Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3785results about "Oscillating piston engines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compressor

ActiveUS6960070B2Easy to fixPrecise alignmentRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaftEngineering

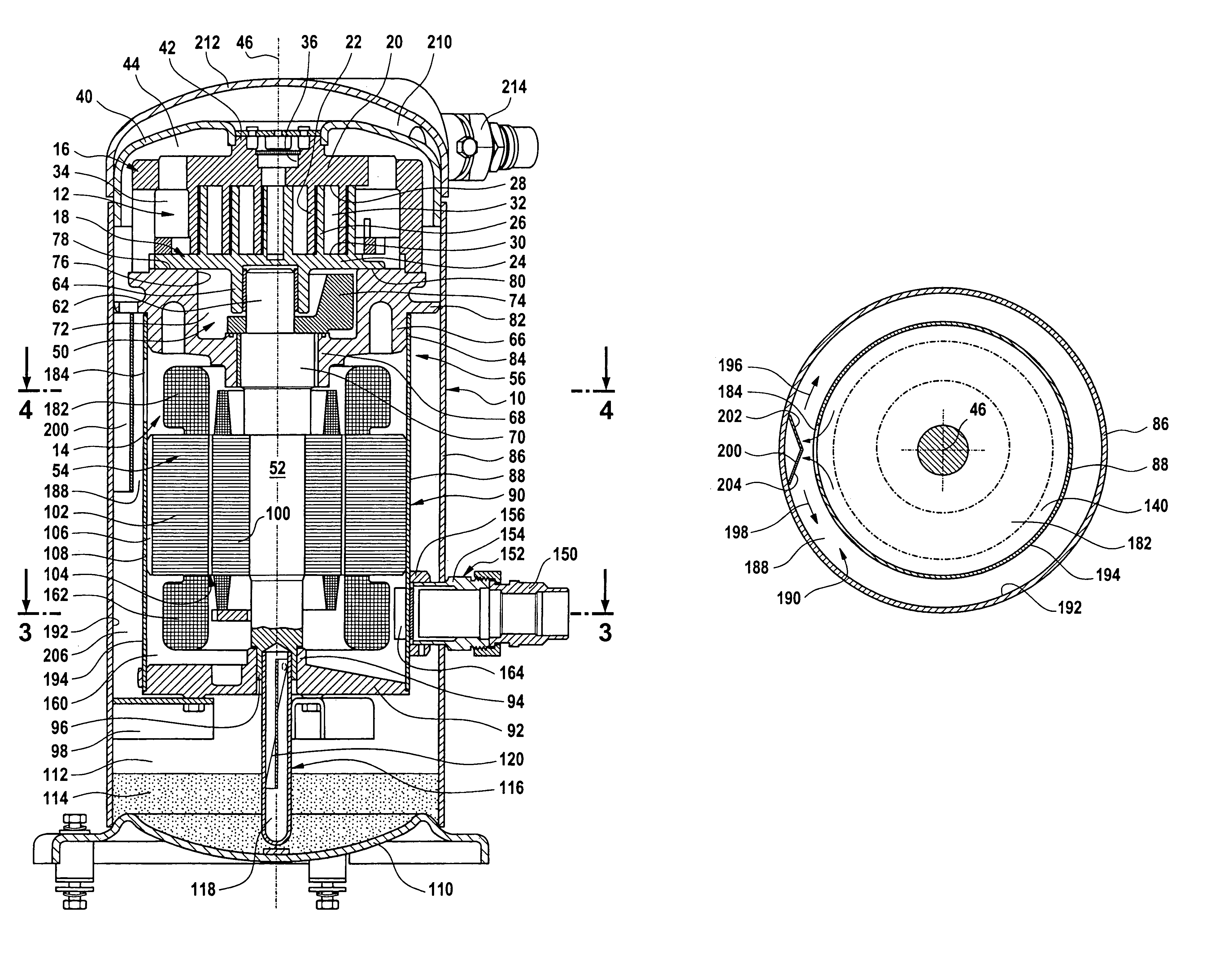

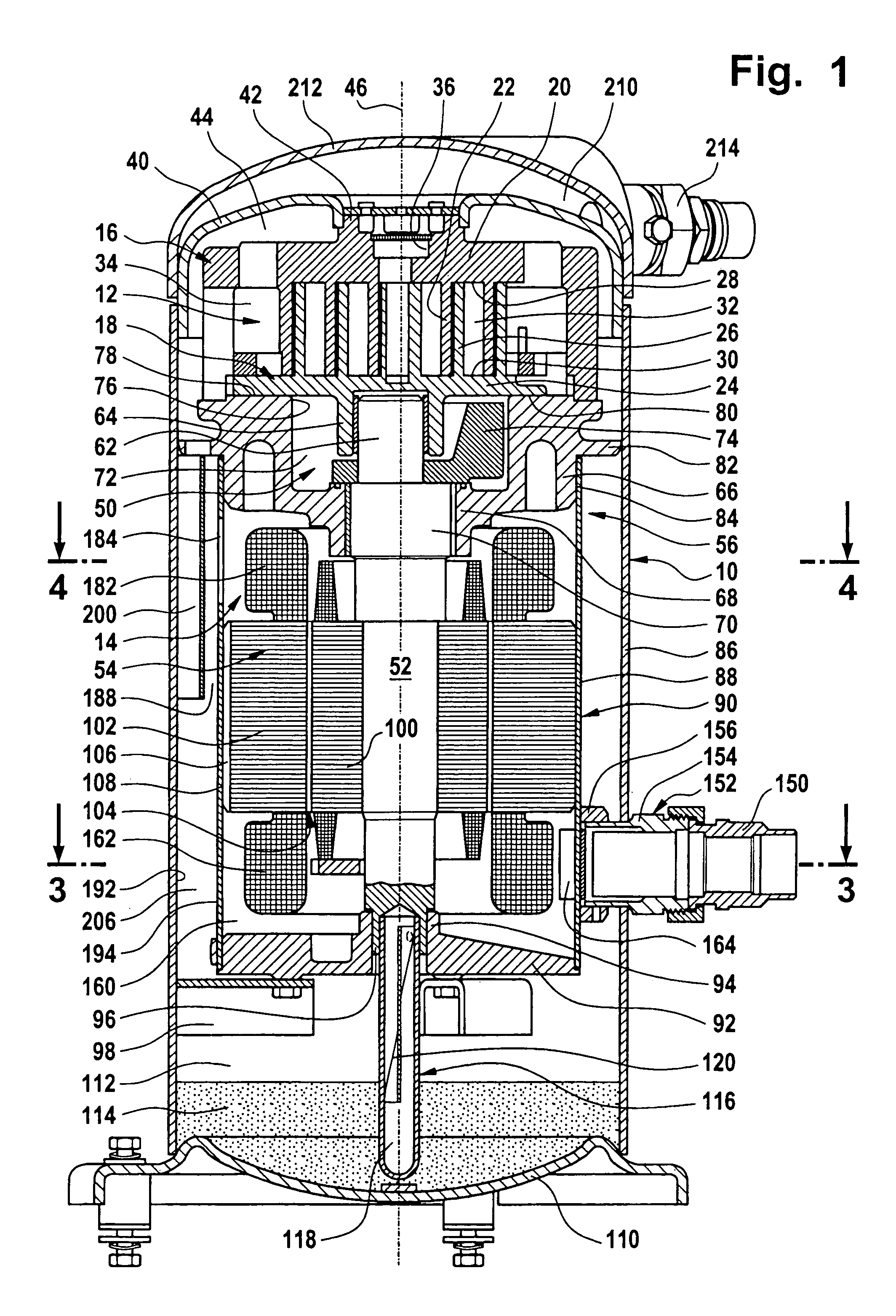

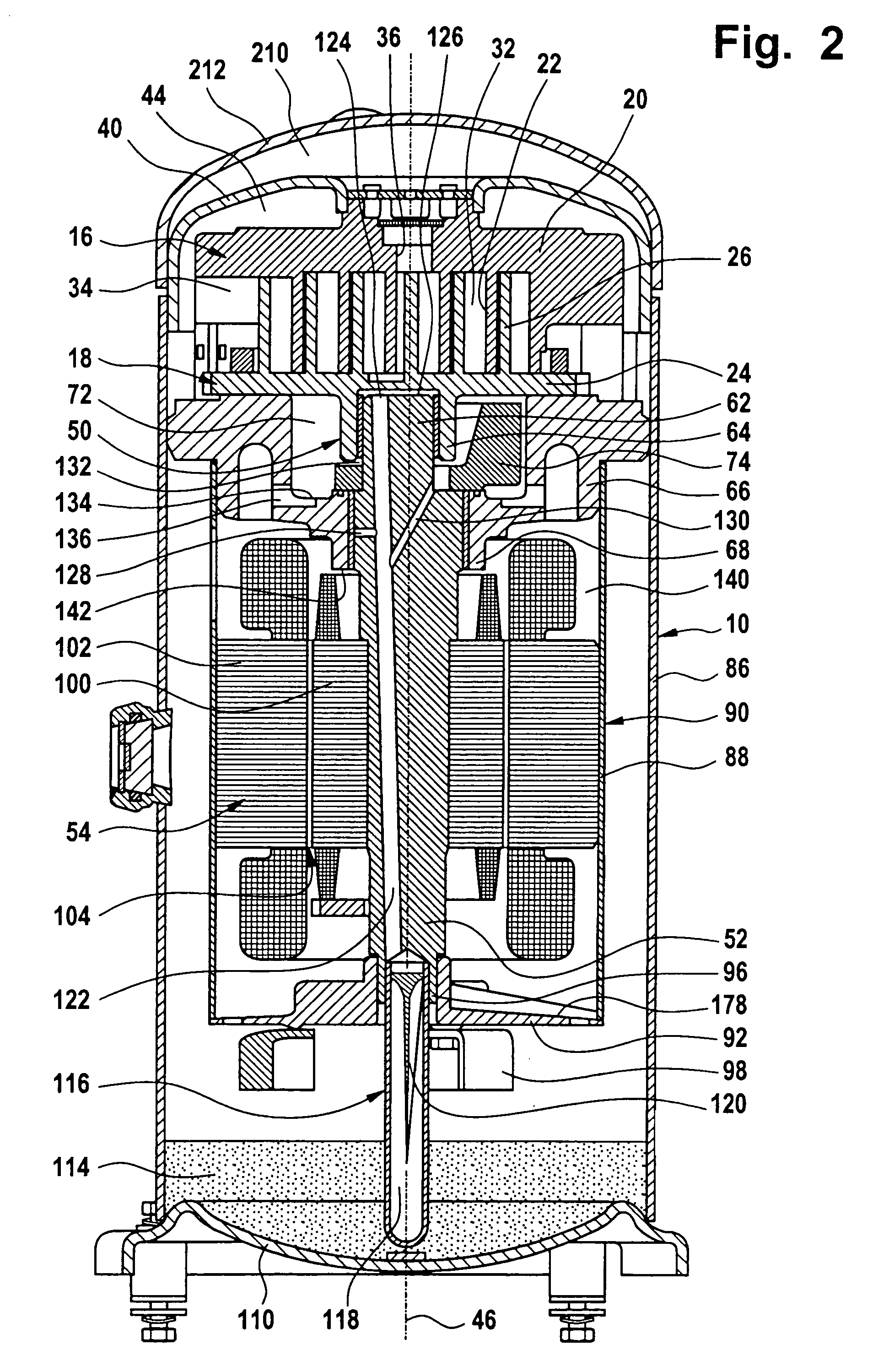

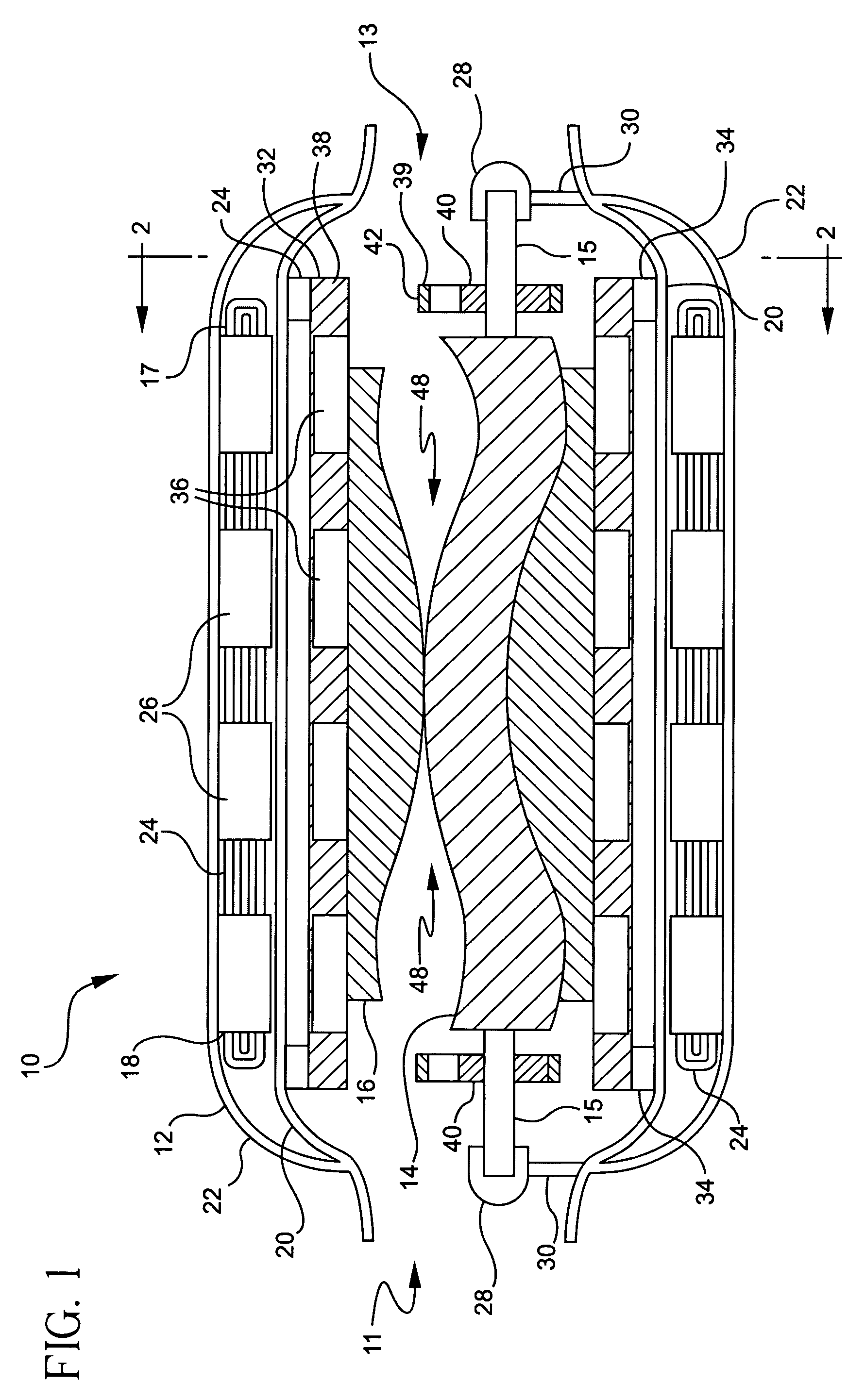

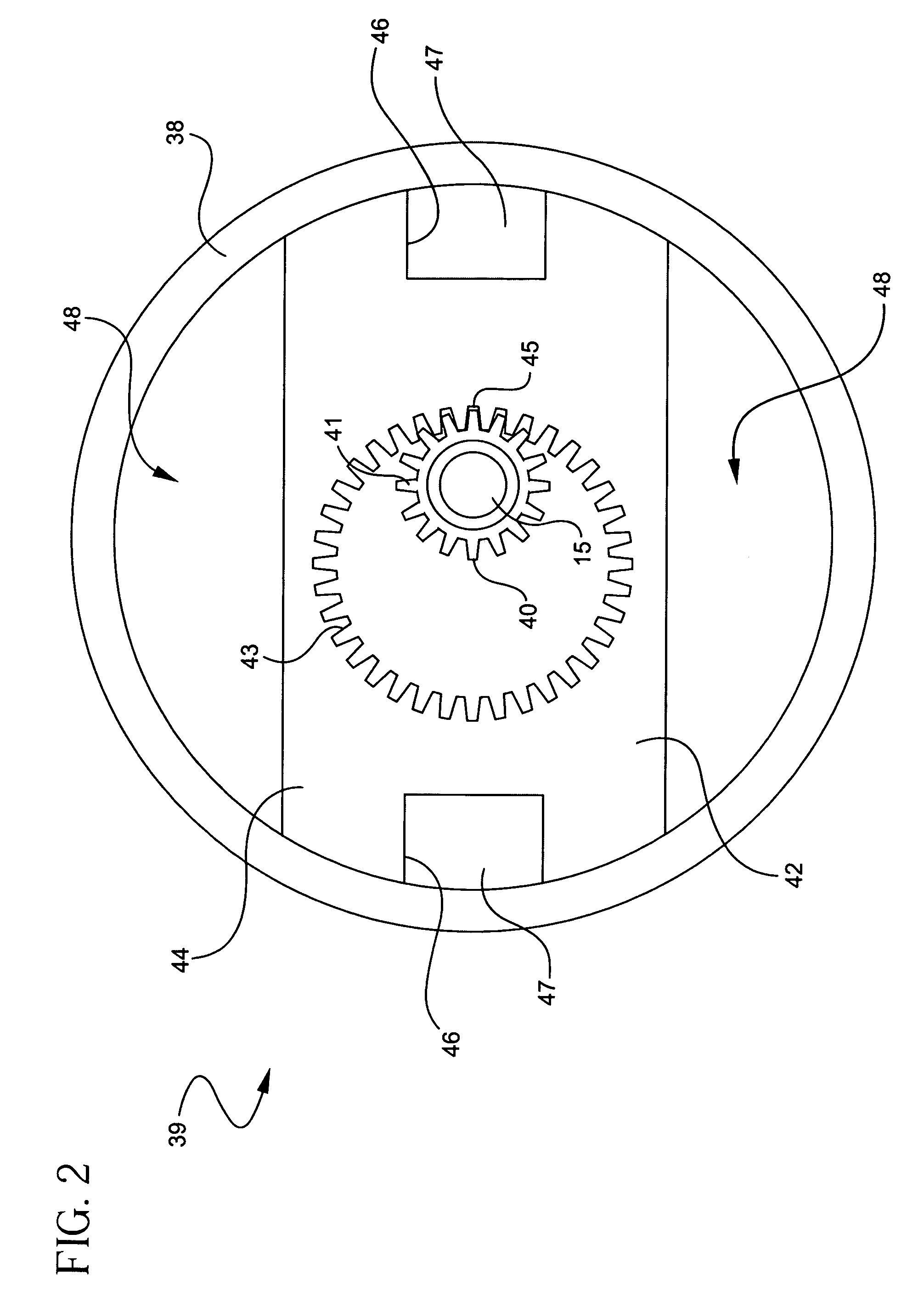

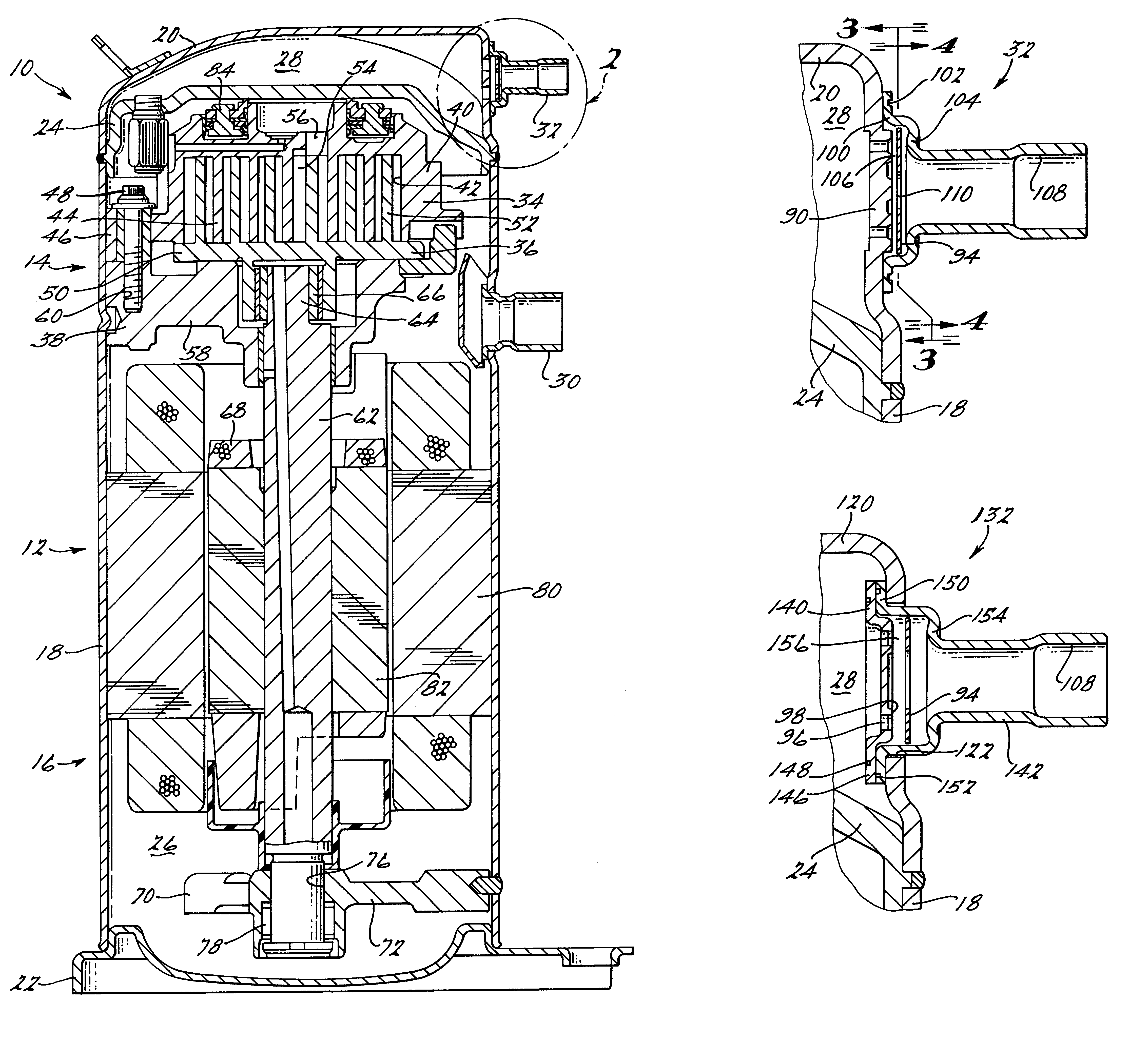

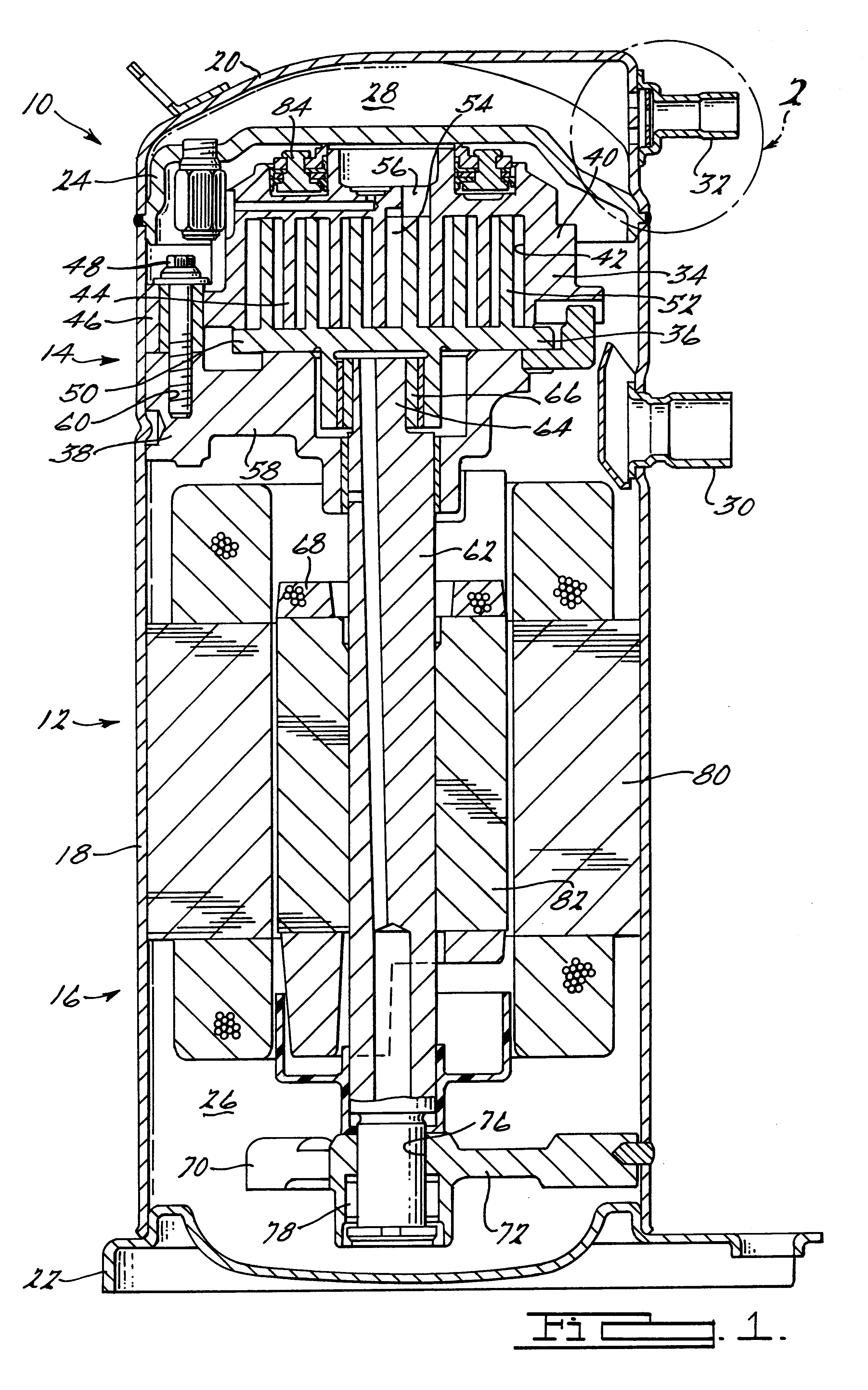

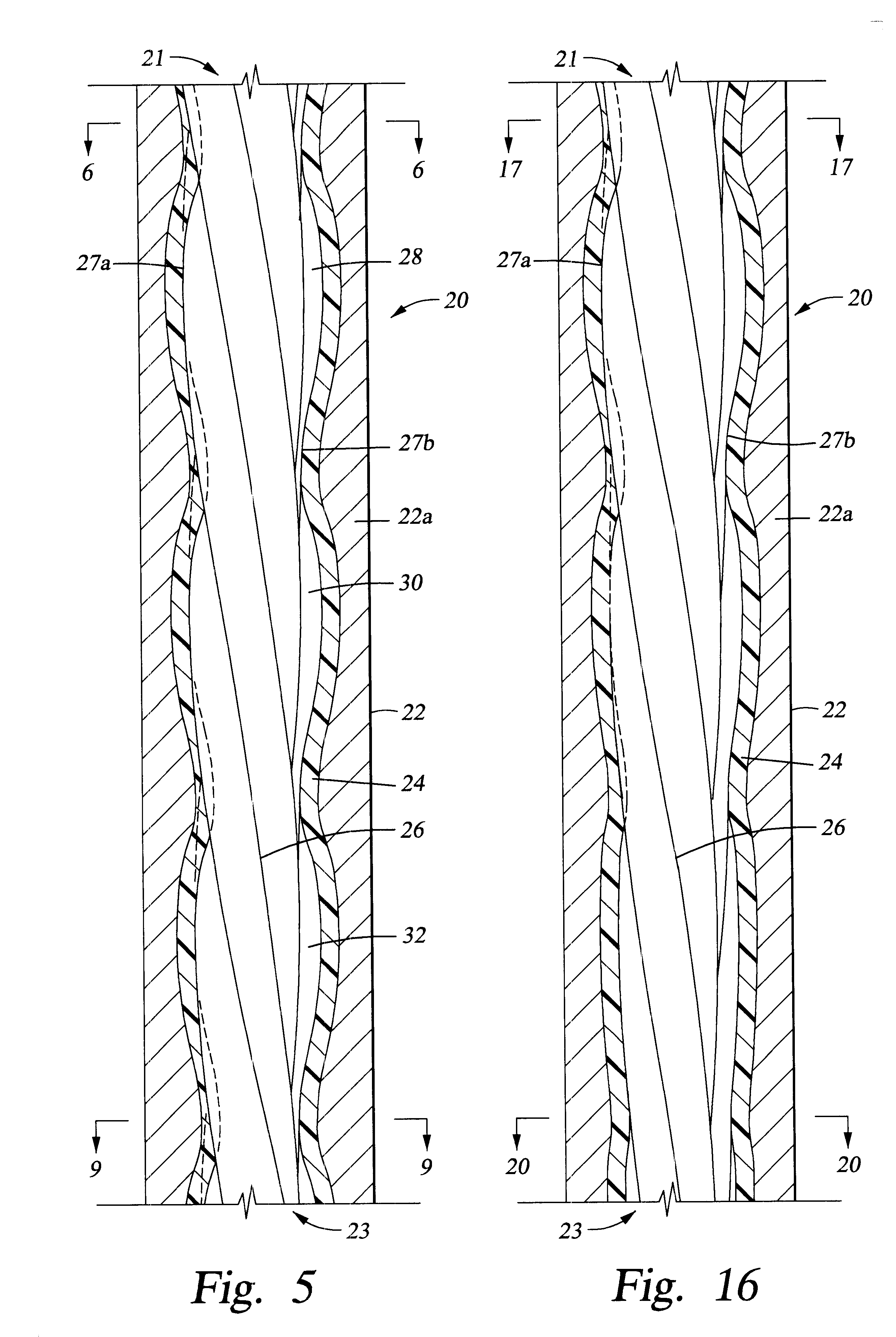

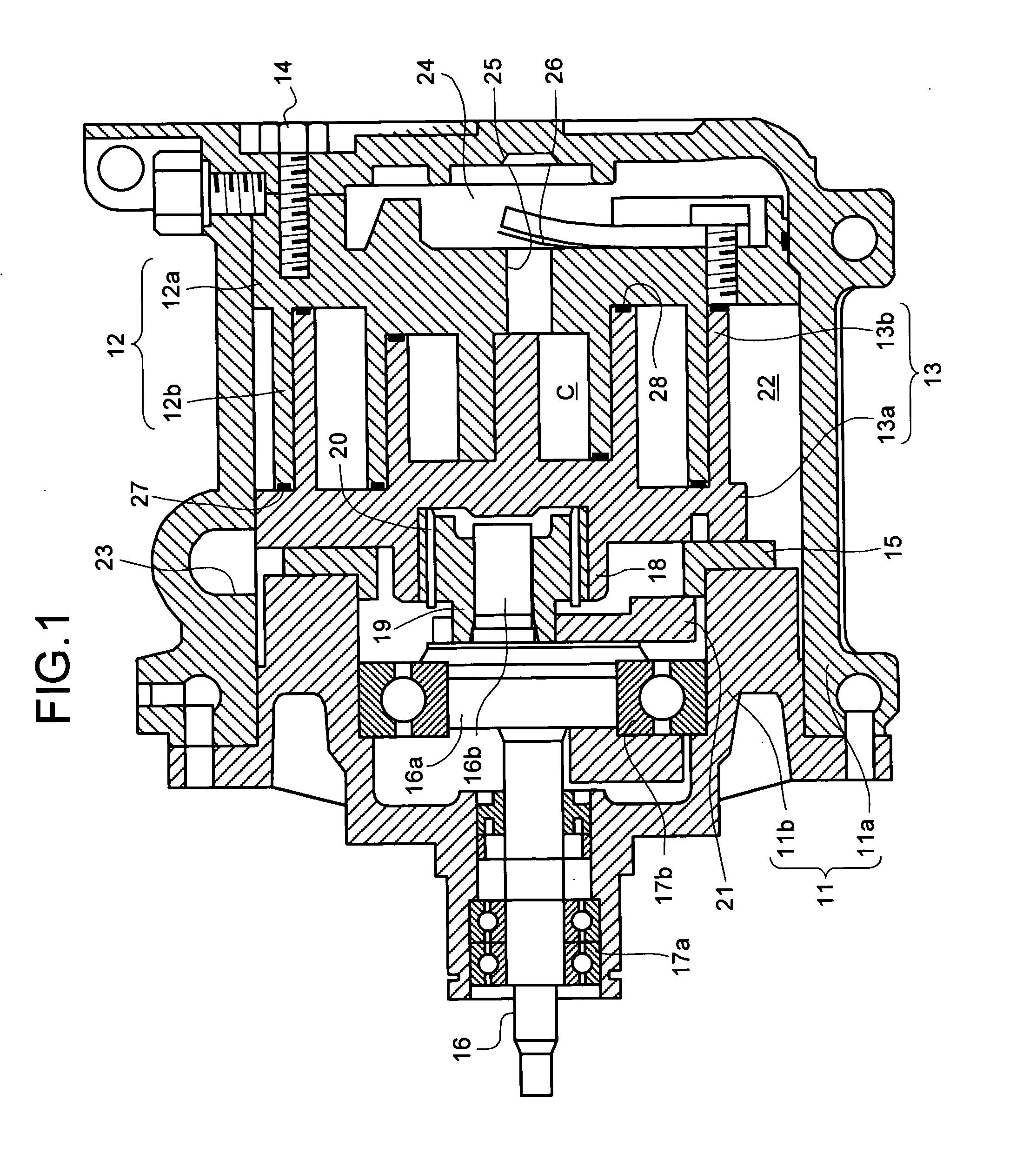

In order to improve a compressor for refrigerant, comprising an outer housing, a scroll compressor arranged in the outer housing and having a first compressor member arranged stationarily in the outer housing and a second compressor member which is movable relative to the first compressor member, the compressor members each having a base and first and second scroll ribs, respectively, which rise above the respective base and engage in one another such that the second compressor member is movable relative to the first compressor member on an orbital path about a central axis for the purpose of compressing the refrigerant, a drive unit for the second compressor member having an eccentric drive, a drive shaft, a drive motor arranged in a motor housing and having drawn-in refrigerant flowing around it as well as a bearing unit for the drive shaft which comprises a first bearing member connected to the outer housing, in such a manner that the refrigerant drawn in by the scroll compressor is free from lubricating oil to as great an extent as possible it is suggested that the refrigerant flow through an oil separator, which is arranged in the outer housing between this and the drive unit, after flowing around the drive motor and prior to entering the scroll compressor.

