Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

178results about How to "Reduce surface friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

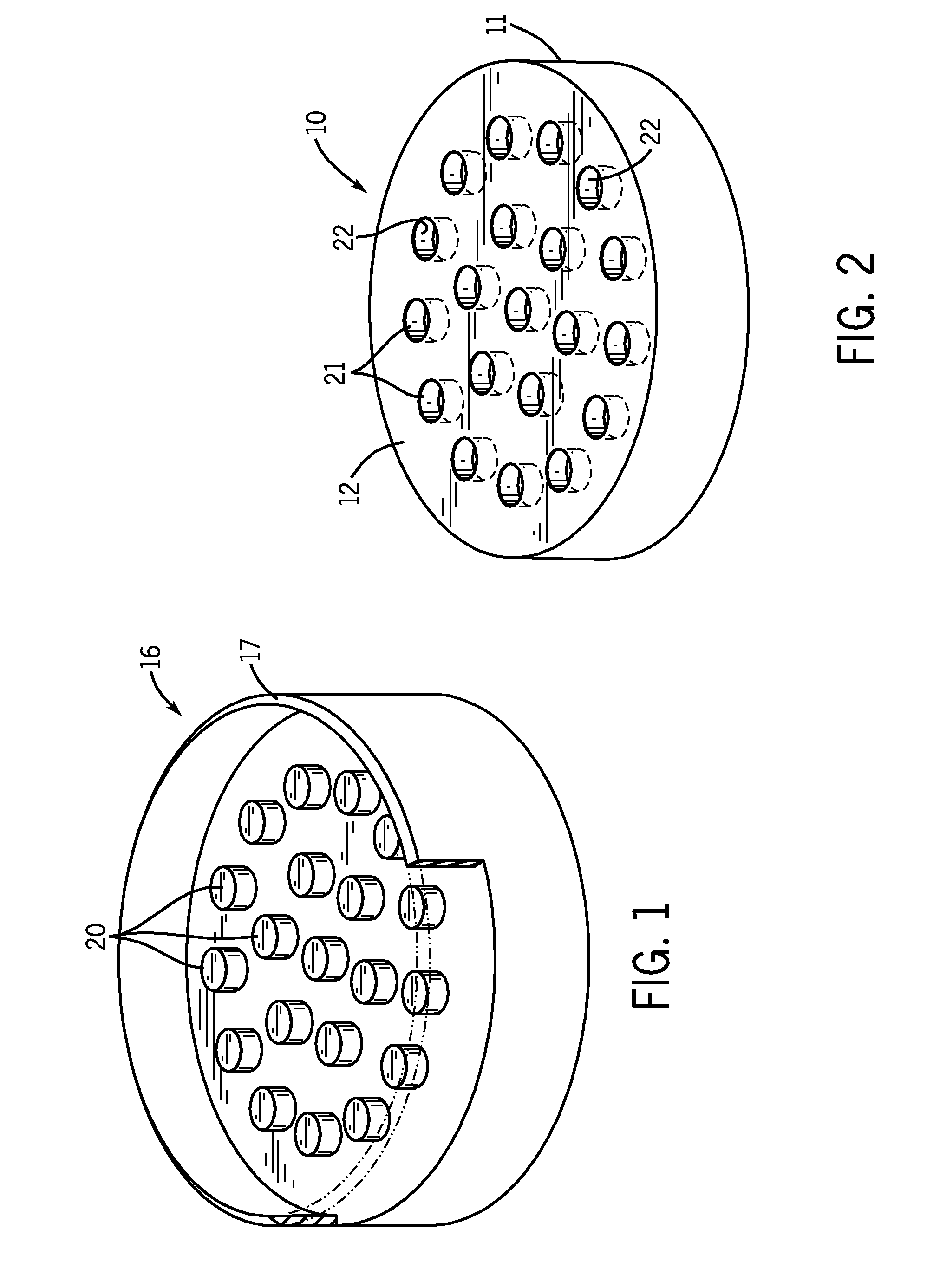

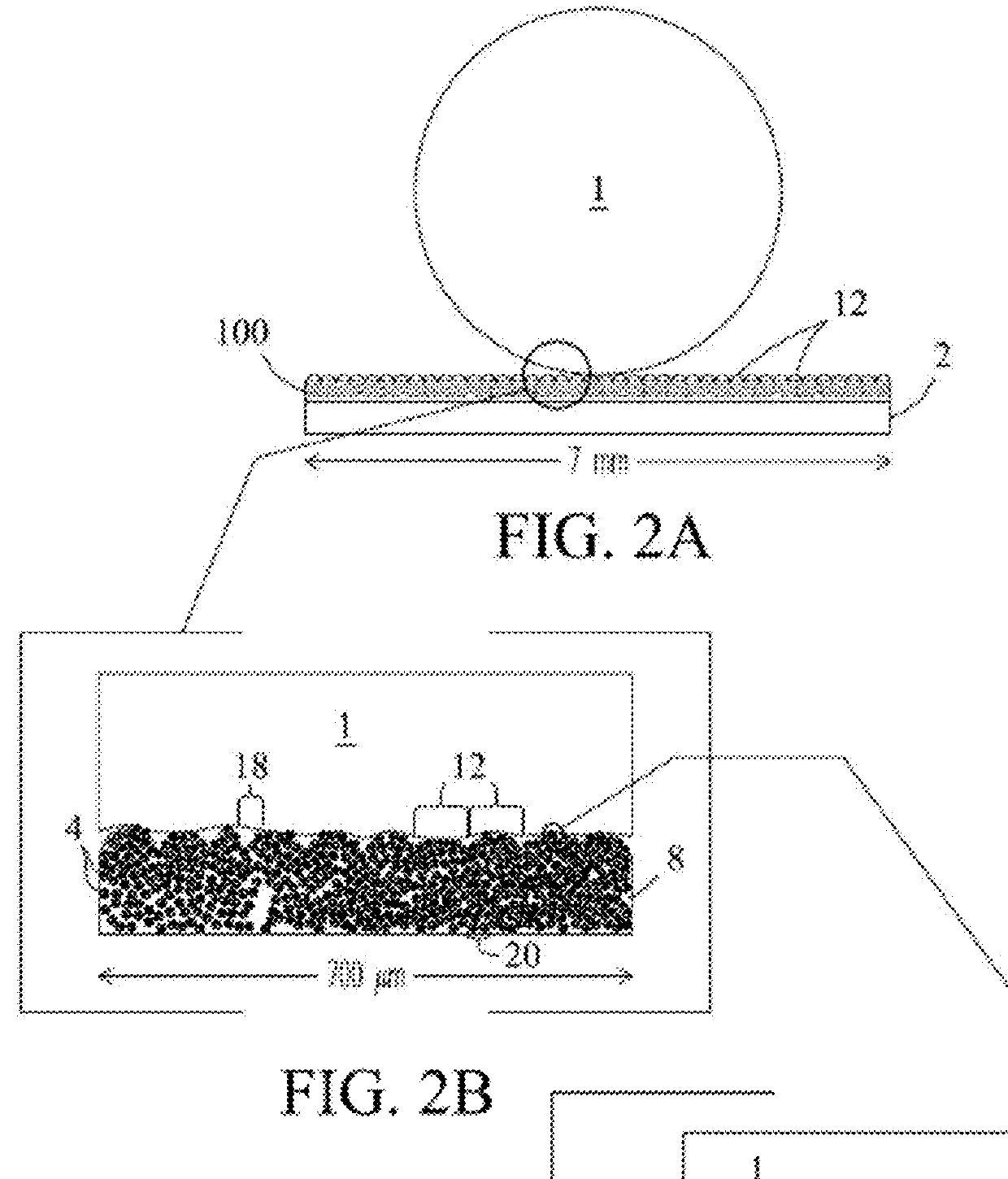

Electrophotographic photoreceptor, and electrophotographic image forming apparatus and process cartridge using the electrophotographic photoreceptor

InactiveUS20050026058A1Increase resistanceReduce surface frictionElectrographic process apparatusCorona dischargeEngineeringFluorosurfactant

An electrophotographic photoreceptor including an electroconductive substrate; a photosensitive layer overlying the electroconductive substrate optionally via an undercoat layer; and optionally a protective layer overlying the photosensitive layer, wherein an outermost layer of the electrophotographic photoreceptor comprises a binder resin; a particulate fluorine-containing resin in an amount of from 20 to 70% by volume based on total volume of the outermost layer, wherein a surface free energy of the particulate fluorine-containing resin is larger than a surface free energy of the binder resin; and a fluorochemical surfactant in an amount of from 5 to 70% by weight based on total weight of the binder resin.

Owner:RICOH KK

Method of forming nanocomposite materials

InactiveUS20050127329A1Evenly dispersedImprove conductivityMaterial nanotechnologyNanoinformaticsGas phaseEvaporation

A method of reinforcing a polymeric material with nanosize materials is provided in which materials such as vapor grown carbon nanofibers, carbon nanotubes, layered silicates, nanosize sphered silica, or graphite nanoparticles are combined with a polymer and a solvent to form a substantially homogeneous mixture, followed by removal of the solvent by evaporation or coagulation. Depending on the nanosize materials used, the resulting polymeric nanocomposite material exhibits high electrical and thermal conductivity, enhanced mechanical strength, abrasion resistance, reduced gas permeation, and / or dimensional stability.

Owner:UNIV OF DAYTON

Packaging solutions

InactiveUS20080110770A1Preserve sterilityIncrease lubricityPackage sterilisationOther accessoriesChemistryOsmolar Concentration

A packaging system for the storage of an ophthalmic device, such as a hydrogel contact lens, employs an aqueous packaging solution including a nonionic, nonpolymeric polyol and a nonionic polymeric conditioning agent. Preferably, the solution has an osmolality of at least about 200 mOsm / kg, a pH of about 6 to about 8 and is heat sterilized.

Owner:BAUSCH & LOMB INC

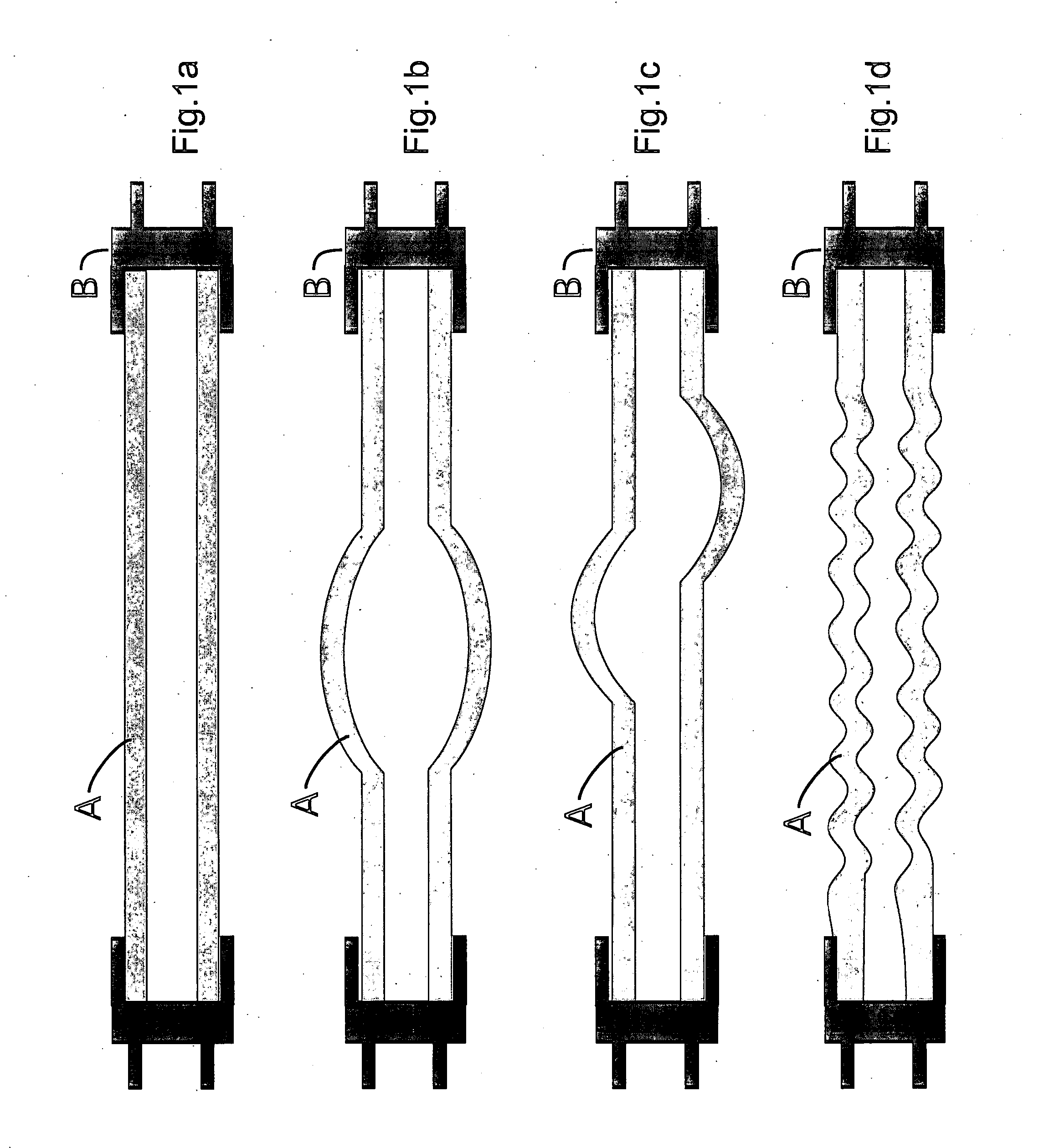

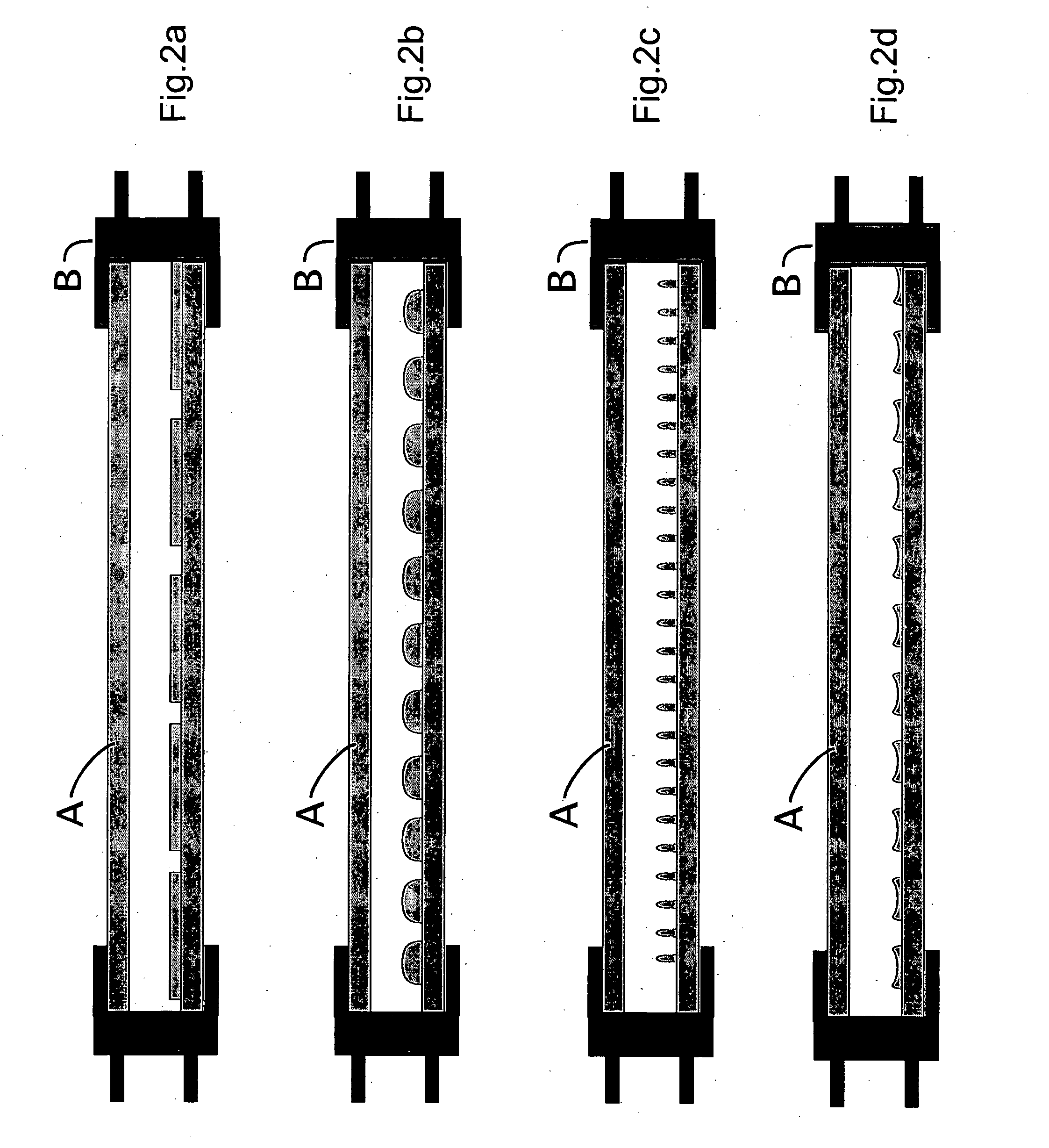

Method of producing structures using centrifugal forces

InactiveUS20050287320A1Simple designReduce surface frictionEnvelopes/bags making machineryLayered productsPolymer scienceSpinning

A variety of hollow structures with unique morphologies were manufactured with a rotational spinning technique. Phase separation of soluble solutions or emulsions was induced within a filled mold as it was being rotated about one of its axis. The density difference between phases results in sediment at the inner lumen of the mold under centrifugal forces. After or during sedimentation, gelation of the phase-separated particles fixes the hollow structure morphology and the solvent remains in the center of the mold. The solvent is removed from the mold resulting in a coating or tube. By controlling the rotational speed and the formulation chemistry, the tube dimensions and wall morphology can be manipulated. This technique offers a new approach to the manufacture of polymeric tubes. It requires small quantities of starting material, permits multi-layering of tubes, is applicable to diverse polymers and can result in highly diffusive hollow structures while maintaining good mechanical strength.

Owner:SHOICHET MOLLY S +3

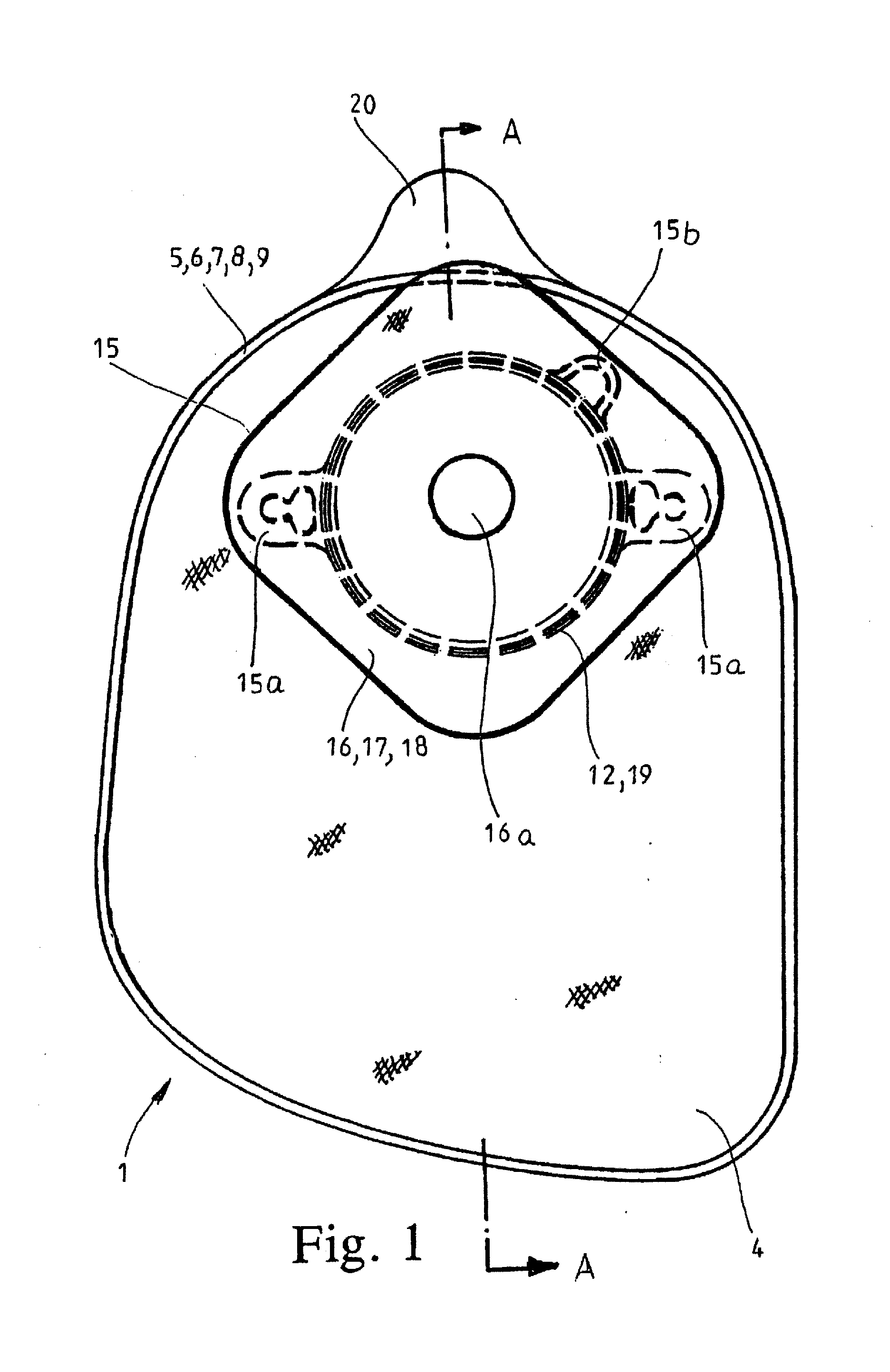

Flushable Body Waste Collection Pouches, Pouch-in Pouch Appliances Using the Same, and Methods Pertaining Thereto

ActiveUS20080294129A1Safely flushedLoaded safely and effectivelySynthetic resin layered productsPharmaceutical delivery mechanismHydrophilic coatingFiber

A flushable biodegradable pouch having water-dispersible fibers along at least a portion of the outer surface of the pouch's cover layer provided with a water-soluble hydrophilic coating. The pouch's cover layer is water-disintegratable, and the water-soluble hydrophilic coating is a lubricating agent capable of becoming slippery when exposed to water and, upon subsequent drying, again becoming water-soluble upon re-exposure to water. As such, the hydrophilic coating serves as a rewettable, redesolving lubricating agent.

