Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6097 results about "Tuyere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tuyere or tuyère ([tɥijɛʁ]; English: /twiːˈjɛər/) is a tube, nozzle or pipe through which air is blown into a furnace or hearth. Air or oxygen is injected into a hearth under pressure from bellows or a blowing engine or other devices. This causes the fire to be hotter in front of the blast than it would otherwise have been, enabling metals to be smelted or melted or made hot enough to be worked in a forge, though these are blown only with air. This applies to any process where a blast is delivered under pressure to make a fire hotter.

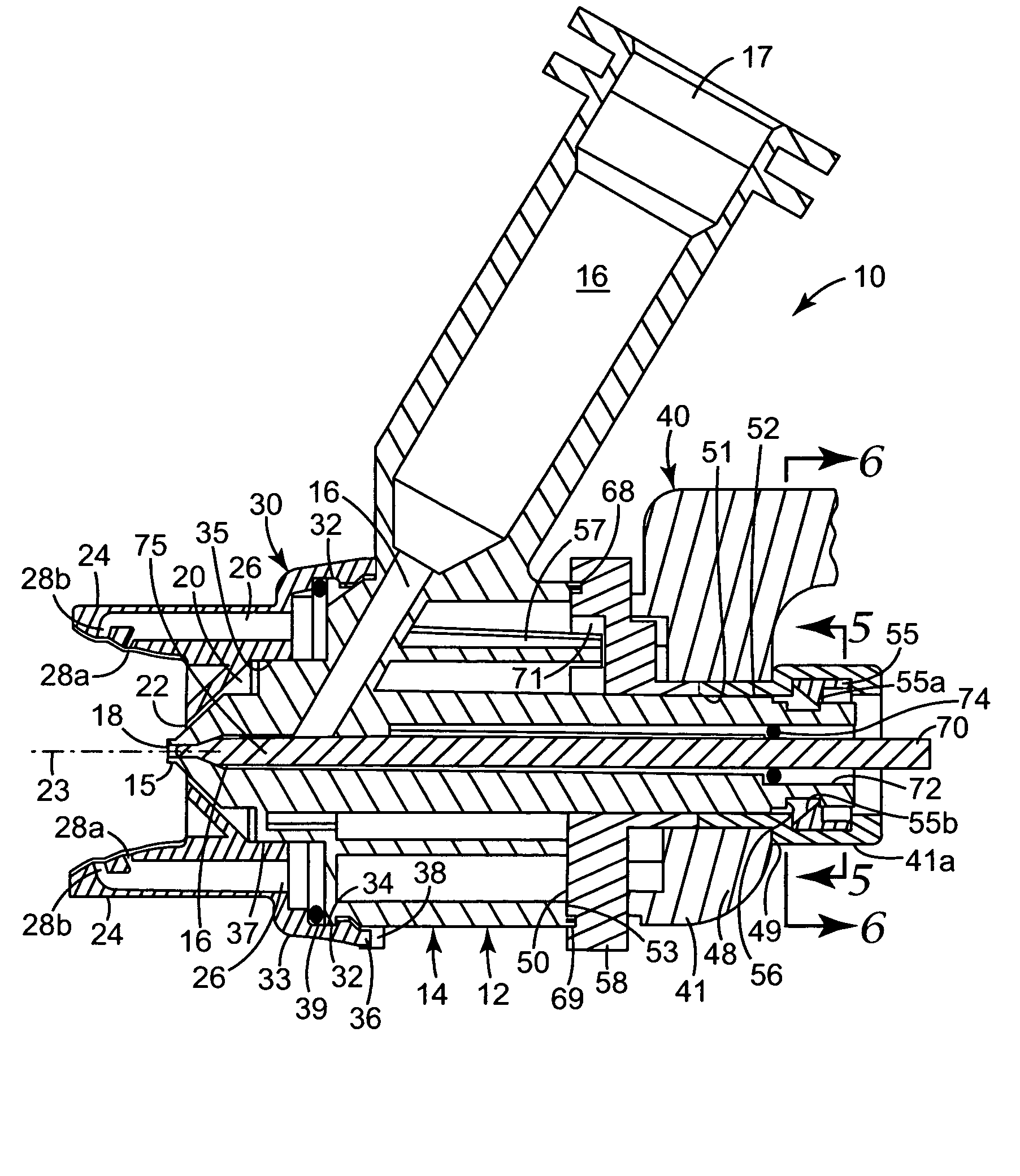

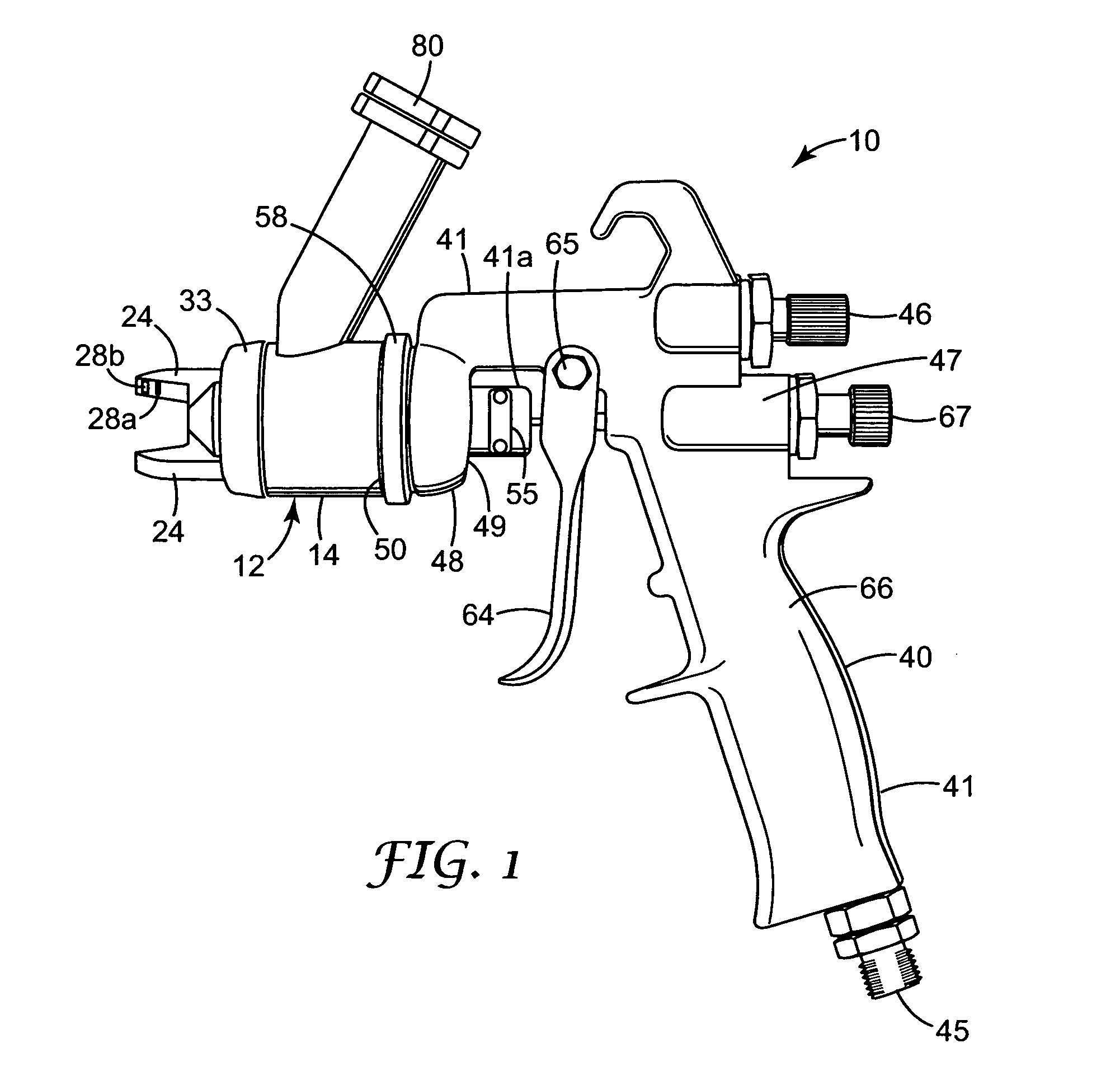

Liquid spray gun with non-circular horn air outlet passageways and apertures

The present invention provides a liquid spray gun with several improved features, including (1) non-cylindrical air passageways on air horns included in an air cap portion of a body assembly that provide improved shape and uniformity for the wide elongate stream of liquid formed by the spray gun; (2) the air cap portion of the body assembly being mounted for manual rotation on a nozzle portion of the body assembly between positions defined by stops and retained at those positions by friction; and (3) the body assembly through which passes liquid sprayed by the spray gun being molded of polymeric material and being manually releasable from a metal platform portion of the spray gun through which air is fed to passageways through the body assembly to spray the liquid.

Owner:3M INNOVATIVE PROPERTIES CO

Cyclonic cleaner

InactiveUS20070144116A1Reduce noiseLow efficiencyDispersed particle separationExhaust-air diffusionForeign matterCyclone

A cyclonic cleaner which includes a cyclone unit enabling a reduction of noise generated from the cyclone unit, and reduction in pressure loss by forming a smooth air flow. The cyclone unit includes a body having an air inlet and an air outlet, a primary cyclone to primarily separate foreign matter from air drawn through the air inlet, a plurality of secondary cyclones to secondarily separate foreign matter from air discharged from the primary cyclone and to discharge the air having the foreign matter removed therefrom through discharge holes of the secondary cyclones, and a noise reduction member positioned in the discharge hole of each secondary cyclone to reduce noise. The cyclone unit also includes a guide plate to allow the air discharged through the discharge holes of the secondary cyclones to be smoothly discharged through the air outlet.

Owner:SAMSUNG ELECTRONICS CO LTD

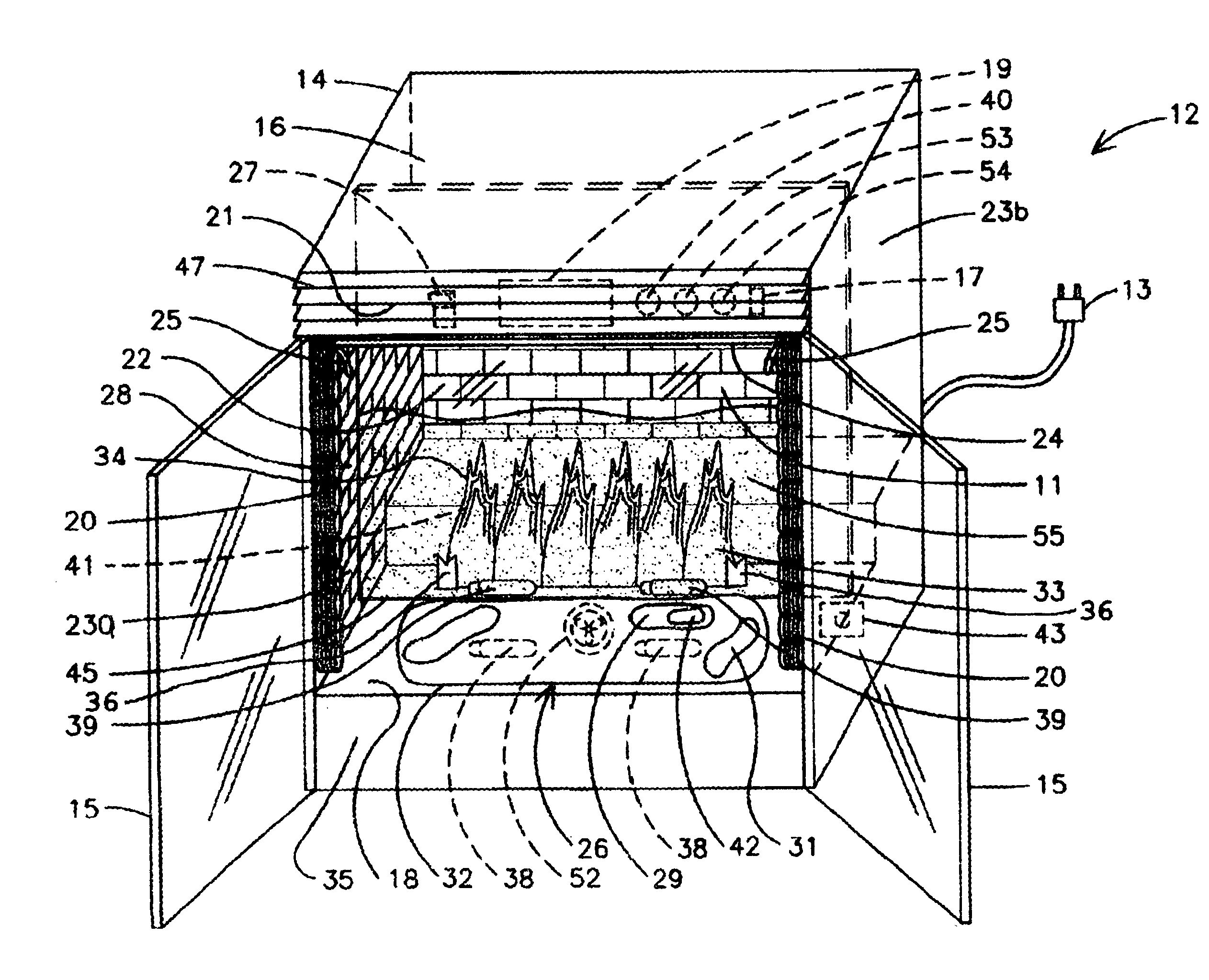

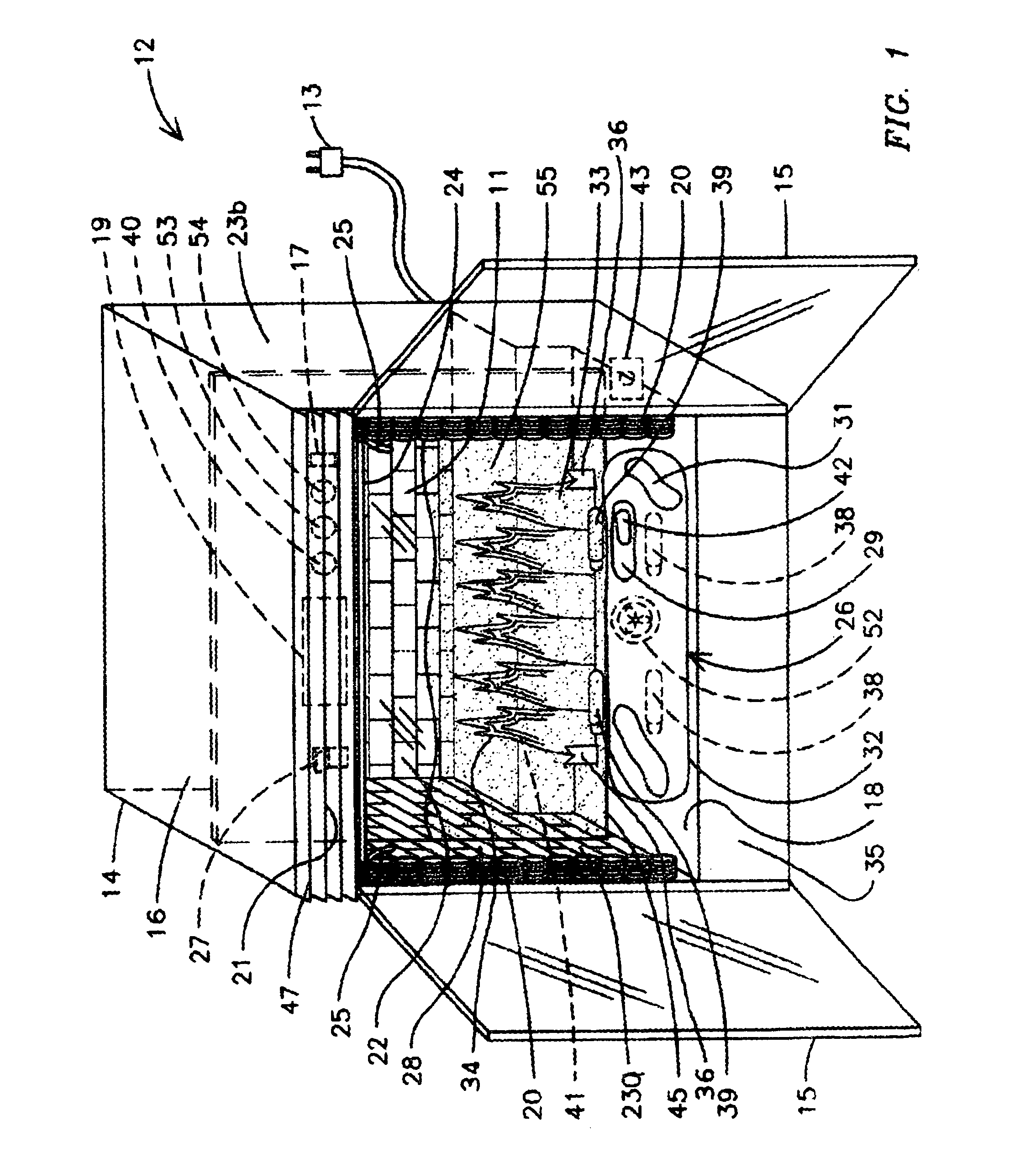

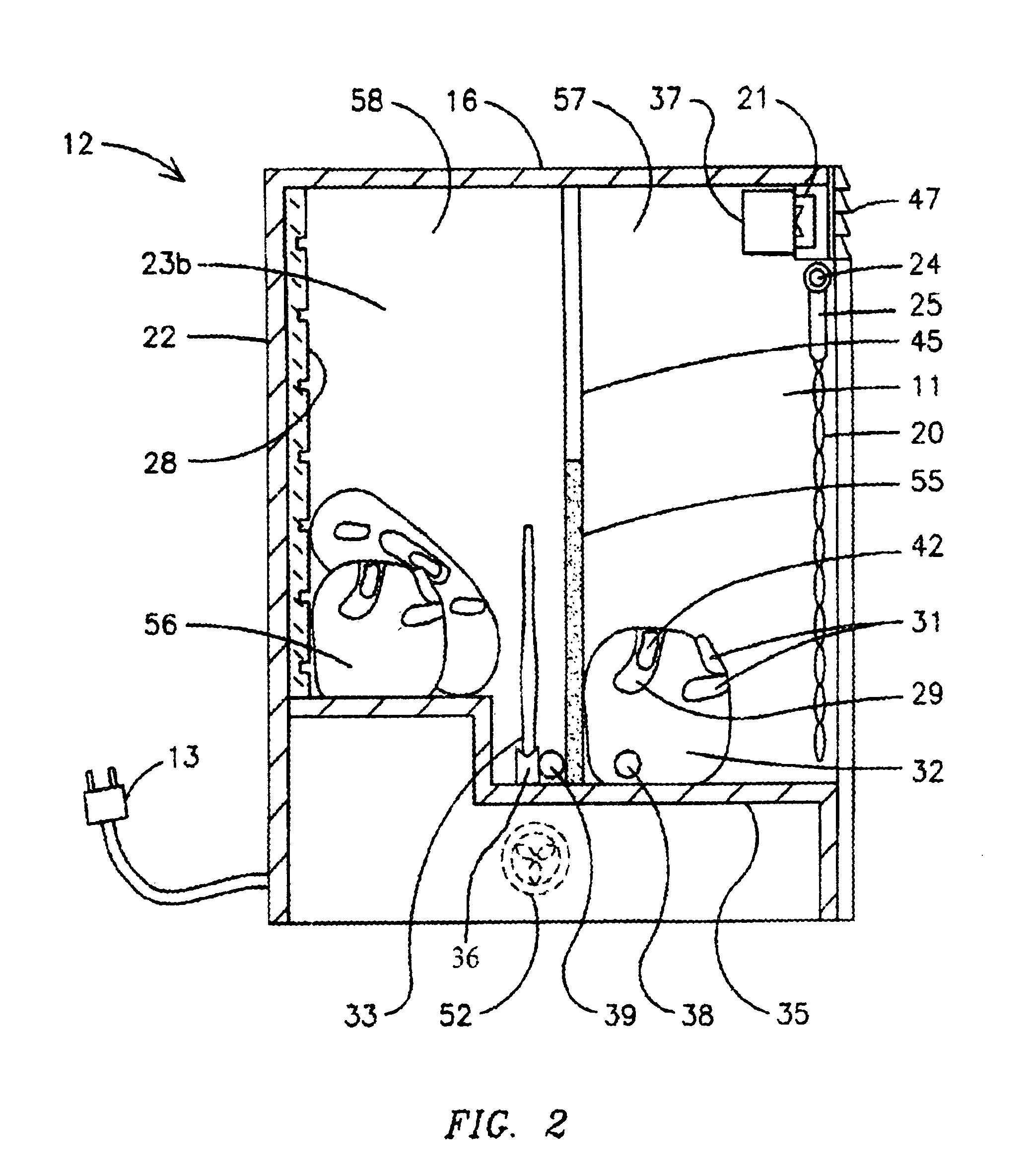

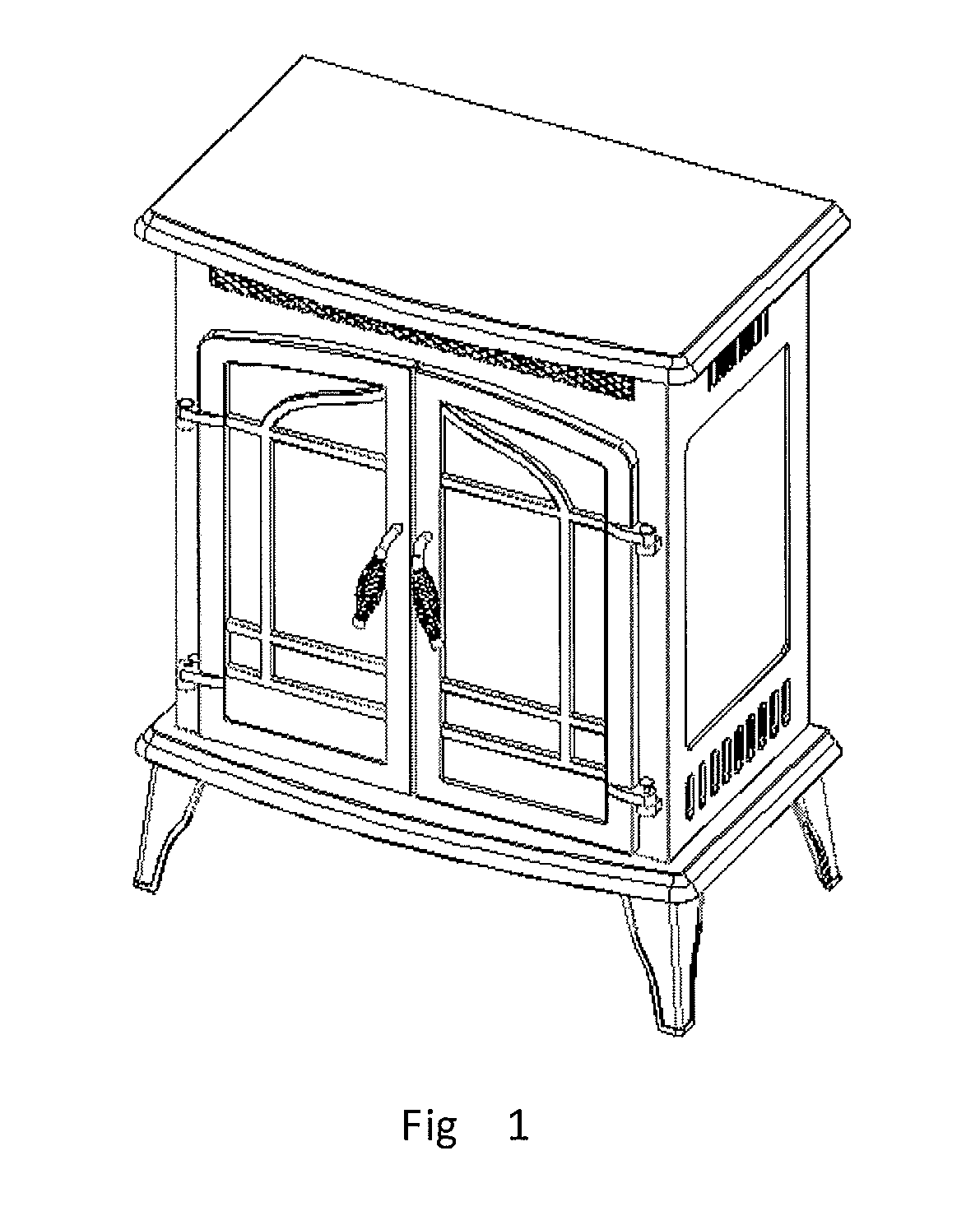

Simulated log burning fireplace apparatus

InactiveUS7111421B2Enhanced RealityDomestic stoves or rangesLighting and heating apparatusEmberBrick

The simulated log fireplace apparatus housing forming a fire box having back, bottom, top wall, two side walls, and an open front containing at least one artificial log and simulated flame sheet. A blower directs air on to the flame sheet to simulate real flame movement. A colored light source provides color of real flames. The light source and blower are adjustable from a control panel under a top louver panel. The artificial log may include a translucent base log and ember bed with a light source beneath the translucent log. A window log having an aperture simulate a burning core. A transparent partition has a partially opaque area just above the simulated flame sheet provides the full depth of real fireplace. The apparatus may include electric blower heater, a crackle box, decorative simulated brick panels placed on back and side walls, metal screen, glass doors, vents and louvers.

