Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3319 results about "Ladle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In metallurgy, a ladle is a vessel used to transport and pour out molten metals. Ladles are often used in foundries and range in size from small hand carried vessels that resemble a kitchen ladle and hold 20 kilograms (44 lb) to large steelmill ladles that hold up to 300 tonnes (330 tons). Many non-ferrous foundries also use ceramic crucibles for transporting and pouring molten metal and will also refer to these as ladles.

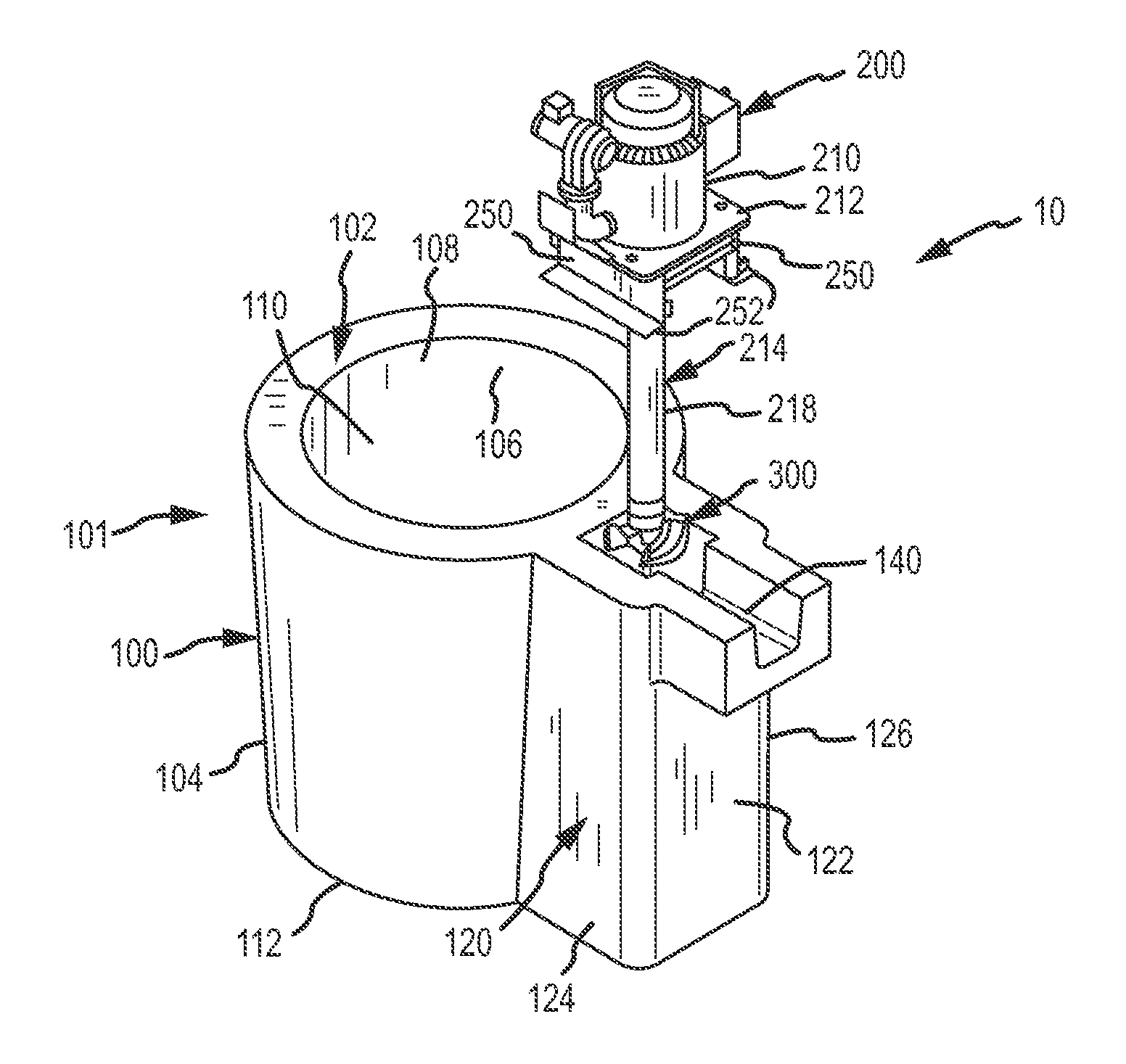

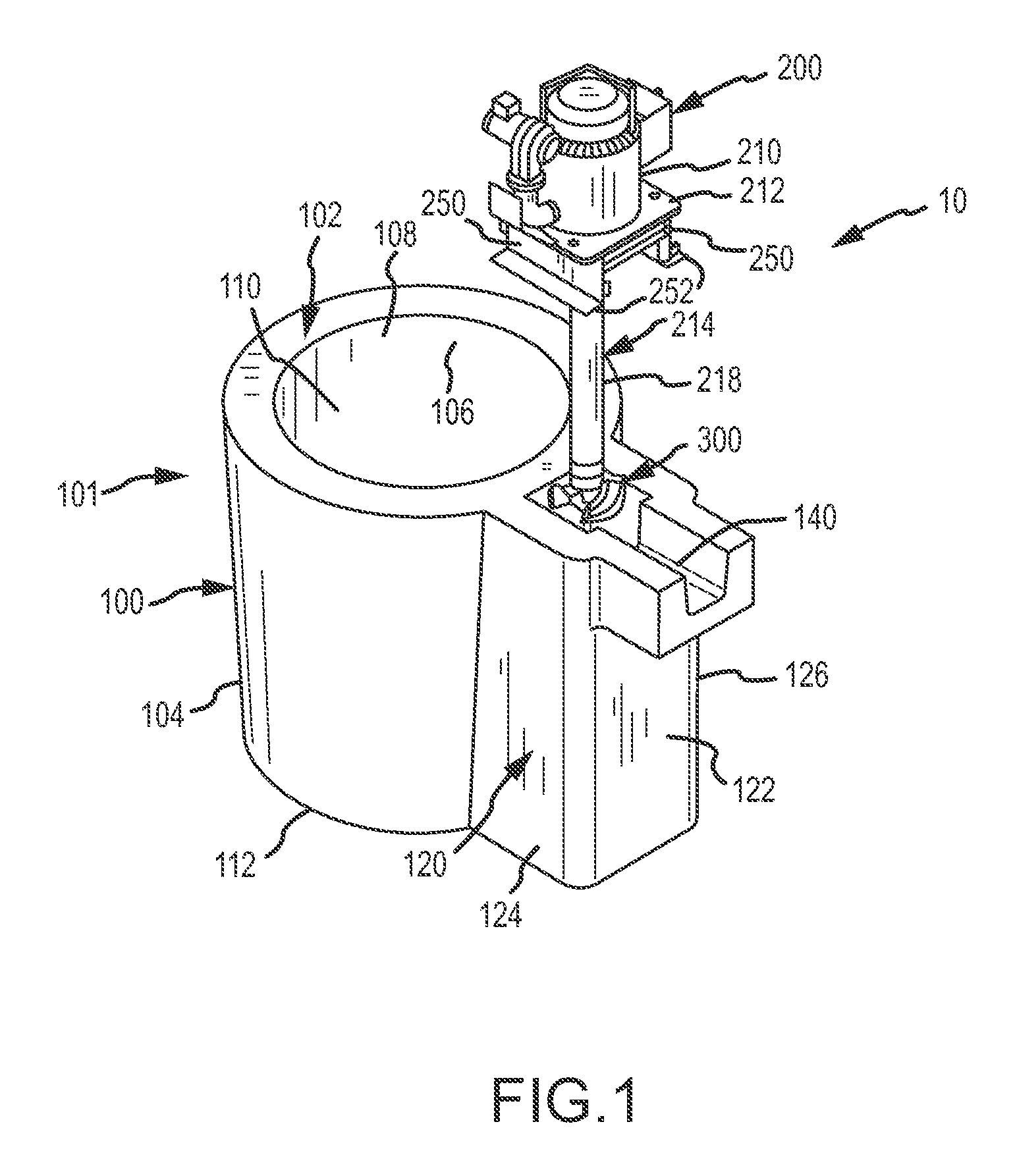

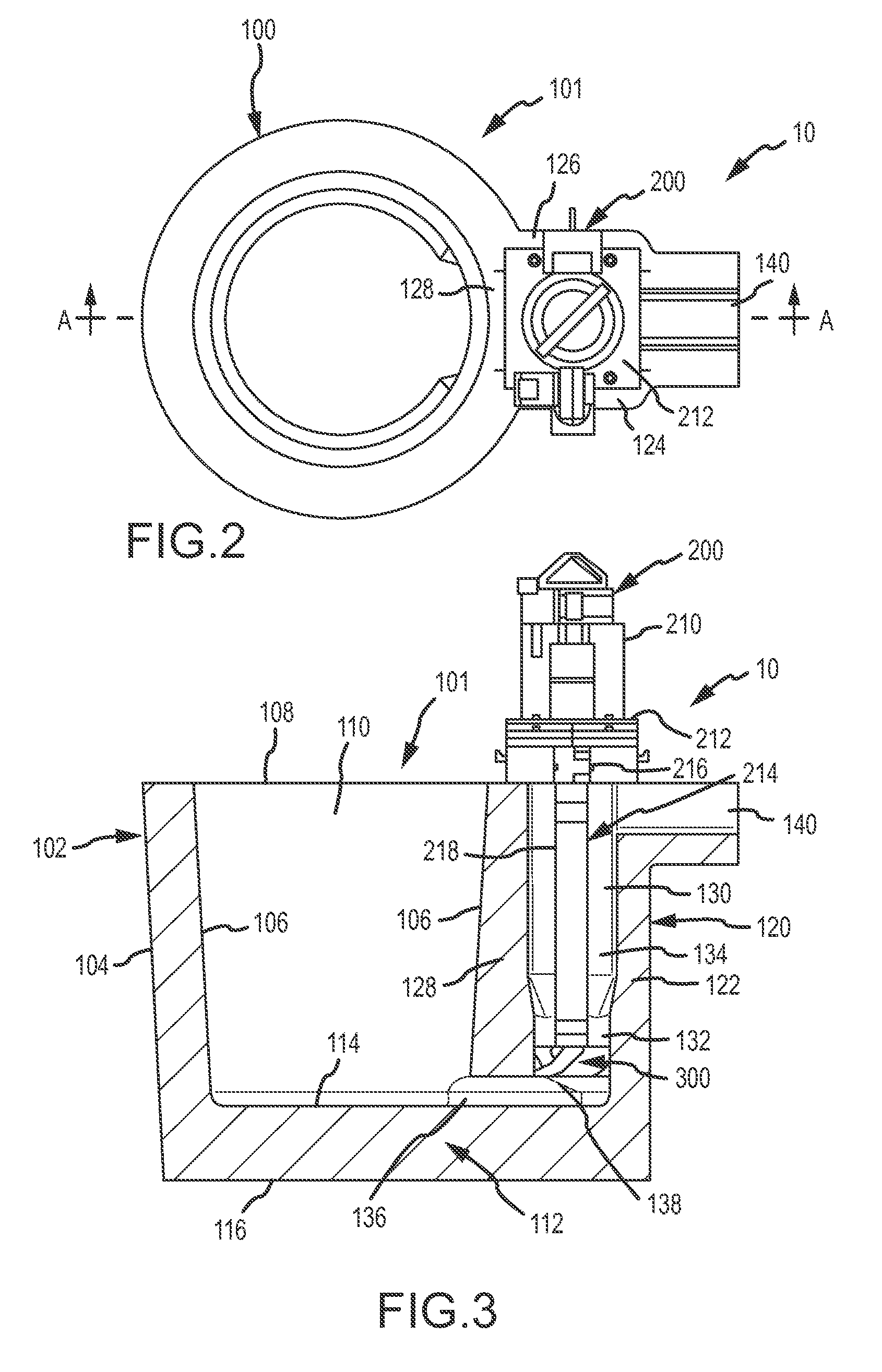

Ladle with transfer conduit

ActiveUS9011761B2Reduce the amount requiredReduce formationMelt-holding vesselsMolten metal supplying equipmentsMarine engineeringGuide tube

Disclosed is a transportable vessel for use in a factory for processing molten metal. The vessel is not connected to a reverbatory furnace and can be moved to different locations in the factory. The vessel includes a transfer conduit in communication with a cavity of the vessel. A molten metal pump can be positioned in the transfer conduit to move molten metal out of an outlet in communication with the transfer conduit and into another vessel without the need to tip or tilt the transportable vessel.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

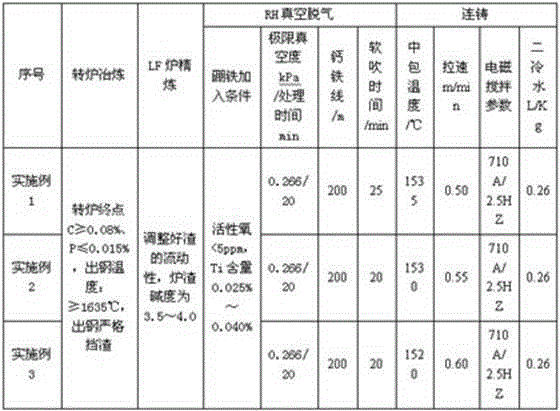

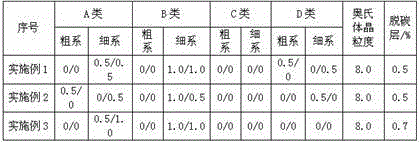

Method for producing ultra-low-carbon steel

A method for producing ultra-low-carbon steel belongs to steel-making technology field. The process route is: molten iron desulfuration preprocess -converter smelting -RH vacuum process -slab continuous casting. The iron desulfuration preprocess applies blowing magnesium granules for desulfuration; the converter smelting terminal carbon content and oxygen activity of molten steel; applying slag dam operation when tapping without deoxidation; the ladle furnace proceeds operation of top slag modification and temperature controlling; RH vacuum processing to control the maximum vacuum; applying Al for deoxidation when the decarburization is finished, and alloying if the deoxidation is finished and assuring the deep vacuum processing time after the deoxidation; calming the molten steel when the vacuum is finished; applying non-carbon covering agent and non-carbon protection slag in the slab casting process; the continuous casting process uses full protection casting, and the casting process controls a reasonable pulling speed according to slab section. The advantages are: the invention resolves problem of nozzle clogging and improves castability of the ultra-low-carbon steel and implements multi-furnace continuous casting, and the components of carbon, phosphorus, sulphur and nitrogen of the completed product conforms smelting request of the ultra-low-carbon steel.

