Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4159 results about "Camshaft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A camshaft is a shaft to which a cam is fastened or of which a cam forms an integral part.

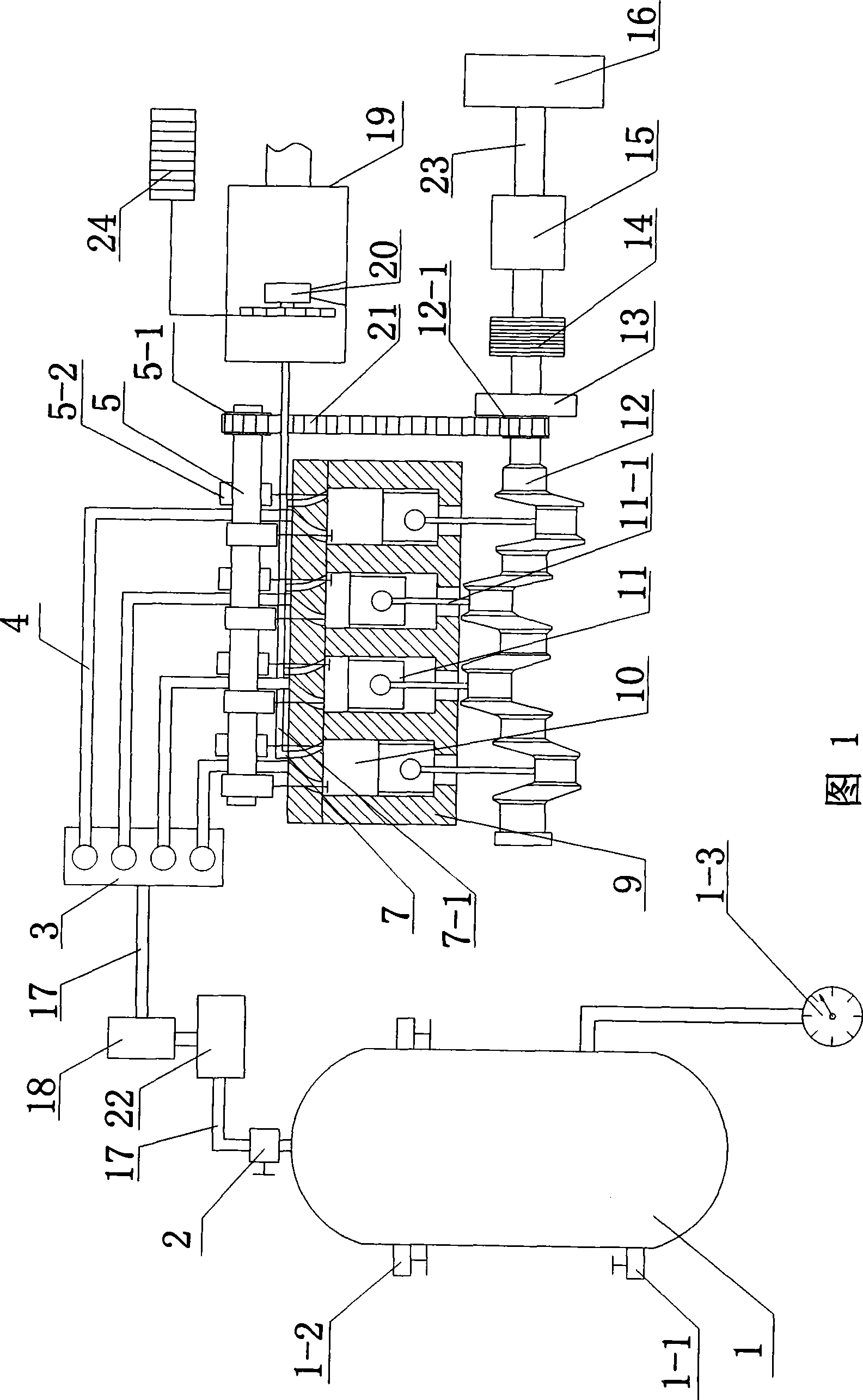

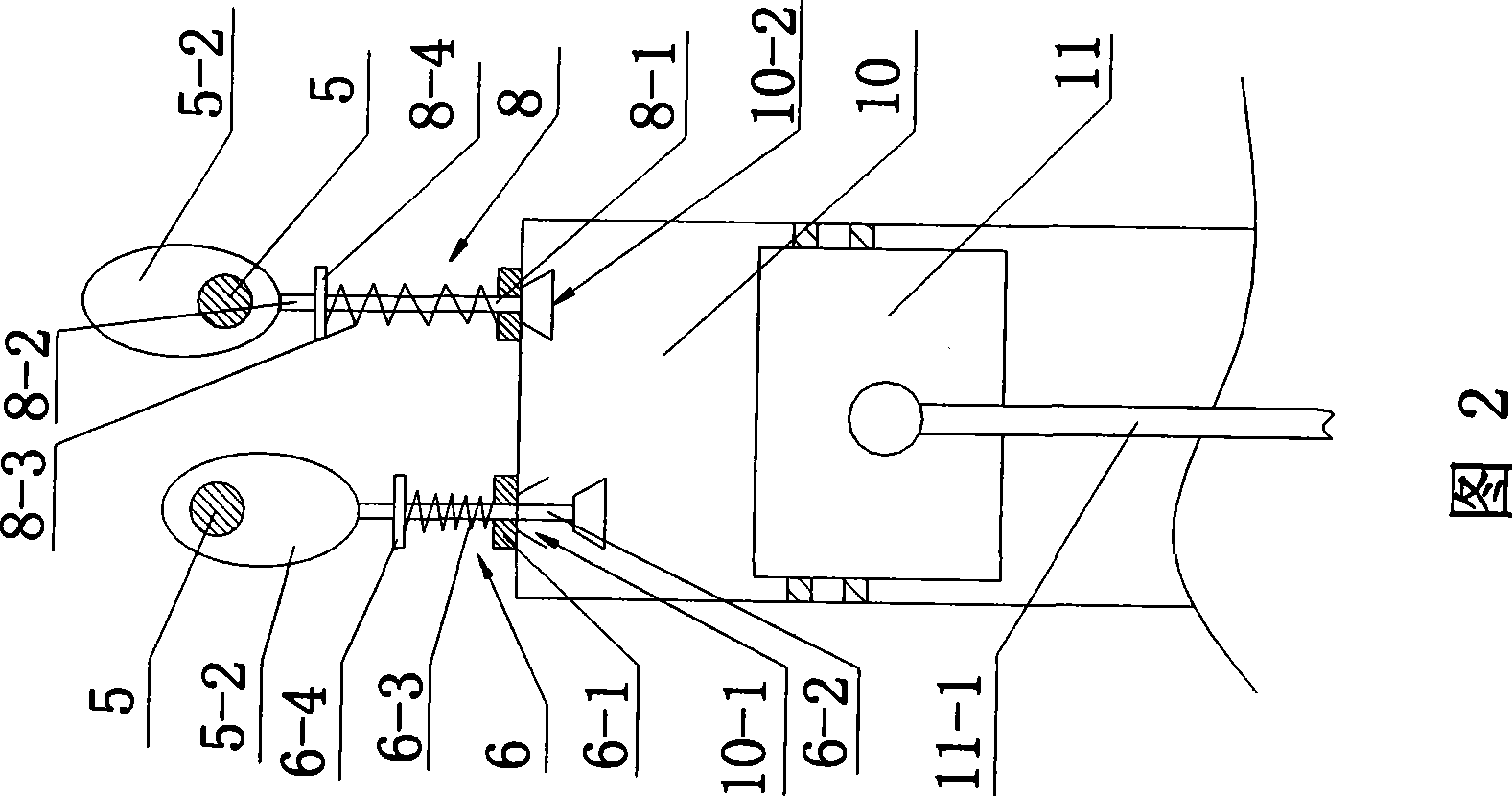

Air power engine assembly

InactiveCN101413403ALow costNo pollutionMechanical power devicesEngines characterised by uniflow principleDistributorPiston

The invention relates to an air-powered engine assembly, which comprises an air tank, an air valve, an air distributor, an intake pipe, camshafts, an intake duct, an exhaust control device, air cylinders, pistons, crankshafts, couplers, clutches, automatic gearboxes and differentials connected with the outside. The assembly is characterized in that the air valve, a constant pressure chamber and a pressure controller are arranged between the air tank and the air distributor; the air distributor is connected with a plurality of air cylinders on an air cylinder gasket; each air cylinder is connected with an exhaust chamber through an exhaust manifold; the exhaust chamber is provided with a turbine generator which is connected with a storage batter; the air cylinders are provided with the camshafts for controlling the air intake and exhaust of the air cylinders; the air cylinders are provided inside with the pistons for driving the crankshafts to rotate; the camshafts and the crankshafts are connected by chains; and the crankshafts are connected with the differentials through the couplers, the clutches and the gearboxes in turn. Therefore, doing work through air compression rather than fuel, the air-powered engine assembly has the advantages of avoiding waste gas discharge and air pollution, along with reliable operation, convenient operation, economical efficiency, practicality and so on. In addition, due to recycle of the waste gas for power generation, the air-powered engine assembly saves energy and reduces costs.

Owner:周登荣 +1

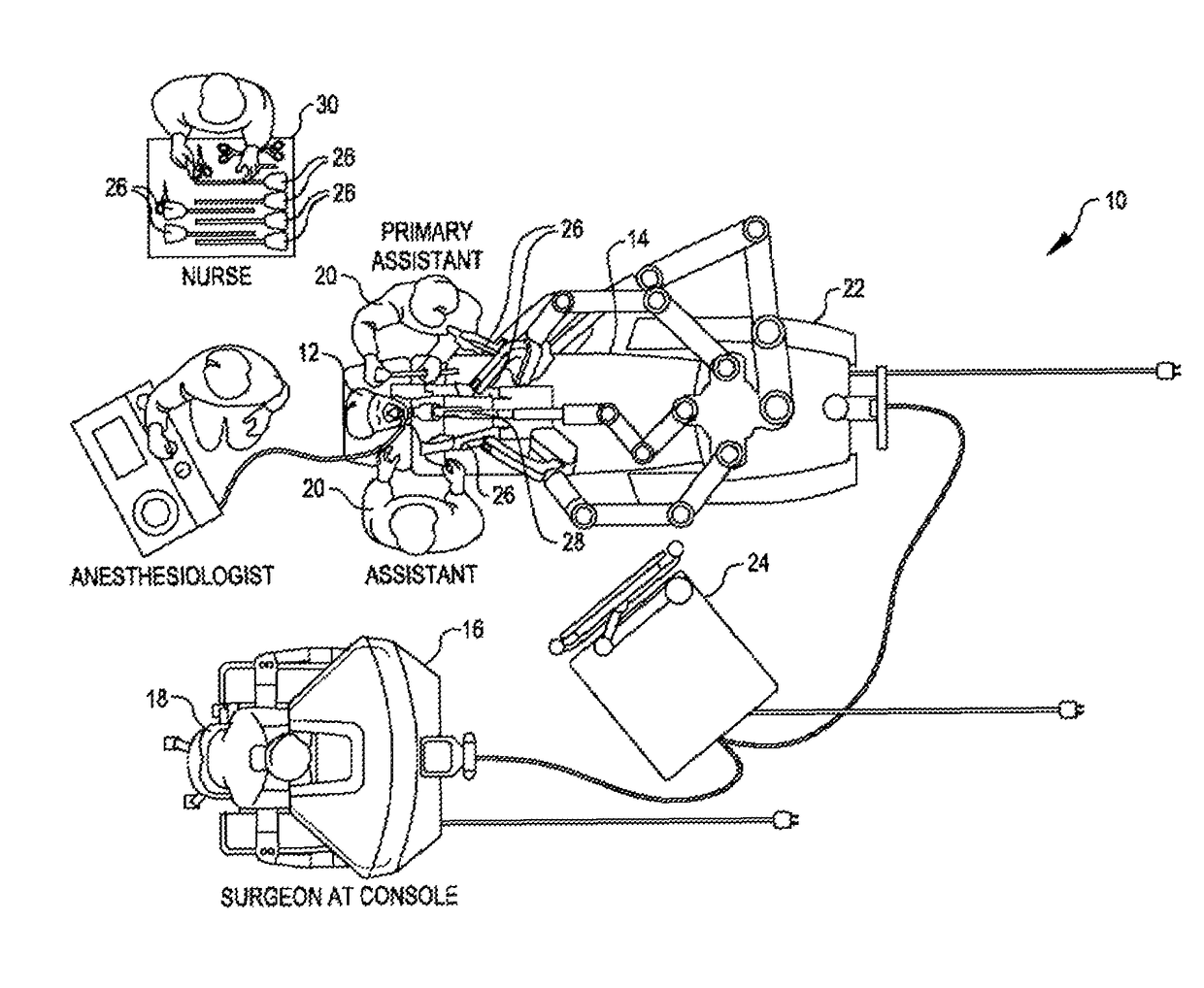

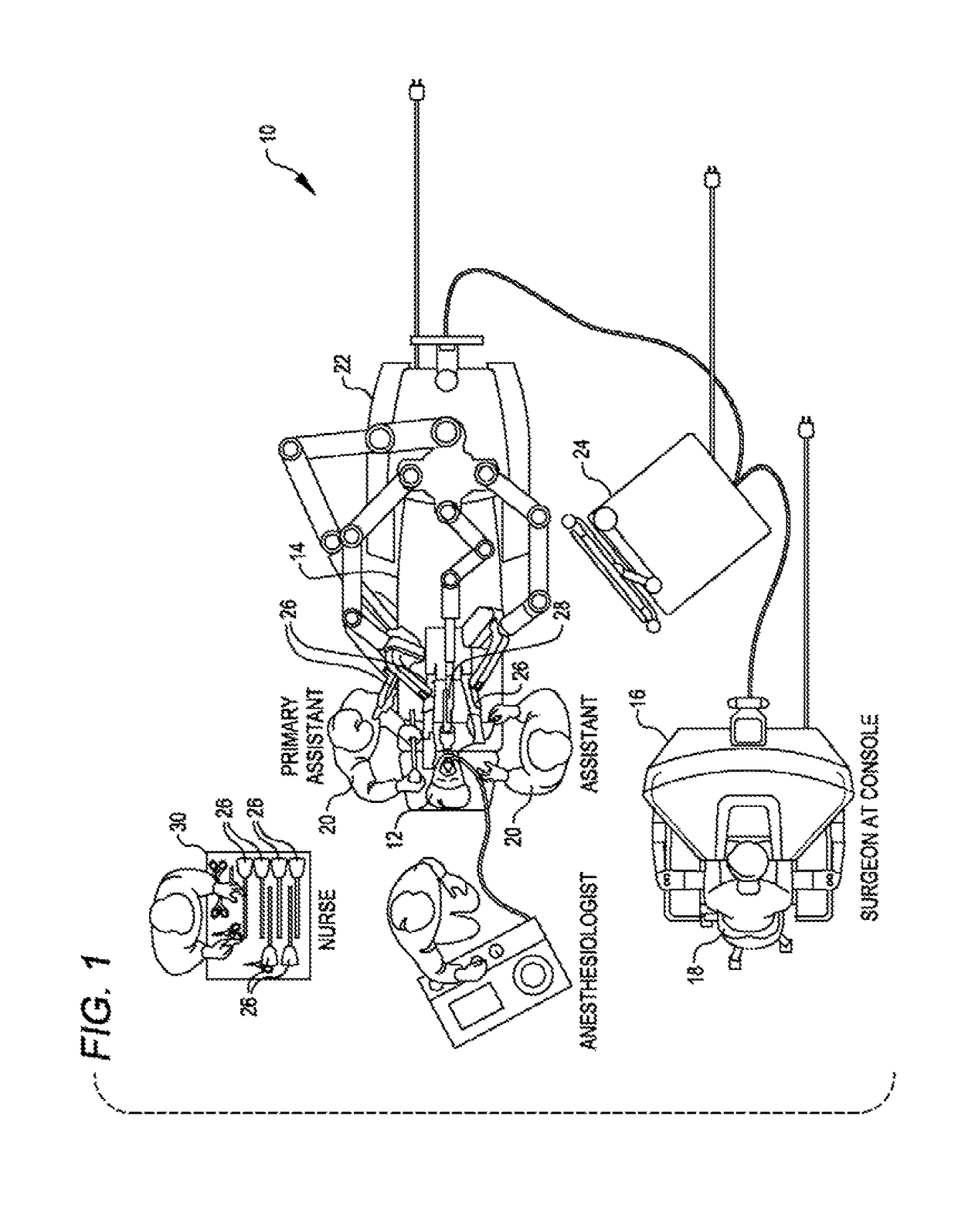

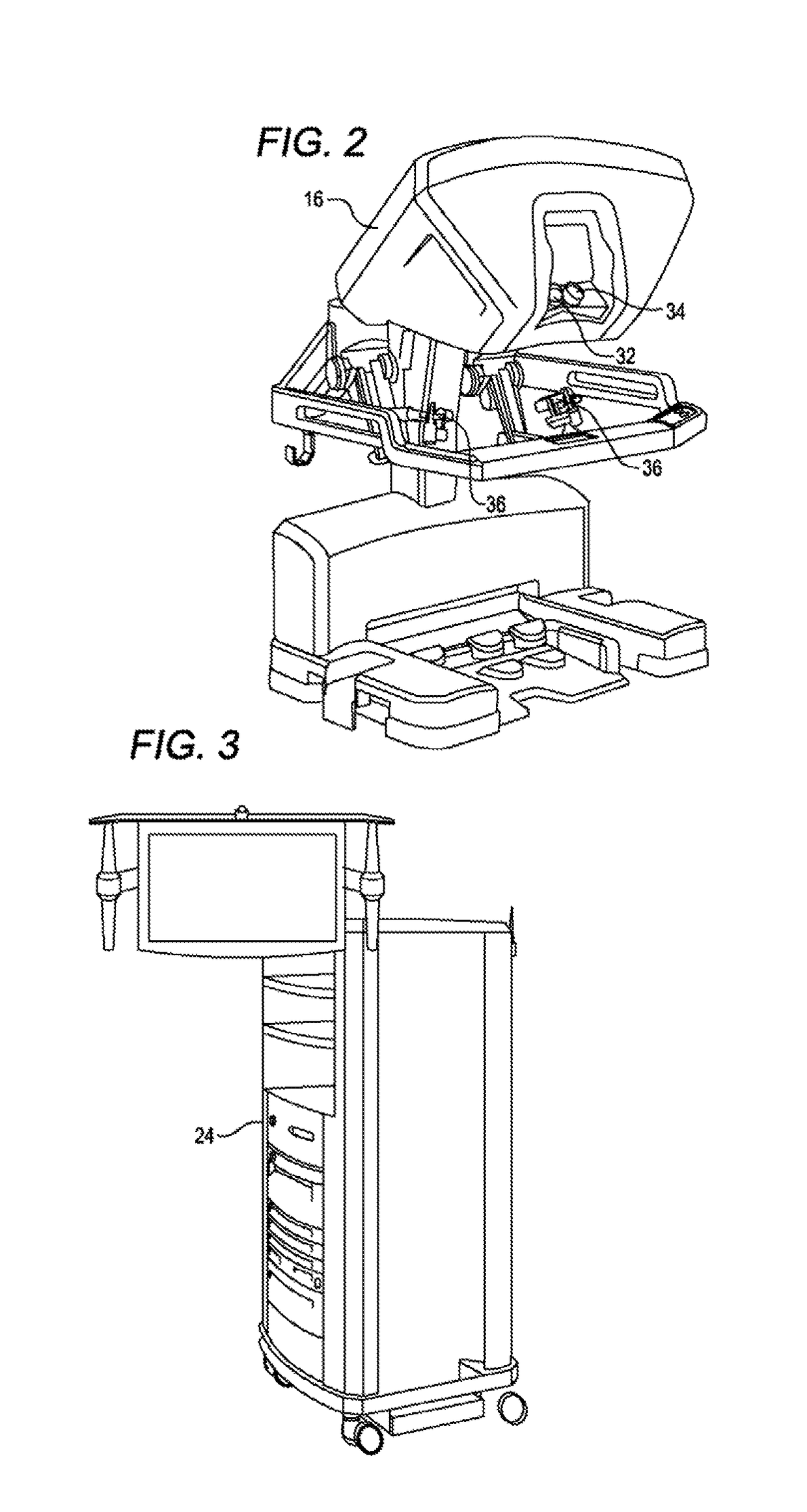

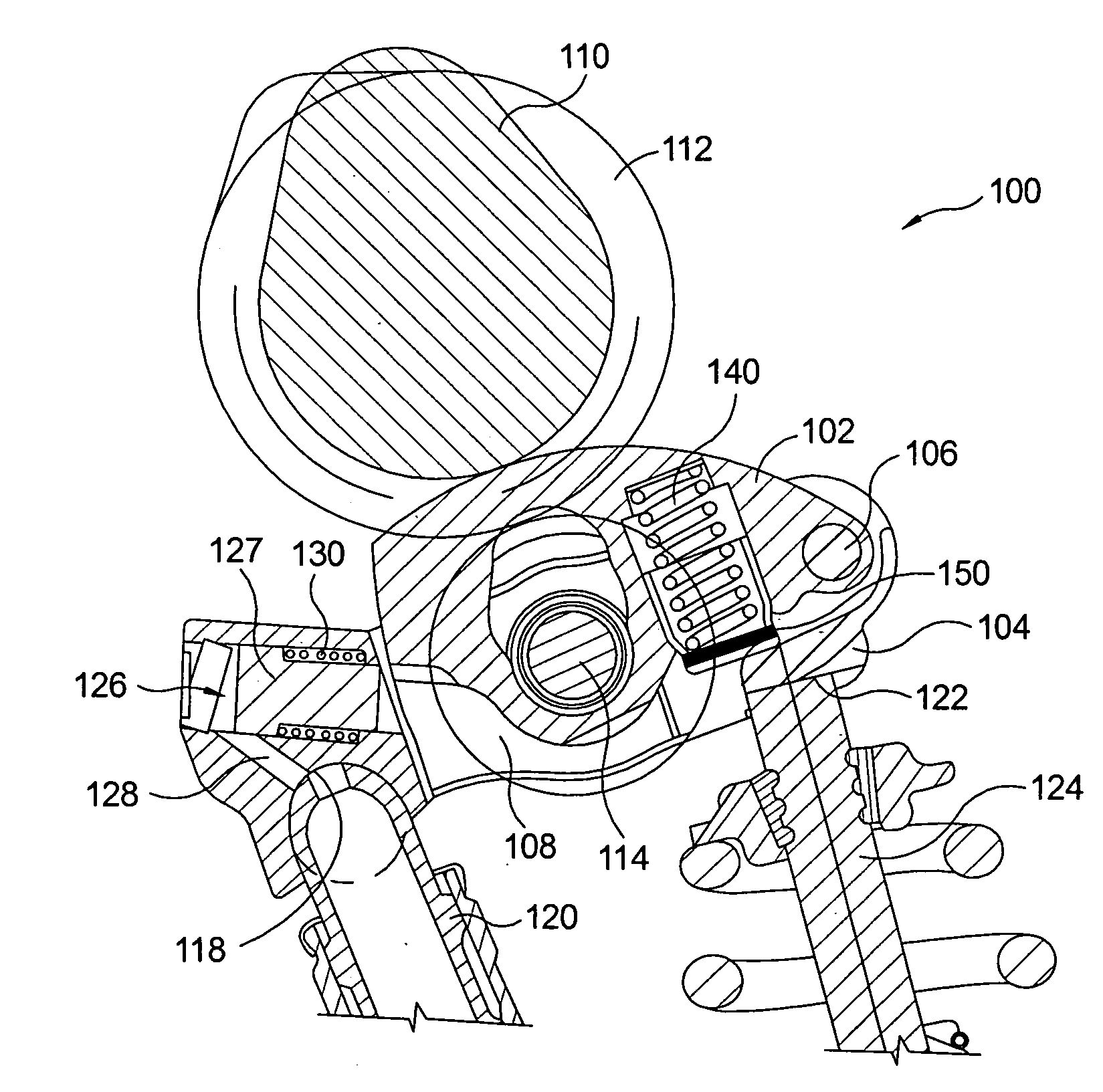

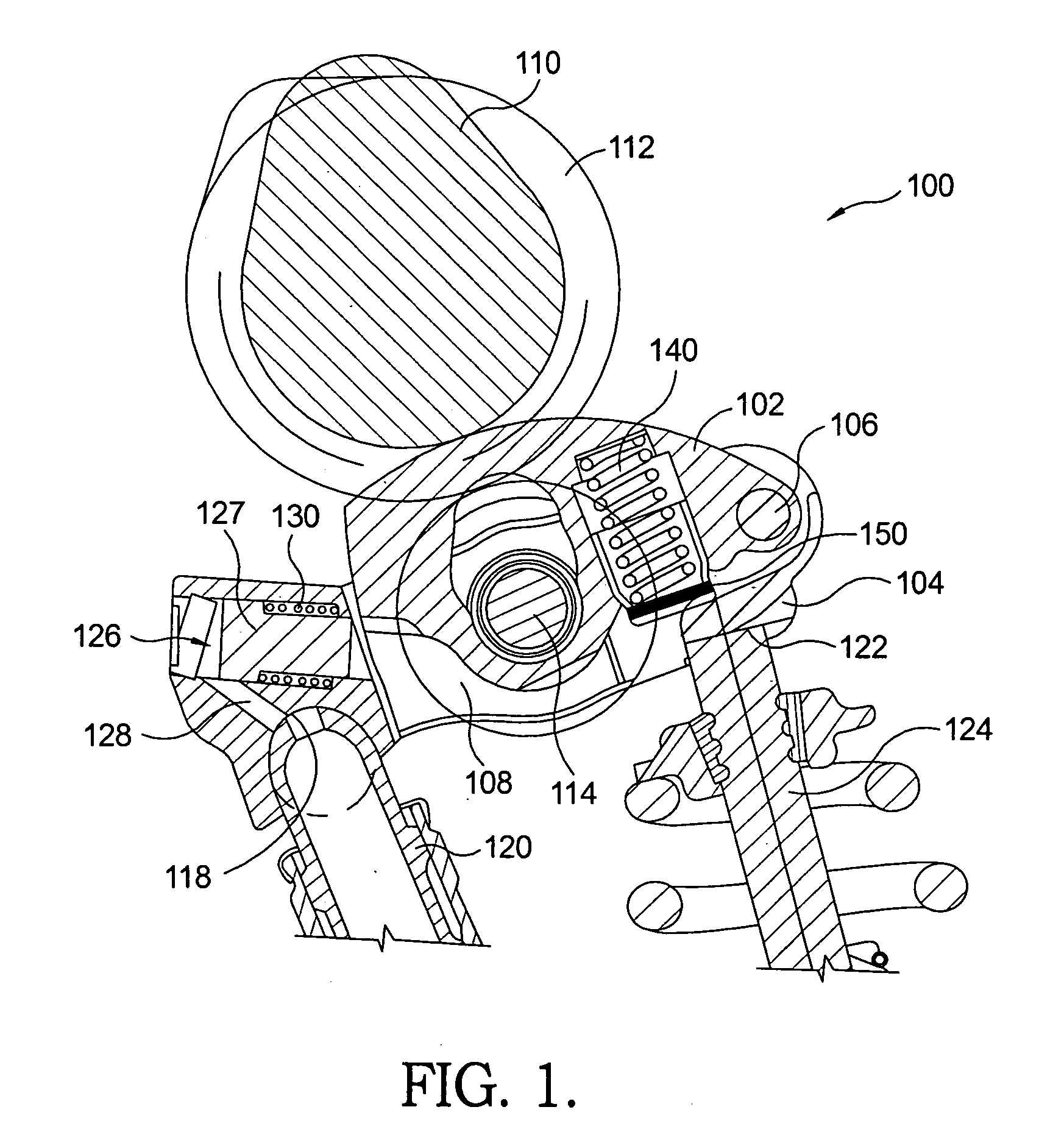

Control input accuracy for teleoperated surgical instrument

A surgical system having a patient side cart having at least one telesurgically operated instrument, the at least one telesurgically operated instrument comprising a surgical end effector having a plurality of effector components. A transmission is coupled to a motor. The drive train includes at least a first effector drive train and a second effector drivetrain. A controller comprises at least one processor for controlling the transmission. The controller is performs a method by locking an output gear of the second effector drivetrain rotating a camshaft to shift coupling of the motor from the first effector drivetrain to the second effector drivetrain; determining that the output gear is aligned by driving the locked output gear using a first torque; determining that the output gear is properly braked by driving the locked output gear using a second torque; disengaging the lock from the output gear; and driving the second effector drivetrain using the motor.

Owner:INTUITIVE SURGICAL OPERATIONS INC

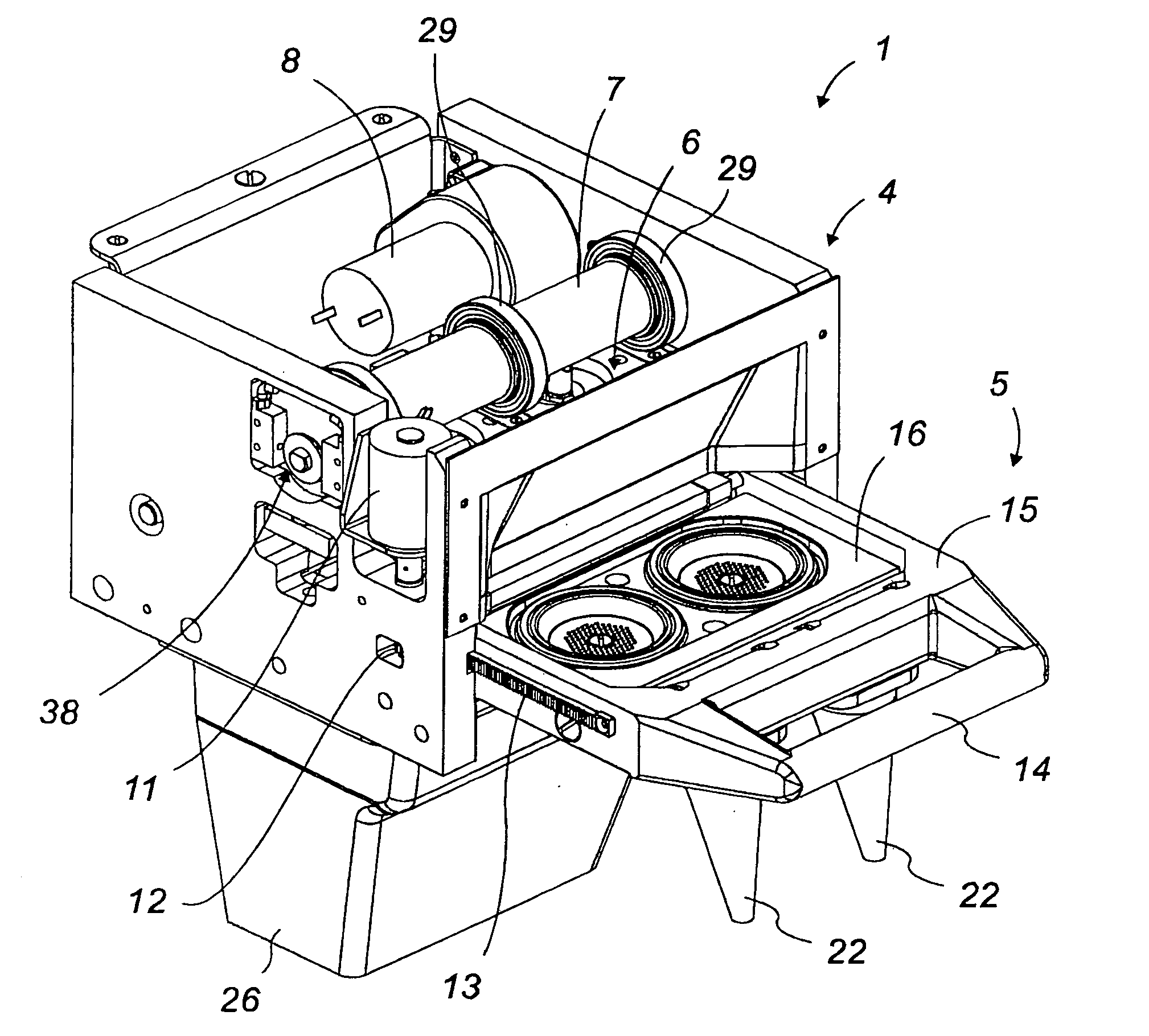

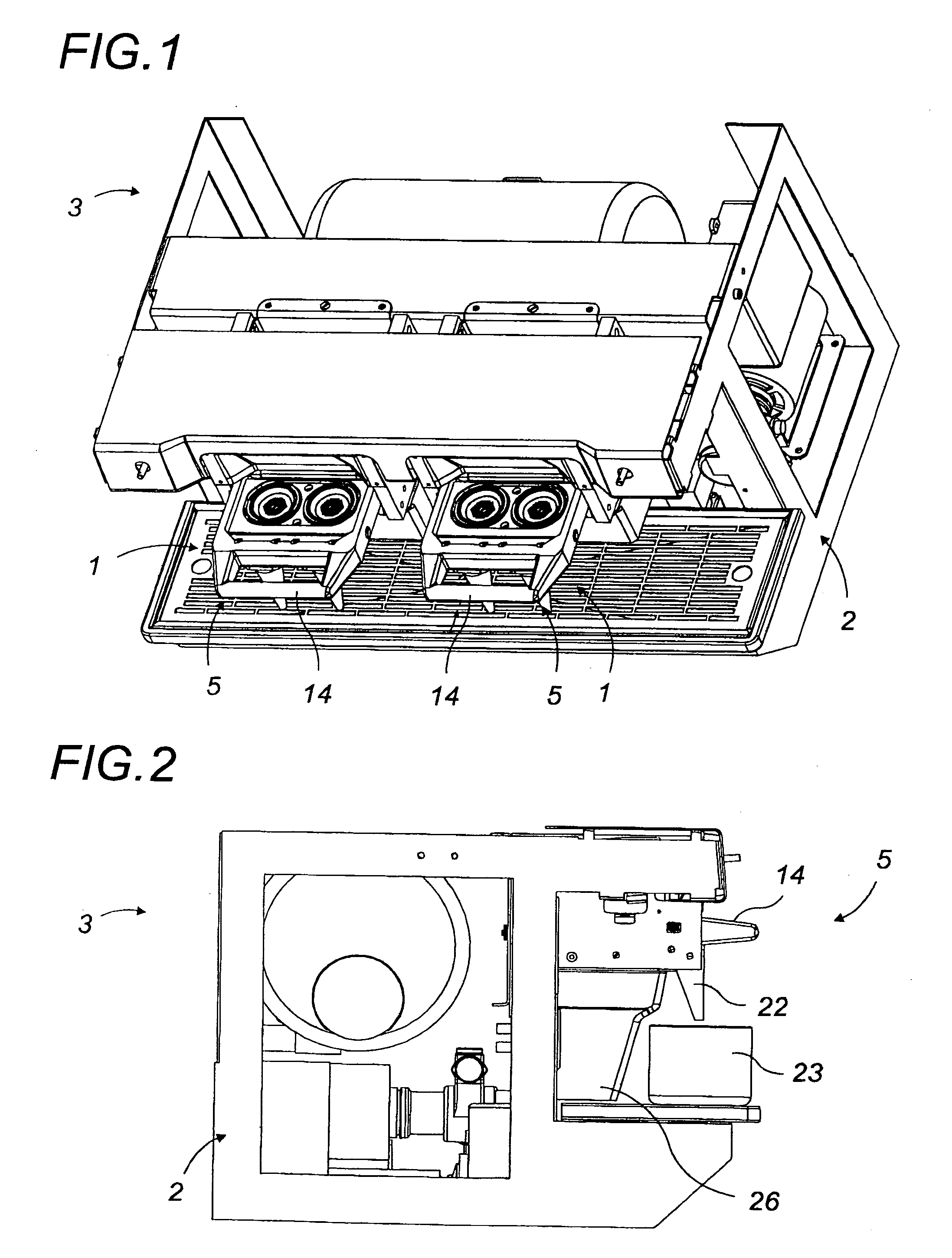

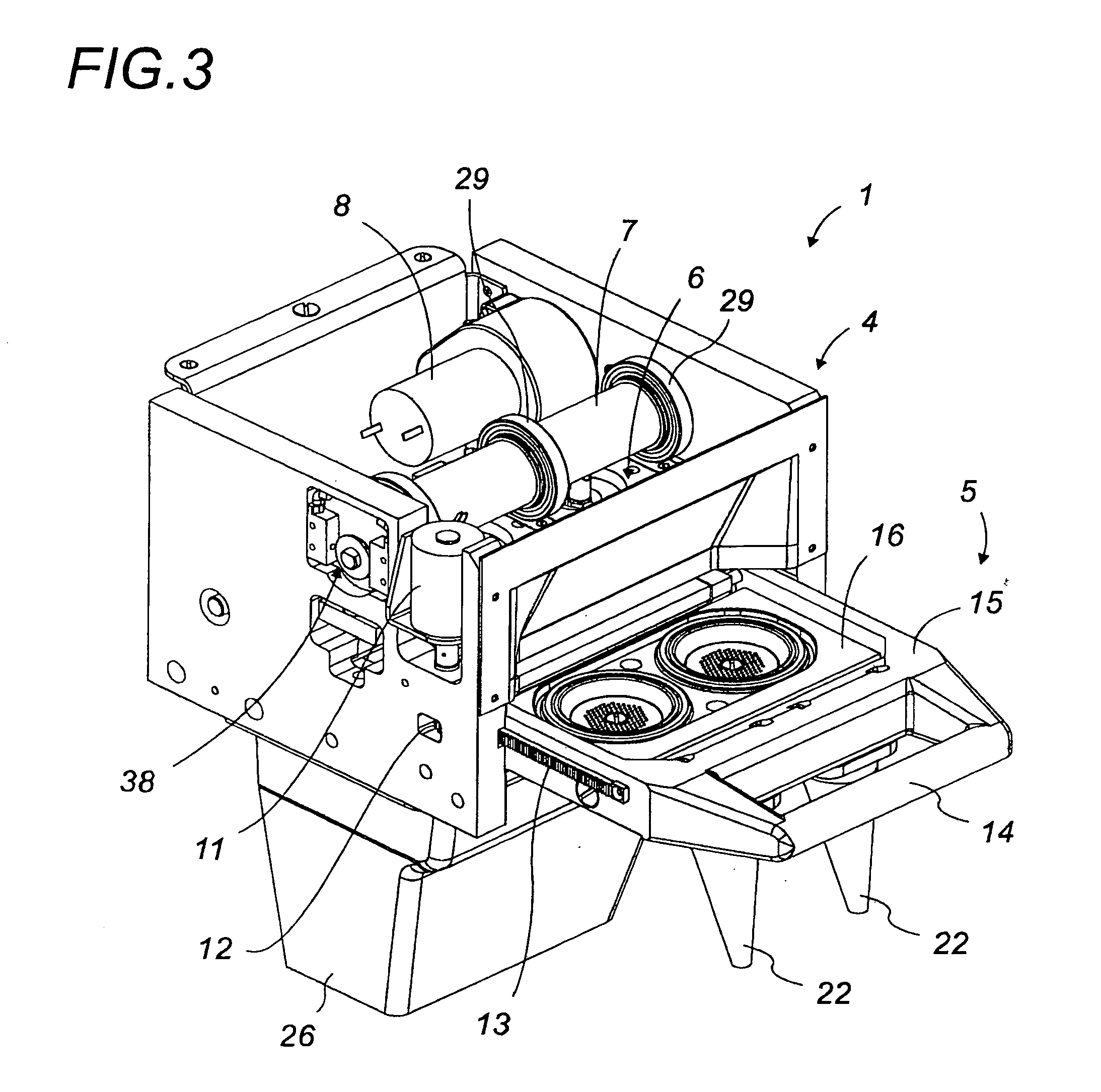

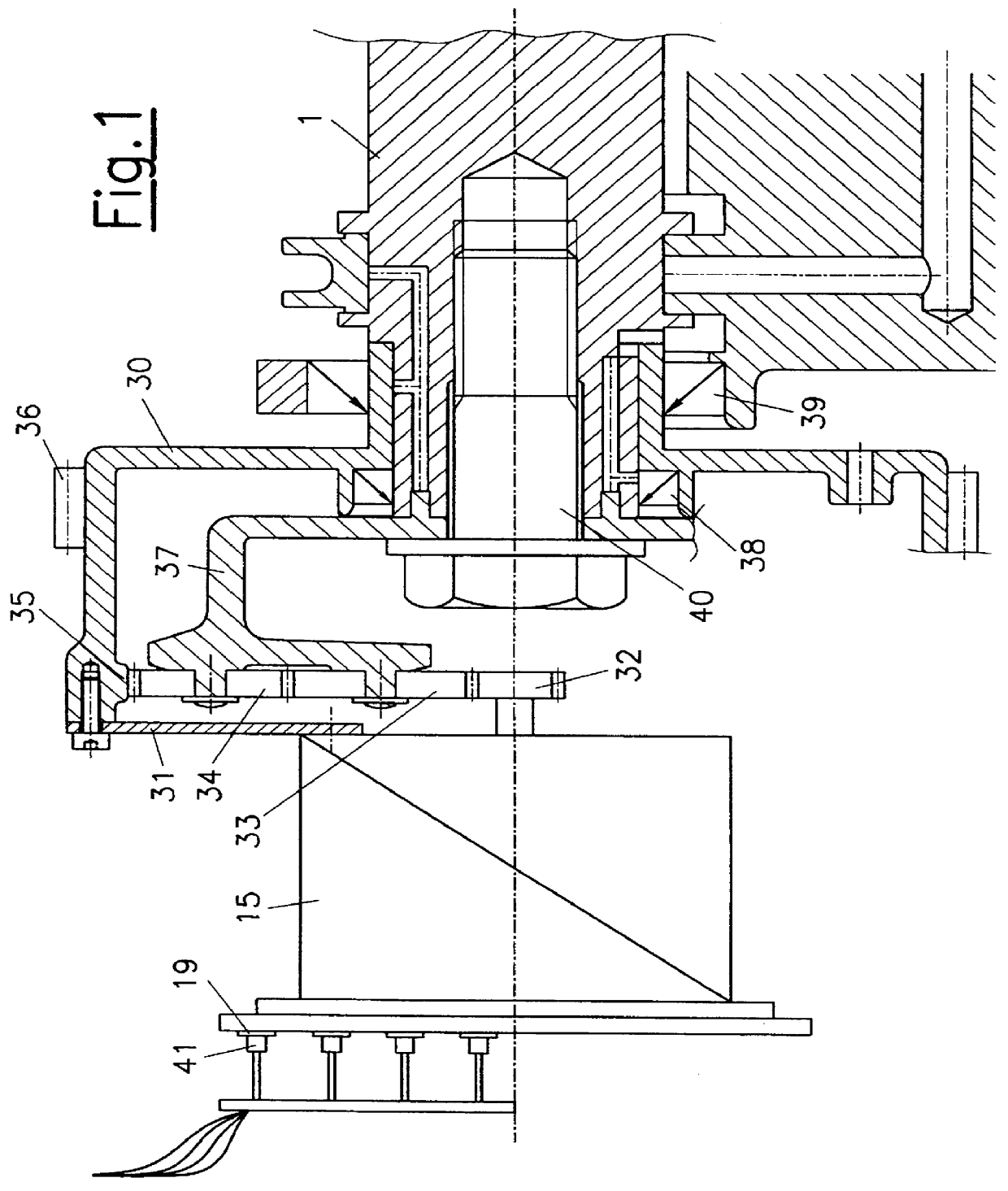

Unit for Preparing at Least One Espresso Coffe Cup or Other Hot Beverage From a Prepackaged Single So-Called Coffee Pod

The invention concerns a unit (1) for automatically preparing espresso coffee from prepackaged coffee pods containing one or two coffee pods and comprising a mechanism for individually detecting the presence of each pod in its location. It comprises a drawer (5) movable between a position for extracting, a position for loading and a position for discharging pods and an injection unit (6) closing the support of the preparation unit (1) in its front part above the drawer (5) in its extracting position and entirely mobile to be brought closer to the drawer through the cams (29) of the camshaft (7) driven by a single motor (8), being automatically returned away from the injection unit (6) through a return force. The invention is of interest to professional coffee machine manufacturers.