Owner:BITZER KUEHLMASCHINENBAU GMBH

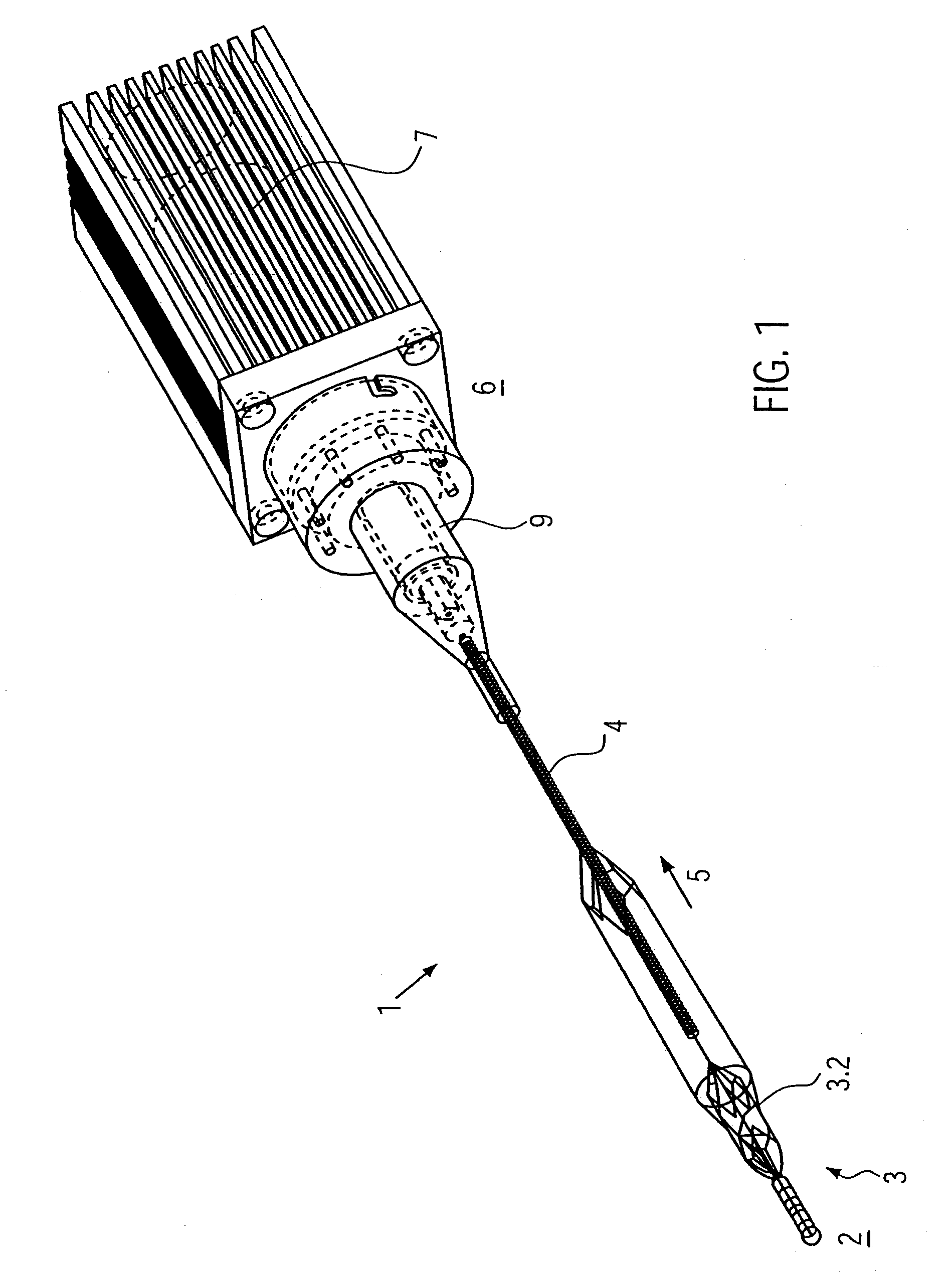

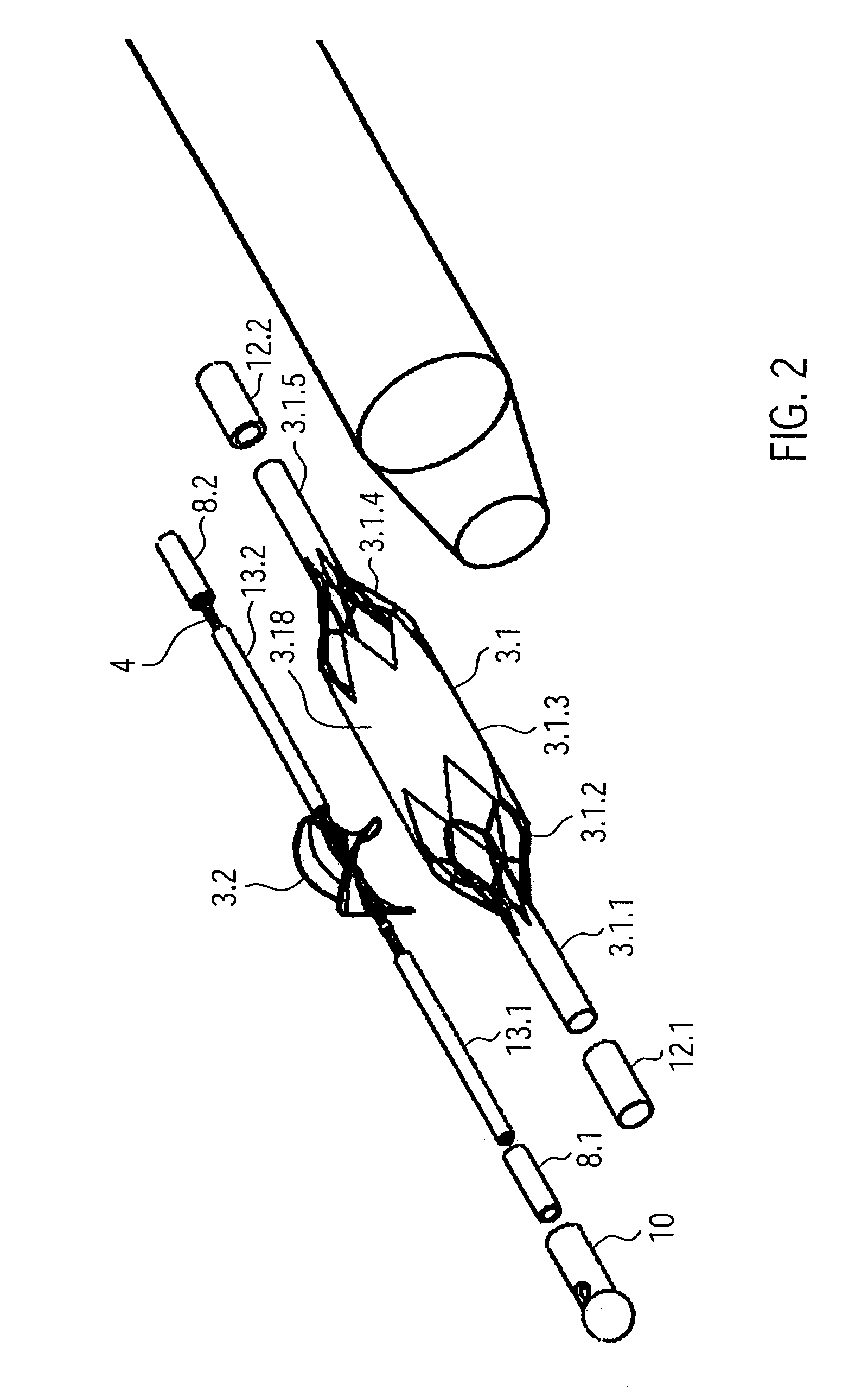

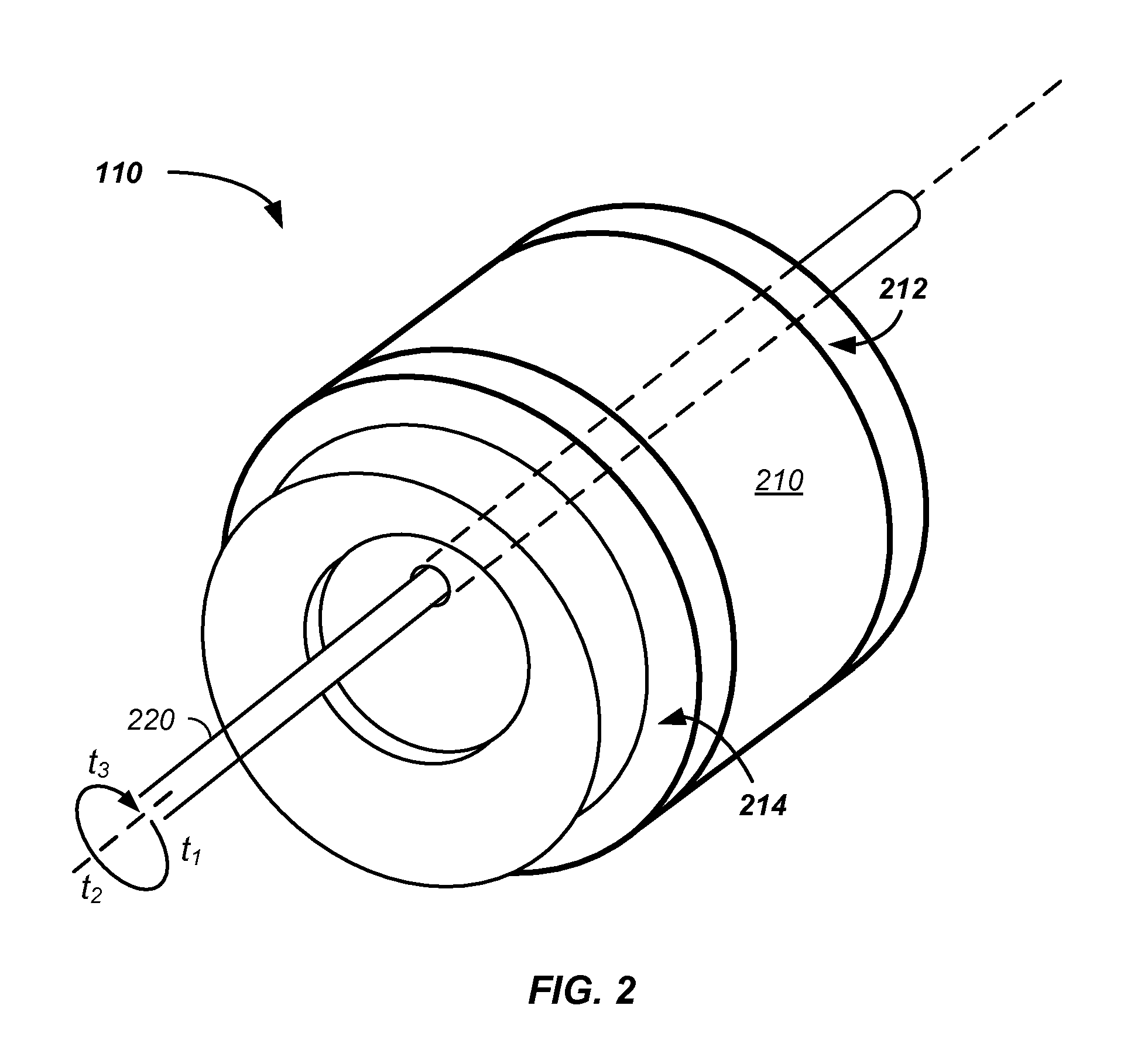

Catheter device

ActiveUS8439859B2Maximum pump performanceImprove performanceStarters with fluid-driven auxillary enginesHeart stimulatorsDrive shaftCatheter device

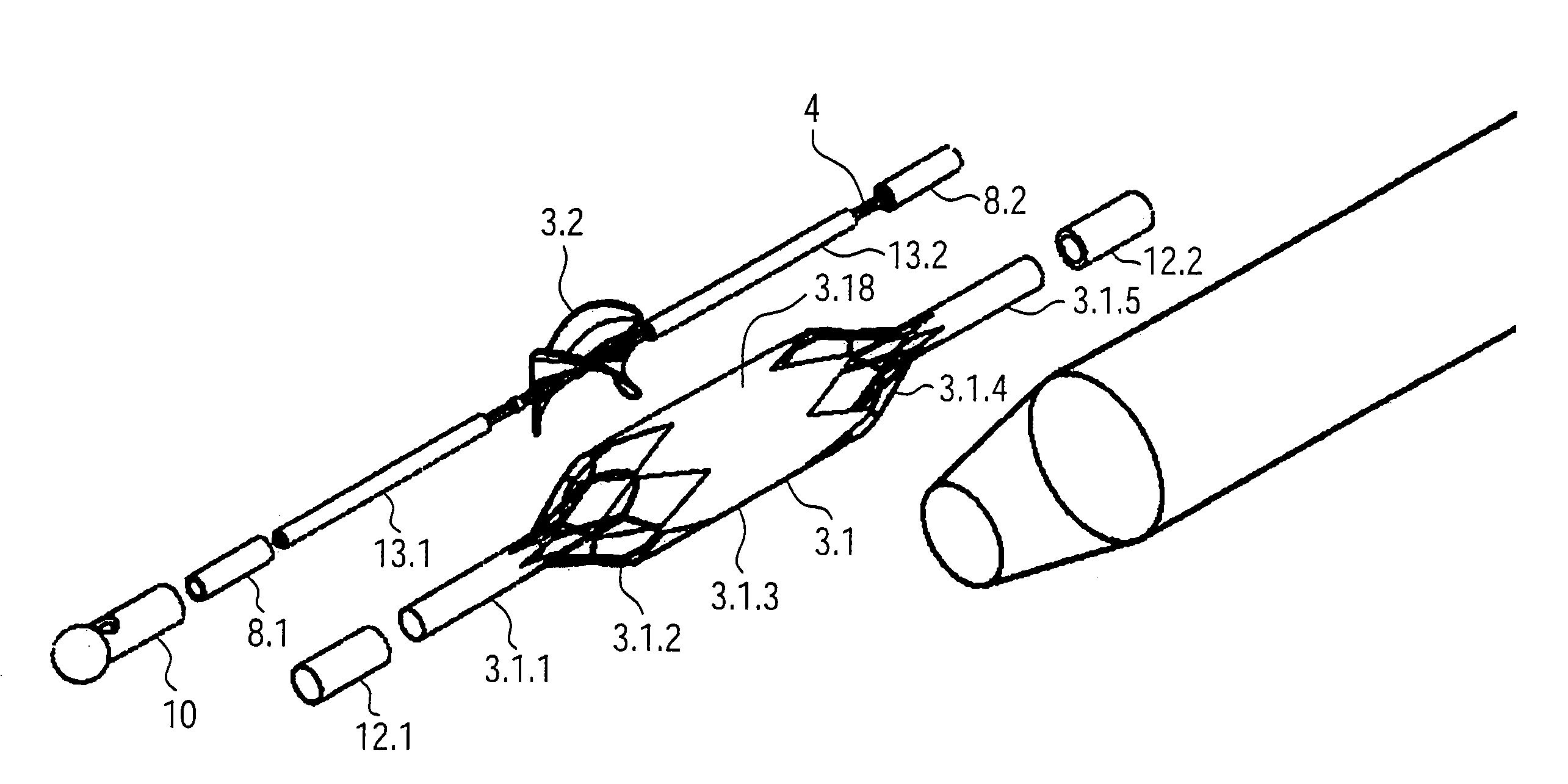

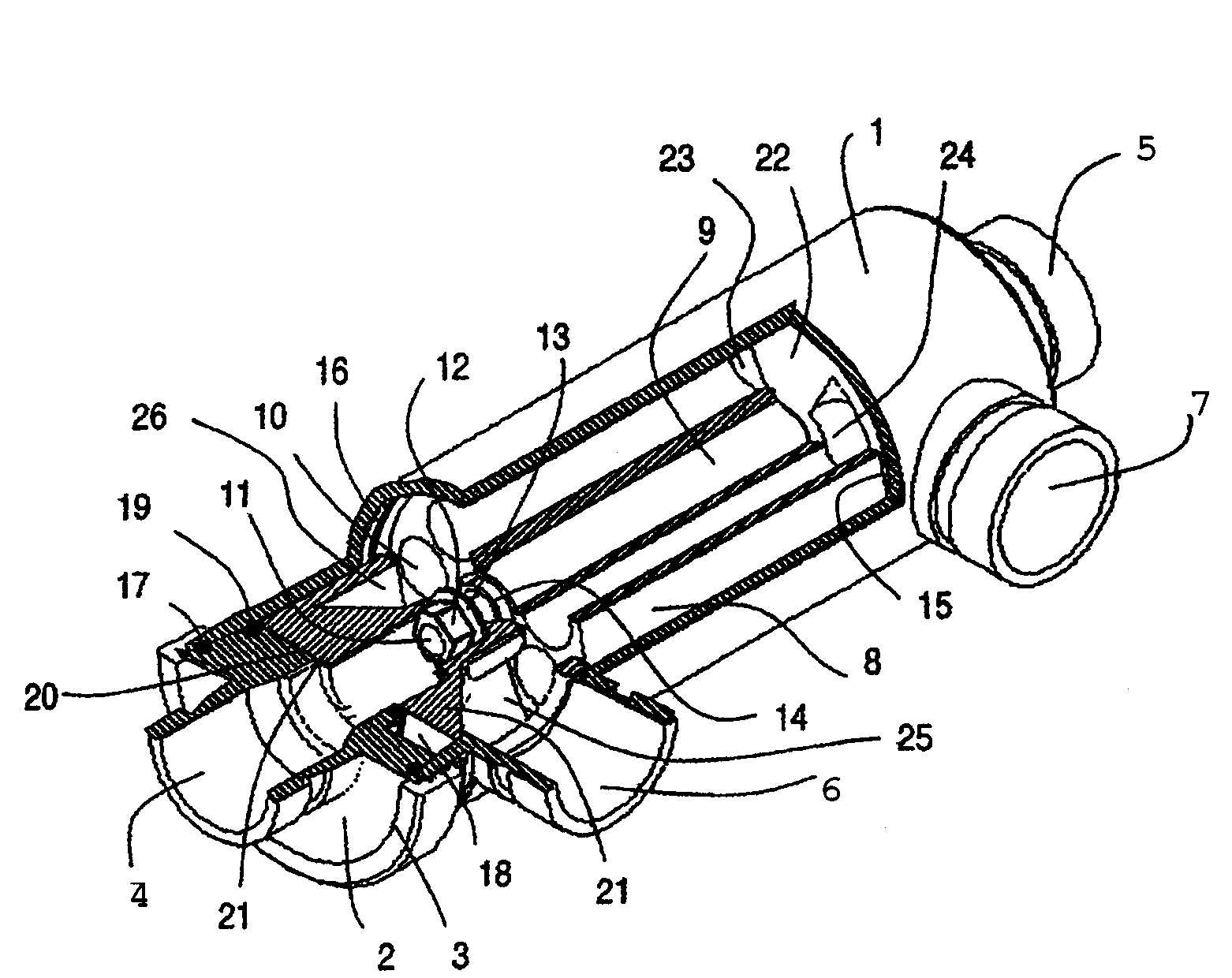

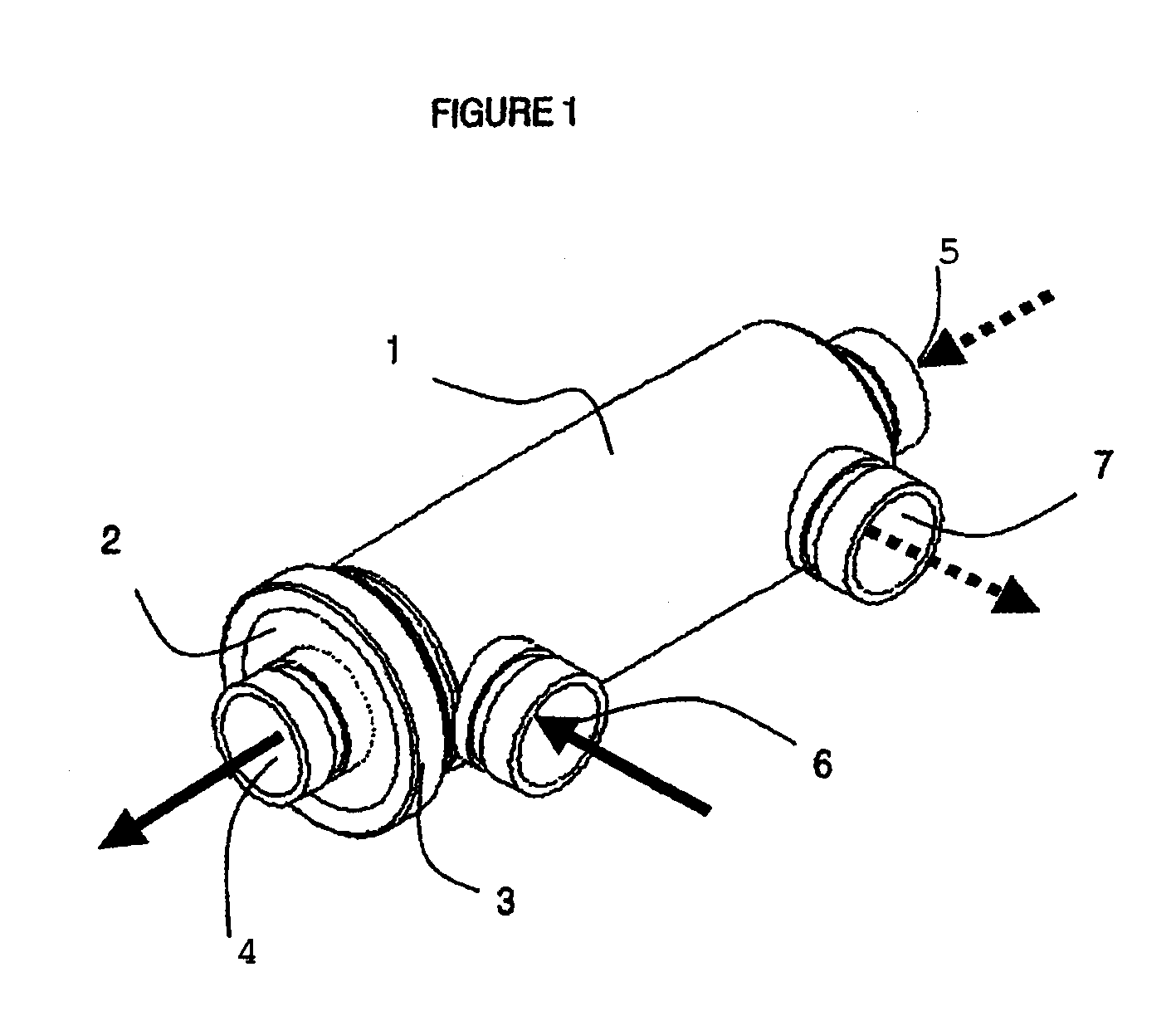

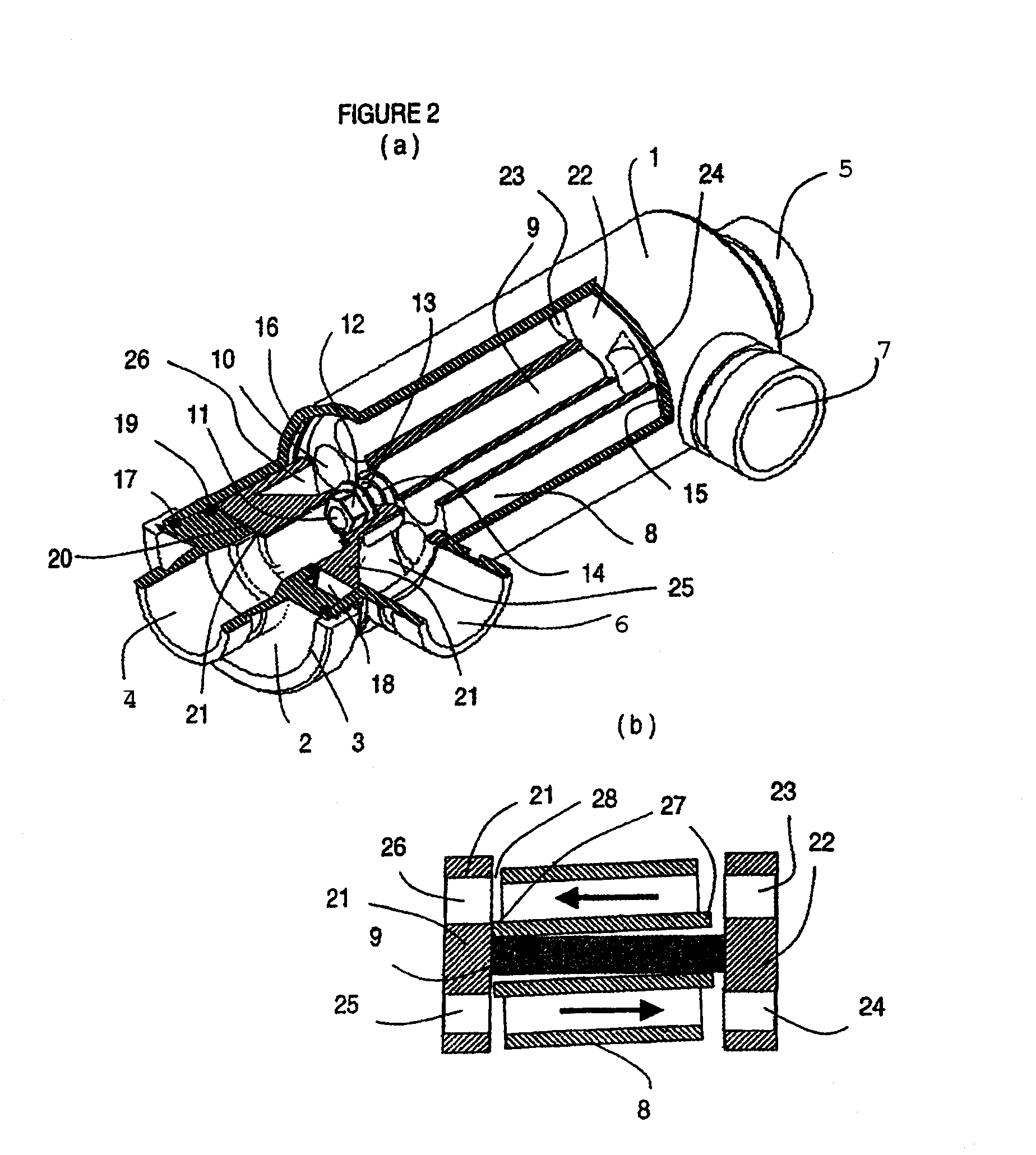

The catheter device comprises a drive shaft connected to a motor, and a rotor mounted on the drive shaft at the distal end section. The rotor has a frame structure which is formed by a screw-like boundary frame and rotor struts extending radially inwards from the boundary frame. The rotor struts are fastened to the drive shaft by their ends opposite the boundary frame. Between the boundary frame and the drive shaft extends an elastic covering. The frame structure is made of an elastic material such that, after forced compression, the rotor unfolds automatically.

Owner:AIS AACHEN INNOVATIVE SOLUTIONS

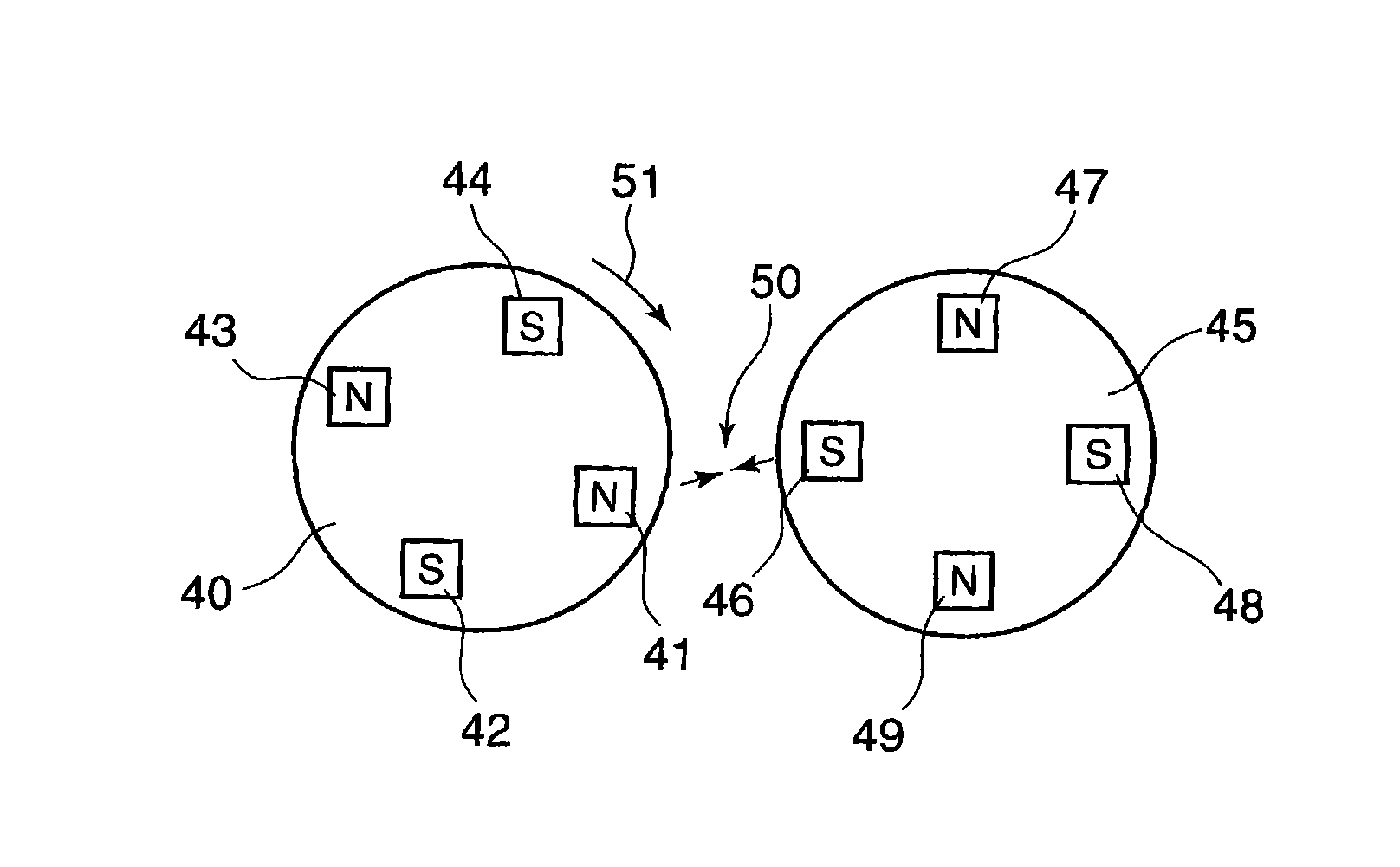

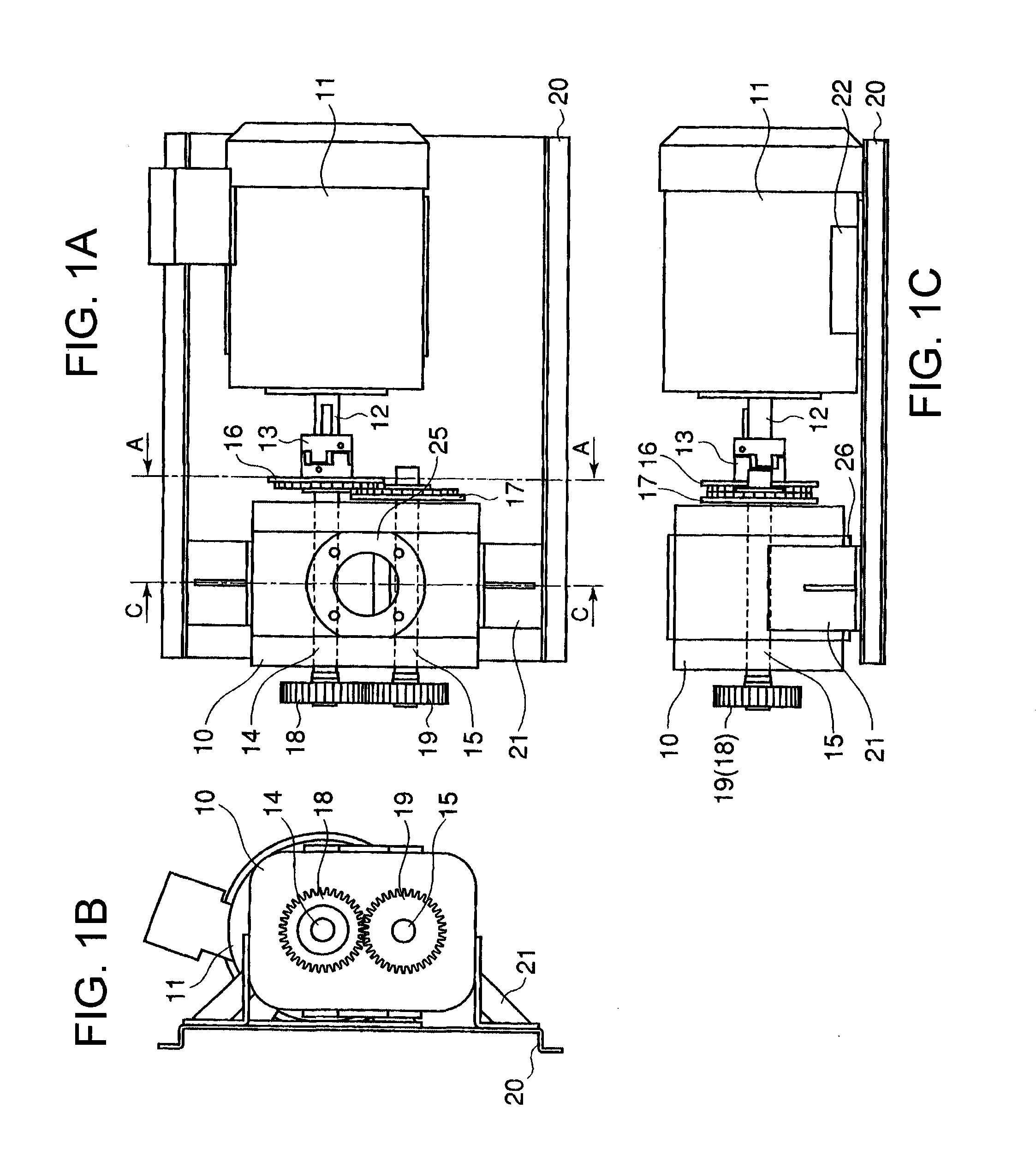

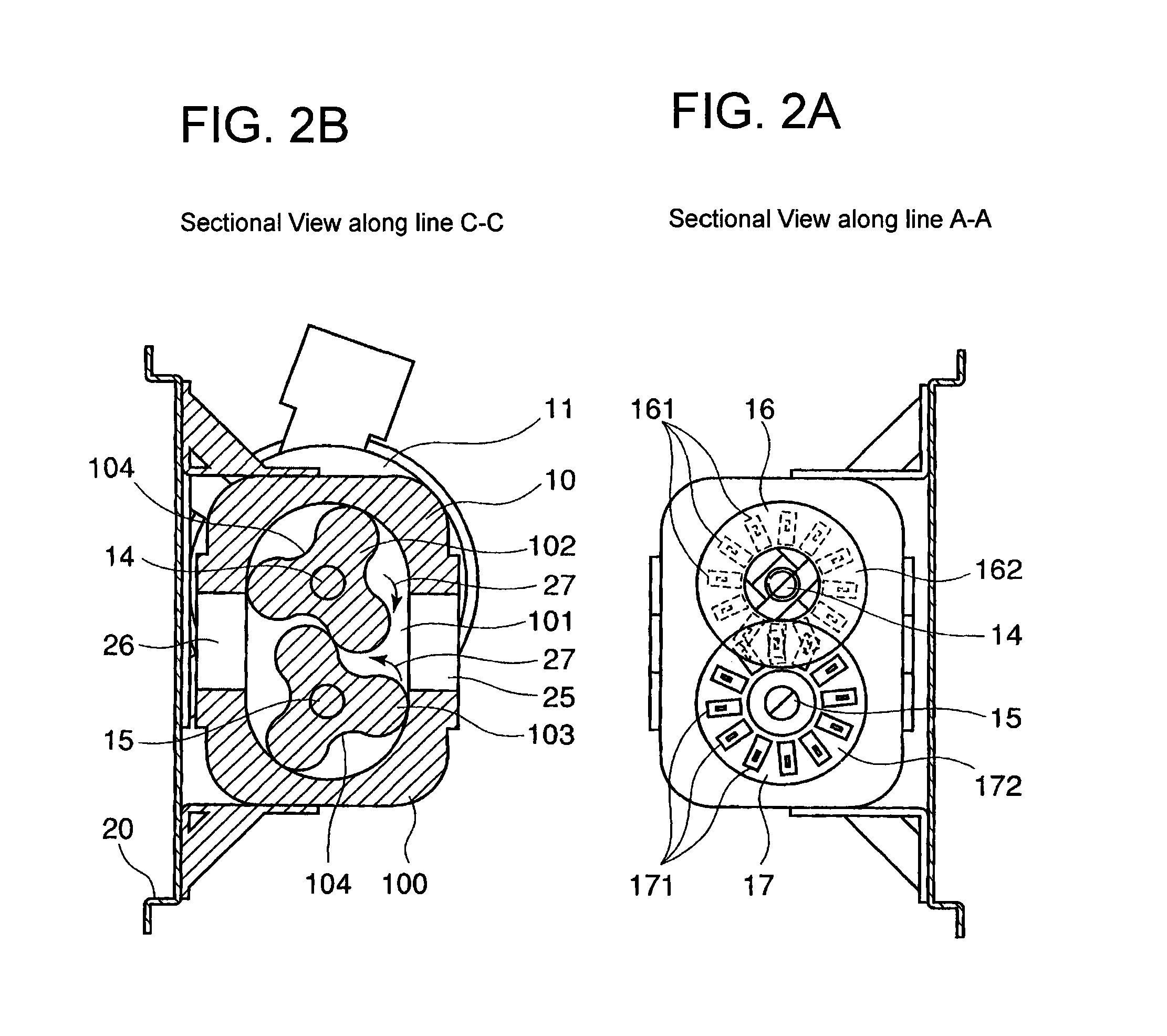

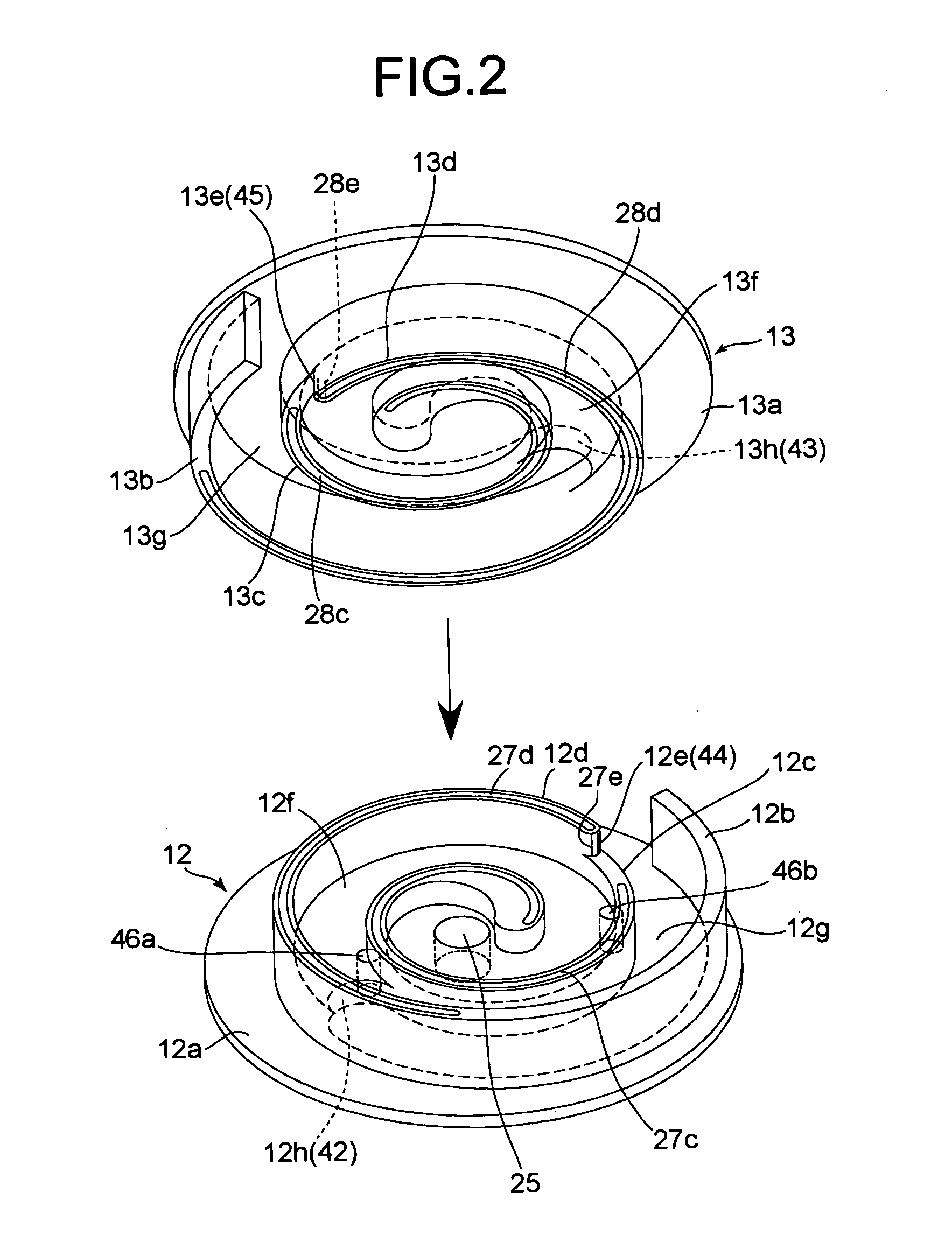

Drive transmission mechanism between two or more rotary shafts and oil-free fluid machine equipped with the mechanism

InactiveUS20080181804A1Reduced service lifeEliminate pollutionDynamo-electric brakes/clutchesEngine of counter-engagement typePlastic materialsOil free

A drive transmission mechanism for transmitting torque between two or more rotary shafts in synchronization with one another without need for lubrication thereby eliminating occurrence of oil contamination, and an oil-free fluid machine equipped with the mechanism, are provided. A magnetic drive disk 16 and a synchronization gear 18 are attached to a rotary shaft 14 connected to a drive motor 11, a magnetic drive disk 17 and a synchronization gear 19 is attached to a rotary shaft 15, torque transmission from the rotary shaft 14 to the rotary shaft 15 is carried out in two ways, via the magnetic drive disks 16, 17 and via the synchronization gears 18, 19, and at least one of the synchronization gears is made of plastic material. With the construction, torque transmit load between the rotary shafts via the synchronization gears is decreased, and a plastic gear or gears can be adopted for synchronization gears without reducing life of the gears without need for lubrication oil.

