Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4439results about "Clutches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

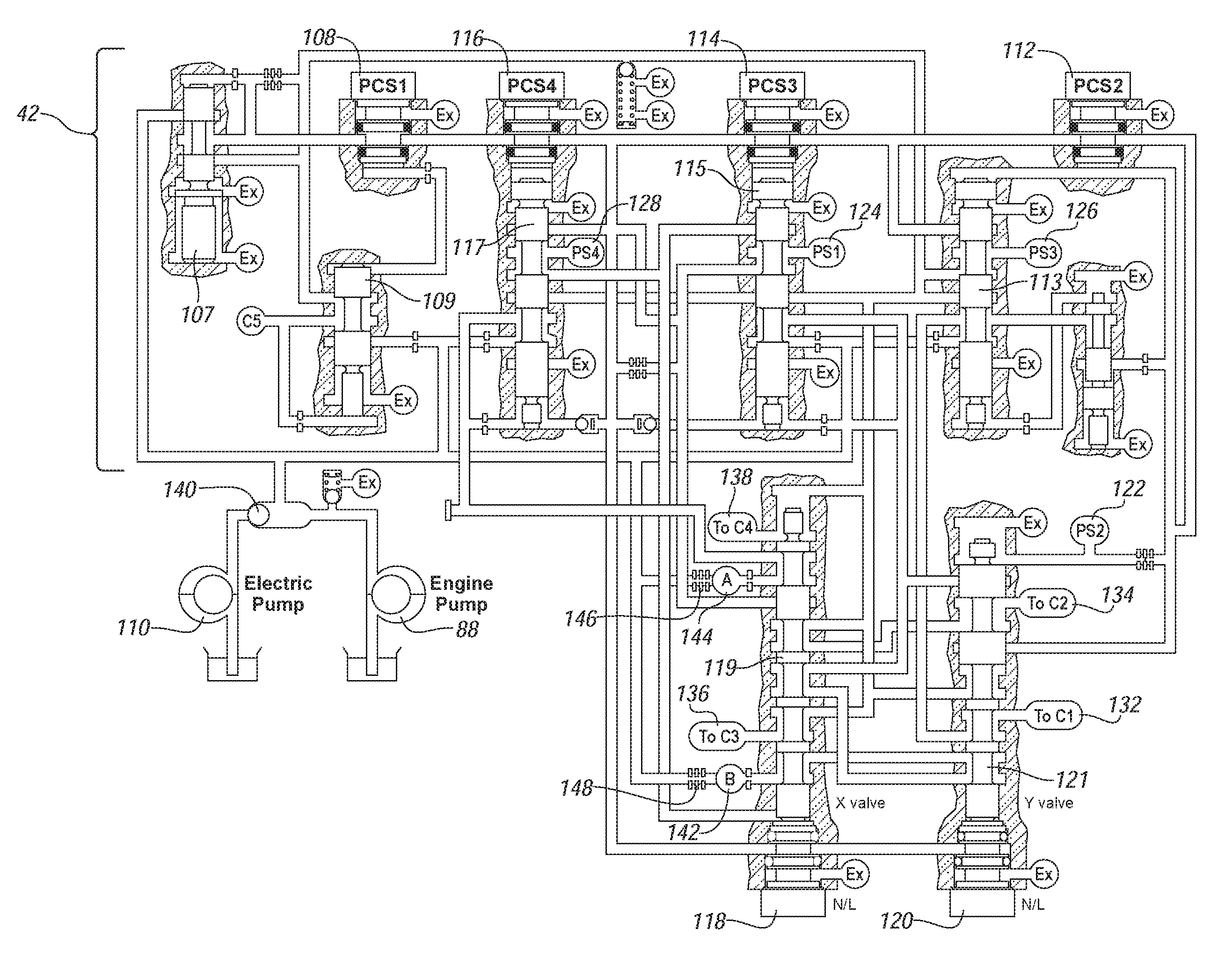

Hydraulic circuit for automatic transmission

ActiveUS9488197B2Rapidly and effectively removing foreign materialFluid-pressure actuator safetyClutchesProportional controlAutomatic transmission

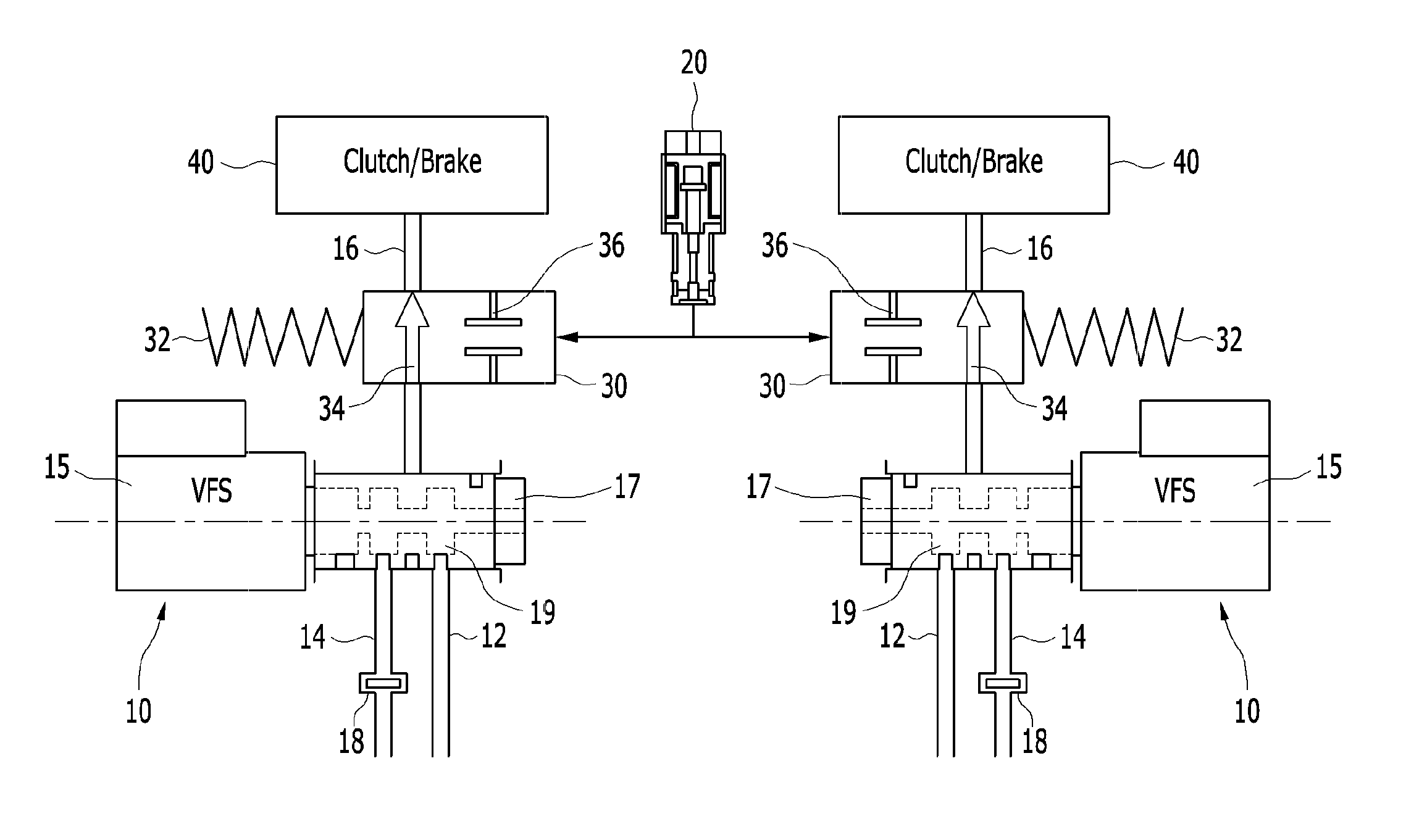

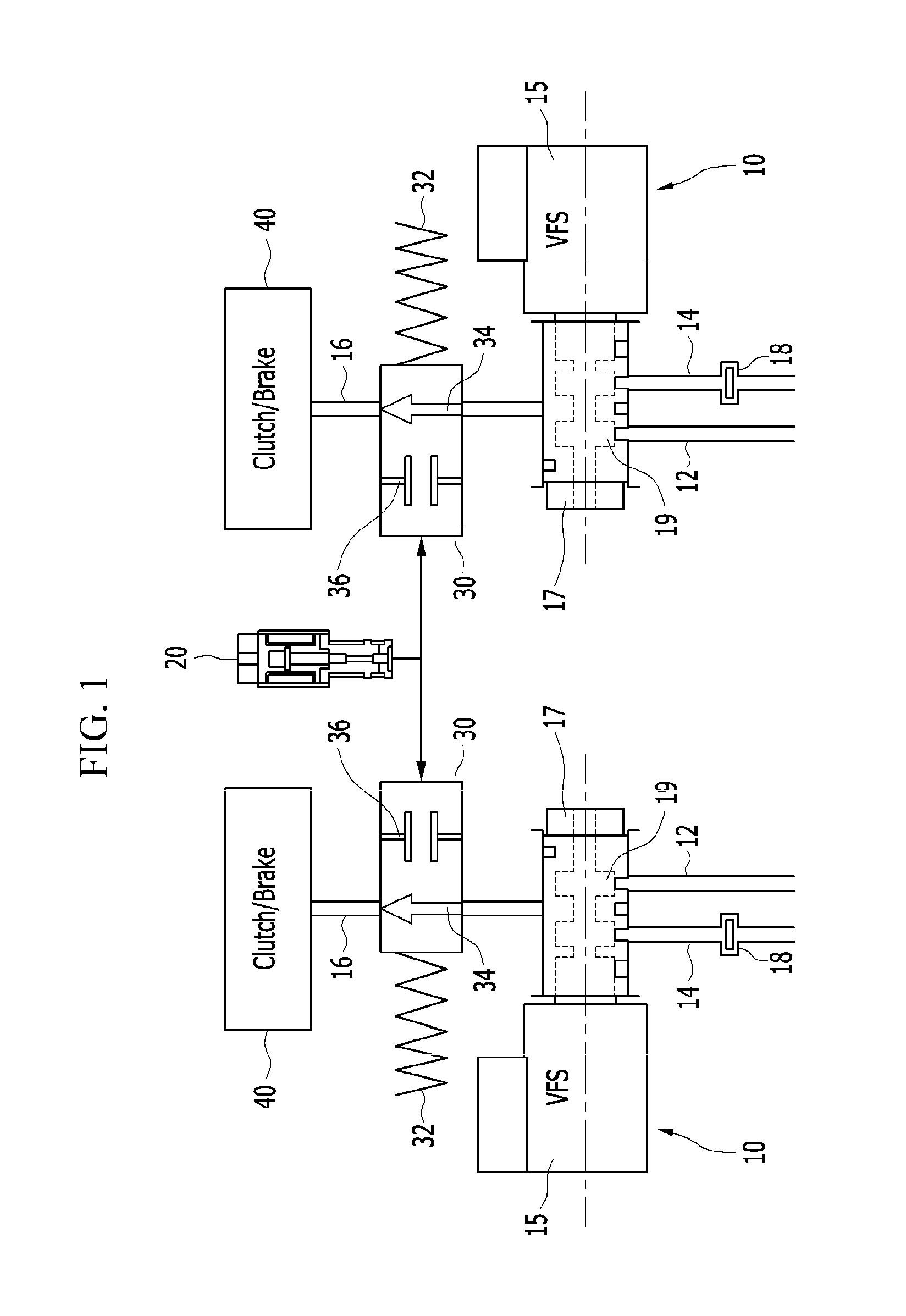

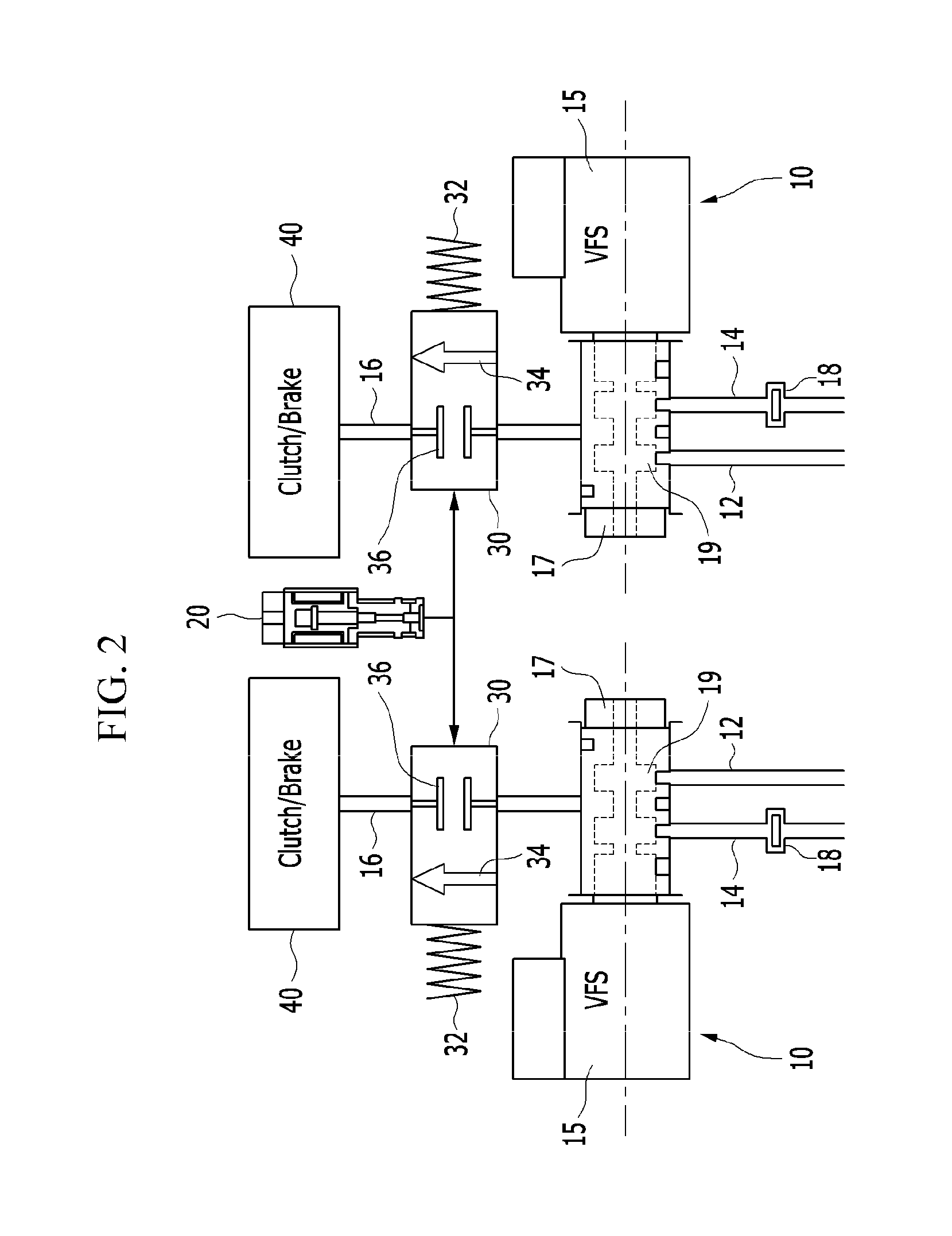

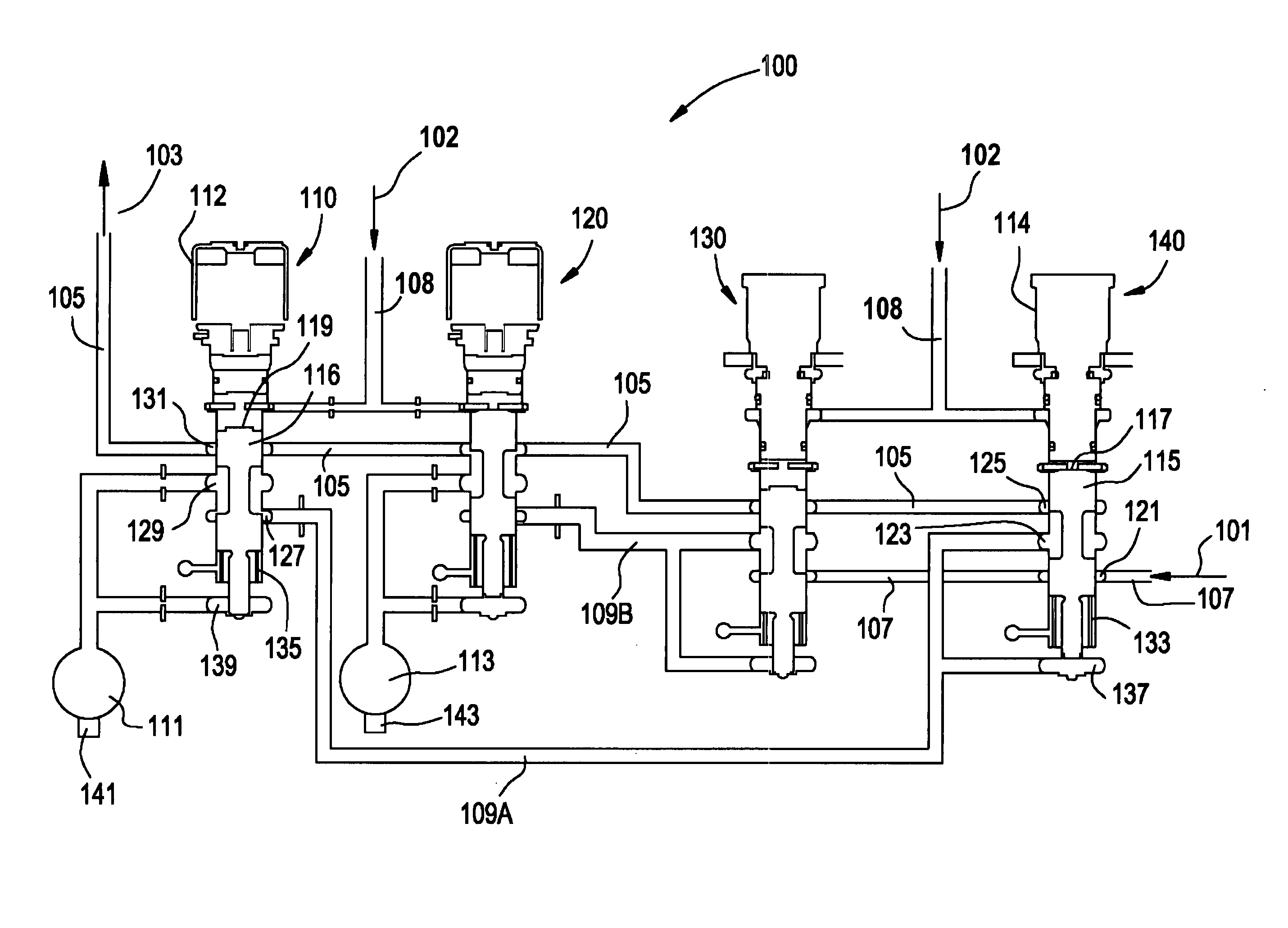

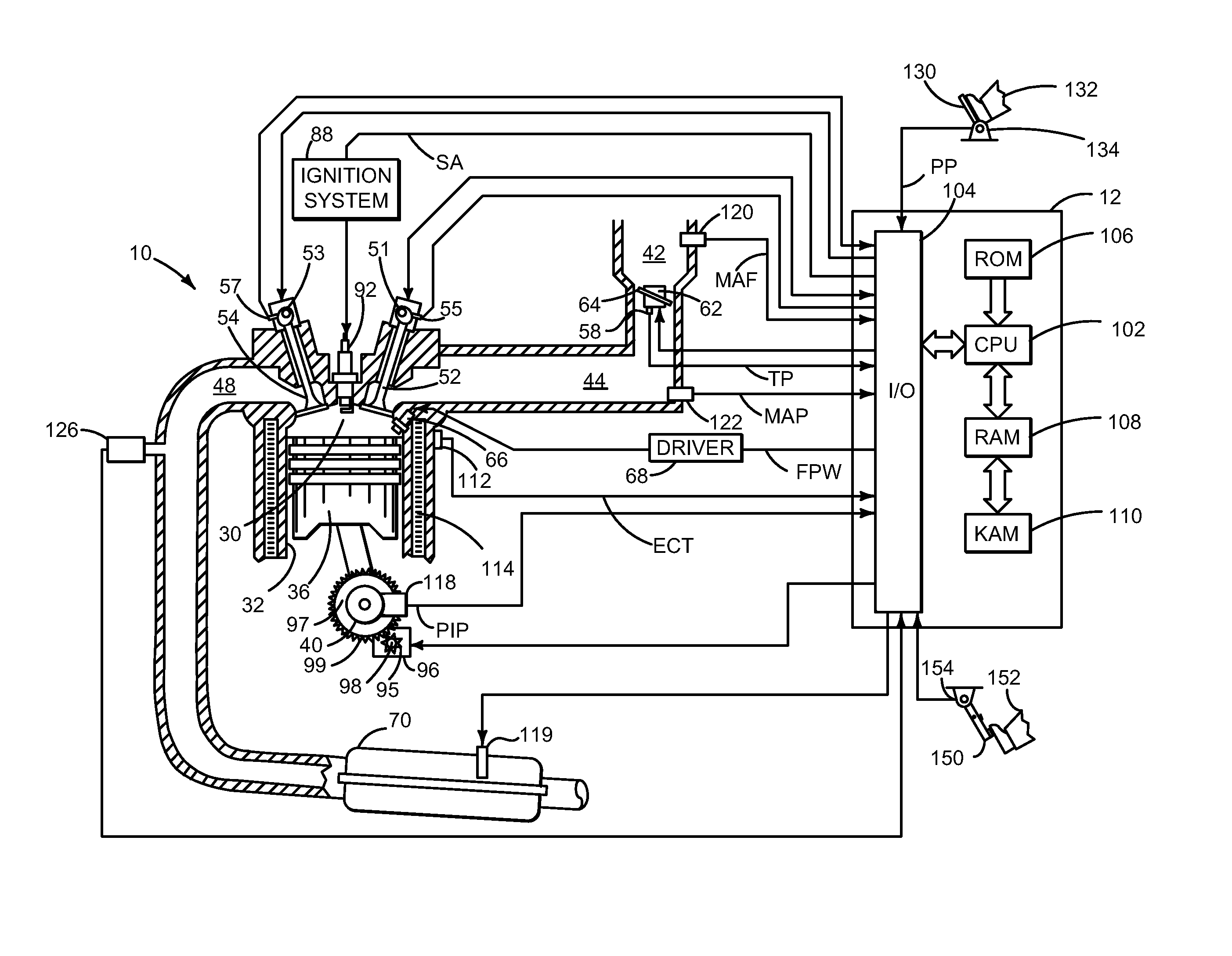

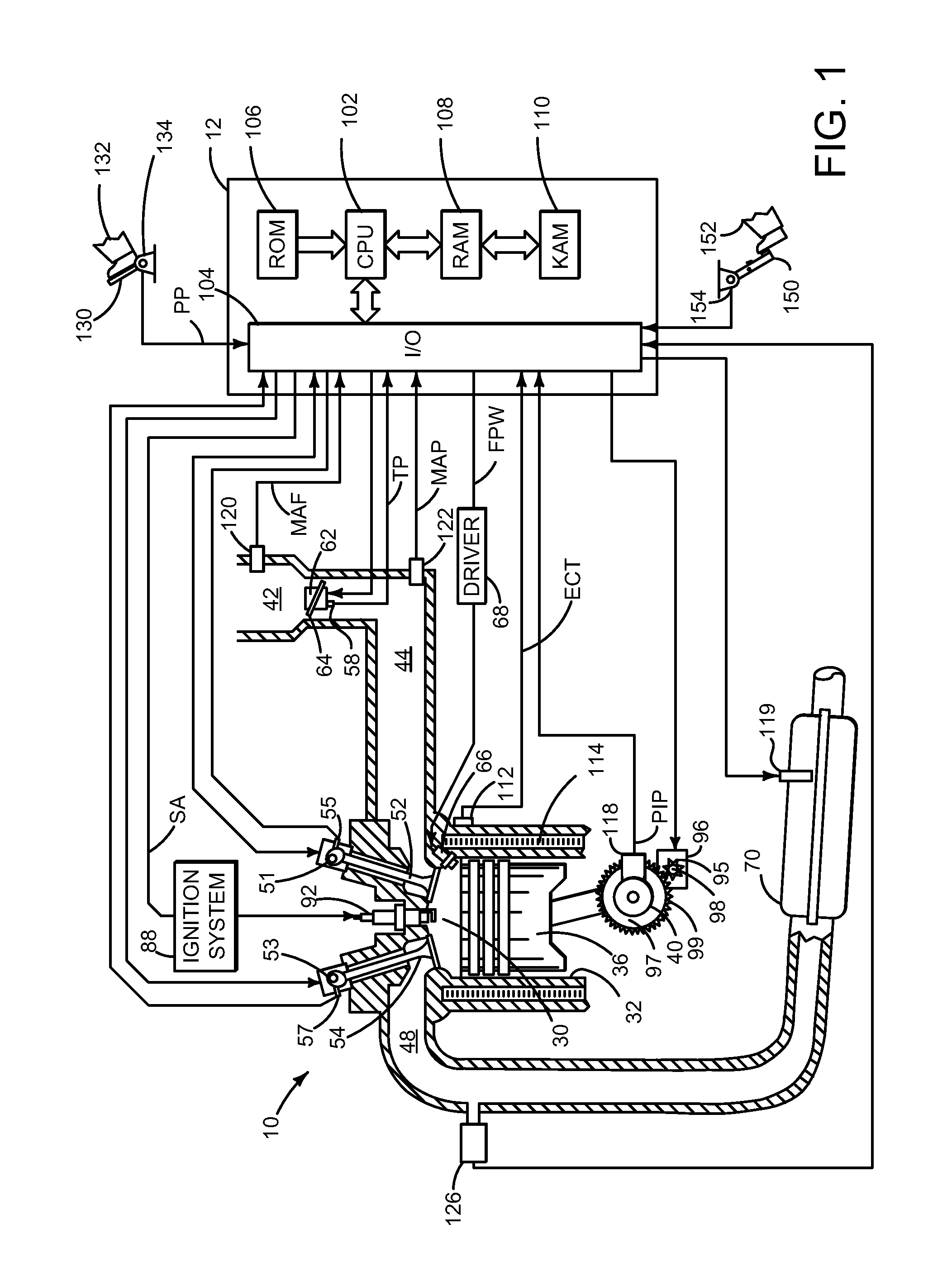

A hydraulic circuit may include a proportional control solenoid valve controlling hydraulic pressure such that an operating hydraulic pressure required by the friction member is supplied to the friction member; a supply hydraulic path connecting the proportional control solenoid valve with the friction member, and adapted to supply hydraulic pressure controlled by the proportional control solenoid valve to the friction member; and a switch valve disposed in the supply hydraulic path so as to selectively open / close the supply hydraulic path.

Owner:HYUNDAI MOTOR CO LTD

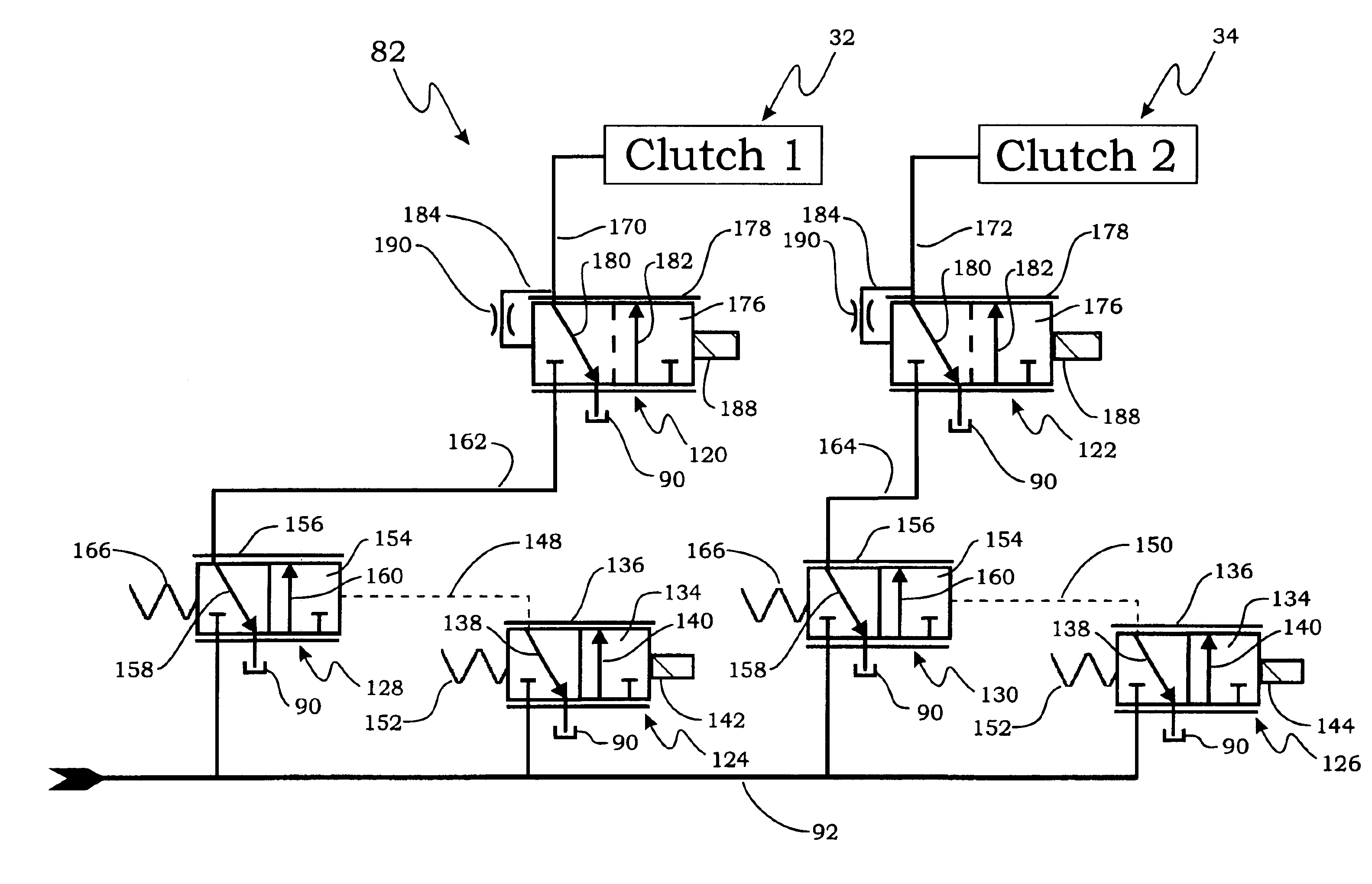

Control apparatus, method and diagnostic for hydraulic fill and drain

ActiveUS20050076958A1Improve robustnessHybrid vehiclesFluid-pressure actuator safetyControl theoryControl equipment

Hydraulic fill and drain of a clutch chamber is controlled with a blocking valve and a trim valve. The blocking valve selectively provides pressurized fluid to the trim valve which in turn selectively provides the pressurized fluid to the clutch chamber. Exhausting of the clutch chamber is effected through one of two alternate paths utilizing deactivation of one of the trim and blocking valves. Back up exhausting of the clutch chamber is effected through the other of the alternative paths. Such system allows for determination of valve failures and continued operation until such failures can be rectified.