Owner:HOLLISTER INCORPORAED

Conductive polymeric nanocomposite materials

InactiveUS7029603B2Evenly dispersedImprove conductivityMaterial nanotechnologyNanostructure manufactureConductive polymerEvaporation

A method of reinforcing a polymeric material with carbon nanofibers is provided in which carbon nanofibers are combined with a polymer and a solvent for the polymer to form a substantially homogeneous mixture, followed by removal of the solvent by evaporation or coagulation. The resulting conductive polymeric nanocomposite material exhibits high electrical and thermal conductivity, enhanced mechanical strength, abrasion resistance, and dimensional stability.

Owner:UNIV OF DAYTON

Polymer powders, pressure sensitive adhesives and methods of making the same

InactiveUS7019067B2Stable in solutionEnhance sheet feedingCosmetic preparationsLiquid surface applicatorsPressure sensitiveEthyl ester

A method for making hydrophilic homopolymers and copolymers of poly 2-hydroxyethyl methacrylate. Also disclosed are coatings, films, hydrogels, cosmetic compositions, dermatological compositions, pressure sensitive adhesives containing the hydrophilic homopolymers or copolymers of poly 2-hydroxyethylmethacrylate. Further disclosed are methods of coating substrates with the hydrophilic homopolymers and copolymers of poly 2-hydroxyethyl methacrylate and hydrophilic pressure sensitive adhesives.

Owner:AVERY DENNISON CORP

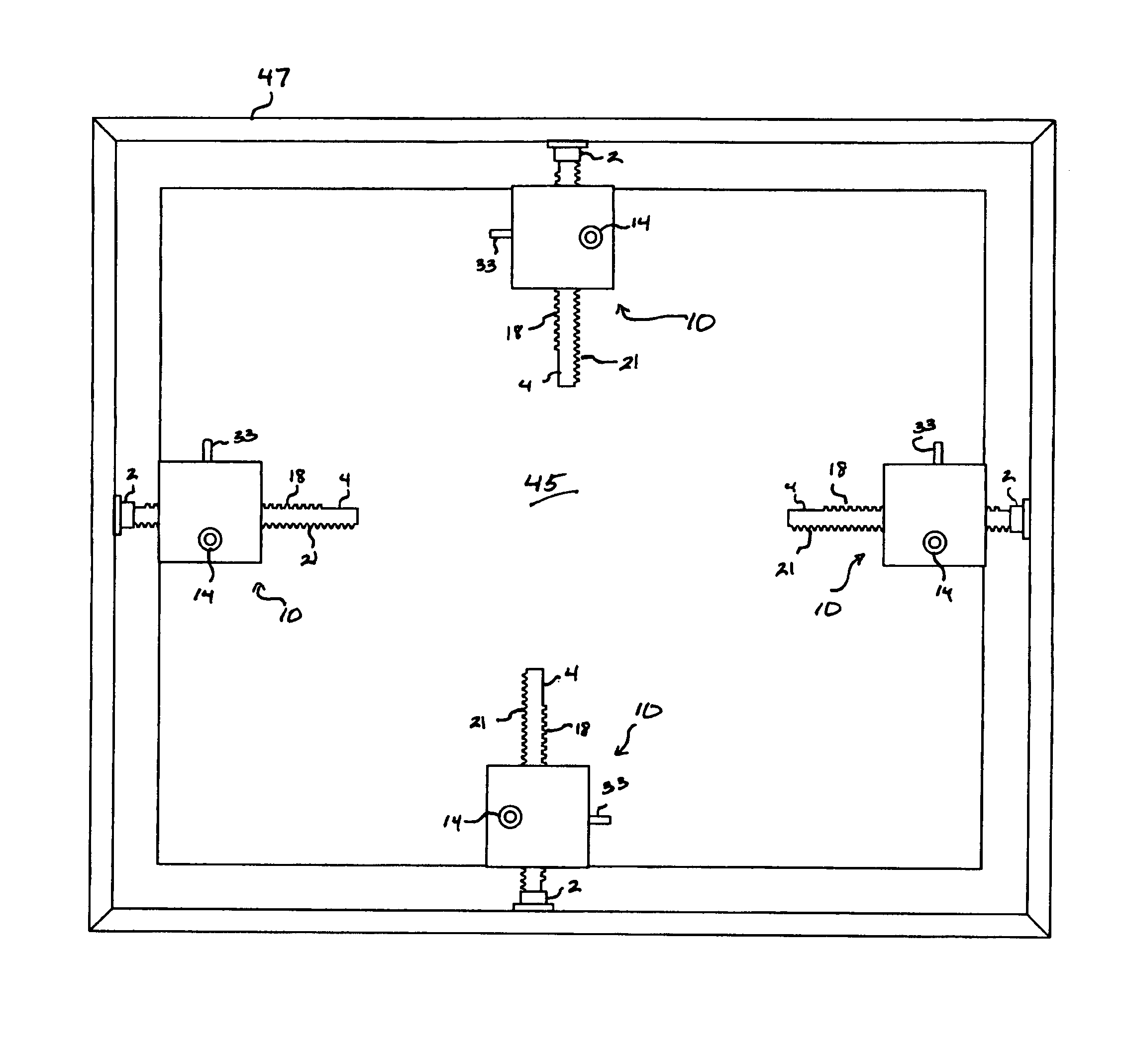

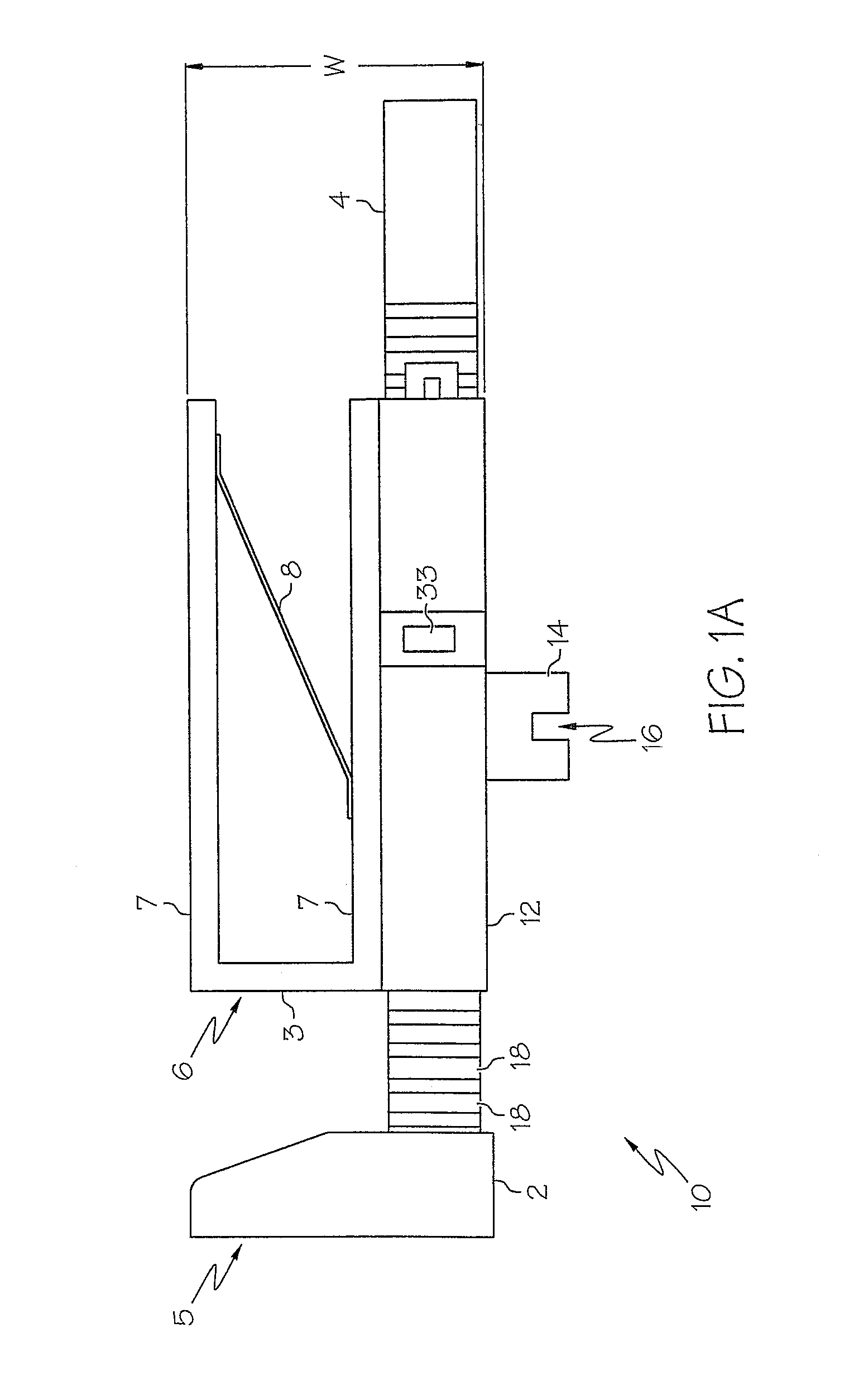

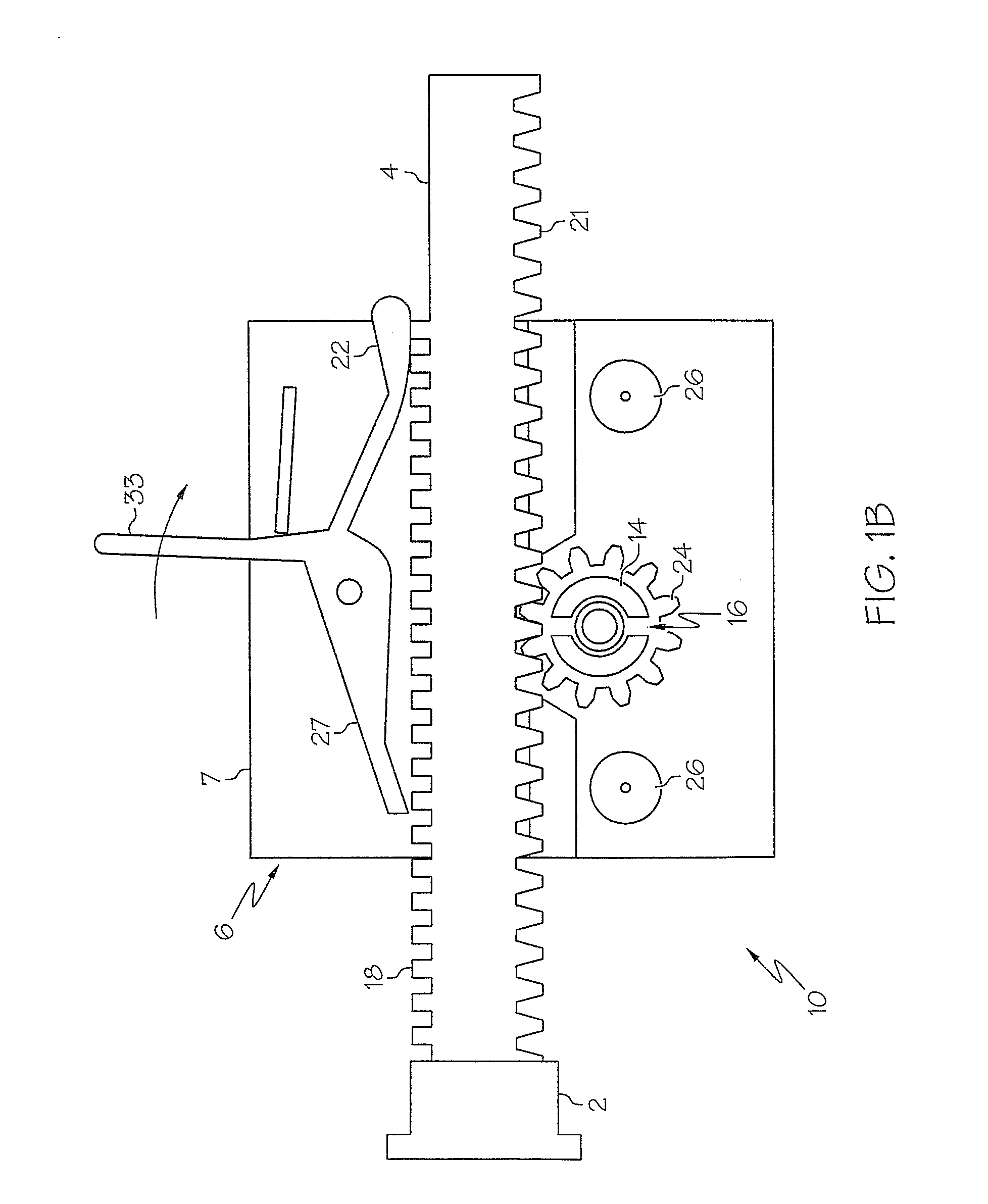

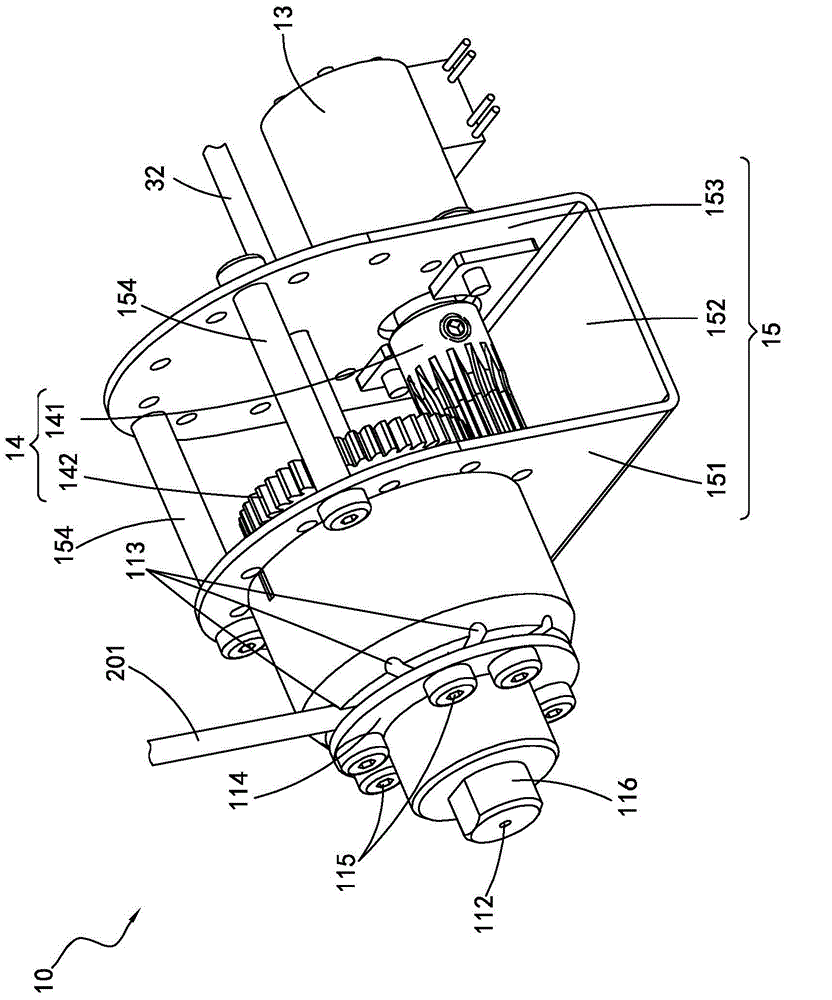

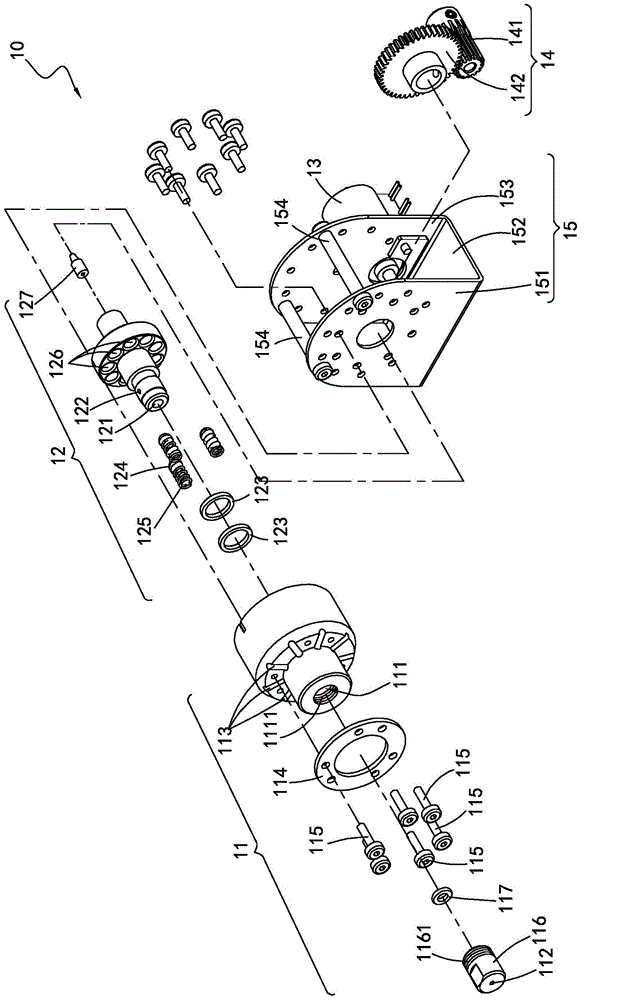

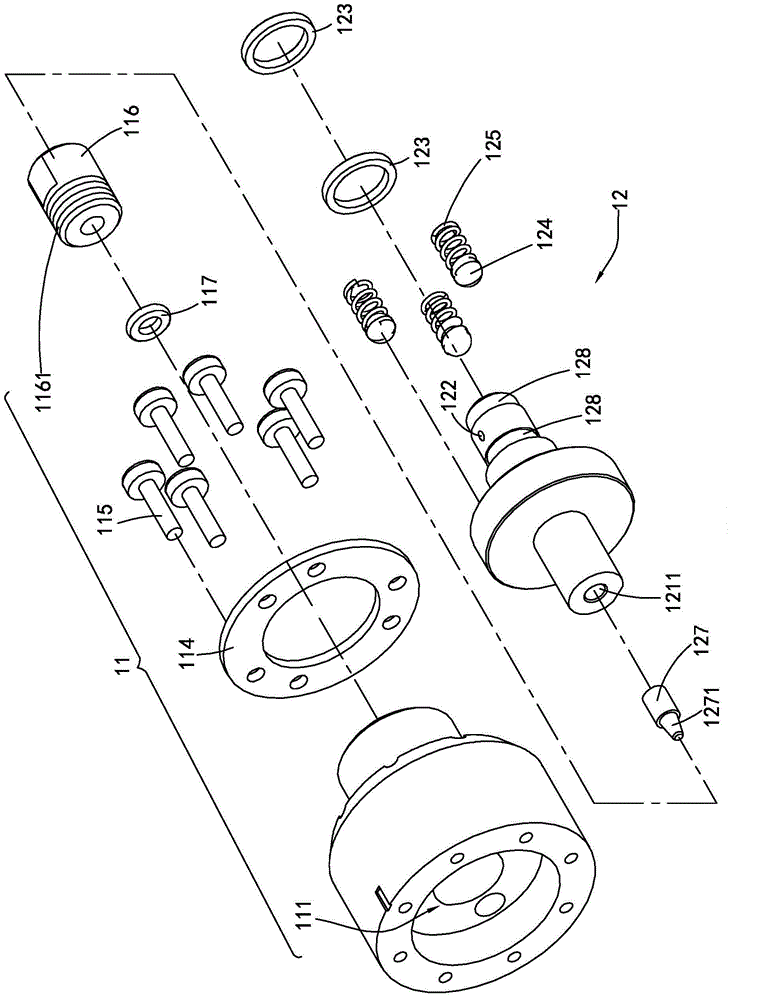

Storm barrier assembly

InactiveUS7305800B1Reduce surface frictionFlood panelsShutters/ movable grillesInsertion stentEngineering

An apparatus and assembly for retaining a substantially flat, protective panel within a frame such as a window frame. In one embodiment, the panel retention apparatus of the present invention includes a bracket member for fitting over an edge of the panel, such that the bracket member provides edge and lateral support for the panel. The apparatus further includes a rack and gear mechanism affixed to the bracket member. The rack and gear mechanism preferably includes a circular driving gear and a rack member having a foot member attached at one end and further having a rack gear engaging the circular driving gear such that the rack member is linearly movable with respect to the bracket member responsive to rotational actuation of the circular driving gear. In a preferred embodiment, the rack and gear mechanism components are fabricated of a Delrin composite material which provides a lightweight, corrosion resistant, and low surface friction actuation assembly.