Owner:CORRY ARTHUR A +1

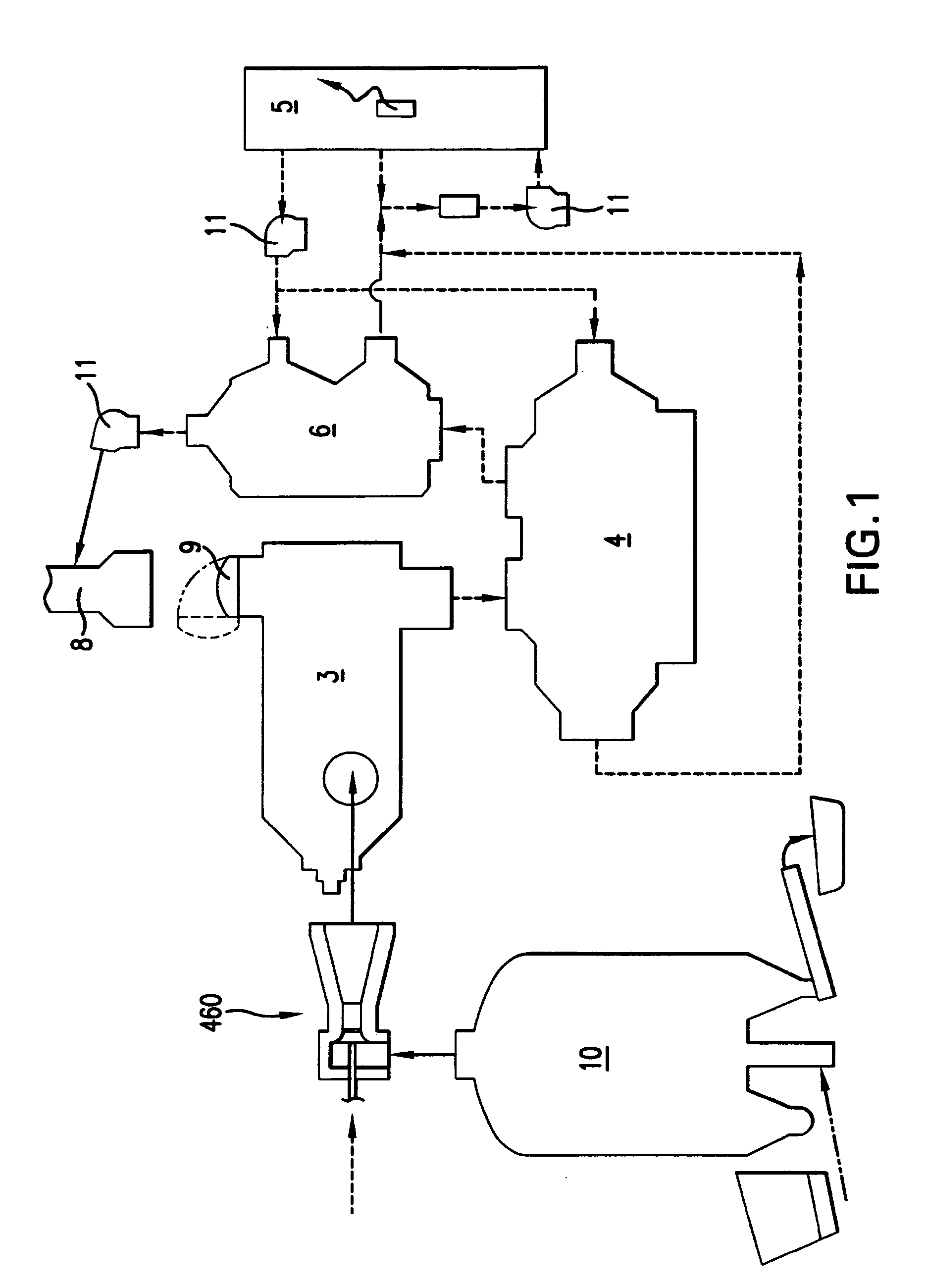

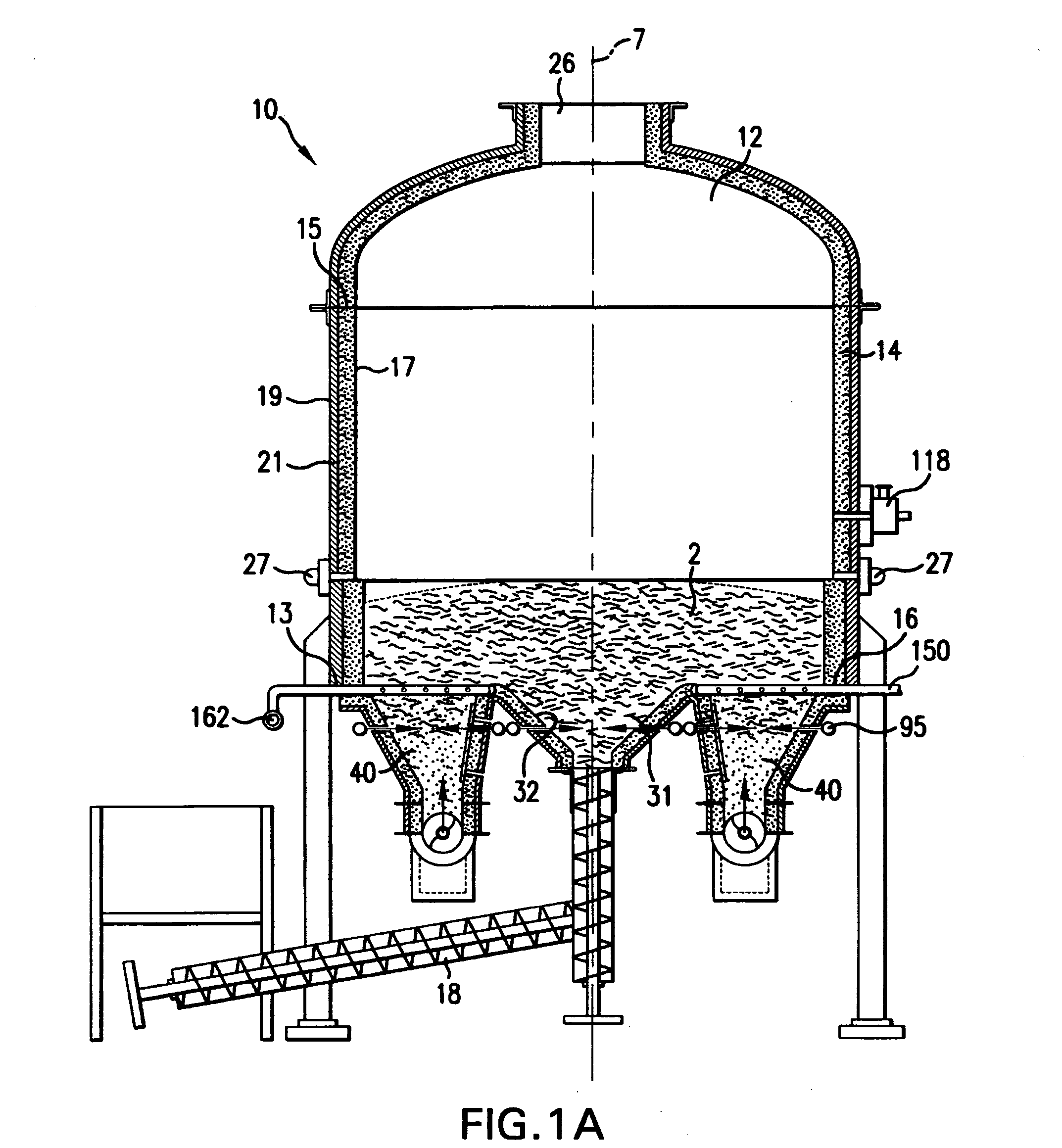

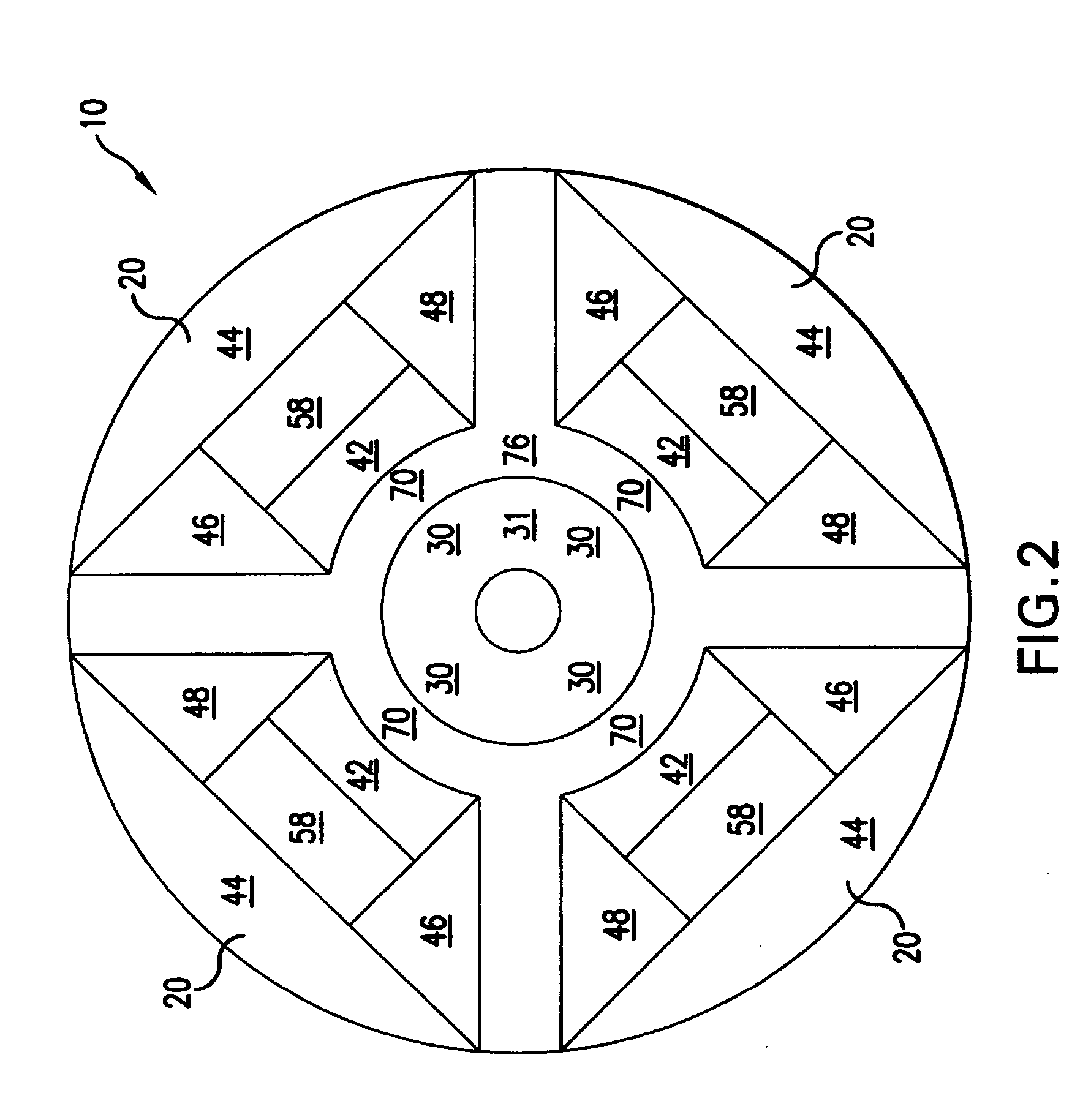

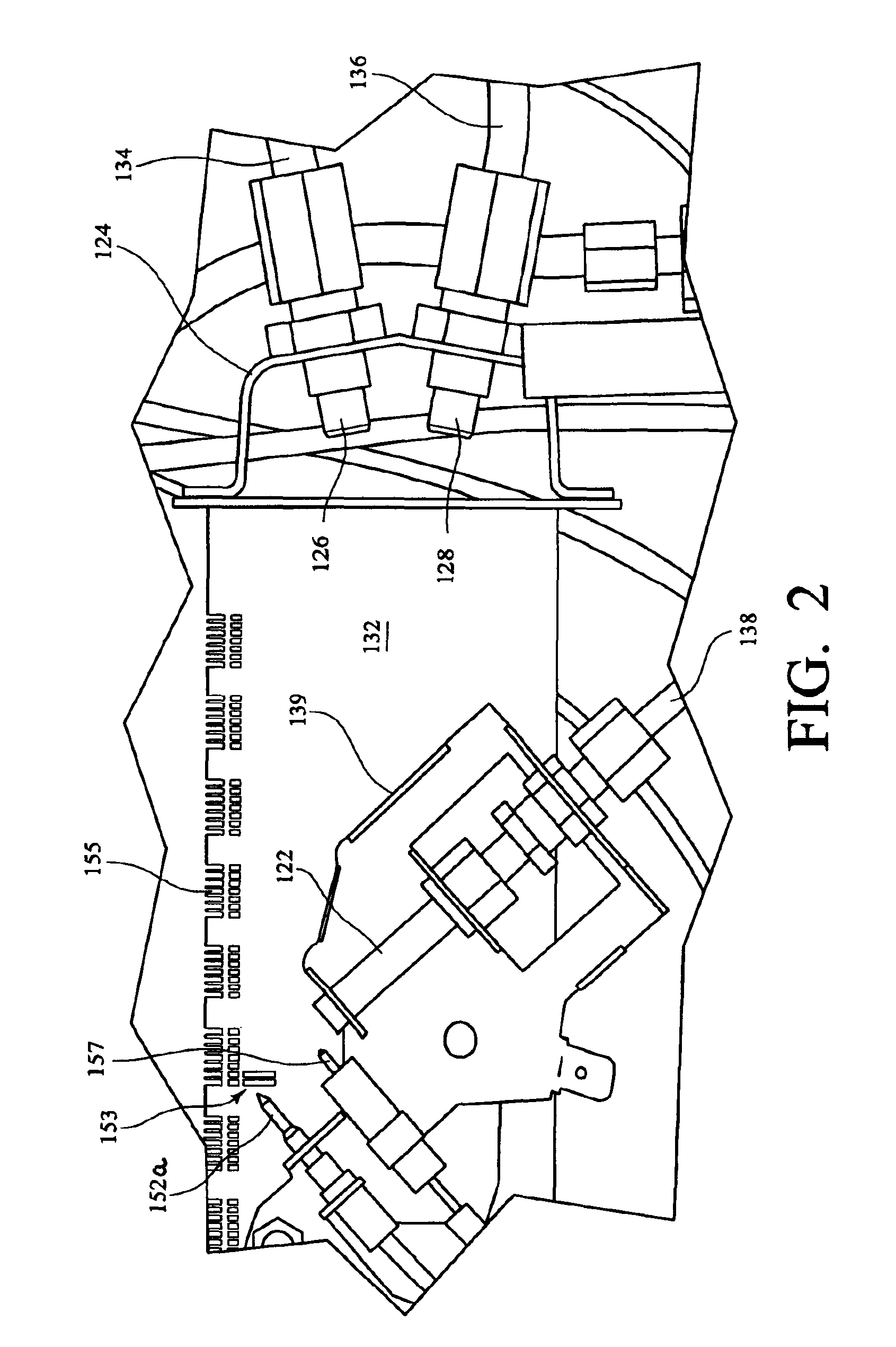

Pyrolyzing gasification system and method of use

InactiveUS20050109603A1High gasifier discharge temperatureEfficient processGasifier mechanical detailsBiofuelsHydrocotyle bowlesioidesExternal combustion engine

Pyrolyzing gasification system and method of use including primary combustion of non-uniform solid fuels such as biomass and solid wastes within a refractory lined gasifier, secondary combustion of primary combustion gas within a staged, cyclonic, refractory lined oxidizer, and heat energy recovery from the oxidized flue gas within an indirect air-to-air all-ceramic heat exchanger or external combustion engine. Primary combustion occurs at low substoichoimetric air percentages of 10-30 percent and at temperatures below 1000 degrees F. Secondary combustion is staged and controlled for low NOx formation and prevention of formation of CO, hydrocarbons, and VOCs. The gasifier includes a furnace bed segmented into individual cells, each cell is independently monitored using a ramp temperature probe, and provided with controlled air injection. Gasifier air injection includes tuyere arrays, lances, or both. The oxidizer includes three serially aligned stages separated by air injecting baffles, and ability to adjust the exit air temperature.

Owner:HEAT TRANSFER INT

Laser Cladding on Low Heat Resistant Substrates

InactiveUS20080226843A1Sufficient powerMolten spray coatingVacuum evaporation coatingMetal alloyLength wave

This invention relates to laser cladding of components used in high temperature-corrosive applications, such as those associated with metallurgical vessels' lances, nozzles and tuyeres, for extending their service life under such severe conditions. In particular, this invention relates to a method for applying a high melting point material onto a substrate, said substrate having a melting point temperature below the melting point temperature of the high melting point material, comprising: (a) moving a laser beam generated from a laser over the surface of said substrate, said laser beam comprised of wavelengths from about 300 to about 10,600 nanometers; (h) providing a metal, alloy, or metal-alloy composite powder to the surface of said substrate; and (c) generating sufficient power to the laser to superficially heat said substrate and to effect a fusion bond between the metal, alloy or metal-alloy composite powder and the surface of said substrate.

Owner:PRAXAIR ST TECH INC

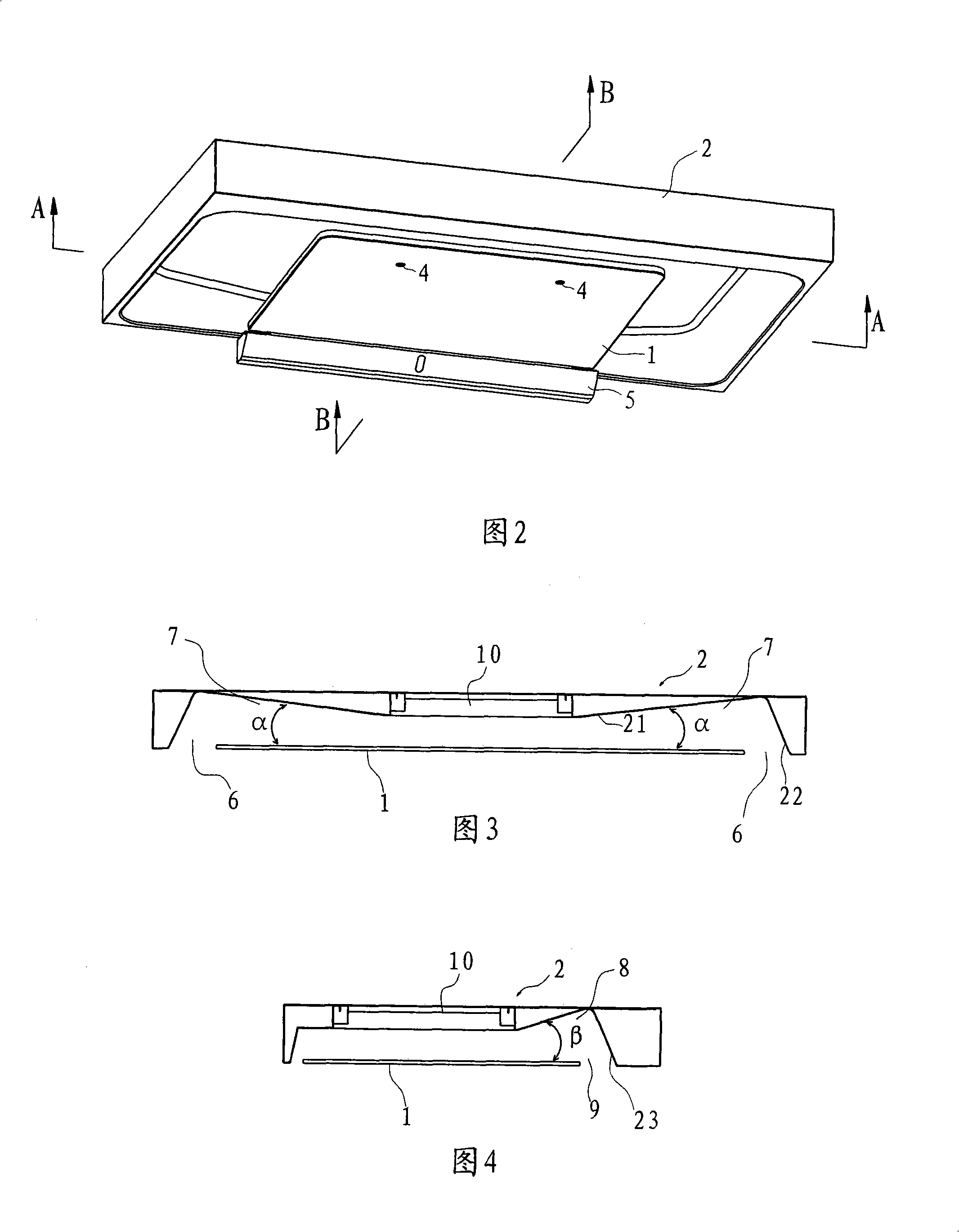

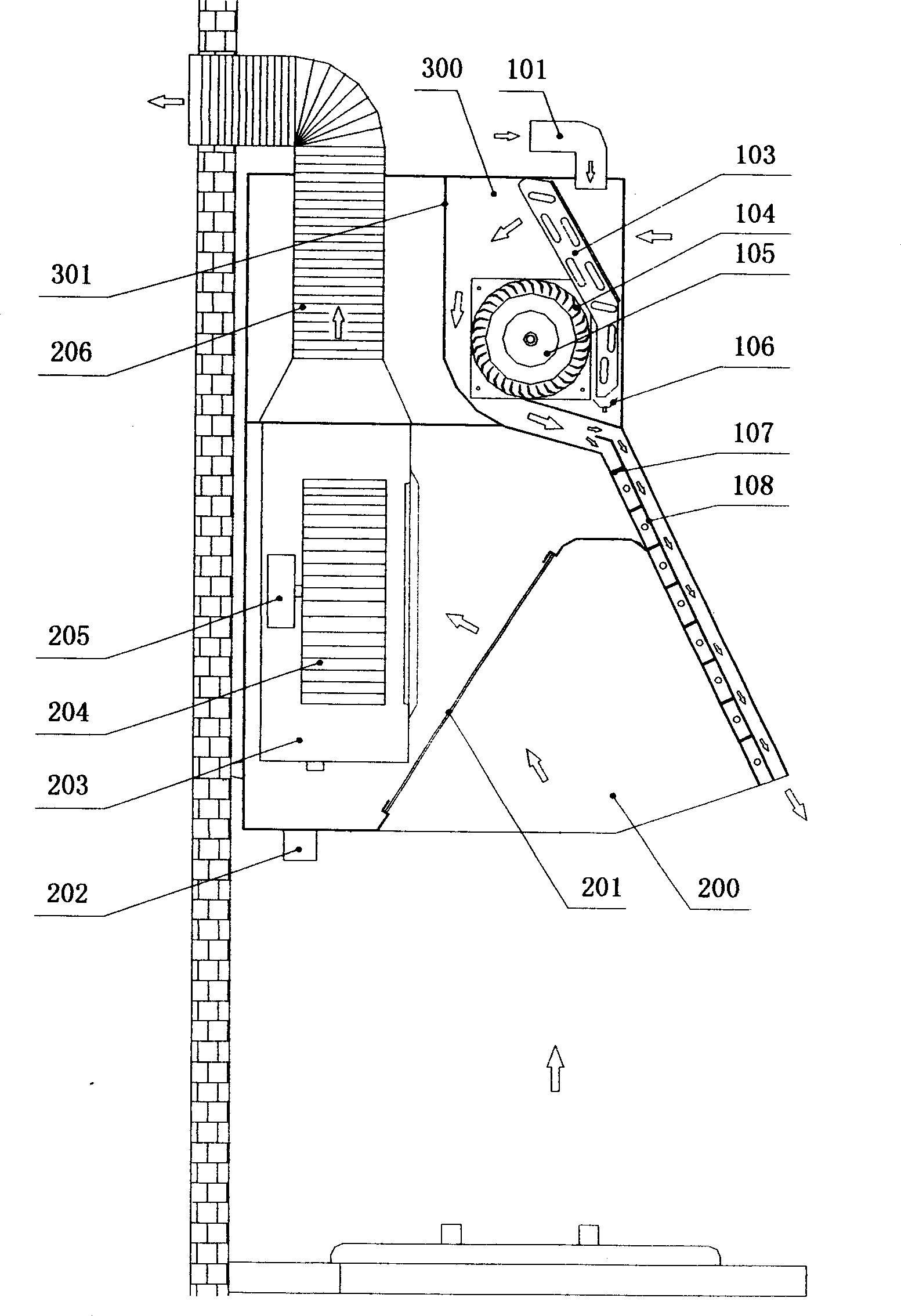

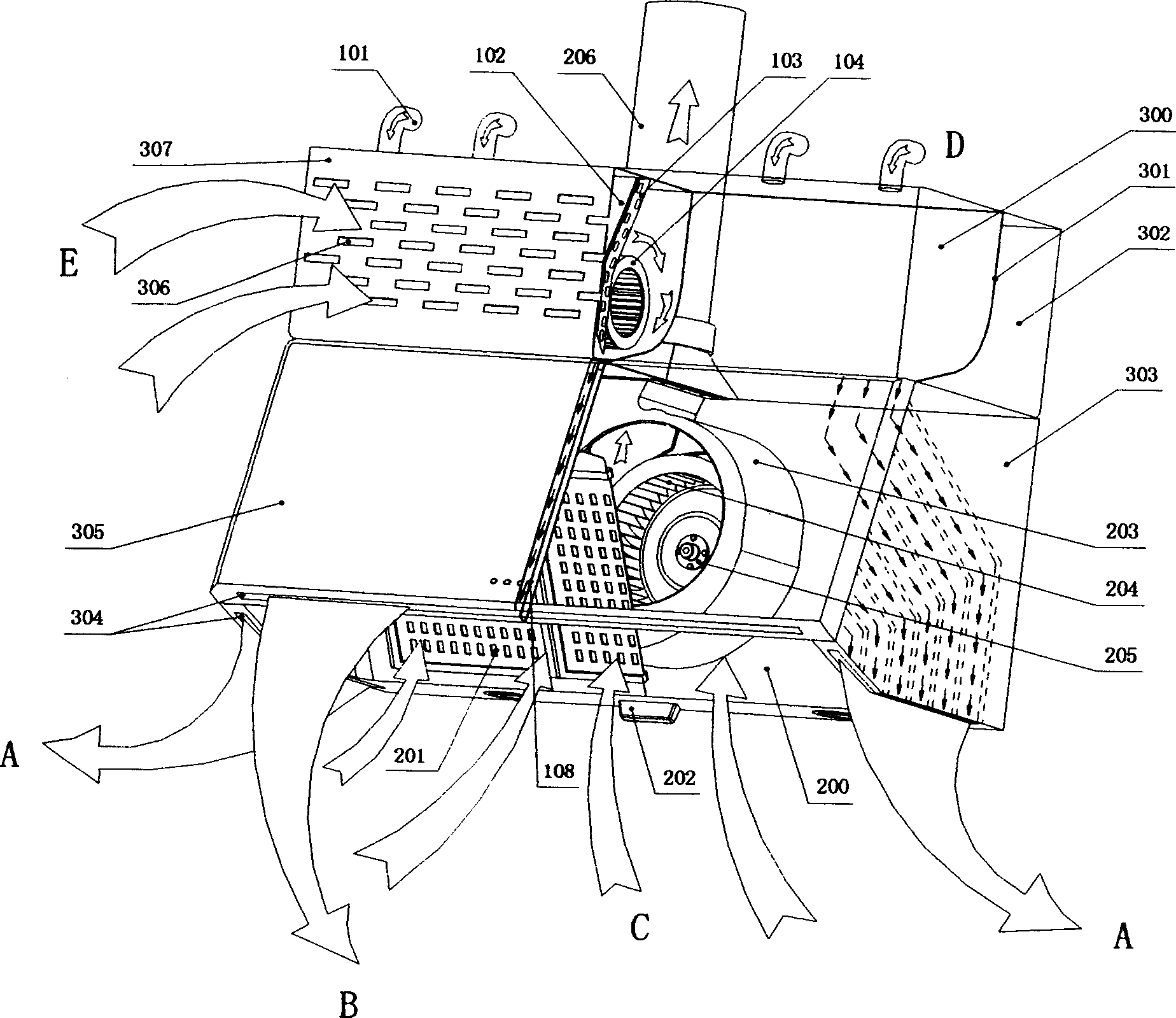

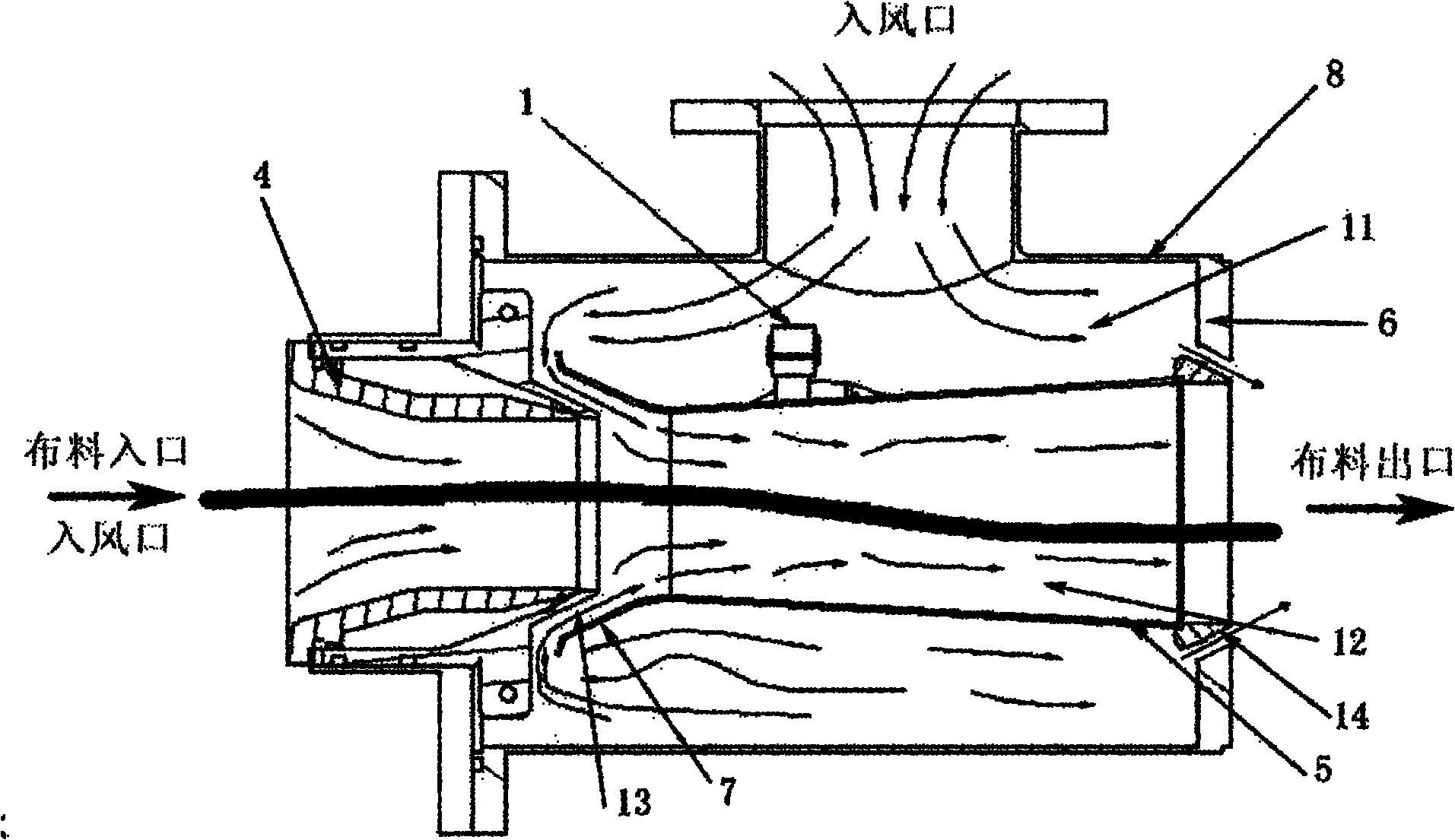

Range hood with smoke deflector

ActiveCN101514823ASpeed up the flowNo streamingDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke hood

A range hood with a smoke deflector, comprises a body, a smoke collecting cover and the smoke deflector, wherein an air inlet is arranged on the smoke collecting cover, the smoke deflector faces to the air inlet and be in the predetermined distance from the smoke collecting cover, thus a oil smoke channel through which the oil smoke can pass is formed between the smoke deflector and the smoke collecting cover, the range hood is characterized in that the distance between the smoke deflector corresponding to the oil smoke channel and the smoke collecting cover is gradually reduced from the periphery of the smoke deflector to the air inlet. Compared with the prior art, the invention has the advantages: the smoke deflector is used for forming the wall-attachment effect, the oil smoke flow uniformly without series flow, the distance between the smoke deflector and the smoke collecting cover is gradually reduced from the periphery of the smoke deflector to the air inlet, so that the Venturi effect is formed conveniently, thus accelerating the sucking of smoke by the blower fan.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Process for reclaiming combustion residues

InactiveUS6039787AEmission reductionImprove heat transfer performanceManufacturing convertersProcess efficiency improvementCombustionWater vapor

PCT No. PCT / AT97 / 00201 Sec. 371 Date May 15, 1998 Sec. 102(e) Date May 15, 1998 PCT Filed Sep. 12, 1997 PCT Pub. No. WO98 / 12359 PCT Pub. Date Mar. 26, 1998In a process for working up combustion residues and slags from waste incineration plants or steel works slags, the slag is charged at a slag layer height of above 1.2 m into a converter (1), in which the molten slag is reacted with a metal bath (4) through which oxygen is blown. The oxygen is introduced into the bath (4) for cooling the submerged tuyeres (7, 8) in the form of air or along with CO2 or water vapor.