Owner:ALLISON TRANSMISSION INC

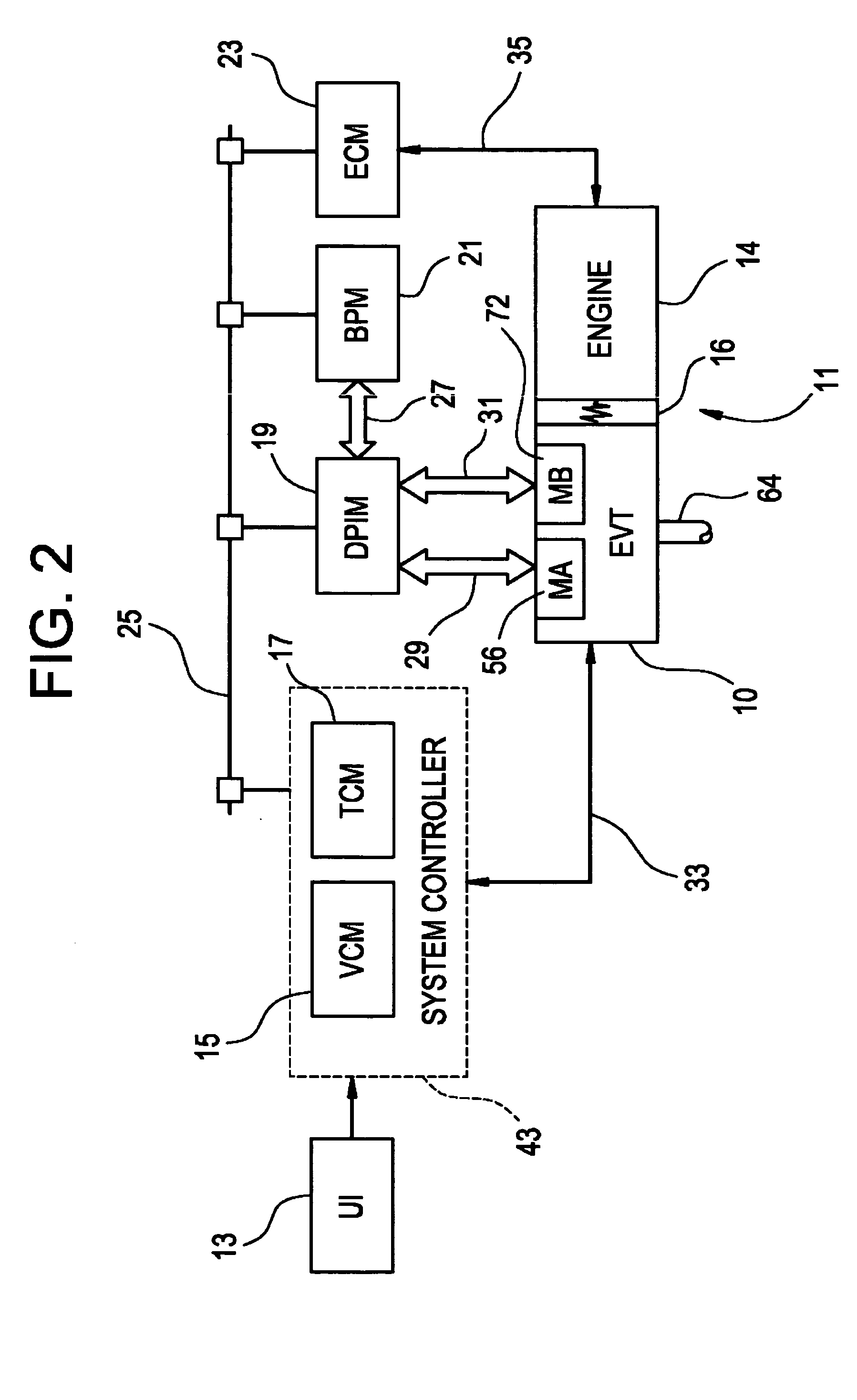

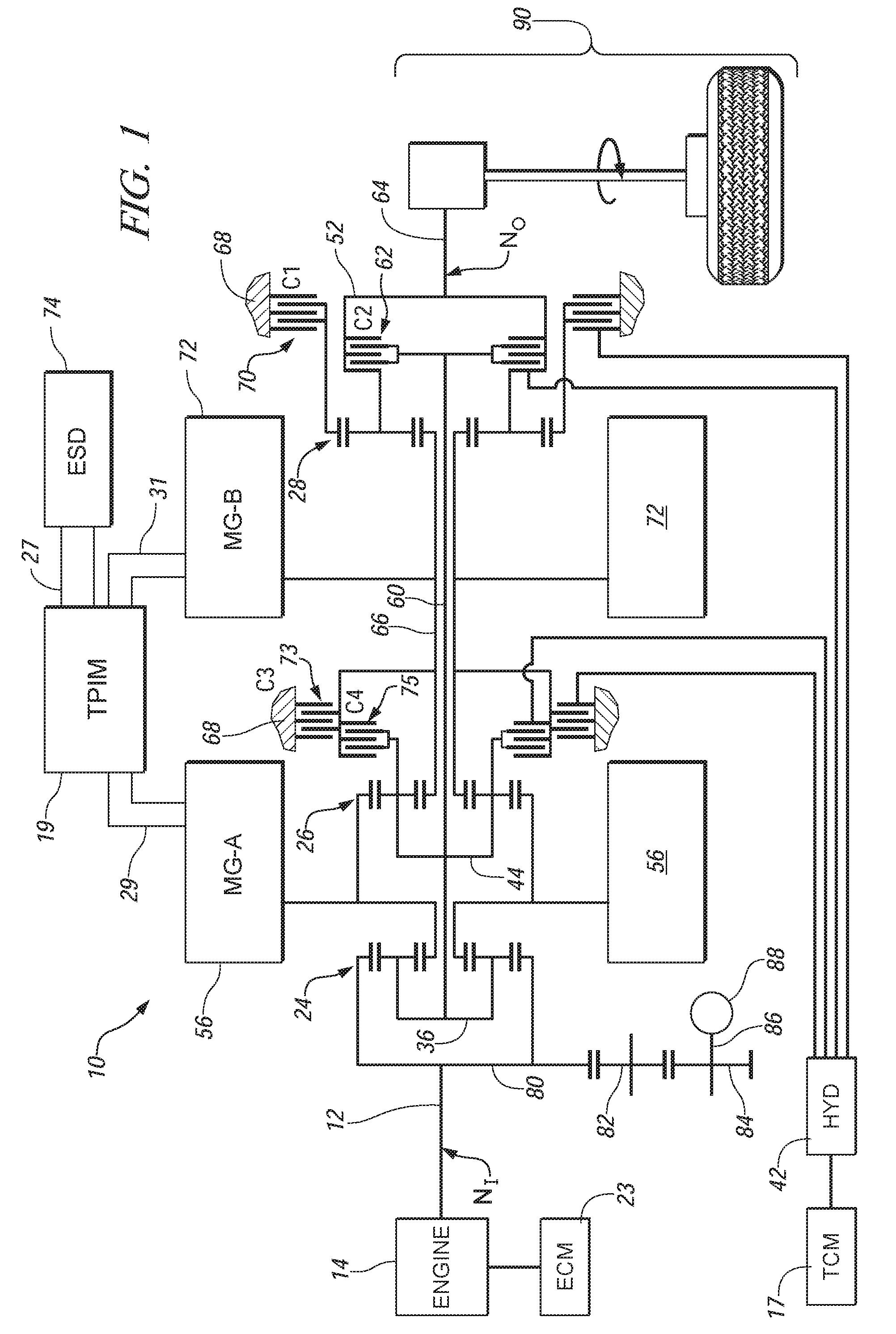

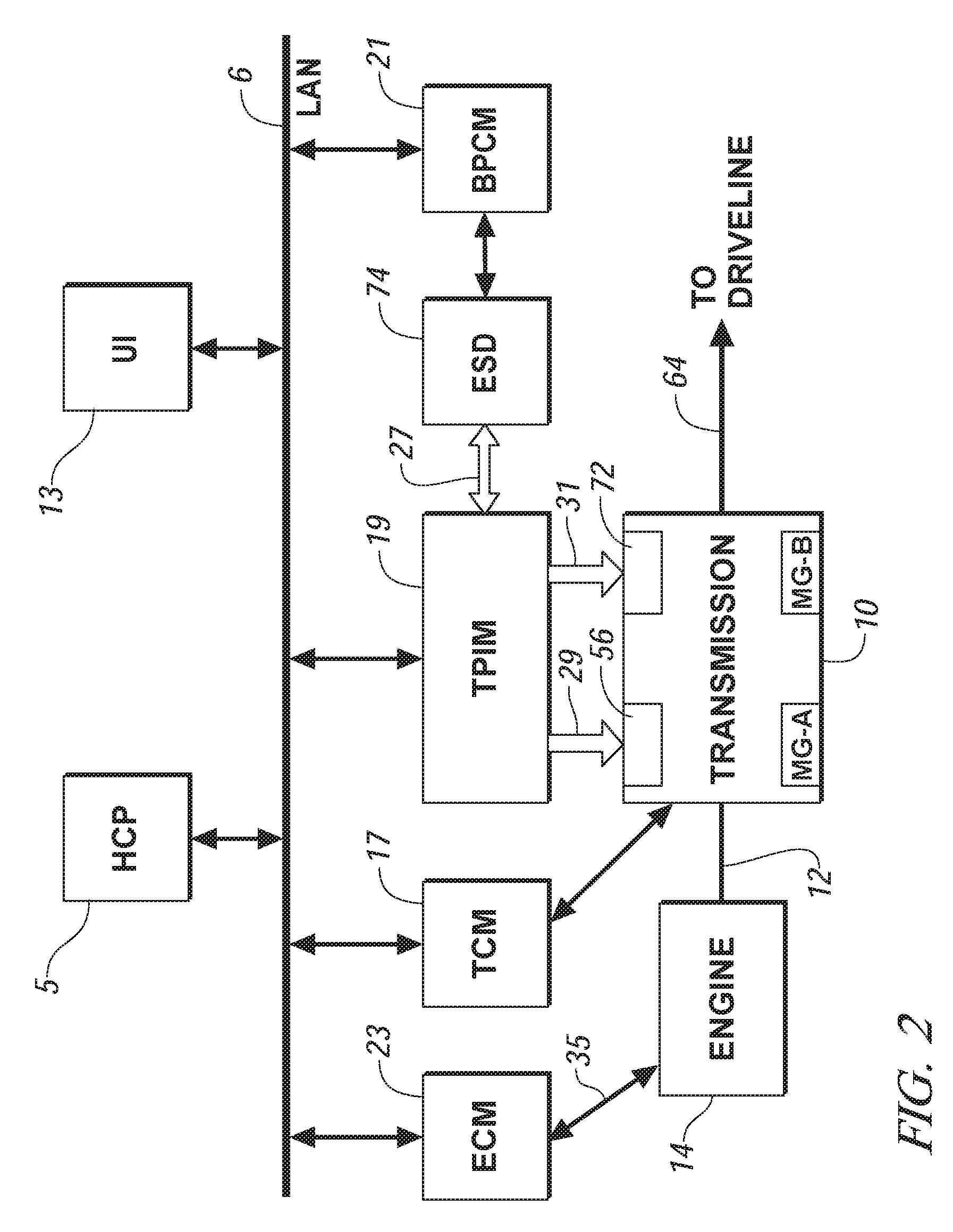

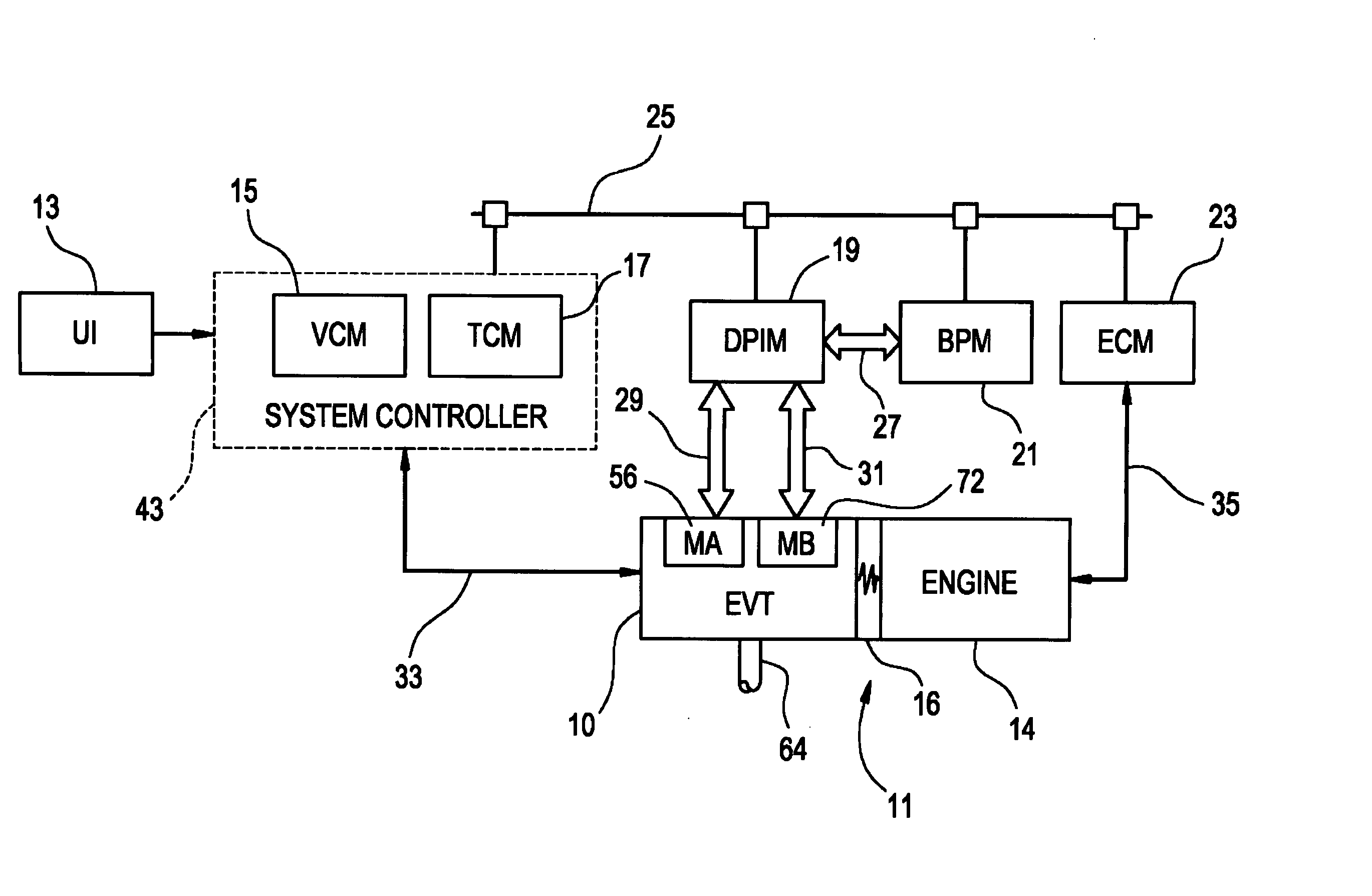

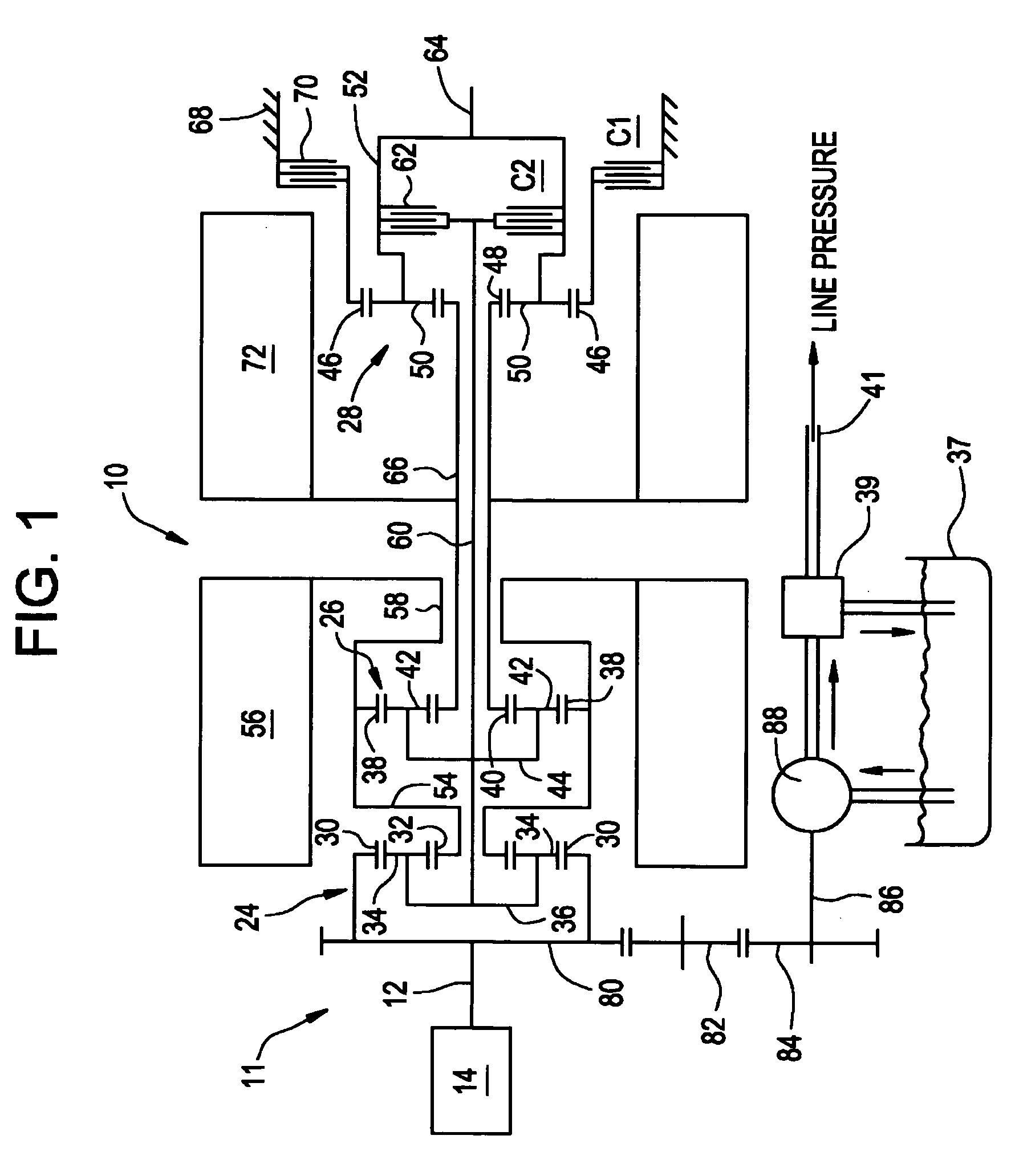

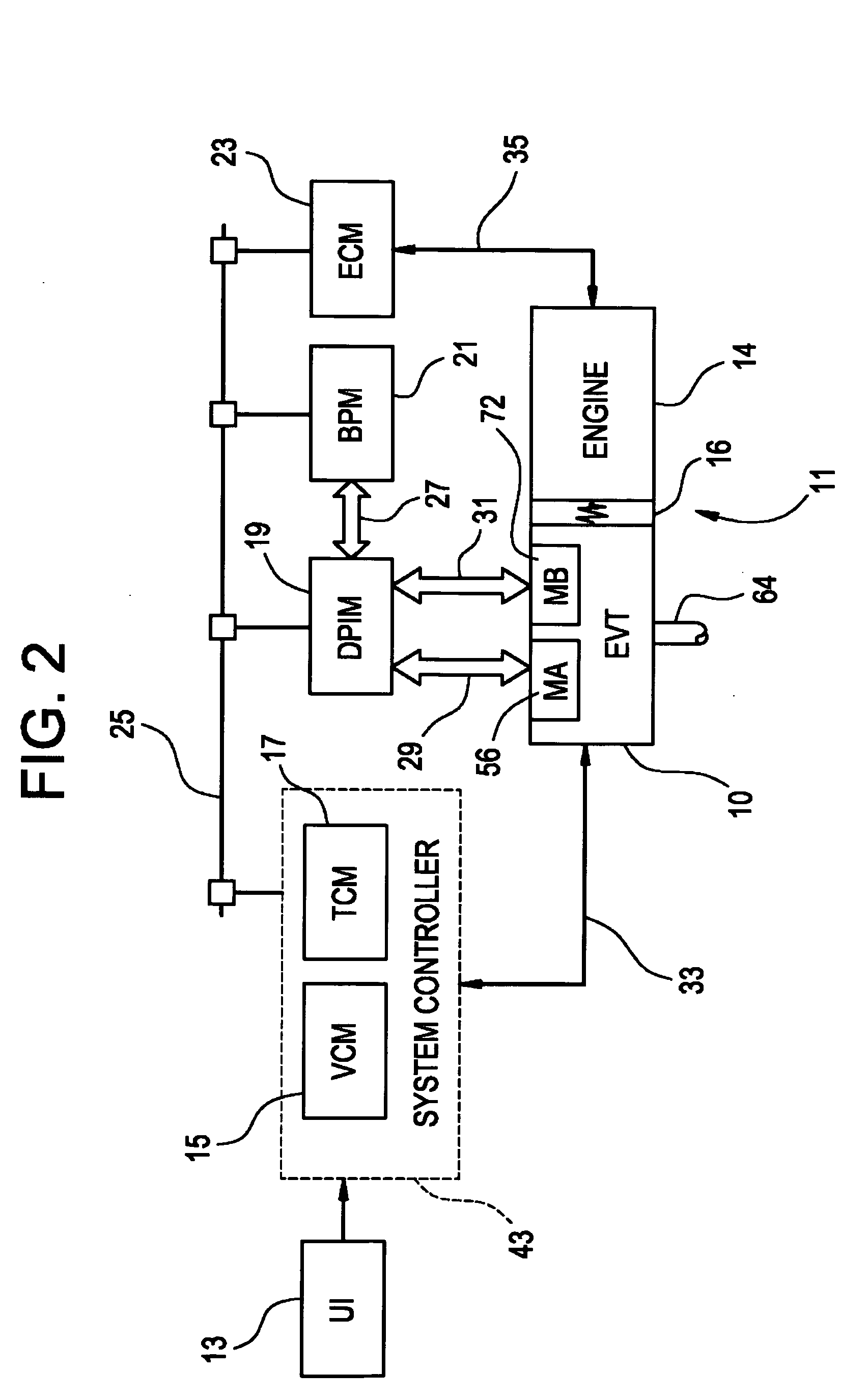

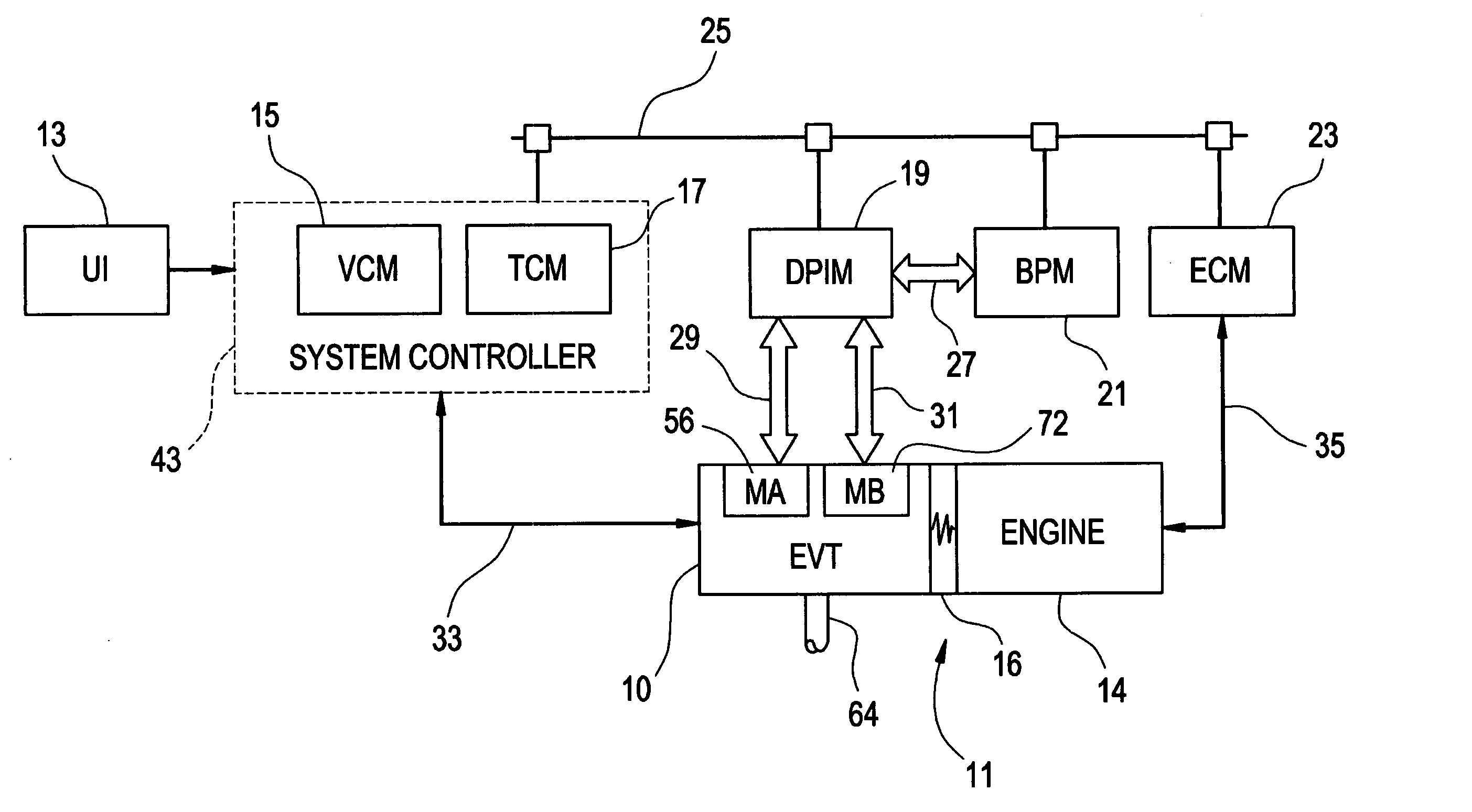

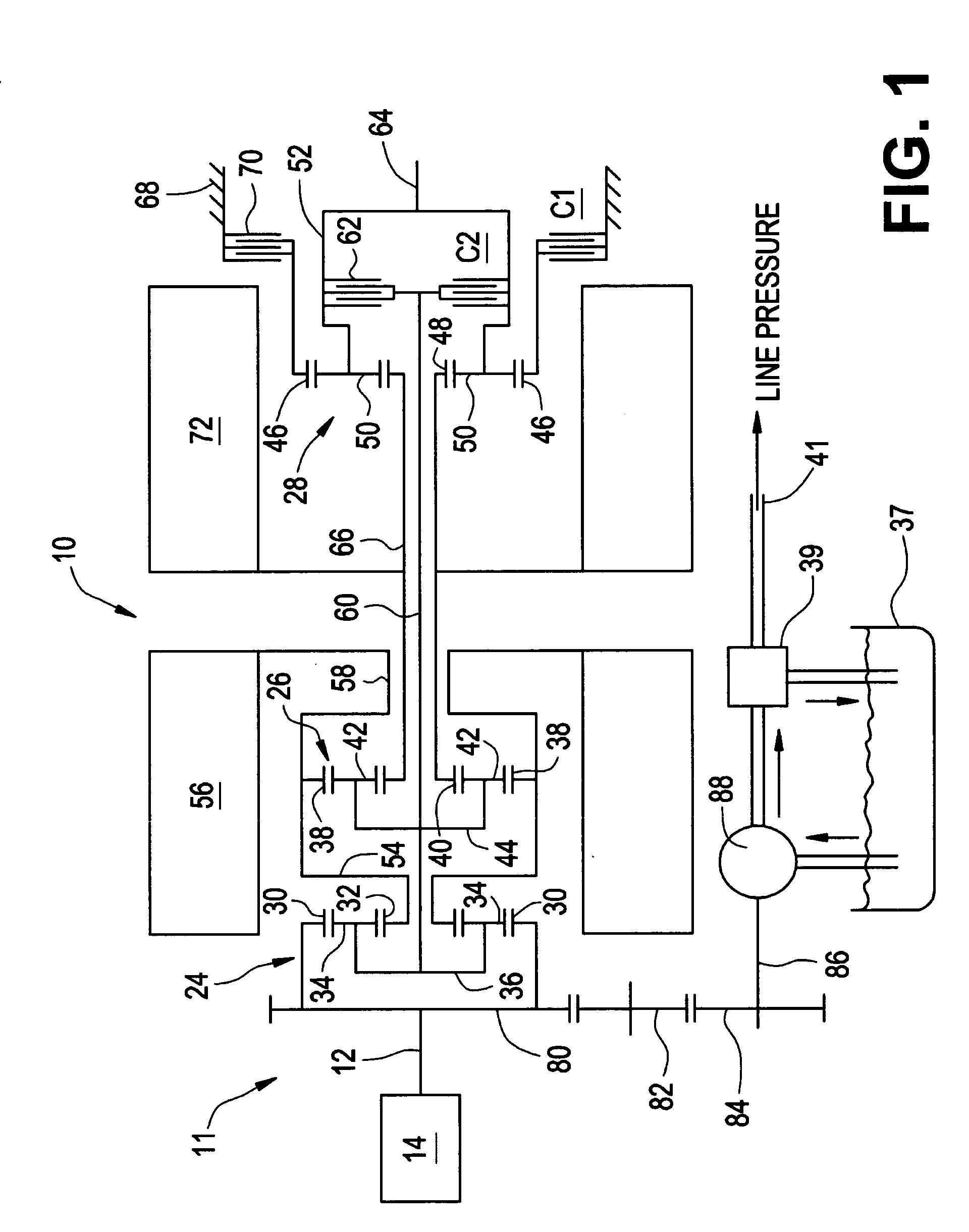

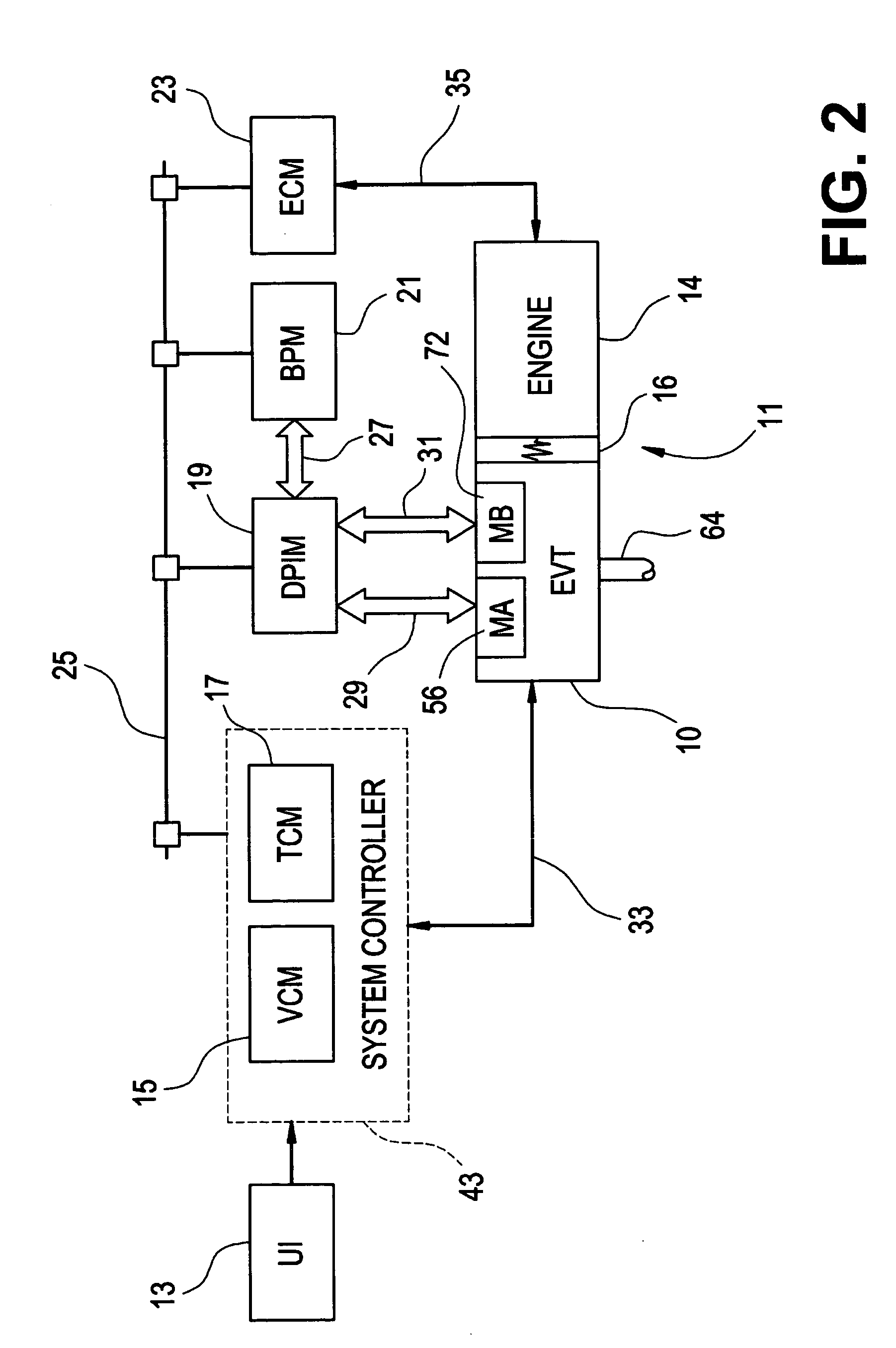

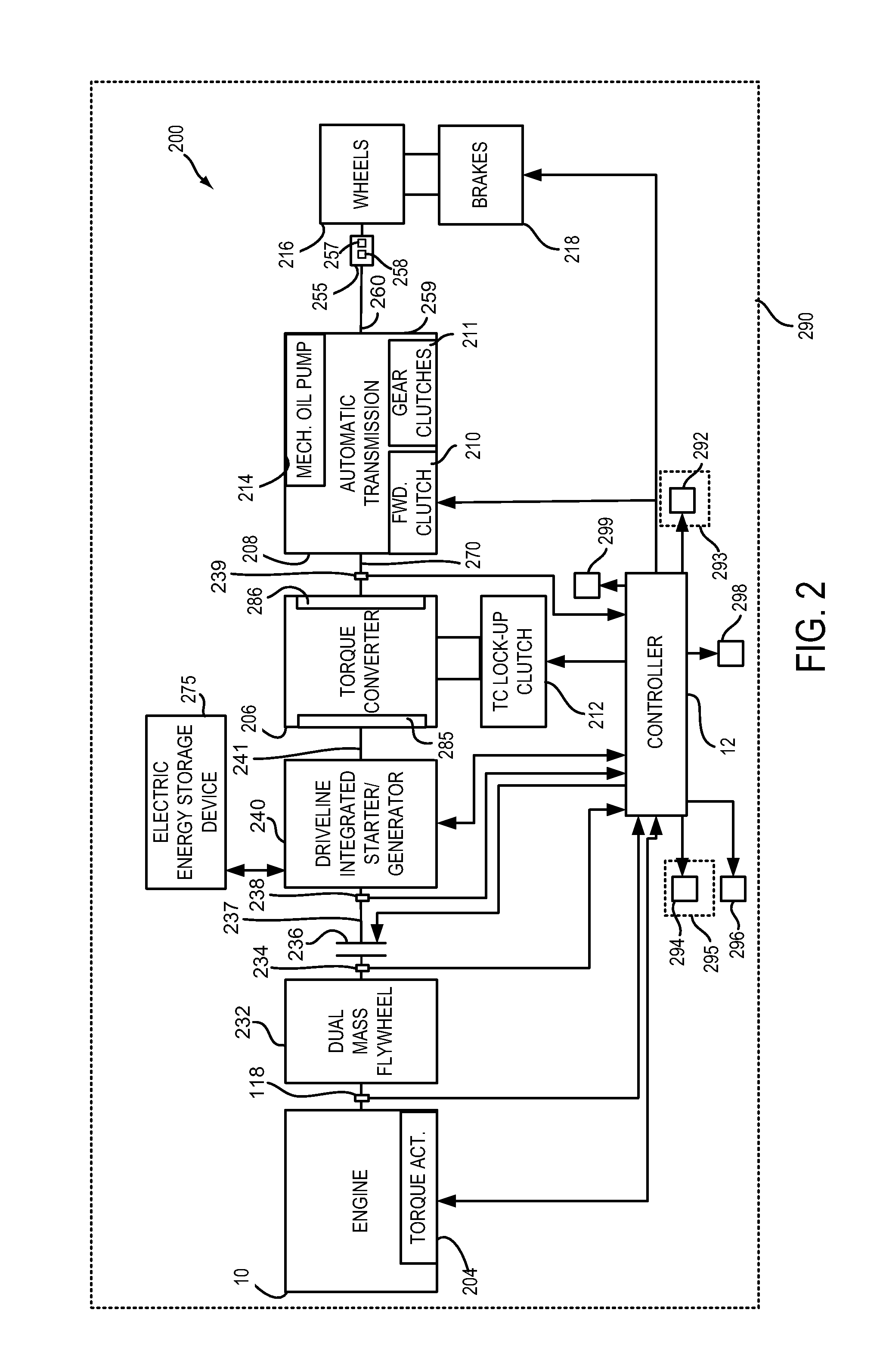

Method and apparatus to monitor devices of a hydraulic circuit of an electro-mechanical transmission

A method and an apparatus are provided to control operation of an electro-mechanical transmission device selectively operative in one of a plurality of fixed gear modes and two continuously variable modes. The method comprises controlling the flow control devices of the electro-hydraulic control circuit, and monitoring a plurality of pressure monitoring devices in the electro-hydraulic control circuit. A fault is identified in the electro-hydraulic control circuit when a signal output of one of the pressure monitoring devices does not correspond to an expected signal output for the pressure monitoring device after an elapsed time period.

Owner:GM GLOBAL TECH OPERATIONS LLC

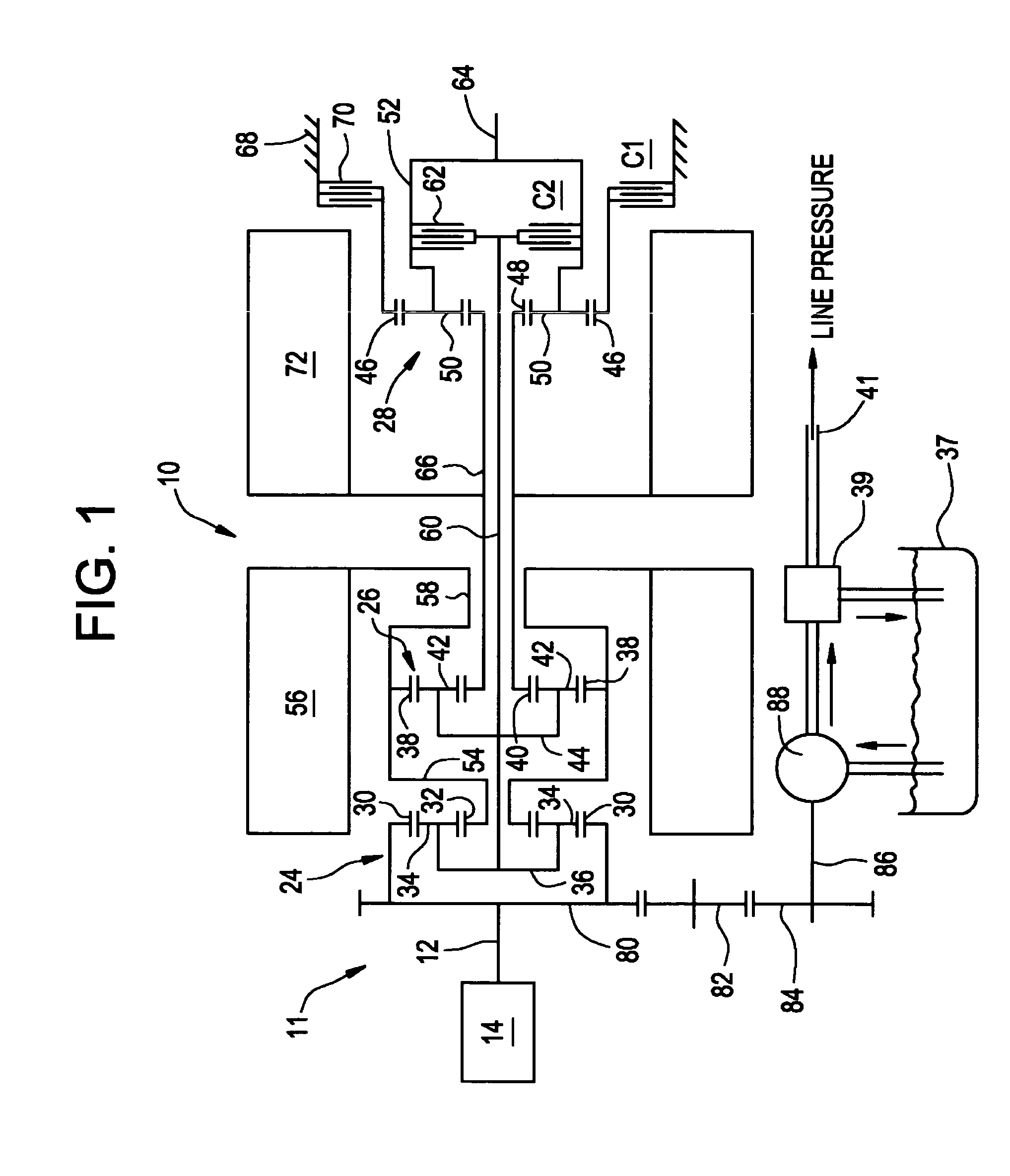

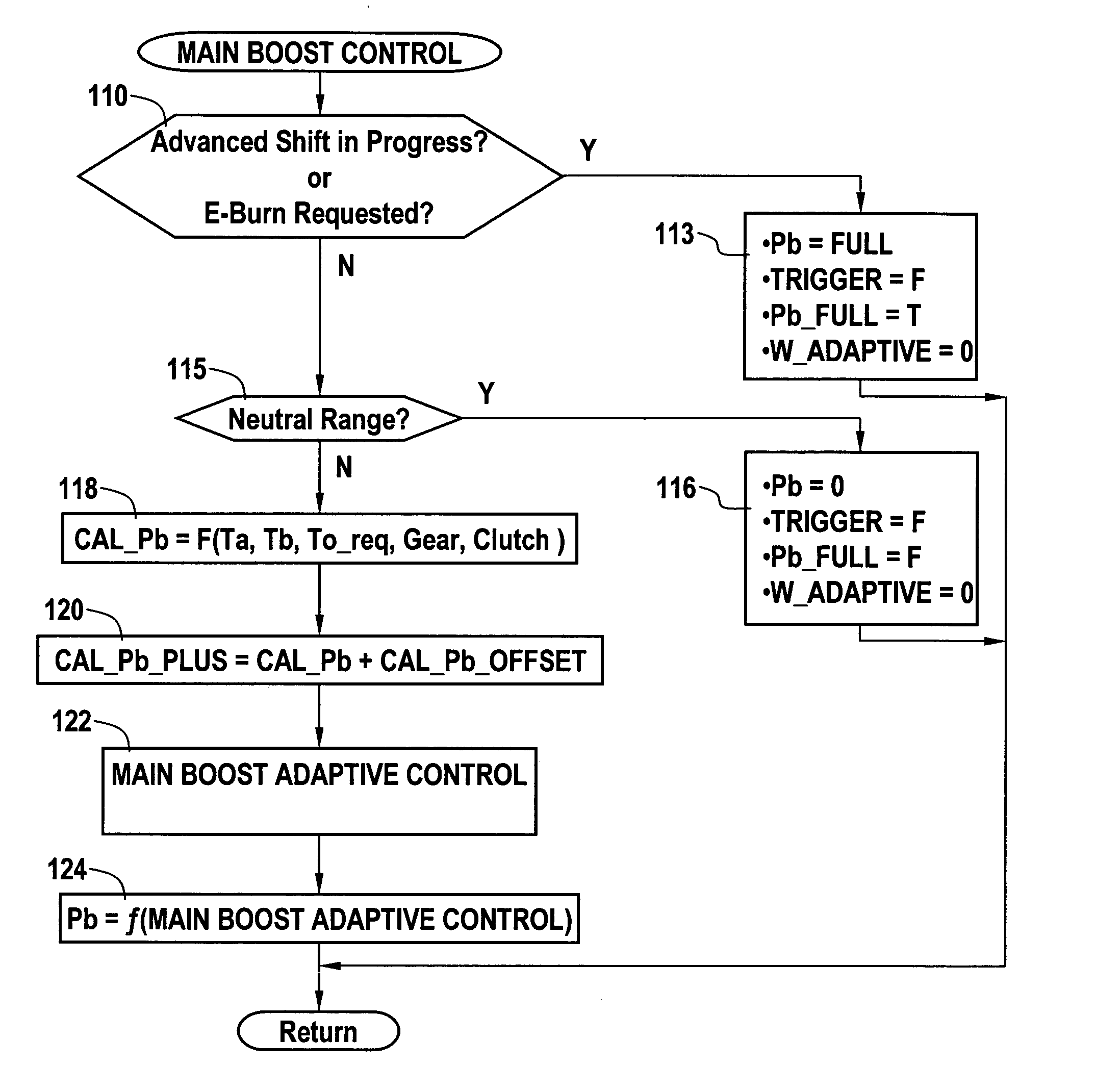

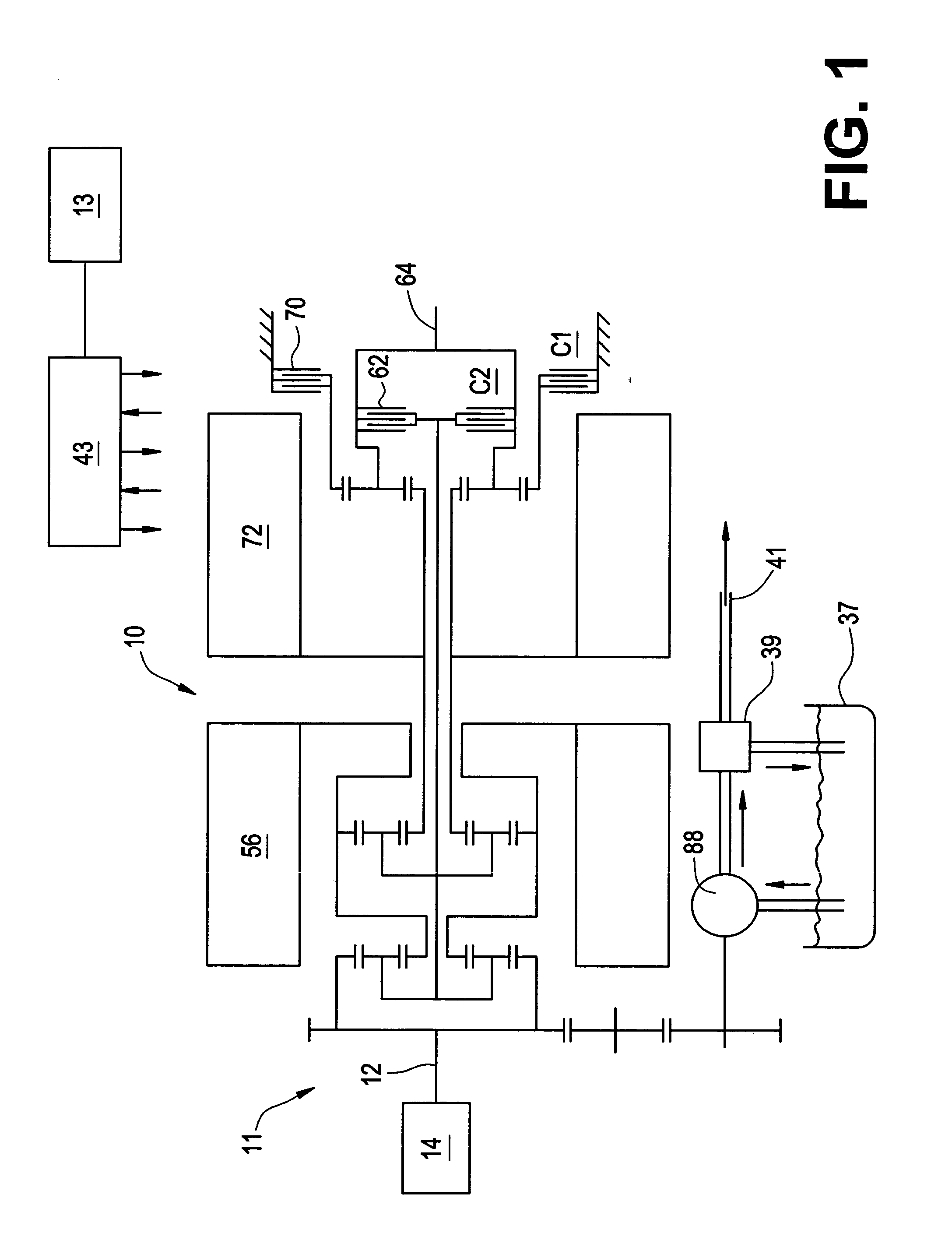

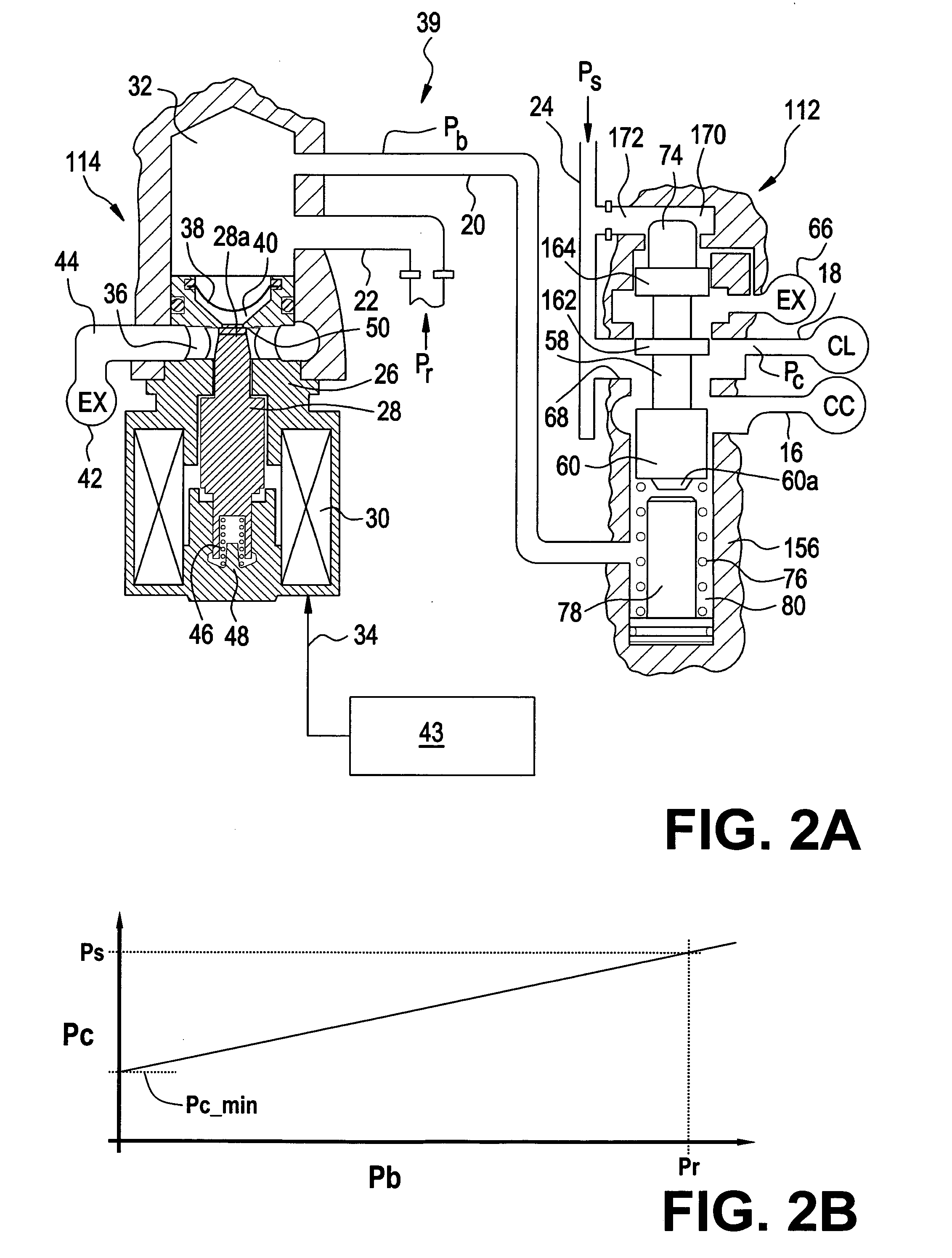

Method and apparatus to control hydraulic pressure in an electrically variable transmission

A method and apparatus to control an electrically variable transmission, by dynamically controlling system main hydraulic clutch pressures, based upon required clutch capacity, as determined by output load of the transmission. Included is a method to regulate hydraulic clutch pressure in an electrically variable transmission equipped with at least one clutch. This comprises monitoring magnitude of slippage of the clutches and controlling hydraulic