Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

589 results about "Polybutene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polybutene is an organic polymer made from a mixture of 1-butene, 2-butene, and isobutylene. Ethylene steam cracker C4s are also used as supplemental feed for polybutene. It is similar to polyisobutylene (PIB), which is produced from essentially pure isobutylene made in a C4 complex of a major refinery. The presence of isomers other than isobutylene can have several effects including: 1) lower reactivity due to steric hindrance at the terminal carbon in, e.g., manufacture of polyisobutenyl succinic anhydride (PIBSA) dispersant manufacture; 2) the molecular weight—viscosity relationships of the two materials may also be somewhat different.

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

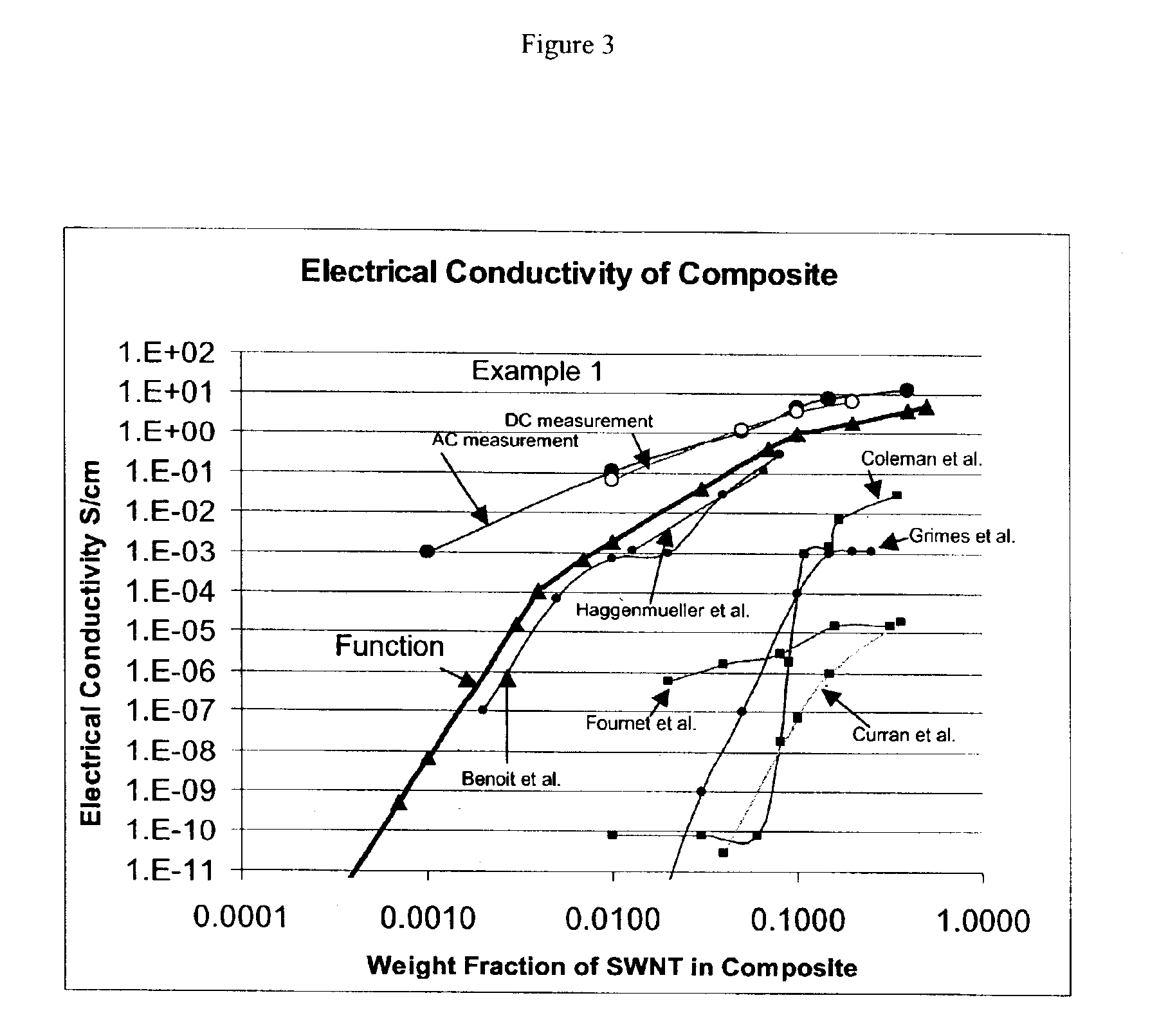

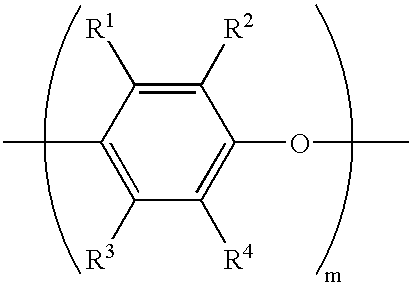

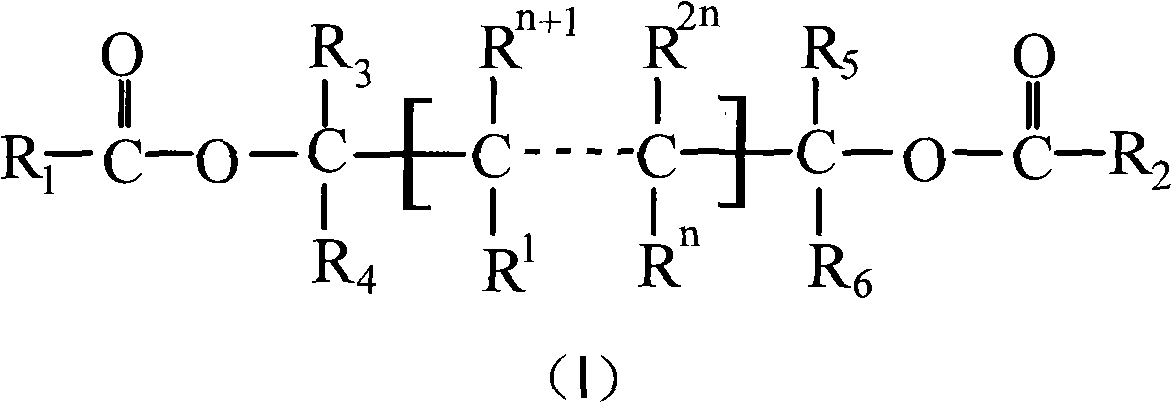

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

Pressure Sensitive Adhesive Composition

A pressure sensitive adhesive composition suitable for medical purposes comprising a rubbery elastomeric base and one or more water soluble or water swellable hydrocolloids, the adhesive composition comprising a substantially homogeneous mixture of 35-50% of one or more polybutenes, 5-20% of one or more styrene copolymers, and 20-60% of one or more hydrocolloids has very good properties as an adhesive for ostomy appliances.

Owner:COLOPLAST AS

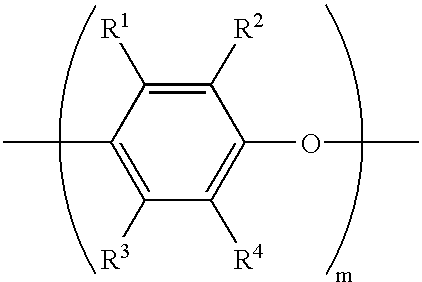

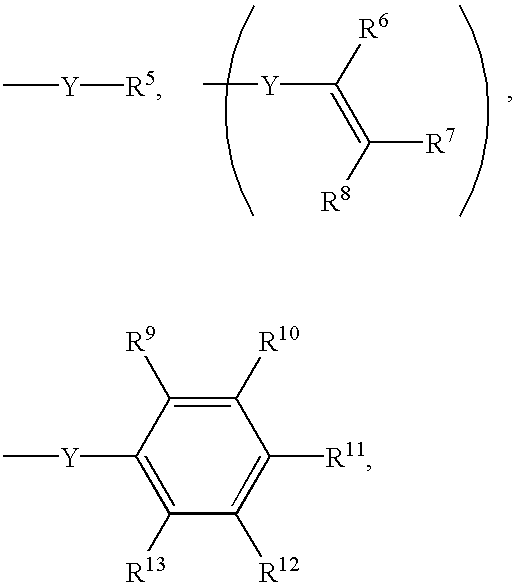

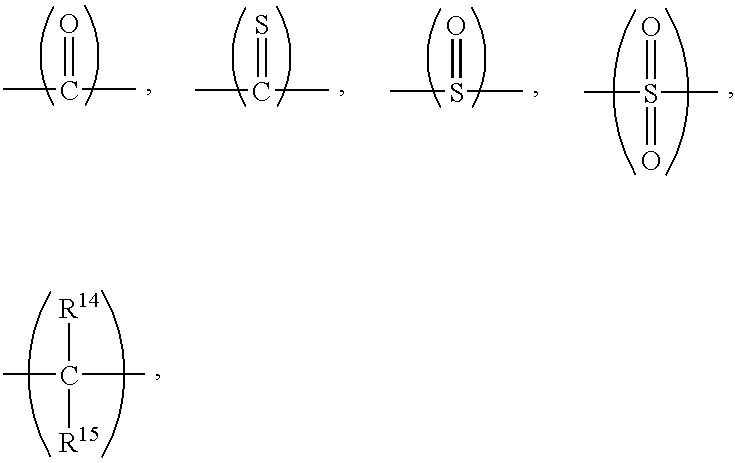

Thermoset composition, method, and article

InactiveUS20030215588A1Improve as-molded surface characteristics of polyReduce shrinkage on moldingSynthetic resin layered productsThin material handlingVinyl etherPolystyrene

A curable composition includes a functionalized poly(arylene ether), an alkenyl aromatic monomer, an acryloyl monomer, and a polymeric additive effective selected from polystyrene, poly(styrene-maleic anhydride), poly(styrene-methyl methacrylate), polybutene, poly(ethylene-butylene), poly(vinyl ether), poly(vinyl acetate), and combinations thereof. The composition exhibits low shrinkage on curing and improved surface smoothness. It is useful, for example, in the manufacture of automotive body panels.

