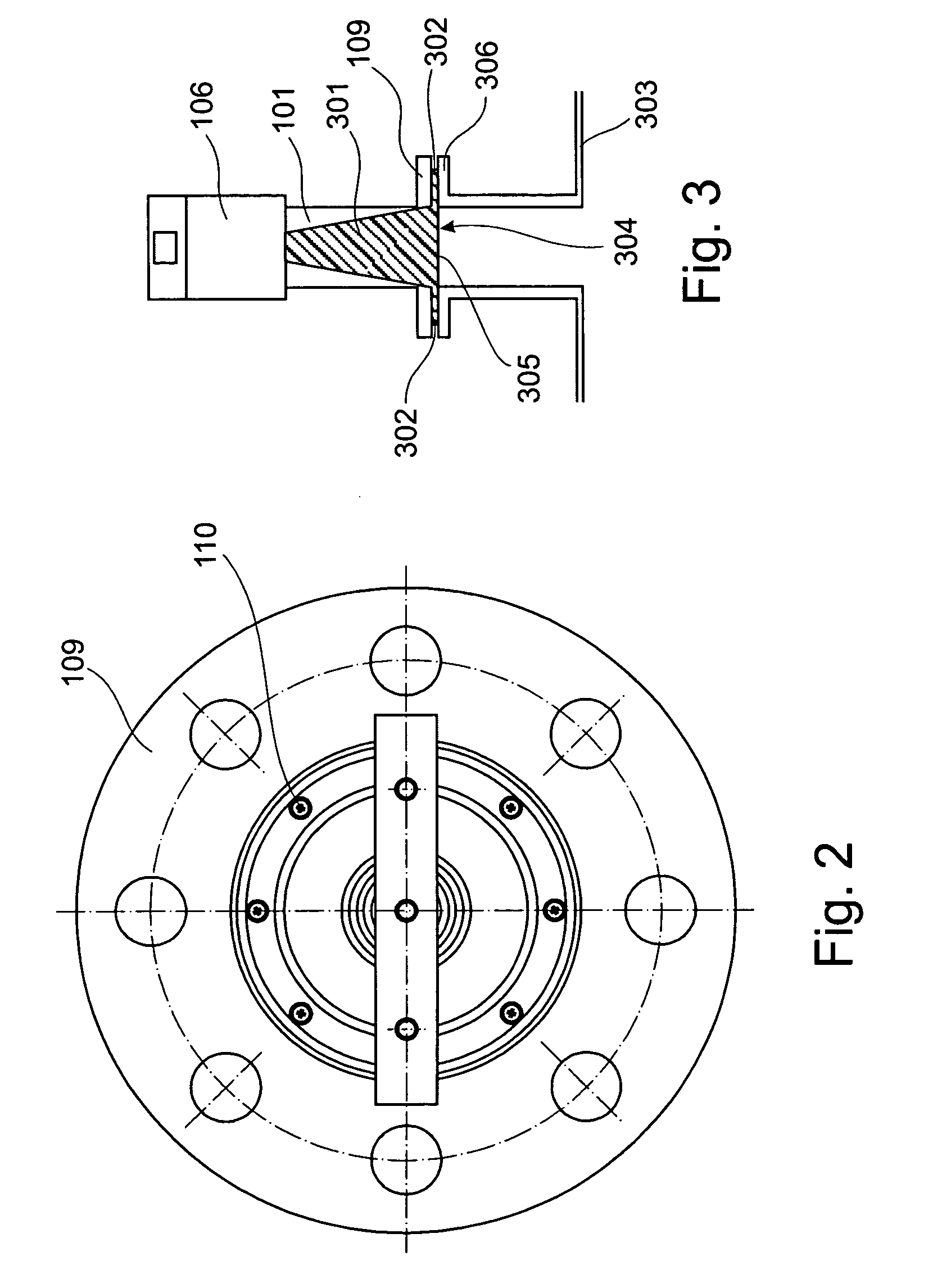

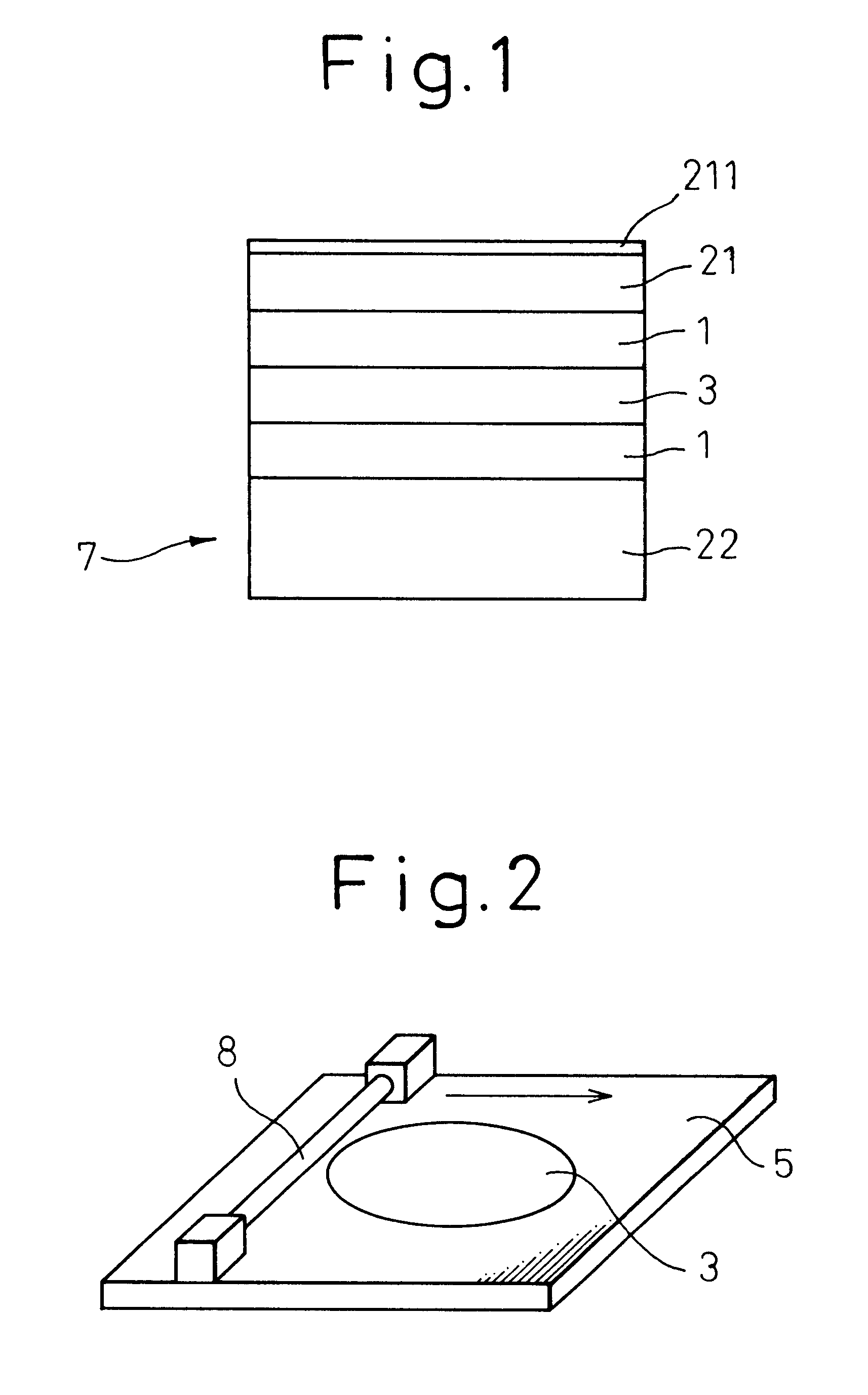

Film forming method and film forming device

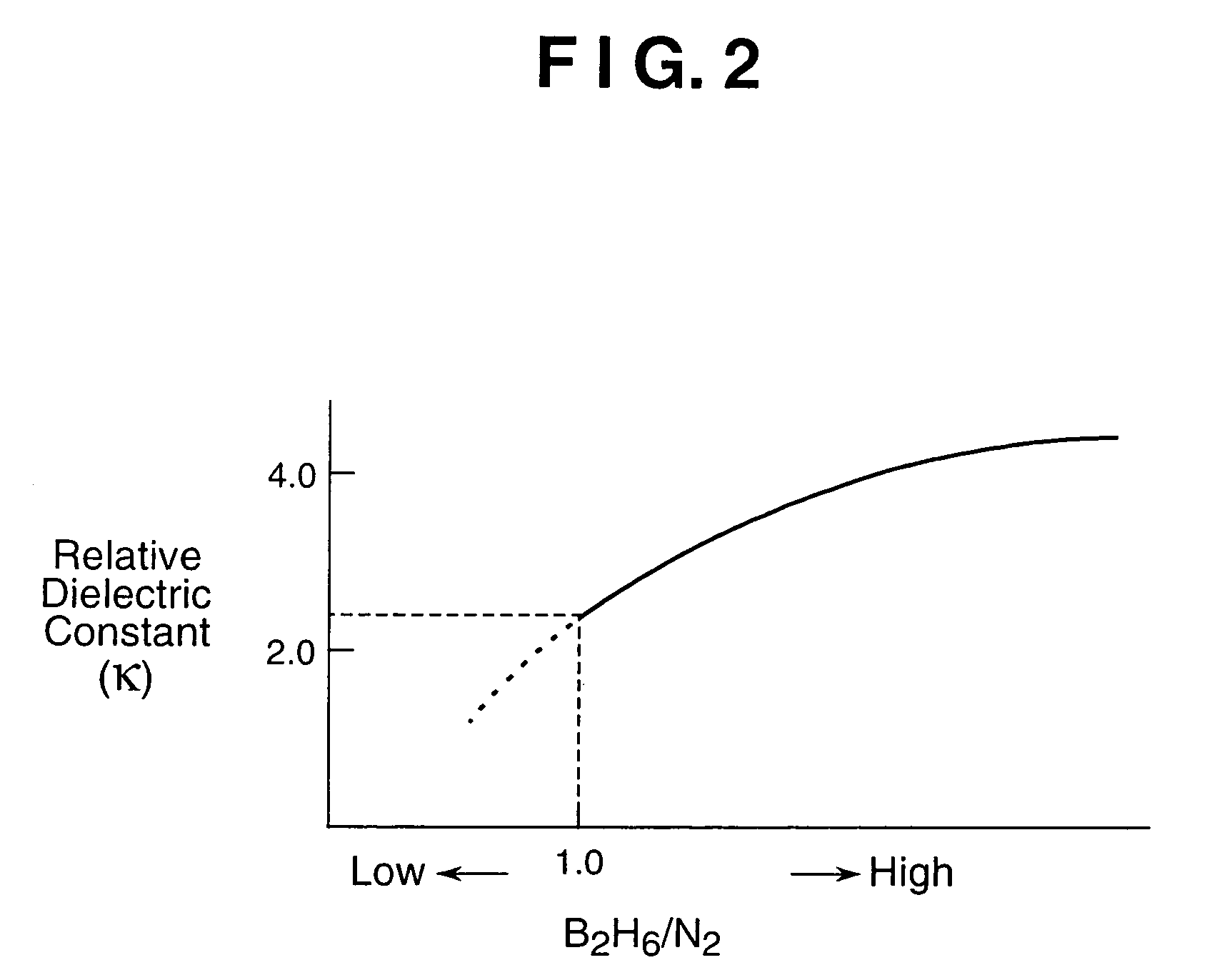

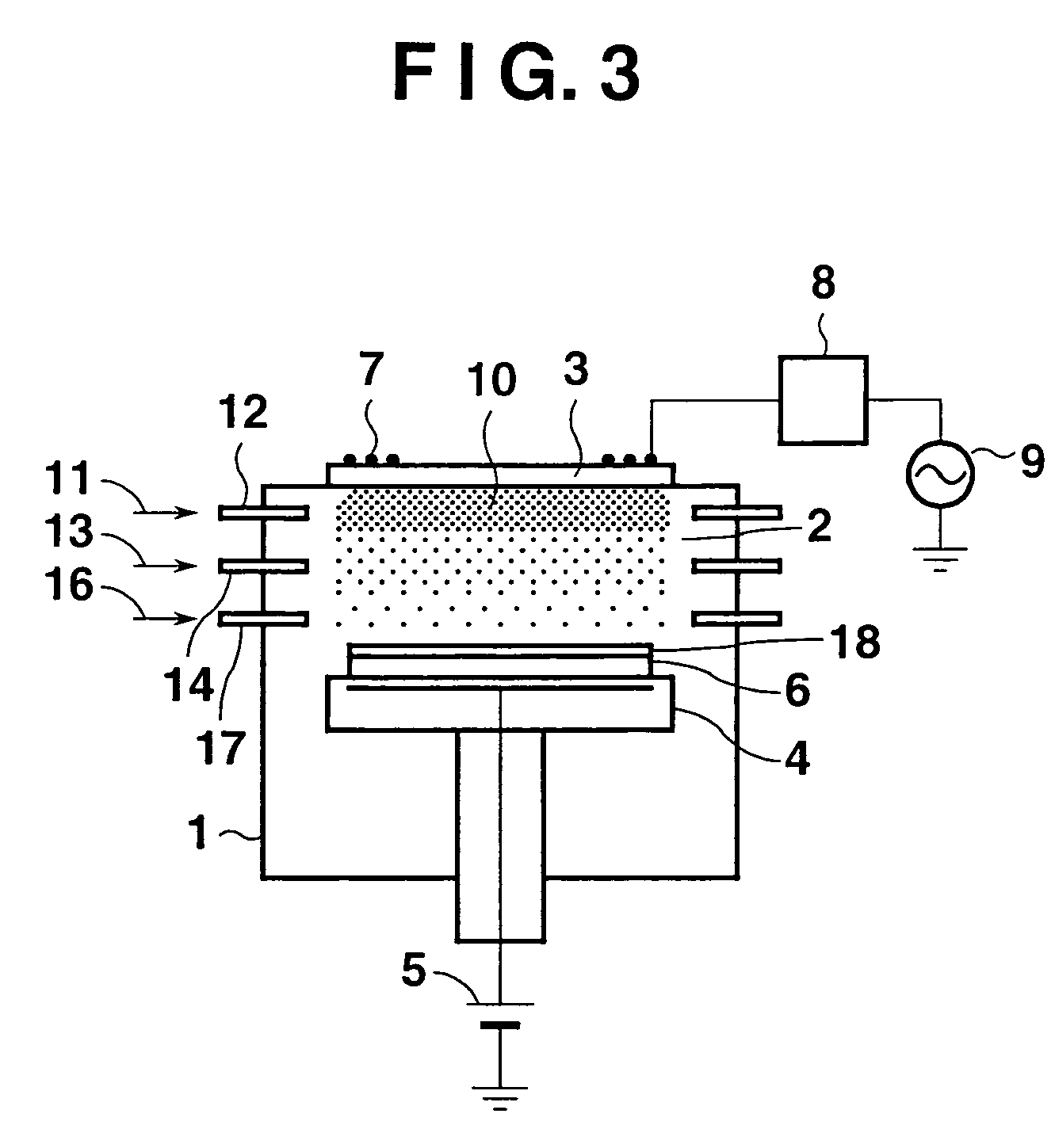

InactiveUS6958175B2Increase resistanceImprove thermal conductivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenOptoelectronics

A plasma 10 is generated within a film formation chamber 2, and mainly a nitrogen gas 11 is excited within the film formation chamber 2. Then, the excited nitrogen gas 11 is reacted with a diborane gas 13 diluted with a hydrogen gas, thereby forming a boron nitride film 15 on a substrate 4. Thus, the boron nitride film 15 excellent in mechanical and chemical resistance, high in thermal conductivity, and having a low relative dielectric constant κ can be formed speedily.

