Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

349results about How to "Reduced adhesion strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

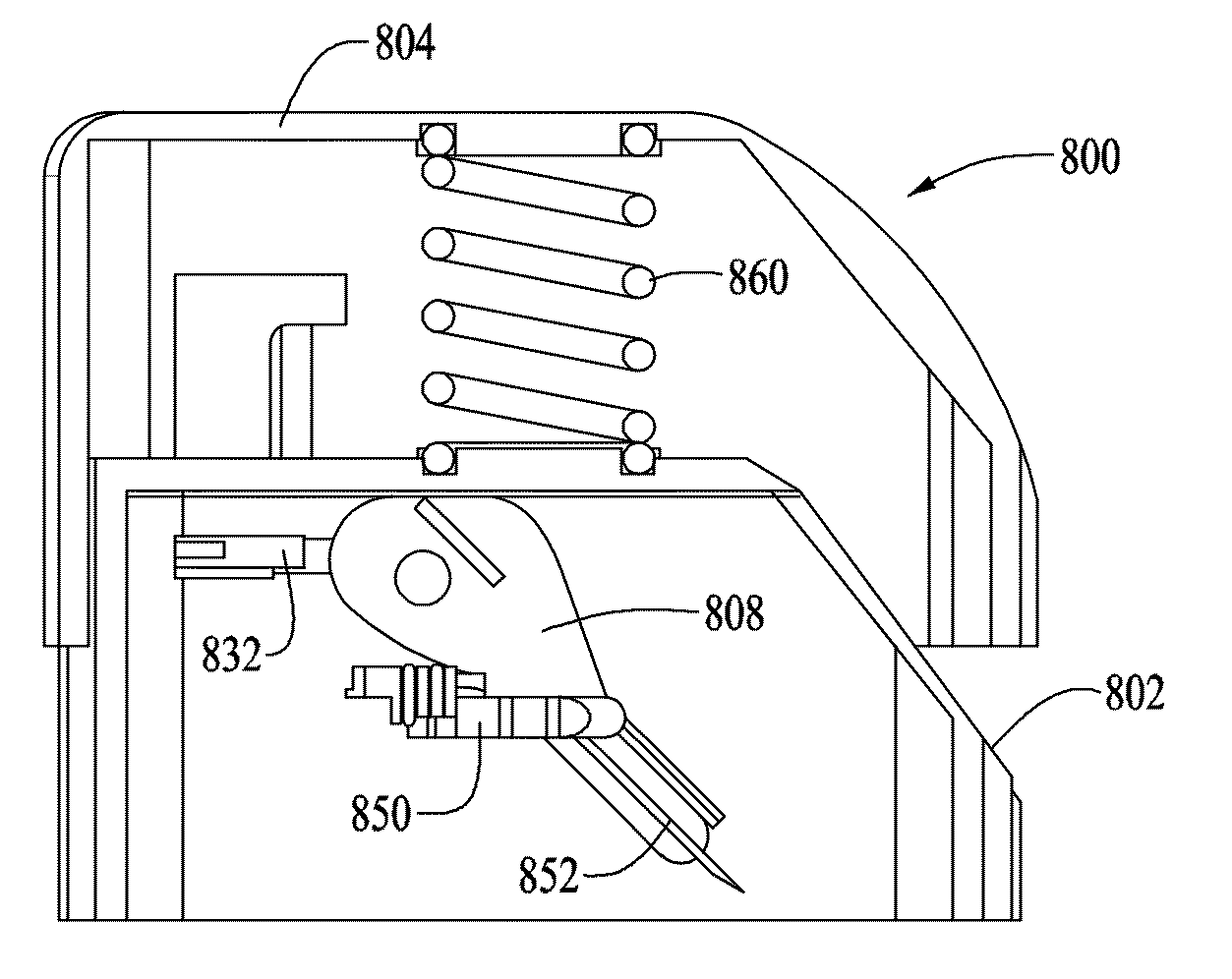

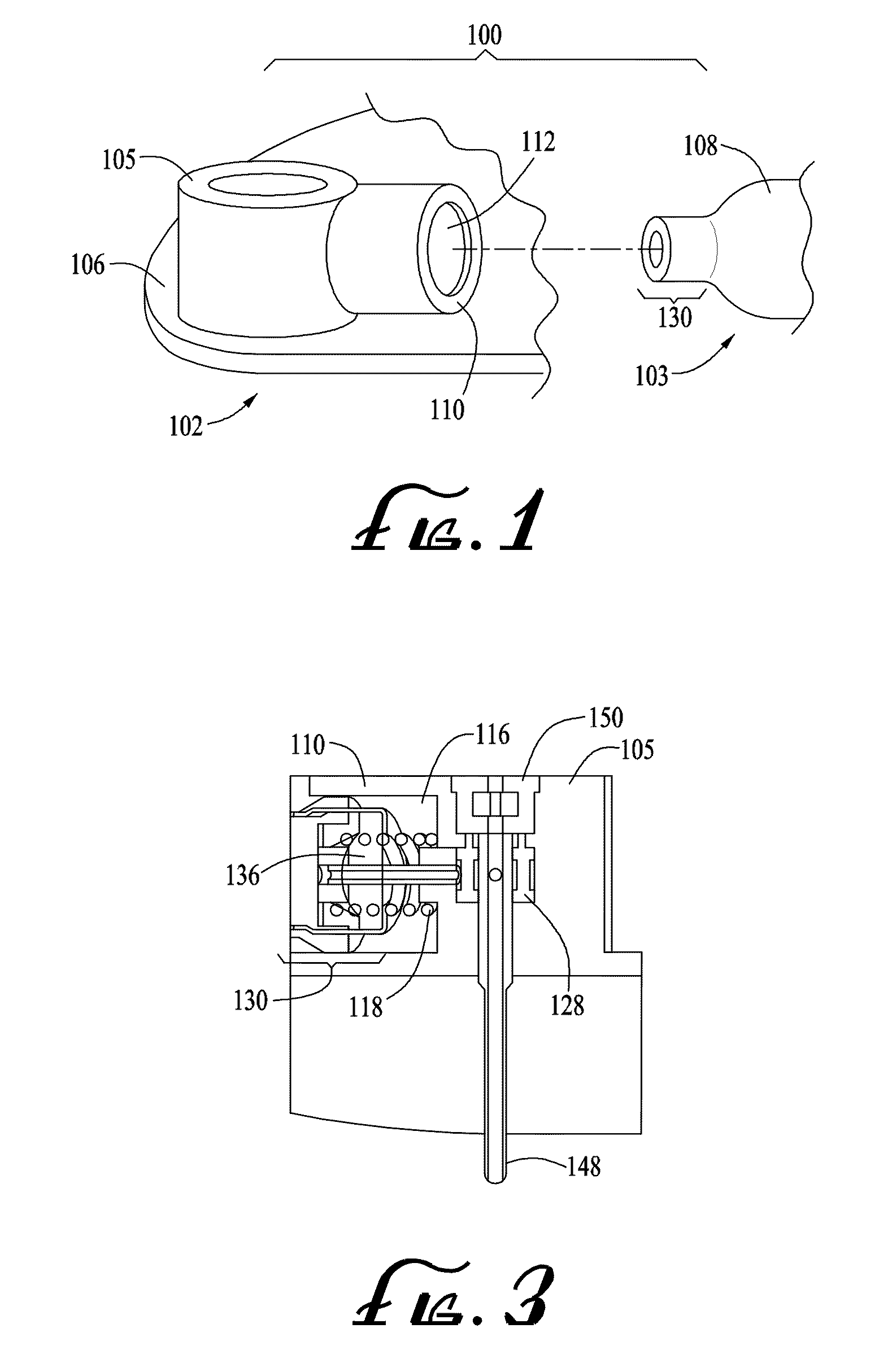

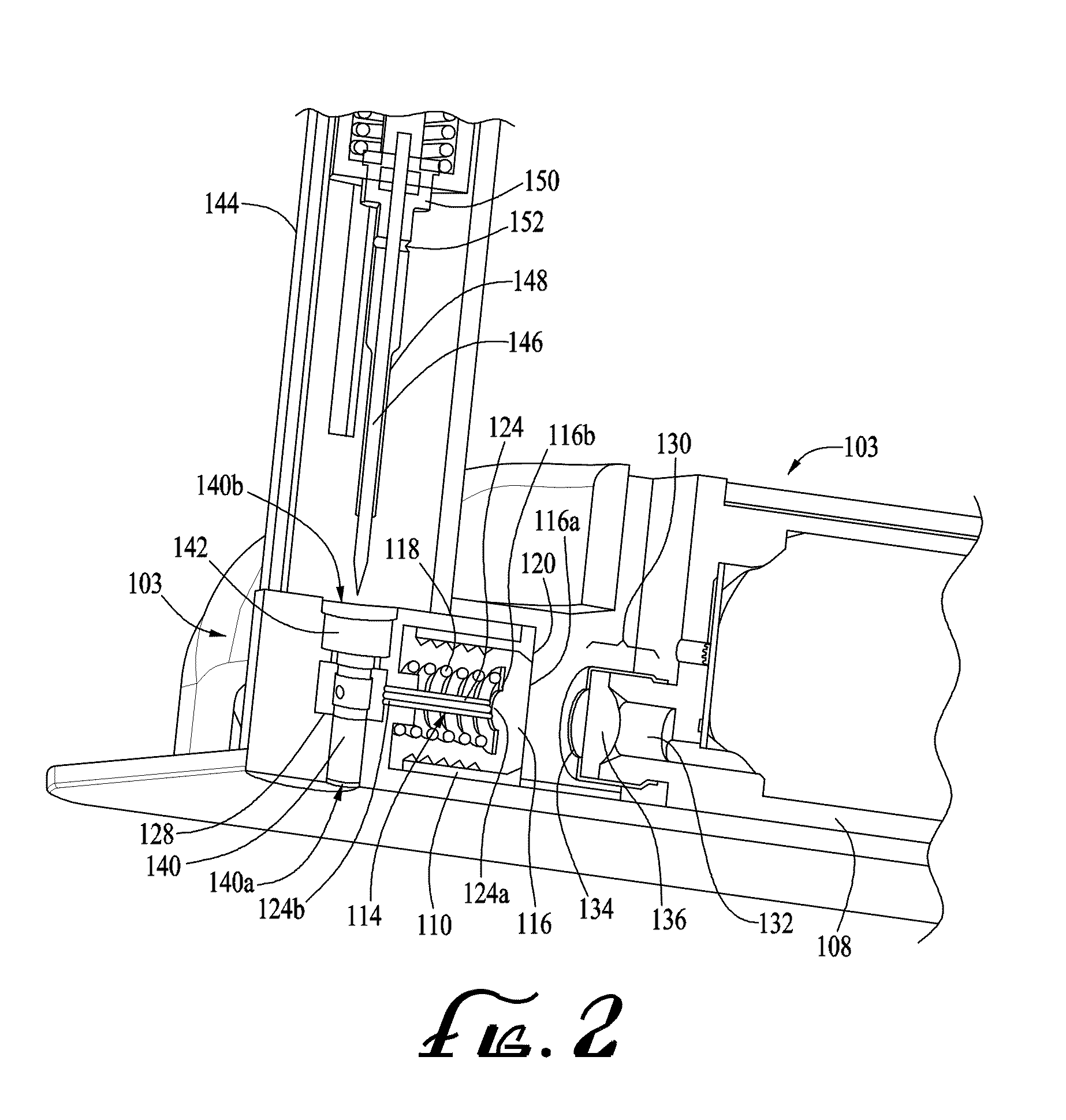

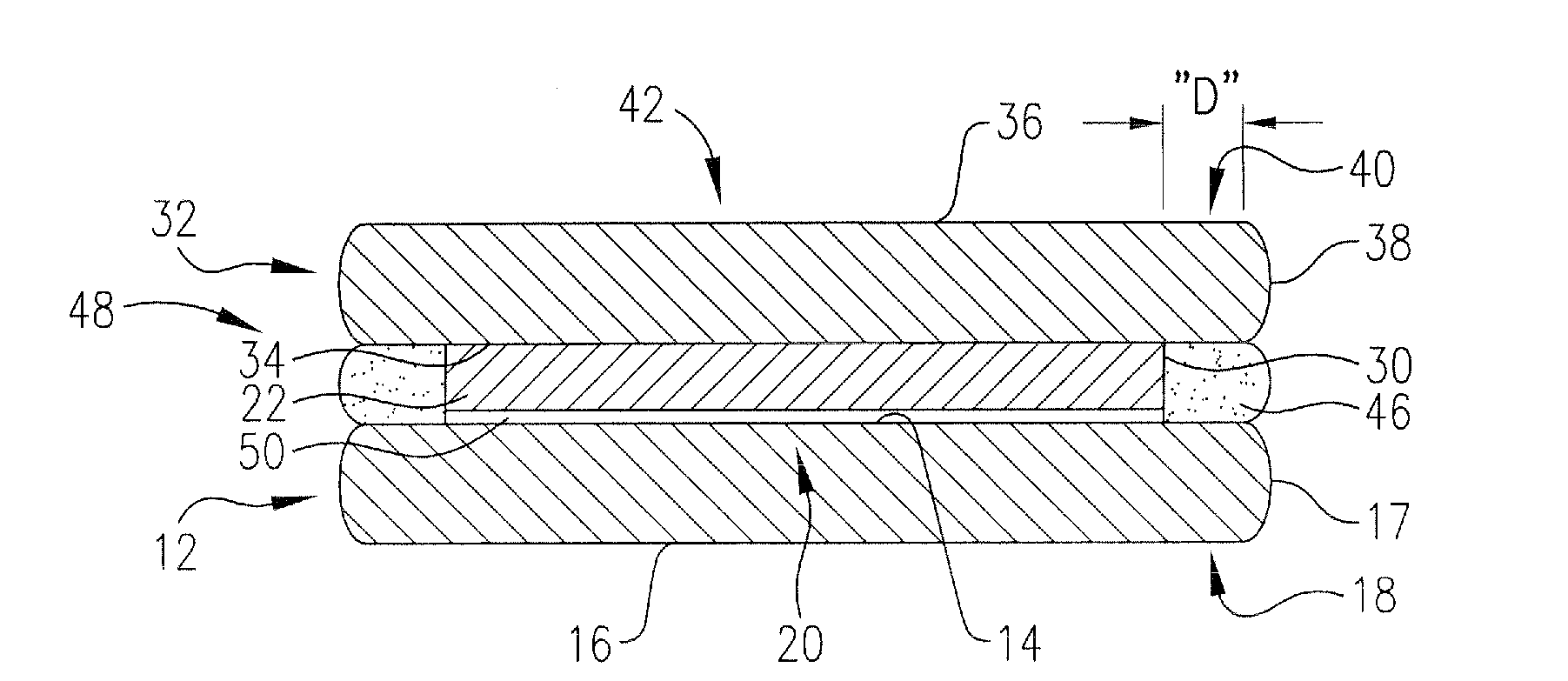

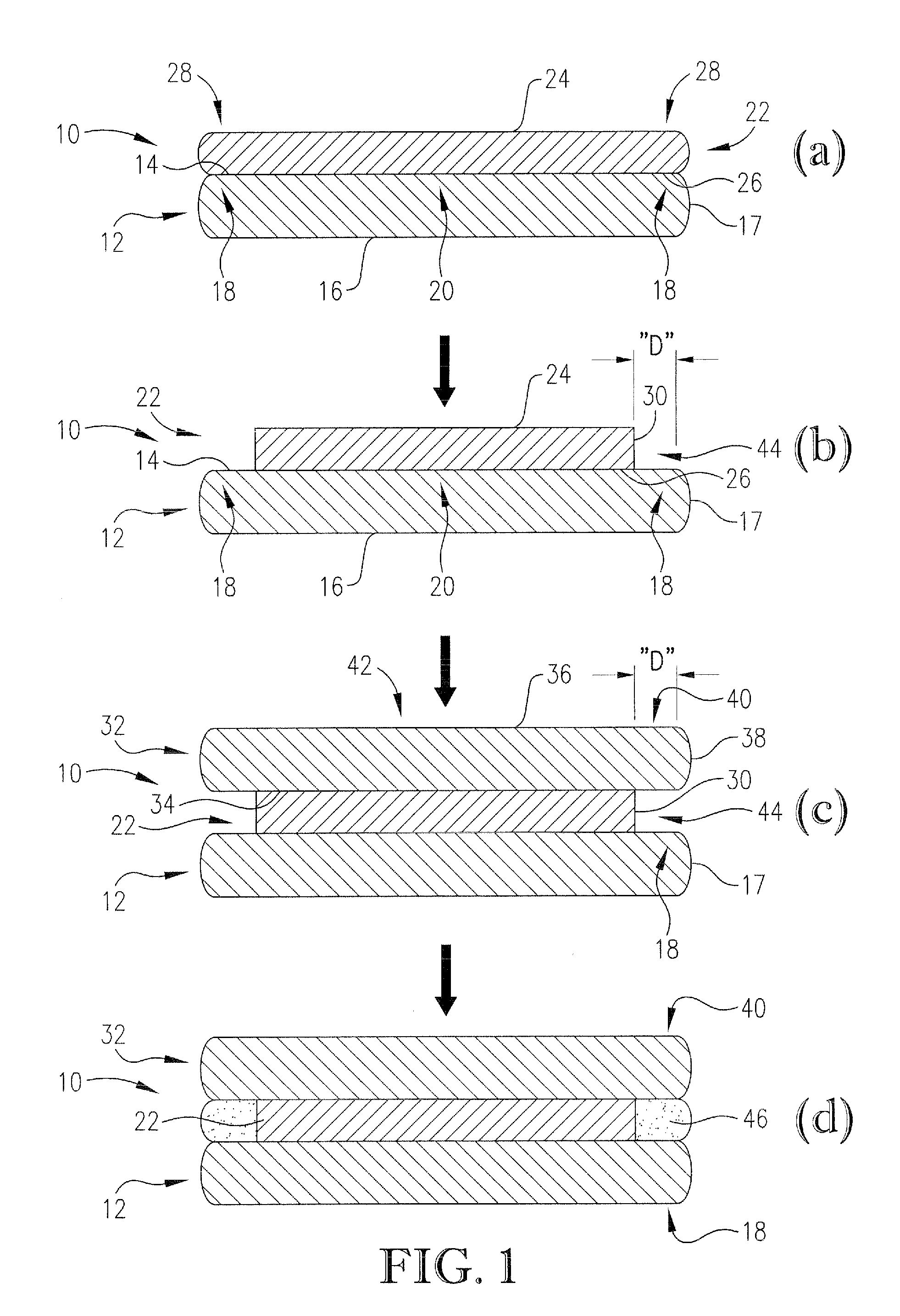

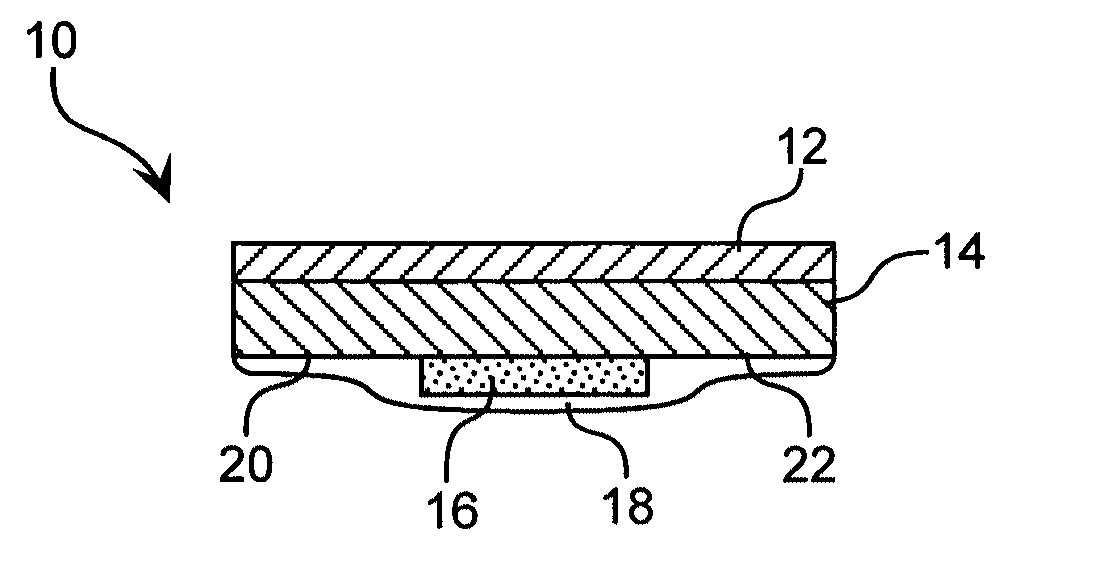

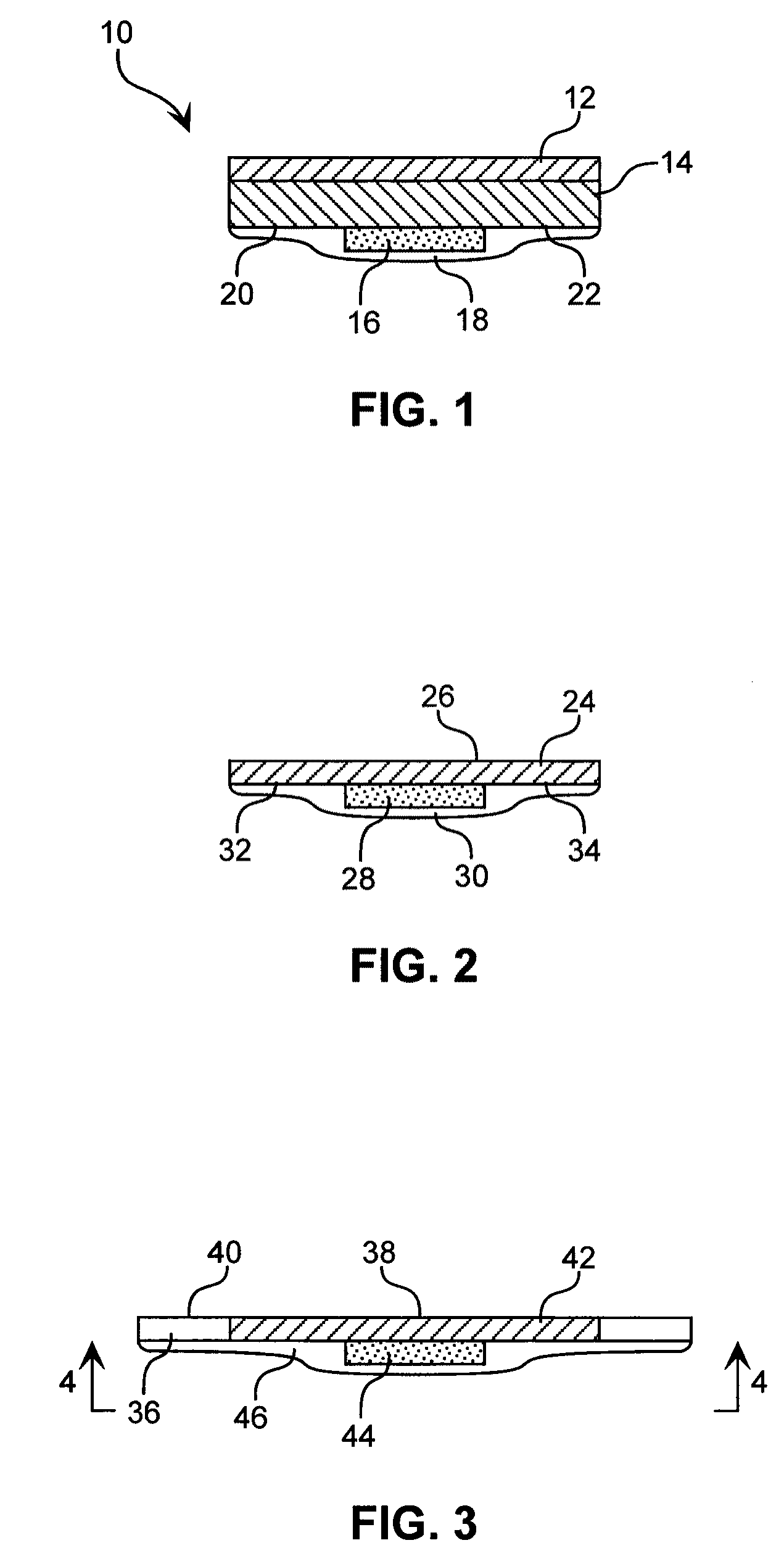

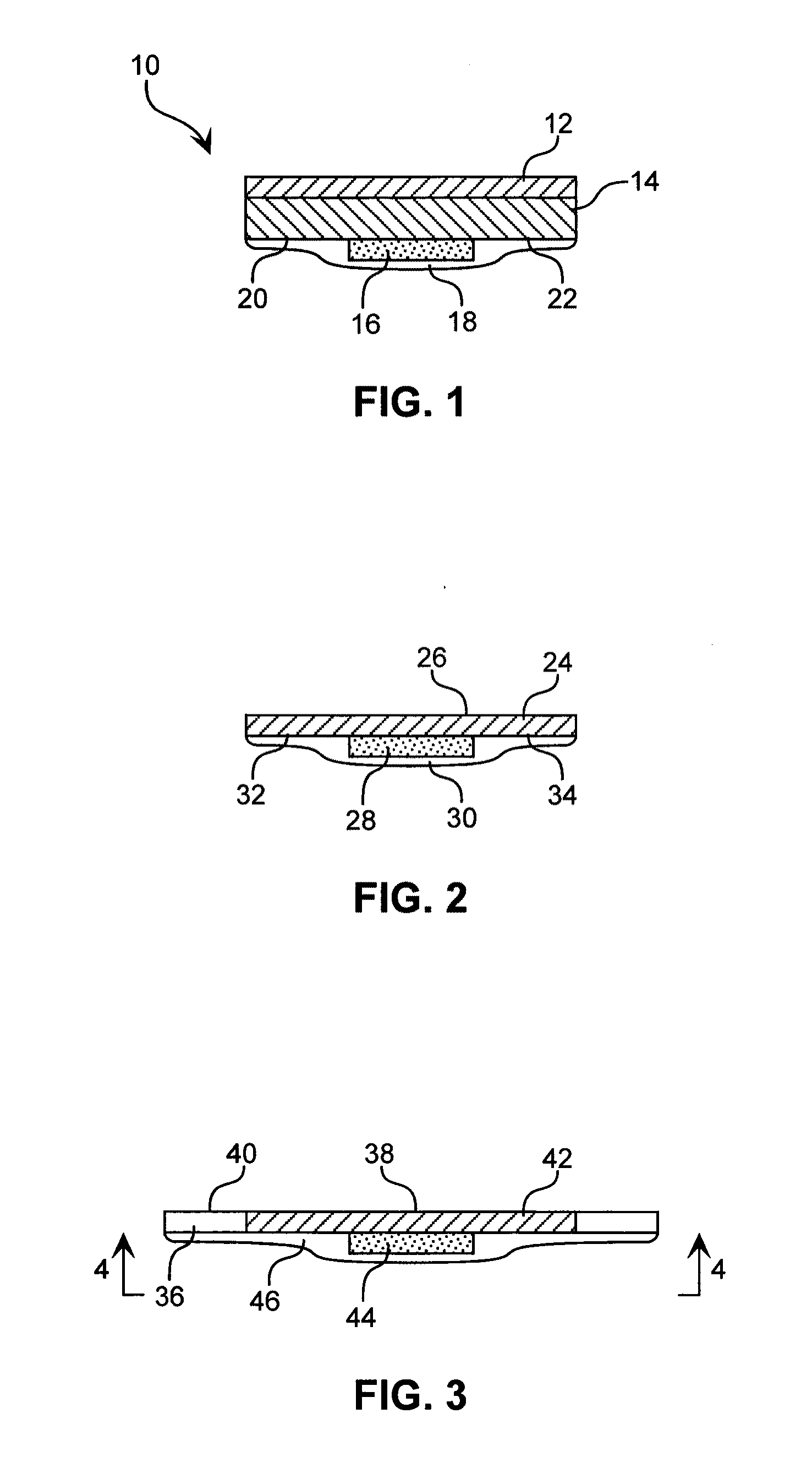

Adhesive patch systems and methods

ActiveUS20090198215A1High bonding strengthReduced adhesion strengthInfusion syringesFiltering accessoriesUltimate tensile strengthAdhesion strength