Owner:SHOUGANG CORPORATION

Metallic composite low carbon magnesium carbon brick for ladle slag wire and manufacture method thereof

The invention discloses a metal complex low-carbon magnesia carbon brick used for ladle slag lines, the weight percentage of the added materials is as following, 50 to 70 percent of magnesia particles, 25 to 35 percent of magnesia powder, and 3 to 6 percent of organic binder, furthermore, the following components are added which are produced by mixing, striating materials, forming and heat-treatment, 0 to 4 percent of flake graphite, 3 to 15 percent of metal powder, and 0.5 to 3 percent of antioxidant containing boron. The antioxidant properties, slag-resistance performance, high temperature strength and the thermal shock resistance of the ladle slag line used metal complex low-carbon magnesia carbon brick are greatly improved, the service life is prolonged, the consumption cost of each ton of refractories is lowered. The preparation method of ladle slag line used metal complex low-carbon magnesia carbon bricks is also disclosed, and the carbon content in the ladle slag line used metal complex low-carbon magnesia carbon bricks produced by the method is less than or equal to 6 percent, little carbon is added so as to reduce the pollution towards liquid steel, and residual strength ratio of the thermal shock resistance is kept at 70 to 80 percent.

Owner:ZHENGZHOU UNIV +1

Thermal-shock-resistant corundum-spinel refractory castable and preparation method thereof

The invention discloses thermal-shock-resistant corundum-spinel refractory castable which comprises the following raw materials in percentage by weight: 65-80% of corundum particles and fine powder, 3-10% of aluminum oxide fine powder, 2-8% of materials containing Zr, 10-15% of magnesium-aluminum spinel fine powder, 3-8% of bonding agent, 0.05-0.1% of organic fiber (additional) and 0.2-0.6% of water reducing agent (additional). The preparation method of the corundum-spinel refractory castable comprises the following process steps of burdening, mixing, molding, maintaining, drying, storage and transportation, using and the like. Compared with the prior art, the thermal-shock-resistant corundum-spinel refractory castable provided by the invention has high thermal-shock-resistant property, and favorable high-temperature resistance and anti-erosion capability, and is suitable for steel ladles, intermediate ladles, RH (relative humidity) immersion tubes, cement high-temperature kilns and the like.

Owner:LUOYANG LIER REFRACTORY MATERIAL +2

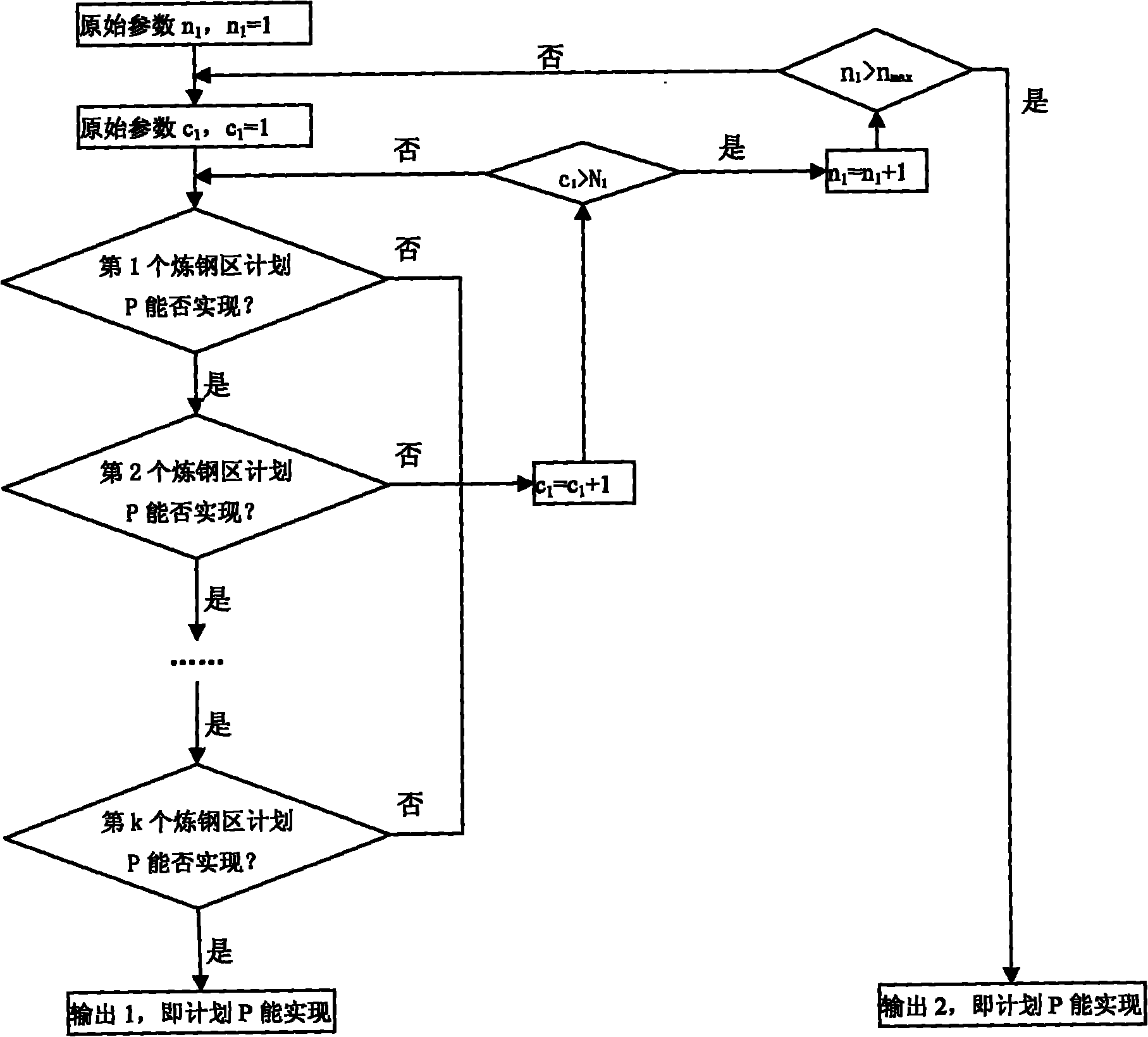

Iron-making and steel-making continuous casting integrated dispatching system

InactiveCN101908092ASolve the integrated scheduling problem of ironmaking-steelmaking-continuous castingFast Online SchedulingSpecial data processing applicationsData acquisitionSteelmaking continuous casting

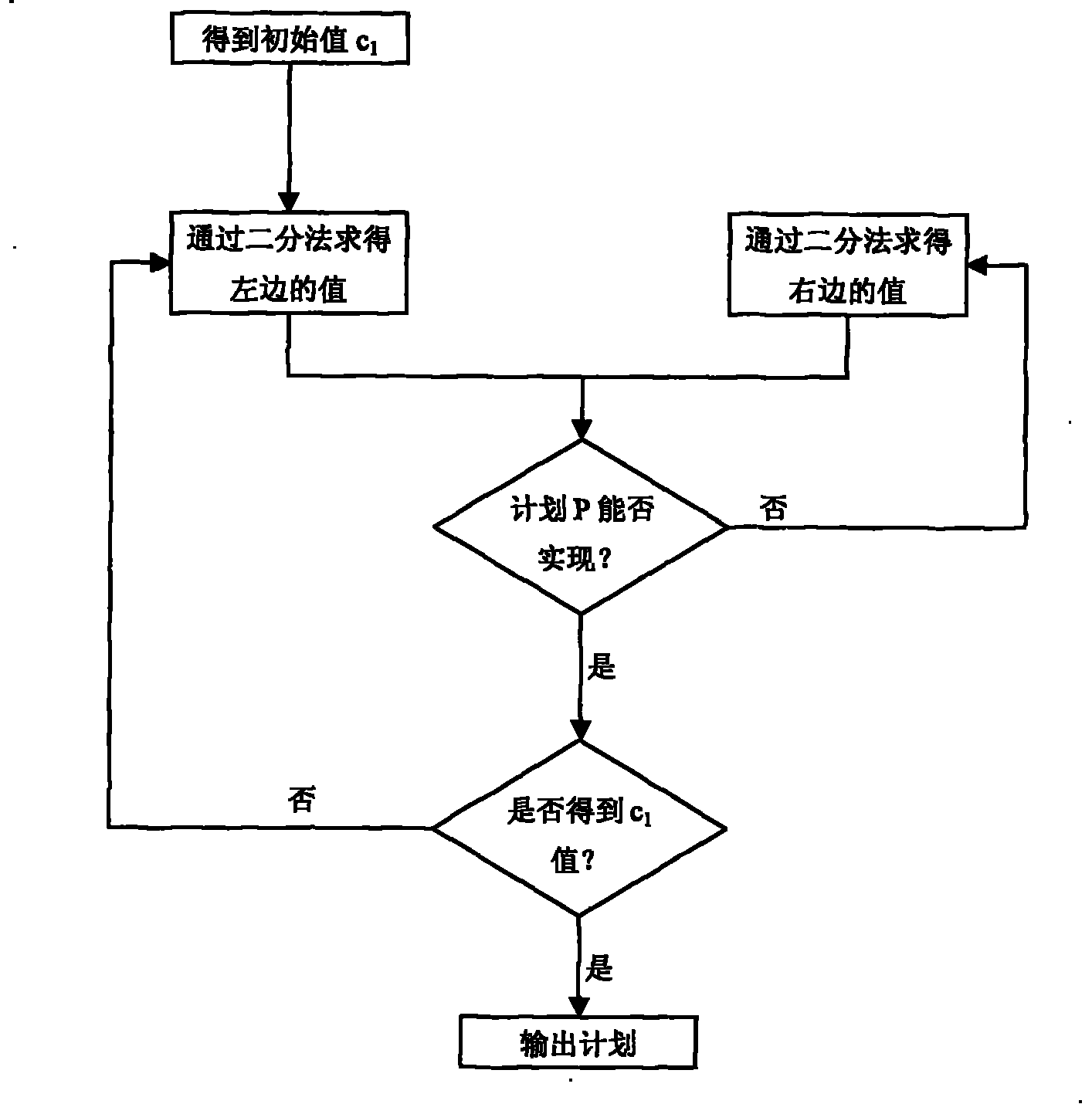

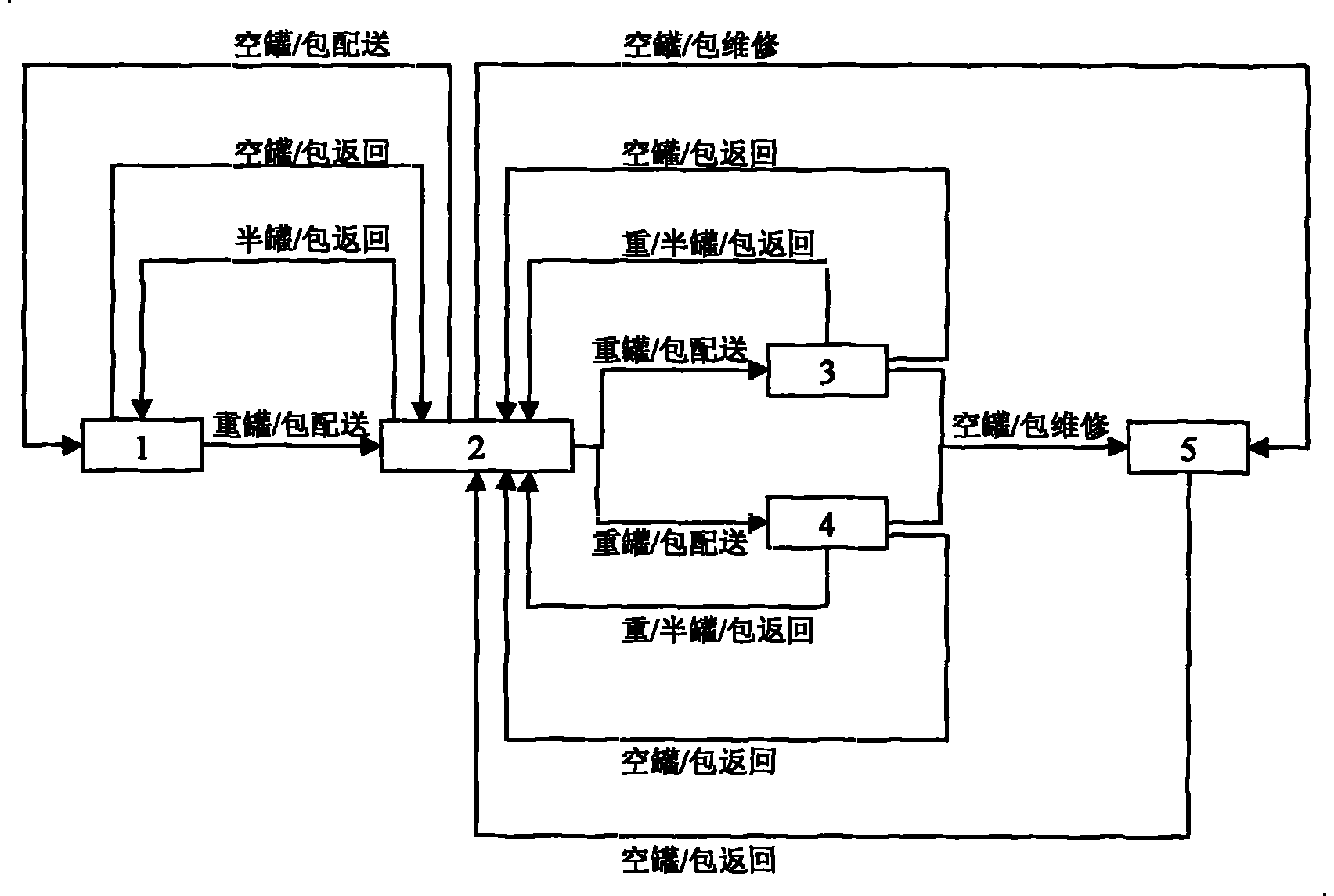

The invention discloses an iron-making and steel-making continuous casting integrated dispatching system, and belongs to the planning and dispatching field of iron-making and steel-making continuous casting production. The dispatching system comprises system implementing conditions and four sub-modules, wherein the system implementing conditions comprise equipment state and data acquisition programs, a database server, a database management program, database software and a client application program; and the four sub-modules comprise a torpedo ladle and foundry ladle dispatching planning and blast furnace area-converter area molten iron planning matching model module, an iron-steel interface molten iron dispatching framework module, a molten iron pretreatment-continuous casting dispatching module and an information communication module. Iron-steel interface torpedo ladle dispatching is implemented by monitoring the equipment state, judging the abnormal condition of the production, recording the operation performance, combining the setting parameters of dispatching personnel and establishing a blast furnace area-converter area molten iron planning matching model; static dispatching of a molten iron pretreatment-continuous casting section is generated by adopting a heuristic algorithm, and dynamic dispatching is implemented by using a hybrid genetic algorithm; and quick and flexible on-line dispatching of the molten iron pretreatment-continuous casting section is implemented.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL +2

