Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5280results about "Engine lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compressor

ActiveUS6960070B2Easy to fixPrecise alignmentRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaftEngineering

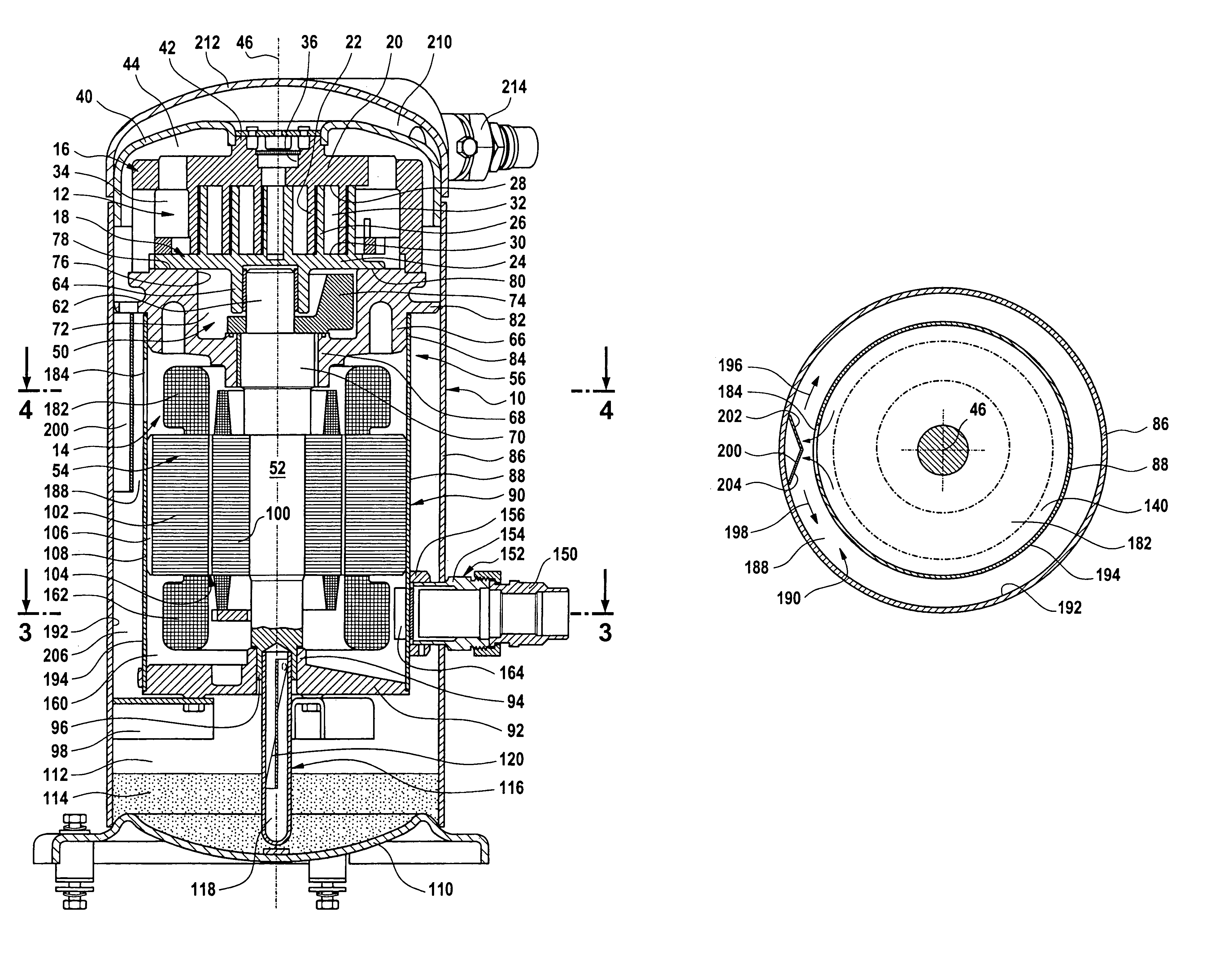

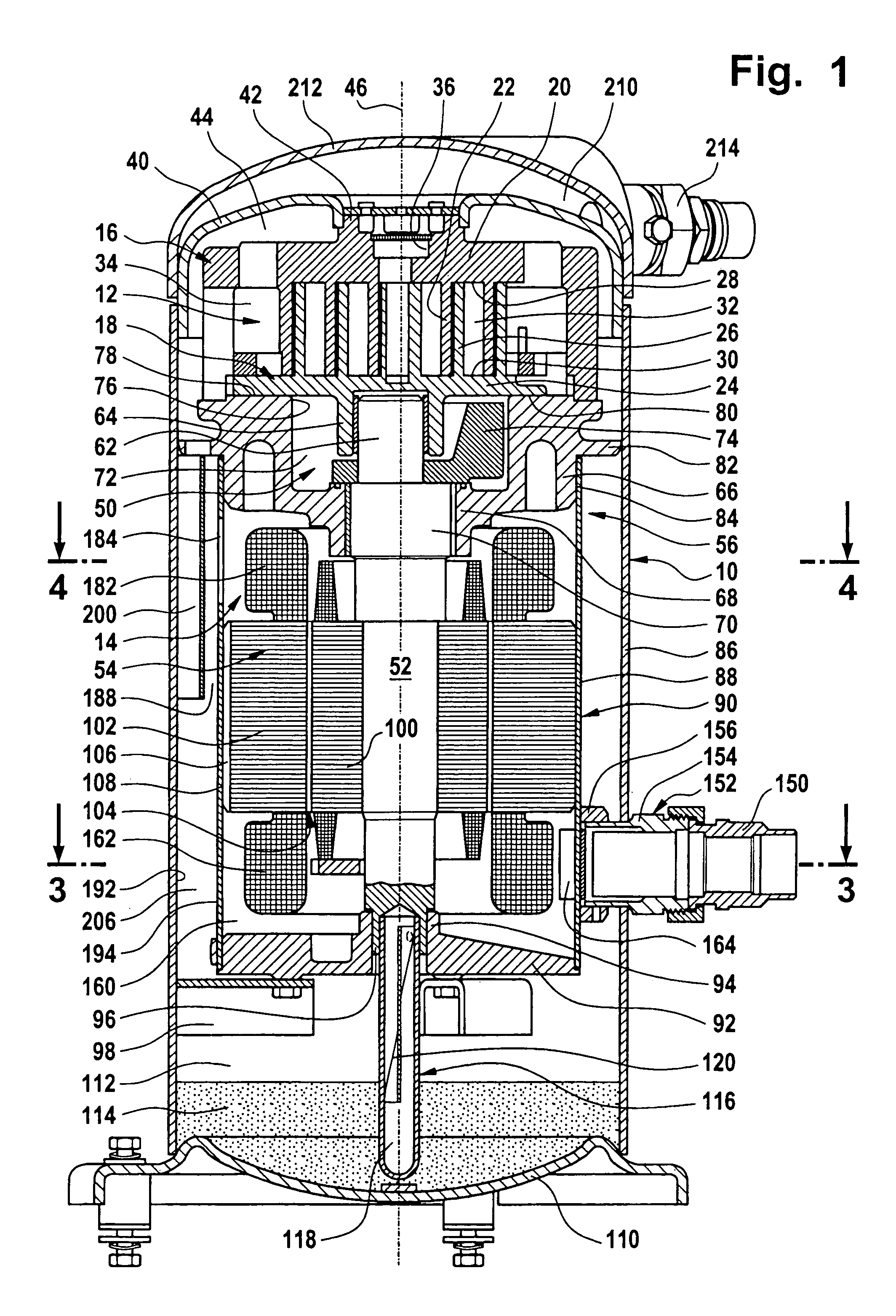

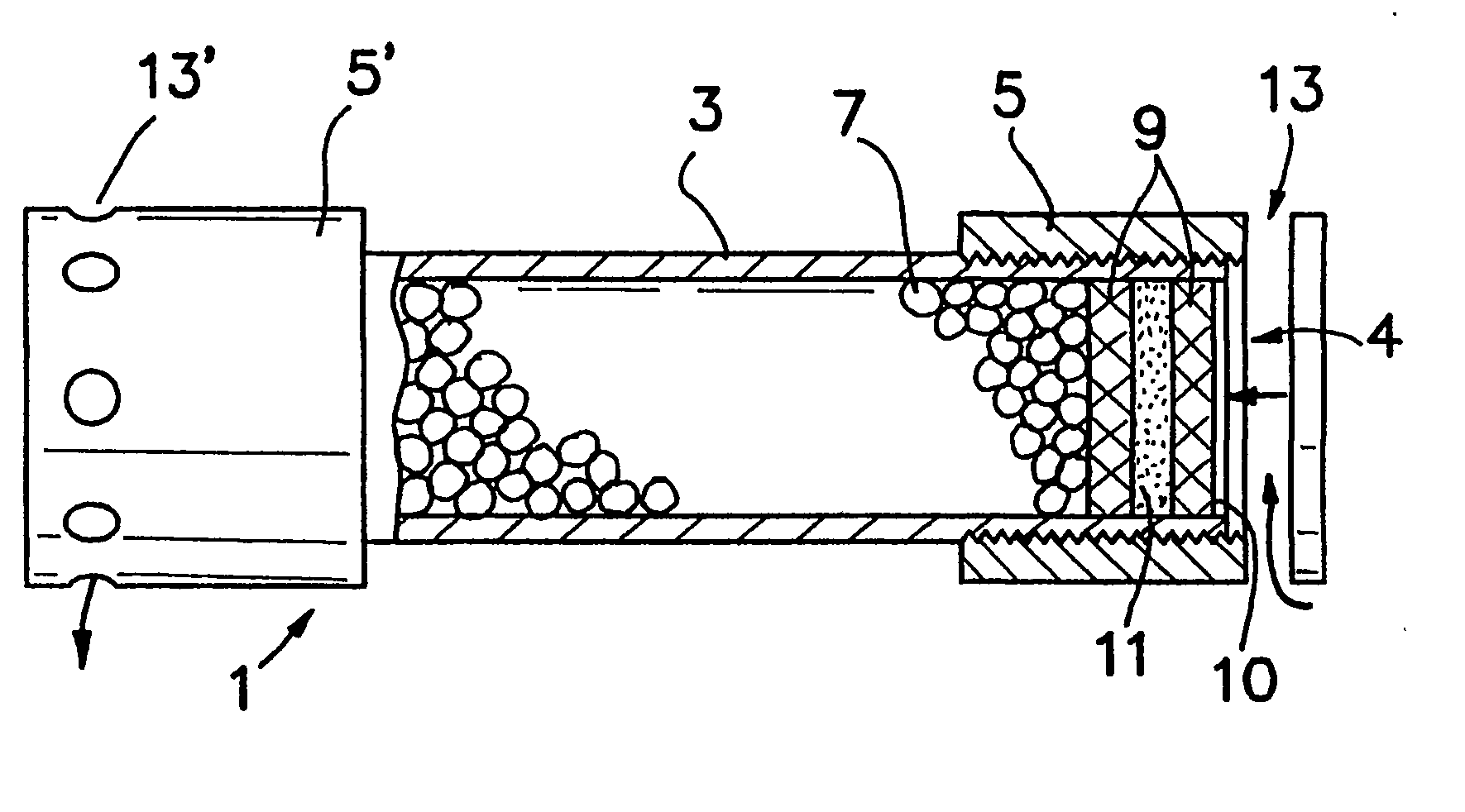

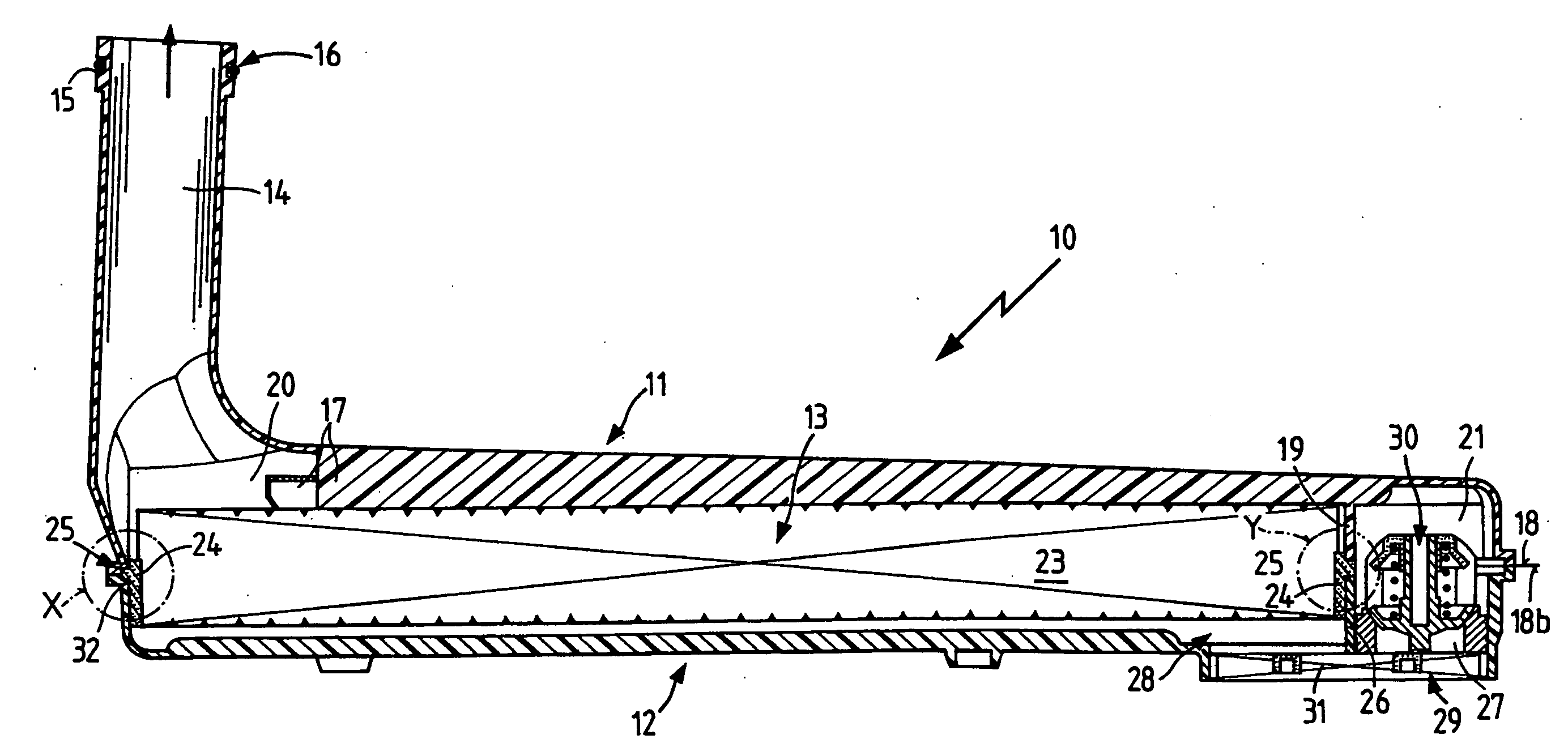

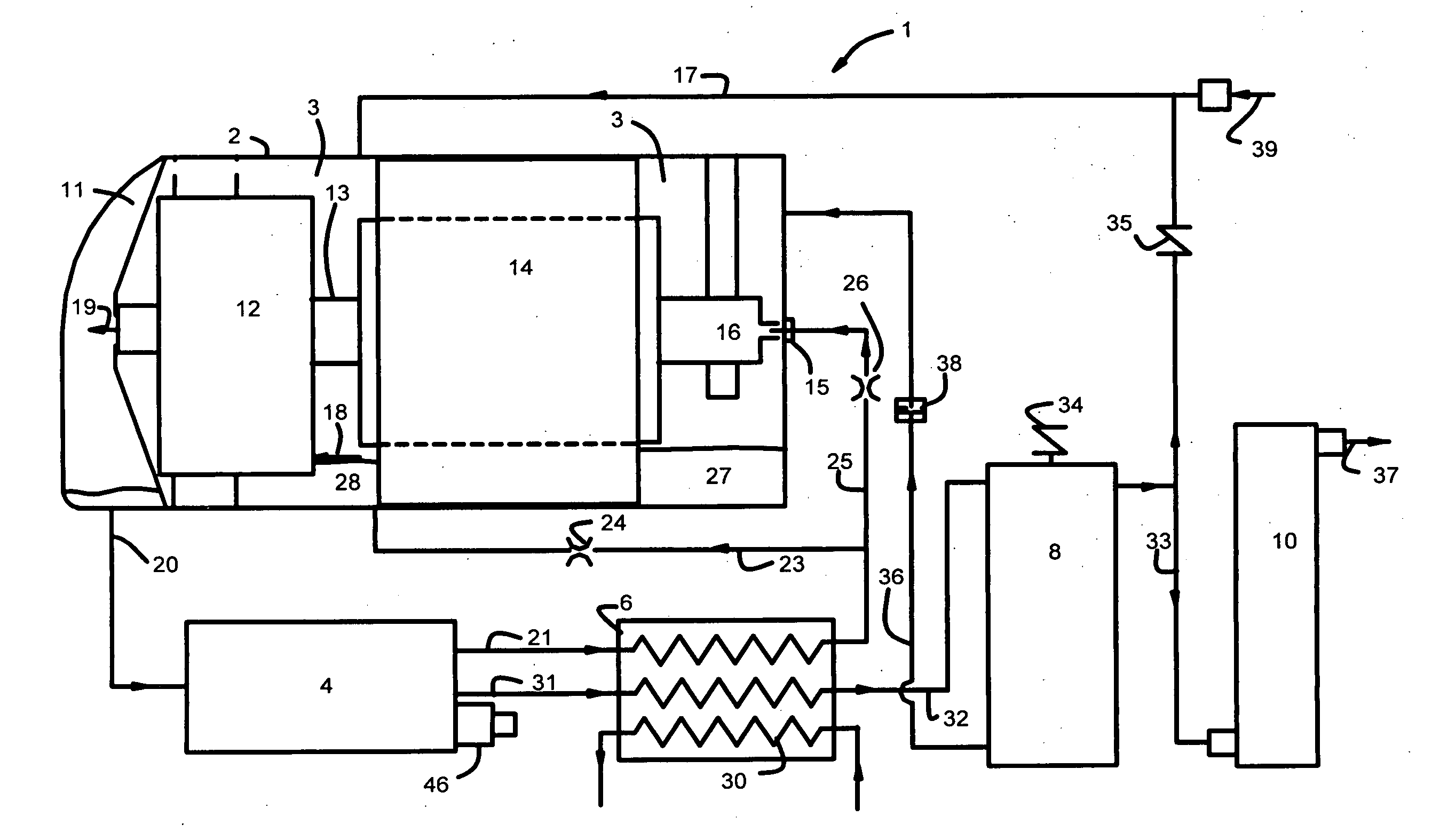

In order to improve a compressor for refrigerant, comprising an outer housing, a scroll compressor arranged in the outer housing and having a first compressor member arranged stationarily in the outer housing and a second compressor member which is movable relative to the first compressor member, the compressor members each having a base and first and second scroll ribs, respectively, which rise above the respective base and engage in one another such that the second compressor member is movable relative to the first compressor member on an orbital path about a central axis for the purpose of compressing the refrigerant, a drive unit for the second compressor member having an eccentric drive, a drive shaft, a drive motor arranged in a motor housing and having drawn-in refrigerant flowing around it as well as a bearing unit for the drive shaft which comprises a first bearing member connected to the outer housing, in such a manner that the refrigerant drawn in by the scroll compressor is free from lubricating oil to as great an extent as possible it is suggested that the refrigerant flow through an oil separator, which is arranged in the outer housing between this and the drive unit, after flowing around the drive motor and prior to entering the scroll compressor.

Owner:BITZER KUEHLMASCHINENBAU GMBH

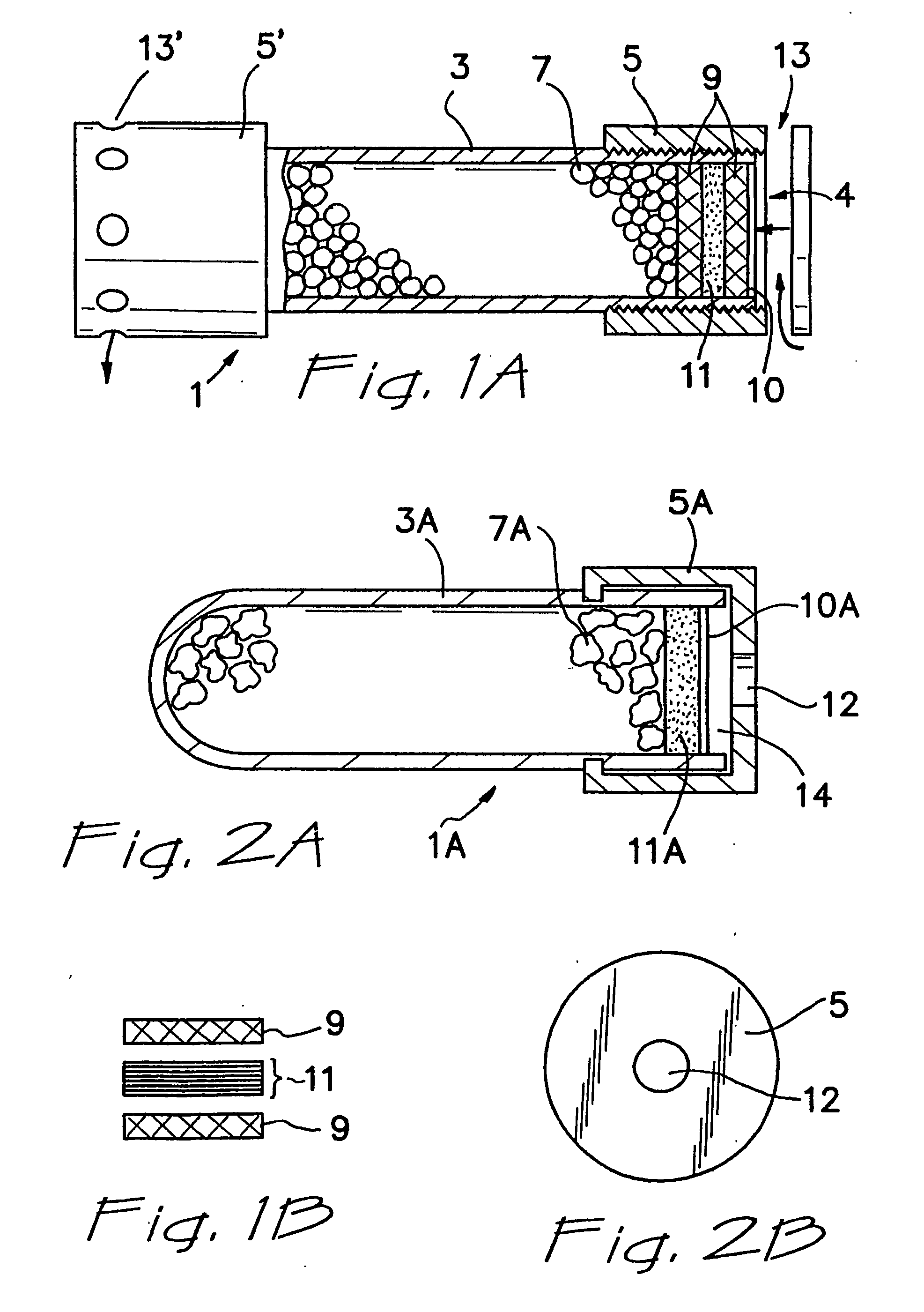

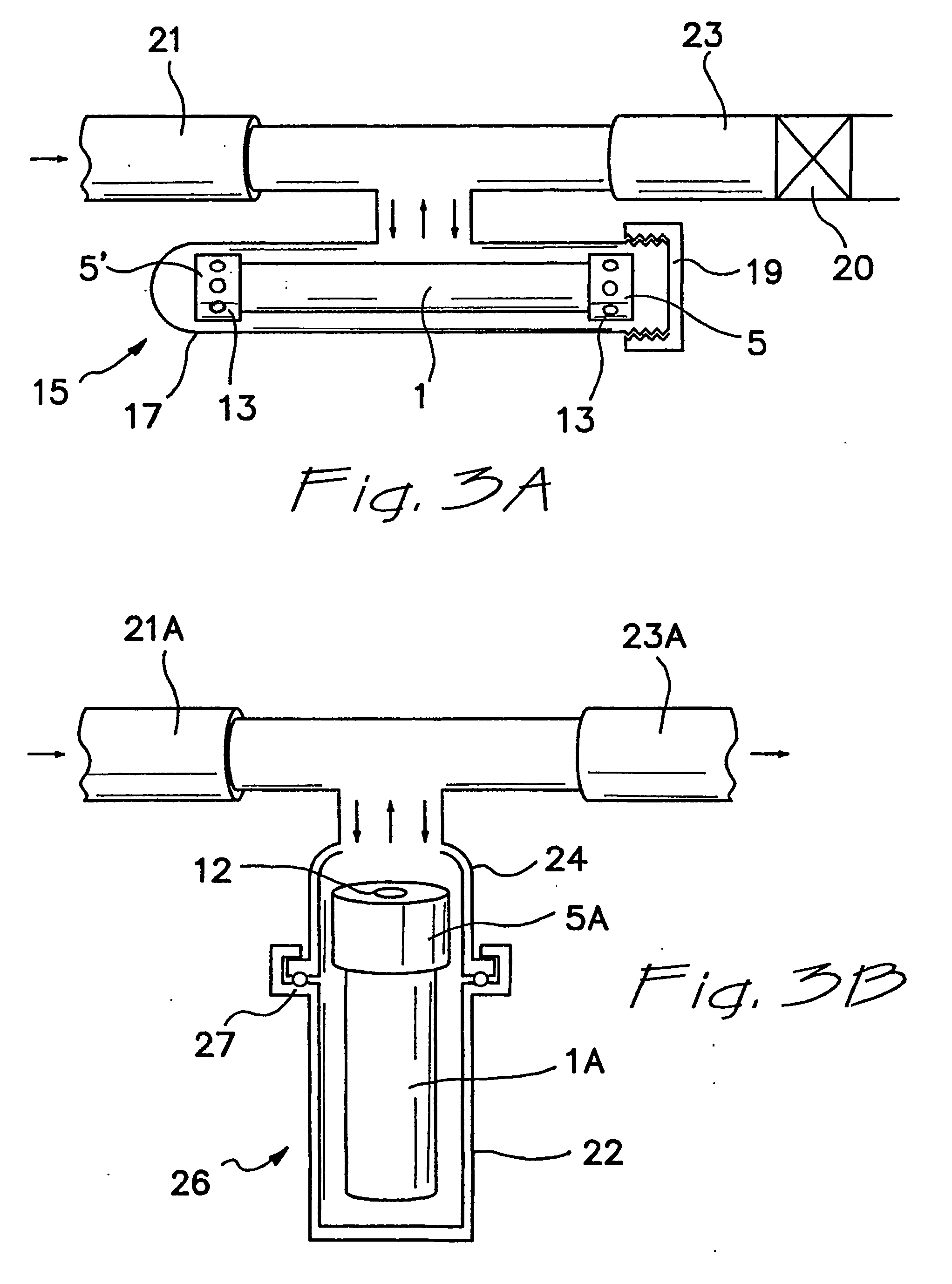

Controlled release of additives in fluid systems

ActiveUS20050019236A1Easy and straightforward to manufacture cost effectivelyCost-effective manufacturingFlow mixersSolid sorbent liquid separationControlled releaseCompound (substance)

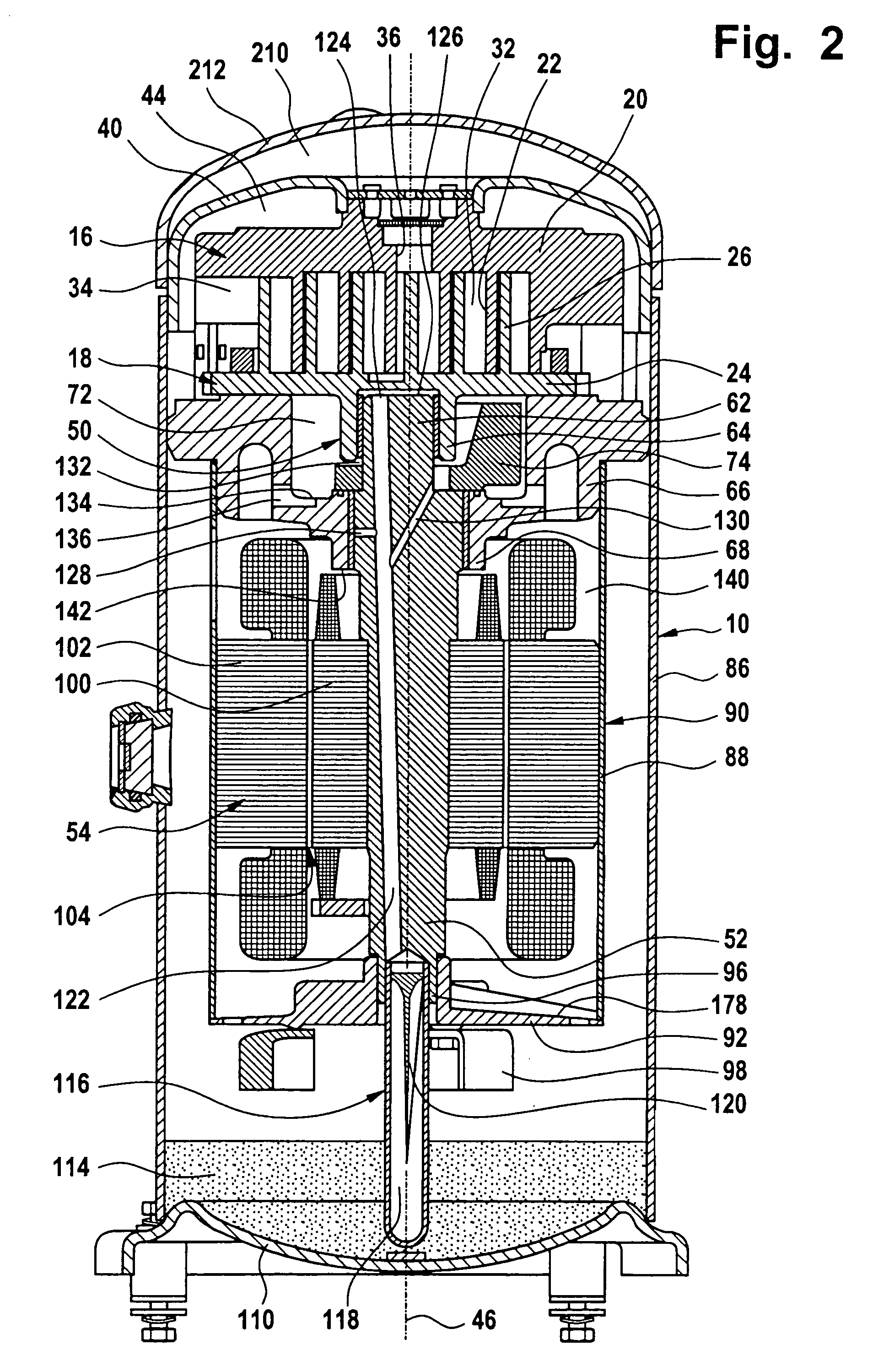

A container (1) for releasing a chemical additive (7) in a fluid material selected from a lubricant or hydraulic fluid composition comprises a fluid material-impermeable casing (3) having a hollow interior and an additive composition (7) comprising at least one fluid material-soluble additive. The additive (7) is held within the container (1) by a least one fluid material-permeable element (11) provided at or near an opening (13) in the casing (1) and is effective to provide for release of additive(s) (7) into the fluid material. Methods of releasing additives (7) into fluid material are also provided.