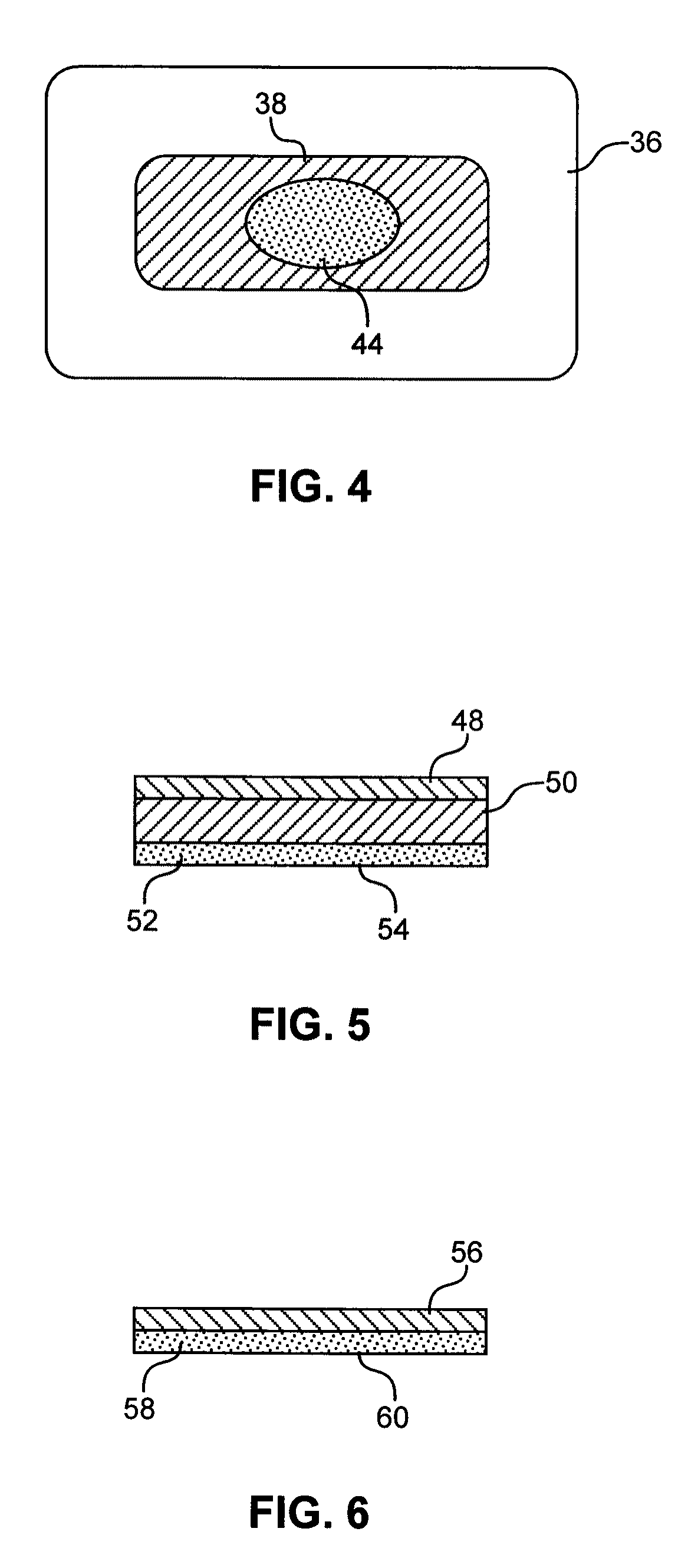

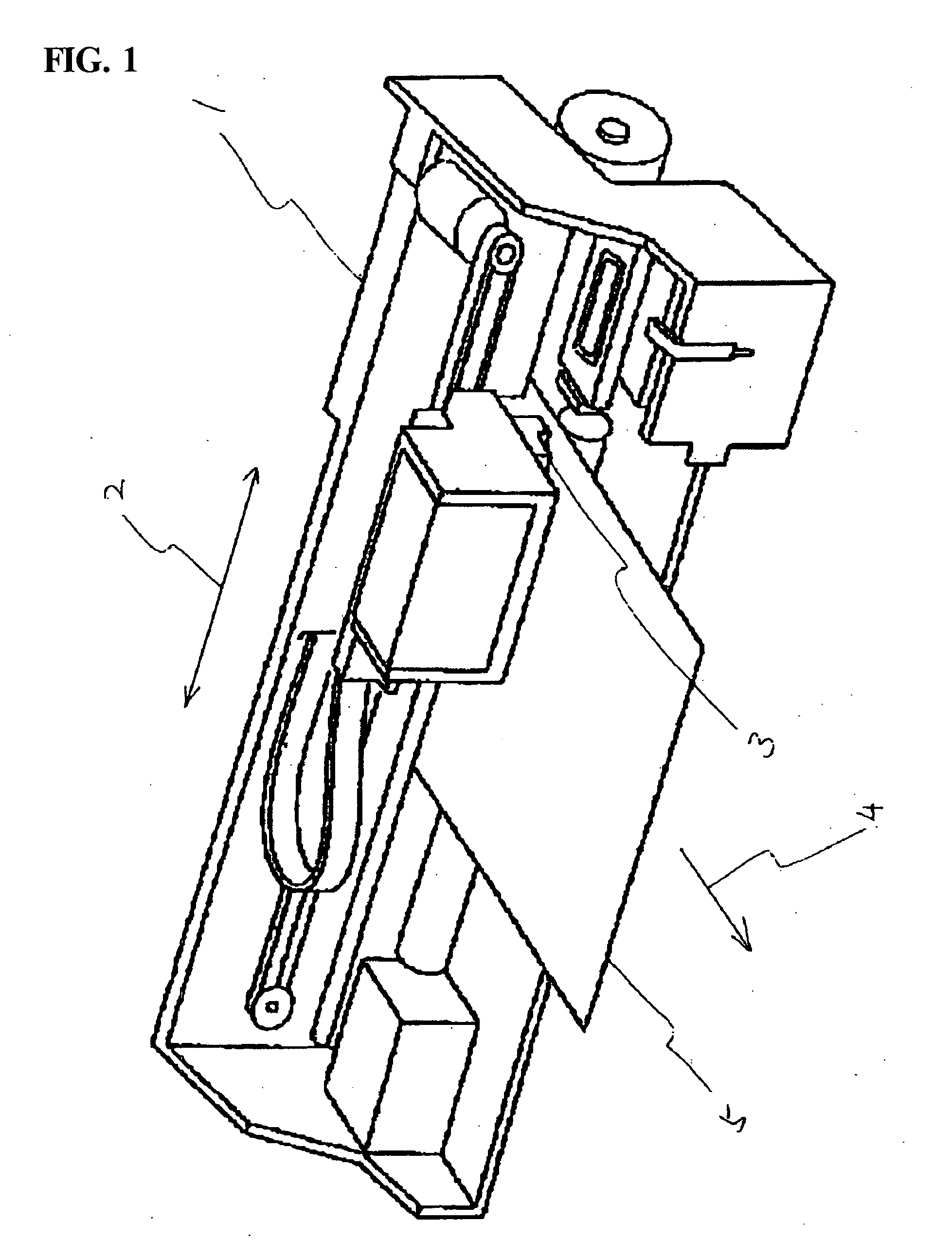

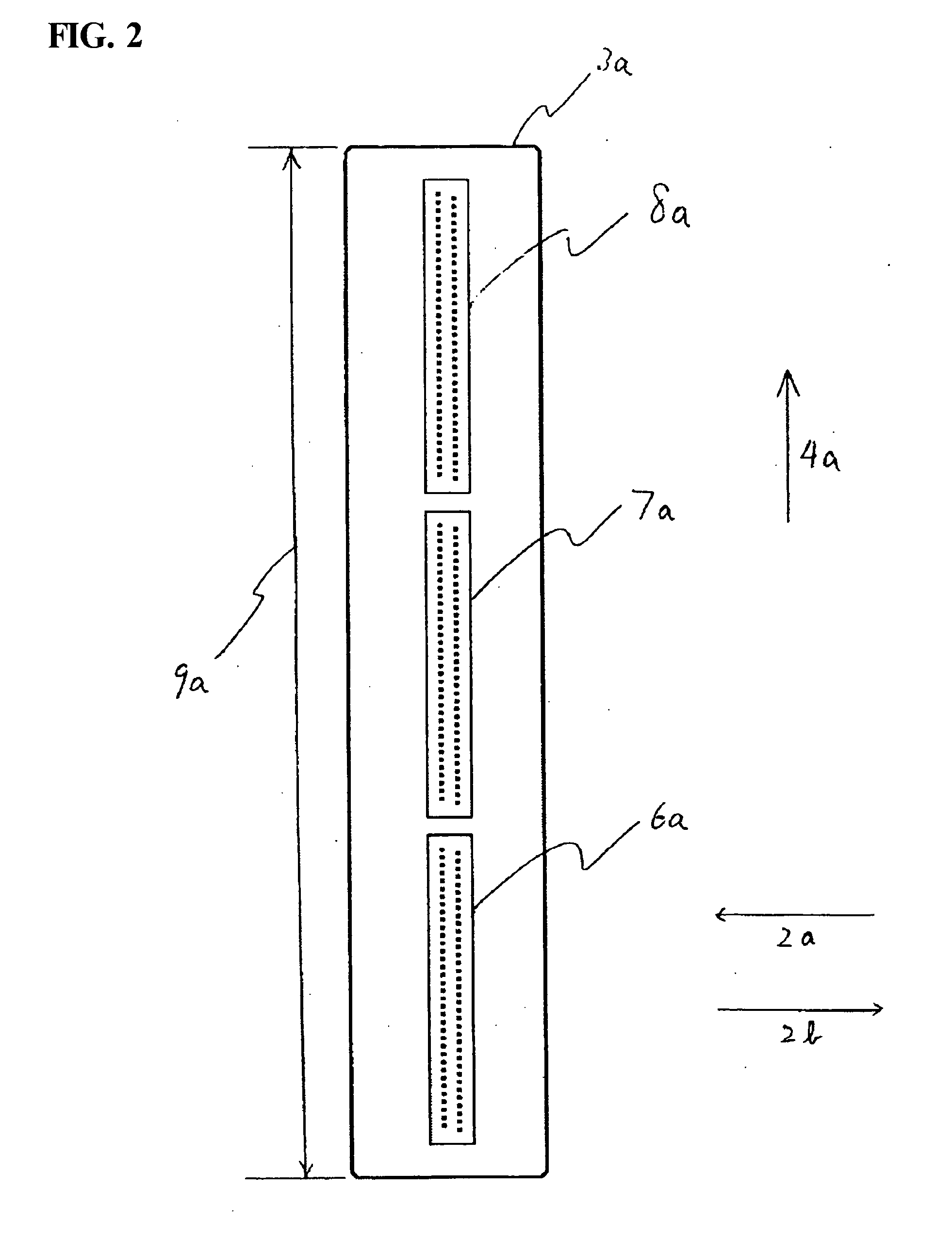

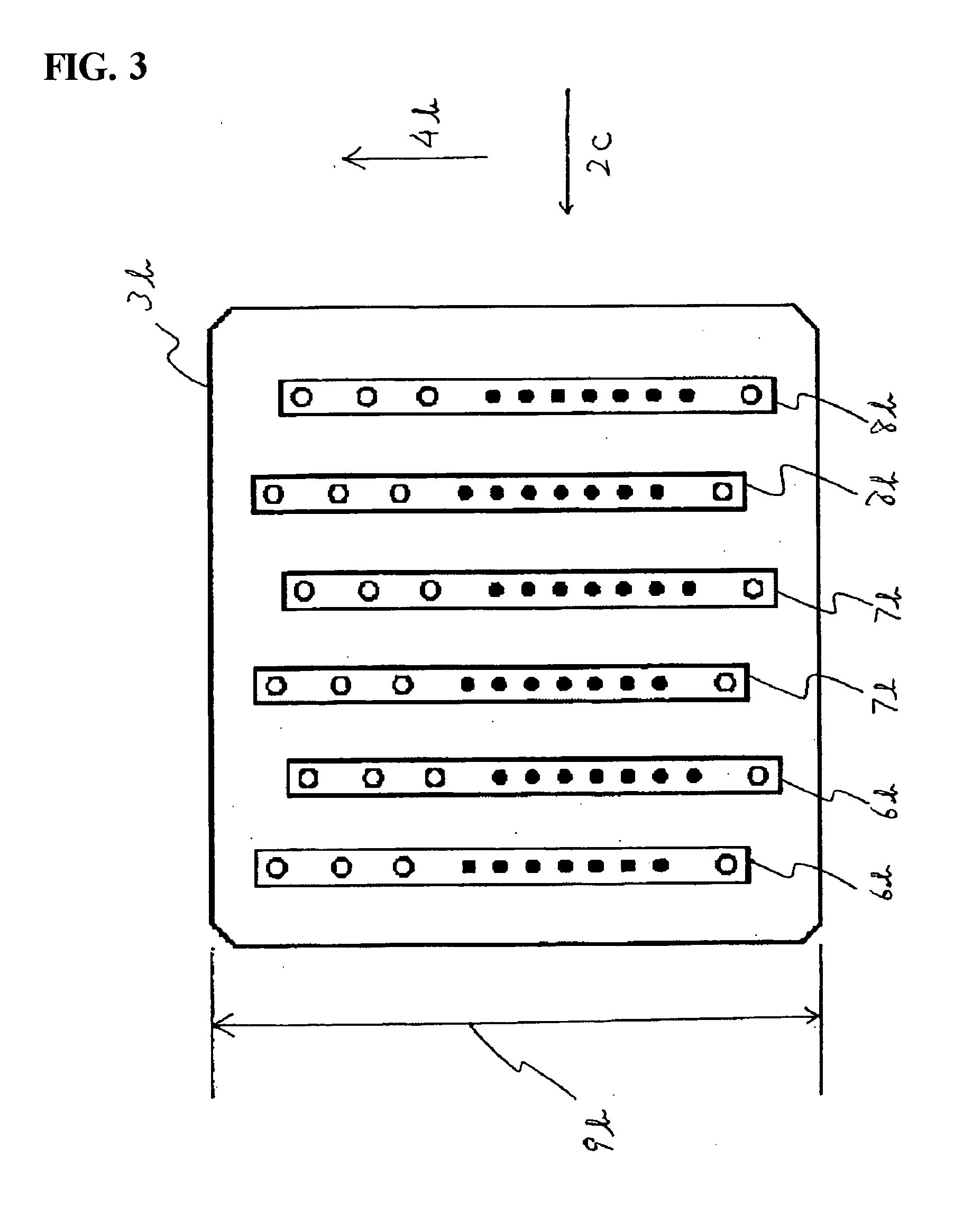

Various embodiments of the present invention are directed to patches for medical devices. In various embodiments, an adhesive patch of a medical device may have selective areas with adhesive material of varying adhesion strengths. In other embodiments, an adhesive patch of a medical device may include adhesive material that may be activated by a catalyst to increase or decrease the adhesion strength of the adhesive material. In further embodiments, a medical device may include a pierceable membrane containing an agent, the pierceable membrane positioned to be pierced by a needle and to cause some of the agent to be carried to the user-patient.

Owner:MEDTRONIC MIMIMED INC

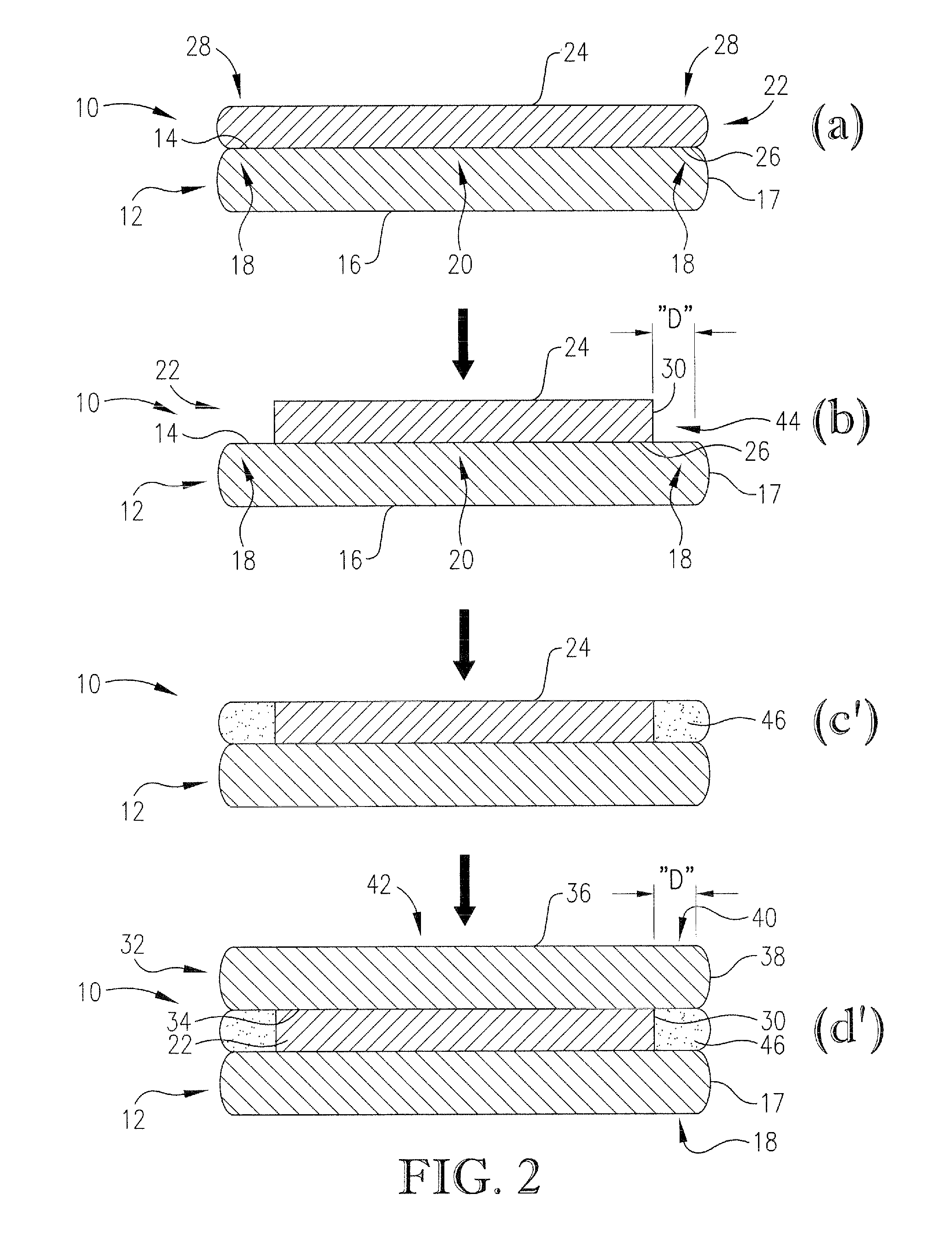

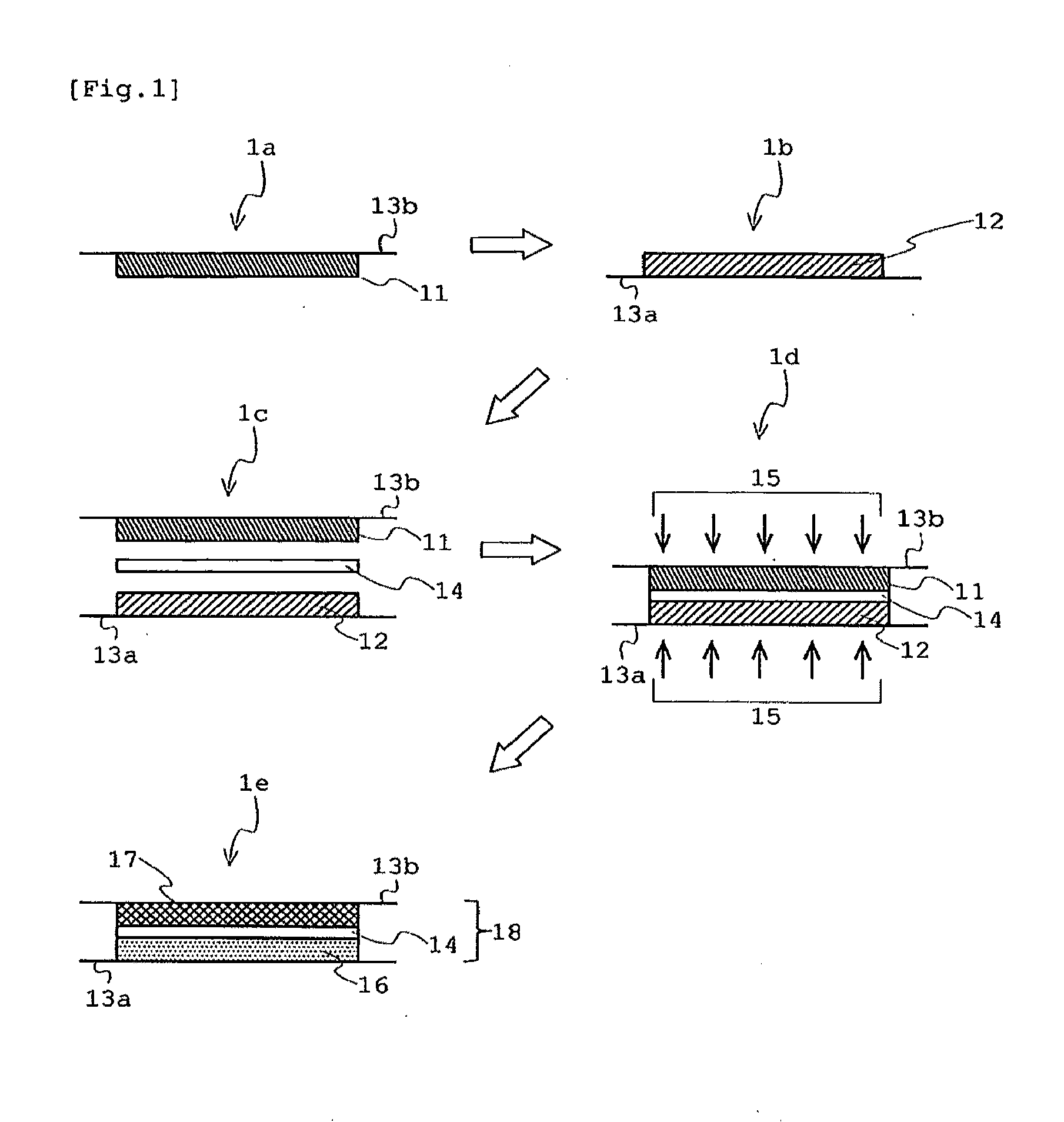

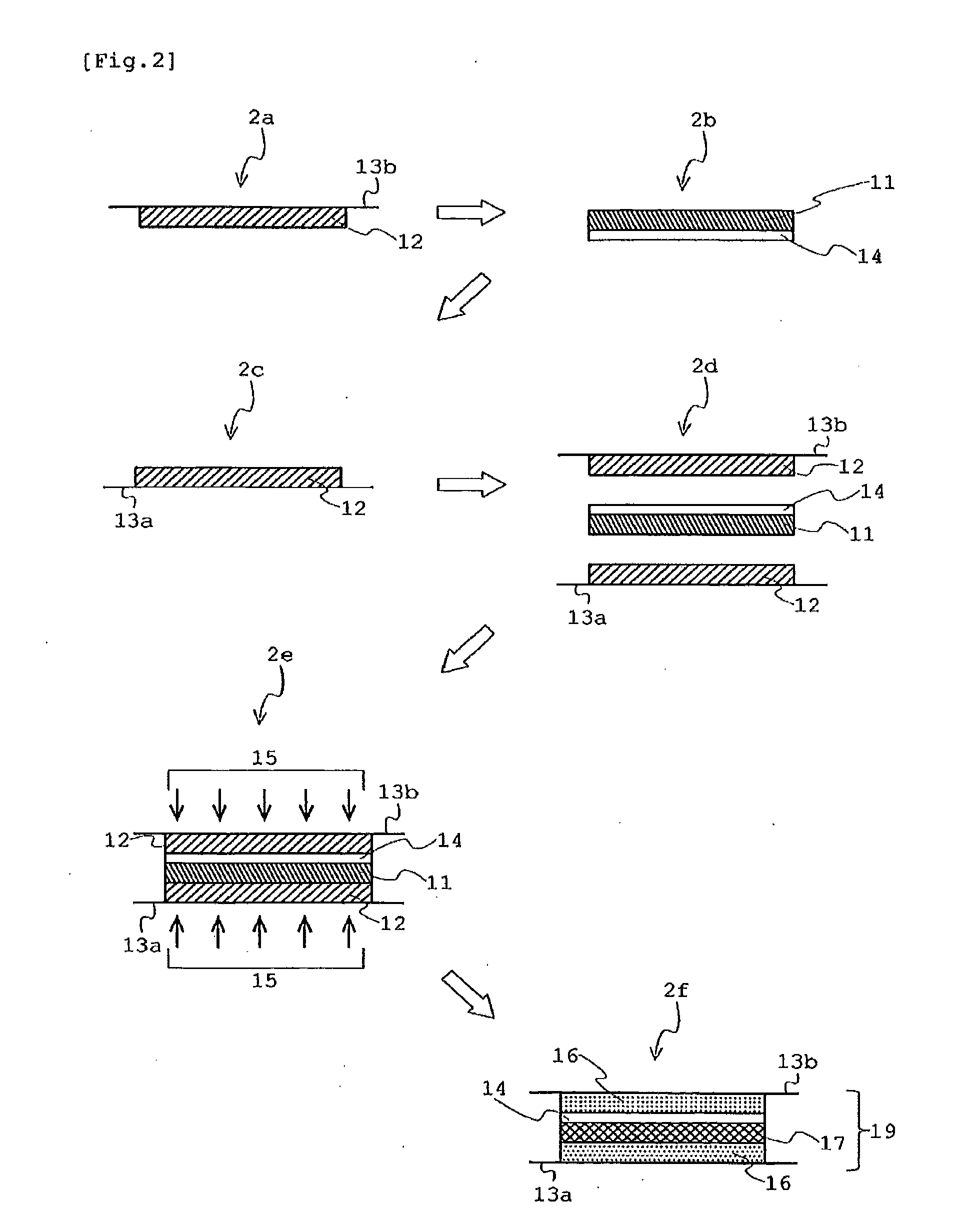

Method for reversibly mounting a device wafer to a carrier substrate

ActiveUS20090218560A1Reduced adhesion strengthLamination ancillary operationsSemiconductor/solid-state device detailsHeat resistanceRoom temperature

New temporary bonding methods and articles formed from those methods are provided. The methods comprise bonding a device wafer to a carrier wafer or substrate only at their outer perimeters in order to assist in protecting the device wafer and its device sites during subsequent processing and handling. The edge bonds formed by this method are chemically and thermally resistant, but can also be softened, dissolved, or mechanically disrupted to allow the wafers to be easily separated with very low forces and at or near room temperature at the appropriate stage in the fabrication process.