Owner:RENEKA INT

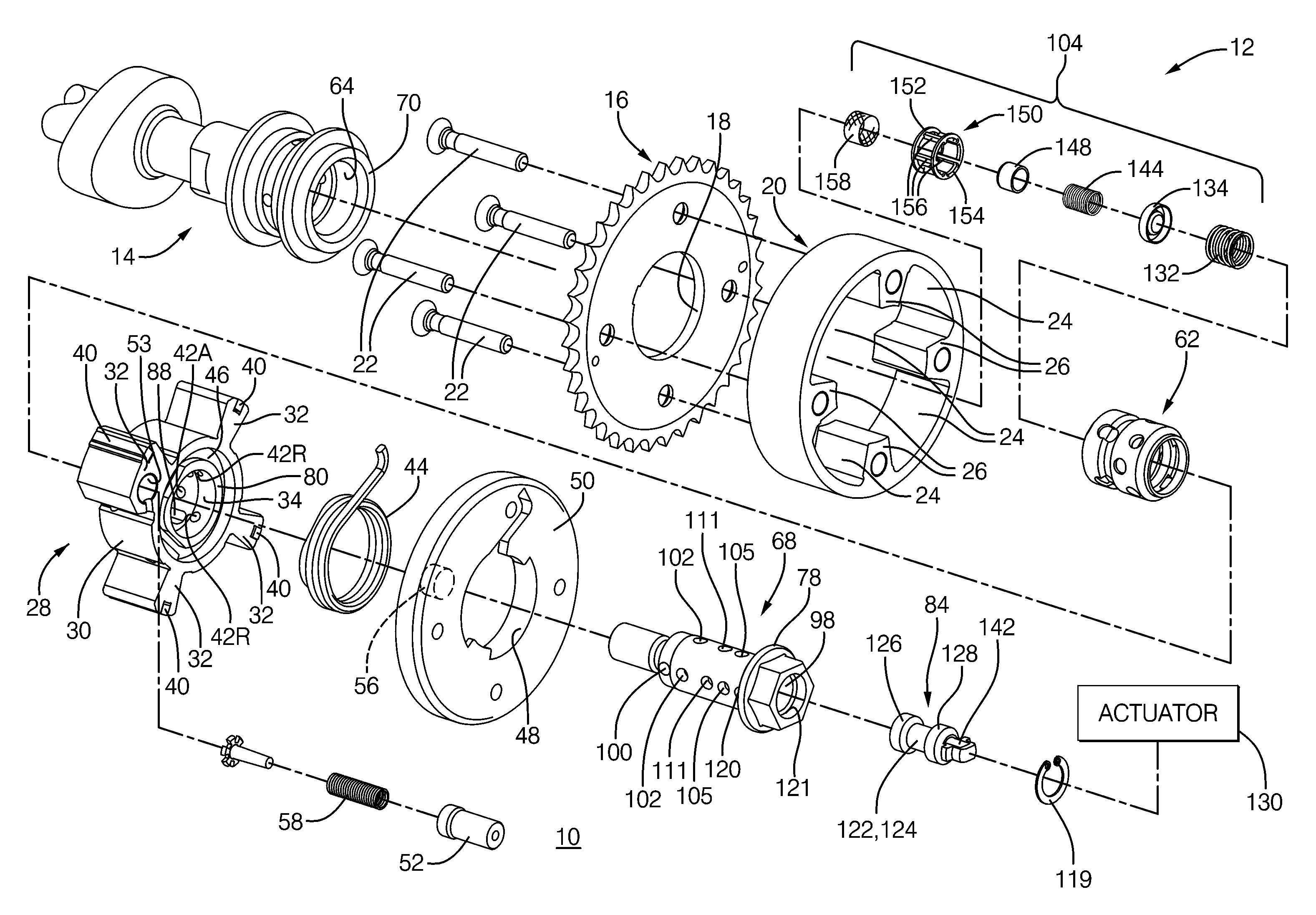

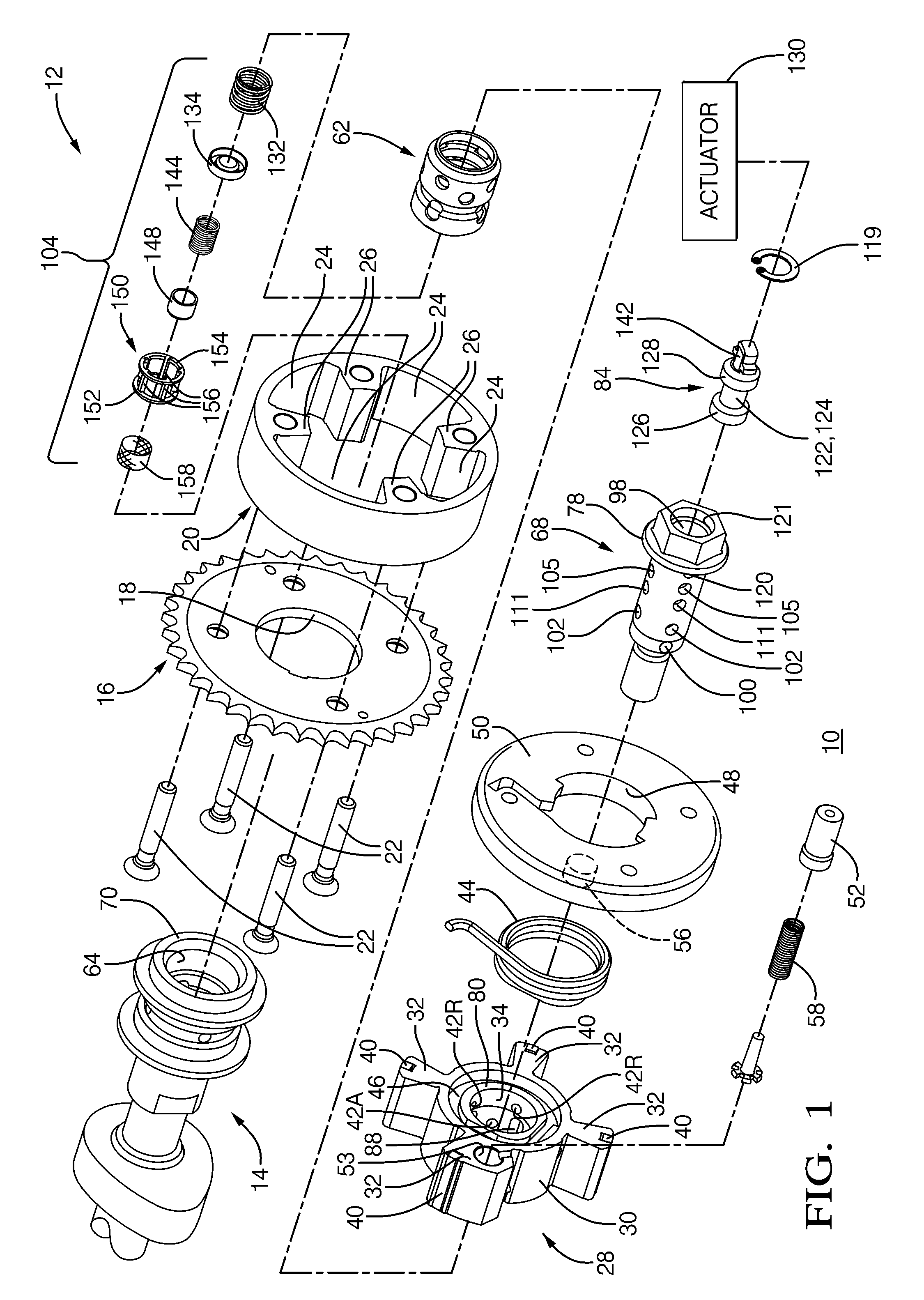

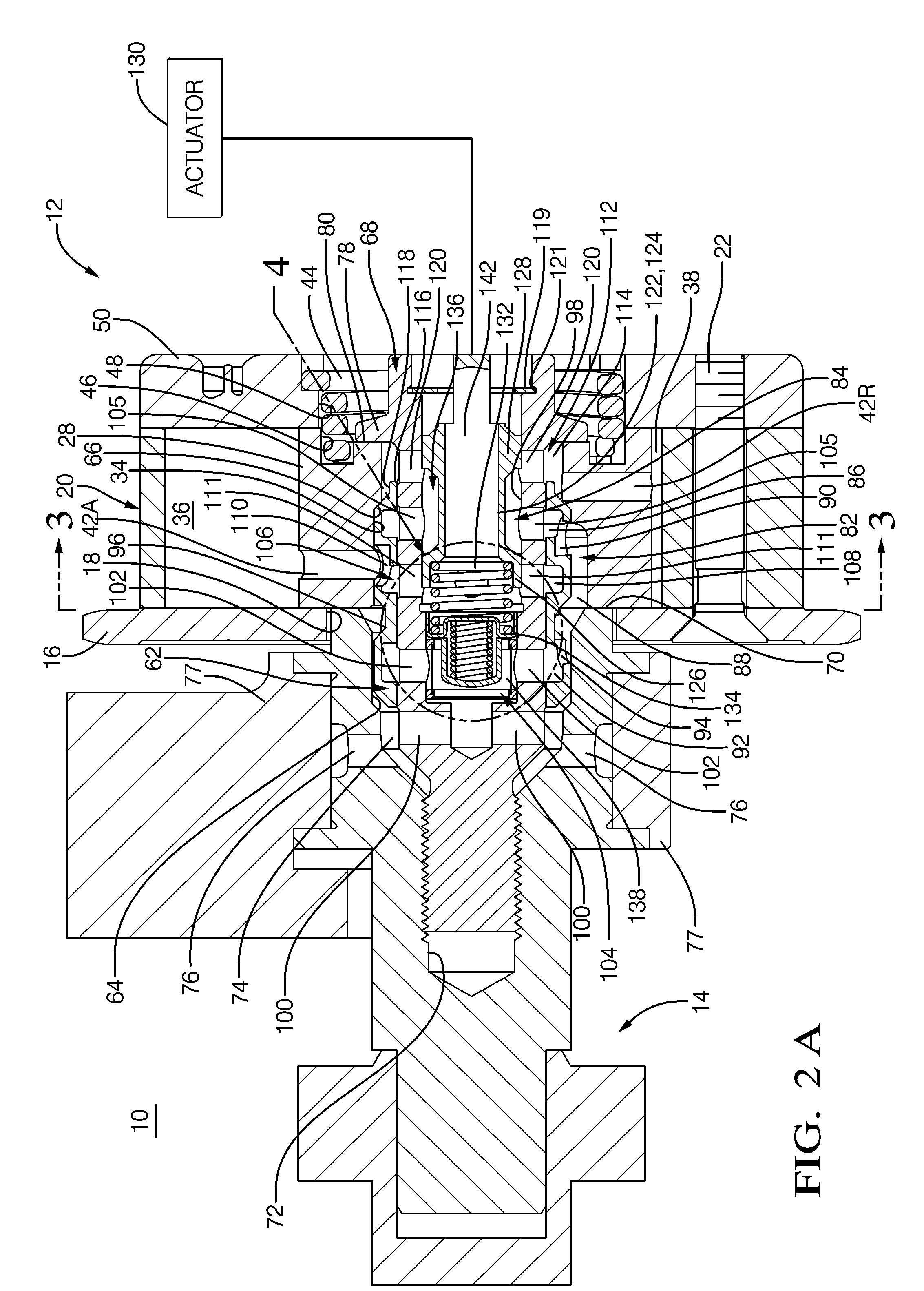

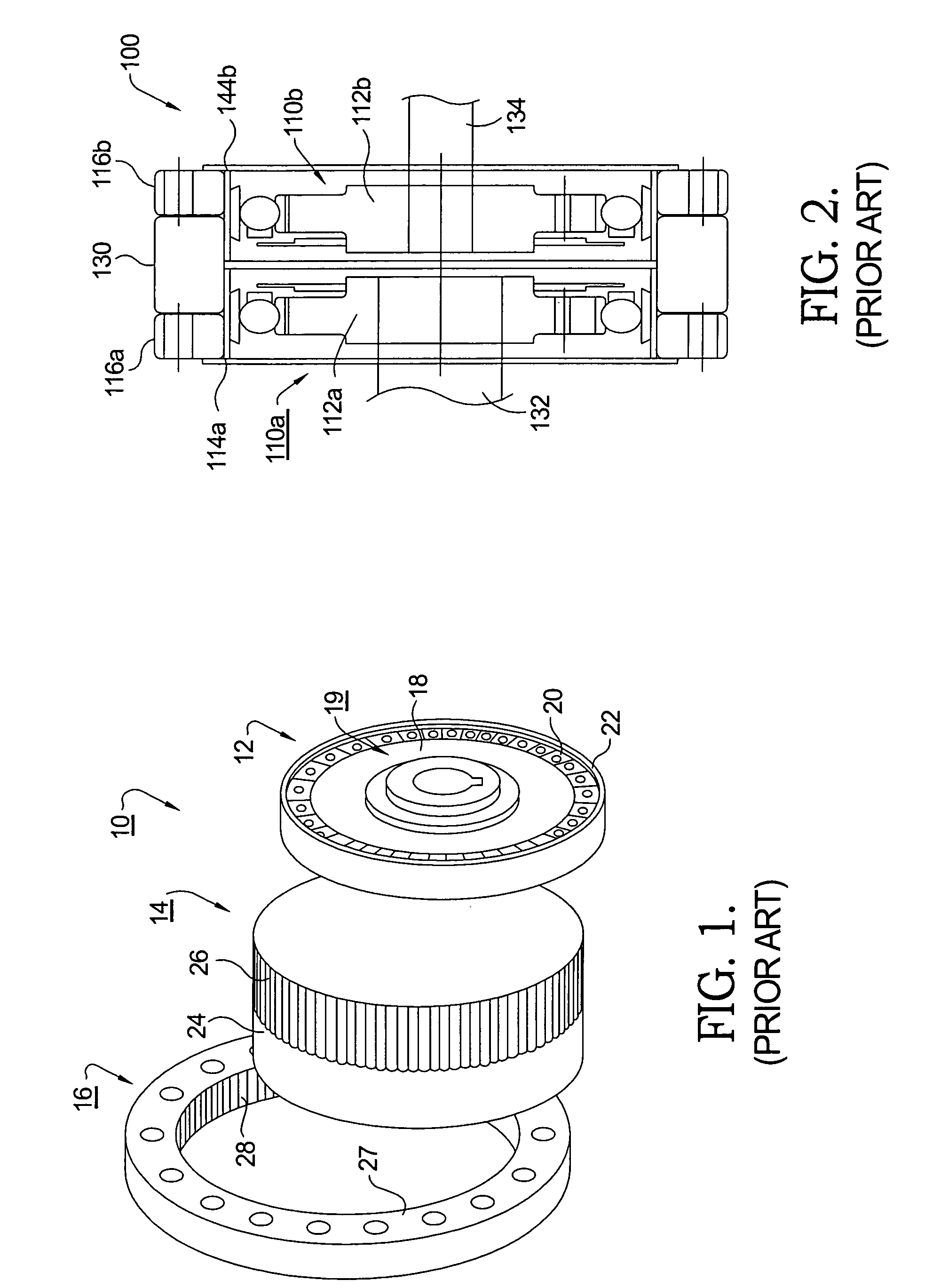

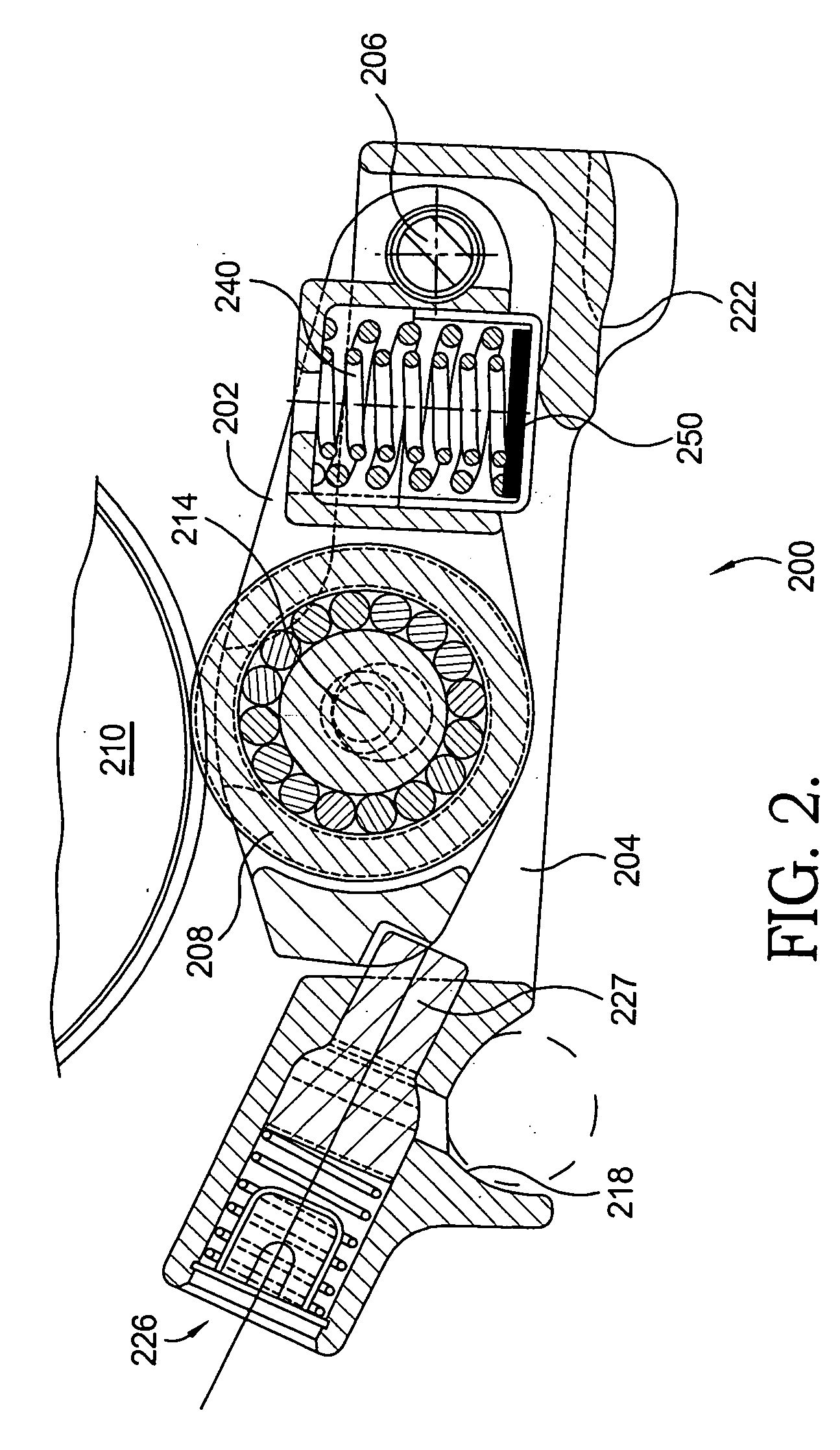

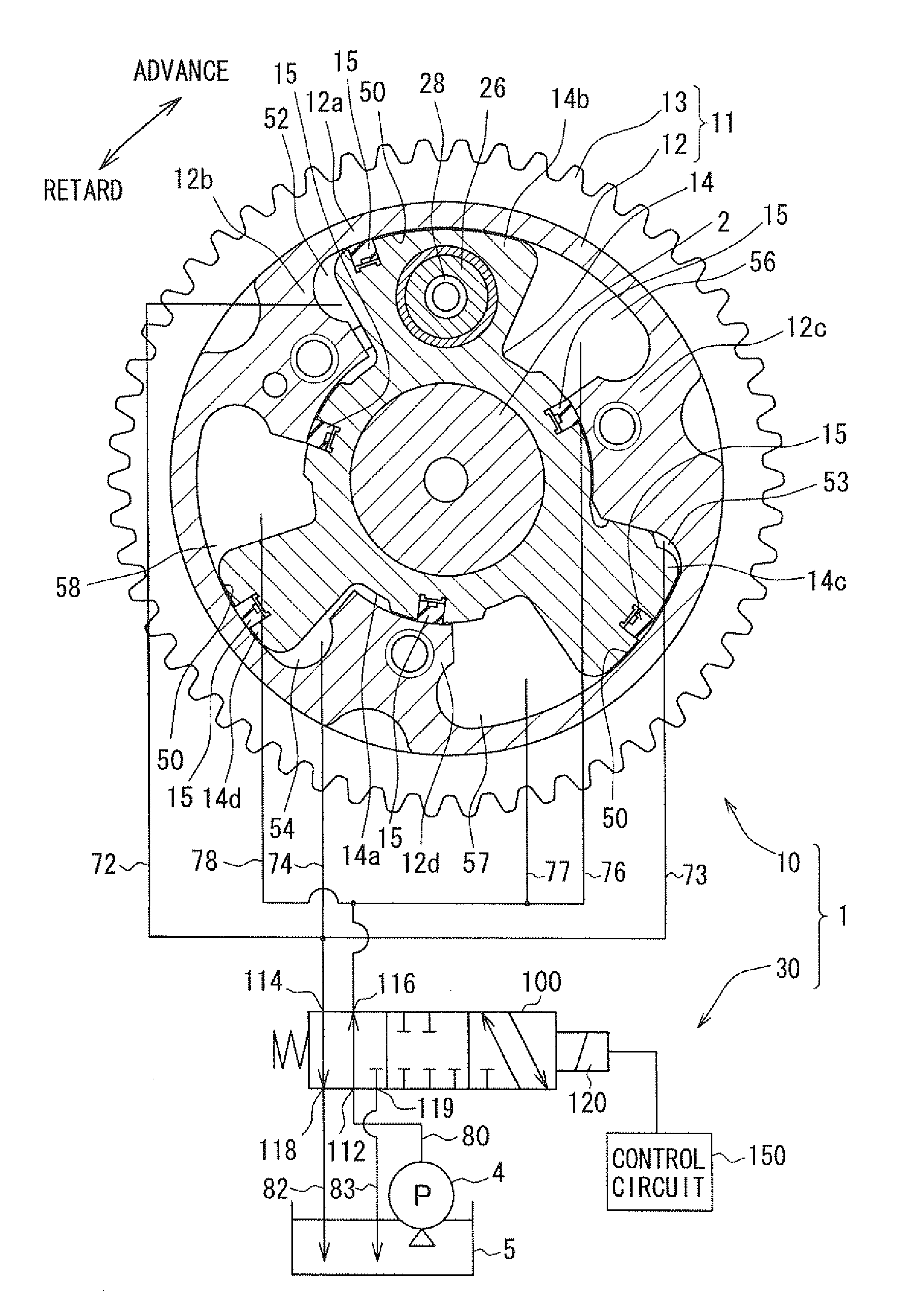

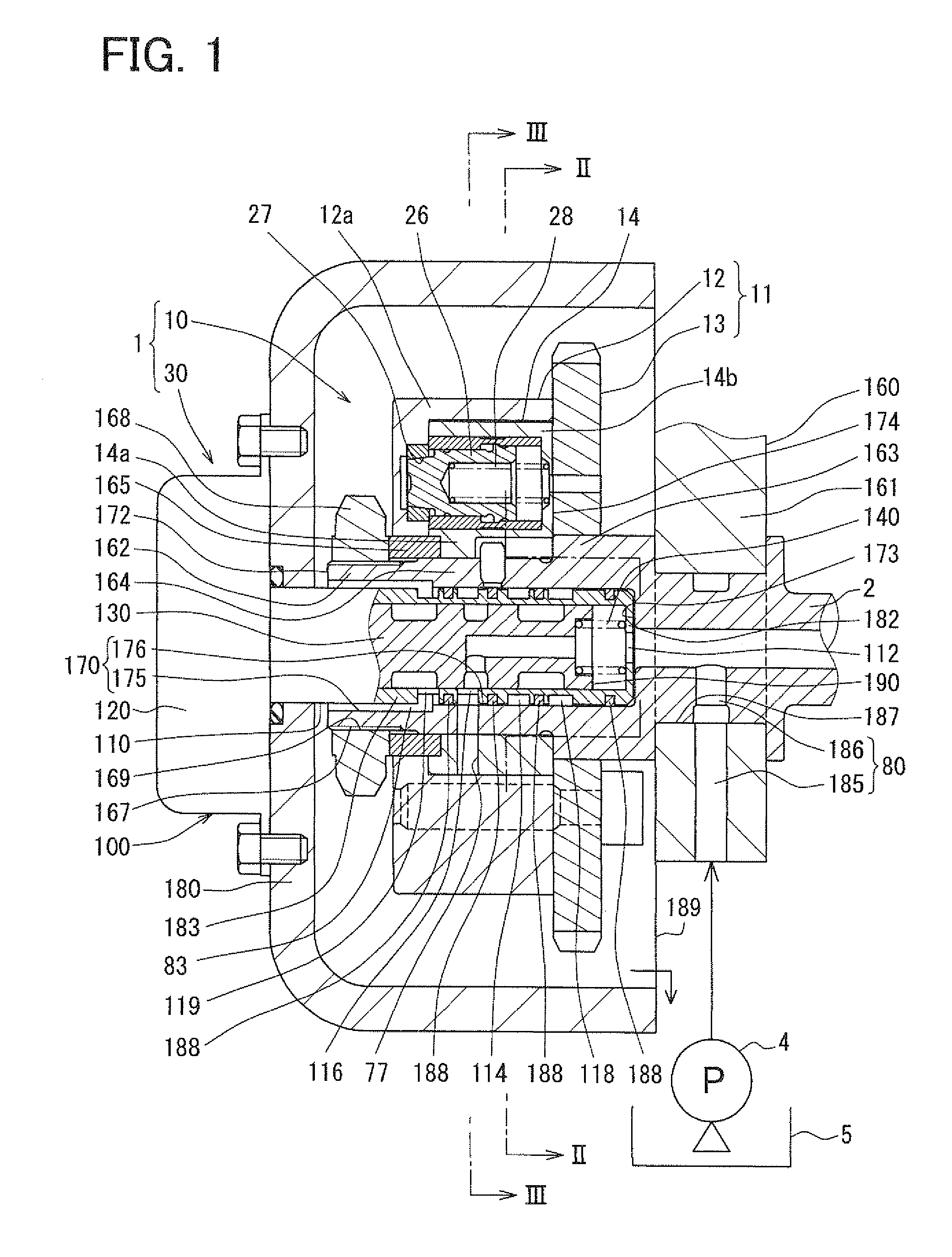

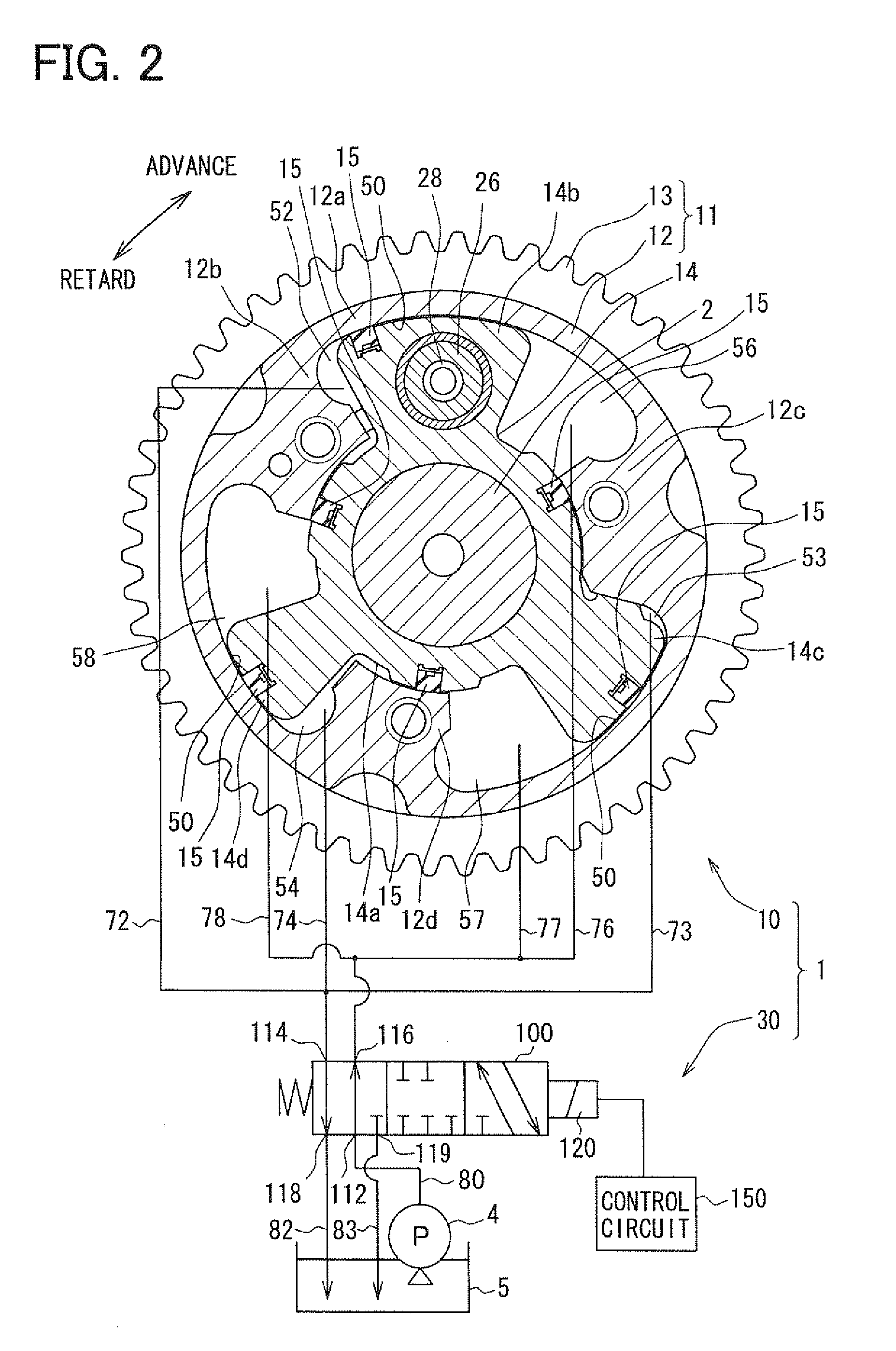

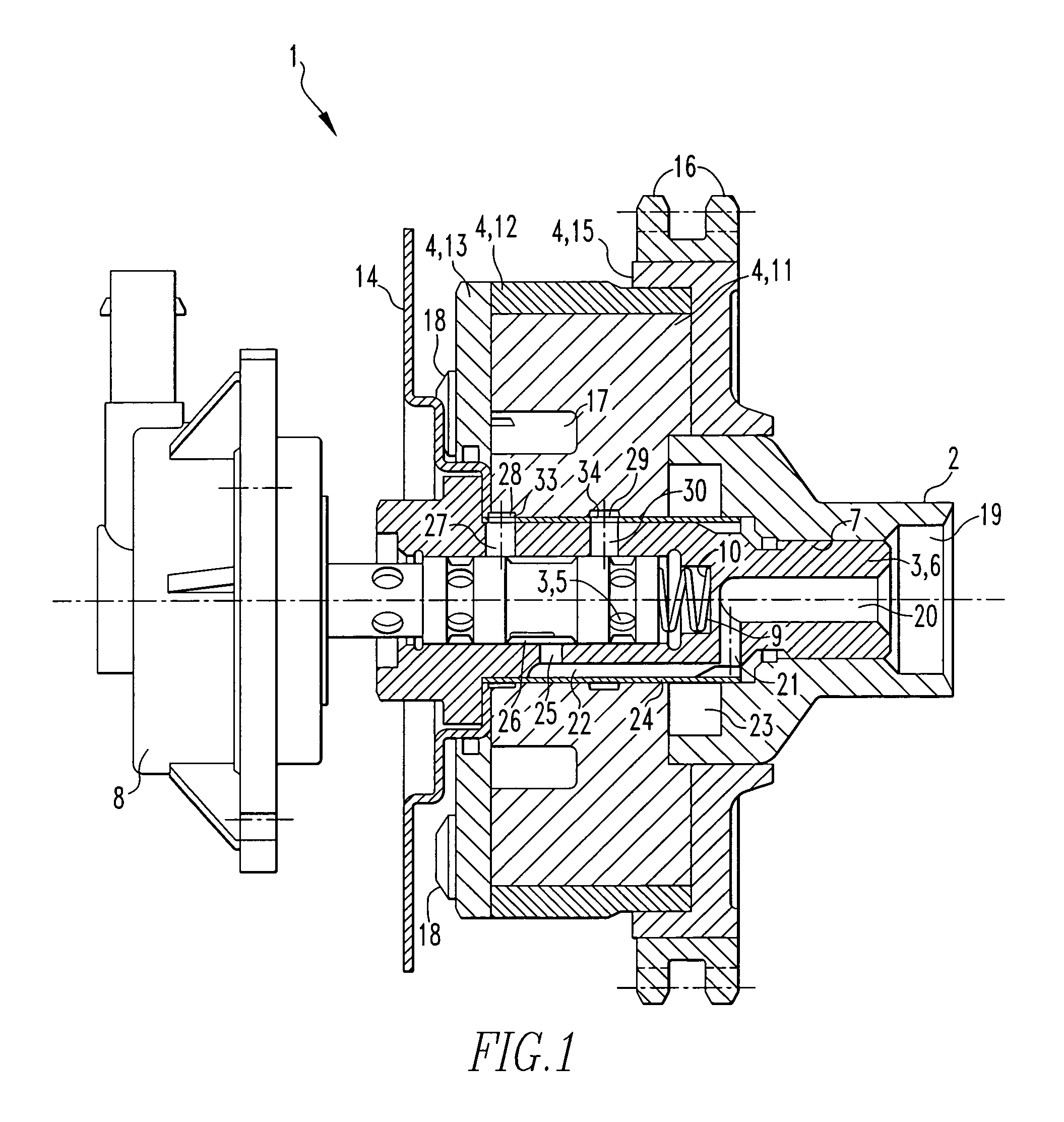

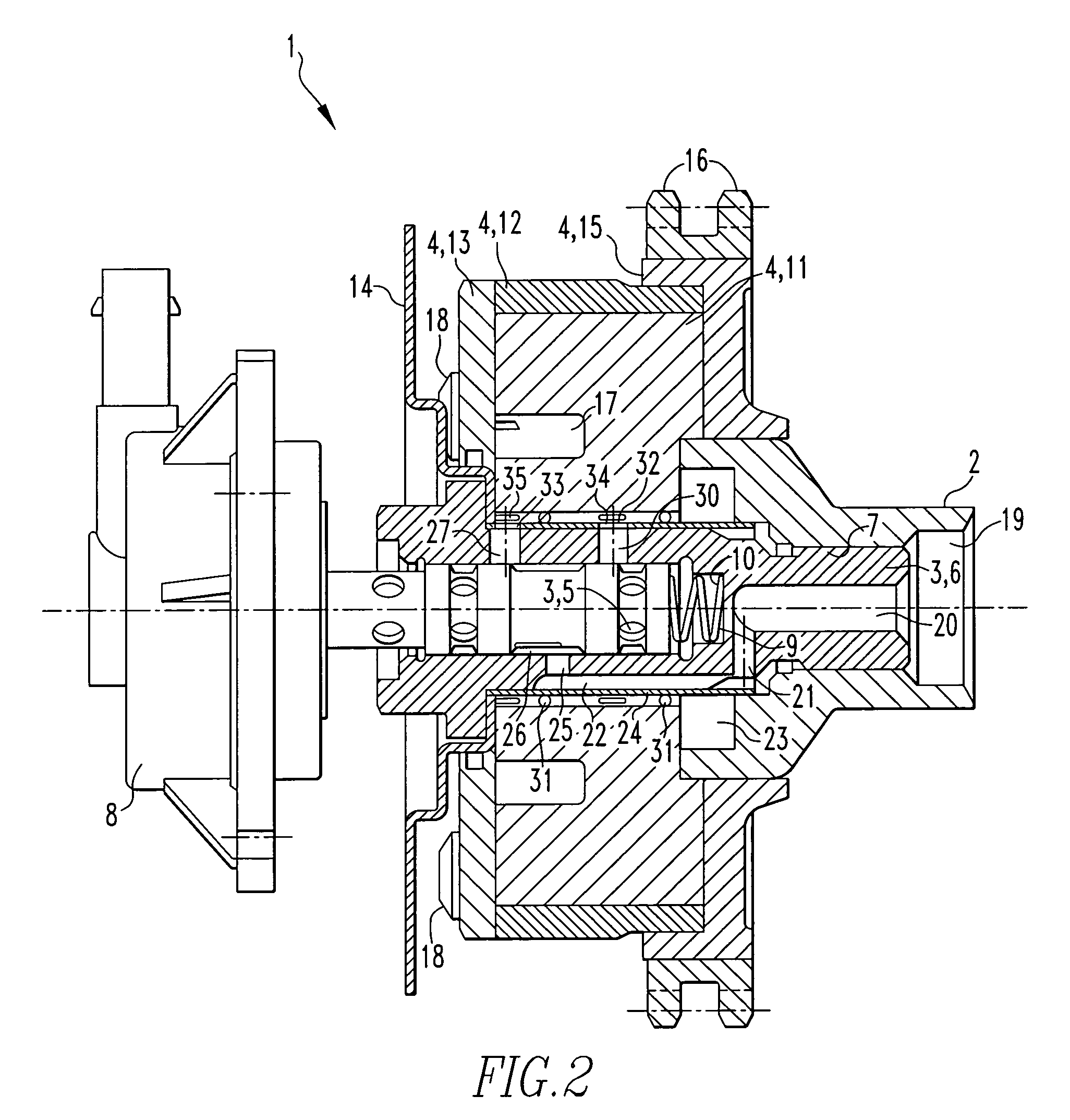

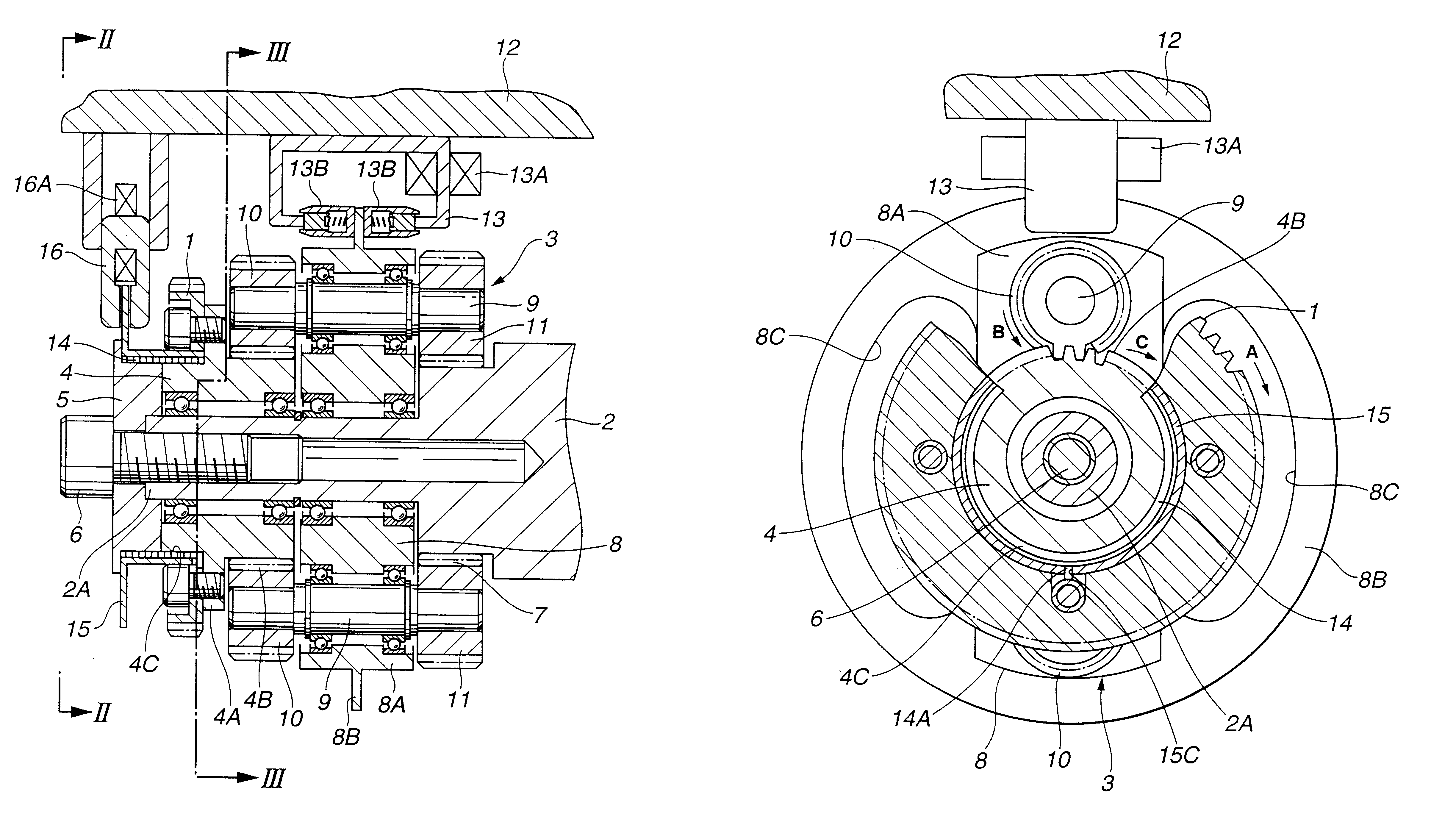

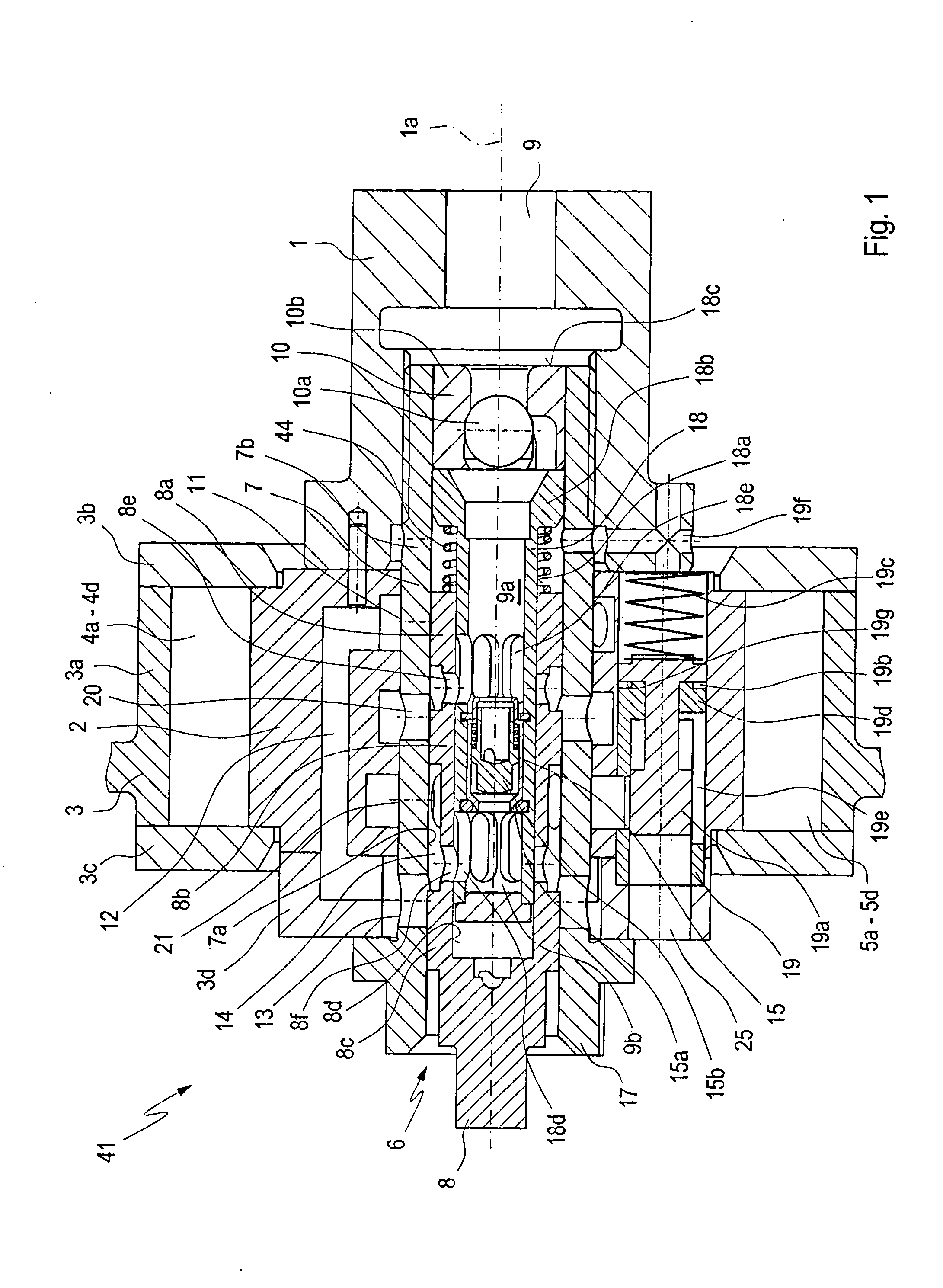

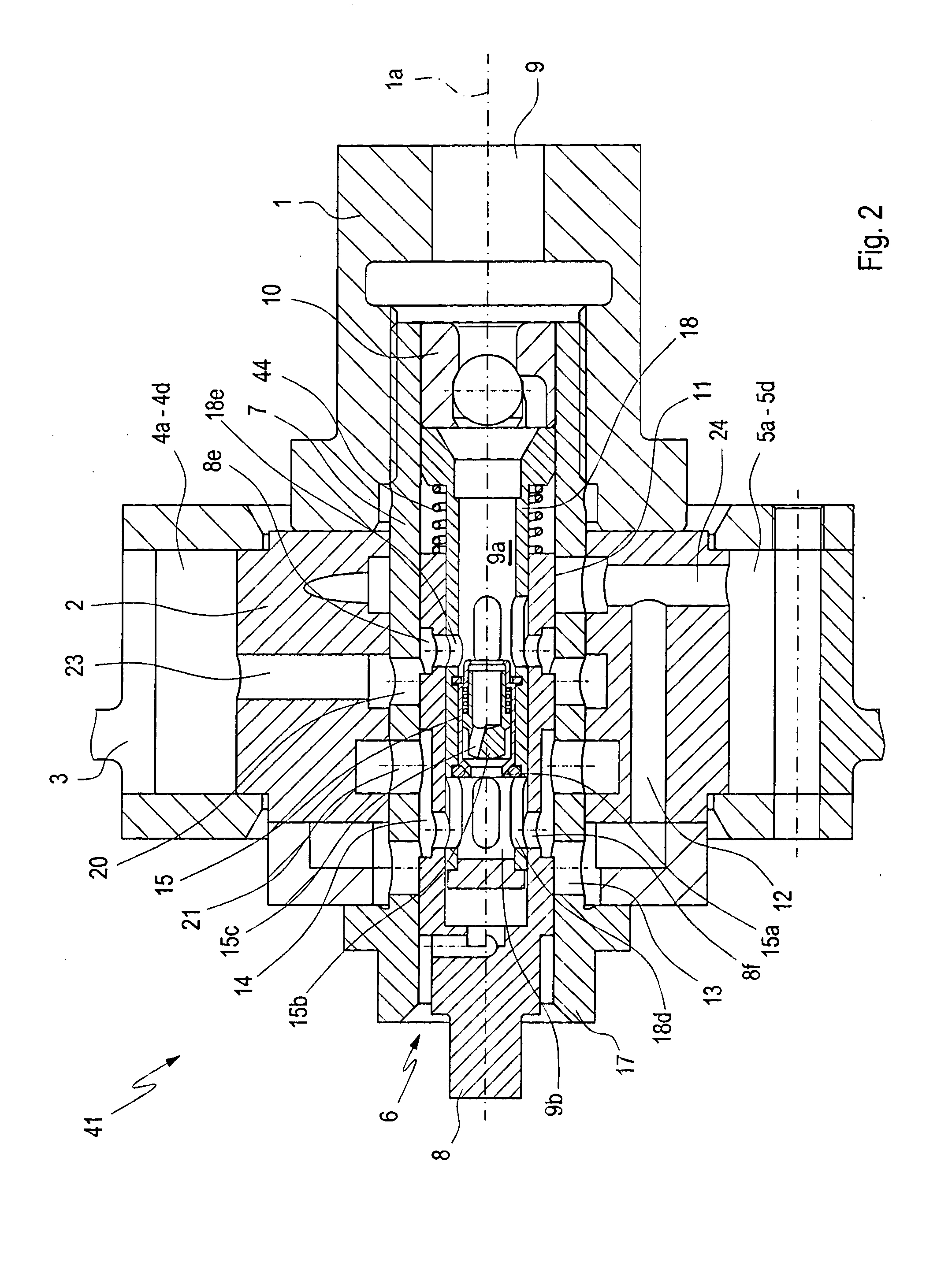

Axially compact camshaft phaser

A camshaft phaser is provided for varying the phase relationship between a crankshaft and a camshaft in an internal combustion engine. The camshaft phaser includes a stator having a plurality of lobes. A rotor is disposed within the stator and includes a plurality of vanes interspersed with the stator lobes to define alternating advance and retard chambers. A bushing adaptor of the camshaft phaser is disposable axially within a pocket of the camshaft and is disposed axially within the rotor. The bushing adaptor defines at least in part a supply passage for communicating pressurized oil from the internal combustion engine to a control valve, an advance passage for selectively communicating pressurized oil from the control valve to the advance chambers, and a retard passage for selectively communicating pressurized oil from the control valve to the retard chambers.

Owner:DELPHI TECH IP LTD

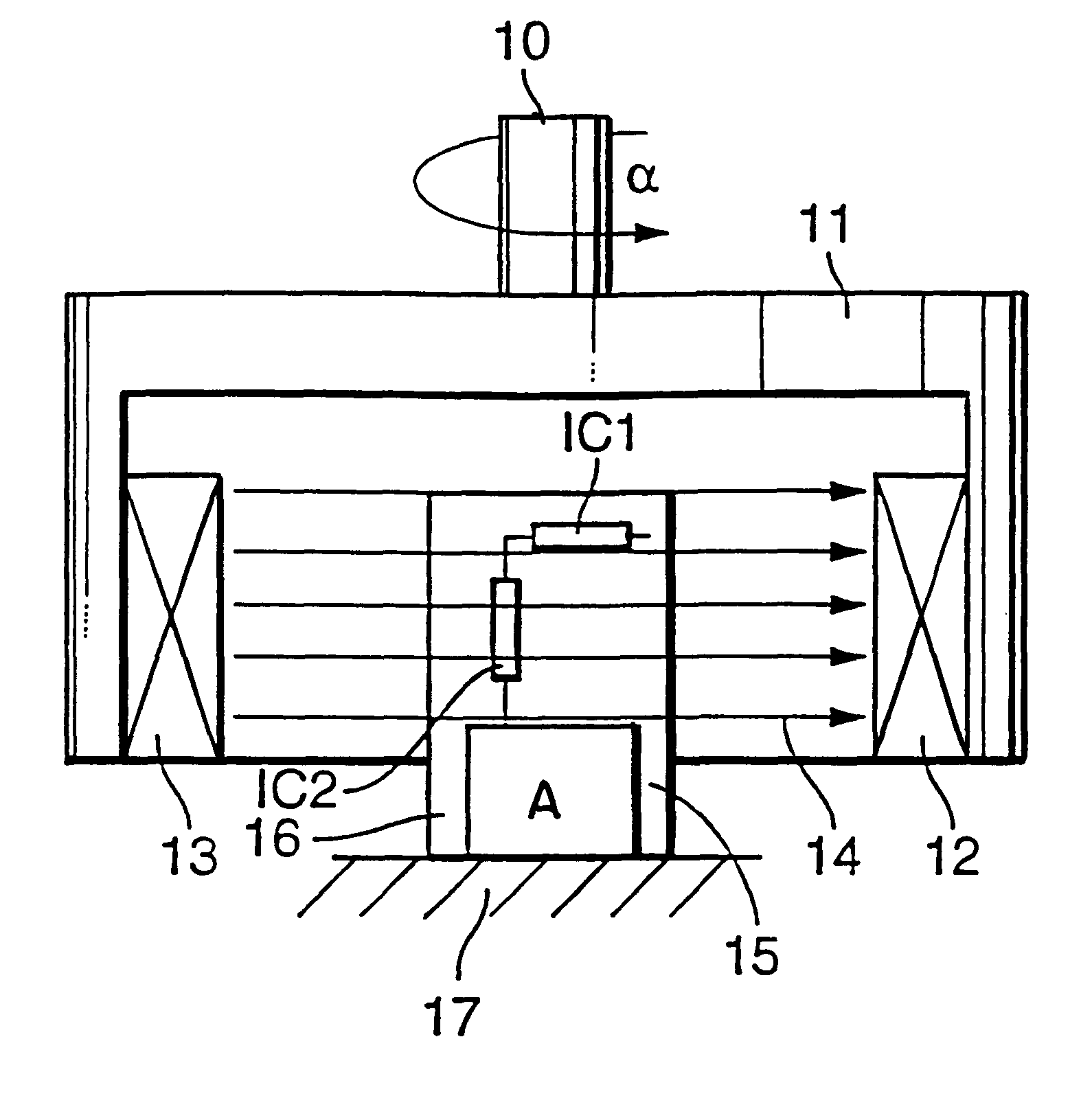

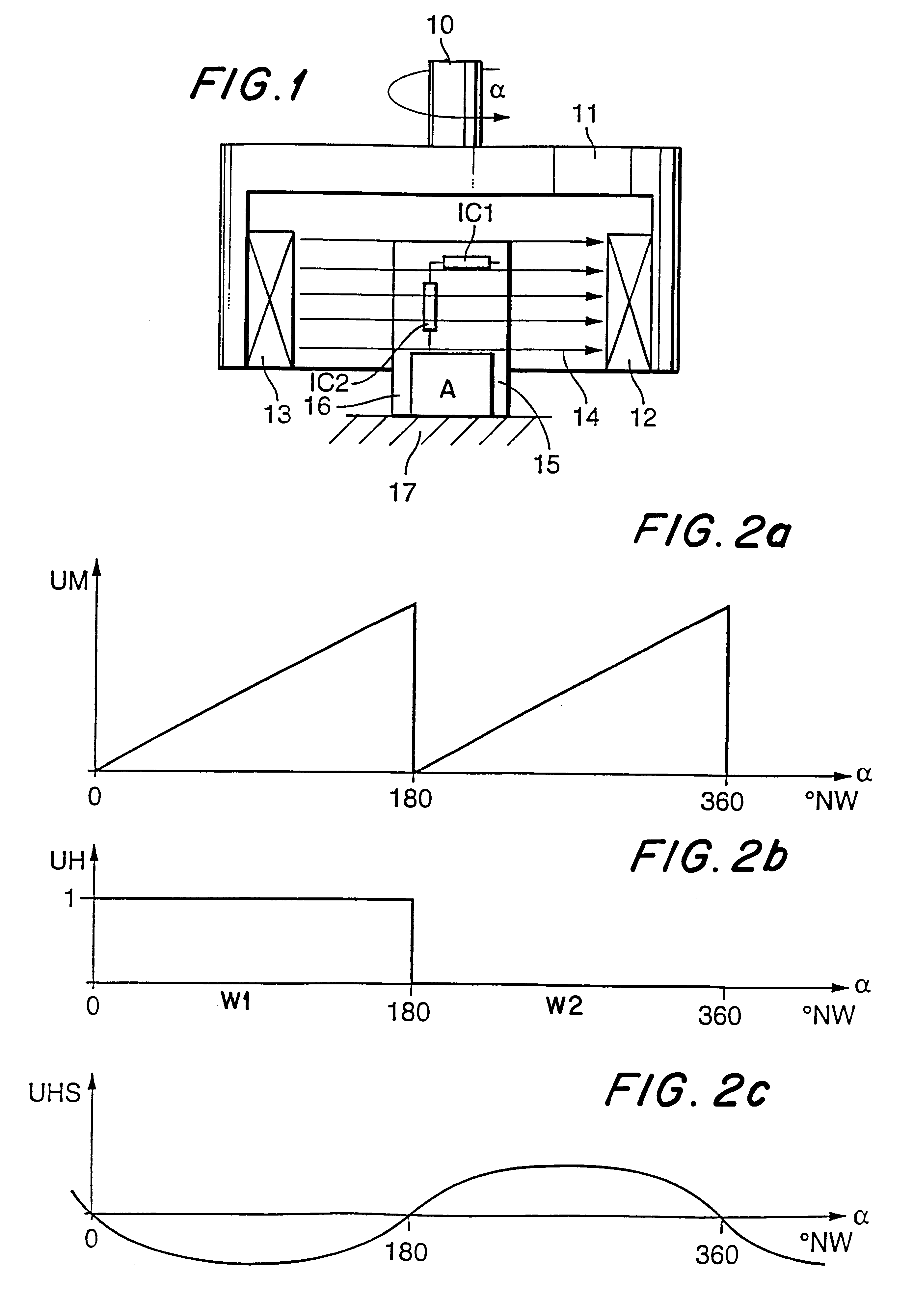

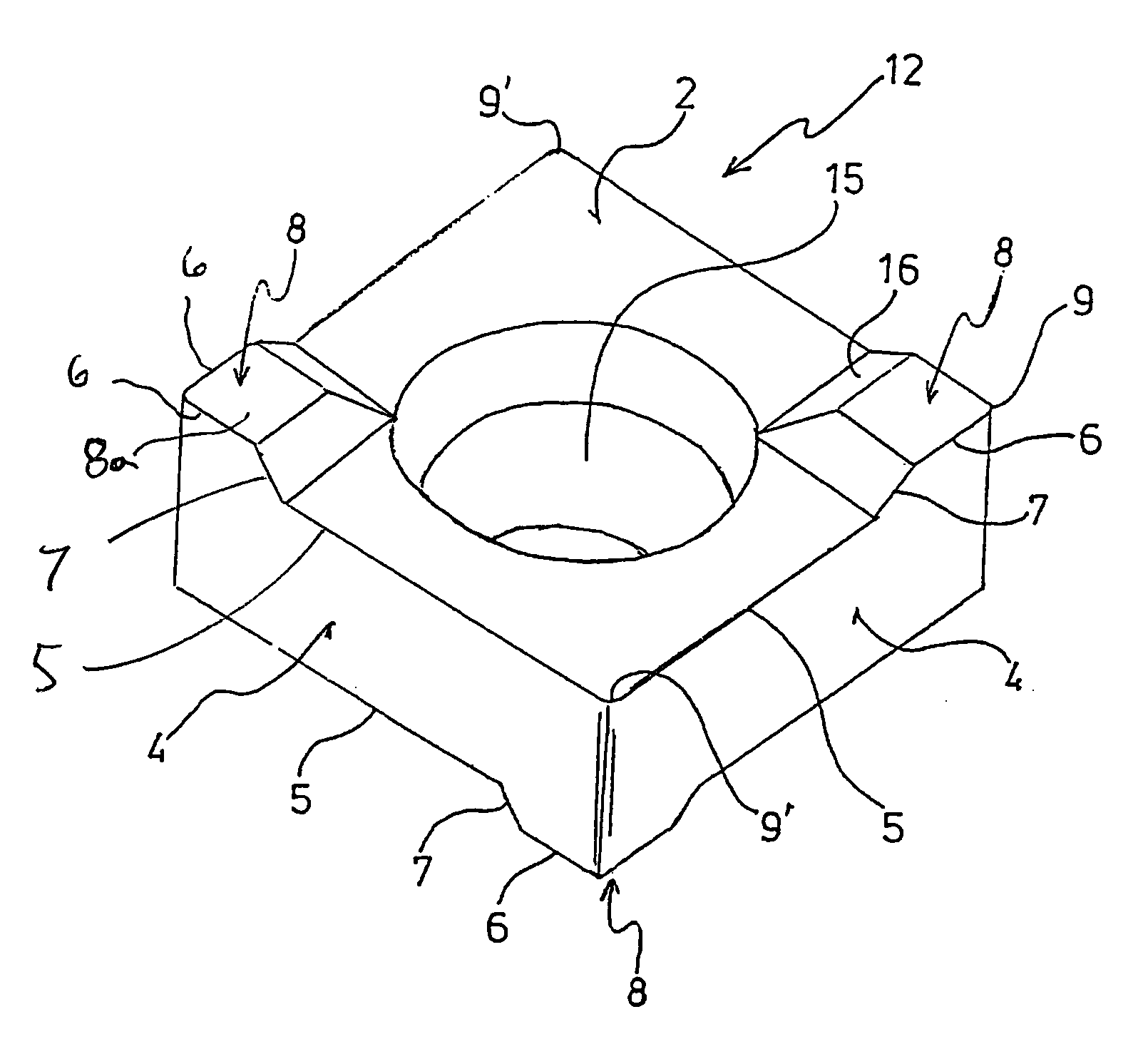

Non-contact system for detecting an angle of rotation

InactiveUS6212783B1Angles/taper measurementsElectric ignition installationAngular orientationInternal combustion engine