Owner:M WATANABE CO LTD

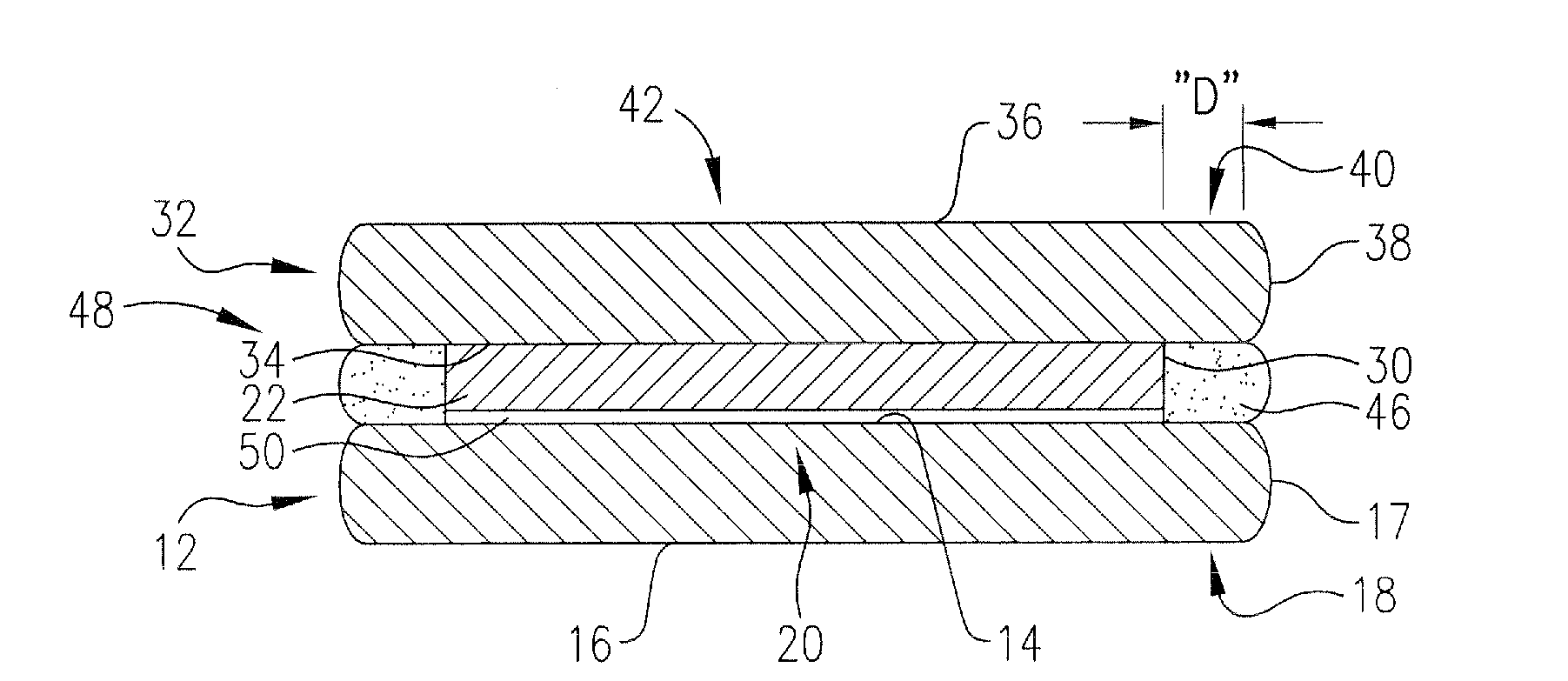

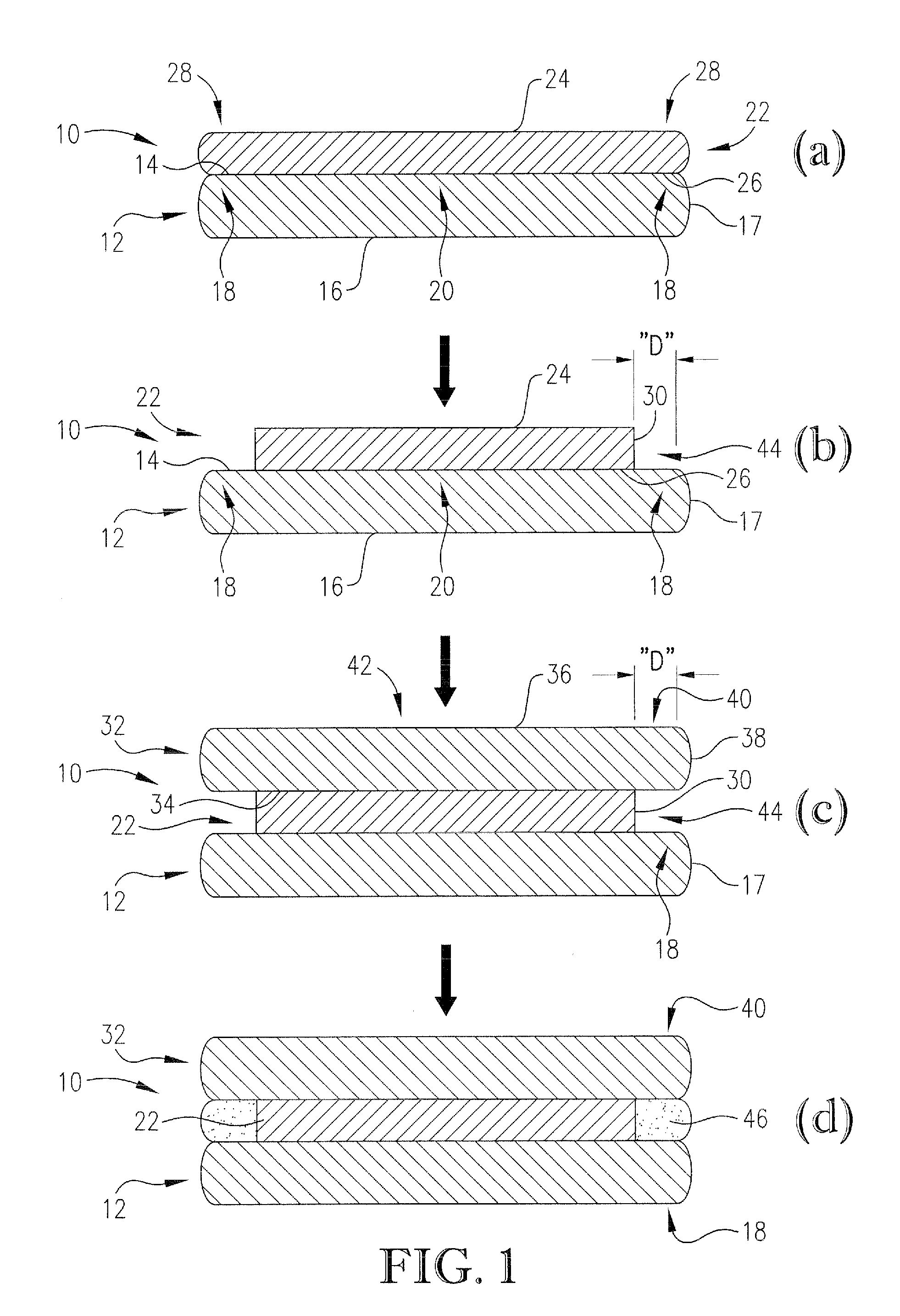

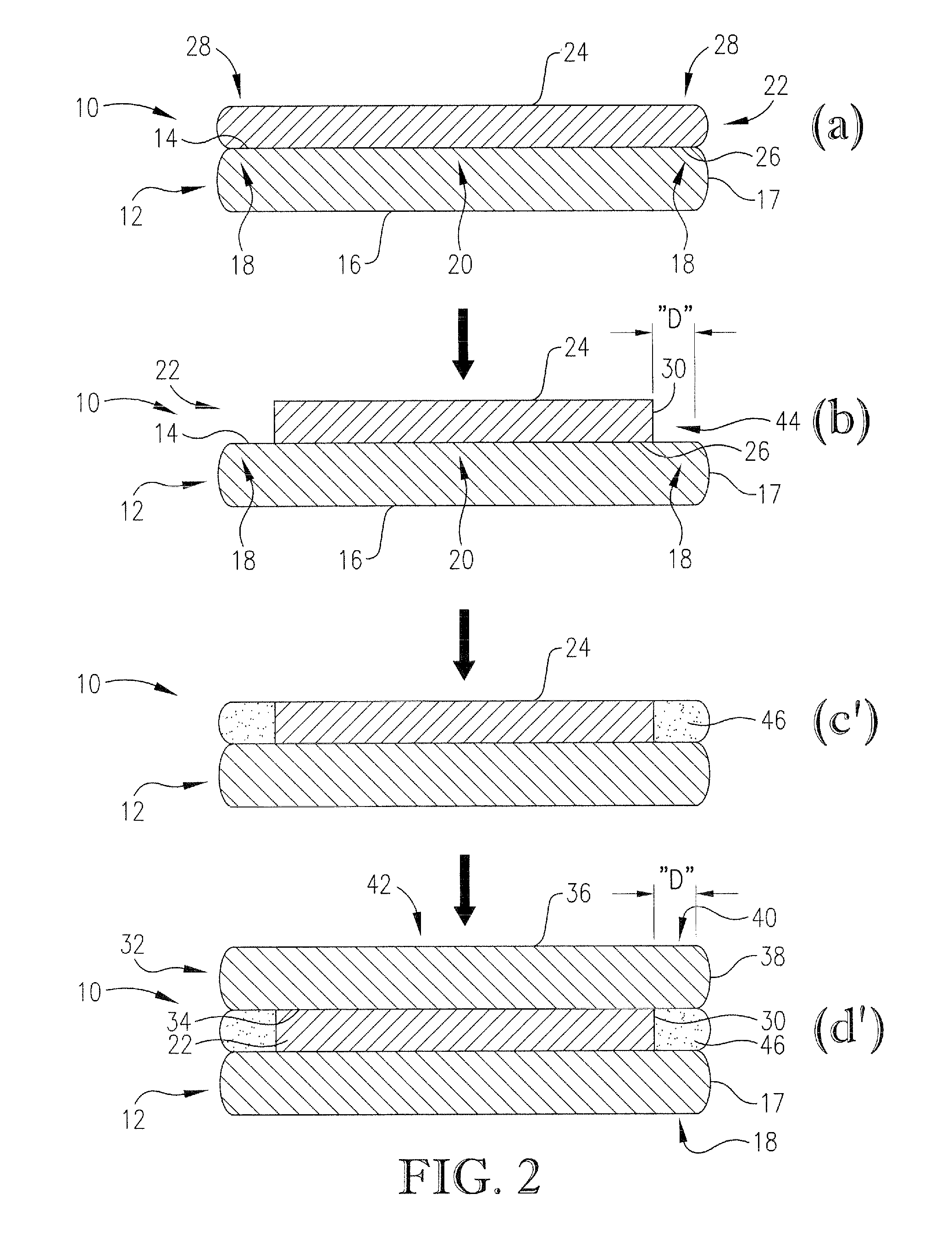

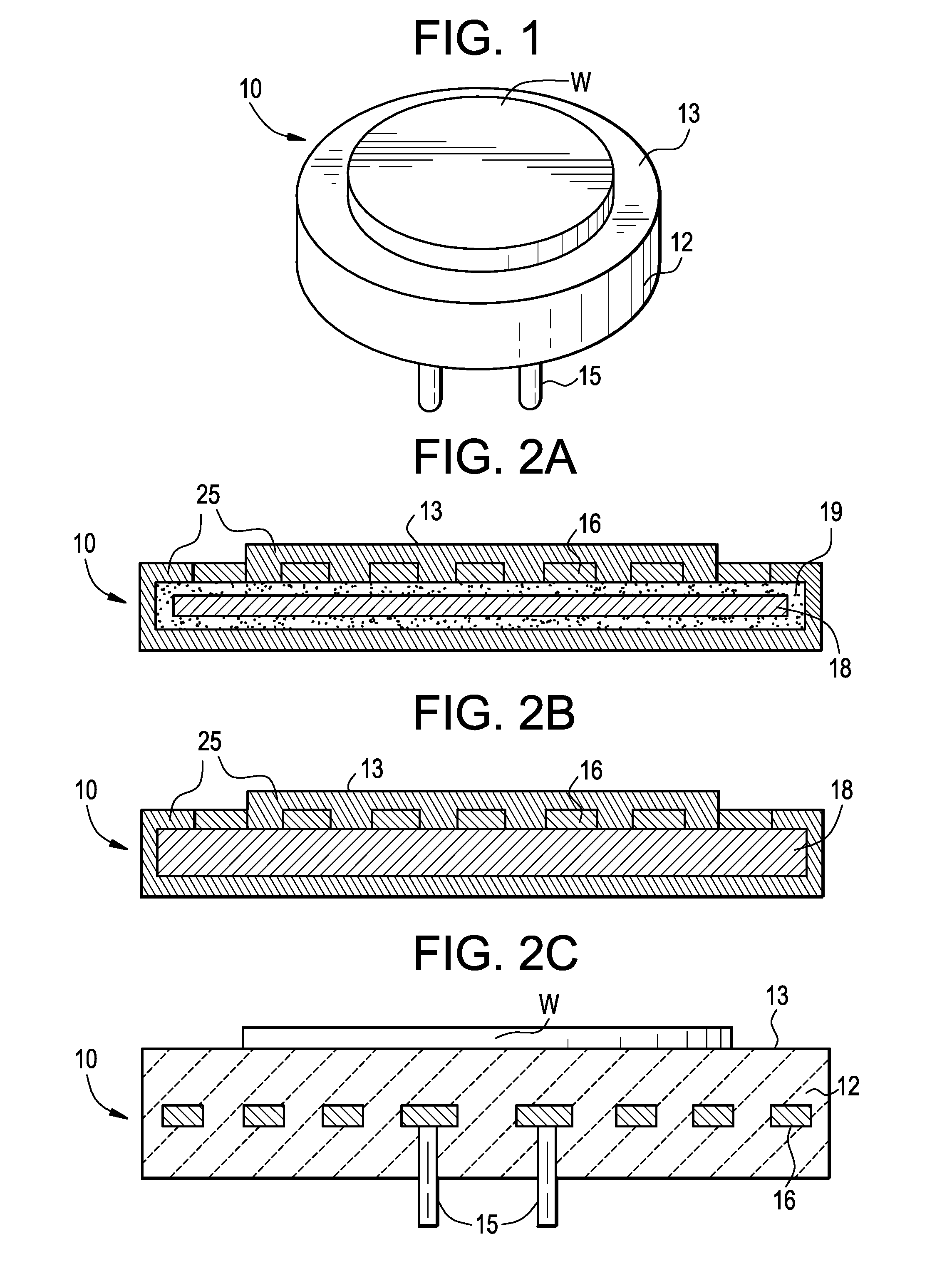

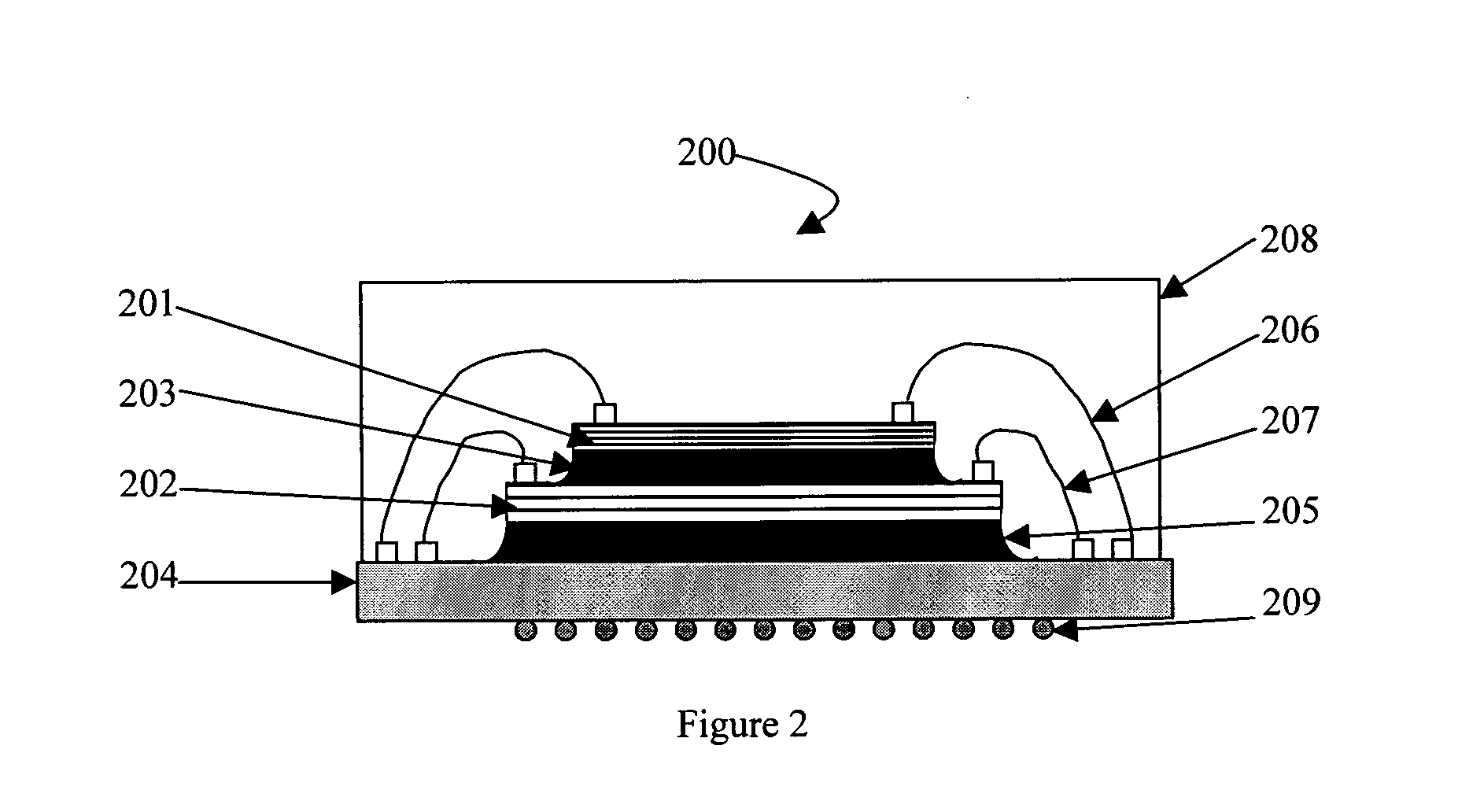

Method for reversibly mounting a device wafer to a carrier substrate

ActiveUS20090218560A1Reduced adhesion strengthLamination ancillary operationsSemiconductor/solid-state device detailsHeat resistanceRoom temperature

New temporary bonding methods and articles formed from those methods are provided. The methods comprise bonding a device wafer to a carrier wafer or substrate only at their outer perimeters in order to assist in protecting the device wafer and its device sites during subsequent processing and handling. The edge bonds formed by this method are chemically and thermally resistant, but can also be softened, dissolved, or mechanically disrupted to allow the wafers to be easily separated with very low forces and at or near room temperature at the appropriate stage in the fabrication process.