Owner:BREWER SCI

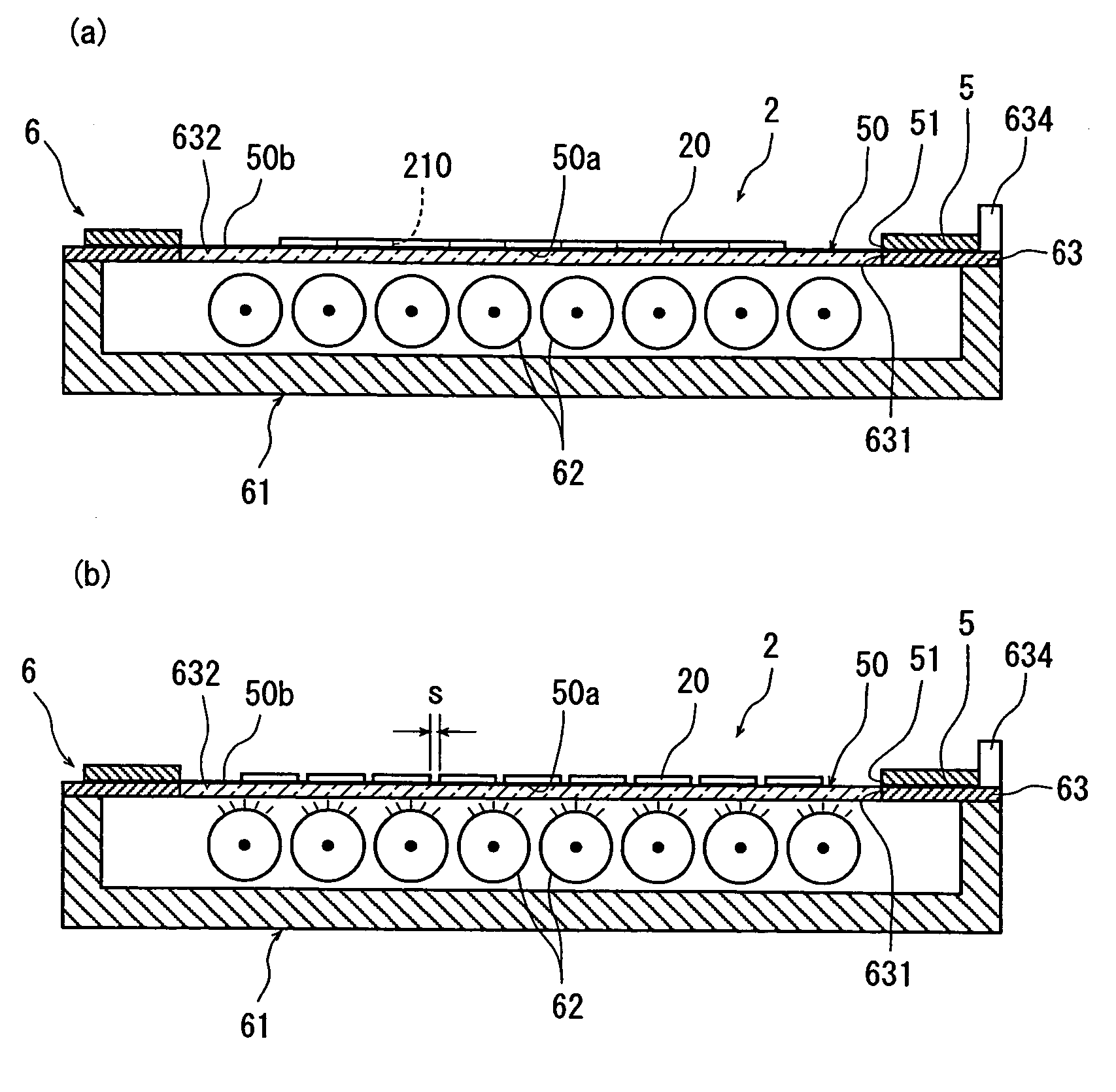

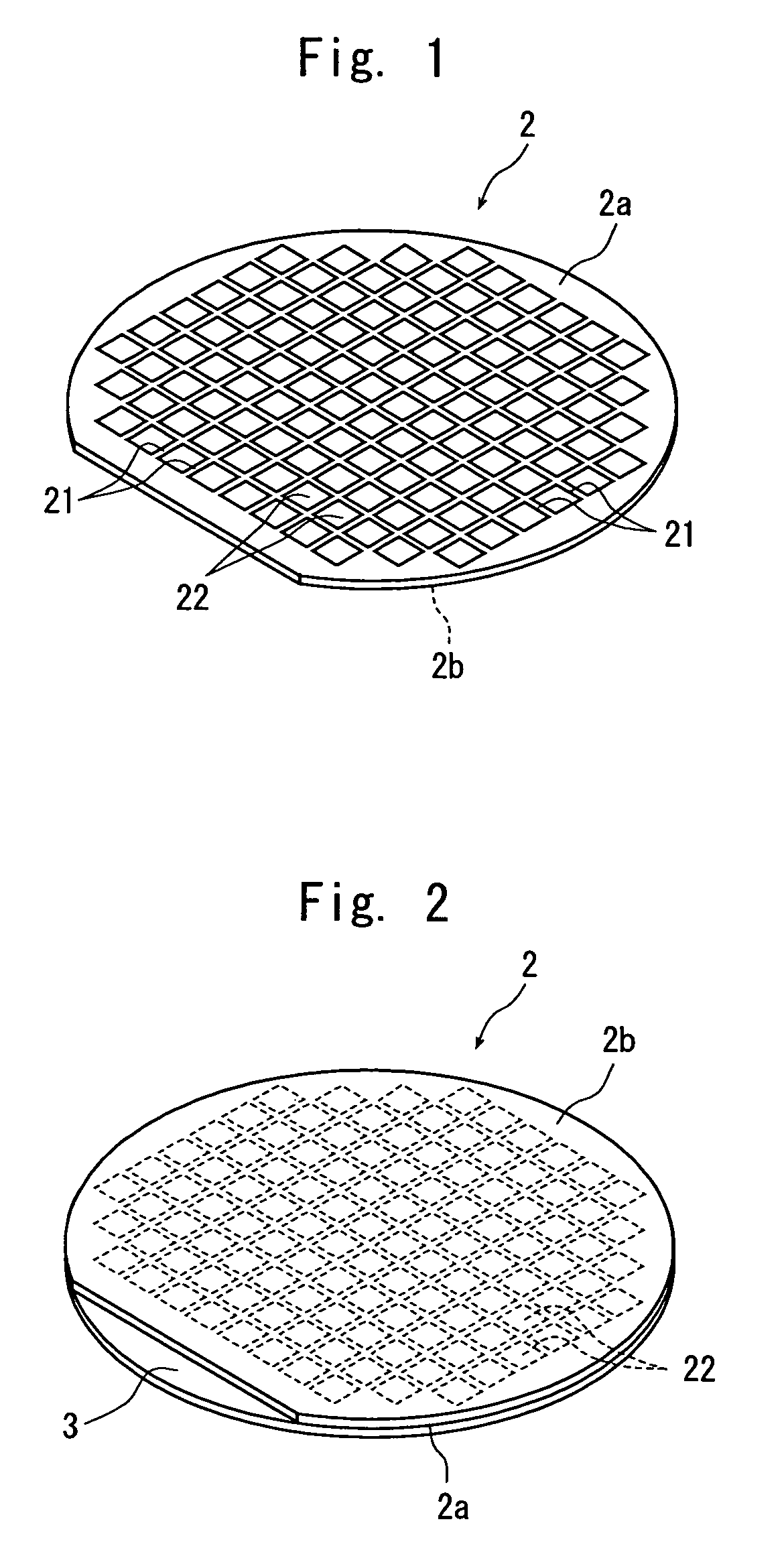

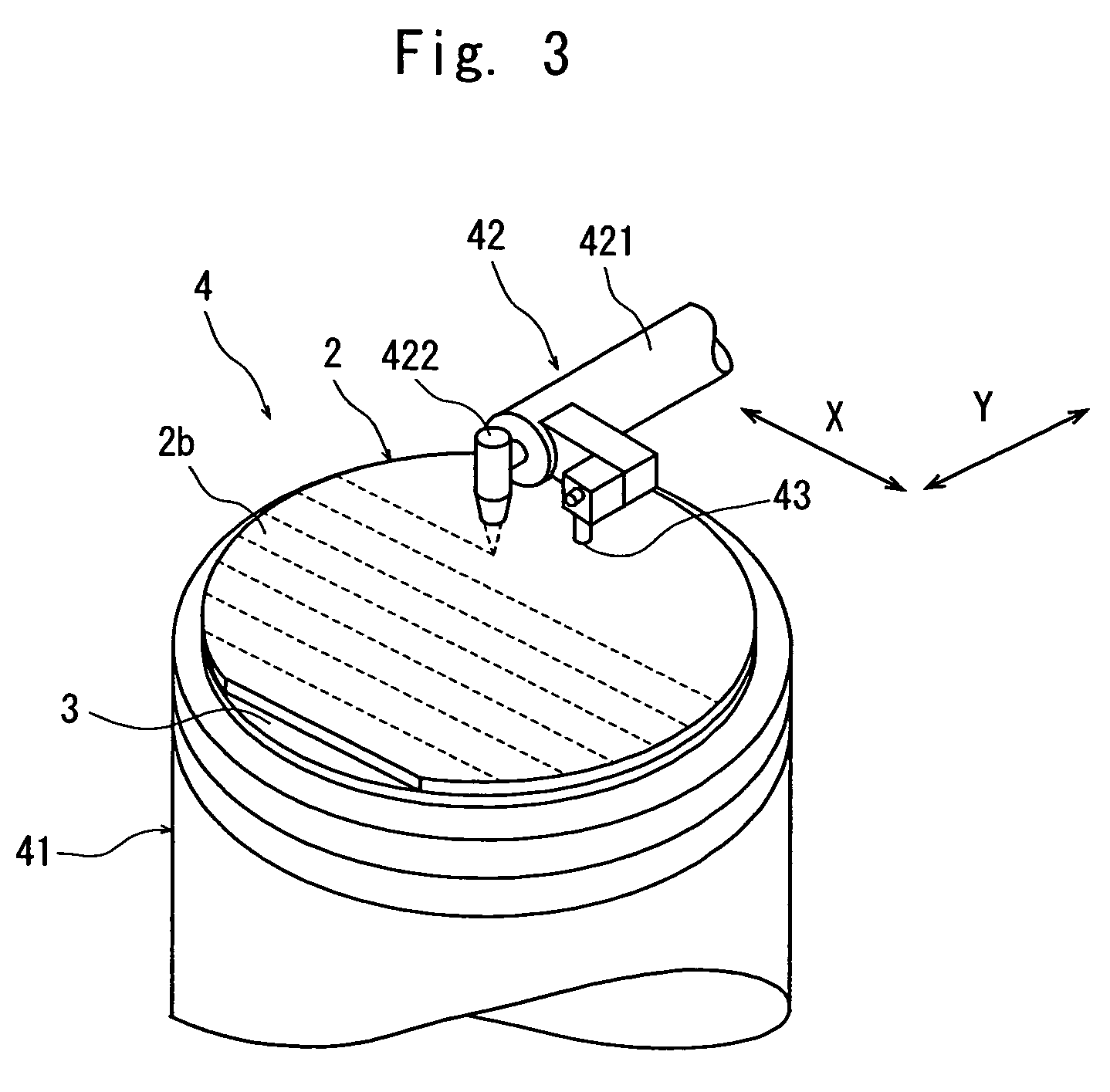

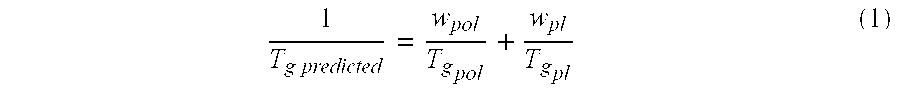

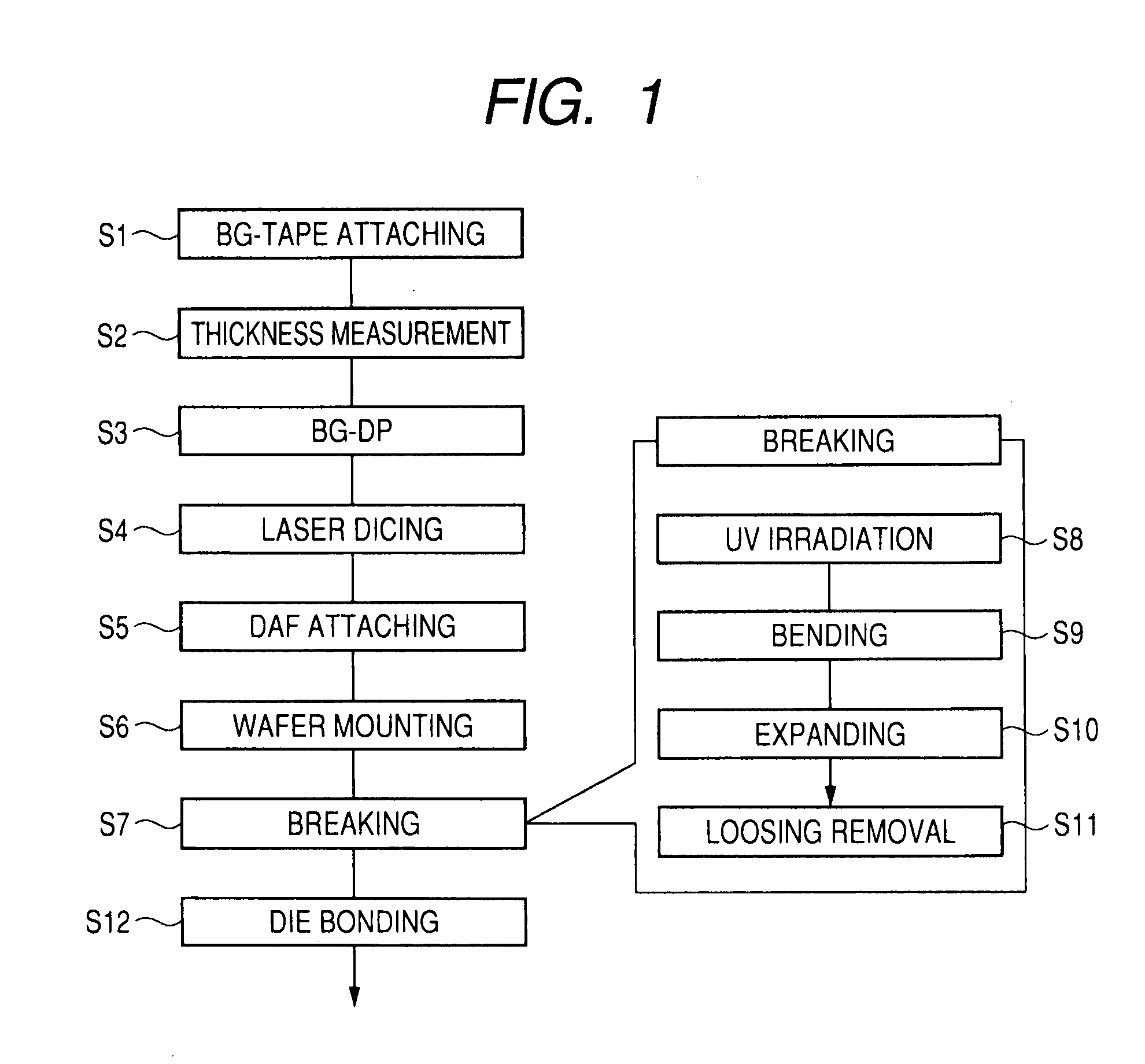

Wafer dividing method

ActiveUS7507639B2Reduced adhesion strengthIncrease spacingSemiconductor/solid-state device manufacturingFine working devicesSplit linesDevice form

A method of dividing a wafer having devices formed in a plurality of areas sectioned by a plurality of dividing lines, into individual chips along the dividing lines, comprising a deteriorated layer forming step for forming a deteriorated layer by applying a laser beam of a wavelength having permeability for the wafer along the dividing lines; a wafer supporting step for putting the rear surface of the wafer on the surface of an adhesive tape which is mounted on an annular frame and whose adhesive strength is reduced by applying ultraviolet radiation thereto; and a chips-spacing forming step for reducing the adhesive strength of the adhesive tape and shrinking a shrink area between the inner periphery of the annular frame and the area to which the wafer has been affixed, of the adhesive tape by applying ultraviolet radiation to the adhesive tape to which the wafer has been affixed so as to divide the wafer into individual chips along the dividing lines where the deteriorated layer has been formed and widen the space between adjacent chips.

Owner:DISCO CORP

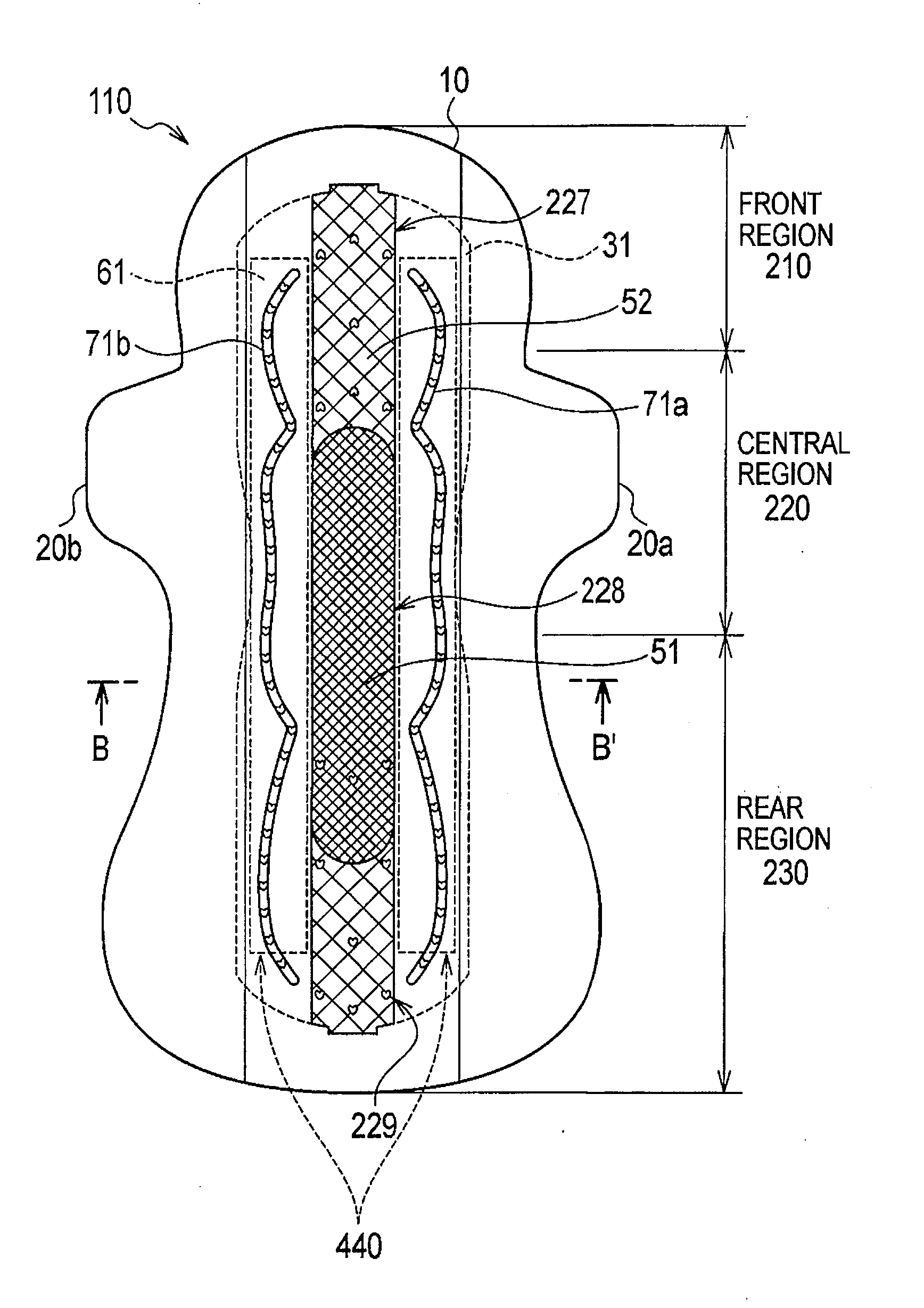

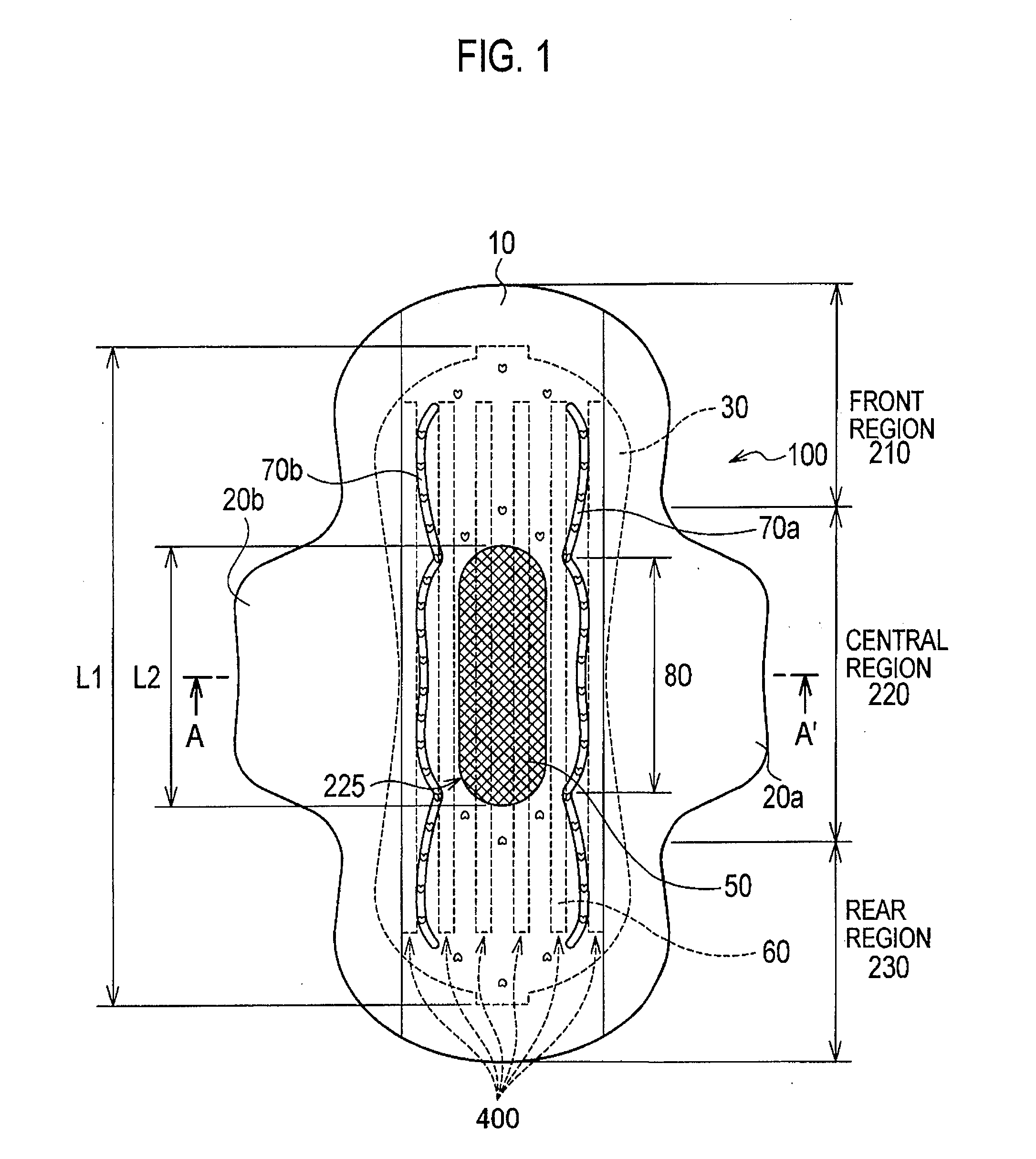

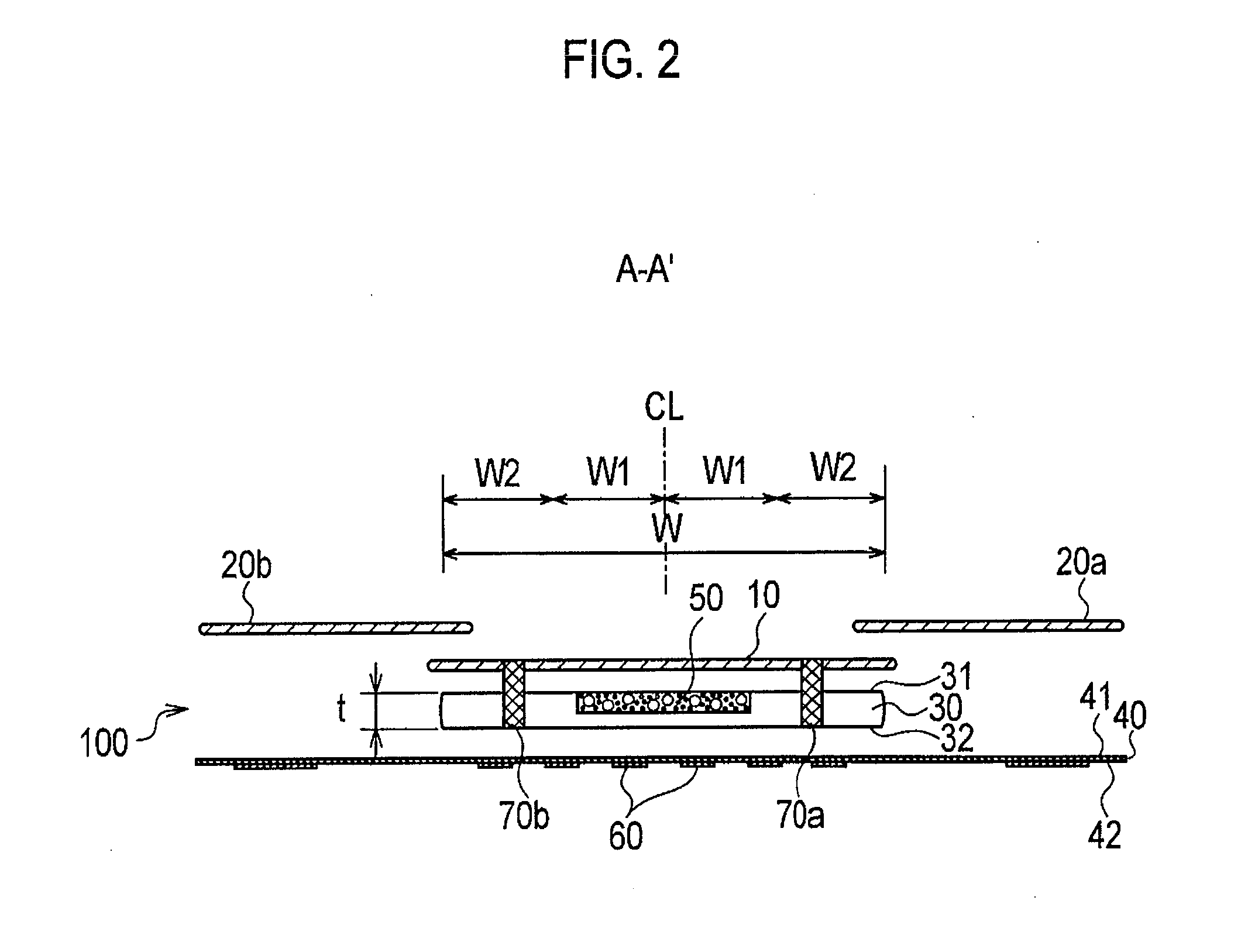

Absorbent article and sanitary napkin

InactiveUS20110144604A1Suppressing stuffinessSuppress stuffinessSanitary towelsBaby linensAdhesiveEngineering

