Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

253 results about "Liquid iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High intensity and high-toughness hot-rolled steel sheet and method for producing the same

ActiveCN101397626ALow costReduced Hot Brittle TendencyTemperature control deviceLiquid ironProduction control

The invention discloses a high strength and high toughness hot-rolled steel plate, the chemical components thereof and the weight percentages of the component are: 0.03 to 0.09 percent of C, 0.15 to 0.35 percent of Si, 1.40 to 2.0 percent of Mn, 0.02 to 0.05 percent of Al, 0.05 to 0.13 percent of Nb, 0.010 to 0.025 percent of Ti, being equal to or less than 0.30 percent of Cu, being equal to or less than 0.30 percent of Cr, being equal to or less than 0.012 percent of P, being equal to or less than 0.004 percent of S, being equal to or less than 0.004 percent of N and the rest are Fe; and Ceq can not be more than 0.44, crack sensitive index Pcm can not be more than 0.23, the production steps thereof are: liquid iron pre-desulphurization, bessemerizing, LF refining, RH(VD) processing, slab blank continuous casting, slab blank reheating, temperature controlling rolling, controlled cooling, hot straightening, cold bed cooling and cooling in heap; the advantages thereof are as follows: molybdenum can be omitted and nickel can be saved, thus reducing the cost; the steel plate has good weldability, high rolling efficiency and precise production control.

Owner:SHAGANG GROUP

Wear-resisting white cast iron and preparation method thereof

The invention provides a wear-resisting white cast iron and a preparation method thereof, and belongs to the technical field of wear-resisting materials. The liquid wear-resisting white cast iron is smelted in an electric furnace at first, and the liquid iron is composed of 2.9-3.3% of C, 4.5-5.5% of Mn, 6.0-7.2% of Cr, 0.45-0.70% of B, 0.50% of Si<, 0.05% of S<, 0.05% of P< and the balance of Fe by mass fraction. Modification treatment is performed on the wear-resisting white cast iron by adding a compound modificator to a casting ladle, wherein the addition amount of the compound modificator accounts for 1.8-3.0% of the mass fraction of the liquid iron in the casting ladle; besides, the wear-resisting white cast iron has excellent properties after being quenched by air cooling at a temperature ranging from 950 to 1000 DEG C and tempered at a temperature ranging from 280 to 320 DEG C.