Owner:HOLCIM

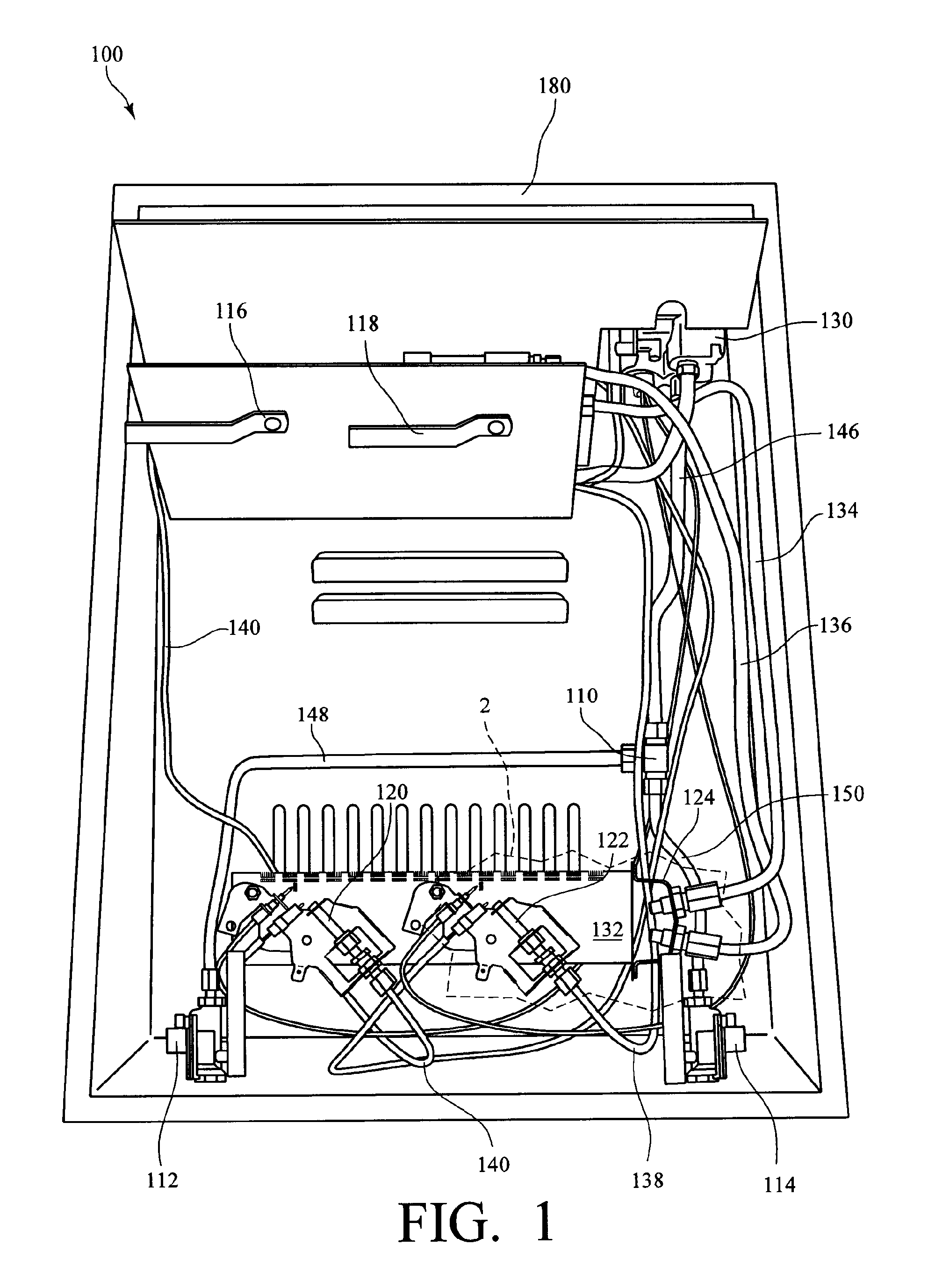

Dual fuel vent free gas heater

A dual fuel vent free gas heater having at least one gas burner with a plurality of gas outlet ports in an upper surface thereof. The gas outlet ports are in flow communication with at least one pilot flame burner. An adjustable fuel injector or at least two fuel injectors feed fuel to the burner providing for introduction of more than one fuel to the burner. Optionally, an oxygen detection system, manual fuel selection control valve, and / or temperature shut off control system may be incorporated into the dual fuel vent free heater.

Owner:COPRECITEC

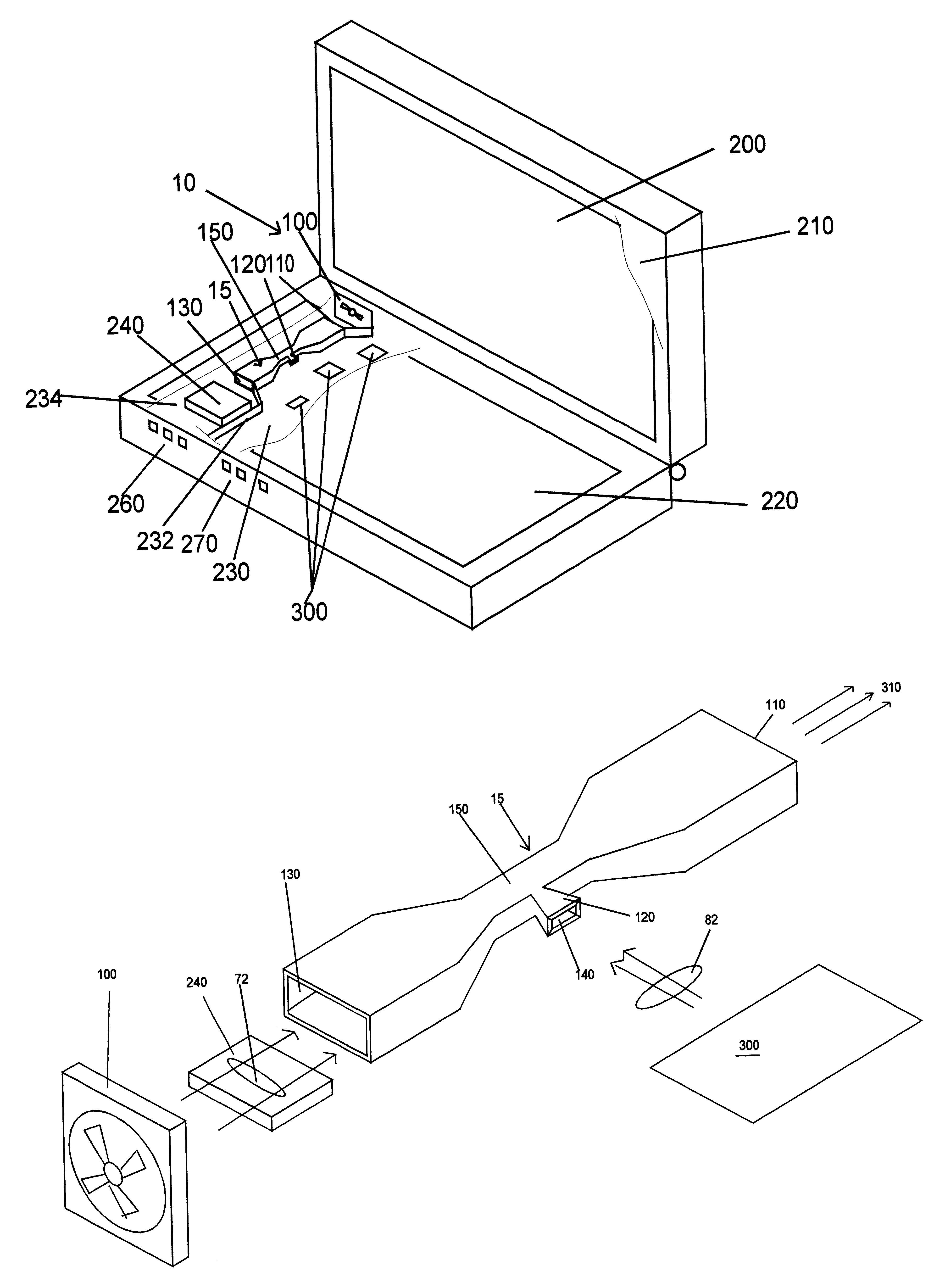

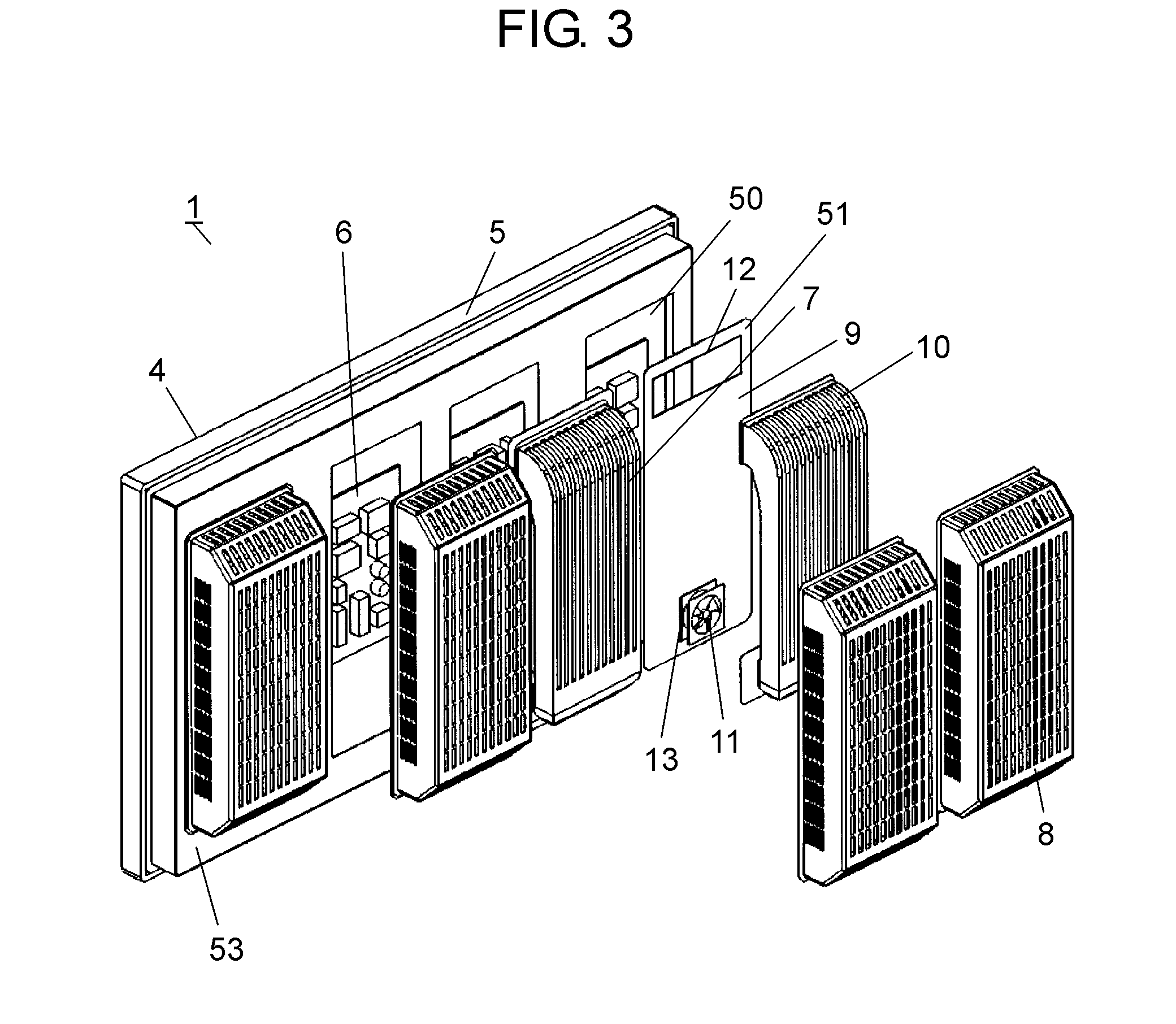

Apparatus to enhance cooling of electronic device

InactiveUS6253834B1Digital data processing detailsSemiconductor/solid-state device detailsElectronWaste management

