Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13829 results about "Polyimide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyimide (sometimes abbreviated PI) is a polymer of imide monomers. Polyimides have been in mass production since 1955. With their high heat-resistance, polyimides enjoy diverse applications in roles demanding rugged organic materials, e.g. high temperature fuel cells, displays, and various military roles. A classic polyimide is Kapton, which is produced by condensation of pyromellitic dianhydride and 4,4'-oxydianiline.

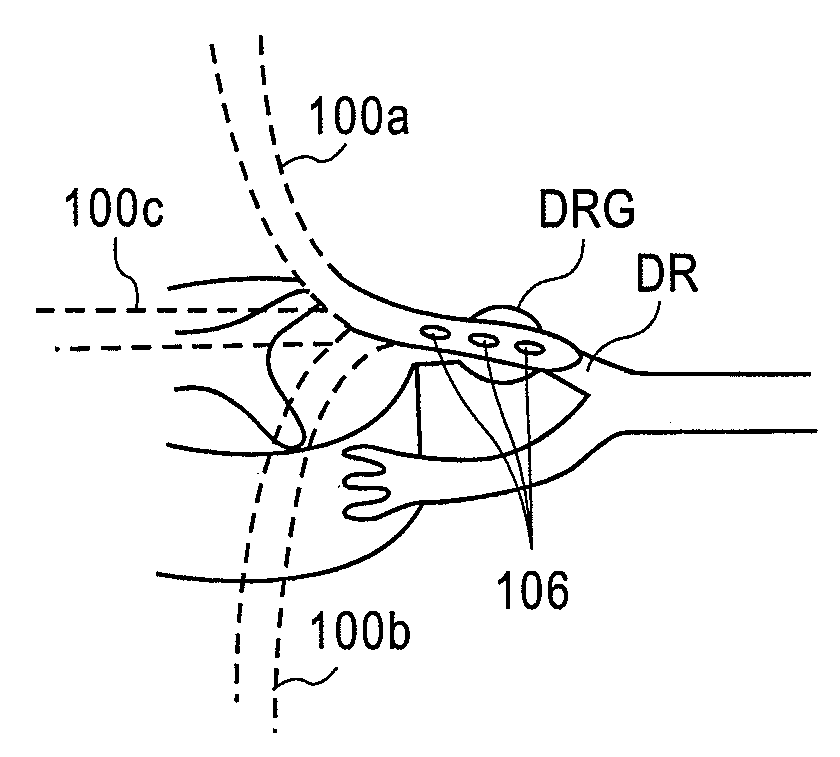

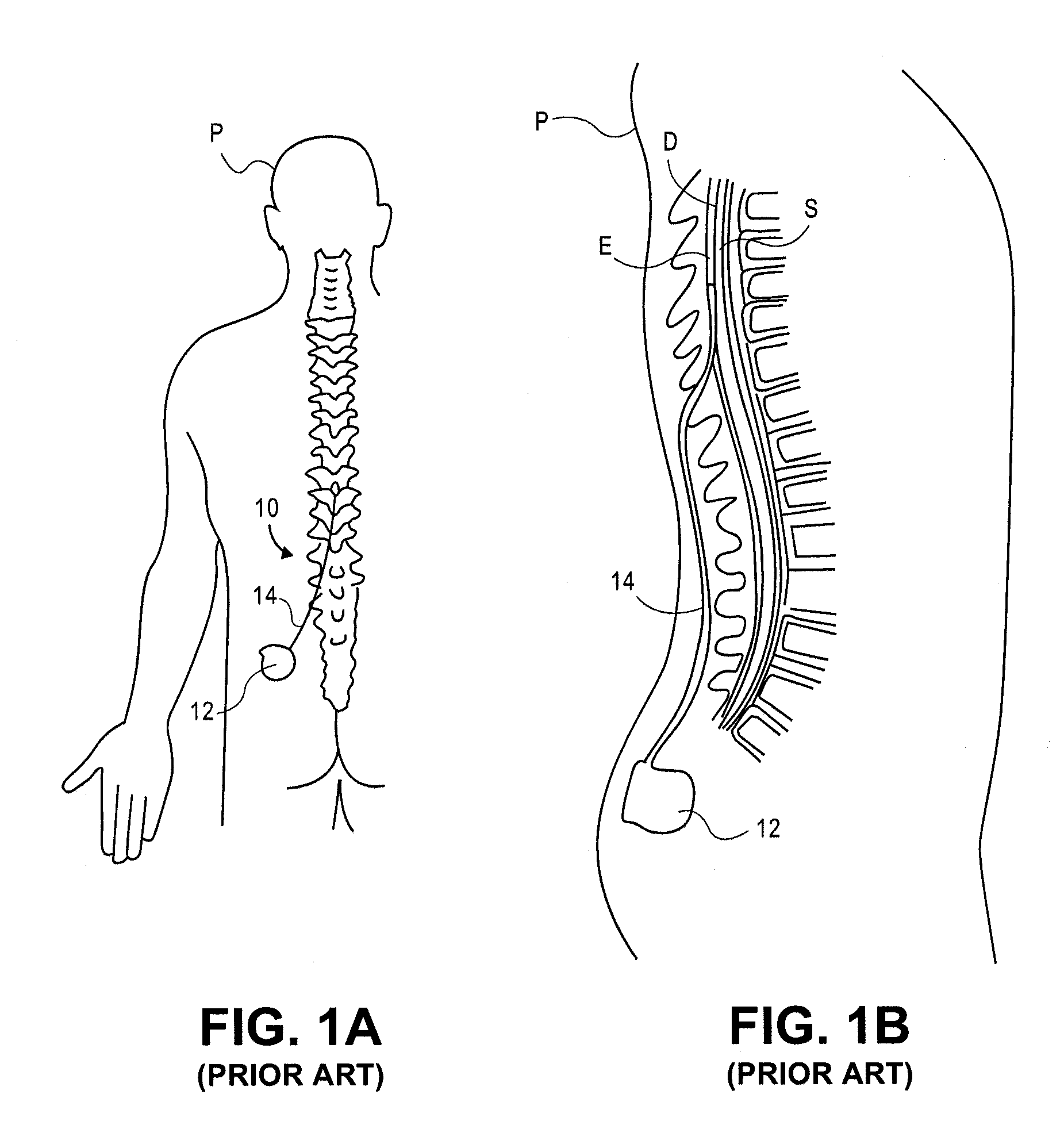

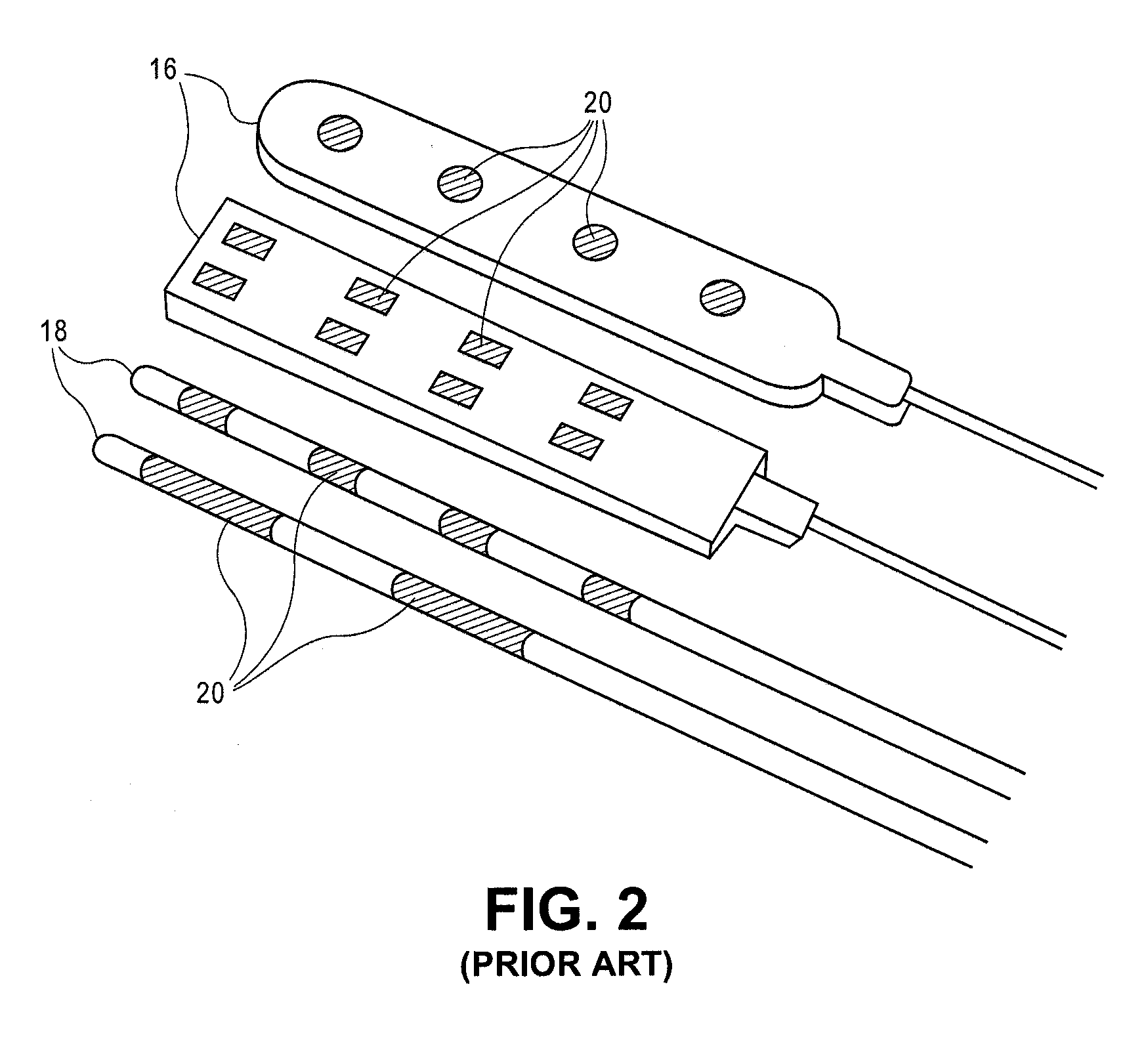

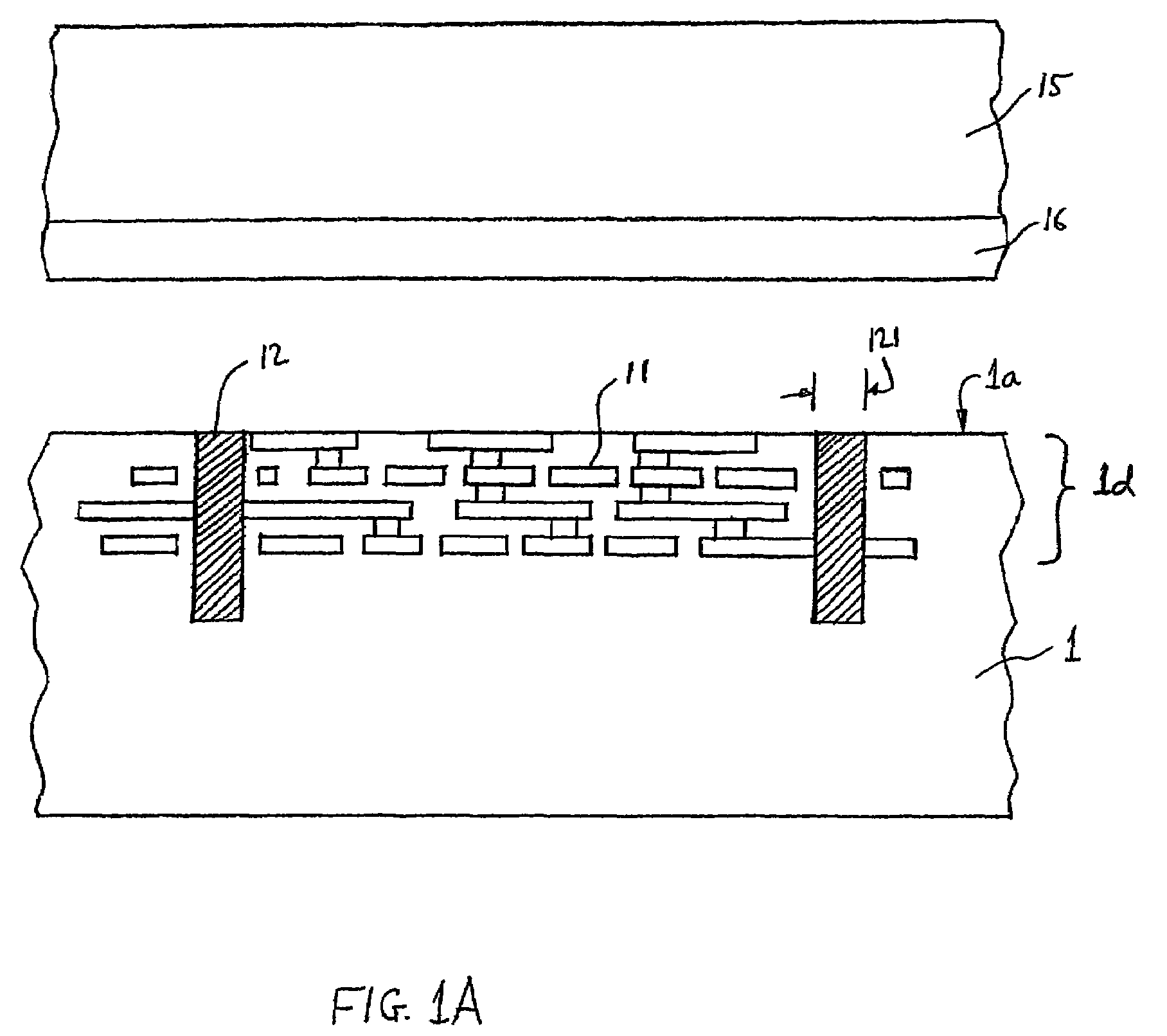

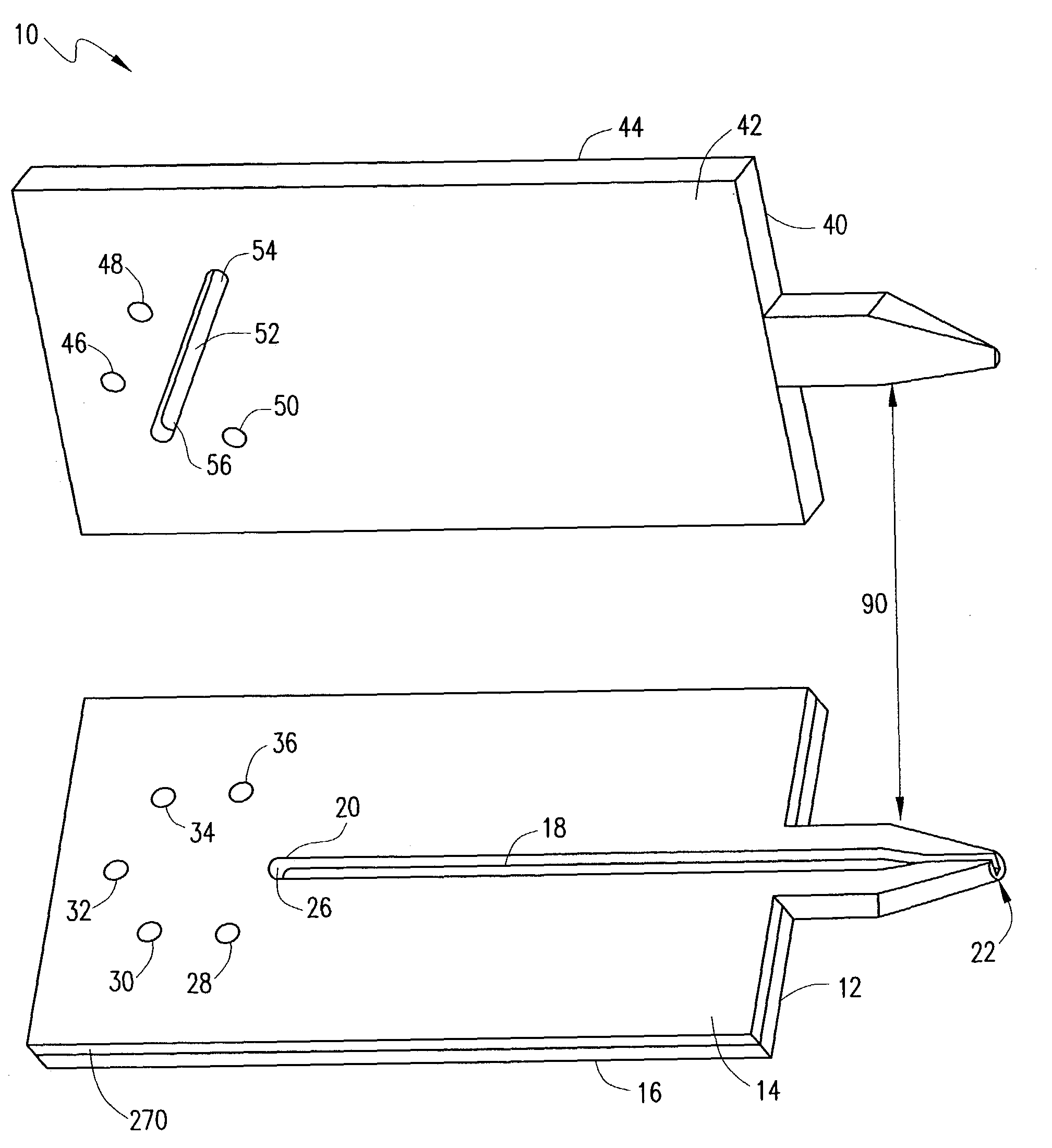

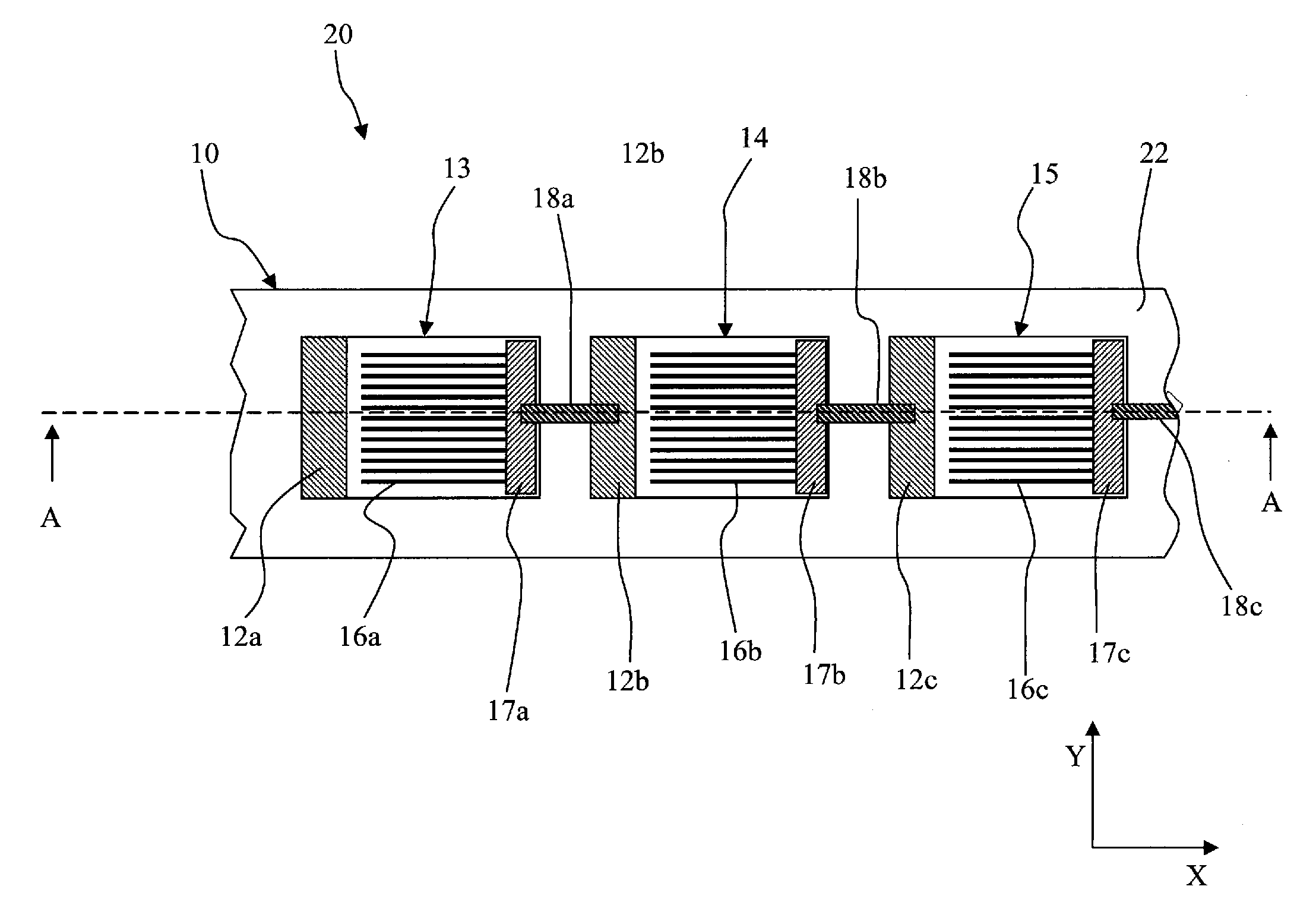

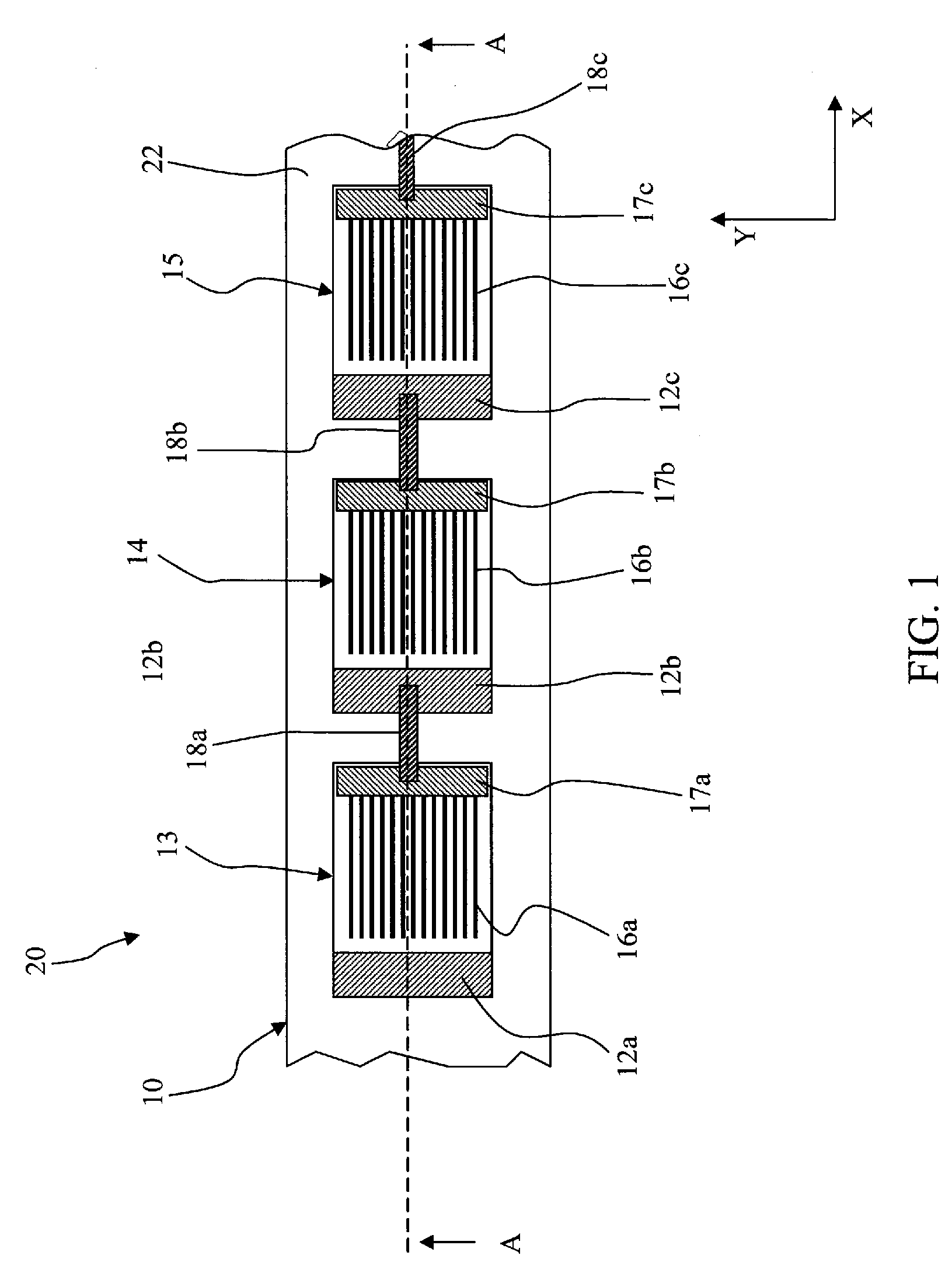

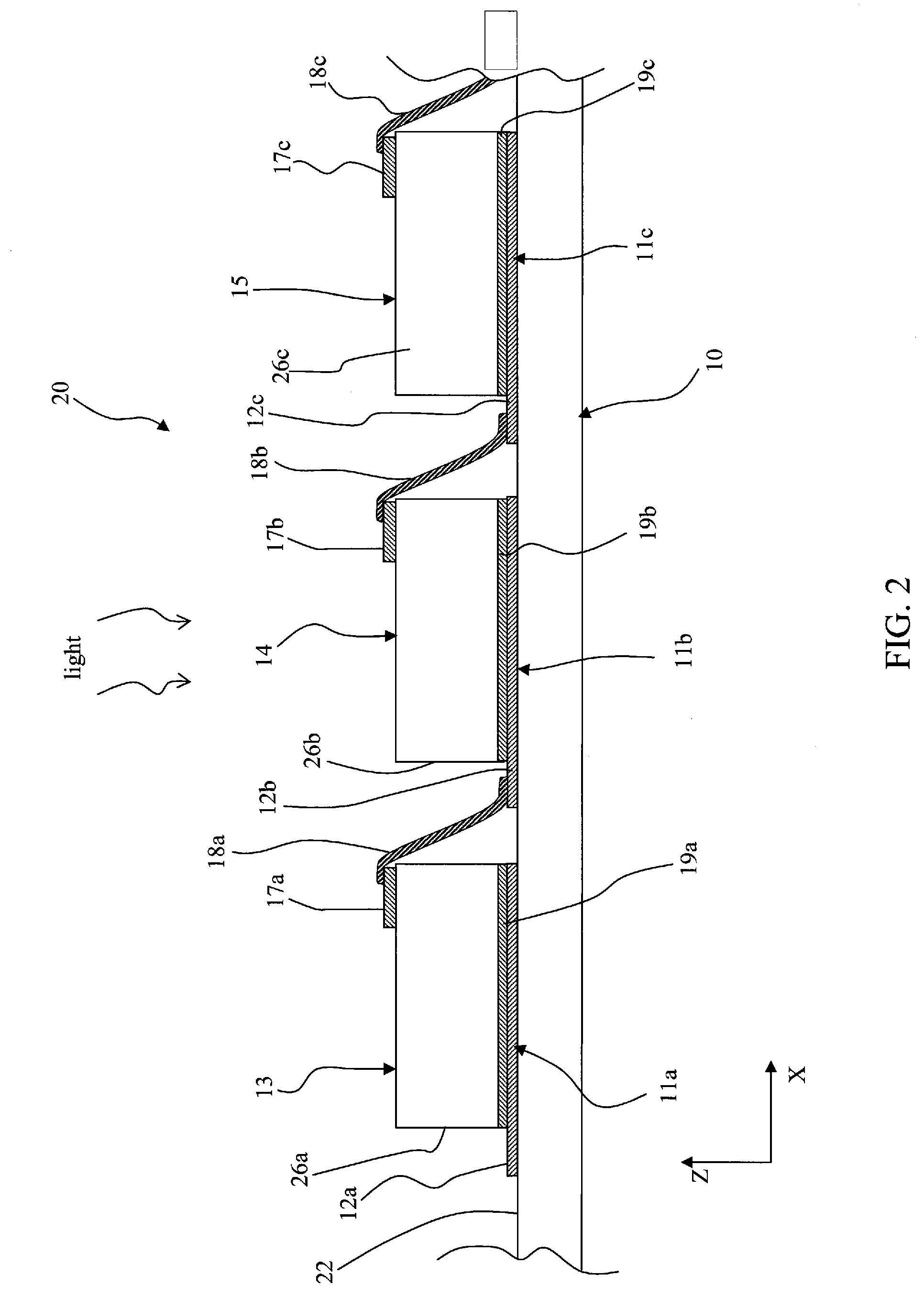

Implantable flexible circuit leads and methods of use

InactiveUS20080140152A1Easy to manufactureStrong specificitySpinal electrodesExternal electrodesDielectricFlexible circuits

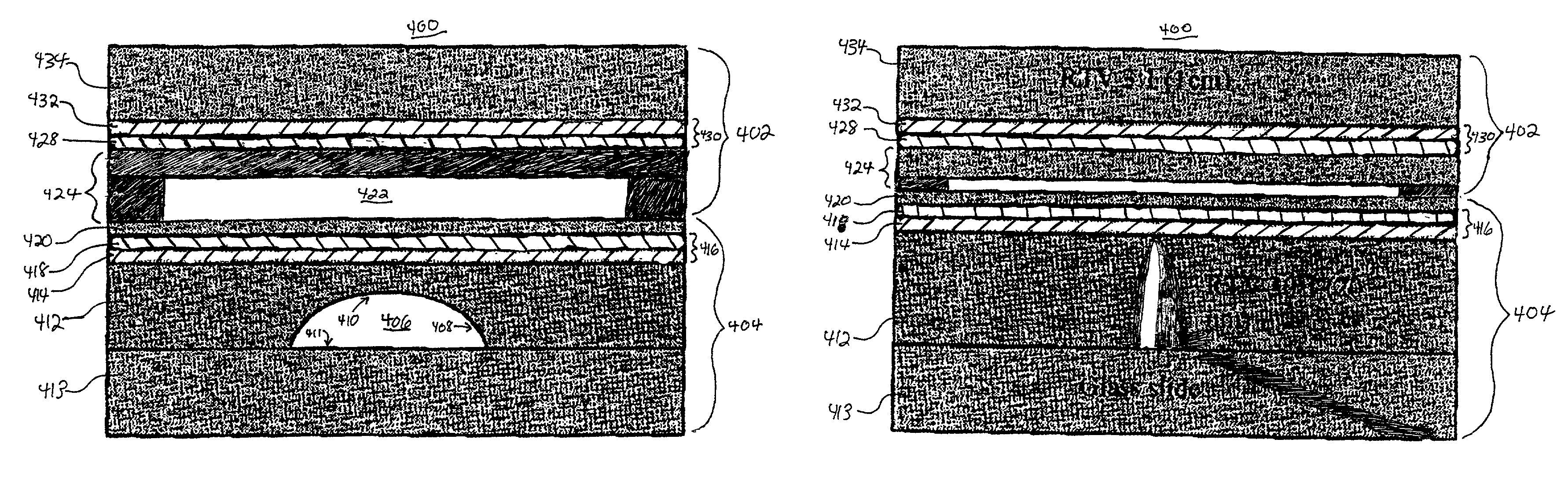

Devices, systems and methods are provided for stimulation of tissues and structures within a body of a patient. In particular, implantable leads are provided which are comprised of a flexible circuit. Typically, the flexible circuit includes an array of conductors bonded to a thin dielectric film. Example dielectric films include polyimide, polyvinylidene fluoride (PVDF) or other biocompatible materials to name a few. Such leads are particularly suitable for stimulation of the spinal anatomy, more particularly suitable for stimulation of specific nerve anatomies, such as the dorsal root (optionally including the dorsal root ganglion).