Owner:BREWER SCI

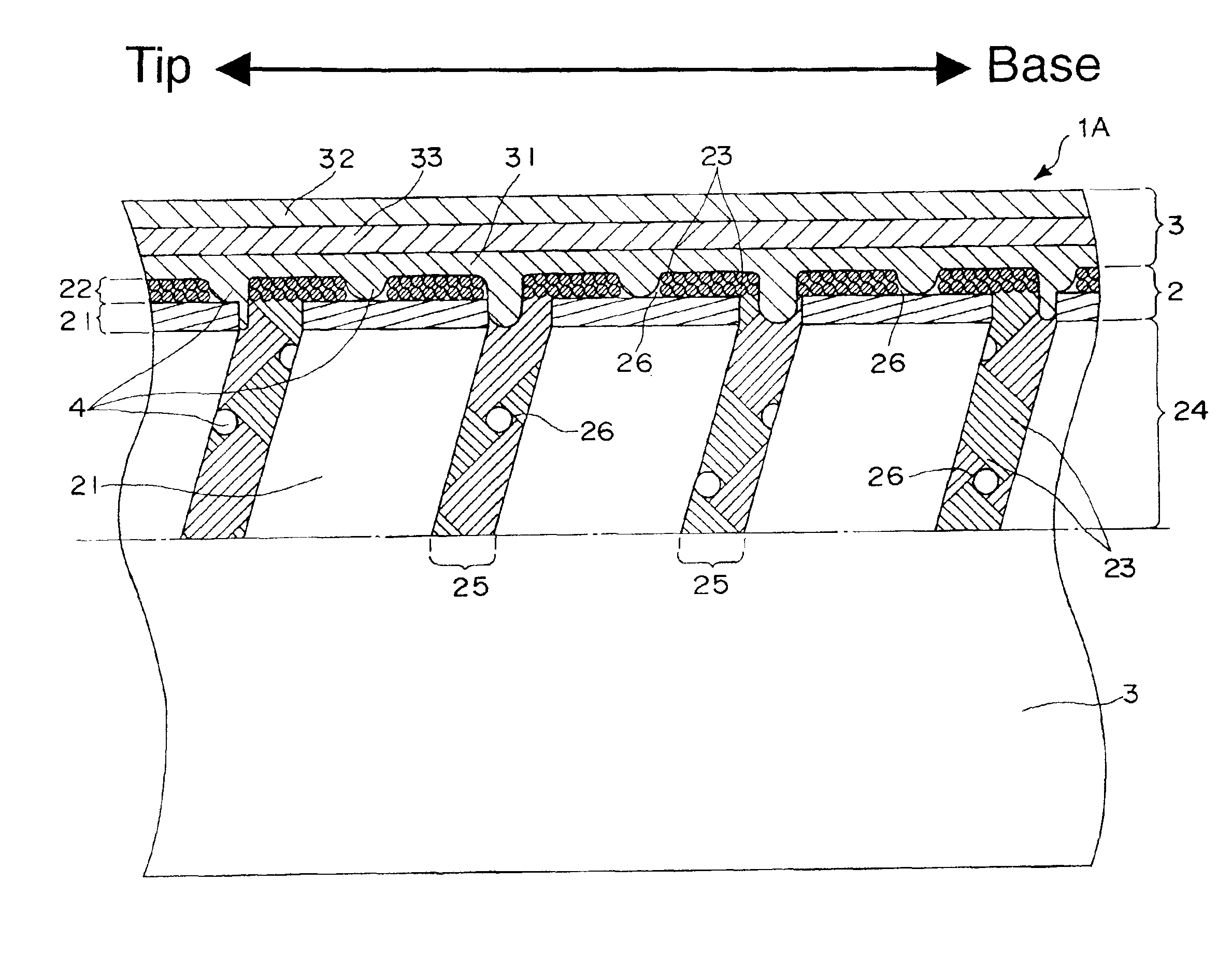

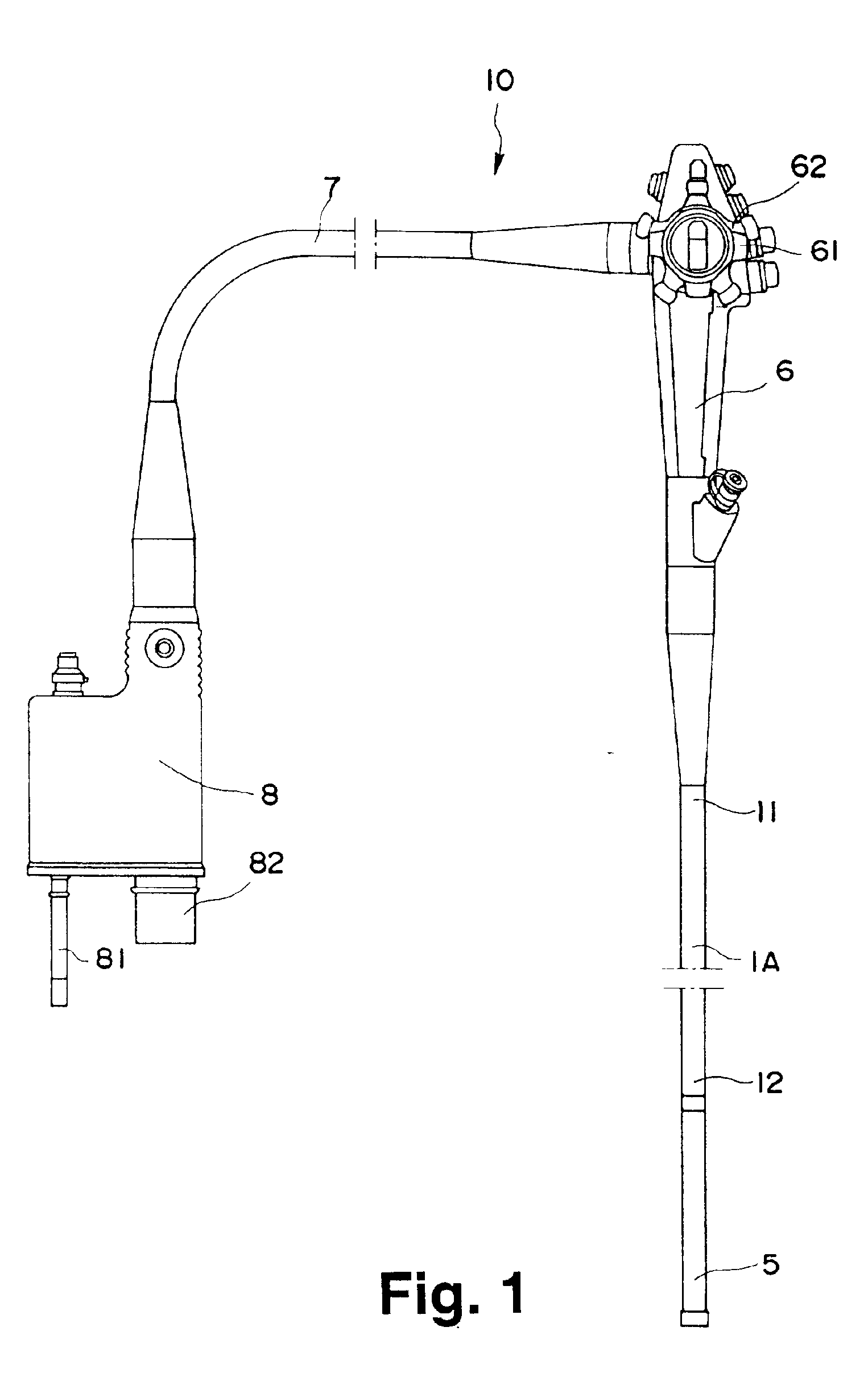

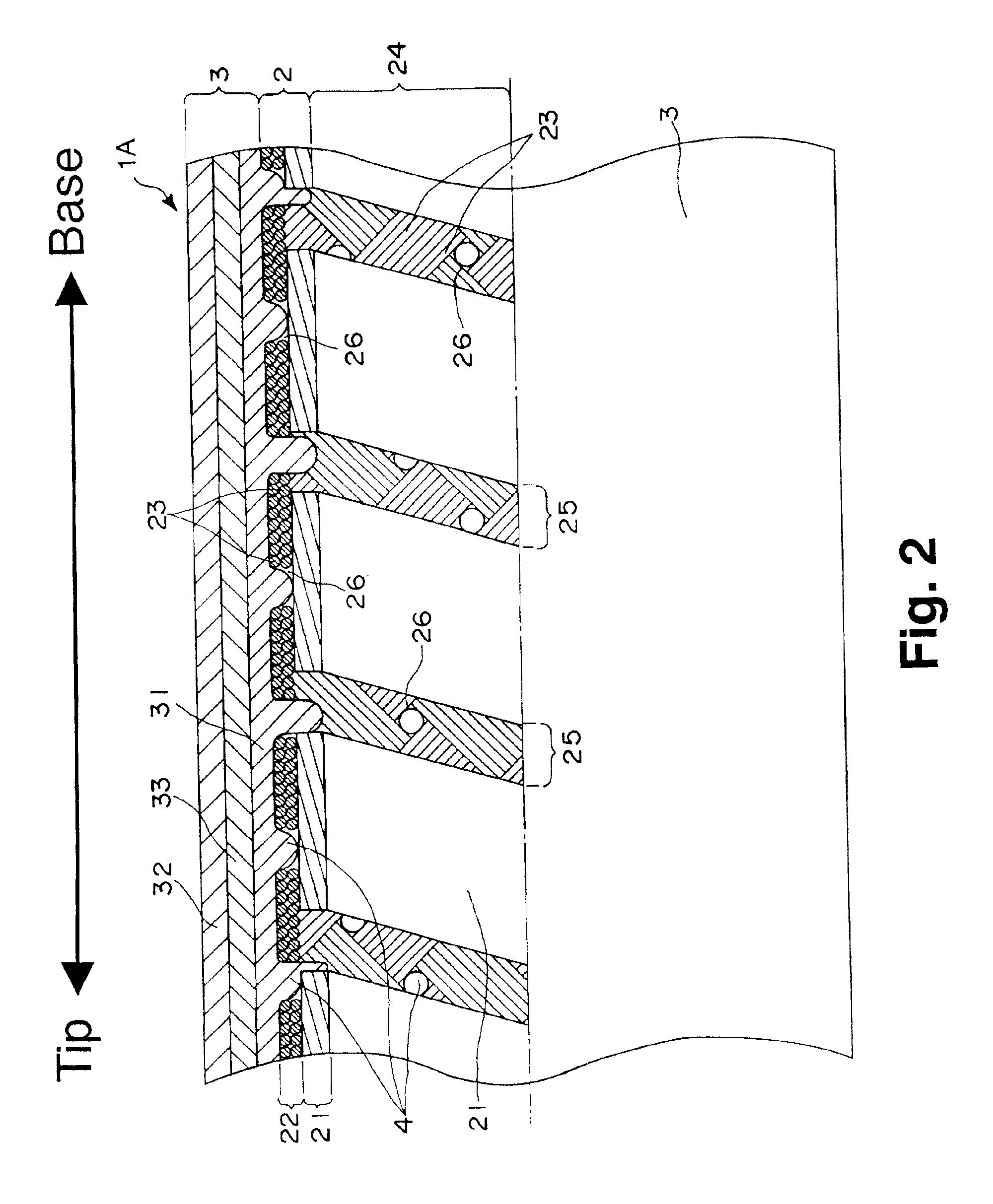

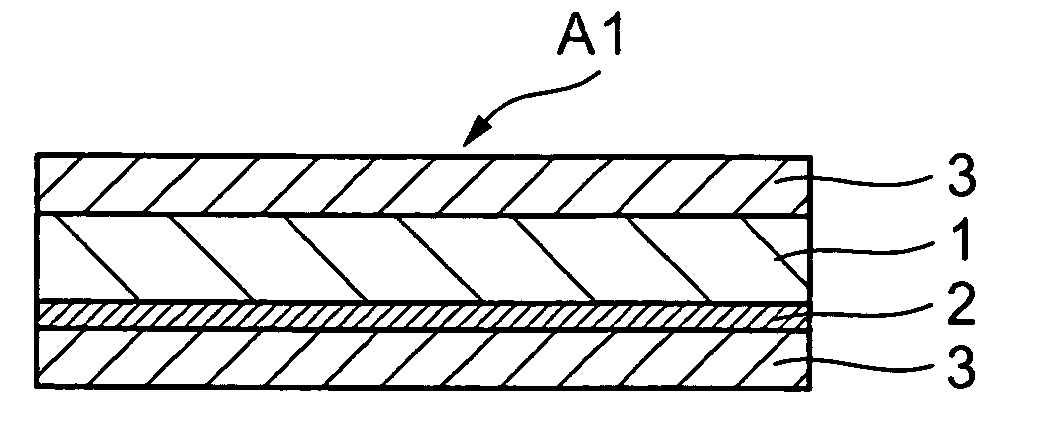

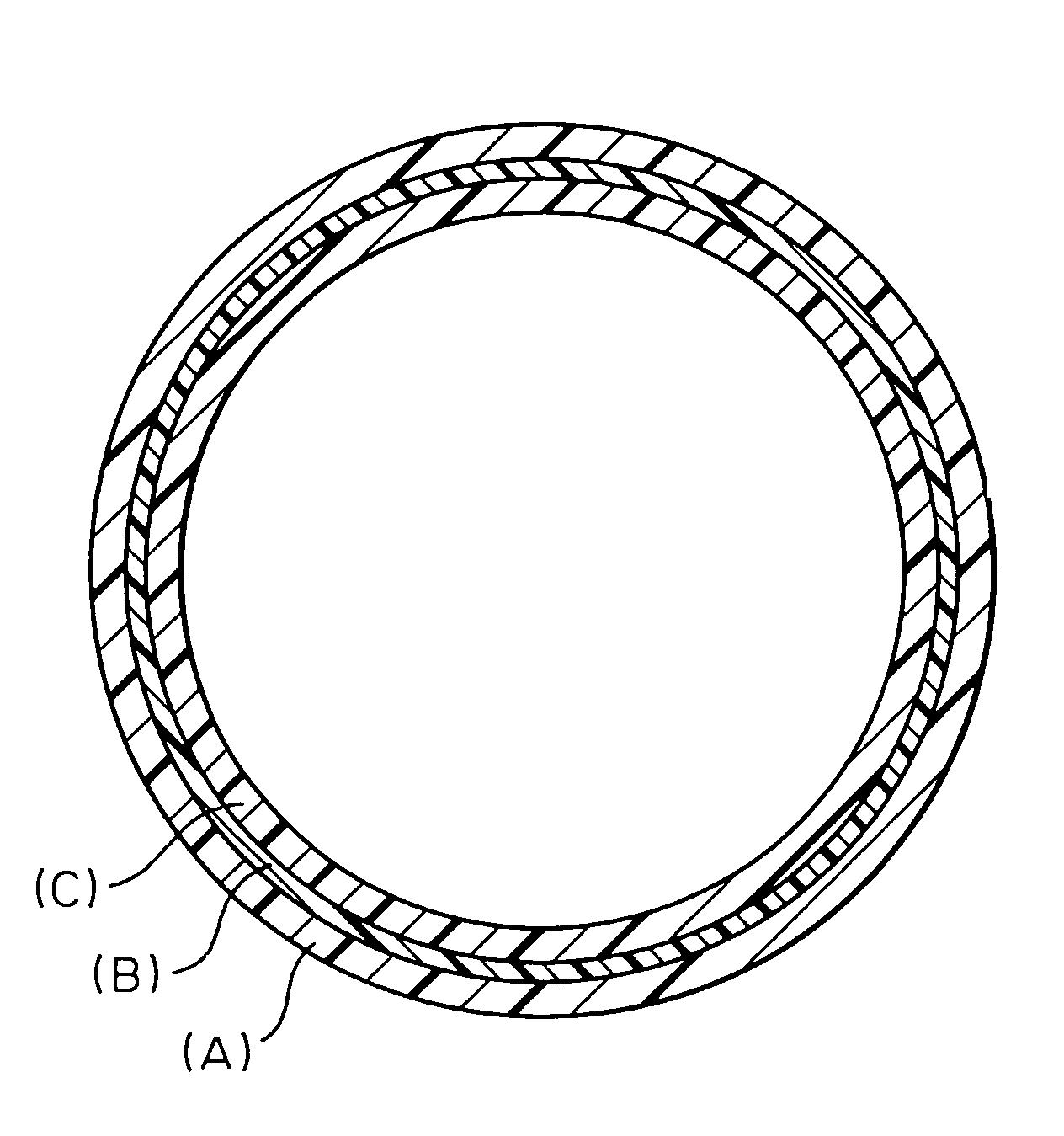

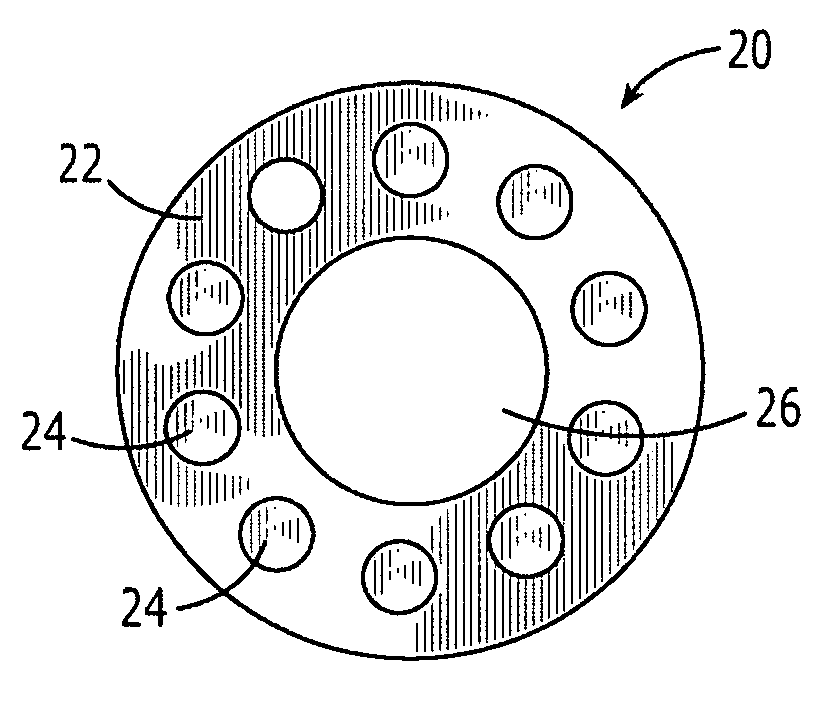

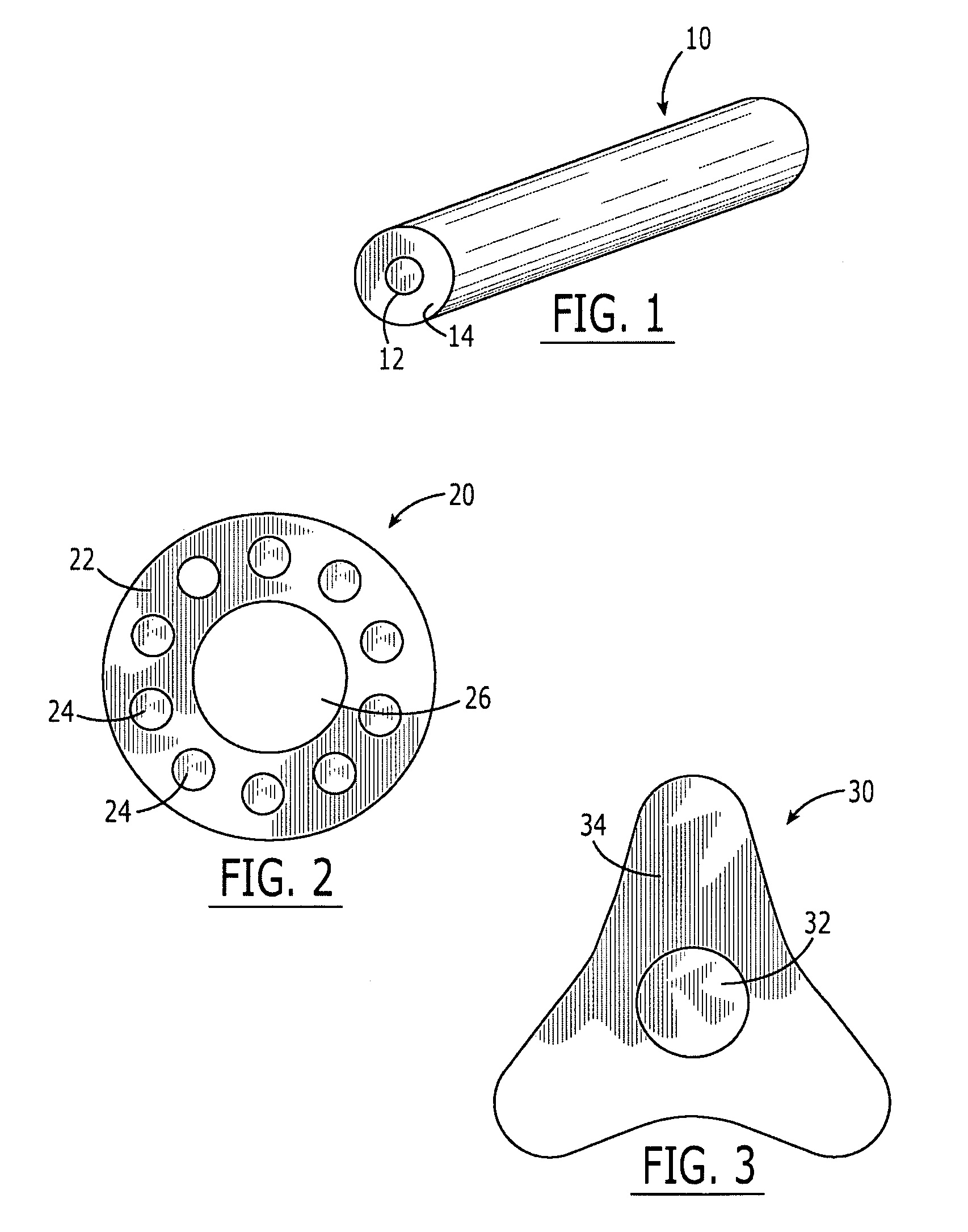

Flexible tube for an endoscope

InactiveUS6860849B2Excellent in operability of insertion and resistance to chemicalIncrease flexibilitySurgerySynthetic resin layered productsInter layerEngineering

A flexible tube for an endoscope has an elongated tubular core body, and an outer cover which is provided over the core body. The outer cover is composed of an inner layer, an outer layer and at least one intermediate layer. In this flexible tube, any one of the layers is different from one of the other layers in its property. Further, at least one of the layers has a thickness-varying region where the thickness of the layer varies in its longitudinal direction. In addition, the inner layer of the outer cover has projections which are integrally formed on the inner layer so that the projections project into holes and / or the recesses formed on the core body. This structure makes it possible to produce a flexible tube for an endoscope that has high durability, high flexibility and high chemical resistance as well as excellent operationability.