Owner:CUMMINS FILTRATION IP INC +1

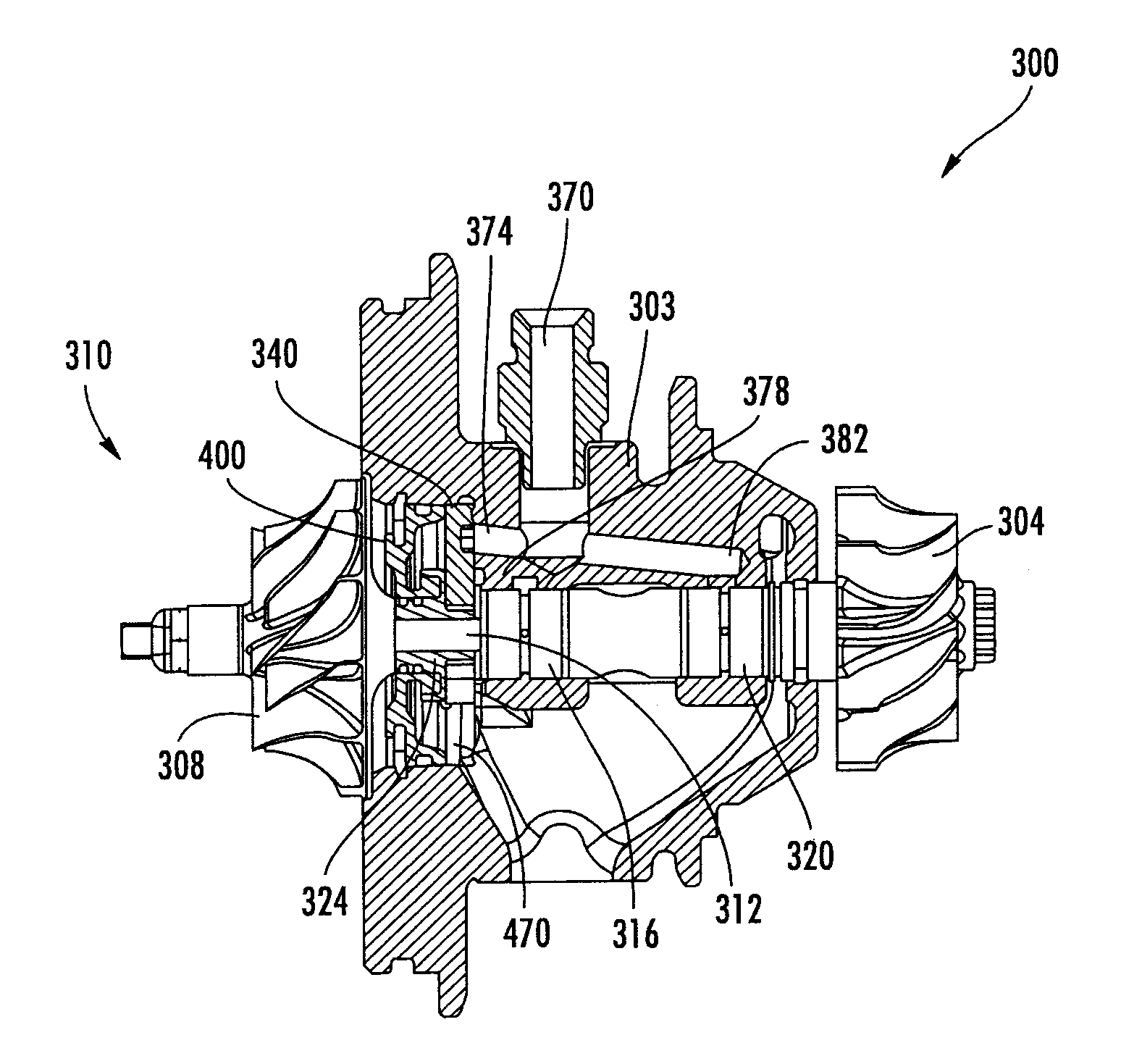

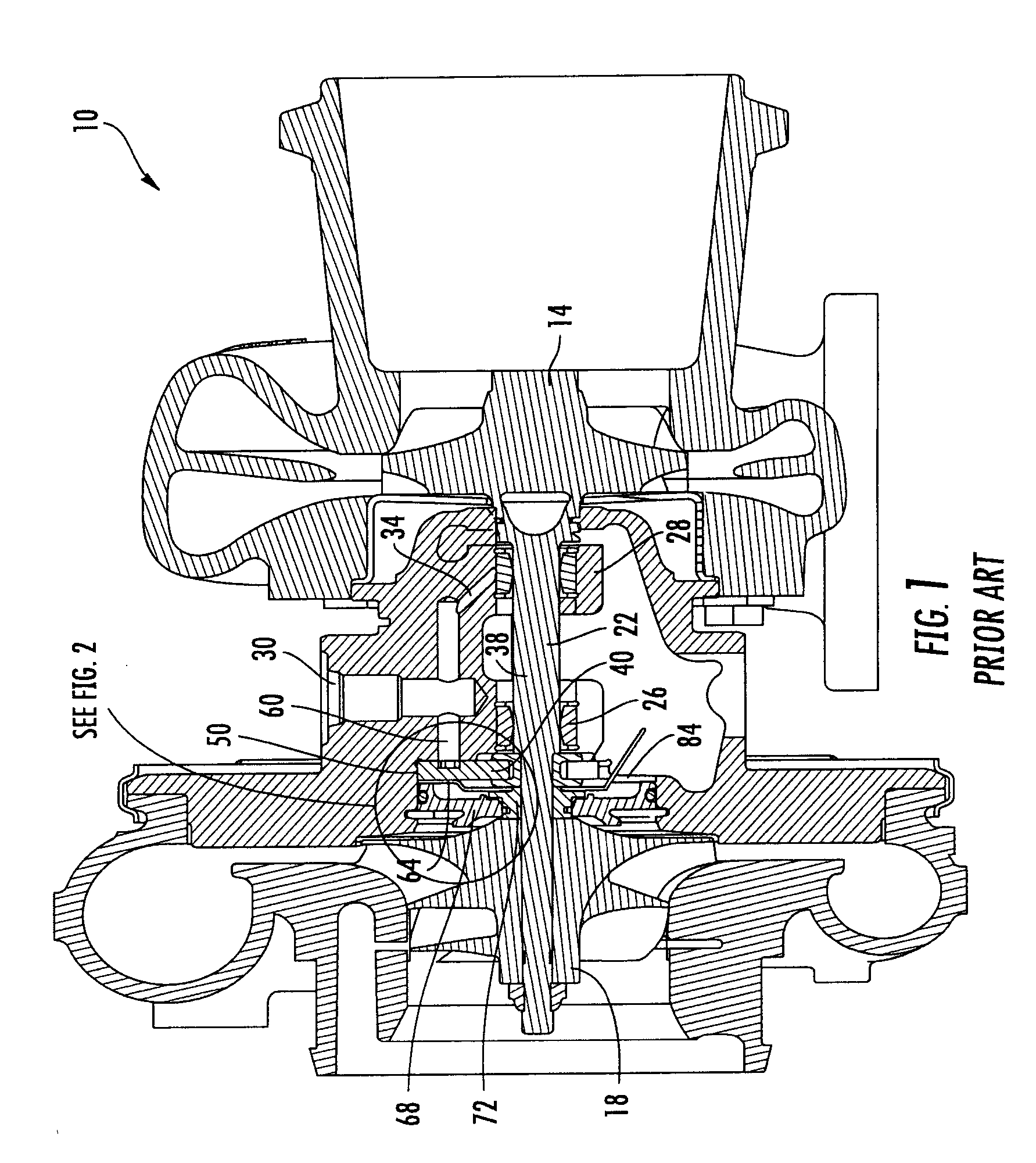

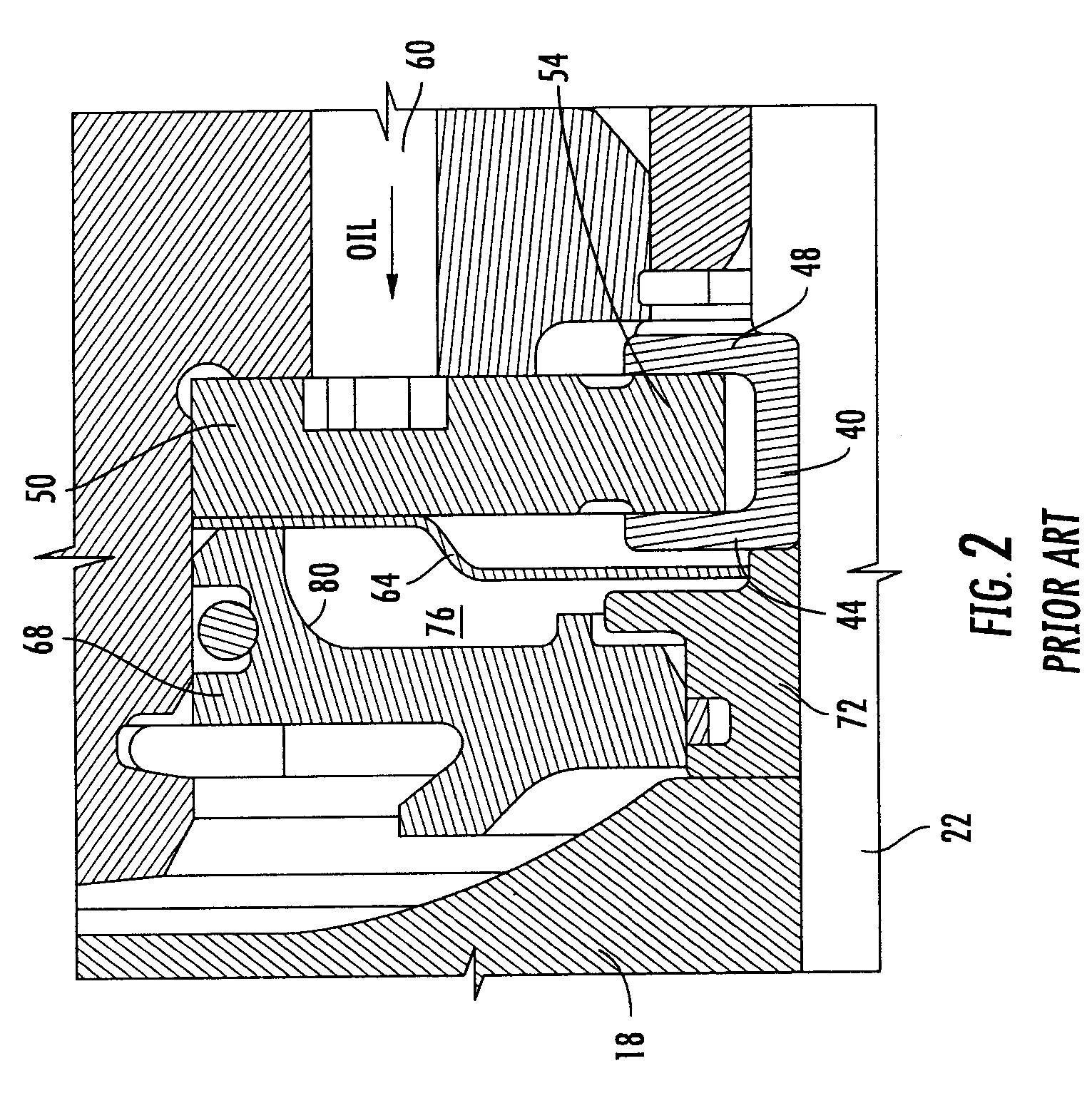

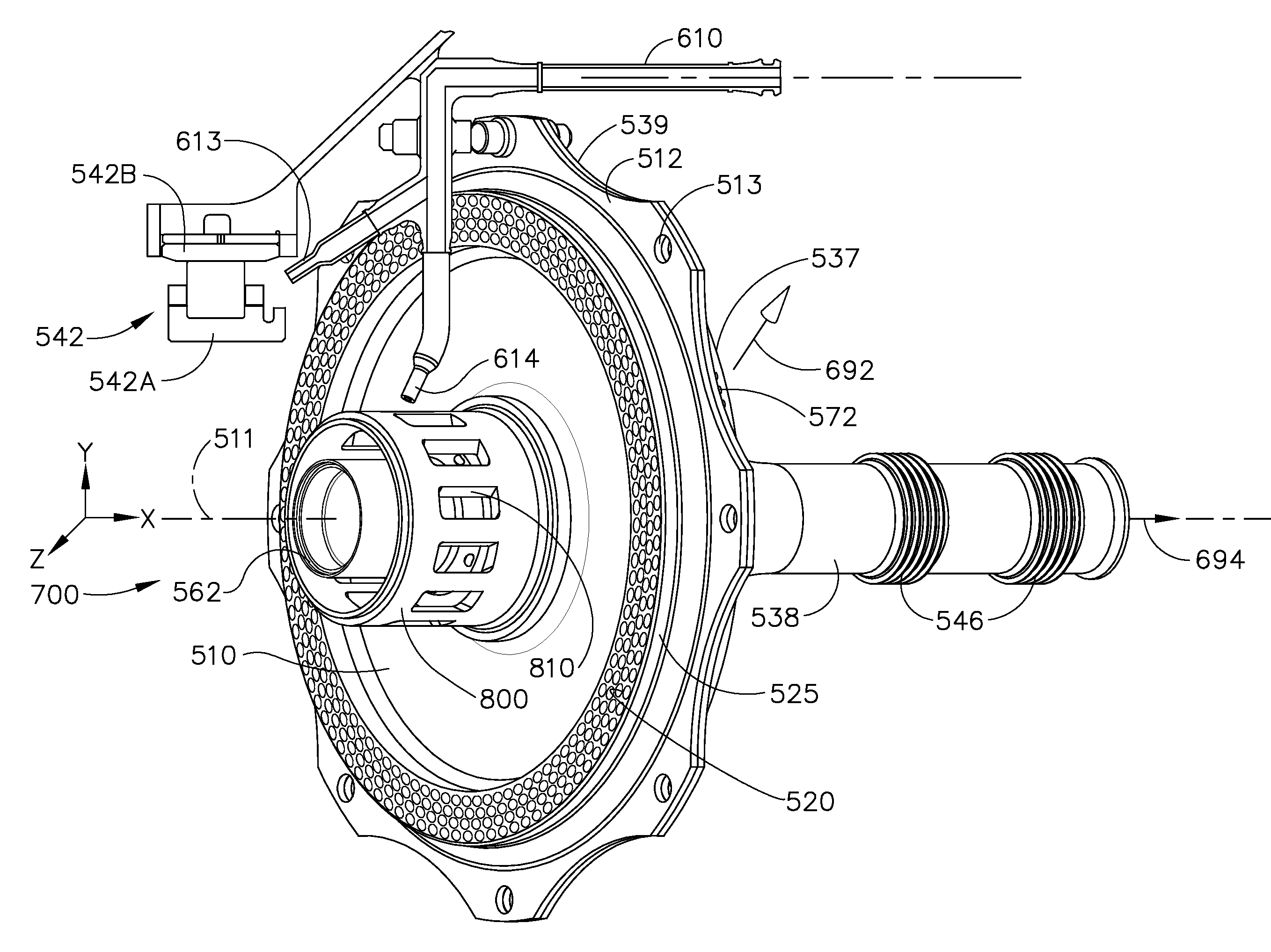

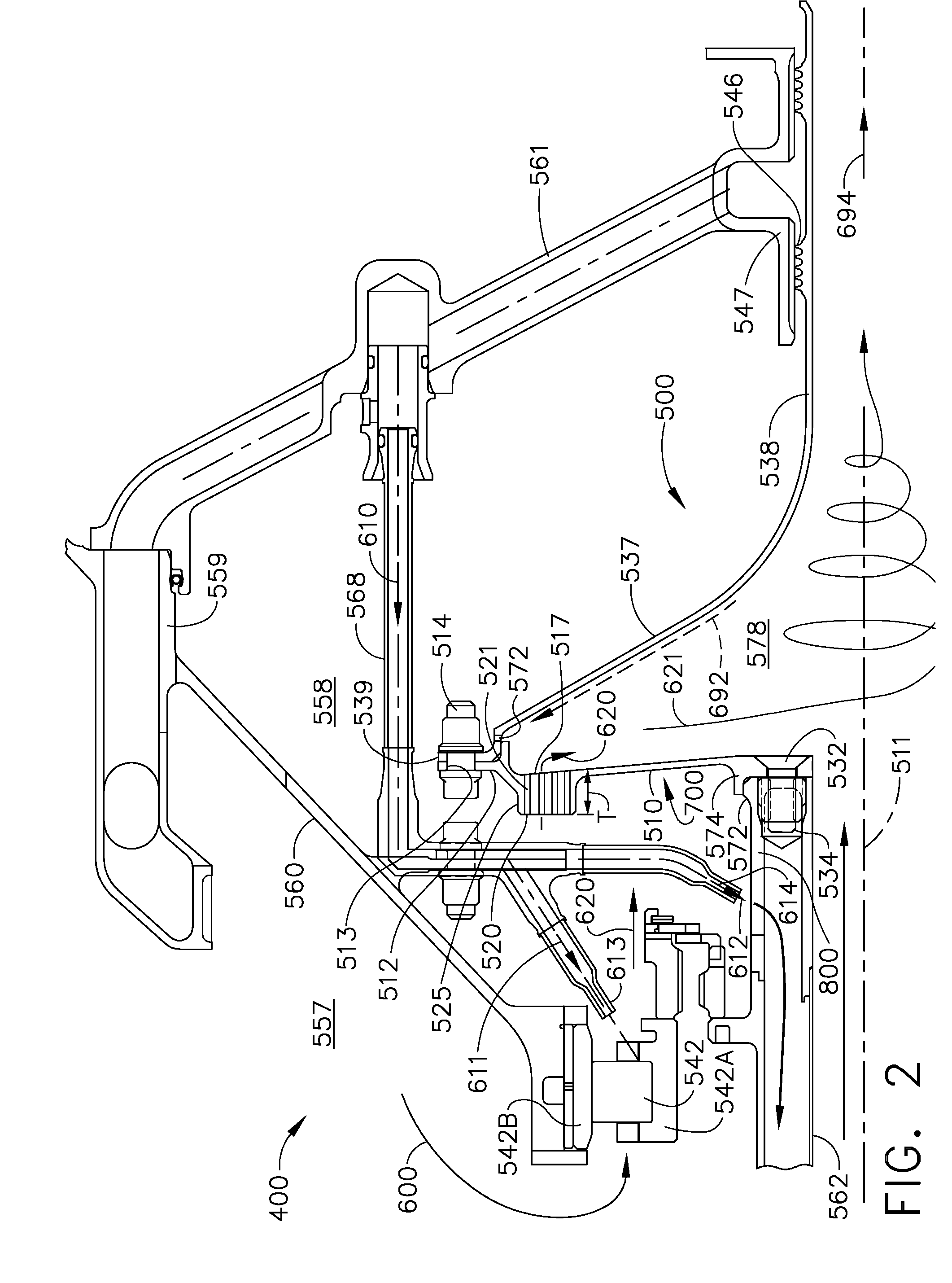

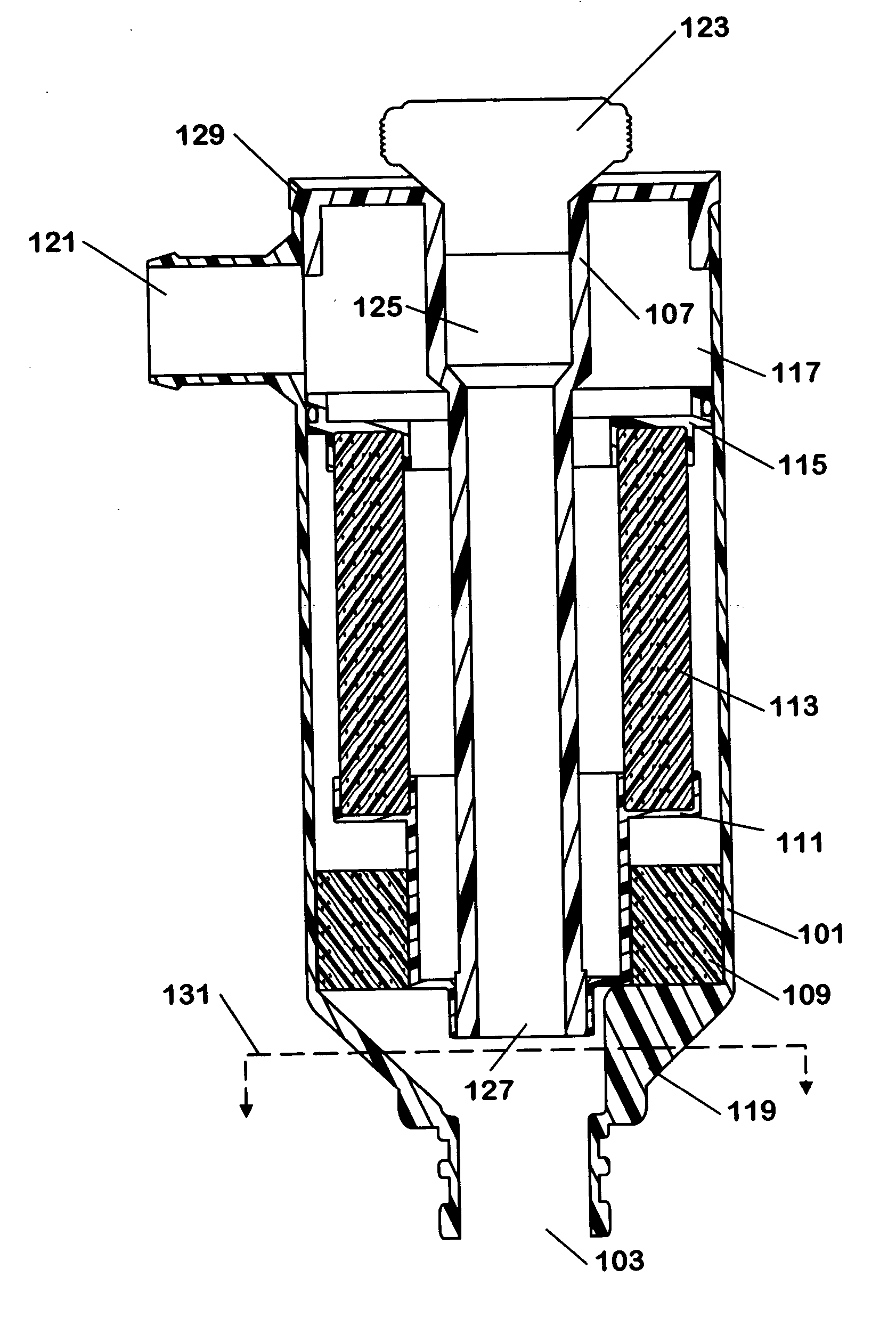

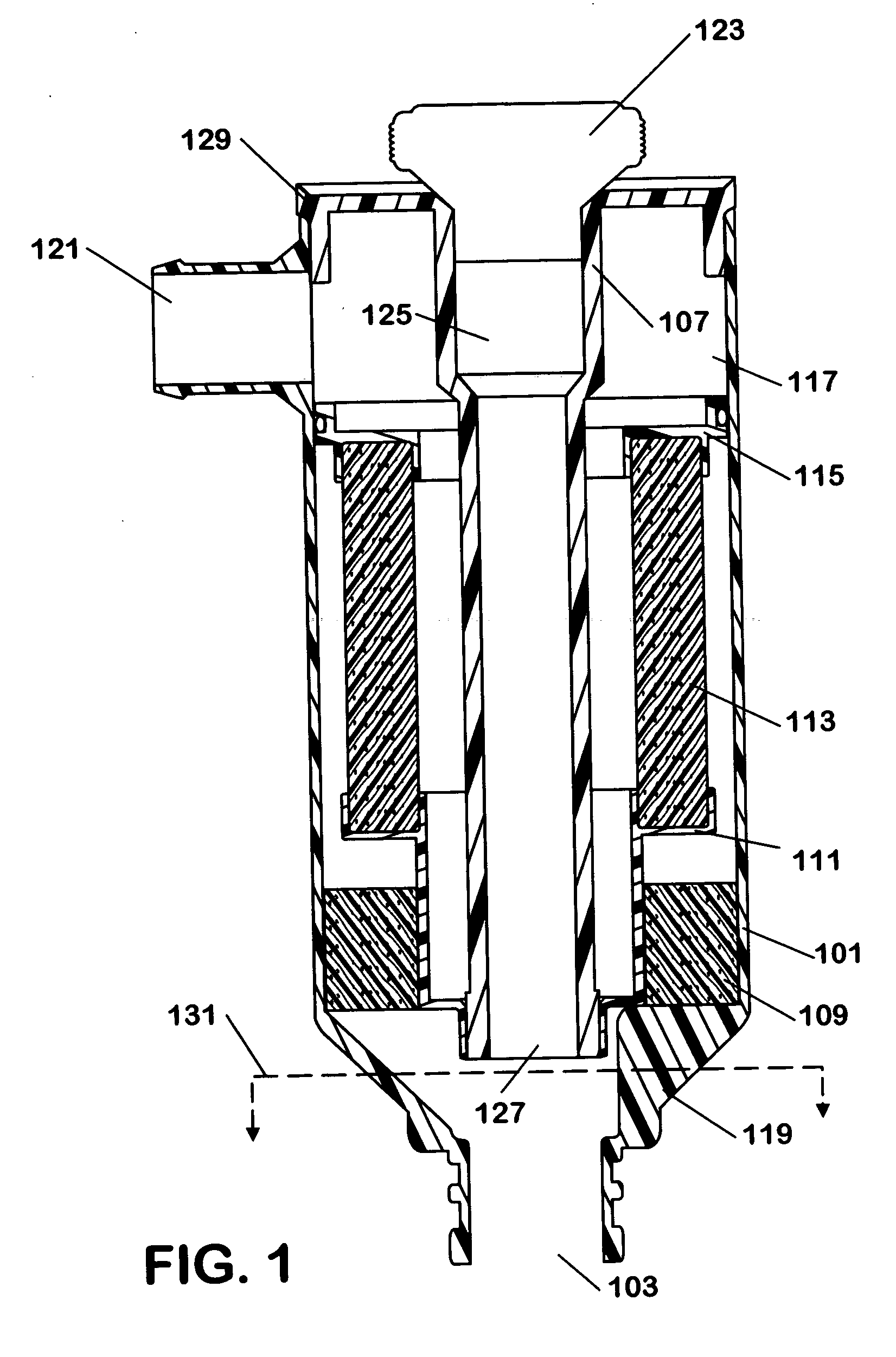

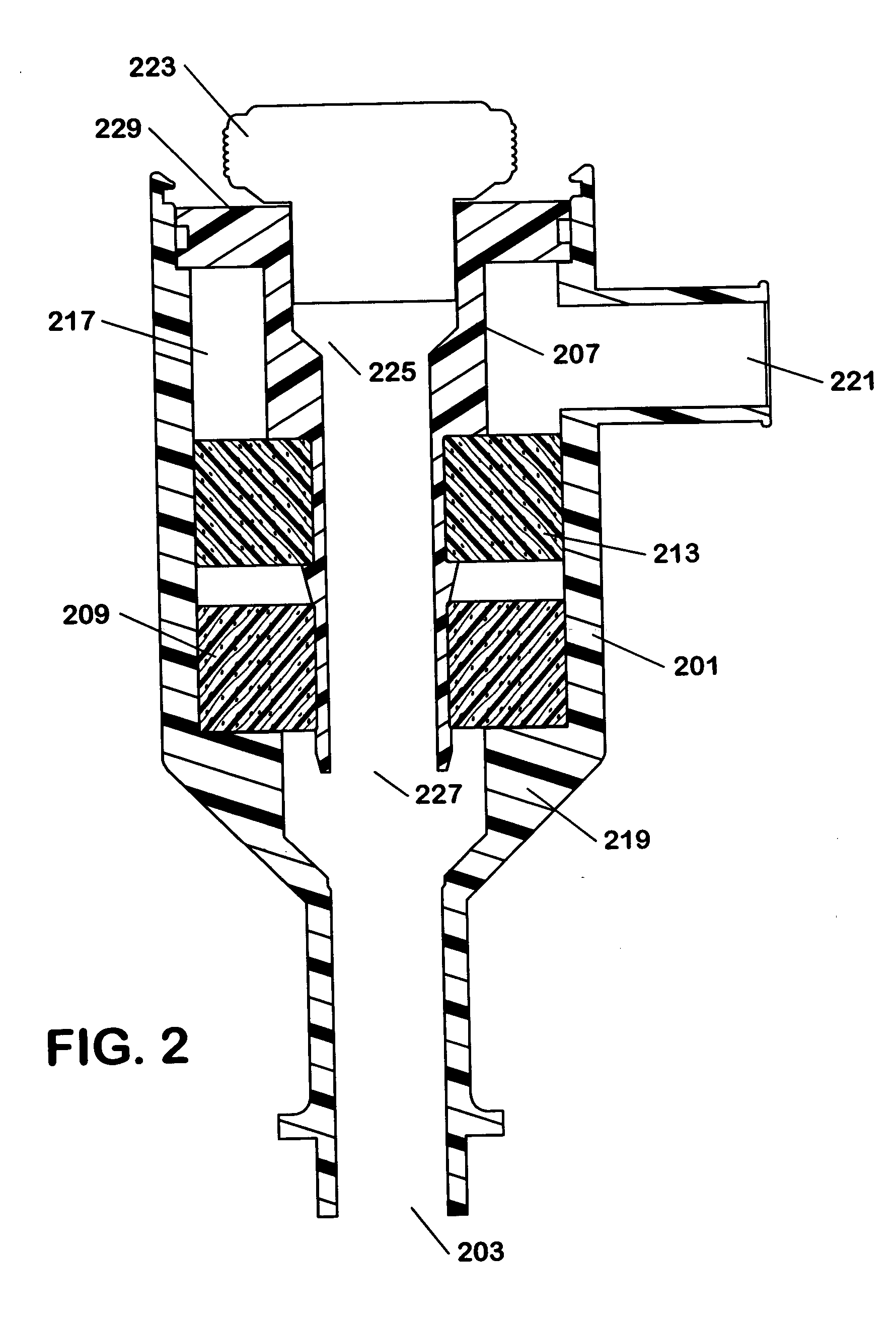

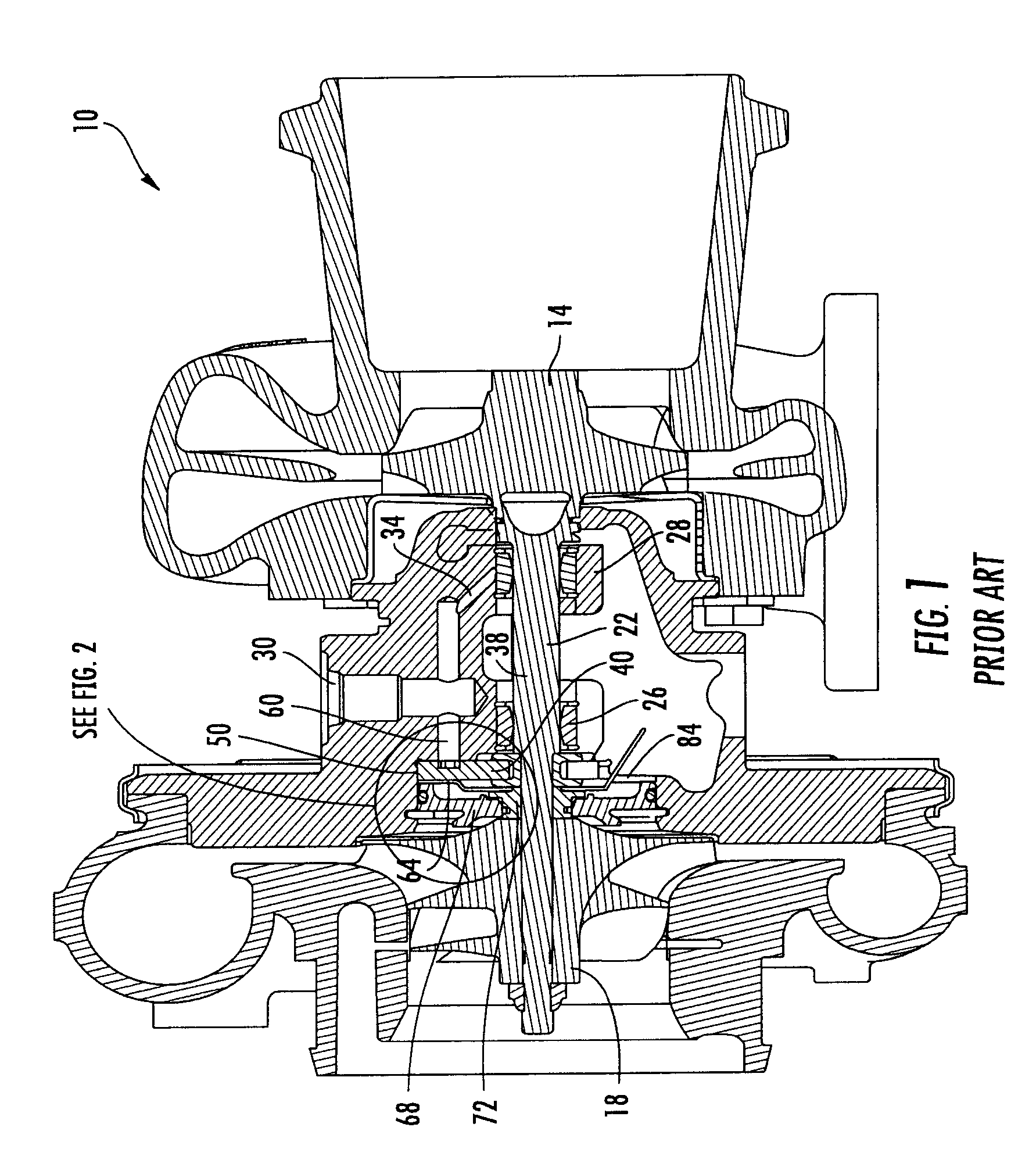

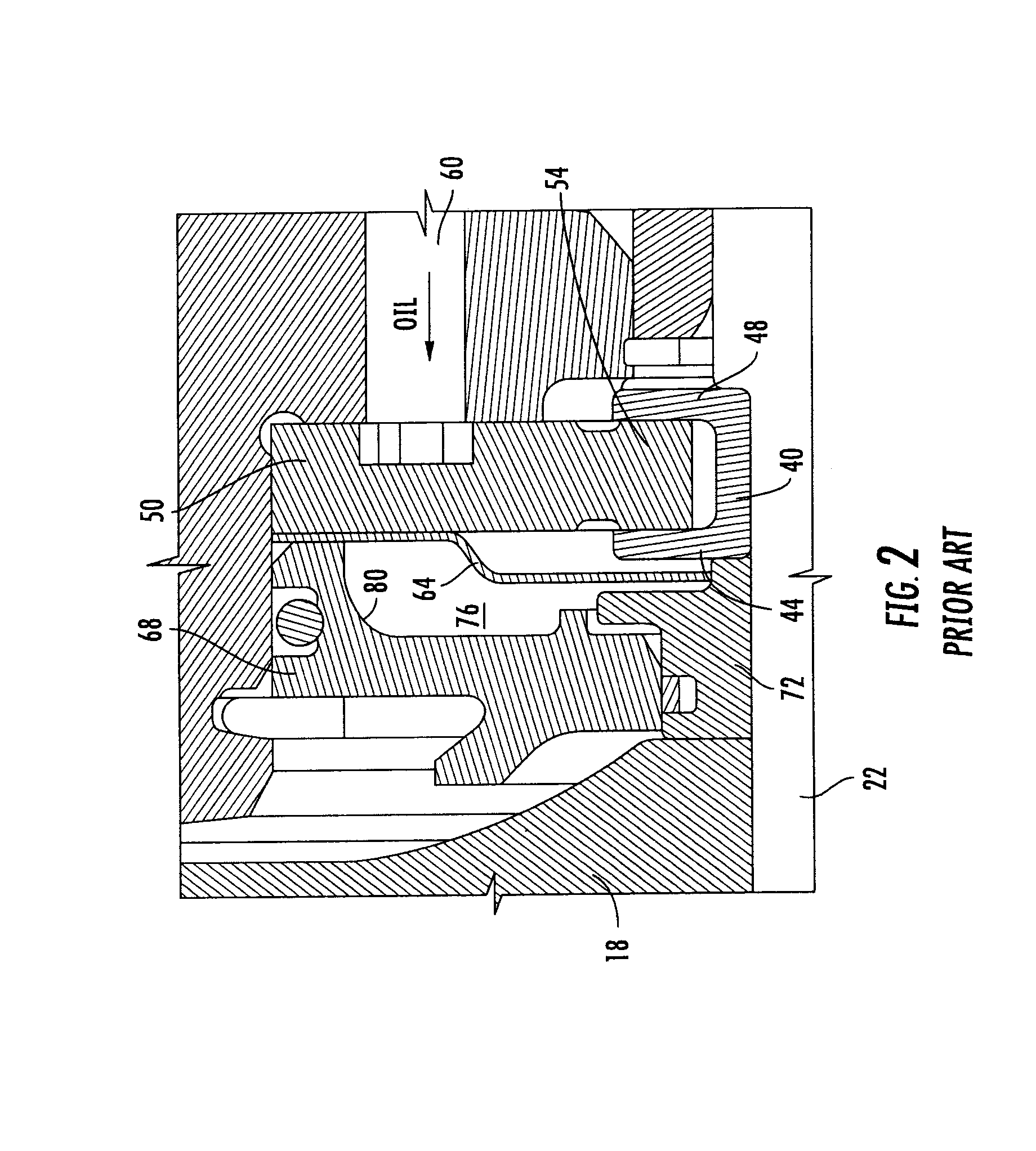

Sealing system between bearing and compressor housing

ActiveUS20100139270A1Efficient and cost-effectiveExtend your lifeCrankshaftsPump componentsTurbochargerThrust bearing

A turbocharger oil discharge assembly (301, 501, 701, 901) can have a thrust collar (324, 524, 724, 924) with a first radially outwardly extending wall and a second radially outwardly extending wall to define a first annular channel. The first radially outwardly extending wall can have an annular flange that at least in part defines a second annular channel. The assembly can also have a thrust bearing (340, 540, 740, 940) having a radially inner end received in the first annular channel, and an insert (400, 600, 800, 1000). An oil collection chamber (440, 640, 840, 1040) can be defined at least in part by a drainage channel of the insert (400, 600, 800, 1000), the annular flange of the thrust collar (324, 524, 724, 924) and the thrust bearing (340, 540, 740, 940). Pressurized oil discharged from an oil release interface can be directed towards a radially outer region of the oil collection chamber (440, 640, 840, 1040) and can be collected in the oil collection chamber (440, 640, 840, 1040) for subsequent exhaust.

