Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69 results about "Trimmer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A trimmer is a miniature adjustable electrical component. It is meant to be set correctly when installed in some device, and never seen or adjusted by the device's user. Trimmers can be variable resistors (potentiometers), variable capacitors, or trimmable inductors. They are common in precision circuitry like A/V components, and may need to be adjusted when the equipment is serviced. Trimpots are often used to initially calibrate equipment after manufacturing. Unlike many other variable controls, trimmers are mounted directly on circuit boards, turned with a small screwdriver and rated for many fewer adjustments over their lifetime. Trimmers like trimmable inductors and trimmable capacitors are usually found in superhet radio and television receivers, in the intermediate frequency (IF), oscillator and radio frequency (RF) circuits. They are adjusted into the right position during the alignment procedure of the receiver.

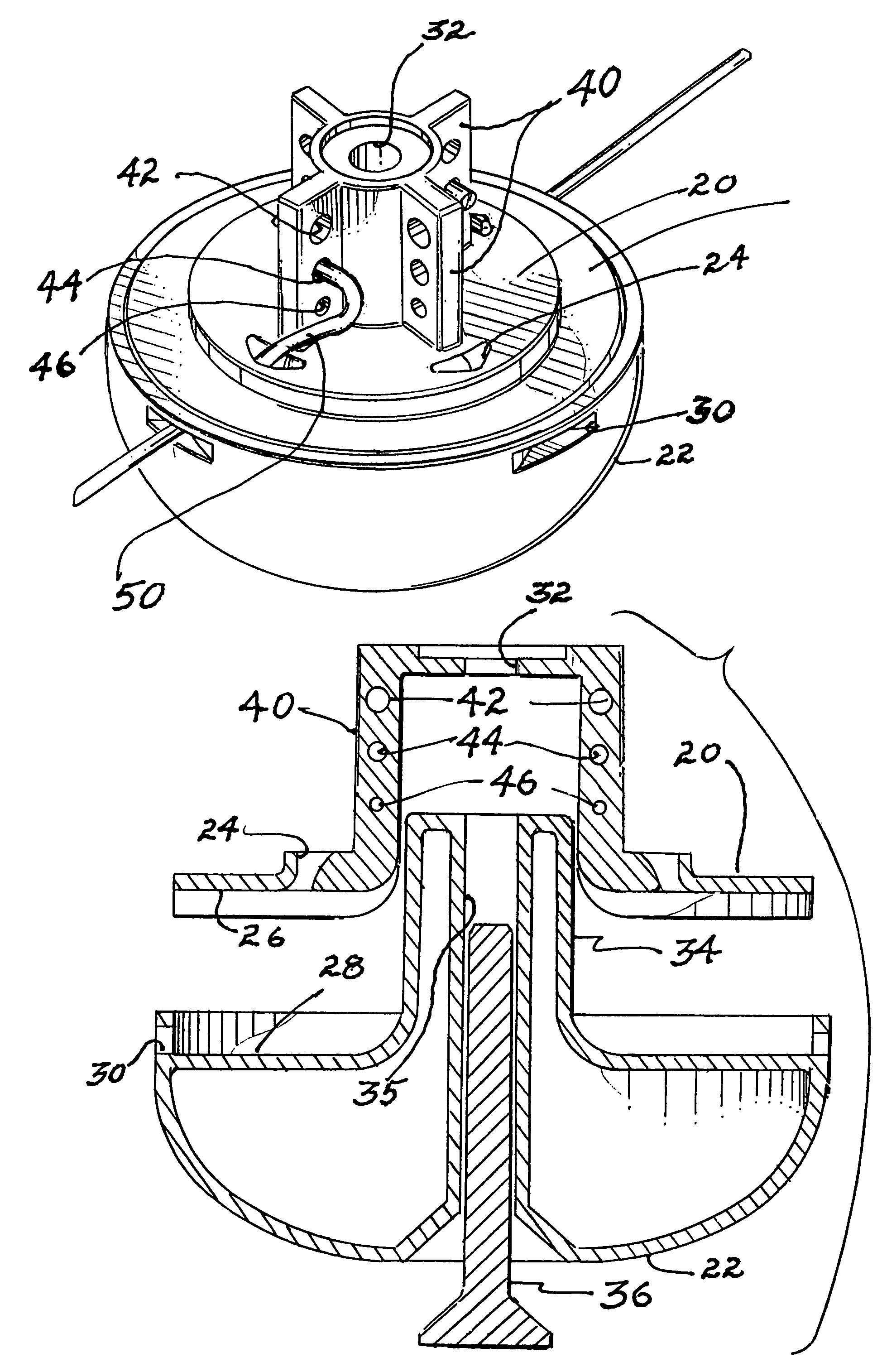

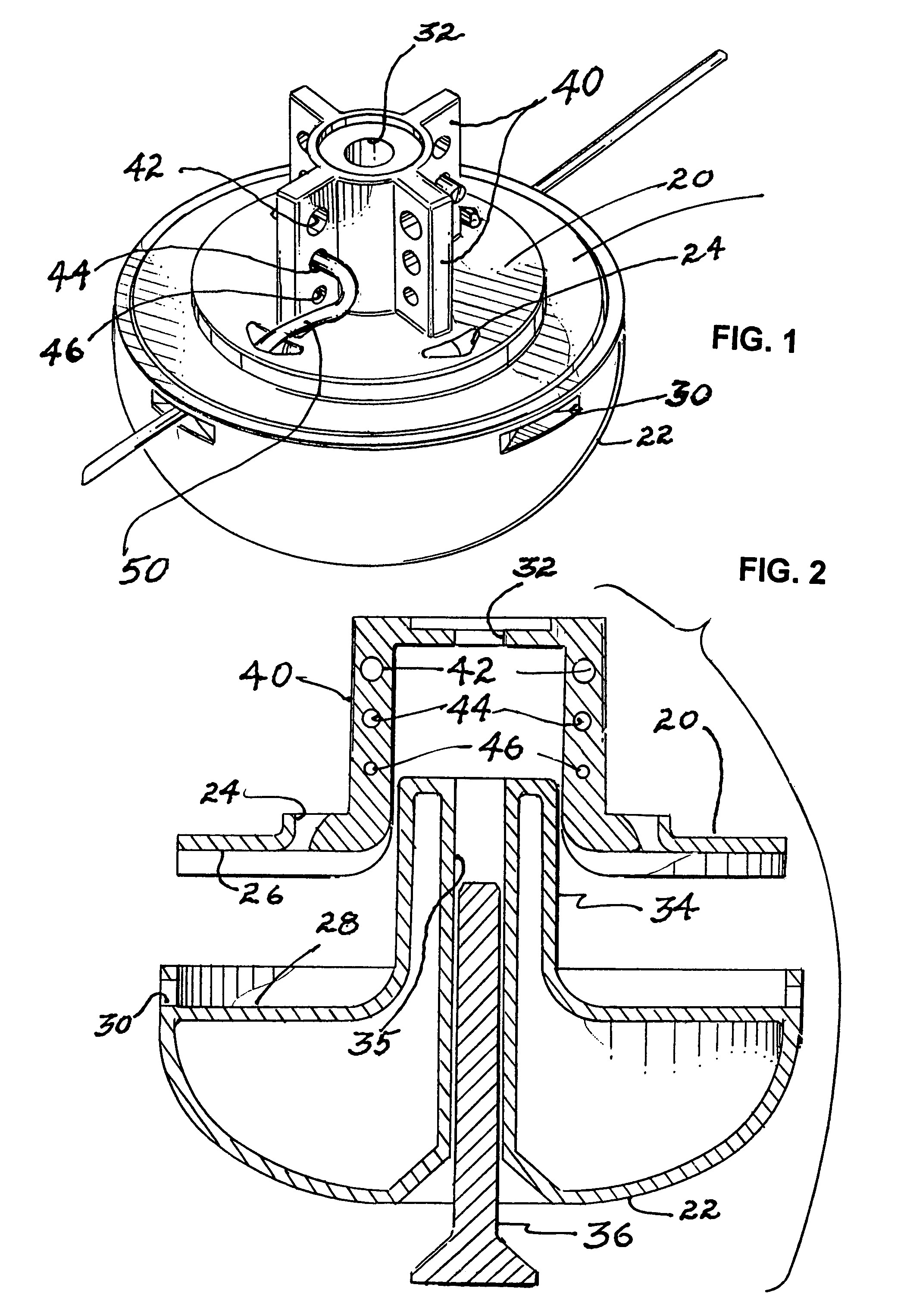

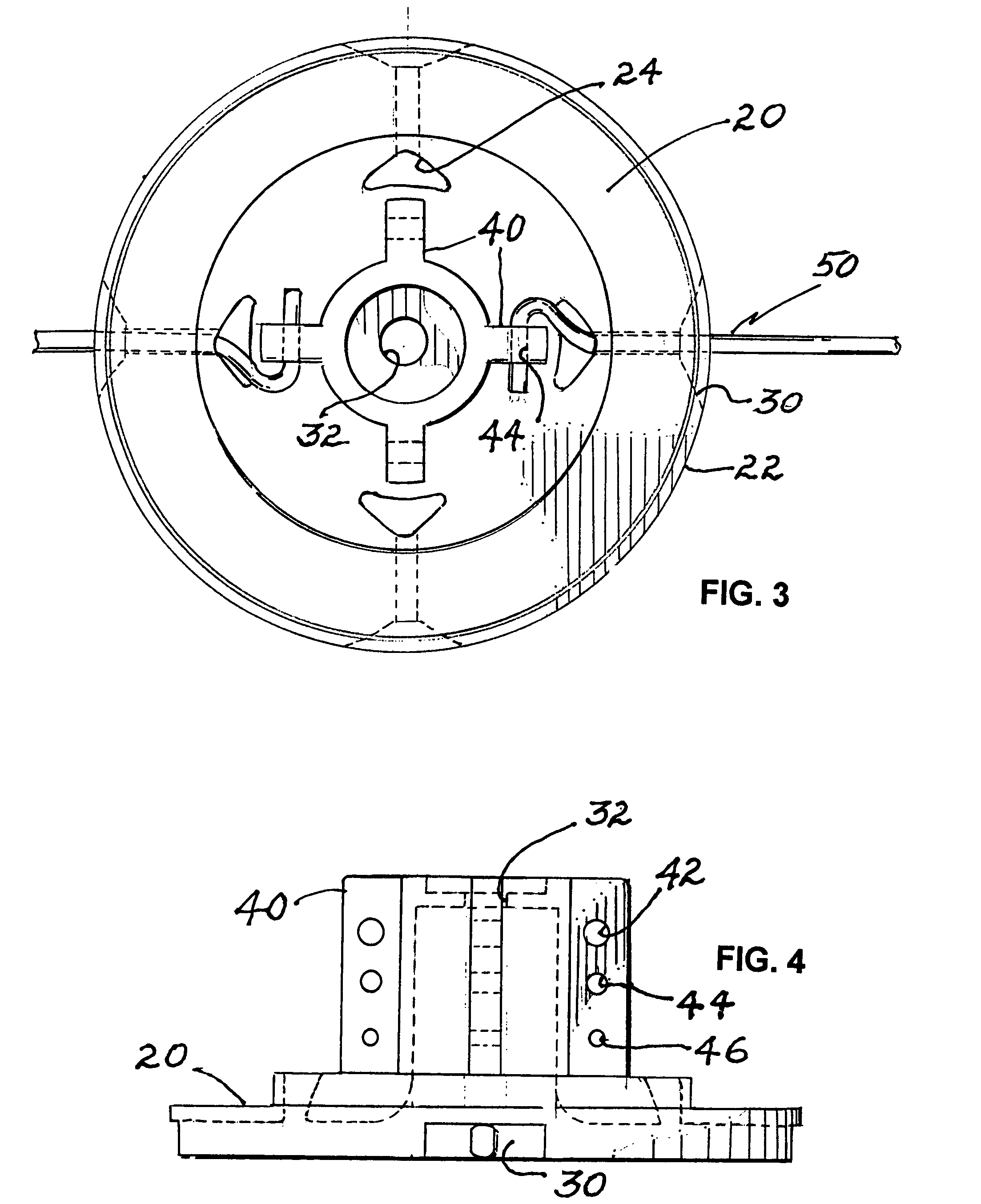

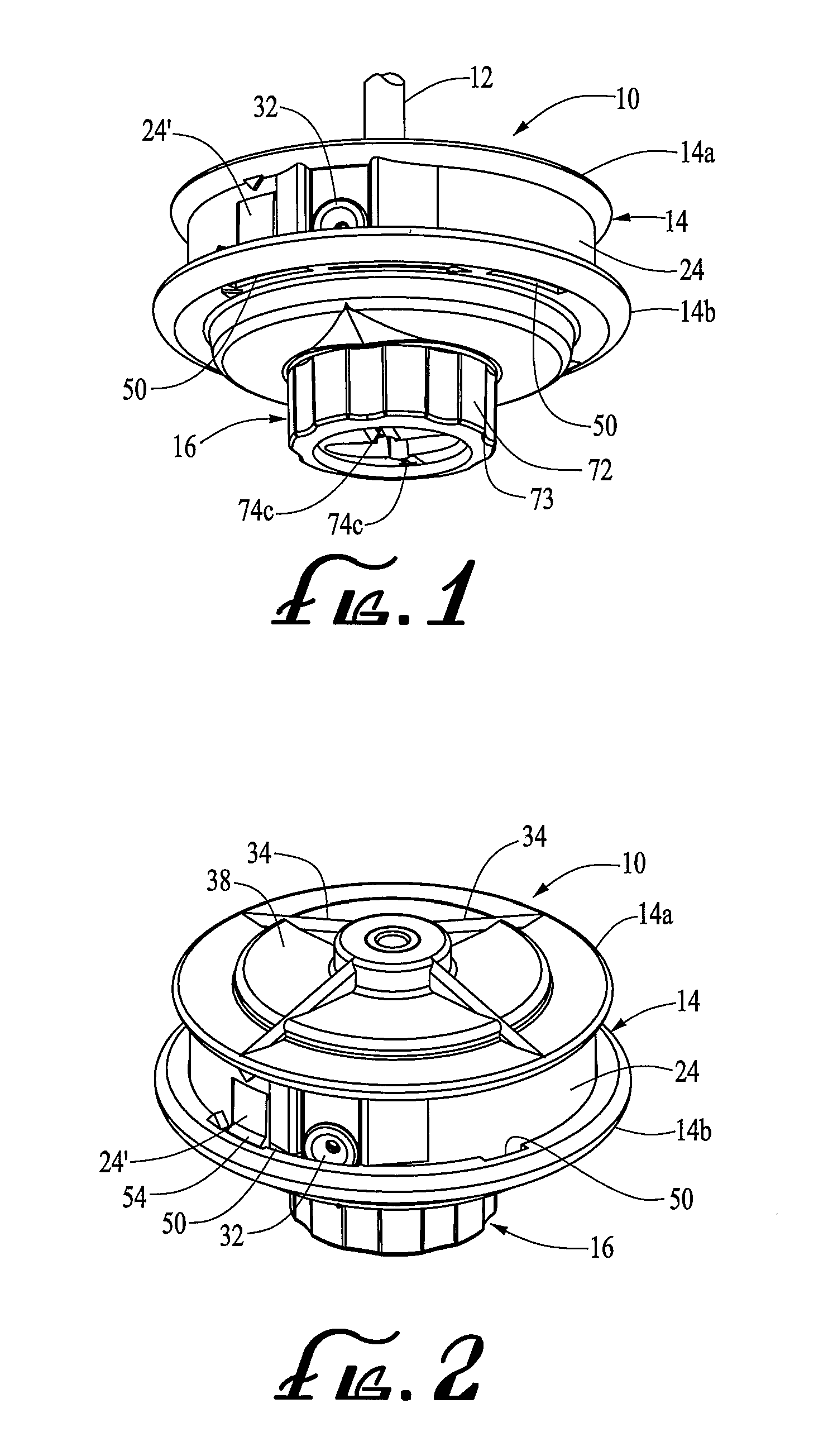

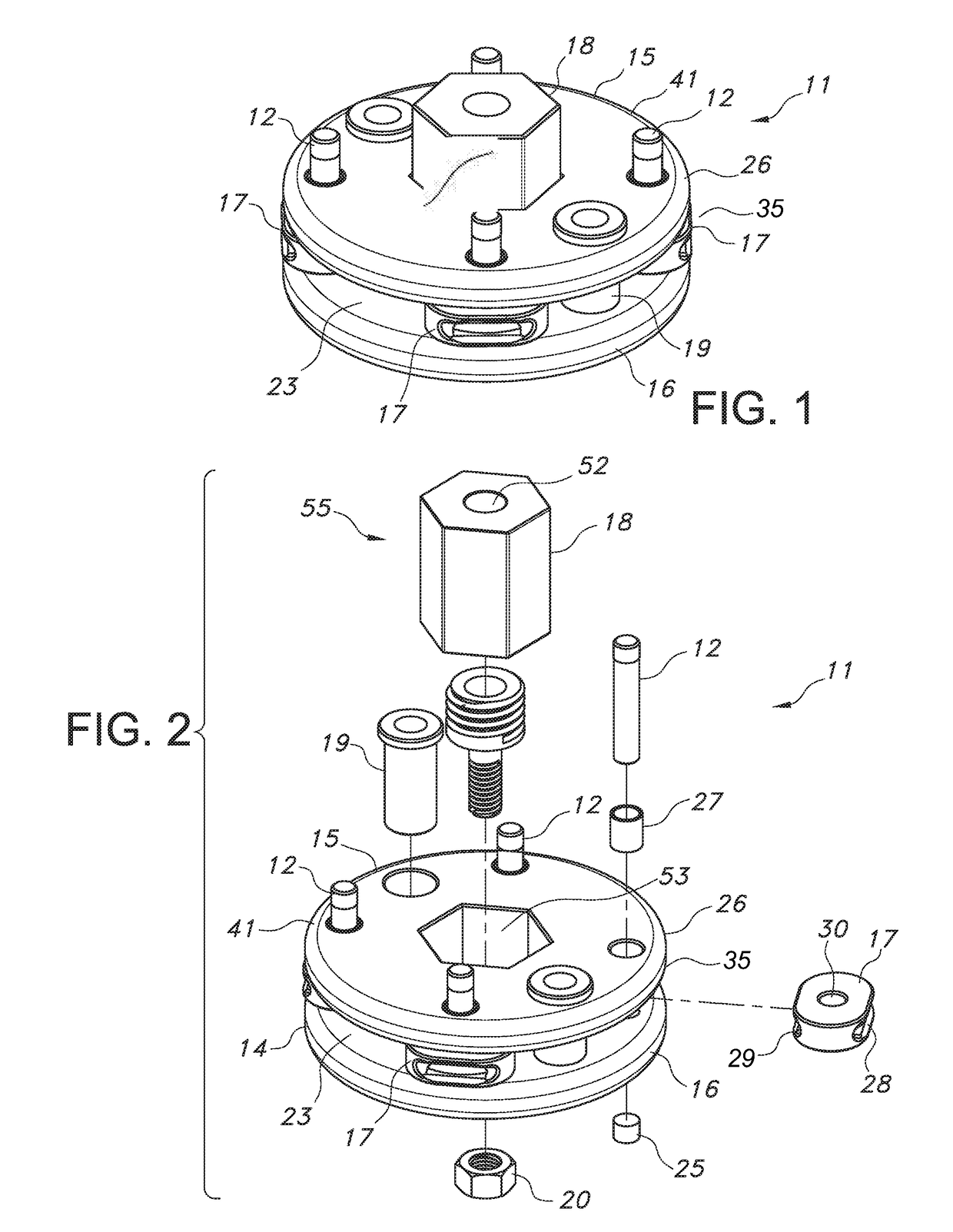