Owner:ANEST IWATA CORP

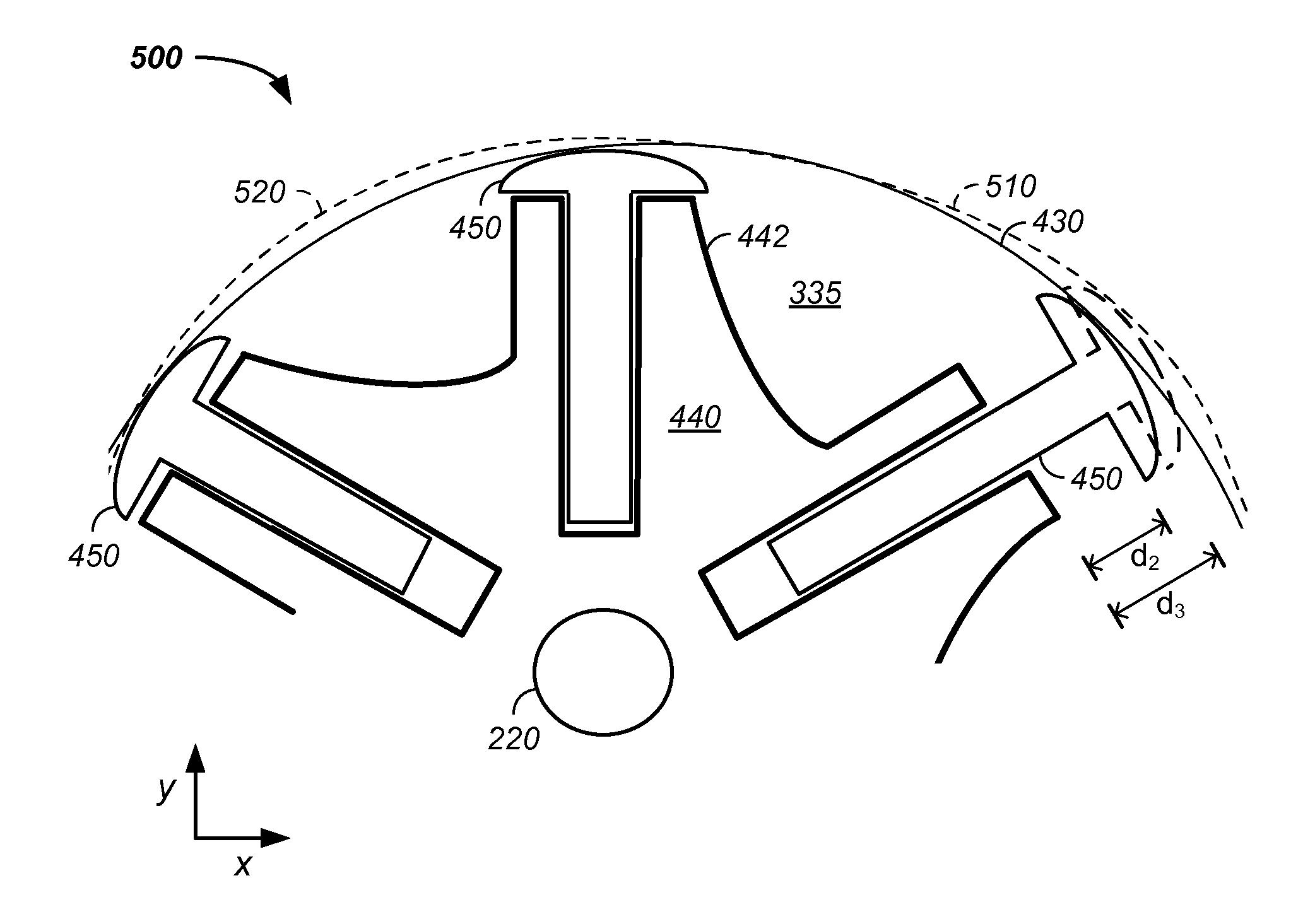

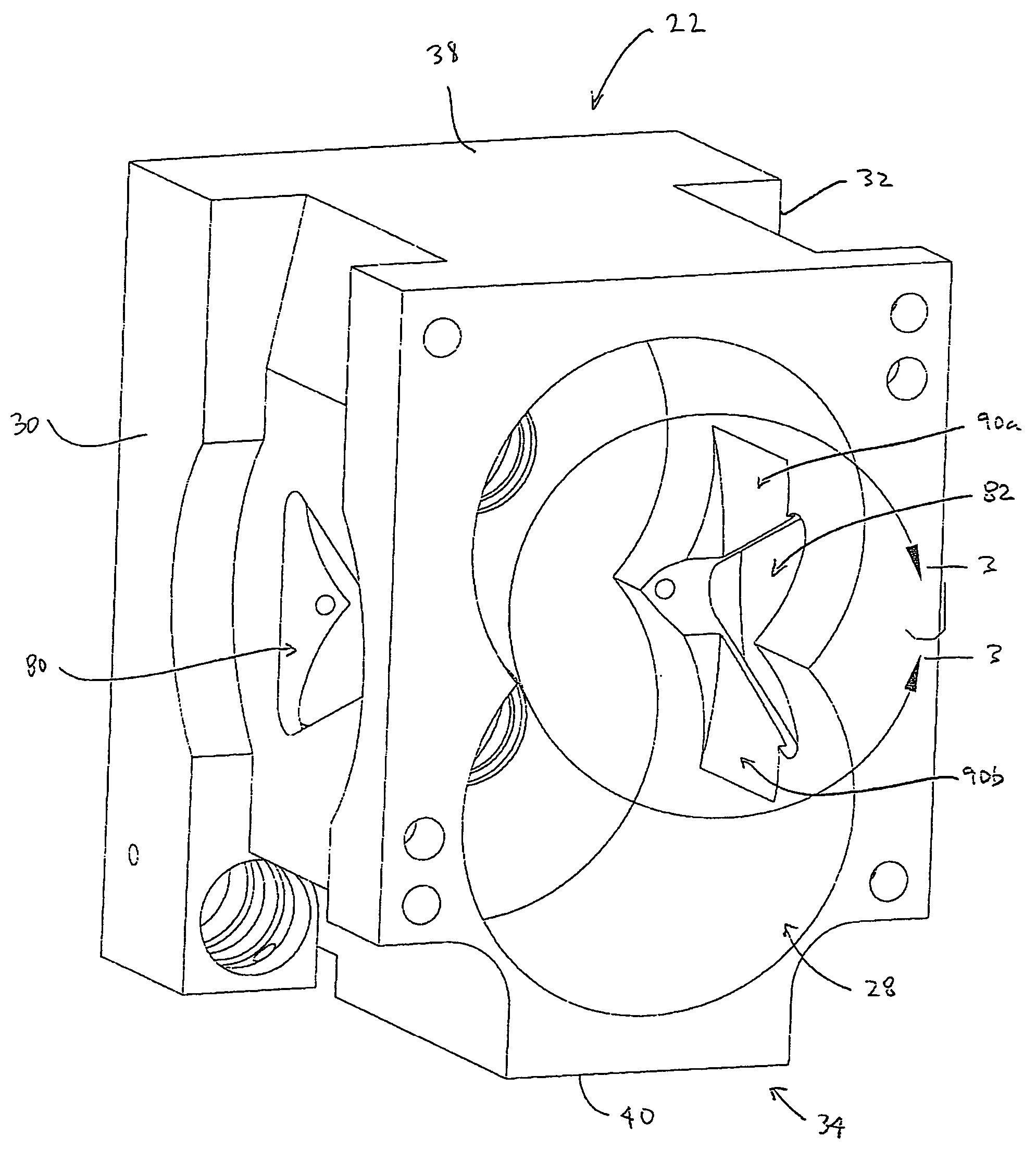

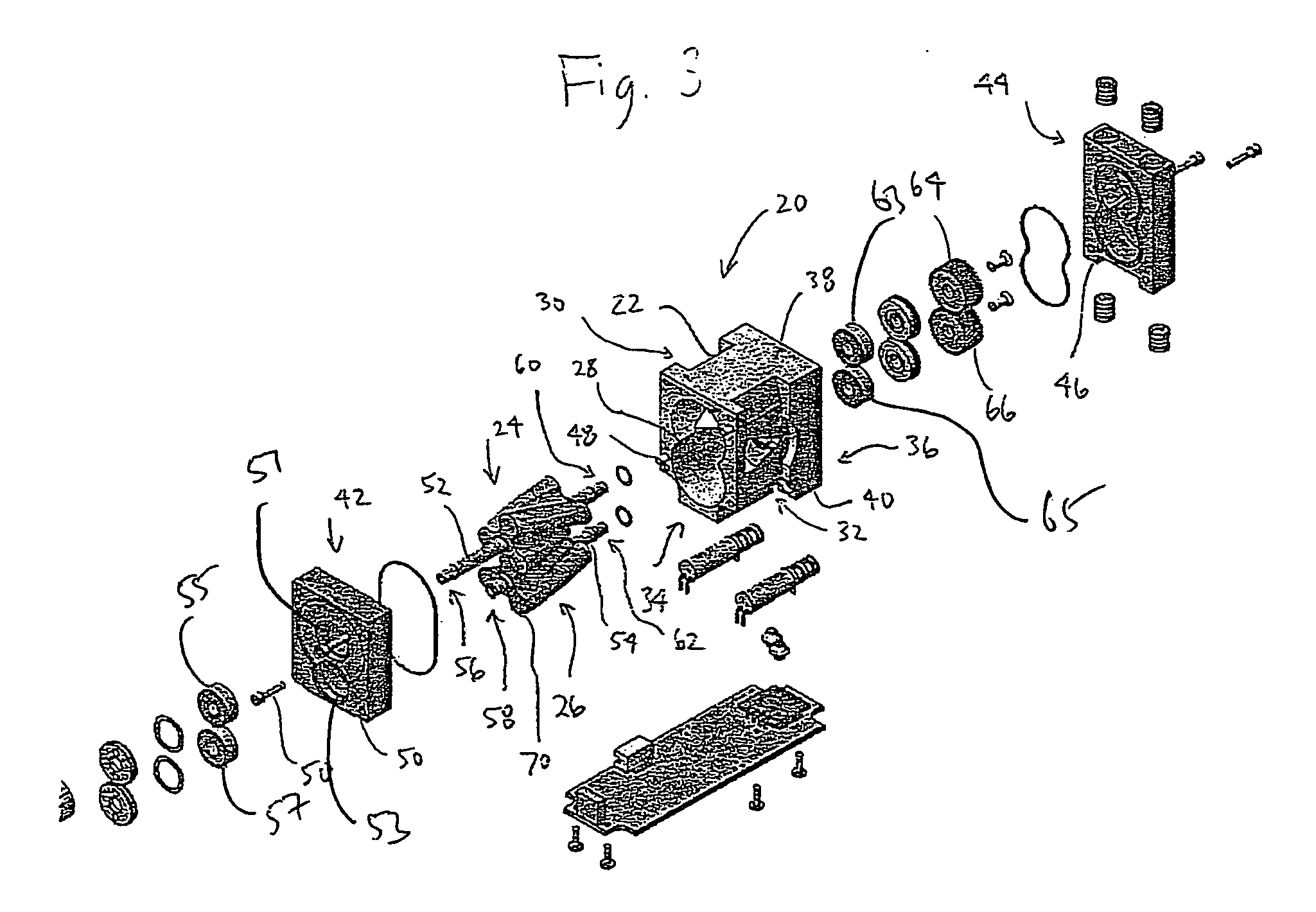

Rotary engine expansion chamber apparatus and method of operation therefor

ActiveUS8523547B2Internal combustion piston enginesOscillating piston enginesRotary engineExpansion chamber

Owner:PEKRUL MERTON W

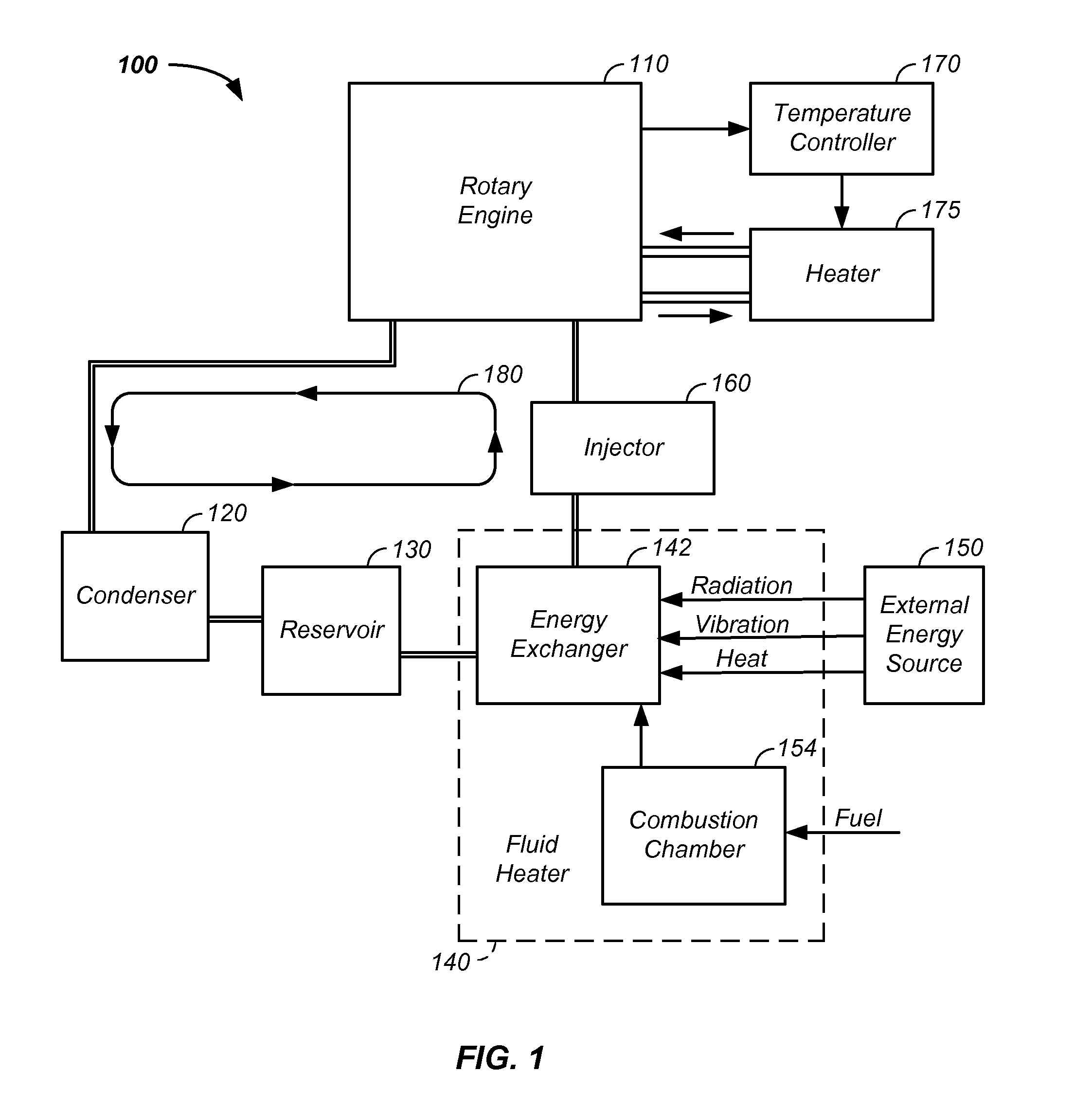

Low emission energy source

Owner:BRIGHTSOURCE ENERGY

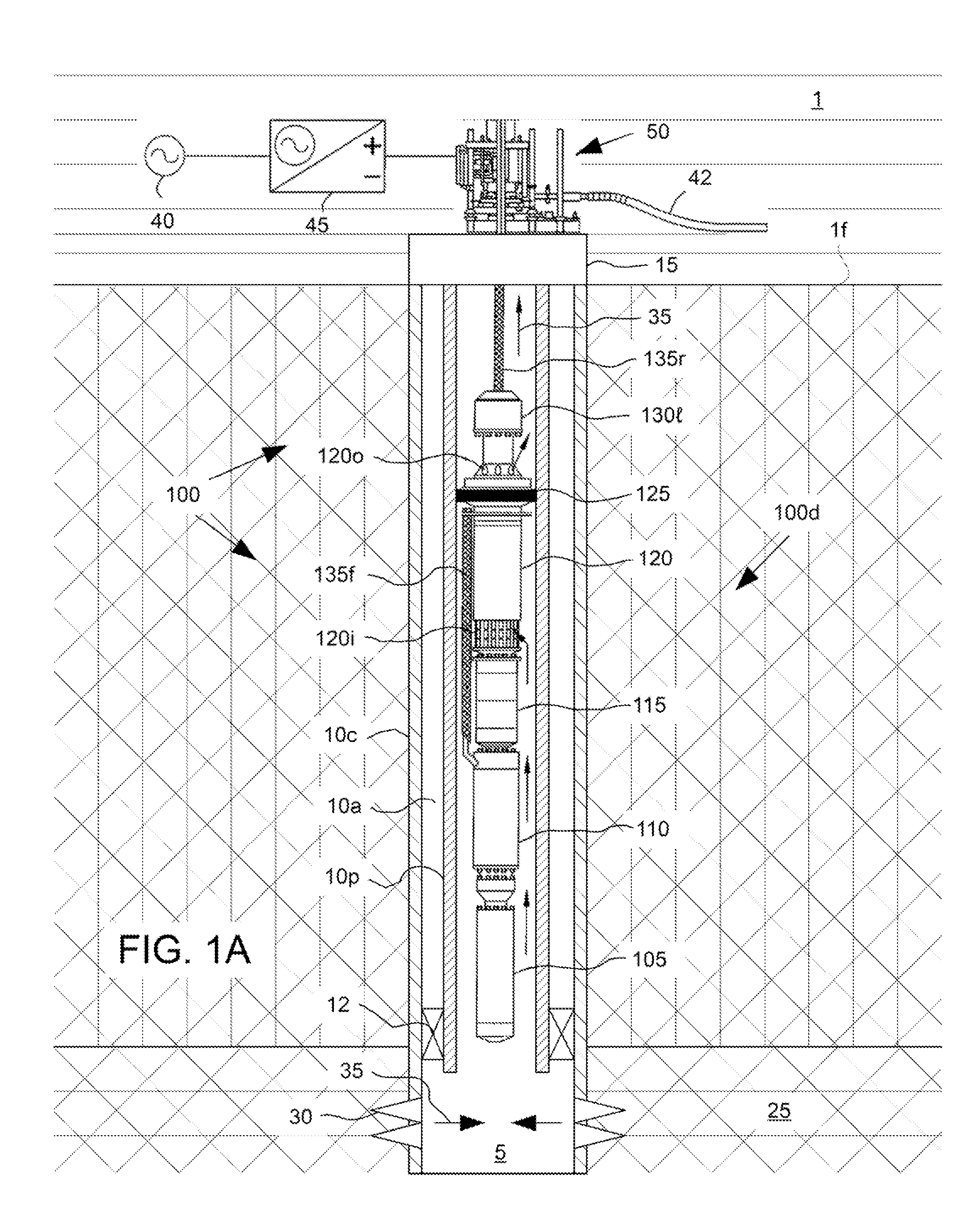

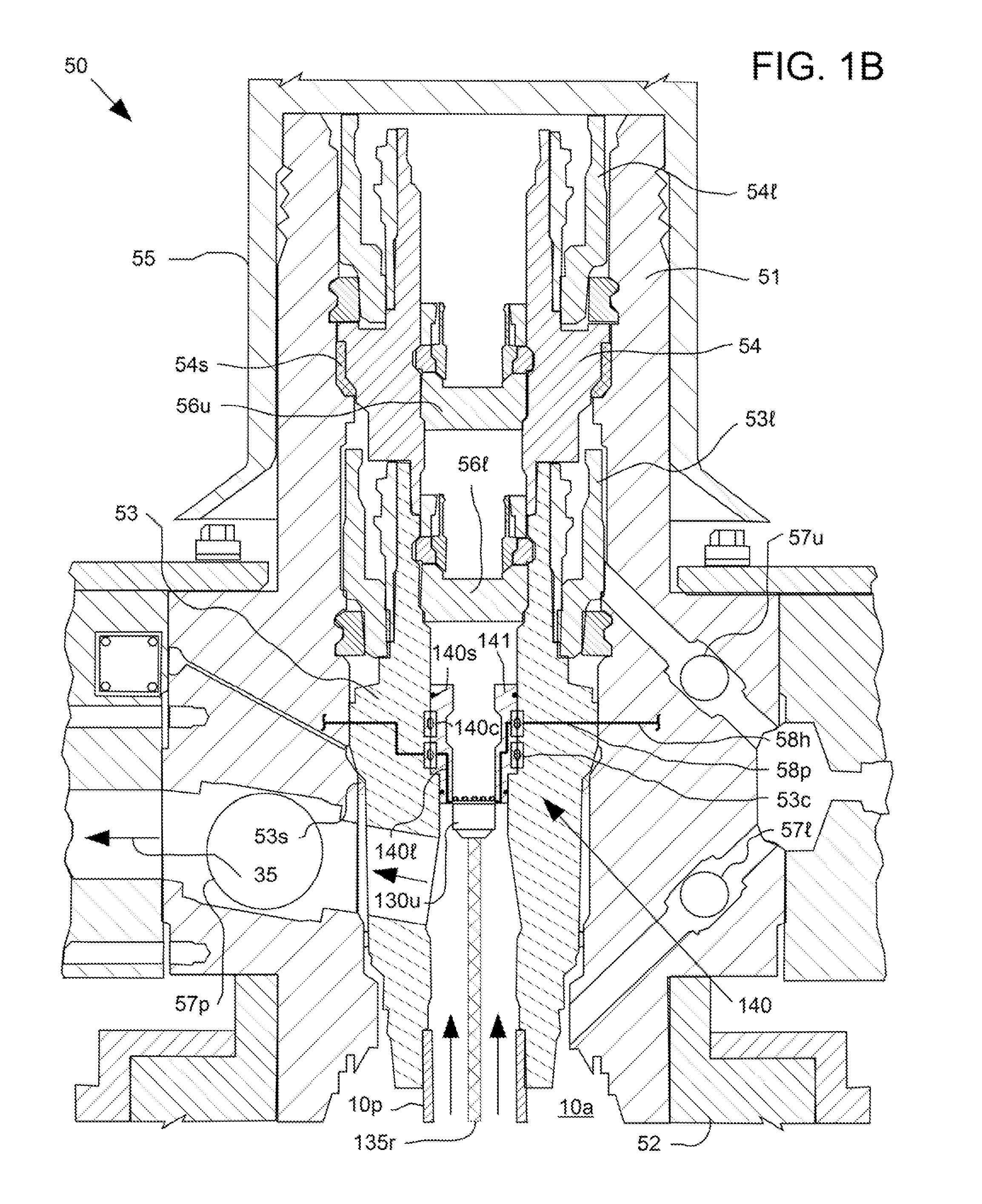

Direct drive linear flow blood pump

A ventricular assistive device (VAD) based on a progressive cavity pump includes a pump housing having an inlet and an outlet, a pump stator contained within the pump housing, a pump rotor rotatably disposed within the pump stator, a motor including a motor rotor contained within the pump housing and a direct drive means connected between the motor rotor and an axial shaft of the pump rotor for rotating the pump rotor. The motor rotates the motor rotor, which in turn rotates the pump rotor through the direct drive means. The rotation of the pump rotor within the pump stator forms a plurality of cavities that carry blood forward through the pump housing from the inlet to the outlet as the motor drives the direct drive means.