Owner:TEMERITY CREATIVE

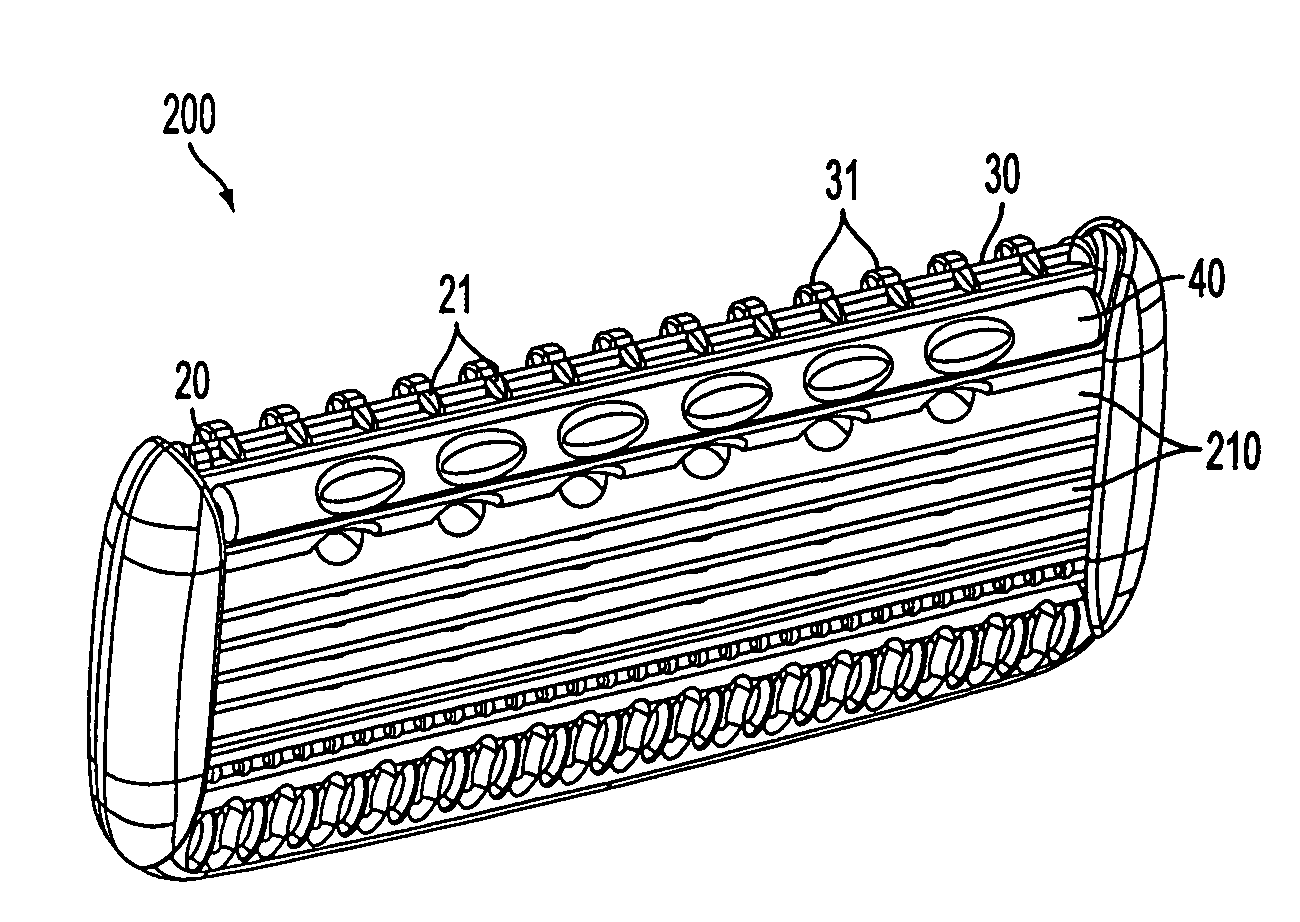

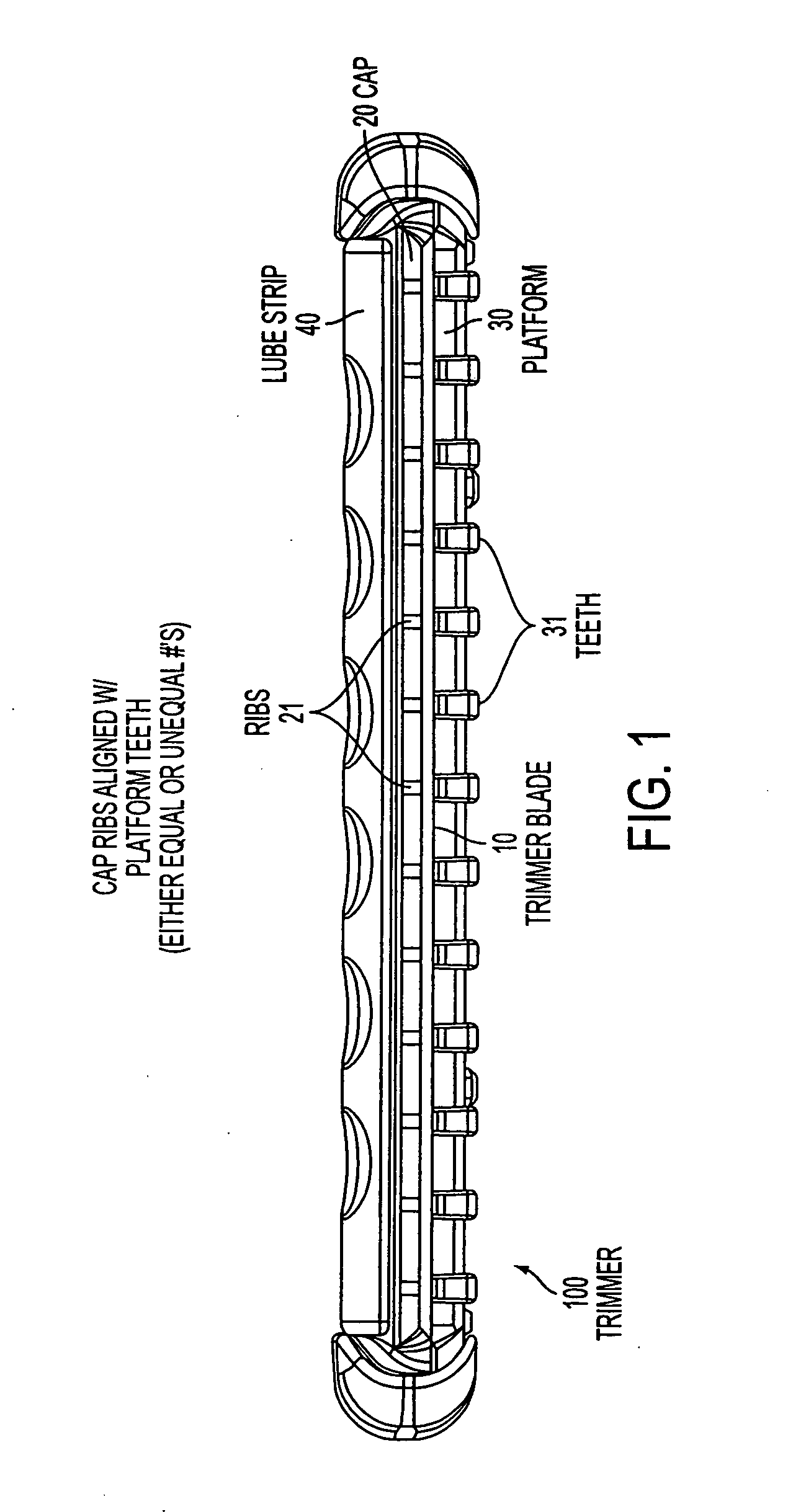

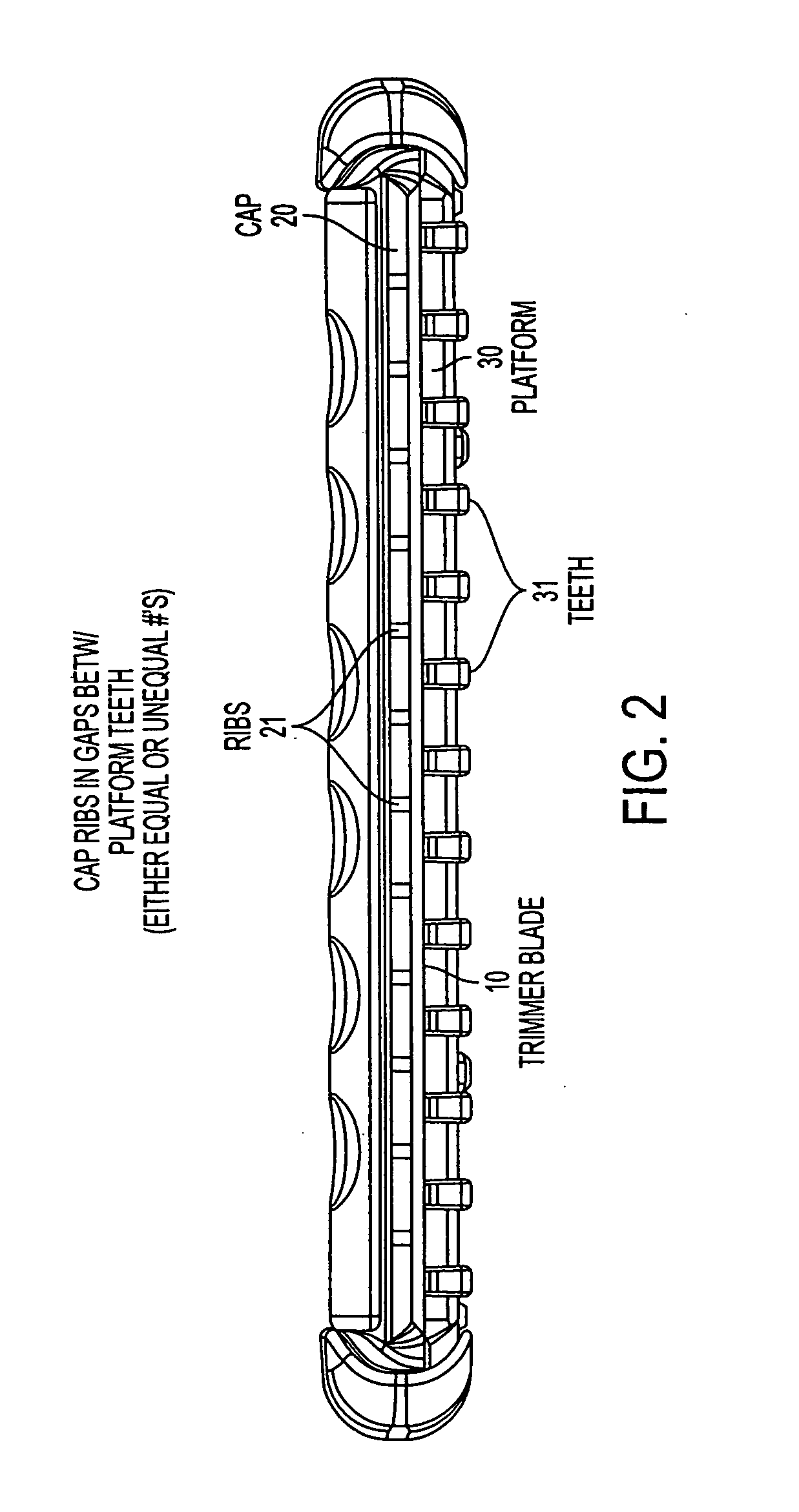

Trimmer for shaving razor

InactiveUS20100071215A1Avoid problemsReduce contact areaMetal working apparatusRazor stropEngineering

A trimmer for a shaving razor comprises a blade having a cutting edge. A plurality of teeth are located on one side of said blade at the cutting edge. On a second side of the blade opposite the plurality of teeth are a plurality of ribs located at the cutting edge. Each of the teeth are aligned with the ribs in a direction perpendicular to the blade. Alternatively, the teeth and ribs are spaced alternating along the cutting edge of the blade. The number of teeth are equal to or alternatively, not equal to the number of ribs.

