Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9532 results about "Constant speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Constant Speed. If an object moves so that its instantaneous speed is always the same, it is moving with constant speed. Notice that, if the speed is constant, instantaneous speed equals average speed.

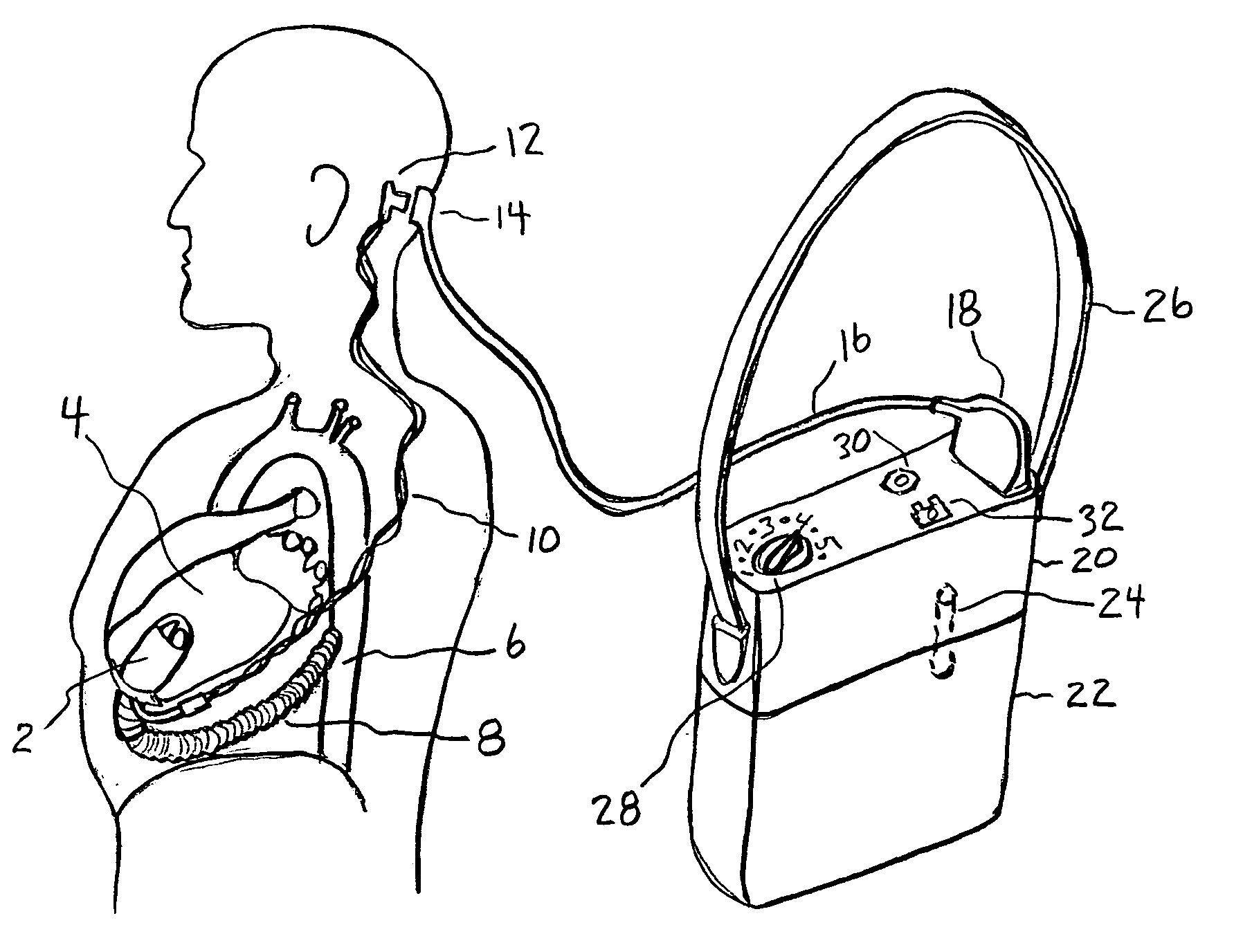

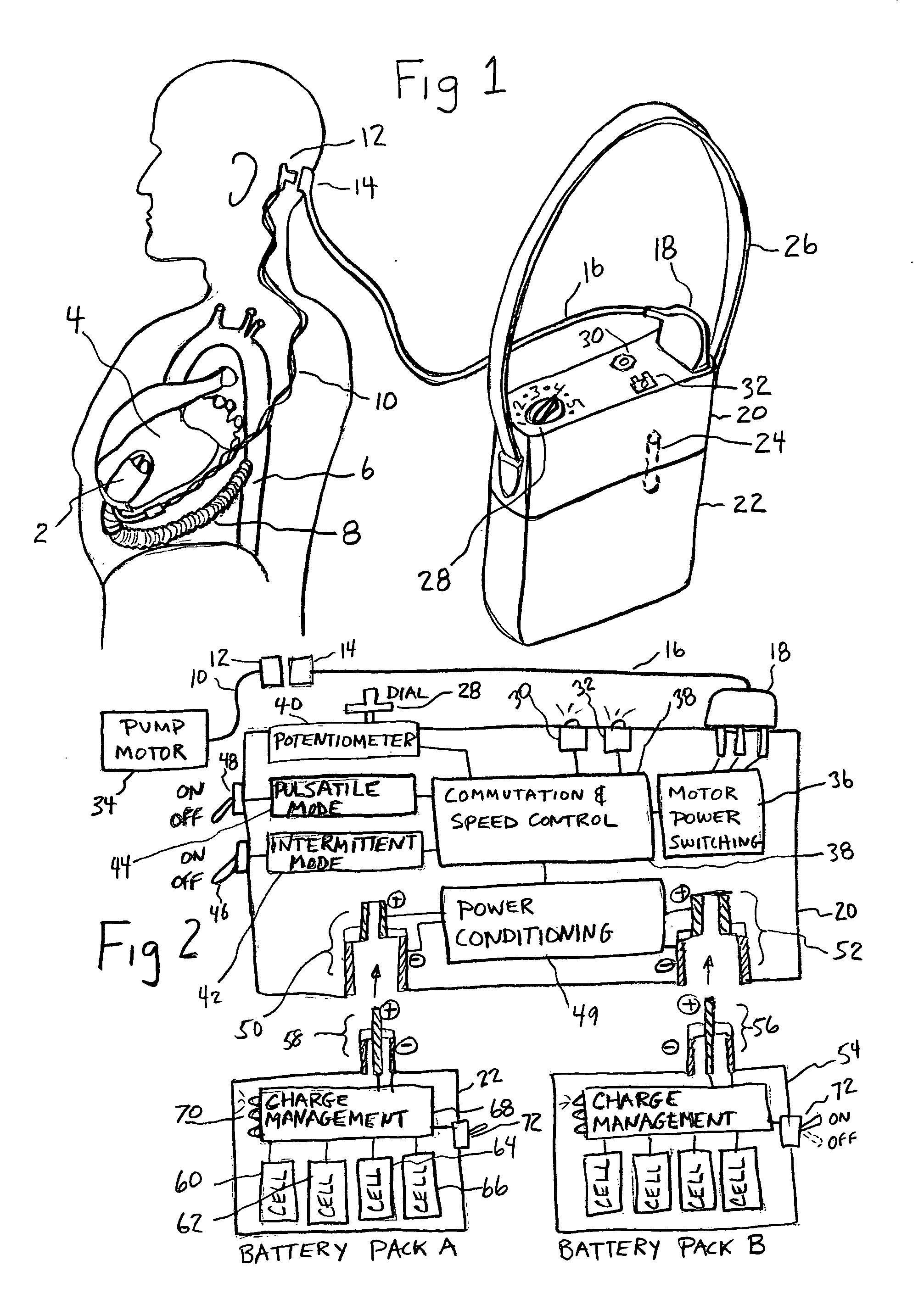

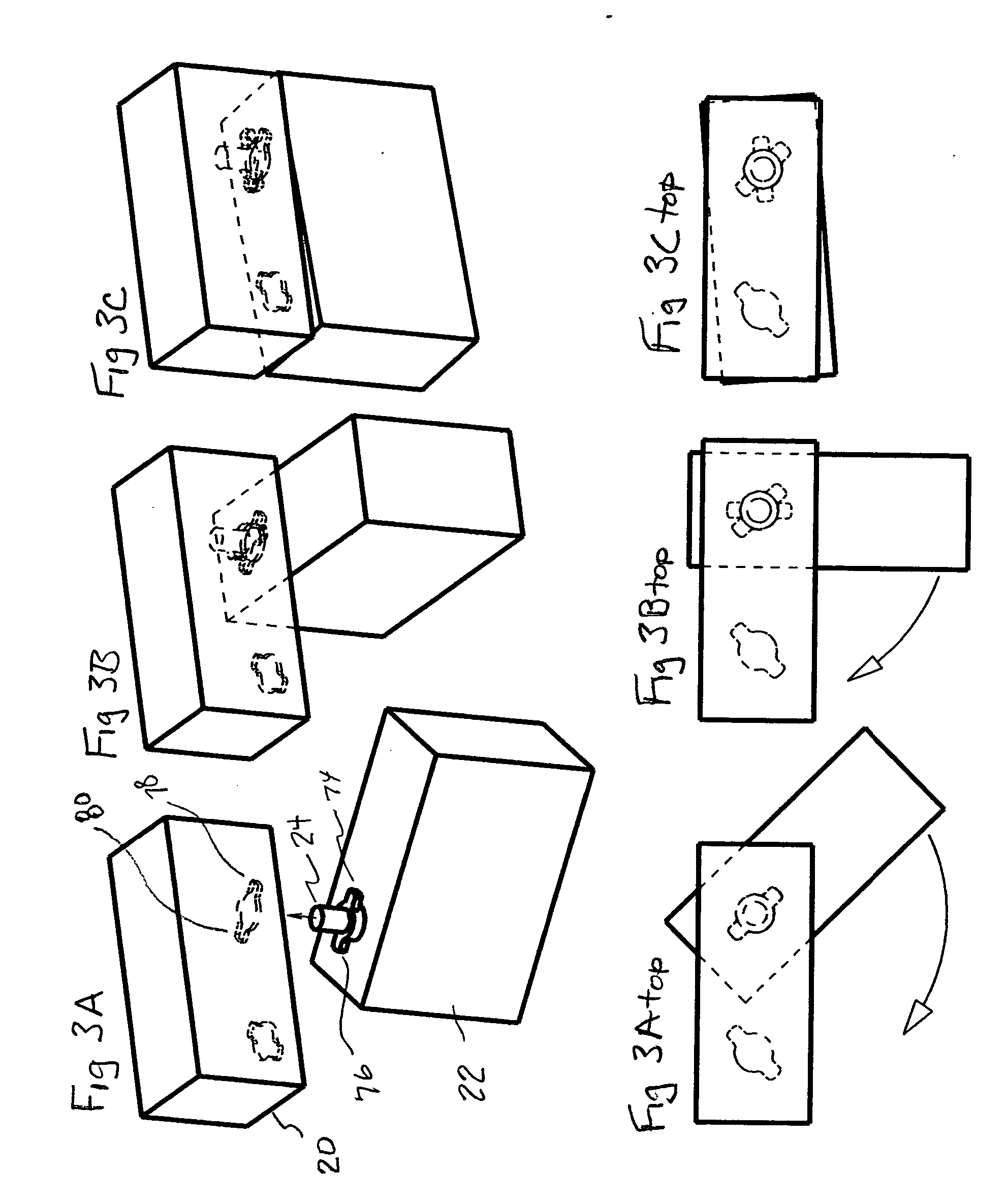

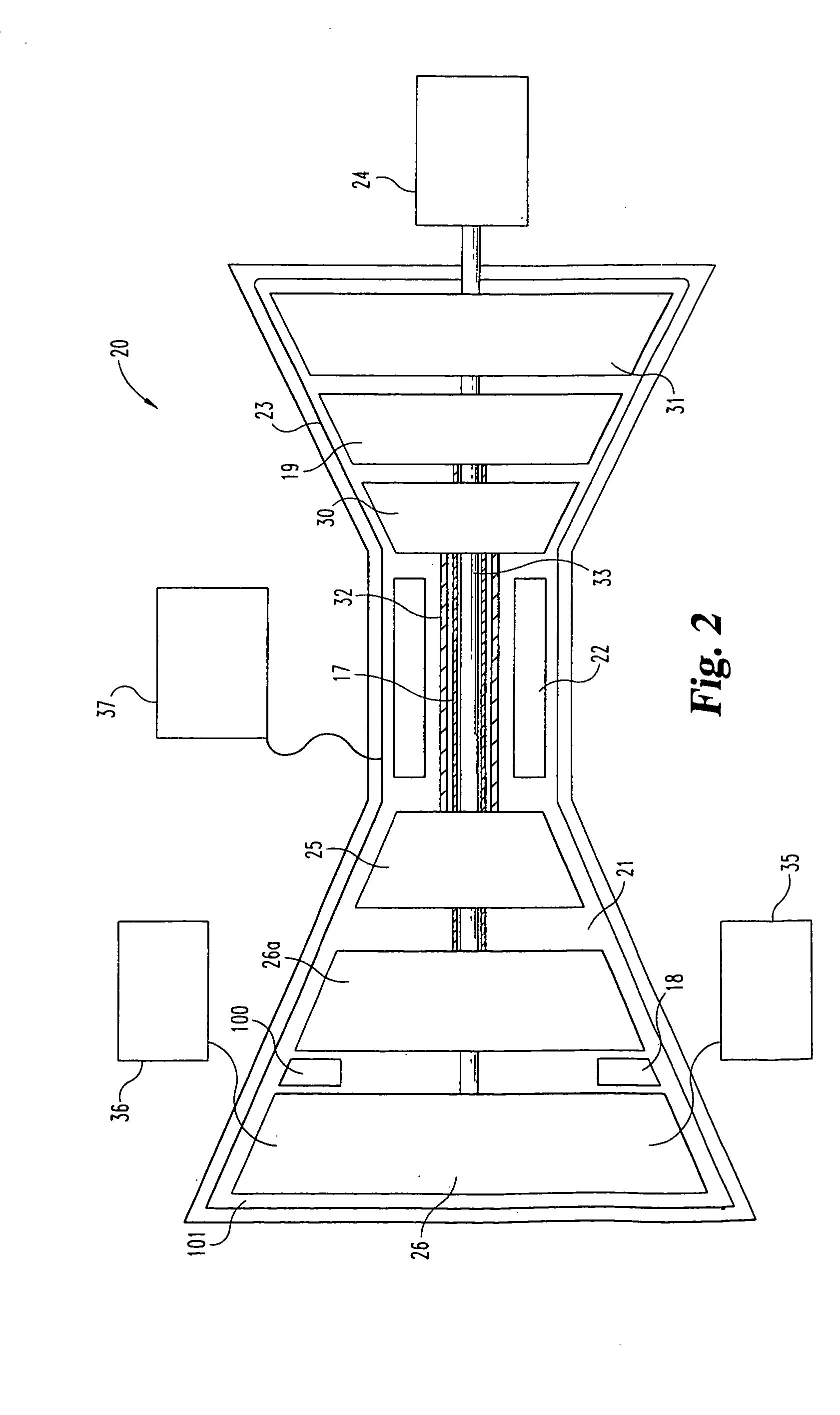

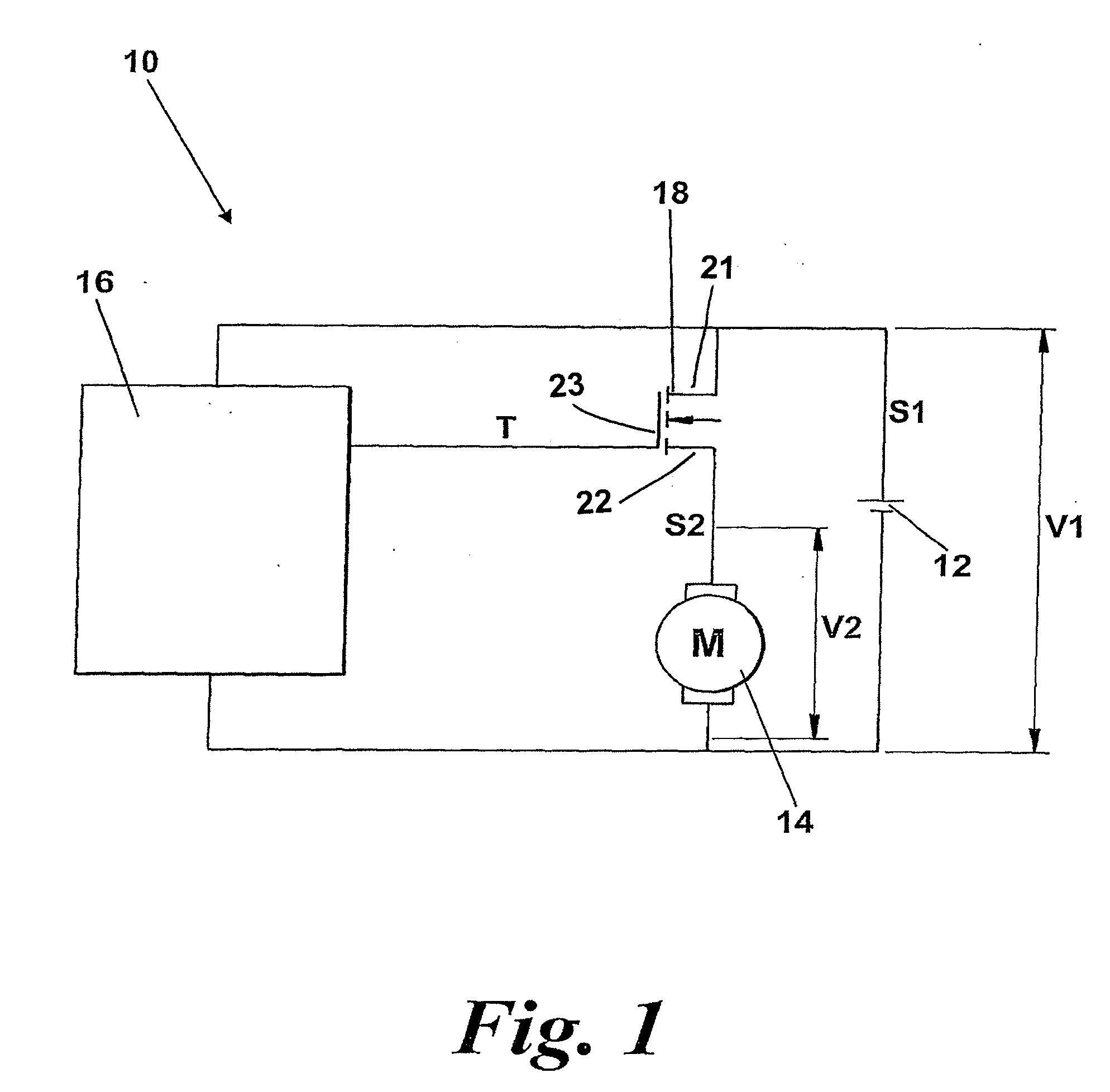

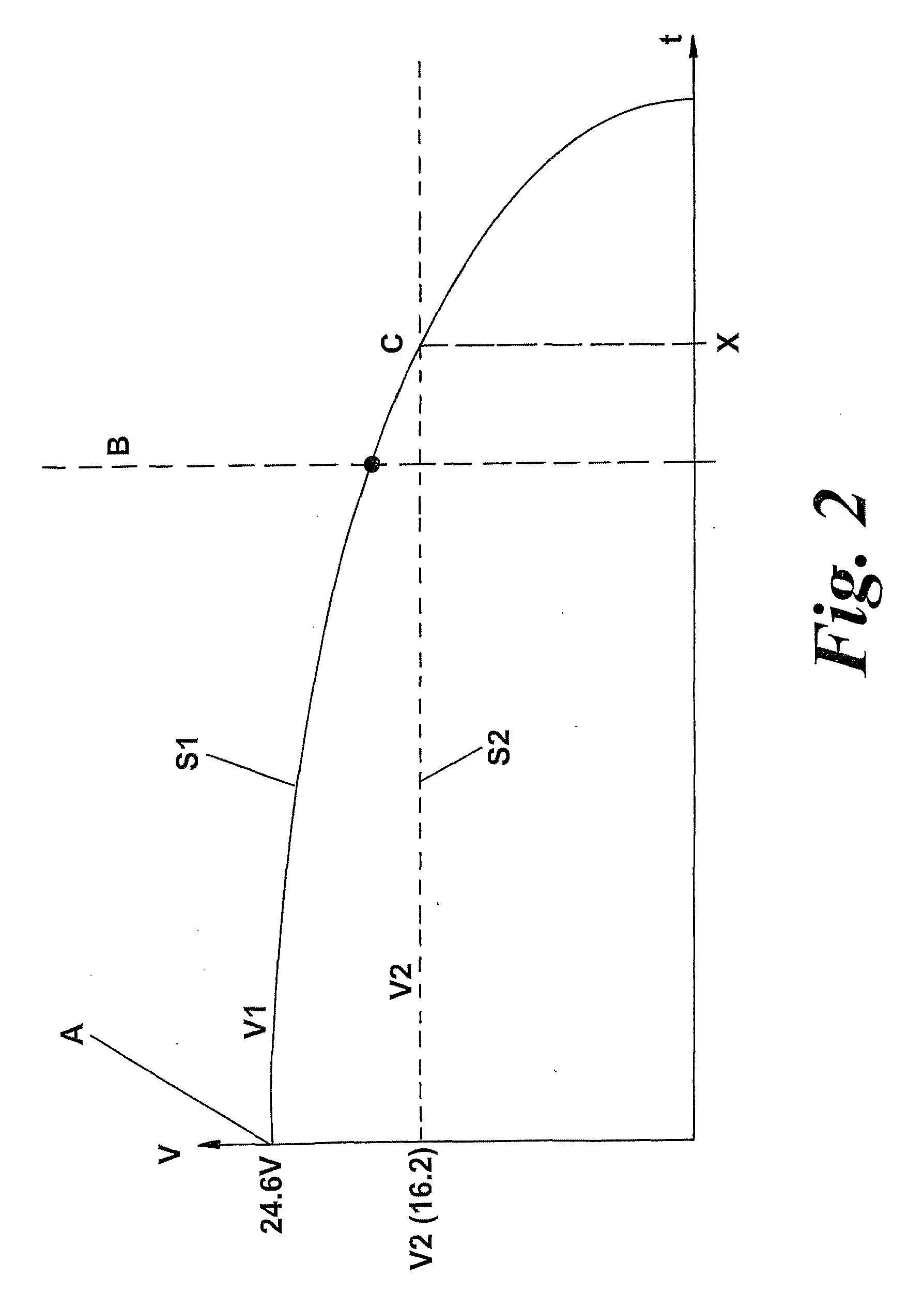

Artificial heart power and control system

InactiveUS20050071001A1Secure attachmentReduce trafficPrimary cell maintainance/servicingControl devicesControl theoryElectric cables

The present invention provides a human engineered power and control system for artificial hearts or assist devices configured for ease of use, ruggedness, and high reliability. Battery powered systems of the prior art have required multiple cables and connectors that are subject to failure due to damage or wear. In the present invention, direct connection of the batteries to the control system eliminates multiple cables and connectors used with previous designs. A novel method of connecting batteries to the control system and exchanging batteries without interruption of power is provided in a compact user friendly configuration. The control system may provide periodic reductions in assist device flow to permit the natural ventricle to eject blood through the natural outflow valve, open the valve leaflets to prevent them from adhering together, and achieve sufficient washout to prevent thrombosis. Using either software based control or software independent electronic circuitry, the flow pumped by the artificial heart is reduced for a long enough period of time to permit at least a few beats of the natural heart to generate sufficient pressure to open the outflow valve. In a control system embodiment in which the patient manually adjusts the pump speed to incremental settings for rest and exercise conditions, a pulsatile flow mode is disclosed which provides approximately the same flow at a given incremental setting as the pump produces when running in a constant speed mode at the same setting. As the patient learns which speed setting is best for daily activities, the patient may use the same setting with either a pulsatile or constant pump speed mode.

Owner:EDER JEFFREY

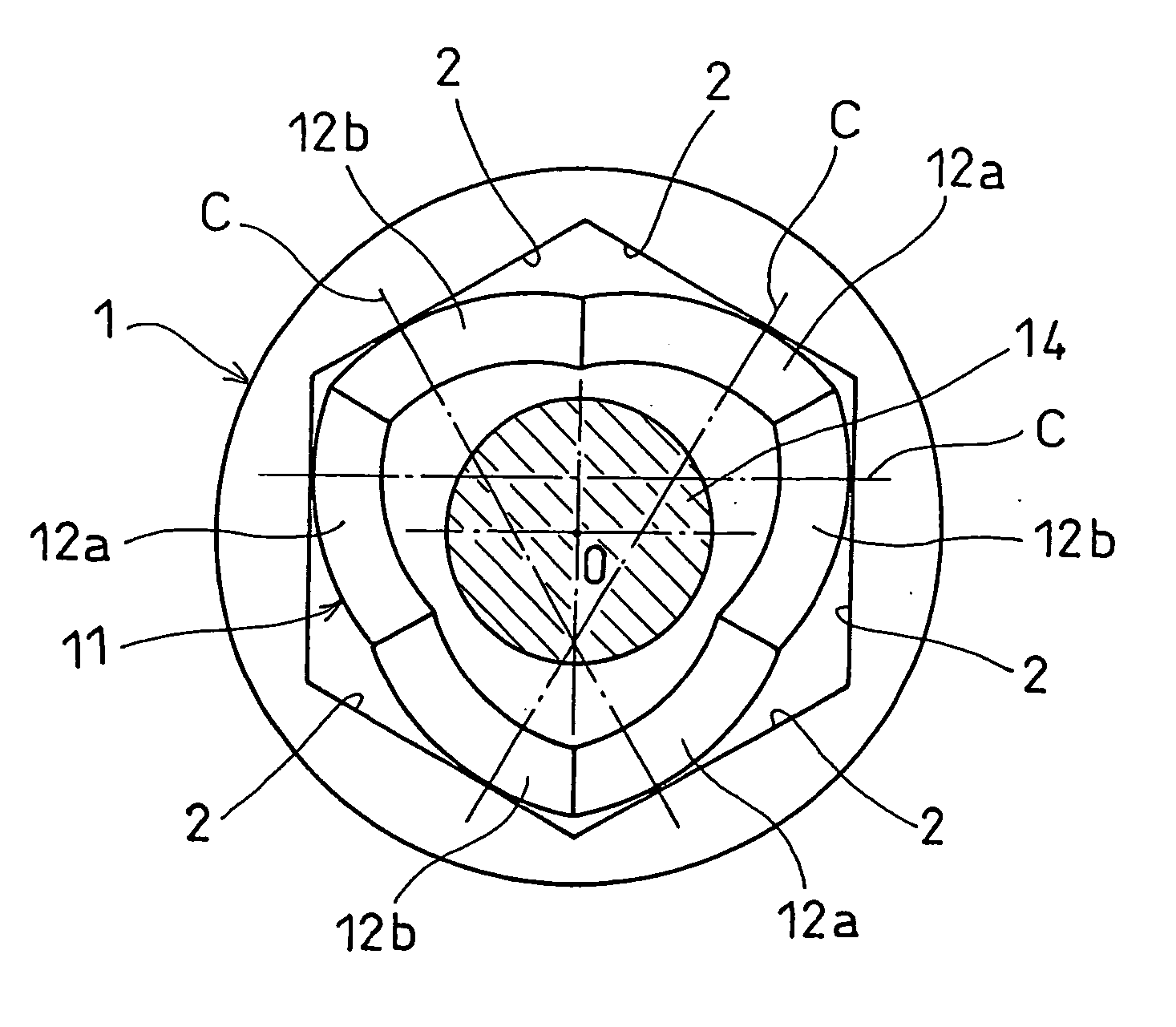

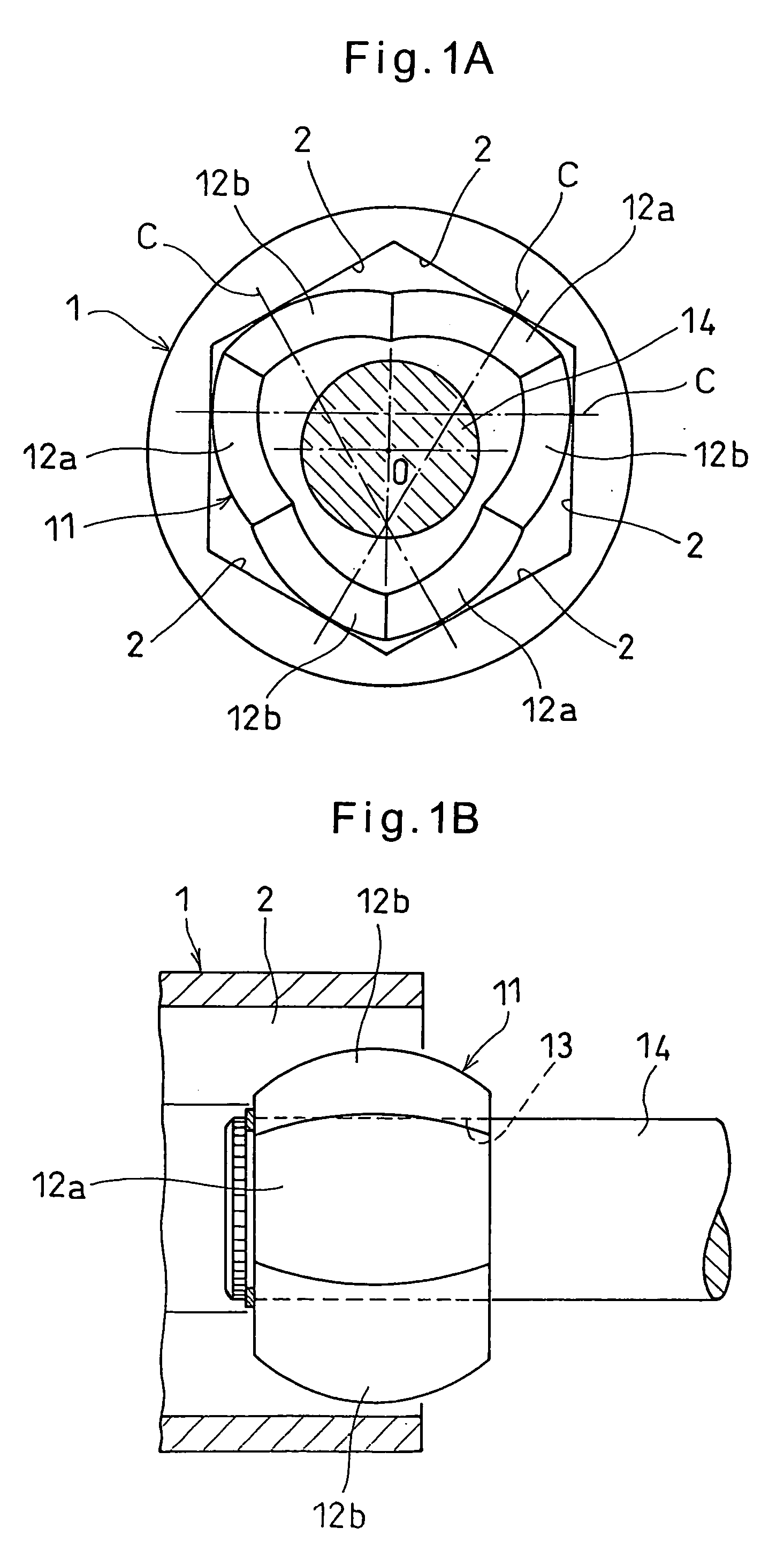

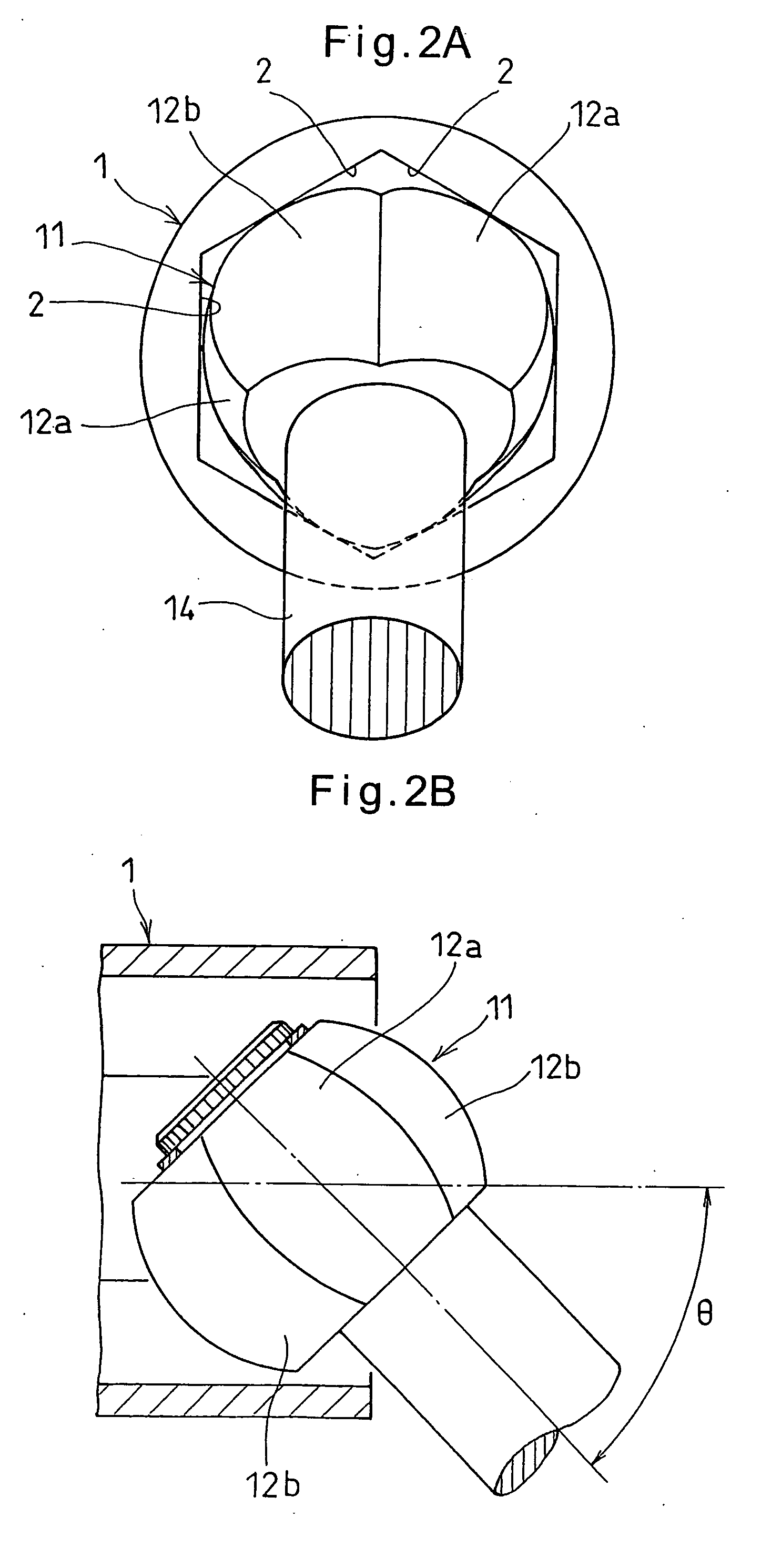

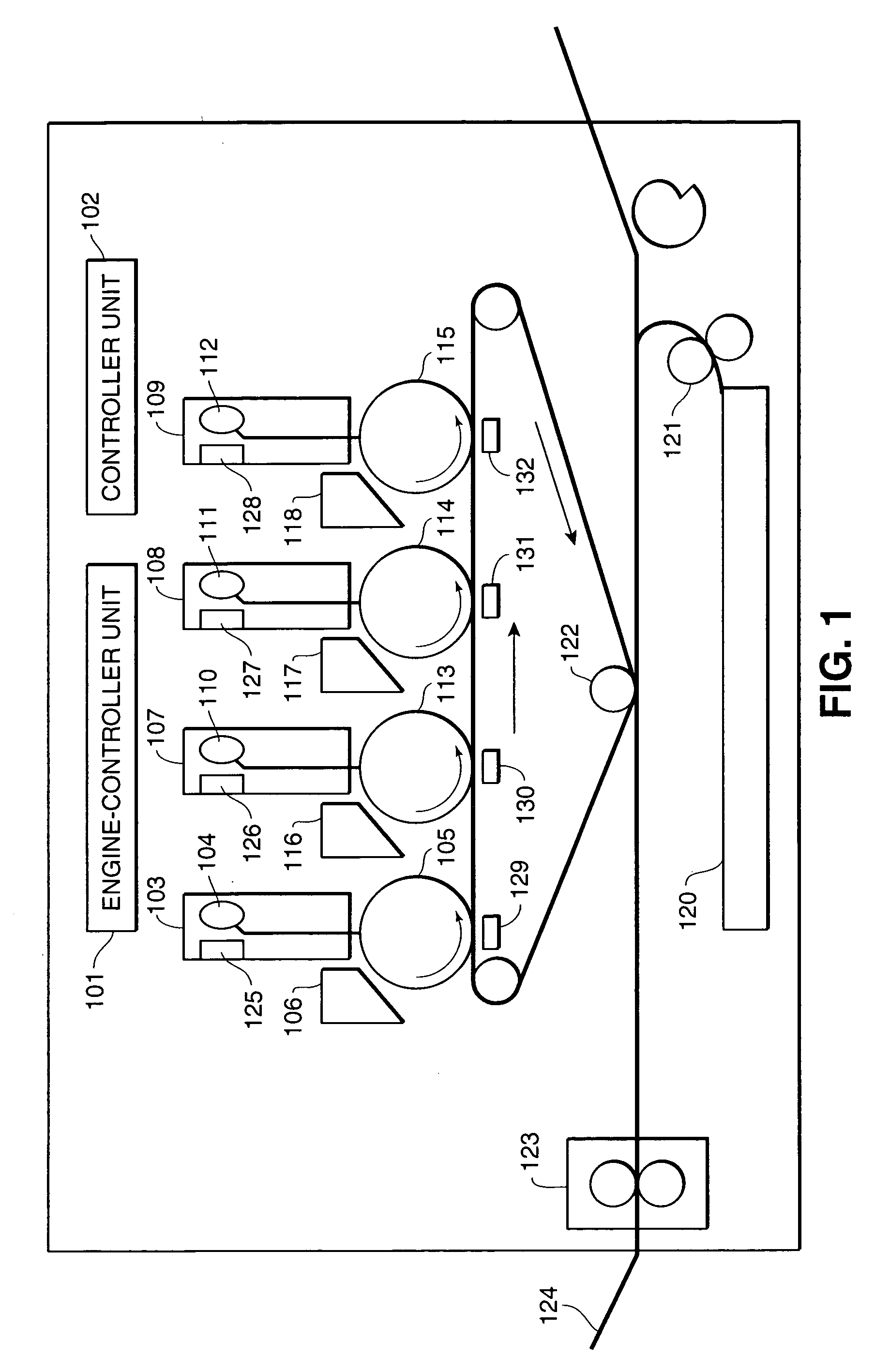

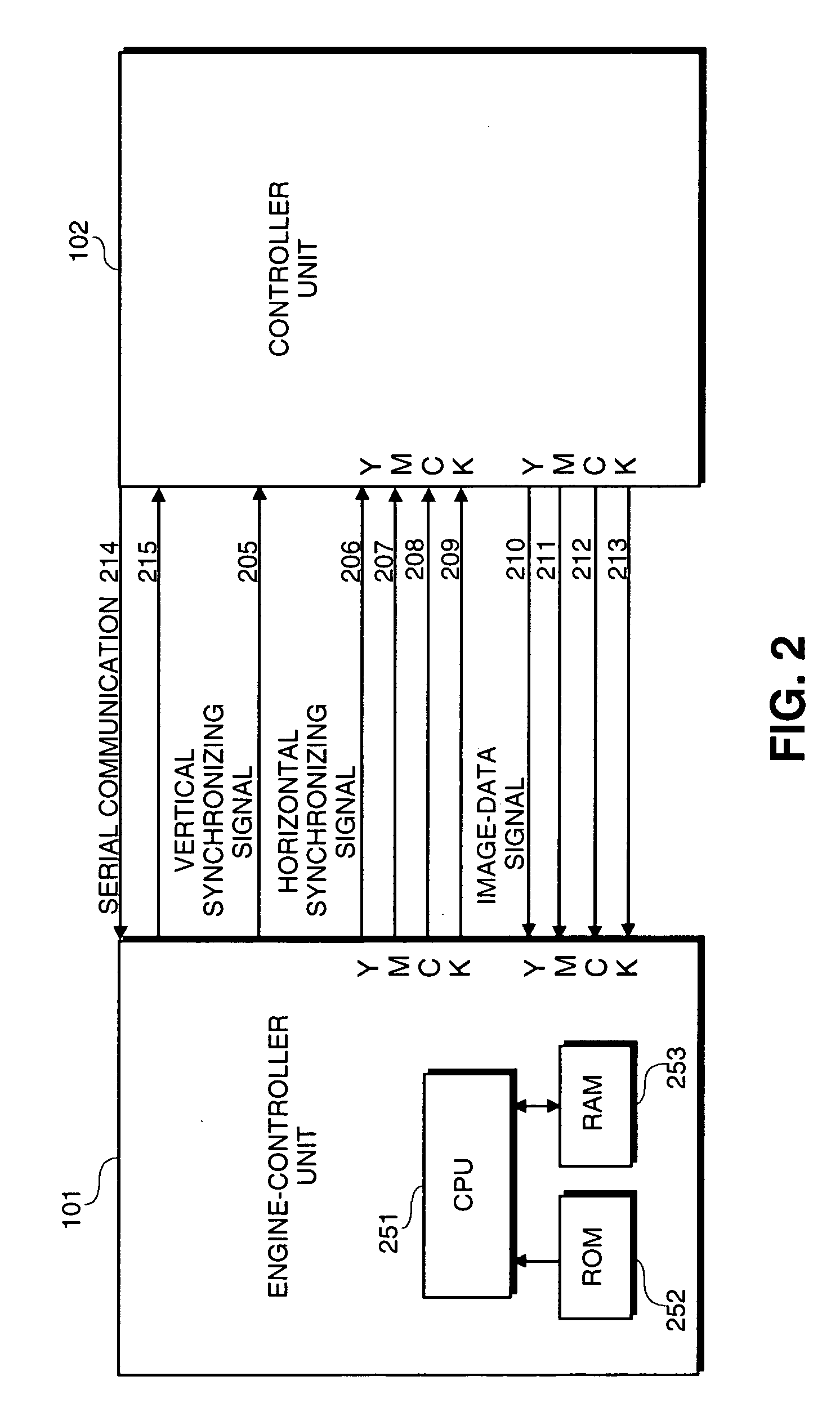

Constant-velocity joint and image forming device

InactiveUS20060240896A1Prevent leakageReduce noiseYielding couplingCouplings for rigid shaftsEngineeringSynthetic resin

A constant-velocity joint includes an outer ring formed formed with a bore defined by six flat surfaces parallel to its axis, and a trunnion member received in the bore of the outer ring. The trunnion member has an outer periphery formed with three first spherical surfaces circumferentially spaced apart from each other and three second spherical surfaces circumferentially spaced apart from each other and each disposed between adjacent first spherical surfaces. Each first spherical surface is in contact with one of the flat surfaces at a point offset from the circumferential center of the flat surface in one circumferential direction. Each second spherical surface is in contact with another flat surface at a point offset from the circumferential center of the flat surface in the other circumferential direction. At least one of the outer ring and the trunnion member is made of a synthetic resin.