Owner:SABIC INNOVATIVE PLASTICS IP BV

A kind of polybutene alloy material and preparation method thereof

The invention discloses a polybutene alloy material and a preparation method thereof, and belongs to the field of polyolefin material, specifically relates to a polybutene alloy material and a preparation method thereof. The polybutene alloy material provided by the present invention comprises, by mass, 50-99% of poly-1-butene, 1-40% of polypropylene and 0-10% of a butane-propylene copolymer. Thepreparation method is characterized by: adopting a TiCl4 / MgCl2 supported titanium catalyst for synthesis of the polybutene alloy material through a two-phase polymerization method. The polybutene alloy material provided by the present invention has a core-shell structure, and has advantages of the combination of the excellent impact resistance of the poly-1-butene, the heat resistance and creep property of the poly-1-butene, the low shrinkage rate of the poly-1-butene, the high modulus of the polypropylene, the high surface hardness of the polypropylene, the rapid shaping of the polypropylene, and the like, such that the polybutene alloy material can replace the partial use of the poly-1-butene and the polypropylene. In addition, the polybutene alloy material can be applicable for preparation of the pipe and the pipe fitting, toughening modification of the polypropylene, or the polybutene alloy material can be used as the general polyolefin material.

Owner:QINGDAO UNIV OF SCI & TECH +1

Bulk depositing synthesis process of isotactic polybutylene-1

The invention discloses a bulk precipitation synthesis method of high isotactic polybutene-1, which belongs to high molecular polymer technology. It uses butene-1 as monomer and reaction medium, under the condition of reaction temperature of 0-70 ℃, adopts supported titanium catalyst to catalyze butene-1, and synthesizes powdery polybutene-1 polymerization by bulk precipitation polymerization The unpolymerized monomers are removed and re-polymerized by flash evaporation to obtain a powdery granular product of high isotactic polybutene-1. It can adopt organometallic aluminum AlR 3 As a cocatalyst, an external electron donor compound can be added to the catalyst system, and hydrogen can also be added as a molecular mass regulator. The polymerization process is carried out in a polymerization tank with ribbon stirring. It has simple process, high efficiency and low cost. The prepared high stereoregular polybutene-1 polymer with an isotactic content of more than 98% has a crystallinity of more than 60% and a melting point of 127.5°C, which is completely close to similar foreign products. Can be widely promoted and applied.

Owner:SHANDONG ORIENT HONGYE CHEM +1

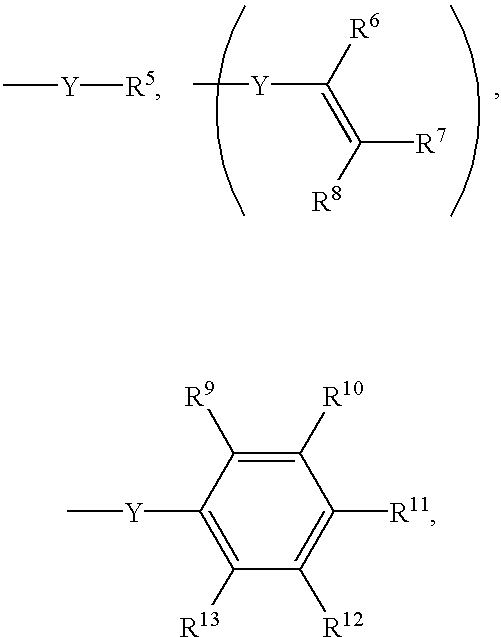

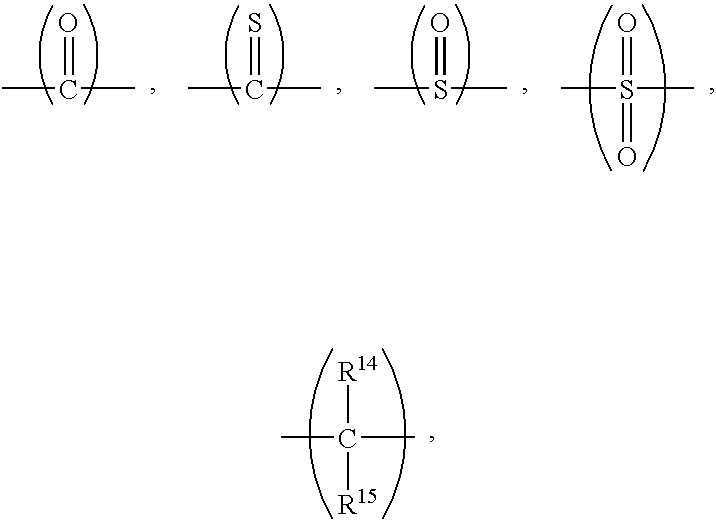

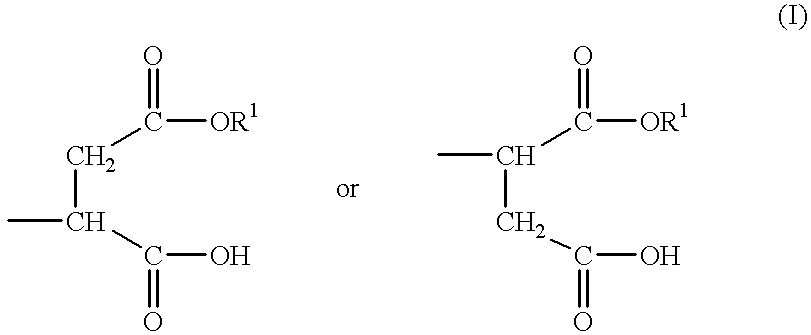

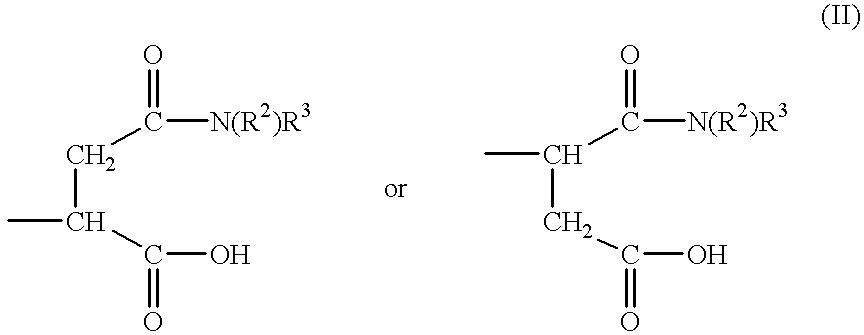

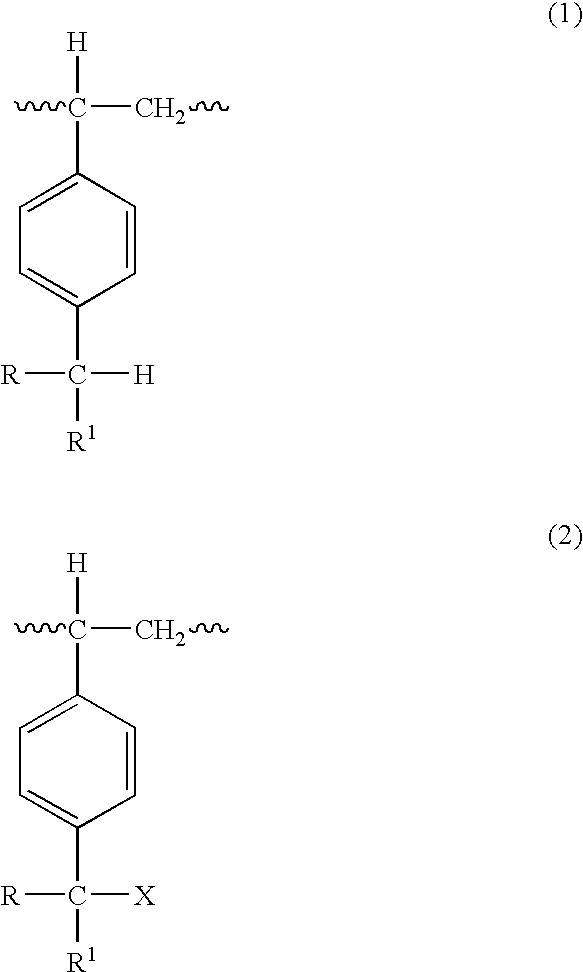

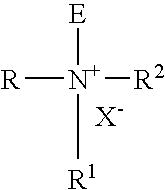

Polymer containing isobutylene as repeating unit and rubber composition containing the same

A modified polybutene(polyisobutylene) containing isobutylene repeating units and having, in the main chain, at the ends, and / or at the side chains of the polymer chain thereof, free radicals stable at a room temperature and in the presence of oxygen, or having a half-ester structure, amide structure, onium salt structure, or imide structure or acid anhydride residual group, as well as a rubber composition containing the same.