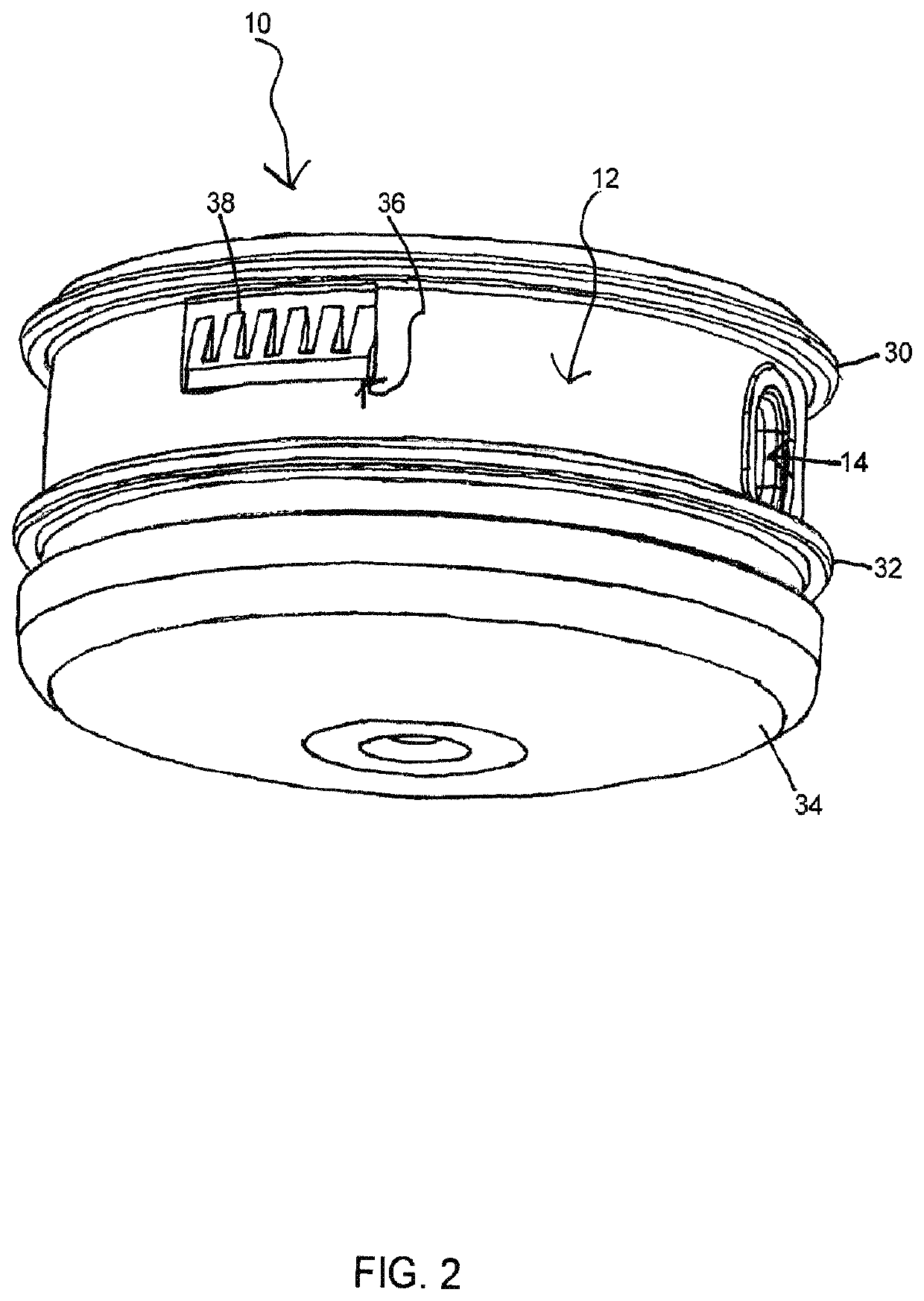

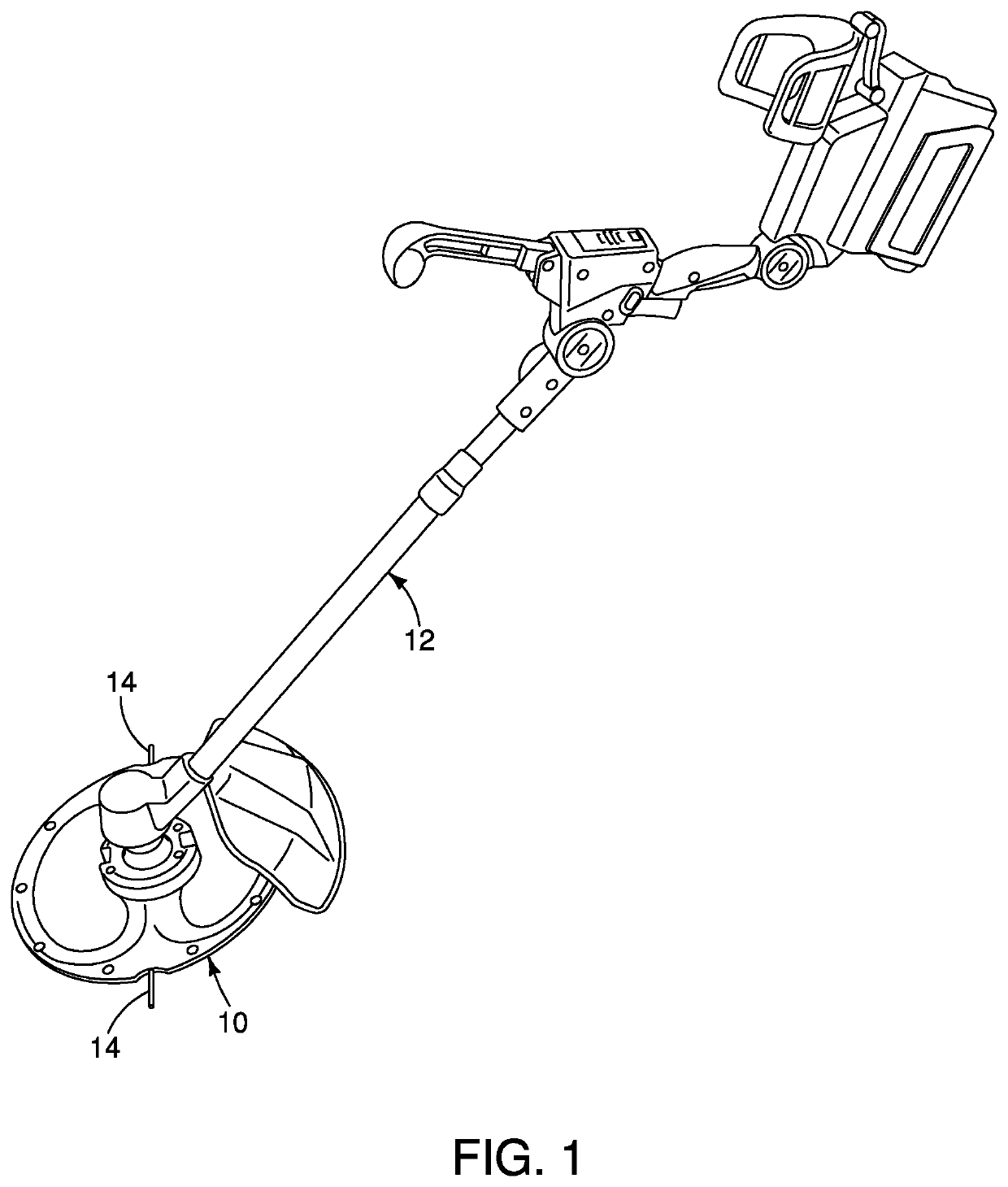

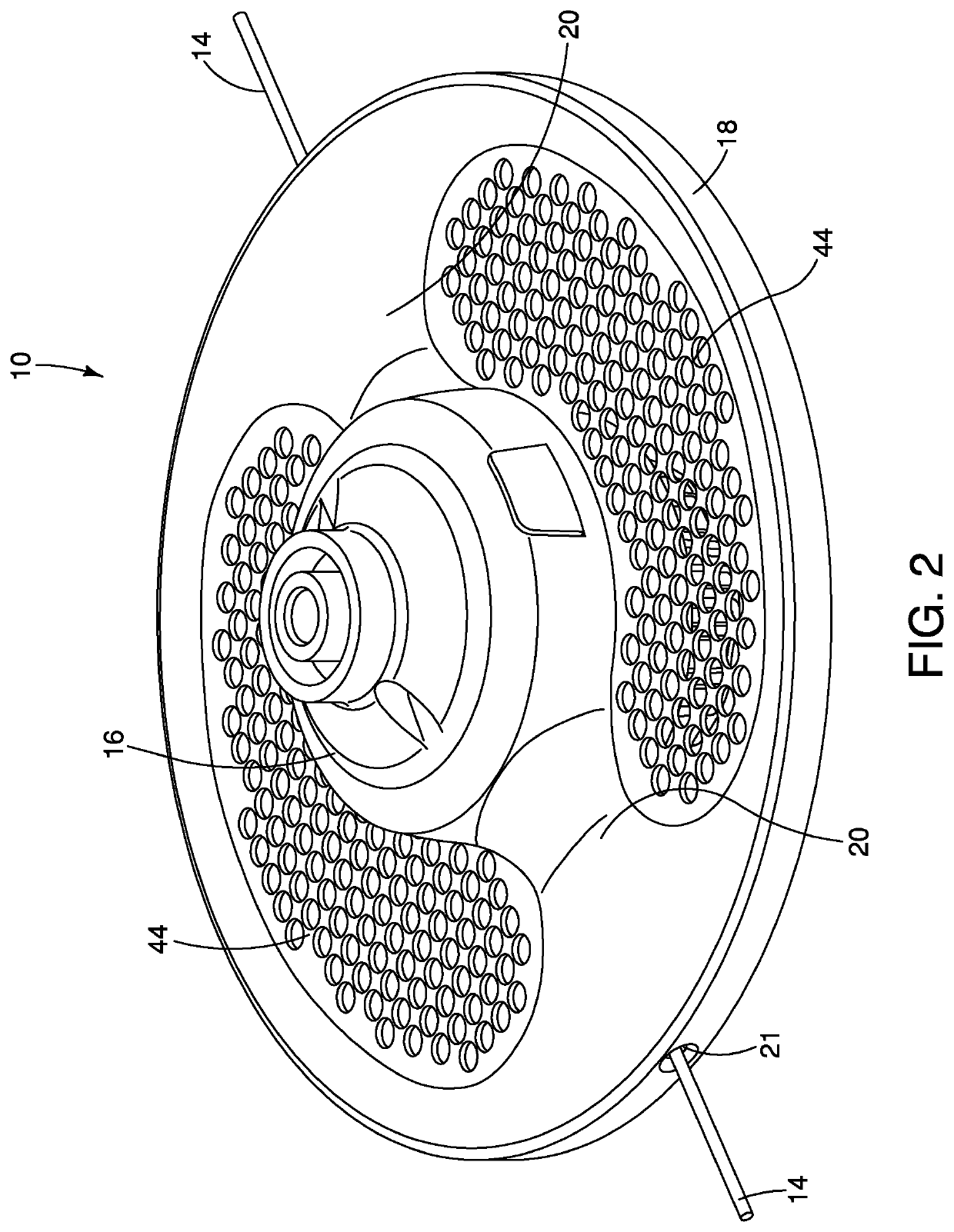

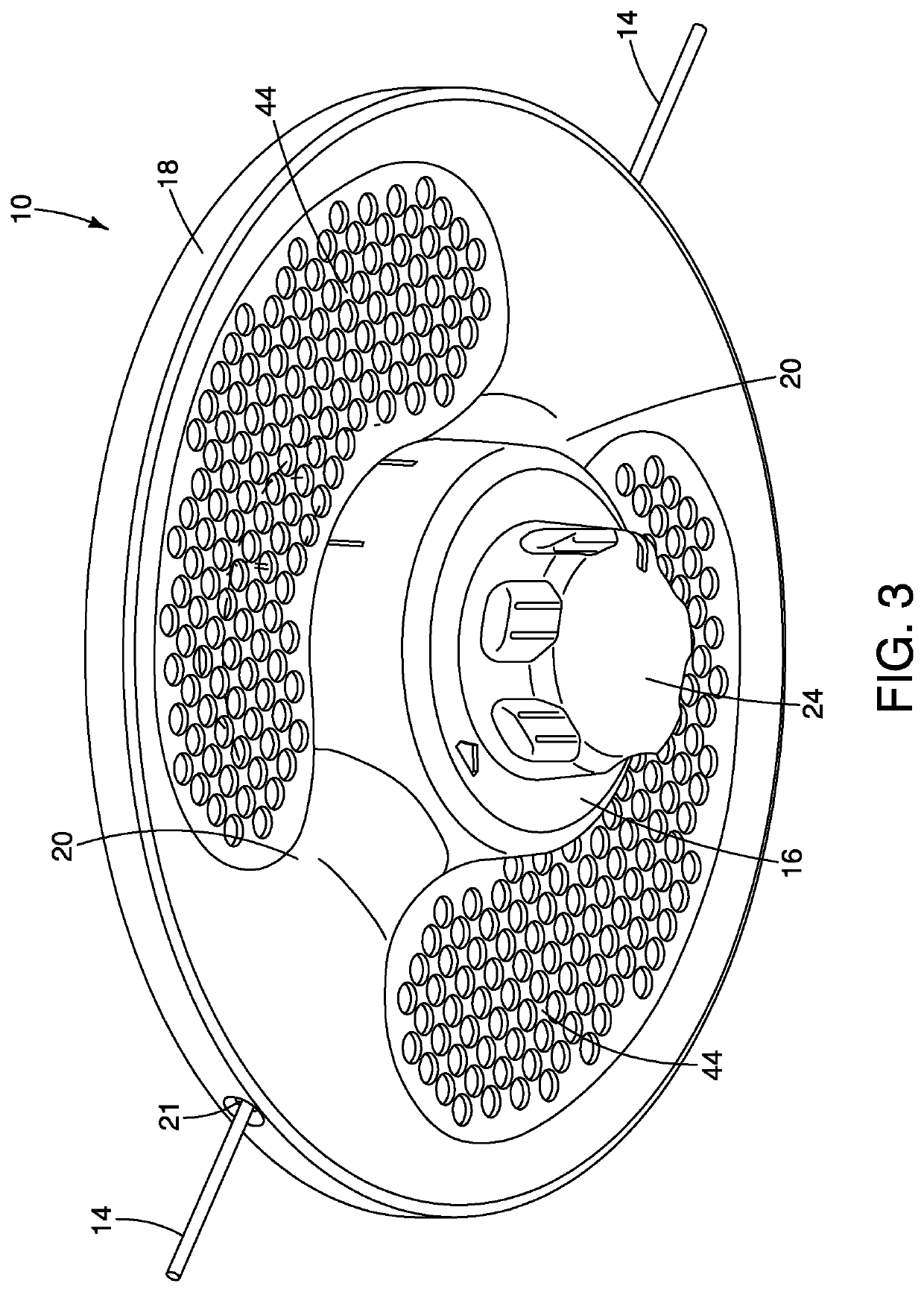

Top loading fixed line trimmer head

InactiveUS7000324B2Simple to install and replaceEasy loadingMowersMetal working apparatusLine segmentFlange

A fixed line top-loading trimmer head for string trimmer machines, uses line segments of a predetermined length. The head has a central hub designed for attachment to the drive shaft of a string trimmer machine. A circular flange is attached to, and extends outwardly from, the central hub. This circular flange has one or more trimmer line exit openings on the circumference. The hub, located above the upper surface of the circular flange, is provided with either line termination apertures in the form of holes or channels which are angularly offset from the exit openings in the circular flange; or it is provided with an offset guide channel through which a trimmer line is passed between the exit openings. A line guide channel is located in the flange between the line exit openings and the line termination apertures, or the offset channel on the hub, for guiding line between the exit openings and the offset channel or termination apertures.