Owner:BORGWARNER INC

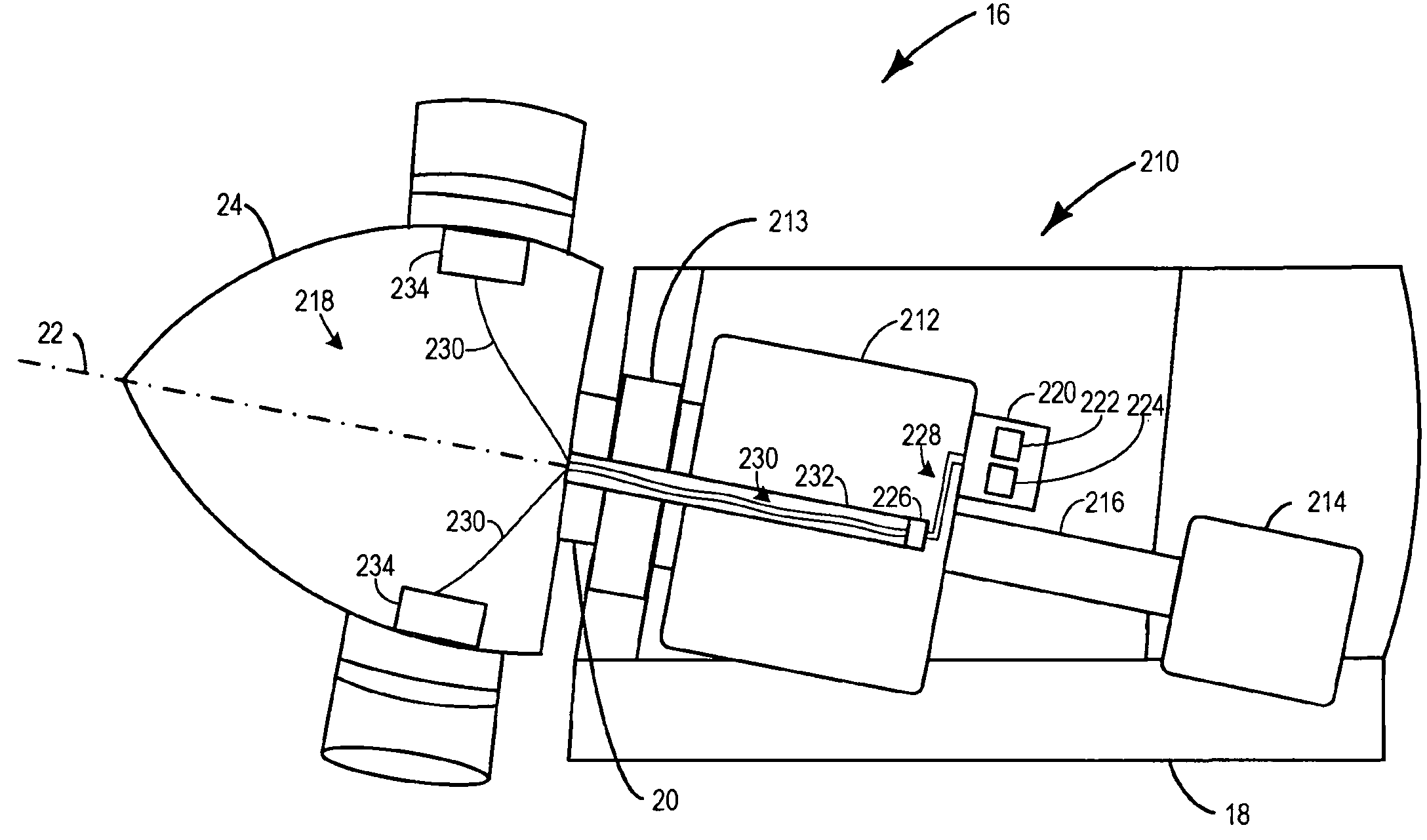

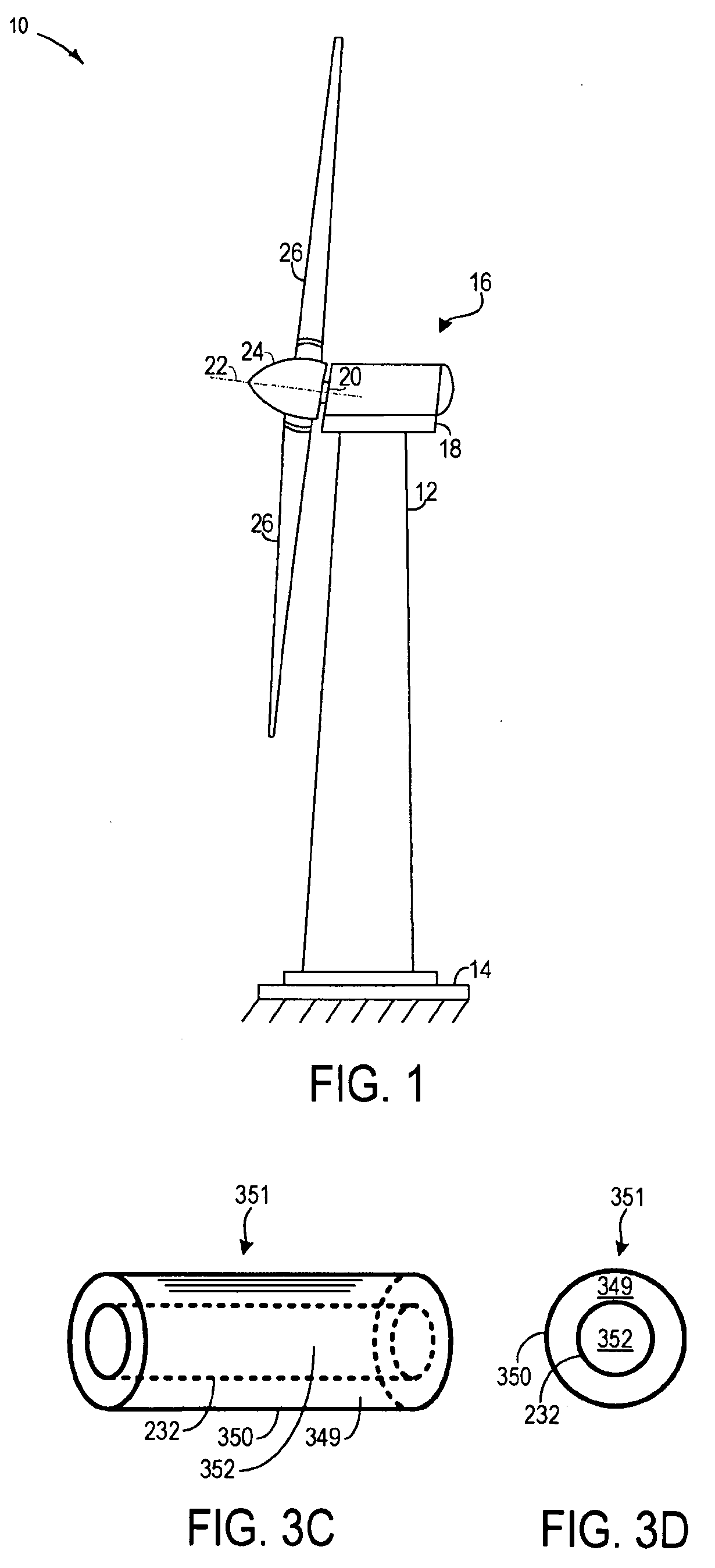

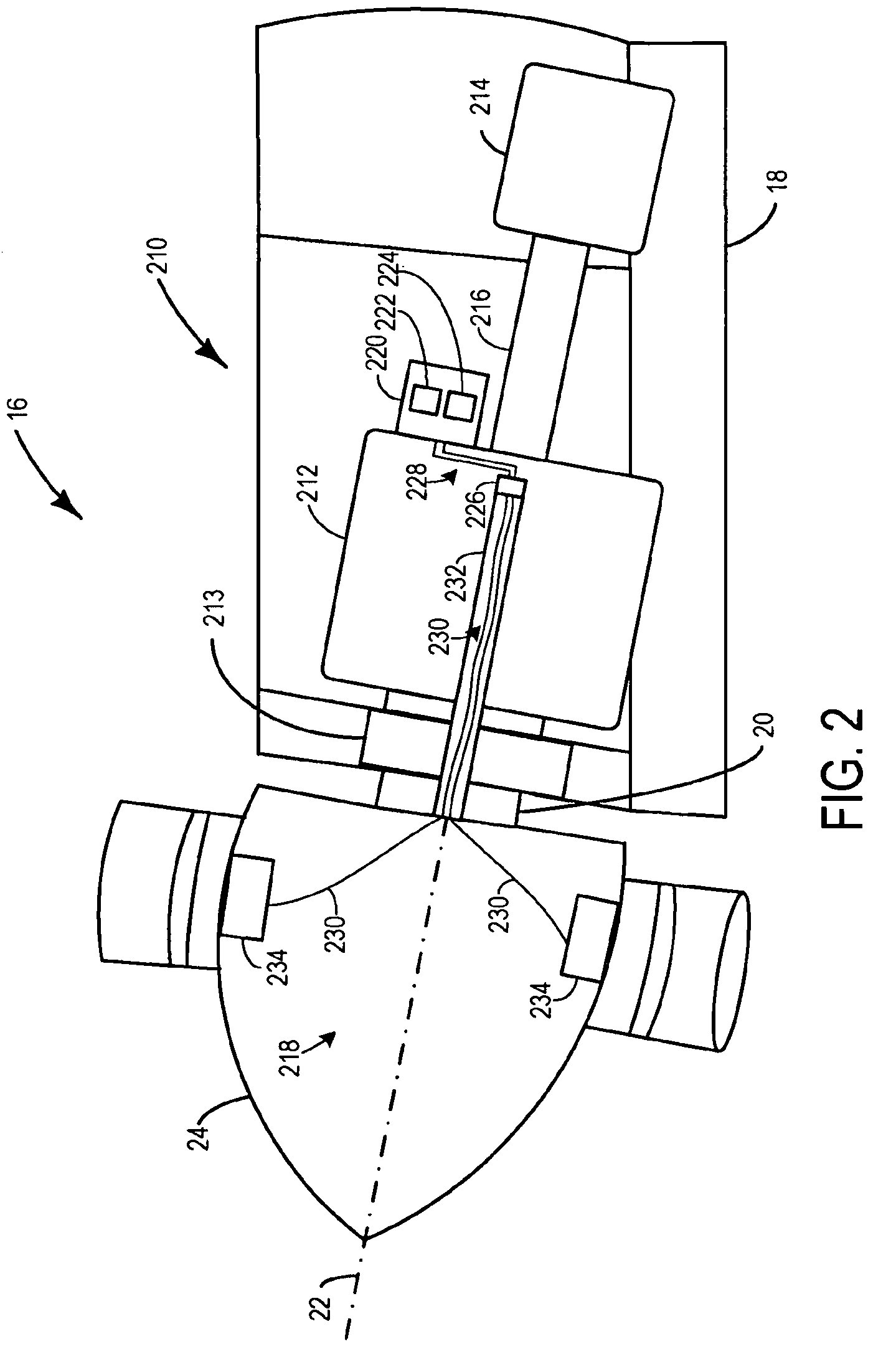

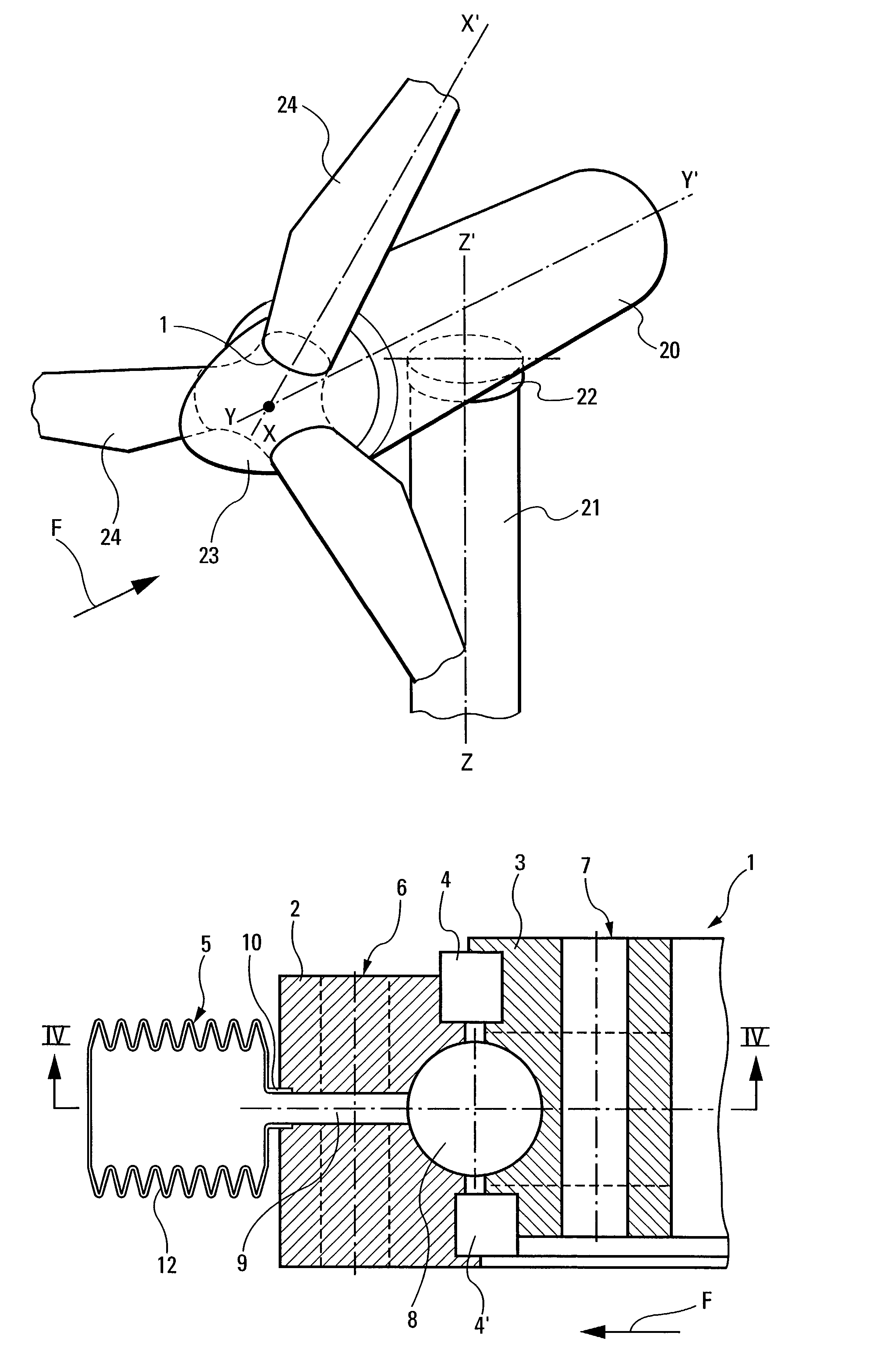

Internal lubrication for a gearbox, a power-generating wind turbine system, and a power-generating system

InactiveUS20100007151A1Improve the lubrication effectExtend your lifeEngine fuctionsToothed gearingsEngineeringGear train

A gearbox including a gear-train including an input and an output and a rotating conduit internally traversing the gear-train is provided. The rotating conduit is configured to receive lubrication fluid from one or more components downstream of the rotating conduit and deliver lubrication fluid to one or more components upstream of the rotating conduit. The components downstream of the rotating conduit rotate at a different speed than components upstream of the rotating conduit.

Owner:HANSEN TRANSMISSIONS

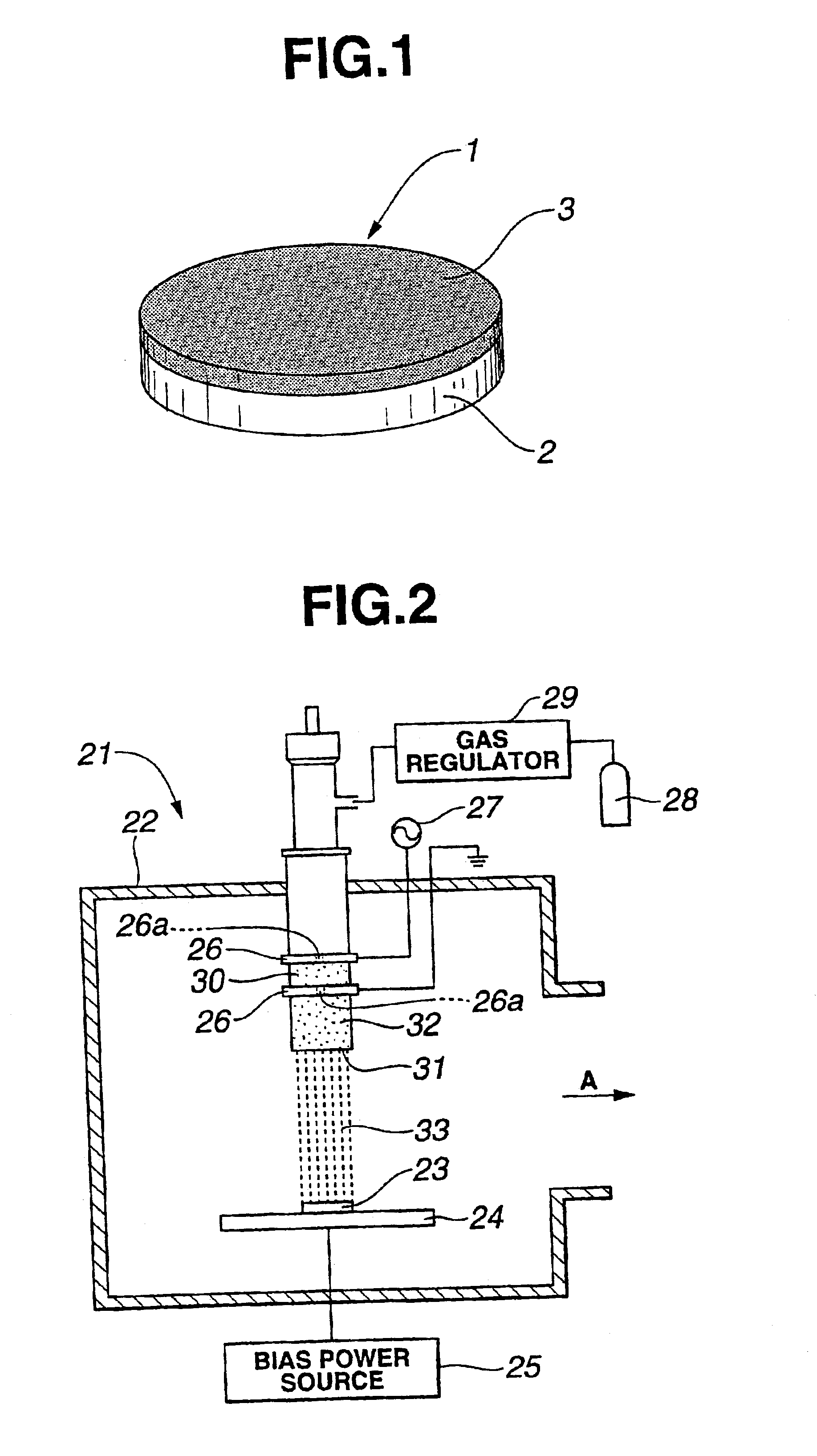

Liquid spray device and cutting method

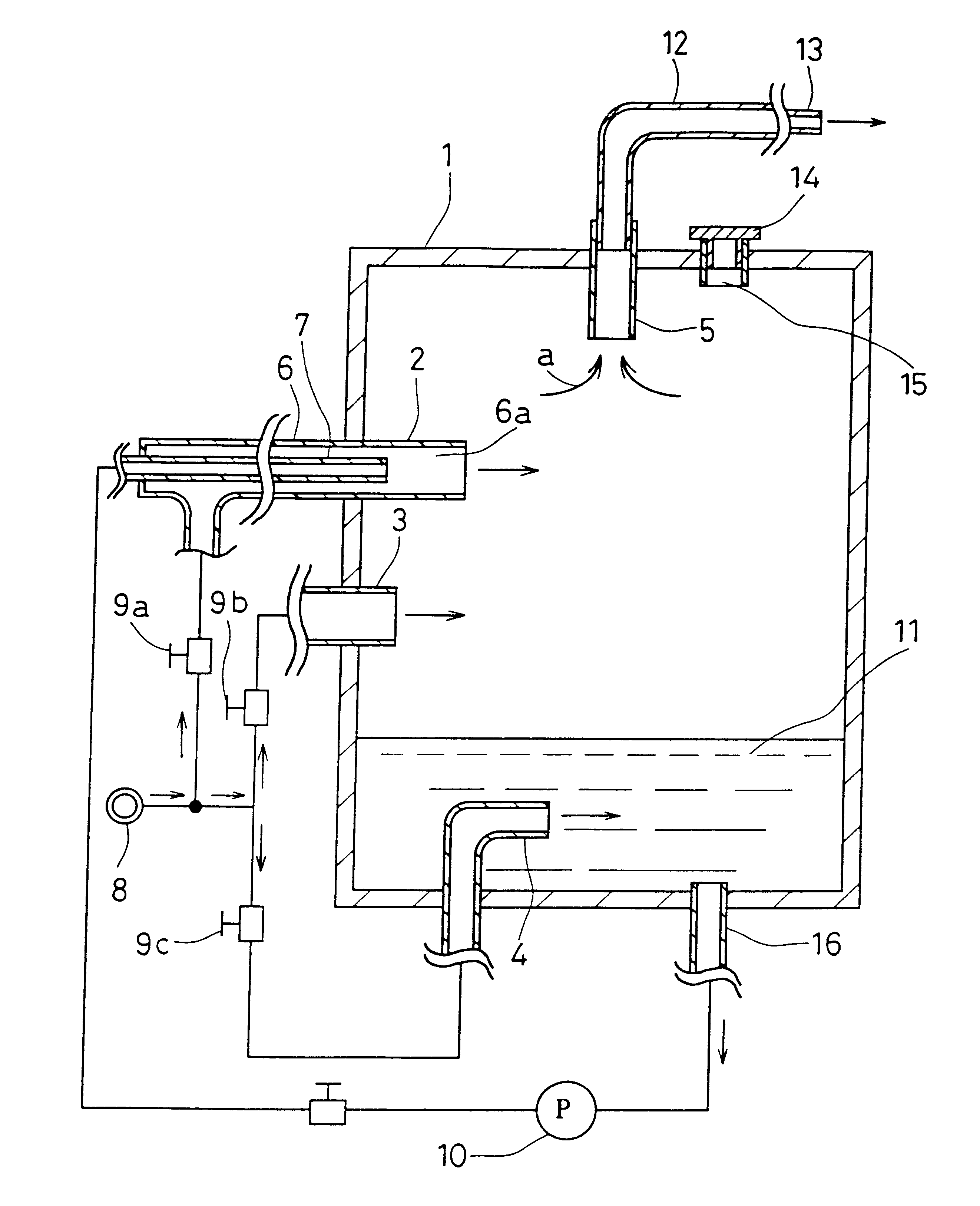

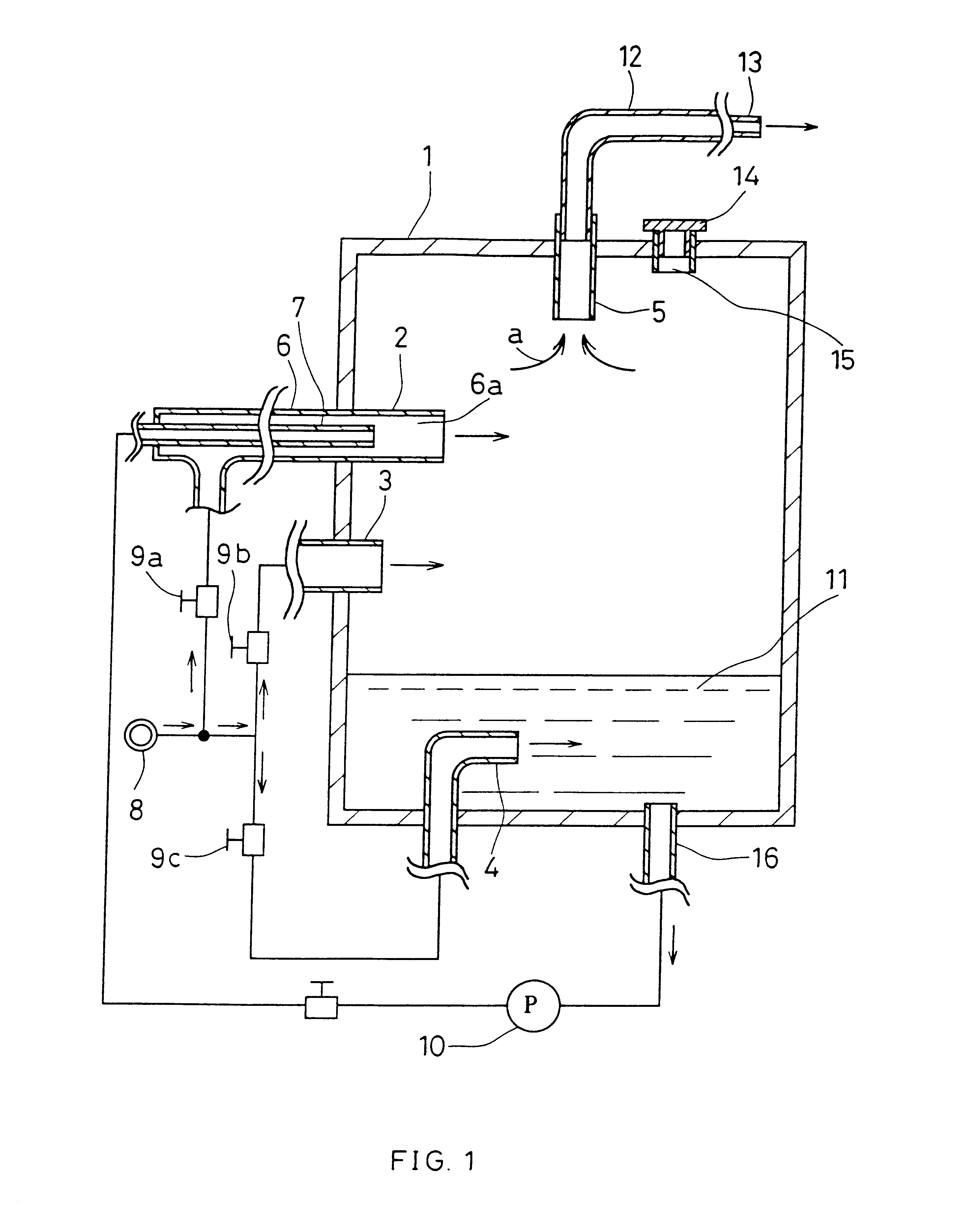

InactiveUS6659370B1Reliably producedSimple structureSpray nozzlesLiquid spraying apparatusLiquid jetInternal pressure

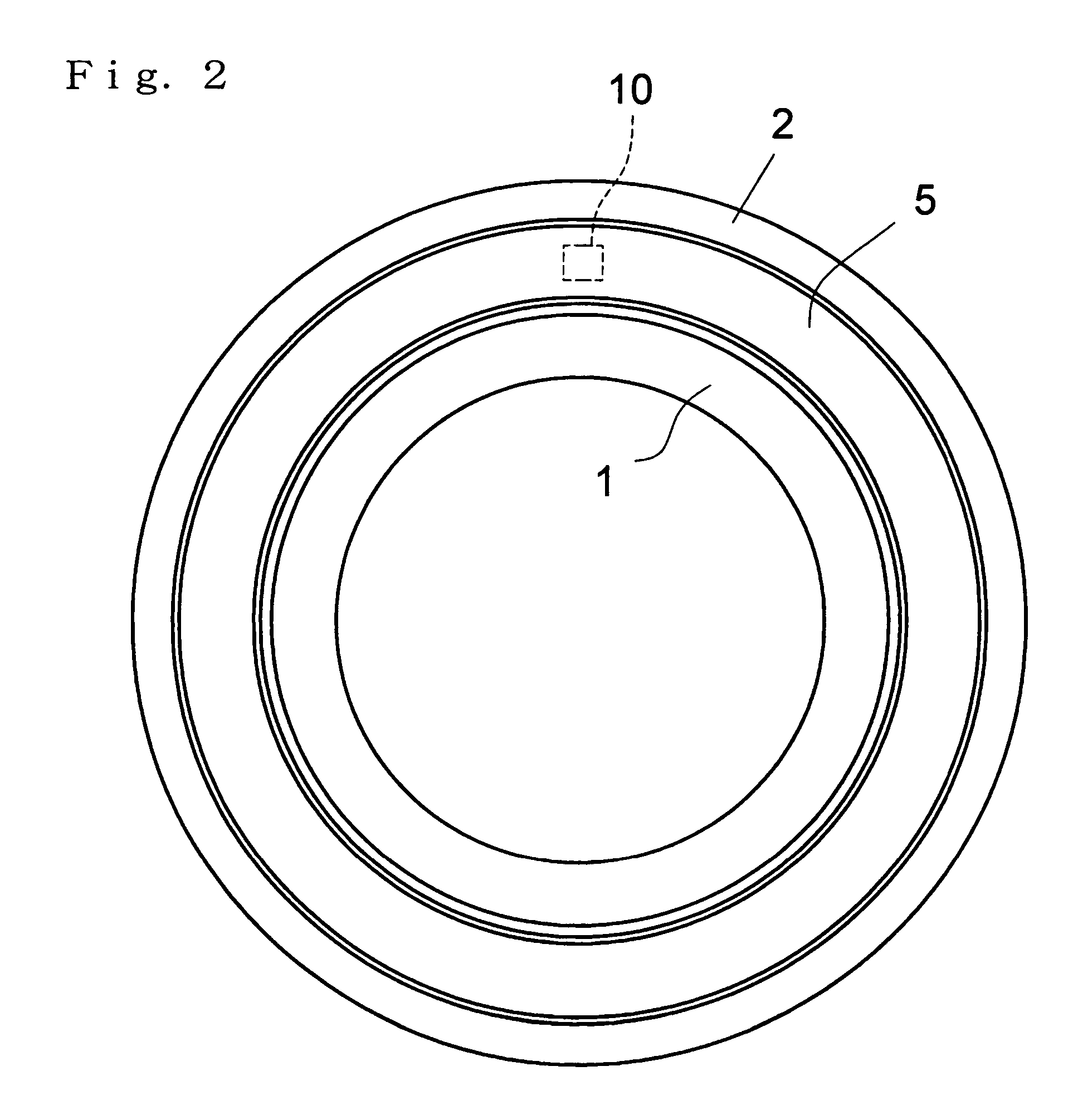

A liquid spray device, comprising a container (1), a spray injection nozzle (2) for injecting oil spray into the container (1), a spray feeding path (5) for feeding oil spray in the container (1) to the outside of the container (1), oil (11) stored in the container (1), a gas exhaust port provided in the oil (11) by discharging gas into the oil (11), whereby the flow velocity of the oil spray in the spray feeding path can be increased and the amount of oil spray can be increased because an internal pressure of the container can be increased and an oil spray different from the oil spray from the spray injection nozzle can be produced.

Owner:FUJI BC ENG

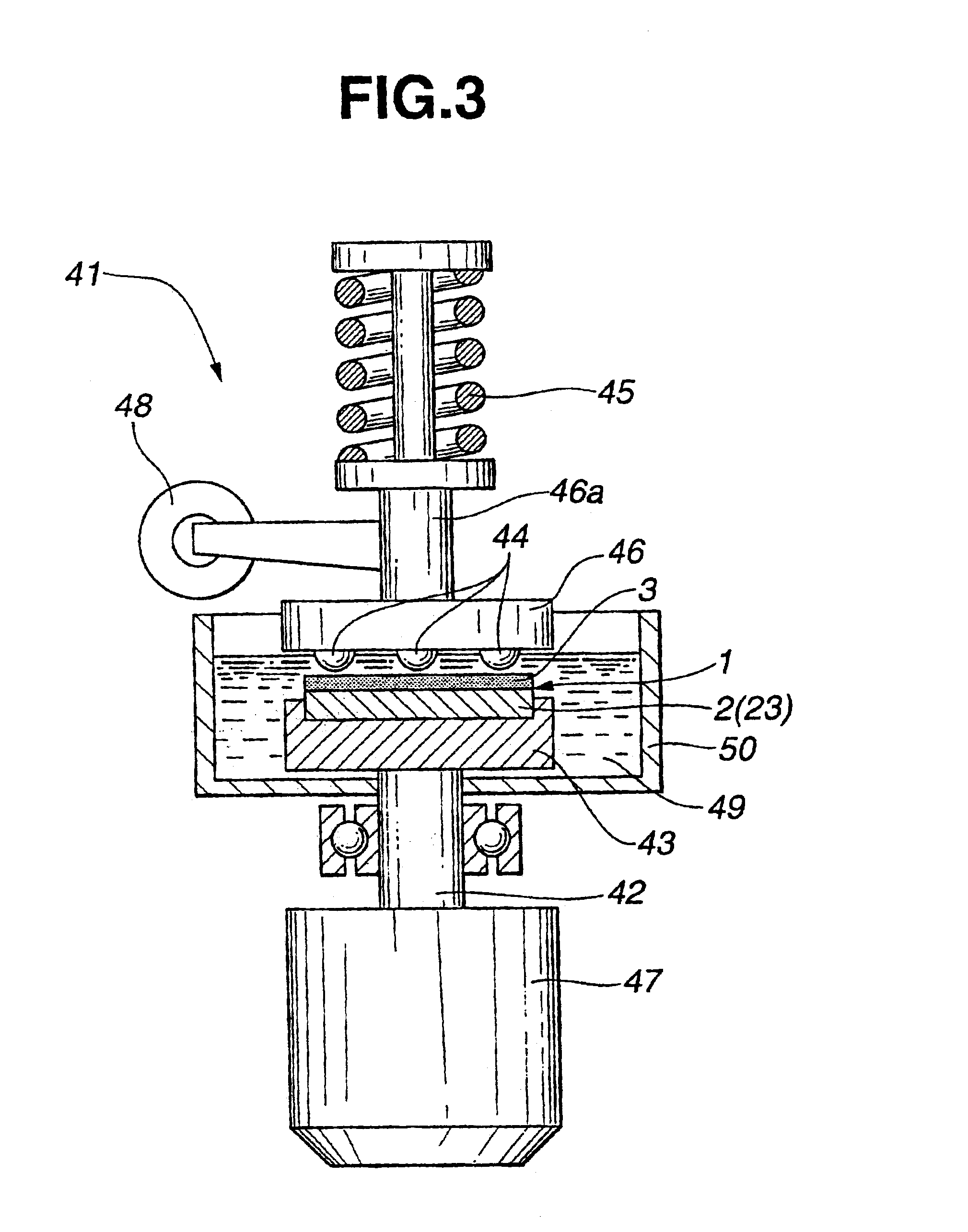

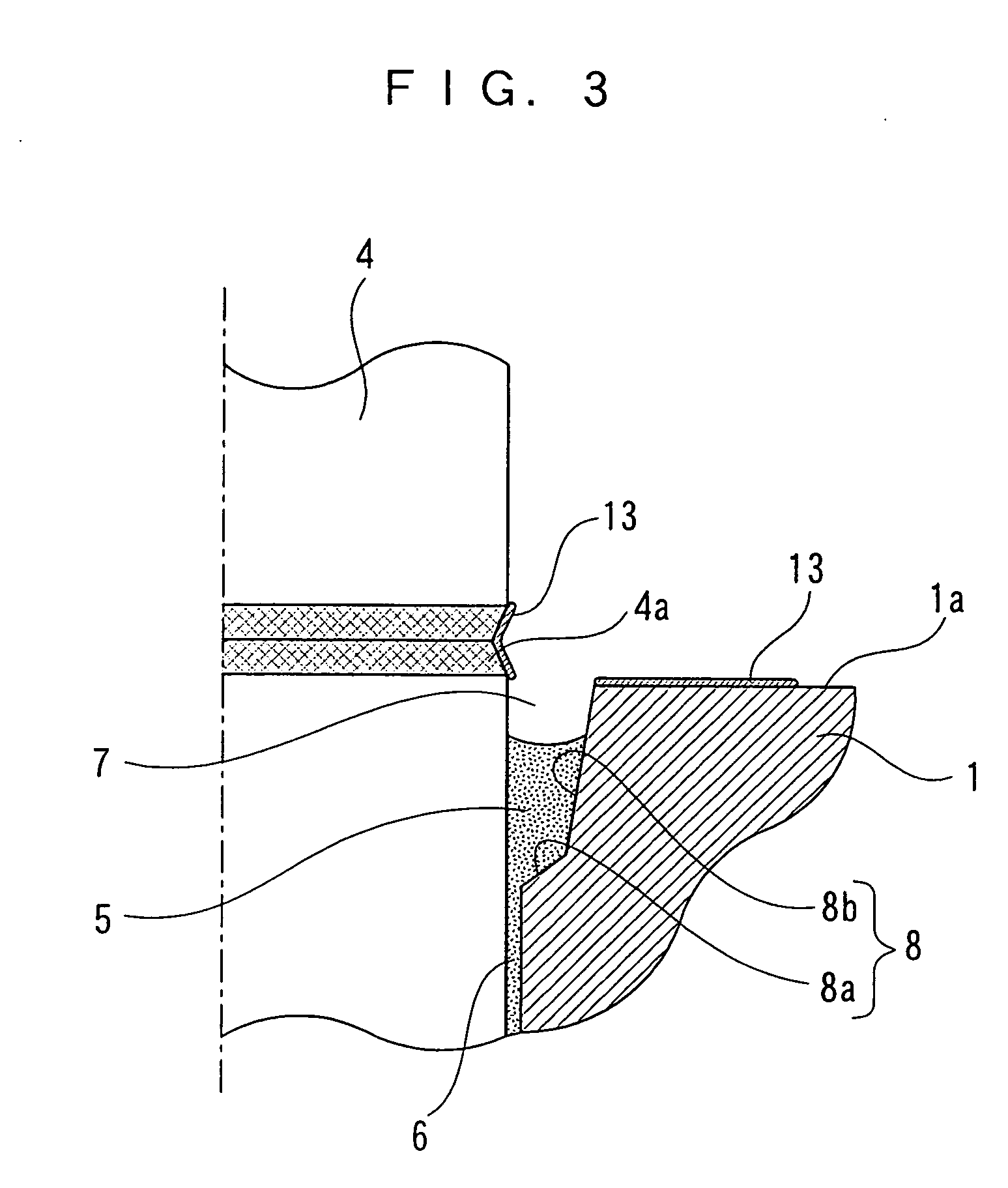

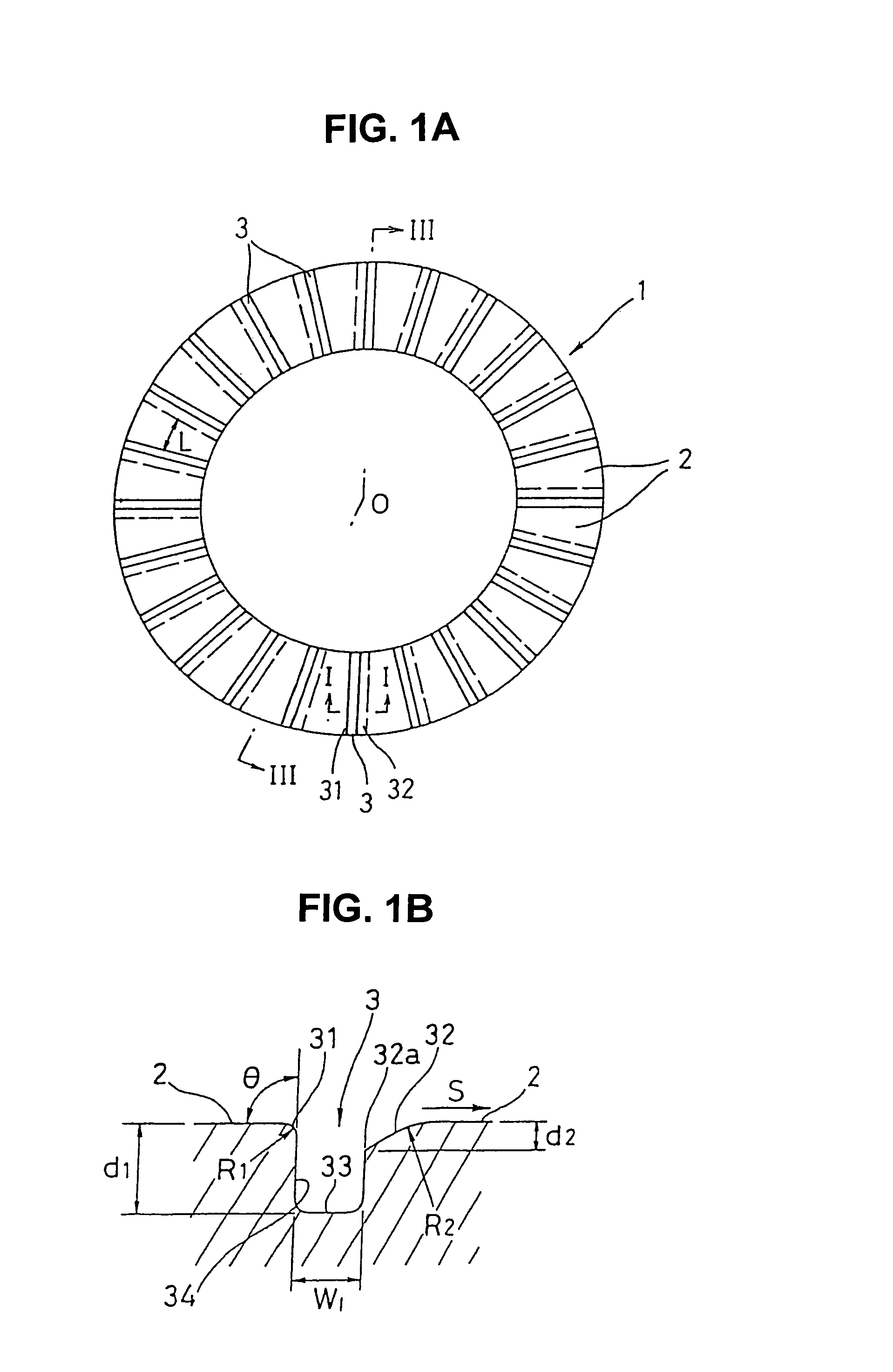

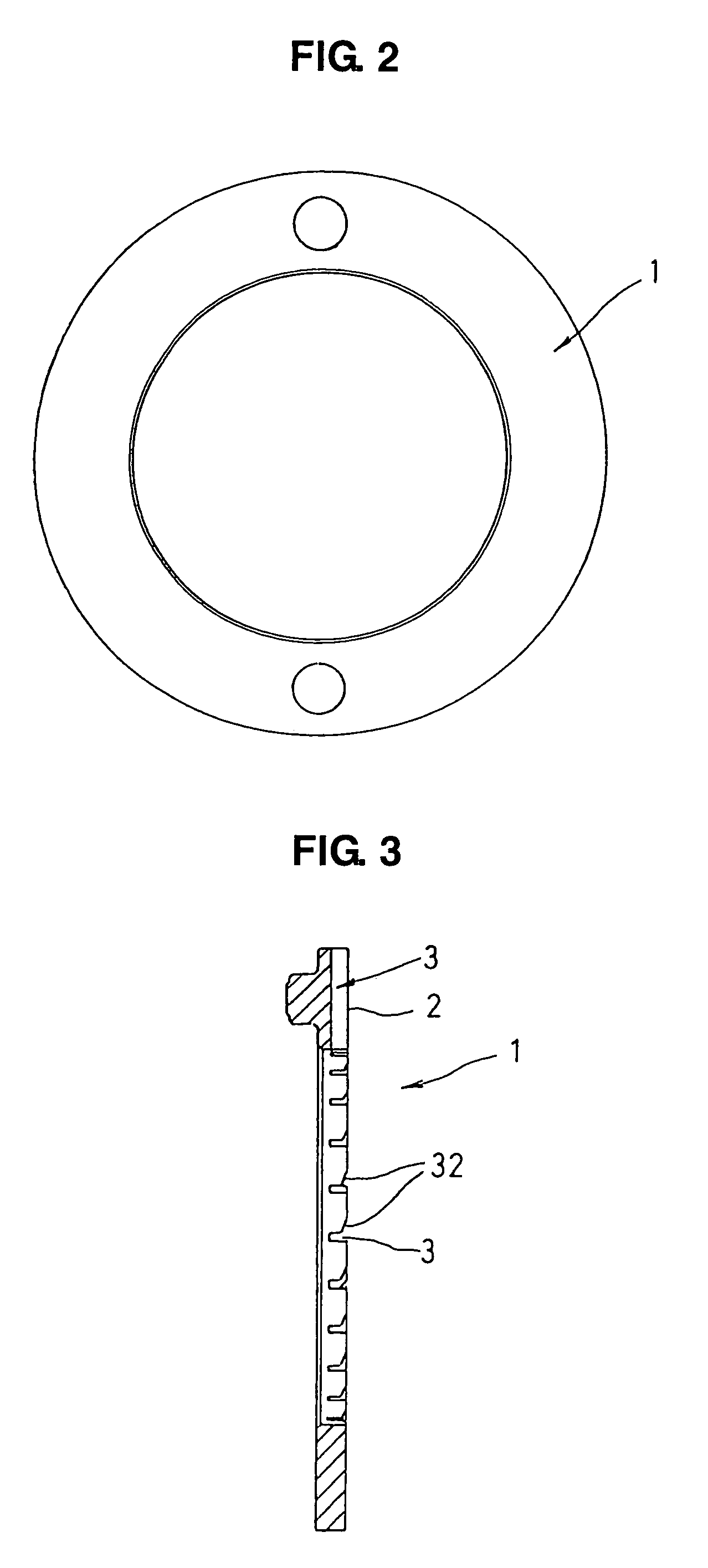

Slidably movable member and method of producing same

InactiveUS6844068B1Improve wear resistanceLow friction propertiesValve arrangementsCam-followersHydrogenNitrogen