Owner:HOYA CORP

Method of topology-selective film formation of silicon oxide

ActiveUS20200251328A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectric membraneSilicon oxide

A method for forming a dielectric film containing a Si—O bond a trench formed in an upper surface of a substrate, includes: designing a topology of a final dielectric film containing a Si—O bond formed in the trench by preselecting a target portion to be selectively removed relative to a non-target portion of an initial dielectric film resulting in the final dielectric film; conformally depositing the initial dielectric film on the upper surface and in the trench; and relatively increasing an amount of impurities contained in the target portion of the initial dielectric film relative to an amount of impurities contained in the non-target portion of the initial dielectric film to obtain a treated dielectric film, thereby giving the target portion and the non-target portion different chemical resistance properties when subjected to etching.

Owner:ASM IP HLDG BV

Shaped articles from cycloaliphatic polyester compositions

ActiveUS20050124779A1Improve melt processing characteristicIncrease stiffnessEnvelopes/bags making machinerySynthetic resin layered productsFiberPolyester

Disclosed are oriented, shaped articles such as, for example, film, fibers, bottles, and tubes, with excellent strength, toughness, clarity, chemical resistance, and UV resistance. The articles can be prepared from cycloaliphatic polyesters and from compositions comprising cycloaliphatic polyesters and cycloaliphatic polyester elastomers. The articles may be oriented by stretching in at least one direction and have a modulus which results in a soft feel. Also disclosed are polyester compositions comprising cycloaliphatic polyesters and polyester elastomers.

Owner:EASTMAN CHEM CO

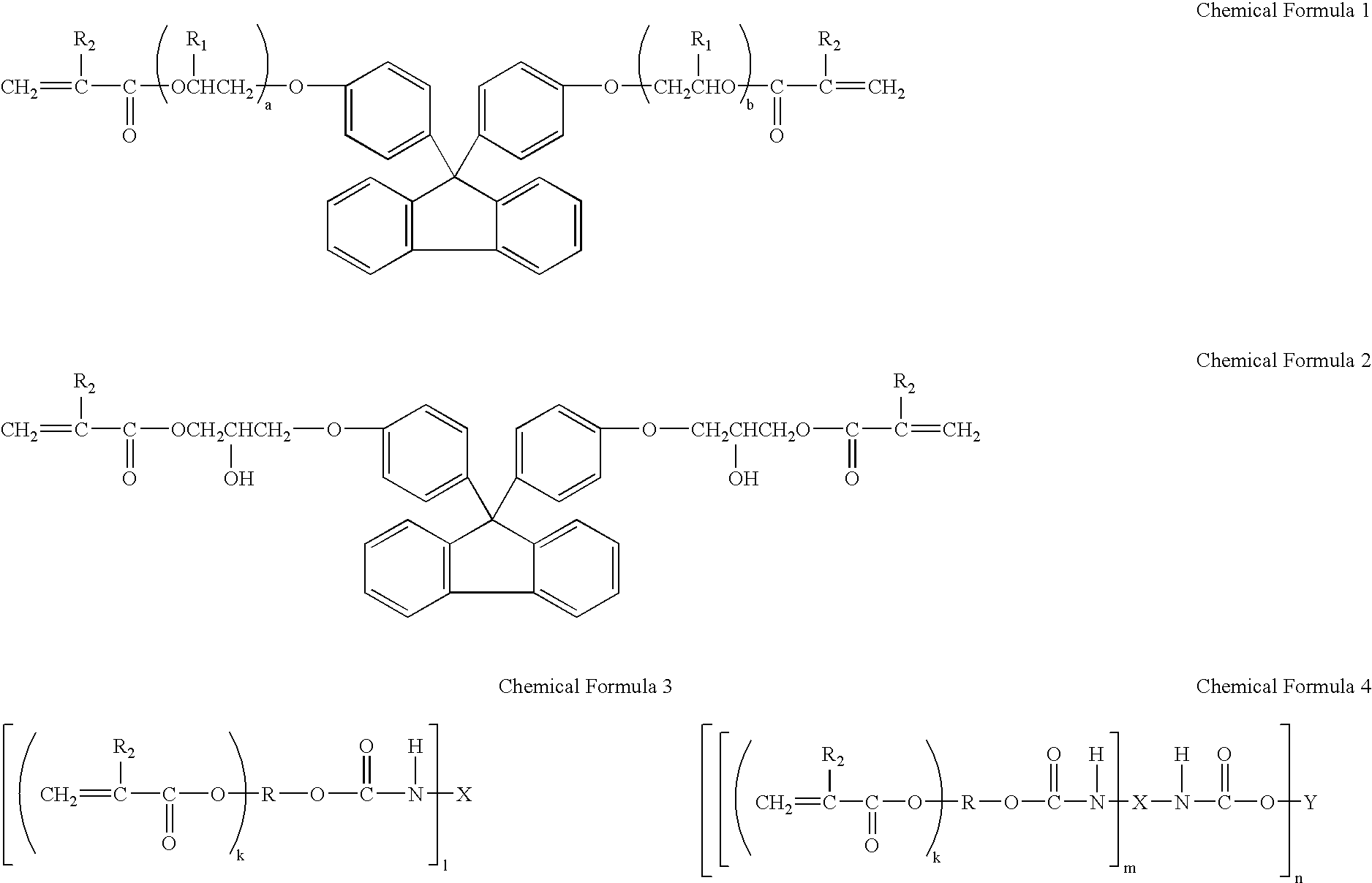

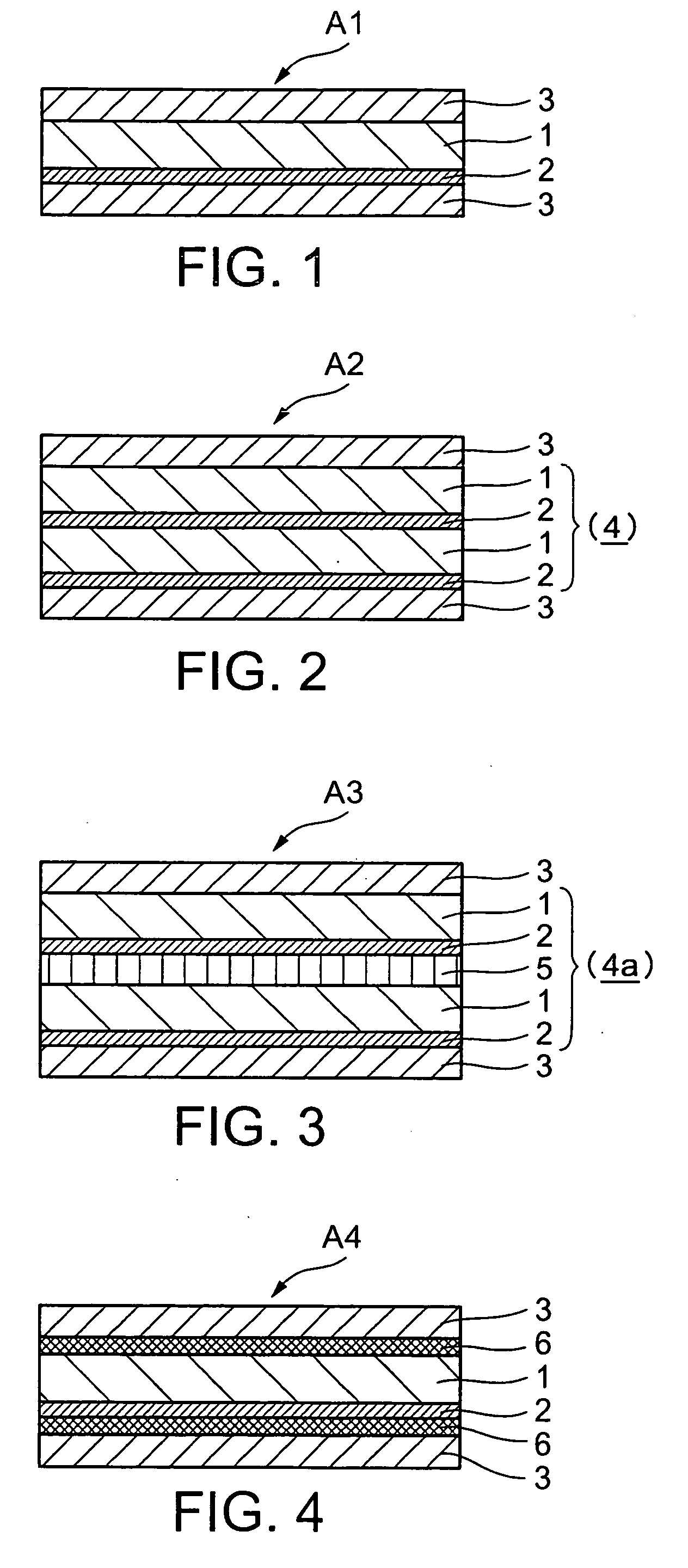

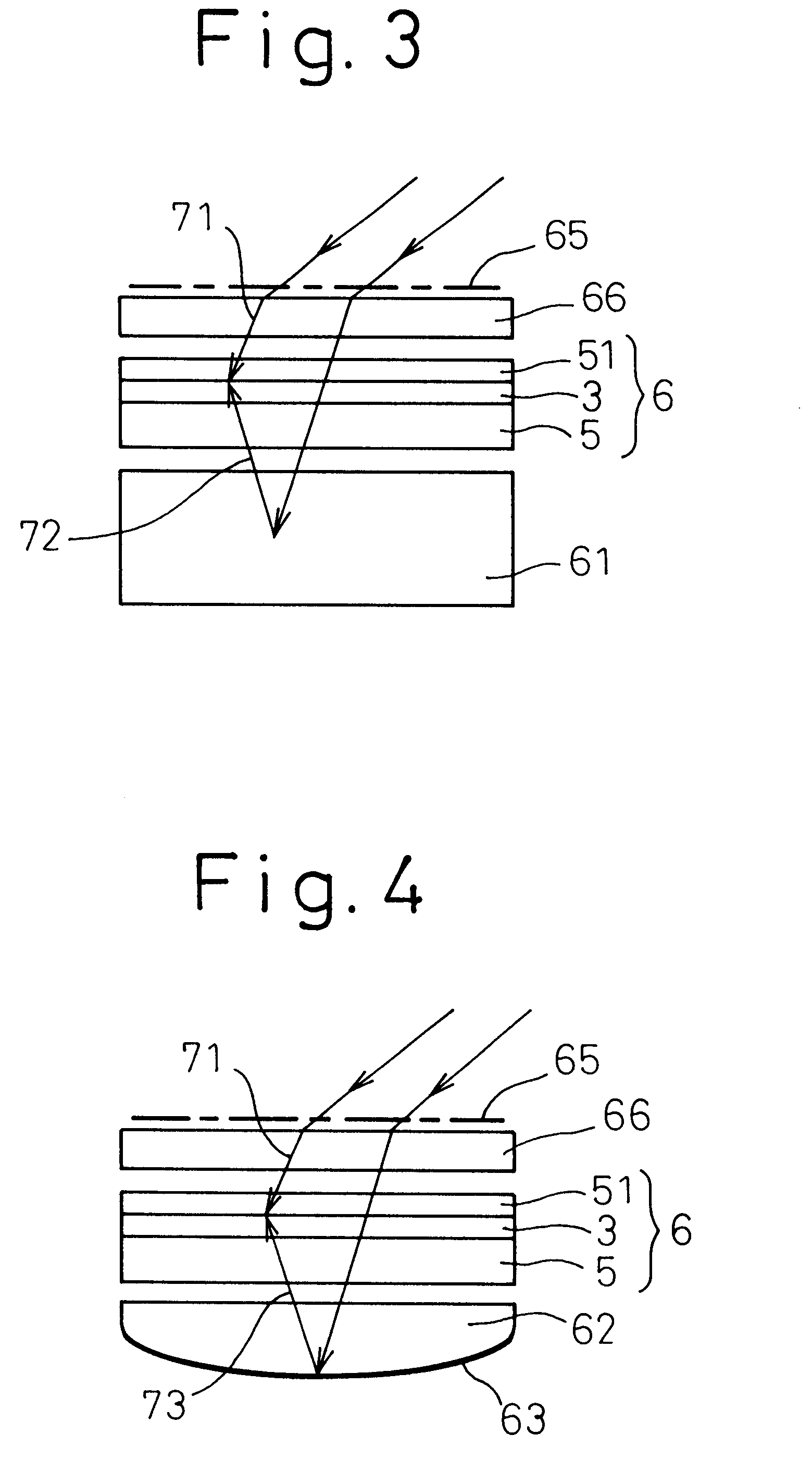

Antireflection material and polarizing film using the same

InactiveUS6777070B1Improve anti-reflection effectReduce image contrastSynthetic resin layered productsCoatingsRefractive indexDisplay device

An anti-reflection material and a polarization film which exhibit superior anti-reflection properties by preventing external light such as sunlight, fluorescent light, etc., from being reflected on a display, which yield a clear image without sparkling and reduces image contrast, and which exhibit superior wear resistance, chemical resistance, and contamination resistance, as well as exhibit optical stability. A hard coat layer is provided on one surface or two surfaces of a transparent substrate directly or via another layer, and an anti-reflection film having a lower refraction index than the hard coat layer is further provide on the hard coat layer. The hard coat layer consists of at least {circle around (1 a polymer polymerizing (metha)acrylate compound having a fluorene structure; {circle around (2 a polymer polymerizing urethane (metha)acrylate compound and ultrafine particles having a high refraction index; and {circle around (3 radiation and / or thermosetting resin and surface-treated titanium oxide ultrafine particles.

Owner:TOMOEGAWA PAPER CO LTD

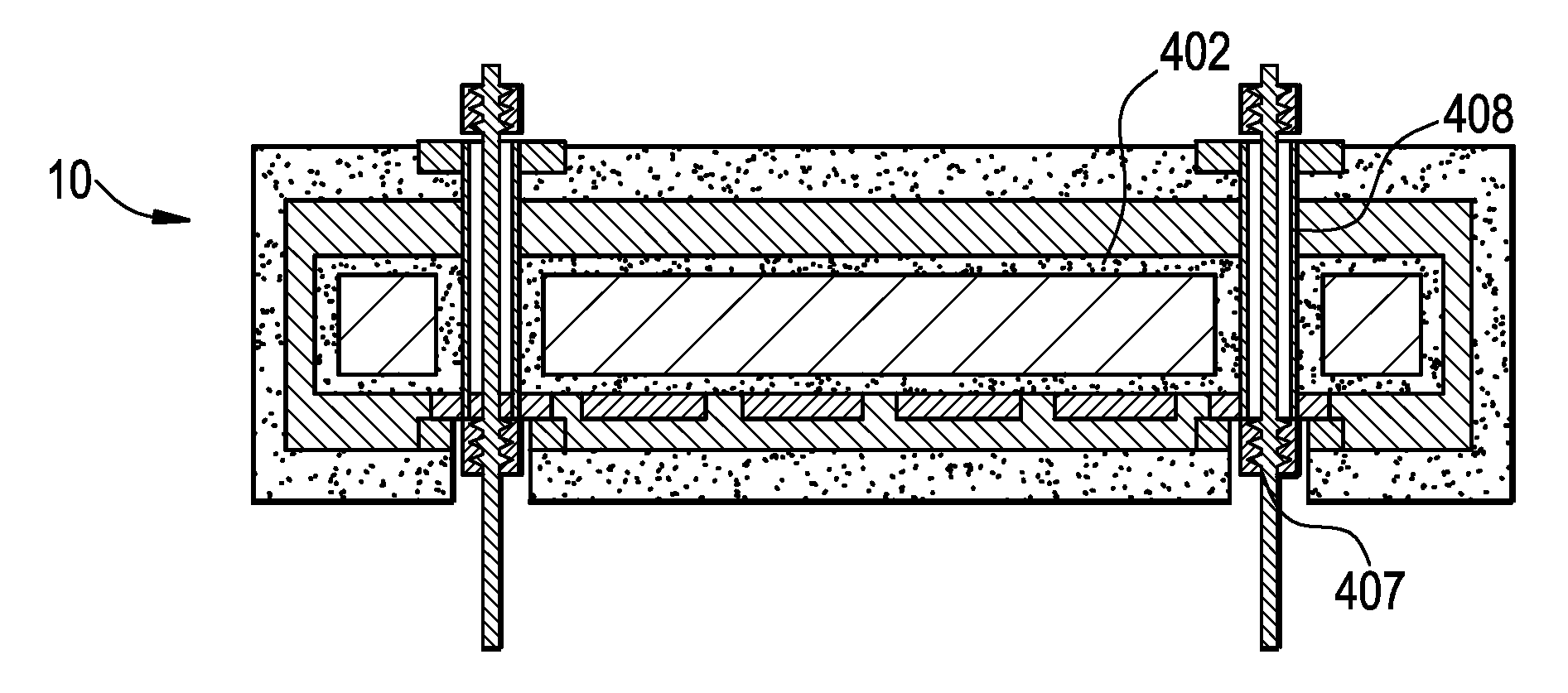

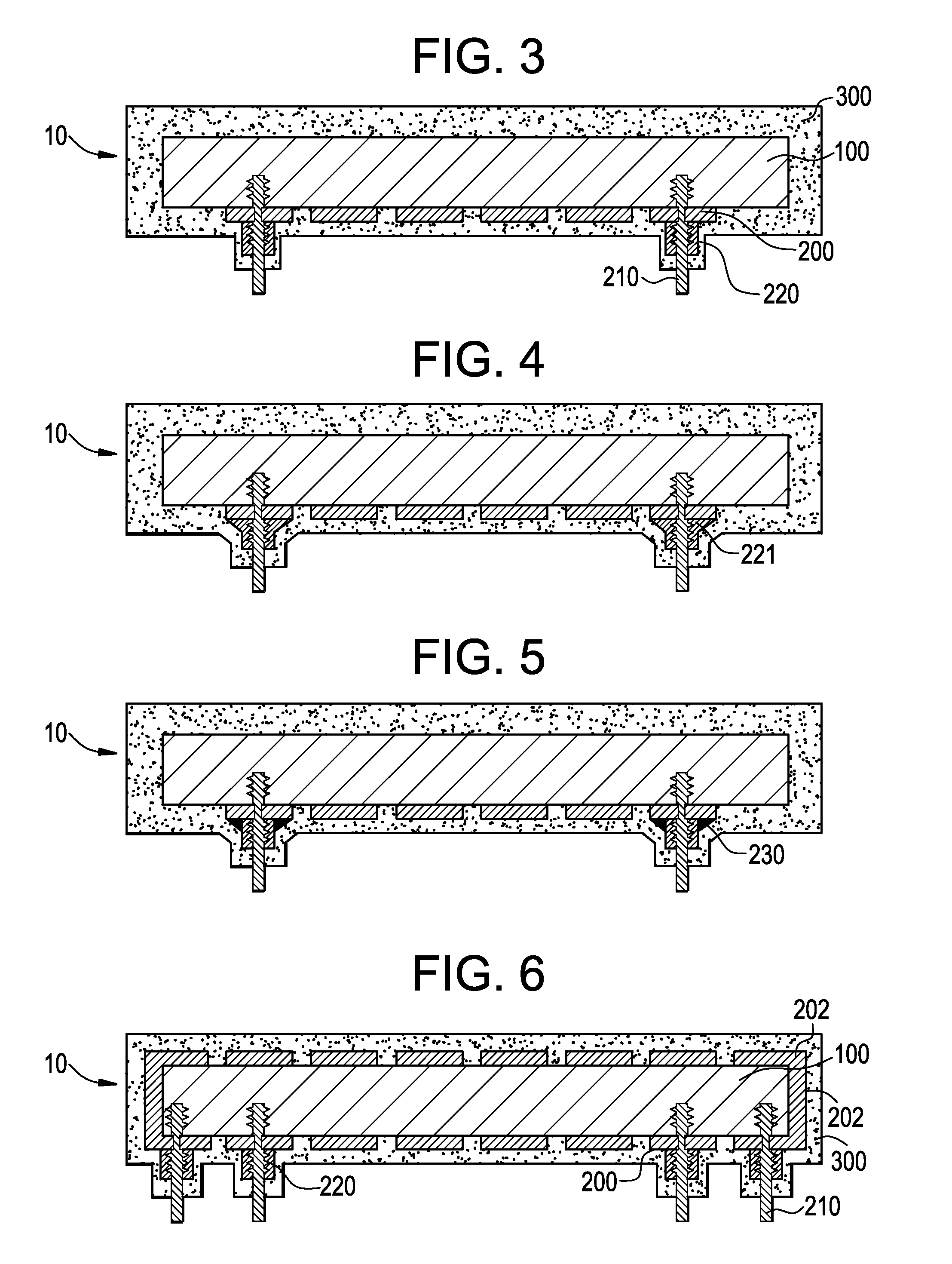

Corrosion resistant wafer processing apparatus and method for making thereof

InactiveUS20080016684A1Line/current collector detailsSemiconductor/solid-state device manufacturingElectrical connectionWadding

A wafer processing apparatus characterized by having corrosion resistant connections for its electrical connections, gas feed-through channels, recessed areas, raised areas, MESA, through-holes such as lift-pin holes, threaded bolt holes, blind holes, and the like, with the special configurations employing connectors and fillers having excellent chemical resistant properties and optimized CTEs, i.e., having a coefficient of thermal expansion (CTE) that closely matches the CTE of the base substrate layer, the electrode(s), as well as the CTE of coating layer. In one embodiment, a nickel plated molybdenum insert is employed.