Owner:DESERT EXTRUSION CORP

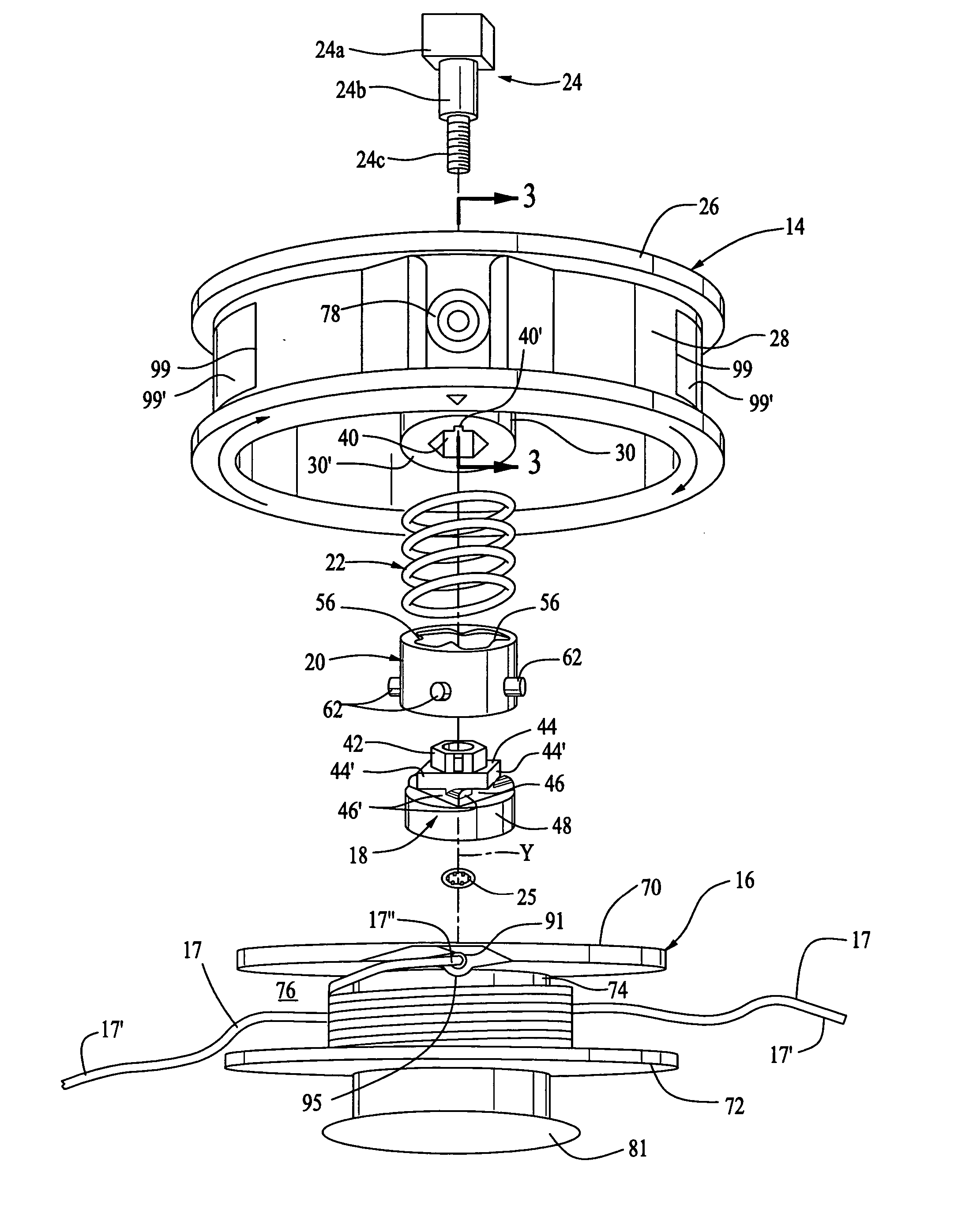

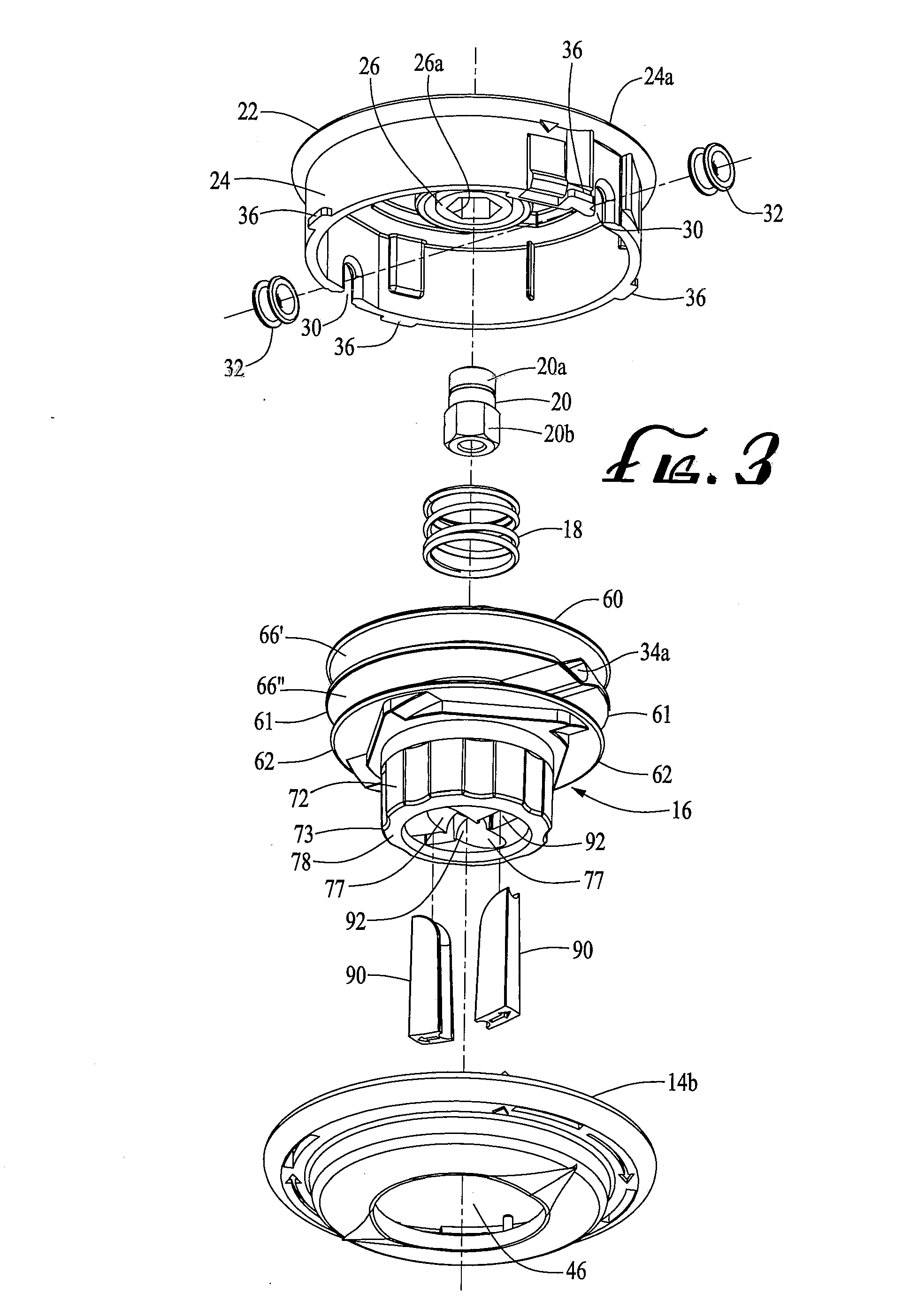

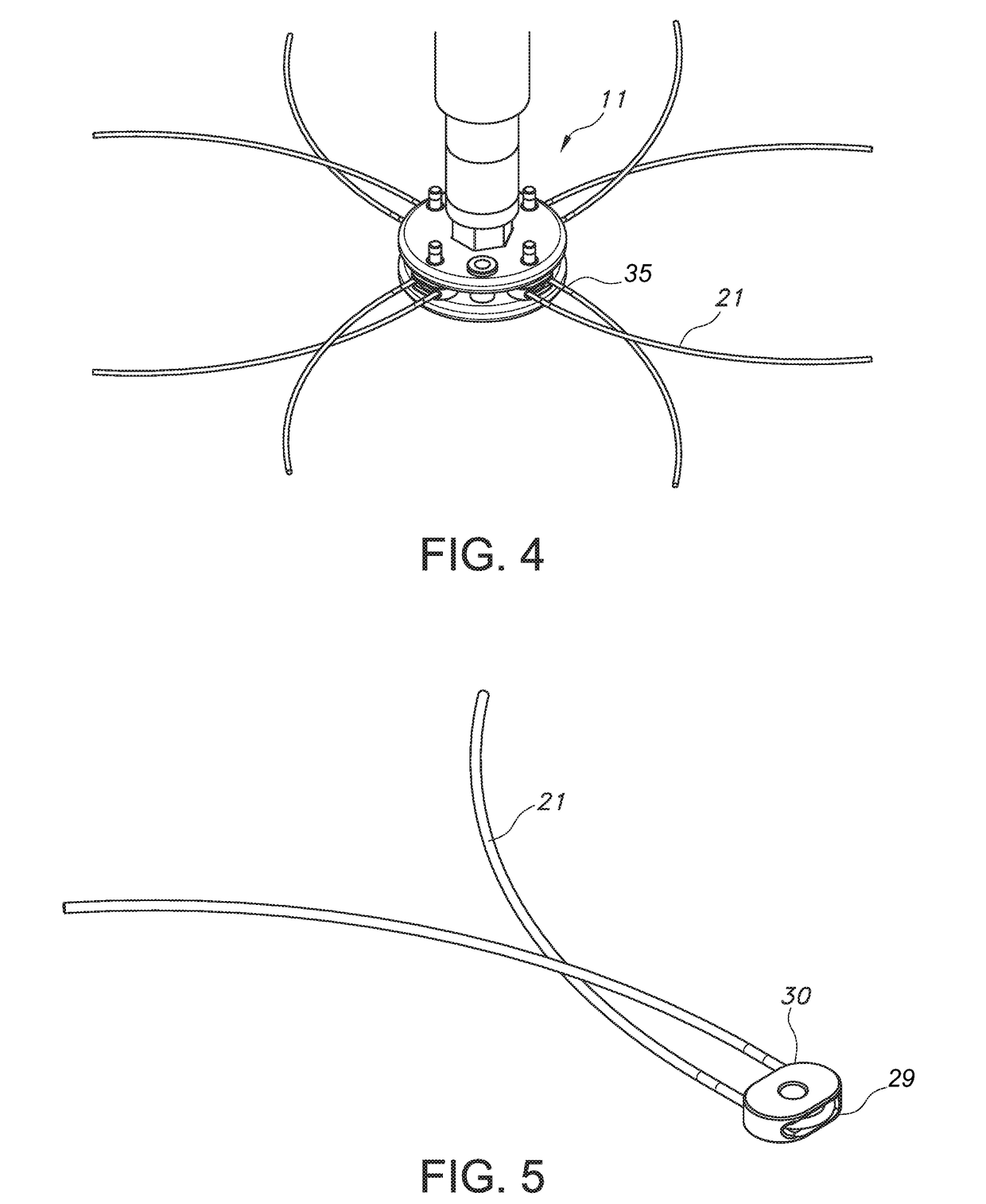

Trimmer Head For Use In Flexible Line Rotary Trimmers Having Improved Line Loading Mechanism

ActiveUS20110000091A1Avoid tanglesEqually distributedMowersMetal working apparatusEngineeringMechanical engineering

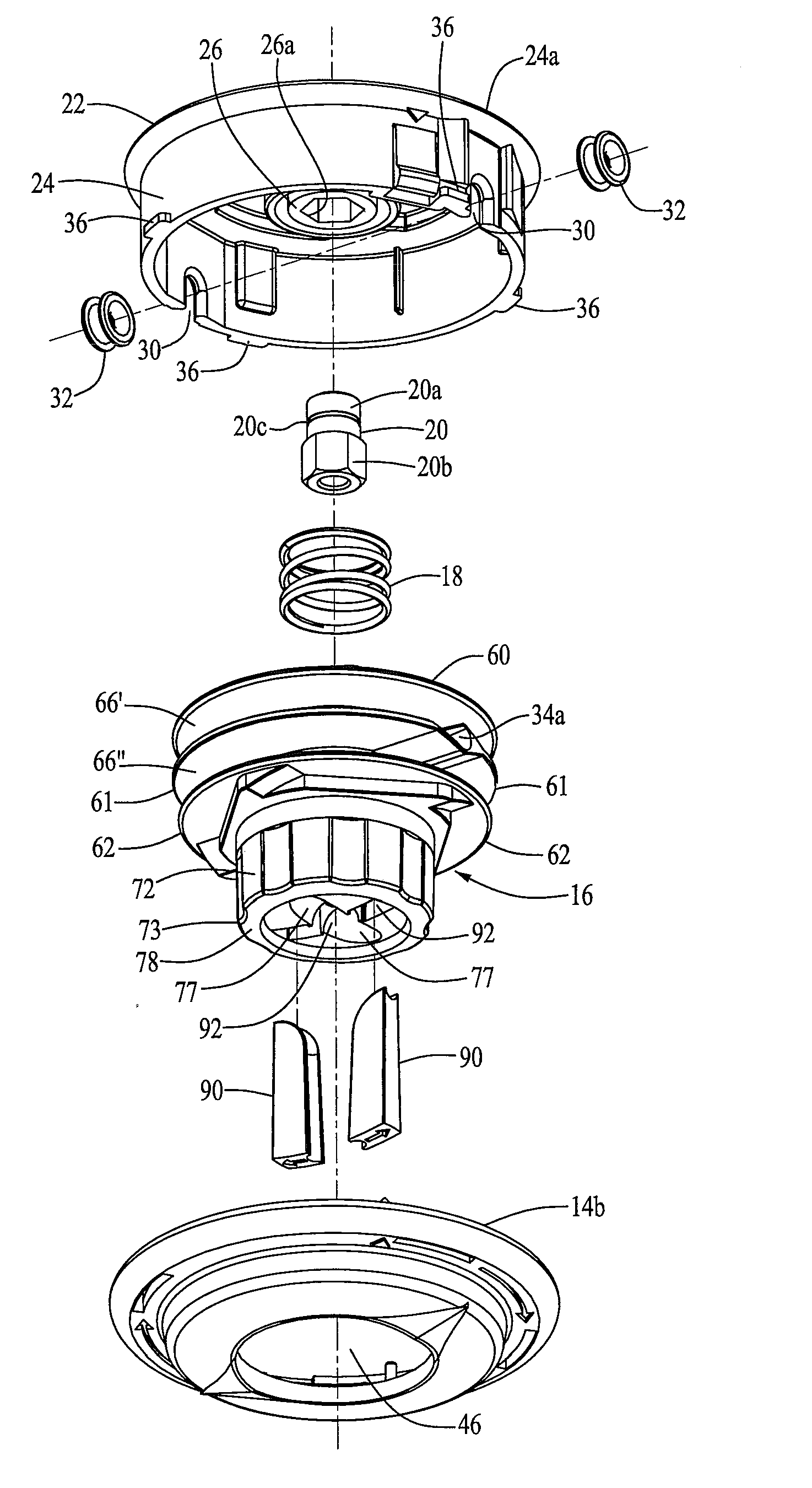

A trimmer head for a rotary line trimmer including a housing operatively connected to the trimmer and a spool for carrying cutting line thereon. The spool is operatively connected to the housing for rotation therewith and defines a pair of opposed line receptor channels having opposed open ends, traversing opposed portions of the spool and defining opposed outlet openings above a lowermost end of the spool. The channels can be aligned with the eyelets in the housing skirt such that lengths of cutting line can be inserted therethrough and wrapped about the spool upon relative rotation of the spool and housing without having to interrupt the operative connection therebetween. The channel outlet openings provide access to the inner ends of the line so that the line also can be pulled from the head without having to interrupt the operative connection therebetween.

Owner:PROULX MFG

Trimmer Head For Use In Flexible Line Rotary Trimmers Having Improved Line Loading Mechanism

ActiveUS20080052917A1Avoid tanglesEqually distributedMowersMetal working apparatusEngineeringMiddle line

A trimmer head for use with a length of flexible cutting line in a rotary trimmer comprising a housing operatively connected to the trimmer to effect rotation of the head and a spool for carrying the cutting line thereon. The spool is operatively connected to the housing for rotation therewith and defines a line receptor channel having opposed open ends and traversing the spool. The channel can be aligned with the eyelets in the housing skirt such that cutting line can be inserted therethrough and wrapped about the spool upon relative rotation of the spool and housing without having to interrupt the operative connection therebetween. A central portion of the channel intermediary its open ends is exposed to provide access to the portion of line therein so that line wound about the spool can be pulled from the head without having to interrupt the operative connection therebetween.

Owner:PROULX MFG

Trimmer head for use in flexible line rotary trimmers having improved line loading mechanism

InactiveUS7275324B2Easy loadingSecurely holdMowersMetal working apparatusTrimmerReciprocating motion

Owner:PROULX MFG

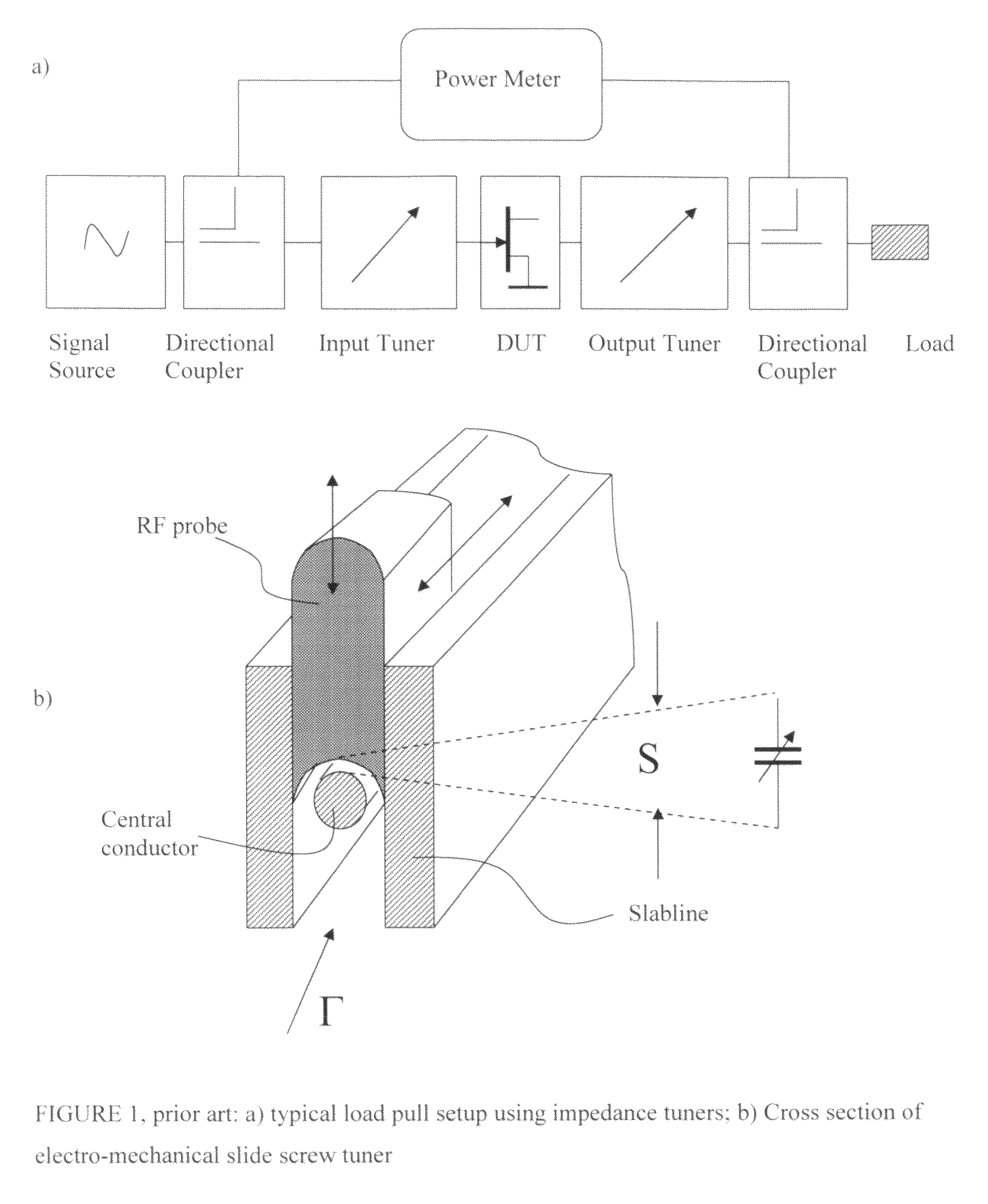

Compact multi frequency-range impedance tuner

An automatic multi frequency-range electro-mechanical impedance tuner covers frequencies from a low megahertz to a high gigahertz range, by combining a high frequency with one or two a low frequency tuner modules; the low frequency module is made using either variable phase shifter-capacitor or multi-capacitor-transmission line tuner structures. The high frequency module is a single, double or triple probe slide screw tuner covering up to 1.5 decades in frequency; the low frequency tuner is using cascades of three or more capacitor-coax cable tuning sections or a low frequency phase shifter combined with a variable shunt capacitor; the low frequency tuner can operate as low as a few megahertz whereas the high frequency tuner can operate up to several gigahertz. Depending on the application, low frequency parallel-blade capacitors or high frequency coaxial trimmers are used. Typical cross-over frequencies between low and high frequency modules range from 200 to 800 megahertz, lowest frequencies can reach below 10 megahertz and highest frequencies 26 to 40 gigahertz. Appropriate calibration, control and tuning procedures allow for a fully integrated operation.

Owner:TSIRONIS CHRISTOS

Easy load trimmer head spool with non-radial guide channel

A trimmer head spool for a vegetation trimmer machine. The spool includes a hub that defines a bore and has at least one flange or a plurality of spokes extending radially outwardly therefrom. A trimmer line conduit defined in the spool includes a first funnel defined in a first region of the flange or spokes and a second funnel defined in a second region of the flange or spokes. A non-radial guide channel is in fluid communication with the first and second funnels. The non-radial guide channel spans the hub's bore and does not extend through a central axis of the spool about which the spool is rotatable. The non-radial guide channel may be provided on a module that is selectively inserted into the bore and aligned with the first and second funnels. In other embodiments the entire trimmer line conduit is integrally formed in the spool.

Owner:FIRST TO INVENT LLC

Trimmer Head For Use In Flexible Line Rotary Trimmers Having Improved Line Loading Mechanism

ActiveUS20080127496A1Easy loadingAvoid tanglesMowersMetal working apparatusMechanical engineeringHead rotation

A trimmer head for use with a length of flexible cutting line in a rotary trimmer comprising a housing operatively connected to the trimmer to effect rotation of the head and a spool for carrying the cutting line thereon. The spool is operatively connected to the housing for rotation therewith and defines a line receptor channel having opposed open ends and traversing the spool. The channel is formed by line guide inserts held within the spool body preferably utilizing the shrinkage of the molded spool material about the inserts. The channel can be aligned with the eyelets in the housing skirt such that cutting line can be inserted therethrough and wrapped about the spool upon relative rotation of the spool and housing without having to interrupt the operative connection therebetween. A central portion of the channel is exposed to provide access to the line so that the line can be pulled from the head without having to interrupt the operative connection therebetween.

Owner:PROULX MFG

Trimmer head system

InactiveUS20180368315A1Quickly and efficiently interchangedImprove attachment efficiencyManure treatmentMowersOff the shelfEngineering

A method and device for increased efficiency of attachment of traditional accessories at the perimeter of a standard trimmer head via improved attachment means comprising a trimmer head having an upper portion and a lower portion, a cutting medium, and attachment means. The system further comprising an adapter plate for attaching custom accessories and commercially available, off the shelf rotary accessories at the center of the trimmer head, thus increasing the functionality of the trimmer head.