Owner:NTN CORP

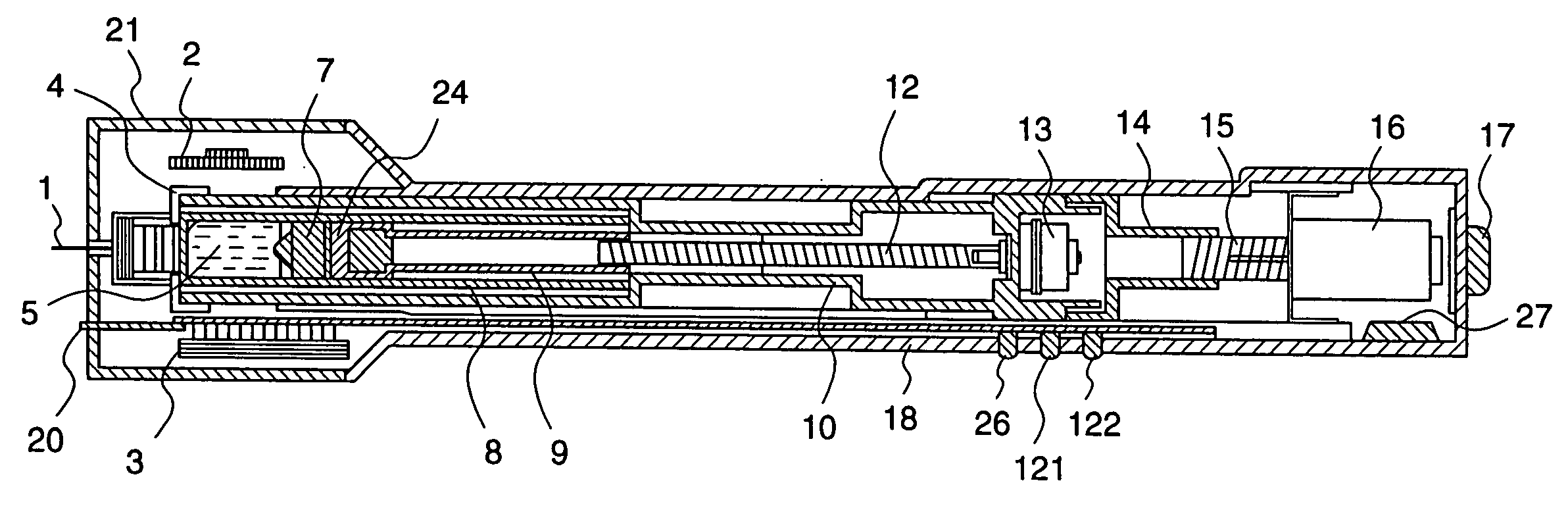

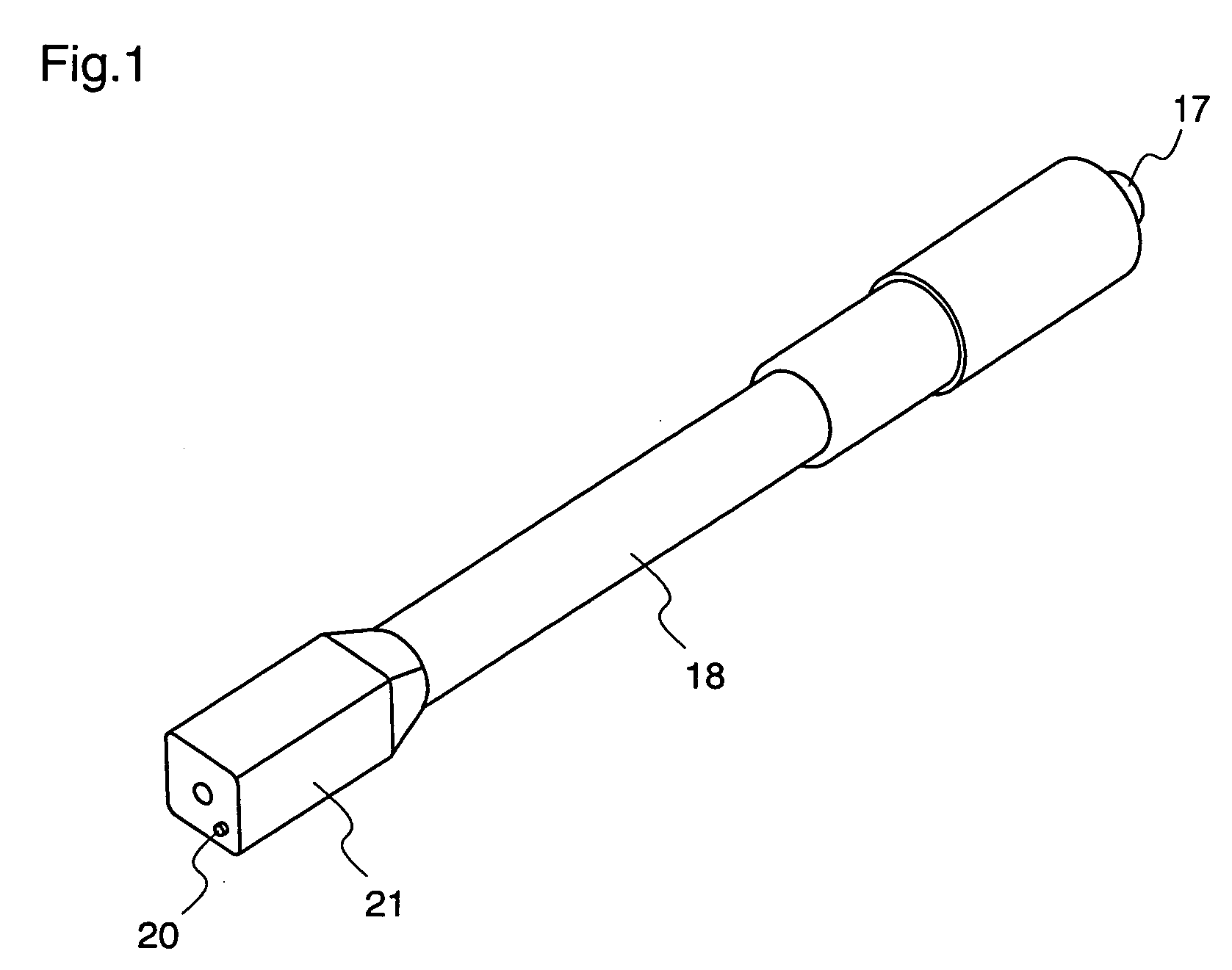

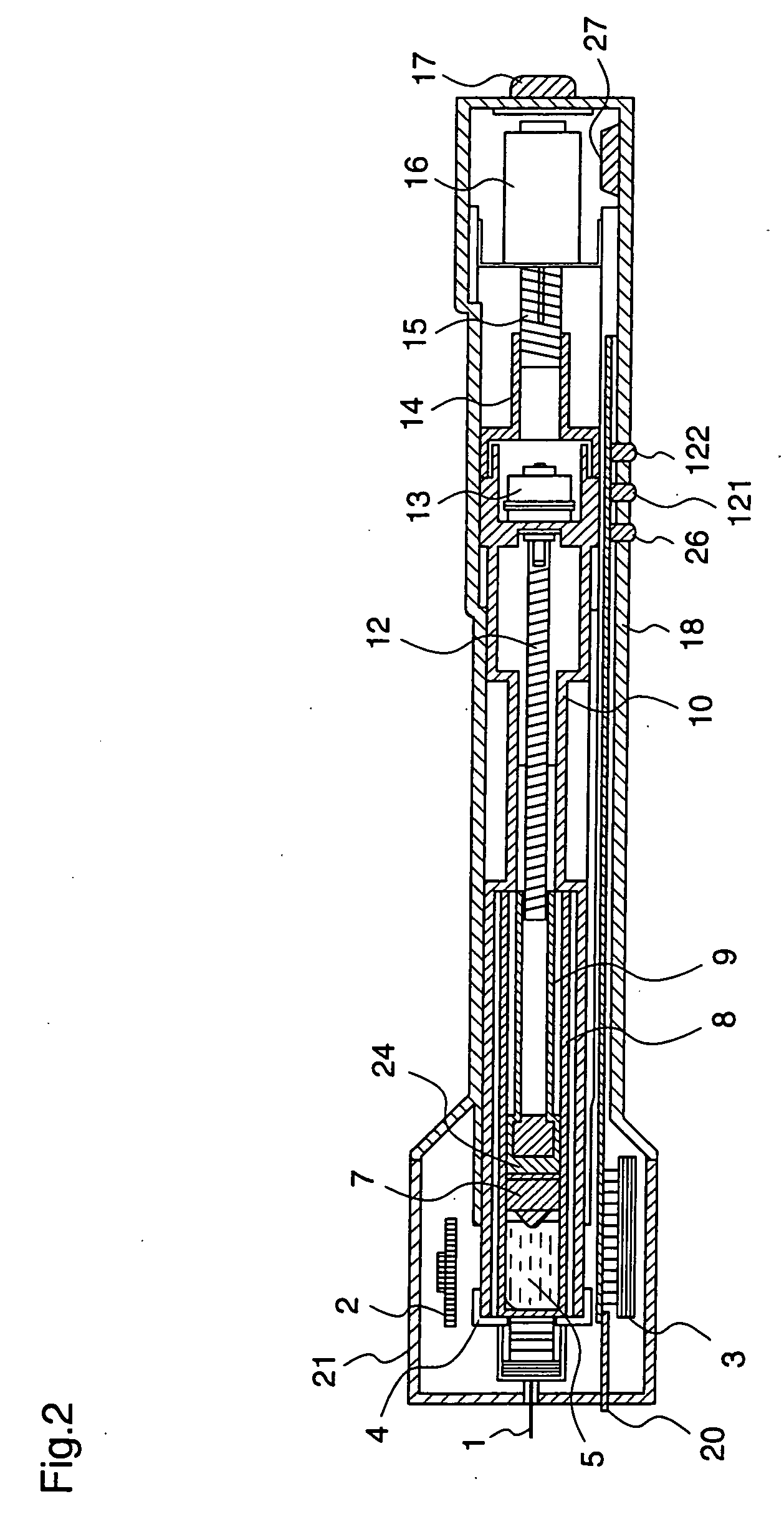

Medical automatic medicator

ActiveUS20050209569A1Control depthReduce painAmpoule syringesAutomatic syringesDrugs solutionNeedle insertion

After pressing a part of the exterior of a body of an administration instrument against a body region of a patient to which a drug solution is to be administered, an injection needle that is housed in the instrument body is automatically protruded from the body to insert the needle into the body region, and further, the injection needle being inserted into the body region is automatically housed in the instrument body to remove the needle from the body region. Thereby, the pain of the patient during needle insertion and needle removal is reduced, and administration at a constant speed is possible during injection of the drug solution. Furthermore, even when two kinds of drug solutions or a dissolving and mixing type drug solution are / is used, mixing can be easily and reliably carried out.

Owner:PHC HLDG CORP

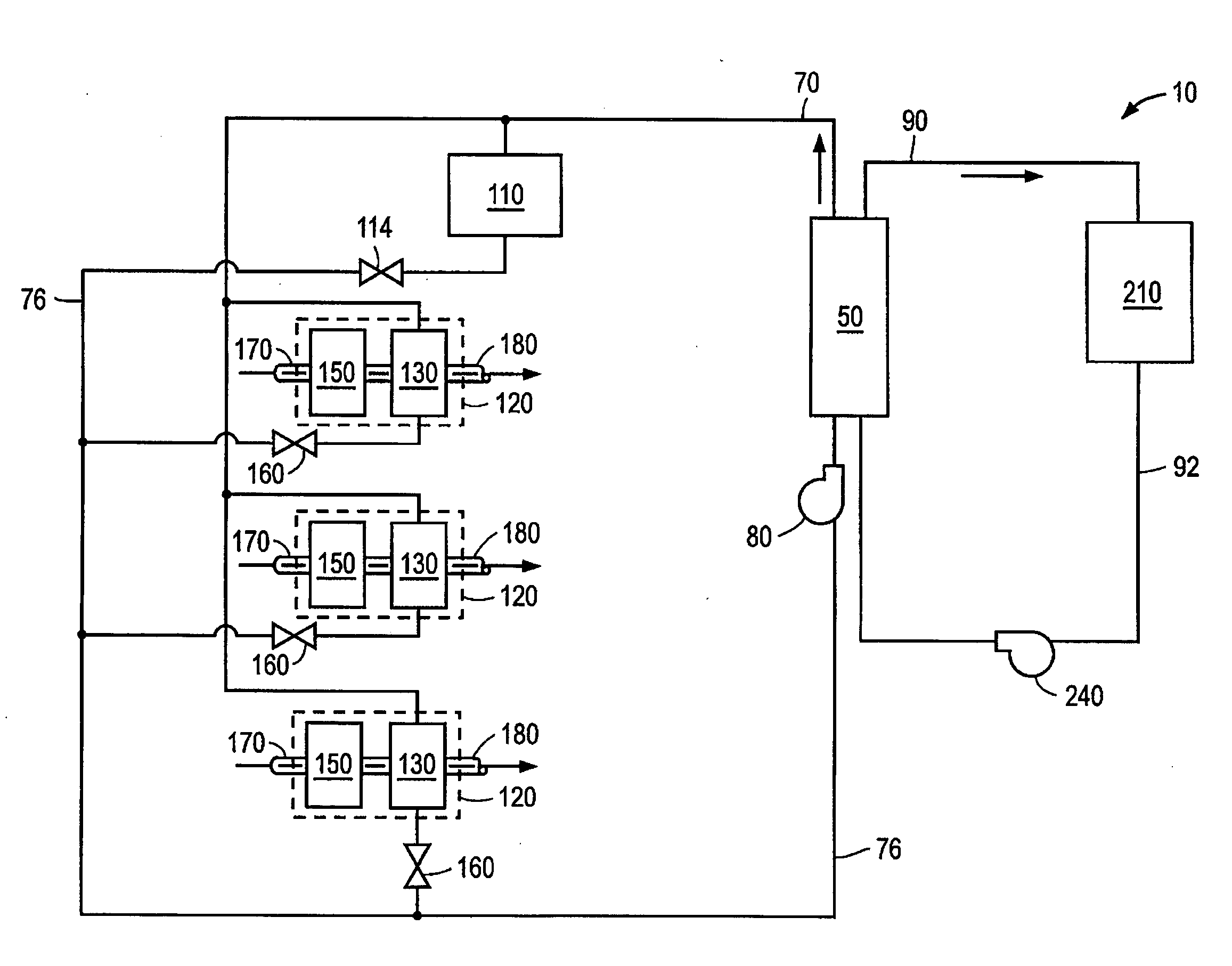

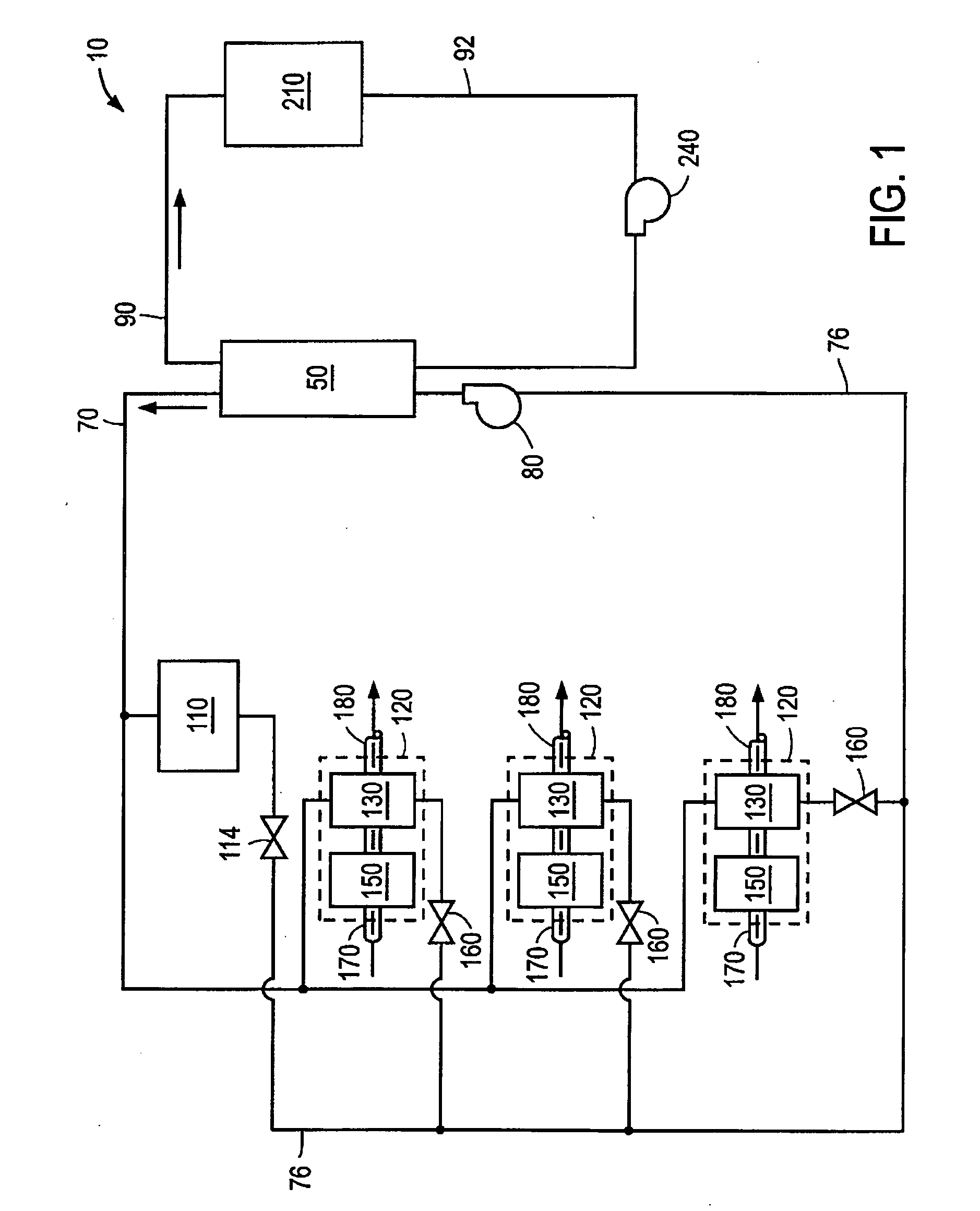

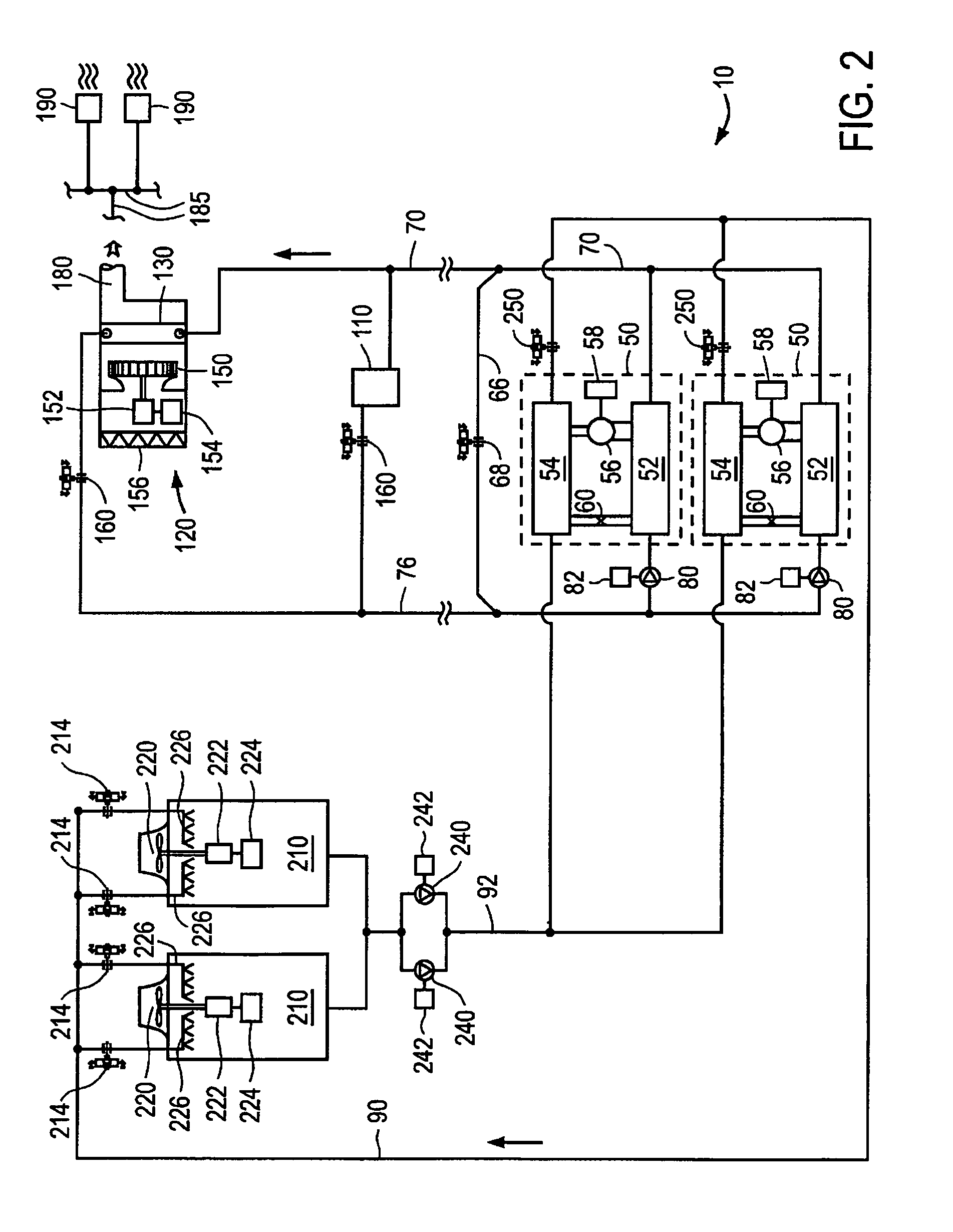

Optimized Control System For Cooling Systems

ActiveUS20090171512A1Reduce energy consumptionImprove energy efficiencySampled-variable control systemsMechanical apparatusCooling towerControl system

A cooling system for providing conditioned air to a facility includes a chiller or other cooling subsystem, a cooling tower subsystem and one or more air handling units or process cooling units. The cooling subsystem may advantageously include one or more chillers (e.g., variable speed chillers, constant speed chillers, absorption chillers, etc.) and chilled fluid pumps. The cooling tower subsystem includes one or more cooling tower units and condenser fluid pumps. In some implementations, the air handling unit has a cooling coil and a variable volume fan. In some implementations, direct expansion (DX) cooling systems comprise compressors, evaporators and air-cooled, water-cooled or evaporatively-cooled condensing systems. Such systems can be controlled to reduce energy waste, improve occupant comfort and / or improve the thermal characteristics of the process cooling unit. The cooling system further comprises a control system which is configured to evaluate a cooling load value at the air handling unit and use the cooling load value to calculate at least one operational setpoint. The operational setpoint may advantageously be selected to improve the energy efficiency of the overall cooling system.

Owner:YARDI SYST

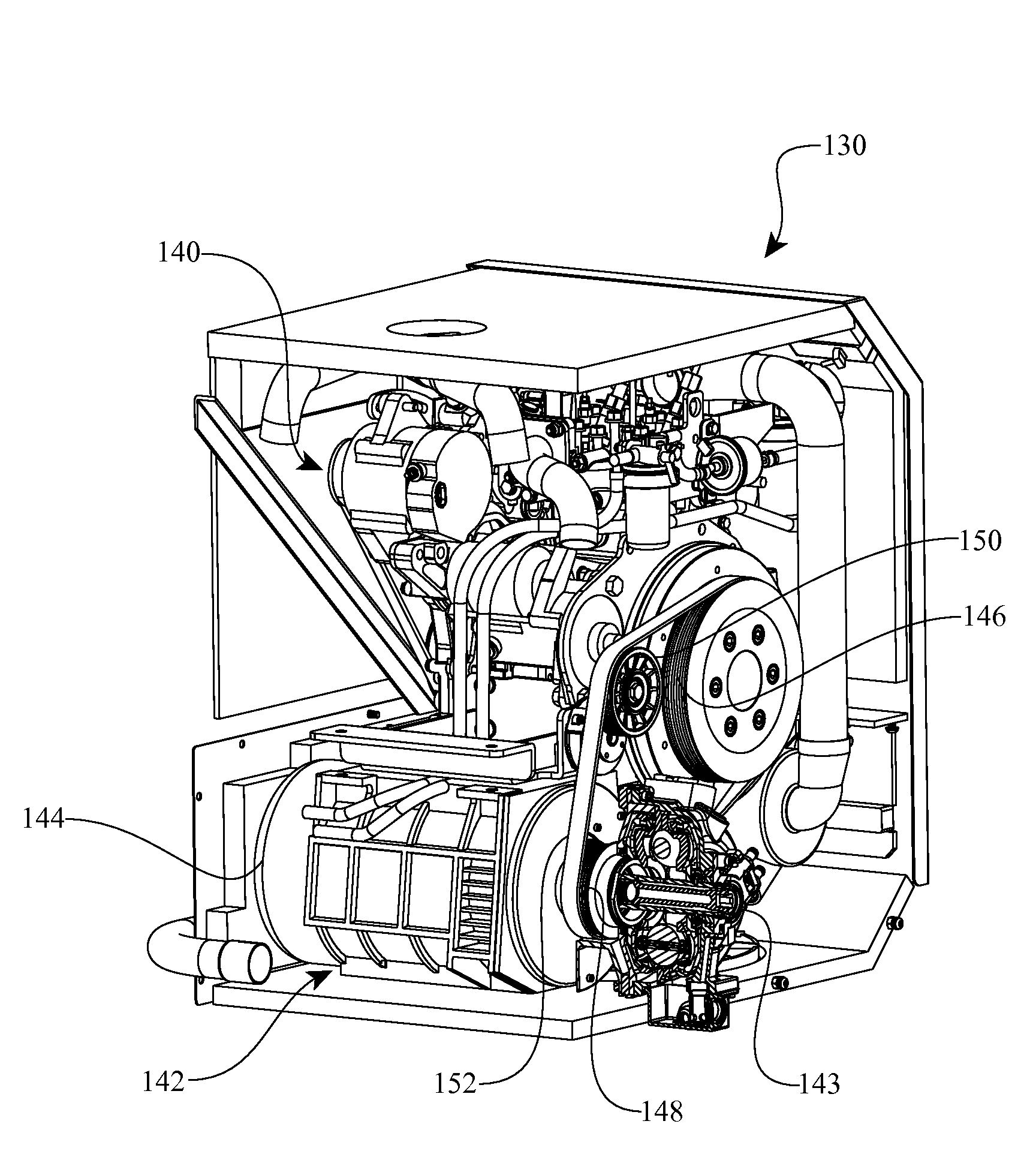

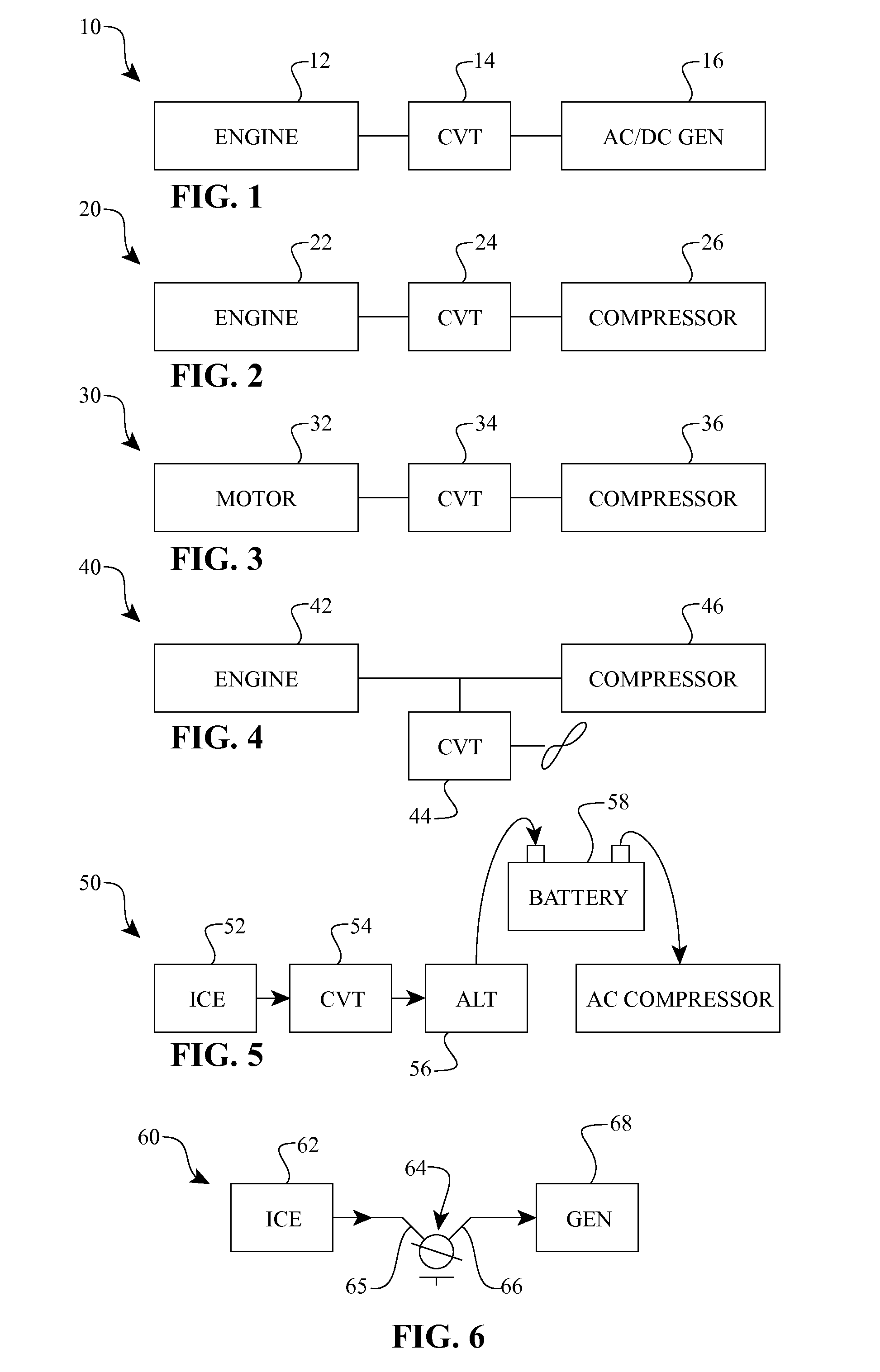

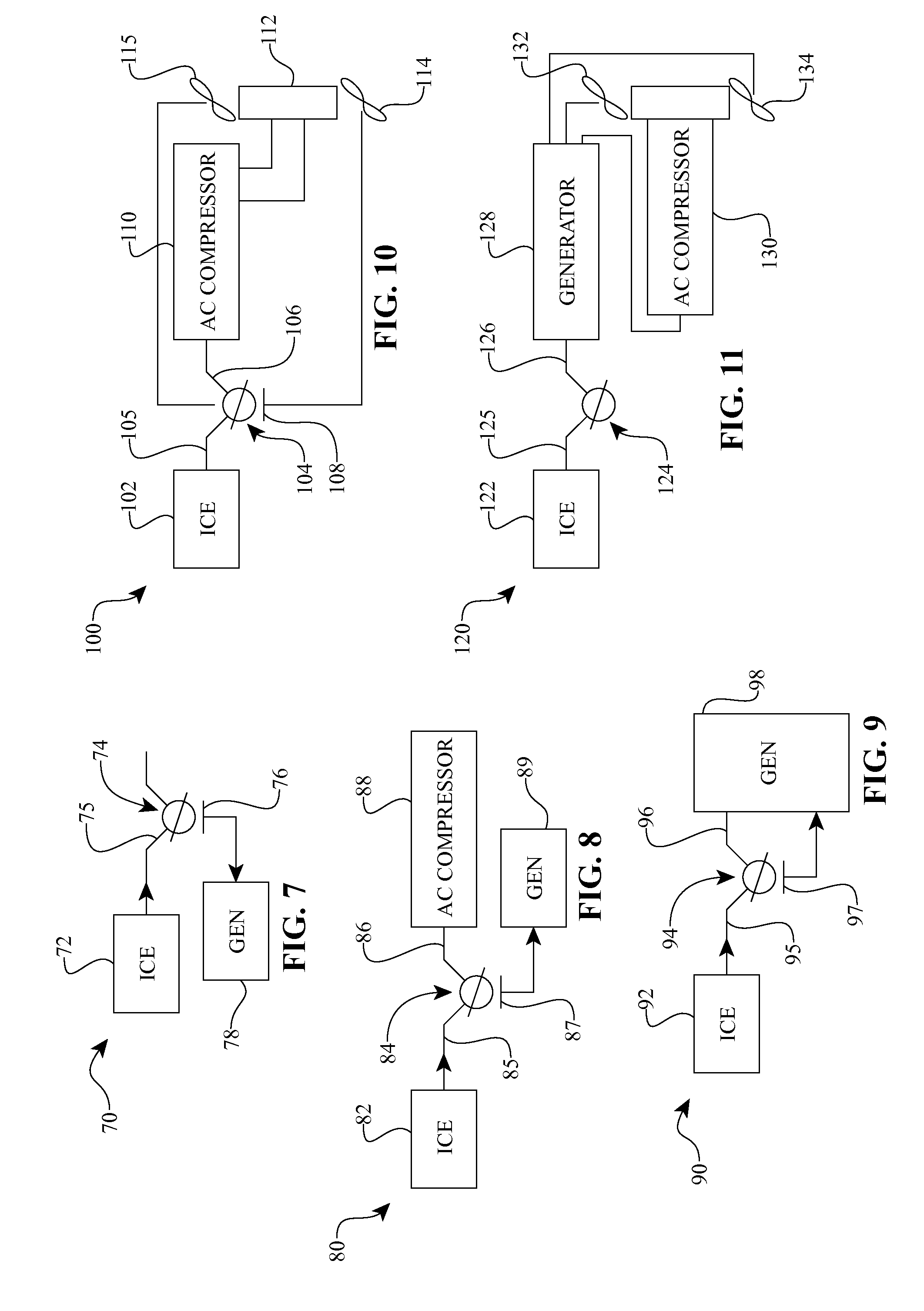

Auxiliary power unit having a continuously variable transmission

InactiveUS20120258839A1Fuel consumption is minimizedIncreased power demandAuxillary drivesVehicle fittingsCombustionControl system

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for auxiliary power units (APU). In one embodiment, the APU includes a source of rotational power such as a combustion engine operably coupled to a continuously variable transmission (CVT). The CVT can be coupled to a load. In some embodiments, the load is provided by a generator. In one embodiment, the APU has a control system configured to control the operation of the engine and the operation of the CVT. The control system can facilitate substantially constant speed operation of the generator in the presence of variable operation of the engine. In another embodiment, the APU includes a continuously variable accessory drive (CVAD) operably coupled to an engine. The CVAD can include a continuously variable transmission operably coupled to a generator. In one embodiment, a skew-based control system is adapted to facilitate a change in the ratio of a CVAD.

