Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

384results about How to "Consistent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Information safety penetration testing method for distribution automation system

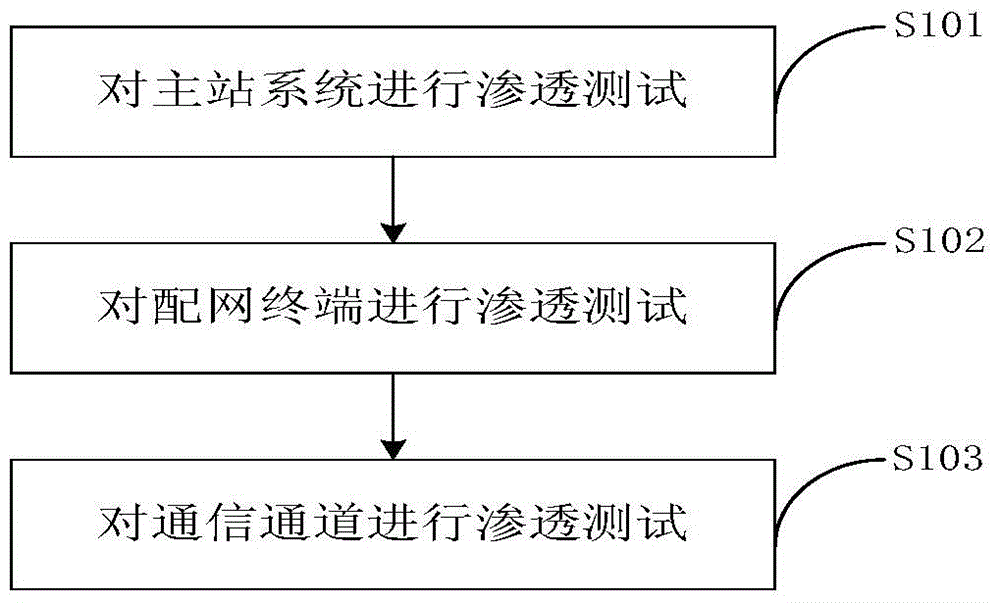

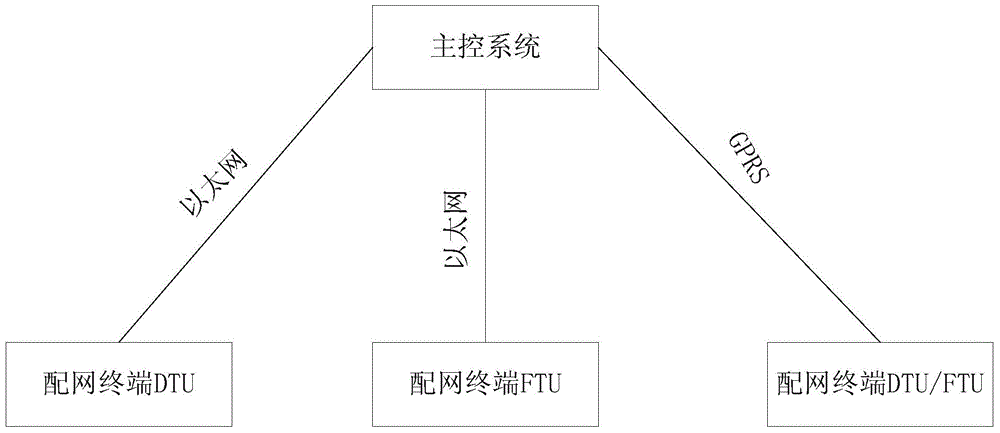

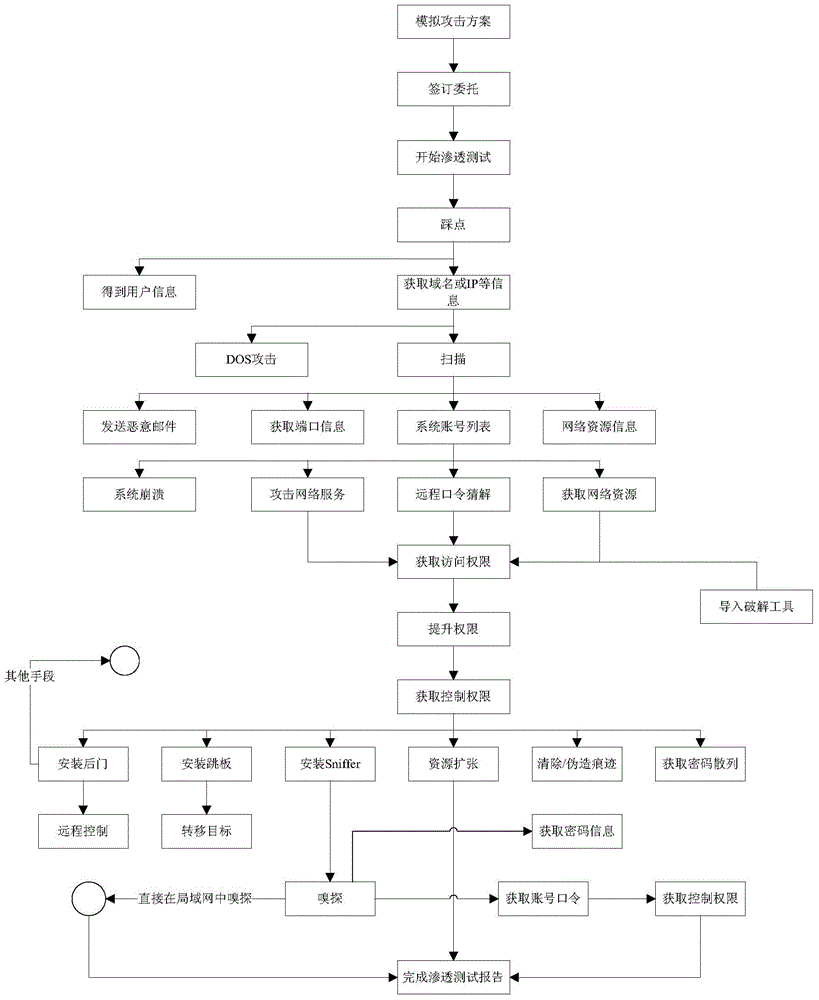

ActiveCN104468267AAchieve consistencyImplementations should be consistent withData switching networksThe InternetMaster station

The invention discloses an information safety penetration testing method for a distribution automation system. Penetration testing is carried out on a master station system, a distribution network terminal and a communication channel, the information system vulnerability penetration testing technology is fully used, the safety of the distribution automation system is evaluated by simulating the attack method of a hacker, and the information safety penetration testing method includes the active analysis for any weakness, technical defects or loopholes of the master station system, the communication circuit and the distribution network terminal. The information safety penetration testing method for the distribution automation system can be used for safety risk analysis work before the distribution automation system is connected to the internet, guidance is provided for finishing problem rectification and reformation and retest work of manufacturers with safety risks, and the method is high in pertinence and wide in test range. Compared with a traditional penetration testing method, the test time can be largely shortened, offline repairing events caused by safety problem failures after equipment is on line are reduced, the information safety penetration testing for the distribution automation system is realized, and the information safety penetration testing method can be applied to industrial control systems inside and outside the industry.

Owner:STATE GRID CORP OF CHINA +1

Intelligent emotional robot multi-modal behavioral associative expression system

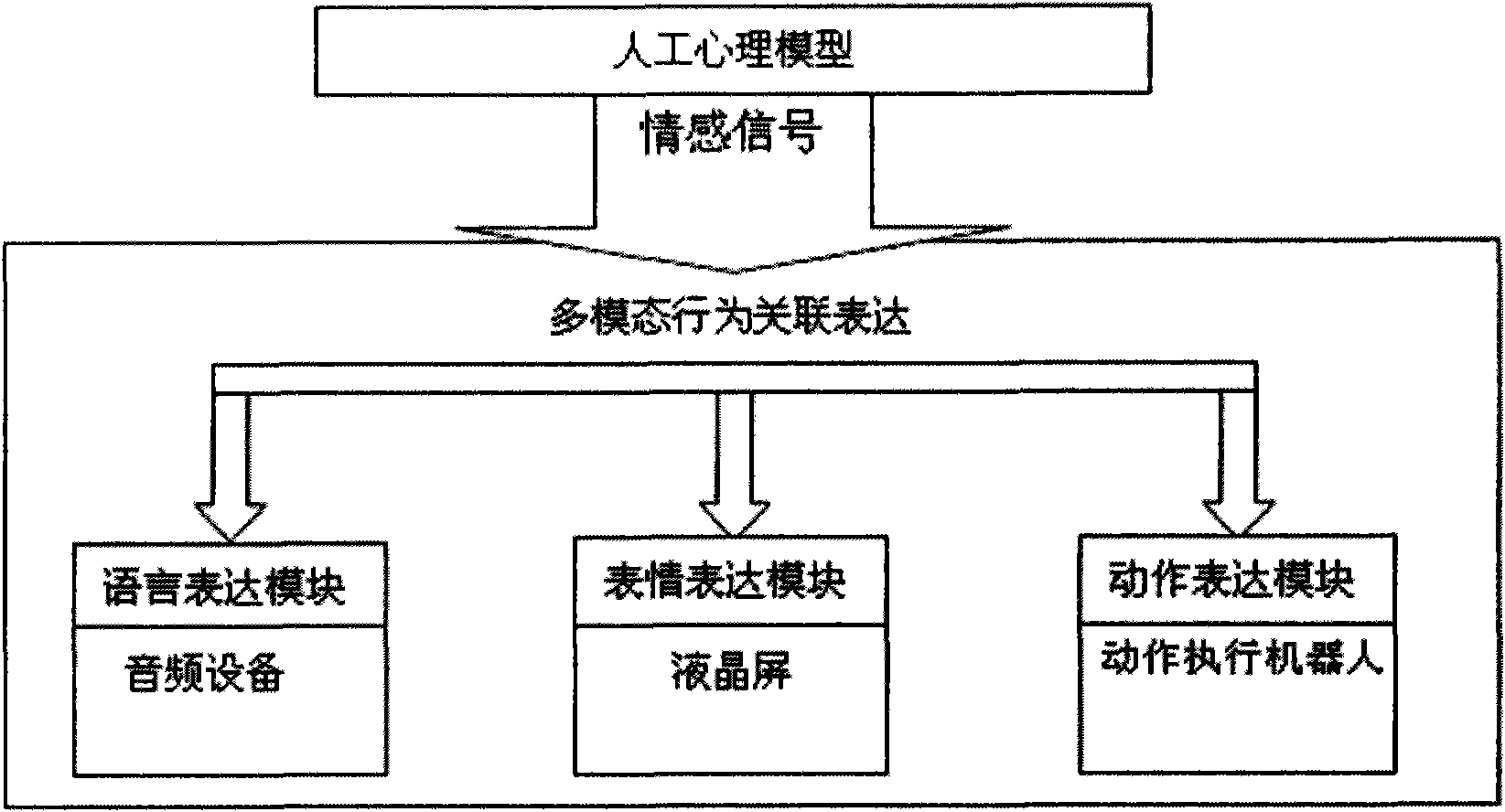

ActiveCN101661569AConsistentBiological modelsTotal factory controlFacial expressionHuman–computer interaction

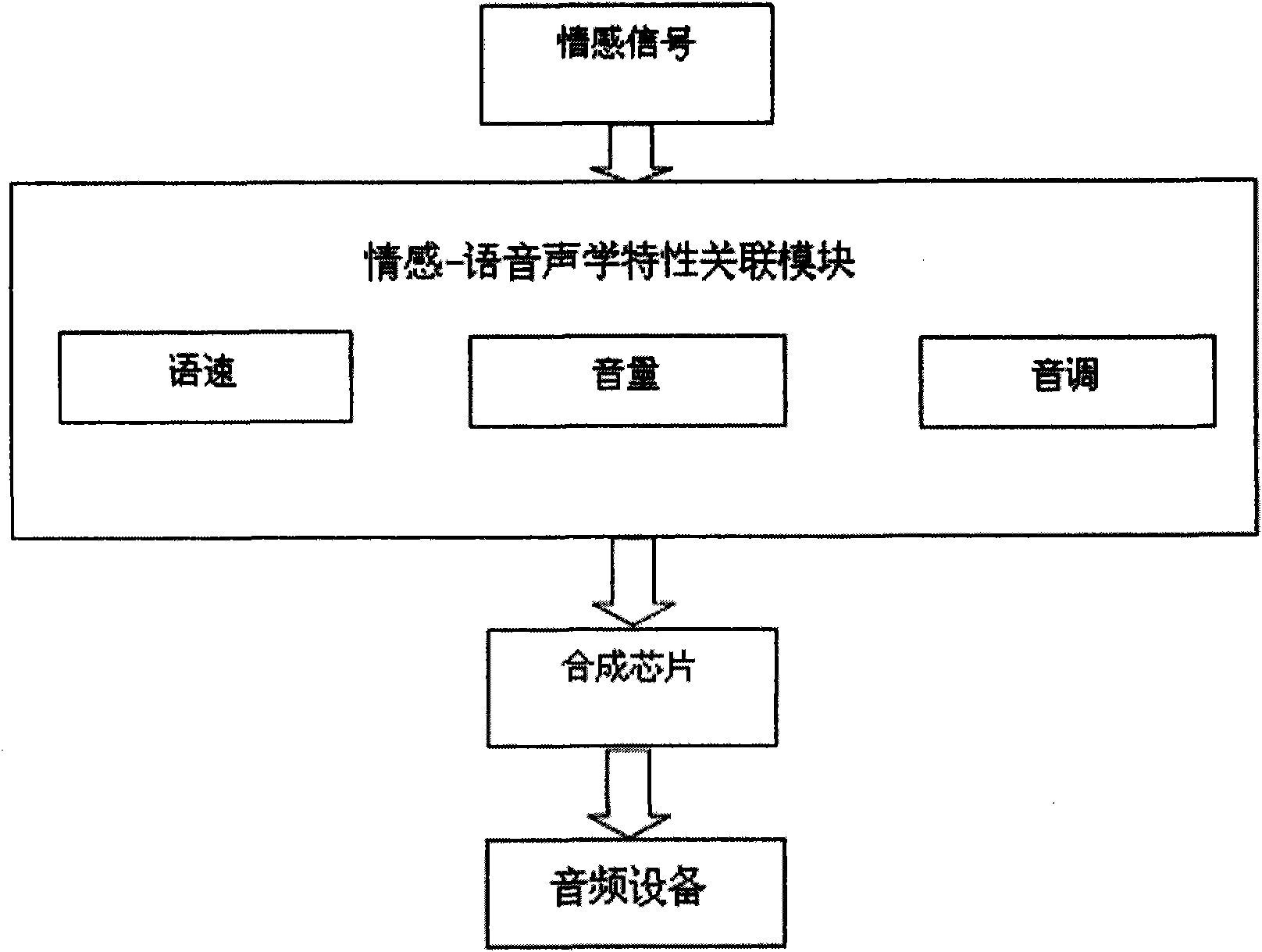

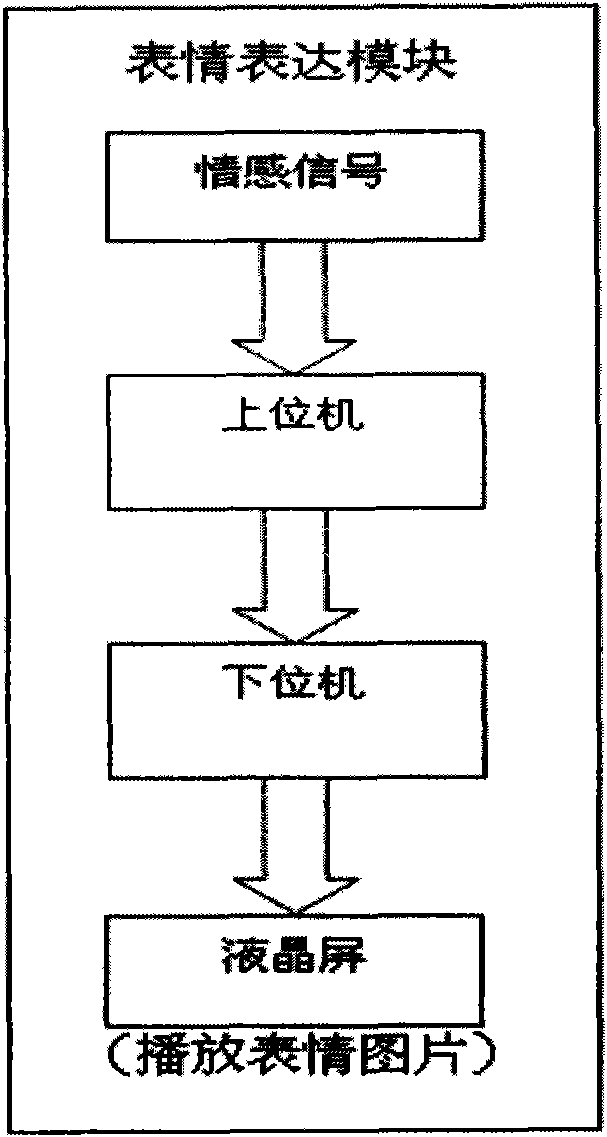

On the basis of an artificial mental model, the invention researches a behavioral expression mode and a method of a robot from the view of psychology, and provides an intelligent emotional robot multi-modal behavioral associative expression system. The system accepts the unified driving of emotional signal output by the artificial mental model and is provided with a unified behavioral driving mechanism; therefore, the behavioral expressions are more harmonious. The intelligent emotional robot multi-modal behavioral associative expression system comprises three modules, namely a language expression module, a facial expression module and an action expression module; the three modules accept the unified driving of an emotional signal output by the artificial mental model; and to the expression of the language, face and action of the intelligent emotional robe, the expression of language, face and action are executed synchronously on time sequence, and the unified driving of the emotionalsignal is accepted logically, thereby having consistency.

Owner:UNIV OF SCI & TECH BEIJING

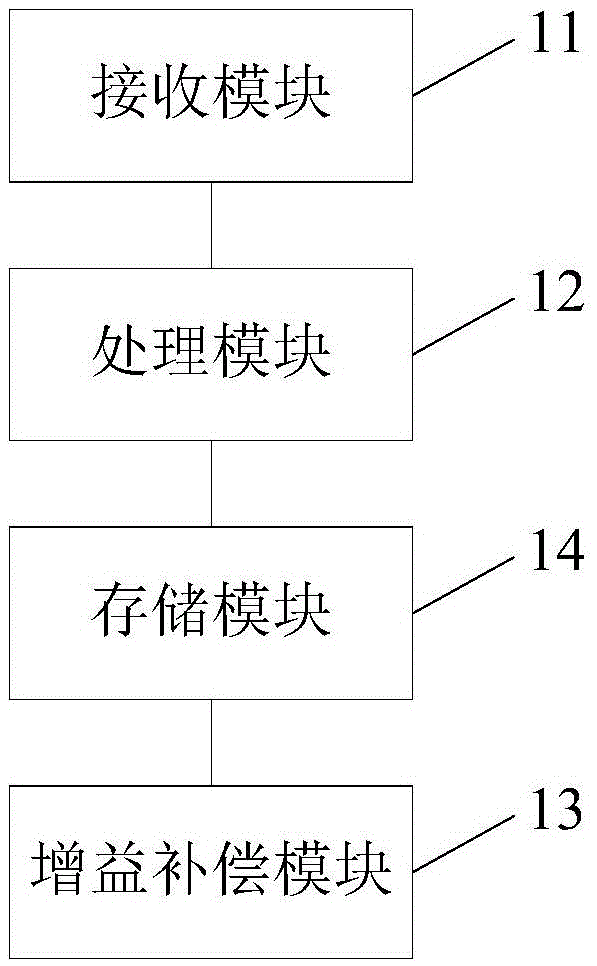

Microphone calibration method, device and mobile terminal

InactiveCN105554674ASolve the problem of differences in signal strengthConsistentSignal processingLoudnessComputer science

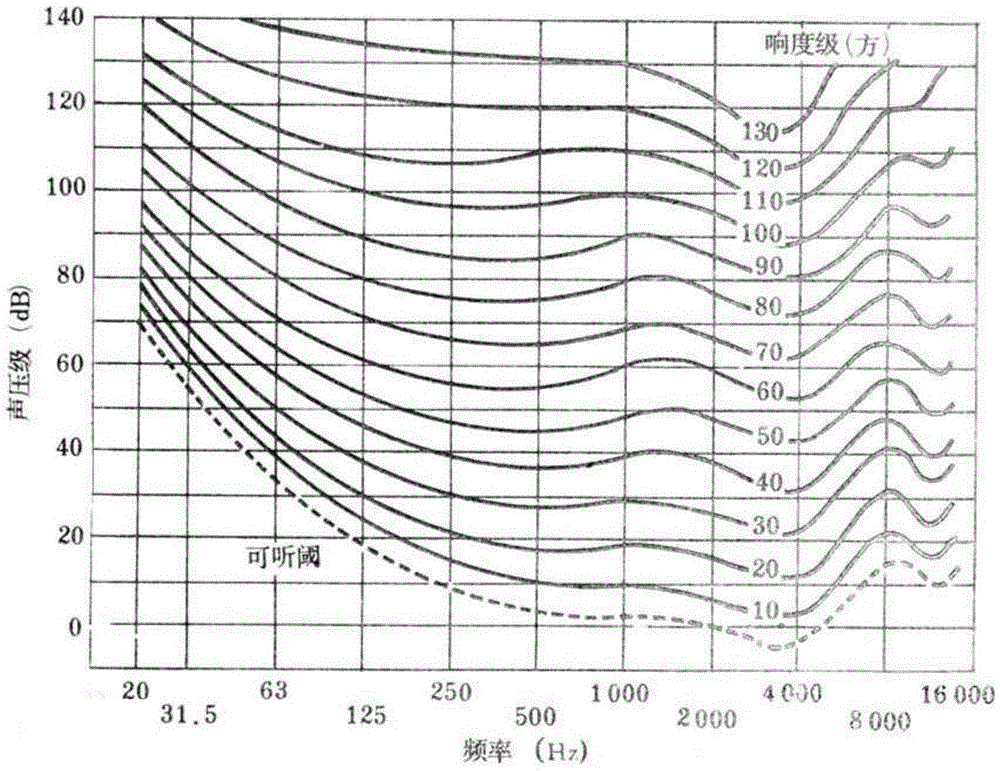

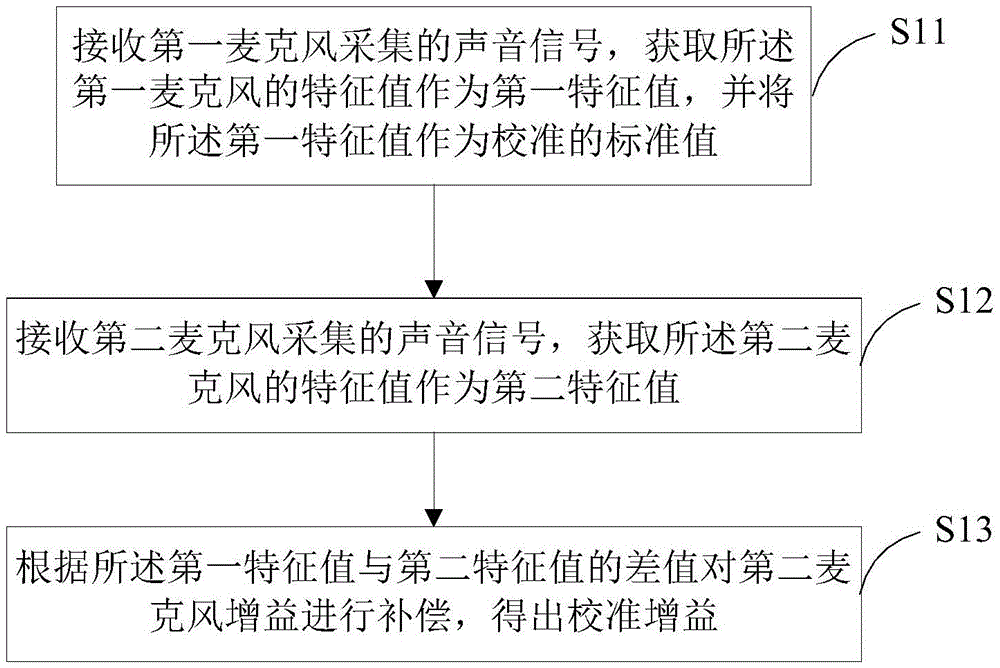

The invention discloses a microphone calibration method, device and a mobile terminal. The microphone is applied to the mobile terminal. The microphone calibration method is characterized by comprising the following steps: receiving an acoustical signal acquired by a first microphone, acquiring a characteristic value of the first microphone as a first characteristic value, and taking the first characteristic value as a calibration standard value; receiving an acoustical signal acquired by a second microphone, and acquiring a characteristic value of the second microphone as a second characteristic value; and compensating a second microphone gain according to a difference value of the first characteristic value and the second characteristic value, and obtaining a calibration gain. The microphone calibration method, device and the mobile terminal provided by the invention have the following beneficial effect that the problem that the sound loudness of the microphone does not have the consistency due to production or assembly and other reasons can be solved.

Owner:NUBIA TECHNOLOGY CO LTD

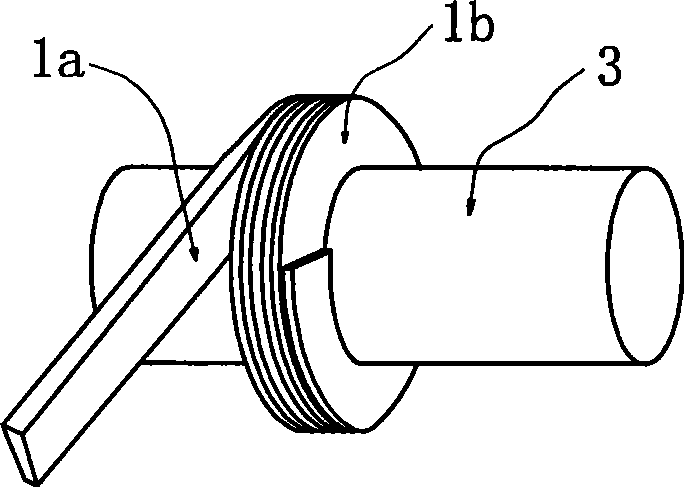

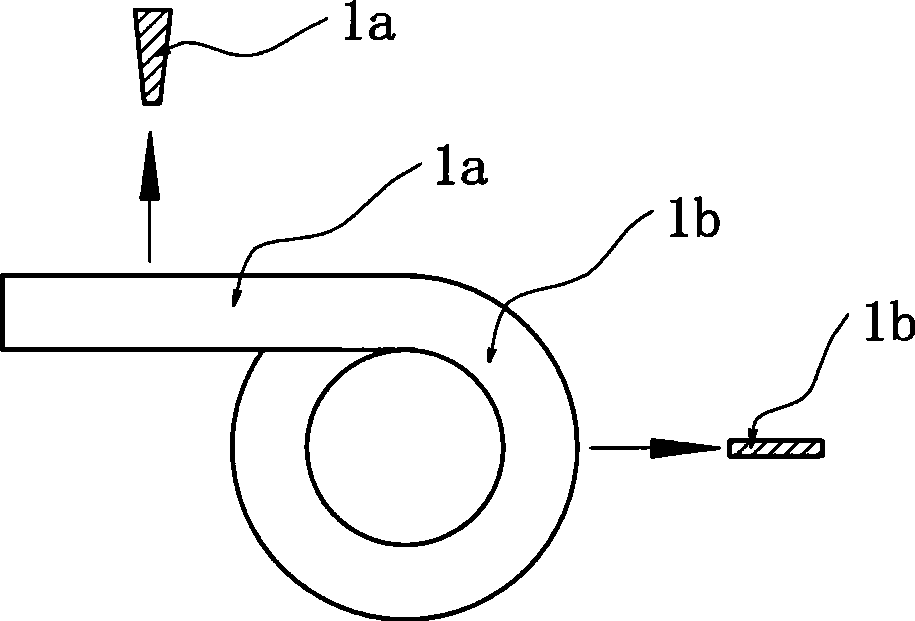

Spinning forming method and device based on laser heating

InactiveCN106424286AImprove heating efficiencyGood process flexibilityShaping toolsProcess equipmentSpinning

The invention discloses a spinning forming method and device based on laser heating. The spinning forming device is characterized by comprising a numerically-controlled spinning machine, spinning process equipment, a laser device, a light guide system, a six-degree-of-freedom robot machining system, a laser machining head, a temperature measuring device and the like. The spinning forming device conducts high-accuracy flexible control over a heating area according to the characteristics of high laser heating speed, accurate and controllable heating parts and temperatures and high degree of freedom and accurate control of the six-degree-of-freedom robot machining system, and spun blanks can be dynamically and locally heated while the spinning process equipment is not heated. The purposes of improving the material spinnability and reducing damage to the spinning machine are achieved. Meanwhile, closed-loop control over the heating temperature and laser output is realized, and realization of production automation is realized. The spinning forming method and device based on laser heating have the advantages of being high in production efficiency, good in process stability, high in forming precision, convenient to operate and the like.