The arrangement for contactless determination of an angular position of a rotatable element, such as a camshaft of an internal combustion engine, which includes a magnet arranged to rotate with the rotatable element; a magnetic field sensor stationary in relation to the rotatable element and including a first sensor element (IC1) and a second sensor element (IC2), wherein the first sensor element generates a first output signal linearly dependent on an angle between the magnetic field and the magnetic field sensor according to a magnetoresistive effect, whereby the first output signal has respective values between 0° and 180° that repeat between 180° and 360°, and the second sensor element generates a second output signal having a high value between 0° and 180° and a low value between 180° and 360° according to a Hall effect; and an evaluation circuit (A) for analyzing output signals of both sensor elements to determine the angular position of the rotatable element between 0° and 360°. The evaluating circuit finds that the absolute angular position is either of two angular orientations spaced 180° from each other only from the signal from the first sensor element and selects one of them as the absolute angular position according to the second output signal.

Owner:ROBERT BOSCH GMBH

Harmonic drive camshaft phaser

Owner:DELPHI TECH IP LTD

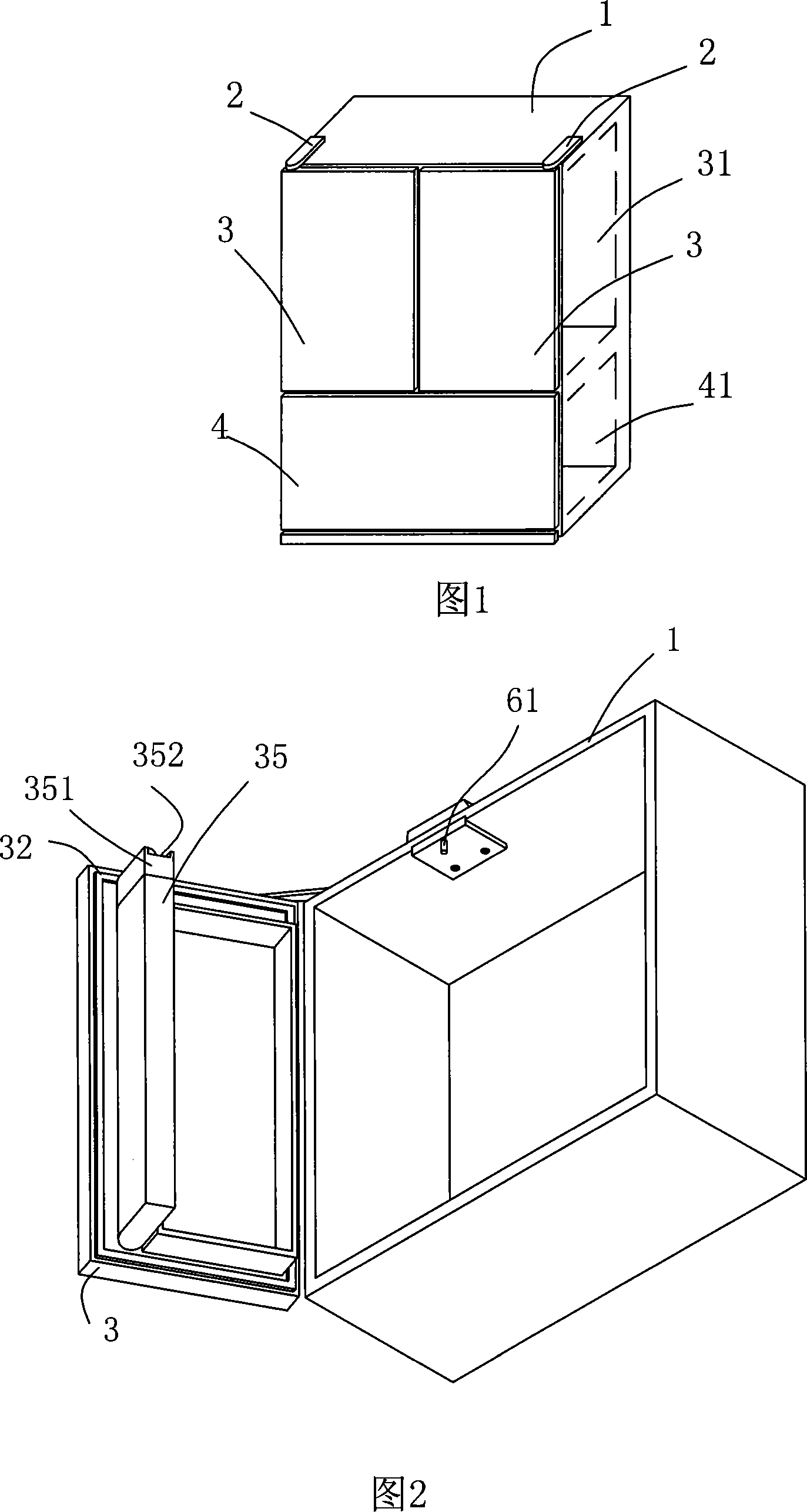

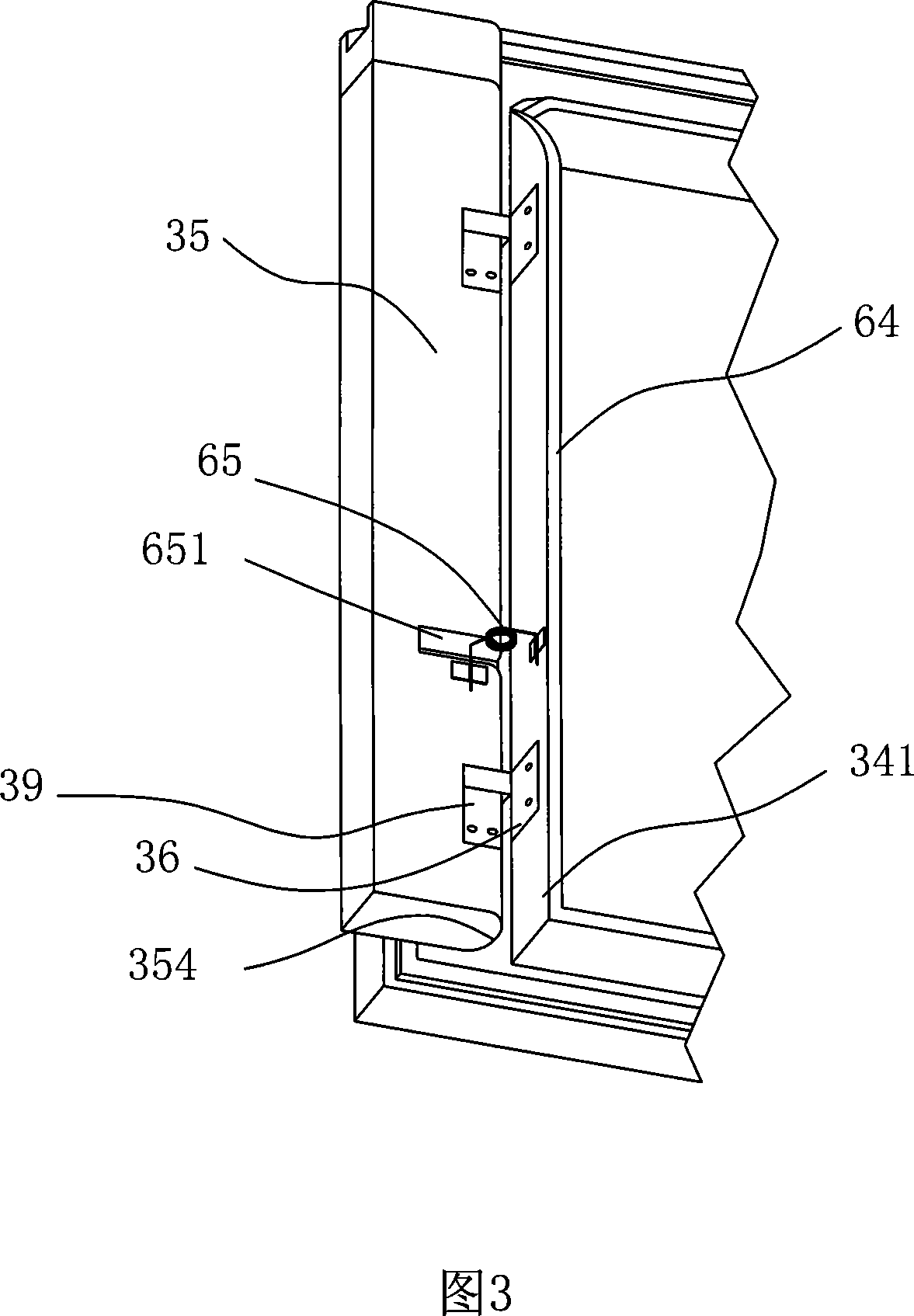

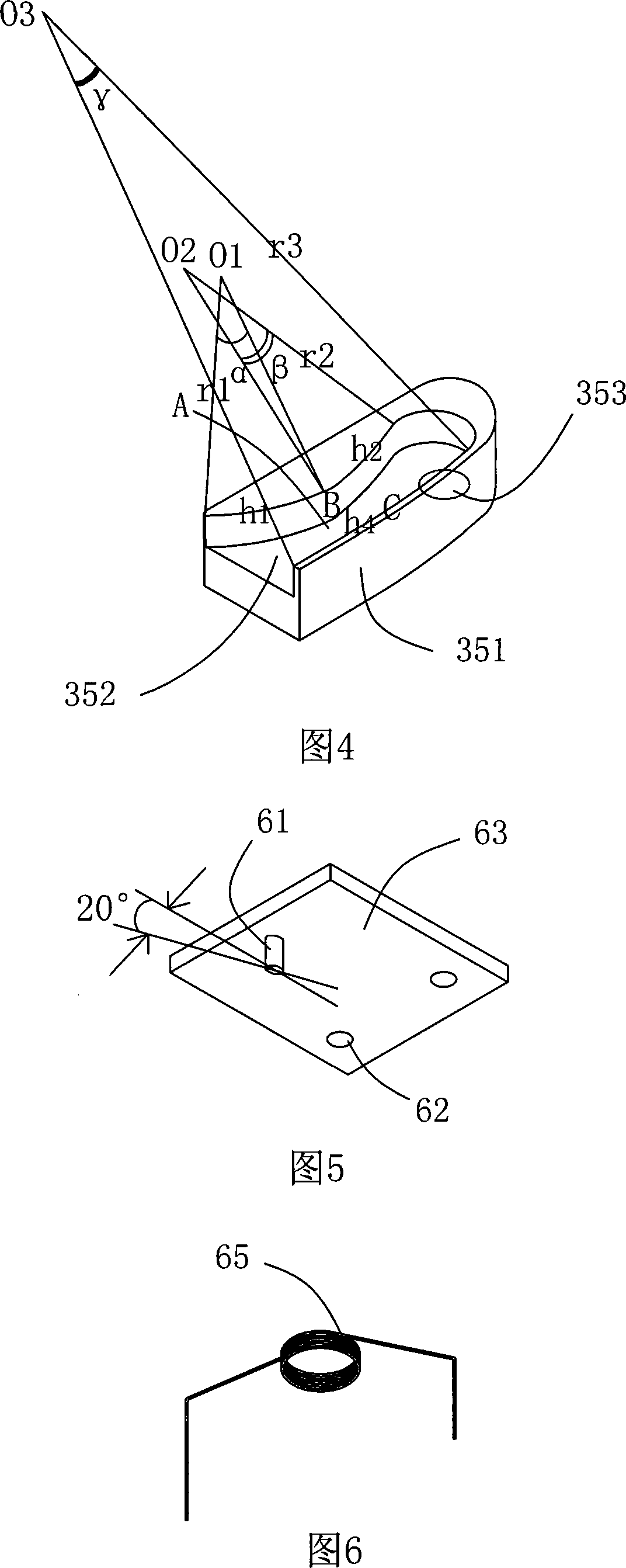

Fridge with movable middle beam Split door

ActiveCN101135531APrevent leakageGuaranteed ambient temperatureDomestic cooling apparatusLighting and heating apparatusEngineeringJamb

The invention discloses a side- by- side combination electric refrigerator with moving centre sill. A moving centre sill is hinge jointed at vertical direction near opening side part in the one side of door body, and hinged with door frame via one side of the moving centre sill, a curve box with internal concave guiding slot or protrude sliding block is fixed at its upper or lower end , a camshaft or sliding slot is mounted at the fixing plate of the inner wall of the moving centre sill end; the guiding slot or sliding slot include a closing section, and a opening section connected with the closing section.