boost pressure based upon the magnitude of clutch slippage. Controlling hydraulic boost pressure based upon the magnitude of clutch slippage comprises monitoring operator inputs, determining a requested operator torque command, and determining a required main boost pressure. The main boost pressure is based upon the requested operator torque command, the monitored operator inputs, parameters of the EVT and clutches. Commanded main boost pressure is then determined based upon the determined required main boost pressure.

Owner:GM GLOBAL TECH OPERATIONS LLC

Shift through neutral control in an electrically variable transmission

InactiveUS20050182543A1Reduce output torqueReduce slippageHybrid vehiclesClutchesFixed ratioControl theory

A shift control for an electrically variable transmission shifts between modes through a neutral mode wherein the output is decoupled from the transmission. Normally, shifts between modes are accomplished synchronously through a duration of fixed-ratio operation. Extreme driving conditions may invoke shifts through neutral mode. Ratio violations characterized by one mode being active in a preferred input / output ratio range for another mode are handled by a shift through neutral. Similarly, rapid acceleration and deceleration conditions likely to result in undesirable engine speeds if synchronous shifting is employed are handled by a shift through neutral.

Owner:ALLISON TRANSMISSION INC

Hydraulic clutch state diagnostic and control

Clutch engagement is preferably determined in accordance with monitored pressure conditions within a clutch control chamber. Clutch slip is monitored and information respecting clutch engagement inferred therefrom is stored for subsequent retrieval and use in a redundant slip based clutch engagement determination. Clutch slip is also monitored for information respecting clutch disengagement for use in a redundant slip based clutch disengagement determination.