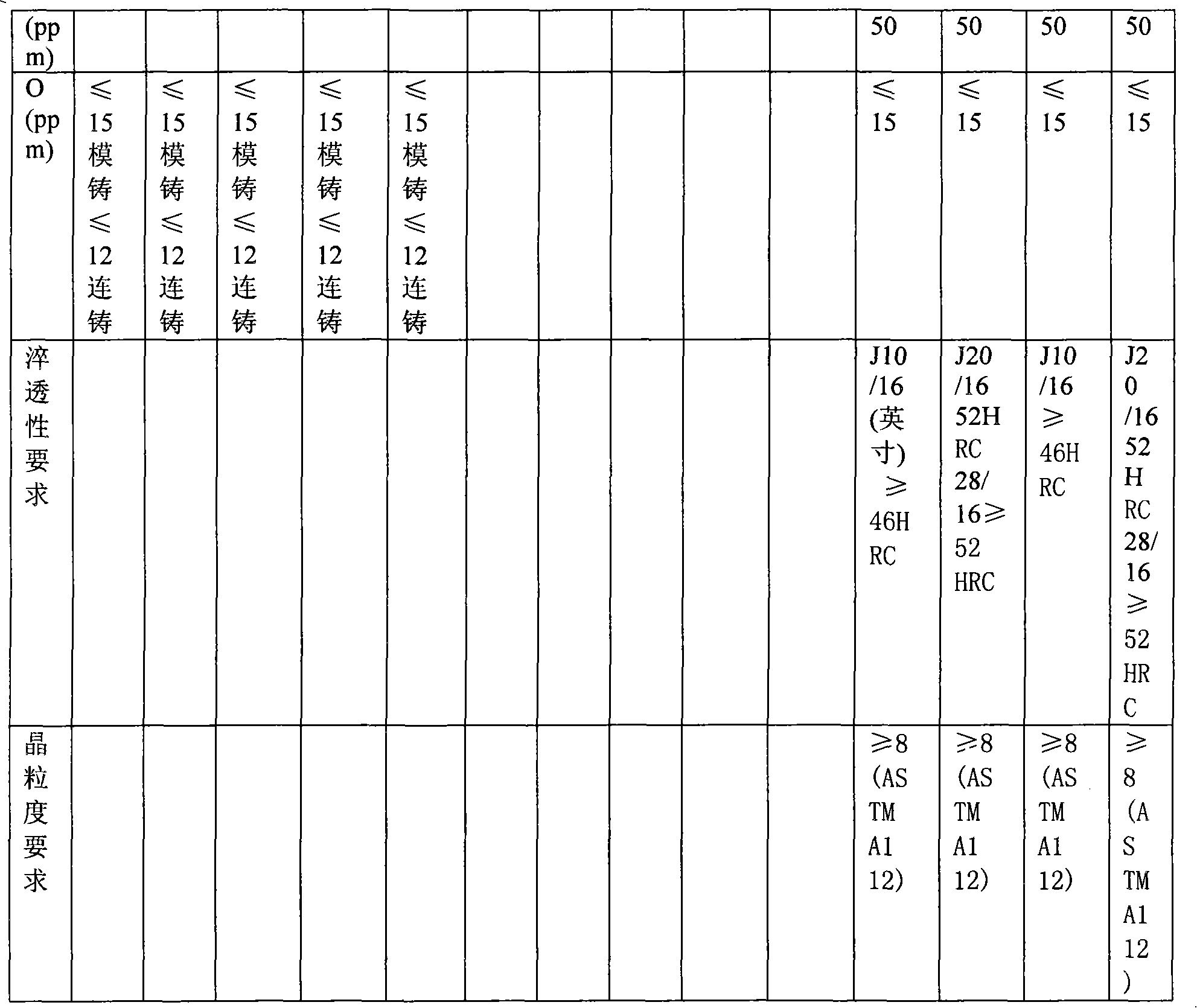

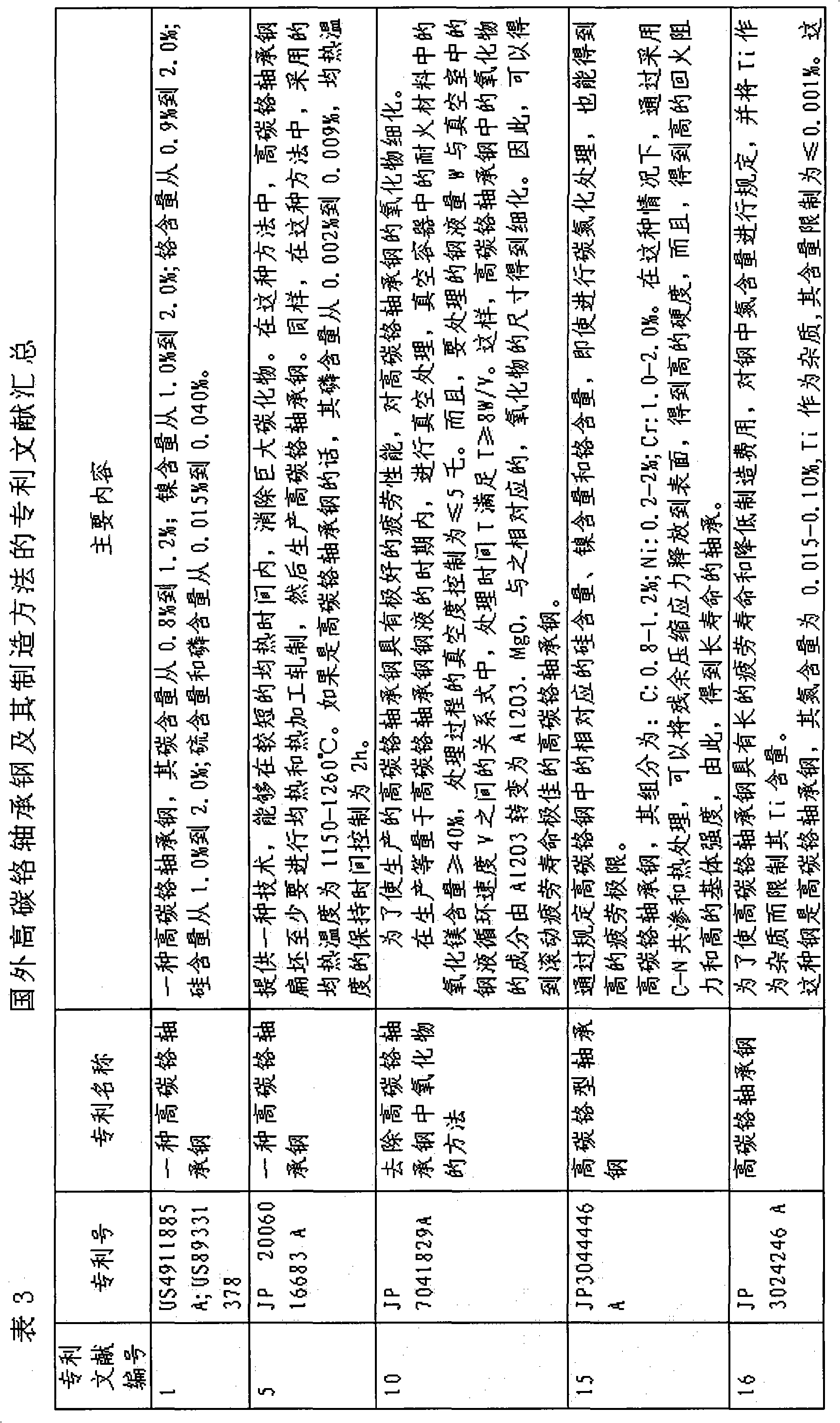

High-carbon-chromium bearing steel and manufacture method thereof

The invention discloses high-carbon-chromium bearing steel and a manufacture method thereof. The high-carbon-chromium bearing steel comprises the following chemical compositions by weight percentage: C: 0.90-1.05; Cr: 0.90-1.20; Mn: 0.90-1.25; Si: 0.45-0.75; Al: 0.02-0.04; oxygen is less than or equal to 0.0007; phosphorus is less than or equal to 0.010; sulfur is less than or equal to 0.005; titanium is less than or equal to 0.0025; copper is less than or equal to 0.15; nickel is less than or equal to 0.10; nitrogen is less than orequal to 0.0070; and the balance of unavoidable impurities and Fe. The manufacture method comprises the following steps: smelting in an electric furnace, refining in a ladle arc furnace, degassing in a vacuum furnace, pouring steel liquid into steel ingots, heating steel ingots in a heating furnace, rolling the steel ingots into square billets by a rolling mill, heating the steel ingots in a heating furnace and rolling the steel ingots into round steel by a rolling mill. Compared with the prior art, the invention has high hardenability, high crystal grain size of more than 8 grade, high commonality in technology and wide application.