Owner:UNI CHARM CORP

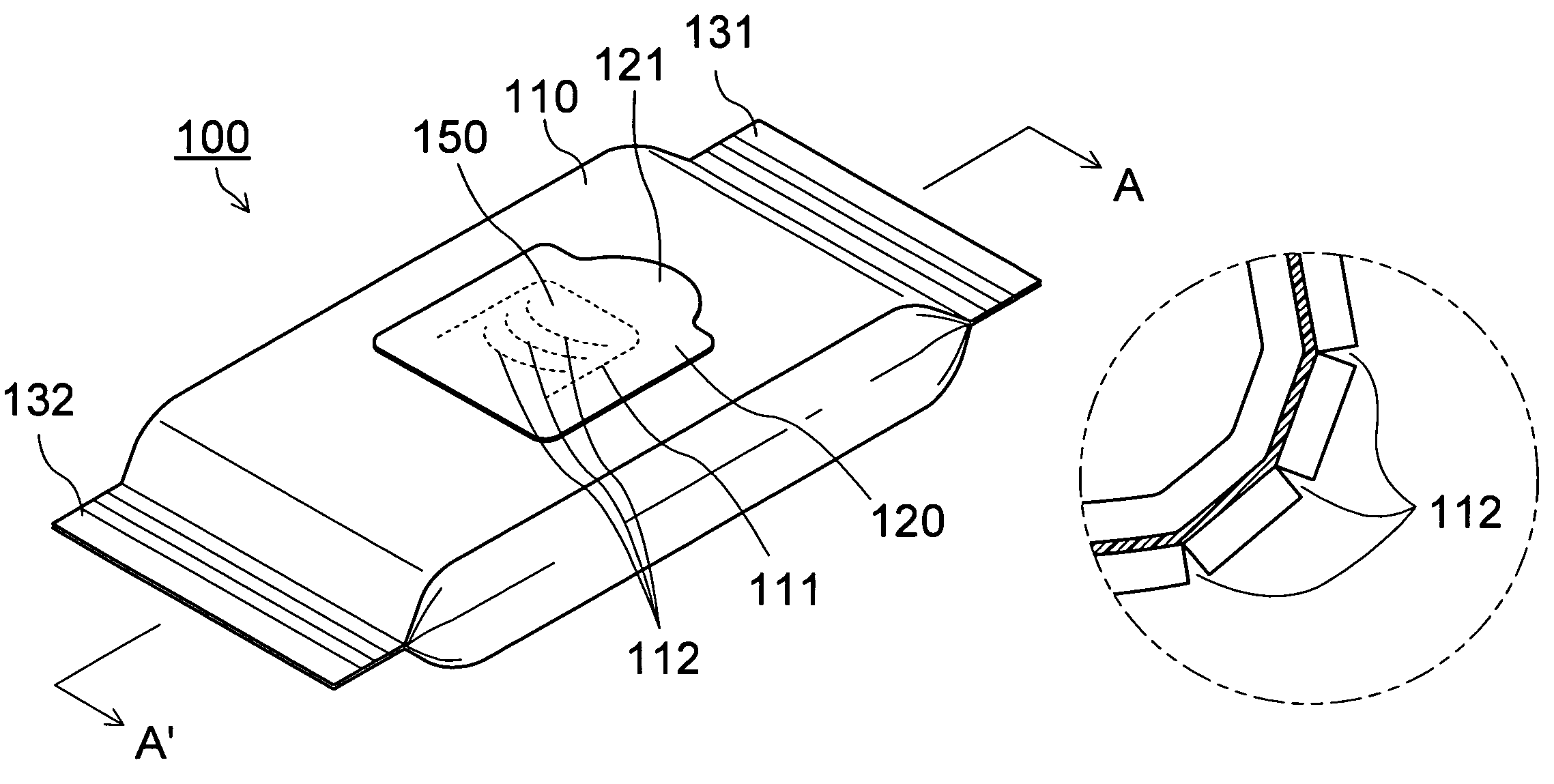

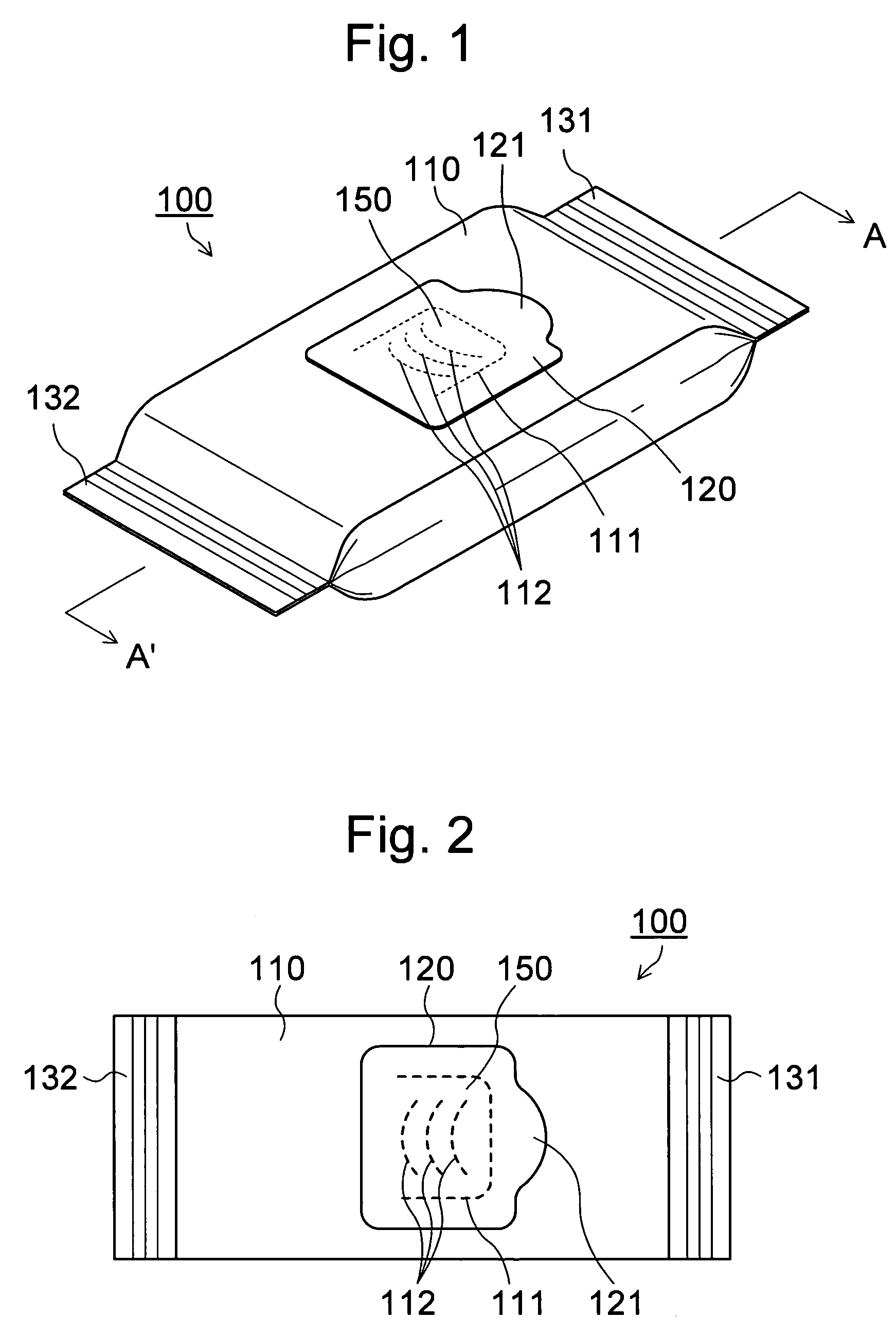

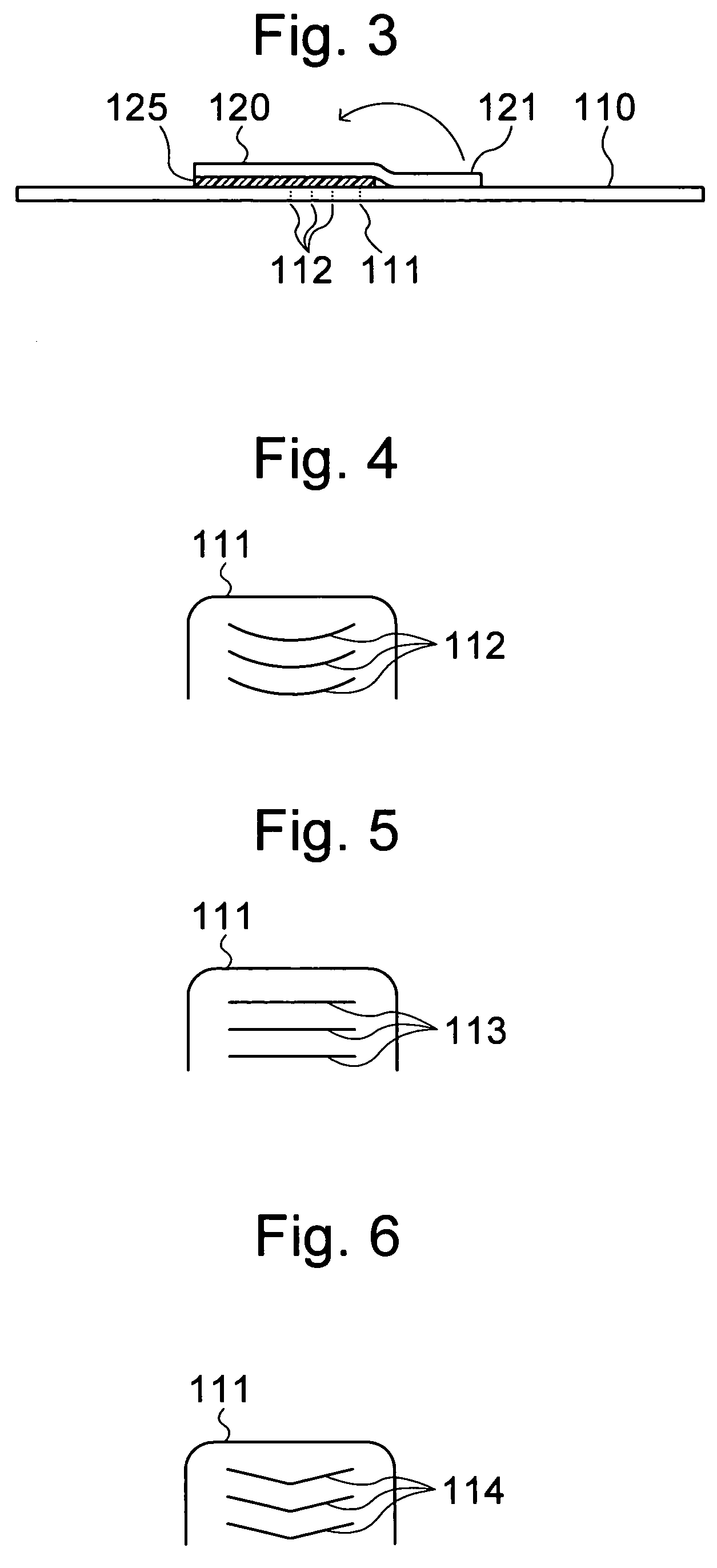

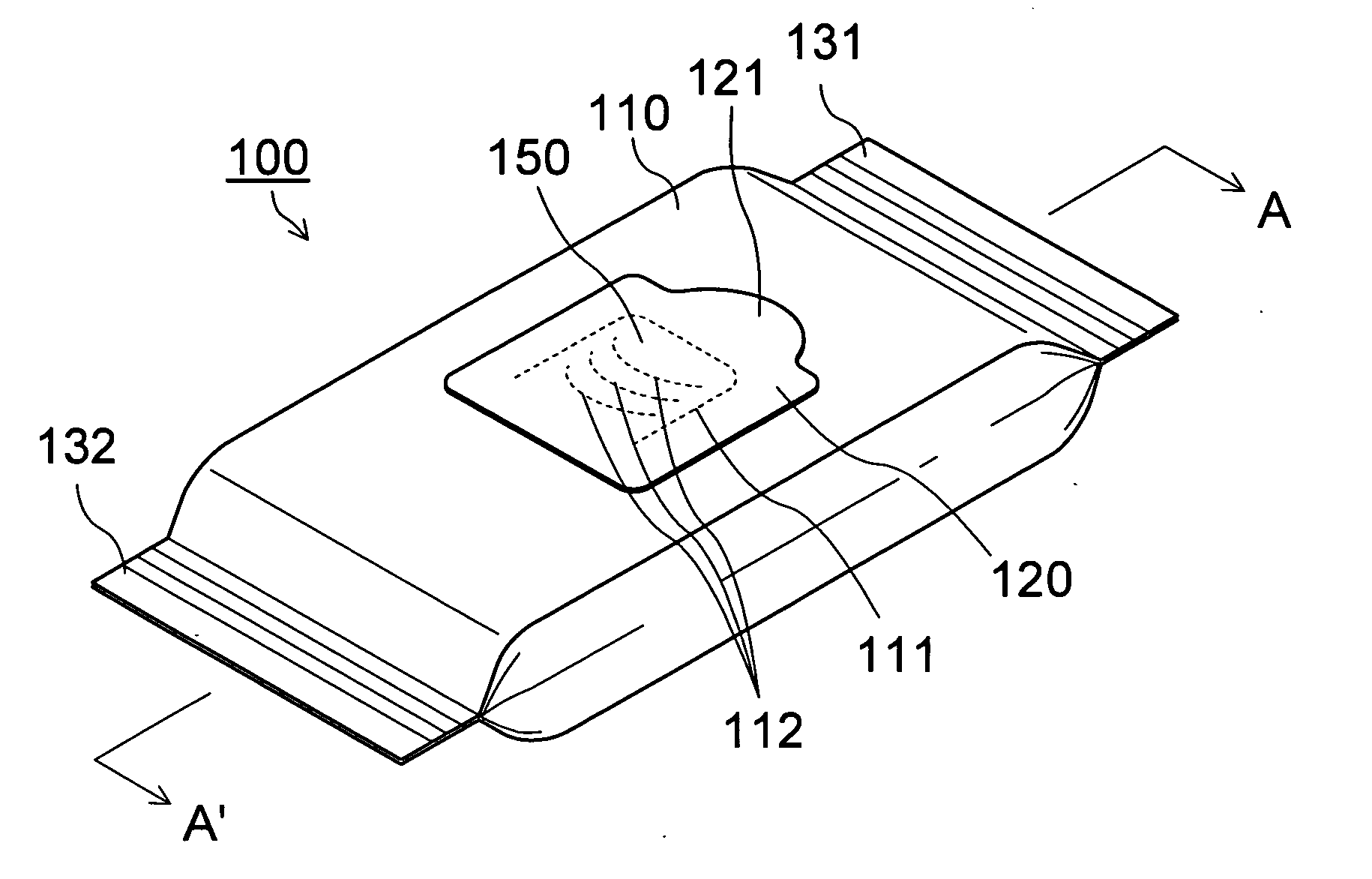

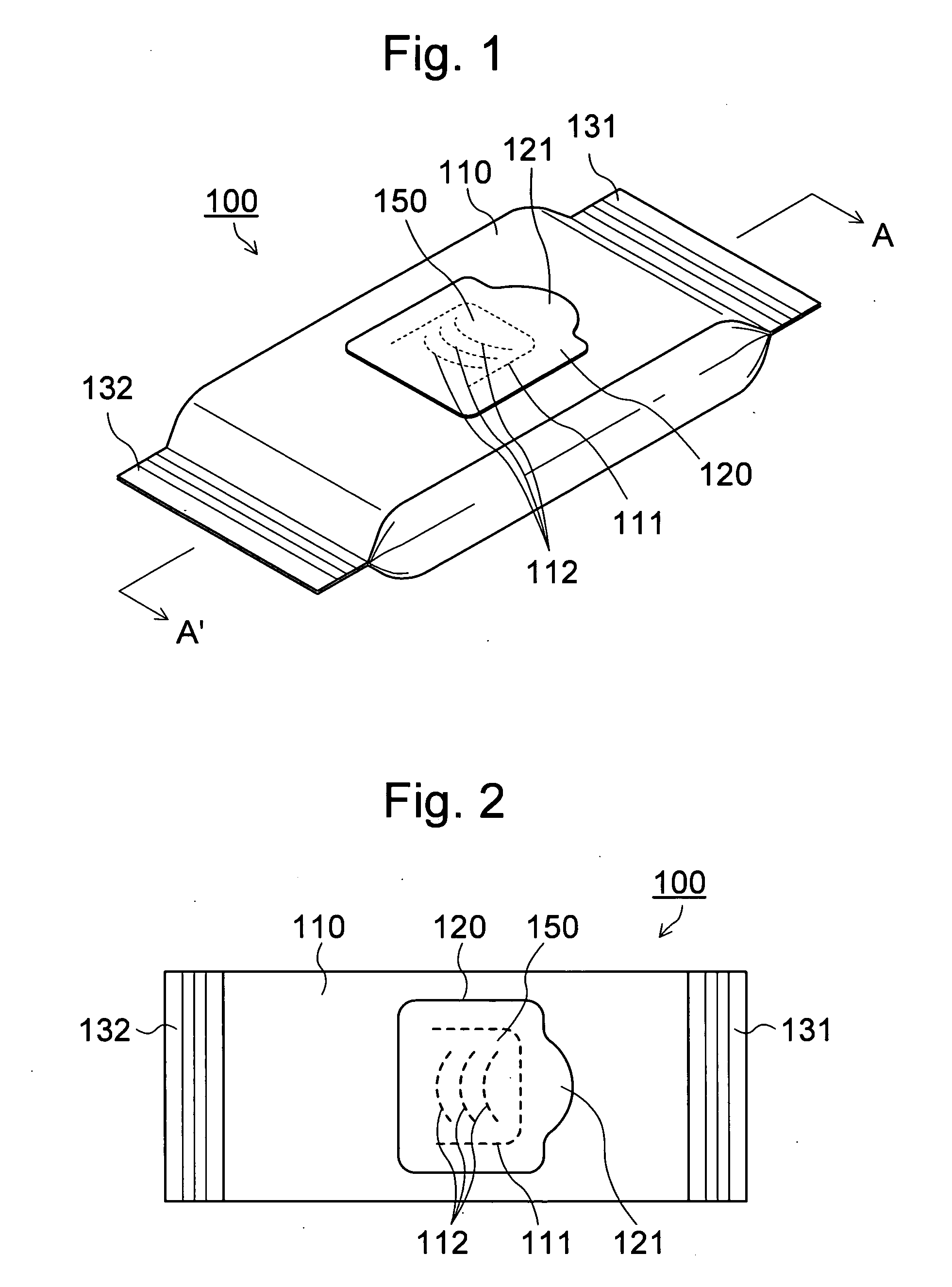

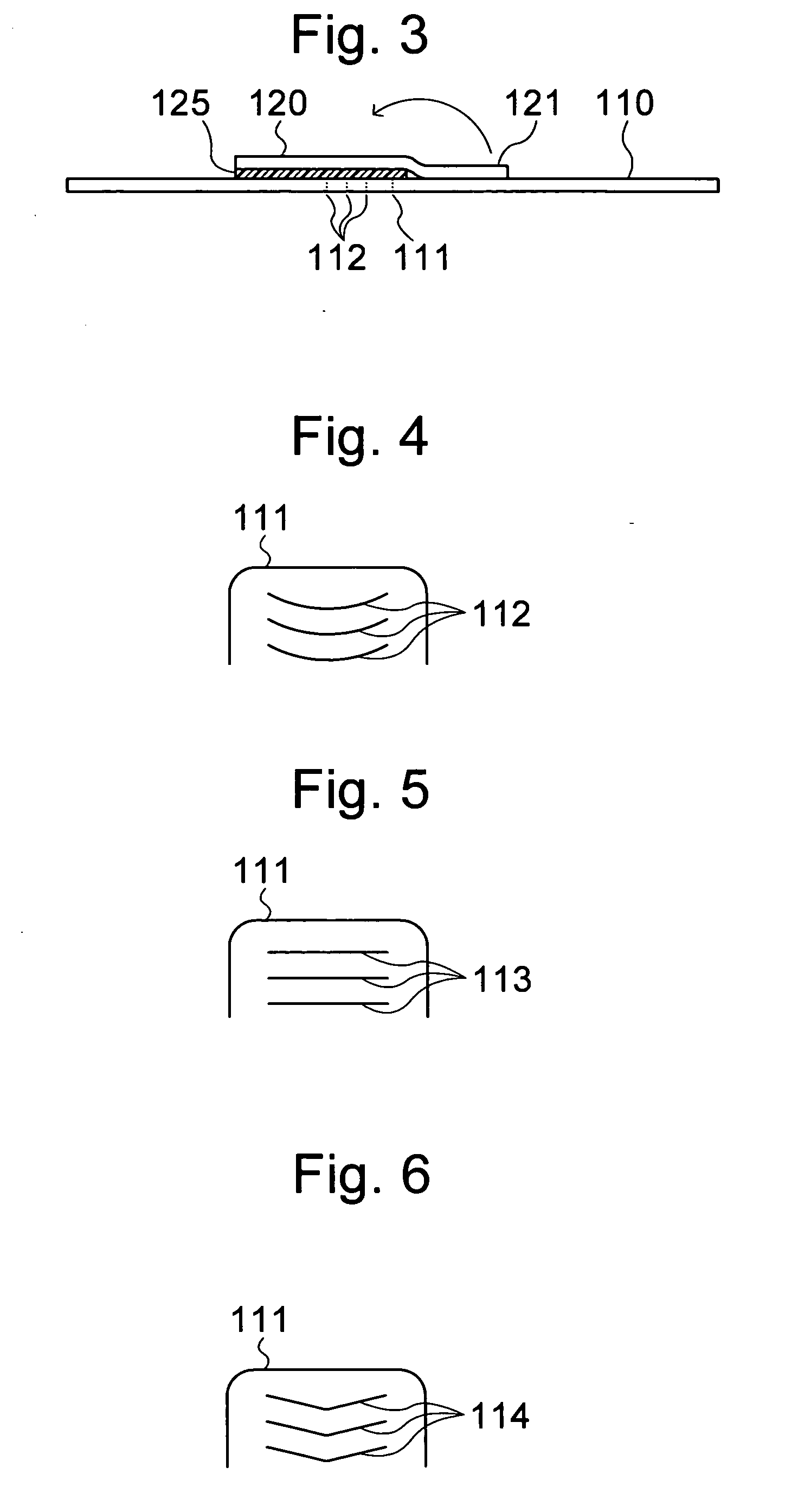

Easy-open package

InactiveUS7475781B2Reduce stiffnessEasy to stickWrappersDiagnosticsMechanical engineeringEngineering

A package is presented from which contents can be easily taken out. This package includes a film with a soft packaging material. On the surface of the soft packaging material is a cut line, such that, inside the cut line, an openable region is formed for taking contents out from the package. Further, inside the openable region, dashed lines are provided. When a lid member adhering to cover the openable region is peeled, the openable region easily adheres to the lid member side owing to the dashed lines to reliably form the opened portion.

Owner:UNI CHARM CORP

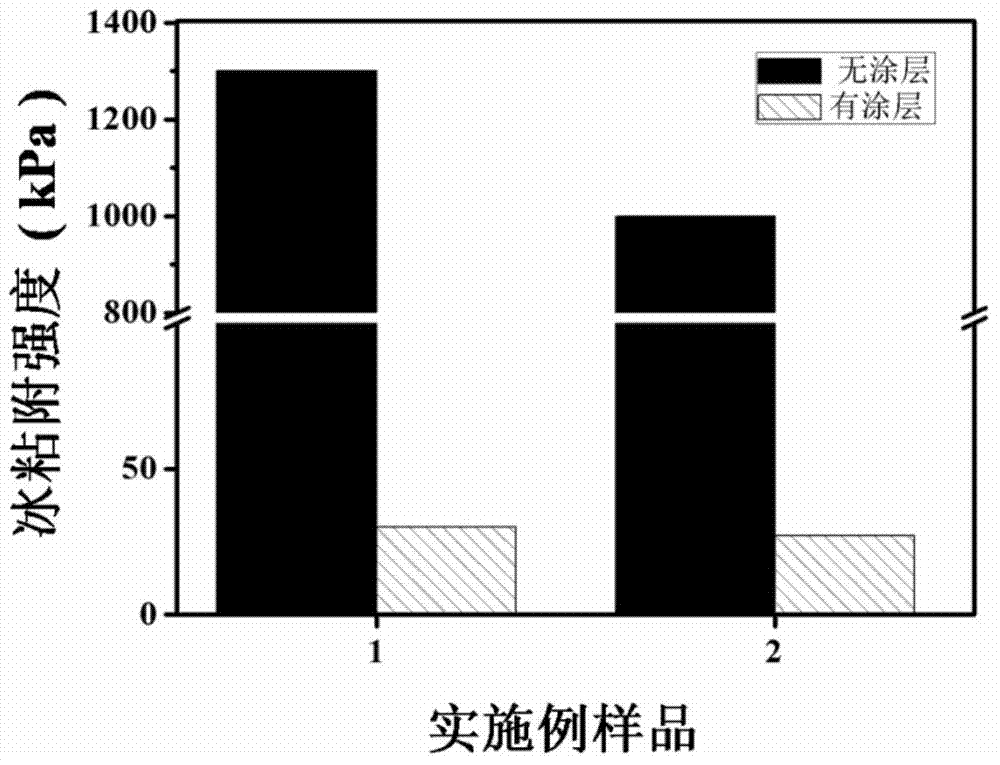

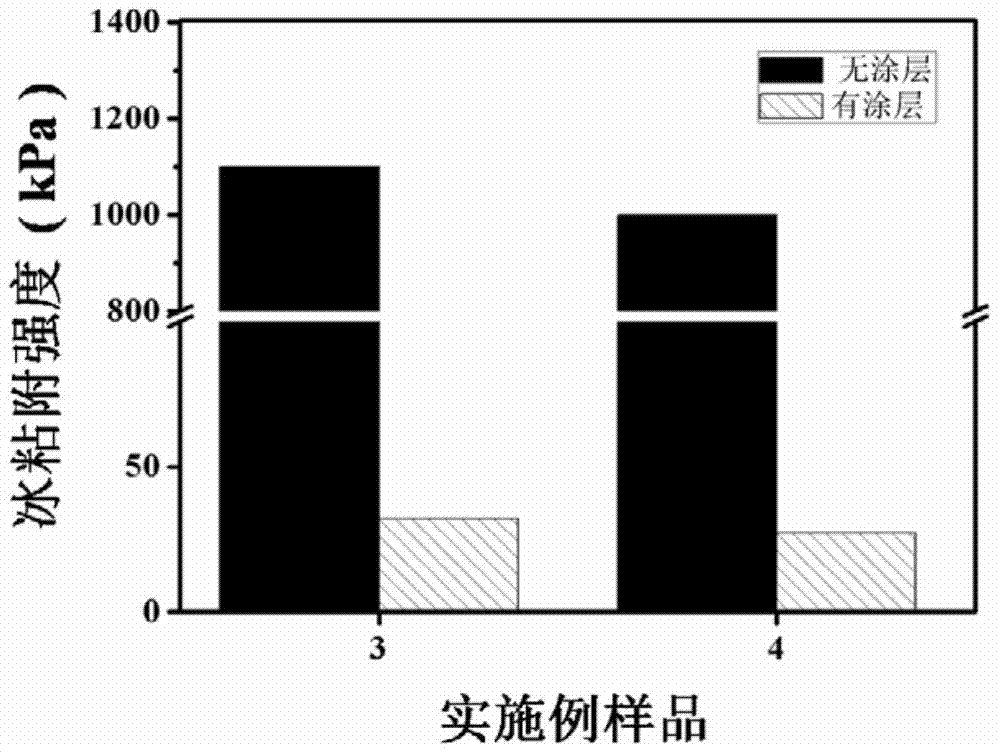

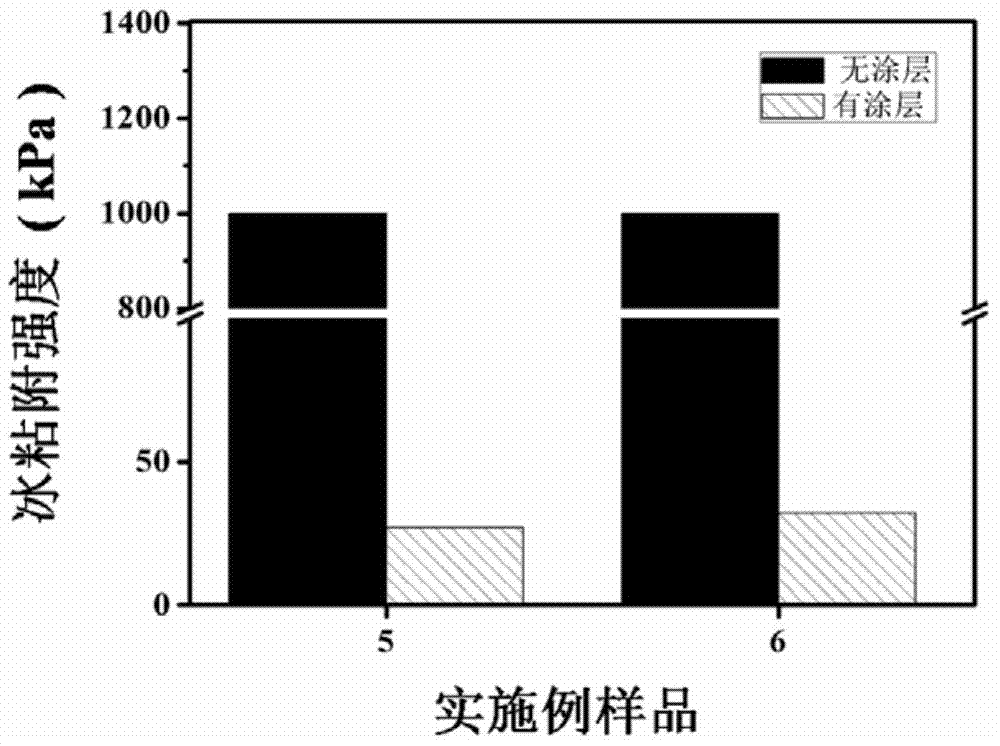

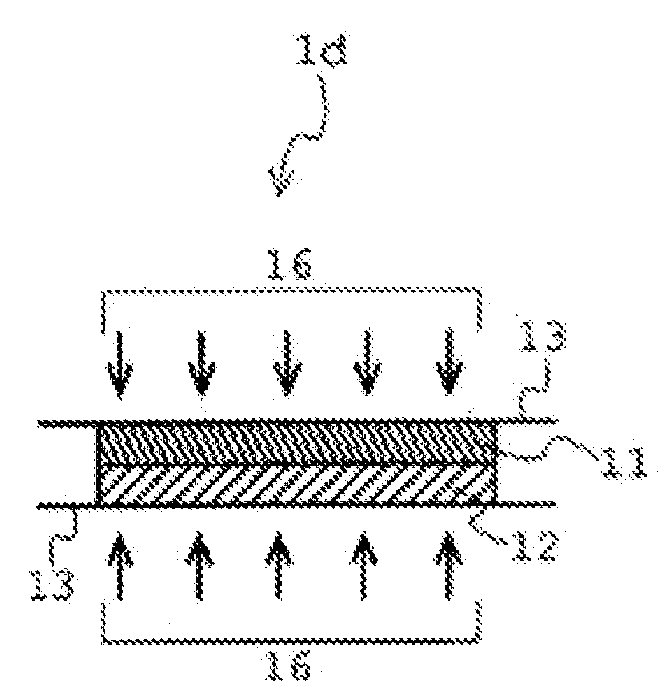

Composite for Preventing Ice Adhesion

ActiveUS20140127516A1Robust and durableReduced adhesion strengthOther chemical processesRadiation applicationsChemistryIce adhesion

The present invention relates to a novel composite for preventing ice adhesion. A superhydrophobic or superhydrophilic surface with a hydrophobic, low freezing point liquid adsorbed onto surface asperities results in a durable, renewable anti-icing surface. The preparation method for novel icing and rain protecting surface is disclosed.

Owner:WANG LIANG +1

Easy-open package

InactiveUS20050284776A1Reduce stiffnessEasy to stickDiagnosticsSurgical needlesBiomedical engineeringEngineering

A package is presented from which contents can be easily taken out. This package includes a film with a soft packaging material. On the surface of the soft packaging material is a cut line, such that, inside the cut line, an openable region is formed for taking contents out from the package. Further, inside the openable region, dashed lines are provided. When a lid member adhering to cover the openable region is peeled, the openable region easily adheres to the lid member side owing to the dashed lines to reliably form the opened portion.

Owner:UNI CHARM CORP

Hydrogel compositions

InactiveUS8481059B2Less tackyProperty is limitedCosmetic preparationsToilet preparationsElastomerHydrophilic polymers

Owner:CORIUM PHARMA SOLUTIONS INC

Inkjet Recording Ink

InactiveUS20070263054A1Improve discharge stabilityGood storage stabilityMeasurement apparatus componentsInksPolymer scienceMeth-

The present invention aims to provide an ink for ink jet recording that is excellent in storage stability and discharge stability and attains high coloration on regular paper or gloss paper and high glossiness on gloss paper. The ink for ink jet recording of the invention includes: water; and a pigment dispersed by using a polymer which is obtained by polymerizing at least 50% by weight or more of benzylacrylate and 15% by weight or less of (meth)acrylic acid as components of the polymer and has an acid value of no less than 50 mgKOH / g and no more than 120 mgKOH / g and a weight average molecular weight of no less than 10000 and no more than 120000.

Owner:SEIKO EPSON CORP

Hydrogel Compositions

InactiveUS20090258060A1Improve attributesLess tackyCosmetic preparationsPowder deliveryElastomerHydrophilic polymers

Hydrogel compositions are provided (a) that have a continuous hydrophobic phase and a discontinuous hydrophilic phase, (b) that have a discontinuous hydrophilic phase and a continuous hydrophilic phase, or (c) that are entirely composed of a continuous hydrophilic phase. The hydrophobic phase, if present, is composed of a hydrophobic polymer, particularly a hydrophobic pressure-sensitive adhesive (PSA), a plasticizing elastomer, a tackifying resin, and an optional antioxidant. The discontinuous hydrophilic phase, if present, is composed of a crosslinked hydrophilic polymer, particularly a crosslinked cellulosic polymer such as crosslinked sodium carboxymethylcellulose. For those hydrogel compositions containing a continuous hydrophilic phase, the components of the phase include a cellulose ester composition or an acrylate polymer or copolymer, and a blend of a hydrophilic polymer and a complementary oligomer capable of hydrogen bonding thereto. Films prepared from hydrogel compositions containing or entirely composed of the aforementioned continuous hydrophilic phase can be made translucent, and may be prepared using either melt extrusion or solution casting. A preferred use of the hydrogel compositions is in wound dressings, although numerous other uses are possible as well.