Owner:THE YOKOHAMA RUBBER CO LTD

Filler masterbatch used for increasing polarity of polypropylene and preparation method thereof

The invention discloses a filler masterbatch used for increasing the polarity of polypropylene and a preparation method thereof. The filler masterbatch is characterized by comprising the following components by weight percent: 50%-79% of inorganic filler, 15%-30% of carrier, 5%-17% of polar additive and 1%-3% of processing additive; and the polar additive is one or more of thermoplastic polyurethane resin (TPU), maleic anhydride grafted polypropylene, epoxy resin, ethylene acrylate, ethylene vinyl acetate, polyether amine and polybutylene polyol. In the preparation method of the invention, the added carrier can not improve the polarity of polypropylene, the inorganic filler is used to increase the rigidity of the material; the key is to introduce the polar additive with high unipolarity, thus the filler masterbatch used for increasing the polarity of polypropylene can be prepared; when the filler masterbatch is combined with the polypropylene material for production, the surface polarity of the filled and modified polypropylene material can be increased, the surface energy of the filled and modified polypropylene can be reduced, the dimension stability can be increased, the modified polypropylene material can have good paint adhesion and the material can be used to form exterior trimming parts such as bumpers and interior trimming parts such instrument panels.

Owner:KINGFA SCI & TECH CO LTD +3

Thermoplastic elastomers with improved coring properties

Thermoplastic vulcanizates having improved coring properties, comprising a blend of thermoplastic polypropylene resin, vulcanized butyl rubber, a SEPS block copolymer and a polybutene oil plasticizer.

Owner:ADVANCED ELASTOMER SYST LP

Innerliners for use in tires

The invention discloses tires including innerliners, the innerliners made from at least one polybutene processing aid and at least one elastomer having C4 to C7 isoolefin derived units.

Owner:EXXONMOBIL CHEM PAT INC

Hydrocolloid adhesive mass useful for medical purposes

The present invention relates to a novel hydrocolloid adhesive mass useful for medical purposes, characterized in that said hydrocolloid adhesive mass comprises:a) 0.2 to 5 parts by weight of an ethoxylated sorbitan fatty acid ester;b) 20 to 50 parts by weight of a hydrocolloid;c) 32 to 120 to parts by weight of an adhesive matrix made up of one or more polymers selected from poly(styrene / olefin / styrene) block copolymers, low-molecular polyisobutylenes and high-molecular polyisobutylenes, and one or more compounds selected from sticky resins, or tackifying resins, plasticizers, polybutenes, antioxidants, ethylene / vinyl acetate copolymers, butyl rubbers and ethylene / propylene block copolymers; andd) 0 to 15 parts by weight of an acrylate copolymer with a glass transition temperature below -20° C. It further relates to the use of this hydrocolloid adhesive mass for the production of dressings, especially for the treatment of superficial, deep, chronic or acute dermo-epidermal lesions, exudative wounds and bums.

Owner:LABORATOIRE URGO

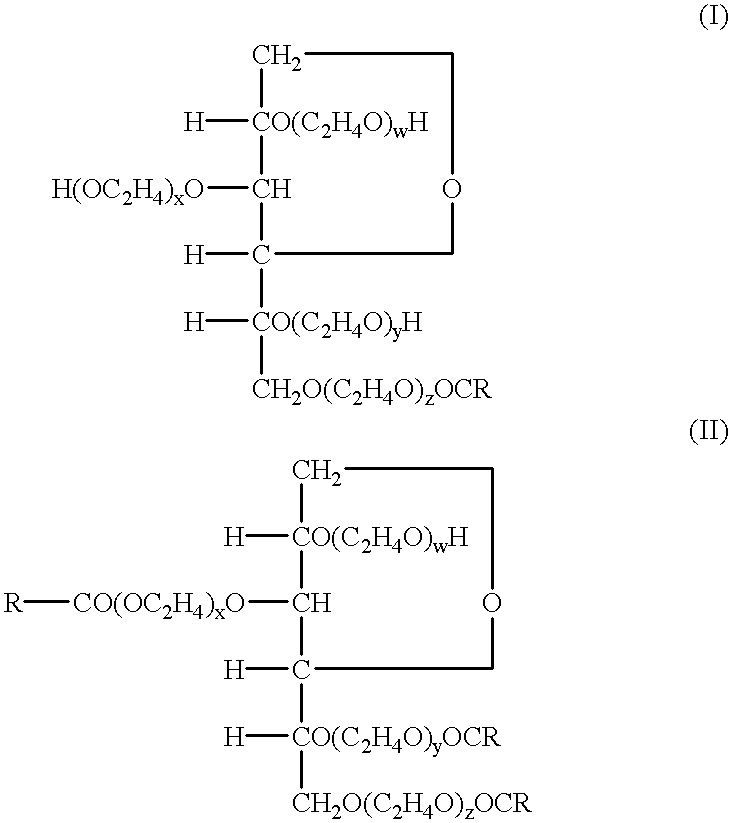

Liquid ester compositions and cosmetic compositions containing the same

ActiveUS20070110702A1Sustain feelingImprove gloss feelingCosmetic preparationsHair cosmeticsIsostearic acidOctanoic Acids

The present invention provides a liquid ester composition which is obtained by esterifying a branched isostearic acid such as 2-(1,3,3-trimethyl)butyl-5,7,7-trimethyl octanoic acid with dipentaerythritol, and said liquid ester composition having a viscosity at 25° C. of 100,000 to 2,000,000 mPa·s; hydroxyl value of 10 to 160; and cloud point of less than 5° C. This liquid ester composition has pigment dispersibility and hydrating ability that polybutene, which is one of the raw materials of oil compositions for cosmetic compositions, does not have, together with their abilities to sustain feeling of cosmetic film and improve gloss and moisture feeling of cosmetic compositions and shape retaining ability of lipsticks and the like equal to those containing polybutene.