Owner:GM GLOBAL TECH OPERATIONS LLC

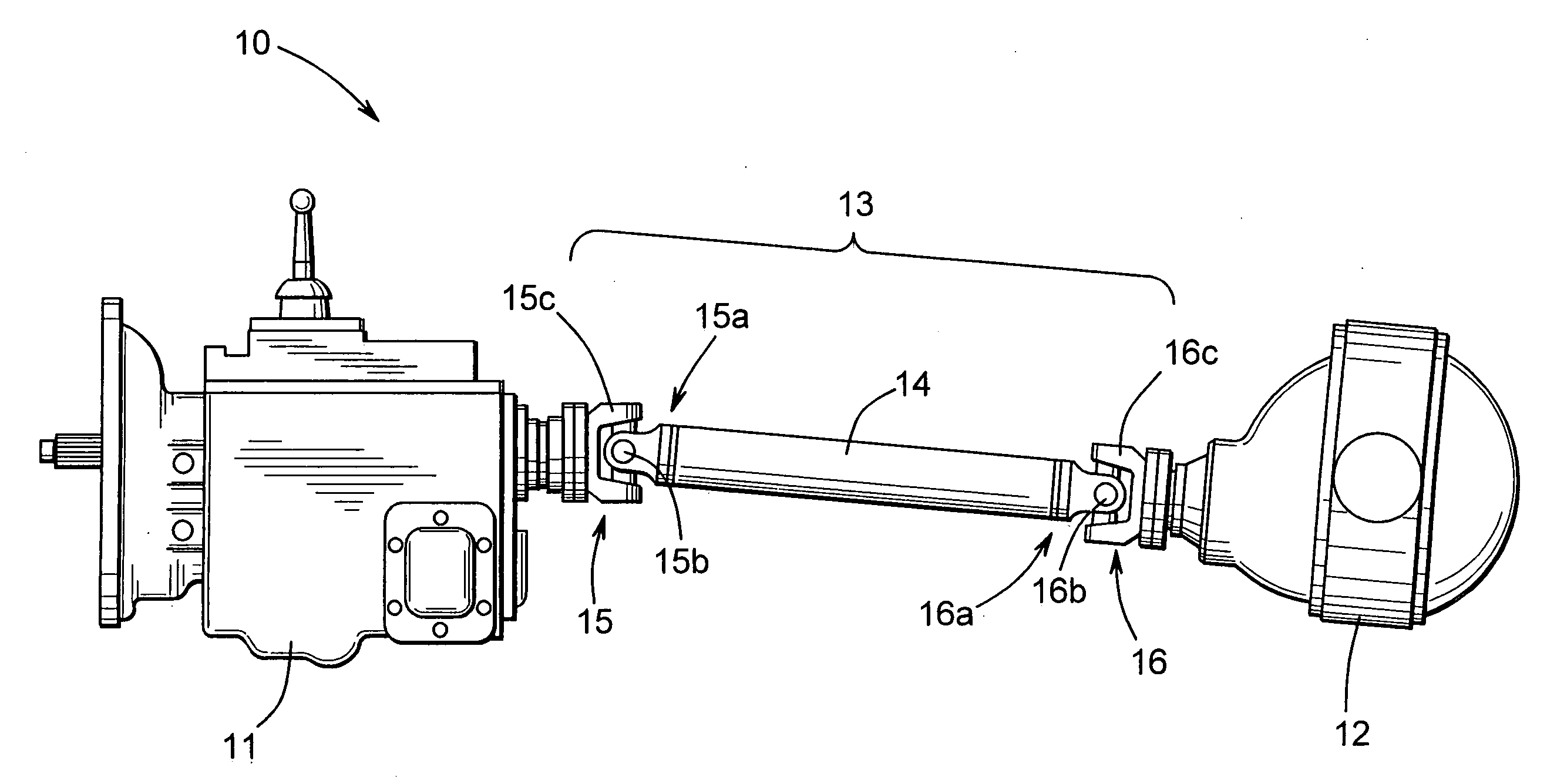

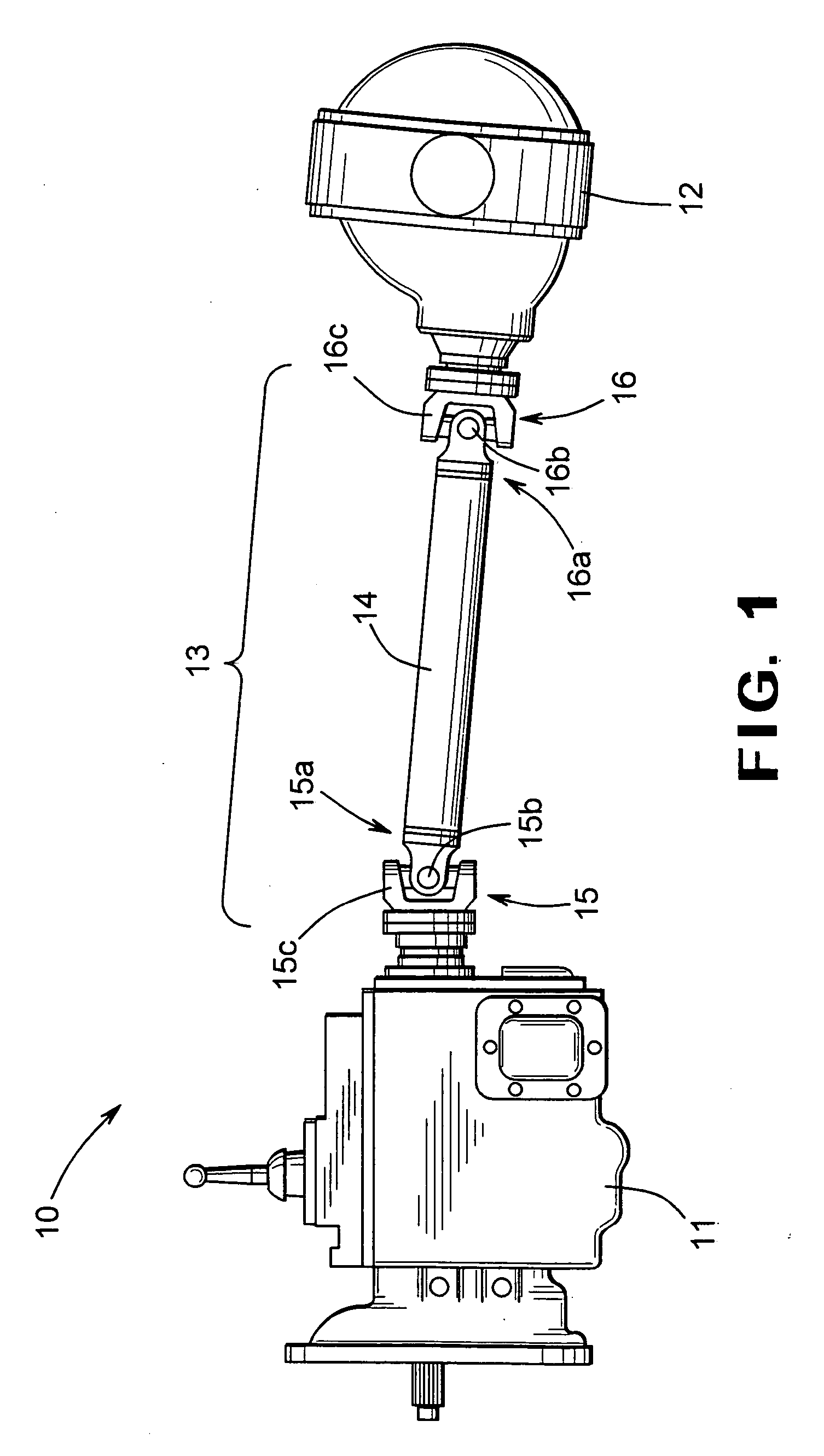

Driveshaft assembly and method of manufacturing same

InactiveUS20070066406A1Protection from damageSimple structureClutchesYielding couplingEngineeringMagnetic pulse welding

A driveshaft assembly includes a yoke including a body portion, a pair of opposed yoke arms that extends generally in a first axial direction from the body portion, and a neck portion that extends generally in a second axial direction from the body portion. A driveshaft tube is secured to the neck portion of the yoke, such as by magnetic pulse welding. A ring is secured to the body portion of the yoke, such as by press fitting, and a balance weight is secured to the ring, such as by welding.

Owner:DANA AUTOMOTIVE SYST GRP LLC

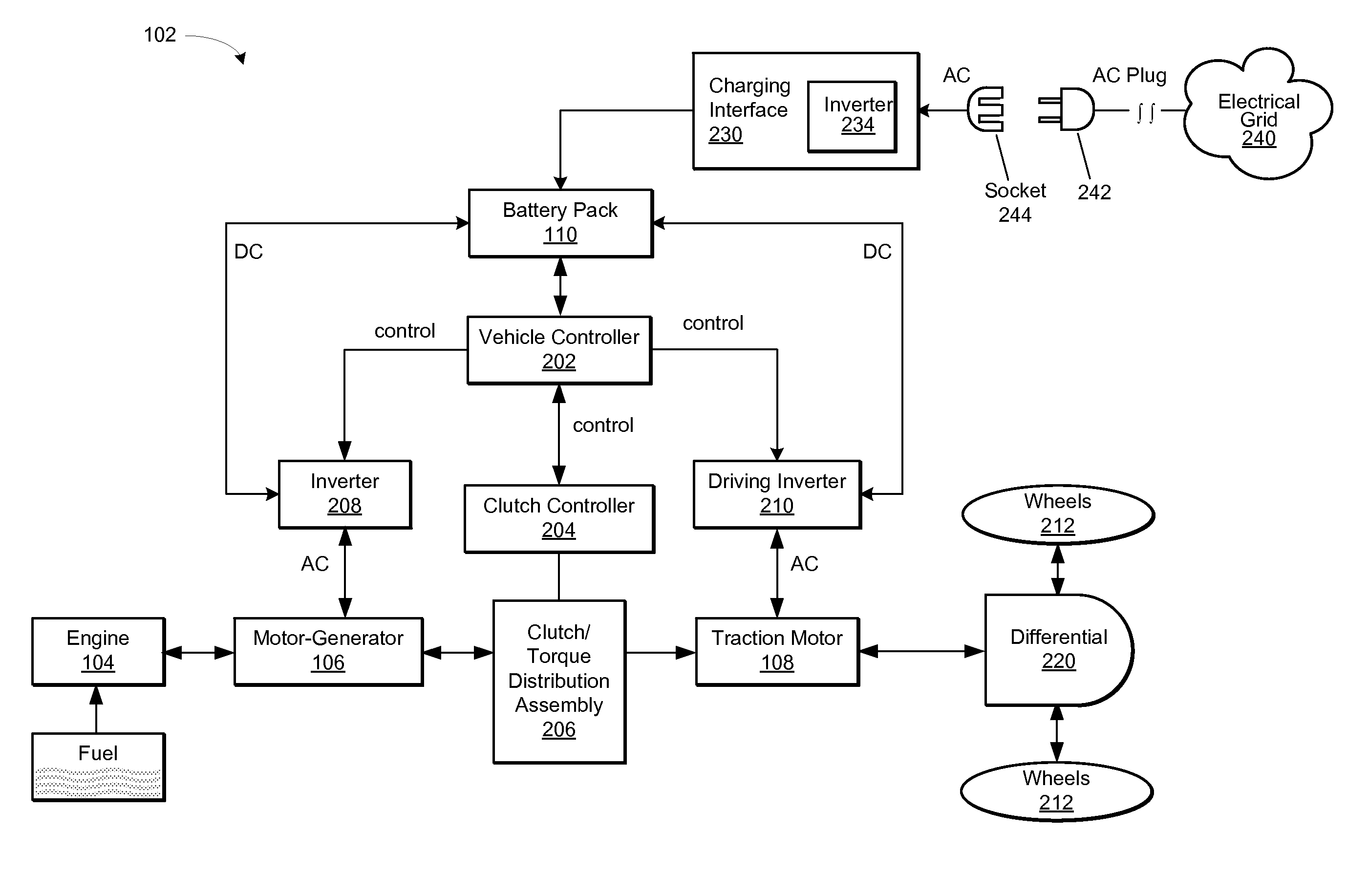

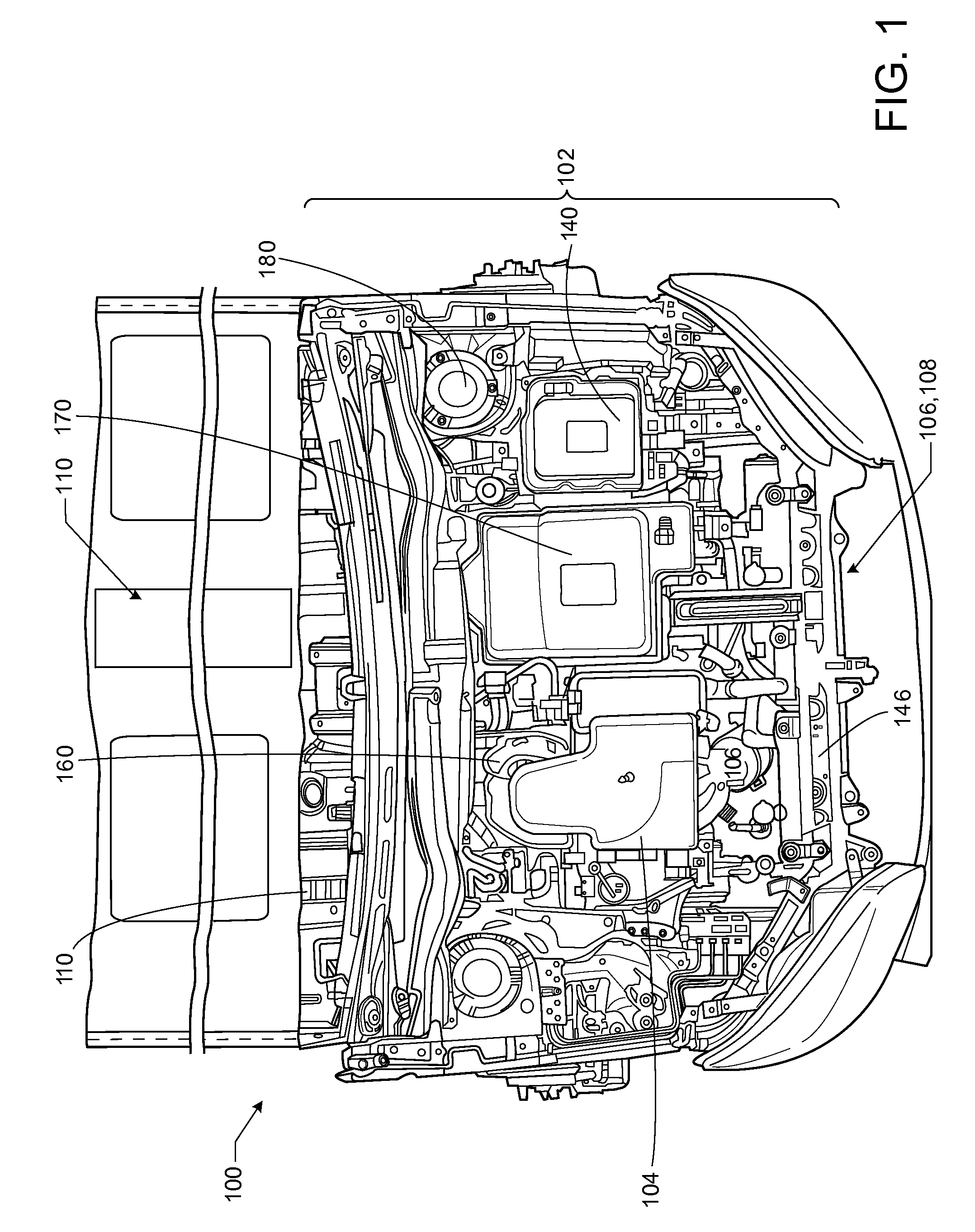

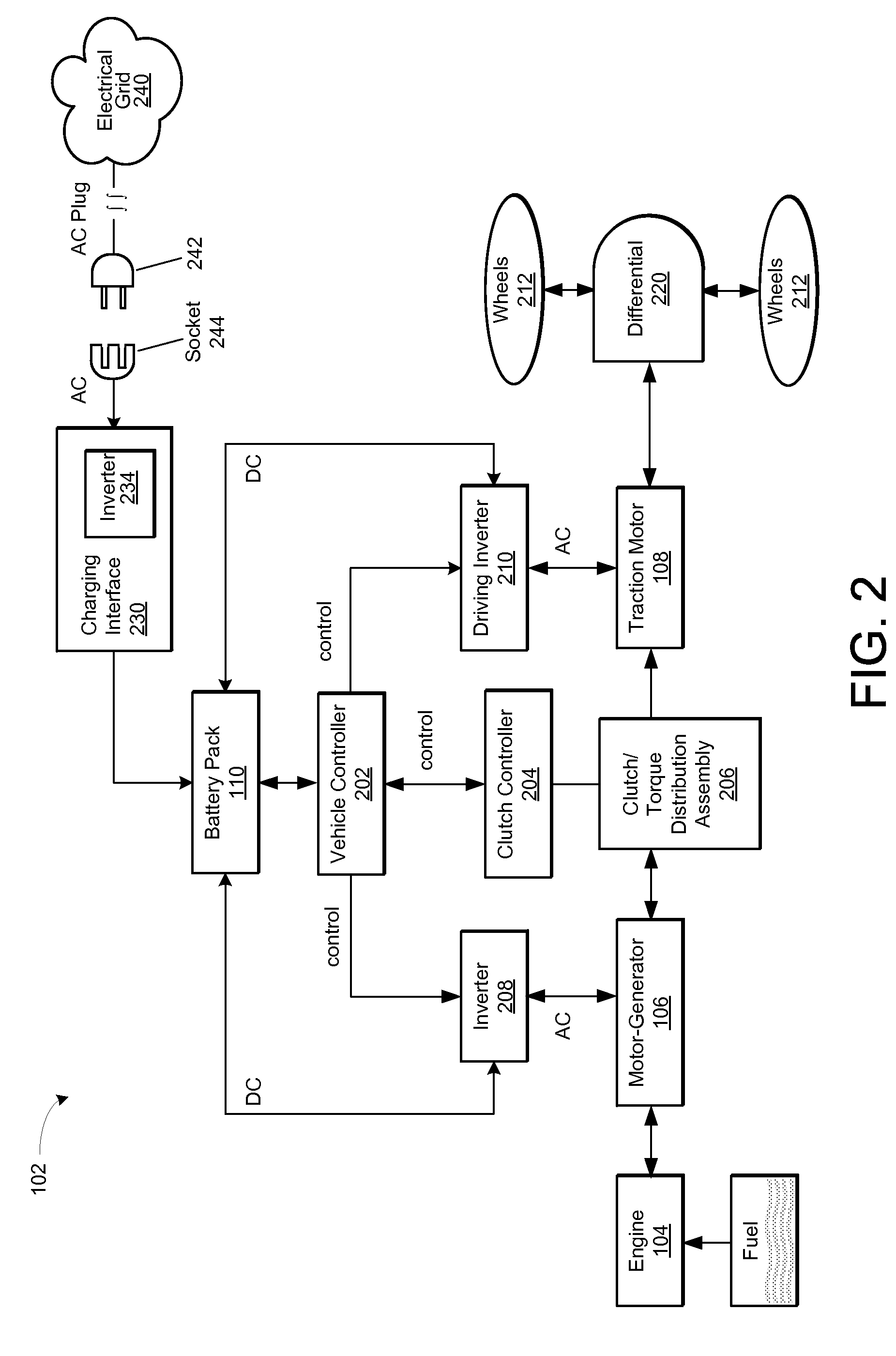

Hybrid Vehicle Having Multi-Mode Controller

A control system for a hybrid vehicle controls the various operating modes of the hybrid vehicle. Operating modes of the hybrid vehicle include an electric-only power mode, a series hybrid mode, a series hybrid dual-power mode, and a parallel hybrid tri-power mode. The control system selects one of the operating modes for the hybrid vehicle based on one or more inputs and comparisons. Examples of inputs for the control system include a gear-mode, a present battery storage capacity, a present velocity of the hybrid vehicle, and the previous operating mode of the hybrid power system. The control system may also take into account whether a user has selected the electric-only power mode. The control system may also control the operations of one or more components of the hybrid vehicle while operating in one of the operating modes.