Owner:NISSAN MOTOR CO LTD +1

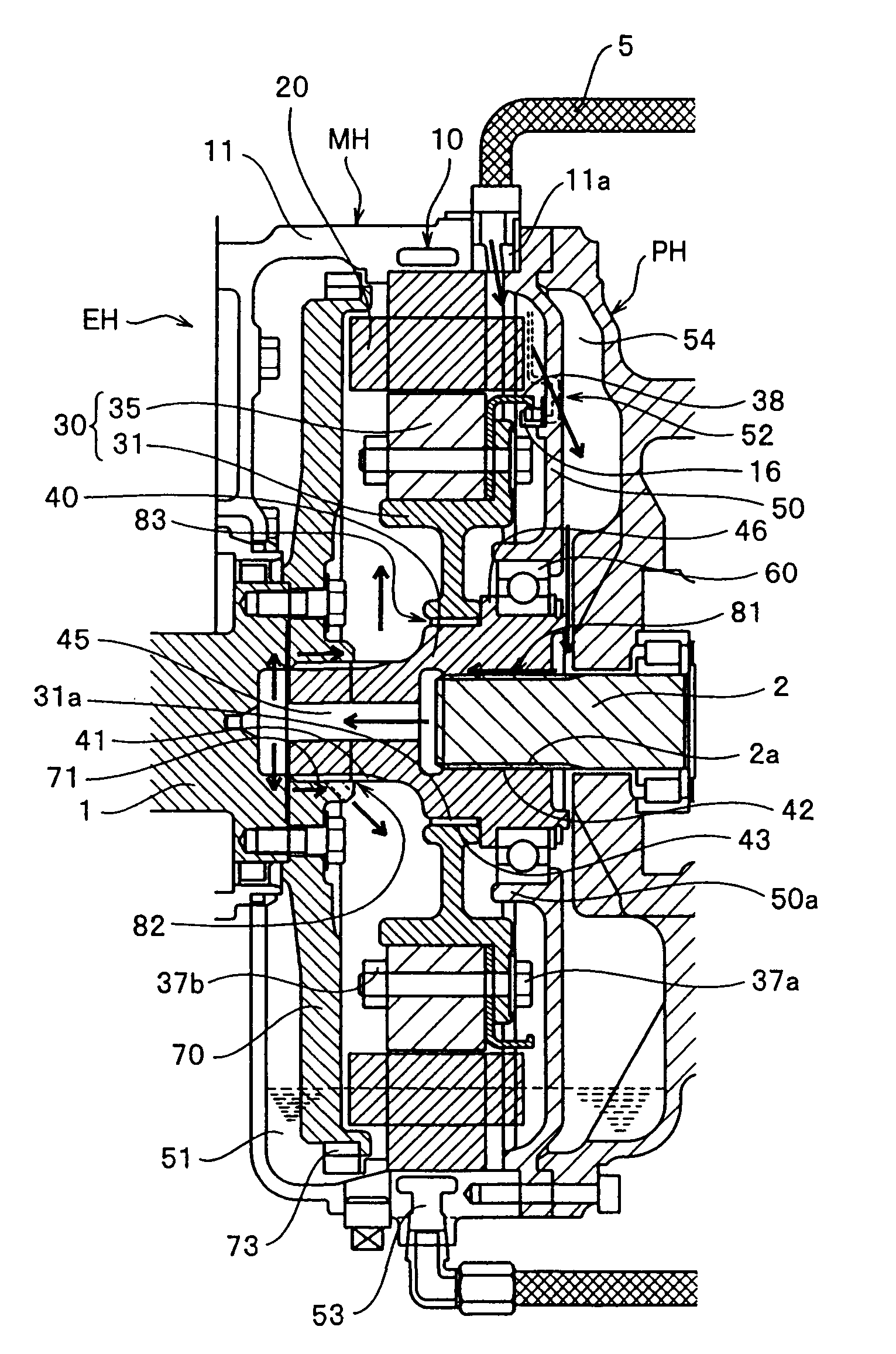

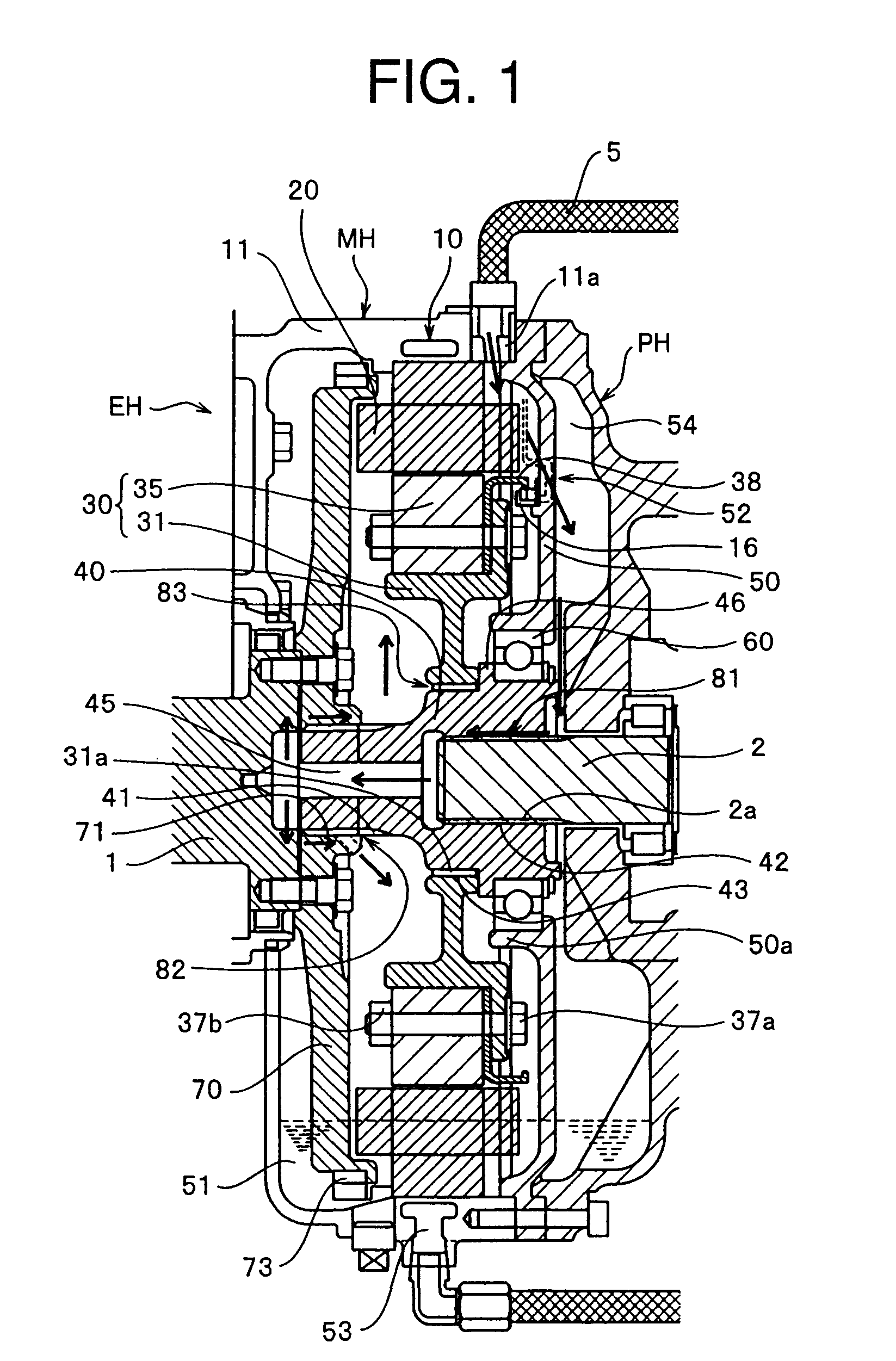

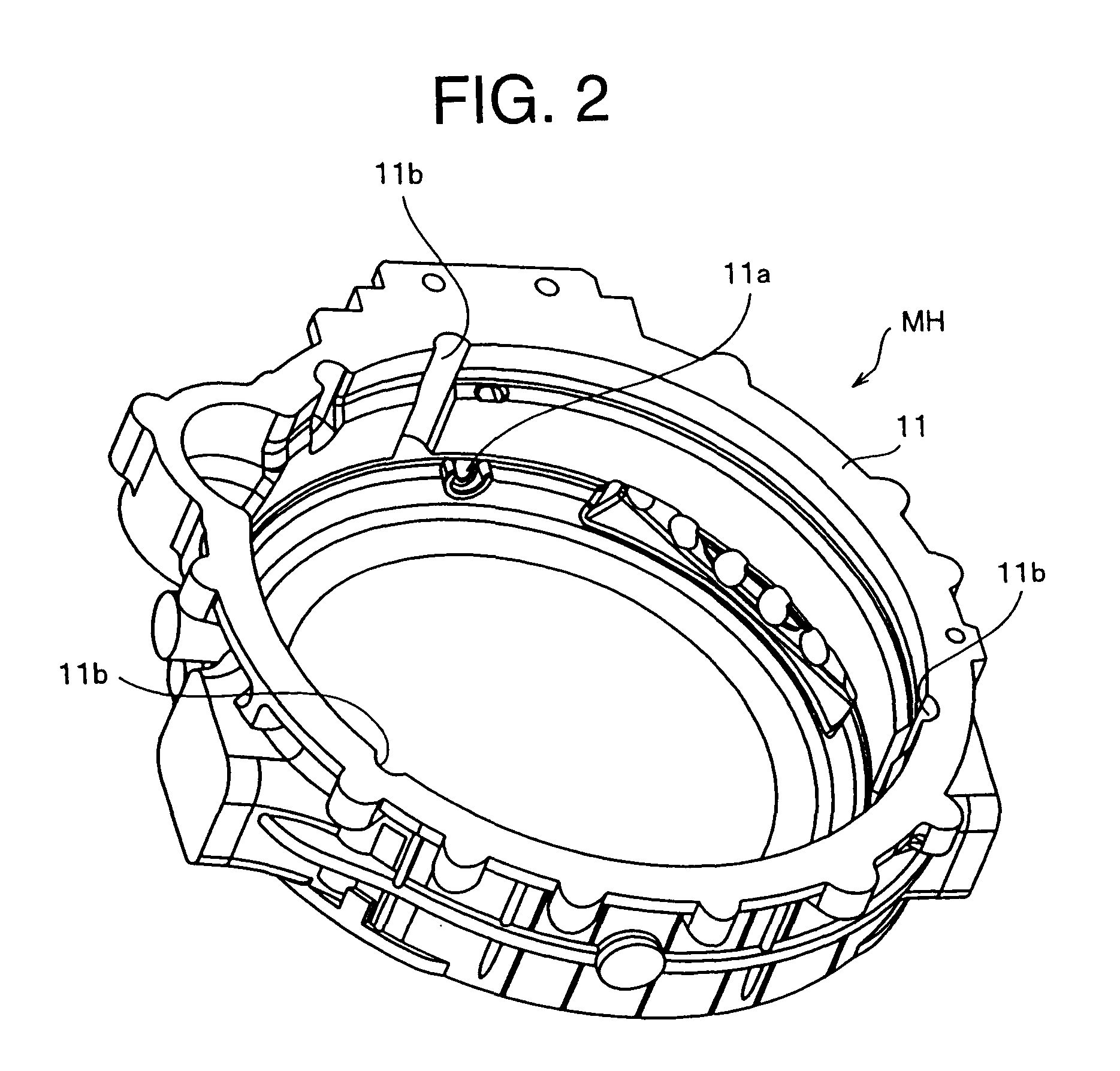

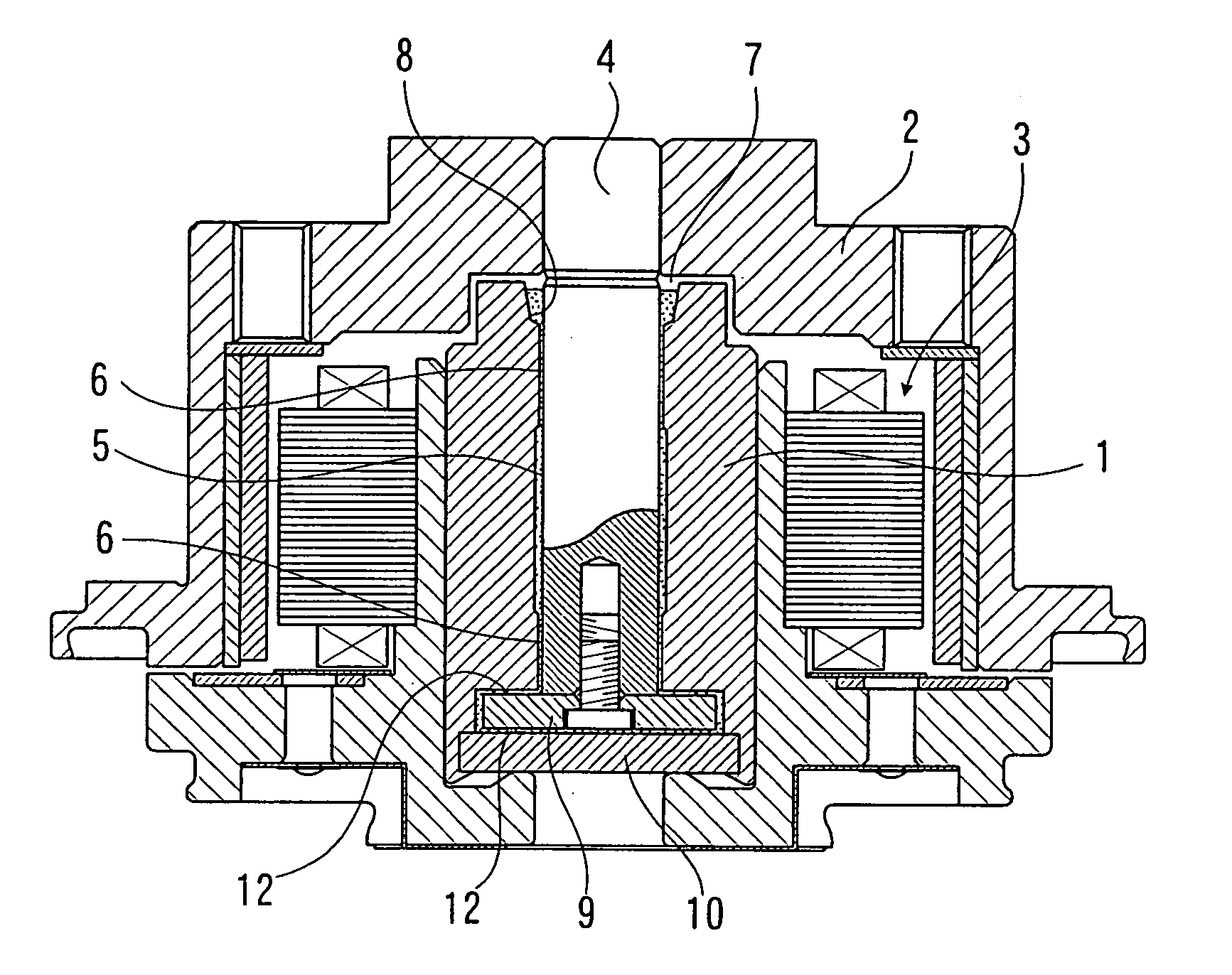

Power Unit

InactiveUS20110001400A1Smooth supplySimple configurationClutchesGearboxesEngineeringCentrifugal force

An output shaft and an input shaft are connected with a connection member interposed therebetween, and a motor rotor is provided outside the connection member. Part of oil flowing down from an oil supply opening 11a of a motor housing MH is supplied to a first spline joint section of the input shaft and the connection member through a space and an opening of a bearing flange fixed to the motor housing MH. The oil lubricating the first spline joint section moves along an inner circumferential surface of a hole by a centrifugal force generated by rotation of the connection member, the oil moves in a radial direction along an end face on one end section side of the connection member 40 in one end section of the connection member, and the oil is supplied to a second spline joint section of the output shaft and the connection member.

Owner:KOMATSU LTD

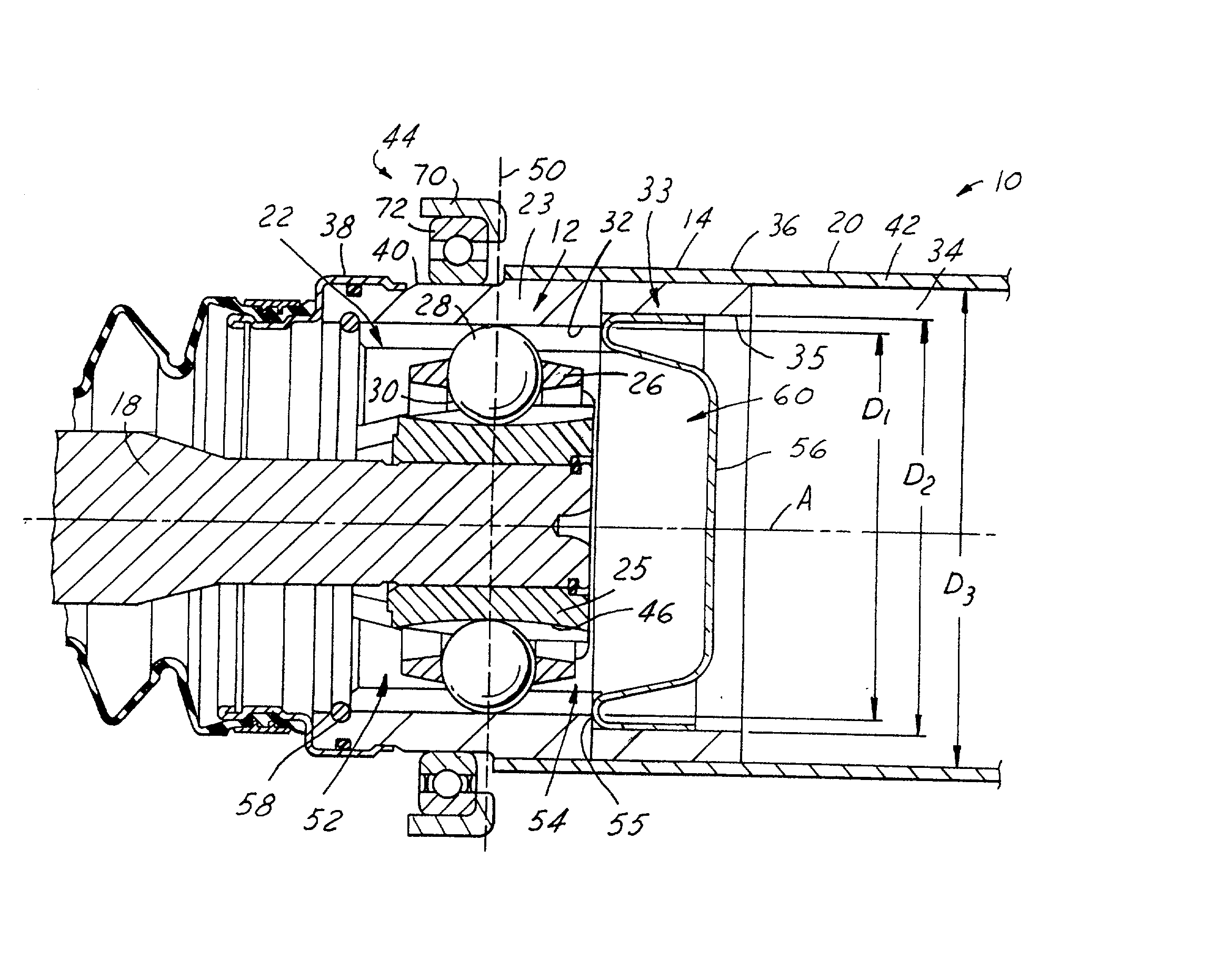

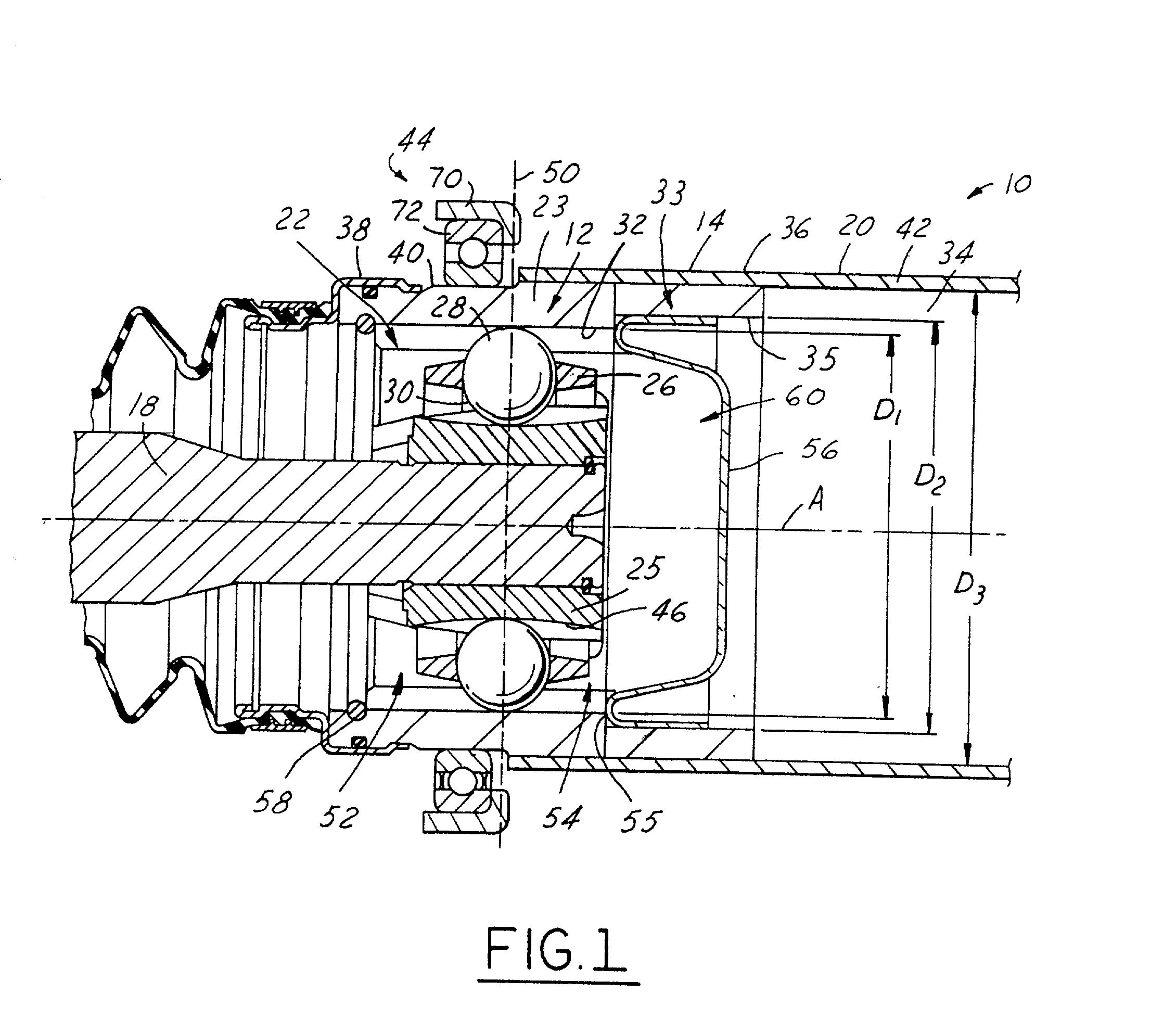

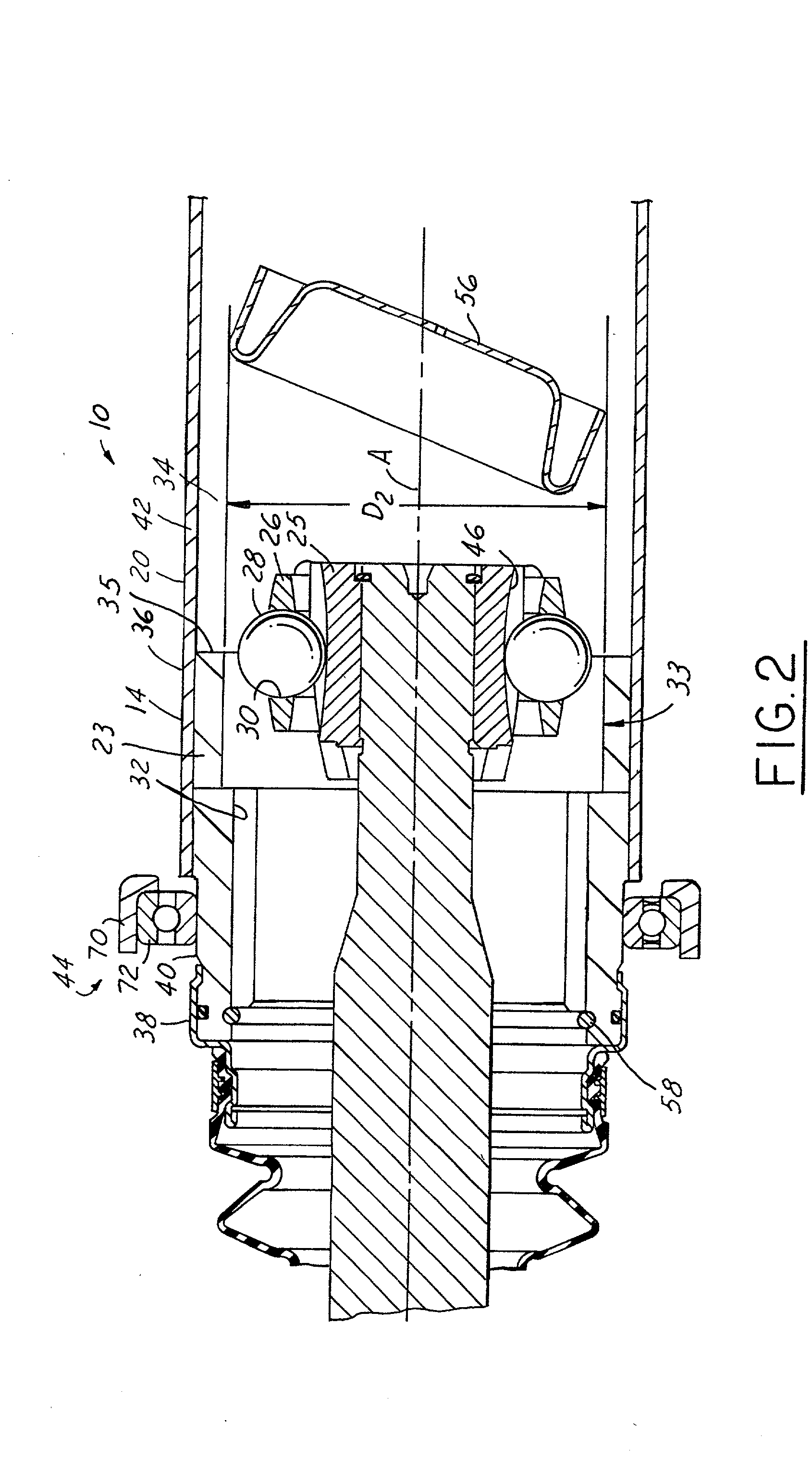

Crash optimized plunging CV joint

InactiveUS20030008716A1Minimize the number of componentsReduce the total massClutchesYielding couplingDrive shaftUniversal joint

A propeller shaft assembly (10) comprising a constant velocity universal joint (12) including a hollow shaft (20) and a connecting shaft (18) is provided. The hollow shaft (20) includes an aft open area (34) and is connected to an outer joint part (23) that has outer ball tracks (32). The connecting shaft (18) is connected to an inner joint part (25) that has inner ball tracks (46). A ball cage (26) that has a plurality of balls (28) is included. A standard plunge (22) that has an aft plunge portion (54) is also included. The aft plunge portion (54) and the aft open area (34) having inner diameters that are greater then or equal to an inner diameter D.sub.1 of the outer joint part (23). A first stop (55) limits the ball movement of travel in the aft direction. The first stop (55) is forcibly dispensable such that the connecting shaft (18) may release the first stop (55) and intrude significantly within the aft open area (34) which is outside a normal operating range (24).

Owner:GKN AUTOMOTIVE INC

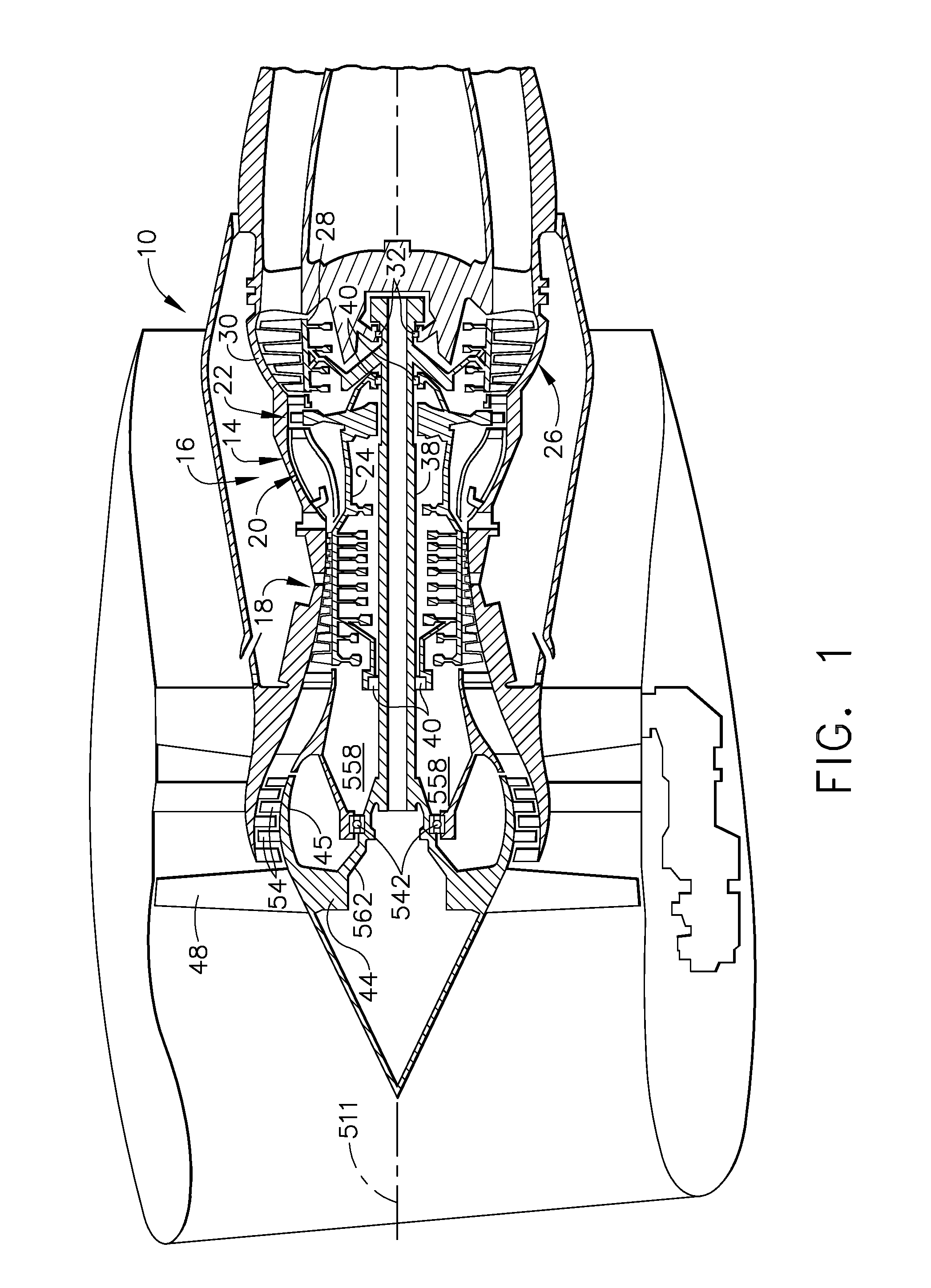

Vortex air-oil separator system

The present invention provides a vortex generator that may be used in systems for separating oil from air oil mixtures. The vortex generator comprises a rotating disk having a rim having a plurality of passages extending through it and a cavity formed by the rotating disk and a cavity wall wherein a vortex is created when there is a flow through the plurality of passages into the cavity.

Owner:GENERAL ELECTRIC CO

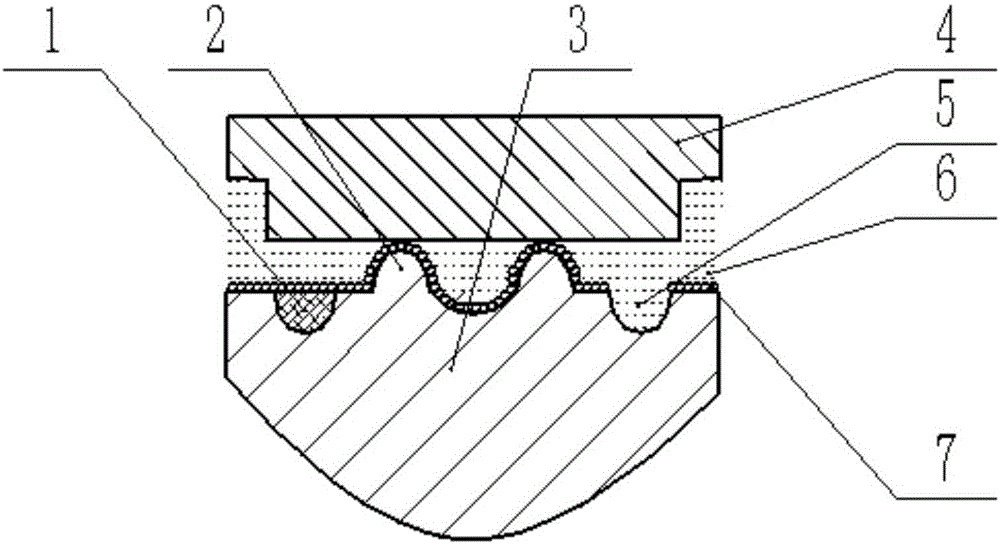

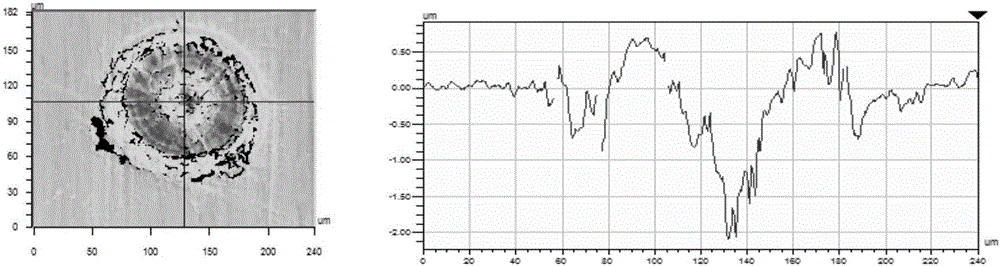

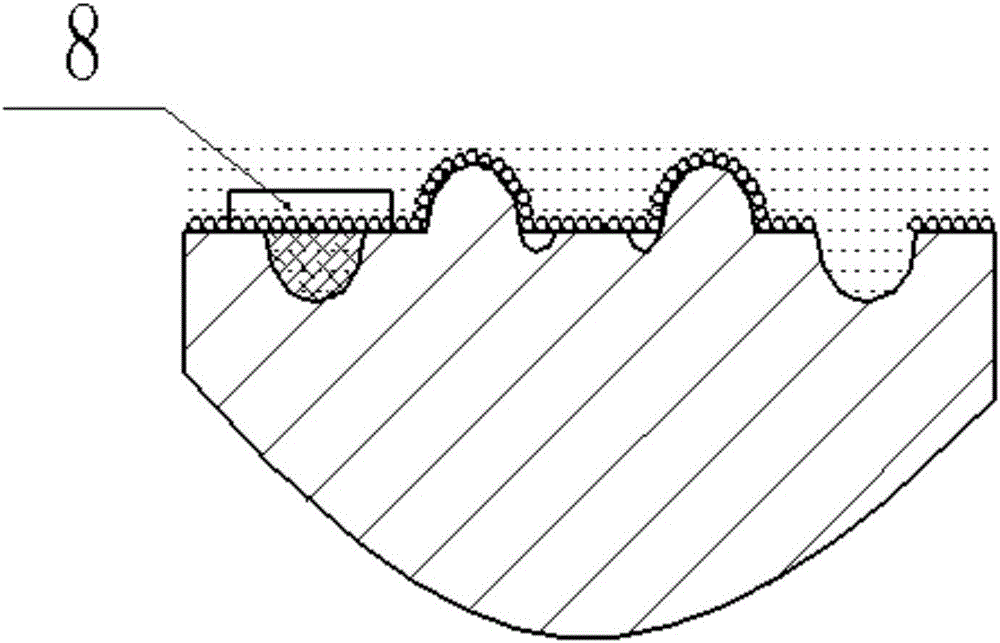

Guiding sliding friction pair of multi-element composite texture, processing method and application of guiding sliding friction pair

ActiveCN106090001AReduce friction and wearInhibit crawling phenomenonLinear bearingsShaftsLow speedMicro texture

The invention provides a guiding sliding friction pair of a multi-element composite texture, a processing method and application of the guiding sliding friction pair. Composite micro-texture morphology with orderly and uniformly distributed miniature pits and miniature protrusions is processed on a working plane of the friction pair through a laser device, and the miniature pits are filled with composite nanometer solid lubricants through a filling-pressing process. The laser micro-texture method is adopted to carry out non-contact processing and nanometer composite material filling and coating on a working plane of a guide rail, the creeping phenomenon of the machine tool guide rail can be effectively suppressed, the guide rail can be effectively lubricated under complex working conditions of a low speed, heavy load and the like, and the effects of reducing friction and resisting bonding are achieved.