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG SMI S A R L SJM LUX SMI

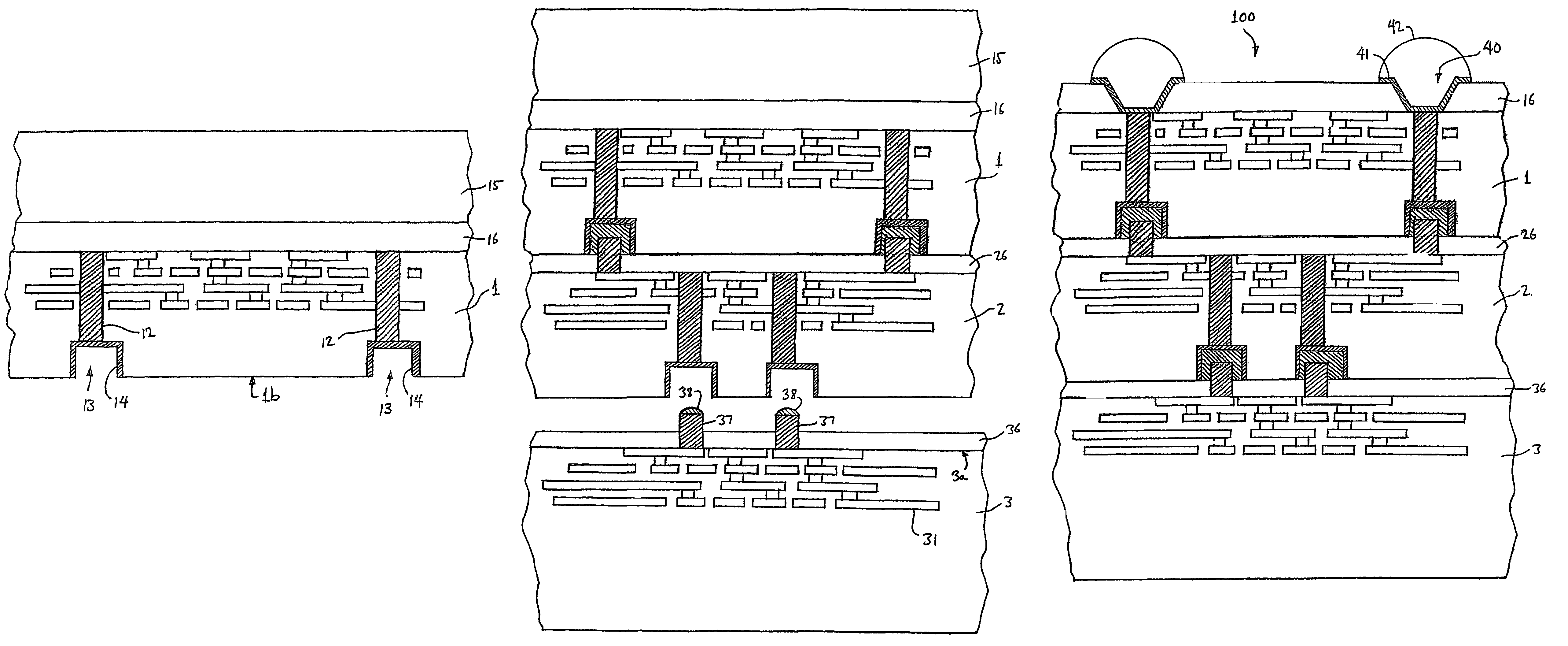

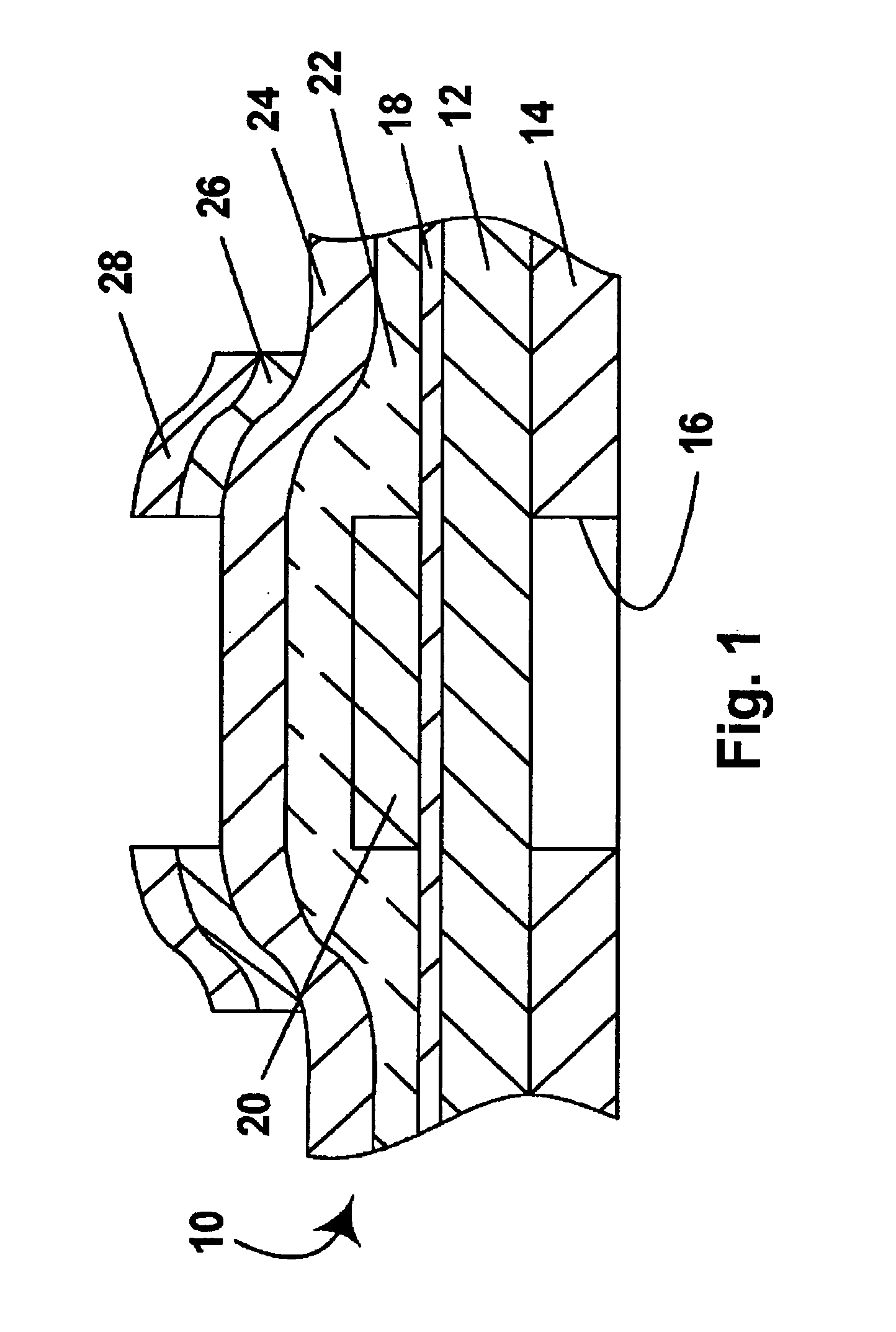

Three-dimensional device fabrication method

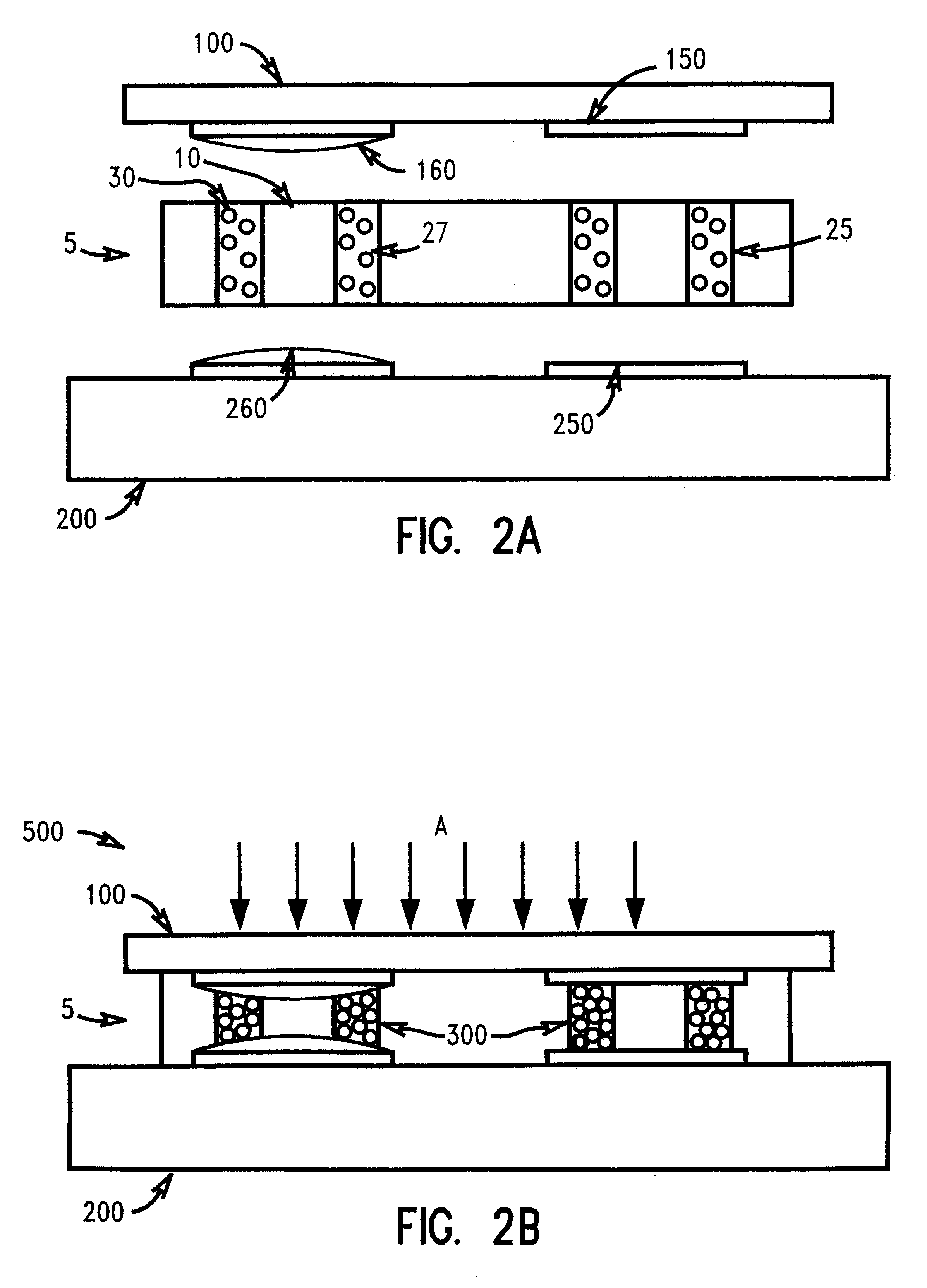

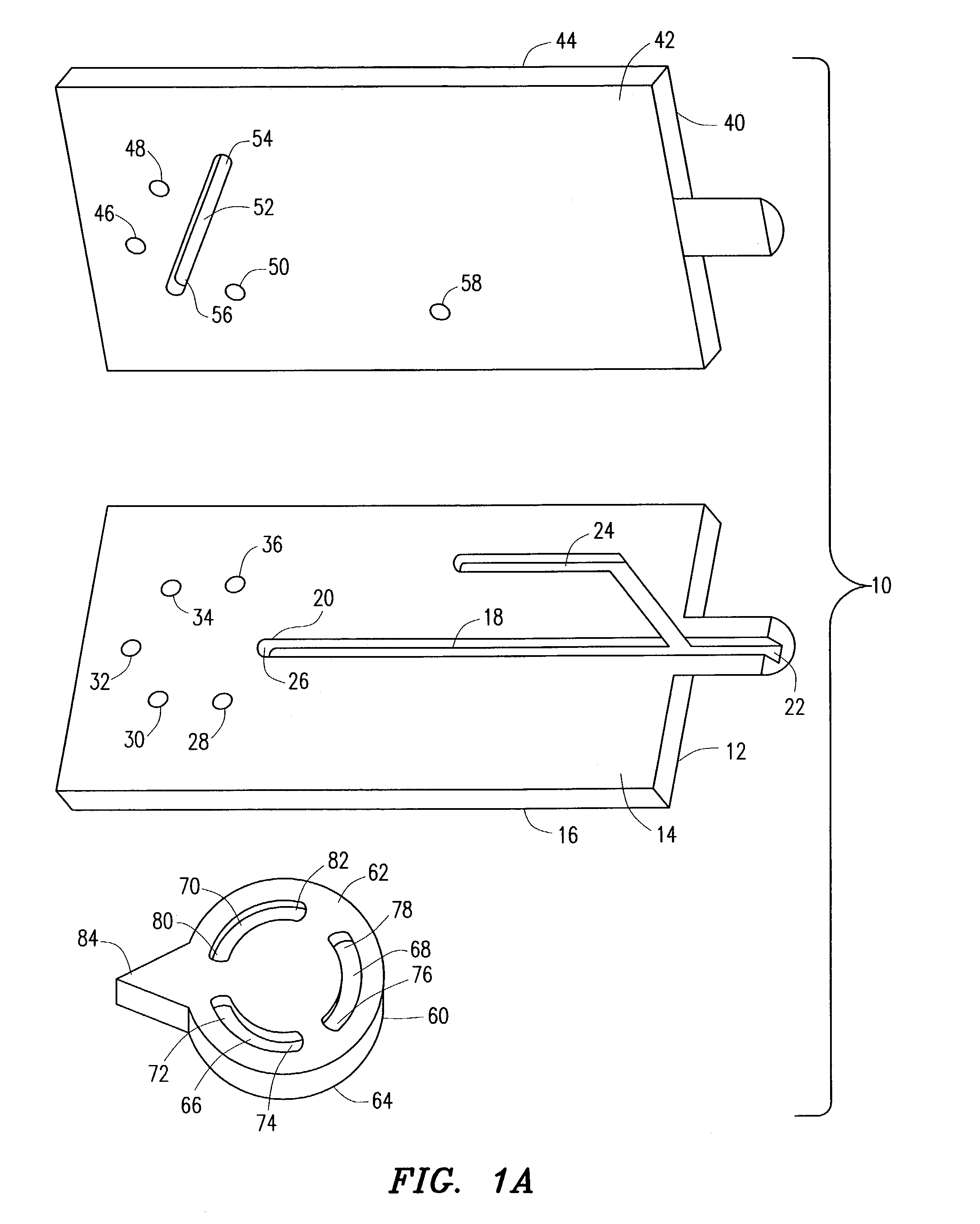

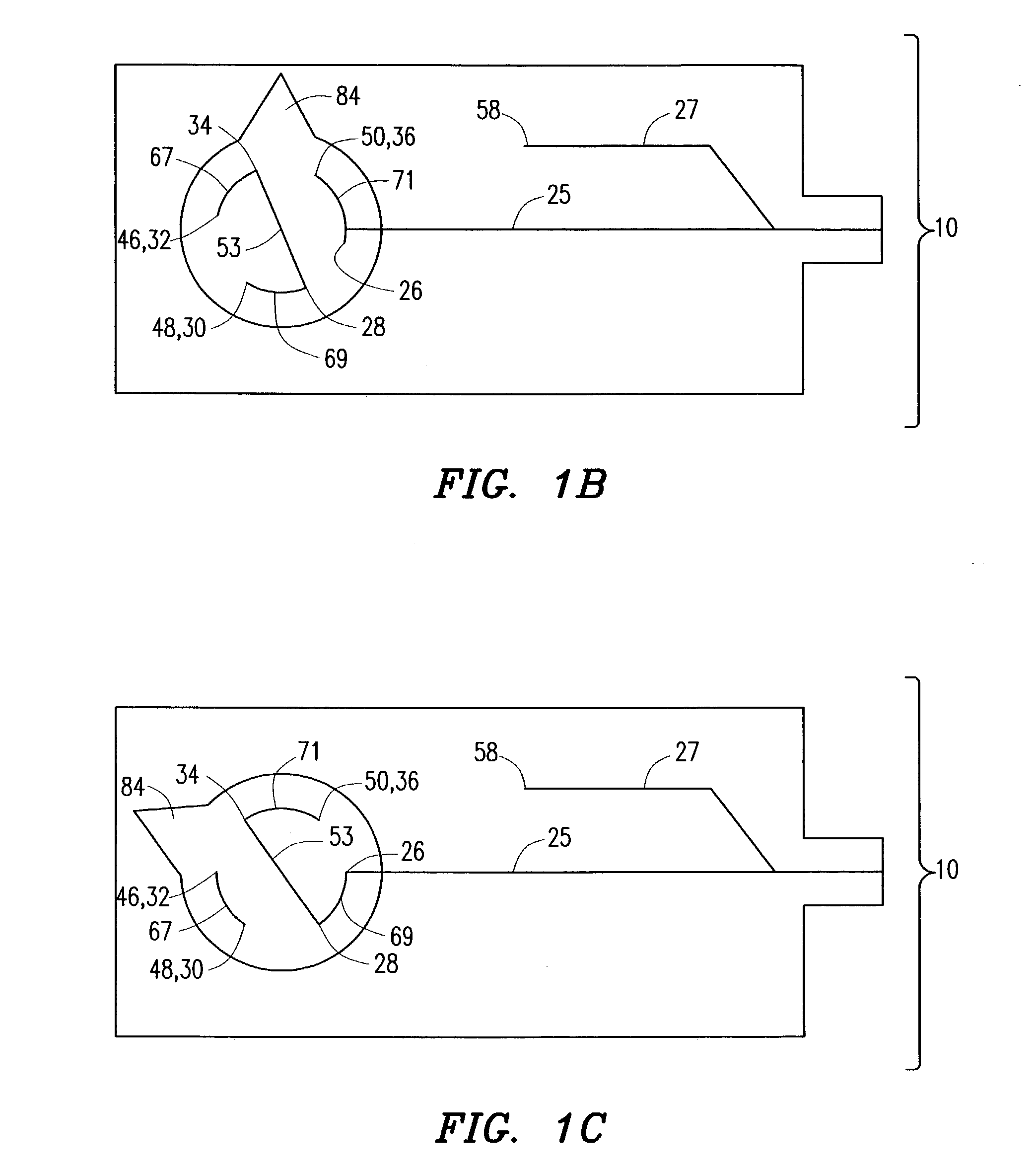

InactiveUS7354798B2Semiconductor/solid-state device detailsSolid-state devicesConduction pathwayElectrical connection

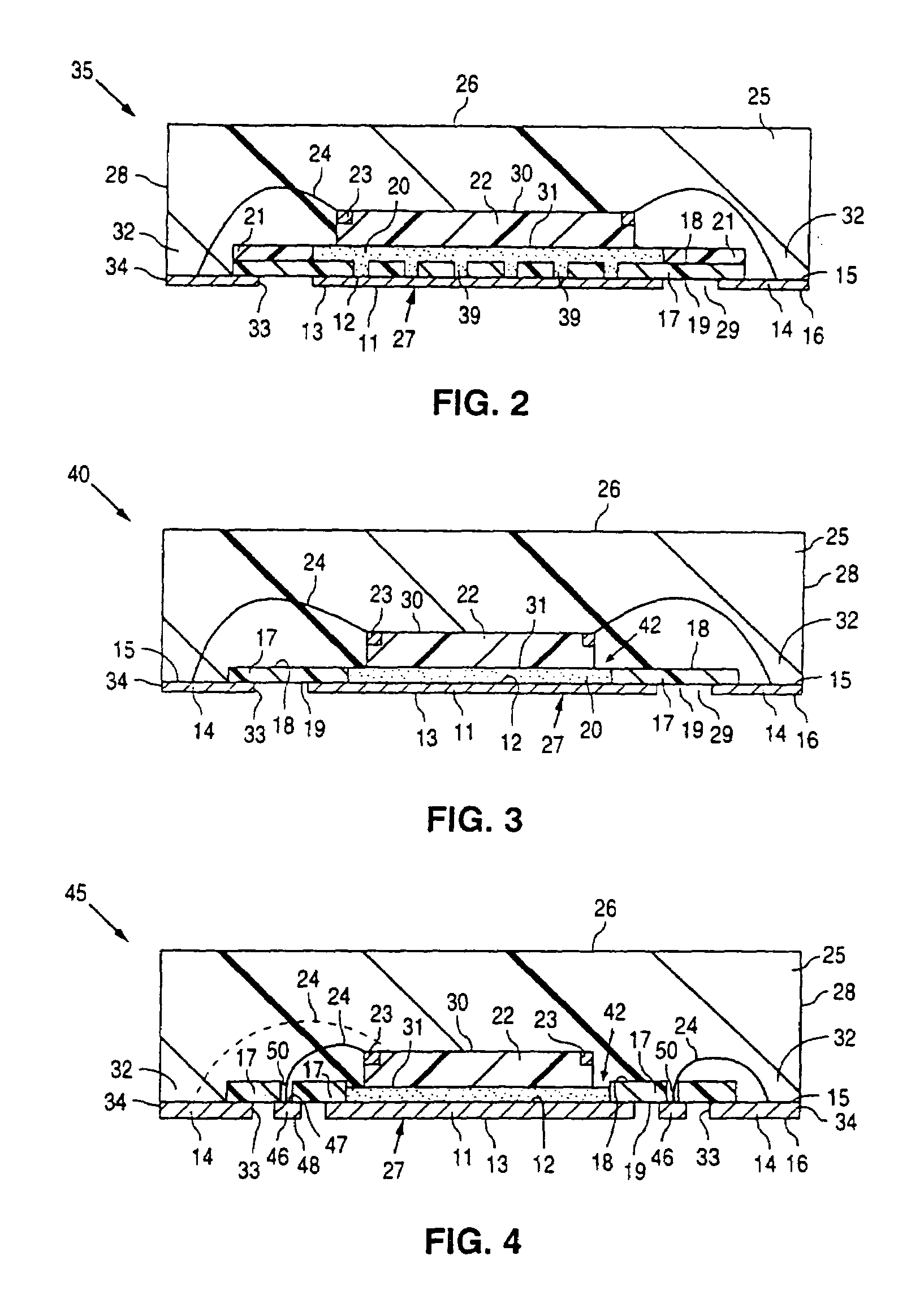

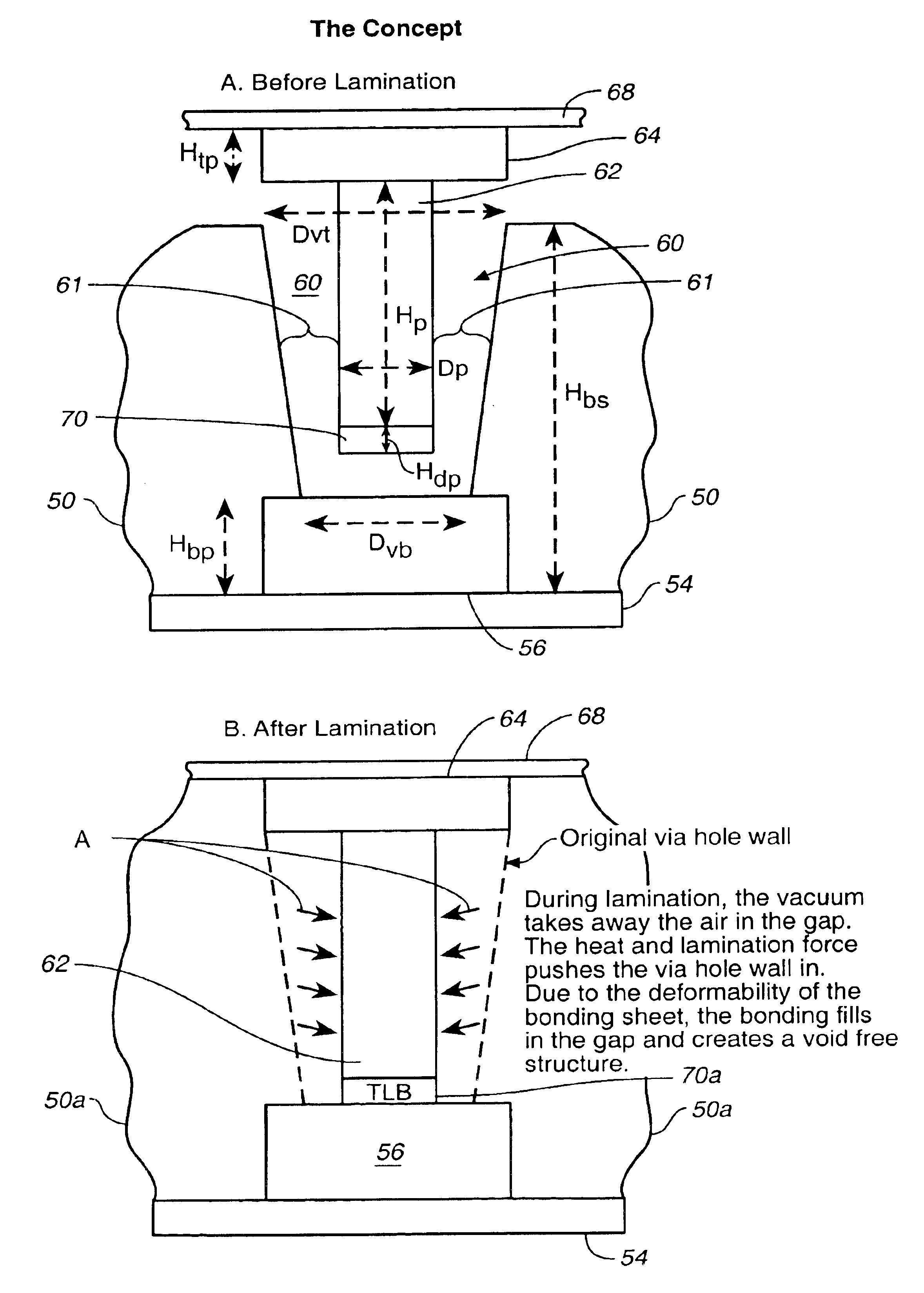

A method is described for fabricating a three-dimensional integrated device including a plurality of vertically stacked and interconnected wafers. Wafers (1, 2, 3) are bonded together using bonding layers (26, 36) of thermoplastic material such as polyimide; electrical connections are realized by vias (12, 22) in the wafers connected to studs (27, 37). The studs connect to openings (13, 23) having a lateral dimension larger than that of the vias at the front surfaces of the wafers. Furthermore, the vias in the respective wafers need not extend vertically from the front surface to the back surface of the wafers. A conducting body (102) provided in the wafer beneath the device region and extending laterally, may connect the via with the matallized opening (103) in the back surface. Accordingly, the conducting path through the wafer may be led underneath the devices thereof. Additional connections may be made between openings (113) and studs (127) to form vertical heat conduction pathways between the wafers.

Owner:IBM CORP

Process for fabricating thin film transistors

Transistors are formed by depositing at least one layer of semiconductor material on a substrate comprising a polyphenylene polyimide. The substrate permits the use of processing temperatures in excess of 300° C. during the processes used to form the transistors, thus allowing the formation of high quality silicon semiconductor layers. The substrate also has a low coefficient of thermal expansion, which closely matches that of silicon, thus reducing any tendency for a silicon layer to crack or delaminate.

Owner:E INK CORPORATION

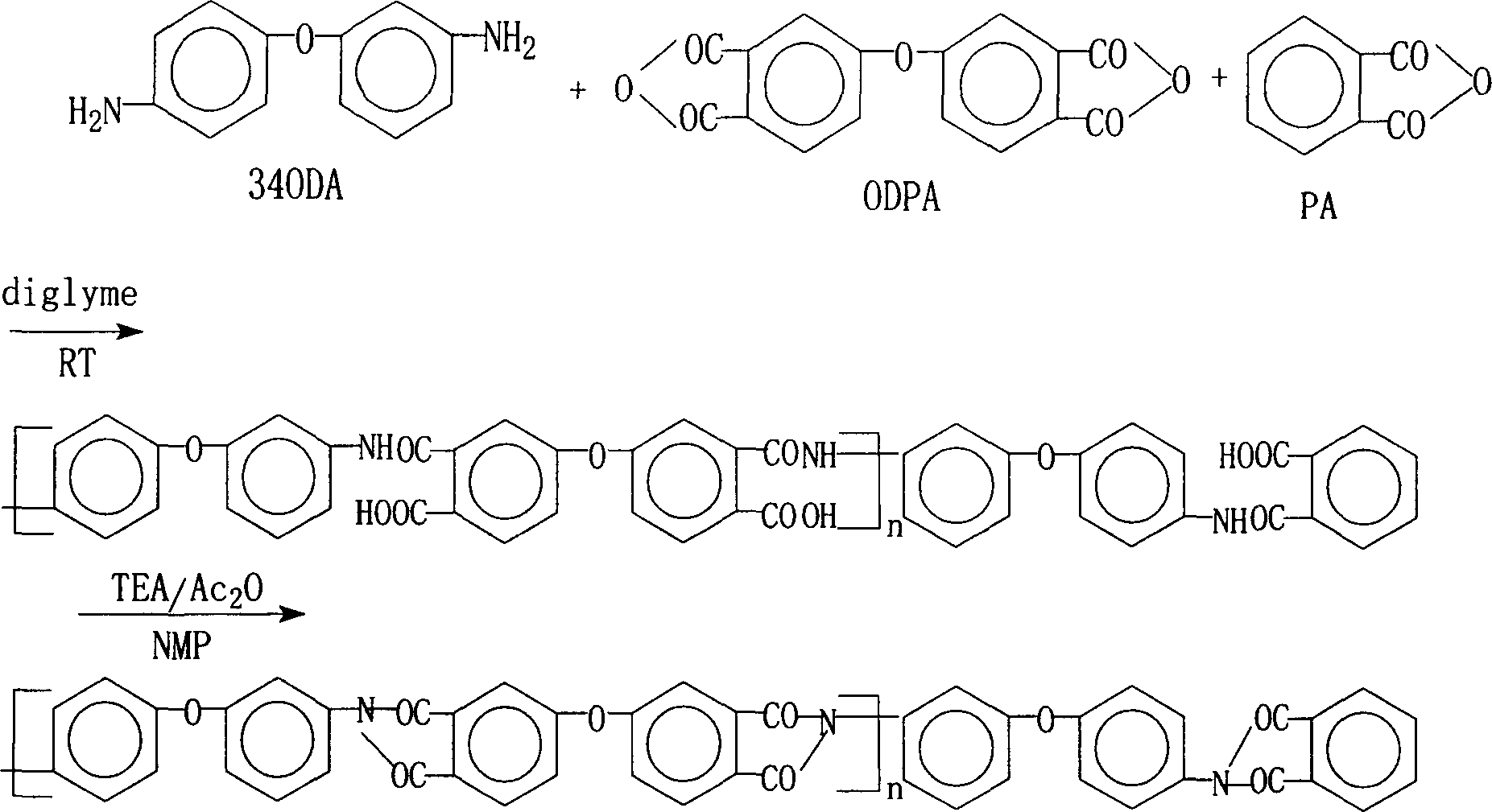

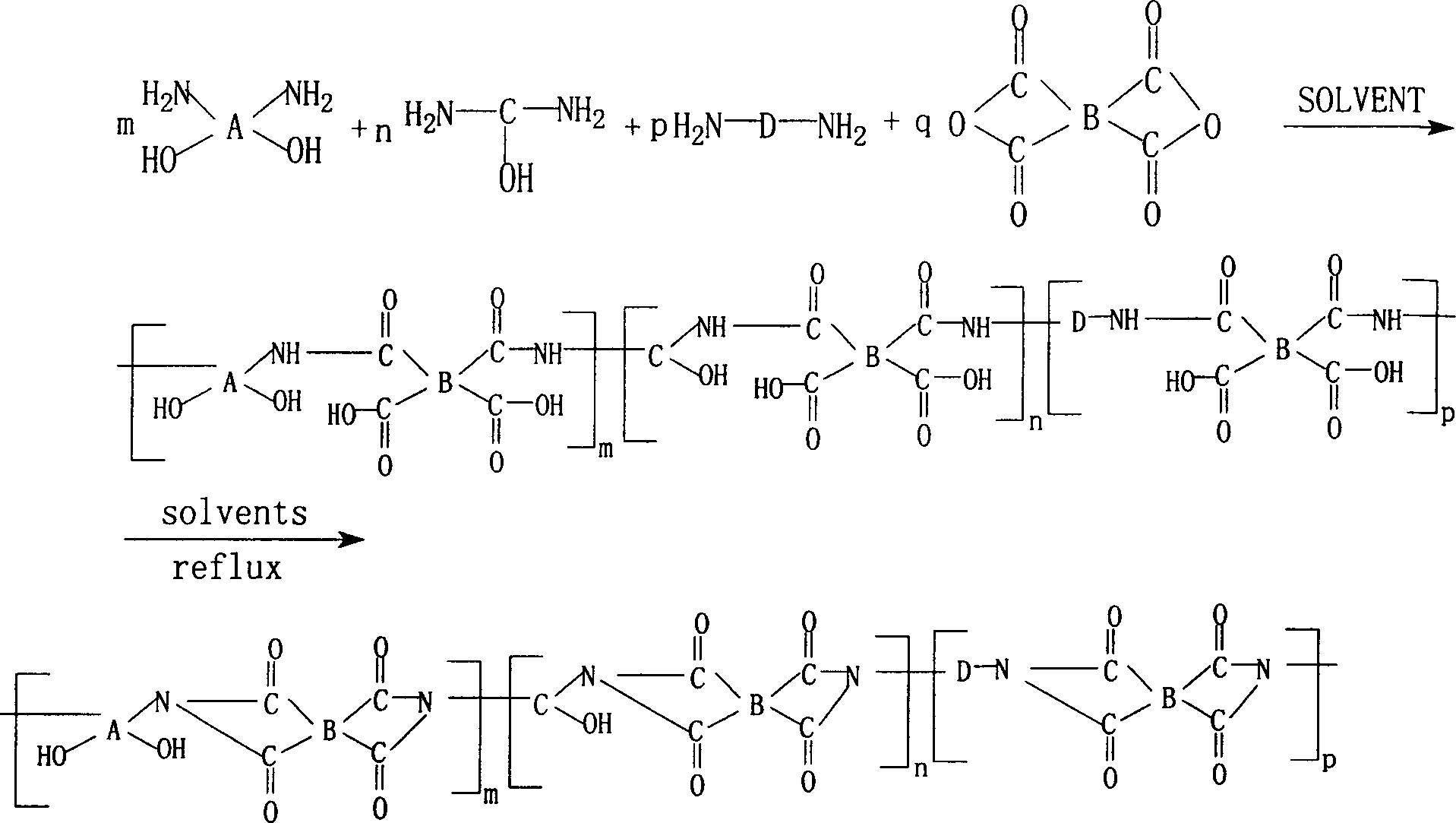

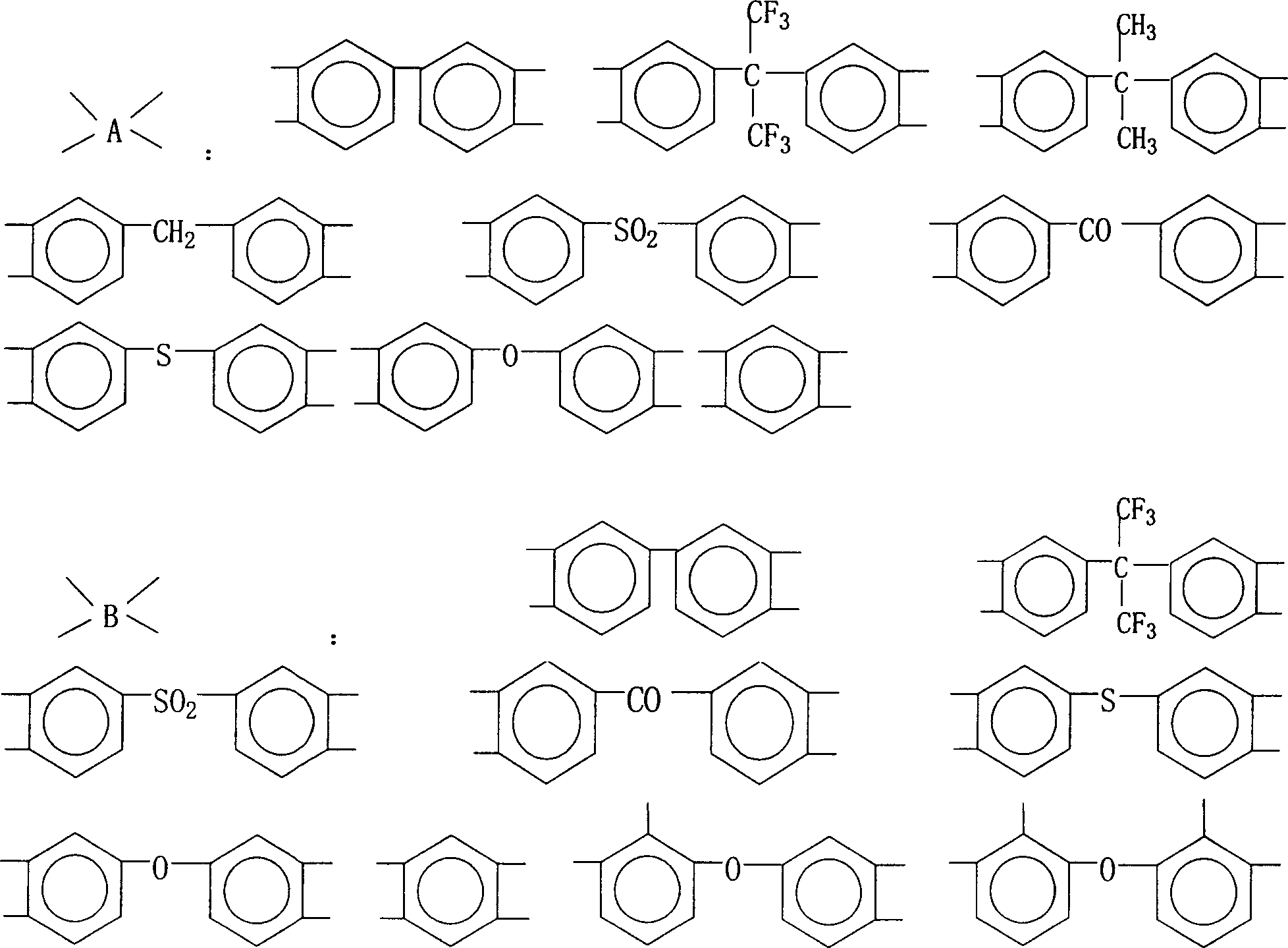

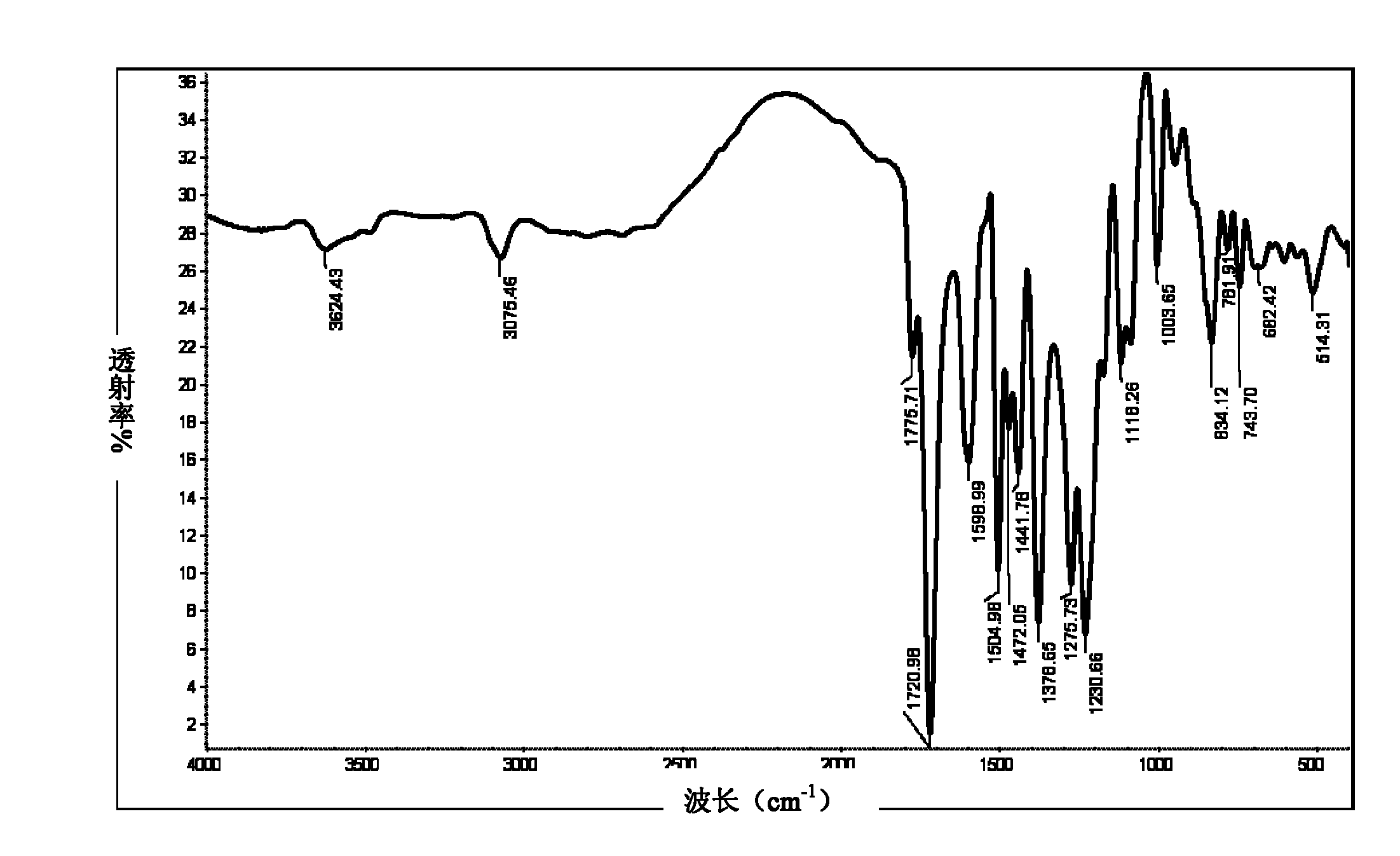

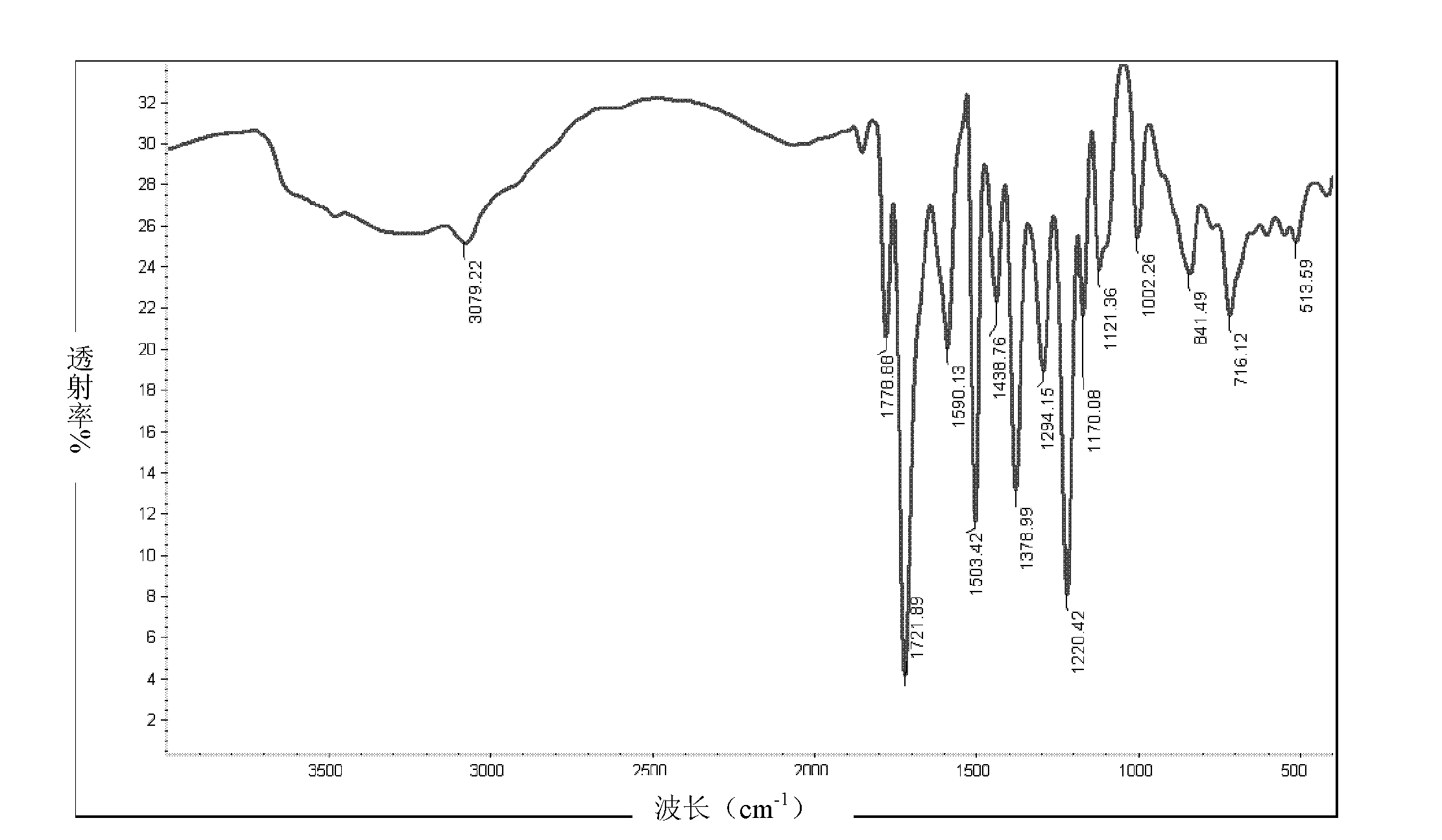

Preparation method of phenolic hydroxyl group containing polyimide powder

The preparation process of phenolic hydroxyl group-containing polyimide powder includes the following steps: 1. reaction of phenolic hydroxyl group-containing aromatic diamine compound or its mixture with other diamine compound and aromatic binary anhydride in the molar ratio of 1 to 1 in strong polar non-protonic organic solvent under protection of nitrogen at 0-30 deg.c for 3-12 hr to obtain transparent ropy polyhydroxy amido acid solution; and 2. adding azeotropic dewatering agent in nitrogen atmosphere and heating to 120-160 deg.c to reflux, azeotropically dewater and imidize for 5-18 hr, cooling to room temperature, washing and vacuum drying to obtain phenolic hydroxyl group-containing polyimide powder. The industrial production process has environment friendship, simple operation, low cost and easy solvent recovery.