Owner:AMERICAN SAFETY RAZOR CO

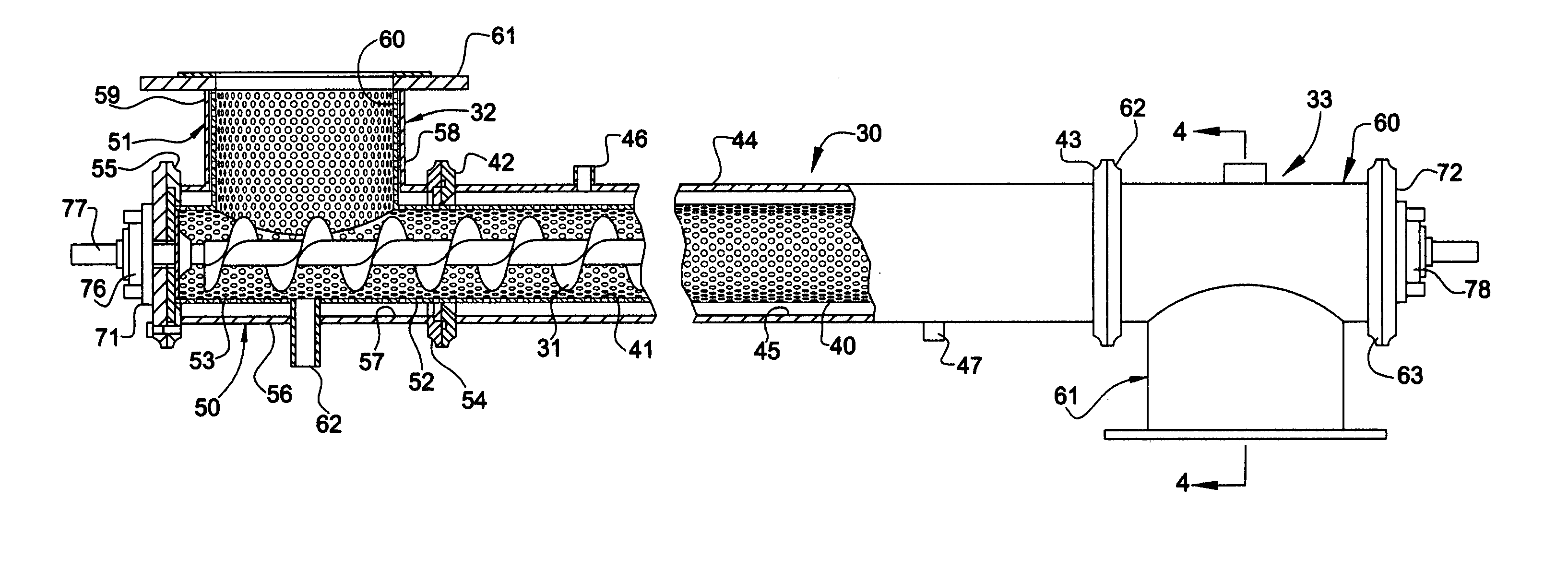

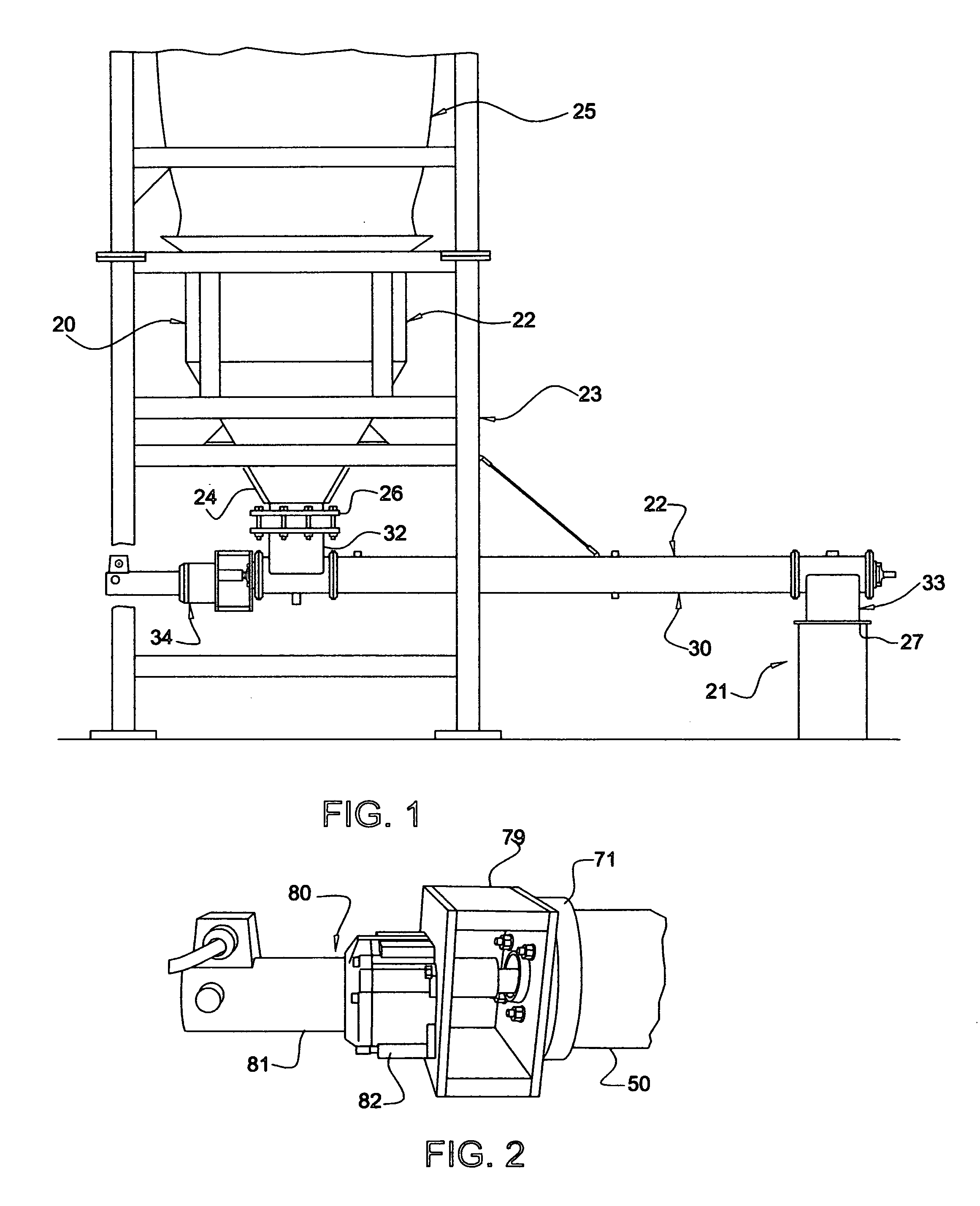

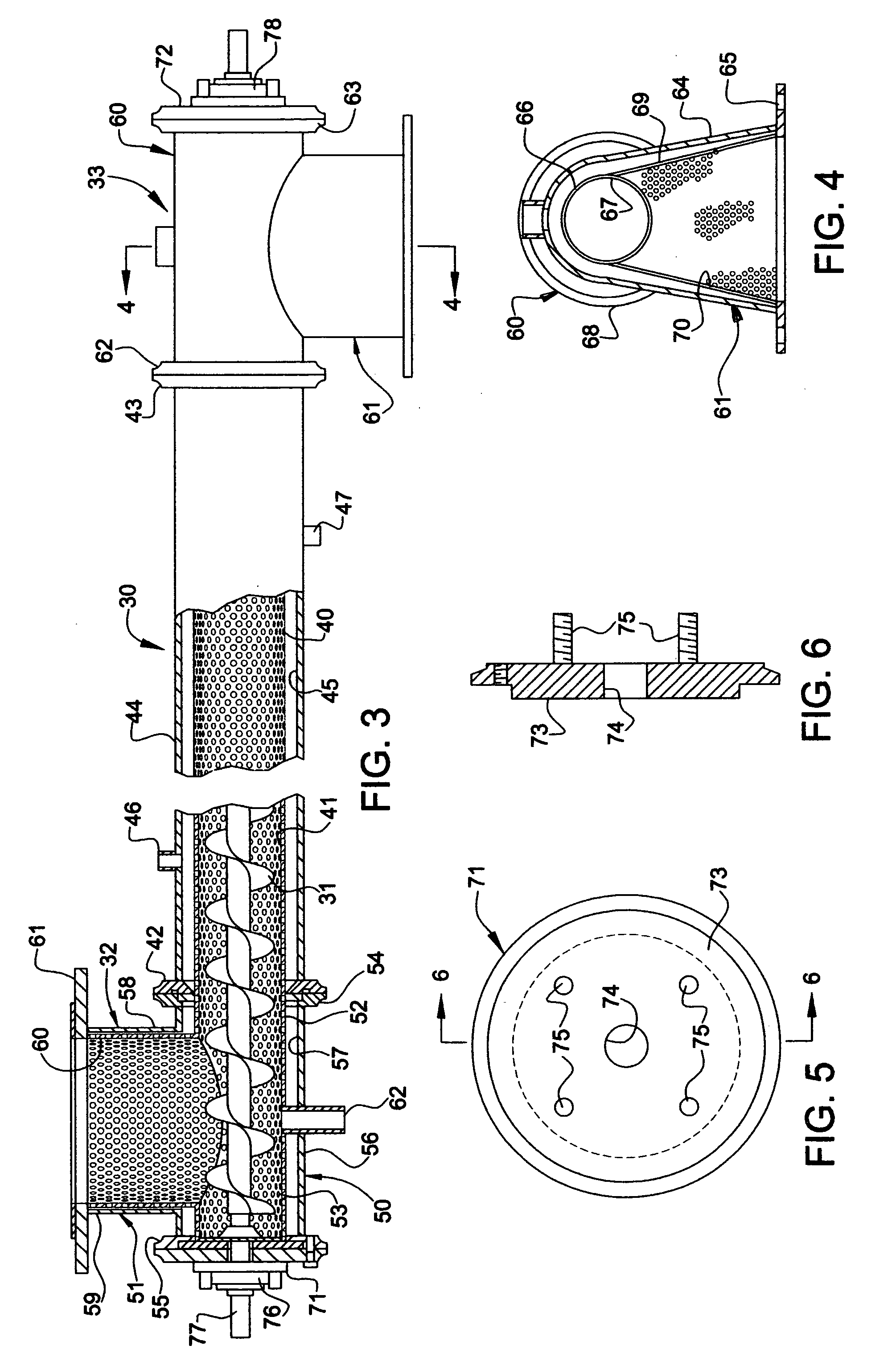

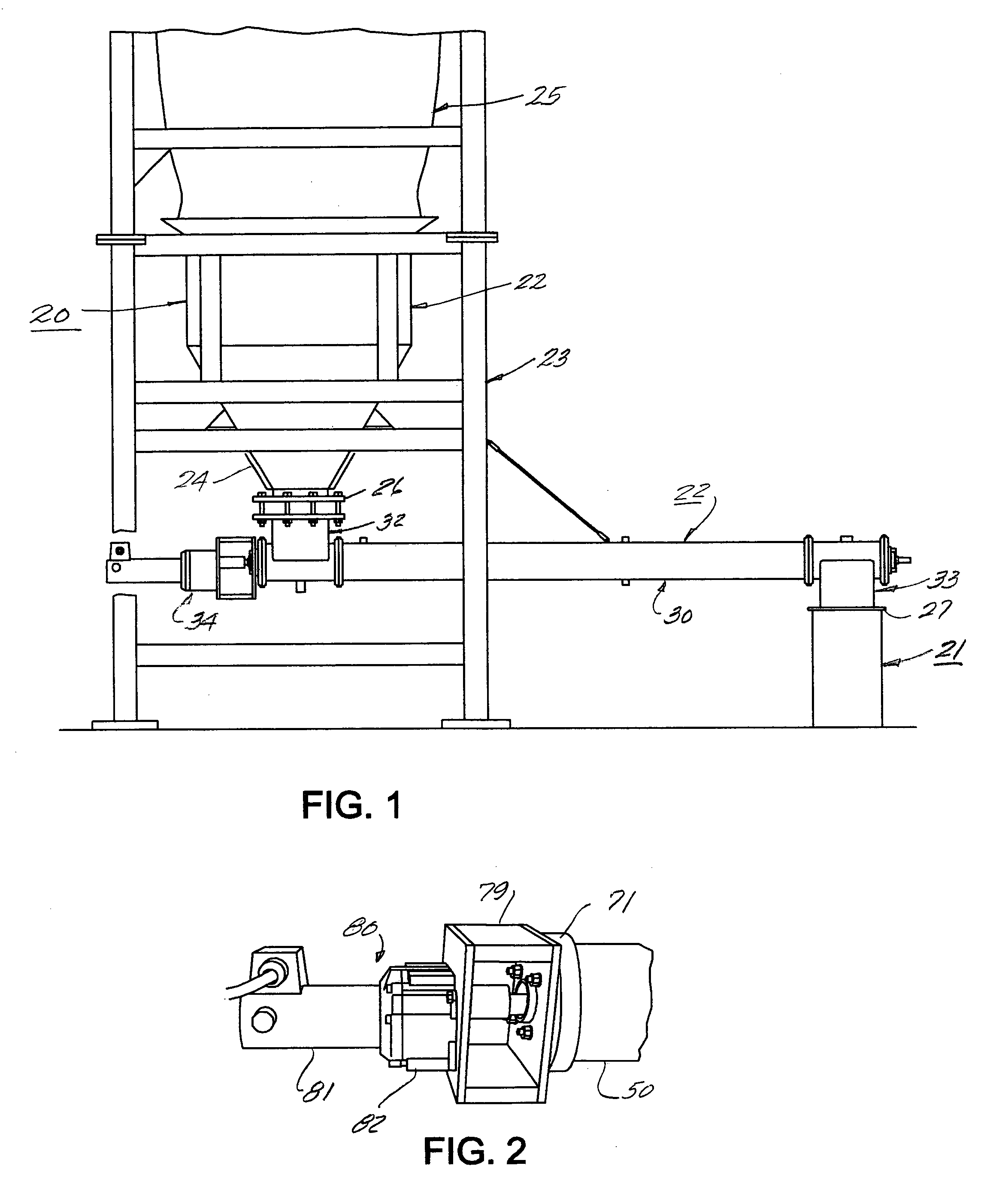

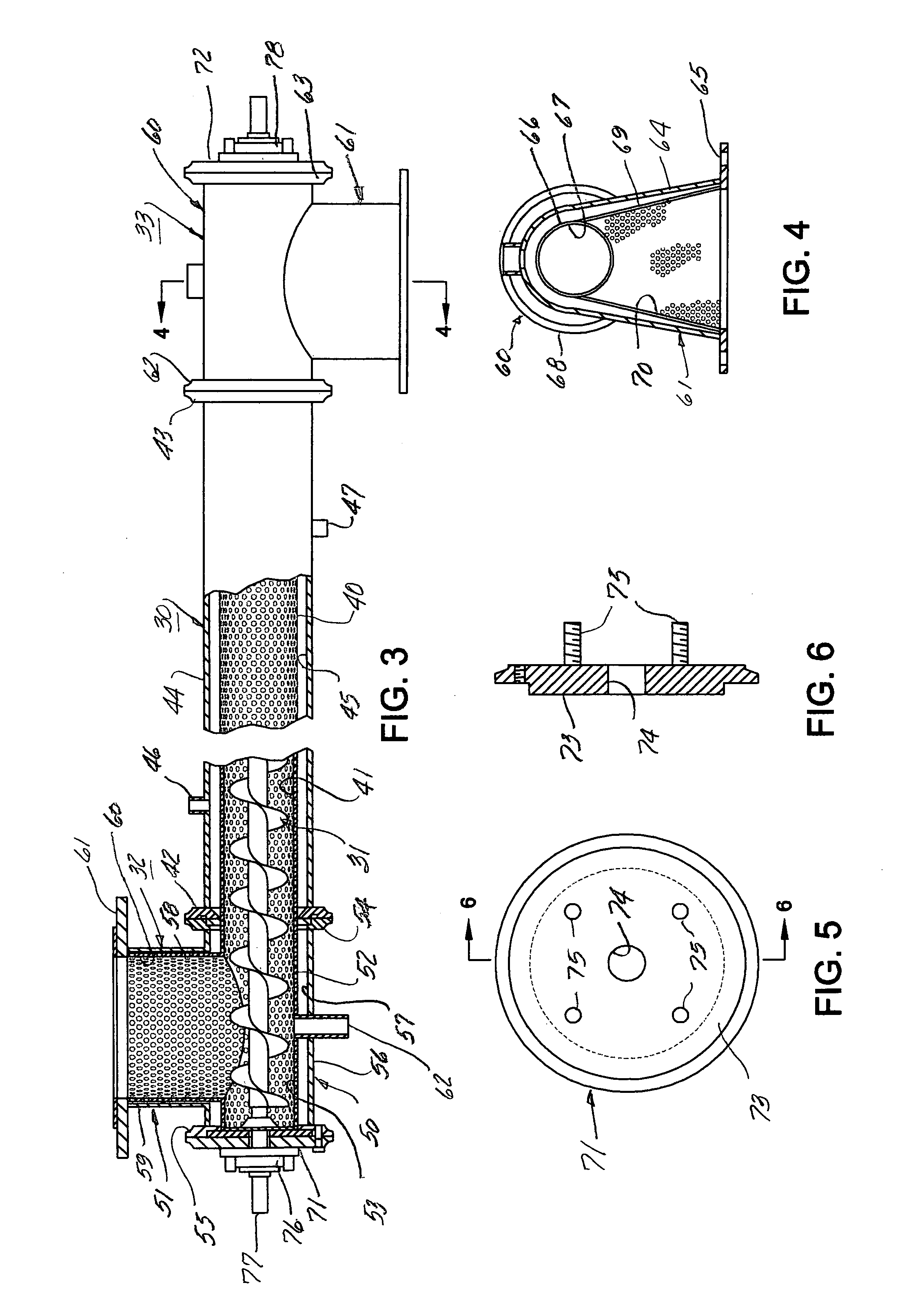

System and method for handling bulk materials

ActiveUS7137759B1Facilitate material flowFlow rate may be more readily controlledBulk conveyorsMechanical conveyorsGuide tubeBulk material handling

A bulk material handling system generally consisting of means for holding the material; means for conveying the material including a first conduit formed of a permeable material having an inlet communicating with an outlet of the material holding means and an outlet, a second conduit formed of an impermeable material encompassing and spaced from the first conduit, providing a chamber therebetween, and an auger disposed in the first conduit for transporting material received through the inlet to the outlet thereof; means for rotatably driving the auger; and means for supplying a fluidizing gas under pressure to the chamber between the first and second conduits.

Owner:YOUNG INDS

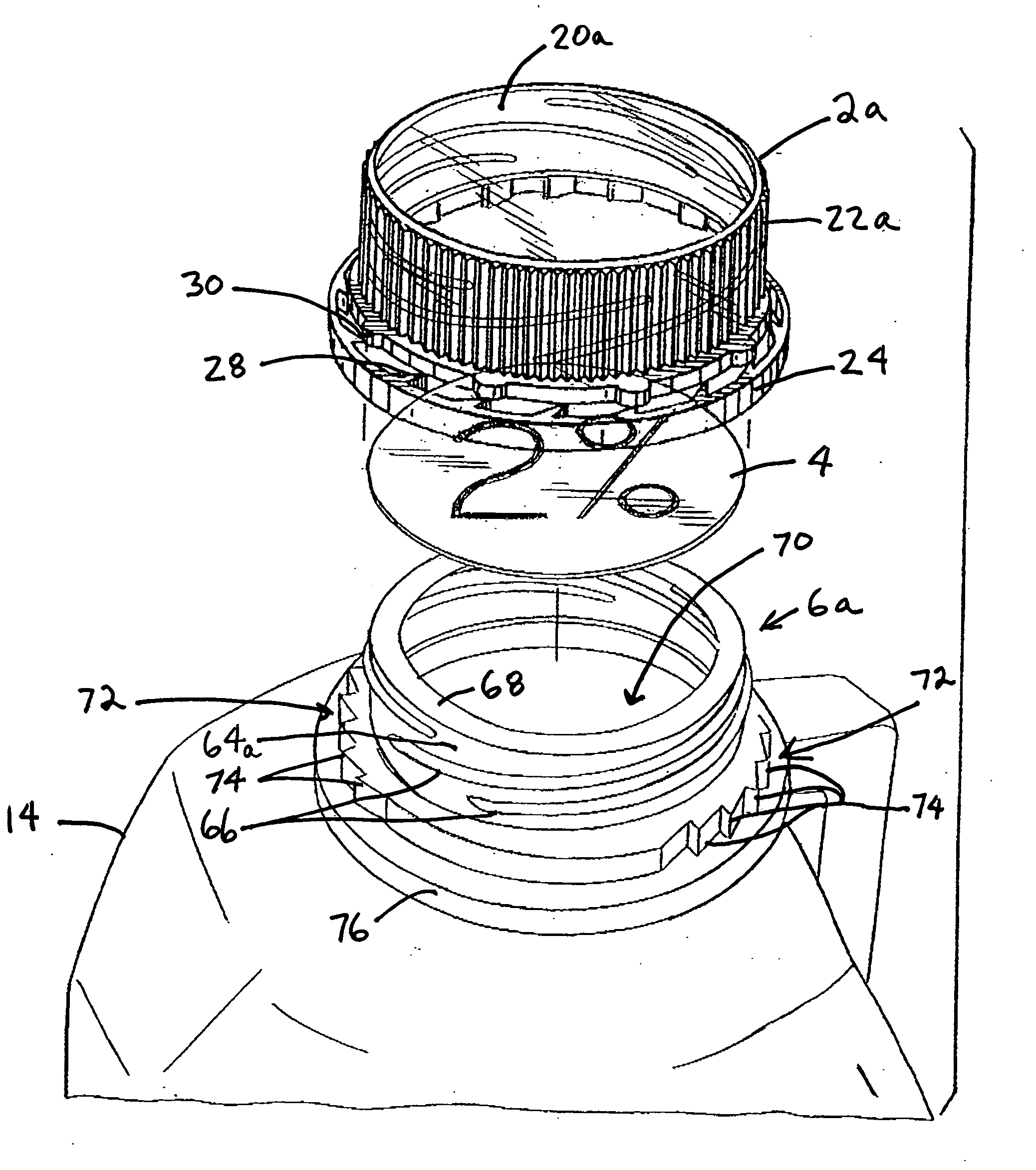

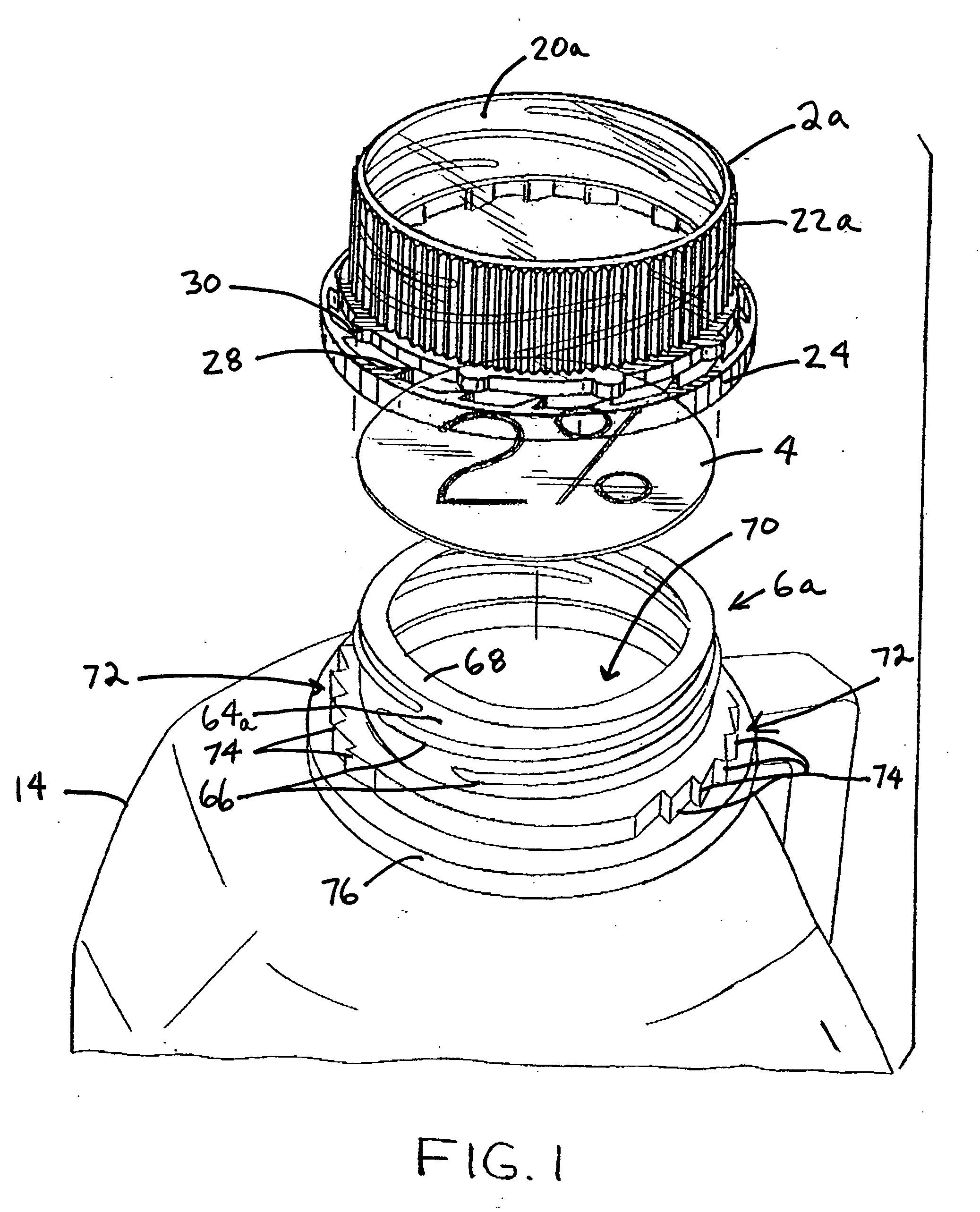

Cap with visible tamper-indicating seal

InactiveUS20070051691A1Easy to customizeImprove efficiencyCapsContainer decorationsMechanical engineeringRidge

The inventions disclosed herein include a clear cap and tamper-indicating seal combination, a translucent cap and seal combination, an improved cap embodying a raised ridge for providing a contact surface on the top of the cap, among other inventions. The preferred cap is at least partially non-opaque to allow a customer to perceive the tamper-indicating seal through the cap at the point of purchase. In a first embodiment, the tamper-indicating seal serves as a label, wherein the customer can perceive, through the cap, information such as printing which is indicative of the contents of the container. In a second embodiment, the tamper-indicating seal serves as a tamper evident seal, wherein the customer can perceive, through the cap, at the point of purchase, whether the seal has been breached. In a third embodiment, the tamper-indicating seal serves as both a label and a seal, wherein the tamper-indicating seal creates a liquid resistant seal between the cap and the opening of the container. In a forth embodiment, the tamper-indicating seal serves as both a label and a tamper evident seal. In a fifth embodiment of the present invention, a cap is provided with a raised portion on a top surface of the cap for reducing the frictional surface area of the cap during capping operations.

Owner:BLACKHAWK MOLDING

Paintable hydrophobic and lubricant-infused surface coatings and processes for making and using same

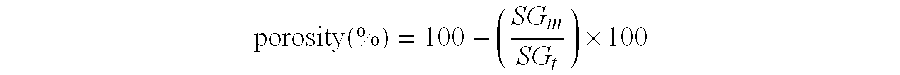

ActiveUS20170058130A1High porosityReduce surface frictionCoatingsSpecial surfacesSelf-healingMetallurgy

Compositions and processes are disclosed for forming hydrophobic coatings and lubricant-infused surface coatings. Coatings may be applied to various substrates without prior chemical or temperature treatment of the substrates and over large and irregular surfaces. Coatings are self-healing, anti-fouling, and have enhanced lifetimes.