Owner:JIANGSU UNIV

Method of producing coated engine components

InactiveUS20050016489A1Reduce frictionProvide wear resistanceMolten spray coatingPlungersPorous coatingEngineering

To improve engine performance and reduce wear and friction, a porous coating is applied to piston skirts and cylinder bores via a thermal spray process. The porous nature of the coating allows for oil to be held on the surfaces enhancing lubrication.

Owner:WIDE OPEN COATINGS

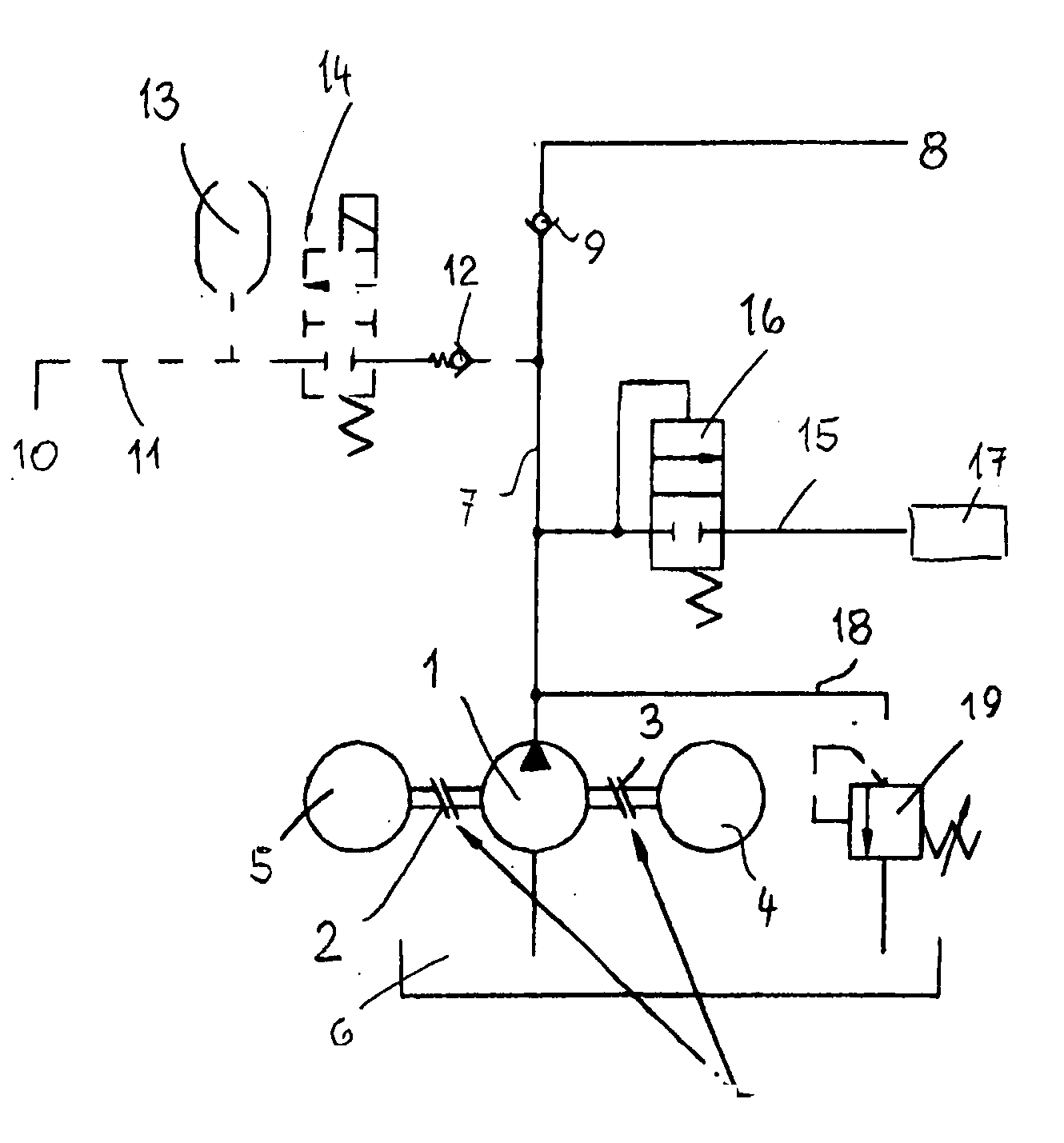

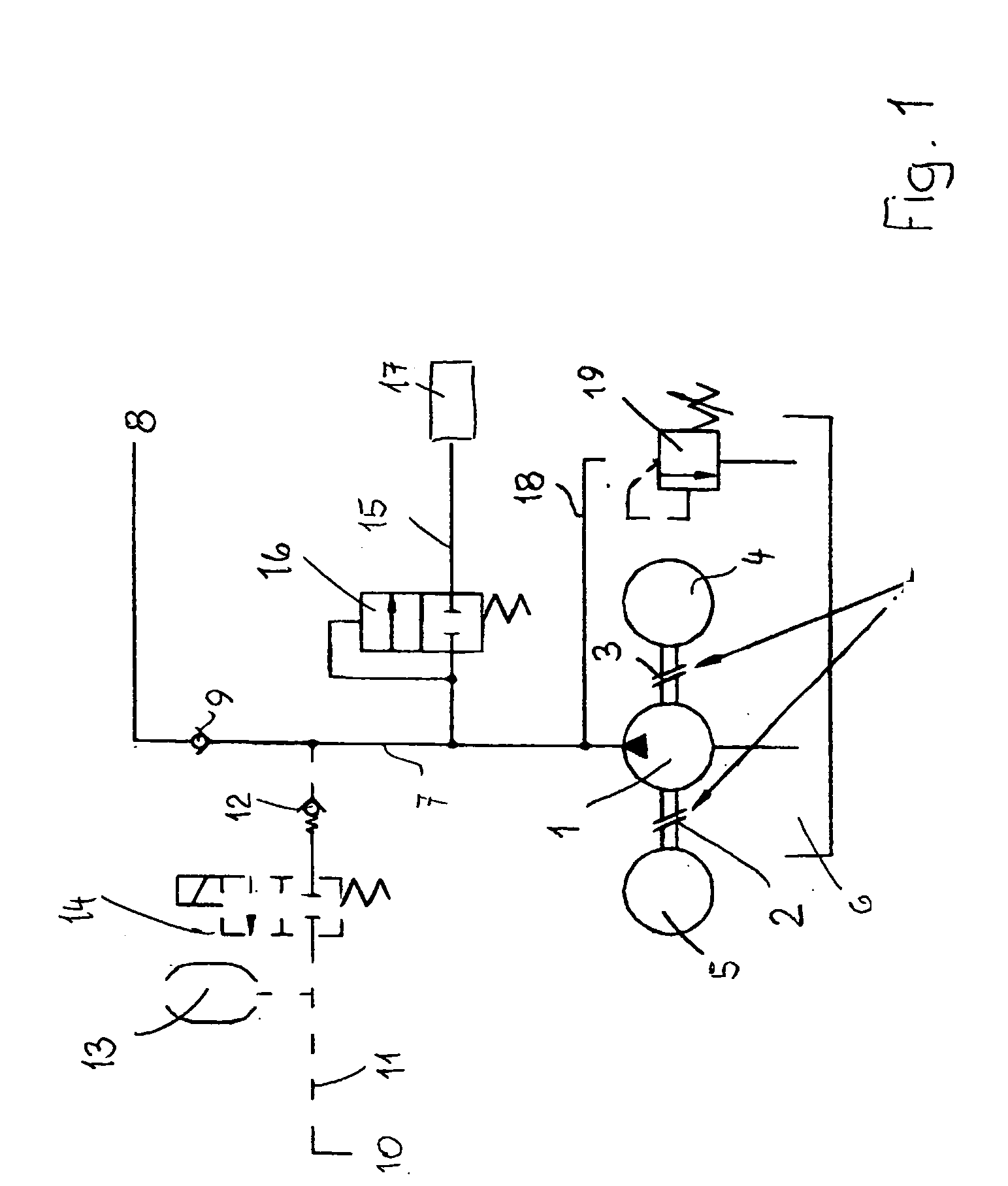

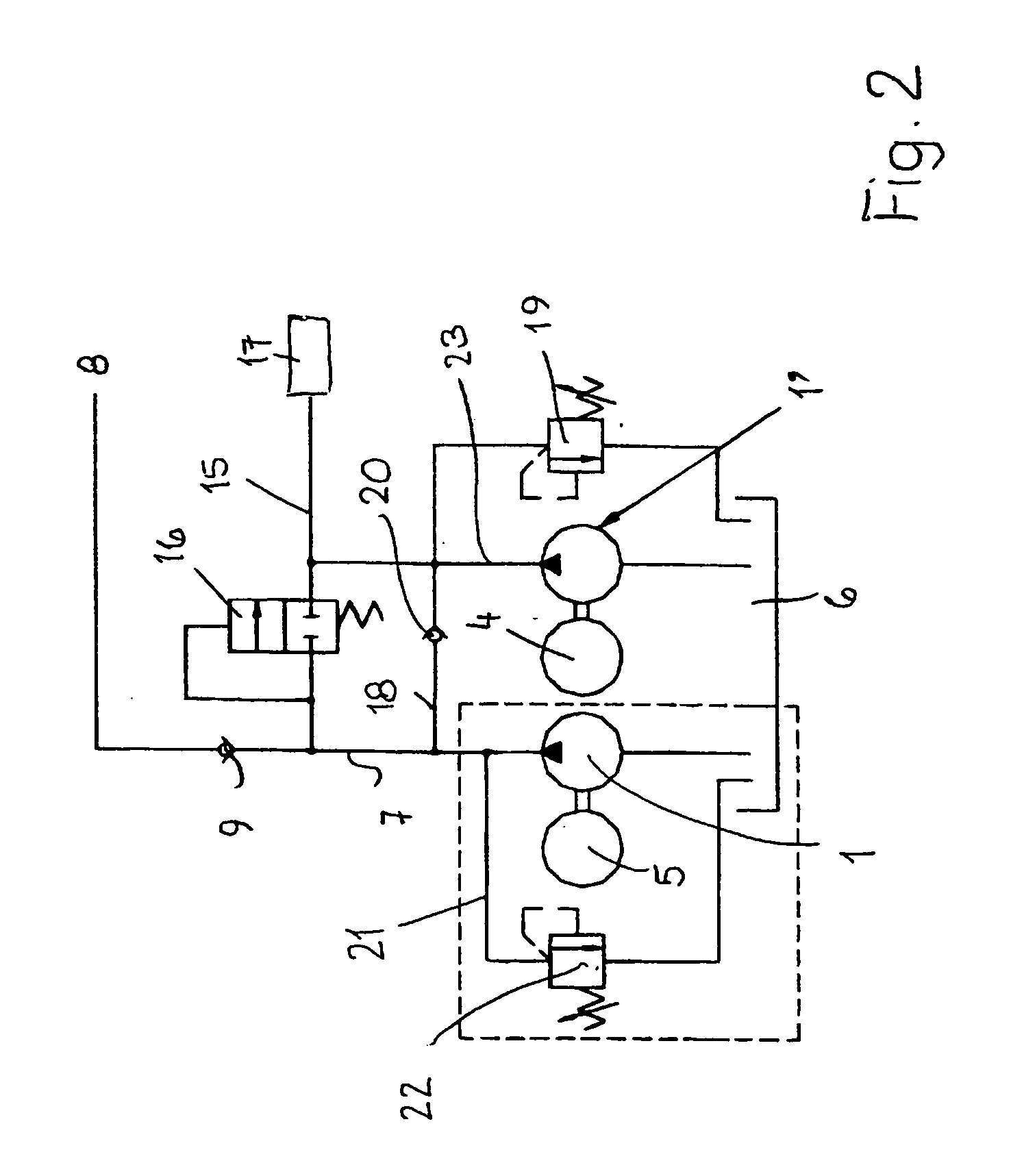

Control device for at least one consumer, such as a camshaft adjuster, automatic transmsion and the like, of motor vehicles

InactiveUS20050072397A1Increase supplyFluid-pressure actuator safetyValve arrangementsMobile vehicleAutomatic transmission

A control device for at least one consumer of a motor vehicle, having an engine and at least one pump for supplying a medium via at least one pressure line to the at least one consumer, is configured to supply the medium to the at least one consumer before the engine is started. The pump can be driven by an electric motor or by the engine of the motor vehicle or alternatingly by the electric motor and the engine.

Owner:HYDRAULIK RING

Bearing cleaning composition and method of use

ActiveUS7241723B2Easy to distinguishHigh in calciumRotary combination bearingsBearing componentsSulfonateEngineering

A composition for cleaning bearings in rotating equipment and industrial machinery that contains powdered limestone having a high calcium content dispersed in a calcium sulfonate grease, together with a colorant that readily enables a user to differentiate between contaminated grease, cleaning composition and fresh grease. A method is also disclosed that enables a user to clean and re-lubricate bearings without the need for removing the bearings from service or for shutting down the associated equipment or machinery.

Owner:NCH CORP

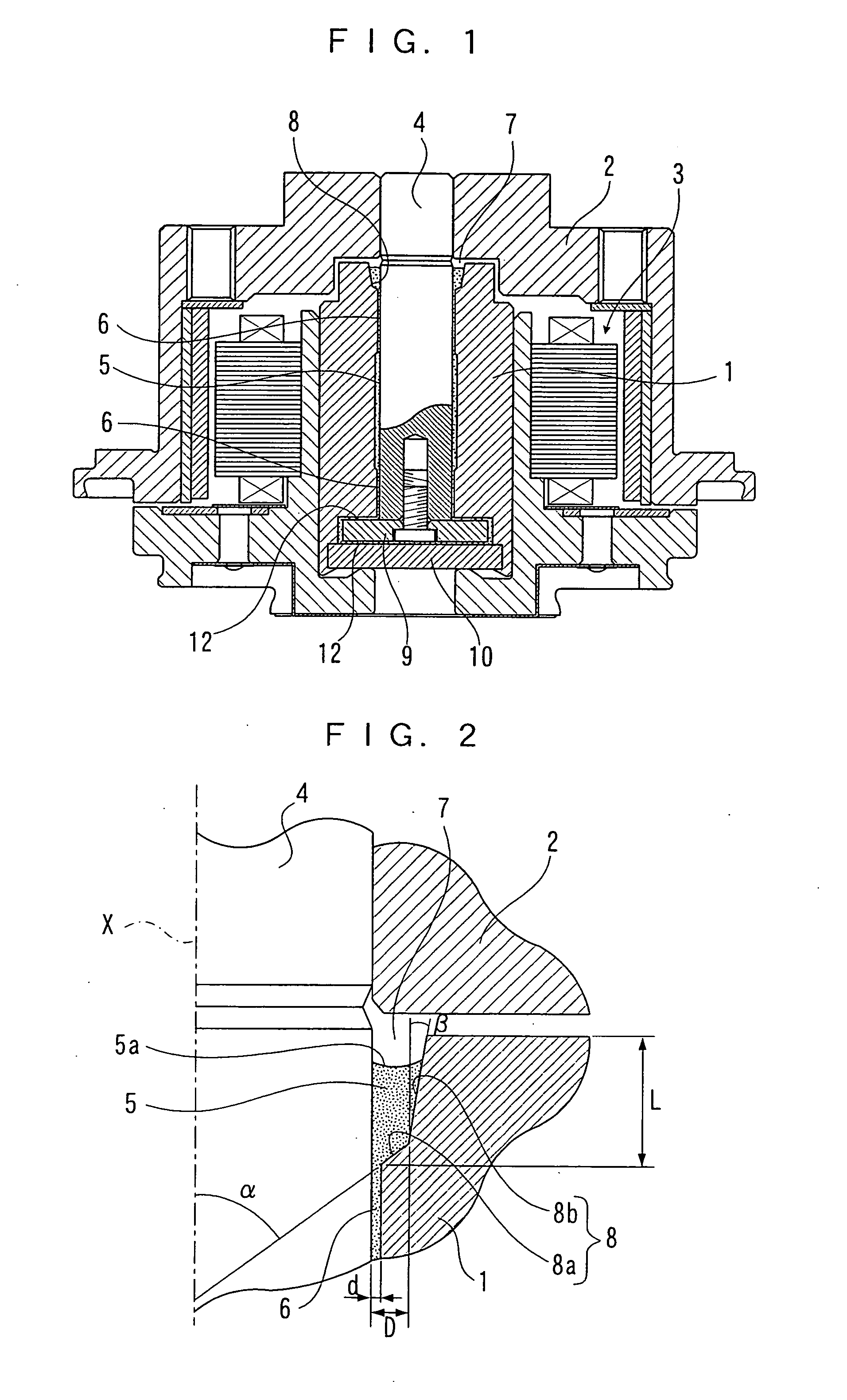

Fluid bearing device

ActiveUS20050111769A1Sufficient length dimensionSmall depthCrankshaftsRecord information storageEngineeringFluid bearing

A fluid bearing device capable of preventing a lubricant from scattering outward even during rotation thereof, while holding a relatively large amount of lubricant at a seal surface portion. A lubricant is filled between a sleeve and a shaft, a seal surface portion is formed on the sleeve in a location facing an open end thereof, the seal surface portion has a sectional shape defined by a plurality of inclined surfaces, and an inclination angle α of the inclined surface of the seal surface portion adjacent a radial bearing portion with respect to a shaft axis is formed to be larger than an inclination angle β of the inclined surface of the seal surface portion distant away from the radial bearing portion with respect to the shaft axis.

Owner:PHC HLDG CORP

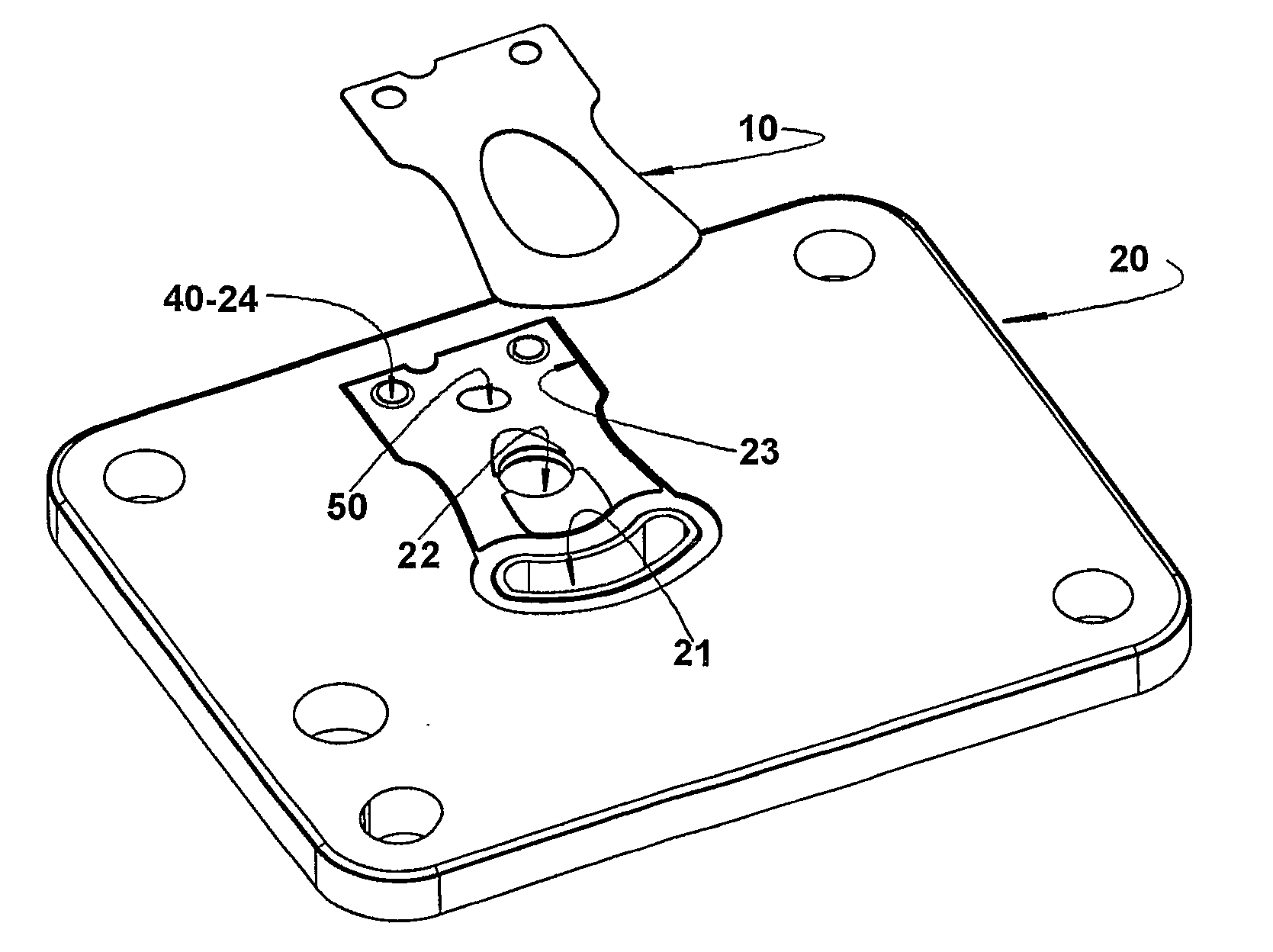

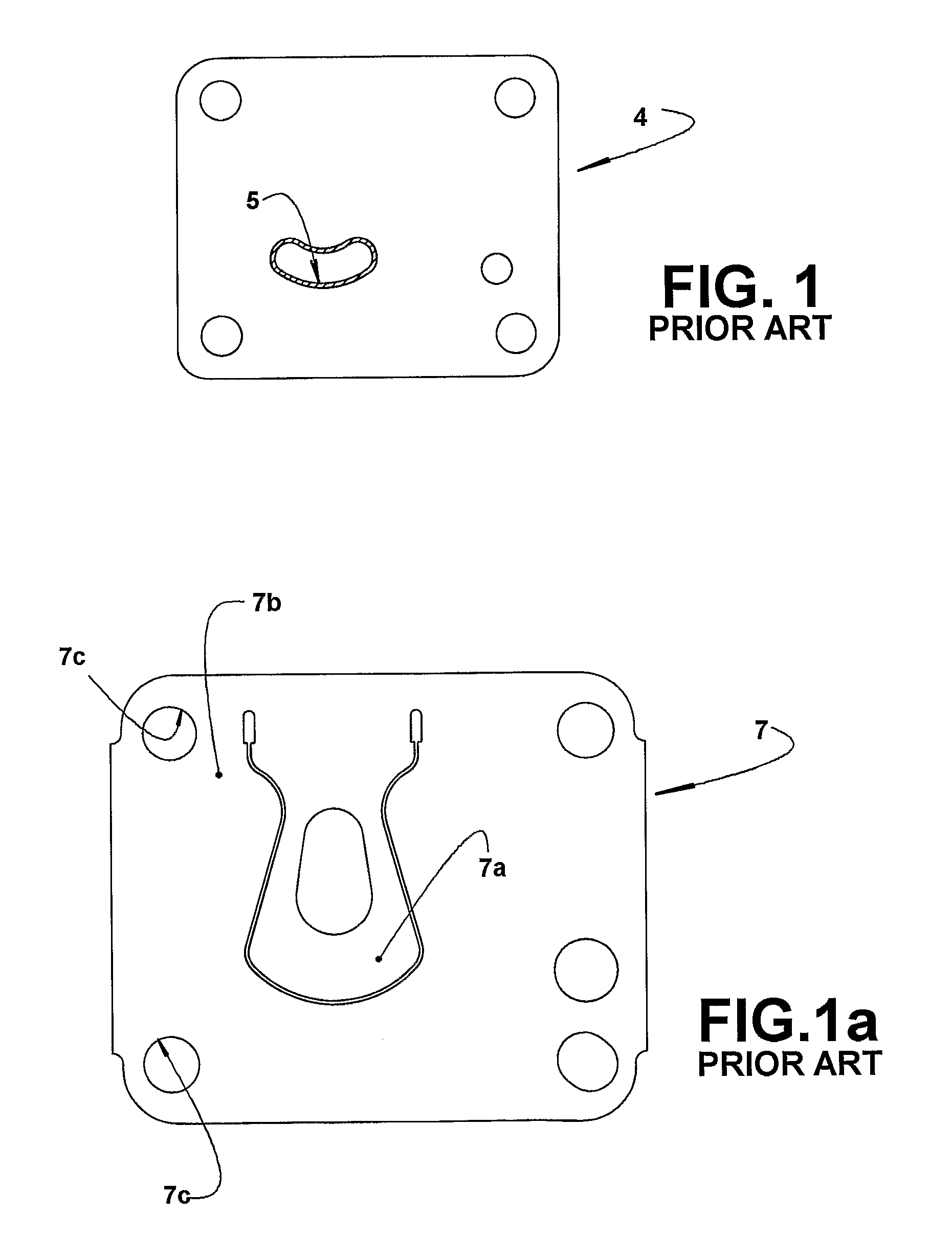

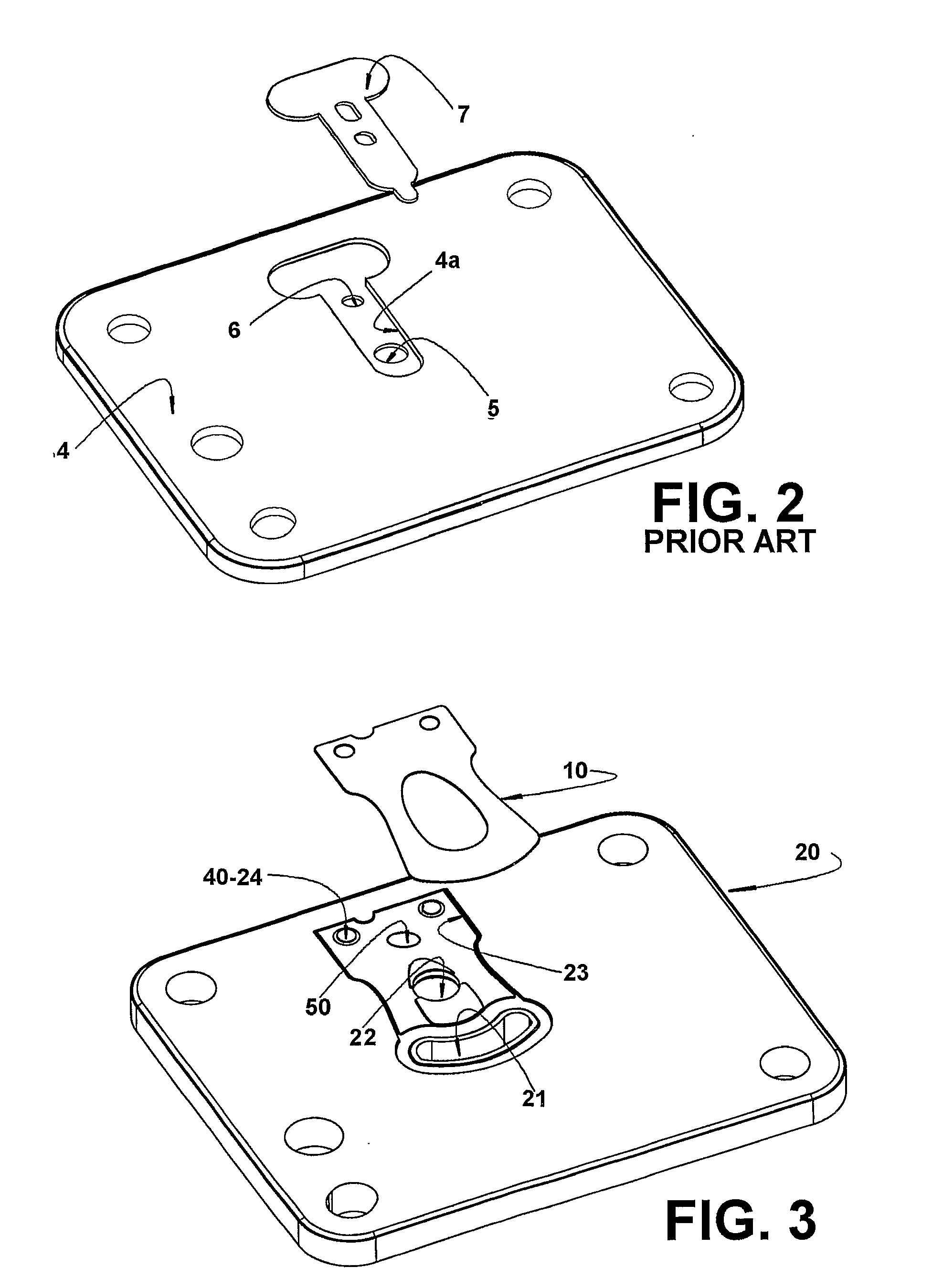

Valve Mounting Arrangement For a Refrigeration Compressor

InactiveUS20080310980A1Simple and reliable processReduce processing stepsCompressorFurniture joining partsRefrigeration compressorEngineering

A valve mounting arrangement for a refrigeration compressor which presents a compression chamber closed by a valve plate having a suction orifice closed by a valve element having a mounting end portion. The mounting arrangement comprises: a first retaining means to retain the mounting end portion of the valve element inside a receiving recess of the valve plate; and at least one orientation projection carried by receiving recess and / or the mounting end portion of the valve element and to be fitted into an orientation recess in the other part; and / or a second retaining means provided between the receiving recess and the mounting end portion of the valve element, so as to avoid the latter from moving from the receiving recess before mounting the first retaining means.

Owner:WHIRPOOL SA

Combined filter and fill tube

Owner:INT ENGINE INTPROP CO LLC

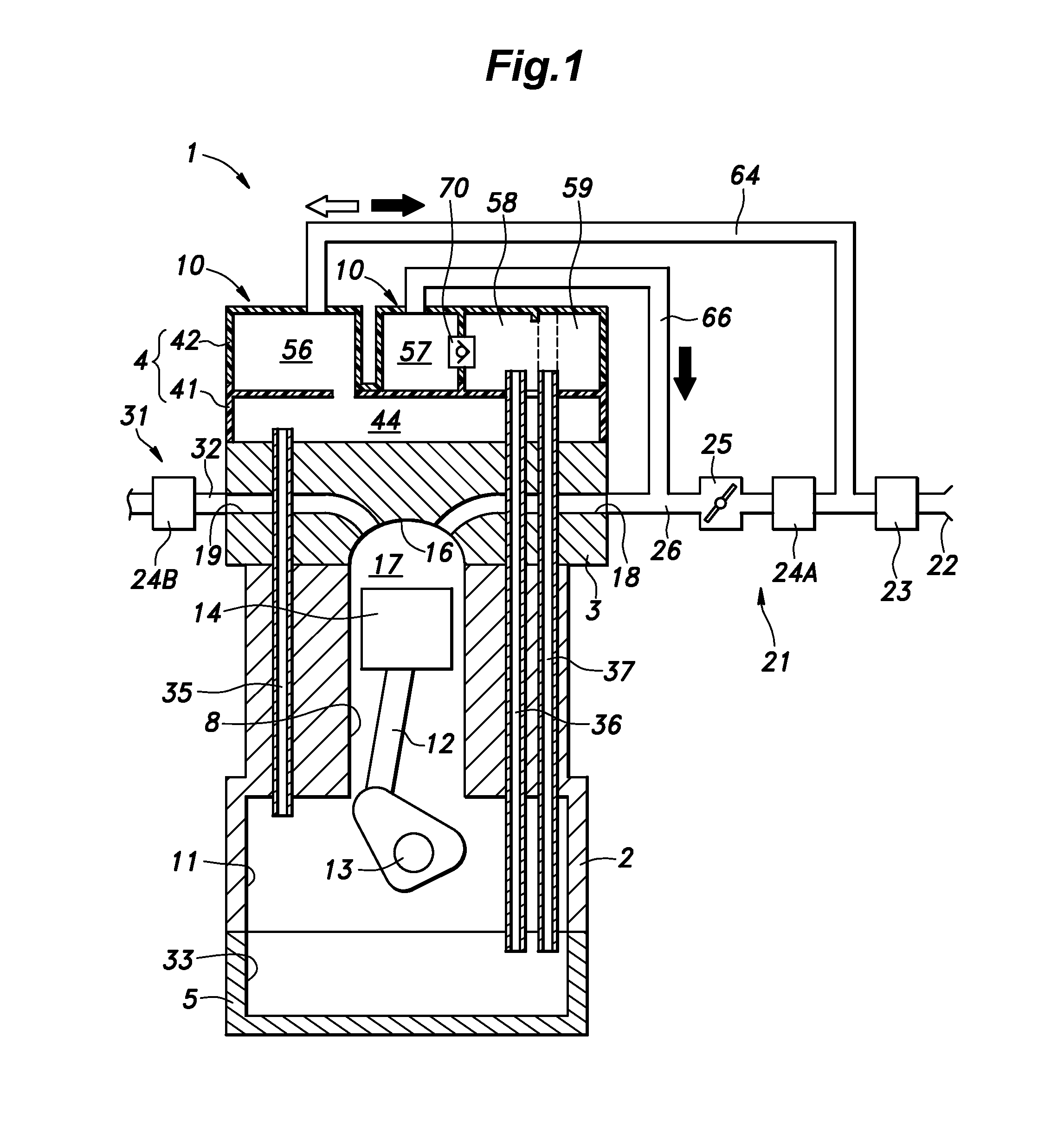

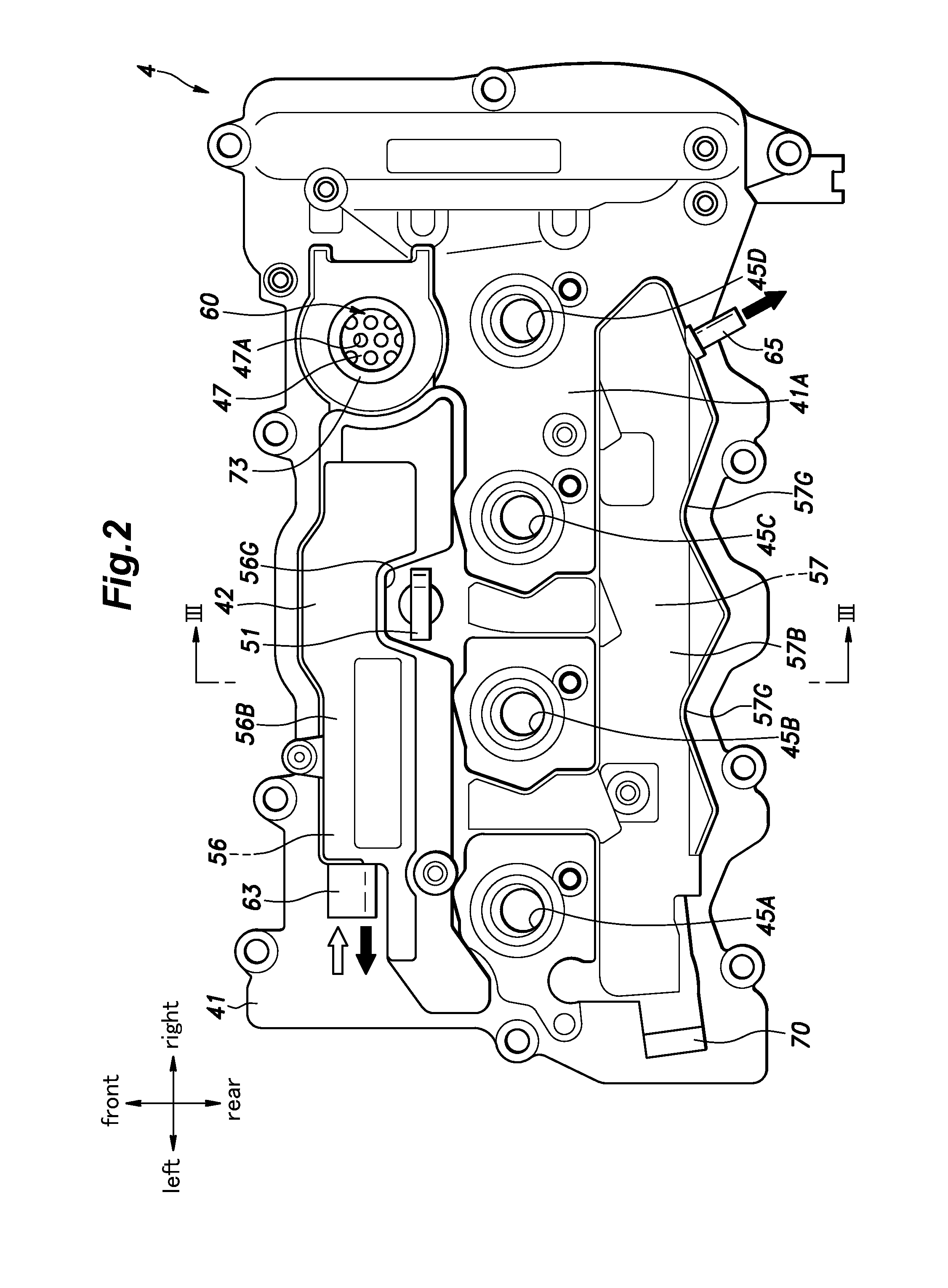

Oil separation device for internal combustion engine

ActiveUS20160265404A1Improve oil separation effectInternal combustion piston enginesNon-fuel substance addition to fuelOil separationInternal combustion engine

To improve the oil separation performance in an oil separation device for an internal combustion engine. The oil separation device (10) comprises a gas liquid separation passage (56) internally defined by a lower wall, an upper wall and a pair of side walls, and extending in a horizontal direction, a gas inlet (54) and a gas outlet (63) provided on either end of the gas liquid separation passage, a plurality of lower partition walls (56H) projecting upward from the lower wall, and a plurality of upper partition walls (56J) projecting downward from the upper wall. The lower partition walls and the upper partition wall are tilted with respective the length wise direction in plan view so as to define a spiral passage. The lower wall is inclined with respect to a horizontal plane such that an upstream part of the lower wall is lower than a downstream part of the lower wall with respect to a direction of the swirl flow.