Owner:GENERAL ELECTRIC CO

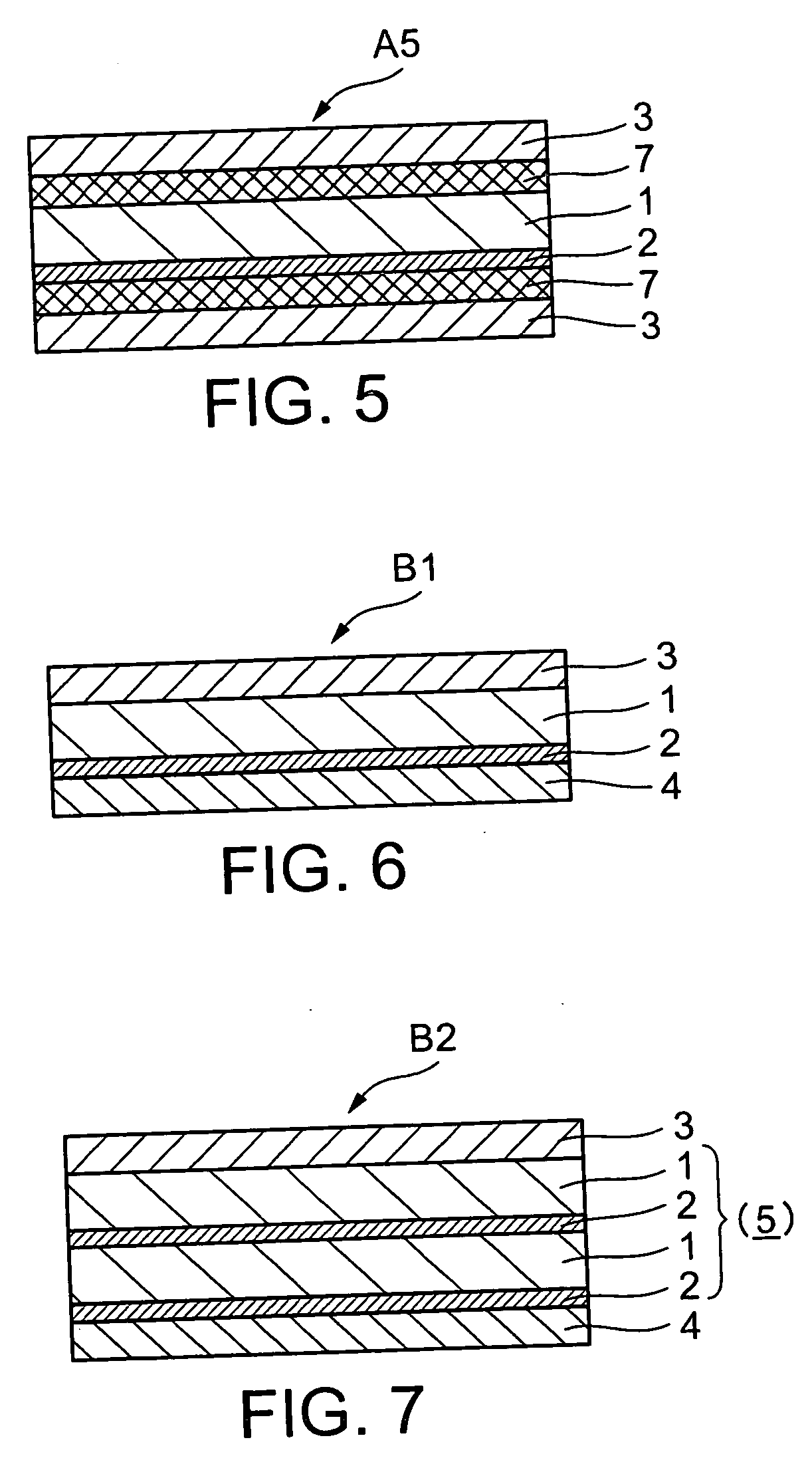

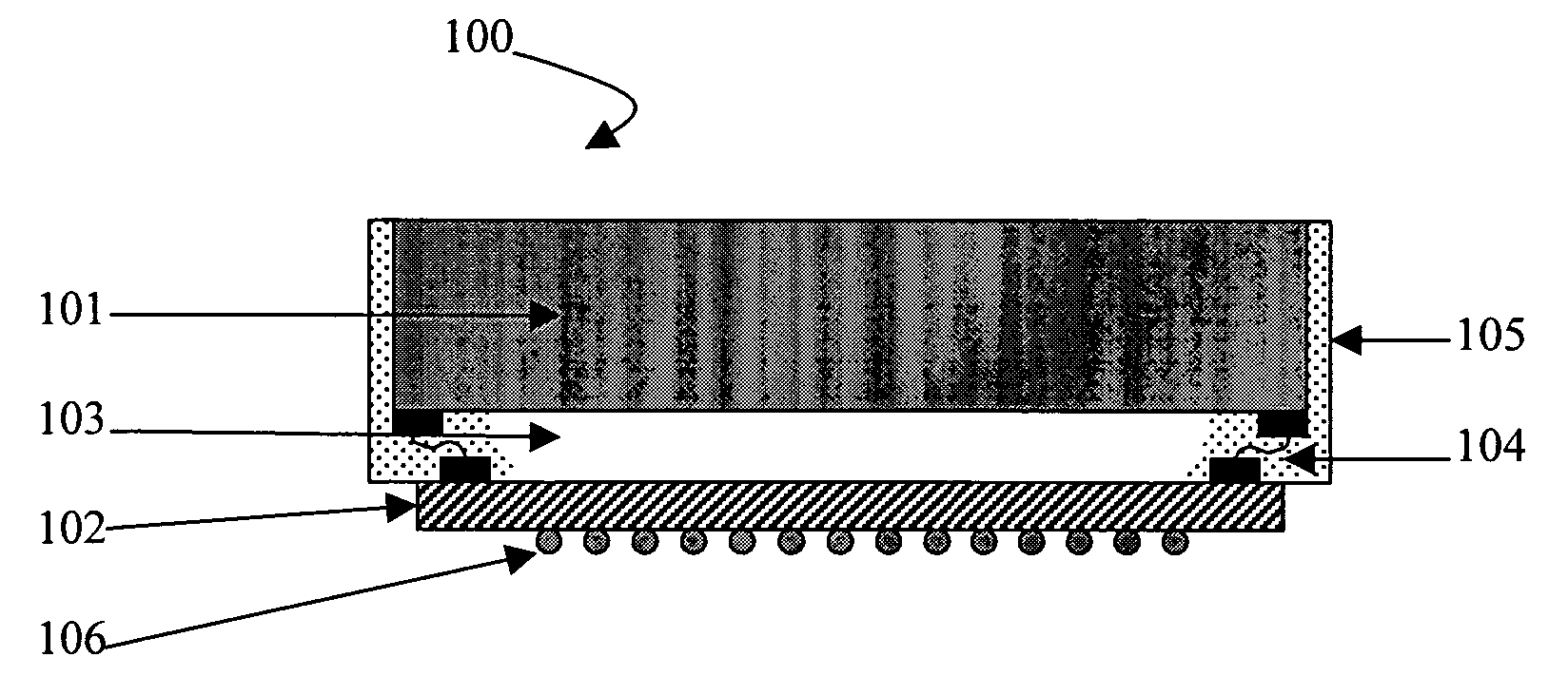

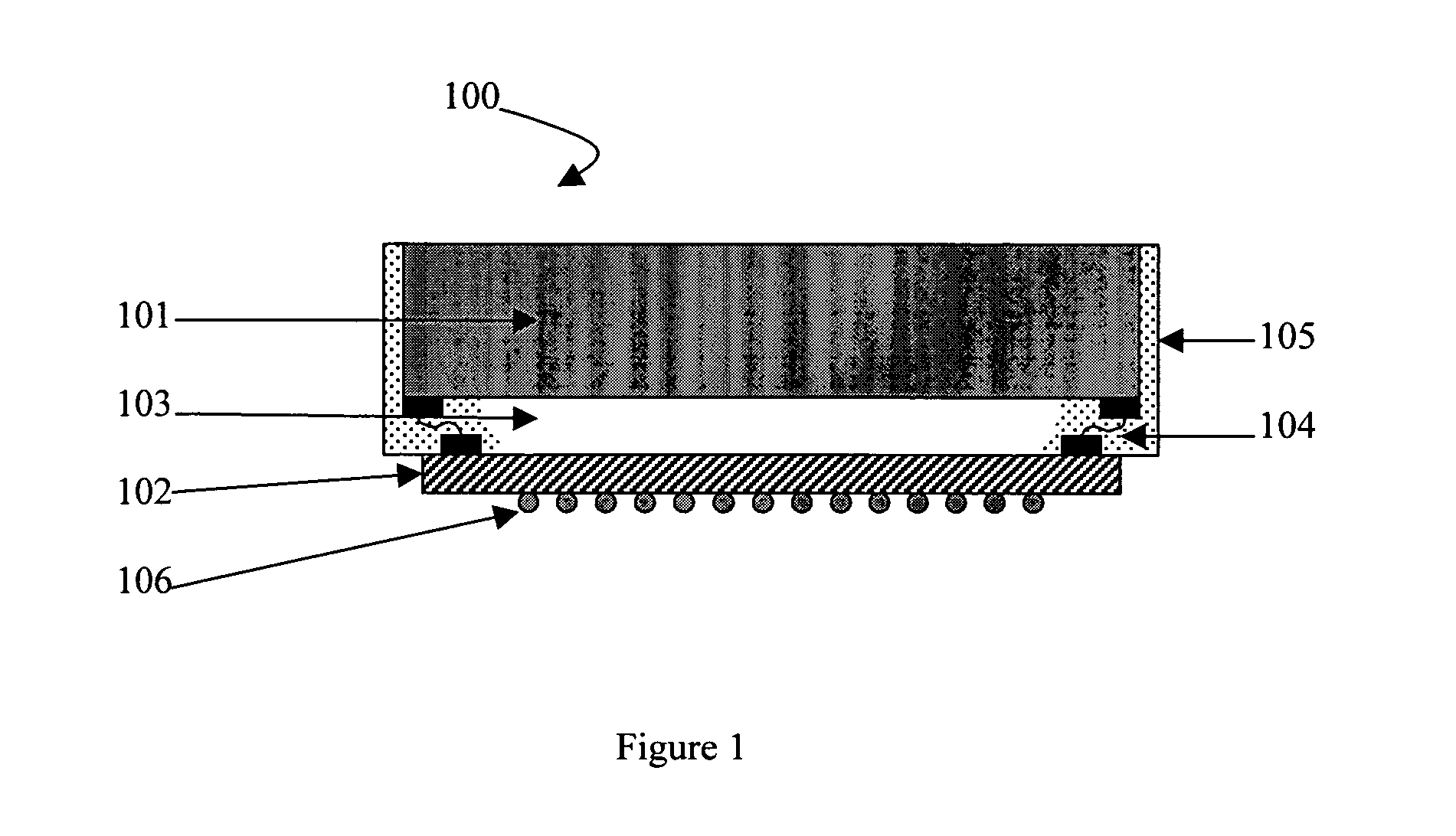

Backside protective sheet for solar battery module and solar battery module using the same

InactiveUS20060166023A1High strengthConvenient inventory managementSynthetic resin layered productsGlass/slag layered productsPolyolefinElectrical battery

There is provided a backside protective sheet for a solar battery module that is excellent in strength as well as in various properties such as weathering resistance, heat resistance, water resistance, light resistance, wind pressure resistance, hailstorm resistance, chemical resistance, moisture resistance, antifouling properties, light reflectivity, light diffusivity, and design, and is particularly excellent in the so-called “moisture resistance,” which is the ability to prevent the entry of moisture, oxygen and the like, and durability against performance degradation with time, particularly against hydrolytic degradation and the like, and is also excellent in protective capability. There is also provided a backside protective sheet for a solar battery module, which can facilitate inventory control by properly using the front side and back side of the protective sheet depending upon applications and is excellent in cost performance, and a solar battery module using the same. The backside protective sheet for a solar battery module comprises: a deposited assembly comprising a vapor-deposited film of an inorganic oxide provided on at least one side of a substrate; and a transparent or translucent heat-resistant polyolefin resin layer provided on both sides of the deposited assembly.