Owner:MULTICRAFT VENTURES LLC

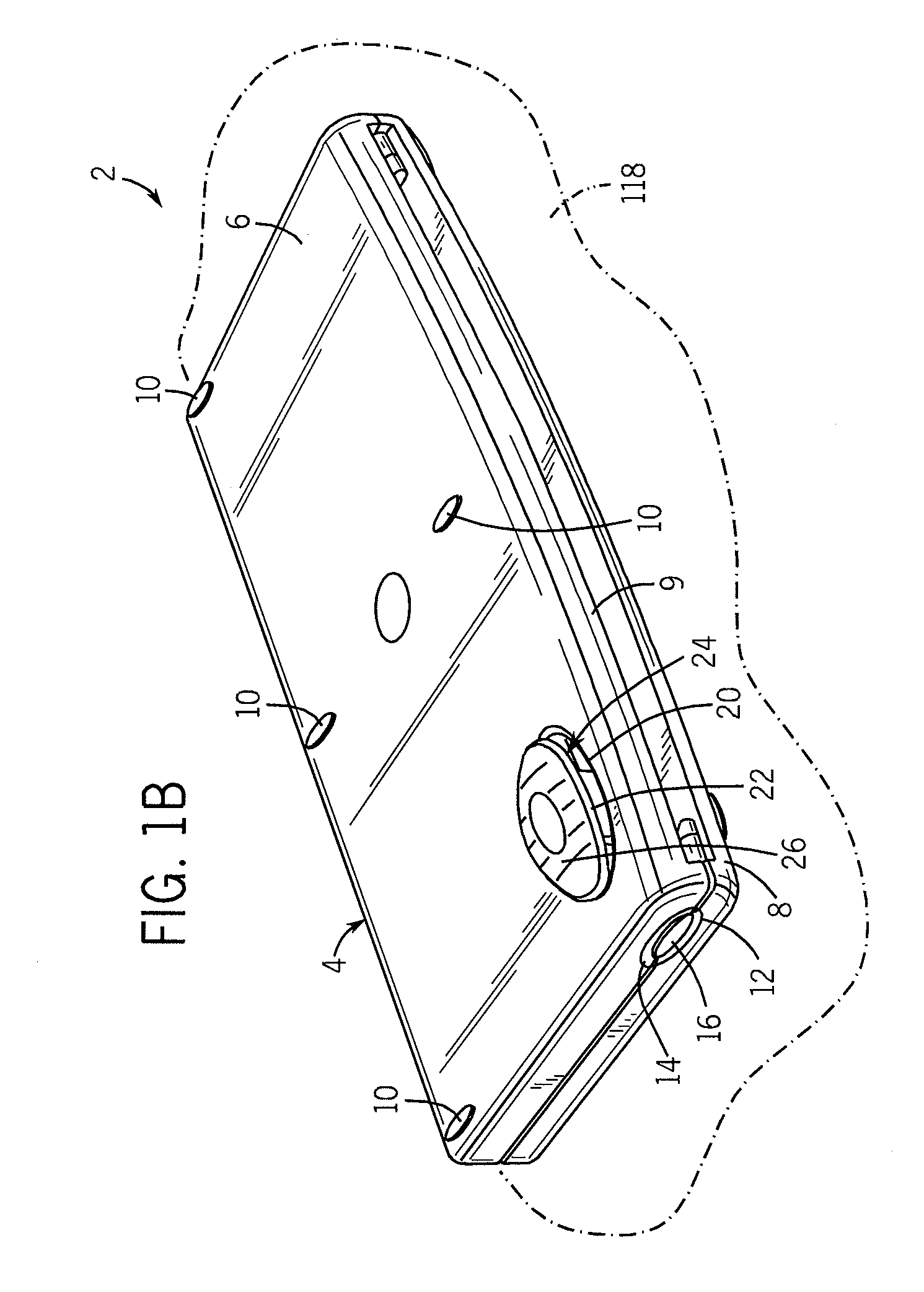

Trimmer

InactiveUS20100132522A1Promote rotationCross-cut reciprocating sawsShearing machinesRange of motionEngineering

A trimmer having a trimmer housing is disclosed. In accordance with at least some embodiments, the trimmer housing includes a first housing portion and a second housing portion, the first housing portion being pivotally connected at least indirectly to the second housing portion. The trimmer additionally includes a cutting platform having a first platform connected at least indirectly to the first housing portion and a second platform connected at least indirectly to the second housing portion. The trimmer is configured wherein the second housing portion is substantially stationary and the first housing portion rotates approximately in a 180 degree range of motion from a close position to an open position, such that a flat and continuous cutting surface formed by the first and the second platforms is obtained.

Owner:ACME UNITED CORPORATION

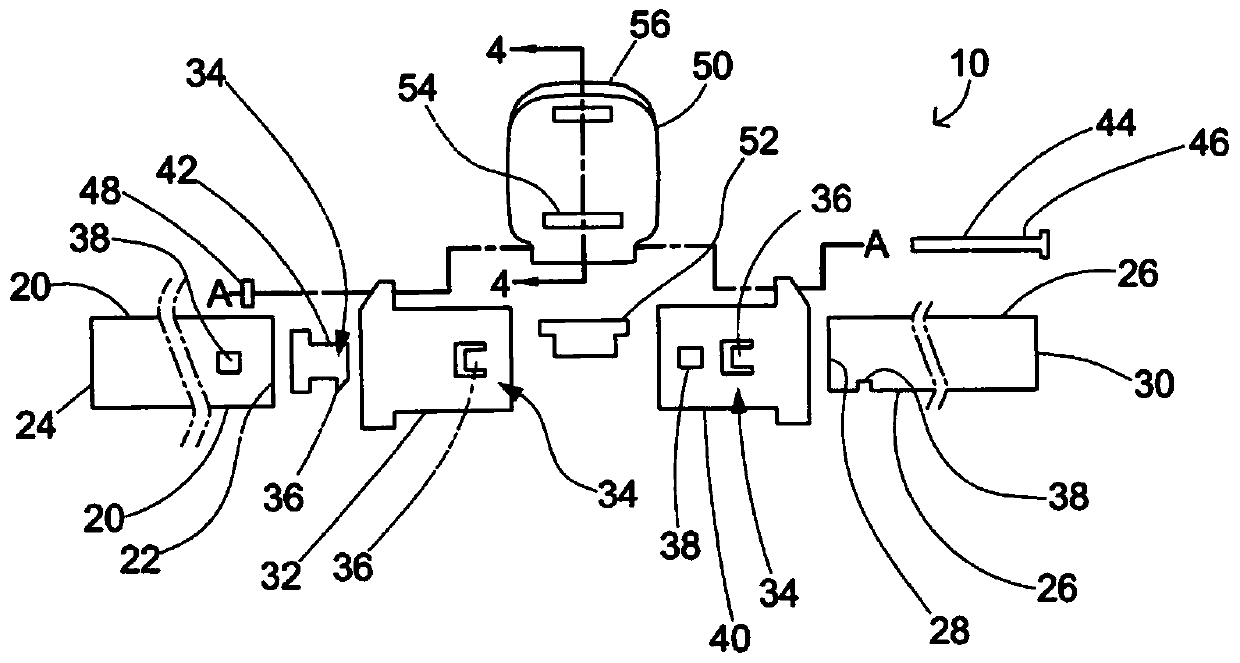

Trimmer head assembly for a trimmer

Trimmer heads for trimmers are provided. A trimmer head includes a drive plate defining a lug slot, and a locking lug, the locking lug movably positioned in the lug slot and movable between an unlocked position and a locked position. A trimmer head further includes a drive plate cover connectable to the drive plate such that the locking lug is disposed between the drive plate and the drive plate cover. A trimmer head farther includes at least one operational head, the at least one operational head connectable to the drive plate. The connected operational head is locked to the drive plate when the locking lug is in the locked position and the connected operational head is unlocked from the drive plate when the locking lug is in the unlocked position.

Owner:TECHTRONIC CORDLESS GP

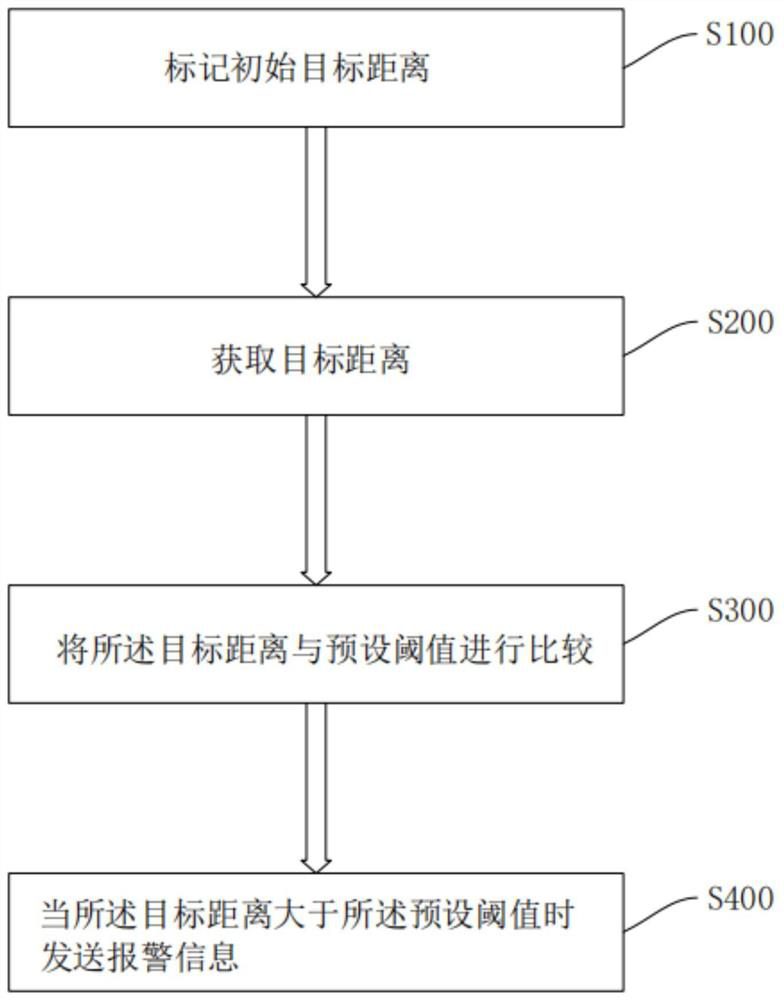

Device and method for monitoring depth changes of groove of polishing pad

PendingCN113524028ADepth change is convenientReduce workloadLapping machinesGrinding feed controlAlarm messageTrimmer

The invention relates to the technical field of polishing pads, in particular to a device and method for monitoring depth changes of a groove of a polishing pad. The device comprises a trimmer, a trimming disc, a sensor, a monitoring system and an alarm system, and the trimmer is used for being connected with an external machine body; the trimming disc is in sliding connection with the trimmer and is used for trimming the polishing pad; the sensor is connected with the trimmer and used for measuring the target distance between the sensor and the trimming disc; the monitoring system is electrically connected with the sensor and is used for receiving the target distance and comparing the target distance with a preset threshold value; and the alarm system is electrically connected with the monitoring system and is used for sending alarm information when the target distance is greater than the preset threshold value. The device and method can overcome the defect that the depth changes of the groove of the polishing pad are inconvenient to monitor in the prior art.

Owner:BEIJING SEMICORE PRECISION MICROELECTRONICS EQUIP CO LTD

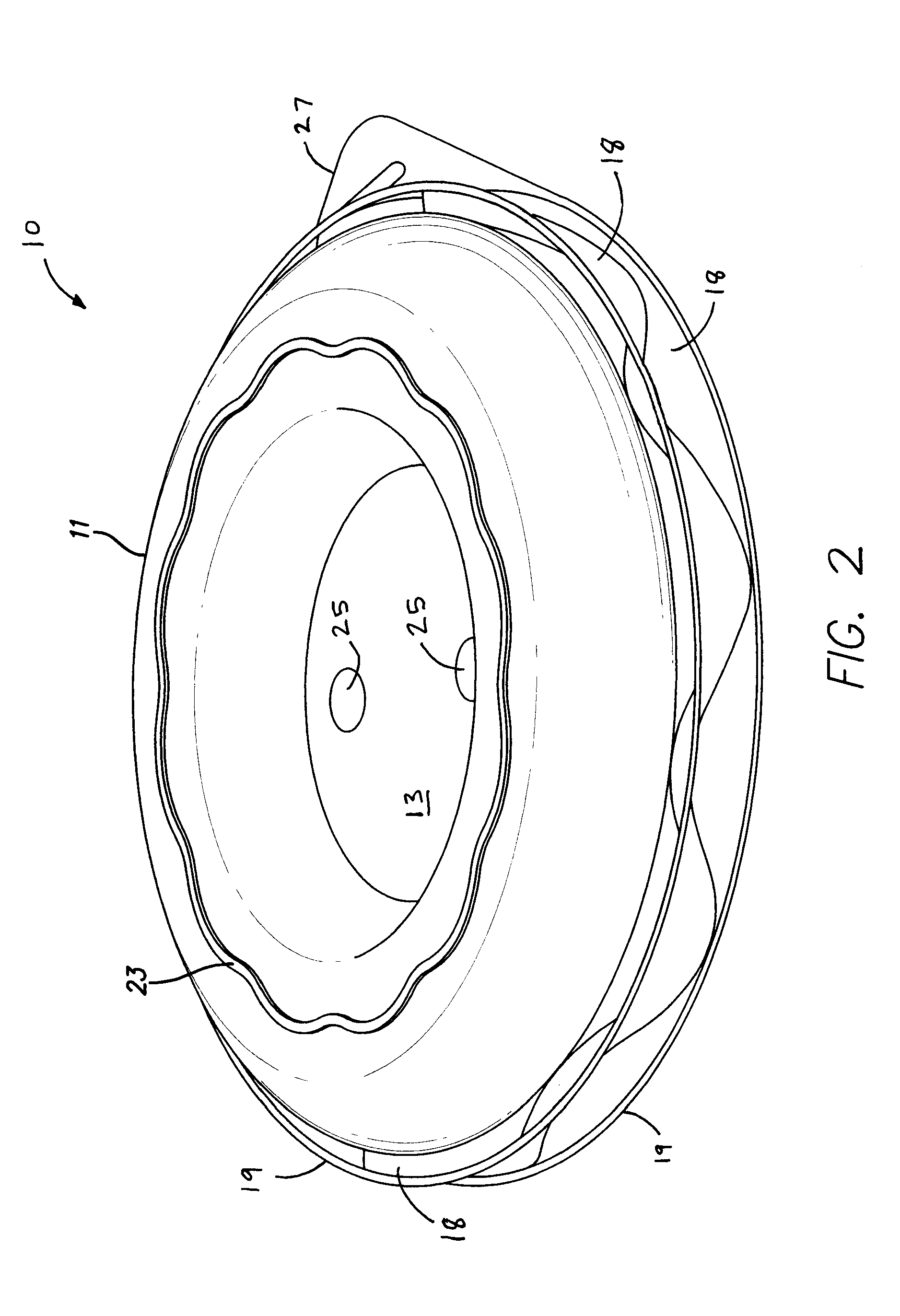

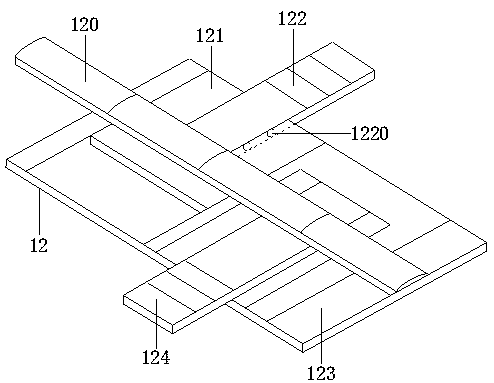

Container and Packaging Method for Vegetation Trimmer Line

A substantially toroidal container for coiled vegetation trimmer line has a front shell and a rear shell capable of bonding at the center with heat and pressure, radio frequency, ultrasonic welding, adhesive, or attachment mechanisms. The bonding of the shells leaves a separation between the outer edges of the shells. The separation is nonlinear around the circumference of the container, so that a user can access the trimmer line, but the trimmer line cannot uncoil and spill out of the container. The separation is preferably defined by a series of offset uniform teeth on the outer edges of the shells. One or more teeth may be removed, providing a line aperture through which the end of the trimmer line extends out of the container. Male and female indices on each shell are used to align the teeth during packaging.