Owner:BYD CO LTD

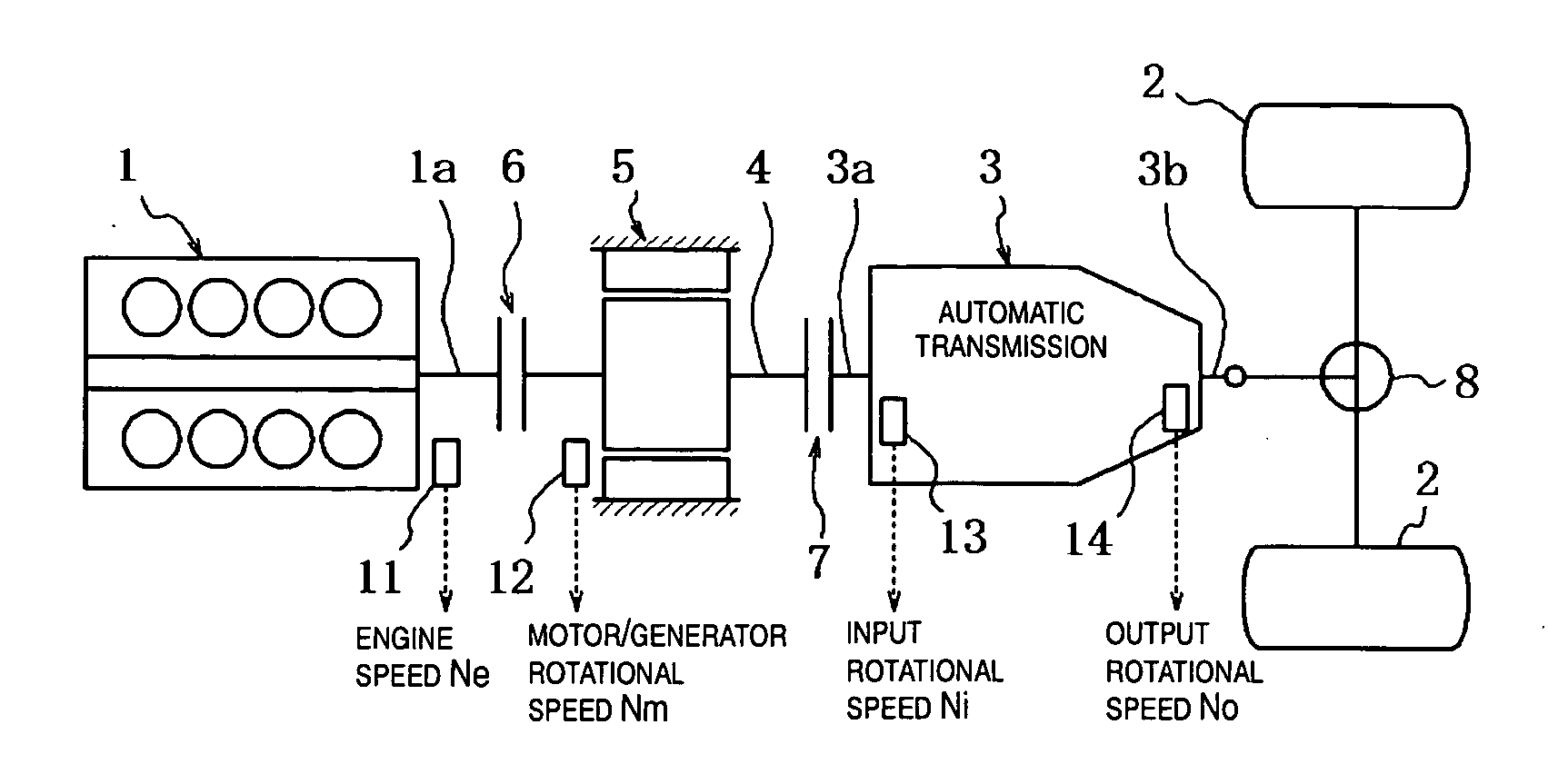

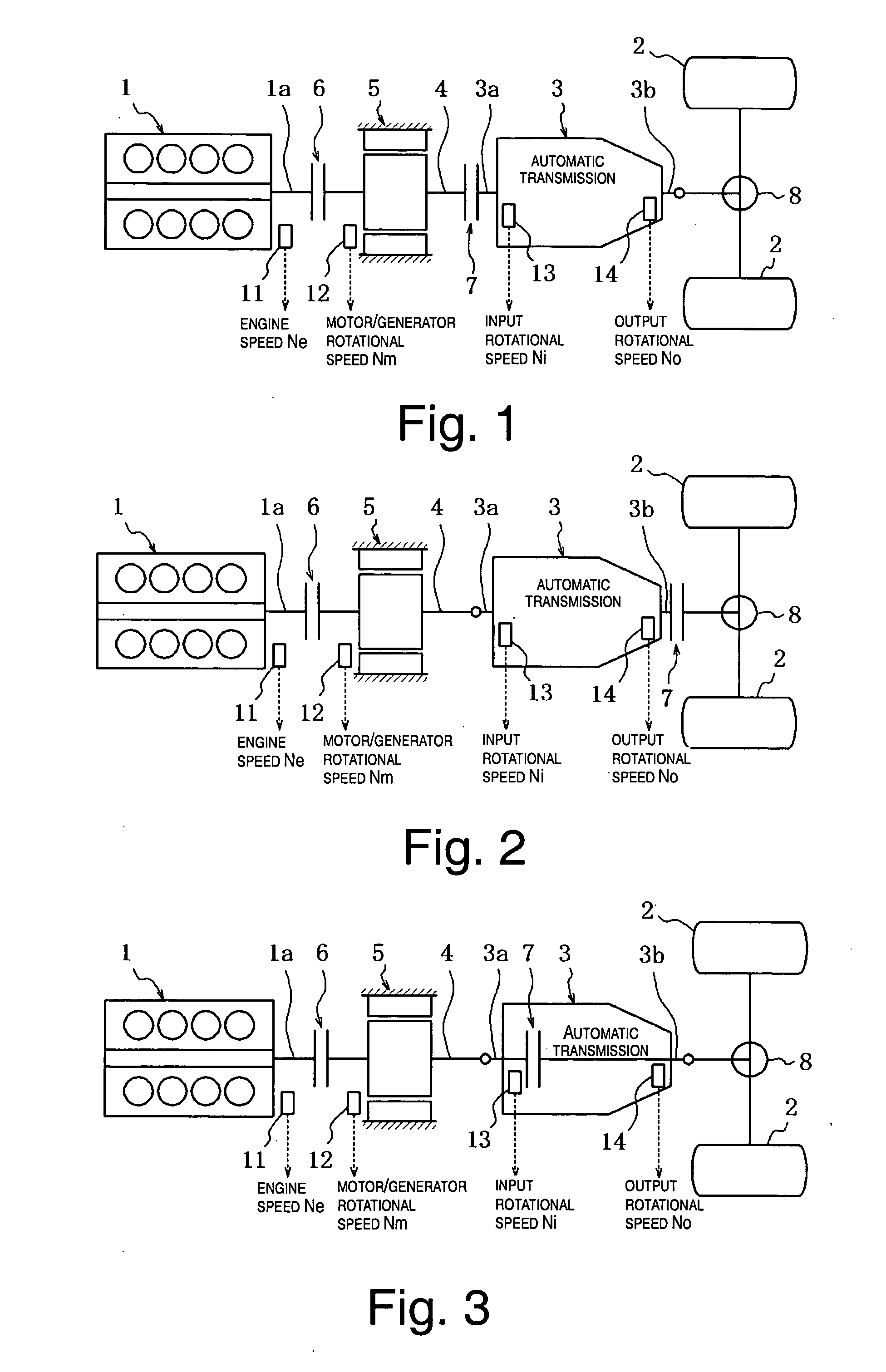

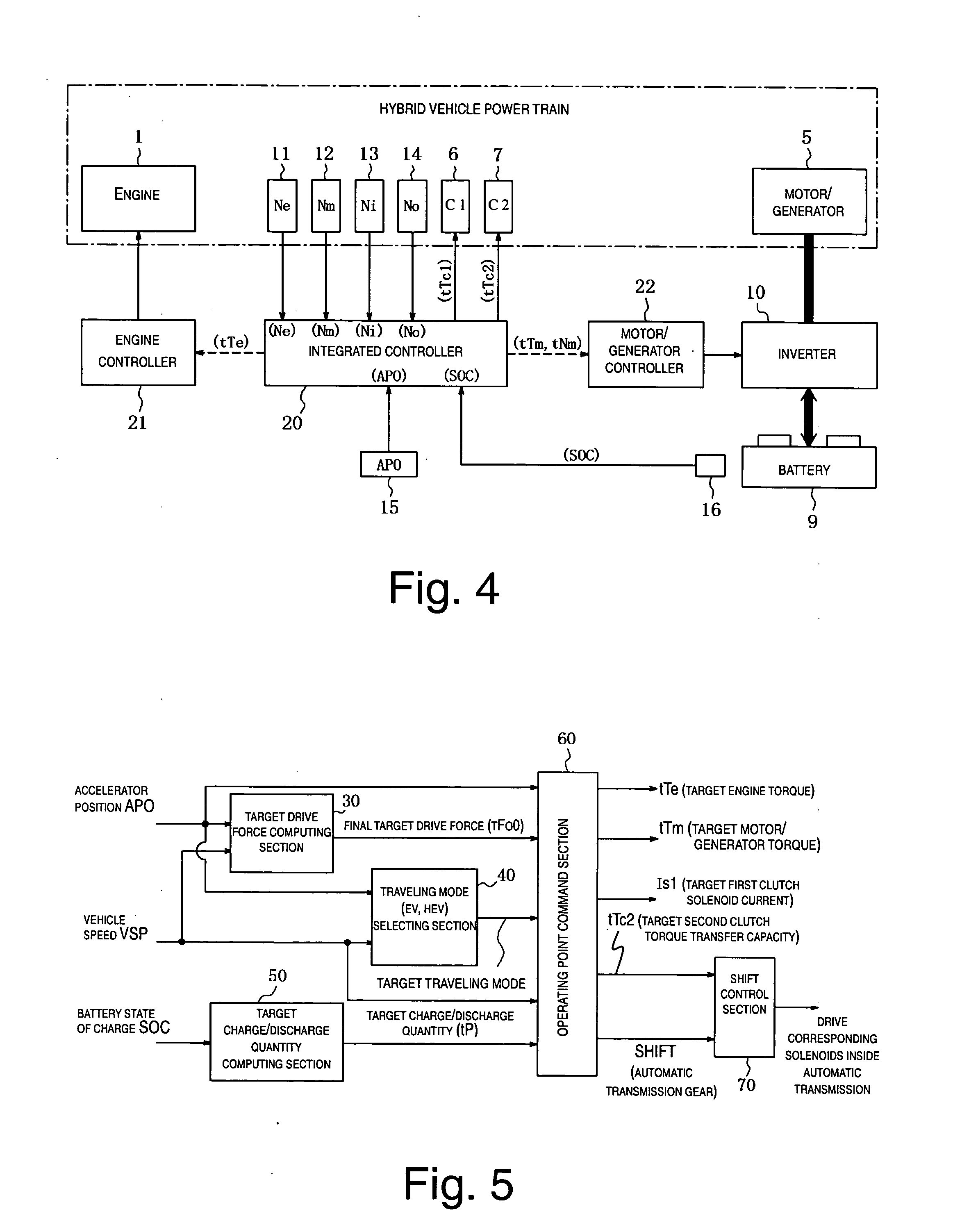

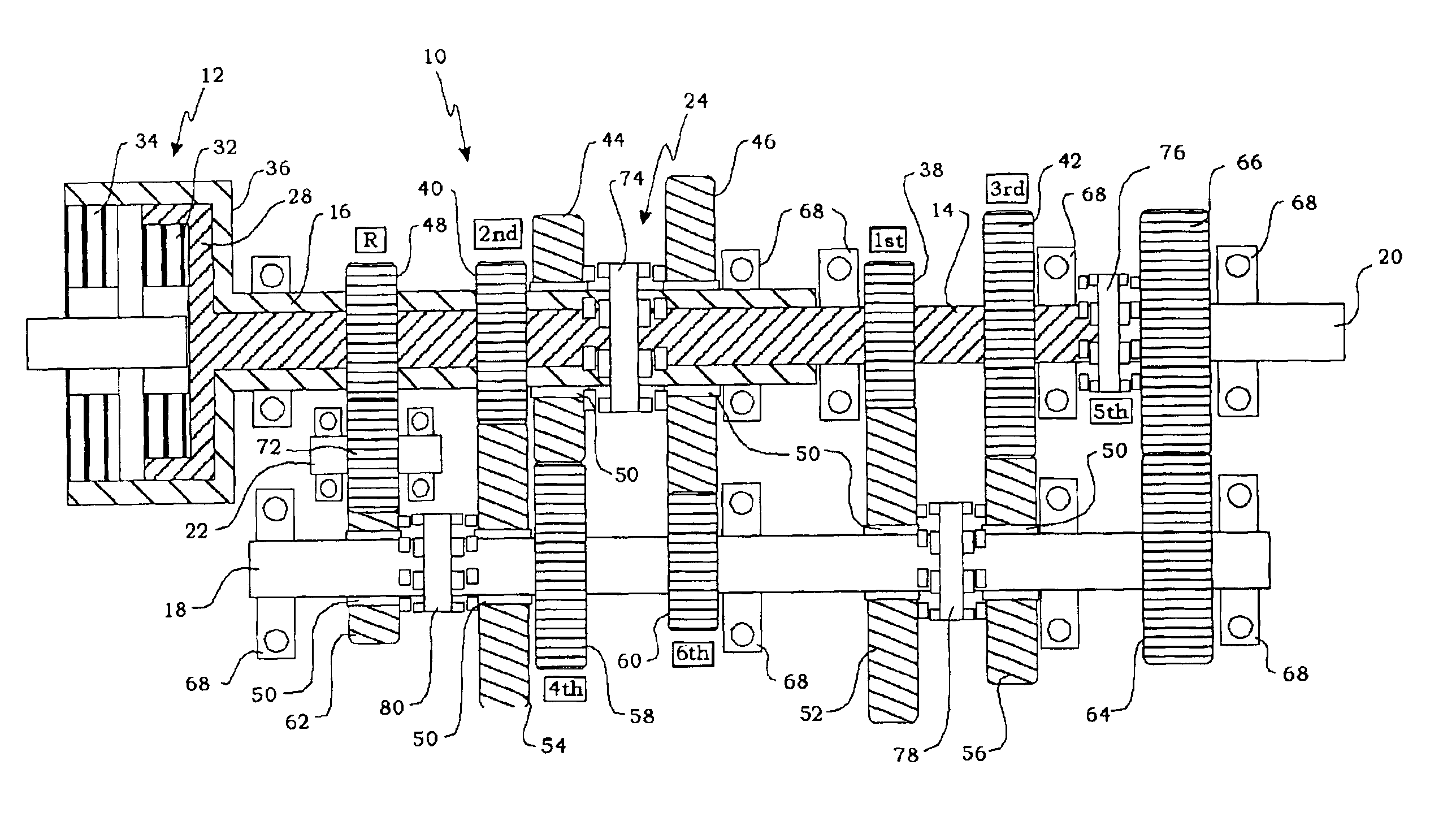

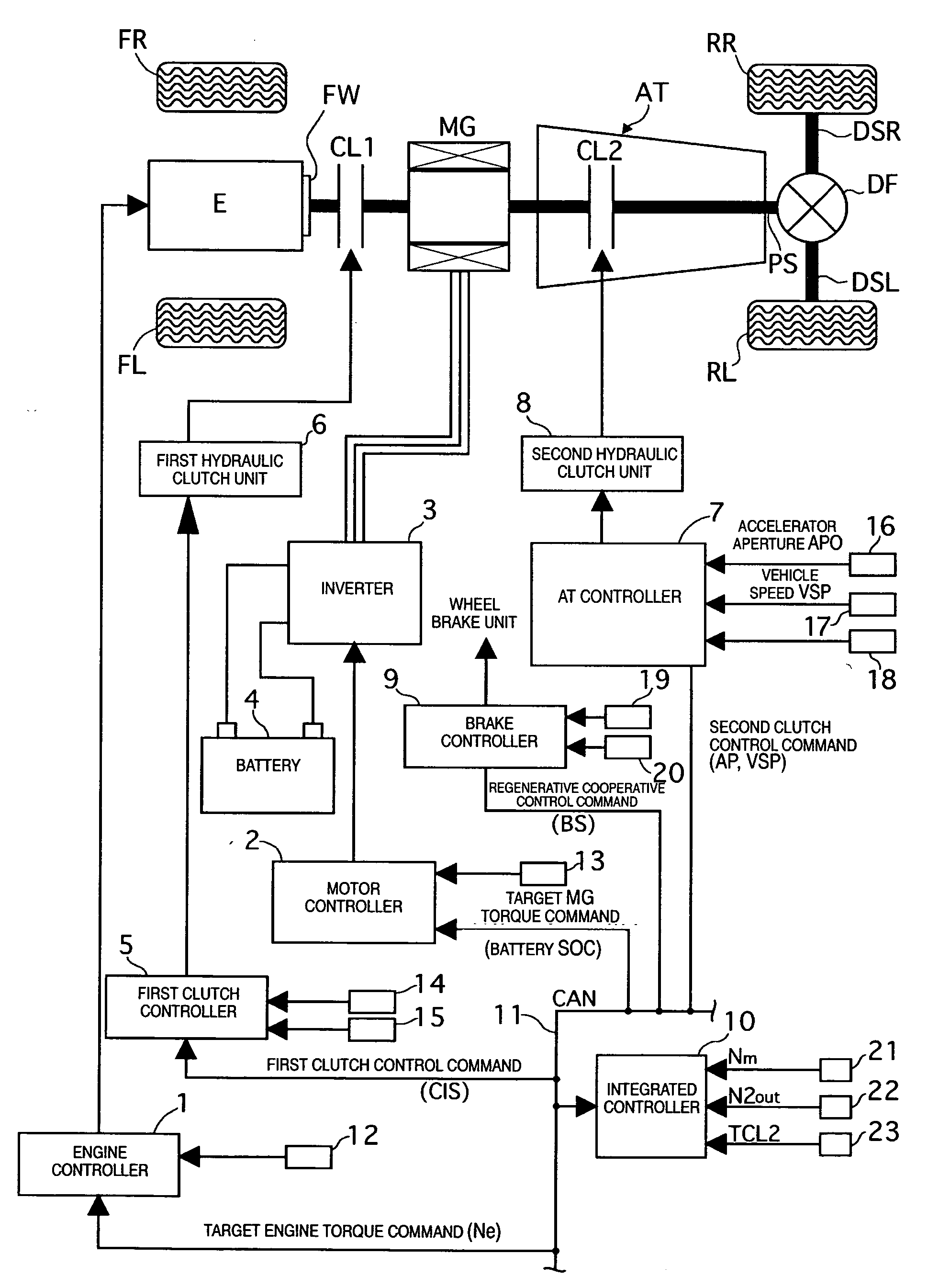

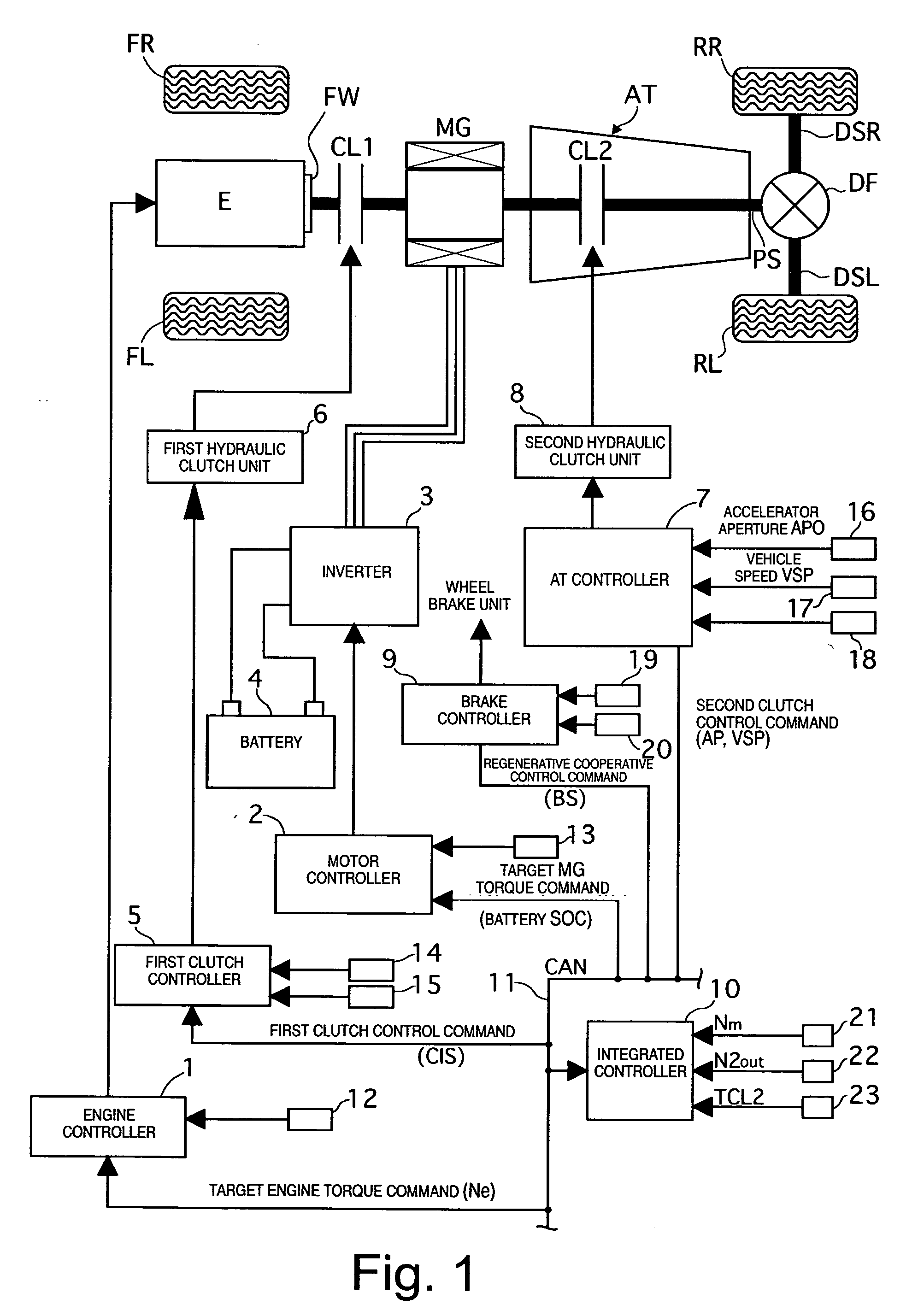

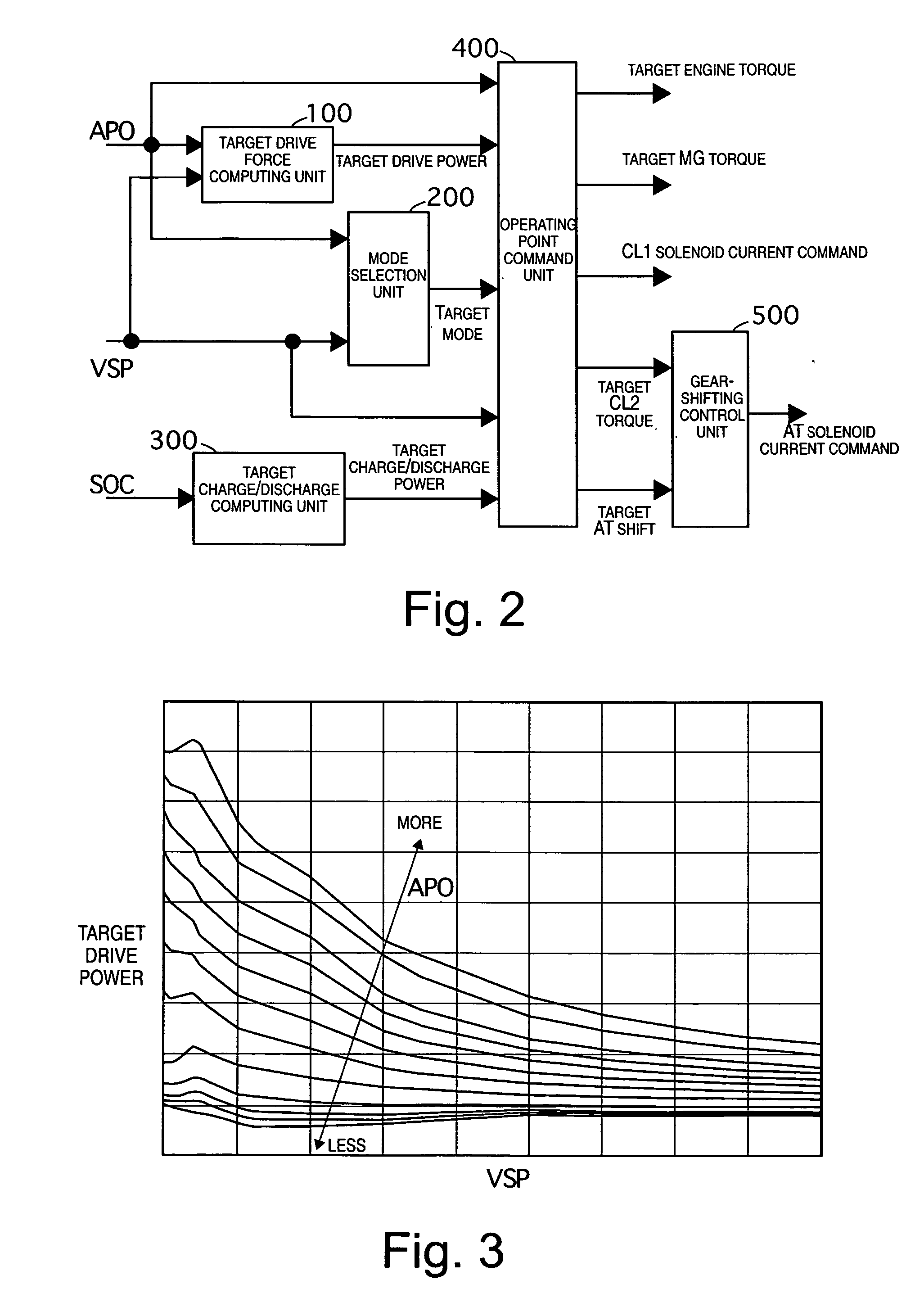

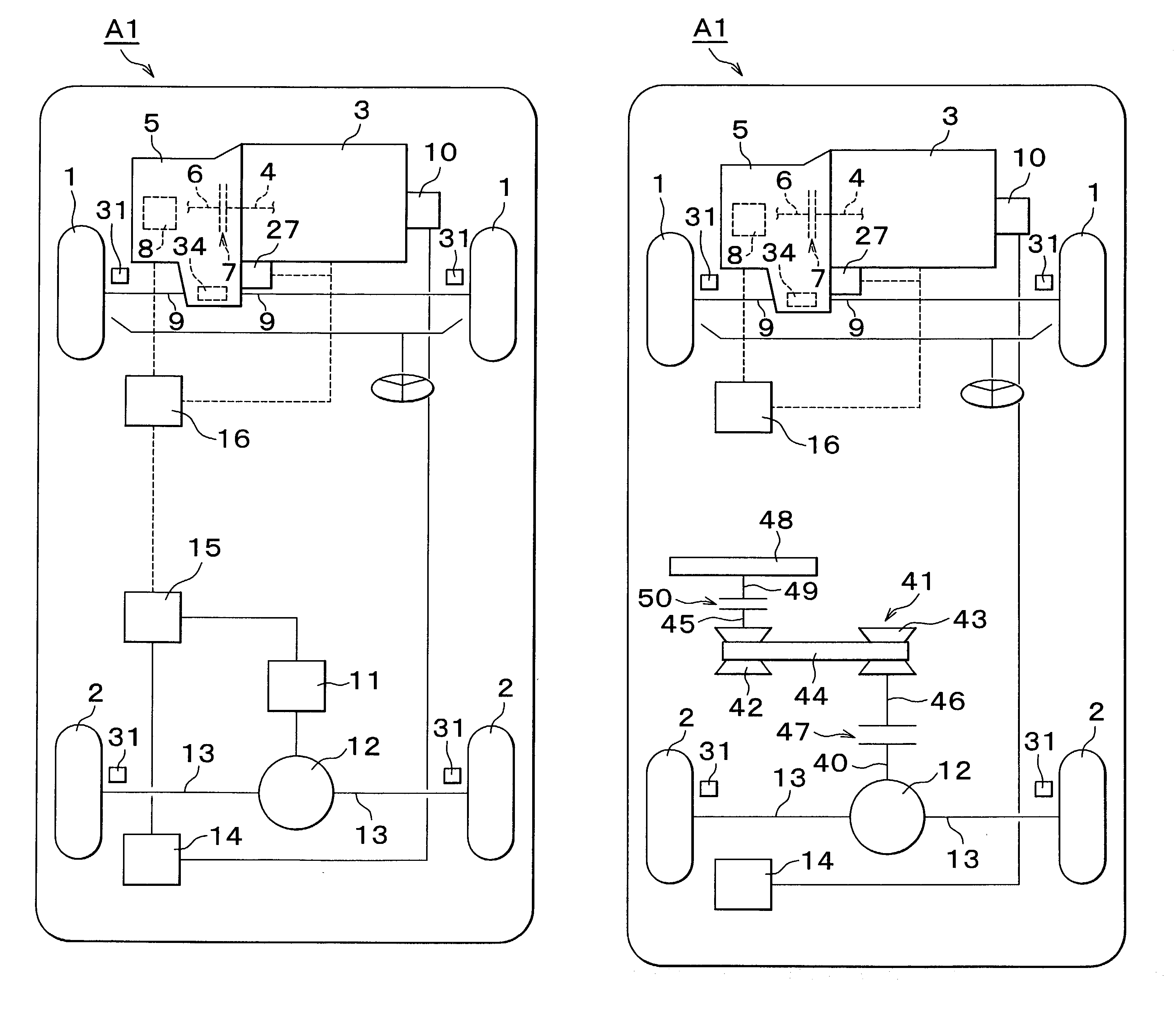

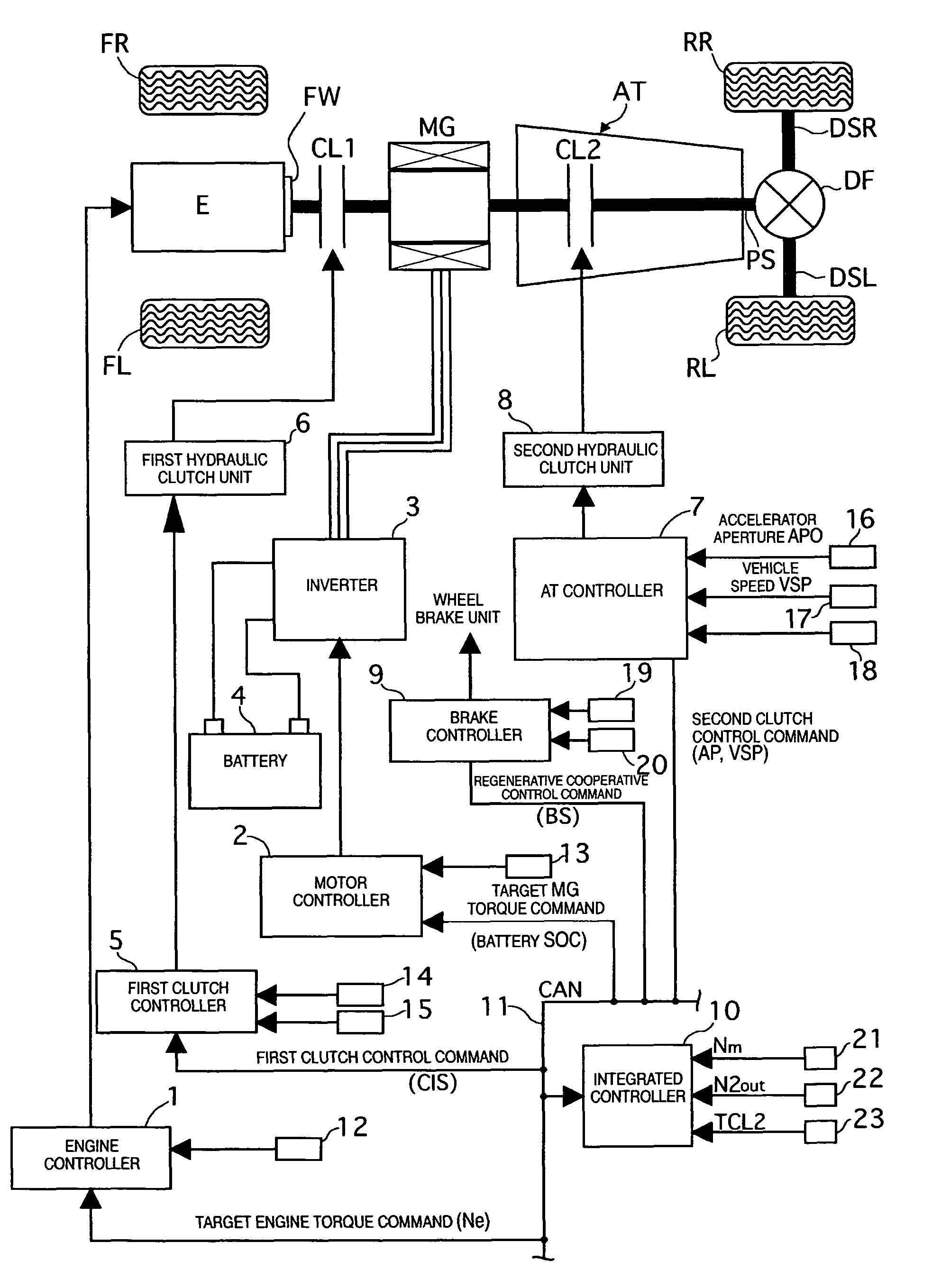

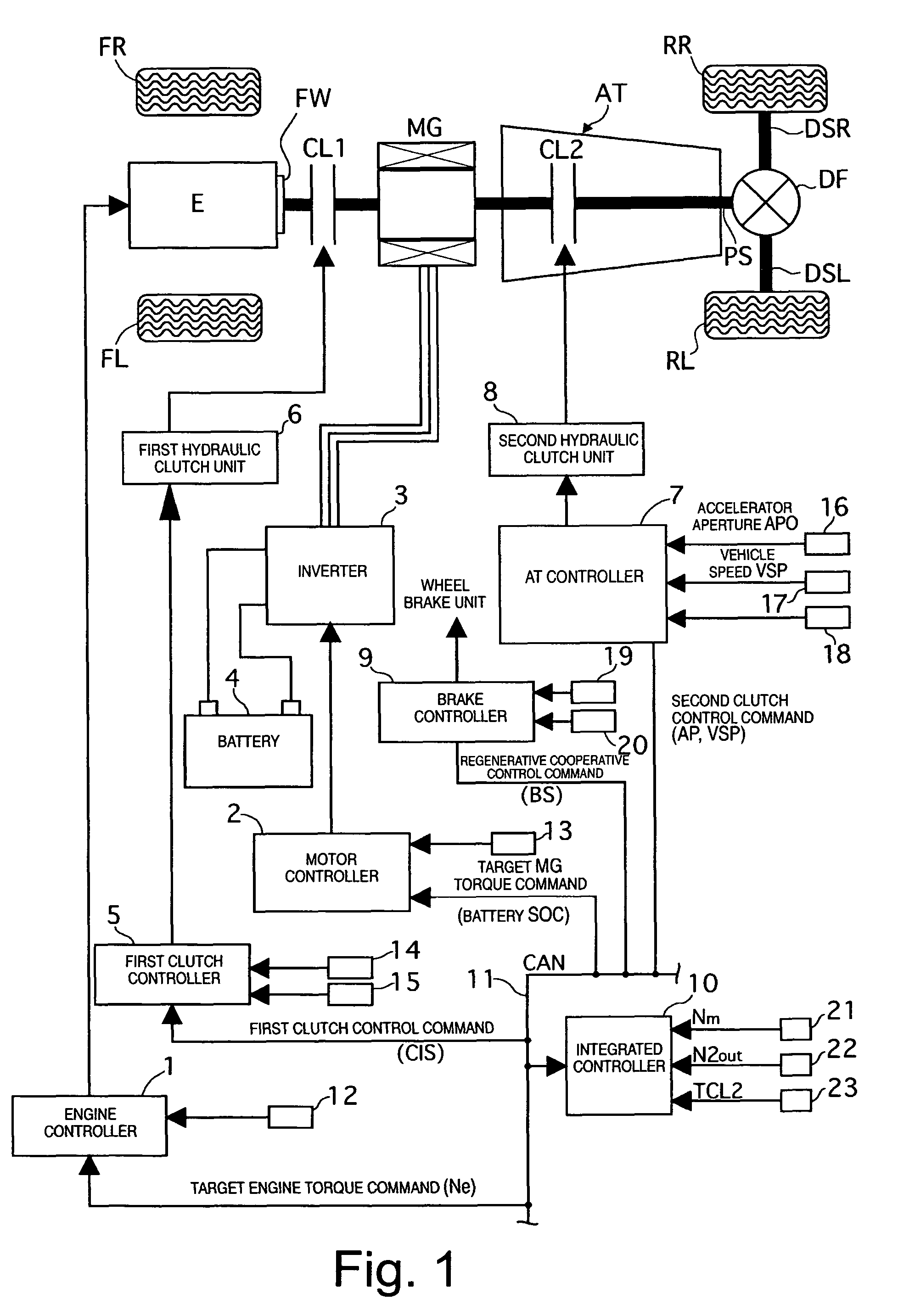

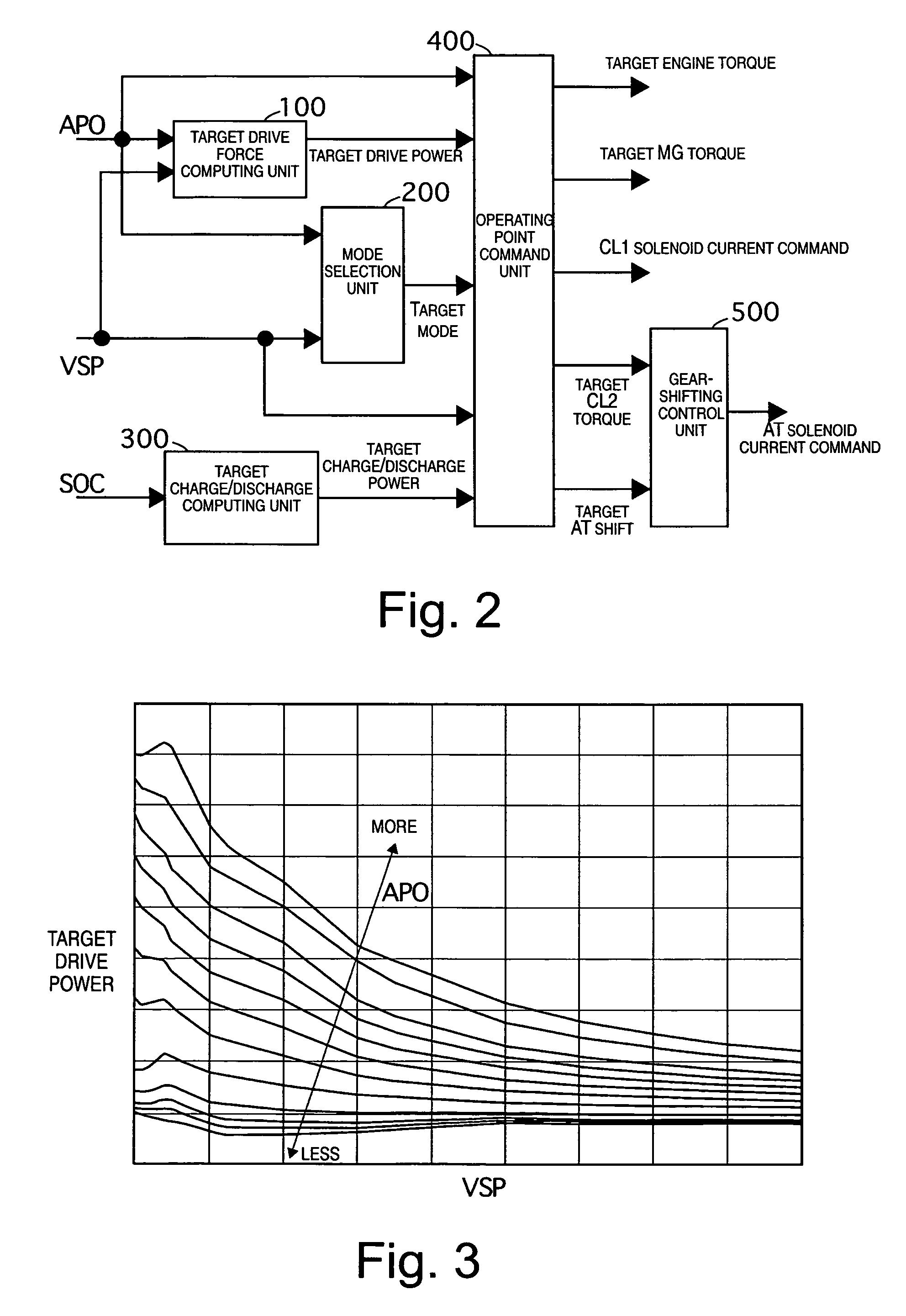

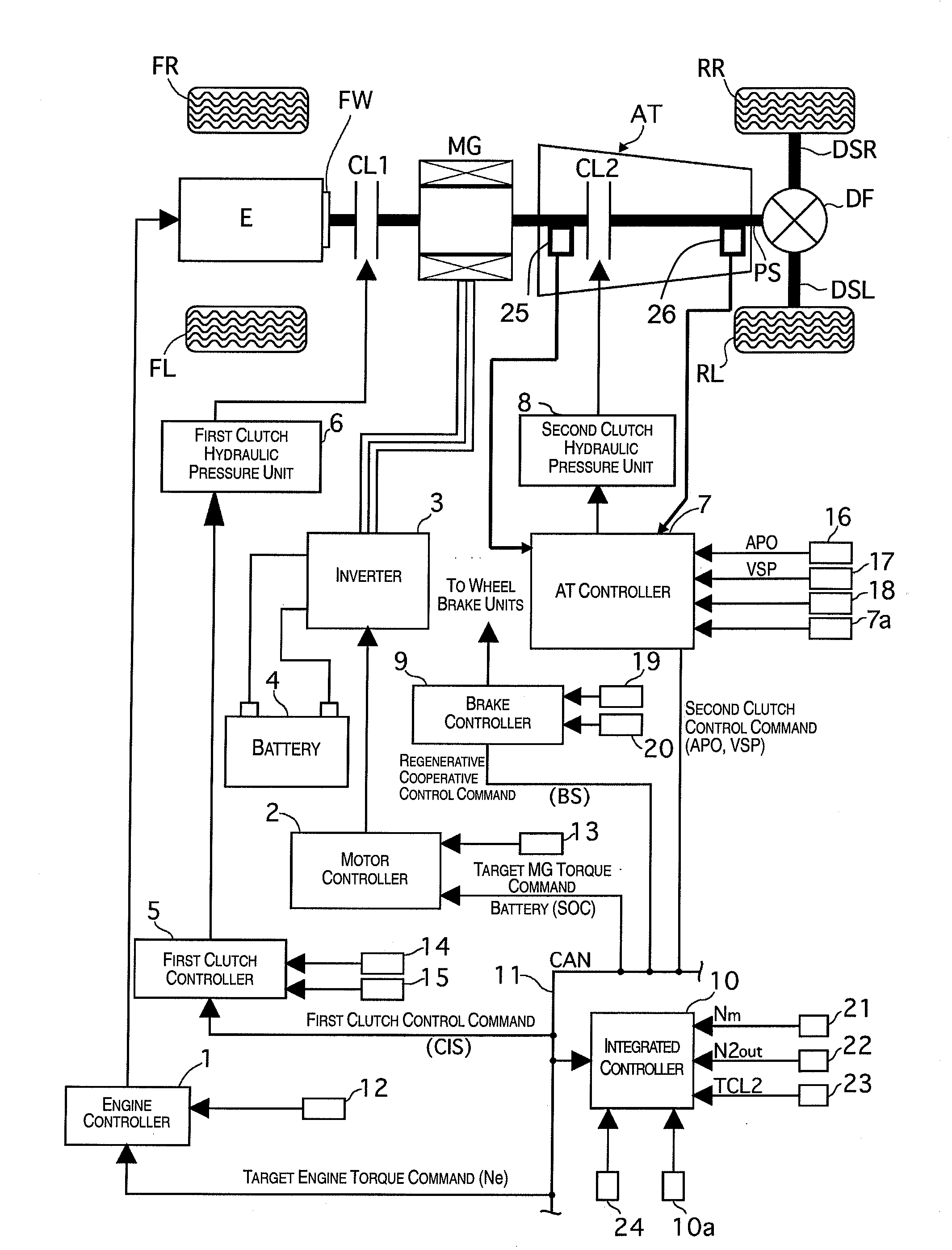

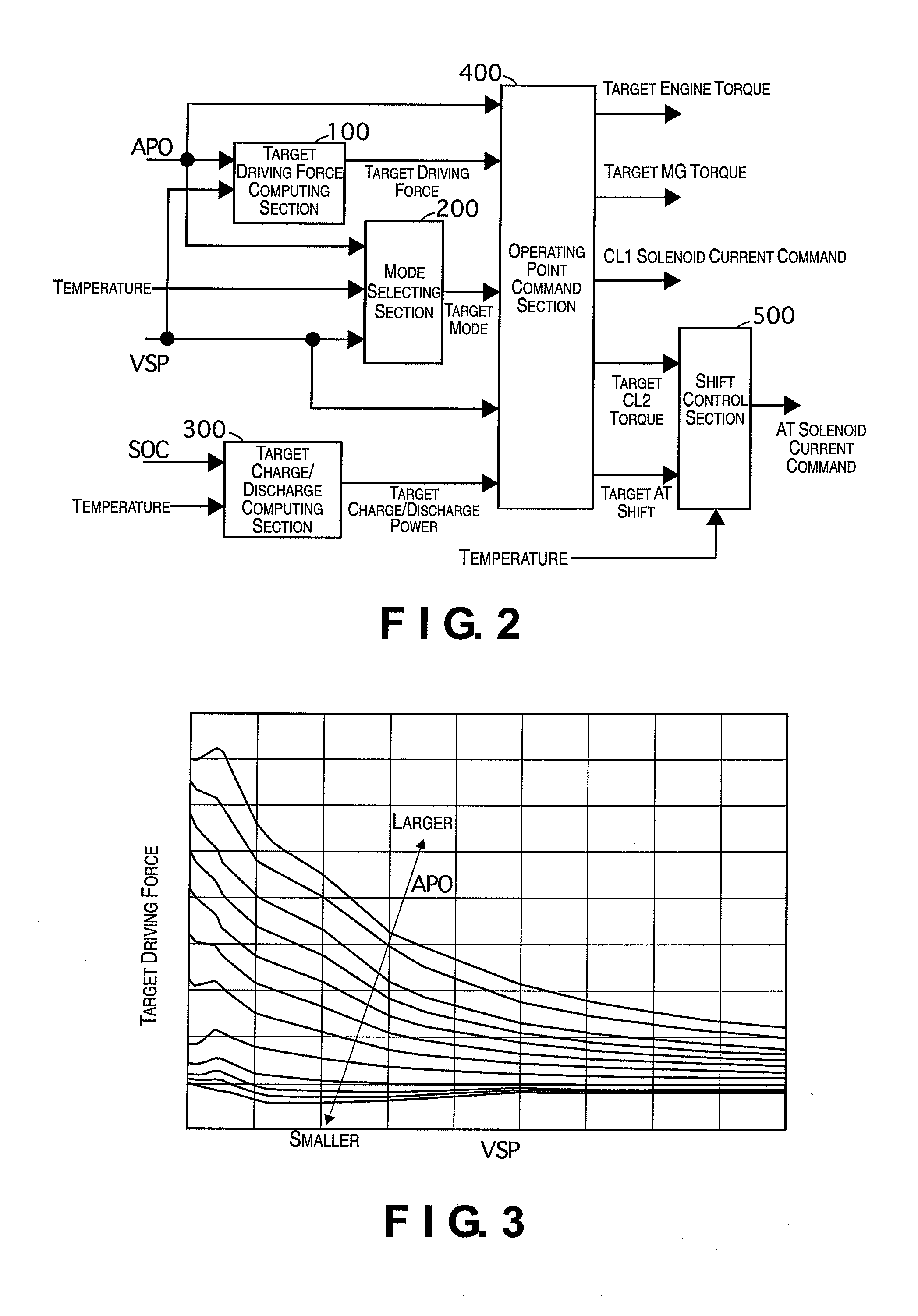

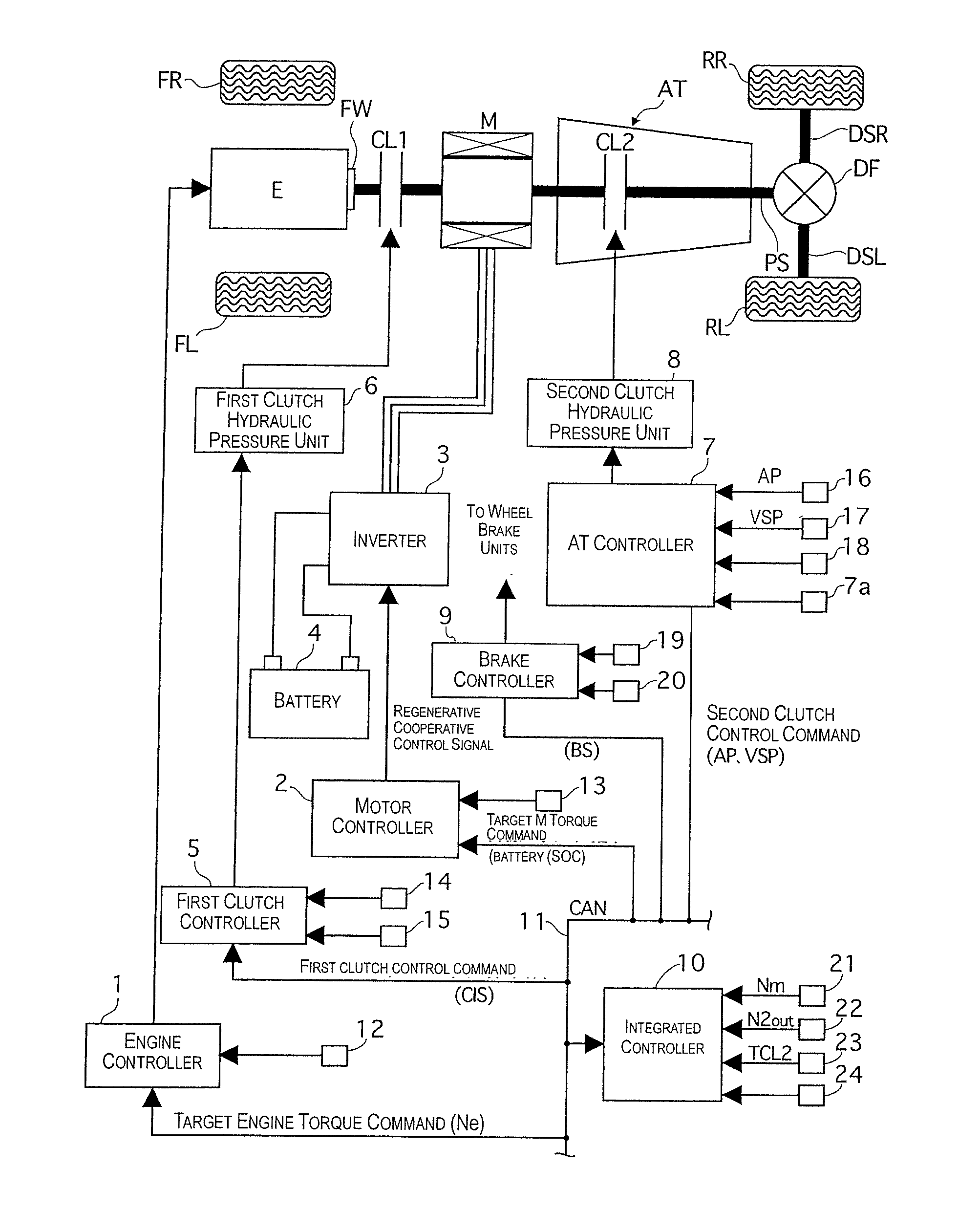

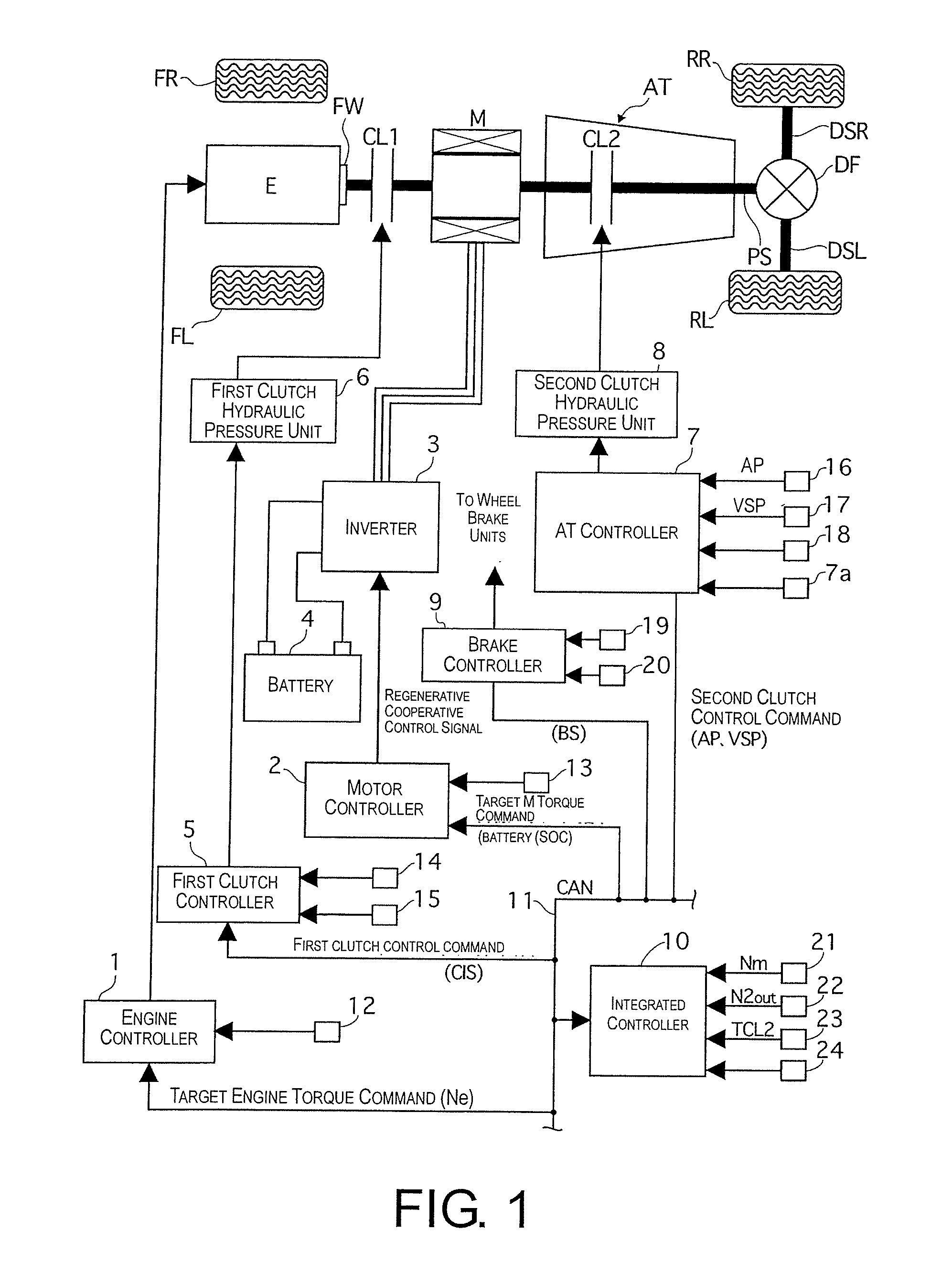

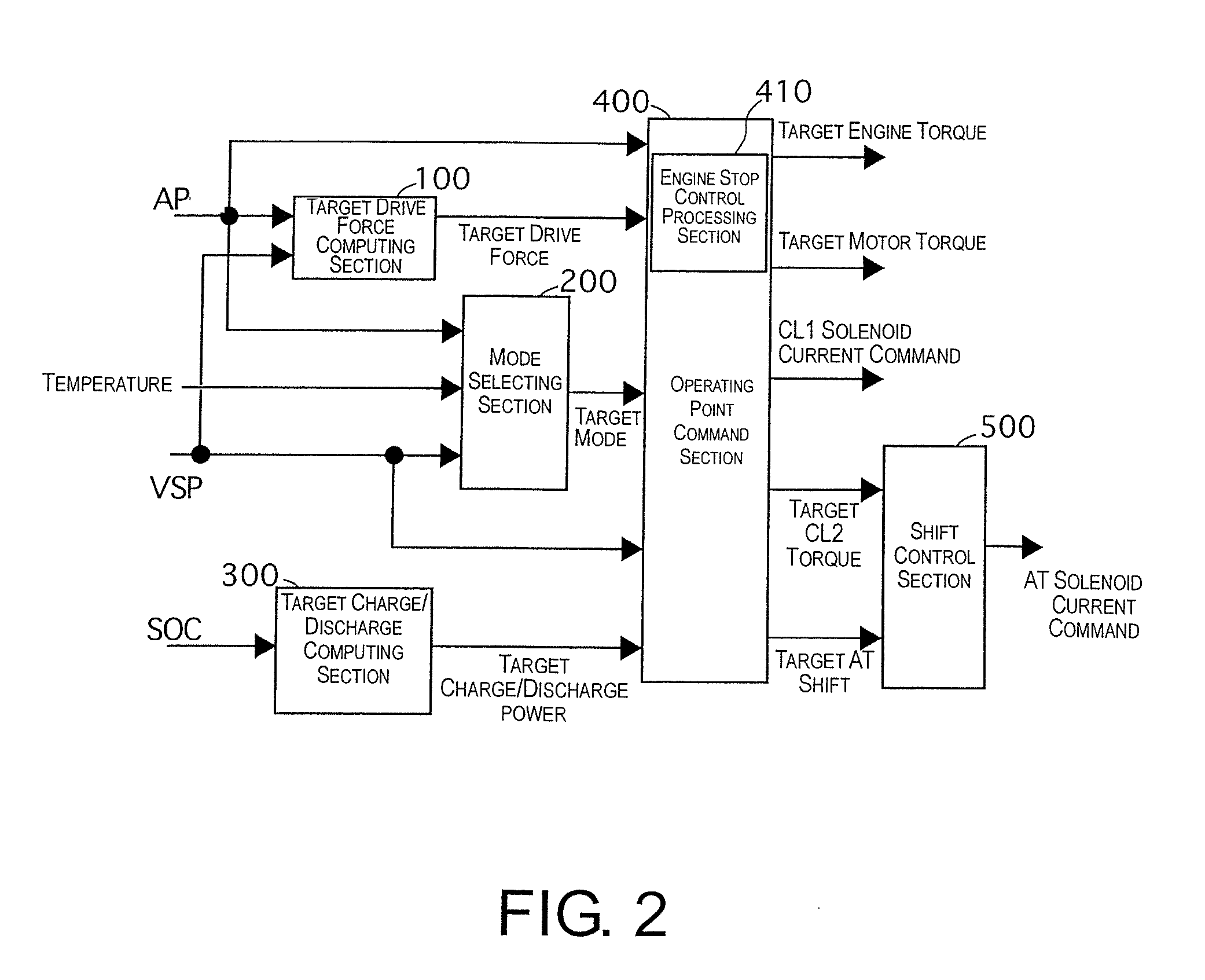

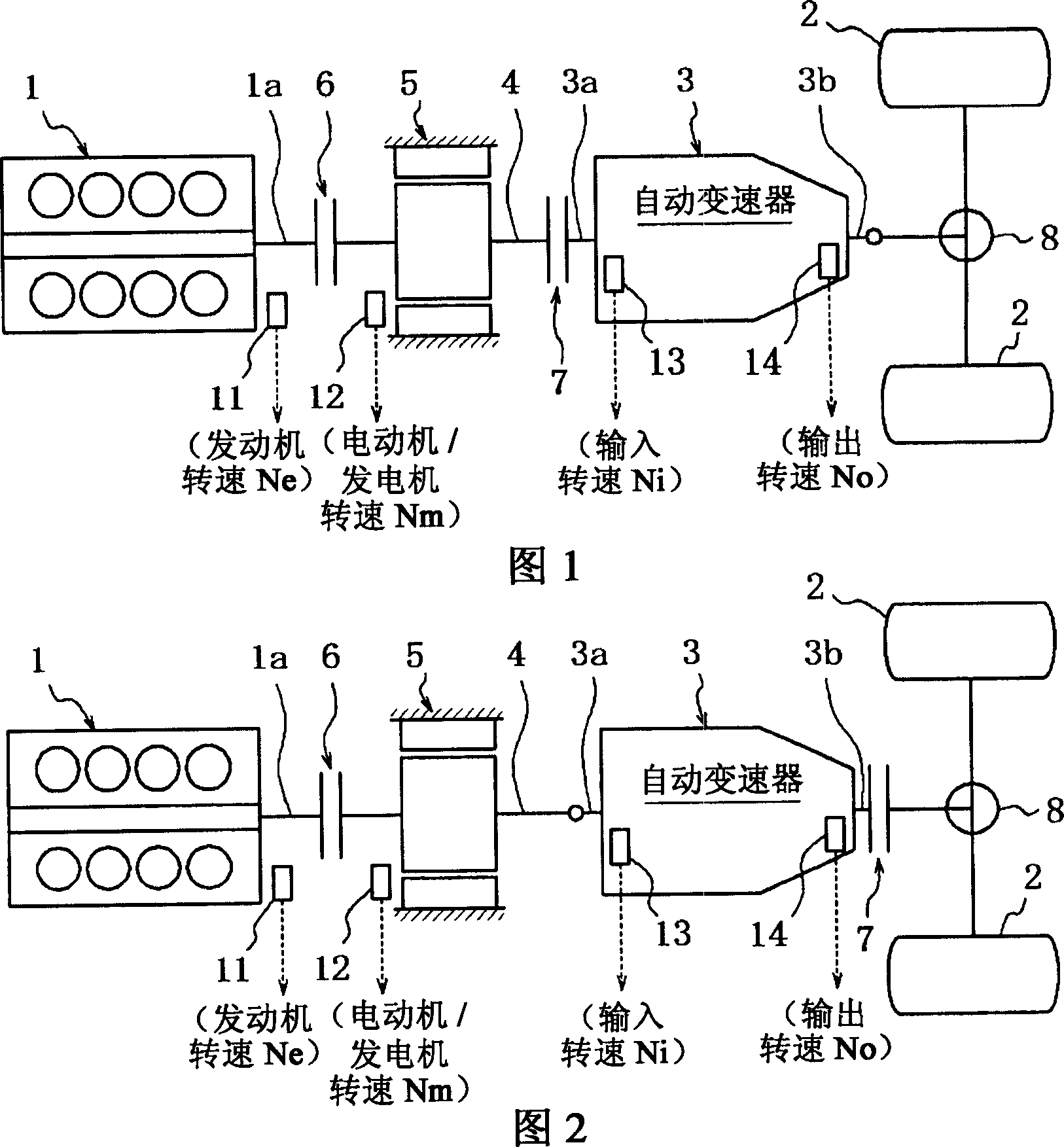

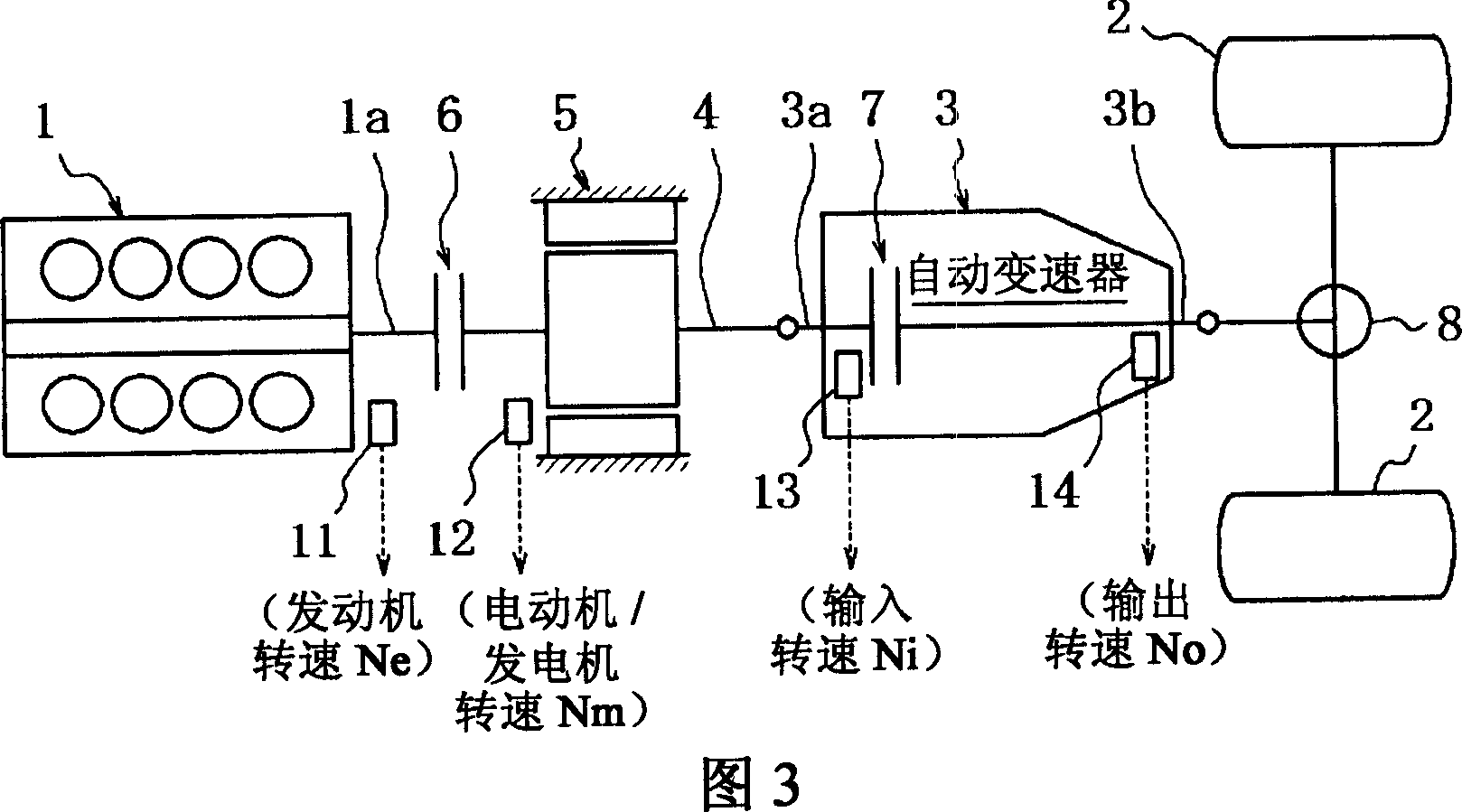

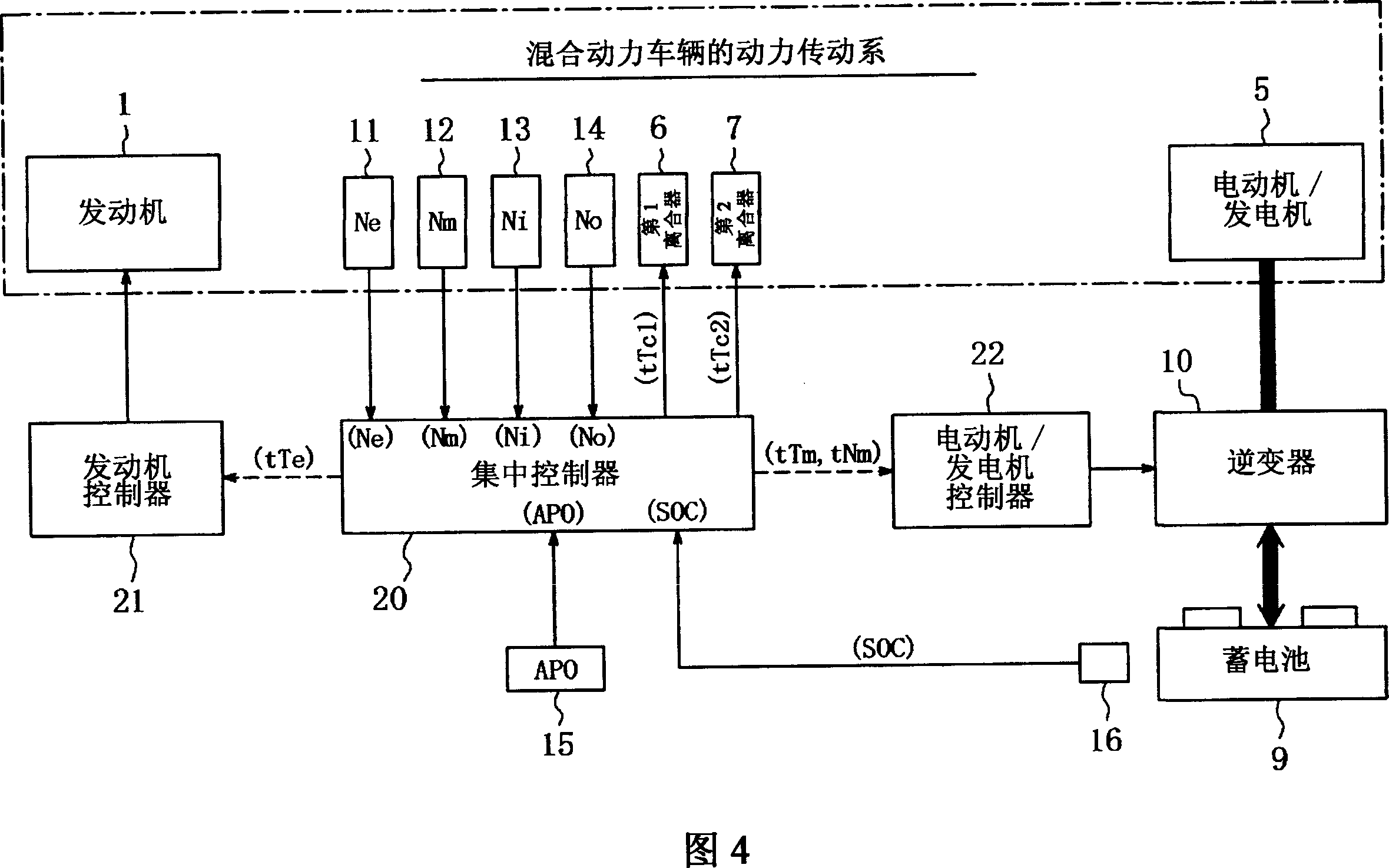

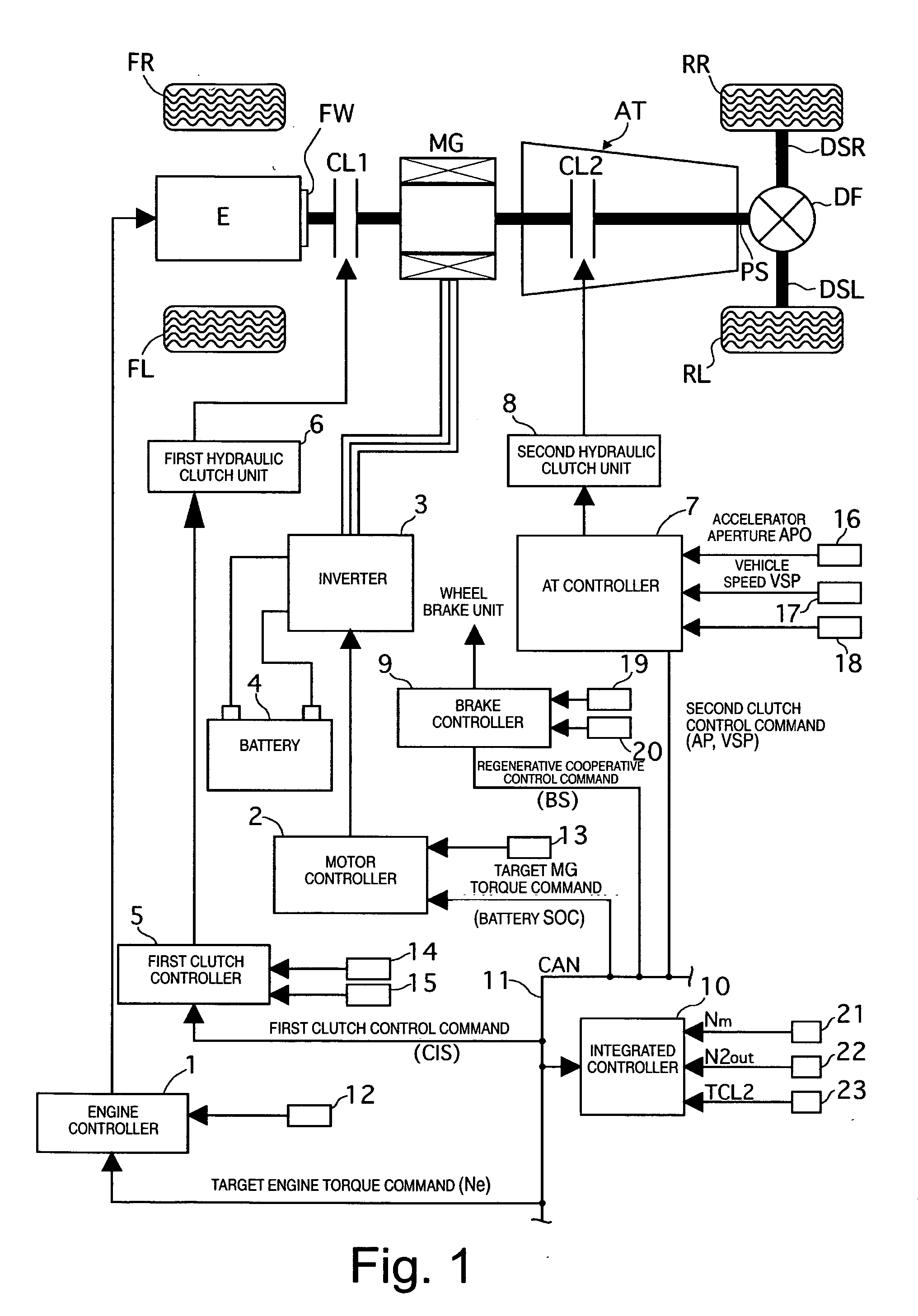

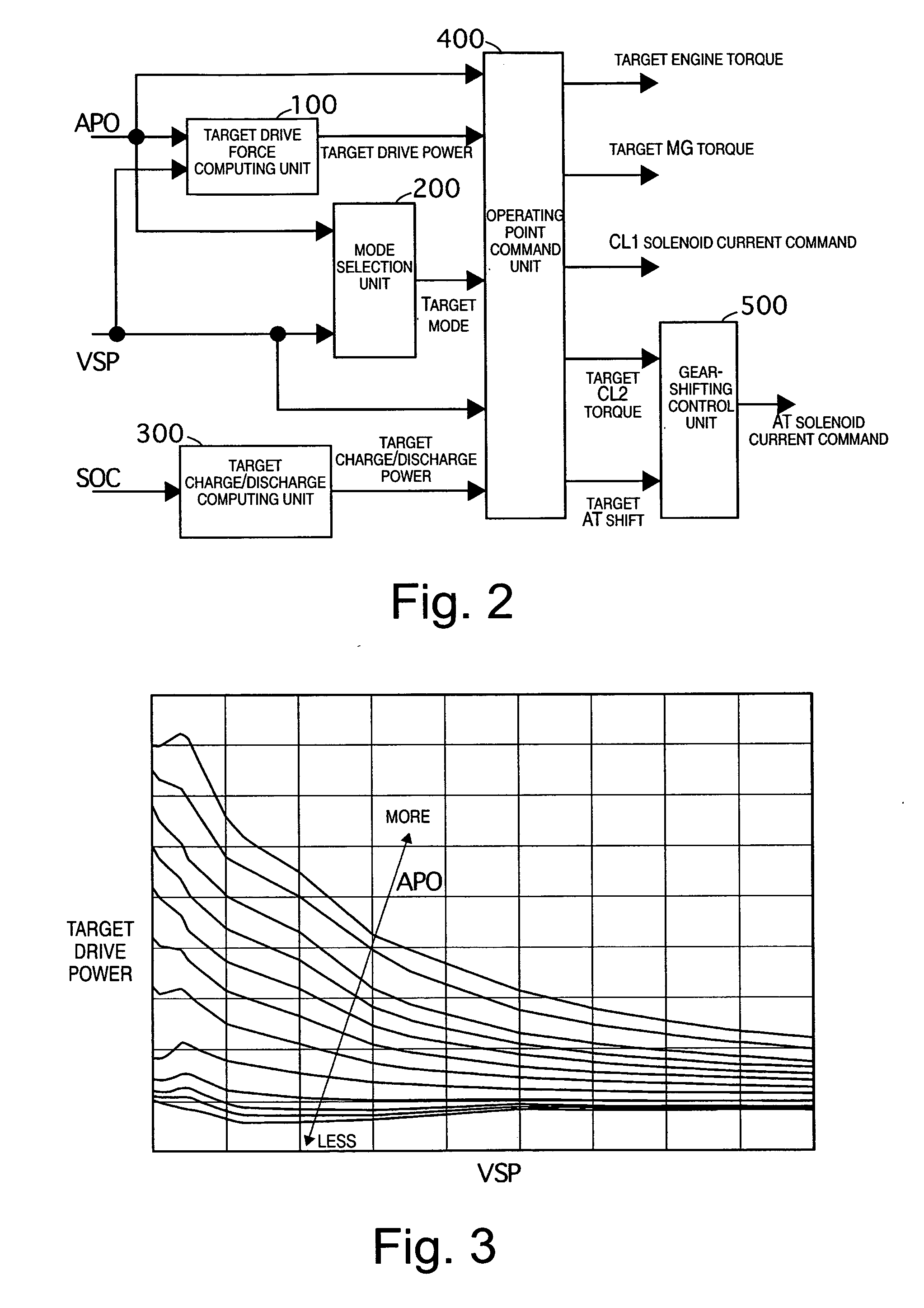

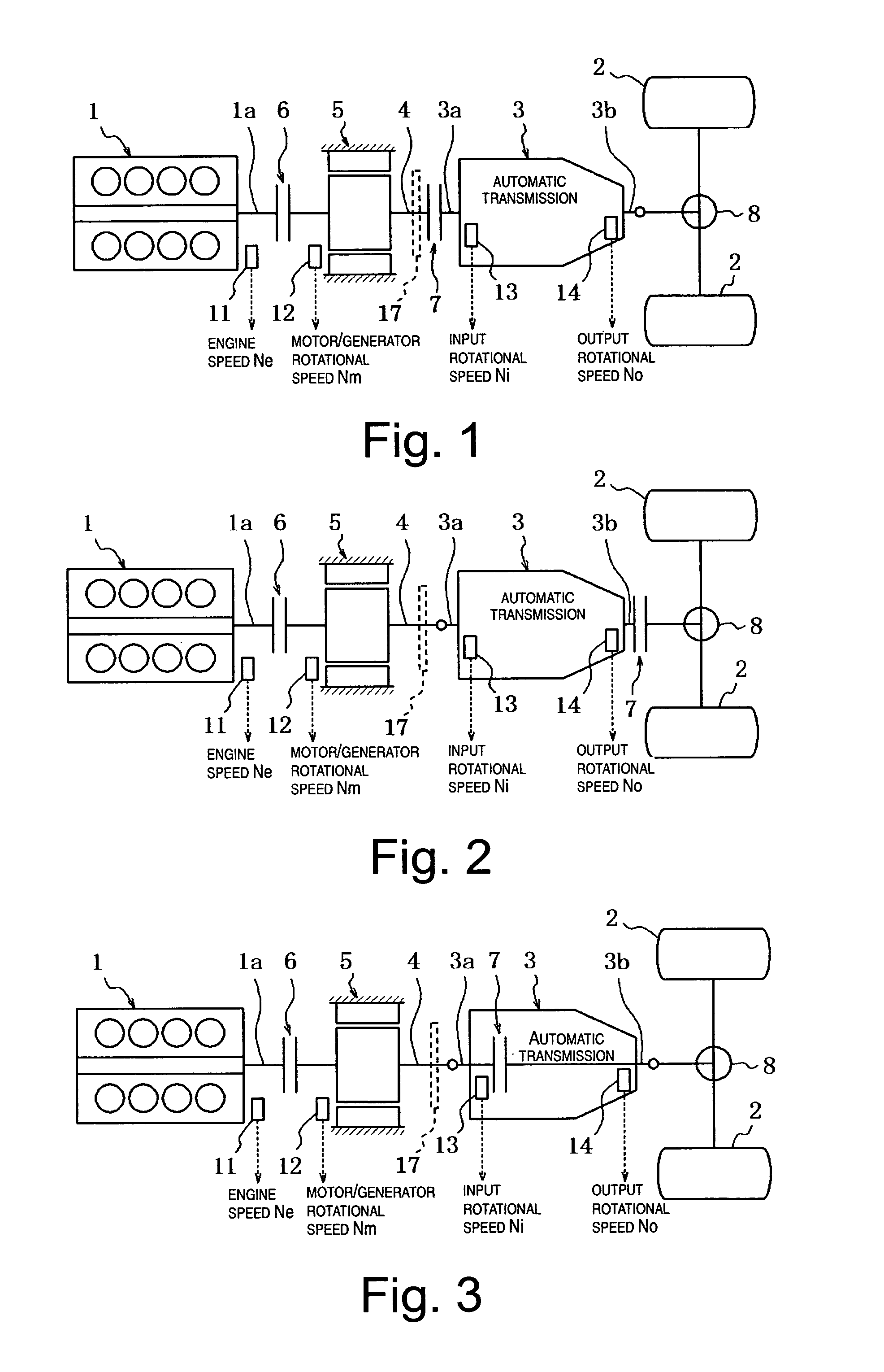

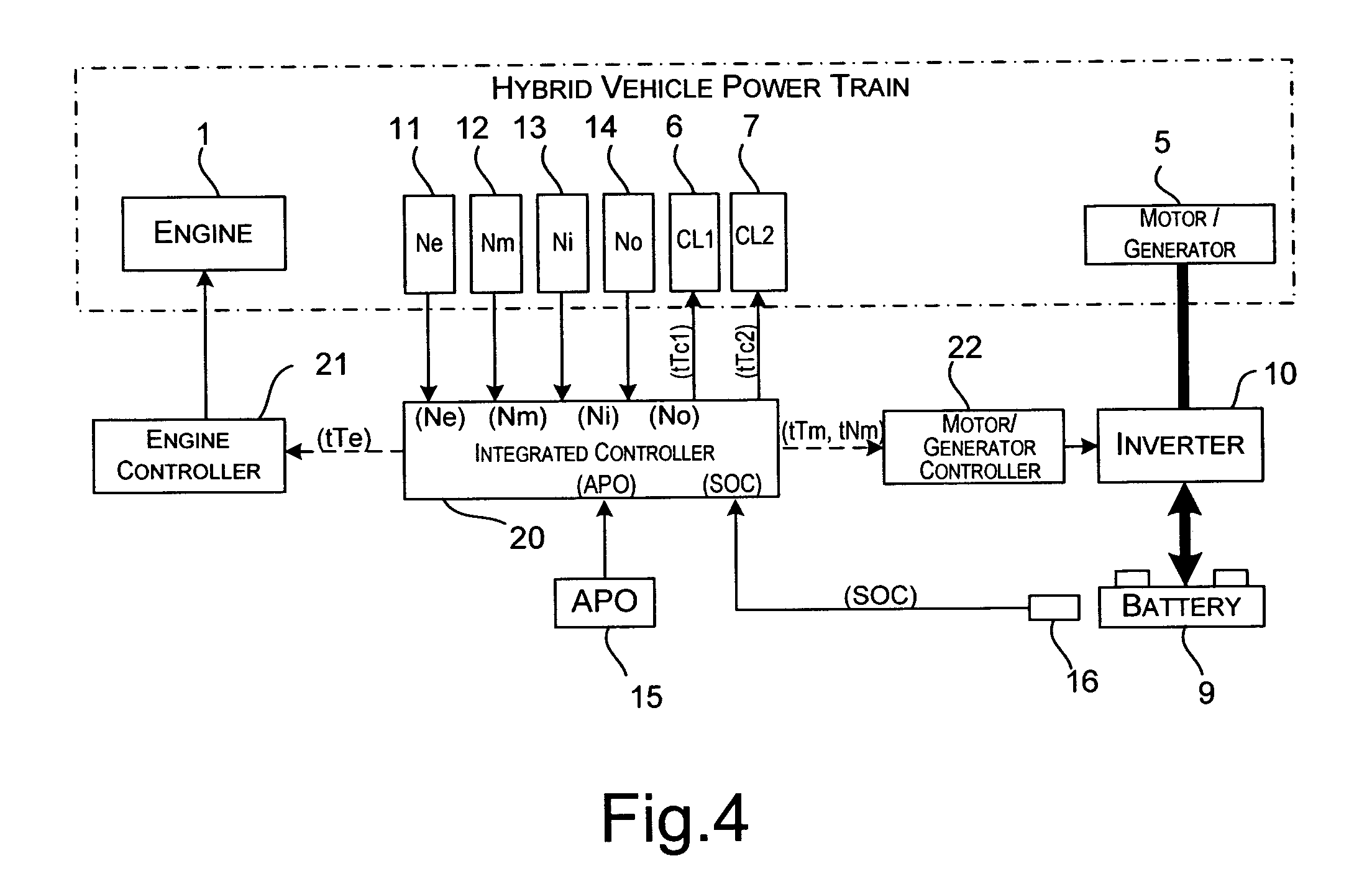

Hybrid vehicle drive control system

InactiveUS20070080005A1Suppresses torque fluctuationsReliably resolveClutchesInternal combustion piston enginesControl systemElectric drive

A hybrid vehicle drive control system selectively switches from an electric drive (EV) mode in which a first clutch is released and a second clutch is engaged, and a hybrid drive (HEV) mode in which both clutches are engaged. A slip control of the second clutch is executed when the first clutch