Owner:BATTELLE MEMORIAL INST

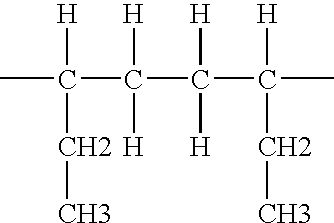

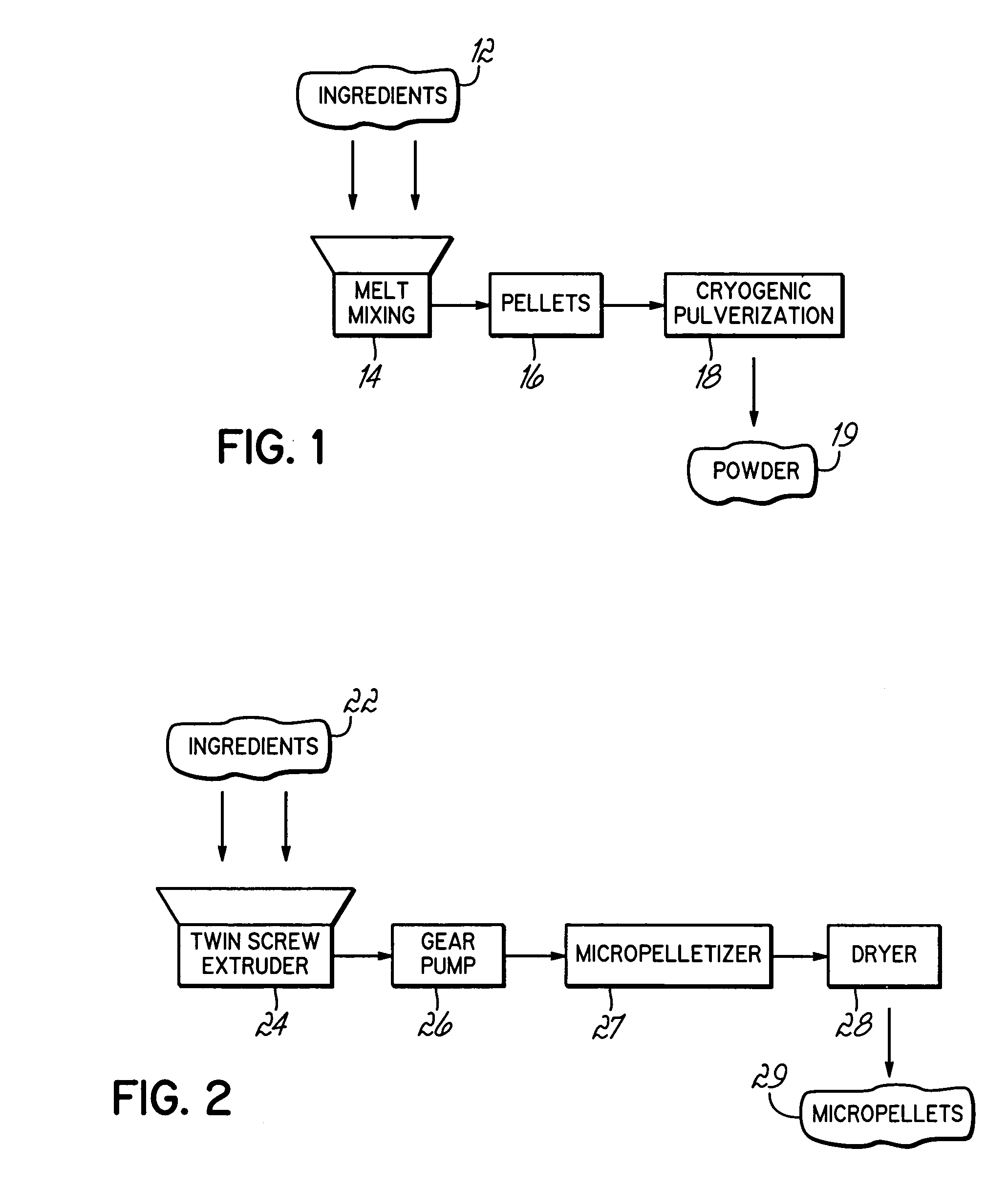

Thermoplastic compositions and method of use thereof for molded articles

InactiveUS20060135679A1Reduce surface frictionImprove performanceDomestic articlesElastomerPolymer science

A polyolefin composition containing elastomers (plasticizers), crystalline polypropylene, modified by mixing with polybutene-1 and a coupling agent and a bicyclic dicarboxyl acid salt nucleating agent and / or a lubricant which comprises an unsaturated fatty acid ester which acts as a surface modifier in a molded article is described. The composition is adapted to be used with pigments to make finished molded articles which have an appearance of paint covered by a clear coat and which are scratch resistant and have good low temperature (−30° C.) impact properties.

Owner:ADVANTAGE POLYMERS

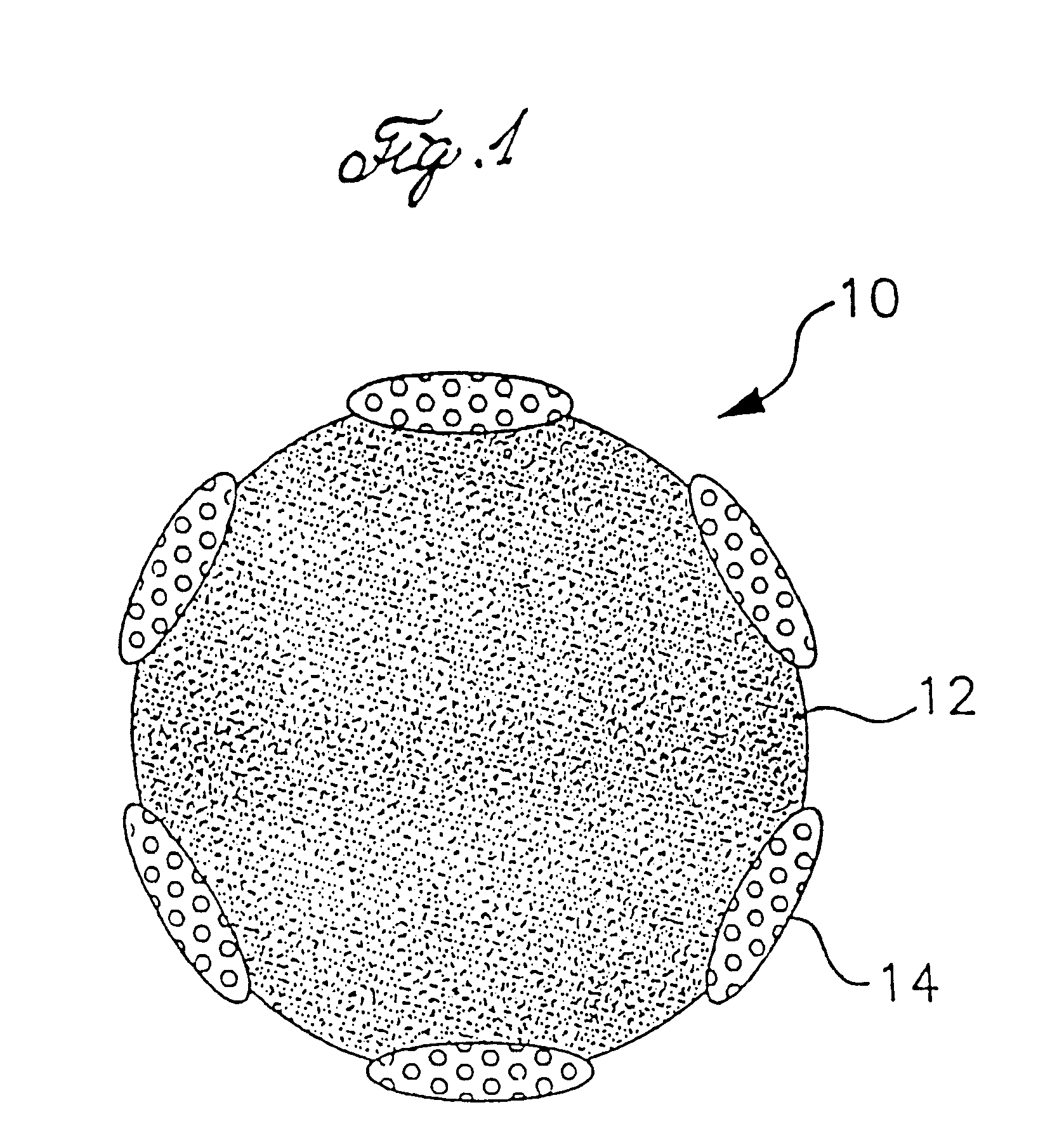

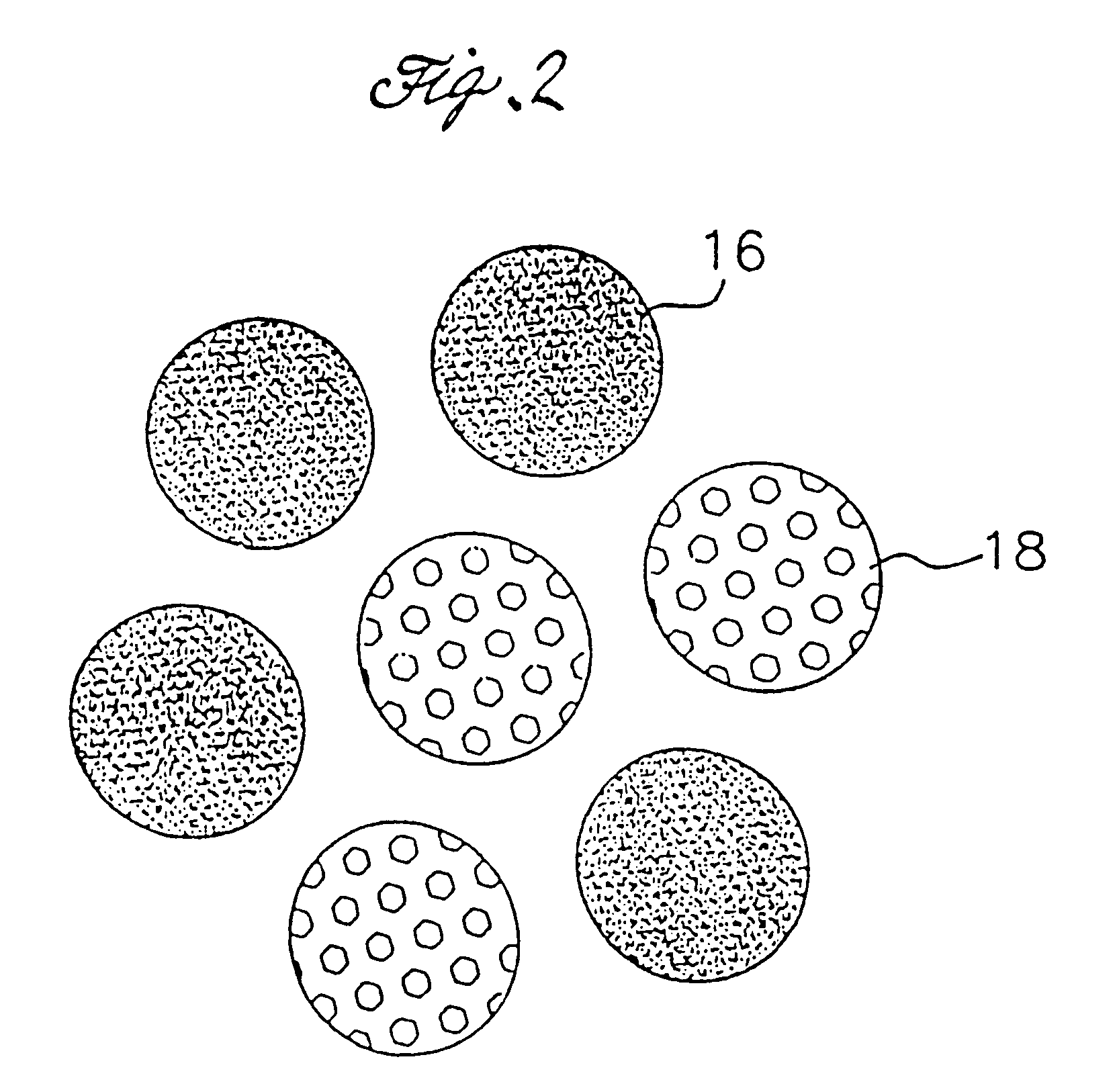

Low Surface Friction Proppants

ActiveUS20130014945A1Overcome disadvantagesReduce surface frictionFluid removalFlushingMaterials scienceHydrocarbon

A proppant having low surface friction is described, which is useful in hydrocarbon recovery. Methods of making low surface friction proppants are further described, as well as uses thereof.

Owner:HALLIBURTON ENERGY SERVICES INC

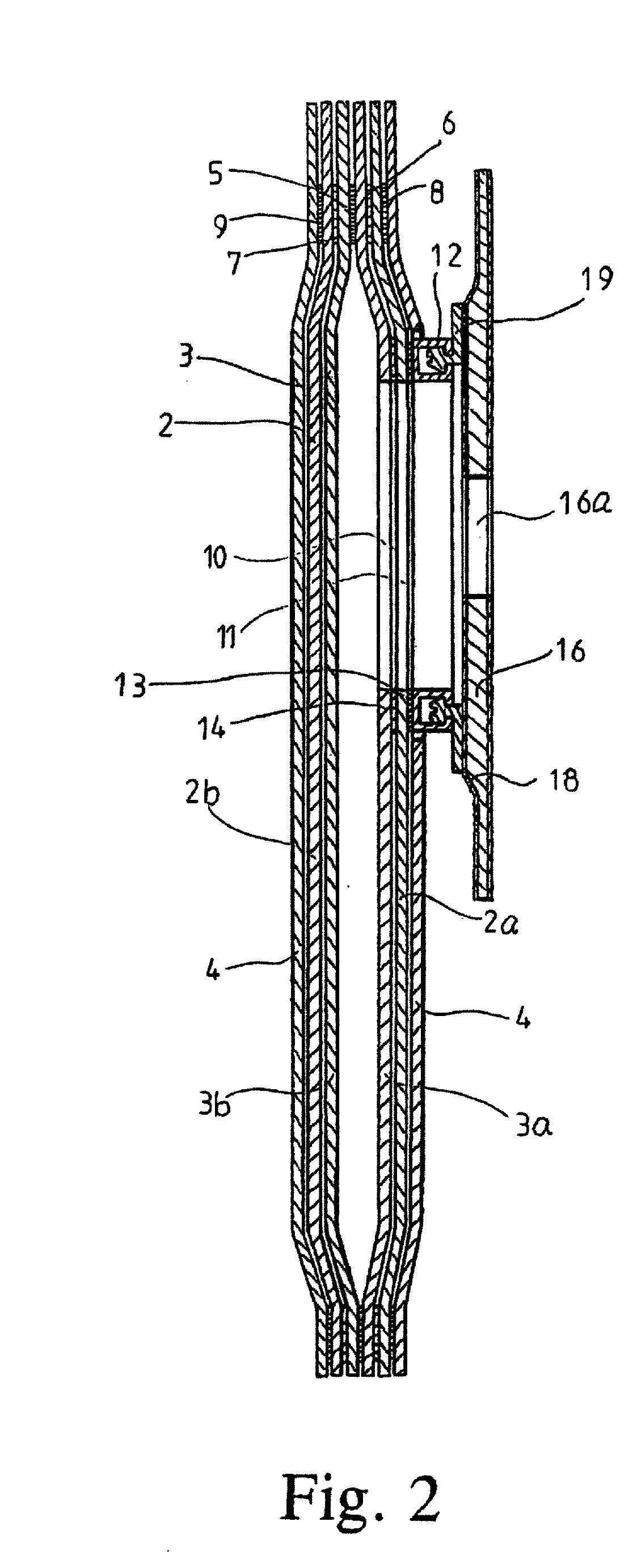

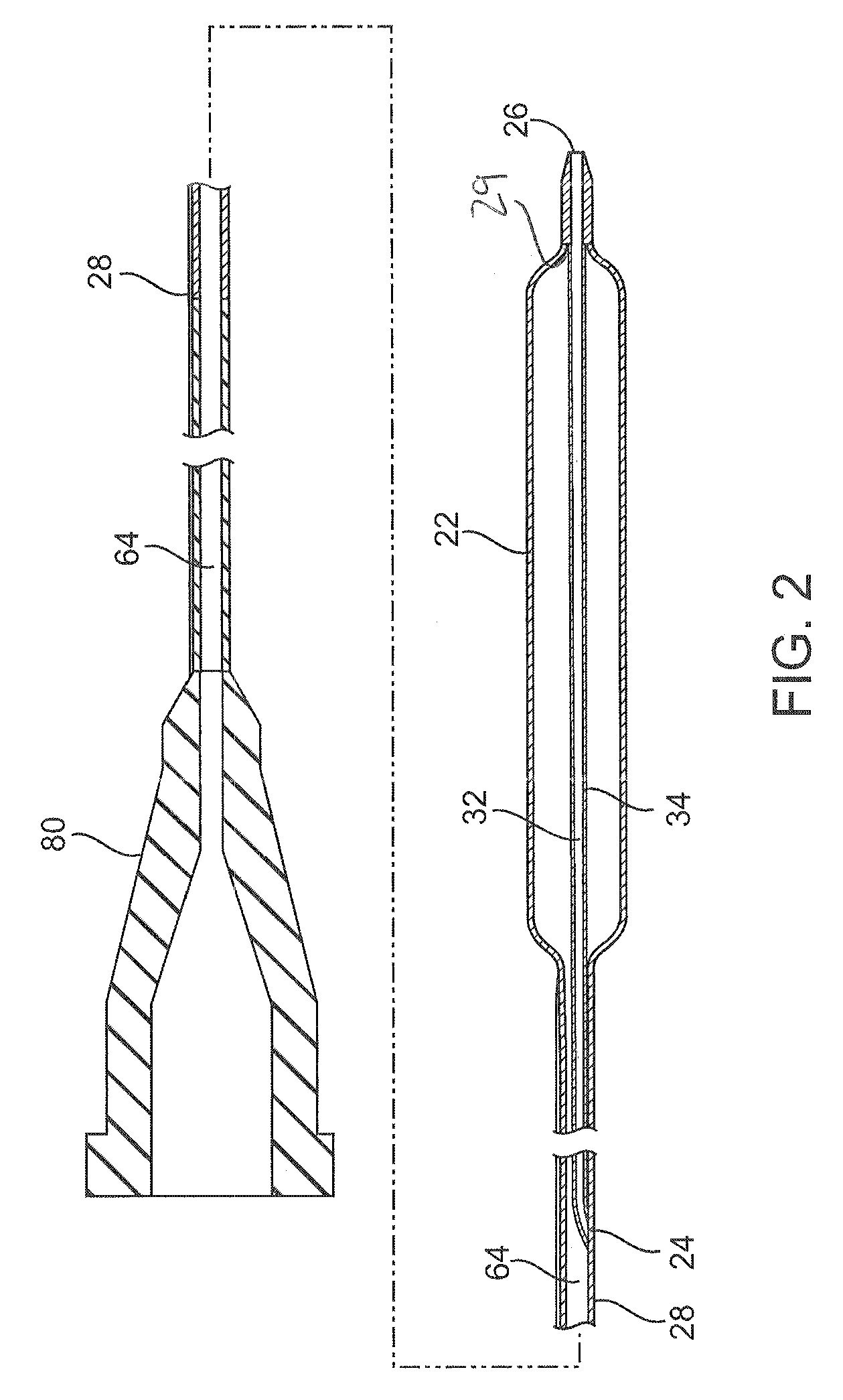

Catheter components formed of polymer with particles or fibers

A guidewire lumen for a catheter includes a tubular member. At least a portion of the tubular member is formed of a compound comprising a polymer and particles or fibers. The particles or fibers can reduce a friction coefficient of the portion of the tubular member while having minimal to no adverse effects with respect to bondability, flexibility, and processability.