Owner:HEWLETT PACKARD DEV CO LP

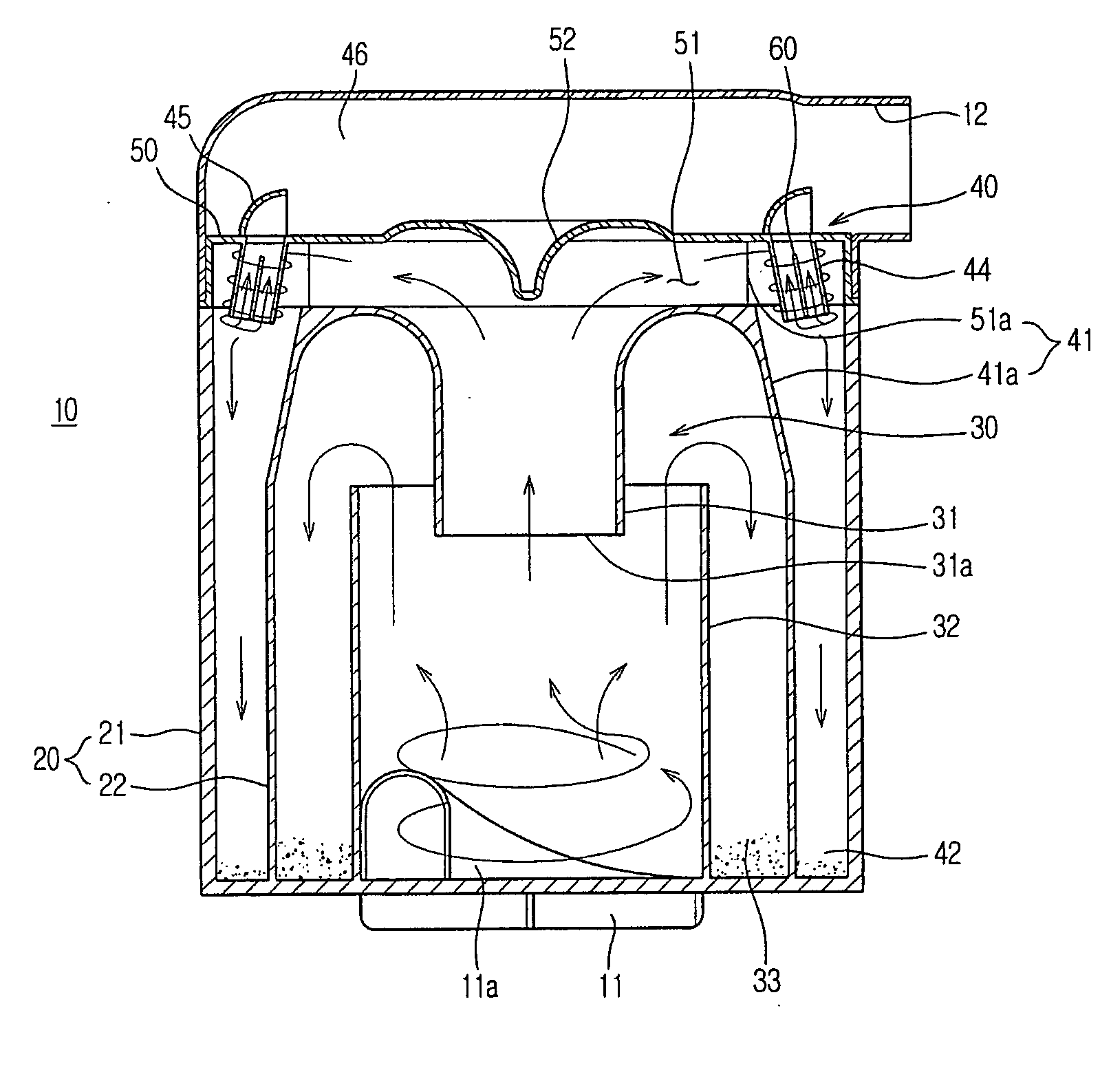

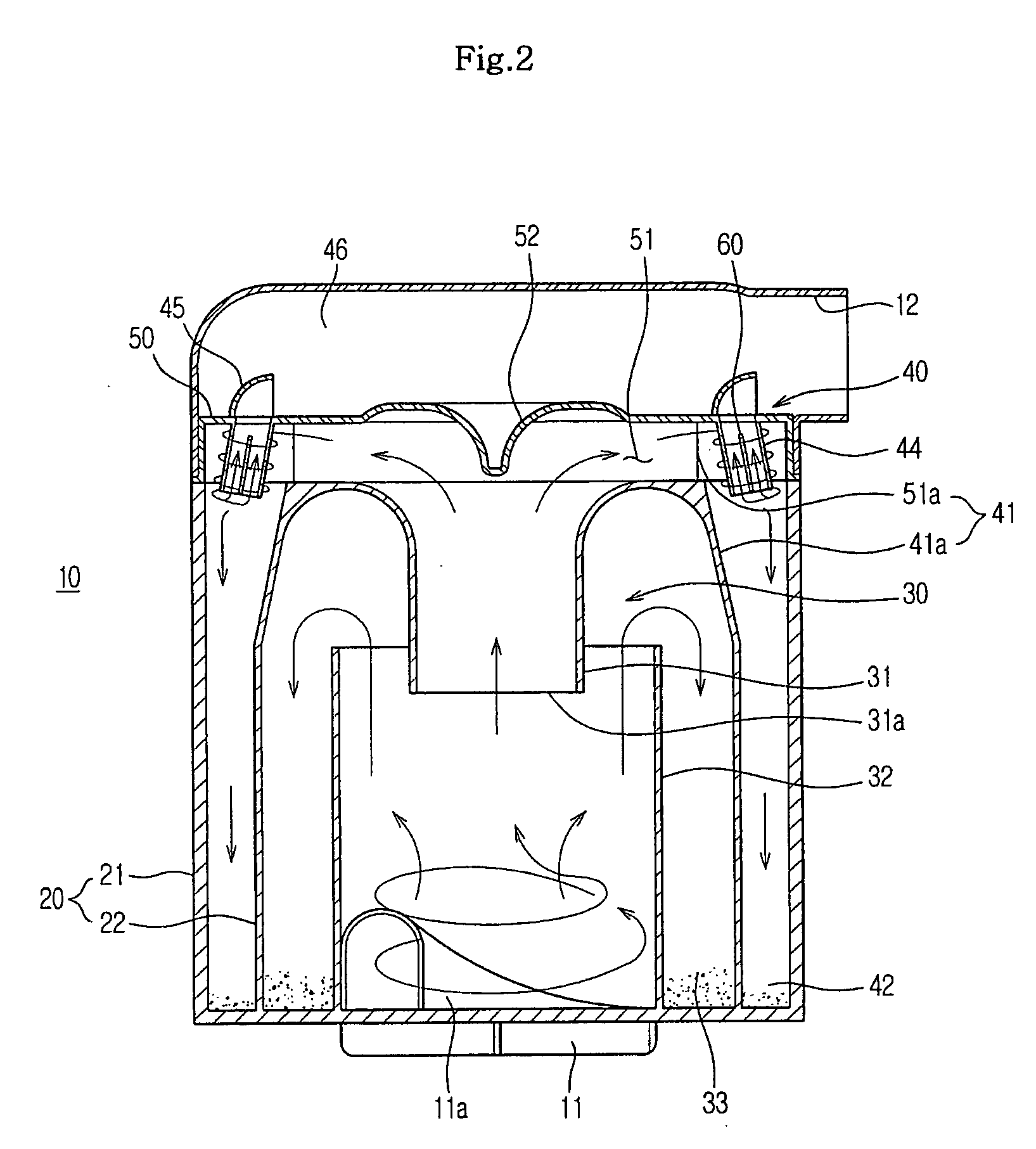

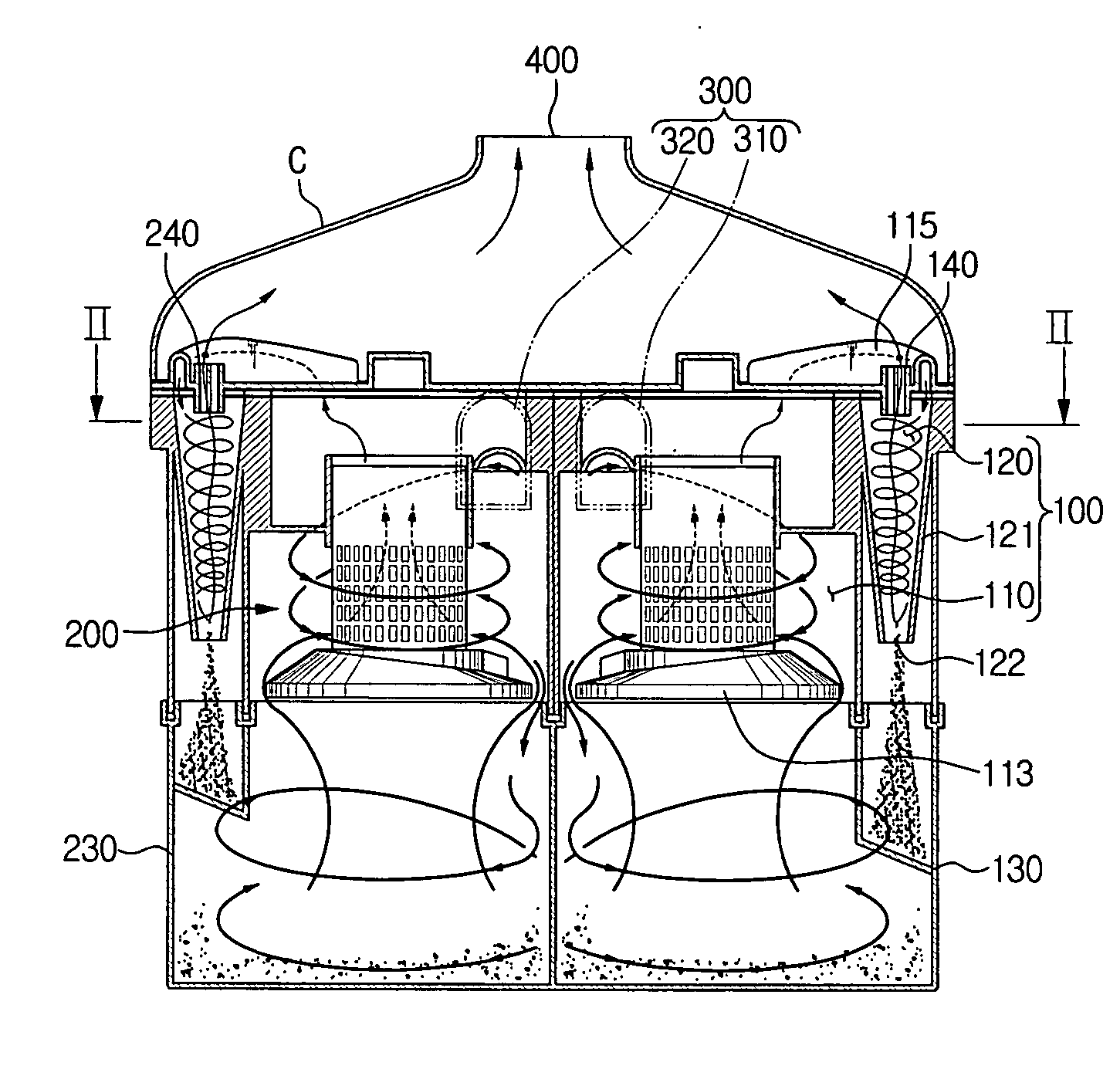

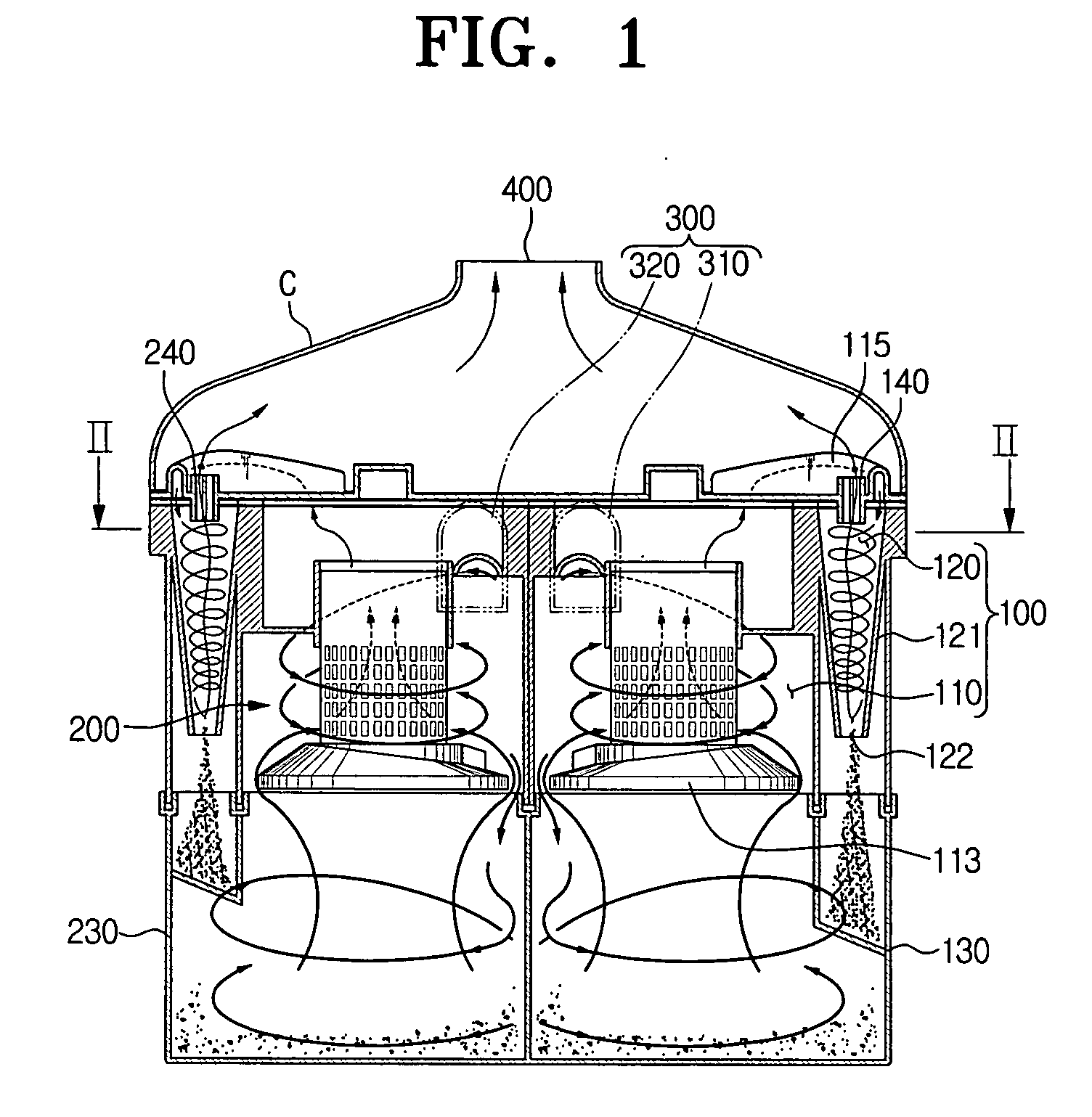

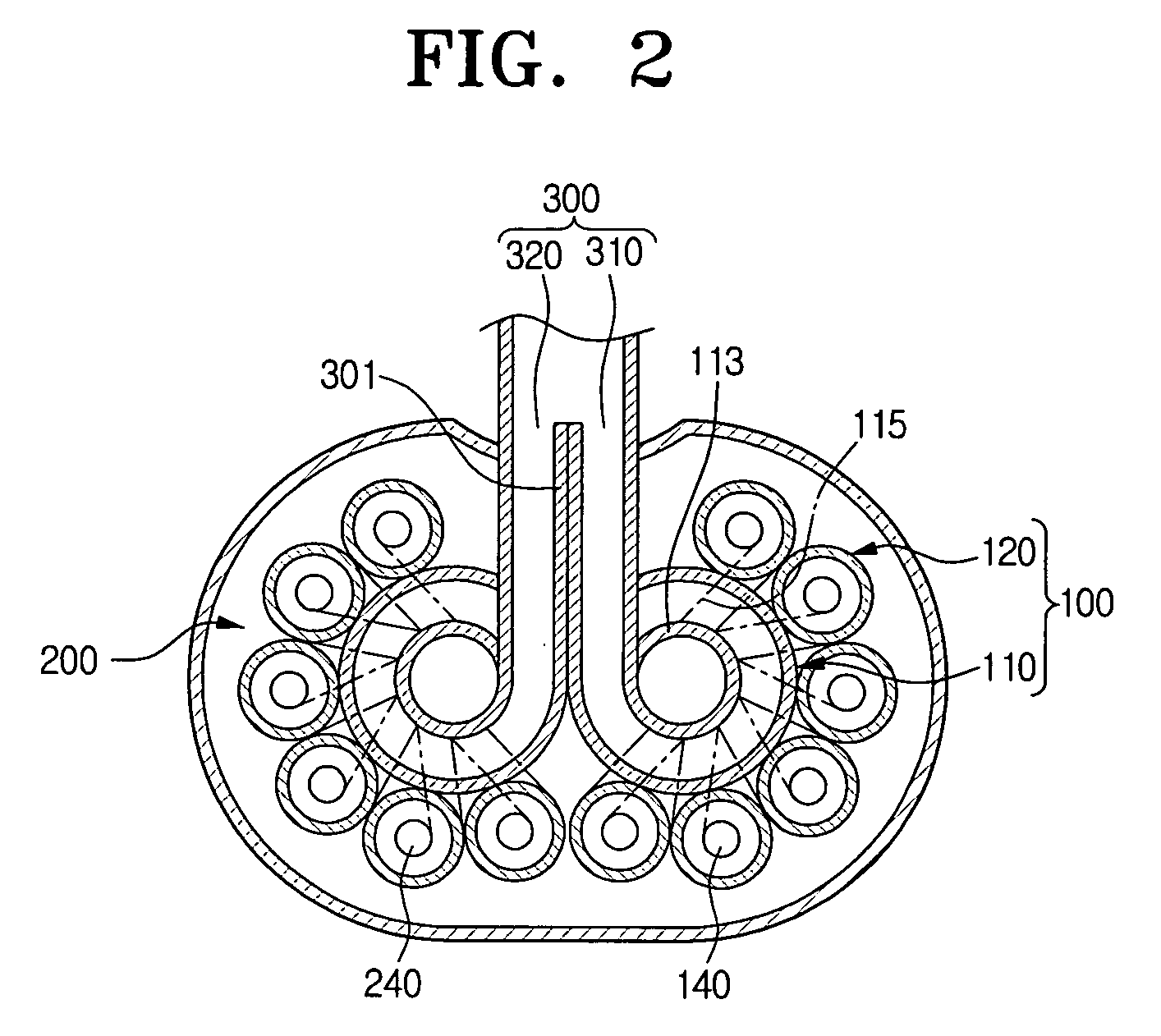

Multi-cyclone dust collecting apparatus

InactiveUS20060230717A1Increase flow rateImprove collection efficiencyReversed direction vortexDispersed particle filtrationCycloneSuction force

A multi-cyclone dust collecting apparatus with improved dust collecting efficiency and suction force is provided. The multi-cyclone dust collecting apparatus includes a first and a second multi-cyclone units having a first cyclone which collects large particles of dust and a second cyclone for collecting fine particles of dust; an air inlet through which an air inlet through which dust-laden air is separated and flowed into the first and the second multi-cyclone units, respectively; and an air outlet through which air from the second cyclone of the first and the second multi-cyclone units is gathered and externally discharged. Because air is branched off once it is drawn into a single gate and dust is separated from the drawn air simultaneously in the plurality of multi-cyclone dust collecting apparatuses, reduction of flow speed in the dust-laden air from the suction brush can be prevented.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

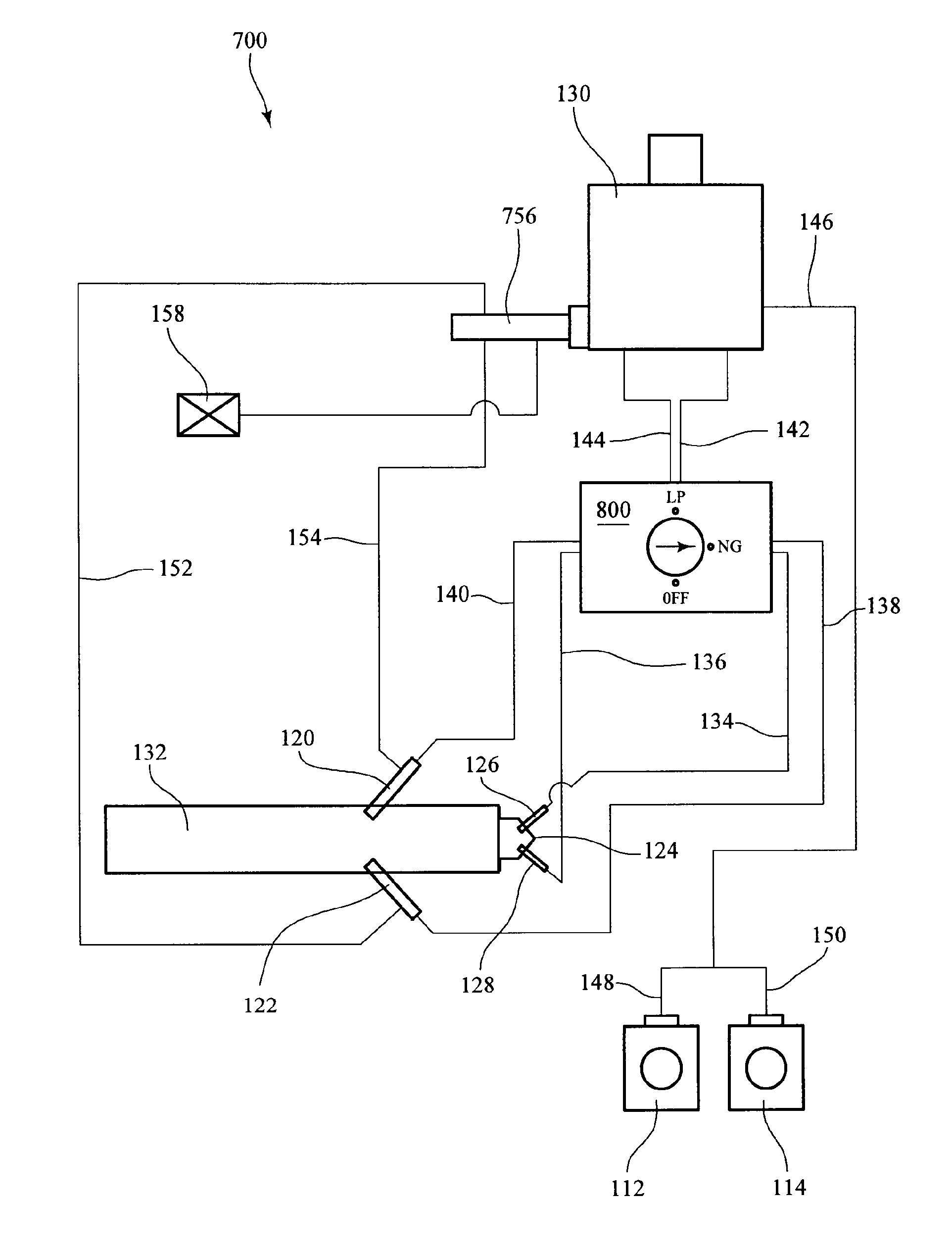

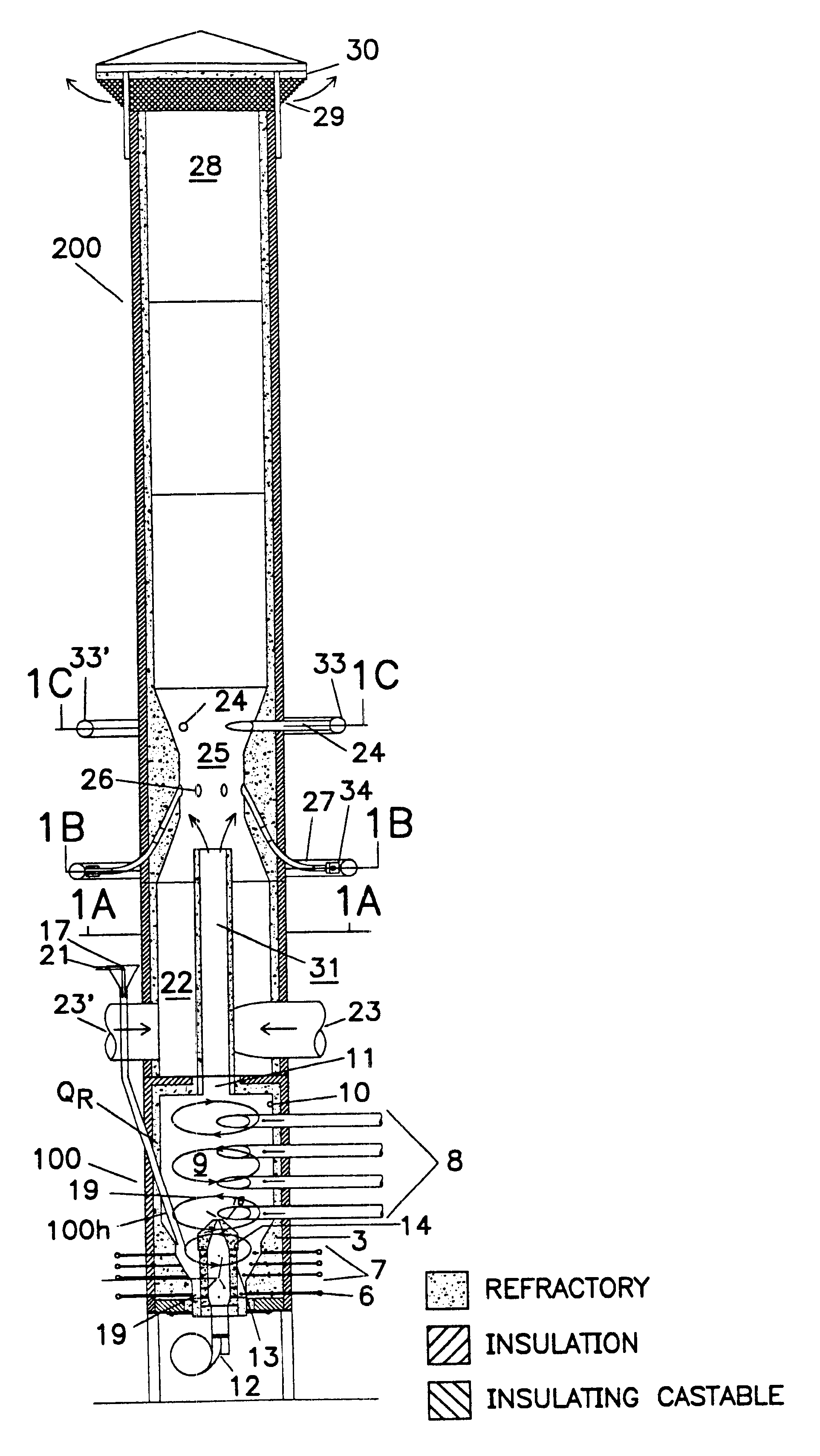

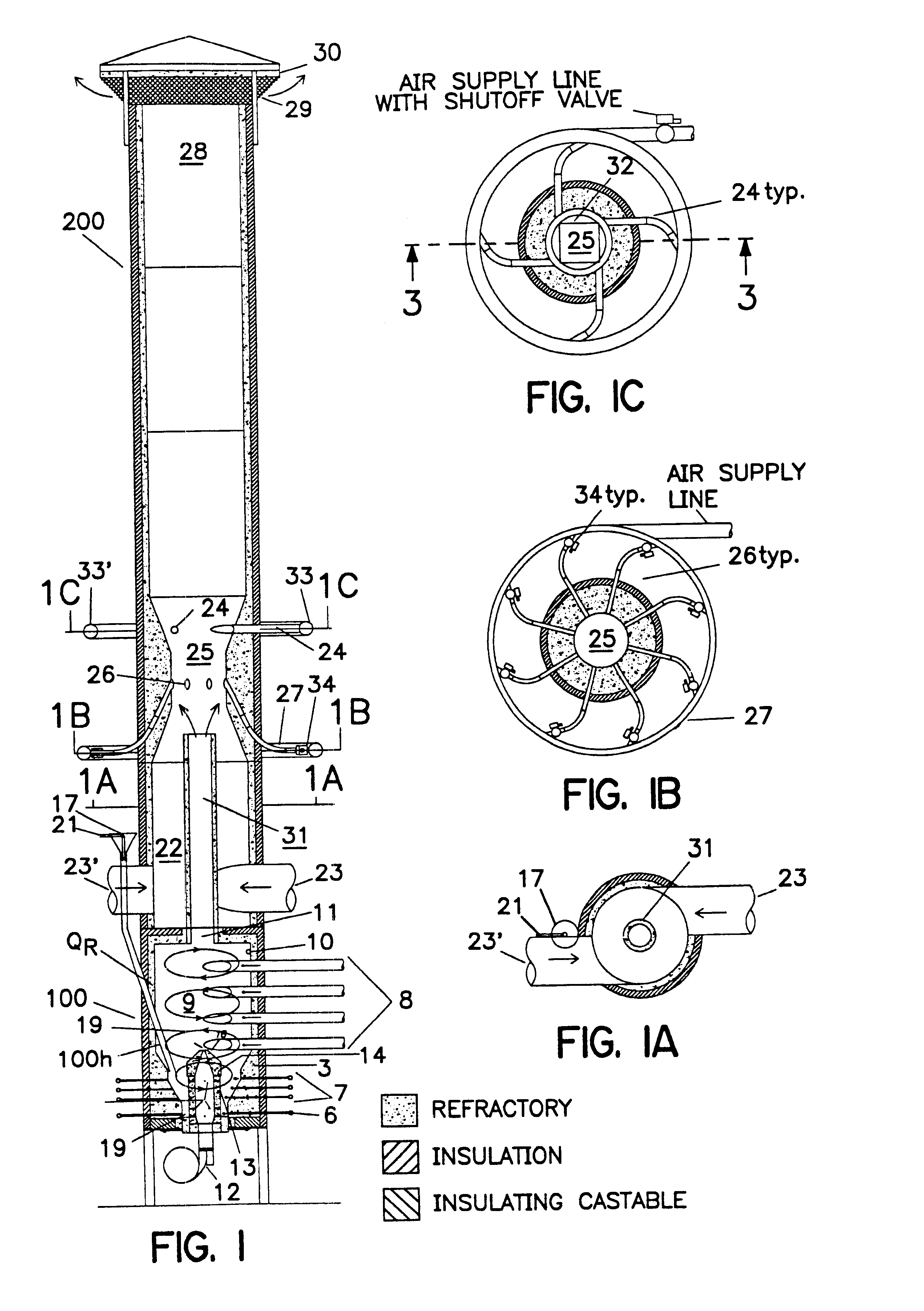

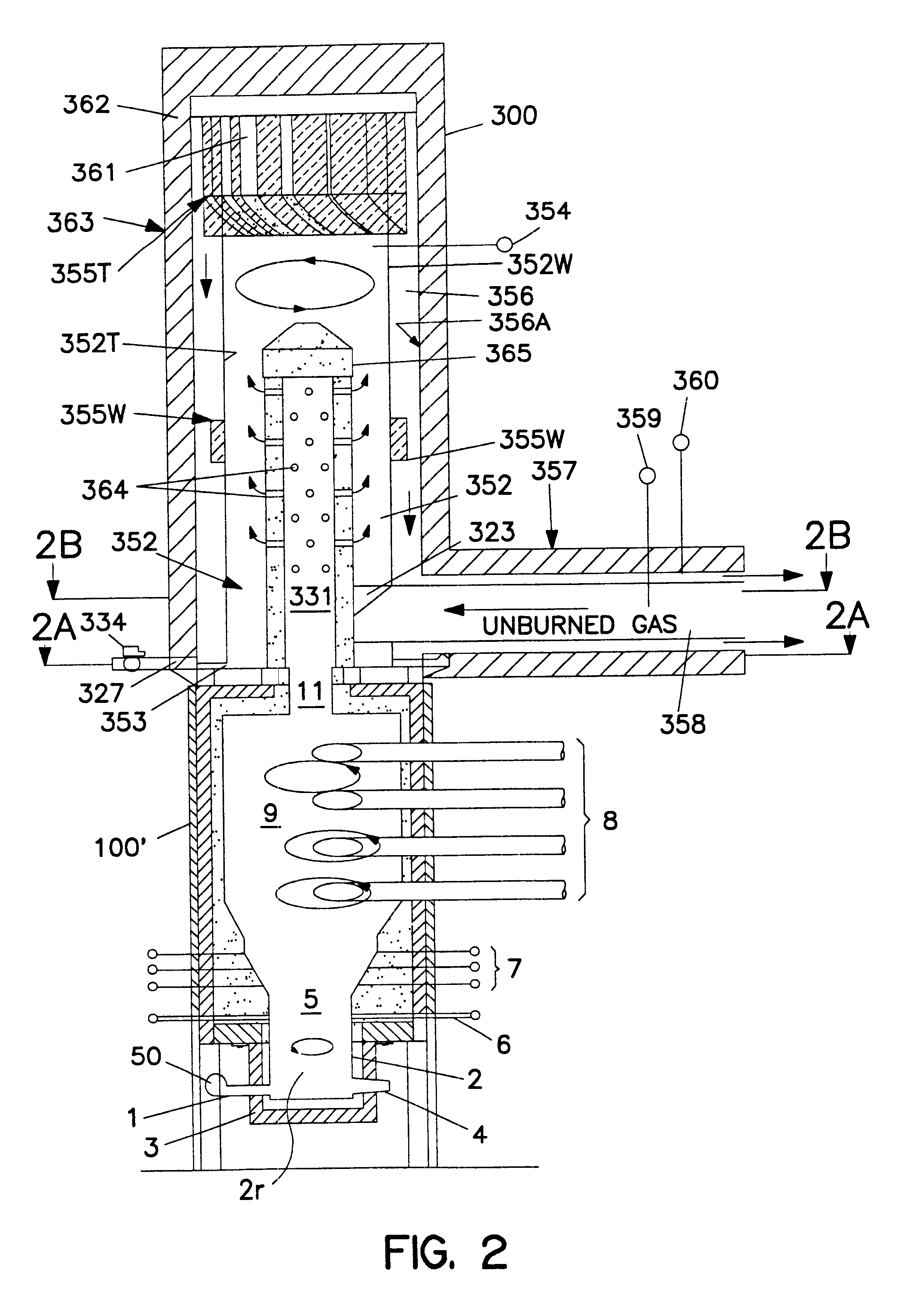

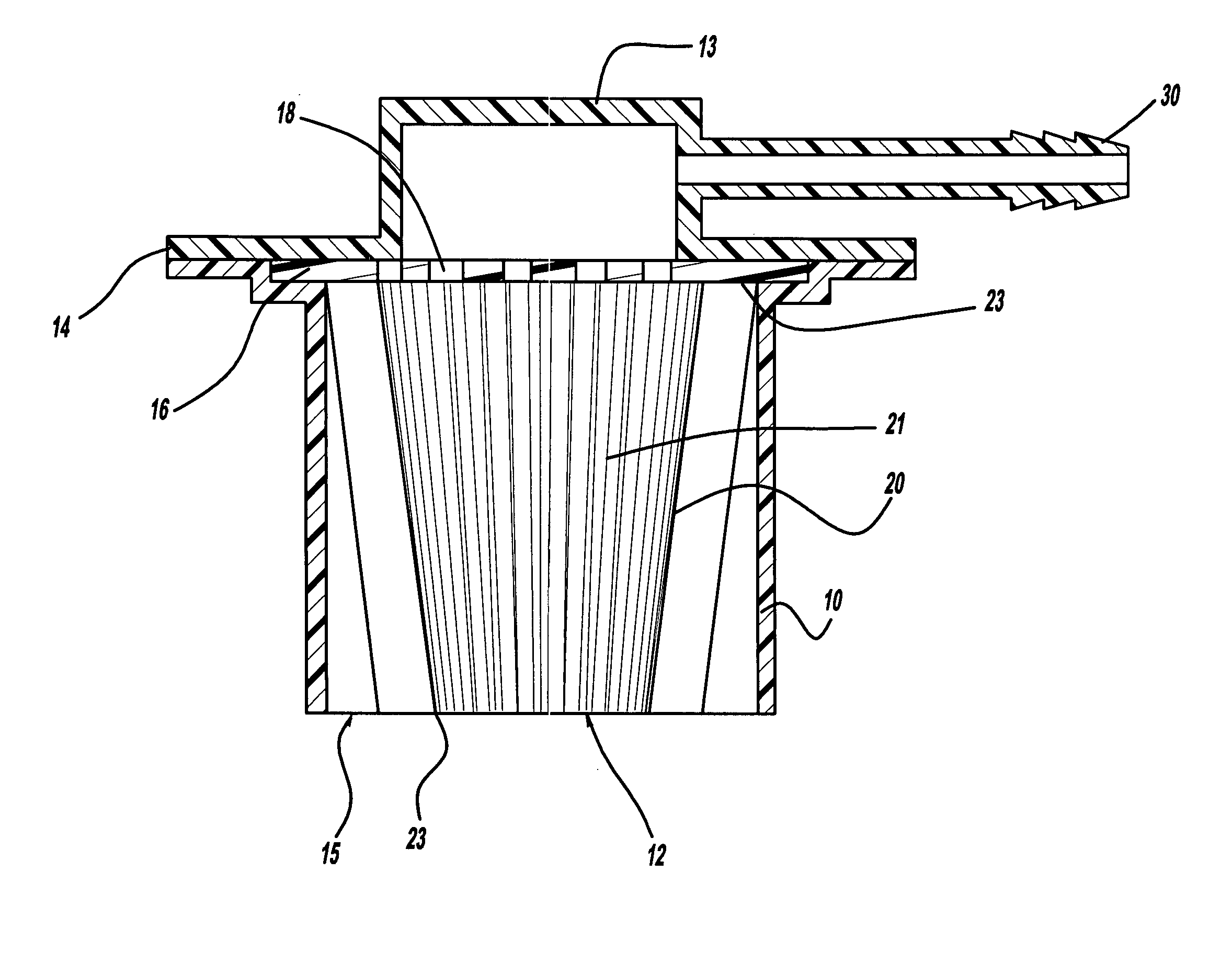

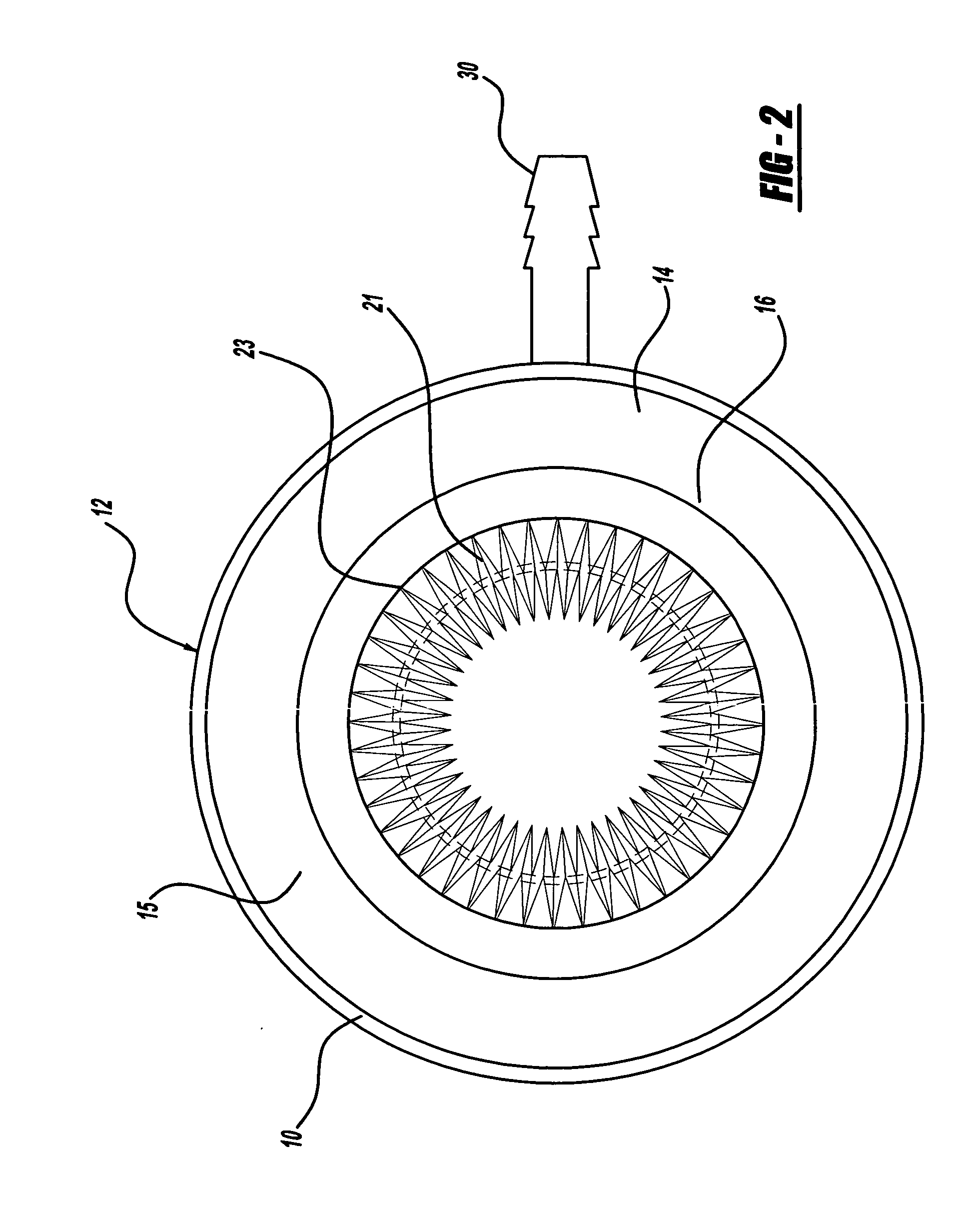

Combustors and burners with high turndown ratio

InactiveUS6363868B1Improve efficiencyIncrease flexibilityFuel supply regulationSolid waste disposalParticulatesCombustion chamber

Various smoke and combustible gas combustors (200, 300) are disclosed, and also disclosed are systems (100, 200) combining gas combustor with inventive burner. Such a burner (100 or 100') provides combustion of a particulate fuel such as sawdust, and many types of varying moisture content biomass fuels such as poultry litter. The combustors and burners exhibit a high turndown ratio ["TDR"].The smoke or combustible gas combustors (200, 300) are combined synergistically with such a burner (100, 100'), or combined with another suitable burner, so as to provide high temperature burner output gases to the combustor, which has coaxial inner and outer combustion chambers (352, 356) inlet tuyere(s) connected to the inner combustion chamber for introducing combustible smoke or other gases to be burned into the inner combustion chamber at one end thereof with cyclonic flow, and in which combustion air is mixed with combustible smoke or other gases to form a gas stream moving through the inner combustion chamber with cyclonic movement. A preheat tube (331) within the combustible gas heating chamber receives heated exhaust gases from the burner, and communicates with the inner combustion chamber exit through a plurality of apertures (364) for controlled flow of said heated exhaust gases into the gas stream and so heating same by mixing the exhaust gases with the stream of air and combustible gases.