Owner:CHANG SHELDON

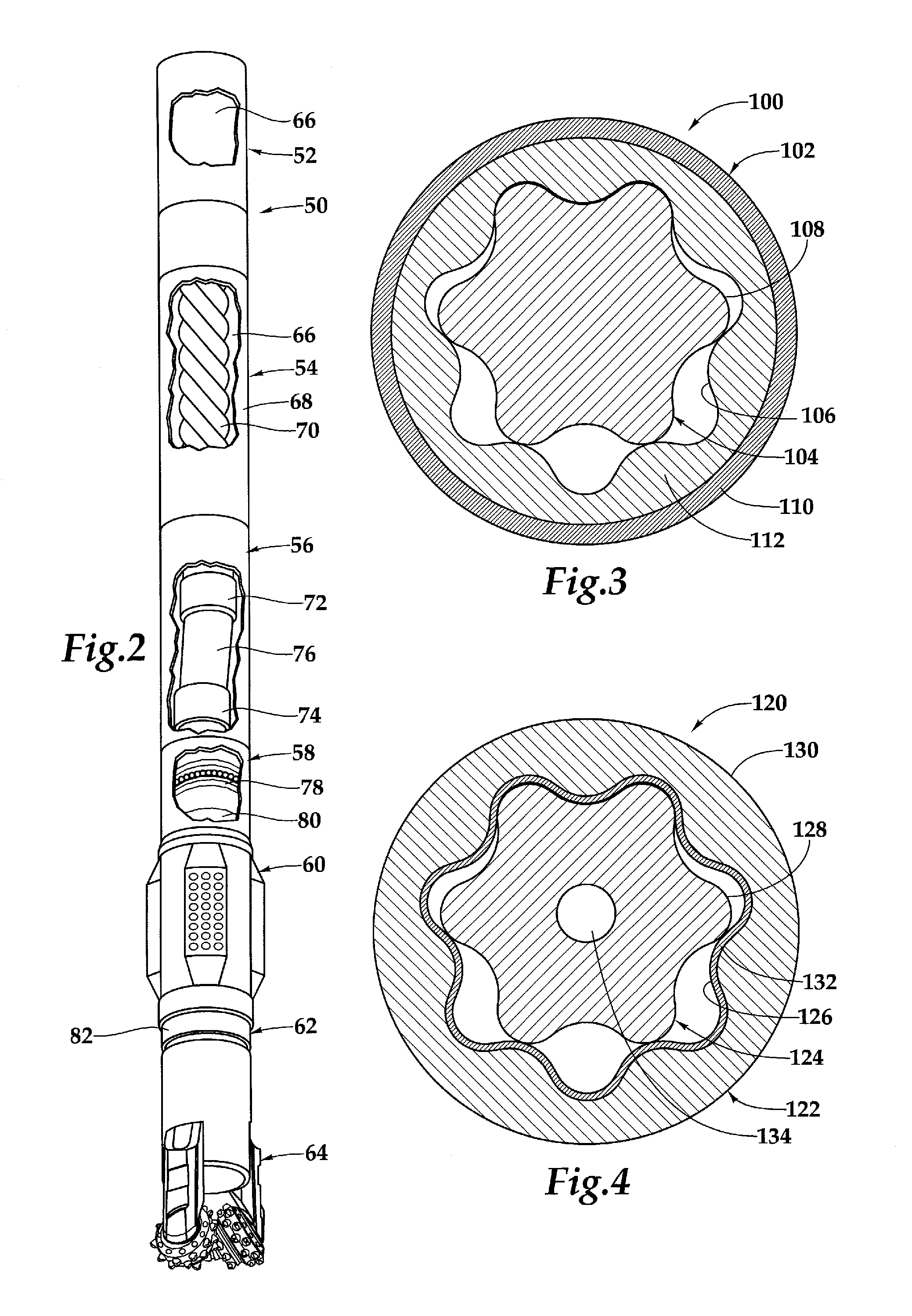

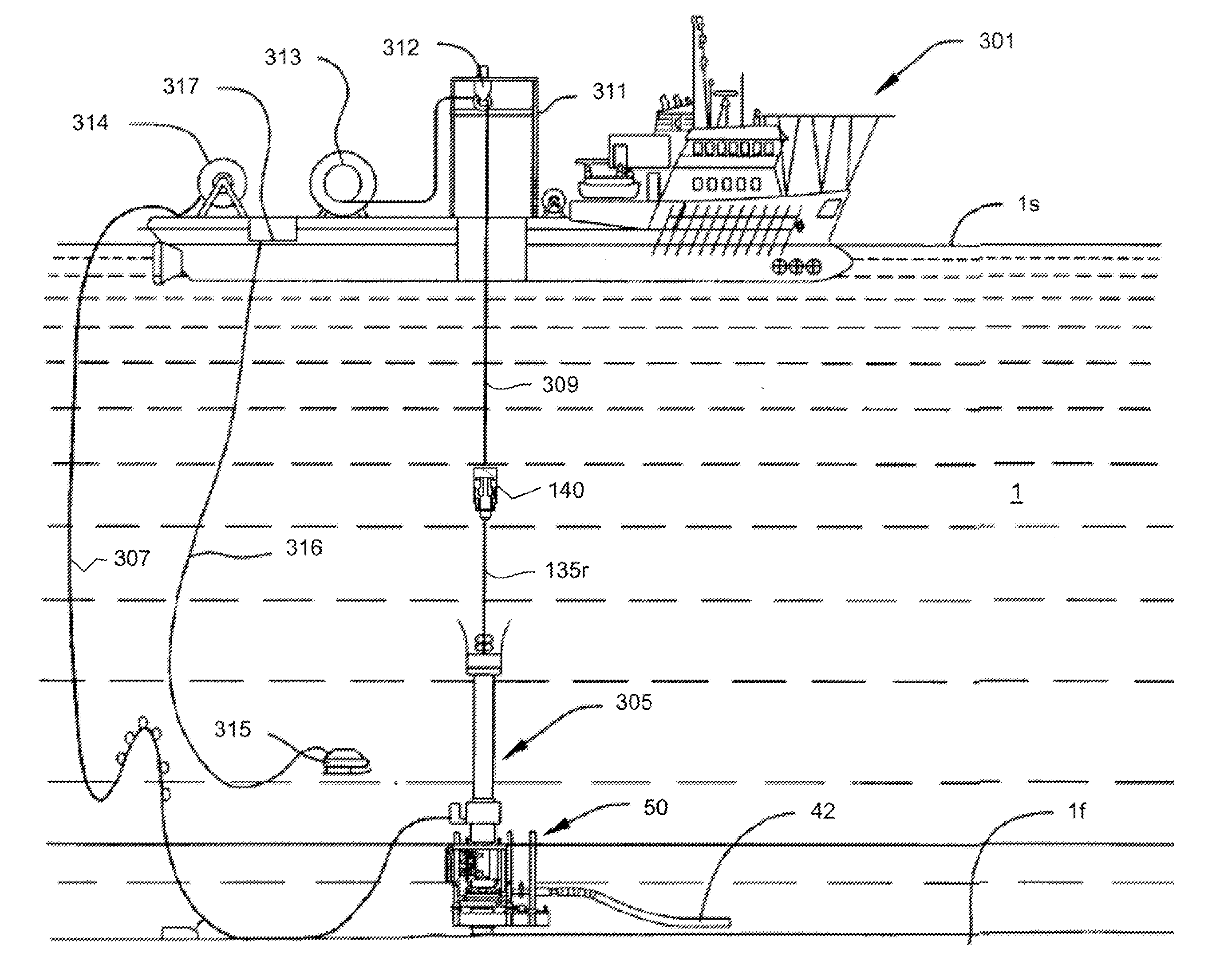

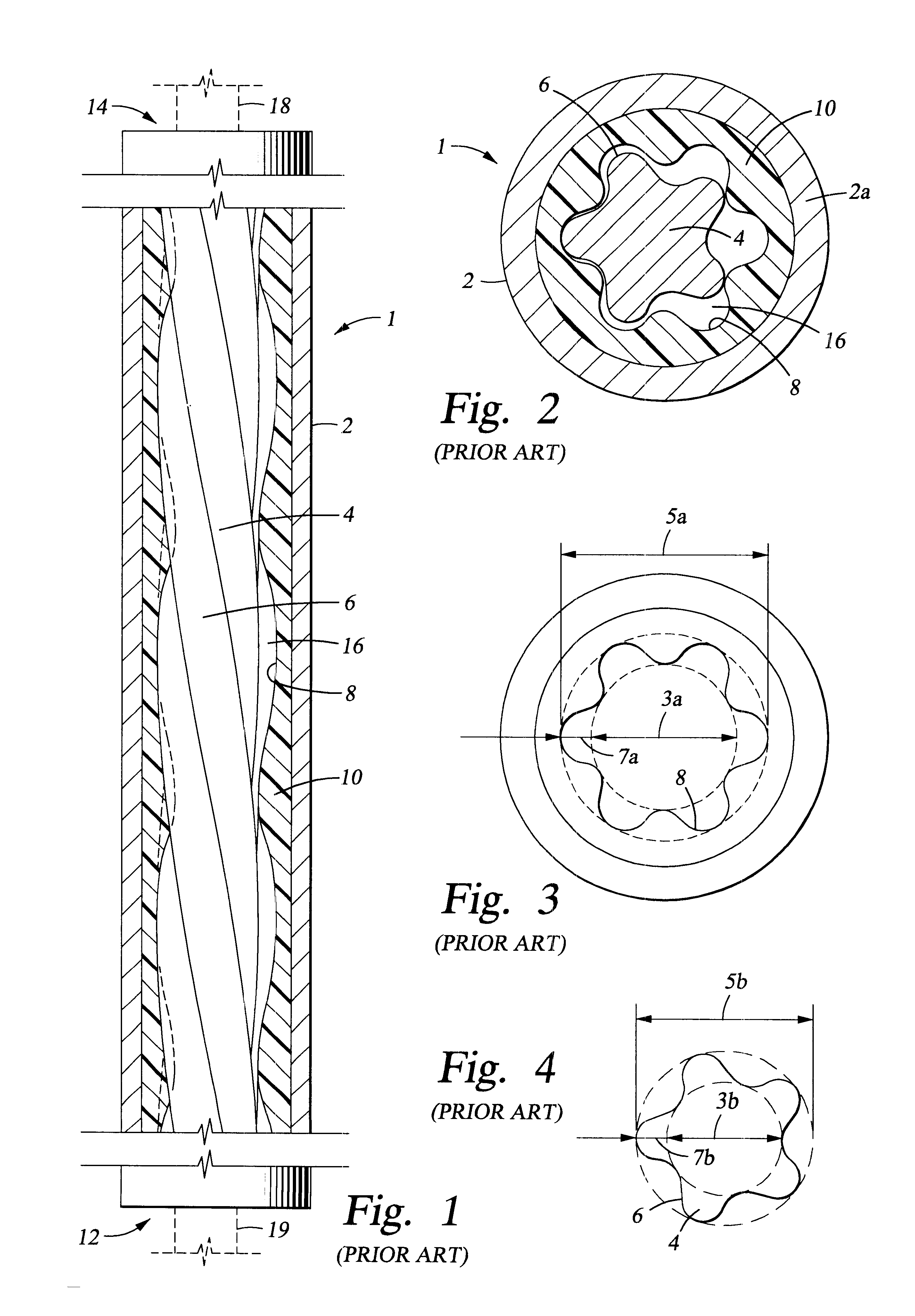

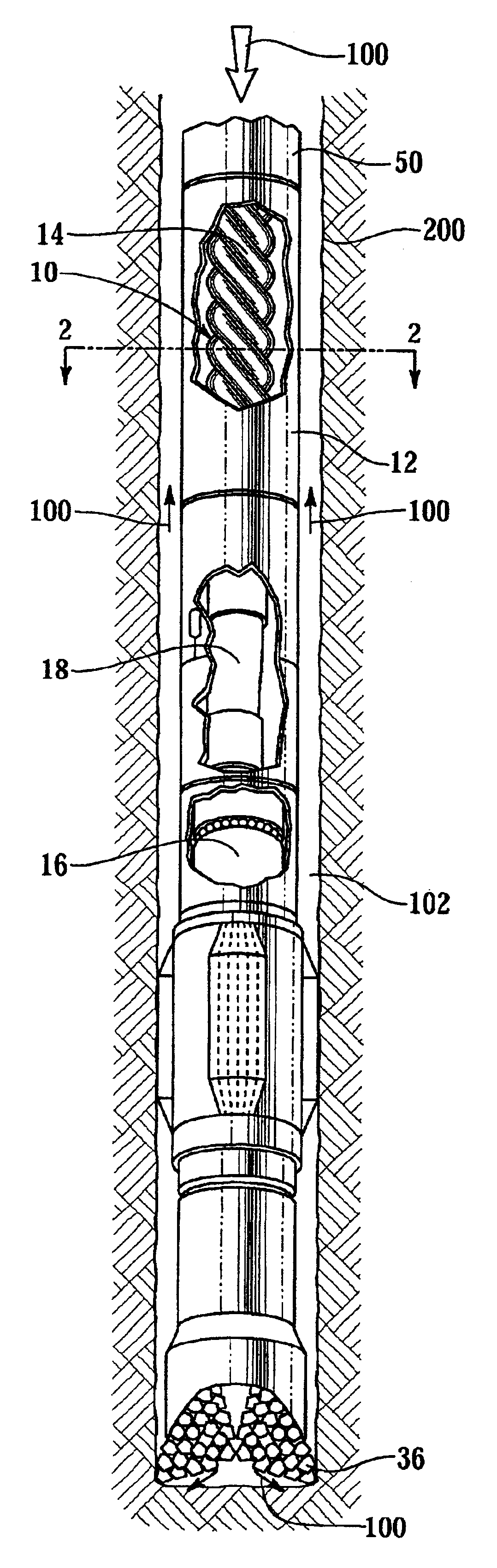

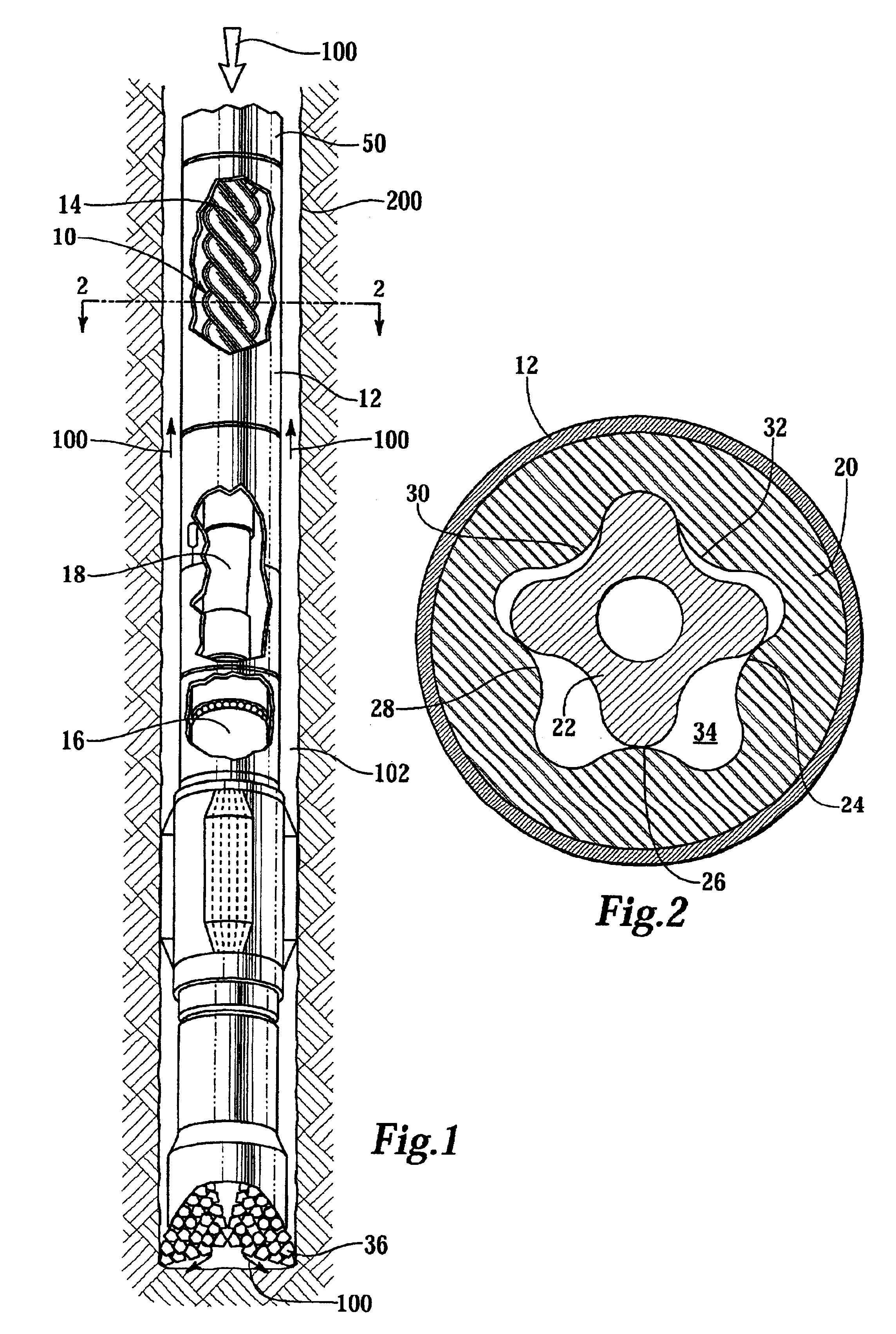

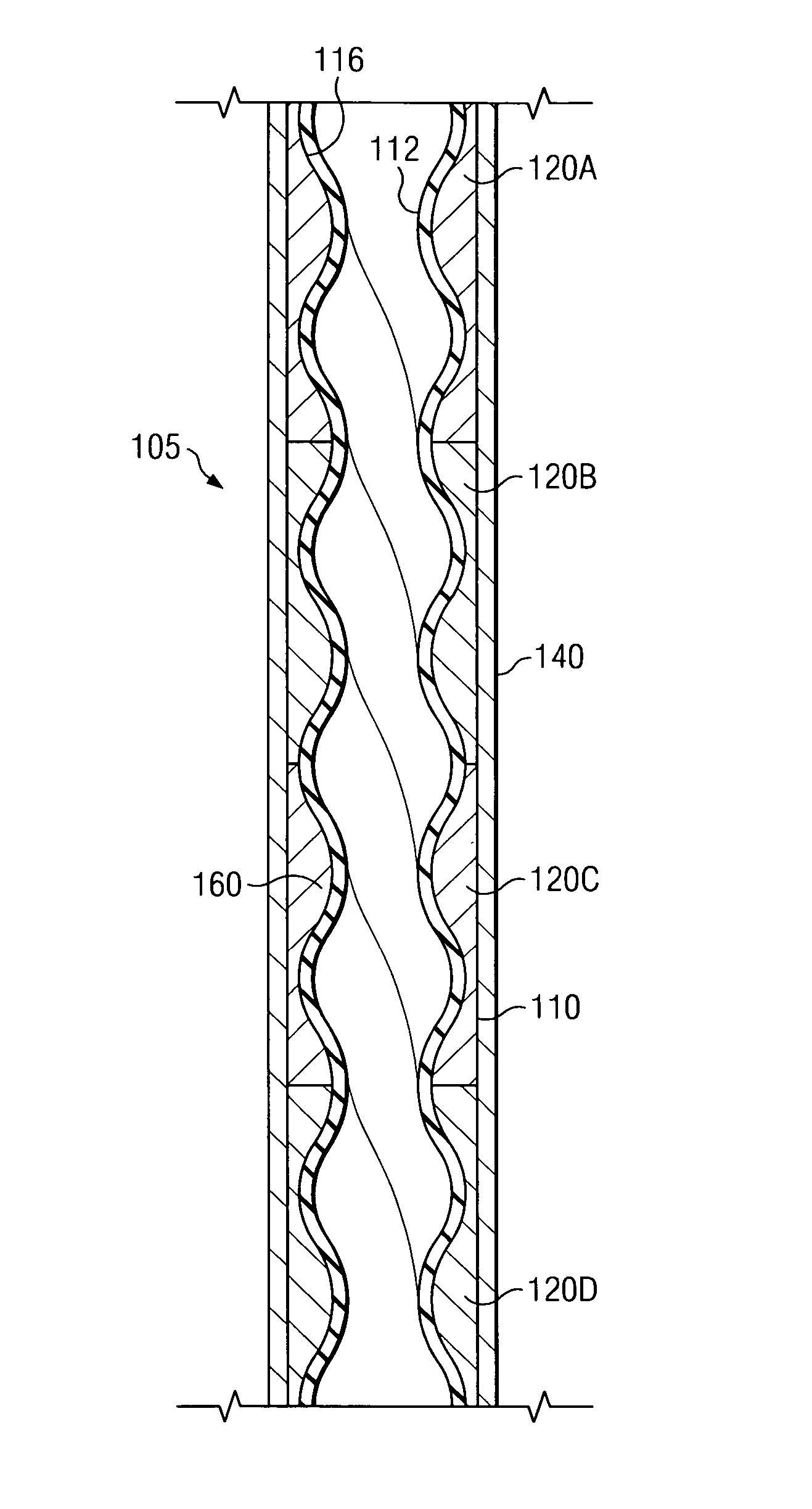

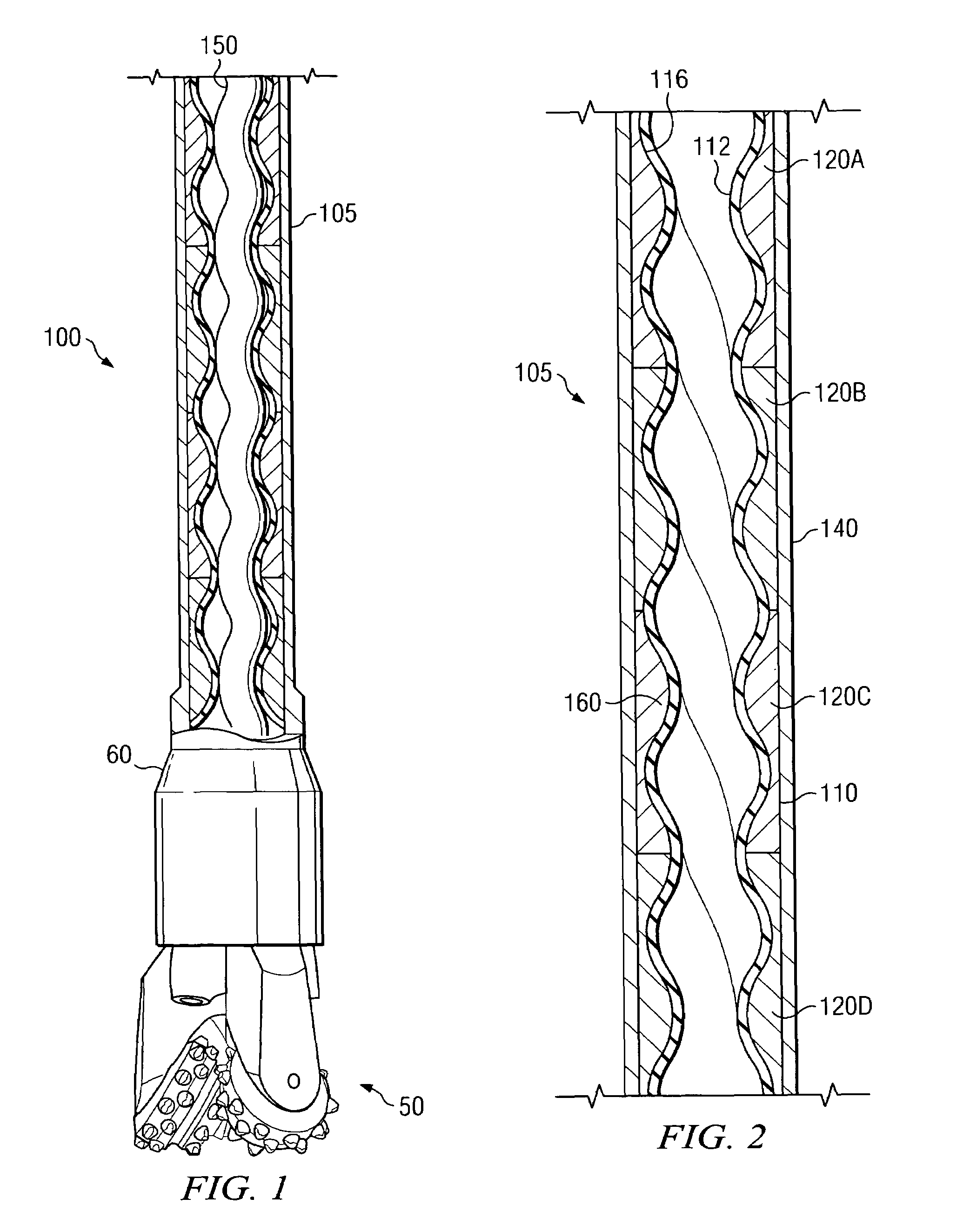

Apparatus and method for high temperature drilling operations

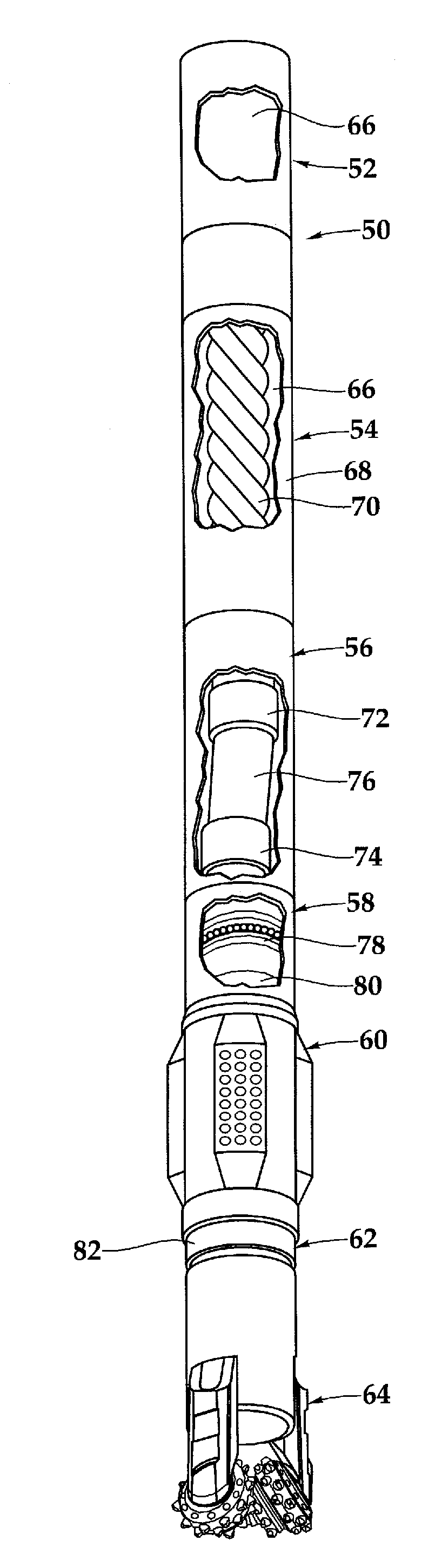

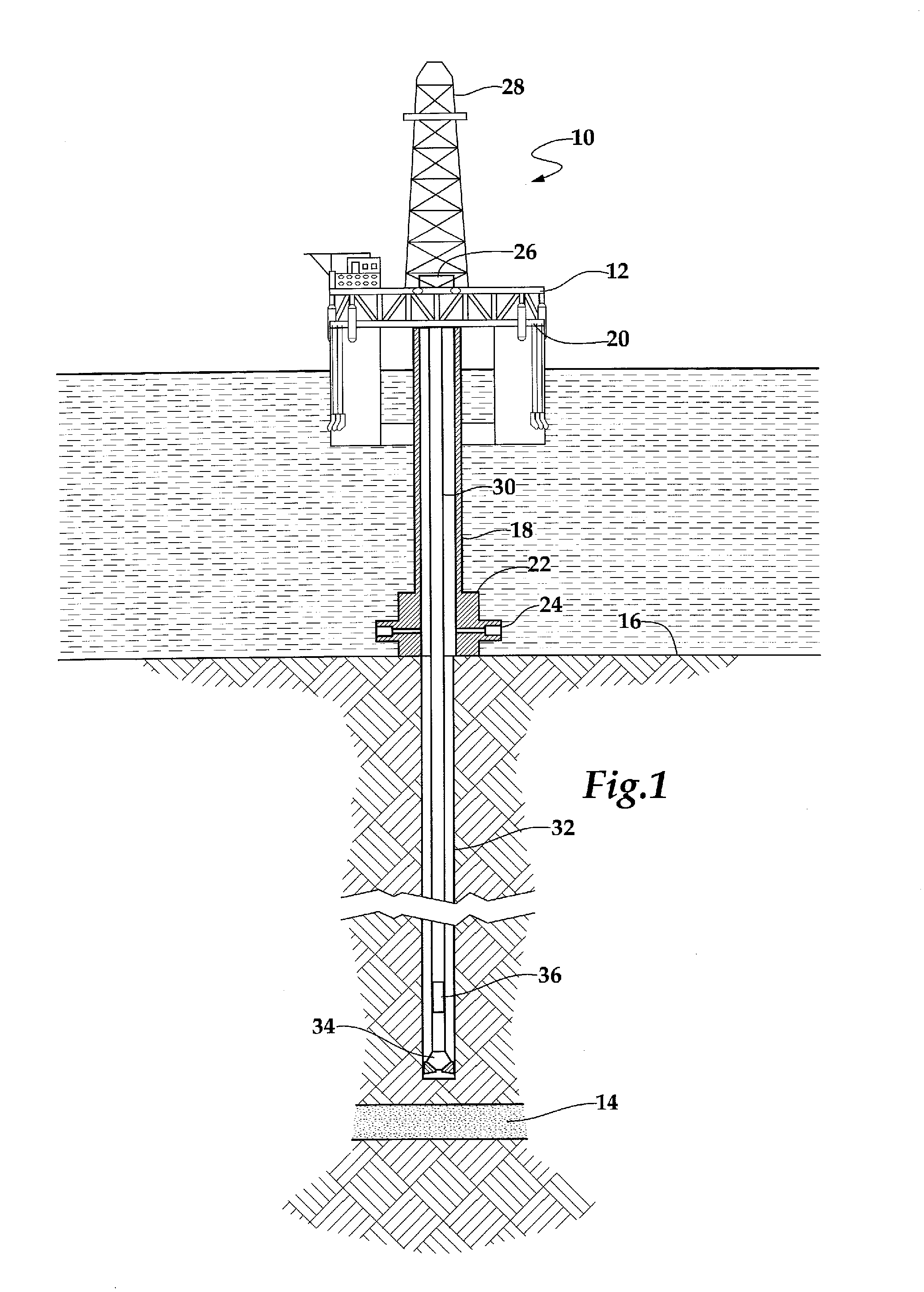

InactiveUS20100038142A1High mechanical loadPump componentsOscillating piston enginesEngineeringWellbore

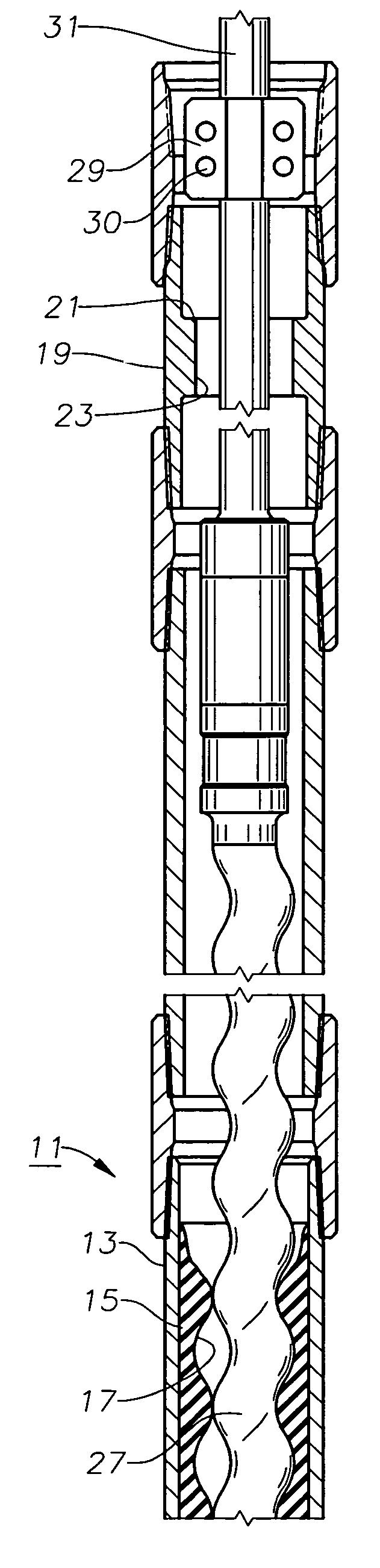

An apparatus (50) for drilling a wellbore that transverses a subterranean hydrocarbon bearing formation. The apparatus (50) includes a drill string (52) having an inner fluid passageway (66). A drill bit (64) is disposed at a distal end of the drill string (52) and is operable to rotate relative to at least a portion of the drill string (52). A fluid motor (54) is disposed within the drill string (52) and is operable to rotate the drill bit (64) in response to a circulating fluid received via the inner fluid passageway (66) of the drill string (52). The fluid motor (54) has a stator (68) with (n) lobes and a rotor (70) with (n−1) lobes. The stator (68) includes an inner surface formed from a first material and the rotor (70) includes an outer surface formed from a second material that is dissimilar to the first material.

Owner:HALLIBURTON ENERGY SERVICES INC

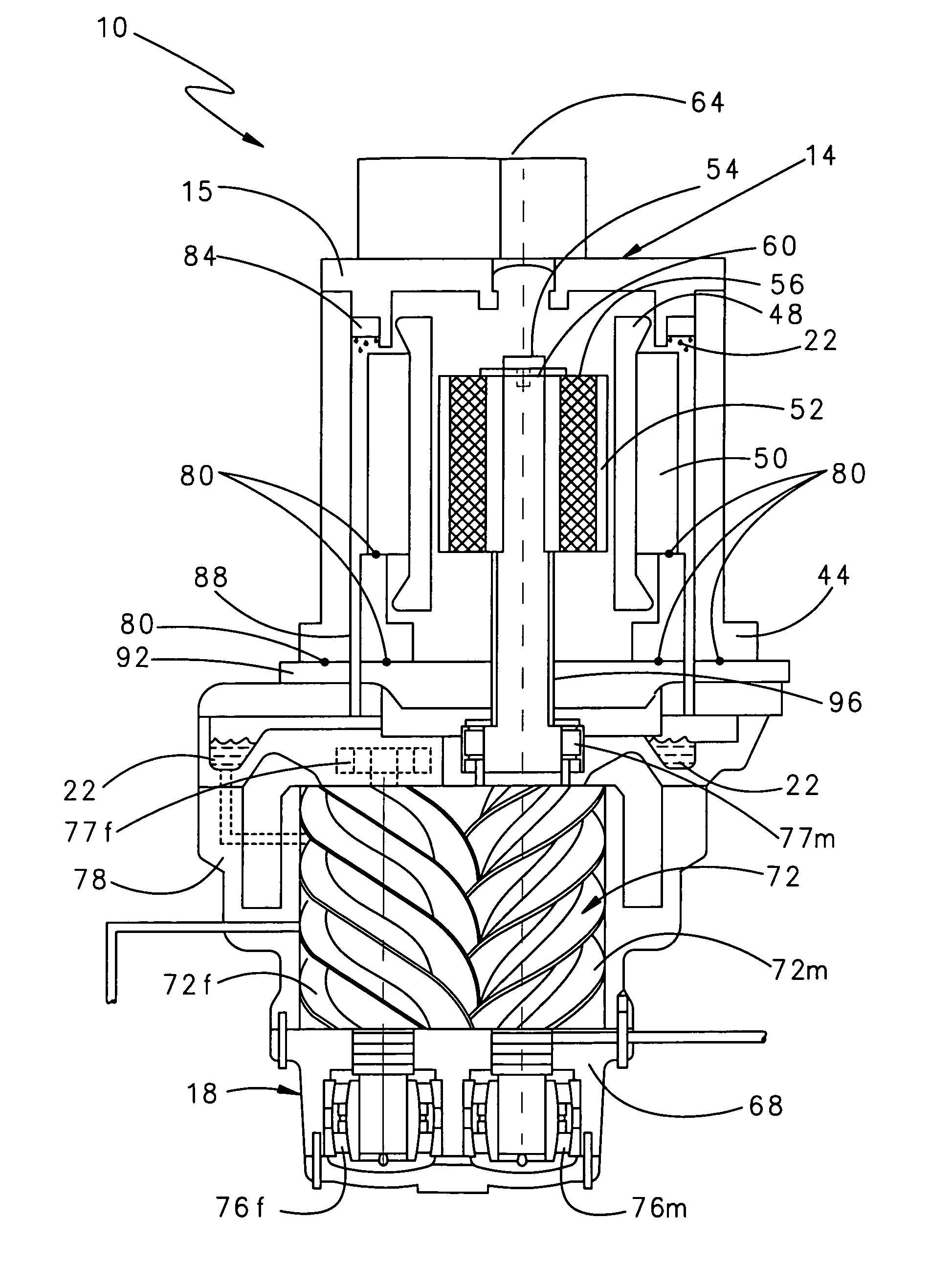

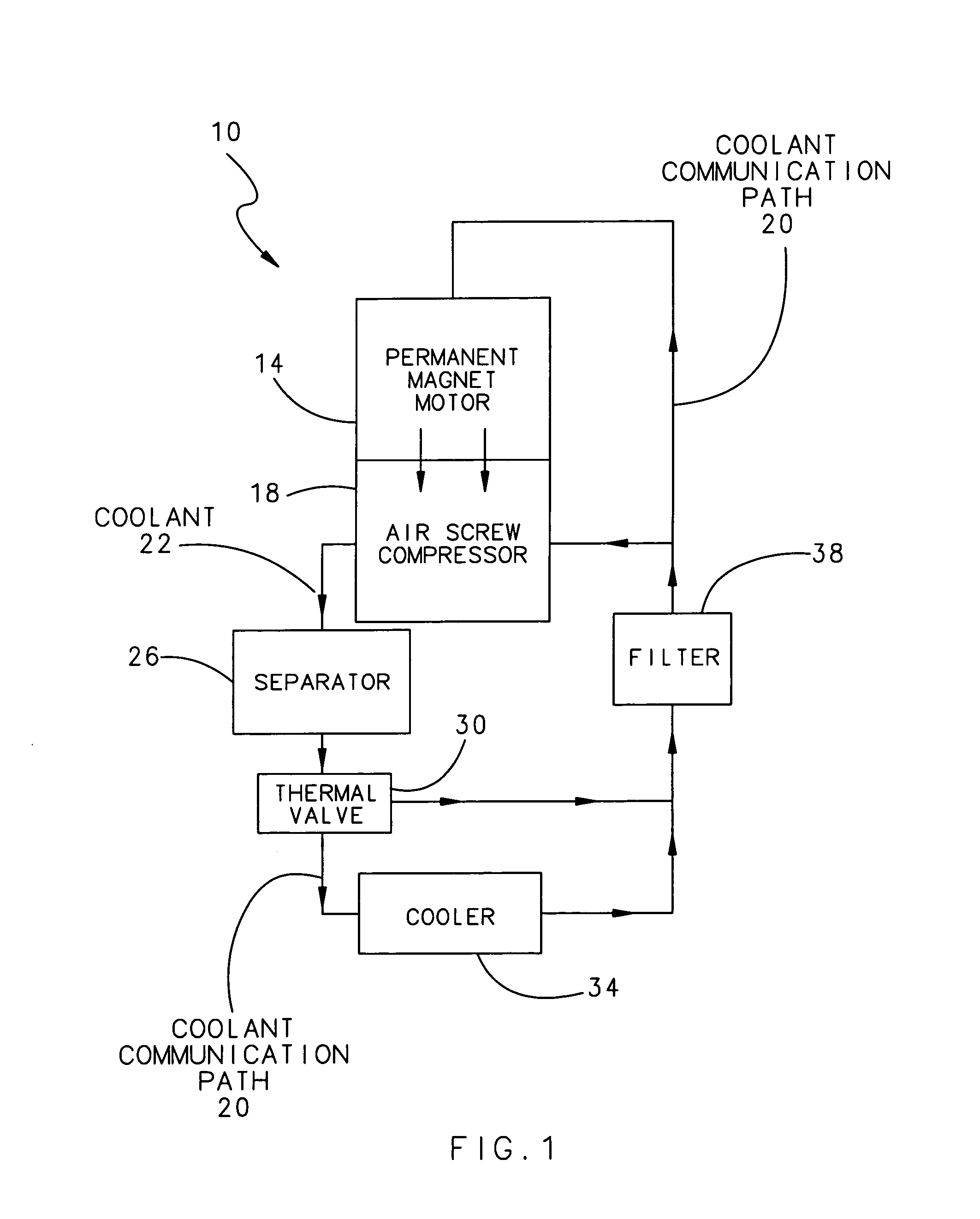

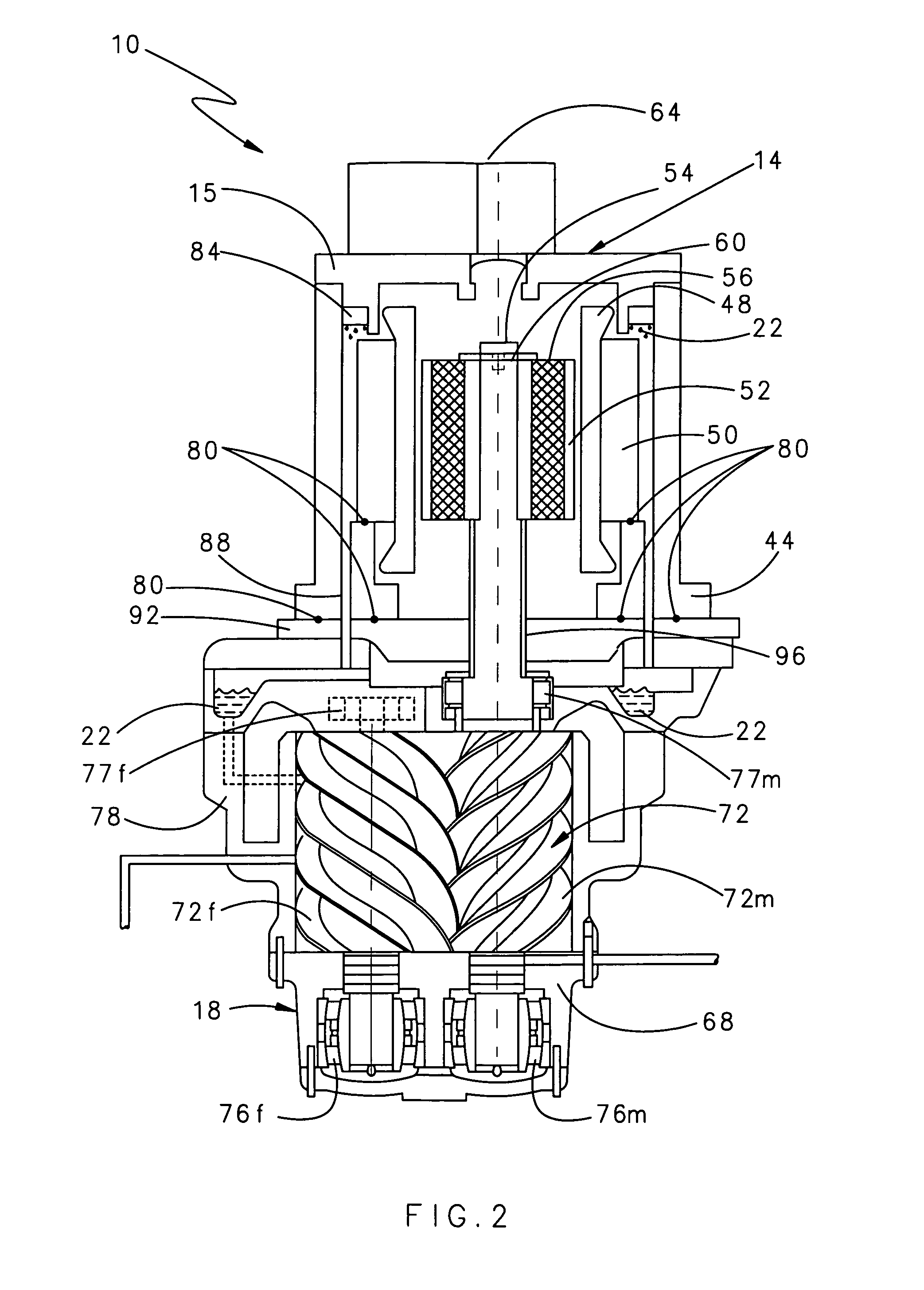

Lubricant cooled integrated motor/compressor design

InactiveUS20070241627A1Prevent overboard leakageThe process is compact and efficientRotary/oscillating piston combinations for elastic fluidsEngine of counter-engagement typePermanent magnet motorGear train

A compressor system according to the present invention utilizes direct rotational input from a permanent magnet motor to generate compressed air. The permanent magnet motor is mounted directly to an air screw compressor. The rotational input is provided by the permanent magnet motor to the air screw compressor without a gear train. The permanent magnet motor and associated variable speed drive controls the rotational speed of the permanent magnet motor and hence the screw compressor. Differing motors may selectively mount, and provide rotational input to, the air screw compressor.

Owner:SULLAIR CORP

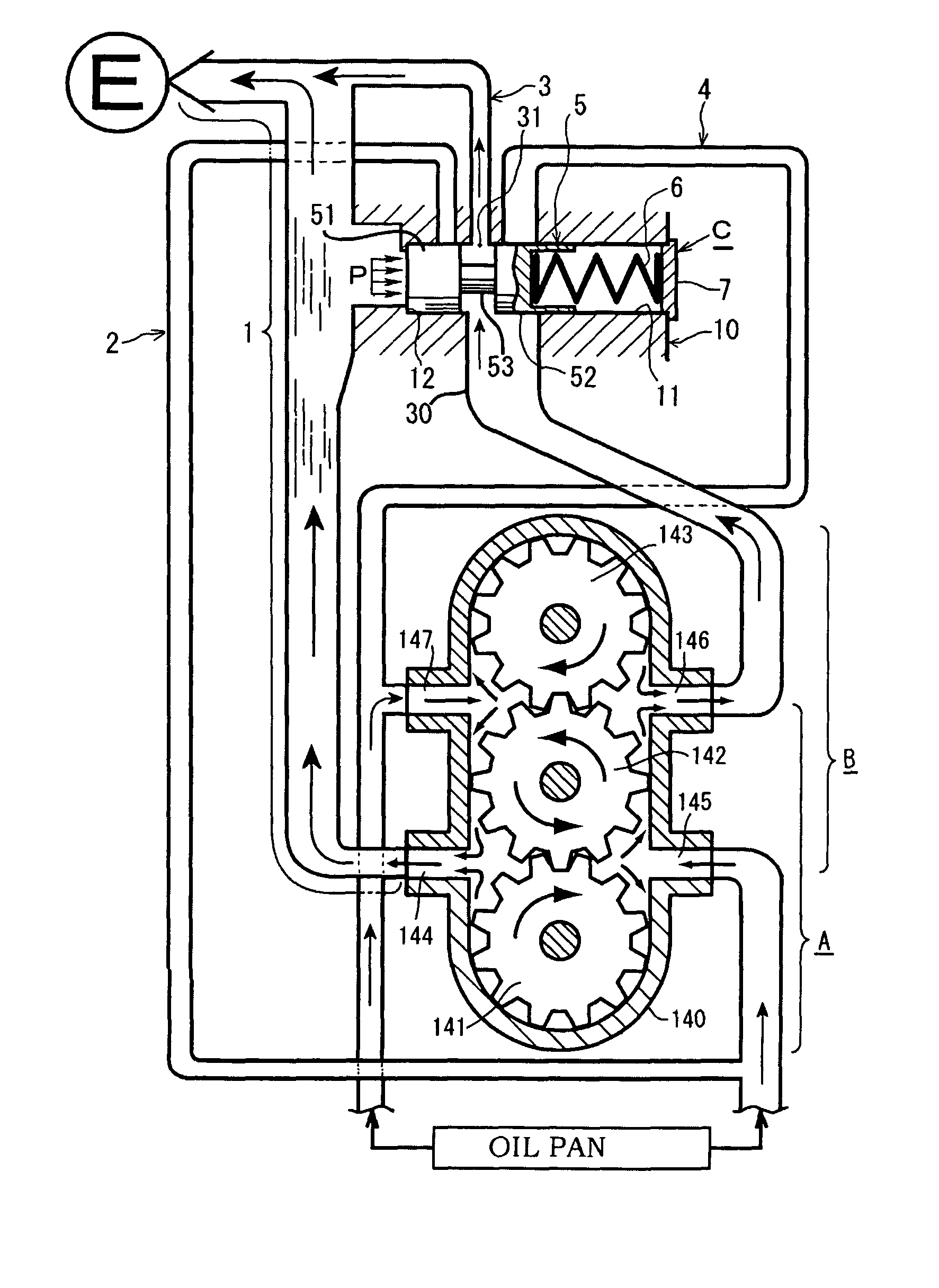

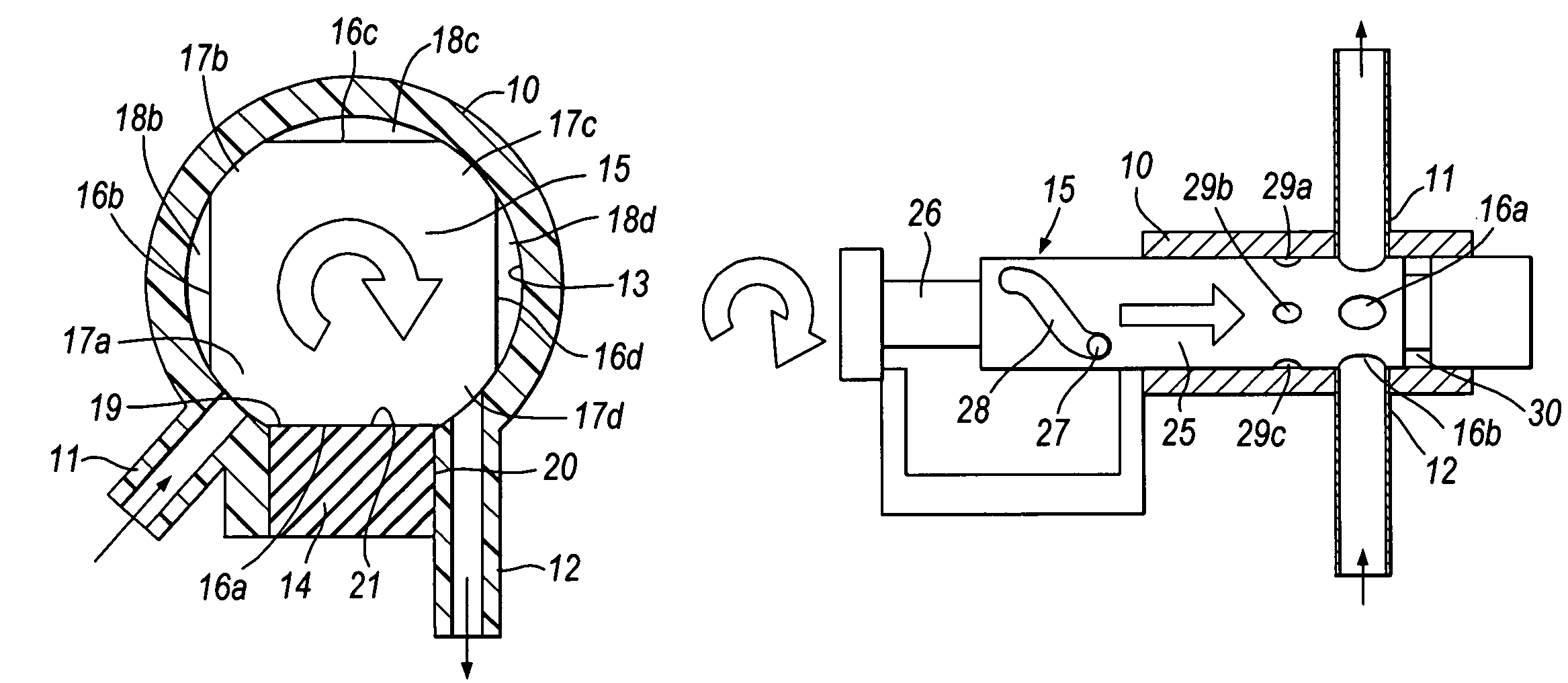

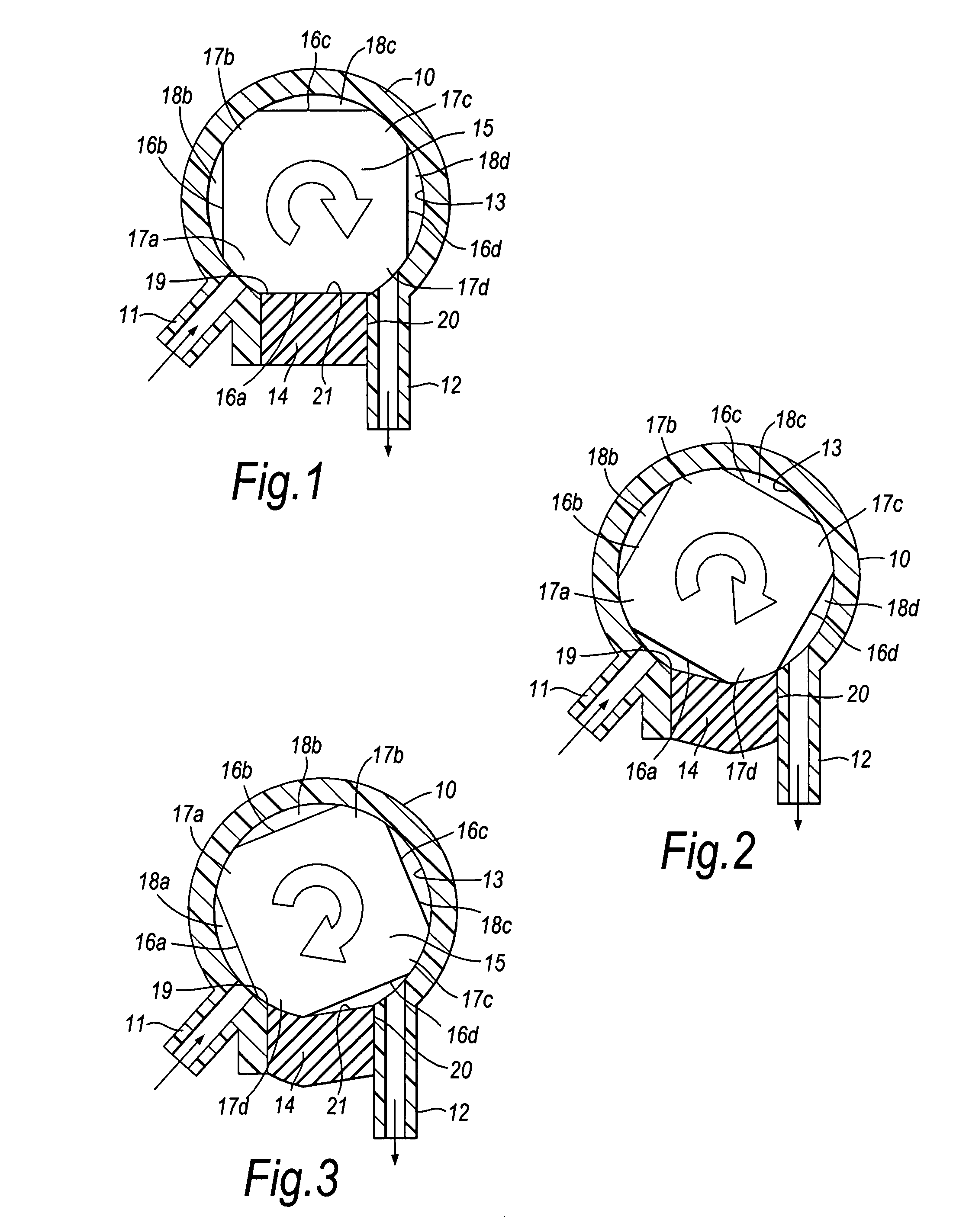

Oil pump pressure control device

InactiveUS8038416B2Drop in overall pump pressureWork moreOscillating piston enginesEngine of counter-engagement typeControl valvesReturn channel

A device including a first discharge passage from a first rotor assembly to an engine, a first return passage that returns to an intake side of the first rotor assembly, a second discharge passage from a second rotor assembly to the engine, a second return passage that returns to an intake side of the second rotor assembly, and a pressure control valve whose valve main body is provided between a discharge port from the second rotor assembly and the first discharge passage. The first discharge passage and the second discharge passage are coupled, and a flow passage control is executed in each of: a low revolution range; an intermediate revolution range; and a high revolution range.