Owner:BEIJING UNIV OF TECH

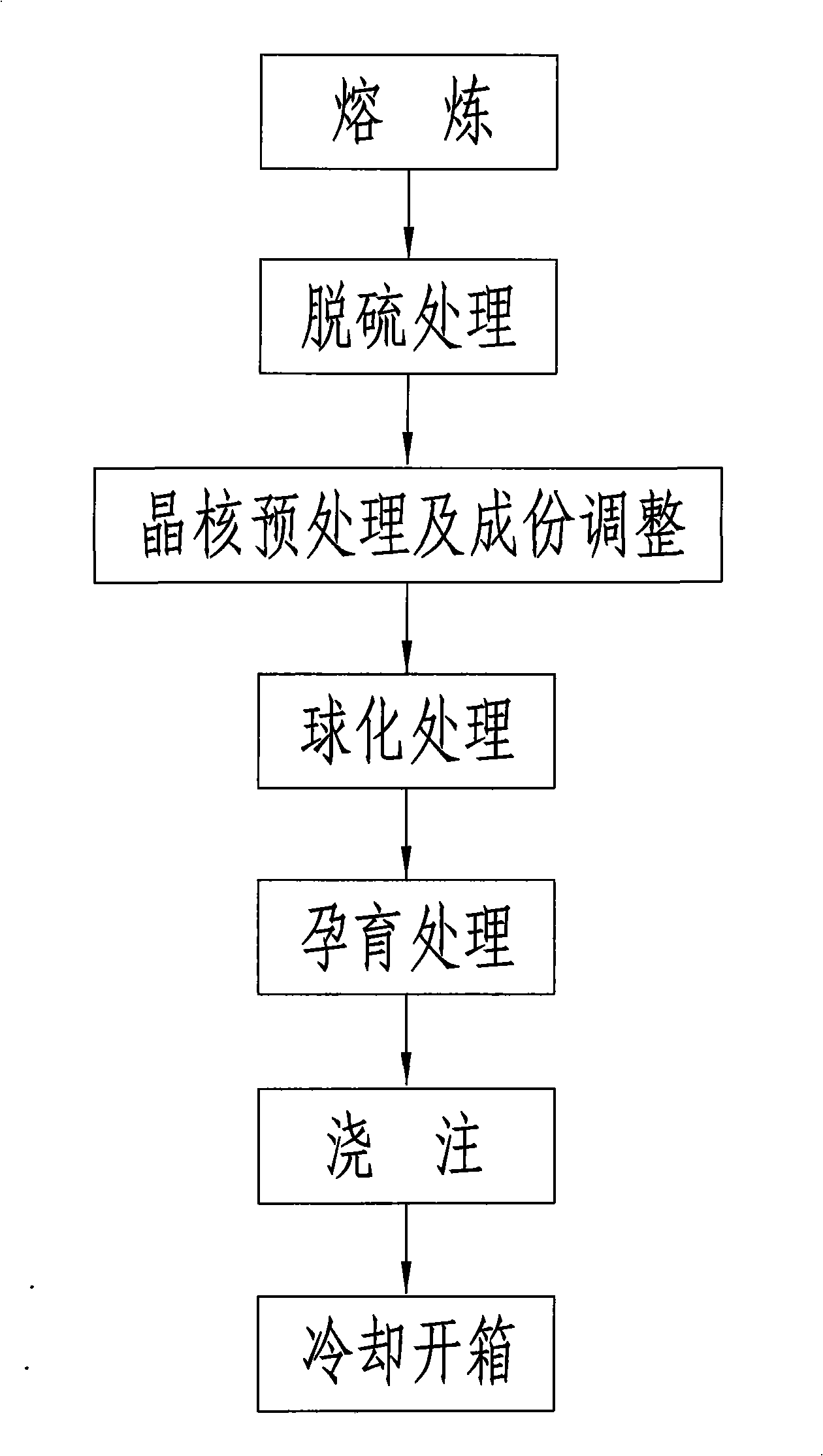

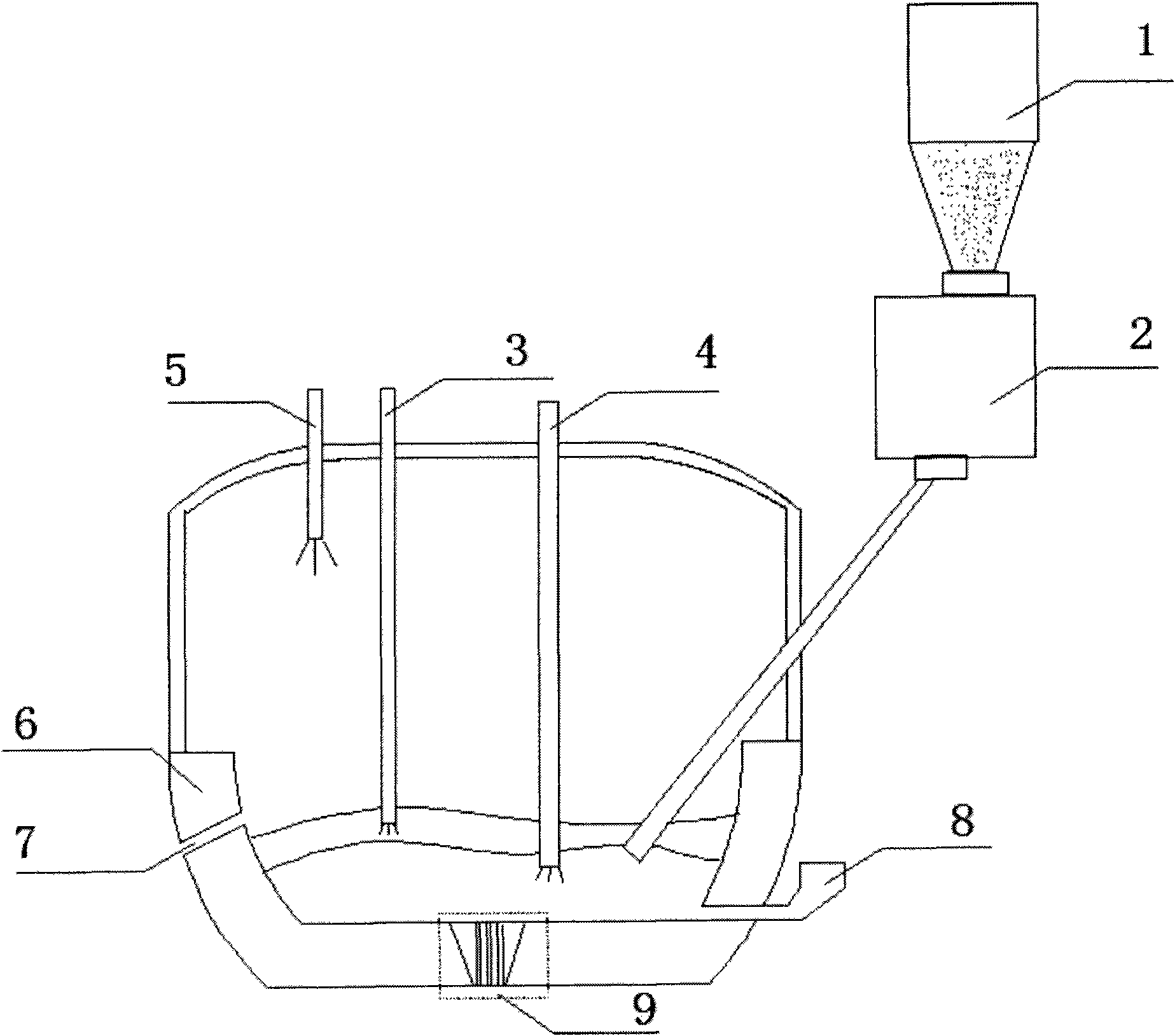

Smelting technique for cast of wind energy apparatus

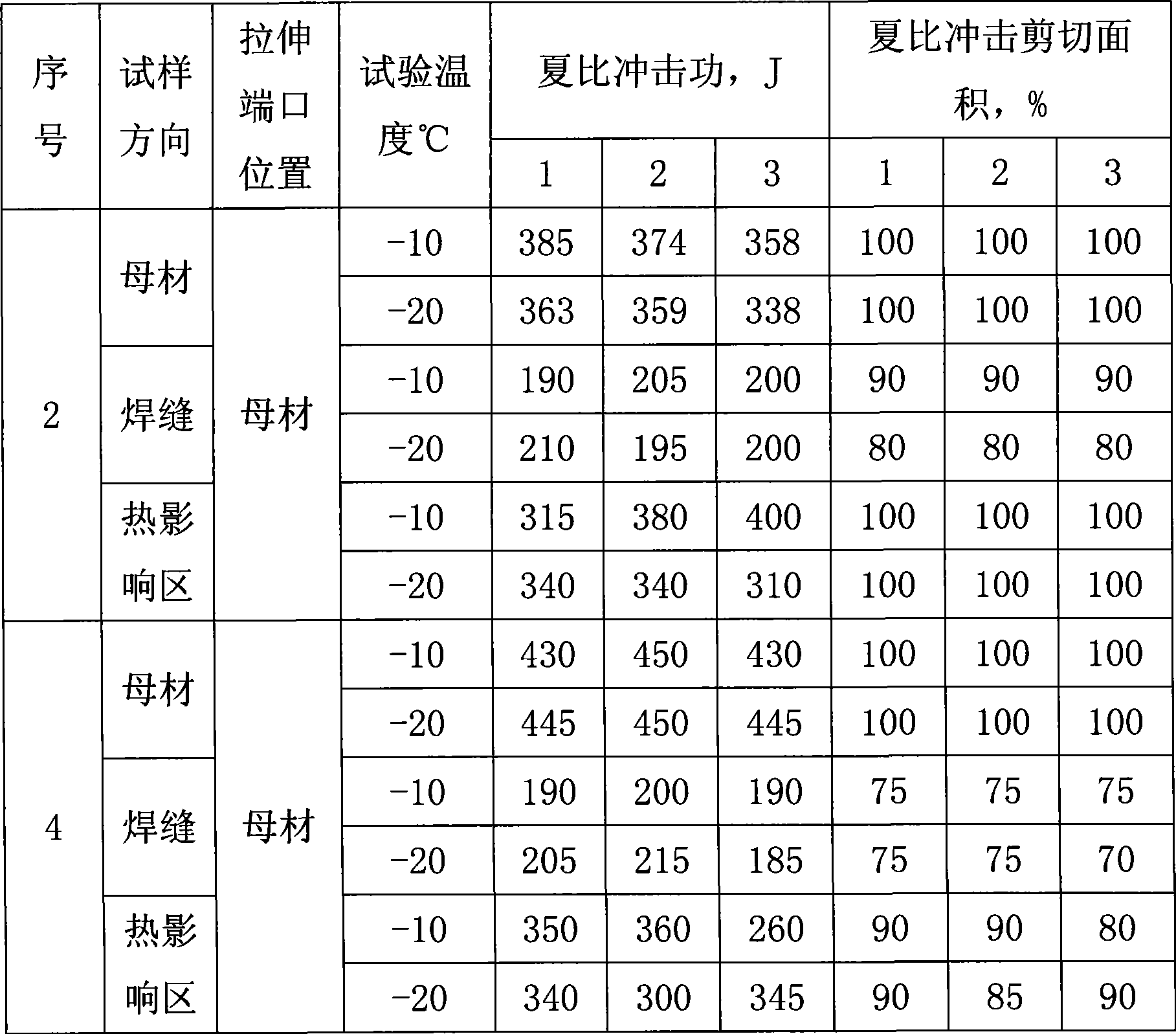

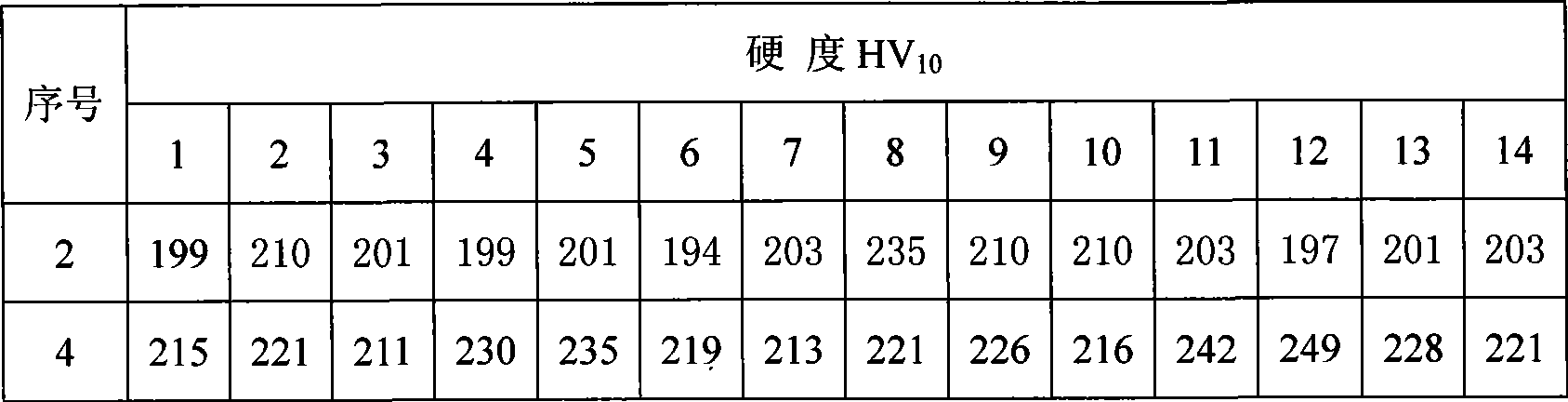

InactiveCN101407884AHigh nodularityMeet mechanical performance requirementsSmelting processLiquid iron

The invention discloses a smelting process of castings of wind energy equipment, which is suitable for the smelting production of castings of wind energy equipment with the wall thickness of 60 to 200mm and includes the following steps: a. new pig iron, scrap steel and carburants with special requirements are sent into a melting electric furnace for smelting; b. high temperature liquid iron is subjected to desulfurization treatment by a desulfurization agent; c. the desulfurized liquid iron is returned into a heat insulation electric furnace for component adjustment, and the carburant is added for carrying out pre-treatment of crystal nucleus to graphite in the liquid iron; d. spheroidization treatment is carried out to the liquid iron; e. an inoculant is added into the liquid iron for inoculation; f. the liquid iron is poured to casting sand mold; and g. the castings are naturally cooled to 500 to 550 DEG C for unpacking after finishing pouring. The smelting process of castings of wind energy equipment can increase the spheroidization efficiency of ductile iron castings used by the wind energy equipment, which causes the castings to have good intensity of tension, extensibility and high impact ductility in low temperature environments, thus meeting the requirements on the castings used by the wind energy equipment.

Owner:CHANGZHOU ZHUORUN WIND POWER EQUIP

Direct steel making process for iron ore

InactiveCN101665848AImprove productivityOxidation controlFluidised-bed furnacesMelting tankAutomatic control

The invention discloses a direct steel making process for iron ore, which comprises the following steps: adding the iron ore or pre-reduced ore powder into slag iron bath in advance, dissolving the iron ore or the pre-reduced ore powder to form slag, directly reducing liquid iron oxide by carbon, and blowing oxygen to a slag area and a liquid iron area of the slag iron bath to control the oxidizing property of the molten slag and the iron bath so as to obtain molten steel of which carbon content is less than 1.3 percent. CO produced in the reduction reaction is mainly used for secondary combustion to compensate the heat required by the reduction reaction, and the waste gas is used for pre-heating and pre-reducing (the iron mineral can be pre-reduced in weak reducing atmosphere). The process makes full use of characteristic of high direct carbon reduction speed of the liquid iron oxide, realizes molten steel production with iron-containing minerals only by using one direct steel makingfurnace, has high production rate and low ton steel-carbon consumption, saves equipment and capital construction investment, fully simplifies material flow, avoids temperature loss of the liquid ironduring transportation, and is easy to realize continuous production and automatic control.

Owner:LAIWU IRON & STEEL GRP

Blast furnace liquid iron quality online forecasting system and method based on multivariable online sequential extreme learning machine

ActiveCN104651559ARealize multivariate dynamic online forecastingEasy to controlBlast furnace componentsBlast furnace detailsTime lagData acquisition

The invention provides a blast furnace liquid iron quality online forecasting system and method based on a multivariable online sequential extreme learning machine. The forecasting system is composed of a conventional measurement system, a data acquisition unit, M-OS-ELM online forecasting software and a computer system for running the software. The forecasting method comprises the following steps of (1) auxiliary variable selection and model input variable determination; and (2) M-SVR soft measurement model training and utilization. According to the forecasting system and the forecasting method, a multivariable liquid iron quality forecasting model having output self-feedback and considering the timing sequence and time lag relation of input and output is established by use of the online process data provided by the conventional detection system and based on the M-OS-ELM intelligent modeling technology, and the multivariable online dynamic determination of four major liquid iron quality indexes, namely Si content, P content, S content and liquid iron temperature, is realized simultaneously; in short, the model has the characteristics of good practicability, more accurate measurement effects and stronger generalization ability.

Owner:NORTHEASTERN UNIV

Casting technique for manufacturing mold core by using resin sand

InactiveCN101569921AFast curingIncrease productivityFoundry mouldsFoundry coresWater basedLiquid iron

The invention discloses a casting technique for manufacturing a mold core by using resin sand, which sequentially comprises the following steps: 1) liquid iron is melted down: the measured raw materials are put into a line-frequency furnace and heated to be melted into the liquid iron; 2) molding sand is sent into a dry furnace to be dried, and then put into a sand mixer and simultaneously added with phenol resin and curing agent to be mixed with the dried molding sand, wherein, the curing agent comprises phenol-based polyisocyanate and triethylamine, and the weight of the phenol resin is 10-20 times as heavy as that of the triethylamine; the mixed sand is put into a casting model machine for manufacturing the mold core; 3) after being molded, the mold core is processed by spraying, water based paint is mainly applied in the spraying treatment, and then the sprayed mold core is dried in a dryer. As the curing agent in the technique is formed by the phenol-based polyisocyanate and the triethylamine, external heating is not needed in the technique for manufacturing the core; the resin sand can be rapidly cured under the catalysis of the triethylamine, thus improving the production efficiency.

Owner:TONGLING ANDONG CAST STEEL

Production method of cold-rolled steel plate for electro-galvanization

The invention discloses a production method of a cold-rolled steel plate for electro-galvanization. The steel plate is smelted according to components. The production method comprises the following concrete technological steps: (1) pretreating liquid iron; (2) smelting in a rotary furnace; (3) finely tuning alloy; (4) refining in an RH furnace; (5) continuously casting; (6) performing hot rolling; (7) rolling; (8) performing cold rolling; (9) continuously annealing; (10) flattening. By precisely controlling the components in the steel and being combined with a production process of the cold-rolled steel plate for electro-galvanization, the production method disclosed by the invention can be used for obtaining the cold-rolled steel plate which is 150 to 40Mpa in yield strength, higher than 270MPa in tensile strength, larger than 37% in percentage elongation, capable of satisfying the requirements of deep drawing and molding, good in plate form and surface quality (above FC) and capable of satisfying the requirements of electro-galvanization and subsequent passivation and anti-fingerprint treatment; the surface quality of the steel plate for electro-galvanization can be improved; the steel plate for electro-galvanization is enabled to have the good plate form.