Owner:BAOSHAN IRON & STEEL CO LTD

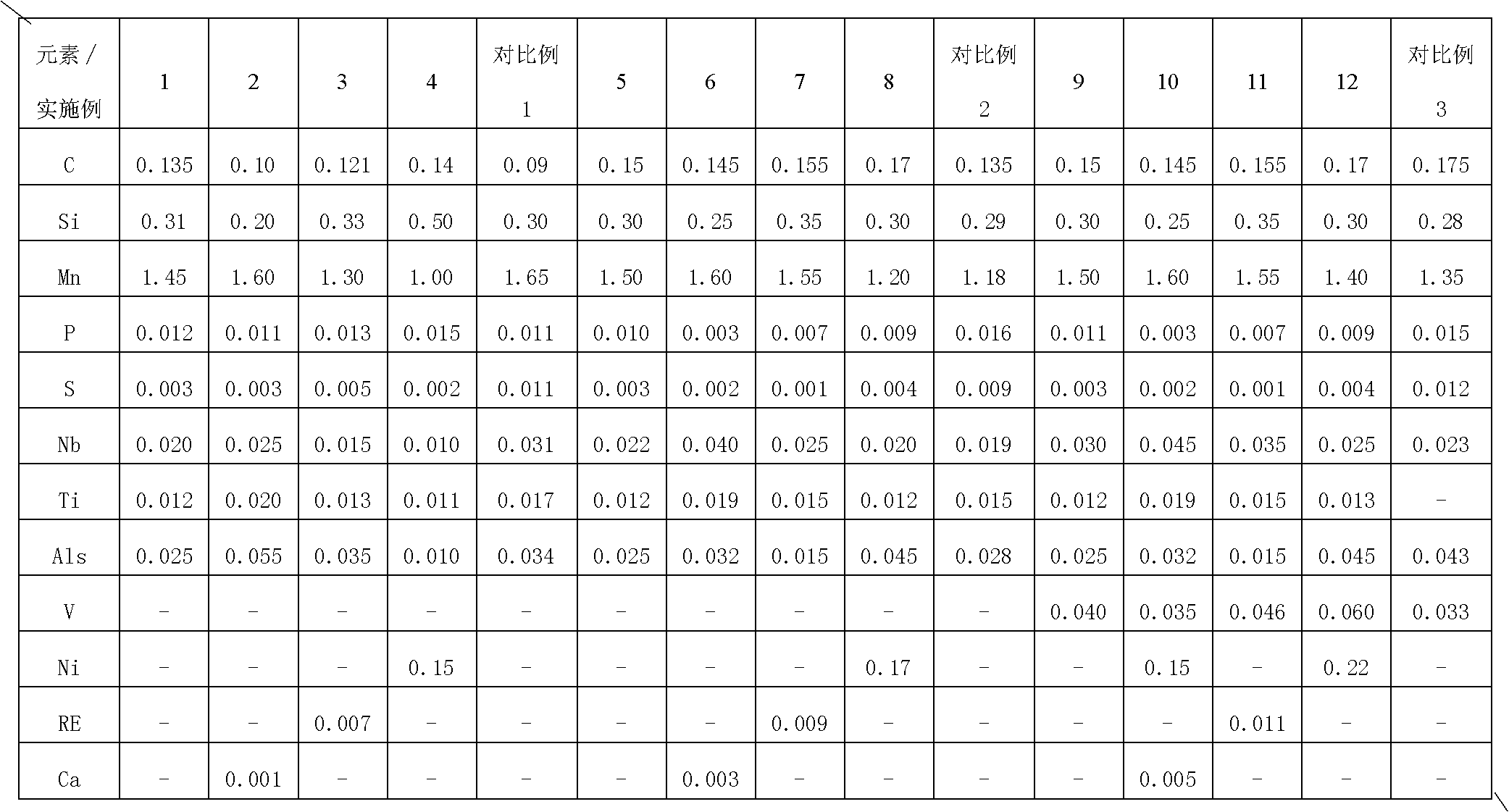

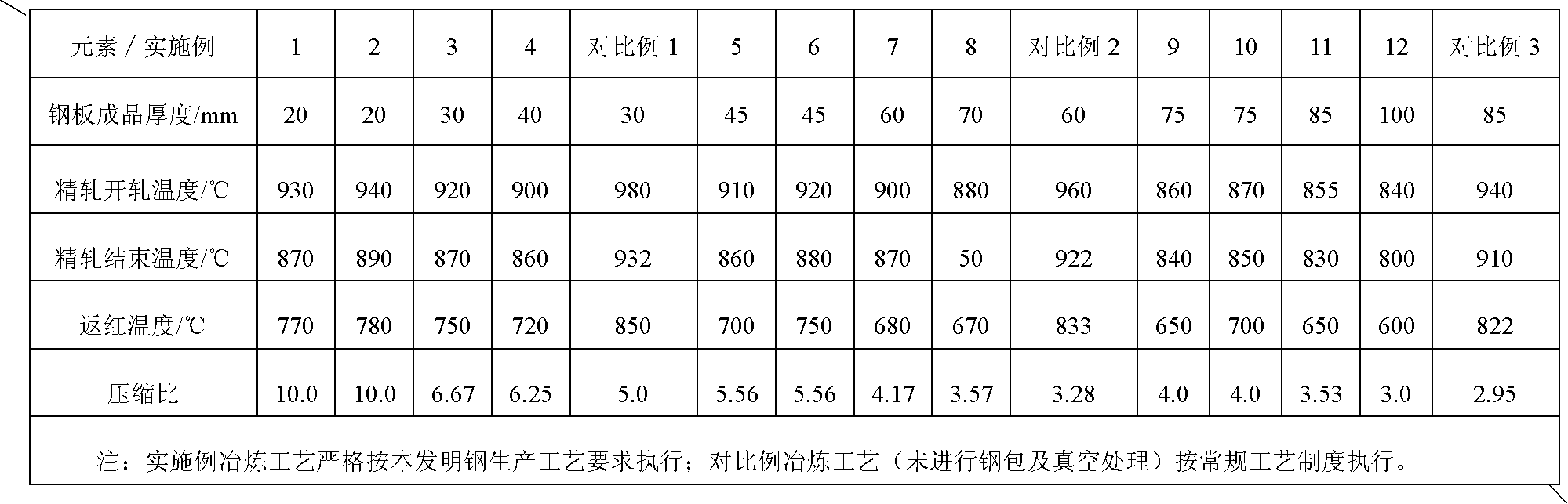

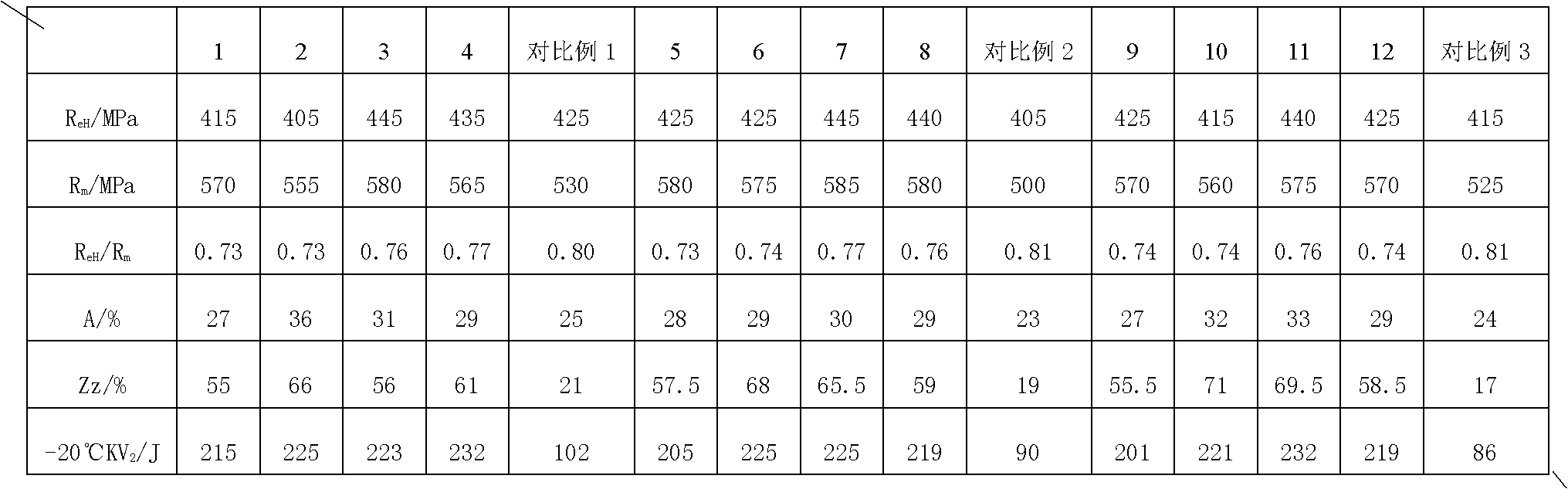

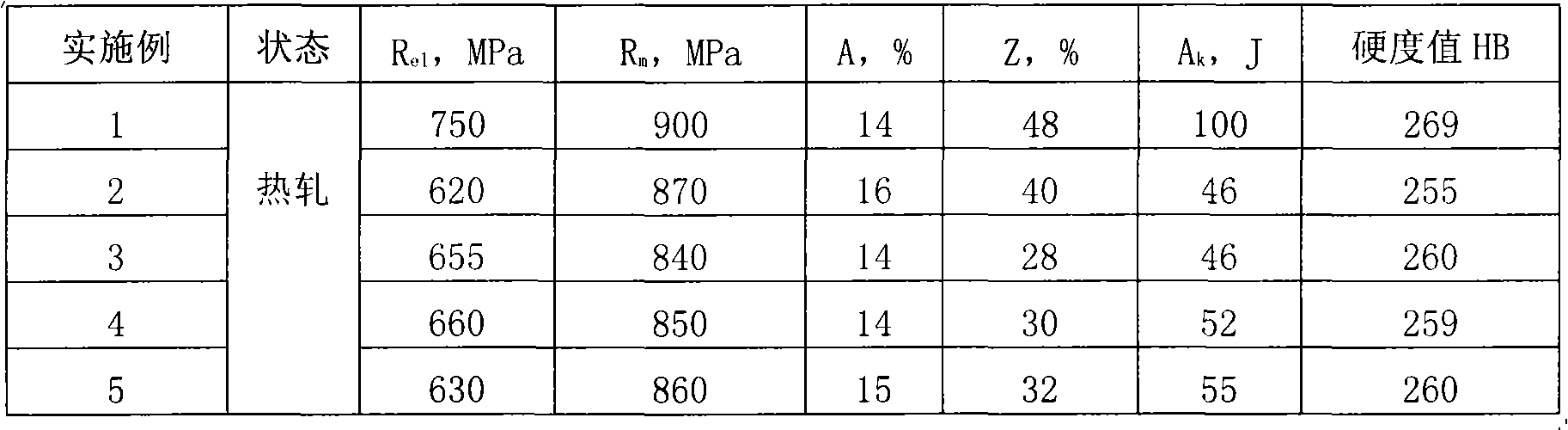

Quake-proof construction steel with lamellar tearing resistance and excellent performance and production method thereof

InactiveCN101994058AGood welding performanceSimplify welding production processProof constructionSheet steel

The invention relates to quake-proof construction steel with lamellar tearing resistance and excellent performance and a production method thereof. The steel is suitable for steel plates of which the thicknesses are between 20 and 100 millimeters and comprises the following chemical components: less than or equal to 0.015 percent of C, less than or equal to 0.015 percent of Si, less than or equal to 0.015 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.02 to 0.04 percent of Nb, 0.005 to 0.020 percent of Ti, 0.010 to 0.060 percent of Als and the balance of Fe. The method comprises the following steps of: performing the pretreatment of molten iron; performing desulfuration treatment; controlling target components of a smelting terminal point, wherein the target components comprise 0.05 to 0.07 percent of [C] and less than or equal to 0.015 percent of [P]; refining through a ladle furnace, and feeding aluminum wires and blasting argon; performing relative humidity (RH) vacuum treatment, and introducing the argon before the treatment; adding SiCa wires; casting continuously and performing the pouring of full-process protection; heating casting blanks; performing rough rolling; performing precision rolling; and cooling. The steel of the invention has the excellent quake-proof performance (ReH / Rm is less than or equal to 0.77); and the contractibility rate of a cross section in the full-thickness direction is between 40 and 70 percent, so the steel meets the requirements of key stressed points of major constructions such as steel structure work and the like fully.

Owner:武钢集团有限公司

Wear-resisting white cast iron and preparation method thereof

The invention provides a wear-resisting white cast iron and a preparation method thereof, and belongs to the technical field of wear-resisting materials. The liquid wear-resisting white cast iron is smelted in an electric furnace at first, and the liquid iron is composed of 2.9-3.3% of C, 4.5-5.5% of Mn, 6.0-7.2% of Cr, 0.45-0.70% of B, 0.50% of Si<, 0.05% of S<, 0.05% of P< and the balance of Fe by mass fraction. Modification treatment is performed on the wear-resisting white cast iron by adding a compound modificator to a casting ladle, wherein the addition amount of the compound modificator accounts for 1.8-3.0% of the mass fraction of the liquid iron in the casting ladle; besides, the wear-resisting white cast iron has excellent properties after being quenched by air cooling at a temperature ranging from 950 to 1000 DEG C and tempered at a temperature ranging from 280 to 320 DEG C.

Owner:BEIJING UNIV OF TECH

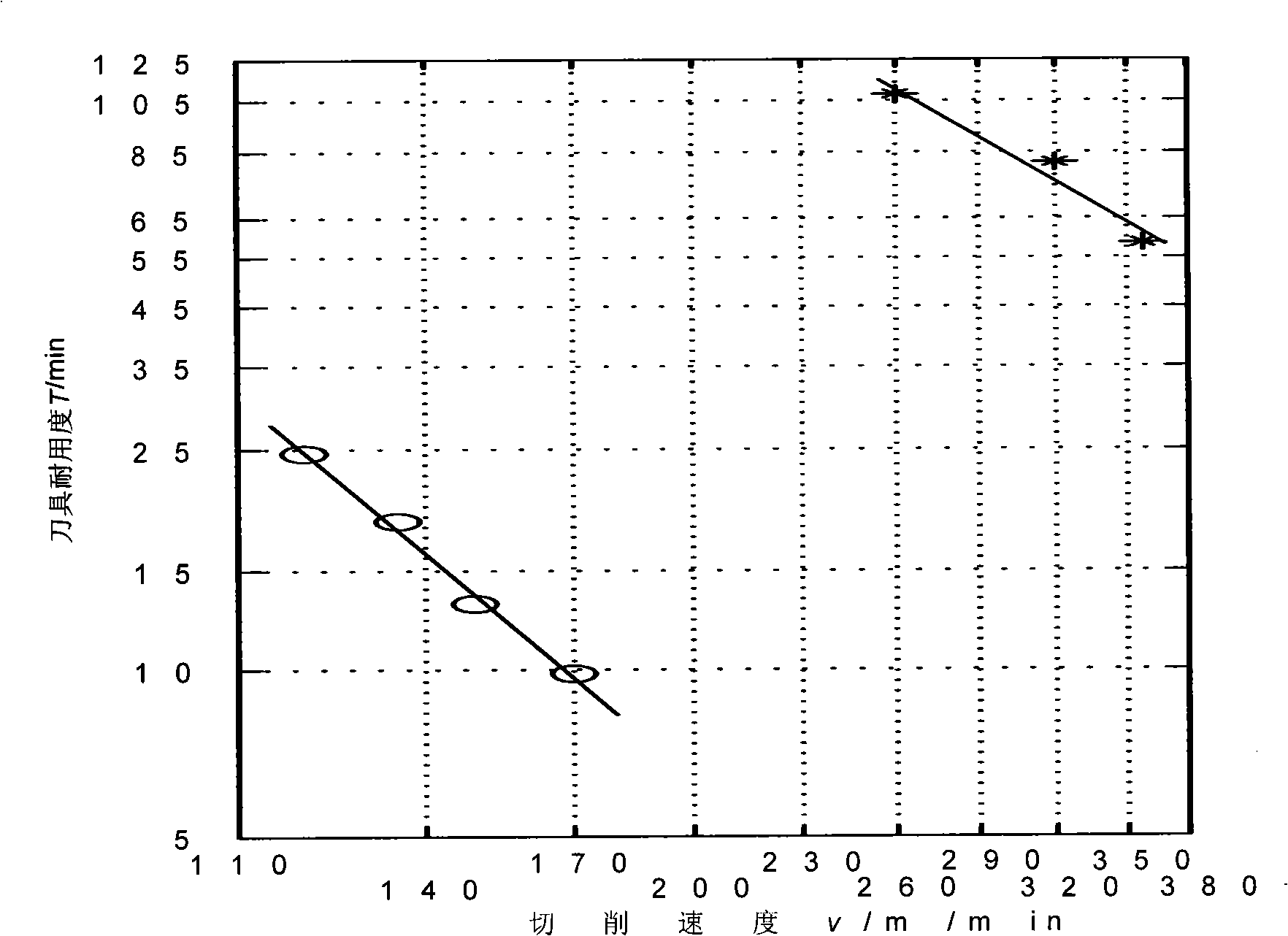

Easy-cutting untempered steel and method for manufacture thereof

InactiveCN101255535AEasy to shapeAdverse effects of improved mechanical propertiesProcess efficiency improvementElectric furnaceHeating timeHeating furnace

The invention discloses a Ca-S composite free-cutting non-quenched and tempered steel for cutting which has high cutting property and the manufacturing method thereof. The steel is composed of 0.44% to 0.49% of C, 0.30% to 0.60% of Si, 1.20% to 1.50% of Mn, 0.08% to 0.12% of V, no more than 0.30% of Cr, Ni and Cu, 0.040% to 0.065% of S, no more than 0.035% of P, 0.001% to 0.010% of Ca, 0.01% to 0.03% of Al, and the balance Fe and unavoidable impurity. According to the method, the compositions of inclusion in steel are controlled by ladle argon blowing and Ca-S composite processing, casting blank is poured by continuous casting, the average temperature for heating billet in a heating furnace is 1180 DEG C to 1220 DEG C, the heating time is 2 to 3 hours, the rolling starting temperature is 1100 DEG C to 1150 DEG C, the rolling finishing temperature is 850 DEG C to 1000 DEG C, the cooling speed of the rolled steel is 1.5 DEG C per second to 2.5 DEG C per second, the cooling bed cooing in pile temperature is 600 DEG C to 700 DEG C. The steel has superior mechanical property and free-cutting property.