Owner:YAMADA MANUFACTURING CO LTD

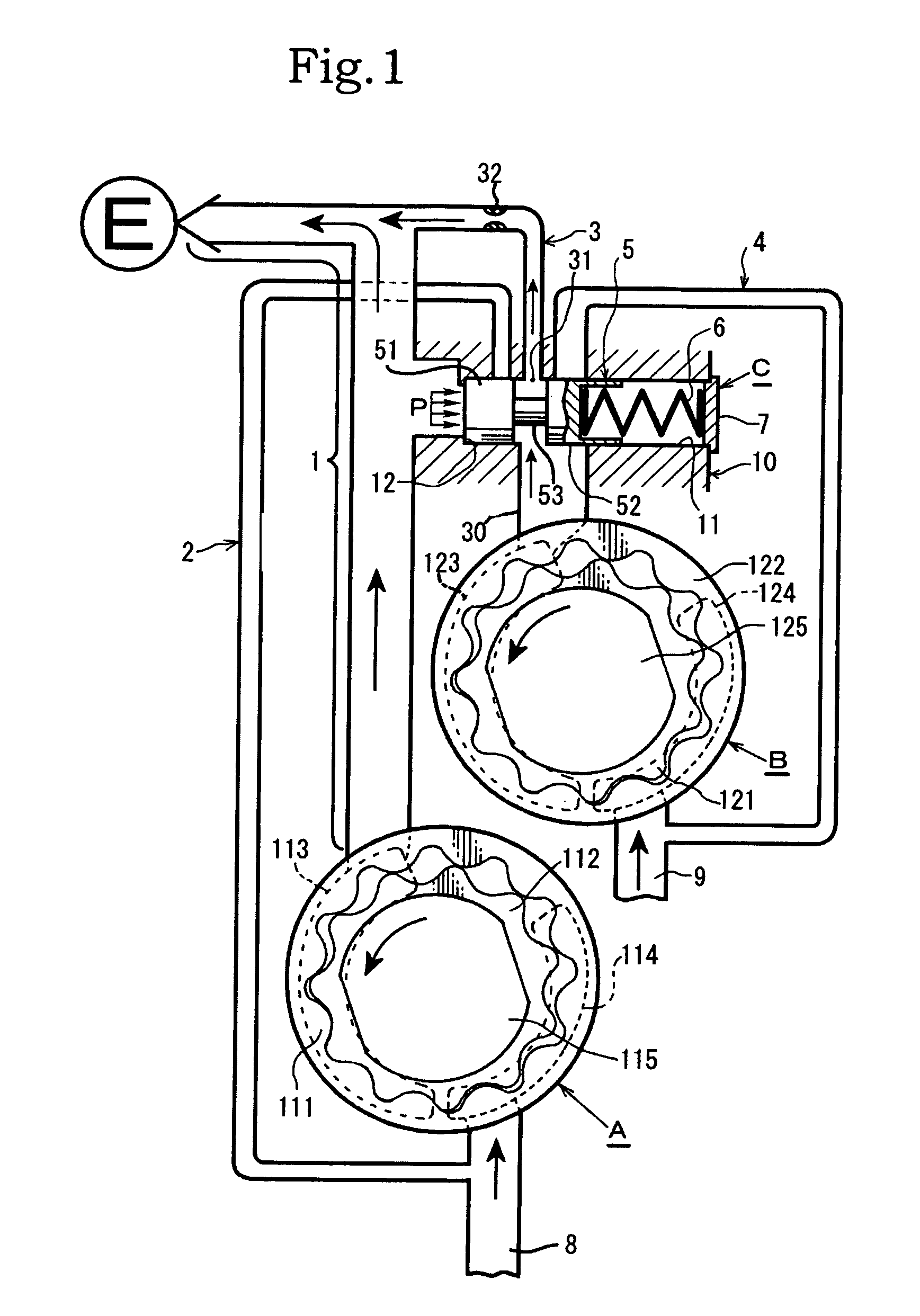

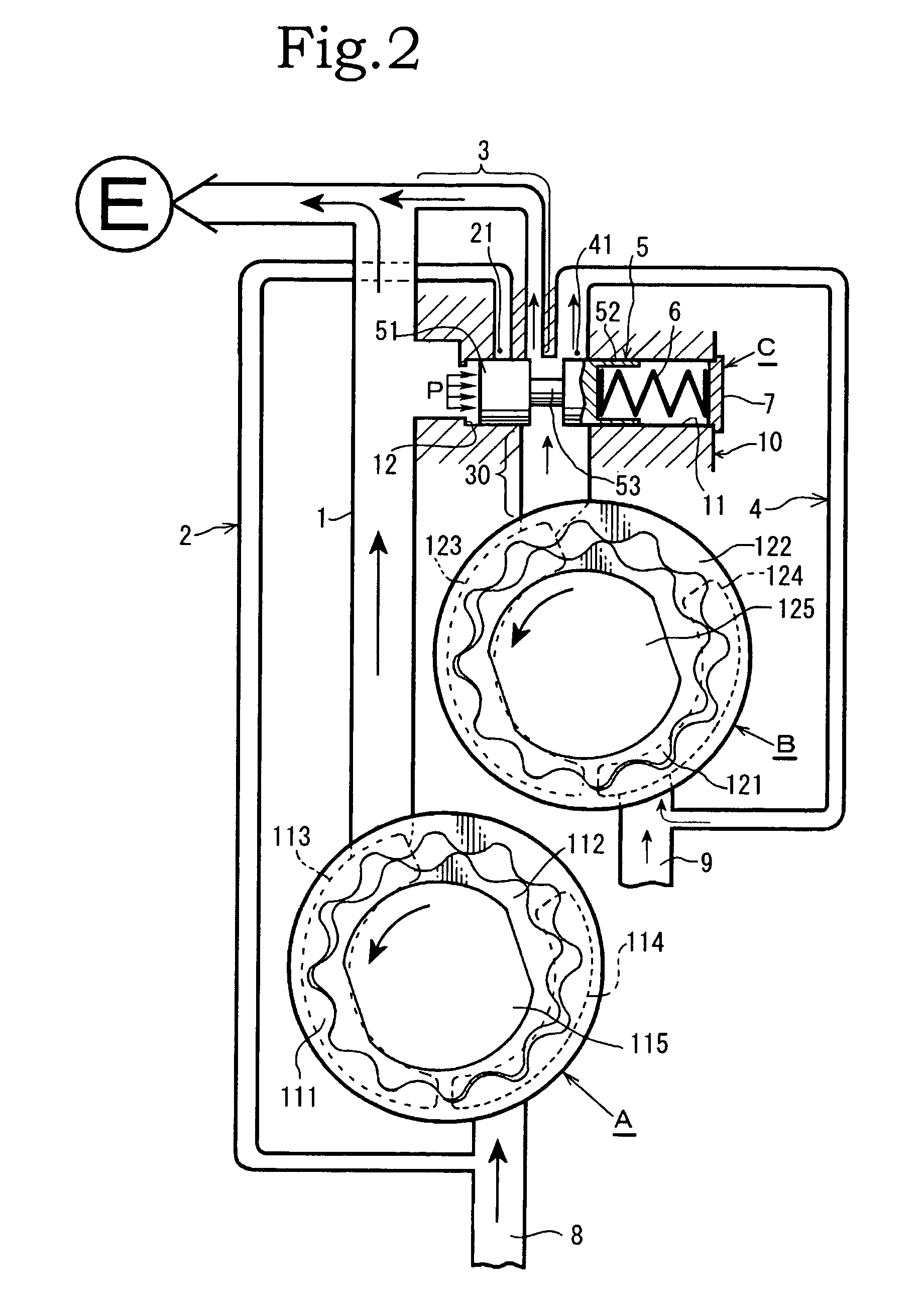

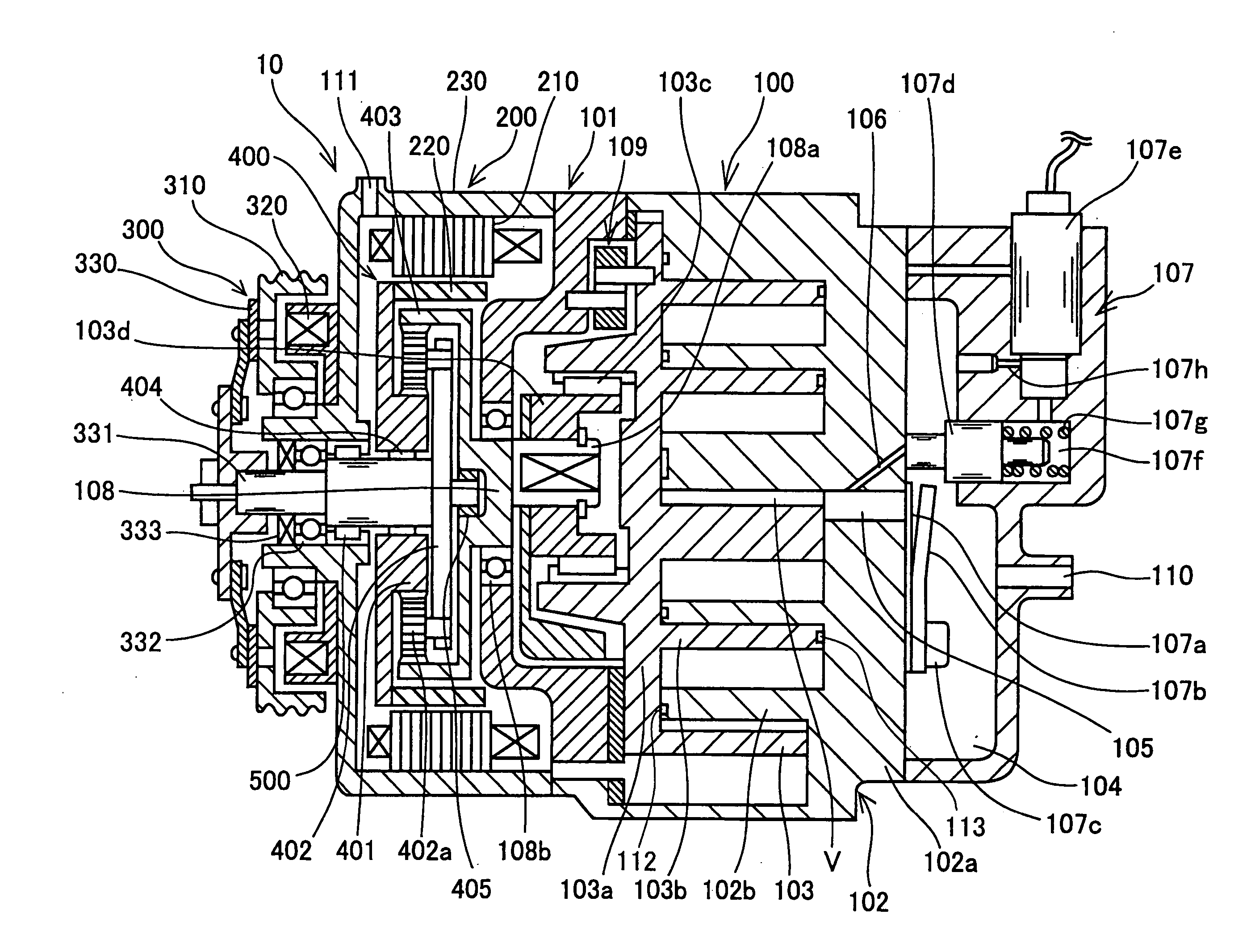

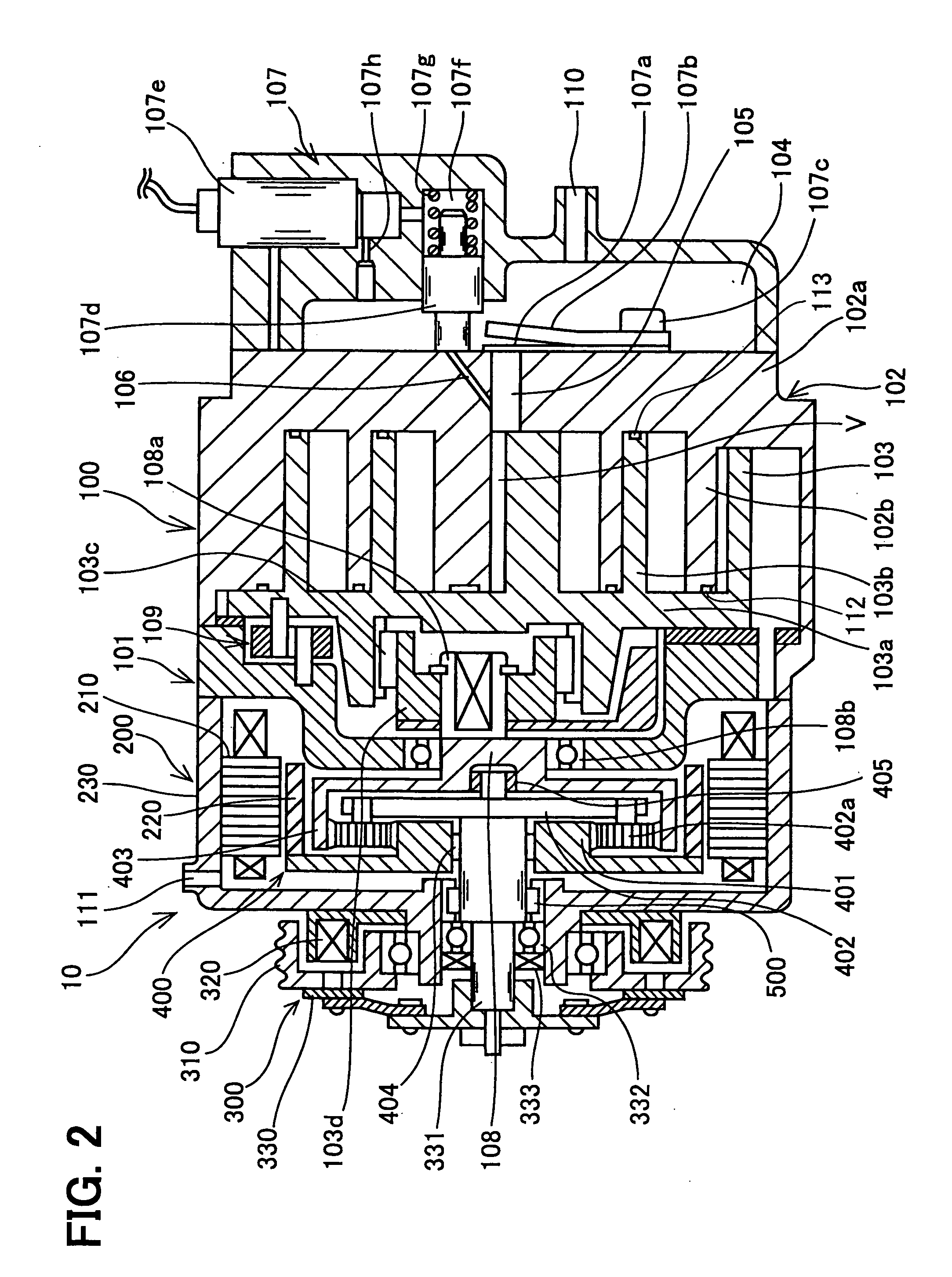

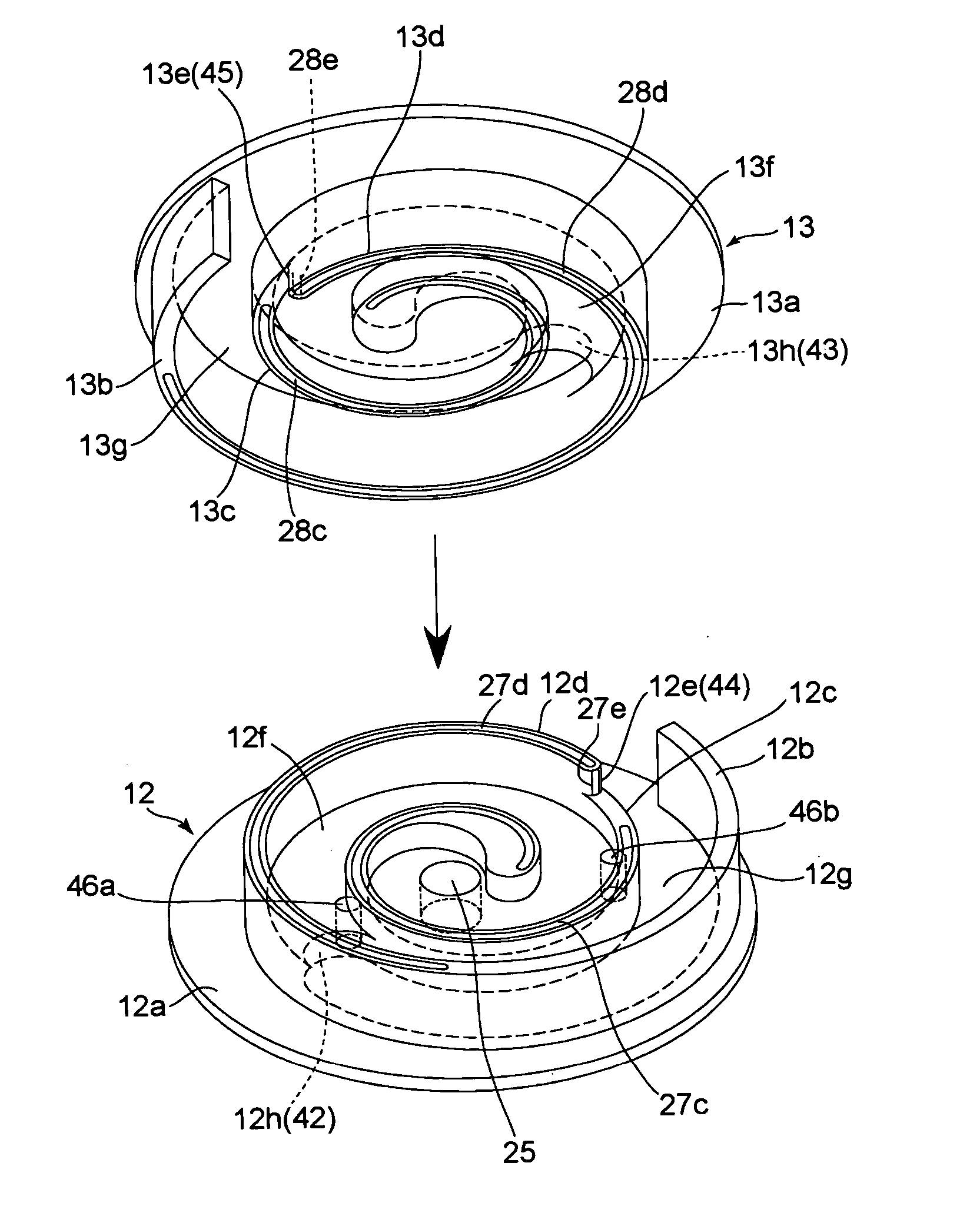

Fluid machine

InactiveUS20050214148A1Improve sealingSmall sizeCompressorEngine of arcuate-engagement typeEngineeringSliding contact

An outer end of a seal element for a fixed scroll is extended to a position close to an end of an inside spiral wall of the fixed scroll, and an outwardly extended portion is formed at an outer periphery of a disc-shaped base plate of a movable scroll, so that a bottom surface of the movable scroll is always kept in a sliding contact entirely with the seal element during the orbital movement of the movable scroll. A thickness of the outwardly extended portion formed at the outer periphery of the disc-shaped base plate is made smaller than that of the disc-shaped base plate, so that the weight of the fluid machine can be smaller.

Owner:NIPPON SOKEN +1

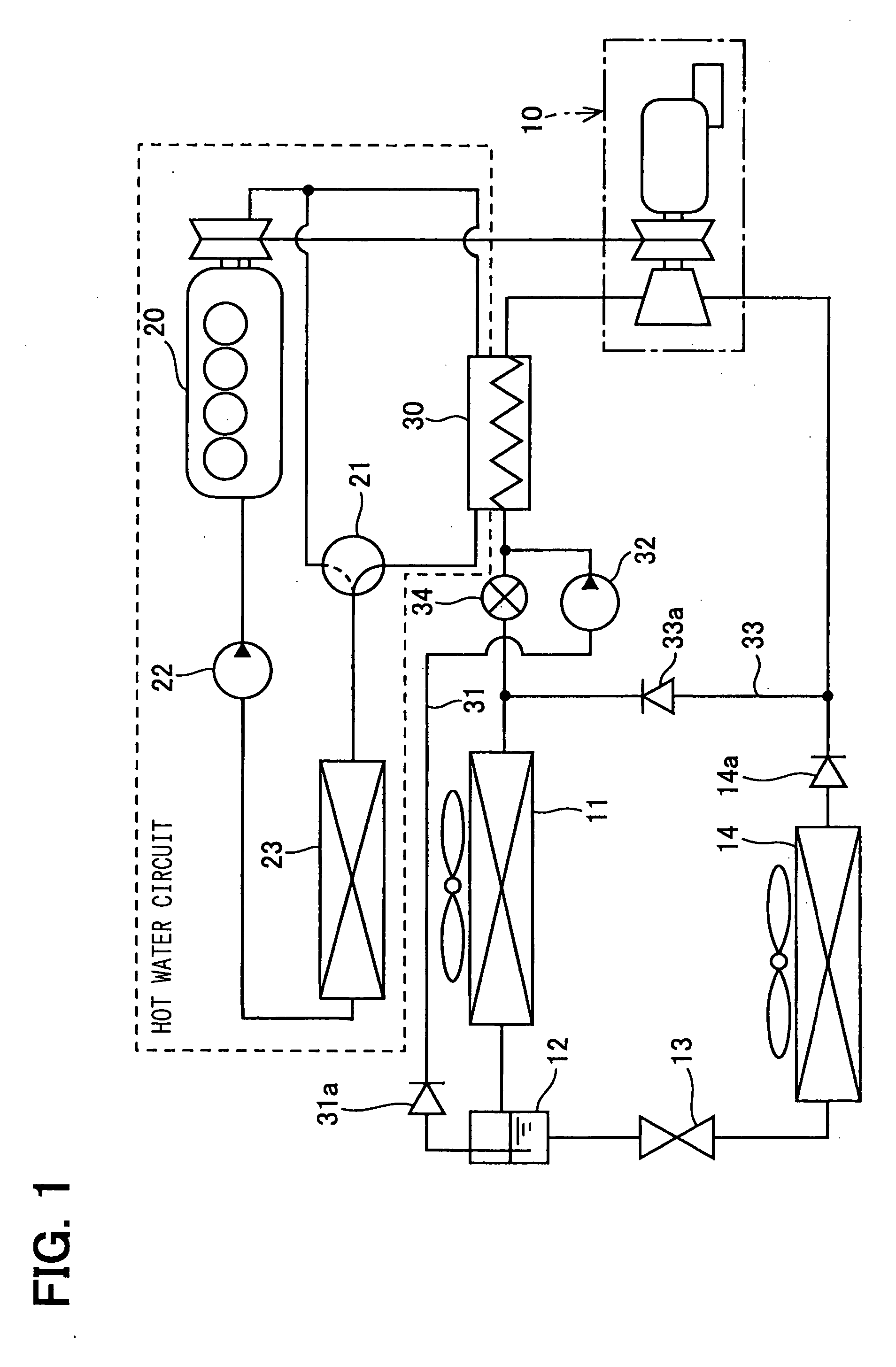

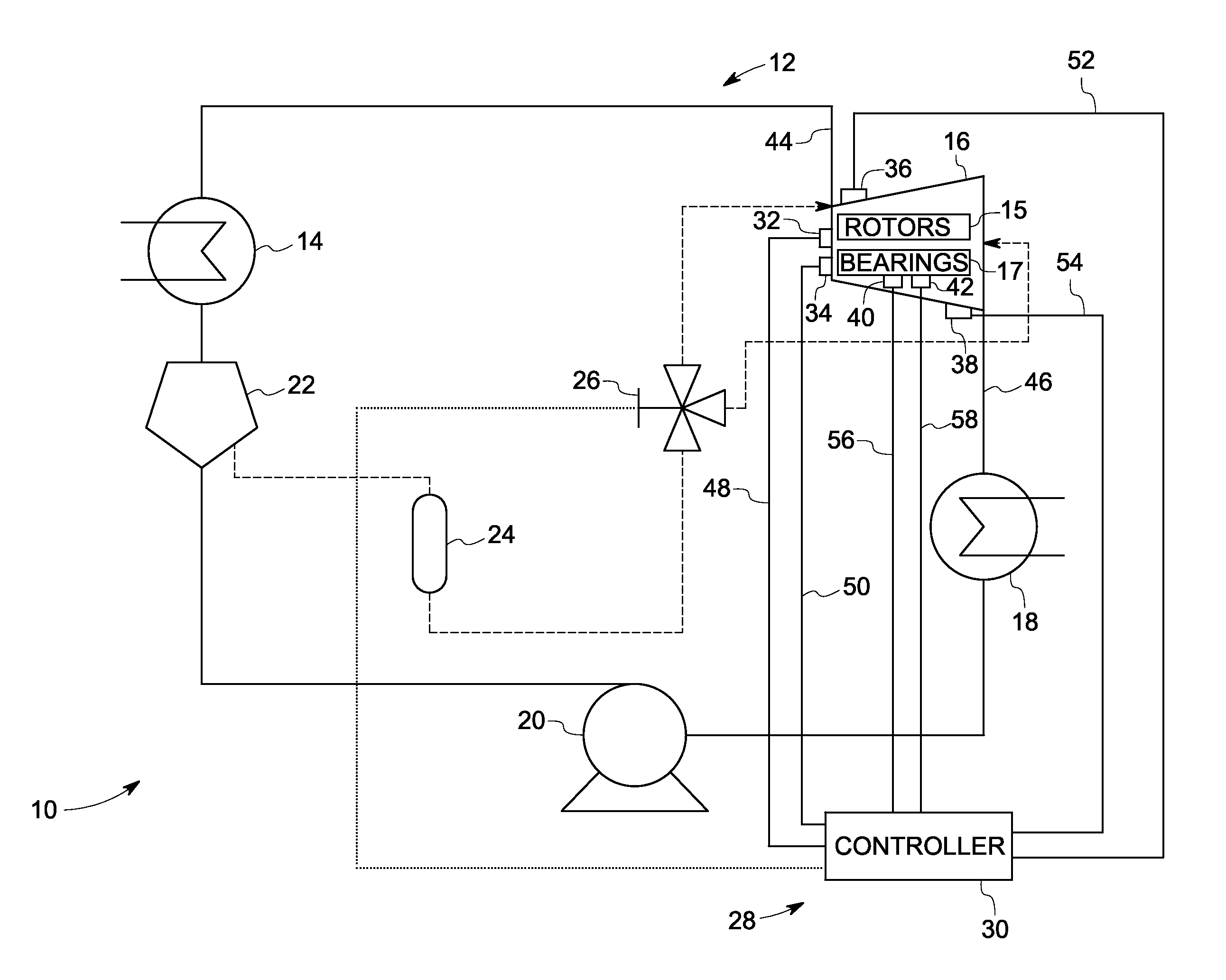

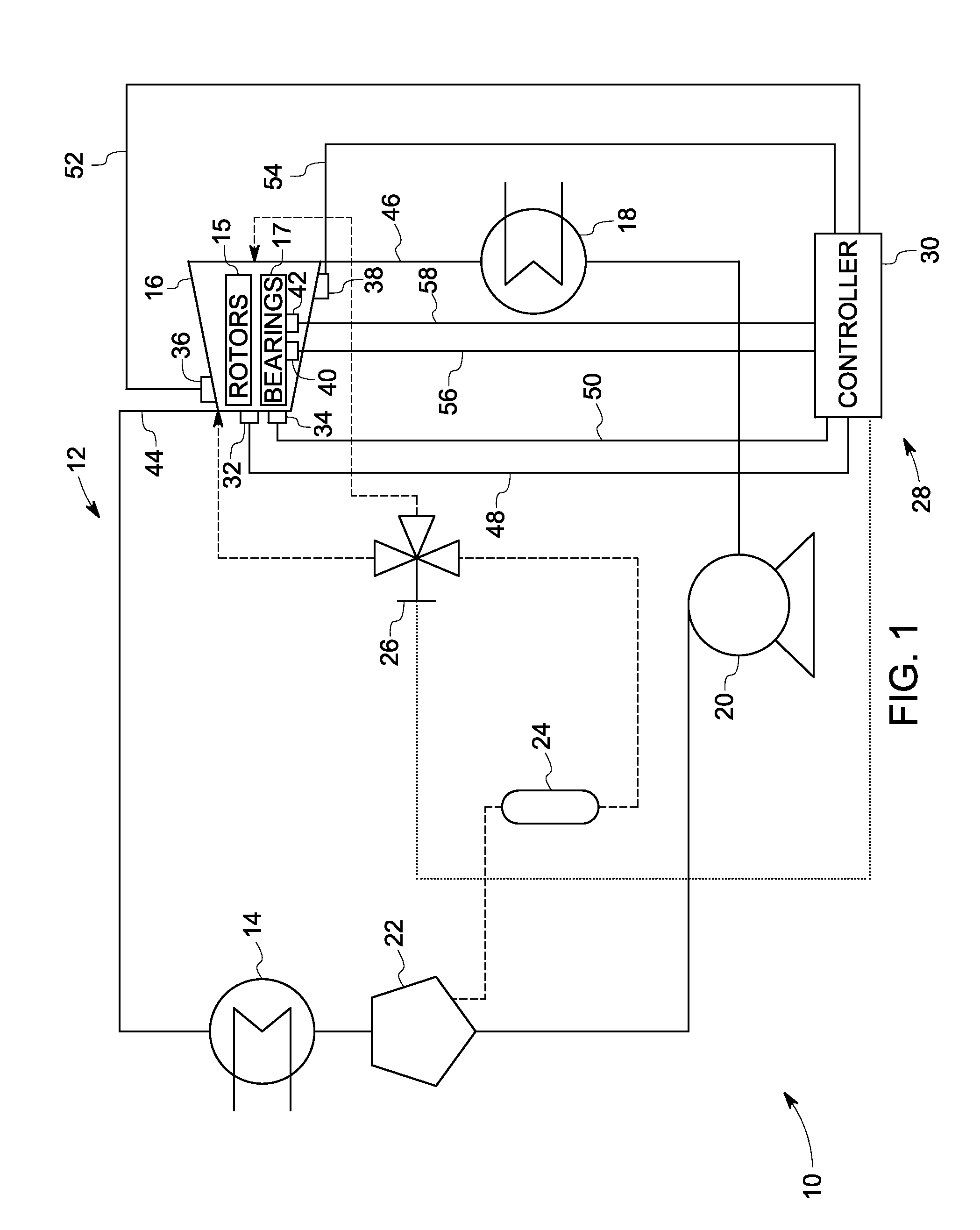

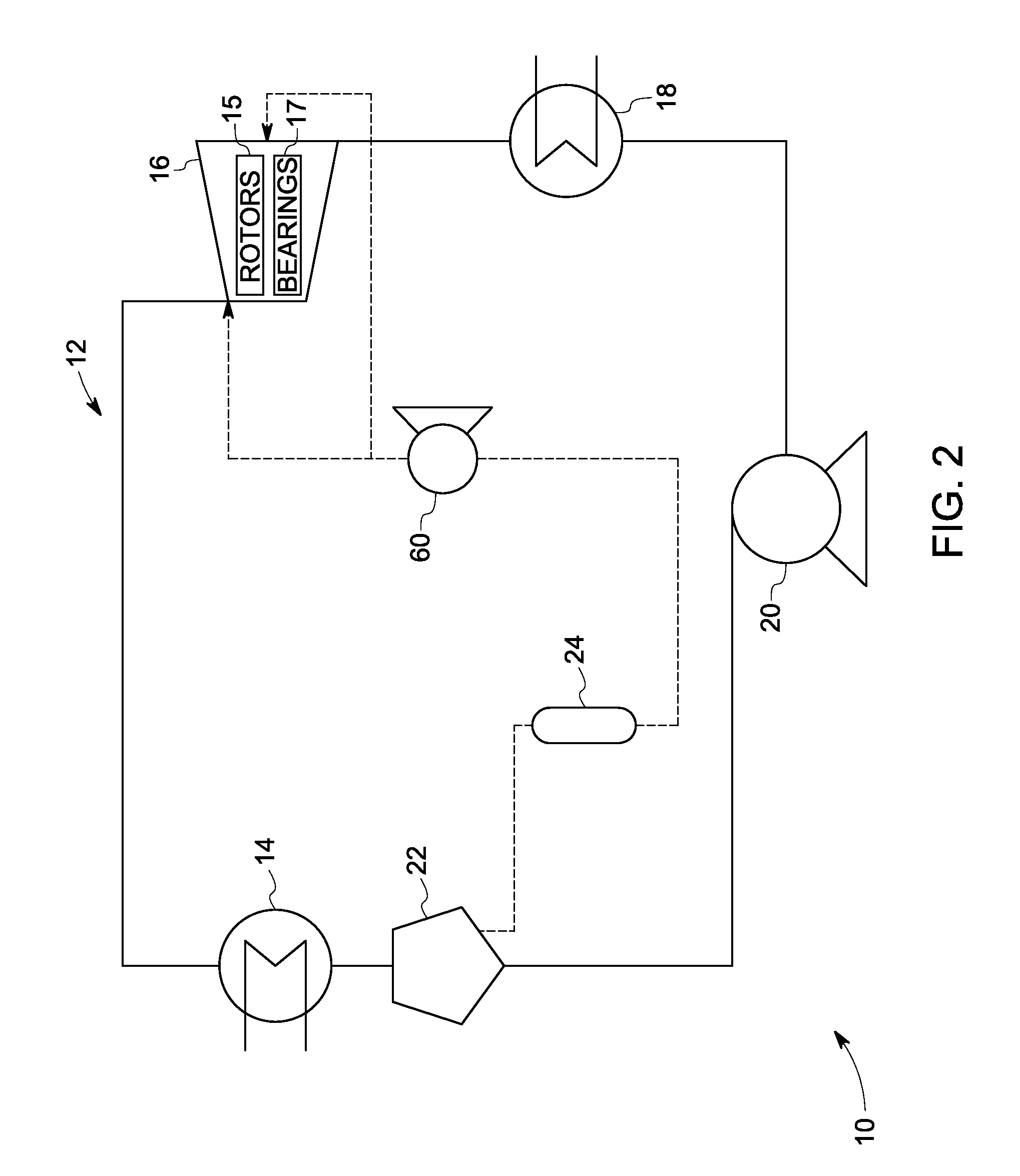

Method for lubricating screw expanders and system for controlling lubrication

A method for lubricating a screw expander includes condensing a mixture of working fluid and lubricant fed from the screw expander, through a condenser. At least a portion of the mixture of working fluid and lubricant fed from the condenser is pressurized from a first pressure to a second pressure through a pump. The method also includes separating the lubricant from the condensed working fluid of the at least portion of the mixture via a separator and feeding the lubricant to the screw expander; or separating the lubricant from the working fluid of the at least portion of the mixture via an evaporator and feeding the lubricant to the screw expander; or feeding the at least portion of the mixture of condensed working fluid and lubricant to the screw expander; or combinations thereof.