Owner:马钢(合肥)钢铁有限责任公司

Secondary cold-rolled high-hardness stamping steel with high isotropy and manufacturing method thereof

InactiveCN102234736ASolve the ear phenomenonHigh strengthTemperature control deviceMetal rolling arrangementsChemical elementAcid washing

The invention relates to a secondary cold-rolled sheet with high hardness and plane isotropy and a manufacturing method thereof, which are particularly suitable for steel for making an unscrewing cover, a shallow drawn can and the like with low earing requirements. The secondary cold-rolled sheet comprises the following chemical element components in percentage by weight: 0.02 to 0.06 percent of C, less than or equal to 0.03 percent of Si, 0.10 to 0.30 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.015 percent of S, 0.03 to 0.10 percent of Al, less than or equal to 0.0035 percent of N and the balance of Fe and inevitable inclusions. The secondary cold-rolled sheet is prepared by the following steps of: pretreating the proportioned materials by using liquid iron; smelting in a converter; performing post-refining by using the converter; hot-rolling; performing acid washing; cold-rolling; continuously annealing; performing secondary cold-rolling; and finishing to obtain finished rolls, wherein a heating temperature is controlled to be less than or equal to 1,180 DEG C during the hot-rolling, the final rolling temperature is more than Ar3, and a coiling temperature is between 620 and 750 DEG C; cold-rolling deformation is controlled to be between 75 and 90 percent, and a continuous annealing temperature is between 640 and 700 DEG C; annealing time is between 50 and 150 seconds; secondary cold-rolling rate is between 15 and 35 percent, and other conditions meet the requirements of the conventional process; and an obtained product has the hardness of HR30T 60 to 80 and the earing rate of less than or equal to 5 percent.

Owner:BAOSHAN IRON & STEEL CO LTD

Aluminum-containing and sulfur-containing series gear steel smelting process

ActiveCN104611502AControl Si contentInhibit peroxidationProcess efficiency improvementElectric furnaceGranularitySmelting process

The invention discloses an aluminum-containing and sulfur-containing series gear steel smelting process. Liquid iron is required to contain 0.20-0.50% of Si, less than or equal to 0.035% of S, and less than or equal to 0.110% of P, and at a temperature T greater than or equal to 1250 DEG C; lime for an electric furnace and refining is required to contain greater than or equal to 90% of CaO and less than or equal to 1.2% of SiO2, and has the activity degree of greater than or equal to 300 and the granularity of 10-40mm; a low-silicon refining agent is required to contain greater than or equal to 45% and less than or equal to 55% of CaO, less than or equal to 2.0% of SiO2, and greater than or equal to 35% and less than or equal to 40% of Al2O3. The liquid iron hot charge ratio of the electric furnace reaches up to 90%; for LF refining, a first strong and later weak deoxidization manner is adopted; at the middle-late stages, a weak deoxidizer is adopted for furnace slag maintenance to realize further deoxidization. Meanwhile, deoxidization and S removal are performed, and then an S wire is fed to obtain a certain S content; in addition, the S wire is allowed to be fed only in more than 5 minutes after the denaturalization treatment of feeding a calcium-iron wire into VD liquid steel, and therefore, the formation of CaS inclusion in a clogging material at other water gap is prevented; and at last, the castability of the liquid steel is guaranteed while excellent structural properties of the steel product are obtained, and the purity of the liquid steel is improved.

Owner:ZENITH STEEL GROUP CORP +1

Molten iron slagging-off method

The invention relates to the field of molten iron pretreatment technologies, in particular to a molten iron slagging off method which is characterized in that an inert gas is continuously blown into a liquid iron tank at the farthest end on the slagging-off side at the later period of slagging off. The method comprises the following steps of: (1) carrying out slagging off by using a slagging off machine after iron is molten until the thickness of a slag layer is smaller than 50 mm; (2) stretching a slag blowing pipe 300-400 mm below the level of the molten iron at the farthest end on the slagging off side, and controlling air pressure at 0.6-0.8 MPa and air flow at 15-30 Nm3 / h; and (3) stopping blowing the gas after slagging off is completed. The gas is nitrogen, and the purity is greater than 98%. The invention has the advantages that slag is discharged to the slagging off side and gathered through gas churning, the slagging off time can be obviously shortened and is controlled within 10 min, the sulfur moisture content of a deeply-desulfurized steel grade can be well satisfied, the resulfurization of the melting process is reduced, and simultaneously, the slagging off iron content is reduced.

Owner:ANGANG STEEL CO LTD

Production method for eliminating edge defects of hot rolled strip steel

The invention discloses a production method for eliminating edge defects of hot rolled strip steel. The process flow comprises the following steps of: desulfurizing liquid iron; smelting by using a converter; performing external refining; continuously casting medium-thin slabs; heating; performing rough rolling; performing finish rolling; performing laminar cooling; and reeling. The method is characterized in that: a vertical bending type medium-thin slab continuous casting machine is adopted in the continuous casting process; the casting speed of the continuous casting machine is 1.5 to 4.0 m / min; an edge shielding baffle plate is arranged in a continuous casting secondary cooling region or an edge nozzle in the horizontal section of the continuous casting machine is closed; an intermittent side pressure and intermittent descaling method is adopted in a hot rolling rough rolling process; and a rough rolled vertical roll adopts a box-shaped hole type. The method has the advantages that: the continuous casting billet avoids a low-temperature fragile region at a straightening section and eliminates edge cross crack; and high temperature-reducing speed is avoided during the contact of the hot rolled strip steel edge part and the rough rolled vertical roll and the plasticity of the edge part is improved. By the method, the edge defects of the hot rolled strip steel can be eliminated and energy can be saved by 30 percent.

Owner:ANGANG STEEL CO LTD

Process for producing gray cast iron with high carbon equivalent, low alloy and middle-high strength

The invention belongs to the gray cast iron production method technical field, and in particular relates to a method for producing gray cast iron with high carbon equivalent, low alloy and mid-high strength, which solves the problem that the high carbon equivalent gray cast iron produced by adopting the prior art is low in mechanical property. Pig iron added in the method of the invention is low-silicon casting pig iron instead of mid-high silicon casting pig iron used in the casting tradition, and discharge liquid iron in the method is high-carbon liquid iron. When the discharge liquid iron is poured into a big ladle, self-made special composite inoculant made from rare earth ferro-silicon alloy, ferromanganese and silicon-calcium-barium inoculant is added to the stream, which greatly improves the mechanical property of the gray cast iron. The method solves the acknowledged difficult problem in the casting community that the gray cast iron is very low in mechanical property within the range of high carbon equivalent component. As new casting material, iron castings produced through the method can be popularized and applied on brake discs or brake hubs of automobiles in large quantities.

Owner:山西恒泰制动器股份有限公司

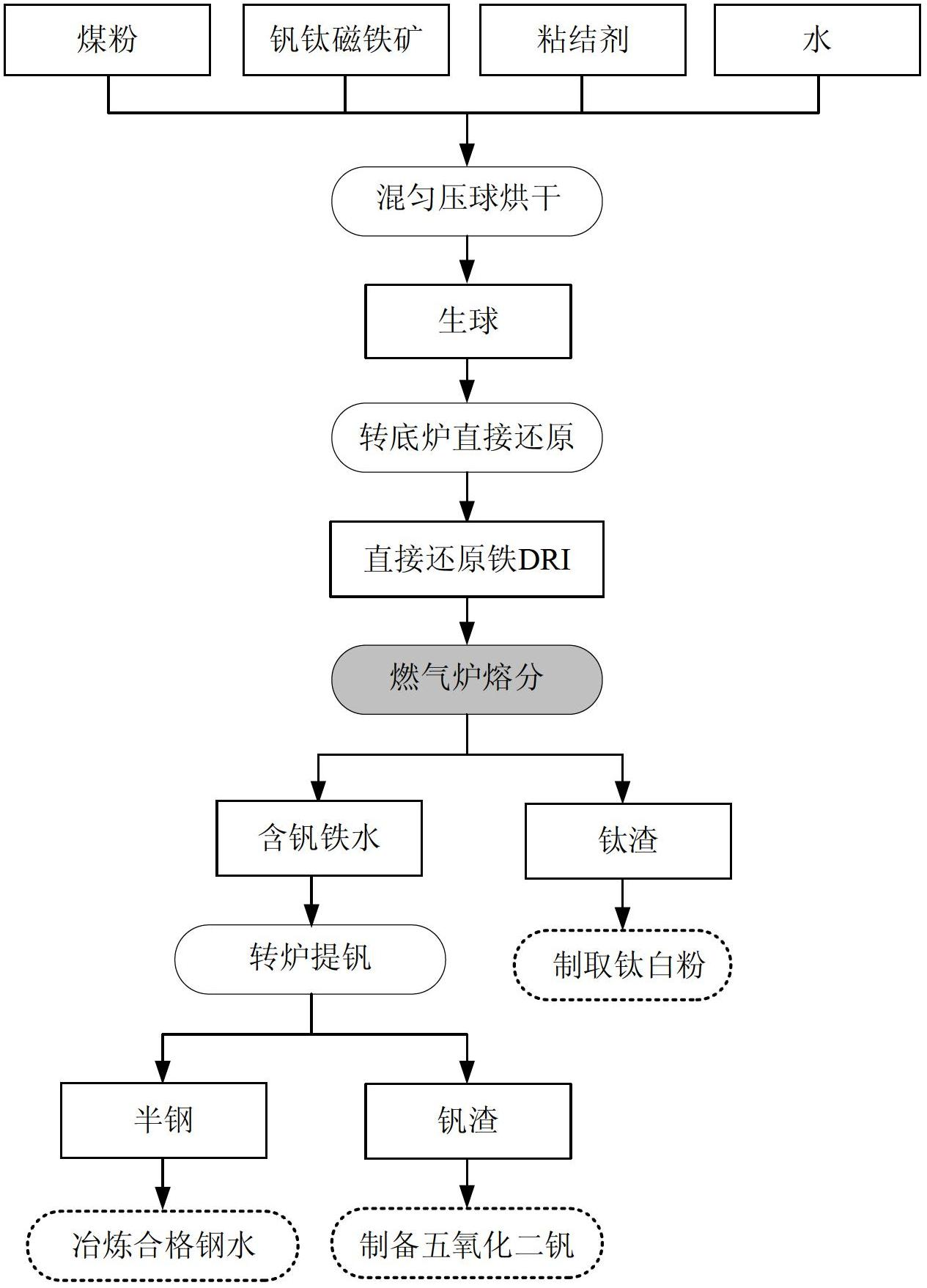

Method for comprehensively utilizing vanadium titano-magnetite by melting and separating through reduction-fuel smelting furnace of rotary hearth furnace