Owner:THE NISSHIN OILLIO GRP LTD

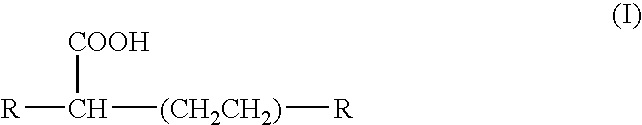

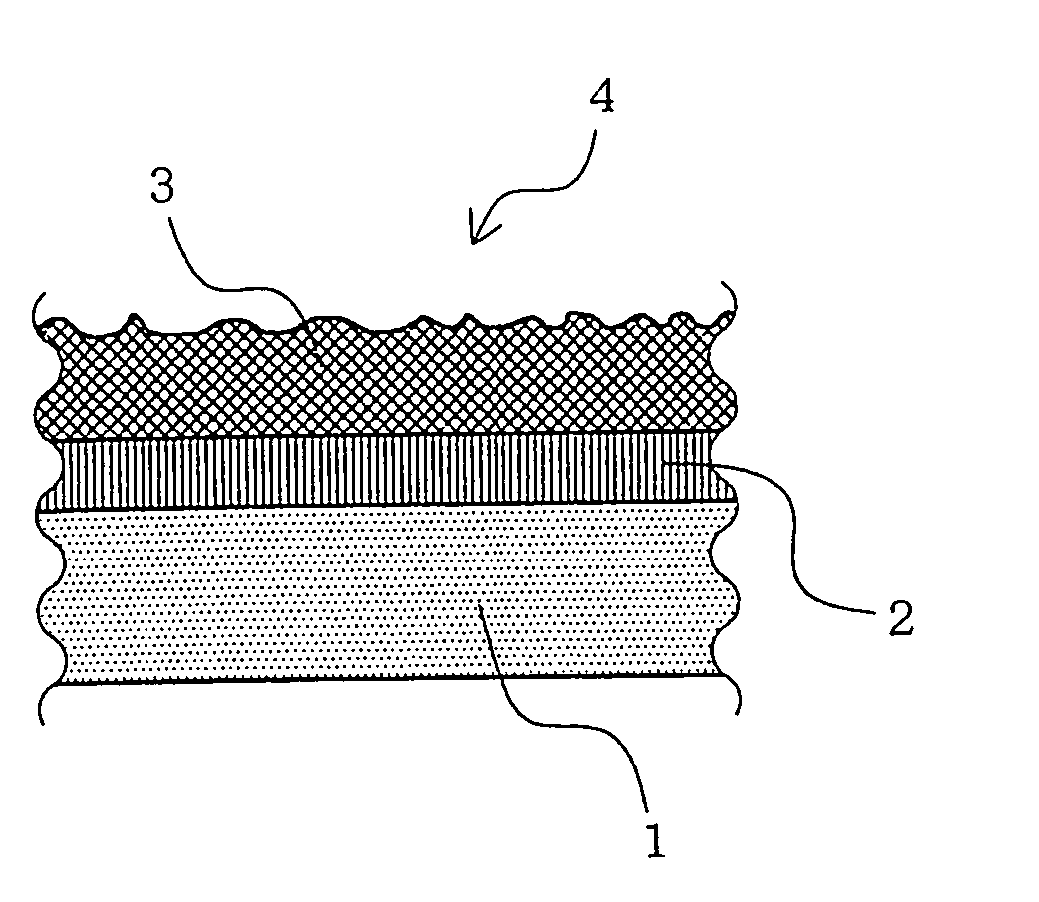

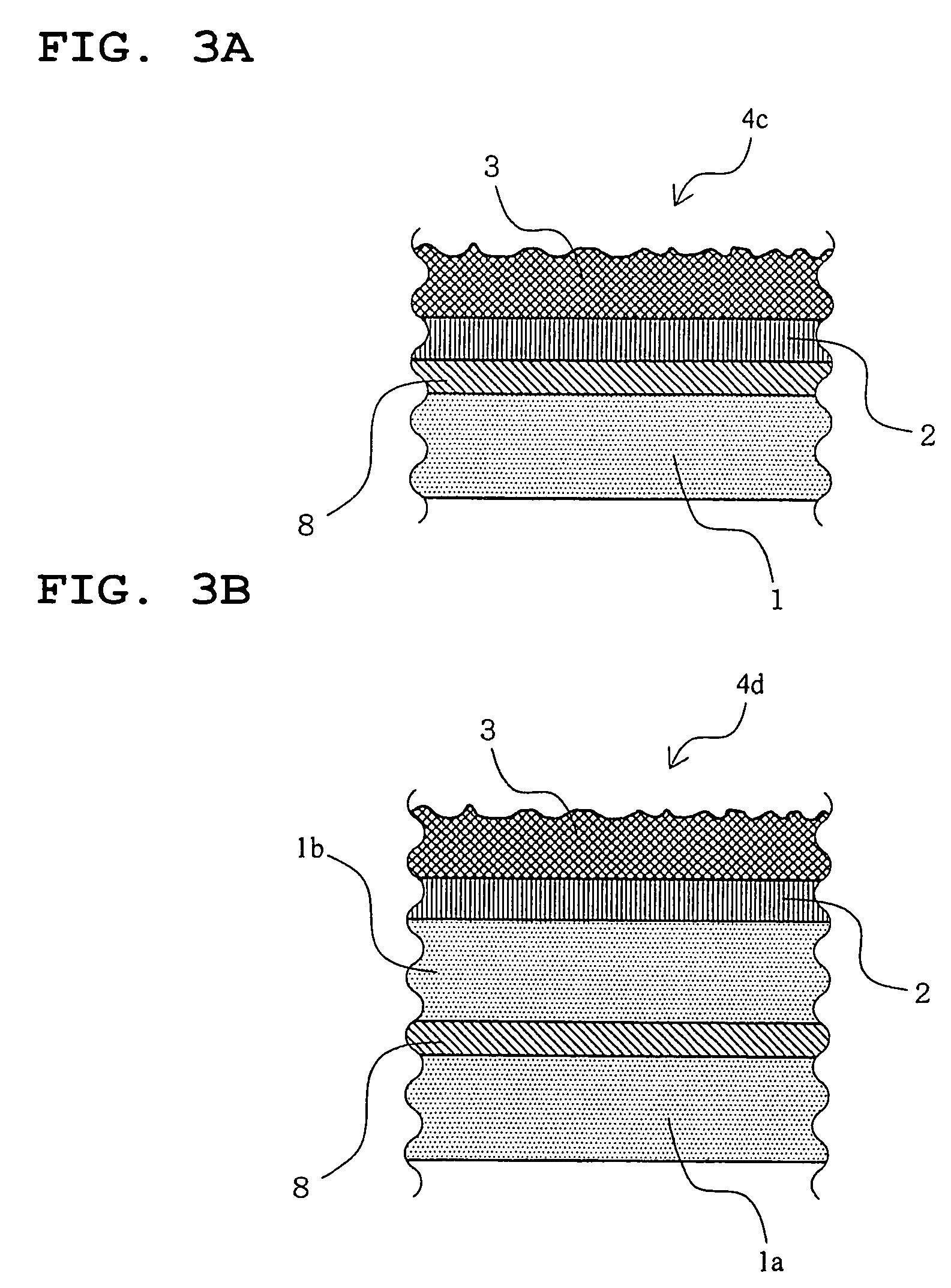

Release liner and pressure-sensitive adhesive tape or sheet employing the same

ActiveUS20050266195A1Stable separationReduce the voltage levelFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePolyolefin

The release liner includes a release layer constituted of at least one polyolefin resin, wherein the release layer has surface irregularities. The surface irregularities of the release layer may be constituted of recesses and protrusions which are irregularly different in shape and have been disposed in irregular arrangement. The release layer preferably has a surface roughness Ra of 1-3 μm. As the polyolefin resin constituting the release layer can be used at least one polyolefin resin selected from the group consisting of polyethylenes, polypropylene, polybutenes, poly(4-methyl-1-pentene), and copolymers of ethylene with one or more α-olefins having 3-10 carbon atoms.

Owner:NITTO DENKO CORP

Thermoset composition, method, and article

InactiveUS20030220460A1Low viscosityFacilitating good glass carryHydrocarbonsHydrocarbon from saturated and unsaturated hydrocarbon additionVinyl etherPolystyrene

Owner:SABIC INNOVATIVE PLASTICS IP BV

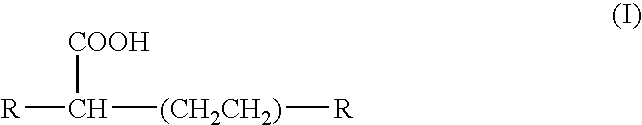

Method for producing polybutene

InactiveUS7411104B2Easy to getHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsAlcoholBoron trifluoride

A method for producing high reactive polybutene (HRPB), in which carbon-carbon double bond is positioned at an end of polybutene, is disclosed. The high reactive polybutene having 300˜5000 of number average molecular weight (Mn) can be produced from a raw material containing isobutene, wherein a polymerization reaction of the isobutene is carried out in the presence of a catalyst system including secondary alkylether, tertiary alcohol, and boron trifluoride, the amount of boron trifluoride is 0.05˜1.0 weight part per 100 weight part of isobutene, the mole ratio of a co-catalyst including secondary alkylether and tertiary alcohol:boron trifluoride is 1.0˜2.0:1, and the mole ratio of secondary alkylether:tertiary alcohol is 0.5˜1.2:1.