Owner:TAYLOR MEDICAL INC

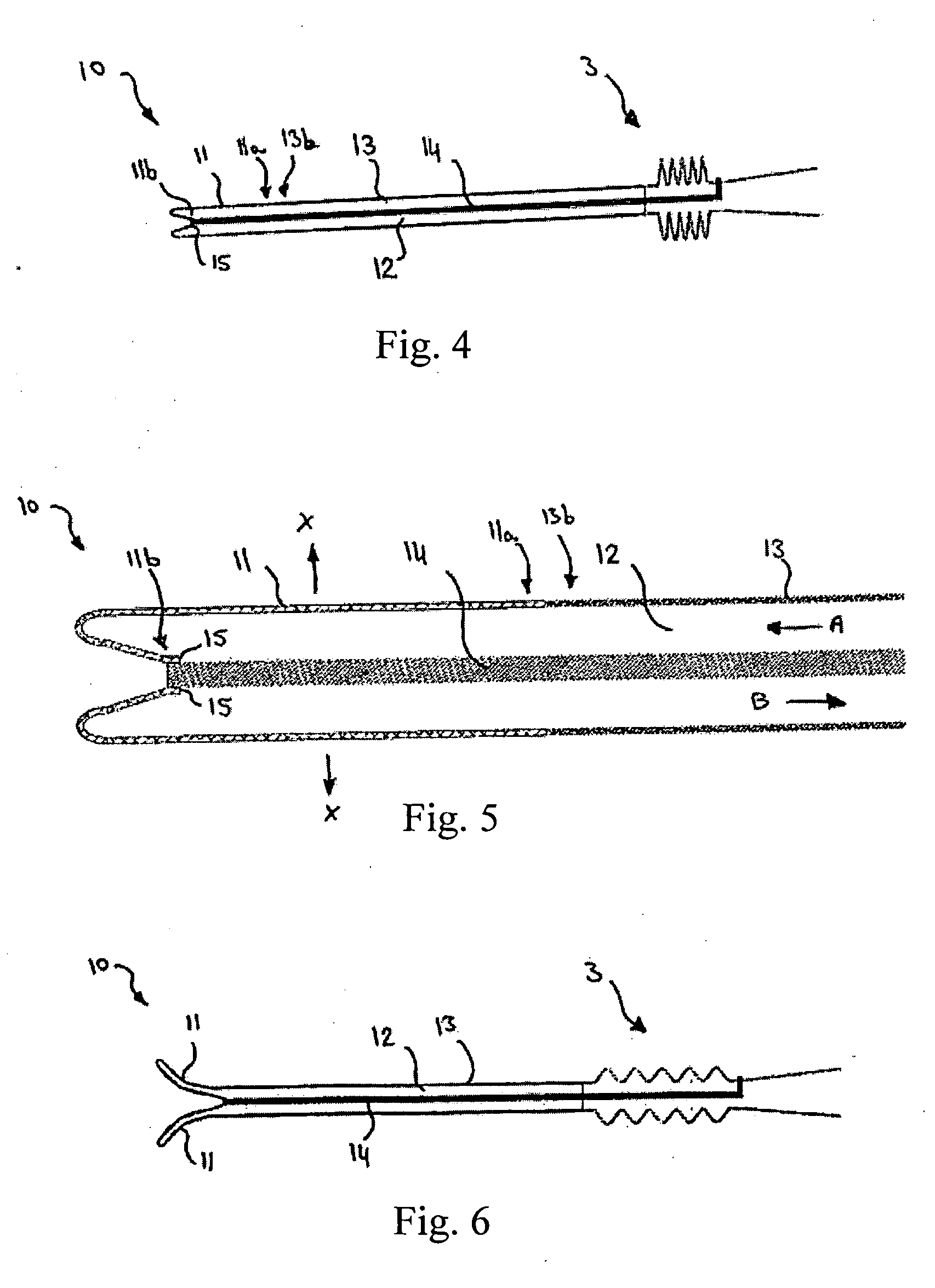

Medical device

1. A medical device with a proximal end for insertion into a body of a living being and an axially opposite distal end, the device comprising: a tip which in a first position forms the proximal end of the device, a drainage section forming a conduit extending in an axial direction of the device, and a retention section extending between the draining section and the tip, wherein the tip is operable between the first position and a second position so as to move the retention section between a first configuration and a second configuration, in which second configuration the retention section is expanded in a direction transverse to the axial direction. The conduit and the tip may be dimensioned to allow the tip to be received within the conduit. One advantage of such a system is that the retention system may be retracted entirely into the conduit so as to make insertion and retraction of the device more comfortable for the patient.

Owner:RANIER LIMITED

Laminated metal sheet for two-piece can body and two-piece laminated can body

ActiveUS20100310824A1Improve film formabilityReduce surface frictionSynthetic resin layered productsRecord information storageSteel platesSheet steel

There is provided a laminated metal sheet used for making a highly processed two-piece can body which endures harsh conditions such as retort treatment, and a two-piece can body made of the laminated steel sheet. A laminated metal sheet for a two-piece can body, including a metal sheet having a polyester resin film layer on each side of the metal sheet, the polyester resin film layer to be the outside of the can body having a crystallization temperature of 60 to 100° C., and the surface of the polyester resin film layer having a center line surface roughness (Ra) of 0.2 to 1.8 μm. The polyester resin film layer to be the outside of the can body is preferably composed of 40 to 100% by mass of a resin composed mainly of butylene terephthalate and 0 to 60% by mass of a resin composed mainly of ethylene terephthalate.

Owner:JFE STEEL CORP

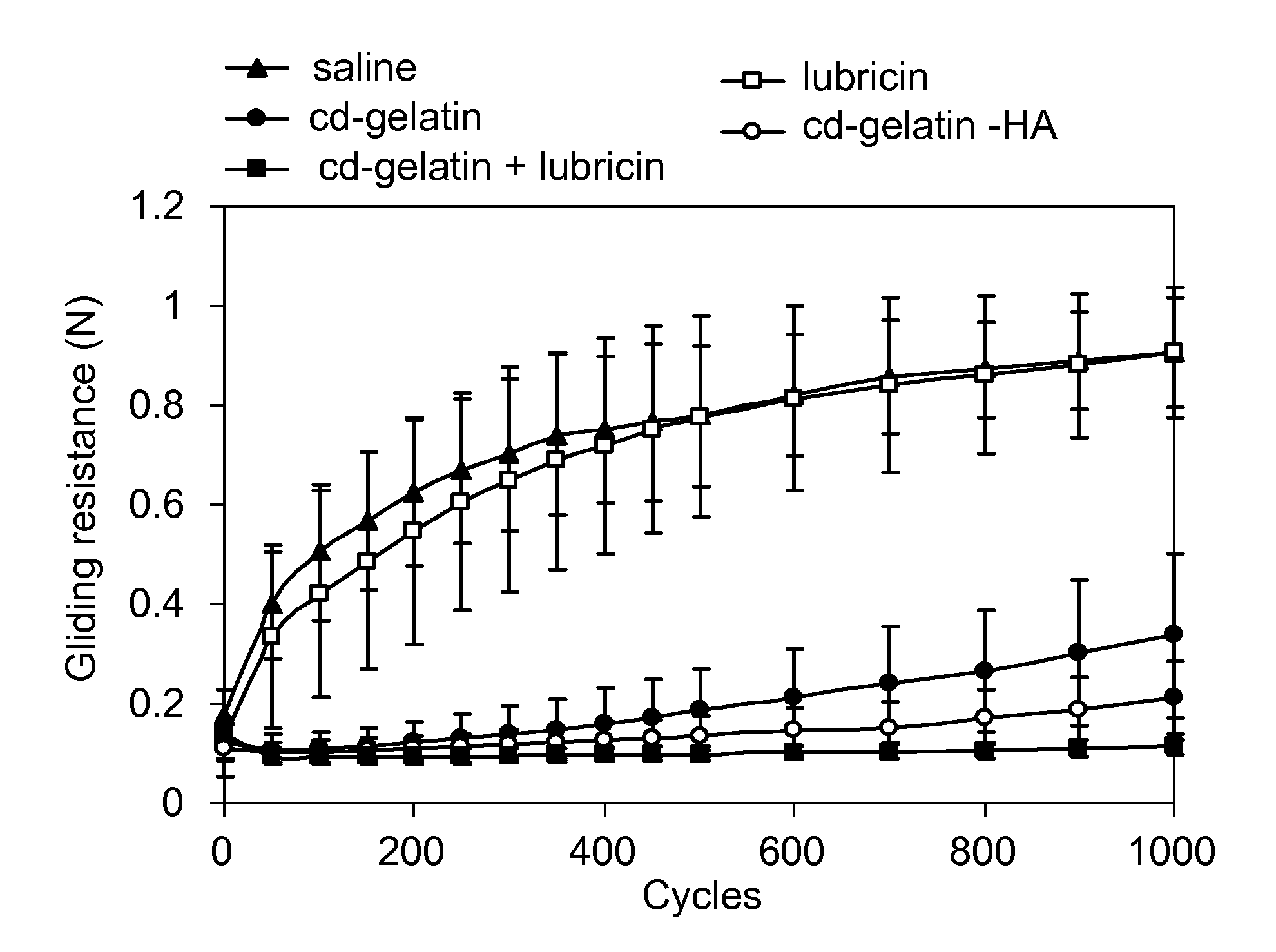

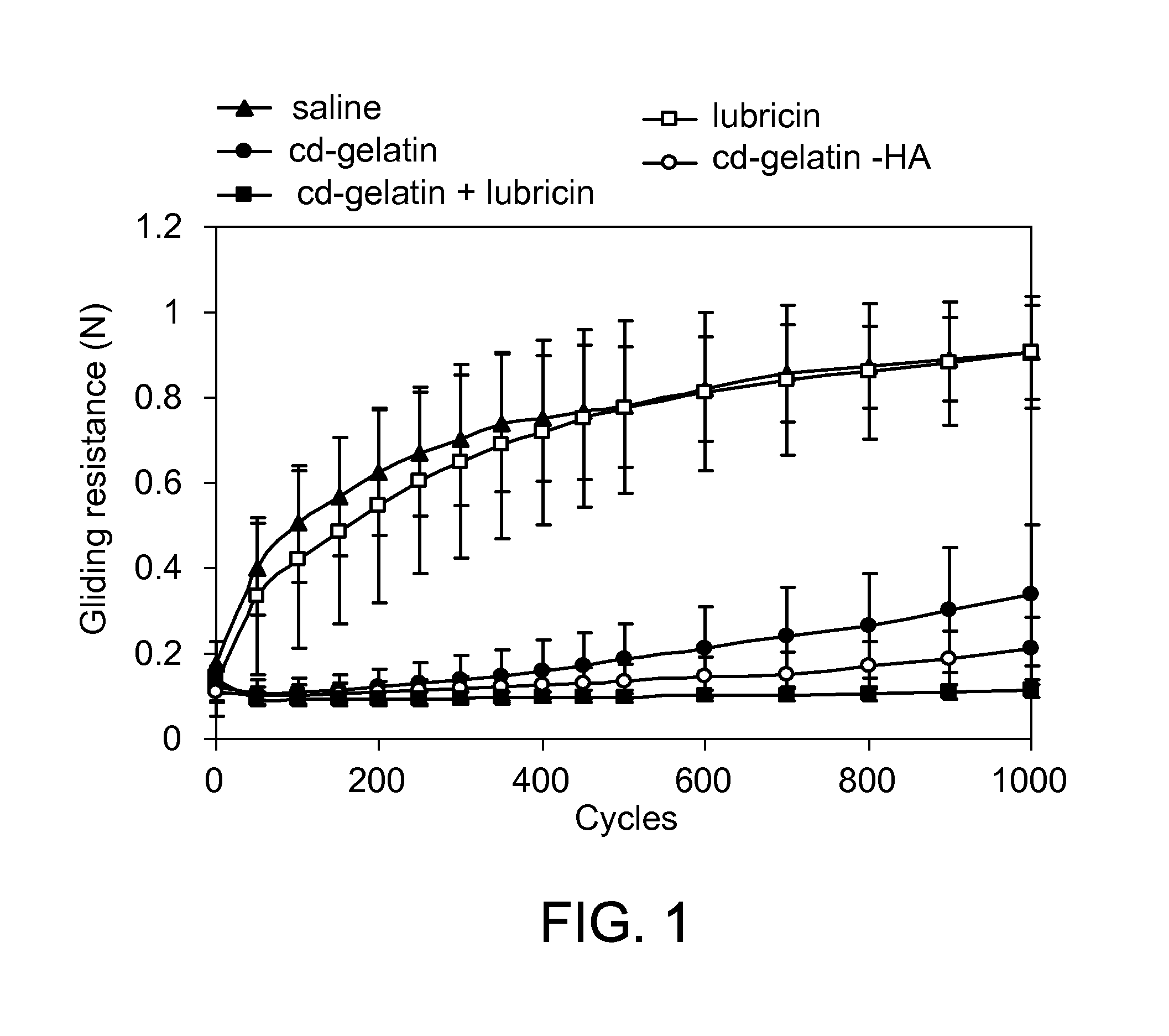

Methods and materials for tissue repair

InactiveUS20120114755A1Promote healingSignificant valuePowder deliveryBiocideTissue repairSurgical repair

This document relates to methods and materials for treating tendon injury. Specifically, methods and materials for preventing adhesion formation and promoting tissue healing following tendon injury and surgical repair are provided.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

Slush moldable thermoplastic polyolefin formulation for interior skin

A thermoplastic polyolefin composition suitable for slush molding comprising a blend of polypropylene, styrenic elastomer, linear low density polyethylene and a hydrocarbon-based process oil. Optional components include an ethylene copolymer elastomer, polymer additives such as polymer surface modifiers, powder flow additives, stabilizers and / or color pigments. The compositions exhibit a low melt viscosity during processing and improved surface quality for the molded article. An exemplary composition includes about 20-50 wt. % polypropylene or copolymer thereof, about 20-60 wt. % of a styrenic elastomer, about 5-50 wt. % linear low density polyethylene, and about 2-25 wt. % of a hydrocarbon-based process oil. The zero shear viscosity of the composition suitable for slush molding is in the range of about 300-900 Pa·s over a processing temperature range of 180-260° C.

Owner:DELPHI TECH INC

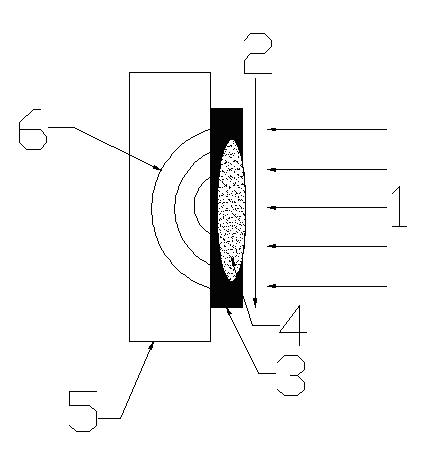

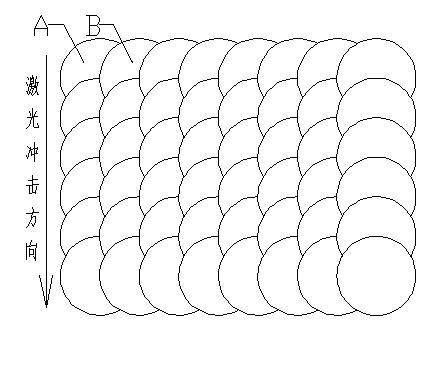

Preparation method for simulated surfaces

InactiveCN102513697AImproved resistance to fatigue and stress corrosionImprove processing efficiencyLaser beam welding apparatusLubricationHigh power lasers

The invention discloses a laser impact preparation method for simulated surfaces. Metal pretreated is fixed on a numerical control workbench through a clamp, then wave length, pulse width, pulse energy, and light spot radius parameters of a high power laser can be adjusted according to the appearance of the surfaces of special metal required, programming is performed to the running route of the numerical control workbench, and then laser impacts to the well adjusted metal surface can be performed so as to form various special surface appearances. The special surface appearances can be used for storing oil under the lack of oil, and certain microbubbles can also be stored, so as to enable gas to participate lubrication. Therefore, skin friction can be lowered and an antifriction surface is formed; and while the special surface appearances are prepared, strengthening to metal surface can be performed, and the service life and the stress and corrosion resisting effect are improved. The method has the advantages of high processing efficiency, good controbility and convenience in preparation.

Owner:JIANGSU UNIV

Fabric softeners and treatment agents and methods of use thereof

InactiveUS20030236181A1Low costGood fluidityCationic surface-active compoundsOrganic detergent compounding agentsFabric softenerTarget fibers

Specific types of compounds that impart highly effective softening, antistatic, and ironability characterostics to and for various types of launderable fabrics (such as garments, tablecloths, draperies, and the like) through a rinse-cycle application within a standard machine laundering process are provided. Such compounds provide effective lubricity to target fibers as well as simultaneous static dissipative characteristics either alone or, as one preferred embodiment, in combination with other typical fabric softening agents. Such a composition comprising or method utilizing such compounds thus provides a relatively simple, yet highly effective manner of imparting these highly desired properties to fabrics. A fabric treated with such compounds or in accordance with this method is also provided.