Owner:GENERAL ELECTRIC CO

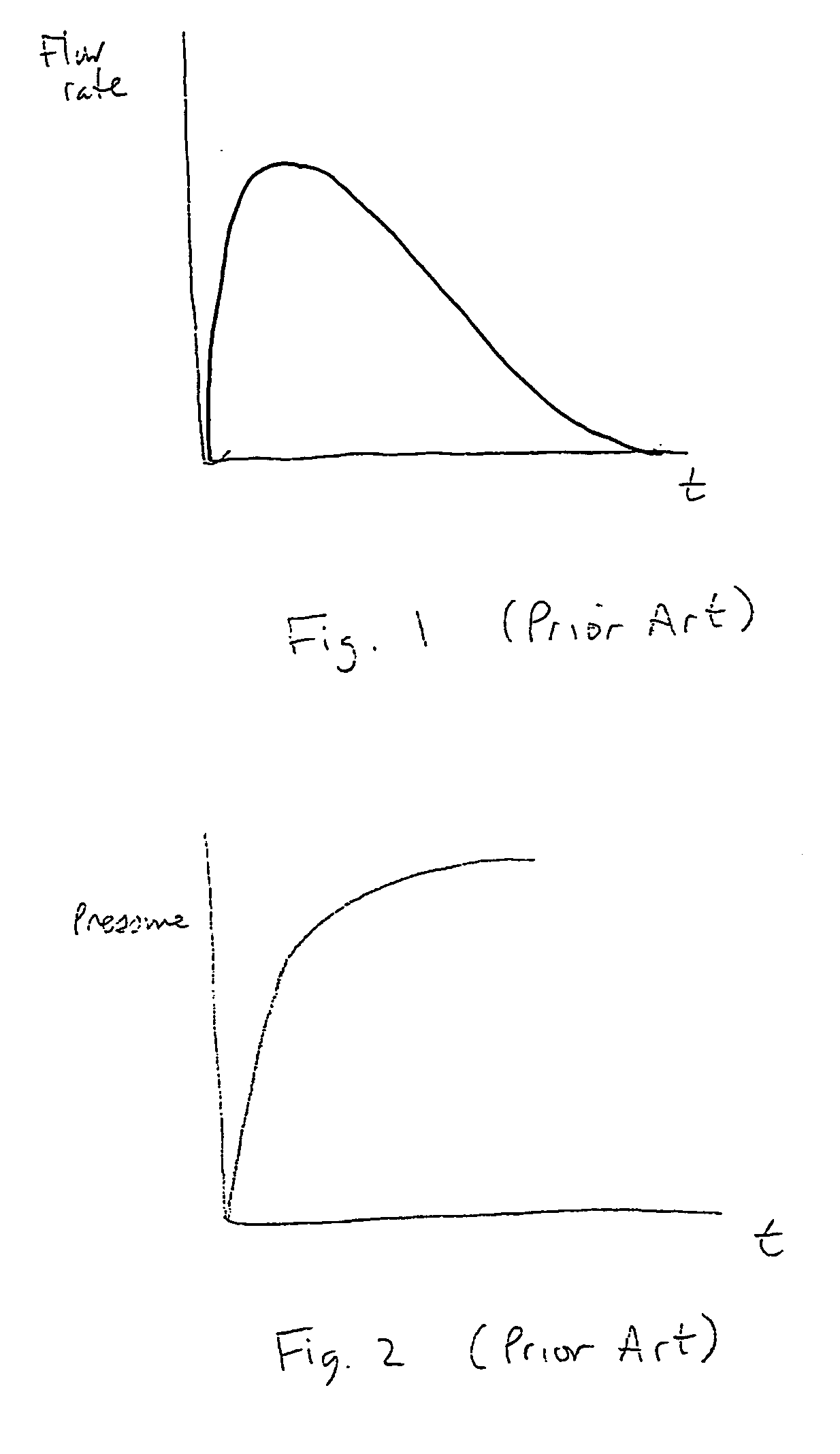

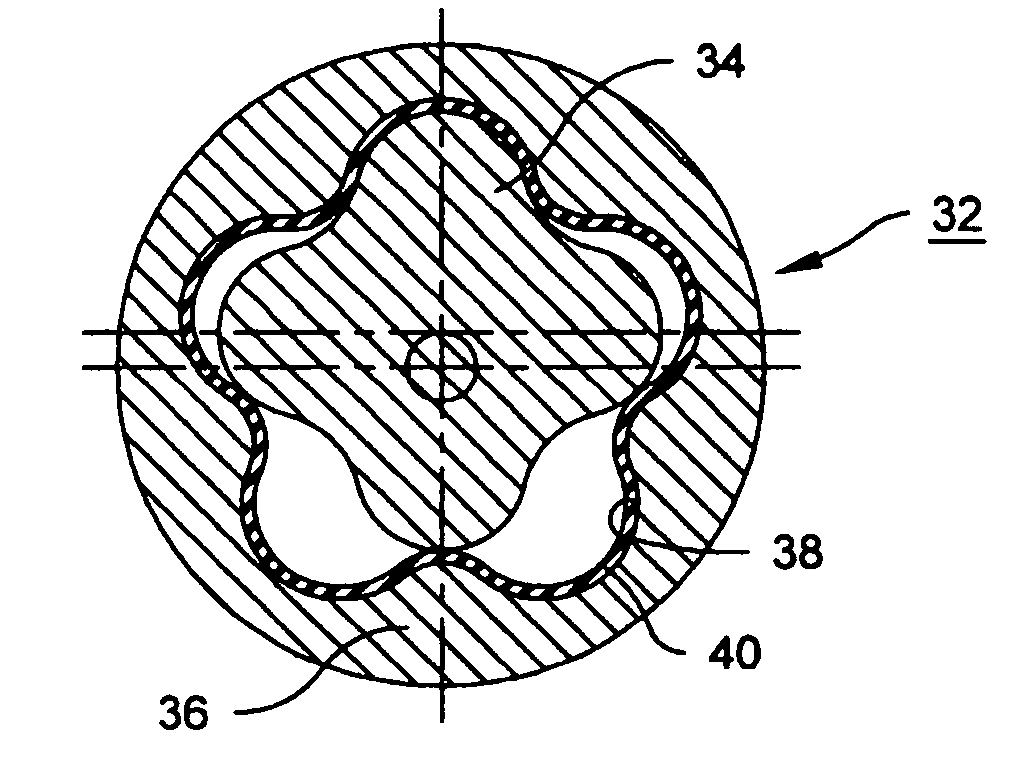

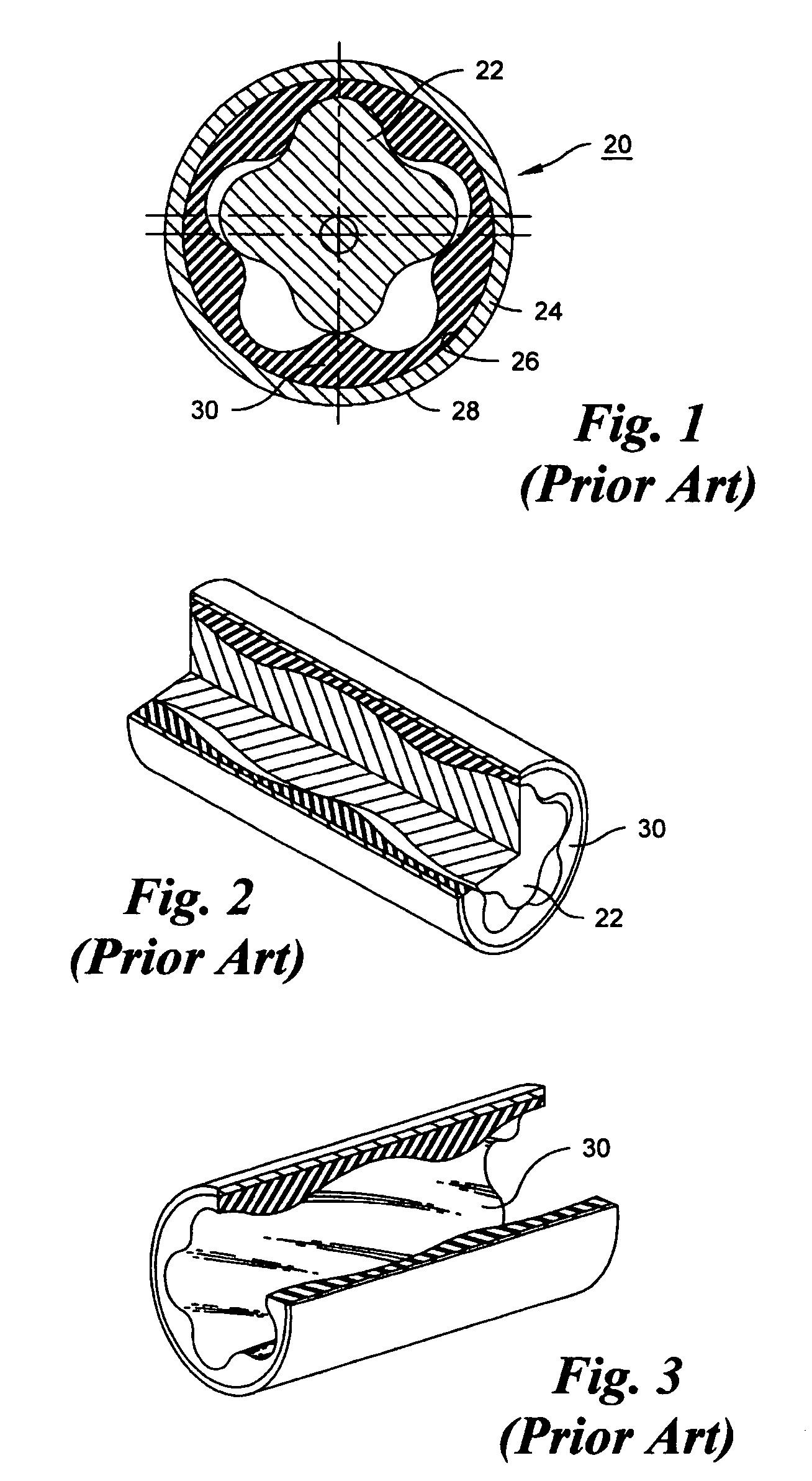

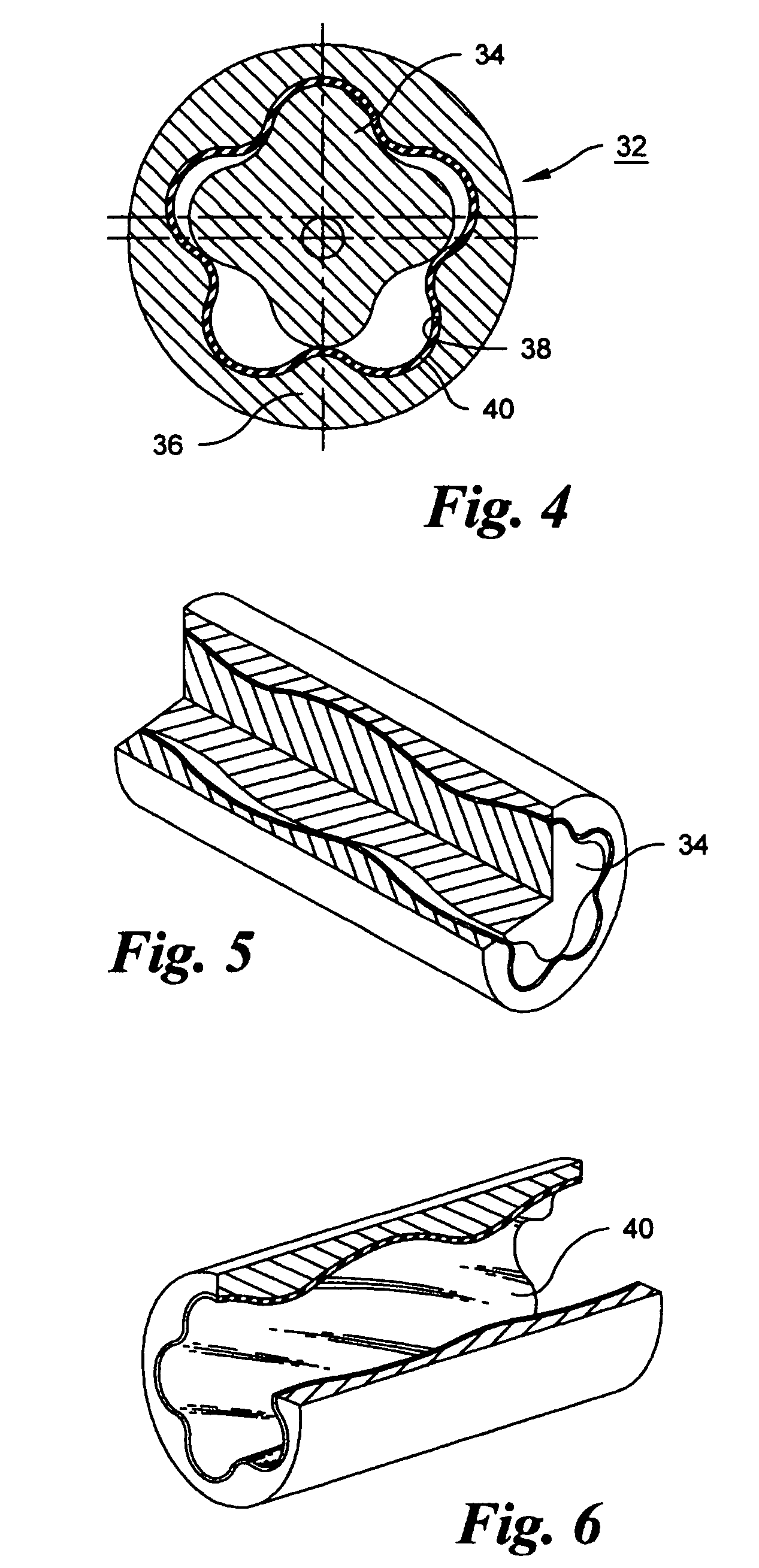

Method and apparatus for reducing noise in a roots-type blower

InactiveUS20050112013A1Reduce noisePhysical therapyEngine of counter-engagement typeNoise levelEngineering

A Roots-type blower comprises a housing defining a rotor chamber and an inlet and outlet to the rotor chamber. First and second rotors are mounted in the rotor chamber, each rotor defining a plurality of lobes, adjacent lobes and the housing cooperating to define gas transport chambers. The blower is configured so that a net flow rate of gas into a gas transport chamber is generally or approximately constant, whereby a change in gas pressure in the gas transport chamber is generally or approximately linear, as the gas transport chamber approaches the outlet. In one embodiment, this is accomplished by providing flow channels extending from the outlet towards the inlet, and from the inlet towards the outlet, corresponding to each rotor. The flow channels permit gas to flow from the high pressure outlet to a gas transport chamber and from the gas transport chamber to the low pressure inlet. The resulting amelioration of pressure spikes associated with flow back substantially reduces the operational noise level of the blower.

Owner:PULMONETIC SYST

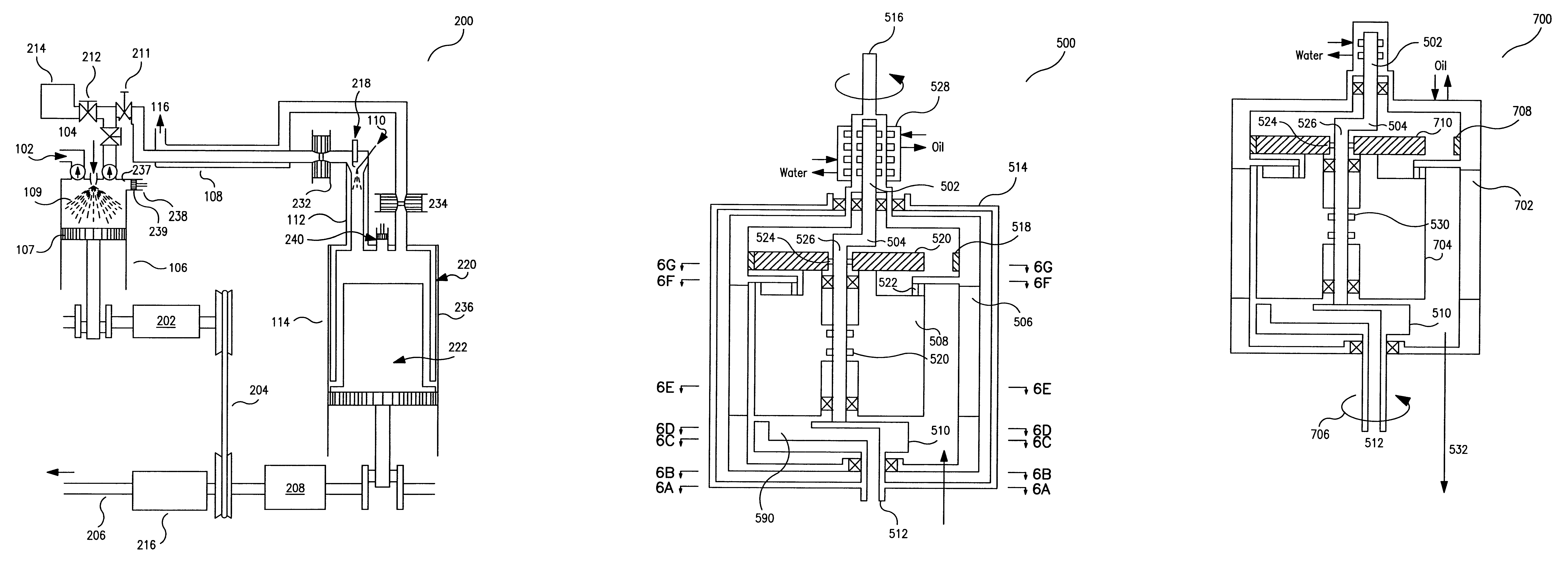

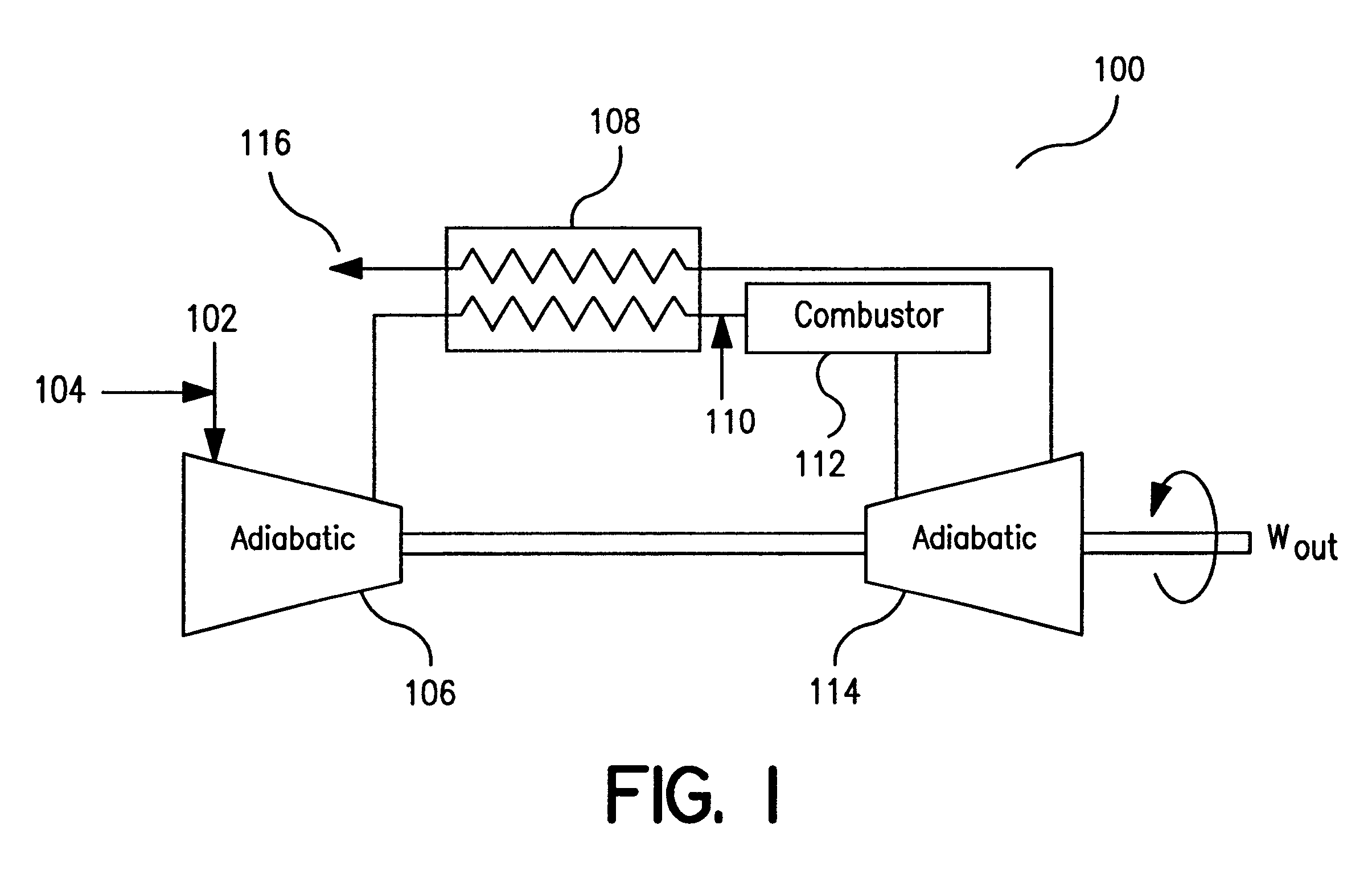

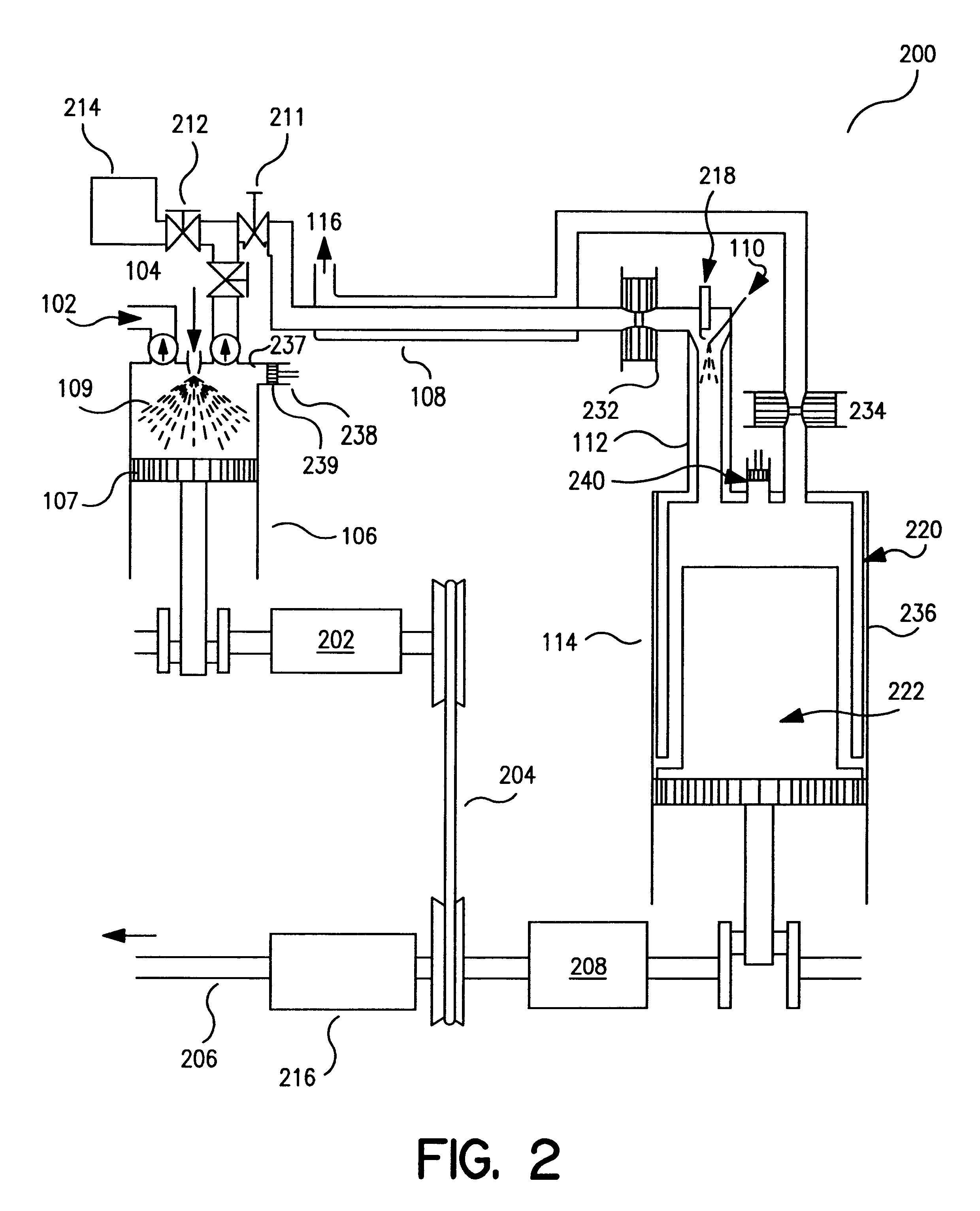

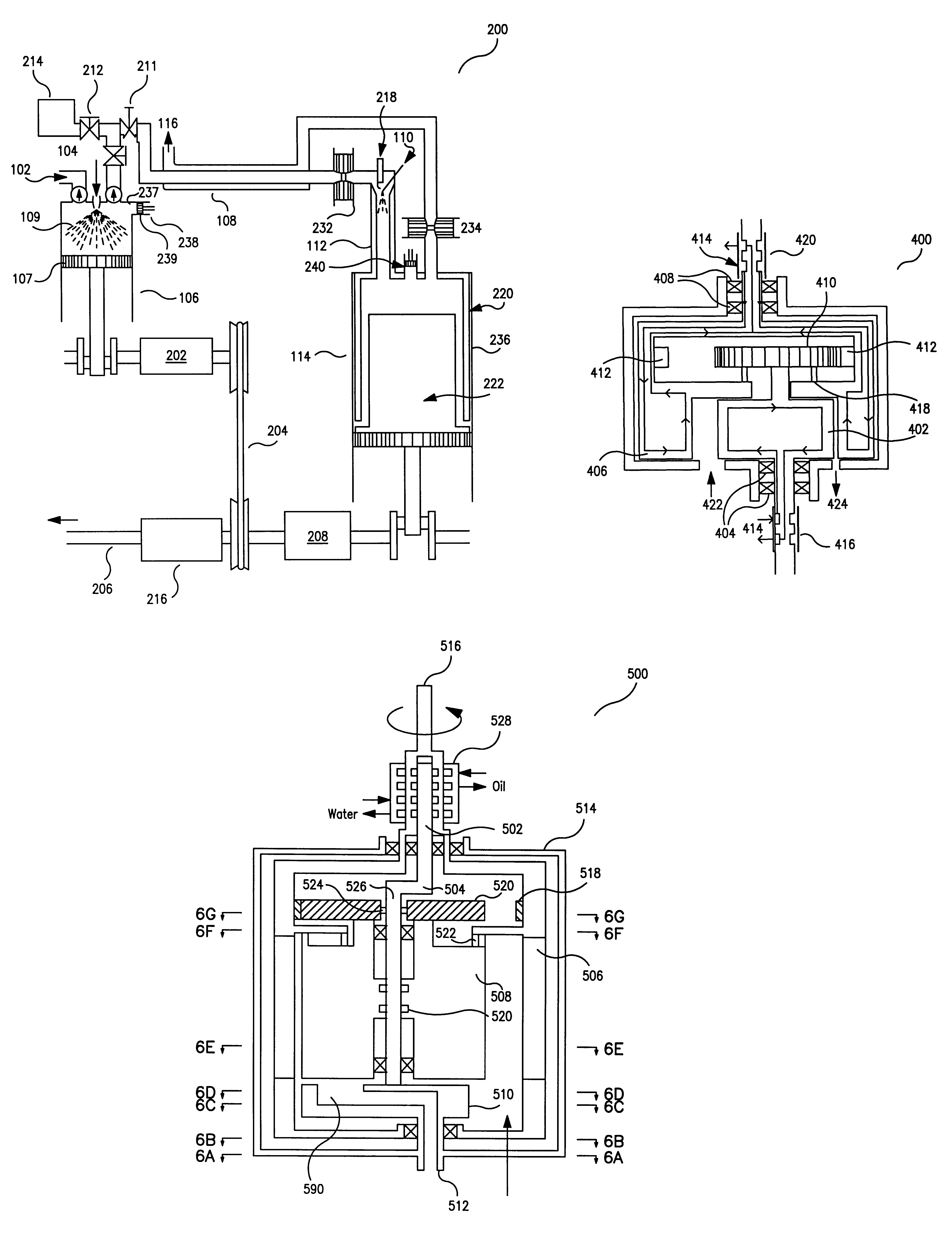

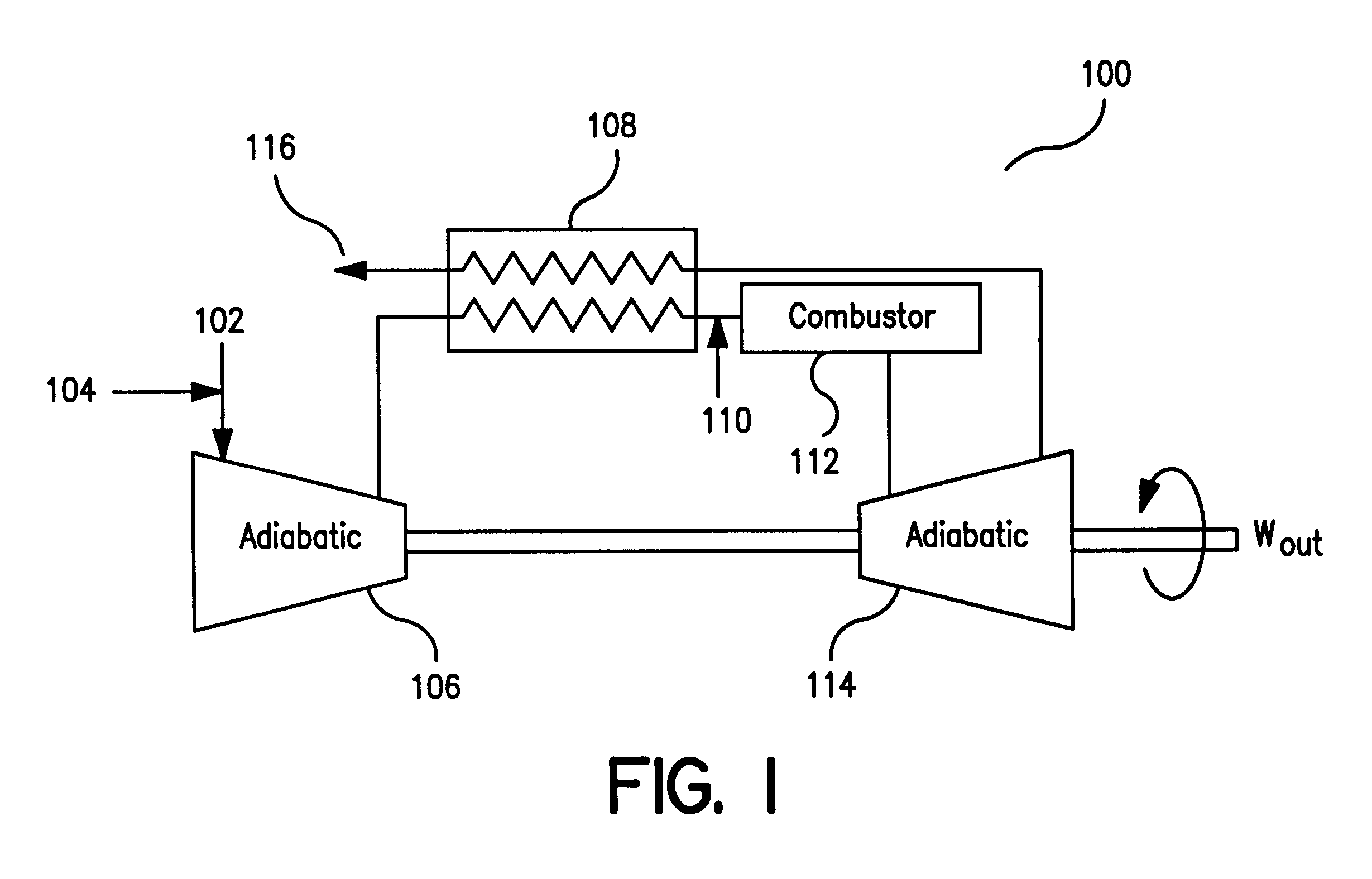

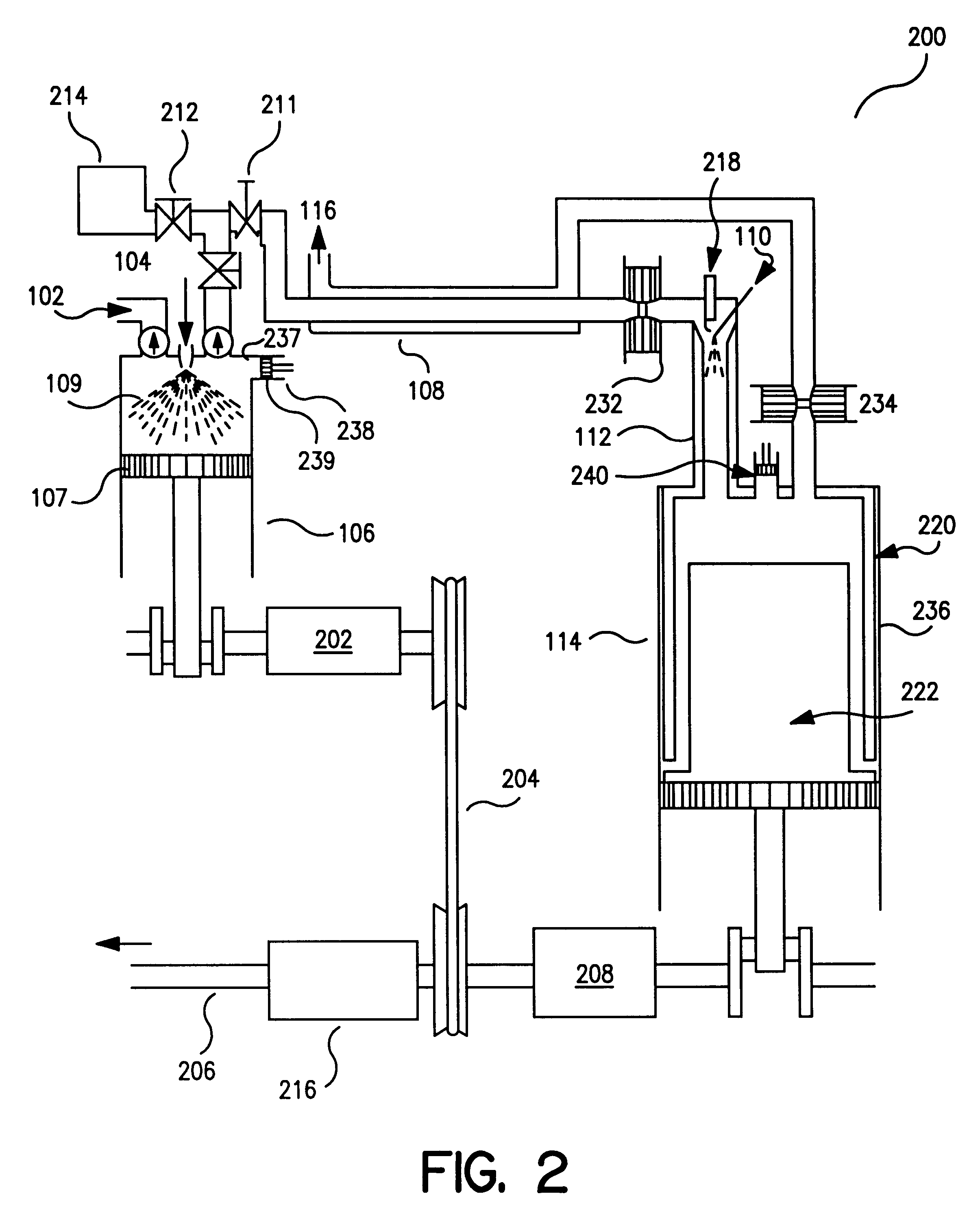

Quasi-isothermal Brayton Cycle engine

InactiveUS6530211B2Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesEngine of arcuate-engagement typeBrayton cycleCombustor

Owner:HOLTZAPPLE MARK T +1

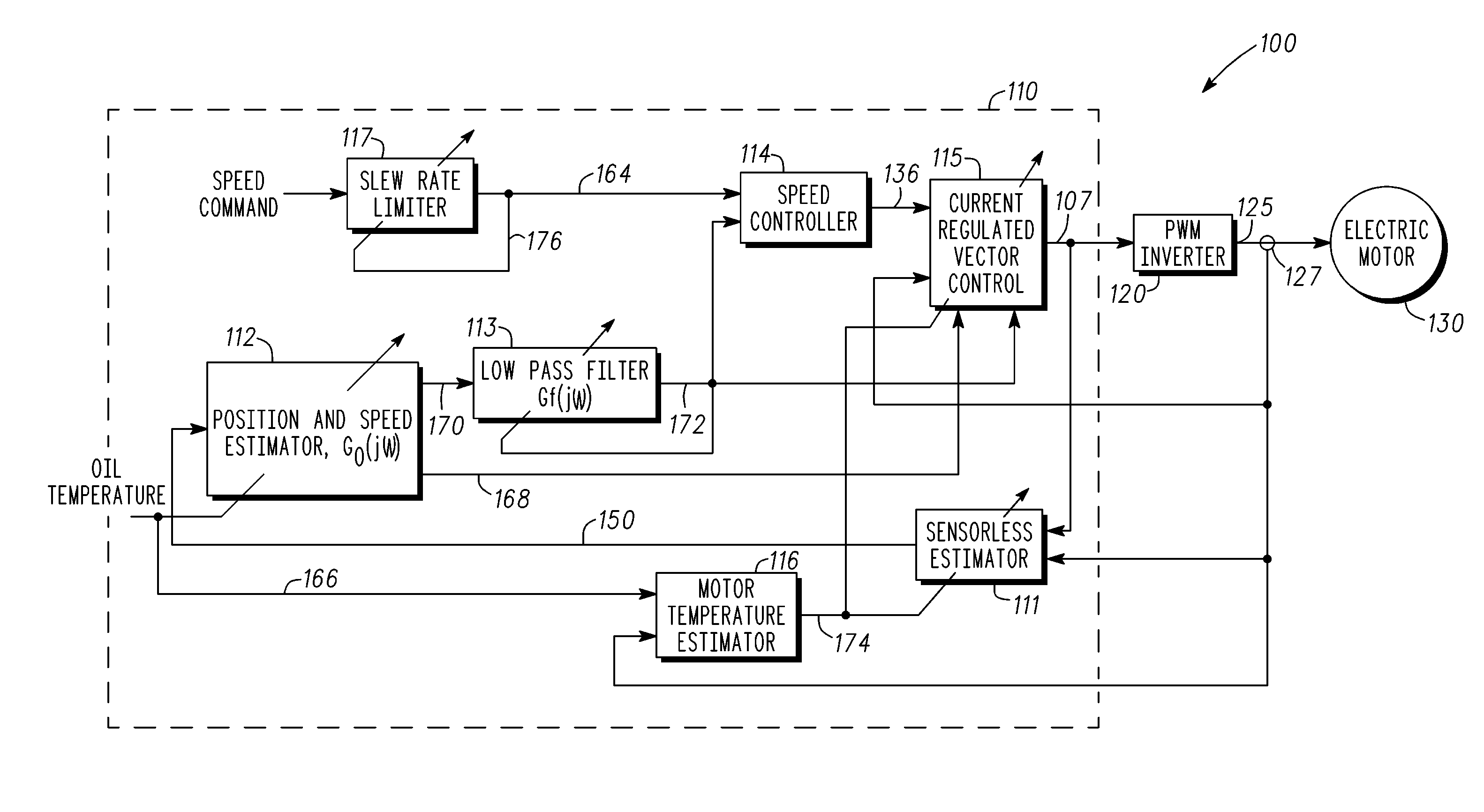

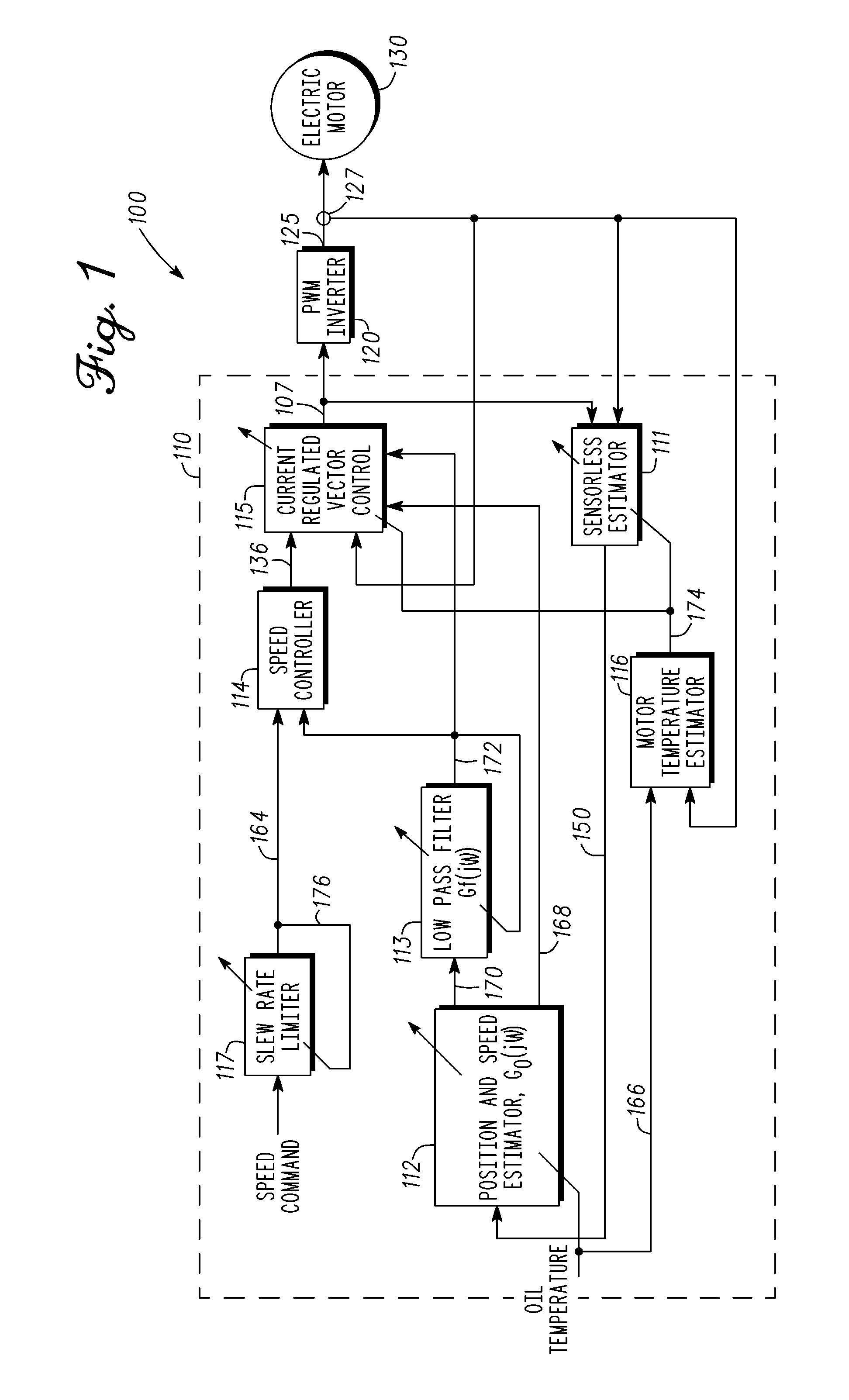

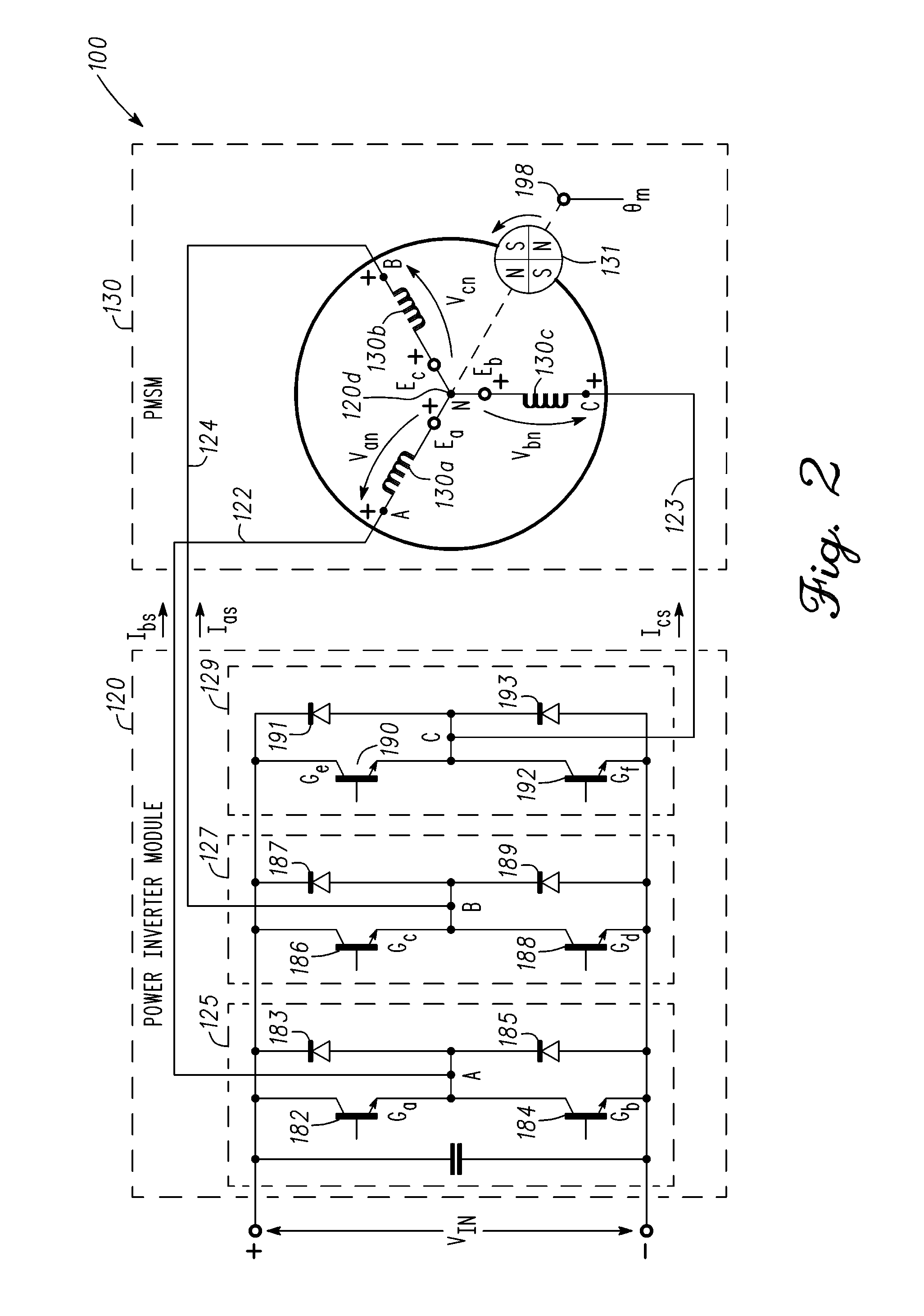

Methods, systems and apparatus for dynamically controlling an electric motor that drives an oil pump

ActiveUS20110084638A1Multiple motor speed/torque controlSingle motor speed/torque controlMotor driveEngineering

Methods, system and apparatus are provided for sensorless control of a vector controlled motor drive system that includes an electric motor used to drive an auxiliary oil pump.