Owner:HAIER GRP CORP +1

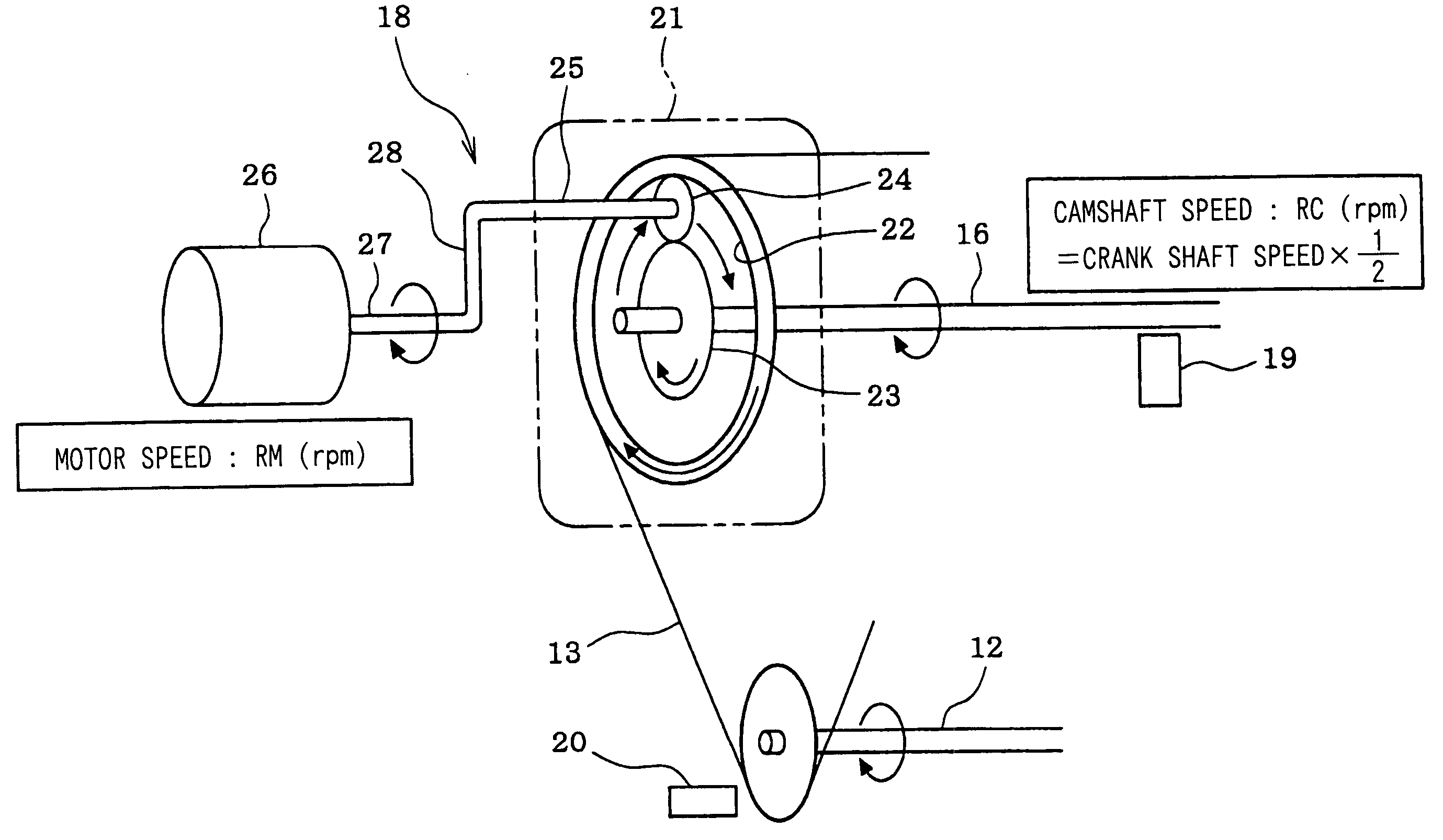

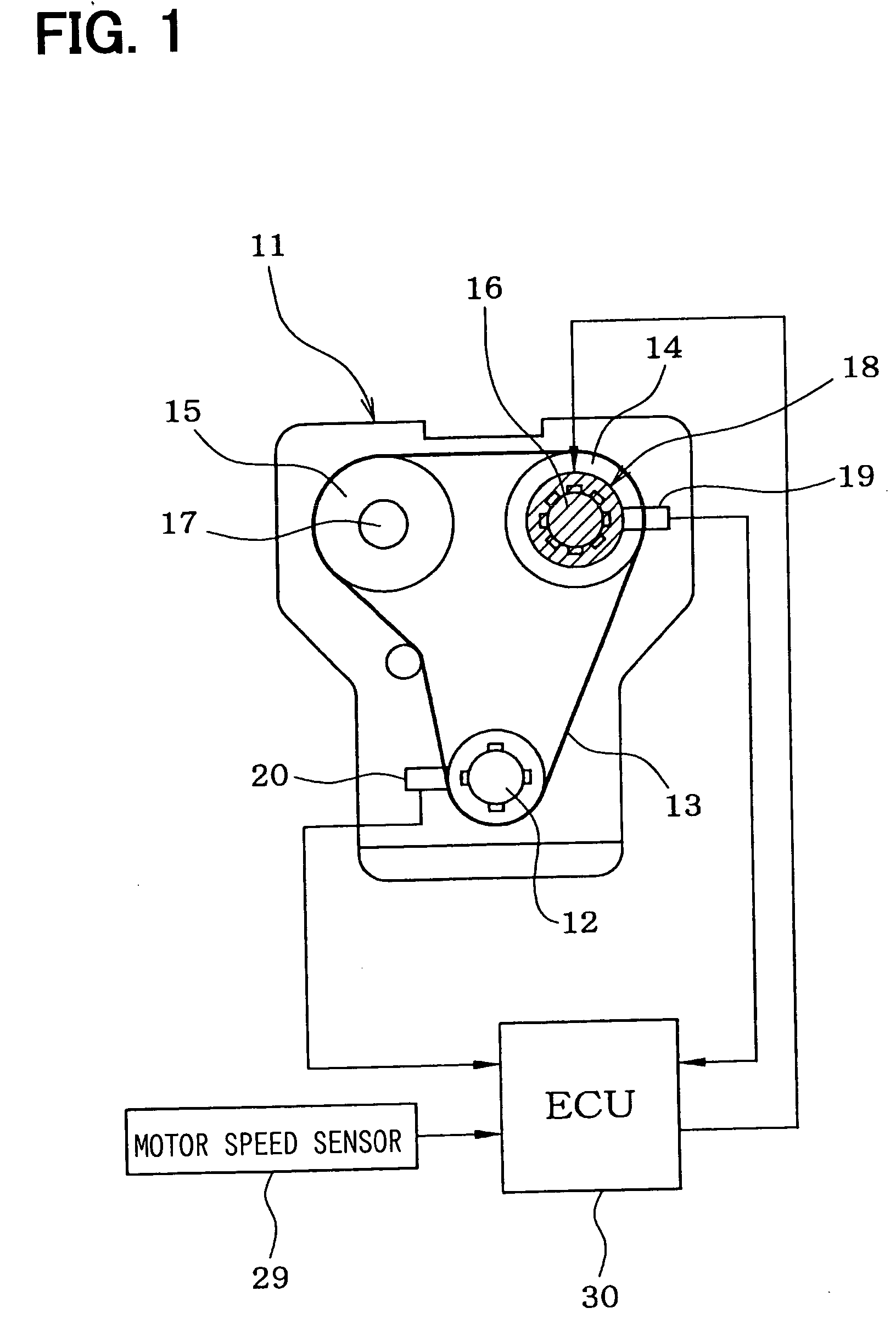

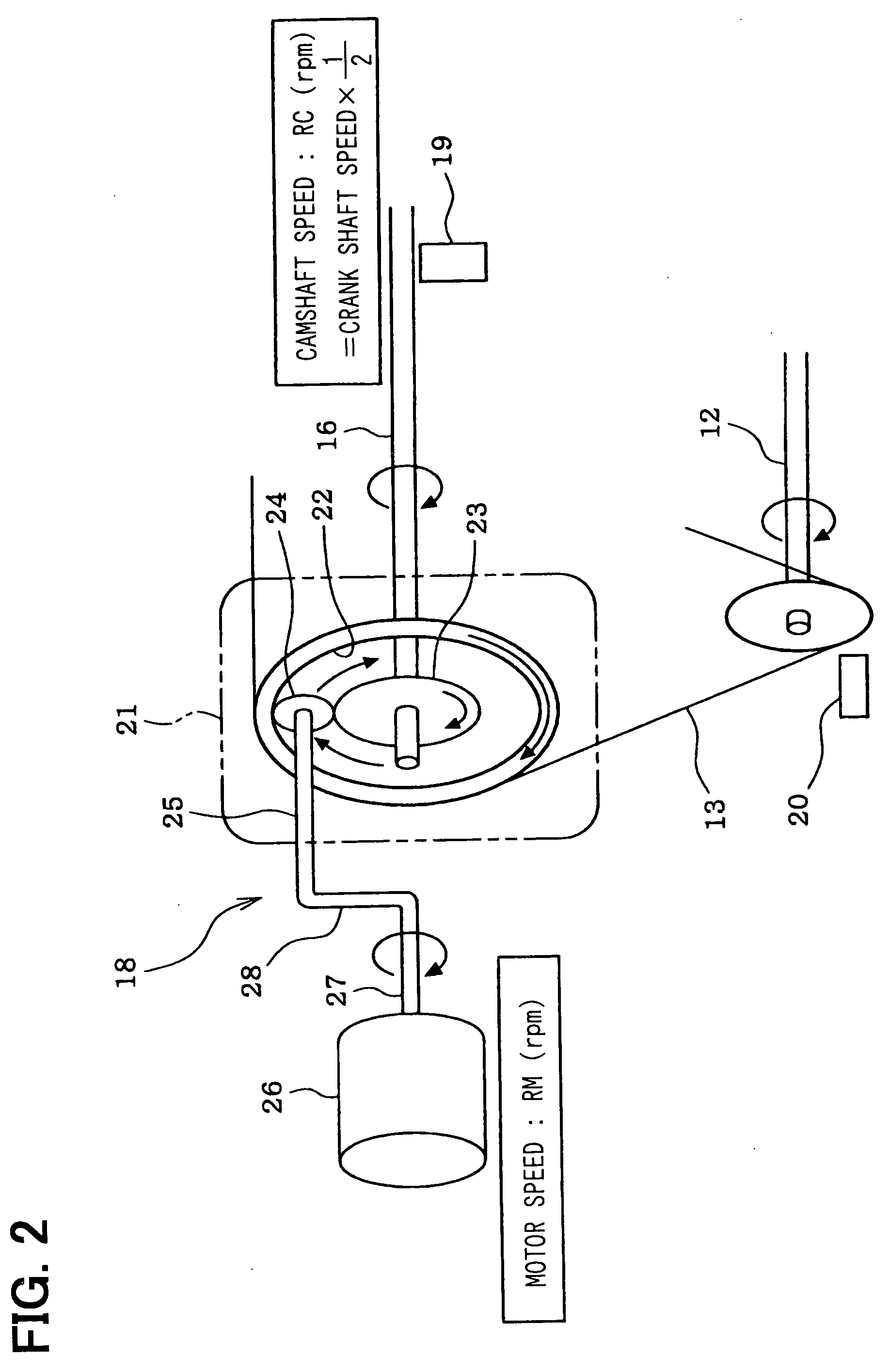

Variable valve timing control device of internal combustion engine

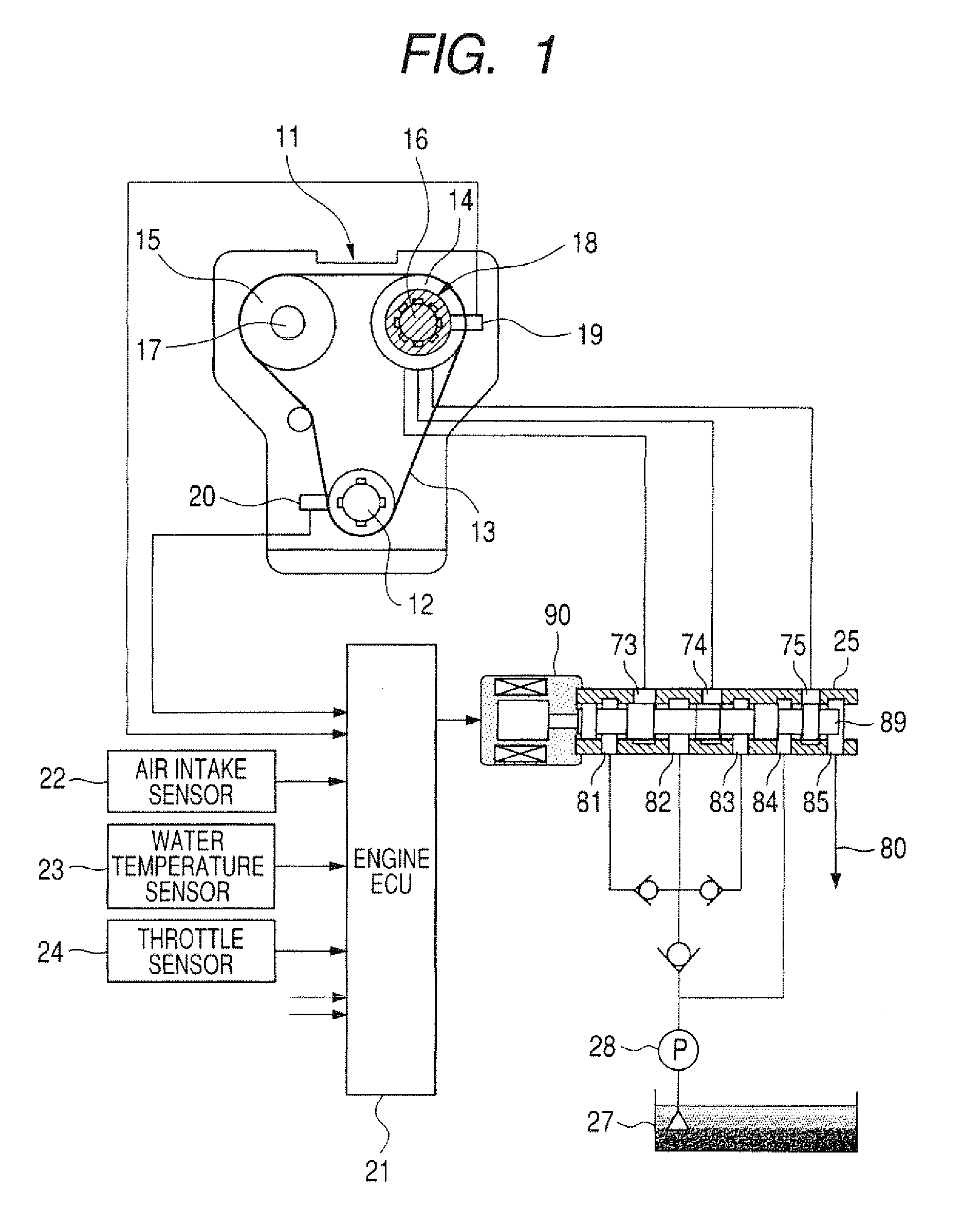

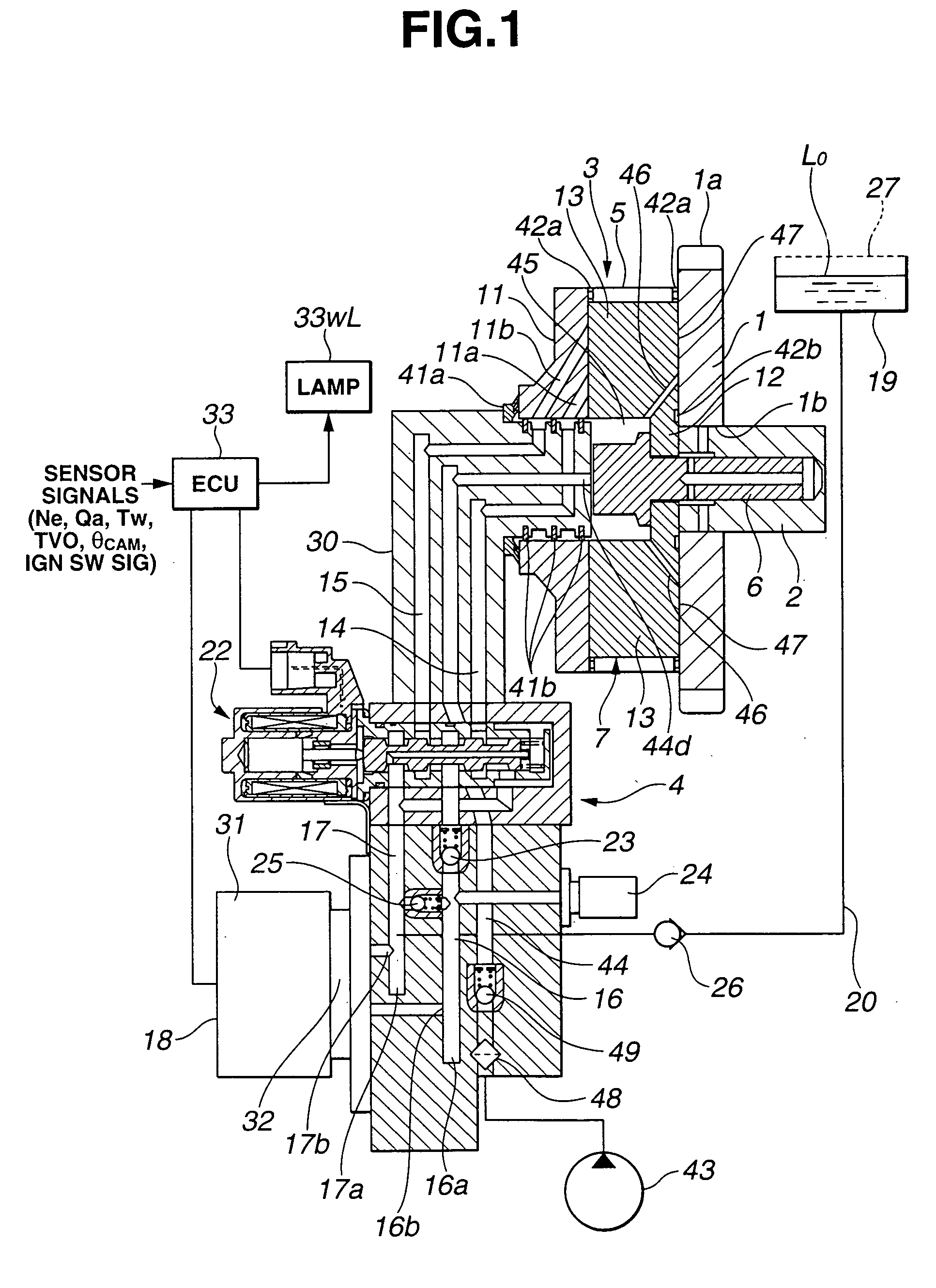

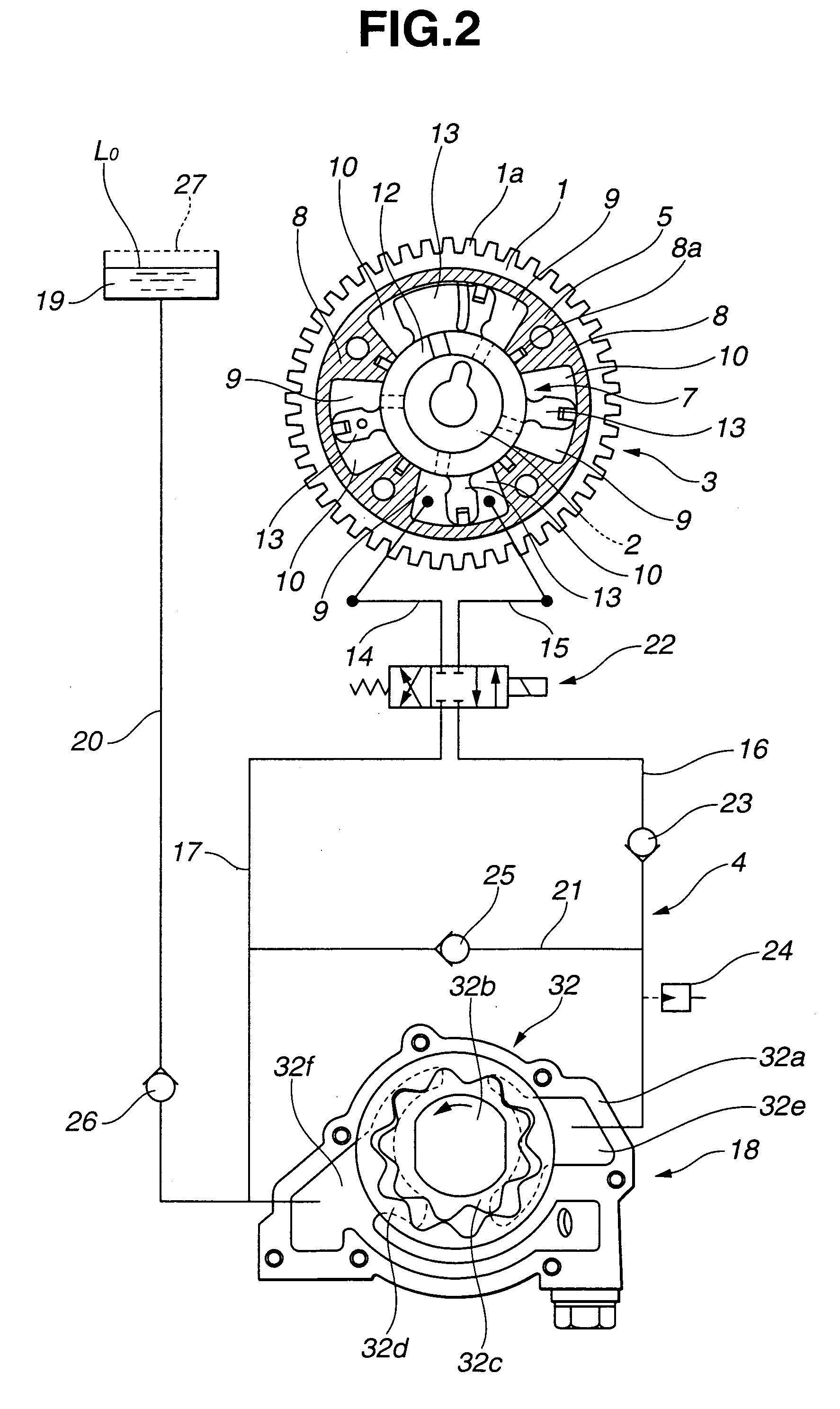

A required valve timing change rate Vreq is calculated so as to make a deviation D between a target valve timing VTtg and an actual valve timing VT small and then a required speed difference DMCRreq between a motor 26 and a camshaft 16 is calculated on a basis of the required valve timing change rate Vreq. When the deviation D is larger than a predetermined value, a required motor speed Rmreq is calculated by adding the required speed difference DMCRreq to a camshaft speed RC and a motor control value is calculated so as to control the motor speed RM to the required motor speed Rmreq. When the deviation D is not larger than the predetermined value, the camshaft speed RC is set as the required motor speed Rmreq and the motor control value is calculated so as to control the motor speed RM to the camshaft speed RC.

Owner:DENSO CORP

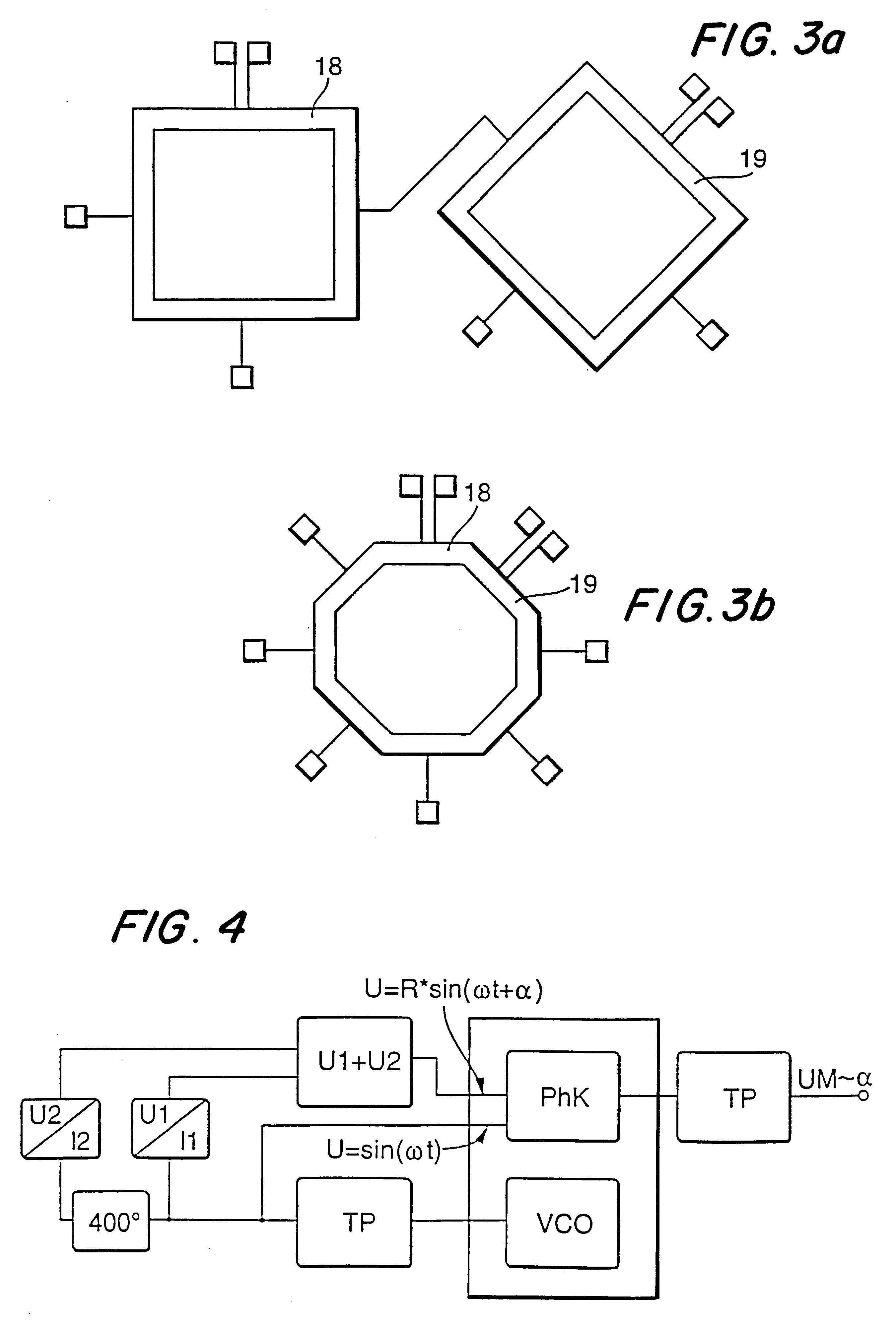

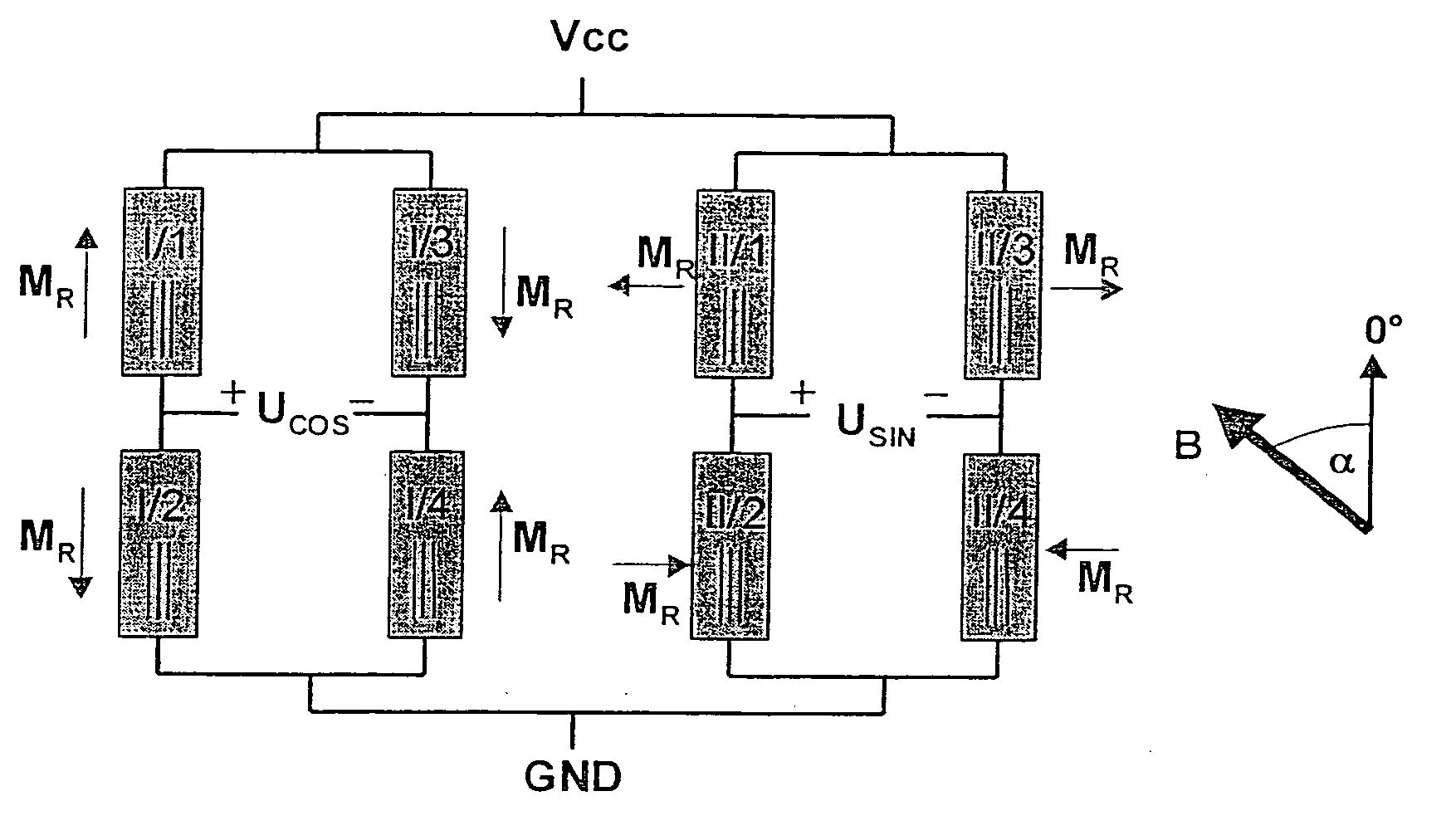

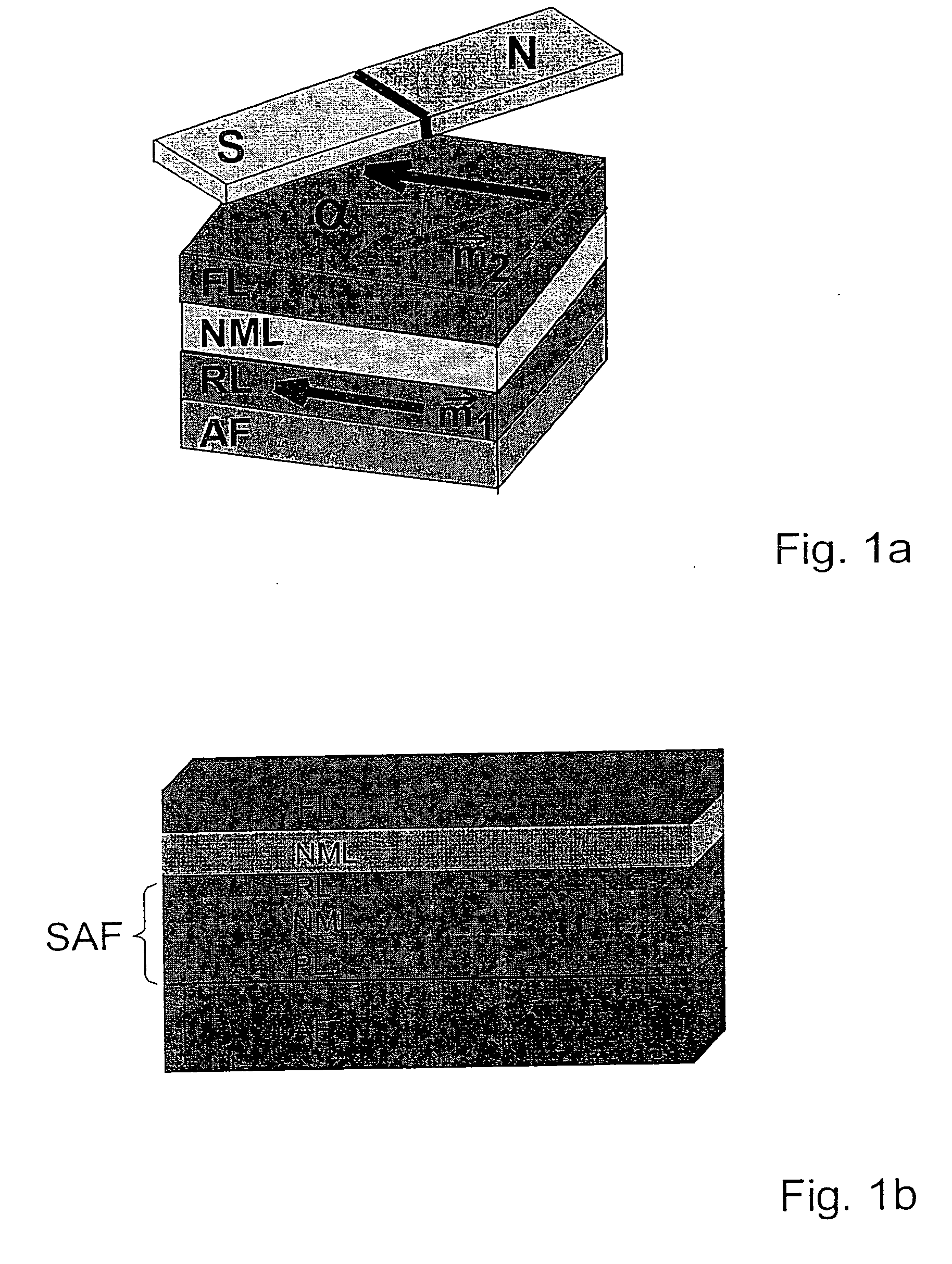

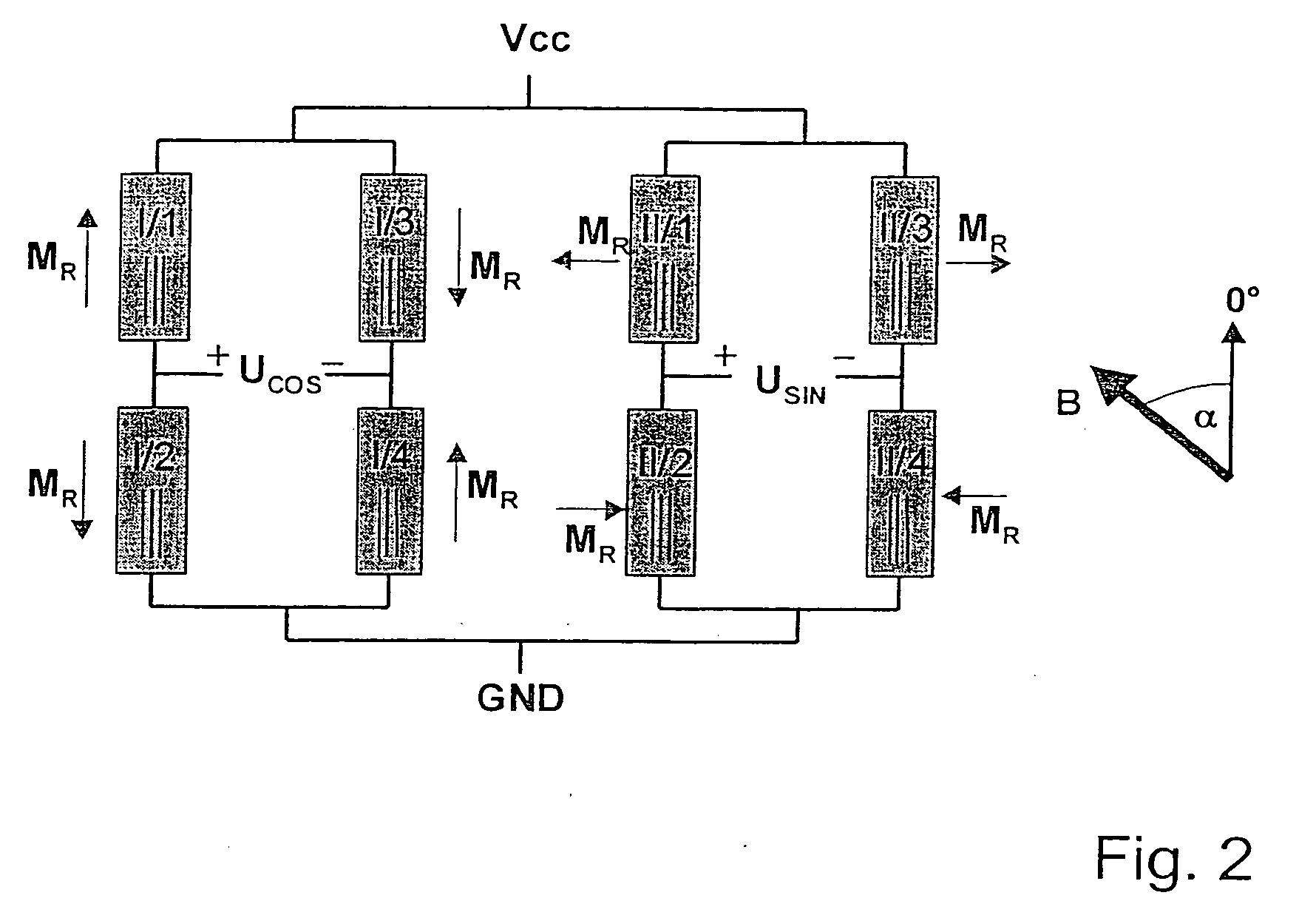

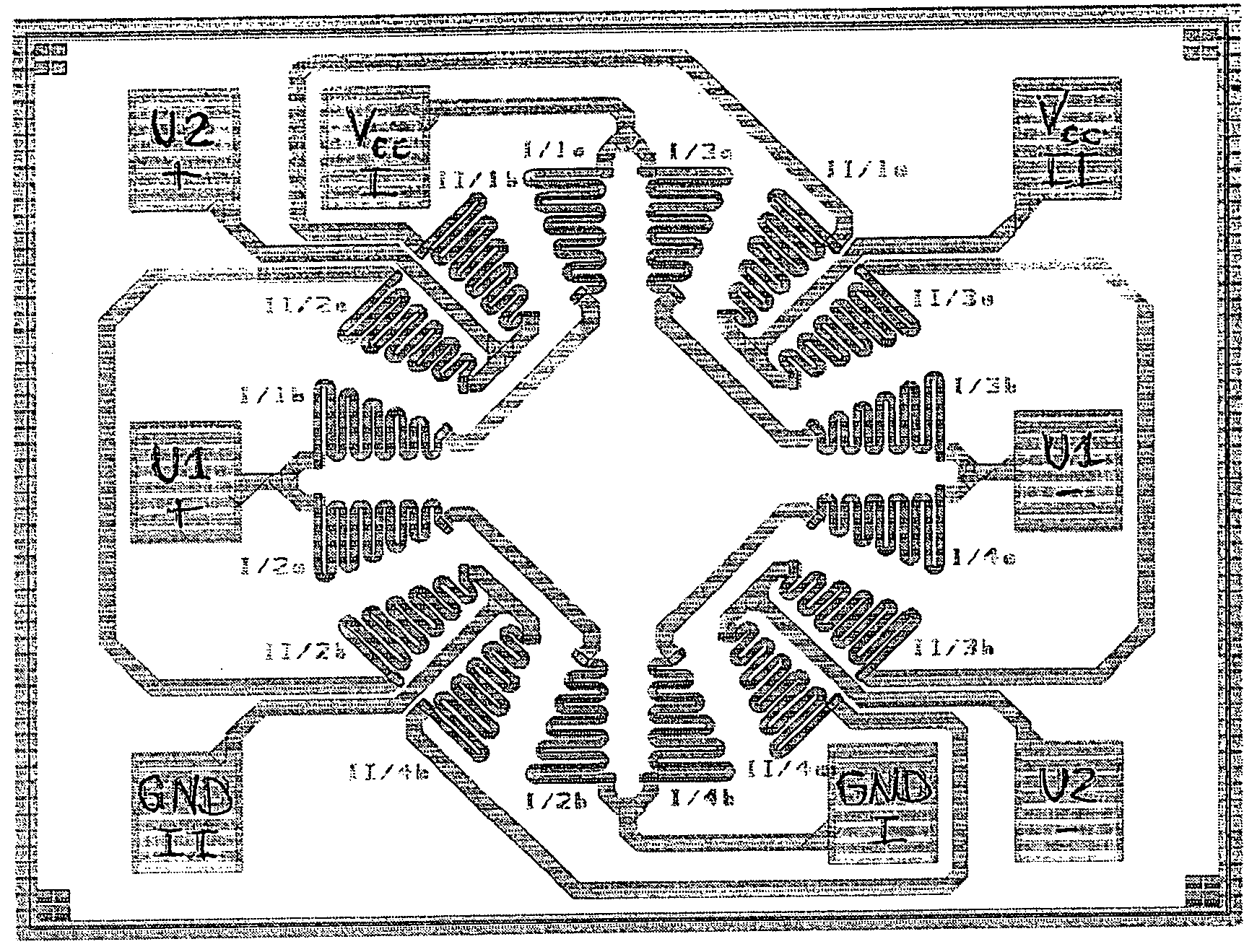

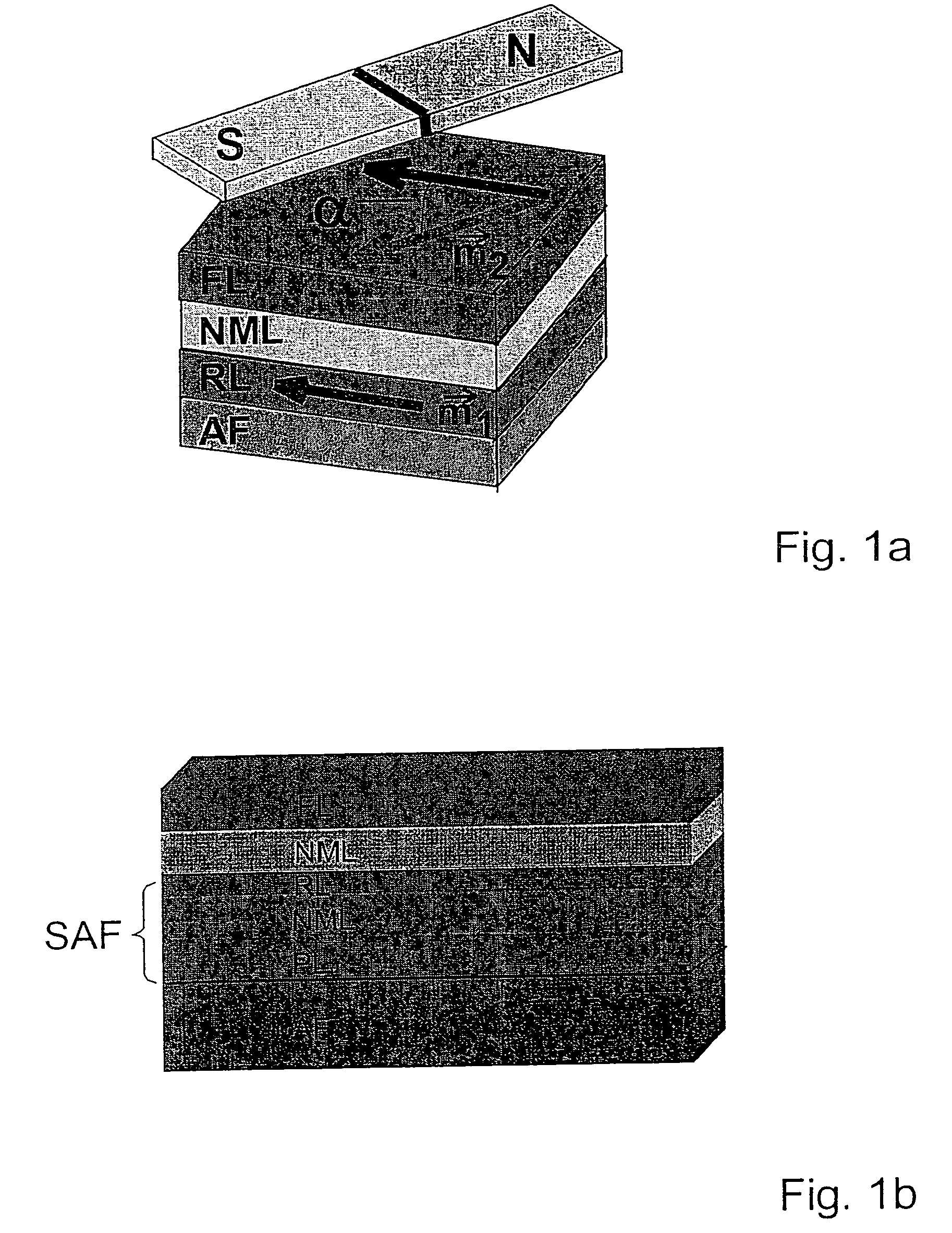

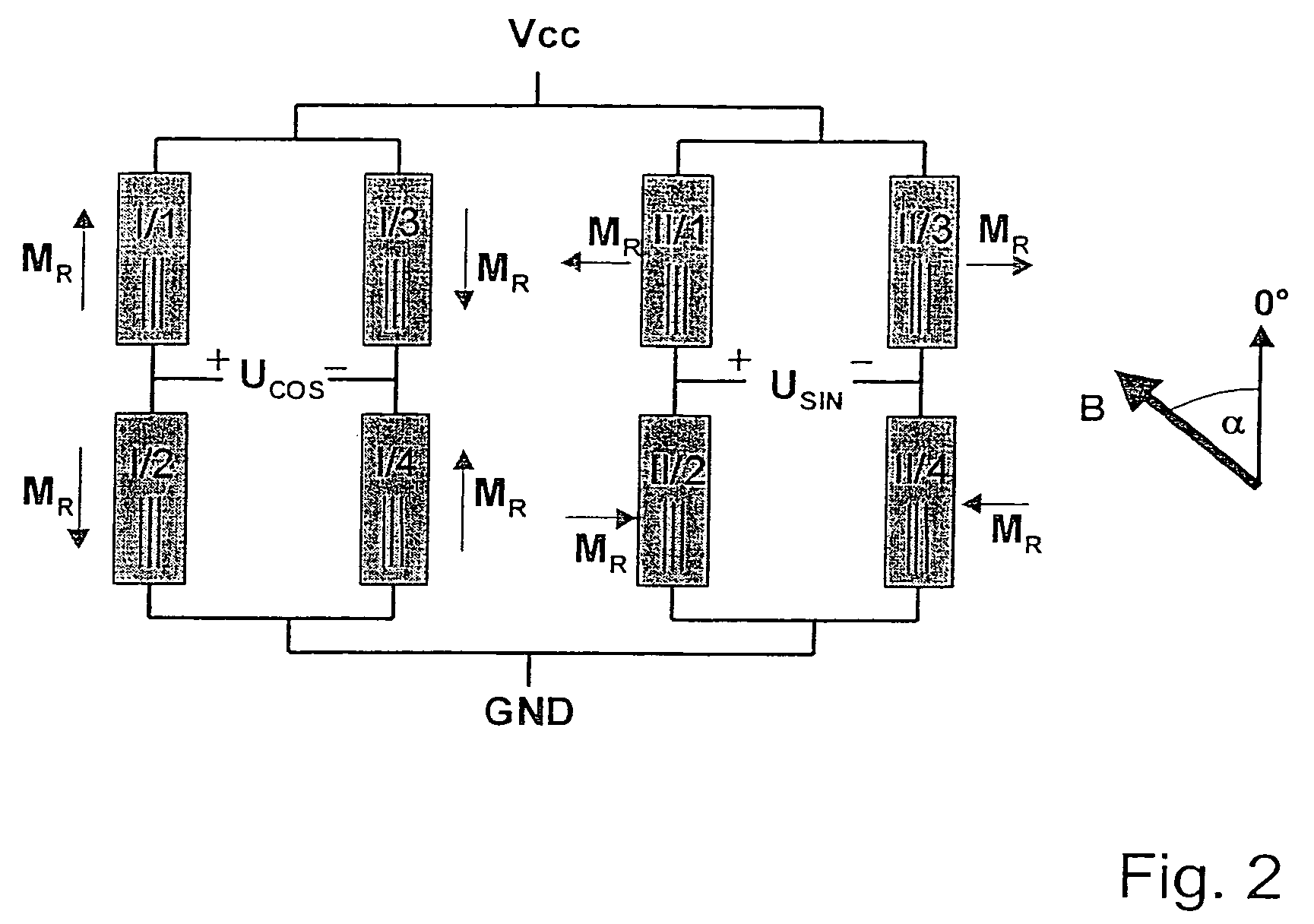

Gmr sensor element and its use

InactiveUS20060103381A1Improve long-term stabilityImprove signal stabilityValve arrangementsNanomagnetismSteering angleFull bridge

A GMR sensor element is proposed, having a rotationally symmetrical positioning of especially eight GMR resistor elements which are connected to each other to form two Wheatstone's full bridges. This GMR sensor element is especially suitable for use in an angle sensor for the detection of the absolute position of the camshaft or the crankshaft in a motor vehicle, particularly in the case of a camshaft-free engine having electrical or electrohydraulic valve timing, of a motor position of an electrically commutated motor, or of detection of a windshield wiper position, or in the steering angle sensor system in motor vehicles.