Owner:INDEPENDENT STAVE

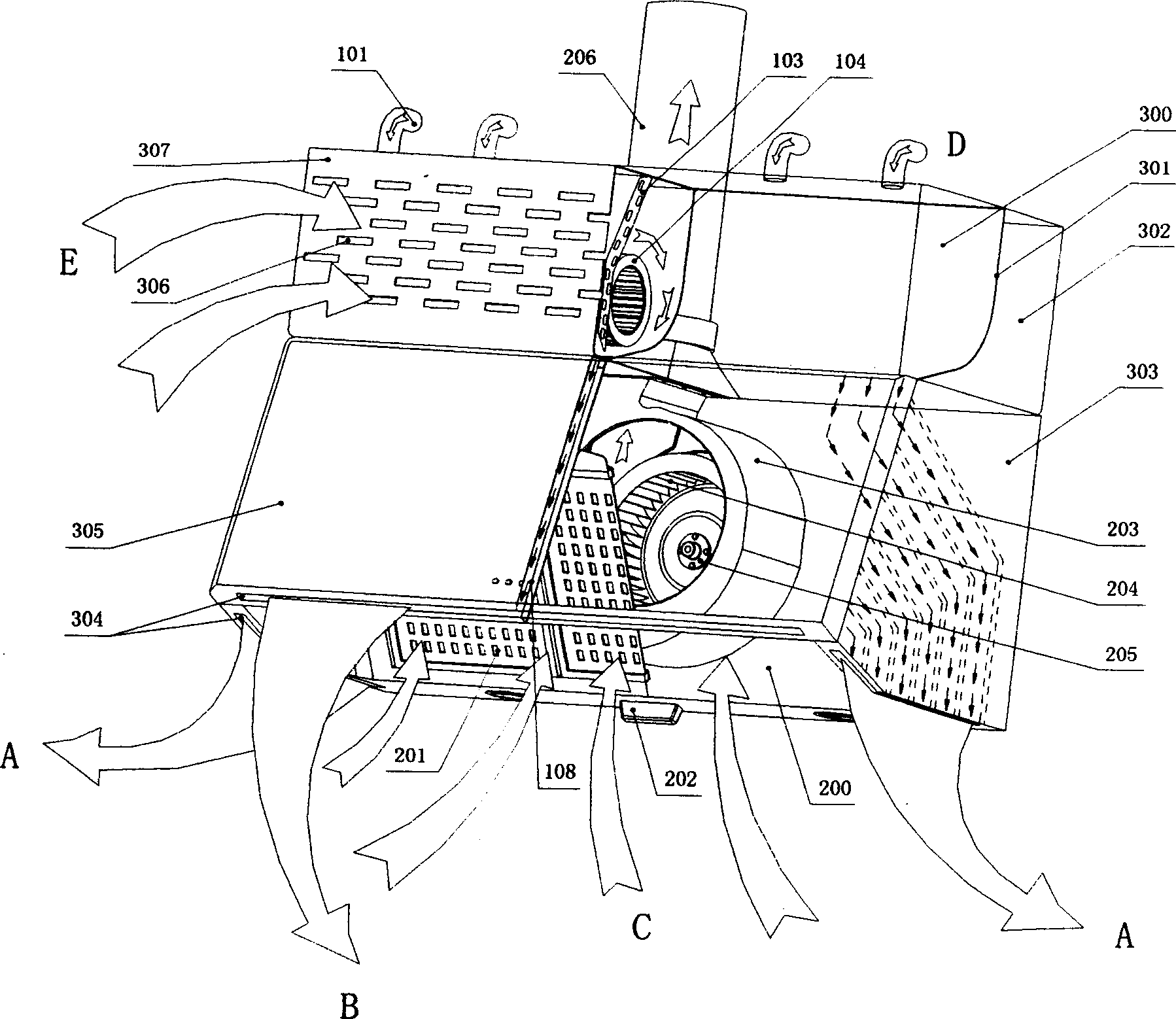

Radiation unit of electronic device and electronic device using same

InactiveUS20120236499A1Effective coolingTelevision system detailsCooling/ventilation/heating modificationsEngineeringElectric devices

A cooling unit includes a partition board, a heat exchanger, and a blower. The partition board is disposed on one of a plurality of surfaces of an electronic device so as to partition the inner and the outer side of the electronic device. The heat exchanger is disposed on the outer side so as to exchange heat generated by the electronic device with outside air. The blower is disposed on the outer side. The heat exchanger includes hot-air passage bodies and air pathways. The hot-air passage bodies include a plurality of air passages arranged side by side at predetermined intervals in such a manner as to connect a first vent and a second vent of the partition board on the outer side. The blower blows air of the inner side from the first vent to the second vent through the hot-air passage bodies.

Owner:PANASONIC CORP

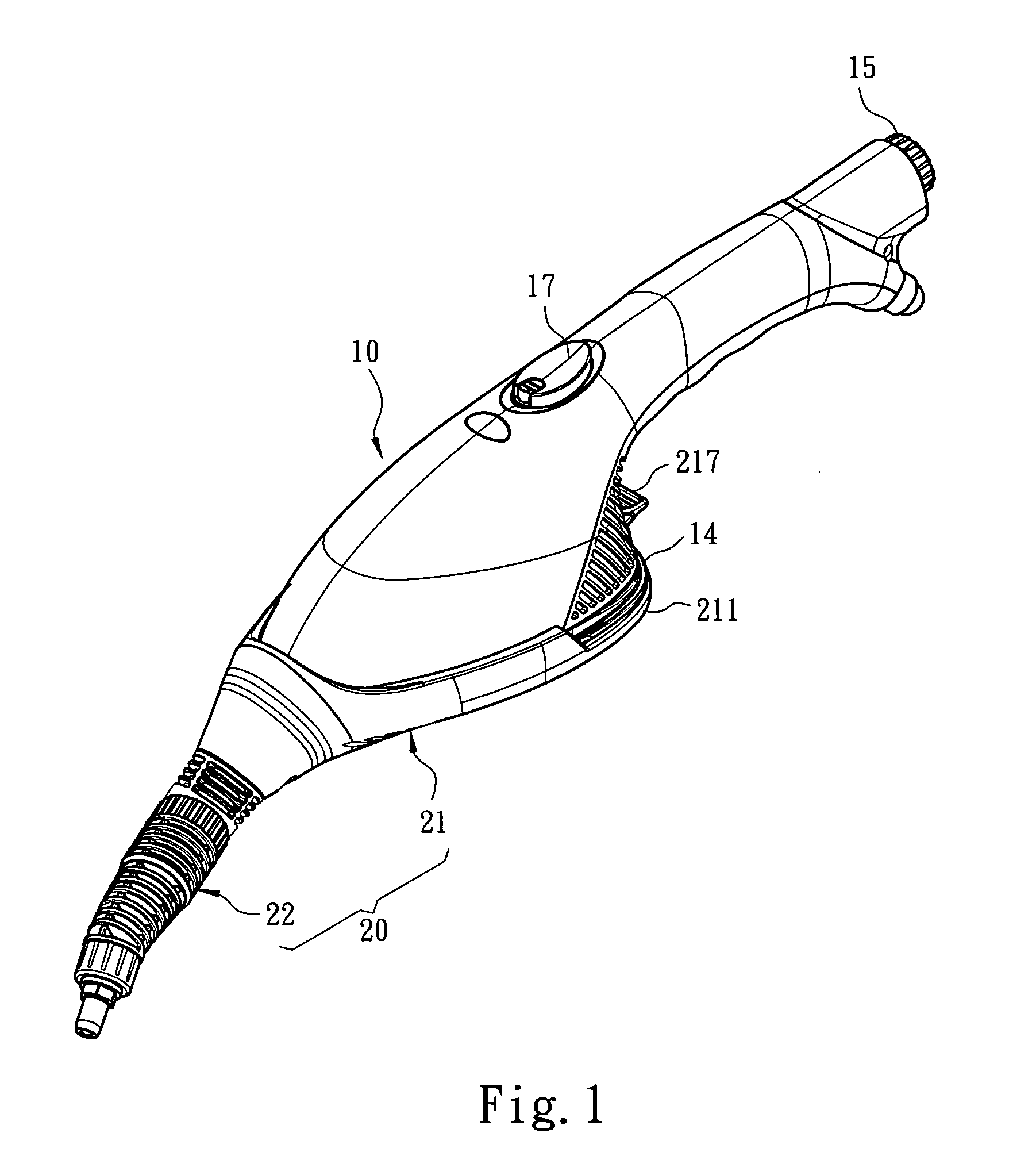

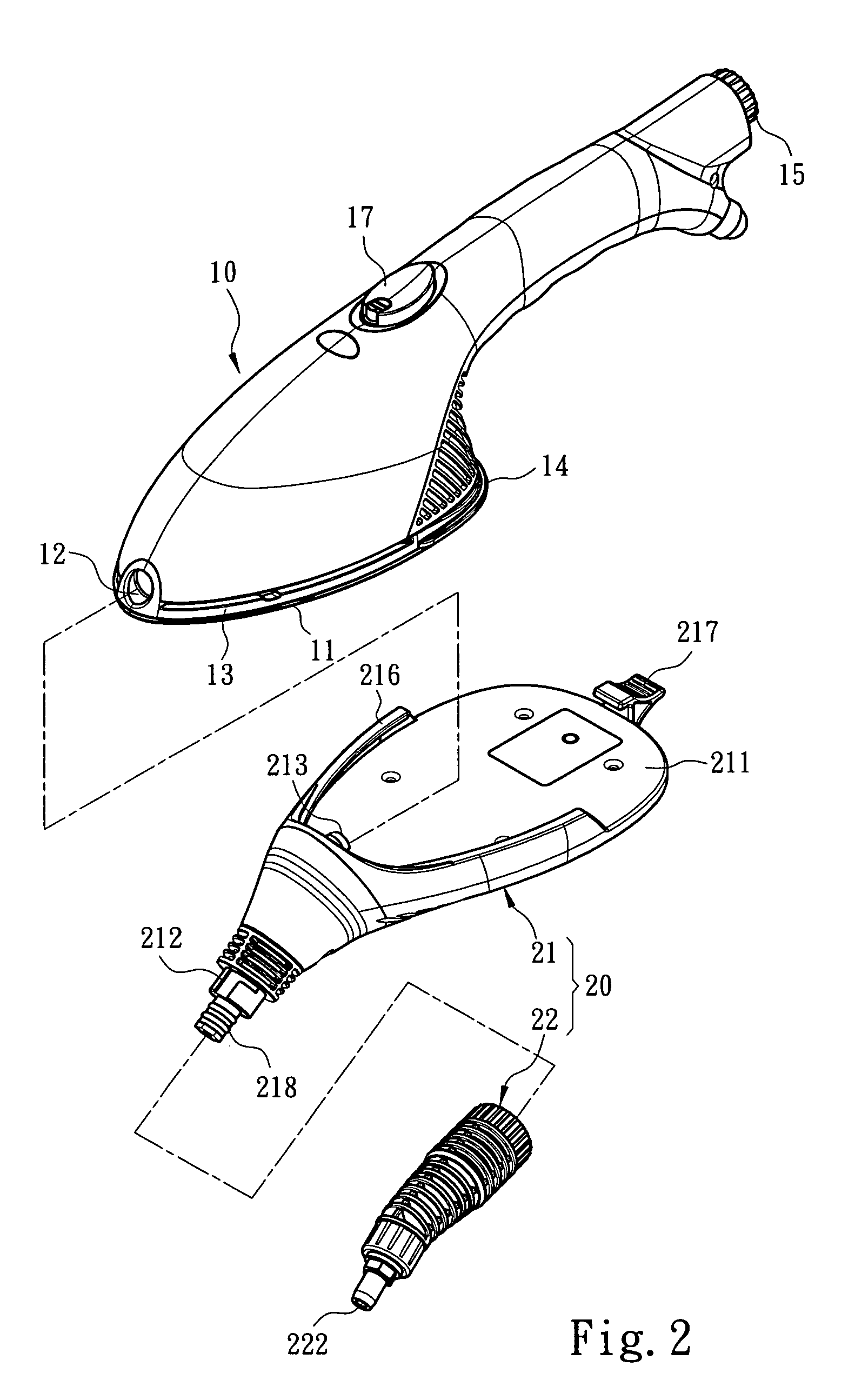

Steam channeling structure

A steam channeling structure adopted for use on a steam iron to transfer steam to perform cleaning function. The steam iron includes at least a soleplate heated to perform ironing function and at least one steam vent. The steam channeling structure includes a coupling dock and at least one cleaning tool mounted onto the coupling dock. The coupling dock has a protective portion to cover the soleplate and a steam directing portion communicating with the steam vent to direct steam discharged through the steam vent. The cleaning tool has a steam passage connecting to the steam directing portion and a steam channeling vent located in the steam passage. Steam generated by the steam iron is conveyed through the steam directing portion to the steam channeling vent to be discharged to perform steam cleaning function on a selected article.

Owner:TSEN SAMSON

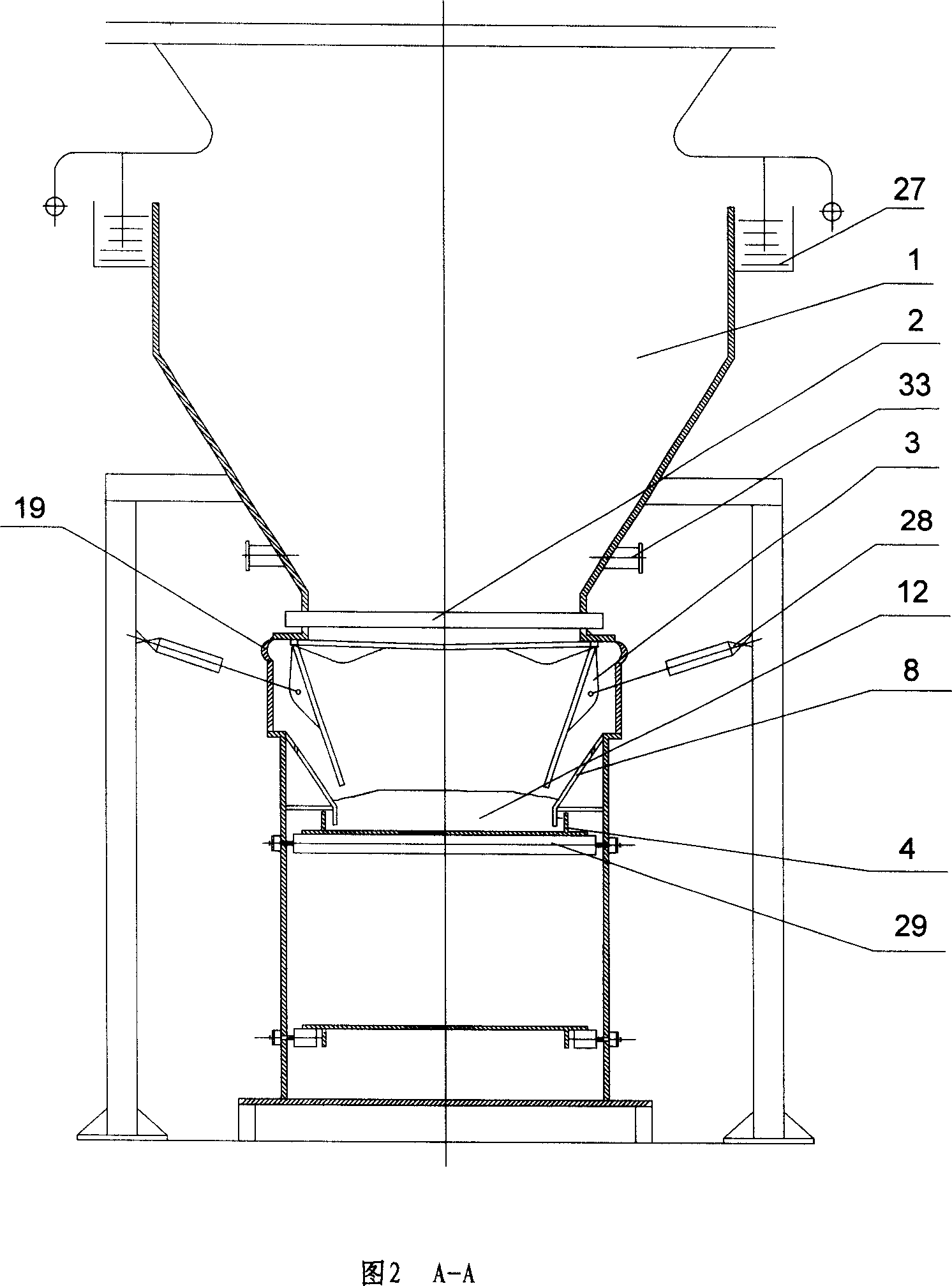

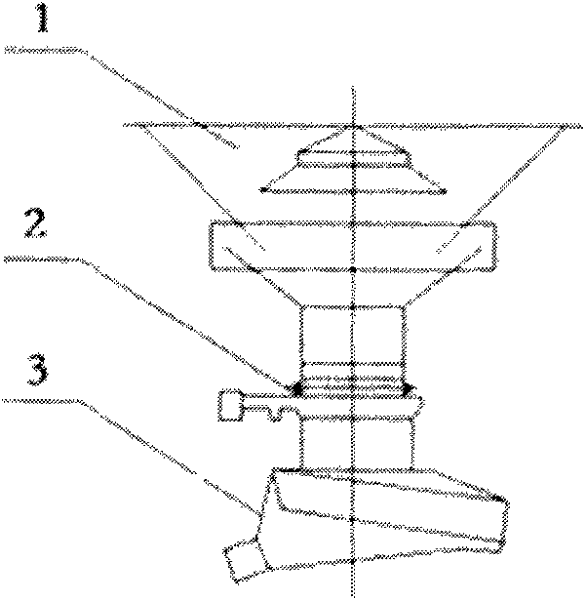

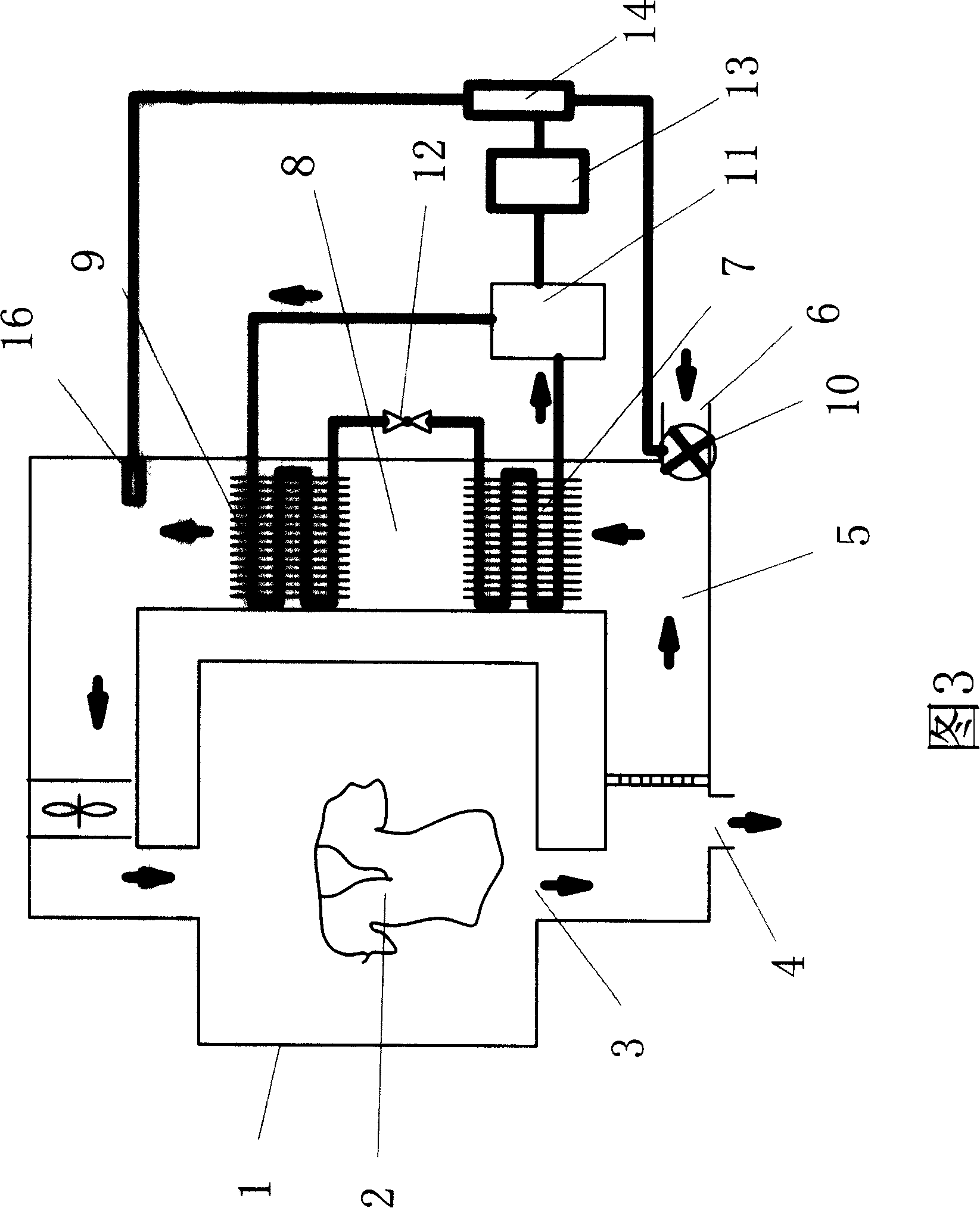

Dry slag-draining device of coal boiler

InactiveCN101008492AImprove cooling effectGuaranteed uptimeLighting and heating apparatusSlagEngineering

The invention discloses a coal boiler dry-type slag discharger, which comprises a seal box sealed and connected with the slag hopper of boiler. The seal box contains a high-temperature resistant transmission band; the descending part along the direction of transmission band between the seal box and the slag hopper is arranged with a wind inlet; the seal box is arranged with a wind valve for limiting the inlet cooling air into the slag hopper, while the wind valve is between the connection of seal box and slag hopper and the wind inlet; the seal box is also arranged with a wind outlet for outputting the hot air outside the seal box; along the direction of transmission band, and at the ascending part of the connection part between the seal box and the slag hopper, a baffle device is arranged for baffling the cooling air into the slag hopper. The invention can effectively improve the amount of cooling air to cool the slag and control the amount of cooling air at the bottom of boiler to operate the boiler normally.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