ActiveCN102690921AImprove purityReduce carbon contentRotary drum furnacesManufacturing convertersMagnetiteLiquid iron

The invention discloses a method for comprehensively utilizing vanadium titano-magnetite by melting and separating through a reduction-fuel smelting furnace of a rotary hearth furnace, comprising the following steps of: firstly, uniformly mixing the vanadium titano-magnetite, reduced coal and a bonding agent and pressing into a pellet; drying the pellet and filling into the rotary hearth furnace to be heated to be at 1150-1350 DEG C, and reducing for 30-40 minutes; directly conveying an obtained high-temperature metallized pellet into a heat accumulating type fuel melting furnace in which coal-derived gas is taken as fuel for melting and separating; controlling the temperature of the fuel melting furnace to be at 1500-1620 DEG C to obtain liquid iron containing vanadium and titanium slag; producing titanium dioxide powder by taking the titanium slag as a raw material or producing a titanium-enriched material through using a flotation process; conveying the liquid iron containing the vanadium into a converter to blow oxygen to obtain vanadium slag and semi-steel; and removing the vanadium slag and continually smelting the semi-steel into steel liquid. The method takes the coal-derived gas with a low calorific value as motive power for the melting and the separating of the heat accumulating type fuel melting furnace so as to combine a coal-derived gas procedure and a melting and separating procedure; blast furnace gas and coal-derived natural gas which have the low calorific value can be used; and the carbon content of the liquid iron containing the vanadium obtained by the melting and the separation of the fuel furnace is very low and the purity is very high.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Interstitial free (IF) hot rolled strip and manufacturing method thereof

ActiveCN101608285AReduce intensityImprove plasticityManufacturing convertersChemical compositionLiquid iron

The invention provides an interstitial free hot rolled strip and a manufacturing method thereof. The mass percents of the chemical constituents of the strip are as follows: 0<C<=0.005, 0<P<=0.018, 0<S<=0.015, 0<N<=0.004, 0<Si<=0.03, Mn 0. 10-0.20, Al 0.02-0.06, 0<Ti<=0.070, 0<Nb<=0.020, 0<Cr<=0.05, 0<Ni<=0.07, 0<Cu<=0.07, 0<Mo<=0.020 and the balance of Fe and other inevitable impurities. The manufacturing method comprises the steps of preparing continuous castings according to the constituent requirement and processing the continuous castings into the hot rolled strip. The manufacturing method of the strip comprises the following steps: A. preparing continuous castings to be desulfurized by liquid iron pretreatment, smelted in a top-bottom combined blowing converter, RH refined and continuously cast by heavy slabs; B. adopting the traditional hot continuous rolling process to process the continuous castings into the hot rolled strip; the finishing temperature is 880-930 DEG C; the hot rolled strip is quickly water-cooled to the temperature of 680-750 DEG C to be reeled up and then is cooled to the room temperature. The strip manufactured by the method has low strength, high plasticity and good processing technic.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Engine camshaft chilled cast iron and manufacturing method thereof

InactiveCN101660084AImprove scratch resistanceGood anti-adhesionValve arrangementsMolten metal pouring equipmentsLiquid ironFerrosilicon

The invention discloses an engine camshaft chilled cast iron and a manufacturing method thereof, and the engine camshaft chilled cast iron is manufactured by the following steps: A. molding; B. batching: 50-55% of steel scrap, 8-12% of pig iron, 28-37% of foundry returns, 2.2% of carburant (graphite electrode), 0.45% of elements and iron alloy-copper, 3.2% of silicon iron and 0.85% of ferrochrome;C. melting: comprising the following substeps: a. adding the above ingredients according to a certain sequence in turn; b. melting liquid iron; c. superheating and standing; and d. inoculating; D: pouring the liquid iron obtained in the step C; E: cooling and opening a box; F: cleaning sand; and G: detecting camshaft parts. In the engine camshaft chilled cast iron of the invention, the depth andhardness of a chilled layer is effectively controlled and the wearing resistance, galling force resistance, adhesiveness resistance and anti-strip toughness are fine, thereby satisfying the requirements of high speed and high load and alternating exchange load, needing no subsequent quenching and hardening treatment, saving work time and lowering cost.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Method for casting super-large centrifugal cold mould by adopting nodular cast iron

InactiveCN101748324AGuaranteed StrengthHigh tensile strengthFoundry mouldsFoundry coresLiquid ironPearlite

The invention relates to a method for casting a super-large cold mould of nodular cast iron. The cold mould comprises the following main matrixes in percentage by weight: 75 to 95 percent ferrite and 5 to 25 percent pearlite. The liquid iron after inoculation and spheroidization comprises the following components in percentage by weight: 2.9 to 4.5 percent of C, 2.0 to 3.5 percent of Si, less than 0.6 percent of Mn, less than 0.2 percent of P, less than 0.03 of S, 0.02 to 0.08 percent of Mg, 0.02 to 0.08 percent of Re and the balance of Fe, wherein the total amount of the components is 100 percent. The method realizes the super-large centrifugal cold mould cast from the nodular cast iron, ensures the strength of the cold mould, shortens the manufacturing period, greatly reduces the manufacturing cost and ensures the quality of rollers.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

Continuous steel making process for iron ore

InactiveCN101665849AImprove productivityMeet the needs of heat balanceFluidised-bed furnacesProduction rateAutomatic control

The invention discloses a continuous steel making process for iron ore, which comprises the following steps: by adopting a direct carbon reduction mode of liquid iron oxide, adding the iron ore or pre-reduced ore powder into slag iron bath in advance, dissolving the iron ore or the pre-reduced ore powder to form slag, then using carbon to quickly reduce the liquid iron oxide to obtain liquid iron,next blowing oxygen at the other end of a furnace to remove the carbon so as to obtain molten steel, namely realizing iron mineral addition and molten steel production in the same furnace. CO produced in the reduction reaction is mainly used for secondary combustion to compensate the heat required by the reduction reaction, and the waste gas is used for pre-heating and pre-reducing (the iron mineral can be pre-reduced in weak reducing atmosphere). The process makes full use of characteristic of high direct carbon reduction speed of the liquid iron oxide, has high production rate and low ton steel-carbon consumption, saves equipment and capital construction investment, fully simplifies material flow, avoids temperature loss of the liquid iron during transportation, and is easy to realize continuous production and automatic control.

Owner:LAIWU IRON & STEEL GRP

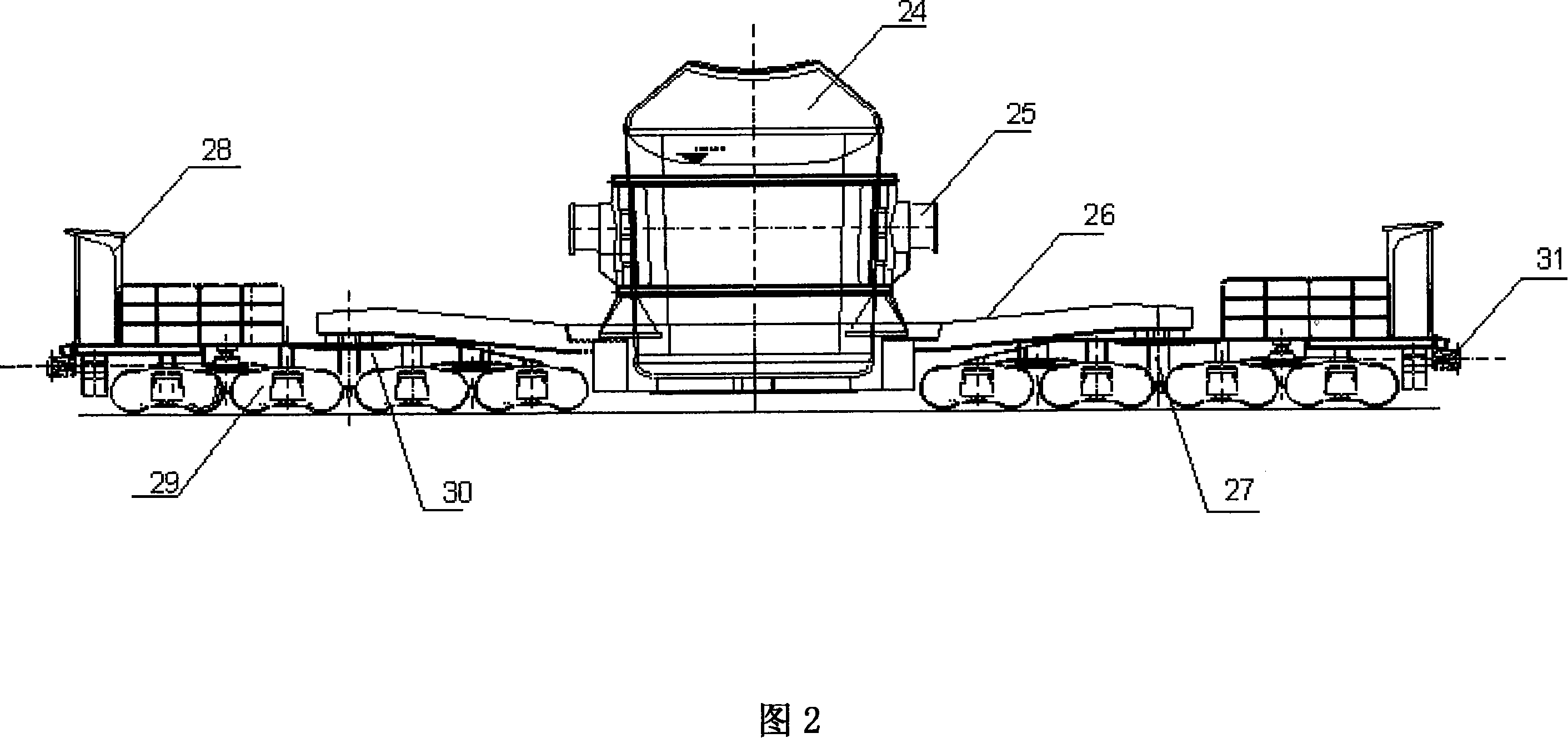

System and technique for transporting rail heterotype considerable tank truck

InactiveCN101108419AAvoid pouringEmission reductionMelt-holding vesselsCasting plantsMeasurement deviceHigh energy

The invention relates to a rail allotype high capacity tank car transport liquid iron system and technics, which is suitable for liquid iron transport among iron and steel in large-size steel plant. The utility model is characterized in that: firstly, a liquid iron transport line and a steel-making workshop are laid in parallel; secondly, a blast furnace and the steel-making workshop are laid closely, the straight line distance is 900 to 1000 meters; thirdly, a liquid tank car for transporting liquid iron is arranged between the blast furnace and the steel-making workshop; fourthly, a test tank chamber is arranged between the steel-making workshop and a liquid railway switchyard; fifthly, a measurement device for continuous weighting is arranged on the orbit at the position of receiving iron in iron producing plant; sixthly, an intelligent transport dispatch system is provided. The invention overcomes the problem that the traditional rail allotype liquid iron transport has multiple sections, low production efficiency, large heat consumption, high energy consumption, poor three-slipping effect, large one-time investment, high running cost and poor environment condition.