Owner:ROBERT BOSCH GMBH

Diagnostics for two-mode variable valve activation devices

ActiveUS20090228167A1Vehicle testingInternal-combustion engine testingElectricityRadio frequency signal

A method for detecting a low-lift or zero-lift failure mode in a variable valve activation system of an internal combustion engine includes the steps of positioning a piezo-electric element that acts as a radio frequency transmitter relative to a lost motion spring of a two-mode variable valve activation lost motion device, subjecting the piezo-electric element to a compression load when a load from displacement of a lobe of a camshaft acts on the lost motion spring, broadcasting a radio frequency signal each time the piezo-electric element is subjected to the compression load, and evaluating the presence or absence of the broadcasted radio frequency signal in relation to an expected presence or absence of the radio frequency signal. The direct measurement of the mode of each two-mode device is both more reliable and more efficient in the use of engine controller resources compared to currently existing diagnostic methods.

Owner:DELPHI TECH IP LTD

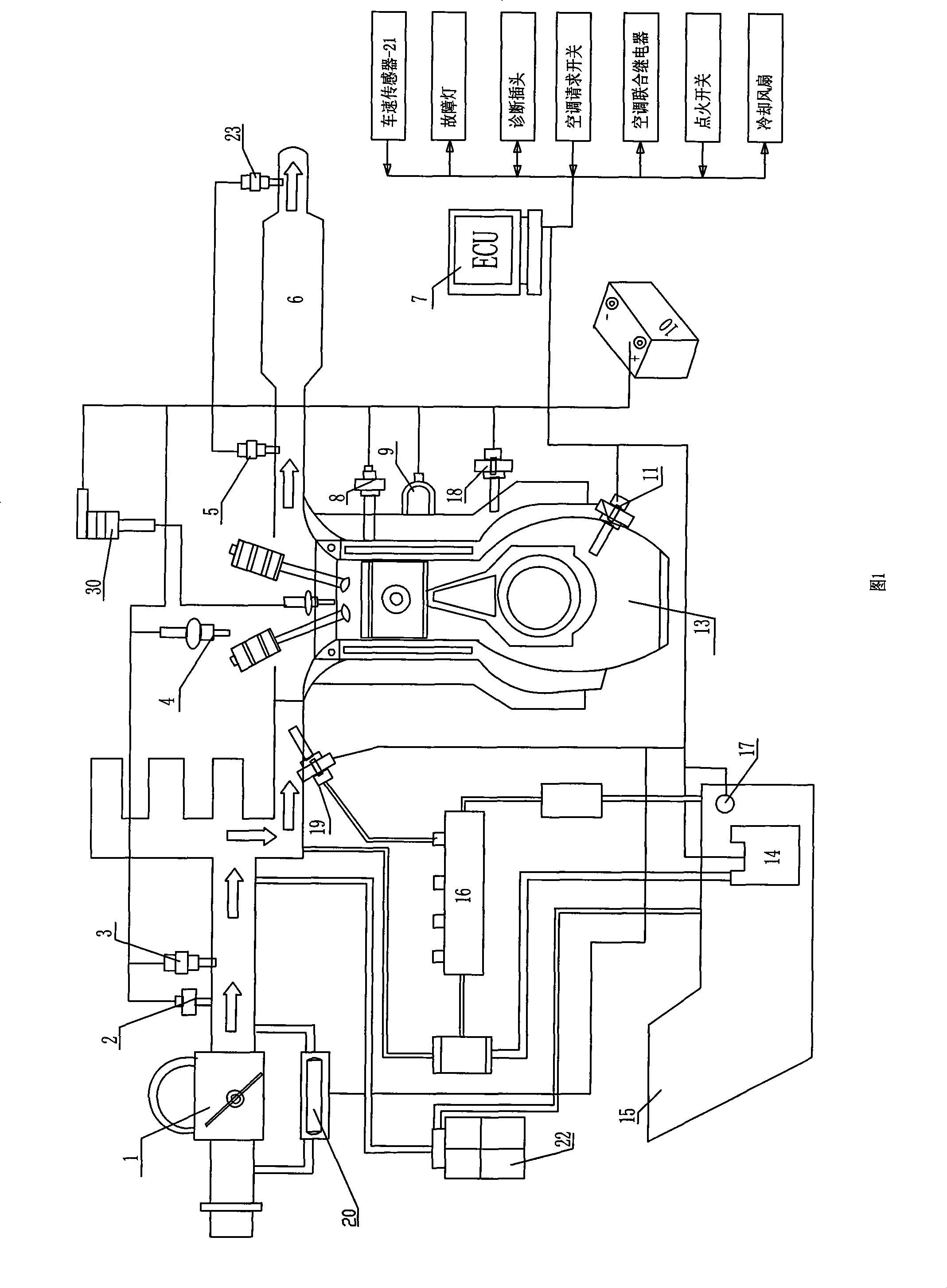

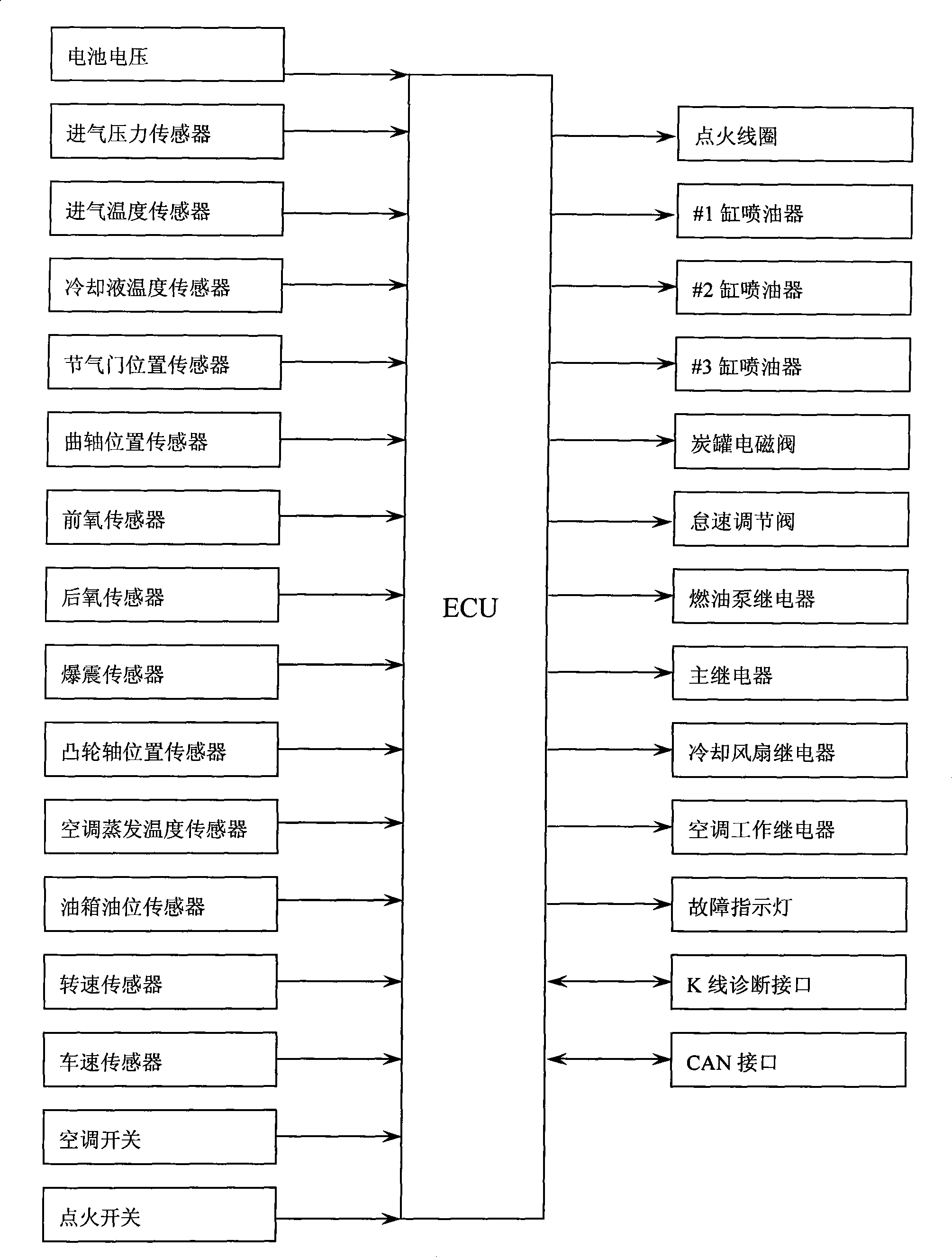

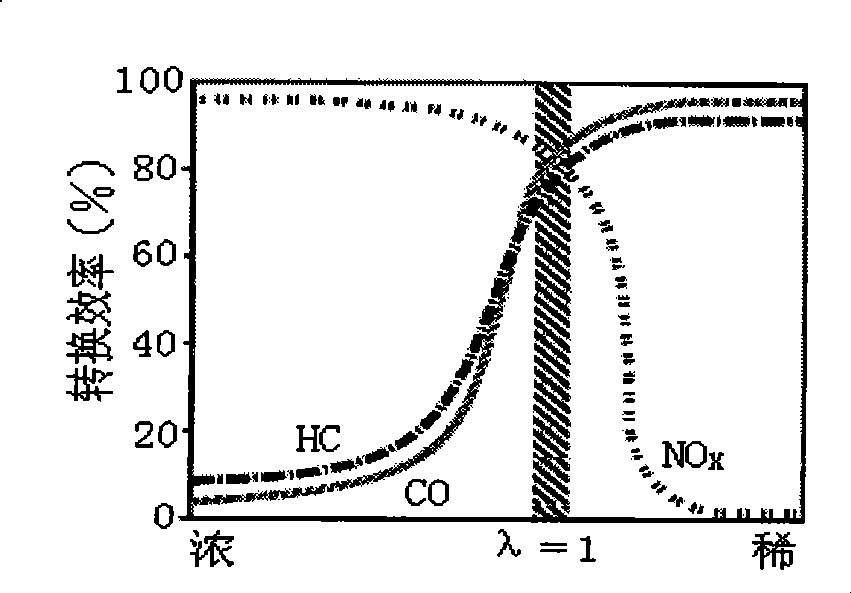

Electric-controlled petrol engine work system

InactiveCN101363380ARich control functionsGood control function integration performanceElectrical controlMachines/enginesIdle speed controlIgnition coil

The invention provides a work system of an electronically controlled gasoline engine, comprising an air intake system, a fuel oil supply system, an ignition system as well as an electronic control system; the electronic control system consists of a sensor section, an electronic control unit ECU and an actuator section, wherein, the sensor section includes a throttle position sensor, an intake pressure and temperature sensor and an intake temperature sensor which are arranged on an intake pipe of an intake system, a camshaft position sensor, a coolant temperature sensor and a crankshaft position sensor which are arranged on the engine, a front oxygen sensor arranged in front of a three-way catalyst converter on an exhaust pipe of the engine, and the components of the sensor section are all connected with the ECU, and the actuator section consists of an electric fuel pump, an oil sprayer, an idle speed regulating valve and an ignition coil; the components of the actuator section are all connected with the ECU, and the ECU includes a fuel injection control program, an ignition control program and an idle speed control program; the system adopts reasonable control strategy and has comprehensive control function, good integrated performance of control function and fine system portability.

Owner:张和君 +1

GMR sensor element and its use

InactiveUS7312609B2Reduce sensitivityUndesired AMR signal contributionValve arrangementsNanomagnetismMobile vehicleSteering angle

A GMR sensor element is proposed, having a rotationally symmetrical positioning of especially eight GMR resistor elements which are connected to each other to form two Wheatstone's full bridges. This GMR sensor element is especially suitable for use in an angle sensor for the detection of the absolute position of the camshaft or the crankshaft in a motor vehicle, particularly in the case of a camshaft-free engine having electrical or electrohydraulic valve timing, of a motor position of an electrically commutated motor, or of detection of a windshield wiper position, or in the steering angle sensor system in motor vehicles.

Owner:ROBERT BOSCH GMBH

Overhead rotary valve for engines

InactiveUS6308677B1Simple sealing deviceImprove sealingMachines/enginesRotary slide valveCombustion chamberExhaust valve

An overhead rotary valve fitted into a cylinder head with diametrical polygonal openings formed therein for use in combination with an internal combustion engine, driven to bring intake and exhaust ports into and out of alignment with passages leading to and from the combustion chamber. Sleeve bearings are fitted in the cylinder head that provide surface sealing, and annular sealing members prevent the air / fuel mixture or exhaust gases from flowing into regions intermediate ports and individual cylinders. Utilizing this overhead rotary valve and associated seals and bearings increases the efficiency and performance of an internal combustion engine. The overhead rotary valve rotating, at one quarter the speed of the crankshaft, minimizes wear and noise levels, self cleans the ports, allows the engine to operate at higher rpm and imparts proper opening and closing of passages at the proper sequence of valve timing without concern of valve float. The instant invention removes the need for reciprocating intake and exhaust valves, camshafts, rocker arms, lifters, push rods, valve guides and retainers, and other related hardware for actuation, significantly increasing the reliability and effectiveness of the internal combustion engine, while reducing overall manufacturing costs.

Owner:BOHACH WILLIAM LOUIS +1

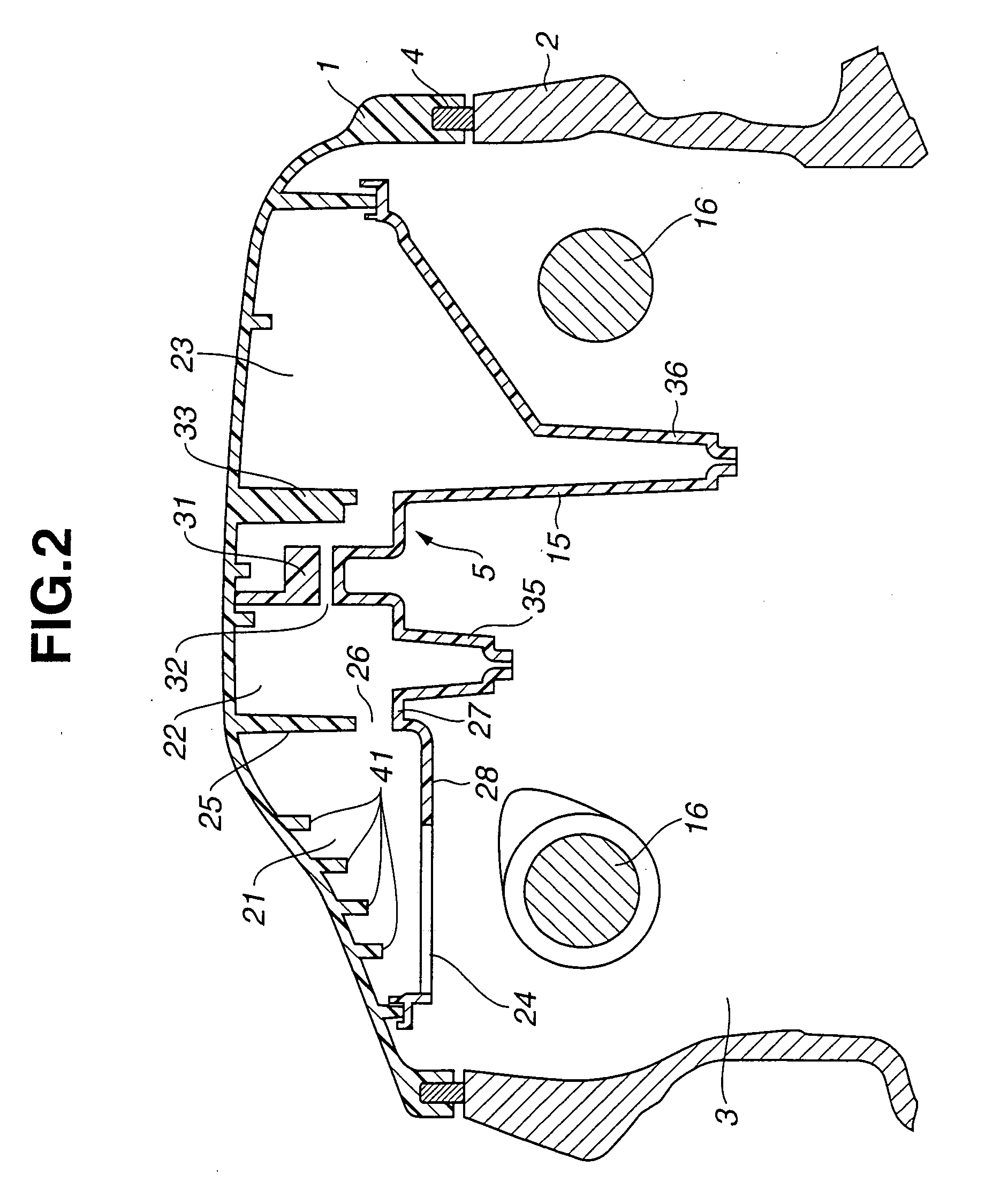

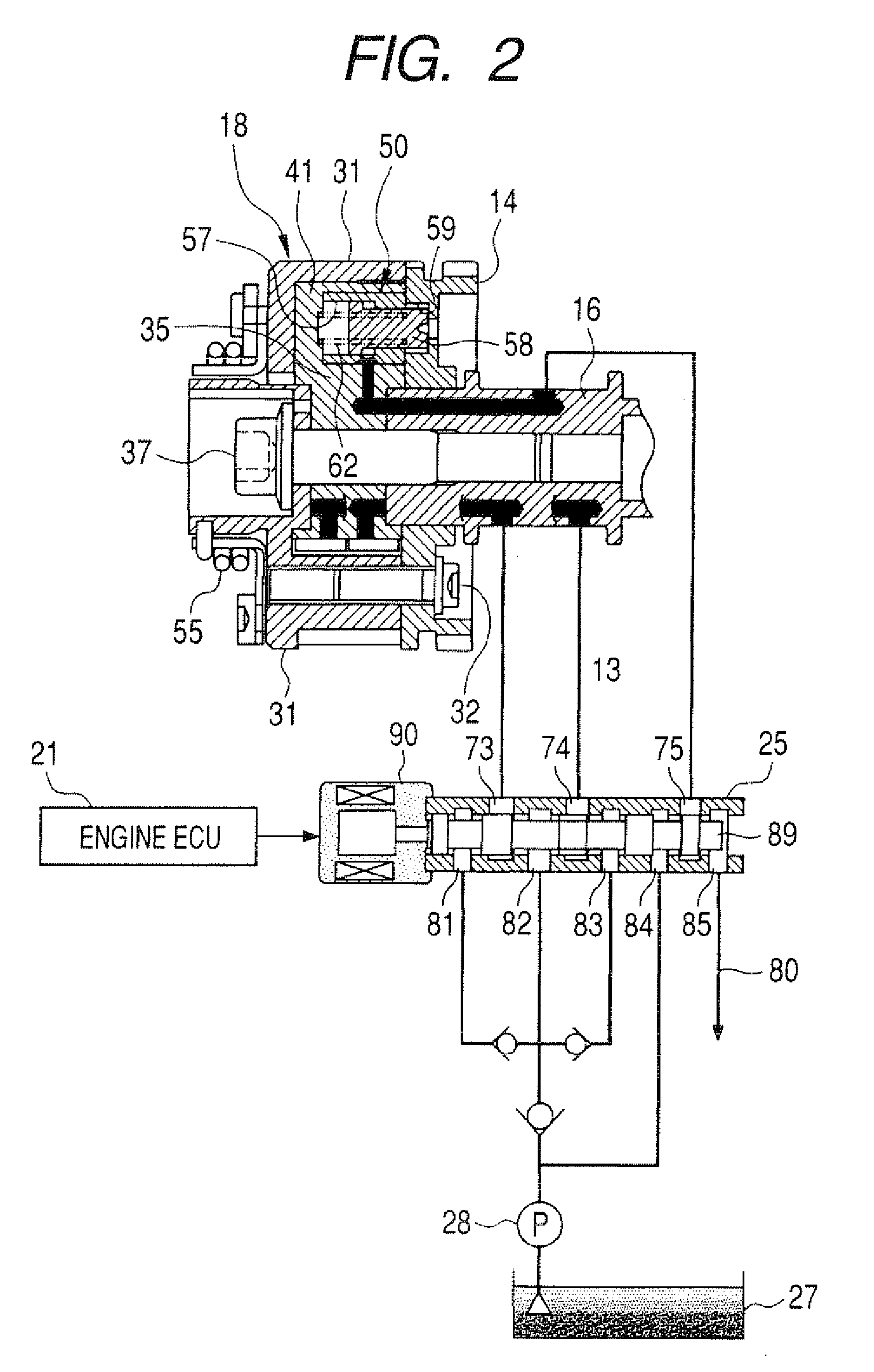

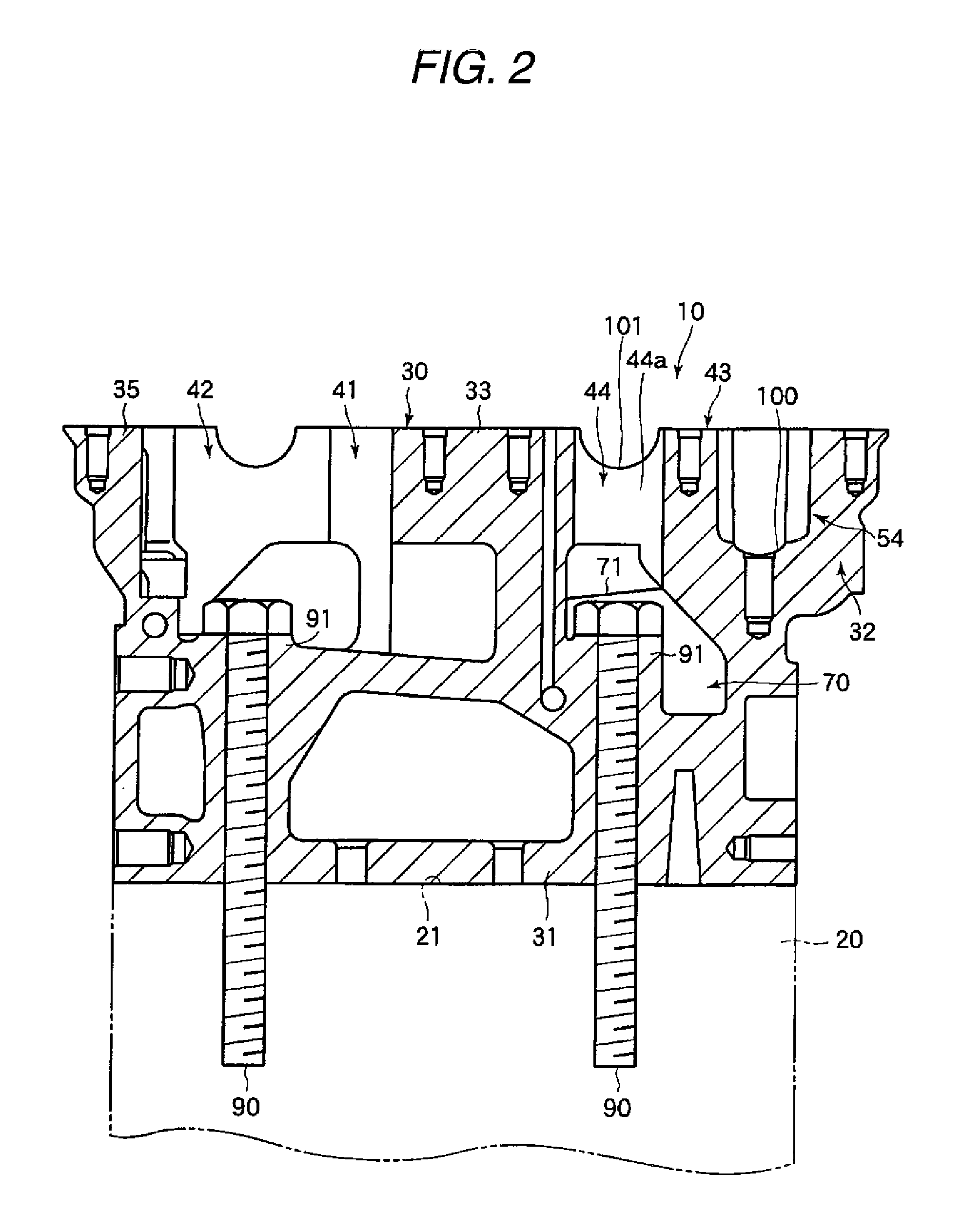

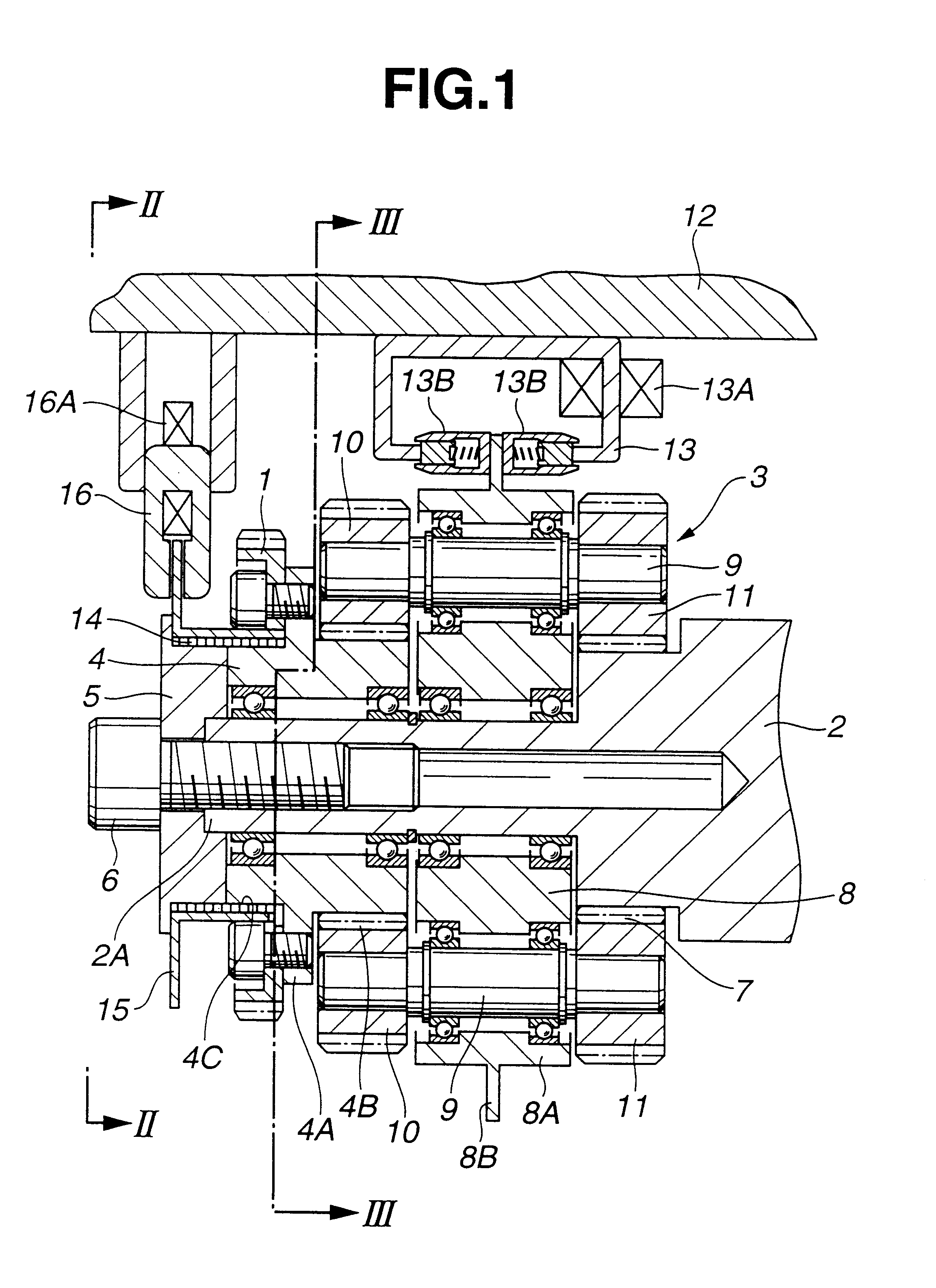

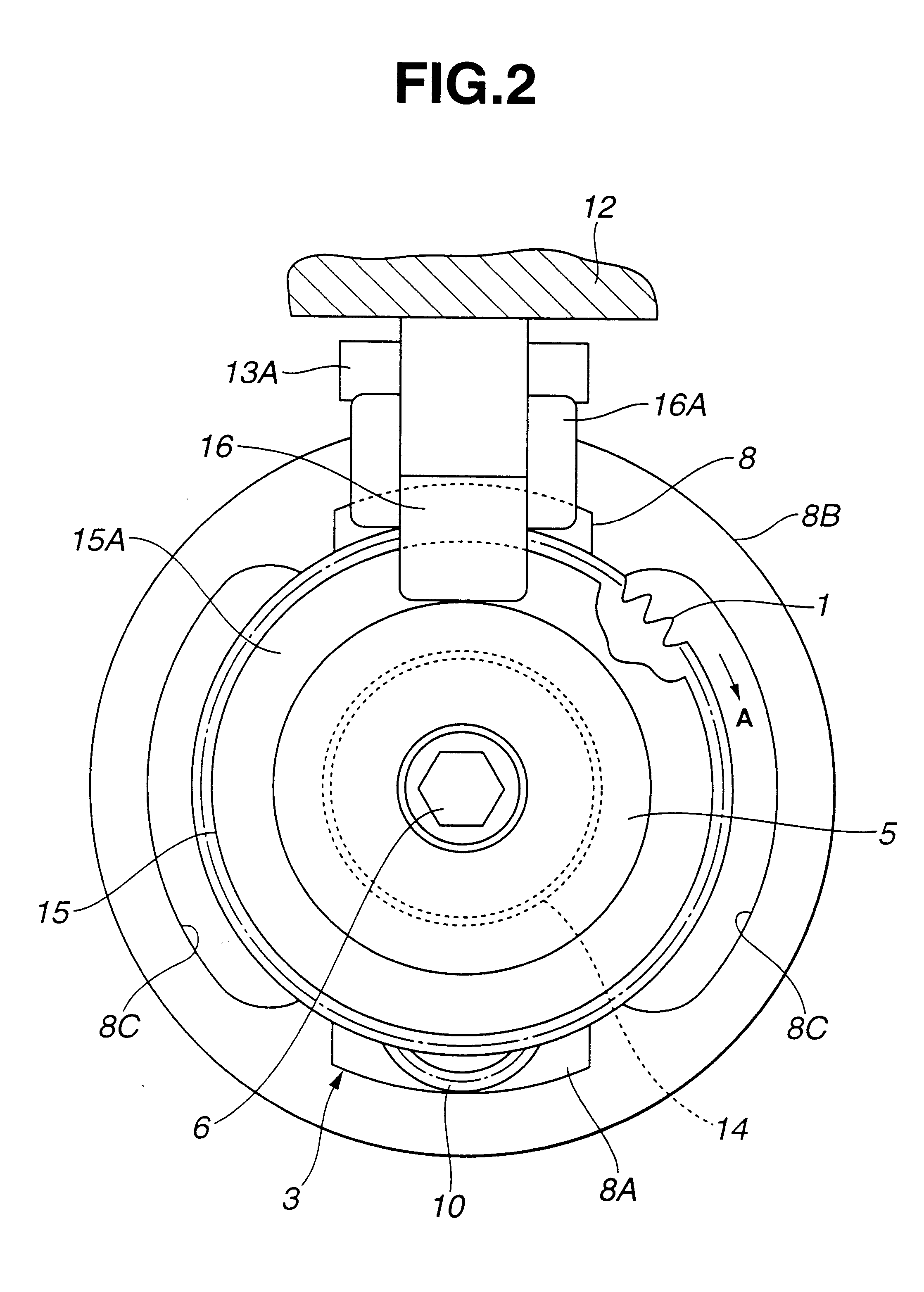

Valve timing adjusting apparatus

A valve timing adjusting apparatus for an internal combustion engine having a bearing includes a camshaft, a housing, a vane rotor, a control valve, and a fastening member. The fastening member is mounted on an axial end portion of the camshaft on a side of the vane rotor opposite from the bearing. The vane rotor is coaxially fastened to the camshaft between the fastening member and a step portion, which is provided to the camshaft on a side of the bearing. A sleeve of the control valve is coaxially received in an axial hole of the camshaft, which opens at an end surface of the end portion of the camshaft. Each of the advance output port and the retard output port is communicated with a corresponding one of the advance chamber and the retard chamber through the camshaft.

Owner:DENSO CORP

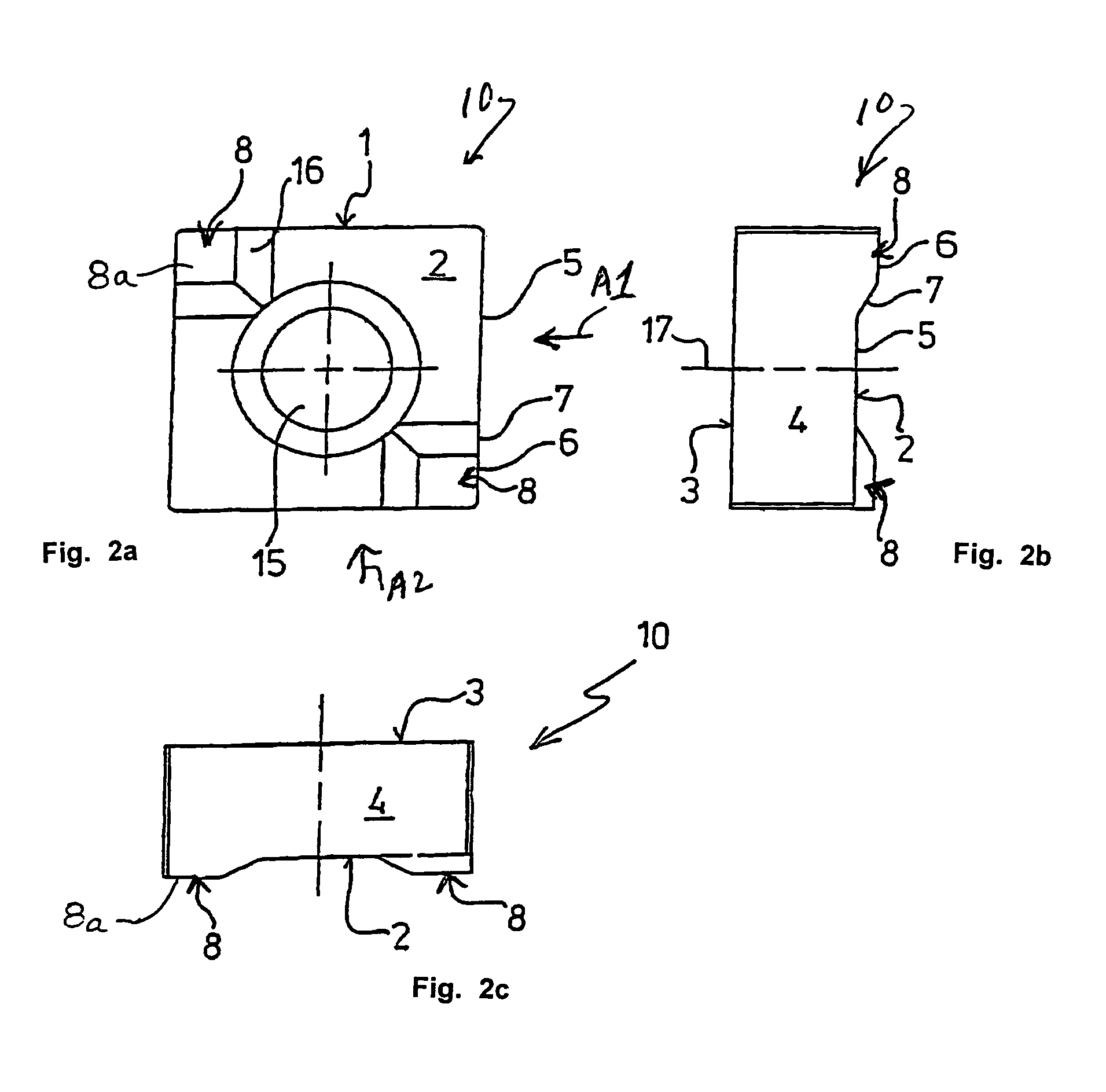

Cutting insert and cutting insert holder therefor

A milling cutter for machining camshafts includes a rotary disc and an annular row of cutting bits mounted in pockets formed in the disc. Each cutting bit includes a top surface having a pair of diagonally spaced raised portions. Cutting edges are formed where the top surface and the raised portions intersect side surfaces of the bit. The pockets are arranged along an edge of the disc where a cylindrical outer periphery of the disc intersects an end face of the disc. Each pocket is configured with an internal cavity for receiving a raised portion of an inactive cutting portion of the respective bit.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

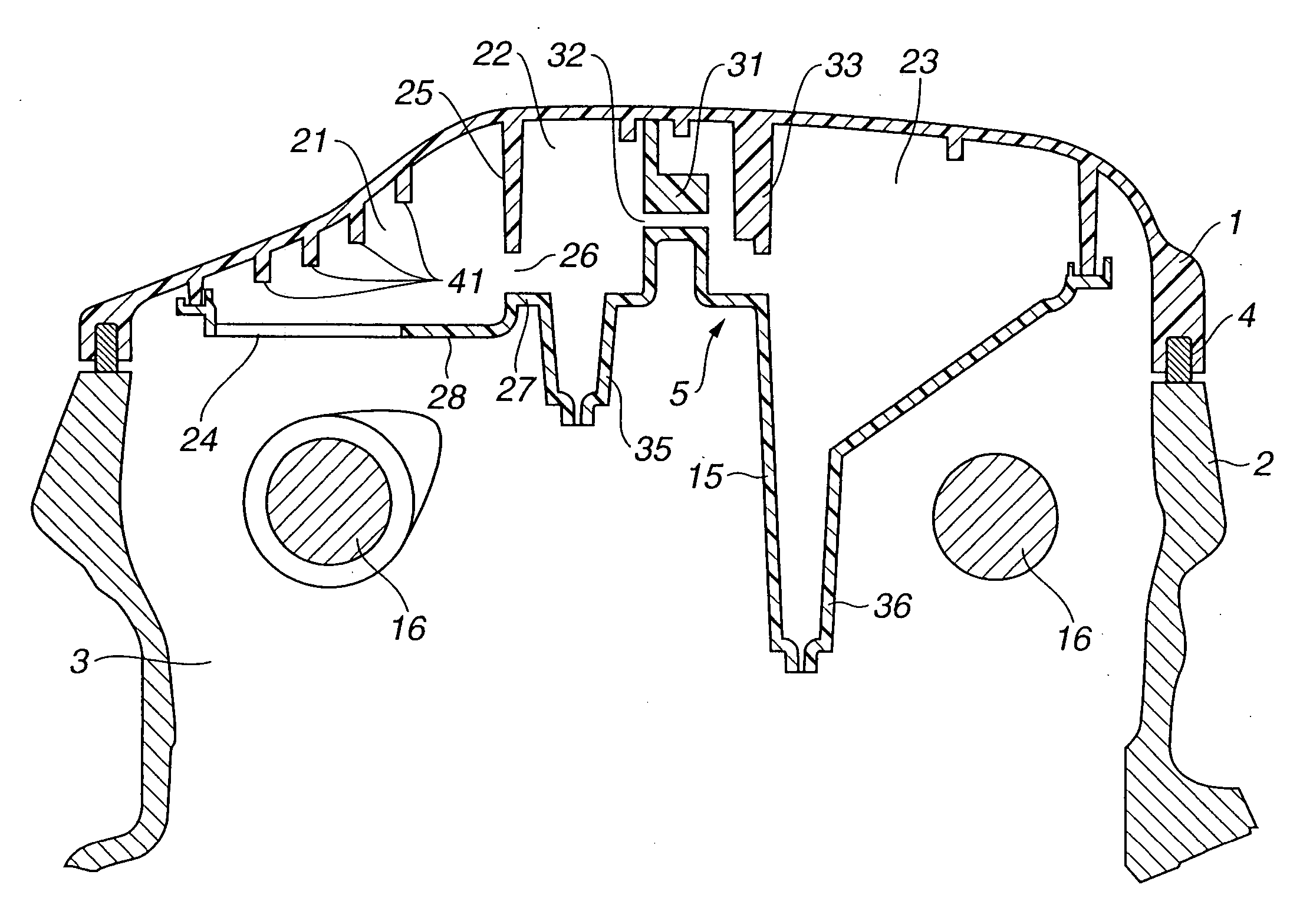

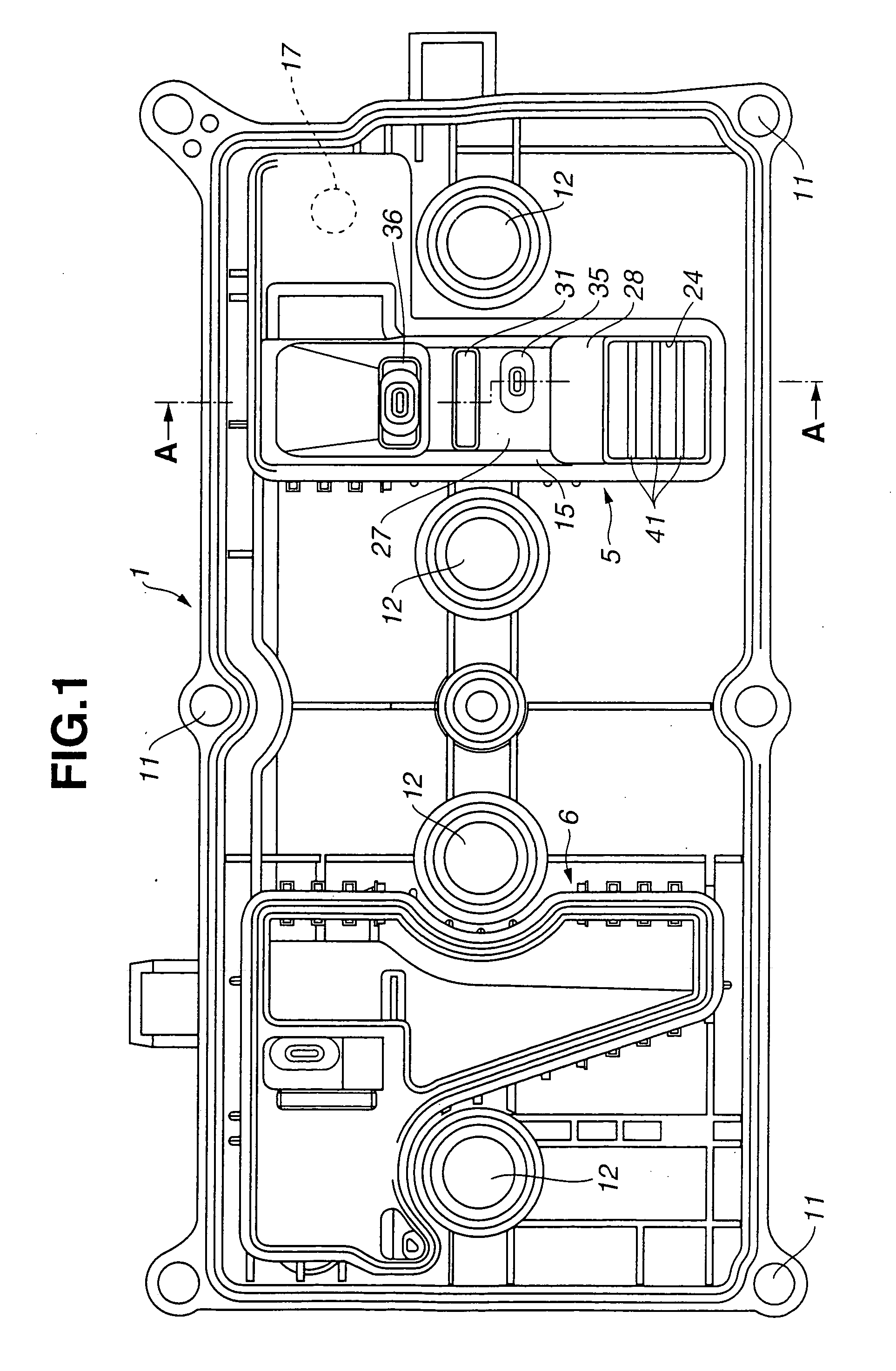

Oil separator combined with cylinder head cover

InactiveUS20050092267A1Effectively overcome drawbacksReduce the overall heightCasingsLubrication of auxillariesCylinder headEngineering

An oil separator provided in combination with a cylinder head cover of an internal combustion engine. The oil separator includes a separator cover fixed to an inner surface of the cylinder head cover defining a space extending in a first direction perpendicular to axis of a camshaft in plan, between the separator cover and the cylinder head cover. The separator cover has an opening through which the space is opened to a valve operating chamber. A partition wall is provided to define in the space an inlet-side separator chamber and an outlet-side separator. The partition wall extends in a second direction parallel with the axis of the camshaft and being formed with a plurality of fine passages. Additionally, a plurality of projection walls project from a part of the inner surface of the cylinder head cover which faces the valve operating chamber through the opening.