Owner:FALLBROOK INTPROP COMPANY

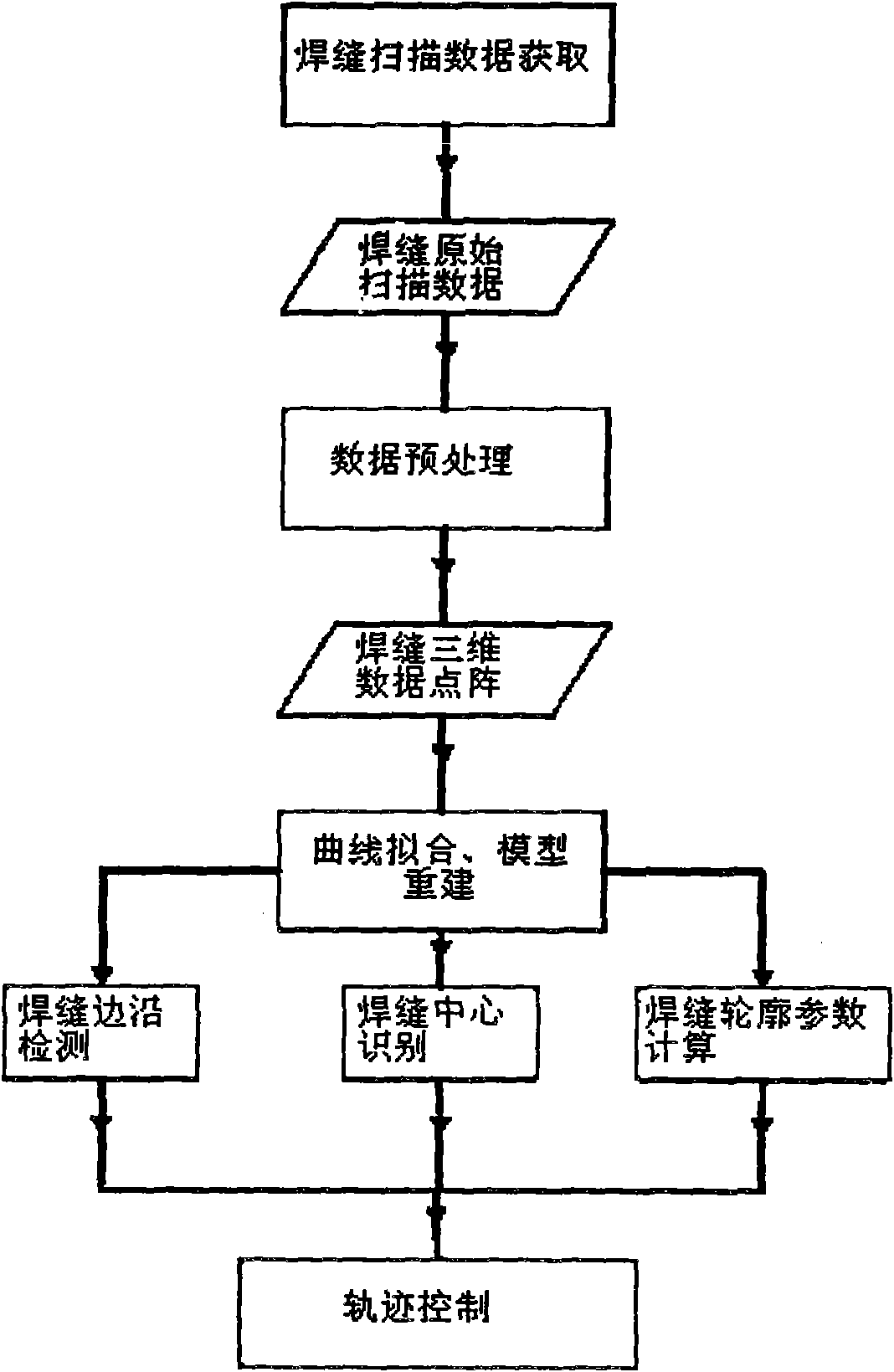

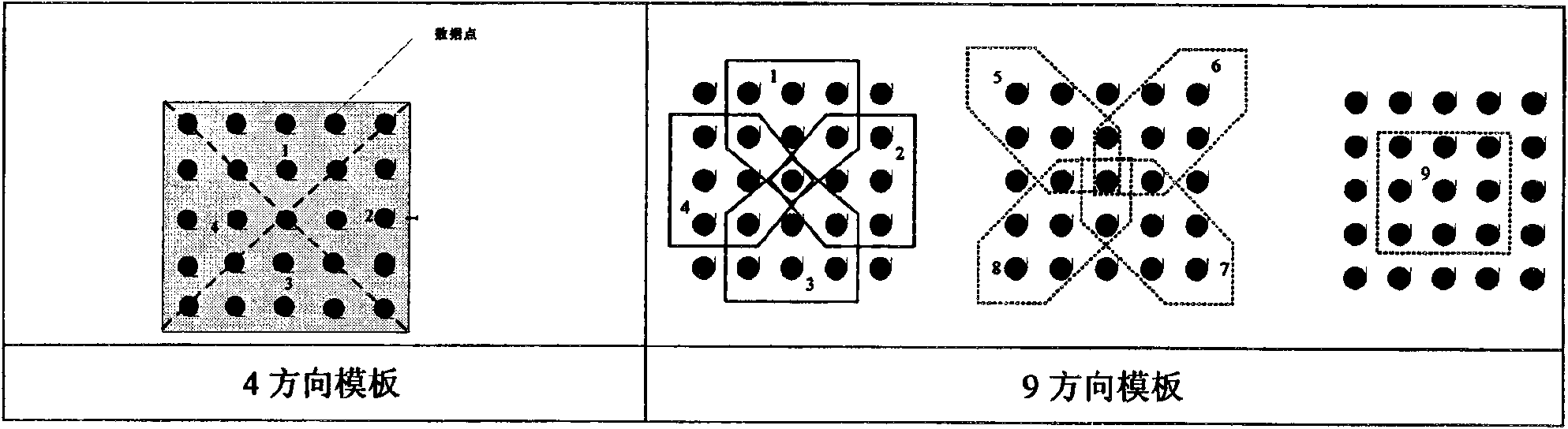

Welding track detection and control method of plate butt weld based on laser ranging

InactiveCN101559512ATo achieve the purpose of seam trackingTo achieve the purpose of trackingArc welding apparatusNumerical controlLaser rangingField tests

The invention relates to a welding track detection and control method of plate butt weld based on laser ranging, including the following steps: A. track detection is carried out; B. track identification and extraction are carried out; C. track control is carried out; D. the relative position relation between a welding gun and a welding seam is adjusted at last by performing mechanism actions. In the invention, the information of welding seam profile is obtained by transverse scanning of a laser sensor, and welding seam is rebuilt after effective wave filtering treatment to realize three-dimensional detection of the welding seam; simultaneously, the welding track curve is obtained by fit while detecting welding seam by using dynamic B spline fit algorithm, and the track control is carried out in combination with constant speed B spline track interpolation algorithm, thereby fundamentally solving the problem of track detection and control in automatic welding of plate butt weld. By using the method in the invention, the field test welding has welding profile identification precision of 0.15mm and welding track identification precision of 0.2mm, and the welding speed is more than four times of common manual welding.

Owner:SHANDONG UNIV

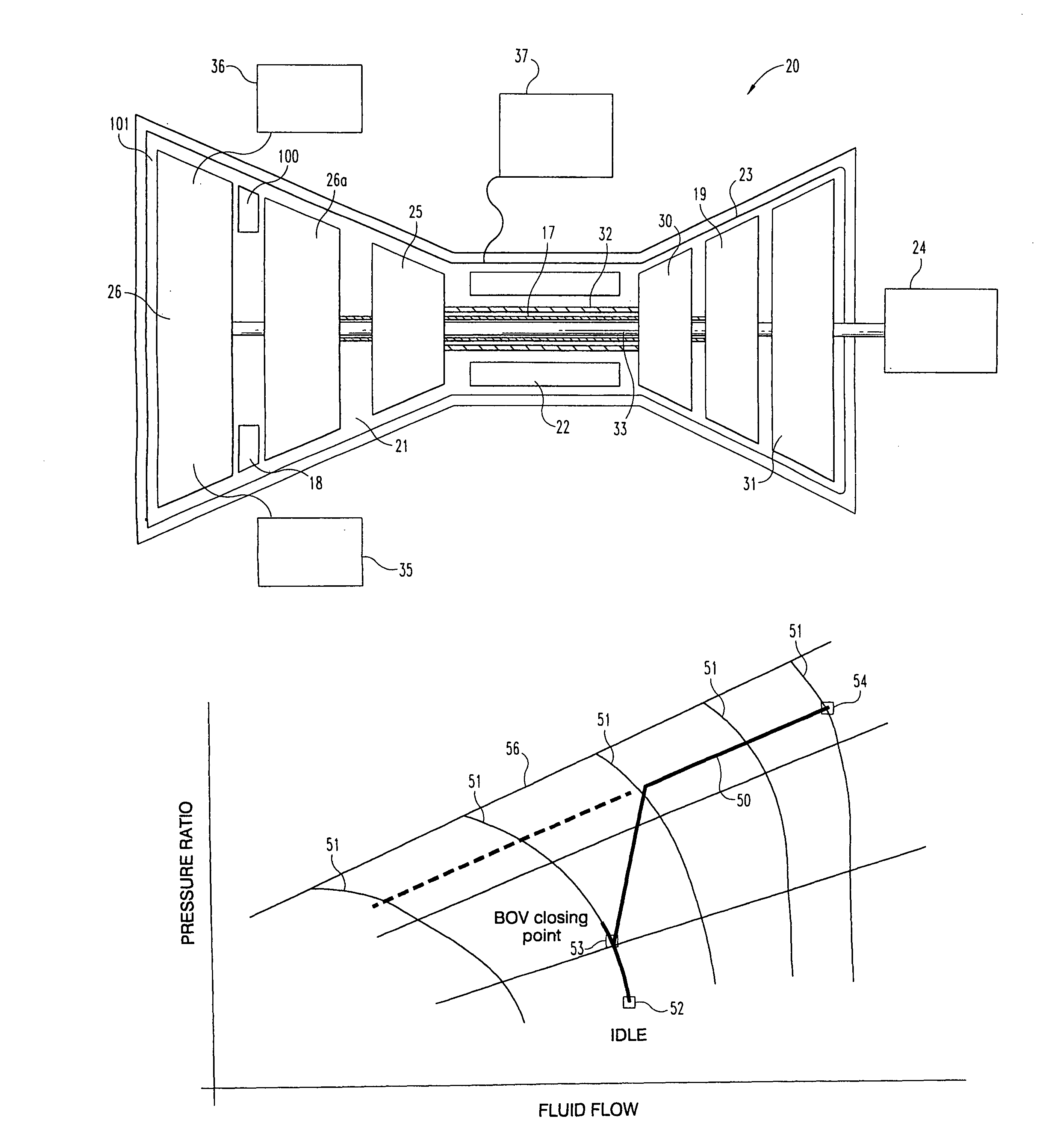

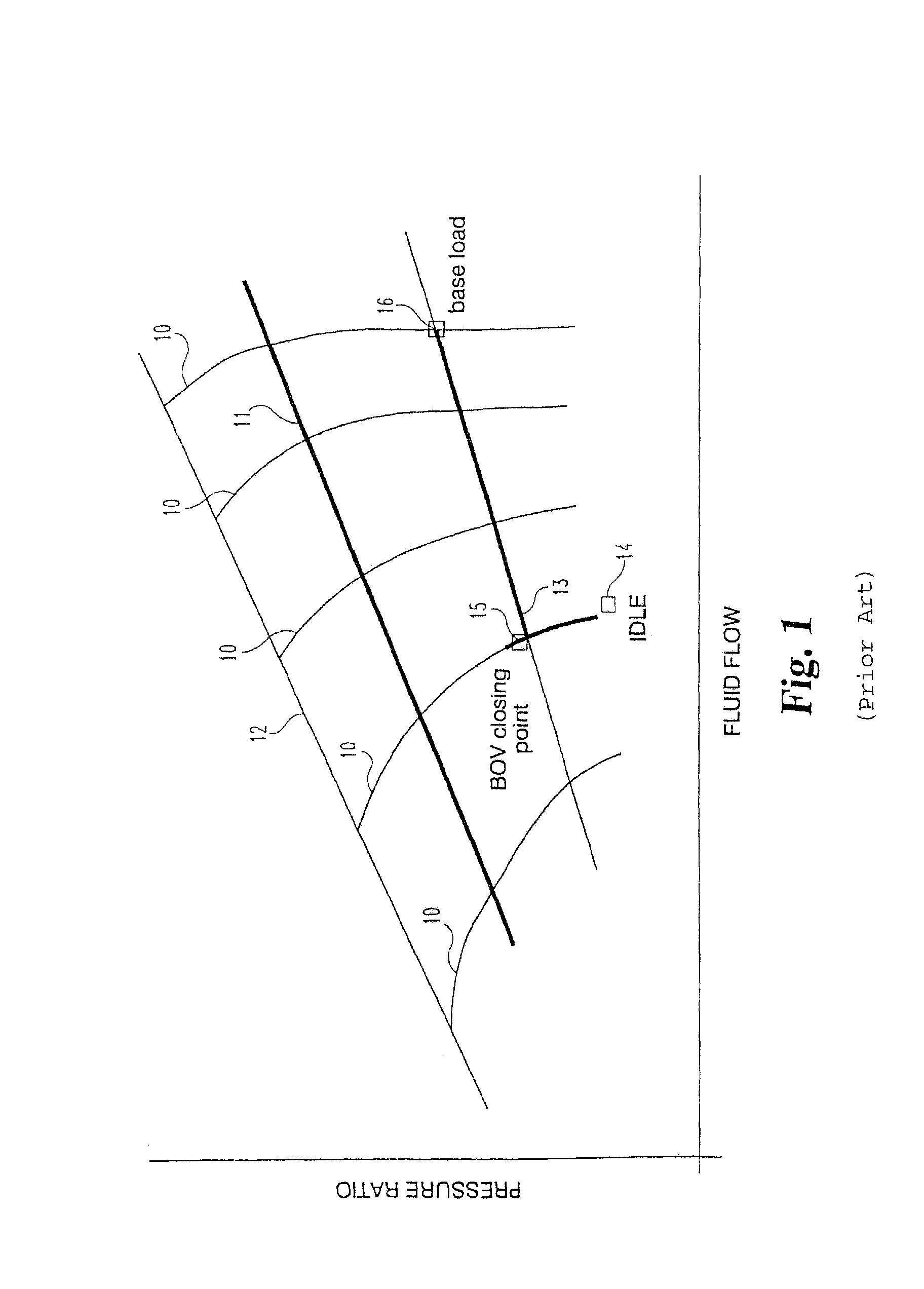

System and method for controlling the working line position in a gas turbine engine compressor

InactiveUS7762084B2Constant speedReducing the surge marginGas turbine plantsEngine controlEngineeringTurbine

A system for actively controlling the working line location within a low pressure compressor. The system includes a plurality of variable inlet guide vanes that are adjusted to maintain the working line at a constant level as the low pressure compressor rotates at a constant speed.

Owner:IND TURBINE COMPANY UK

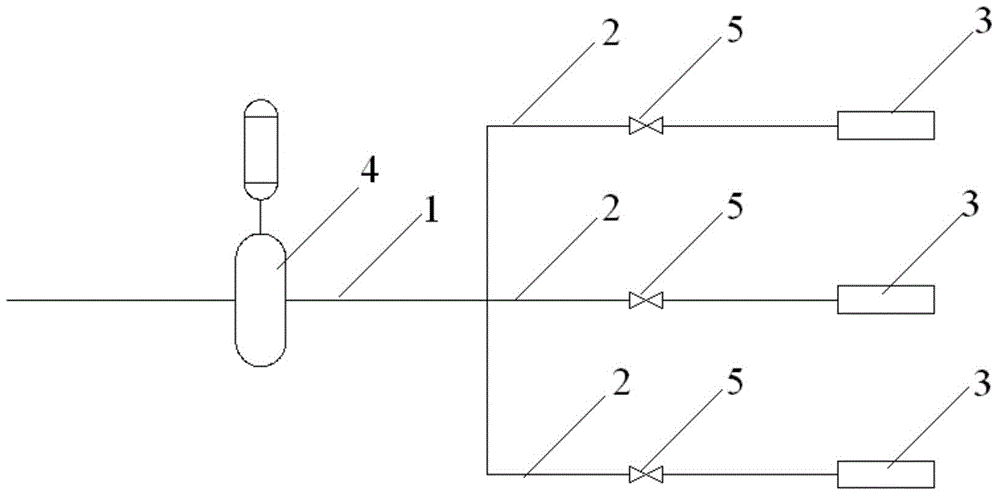

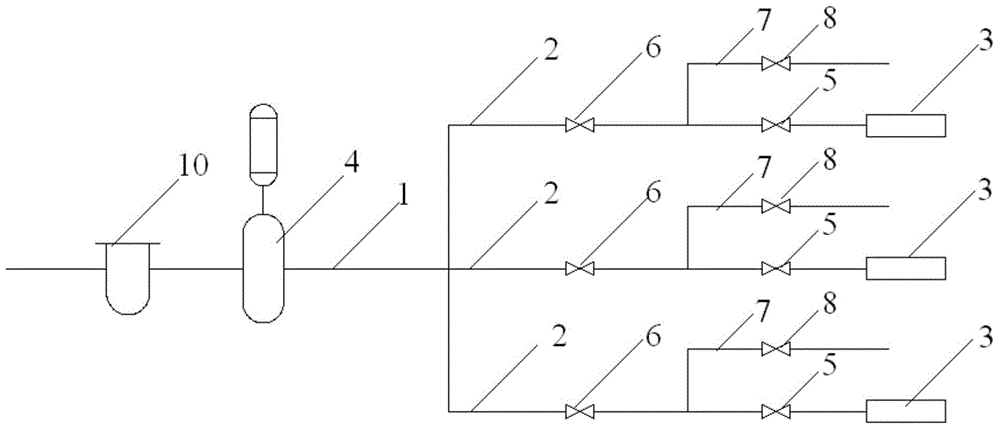

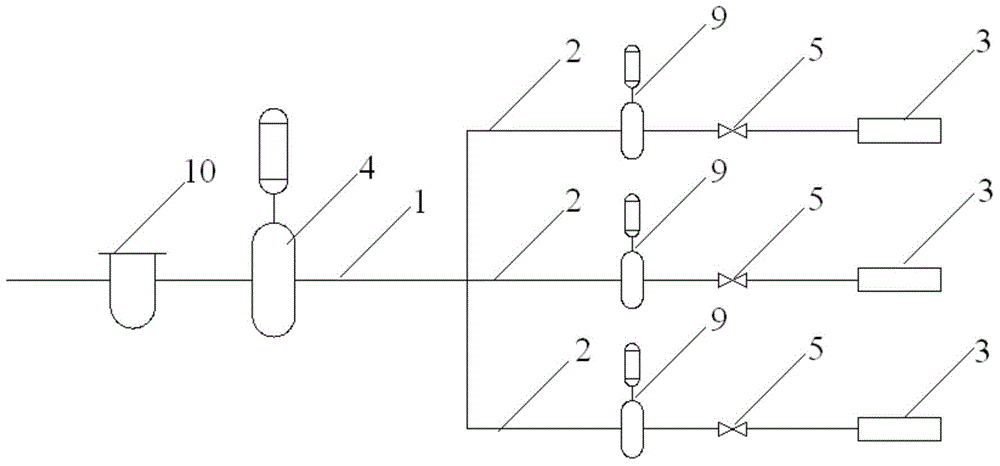

Feeding device for oil field waste treatment system and work method of feeding device

ActiveCN104803568AStrong continuity of processing operationsRealize deliverySludge treatment by pyrolysisCombustorWaste treatment

A feeding device for an oil field waste treatment system comprises a main pipe and multiple branch pipes, wherein front ends of the branch pipes are all connected with the rear end of the main pipe, and rear ends of the branch pipes are all connected with corresponding heating cavities; a main slurry pump which is a positive displacement pump is mounted on the main pipe; root valves are mounted on all of the branch pipes. The feeding device for the oil field waste treatment system adopts the positive displacement pump for pumping, materials with higher fluidity can be conveyed and distributed, and the feeding quantity can be measured, so that a proper quantity of materials are conveyed into the heating cavities, the materials are completely treated, the heat energy of a burner can be more efficiently utilized, and the treatment efficiency is improved. The materials can be constantly conveyed into the heating cavities quantitatively at a constant speed for a long time through measurement of calibration ports and regulation of branch regulation valves, the continuity of waste treatment work can be higher, and the work efficiency is further improved.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

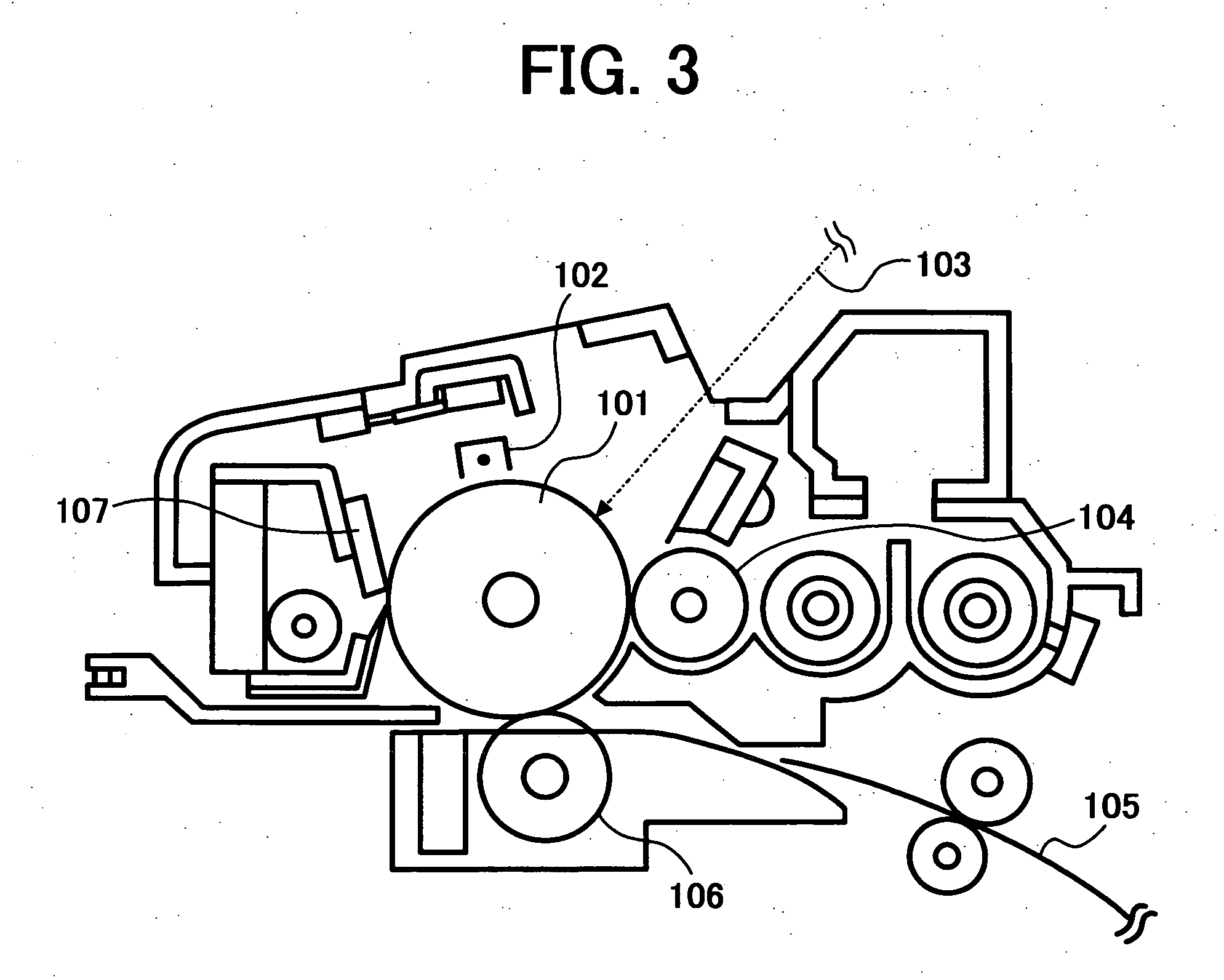

Toner and developer, toner container, process cartridge, image forming method and image forming apparatus

InactiveUS20060210902A1DevelopersElectrographic processes using charge patternImage formationEngineering

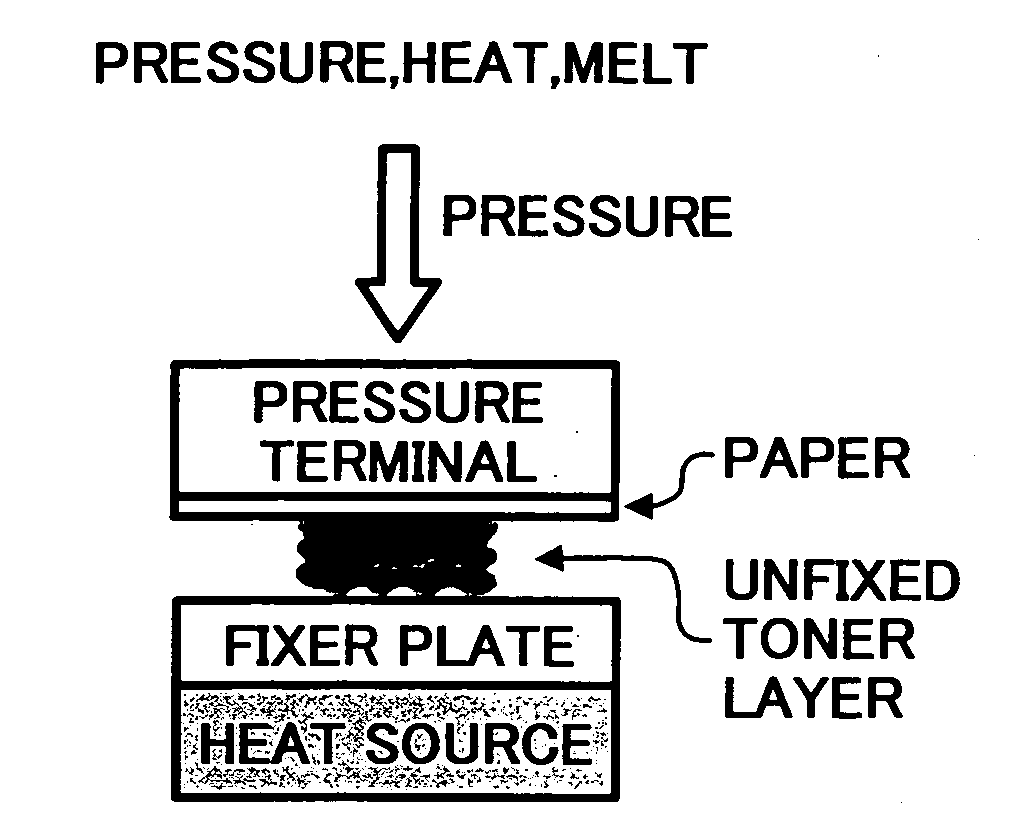

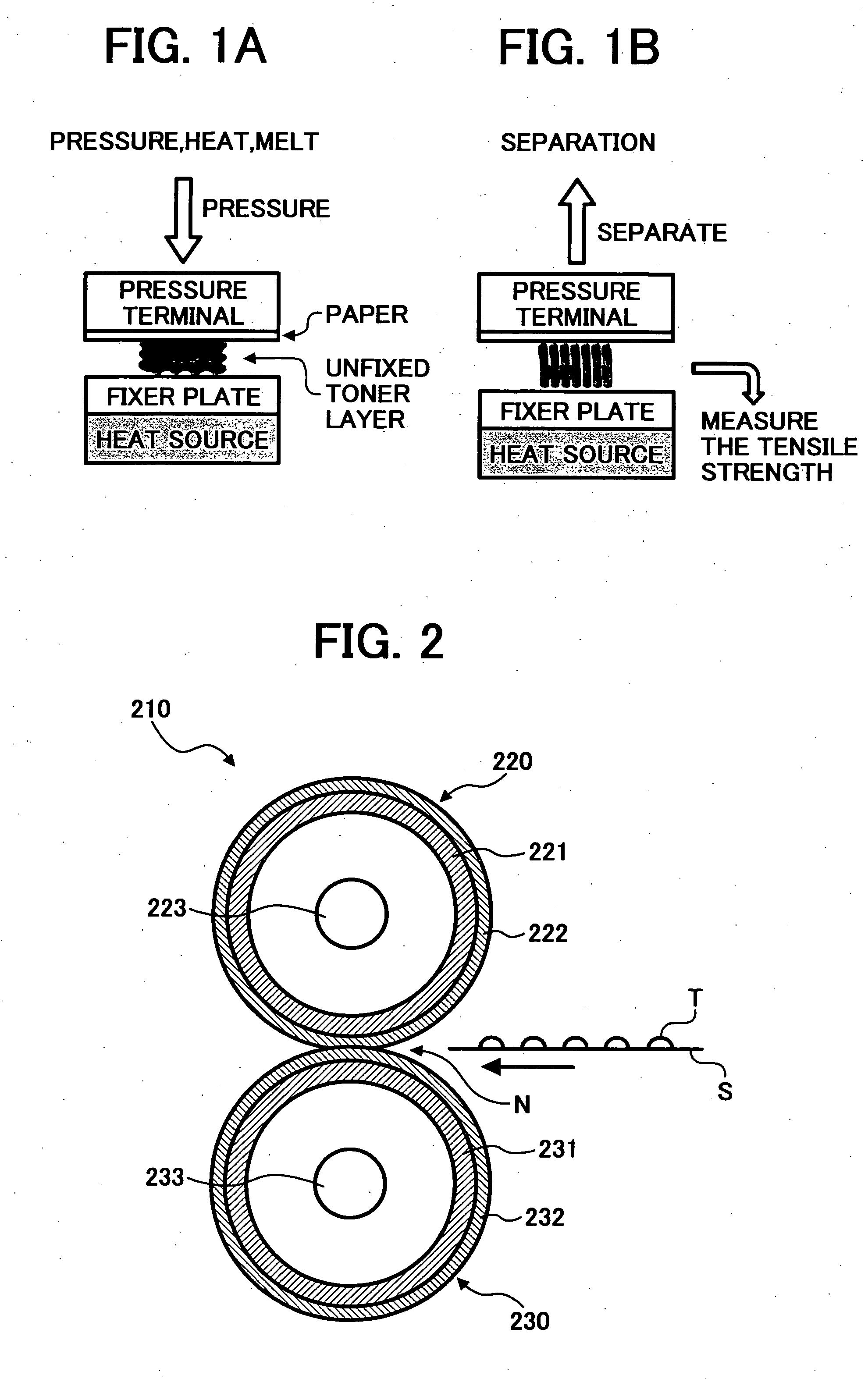

A toner including a binder resin, a colorant and a release agent, and satisfying the following relationships (1) and (2): 1.0≦FT120 / FT160≦1.5 (1) wherein FT120 is a maximum tensile strength (N) when a recording medium having the toner unfixed on is vertically separated from the surface of a substrate having a temperature of 120° C. at a constant speed after pressed thereto at a pressure of 100 kPa, and FT160 is same except that the substrate has a temperature of 160° C.; 1.0≦FP100 / FP200≦1.5 (2) wherein FP100 is a maximum tensile strength (N) when a recording medium having the toner unfixed on is vertically separated from the surface of a substrate having a temperature of 160° C. at a constant speed after pressed thereto at a pressure of 100 kPa, and FP200 is same except that the pressure is 200 kPa.