Owner:GM GLOBAL TECH OPERATIONS LLC

Quasi-isothermal Brayton cycle engine

InactiveUS6336317B1Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesCombination enginesBrayton cycleCombustor

An engine is disclosed. According to one embodiment of the present invention, the engine comprises a compressor, and combustor, and an expander. The compressor compresses ambient air. The combustor burns the compressed air, and produces exhaust gasses. The expander receives the exhaust gases from the combustor, and expands the exhaust gasses. The compressor may be a gerotor compressor or a piston compressor having variable-dead-volume control. The expander may be a gerotor expander or a piston expander having variable-dead-volume control. In another embodiment, an engine comprises a piston compressor, a combustor, a piston expander, and a pressure tank. The piston compressor compresses ambient air. The combustor burns the compressed air, and produces exhaust gasses. The piston expander receives the exhaust gasses from the combustor, and expands the exhaust gasses. The pressure tank receives and stores the compressed air from the compressor. In another embodiment, a gerotor compressor or a gerotor expander comprises an inner gerotor, and an outer gerotor. The inner gerotor and the outer gerotor are driven so that they do not touch. The gerotors may be cantilevered or non-cantilevered.

Owner:TEXAS A&M UNIVERSITY

Discharge valve

InactiveUS6171084B1Easy to operateRaise the possibilityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringValve seat

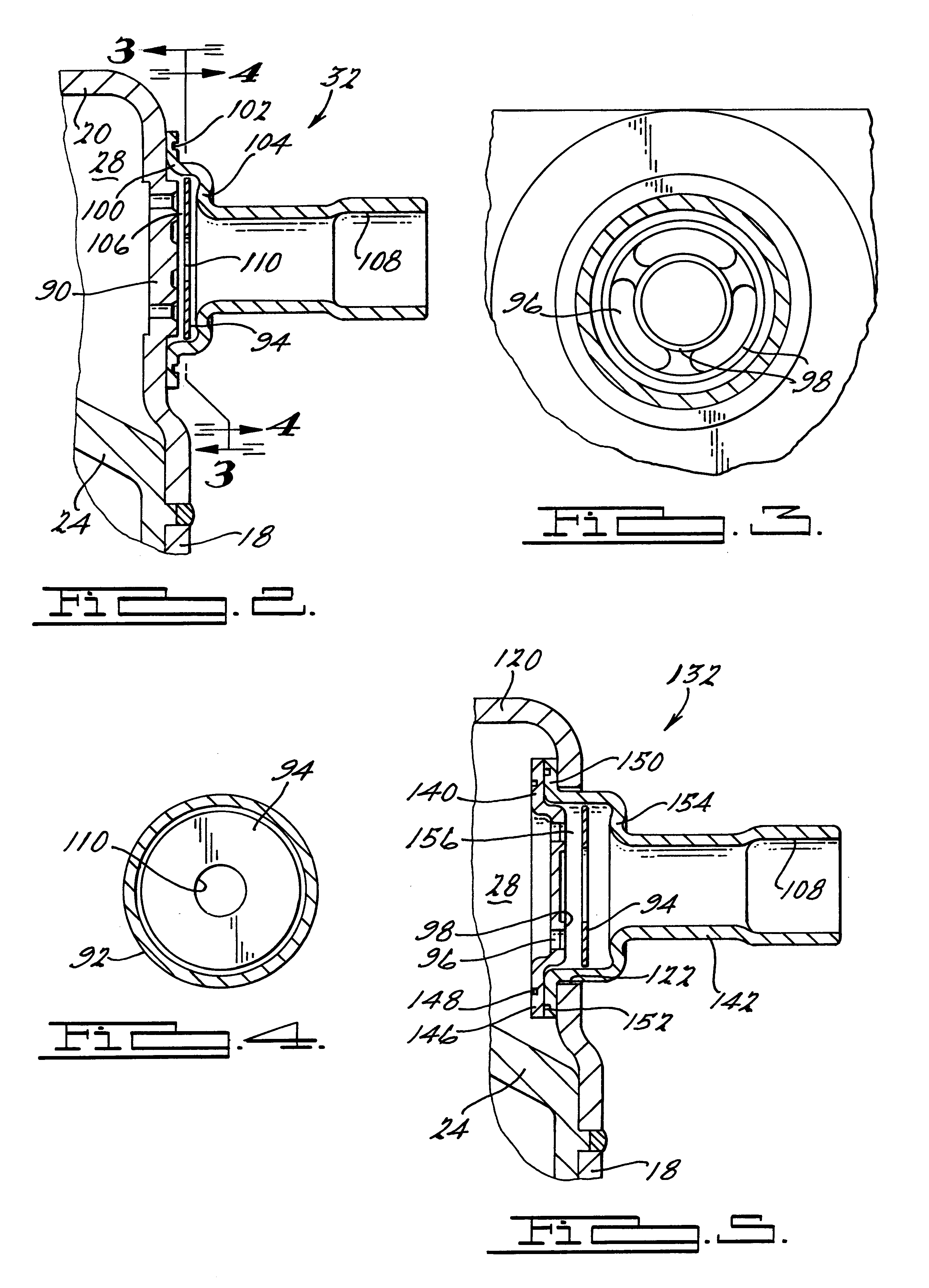

A compressor assembly includes a shell which defines a discharge chamber. A discharge valve assembly is attached to the shell in communication with the discharge chamber. The discharge valve assembly includes a stamped or coined valve seat, a drawn tubular element and a stamped valve member. The stamping, drawing and coining operations used to manufacture the discharge valve assembly significantly reduce the manufacturing costs for the discharge valve assembly.

Owner:EMERSON CLIMATE TECH INC

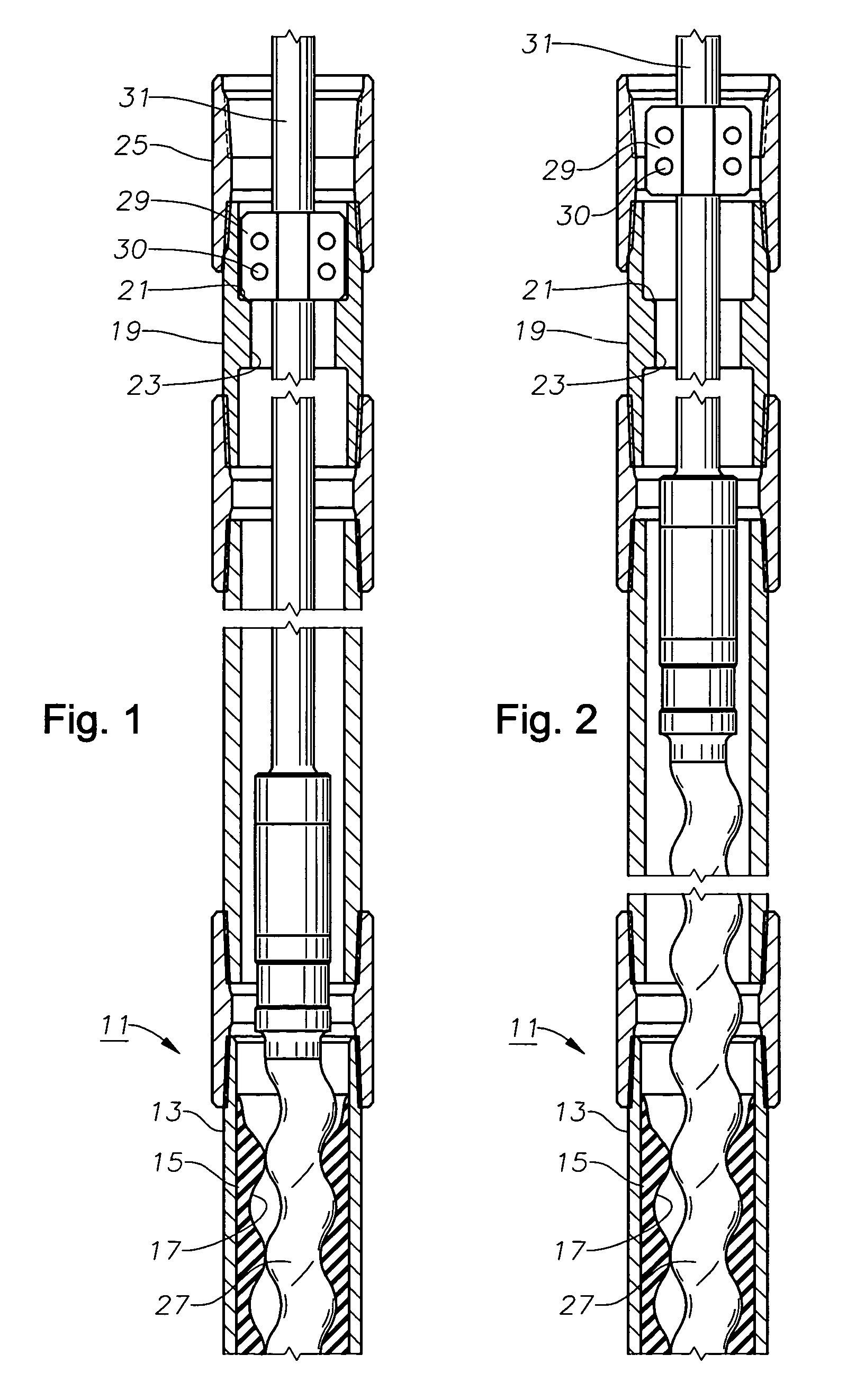

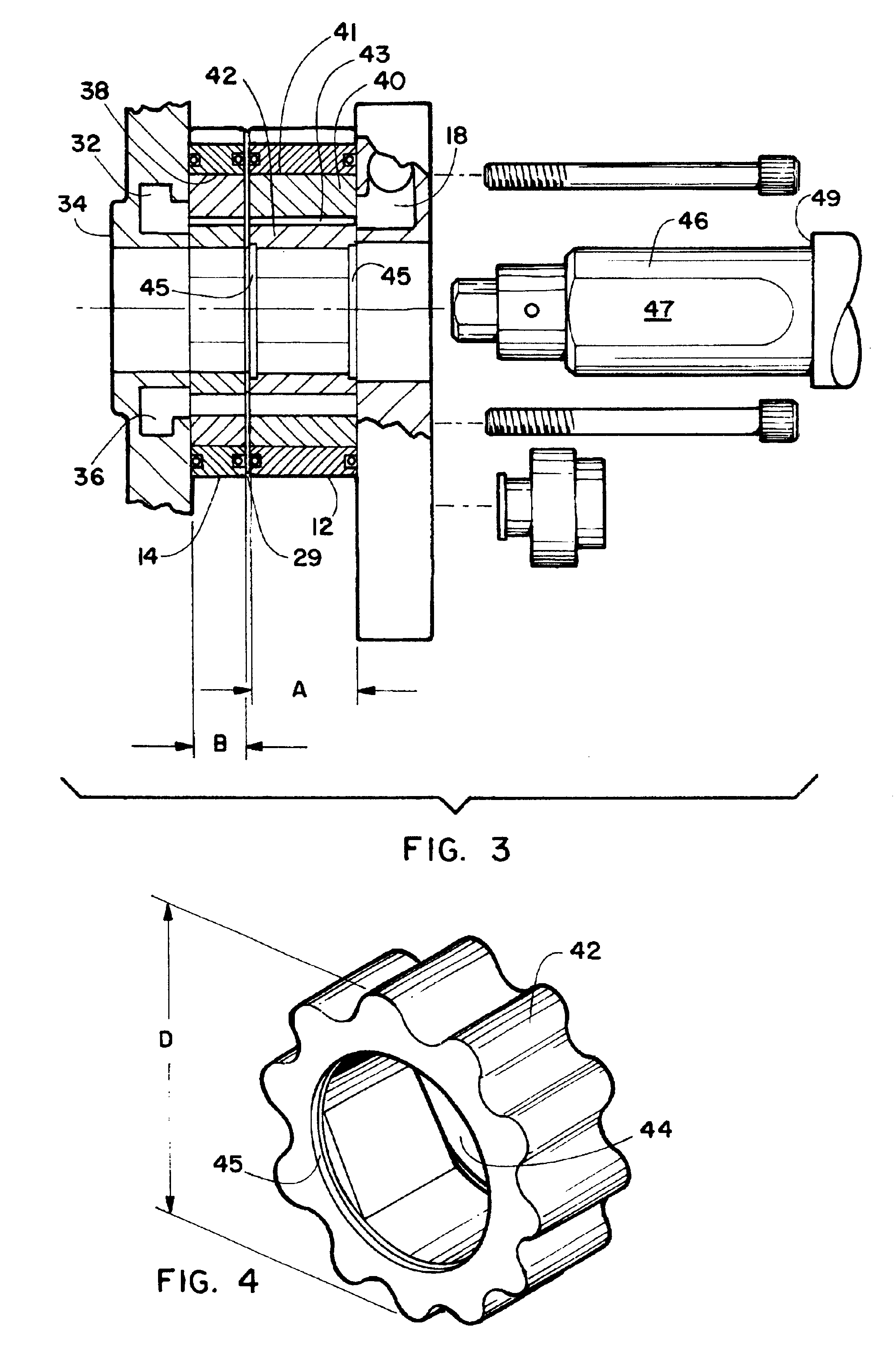

Method and apparatus for aligning rotor in stator of a rod driven well pump

InactiveUS7201222B2Oscillating piston enginesEngine of intermeshing engagement typeMechanical engineeringHelix

A progressing cavity rod-driven well pump utilizes a tag shoulder above a helical passage of the stator. The pump stator is located at the lower end of a string of tubing. The tag shoulder is more restrictive than a passage through the tubing. A pump rotor is secured to a string of rods and has a stop located above the rotor. The rotor is lowered on the rods until the stop lands on the tag shoulder. Then the operator lifts the rods and the rotor to accommodate for expected stretch during operation. By removing the rods and rotor, monitoring tools can be lowered through the tag shoulder and stator.

Owner:BAKER HUGHES INC

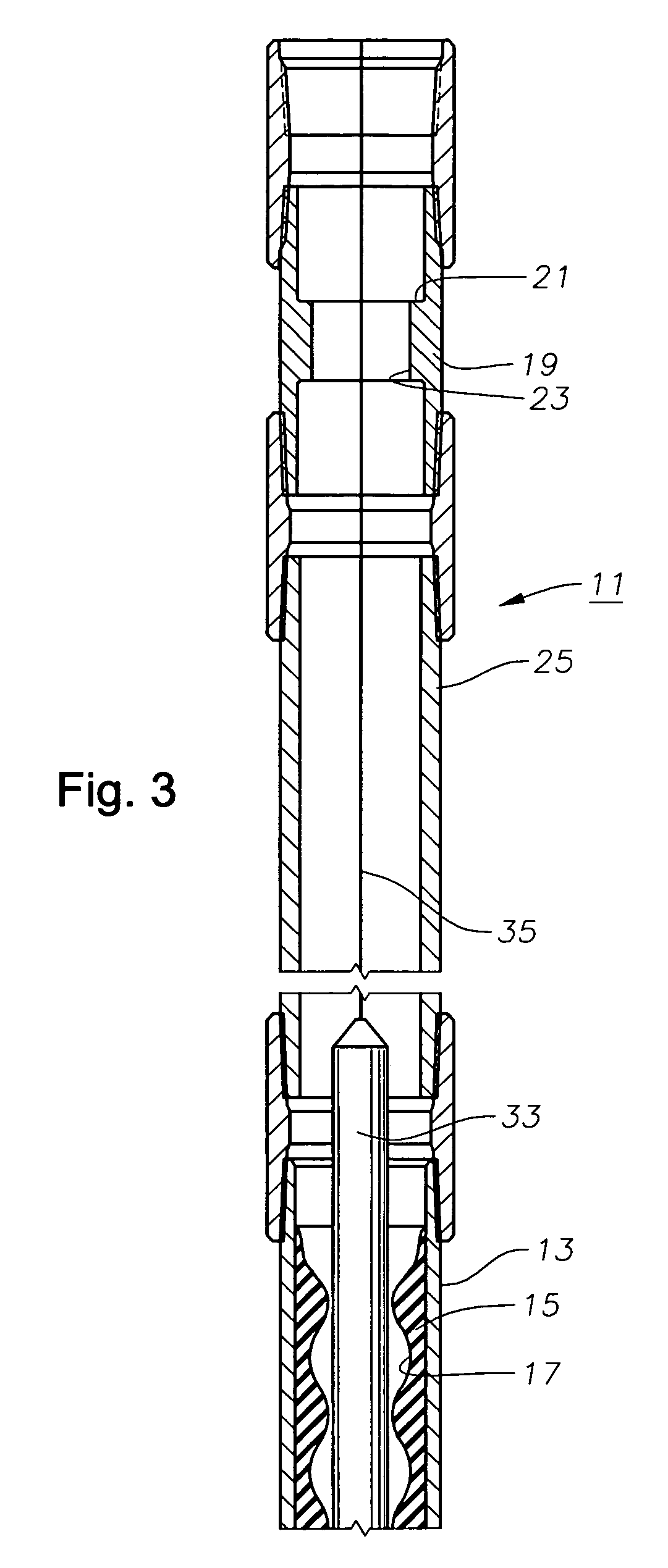

Self compensating adjustable fit progressing cavity pump for oil-well applications with varying temperatures

The present invention provides an adjustable rotor and / or stator, so that the interference fit and / or clearance can be adjusted. The rotor and / or stator are tapered to provide a difference in fit between the rotor and stator by longitudinal adjustment of their relative position. The relative longitudinal adjustment is achieved in response to a change in temperature and is matched to the taper angle of the stator / rotor to maintain a desired interference fit.

Owner:WEATHERFORDLAMB

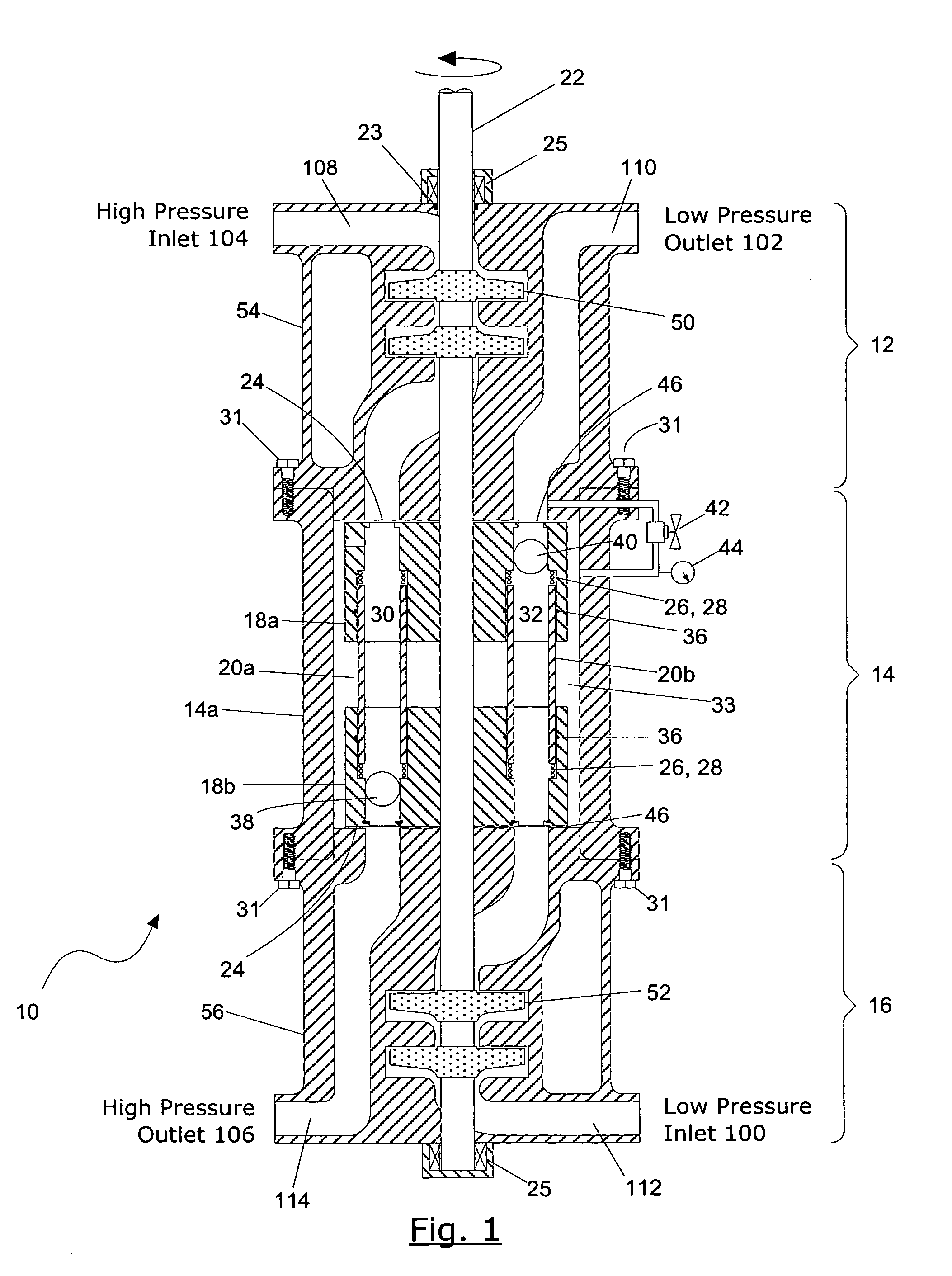

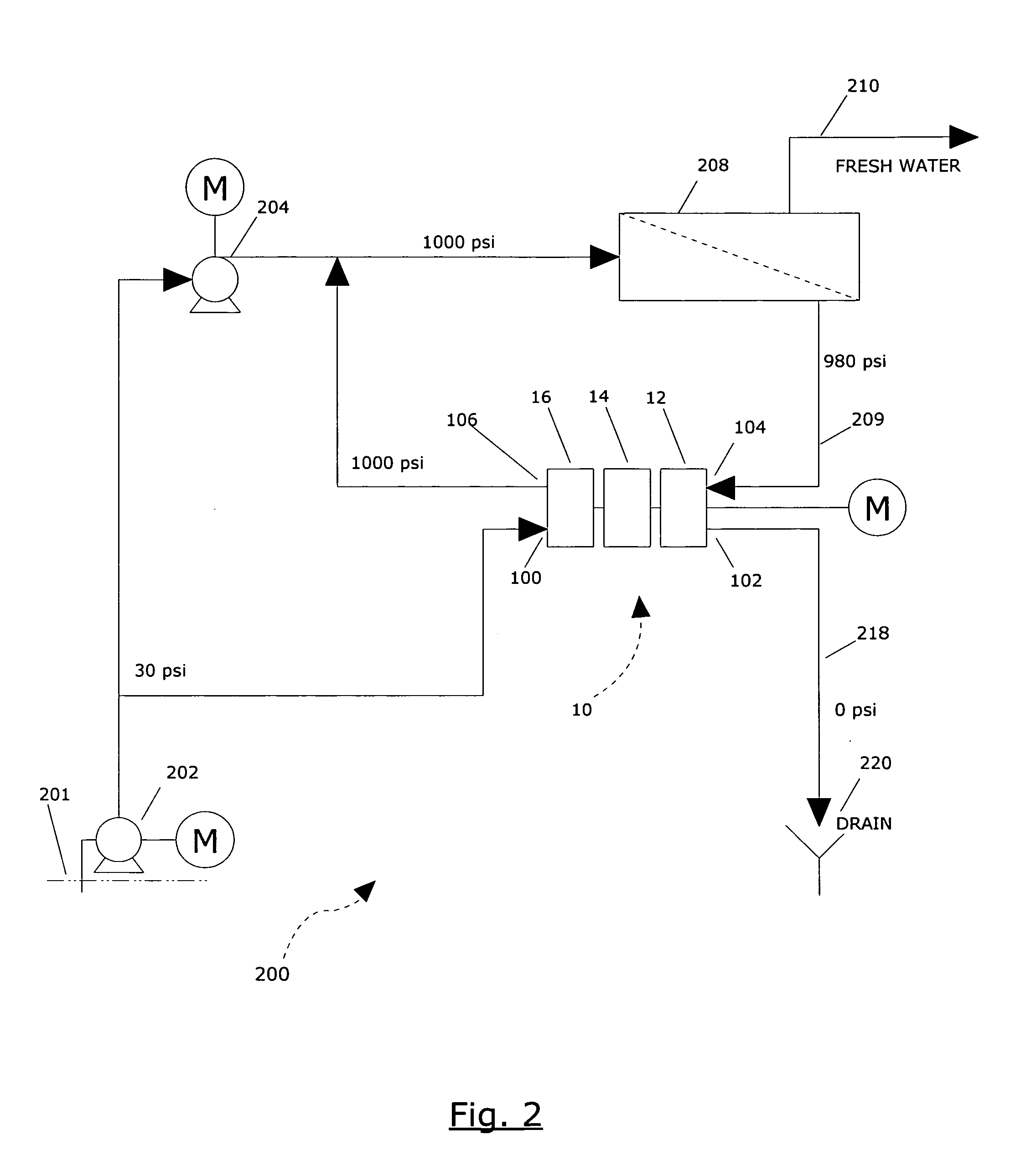

Pressure exchanger

ActiveUS7306437B2Increase capacityIncrease momentumRotary/oscillating piston combinations for elastic fluidsGeneral water supply conservationCavitationMomentum

Owner:ISOBARIC STRATEGIES INC

Progressive cavity pump/motor stator, and apparatus and method to manufacture same by electrochemical machining

ActiveUS7192260B2Improve heat transfer performanceReduce adverse effectsElectrolysis componentsEngine of intermeshing engagement typeElastomerElectricity

Electrochemical machining is used to generate the helical lobe profiles of the stator of a progressive cavity pump or motor. A thin, elastomeric liner, of uniform thickness is bonded either to the interior of the stator, or to the exterior of the rotor. Where the elastomeric liner is to be bonded to the interior of the stator, bonding is improved by electrically etching the interior of the stator during the electrochemical machining process to produce a roughened surface.

Owner:LEHR PRECISION

Scroll compressor

InactiveUS20050053507A1Reduced compression lossEngine of arcuate-engagement typeOscillating piston enginesEngineeringHelix

A scroll compressor includes a first scroll and a second scroll. The first scroll has a step portion that separates an elevated portion and a recessed portion of a surface of the first scroll. A spiral wall of the second scroll has a step that separates an elevated portion and a recessed portion of the wall. A first bypass hole is provided in the elevated portion of the surface of the first scroll. A second bypass hole is provided in the recessed portion of the surface of the first scroll. The second bypass hole is within 360 degrees toward a center of the spiral of the first scroll from an outer end of the spiral. The first bypass hole is within 360 degrees from the second bypass hole toward the center of the spiral.

Owner:MITSUBISHI HEAVY IND LTD

Pump with conveying chamber formed in outer rotor surface

ActiveUS7674100B2Avoid flowEngine of arcuate-engagement typeRotary piston pumpsMechanical engineeringMedical treatment

Owner:QUANTEX ARC LTD

Stator for down hole drilling motor

InactiveUS6905319B2Reduced susceptibility to stator damageSufficient wear characteristicOscillating piston enginesEngine of intermeshing engagement typeDrill holePhysics

An improved down hole drilling motor suitable for drilling applications. The down hole drilling motor comprising a stator disposed in the tubular housing. The stator includes an internal cavity having one or more lobes. A rotor operatively positioned in the cavity of the stator is adapted to cooperate with the one or more lobes of the stator. The stator comprising a compound having improved manufacturing and performance characteristics.

Owner:HALLIBURTON ENERGY SERVICES INC

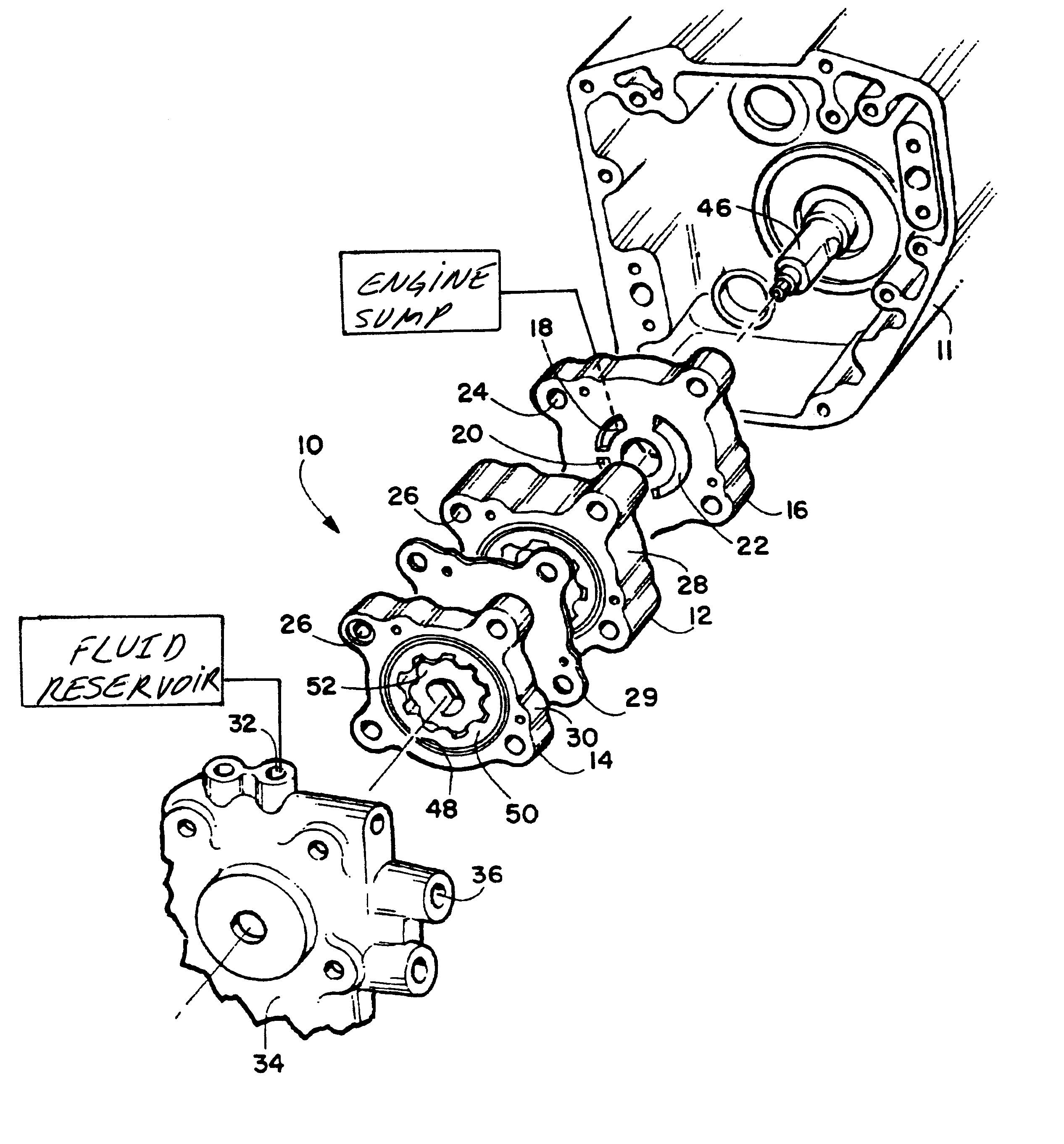

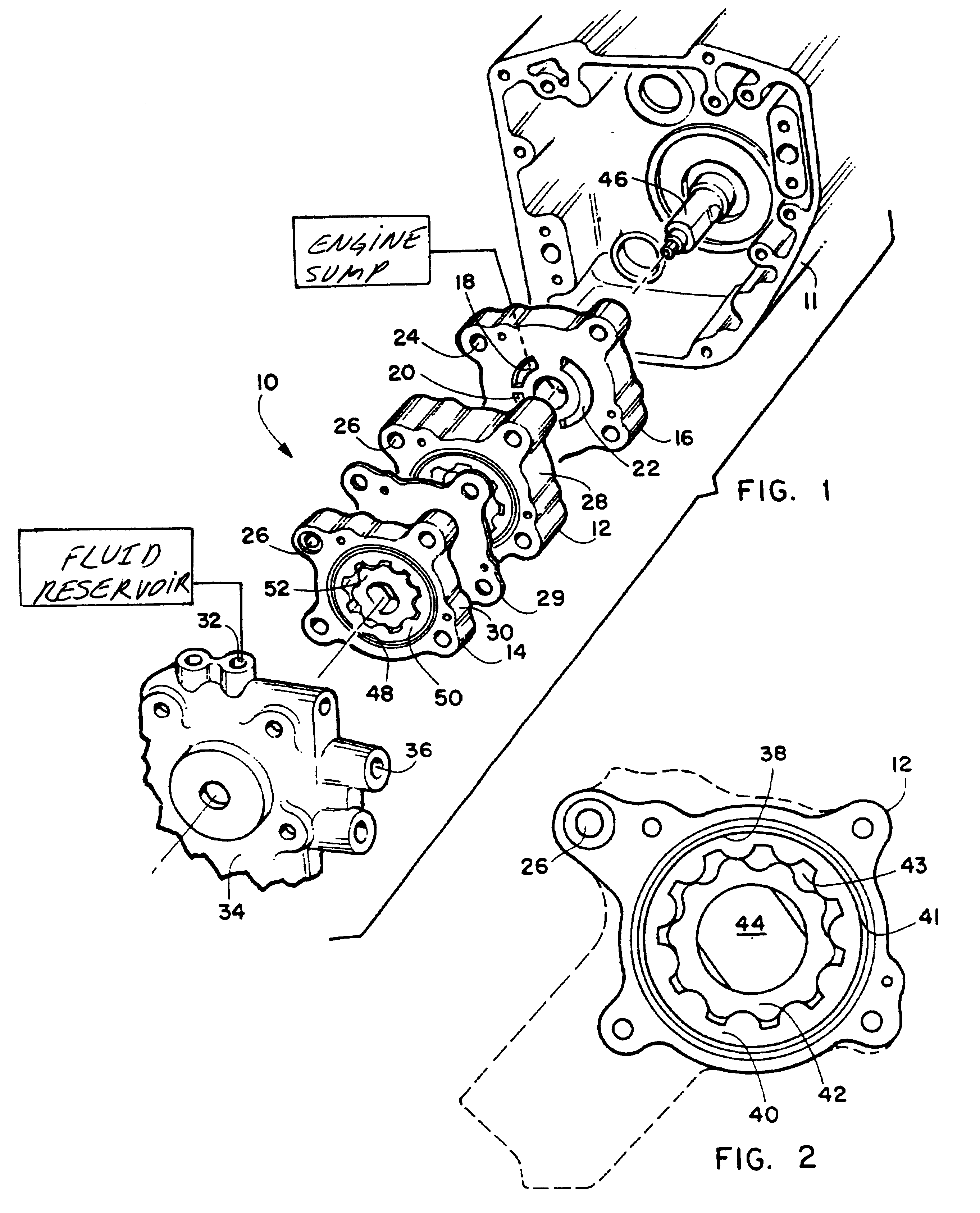

Oil pump

InactiveUS6679692B1Easy to replacePromote repairRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesFuel tankEngineering

A modular oil pump for use in combination with an internal combustion engine having a dry sump lubrication system. The device features a first gerotor pump having an intake port engageable in communication with at least one engine sump and having an discharge port engageable in sealed communication with a fluid reservoir for the dry sump system. A second gerotor pump, engageable in sealed communication with the fluid reservoir has a discharge port fluidly engageable with the engine lubrication system oil supply conduit. Both the first pump and second pump are assembled from separate housings, and cooperatively engaged inner and outer gears sized for rotation and in line mounting on the engine crankshaft inside a cavity in the housings. The volume pumping capacity of the first pump at a ratio to efficiently drain fluid and gas from the engine sumps and supply the reservoir with a constant supply of lubrication fluid. The device may be assembled from a kit having a plurality of different sized components to adjust the ratio of the pumping volume of the first pump to the second pump.