Owner:JIANGSU UNIV OF TECH

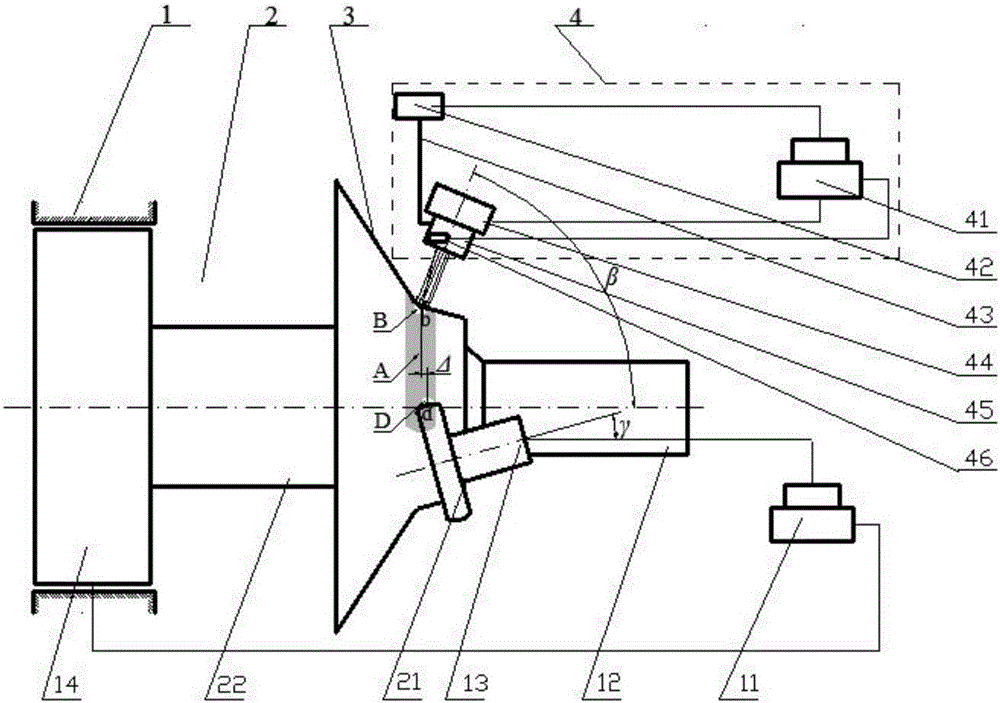

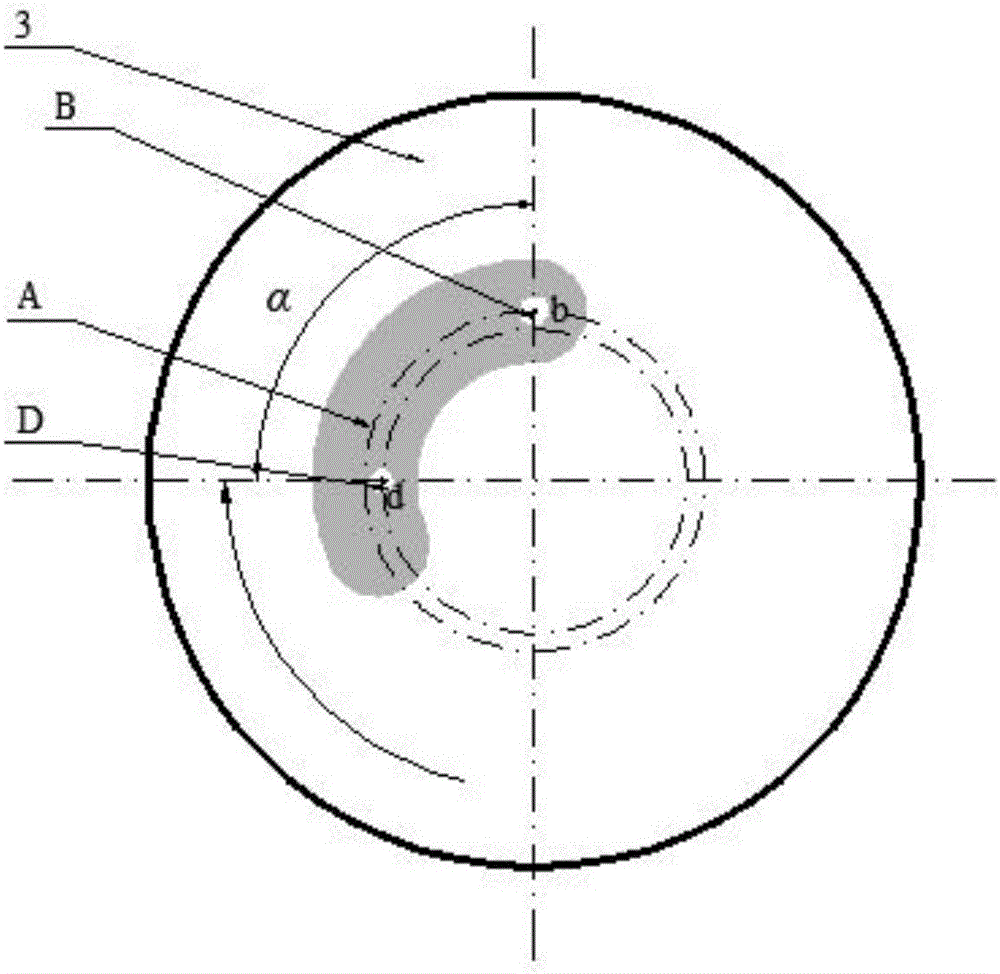

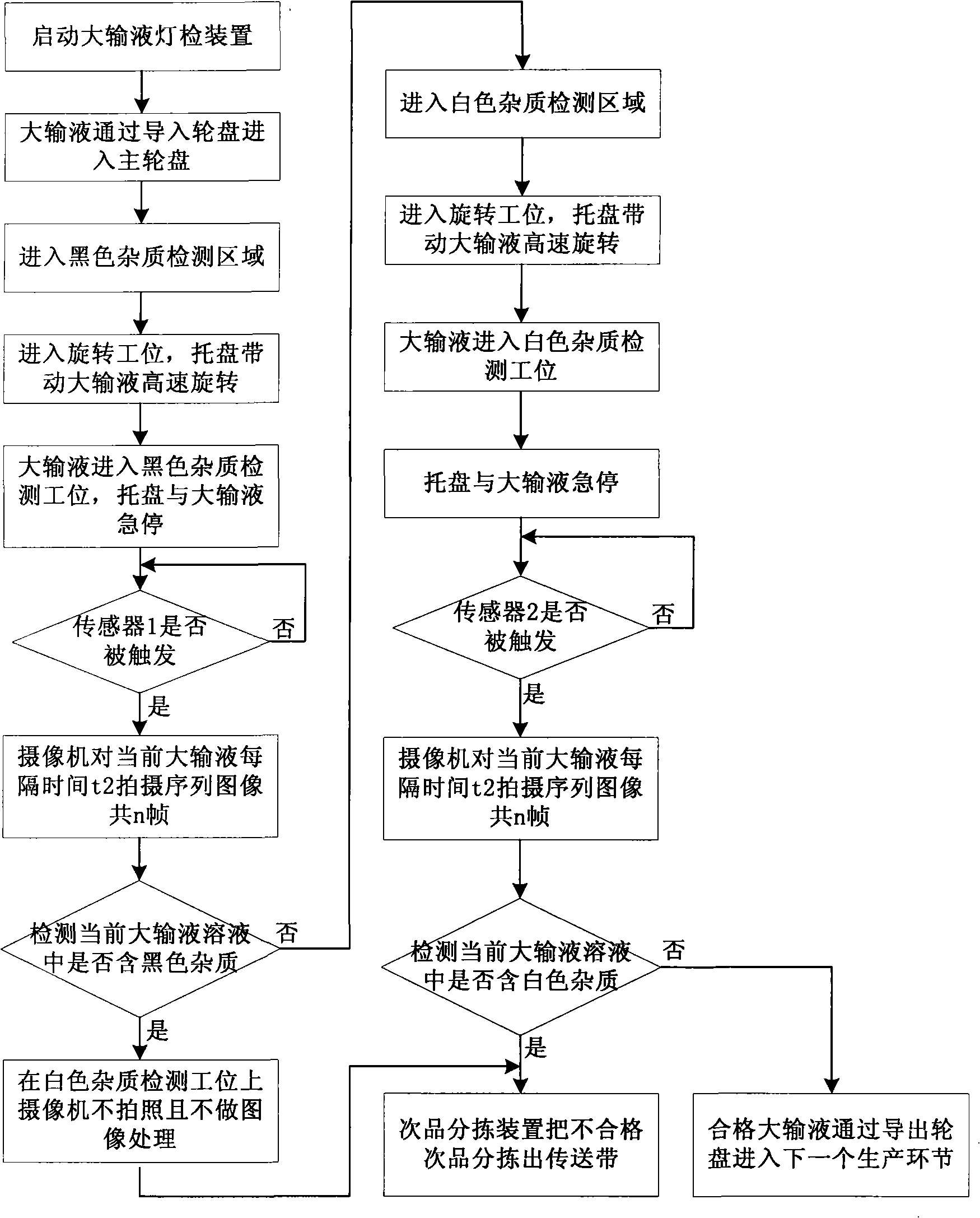

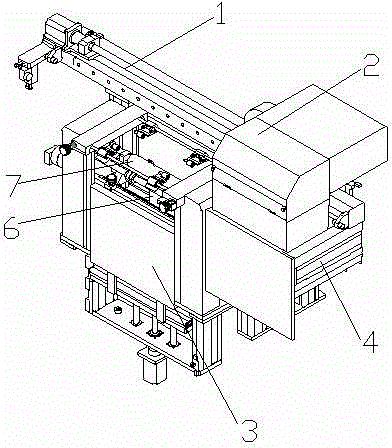

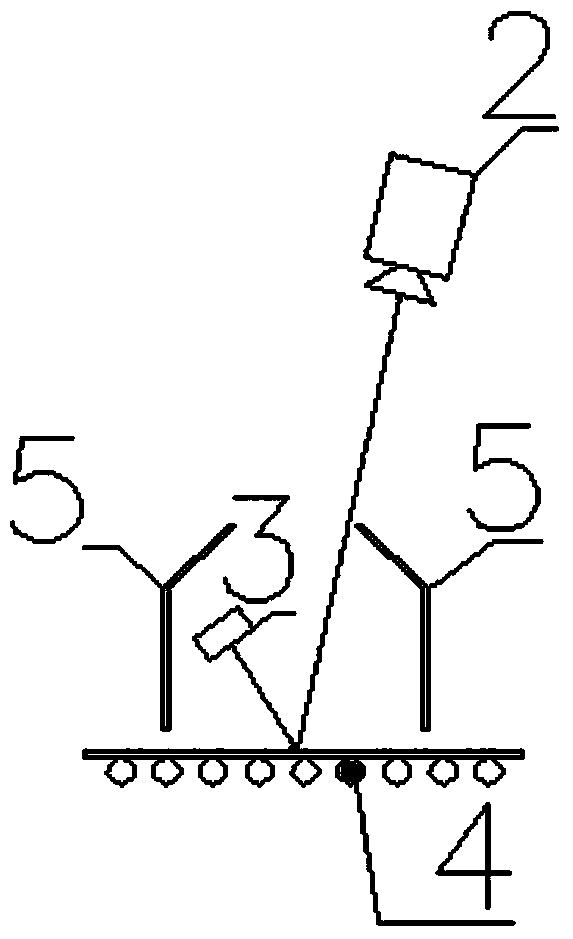

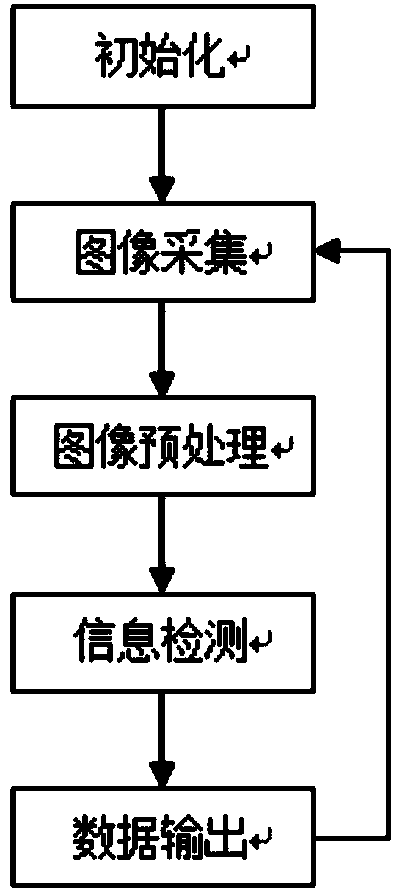

Method and apparatus for automatic detection on large infusion production line

InactiveCN101303316AObjective reflectionReliable reflectionPharmaceutical containersMedical packagingProduction lineForeign matter

The invention discloses an automatic detection method for a large transfusion production line, including the following steps: 1, making a transfusion bottle filled with liquid medicine rotate in a high-speed, then rapidly stopping the transfusion bottle, so that the liquid medicine in the bottle has a self-rotating movement under the inertia; 2, picking-up a plurality of images of the transfusion bottle in which the liquid medicine is in a self-rotating state; 3, respectively digitally processing and mutually comparing to the plurality of images, distinguishing the exogenous impurity in the liquid medicine, in order to judge whether the bottle of liquid medicine is qualified. The invention also discloses an automatic detection apparatus for a large transfusion production line, which is characterized by including a rotation device, a controller, a video camera and an image processing apparatus, wherein, the output end of the controller is connected with the control terminal of the rotation device, a gripping device for fixing up the transfusion bottle, a rotating work station and a detecting work station are provided on the rotation device, and the video camera outputs data to the image processing apparatus. The invention can automatically detect whether impurity exists in the liquid medicine, with high testing accuracy and fast testing velocity.

Owner:HUNAN UNIV

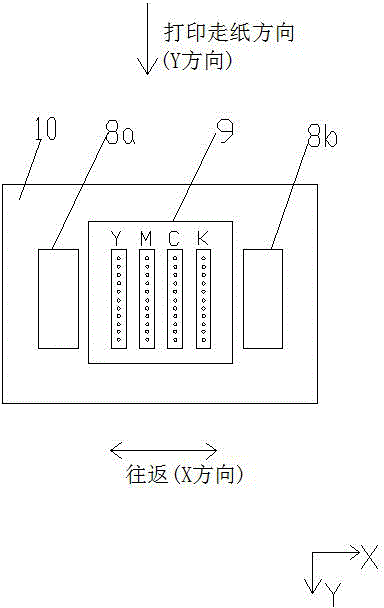

Ink-jet printing device and printing method thereof

InactiveCN104669791AAvoid cloggingImprove qualityDuplicating/marking methodsOther printing apparatusSprayerUltraviolet lights

The invention discloses an ink-jet printing device and a printing method thereof. The printing device comprises a printing unit, a material feeding unit, a control unit and a curing device, wherein the printing unit comprises a printing bracket and a printing trolley; the printing trolley can perform stepping motion in a first axis direction along the printing bracket; the material feeding unit is arranged below the printing unit and used for mounting a print object and driving the print object to rotate around a second axis direction; the control unit is used for controlling the printing trolley to move in the first axis direction, controlling a sprayer on the printing trolley to jet image texts, and controlling the print object to rotate around the second axis direction; the curing device is used for irradiating the printing area of the print object, so as to cure the ink droplets on the print object; the ink-jet printing device is characterized in that the curing device comprises at least two bulbs; the bulbs can be separately controlled to be switched on or off; the curing irradiation intensity of the bulbs can be regulated. According to the ink-jet printing device and the printing method thereof disclosed by the invention, the curing irradiation intensity can be adjusted according to the requirement; the situation that unnecessary ultraviolet light is exposed to the surface of the sprayer nozzle by the curing device can be effectively avoided, and further the nozzle blockage can be avoided.

Owner:BEIJING MEIKEYI

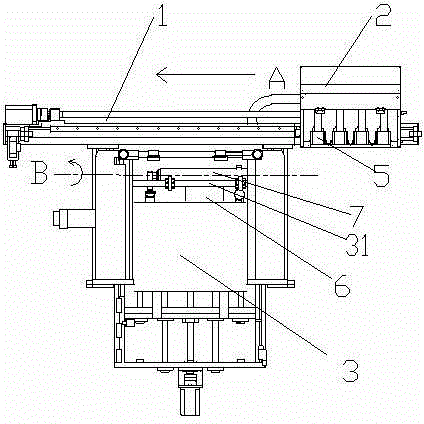

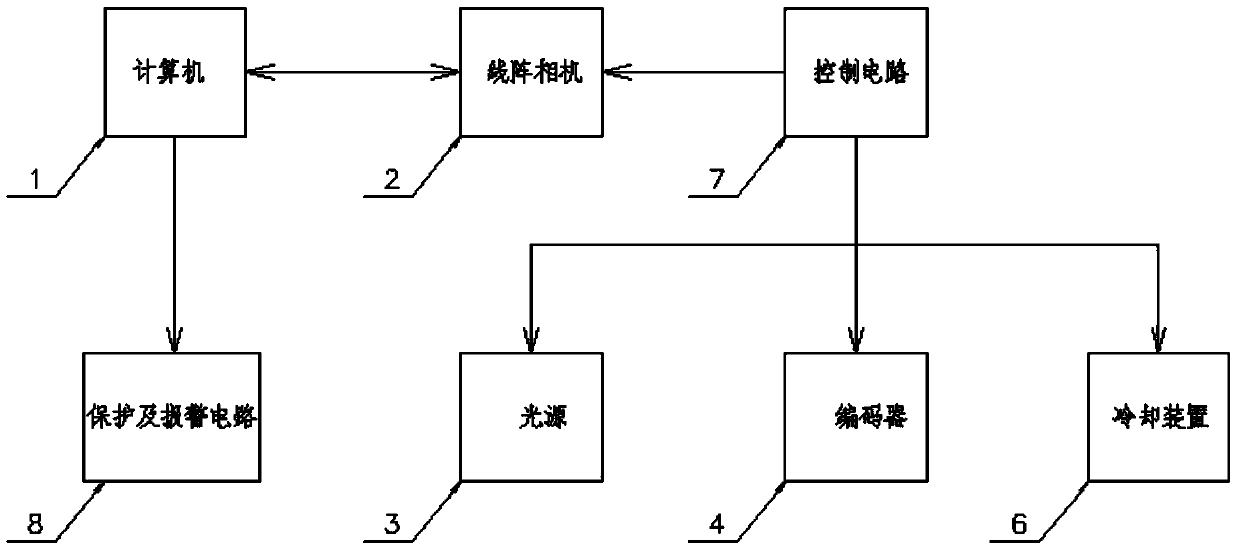

Glass plate width detection system based on machine vision

ActiveCN103471512AFast image processingProcessing speedUsing optical meansImaging processingMachine vision

The invention relates to the technical field of glass production, in particular to a glass plate width detection system based on machine vision. The system comprises a line-scan digital camera, an encoder, a light source and a light-shielding cover, and is characterized in that the line-scan digital camera and the light source are located above a to-be-detected glass plate, the light source and the line-scan digital camera are not on the same vertical plane, the light-shielding cover is arranged on the outside of the light source, the line-scan digital camera is arranged on the outer side of the light-shielding cover, the two ends of the light-shielding cover are sealed, the upper portion of the light-shielding cover is provided with a hole, imaging of the light source on the to-be-detected glass plate can be seen in the hole through the line-scan digital camera, the to-be-detected glass plate is arranged on a roller bed, the roller bed is provided with the encoder, and the encoder collects the speed of the roller bed to control the speed of the line-scan digital camera in catching an image. Compared with the prior art, the system has the advantages that the image can be directly processed, information on the left side and the right side of the glass plate is information at the same moment, and consistency of data is achieved; the image processing speed is high, information of the glass plate is detected in real time, measured data are high in precision and high instantaneity and accuracy are achieved.