Owner:SHOUGANG CORPORATION +1

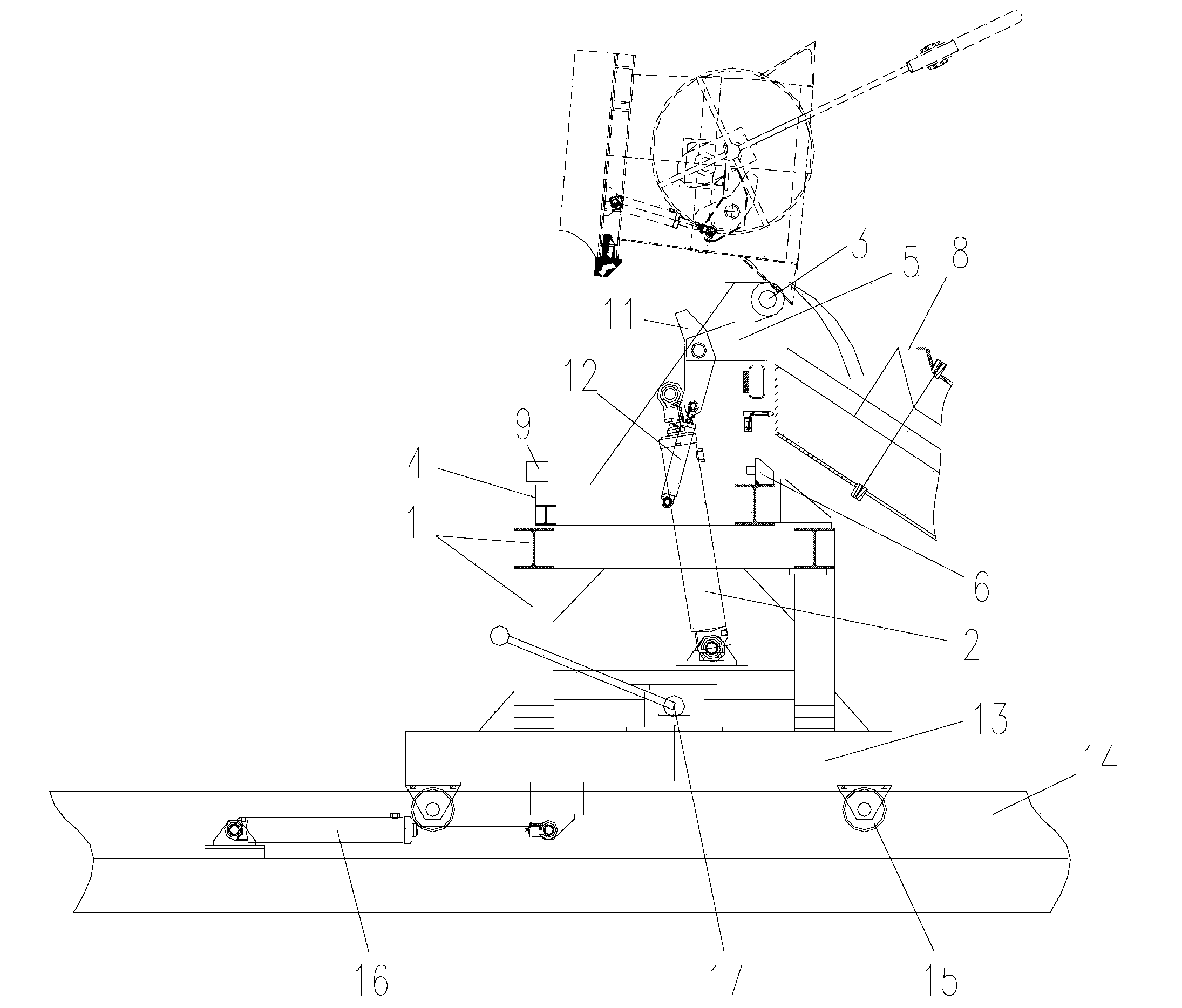

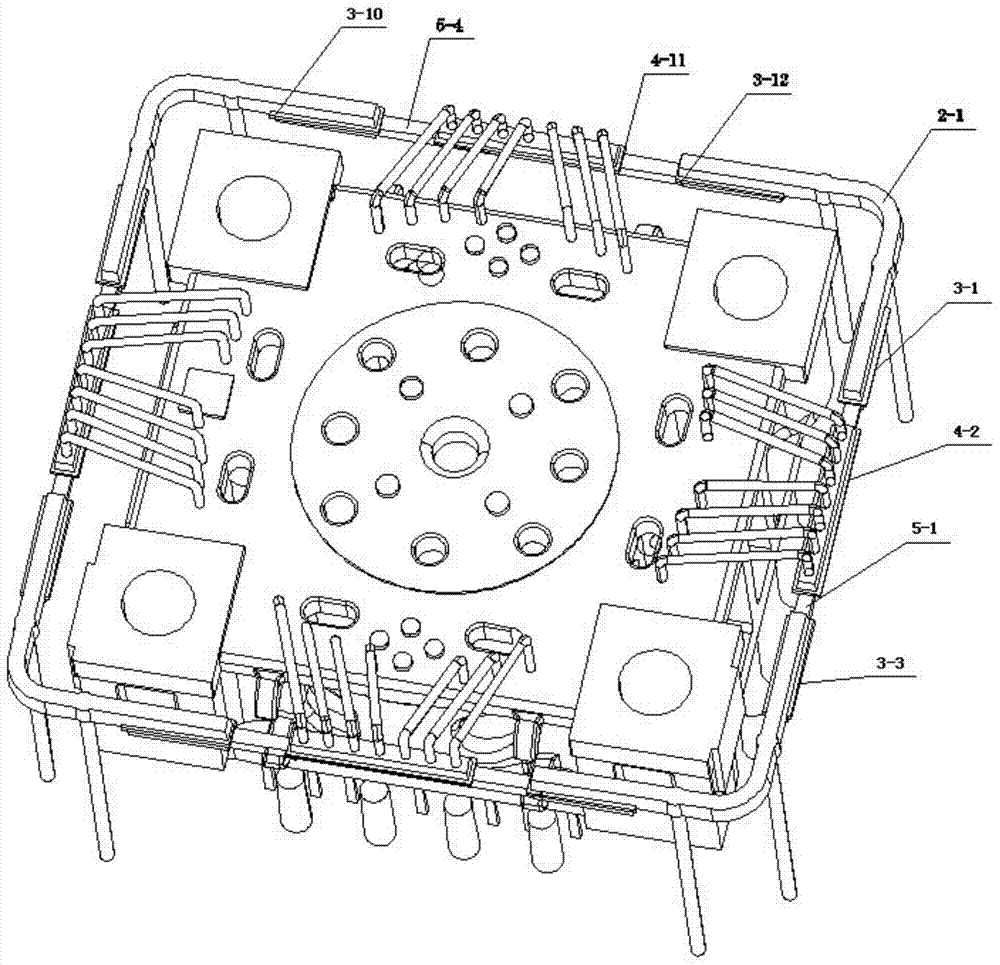

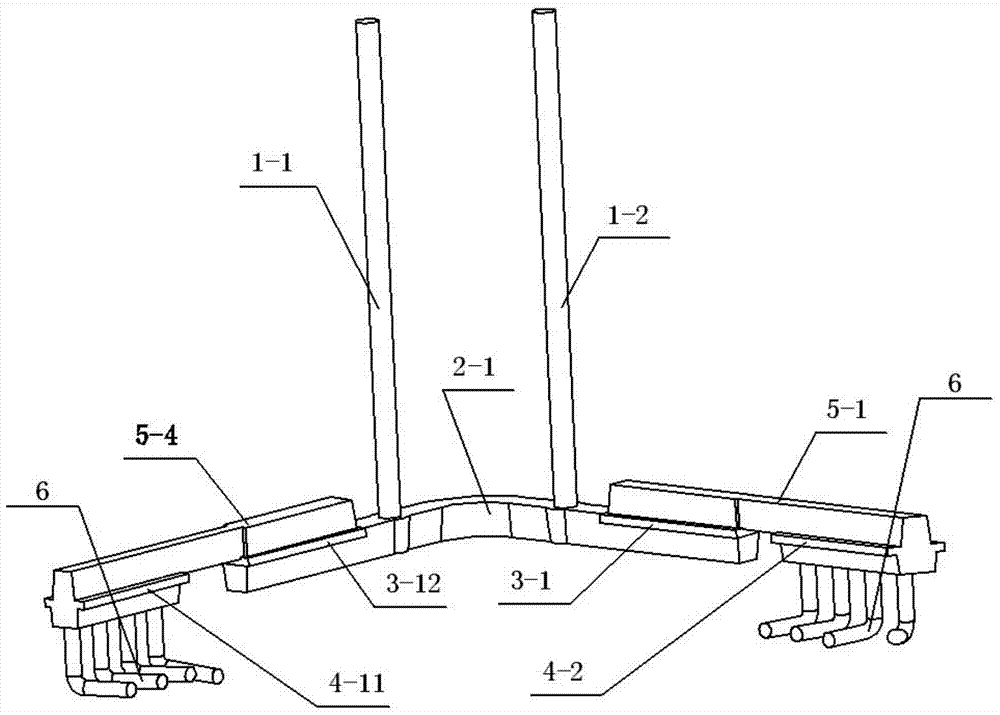

Ladle overturning and dumping machine

The invention discloses a ladle overturning and dumping machine. The ladle overturning and dumping machine comprises a work table, an overturning driving cylinder, an overturning center shaft, an overturning base which is placed on the work table, a shaft bracket which is fixed on the work table, and an overturning frame which is connected with the overturning center shaft and the overturning base, wherein one end of the overturning driving cylinder is hinged to the work table, and the other end of the overturning driving cylinder is hinged to the overturning frame; a ladle block, a horizontal compacting mechanism and a vertical compacting mechanism are arranged on the overturning base. The ladle overturning and dumping machine is used for dumping liquid iron of ladles, the ladles are reliable to fix, the dumping process is directly completed by the overturning driving cylinder, and working safety is high; at the same time, the processes of compacting, fixing and dumping the ladles are all automatically completed, the relative position of the ladles and a material receiving opening of an automatic casting machine can be adjusted, the labor intensity is small, and the production efficiency is high; furthermore, the ladles of national standard series do not need to be customized or changed to be used on the ladle overturning and dumping machine, so that the adaptability is good.