Owner:RICOH KK

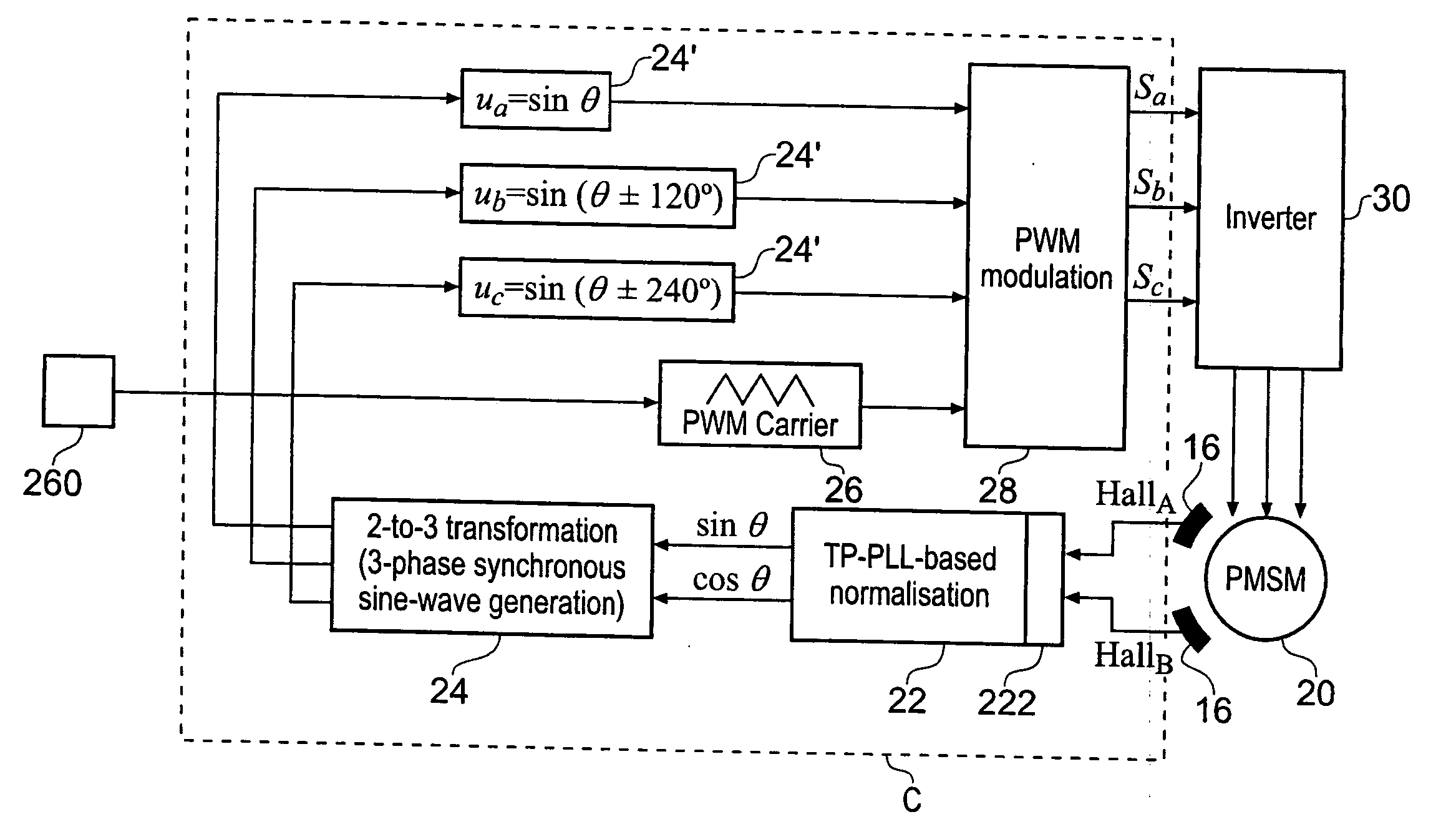

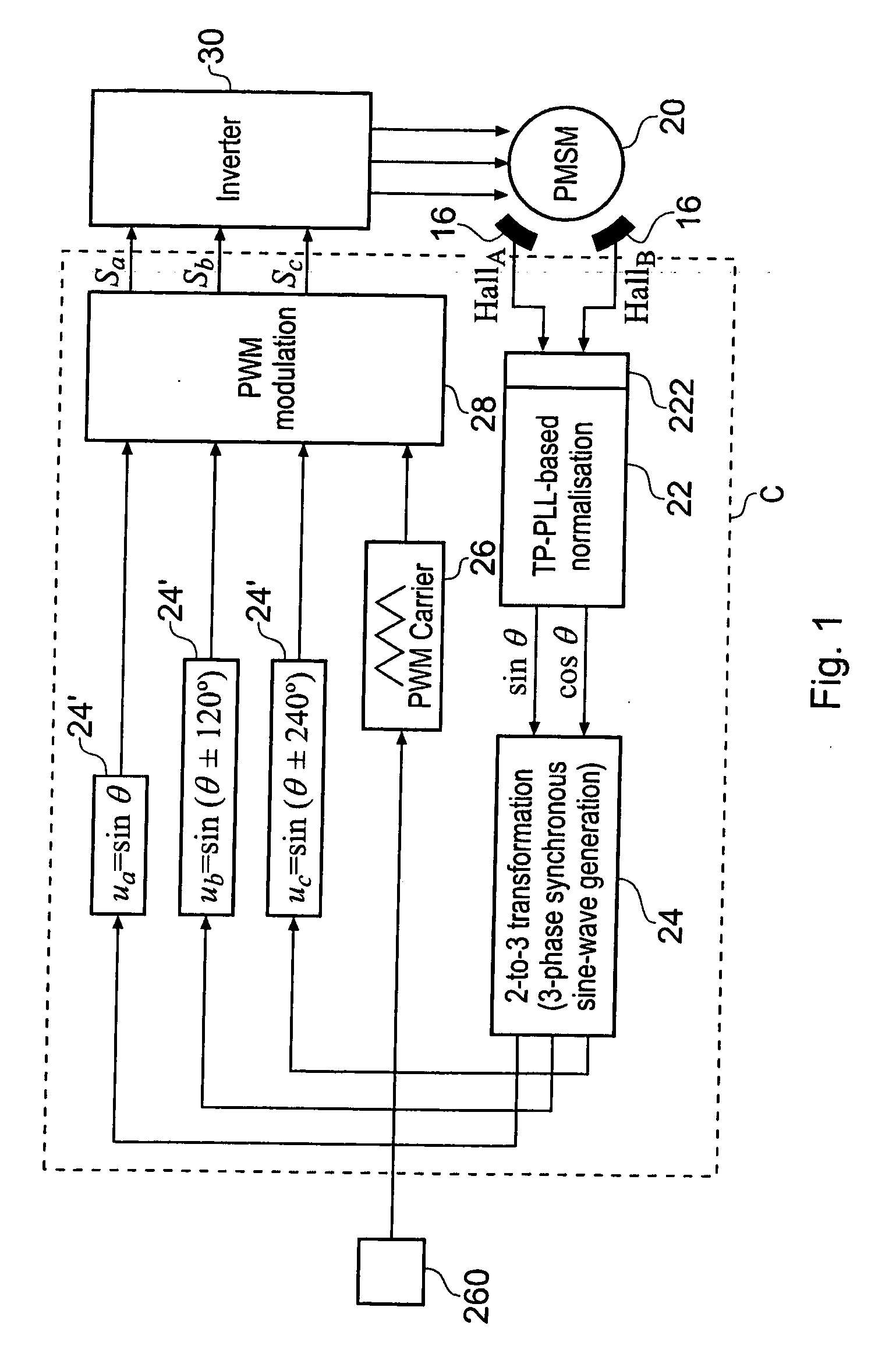

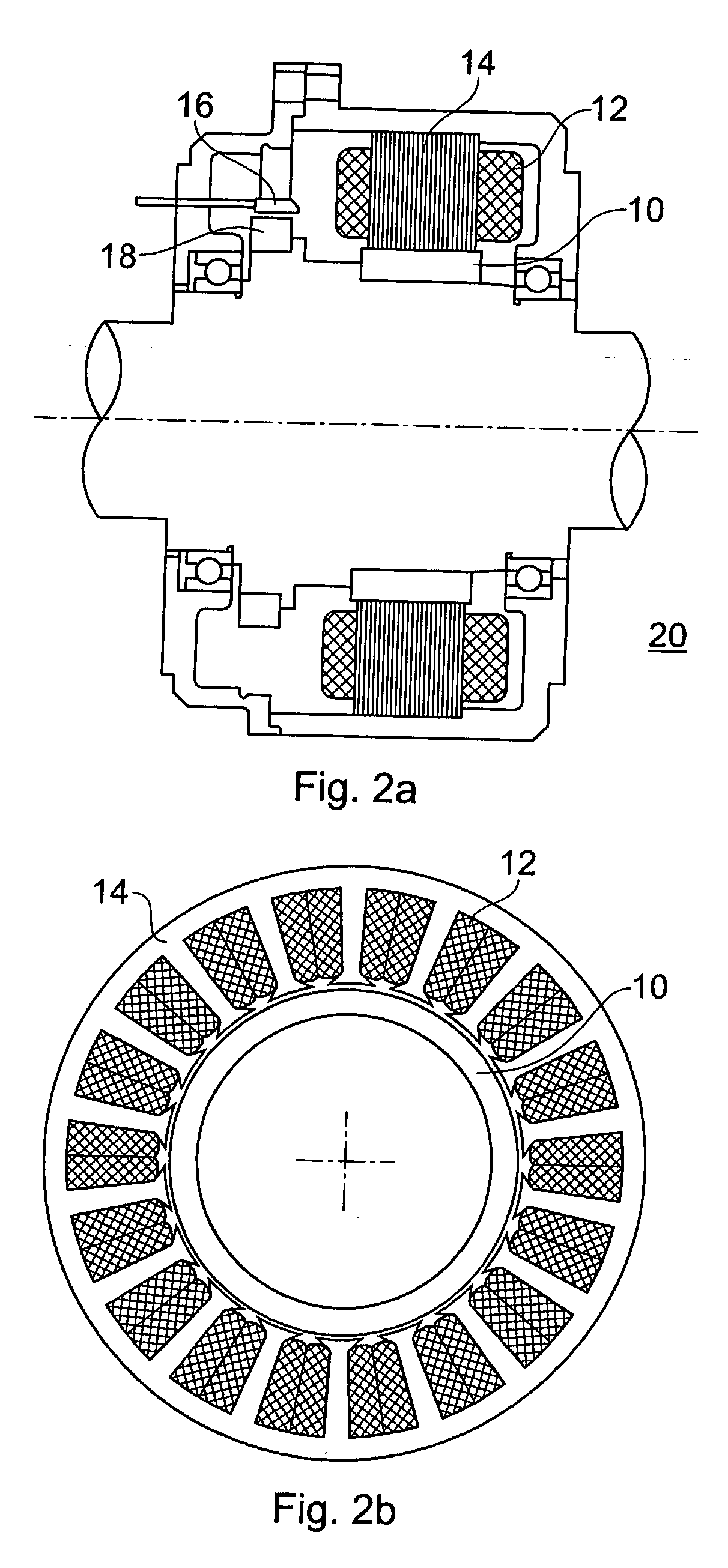

Permanent magnet synchronous motor and controller therefor

InactiveUS20050248306A1Low costReduce impactTorque ripple controlMotor/generator/converter stoppersPhase currentsLoop control

A low-cost sine-wave drive for a 3-phase permanent magnet synchronous AC machines (PMSM) in open-loop control is based on the measurements of two linear Hall sensors. The two Hall sensors are excited by a magnetic ring with the same pole number as the PMSM rotor magnet and sinusoidal flux distributions. The output signals of the Hall sensors are unified through a two-phase-type phase-lock-loop in order to reduce the impact of the sensor mounting non-uniformity during mass production. The peak torque and speed of motor is simply controlled by adjusting the amplitude of pulse-width-modulation carrier. Smooth torque control is achieved due to sinusoidal 3-phase currents. Such a simple sine-wave drive can be achieved with or without the assistance of a micro-controller unit (MCU). No current sensor is required for the motor phase current detection. This motor can be used in industrial applications where there is no strict requirement on torque response and constant speed control of PMSM machines.

Owner:AISIN SEIKI KK

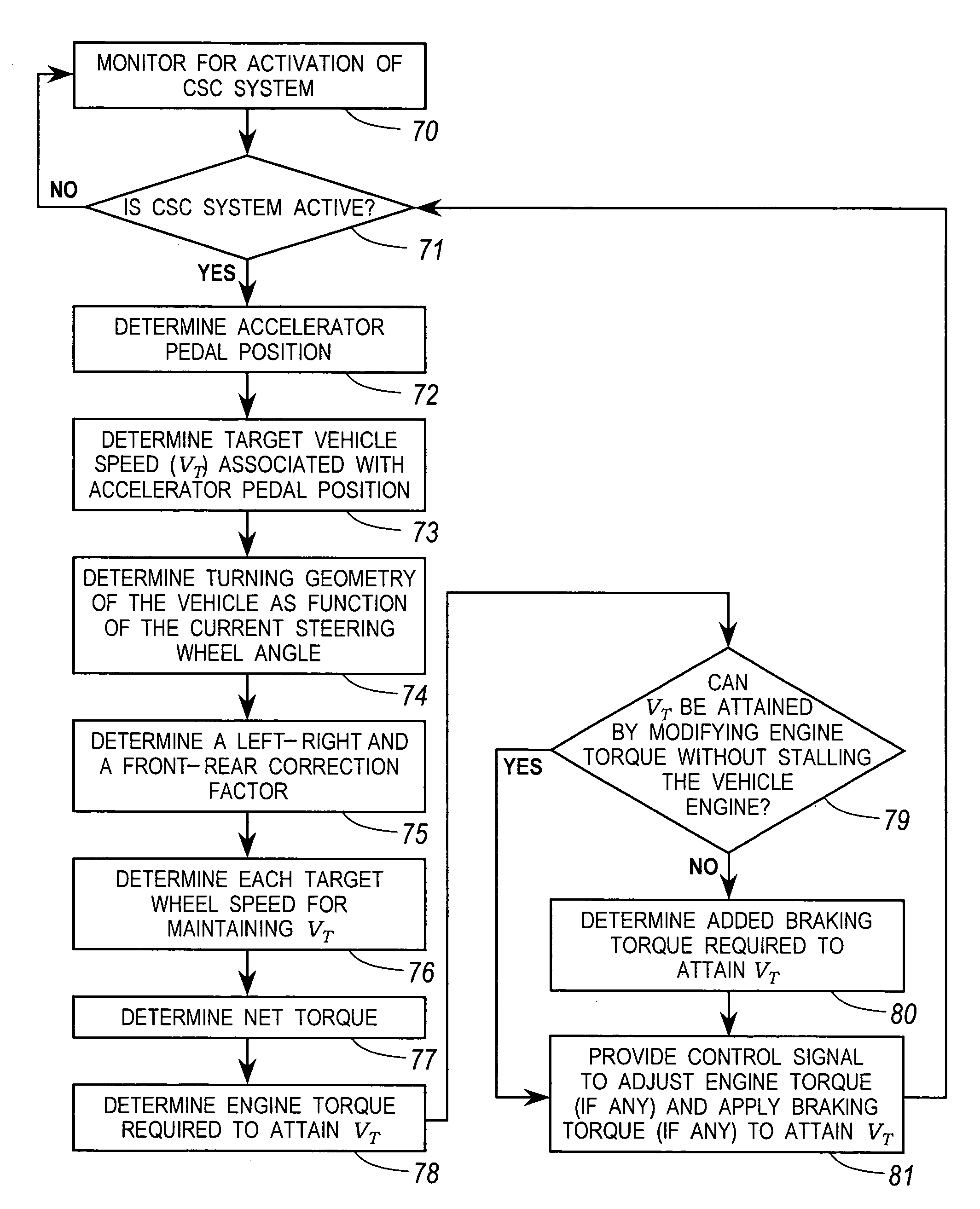

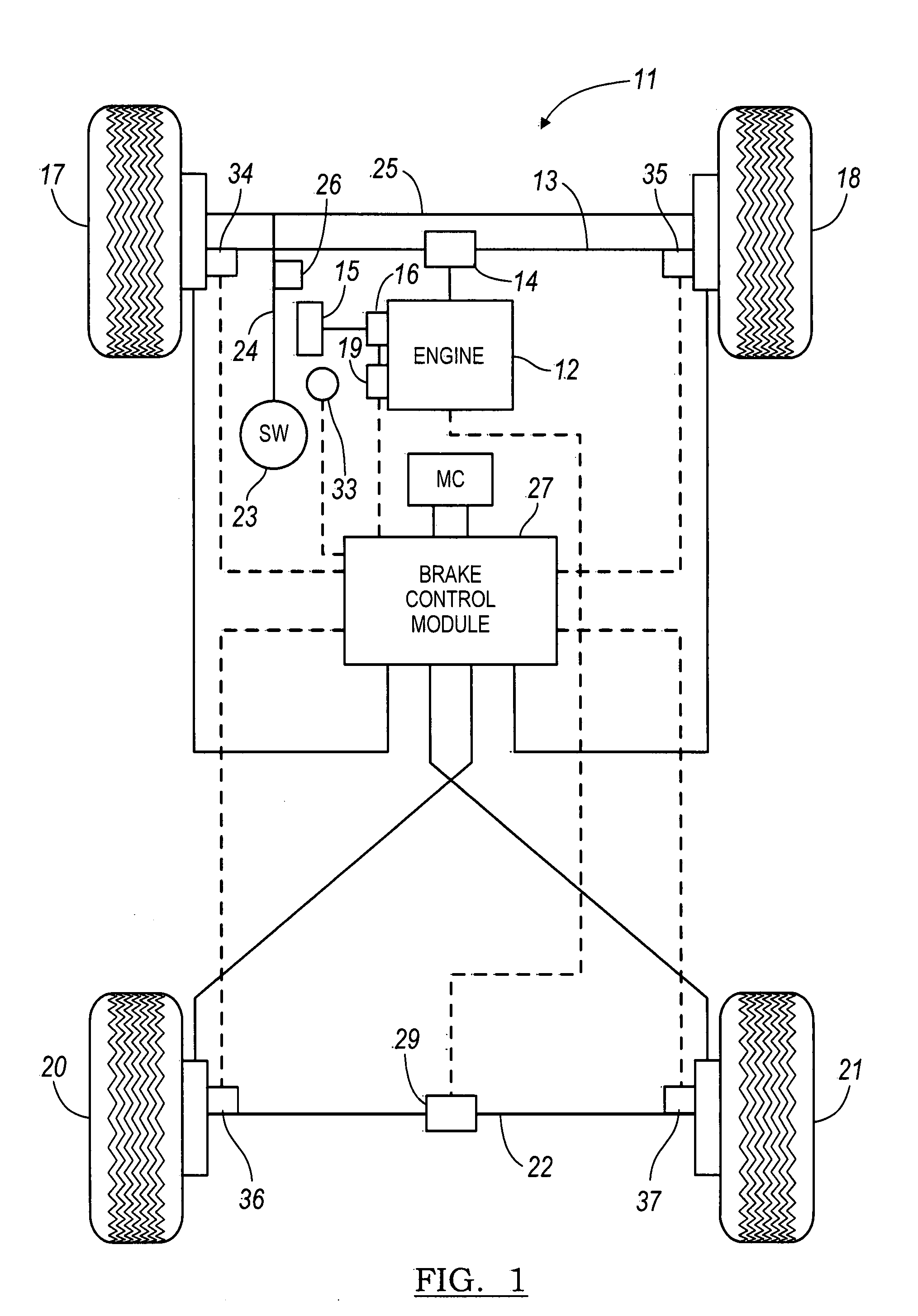

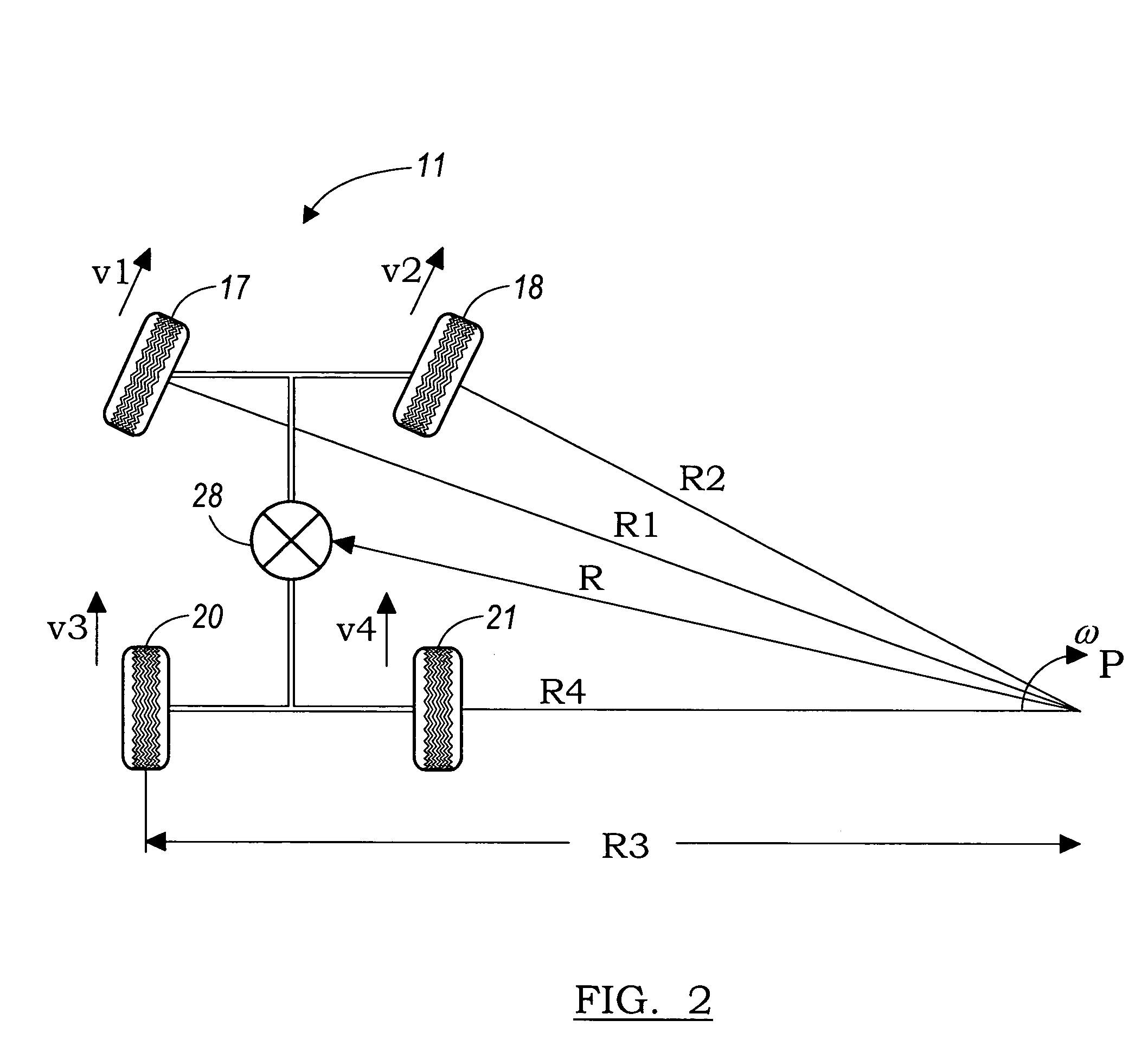

Constant speed control system

A method is provided for controlling a low speed operation of a vehicle. A speed activation switch is activated. A target vehicle speed is calculated in response to an accelerator pedal demand as determined by an accelerator pedal position where each respective accelerator pedal position is associated with a respective predetermined target vehicle speed. A vehicle turning geometry is determined in response to a steering wheel angle input. A target wheel speed of each of a plurality of vehicle wheels is calculated as a function of the target vehicle speed and turning geometry. An actual wheel speed of each wheel is measured. A net torque is determined in response to the target wheel speeds and actual wheel speeds. An engine output torque and a braking torque are determined in response to the net torque. The engine output torque and the total vehicle braking torque are controlled for cooperatively maintaining the target vehicle speed.

Owner:KELSEY HAYES CO

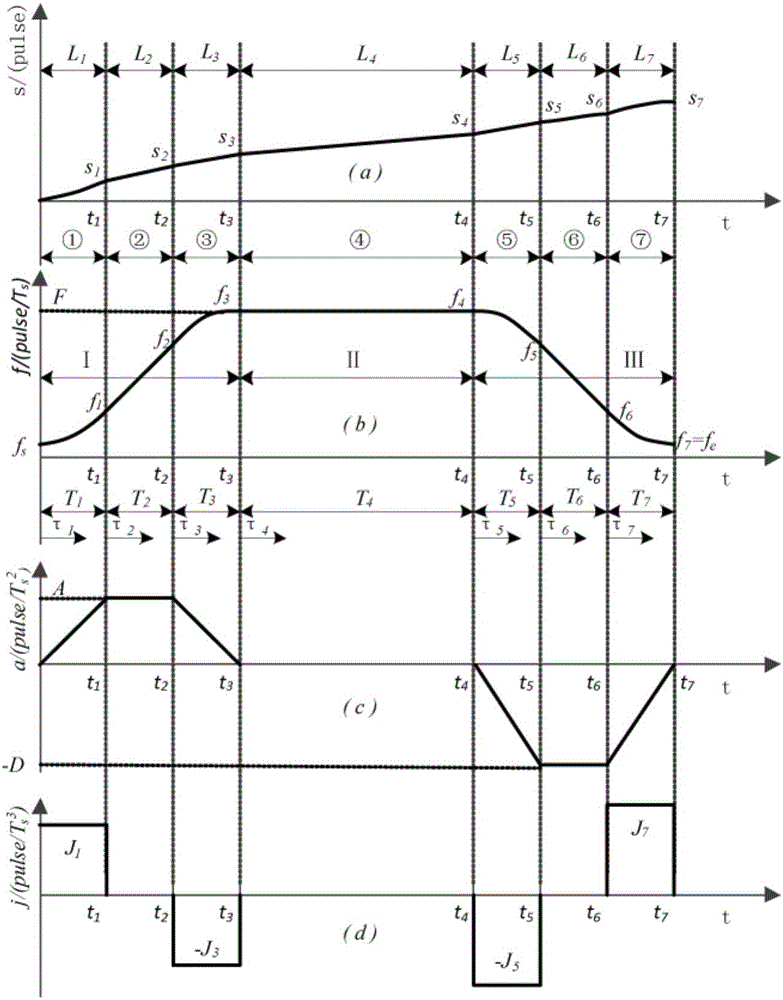

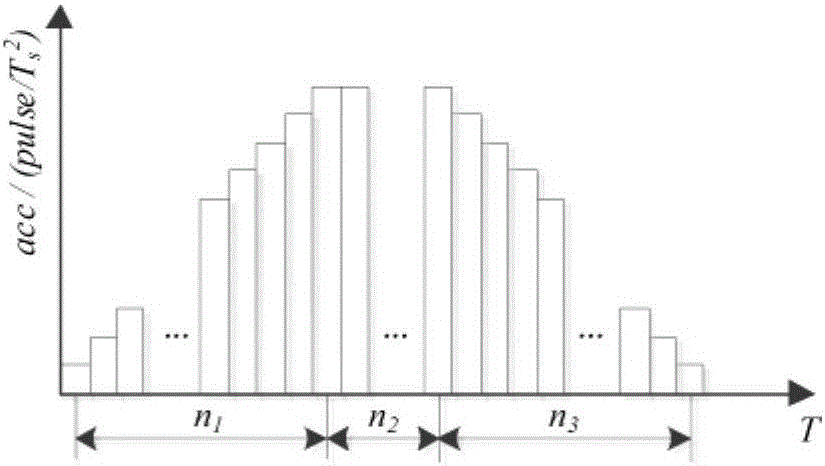

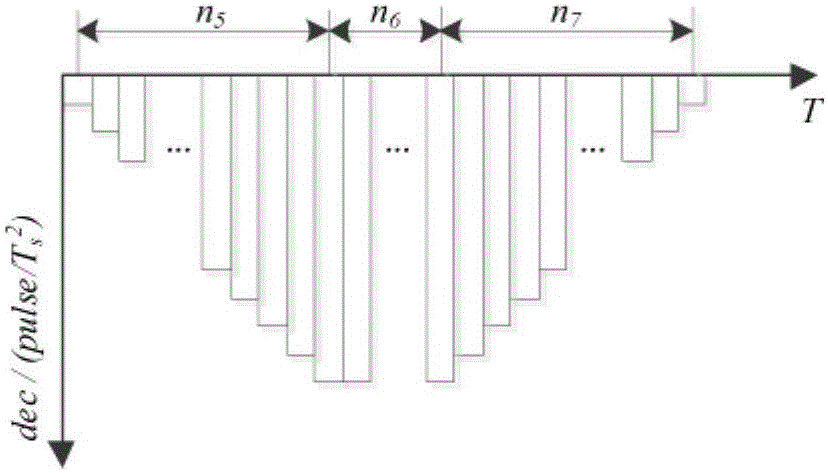

S-shaped acceleration and deceleration control method for changing speed and position of object on line

ActiveCN106168790AAcceleration curve continuousNo mutationNumerical controlDiscretizationPlanning method

The present invention provides an S-shaped acceleration and deceleration control method for changing speed and position of an object on line. The method comprises the acceleration phase speed planning, the deceleration phase speed planning, the constant speed phase speed planning, the real speed reduction point predication, the maximum speed processing, the surplus distance compensation, the online object speed changing algorithm and the online object position changing algorithm. An acceleration and deceleration discretization speed planning method is employed and the user input parameters are combined to calculate the operation time of a seven-phase speed planning phase. It is determined whether the maximum acceleration and the maximum speed can reach the criterion or not, the integration problem of a sampling period Ts according to the acceleration / deceleration acceleration, the acceleration / deceleration speed and the final position L after discretization is considered, and the real reachable acceleration / deceleration acceleration, the acceleration / deceleration speed and the feed rate are corrected. The S-shaped acceleration and deceleration control method for changing speed and position of the object on line greatly simplifies an original calculation formula and saves lots of operation time of a computer, and the surplus distance employs a one-time compensation method in the speed reduction process.

Owner:SOUTH CHINA UNIV OF TECH

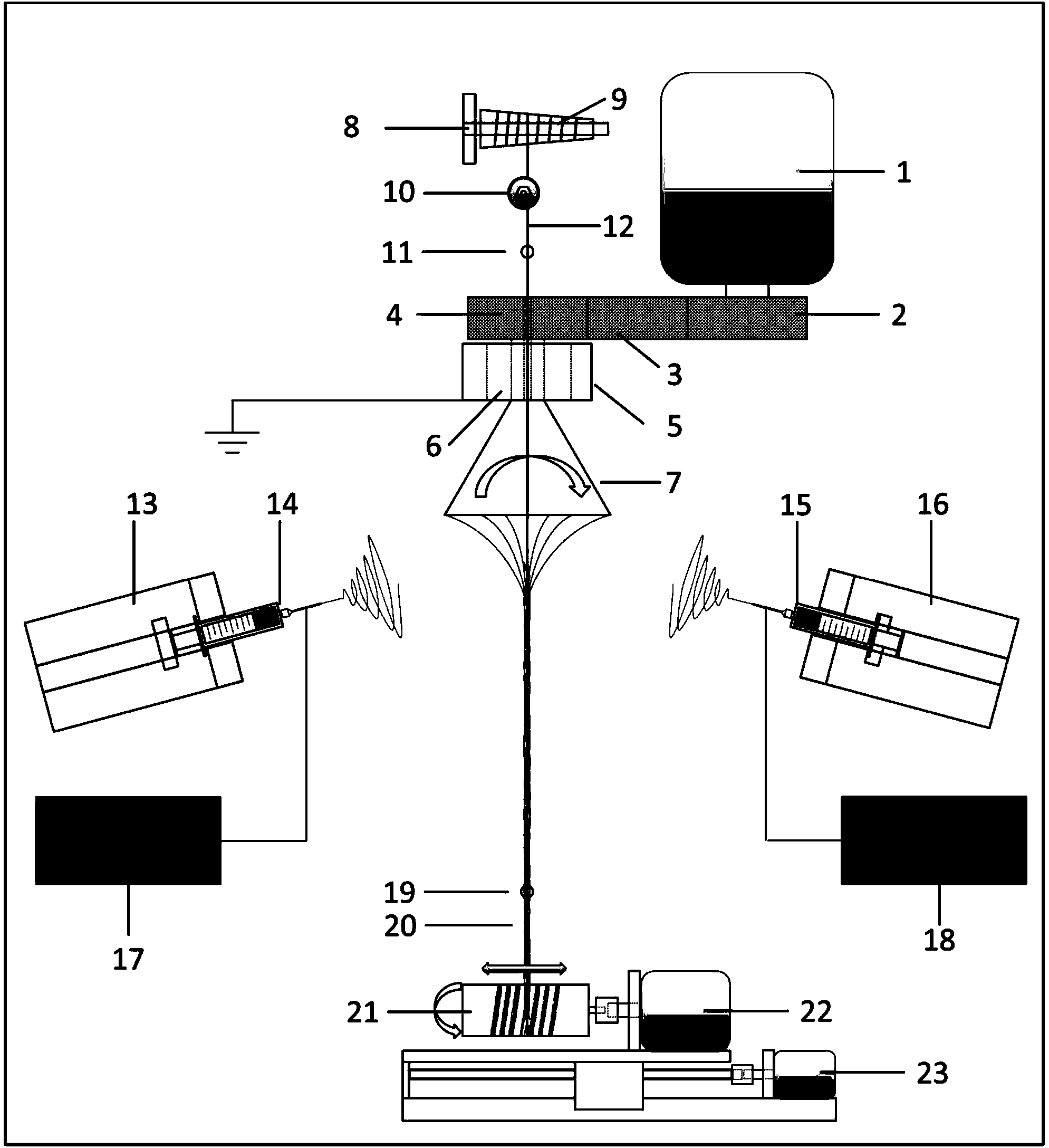

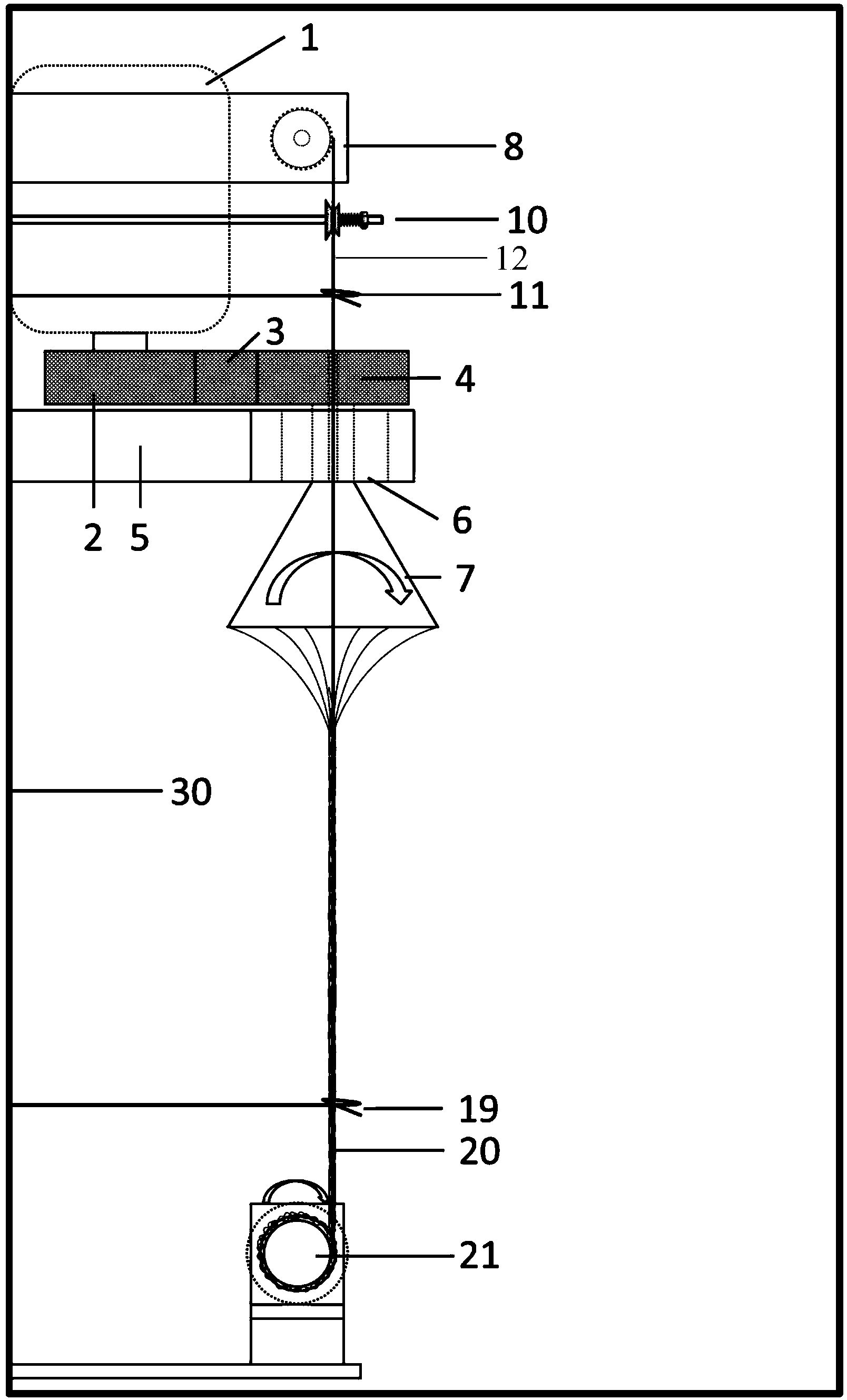

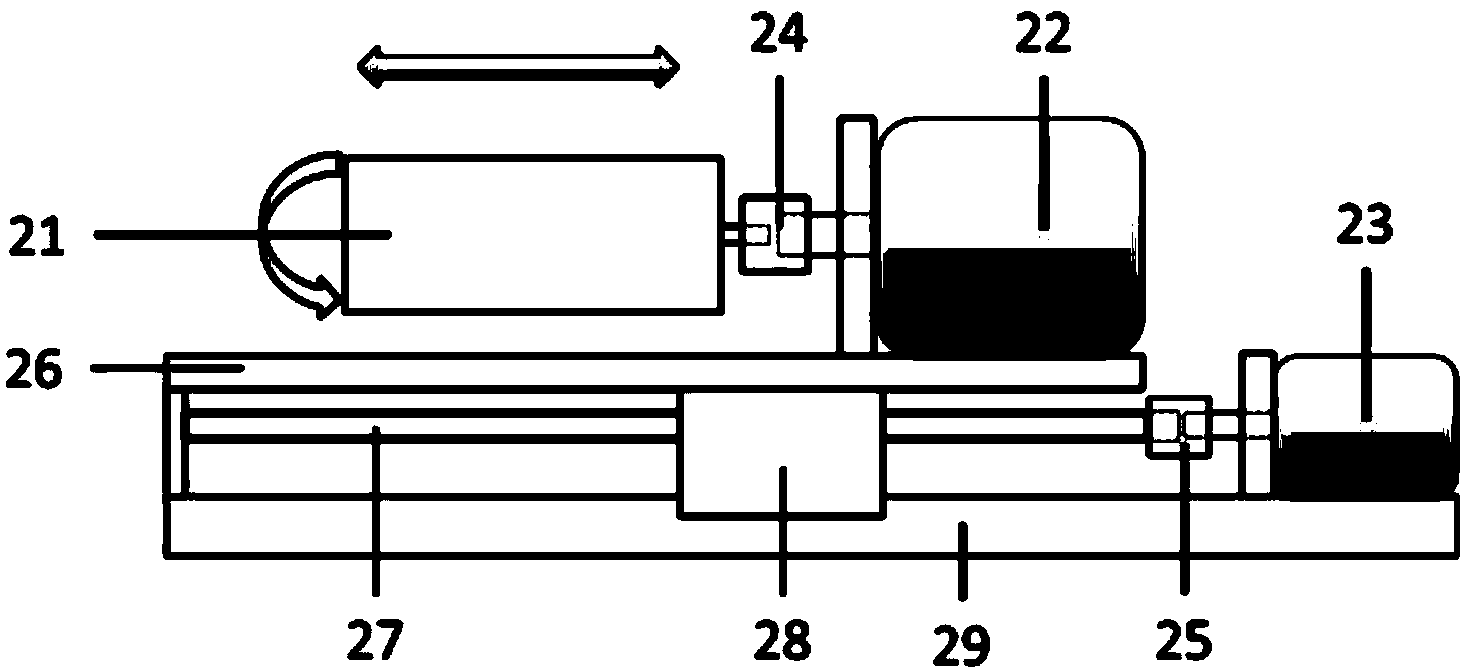

Nano-fiber covering yarn electrostatic spinning device and application thereof

ActiveCN104032423AArrangement structure controllableControllable twistWeft knittingWarp knittingTextile technologyFiber

The invention relates to a nano-fiber covering yarn electrostatic spinning device and application thereof. The nano-fiber covering yarn electrostatic spinning device comprises a twisting device, a backing-off device, a winding device, a double-needle electrostatic spinning device and a control system. The invention also provides a method for preparing electrostatic spinning nano-fiber covering yarns. The method comprises the following steps of performing spinning by using prepared spinning liquor through the double-needle electrostatic spinning device; depositing nano-fibers on a metal funnel and core yarns; uniformly winding the nano-fibers on the core yarns moving at constant speed by rotating the metal funnel; and finally forming the nano-fiber covering yarns of which skin layers are nano-fibers. The invention also provides another method for preparing a nano-fiber fabric. The other method for preparing the nano-fiber fabrics comprises the following steps of using water soluble yarns as core yarns; preparing the nano-fiber covering yarns by using the method; preparing a covering yarn fabric by using a textile technology; and dissolving the core yarns to obtain the nano-fiber fabric. The maneuverability is high; the nano-fiber covering yarn electrostatic spinning device is novel in structure; and the nano-fibers on surfaces of the covering yarns are arranged controllably.