Owner:CHINA TRIUMPH INT ENG

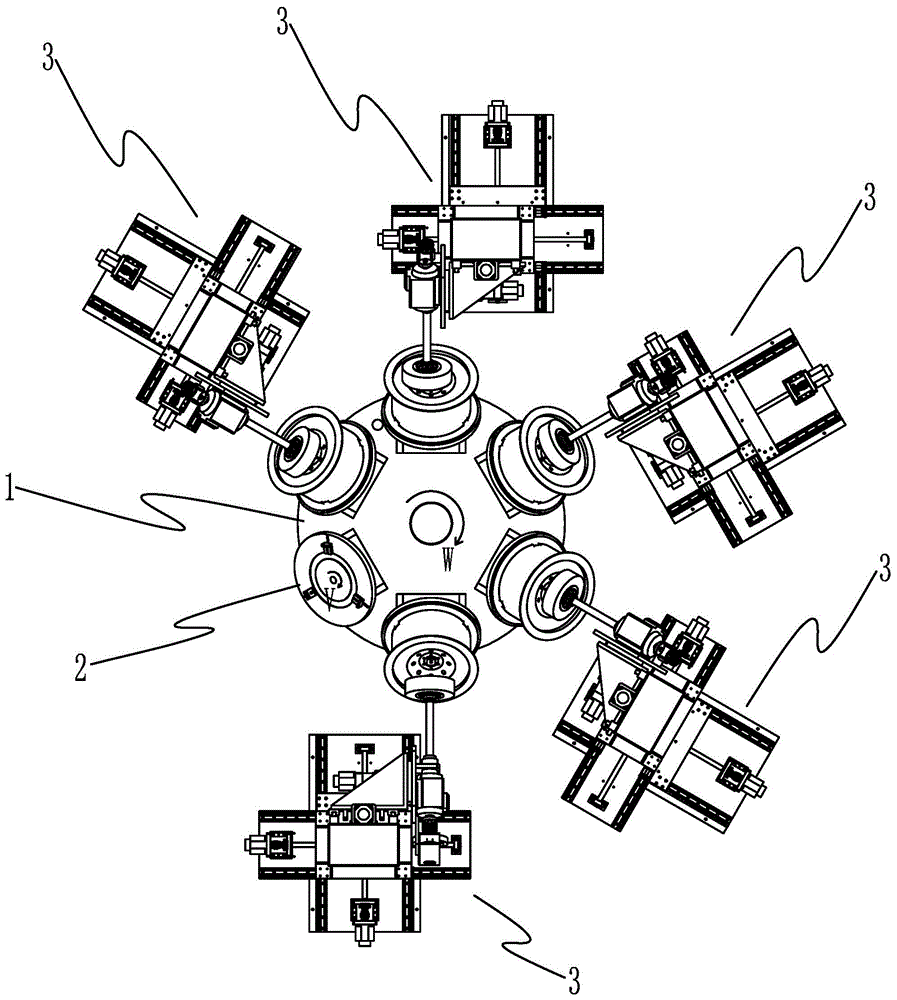

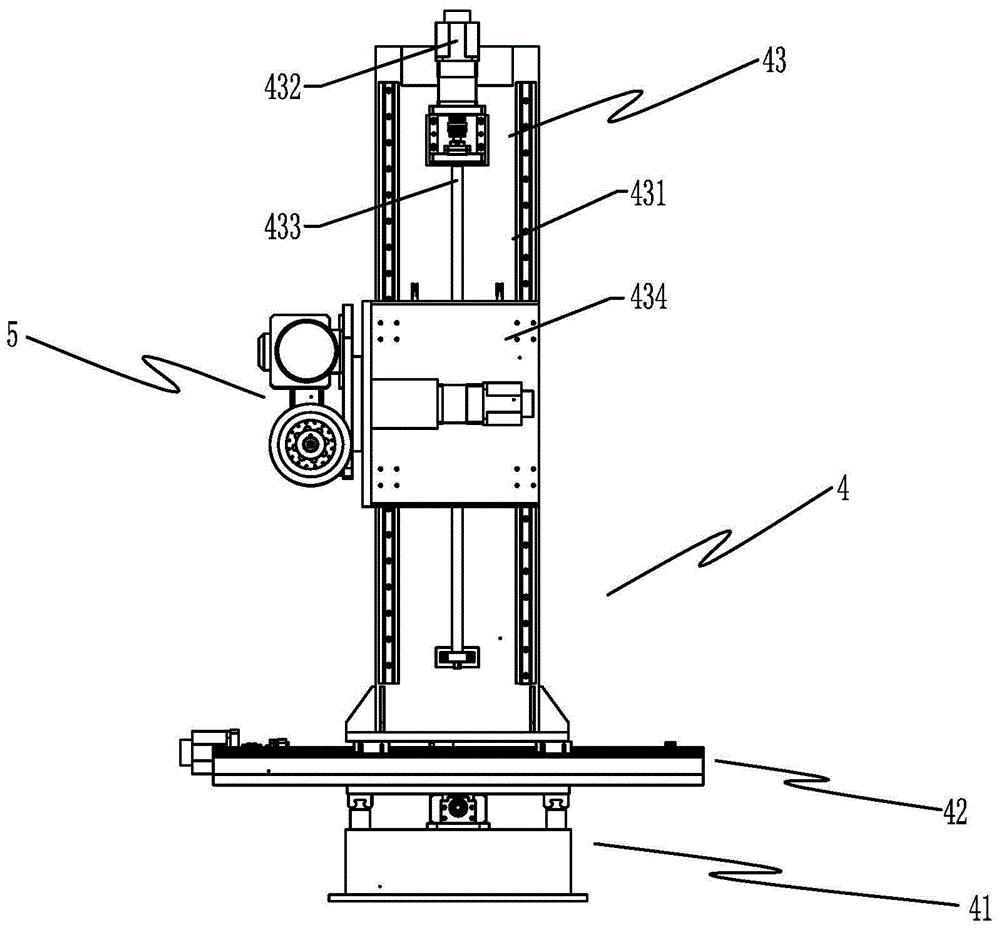

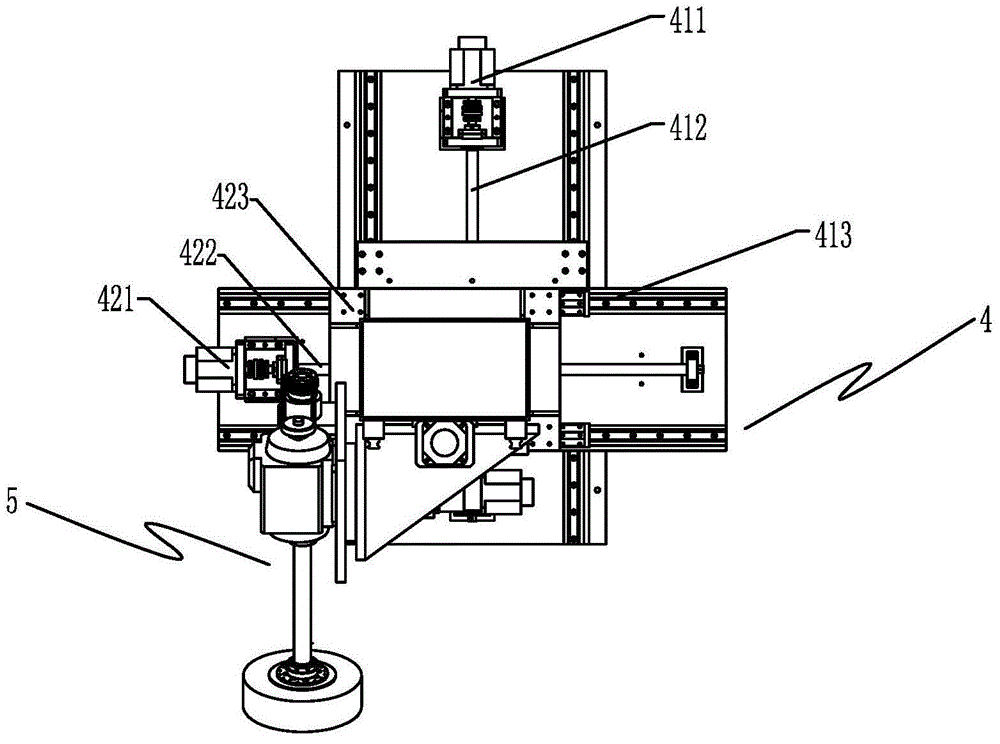

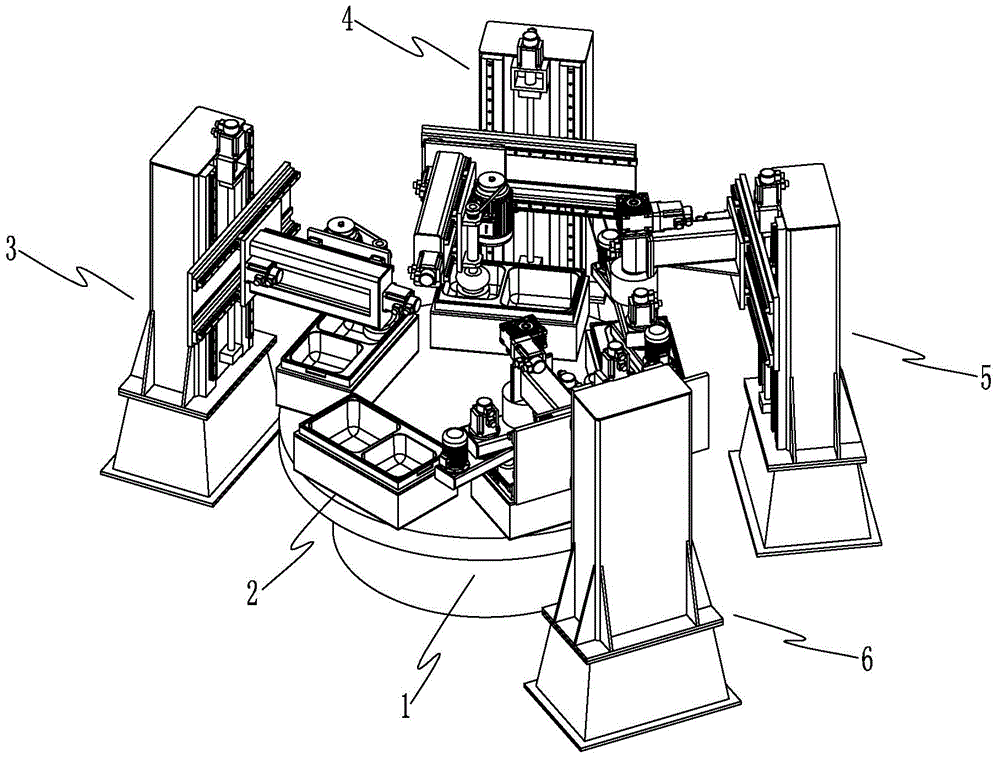

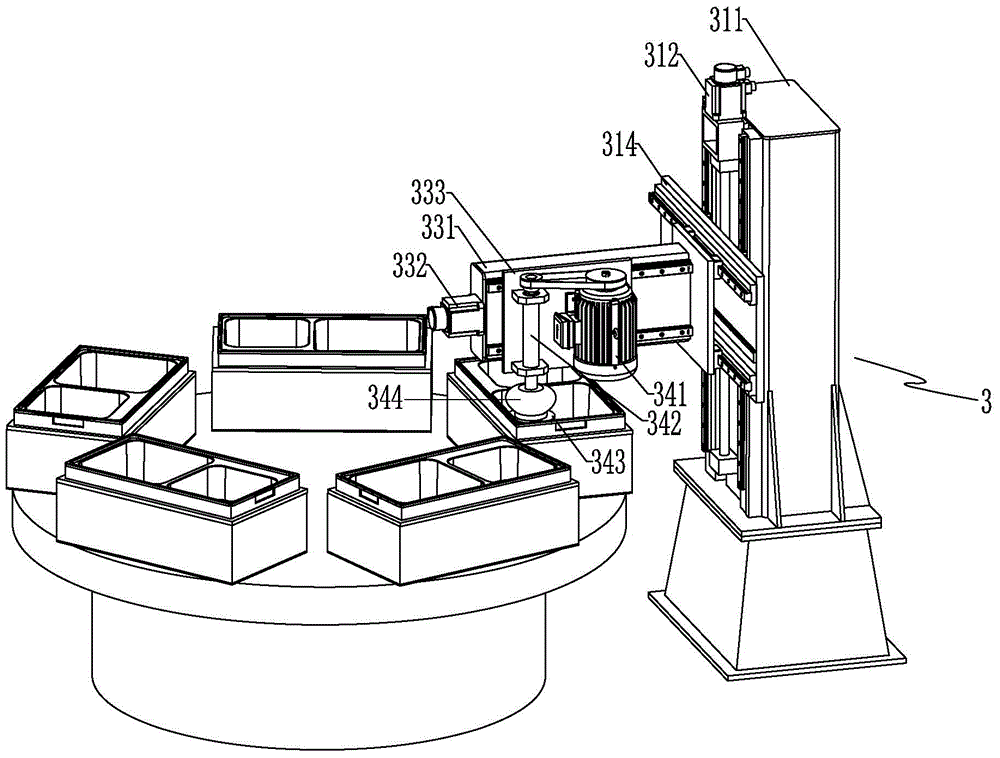

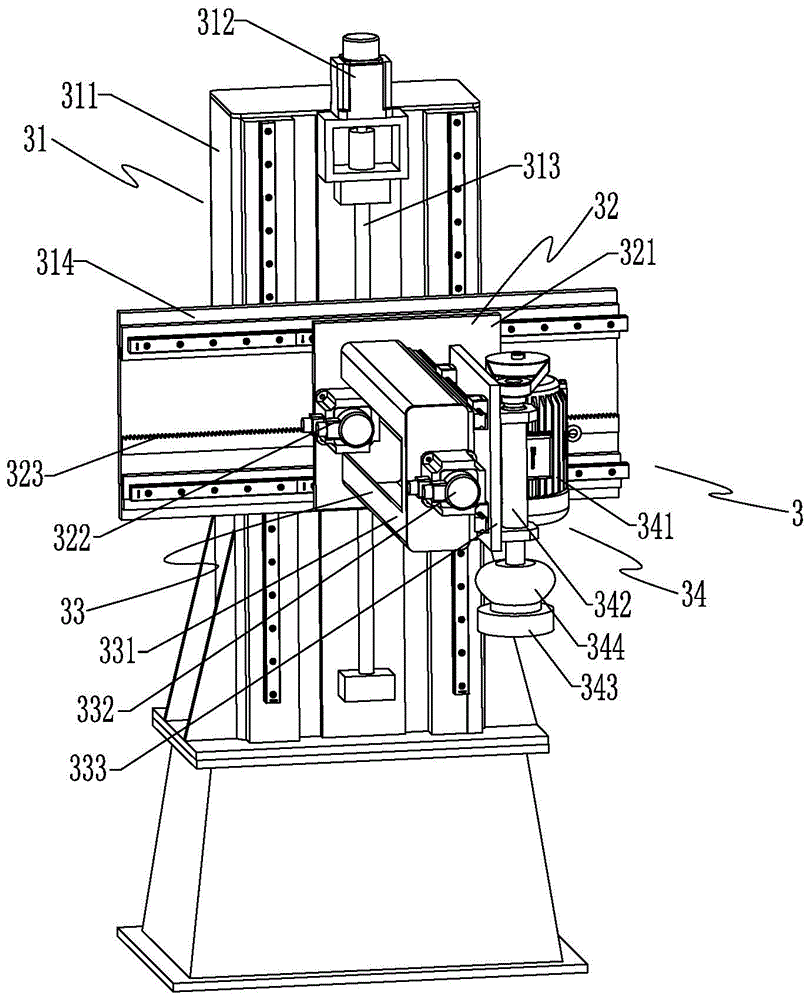

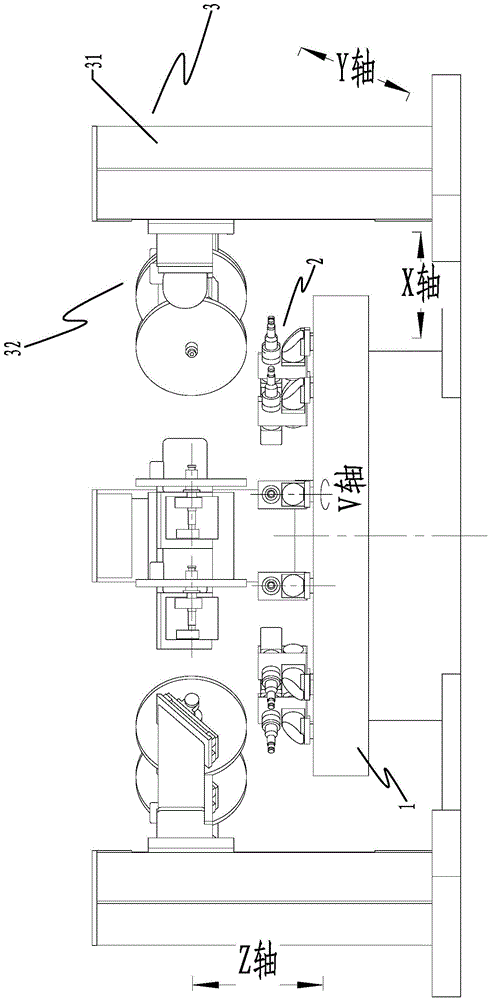

Multi-station circular-disc type novel numerical control automobile hub polishing machine

ActiveCN105014511AStable polishing qualityEnsure continuous and stable workPolishing machinesGrinding drivesNumerical controlCircular disc

The invention discloses a multi-station circular-disc type novel numerical control automobile hub polishing machine. The multi-station circular-disc type novel numerical control automobile hub polishing machine comprises a revolution circular disc assembly in the middle. Autoroatation hub clamp assemblies of multiple stations are evenly arranged on the revolution circular disc assembly in the circumferential direction at equal angles. Asynchronous polishing wheel assemblies of the stations and a loading and unloading station of one station are arranged around the autoroatation circular disc assemblies and correspond to the autoroatation hub clamp assemblies of all the stations. The polishing wheel assembly of each station comprises a three-direction displacement component and a polishing wheel machine head component deflecting at the preset angle along the horizontal axis and arranged on the three-direction displacement component. The polishing machine can achieve four-axis linkage and automatic compensation for the polishing wheel wear radius, and therefore production efficiency is improved greatly; meanwhile, the application range of complex-spoke hub polishing is enlarged, and the stable and consistent hub polishing quality is guaranteed; and the requirement on the experience of operators is lowered, and thus production efficiency and economic benefits are improved.

Owner:广东博科数控机械有限公司

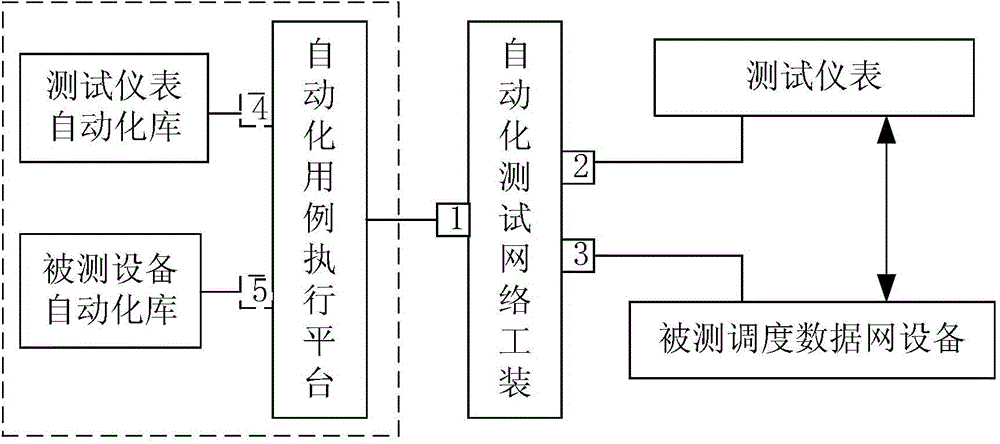

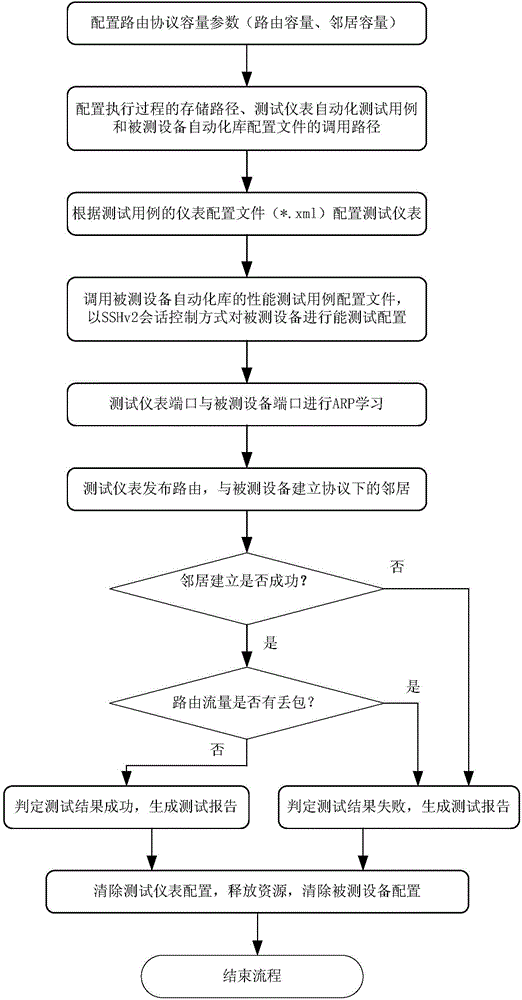

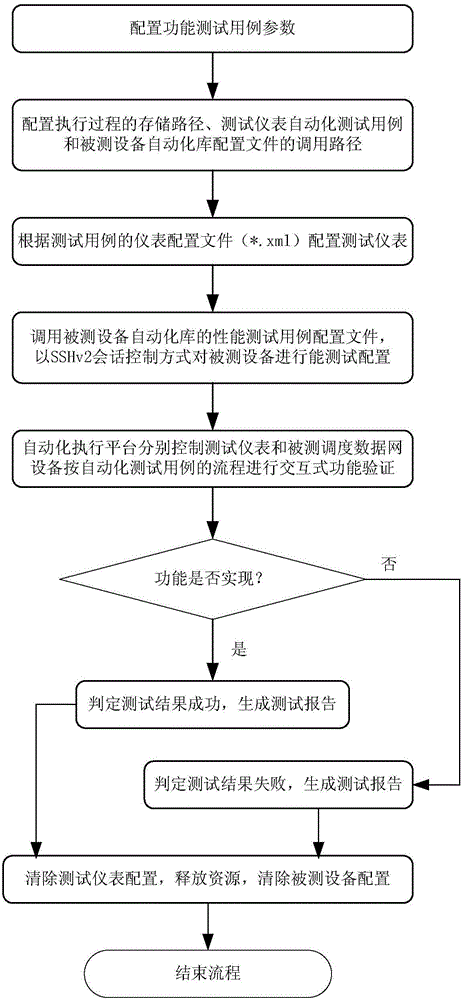

Automatic test system and test method for dispatching data network equipment

ActiveCN104980317AConsistentImprove test efficiencySoftware testing/debuggingData switching networksEquipment under testSoftware engineering

The invention discloses an automatic test system and a test method for dispatching data network equipment. An execution interface of a test instrument automatic case execution platform is connected with an interface 1 of an automatic test network tool. A control interface of a test instrument is connected with an interface 2 of the automatic test network tool. A control interface of measured dispatching data network equipment is connected with an interface 3 of the automatic test network tool. A test instrument automation library and a measured equipment automation library are called by the automatic case execution platform through a logic interface 4 and a logic interface 5 respectively. Dispersed links such as test instrument operation, measured equipment control, test log archiving and test version maintenance are integrated. Automatic test of a dispatching data network router and a switch is realized. The problems existing in traditional manual test such as difference, low efficiency and long test cycle are solved. Standard, consistent and fair test is realized. The working efficiency is greatly improved.

Owner:NANJING NARI GROUP CORP +1

Multi-station disc type novel numerical control polishing machine for pot type workpieces

ActiveCN104972382AConsistentAchieve consistencyGrinding carriagesPolishing machinesNumerical controlEngineering

The invention discloses a multi-station disc type novel numerical control polishing machine for pot type workpieces. The multi-station disc type novel numerical control polishing machine comprises a rotating disc assembly arranged in the middle. Multi-station pneumatic sucker components are evenly arranged in the circumference direction of the upper surface of the rotating disc assembly with equal angles. A loading and unloading station is arranged in the position, corresponding to one pneumatic sucker component, of the periphery of the rotating disc assembly. Single-polishing wheel assemblies and / or double-polishing wheel assemblies are arranged in the positions, corresponding to the rest of the pneumatic sucker components, of the periphery of the rotating disc assembly. The single-polishing wheel assemblies comprise three-direction displacement components and single-polishing wheel machine head components arranged on the three-direction displacement components. The double-polishing wheel assemblies comprise two-direction displacement components and double-polishing wheel machine head components arranged on the two-direction moving components. The multi-station disc type novel numerical control polishing machine for the pot type workpieces is provided with the single-polishing wheel assemblies and the double-polishing wheel assemblies so that the multi-station disc type novel numerical control polishing machine can meet the requirement for polishing of side walls and bottom faces of pot type workpieces with different shapes and different sizes, the production efficiency is greatly improved, meanwhile, it is ensured that the polishing quality of the pot type workpieces is stable and consistent, occupied area is saved, energy consumption is reduced, and the production efficiency and the economic benefits are greatly improved.

Owner:广东博科数控机械有限公司

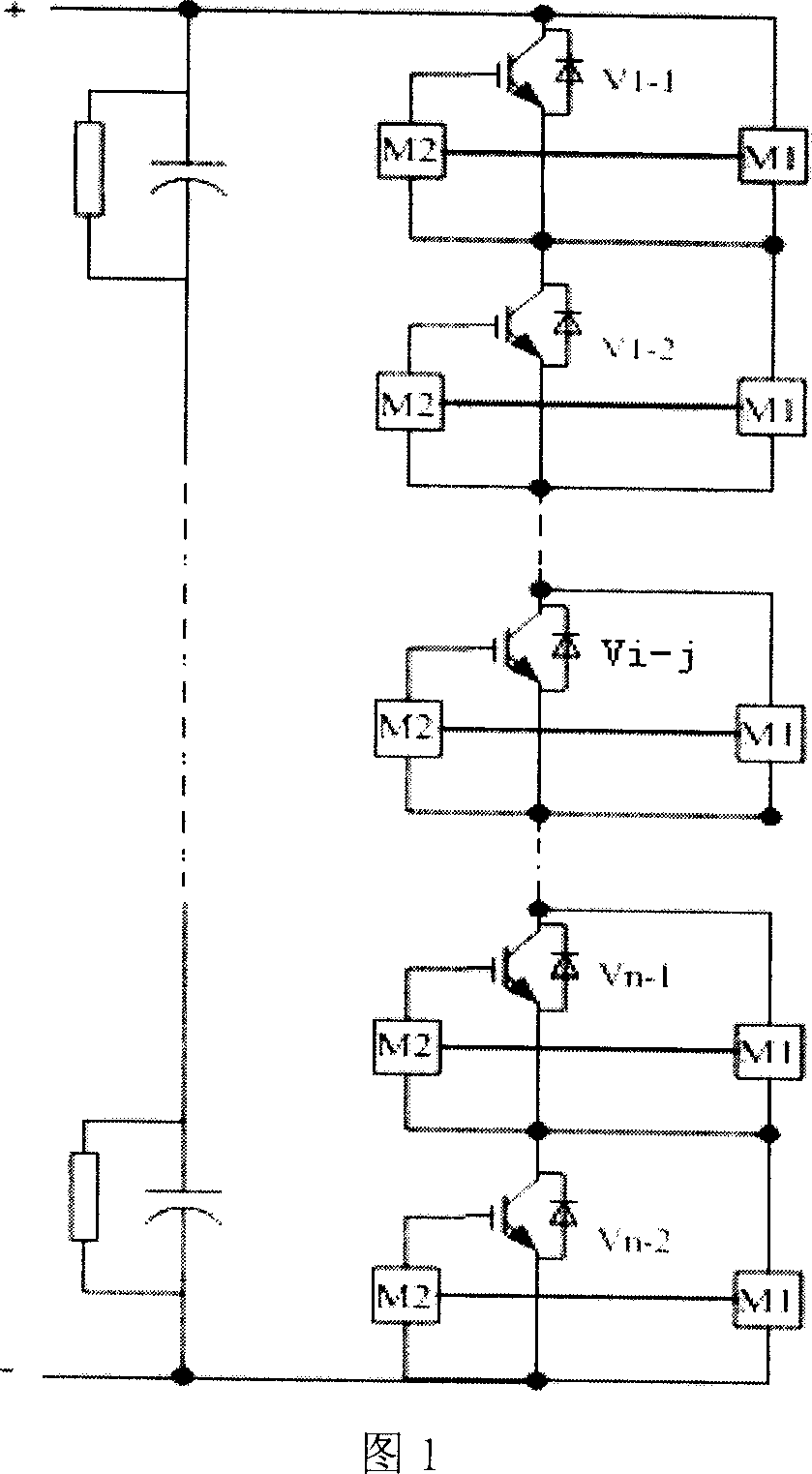

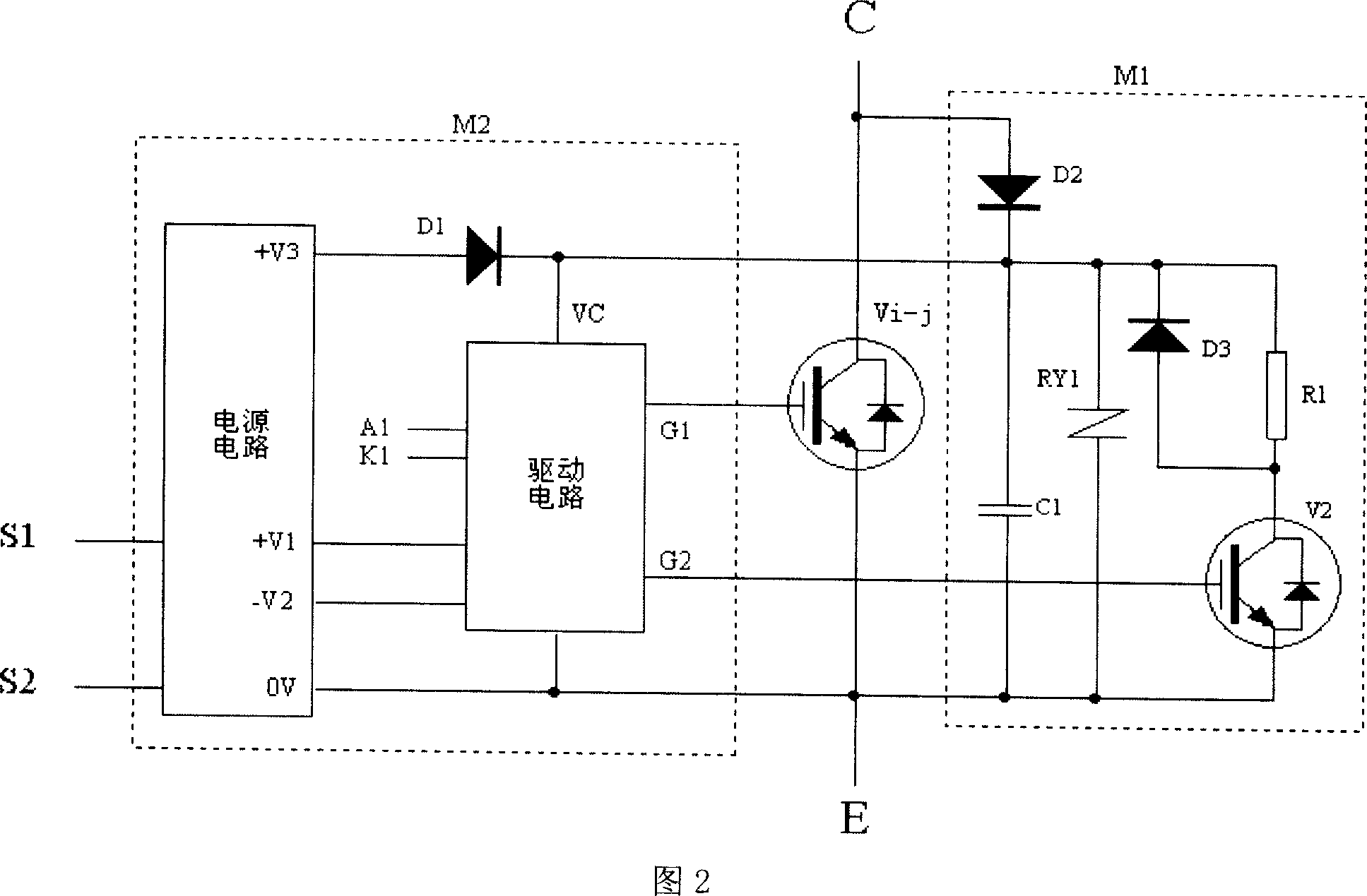

Cascade active voltage-stabilizing controller of power switch

InactiveCN101030701AWide range of choicesStrong pressure equalization control abilityEmergency protective circuit arrangementsControl signalControl theory

The invention is concerned with the active series connection equal-press controlling equipment for the power switch, the characteristic is: sets the active equal-press absorb module for the series power module, the active equal-press absorb module crosses and parallel connects with the C and E end of each main power tube Vi-j; sets the driving controlling module, the outputting controlling signal of the driving controlling module accesses each power module and the active equal-press absorb module. The invention is lower power consumption, simple circuit.