Owner:CMCU ENG

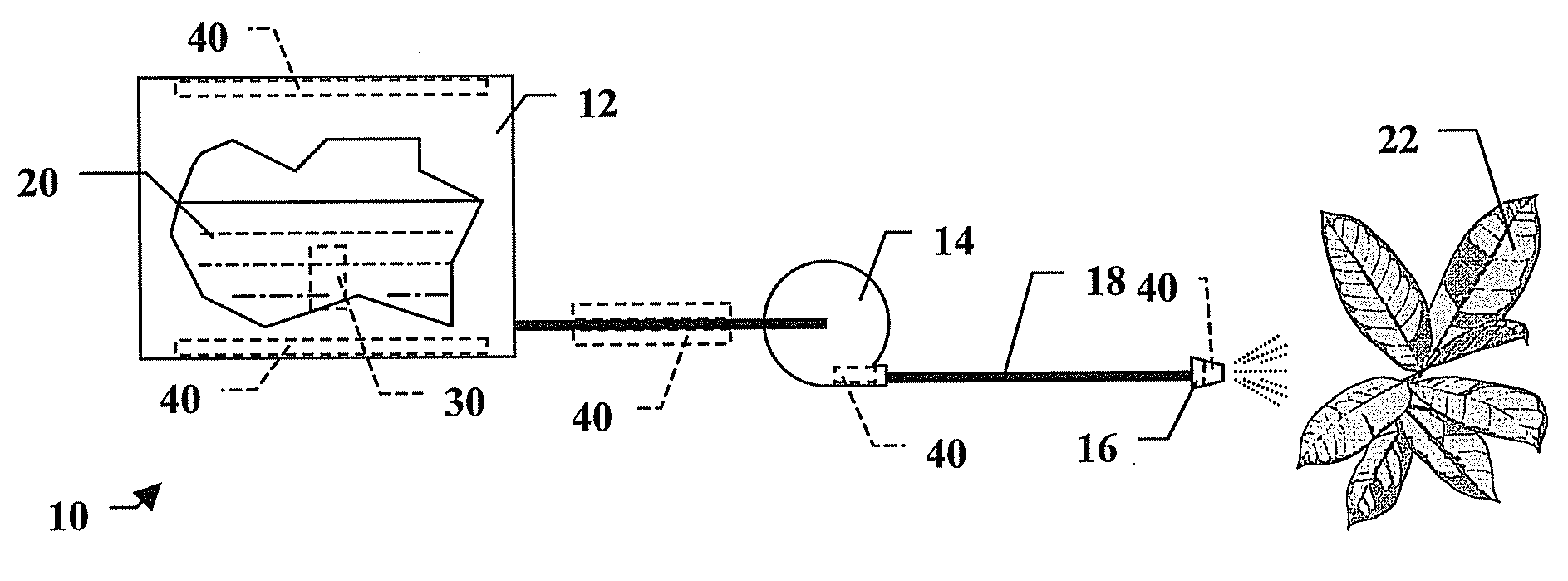

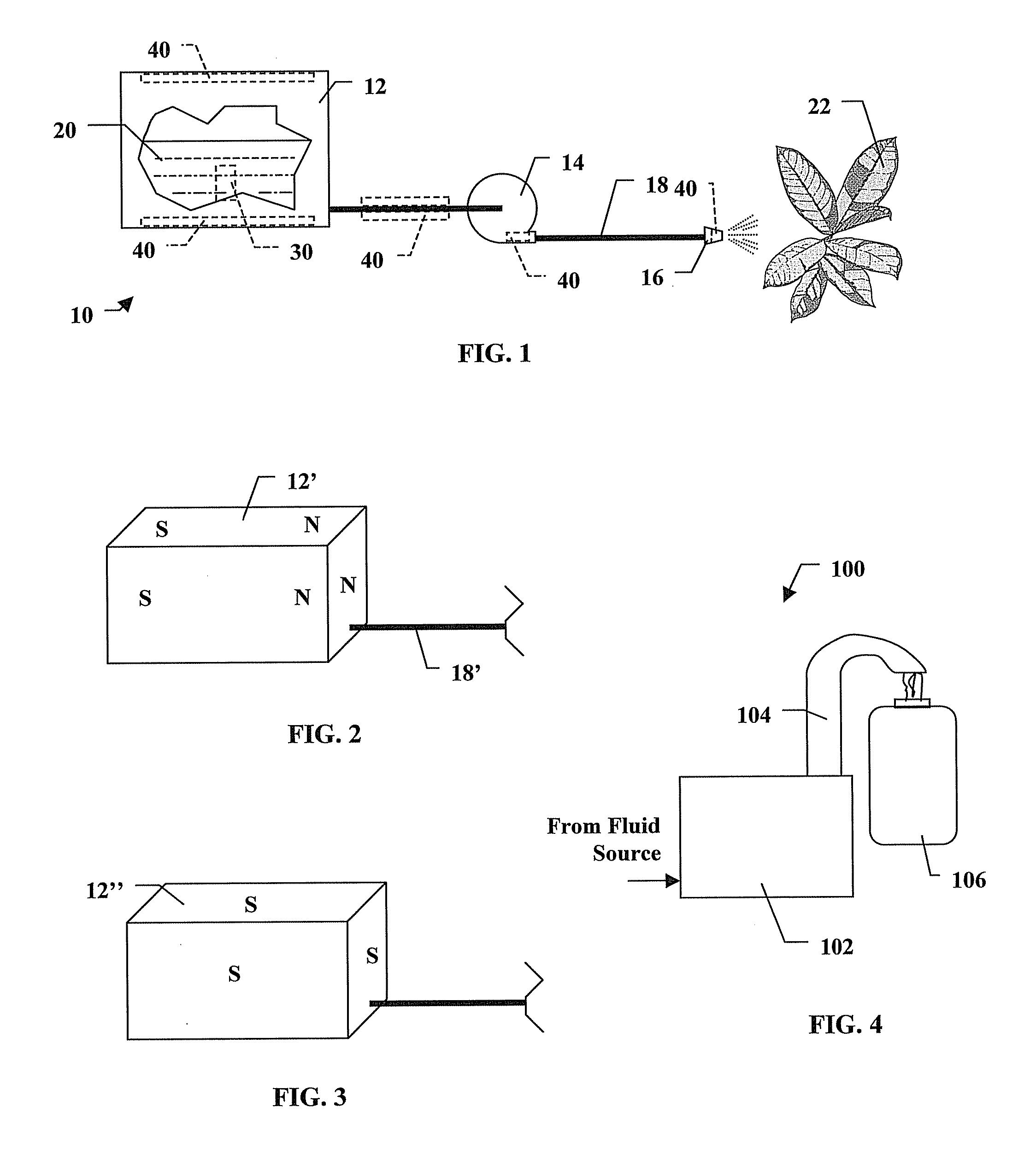

System and method for magnetizing agricultural spray

Vegetation spray is performed with a magnetized material in a spray liquid. The magnetized material can be liquid iron. The magnetized material can be magnetized before or after introduction to the spray liquid, and before or after the spray liquid is introduced to spray equipment. Spray drift can be reduced and spray adhesion increased by the addition of the magnetized material to the spray liquid. Liquid with magnetized materials can also be used in other, non-spray applications.

Owner:AGRI MAGNETICS

Method for realizing dephosphorization of olitic high-phosphorus iron ore by use of biomass charcoal

ActiveCN103290158AShorten the production cycleImprove efficiencyFluidised-bed furnacesDecompositionSlag

The invention discloses a method for realizing dephosphorization of olitic high-phosphorus iron ore by use of biomass charcoal, which realizes direct preparation of low-phosphorus liquid iron by combining direct reduction and high-temperature scrap iron separation. The method comprises the following steps of: preparing high-gasification biomass charcoal; breaking the ore charge; preparing carbon addition-lack carbon-containing pellets; performing direct reduction; and performing high-temperature melting. Compared with the existing method for treating olitic high-phosphorus iron ore, the method disclosed by the invention prepares the carbon addition-lack carbon-containing pellets by taking the widely-available and low-price biomass charcoal as a reducing agent and performs direct reduction in a CO / CO2 mixed atmosphere, and obtains low-carbon residue high-metallization pellets by use of the good gasifying performance of the biomass charcoal under the catalysis of Na2CO3; and the reinforcing effect of Na2O on the dephosphorization of liquid iron is obtained by use of Na2CO3 decomposition in a high-temperature scrap iron separation stage. Since the ash content of the biomass charcoal is low, the slag content in a high-temperature melting process is low. The method disclosed by the invention has the characteristics of high iron recovery rate, good dephosphorization effect and the like.

Owner:UNIV OF SCI & TECH BEIJING

Method for smelting high-titanium liquid iron by utilizing converter

ActiveCN103614508AThe smelting process is stableGuaranteed dephosphorization rateManufacturing convertersAlkalinitySmelting process

The invention discloses a method for smelting high-titanium liquid iron by utilizing a converter. The method is mainly used for smelting the high-titanium liquid iron with the titanium mass percentage of 0.3 to 0.5 percent by utilizing the converter. By adopting a double-slag process, the binary basicity of the furnace slag on the preliminary smelting stage of the converter is 0.8 to 1.2, the mass fraction of TFe is 15 to 25 percent, the temperature of a smelting pool is 1370 to 1420 DEG C, and the slagging quantity can reach 50 to 60 percent, so that the problem that the melting point of the furnace slag is increased because the titanium in the liquid iron is oxidized and enters the furnace slag can be maximally reduced; the decarbonization is carried out according to the conventional converter smelting process. By adopting the production process, the melting point of the furnace slag on the preliminary smelting stage can be lowered, the mobility of the furnace slag is good, the overall phosphorus removal rate can reach more than 85 percent, and the splashing can be avoided.

Owner:SHOUGANG CORPORATION

Casting method of hundred-ton ductile cast iron template casting for two-plate injection molding machine

ActiveCN103882286AMeet quality requirementsNo linear defectsFoundry mouldsFoundry coresFiltrationLiquid iron

The invention discloses a casting method of a hundred-ton ductile cast iron template casting for a two-plate injection molding machine. The casting method comprises the steps of mold making, casting system making, sand mold making and molding by casting, thus obtaining the casting, wherein the reverse side of a mold installing surface is designed at the lower part of a casting position; an inner runner hole is formed on the reverse side of the mold installing surface; in the casting process, liquid iron enters lower horizontal runners via sprues, then enters type A filters via the lower horizontal runners and is subjected to inoculation and filtration purification treatment inside the type A filters; then the liquid iron which enters type B filters via upper horizontal runners and is subjected to purification and filtration again enters a casting mold cavity via the inner runner hole; the final strength of a sand mold is 1.3-1.4MPa, and the final strength of a sand core is 0.9-1.0MPa; the casting temperature is 1290-1310 DEG C, and the casting time is 85-100 seconds. The casting method has the advantages that the casting defects such as graphite degeneration, shrinkage cavity, shrinkage porosity, sand inclusion and the like are not easy to occur, thus improving mechanical properties.