Owner:MAHLE FILTER SYST JAPAN CORP

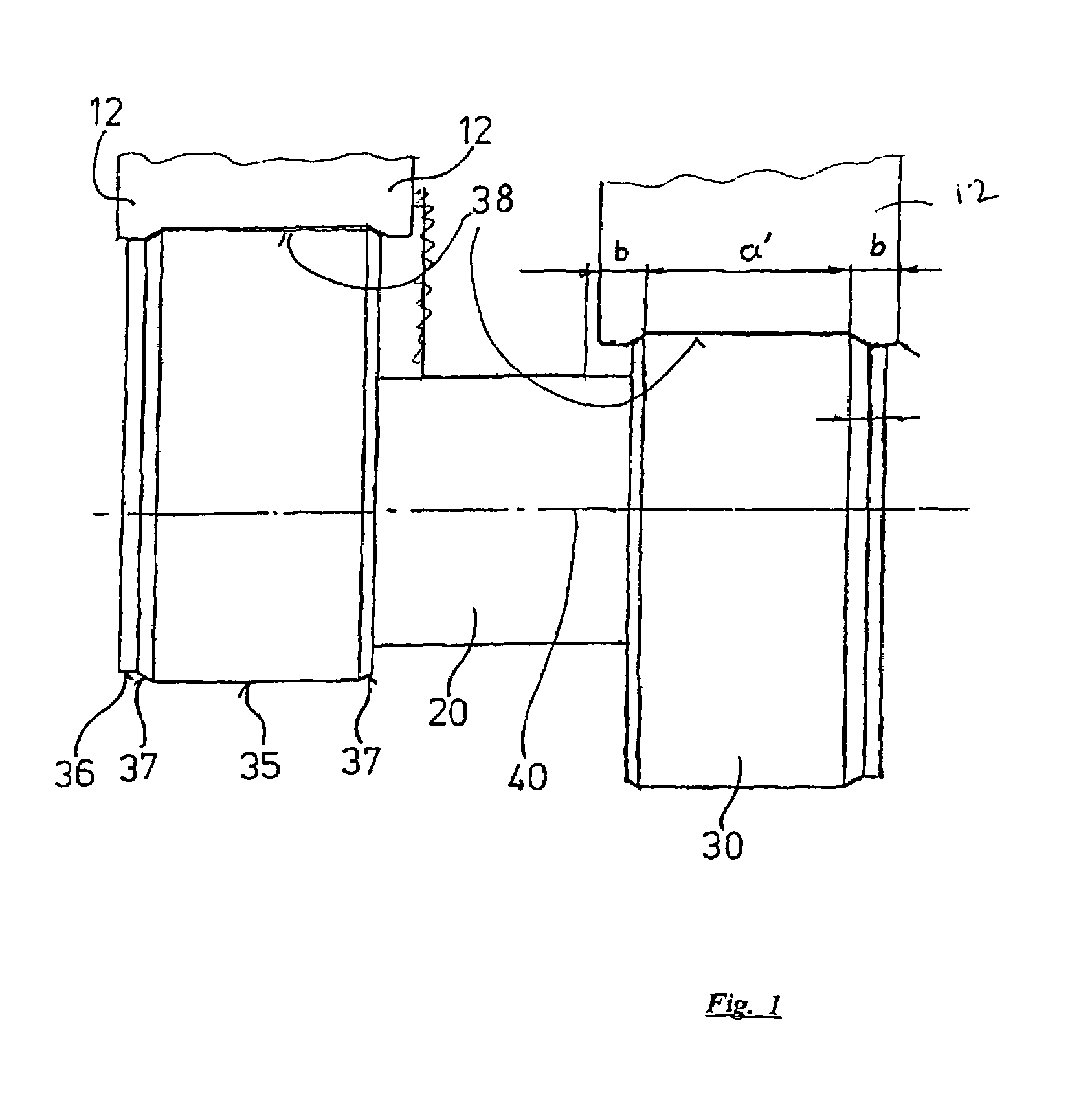

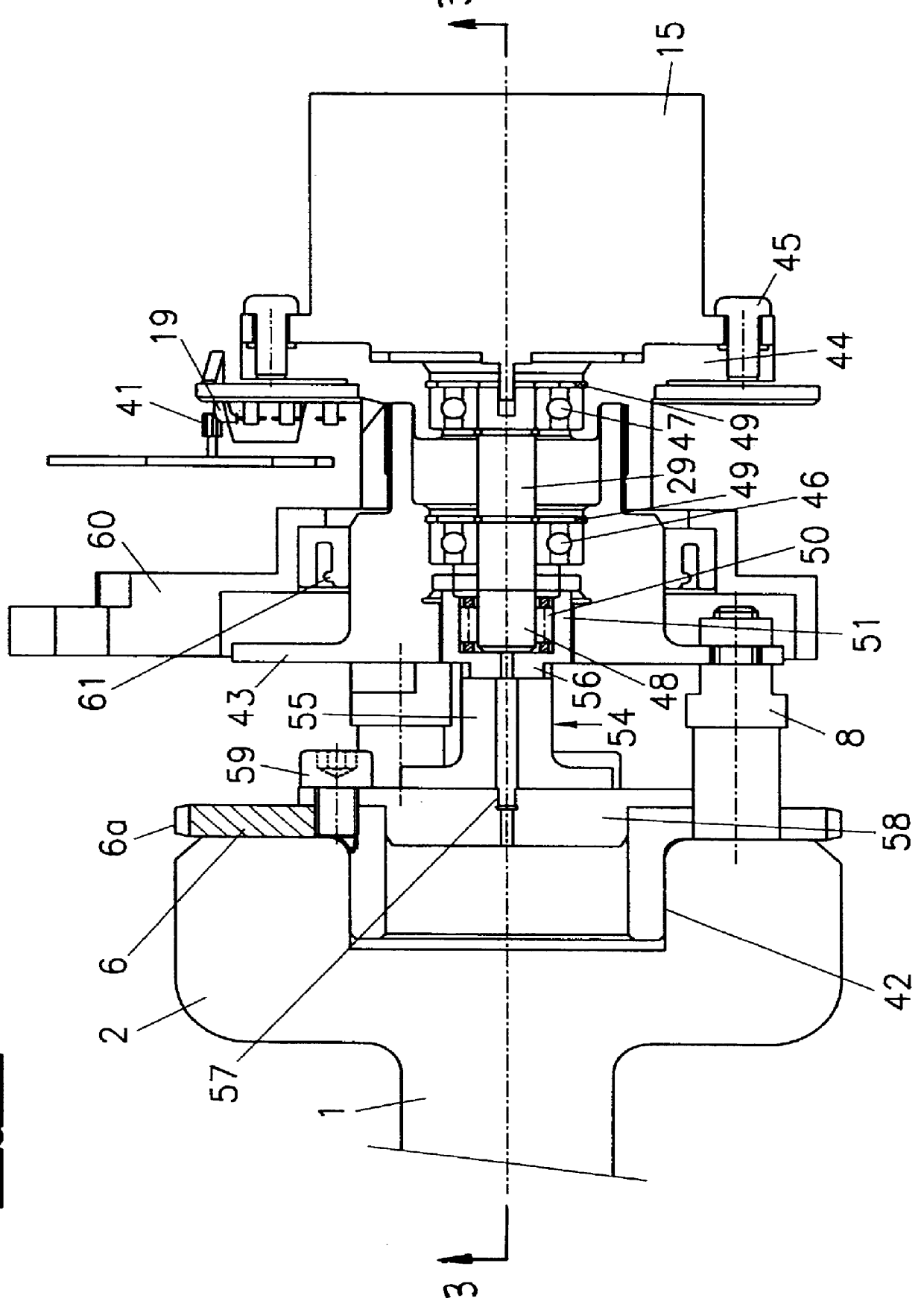

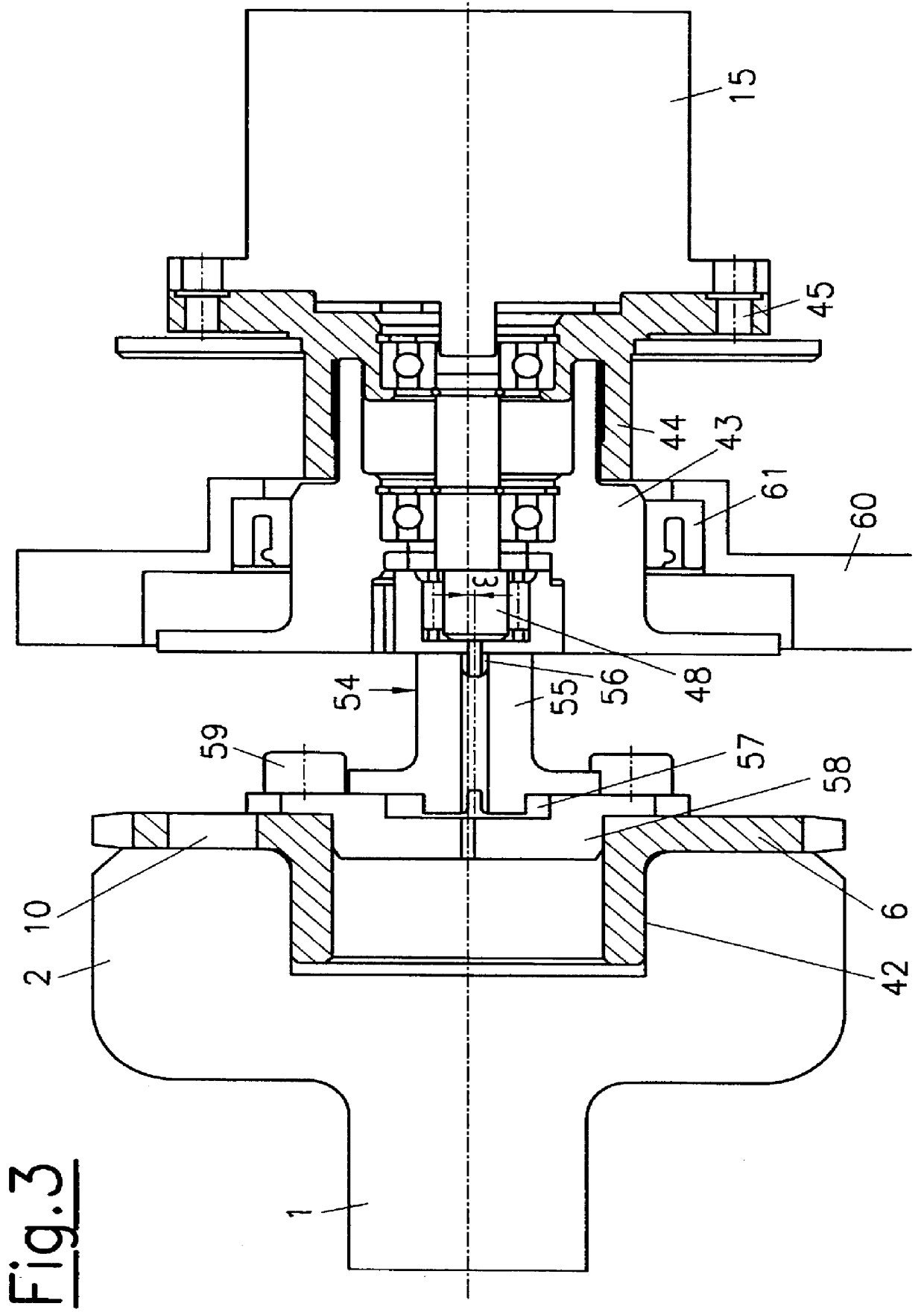

Device for adjusting the phase angle of a camshaft of an internal combustion engine

InactiveUS6138622ASimple designSmall sizeValve drivesMachines/enginesGear wheelExternal combustion engine

A device for adjusting the phase angle of a camshaft of an internal combustion engine includes an adjusting mechanism which is operated by an electric motor, the latter being rigidly connected to the camshaft or the camshaft drive gear. Reliable adjustment is obtained in a simple manner by providing the adjusting mechanism as a planetary gear set.

Owner:TCG UNITECH AKTIENGES

Variable valve timing control apparatus for internal combustion engine

ActiveUS20100269772A1Rapidly and smoothly accomplishedAvoid lostValve arrangementsMachines/enginesVariable valve timingEngineering

Owner:DENSO CORP

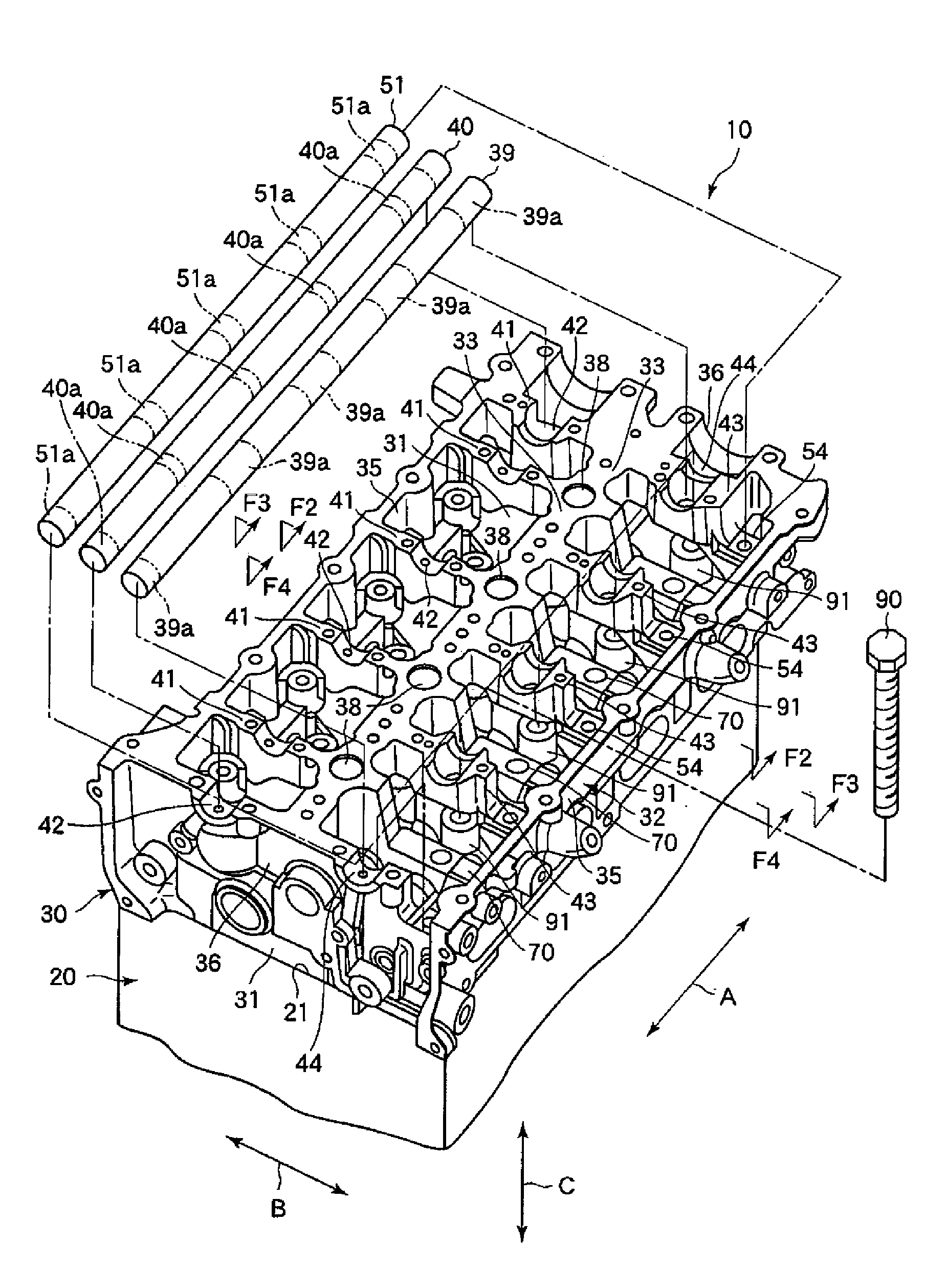

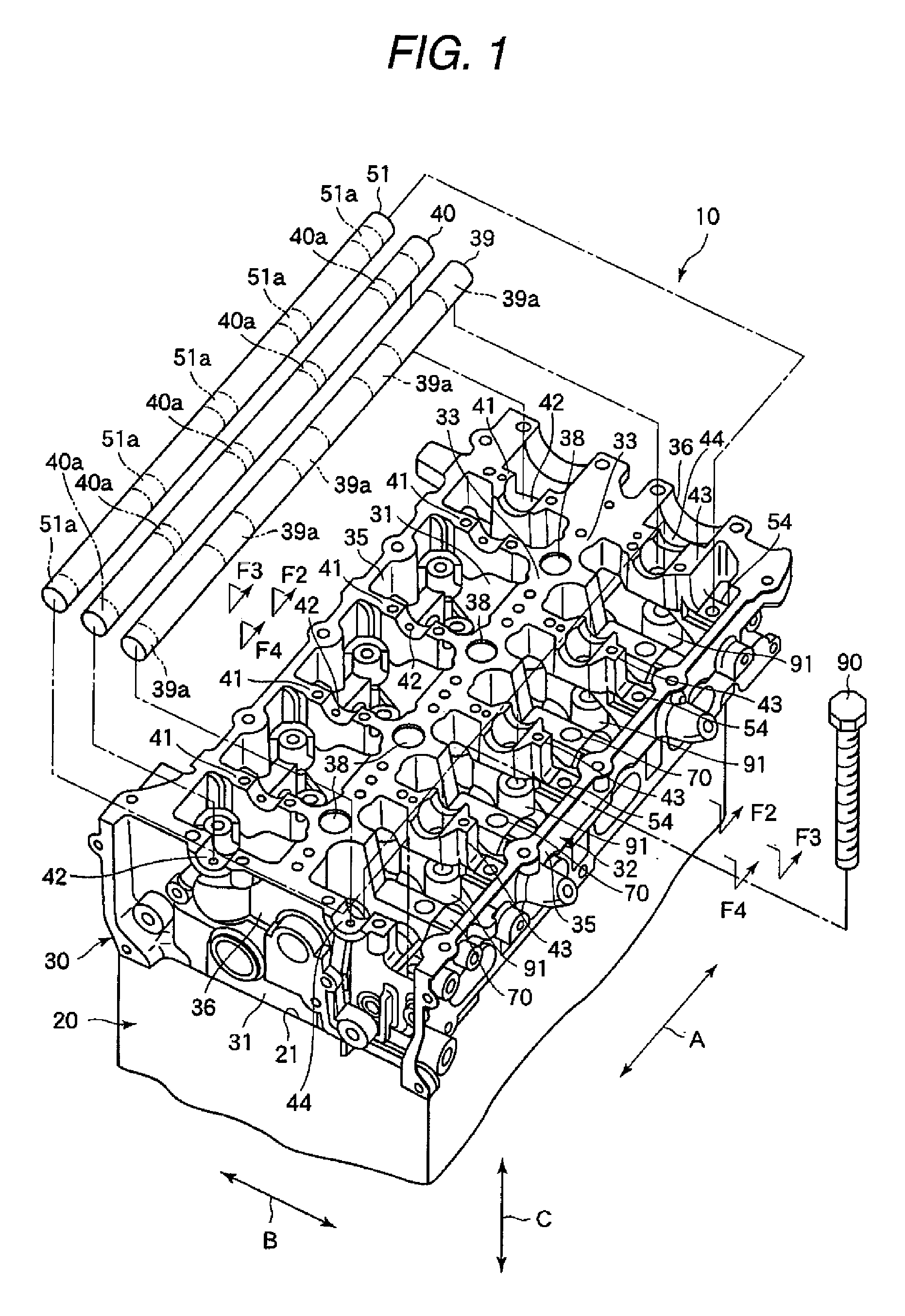

Cylinder head

A cylinder head includes: a bottom wall portion; an outer circumferential wall portion defining inside thereof a disposition space where valves which open and close combustion chambers, rocker arms, a camshaft which actuates the rocker arms, and a rocker arm shaft which supports the rocker arms are disposed; a longitudinal wall portion; a lateral wall portion, integrally formed with the longitudinal wall portion and the outer circumferential wall portion; a camshaft support portion, formed on the lateral wall portion; a rocker arm shaft support portion, formed on the lateral wall portion in such a manner that a height position of the rocker arm shaft is shifted from a height position of the camshaft; and a head bolt boss portion, formed on the bottom wall portion in such a manner as to overlap the lateral wall portion in a height direction. The lateral wall portion includes a passage portion through which a head bolt is passed into the head bolt boss portion and which overlaps the head bolt boss portion in the height direction.

Owner:MITSUBISHI MOTORS CORP

Hydraulic detent for a variable camshaft timing device

InactiveUS6666181B2Quickly reachImprove vibrationValve arrangementsOscillating piston enginesDetentEngineering

A phaser which includes a housing and a rotor disposed to rotate relative to each other is provided. The housing has at least one cavity disposed to be divided by a vane rigidly attached to the rotor. The vane divides the cavity into a first chamber and a second chamber. The phaser further includes passages connecting the first and the second chamber, thereby facilitating the oscillation of the vane within the cavity. The phaser includes: a) a valve disposed to form at least two openings for fluid flowing between the first chamber and the second chamber and being disposed to keep at least one opening closed; and b) at least one by-pass disposed to stop or slow down the rotation between the housing and the rotor, thereby allowing a locking mechanism to lock the housing and the rotor together independent of fluid flow.

Owner:BORGWARNER INC

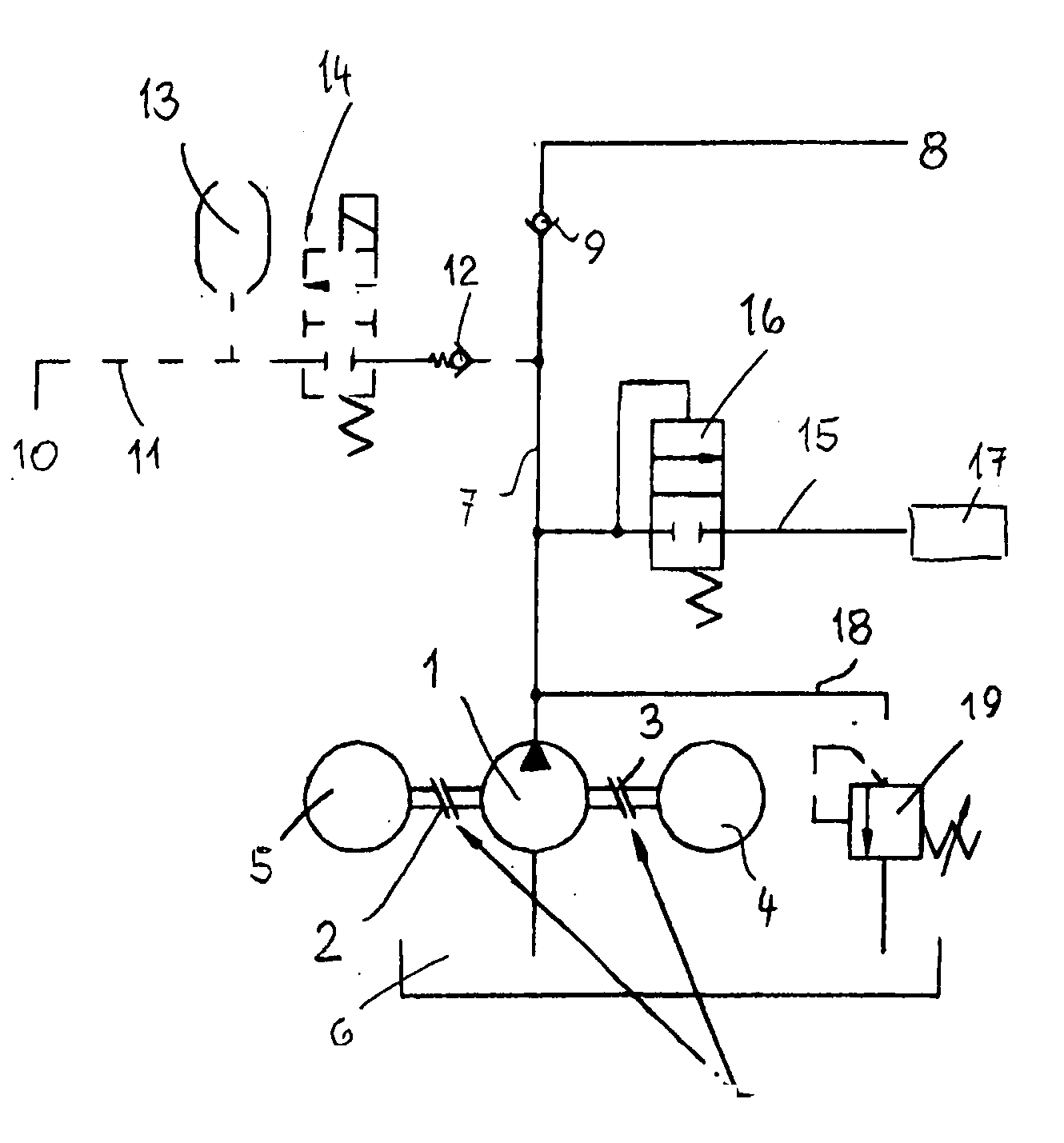

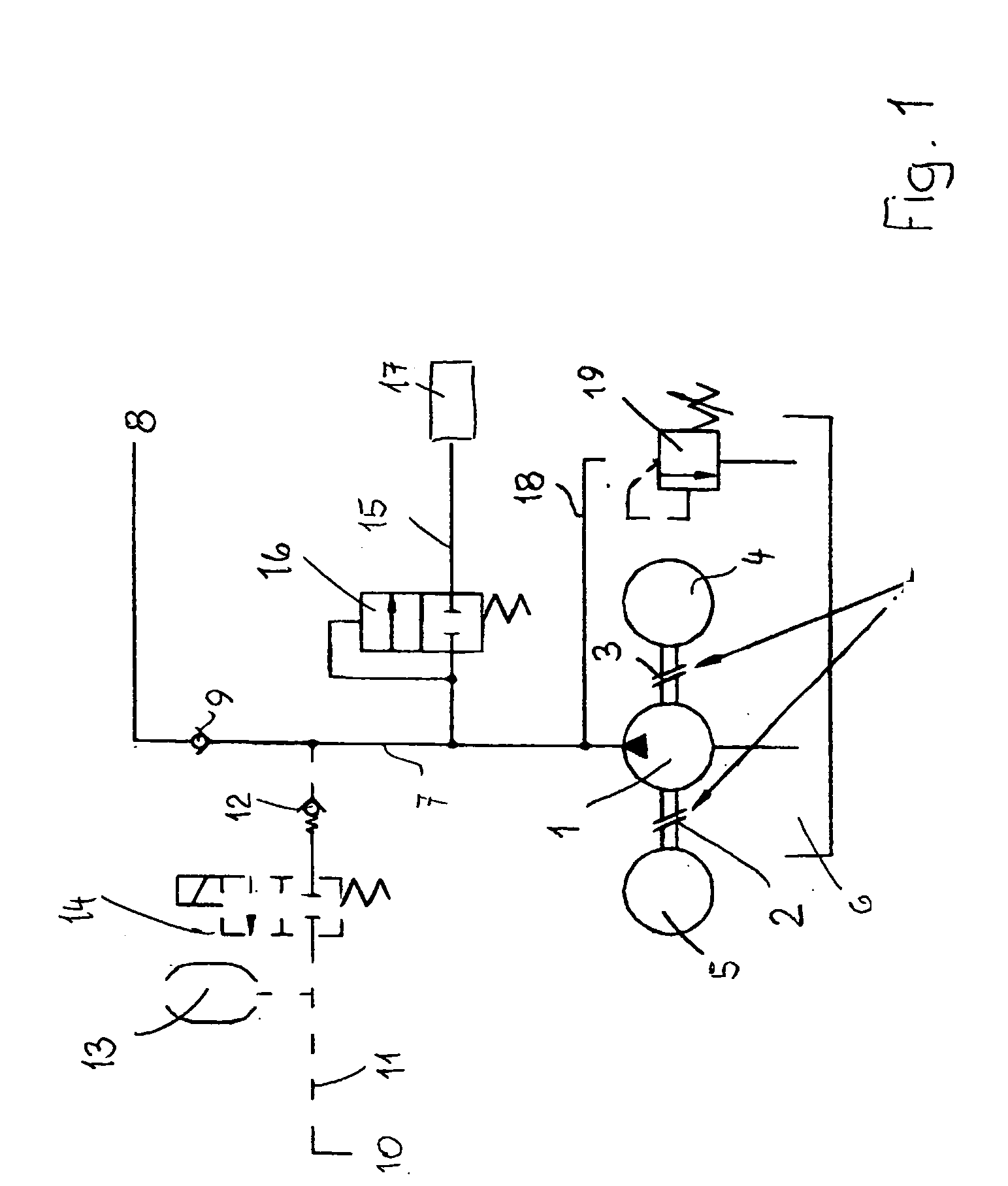

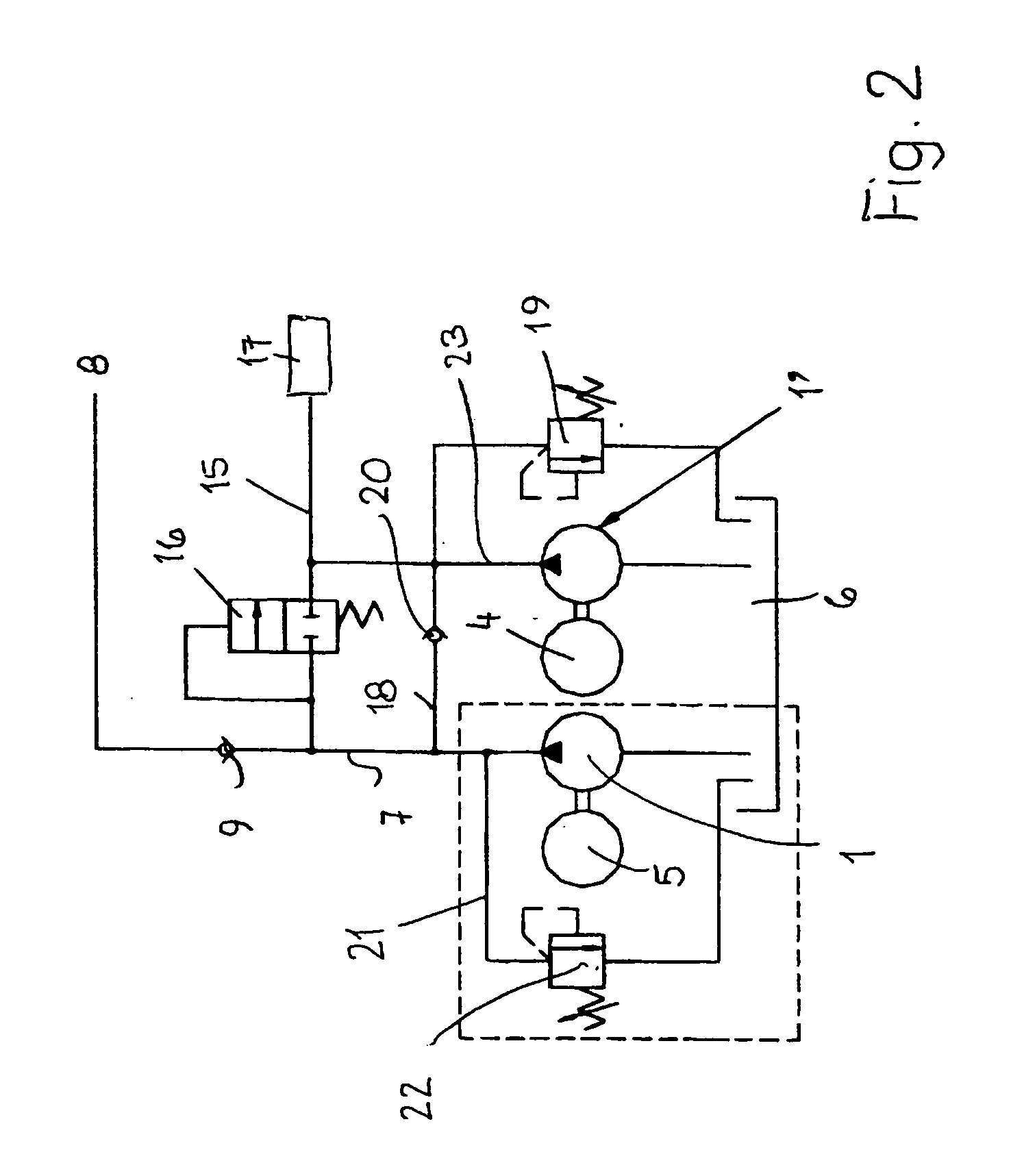

Control device for at least one consumer, such as a camshaft adjuster, automatic transmsion and the like, of motor vehicles

InactiveUS20050072397A1Increase supplyFluid-pressure actuator safetyValve arrangementsMobile vehicleAutomatic transmission

A control device for at least one consumer of a motor vehicle, having an engine and at least one pump for supplying a medium via at least one pressure line to the at least one consumer, is configured to supply the medium to the at least one consumer before the engine is started. The pump can be driven by an electric motor or by the engine of the motor vehicle or alternatingly by the electric motor and the engine.

Owner:HYDRAULIK RING

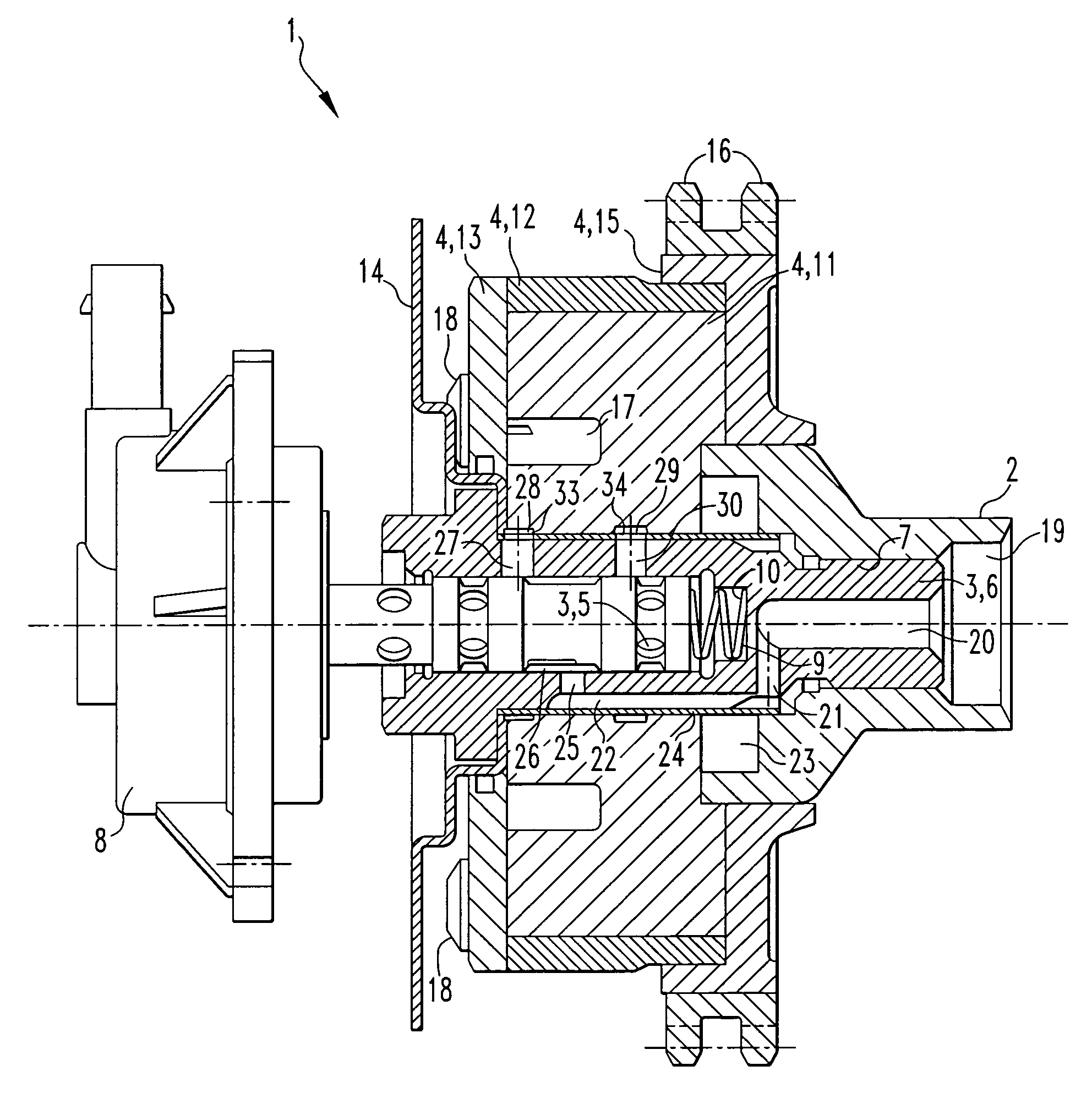

Hydraulic camshaft adjuster for an internal combustion engine

InactiveUS7025023B2Easy to manufactureIncrease expensesCamsYielding couplingExternal combustion engineEngineering

In a hydraulic camshaft adjuster for an internal combustion engine including a hydraulic operating unit for adjusting the angular position of the camshaft relative to a camshaft drive by way of a hydraulic control valve with a valve housing in which a control piston is disposed for controlling the supply of hydraulic fluid to, and its removal from, the hydraulic operating unit and to which hydraulic fluid is supplied from the camshaft by way of a pressure channel which is formed into the valve housing so as to extend along the outer surface thereof and a sleeve tightly surrounds at least the part of the valve housing which includes the channel for tightly covering the channel.