Owner:DONGHUA UNIV

Non-aqueous electrolyte secondary battery, negative electrode material, and making method

ActiveUS20090239151A1Improve cycle performanceImprove efficiencyNon-aqueous electrolyte accumulatorsActive material electrodesSilicon oxideSilicon particle

A negative electrode material comprising an active material and 1-20 wt % of a polyimide resin binder is suitable for use in non-aqueous electrolyte secondary batteries. The active material comprises silicon oxide particles and 1-50 wt % of silicon particles. The negative electrode exhibits improved cycle performance while maintaining the high battery capacity and low volume expansion of silicon oxide. The non-aqueous electrolyte secondary battery has a high initial efficiency and maintains improved performance and efficiency over repeated charge / discharge cycles by virtue of mitigated volumetric changes during charge / discharge cycles.

Owner:SHIN ETSU CHEM IND CO LTD

Polyimide sulfones, method and articles made therefrom

InactiveUS7041773B2Synthetic resin layered productsCeramic shaping apparatusVitrificationPolymer science

Polyimide sulfone resins are provided with a glass transition temperature of from 200–350° C., residual volatile species concentration of less than 500 ppm and a total reactive end group concentration of less than about 120 milliequivalents / kilogram resin. The resins have high heat capability and good melt stability. Methods to prepare the said resins and articles made from the resins are also provided.

Owner:SHPP GLOBAL TECH BV

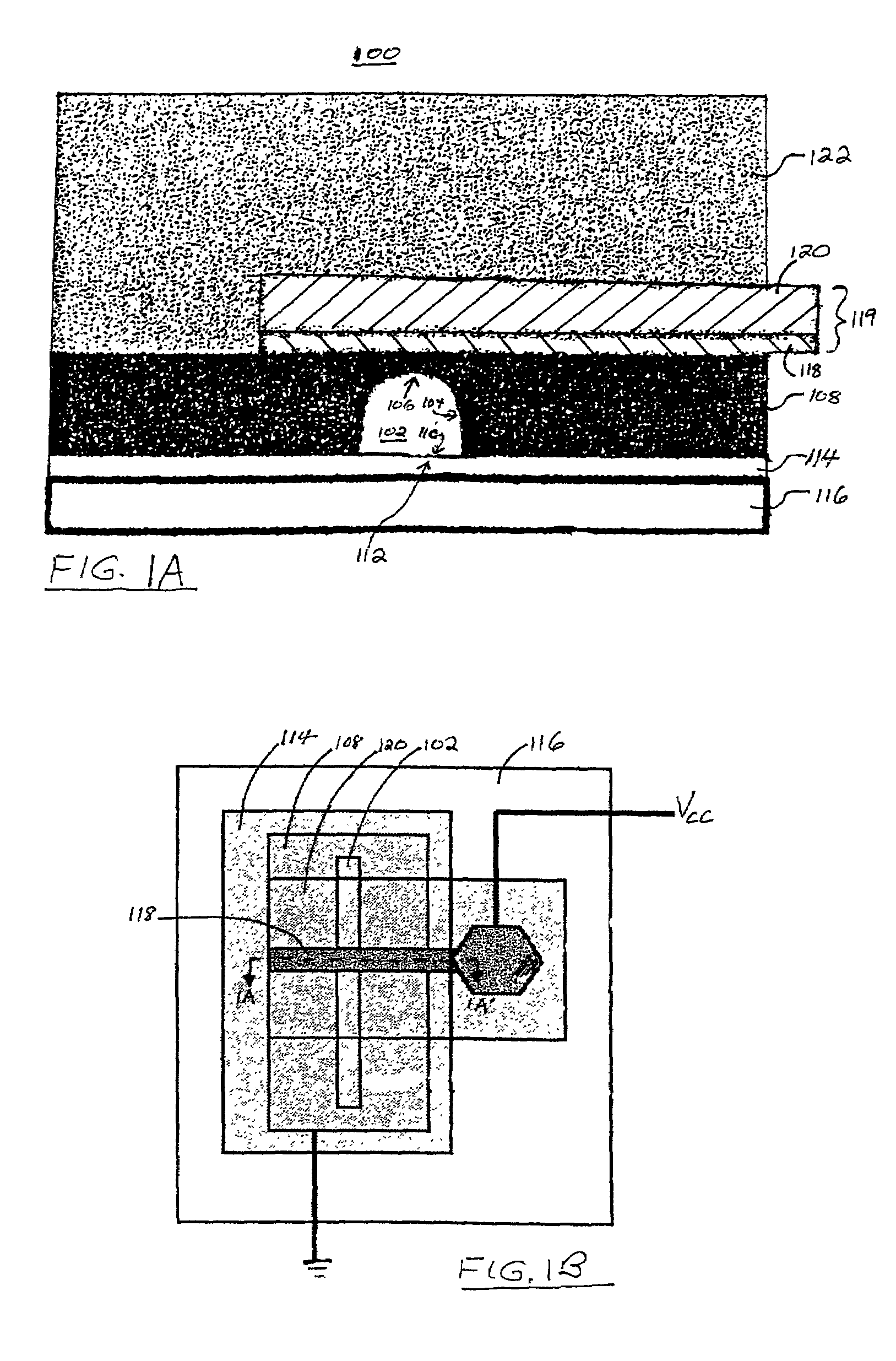

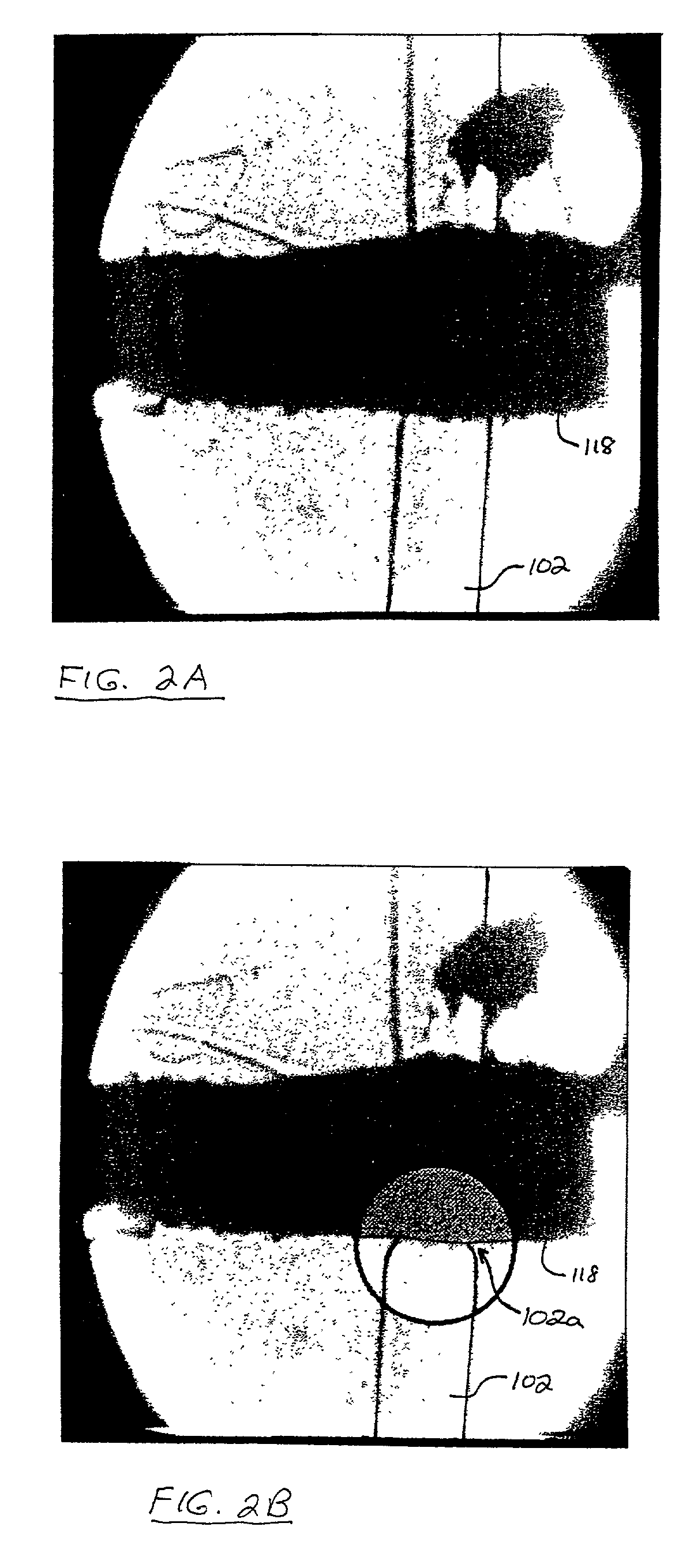

Non-volatile organic resistance random access memory device and method of manufacturing the same

A non-volatile organic resistance memory device including a first electrode, a second electrode, and a polyimide layer interposed between the first and second electrodes. The polyimide layer has a thickness such that a resistance of the polyimide layer varies in accordance with a potential difference between the first and second electrodes.

Owner:SAMSUNG ELECTRONICS CO LTD

Electrostatic valves for microfluidic devices

InactiveUS7232109B2Additive manufacturing apparatusOperating means/releasing devices for valvesElastomerPolyester

Valve structures formed in elastomer material are electrostatically actuated by applying voltage to a flexible, electrically conductive wire pattern. An actuation force generated between the patterned wire structure and an electrode result in closure of a flow channel formed in elastomer material underlying the wire. In one embodiment of a valve structure in accordance with the present invention, the wire structure is patterned by lithography and etching of a copper / polyimide laminate, with an underlying gold plate positioned on the opposite side of the flow channel serving as an electrode. In an alternative embodiment, a first wire structure is patterned by physically cutting out a first pattern of strips from an Aluminum / Mylar(®) laminate sheet. A second patterned wire structure serving as the electrode is formed by the same method, and positioned on the opposite side of a control channel. Application of an actuation force between the first and second patterned strips closes the control channel and an associated flow channel underlying the control channel.

Owner:CALIFORNIA INST OF TECH

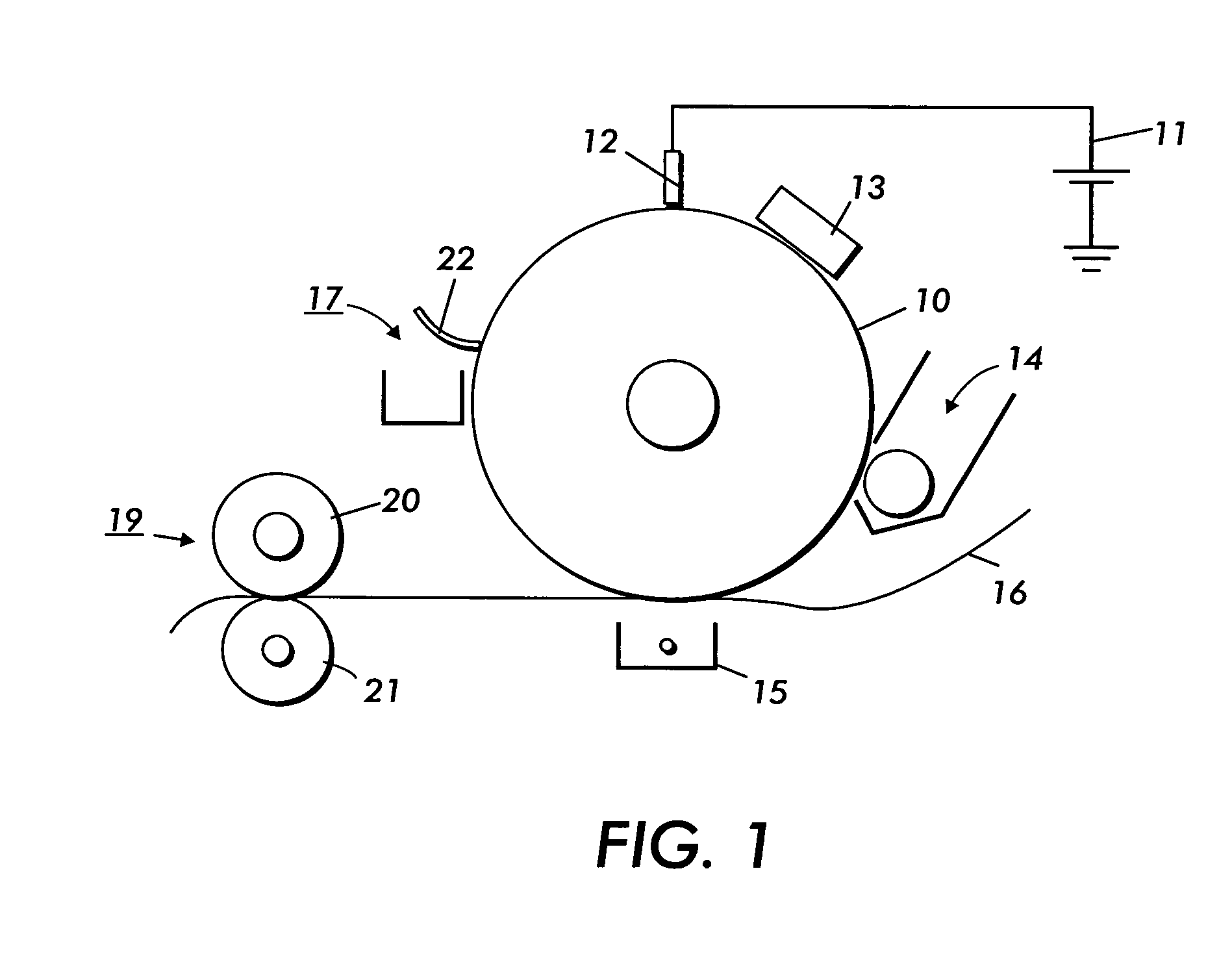

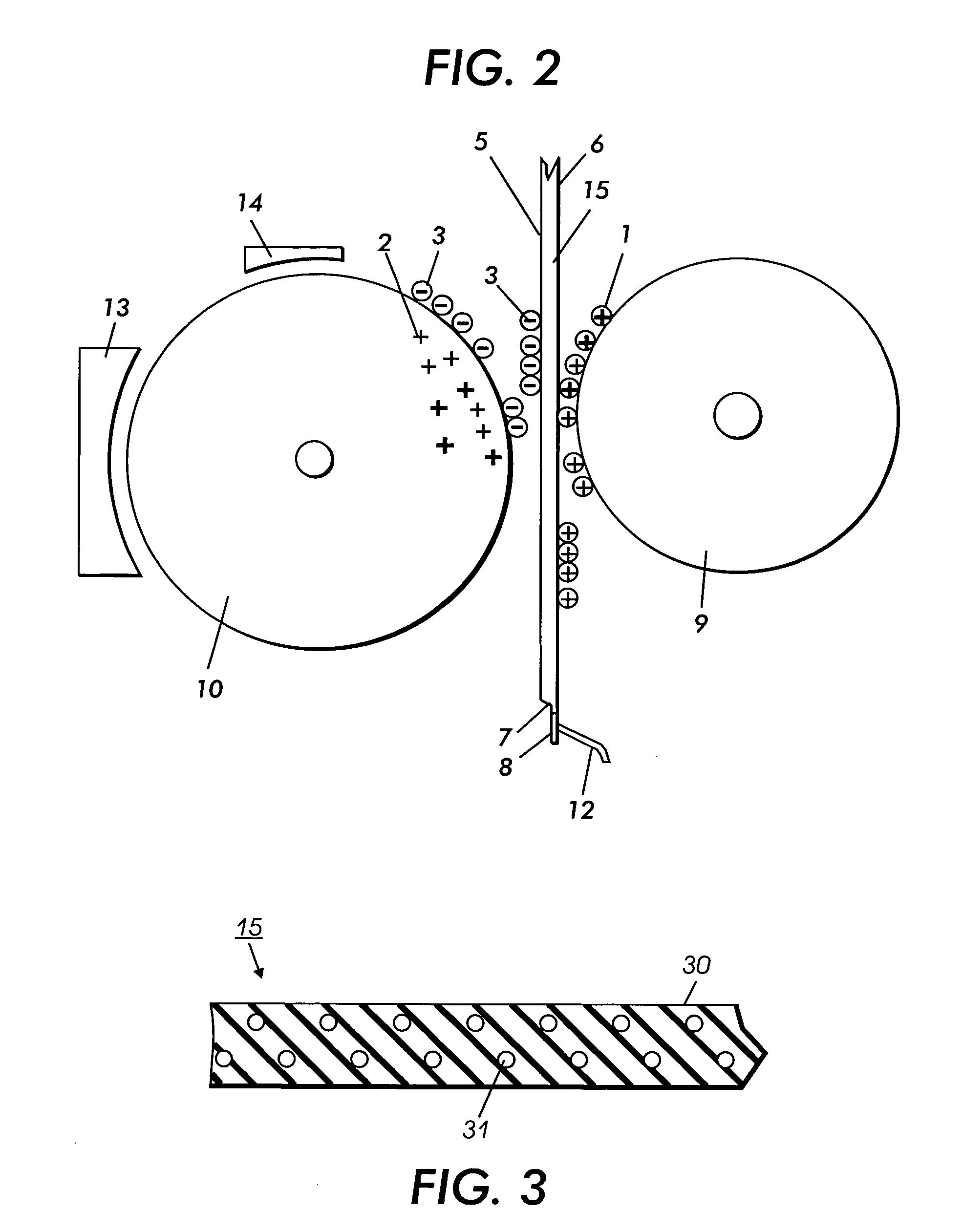

Welded polyimide intermediate transfer belt and process for making the belt

A welded intermediate transfer belt and process for making the same having a substrate made primarily of at least one polyimide polymer. The weld may be ultrasonically or otherwise welded and may have favorable properties such as relatively thin seam thickness and small weld steps. The weld may be overlapped or miter cut.

Owner:XEROX CORP

Process for fabricating thin film transistors

Transistors are formed by depositing at least one layer of semiconductor material on a substrate comprising a polyphenylene polyimide. The substrate permits the use of processing temperatures in excess of 300° C. during the processes used to form the transistors, thus allowing the formation of high quality silicon semiconductor layers. The substrate also has a low coefficient of thermal expansion, which closely matches that of silicon, thus reducing any tendency for a silicon layer to crack or delaminate.

Owner:E INK CORPORATION

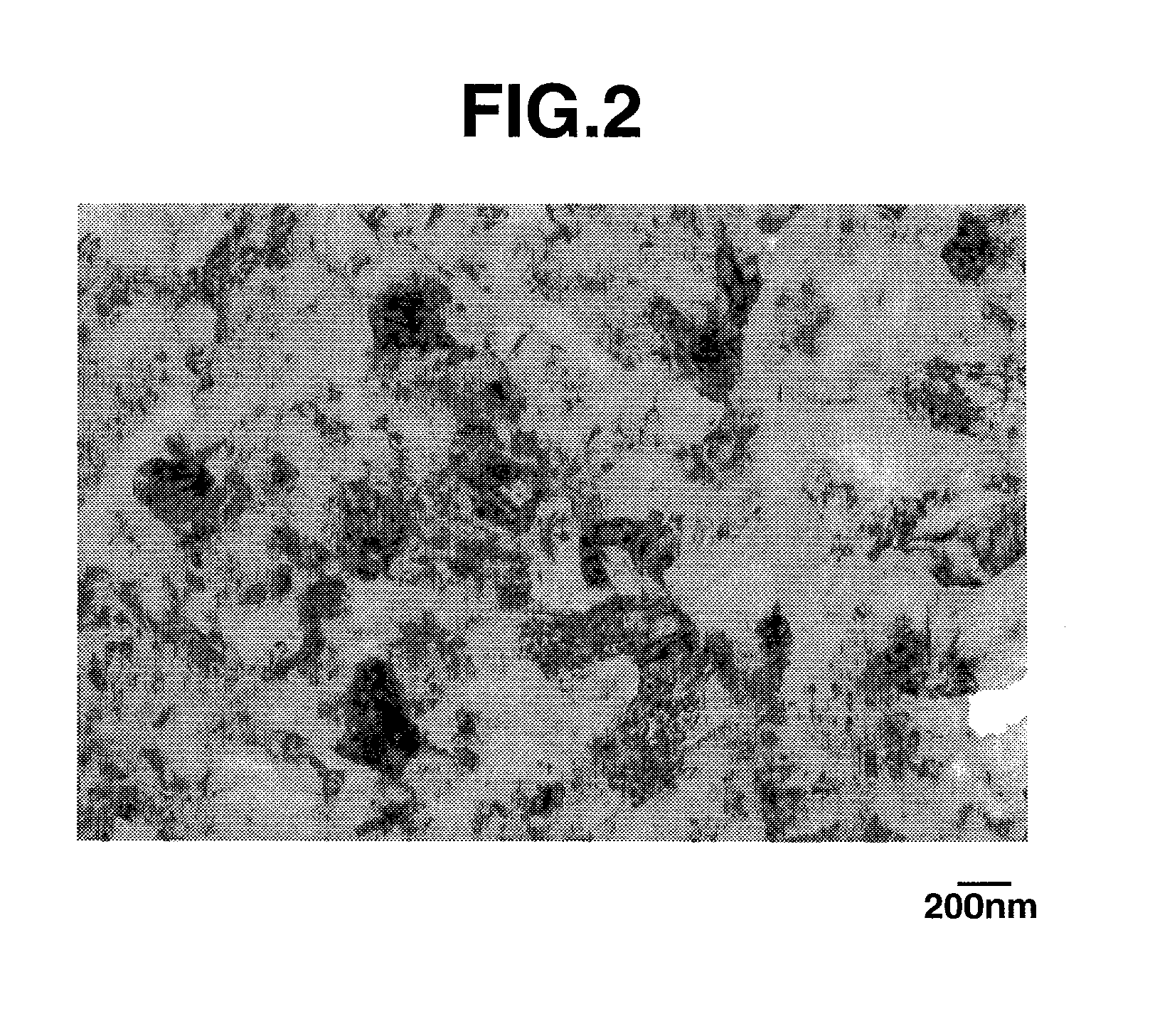

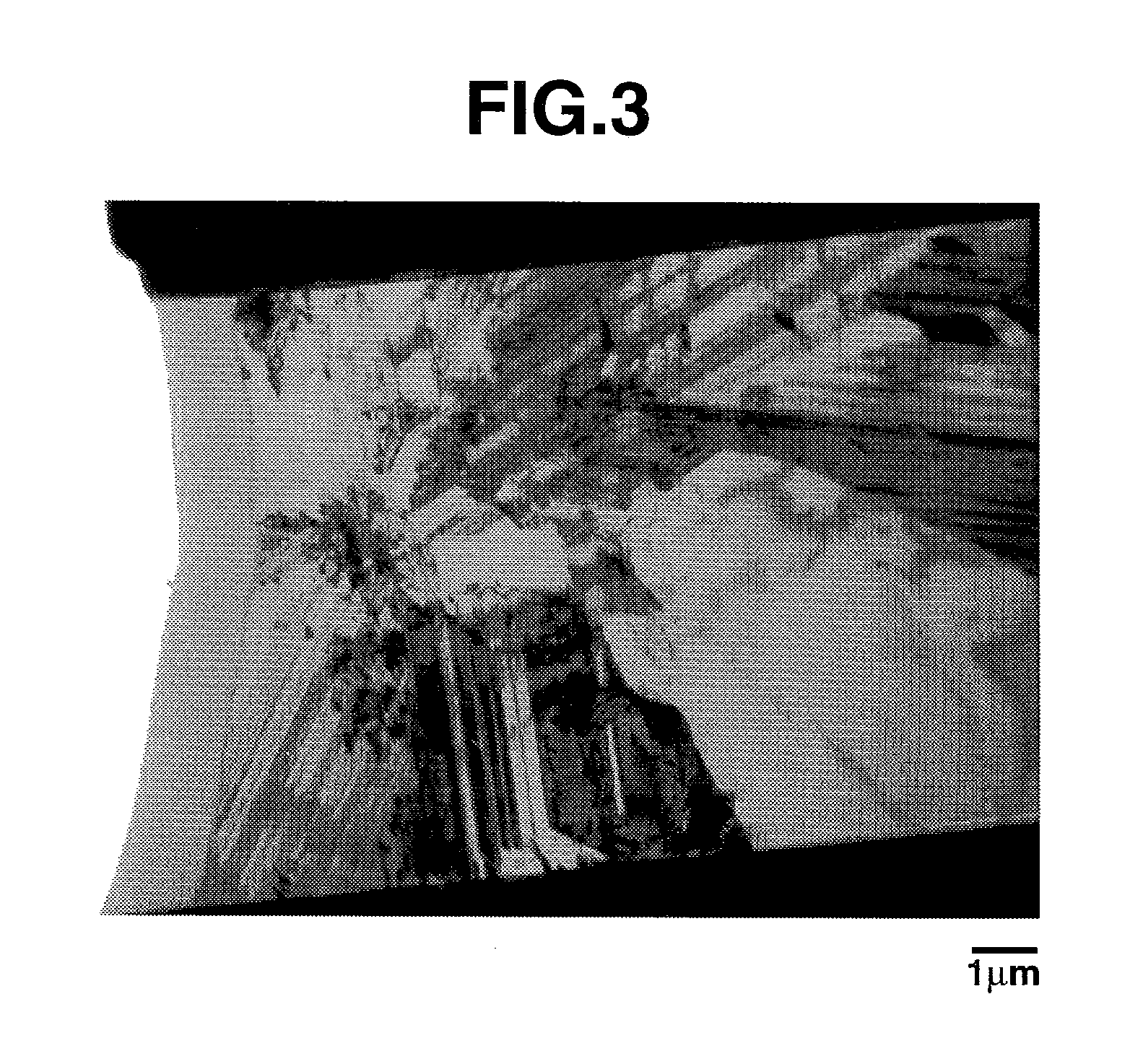

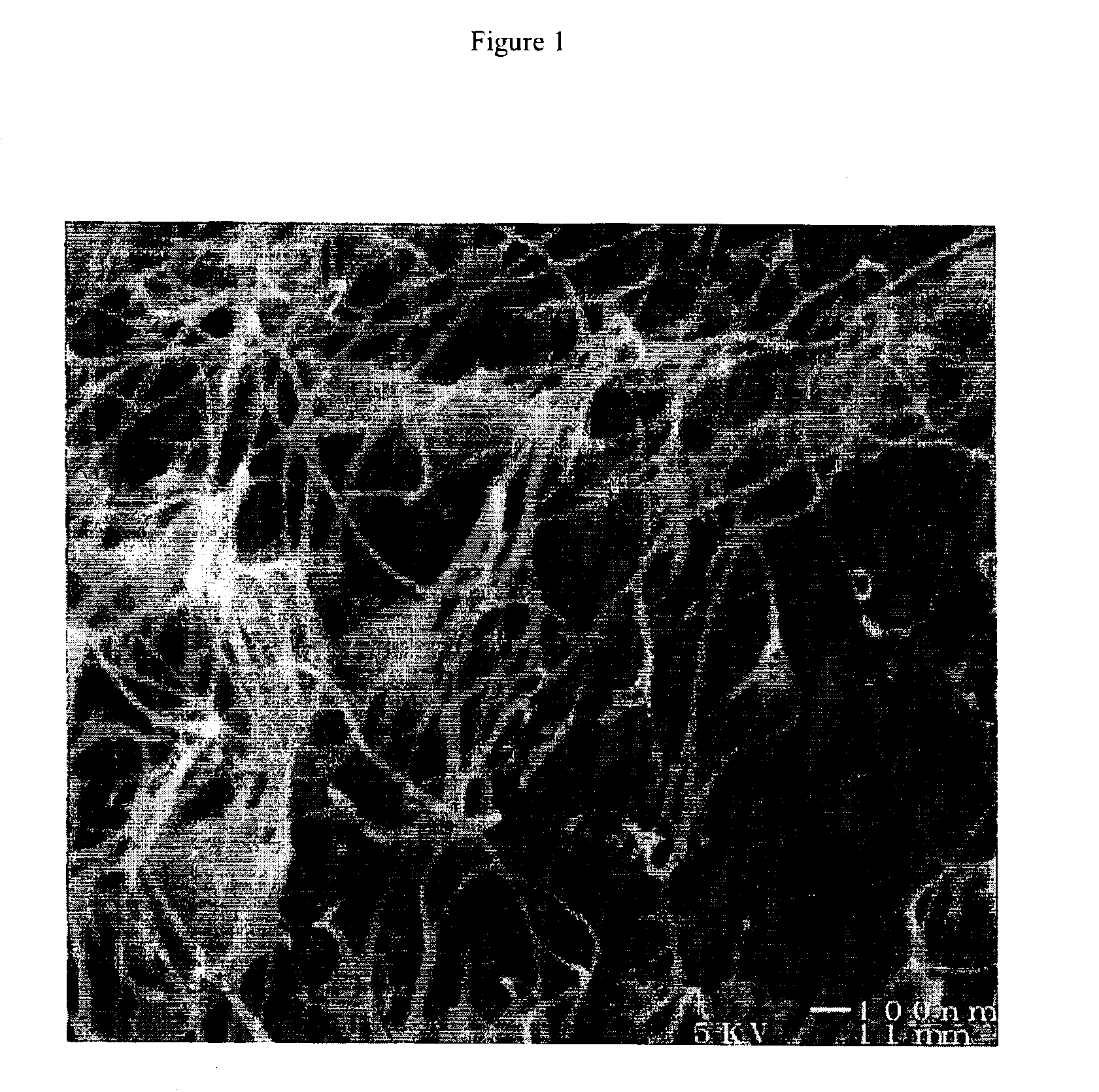

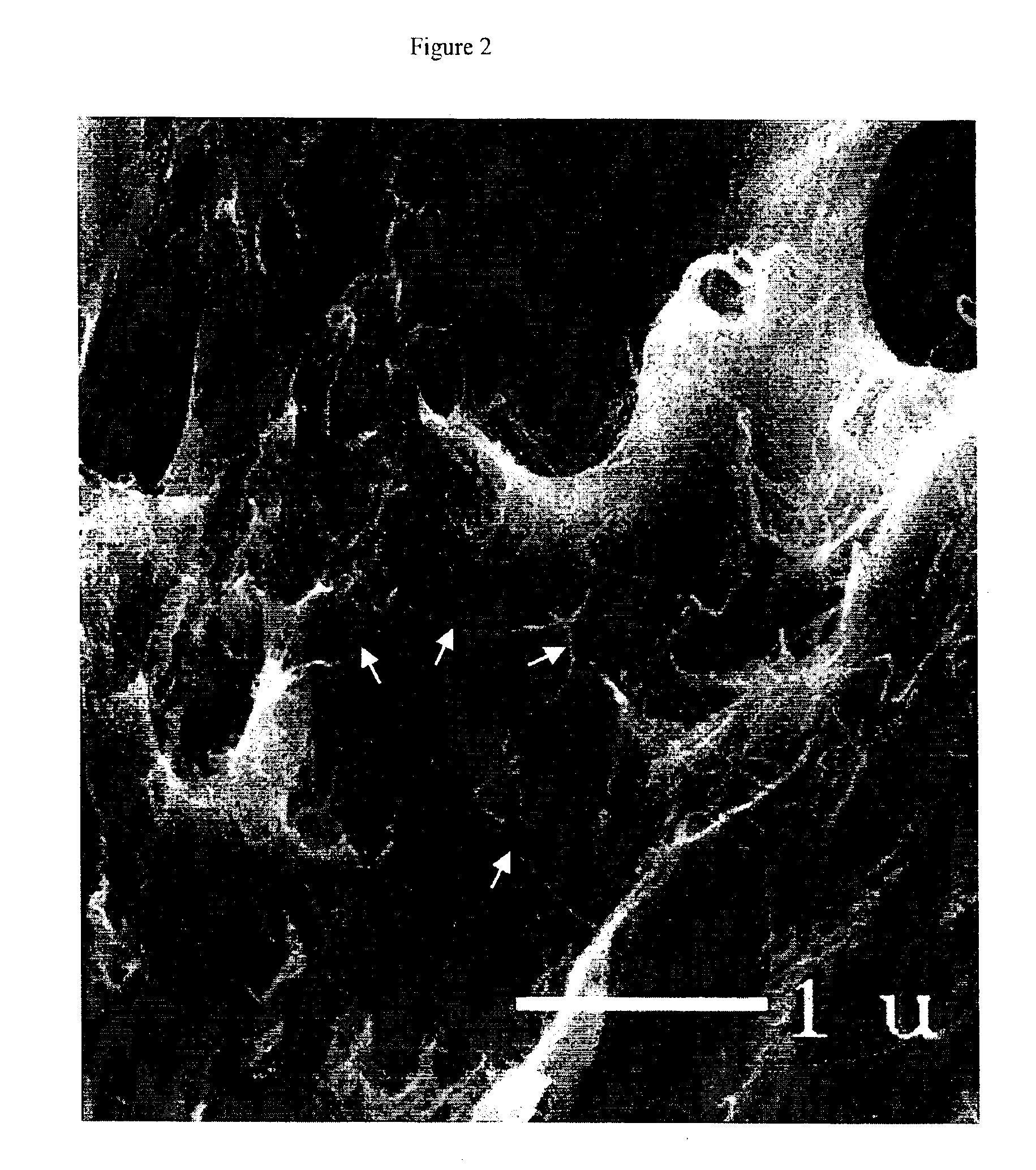

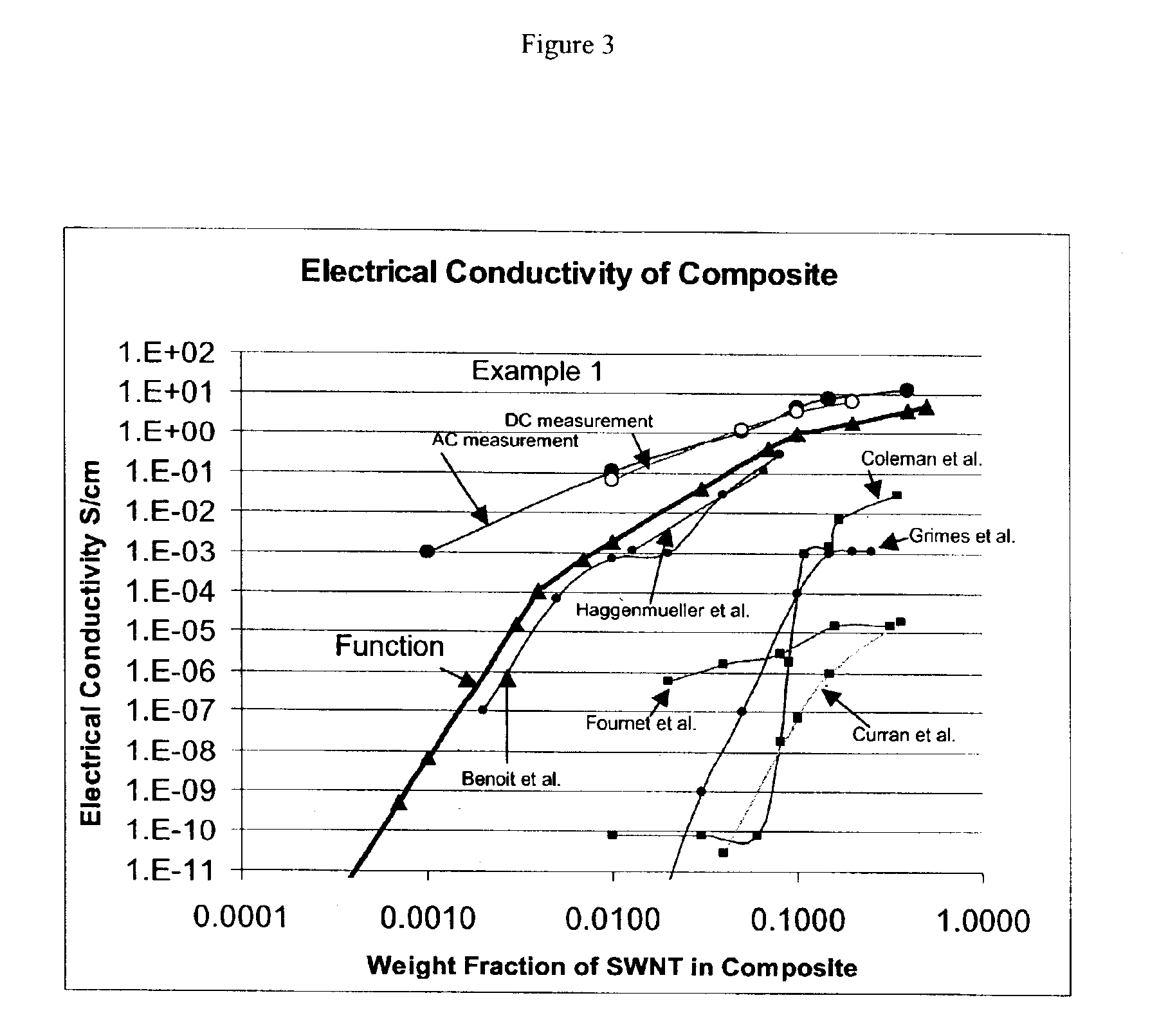

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

Colorless and transparent polyimide nano-composite material membrane and preparation method thereof

The invention relates to a colorless and transparent polyimide nano-composite material membrane and a preparation method thereof. The polyimide nano-composite material membrane is prepared by a method of compounding alicyclic dianhydride and fluorinated diamine serving as monomers with a certain amount of inorganic nano-particles by using nano-composite technology and performing thermal imidization with gradient temperature increase. The amount of added nano-particles is controlled between 0.01 and 5.00 weight percent to obtain the colorless and transparent polyimide nano-composite material membrane with high heat resistance. The membrane has a glass transition temperature of over 250 DEG C, a light transmittance of over 90 percent at 450 nanometers and an ultraviolet wavelength of about 300 nanometers, and can be used as a substrate material for a photoelectric device, a semiconductor material, an optical waveguide material and the like.