Owner:诺一迈尔(山东)医学科技有限公司

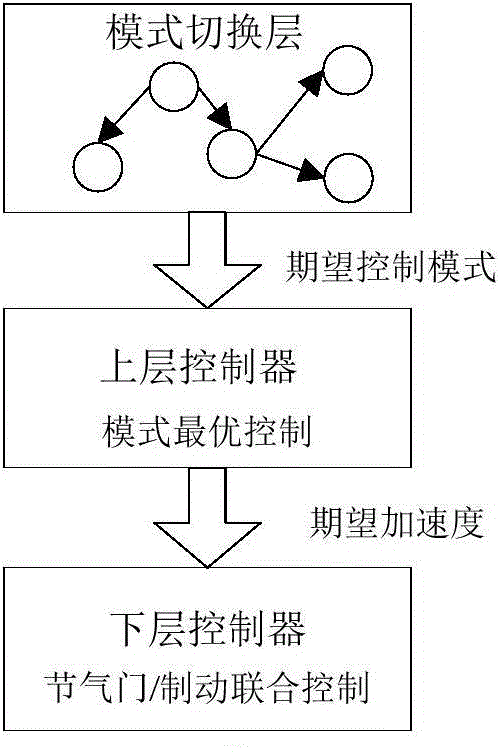

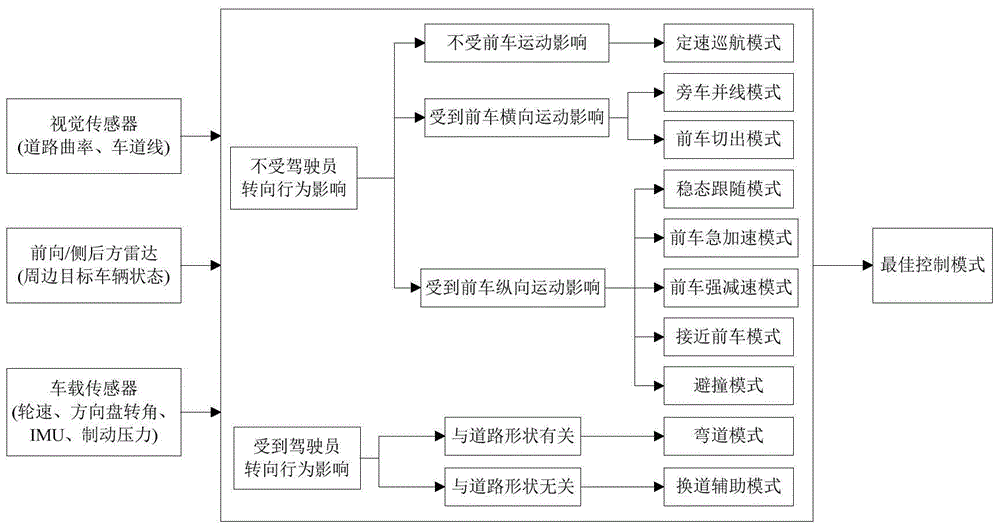

Automotive self-adaptive cruising system with multi-mode switching system and control method thereof

The invention discloses an automotive self-adaptive cruising system with a multi-mode switching system and a control method thereof. The system is divided into three layers of control structures including a mode switching layer, an upper-layer controller and a low-layer controller; a set of automobile traveling mode comprehensively arbitrating and switching mechanism is designed in the mode switching layer and is used for picking out the ideal working mode which is most suitable for the current traveling working condition from ten control modes. The ten control modes include the constant-speed cruising mode, the steady-state automobile following mode, the front automobile approaching mode, the urgent acceleration mode, the forcible deceleration mode, the curve mode, the lane changing assisting mode, the collision avoidance mode, the doubling mode and the switching-out mode. The upper-layer controller is responsible for specifically achieving the corresponding control mode and conducting continuous handling before an expected accelerated speed is output so as to avoid sudden change of the accelerated speed; the lower-layer controller is responsible for tracking the expected accelerated speed by controlling an execution mechanism of the automobile. According to the automotive self-adaptive cruising system with the multi-mode switching system and the control method thereof, the multi-mode switching system is adopted, in this way, the automotive self-adaptive cruising system can be better adapted to a complicated traveling environment, and the acceptability of drivers is improved.

Owner:WUHAN UNIV OF TECH

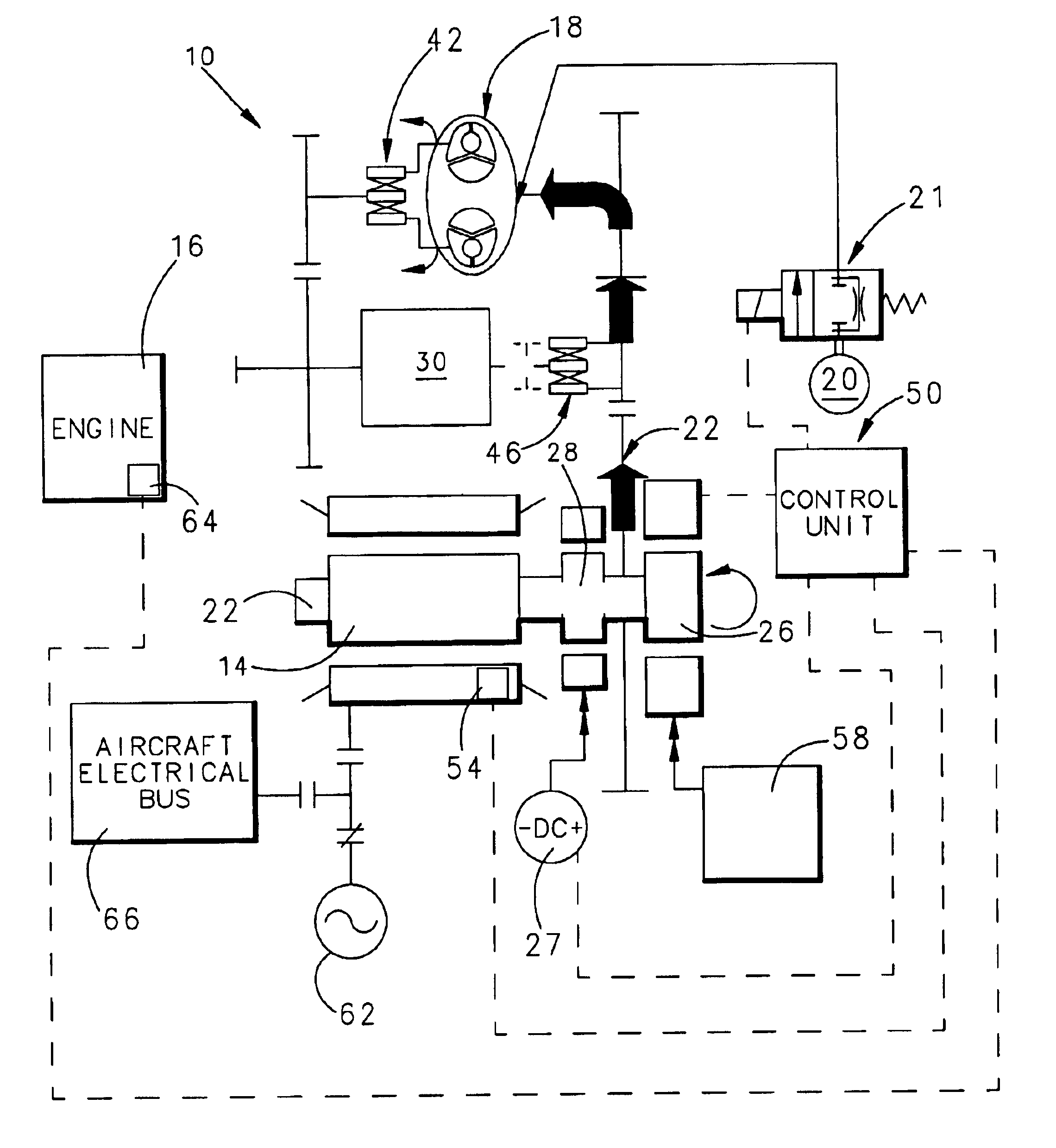

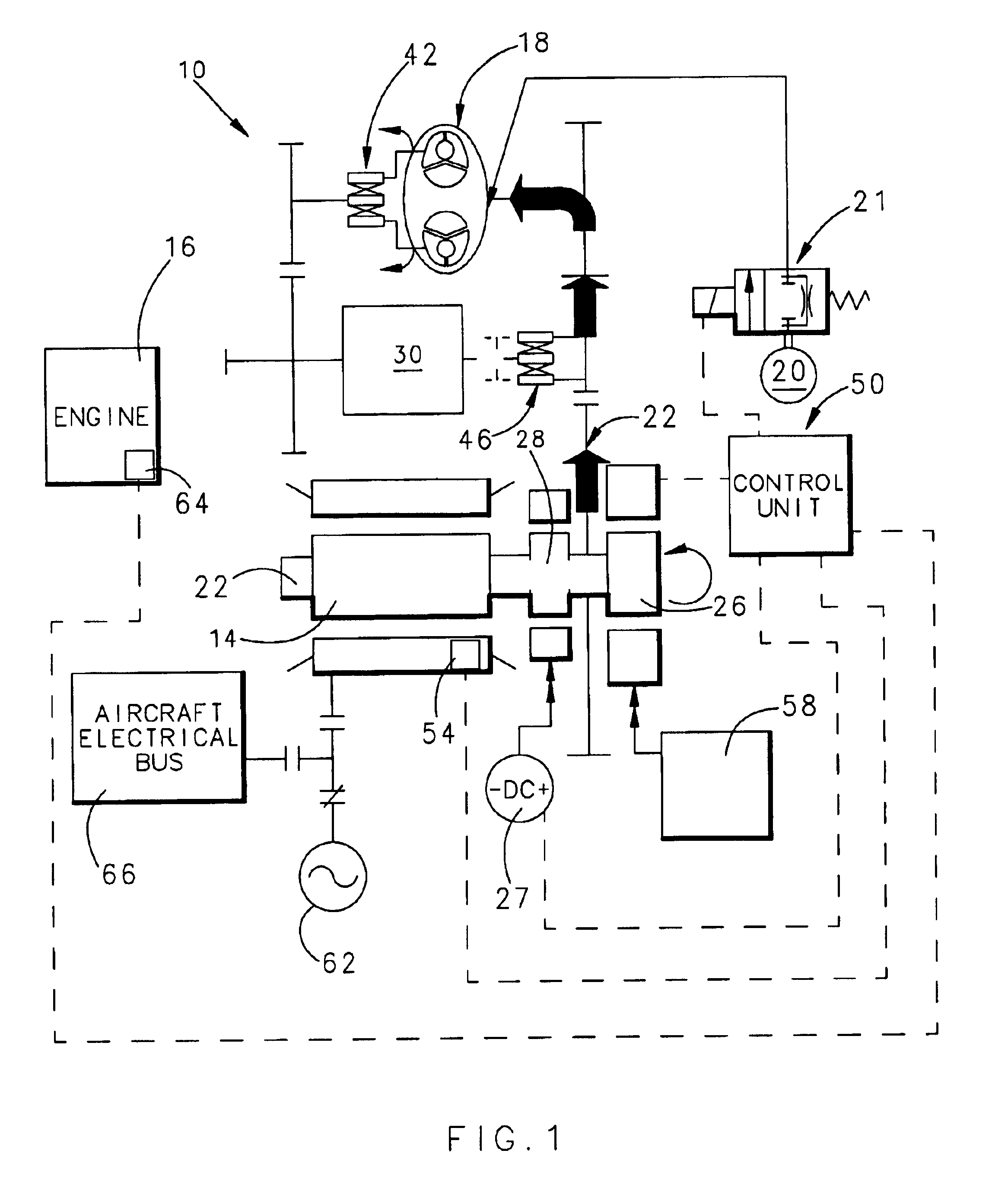

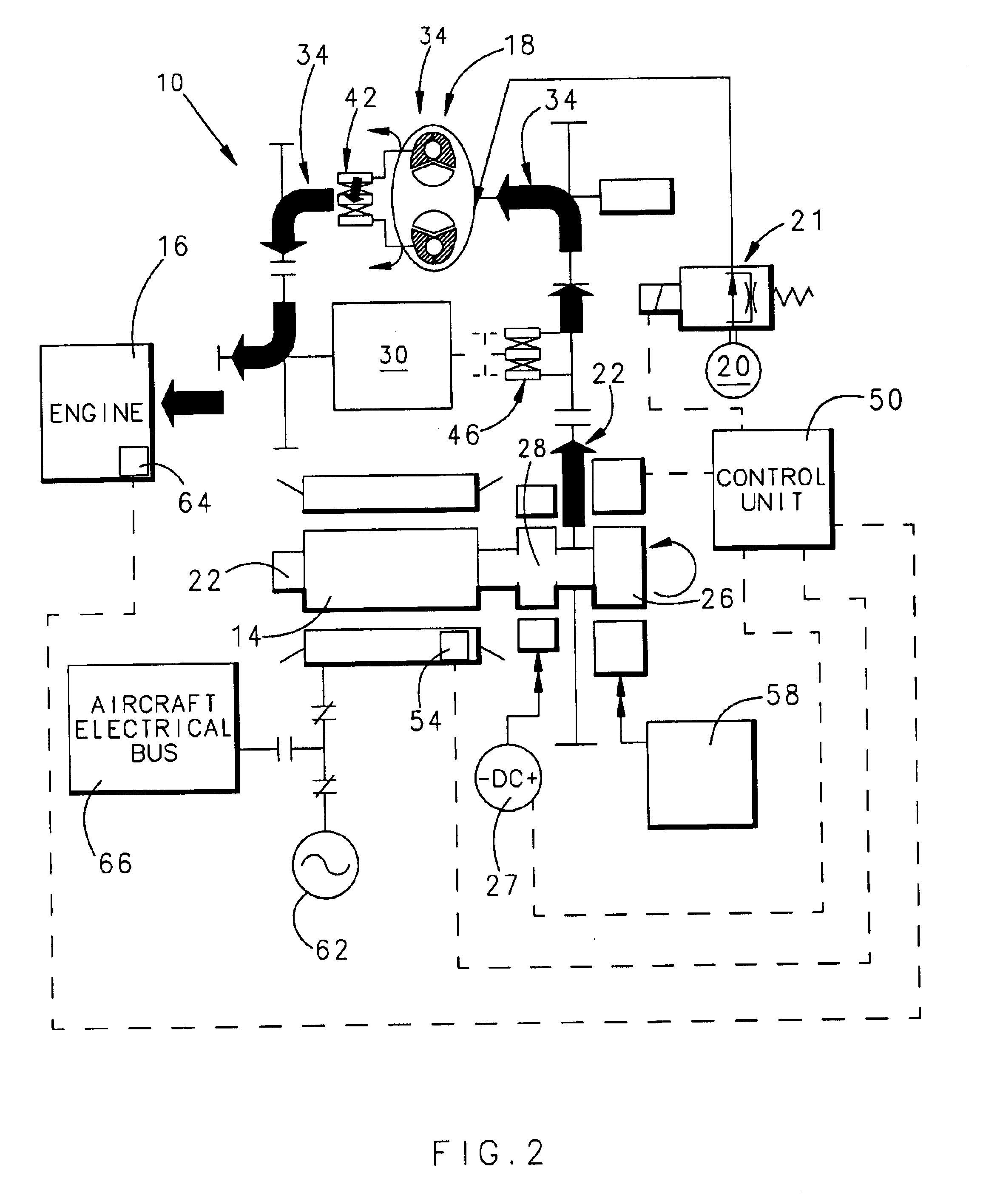

Integrated starter generator drive having selective torque converter and constant speed transmission for aircraft having a constant frequency electrical system

InactiveUS6838778B1Reduce loadStarters with fluid-driven auxillary enginesTurbine/propulsion engine ignitionStarter generatorConstant frequency

A starter-generator for an aircraft engine comprises a dynamoelectric machine alternatively operable as a motor or as a generator, having a rotor. A support motor is coupled to the dynamoelectric machine to assist the machine. A torque converter selectively couples and decouples the rotor to the engine, coupling the rotor to the engine at some point when dynamoelectric machine is operated as a motor. A constant speed transmission has an input adapted to be connected to the engine and an output to be connected to the rotor. The unit provides a desired speed relation between input and output. The engine may be started by the dynamoelectric machine when operated as a motor through a first power train including the torque converter and may drive the dynamoelectric machine as a generator through a second power train including the constant speed transmission.

Owner:HAMILTON SUNDSTRAND CORP

Beam irradiation apparatus, beam irradiation method, and method for manufacturing a thin film transistor

InactiveUS20050036190A1Uniform crystallinityUniform characteristicsLaser beam welding apparatusOptical elementsGalvanometerLight beam

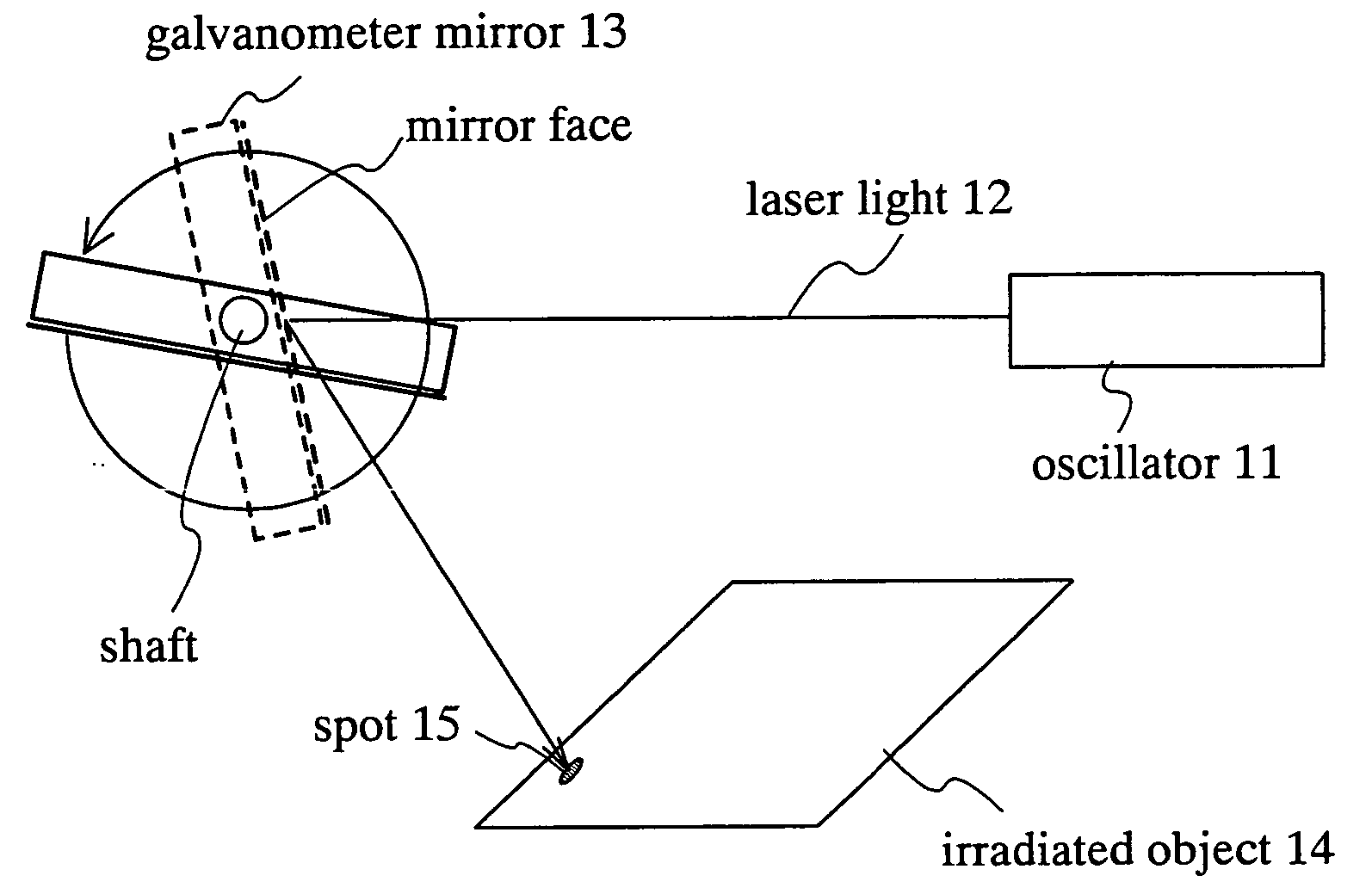

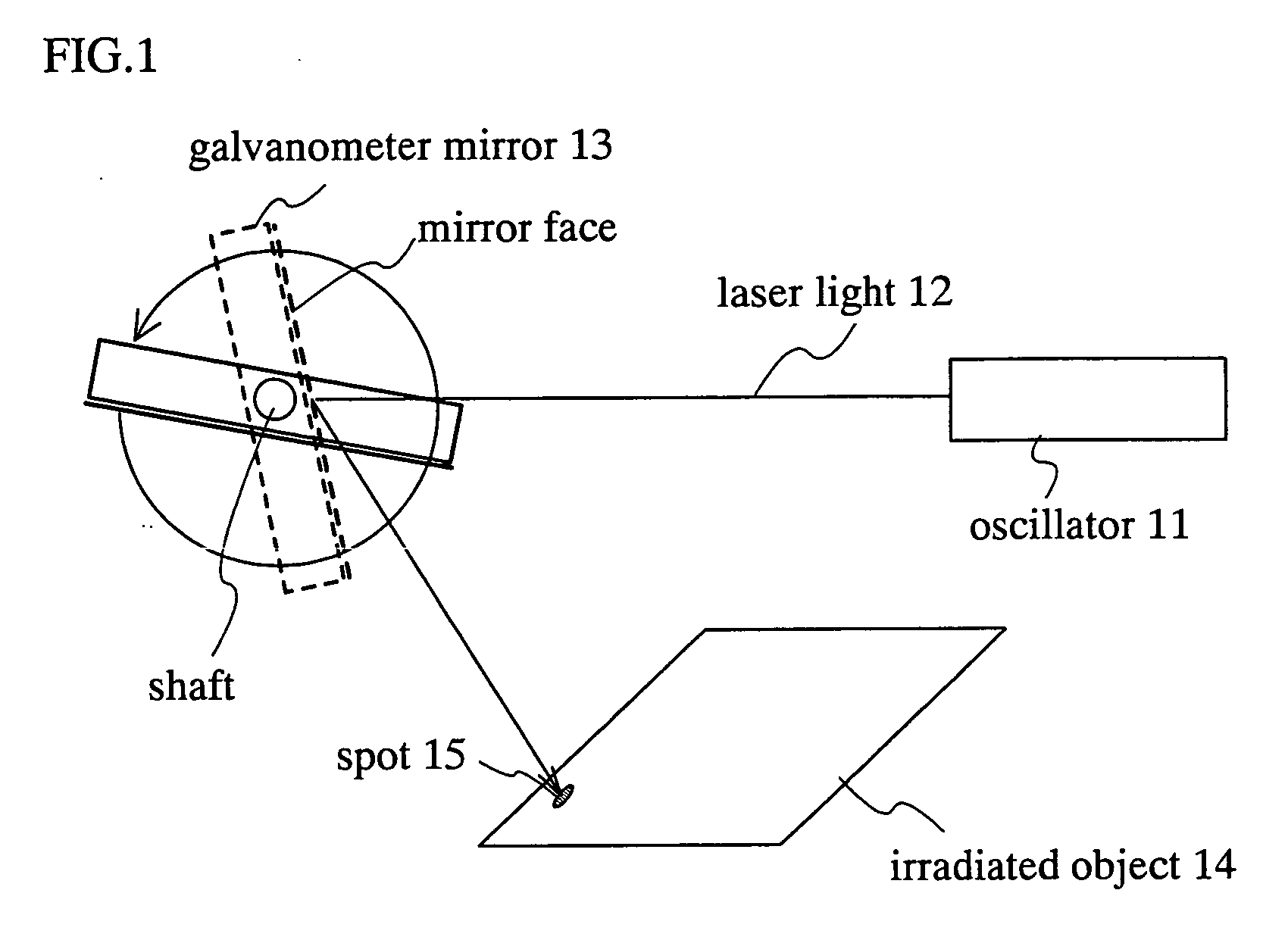

A galvanometer mirror rotates in one direction when the galvanometer mirror is used. A spot can be scanned on an irradiated surface at a more constant speed by rotating the galvanometer mirror and by using the inertia. Moreover, it is preferable to make the galvanometer mirror heavy because the inertia becomes higher so that the spot is scanned at a more constant speed. In addition, in a polygon mirror of this invention, mirrors are arranged so as not to contact each other because a change time of the scanning position between the mirrors is provided. By moving the irradiated object with timing together when the laser light is not irradiated, the laser process can be performed efficiently.

Owner:SEMICON ENERGY LAB CO LTD

Efficient rasterization system and method

InactiveUS7072052B1Efficiently rasterizedDigitally marking record carriersVisual presentation using printersColor imageDescription format

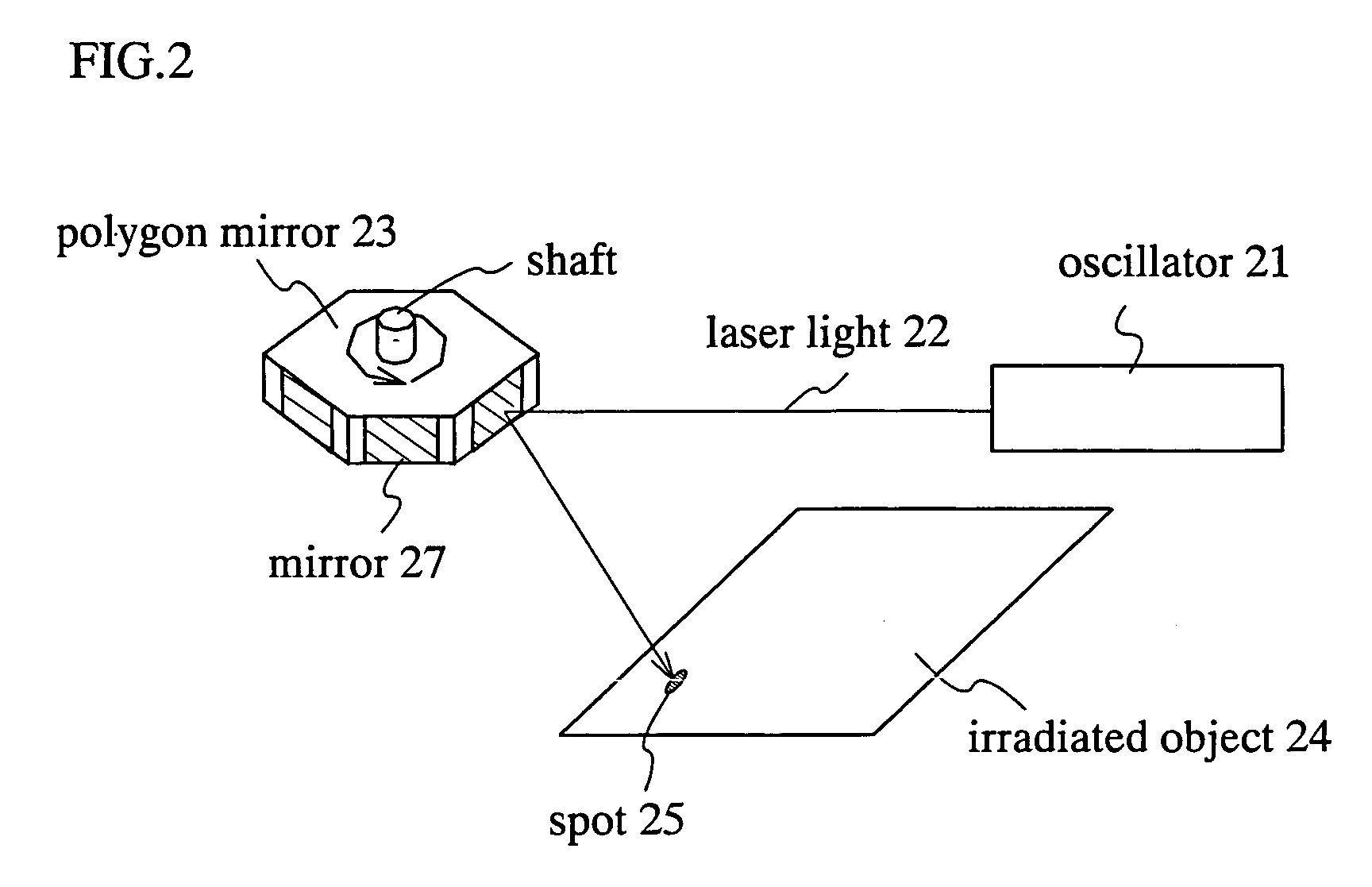

An image processing method and system is provided wherein a plurality of processors perform a conversion process from a page description language format of data into raster image data, and a printing engine which continuously receives color image data having at least three color components in page unit and prints the at least three color components of color image data on a recording medium in parallel at a constant speed. A page description language format of data is received that includes at least two of the at least three color components as at least an object constituting the page description format data, the page description language format of data is analyzed and, based on the analysis, each color component data of the object in the received data is assigned to each processor such that the plurality of processors perform the conversion processes of the at least two of the at least three color components in parallel thereby producing raster image data of each color component from the plurality of processors to the printing engine in parallel.