Owner:CORIUM PHARMA SOLUTIONS INC

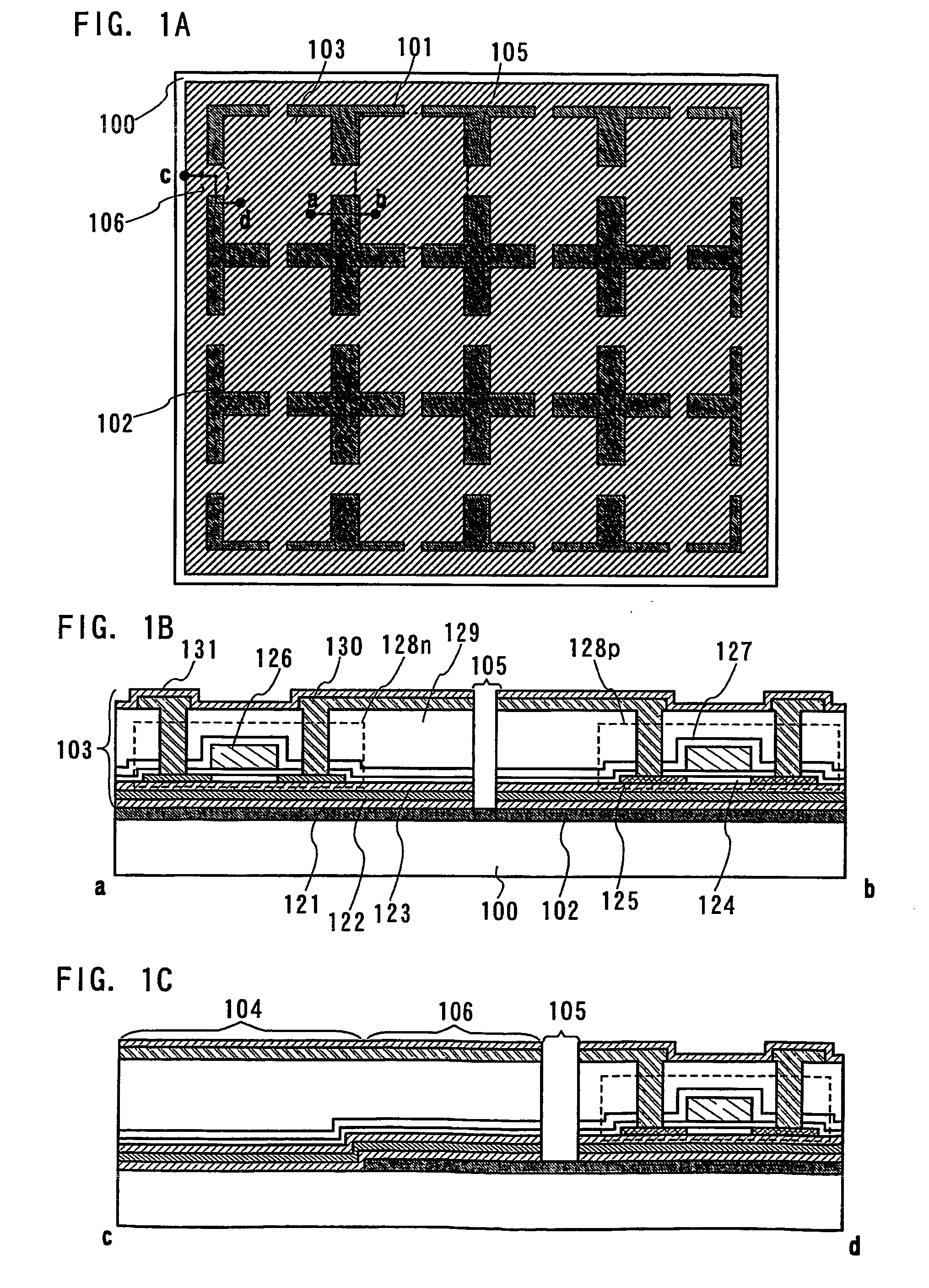

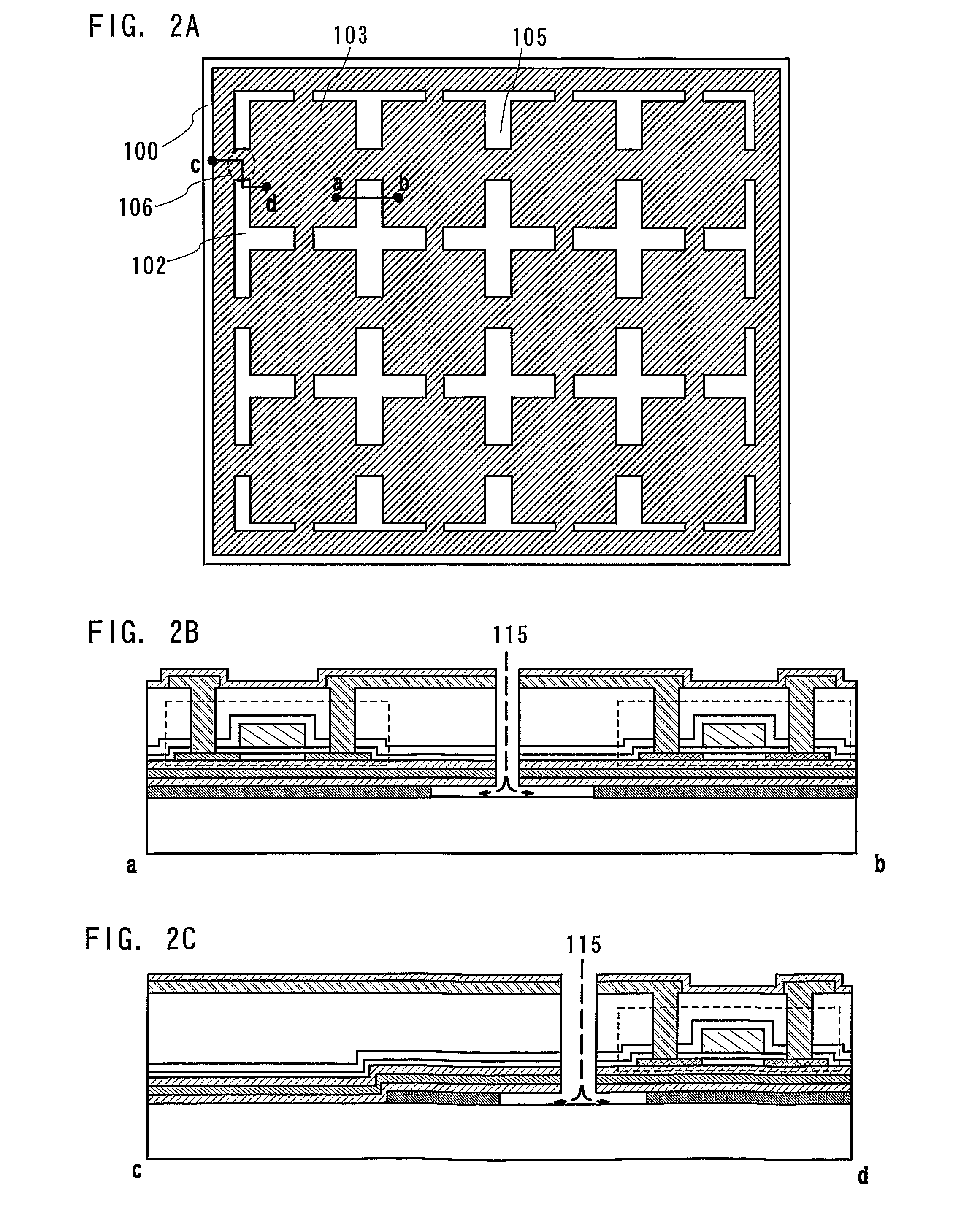

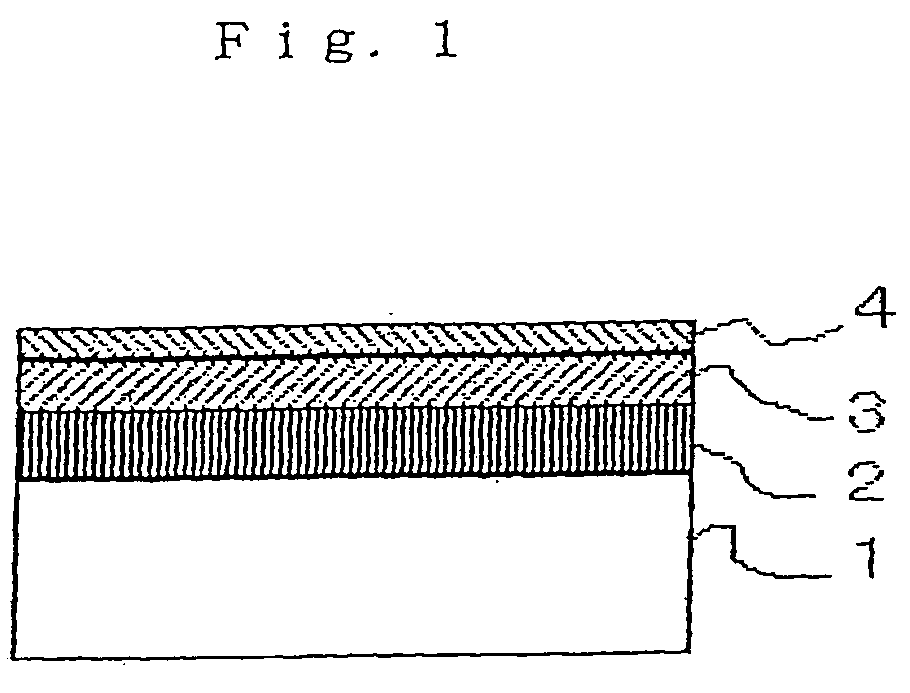

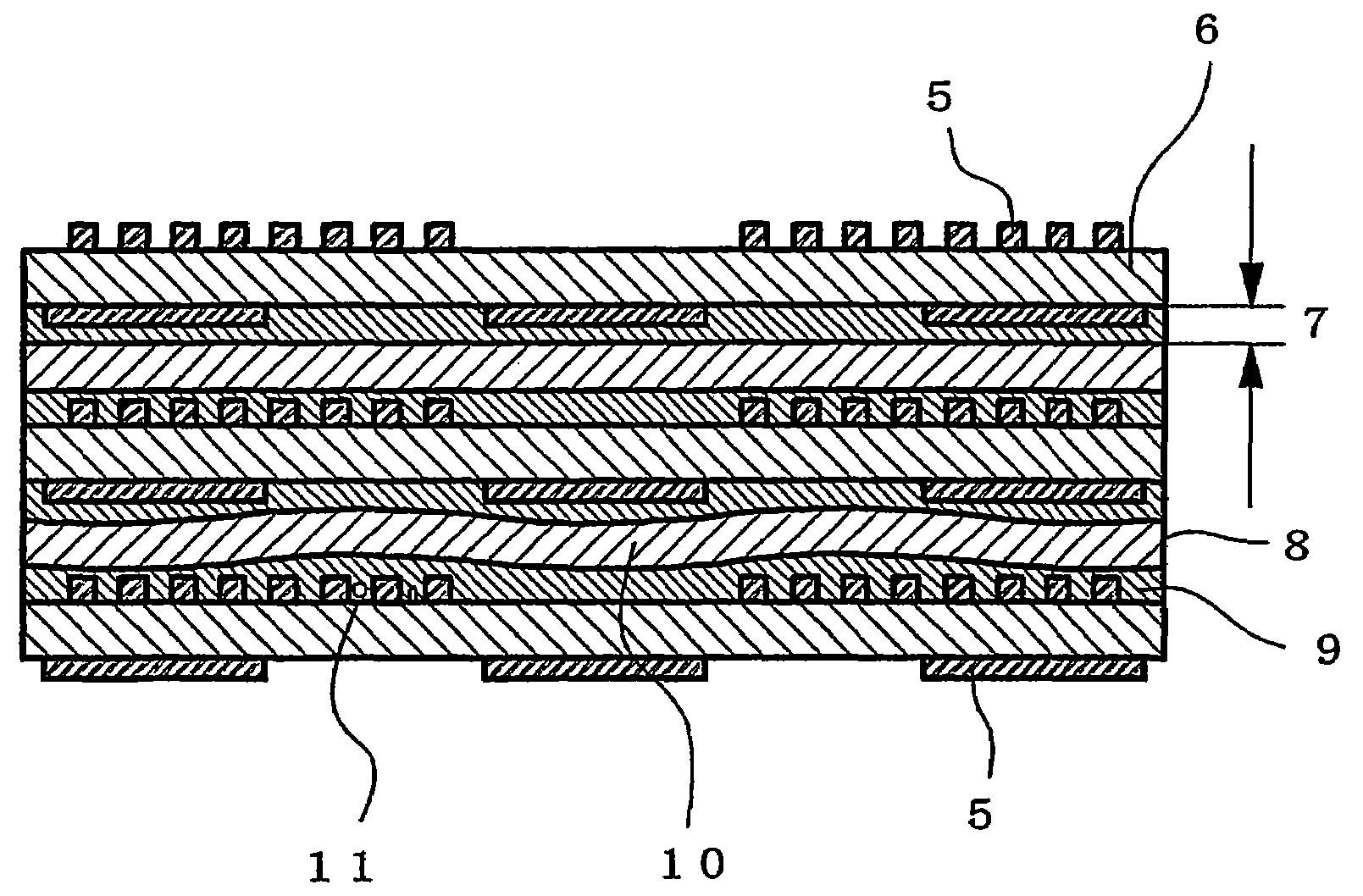

Method for manufacturing integrated circuit

InactiveUS20070173034A1Ease of mass productionIncrease elasticityTransistorSolid-state devicesEngineeringIntegrated circuit

A method for separating an integrated circuit formed by a thin film having a novel structure or a method for transfer-ring the integrated circuit to another substrate, that is, so-called transposing method, has not been proposed. According to the present invention, in the case that an integrated circuit having a thin film having a novel structure formed over a substrate via a release layer is separated, the release layer is removed in the state that the thin film integrated circuit is fixated, the thin film integrated circuit is transposed to a supporting substrate having an adhesion surface, and the thin film integrated circuit is transposed to another substrate having an adhesion surface with higher strength of adhesion than that of the supporting substrate.

Owner:SEMICON ENERGY LAB CO LTD

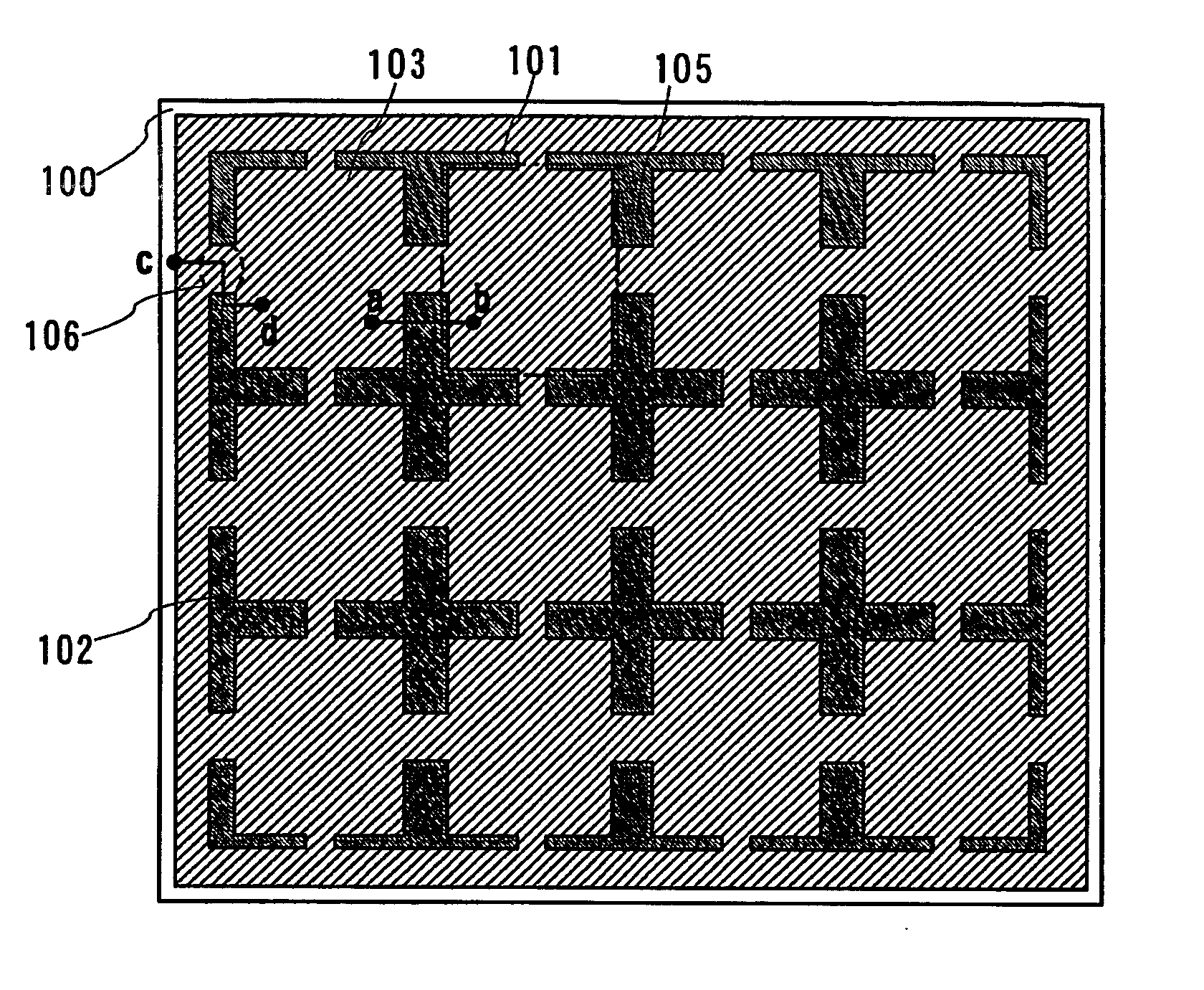

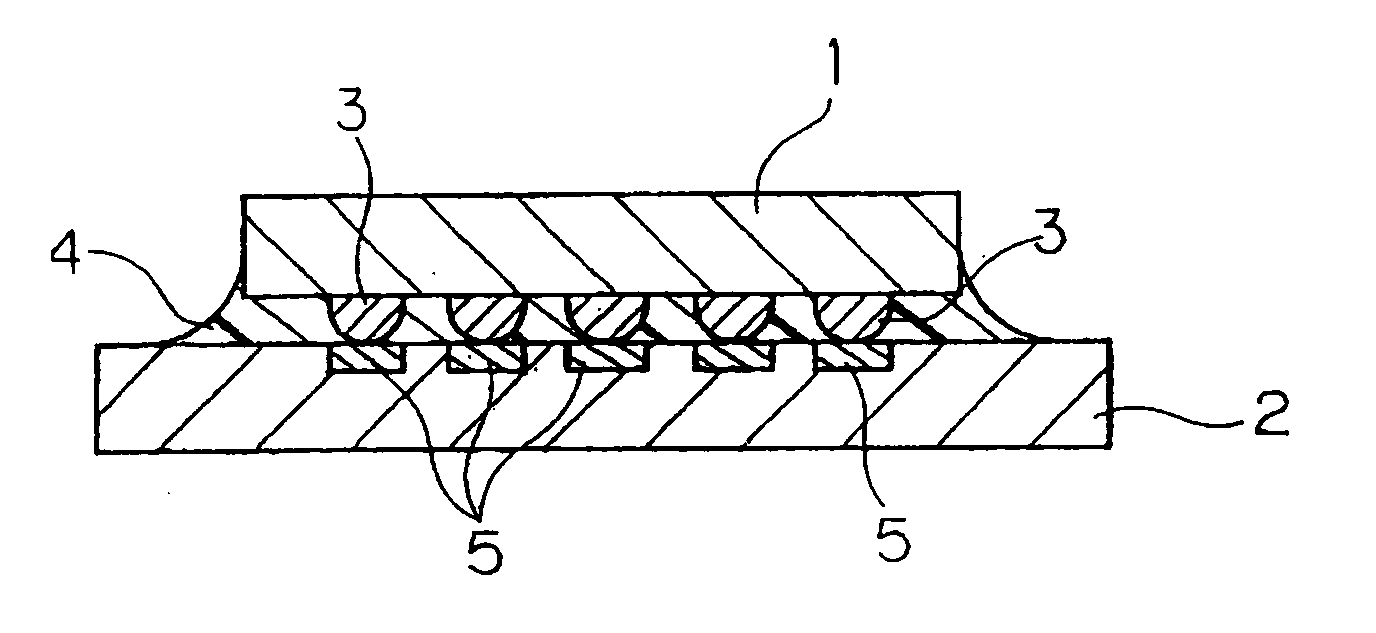

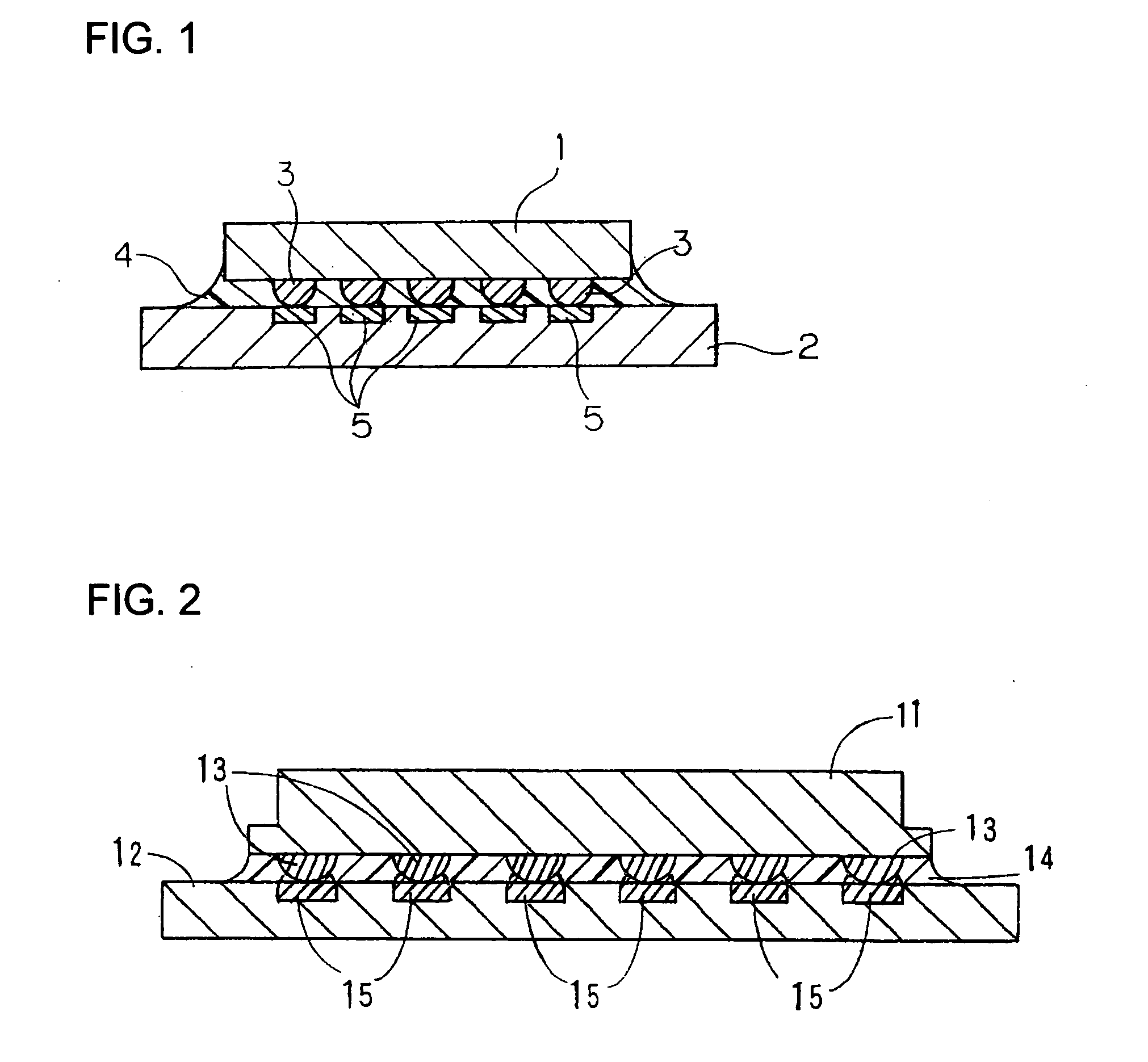

Liquid epoxy resin composition

InactiveUS20070196612A1Low viscosityEasily show solvation and swellingLayered productsSemiconductor/solid-state device detailsPolymer scienceElectrical connection

There is provided a low viscosity liquid epoxy resin composition which has excellent repairability because of the capability to remove residues at around room temperature even in the case of an electronic part device having a deficiency in the electric connection after once carrying out underfill, and what is more, wherein an electric parts device having a connected mounted structure shows high reliability. The liquid epoxy resin composition is used for resin-filling the gap between a circuit substrate and a semiconductor part on an electronic part device, wherein said electronic part device comprises a circuit substrate having an electrode part for connection and a semiconductor part having an electrode part for connection and being mounted on the circuit substrate in such a way that the electrode part of the circuit substrate and the electrode part of the semiconductor part are facing each other. In addition, the liquid epoxy resin composition comprises the following components (A) to (C) together with the following component (D). (A) A liquid epoxy resin. (B) An aromatic diamine curing agent. (C) An inorganic filler. (D) An organic additive.

Owner:NITTO DENKO CORP

Resin-lined steel pipe and method for production thereof

InactiveUS20060108016A1Improve adhesionReduced adhesion strengthSynthetic resin layered productsFlexible pipesChemical treatmentAdhesion strength

A plastic lined steel pipe characterized by having an adhesive layer on an inner surface of a steel pipe, having a plastic layer on its further inner side, and having an initial shearing adhesion strength between the steel pipe and the plastic layer of 2.0 MPa or more, said steel pipe being a steel pipe given substrate treatment on its inner surface in advance, said substrate treatment comprising forming a phosphate chemical treatment coating treated for grain refinement, and preferably having an epoxy primer layer between the steel pipe and the adhesive layer. A method for producing a plastic lined steel pipe characterized by inserting a plastic pipe having an outside diameter smaller than the inside diameter of the steel pipe subjected to the substrate treatment and having an adhesive layer on its outer surface into the steel pipe, reducing the outside diameter of the steel pipe so as to make the plastic pipe closing contact it, and heating the result at a temperature not less than a melt end temperature of the adhesive layer and less than a melt start temperature of the plastic pipe.

Owner:NIPPON STEEL CORP

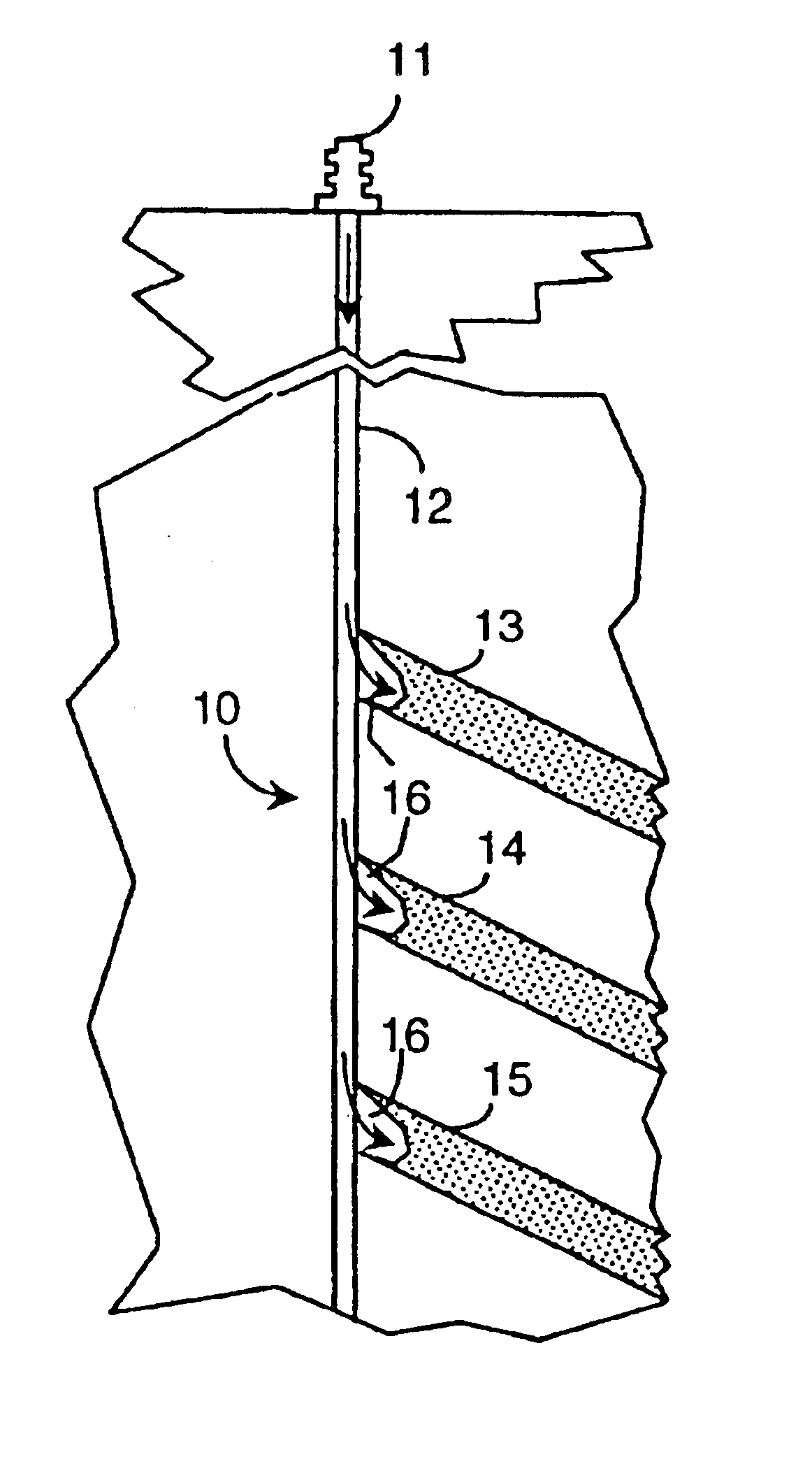

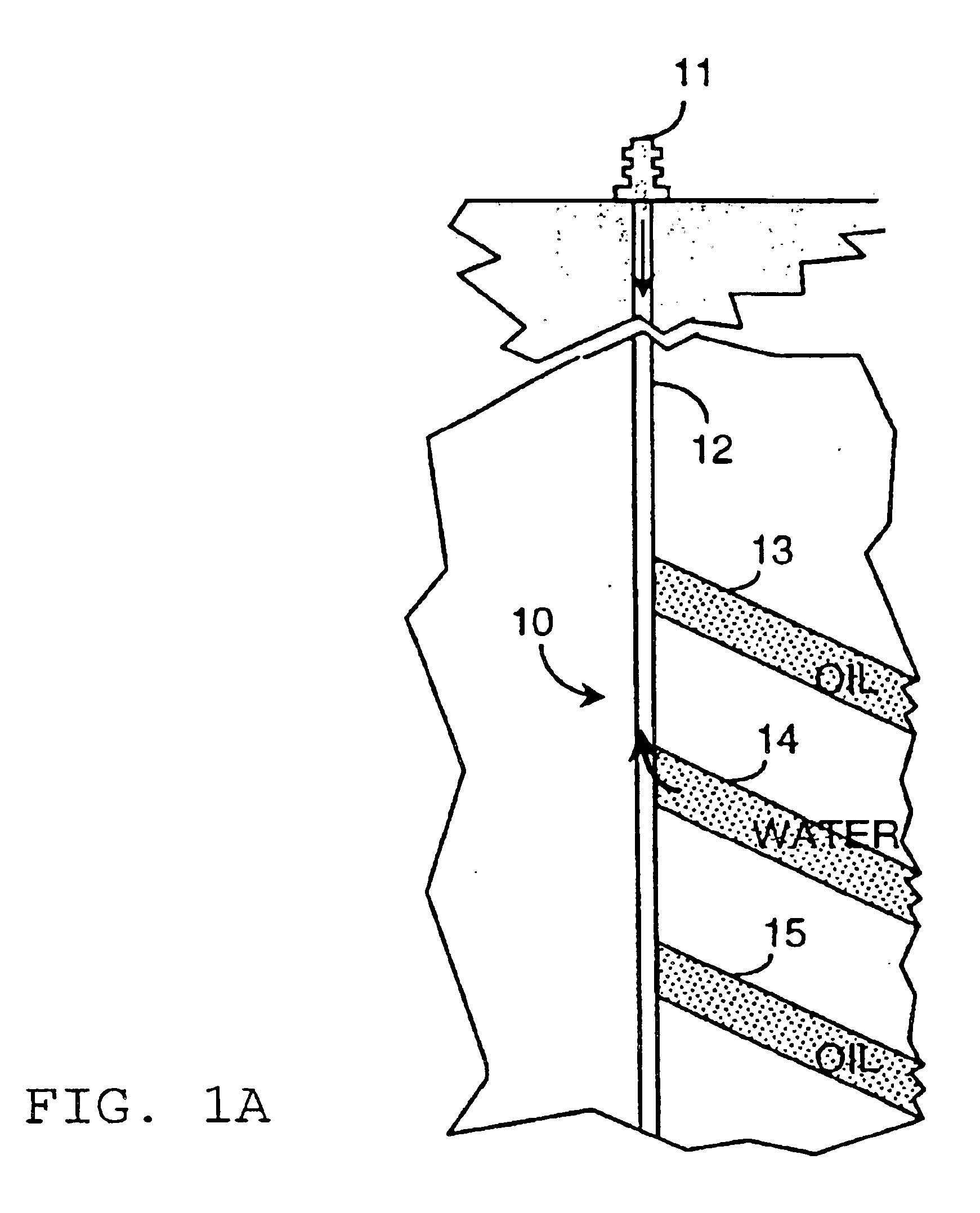

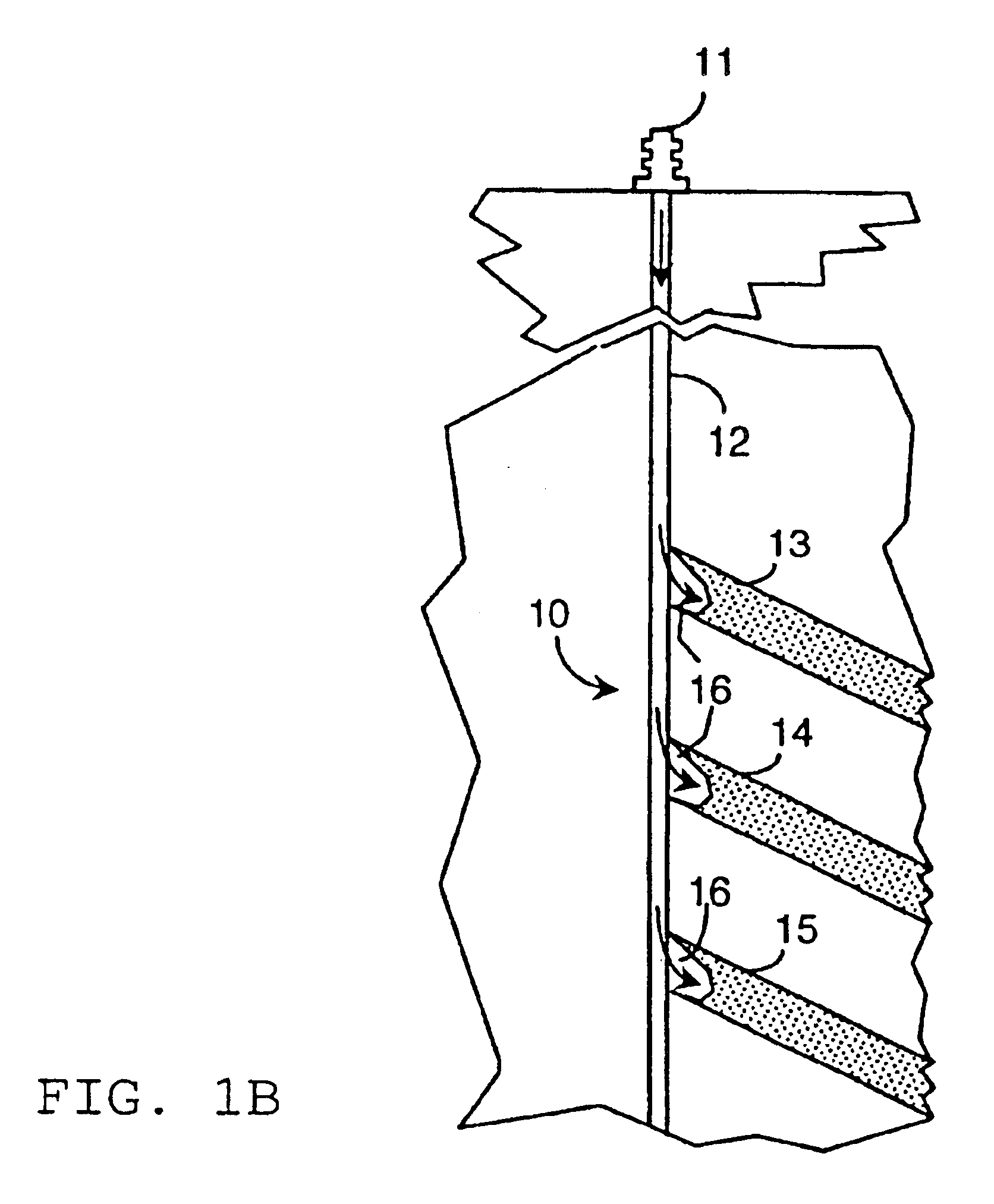

Method for water control

InactiveUS6920928B1High strengthReduced adhesion strengthFluid removalDrilling compositionCross-linkChemical composition

A method to reduce water influx into a producing well is described comprising the steps of pumping a chemical composition into a production interval and into surrounding formation; said composition being capable of forming, firstly, a physically stabilized structure and, secondly, a chemically stabilized structure, wherein said physically stabilized structure being dissolvable by hydrocarbon containing fluids; letting said composition form said physically stabilized structure within the formation surrounding said production interval; changing pressure condition in said production interval such that the fluid flow within the surrounding formation is reversed; letting thereby in some portions of the formation hydrocarbon containing fluids dissolve said physically stabilized structure and chemically stabilize said structure in the remaining portions by a cross-linking reaction. The time constants of the two stabilizing reactions are selected such that the physical stabilization is essentially completed before the pumping direction is reversed and the chemical stabilization is essentially completed after the pump-out / cleaning operation.