Owner:HEFEI UNIV OF TECH

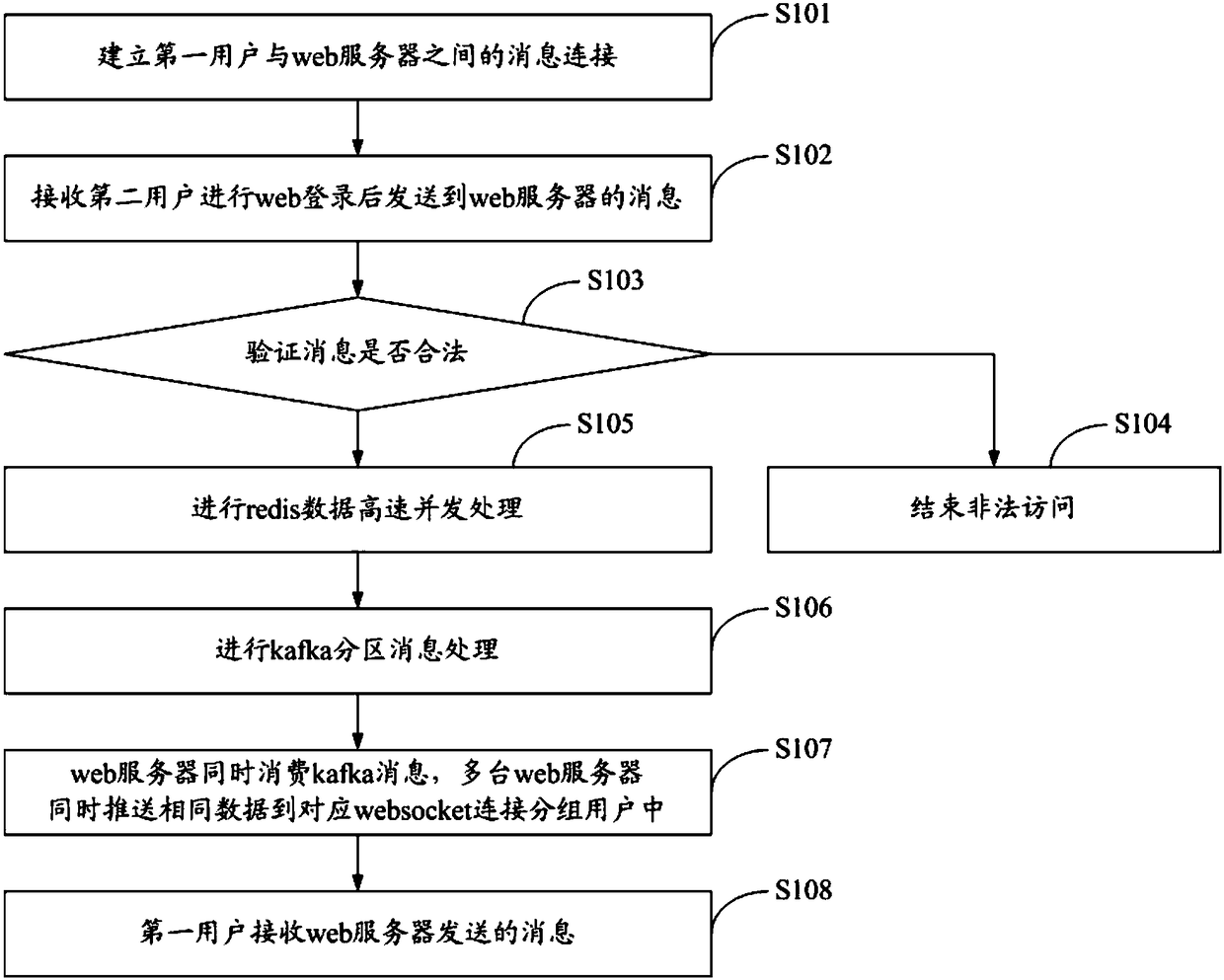

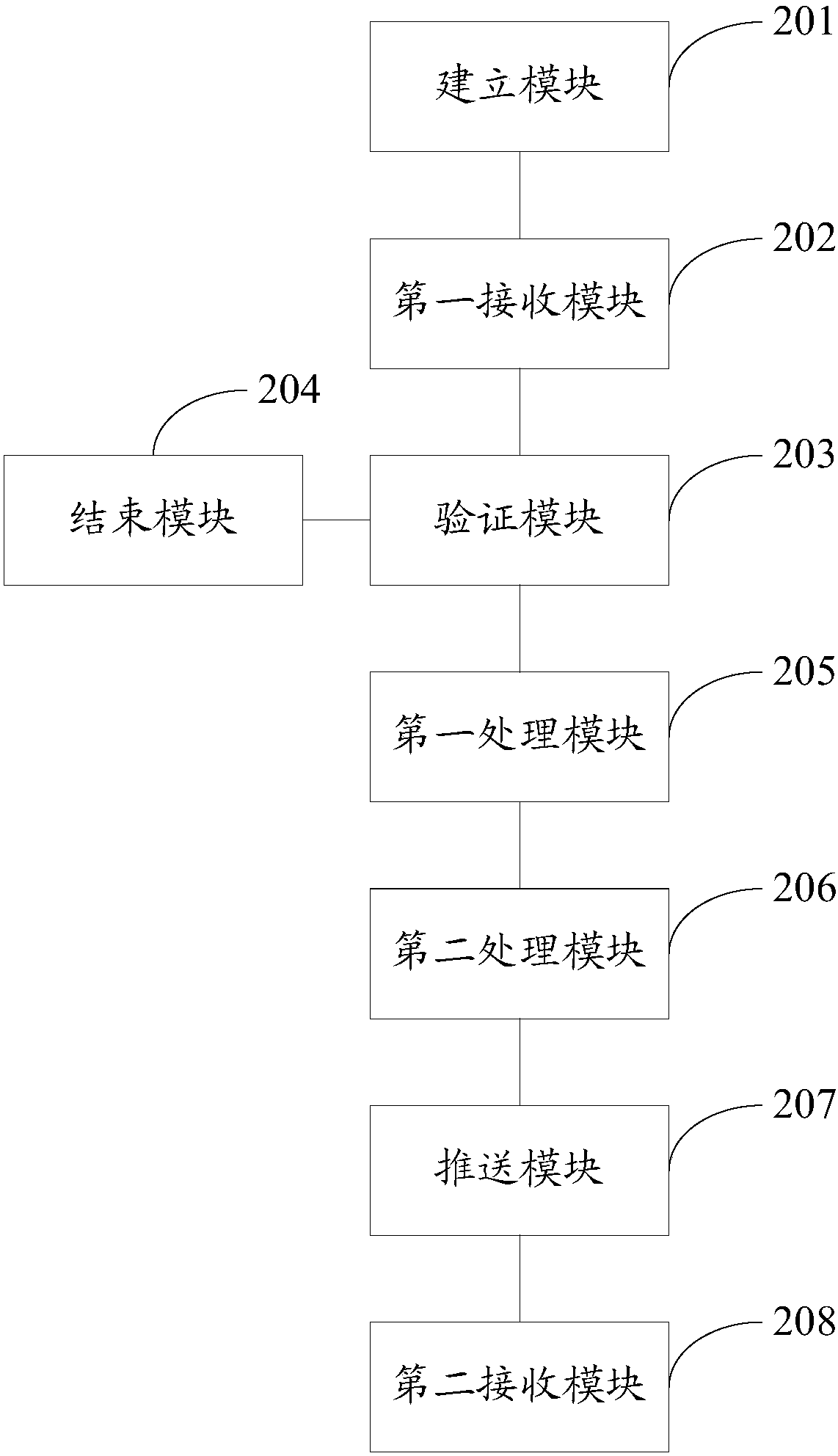

Distributed high concurrent real-time message pushing method and system

The invention provides a distributed high concurrent real-time message pushing method and a distributed high concurrent real-time message pushing system. The method comprises the steps of building a message connection between a first user and a web server, receiving a message sent by a second user to the web server after the second user logs in a web, verifying whether the message is valid, if no,ending an illegal access, if yes, performing high speed concurrent treatment on redis data, and performing kafka partition message treatment; synchronously consuming a kafka message via the web servers, and synchronously pushing same data via the multiple web servers to corresponding grouped users of a websocket connection, and receiving the message sent by the web server via the first user. According to the method and system provided by the invention, the retardance of the websocket instant messaging under the high concurrent scene can be reduced, and the expandability of the same can be improved.

Owner:成都博点科技有限公司

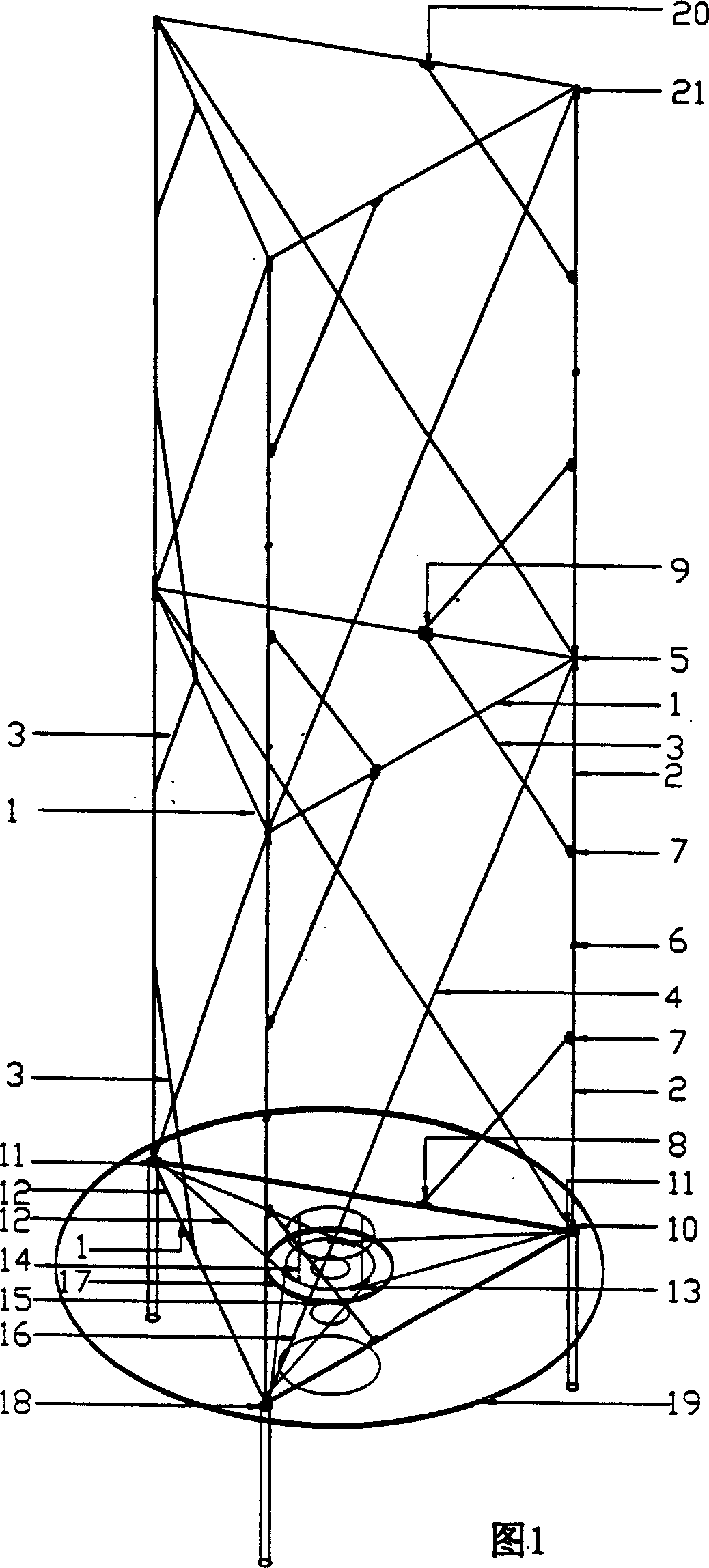

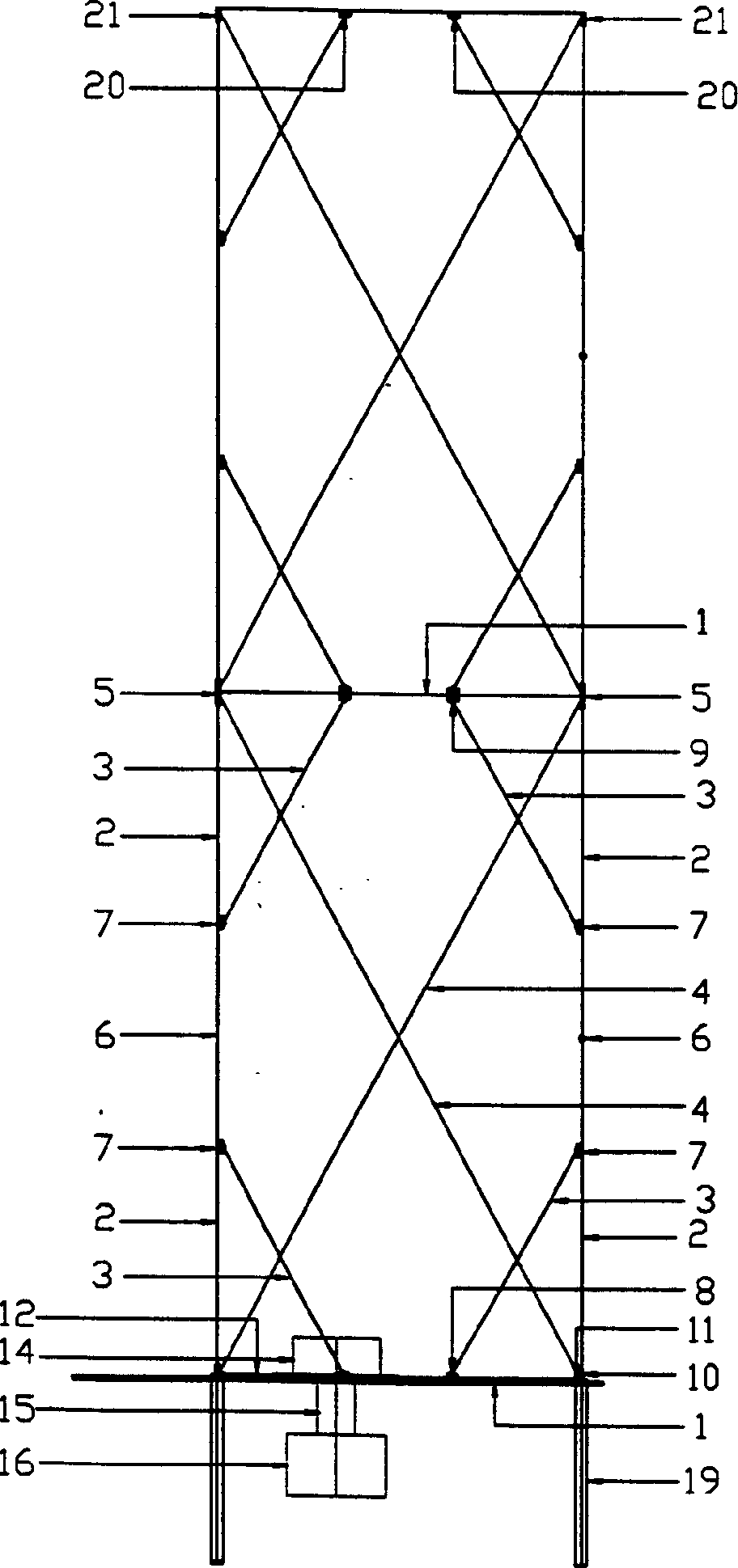

High-rigidity synchronously spreading folded space extension arm

InactiveCN1474069AImprove structural rigiditySimple organizationElongated constructional elementsRod connectionsDrive shaftEngineering

The high-rigidity synchronously spreading folded space extension arm consists of folded truss units capable of being expanded repeatedly and being spread, driving system, power supply system and supporting space platform. The folded truss units are basic units to constitute the extension arm and are connected mutually via standard triangular joints; the driving system is inside the triangular space in the bottom of the extension arm and is connected to the supporting space platform and to the power supply system through the transmission shaft. The truss structure in triangular prism form of the present invention has geometrical stability, high structural rigidity and high unit repeatability, and may be spread and folded synchronously in high precision. The present invention may be used in large communication satellite, electronic reconnaissance satellite and space station platform.

Owner:SHANGHAI JIAO TONG UNIV

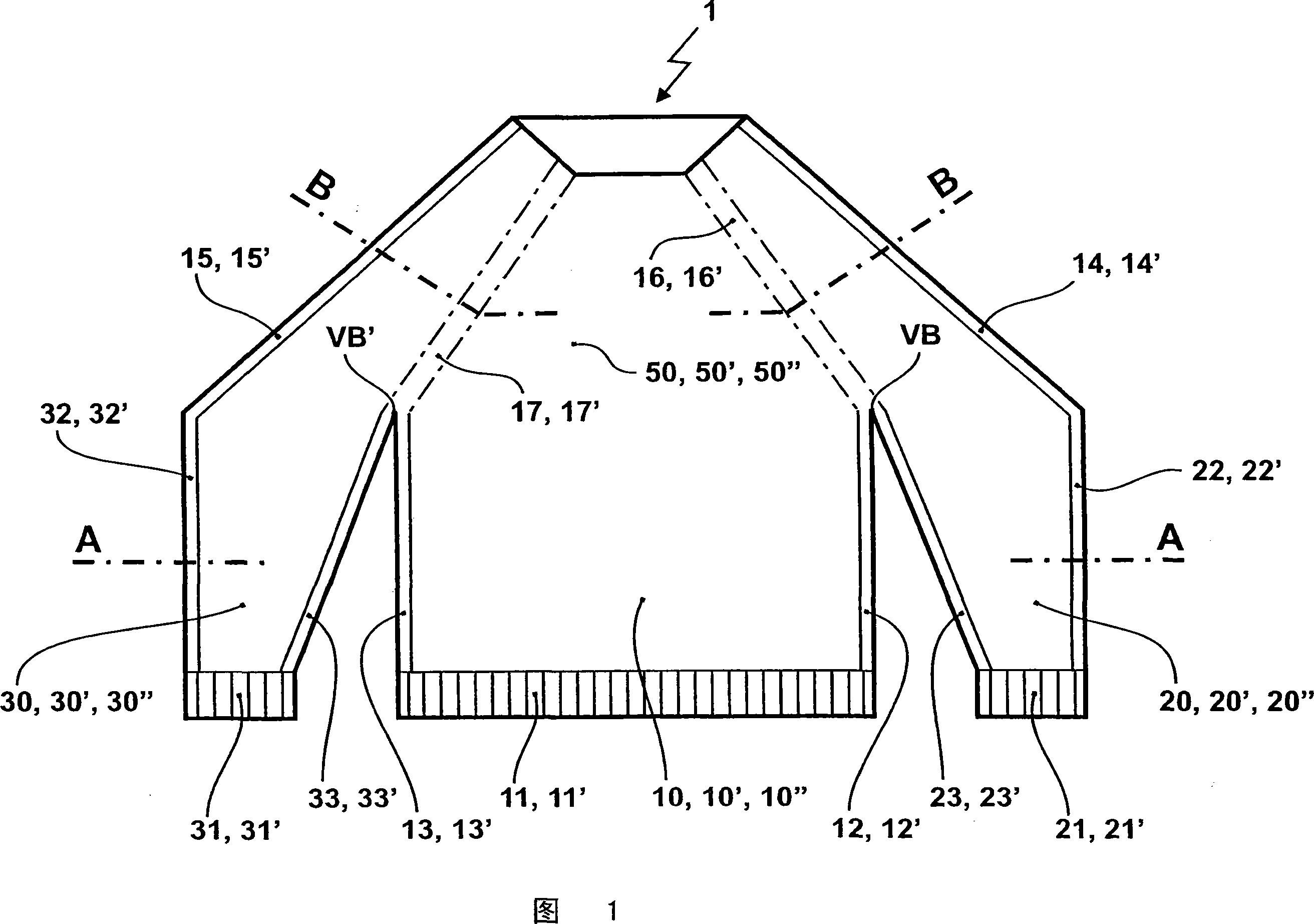

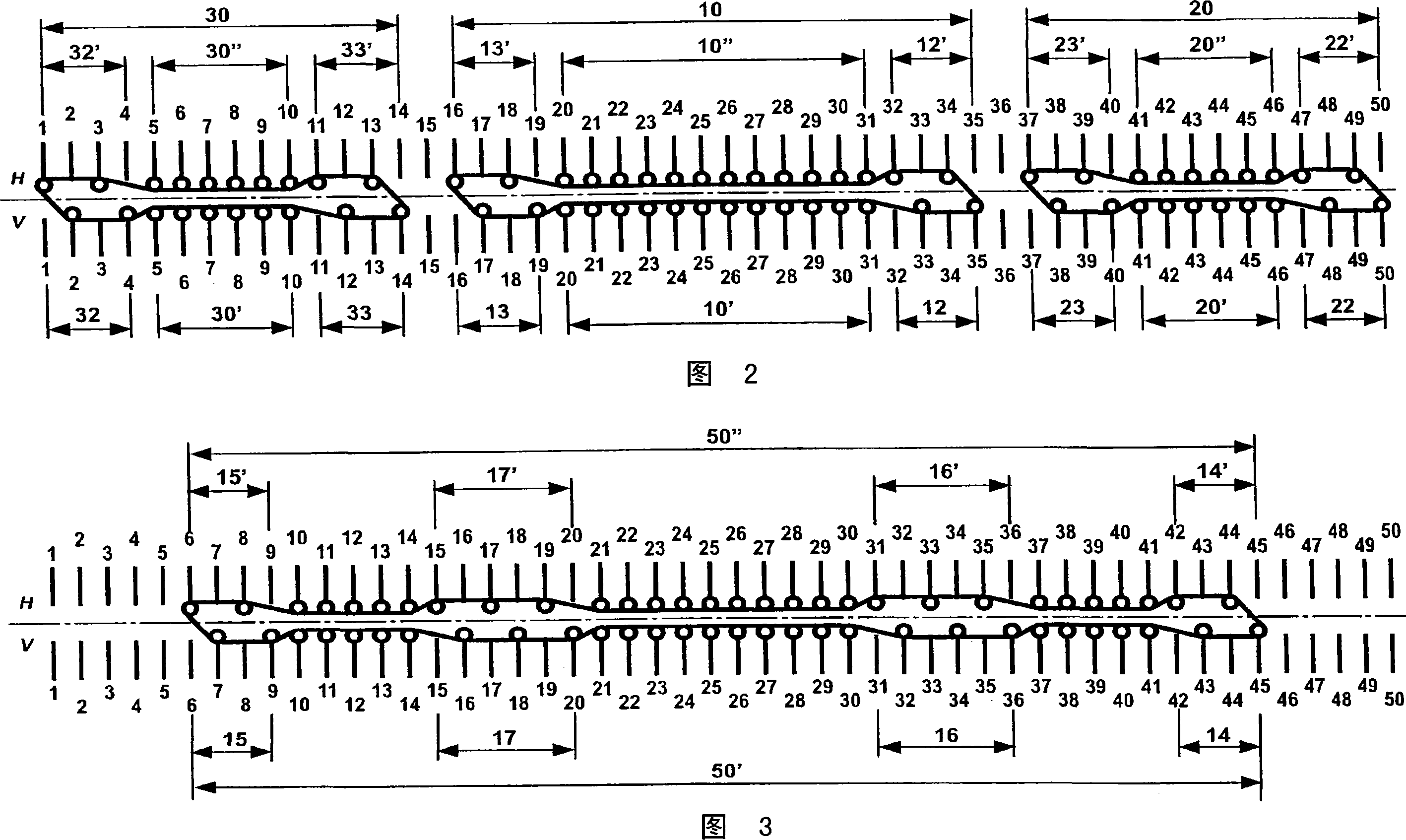

Method for producing a tubular flat knit fabric with the plating technique

InactiveCN101168883AAvoid Plating DefectsConsistentOrnamental textile articlesFlat-bed knitting machinesEngineering

The method involves changing a knitting direction according to formation of edge stitches of a knitted hosiery garment. The edge stitches in a row is enlarged / increased to another row by a transferring process such that the edge stitches have the same size as that of the remaining stitches of the knitted hosiery garment. The stitches in the formed row are transferred to a needle bed and are knitted as needle stitches. Edge areas (12, 12', 13, 13') are formed with needle stitches.