Owner:CANON KK

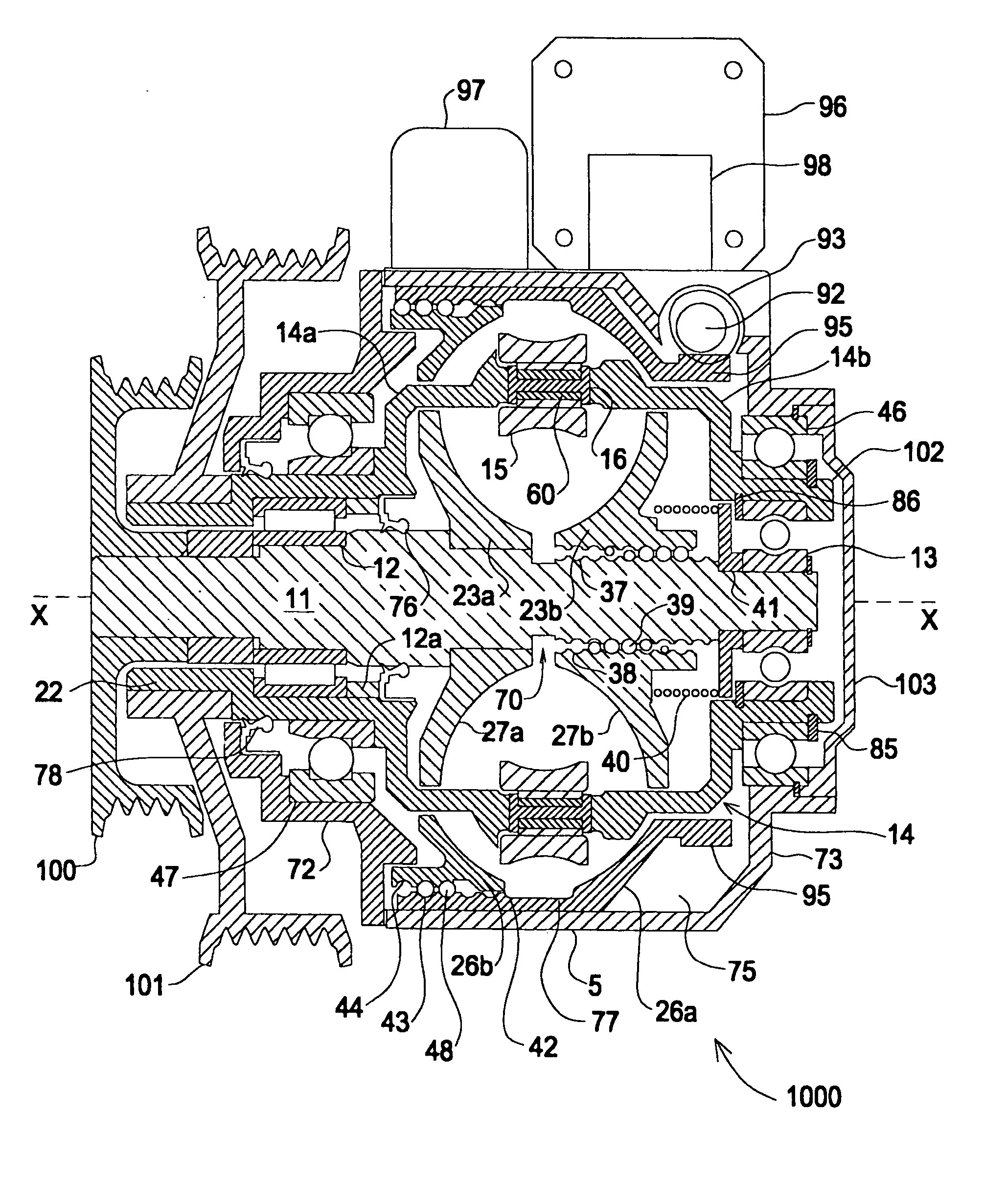

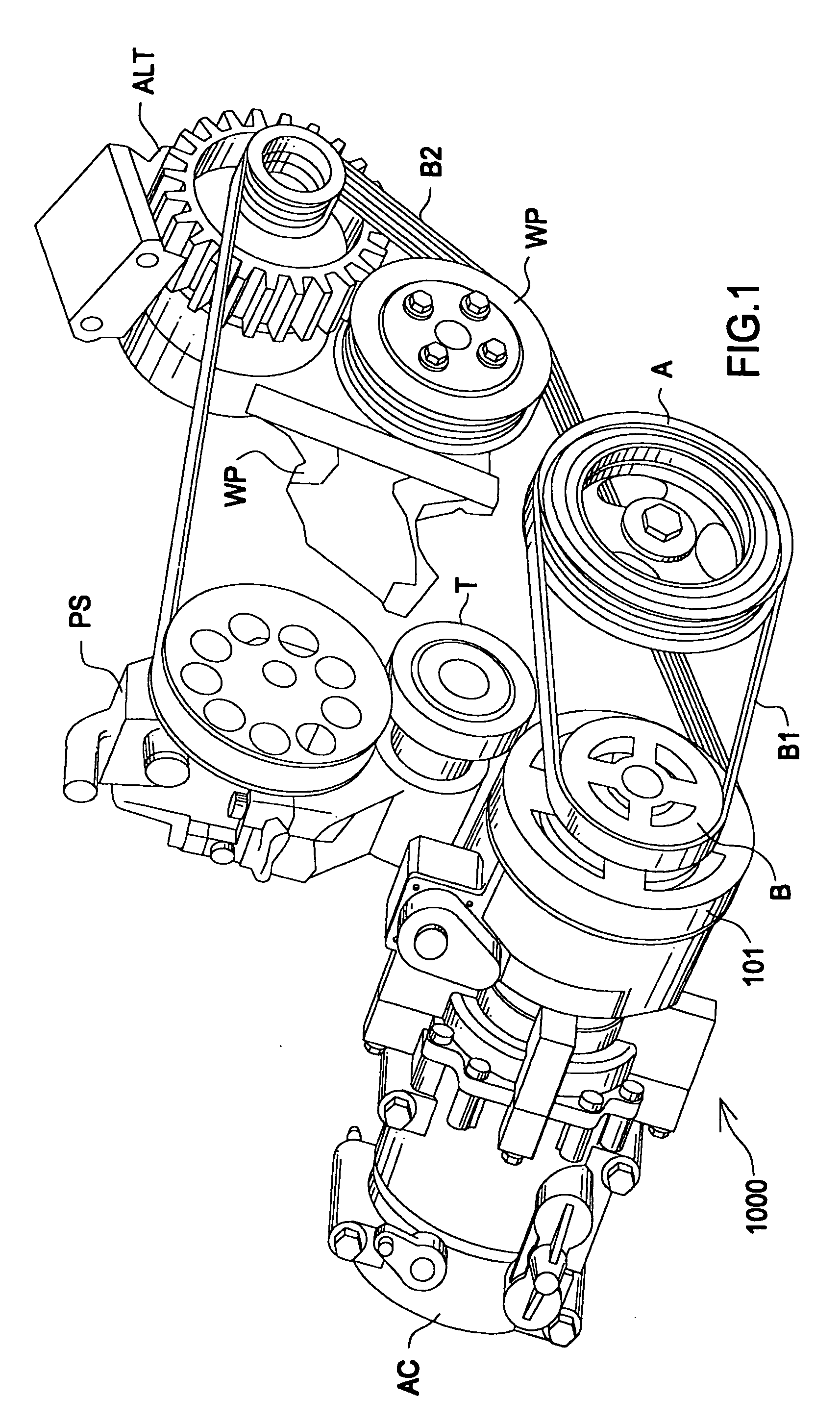

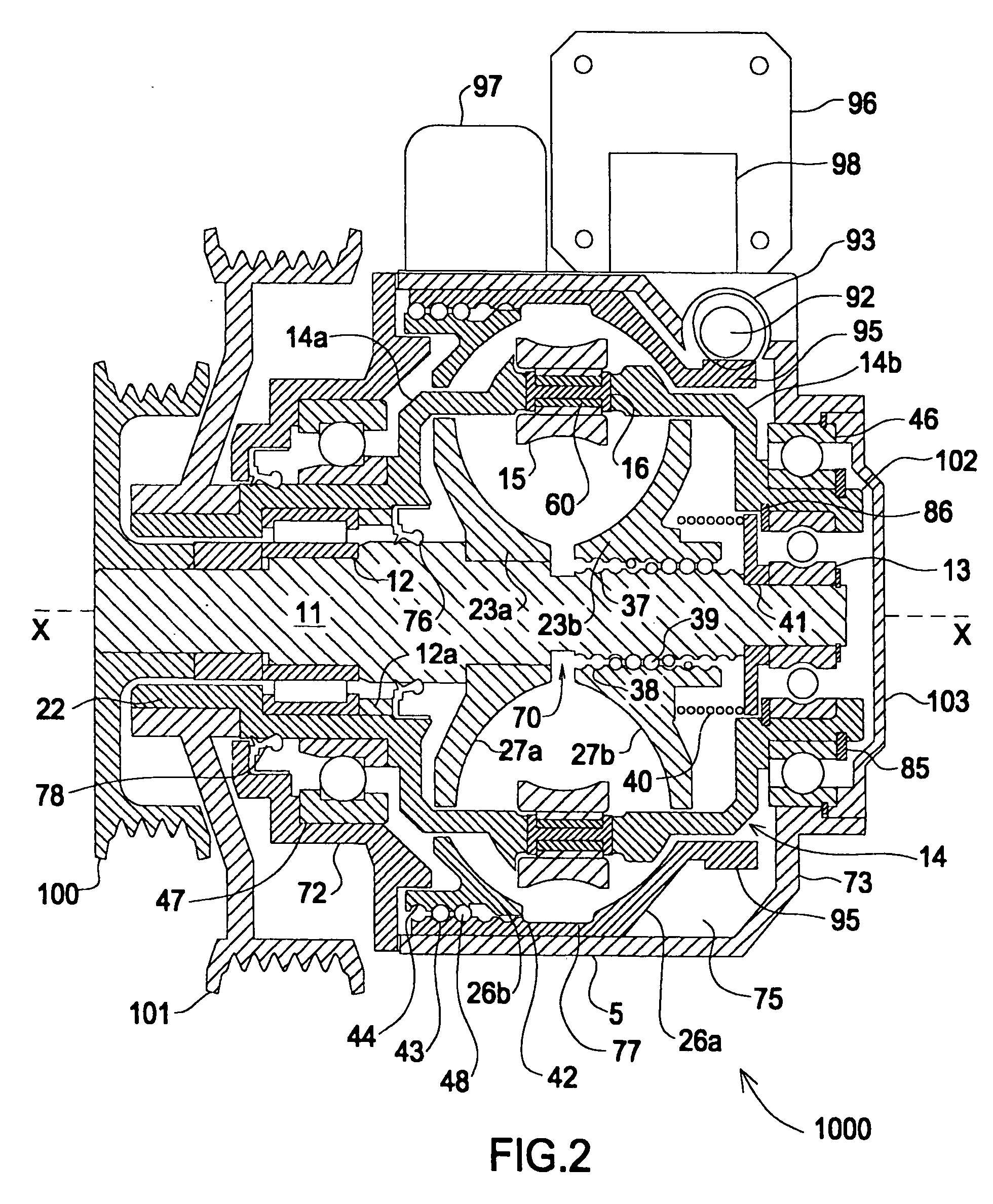

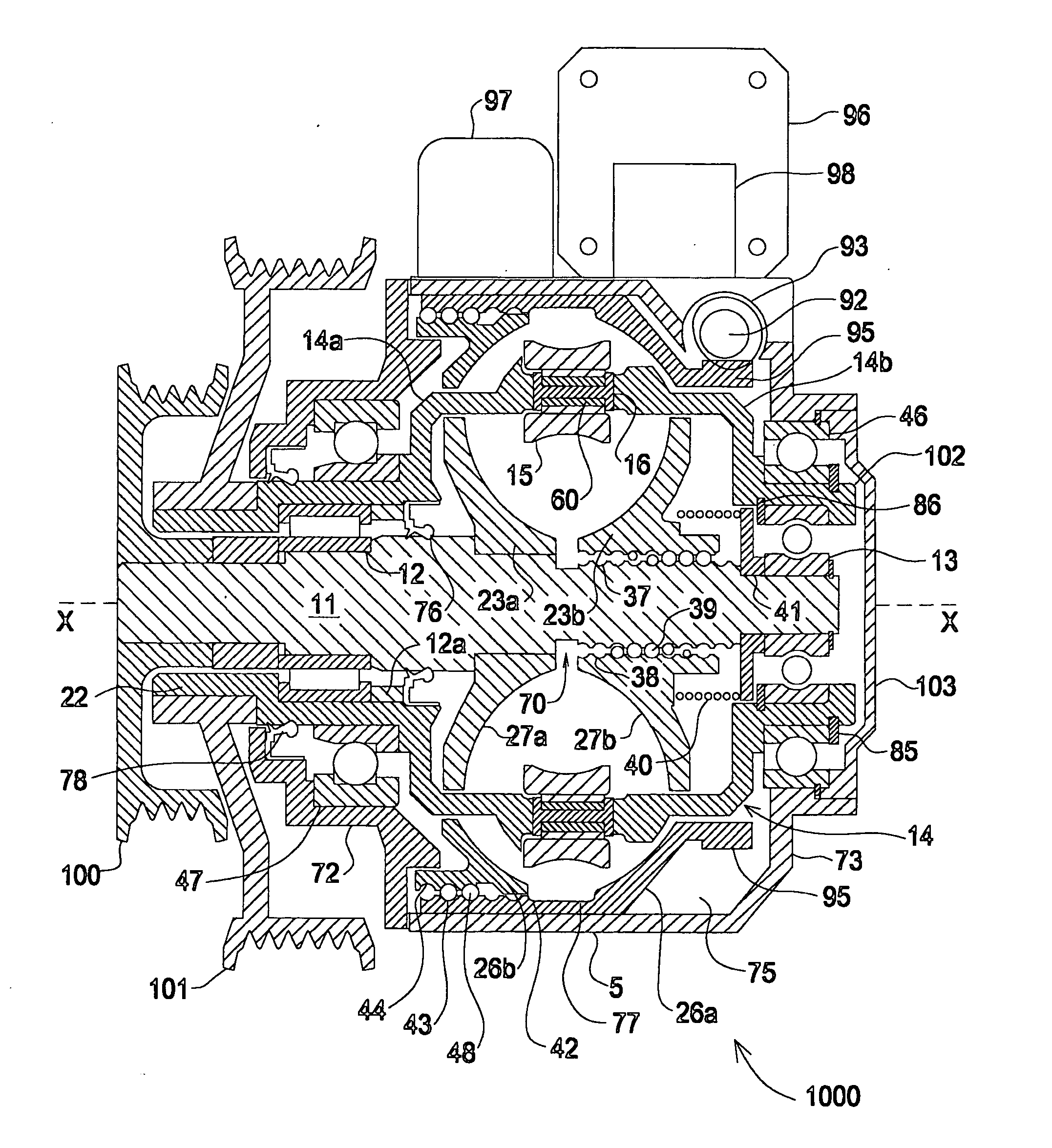

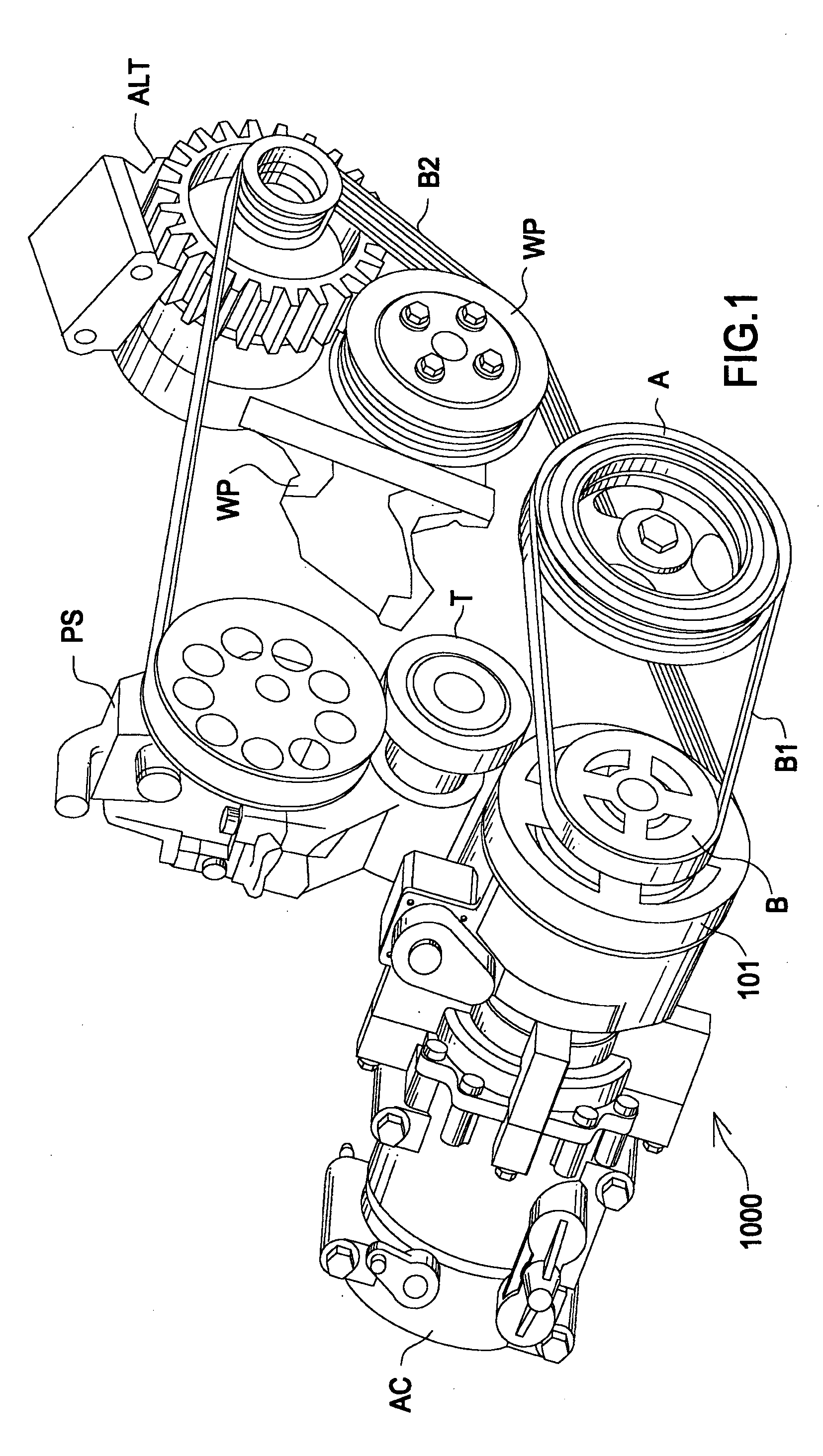

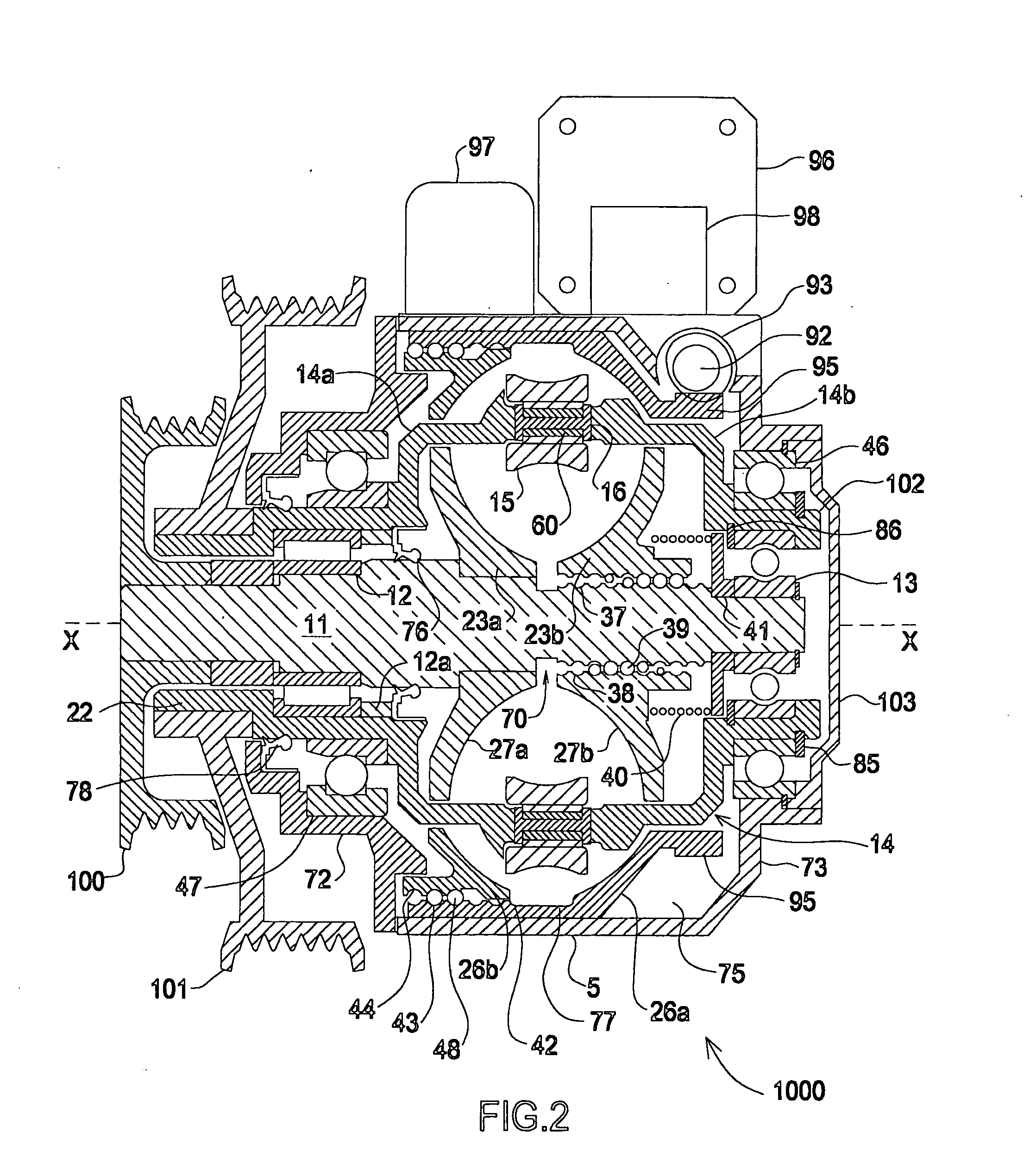

Transmission and constant speed accessory drive

A method of operating a belt drive accessory system comprising the steps of transmitting a torque with a first endless member from a driver member to a planetary ball transmission input, coaxially aligning the planetary ball transmission input with a planetary ball transmission output, transmitting a torque by a second endless member from the planetary ball transmission output to a driven accessory, selecting a speed ratio of the planetary ball transmission according to a driver member rotational speed, thereby operating the driven accessory at a substantially constant speed at a point of substantially maximum efficiency over a drive member rotational speed range, and frictionally locking the speed ratio of the planetary ball transmission when a drive member speed is constant.

Owner:THE GATES CORP

Transmission and constant speed accessory drive

InactiveUS20050181905A1Constant output speedGearing controlFriction clutchesControl systemDirect coupling

An infinitely variable speed ratio planetary ball transmission comprising planetary members in rolling contact with moveable inner and outer races and a constant speed accessory drive system utilizing the transmission. The transmission is infinitely variable between ratios of approximately 0.3 and 1.0. A transmission input shaft is connected to a prime mover such as a vehicle engine crankshaft by a drive belt. The transmission comprises at least one output shaft that is coaxial with the input shaft. An output pulley is attached to the output shaft. A belt is engaged between the output pulley and various engine accessories. A second end of the transmission output shaft may be directly coupled to an engine accessory mounted on the transmission. An included control system senses a crankshaft speed. A processor analyses the crankshaft speed and accordingly adjusts the transmission ratio using a stepper motor connected to a worm drive to maintain a constant output speed regardless of crankshaft speed.

Owner:THE GATES CORP

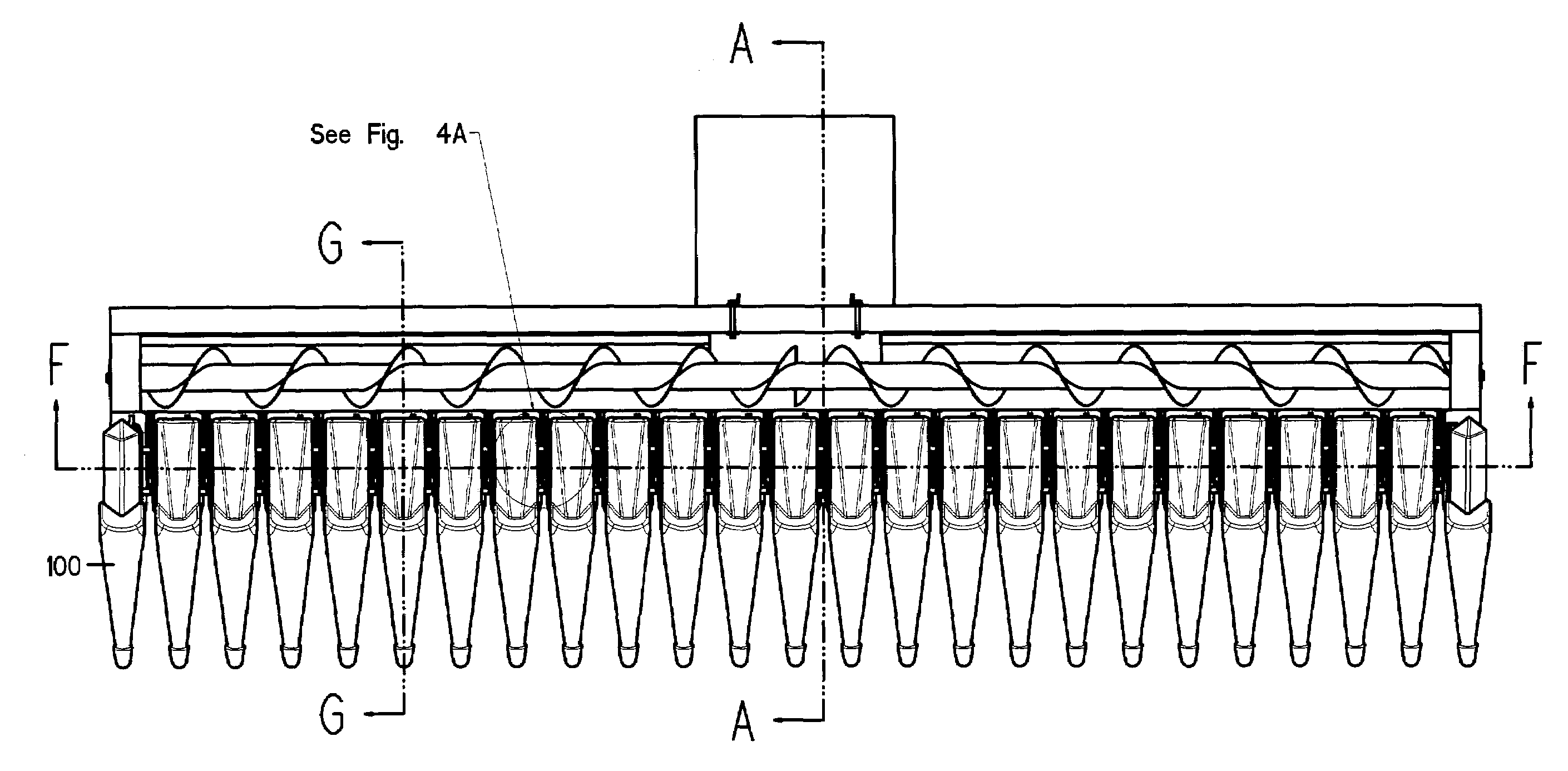

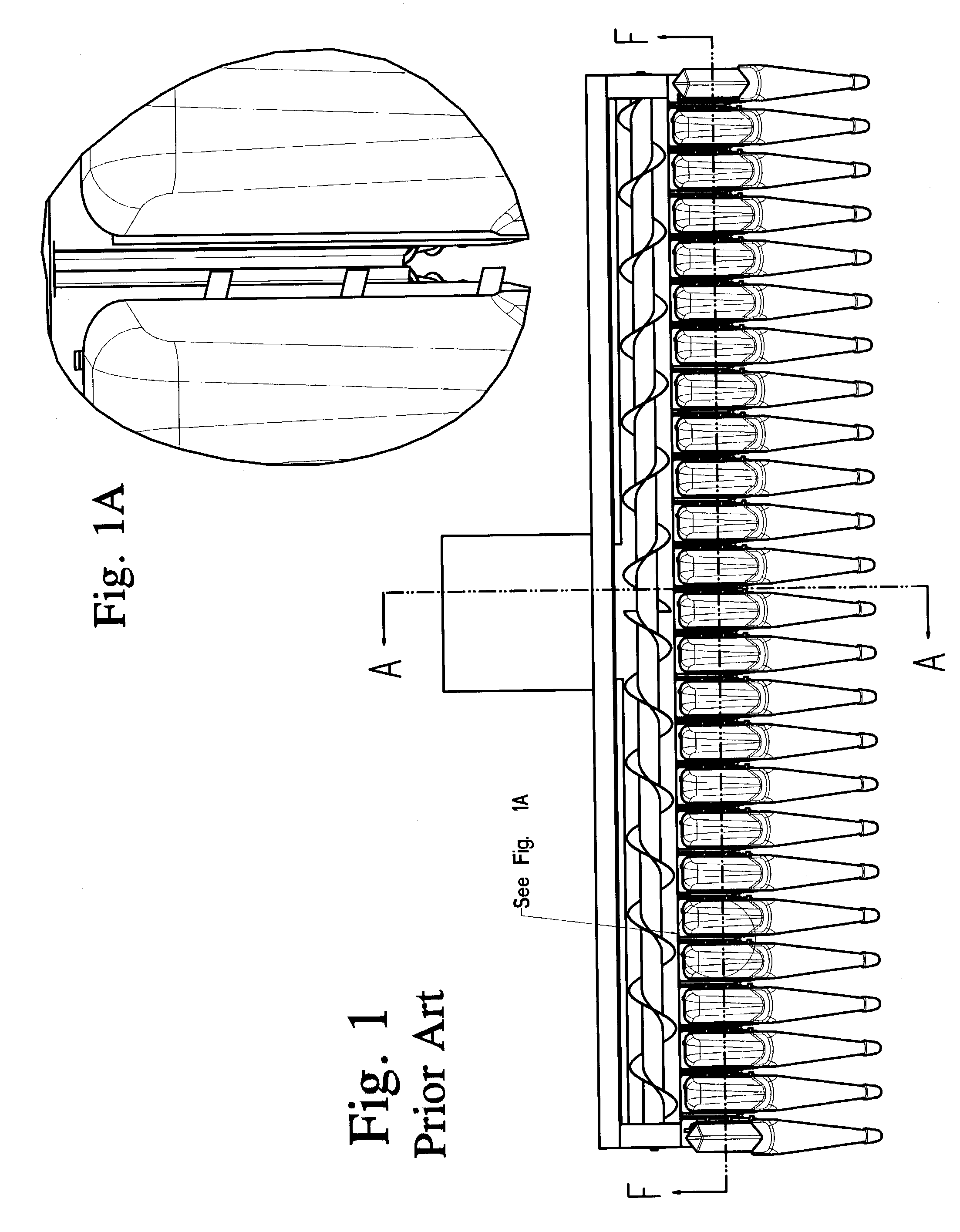

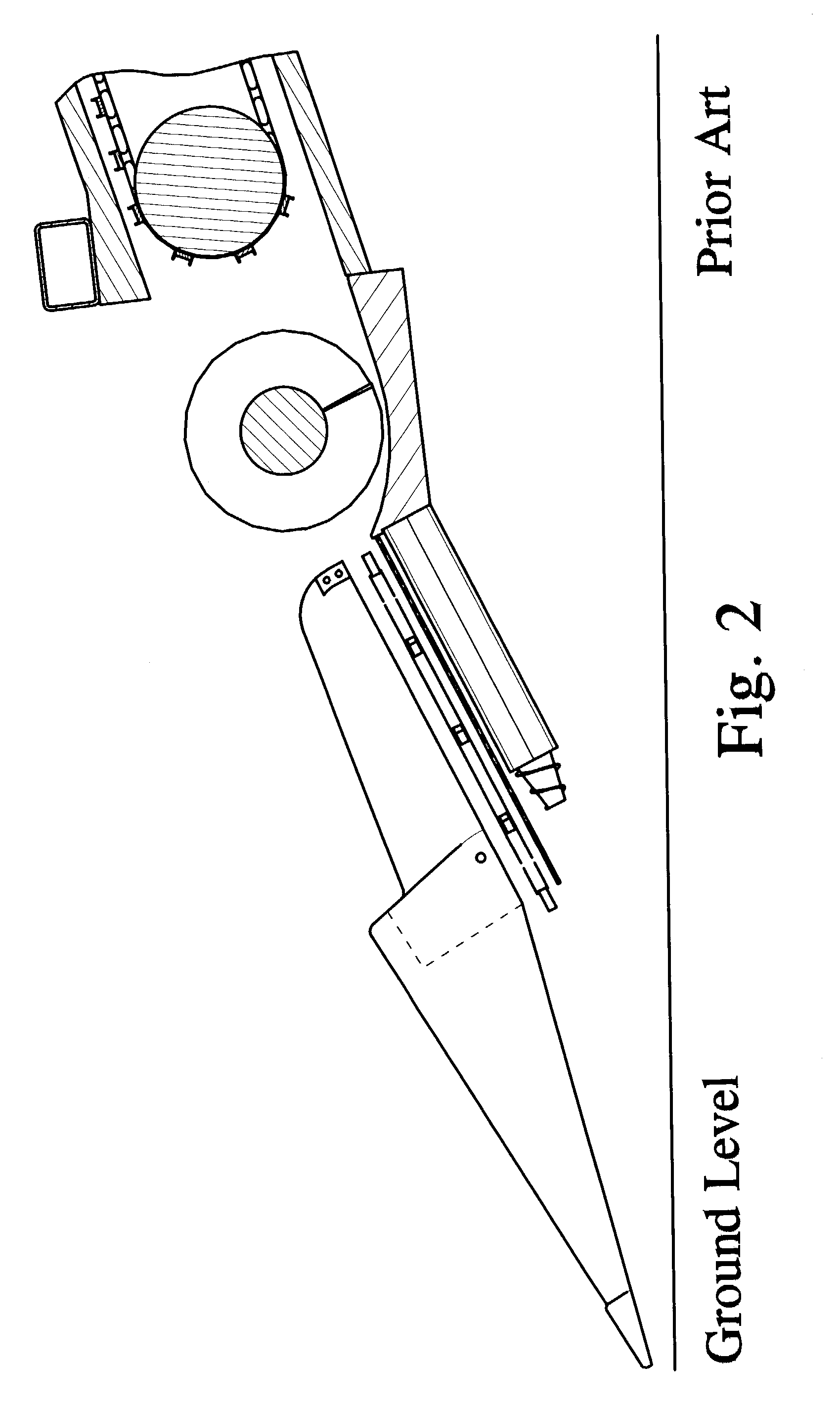

Corn head row unit

This row unit utilizes an improved multi-zone, multi-functional stalk roll, which contains a novel revolving entry window to improve entry and increase engagement of the fluted portion of the stalk roll flutes with the corn stalk. The stalk rolls described are multi-sectional and contain multi-length variable flutes. The number of flutes described for each zone may vary as well as whether the flutes are meshing or non-meshing and angled or non-angled. The stalk rolls described allow a constant speed drive shaft to create lower and / or higher effective circumferential contact speeds within each zone of the stalk roll. The invention provides that the rotating transport vanes located on the helical nose cone at the entry area to the stalk roll flutes lock the corn stalk into a revolving entry window. This novel row unit contains a multi-zone, multi-functional stripper plate that ensures minimal ear wedging and maximum discharge of material other than ears. This row unit utilizes a novel gathering / conveying chain(s), which reduces the number of and increases the angle and size of the paddles. This row unit design optimizes operation between the components imparting force to the corn plant and ears. The invention has a smooth uninterrupted improved flow of corn stalk material through the ear separation chamber and is the first row unit designed to be environmentally friendly by ensuring that the majority of the corn plant remains connected to its original root system which prevents it from rapidly decomposing, blowing or washing away. The row unit cover is spatially designed for improved flow in down, damp and tough harvesting conditions.

Owner:CALMER MARION

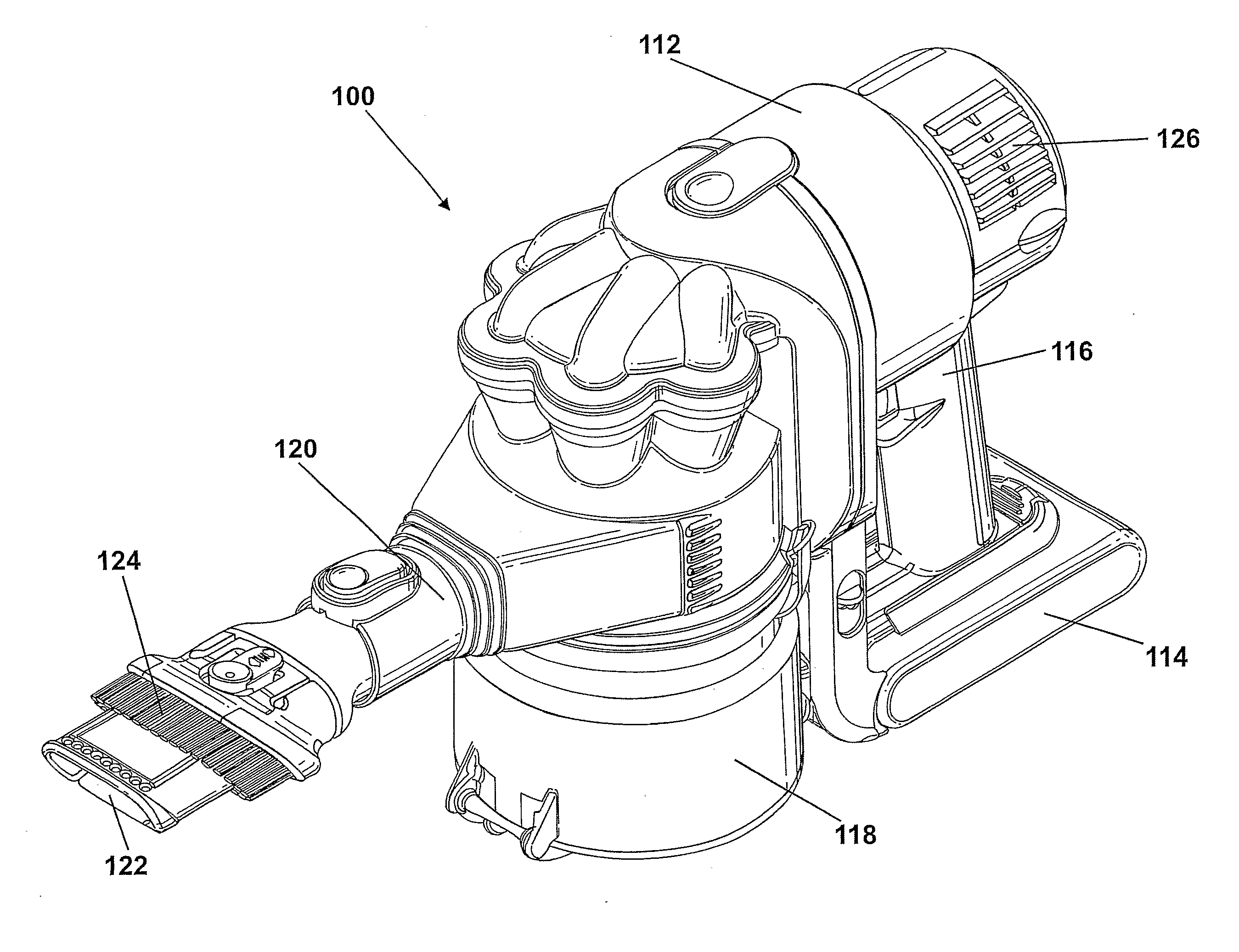

Motor driving apparatus

ActiveUS20100045215A1Eliminate needEasy to cleanBatteries circuit arrangementsSingle motor speed/torque controlPower controllerMotor drive

A motor driving apparatus for a cleaning appliance includes a battery source and a power controller. The battery source supplies the power controller with an output having a first voltage which decreases as the battery source is discharged. The power controller modulates the output to produce a drive signal for driving a motor that has a second voltage and a variable duty cycle. The power controller increases the duty cycle of the drive signal as the first voltage decreases in order to maintain the second voltage at a substantially constant average value per unit time. By providing the above arrangement, the motor can be supplied with a constant voltage throughout the available run time of the battery. When forming part of a cleaning appliance having a motor, the above arrangement allows the motor to operate at a substantially constant speed throughout the run time of the battery.

Owner:DYSON TECH LTD

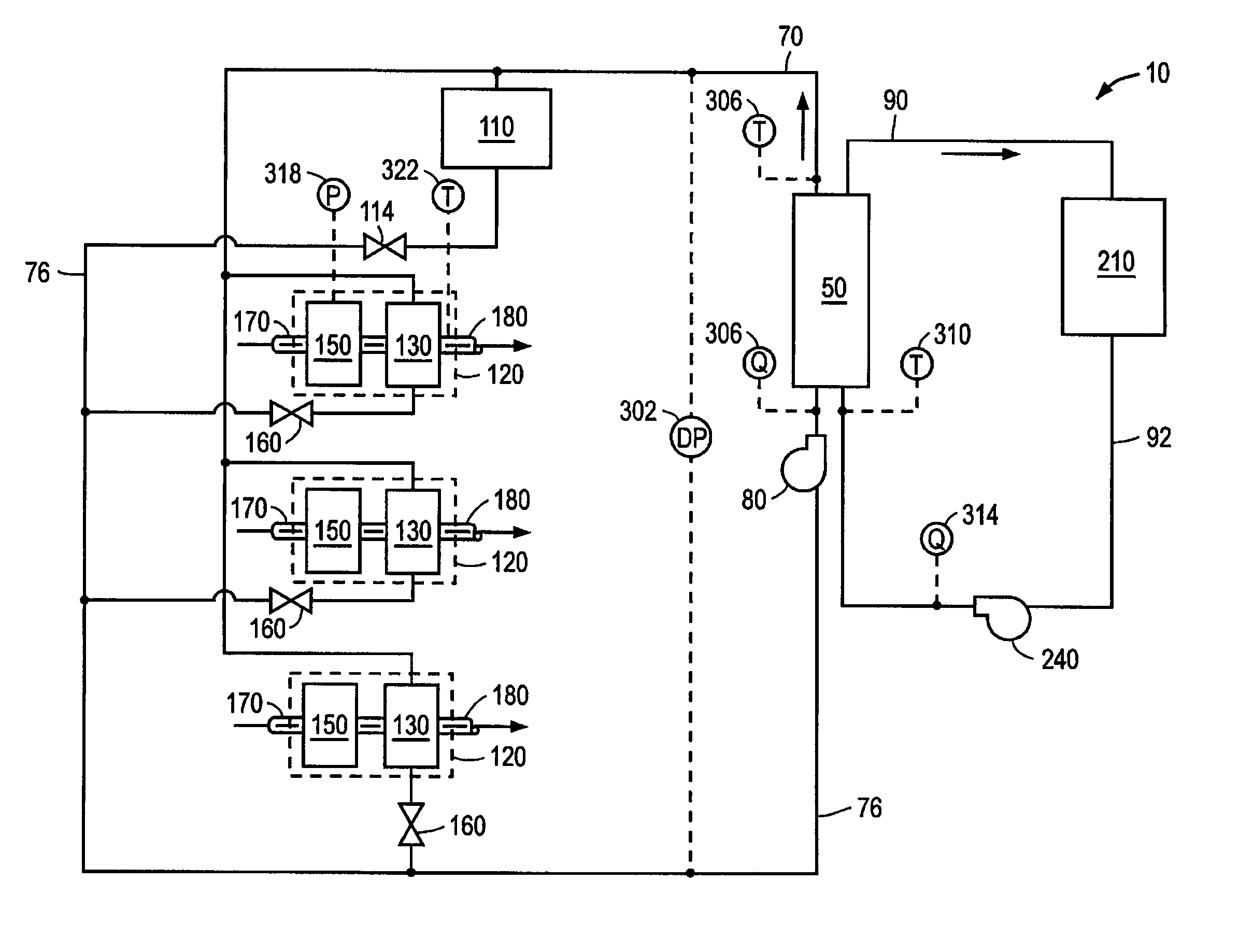

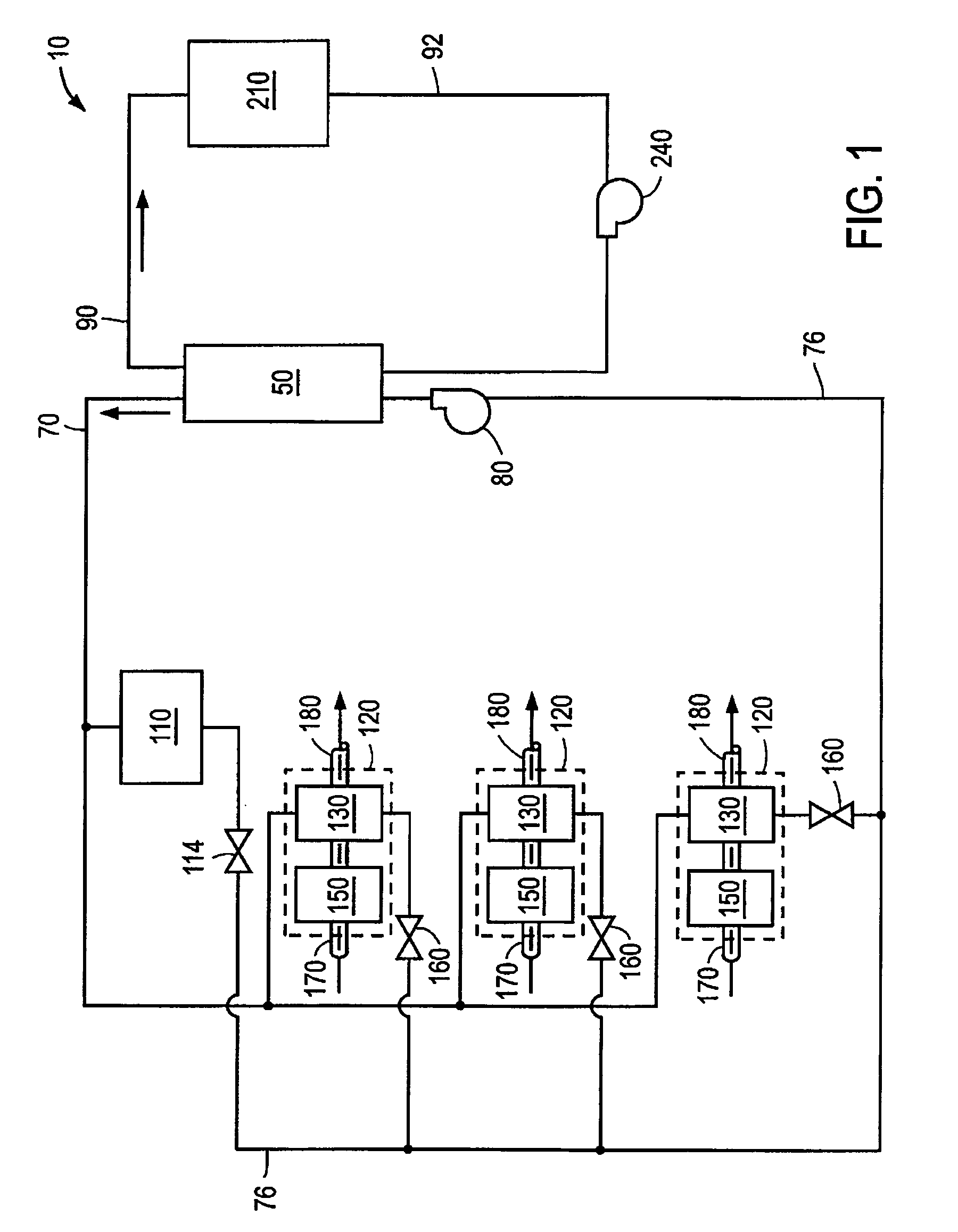

Optimized control system for cooling systems

ActiveUS7890215B2Reduce energy consumptionImprove energy efficiencySampled-variable control systemsMechanical apparatusCooling towerControl system

A cooling system for providing conditioned air to a facility includes a chiller or other cooling subsystem, a cooling tower subsystem and one or more air handling units or process cooling units. The cooling subsystem may advantageously include one or more chillers (e.g., variable speed chillers, constant speed chillers, absorption chillers, etc.) and chilled fluid pumps. The cooling tower subsystem includes one or more cooling tower units and condenser fluid pumps. In some implementations, the air handling unit has a cooling coil and a variable volume fan. In some implementations, direct expansion (DX) cooling systems comprise compressors, evaporators and air-cooled, water-cooled or evaporatively-cooled condensing systems. Such systems can be controlled to reduce energy waste, improve occupant comfort and / or improve the thermal characteristics of the process cooling unit. The cooling system further comprises a control system which is configured to evaluate a cooling load value at the air handling unit and use the cooling load value to calculate at least one operational setpoint. The operational setpoint may advantageously be selected to improve the energy efficiency of the overall cooling system.