Owner:DL CHEM CO LTD

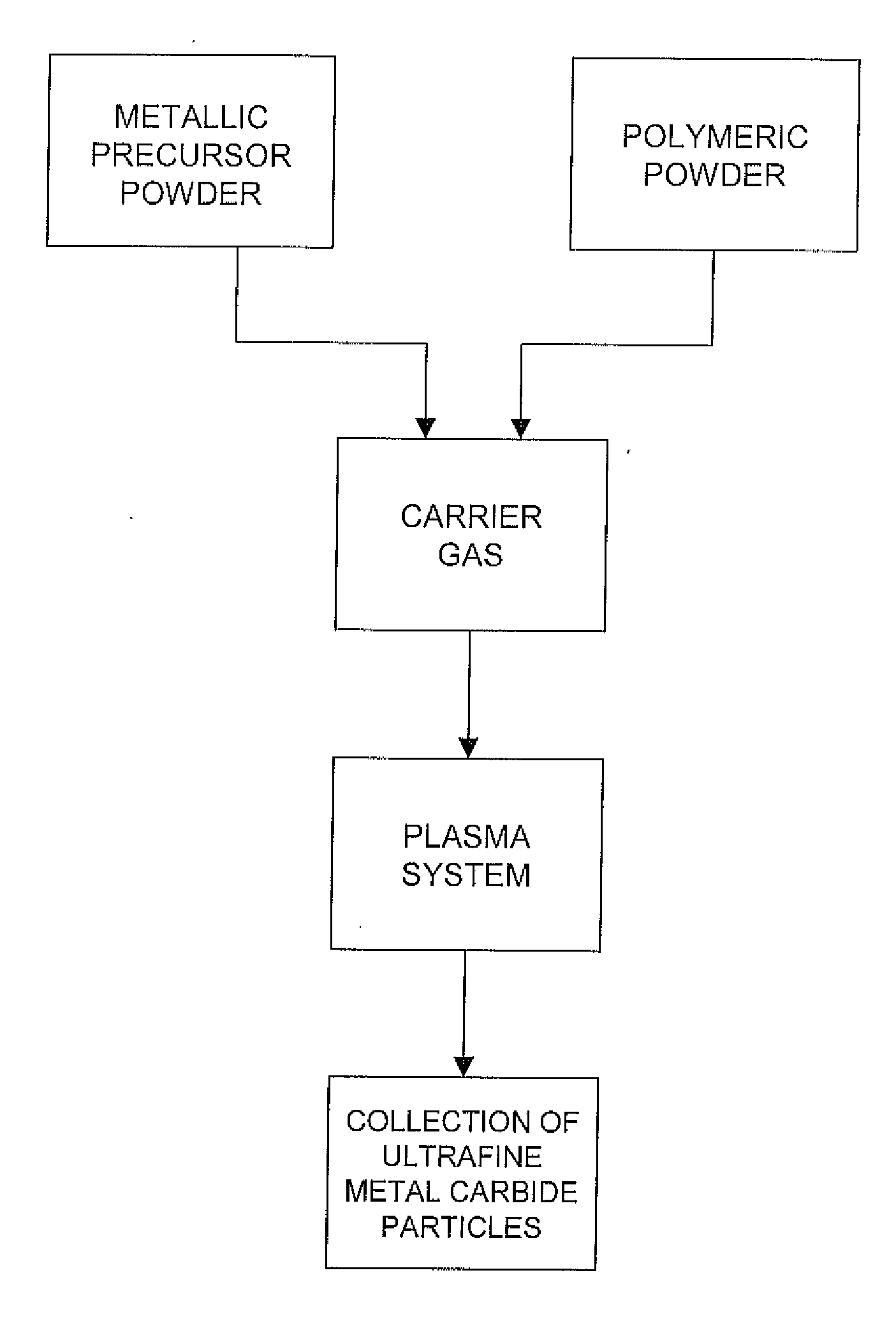

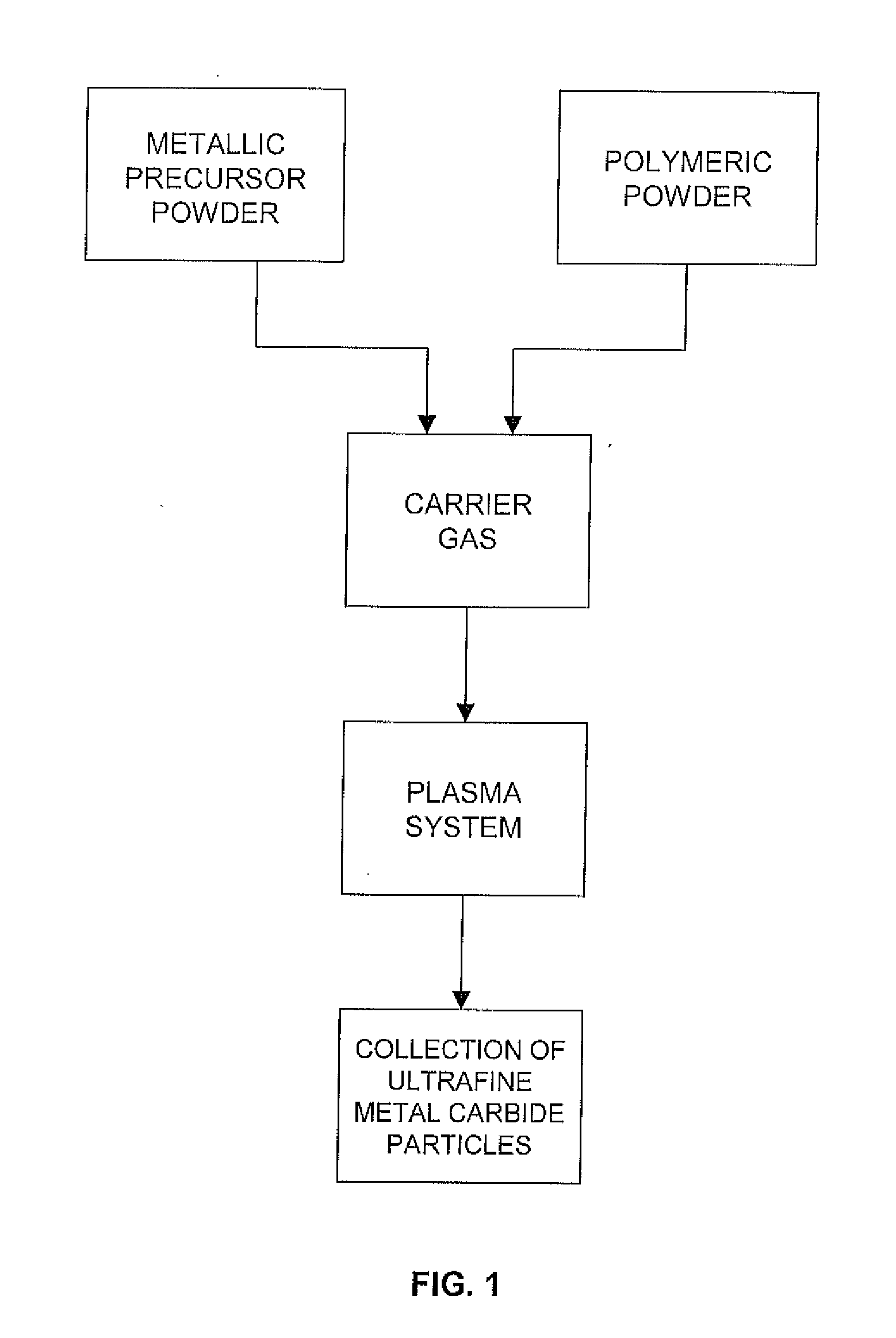

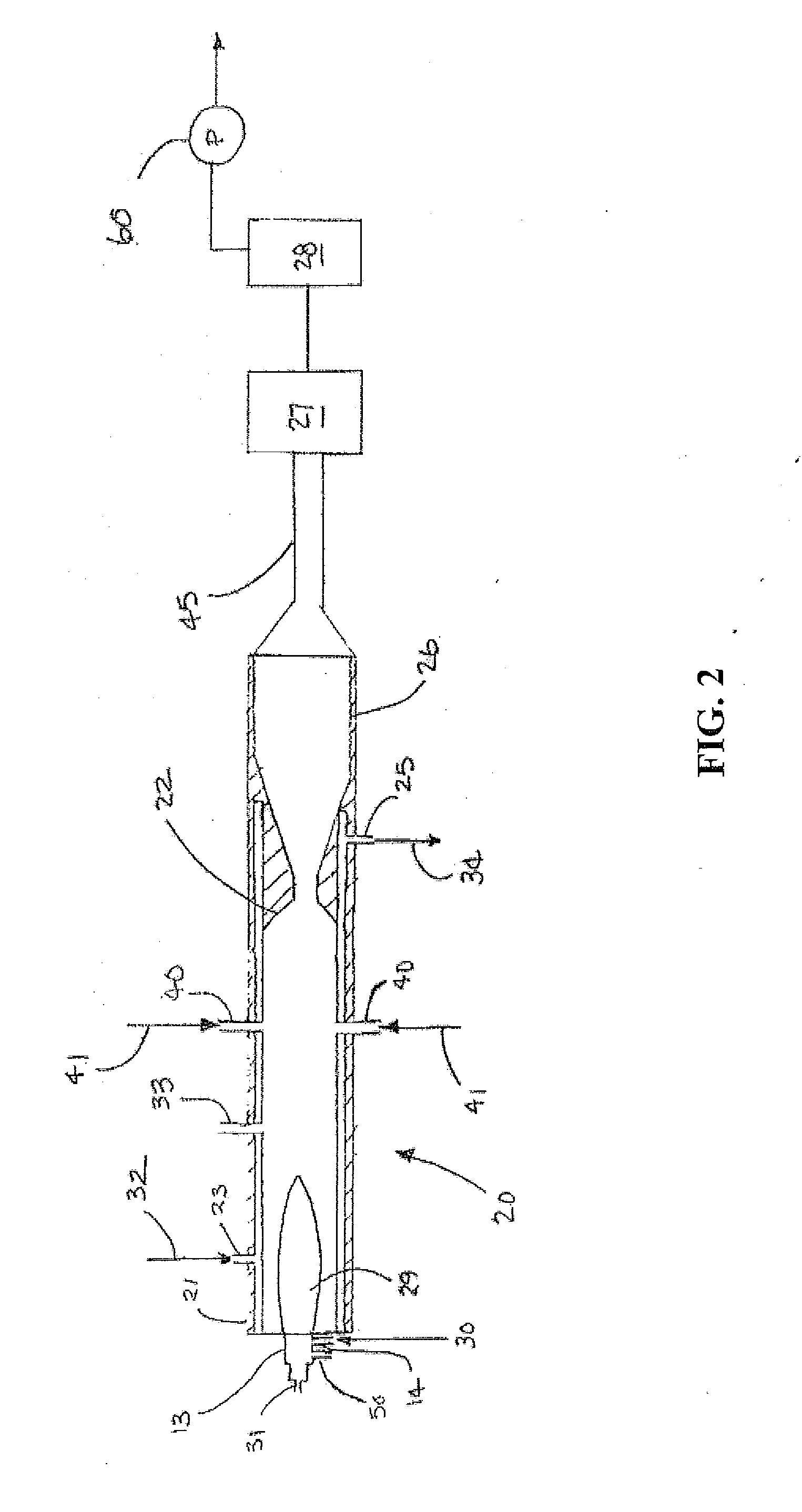

Production of ultrafine metal carbide particles utilizing polymeric feed materials