Owner:H STOLL GMBH & CO KG

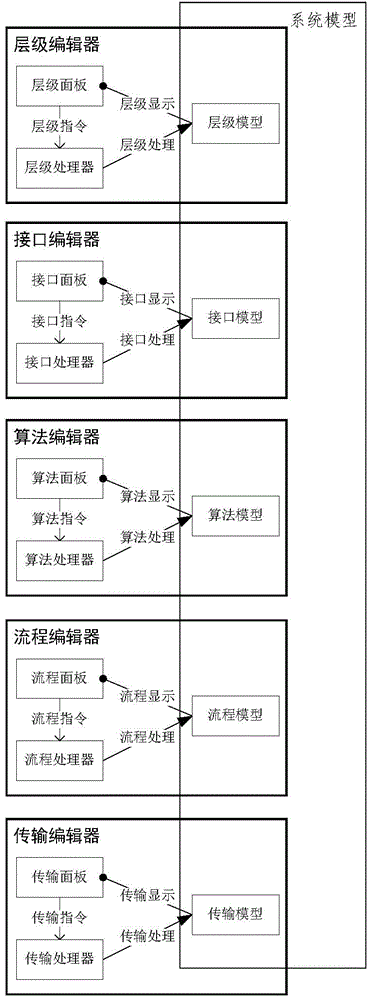

Visual modeling editor for constructing system model

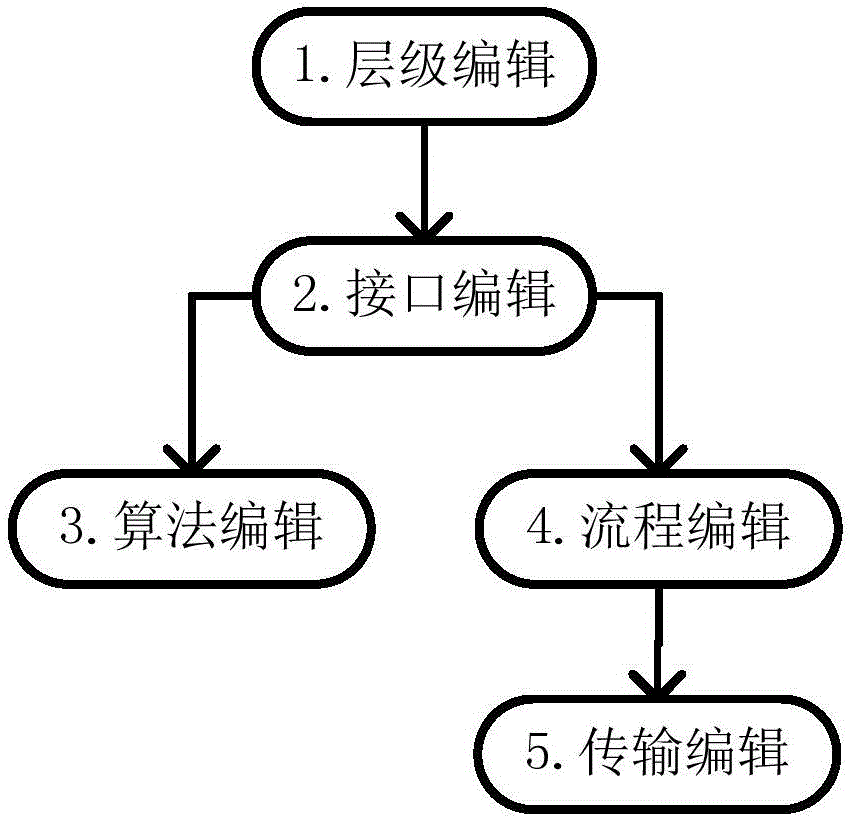

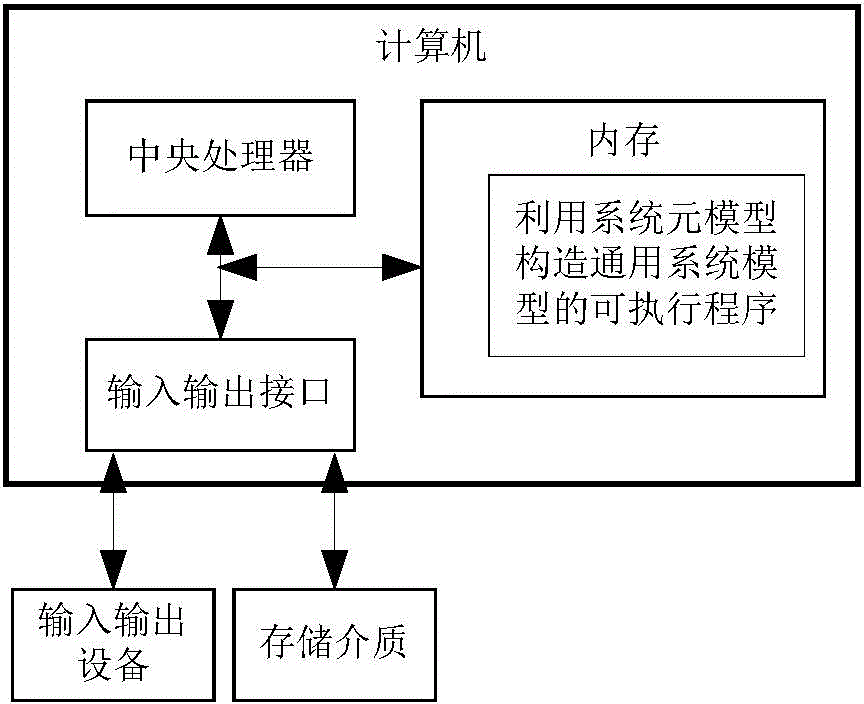

ActiveCN105302532AOperationalVersatilitySpecific program execution arrangementsSoftware systemSimulation

The invention discloses a system meta-model based visual modeling editor for constructing a system model. The editing of the system model and a system view is finished by taking a hierarchical model, an interface model, an algorithm model, a process model, a transmission model and a corresponding view as editing objects through a hierarchical editor, an interface editor, an algorithm editor, a process editor and a transmission editor. A visual system modeling tool with the advantages of computability, universality and usability is provided for various fields. The system model and the system view constructed by the editor are explicit in structure, adjustable in hierarchy and controllable in modeling granularity, and have computable full consistency. Methods are unified, so that top-down analysis design and bottom-up integration are convenient, and the editor is suitable for modeling various systems including software systems and information systems in various application environments. The modeling method is simple and complete in visual modeling, so that even personnel in general fields can independently and easily edit the system model and the system view.

Owner:CHENGDU PUZHONG SOFTWARE CO LTD

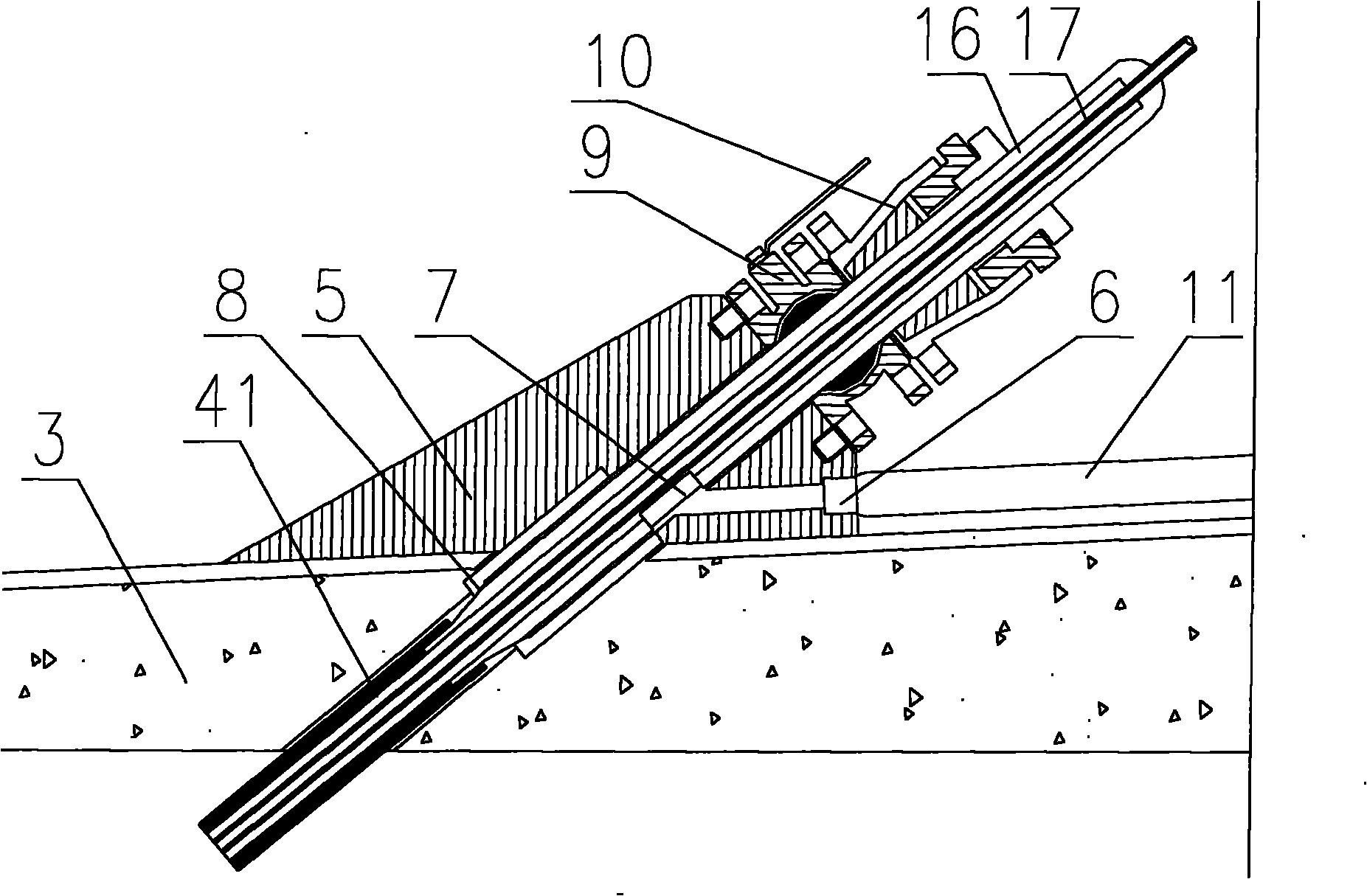

Method and device for blast furnace to blow coal powder

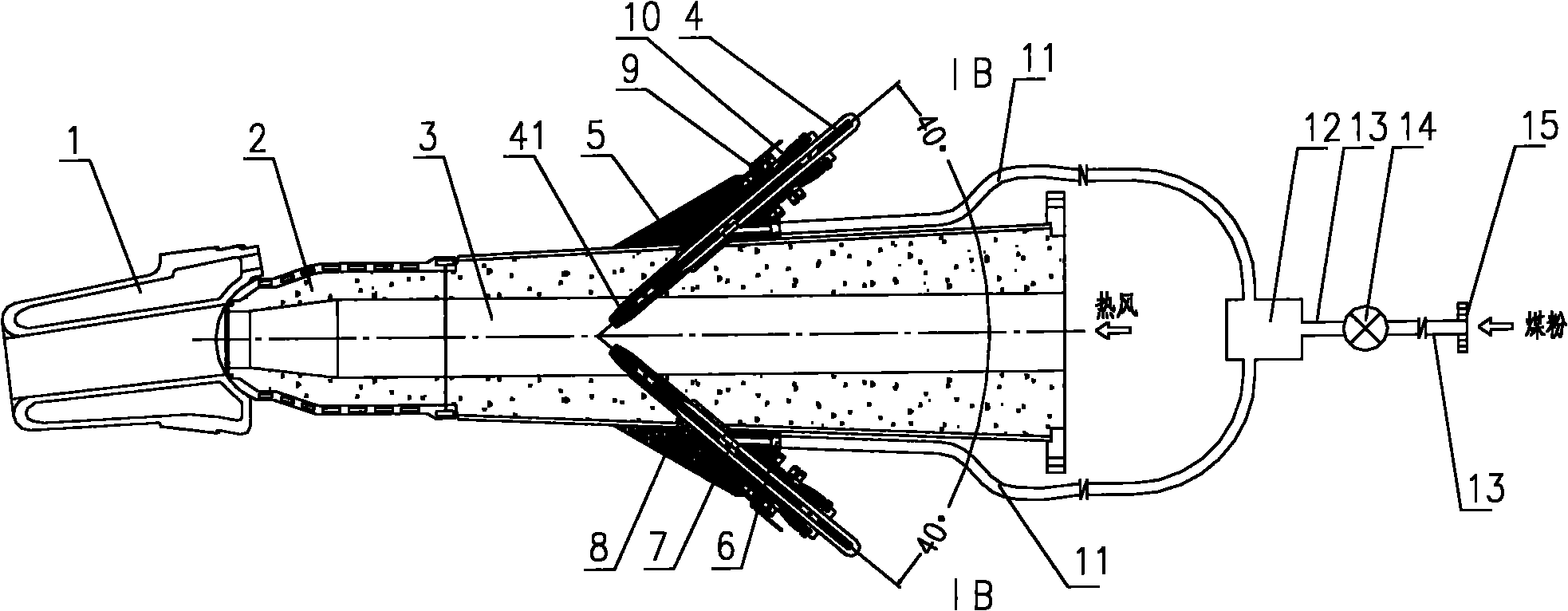

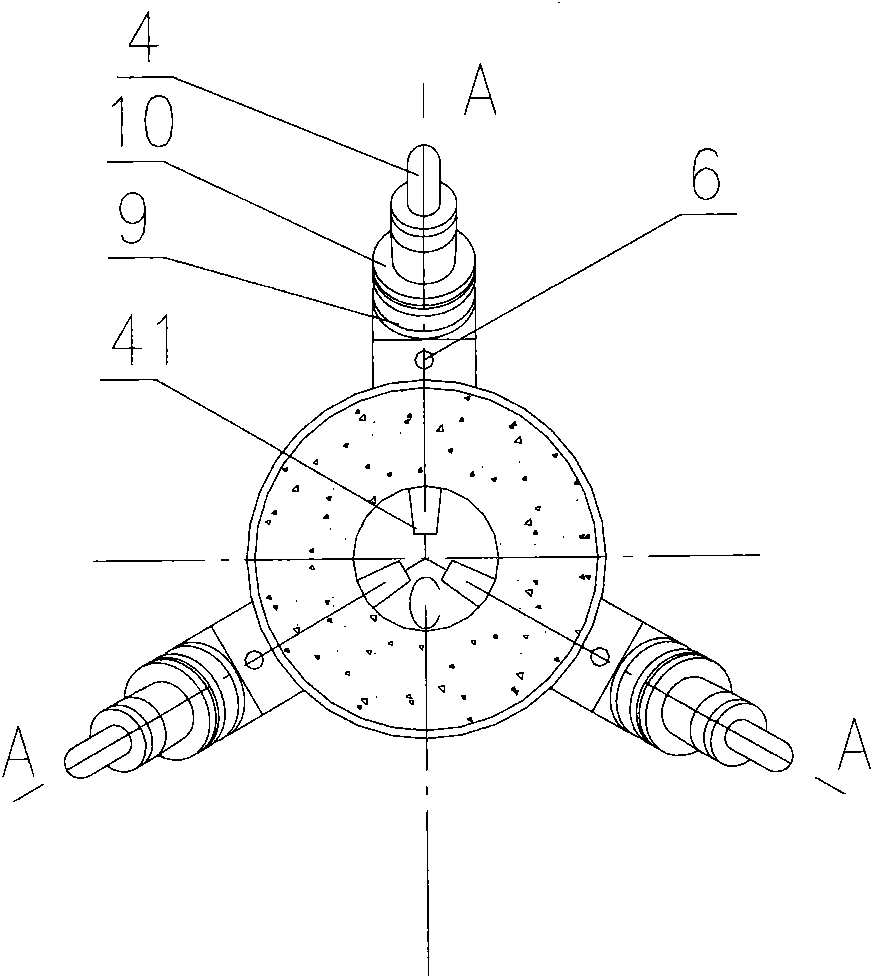

InactiveCN102485913AEnhance heat and mass transferExtended stayTuyeresBlast furnace detailsBall valveNew device

The invention puts forward a method and device for a blast furnace to blow coal powder. Characterized by employment of several short spray guns, a large incidence angle, accurate positioning of spray guns, small heat radiation and long life of blowpipes, and adoption of ceramic nozzles, the new method and new device of the invention aims to eliminate various defects in prior art, such as small coal powder incidence angle, restriction by high speed hot airflow, inadequate mixing with hot air, long length and long service life of spray guns, large heat radiation and short service life of blowpipes, and hard use of oxygen-coal lances, etc. According to the invention, on the blowpipes of each air ports, each short spray gun is inserted into each installation seat, and coal powder blown into a blast furnace enters from blowing inlets positioned on a lateral side of each installation seat, then reaches the inside of each short spray gun through coal spraying holes that are disposed on tube walls of the short spray guns and are over against the blowing inlets, and is finally blown into the furnace through each short spray gun. The device of the invention at least comprises: a blowpipe with a coal powder precombustion function, short spray guns, installation seats, ball valves, locking devices, coal conveying branch pipes, a distributor, a small ball valve, a coal conveying pipe, and an inlet connecting piece.

Owner:张昭贵

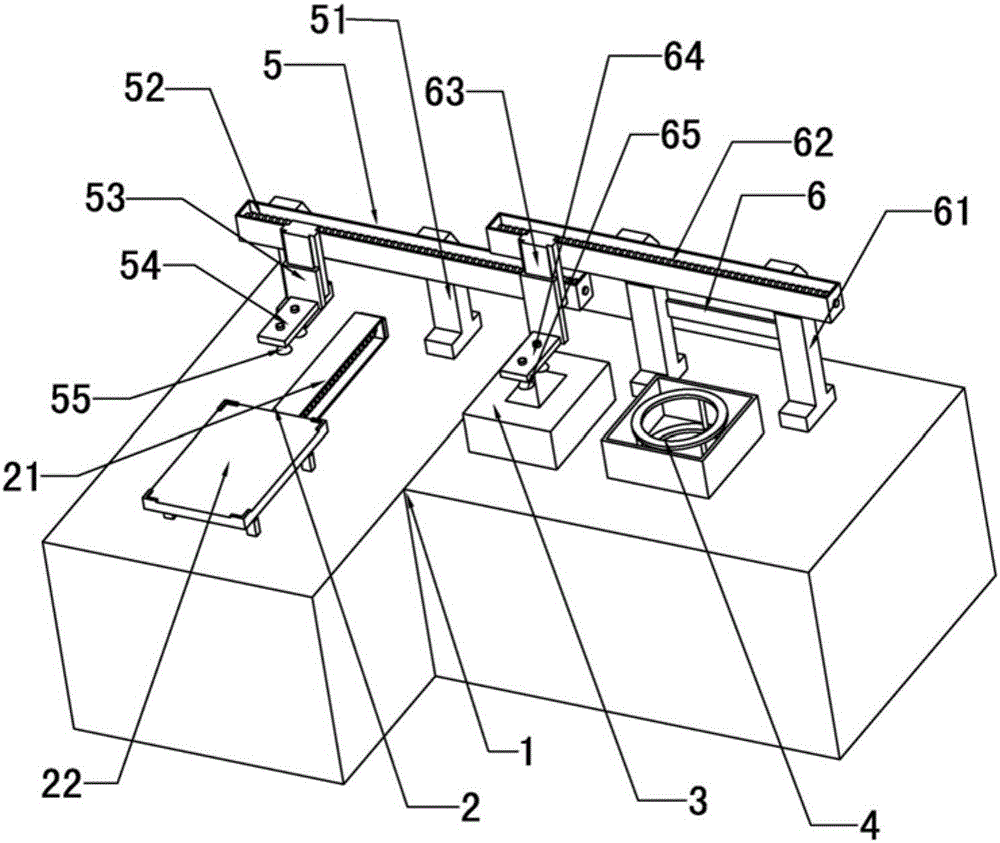

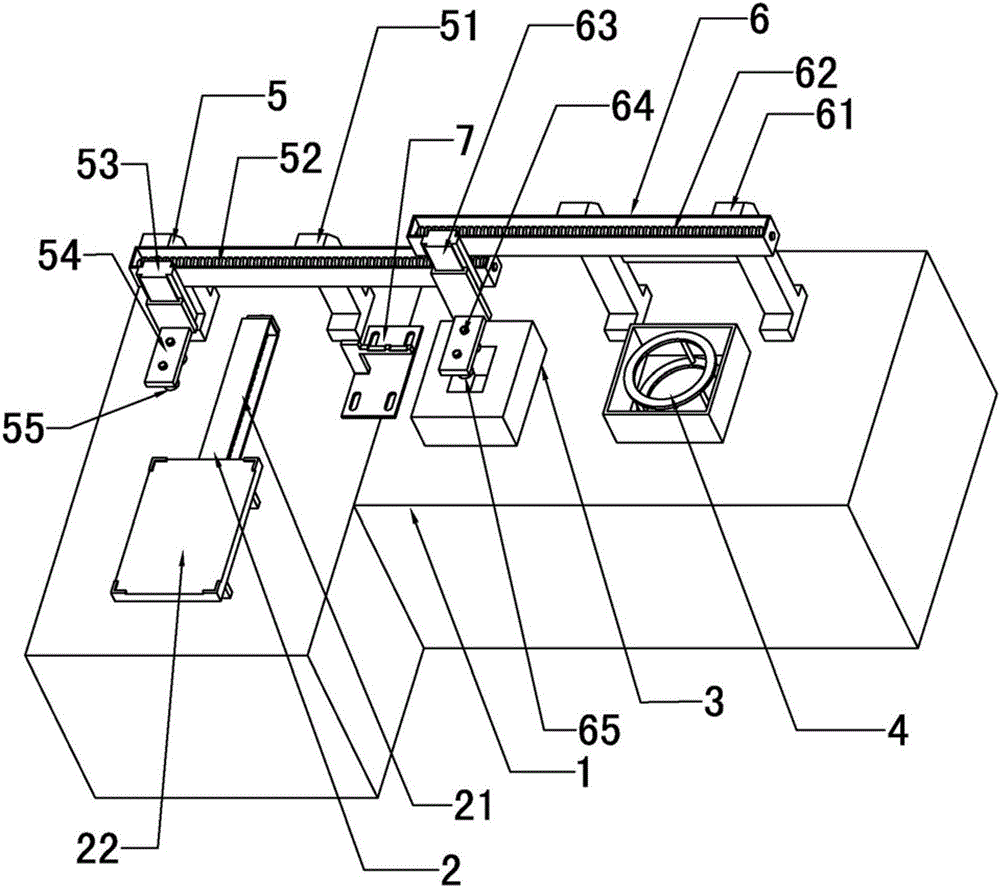

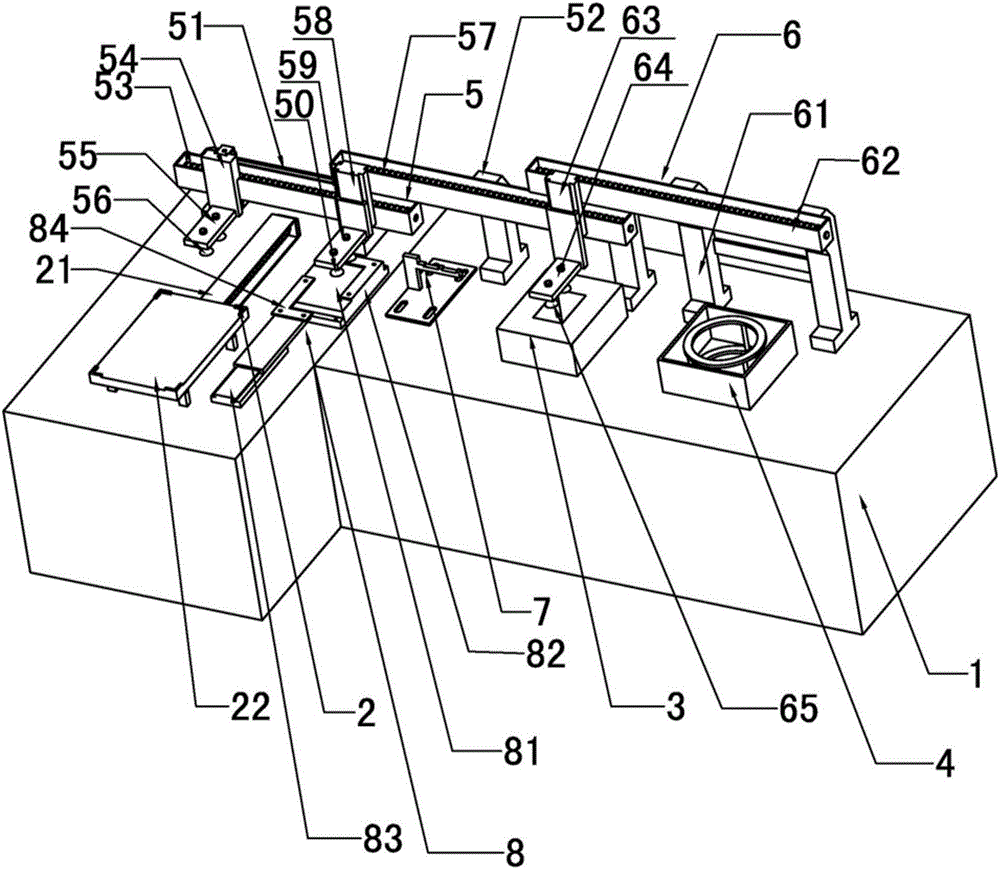

Magnetic steel magnetization and magnetic flux detection integrated equipment

InactiveCN106144579ARealize integrated operationOmit the transfer processMagnetic bodiesMagnitude/direction of magnetic fieldsIntegrated operationsMagnetization

The invention discloses magnetic steel magnetization and magnetic flux detection integrated equipment. The integrated equipment comprises a worktable; a feeding station, a magnetizing station and a magnetic flux detecting station are arranged on the worktable in sequence; a feeding device is arranged in the feeding station; a magnetizing coil connected with a magnetizing machine is arranged in the magnetizing station; a magnetic flux measurer is arranged in the magnetic flux detecting station; a first conveying device for conveying magnetic steel from the feeding station to the magnetizing station is arranged between the feeding station and the magnetizing station; and a second conveying device for conveying the magnetized magnetic steel to the magnetic flux detecting station is arranged between the magnetizing station and the magnetic flux detecting station. The equipment has the advantages of realizing integrated operation of magnetization and magnetic flux detection, saving both manpower and material resources, reducing the production cost and improving the production efficiency.