Owner:SHANDONG IRON & STEEL CO LTD

Production method for low-alloy medium-thick steel plate

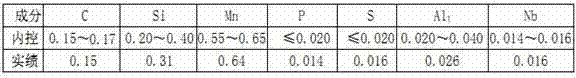

The invention discloses a production method for a low-alloy medium-thick steel plate. The process route comprises the following stages in turn: converter steelmaking, external refining, continuous casting, heating, rolling, and accelerated cooling. Steel comprises the following components by weight percent: 0.15-0.17% of C, 0.20-0.40% of Si, 0.55-0.65% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.020-0.040% of Al, 0.014-0.016% of Nb, and less than or equal to 0.30% of CEV. The (P+F) micro-structural feature of the traditional Q345D steel plate is maintained by the steel plate; according to the design of the components of the steel plate, the Mn is reduced by 0.9%, no Ni is added and 0.015% of Nb is increased, so that the cost per ton of steel alloy is reduced; the Nb micro-alloying treatment is supplemented with TMCP (Thermo Mechanical Control Process) technology, so that the demand on the performance of the steel plate is met, the percentage elongation is increased by 2%-3% and the impact toughness is increased by about 90J; the CEV of the steel plate is reduced to below 0.30% and the welding property of the steel plate is greatly improved; and the measures, such as, the great reduction of the alloy, the eliminating of ladle furnace process route, the Direct Hot Charging Rolling (DHCR) of hot casting blank, and the like, are taken, so that the production cost of the steel plate is greatly lowered.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

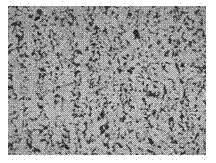

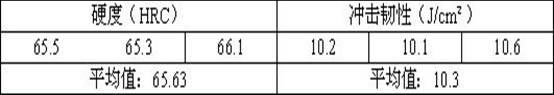

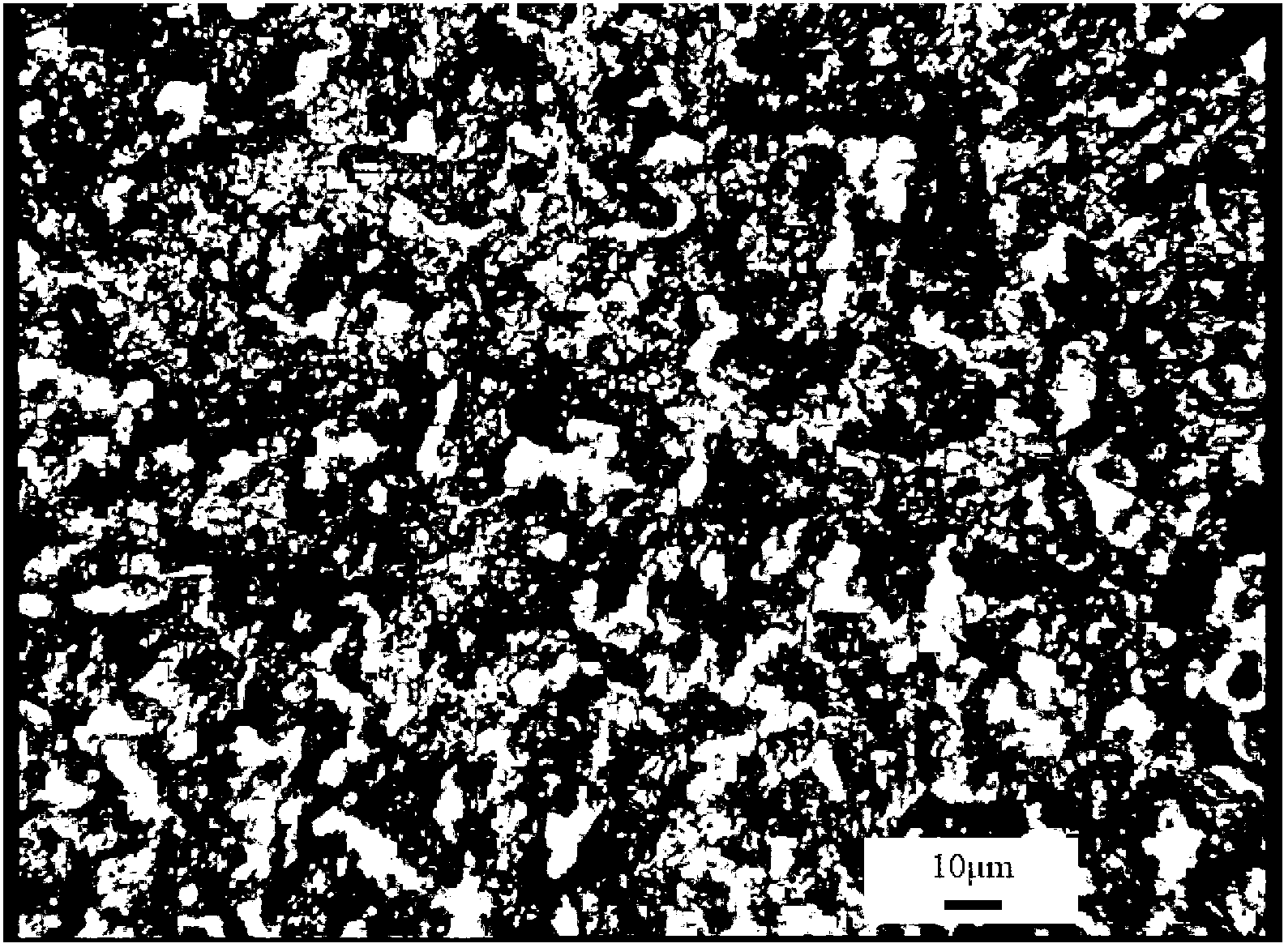

Hypoeutectic high-chromium white cast iron and preparation method thereof

The invention discloses a hypoeutectic high-chromium white cast iron, which comprises the following components calculated according to mass fraction: 1.9-2.4 of C, 16-22 of Cr, less than or equal to 0.8 of Si, less than or equal to 0.7 of Mn, 0.5-1.0 of Ni, 1.0-1.7 of Mo, less than 0.04 of S, less than 0.06 of P, 0.05-0.4 of RE, 0.5-1.0 of Cu, 0.05-0.15 of Zn, 0.1-0.3 of V and the balance of Fe. The preparation method comprises the following steps of: defining the mixture ratio according to the requirement of mass fraction and mixing; mixing scrap steel and pig iron in an intermediate-frequency induction furnace and heating the mixture to be melt; after molten iron is smelt, sequentially adding high carbon ferro-chrome, manganese iron, nickel and molybdenum and smelting again; feeding a zinc ingot with small granularity and rare earth or vanadium at the bottom of a casting ladle, covering a steel sheet or scrap iron and compacting; pouring the molten iron into the casting ladle and carrying out metamorphism and deslagging treatment; casting the molten iron and forming to obtain a hypoeutectic high-chromium white cast iron piece; then placing the hypoeutectic high-chromium white cast iron piece into a heat treatment furnace for thermally treating; and quenching and tempering to obtain a hypoeutectic high-chromium white cast iron material with the hardness of 60-66HRC (Hardness Rockwell) and the impact ductility of 10-14J / cm<2>. The hypoeutectic high-chromium white cast iron has the advantages of low cost, high wear resistance and reliable use safety. In addition, the preparation method of the hypoeutectic high-chromium white cast iron is simpler, and is easy in operation and strong in practicability.

Owner:云南化铸科技有限责任公司

High-boron high-speed steel roller material and smelting process thereof

ActiveCN102994692AHigh yieldEasy to useProcess efficiency improvementElectric furnaceMetallic aluminumSilicon alloy

The invention provides a high-boron high-speed steel roller material and a smelting process thereof. The smelting process of the high-boron high-speed steel roller material comprises the following steps: firstly, adopting Q235 waste steel, ferrotungsten, ferromolybdenum, ferrovanadium, high carbon ferro-chrome, metal copper, metal aluminum, calcium-silicon alloy, rare earth ferrosilicon magnesium alloy, ferrocolumbium, ferroboron, ferrosilicon, vanadium-nitrogen alloy, zirconium ferrosilicon and ferrotitanium as materials for smelting low-alloy high-speed molten steel in an electric furnace; then, adding the ferrovanadium and part of ferroboron to carry out alloying in a discharging process; finally, adding part of ferroboron and composite modificator in a casting ladle, adding the vanadium-nitrogen alloy, the zirconium ferrosilicon, the ferrosilicon and part of ferroboron in the casting process. The obtained casting piece has a little alloy elements, excellent abrasive resistance and good thermal fatigue resistance. When the high-boron high-speed steel roller material is used as a roller, the service life is prolonged by more than six times relative to a high nickel-chrome infinite cast-iron roller, and prolonged by 20% relative to a high-vanadium high-speed steel roller. Moreover, the roller is safe to use and reliable.

Owner:YUNNAN HEAVY EQUIP MFG GRP

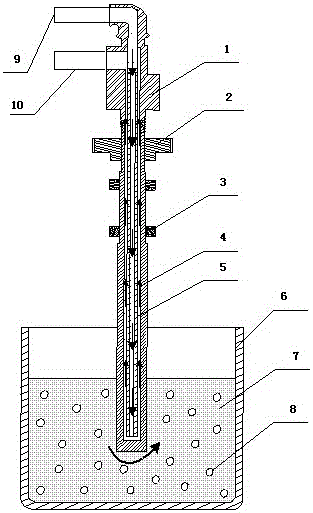

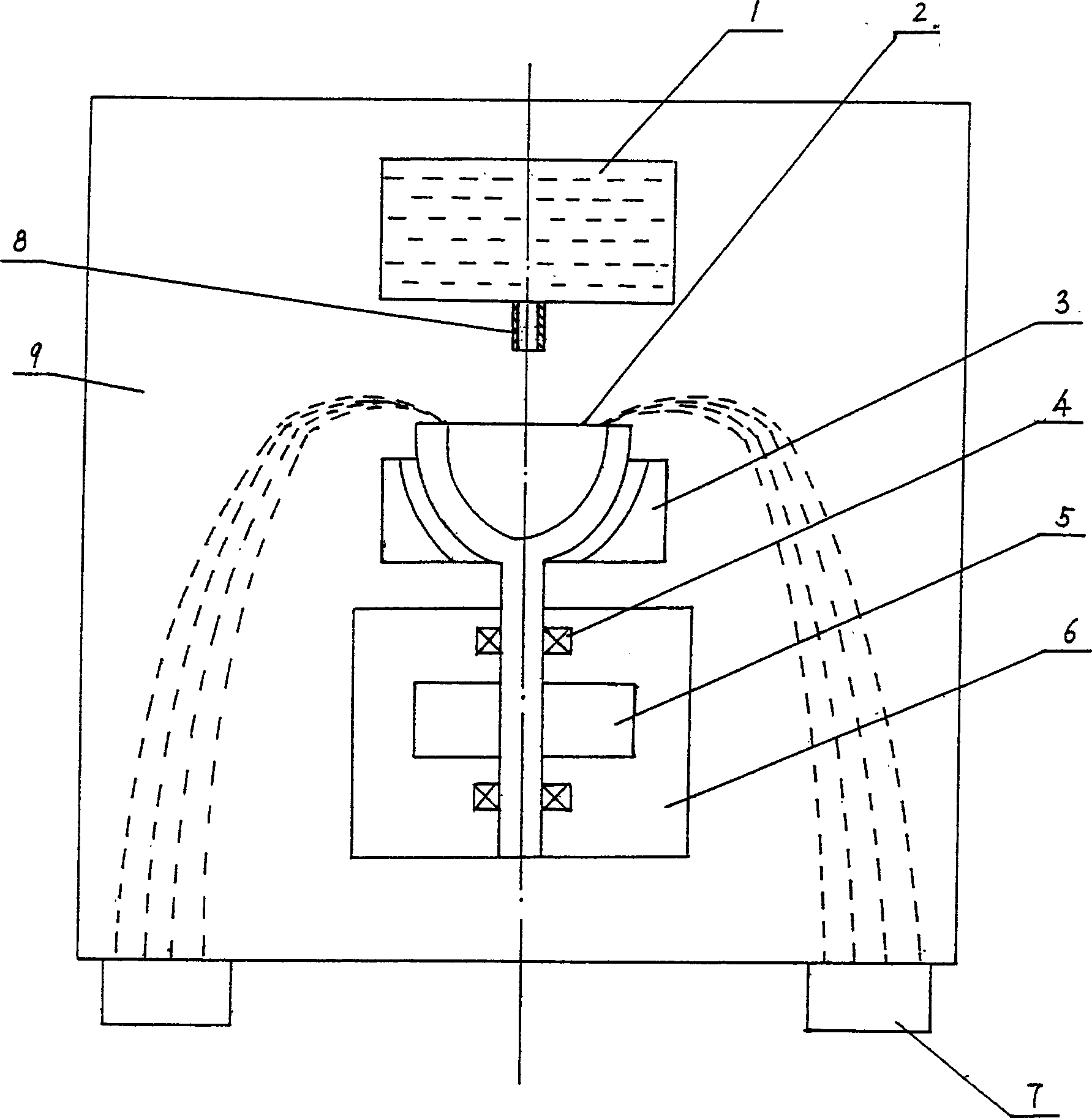

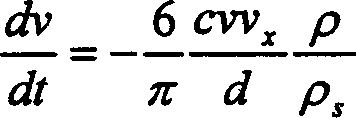

Method and device for preparing semi-solid state slurry through intensive cooling stirring

The invention discloses a method for preparing semi-solid state slurry through intensive cooling stirring. The method comprises the following steps: placing overheated alloy melt in a crucible or a casting ladle, descending a rotary stirring shaft internally introduced with a circular cooling medium in the alloy melt through a lifting device, driving the convection heat exchange of the alloy melt through stirring, continuously cooling the rotary stirring shaft through the circular cooling medium, stirring for a fixed period of time or cooling the melt to a set temperature, raising the rotary stirring shaft to prepare the semi-solid state slurry and form an ingot casting; closing the casting ladle containing the semi-solid state slurry to formation equipment and pouring the semi-solid state slurry into a cavity or material chamber of the formation equipment to take the shape; and taking out a formed part and moving the crucible or the casting ladle back to an original position and filling the overheated alloy melt to perform the next semi-solid state slurry preparation. The invention further provides a device for realizing the above method. Through the adoption of the method and device provided by the invention, large volume of semi-solid state slurry can be prepared once, and the semi-solid state slurry can be continuously produced in batch, and then the rheolytic formed part can be prepared through the combination of pressure casting, rolling, die-forging and other conventional formation equipment.