Owner:RIYUE HEAVY IND

Monitoring device for liquid level and flow velocity of liquid iron in torpedo tank truck

InactiveCN102589642AIncrease profitGuaranteed accuracyTransmission systemsFluid speed measurementBogieSignal conditioning circuits

The invention discloses a monitoring device for liquid level and flow velocity of liquid iron in a torpedo tank truck. The monitoring device comprises a foundation brake device and a piezoelectric sensing device. The foundation brake device is placed in a bogie of the torpedo tank truck, the piezoelectric is arranged at a gap between swing bolsters and consists of a base, a sleeve, a transmissionrod, a transmission spring and a piezoelectric sensor, the base, the sleeve, the transmission rod and the transmission spring are mounted at the bottom of the gap, the piezoelectric sensor is embedded into a groove of the surface of the base, the sleeve is arranged above the piezoelectric sensor, the upper end of the sleeve is abutted to the top of the gap, the transmission rod is in sliding fit with the inside of the sleeve, the transmission spring is disposed between the transmission rod and the sleeve, the transmission rod presses on the piezoelectric sensor, the piezoelectric sensor is externally connected with the direct-current power source, a signal output end of the piezoelectric sensor is connected with a signal conditioning circuit, a signal output end of the signal conditioningcircuit is connected into a wireless receiving / transmitting module, a single chip microcomputer control system is arranged in a control room, and a single chip microcomputer is connected with a wireless transmitting / receiving module, is in control connection with a liquid iron switch and is externally connected with a display module, an alarm system and a single threshold controller. The monitoring device for the liquid level and the flow velocity can be used in severe environments with high temperature, dust and the like, and is easy to install and maintain without destroying an original structure of the torpedo tank truck.

Owner:HEFEI UNIV OF TECH

Puddling additive and predation method thereof

The invention relates to a puddling additive which is prepared from the following materials by weight percent: 60-120 percent of boric sludge and 5-40 percent of calcium oxide. Adding the puddling additive in sintering and pellet materials can ensure stable operation of a blast furnace, increase the yield by as high as 6 percent, reduce coke ratio by 35kg / t iron, improve the quality of cast iron, reduce the sulphur content, increase the first-grade product rate, ensure abundant heat of slag iron and favorable flowability, reduce the iron condensing amount of liquid iron in the slag iron runner and liquid iron tank, lower the consumption of metal iron, make it easy to discharge iron slag, reduce the labor intensity for furnace men, reduce the consumption of auxiliary materials such as lime stone and reduce the blowout amount of furnace dust.

Owner:张旭东

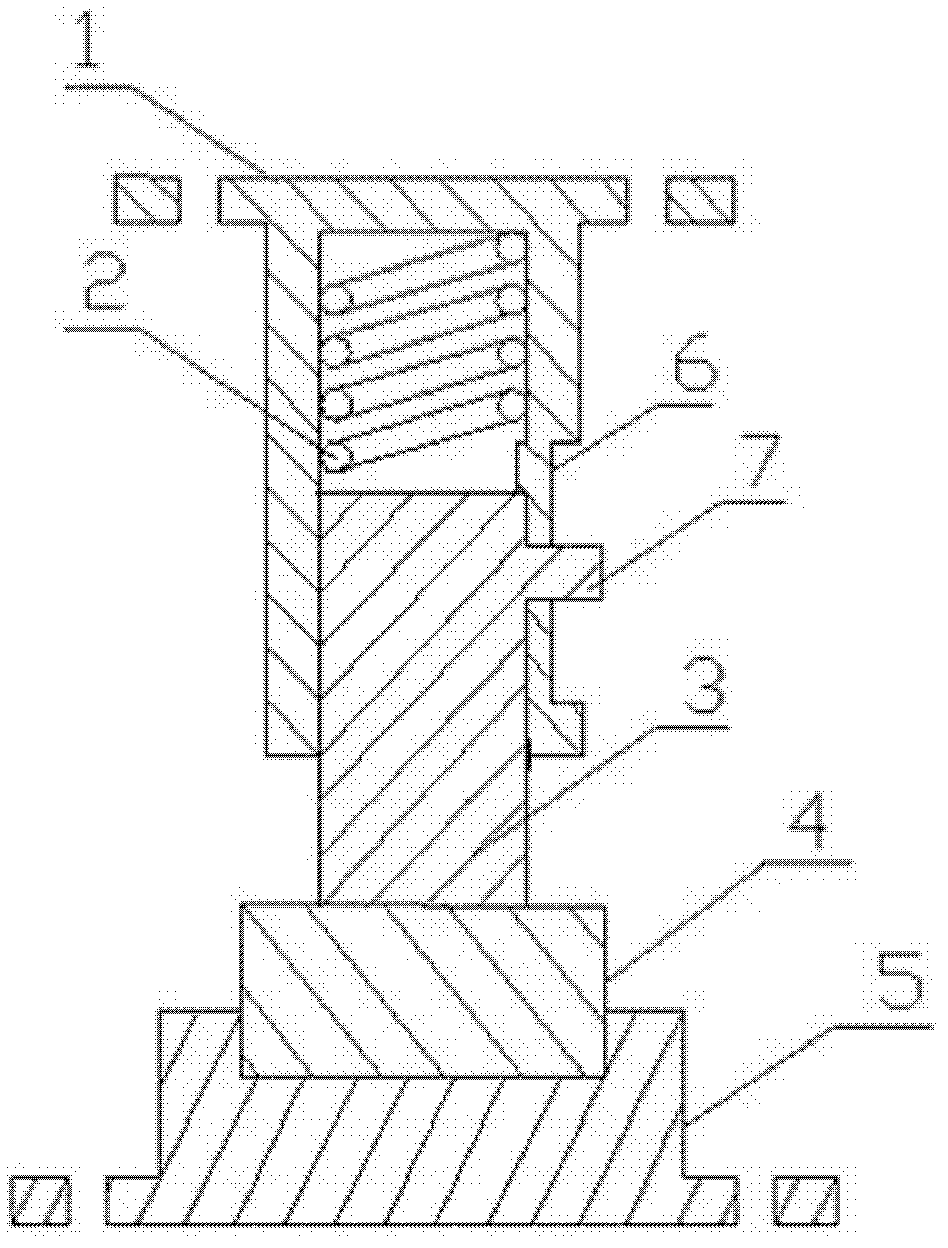

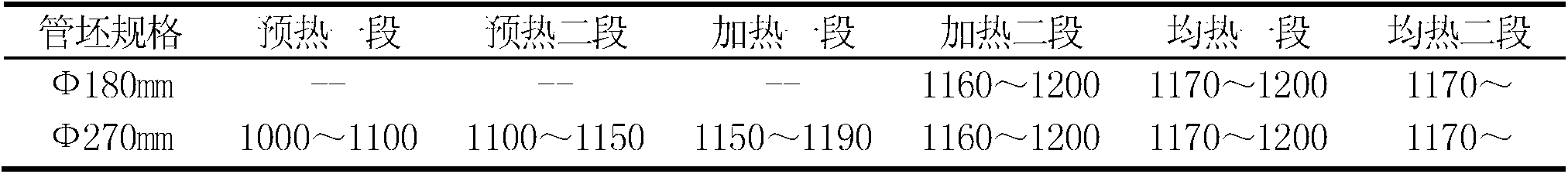

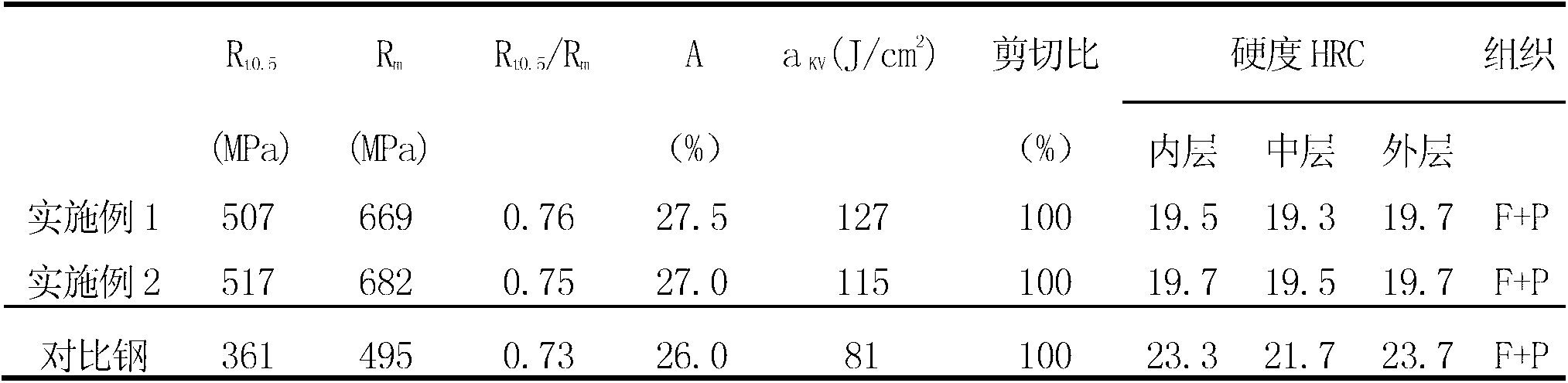

Atmosphere corrosion resistance seamless steel tube containing rare earth and production method thereof

InactiveCN103290334AGood atmospheric corrosion resistanceImprove hot brittlenessProcess efficiency improvementRigid pipesLiquid ironRare earth

The invention discloses an atmosphere corrosion resistance seamless steel tube containing rare earth and a production method thereof, and belongs to the technical field of metallurgy and molding. The atmosphere corrosion resistance seamless steel tube comprises the materials by weight percent (Wt%): 90% of blast furnace liquid iron and 10% of excellent steel scrap, and the chemical ingredients of a tube blank comprise the following chemical components by weight percent (Wt%): 0.05-0.10% of C, 0.10-0.30% of Si, 1.30-1.60% of Mn, not more than 0.020% of P, not more than 0.005 of S, 0.20-0.50% of Cr, 0.10-0.30% of Mo, 0.20-0.40% of Ni, 0.30-0.50% of Cu, 0.05-0.20% of V, 0.01-0.03% of Ti, 0.01-0.04% of Al, 0.0005-0.0100% of RE, and the balance of Fe and non-detectable microelements. The preparation method comprises the technological processes of: preprocessing of molten iron, top and bottom combined-blowing converter smelting, LF furnace refining, VD vacuum treatment, continuously casting of a round billet, cutting, heating of the tube blank, perforating, continuously rolling, reheating, coining (reducing tension), straightening, cooling, cutting via a saw, and flaw detection; the mechanical properties of the steel tube are as follows: the yield strength is 460-520 MPa; the tensile strength is 600-660 MPa; the yield ratio is smaller than or equal to 0.80; the elongation percentage is greater than or equal to 25%; the transverse impact value is greater than or equal to 100J / cm<2> (0 DEG C); the shear ratio is 100%; the grain size is greater than or equal to 8.5 grades; the hardness is smaller than or equal to 21.0 HRC (rockwell hardness); the residual stress is smaller than or equal to 30 MPa. The product disclosed by the invention has the characteristics of high hardness matching degree, small grain size and good air-corrosion resistance.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

High-efficient iron-series catalyst and its preparation method

InactiveCN101099932AGood dispersionImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsLiquid ironNitrogen

The present invention discloses one kind of nanometer iron catalyst and its preparation process and apparatus. The nanometer iron catalyst is prepared through the following steps: adding liquid iron pentacarbonyl; heating iron pentacarbonyl in a reactor for the iron pentacarbonyl to infiltrate into the pores of catalyst carrier; further heating or introducing high temperature pressurized high purity nitrogen or other inert gas to decompose iron pentacarbonyl to obtain nanometer level iron particle; cooling, filling the prepared nanometer iron catalyst into package filled with high purity nitrogen and sealing for preserving. The present invention utilizes solid carrier to block the aggregation of iron particle for obtain nanometer iron particle. The nanometer iron catalyst has high activity, high dispersivity, high stability and simple preparation process, and is suitable for industrial production.