Owner:ROTARY CORP

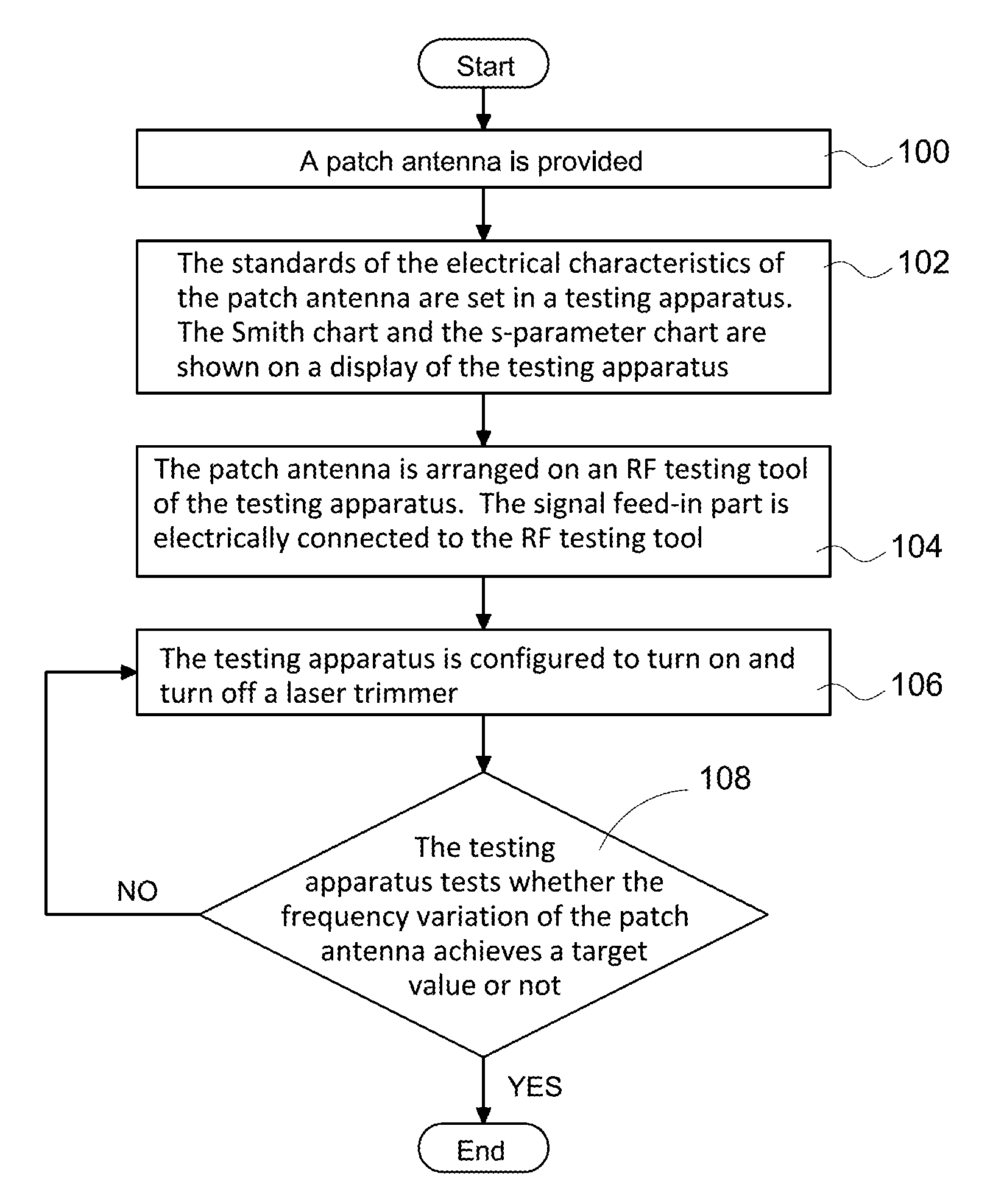

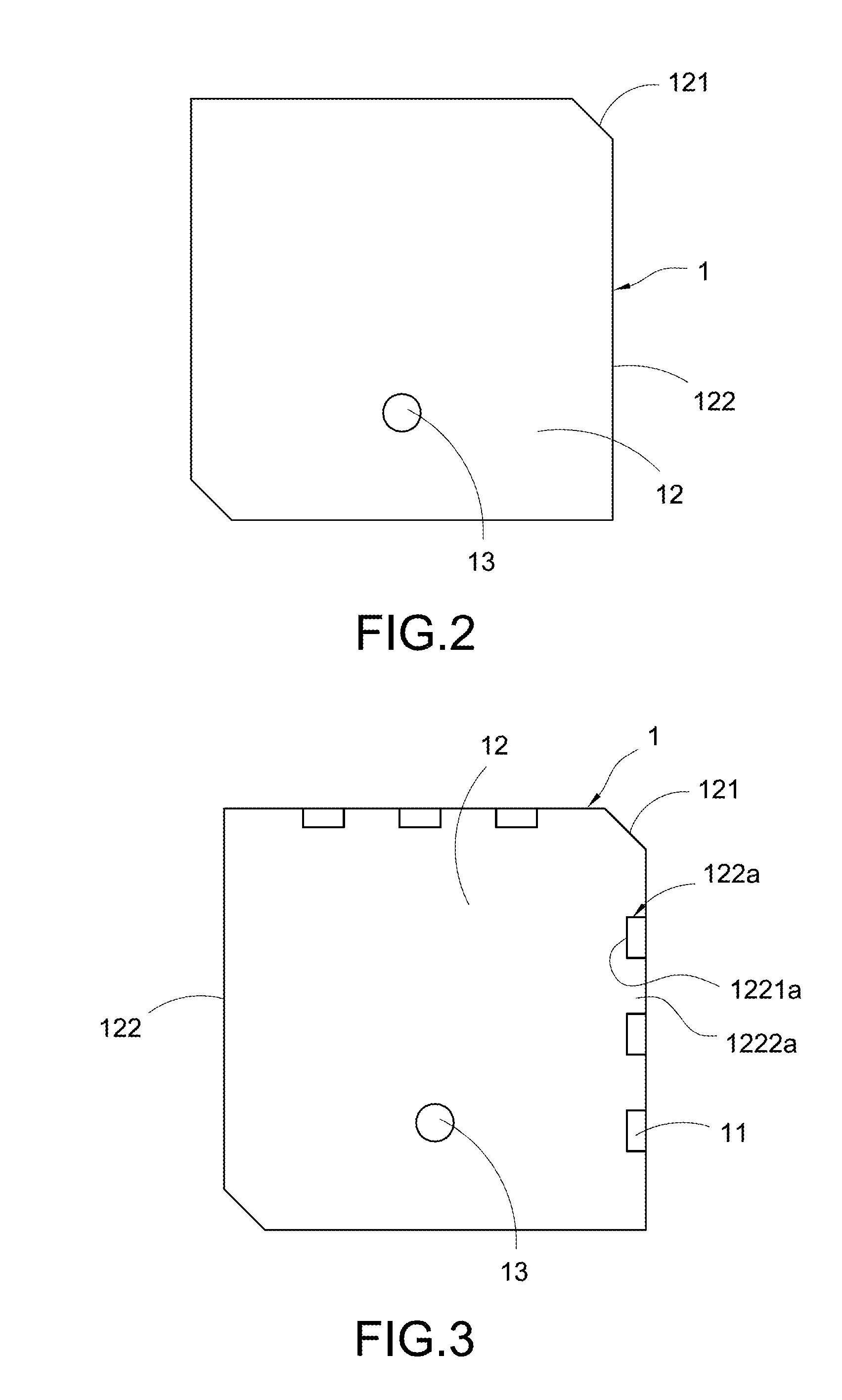

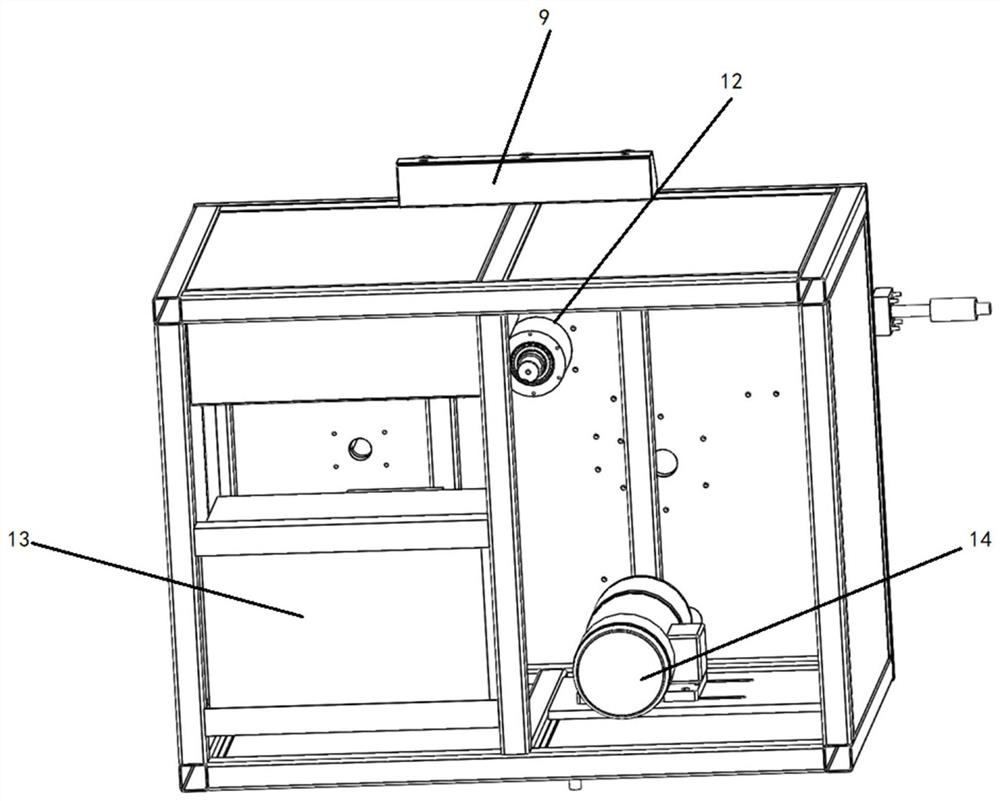

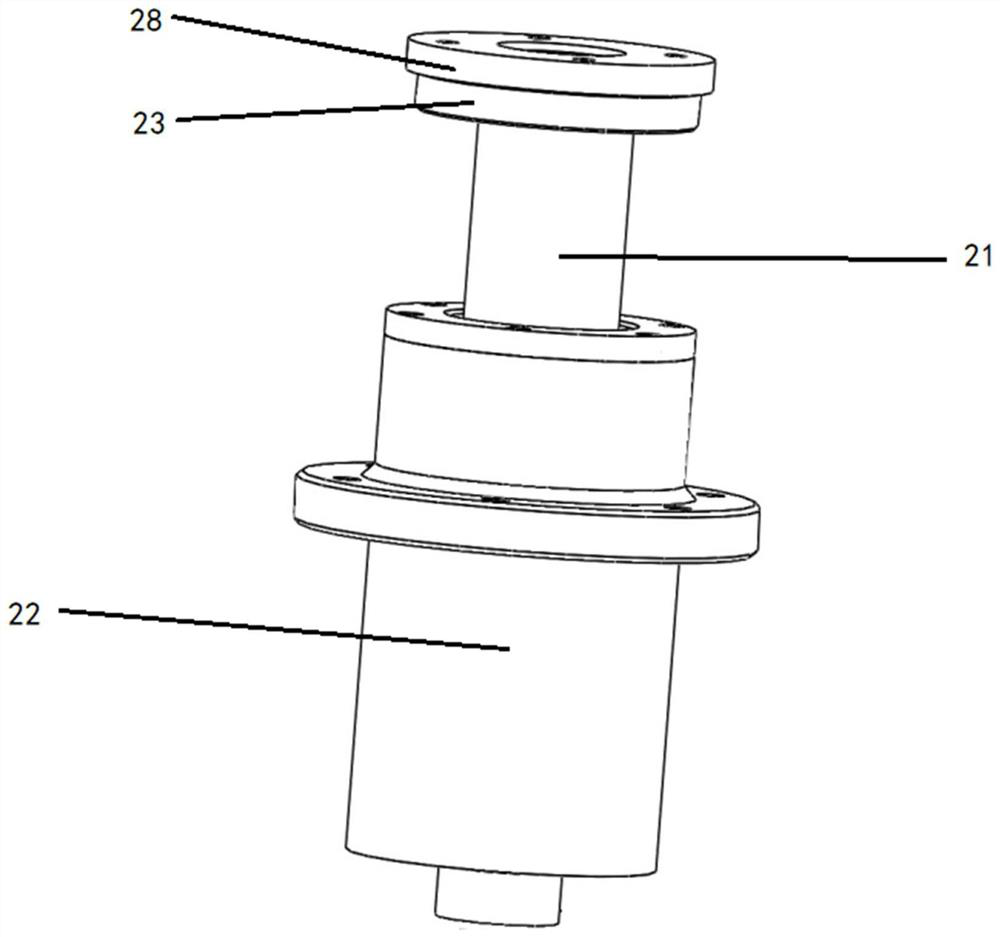

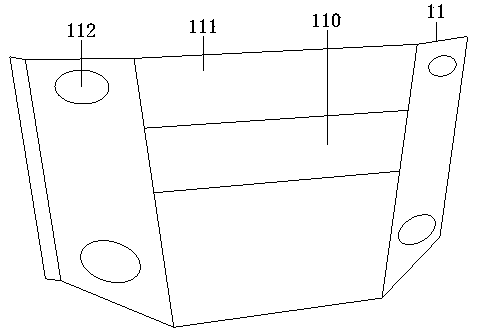

Trimming method for patch antenna and patch antenna structure

InactiveUS20150180130A1Small sizeSimultaneous aerial operationsElectronic circuit testingLaserTest facility

A testing apparatus drives a laser trimmer to adjust a frequency variation of a patch antenna. A trimming method for the patch antenna includes following steps. The patch antenna is provided. The patch antenna includes an underlying carrier. A radiation metal surface is arranged on a top side of the underlying carrier. The patch antenna is arranged on a testing tool of the testing apparatus. The testing apparatus is configured to turn on and turn off the laser trimmer, so that four or any two of four straight edges of the radiation metal surface are dashed cut to form dashed edges. The testing apparatus tests whether the frequency variation of the patch antenna achieves a target value or not. The testing and adjustment of the frequency variation of the patch antenna are finished if the frequency variation of the patch antenna achieves the target value.

Owner:CIROCOMM TECH CORP

Automatic edge trimmer

ActiveCN113020396AThe cutting process is smooth and preciseImprove pass rateMetal-working feeding devicesPositioning devicesTrimmerStructural engineering

The invention discloses an automatic edge trimmer. The automatic edge trimmer comprises a main shaft rotating mechanism, an upper pressing mechanism, a cutting mechanism, a waste cutting-off mechanism, a waste clamping and disassembling mechanism and a machine frame structure. The main shaft rotating mechanism, the upper pressing mechanism, the cutting mechanism, the waste cutting-off mechanism and the waste clamping and disassembling mechanism are all arranged on the machine frame structure, the upper pressing mechanism, the cutting mechanism, the waste cutting-off mechanism and the waste clamping and disassembling mechanism are all arranged on the periphery of the main shaft rotating mechanism, a workpiece is fixed to the main shaft rotating mechanism through the upper pressing mechanism, and an upper pressing guide rod is driven by an upper pressing air cylinder of the upper pressing mechanism to tightly press the upper pressing mechanism; an edge cutting oil cylinder of the cutting mechanism pushes a hobbing blade to make contact with the workpiece and complete cutting. a waste cutting-off oil cylinder of the waste cutting-off mechanism pushes a waste cutter to cut off annular cutting waste generated after cutting is completed; and the waste clamping and disassembling mechanism clamps a clamping block of the air cylinder, clamps broken annular cutting waste and discards the broken annular cutting waste to a designated position. The whole operation of the automatic edge trimmer is controlled electronically, so that the cutting process is smooth, accurate and efficient.

Owner:宁波华宝弘瑞五金有限公司

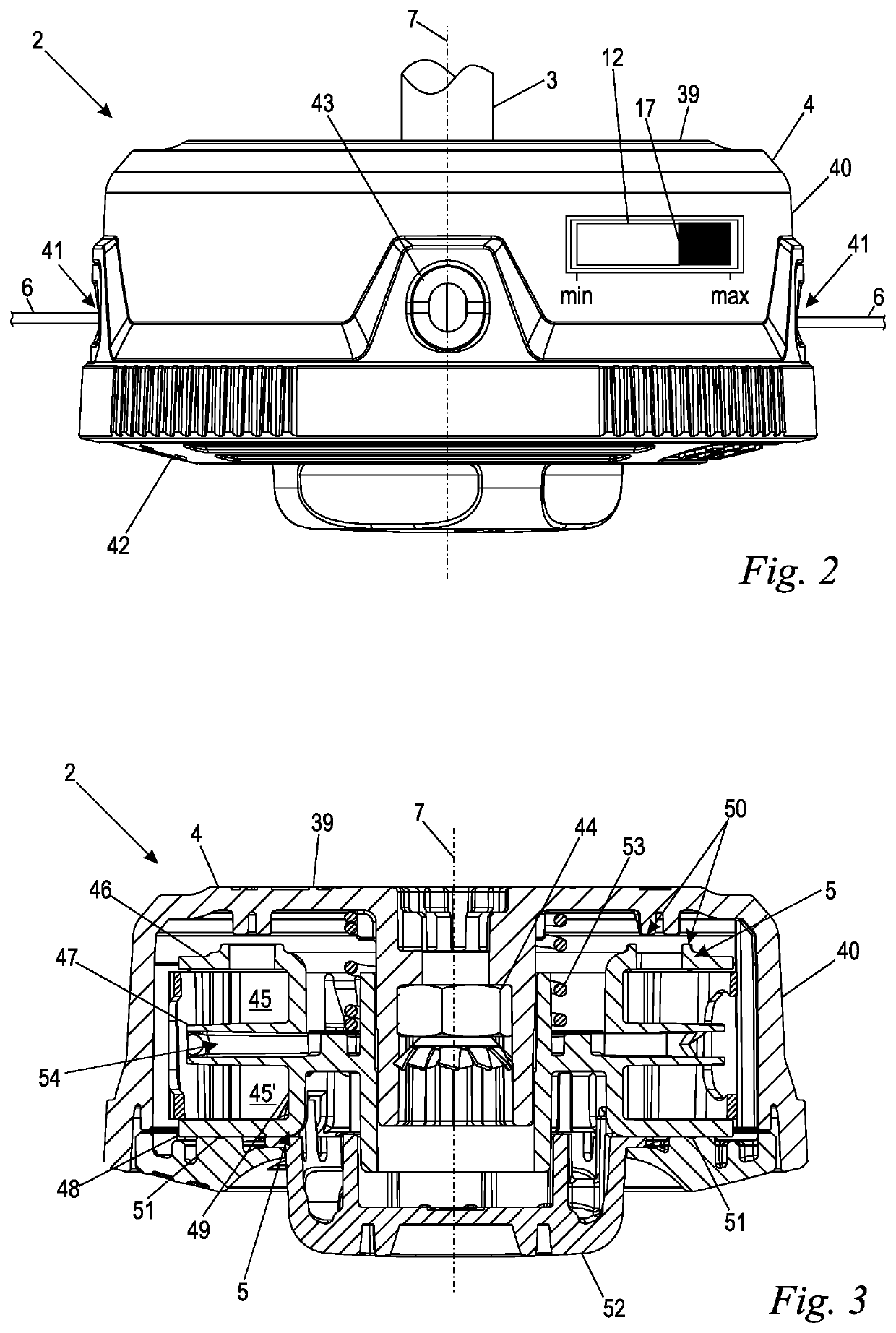

Trimmer Head with Residual Trimmer Line Indicator

A trimmer head for mounting on a drive shaft of a trimmer has a housing and a trimmer line spool for winding and unwinding a trimmer line. The trimmer line spool is rotatably supported in the housing about an axis of rotation. The trimmer line spool has a first rotational direction in relation to the housing and a second rotational direction in relation to the housing, wherein the second rotational direction is opposite to the first rotational direction. A counting device detects a residual trimmer line length of the trimmer line remaining on the trimmer line spool. The counting device is connected to the trimmer line spool such that the counting device counts up when the trimmer line spool rotates in relation to the housing in the first rotational direction and counts down when the trimmer line spool rotates in relation to the housing in the second rotational direction.