Owner:YARDI SYST

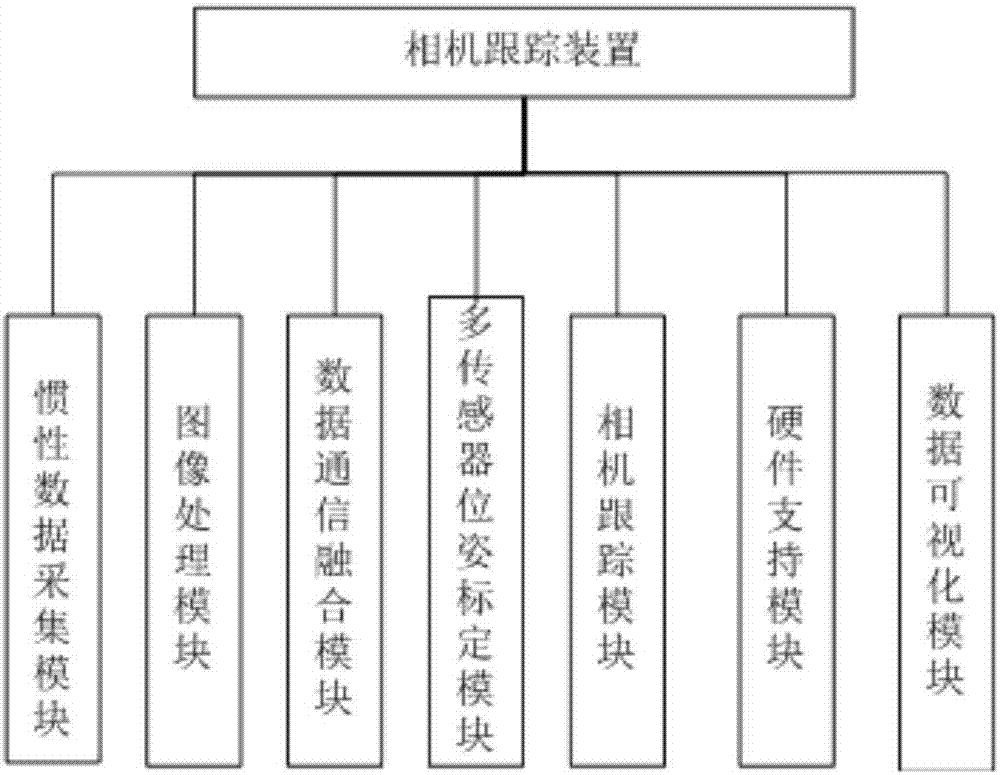

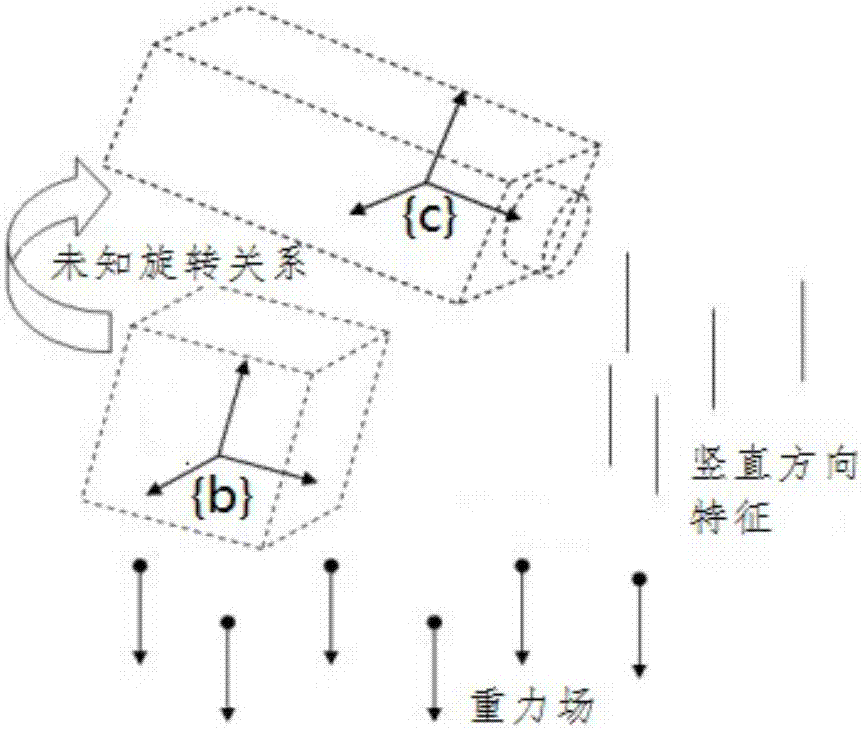

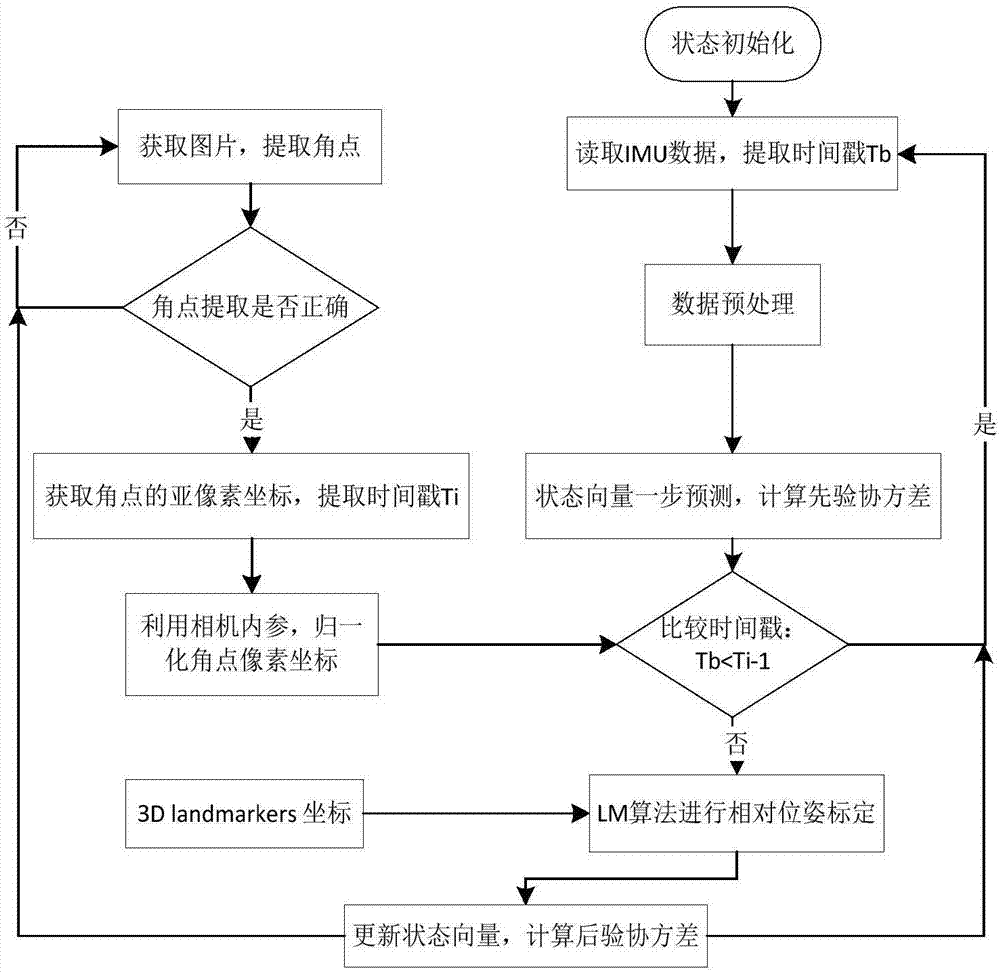

Indoor positioning method and device based on inertial data and visual features

ActiveCN107255476AImprove tracking accuracyImprove robustnessNavigational calculation instrumentsNavigation by speed/acceleration measurementsData modelingVisual perception

The invention discloses an indoor positioning technology based on inertial data and visual features and discloses a corresponding implementation device to implement the steps. The indoor positioning technology specifically comprises: (1) multi-sensor data processing: a camera calibration and image feature extraction method; an IMU data modeling and filtering method; (2) multi-sensor coordinate system calibration: a system modeling, relative attitude calibration and relative position and attitude joint calibration method; (3) an indoor positioning and tracking technology fusing the inertial data and the visual features. Compared with an existing traditional single camera tracking technology, the indoor positioning technology disclosed by the invention has the advantages that single camera tracking is a simple assumption based on constant-speed motion; a better prediction can be provided by using the inertial data of an IMU, so that a search area is smaller during feature matching, the matching speed is higher, the tracking results are more accurate, and the camera tracking robustness in the image degradation and un-textured areas is greatly improved.

Owner:青岛海通胜行智能科技有限公司

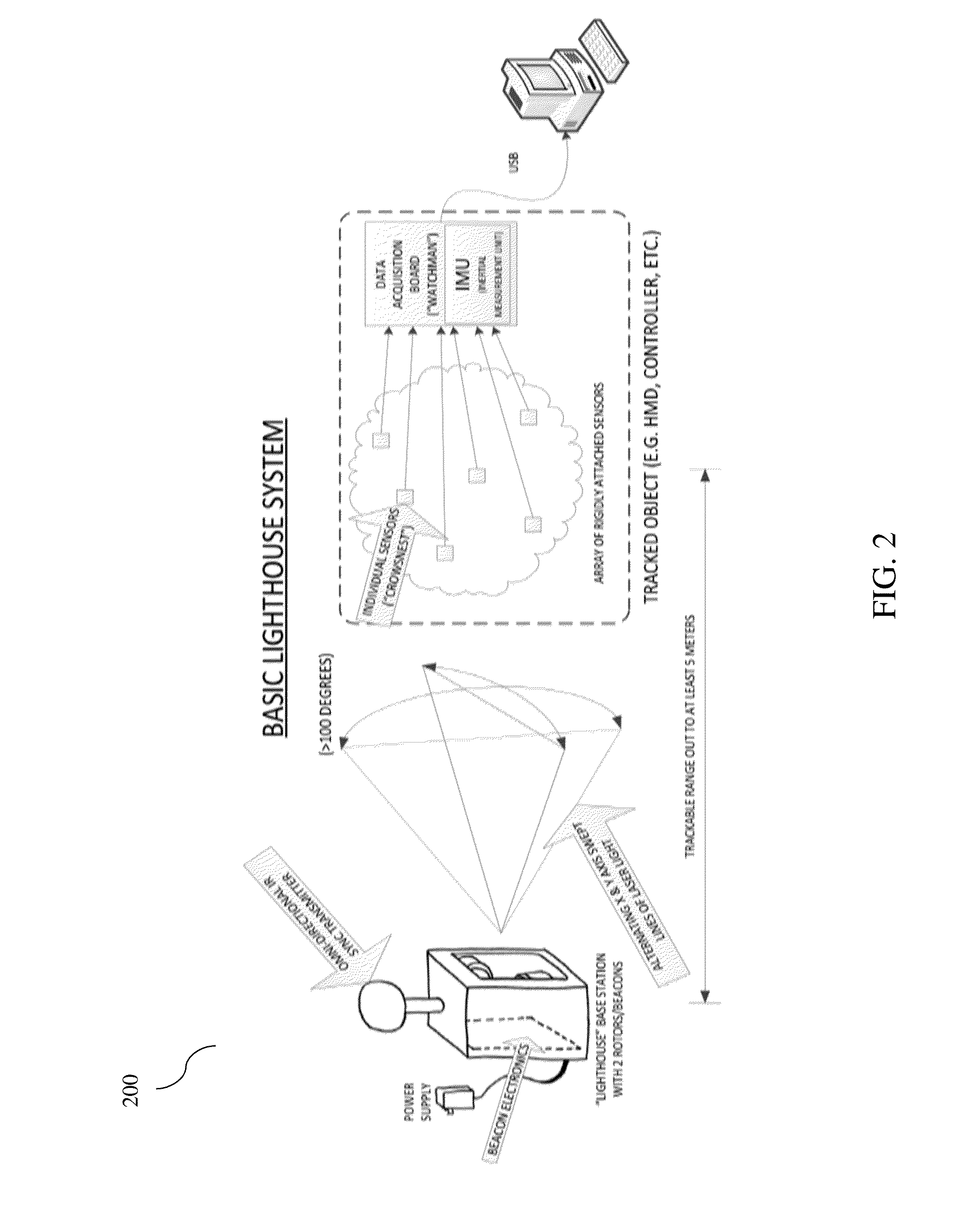

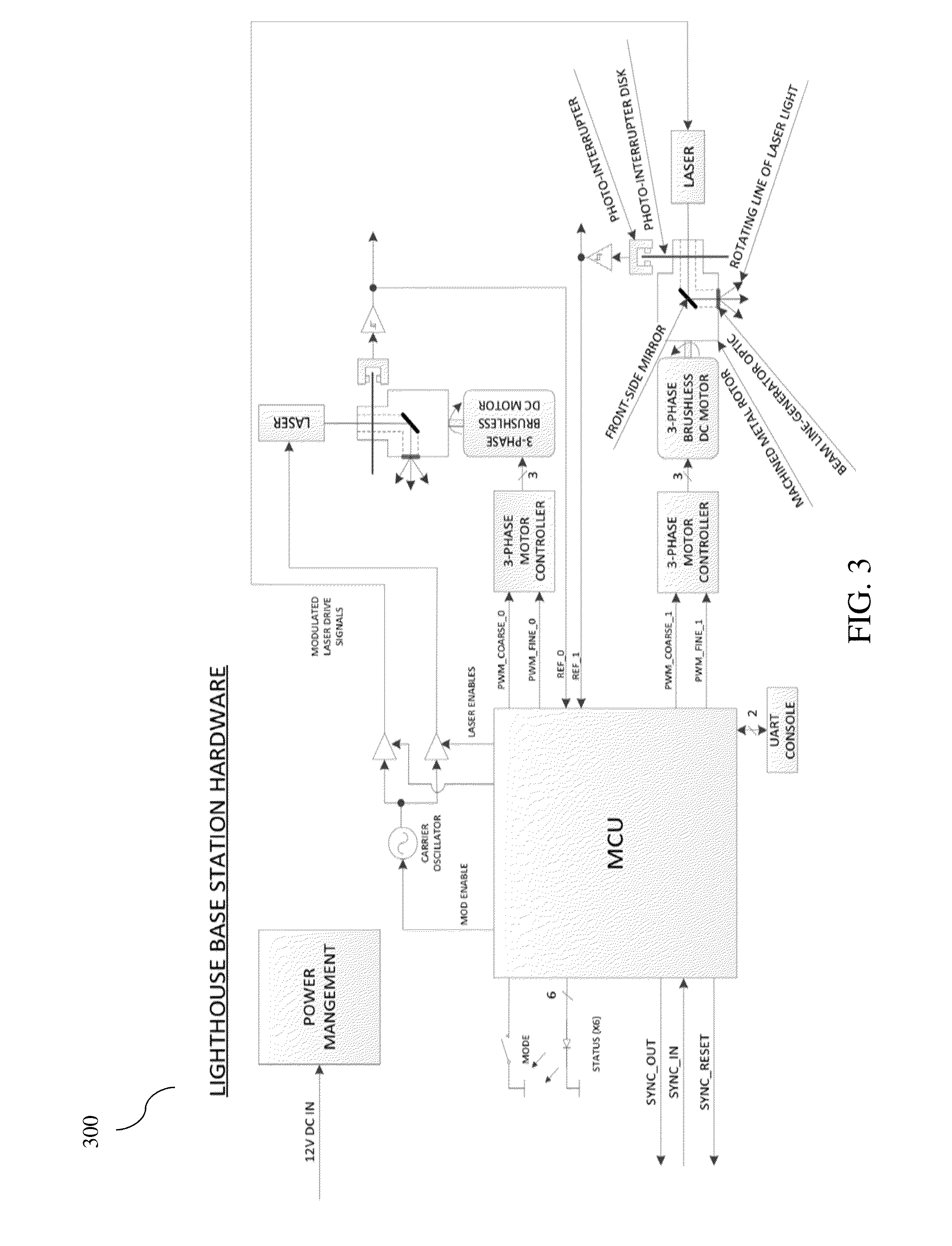

Positional tracking systems and methods

ActiveUS20160131761A1Optical rangefindersBeacon systems using electromagnetic wavesDisplay deviceLight beam

Optical positional tracking systems that may be used in virtual reality (VR) / augmented reality (AR) applications are described. Exemplary implementations comprise one or more receivers and one or more transmitters. Exemplary transmitters contains two orthogonal rotors that each emit a fan-shaped laser beam. Each beam is swept as the rotors are spun at constant speed. Exemplary optical receivers can be relatively small, and mounted at convenient locations on the VR display. These receivers consist of small optical detectors that may be mounted on head-mounted VR displays. Exemplary systems determine position by measuring the time at which each swept beam crosses each receiver / detector.

Owner:VALVE

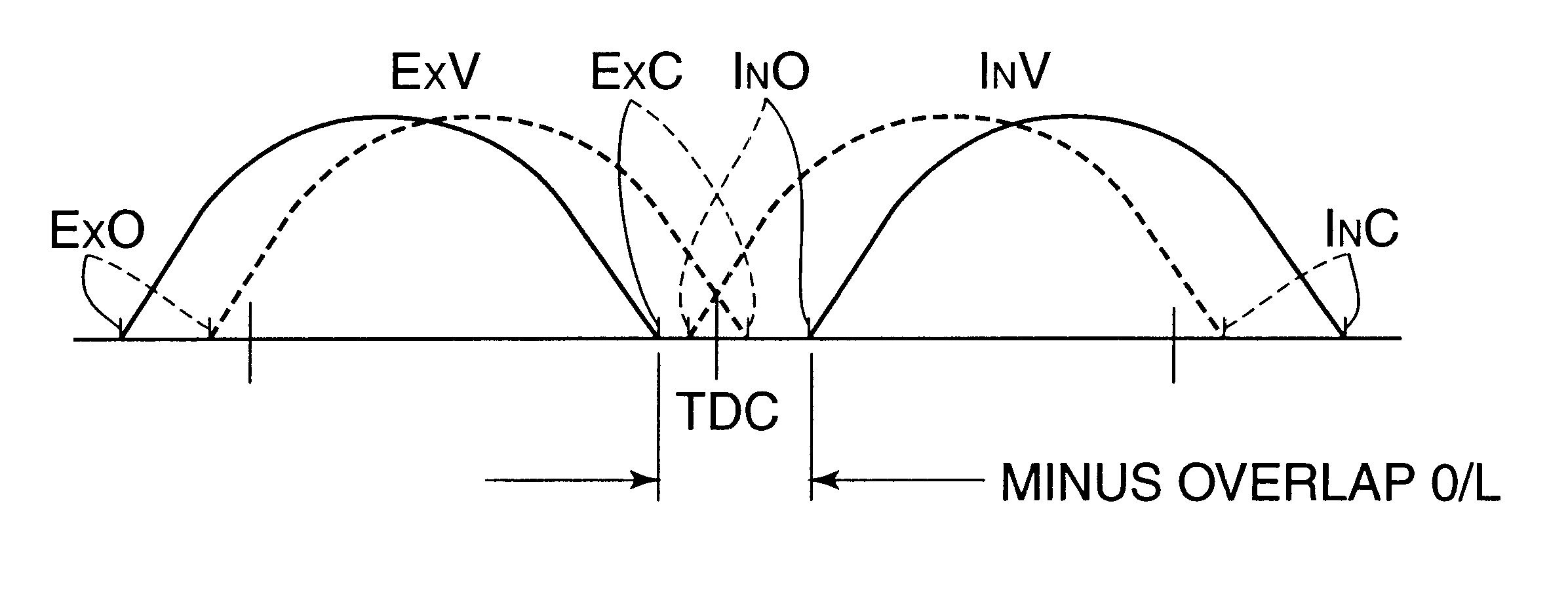

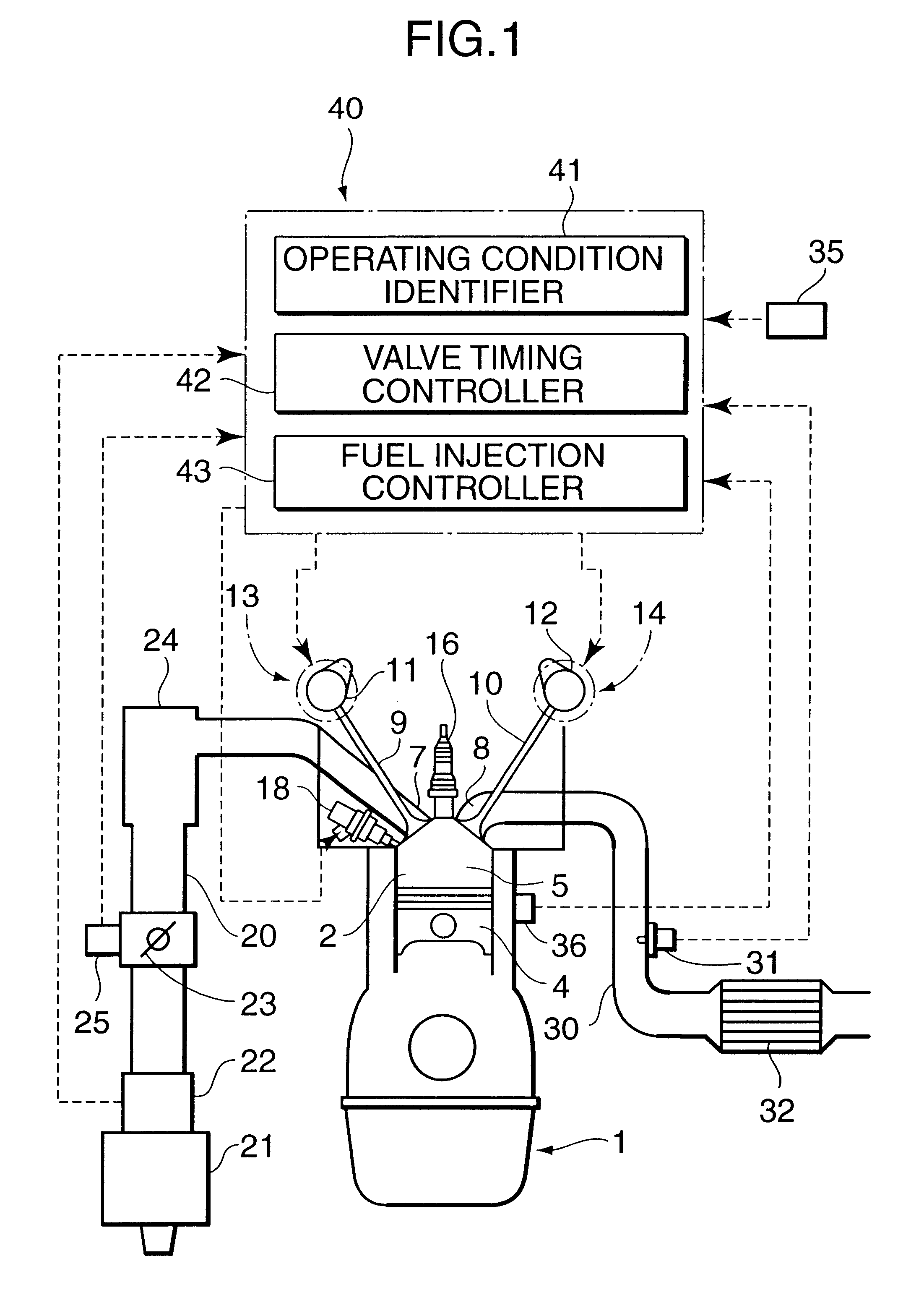

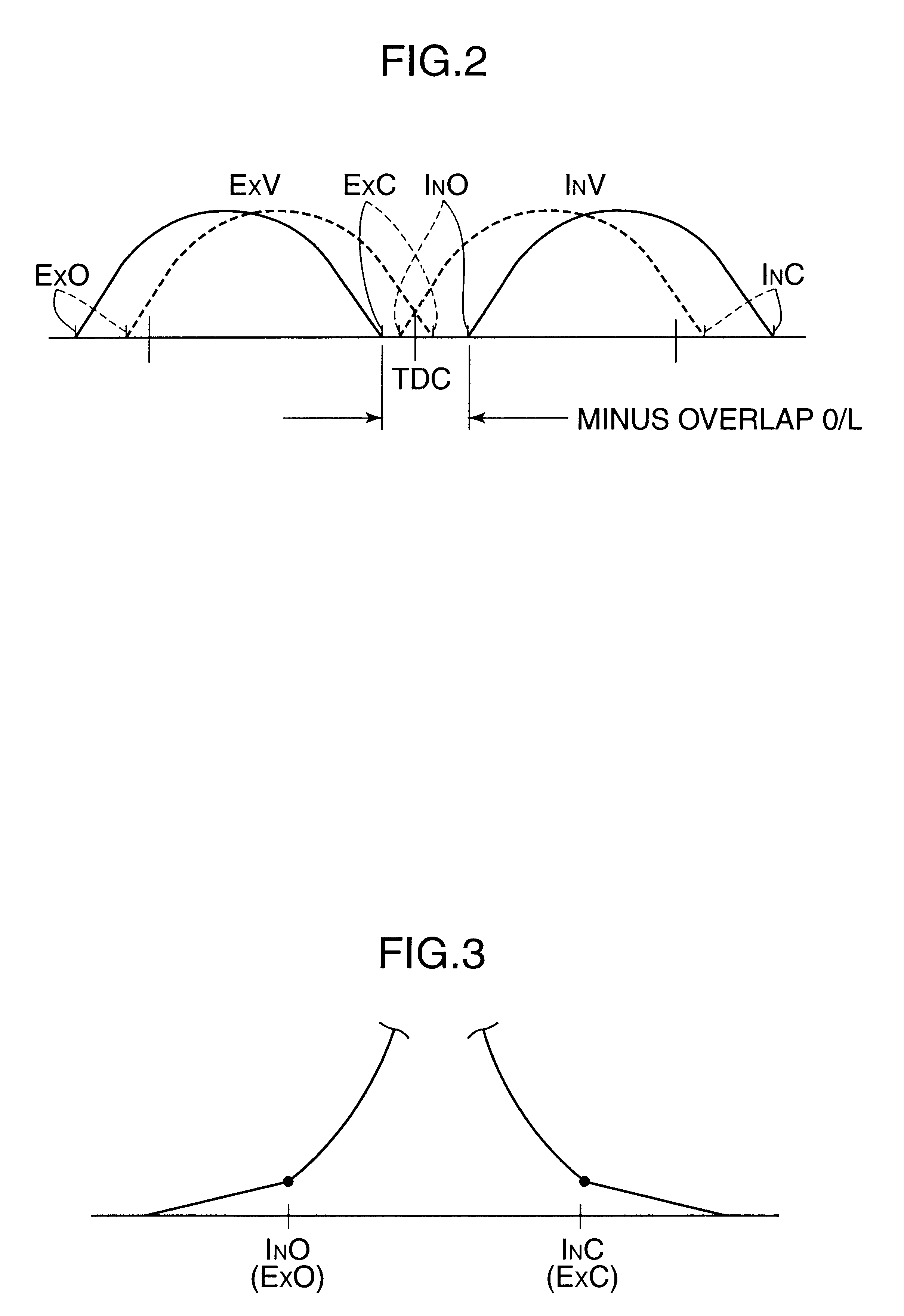

Automotive four-cycle engine

InactiveUS6626164B2Sufficient effectAvoid increase in combustion temperature and exhaust gas temperatureValve arrangementsElectrical controlExhaust valveTop dead center

A four-cycle engine is provided with valve timing adjusters for adjusting opening and closing timing an and an exhaust valve. In medium- to high-speed ranges in medium- to high-load regions of the engine, a closing point (ExC) of the exhaust valve defined as a point of transfer from an acceleration portion to a constant speed portion on its valve lift characteristics curve is set to a point a specific period before an intake top dead center, and an opening point (InO) of the intake valve defined as a point of transfer from a constant speed portion to an acceleration portion on its valve lift characteristics curve is set to a point after the intake top dead center. In addition, the period from the closing point (ExC) of the exhaust valve to the opening point (InO) of the intake valve is made longer in the medium-speed range than in the high-speed range in the medium- to high-load regions of the engine.

Owner:MAZDA MOTOR CORP

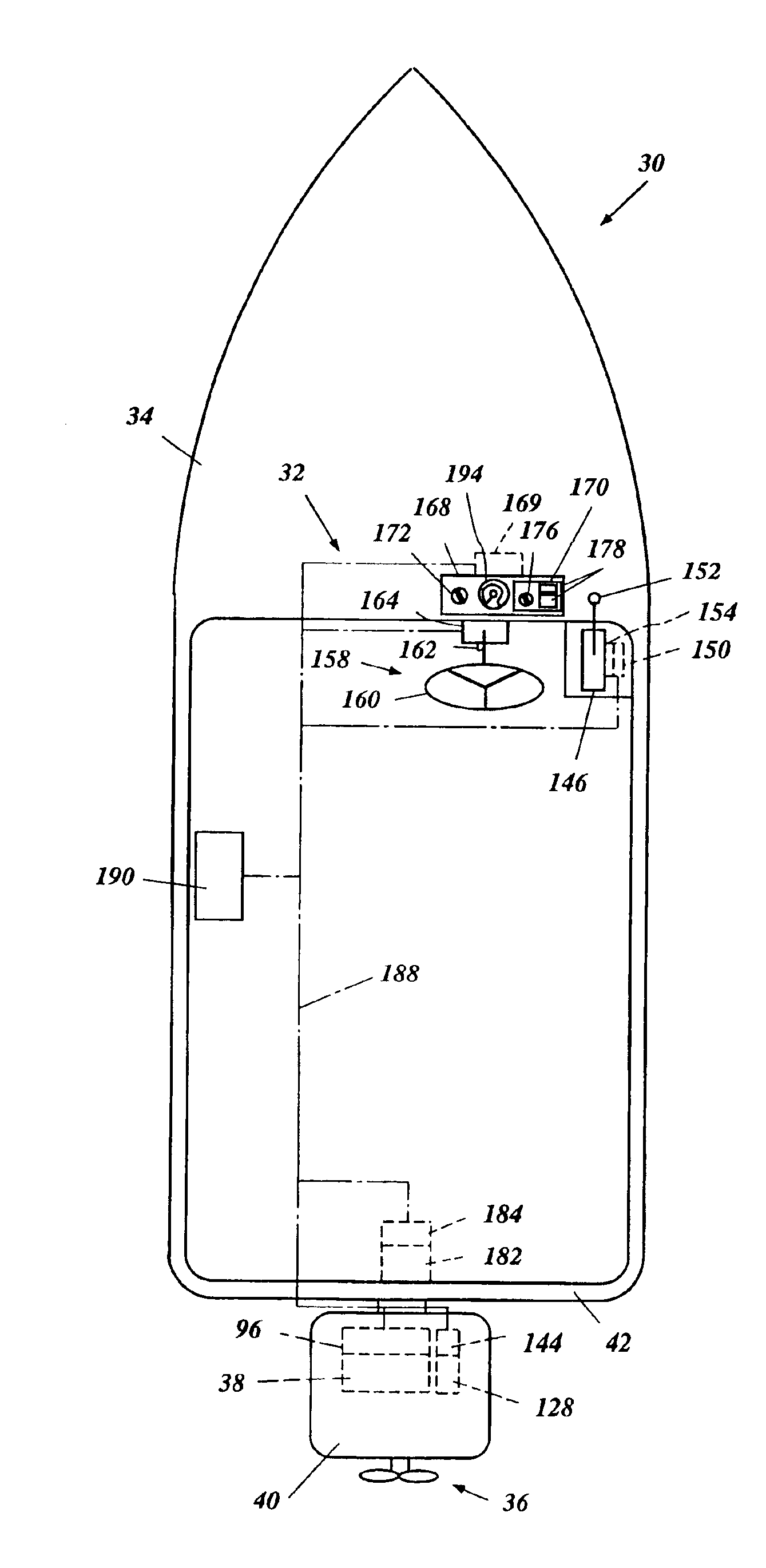

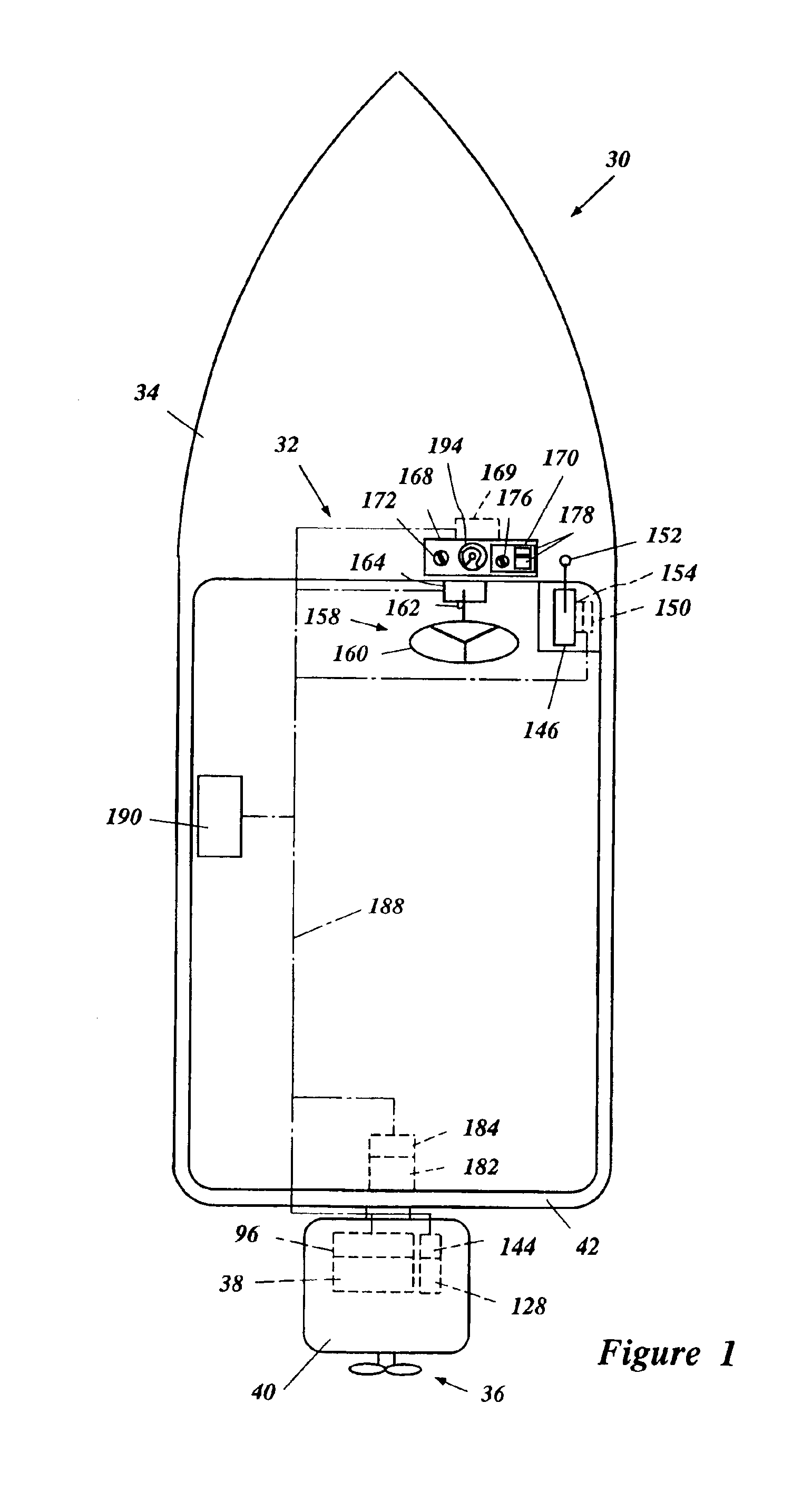

Speed control system and method for watercraft

A watercraft has an engine and a remote controller. The engine has a throttle valve unit. The remote controller provides a command signal indicative of a position of the throttle valve unit. A watercraft velocity sensor senses an actual speed of the watercraft to provide an actual speed signal. A control data input device selectively provides a control device with a manual mode signal and a constant speed mode signal. The constant speed mode signal is accompanied by a target speed signal. The control device controls the throttle valve unit based upon the command signal in the manual mode. The control device controls the throttle valve unit in the constant speed mode such that an actual speed of the watercraft coincides with the target speed of the watercraft once a state of equilibrium is reached. The control device starts the manual mode in place of the constant speed mode without the manual mode signal if the command signal changes while the control device controls the throttle valve unit in the constant speed mode.