Owner:MILLIKEN & CO

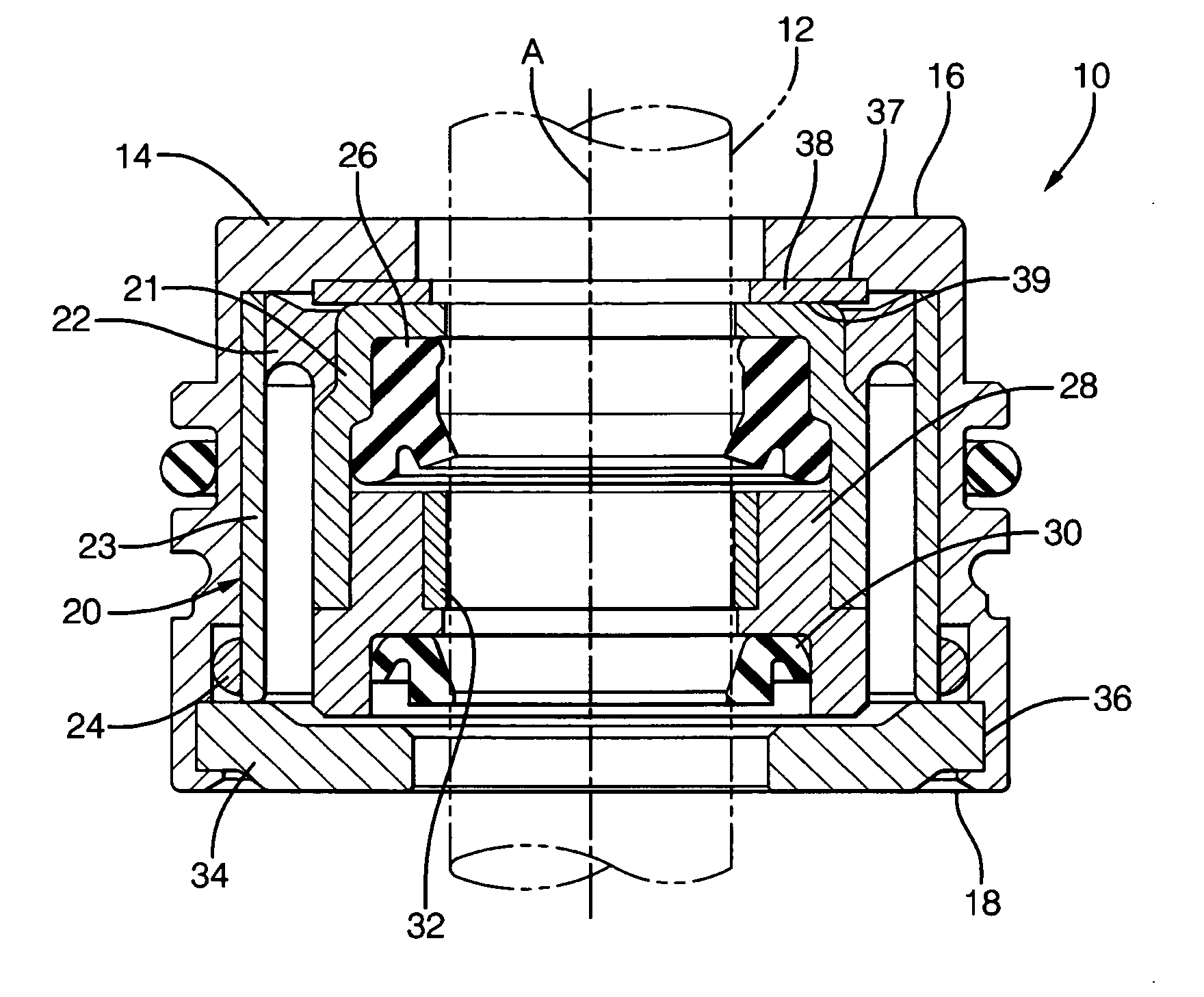

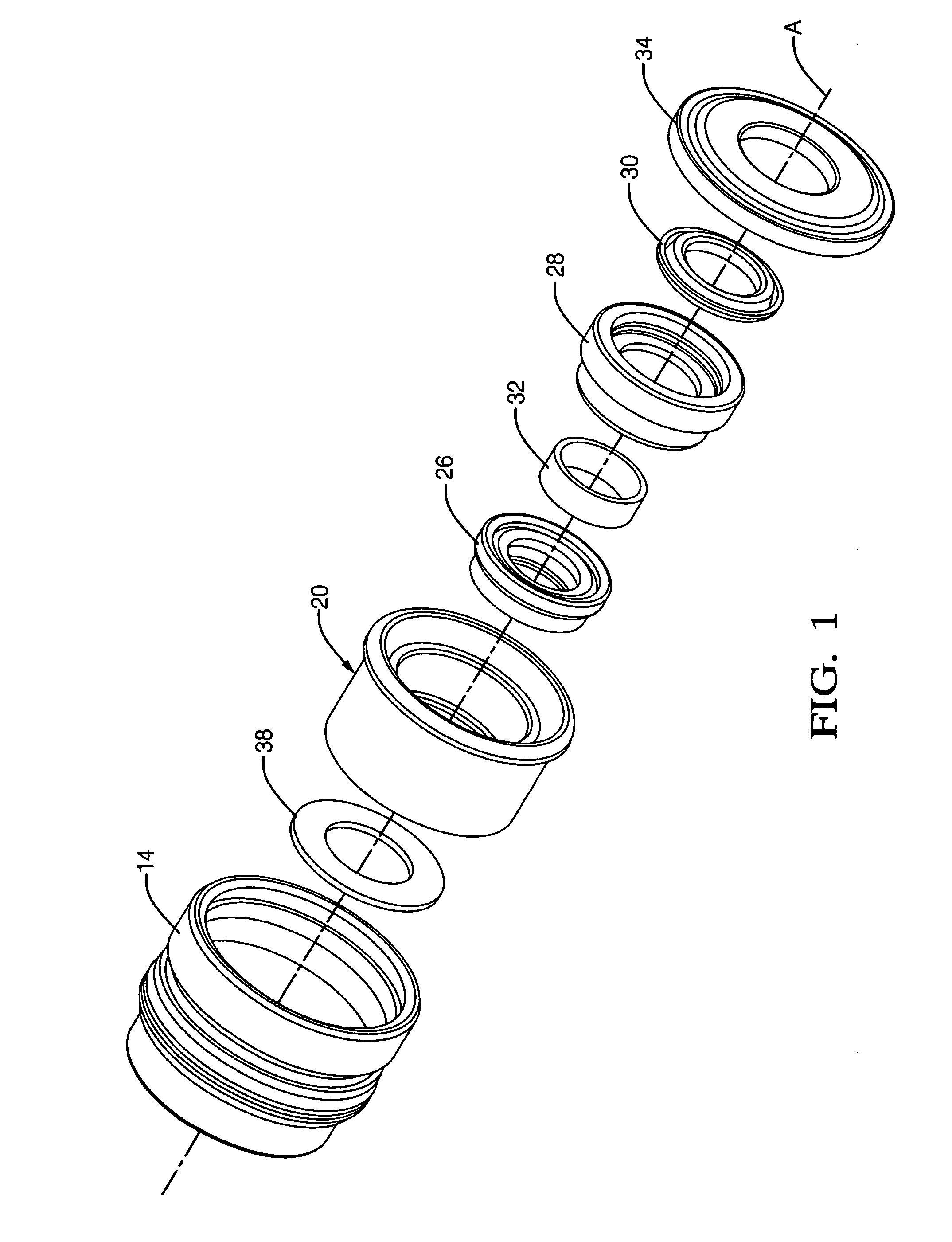

Dual seal rod guide assembly with low friction disc

InactiveUS20100116607A1Reduce surface frictionSpringsNon-rotating vibration suppressionLubricationSurface friction

A dual seal rod guide assembly with low friction disc for use in a magneto-rheological (MR) strut is described. The dual seals separate the functions of abrasion resistance and temperature performance, with the primary seal formed of a material resistant to high temperatures and the buffer seal formed of a material resistant to the ferroelectric microparticles in the MR fluid. The porous rod guide, in conjunction with the buffer seal, allow only the MR carrier fluid to reach the bearing and primary seal. The MR carrier fluid provides internal lubrication of the bearing and primary seal. The retainer holds the assembly together and engages the rod guide flexible assembly to the housing with a low-friction disc therebetween. The disc reduces surface friction during radial movement of the rod guide.

Owner:BWI +1

Foam Buffing Pad with Random or Strategically Placed Collapsed Cell Structures

ActiveUS20070254567A1Reduce absorptionReduce rateFlexible-parts wheelsGrinding devicesSurface finishEngineering

Selected surfaces of a cellular polymeric foam surface finishing pad are heated to cause the surface cells to partially collapse or to fully collapse and glaze over. The selected surfaces may be the planar pad faces or may be formed in one or more depressions formed in the planar faces. The areas of partially collapsed cell structures in the operating face of the pad provide a slow down in the rate of polish or compound absorption, increasing the effectiveness of the finishing process. The fully collapsed cell glazed surface on the rear attachment face of the pad prevents the migration of moisture through the pad to the pad attachment mechanism.

Owner:LAKE COUNTRY MFG

System and method for handling bulk materials

ActiveUS7320561B2Facilitate material flowFlow rate may be more readily controlledBulk conveyorsMechanical conveyorsHandling systemGuide tube

A bulk material handling system generally consisting of means for holding the material; means for conveying the material including a first conduit formed of a permeable material having an inlet communicating with an outlet of the material holding means and an outlet, a second conduit formed of an impermeable material encompassing and spaced from the first conduit, providing a chamber therebetween, and an auger disposed in the first conduit for transporting material received through the inlet to the outlet thereof; means for rotatably driving the auger; and means for supplying a fluidizing gas under pressure to the chamber between the first and second conduits.

Owner:YOUNG INDS

Rotatable Spray Head, Multi-material Spraying Apparatus Using Thereof, And Method For Spraying Multiple Materials

ActiveCN105750115AAvoid mixingAvoid mixing situationsLiquid surface applicatorsMovable spraying apparatusMulti materialMaterial supply

A rotatable spray head, a multiple materials spraying apparatus using thereof and a method of spraying multiple materials are provided. The multiple materials spraying apparatus includes the rotatable spray. An outer shell and an inner tube of the rotatable spray can be correspondingly rotated in order to change the material from one to another. Therefore, multiple materials can be sprayed through one nozzle of the rotatable spray. A recycling step of the method allows the sprayed material to be recycled back to a material supplying pipe or a material holder before switching to the next spraying material, thereby preventing the mixing of different spraying materials during the usage process.

Owner:ZONG JING INVESTMENT

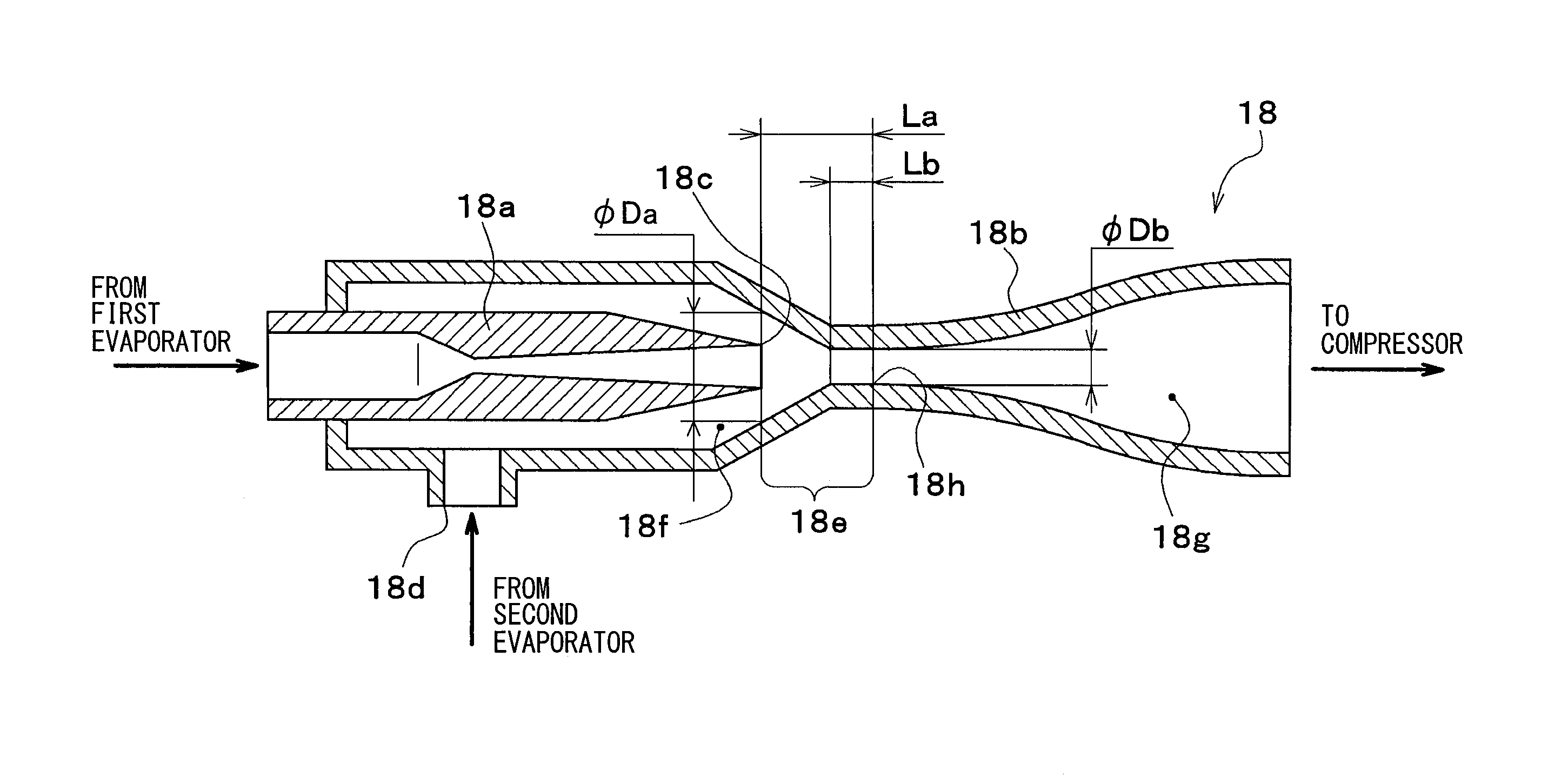

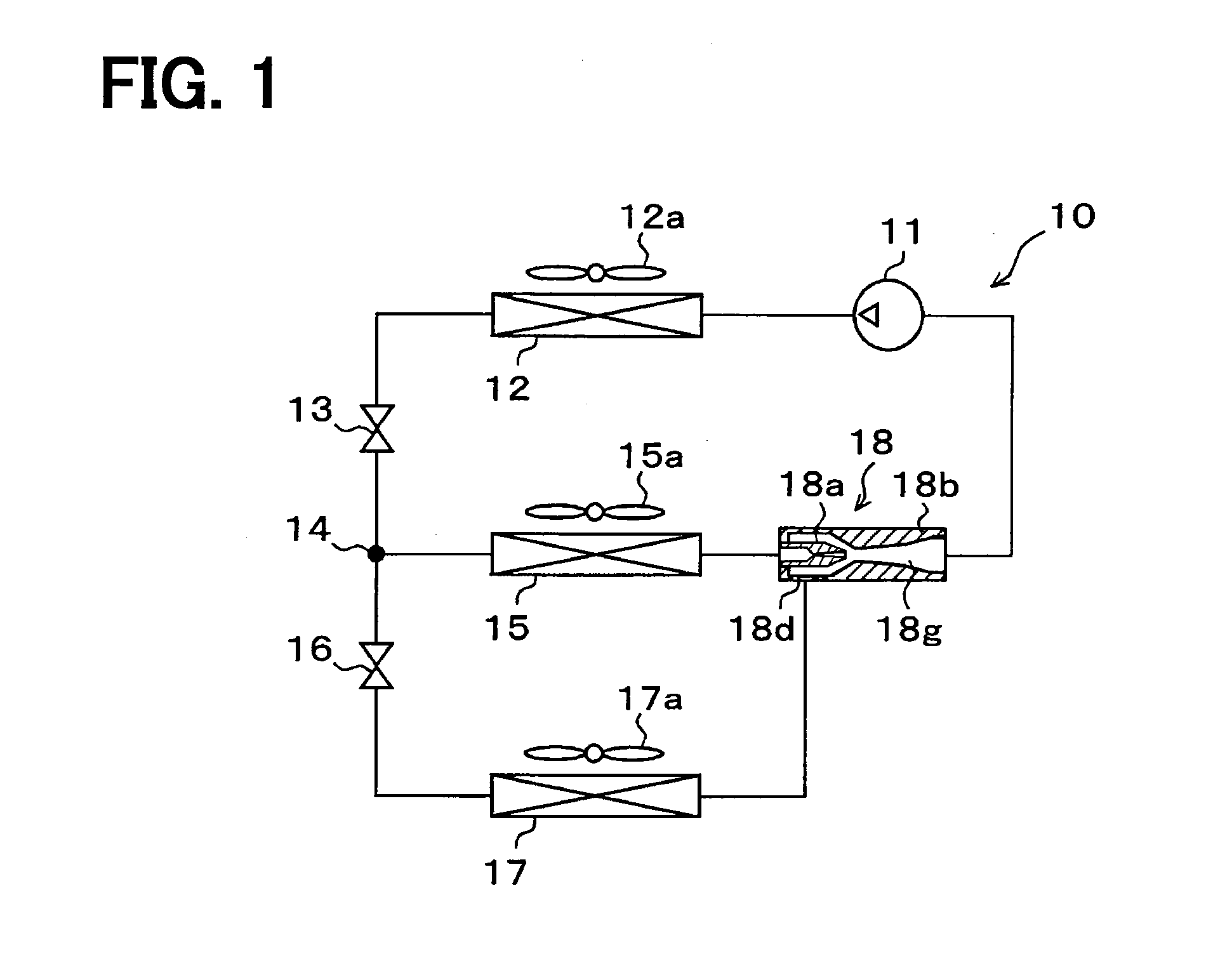

Ejector

ActiveUS20160186783A1Improve performanceImprove COPCompression machines with non-reversible cycleJet pumpsInterior spaceInjection port

A mixing portion that is formed in an area from a refrigerant injection port of a nozzle portion to an inlet section of a diffuser portion in an internal space of a body portion of an ejector and that mixes an injection refrigerant injected from the refrigerant injection port and a suction refrigerant suctioned from a refrigerant suction port is provided. A distance from the refrigerant injection port to the inlet section in the mixing portion is determined such that a flow velocity of the refrigerant flowing into the inlet section of the diffuser portion becomes lower than or equal to a two-phase sound velocity. A shock wave that is generated at a time that a mixed refrigerant is shifted from a supersonic velocity state to a subsonic velocity state is generated in the mixing portion, so as to stabilize pressure increasing performance in the diffuser portion.

Owner:DENSO CORP

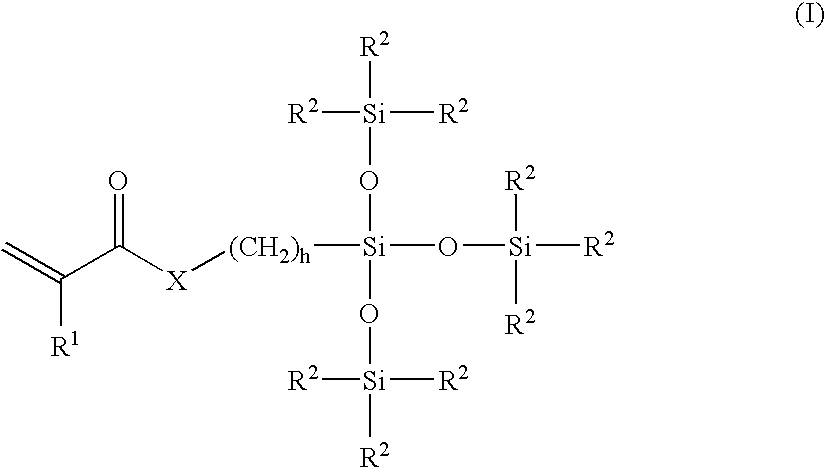

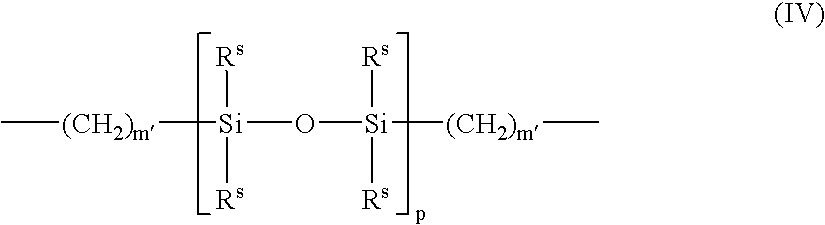

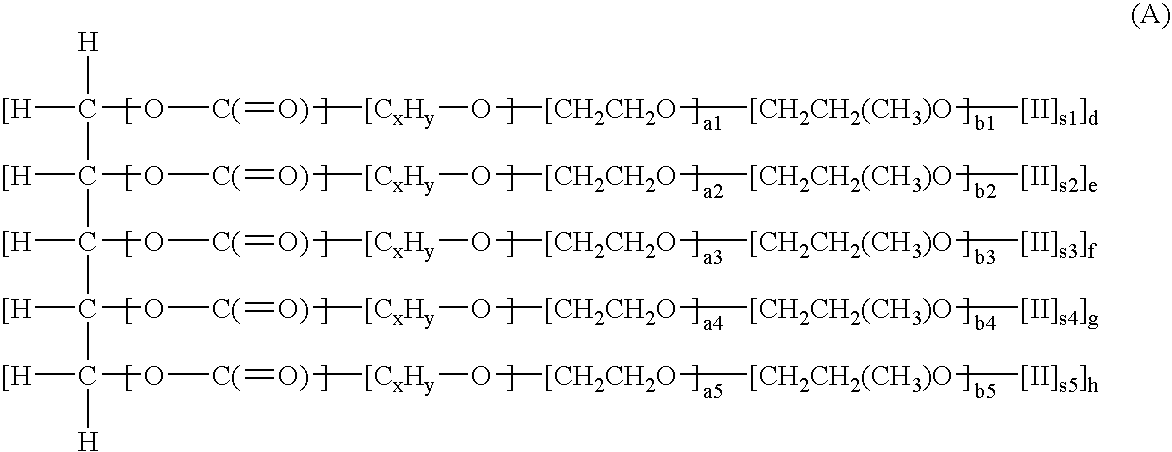

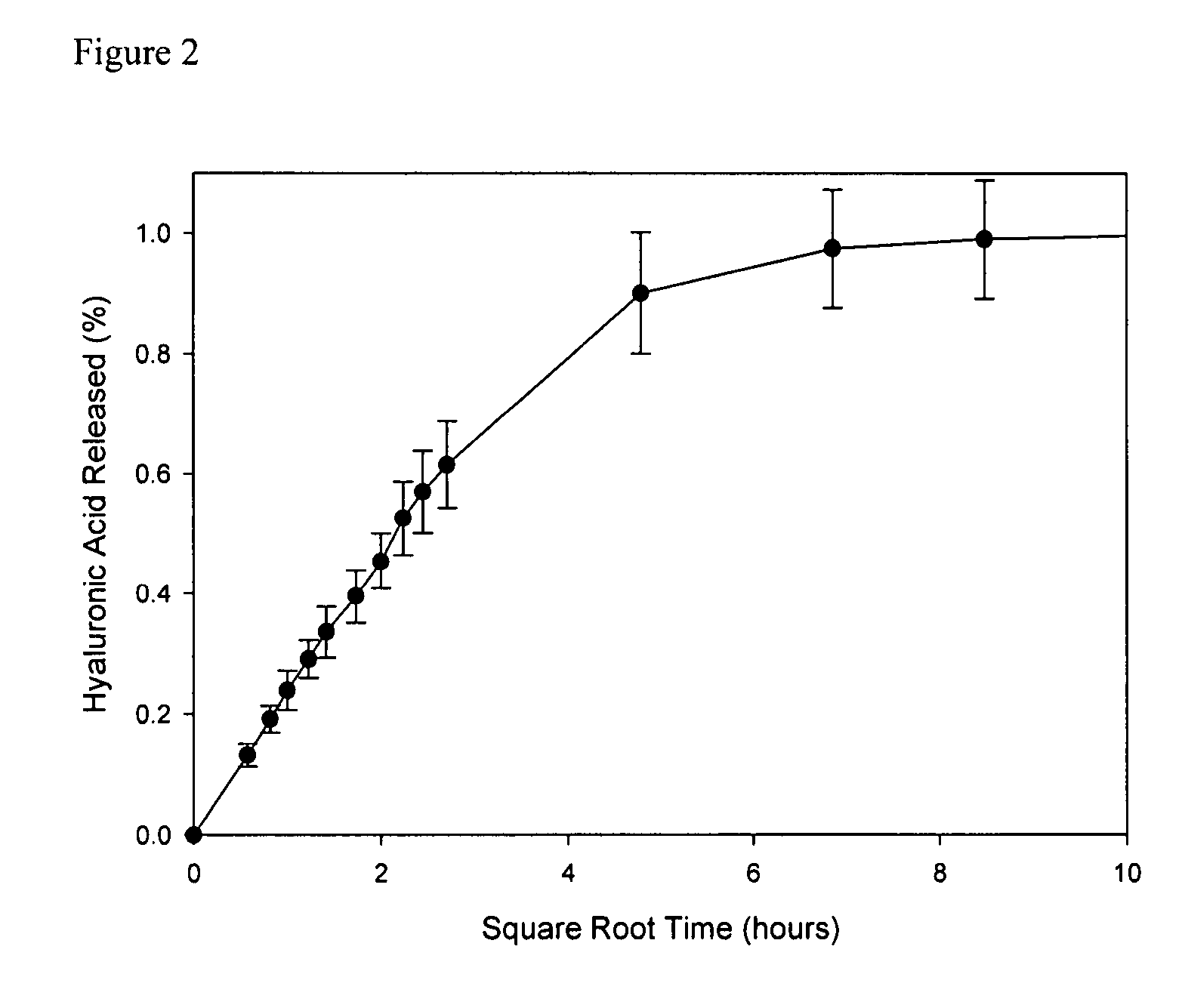

Hyaluronic acid-retaining polymers

InactiveUS7674781B2Improved propertyReduce surface frictionBiocideOrganic active ingredientsBiopolymerHyaluronic acid

Hyaluronic acid-retaining biopolymer is provided which exhibits low levels of protein adsorption and surface friction. The biopolymer is useful for incorporation in products, such as contact lenses, used in biological environments.