Owner:ANDREAS STIHL AG & CO KG

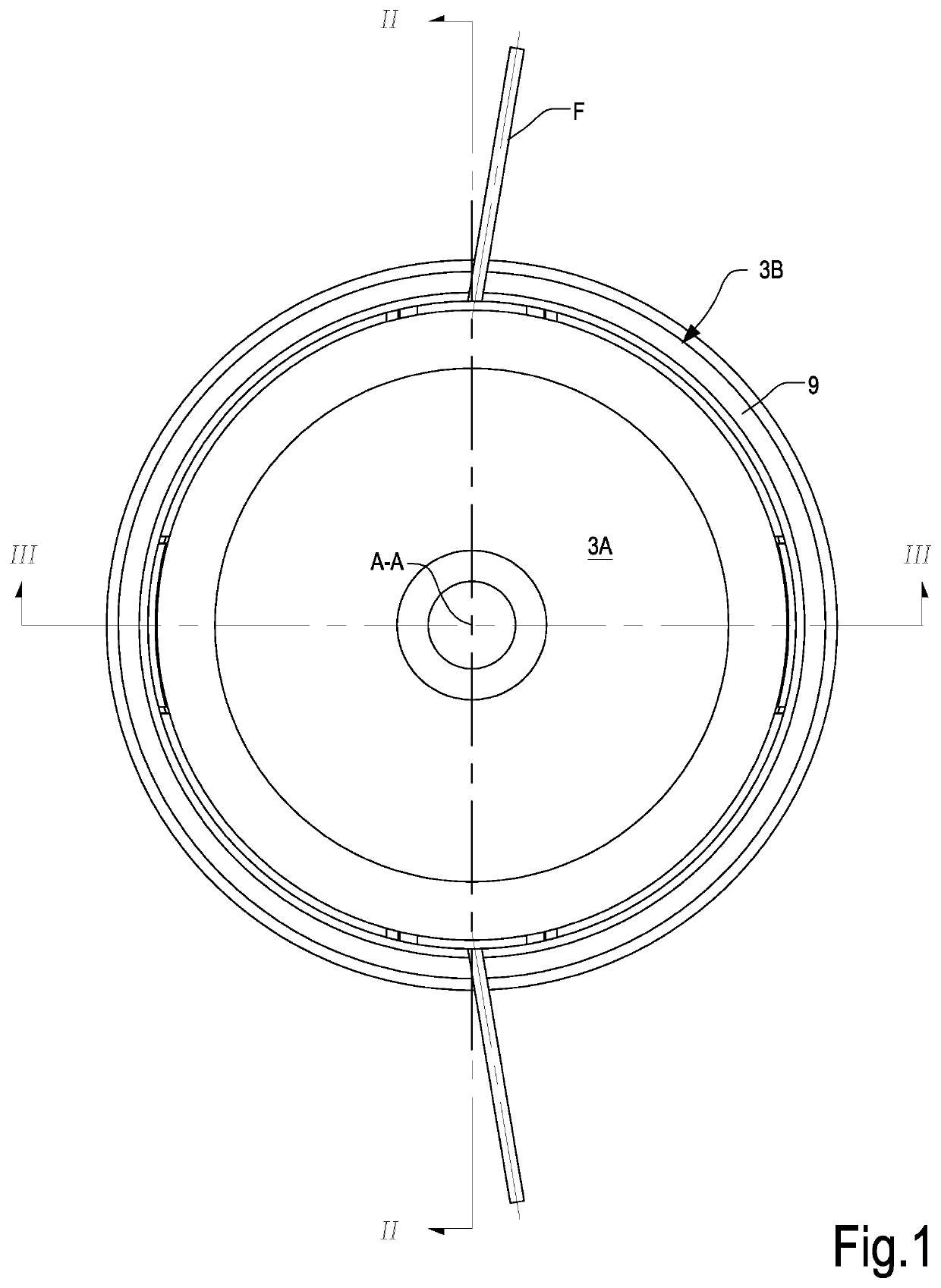

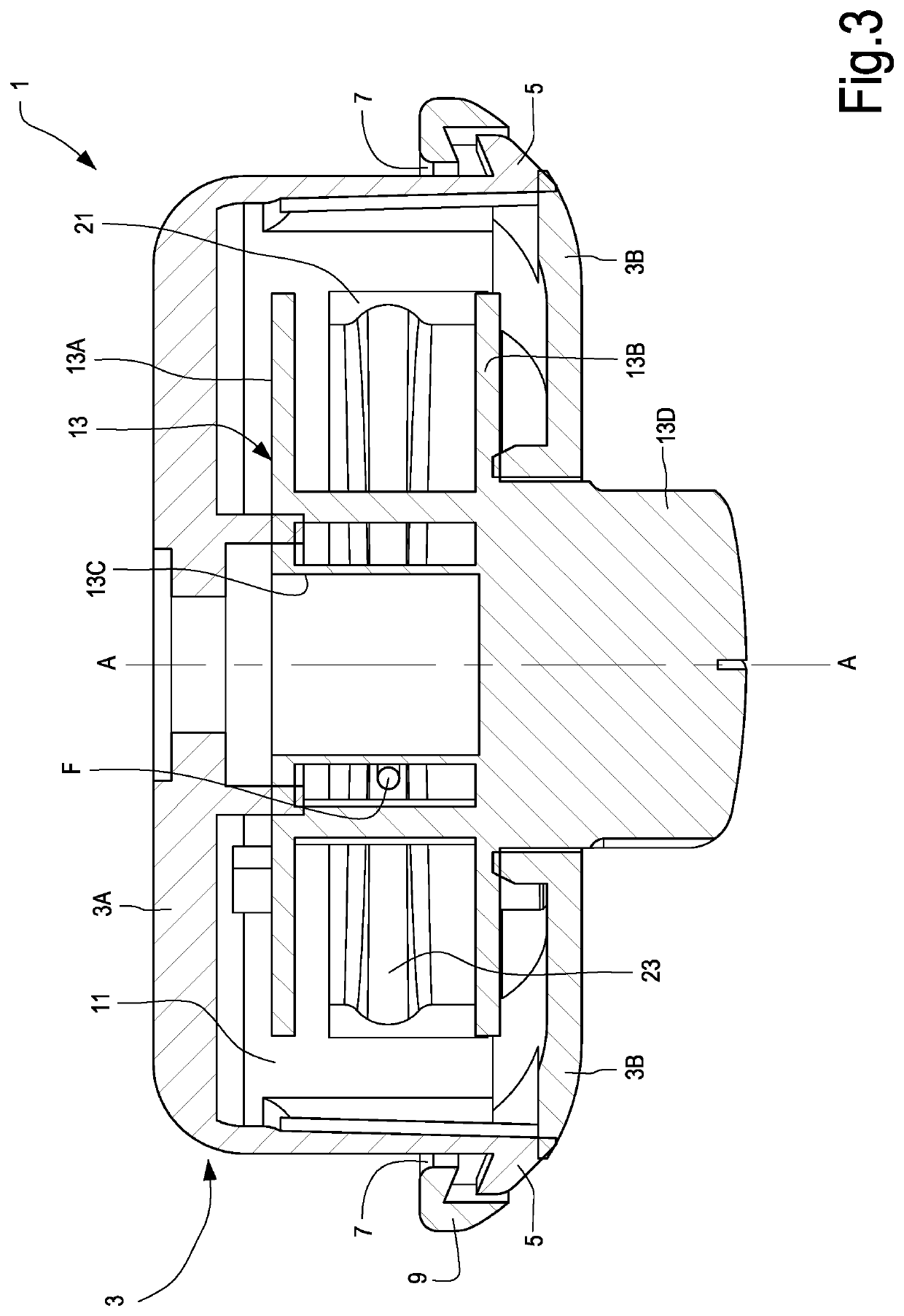

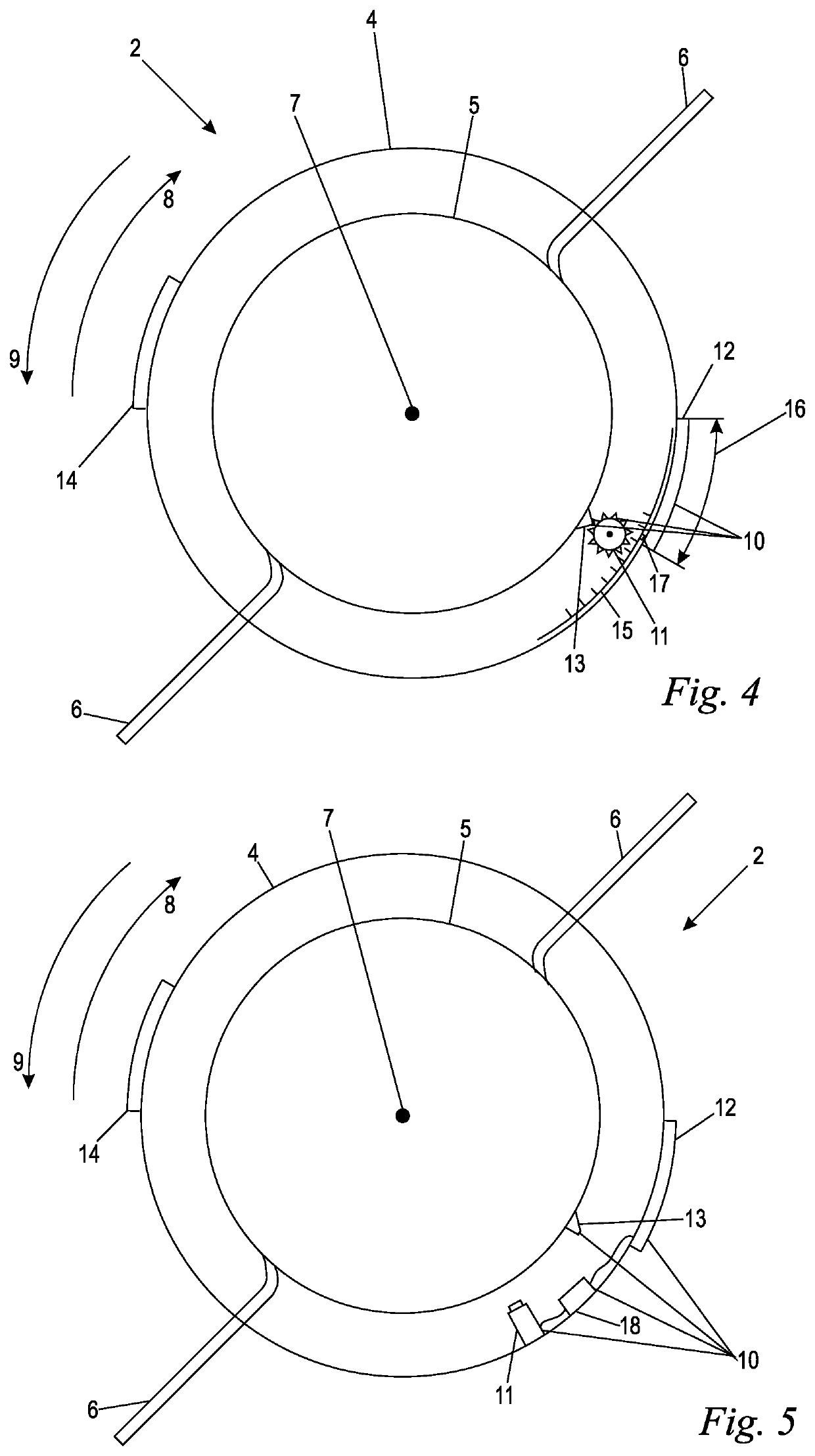

Trimmer Line Cutting Head for Mounting on a Drive Shaft of a Trimmer

A trimmer line cutting head has a trimmer line spool rotatably supported about an axis of rotation and disposed slidably between housing and housing cover along the axis of rotation. A spring element pretensions the trimmer line spool in an operating position of the trimmer line cutting head. An indexing device has a terminal stop connecting the trimmer line spool in the operating position to the housing in fixed connection for common rotation of trimmer line spool and housing. By applying an actuating force to the indexing device, the trimmer line spool is adjustable from the operating position axially into an inoperative state of the trimmer line cutting head for paying out trimmer line. The indexing device has a rotational stop formed in a slot in a wall of the trimmer line spool and limiting rotation of the trimmer line spool relative to the housing in the inoperative state.

Owner:ANDREAS STIHL AG & CO KG

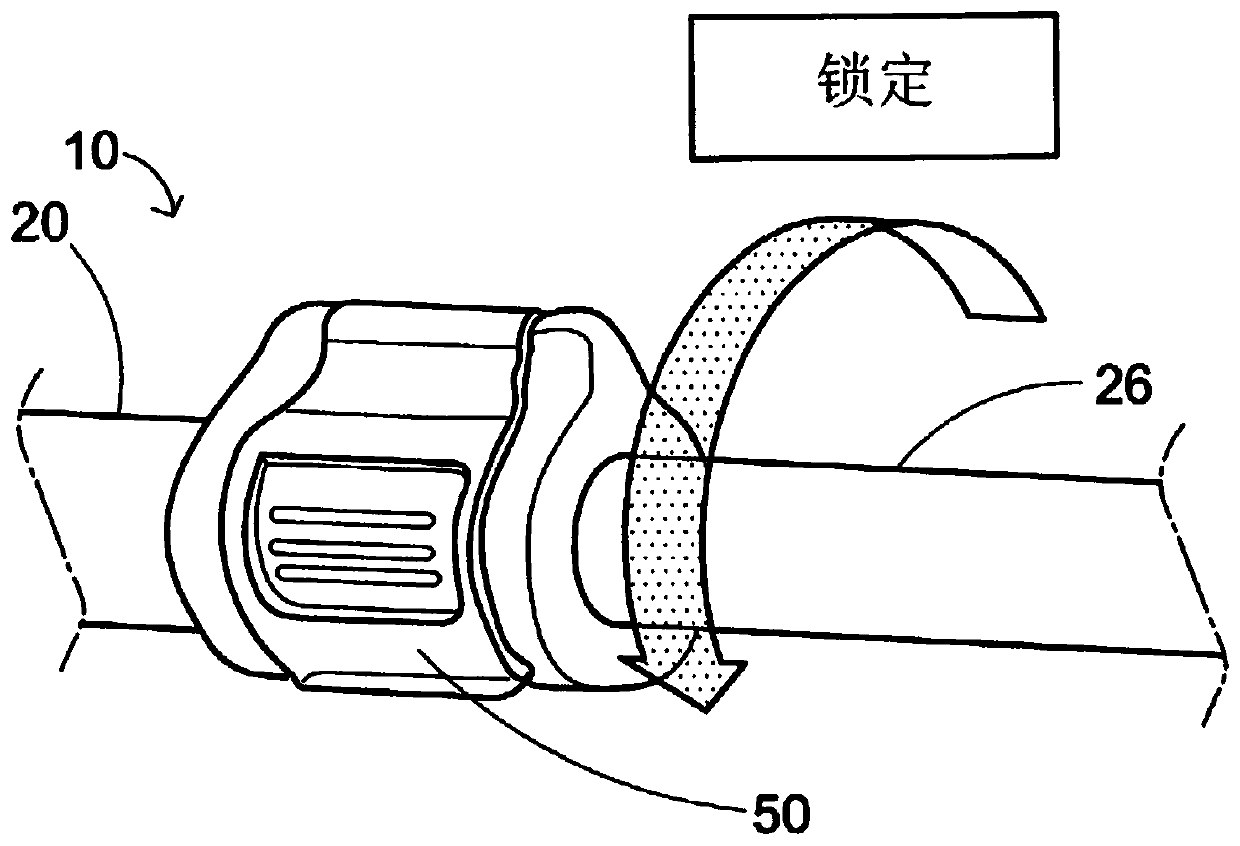

Line trimmer

ActiveCN109963456AConnecting is quick and easyFirmly connectedMowersRod connectionsTrimmerIndustrial engineering

A trimming tool (70) may have a variety of features such as a lockable telescoping tube (10), a tool guard (96) having a snap-fit fastener, an adjustment mechanism comprising a rotational mechanism (112) and a pivoting mechanism (114), or any combination of these features. A method of attaching a tool guard to a trimming tool is also provided.

Owner:TECHTRONIC CORDLESS GP

Trimmer block pad, trimmer, and method of trimming

ActiveUS20120057951A1ReusabilityReduce eliminateMetal working apparatusSheet bindingEngineeringMechanical engineering

The present disclosure relates to a trimmer block pad, a trimmer, and a process of trimming. The process includes inserting a book into a trimmer, positioning a trimmer block pad to abut the book, the trimmer block comprising a first non-square exterior corner and a second non-square exterior corner, and trimming a portion of the book. The positioning of the trimmer block pad applies a distributed force to the book.

Owner:JENCO MICROEDGE

Rotary trimmer apparatus and related rotary head assembly

ActiveUS9642302B2Quick and easy trimmer line insertionEasy to disassembleSleeve/socket jointsMowersTrimmerEngineering

An apparatus and method are provided for removing a retained member from a rotary head assembly configured for attachment to a rotary power source. The rotary head assembly can be configured to permit quick and easy trimmer line insertion in order to resume operation of the apparatus as well as simple and efficient trimmer line removal when changing trimmer line.

Owner:JEREZ ORLANDO

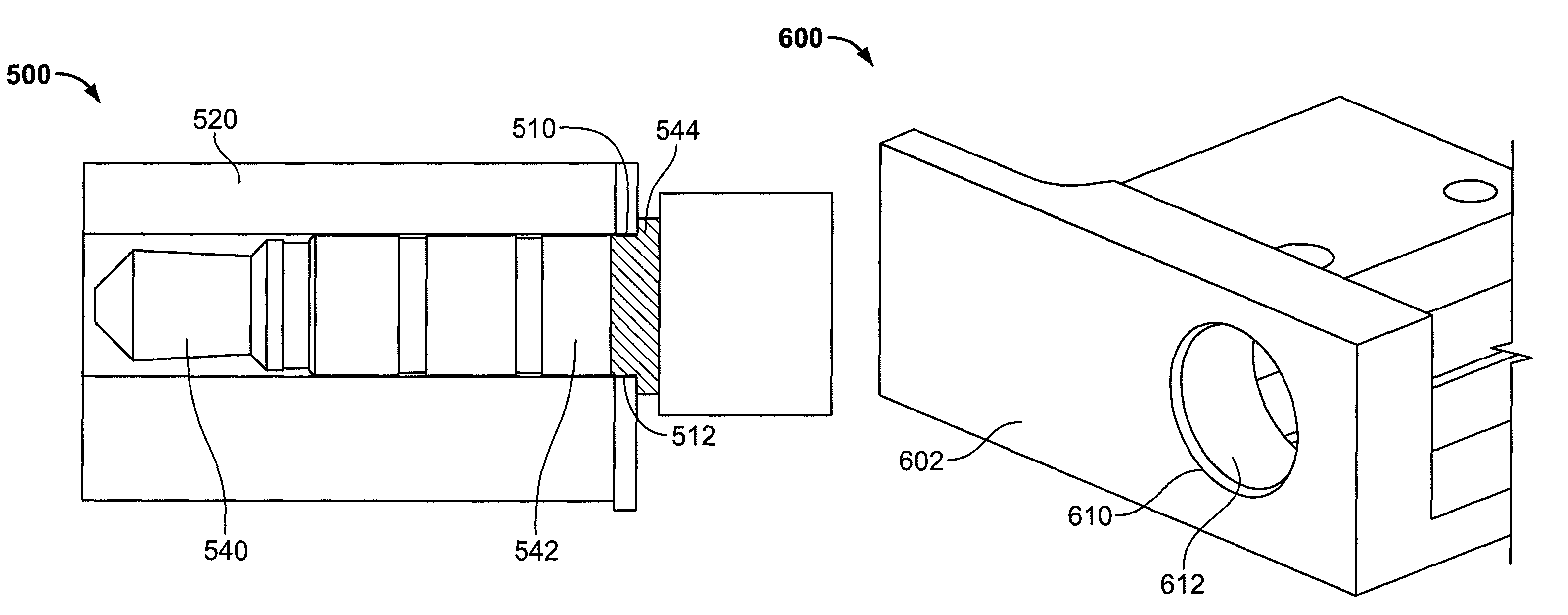

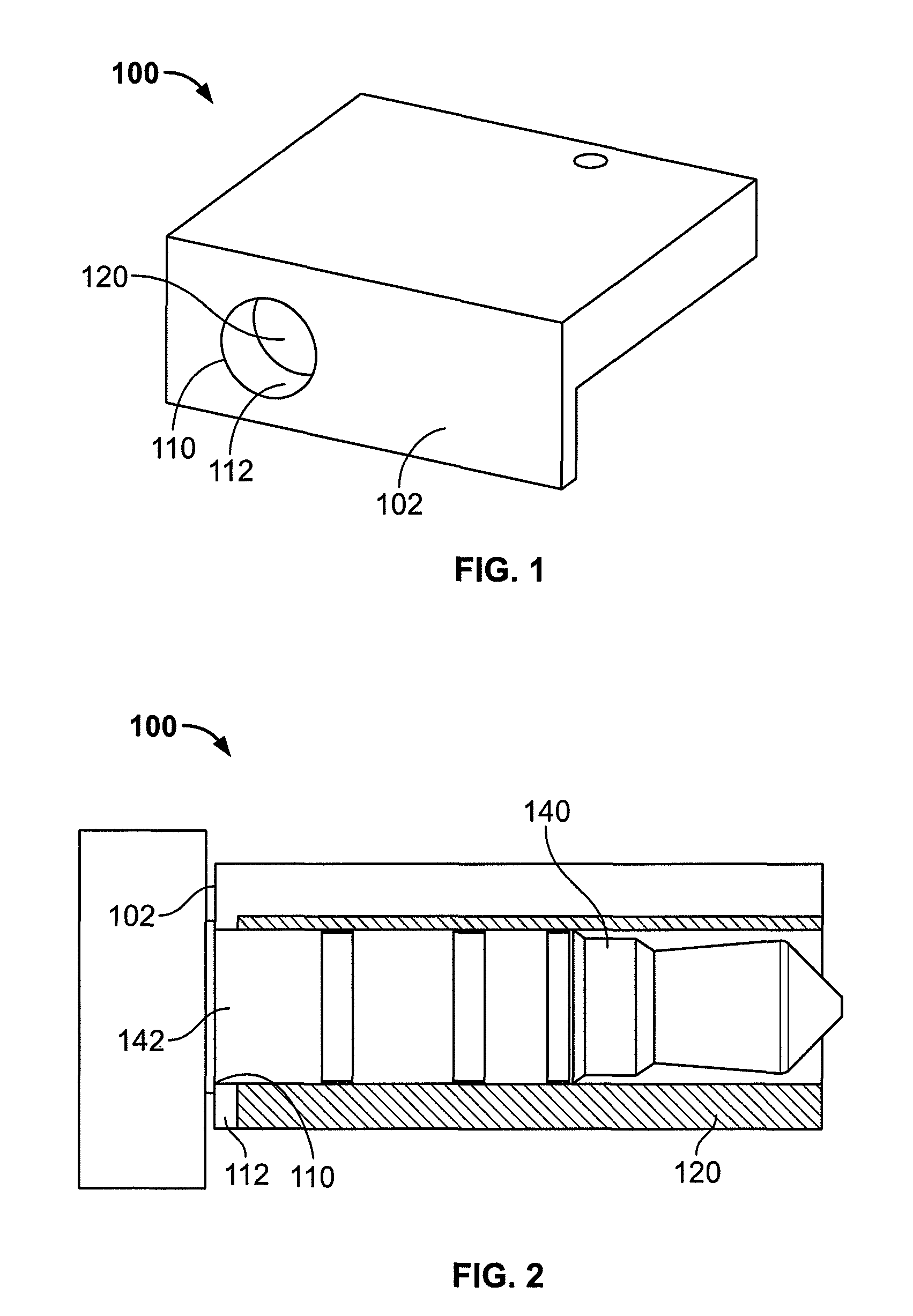

Systems and methods for providing a trimless electronic device port

ActiveUS7771240B2Line/current collector detailsSecuring/insulating coupling contact membersTrimmerThin layer

This invention is directed to systems and methods for providing a port in an electronic device housing that is electrically isolated from a conductive portion of a connector inserted in the port. In some embodiments, the connector may include a non-conductive flange or ring operative to contact the housing and the portions of the housing within the port. In some embodiments, a thin layer of non-conductive material may be applied to the portions of the housing within the port to prevent conductive portions of the connector from coming into contact with the housing (e.g., and grounding the conductive portion. This invention may be of particular interest when the conductive portion that may come into contact with the housing is not used to ground the connector.