is being connected to start the engine during switching from EV mode to HEV mode by controlling a torque transfer capacity of the second clutch to a required drive force, and by simultaneously increasing a motor / generator torque by an amount corresponding to a torque required to start the engine while maintaining a slipping state of the second clutch until connection of the first clutch is completed. Thus, a loss of torque is not felt by the driver and the shock is small when the engine is started during switching from EV mode to HEV mode.

Owner:NISSAN MOTOR CO LTD

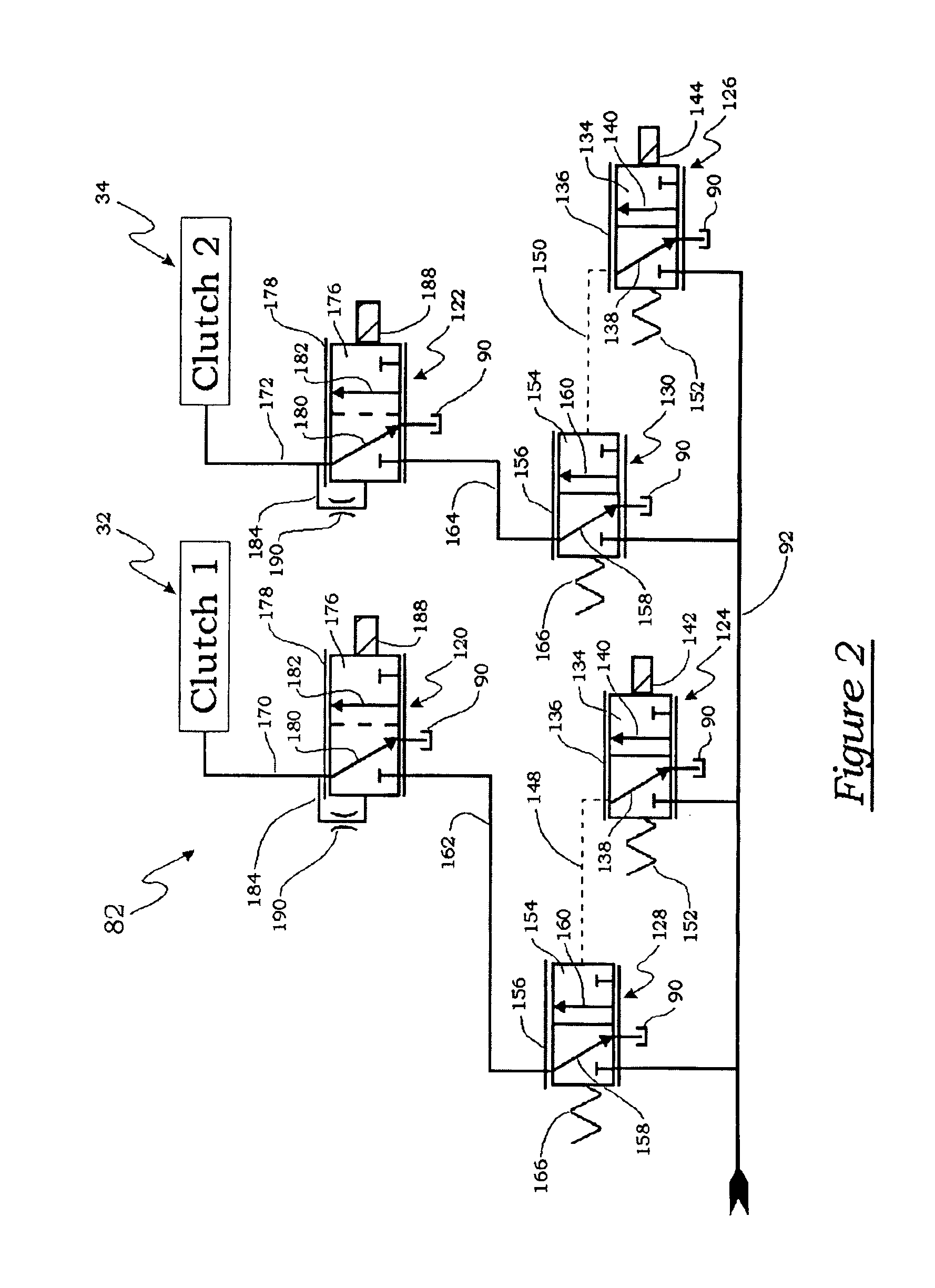

Method of controlling a dual clutch transmission

InactiveUS6887184B2Improving overall drivability and comfortClutchesDigital data processing detailsGear driveTorque transmission

A method of controlling the clutches of a dual clutch transmission during a two-gear positive downshift, wherein the first clutch drives an initial gear and the final gear and the second clutch drives an intermediate gear. The torque transfer across each clutch is controlled so that the torque output of the transmission will be linearly changed over from the first clutch to the second clutch to cause the engine to track a target engine speed profile. The method changes over the gears driven by the first clutch from the initial gear to the final gear as the engine continues to tracks the target speed. The torque transfer across each clutch is controlled so that the torque output will be linearly changed back from the second clutch to the first clutch in an inversely proportional rate to continue to cause the engine to track the target engine speed profile.