Owner:DAI NIPPON PRINTING CO LTD

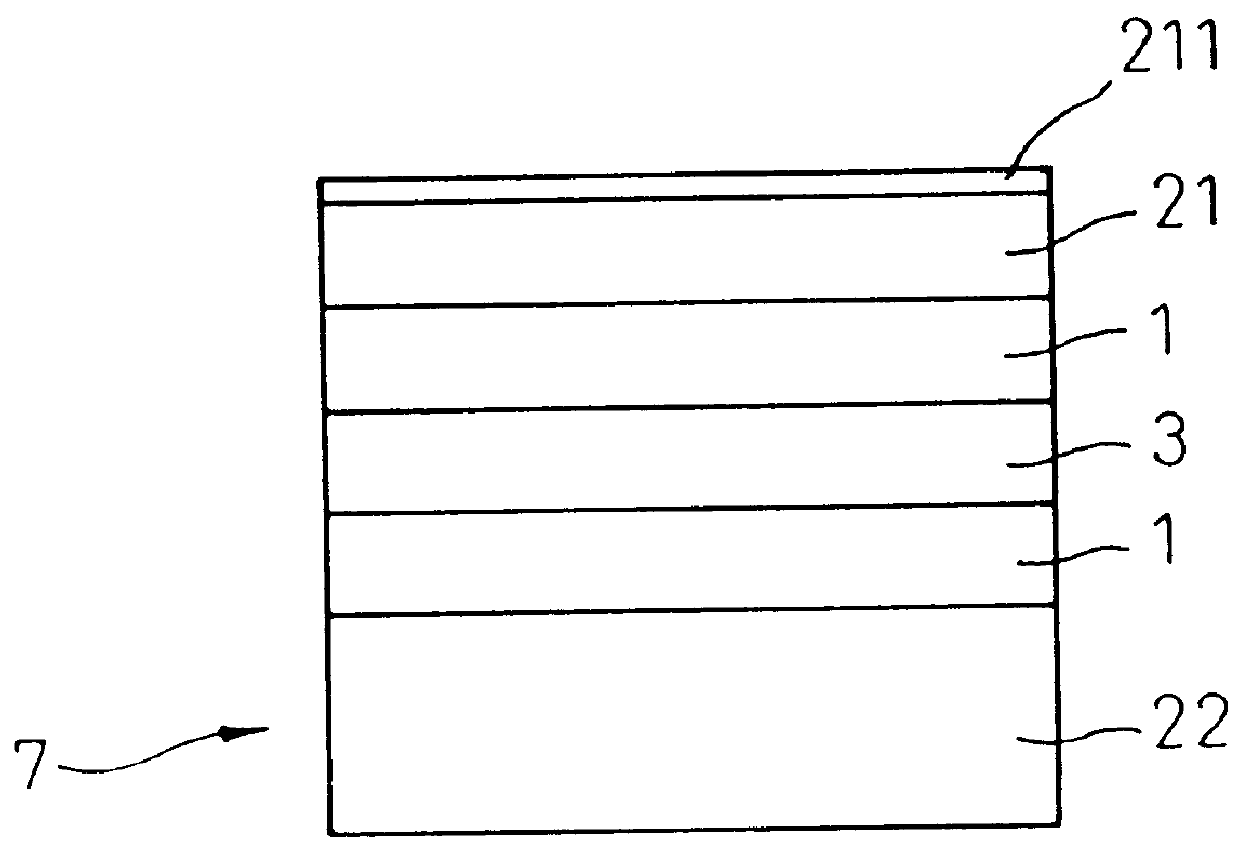

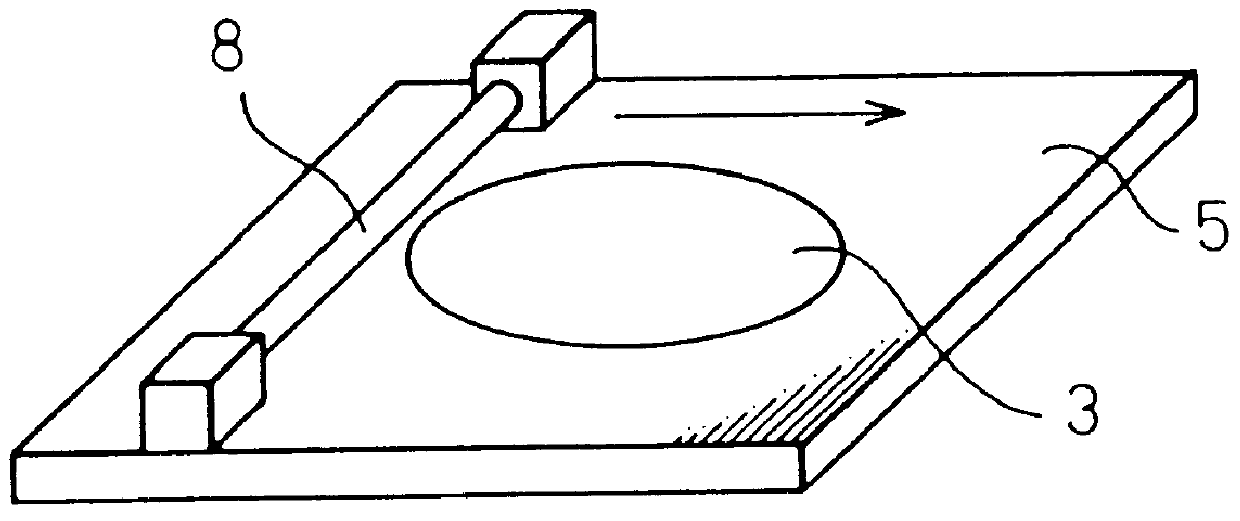

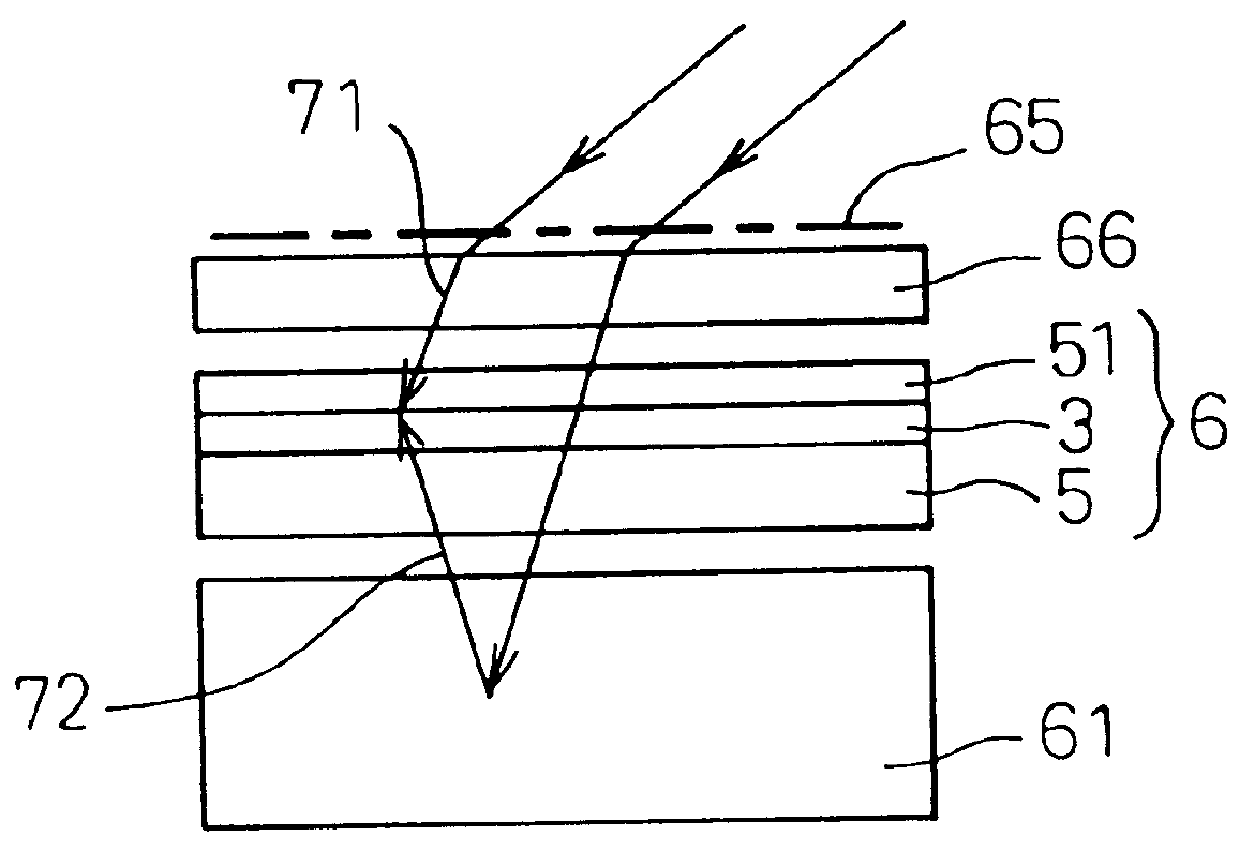

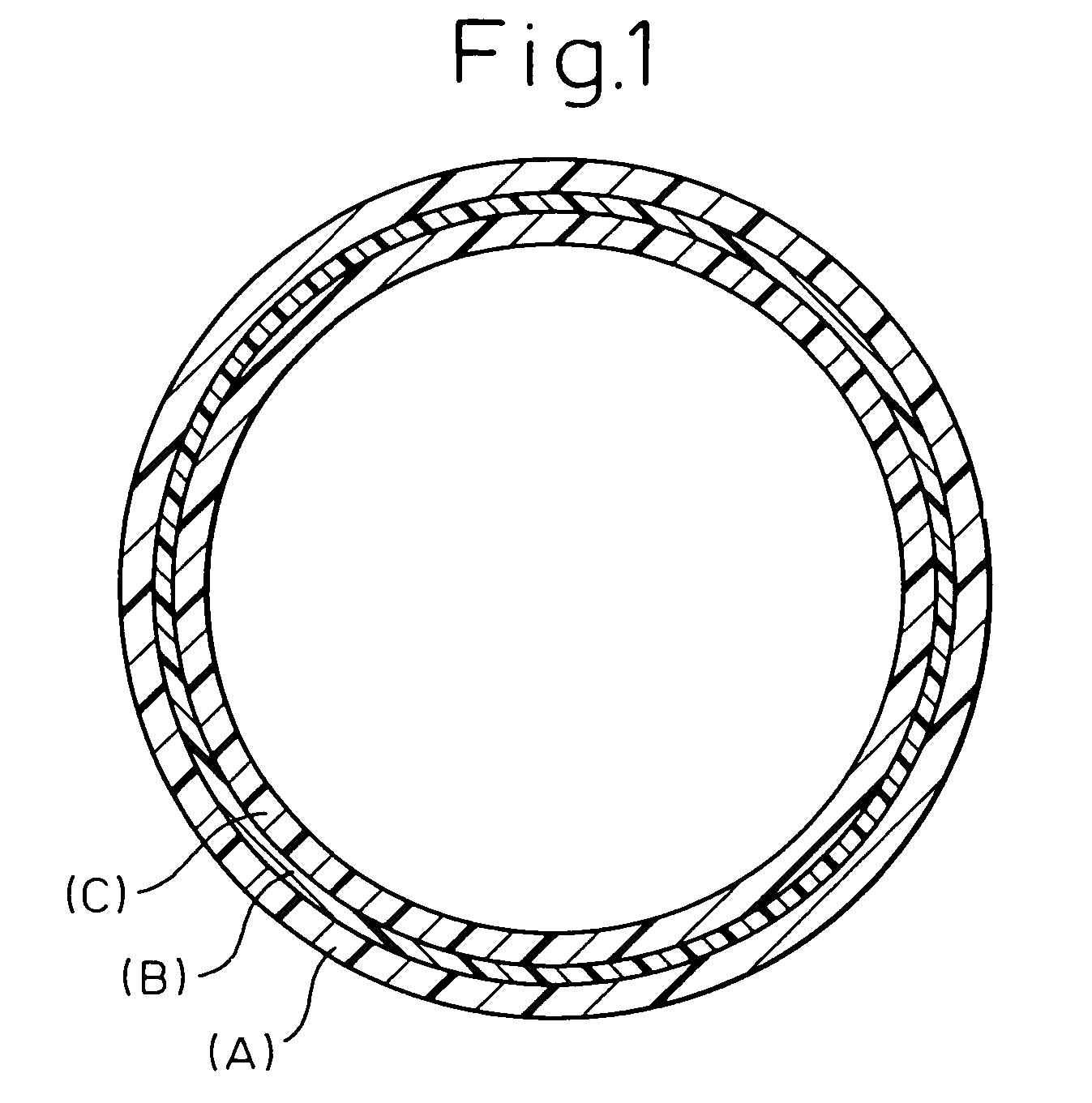

Hologram

A hologram has a hologram element 3 containing a photopolymer and a cover film 22 and cover plate 21 which cover its surfaces. An adhesive 1 is used for bonding the cover film to the hologram element and the cover plate to the hologram element. The hologram has excellent humidity resistance, chemical resistance, solvent resistance and heat resistance, prevents coloration, can maintain its holographic properties and allows easy repositioning of the hologram element.

Owner:DENSO CORP

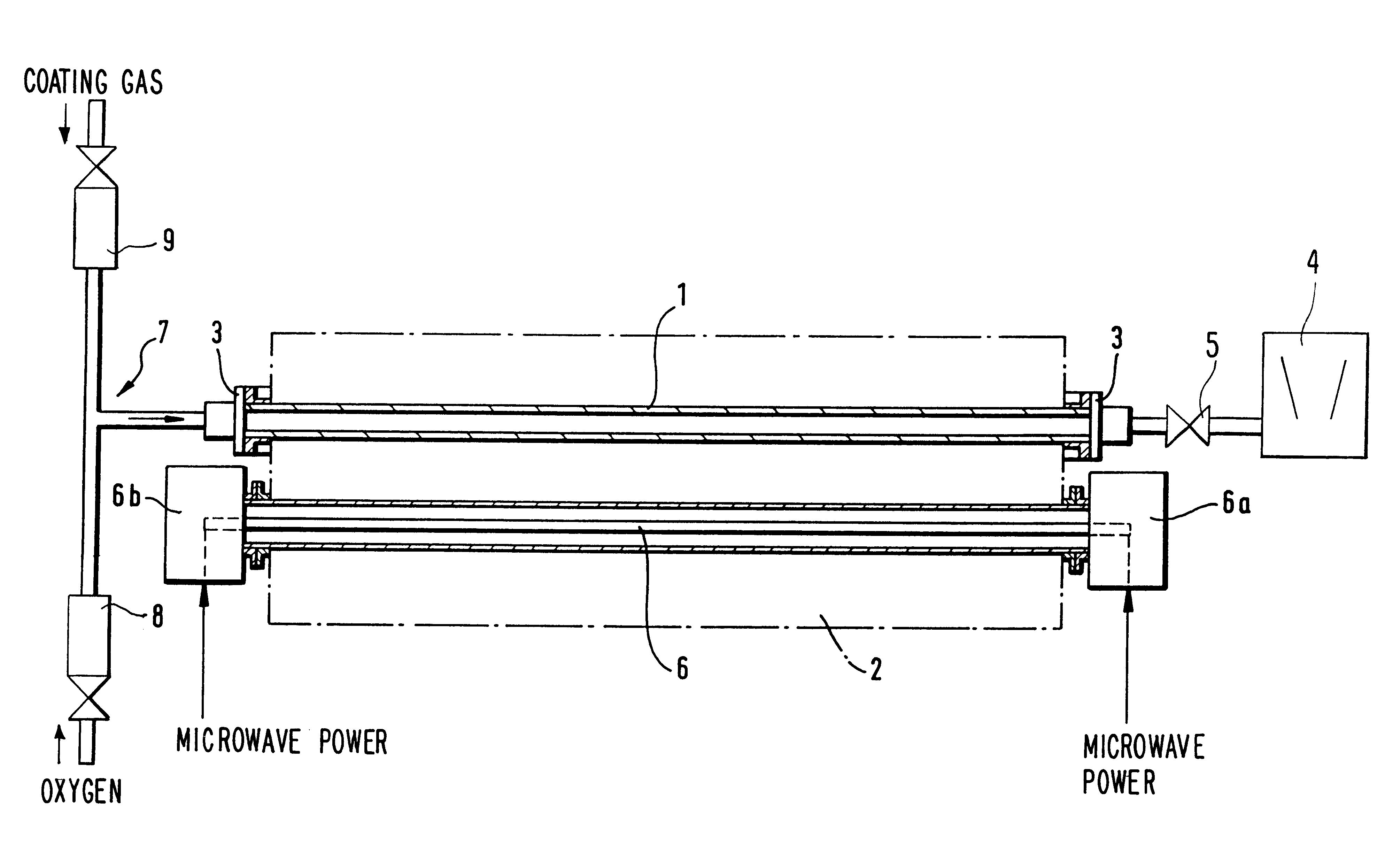

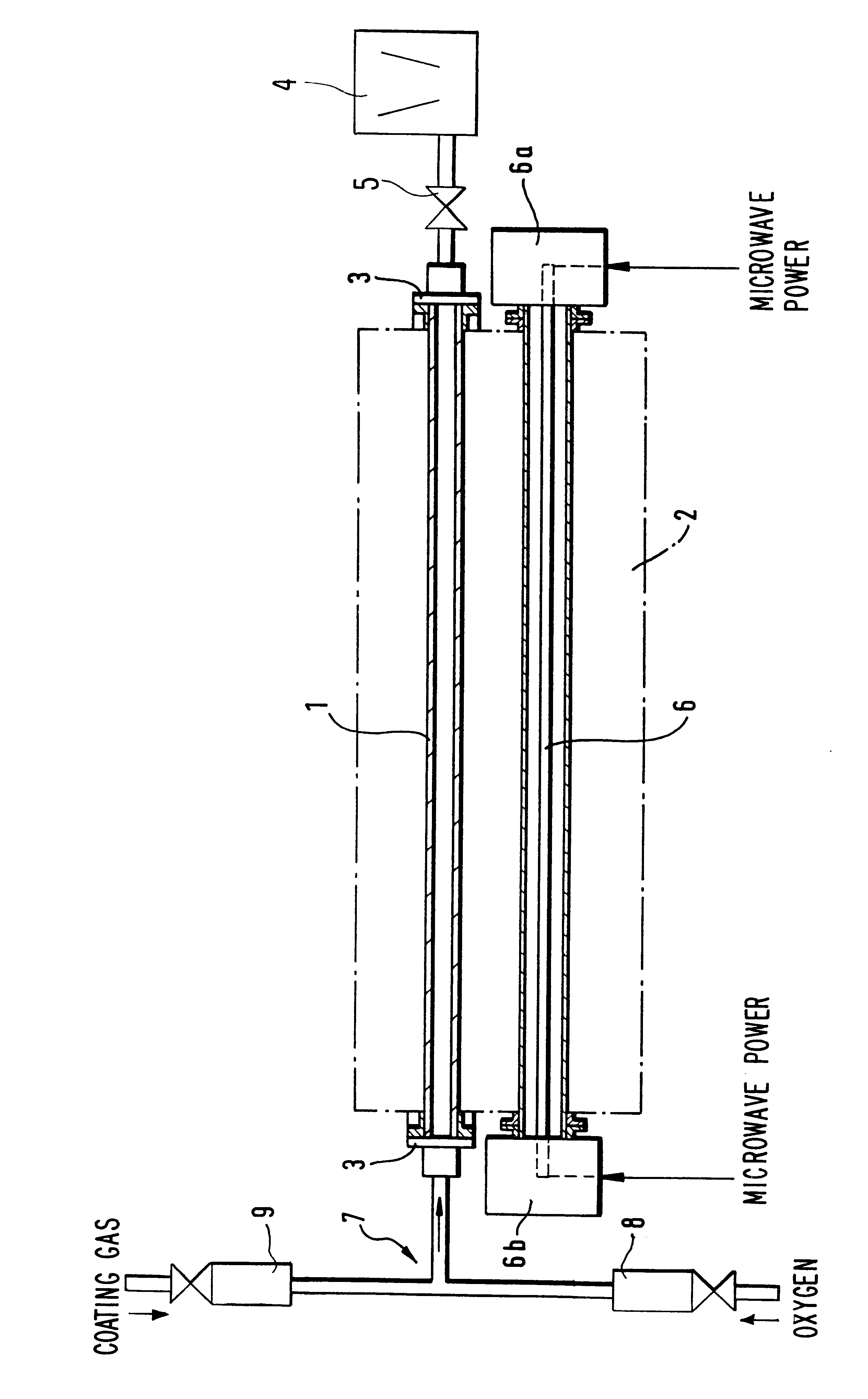

Method of making a hollow, interiorly coated glass body and a glass tube as a semi-finished product for forming the glass body

InactiveUS6200658B1Layered productsLiquid/solution decomposition chemical coatingVitreous BodiesWork in process

Numerous applications for hollow glass bodies made from low melting glass material require an increase in the chemical resistance of the interior surface of the glass body. In order to avoid a disadvantageous de-alkalizing process the hollow glass body must be provided with an interior coating in a comparatively expensive prior art process. In an improved process according to the invention a glass tube acting as a semifinished product from which the hollow glass body is made is provided with an interior coating of oxide material, preferably SiO2, Al2O3, TiO2 or mixtures thereof, having a predetermined coating thickness according to the required chemical resistance or working conditions for forming the glass body and then the hollow glass body is made from the glass tube. The coating is advantageously provided by means of a PICVD process.

Owner:SCHOTT AG

Silicones having improved chemical resistance and curable silicone compositions having improved migration resistance

InactiveUS20050038188A1Improve the immunityTrend downMouldsSemiconductor/solid-state device detailsHydrogenHydrogen atom

A composition is prepared by mixing components including: (I) a polyorganosiloxane having an average of at least two unsaturated organic groups per molecule, with the proviso that component (I) is free of fluorine atoms; optionally (II) an organohydrogenpolysiloxane having an average of at least two silicon-bonded hydrogen atoms per molecule, with the proviso that component (II) is free of fluorine atoms; (III) a hydrosilylation catalyst; (IV) a fluoroorganosilicone, with the provisos that (1) component (IV) has at least one functional group reactive with component (I), component (II), or both, (2) when component (II) is not present, then component (IV) has an average of at least two silicon-bonded hydrogen atoms per molecule, and (3) component (IV) is added to the composition in an amount sufficient to provide chemical resistance to a cured product of the composition; and (V) an adhesion promoter.

Owner:DOW CORNING CORP

Intercalates formed by co-intercalation of monomer, oligomer or polymer intercalants and surface modifier intercalants and layered materials and nonocomposites prepared with the intercalates

The present invention discloses intercalates formed by contacting a layered material, e.g., a phyllosilicate, with an intercalant monomer surface modifier including an alkyl radical having at least 6 carbon atoms and a polymerizable monomer, oligomer or polymer. The intercalant monomer surface modifier converts the interlayer region of the layered materials from hydrophilic to hydrophobic, therefore, polymerizable monomers, oligomers or polymers can be easily intercalated into the interlayer spacing. The co-presence of the intercalant monomer surface modifier and polymerizable monomer, oligomer or polymer provide an environment for more polymerizable monomers, oligomers or polymers to be intercalated into the interlayer spacing and the intercalates are readily exfoliated into polymer matrices to form nanocomposites. The nanocomposites (e.g., epoxy-clay) prepared from the intercalates demonstrated enhanced mechanical, thermal and chemical resistance compared with pristine polymer matrices.