Owner:SCHLUMBERGER TECH CORP

Battery module

InactiveUS20100297494A1Decreasing heat dissipation efficiencyImprove connection strengthElectrolyte holding meansSmall-sized cells cases/jacketsMechanical engineeringBattery cell

A battery module includes a battery cell, a flexible shell and a supporting seat. The battery cell has a main body and two electrodes extended outwardly from the main body; the flexible shell has an upper and lower lid plates, both of which are connected and cooperated to each other to envelop the battery cell, and which are provided for the electrodes to extend out and respectively have an upper and lower adhesive parts, both of which are adhered to each other; and, the supporting seat is provided for arranging the flexible shell, in which the flexible shell further has an extending part, which is extended from one of the upper, lower adhesive parts towards the supporting seat and has an adhesive layer adhered to the supporting seat by a thermal pressing process, such that the flexible shell and the supporting seat can be connected securely.

Owner:AMITA TECH

Pressure-sensitive adhesive sheet for surface protection

ActiveUS20120202058A1High resistanceIncrease suppressionSynthetic resin layered productsThin material handlingRise ratePressure sensitive

A surface-protecting pressure-sensitive adhesive sheet includes: a substrate; and a pressure-sensitive adhesive layer that is provided on at least one side of the substrate and made from a polyester-based pressure-sensitive adhesive composition containing a crosslinking agent and a polyester including at least a lactic acid unit, a dibasic acid unit, and a glycol unit. The dibasic acid unit includes a dimer acid, the polyester has a weight average molecular weight of 20,000 to 200,000 and a glass transition temperature of −70 to −20° C. as measured using a differential scanning calorimeter at a temperature rise rate of 20° C. / minute, the polyester-based pressure-sensitive adhesive composition has a hydroxyl value of 20 to 60 mgKOH / g, and the pressure-sensitive adhesive layer has a gel fraction of 85 to 99% by weight.

Owner:NITTO DENKO CORP

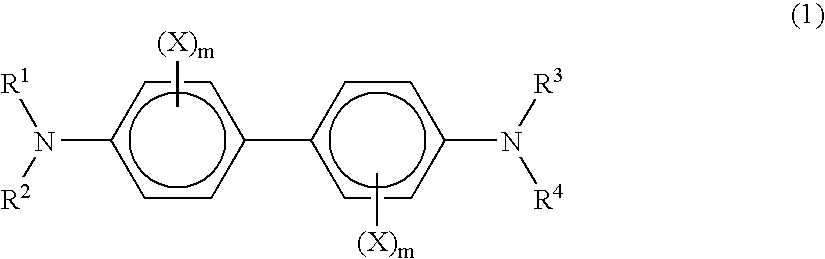

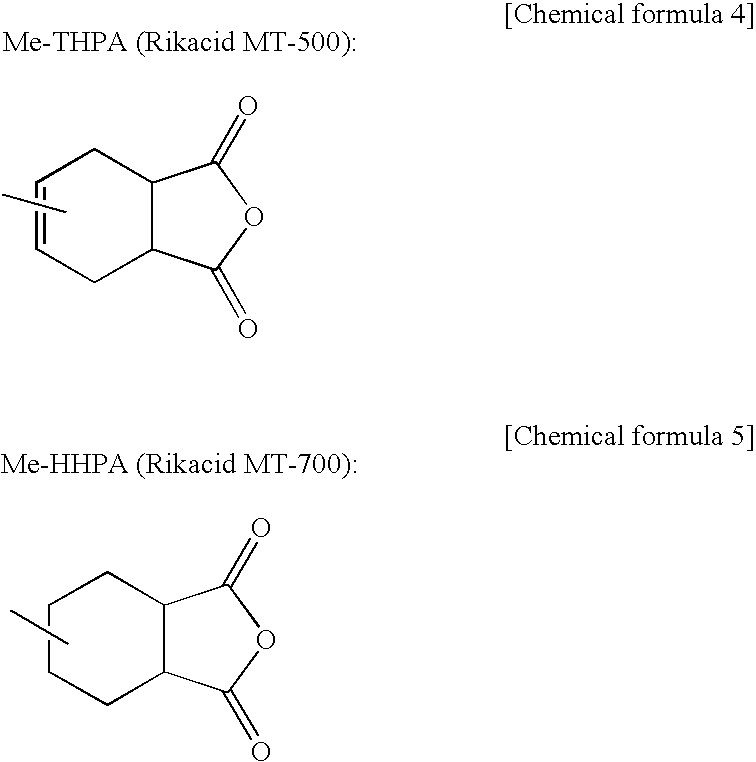

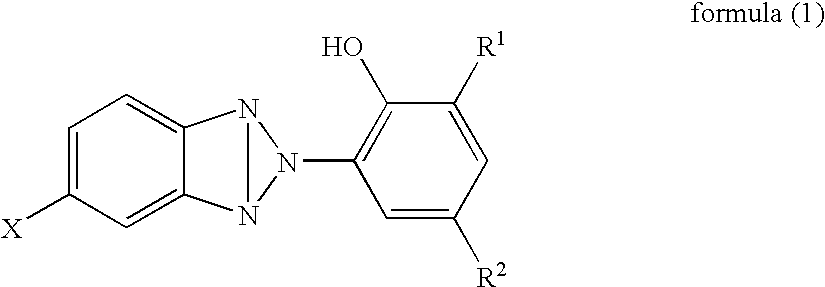

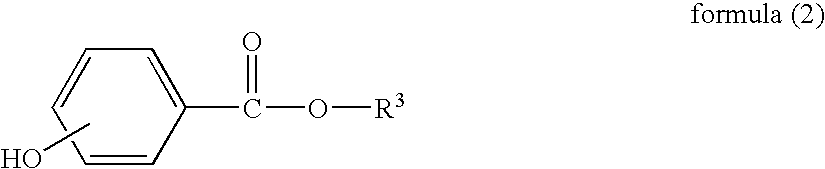

Conductive adhesive

ActiveUS20070185243A1Reduced adhesion strengthImprove long-term reliabilityPrinted circuit assemblingNon-macromolecular adhesive additivesAdhesiveSurface mounting

The present invention provides a conductive adhesive that is applicable as means for forming conductive junction to process for surface mounting of electronic parts for vehicle loading and process for the manufacture of the electronic parts per se for the purpose of substituting soldering therewith. The conductive adhesive according to the present invention is a conductive adhesive produced by dispersing a conductive medium, such as silver powder, in a binder resin component of a one-component epoxy thermosetting resin which has such a composition that the resin comprises, as essential components, an epoxy resin component composed mainly of an epoxy compound with a polycyclic aromatic ring skeleton, and a cyclic acid anhydride as a curing agent component thereof, and is further added with a coupling agent as an adherence imparting agent therefor.

Owner:DENSO CORP +1

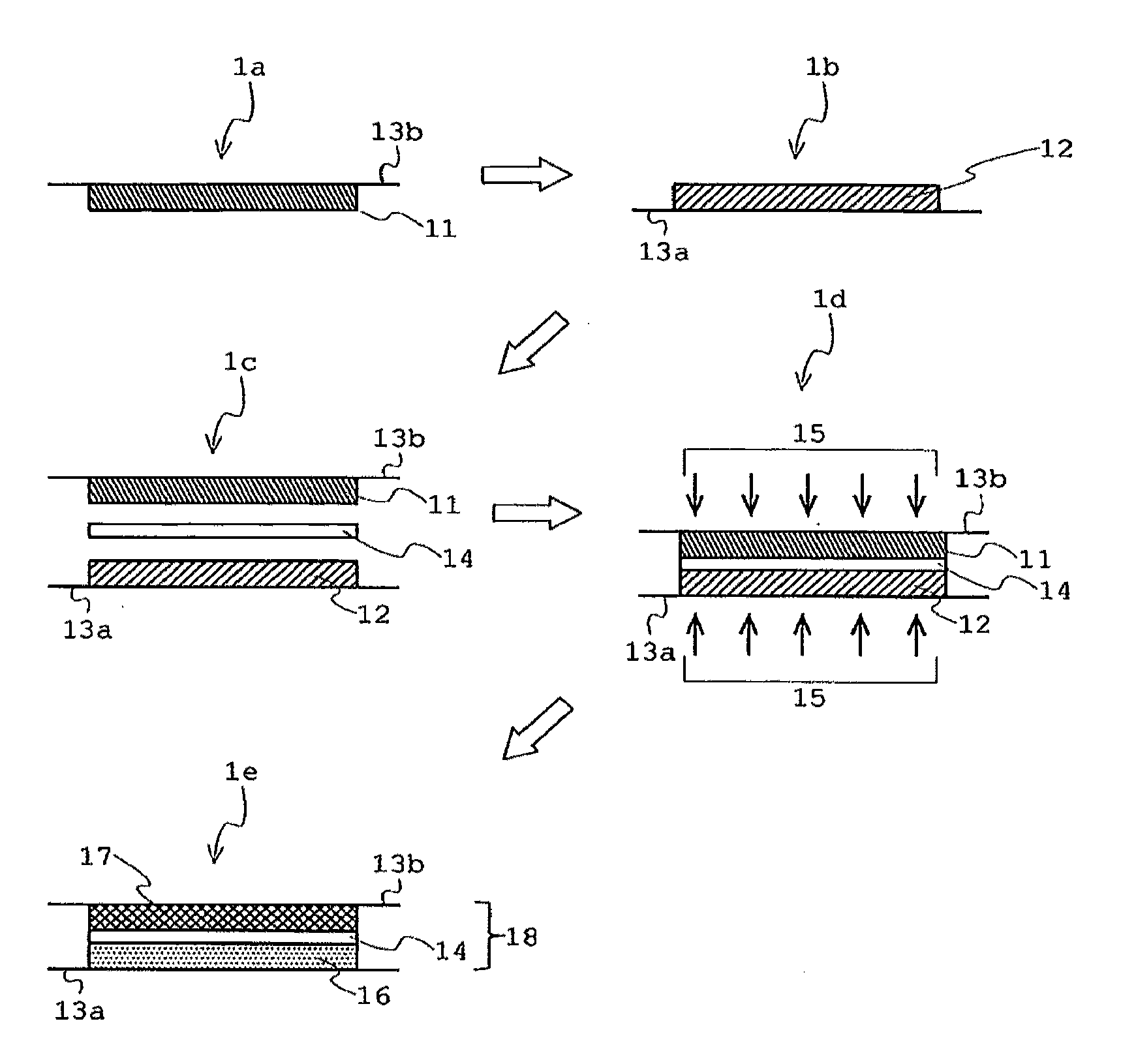

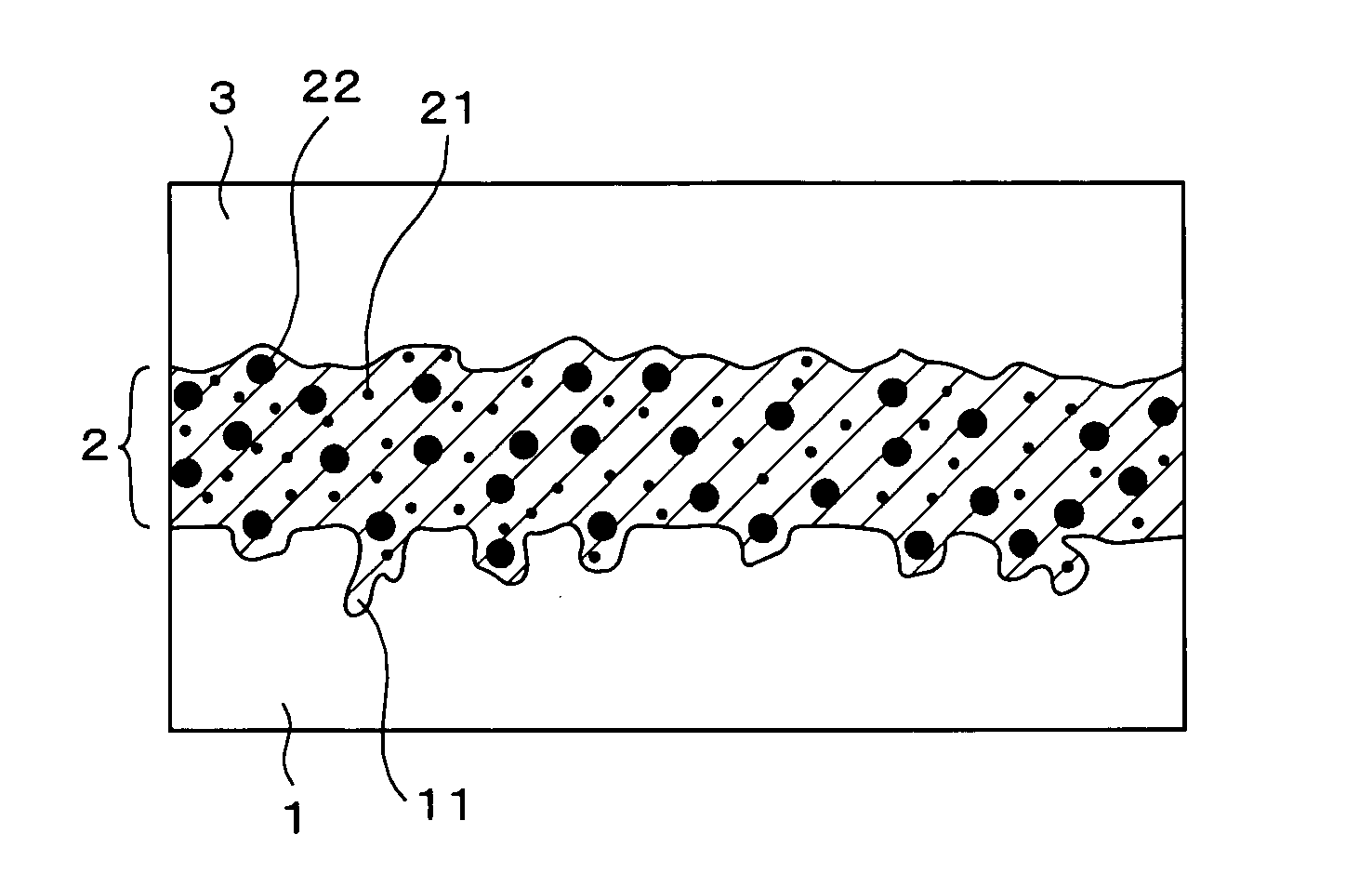

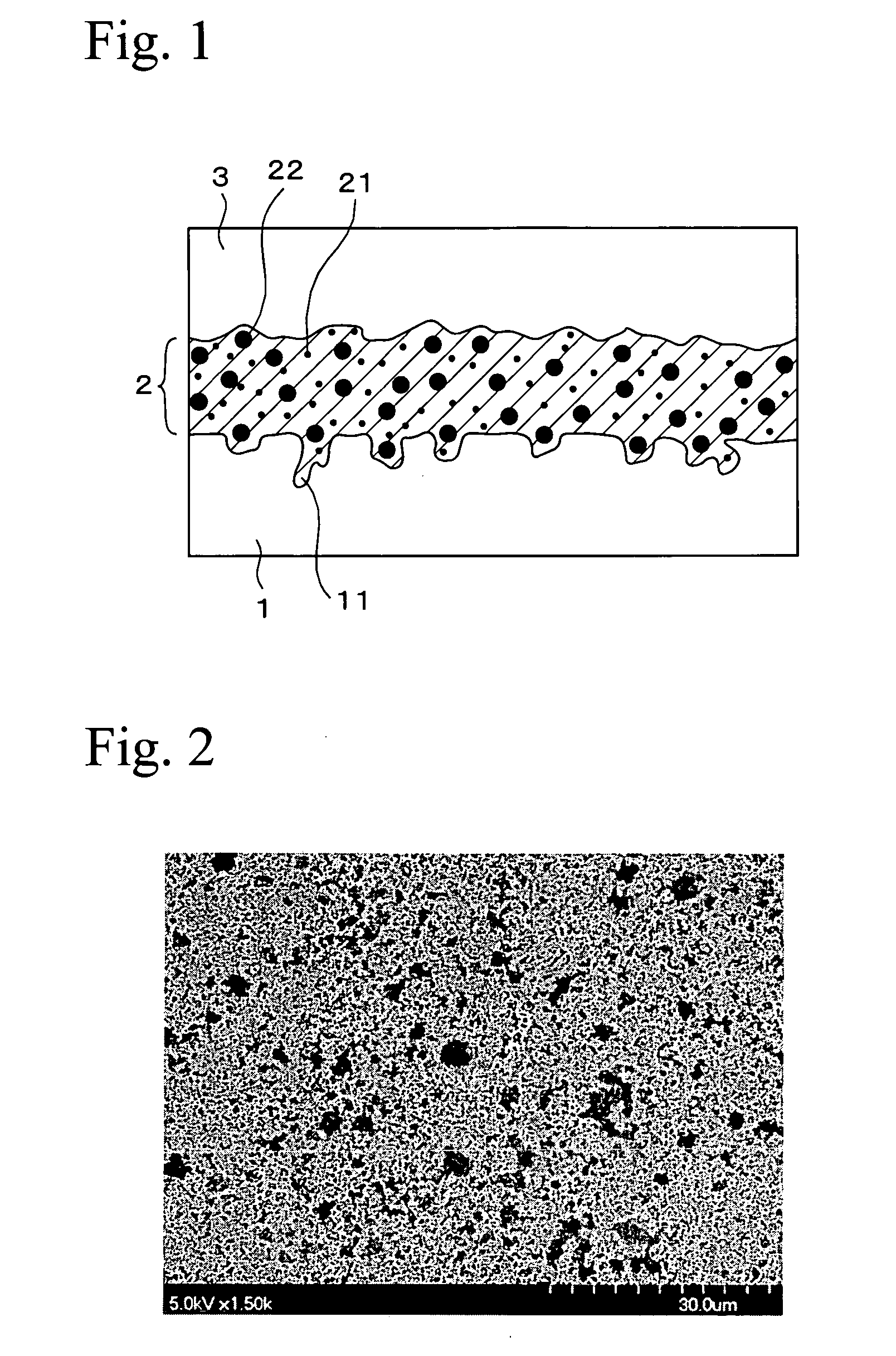

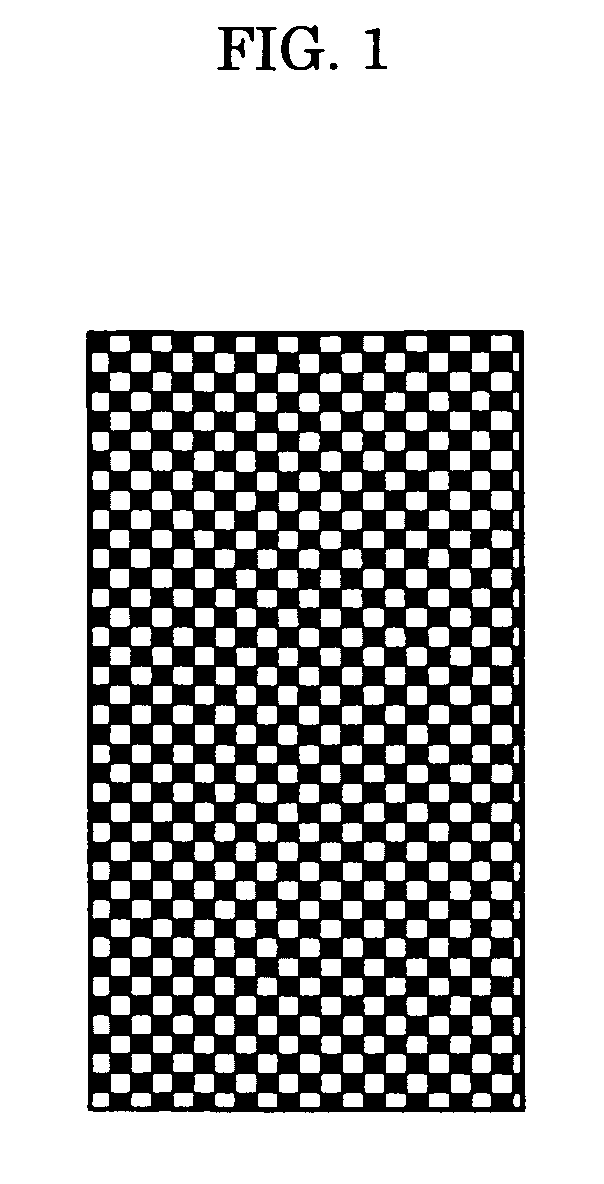

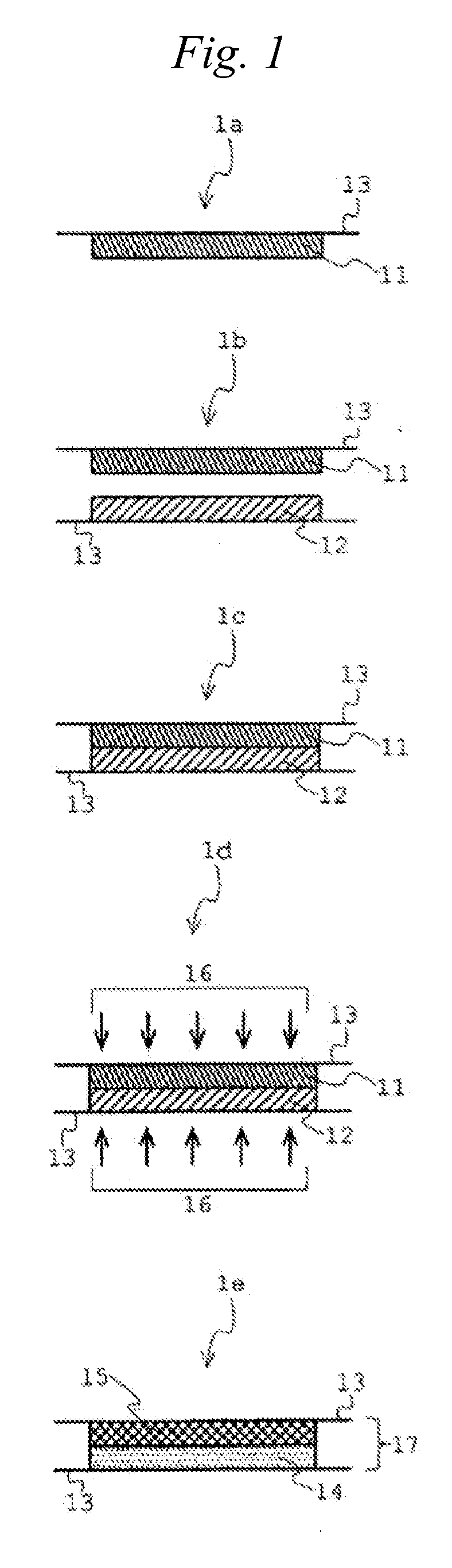

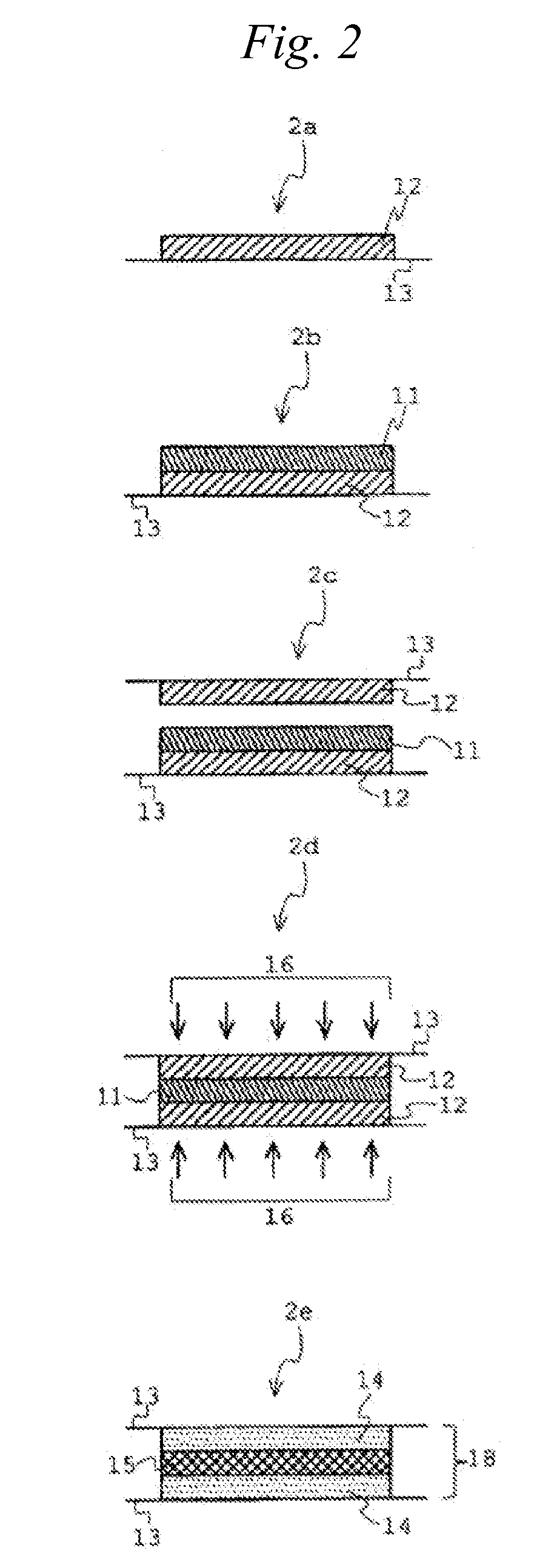

Heat expandable removable acrylic pressure-sensitive adhesive tape or sheet, and method of removing the same

InactiveUS20120034407A1Improve adhesionEasily separated and debondedLamination ancillary operationsFilm/foil adhesivesMicroparticleBlowing agent

An object of the present invention is to provide a heat-expandable / peelable acrylic pressure-sensitive adhesive tape that maintains a high adhesion force, and can be easily separated or debonded at the bonded part by heating, regardless of the material constituting the adherend.Disclosed is a heat-expandable / peelable acrylic pressure-sensitive adhesive tape or sheet which includes at least a pressure-sensitive adhesive layer containing a blowing agent, a peelable or peel-assisting film layer, and a viscoelastic substrate containing microparticles, in which at least the peelable or peel-assisting film layer and the microparticle-containing viscoelastic substrate constitute a multilayer structure, and the multilayer structure is arranged on or above at least one side of the pressure-sensitive adhesive layer so that the blowing agent-containing pressure-sensitive adhesive layer is in contact with the peelable or peel-assisting film layer with or without the interposition of another layer.