Owner:HONDA MOTOR CO LTD

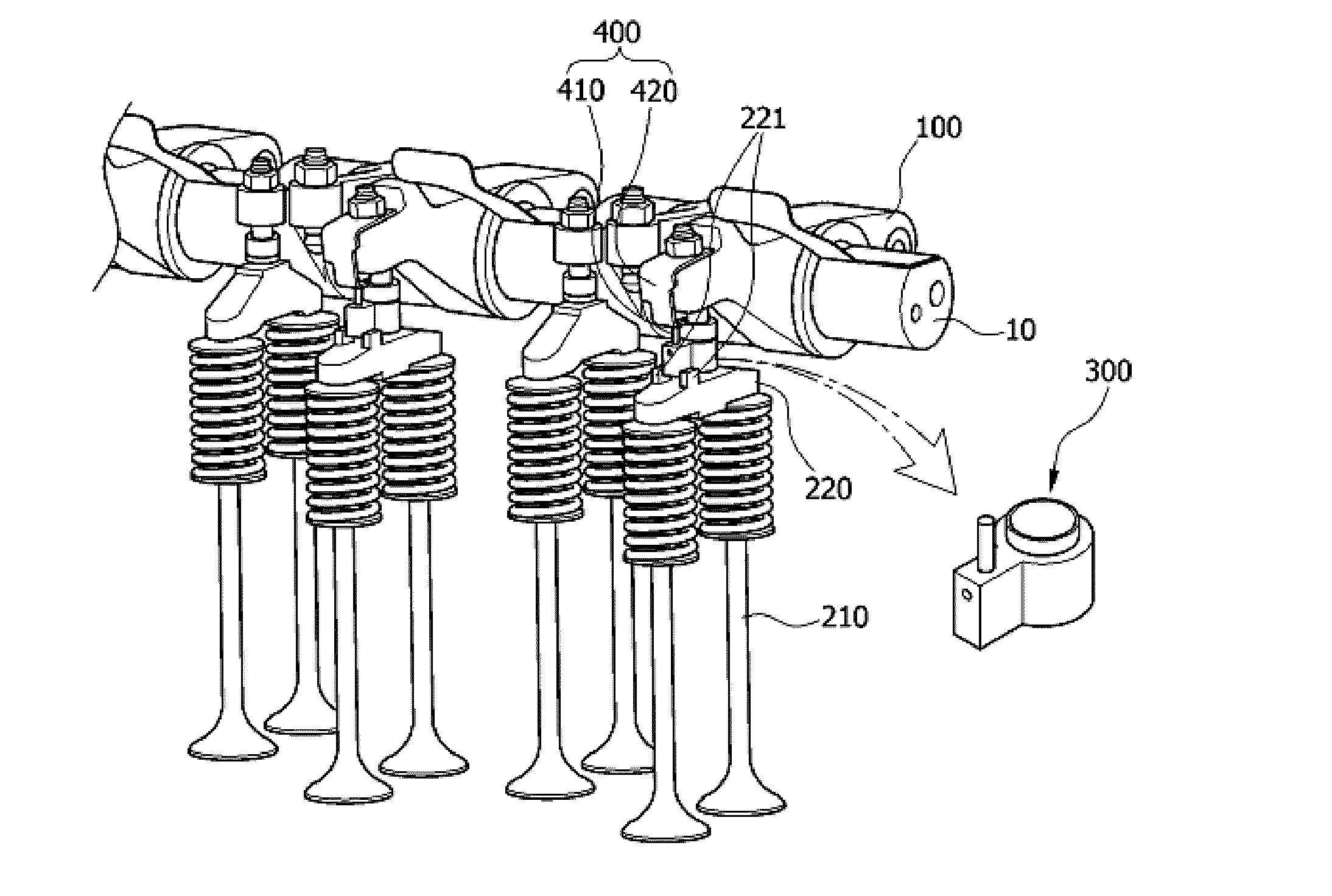

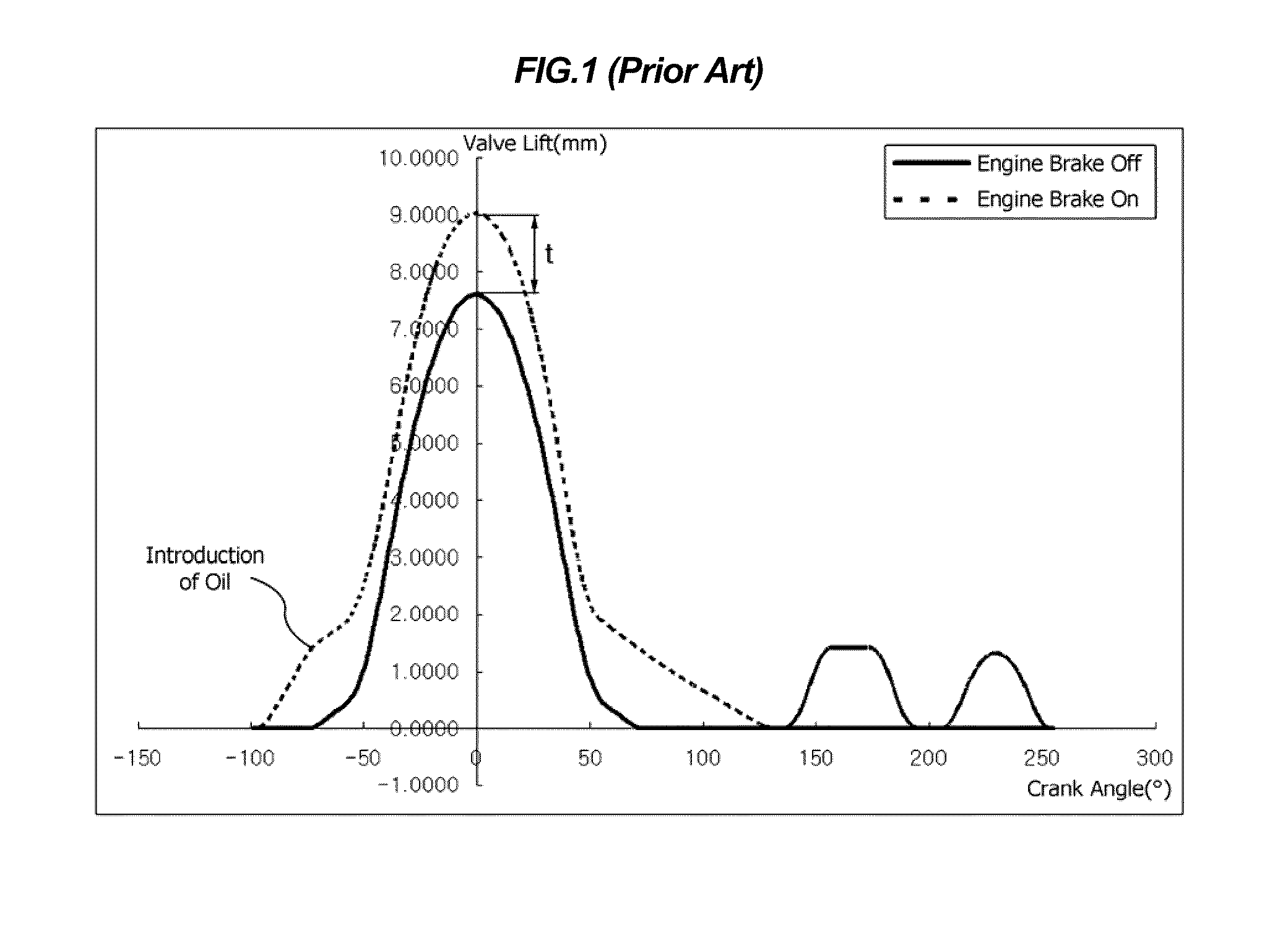

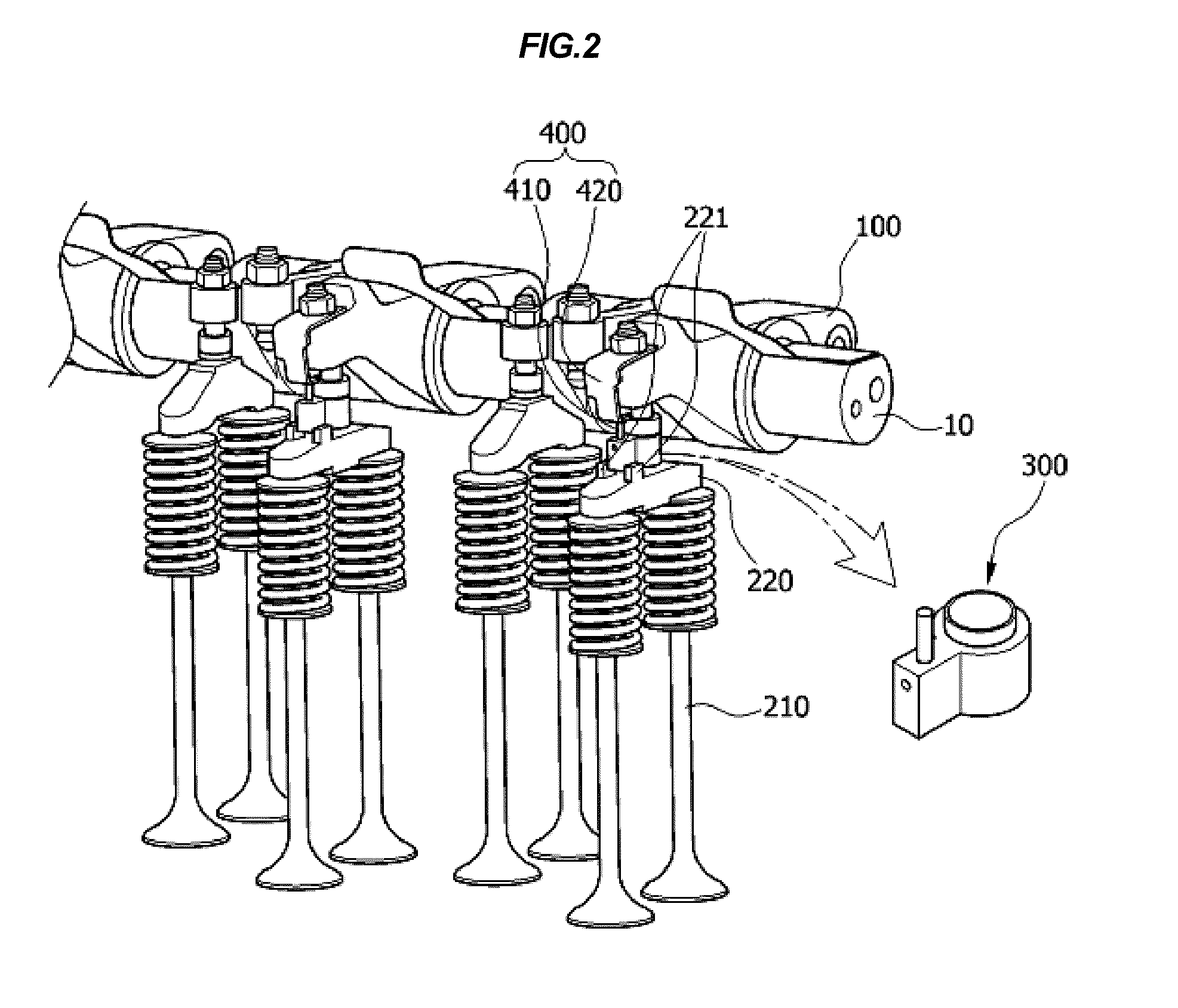

Compression release engine brake unit

A compression release engine brake unit includes an oil outlet passage formed in a socket brake, which stores engine brake oil, and a reset member opening or closing the outlet passage. The reset member discharges the engine brake oil by opening the oil outlet passage in response to the rotation of a rocker arm during engine braking and, thereby, the engine brake restores the initial state. Since the compression release engine brake can restore the initial state, the return valve lift is the same as when the compression release engine brake is not actuated. Accordingly, the valve does not butt against an engine piston.

Owner:HYUNDAI MOTOR CO LTD +1

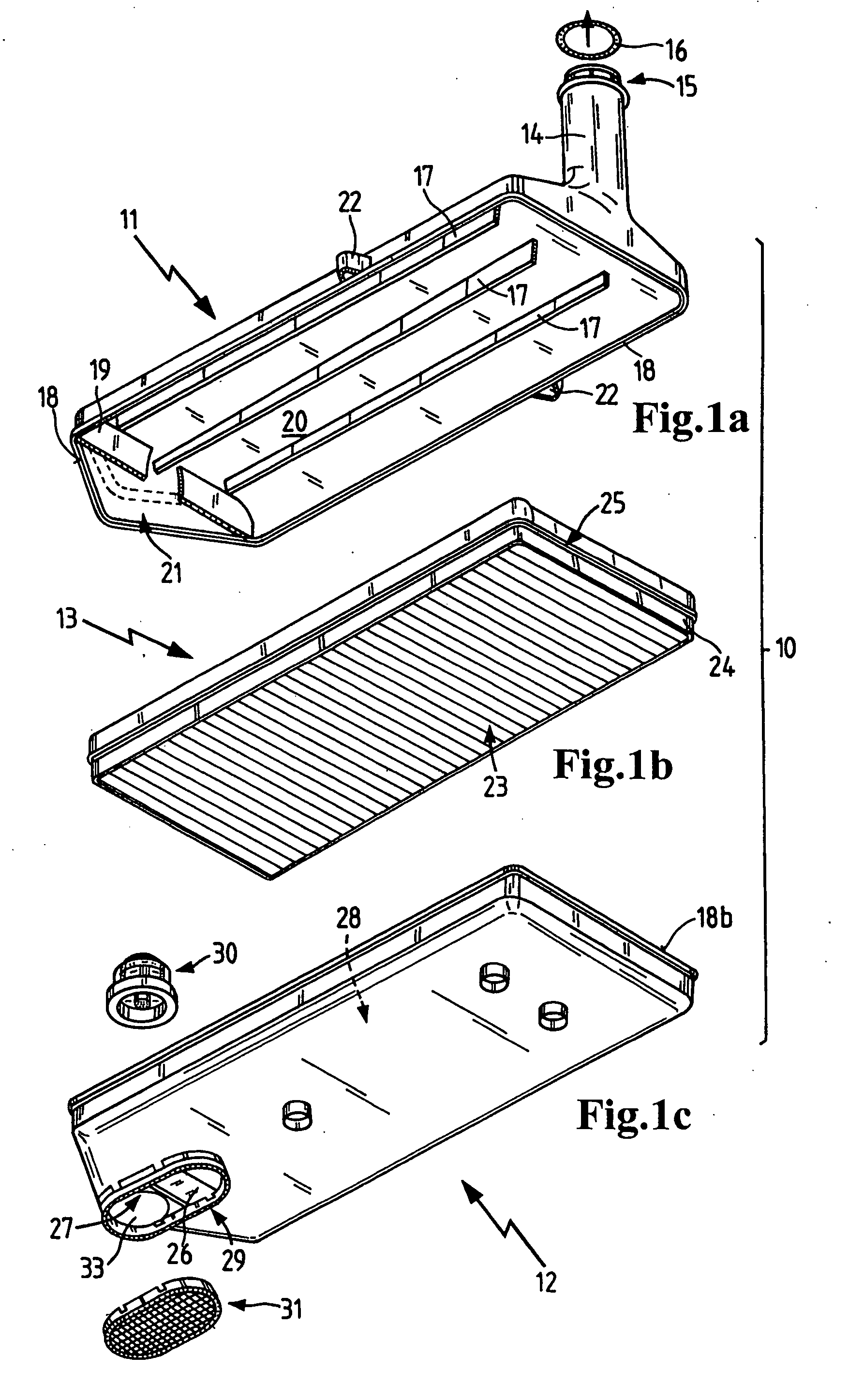

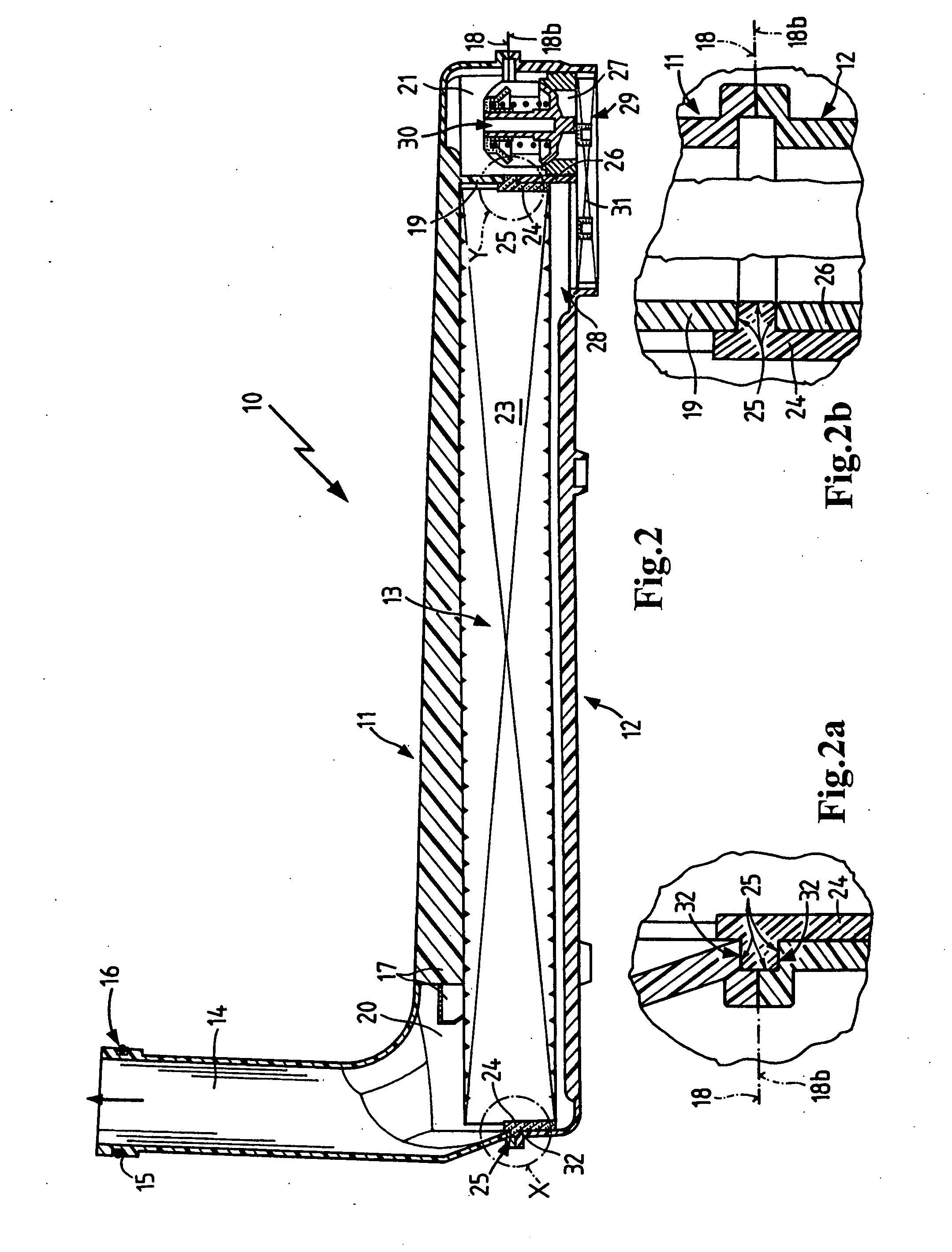

Oil filter unit

ActiveUS20060180541A1Reduce differential pressureImprove dirt holding capacityLoose filtering material filtersCartridge filtersAutomatic transmissionFilter media

An oil filter unit for arrangement in the oil sump of an oil circuit, particularly in an automatic transmission. The oil filter unit has a multi-part filter housing with a filter chamber disposed therein such that an oil inlet and an oil outlet communicate with the filter chamber. A filter element is sealingly mounted in the housing between the oil inlet and the oil outlet. The filter element has a pleated filter medium, which is sealingly enclosed by a frame, and the frame has seal contours designed to cooperate with the contours of the filter housing.

Owner:MANN HUMMEL GMBH

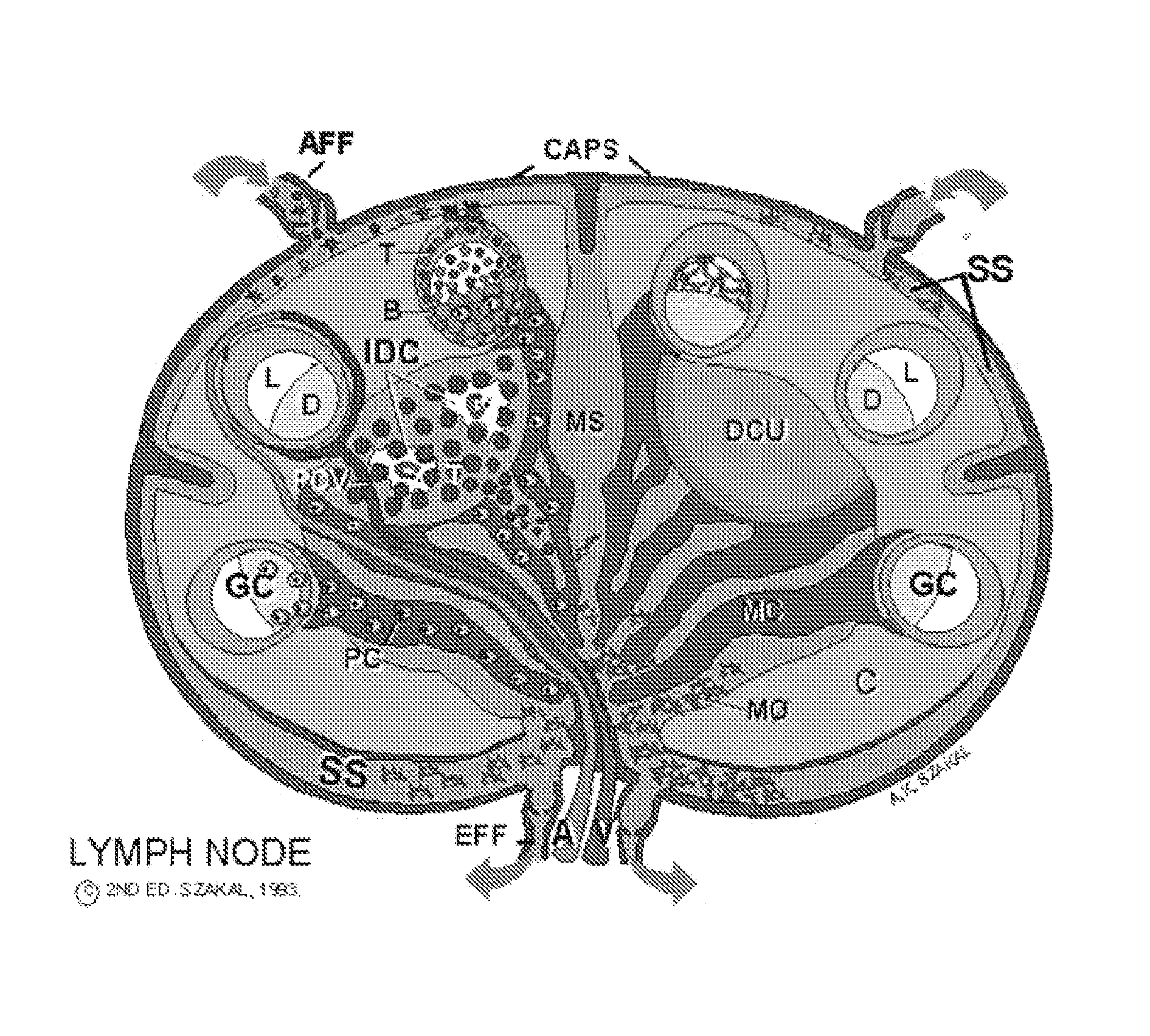

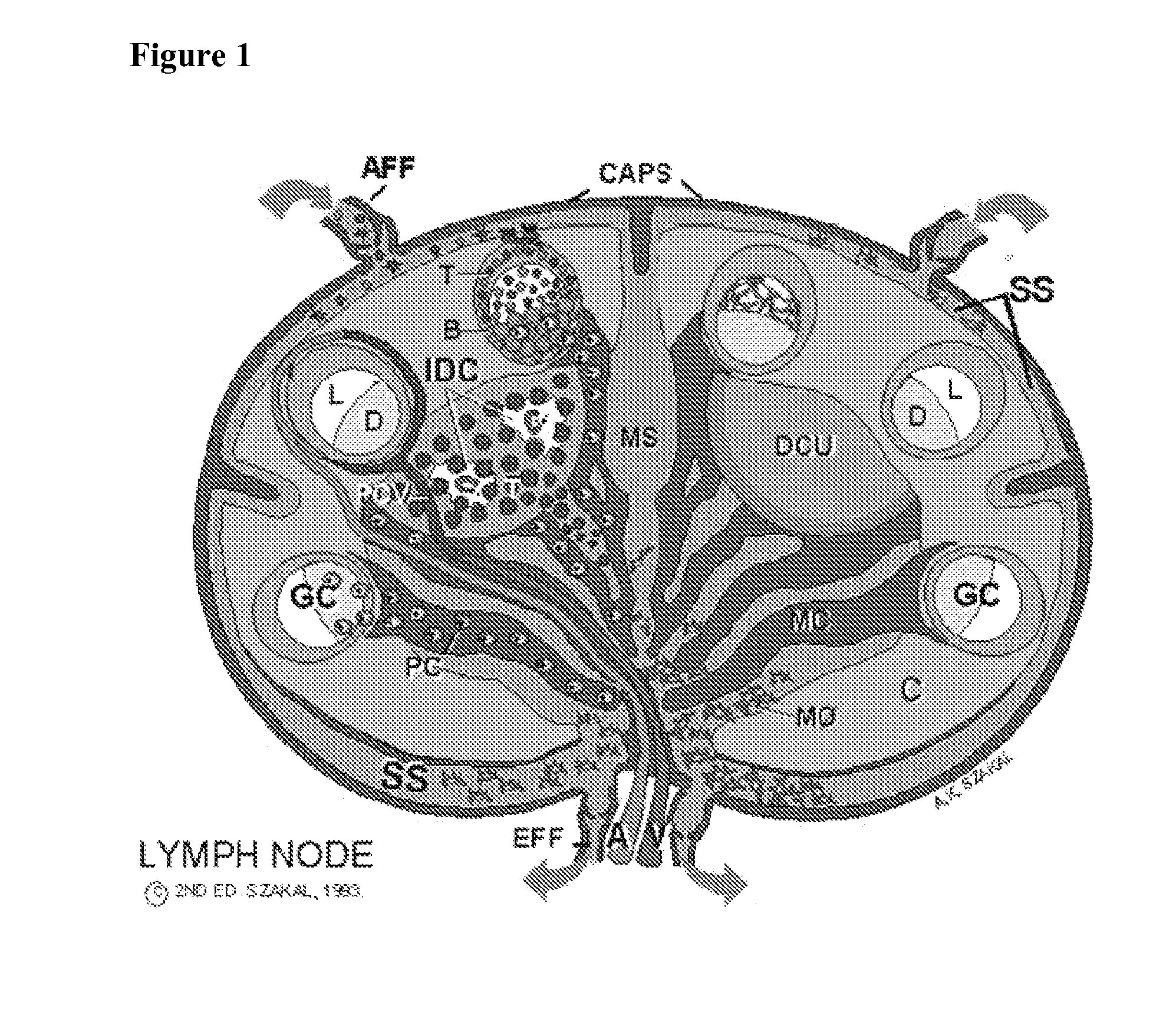

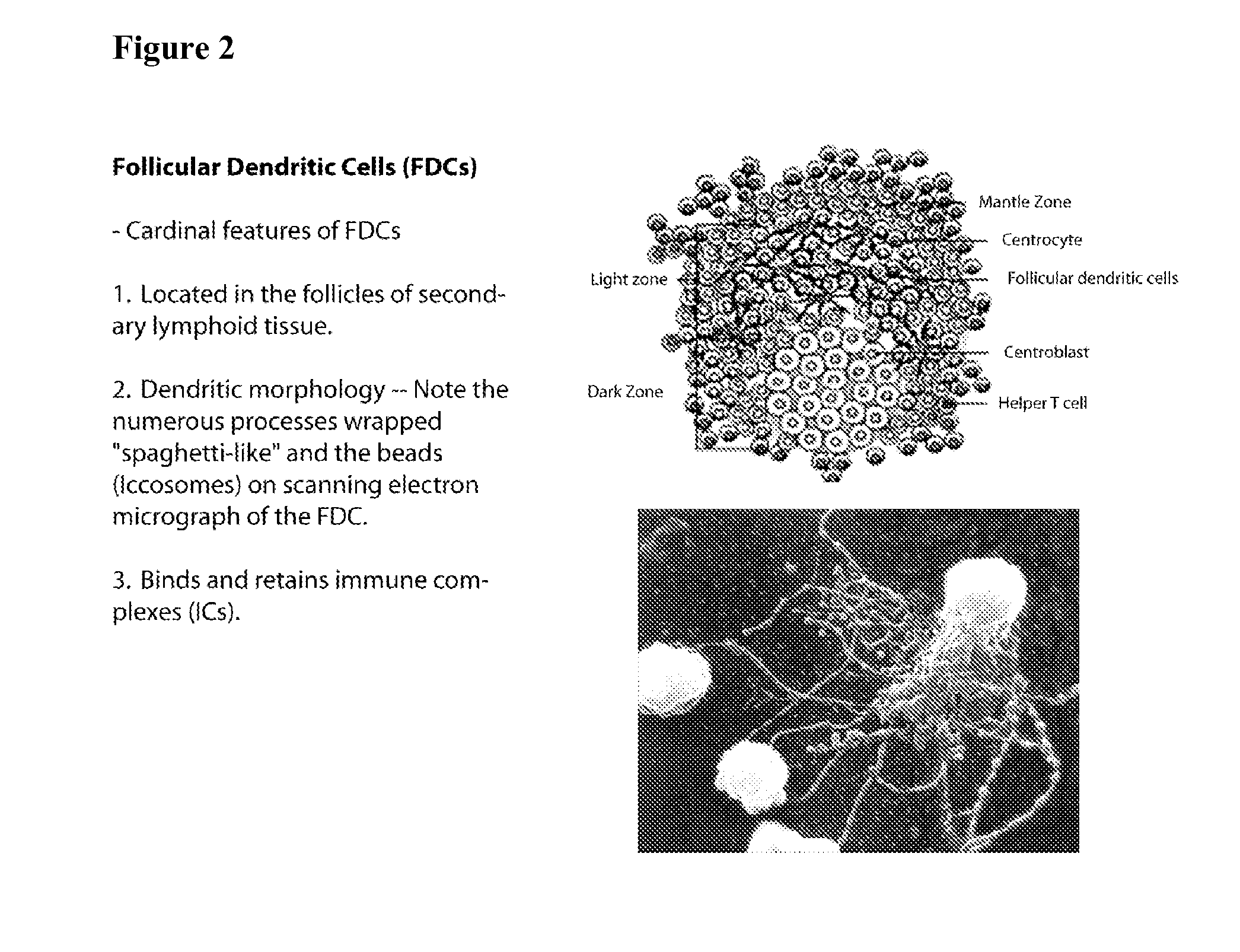

Models for vaccine assessment

ActiveUS20080008653A1Improve accuracyImprove predictabilityCompounds screening/testingCrankshaftsAdjuvantBiological Immunotherapy

The present invention is directed to methods for constructing and using in vivo and in vitro models of aspects of human immunity and, in particular, construction of a human immune system model for the testing of, for example, vaccines, adjuvants, immunotherapy candidates, cosmetics, drugs, biologics and other chemicals. The present invention comprises both in vivo and in vitro models of aspects of human immunity that are useful for assessing the interaction of substances with the immune system, and thus can be used to accelerate and improve the accuracy and predictability of, for example, vaccine, drug, biologic, immunotherapy, cosmetic and chemical development. The invention is also useful for the generation of human monoclonal and polyclonal antibodies.

Owner:VIRGINIA COMMONWEALTH UNIV +1

Sealing system between bearing and compressor housing

ActiveUS8348595B2Extend your lifeEfficient and cost-effective structureCrankshaftsPump componentsTurbochargerThrust bearing

A turbocharger oil discharge assembly (301, 501, 701, 901) can have a thrust collar (324, 524, 724, 924) with a first radially outwardly extending wall and a second radially outwardly extending wall to define a first annular channel. The first radially outwardly extending wall can have an annular flange that at least in part defines a second annular channel. The assembly can also have a thrust bearing (340, 540, 740, 940) having a radially inner end received in the first annular channel, and an insert (400, 600, 800, 1000). An oil collection chamber (440, 640, 840, 1040) can be defined at least in part by a drainage channel of the insert (400, 600, 800, 1000), the annular flange of the thrust collar (324, 524, 724, 924) and the thrust bearing (340, 540, 740, 940). Pressurized oil discharged from an oil release interface can be directed towards a radially outer region of the oil collection chamber (440, 640, 840, 1040) and can be collected in the oil collection chamber (440, 640, 840, 1040) for subsequent exhaust.

Owner:BORGWARNER INC

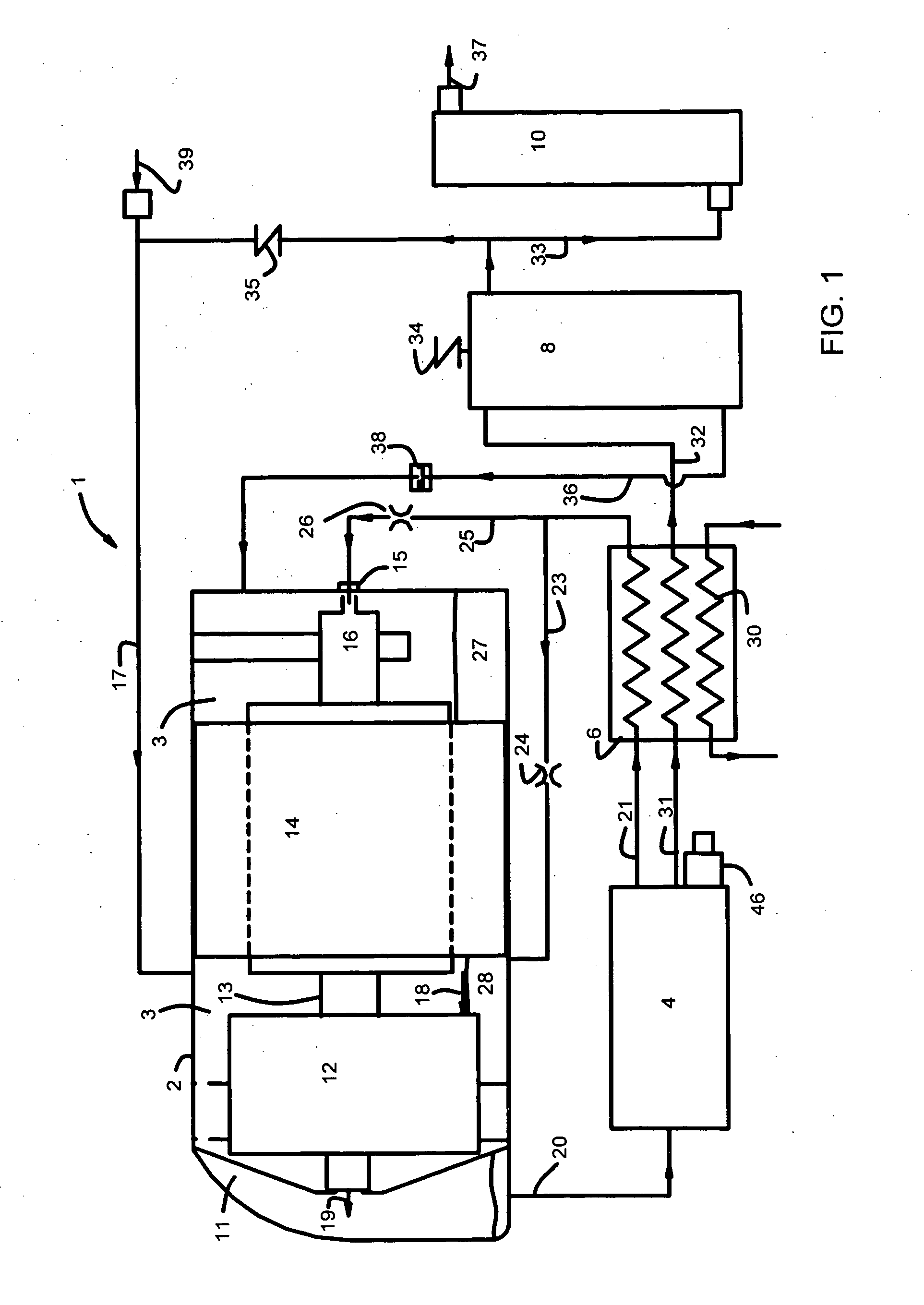

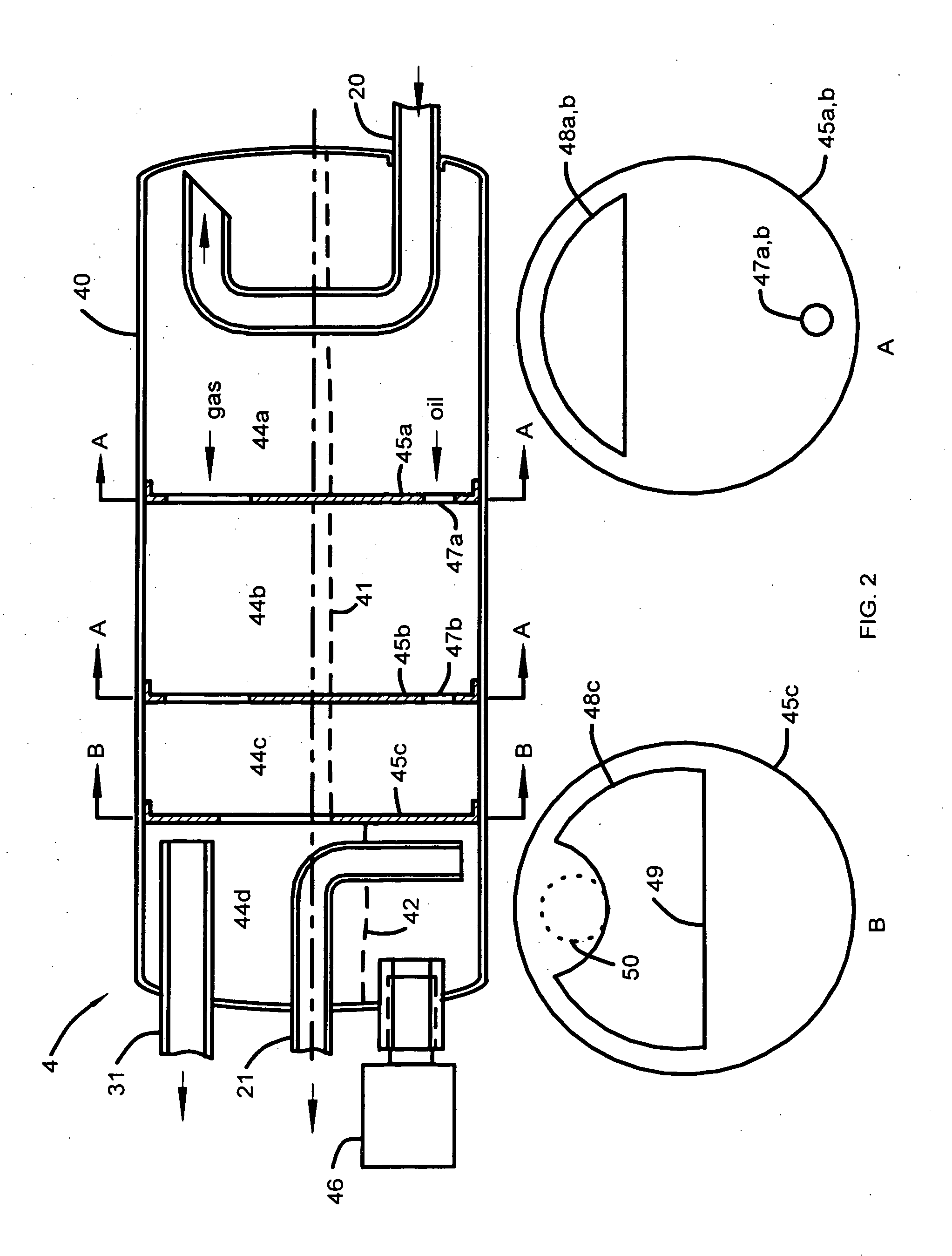

Horizontal bulk oil separator

ActiveUS20080011550A1Enabling useEasy constructionLiquid degasificationDispersed particle separationFuel tankHelium

A high separation efficacy, compact, bulk oil separator oriented horizontally and used with a scroll-type oil-lubricated compressor unit adapted to compressing helium. The horizontal bulk oil separator contains an integral oil reservoir and removes more than 99.9% of the oil from the helium that exits. The bulk oil separator contains successive chambers where oil separates from the gas by impingement.