Owner:AMCOL INTERNATIONAL CORPORATION

Shaped articles from cycloaliphatic polyester compositions

ActiveUS20070071930A1Improve melt processing characteristicImprove orientation and toughness characteristicLayered productsBottlesPolyesterElastomer

Owner:EASTMAN CHEM CO

Shaped articles from cycloaliphatic polyester compositions

ActiveUS7169880B2Improve melt processing characteristicImprove orientation and toughness characteristicEnvelopes/bags making machinerySynthetic resin layered productsFiberPolyester

Owner:EASTMAN CHEM CO

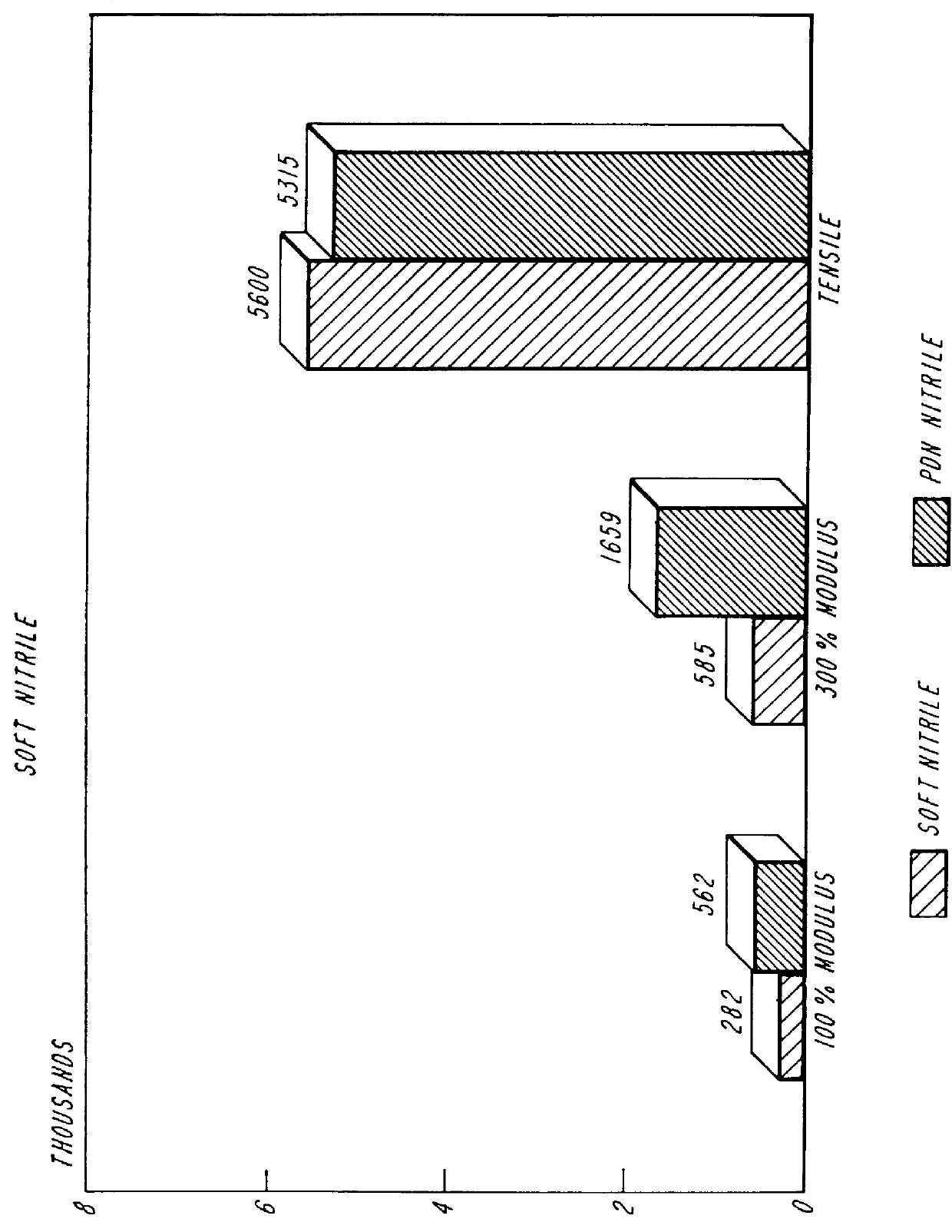

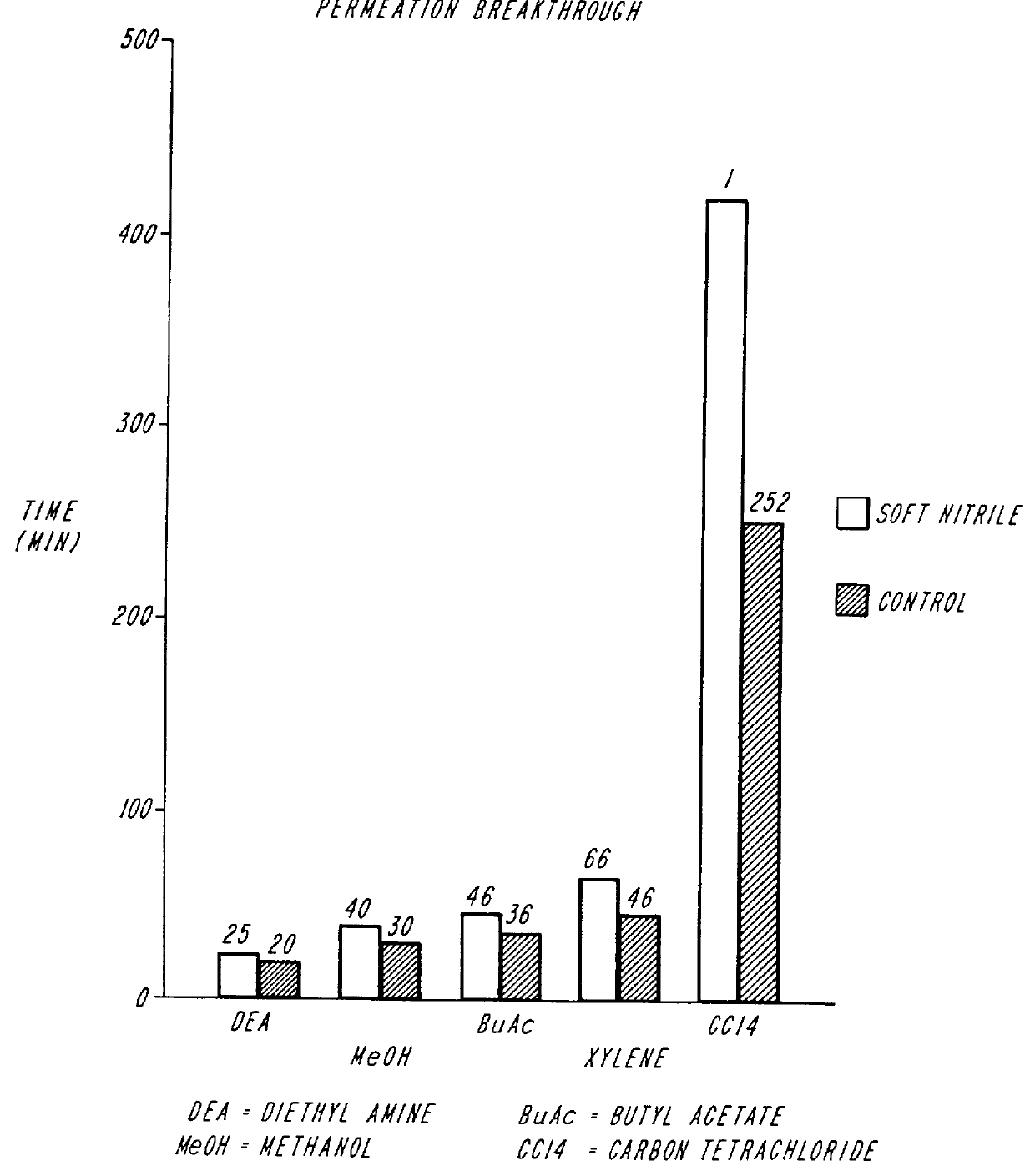

Soft nitrile rubber formulation

Nitrile rubber compositions, articles of manufacture made therefrom, and methods of making them, are disclosed. The nitrile rubber compositions of the invention are substantially free of zinc oxide, and have good strength and chemical resistance while being softer than many conventional nitrile rubbers. The invention provides articles of manufacture, including gloves, which are soft, yet strong, and can be economically manufactured.

Owner:NORTH SAFETY PROD INC

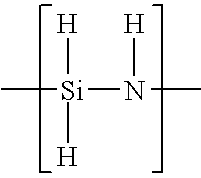

Polysilane-containing coating solution

InactiveUS20050279255A1Easy-to-clean propertyLow shrinkageFireproof paintsImpression capsBrickSolvent

A coating solution comprising 0.1 to 35% by weight of an inorganic or organic polysilazane having repeating units represented by the general formula below and soluble in a solvent and 0.1 to 10% by weight of catalyst such as 4,4′-trimethylenebis(1-methylpiperidine) based on a pure polysilazane content. By applying the coating solution onto the surface of base materials such as metals, plastics, glass, ceramic, wood, cement, mortar, bricks, etc., a silica coating strongly adhered to the base materials can be formed excellent in corrosion resistance and anti-scratch properties and simultaneously excellent in characteristics such as abrasion resistant, long-lasting anti-fouling properties, wetting properties to water, sealing properties, chemical resistance, oxidation resistance, physical barrier effect, heat resistance, fire resistance and antistatic properties.

Owner:CLARIANT INT LTD

Sintered bodies based on niobium suboxide

Disclosed are sintered bodies that include: (a) 30 to 100 mol % of NbOx, wherein 0.5<x<1.5; and (b) 0 to 70 mol % of MgO. The sintered bodies may be used as inert apparatuses in the production of niobium suboxide powder or niobium suboxide anodes, or as chemically resistant components in chemical apparatuses.

Owner:H C STARCK GMBH

Multi-layer structure

ActiveUS6989198B2Improve penetration resistanceLarge containersRefuse receptaclesCarboxylic acidNylon 11

A multi-layer structure excellent in the barrier properties against alcohol gasoline, particularly hydrocarbon components, and also excellent in the interlayer adhesion, low-temperature impact resistance, heat resistance and chemical resistance is provided. The stractive is a multi-layer structure comprising two or more layers including at least a layer (a) comprising (A) nylon 11 and / or nylon 12 and a layer (b) comprising (B) a polyamide resin (nylon 9T) consisting of a dicarboxylic acid component and a-diamine component, with 60 to 100 mol % of the dicarboxylic acid component being a terephthalic acid and 60 to 100 mol % of the diamine component being a diamine component selected from 1,9-nonanediamine and 2-methyl-1,8-octanediamine, and preferably further including a layer (c) comprising (A) nylon 11 and / or nylon 12 or (C) nylon 6.

Owner:KURARAY CO LTD +1

Hologram

A hologram has a hologram element 3 containing a photopolymer and a cover film 22 and cover plate 21 which cover its surfaces. An adhesive 1 is used for bonding the cover film to the hologram element and the cover plate to the hologram element. The hologram has excellent humidity resistance, chemical resistance, solvent resistance and heat resistance, prevents coloration, can maintain its holographic properties and allows easy repositioning of the hologram element.

Owner:DENSO CORP

High chemical resistance borosilicate glass and purpose thereof

InactiveCN101717189AComply with packaging requirementsReduce manufacturing costPharmaceutical containersMedical packagingWorking temperaturePack material

The invention discloses high chemical resistance borosilicate glass, comprising the following components based on oxides in percentage by weight: 71-75 SiO2, 3-6 Al2O3, 8-10 B2O3, 4-10 Na2O and 0-2.5 K2O, 0-1.2 CaO, 0-1 MgO, 1-3 BaO and 0-0.3 CeO2, wherein Na2O+K2O ranges from 7 to 10, and CaO+MgO ranges from 0 to 1.2. The invention has the following advantages: 1. As2O3, Sb2O3, BaSO4 and other harmful substances are not used in constituents, and the borosilicate glass can be used as a material for packing medicines; and 2. tested by experiments, the high chemical resistance borosilicate glass prepared from the constituents by the traditional production equipment has the coefficient of heat expansion ranging from 5.0*10<-6> K<-1> to 6.0*10<-6> K<-1>, the inversion temperature Tg ranging from 520 DEGC to 572 DEGC, the softening point ranging from 765 DEGC to 782 DEGC, the working temperature ranging from 920 DEGC to 1200 DEGC and the density ranging from, 2.32 g / cm<3> to 2.5g / cm<3>, which meet the requirement on medicinal packing and reduces the production cost.

Owner:SHANDONG LINUO NEW MATERIAL

Multicomponent fiber with polyarylene sulfide component

InactiveUS6949288B2Low costSufficient integrityConjugated synthetic polymer artificial filamentsYarnFiberHeat resistance