Owner:江苏晨朗电子集团有限公司

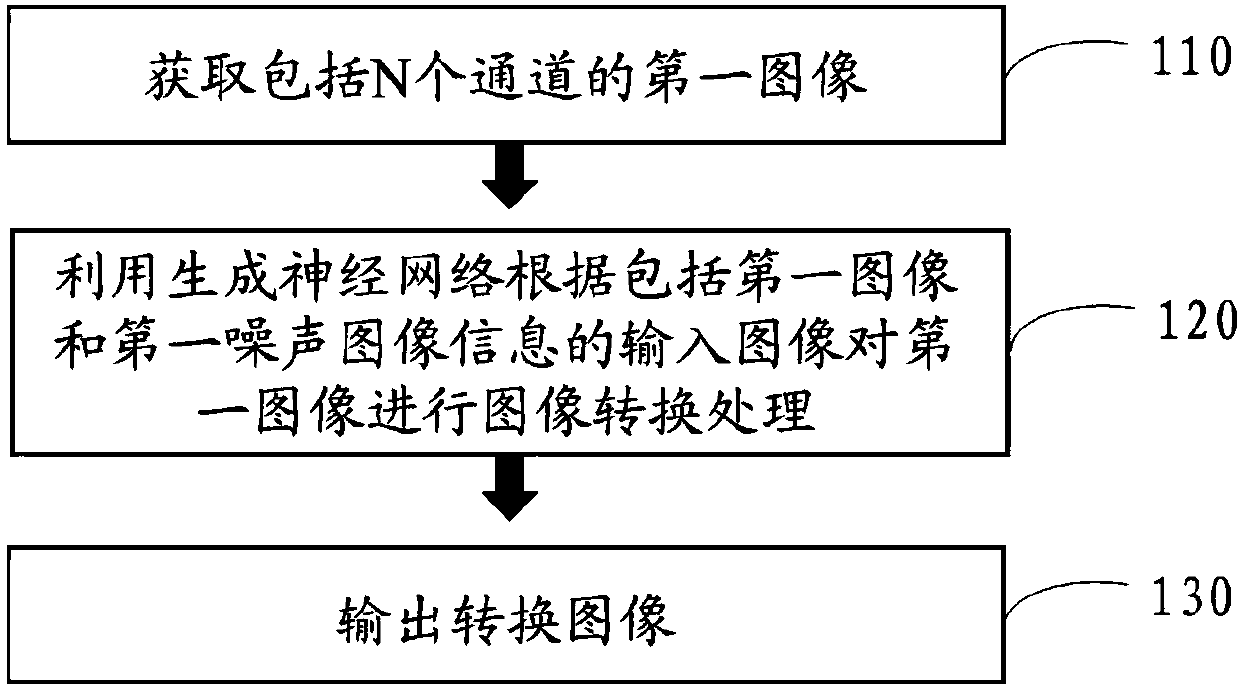

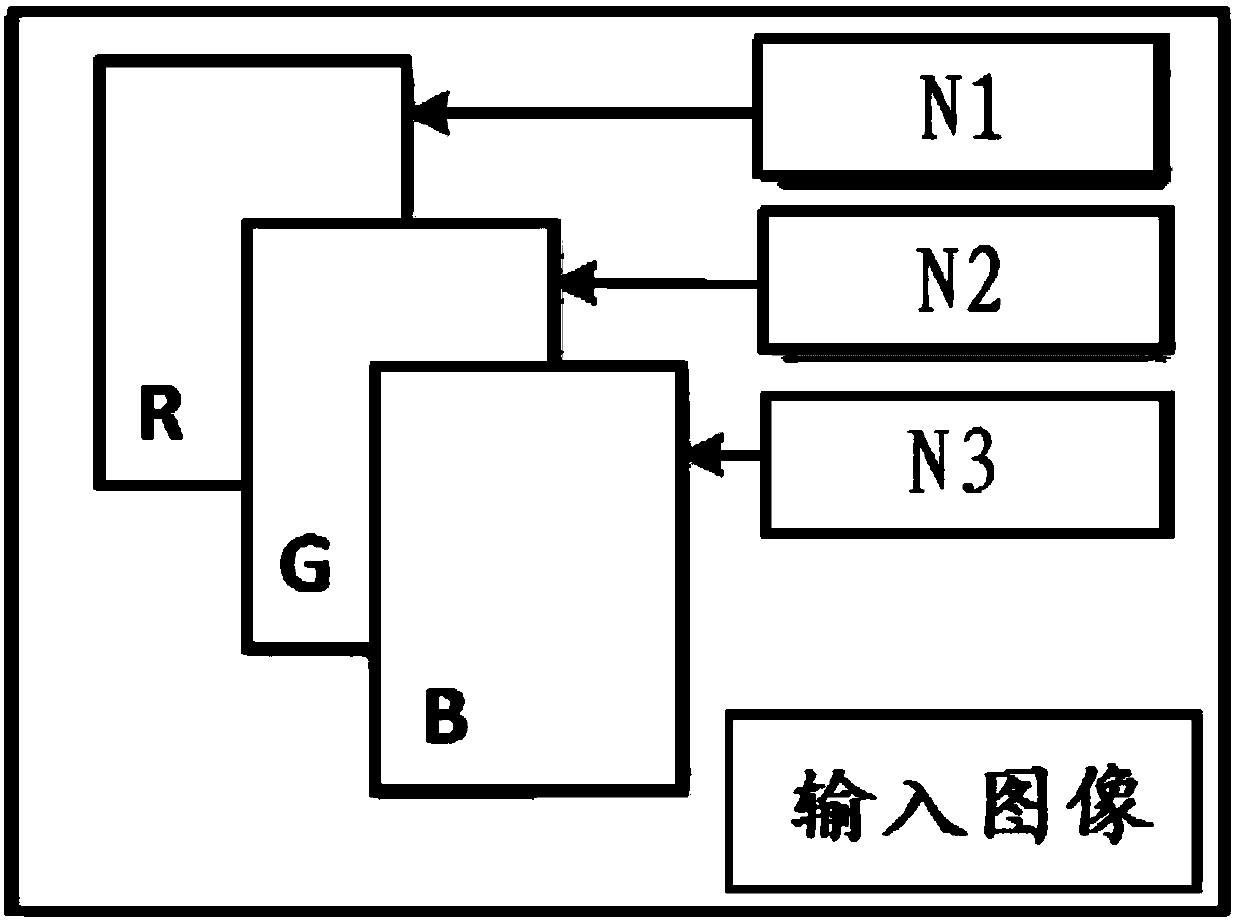

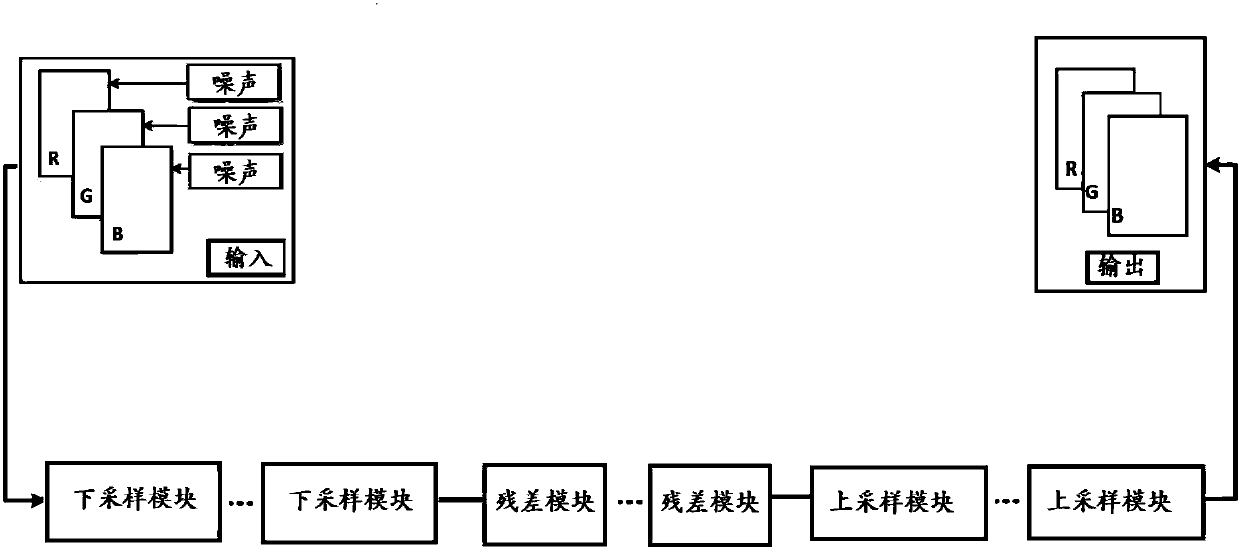

Image processing method, processing apparatus and processing device

ActiveCN107730474AHave diversityConsistentImage enhancementImage analysisImaging processingLaplace transform

Embodiments of the invention provide an image processing method, processing apparatus and processing device. Image conversion is realized in combination with Laplace transformation and image style features by utilizing a generating neural network, so that an output image after conversion has diversity and is kept consistent with an input image; a system is simple; and training is easy. The image processing method comprises the steps of obtaining a first image comprising N channels, wherein N is a positive integer greater than or equal to 1; and performing image conversion processing on the first image by utilizing the generating neural network to output the output image after conversion, wherein the generating neural network is obtained by training based on a Laplace transformation function.

Owner:BOE TECH GRP CO LTD

Welded flange hot-rolling technique

InactiveCN101422860AOvercome Raw Material WasteAccelerateMetal rolling arrangementsStraight segmentSheet steel

The invention relates to a technique of flat welding flange hot rolls, which comprises the procedures of: putting a steel billet into a furnace and heating, then according to the thickness and width of flange blank, immediately rolling the hot billet intoto strip hot-rolled flat plate of which the cross-section approximates an isosceles trapezoid; then arc curling the plate toward the narrow side and making into spiral multi-layer circular steel rings of which the ends are connected successively; next cutting the connected rings into independent rings along the bus; and then flattening the rings and welding docking ports at above 700 DEG C, and making into flange blank. The invention overcomes the disadvantages of the prior flange manufacturing technique such as waste of raw materials, relatively low precision of flange blank and low production efficiency, thereby realizing mass production of multiple circular curling, speeding up production, improving quality, and greatly improving production efficiency. Besides, the technique which is easy to be operated, popularized and implemented, solves the problem existing in head and tail straight segment, raises utilization rate of the raw materials, and has good social and economic benefit.

Owner:CHANGTONG TECH

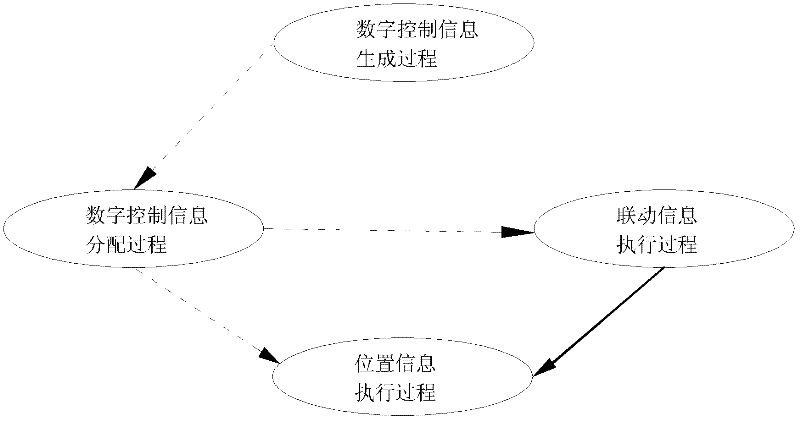

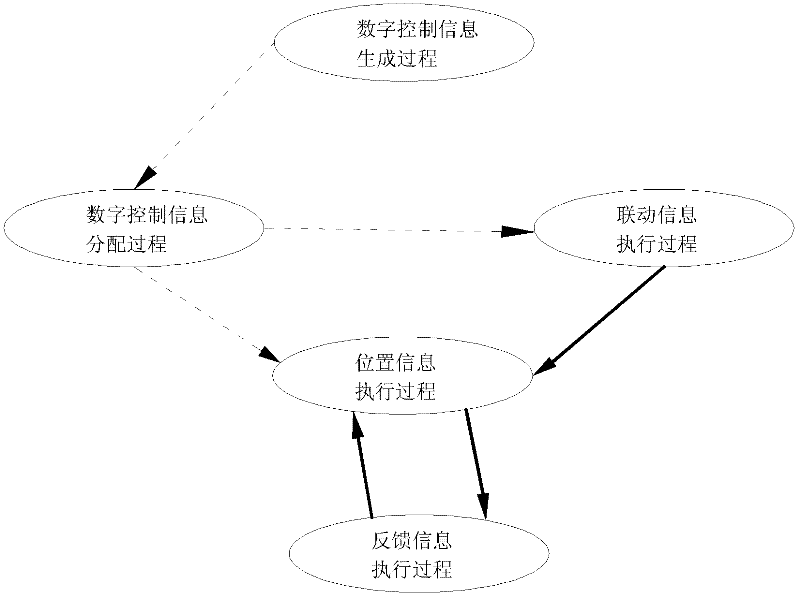

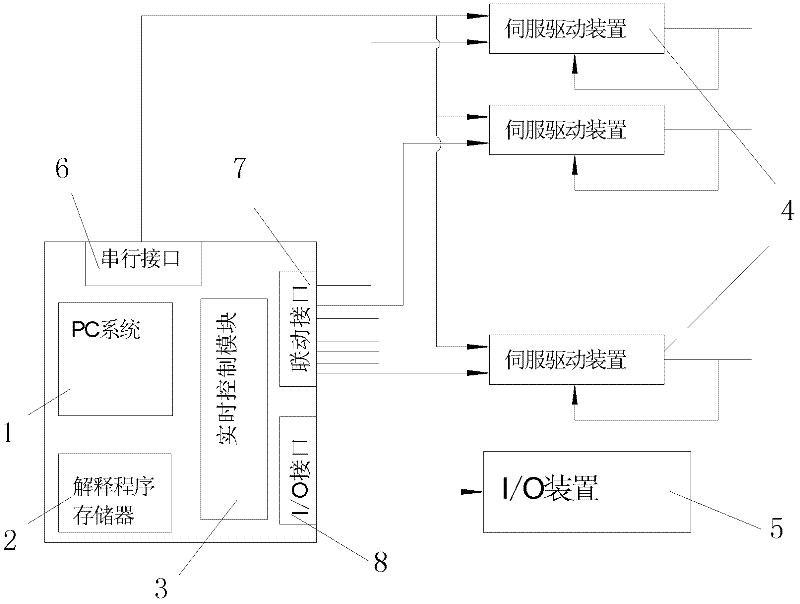

Reconfigurable computer numerical control system, numerical control method thereof and reconstruction method thereof

The invention discloses a standardized reconfigurable computer numerical control system, a numerical control method thereof and a reconstruction method thereof, wherein the computer numerical control system is based on PC and is opened all around. A processing process model, which faces to the process and is open, is provided. Control resources are configured according to a control flow including generation, distribution, sending and execution of numerical control information. And the system has nothing to do with software and hardware platform performces like a digit number and a speed of a processor as well as an operating system performance and the like; and the system also has nothing to do with a programming interface; therefore, the system has good reconfigurability. According to the invention, real-time control of a tool path curve is converted into simplest real-time sending of a linkage instruction; and the system has a simple and reliable multiaxis synchronization capability with high speed and high precision, so that significant transformation of a numerical control method is brought about.

Owner:数驱技术有限公司

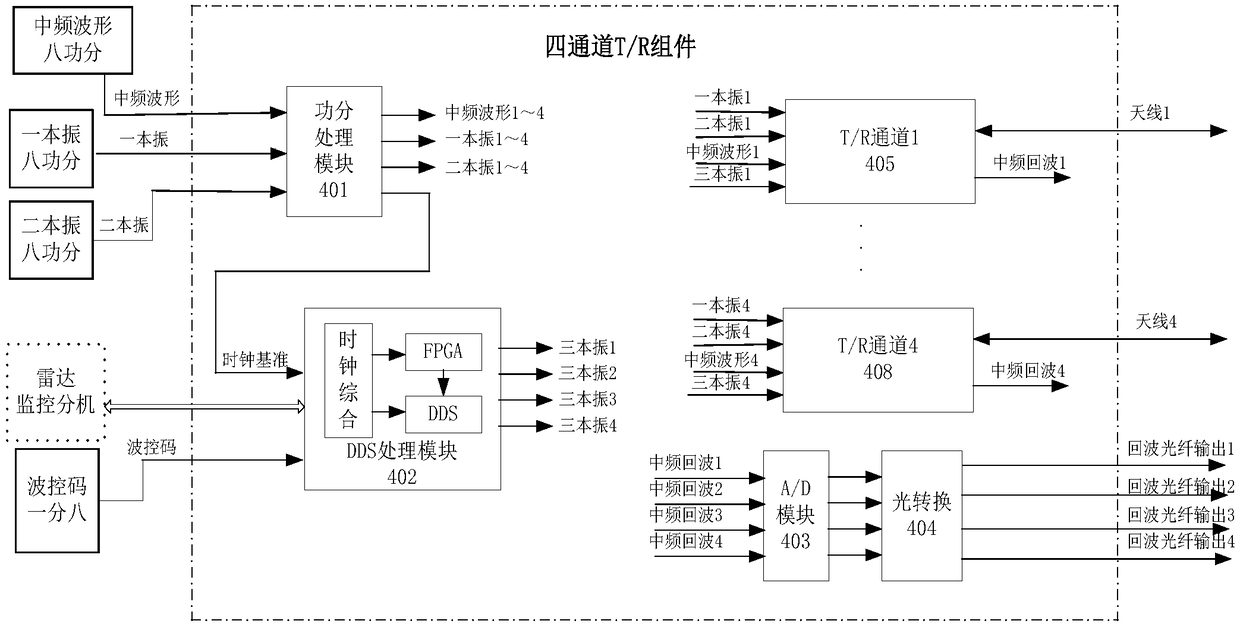

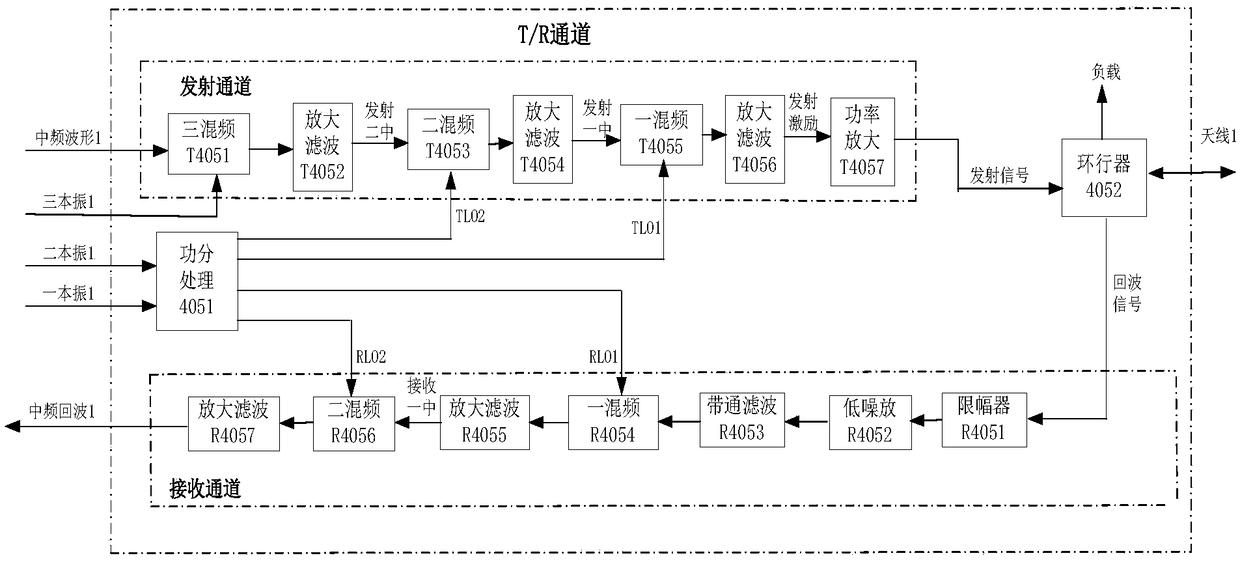

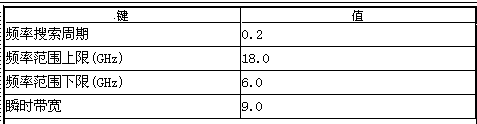

Transceiver system implementation method for implementing digital phase shift and calibration with DDS (Direct Digital Synthesizer) as local oscillator

InactiveCN109031214APhase shifting is simple and feasibleLow priceWave based measurement systemsTransceiverMicrowave

The invention belongs to the field of radar microwave transceiving, and especially relates to a transceiver system implementation method for implementing digital phase shift and calibration with a DDS(Direct Digital Synthesizer) as a local oscillator. The DDS generates four paths of outputs to each path of T / R channel used as a third local oscillator; a waveform generation plug-in of a radar frequency source extension generates an intermediate frequency waveform and then the intermediate frequency waveform is provided to eight four-channel T / R components through an eight-way power divider; afirst local oscillator and a second local oscillator generated by the radar frequency source extension are sent to eight four-channel T / R components through the eight-way power divider; a single DDS processing module can carry out phase shift on four transmitting channels at the same time; and when a radar works in a transmission calibration mode, a calibration plug-in receives and processes signals sent by a calibration network and converts the signals into optical fiber signals to be output. The transceiver system implementation method for implementing the digital phase shift and calibrationwith the DDS as the local oscillator provided by the invention fully utilizes the advantages that DDS phase shift is simple and feasible, large in number of bits, high in precision, lower in price, small in size, multiple in channels and the like, and overcomes the problems that a traditional digital phase shifter is high in price, limited in the number of bits, low in integration level, large inweight and each channel needs a phase shifter.

Owner:WUHAN BINHU ELECTRONICS

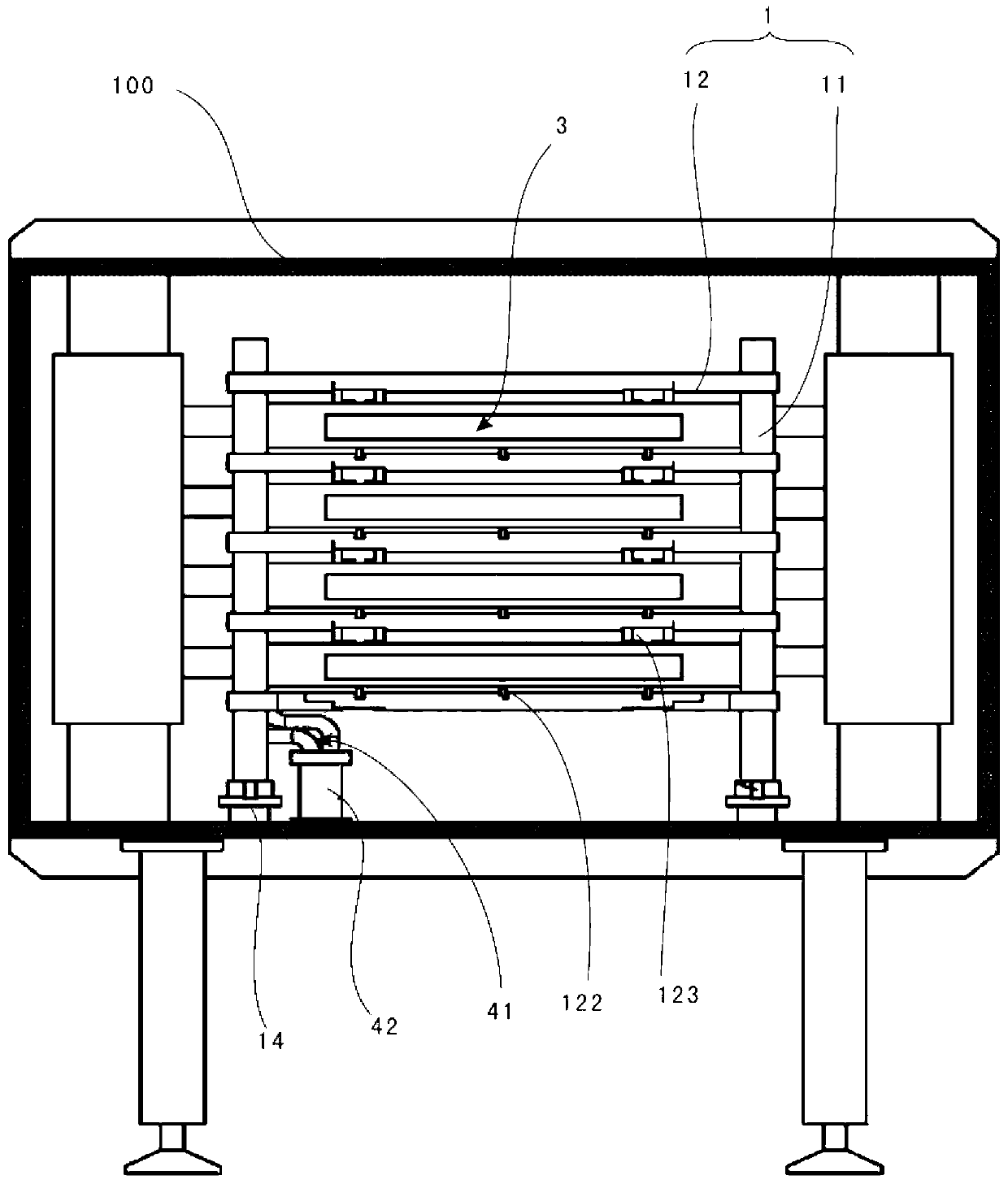

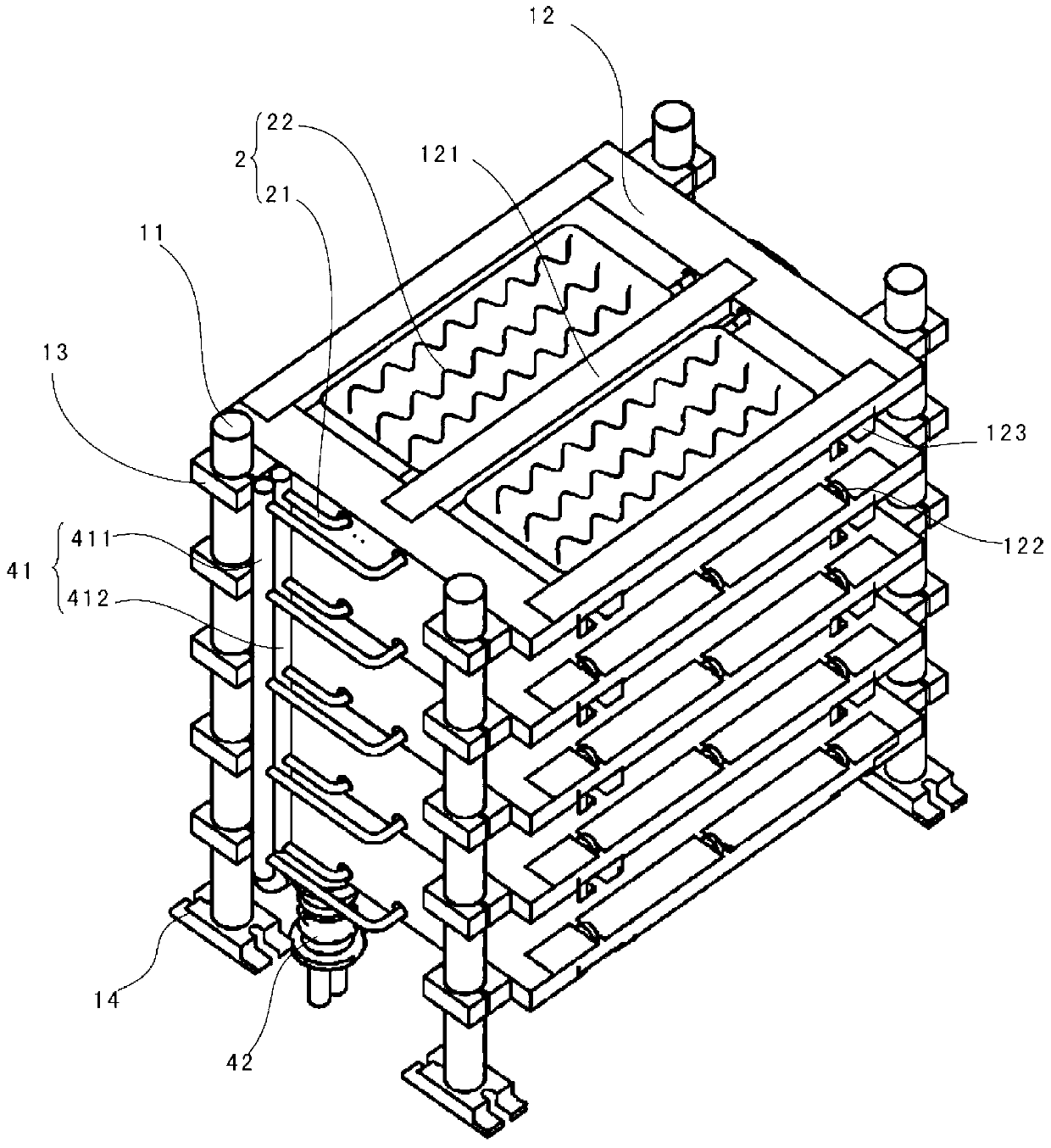

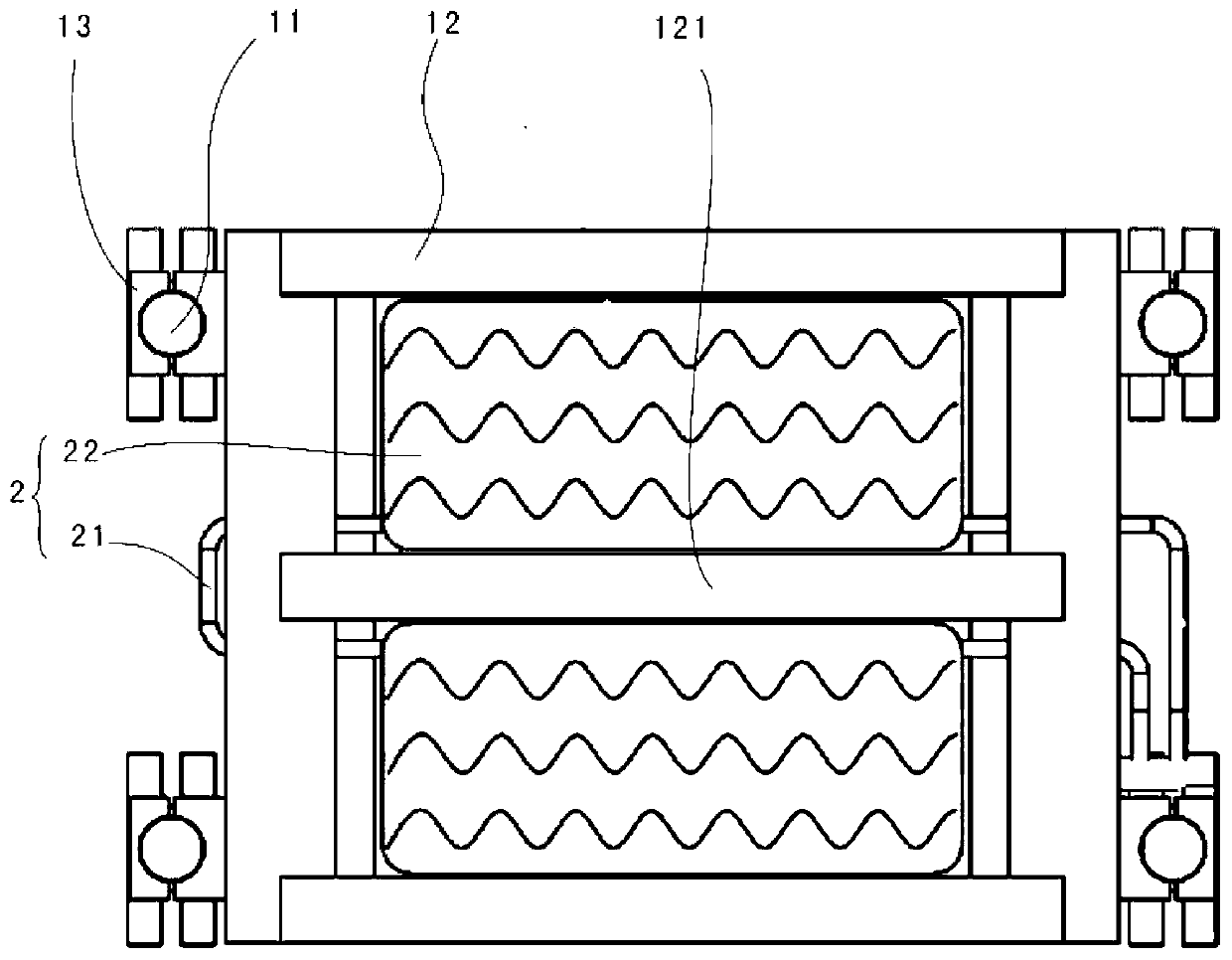

Plasma enhanced chemical vapor deposition (PECVD) device

ActiveCN103276373ATemperature hasIncrease temperatureChemical vapor deposition coatingCooling effectEngineering