Owner:APPLE INC

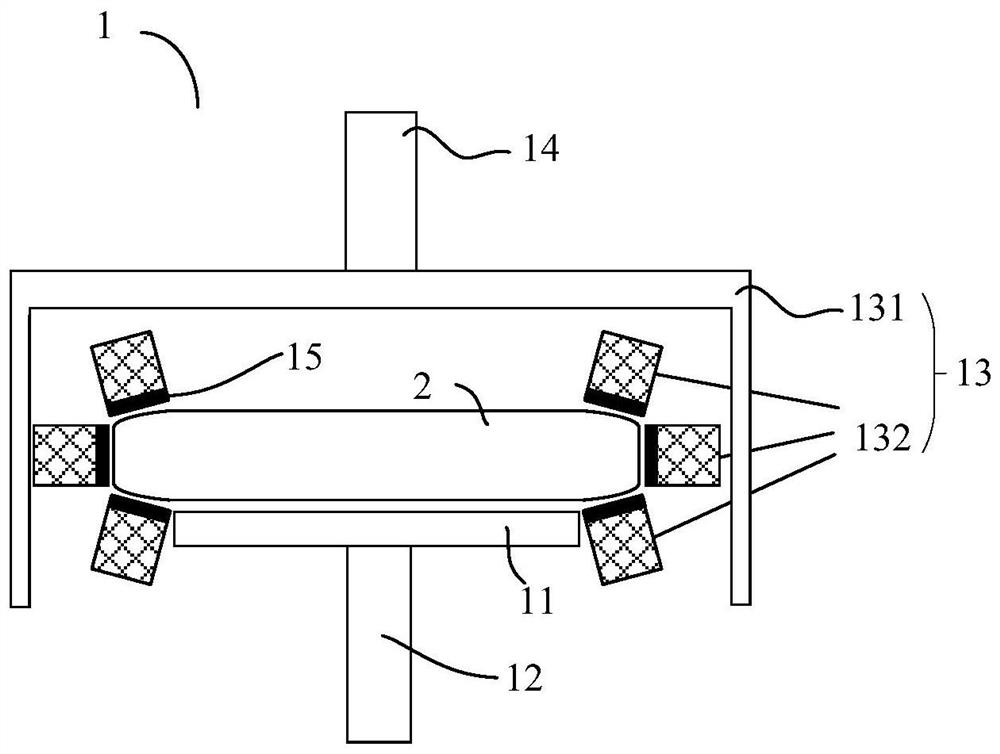

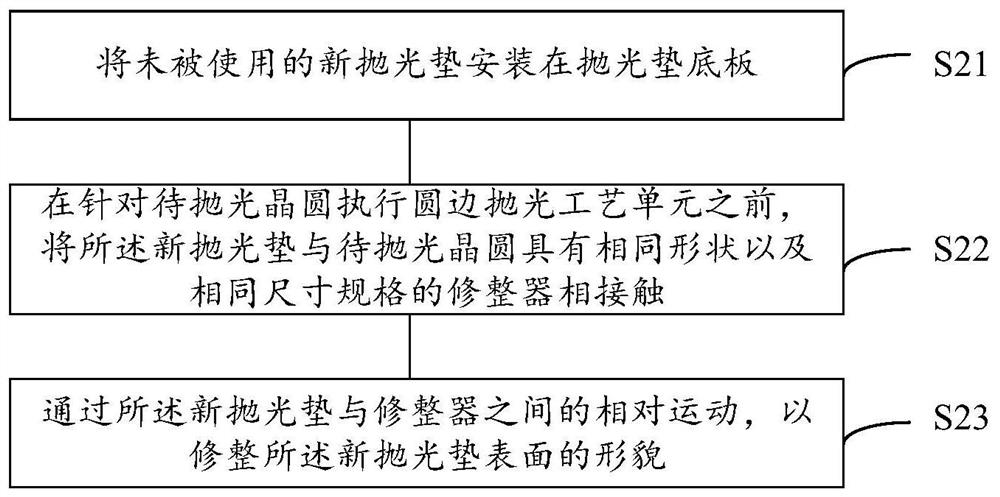

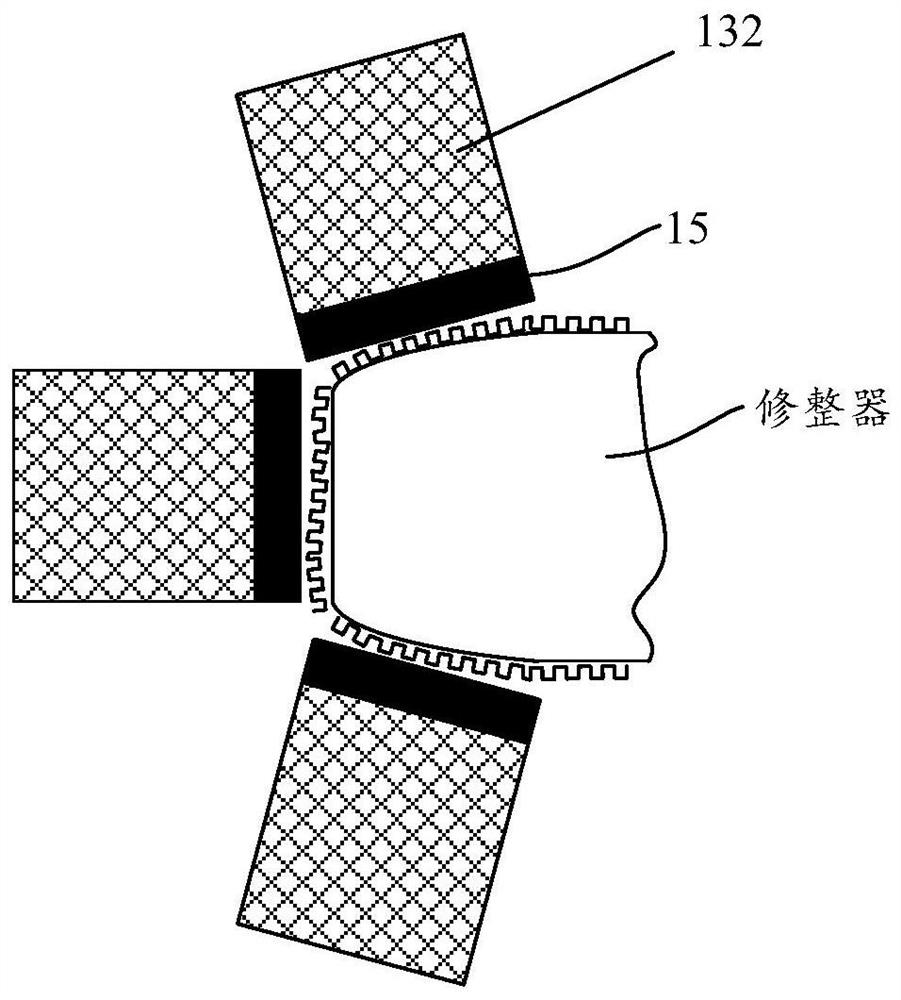

System and method for trimming edge polishing pad

PendingCN112372508AReduce manufacturing costConsistentAbrasive surface conditioning devicesTrimmerPolishing

An embodiment of the invention discloses a system and method for trimming an edge polishing pad. The method can include the steps that an unused new polishing pad is mounted on a polishing pad bottomplate; before a round edge polishing technology unit is executed on a to-be-polished wafer, the new polishing pad makes contact with a trimmer with the same shape and the same size specification as the to-be-polished wafer; and the shape of the surface of the new polishing pad is trimmed through relative movement between the new polishing pad and the trimmer.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

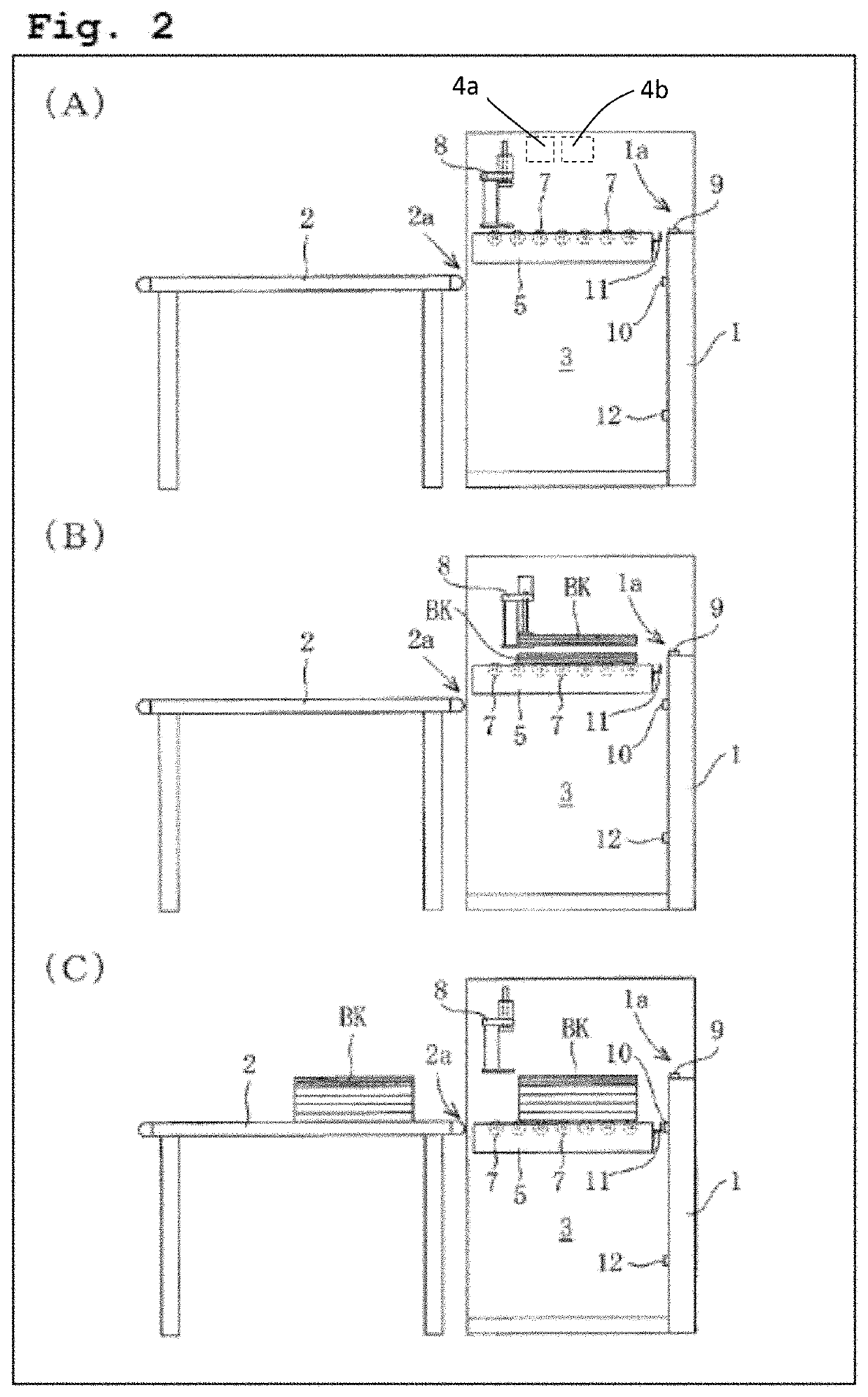

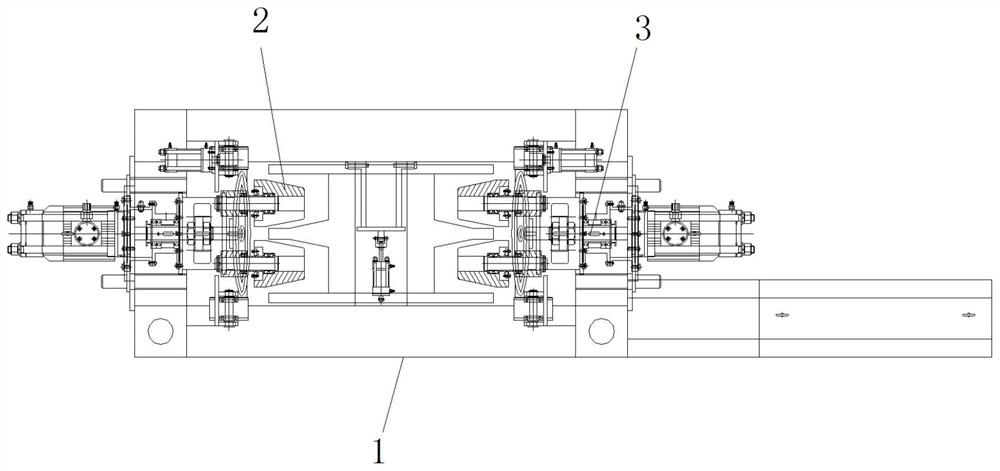

Three side trimmer

A three side trimmer has a trimming unit 1, an accumulating unit 3, a discharge unit 2 and a conveying mechanism 4 conveying trimmed booklets BK to the accumulating unit. The accumulating unit has a shelf 5 movable in a vertical direction, and a drive roller conveyor 7 on the shelf. The accumulating unit, in a mode, delivers the trimmed booklets to the discharge unit at every accumulation of a predetermined number of the trimmed booklets and, in another mode, accumulates the trimmed booklets without delivering.

Owner:HORIZON INTERNATIONAL INC

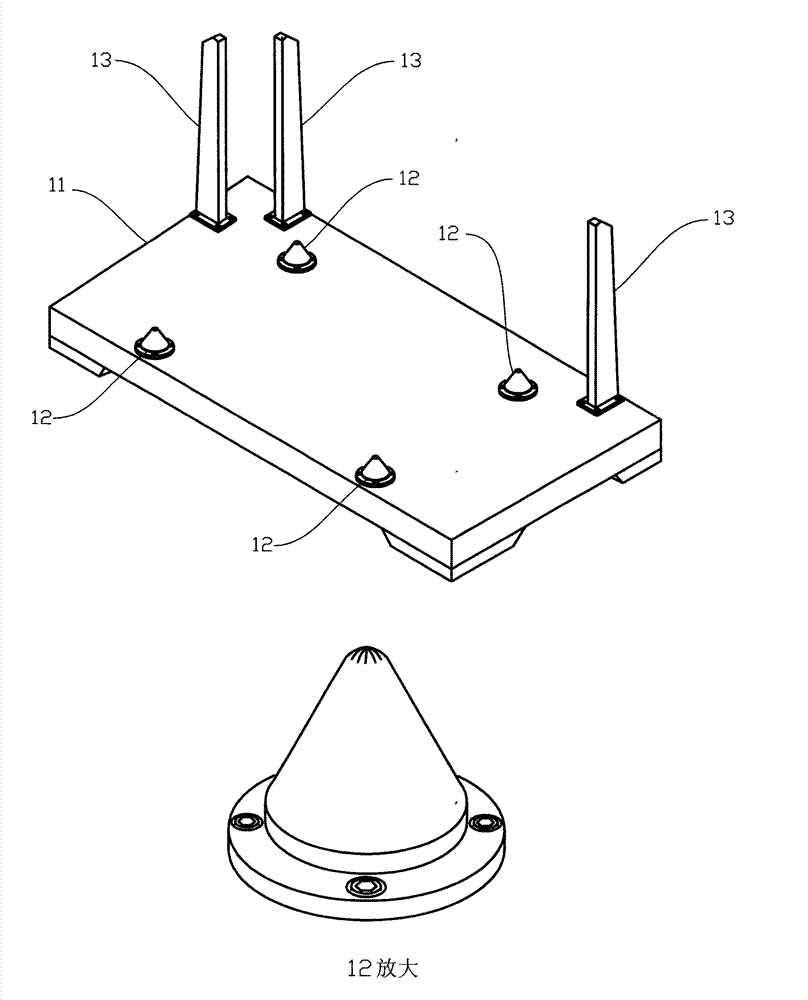

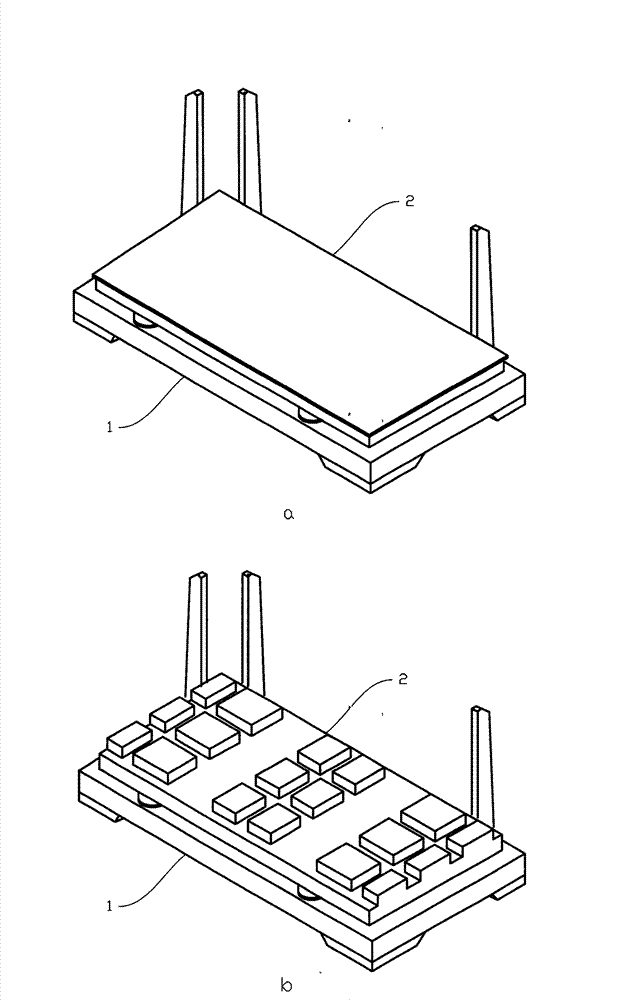

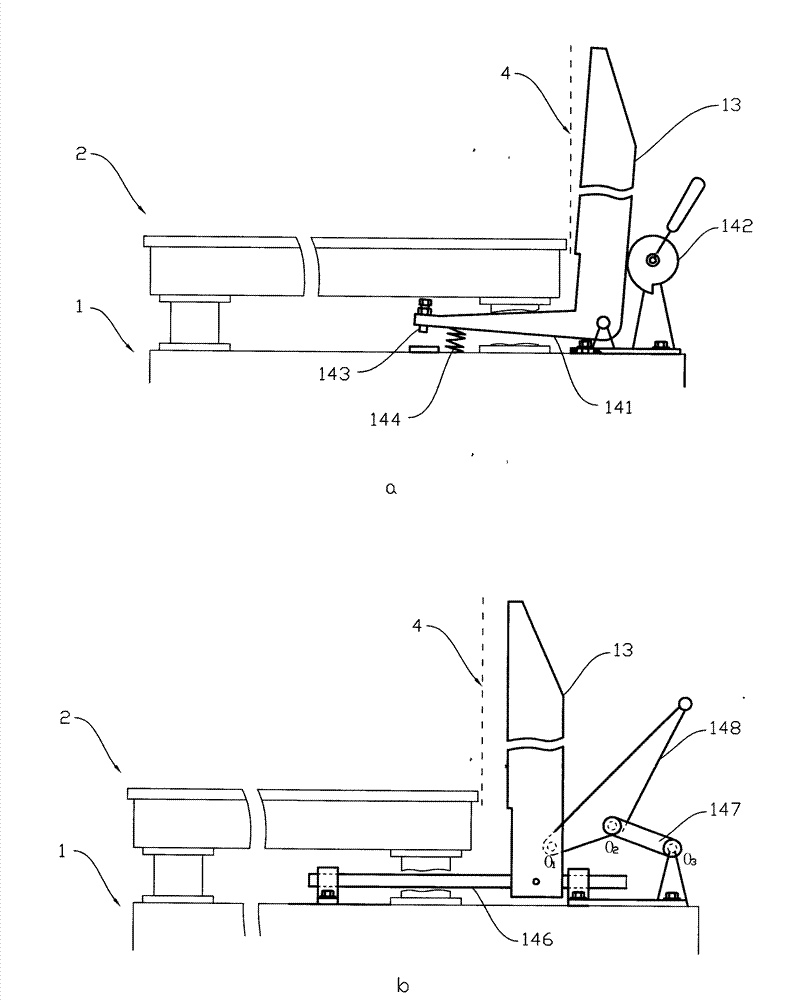

Plate, trimming method of plate, overstowing pedestal, multi-purpose bench and trimmer