Owner:JIANGSU TIANYI ULTRA FINE METAL POWDER

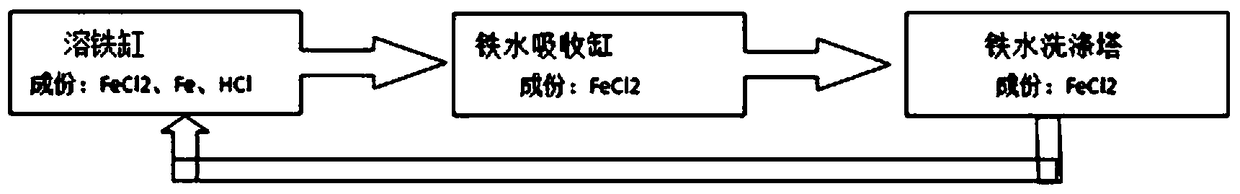

Copper recovery and regeneration system for acidic copper(II) chloride etchant and recovery and regeneration method

ActiveCN109161895ALow reuse rateSolve the problem of energy consumptionPhotography auxillary processesElectrolysis componentsElectrolysisLiquid iron

The invention provides a copper recovery and regeneration system for an acidic copper(II) chloride etchant and a recovery and regeneration method, and relates to the technical field of cyclic regeneration of etchants. The copper recovery and regeneration system for the acidic copper(II) chloride etchant comprises an etchant regeneration system, a waste gas treatment system located in a downstreamposition of the etchant regeneration system as well as a liquid iron cleaning solution treatment system. With the adoption of the copper recovery and regeneration method for the acidic copper(II) chloride etchant, the problems that the conventional recovery and regeneration for the acidic copper(II) chloride etchant is high in energy consumption and low in reuse rate and contains many cathode copper impurities, and secondary pollution to the environment is caused by chlorine are solved effectively, and technical support is provided for comprehensive application of an electrolytic regenerationcycle technique for the acidic copper(II) chloride etchant.

Owner:安徽绿洲危险废物综合利用有限公司

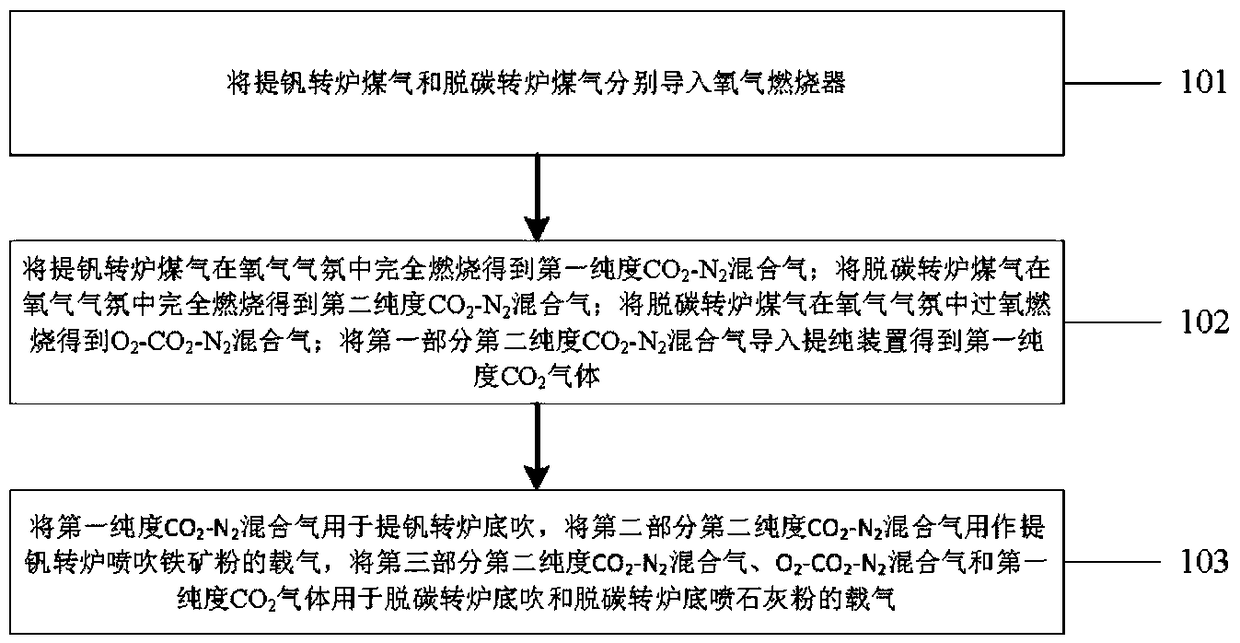

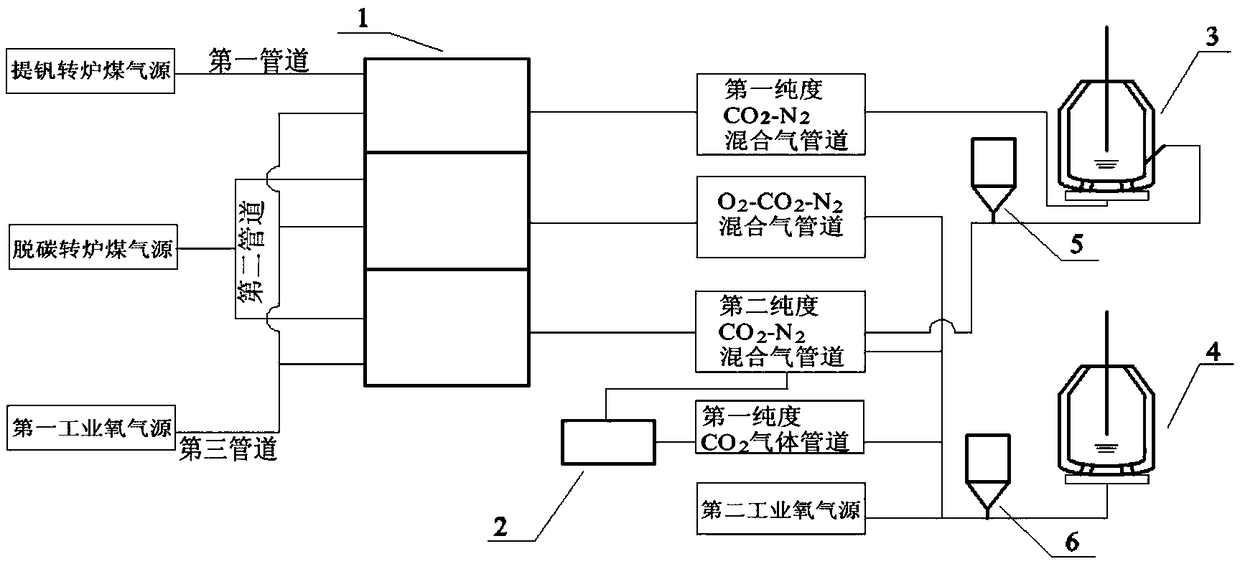

Efficient and long-service-life blowing method and system of vanadium extraction-decarburization dual converter

ActiveCN109234490ALower acquisition costsImprove efficiencyGas treatmentOxide/hydroxide preparationSteelmakingCombustor

The invention discloses an efficient and long-service-life blowing method and system of a vanadium extraction-decarburization dual converter and belongs to the technical field of vanadium-containing liquid iron steelmaking. The efficient and long-service-life blowing method comprises the following steps: conducting vanadium extraction converter coal gas and decarburization converter coal gas intoan oxygen combustor; obtaining CO2-N2 mixed gas with first purity through the vanadium extraction converter coal gas; obtaining CO2-N2 mixed gas with second purity through the decarburization converter coal gas; btaining O2-CO2-N2 mixed gas through decarburization converter coal gas; obtaining CO2 gas with first purity through CO2-N2 with the second purity; carrying out vanadium extraction converter bottom blowing by utilizing the CO2-N2 mixed gas with the first purity; taking the CO2-N2 mixed gas with the second purity as iron ore powder carrier gas of vanadium extraction converter blowing; O2-CO2-N2 mixed gas and the CO2-N2 mixed gas with the first purity are used as lime powder carrier gas of the vanadium extraction converter bottom blowing and decarburization converter bottom spraying.By adopting the efficient and long-service-life blowing method, the vanadium oxidization rate of a vanadium extraction converter is improved and the dephosphorization effect of a decarburization converter is improved; the service life of the vanadium extraction converter and the decarburization converter is prolonged.

Owner:UNIV OF SCI & TECH BEIJING

Converter dephosphorization complex slag former and slagging technology

InactiveCN101532071AUniform compositionImprove performanceManufacturing convertersSlagHigh phosphorus

The present invention discloses a converter dephosphorization complex slag former that includes constituents with percentages by weight below: 30 to 40% of active lime; 30 to 40% of rolled steel sheet iron; 13 to 18% of quartz sand; 11 to 13% of soda; and 0 to 6% of fluorite; said raw materials are smashed into powder, mixed uniformly, sieved and palletized to obtain the complex slag former. The complex slag former is advanced with low melting point, fast slag forming, uniform constituent, stable property, big phosphorus capacity and high dephophorization efficiency of a dephosphorizer, for application in converter dephosphorization with hot metal with higher phosphorus content; the complex slag former is provided with good slagging situation, low alkalinity of final slag after dephosphorization, low content of free calcium oxide; the complex slag former has low content of fluorite, to thereby reduce lining refractory material erosion; the fluorine-free high phosphorus slag can be used as a steel slag phosphate fertilizer when smelting high phosphorus liquid iron.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com