The invention discloses a plasma enhanced chemical vapor deposition (PECVD) device which comprises a process cavity, and a bearing rack, cooling vapor chambers and at least one reaction chamber which are arranged in the process cavity, wherein the multiple vapor chambers are arranged on the bearing rack in a layered arrangement mode along the vertical direction; the reaction chamber is horizontally arranged between two adjacent vapor chambers; and the vapor chambers are arranged on the upper and lower sides of each reaction chamber. The vapor chambers are arranged on the upper and lower sides of each reaction chamber; due to the uniform heating and isolating functions of the vapor chambers, the heat radiation interference between the reaction chambers is eliminated, and the temperature consistency in each reaction chamber is guaranteed; and meanwhile, the cooling vapor chamber has the cooling effect, the temperature of the process cavity is prevented from being extremely high, and the sealing structure of the process cavity is protected, so that the temperature of the process cavity is prevented from being extremely low, and the waste of heating energy is avoided.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

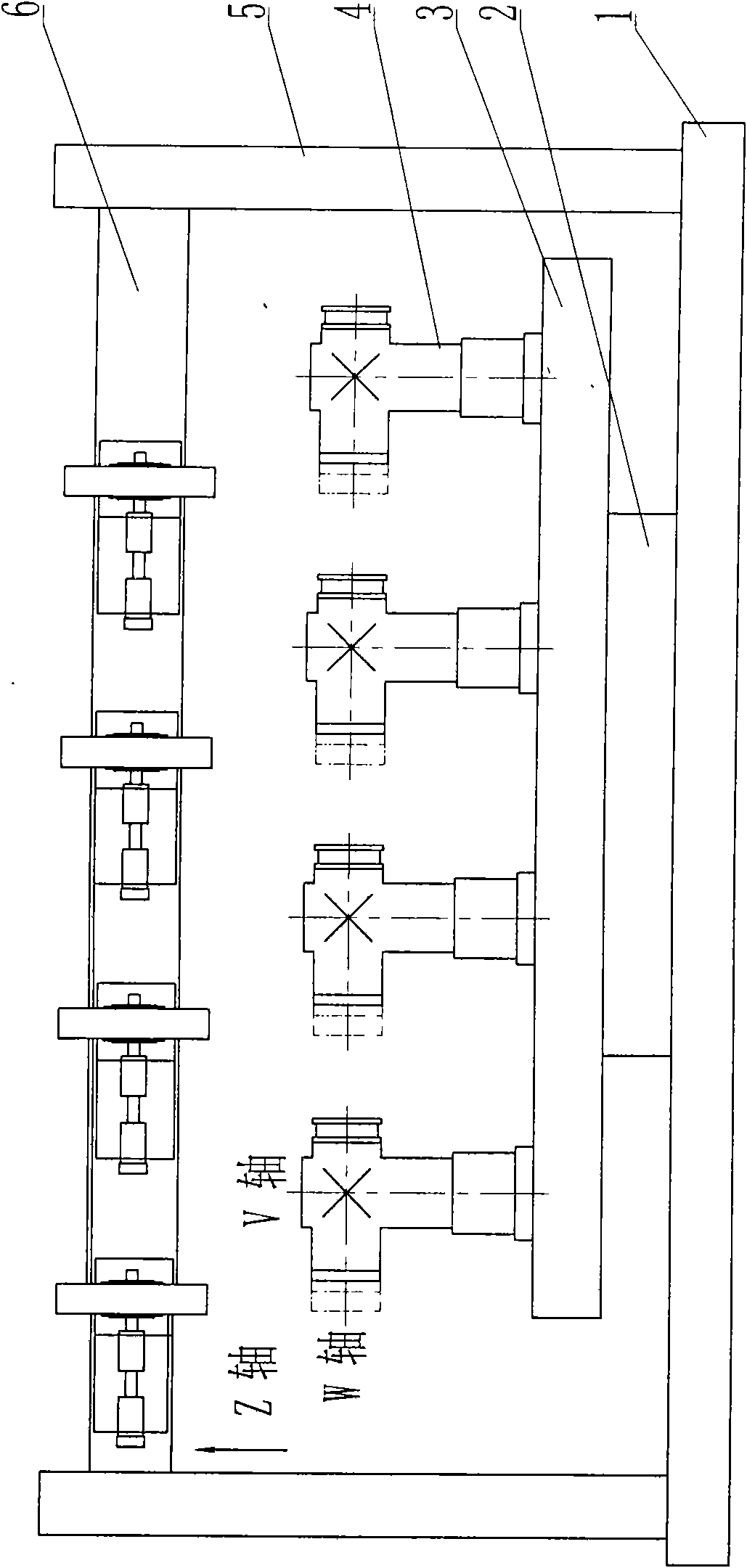

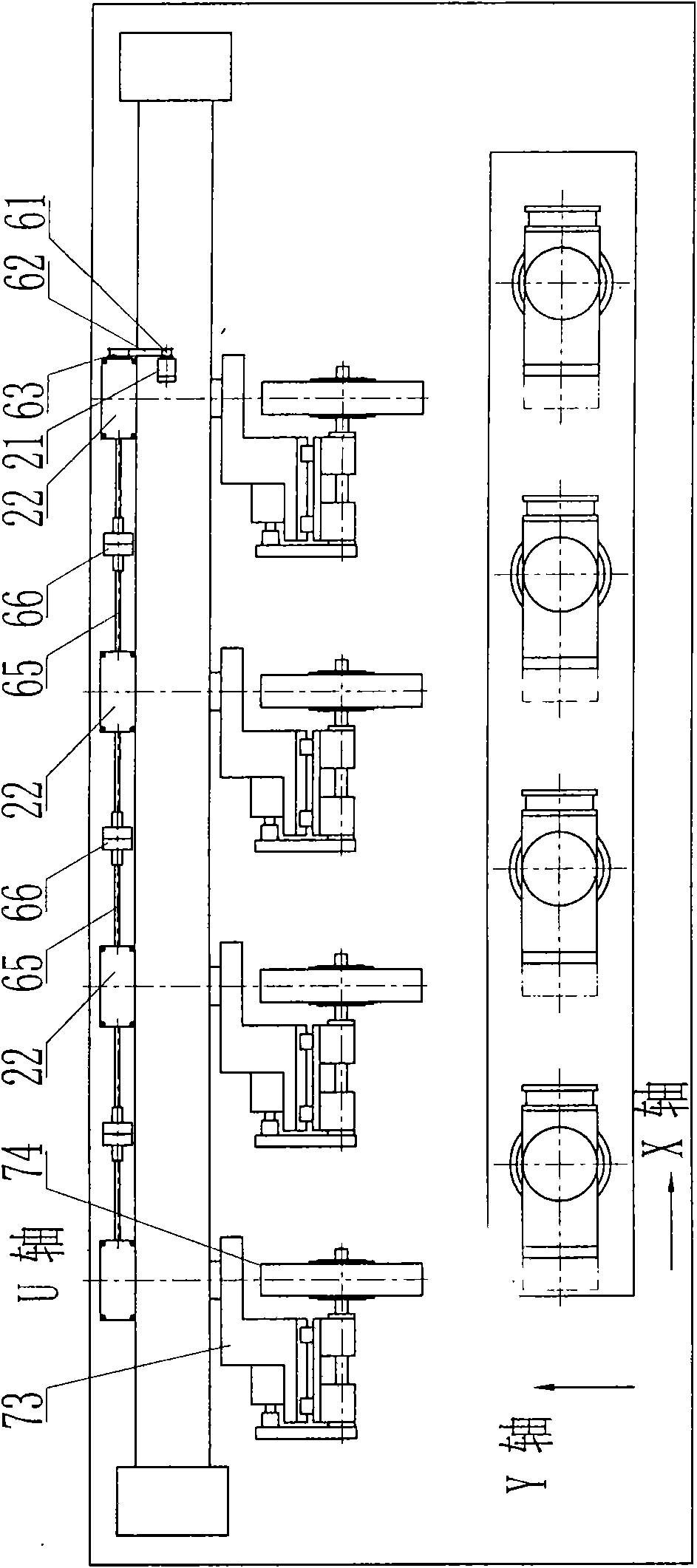

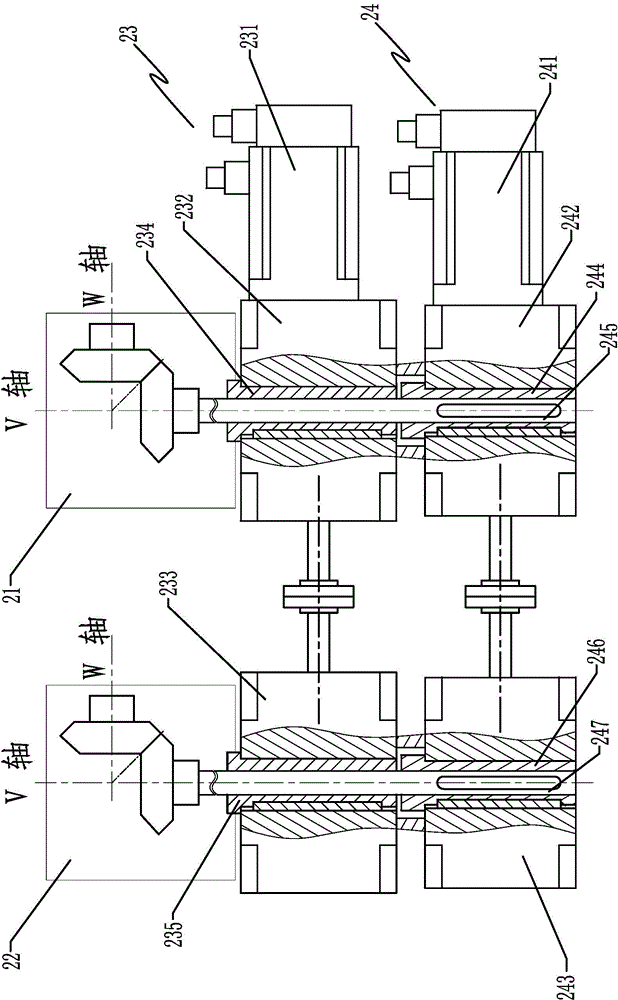

Six-axis linked numerical control polishing machine

InactiveCN101648359AAchieve any angleRealize position processingPolishing machinesGrinding drivesNumerical controlEconomic benefits

The invention relates to a six-axis linked numerical control polishing machine, which comprises a big pedestal, a moveable pedestal, a worktable, a three-way revolving bed, vertical columns, a beam and a machine head frame. A polishing wheel is arranged on the machine head frame; a workpiece is arranged on the three-way revolving bed; the active pedestal linearly moves on the big pedestal along anX-axis direction through a transmission mechanism; the worktable linearly moves on the moveable pedestal along a Y-axis direction through the transmission mechanism; the three-way revolving bed rotates around a V axis on the worktable; the workpiece is clipped on the three-way revolving bed and rotates around a W axis; the beam arranged between the left and right linearly moves along a Z-axis direction through the transmission mechanism; the machine head frame provided with the polishing wheel rotates around a U axis; and the movements in the six directions are driven by an independent servomotor respectively and numerically controlled in the whole process by a servo system. The six-axis linked numerical control polishing machine can machine the workpiece in all directions and at all angles, is stable in machining quality and effectively improves the production efficiency and economic benefit.

Owner:GUANGDONG EVERTEAM ELECTRIC & GAS IND CO LTD

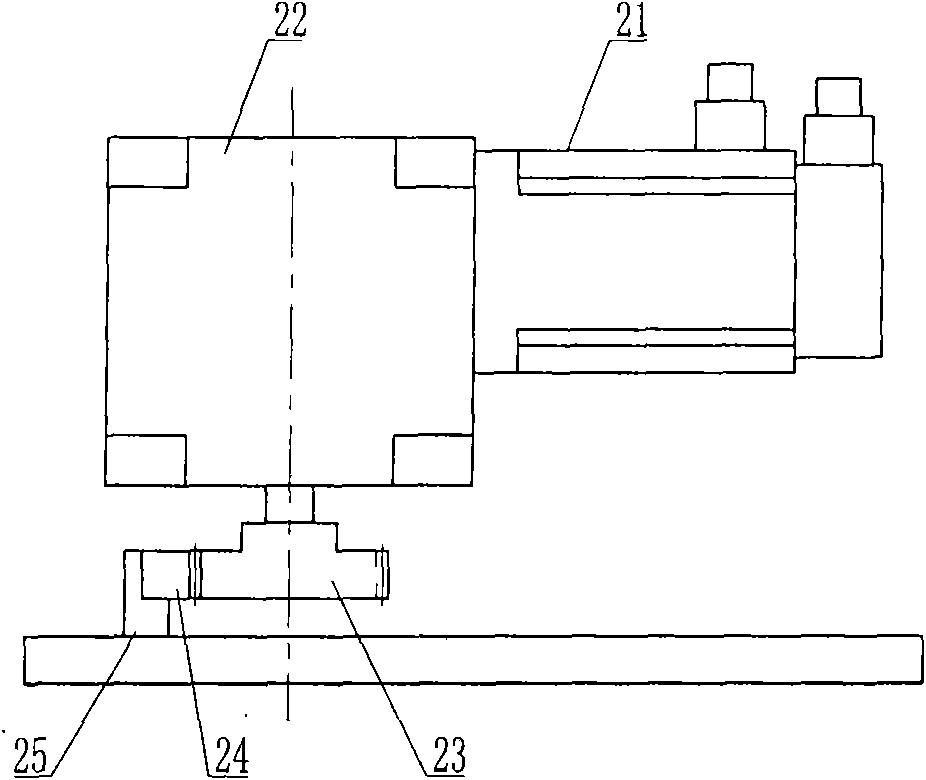

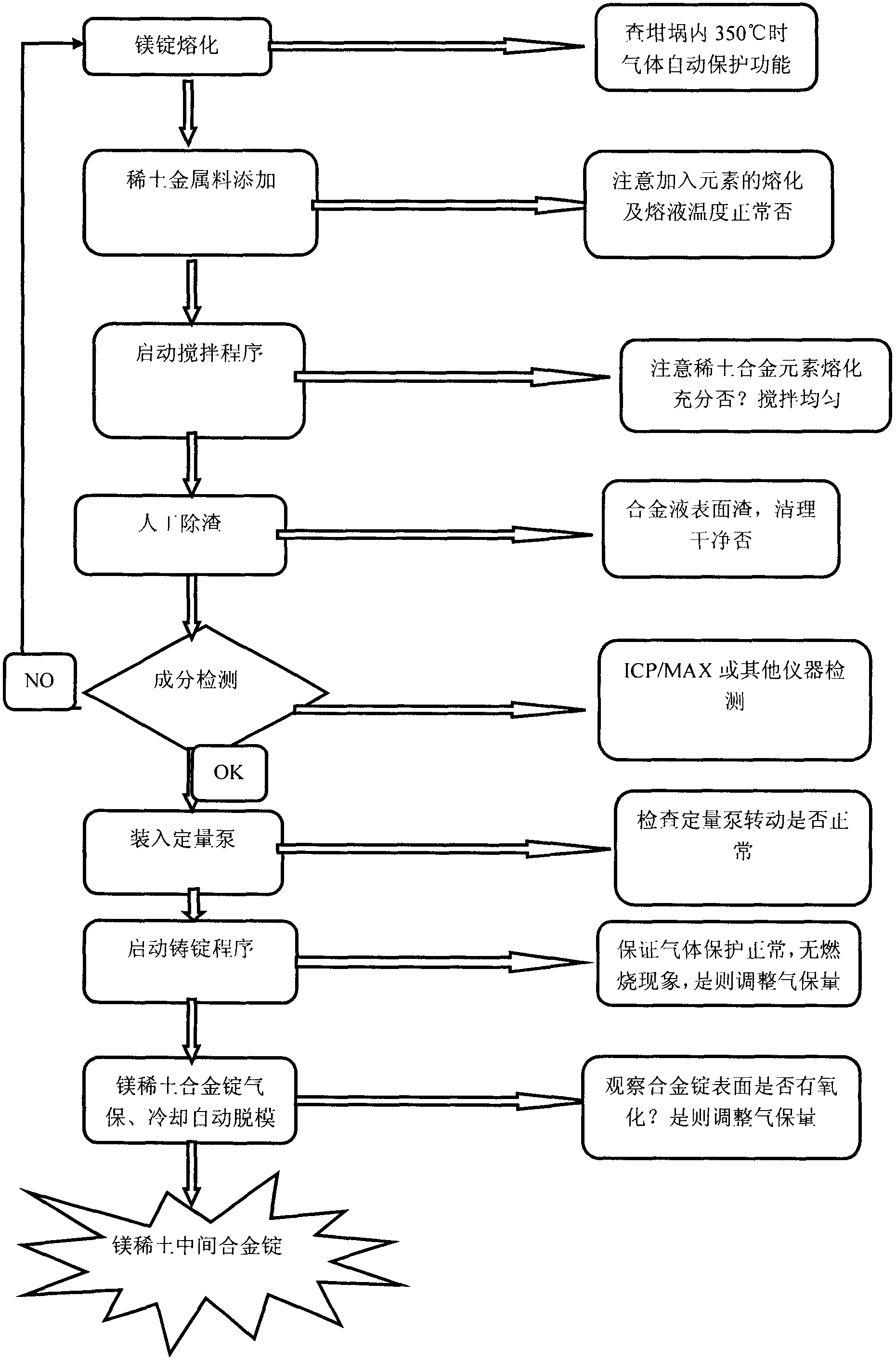

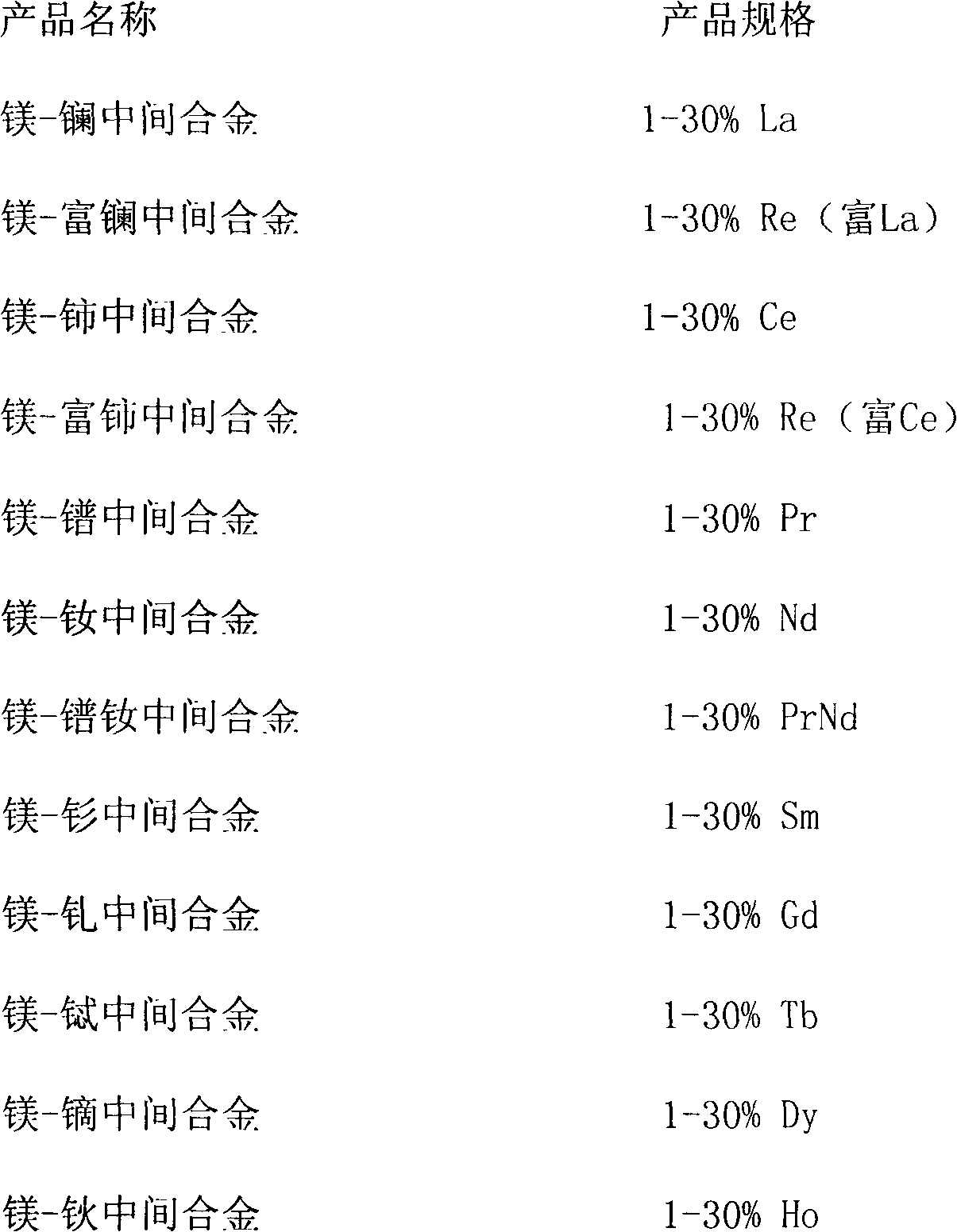

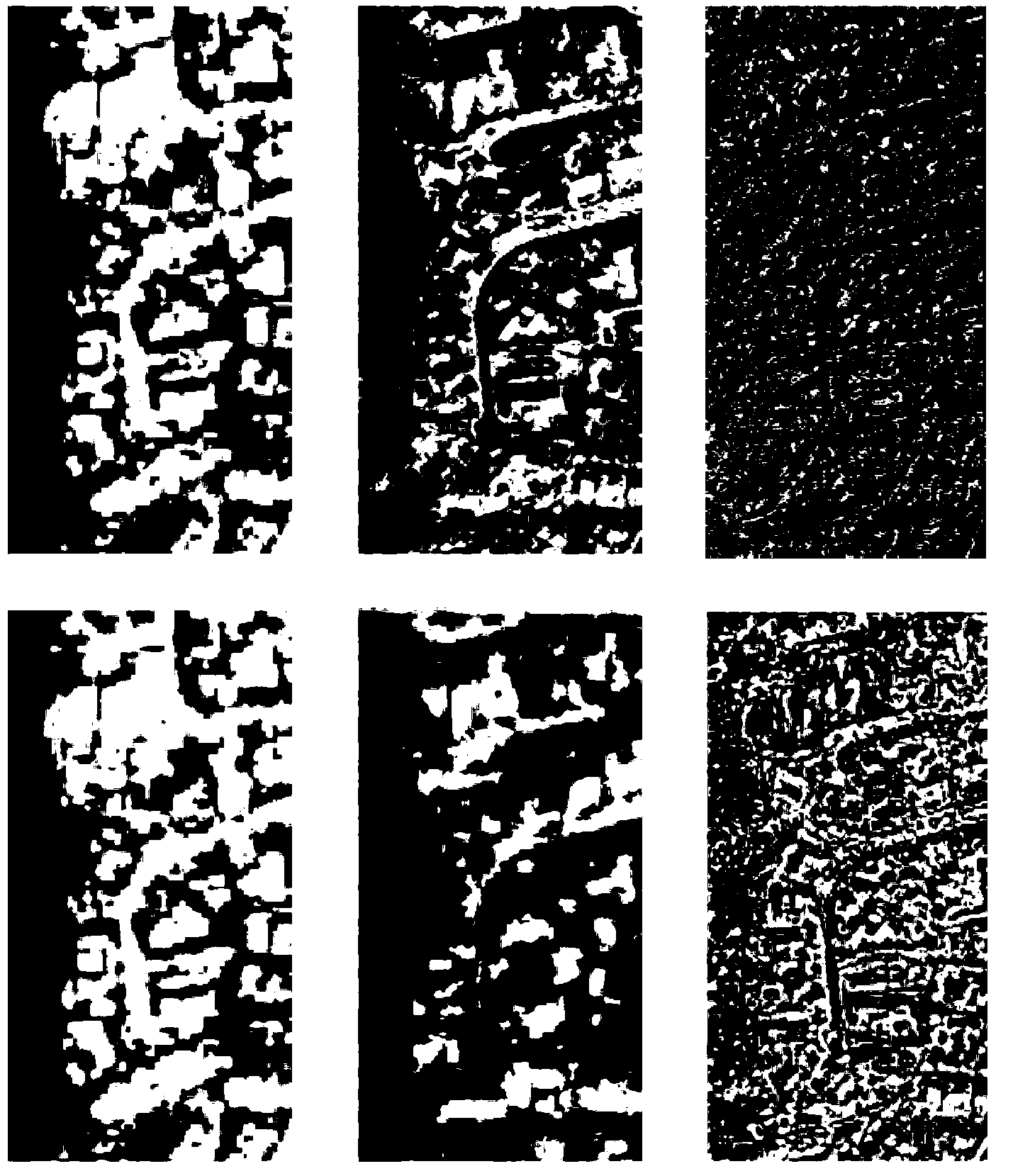

Method for continuously and automatically producing magnesium-rare earth intermediate alloys

ActiveCN103540777ASafe and efficient productionNo pollution in the processMolten metal pouring equipmentsRare earthNickel free

The invention discloses a method of continuously and automatically producing 16 magnesium-rare earth intermediate alloys such as a magnesium-neodymium intermediate alloy. The method comprises the following steps: after melting a magnesium ingot raw material by a finery, adding a rare earth metal material, manually deslagging, and automatically stirring and homogenizing by a system, and sampling and testing alloy components which are qualified; then pouring an alloy liquid to an ingot case of a pig moulding machine through a metering pump to form a continuous and automatic ingot casting; and cooling the alloy liquid to form standard magnesium-rare earth intermediate alloys. The key point of the invention is as follows: the method is applicable to continuous and automatic ingot casting production of 16 magnesium-rare earth intermediate alloys such as the magnesium-neodymium intermediate alloy, so that the labor intensity of production is reduced, and the production safety is greatly improved in anhydrous environment production. The produced product is consistent and high in yield. According to a crucible manufactured by a nickel-free high temperature alloy steel plate, carbon content is not introduced in the production process, the production efficiency is high, and the method is applicable to continuous production on a large scale, free from environmental pollution. Waste residues can be recycled, thereby truly realizing safe and efficient production of the magnesium-rare earth intermediate alloys on a large scale.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Image fusion method based on sparse linear system

The invention relates to the technical field of digital image processing and discloses an image fusion method based on a sparse linear system. The image fusion method based on the sparse linear system includes that a multispectral image conducts integrated heat spreader (HIS) changing so as to obtain luminance information, a full-color image conducts extreme value gaining, and according to the full-color image, a luminance component of the multispectral image and an extreme point of the full-color image, the sparse linear system is constructed. Based on the sparse linear system, an average envelope is gained, and based on the average envelope, high-frequency information is obtained, wherein the high-frequency information is contained in the full-color image, and the multispectral image is out of the high-frequency information. The obtained high-frequency information is injected into a multispectral luminance component so as to obtain the luminance component of a fusion result, the luminance component of the fusion result, and a chromaticity component and a saturation level component of the multispectral image conduct inversed HIS changing, and therefore, the fusion result is obtained. With the image fusion method based on the sparse linear system, fusion effect of a high-resolution full-color image and a low-resolution multispectral image is improved.