Owner:SHI APD CRYOGENICS +1

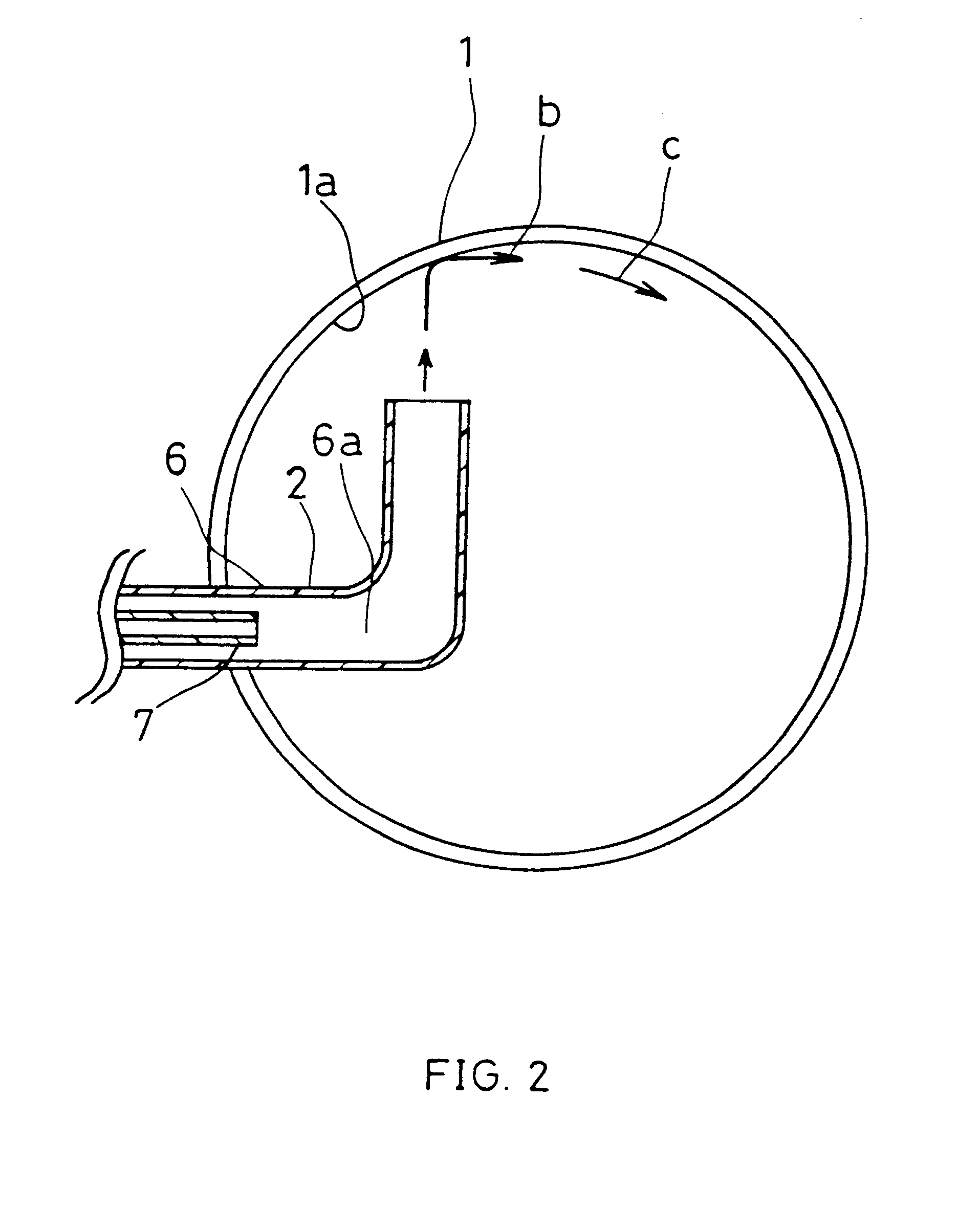

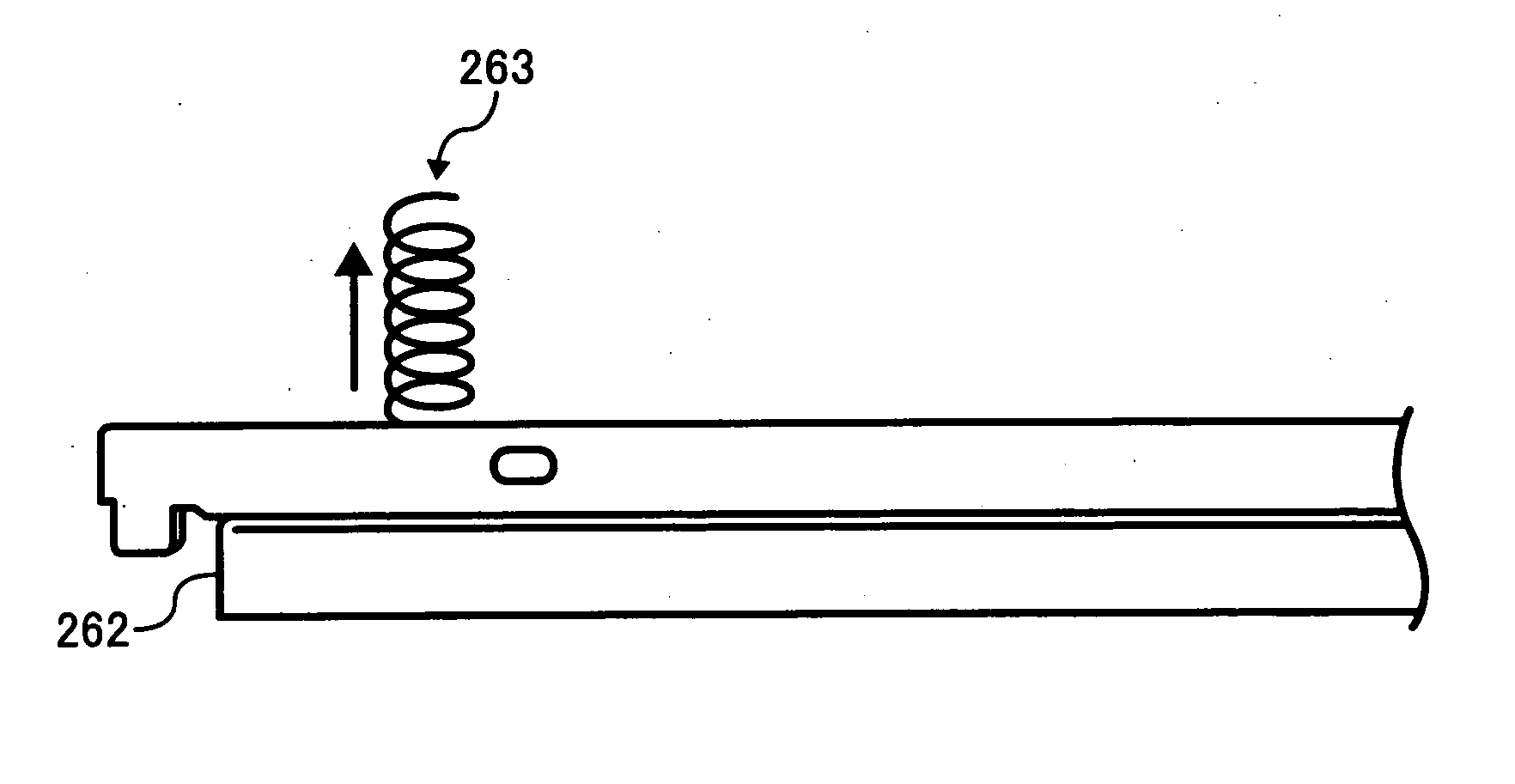

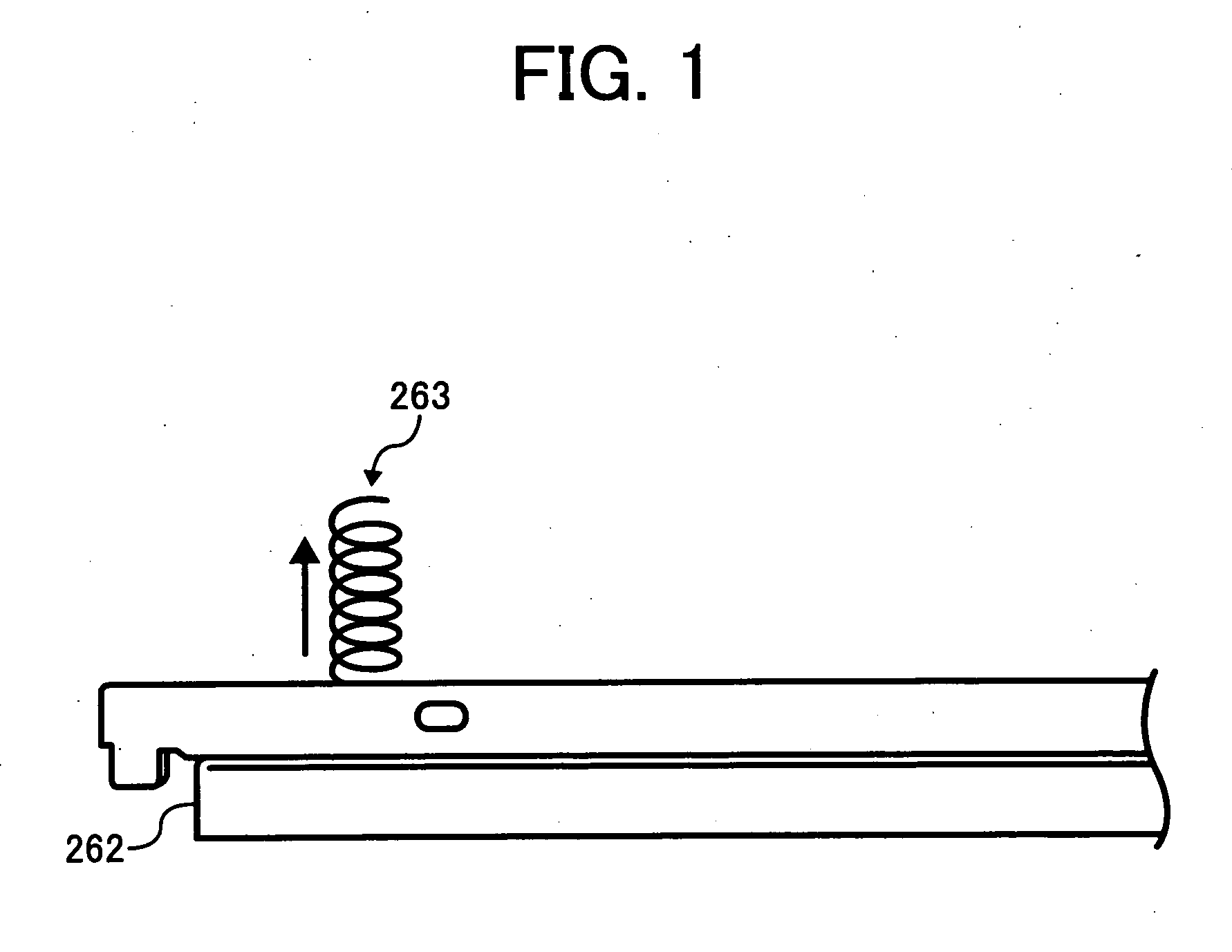

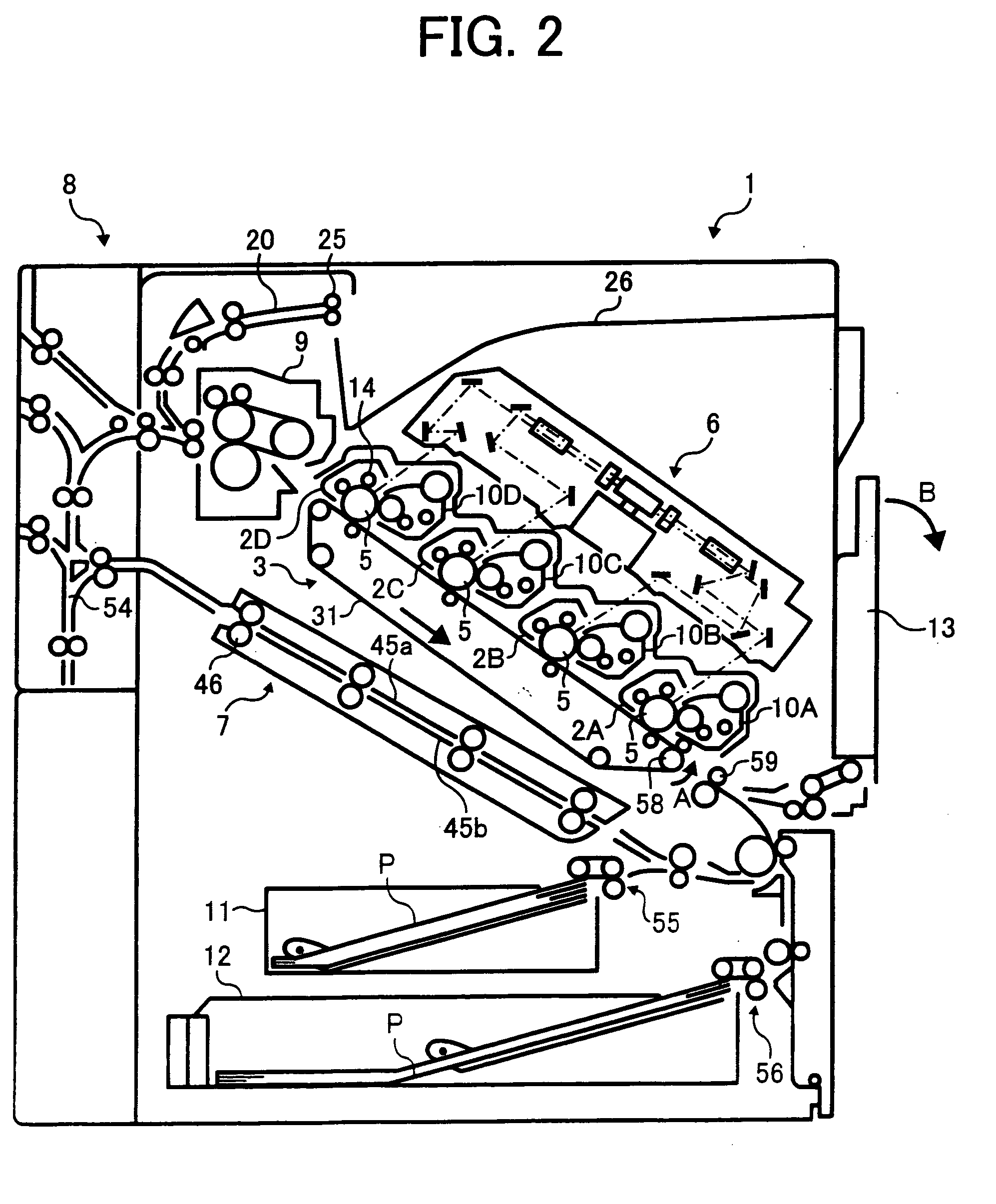

Lubricant supply device, image forming apparatus, and pressing device

ActiveUS20070068738A1Small amountSmall amount of changeElectrographic process apparatusRail lubricationEngineeringLubricant

A lubricant supply device includes a solid lubricant, a supply member contacting and rubbing the solid lubricant and thereby scraping a lubricant off the solid lubricant and supplying the lubricant to a lubricant supplying target, and a pressing mechanism pressing the solid lubricant against the supply member. The pressing mechanism includes a biasing device, and a plurality of pressing members receiving a biasing force of the biasing device and thereby pressing places of the solid lubricant at symmetrical positions with respect to a center of a contact part of the solid lubricant contacting the supply member, respectively.

Owner:RICOH KK

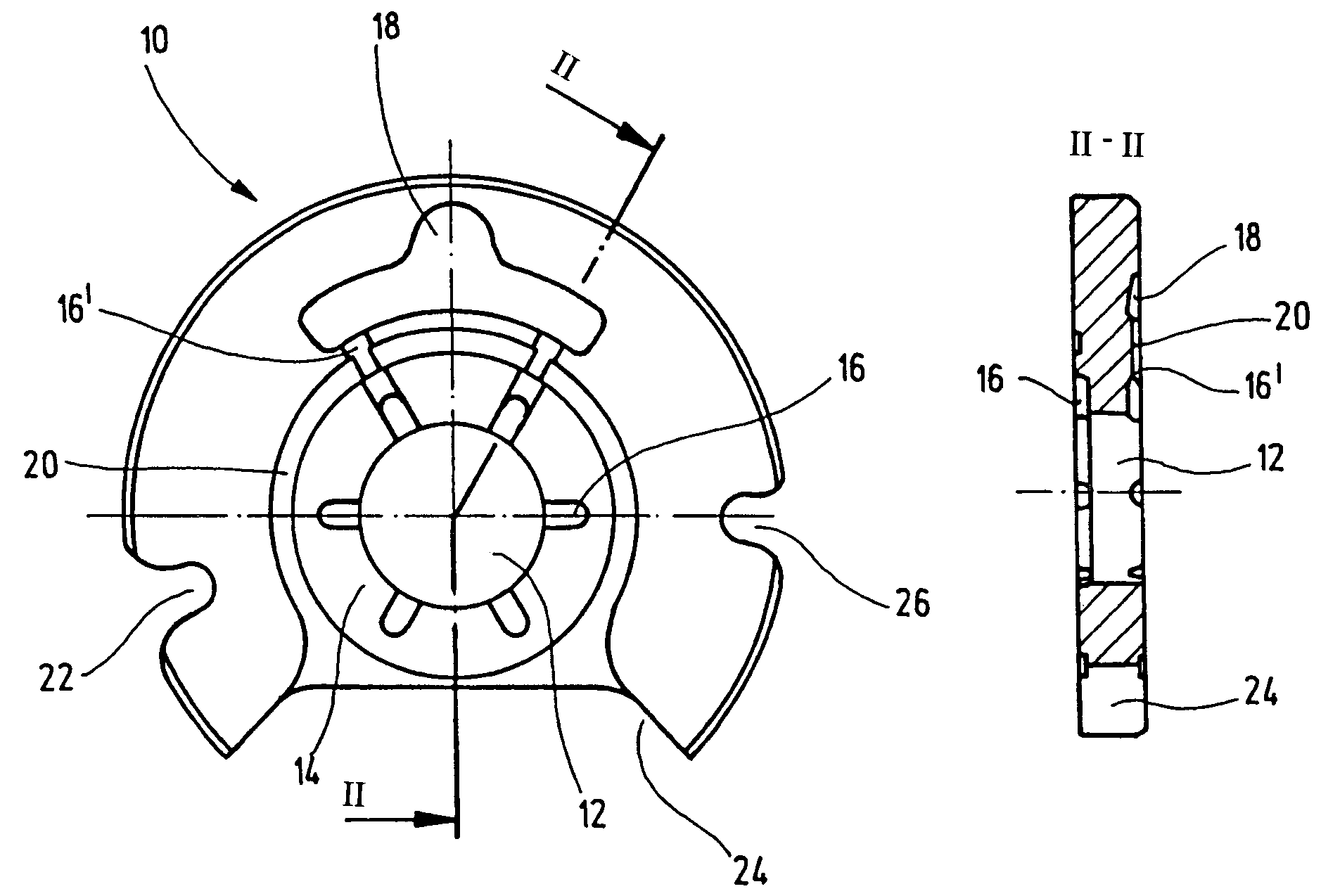

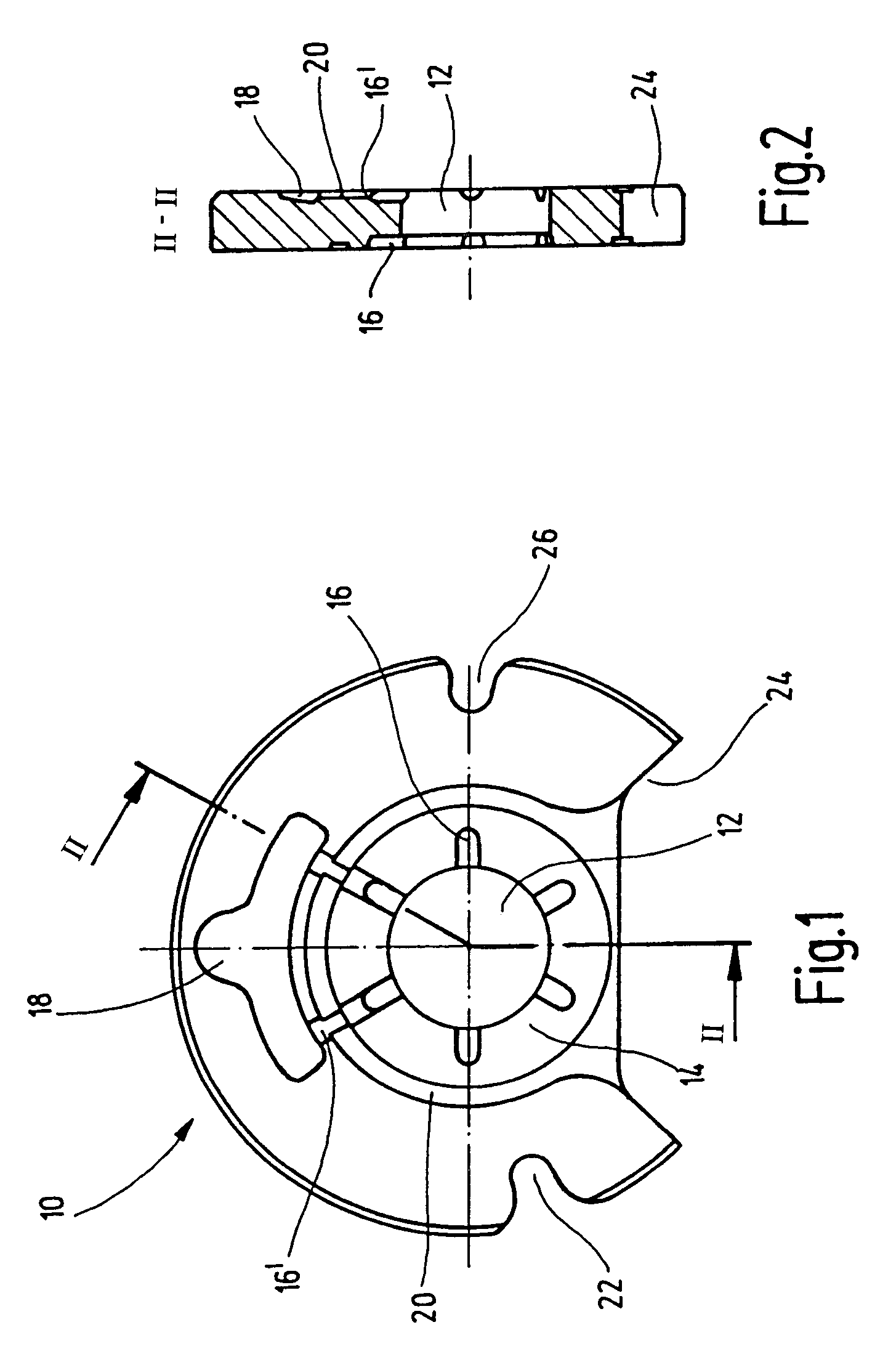

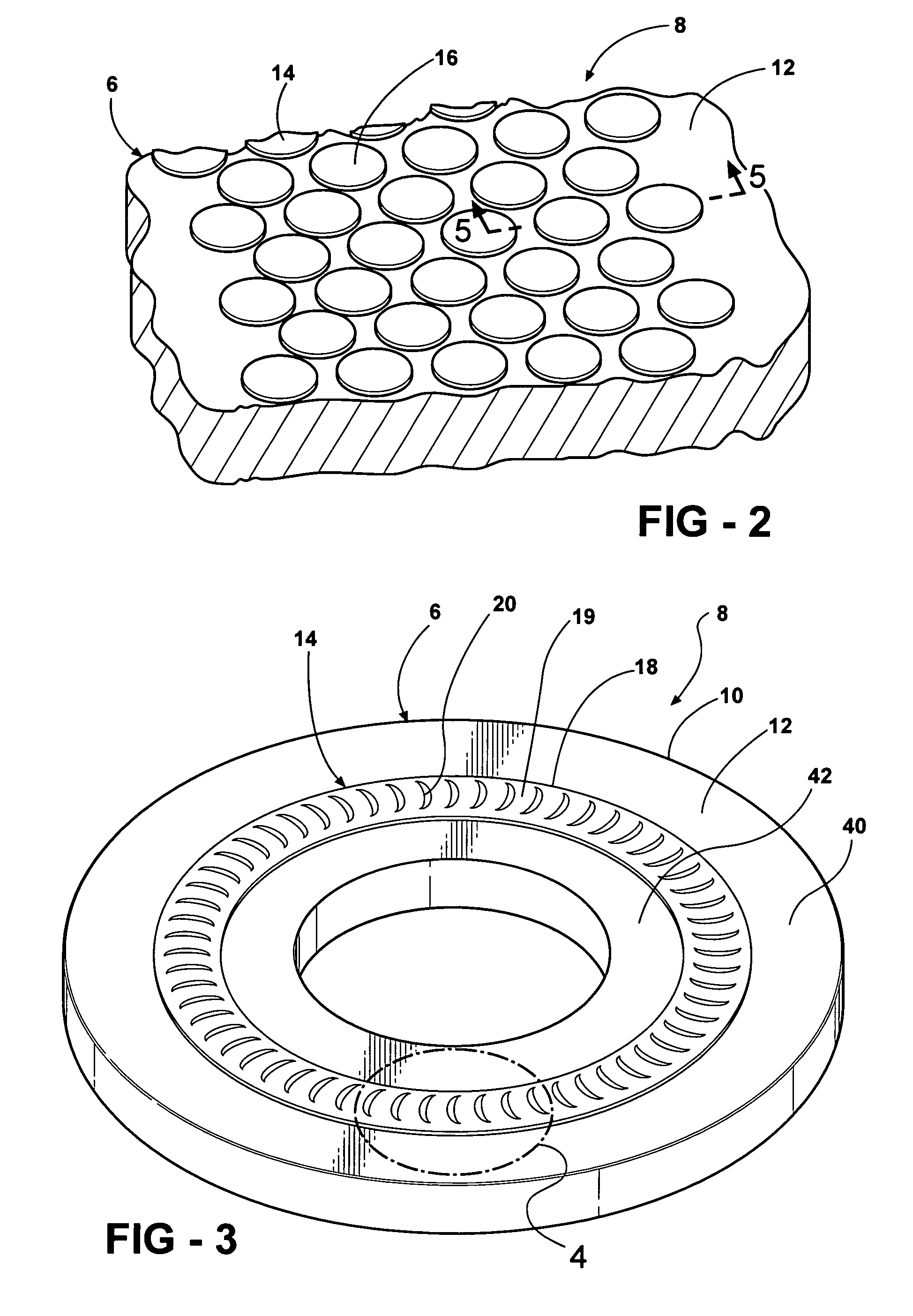

Axial bearing

ActiveUS7401980B2Safe and cost-effectiveReduce manufacturing costCrankshaftsCrossheadsTurbochargerThrust bearing

A thrust bearing, in particular for a turbo charger, has an essentially disc shaped bearing body (10) with a central through opening (12) for a shaft, at least one bearing surface (14) surrounding the through opening (12) for a collar which is placed on the shaft, and at least one oil supply channel which leads from a radially outer region of the bearing body to the through opening (12). In order to realize a cost effective manufacture of the thrust bearing it is proposed according to the invention that the at least one oil supply channel is designed to be a groove (16′).