Owner:UNIV OF SCI & TECH LIAONING

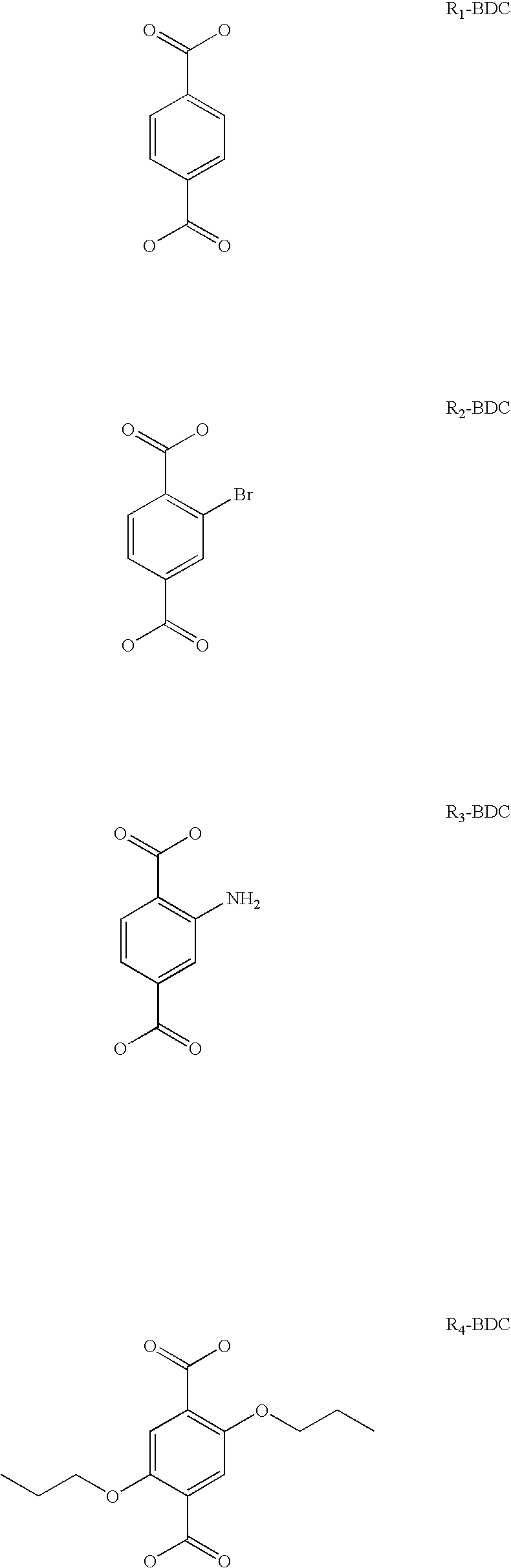

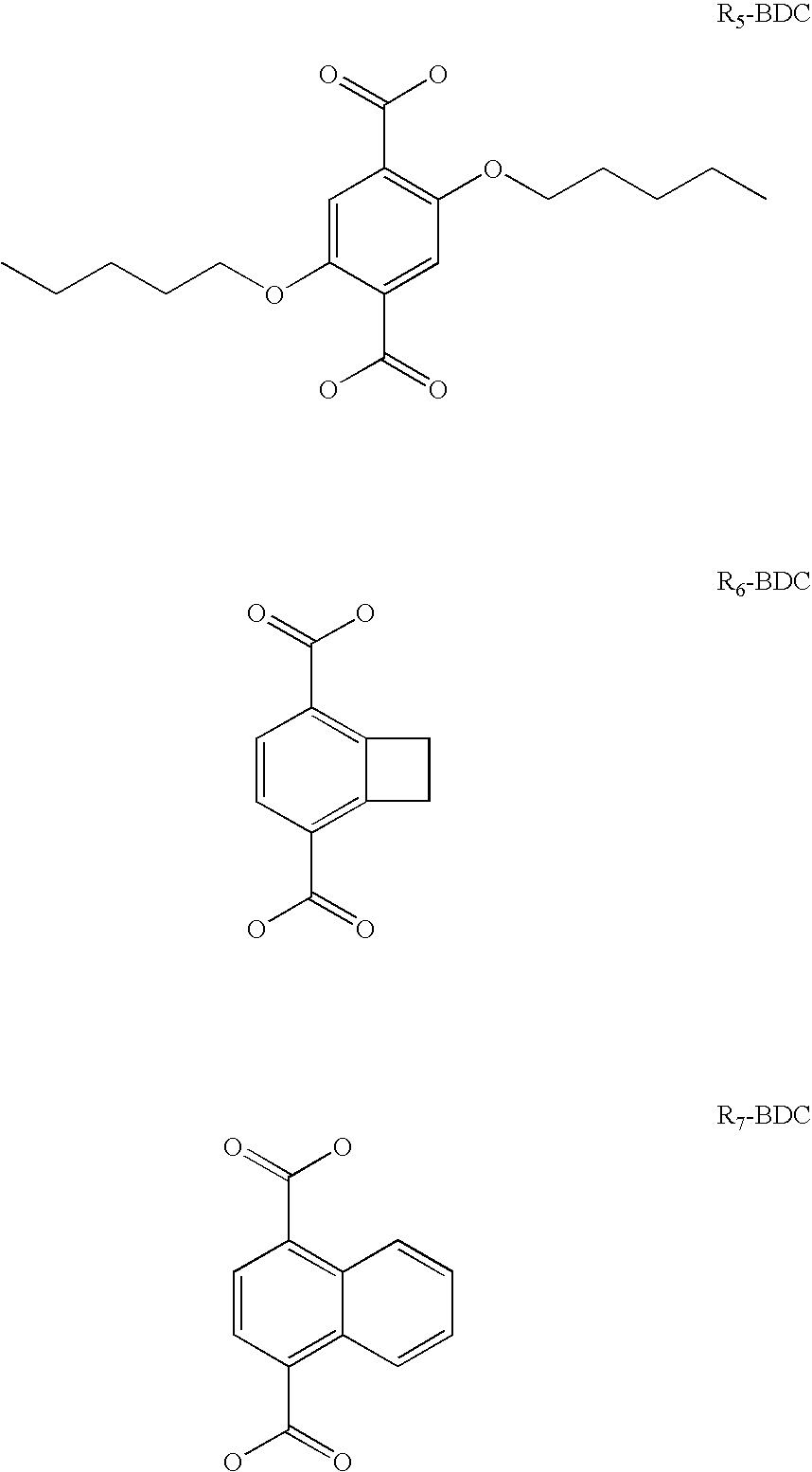

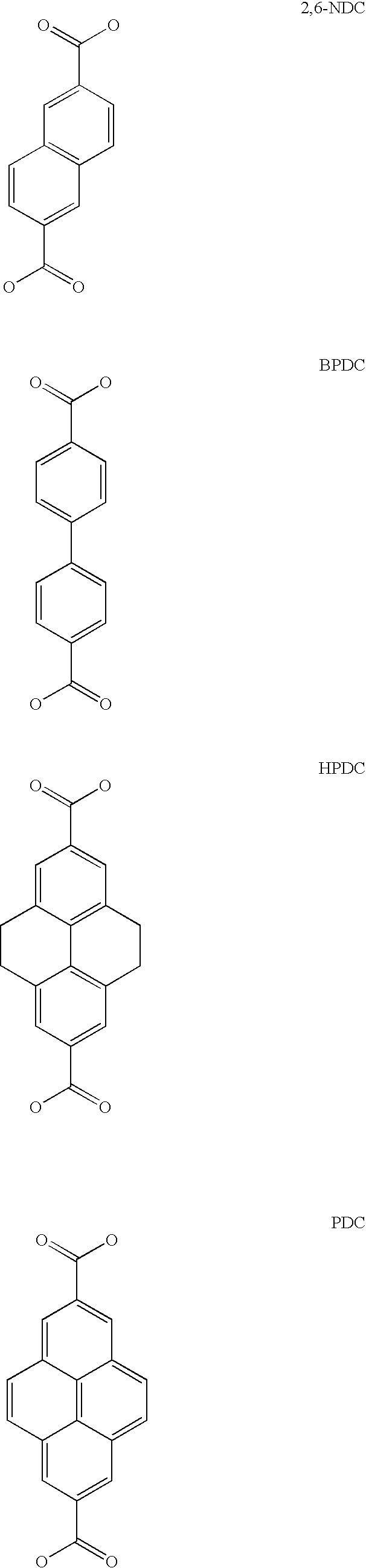

Metal organic framework-polymer mixed matrix membranes

InactiveUS7637983B1Reduce hydrocarbon fouling problemEnhanced gas separation permeability performanceSemi-permeable membranesSolid sorbent liquid separationMetal-organic frameworkPermeation

Metal-organic framework (MOF)-polymer mixed matrix membranes (MOF-MMMs) have been prepared by dispersing high surface area MOFs (e.g. IRMOF-1) into a polymer matrix (e.g. Matrimid 5218). The MOFs allow the polymer to infiltrate the pores of the MOFs, which improves the interfacial and mechanical properties of the polymer and in turn affects permeability. Pure gas permeation tests show the incorporation of 20 wt-% of IRMOF-1 in Matrimid 5218 polyimide matrix results in 280% improvement in CO2 permeability without a loss of CO2 / CH4 selectivity compared to those of the pure Matrimid 5218 membrane. This type of MOF-MMMs has significantly improved gas separation performance with dramatically high CO2 permeability (>35 barrer) and higher than 29 CO2 / CH4 selectivity at 50° C. under 100 psig pressure, which are attractive candidates for practical gas separation applications such as CO2 removal from natural gas.

Owner:UOP LLC

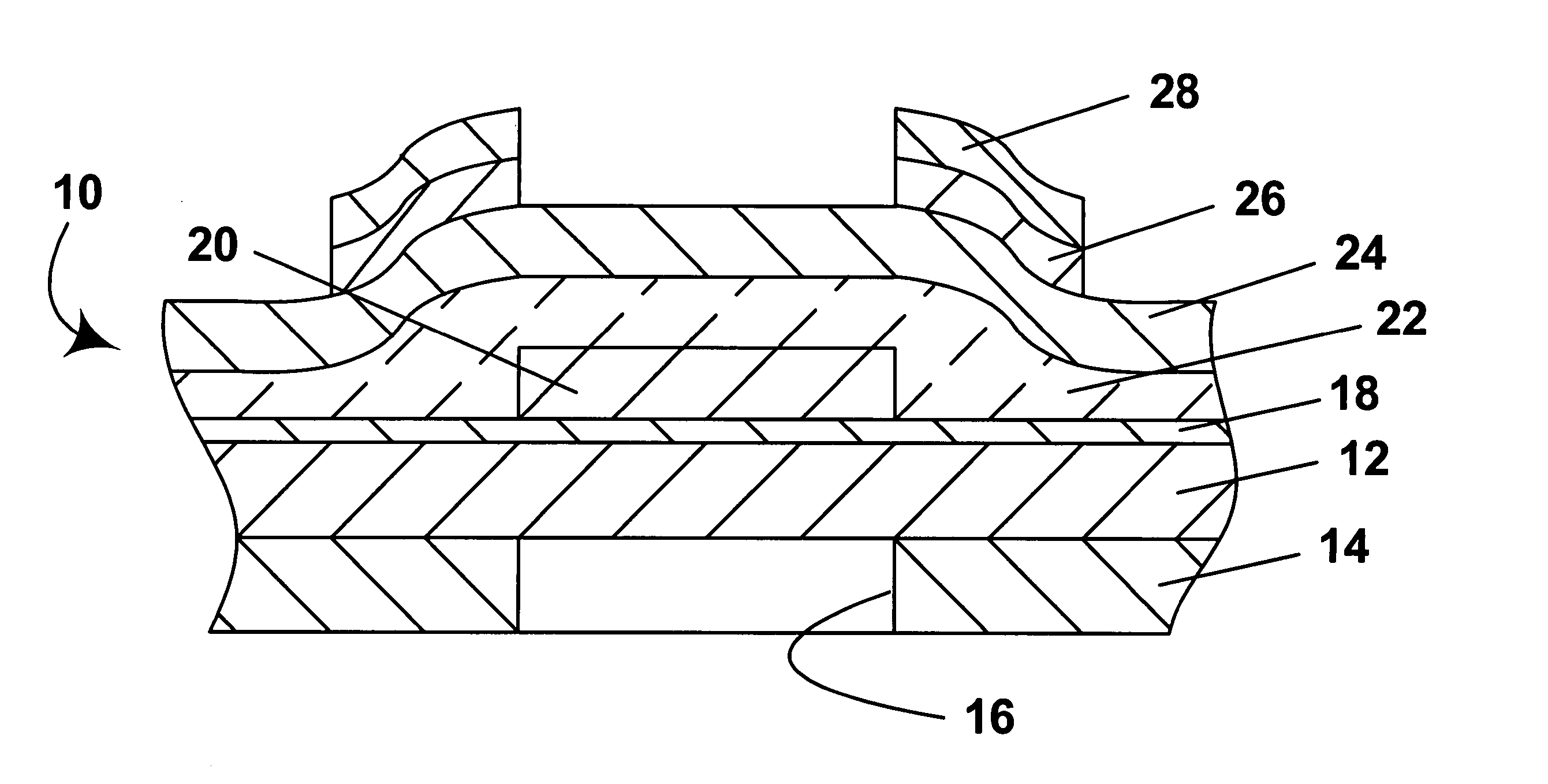

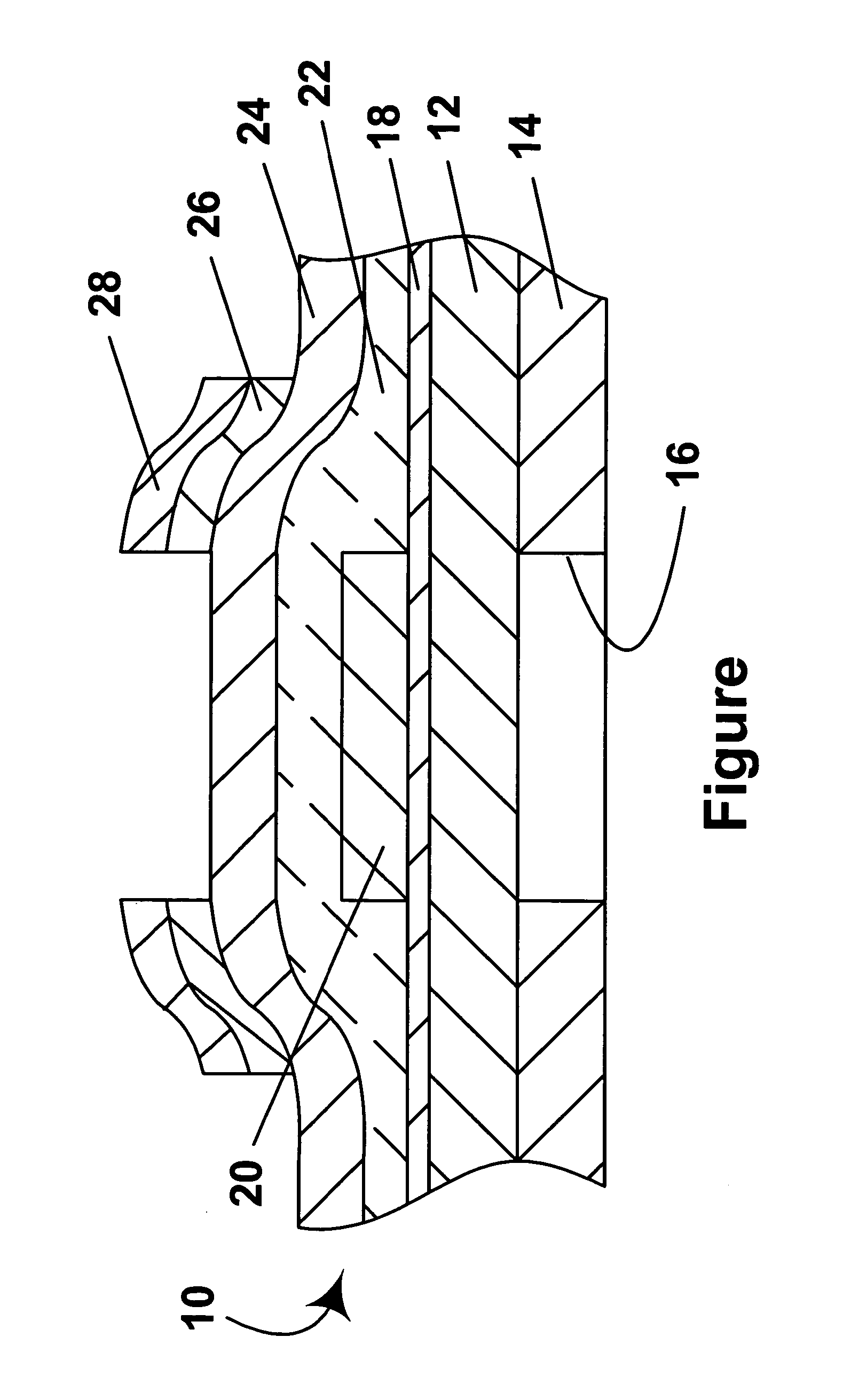

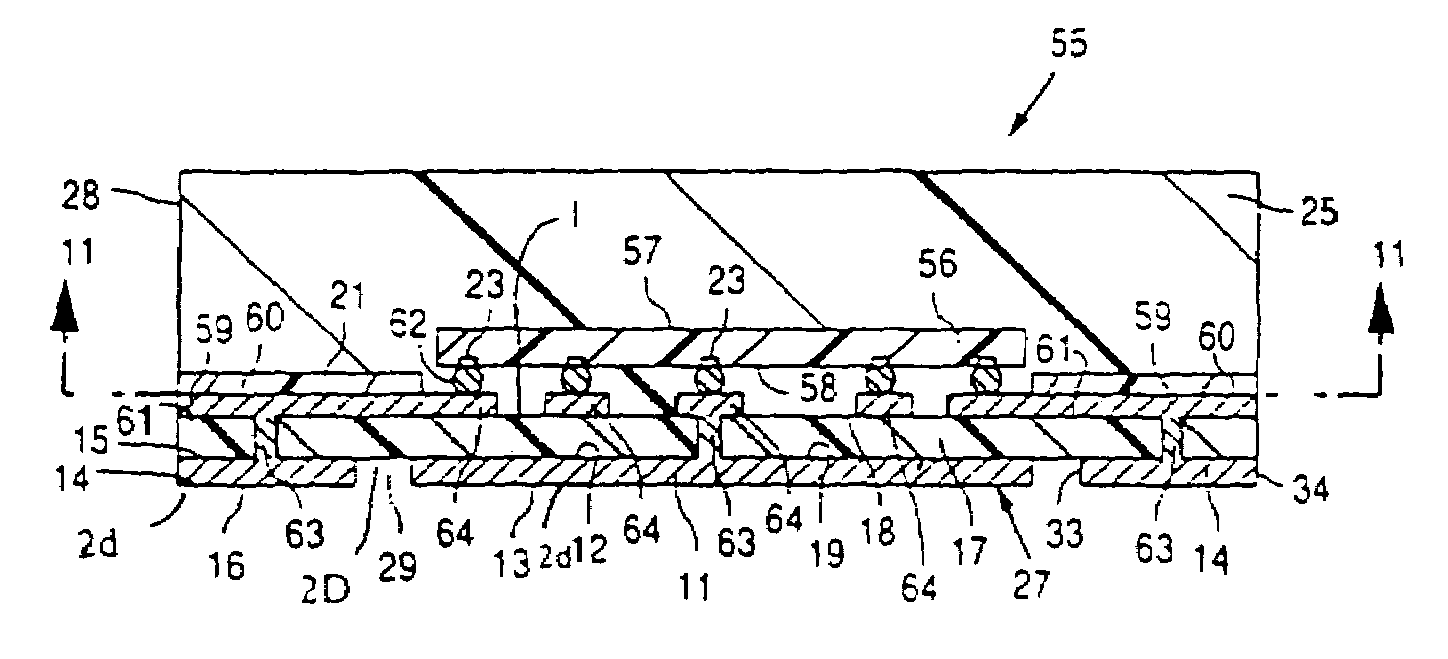

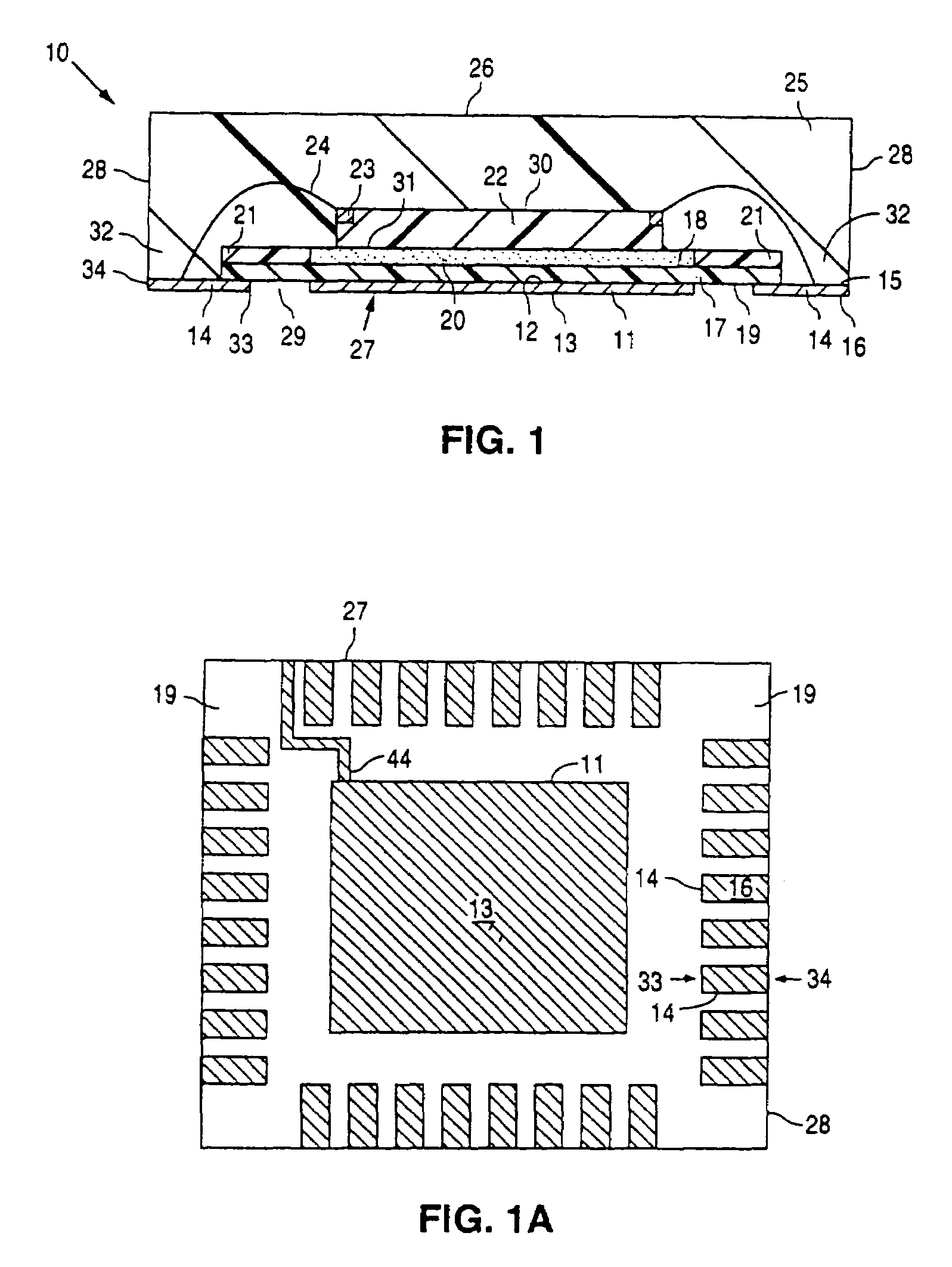

Integrated circuit device packages and substrates for making the packages

InactiveUS7253503B1Improve thermal efficiencyLow costSemiconductor/solid-state device detailsSolid-state devicesBone WiresMetal

Integrated circuit device packages and substrates for making the packages are disclosed. One embodiment of a substrate includes a planar sheet of polyimide having a first surface, an opposite second surface, and apertures between the first and second surfaces. A planar metal die pad and planar metal are attached to the second surface of the polyimide sheet. The apertures in the polyimide sheet are juxtaposed to the leads. A package made using the substrate includes an integrated circuit device mounted above the first surface of the polyimide sheet opposite the die pad. Bond wires are connected between the integrated circuit device and the leads through the apertures in the polyimide sheet. An encapsulant material covers the first surface of the polyimide sheet, the integrated circuit device, the bone wires, and the apertures. The die pad and leads are exposed at an exterior surface of the package.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Oral care composition with cross-linked polymer peroxide

InactiveUS20060045854A1Low costImprove convenienceCosmetic preparationsToilet preparationsCross-linkWhitening Agents

Oral care compositions comprising: (a) a peroxide complex comprising a peroxide component and an N-vinyl heterocyclic polymer (e.g., poly-N-vinyl polylactam, or poly-N-vinyl-polyimide); (b) a whitening agent (e.g., hydrogen peroxide); and (c) an orally acceptable carrier. In one embodiment, the carrier comprises a film forming material. Methods are also provided for making an oral care composition comprising: (a) mixing a whitening agent, silicone adhesive and carrier fluid to form a homogenous mixture; (b) adding a peroxide complex to said homogenous mixture, wherein said complex comprises hydrogen peroxide and an N-vinyl heterocyclic polymer; and (c) mixing under vacuum.