Owner:DAIMLER AG

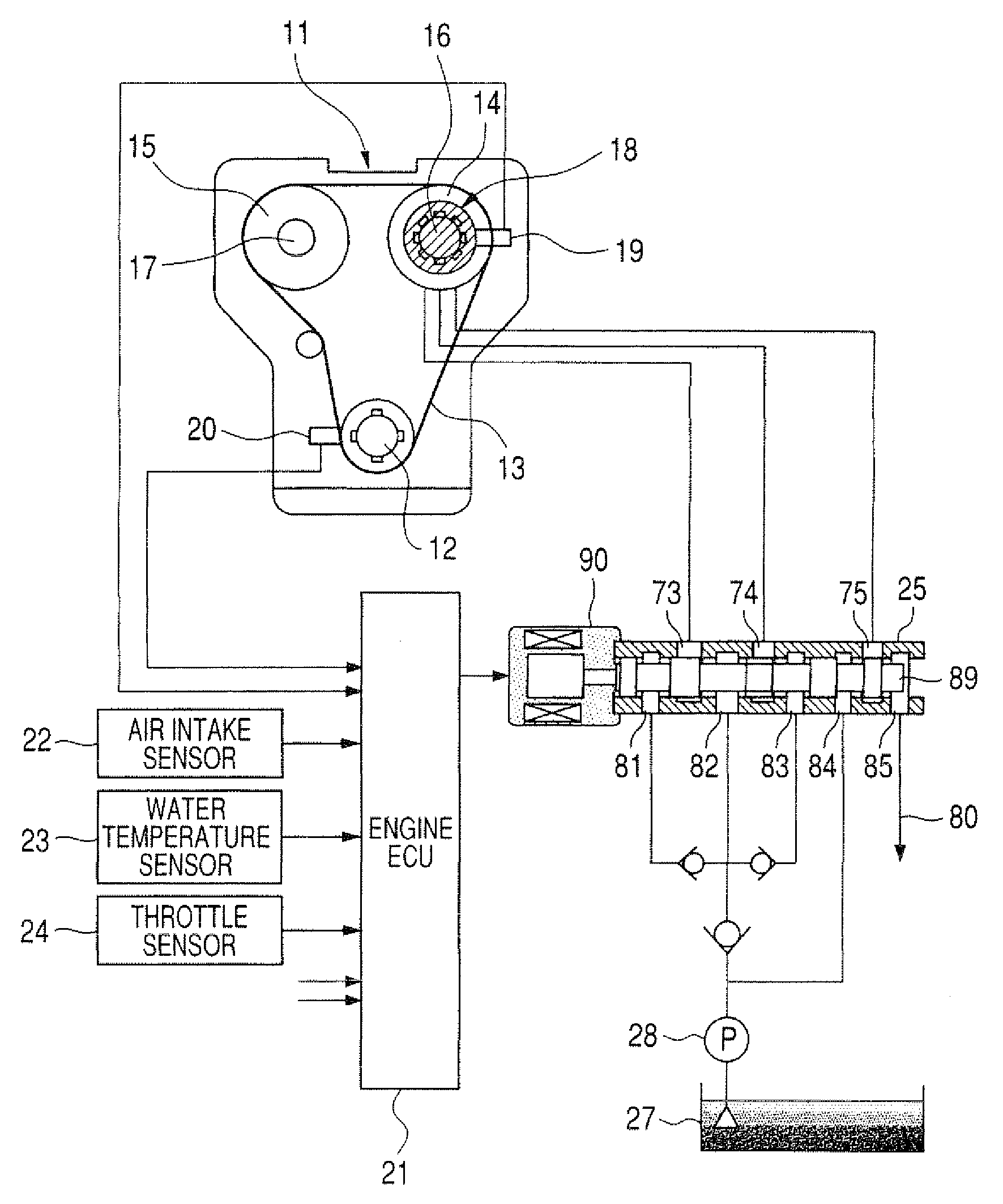

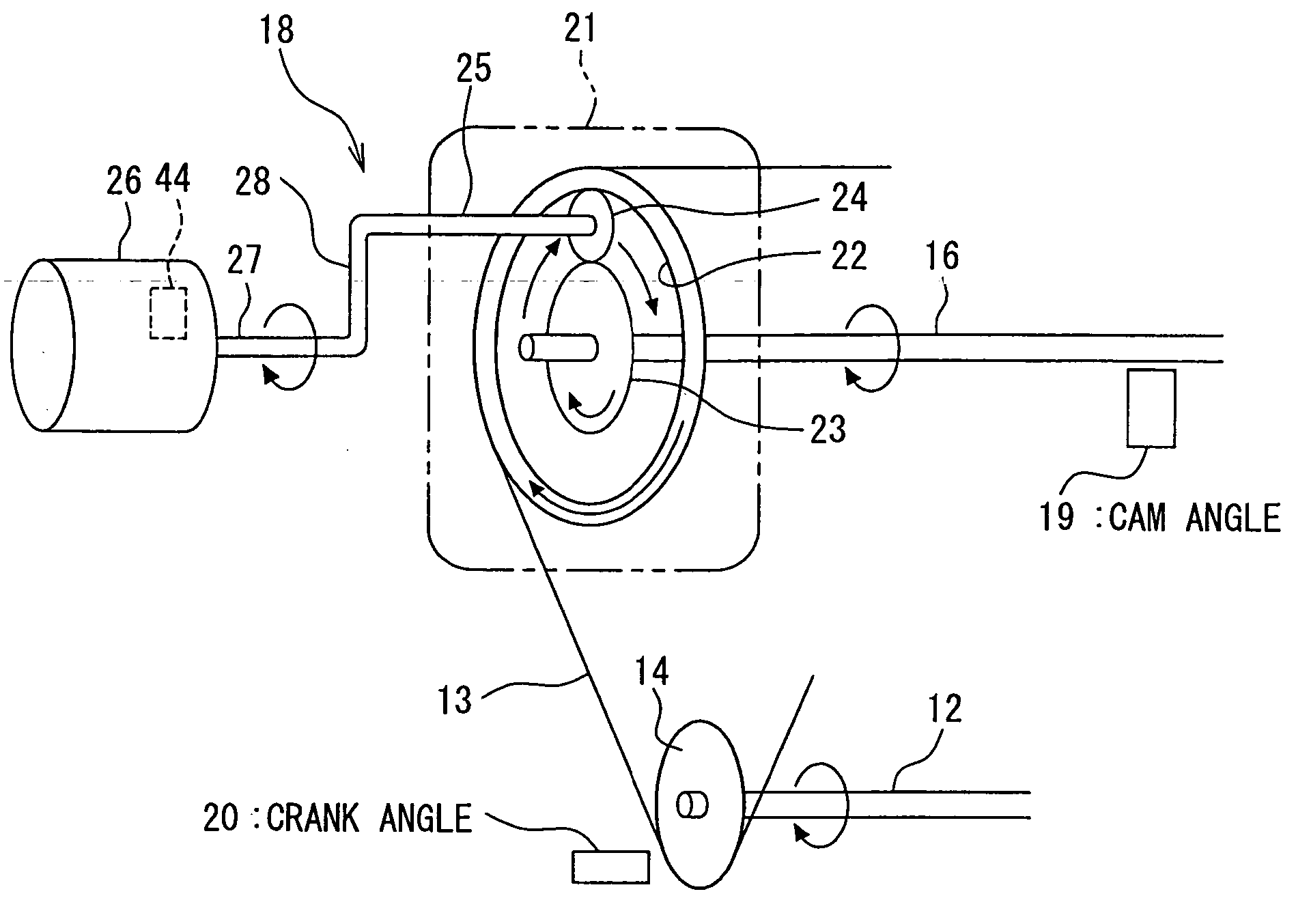

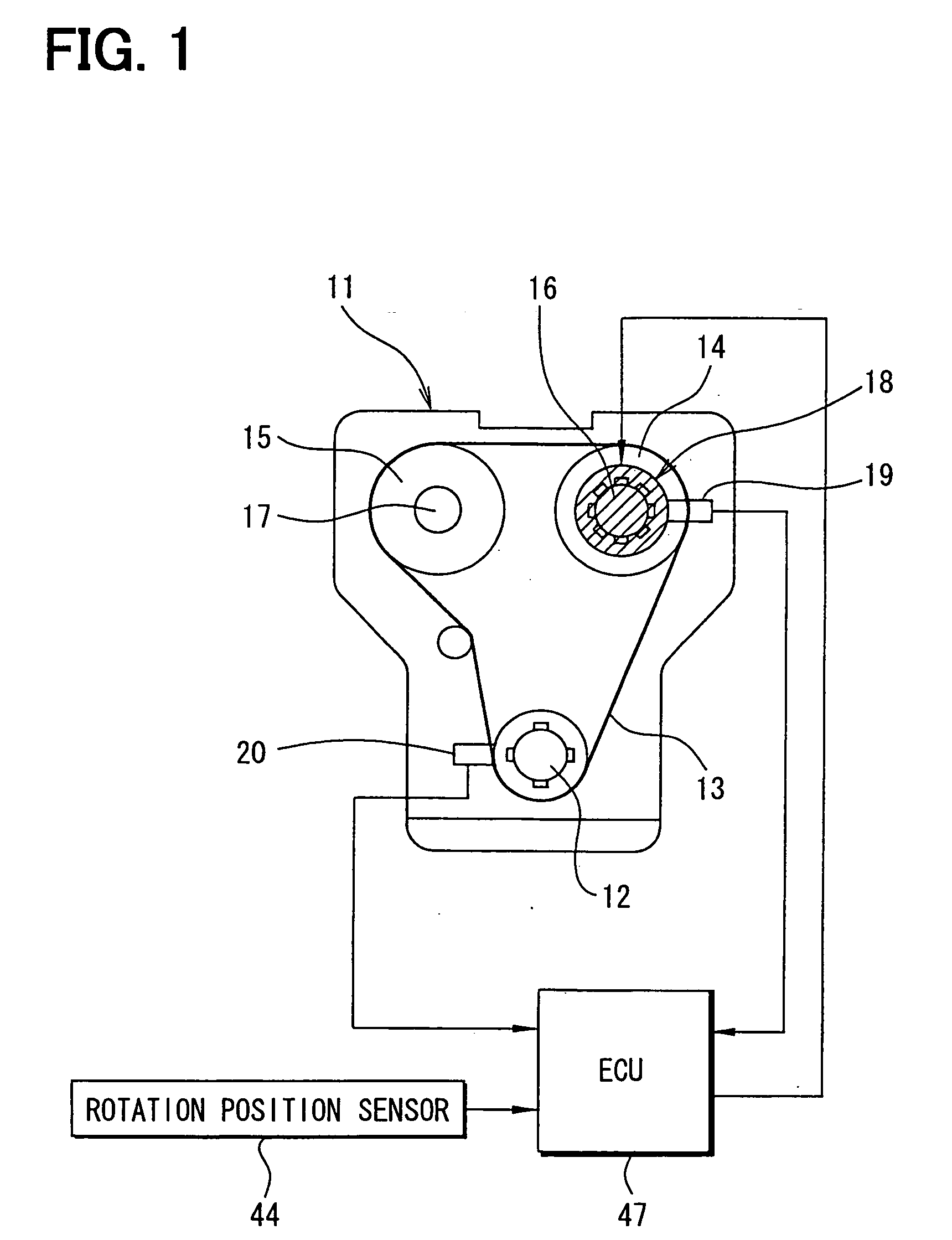

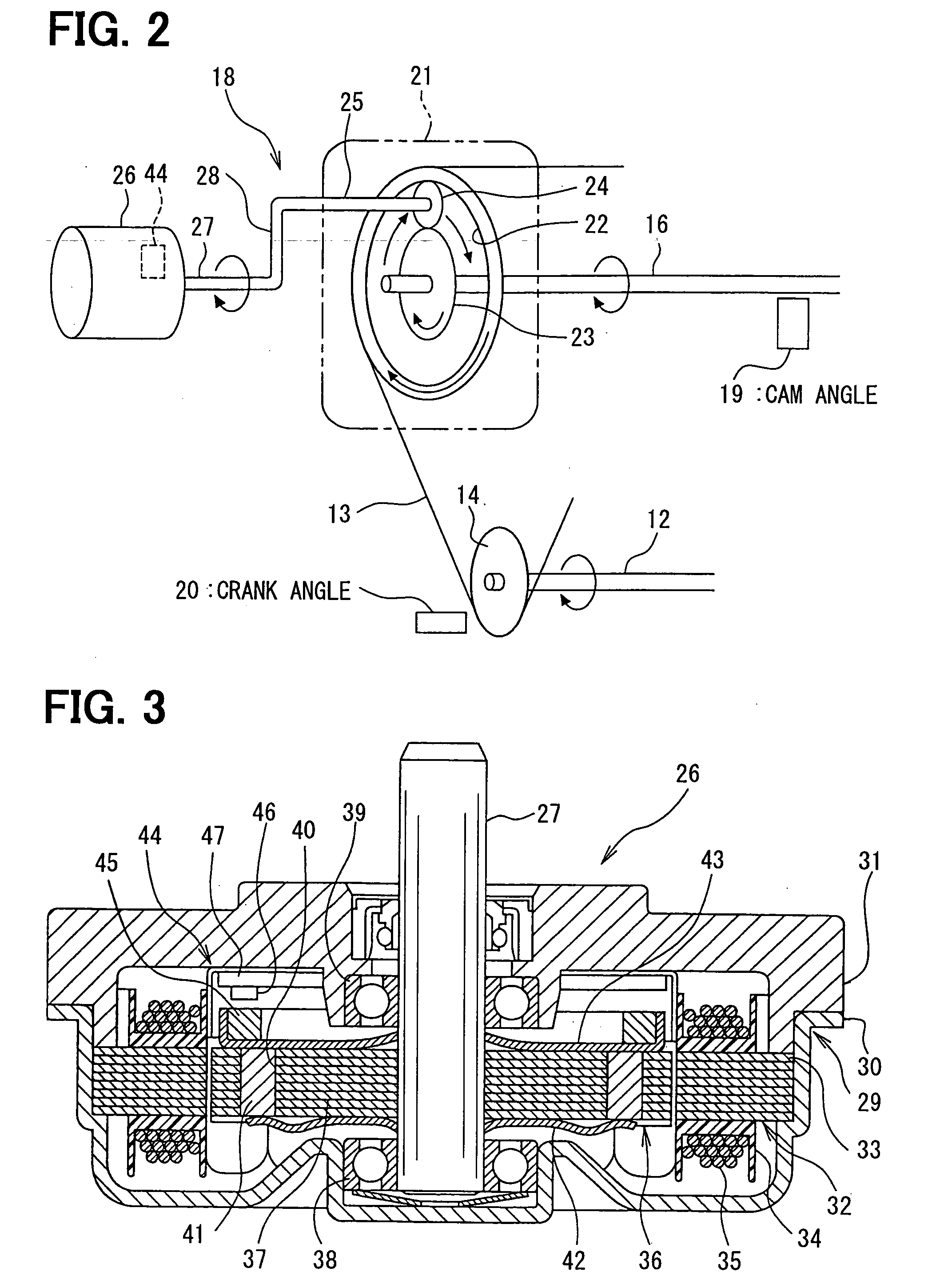

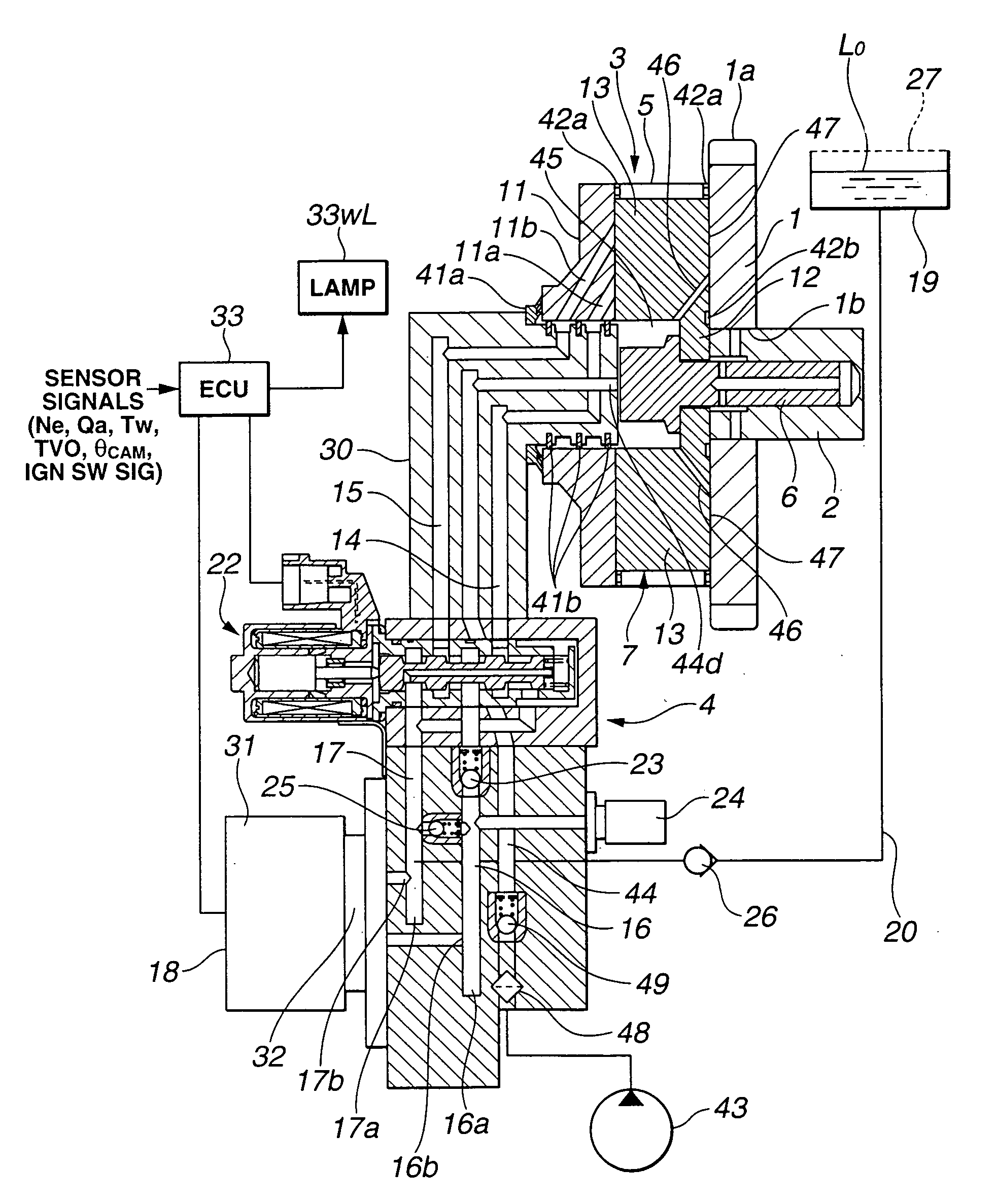

Engine rotation condition detecting system and engine control method

InactiveUS20060042578A1Accurate detectionLow costValve drivesMachines/enginesVariable valve timingRotation velocity

An internal combustion engine has a variable valve timing apparatus including a driving motor between a crankshaft and a camshaft. The driving motor rotates synchronously with the camshaft when the valve timing apparatus is not in operation. A motor rotation sensor produces a motor rotation signal. When the engine rotation speed is below a reference speed, the driving motor is not energized. Under this condition, the rotation speed and the rotation direction of the engine are calculated based on the motor rotation signal in place of a crank rotation signal produced by a crank angle sensor. Further, the rotation stop position of the engine is calculated based on the motor rotation signal when the engine is stopped.

Owner:DENSO CORP

Variable valve timing control system of internal combustion engine

InactiveUS20050257762A1Tendency increaseIncrease system costValve drivesMachines/enginesWorking fluidVariable valve timing

A variable valve timing control system of an internal combustion engine includes a hydraulically-operated phase converter disposed between a sprocket and a camshaft, and having a phase-advance hydraulic chamber and a phase-retard hydraulic chamber for changing an angular phase of the camshaft relative to the sprocket. An electric pump is provided to supply working fluid selectively to one of the hydraulic chambers via a directional control valve. Also provided is a check valve disposed in a discharge line of the pump for permitting flow in a direction that the working fluid flows from the pump to the directional control valve and preventing any flow in the opposite direction, so as to prevent a pulse pressure arising from alternating torque exerted on the camshaft from being transmitted from either one of the hydraulic chambers via the discharge line to a discharge port of the pump.