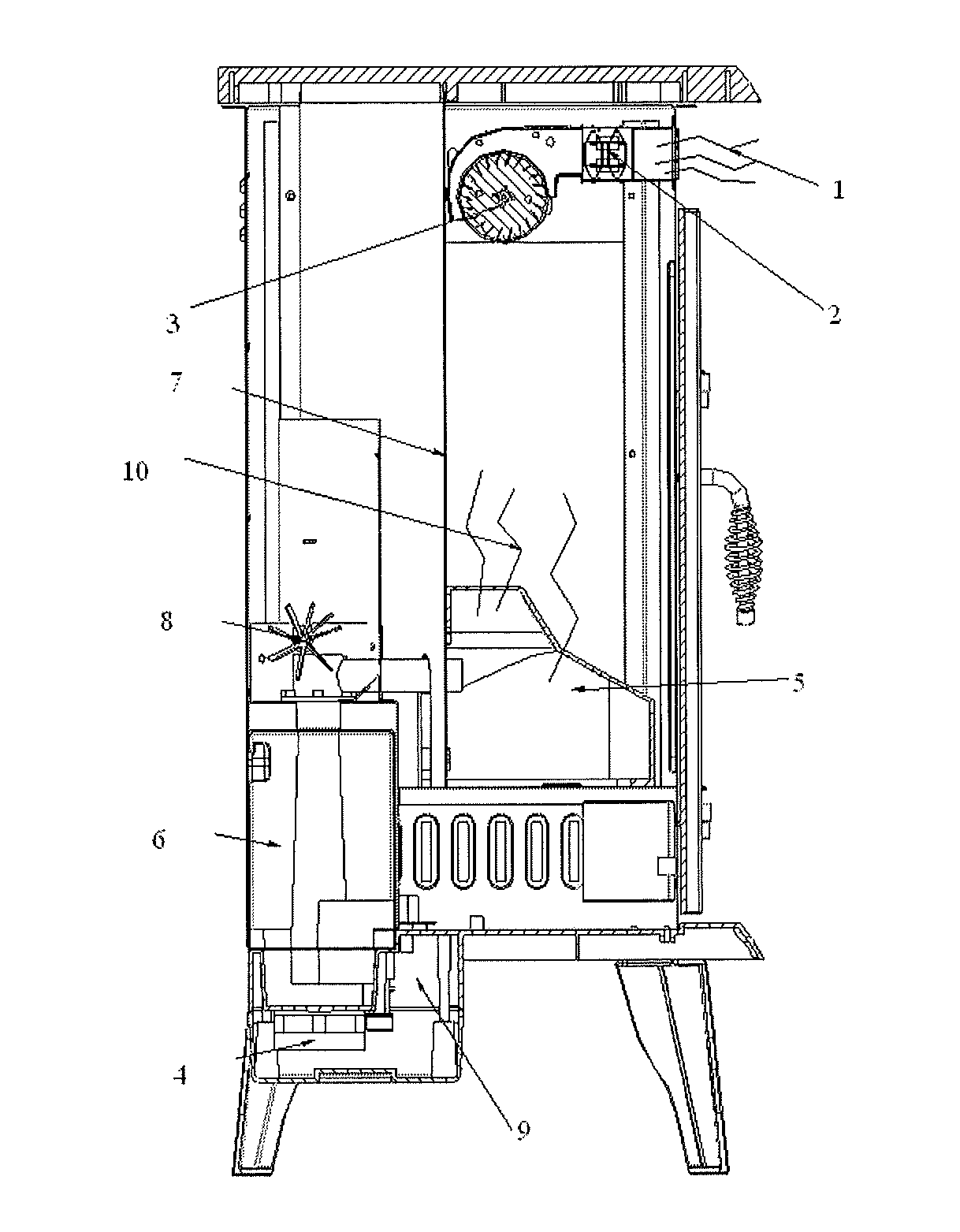

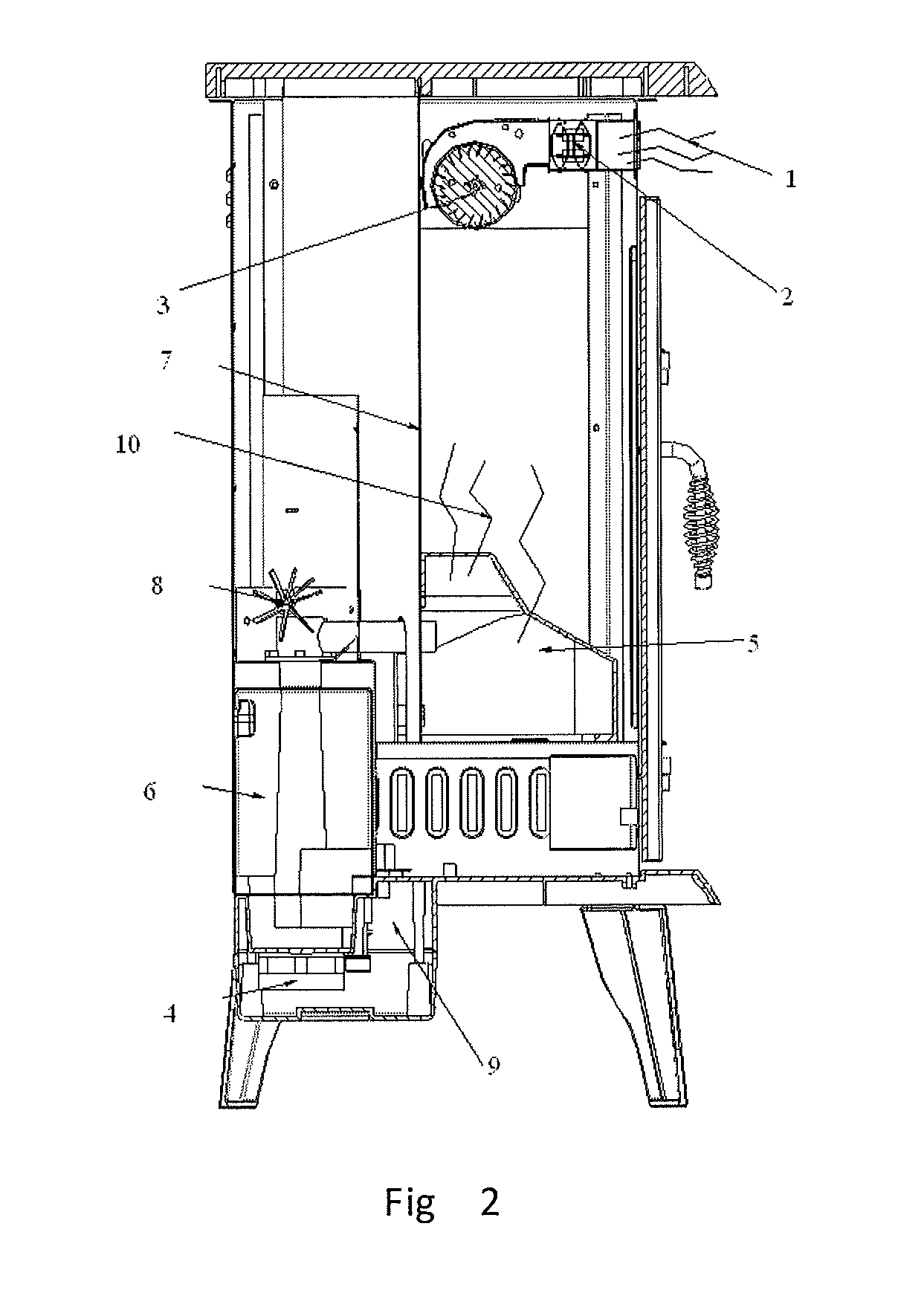

Simulation electric fireplace having mist, humidifying and heating functions

InactiveUS20160195277A1Realistic simulation effectMore simulation effectDomestic stoves or rangesLighting and heating apparatusElectricityCombustion

A simulation electric fireplace having mist, humidifying and heating functions, which includes a shell with air inlets and outlets; a heating device arranged in the shell and used for heat provision upon being powered on; an air channel arranged in the shell and communicated with the air outlet; a fan and a combustion simulation device, which are arranged in the shell, wherein air taken from the air inlet is heated by the heating device for being delivered to the air channel, wherein the simulation electric fireplace further includes a humidifying device, the air outlet includes a first air outlet for sending out the hot air and a second air outlet for sending out the humidified hot air, the air channel includes a hot air channel communicated with the first air outlet and a humidifying air channel communicated with the second air outlet, the humidifying device is arranged in the humidifying air channel for humidifying the hot air.

Owner:ZHONGSHAN CITY SHENDE ELECTRICAL APPLIANCE LTD

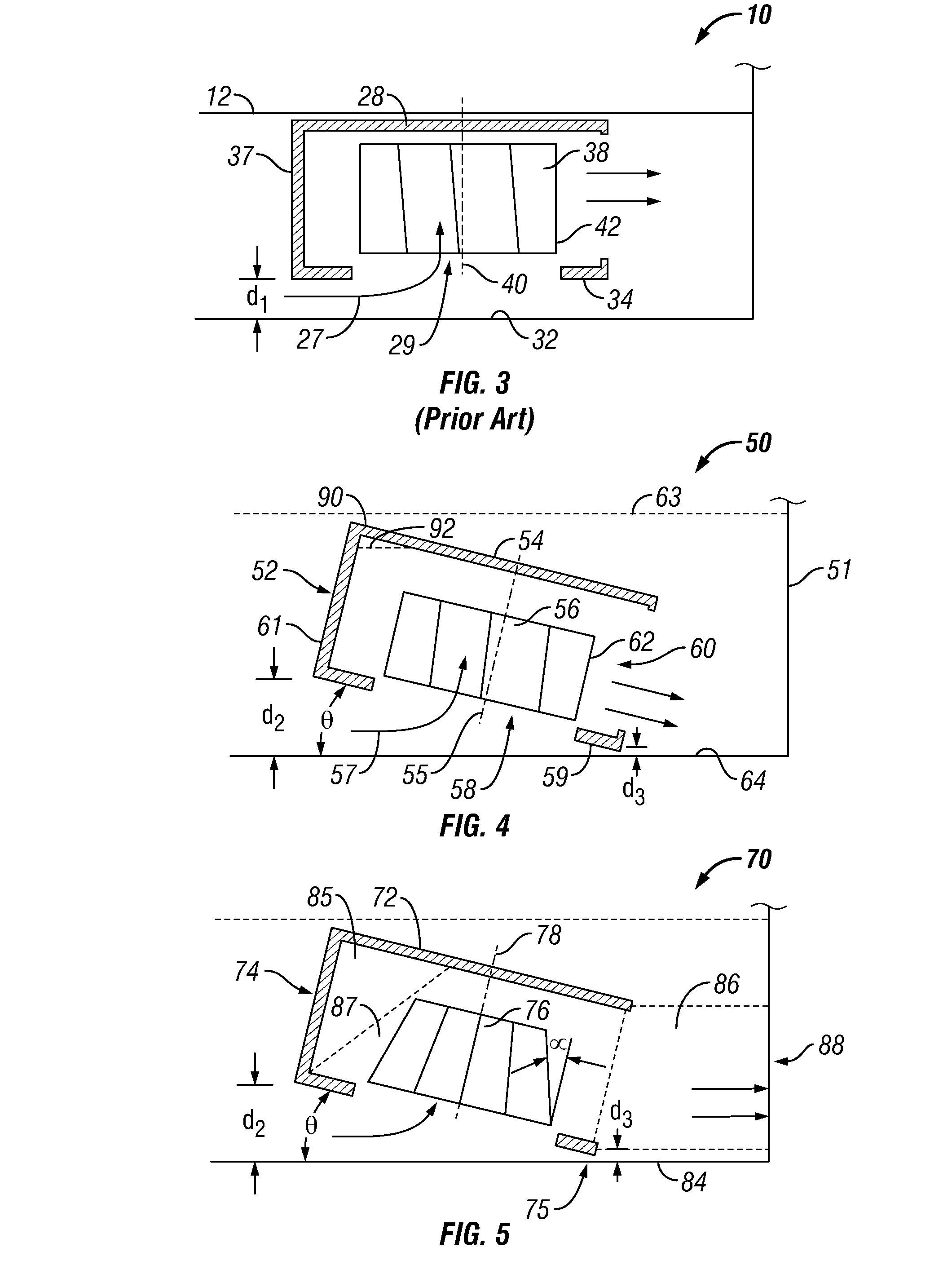

Cooling system with angled blower housing and centrifugal, frusto-conical impeller

InactiveUS20080112127A1Digital data processing detailsCooling/ventilation/heating modificationsImpellerConoid

An improved cooling system for a computer is disclosed. In one embodiment, the improved cooling system includes an angled blower housing and a frusto-conical, centrifugal impeller. The computer chassis has a chassis air inlet and a chassis air outlet. A blower housing is disposed in the computer chassis. The blower housing has a blower inlet face spaced within 0.512 inches (1.3 cm) from a wall of the computer chassis and facing the wall. A blower air inlet is disposed on the blower inlet face and a blower air outlet is in communication with the chassis air outlet. A centrifugal impeller is rotatably supported in the blower housing about an axis of rotation to move air from the blower air inlet to the blower air outlet. The centrifugal impeller defines a generally frusto-conical profile when rotated about the axis of rotation.

Owner:IBM CORP

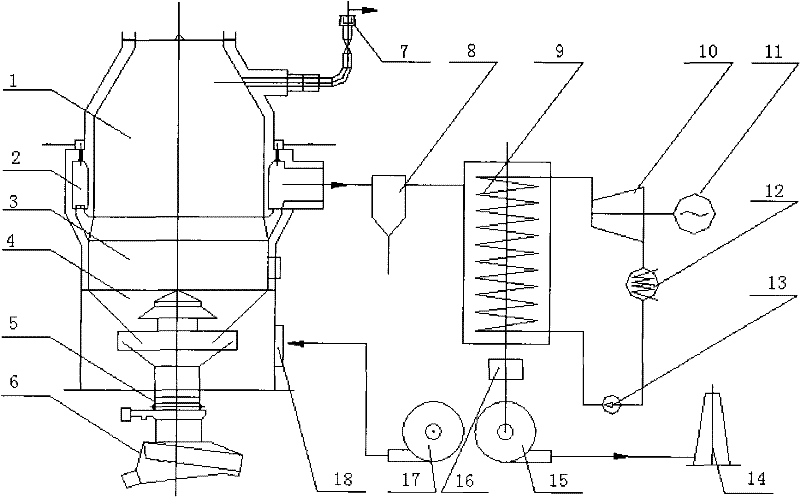

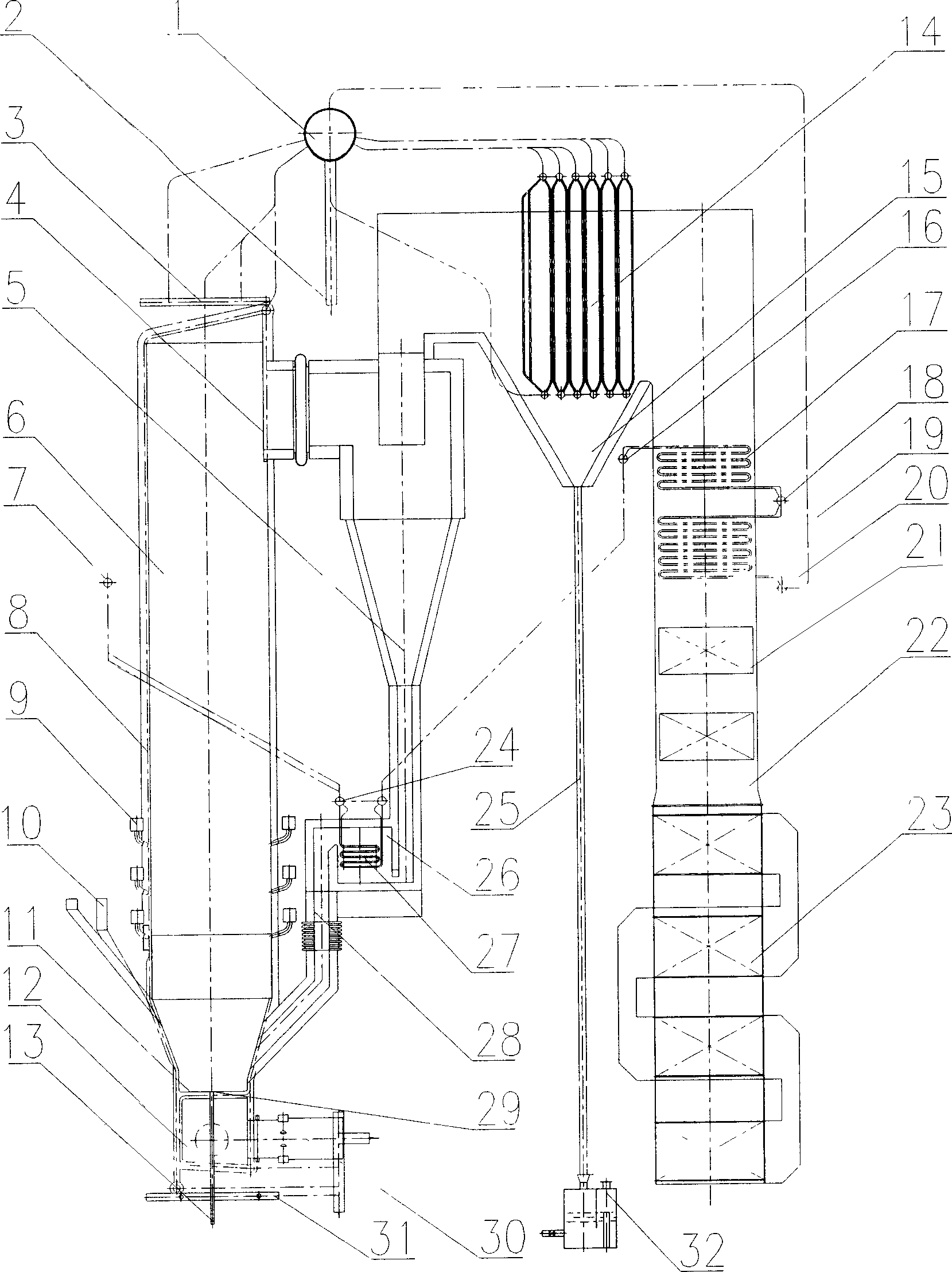

Sintering ore cooling device and waste heat recovery system thereof

InactiveCN102345981AImprove cooling effectEnsure safe and continuous productionIncreasing energy efficiencyHandling discharged materialCold airAir blower

The invention relates to the physical heat recovery field of solid high temperature materials. The system can be applied in the waste heat recovery of extra-large high-temperature particles such as high-temperature sintering ore and the like and the process is as follows: the high-temperature sintering ore from a sintering machine falls into a cold sinter furnace through a feeding system, gradually falls with ore discharge and enters a cooling section to radiate heat. The cooled sintering ore enters a vibrator feeder discharging system through a blanking hopper and a regulating gate. The process can be adopted to cool the sintering ore from about 700-800 DEG C to about 100 DEG C. Cold air provided by an air blower enters the cold sinter furnace through an air inlet and a blast cap, absorbs heat in the cooling section and then enters an annular channel, the high-temperature gas from the annular channel enters a waste heat boiler through a dust remover, the heat is transferred to a working medium and then pumped by the draft fan through the dust remover, and the gas is discharged in a chimney when reaching the dedusting standard. The heat-absorbing working medium (usually water) is converted to superheated steam with a certain parameter in the waste heat boiler to do work in a turbine and drive a generator to generate power. Dead steam after doing work enters a condenser and is sent back to the waste heat boiler through a circulating water pump, thus, a thermal cycle is completed.

Owner:刘柏谦

Cooking fume exhauster with refrigerating and air purifying treatment functions

InactiveCN1451913ASolve the problem of overheatingSolve high temperatureDomestic stoves or rangesLighting and heating apparatusControl systemExhaust fumes

A cooking fume exhauster with refrigerating and air-cleaning functions for exhausting cooking fume fully and lowering temp of kitchen is composed of casing, cooking fume exhausting system, refrigerating system and electric control system. The compressor, condenser and axial-flow fan of said refrigerating system are installed in the outdoor unit, and its evaporator and cross flow fan are installedin the heat exchange chamber of indoor unit.

Owner:NINGBO OULIN KITCHEN APPLIANCE

Air thermalization gas burner

InactiveCN101196308AReduce dosageHarm reductionDomestic stoves or rangesStoves/ranges topsCombustion chamberProduct gas

The invention discloses an air thermalization gas burner, which comprises a burner base, a furnace ring and a burning head. The burner base is provided with an air supply port and a plurality of air nozzles as well as an air supply channel communicated with the air nozzles at external side; the air supply channel is positioned with a blower air inlet; the furnace ring, a popper and a burner base form a firebox; wherein, the furnace ring is a hollow interlayer, which is provided with a plurality of back-wind ports on the internal layer interning wall near to the port; an internal cavum of the furnace ring is communicated with the air supply channel; the blower preaches the air form the air inlet, the air supply channel and the air nozzles into the firebox and the air can burn with the gas entered from the air supply port in the firebox to heat the popper; the high temperature air can pass through the back-wind ports and then return to the firebox for burning after passing through the internal cavum of the furnace ring, the air supply channel and the air nozzles; the heat of the high temperature air can be recovered and utilized as well as sufficiently burned, thereby reducing the usage of gas and restraining the generation of gas harmful to human's health as well as deducing the pollution for environment.

Owner:姜亦迎

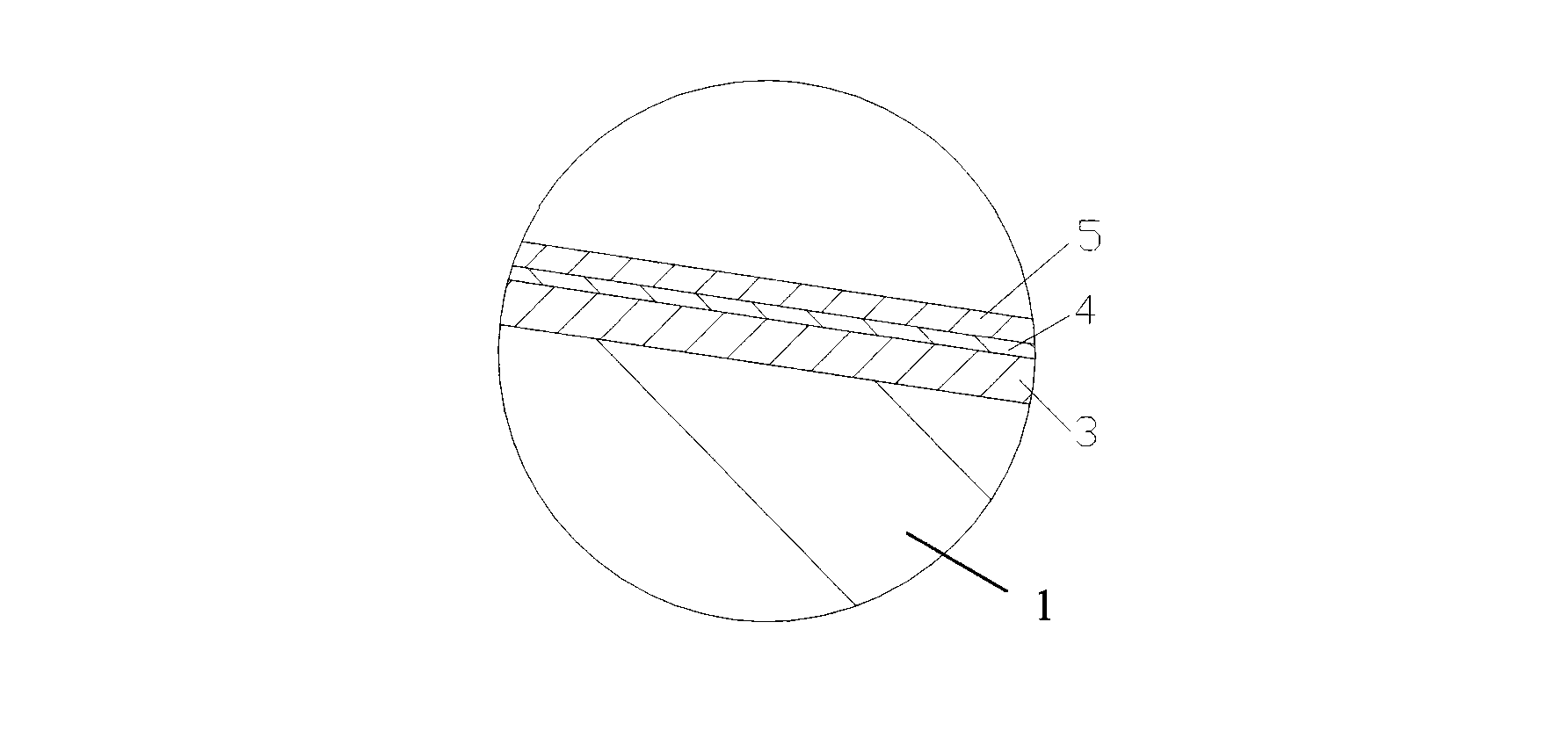

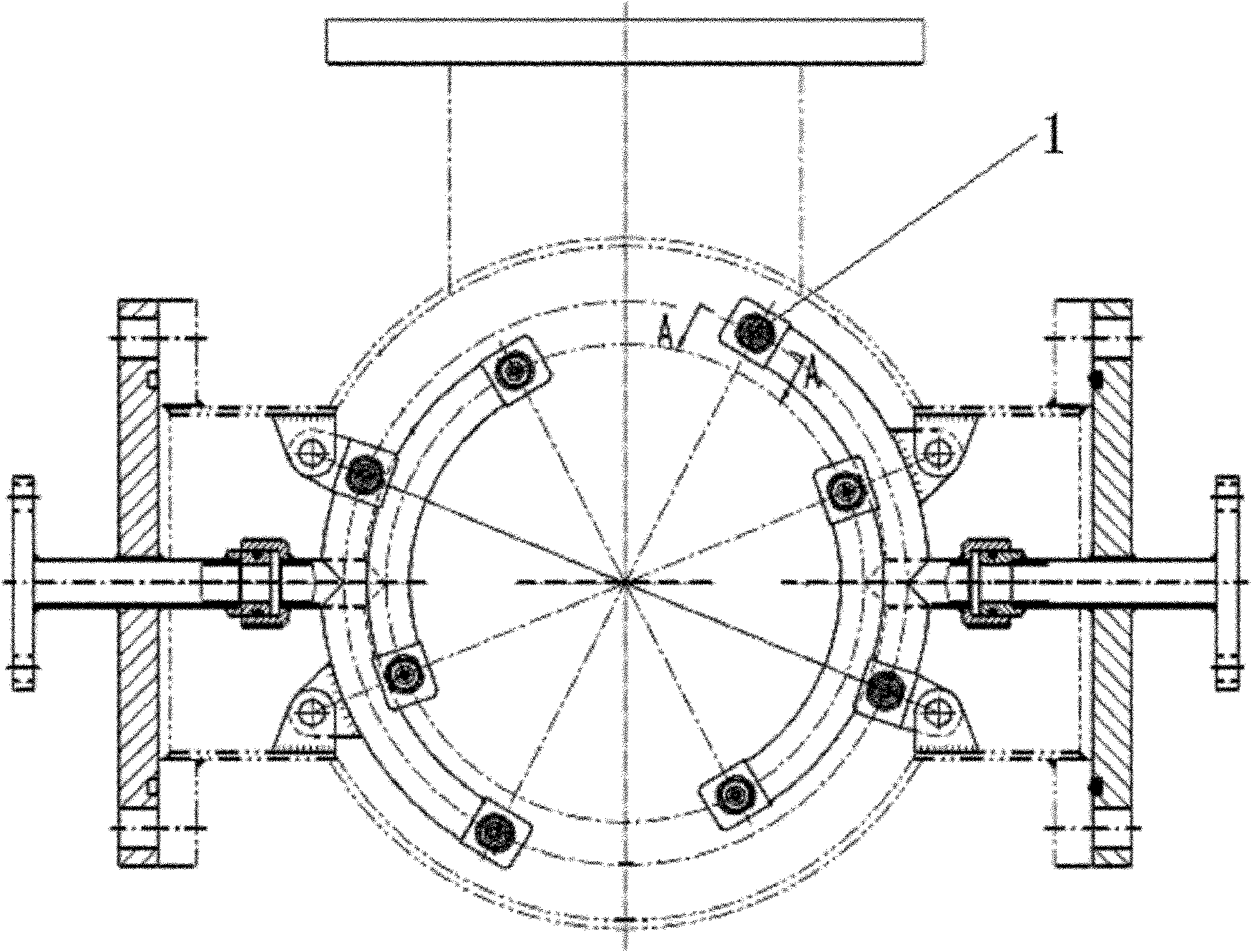

Tuyeres of blast furnace surface recombination coating and method for preparing the same

ActiveCN101492749AImprove thermal shock resistanceReasonable distribution of temperature fieldMolten spray coatingArc welding apparatusAlloyThermal shock

Owner:BAOSHAN IRON & STEEL CO LTD +1

Ironmaking and aluminum extraction comprehensive utilization method of high-iron red mud

ActiveCN102816880ASolve wasteAvoid Condensation RefluxBlast furnace detailsIncreasing energy efficiencyAluminateSlag

The invention provides an ironmaking and aluminum extraction comprehensive utilization method of high-iron red mud. The method is characterized in that a blast furnace is used as main equipment; red mud is utilized to prepare micropellet composite sinter or pellet; micropellet composite sinter or pellet and coke are then treated with hot charging into the furnace layer by layer at no less than 400 DEG C; rich oxygen to full oxygen blast is employed; and tuyeres on the furnace body are increased, and reducing gas rich in hydrogen is blown into the furnace, so as to realize red mud ironmaking. At the same, calcium oxide is added during a deslagging process; the slag is treated with temperature control cooling to obtain self-pulverization calcium aluminate slag, which is leached and extracted with alumina; and sodium element is synchronously recovered from high temperature exhaust of the furnace top, so as to complete efficient separation and recycling of aluminum, iron and sodium in the red mud.