Owner:BORGWARNER INC

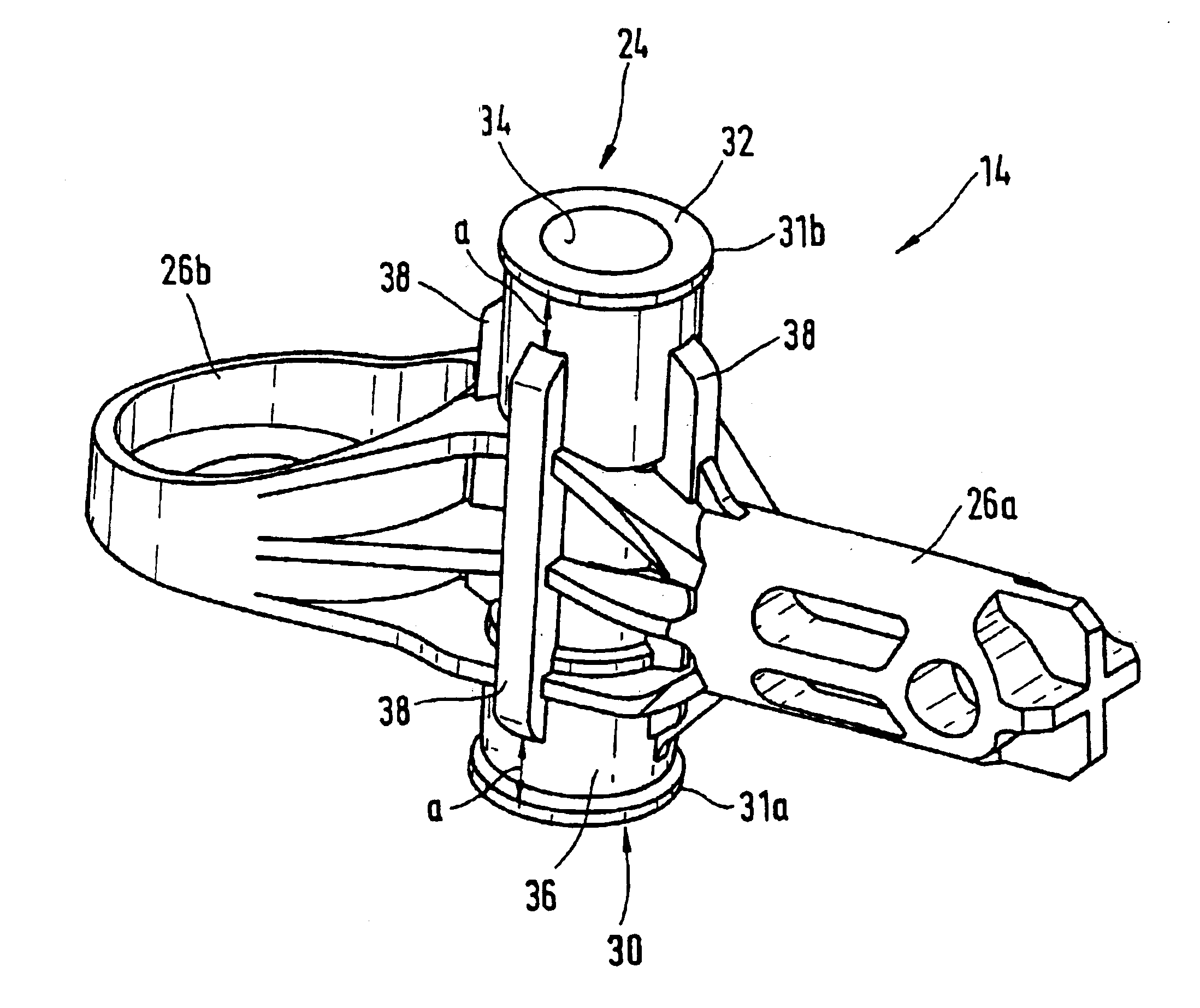

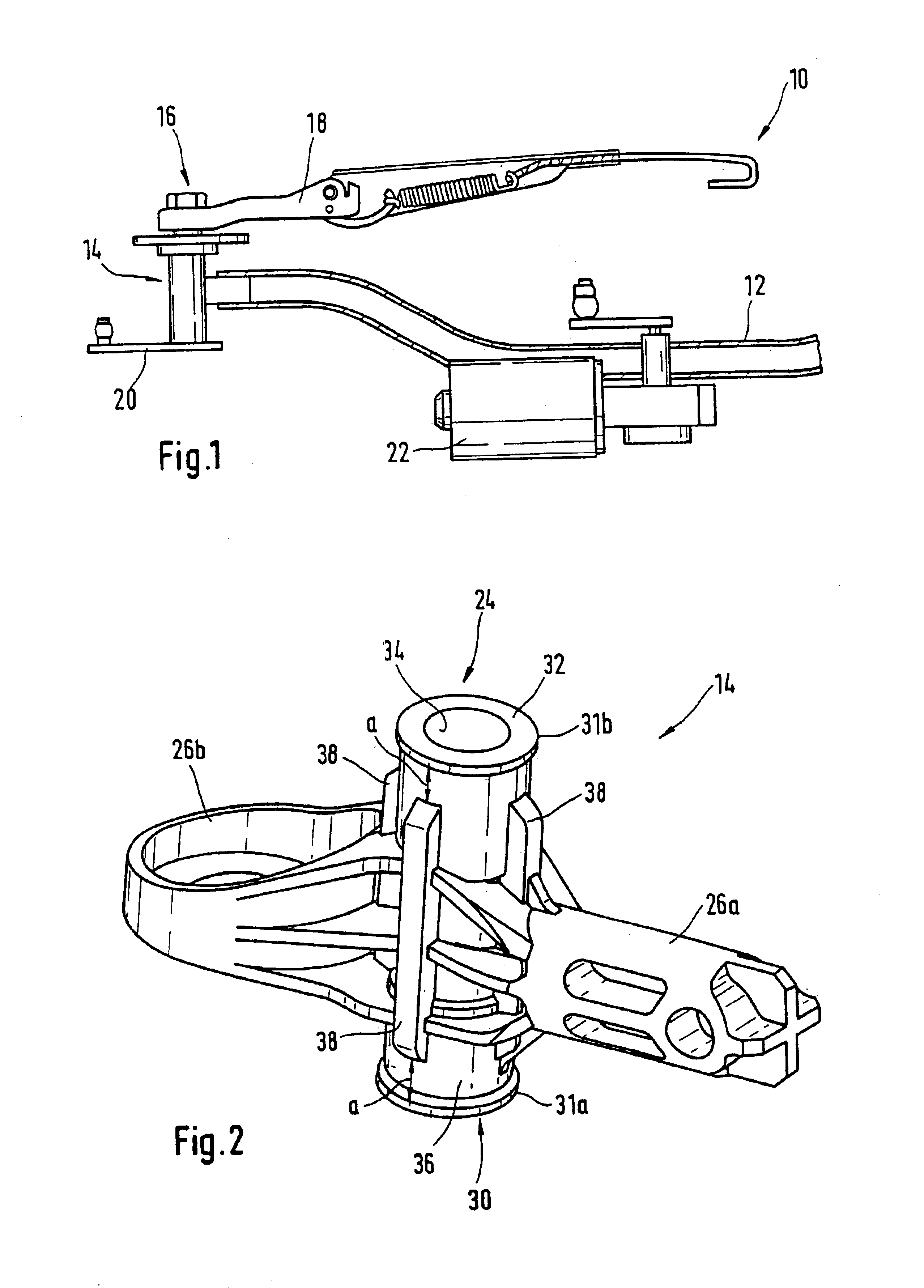

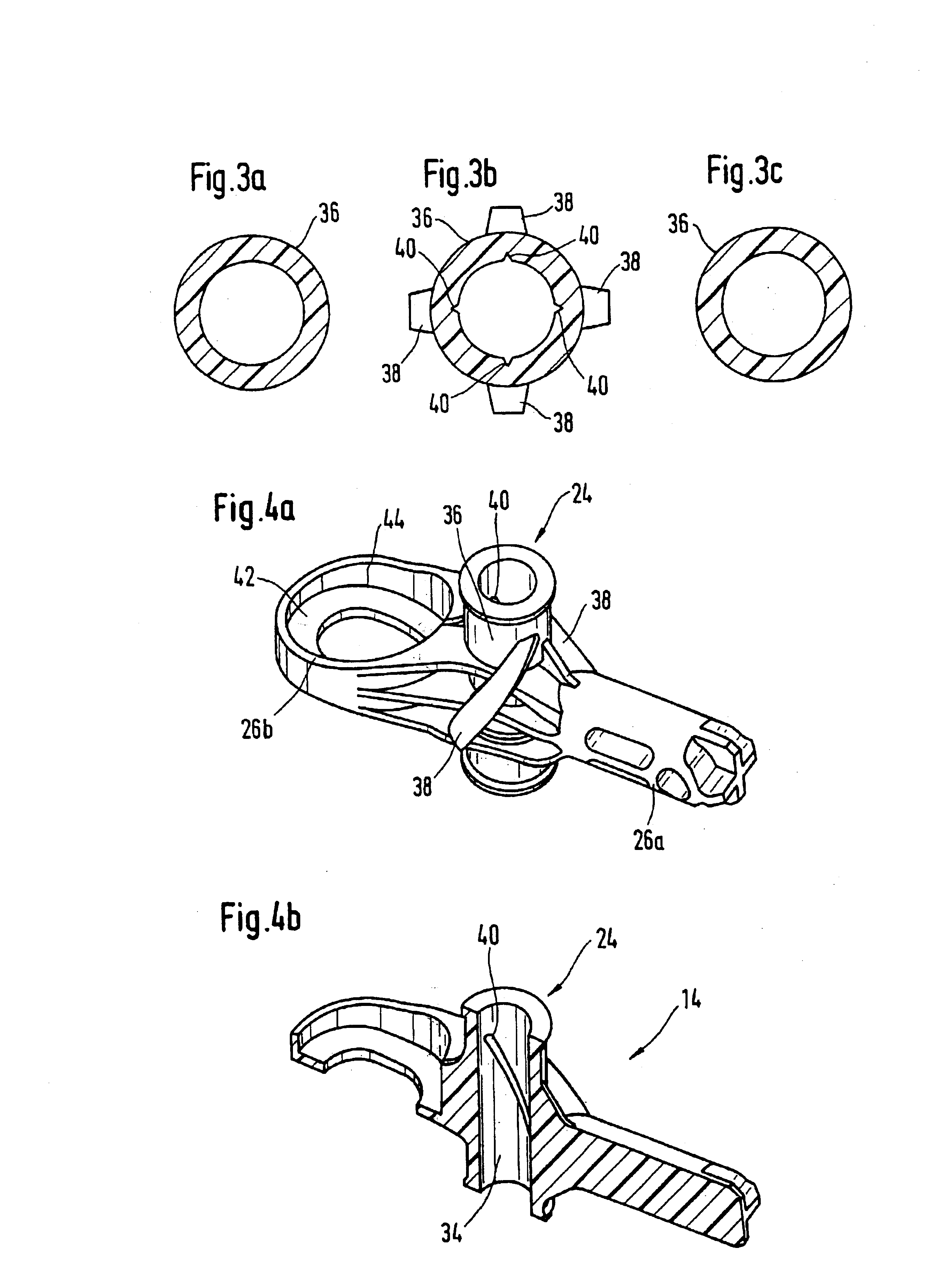

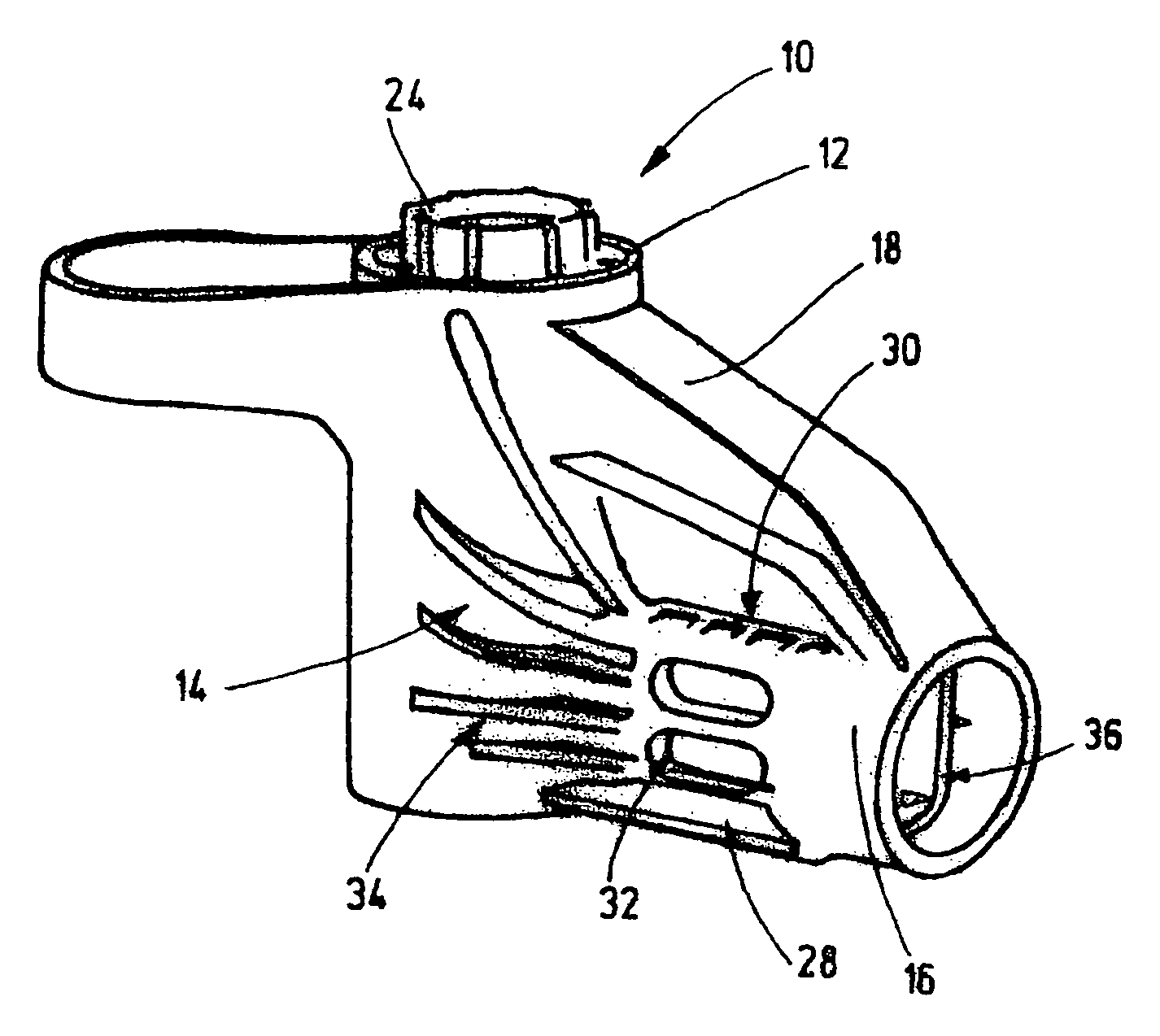

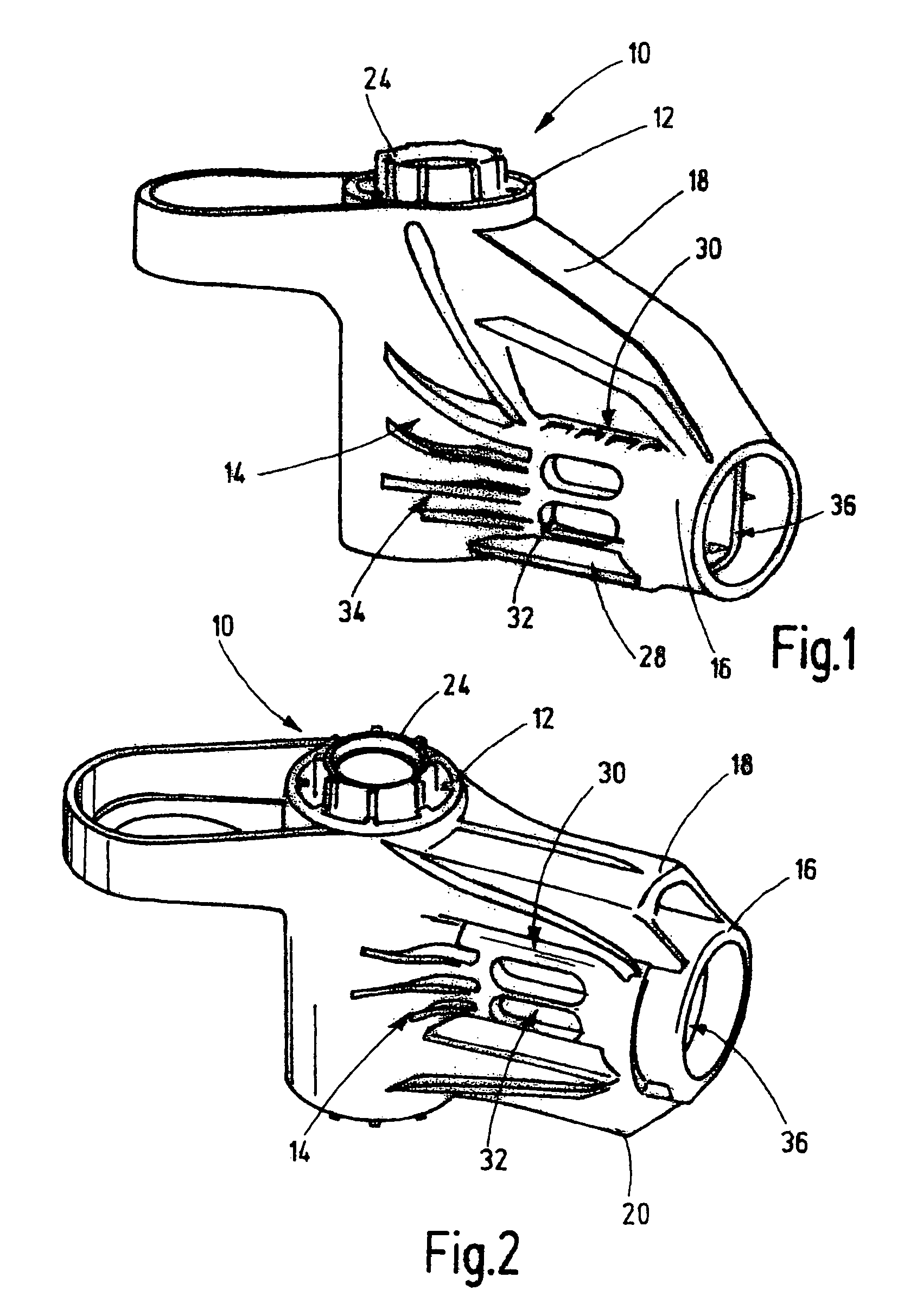

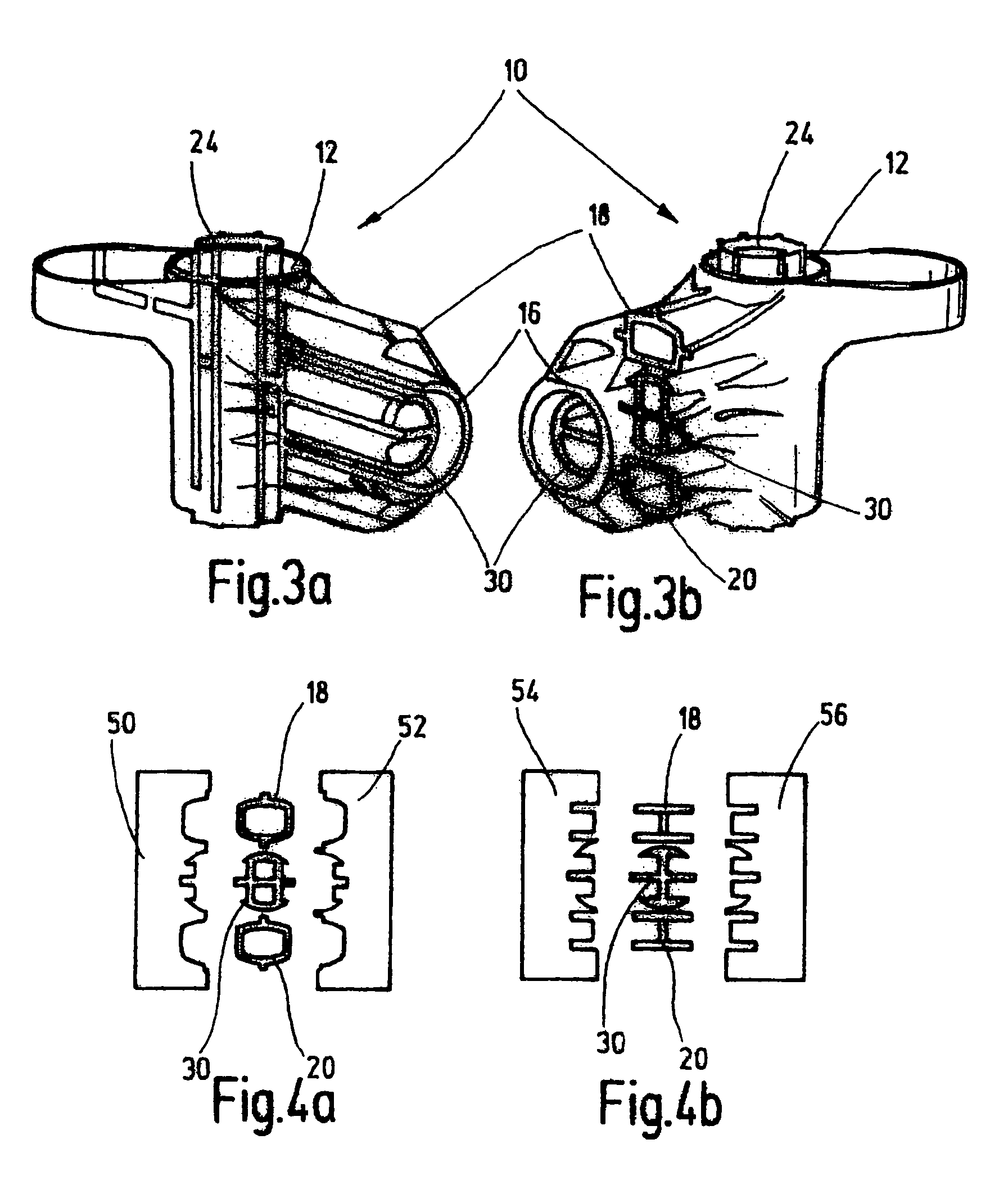

Windshield wiper, especially for motor vehicles and method for production of said windshield wiper

InactiveUS6883966B2Reduce tooling costsSmall diameterCrankshaftsCrossheadsMobile vehicleMotor vehicle part

A windshield wiper system, and a method for producing such a system, in particular for a motor vehicle, having at least one wiper bearing (14) substantially comprising an injection-moldable material, in particular plastic, in which a wiper shaft (16) is supported at least in such a way that it can swing back and forth, and in the region of the wiper shaft (16), the wiper bearing (14) has a substantially hollow-cylindrical segment (24) on whose inner surface (34) at least one groove (40) is provided; at least one, in particular riblike, accumulation of material (38) is provided on the outer surfaces of the hollow-cylindrical segment (24), which accumulation is disposed in the radially outward direction of the groove (40) relative to the axis of rotation of the wiper shaft (16).

Owner:ROBERT BOSCH GMBH

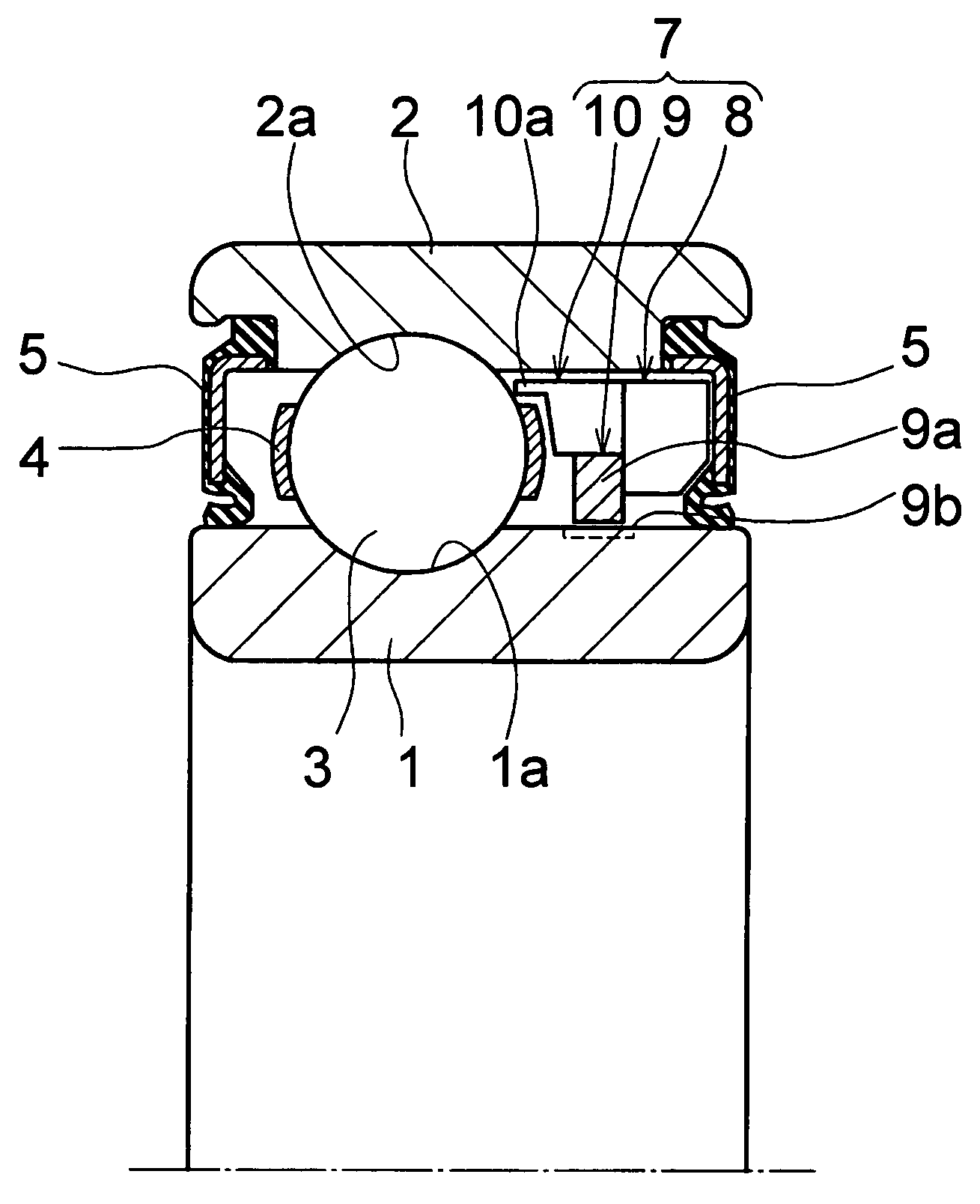

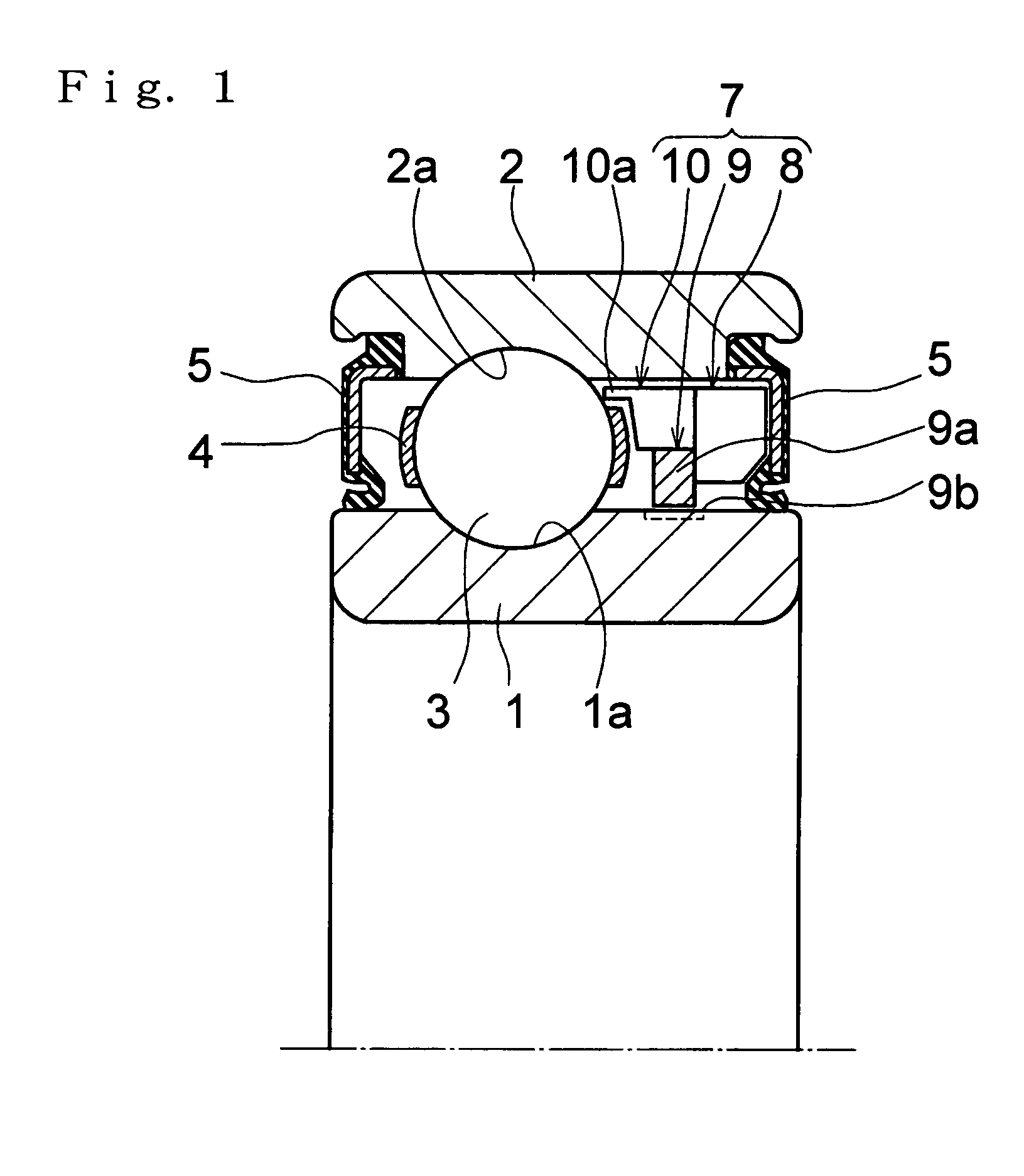

Bearing device

InactiveUS7293919B2Easy to installContribute to long-term stabilization of rolling propertyPositive displacement pump componentsBearing assemblyEngineeringControl circuit

Owner:JTEKT CORP

Method of making a sliding bearing

InactiveUS7458158B2Improve performanceCompromising performanceCrankshaftsBearing assemblyEffective surfaceFriction loss

This invention introduces a new category of engineered surfaces and corresponding production processes for better wear resistance and lower friction loss. The structured surfaces can be applied on many automobile components with frictional surfaces. The composite structure settles the usual conflicts between surface functions and stresses. Two sets of multiple-step processes are introduced to achieve high production efficiency and low cost. Unlike traditional surface technologies that generate single and uniform layers on the whole part surface, the new technology processes the part surface selectively for more effective surfaces with versatile functions.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Wiper bearing

InactiveUS7581887B2Improve stabilityGuaranteed ease of connectionCrankshaftsCrossheadsEngineeringTube forming

The invention relates to a wiper bearing for a windshield wiper system comprising a bearing housing (12) provided with an outer tube forming the bearing housing (12) and an inner tube (24) arranged in a concentric manner in relation thereto and a journal (30) arranged on a bearing area (14) on the bearing housing (12) for receiving a tubular plate (40). It is proposed that an annular element (16), which is arranged in a coaxial manner on the journal (30), be provided outside the journal (30) in the region of the front side thereof (36).

Owner:ROBERT BOSCH GMBH

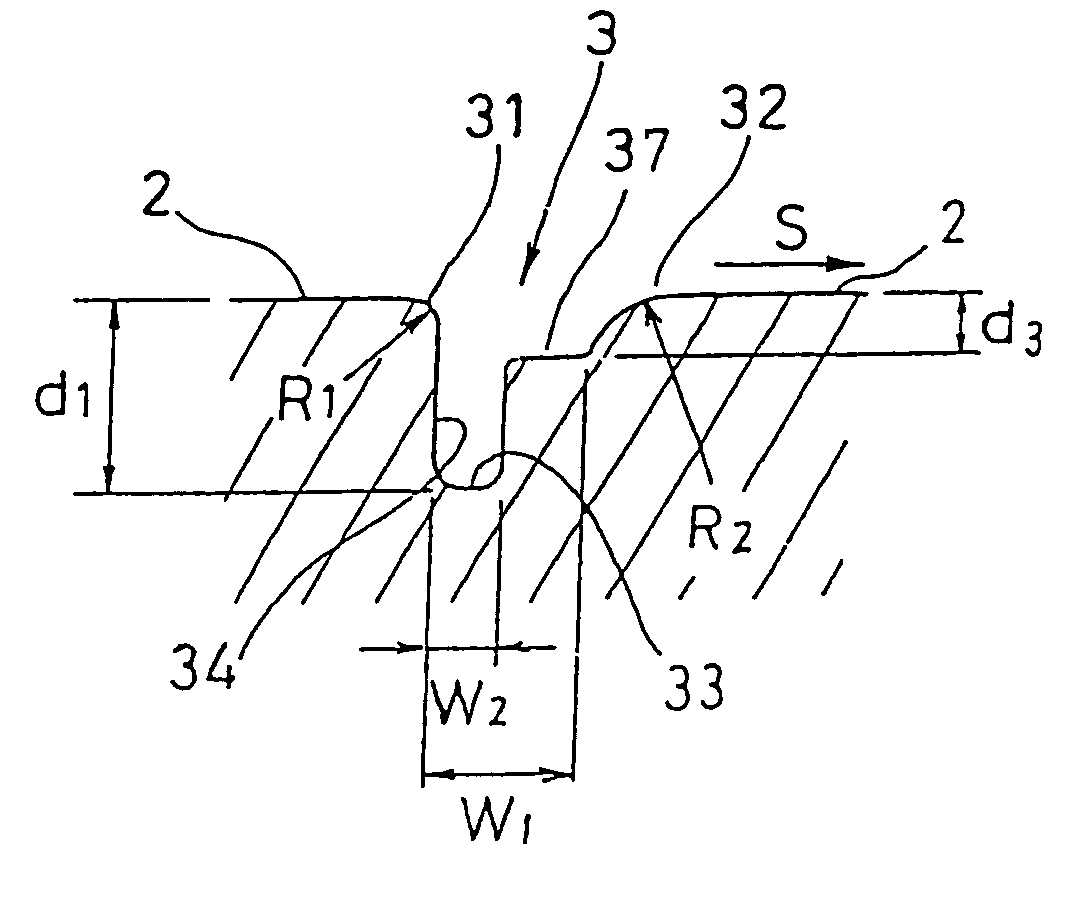

Thrust bearing

In a thrust bearing supporting a load in a thrust direction in a rotary portion, a size of a curved surface in the forward side of a lubricating groove with respect to a relative rotating direction of an opposing sliding member is set to be larger than a size of a curved surface in the rearward side of the lubricating groove with respect to the relative rotating direction, and a depth of the lubricating groove is set to be deeper than a starting point in the side of a groove bottom of the curved surface formed in the groove shoulder in the forward side of the lubricating groove with respect to the rotating direction, so that a lubricating effect and a cooling effect are increased.

Owner:NOK CORP

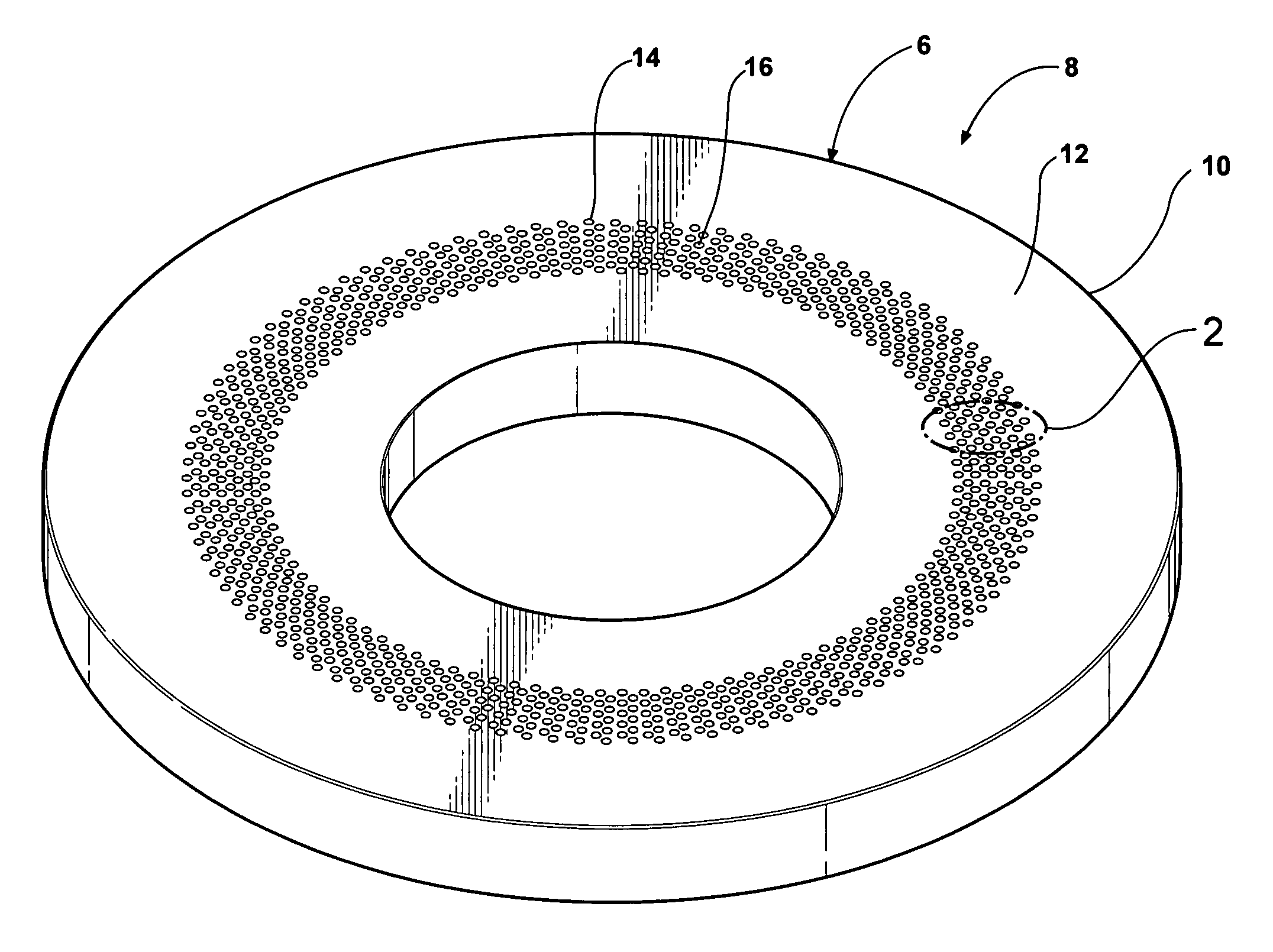

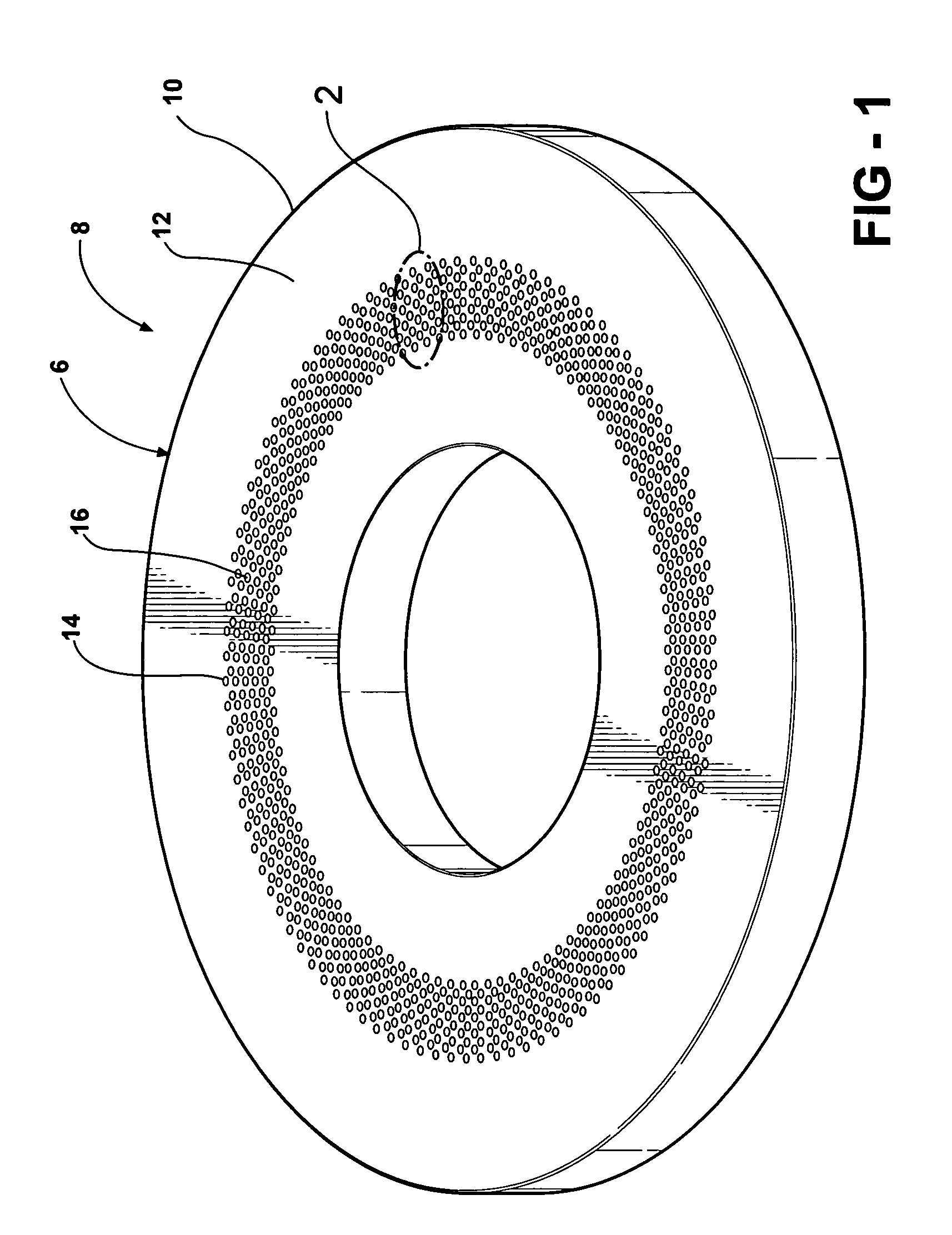

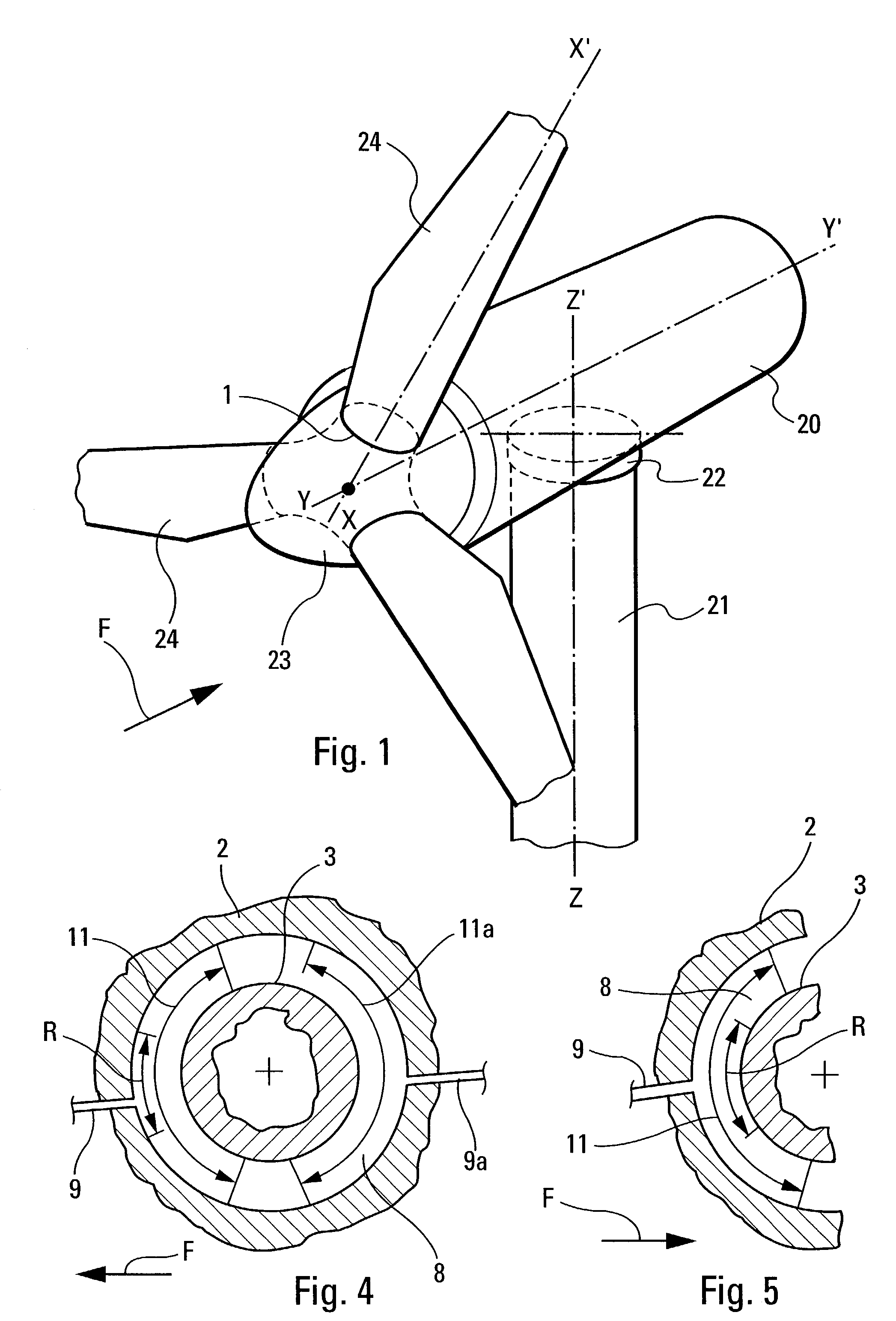

Device for improving the lubrication of bearings, particularly in wind turbines

InactiveUS6991378B2Grease leaks through the seals are almost entirely suppressedContainment leakPropellersRotary propellersEngineeringTurbine

For a bearing mounted between two concentric races rotating relative to each other, and forming an annular gap that accommodates the bearing and is closed by seals, at least one grease tube is provided between the periphery of one of the two races and the annular gap, and is connected to a corresponding grease reservoir. At least one main grease tube opens into the annular gap in an angular sector where an overpressure occurs, a corresponding main grease reservoir is adapted to collect grease flowing from the annular gap through the main grease tube due to the overpressure that may occur within the annular gap in the angular sector.

Owner:DEFONTAINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com