Owner:COLGATE PALMOLIVE CO

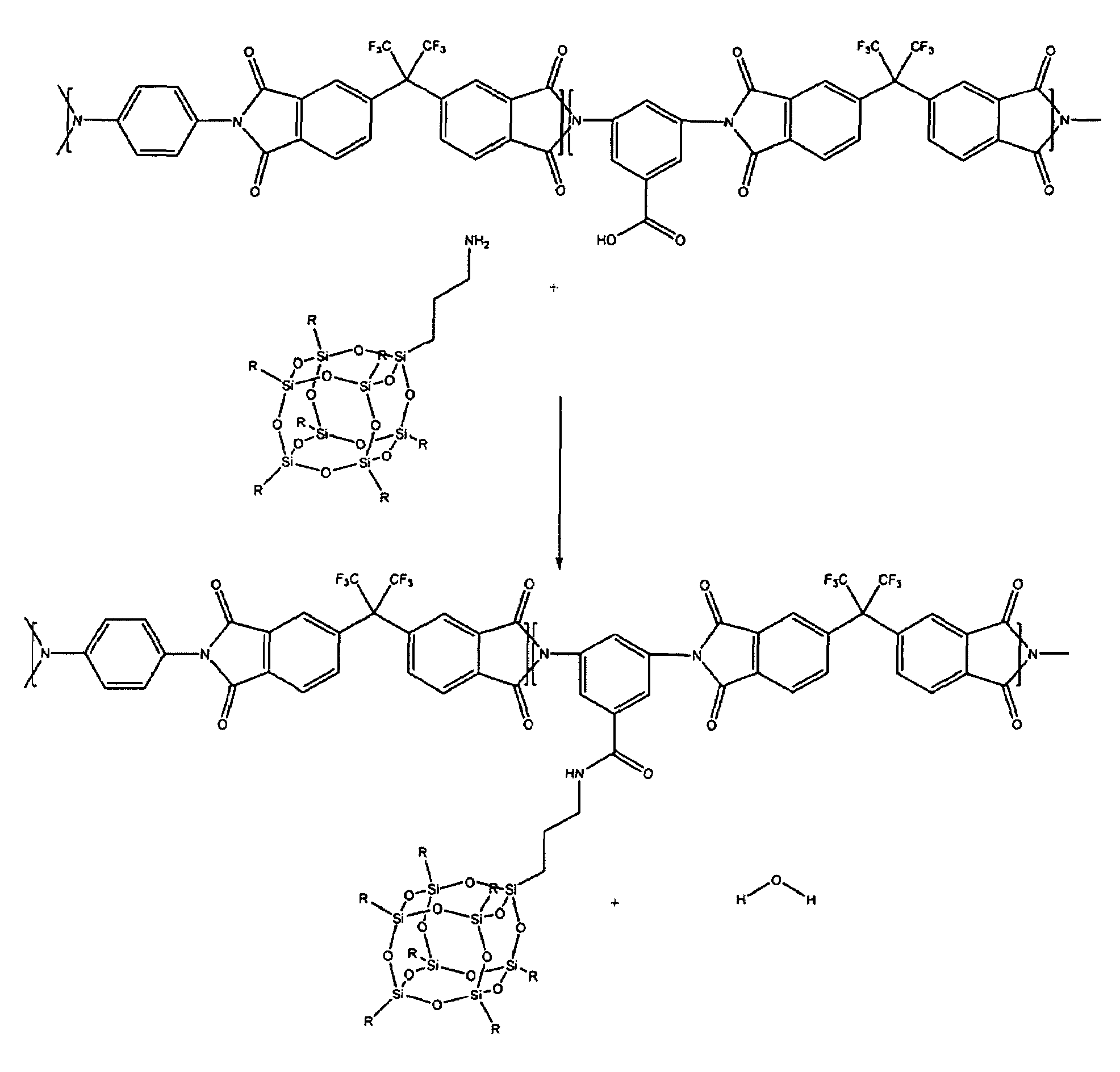

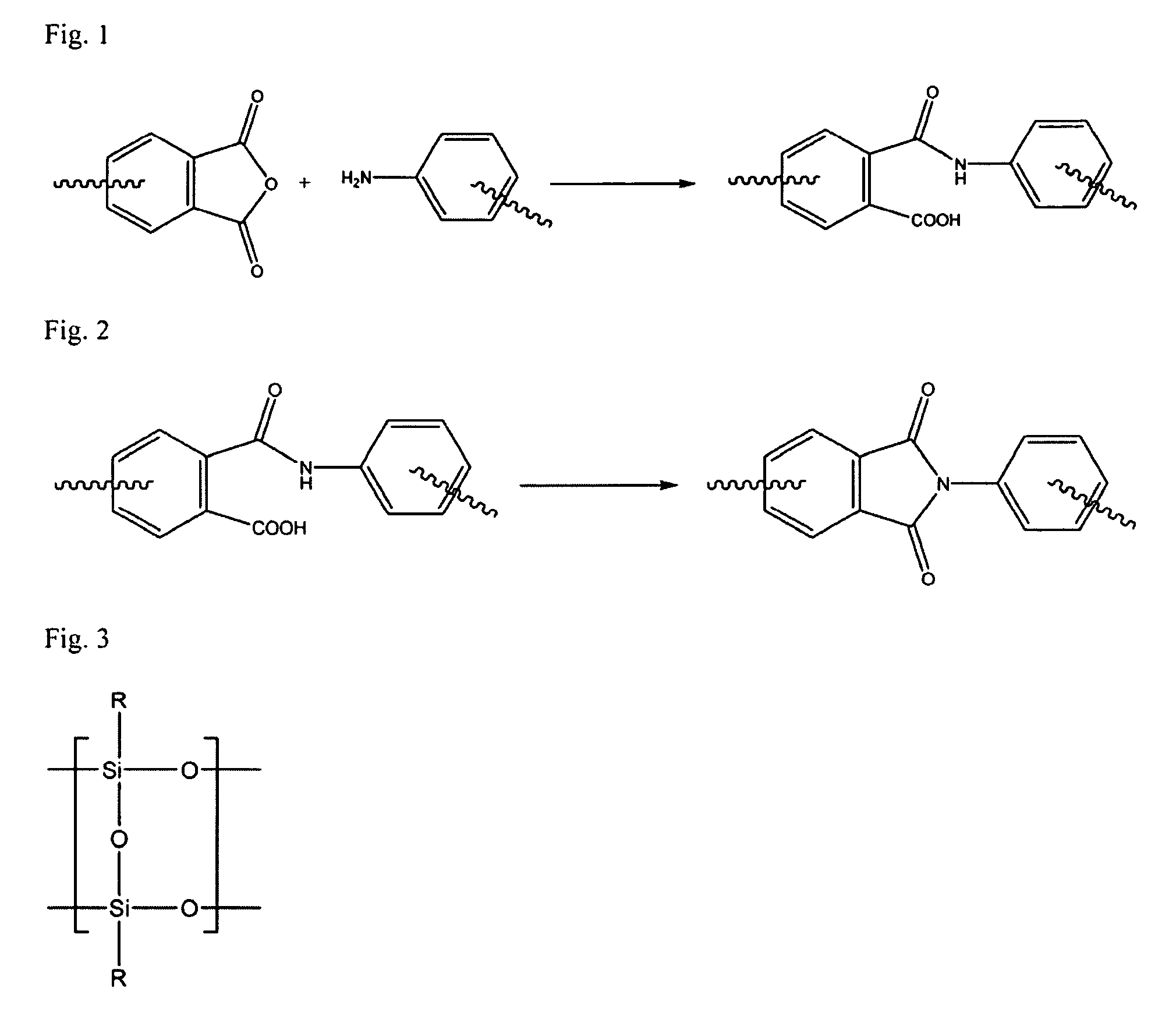

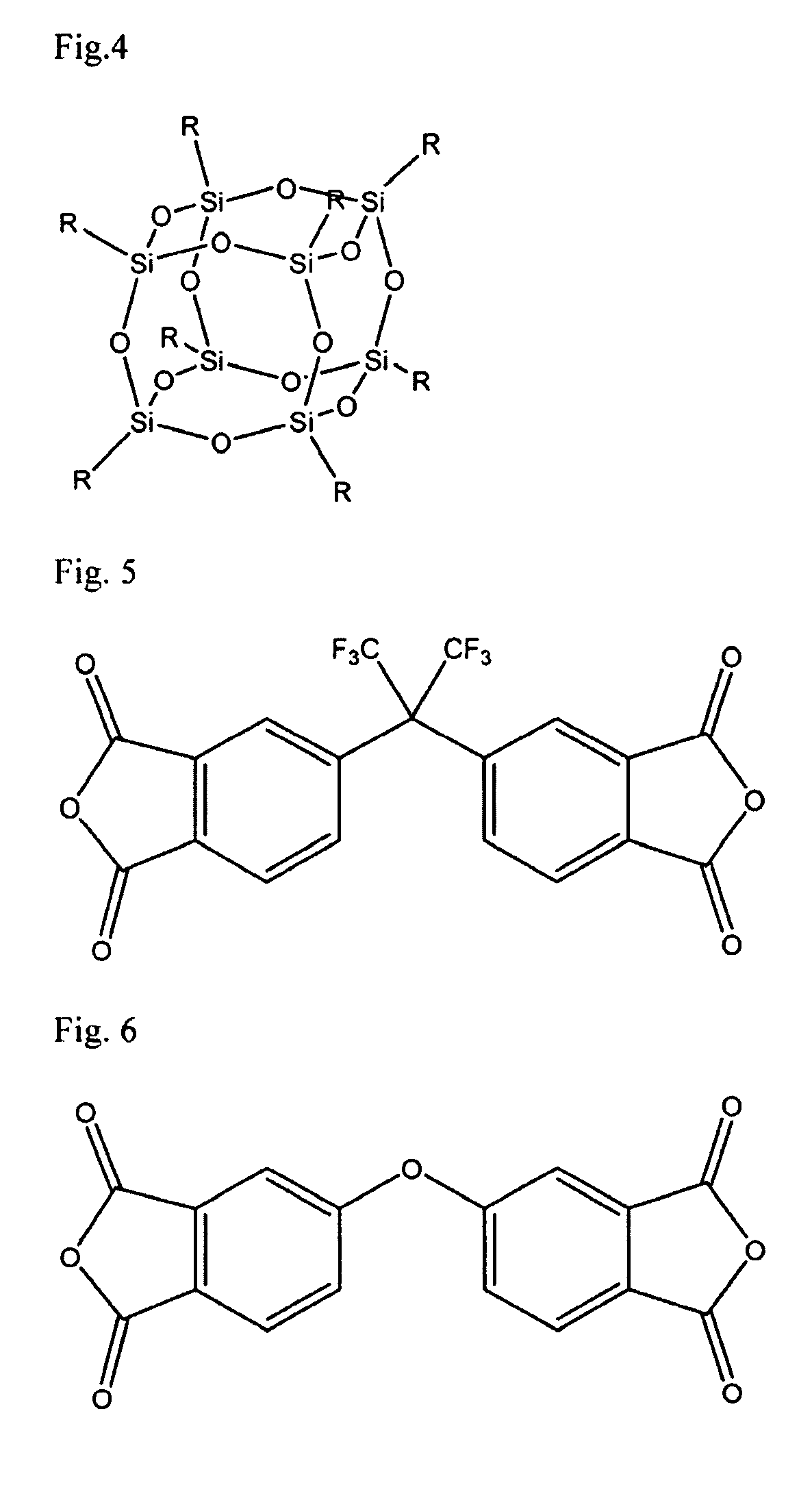

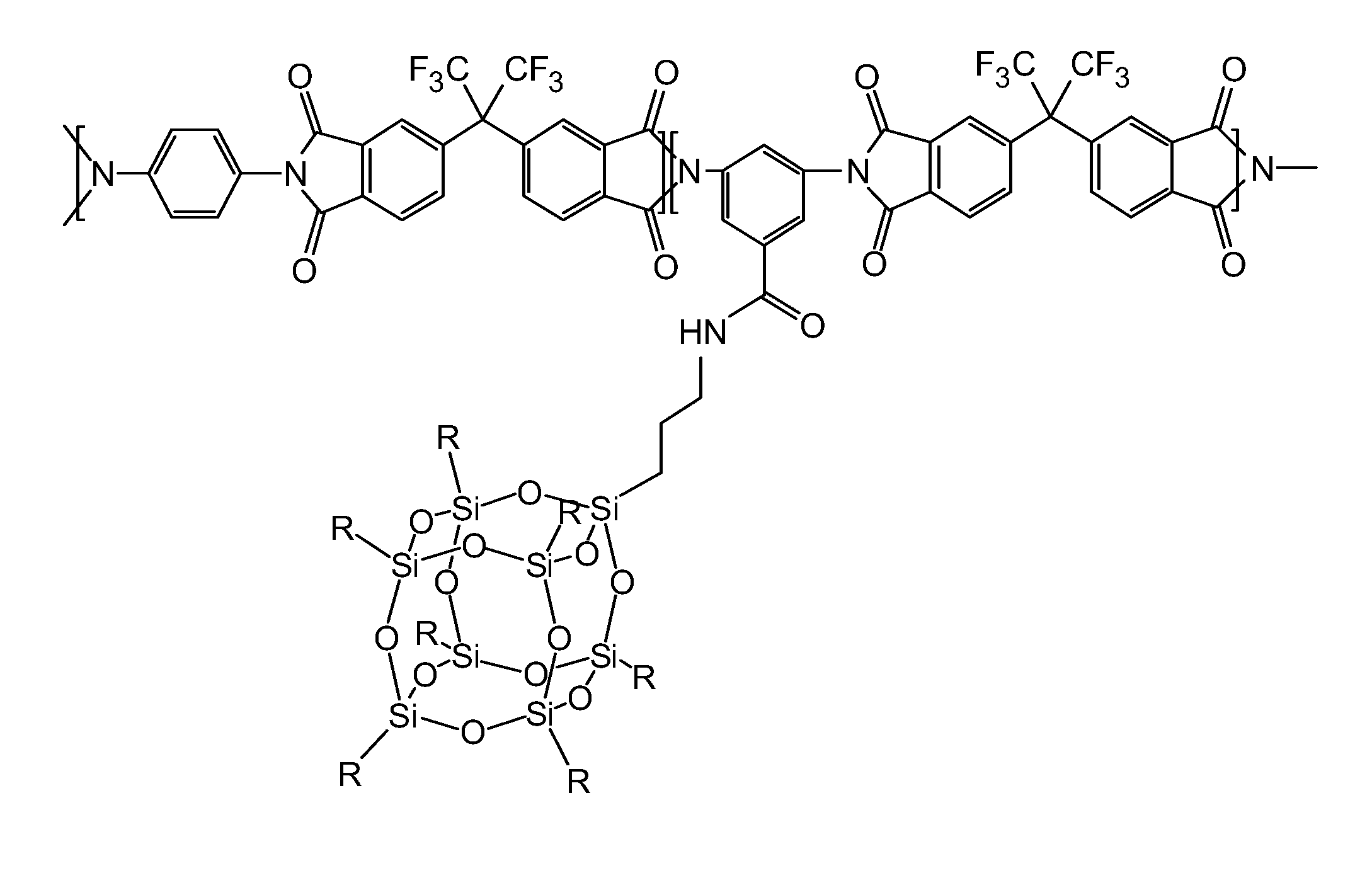

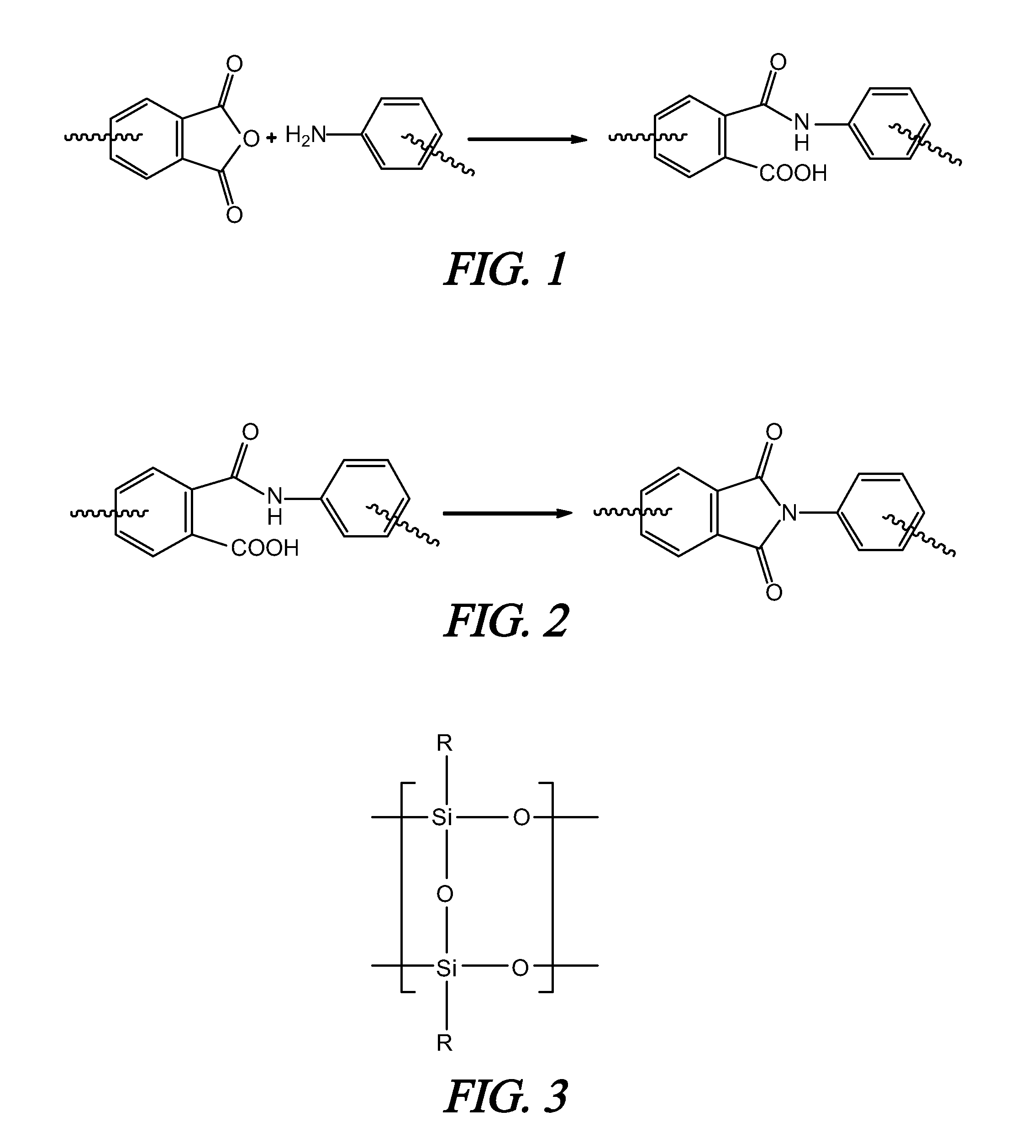

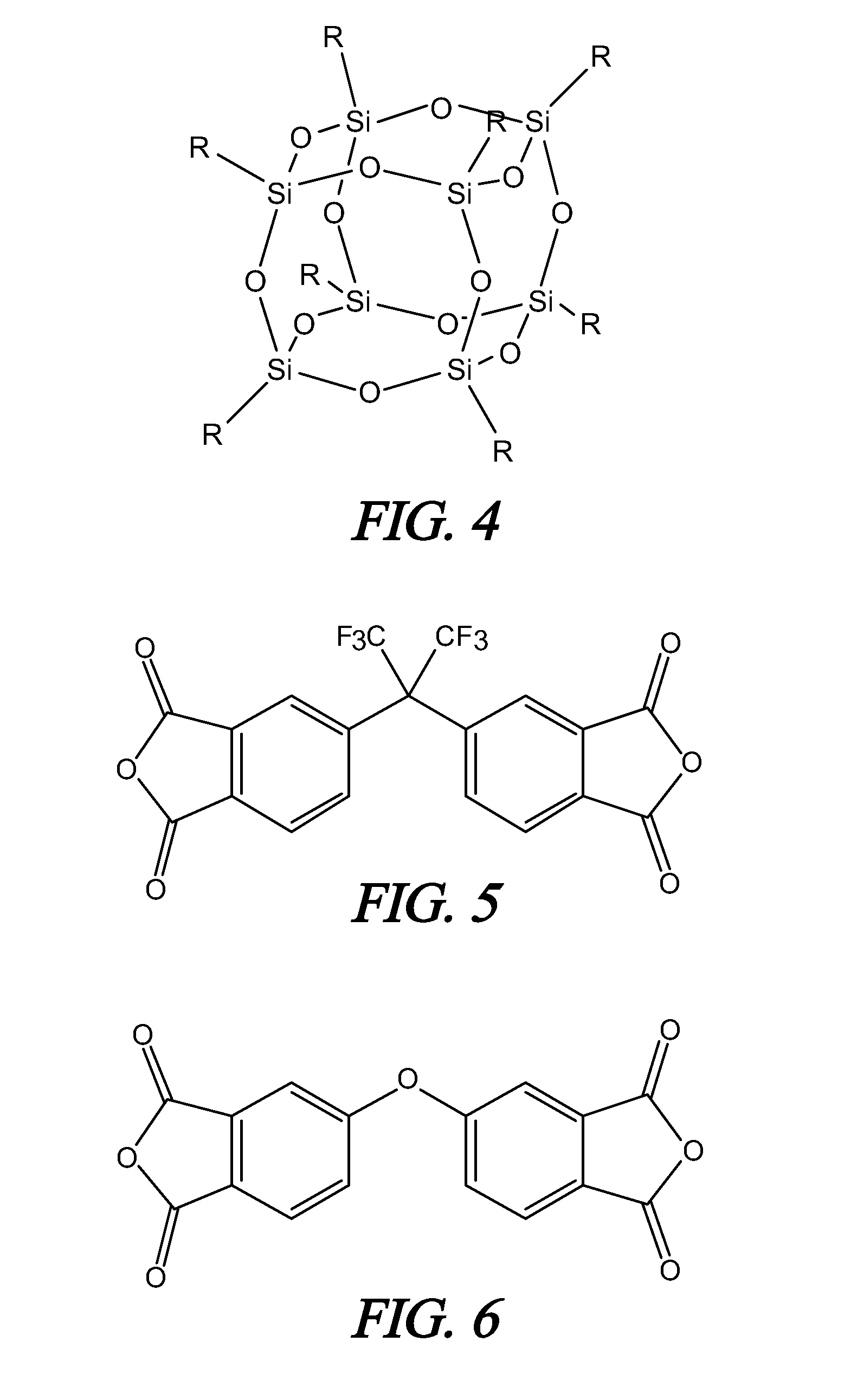

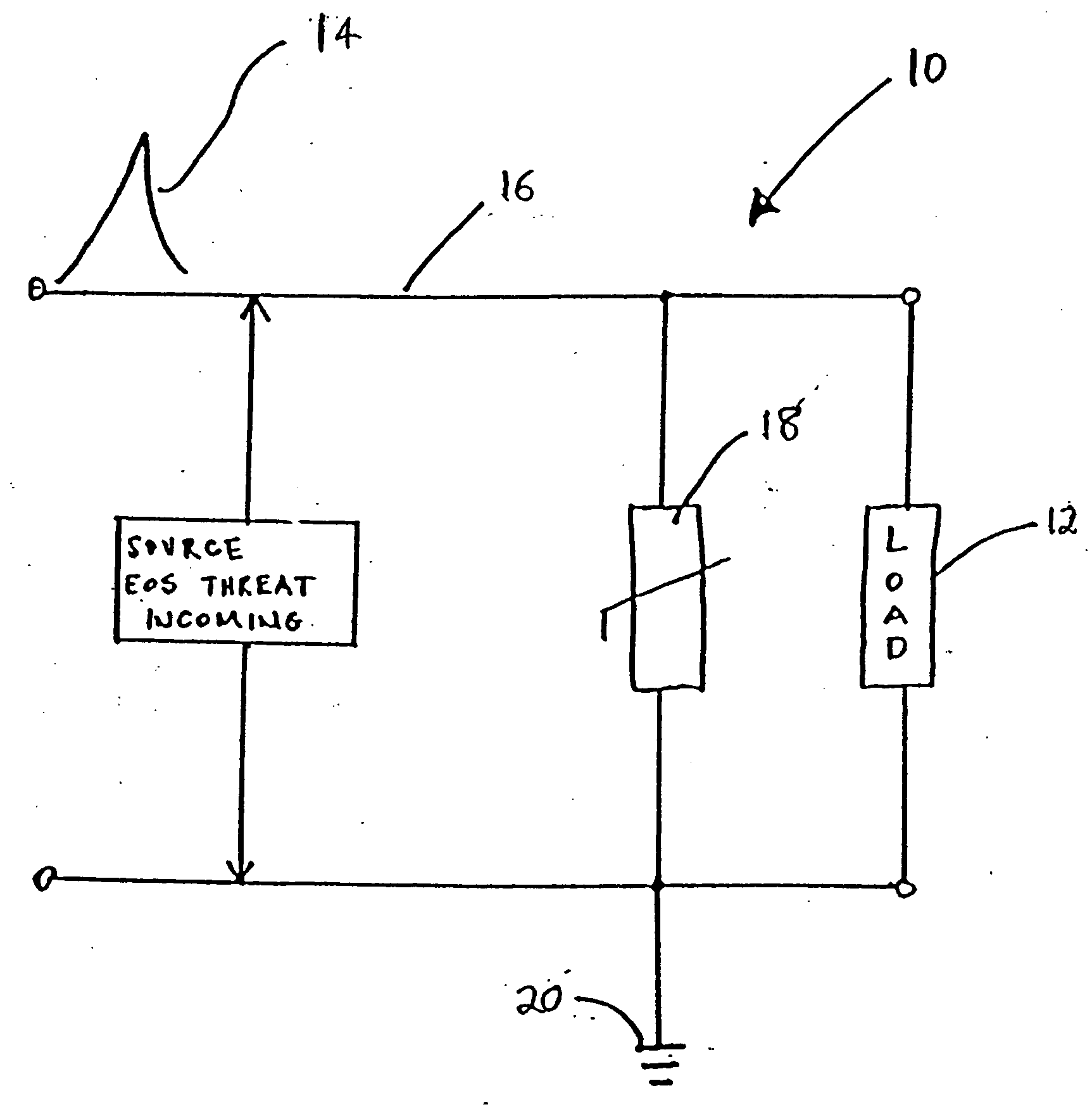

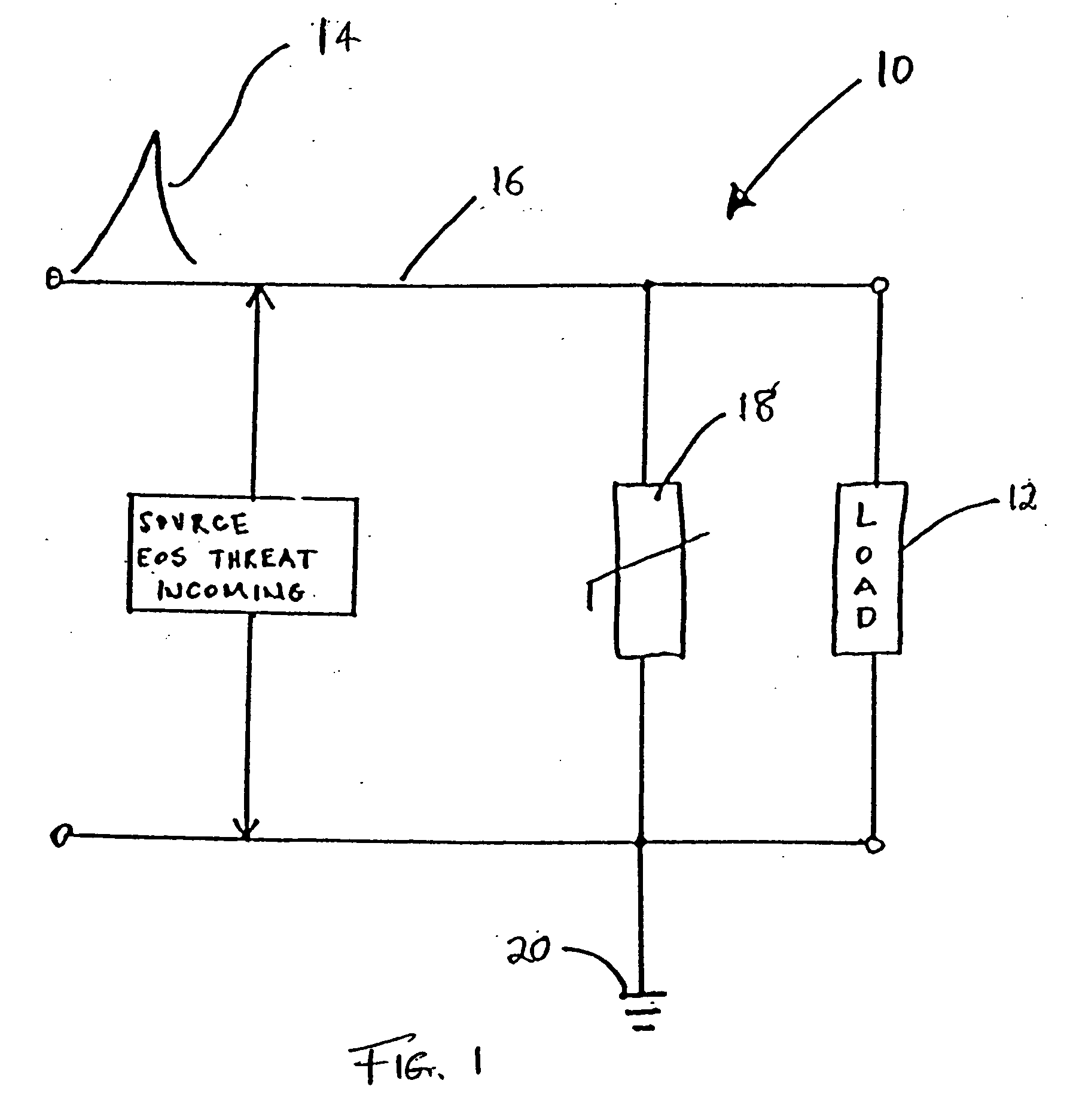

Polyimide polymer with oligomeric silsesquioxane

A soluble polyimide polymer with tethered oligomeric silsesquioxane compounds is produced using efficient, gentle reactions. A carboxylic acid attachment point on the polymer backbone is used to connect the oligomeric silsesquioxane. The oligomeric silsesquioxane compound includes an amine or an alcohol on an organic tether, which reacts with the carboxylic acid attachment point to produce either an amide or an ester bond. The amide or ester bond includes a carbonyl carbon directly connected to a phenyl group in the polymer backbone. The resultant polyimide polymer has many beneficial properties.

Owner:NEXOLVE HLDG CO LLC

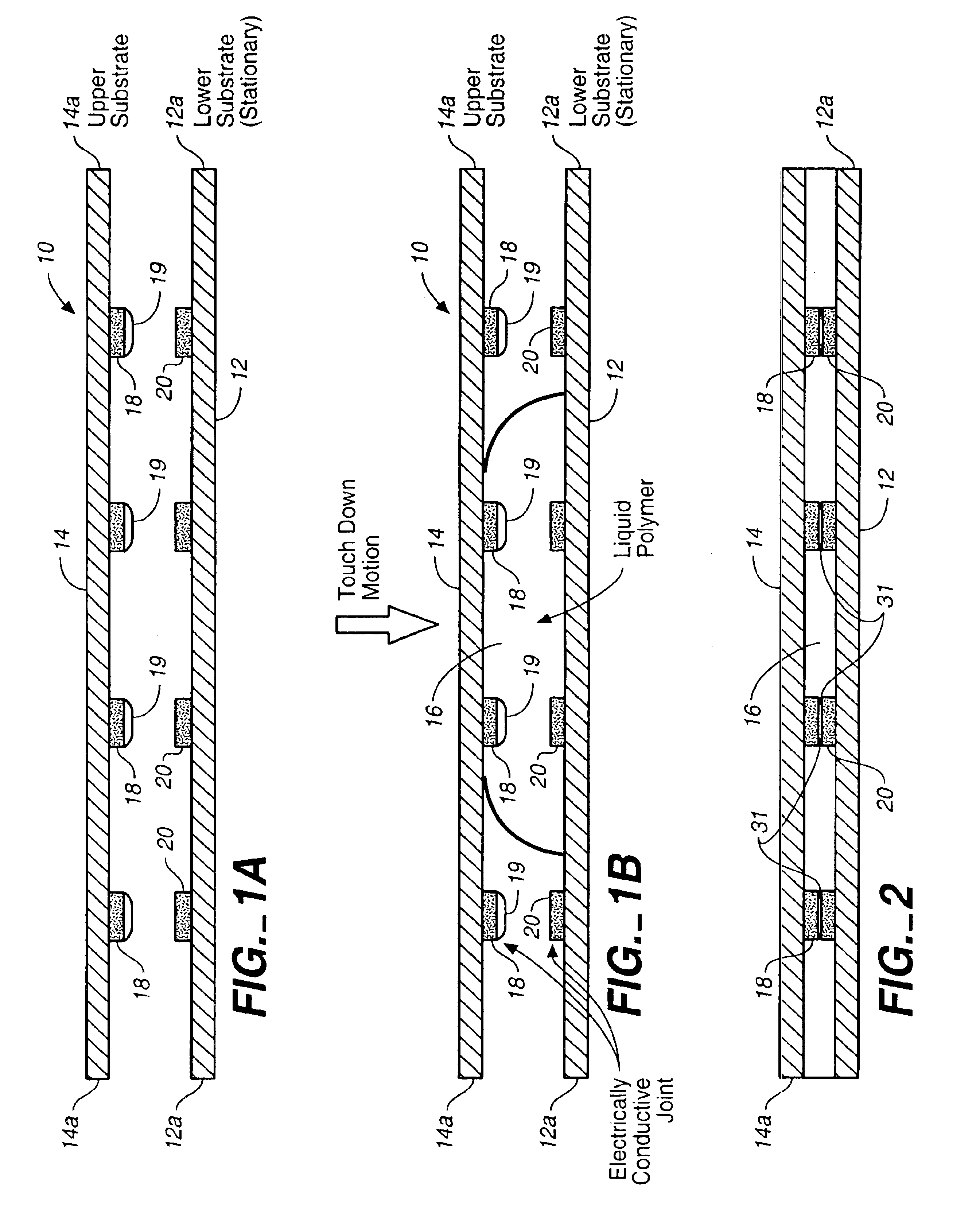

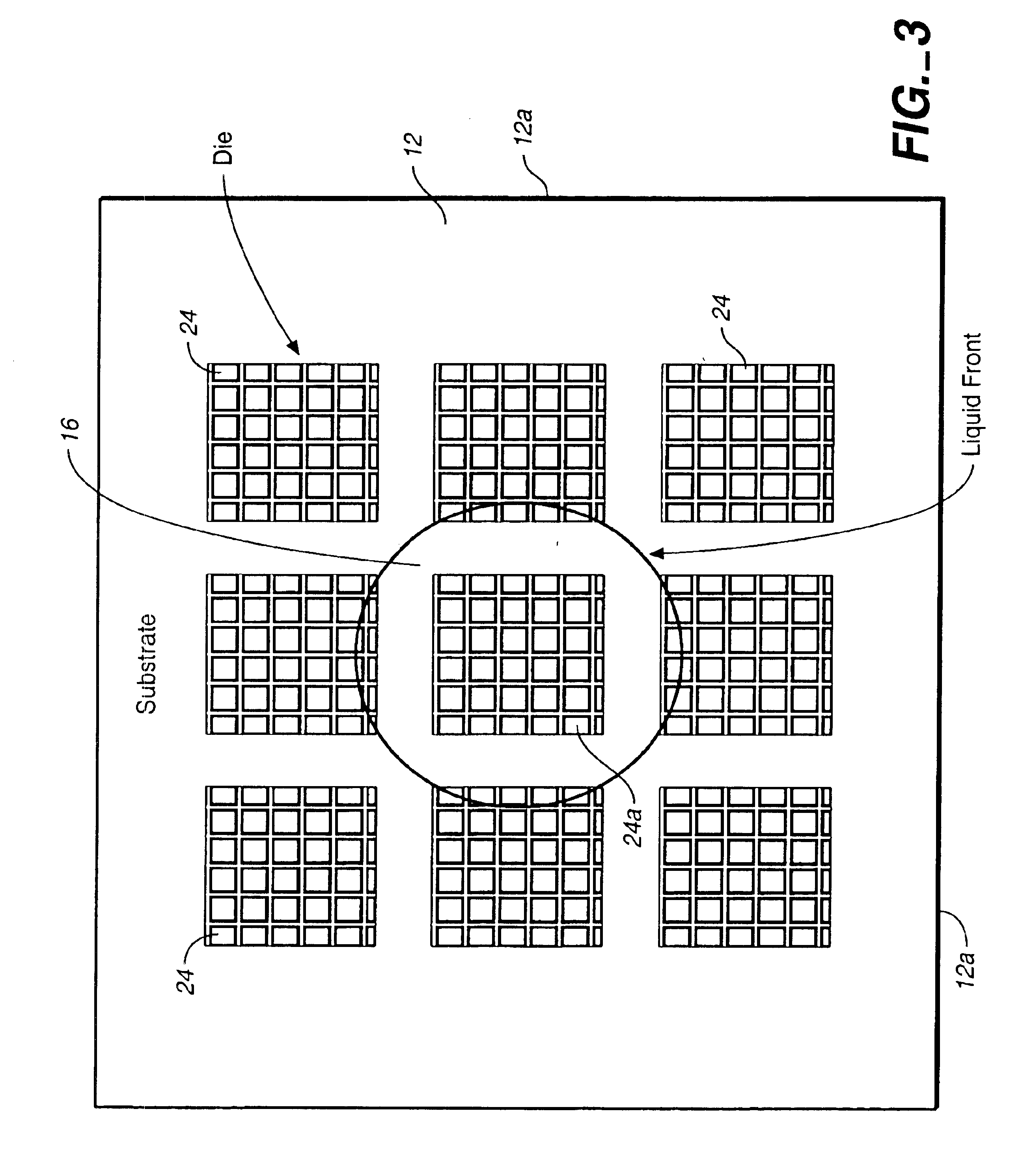

Method for joining conductive structures and an electrical conductive article

Embodiments of the invention include a method comprising disposing a thin metallic layer having a low melting temperature between one end of a conductive post on a substrate and a conducting structure on an opposing substrate. Heated platens in contact with the substrates can apply pressure and heat to the thin metallic layer and cause it to be entirely consumed and subsequently transformed into a bonding layer having a melting temperature higher than the melting temperature of the original thin metallic layer. Prior to, during, or after the conductive post is bonded to the conducting structure, the region around the conductive post and between the substrates may be filled with a dielectric material, such as polyimide.

Owner:FUJITSU LTD

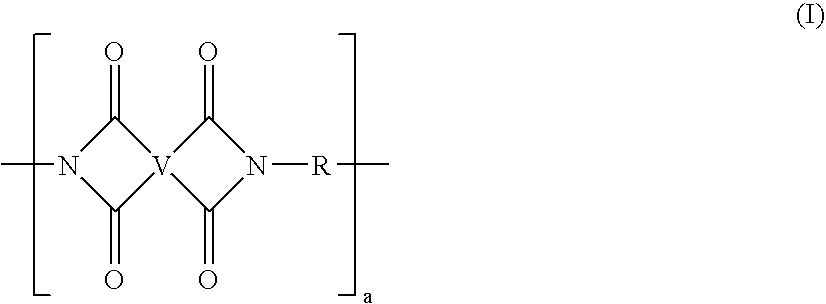

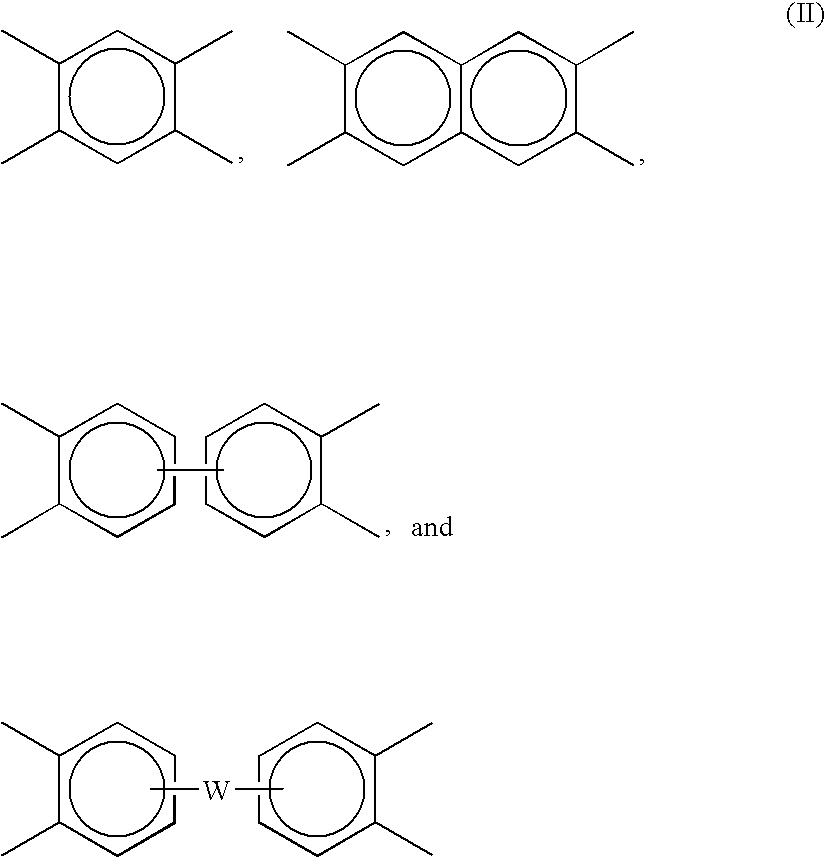

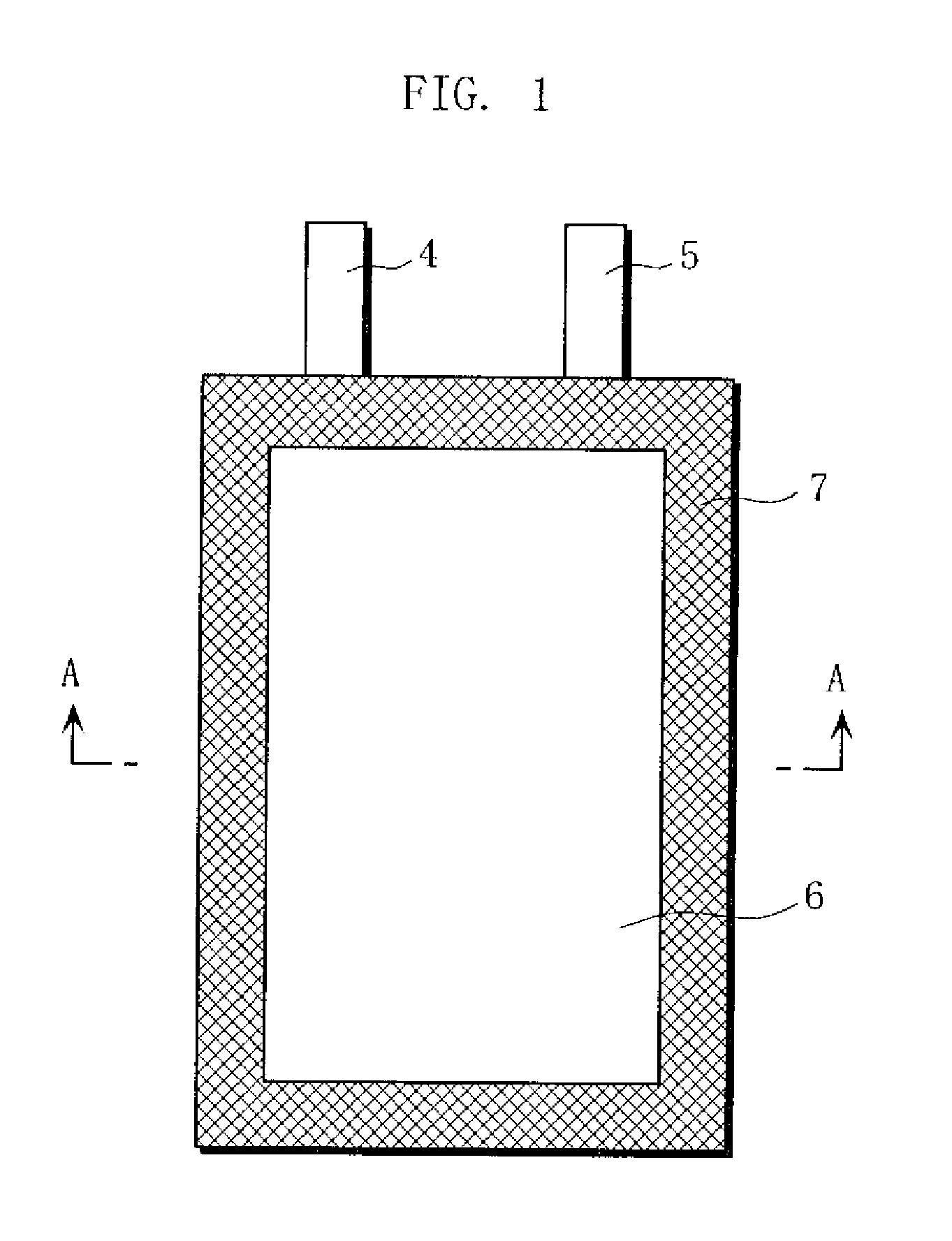

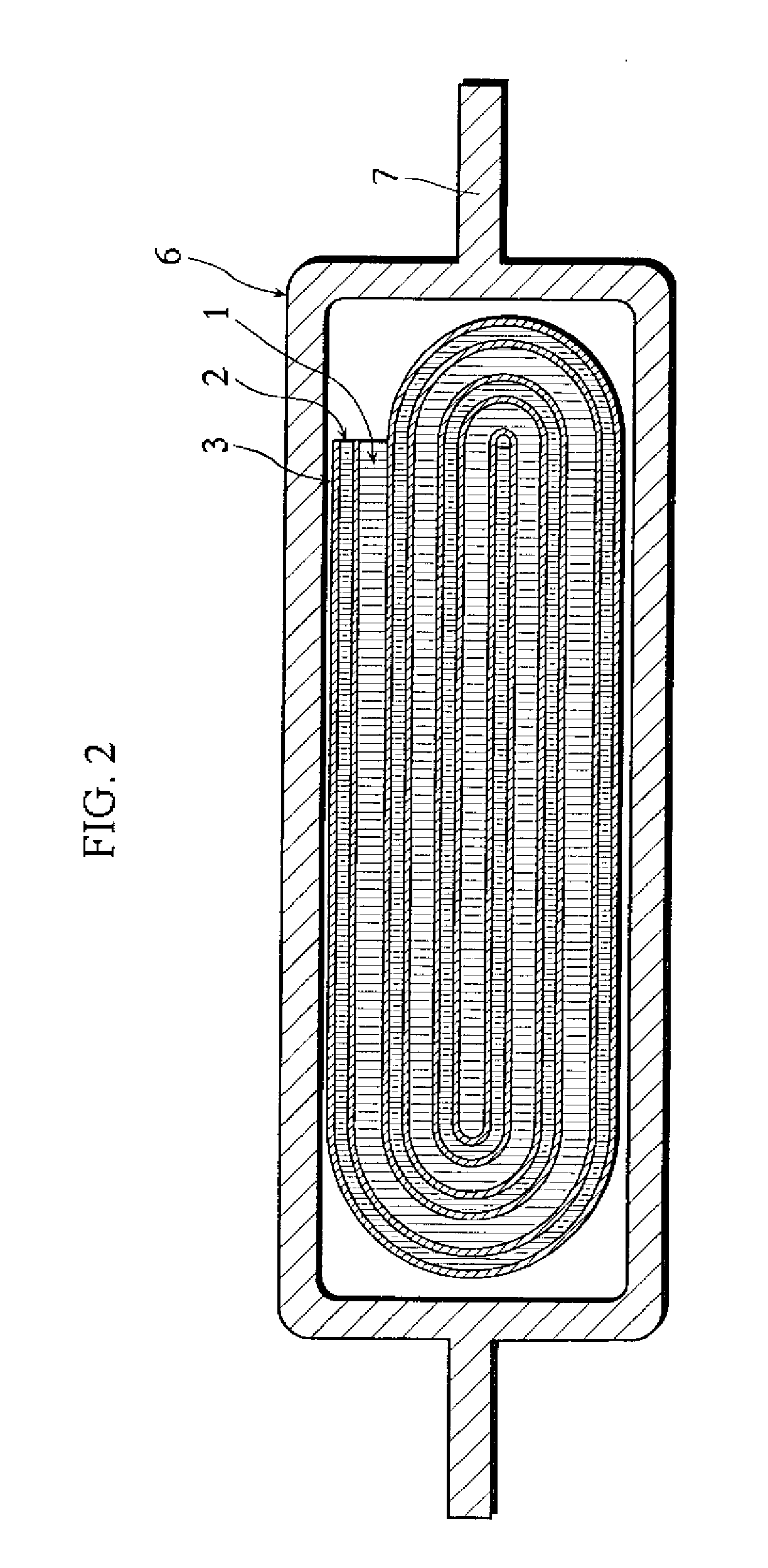

Lithium secondary battery and method of manufacturing the same

ActiveUS20080124631A1Avoid fracturesImprove cycle performanceElectrode carriers/collectorsNegative electrodesSilicon alloyMaterials science