The production of ultrafine metal carbide powders from polymeric powder and metallic precursor powder starting materials is disclosed. In certain embodiments, the polymeric powder may comprise polypropylene, polyethylene, polystyrene, polyester, polybutylene, nylon, polymethylpentene and the like. The metal precursor powder may comprise pure metals, metal alloys, intermetallics and / or metal-containing compounds such as metal oxides and nitrides. In one embodiment, the metal precursor powder comprises a silicon-containing material, and the ultrafine powders comprise SiC. The polymeric and metal precursor powders are fed together or separately to a plasma system where the feed materials react to form metal carbides in the form of ultrafine particles.

Owner:PPG IND OHIO INC

Process for preparing shaped phase change material

InactiveCN1369537ANo leaksThe phase transition process is reversibleHeat-exchange elementsParaffin waxPhase change enthalpy

A process for preparing a form-fixed phase change material includes plasticizing olefine polymer (10-50 wt.%) to become chips, gradually adding paraffine until its content is 90-50 wt%, breaking, smelting-extruding out, water cooling and baking. The said polymer may be at least one of polyethene, polypropene, polybutene, etc. The resultant material features 25-70 deg.c for phase-changing temp, high phase-changing enthalpy up to 175 KJ / kg and no molecular leakage.

Owner:TSINGHUA UNIV

Gas-phase polymerization method and polymer of polybutene-1

The invention provides a gas-phase polymerization method of polybutene-1 for preparing high-quality butene-1 polymer, which comprises: performing homopolymerization of butene-1 serving as a monomer and a reaction medium or copolymerization of butene-1 and other alpha-olefins in a gas-phase polymerization reactor at a reaction temperature of 0 to 110 DEG C in the presence of a Ziegler-Natta catalyst with high stereoselectivity, and standing for 1 to 6 hours optimally. The method is simple in process, easy in operation and low in cost. The prepared polybutene-1 product is sphere-like or spherical particles and contains little fine powder, thereby contributing to the long-term operation o devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

Borated-epoxidized polybutenes as low-ash anti-wear additives for lubricants

An engine lubricant that is substantially free of zinc and phosphorous contains an antiwear additive comprising borated 1,2 epoxy mixed polybutenes having an average carbon number in the range of C20 to about C120.

Owner:EXXON RES & ENG CO

High-expansion fireproof sealant and preparation thereof

ActiveCN101302420AImprove sealingSmall volume shrinkageNon-macromolecular adhesive additivesOther chemical processesFire resistanceSealant

The invention discloses high intumescent fire stopping mastic and a method for preparing the same. The mastic is prepared by taking acrylate emulsion (or elastic styrene-acrylate emulsion), polybutene (or polyisobutylene), glycol, emulsifying agent and tritolyl phosphate as base materials with addition of certain auxiliary materials. The preparation method is as follows: the base materials are added into a reaction kettle according to certain mass portion, stirred, slowly heated and insulated for a period of time, and transferred into a colloid stirrer; auxiliary materials such as ammonium polyphosphates, flame-retarding aluminum hydroxide, flame-retarding zinc borates, calcium carbonates, expandable graphite, iron oxide red and glass fibers are gradually added into the mixture under the condition of stirring; and the process of stirring is continued until a colloid is uniform. The fire stopping mastic prepared by adoption of the method can be quickly carbonized and expanded to 5 to 8 times of the prior volume in case of fire, and can not fall off; the strength and the heat insulation after solidification are good, and the fire resistance is very good; and the adhesion is strong and the elasticity is good. The high intumescent fire stopping mastic and the method are particularly suitable for fire compartmentation of various penetrating penetration assemblies such as cables, cable bridges, pipes and so on.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Thermoplastic compositions and method of use thereof for molded articles

InactiveUS20060135679A1Reduce surface frictionImprove performanceDomestic articlesElastomerPolymer science

A polyolefin composition containing elastomers (plasticizers), crystalline polypropylene, modified by mixing with polybutene-1 and a coupling agent and a bicyclic dicarboxyl acid salt nucleating agent and / or a lubricant which comprises an unsaturated fatty acid ester which acts as a surface modifier in a molded article is described. The composition is adapted to be used with pigments to make finished molded articles which have an appearance of paint covered by a clear coat and which are scratch resistant and have good low temperature (−30° C.) impact properties.

Owner:ADVANTAGE POLYMERS

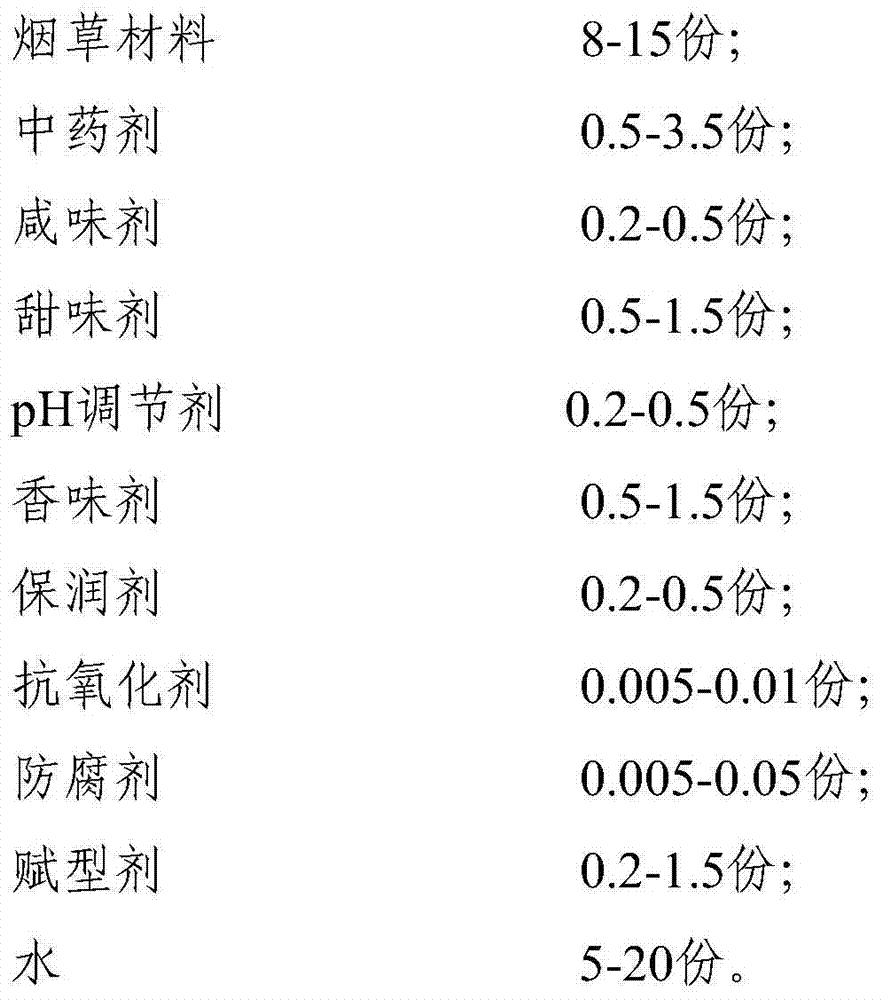

Mouth-holding type smokeless tobacco product and preparing method thereof

InactiveCN104770861AImprove safety and hygieneRich aroma styleTobacco treatmentAntioxidantAntibacterial property

The invention relates to the field of smokeless tobaccos, and particularly relates to a mouth-holding type smokeless tobacco product and a preparing method thereof. The mouth-holding type smokeless tobacco product comprises, by weight, 5-25 parts of a tobacco material, 0.2-8 parts of a traditional Chinese medicine agent, 0.1-2 parts of a saline taste agent, 0-6 parts of a sweetening agent, 0.1-2.5 parts of a pH conditioning agent, 0.1-6 parts of a flavouring agent, 0.2-2.5 parts of a humectant, 0-1.2 parts of an antioxidant, 0.001-0.5 part of a corrosion remover, 0-4 parts of a polybutene and 5-25 parts of water. By means of the mouth-holding type smokeless tobacco product, sun-cured tobaccos produced in Guizhou serve as main tobacco raw materials, nicotine reducing and aroma enhancement are carried out on the tobaccos, and the traditional Chinese medicine agent is added, so that oral cavity and throat excitements caused by contents such as the nicotine are reduced, and the taste quality and the fragrance style are improved. In addition, the traditional Chinese medicine agent further has a certain antibacterial property, and the using safety performance of the product is improved.