Owner:NORTHEASTERN UNIV

Fuel vent assembly with floatless rollover protection

ActiveUS20050098160A1Reduce manufacturing costNon-fuel substance addition to fuelLarge containersRolloverFuel tank

A valve for use between a vehicle fuel tank vent and a vapor recovery canister in a vehicle fuel tank containing liquid fuel, such a valve comprises: a housing having a fuel tank side and a vapor recovery canister side; and a vapor permeable membrane fixed to the housing to block the passage of liquid fuel.

Owner:FCA US

Straw circulation fluidized-bed combustion boiler

InactiveCN1912461AGood load regulation performanceAvoid corrosionFluidized bed combustionCombined combustion mitigationAir preheaterCombustion chamber

A recirculation fluidized bed combustion boiler of straw is prepared as setting material feed mouth and residue extraction mouth on firepot, setting cooling device being connected to ignition combustion chamber and refeeder with secondary wind opening at bottom of firepot, using water cooling wall with top and bottom collection boxes as side wall of firepot, connecting outlet of firepot to separation device being connected to refeeder and two stages of thermo reduction devices separately, connecting one stage of thermo reduction device to a overheat unit with economizer and preheater as well as setting steam pocket and water supply pipe at top of firepot.

Owner:SHANDONG GUODIAN TECH CONSULTING +1

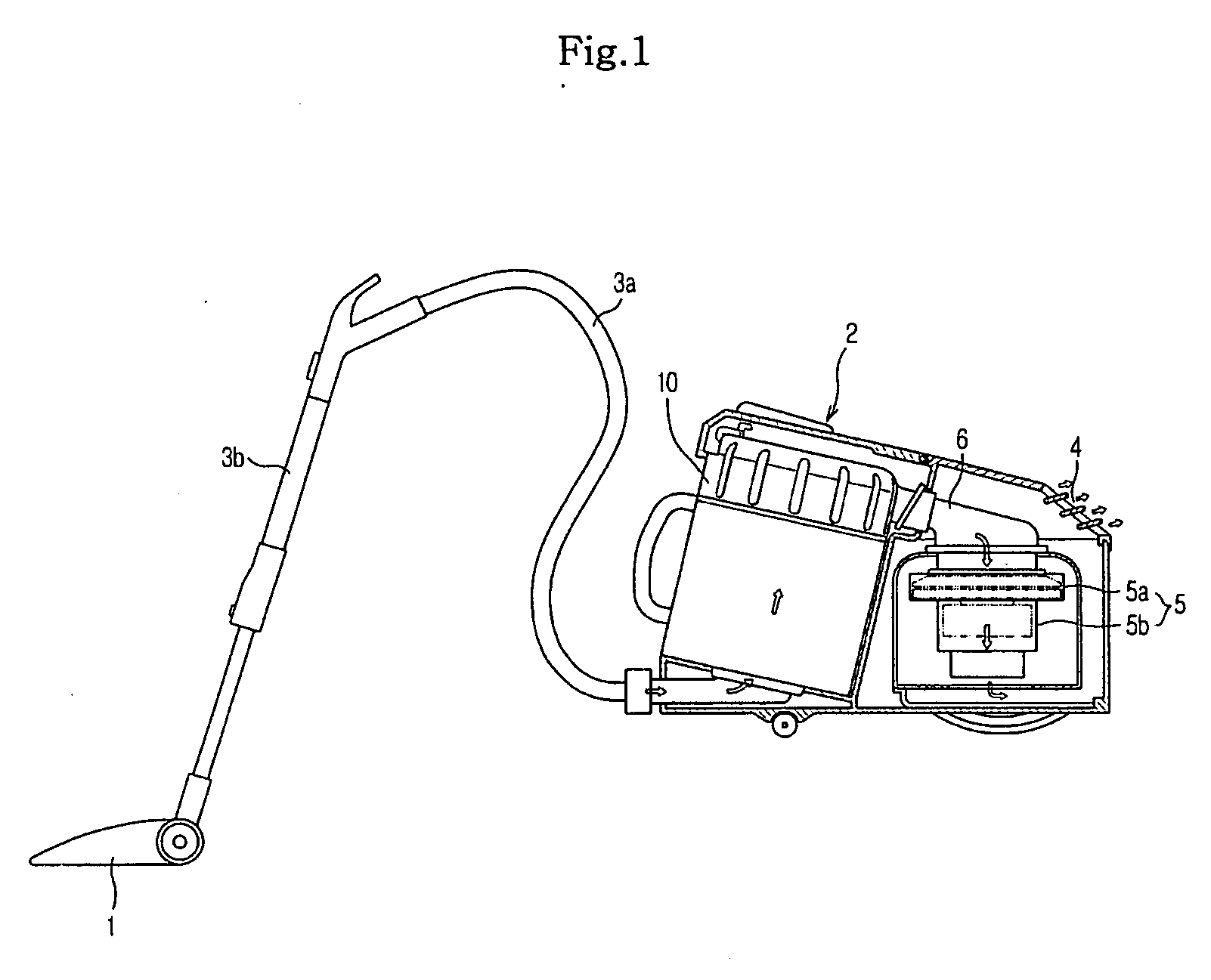

Multi-cyclone dust collection apparatus

InactiveUS20070079583A1Shorten the length of the flow pathReduce suctionCleaning filter meansSuction filtersCycloneEngineering

A multi-cyclone dust collection apparatus is disclosed that comprises a first cyclone having an air inlet, in which the air introduced into the first cyclone through the air inlet is caused to swirl and ascend in the first cyclone so that dust is separated from the air; and a plurality of second cyclones arranged around the lower part of the first cyclone, in which the air discharged from the first cyclone into the second cyclones is further caused to swirl and ascend so that dust is separated from the air. Each of the second cyclones is provided with an air outlet through which the purified air is discharged. The air inflow port is provided at the bottom of the first cyclone and the outflow ports are provided at the lower ends of the second cyclones.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

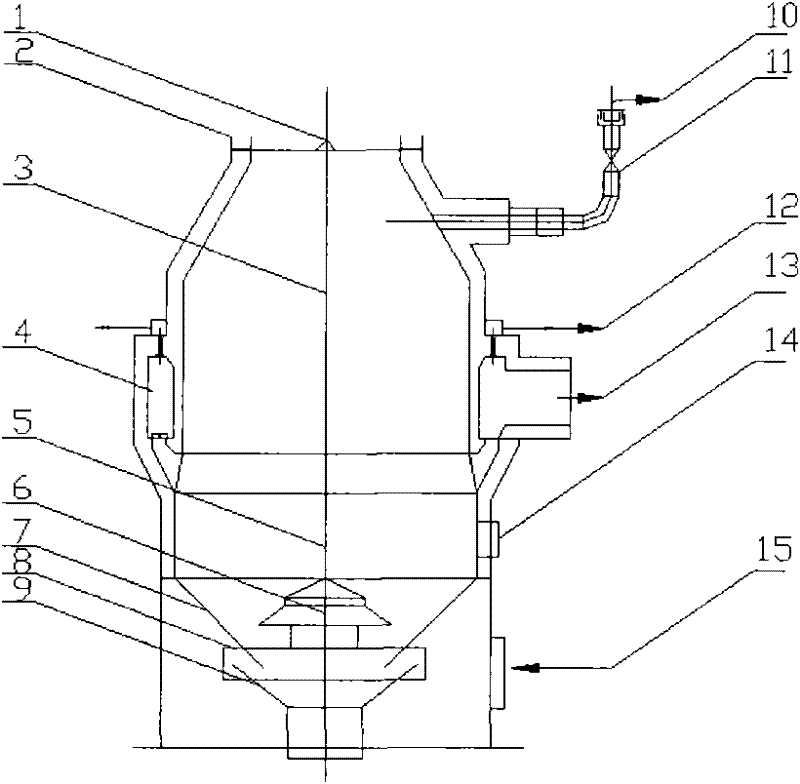

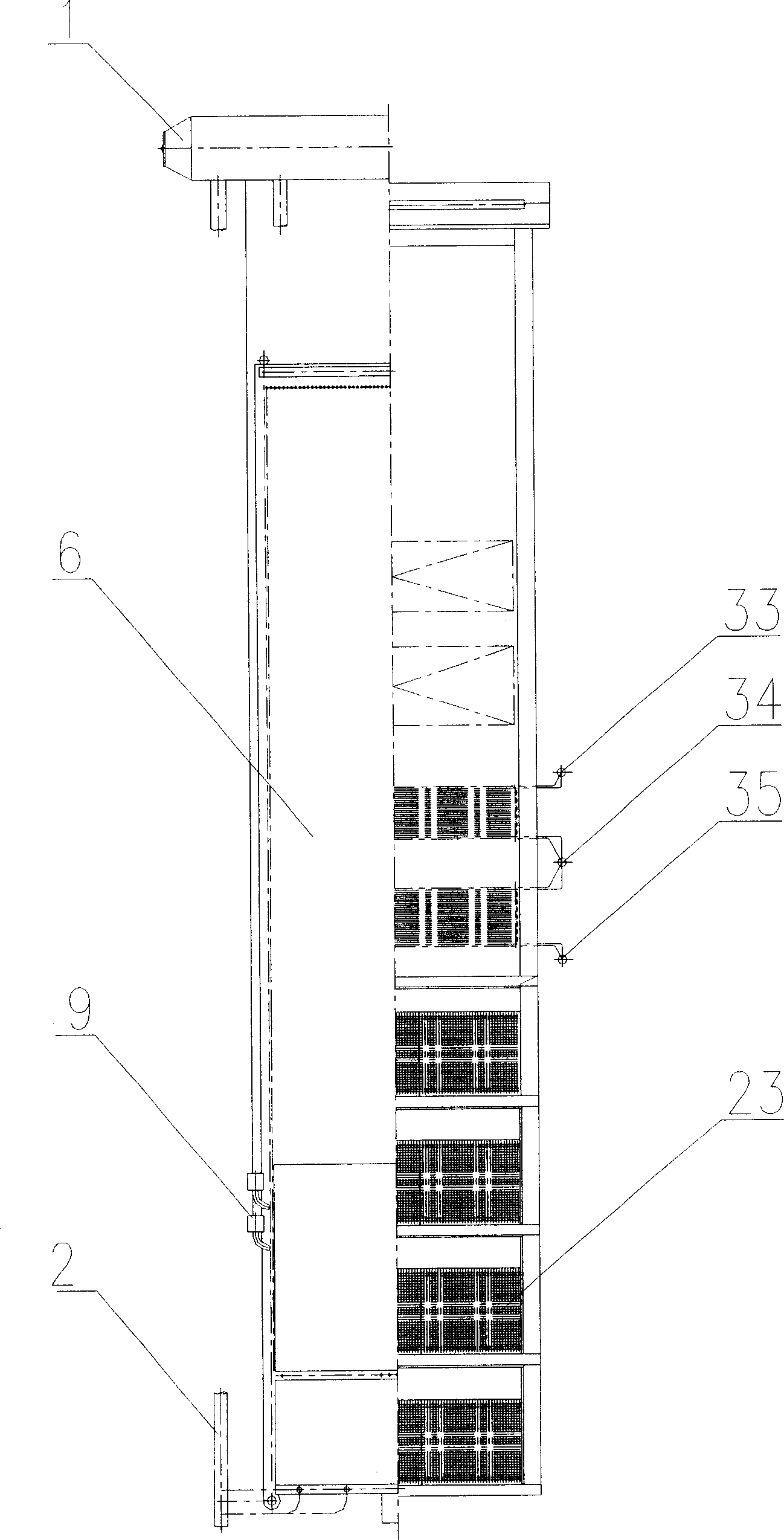

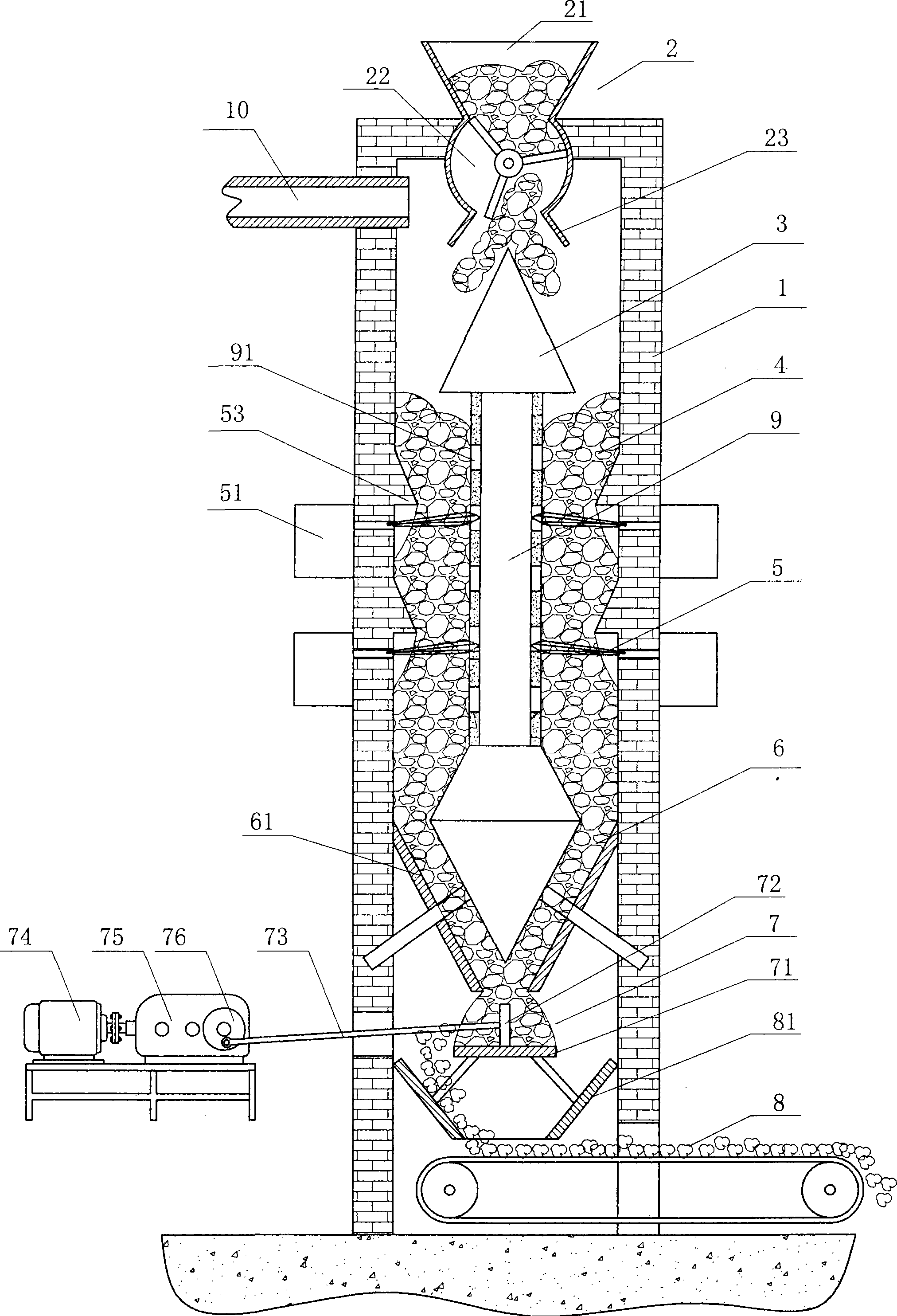

Vertical continuous calcination lime burner

InactiveCN101195520AHigh activityCalcination process is reasonableLime productionInterior spaceLime kiln

The invention discloses a vertical and continuously calcining lime kiln, including a cylindrical kiln body. From the top down, the kiln body is successively provided with an air-lock feeding device, a distributing device, a preheating zone, calcining zone, cooling zone and a continuously discharging device. The air-lock feeding device is located on the top of the kiln body, the distributing device is located on the upper of the inner chamber of the kiln body, the preheating zone is located below the distributing device, the calcining zone is located below the preheating zone, the cooling zone is located below the calcining zone and the continuously discharging device is located below the discharge port but at the cooling zone. The top of the kiln body is equipped with air discharge pipe, heat wind exhaust passage which is devised axially along the kiln body and can extend to the preheating zone is equipped in the inner space of the kiln body, and a plurality of air outlets and inlets are equipped on the copper wall of the heat wind exhaust passage. The invention enables to continuously manufacture, can control the lime in the kiln to drop with a uniform speed, has no sintering phenomenon, can control the lime to fall with constant speed on every level surface in the kiln and completely put an end to undersintering and oversintering.

Owner:黄官禹

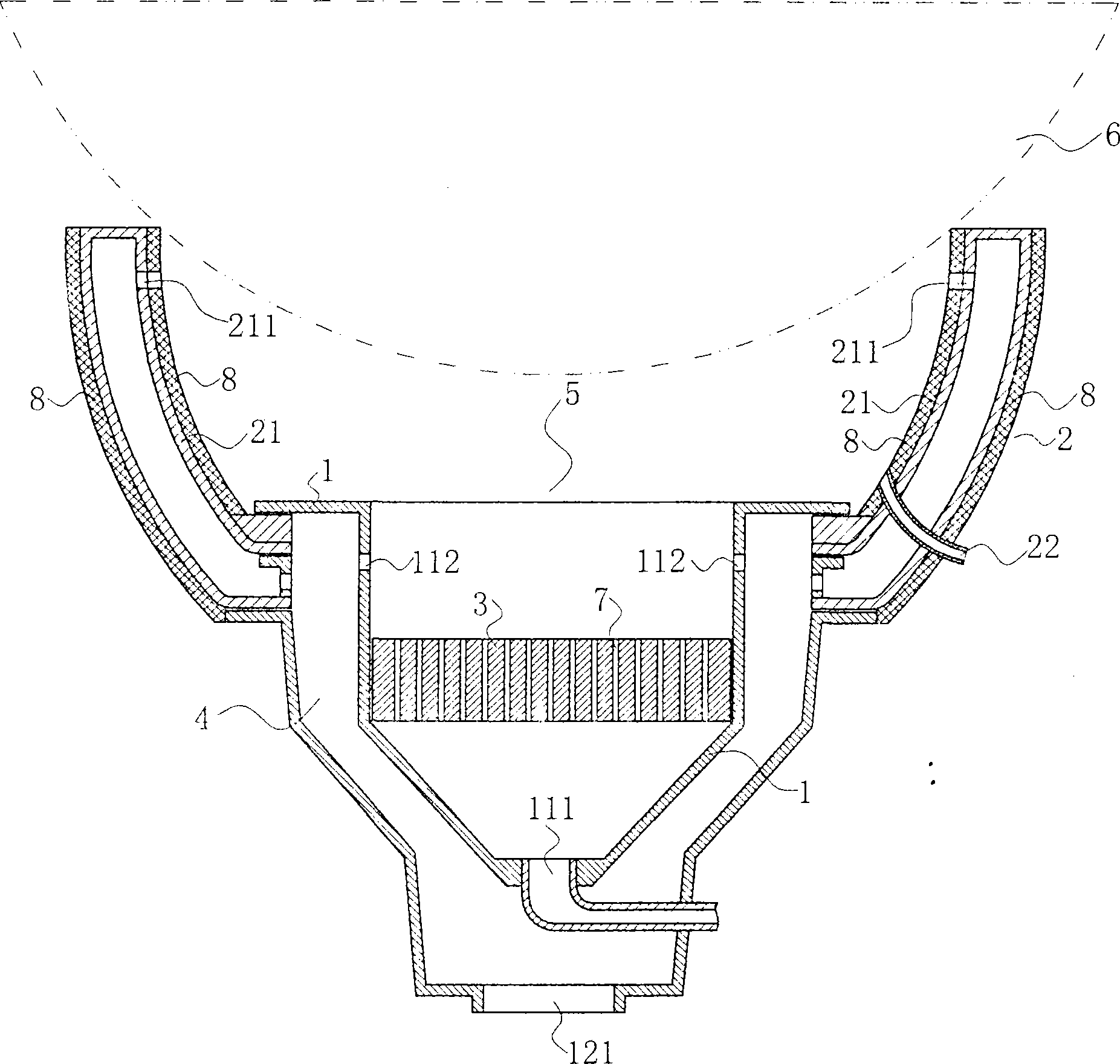

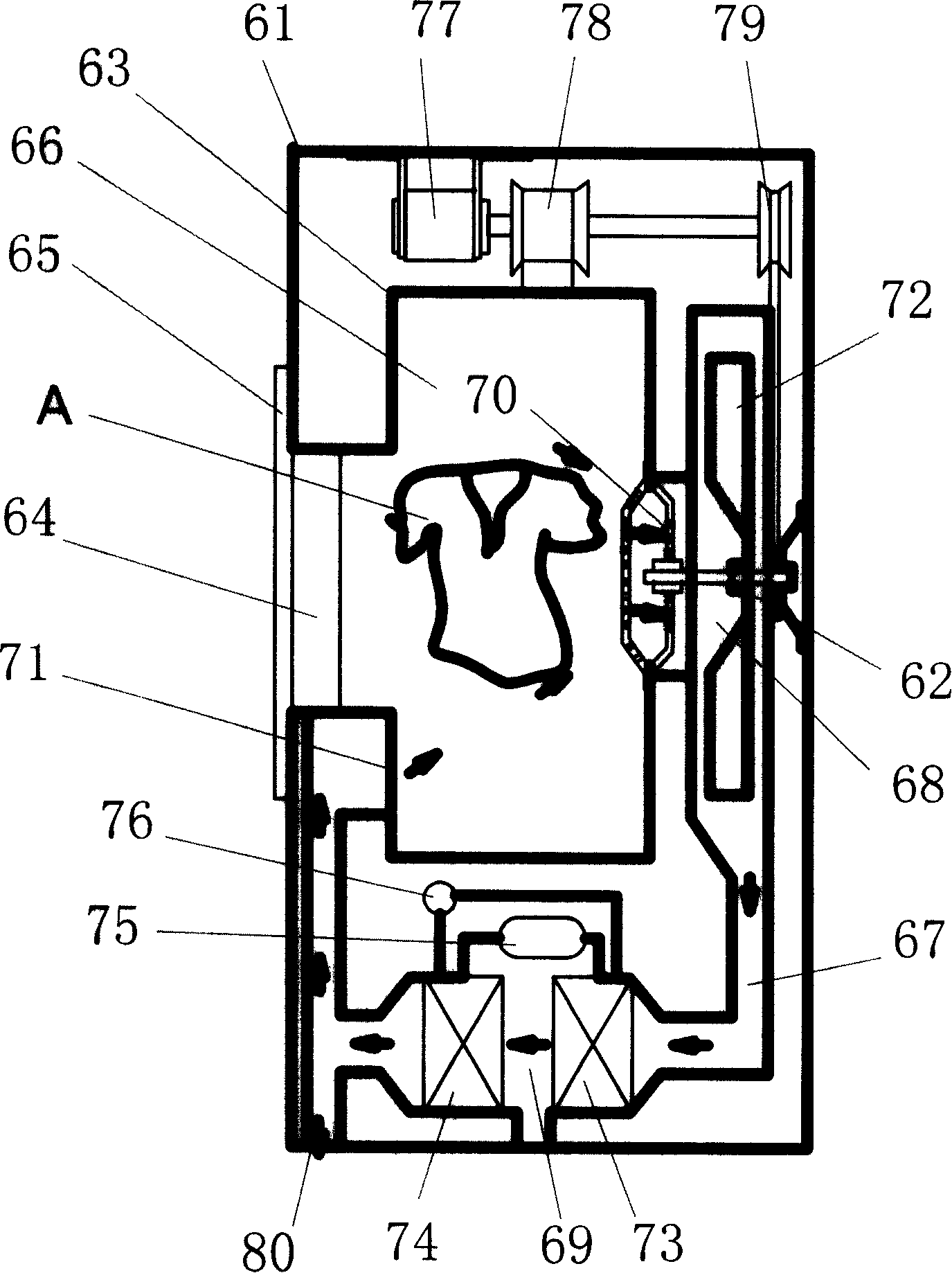

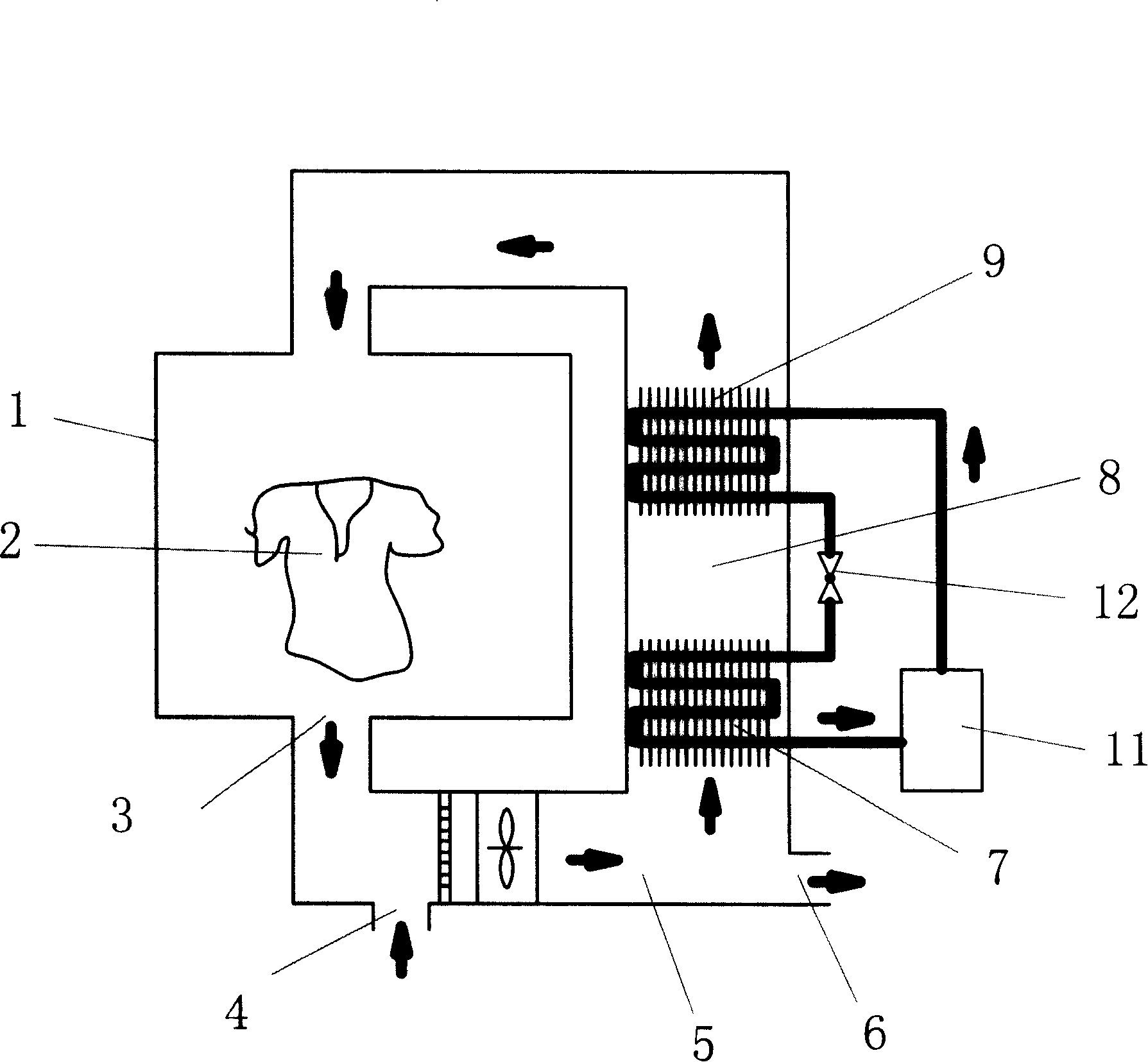

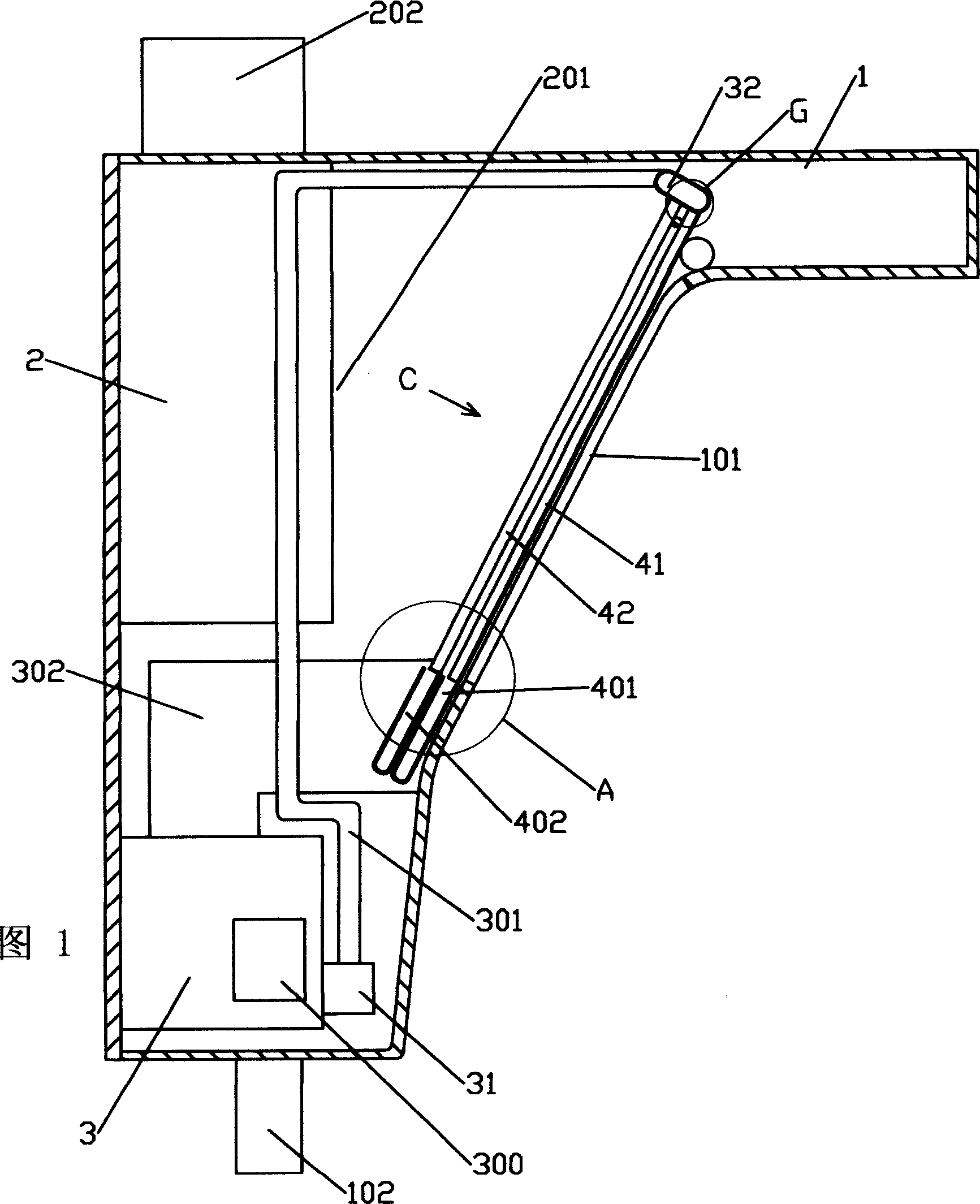

Heat pump clothes drying or clothes drying washing machine

ActiveCN101235587AReduce temperature and pressureReduce the temperatureWashing machine with receptaclesTextiles and paperAir cycleEngineering