Owner:NITTO DENKO CORP +1

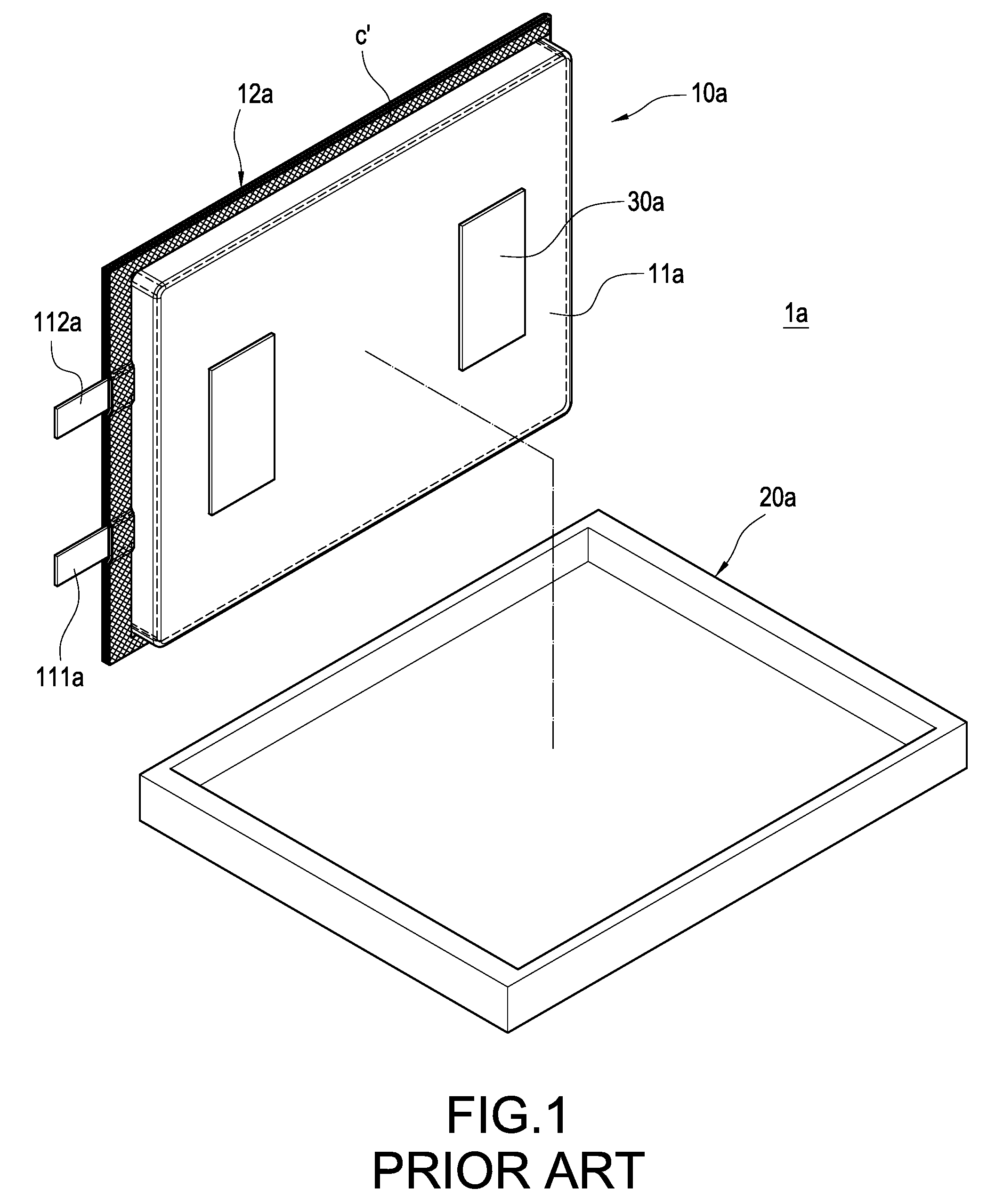

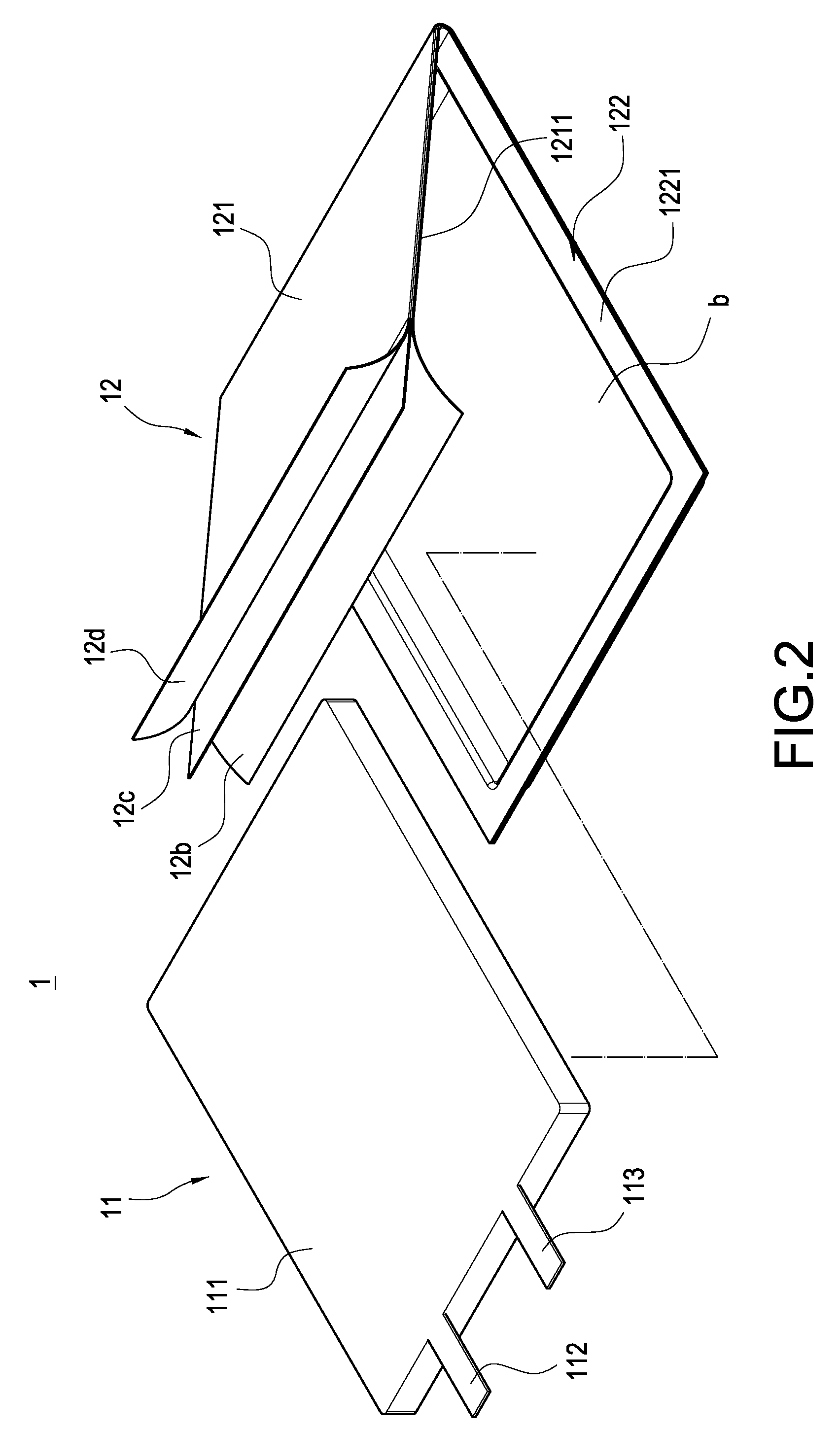

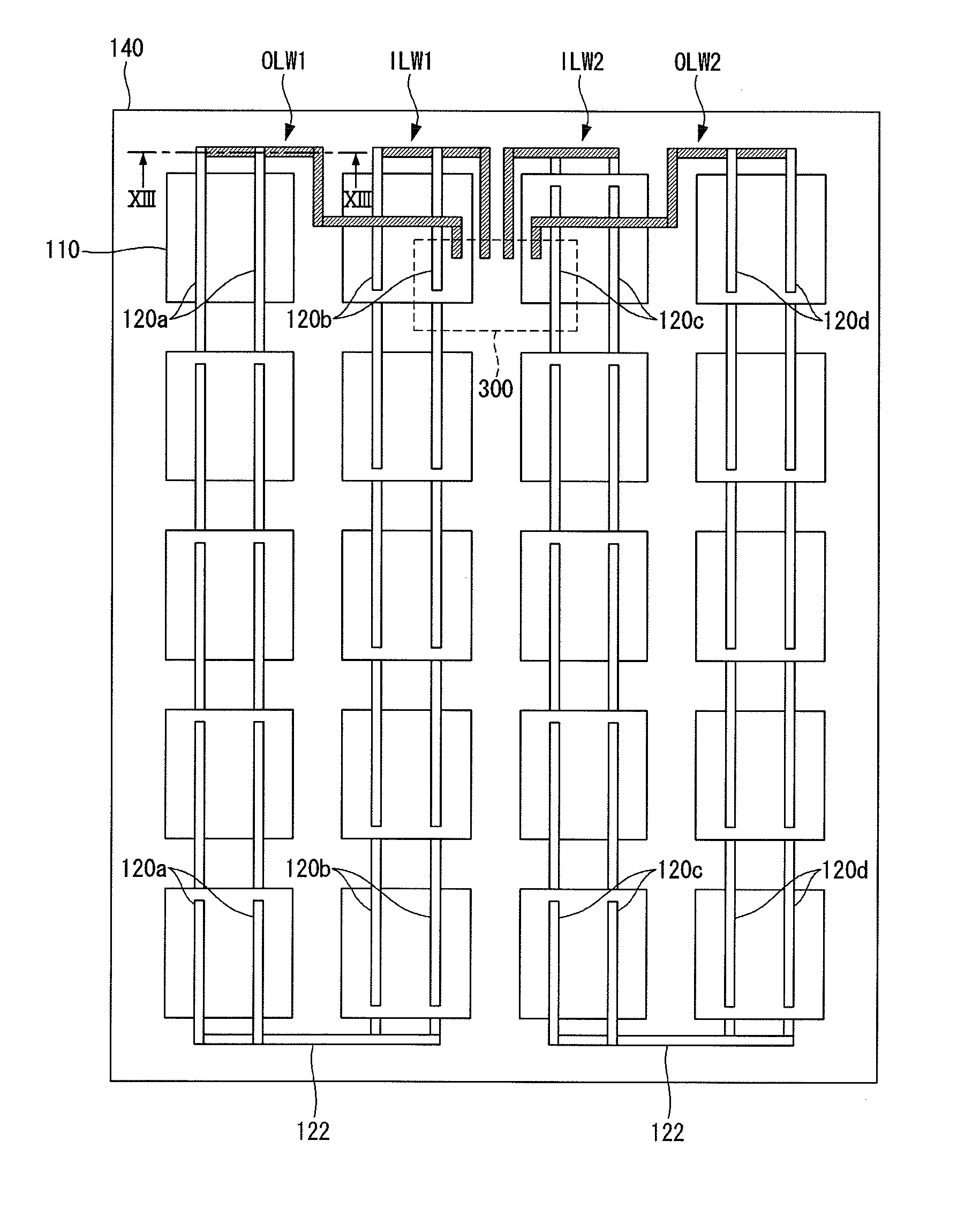

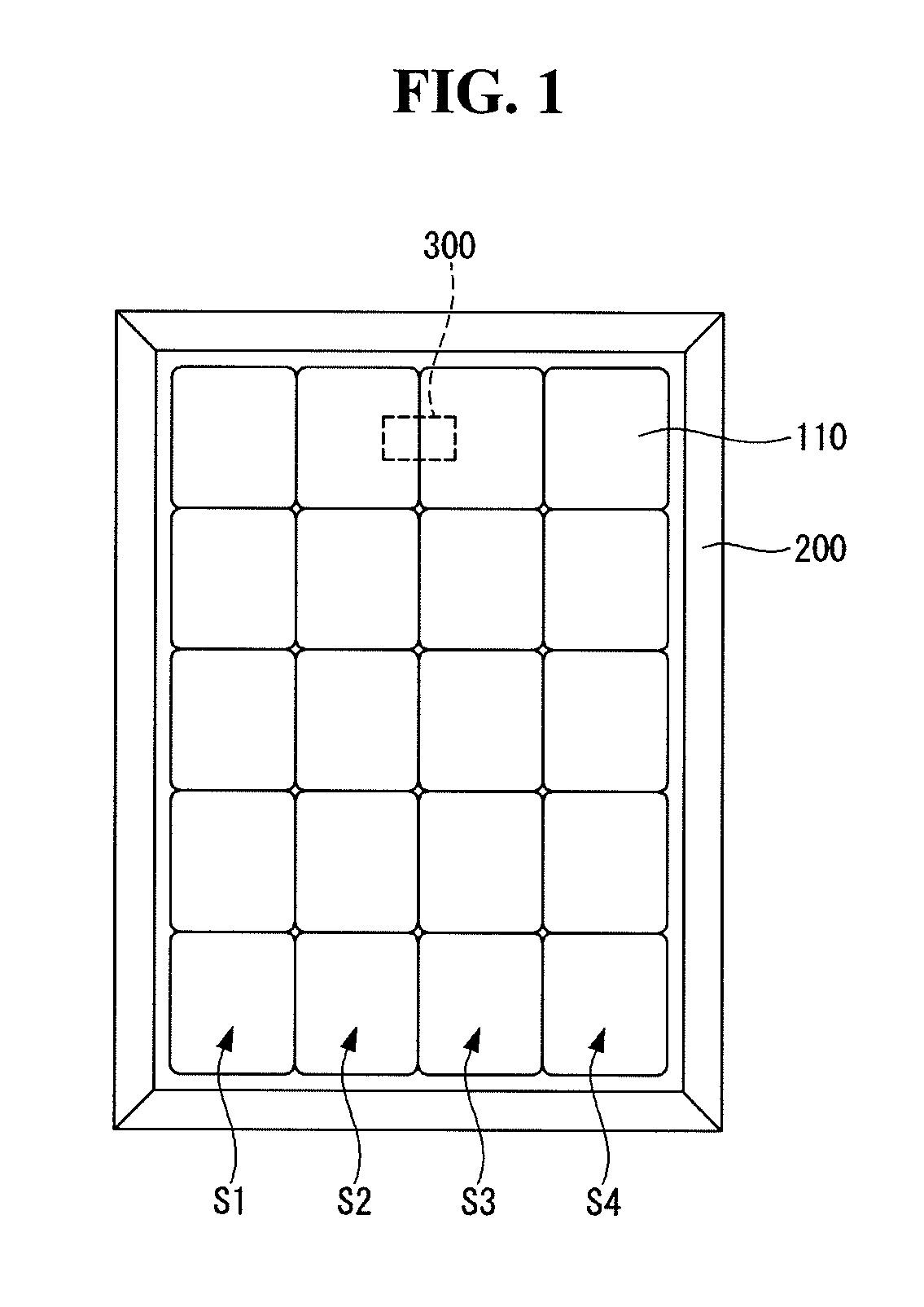

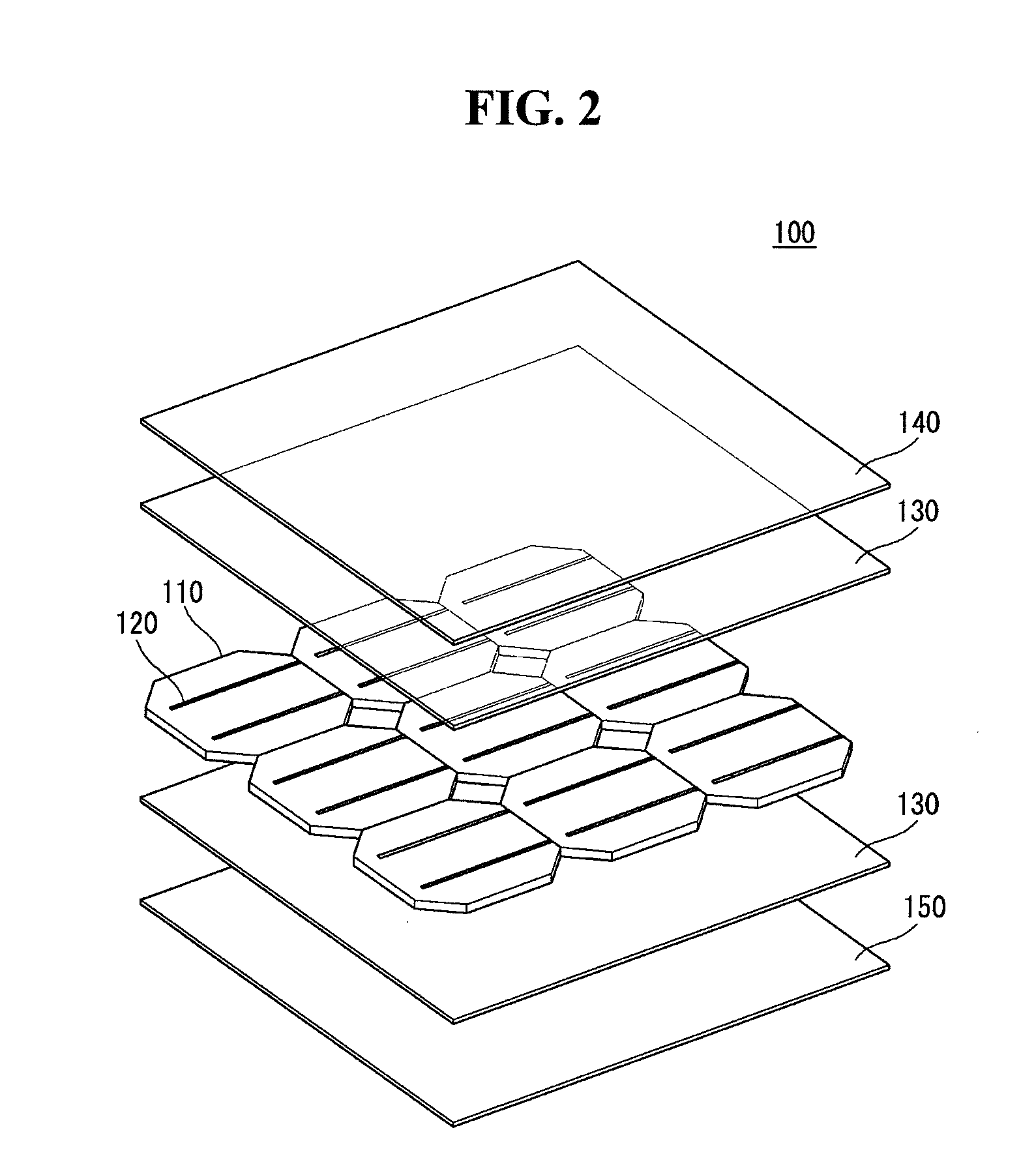

Solar cell module

InactiveUS20110088746A1Reduced adhesion strengthPV power plantsPhotovoltaic energy generationInterconnectorSolar cell

A solar cell module is discussed. The solar cell module includes a junction box, a solar cell panel including a plurality of strings of solar cells, each string including a plurality of solar cells that are arranged in a row and are electrically connected to one another, an interconnector for electrically connecting adjacent ones of the plurality of solar cells to one another belonging to at least one of the plurality of strings, a first adhesive member positioned between an electrode part of one of the adjacent solar cells and the interconnector, a lead wire for electrically connecting one end of the interconnector to the junction box, and a second adhesive member positioned between the interconnector and the lead wire. At least one of the interconnector and the lead wire is formed of a lead-free material containing an amount of lead equal to or less than 1,000 ppm.

Owner:LG ELECTRONICS INC

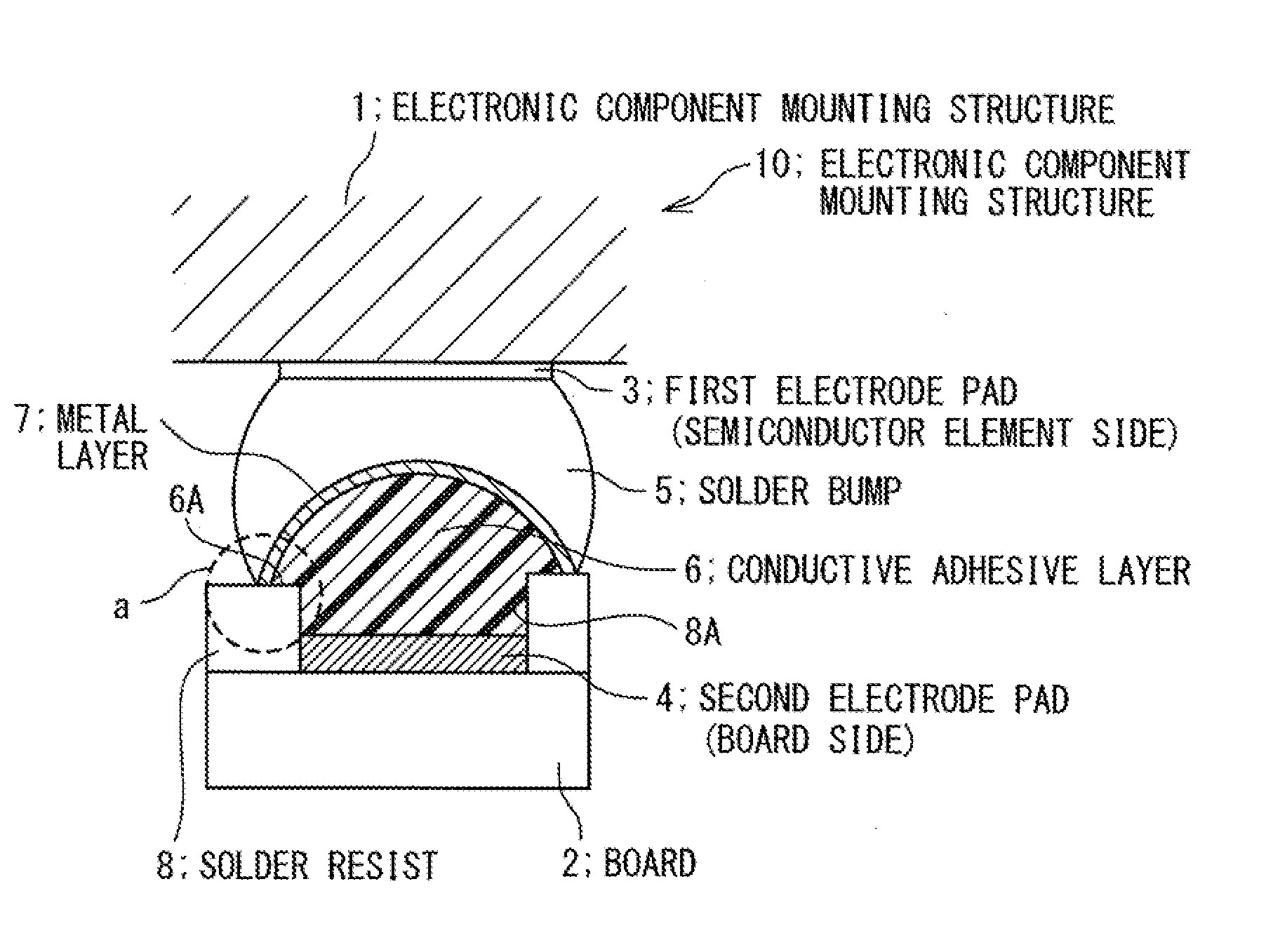

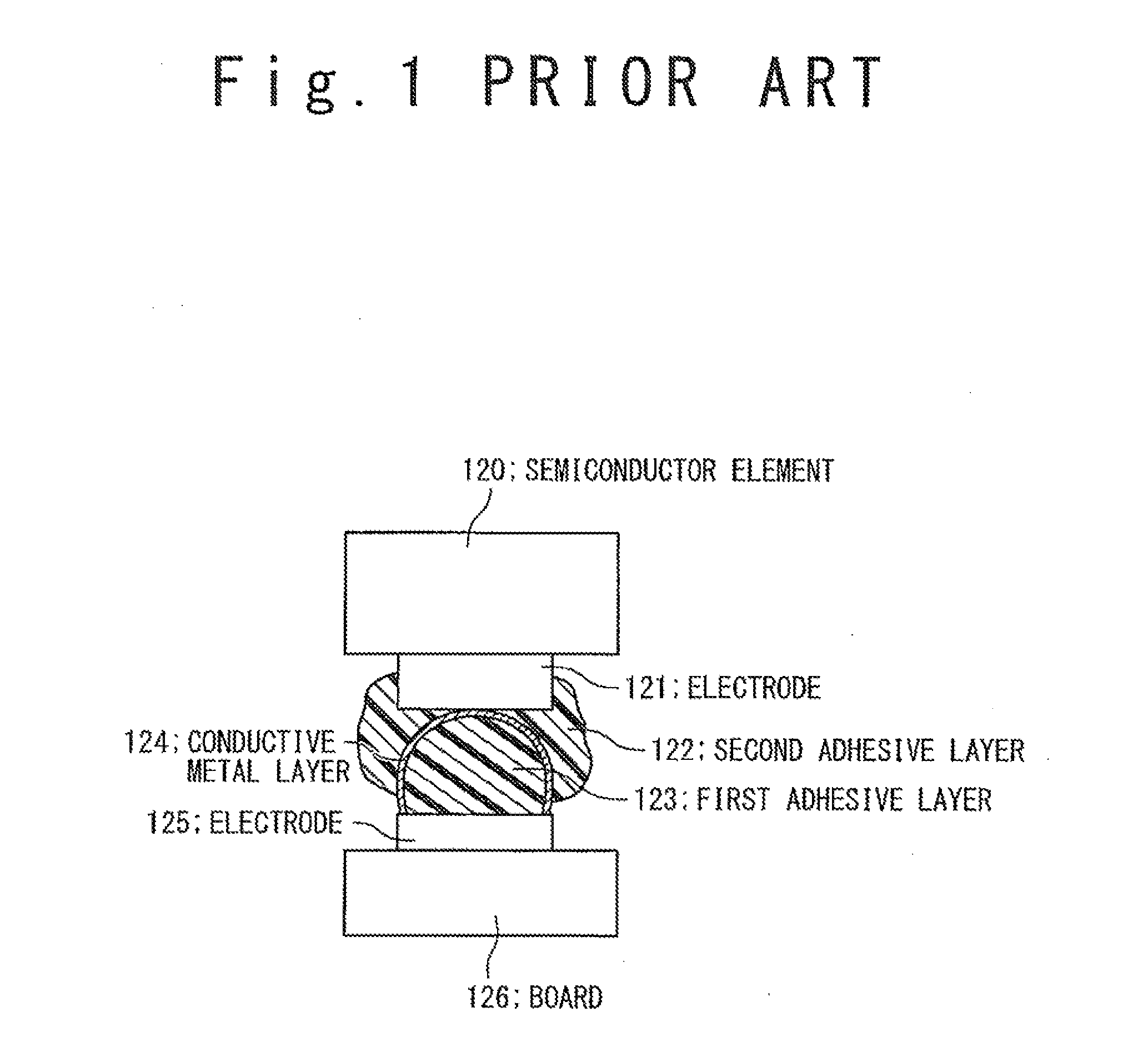

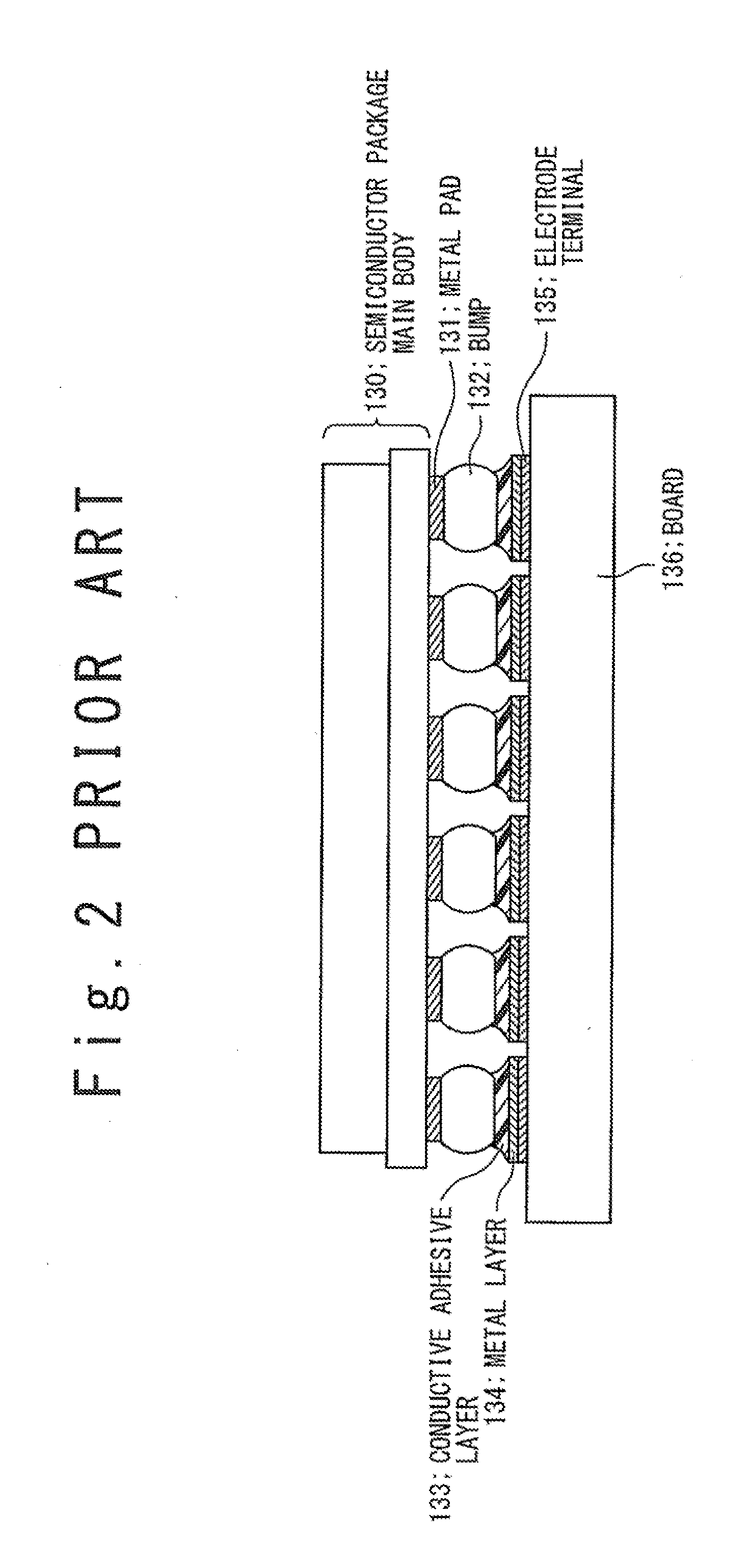

Electronic component mounting structure, electronic component mounting method, and electronic component mounting board

ActiveUS20100295177A1Firmly connectedIncrease freedomFinal product manufactureSemiconductor/solid-state device detailsResistConductive materials

In an electronic component mounting structure, a semiconductor element (an electronic component) provided with an electrode pad and a board provide with an electrode pad corresponding to the electrode pad are connected via a conductive material portion. On a surface of the board, there is formed solder resist having an opening regulating an area of the electrode pad. The conductive material portion is formed to protrude from a surface of the solder resist. An elastic coefficient of the conductive material portion is lower than that of the solder resist. A solder bump and the conductive material portion are connected via a metal layer. The conductive material portion is formed to have an area larger than that of the opening of the solder resist. An edge of the conductive material portion is adhered to a portion of the surface of the solder resist. Thus, in a case of mounting an electronic component on a board by flip-chip connection, a reliability of connection can be secured.

Owner:NEC CORP

Method for manufacturing integrated circuit

InactiveUS7820529B2Increase productivityReduced adhesion strengthTransistorSolid-state devicesEngineeringIntegrated circuit

A method for separating an integrated circuit formed by a thin film having a novel structure or a method for transferring the integrated circuit to another substrate, that is, so-called transposing method, has not been proposed. According to the present invention, in the case that an integrated circuit having a thin film having a novel structure formed over a substrate via a release layer is separated, the release layer is removed in the state that the thin film integrated circuit is fixated, the thin film integrated circuit is transposed to a supporting substrate having an adhesion surface, and the thin film integrated circuit is transposed to another substrate having an adhesion surface with higher strength of adhesion than that of the supporting substrate.