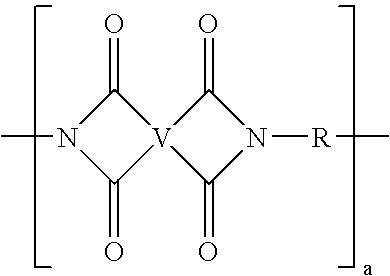

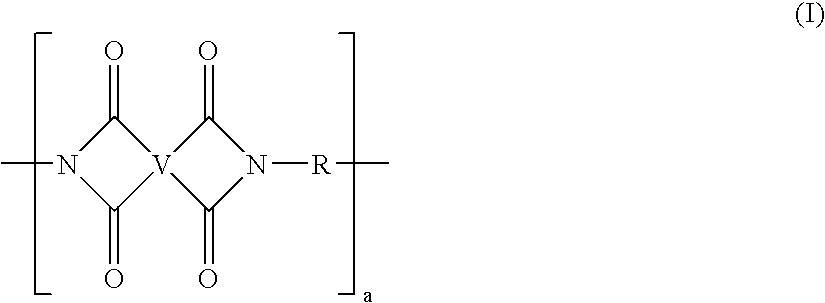

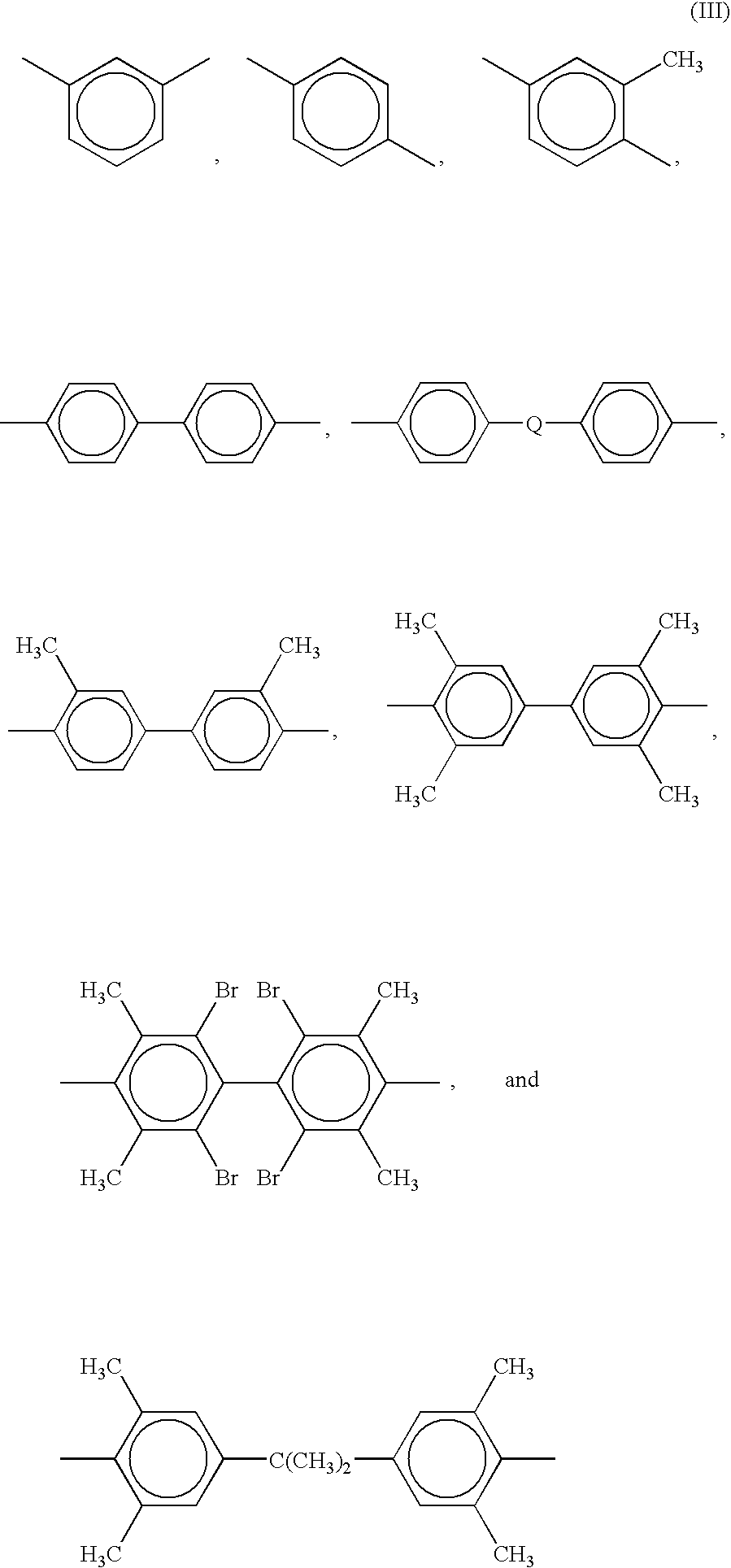

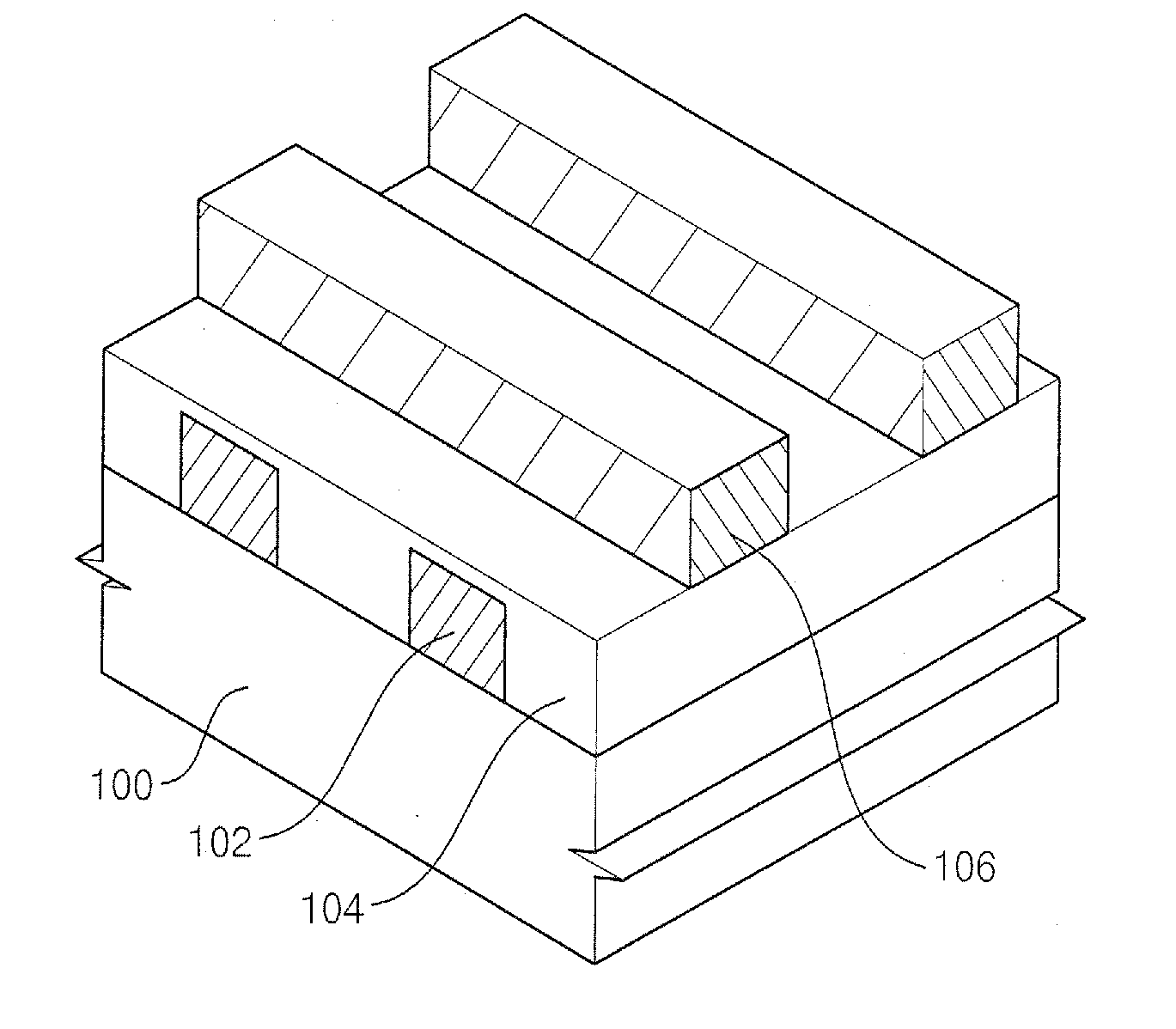

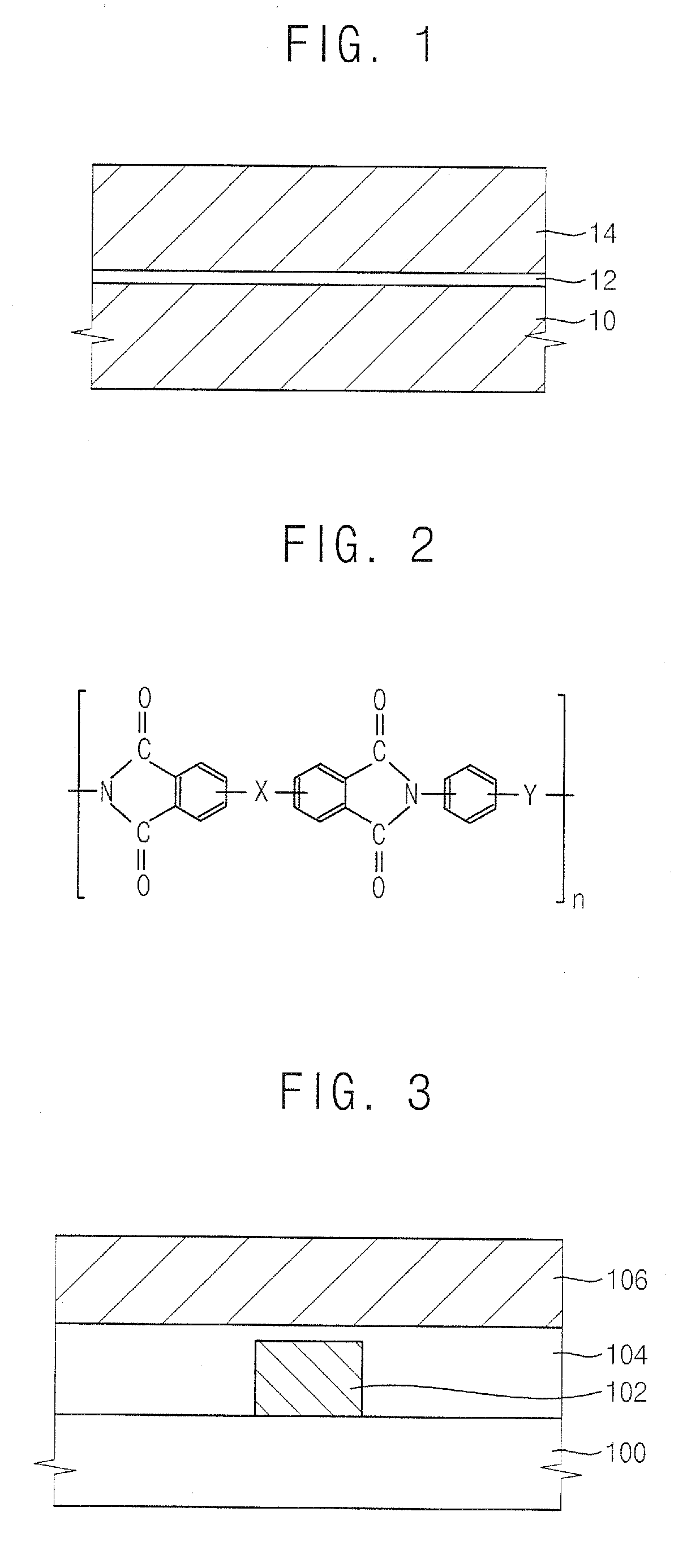

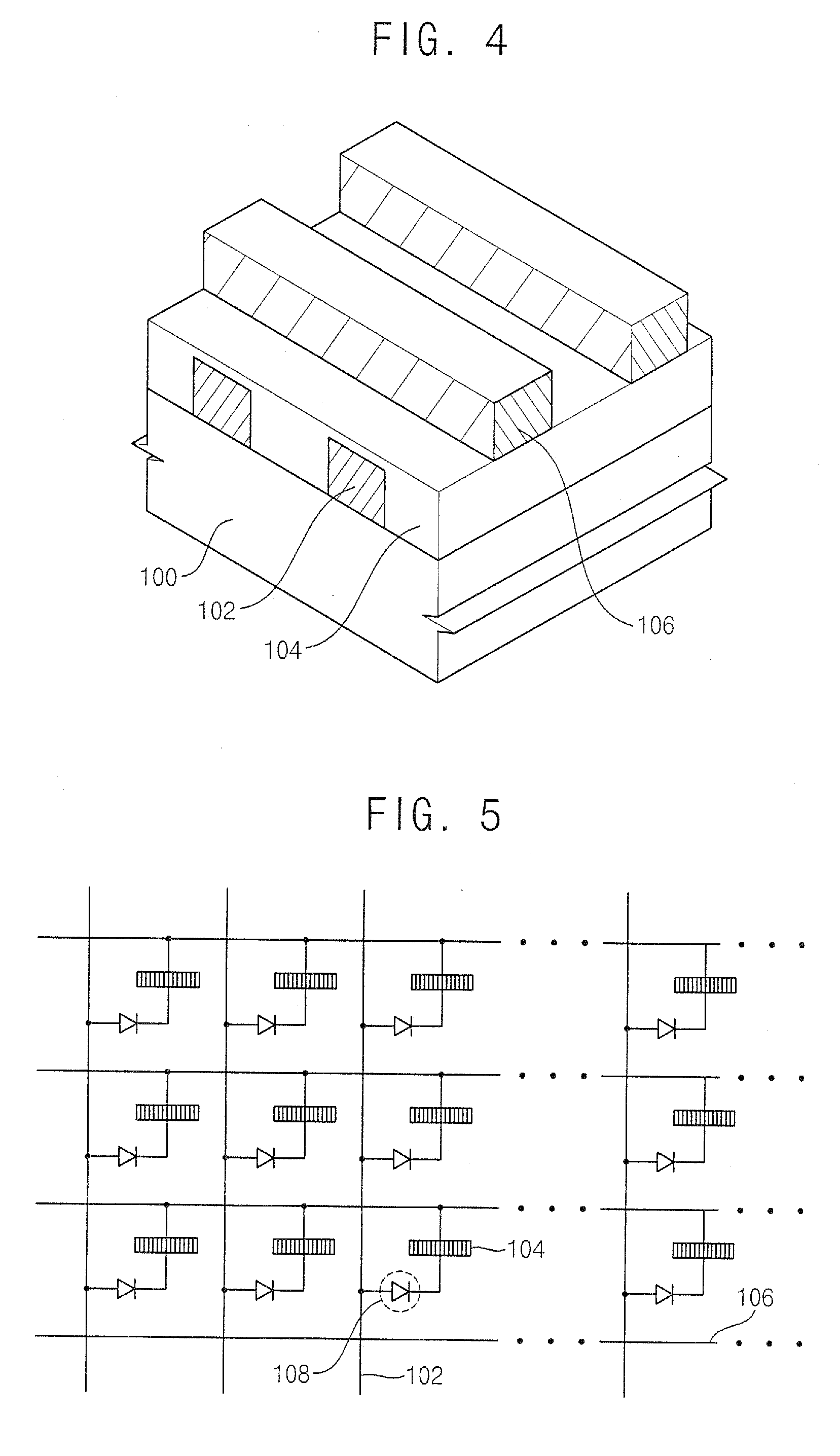

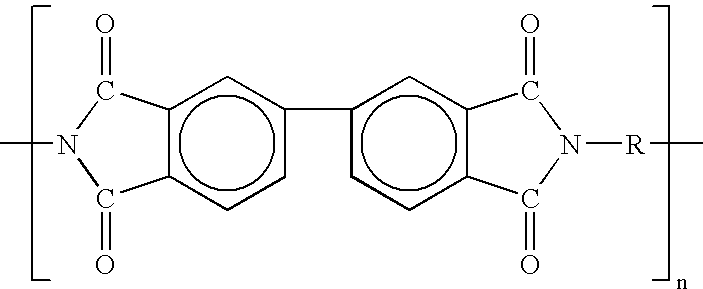

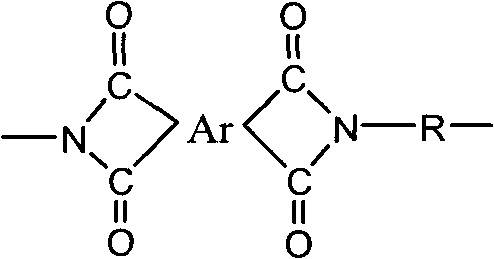

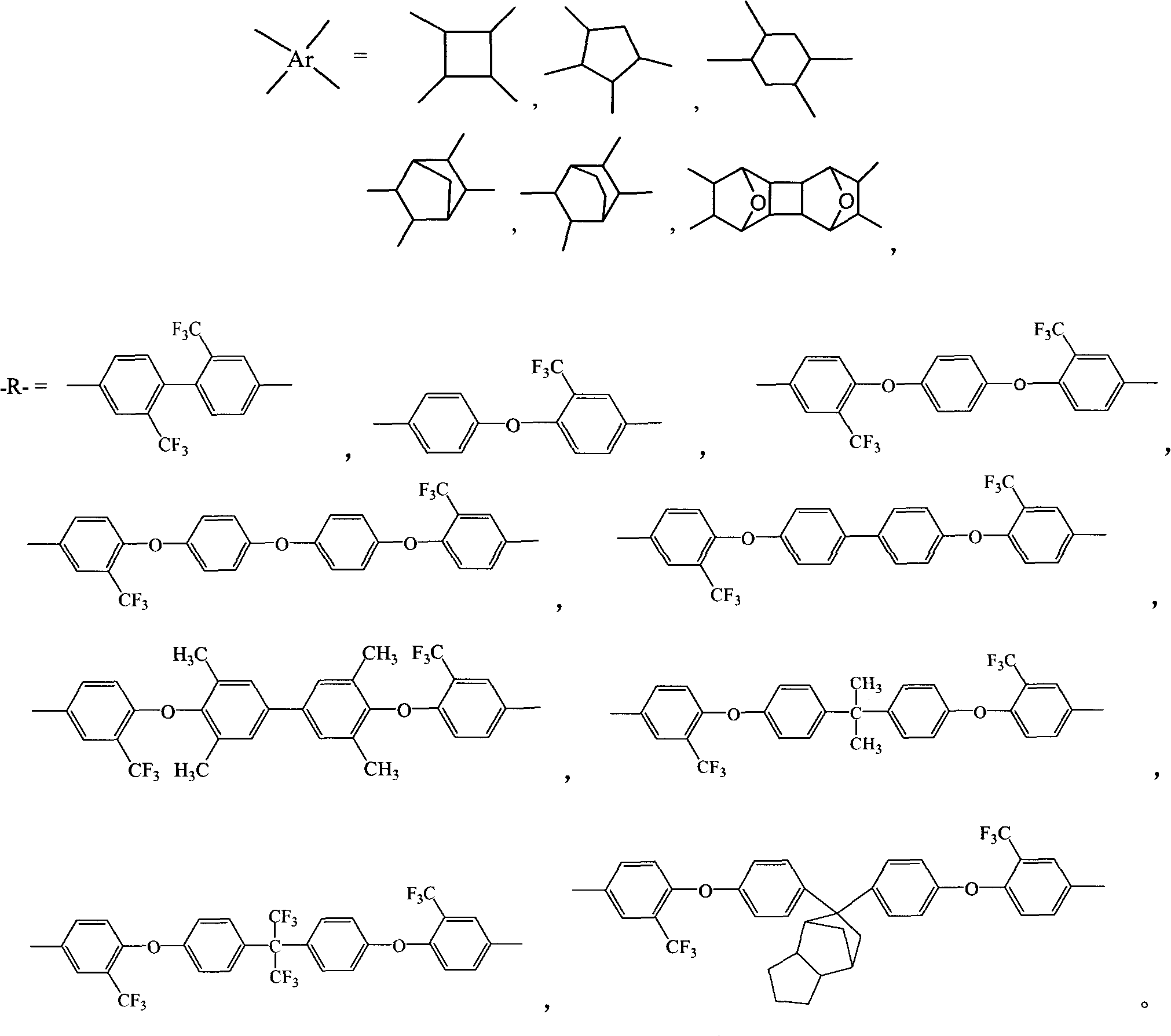

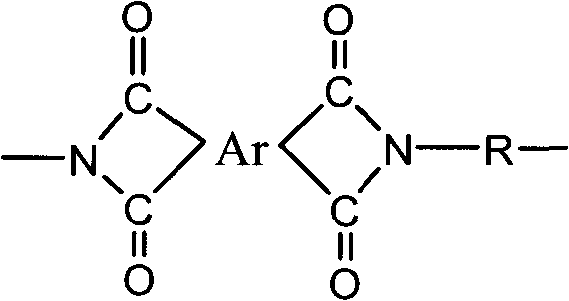

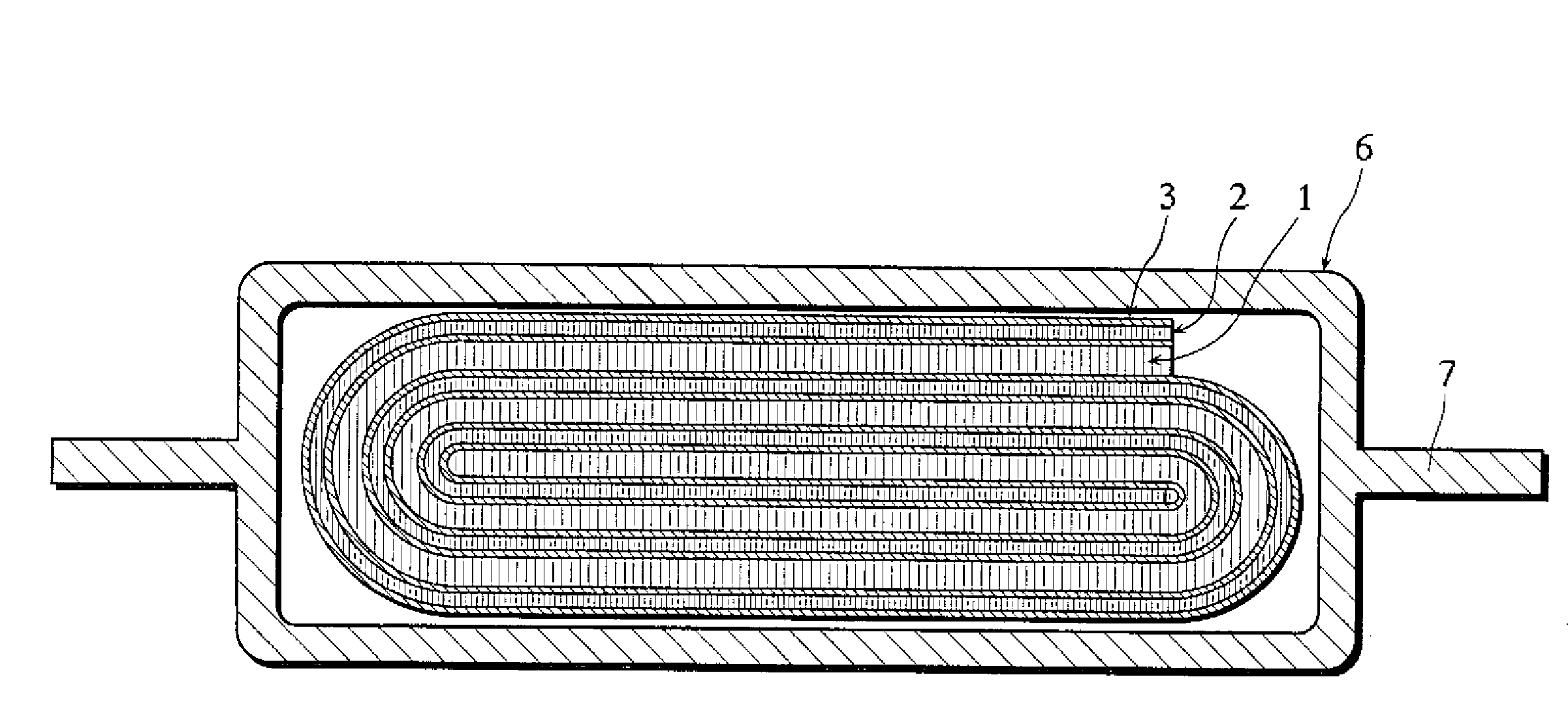

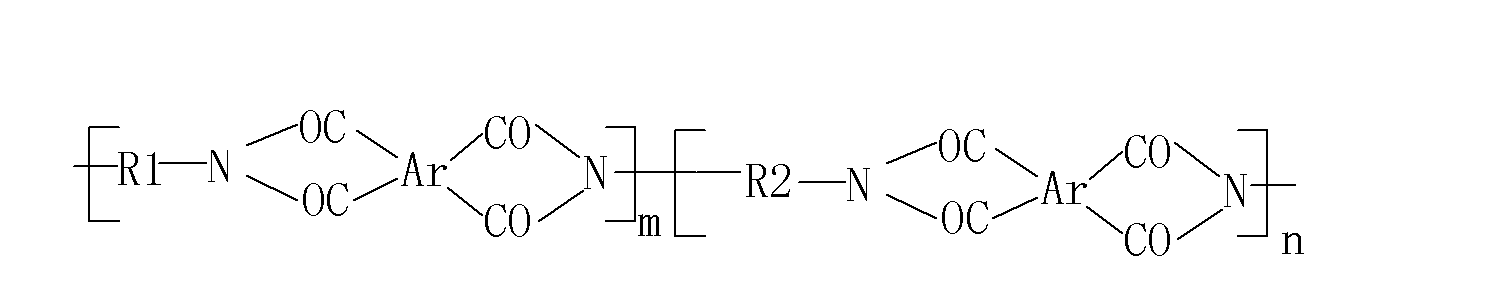

A lithium secondary battery includes an electrode assembly having a positive electrode (1), a negative electrode (2) having a negative electrode current collector and a negative electrode active material layer formed on a surface of the negative electrode current collector and composed of a binder and negative electrode active material particles containing silicon and / or a silicon alloy, and a separator (3) interposed between the electrodes. The electrode assembly is impregnated with a non-aqueous electrolyte. The binder contains a polyimide resin represented by the following chemical formula (1):where R contains at least a benzene ring, and n is within the range of from 10 to 100,000, and the negative electrode active material particles have an average particle size of 5 μm or greater.

Owner:SANYO ELECTRIC CO LTD

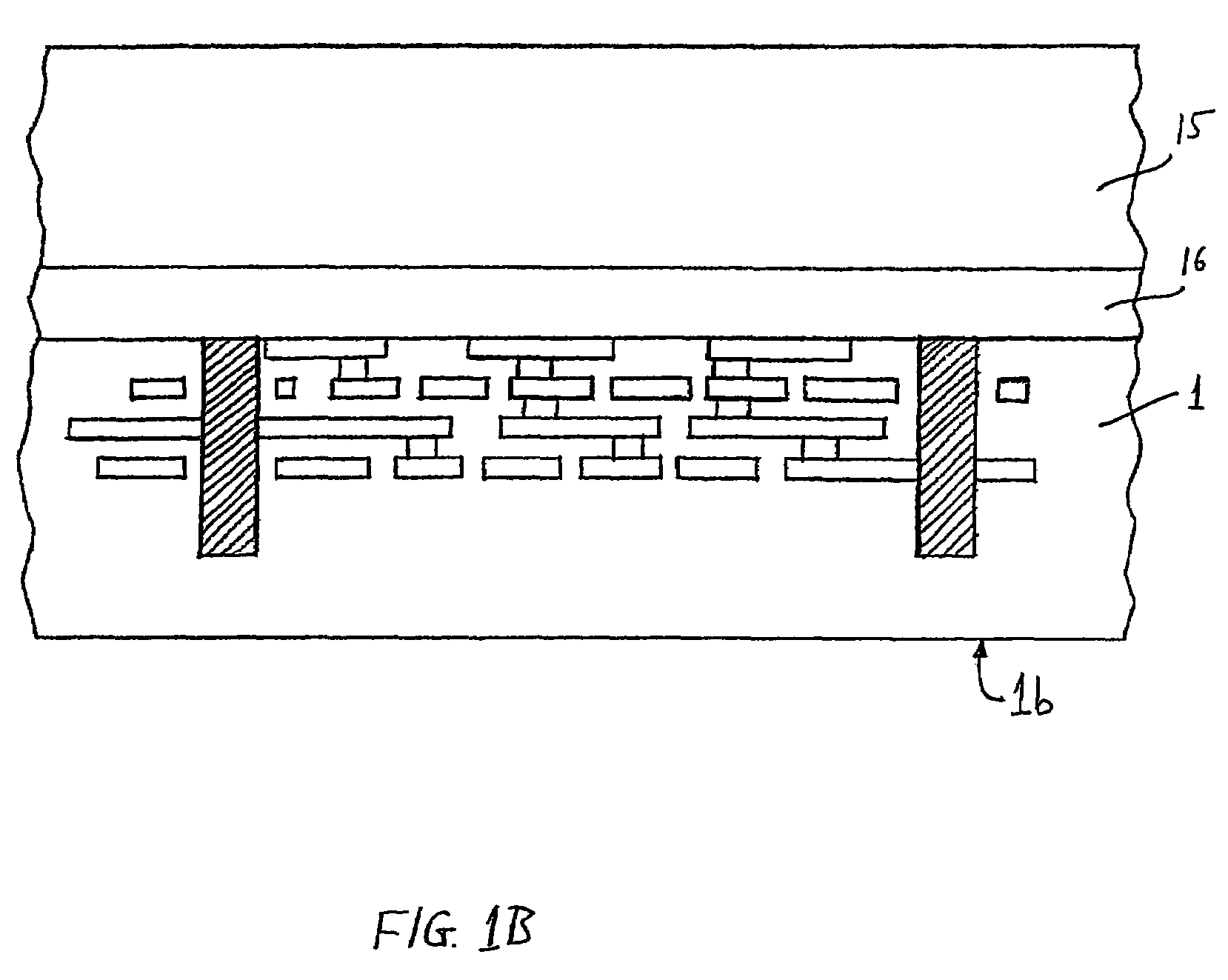

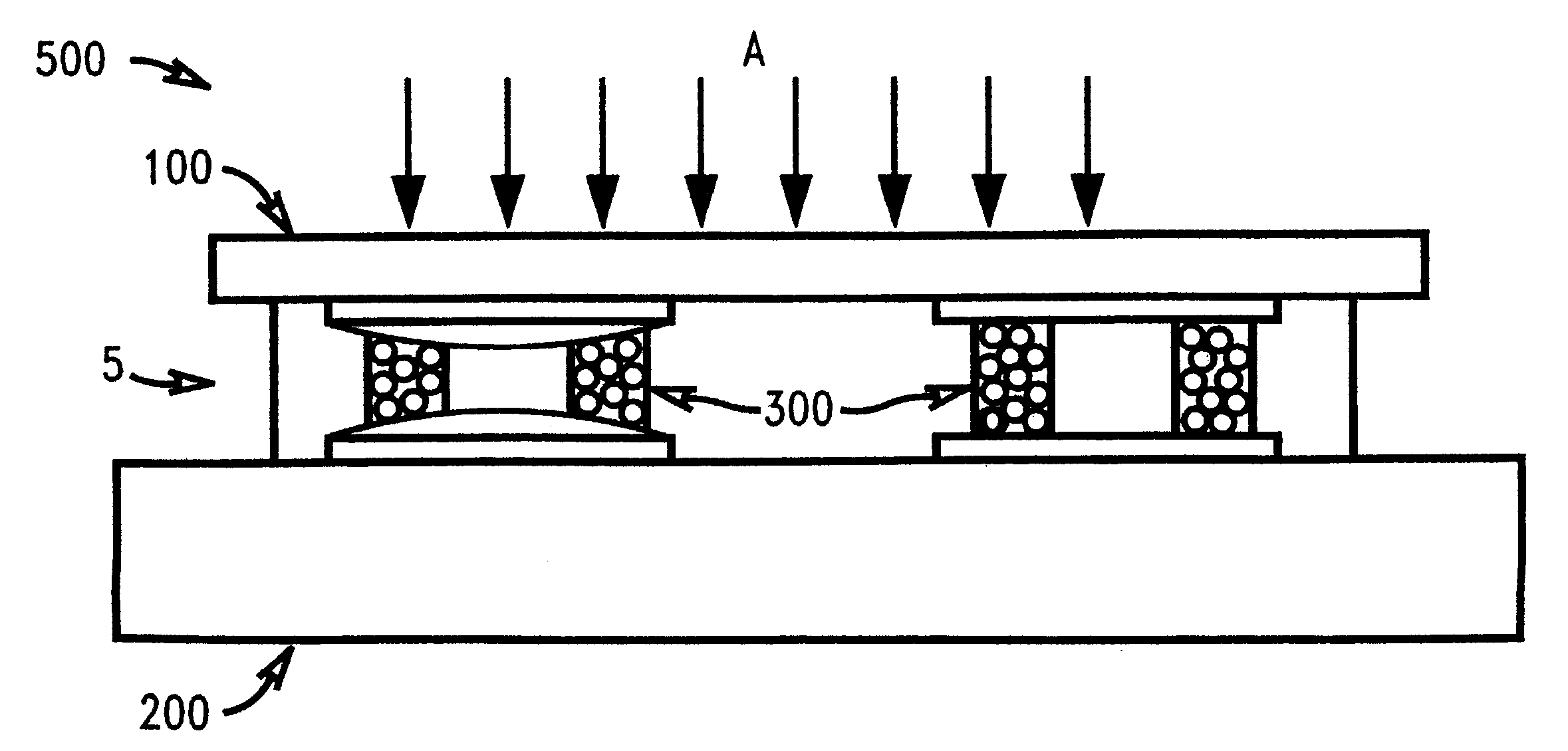

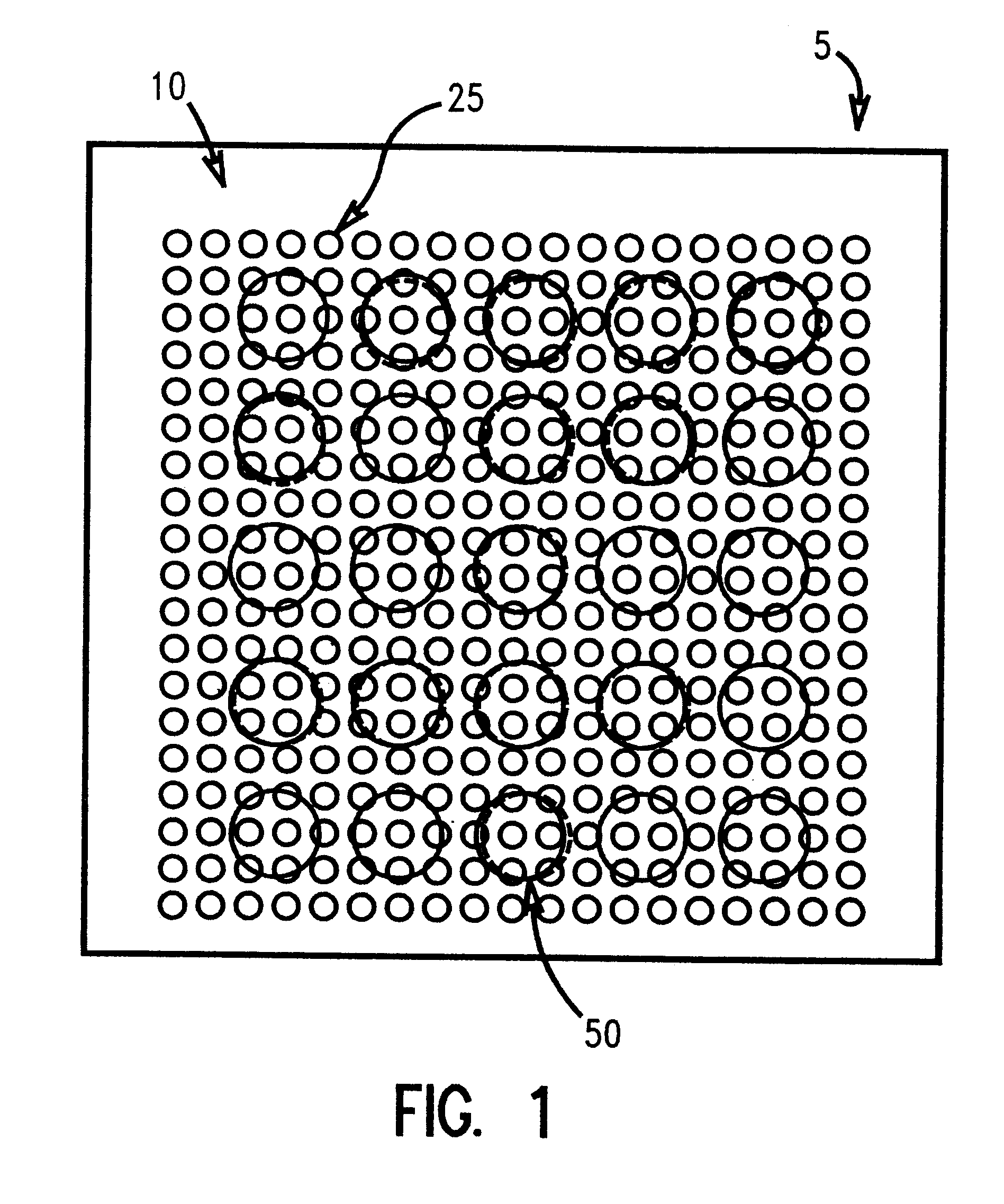

Z-axis compressible polymer with fine metal matrix suspension

InactiveUS6270363B1Reduce openingPrinted circuit assemblingLine/current collector detailsContact padAlloy

A compressible interposer comprising an interposer sheet having a plurality of apertures filled with a dielectric material having a substantially uniform suspension of conductive particles therein forming a plurality of conductive sites. Preferably, the number of conductive sites on the interposer are greater in number than the number of contact pads on the electronic components such that precise alignment of the interposer between the electronic components is not required. The apertures of the interposer sheet confine the conductive particles within the dielectric material such that during compression of the interposer between the electronic components, z-axis conductive pathways are formed without shorting in the x and y directions. Preferably, the interposer sheet comprises polyimide. Preferably, the dielectric material comprises polyimide-siloxane. Preferably, the conductive particles have a diameter of about 2 to about 20 mum and comprise of a material selected from the group consisting of copper, gold, silver, nickel, palladium, platinum, and alloys thereof. The particles may also be coated with an additional conductive material such as solder having a lower melting temperature. Most preferably, the conductive particles comprise solder coated copper particles. The conductive particles are present in an amount of about 30 to about 90 wt. % of the total weight of the conductive particles and the dielectric material.