Owner:CHINA TOBACCO GUIZHOU IND

Denture care composition

A denture care composition comprising one or more denture care actives and one or more water insoluble carriers, wherein the composition is bioerodible, not a denture adhesive, and substantially free of polybutene with a molecular weight of about 300 to about 3000 when the composition is not an article, and is applied to dentures.

Owner:PROCTER & GAMBLE CO

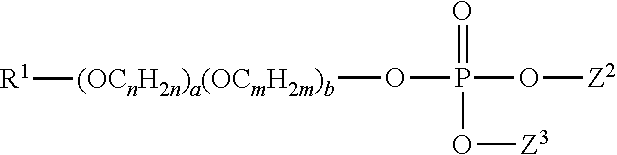

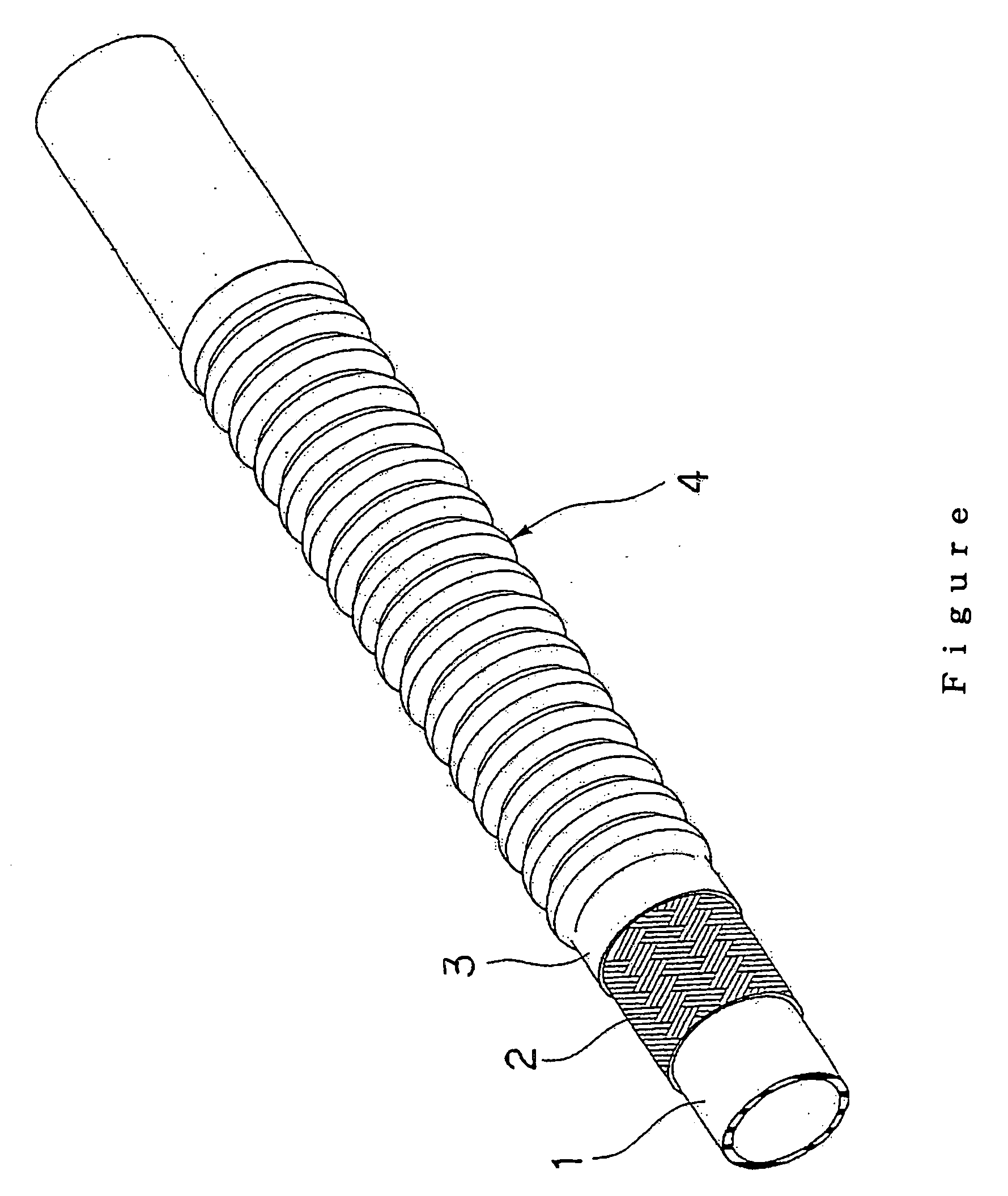

Refrigerant transportation hose

InactiveUS20060011250A1Easy to processIncreased durabilityLayered productsVehicle heating/cooling devicesHigh resistanceEngineering

A refrigerant transportation hose having excellent processability and durability, as well as high resistance to gas permeation (gas barrier properties) and adequate flexibility. The refrigerant transportation hose containing a tubular rubber layer in which refrigerant is circulated, the tubular rubber layer is formed by a material consisting essentially of components (A) to (C): (A) at least one rubber of butyl rubber and halogenated butyl rubber; (B) polybutene; and (C) a white filler.

Owner:SUMITOMO RIKO CO LTD

Colloid for adhering insects for fruit trees

An insect adhering colloid for fruit tree is prepared from polybutene, the viscosity increaser (rosin resin, rosin, and polybutene), and the additive (calcium carbonate, talc powder and TiO20) through mixing.

Owner:赵国栋

Modified polyethylene film and composite film made of same

ActiveCN102717573AImprove bond strengthGood easy to peel performanceSynthetic resin layered productsEthylene propylene copolymerLow-density polyethylene

The invention provides a modified polyethylene film which is characterized by comprising, by weight, 40-60 parts of linear low density polyethylene and / or low density polyethylene, 15-25 parts of polybutylene or modified polybutylene and 25-35 parts of ethylene-propylene copolymer. The invention further provides a composite film made of the modified polyethylene film. Horizontal and longitudinal tensile strength of the modified polyethylene film are improved, no stratification occurs when the modified polyethylene film is processed and used, composite film packing materials which are made further have good sealing effect, and the modified polyethylene film keeps good easy-to-uncover performance.

Owner:ZHEJIANG GOLDSTONE PACKING

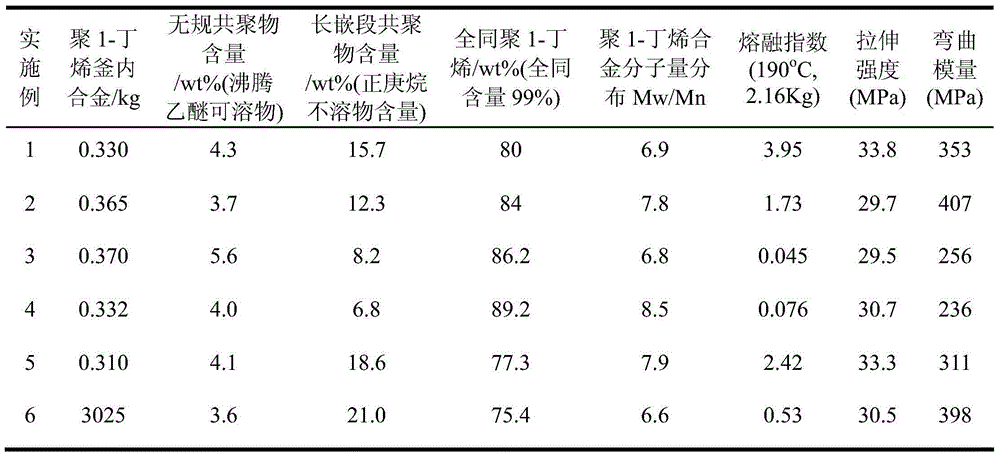

Poly 1-butene/1-butylene-propylene copolymer in-reactor alloy and preparation method thereof

ActiveCN103951898AImprove crystal transformation rateStrong impact resistancePolymer sciencePolyolefin

The invention discloses a poly 1-butene / 1-butylene-propylene copolymer in-reactor alloy material and a preparation method thereof, belongs to the field of polyolefin material, and relates to poly 1-butene in-reactor alloy, and a preparation method and applications thereof. According to the poly 1-butene / 1-butylene-propylene copolymer in-reactor alloy material, a poly 1-butene homopolymer is taken as a main ingredient, and the poly 1-butene / 1-butylene-propylene copolymer in-reactor alloy material comprises a small amount of a 1-butylene / propylene copolymer, wherein molar content of propylene monomer unit ranges from 2 to 25%, molar content of 1-butene monomer unit range from 75 to 98%, mass content of poly 1-butene ranges from 65 to 89%, and mass content of the 1-butylene / propylene copolymer ranges from 35 to 11%. The poly 1-butene / 1-butylene-propylene copolymer in-reactor alloy material is prepared by adopting a high-efficient loaded Ti catalytic system and via two-stage bulk in-suit polymerization. The polybutene alloy material possesses excellent shock resistance and thermal creep resistance, and low shrinking rate of the poly 1-butene homopolymer; is capable of increasing crystal transfer rate of poly 1-butene, and shortening shaping and curing time at the same time; and can be used for replacing a part of polyethylene and polypropylene for preparation of tubular products or for toughening modification of polypropylene.