Owner:BORGWARNER INC

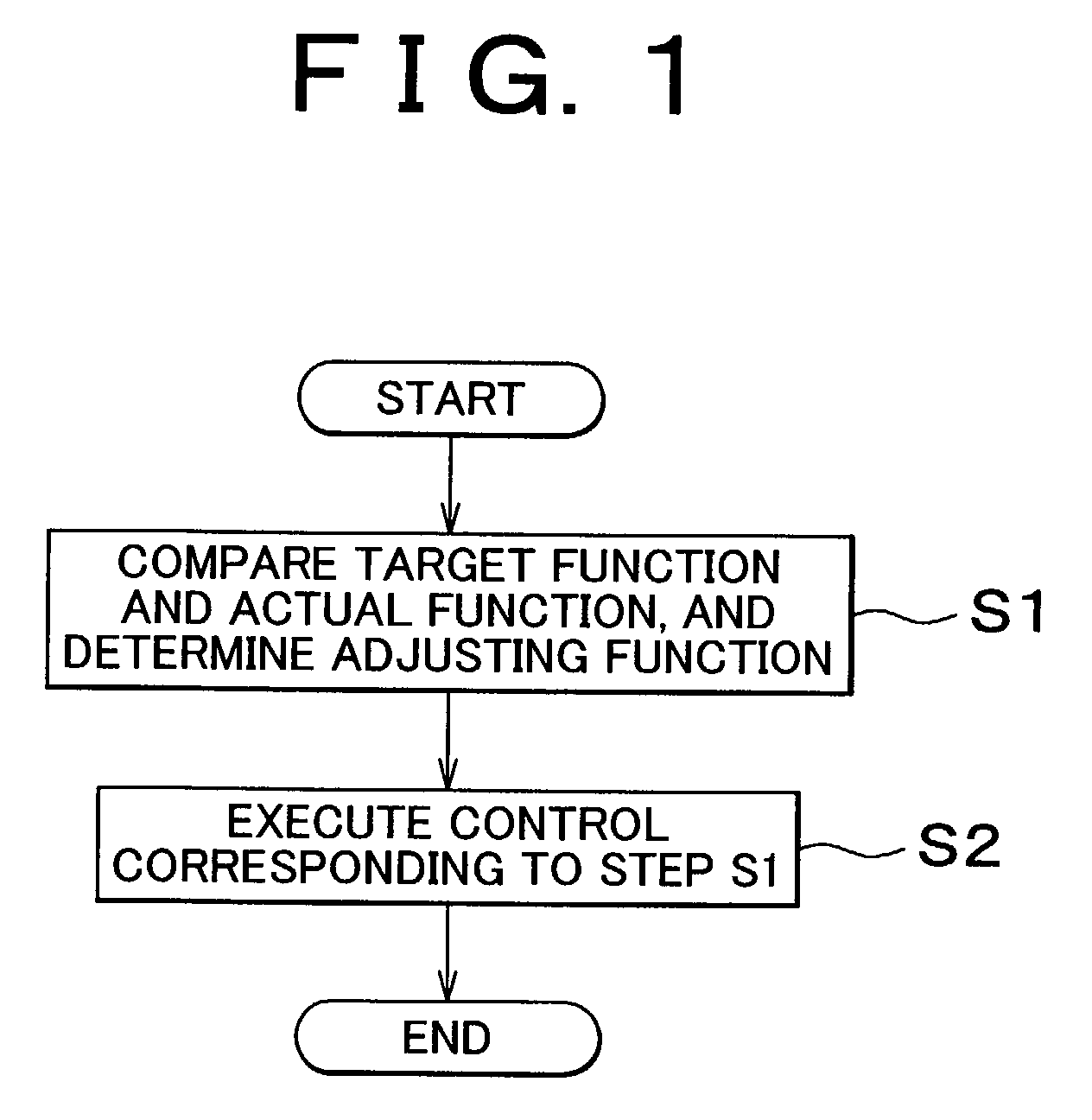

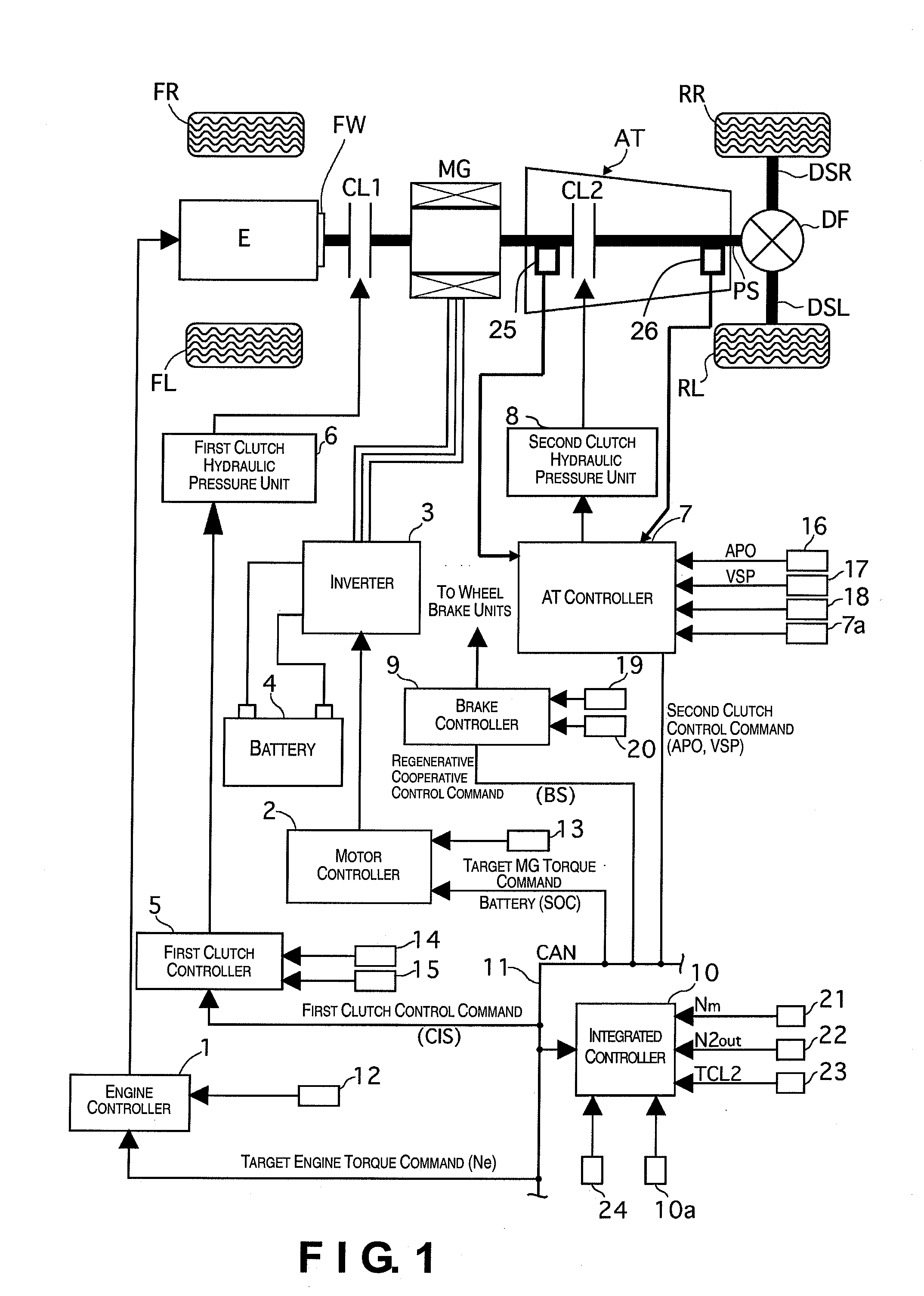

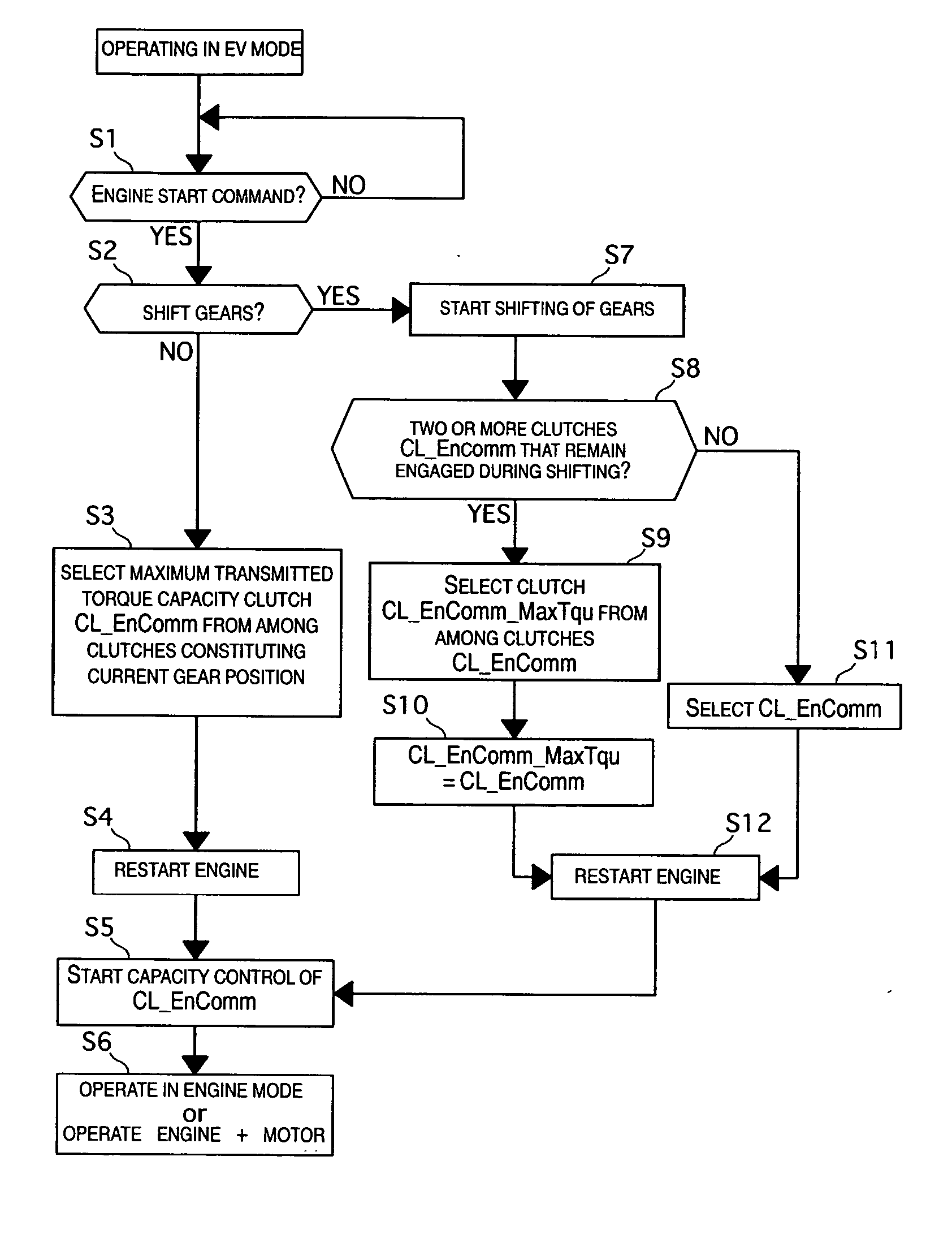

Hybrid vehicle drive control system

ActiveUS20070102211A1Lack of torque transfer capacity can be preventedAvoid it happening againClutchesPower operated startersDrive wheelMode change

A hybrid vehicle drive control system has a first clutch interposed between an engine and a motor / generator, a transmission including several gear position clutches arranged between the motor / generator and a drive wheel, and a controller. The controller selectively starts the engine using torque from the first clutch during a mode drive change from an electric drive mode to a hybrid drive mode. When an engine start command occurs during the drive mode change, the controller selects the engaged gear position clutch that has the maximum torque transfer capacity from the engaged clutches constituting a vehicle running gear occurring during an engine starting process as a second clutch to be controlled. Then the controller executes a slip control of the second clutch when the first clutch is being connected to start the engine during the mode change from the electric drive mode to the hybrid drive mode.