The invention relates to a dry cleaning washing machine and in particular relates to a heat pump cloth drying or cloth drying washing machine, which comprises an air circulation channel which is composed of a drying chamber, a blast chamber and a heat exchange chamber, wherein a heat absorber is arranged on one side of the heat exchange chamber which is close to the upper stream, a heat releaser is arranged on one side which is close to the lower stream, the heat absorber and the heat releaser are formed into a heat pump device through a compressor, a capillary tube and the like, an electronic control circuit is arranged, and an air inlet is arranged on the air circulation channel which connects the drying chamber and the heat exchange chamber, wherein an exhausting valve and a water-cooling condenser which are opened outside the machine are arranged on the upper stream of the heat absorber of the heat exchange chamber. When the environmental temperature is lower than a certain value, the control circuit controls the exhausting valve on the upper stream of the heat absorber to open to exhaust hot air outside the machine, when the environmental temperature is higher than a certain value, the control circuit controls the water-cooling condenser to operate, the temperature of air which enters into the heat absorber is lowered, which enables the temperature pressure of gaseous refrigerant which enters into the compressor to be comparatively low, and humid air is not exhausted outside the machine to deteriorate environment in hot summer.

Owner:HAIER GRP CORP +1

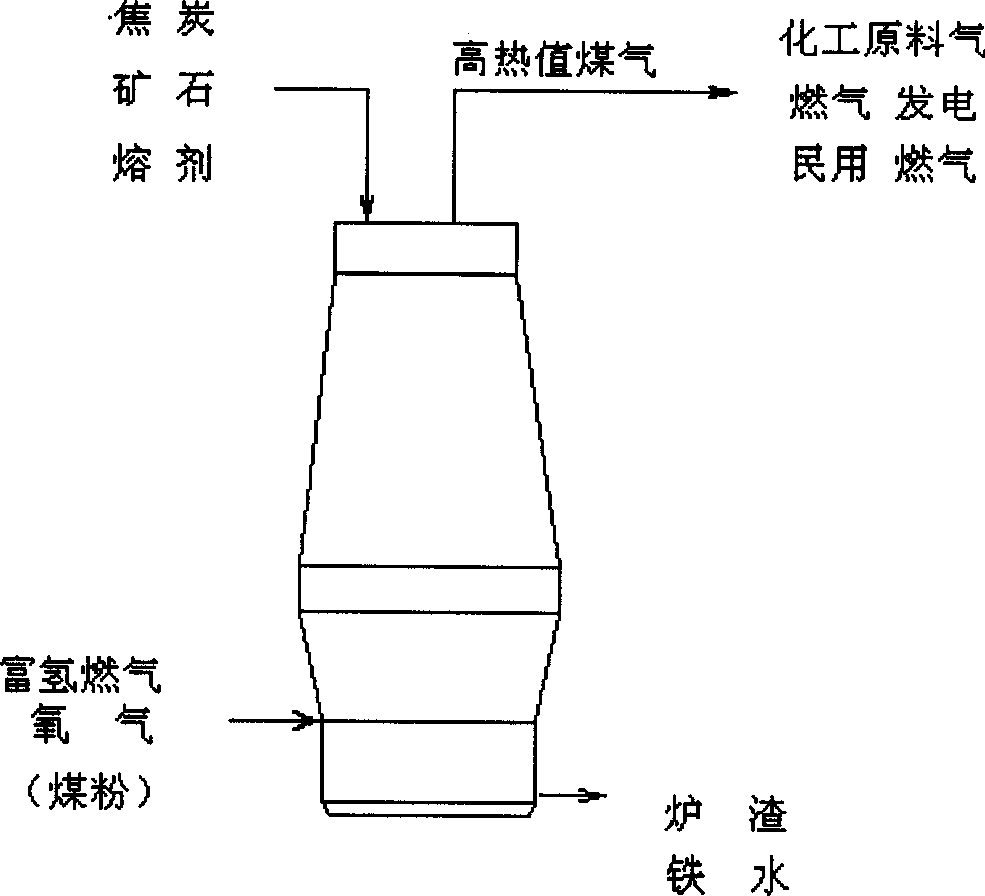

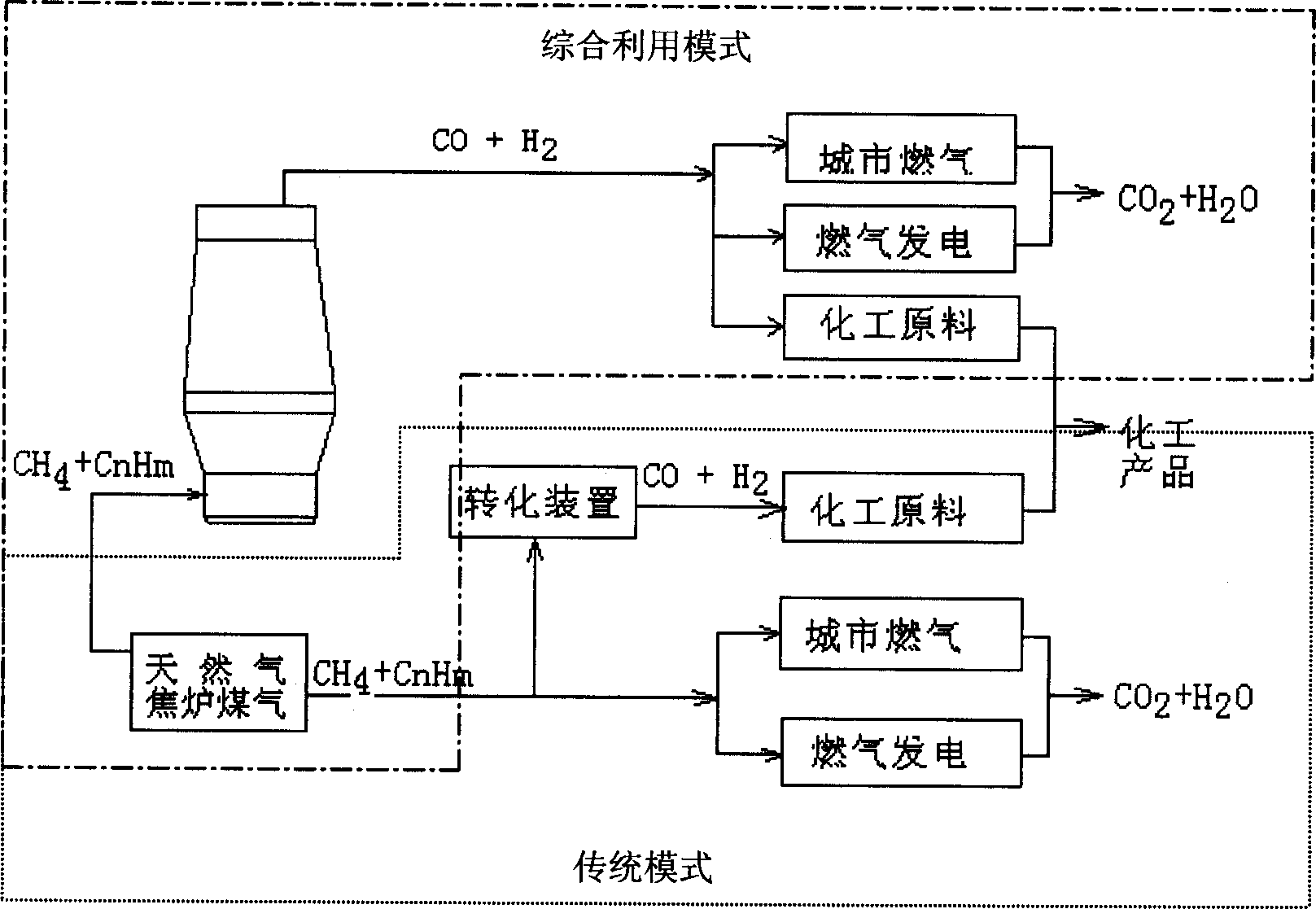

Blast furnace iron-making technique with hydrogen-rich fuel gas, pure oxygen and thus high efficiency and low CO2 exhaust

InactiveCN1487097AReduce focal ratioSolving the Contradiction of Insufficient Heat in the Upper Part of the Blast Furnace due to Less Blast Furnace GasBlast furnace detailsHydrogenCoke oven

The blast furnace iron-making technique includes blowing hydrogen-rich fuel gas in the blast hole of blast furnace of amount 500-1000 cu m / ton iron; normal temperature pure oxygen blasting while eliminating traditional hot blast furnace; gas in bosh containing H2 in 30-60 % except CO; gas in hearth top connecting CO+H2 in 85-95 %; and controlling the theoretic combustion temperature in 1800-2200 deg.c. The blast furnace iron-making technique can lower the blast furnace in 1800-2200 deg.c. The blast furnace iron-making technique can lower the blast furnace coke ratio to below 250 Kg / ton iron, lower CO2 exhaust by 400-600 Kg / ton iron and produce high heat value gas capable of being used as secondary energy source.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Cooking fume remover

InactiveCN1908527AReduce pollutionImprove filtering effectDomestic stoves or rangesLighting and heating apparatusWater circulationSoot

The invention relates to an environment-friendly range hood with simple structure, low cost and capable of effectively separating oil fume, which includes a chassis, a suction channel, an exhaust channel, a fan and a switch, and is characterized in that the fan is located between the suction channel and the exhaust channel Between them, the suction channel and the exhaust channel form a flue; the flue is provided with a number of cooling fins inclined downward along the air inlet direction, and the surface of the cooling fins facing away from the air inlet direction is a water tank set from top to bottom , the lower end of the water tank is connected with the water collection tank, and each cooling fin forms a row of cooling grids on the same plane along the radial direction of the flue, and there is a tuyere between adjacent cooling fins, and a leaking pipe is fixed on the upper part of the cooling fin, and the leaking pipe There are water leakage holes corresponding to the water tanks of each cooling fin; the water tank, water pump, leaking pipe, cooling fin water tank and water collection tank fixed in the chassis form a water circulation loop.

Owner:麦广海

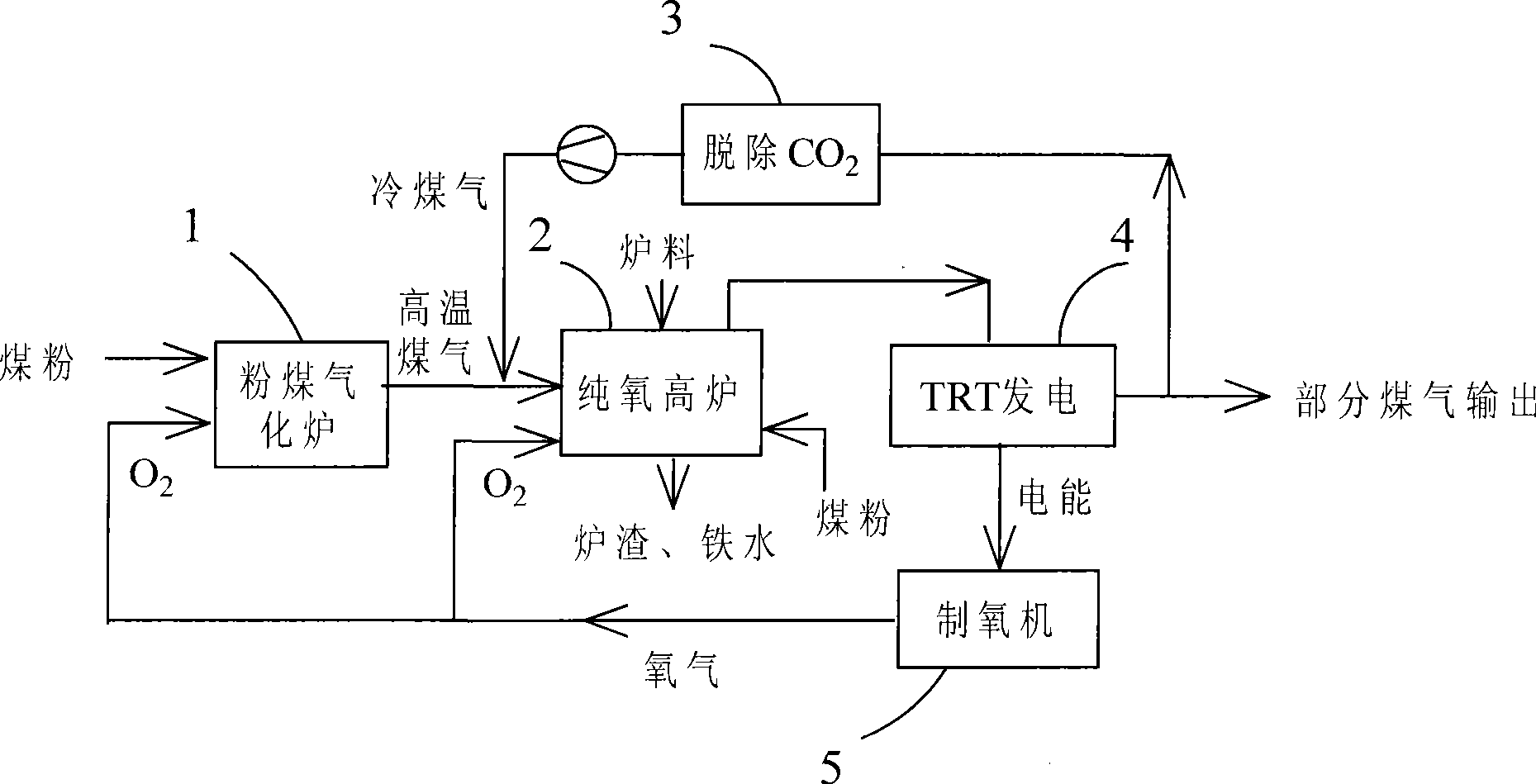

Low-coke-ratio blast furnace ironmaking technique

ActiveCN101519703AReduce energy lossAvoid heating carbon precipitation reaction failureBlast furnace detailsProduction ratePollutant emissions

The invention relates to a low-coke-ratio blast furnace ironmaking technique. Dry coal powder is pressurized and gasified in a separate gasification furnace, the dry coal powder is injected into the gasification furnace to be sufficiently mixed with pure oxygen, burnt and gasified to produce high-temperature coal gas, the pressure in the gasification furnace is 0.3MPa to 0.6MPa, and the temperature of the coal gas at the outlet is 1300 DEG C to 1550 DEG C; the coal gas at the outlet of the gasification furnace is mixed with the purified cold coal gas at the blast furnace top, and the temperature is controlled at 900 DEG C to 1050 DEG C; the high-temperature high-reducibility hot coal gas is then injected into the lower part of the body of the blast furnace, that is, the area above the root of a cohesive zone, so that the metallization ratio of charging can reach 85 percent to 95 percent when reaching the cohesive zone; and part of the coal powder is injected from the tuyere of the blast furnace to be subjected to pure oxygen combustion. The invention, which is a novel blast furnace ironmaking technique taking dead coal and oxygen as main energy sources, can reduce the coke ratio of the blast furnace to be less than 200kg, greatly increase the productivity of the blast furnace and reduce the emission of coke-making pollutant, thus enhancing the competitiveness of the blast furnace ironmaking technique.

Owner:XINJIANG BAYI IRON & STEEL

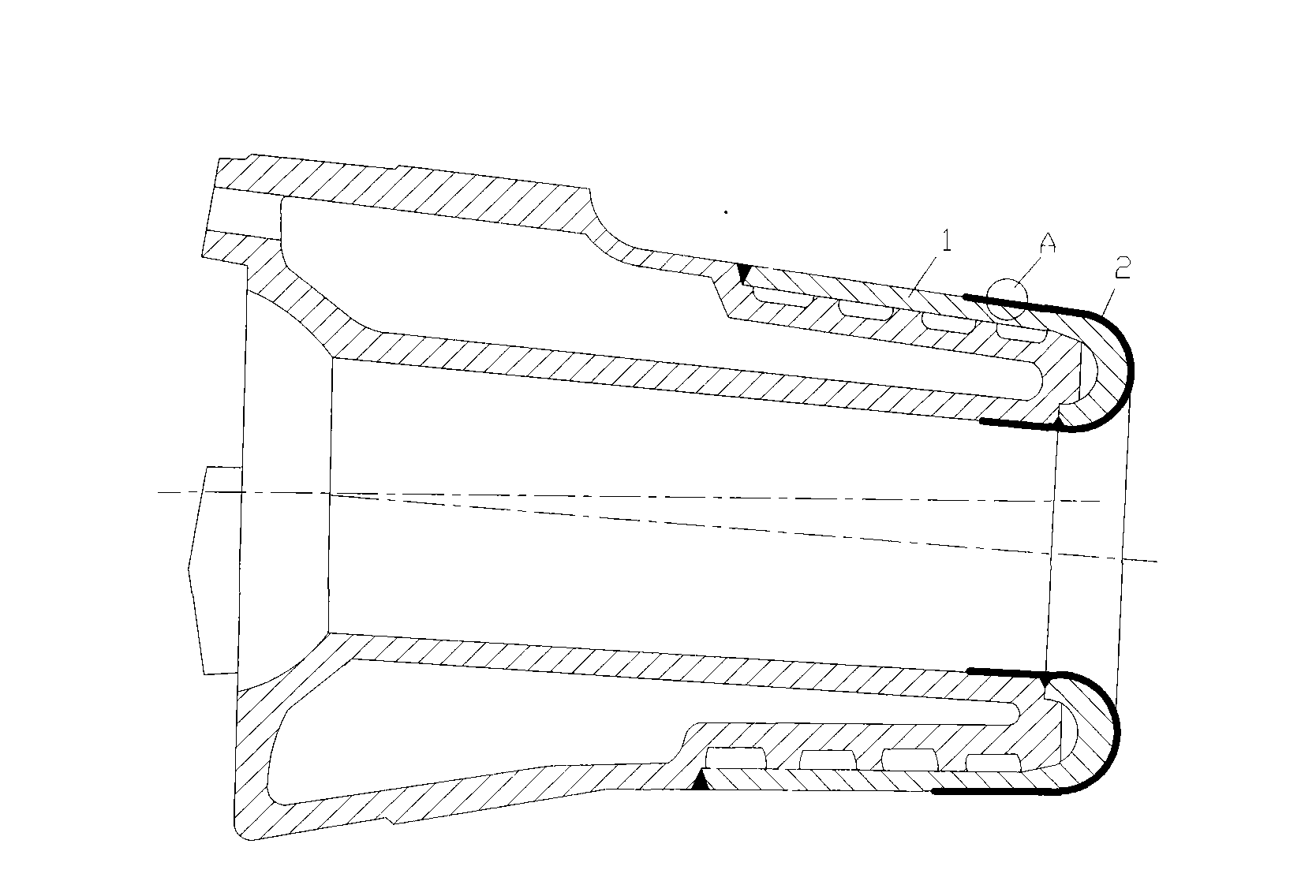

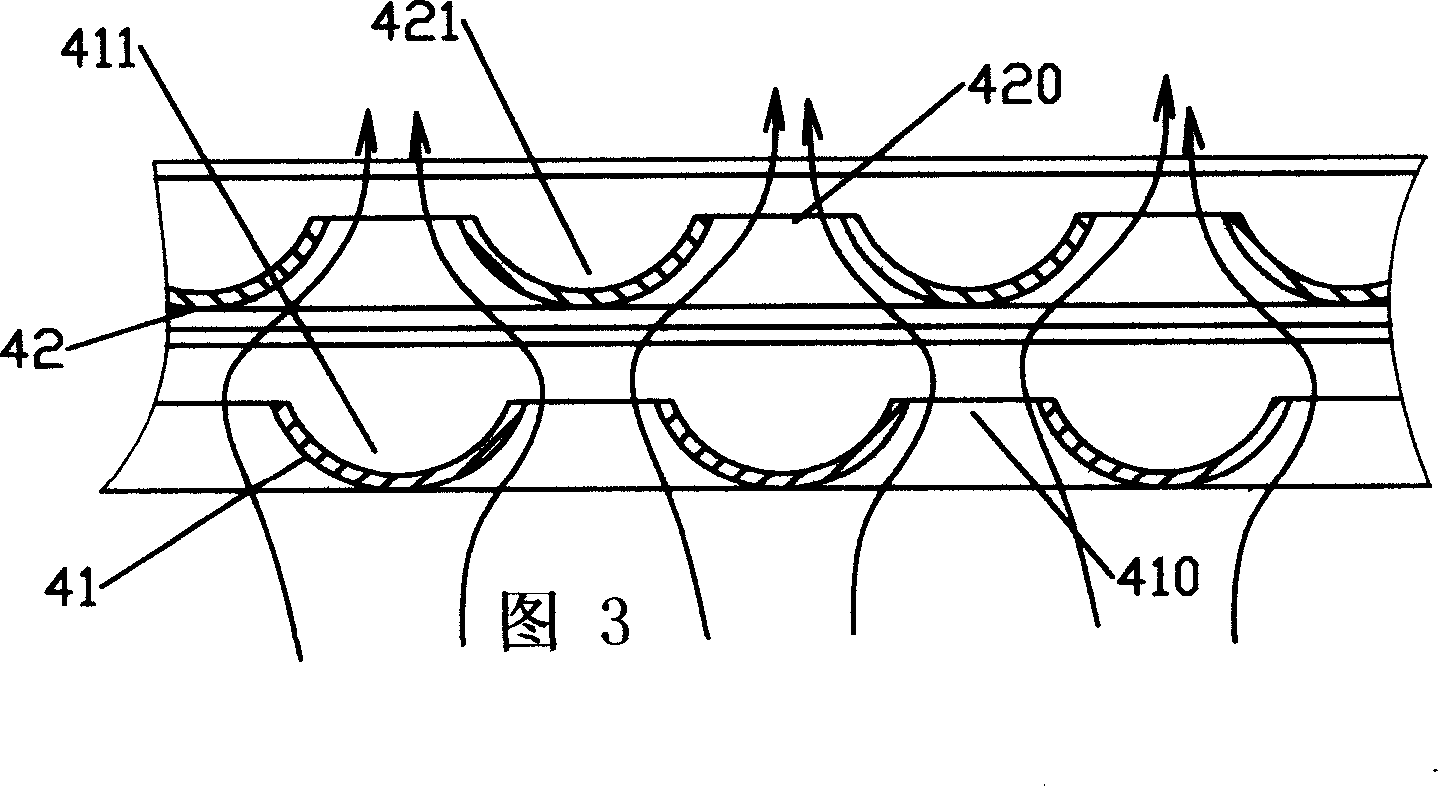

Atomizing nozzle structure of high-temperature high-voltage air flow dyeing machine and control method thereof

InactiveCN102080318AGood level dyeingSuitable for processing environmentLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine partsSpray nozzleHigh pressure

The invention discloses an atomizing nozzle structure of a high-temperature high-voltage air flow dyeing machine and control method thereof. The nozzle structure comprises a front nozzle cover, an inner main stream pipe, a rear nozzle head and a sleeve, wherein the sleeve is sleeved outside the inner main stream pipe, and two ends of the sleeve are respectively connected with the front nozzle cover and the rear nozzle head through a connecting piece; the sleeve is provided with an air inlet which is connected with a fan; and the sleeve and the inner main stream pipe form a circular outer chamber atomizing region; a nozzle head is arranged in the outer chamber atomizing region and is fixed on the outer wall of the inner main stream pipe, and the nozzle head is connected with a dye liquid pipeline; and the outer chamber atomizing region is provided with two outlets which are connected with a channel through which the cloth to be dyed passes in the inner main stream pipe. The invention also provides a control method based on the atomizing nozzle structure of the high-temperature high-voltage air flow dyeing machine. According to the types of the cloth to be dyed, the number of the nozzle heads started in the nozzle structure, the flow rate of the nozzle heads, the air flow of the fan and the temperature process curves adopted are defined. According to the invention, the levelling property is high, and the problem of cloth blocking can not happen.

Owner:高勋绿色智能装备(广州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com