Owner:SHEARDOWN HEATHER +2

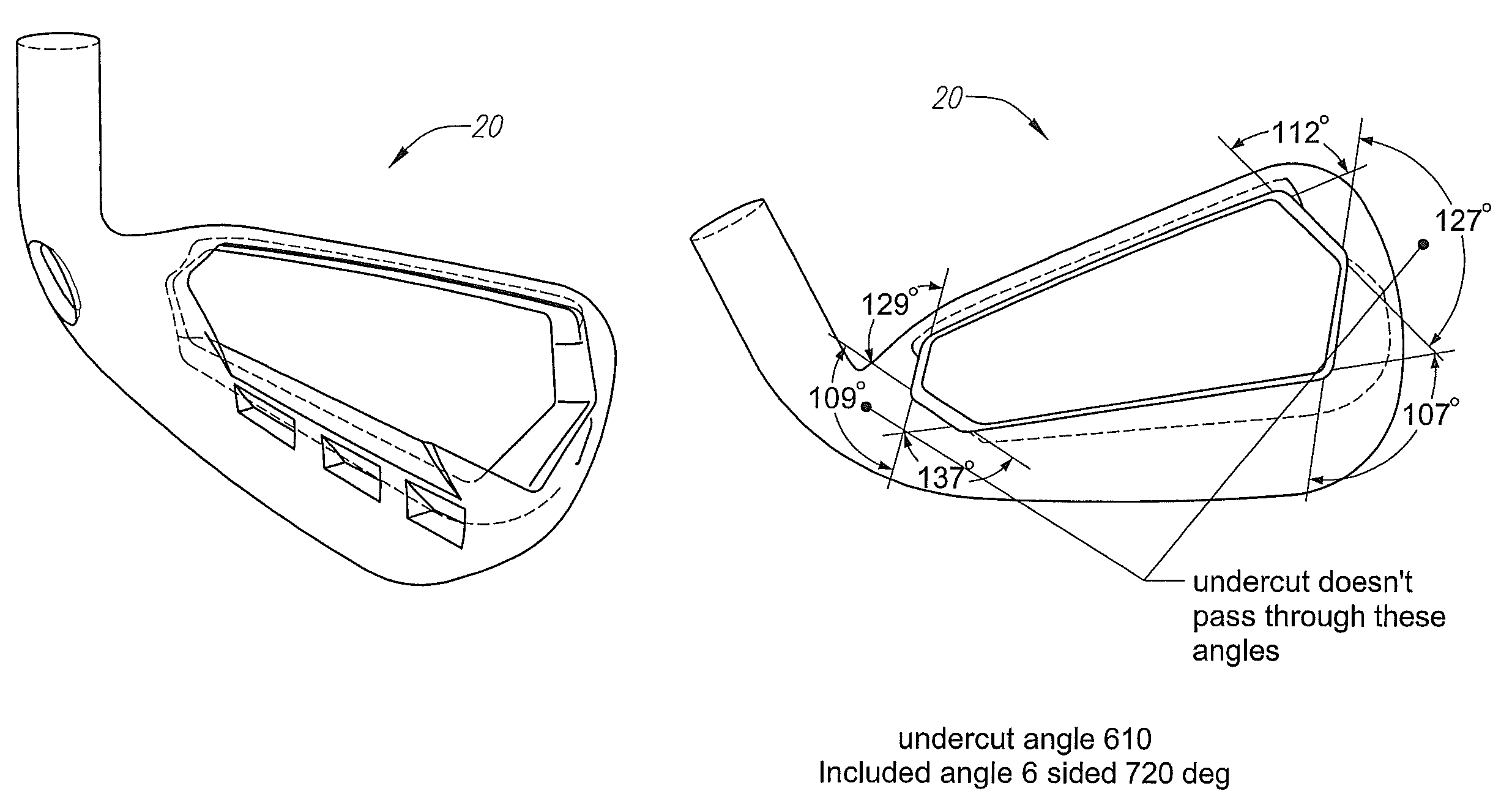

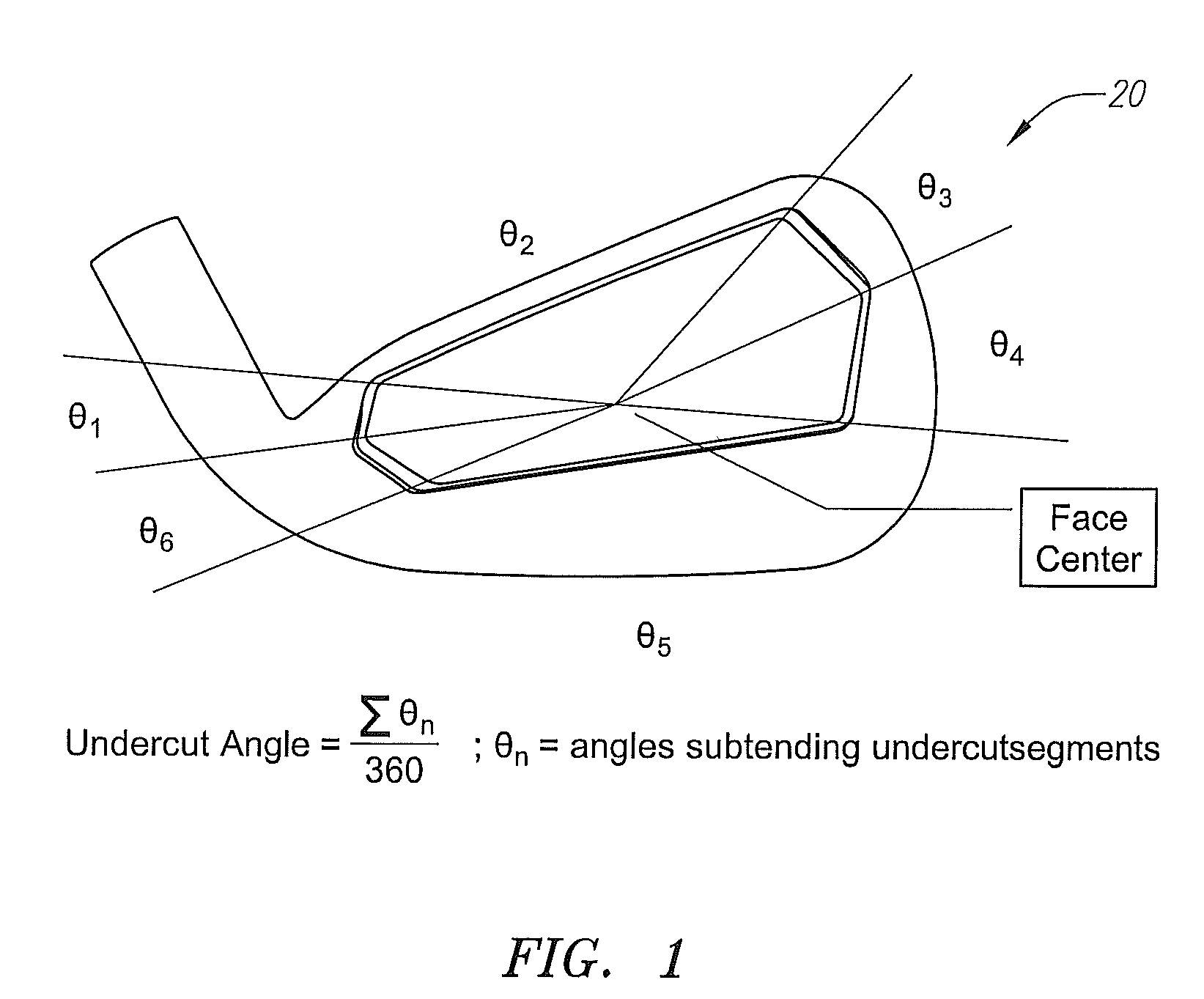

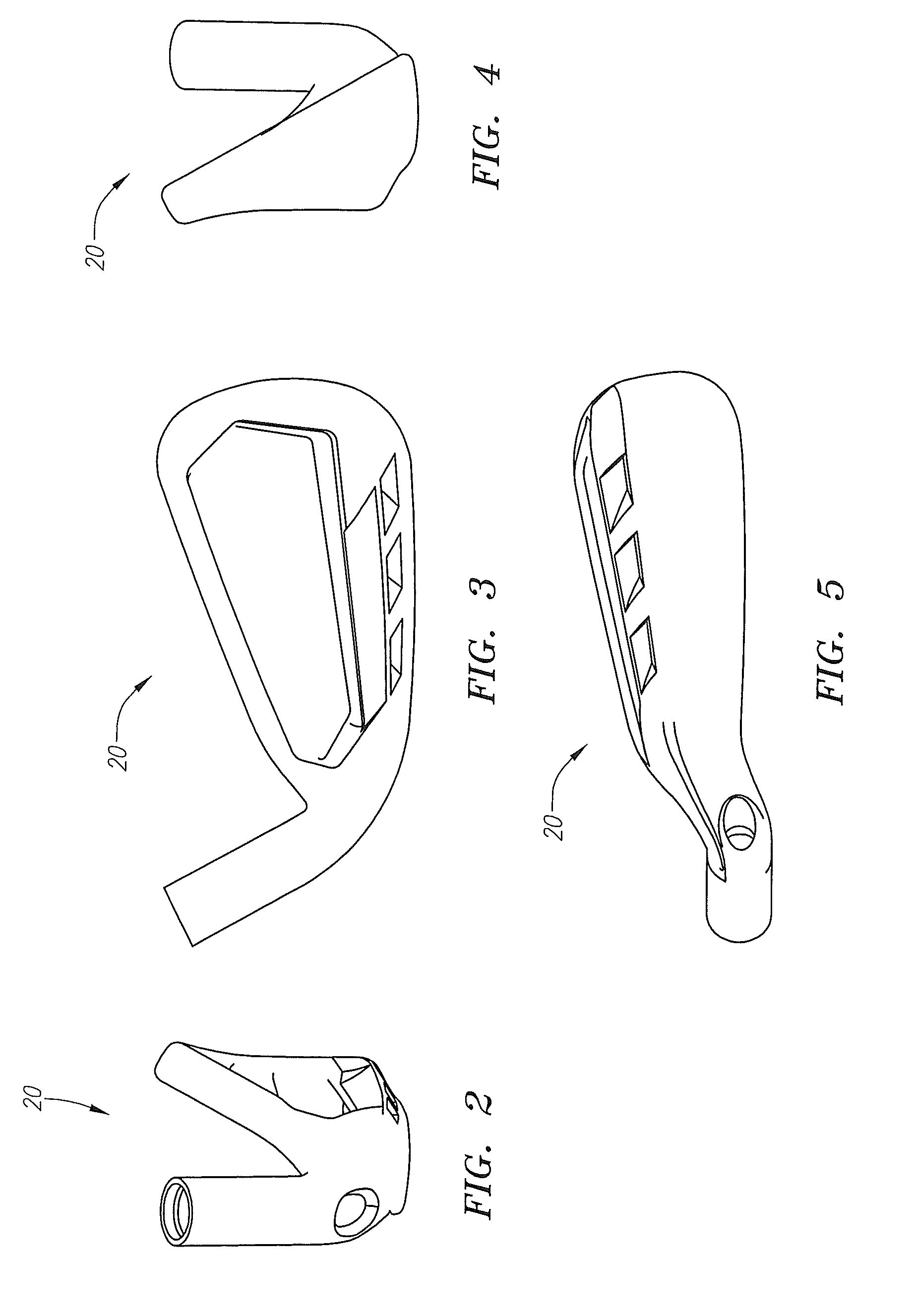

Iron-type golf club head with chamfered leading edge

An iron-type golf club head having a coated stepped sole is disclosed herein. The coated stepped sole is stepped such that the sole surface furthest from the face is raised away from the turf to minimize the turf contact through a golfer's swing particularly for the longer, less lofted irons. The surface friction is reduced by applying a thin dense chromium coating thorough electroplating to the stepped sole.

Owner:TOPGOLF CALLAWAY BRANDS CORP

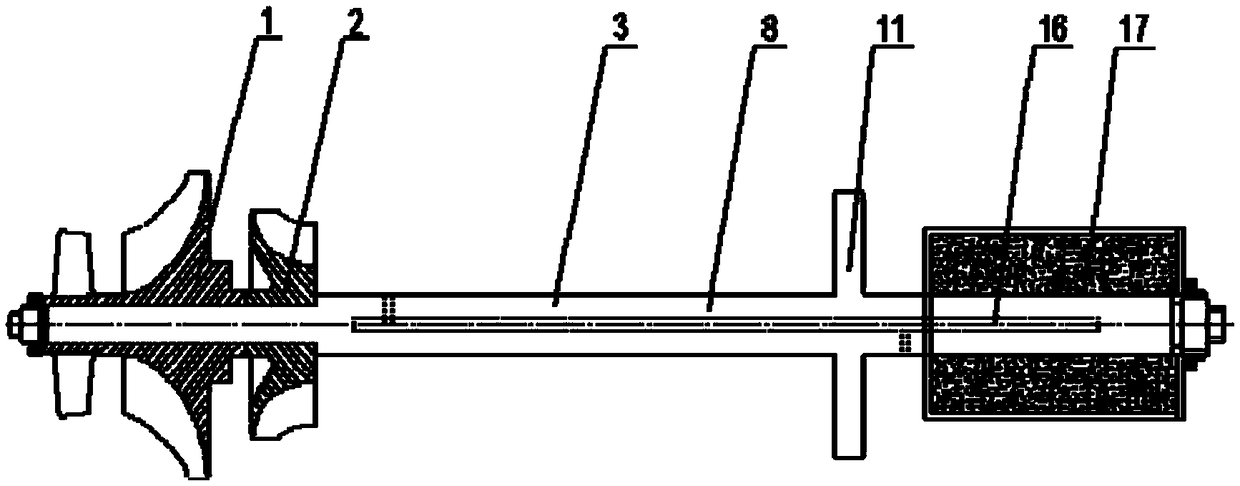

Self-cooling type air suspension air compressor with air storage function

ActiveCN108775289AImprove efficiencyImprove stabilityPump componentsPump controlBrushless motorsAir bearing

The invention discloses a self-cooling type air suspension air compressor with an air storage function. The self-cooling type air suspension air compressor with the air storage function comprises a combined air compressor impeller, an air compressor volute, a cooling turbine, a heat pipe heat exchanger, an air storage cavity, an air bearing assembly, an air compressor shell and a direct current brushless motor. A rotor is coaxially connected with the combined air compressor impeller and the cooling turbine through a rotor core shaft. A thrust bearing assembly and a radial bearing assembly aresequentially arranged on the left side of the direct current brushless motor. The thrust bearing and the radial bearing are foil piece type hydrodynamic gas-lubricated bearings. According to the self-cooling type air suspension air compressor with the air storage function, high-pressure gas stored in the gas storage cavity is controlled to enter an air bearing assembly through the normally open electromagnetic valve during start-stop so as to prolong the time of a dynamic pressure gas film in the start-stop phase, thereby reducing the surface friction between the gas bearing and a rotating shaft to achieve the purpose of prolonging the service life of the gas bearing, and the self-cooling type air suspension air compressor with the air storage function has the advantages of large bearing capacity of the rotating shaft, less friction heat generation, more stable performance and the like by adopting a novel rotating shaft cooling mode.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

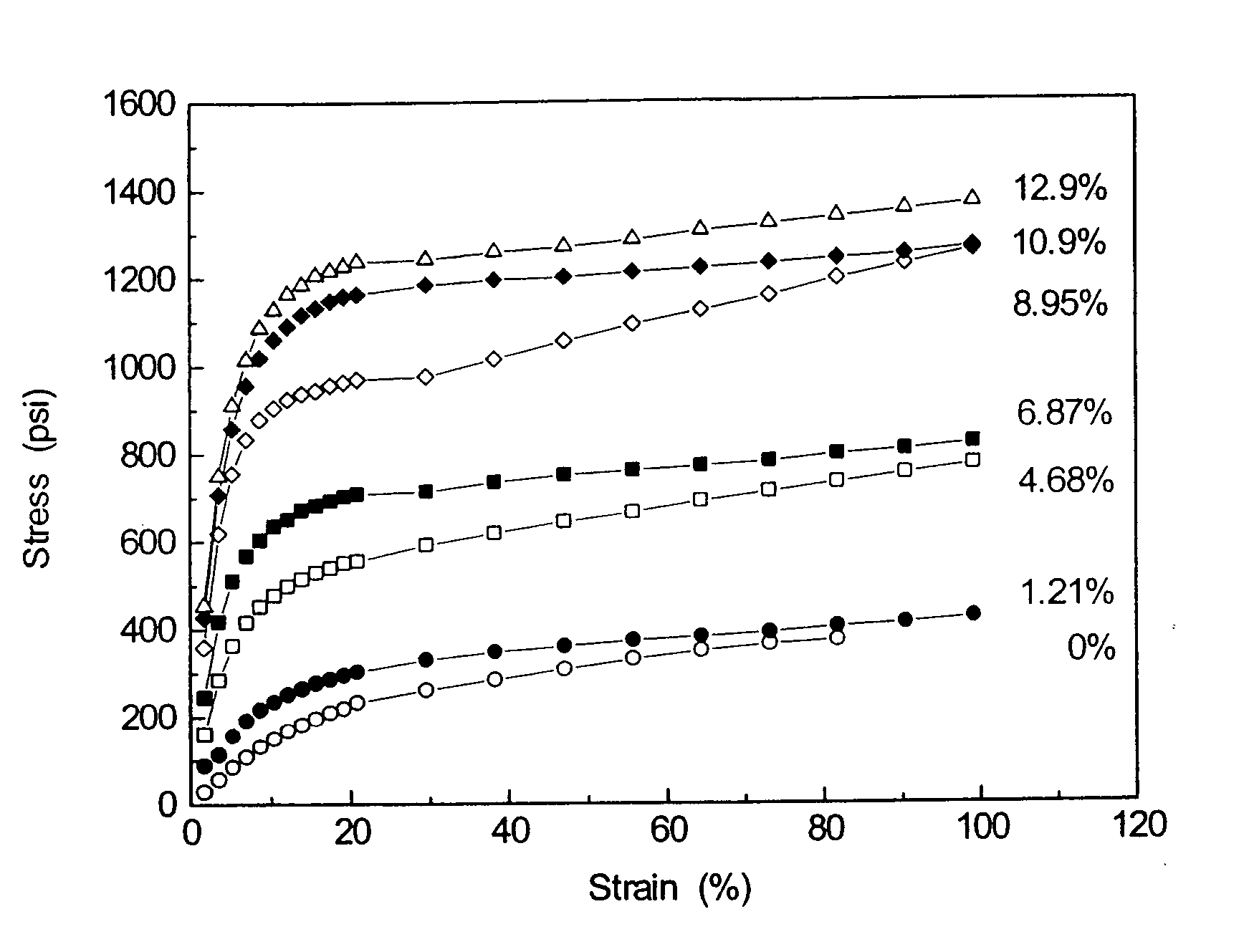

Reinforced composites with repellent and slippery properties

ActiveUS20180094204A1High porosityReduce surface frictionVessel cleaningFouling preventionSelf-healingMetallurgy

Compositions and processes are disclosed for forming hydrophobic coatings and lubricant-infused surface coatings. Coatings may be applied to various substrates without prior chemical or temperature treatment of the substrates and over large and irregular surfaces. Coatings are self-healing, antifouling, and have enhanced lifetimes.

Owner:BATTELLE MEMORIAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com