Owner:SEMICON ENERGY LAB CO LTD

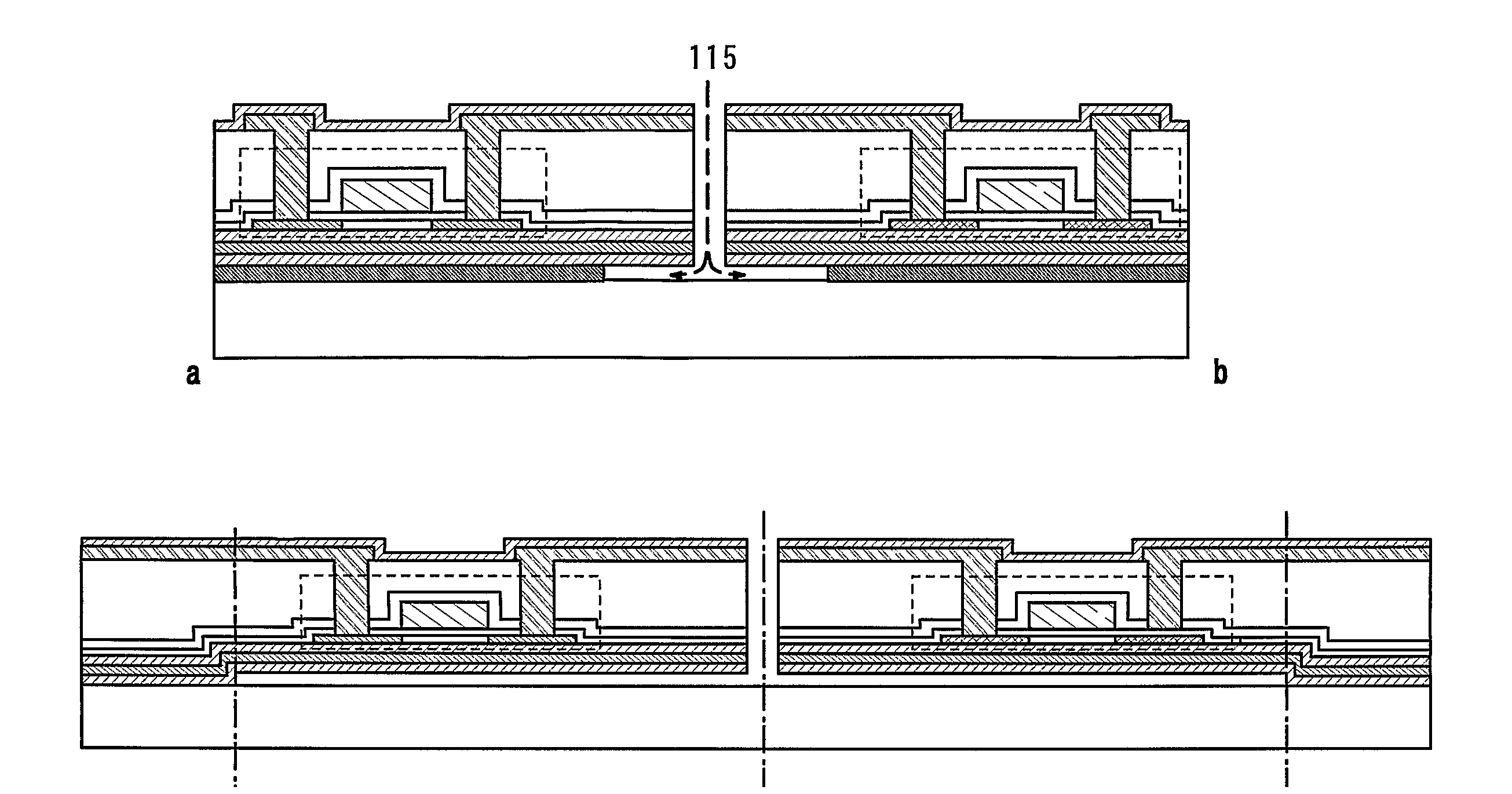

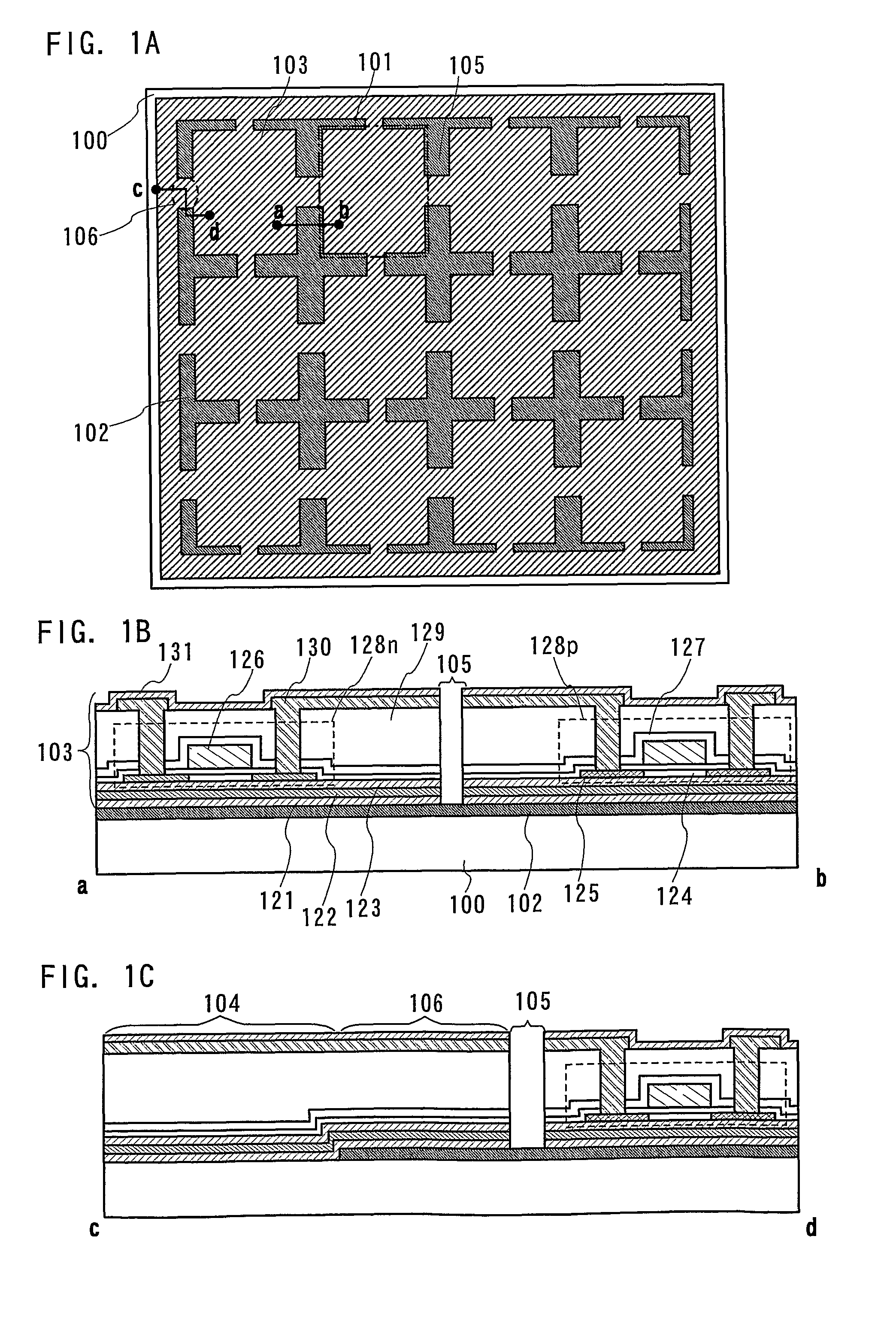

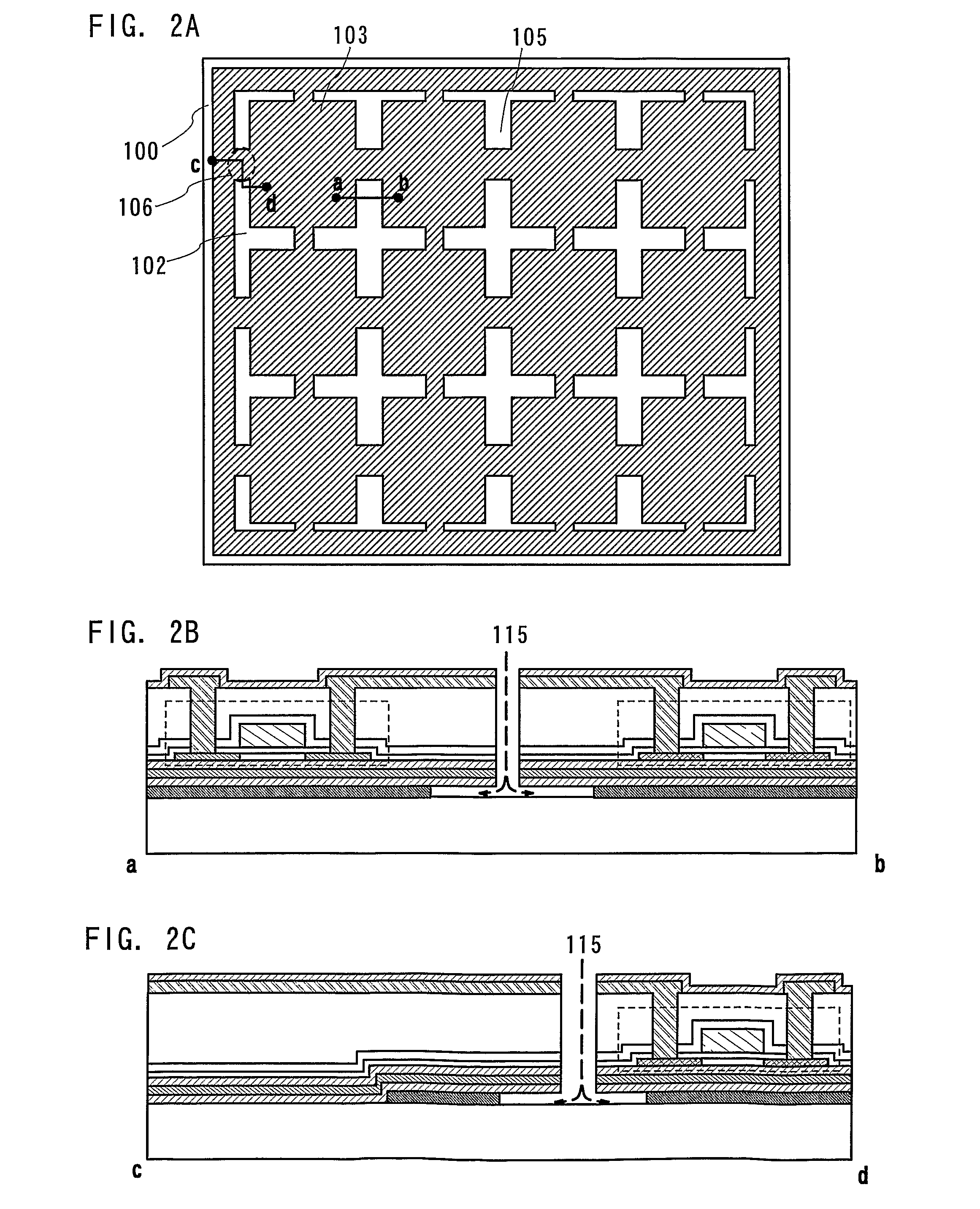

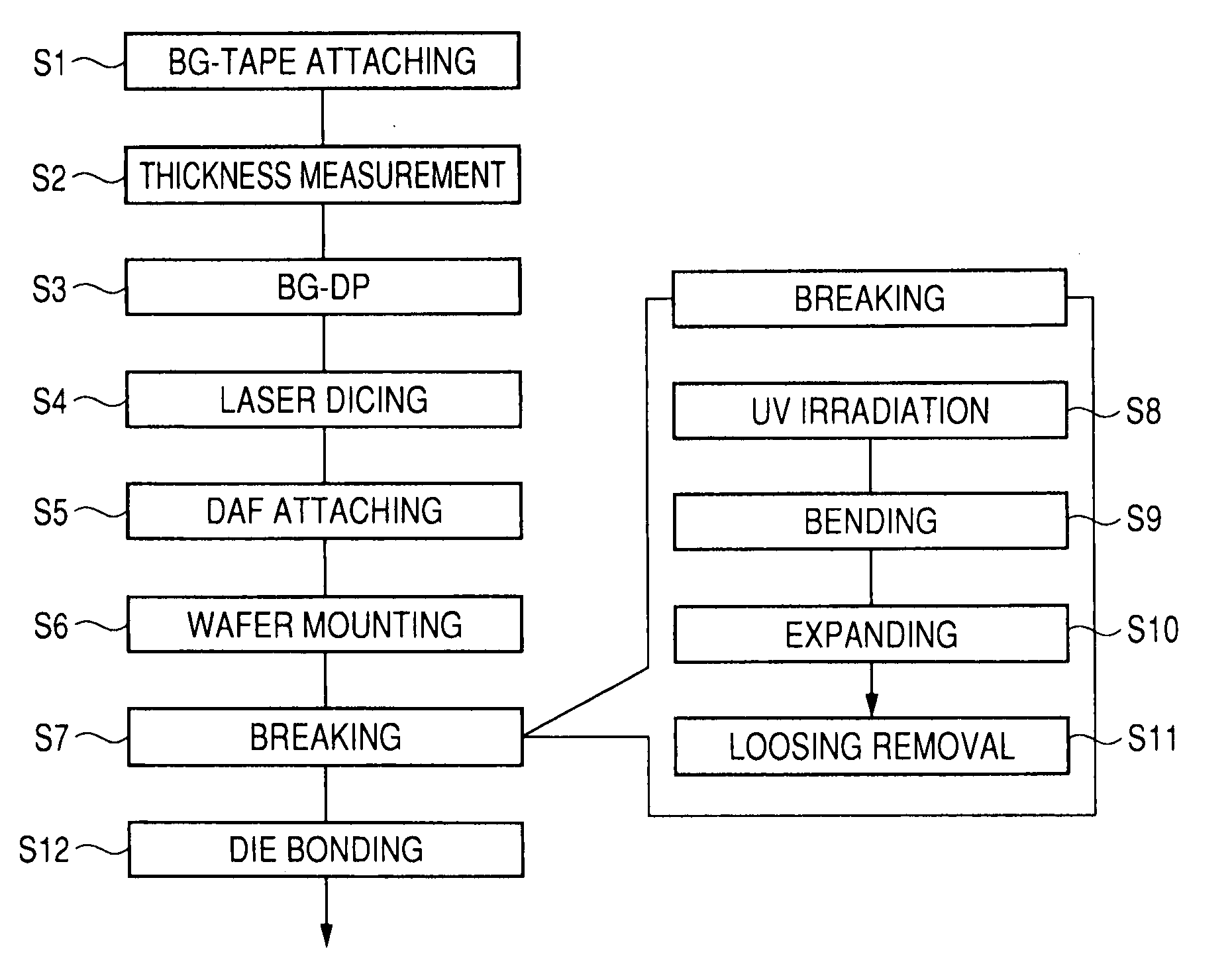

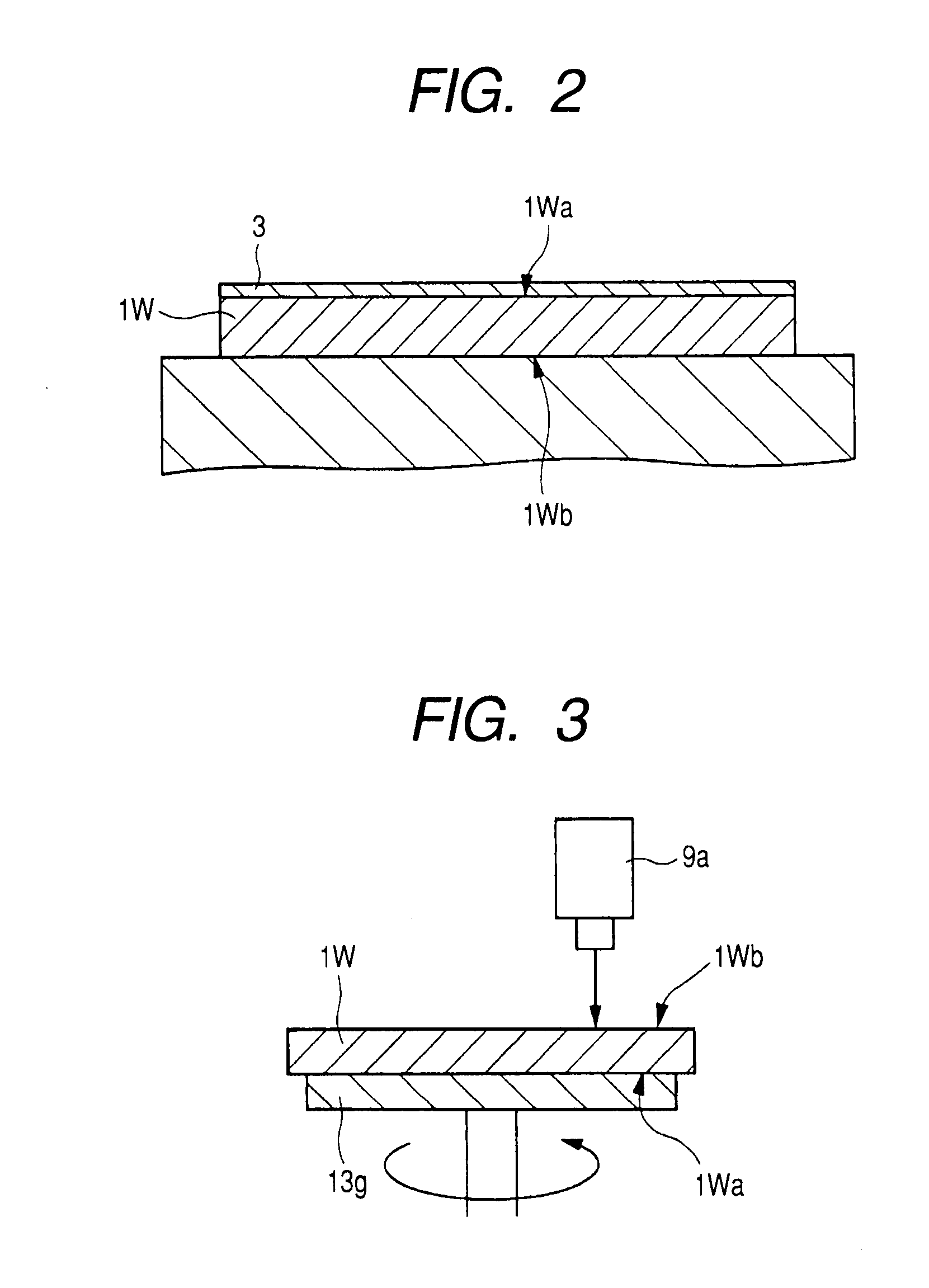

Manufacturing method of a semiconductor device

InactiveUS20070275543A1Improve reliabilityPrevent movementSemiconductor/solid-state device manufacturingDicing tapeSemiconductor package

This invention aims at improvement in reliability of a semiconductor device. In this invention, a semiconductor wafer is irradiated with laser light so as to have a fractured layer formed in the interior of the semiconductor wafer, the semiconductor wafer is mounted on a dicing tape via paste (adhesive layer), then the paste of the dicing tape is hardened by UV irradiation or cooling, and subsequently the semiconductor wafer is bent (breaking). By this process, shifting and movement of semiconductor chips can be prevented because the paste has been hardened at the time of the bending. As a result, the semiconductor chip can be prevented from interfering with adjacent chips and can also be inhibited from generating chipping; therefore, the reliability of a semiconductor device can be improved.

Owner:RENESAS ELECTRONICS CORP

Perfluoropolyether compound and lubricant and magnetic disk using same

InactiveUS20060052262A1Reduce scatterAvoid decompositionOrganic compound preparationRecord information storagePerfluoropolyetherLubricant

A compound of the formula (I), a lubricant and a magnetic disk using the compound A—CH2CF2O(CF2CF2O)m-(CF2O)n-CF2CH2—B (I) wherein A is amino group having hydroxyl group, B is hydroxyl group, or amino group having or not having hydroxyl group, wherein m is a real number of 5 to 36, and n is a real number of from 4 to 30.

Owner:MATSUMURA OIL RES

Surface treated copper film

InactiveUS7651783B2Improve acid resistanceHigh bonding strengthInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentElectrolysisHeat resistance

A surface treated copper foil with improved adhesion to the insulating resin of a copper-clad laminate for higher frequency applications contains a copper foil provided with a heat-resistant layer and an olefin-based silane coupling agent layer sequentially on at least one side thereof. An anticorrosive treatment may be performed after the heat resistance treatment. The copper foil is preferably an electrolytic copper foil, and these layers can be provided on the S side and / or the M side thereof. The copper foil has an adequate adhesive strength, even without the roughening treatment that has been performed in the past. A film of zinc, zinc-tin, zinc-nickel, zinc-cobalt, copper-zinc, copper-nickel-cobalt, or nickel-cobalt can be used favorably as the heat-resistant layer, and a film that has undergone a zinc-chromate or a chromate treatment can be used favorably as the anticorrosive layer.

Owner:JX NIPPON MINING& METALS CORP

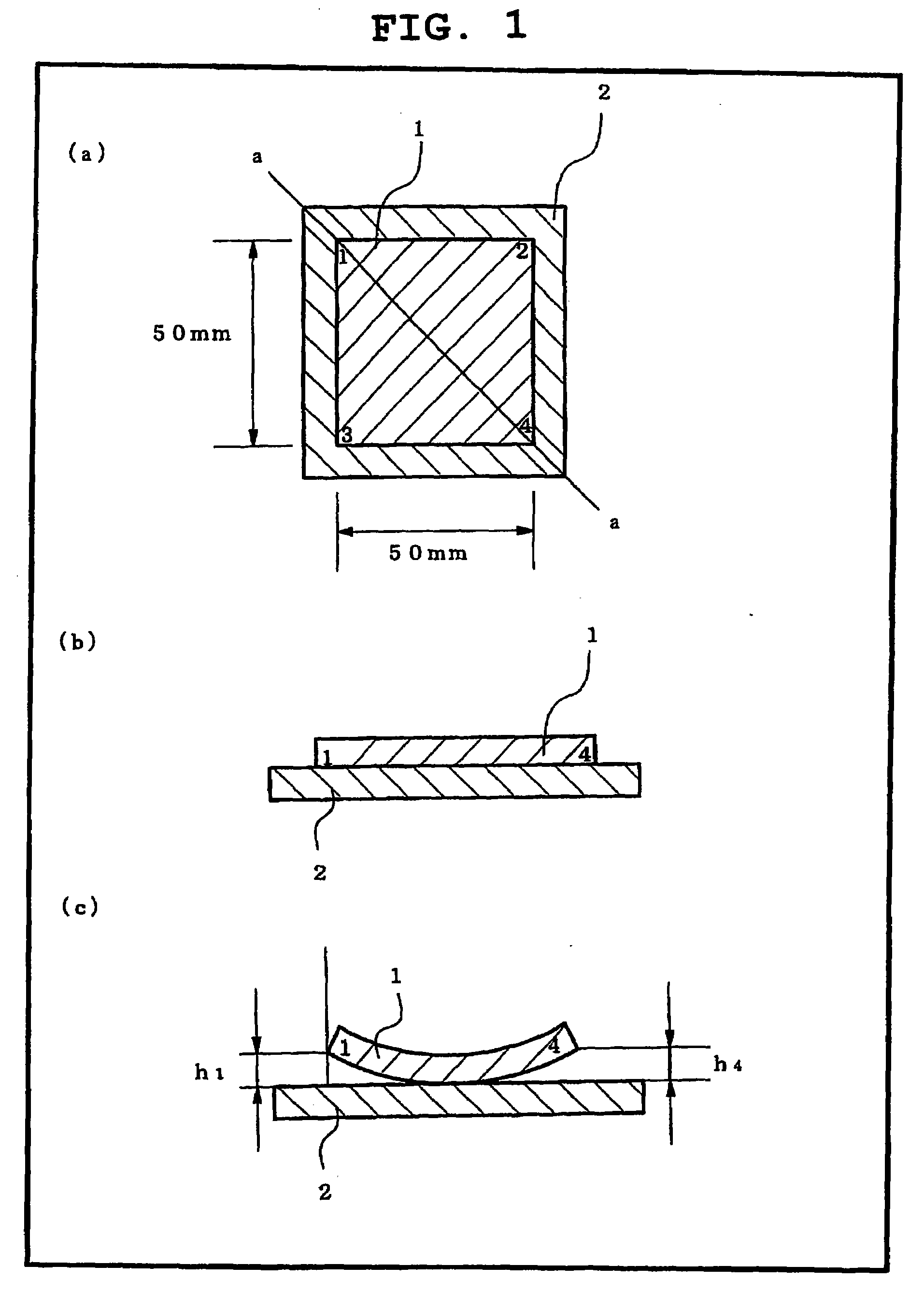

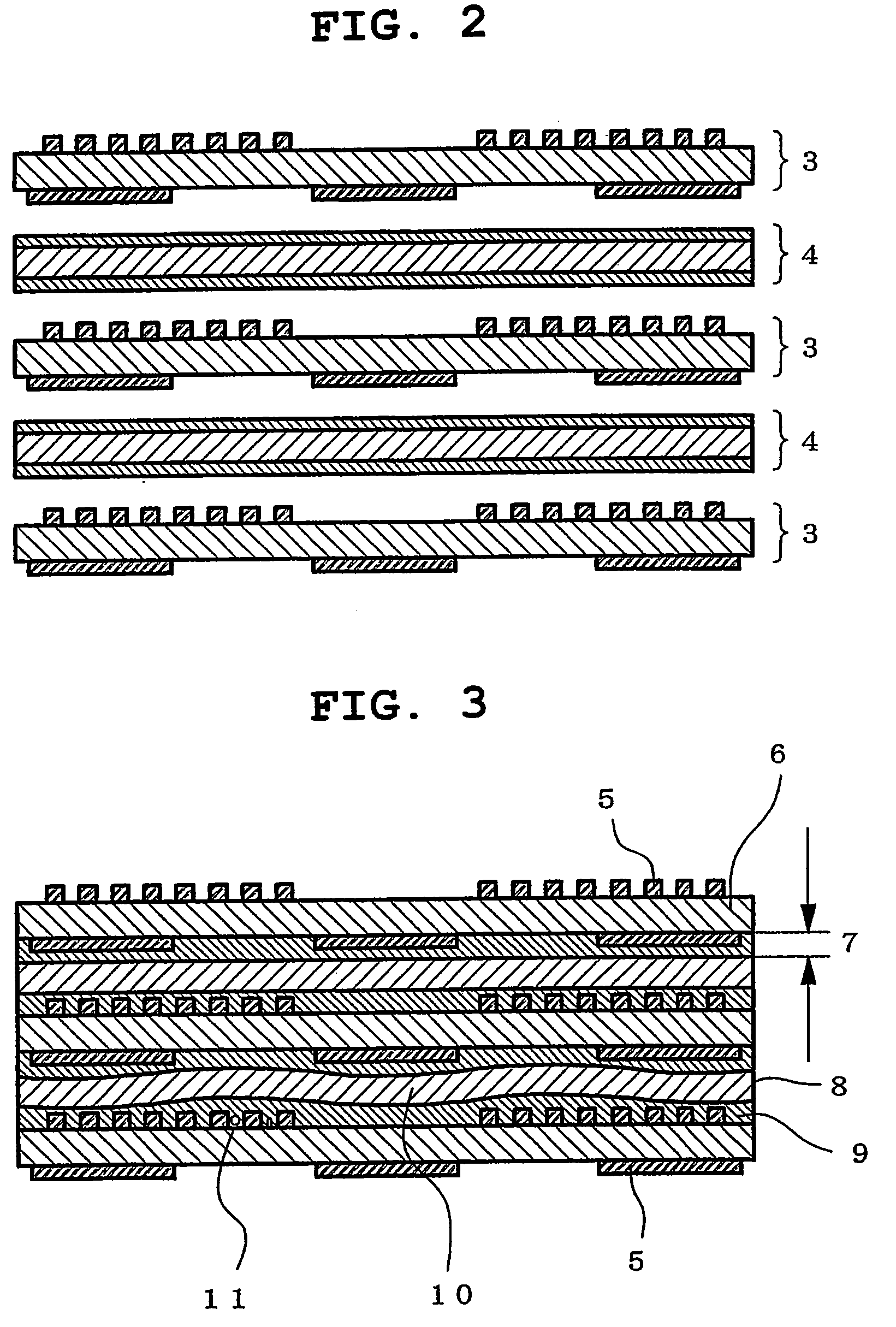

Adhesive sheet, metal-laminated sheet and printed wiring board

InactiveUS20090056995A1Reduced adhesion strengthPrevent gelationPrinted circuit detailsPrinted circuit aspectsEngineeringPolyimide membrane

The adhesive sheet contains a substrate film and an adhesive layer formed at least on one surface of the substrate film. The substrate film is made of a polyimide film showing a degree of curl after a heat treatment at 300° C. of not more than 10%. The adhesive sheet of the present invention can be used for electronic parts and the like exposed to high temperature particularly because warpage and distortion thereof caused by a high temperature treatment are suppressed, and can improve quality and yield of electronic parts and the like.

Owner:TOYOBO CO LTD

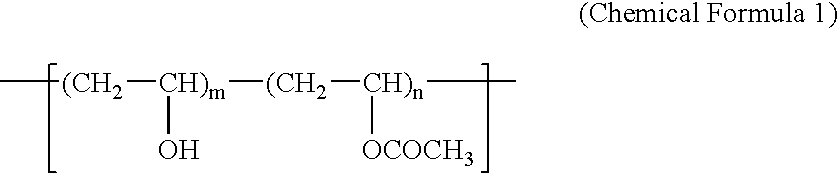

Electrode for electric double layer capacitor

InactiveUS20040130038A1Improve adhesionHigh resistivityLiquid electrolytic capacitorsSemiconductor/solid-state device detailsAdhesivePolyvinyl alcohol

In an electrode for an electric double layer capacitor of the present invention, the peak value of particle size distribution of graphite particles added to a conductive adhesive is in a range of 2.6 to 3.2 mum, not less than 100,000 dimples having a largest outer diameter in a range of 4 to 10 mum and a depth in a range of 4 to 15 mum are formed on the surface of the collector sheet per 1 cm<2>, and the occupied area of the dimples to the entire surface area of the collector sheet is not more than 50%. By determining the saponification value of polyvinylalcohol which is used as a binder component of the conductive adhesive in a range of 90.0 to 98.5, adhesiveness of the collector sheet and the electrode forming sheet is improved. Furthermore, by substituting H atoms contained in the polyvinylalcohol with Si atoms, adhesiveness of the collector sheet and the electrode forming sheet can be further improved.

Owner:DAIDO METAL CO LTD

Method for manufacturing a polyester fiber cord for reinforcing rubber materials

InactiveUS20030198794A1Improve adhesionReduce the burden onFibre typesPretreated surfacesRubber materialPolyester

There is provided a method for manufacturing a polyester fiber cord for reinforcing rubber materials that has an excellent adhesive property to rubber materials, and maintains a good adhesive property even after exposed to high temperatures in a state being compounded with rubber materials. Said method is characterized in that a first aqueous processing liquid comprising a blocked polyisocyanate compound is applied to a polyester fiber that has been beforehand provided with an epoxy compound during a yarn manufacturing process or in a state of a twisted cord in an amount of 0.5 to 5.0% based on the fiber weight in terms of solids of the blocked isocyanate compound; the treated yarn is dried at a yarn temperature of >=(A+20)° C., wherein A° C. is a dissociation temperature of the blocked isocyanate, and then subjected to heat treatment; and a second processing liquid comprising resorcin-formalin-rubber latex is applied to the yarn, followed by heat treatment.

Owner:TOYO TOYOBO CO LTD

Heat-sensitive adhesive material

InactiveUS20060068191A1High bonding strengthImprove the immunityThermographyOther printing apparatusCardboardVitrification

In order to provide heat-sensitive adhesive materials that represent high pressure-sensitive adhesive strength with respect to rough adherends such as cardboards or polyolefin wraps and lower decrease of adhesive strength with time, are thermally activated with lower energy and exhibit excellent blocking resistance, heat-sensitive adhesive materials are disclosed that contain a support, an underlayer, and a heat-sensitive adhesive layer, in this order, wherein the underlayer comprises a thermoplastic resin and a hollow filler, and the glass transition temperature of the thermoplastic resin is −70° C. or higher and below 0° C.

Owner:RICOH KK

Two-component waterborne wear-resisting and low-ice-adhesion anti-icing coating and coating layer, and preparation methods and applications thereof

ActiveCN104762008ASimple preparation processEasy constructionOther chemical processesPolyurea/polyurethane coatingsCoated surfaceWear resistance

The invention provides preparation methods of a two-component waterborne wear-resisting and low-ice-adhesion anti-icing coating and a coating layer thereof. The two-component waterborne anti-icing coating is composed of a component A containing a core-shell structure polymer emulsion and inorganic nanoparticles and a component B containing a curing agent. An outer layer of the core-shell structure polymer emulsion in the component A of the anti-icing coating is a hydrophilic shell layer, so that polymer emulsion particles can be stably dispersed in water, and the advantages of being green and environmentally friendly are provided. The inorganic nano particles in the component A are rigid particles, can improve the mechanical properties of the anti-icing coating layer, endow the coating layer with excellent wear resistance and prolong the service life of the coating layer. After the coating is cured into a film, the hydrophilic shell layer of the polymer emulsion particles can absorb moisture, and thus a water lubricating layer is formed on the surface of the coating layer; when the coating layer surface is iced, due to the existence of the water lubricating layer, the acting force between ice and the coating layer is decreased, besides, the substrate surface roughness is also reduced, and the contact area between the ice and the substrate is decreased.

Owner:CHINA SCI INTELFUSION INT TECH (BEIJING) CO LTD

Thermally-foamable re-releasable acrylic pressure-sensitive adhesive tape or sheet

InactiveUS20100075129A1Easy to disassembleEasy to separateLayered productsAdhesive processes with adhesive heatingFoaming agentEngineering

The present invention relates to a thermally-foamable re-releasable acrylic pressure-sensitive adhesive tape or sheet including a microparticle-containing viscoelastic substrate and a thermal foaming agent-containing pressure-sensitive adhesive layer provided on at least one surface of the microparticle-containing viscoelastic substrate. The thermally-foamable re-releasable acrylic pressure-sensitive adhesive tape or sheet of the present invention can be easily separated or disassembled at the separation or disassembling of the bonded part while maintaining a high normal-state adhesive strength at the bonding.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com