Owner:MITSUBISHI ELECTRIC CORP +1

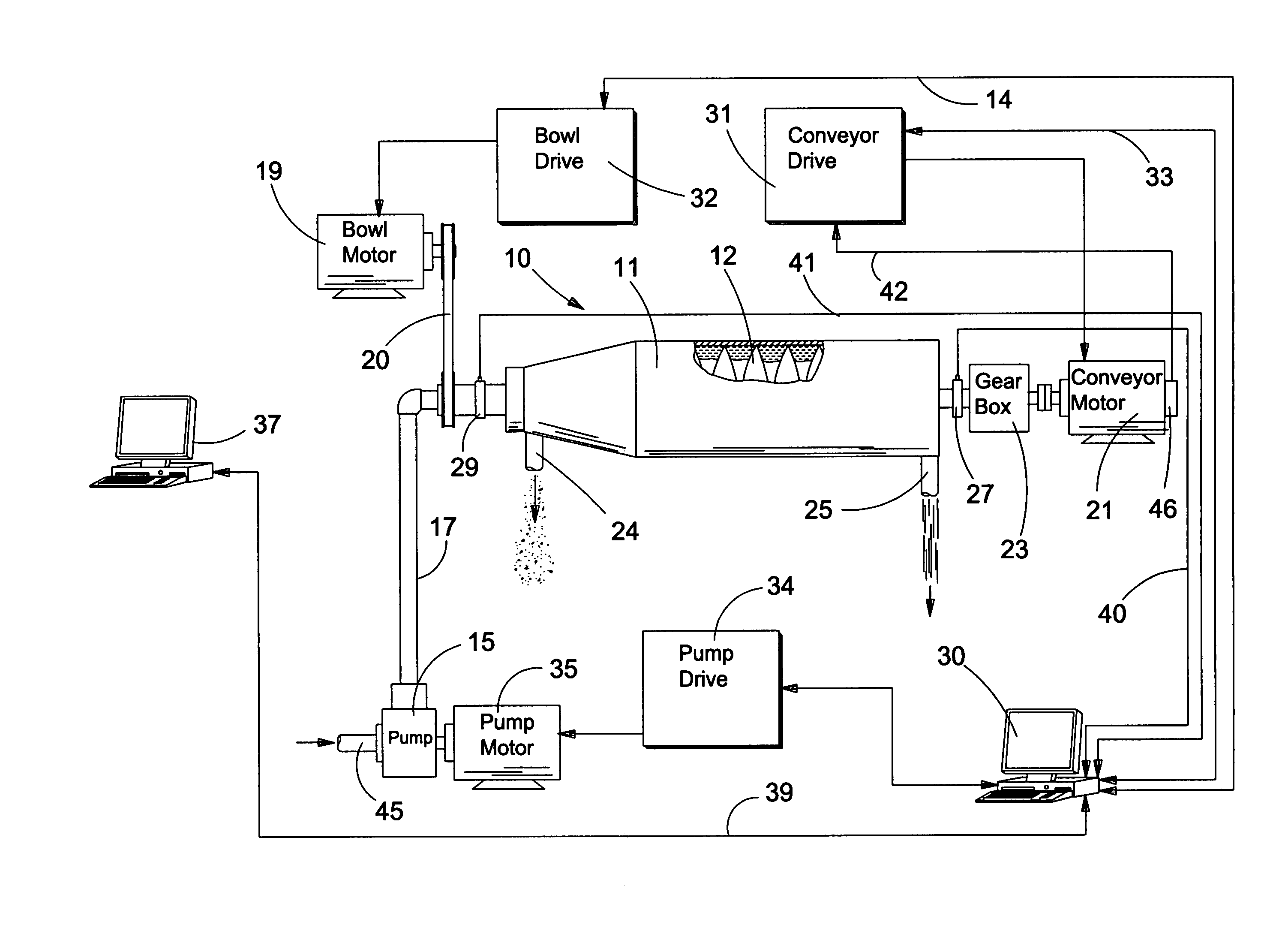

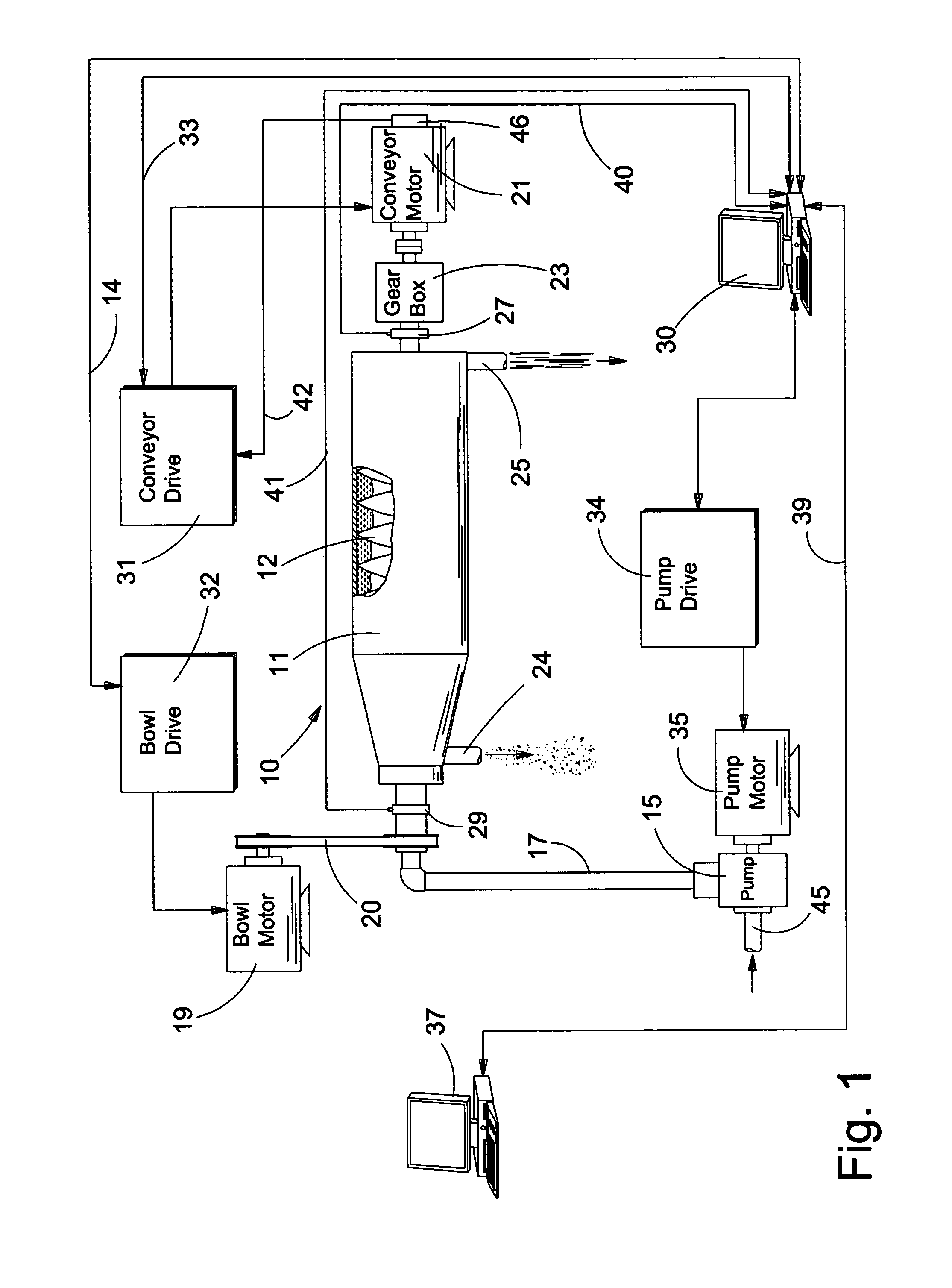

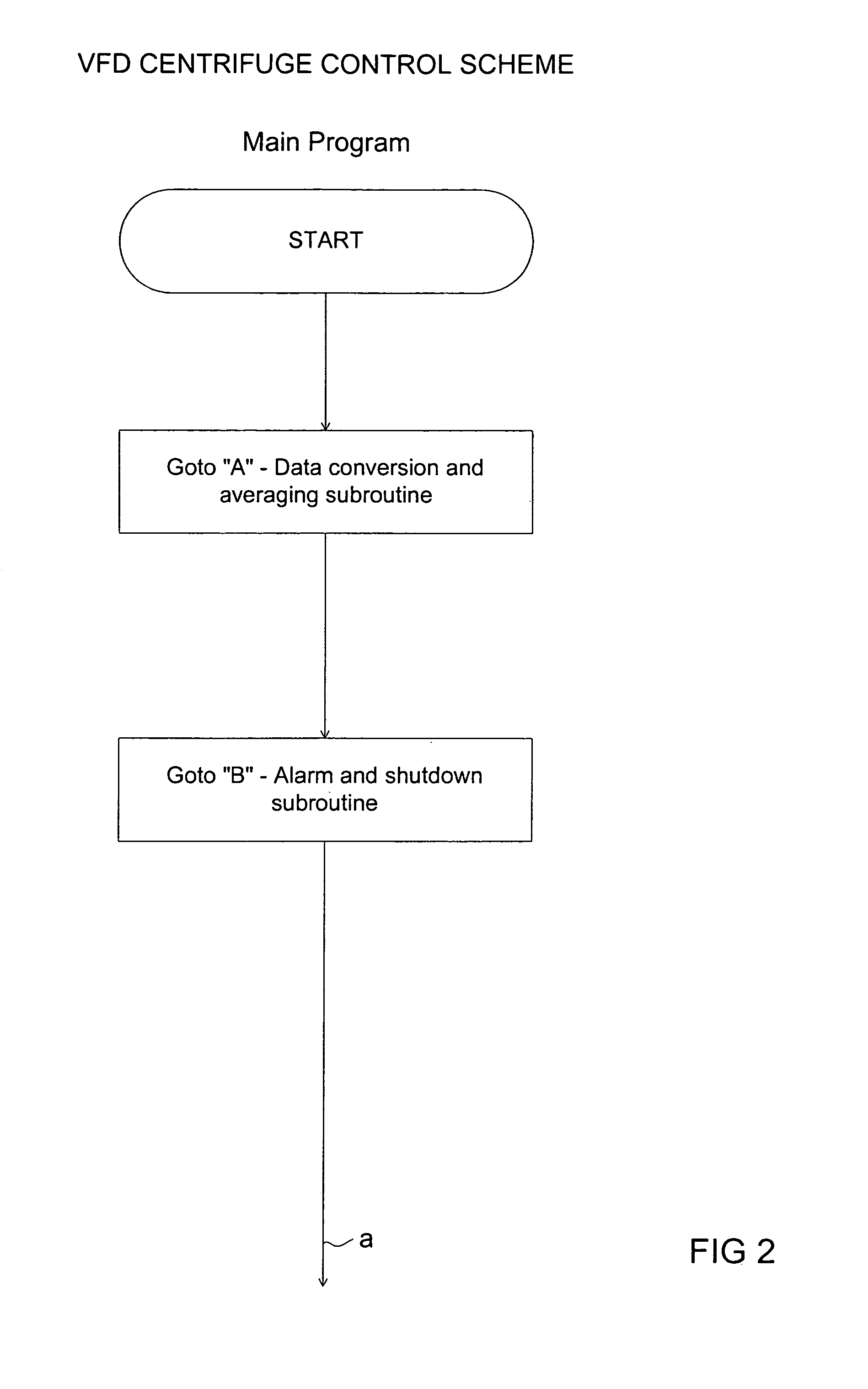

Apparatus for centrifuging a slurry

InactiveUS7387602B1Avoid the needProtection overloadSampled-variable control systemsRotary centrifugesGeneral purposeSlurry

A method and apparatus for centrifuging. The apparatus comprises a centrifuge for centrifuging a slurry, comprising a bowl driven by a bowl drive motor, a screw conveyor driven by a screw conveyor drive motor, a pump driven by a pump motor, a bowl drive unit operatively arranged to drive the bowl drive motor, a conveyor drive unit operatively arranged to drive the screw conveyor drive motor, a pump drive unit operatively arranged to drive the pump drive motor, and, a general purpose first computer specially programmed to control the bowl drive unit to drive the bowl drive motor at a first constant speed and to control the screw conveyor drive unit to drive the screw conveyor drive motor at a second constant speed and to monitor the torques of the bowl drive motor and the screw conveyor drive motor, while simultaneously controlling the pump drive unit to variably control flow of the slurry through the centrifuge so as to drive one of the bowl drive motor or the screw conveyor motor at a pre-set operating torque.

Owner:DERRICK CORP

Producing method of clean steel

The invention discloses a producing method of clean steel, which can further enhance the cleanliness and comprise the following steps of: pretreating with molten iron for desulfurizing until [S] is not more than 0.010%; then delivering to a converter for smelting; dephosphorizing and controlling sulfur; controlling finished molten iron in the converter to be with [P] of not more than 0.0080% and [S] not more than 0.010%; adding a ladle slag modifying agent to ladles in a steel tapping process for regulating and modifying the ladle slag, wherein after treating, in the molten iron, [P] is not more than 0.0060% to 0.0080%, [S] is not more than 0.0080% and roughing slag quantity is not more than 0.5%; controlling refined finished slag components in LF (Low Frequency) refining, wherein soft argon blowing time of the molten iron is not less than 5 minutes after LF refining, and the composition is qualified when [S] is not more than 0.0020%; carrying out VD (Vacuum Degassing) refining to ensure that [H] is not more than 1.5ppm; and continuously casting, wherein a double-layer high-alkalinity covering agent is adopted as a middle ladle, a seal ring and a long water gap are additionally arranged for argon-blowing protective casting, which is carried out at constant speed, and overheat delta T of the molten iron ranged from 15 DEG C to 30 DEG C. Under the condition that the producing cost is not increased basically, the cleanliness of the clean steel is further enhanced by the control of each procedure junction point, and the clean steel comprises the following components by weight percent: S not more than 20ppm, P not more than 100ppm, TO not more than18ppm, H smaller than 2.0ppm, N not more than 35ppm, and A, B, C and D types of impurities not more than 0.5 grade.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

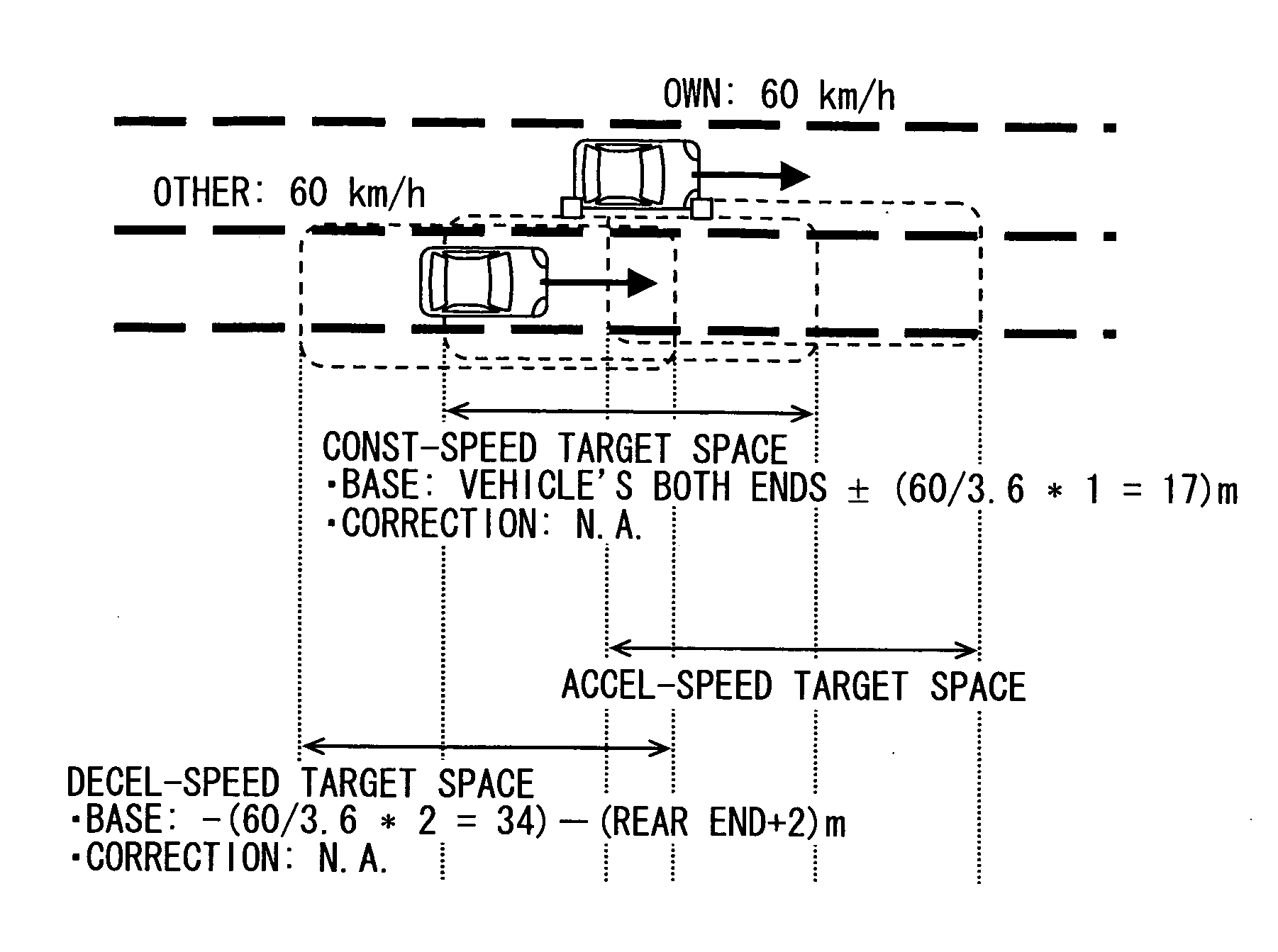

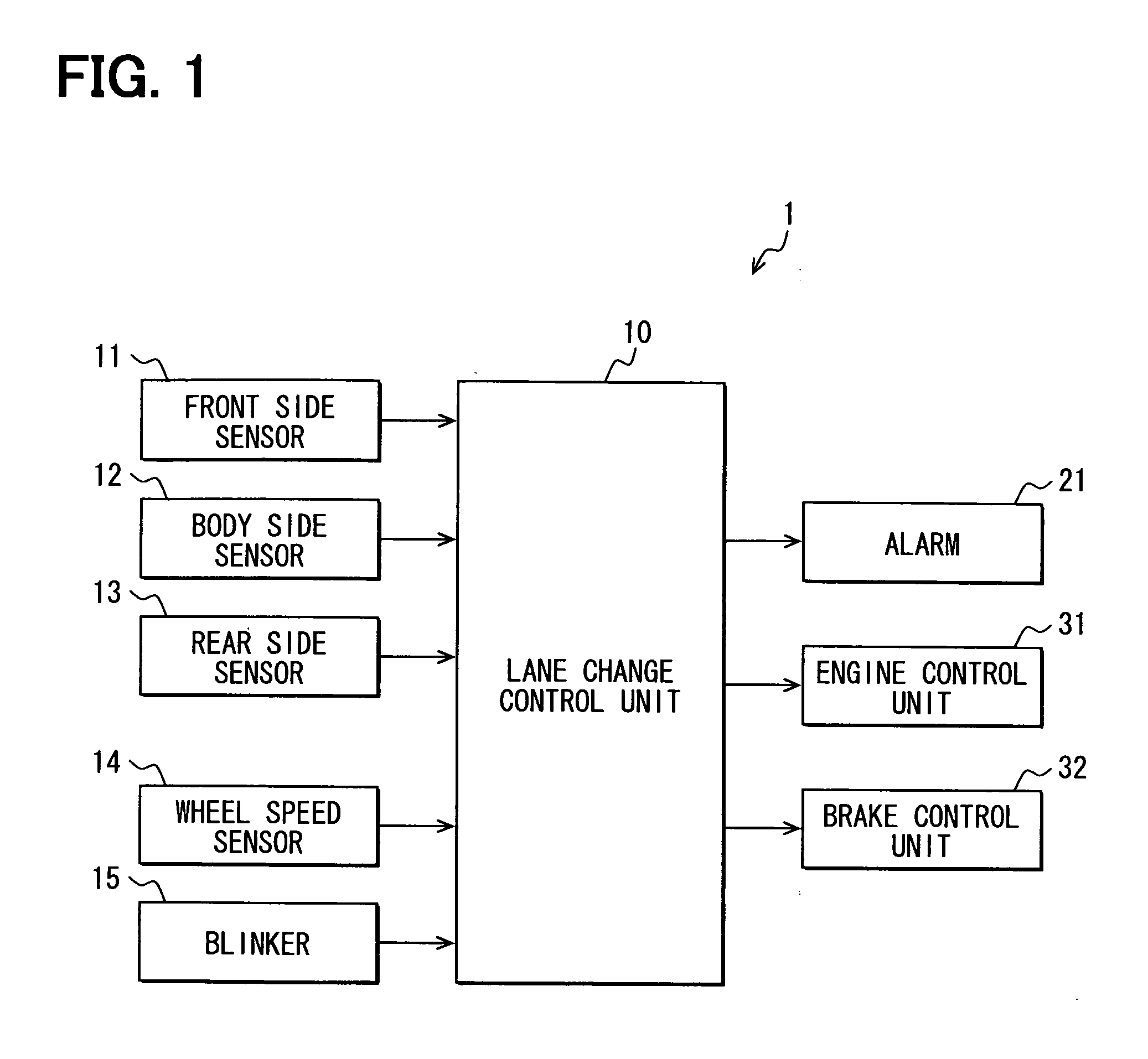

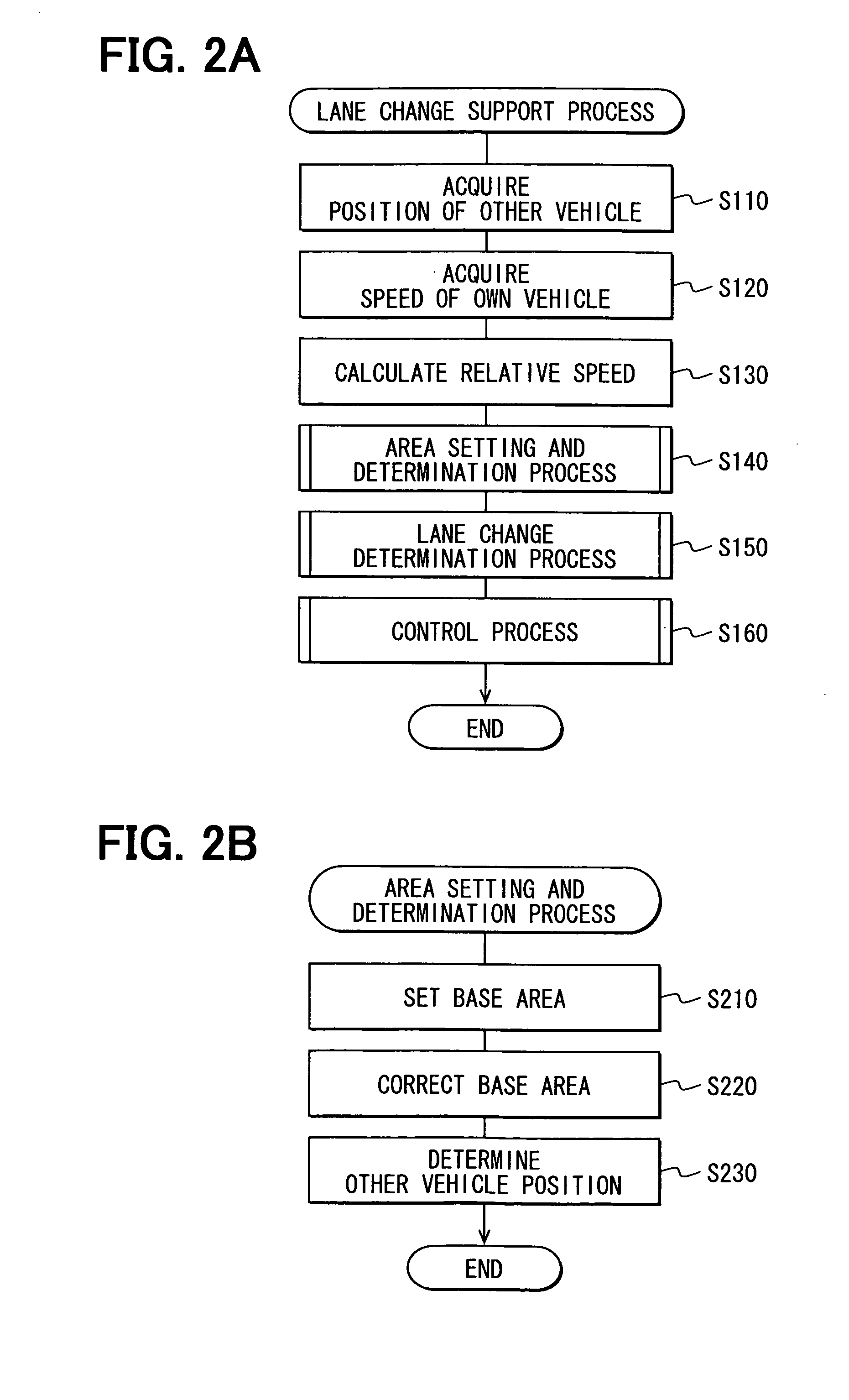

Apparatus, program and method for collision avoidance support

ActiveUS20110130936A1Reduce loadSatisfy safety performance requirementsAnalogue computers for trafficAnti-collision systemsEngineeringConstant speed

A collision avoidance support apparatus sets a side area right beside an own vehicle in an adjacent lane as a constant-speed target space, which is used for lane change at a constant speed, and also sets a diagonally-front area and a diagonally-rear area as alt-speed target spaces, which are used for lane change at an accelerated speed and at a decelerated speed. Then, a target space that is free of other vehicles is extracted by the apparatus. If there is no target space that is free of the other vehicles, the lane change is determined as unsafe. If there is no other vehicle in the constant-speed target space, the lane change is determined to be safe at the constant speed. If there is no other vehicle in at least one of the alt-speed target spaces, the lane change is determined to be safe at an accelerated speed or a decelerated speed.

Owner:DENSO CORP

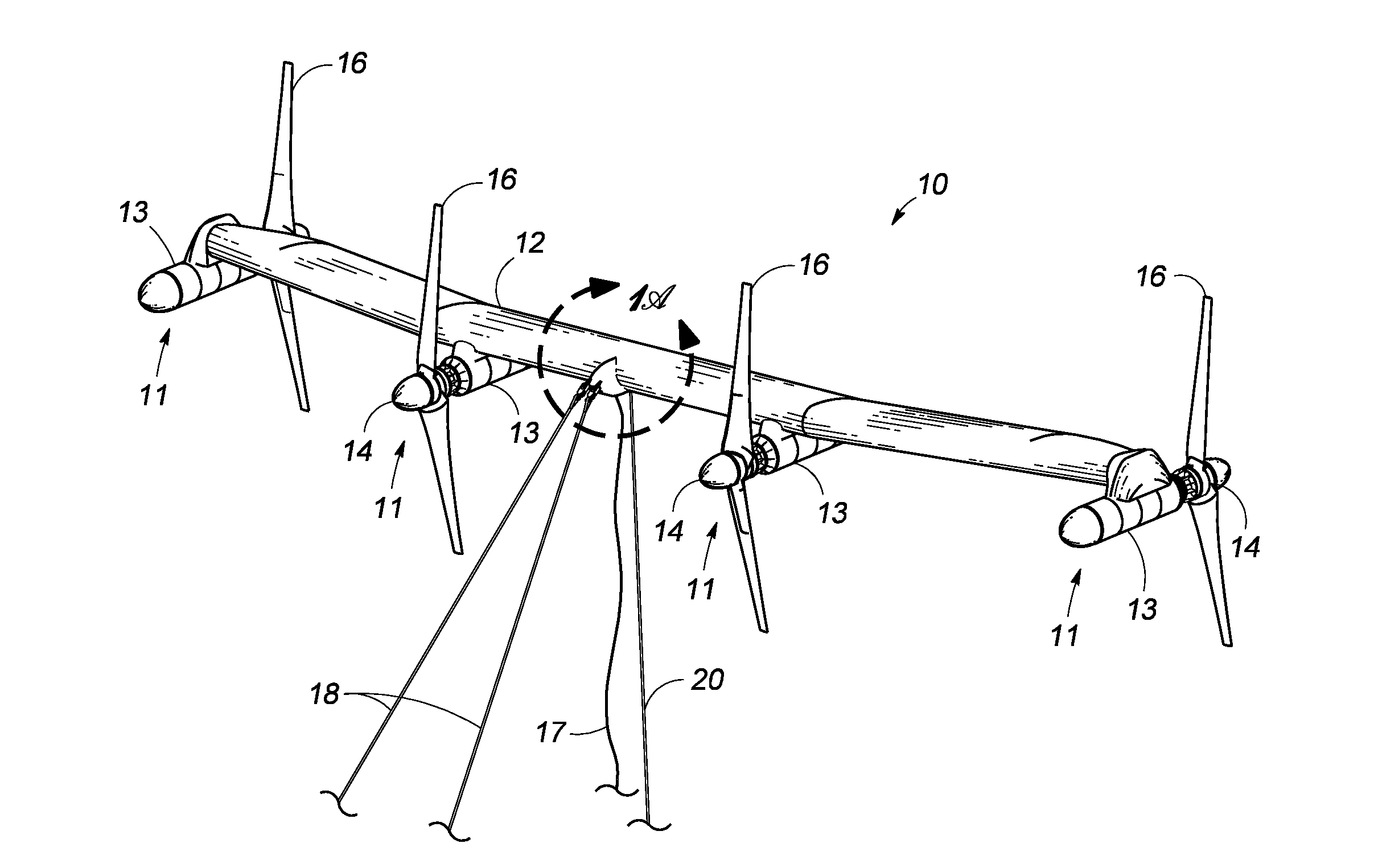

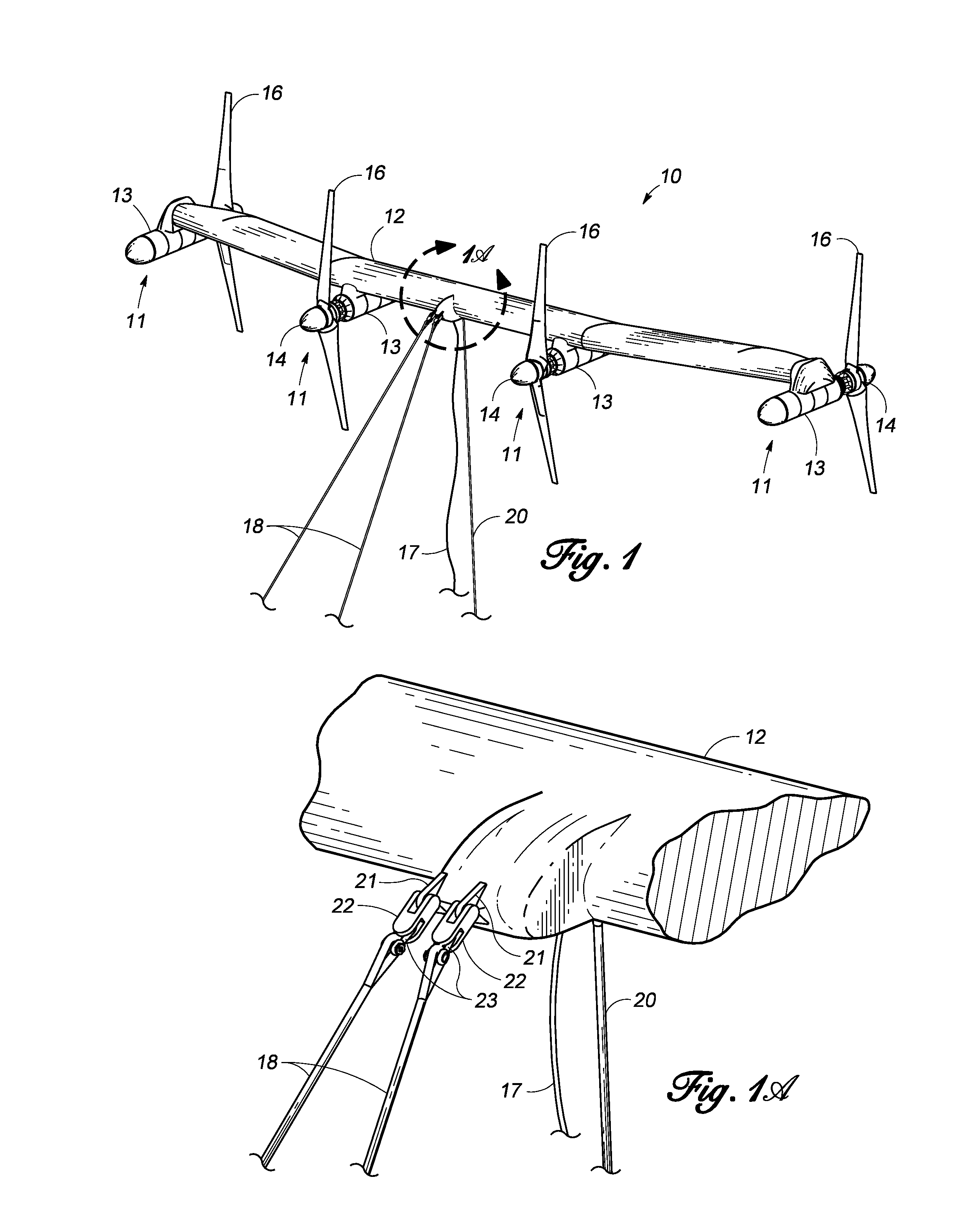

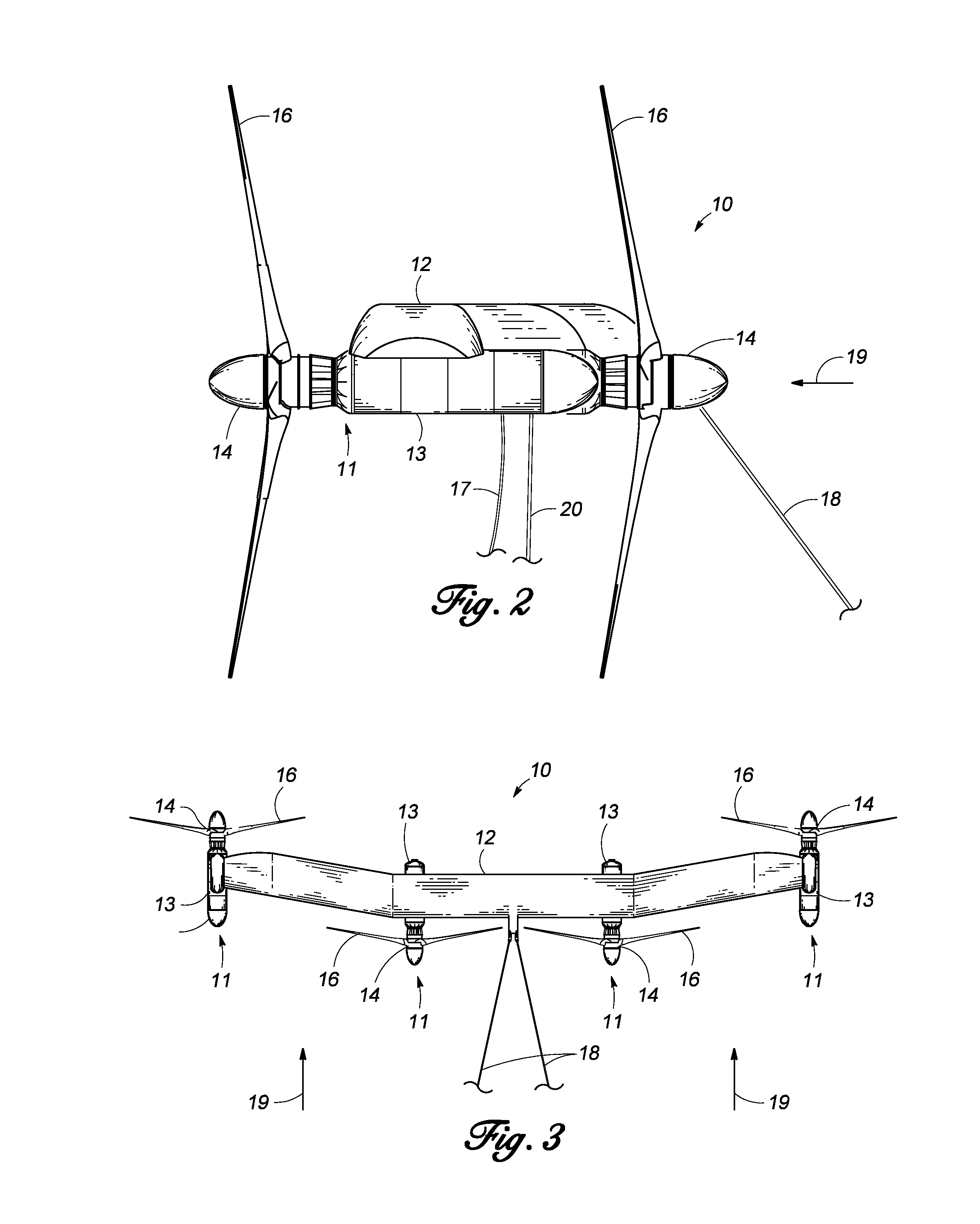

Multi-Megawatt Ocean Current Energy Extraction Device

InactiveUS20130106105A1Counteract buoyancyReduce the average velocityEngine fuctionsBuoyancy controlOcean bottomDrivetrain

An underwater apparatus for generating electric power from ocean currents and deep water tides. A submersible platform including two or more power pods, each having a rotor with fixed-pitch blades, with drivetrains housed in pressure vessels that are connected by a transverse structure providing buoyancy, which can be a wing depressor, hydrofoil, truss, or faired tube. The platform is connected to anchors on the seafloor by forward mooring lines and a vertical mooring line that restricts the depth of the device in the water column. The platform operates using passive, rather than active, depth control. The wing depressor, along with rotor drag loads, ensures the platform seeks the desired operational current velocity. The rotors are directly coupled to a hydraulic pump that drives at least one constant-speed hydraulic-motor generator set and enables hydraulic braking. A fluidic bearing decouples non-torque rotor loads to the main shaft driving the hydraulic pumps.

Owner:AQUANTIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com