Owner:FEULING JAMES J

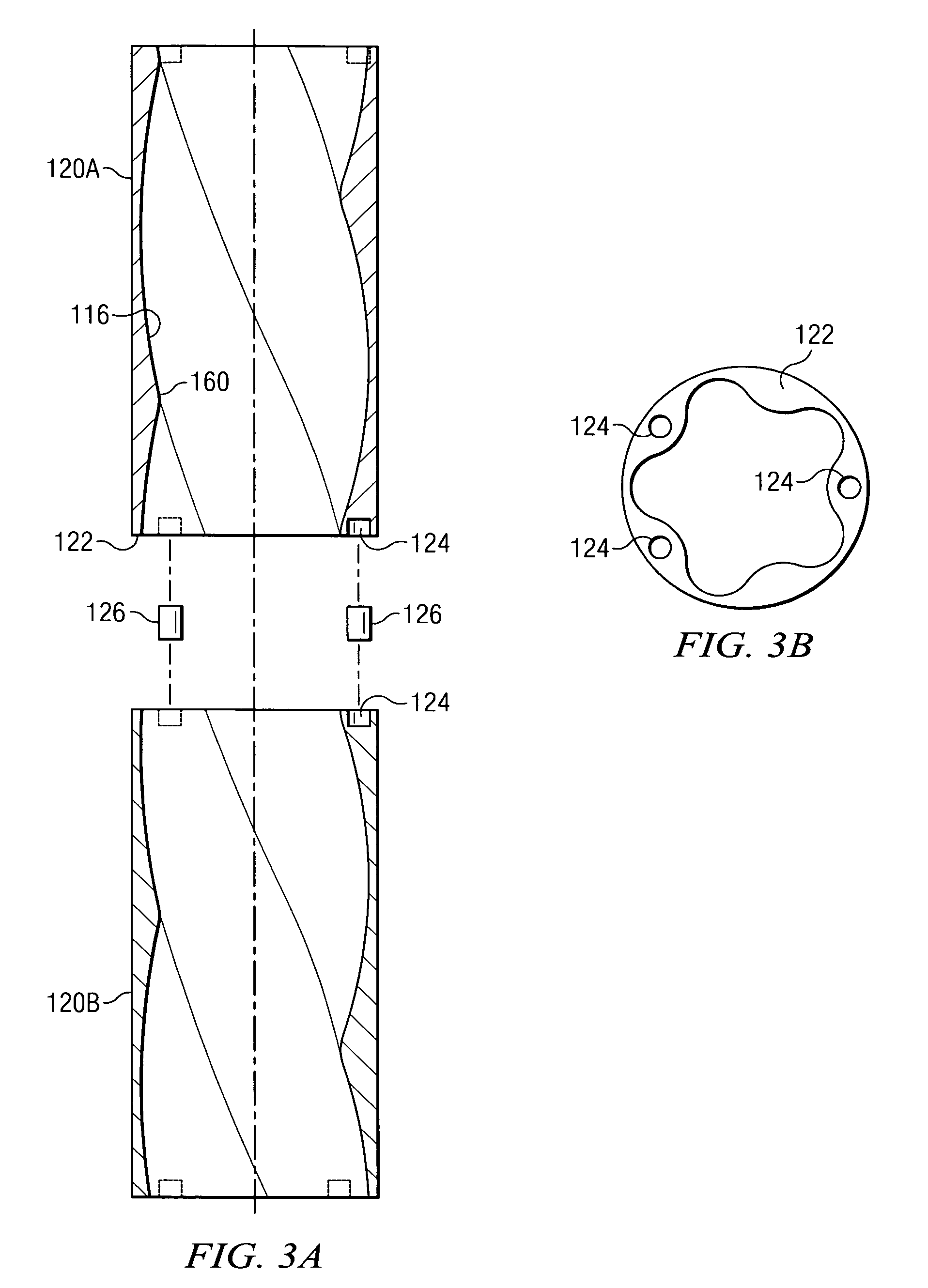

Progressing cavity stator including at least one cast longitudinal section

InactiveUS7396220B2Increased torque outputSimple and inexpensive to manufactureOscillating piston enginesEngine of intermeshing engagement typeElastomerHigh torque

A progressing cavity stator and a method for fabricating such a stator are disclosed. Exemplary embodiments of the progressing cavity stator include a plurality of rigid longitudinal stator sections concatenated end-to-end in a stator tube. The stator sections are rotationally aligned so that each of the internal lobes extends in a substantially continuous helix from one end of the stator to the other. The stator further includes an elastomer liner deployed on an inner surface of the concatenated stator sections. Exemplary embodiments of this invention include a comparatively rigid stator having high torque output and are relatively simple and inexpensive to manufacture as compared to prior art rigid stators.

Owner:SMITH INT INC

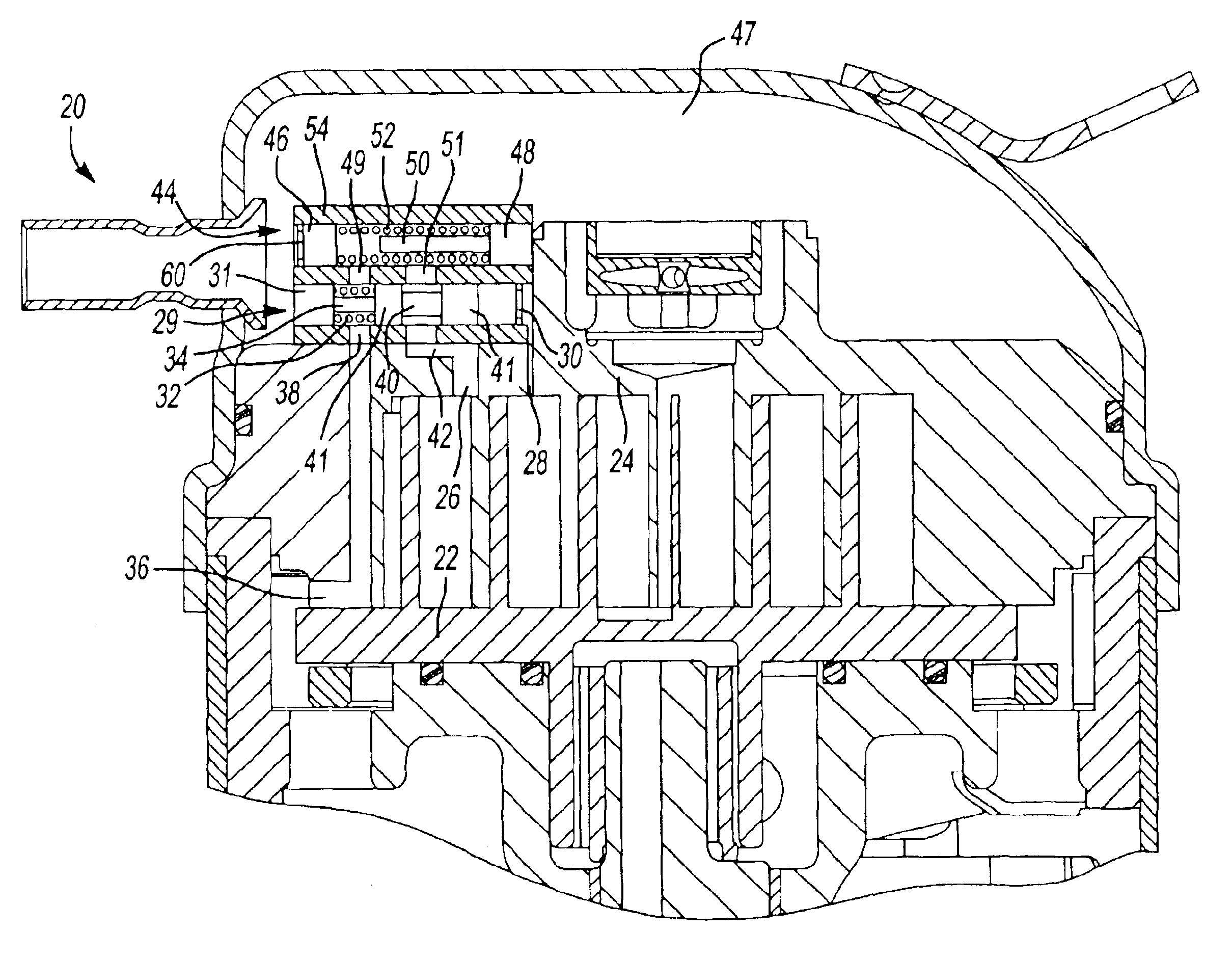

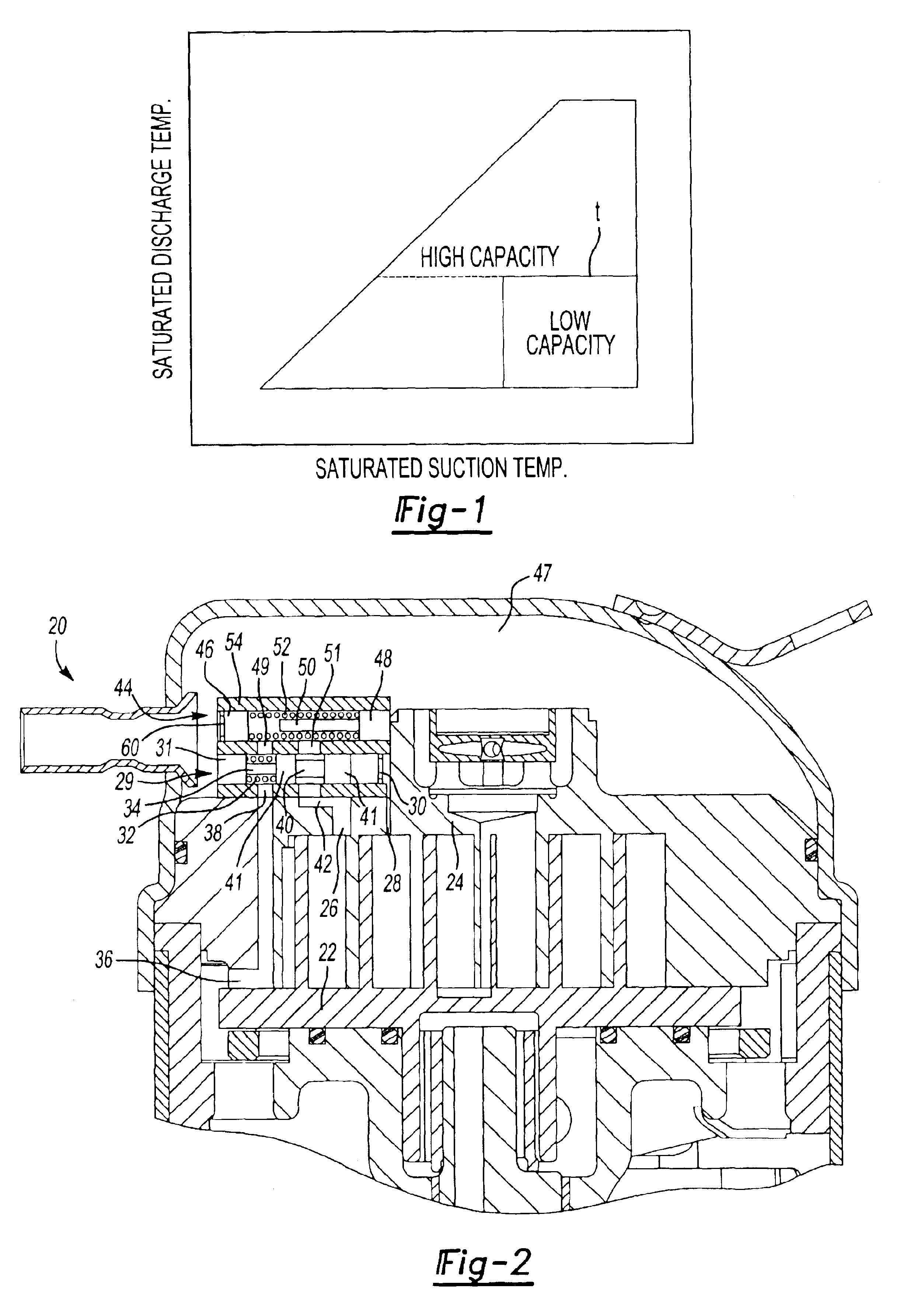

Two-step self-modulating scroll compressor

InactiveUS6884042B2Pump componentsEngine of arcuate-engagement typePressure differenceElectrical and Electronics engineering

A self-modulating scroll compressor includes a pair of valves. A first valve moves to a low capacity position when the pressure differential is below a predetermined amount. A second valve moves to a low capacity position when the suction pressure is above a predetermined amount. Low capacity operation will only occur when both valves are open. The present invention thus provides a scroll compressor design with the ability to self-modulate and control the conditions under which low capacity operation occurs based upon two criteria.

Owner:SCROLL TECH

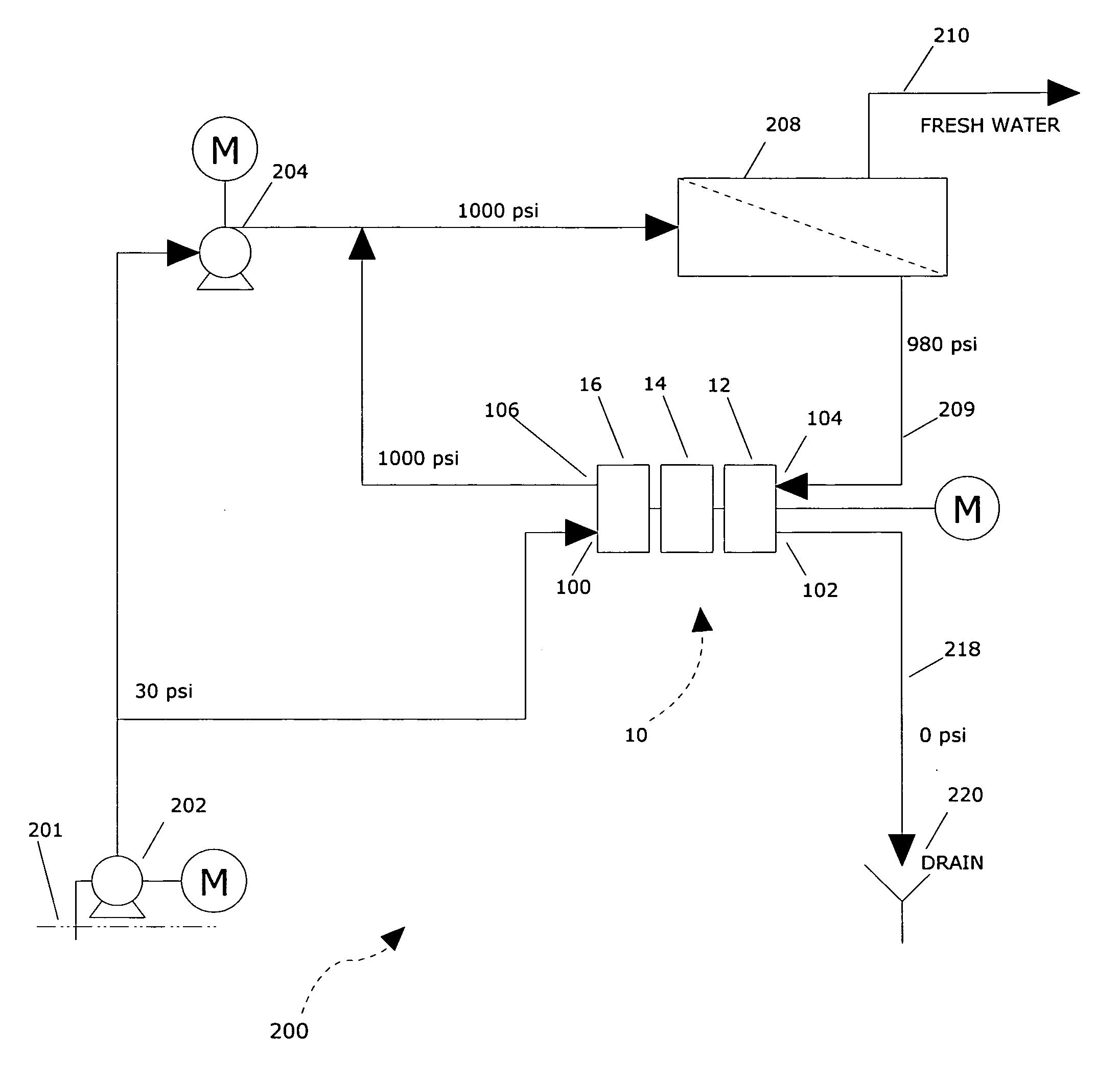

Pressure exchange apparatus with integral pump

InactiveUS20060037895A1Increase pressureRotary/oscillating piston combinations for elastic fluidsPump componentsEngineeringMechanical engineering

A pressure exchange device is provided that utilizes an integral high pressure boost pump that is in fluid communication with a pressure exchange unit. An optional low pressure boost pump unit may also be provided. The pressure exchange unit comprises a rotating rotor assembly inside a housing to transfer the pressure of a fluid from one high pressure fluid to another low pressure fluid.

Owner:SHUMWAY SCOTT

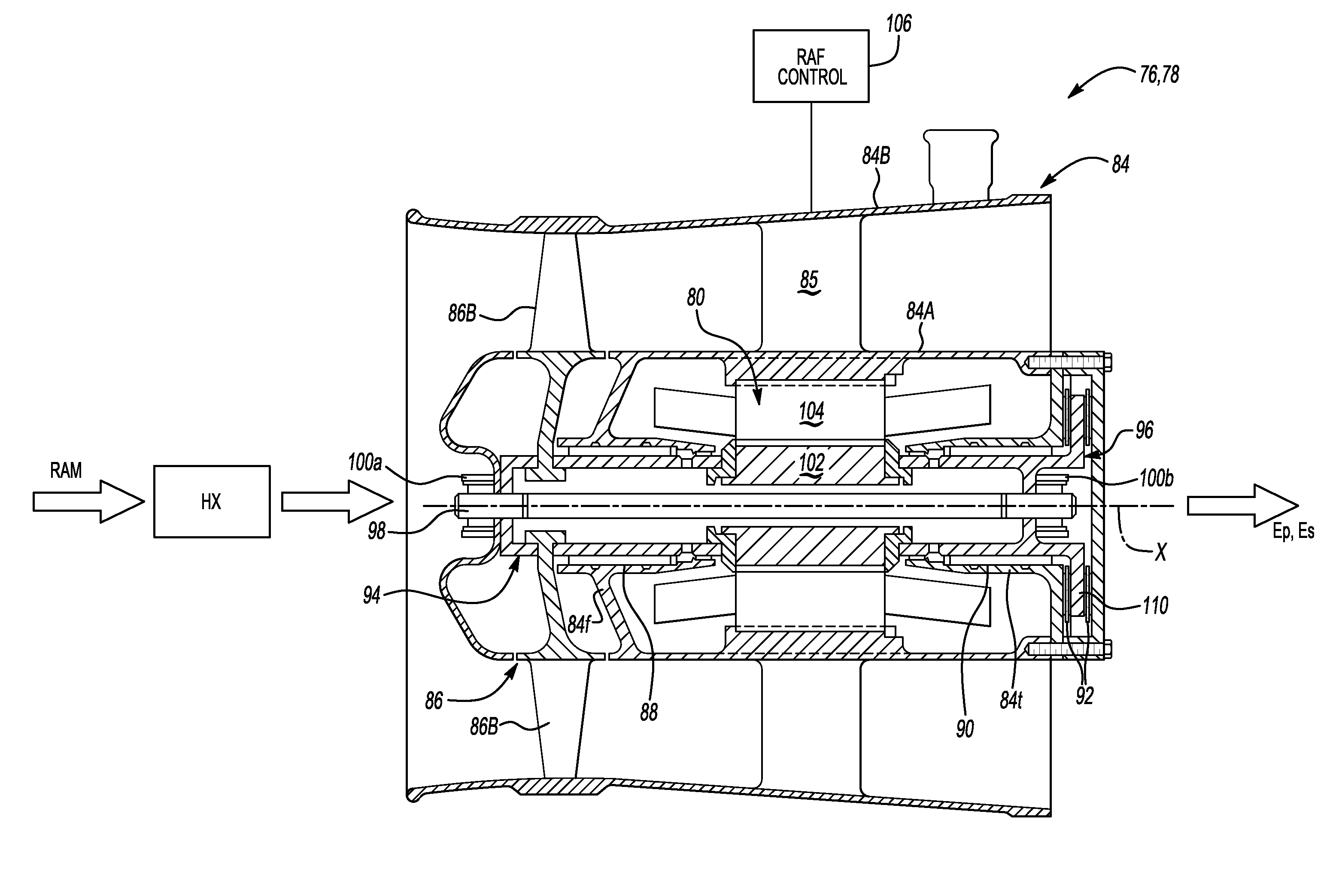

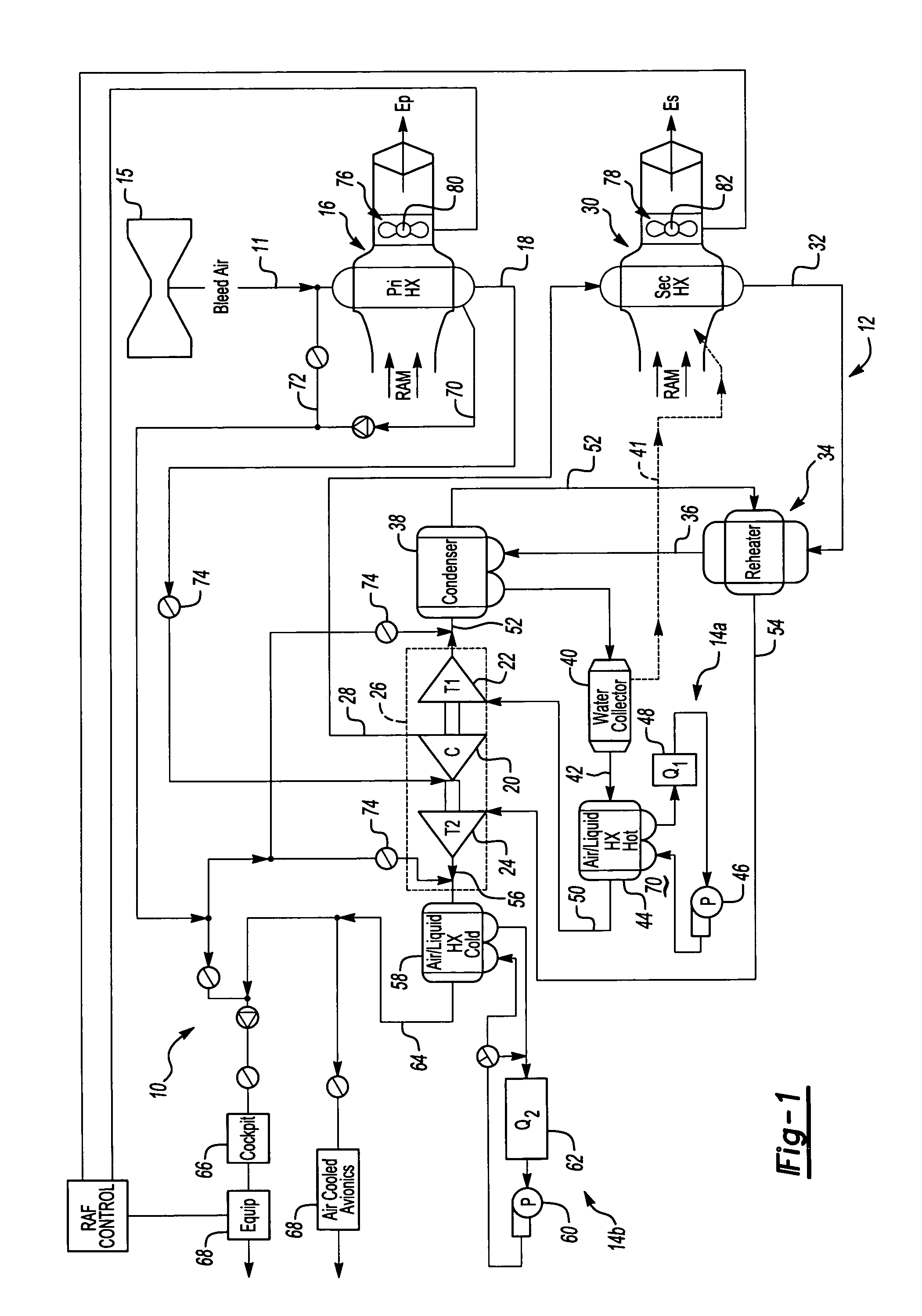

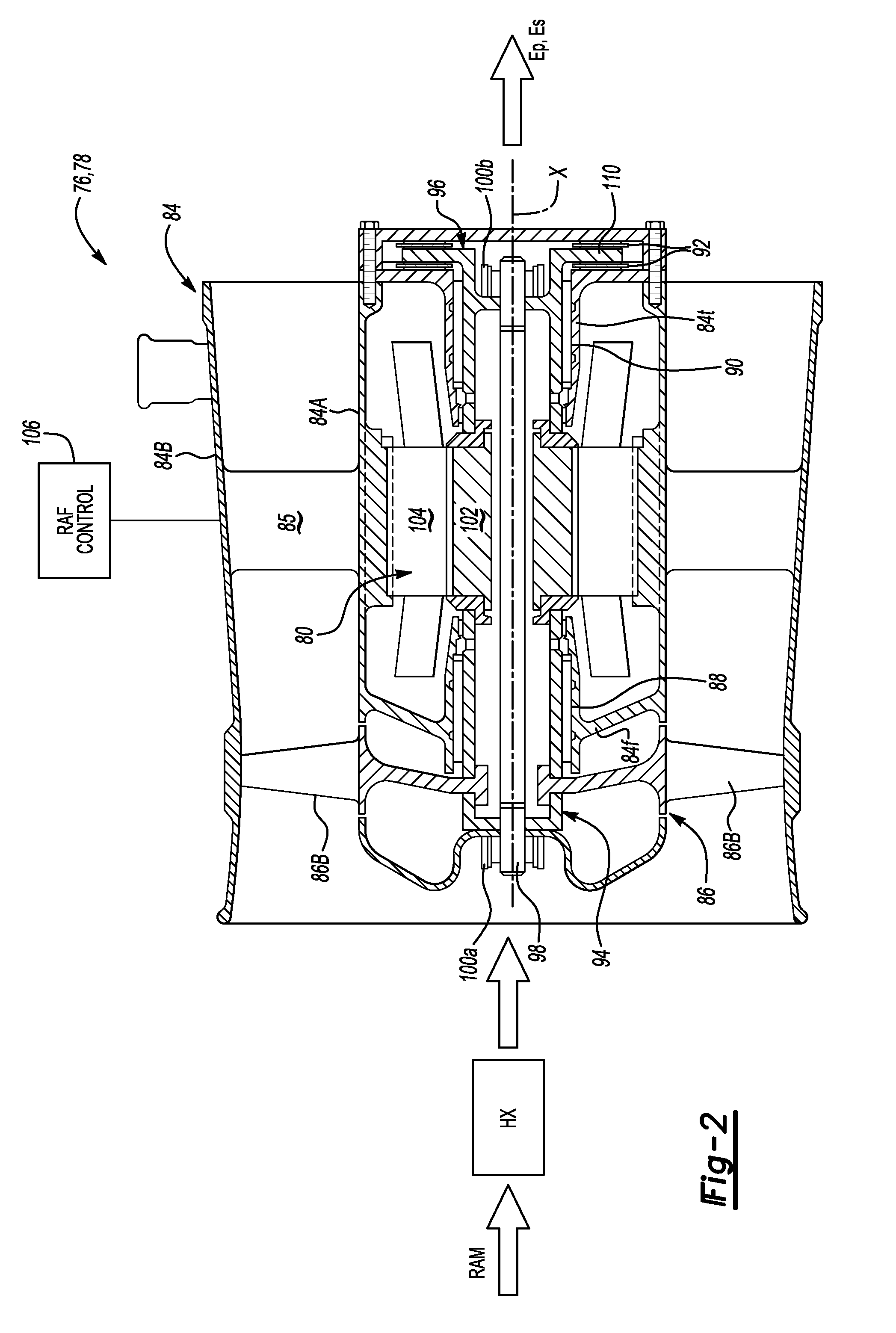

RAM fan system for an aircraft environmental control system

InactiveUS7757502B2Reduce noiseEasy to operateDomestic cooling apparatusSteam/vapor condensersAir cycle machineControl system

An environmental control system includes a RAM air fan system downstream of a respective heat exchanger in the relatively high temperature RAM exhaust. The RAM air fan includes a RAM air fan electric motor such that the RAM air fan is driven at a speed independent of an air cycle machine. A fan rotor is completely supported by hydrodynamic foil journal and thrust bearings. As the RAM air fan is driven by the RAM air fan electric motor the RAM air fan is installed in the environmental control system as a self-contained system.

Owner:HAMILTON SUNDSTRAND CORP

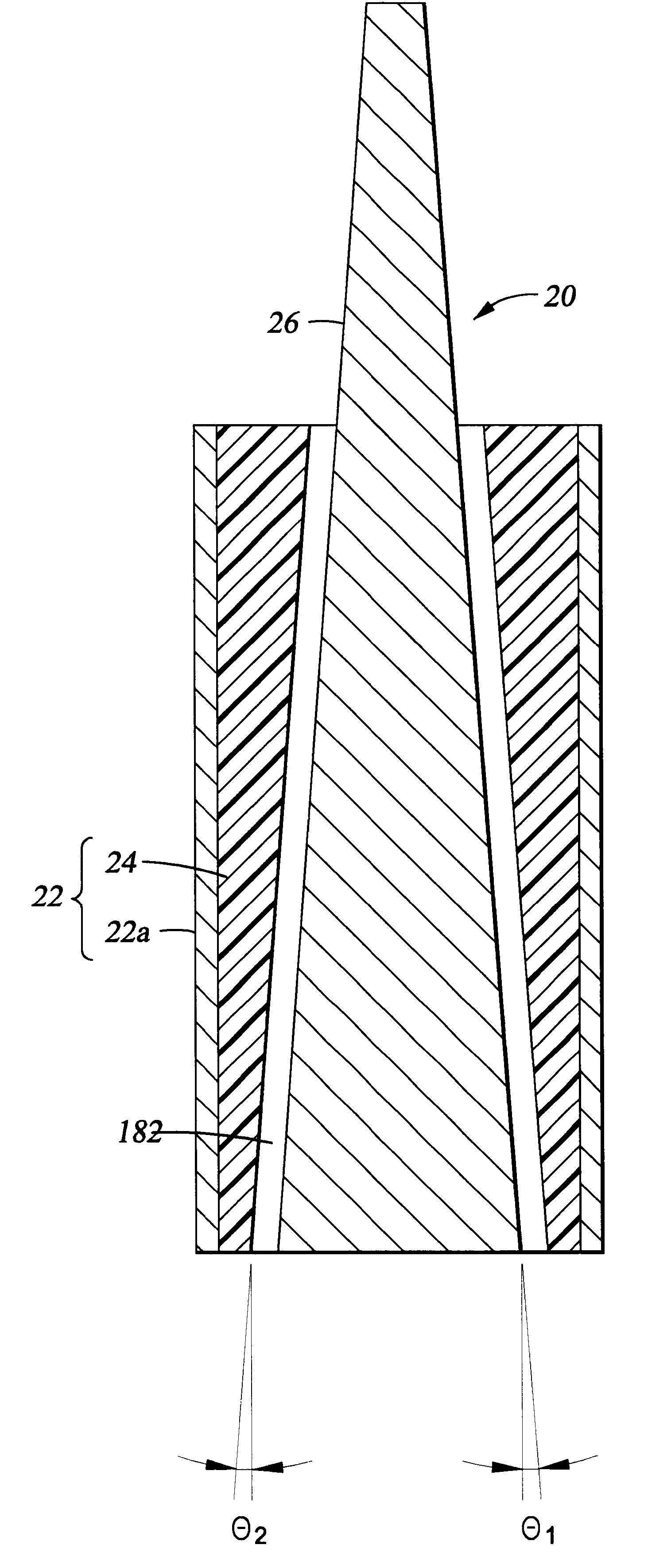

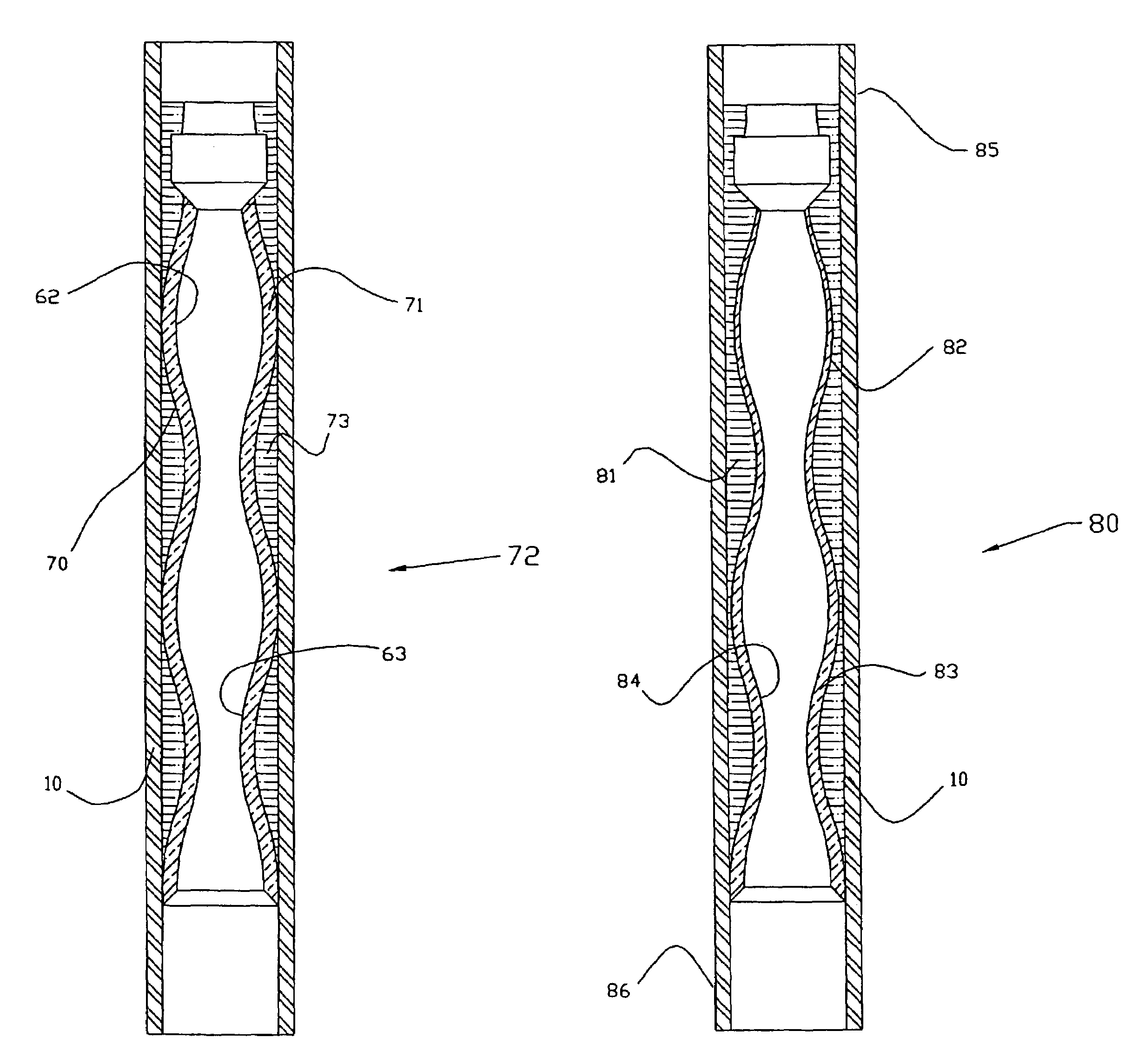

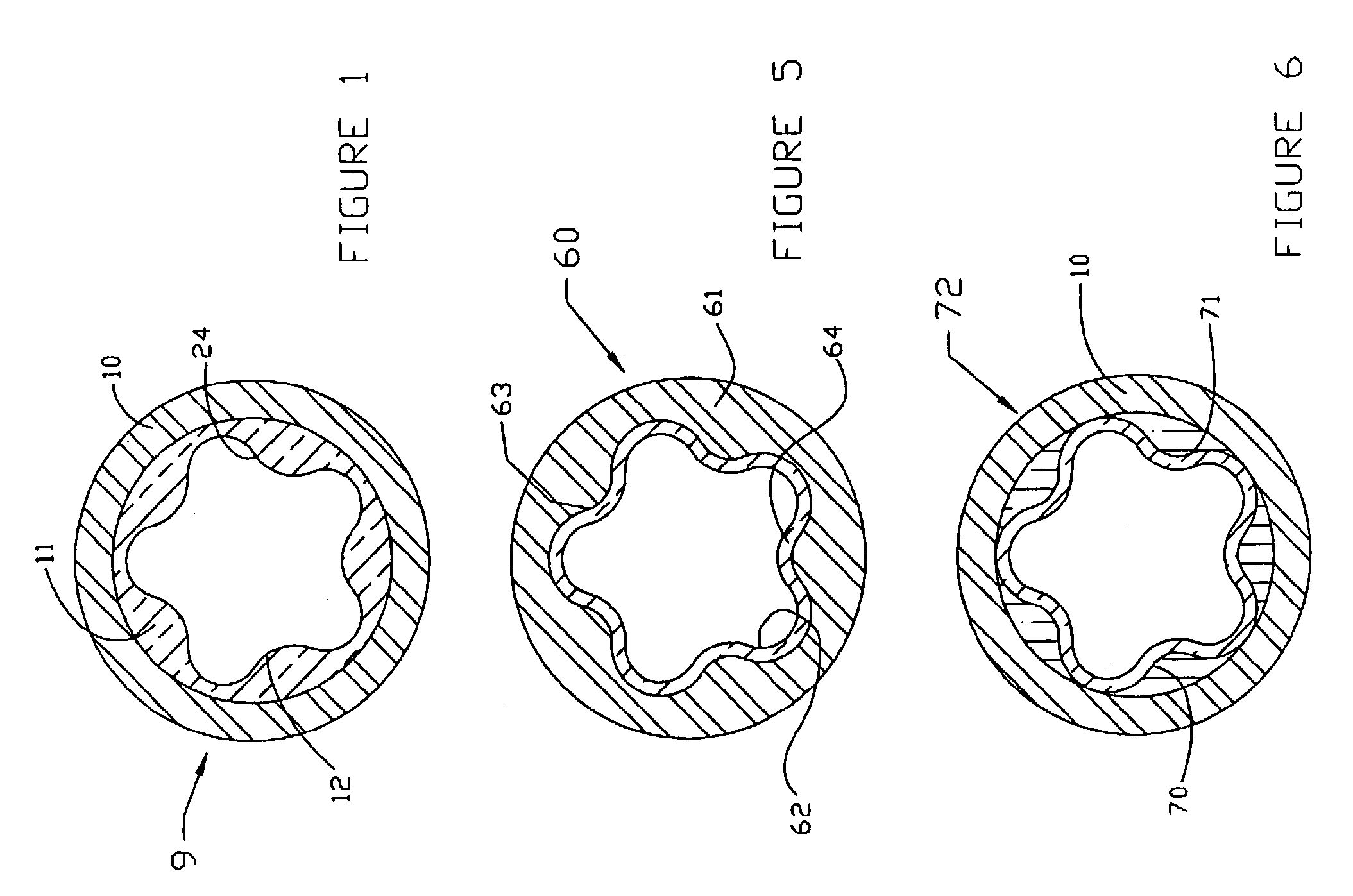

Progressive cavity pump/motor

InactiveUS6881045B2Accurate verificationOscillating piston enginesEngine of intermeshing engagement typeEngineeringDrill bit

A progressive cavity pump or motor, particularly suitable for hydrocarbon recovery operations, includes a rotor 20 and a stator 10. Fluid pressure in cavities between the stator and the rotor create torque which rotates the bit. An interior surface of the stator is rigidly secured to the outer housing of the pump stator and defines an interior profile. A substantially uniform thickness elastomeric layer 62 is supported on the outer housing. The pump rotor has an exterior profile which corresponds with the interior profile of the elastomeric layer.

Owner:ROBBINS & MYERS ENERGY SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com