Owner:IBM CORP

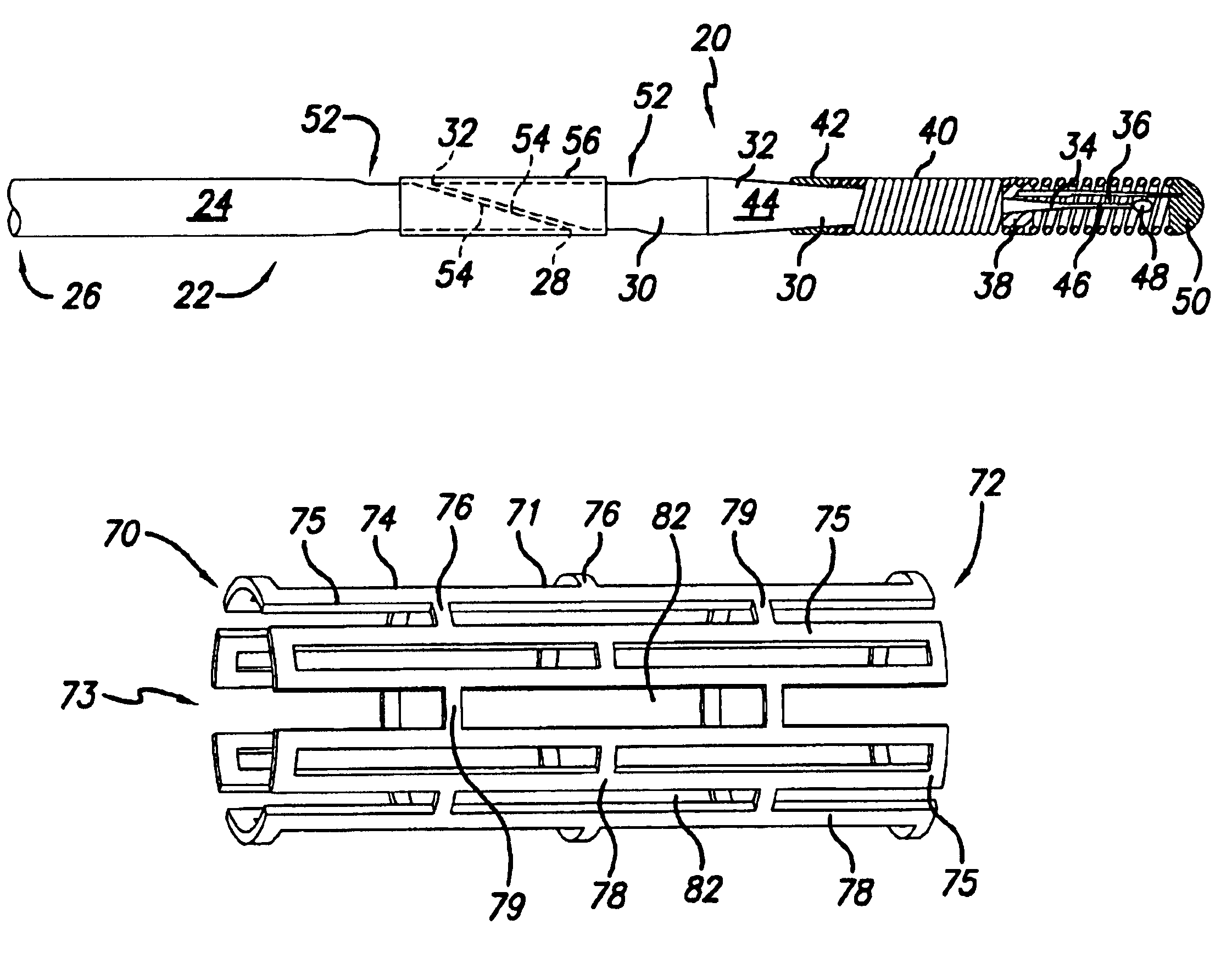

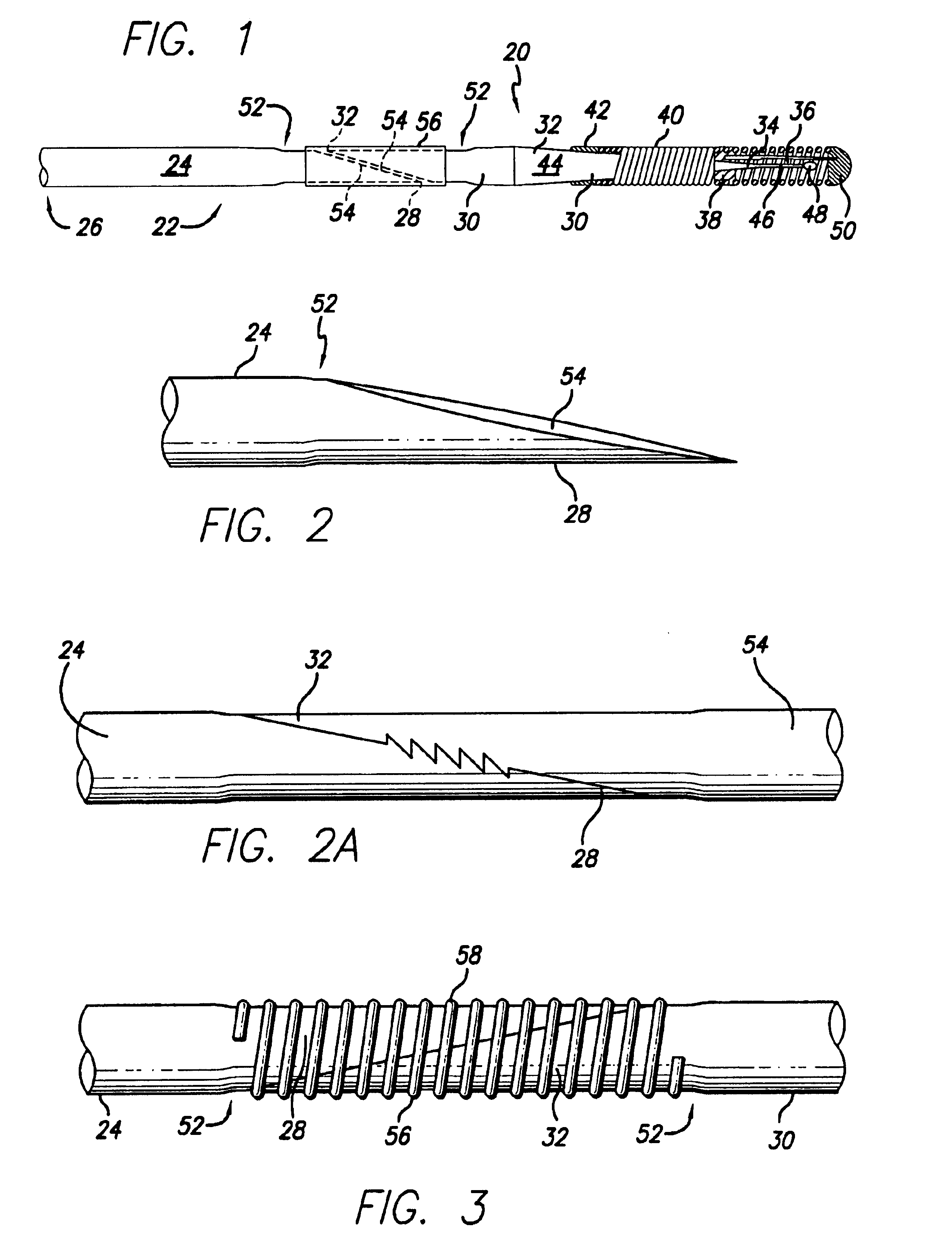

Enhanced method for joining two core wires

An intravascular guide wire having at least two core materials joined together. There is a wire core having a proximal core section with a proximal end and a distal end and a distal core section with a proximal end and a distal end. The distal end of the proximal core section and the proximal end of the distal core section are formed into complementary shapes, and then placed into a flexible sleeve in opposing directions. Inside the flexible sleeve, the complementary shaped ends are joined together through bonding, welding, brazing, cementing, or soldering. The flexible sleeve can be either a stretched coil or a polyimide sleeve, each with an outer diameter similar to the outer diameter of the core wire, therefore the guide wire does not require additional grinding to reduce the outer diameter of the joined section.

Owner:ABBOTT CARDIOVASCULAR

High-temperature resisting adhesive and preparation method thereof

InactiveCN102220102AConvenient sourceLow costNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyOrganic solvent

The invention relates to a high-temperature resisting adhesive and a preparation method thereof; the adhesive is formed by the following ingredients: carboxyl contained polyimide resin powder, epoxide resin, curing agent and organic solvent with weight ratio of 1:10-20:0.1-2:20-30. The preparation method of the high-temperature resisting adhesive comprises the following steps: adding the carboxylcontained polyimide resin powder, the epoxide resin and the curing agent into a reaction kettle, heating the reaction kettle to 80-90 DEG C for carrying out stirring reaction for 0.5-1.5 hours, and then adding the organic solvent continuously, and stirring the mixture uniformly at room temperature, thus obtaining the high-temperature resisting adhesive. The preparation method has simple process and low cost and is environment-friendly, the preparation process can be carried out in a general device, thereby being suitable for industrial production.

Owner:DONGHUA UNIV +1

PAEK-based microfluidic device with integrated electrospray emitter

A polyaryl-ether-ketone (PAEK)-based microfluidic device having an integrated electrospray emitter is disclosed. Bonding of at least one PAEK substrate forming the microfluidic device is accomplished using a solvent-resistant adhesive, such as a polyimide-based adhesive, in combination with an adhesion enhancement treatment. By providing the PAEK-based microfluidic device with an integrated electrospray emitter, efficient and effective analysis of fluid samples is enabled.

Owner:AGILENT TECH INC

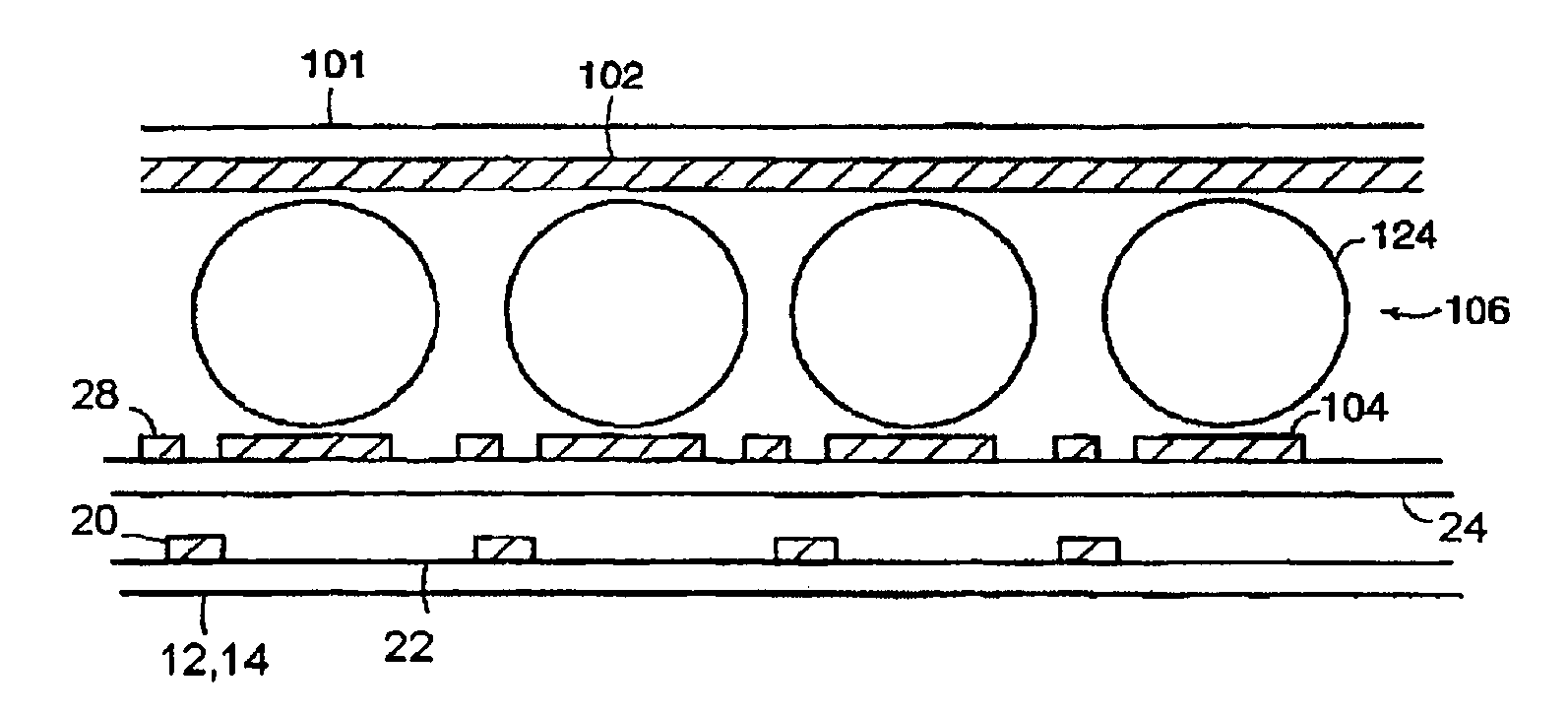

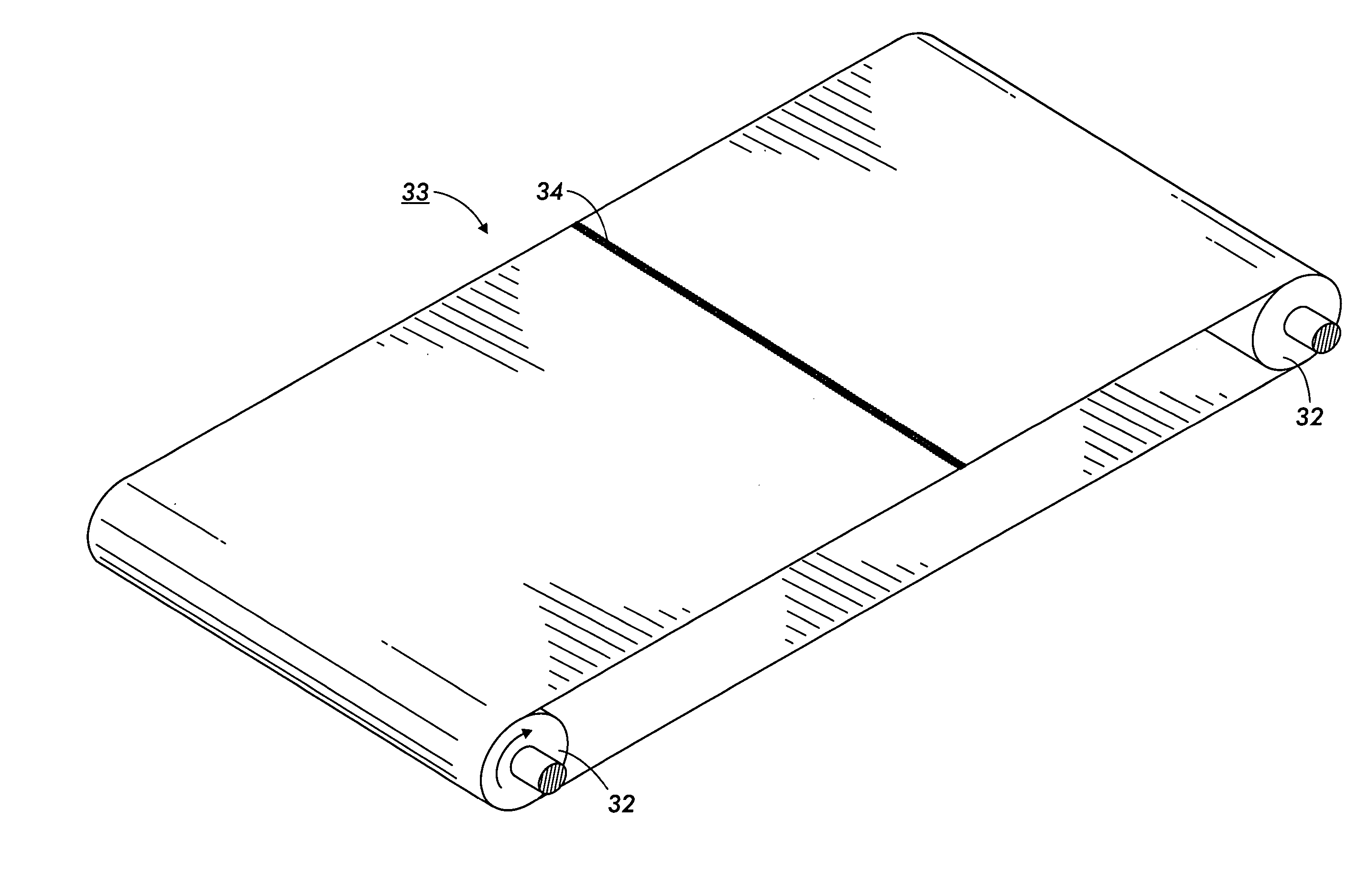

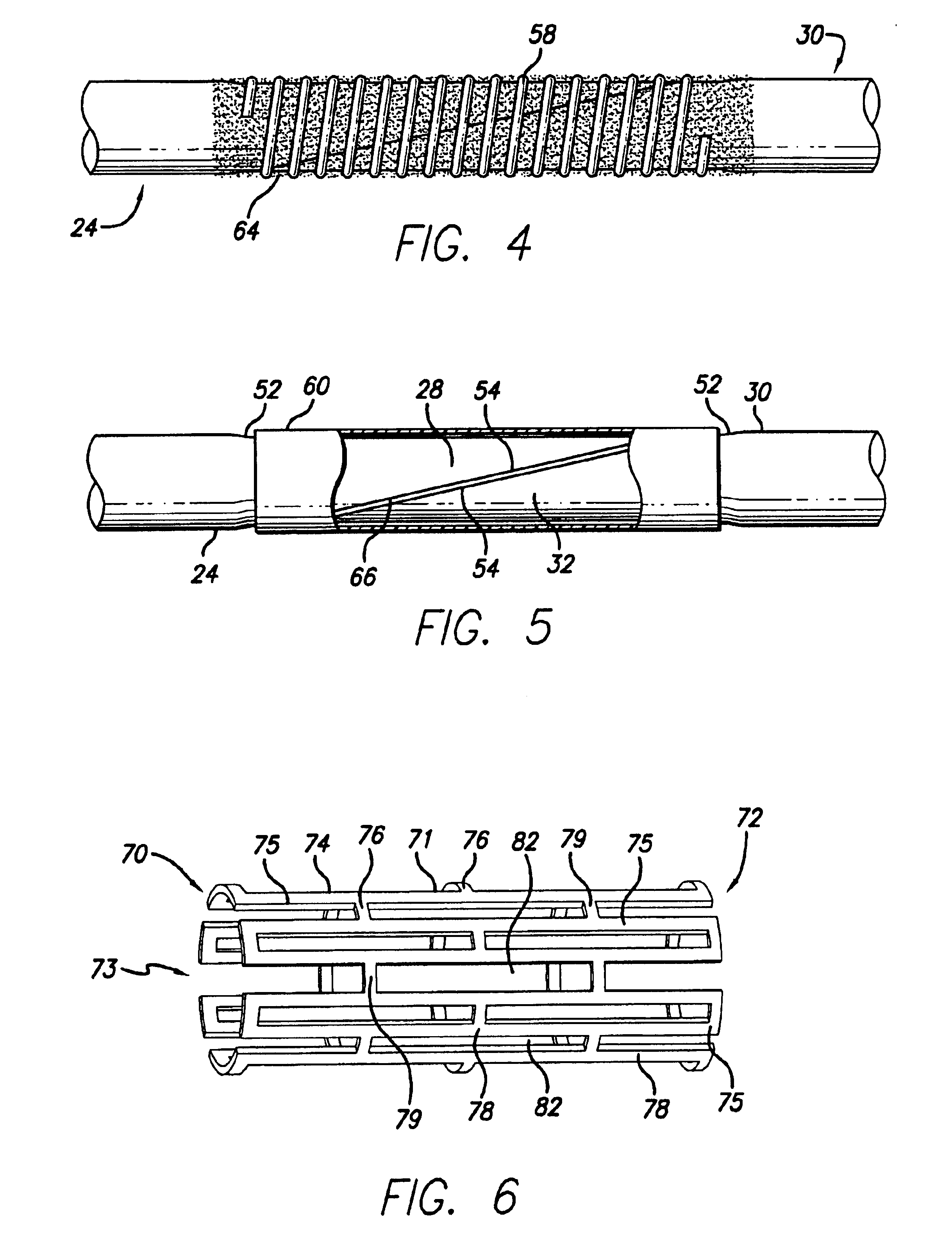

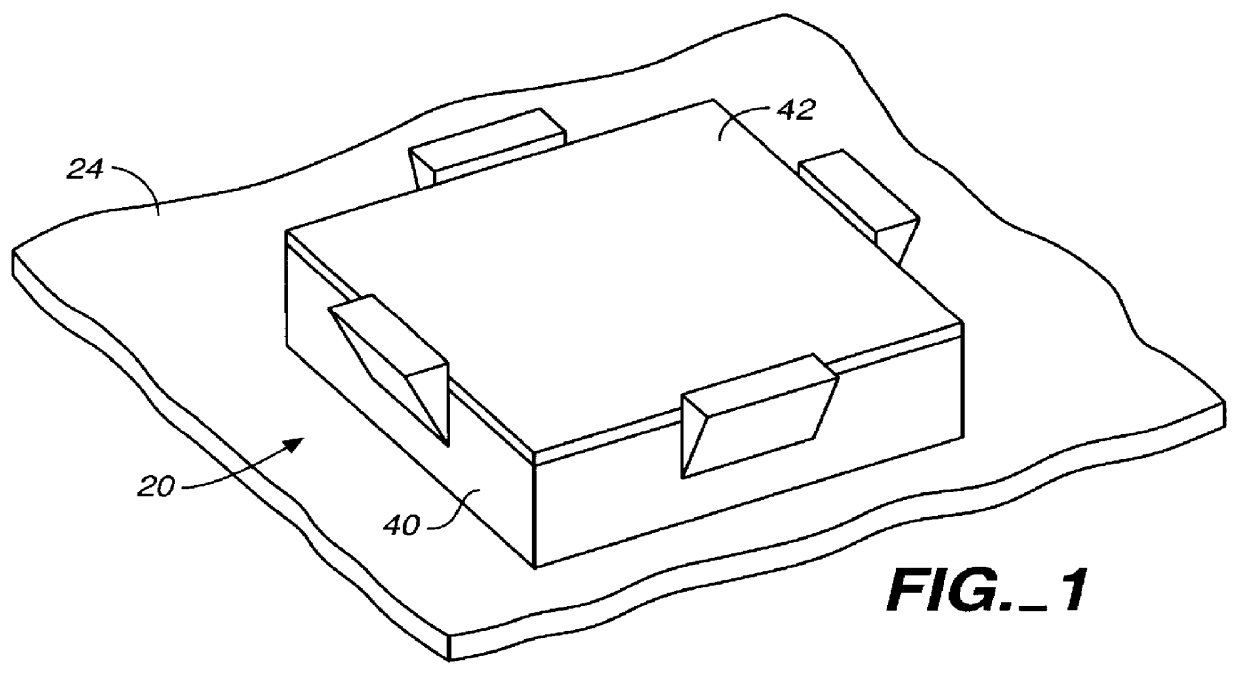

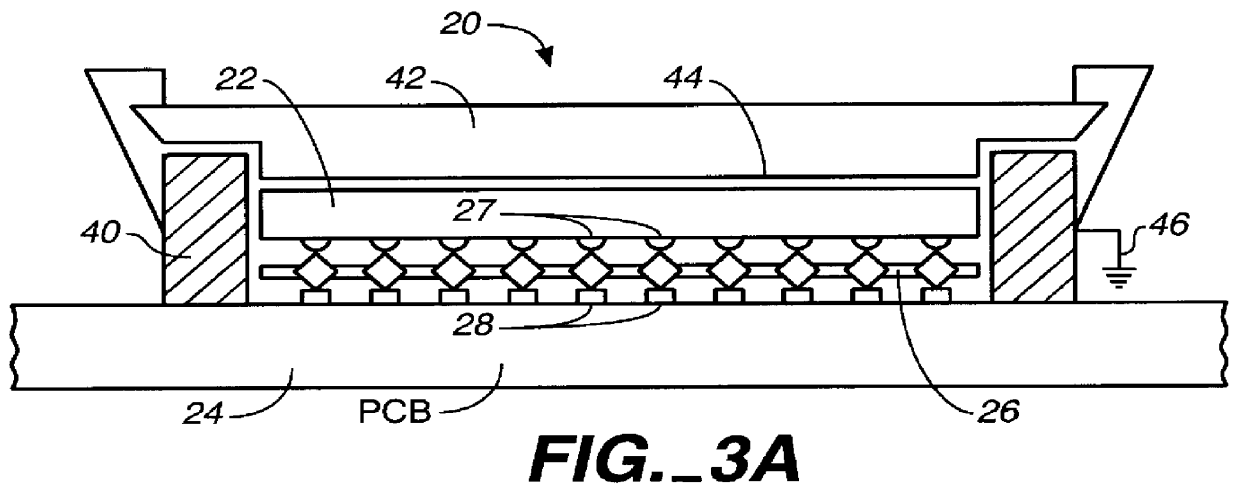

Connector, connector system and method of making a connector

InactiveUS6042387AMass productionLow costElectrically conductive connectionsCoupling contact membersConductive materialsContact element

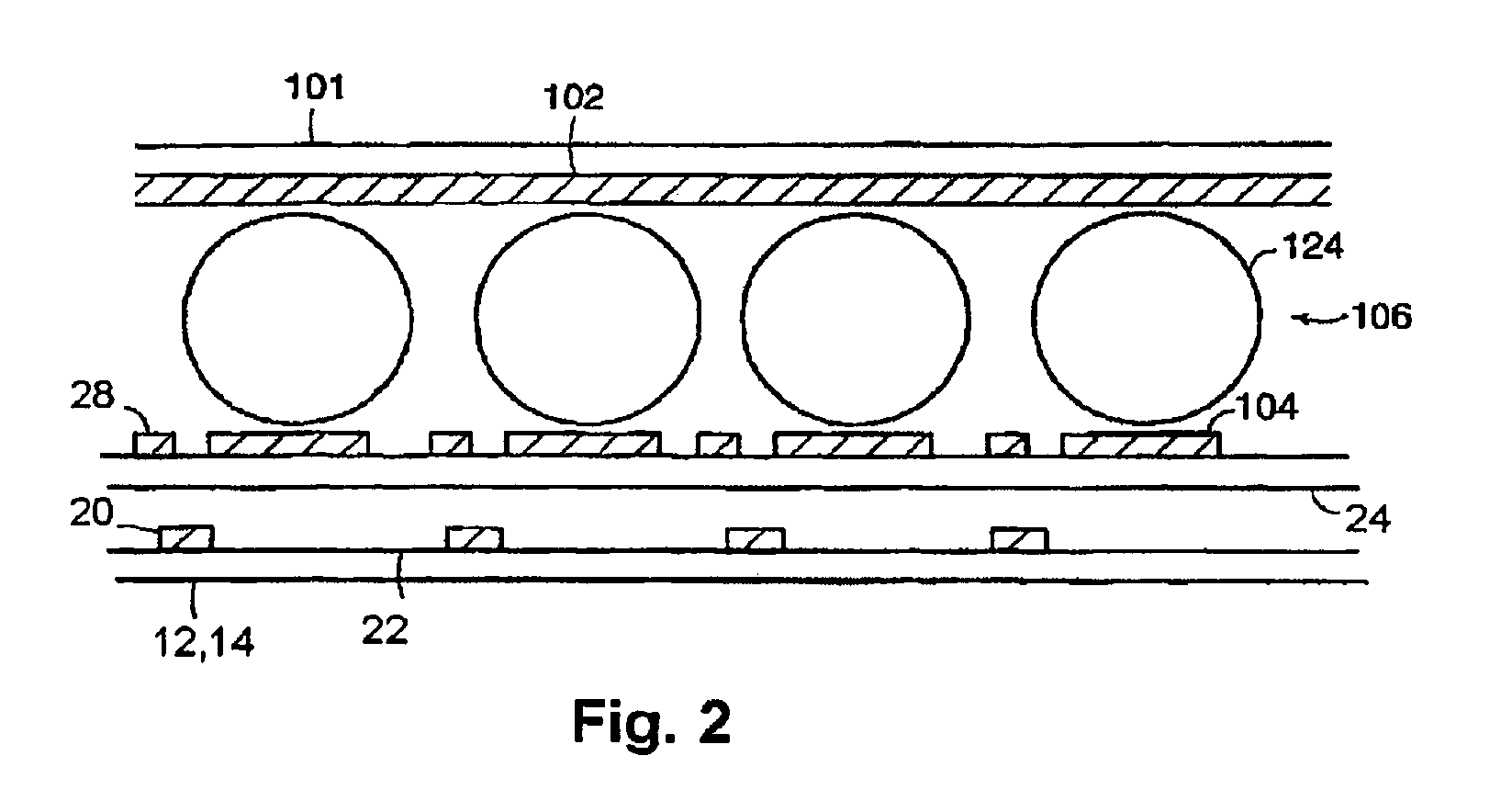

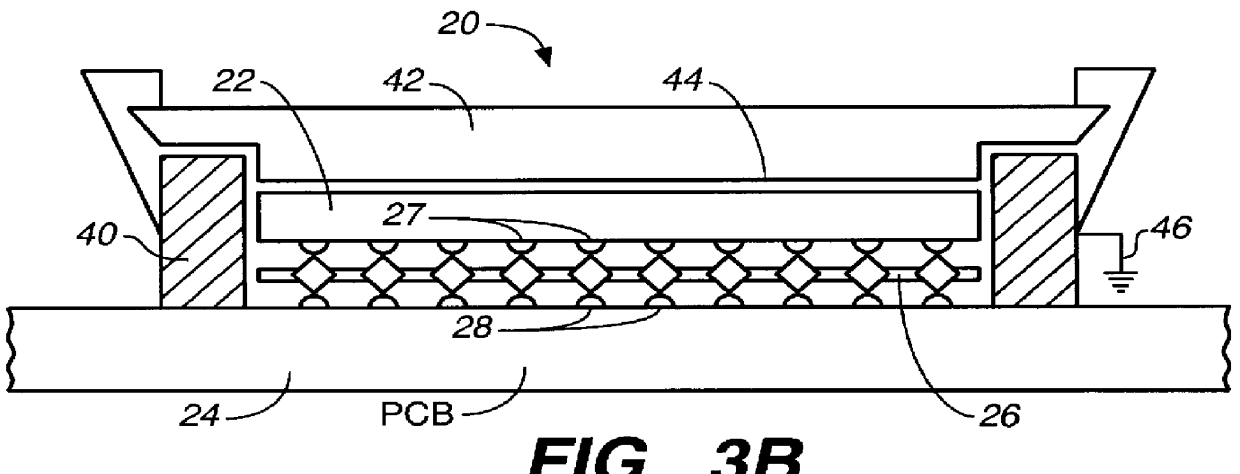

A connector system (20) connects a leadless integrated circuit (IC) device (22) to a printed circuit (PC) board (24) by means of a contact array (26). The contact array (26) connects input-output (I / O) contacts on the IC device (22) to corresponding circuit contacts (28) on PC board (24). The contact array (26) is a generally thin, flexible and rectangular shaped element that is sandwiched between the PC board (24) and the IC device (22). The contact array (26) has a plurality of square cells (30) that are each a portion of the array (26) and are formed from a planar body (32) of a suitable conductive material, such as beryllium copper, sandwiched between suitable insulating films, formed from polyimide. Each cell is divided into a first pair (34) of contact elements (36) extending above the plane of the body (32) and a second pair (38) of contact elements (36) extending below the plane of the body (32).