InactiveCN103112075AGood shape and position consistencyGood shape consistencyOther plywood/veneer working apparatusDomestic articlesButtressMechanical engineering

Provided are a plate, a trimming method of the plate, an overstowing pedestal, a multi-purpose bench and a trimmer. The plate is an artificial wood synthetic plate, and provided with edges which are neat and uniform, and the trimming method of the plate is overstowing cutting. The overstowing pedestal, the multi-purpose bench and the trimmer enable the trimming method to be implemented in a method that seat positioning parts of the overstowing pedestal, the multi-purpose bench and the trimmer are mutually matched by using a carrying or hoisting machine. The overstowing pedestal is provided with a baffle gauge in a paralleling mode and used for overstowing the plate in a high mode in advance outside the trimmer. The multi-purpose bench is mobile, flexible and fast after being carried by the machine, or the multi-purpose bench is positioned to overstowing plate blank of the overstowing pedestal in a sitting mode or to a positioning plate of the trimmer in a sitting mode. A working groove is arranged in a pedestal surface, processes can be saved by carrying finished plates without turning buttresses and packing, a quick-mounting outside baffle gauge is arranged on a pedestal side, and the overstowing pedestal can be replaced according to times and places. A complex conveying mechanism is saved in the trimmer which is provided with a moving pad, the moving pad can be matched with the multi-purpose bench without a base plate, the trimmer is further provided with a mechanism which assists a mobile clamp presser foot to move in a parallel mode and an outside manual clamp, and therefore cutting thickness can be added. The overstowing pedestal, the multi-purpose bench and the trimmer are matched to bring out the best in each other, and improve trimming efficiency, and the plate which is trimmed is neat in edge.

Owner:赵瑞合

Automatic iron barrel reshaping and trimming equipment

PendingCN111974886AEasy to recover deformationImprove quality and safetyShaping toolsHollow articlesTrimmerStructural engineering

The invention discloses automatic iron barrel reshaping and trimming equipment. The equipment comprises a trimmer and a reshaper, wherein the trimmer comprises a first rack, supporting and lifting mechanisms and trimming mechanisms; the supporting and lifting mechanisms are arranged below the two sides of the first rack; the trimming mechanisms are arranged at the middle positions of the two sidesof the first rack; first high-frequency heating devices are arranged on the two sides of the upper parts of the first rack; the reshaper comprises a second rack, a rotating mechanism and a propellingmechanism; supporting wheels are arranged on the two sides on the lower part of the second rack; the rotating mechanism is arranged on the left side of the second rack; the propelling mechanism is arranged on the right side of the second rack; a rolling mechanism is installed above the second rack; and a second high-frequency heating device is arranged at the rear end of the second rack. According to the automatic iron barrel reshaping and trimming equipment, the renovation quality and product safety of iron barrels are greatly improved, the abandonment and stacking of the scrapped iron barrels are reduced, the phenomenon of running, falling and dropping is avoided, the resources are saved, the environmental pollution is reduced, and the environment is favorably protected.

Owner:安徽超越环保科技股份有限公司

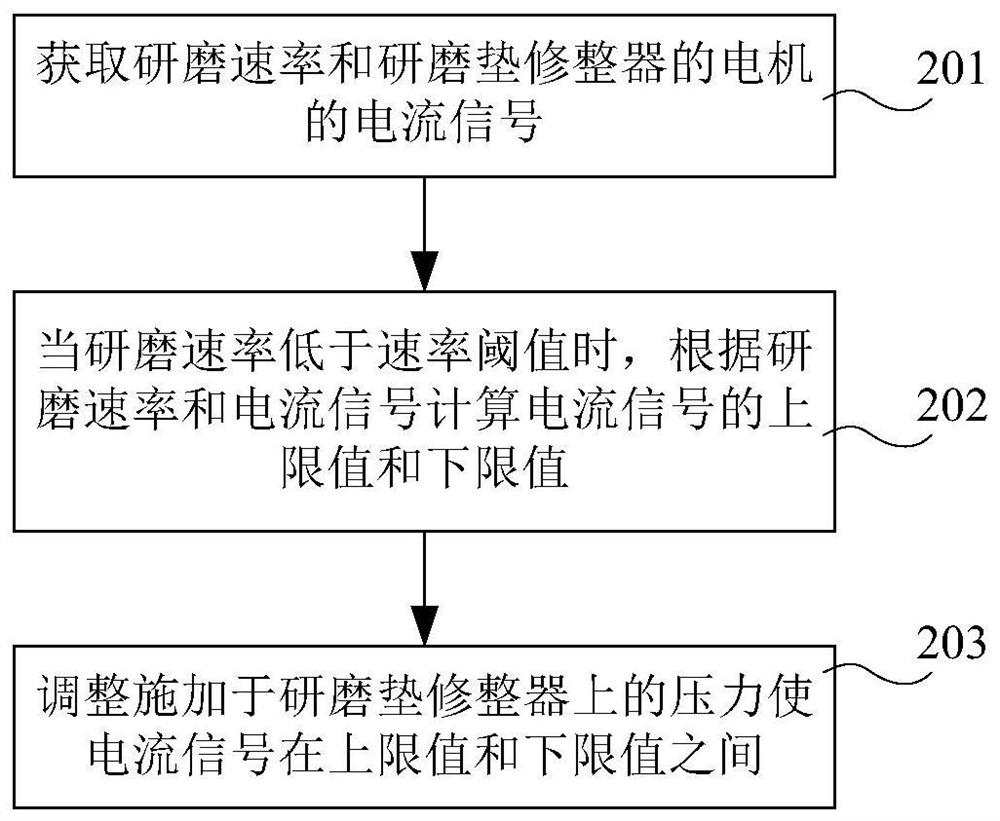

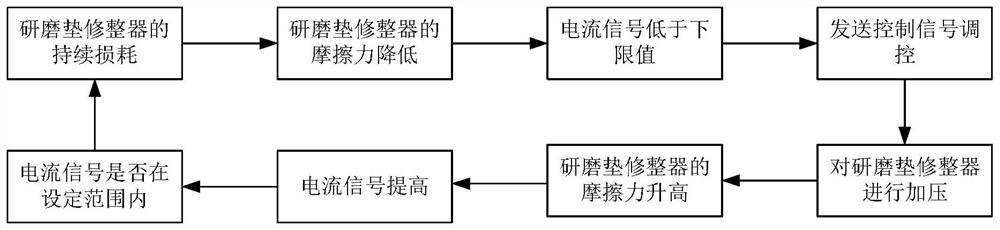

Chemical mechanical polishing control method and equipment

PendingCN113334238AReduce lossStable grinding rateLapping machinesAbrasive surface conditioning devicesTrimmerPolishing

The invention discloses a chemical mechanical polishing control method and equipment. The method comprises the steps that the polishing rate and a current signal of a motor of a polishing pad trimmer are obtained; when the polishing rate is lower than the rate threshold value, an upper limit value and a lower limit value of the current signal corresponding to the polishing rate are obtained; and pressure applied to the polishing pad trimmer is adjusted such that the current signal is between the upper limit value and the lower limit value. The polishing rate and the current signal of the motor of the polishing pad trimmer are obtained, when the polishing rate is lower than the rate threshold value, the value range of the current signal is determined according to the polishing rate, and therefore the pressure applied to the polishing pad trimmer is adjusted according to the value range of the current signal, so that the current signal is within the value range, stability of the polishing rate is ensured, and then the loss of the polishing pad trimmer is reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Easy to load trimmer head with forced discharge

Owner:SHAKESPEARE CO

Teaching platform

The invention discloses a teaching platform. The teaching platform structurally comprises a platform frame, a display screen and a platform column. The display screen is mounted on the platform frame;and the platform frame is locked with the platform column. The platform frame is composed of a supporting arc frame, a baffle, a sidetone wing, a keyboard drawer and a rack. The supporting arc frameis locked with the baffle and the rack; the rack is provided with the sidetone wing; and the keyboard drawer is connected with a rack track; the baffle is spliced and connected with the rack. The sidetone wing comprises a telescopic pressing plate, a left concave plate, a left turning plate, a right turning plate and a right concave plate. The telescopic pressing plate is connected with the left concave plate and the right turning plate through the track; and the left concave plate is connected with the left turning plate. According to the invention, the telescopic pressing plate drives the left concave plate and the right turning plate to be folded in a concave mode, the sidetone wing collects audio in the middle to produce sounds, an audio trimmer processes the audio, high-definition audio and noisy audio are separated; four surrounding loudspeakers cooperate with each other in a circulating sound production mode, three-dimensional circulating sound production is achieved, the propagation distance is long, and the propagation sound quality is clear.

Owner:TONGREN POLYTECHNIC COLLEGE

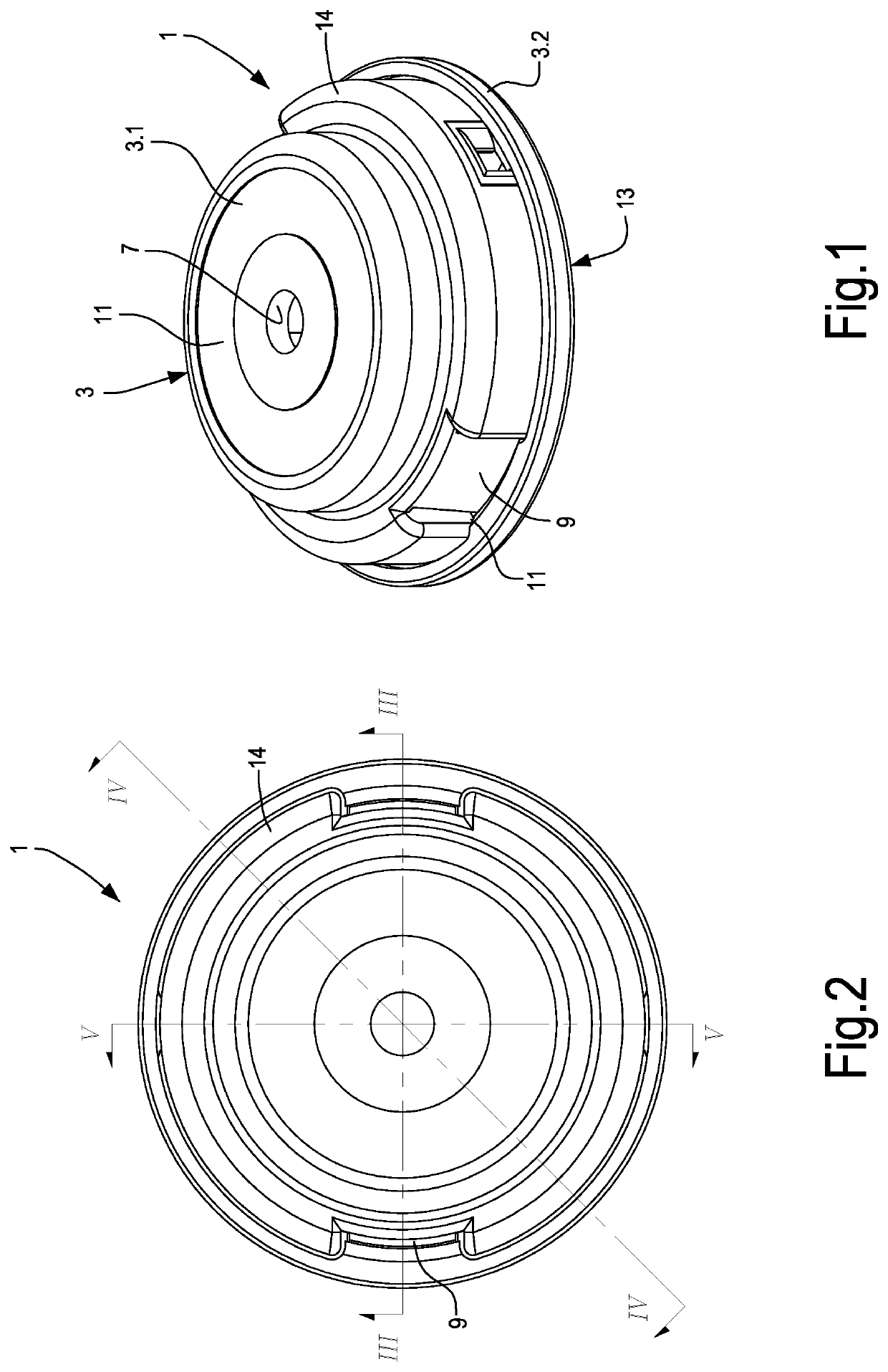

Trimmer head and spool for a trimmer head

The trimmer head (1) includes a housing (3) and a spool (5) that can be housed in the housing. A pair of ring members (35A, 35B) with teeth inclined at opposite inclinations can be selectively coupled to the head, to engage the trimmer head (1) in combination with trimmer apparatuses having engine that rotates selectively in a clockwise or anticlockwise direction.

Owner:ARNETOLI MOTOR

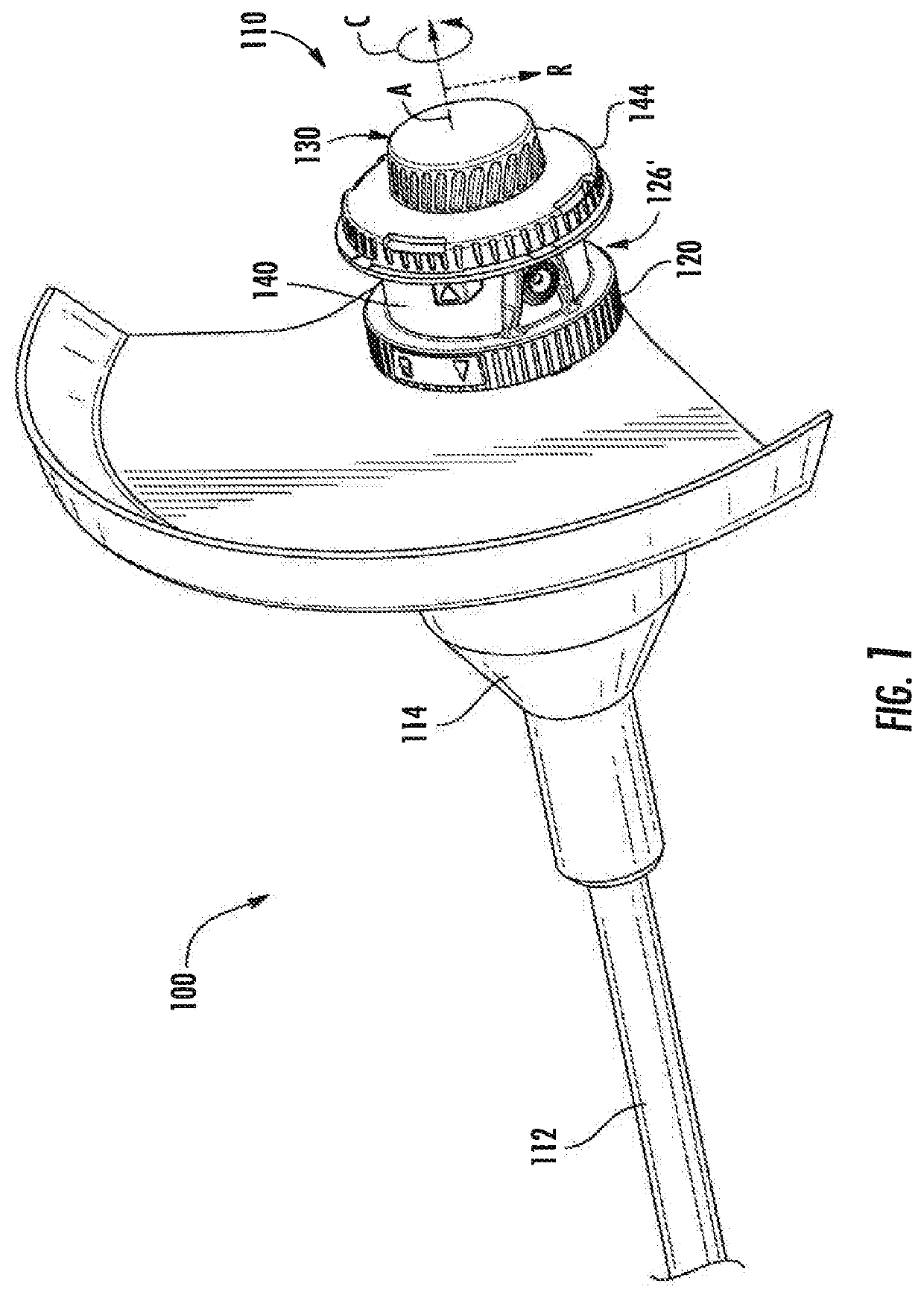

Trimmer head

ActiveUS10939614B2Sufficient rotational velocityReduce the average velocityLawn-mowersTrimmerHand held

A trimmer head for use with a handheld lawn maintenance tool is shaped in a hub-and-spoke manner, wherein the trimmer head includes a housing formed of a hub, a circular rim, and a plurality of spokes extending therebetween. A spool is positioned within the hub, and a pair of pieces of trimmer line are inserted into opposing sides of the circular rim through the spokes for winding onto the spool. The trimmer line extends outwardly from the housing at a location spaced away from the hub.

Owner:MTD PRODUCTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com