Owner:QINGDAO UNIV OF SCI & TECH

Poly-l-butylene resin composition and its usage

InactiveCN1356353AShorten molding cycleIncrease production capacityRigid pipesTubular articlesWarm waterOlefin polymerization

Poly(1-butene) resin composition comprises 90-99.95 wt.% of a poly(1-butene) resin (A) which is obtained by copolymerizing 80-100 mol% of 1-butene with 0-20 mol% of a 2-10C α -olefin except 1-butene and has 0.01-50 g / 10 minutes MFR (190 deg.C) and 0.05-10 wt.% of a polypropylene resin (B) having 0.01-50 g / 10 minutes MFR (230 deg.C). This pipe and this joint for a pipe comprise the composition. According to this present invention a poly(1-butene) resin composition capable of preparing a pipe which shortens a curing time and reduces a molding cycle, namely has excellent productivity and excellent winding properties after extrusion molding, its pipe and a joint suitable for the pipe in which the pipe is suitable for a fluid transportation pipe such as a water supply pipe, a warm water supply pipe, etc., and the joint for a pipe is preferably useful as the joint for the pipe.

Owner:MITSUI CHEM INC

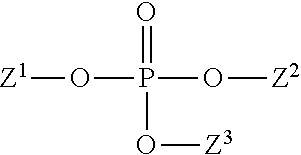

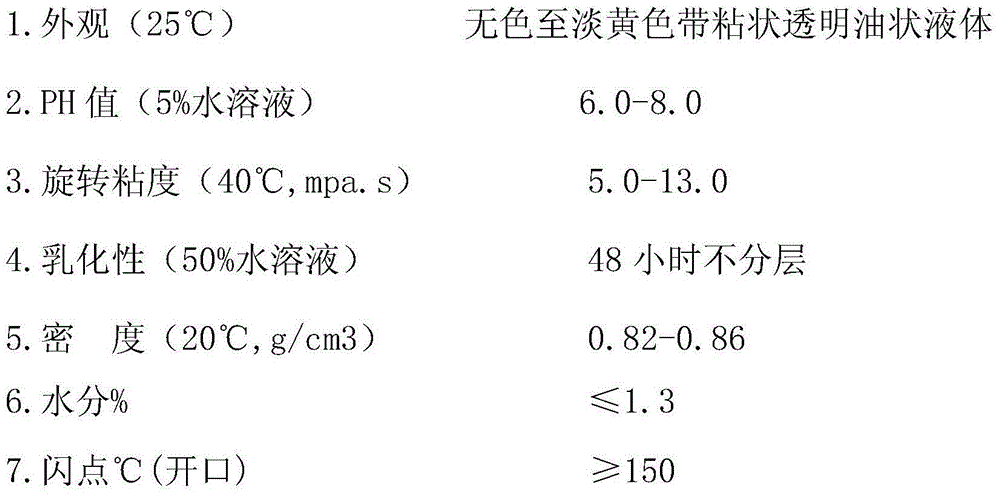

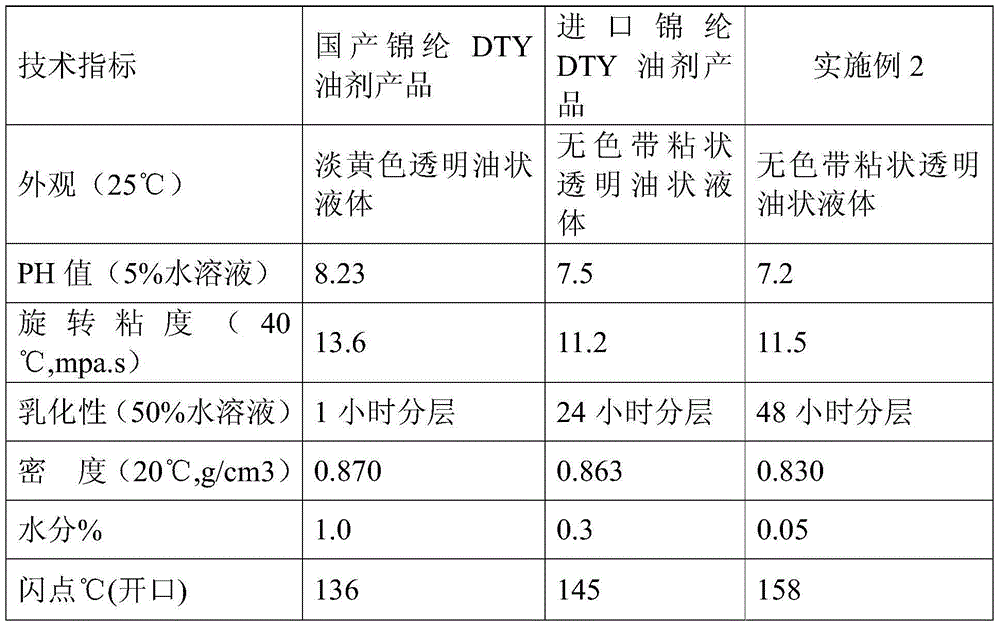

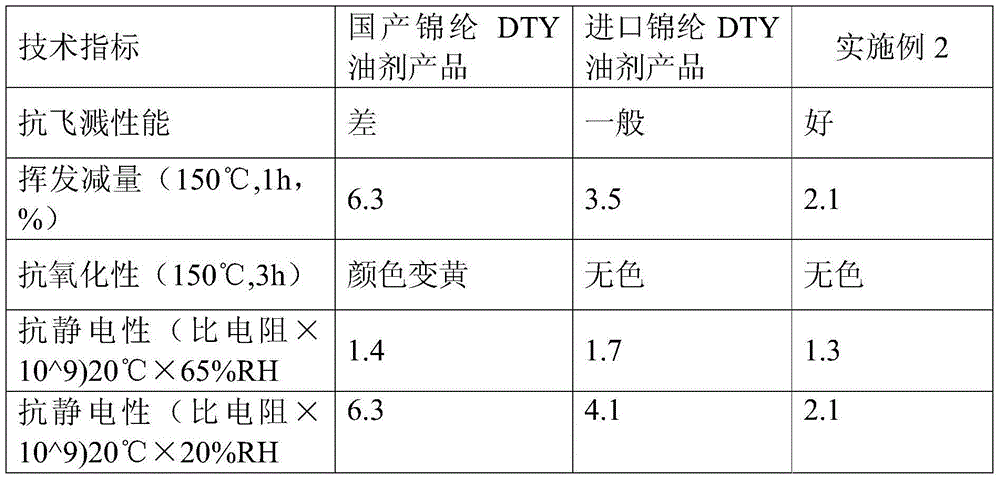

Anti-splashing chinlon DTY oil agent and preparation method thereof

The invention discloses an anti-splashing chinlon DTY oil agent and a preparation method thereof. A conventional chinlon DTY oil agent splashes on various parts when spinning processing speed increases. The anti-splashing chinlon DTY oil agent is composed of following components, by weight, 60-80% of a high-temperature resistance smooth agent, 10-25% of an environment-friendly emulsifier, 3-10% of a bundling agent, 4-6% of a compound antistatic agent, 1-2% of an anti-splashing agent and the balance polymeric additive. The anti-splashing agent is a mixture of an ethene-propylene copolymer and polyisobutylene or polybutene. The anti-splashing agent is good in anti-splashing performance, is free from splashing and causing oil-stained fibers during a production process, is free of APEO and is non-pollution and nontoxic to environment.

Owner:HANGZHOU TRANSFAR CHEM LTD

Oral care kits and compositions

An oral care composition comprises polybutene with a molecular weight of about 300 to about 3000 and an oral care active. The oral care composition may further comprise an oral care carrier. Kits comprising polybutene, a container and instructions for use or an applicator for applying the composition directly to the tooth surfaces are also disclosed. The polybutene component of the kits can further comprise an oral care active or an oral care carrier.

Owner:THE PROCTER & GAMBLE COMPANY

Thermoplastic single ply protective covering

Improved single ply, water proof roof coverings having an extruded pressure sensitive rubber-based adhesive backing for attachment to a substrate such as the roof of a building or a transport vehicle, the adhesive comprising a thermoplastic rubber containing at least 25% butyl rubber in combination with polyisobutylene and low molecular weight polybutene.

Owner:BMIC LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com