Owner:HITACHI LTD

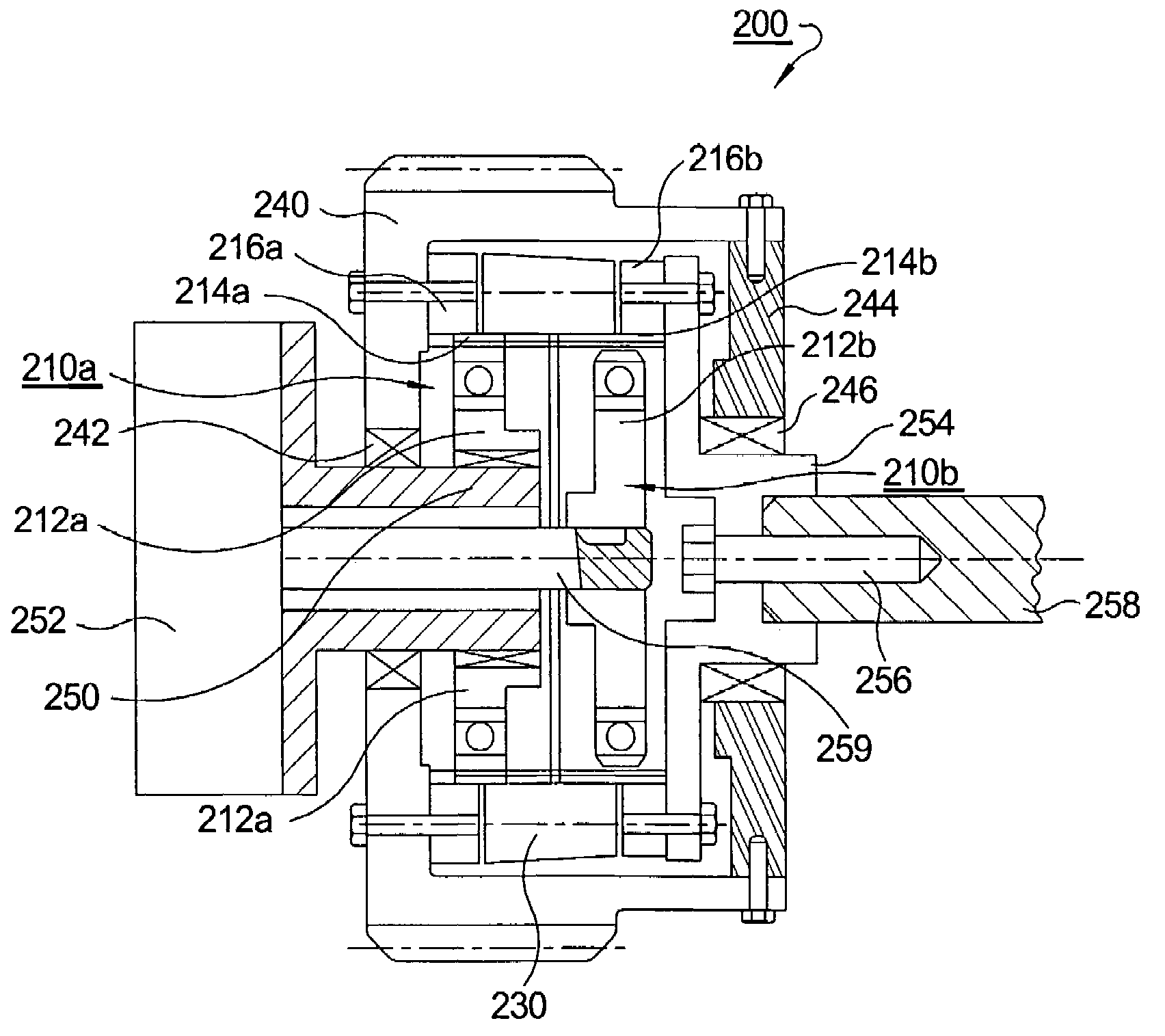

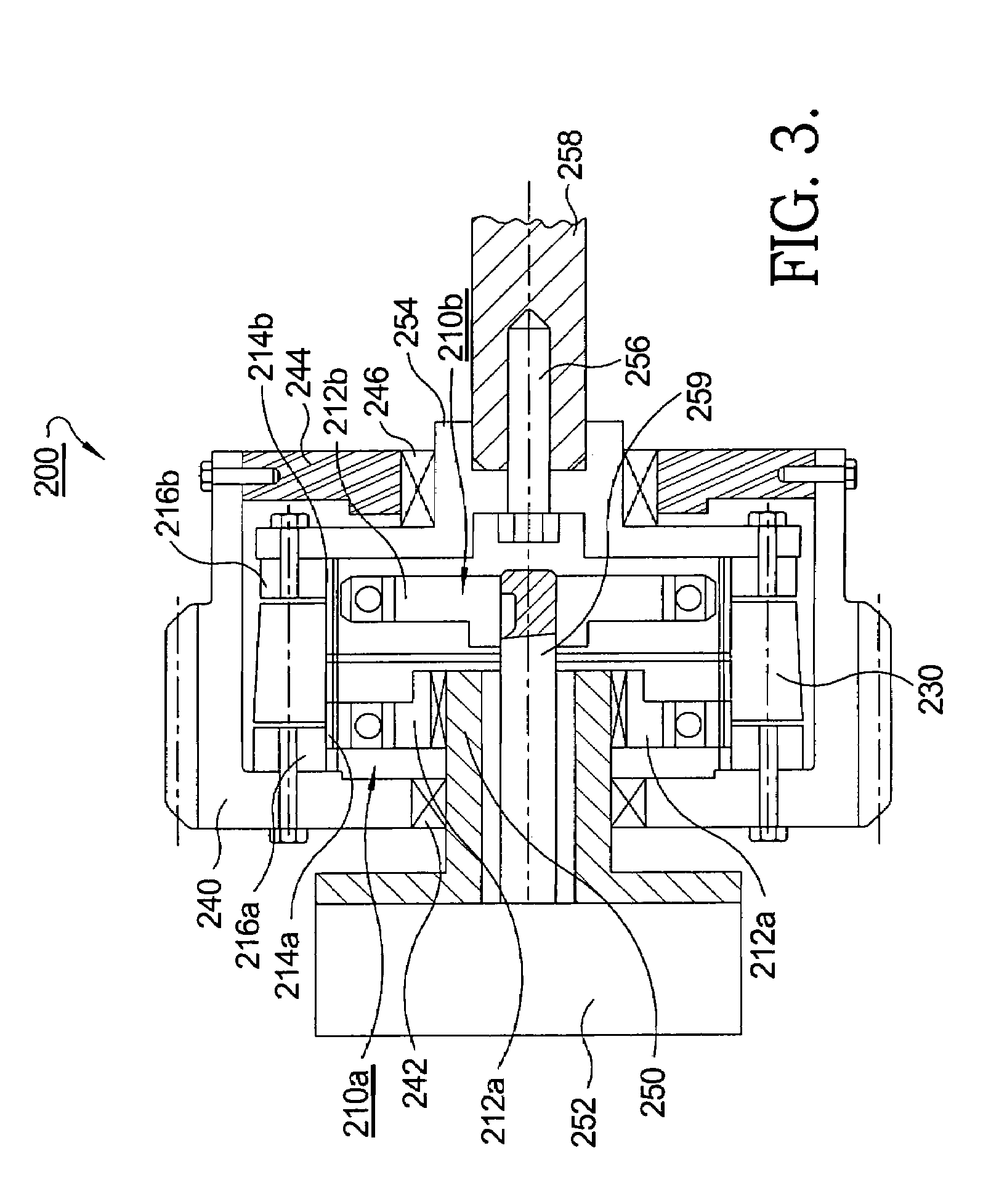

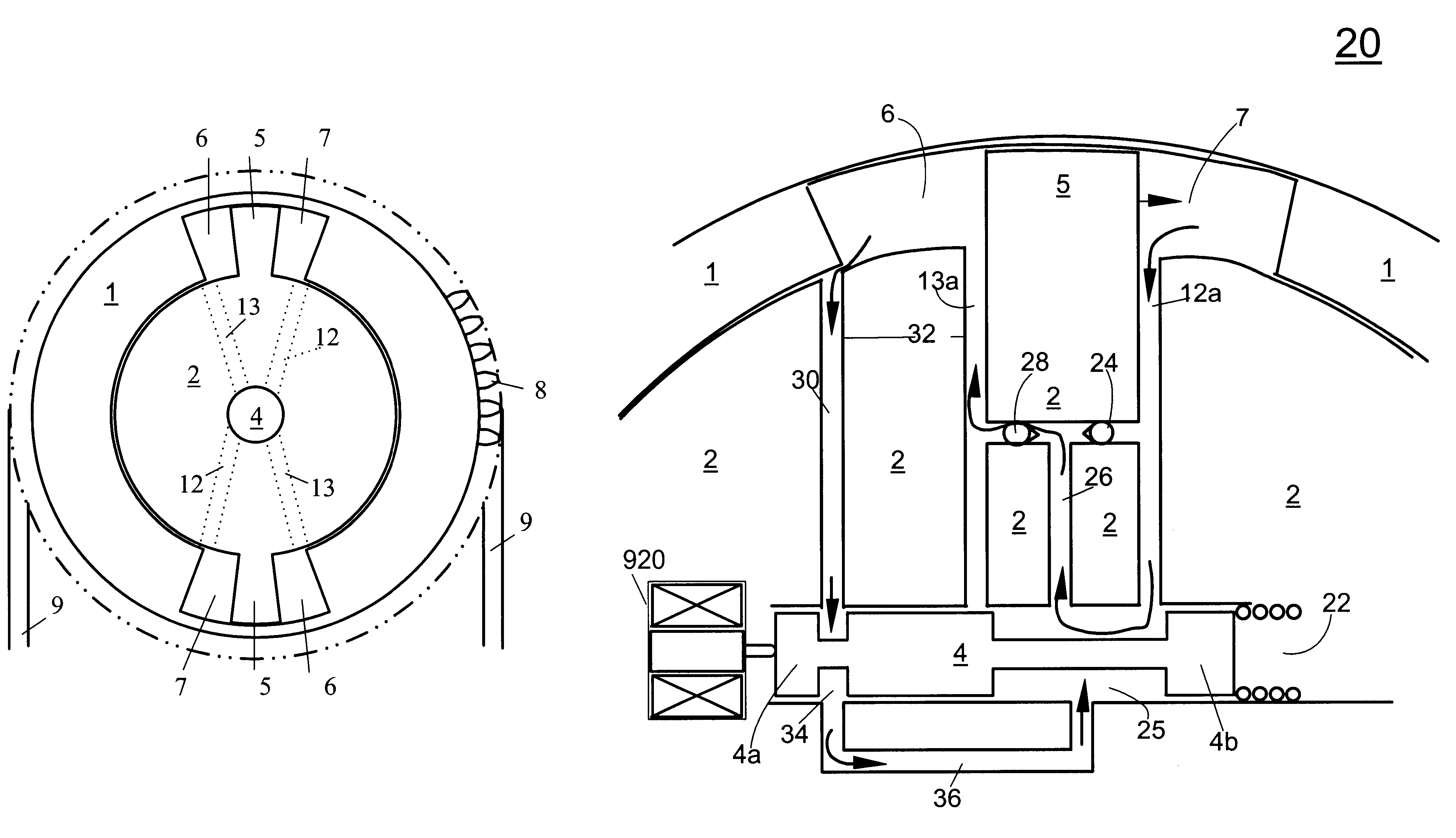

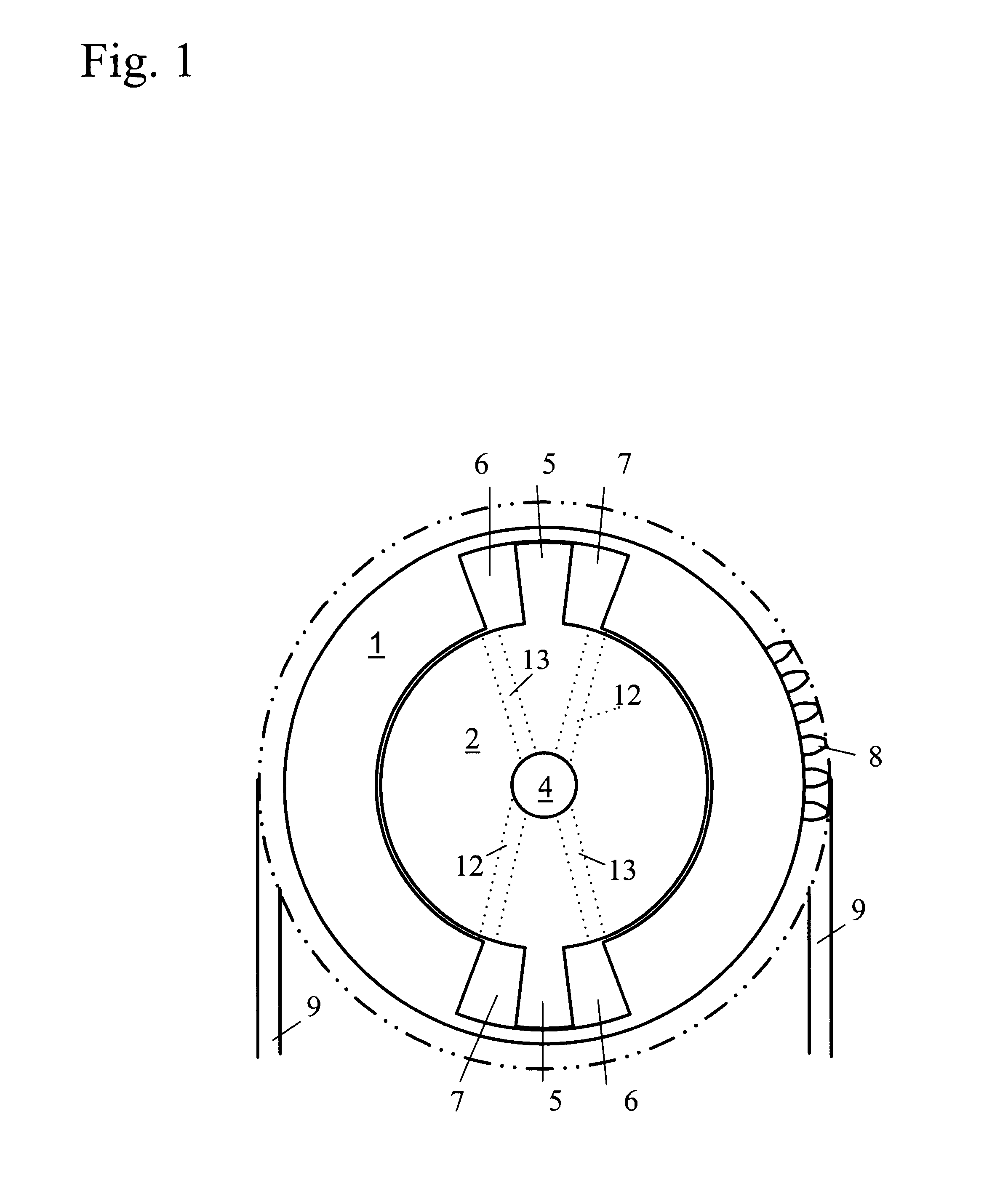

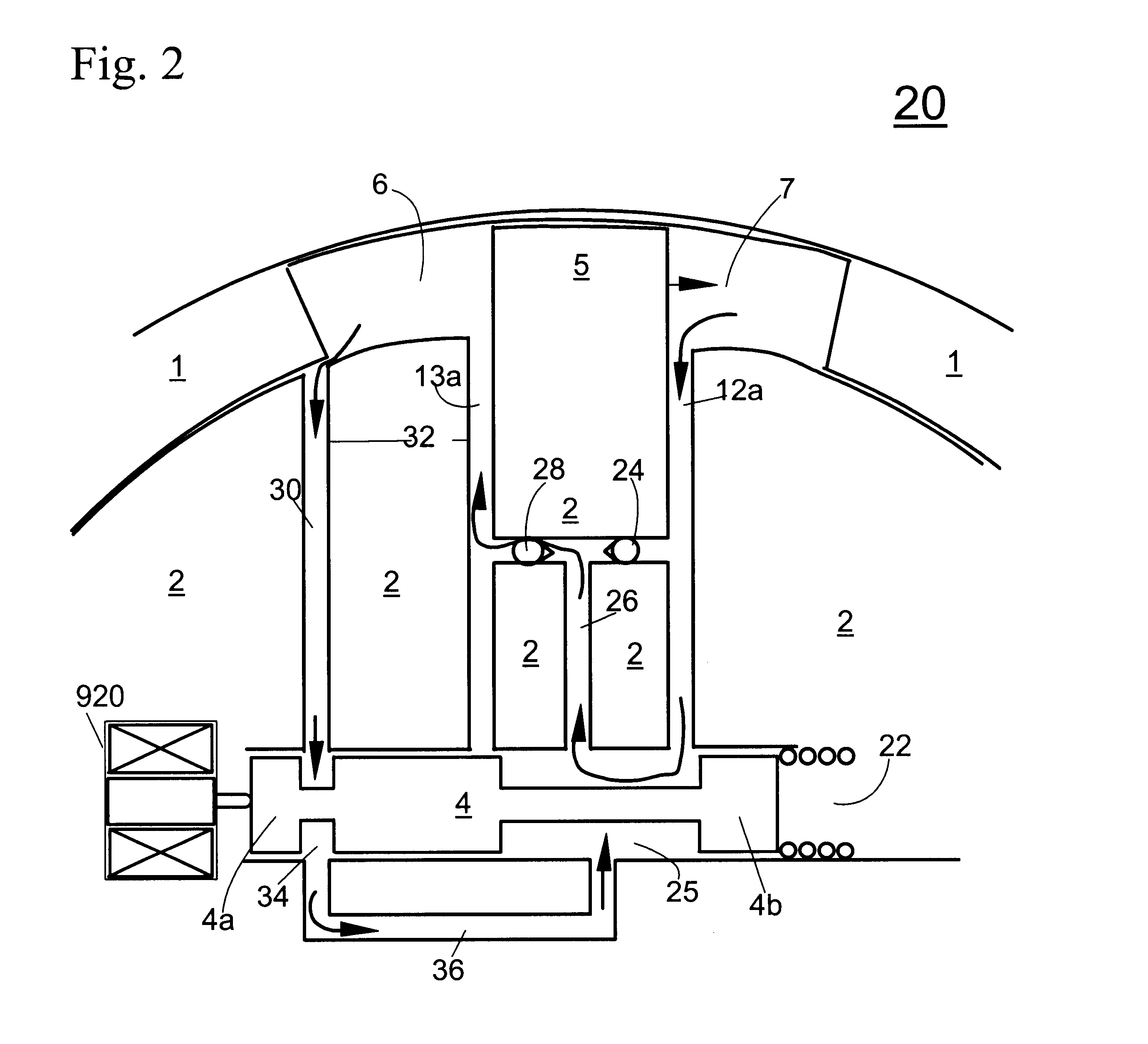

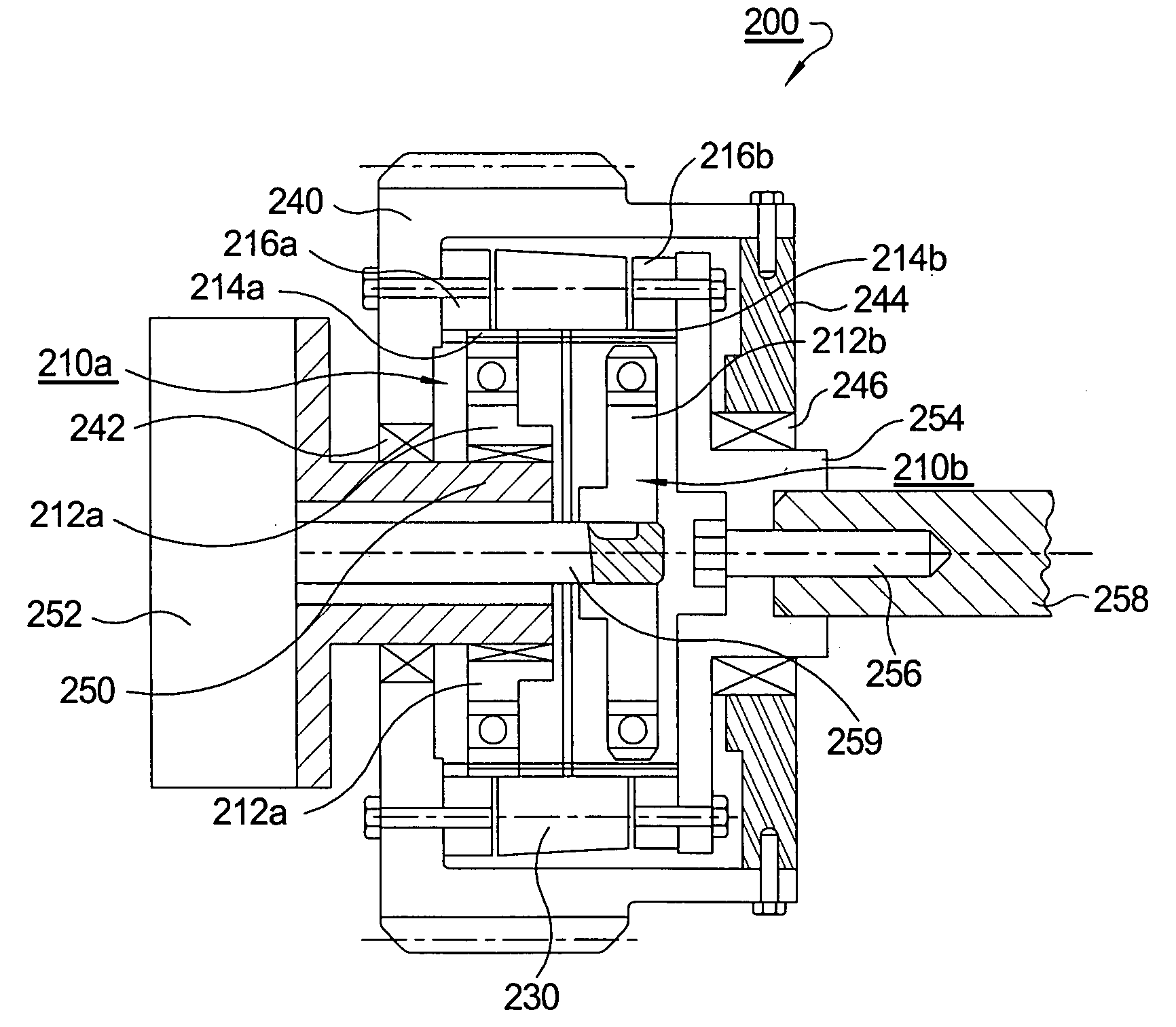

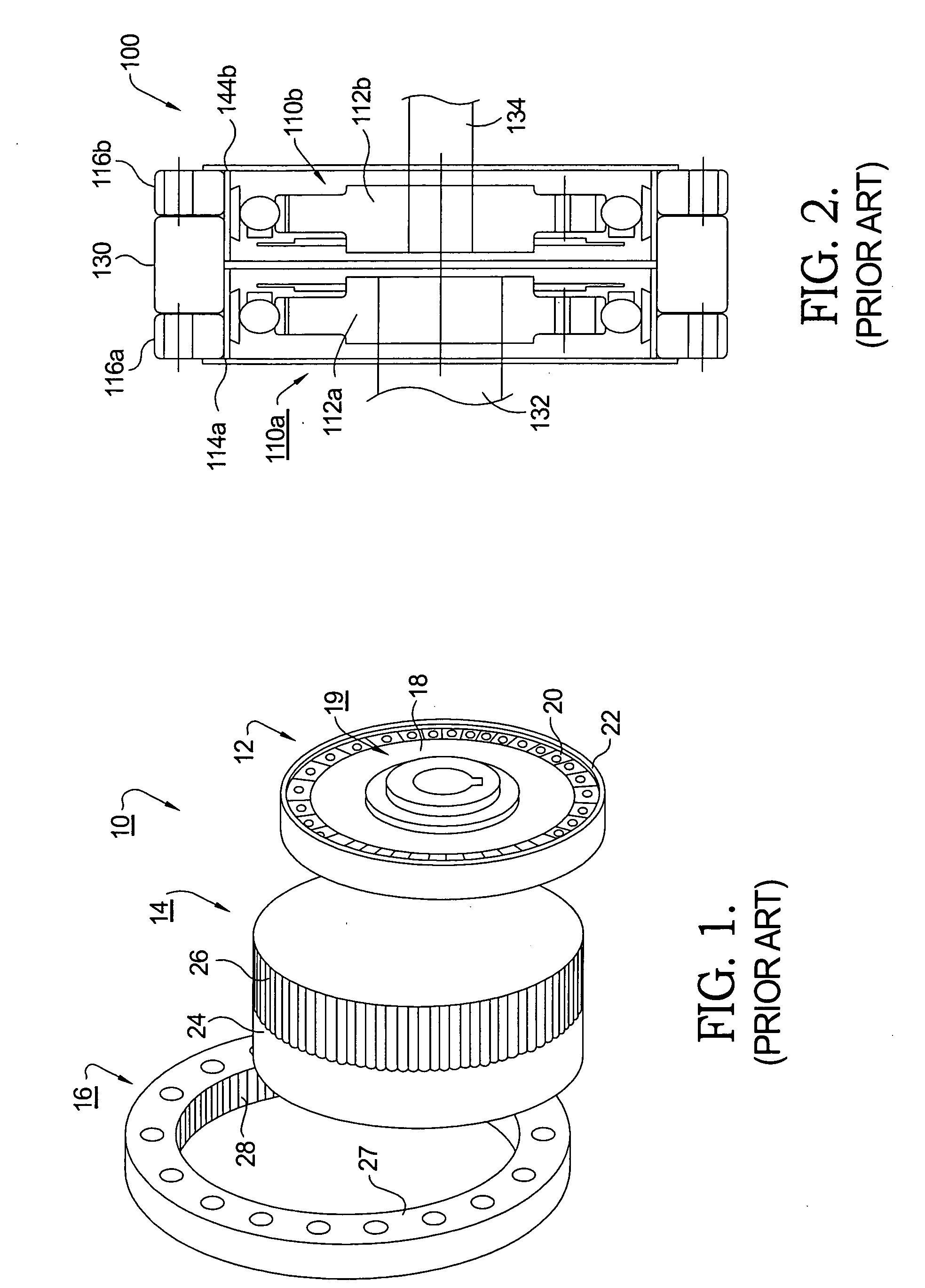

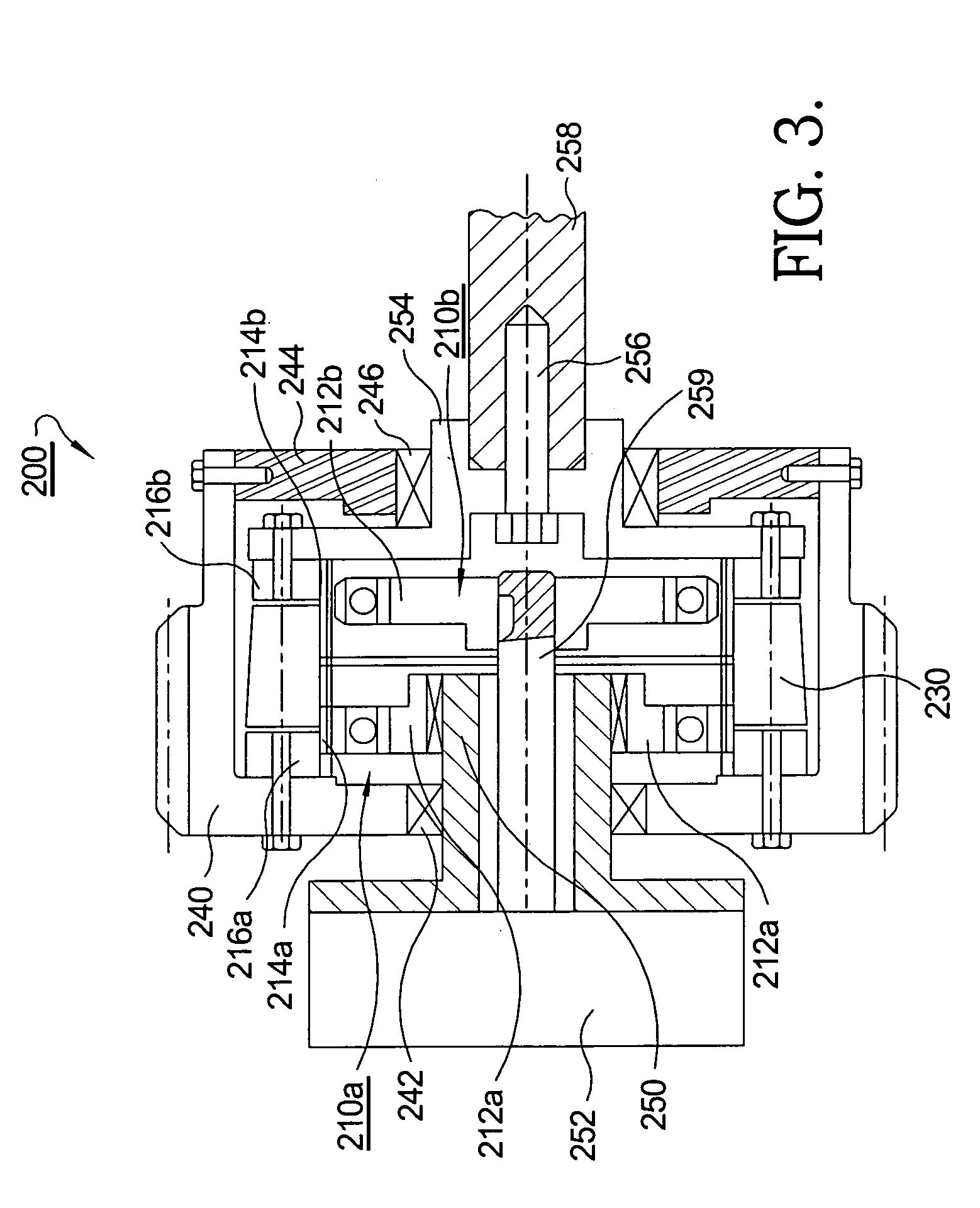

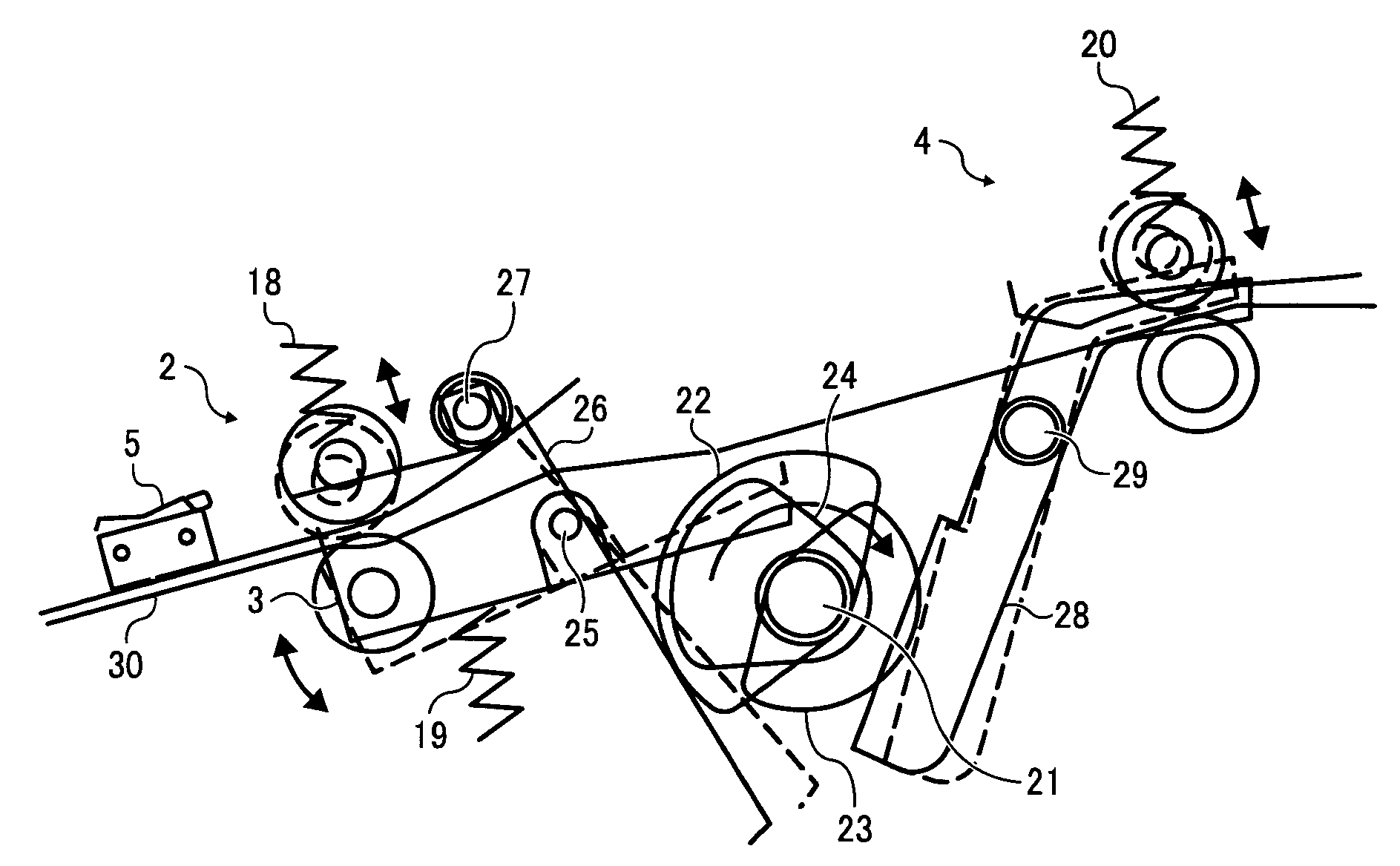

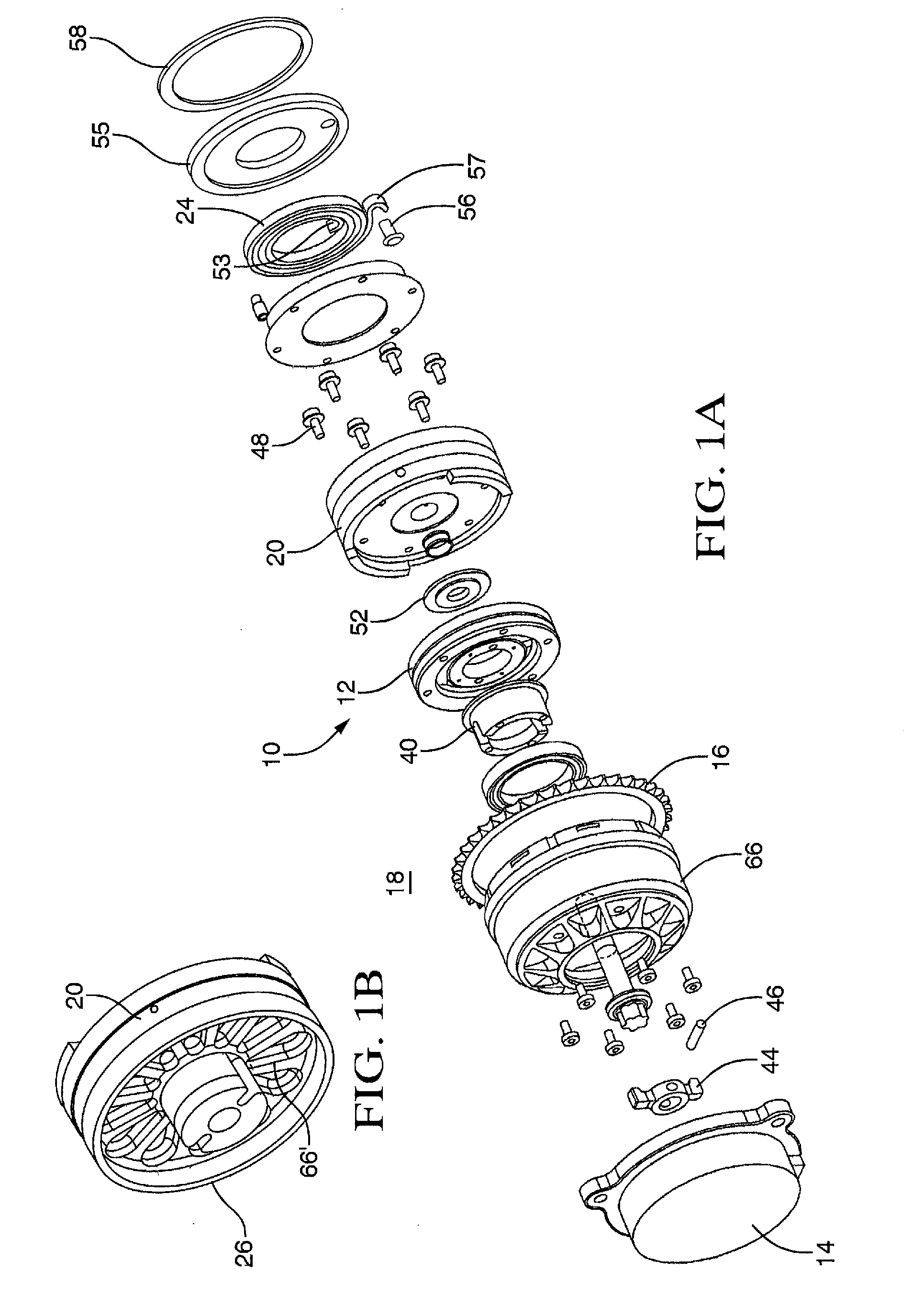

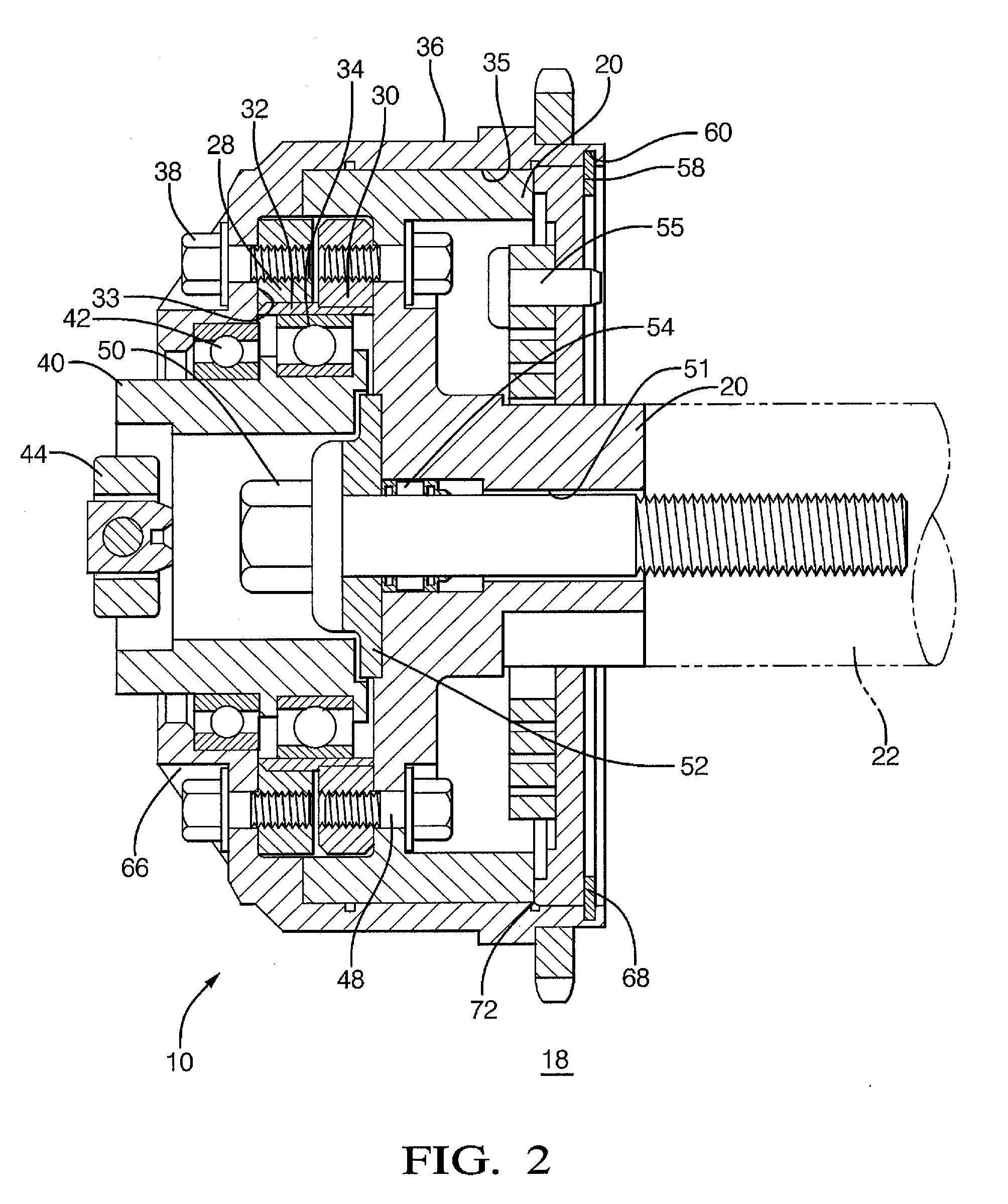

Harmonic drive camshaft phaser

A camshaft phaser comprising first and second harmonic gear drive (HD) units disposed in back-to-back relationship. Each HD includes an elliptical wave generator (WG), a flexspline (FS) deformable by the WG, and a circular spline (CS) for engaging the FS. A dynamic spline (DS) connects the first and second FSs. The first HD is an input HD driven by an engine crankshaft via a sprocket wheel connected to the input CS. The second HD is an output HD driving an engine camshaft. The DS is meshed with both the input FS and the output FS. The phase relationship between the crankshaft and the camshaft may be changed by changing the angular relationship between the first and second WGs. Such change is effected by holding the first WG stationary and varying the angular position of the second WG via an electric motor.

Owner:DELPHI TECH IP LTD

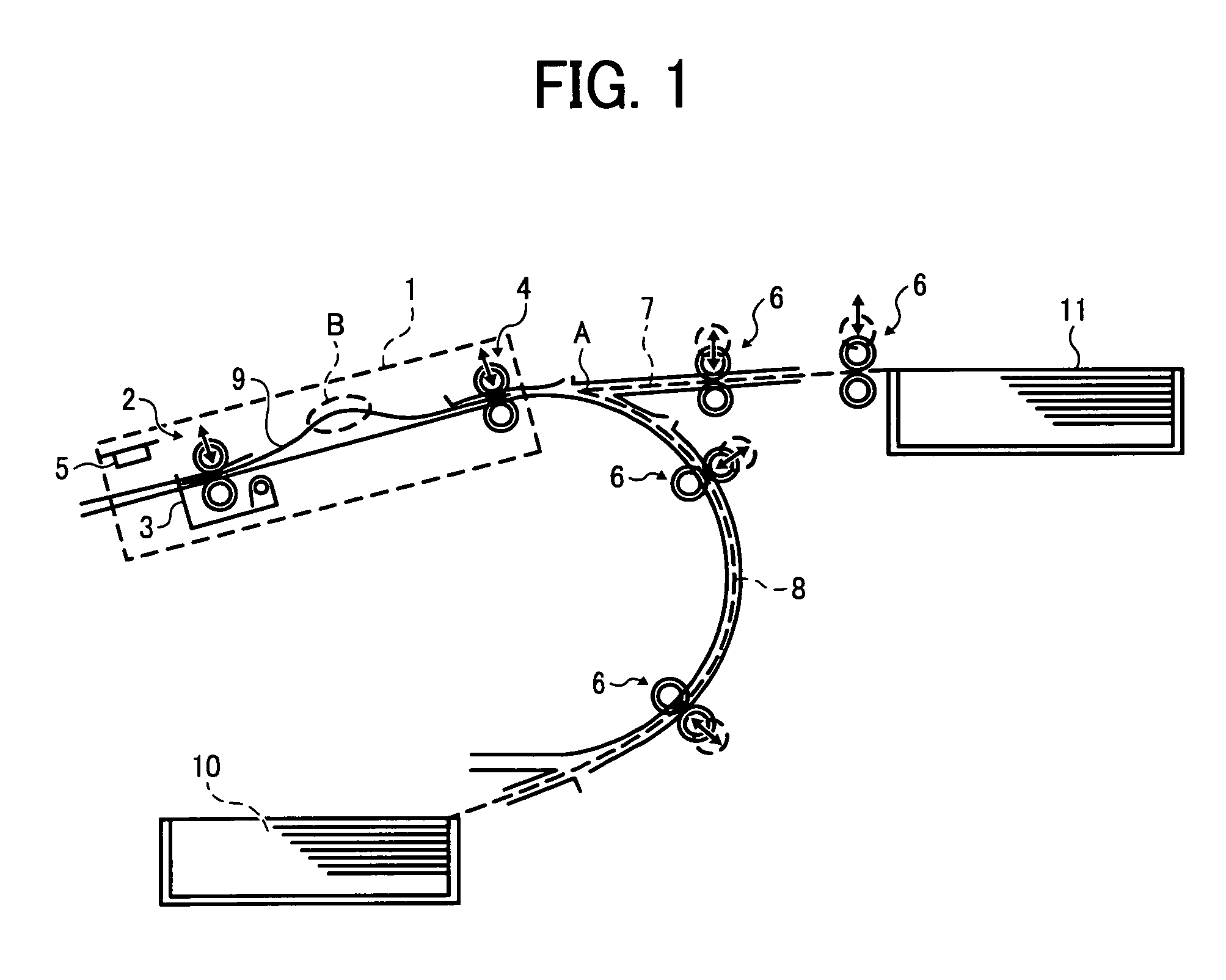

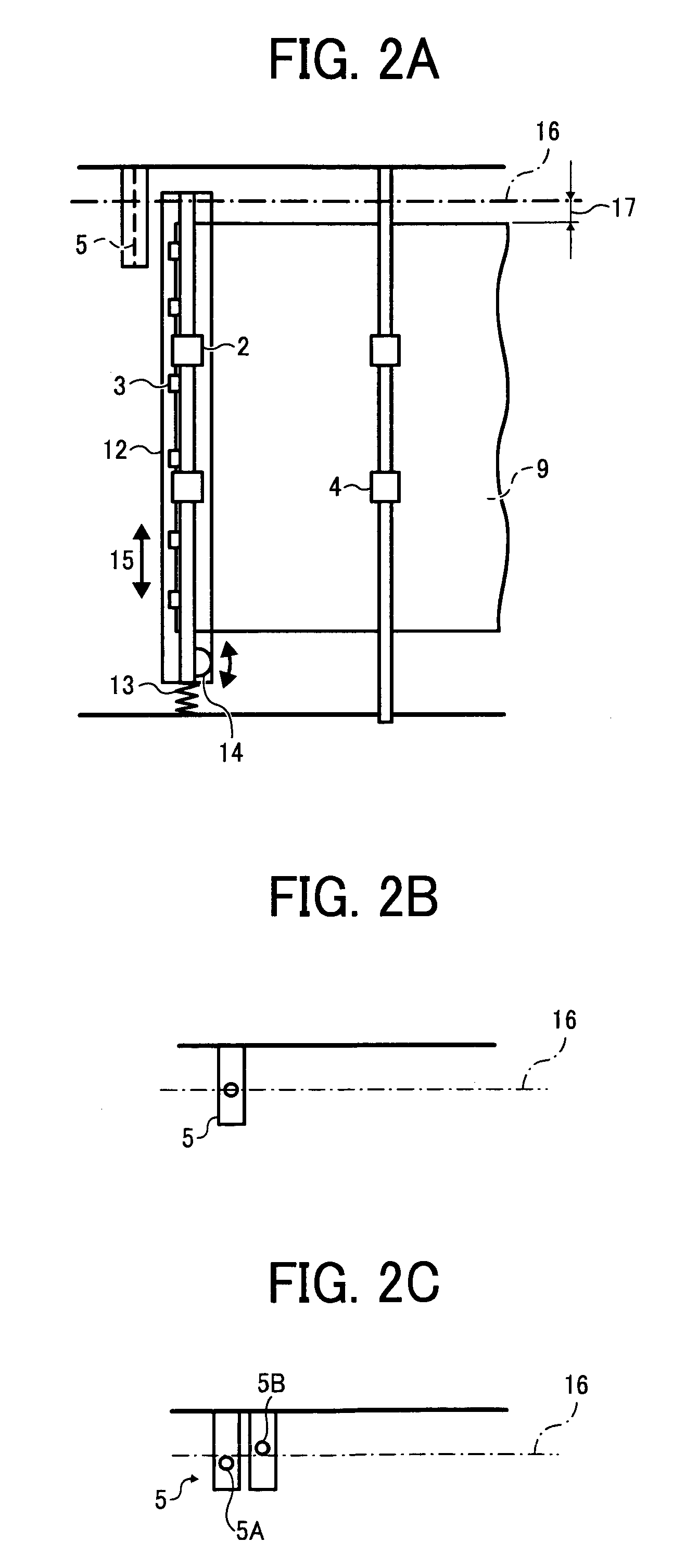

Sheet conveying device and image forming apparatus

A cam unit includes three cams fixed on a common cam shaft for moving a pair of feeding rollers, a pair of lateral registration rollers, and a stopper unit, respectively. A control unit corrects a lateral registration of a sheet whose skew is corrected by the stopper unit, based on a detection result of a detecting unit that detects a position of a side edge of the sheet, while conveying the sheet, controls the rollers not nip the sheet at least during the lateral registration, and controls rotations of the cams according to a length of the sheet.

Owner:RICOH KK

Harmonic Drive Camshaft Phaser with Improved Radial Stability

ActiveUS20110030632A1Obtained inexpensivelyMinimize distortionValve arrangementsMachines/enginesEngineeringHarmonic drive

Improved stiffening and minimized distortion of a housing for an eVCP achieved by forming a plurality of radial housing stiffeners into the housing around the motor mount end and into the eVCP's hub. A back plate is press fit into the rear of the housing, and a straight axial knurl is applied to the surface of the back plate or housing, which knurl permits a larger tolerance-higher press fit class to be used without resulting in significant deformation of the housing. The knurled back plate is harder than the housing, causing the high points of the knurl to plastically deform or plow the housing material during assembly, resulting in less radial deformation of the bore and the journal bearing. An interface between the housing and the hub provides a journal bearing interface to improve axial stability between the hub and housing.

Owner:DELPHI TECH IP LTD

Valve timing control system for internal combustion engine

A valve timing control system includes; a rotor rotated by a crankshaft of the internal combustion engine; a camshaft rotated according to the rotation of the rotor to open and close an intake valve and an exhaust valve of the internal combustion engine; and a rotational phase controller for variably controlling a rotational phase of the camshaft relative to the rotor. The rotational phase controller is disposed between the rotor and the camshaft. The rotational phase controller includes; a clutch selectably put in one of a holding state for forbidding a relative rotation between the rotor and the camshaft in at least one of rotational directions and a releasing state for allowing the relative rotation; and a generator for generating a holding toque directing to the rotational direction forbidden by the clutch and applying the holding torque to the clutch when the clutch is put in the holding state.

Owner:UNISIA JECS CORP

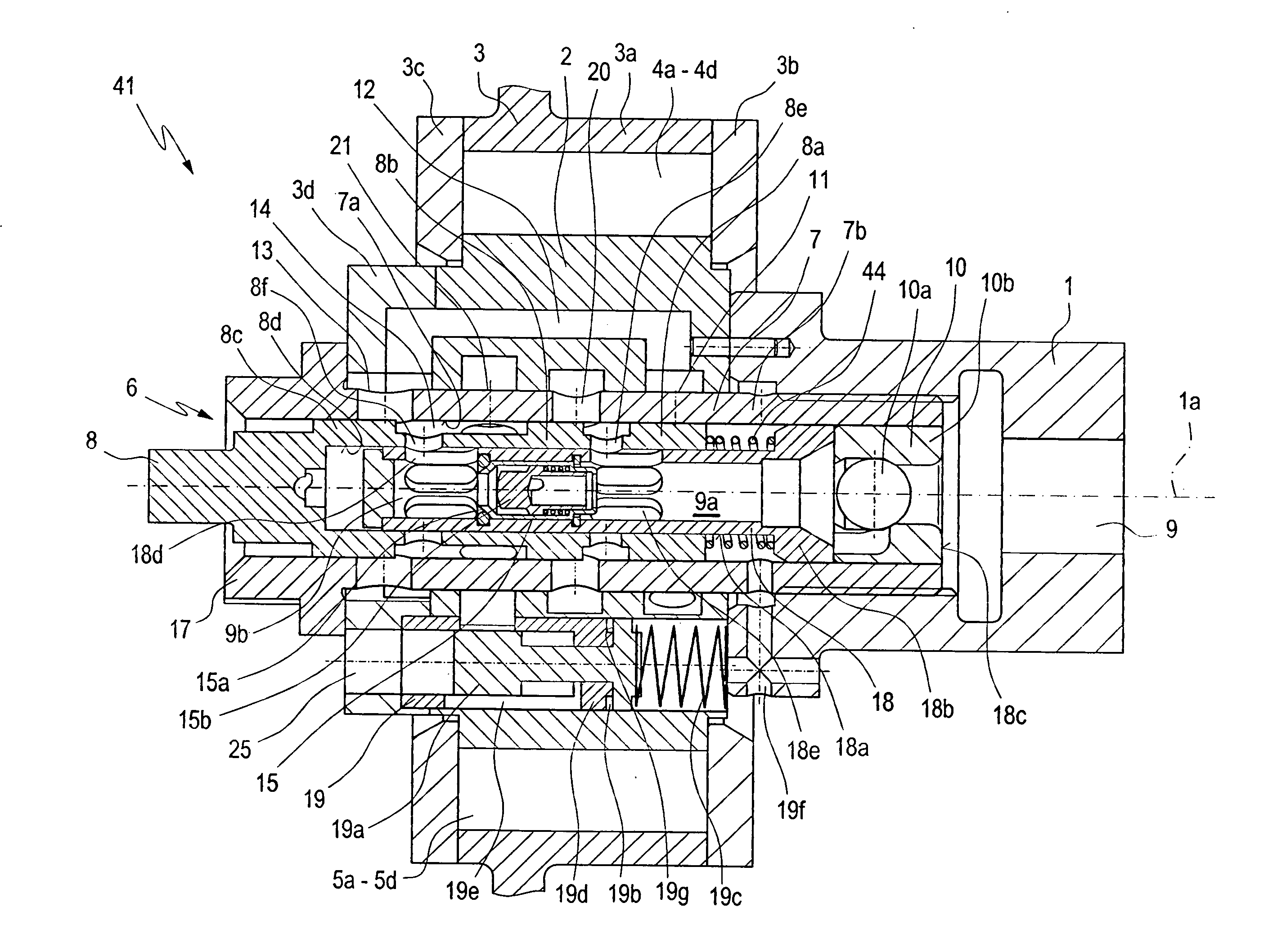

Camshaft adjustment device

ActiveUS20090159024A1Compact designSimple and cost-effective to manufactureYielding couplingValve drivesExternal combustion engineInternal combustion engine

In an adjustment device for adjusting the phase position of a camshaft relative to a crankshaft of an internal combustion engine which includes a hydraulic system for supplying hydraulic fluid under pressure to the adjustment device for the controlled admission to, and release thereof from, operating chambers of the adjustment device under the control of a control device including a control valve, the operating chambers are in communication with one another via control valves to permit flow of hydraulic fluid from one set of operating chambers to another by the varying torques effective on the camshaft or by controlling fluid supply to the operating chambers from the hydraulic fluid supply system.

Owner:DAIMLER AG

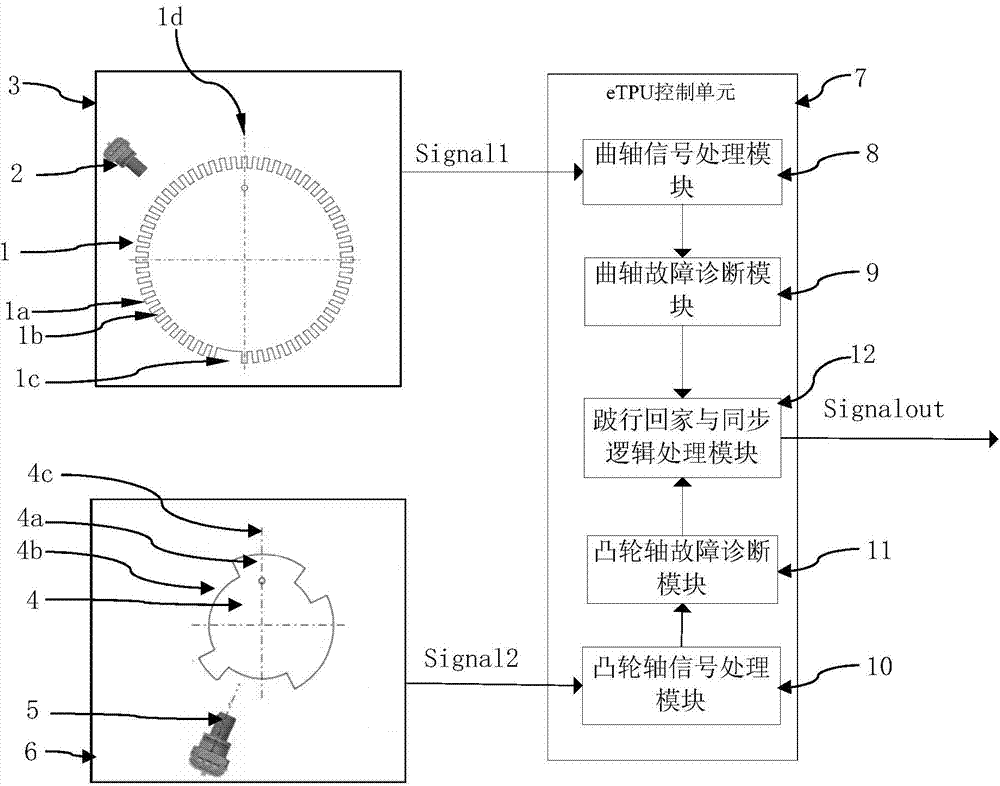

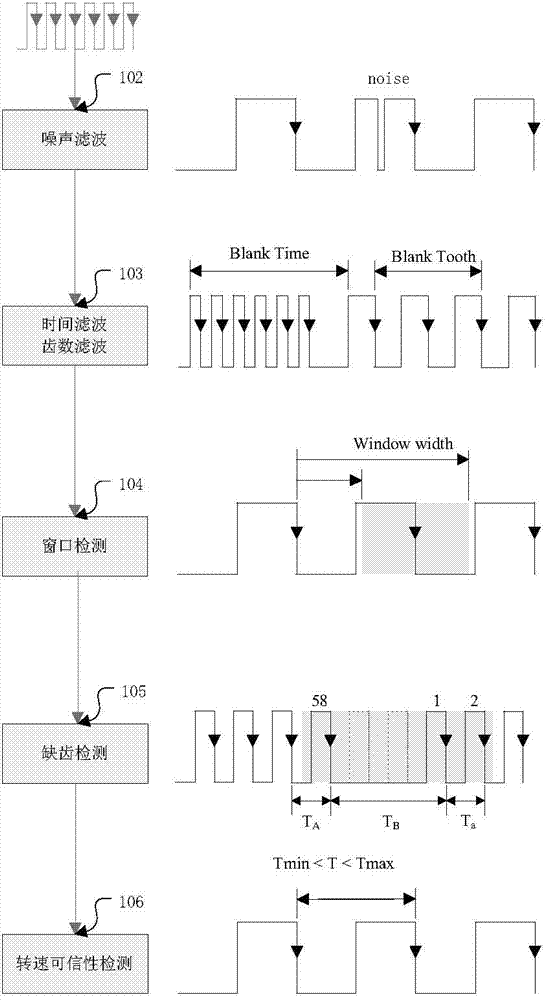

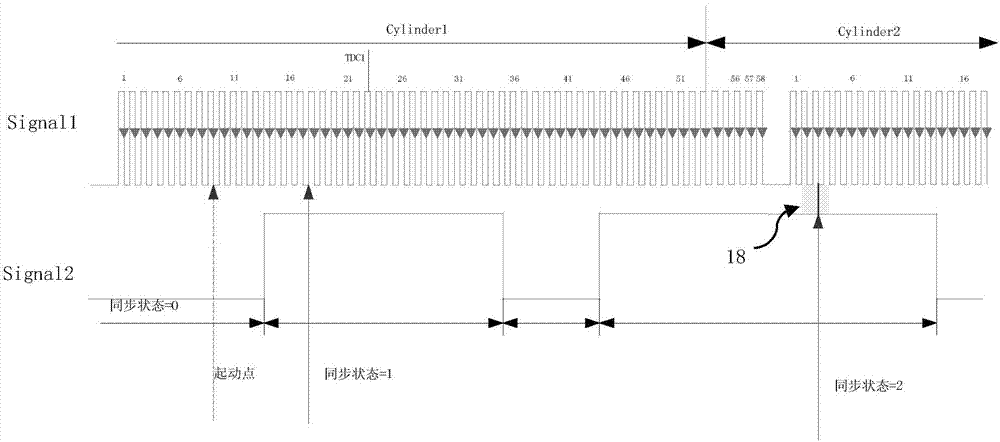

Engine position management system and management method

ActiveCN104747309AAchieve limp homeSync fastElectrical controlMachines/enginesLarge toothPosition sensor

The invention discloses an engine position management system. The engine position management system comprises a crankshaft signal panel, a crankshaft position sensor, a camshaft signal panel, a camshaft position sensor and an eTPU control unit, wherein the crankshaft signal panel comprises multiple convex teeth and tooth gaps; the tooth gaps have a large tooth gap for positioning; and the camshaft signal panel comprises three convex teeth with different central angles and tooth gaps. The eTPU control unit comprises a crankshaft signal processing module, a crankshaft fault diagnosis module, a camshaft signal processing module, a camshaft fault diagnosis module and a limp return and synchronous logic processing module. The engine position management system can use crankshaft signals and camshaft signals for realizing quick cylinder judgment and synchronization of an engine when the camshaft position sensor and the camshaft position sensor are normal, and can use another sensor for realizing the cylinder judgment synchronization and providing the angle information with limited precision to realize the limb return of the engine when one sensor is broken down. The invention further provides a management method of the engine position management system.

Owner:LIANCHUANG AUTOMOBILE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com