Owner:TICONA LLC +1

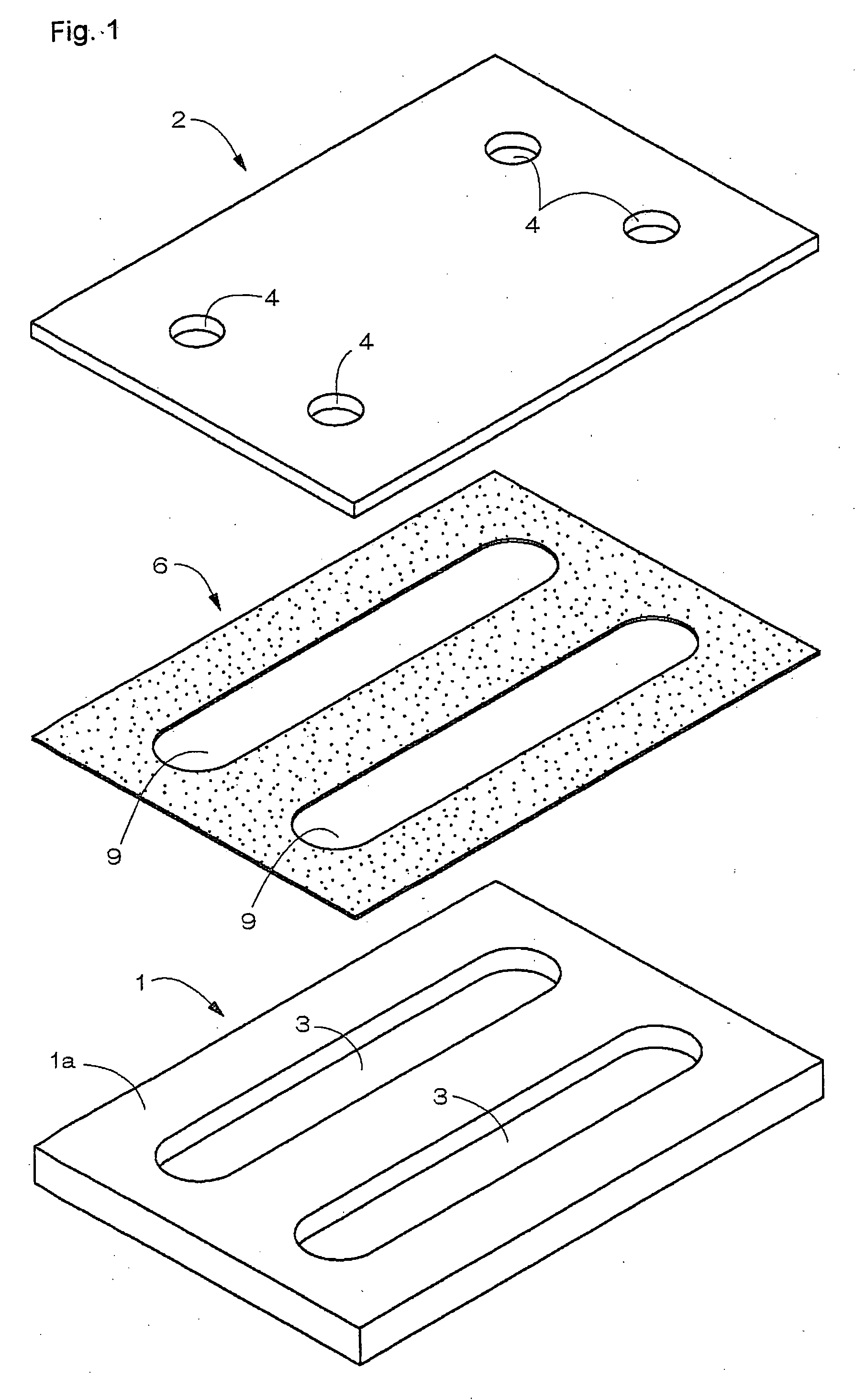

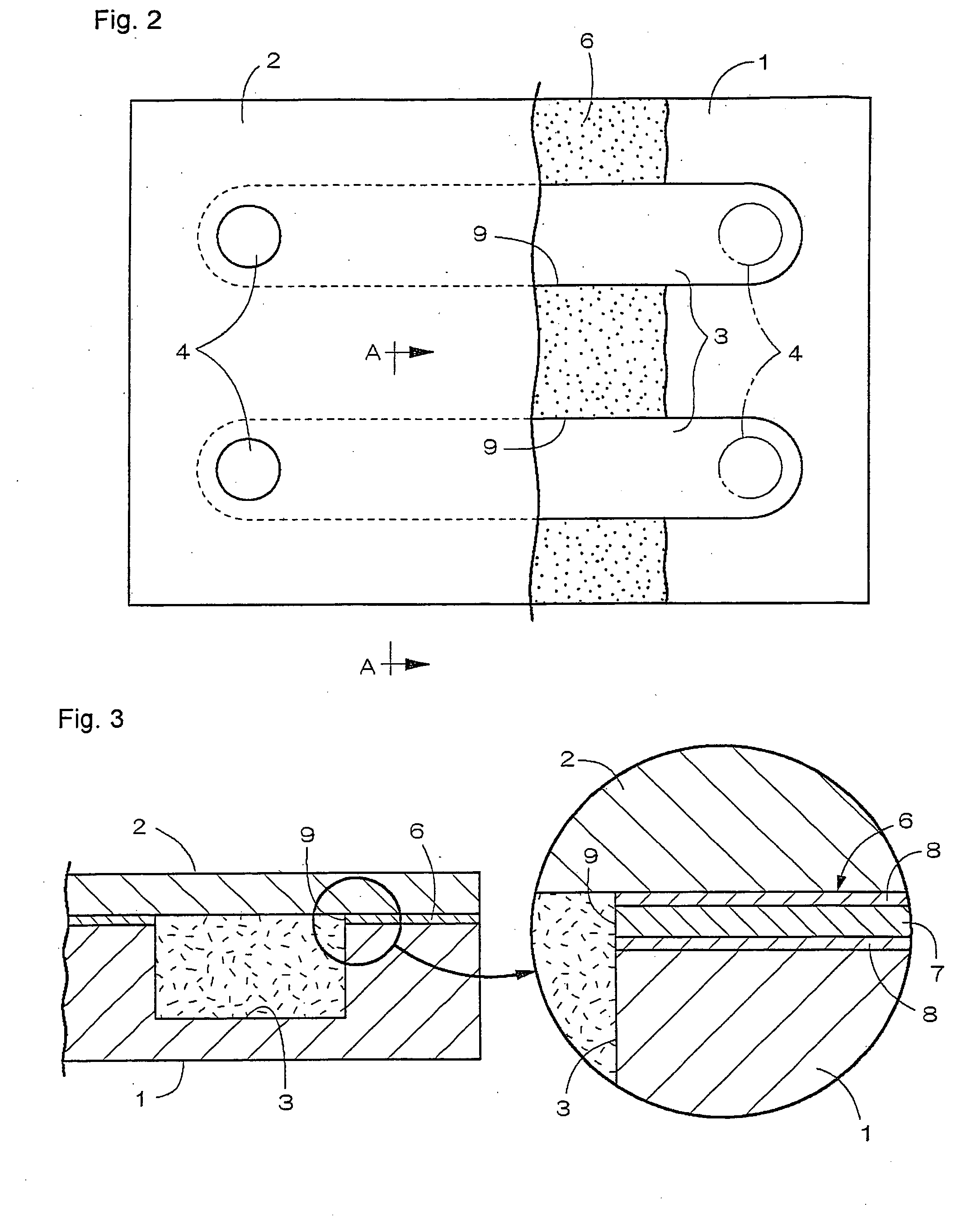

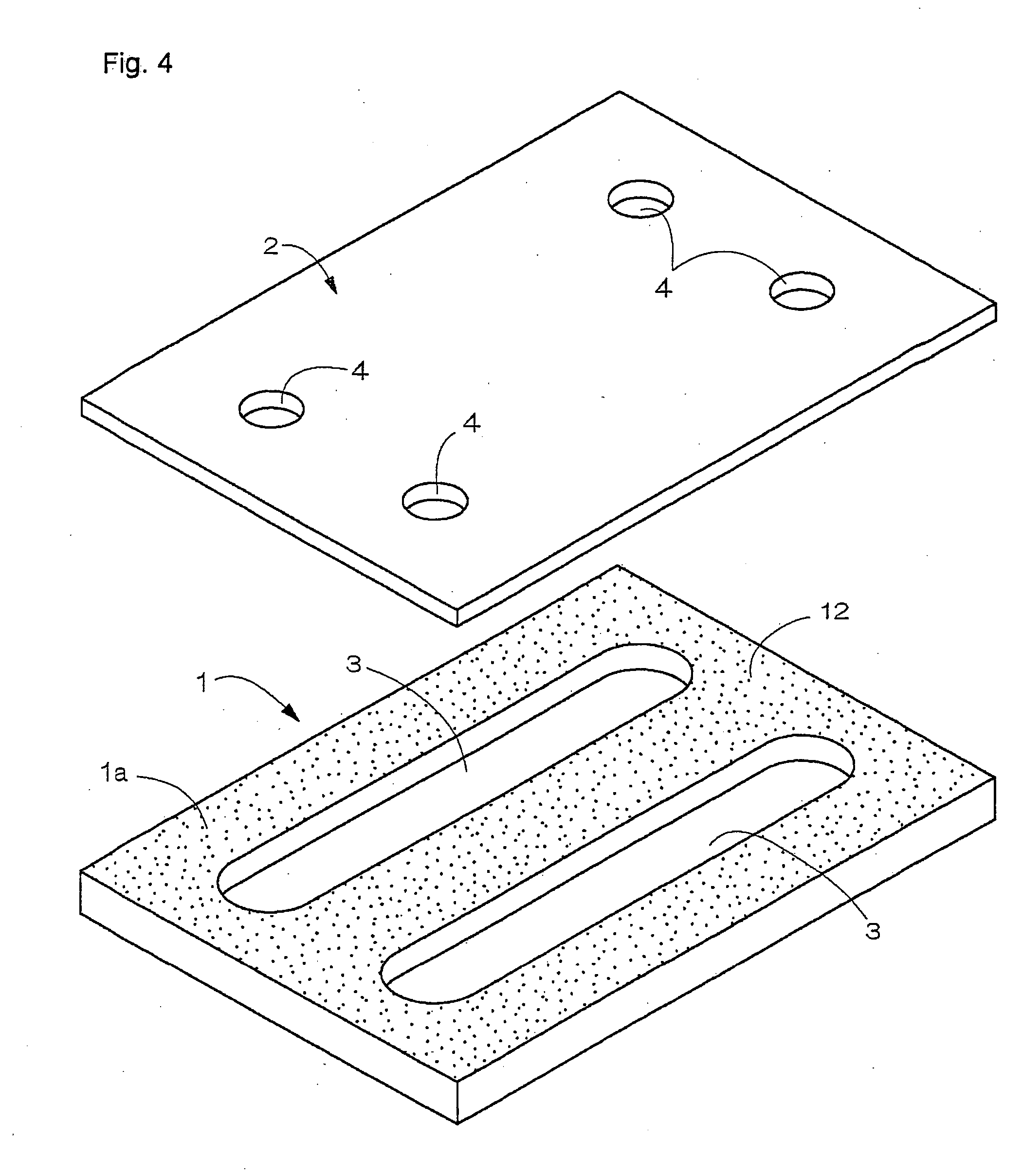

Fluid vessel

InactiveUS20050272142A1Occupies spaceLow production costBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMechanical engineering

A fluid vessel includes a base member in the form of a plate of which one surface has a concave channel and a cover plate which is bonded to the base plate so as to close an opening surface of the channel. The base member and the cover plate are bonded through a double-faced adhesive sheet. The double-faced adhesive sheet has an opening which corresponds to a formation pattern of the channel. The double-faced adhesive sheet includes a flat and smooth sheet substrate which is made of a plastic sheet having a chemical resistance as well as adhesive layers which are laminated onto both surfaces of the sheet substrate. In a state in which the cover plate is bonded to the base member, a space between the cover plate and a periphery of the channel opening is filled with an inner peripheral wall portion which defines the opening of the double-faced adhesive sheet.

Owner:HITACHT MAXELL LTD

Film with outer layer composed of a polyamide composition

InactiveUS20070104971A1Layered product treatmentSynthetic resin layered productsPolymer sciencePolyamide

A decorative film having an outer layer containing a polyamide composition with the following components: a) from 50 to 100 parts by weight of polyamide prepared from: α) from 70 to 100 mol % of diamine selected from m-xylylenediamine, p-xylylenediamine and mixtures thereof, β) from 0 to 30 mol % of other diamines having from 6 to 14 carbon atoms, and γ) from 70 to 100 mol % of aliphatic dicarboxylic acids having from 10 to 18 carbon atoms and δ) from 0 to 30 mol % of other dicarboxylic acids having from 6 to 9 carbon atoms, and b) from 0 to 50 parts by weight of another polyamide, where a) and b) total 100, having good chemicals resistance, good stress cracking resistance, improved scratch resistance, and improved gloss.

Owner:EVONIK DEGUSSA GMBH

Coating composition, process for preparing coating composition and process for preparing dispersing component of inorganic oxide sol

InactiveUS6022919AGood weather resistanceLow appearance requirementsSpecial tyresMixingMeth-Acrylonitrile

A coating composition which comprises (A) a resin having a glass transition temperature of 50 to 120 DEG C., a number average molecular weight of 2,000 to 100,000, a hydroxyl value of 50 to 150 mgKOH / g and an acid value of 1 to 25 mgKOH / g, which is produced by copolymerizing 10 to 90 percent by weight of (a) a (meth)acrylic acid ester of a C1 to C12 alkyl alcohol, 10 to 50 weight % of (b) a first polymerizable double bond-containing and hydroxyl group-containing monomer, 0.1 to 10 weight % of (c) a polymerizable double bond-containing and carboxyl group-containing monomer, 0 to 20 weight % of (d) styrene, 0 to 20 weight % of (e) acrylonitrile and 0 to 10 weight of (f) a second polymerizable double bond-containing monomer, (B) at least one compound selected from the group consisting of a polyisocyanate compound having two or more unblocked isocyanate groups and / or blocked isocyanate groups in the molecule and an aminoplast resin, (C) a dispersing component of at least one inorganic oxide sol selected from the group consisting of an aluminum oxide sol, a silica sol, a zirconium oxide sol and an antimony oxide sol, wherein an amount of a nonvolatile matter of component (C) is 5 to 60 percent by weight based on a total amount of nonvolatile matter of resin (A), compound (B) and component (C). The coating composition provides cured films having excellent weathering resistance, light resistance, stain resistance, stain-removing property, chemical resistance, moisture resistance and appearance and is environmentally friendly and safe.

Owner:BASF NOF COATINGS CO LTD

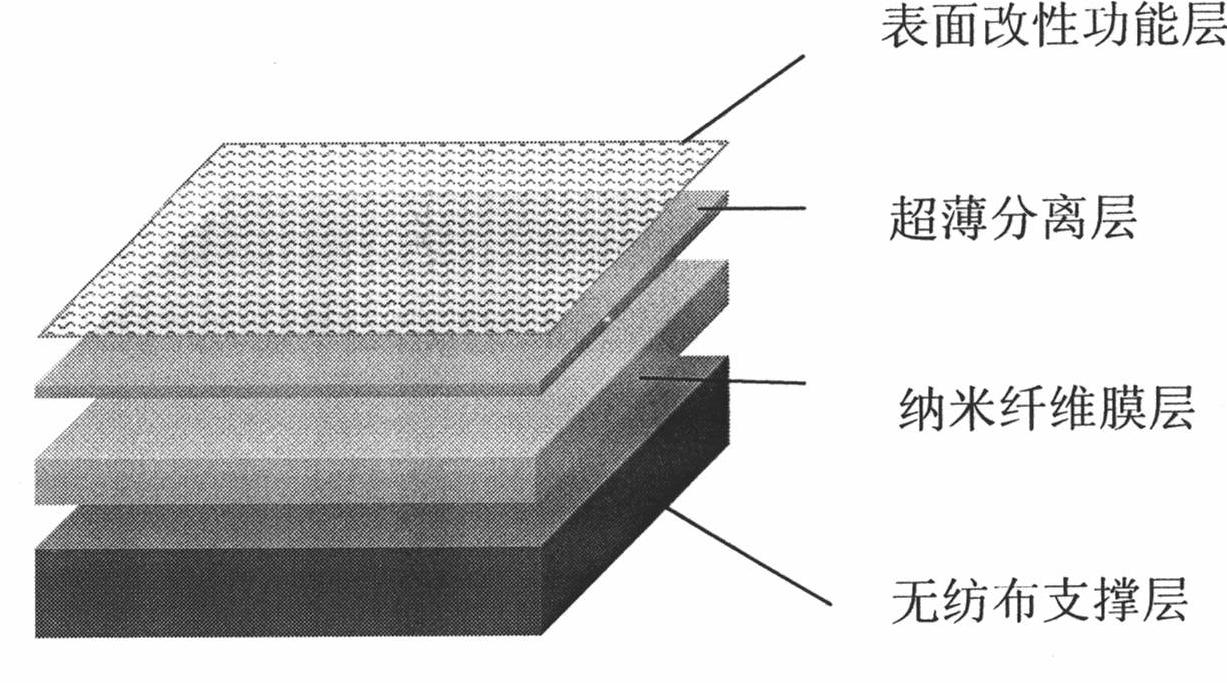

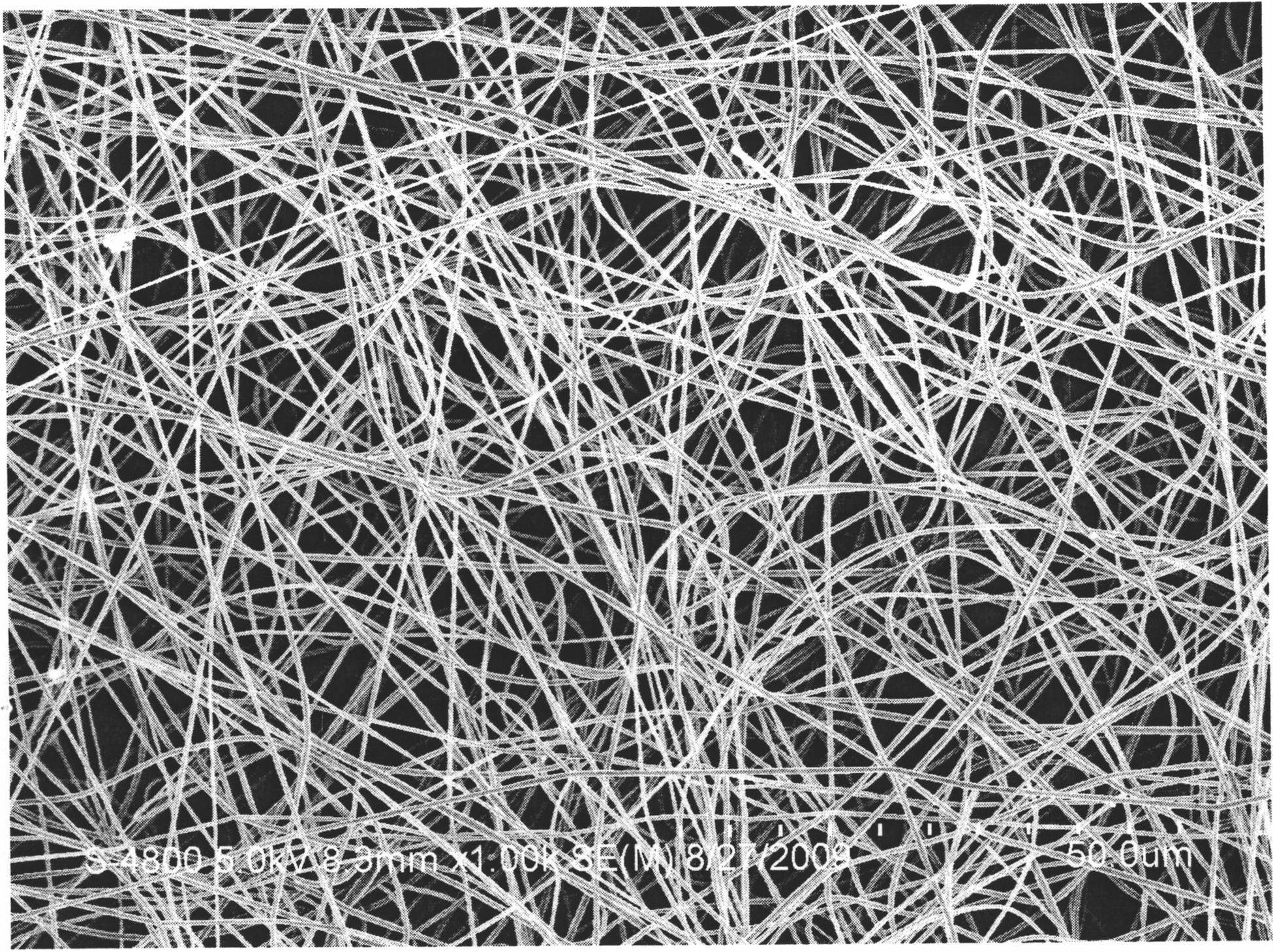

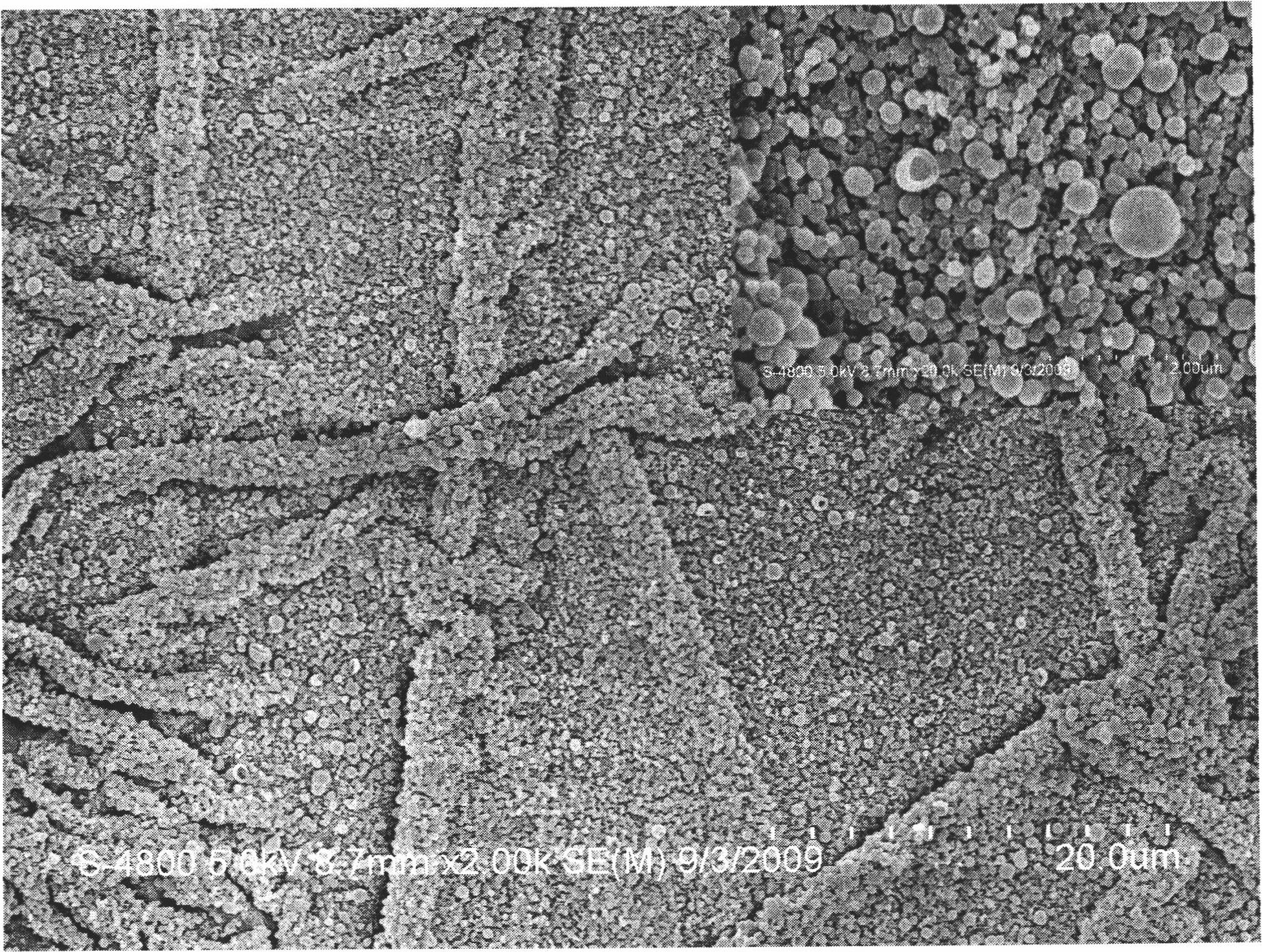

Hyperfiltration membrane or nanofiltration membrane with multi-layered composite structure and preparation method thereof

InactiveCN102139187AIncrease water fluxHigh retention rateSemi-permeable membranesEnvironmental resistanceHydrophilic polymers

The invention relates to a hyperfiltration membrane or nanofiltration membrane with a multi-layered composite structure and a preparation method thereof. The hyperfiltration membrane or nanofiltration membrane is a polymer electrostatic spinning nanofiber membrane layer characterized in strong chemical resistance prepared through an electrostatic spinning method, a hydrophilic polymer ultra-thin separation layer obtained through interfacial polymerization, and a functional group surface modification functional layer formed through the grafting reaction of reactant gases on the surfaces of hydrophilic polymers, or a long-chain polymer surface modification functional layer formed through the grafting reaction of the reaction gases on the surfaces of the hydrophilic polymers, or a functionalgroup-containing long-chain polymer surface modification functional layer through the grafting reaction of the reaction gases with the functional groups on the surfaces of the hydrophilic polymers. The hyperfiltration membrane or nanofiltration membrane with the multi-layered composite structure has the advantages of high water flux, high cutting rate and stable chemical performances. The filtration membrane can be used for the production of domestic water, drinking water or water in special conditions, and is suitable for the medical field, food field, environmental protection field and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com