Owner:SHANGHAI INST OF TECH

Aluminum-magnesium refractory castable material and preparation method thereof

The invention discloses an aluminum-magnesium refractory castable material and a preparation method thereof. The aluminum-magnesium refractory castable material comprises the following raw materials by proportion of weight percentage: 70-80 percent of corundum granules and powder, 5-15 percent of alumina powder, 2-10 percent of magnesium-containing material, 3-8 percent of binding agent, 0.3-1.5 percent of silica micropowder, 0.05-0.1 percent of organic fibers (additional) and 0.2-0.6 percent of water reducing agent (additional). The preparation method of the aluminum-magnesium refractory castable material comprises material preparation, material mixing, formation, curing, drying, storage, transportation, use and other process steps. Compared with the prior art, the aluminum-magnesium castable material has high thermal shock resistance, low cost and excellent performance, can be applied in walls, bottoms, permanent layers, water ports and other parts of large-scale steel ladles, and can also be applied in castable materials for RH (Rockwell hardness) dip pipes. Therefore, the aluminum-magnesium castable material can adapt to a variety of industrial production environments.

Owner:LUOYANG LIER REFRACTORY MATERIAL +2

Production method of chromium-aluminium alloy target material

ActiveCN103182507AHigh densityUniform grain size distributionVacuum evaporation coatingSputtering coatingAl powderHigh density

The invention relates to a production method of a chromium-aluminum alloy target material, which includes the following steps: (1) placing chromium powder and aluminum powder into a V-shaped mixer for mixing; (2) placing the powder into a cold isostatic pressing sheath, vacuumizing, sealing, suppressing for 10 to 20 minutes, then placing in a vacuum self-propagating high-temperature synthetic furnace, and performing self-propagating reaction to acquire foamed chromium-aluminium alloy; (3) smashing the chromium-aluminium alloy into alloy powder with size of -200 mesh, placing the alloy powder in the cold isostatic pressing sheath for suppressing, so as to obtain a chromium-aluminium alloy blank; (4) placing the alloy blank in a steel sheath for vacuum degassing, then, performing hot isostatic pressing sintering treatment to obtain a chromium-aluminium alloy ingot; and (5) machining the chromium-aluminium alloy ingot to obtain a finished chromium-aluminium alloy target material. According to the invention, after the two raw materials are fully mixed and before the hot isostatic pressing sintering treatment is carried out, the alloying treatment in the step (2) is particularly adopted, so the prepared chromium-aluminum alloy target material has high density, uniform crystallite size distribution and excellent vacuum coating property.

Owner:北京九州新科科技有限公司

Integral installation method for mammoth steel converter outer assemblage

InactiveCN101063177ANo increase in infrastructure investmentSave on installation costsAssembly machinesManufacturing convertersSteelmakingBuilding design

The invention discloses an assembling method of steelmaking converter, which comprises the following steps: 1, setting assembling and emplacement device; 2, assembling middle, upper stage furnace jacket; welding; 3, assembling holder ring; 4, assembling holder ring and furnace jacket; 5, assembling tilting arrangement and holder ring; 6, emplacing whole converter; assembling. This invention can decrease assembling cost and work strength, which is fit for assembling converter and repairing project.

Owner:SHANGHAI BAOYE GRP CORP

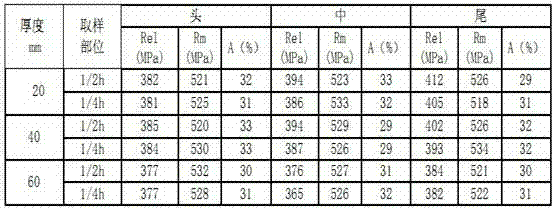

Easy-to-weld container plate with thickness ranging from 40 millimeters to 60 millimeters and excellent center low-temperature toughness, and making method thereof

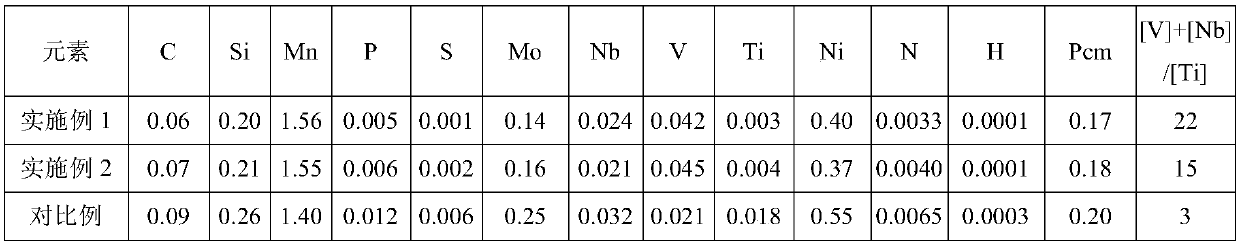

The invention relates to an easy-to-weld container plate with the thickness ranging from 40 millimeters to 60 millimeters and the excellent center low-temperature toughness, and a making method thereof. The steel plate comprises the chemical ingredients, by mass, 0.04% to 0.09% of C, equal to or smaller than 0.40% of Si, 1.00% to 1.60% of Mn, equal to or smaller than 0.008% of P, equal to or smaller than 0.002% of S, 0.12% to 0.30% of Mo, equal to or smaller than 0.10% of the sum of Nb, V and Ti, 0.20% to 0.60% of Ni, 25 ppm to 55 ppm of N, equal to or smaller than 2ppm of H, the balance Fe and unavoidable impurity elements. Meanwhile, the steel plate meets the conditions that Pcm is equal to or smaller than 0.20%, w(Nb+V) / w(Ti) ranges from 10 to 30, the yield strength of the steel plate is larger than or equal to 490MPa, the tensile strength Rm of the steel plate is larger than or equal to 620MPa, the elongation A is larger than or equal to 21%, the yield ratio is equal to or smallerthan 0.88, the side knock power minus 50 DEG C KV2 of the position of one fourth of the thickness of the plate is larger than or equal to 220 J, and the side knock power minus 50 DEG C KV2 of the position of one second of the thickness of the plate is larger than or equal to 100 J. The method comprises the following working steps of molten iron pretreatment, converter smelting, ladle furnace refining, vacuum treatment, continuous casting, casting blank cover cooling, casting blank heating, controlled rolling, controlled cooling, stack retarded cooling, quenching, tempering, flaw detection andperformance examination. The easy-to-weld container plate with the thickness ranging from 40 millimeters to 60 millimeters and the excellent center low-temperature toughness not only has the excellenttoughness matching, but also has the excellent center low-temperature impact toughness, and thereby meeting the requirements on steel for a large spherical tank.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Preparation method of low oxygen content microballon parent metal powder and its special equipment

InactiveCN1559696AImprove yieldGood sphericityLiquid spraying apparatusWelding/cutting media/materialsMicrosphereMetal powder

A method for preparing the microspherial flux powder with low oxygen content includes such steps as smelting the raw materials of flux, pouring in high-speed rotating atomizer at 4000 rpm, centrigual atomizing to become superfine liquid drops, and condensing in the flying procedure. Its apparatus is composed of a sealed atomizing chamber, smelting ladle, atomizer, constant-temp unit and motor.

Owner:王崇琳

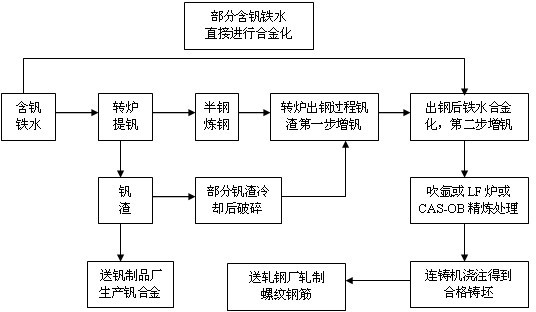

Smelting technology of III grade hot-rolled ribbed bars

InactiveCN102304604AHigh strengthMeet the seismic requirementsManufacturing convertersSlagShock resistance