Owner:SMITHS INTERCONNECT AMERICAS INC

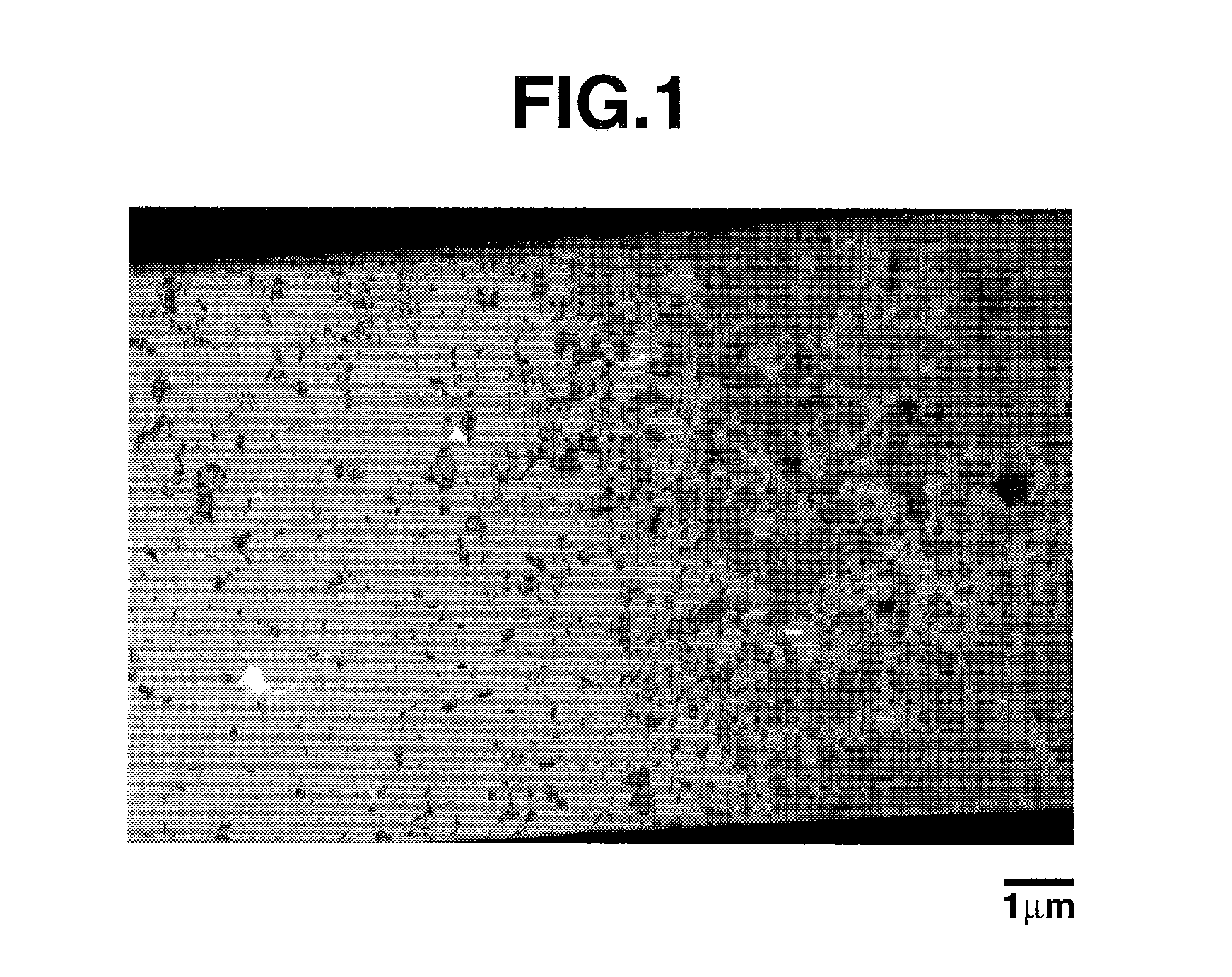

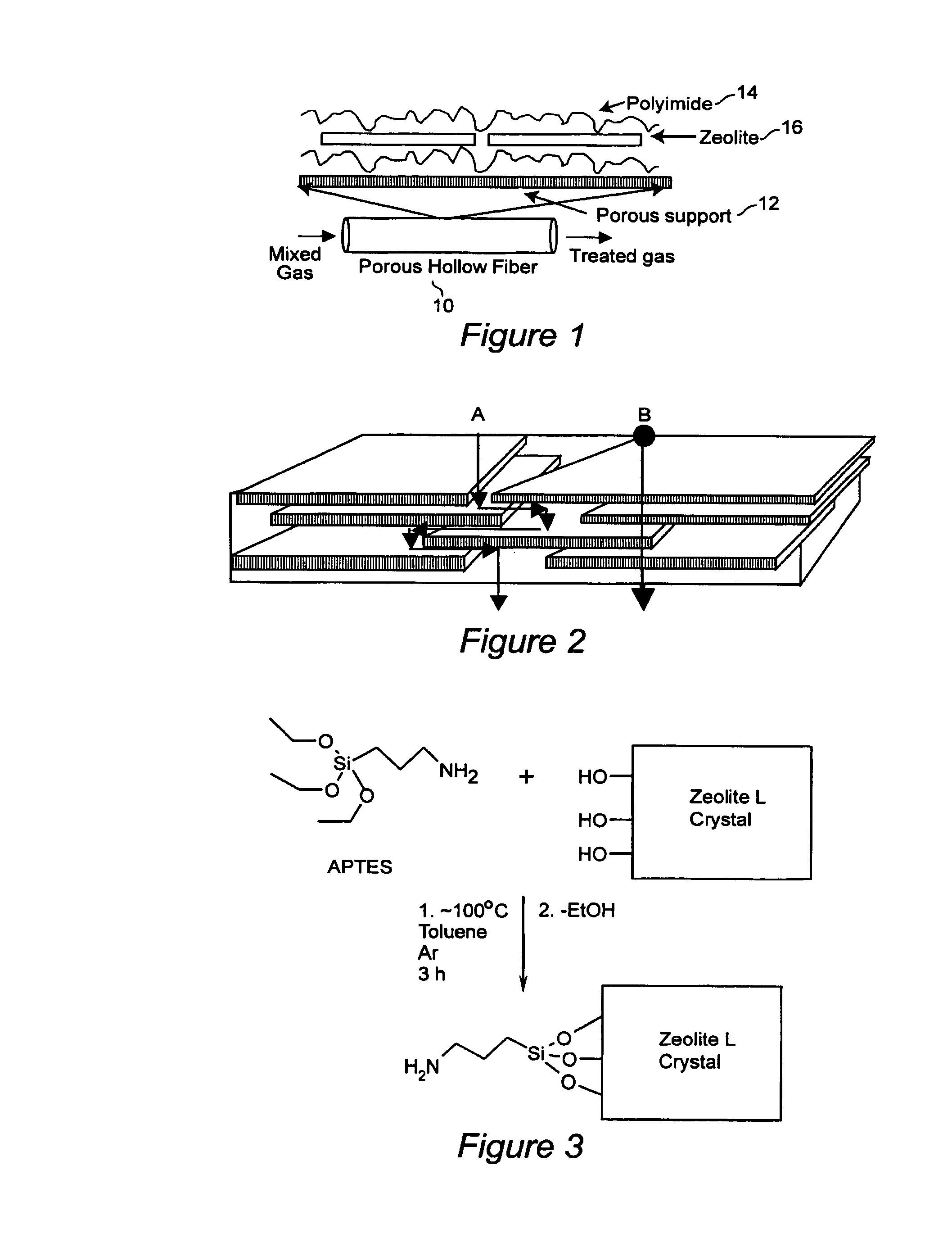

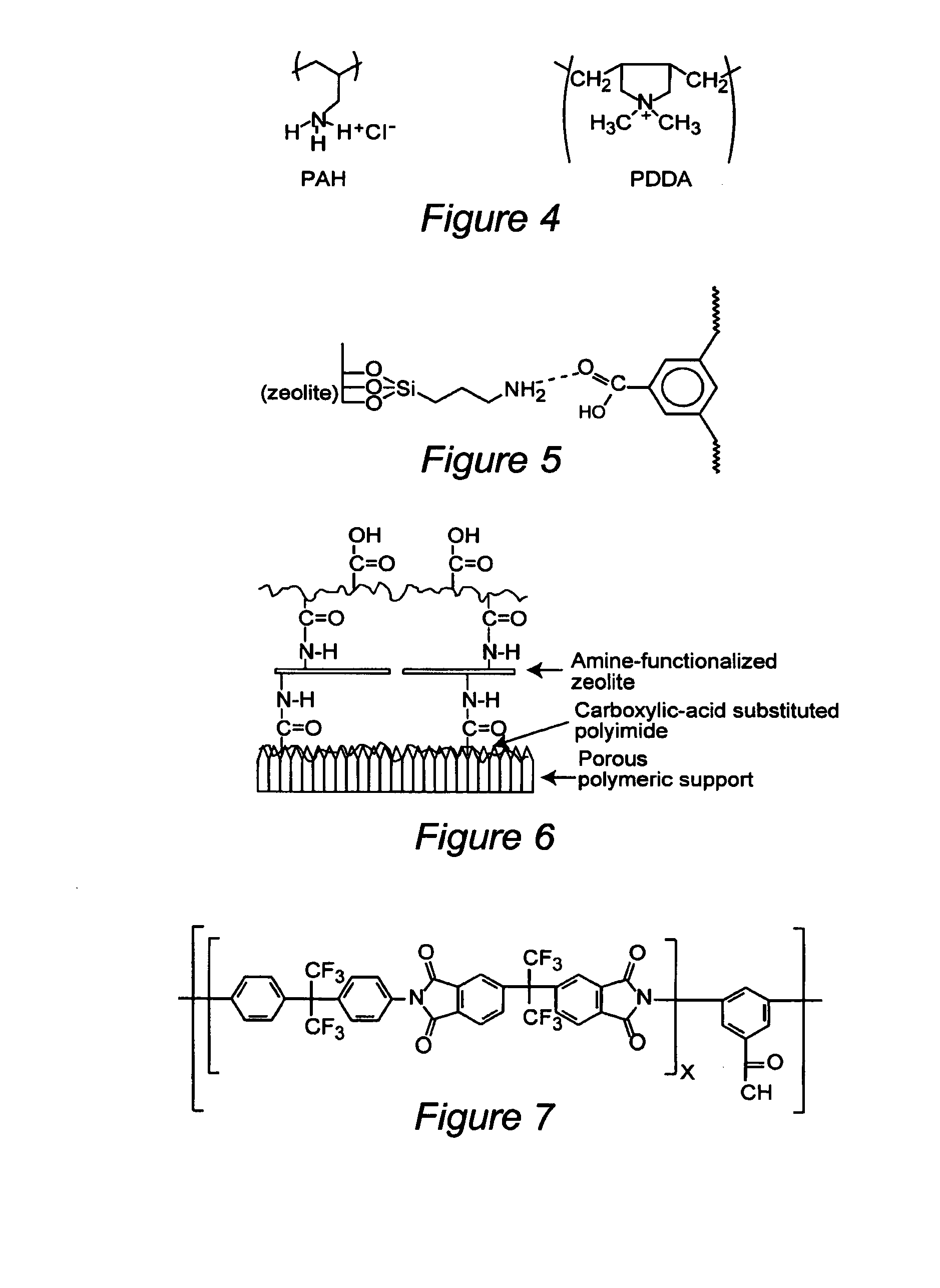

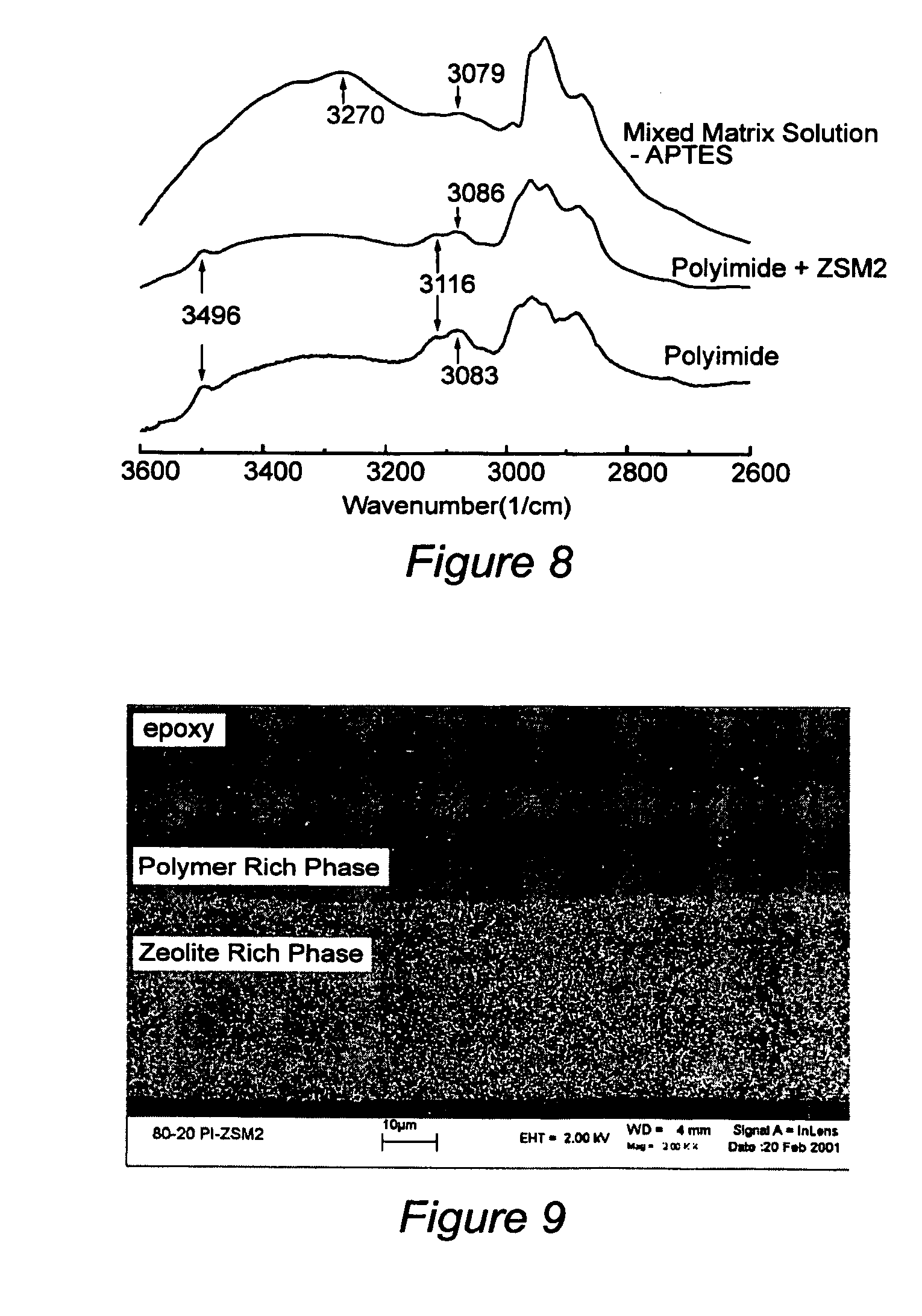

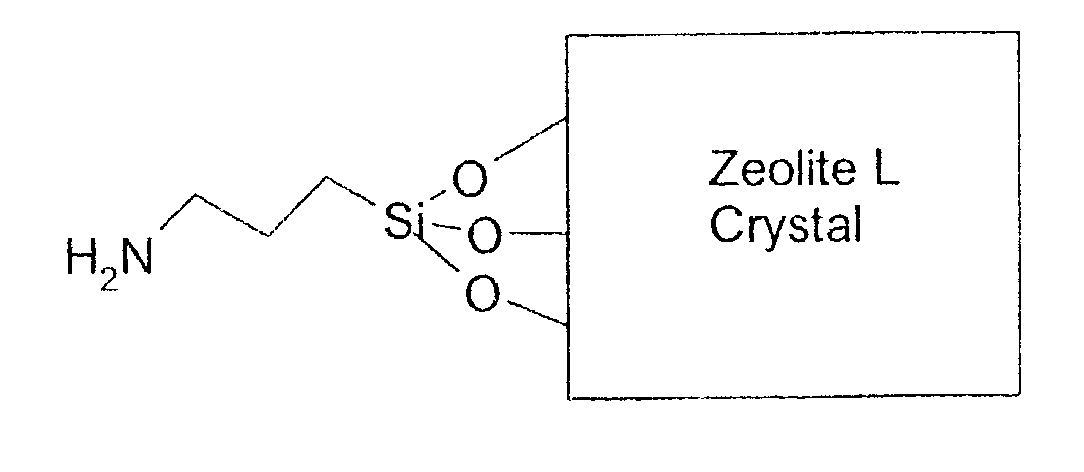

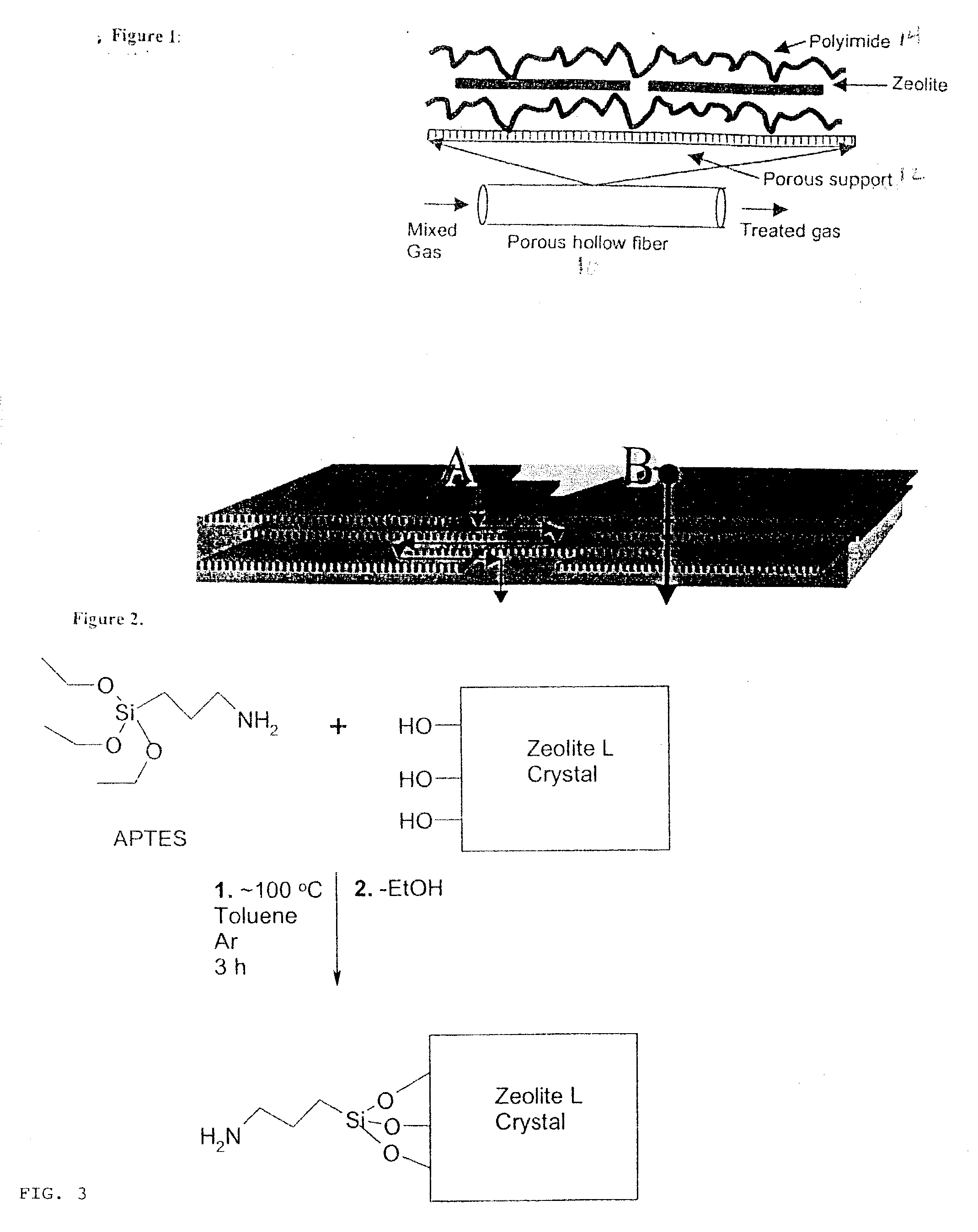

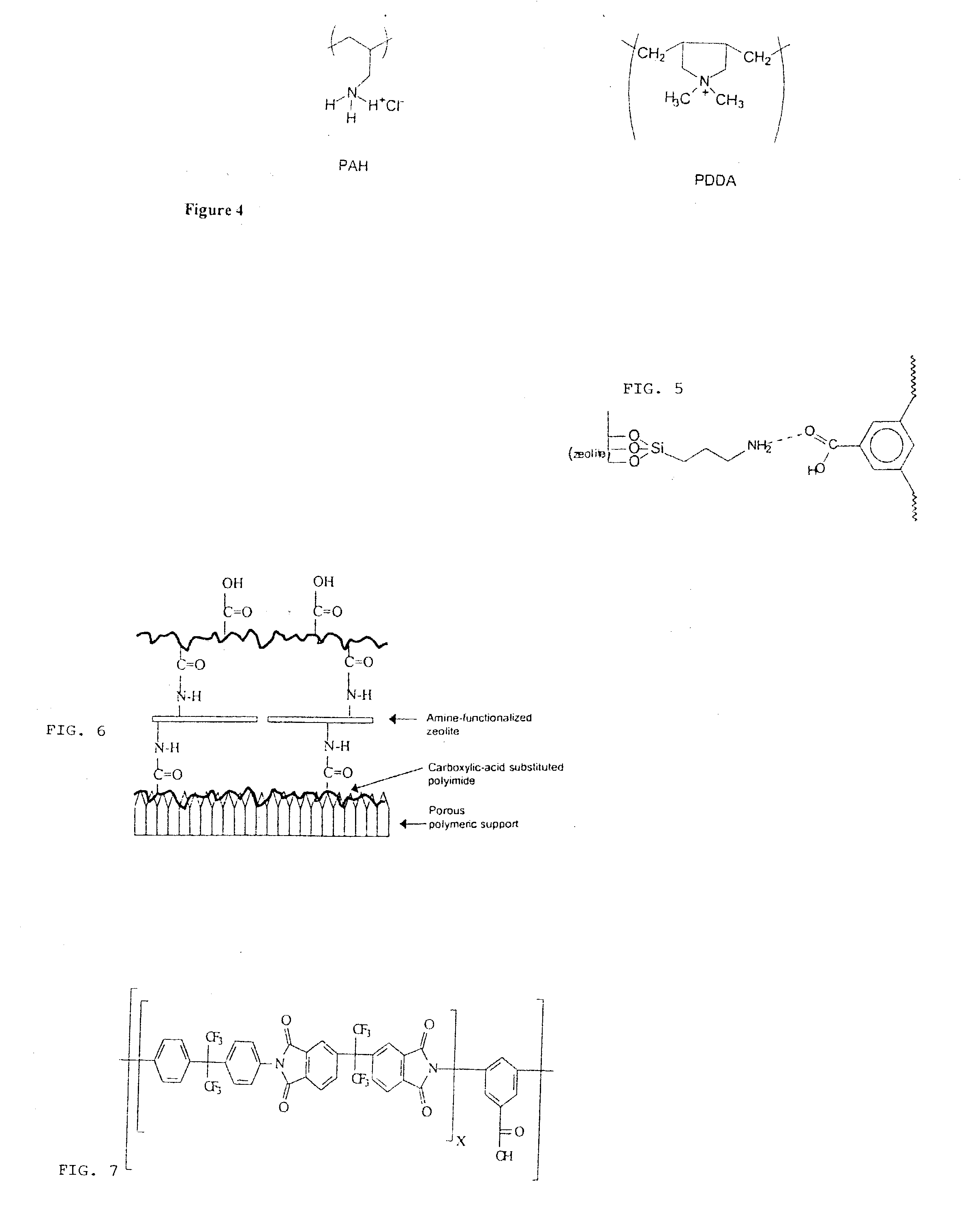

Mixed matrix membranes

InactiveUS7109140B2Enhanced interactionEffectively incorporated into polymer structureSemi-permeable membranesMembranesFiberHollow fibre

Mixed matrix membranes are prepared from zeolites and polymers, such as polyimides, in a void free fashion where either no voids or voids of less than several Angstroms are present at the interface of the polymer and the zeolite by bonding (hydrogen, ionic, or covalent) functional groups on the zeolite with functional groups on the polymer. The mixed matrix membranes may be cast or formed by ISAM processes, and may be present on a variety of supports including hollow fibers.

Owner:VIRGINIA TECH INTPROP INC +1

Mixed matrix membranes

InactiveUS20030220188A1High selectivityIncrease productivitySemi-permeable membranesMembranesFiberHollow fibre

Mixed matrix membranes are prepared from zeolites and polymers, such as polyimides, in a void free fashion where either no voids or voids of less than several Angstroms are present at the interface of the polymer and the zeolite by bonding (hydrogen, ionic, or covalent) functional groups on the zeolite with functional groups on the polymer. The mixed matrix membranes may be cast or formed by ISAM processes, and may be present on a variety of supports including hollow fibers.

Owner:VIRGINIA TECH INTPROP INC +1

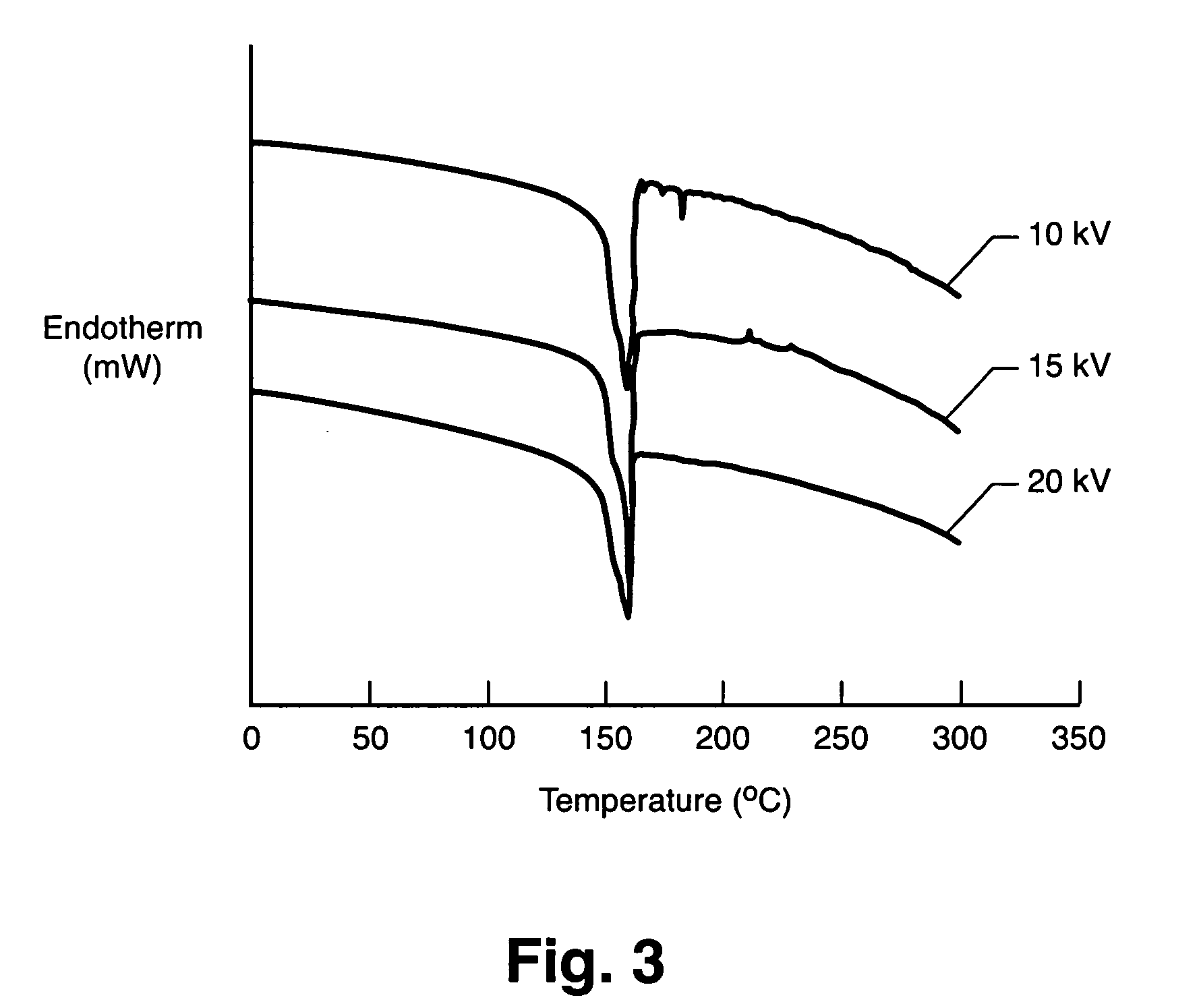

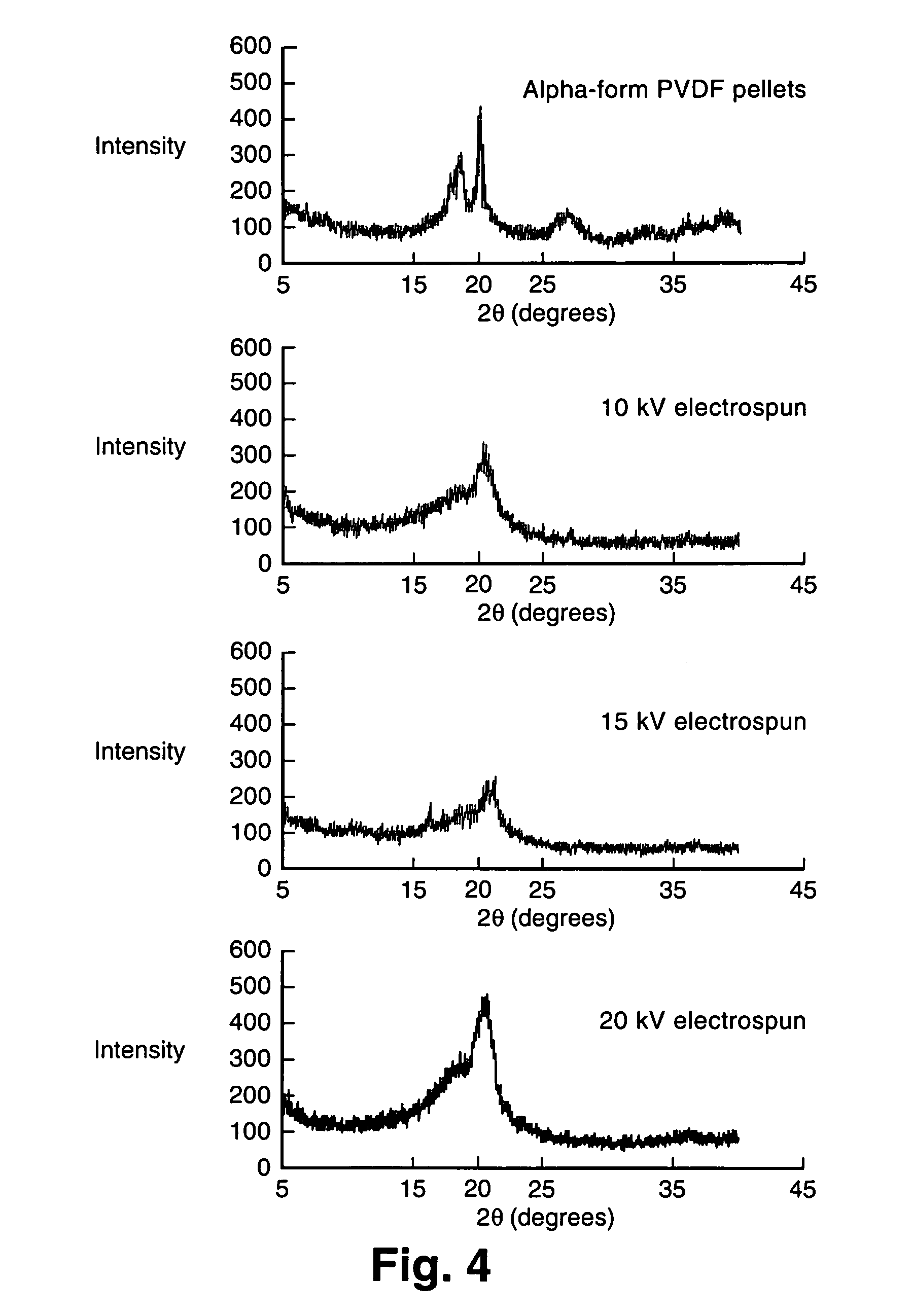

Electrospun electroactive polymers

InactiveUS20060057377A1Easy to set upFast and easy to runMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyPolyesterFiber

Electroactive polymers are produced via electrospinning. The induction of electroactivity via electrospinning can be utilized with one or more soluble polymers with polarizable moieties. Suitable polymer classes include but are not limited to polyimides, polyamides, vinyl polymers, polyurethanes, polyureas, polythioureas, polyacrylates, polyesters, and biopolymers. Any one or more solvents sufficient to dissolve the one or more polymers of interest and make a spinnable solution can be utilized. The polymer can be electrospun into fiber and fibrous nonwoven mat. The electroactive polymer can be doped with inclusions, such as nanotubes, nanofibers, and piezoceramic powders for dielectric enhancement The availability of electroactive polymer fibers and fibrous nonwoven mat will enable many new applications for electroactive polymers.

Owner:NASA +2

Polymeric coating for protecting objects

ActiveUS8053492B2Provide protectionCosmonautic power supply systemsCosmonautic thermal protectionSilsesquioxanePhenyl group

A protective polymeric coating is applied to the surface of various objects which are to be exposed to a harsh environment. The protective polymeric coating covers the exposed surface, where the polymeric coating includes a polyimide polymer. The polyimide polymer in the polymeric coating has a backbone with at least one non-terminal phenyl group. A linkage is connected to the non-terminal phenyl group, where the linkage can be an amide linkage or an ester linkage. An oligomeric silsesquioxane compound is connected to the linkage through an organic substituent, where the oligomeric silsesquioxane is not incorporated into the polymer backbone. The polymeric coating provides protection to the underlying object.

Owner:NEXOLVE HLDG CO LLC

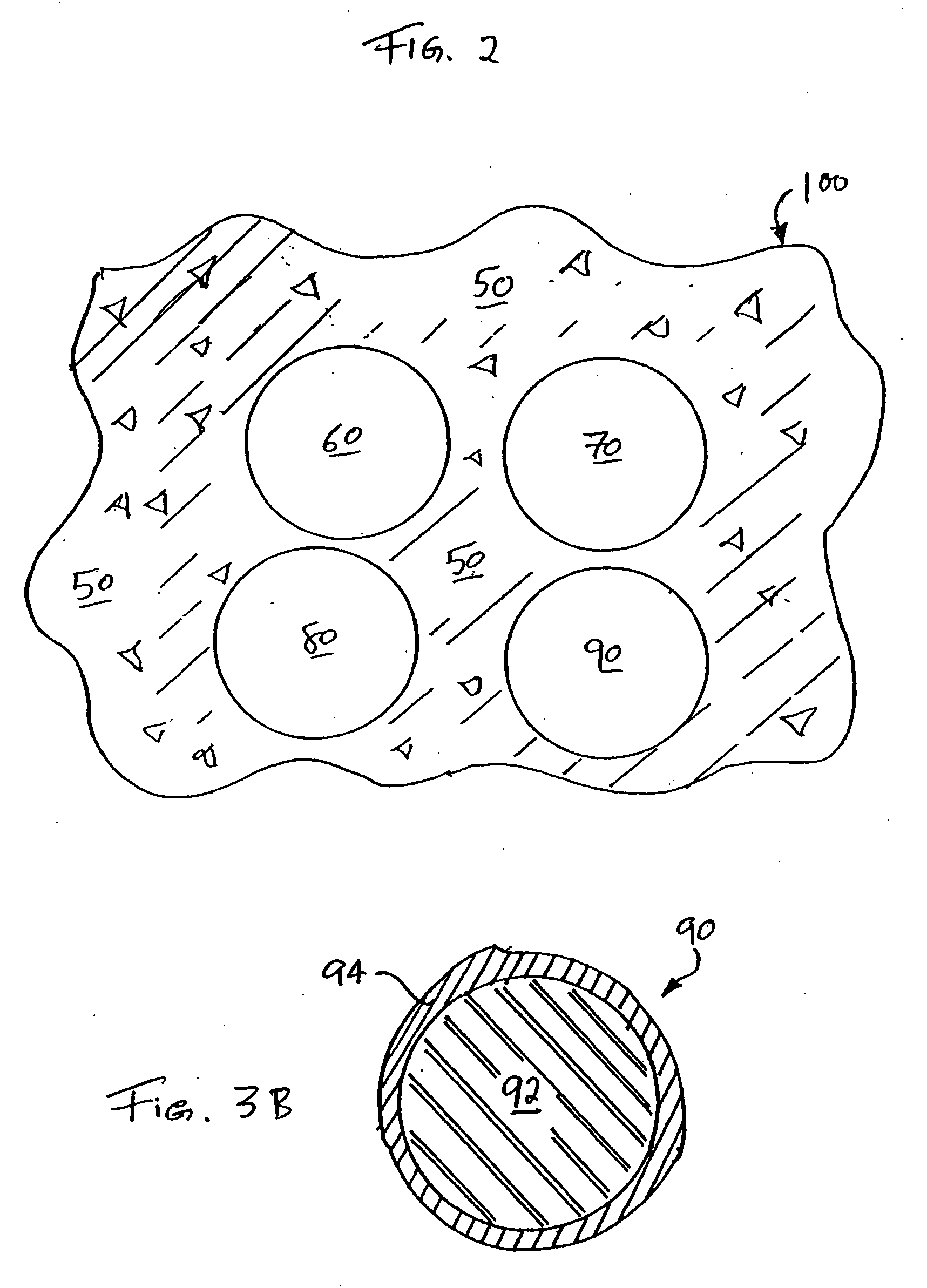

Direct application voltage variable material, devices employing same and methods of manufacturing such devices

ActiveUS20050057867A1Directly appliedCurrent responsive resistorsPrinted circuit aspectsStencil printingMechanical engineering

A voltage variable material (“VVM”) including an insulative binder that is formulated to intrinsically adhere to conductive and non-conductive surfaces is provided. The binder and thus the VVM is self-curable and applicable in a spreadable form that dries before use. The binder eliminates the need to place the VVM in a separate device or to provide separate printed circuit board pads on which to electrically connect the VVM. The binder and thus the VVM can be directly applied to many different types of substrates, such as a rigid FR-4 laminate, a polyimide, a polymer or a multilayer PCB via a process such as screen or stencil printing. In one embodiment, the VVM includes two types of conductive particles, one with a core and one without a core. The VVM can also have core-shell type semiconductive particles.

Owner:LITTELFUSE INC

Solar Cell Interconnection on a Flexible Substrate

InactiveUS20100282288A1High bulk densityRobust interconnectionAdhesive processesPV power plantsElectrical batteryEngineering

A solar cell array comprising: a substrate having a carrier surface on which a plurality of electrically conductive bonding pads are provided, the bonding pads being spaced from one another along a main direction; a plurality of solar cells, each solar cell of the plurality including a back electrode bonded to a first portion of a respective bonding pad, wherein each bonding pad comprises a second portion defining an exposed contact region not covered by the back electrode of the respective solar cell, and wherein an interconnecting lead electrically connects the second portion of the bonding pad associated with a first solar cell with an electrode of a directly adjacent second solar cell.The substrate is an electrically insulating substrate and preferably a flexible film, made for instance of polyimide material.

Owner:EMCORE SOLAR POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com