Electric steaming furnace with hot air flow

An electric steam oven and hot air technology, which is applied to steam cooking utensils, cooking utensils, household appliances, etc., and can solve problems such as potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

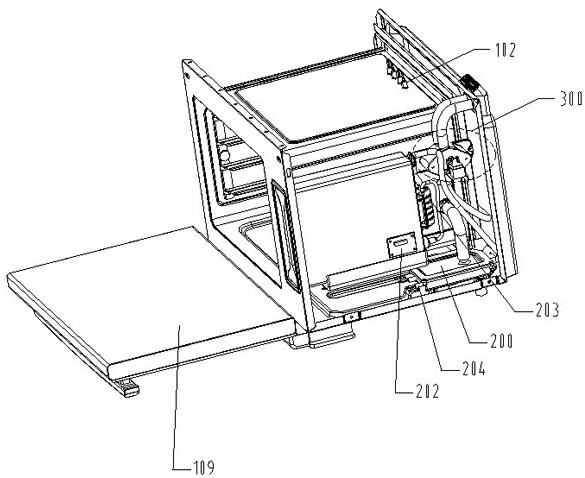

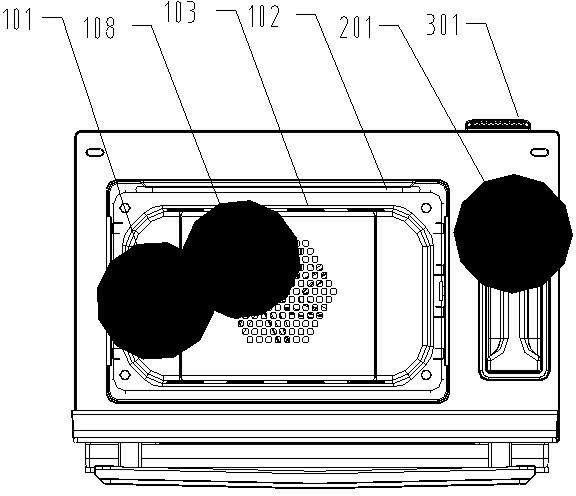

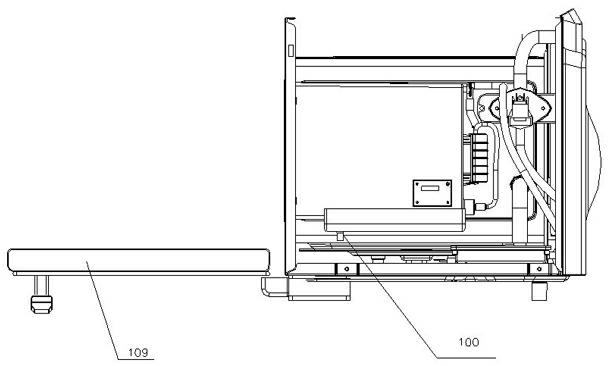

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a hot air convection electric steam oven includes a furnace body 100, a furnace cavity 101, a heating wire 102, a convection plate 103, a centrifugal fan 104, a motor 105, a food bracket 106, food 107, an air inlet 108, and a furnace door 109. Hot air convection device 110, sealing ring 111, convection chamber 112, steam generating device 200, water storage device 201, water level sensing system 202, pumping system 203, heating pipe 204, steam inlet 205, constant pressure exhaust system 300, Exhaust outlet 301, residual water recovery port 302, air inlet 303, spring 304, connecting rod 305, compressible sealing ring 306, power push rod 307, front cover 308, rear cover 309, the furnace body 100 is provided with a furnace Cavity 101, the side of the furnace cavity 101 is provided with a steam generator 200 for providing steam to the furnace cavity 101, a kind of hot air convection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com