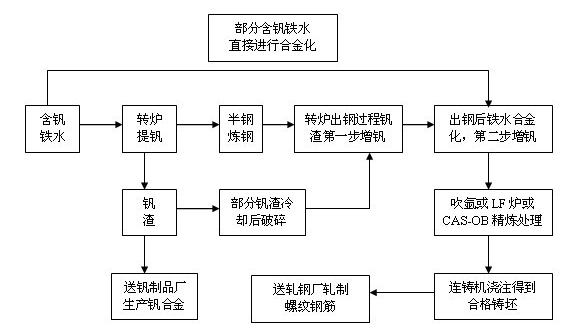

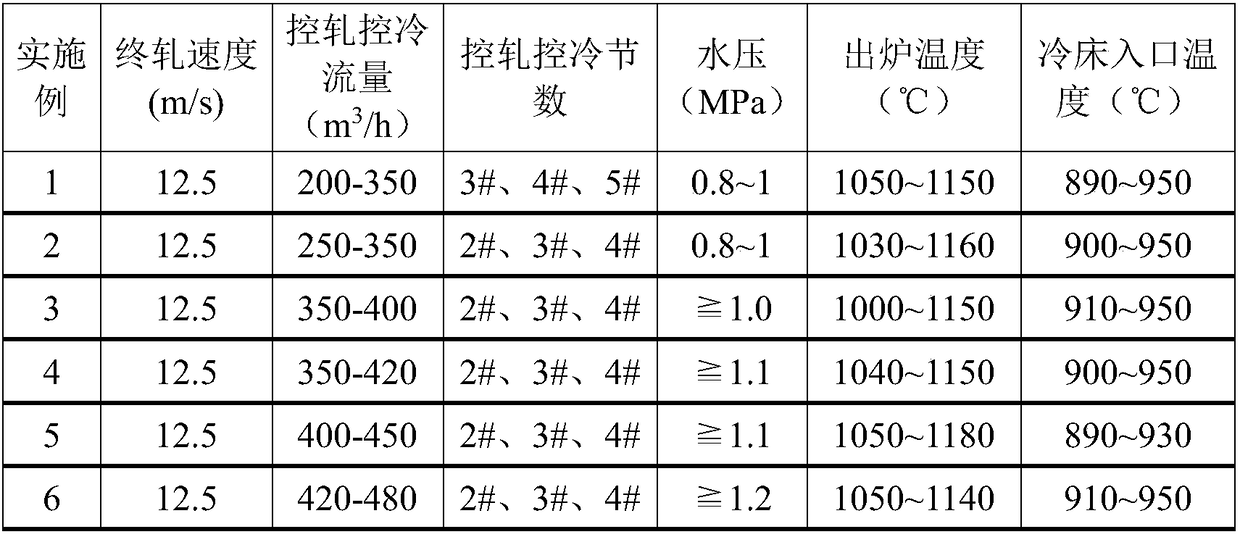

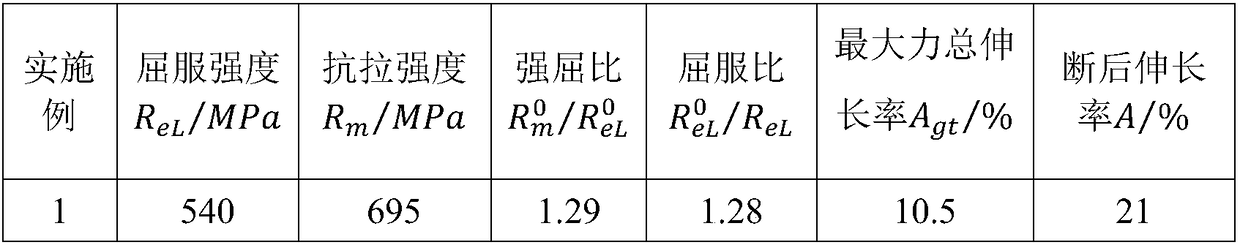

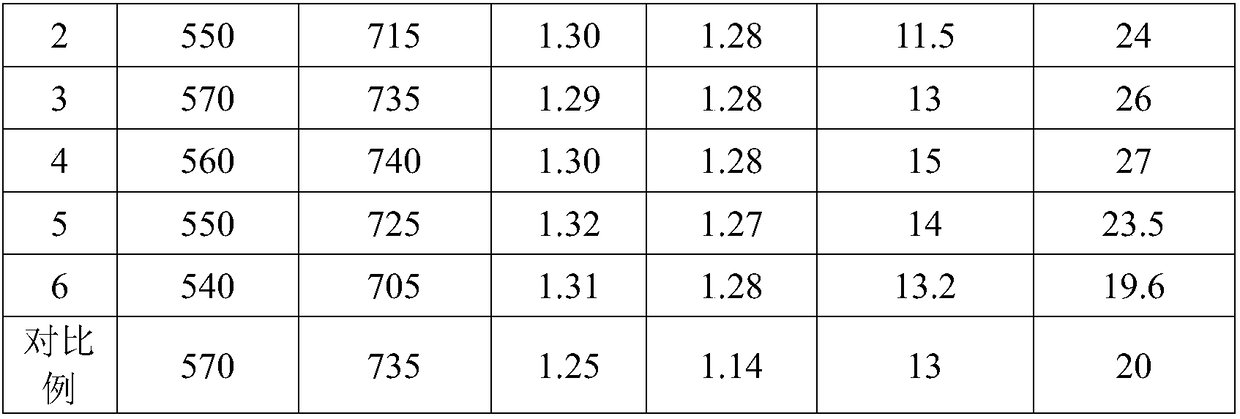

The invention relates to a smelting technology of III grade hot-rolled ribbed bars. The invention belongs to the technical field of steel smelting. The technical scheme of the invention is that: vanadium-containing molten iron is adopted as a raw material; a vanadium increasing process in a bar production procedure is divided into two steps that: first, during a steel producing procedure, vanadium slag extracted from the vanadium-containing molten iron is added, and vanadium elements are reduced and added into molten steel, such that first-step vanadium increasing is carried out; second, when steel is discharged from a converter, vanadium-containing molten iron is directly poured into the ladle, such that second-step vanadium increasing is carried out. During the process, the vanadium elements in the vanadium-containing molten iron are directly converted into the vanadium elements in the vanadium-containing molten steel. The vanadium alloyed raw materials (the vanadium slag and the vanadium-containing molten iron) are internal materials sourced from a steel refinery. With the composite vanadium increasing method, a problem of high cost in the production process of the III grade hot-rolled ribbed bars is solved. The produced ribbed bars satisfy both the performance requirement and the shock resistance requirement. With the method, direct and highly efficient utilization of rare resources is realized, the technology process is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:HEBEI IRON AND STEEL

Ladle bottom castable and preparation method thereof

The invention relates to a ladle bottom castable and a preparation method thereof. The technical scheme is as follows: 60-70wt% of titanium-iron slag particles are taken as aggregate, and 25-35wt% of titanium-iron slag fine powder, 1-4wt% of zirconia micro powder and 2-5wt% of titanium oxide micro powder are taken as substrate materials; according to the content of the aggregate and the substrate materials, the substrate materials are uniformly mixed firstly, and then the uniformly mixed substrate materials are added to the aggregate to be uniformly mixed; silica sol accounting for 3-7wt% of the sum of the substrate materials and the aggregate is added, and the mixture is uniformly stirred, subjected to vibratory compaction, cured for 6-12 h under the condition of room temperature and finally subjected to heat preservation for 12-24 h under the condition of 90-110 DEG C to prepare the ladle bottom castable. The ladle bottom castable and the preparation method have the characteristics of low cost and simple process, and the prepared ladle bottom castable has good high-temperature volume stability and good corrosion resistance to slag.

Owner:WUHAN UNIV OF SCI & TECH +1

Continuous casting process for high-class high-quality chain steel

The invention discloses a continuous casting process for high-class high-quality chain steel. According to the continuous casting process, a method of process control is adopted, a large billet caster is adopted for continuous casting, the portion from a large ladle to a tundish and the portion from the tundish to a crystallizer are poured in a protecting mode, argon gas is filled in the tundish before pouring, the portion from the steel ladle to the tundish is poured in a protecting mode through a long nozzle argon seal, the portion from the tundish to the crystallizer is poured in a protecting mode through a high-quality whole internally-installed submerged nozzle, a high-quality current stabilizer is adopted in the tundish impact area, a covering agent is used in molten steel in the tundish, the temperature of the tundish is measured continuously, automatic water distribution is carried out in the crystallizer and for secondary cooling, and the crystallizer is stirred in an electromagnetic mode and pressed dynamically and slightly. According to the continuous casting process, the internal and external quality of a casting blank is good, no connection blanks and slag pits exist in the surface, and performance of cogging rolled steel meets requirements of users.

Owner:NANJING IRON & STEEL CO LTD

Method for controlling tapping nitrogen content of converter

ActiveCN102978330AReduce carbon contentQuality improvementManufacturing convertersMolten steelDeoxygenation

The invention relates to a method for controlling the tapping nitrogen content of a converter. Requirements for molten iron are as follows: P is less than or equal to 0.150%, T is more than or equal to 1250 DEG C, the sulphur content is lower than 0.015%, and the hot metal ratio is increased by 85-90%; 30-40kg / t iron ore is added in the blowing period of the converter; terminal control comprises is as follows: C is 0.08-0.12%, P is less than or equal to 0.015%, S is less than or equal to 0.020% and T is 1650-1690 DEG C; steel ladle bottom argon blowing is carried out in advance, argon blowing is carried out in the whole tapping course, the bottom argon blowing amount is reduced and soft blowing is carried out under the condition that a molten steel liquid level is not exposed in a tapping process; and a two-step deoxygenation method is adopted in the tapping process. According to the method provided by the invention, no new equipment is required to be added and the equipment is not required to be modified, and the nitrogen content is 25ppm after tapping of the converter is reduced while the cost is not increased, so that the nitrogen content of the finished product is reduced and the steel quality is improved.

Owner:NANJING IRON & STEEL CO LTD

Steel bar with high weather resistance, low cost and seawater corrosion resistance and production process

ActiveCN108251746AGood weather resistanceLow costProcess efficiency improvementWeather resistanceRebar

The invention provides a steel bar with high weather resistance, low cost and seawater corrosion resistance and a production process. The steel bar comprises the following elementary compositions of,by weight, 0.04%-0.10% of C, 0.10%-0.50% of Si, 0.5%-1.6% of Mn, 0.03% or less of P, 0.02% or less of S, 2%-4% of Cr, 0.3%-0.5% of Cu, 0.2%-0.6% of Ni, and the balance Fe and inevitable impurities. According to the steel bar, the mechanical property meets the requirement of the steel bar for corrosion resistance, the aging strain is low, and the corrosion rate is lower than 70% that of common steel bars. The technical path of the process comprises a 70-ton ultrahigh-power electric furnace, LF ladle refining, deoxidation and alloying after steel discharging, argon blowing, continuous casting of165 square billets at four streams by four machines, a heat accumulating type stepping heating furnace, 18 non-twist tandem mills, controlled-rolling and controlled-cold cooling, finishing, packagingand storage.

Owner:福建三宝钢铁有限公司

35MnB steel and preparation method thereof

ActiveCN103952640AReduce the amount addedReduce lossManufacturing convertersProcess efficiency improvementSteelmakingSmelting process

The invention discloses 35MnB steel which comprises the following components in percentage by weight: 0.33-0.36 percent of C, 0.20-0.30 percent of Si, 1.20-1.40 percent of Mn, not more than 0.30 percent of Cr, not more than 0.025 percent of S, not more than 0.025 percent of P, not more than 0.20 percent of Ni, not more than 0.20 percent of Cu, 0.015-0.035 percent of Ti, 0.005-0.0030 percent of B, 0.015-0.035 percent of Al, not more than 20*10<-6> percent of [O] and not more than 35*10<-6> percent of [N], wherein the components are smelted in a rotary furnace, subsequently smelted in an LF ladle furnace, then subjected to RH vacuum degassing and finally cast continuously to obtain an ingot blank. The energy consumption cost for producing the type of steel is lowered fundamentally; loss of an element B of the 35MnB steel is reduced; the yield of ferroboron during a steel smelting process is increased; the stability of hardenability of the 35MnB steel can be improved; in addition, by adopting low superheat degree, electromagnetic stirring and a constant-temperature and constant-speed casting process, segregation of the elements such as C and Mn is alleviated, the components are more uniform and the fluctuation of the hardenability is alleviated.

Owner:SGIS SONGSHAN CO LTD

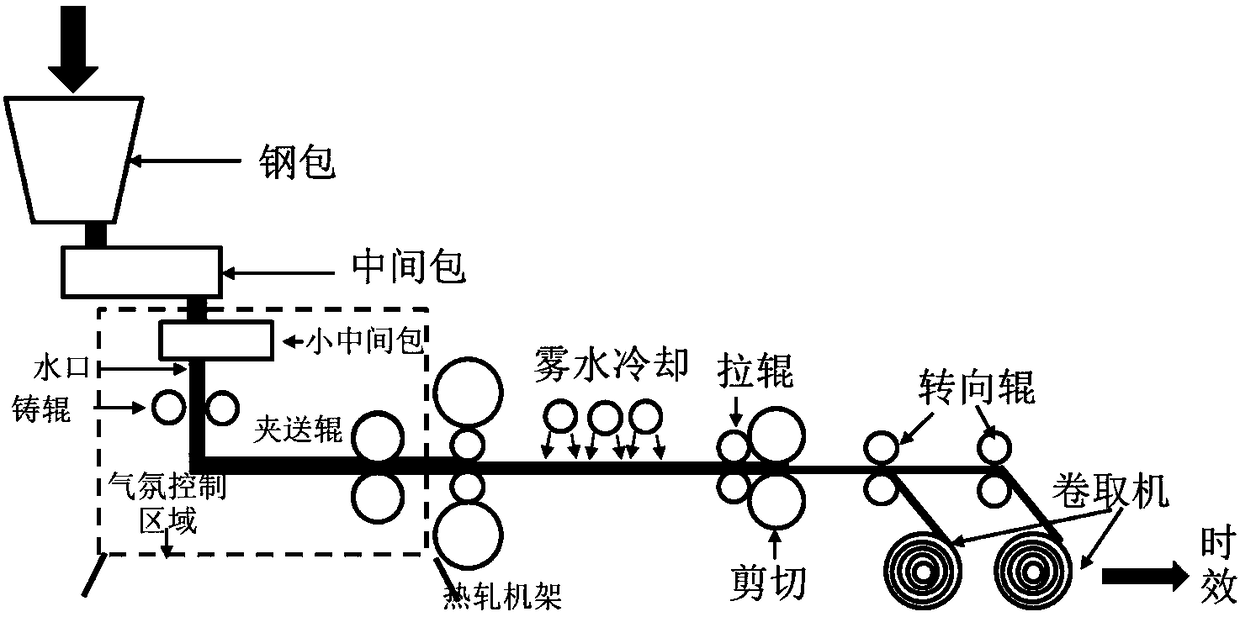

Method for preparing high-strength and toughness martensitic steel through strip cast rolling and aging process

The invention belongs to a method for preparing high-strength and toughness martensitic steel through strip cast rolling and aging process and belongs to the technical field of metallurgical engineering. The method comprises the specific steps: (1) smelting molten steel with qualified components and lifting the molten steel to a ladle turret; (2) injecting the molten steel into a specially designed tundish; (3) enabling the molten steel into a gap of double rolls to start freezing and performing cast rolling; (4) performing online hot rolling on the cast strip billet, cooling and cutting off the head and tail; (5) performing strip steel coiling; (6) performing aging treatment after uncoiling. According to the method disclosed by the invention, the technological process and production timecan be greatly shortened, the energy consumption is greatly reduced, and the production rate is improved. Compared with the conventional martensitic thin steel strips for automobiles, the high-strength and toughness martensitic steel disclosed by the invention has the advantages that the optimization design of micro-alloy components is combined with the rapid solidification characteristic of a thin strip cast rolling process, and due to subsequent aging treatment, the comprehensive mechanical properties of the martensitic steel are further improved.

Owner:大马士革(北京)科技有限公司

Rare earth alloy iron pan and production method thereof

InactiveCN103239139AImprove mechanical propertiesHigh burst resistanceCooking-vessel materialsSocial benefitsVegetable oil

A rare earth alloy iron pan production method includes: (1) smelting cast iron by an intermediate frequency furnace, and heating the iron molten iron till the temperature is higher than 1400 DEG C; (2) smashing rare earth ferrosilicon alloy till the size ranges from 2mm to 6mm, and preheating till the temperature reaches 60 DEG C; (3) placing the rare earth ferrosilicon alloy block with a quantity of weight ratio ranging from 0.3% to 1.8% in a ladle and then pouring the molten iron, and mixing and drossing; (4) casting after the molten iron is cleared, preheating a casting mold and injecting the molten iron to the mold, and pressing an upper pan mold down to form an iron pan; (5) taking out the iron pan after the iron pan is chilled in the mold, and clearing in a mechanical fine grinding and buffing manner; (6) feeding the iron pan into an electric furnace, heating till temperature ranges from 270 DEG C to 330 DEG C, painting edible vegetable oil on the pan body to form an oil film, and allowing oil molecules to penetrate in the pan body; and (7) taking out the iron pan and detecting. The rare earth alloy iron pan production method has good social benefit and economic benefit, and is adaptable to the field of iron pans.