Owner:ZHEJIANG UNIV

Novel six-station disc-type numerical control cloth wheel buffing machine

ActiveCN104526521AConsistentStable polishing qualityGrinding carriagesPolishing machinesNumerical controlCircular disc

The invention discloses a novel six-station disc-type numerical control cloth wheel buffing machine. The cloth wheel buffing machine comprises a base and a rotating disc arranged in the middle of the base. Five-station double buffing wheel assemblies and an one-station assembly and disassembly station are evenly arranged at the parts, around the rotating disc, of the base, and six-station double workpiece clamp assemblies are evenly arranged at the parts, corresponding to the five-station double buffing wheel assemblies and the assembly and disassembly station, of the rotating disc in an equal-angle mode. Each double buffing wheel assembly comprises a movable stand column and a double buffing wheel structure which is arranged on the stand column and corresponds to one double workpiece clamp assembly. The double workpiece clamp assembly on each station comprises two workpiece chucks matched in a linkage mode. Through rotating the double workpiece clamp assemblies and the double buffing wheel assemblies by one circle each time, twelve workpieces can be buffed, in this way, production efficiency is greatly improved, the application range of buffing complex curved-surface workpieces is enlarged, the stability and uniformity of the quality of workpiece buffing are guaranteed, occupied area is reduced, energy consumption is lowered, and the production efficiency and economic benefits are improved by times.

Owner:广东博科数控机械有限公司

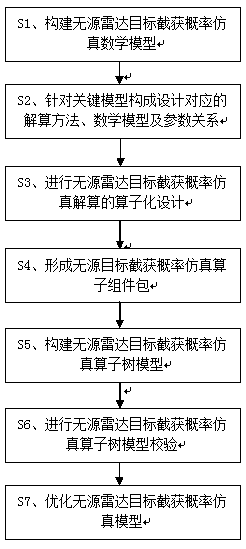

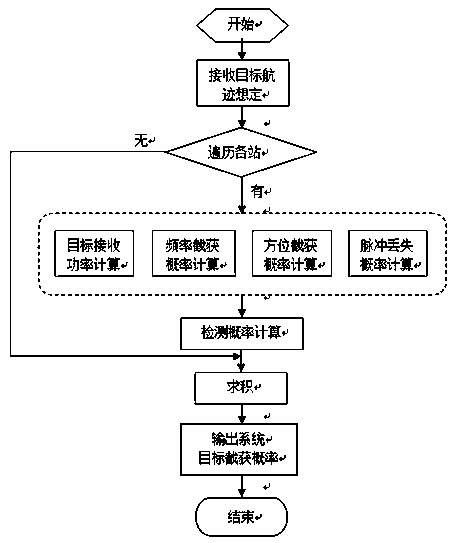

The invention discloses an operator-based passive radar target interception probability flexible simulation modeling method

PendingCN109829251AGood scalabilitySimplify model testing and maintenance processesWave based measurement systemsSpecial data processing applicationsPassive radarStandardization

The invention relates to the field of simulation evaluation and flexible simulation modeling of passive radar battle effectiveness indexes, in particular to an operator-based passive radar target interception probability flexible simulation modeling method, which is characterized by comprising the following steps of: S1, constructing a passive radar target interception probability simulation mathematical model; S2, designing a corresponding resolving method, a mathematical model and a parameter relation according to the composition of the key model; S3, performing operator design of passive radar target interception probability simulation solution; S4, forming a passive target interception probability simulation operator component package; S5, constructing a passive radar target interception probability simulation operator tree model; S6, performing passive radar target interception probability simulation operator tree model verification; And S7, optimizing the passive radar target interception probability simulation model. The passive radar target interception probability simulation modeling method solves the problem of modularization and standardization of passive radar target interception probability simulation modeling, and improves the simulation modeling and mode testing efficiency.

Owner:AIR FORCE EARLY WARNING ACADEMY

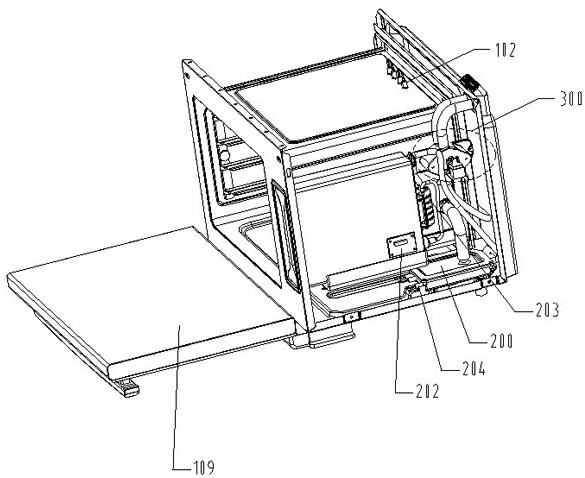

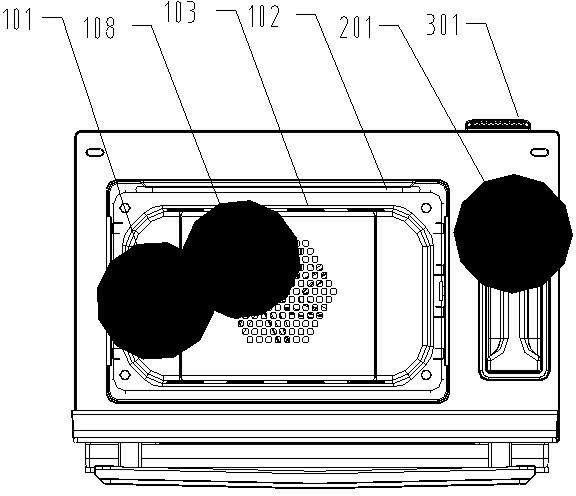

Electric steaming furnace with hot air flow

The invention relates to the technical field of kitchenware and discloses an electric steaming furnace with hot air flow. The electric steaming furnace comprises a furnace body, wherein the furnace body is provided with a furnace cavity, the side of the furnace cavity is provided with a steam generating device which provides steam for the furnace cavity, the furnace cavity is provided with an air intake used for absorbing steam, the air intake is correspondingly provided with an air draft device, the air intake is provided with a hot air flow device which is used for being communicated with the steam, the top of the furnace cavity is provided with a heating cavity, the heating cavity is provided with a heating coil used for heating the steam, the heating cavity is provided with an air outlet used for feeding heated overhigh-temperature steam into a cavity, and the furnace cavity is internally provided with a constant pressure exhaust system. The electric steaming furnace in the structure can cause the temperature of the furnace cavity to be uniform, the utilization rate of heat is high, the energy saving effect can be realized, and the electric steaming furnace has high safety.

Owner:广东天倬智能家居有限公司

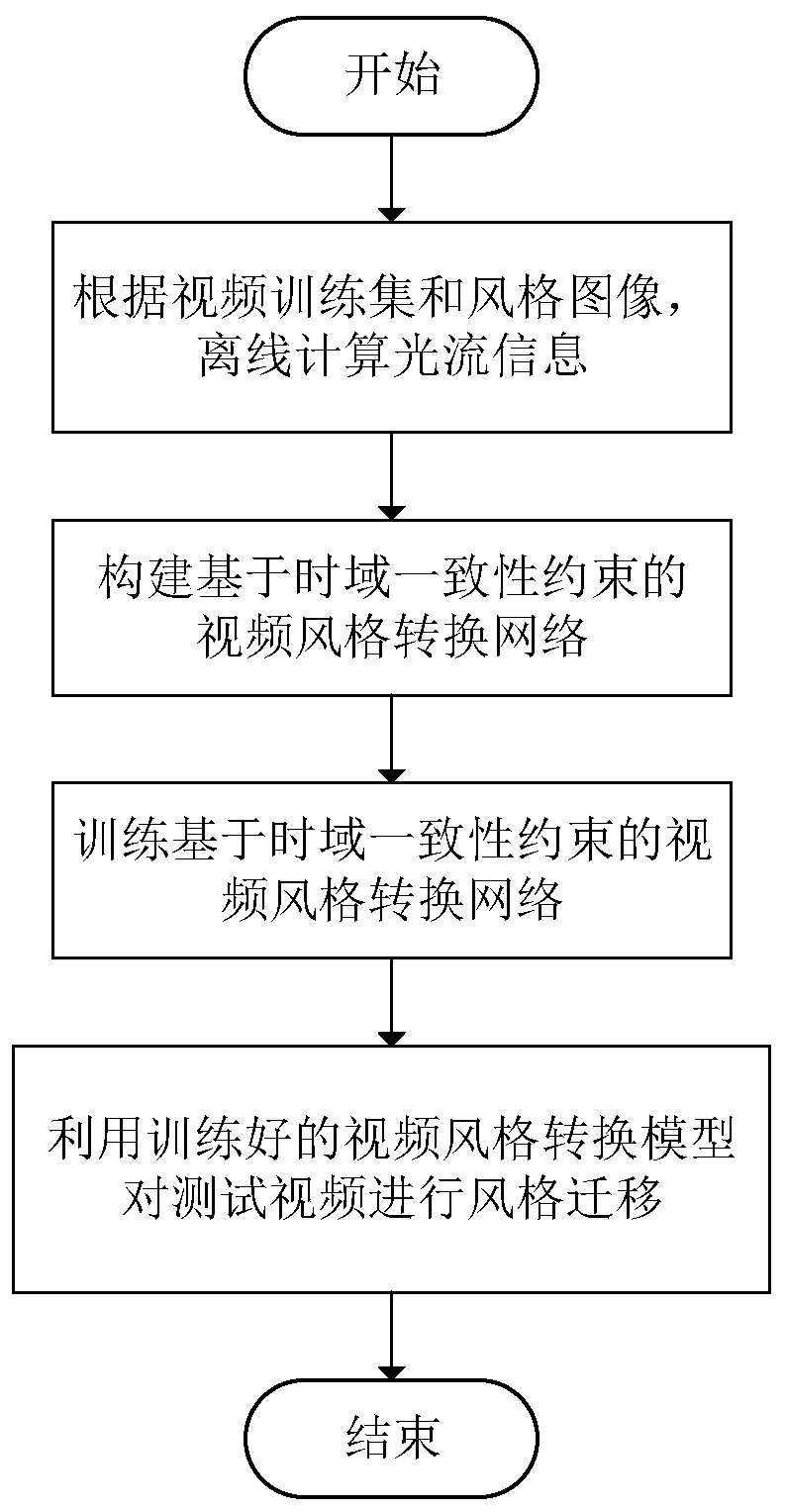

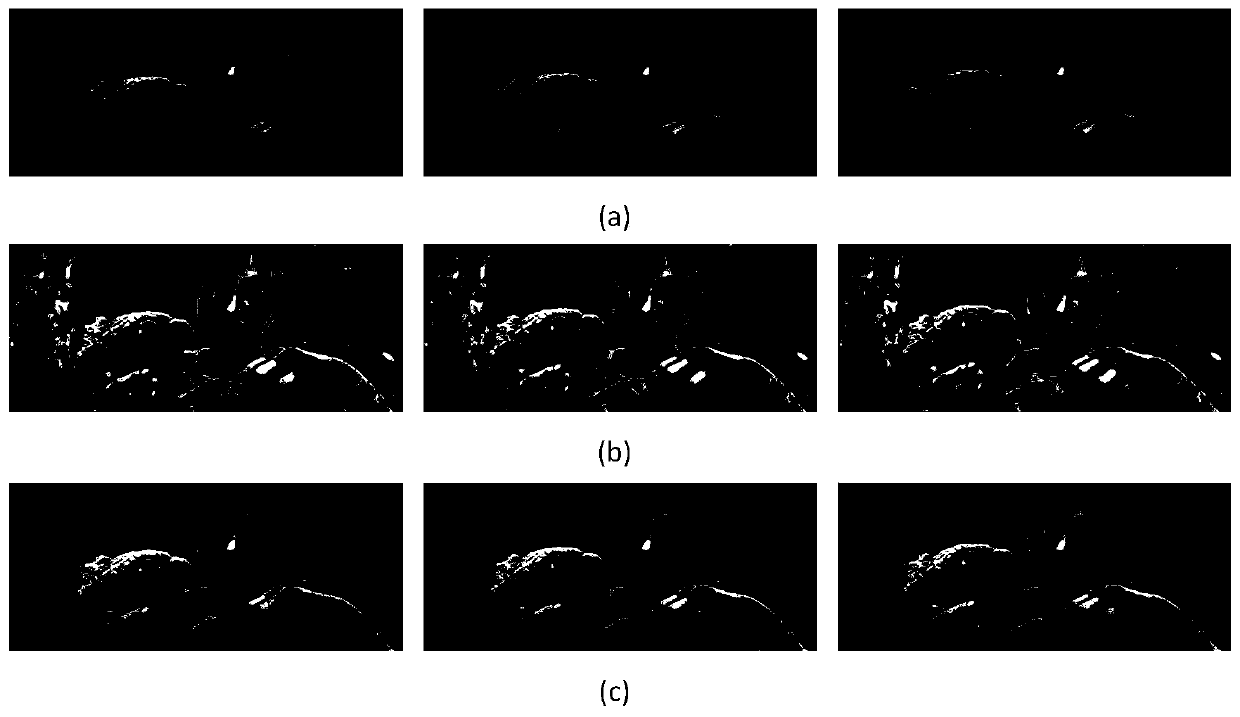

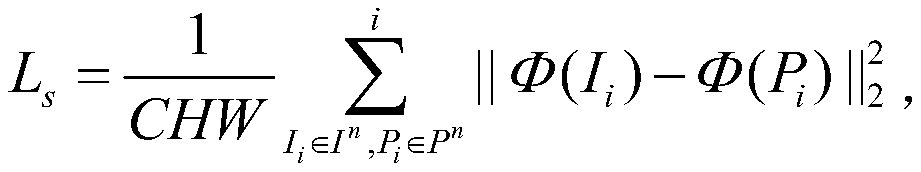

Video style migration method based on time domain consistency constraint

ActiveCN110175951ATemporally consistentMeet real-time requirementsGeometric image transformationTime domainData set

The invention discloses a video style migration method based on time domain consistency constraint, which mainly solves the problems of flickering and incoherence before and after video style migration in the prior art. The implementation scheme comprises the following steps of 1) obtaining a video data set and a style image, and calculating the optical flow information offline; 2) constructing avideo style conversion network based on the time domain consistency constraint; 3) training a style conversion network model by using the video data set, the style image and the optical flow information, and updating the weight and bias of each layer; and 4) inputting the test video into the trained style conversion network model, and outputting a result which is the stylized video. According to the present invention, the nonlinear mapping relation between the input video and the stylized video is fitted through the training style conversion network model, different styles of rendering is conducted on the real video under the guidance of the relation, so that the time domain consistency and the visual effect of the stylized video are improved, and the method can be used for the video processing scenes of video rendering and style conversion.

Owner:XIDIAN UNIV

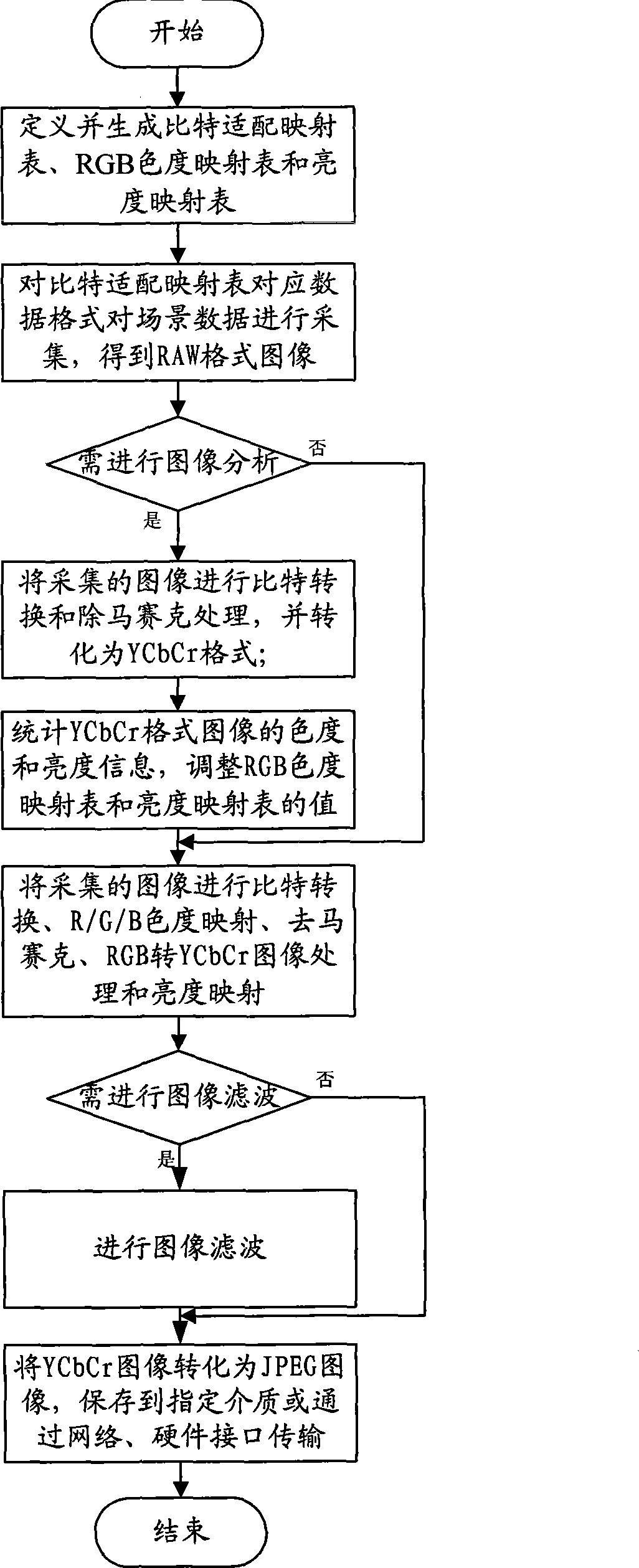

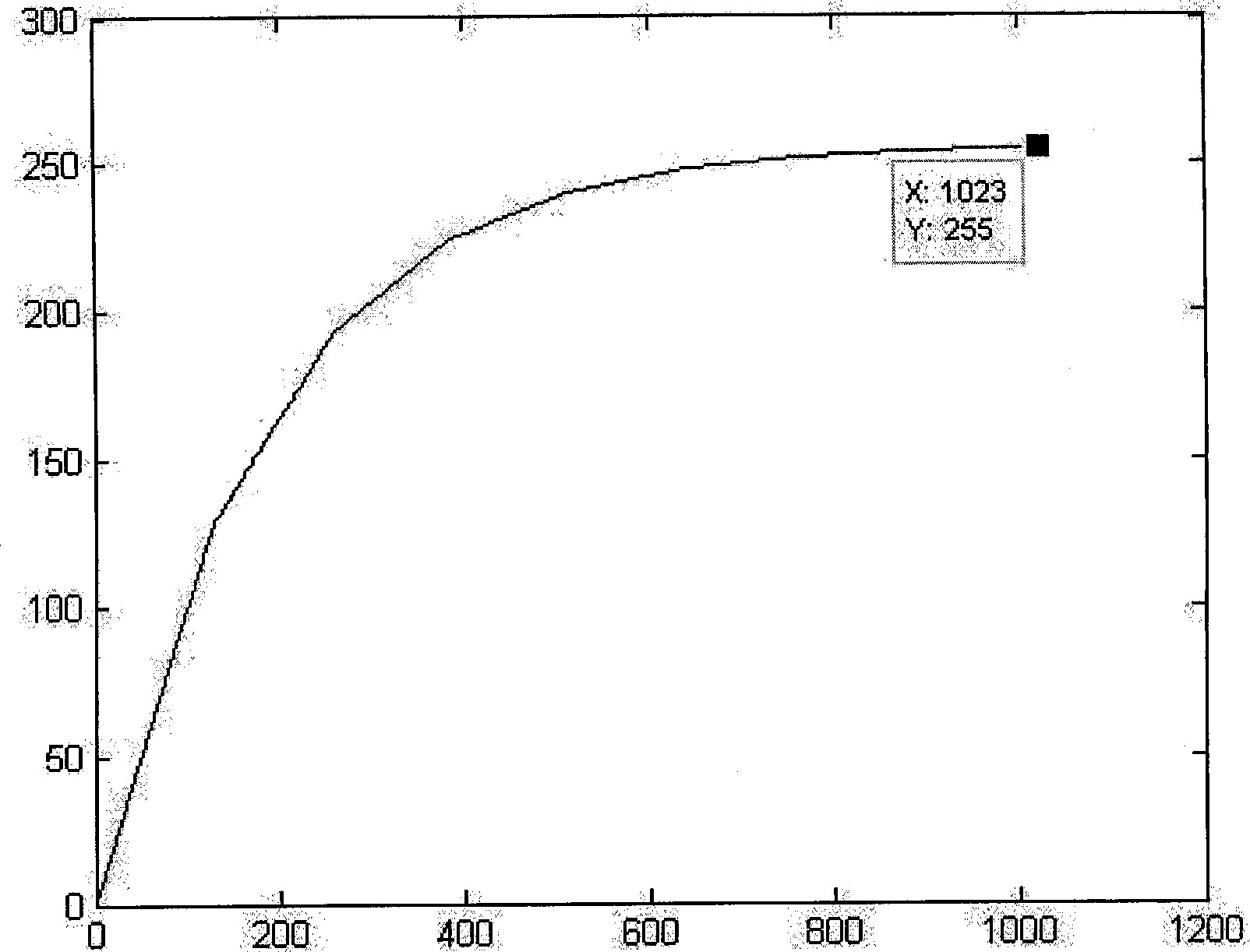

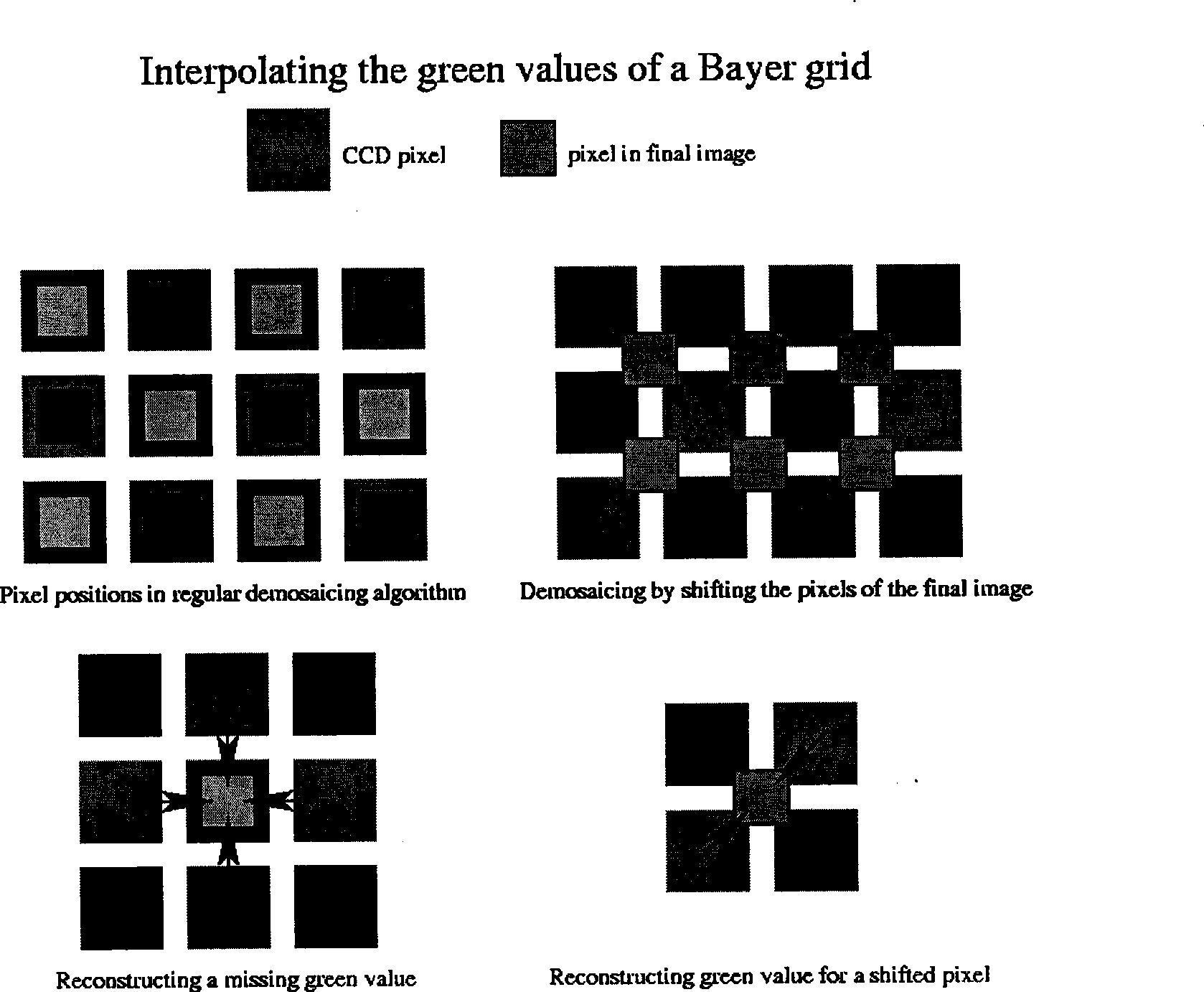

Fast image processing method for high definition camera

The invention provides a fast image processing method for a high-definition camera, which pertains to the field of image processing and comprises the steps of firstly defining and generating a bit adaptive mapping table, an RGB color mapping table and a brightness mapping table; then carrying out statistics to the color and brightness information of the image, determining regulatory factor and brightness of R / G / B, and amending the RGB color mapping table and the brightness mapping table; and then converting the collected image, carrying out R / G / B color mapping, mosaic removing, format conversion and brightness mapping, carrying out filtration to the brightness according to the expected indexes, and generating YCbCr data stream; finally converting the image to a JPEG image for conservation or transmission. The method uses fast table search processing, occupies small resources, is applicable to development of embedded systems, realizes necessary image processing functions, finishes the processing of white balance, color offset remediation, picture contrast adjustment, definition increase, noise filtration and the like fast, increases the reusability of each image algorithm in space and time, and improves the execution efficiency.

Owner:北京数字智通科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com