Owner:SANSUI HONGLI KITCHEN UTENSILS CO LTD

Micropore high-strength corundum-calcium hexaluminate composite refractory raw material and preparation method thereof

The invention relates to a micropore high-strength corundum-calcium hexaluminate composite refractory raw material and a preparation method of the material. The technical scheme adopted by the invention is as follows: 94-98wt% of aluminum oxide fine powder or aluminium hydroxide fine powder is taken as an aluminium source; 1-6wt% of calcium carbonate fine powder or calcium hydroxide fine powder is taken as a calcium source; water is added into the raw materials, and the quantity of the water is 30-60wt% of the total quantity of the raw materials; the raw materials are mixed in the water; wet grinding is carried out on the mixture by virtue of a ball grinding mill for 0.5-2 hours; after being solidified, the slurry processed by wet grinding is subjected to heat preservation for 12-48 hours at the temperature of 110-200 DEG C; then, heat preservation is carried out at 1750-1900 DEG C for 3-5 hours; and finally, after the product is burnt and crushed, the micropore high-strength corundum-calcium hexaluminate composite refractory raw material can be obtained. The micropore high-strength corundum-calcium hexaluminate composite refractory raw material prepared by the method has the characteristics of being high in slag resistance, excellent in thermal shock resistance and heat-insulating property and the like, and can be used at the parts such as a steel ladle and the like contacted with molten steel and used for replacing corundum in other refractory material taking the corundum as a raw material, so that the service life of the material is prolonged, and the energy consumption is reduced.

Owner:JIANGSU JINGXIN NEW MATERIAL

Pre-melted slag for refining ultra-low aluminum steel and preparation method and using method thereof

InactiveCN103642991AControl oxygen contentControl restoreProcess efficiency improvementSocial benefitsReduction treatment

The invention relates to pre-melted slag for refining ultra-low aluminum steel and a preparation method and a using method thereof. The preparation method comprises the steps of firstly burdening BaO, CaO, MgO, B2O3, CaC2 and SiO2 according to a proportion, pre-melting at the temperature of 1450-1500 DEG C, cooling, then breaking into blocky materials, and packaging in a moisture-proof mode. The pre-melted slag is used for secondary refining and slagging by a ladle furnace, after pre-deoxidization of molten steel, slag pulling of a ladle and reduction treatment of residual slag, the ladle is added when the ladle is allocated and transported to a refining bay, and the pre-melted slag can be put into the ladle in the LF (ladle furnace) refining or the ladle argon blowing process. Compared with alkaline refined slag adopted in the prior art, the pre-melted slag has the advantages of absorbing Al2O3 in the steel to the greatest extent and promoting the reaction of O and Al in the steel so as to control the Al content below 0.004%; in addition, the pre-melted slag provided by the invention has the advantages of wide raw material sources, simple method and significant economic benefits and social benefits, and is favorable for reducing the cost and protecting the environment.

Owner:JIANGSU UNIV

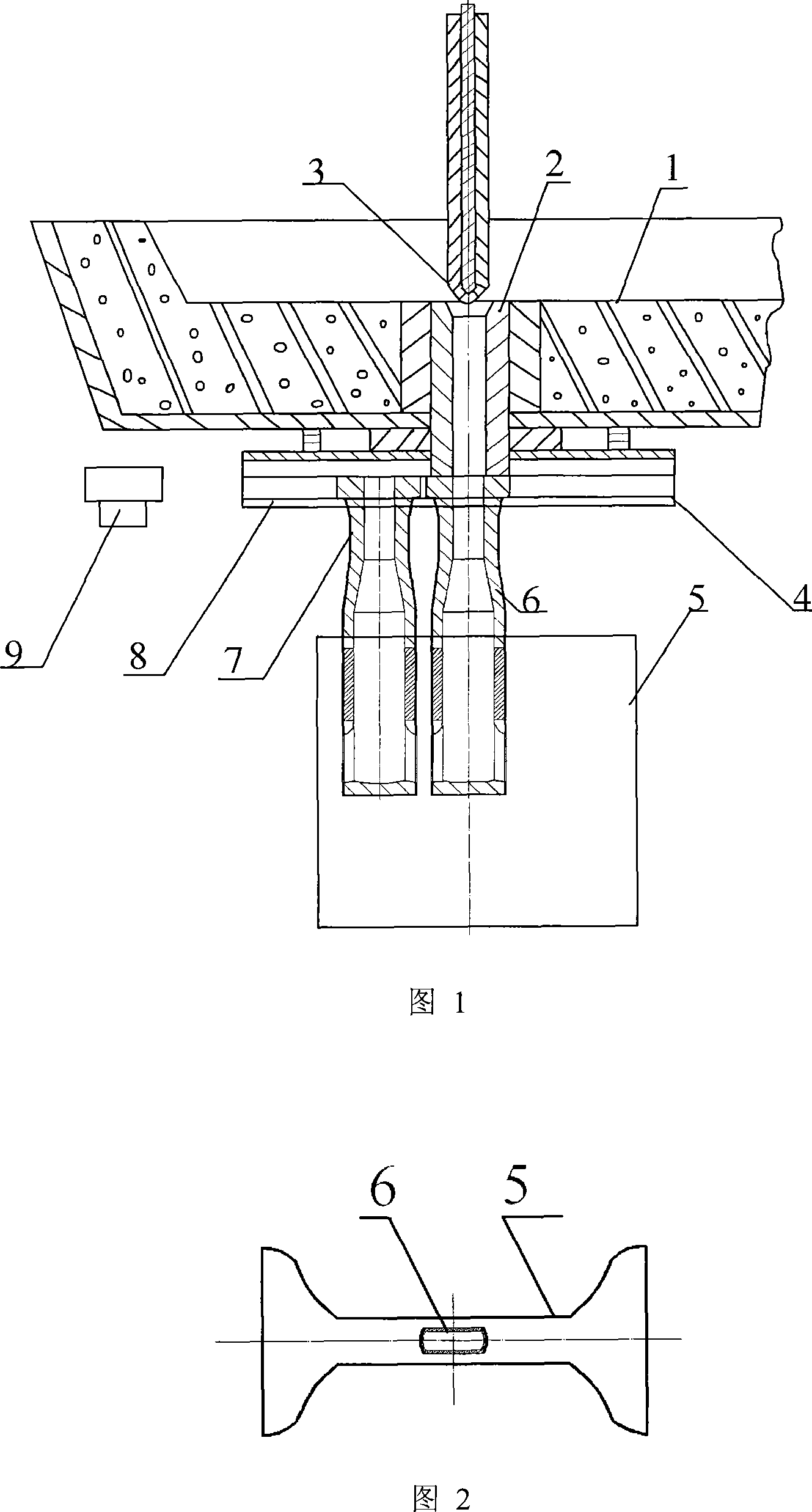

Method and device for carrying out protected casting for shaped blank continuous casting by using single immersed nozzle

InactiveCN101091982AAchieving protective castingReduce the chance of secondary oxidationWater gapTundish

The invention relates to a method and device that adopts water gap to take shaped blank continuous casting protecting casting. It inserts a dipped water gap into the center position of shaped blank crystallizer web to take casting. The upper part of dipped water gap connects to upper water gap of pouring basket. Molten steel flowing channel is formed between pouring basket and crystallizer. The stopper is used to control molten steel flow control to realize indicating control in crystallizer. The invention could realize full process protecting cast of shaped blank continuous casting to ensure cleanliness of molten steel.

Owner:LAIWU IRON & STEEL GRP

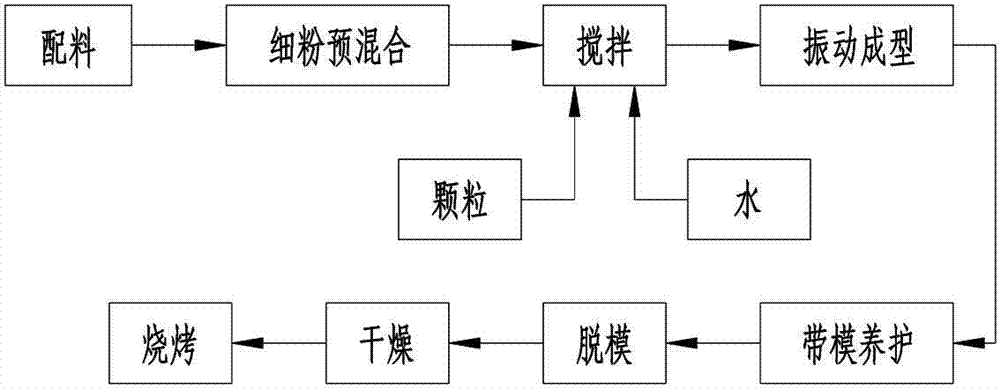

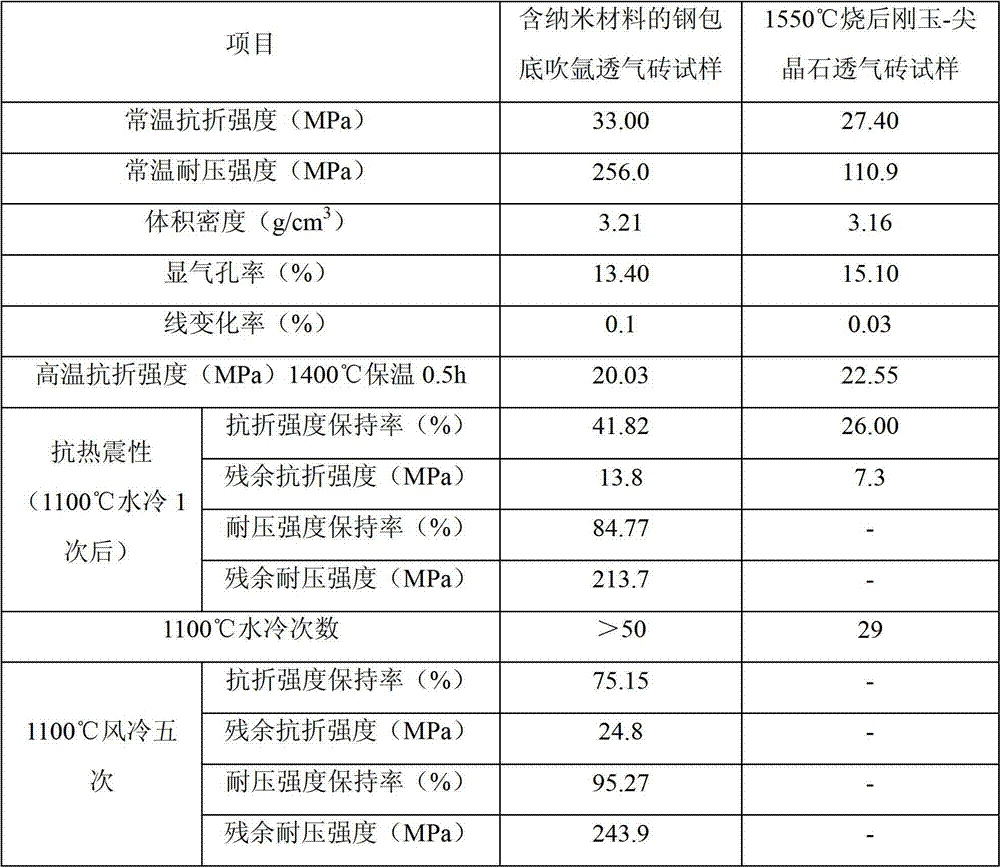

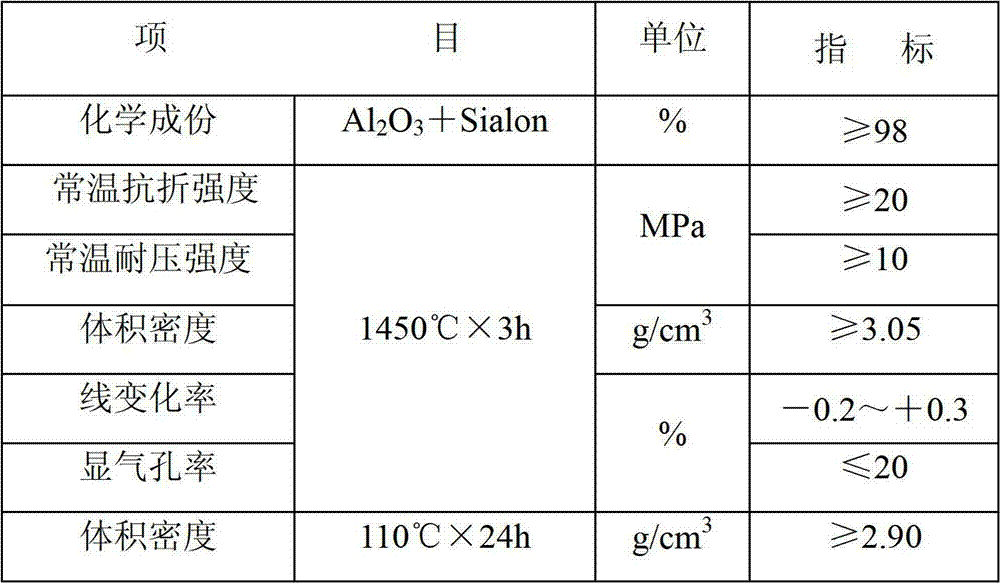

Nanometer material contained ladle bottom argon blowing permeable brick and preparation process thereof

The invention discloses a nanometer material contained ladle bottom argon blowing permeable brick and a preparation process thereof. The permeable brick comprises components of high-purity corundum, spinel, alpha-Al2O3 micro powders, nano calcium carbonate, Si powders, binding agents and antiknock agents. The preparation process of the nanometer material contained ladle bottom argon blowing permeable brick includes the following steps of dosing, fine powder premixing, stirring, vibration forming, curing with molds, demolding, drying and baking. According to the nanometer material contained ladle bottom argon blowing permeable brick and the preparation process thereof, Cr2O3 is not used, and during usage, new pollutants are not generated, so that pollution treatment costs are reduced, and high environmental benefits are achieved; micropores are evenly distributed in the brick, so that cracks are effectively prevented from continuing spreading during usage, the toughness of the permeable brick is improved, the spalling is reduced, the service life of the permeable brick is prolonged, the permeable brick is basically free from bonding slag after usage, cleaning during usage is reduced, and production costs of iron and steel enterprises are reduced.

Owner:成都府天新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com