Owner:NISSAN MOTOR CO LTD

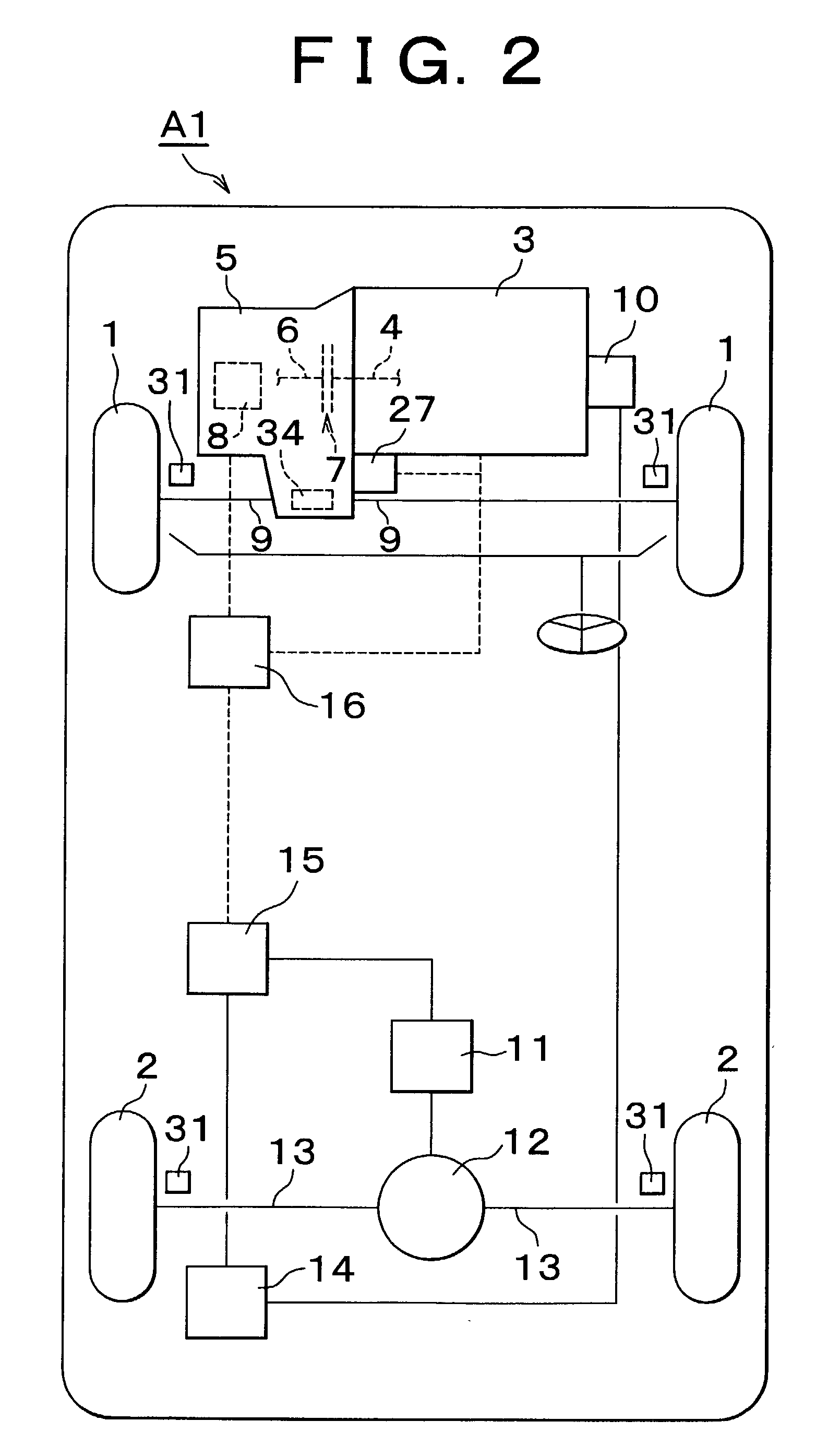

Vehicular control apparatus and method

Owner:TOYOTA JIDOSHA KK

Hybrid vehicle drive control system

ActiveUS7770678B2Lack of torque transfer capacity can be preventedAvoid it happening againClutchesPower operated startersDrive wheelMode change

A hybrid vehicle drive control system has a first clutch interposed between an engine and a motor / generator, a transmission including several gear position clutches arranged between the motor / generator and a drive wheel, and a controller. The controller selectively starts the engine using torque from the first clutch during a mode drive change from an electric drive mode to a hybrid drive mode. When an engine start command occurs during the drive mode change, the controller selects the engaged gear position clutch that has the maximum torque transfer capacity from the engaged clutches constituting a vehicle running gear occurring during an engine starting process as a second clutch to be controlled. Then the controller executes a slip control of the second clutch when the first clutch is being connected to start the engine during the mode change from the electric drive mode to the hybrid drive mode.

Owner:NISSAN MOTOR CO LTD

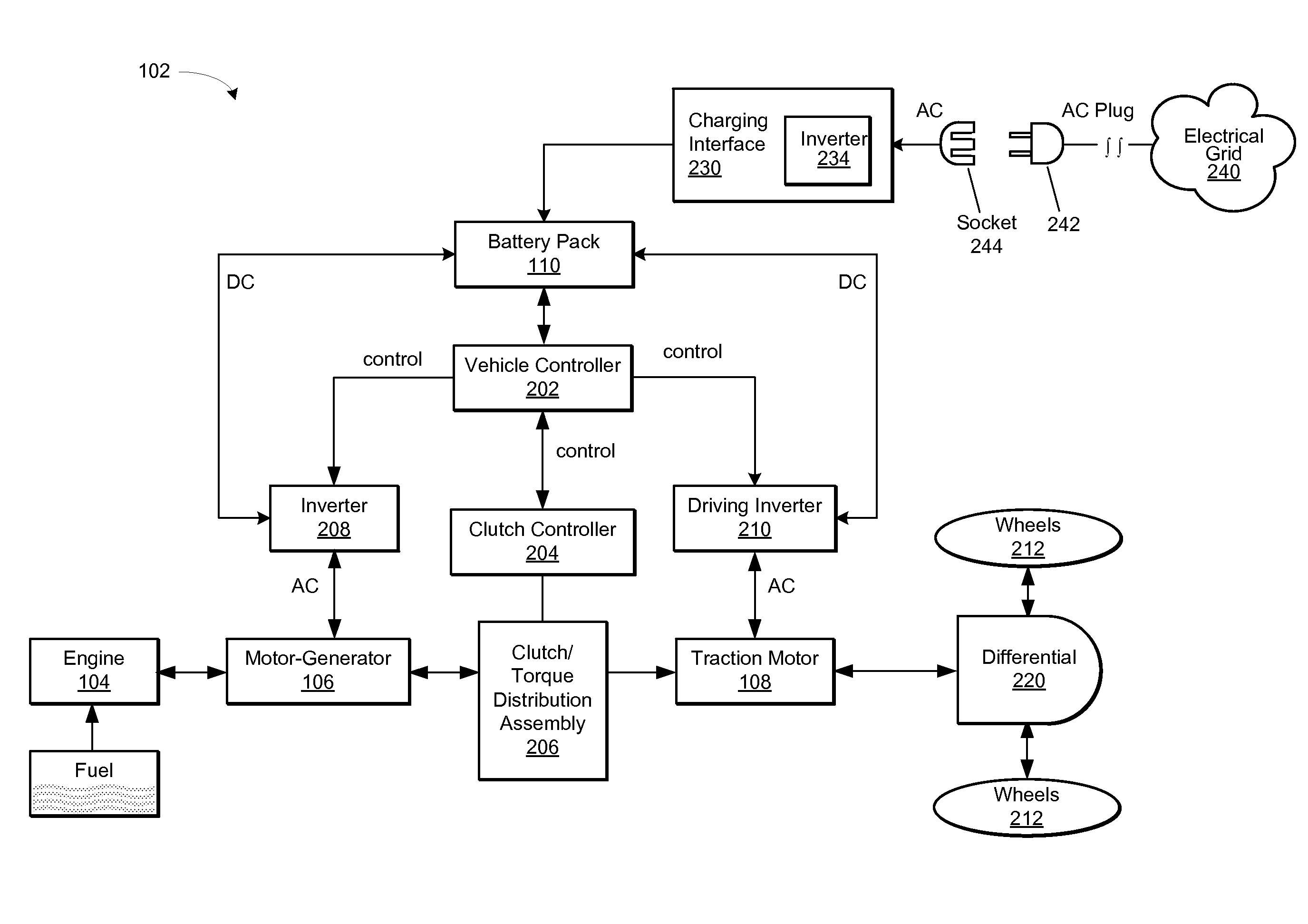

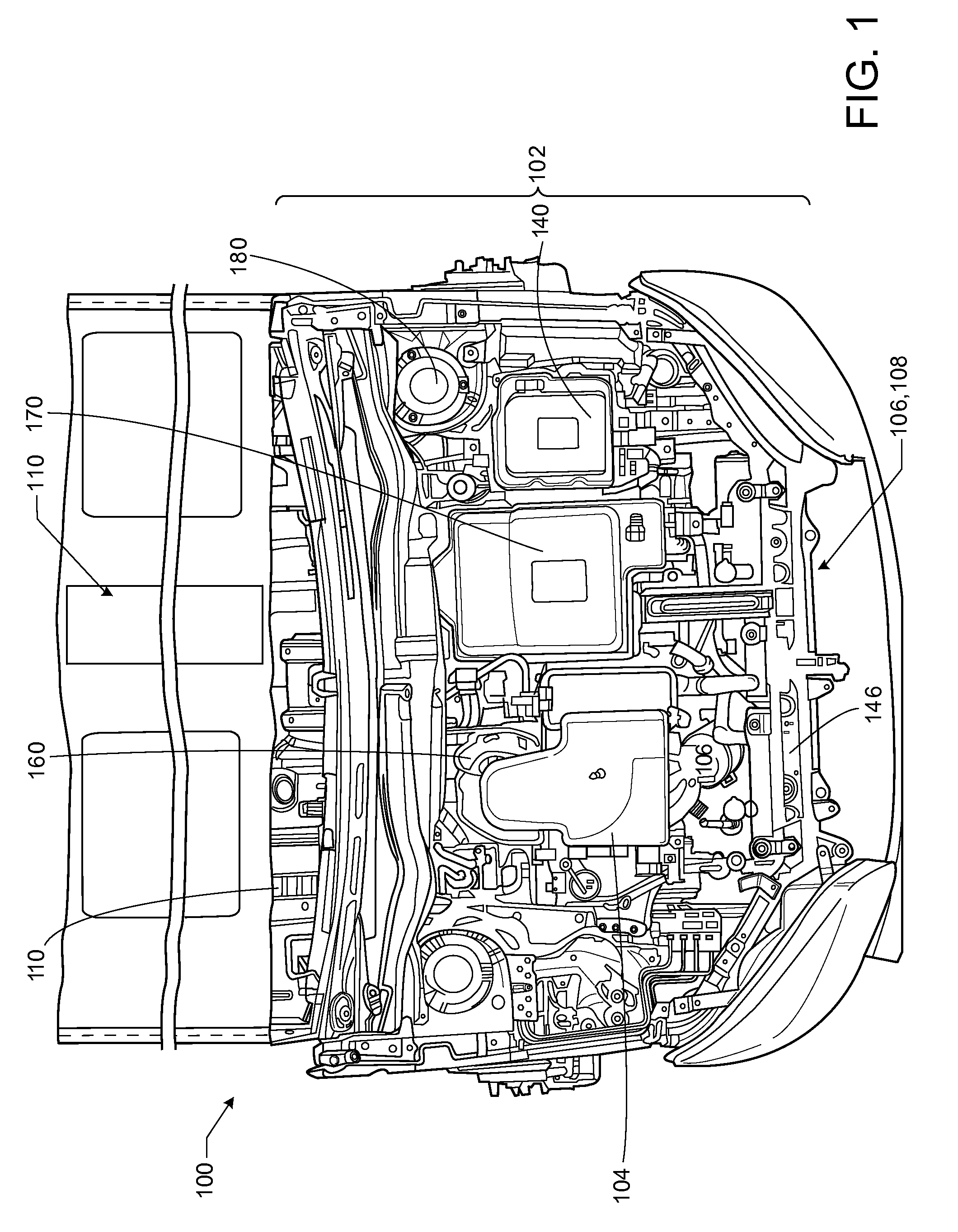

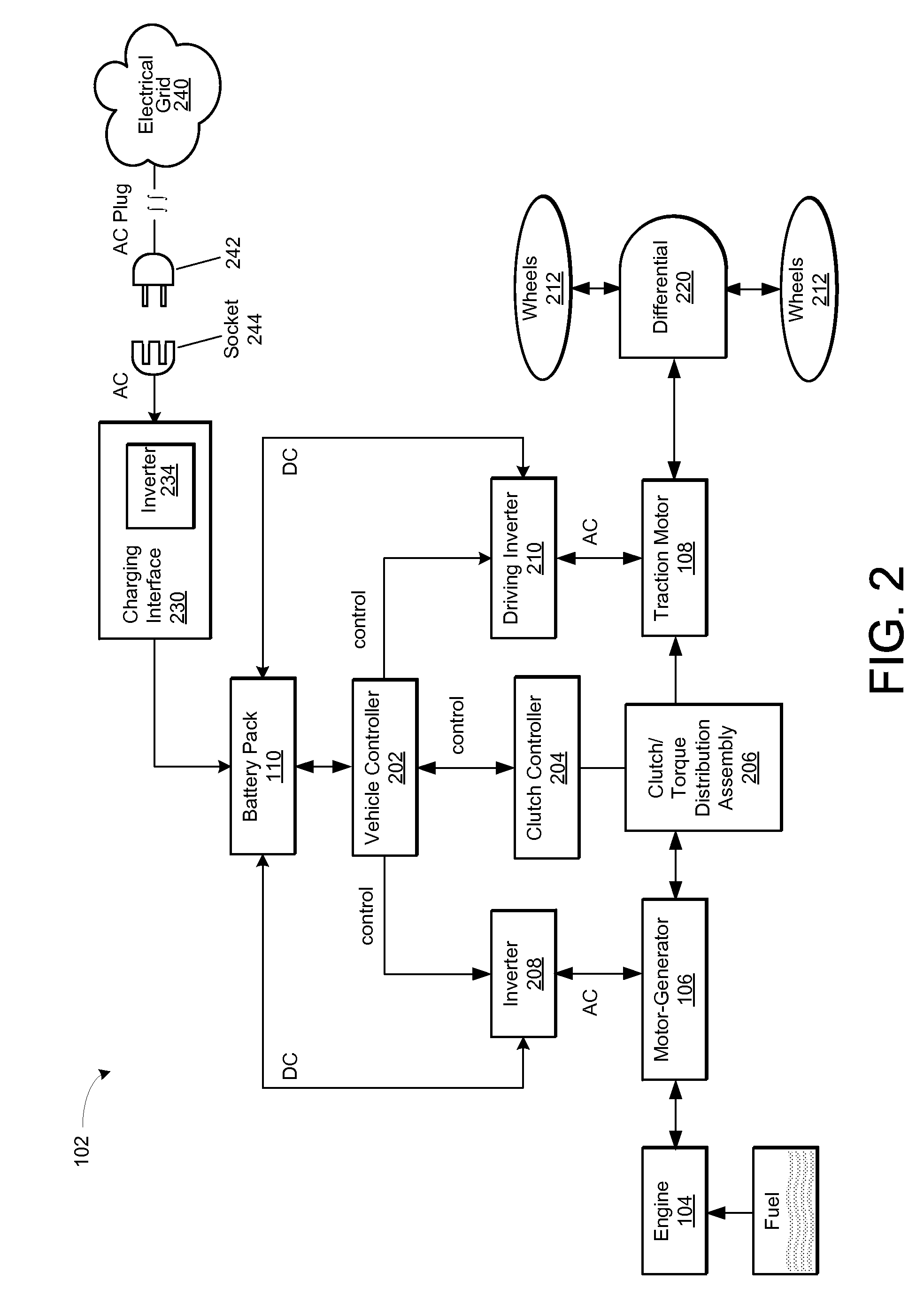

Hybrid Vehicle Having Engagable Clutch Assembly Coupled Between Engine And Traction Motor

A hybrid vehicle includes a battery system, an internal combustion engine, a first motor / generator, a second motor / generator, and an engageable clutch assembly. The engageable clutch assembly is disposed between the internal combustion engine and the first motor / generator. When engaged, the engageable clutch assembly couples the rotor spindle of the second motor / generator with the hollow rotor shaft of the first motor / generator. The engageable clutch assembly may also operate in a first mechanical mode that selectively engages and disengages the internal combustion engine from the second motor / generator, or operate in a second mechanical mode that dampens shock between the internal combustion engine and the first motor / generator when the international combustion engine operates at a rotational speed that is different than a rotational of the first motor / generator.

Owner:BYD CO LTD

Hybrid vehicle control apparatus

A hybrid vehicle control apparatus includes an engine, a motor, first and second engaging elements, an input rotational speed and a controller. The first engaging element is arranged between the engine and the motor to selectively connect and disconnect the engine and the motor. The second engaging element is arranged between the motor and a drive wheel to selectively connect and disconnect the motor and the drive wheel. The input rotational speed detecting section is configured to detect an input rotational speed of the second engaging element corresponding to a rotational speed of the motor. The controller is configured to determine whether the second engaging element is seized based on the input rotational speed when a disengagement command or a slip engagement command has been issued to the second engaging element and a drive force of at least one of the engine and the motor has been changed.

Owner:NISSAN MOTOR CO LTD

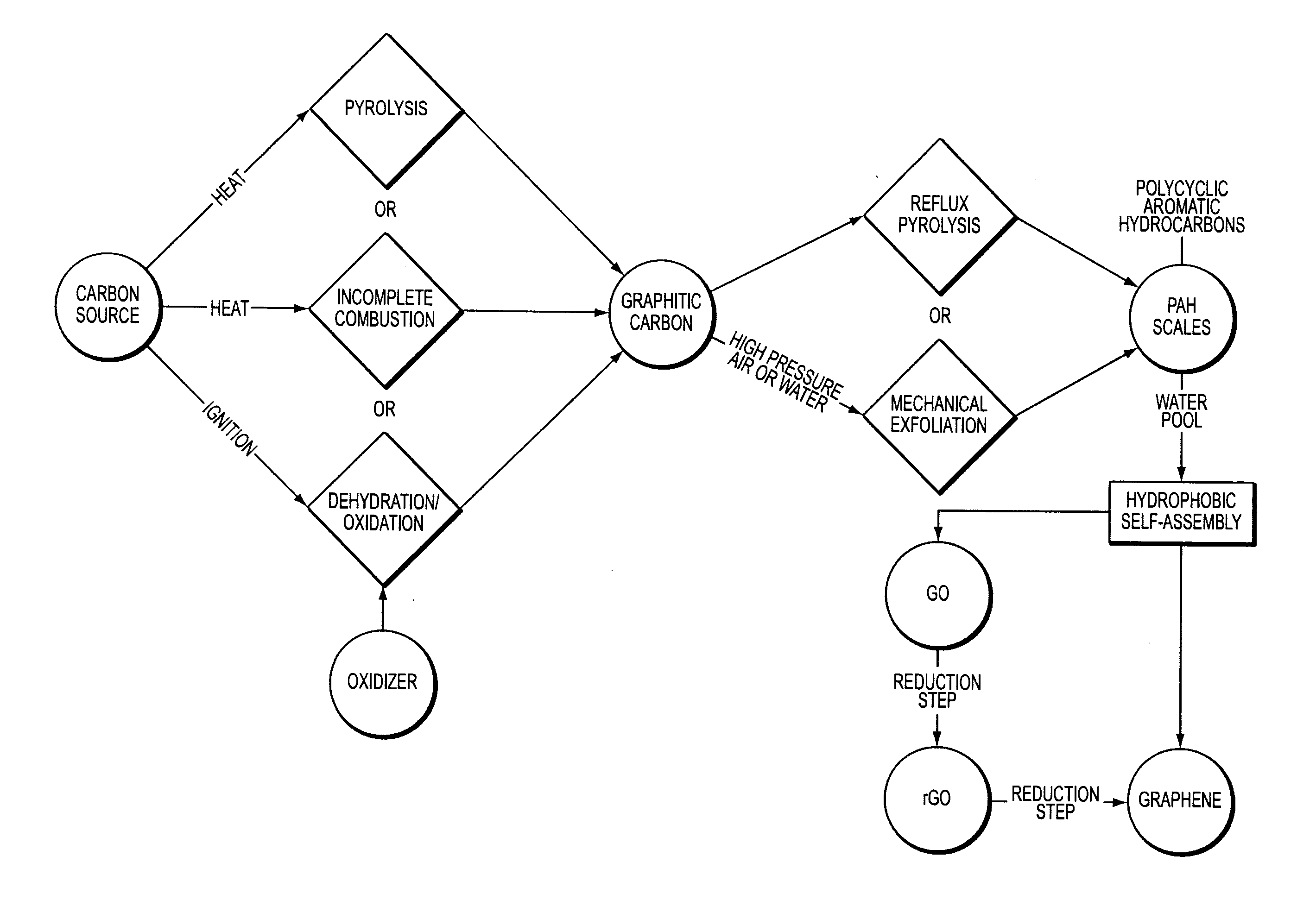

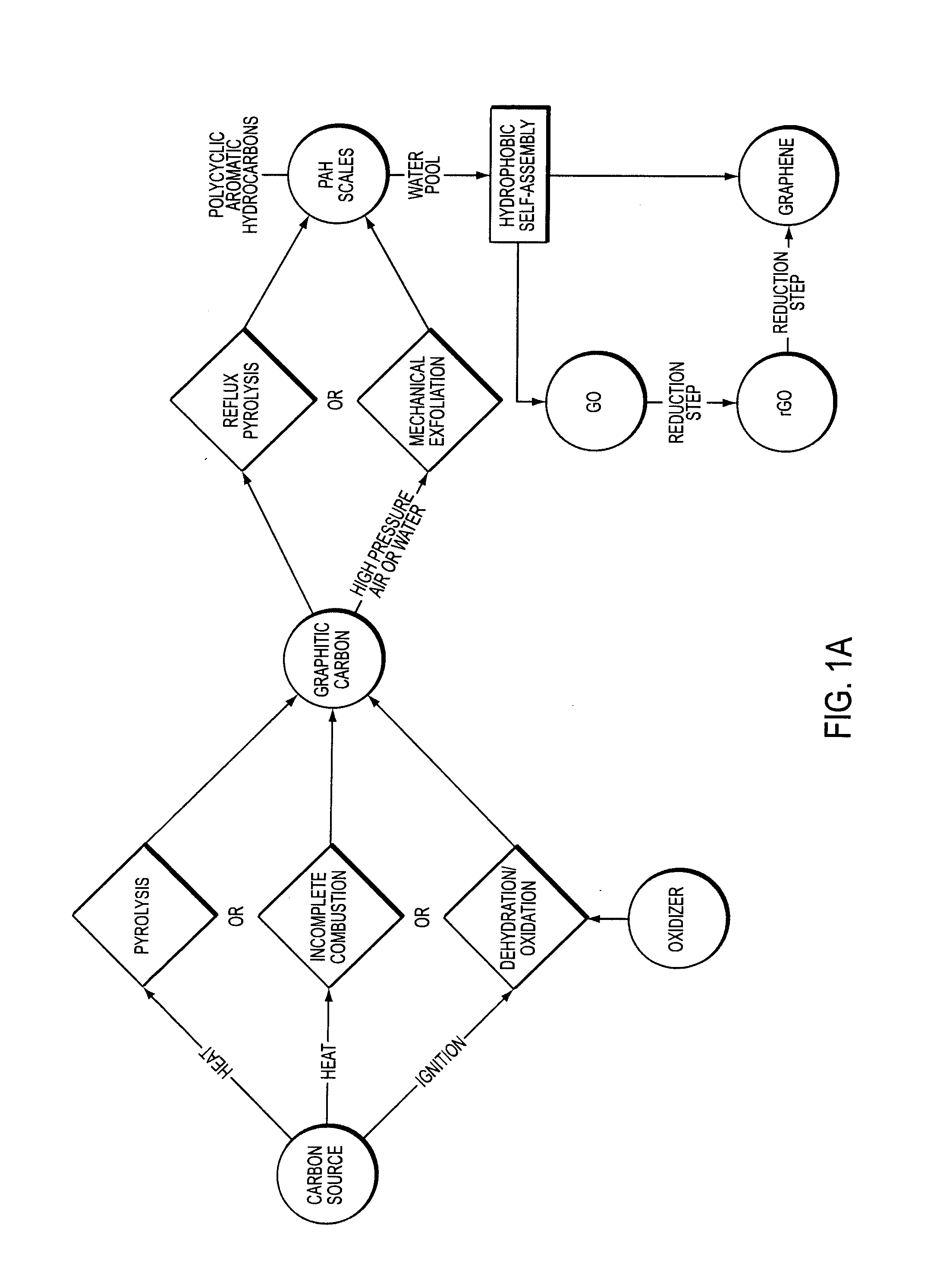

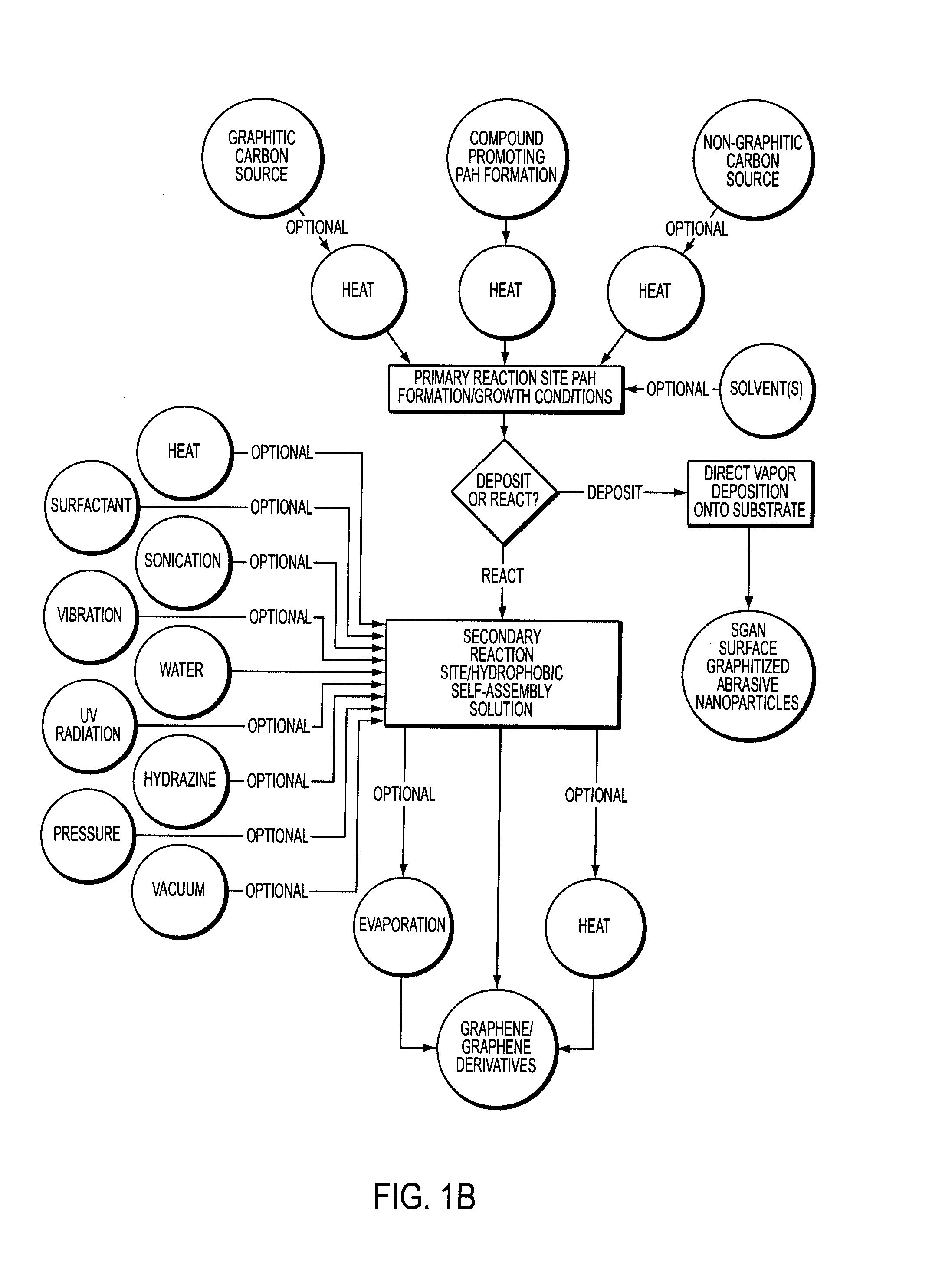

Facile synthesis of graphene, graphene derivatives and abrasive nanoparticles and their various uses, including as tribologically-beneficial lubricant additives

ActiveUS20140134092A1Reduce frictionImprove smoothnessMaterial nanotechnologyCosmetic preparationsNanoparticleGraphene derivatives

Owner:PEERLESS WORLDWIDE

Methods and systems for adapting a driveline disconnect clutch transfer function

Systems and methods for improving operation of a hybrid vehicle are presented. In one example, a transfer function of a driveline disconnect clutch is adapted.

Owner:FORD GLOBAL TECH LLC

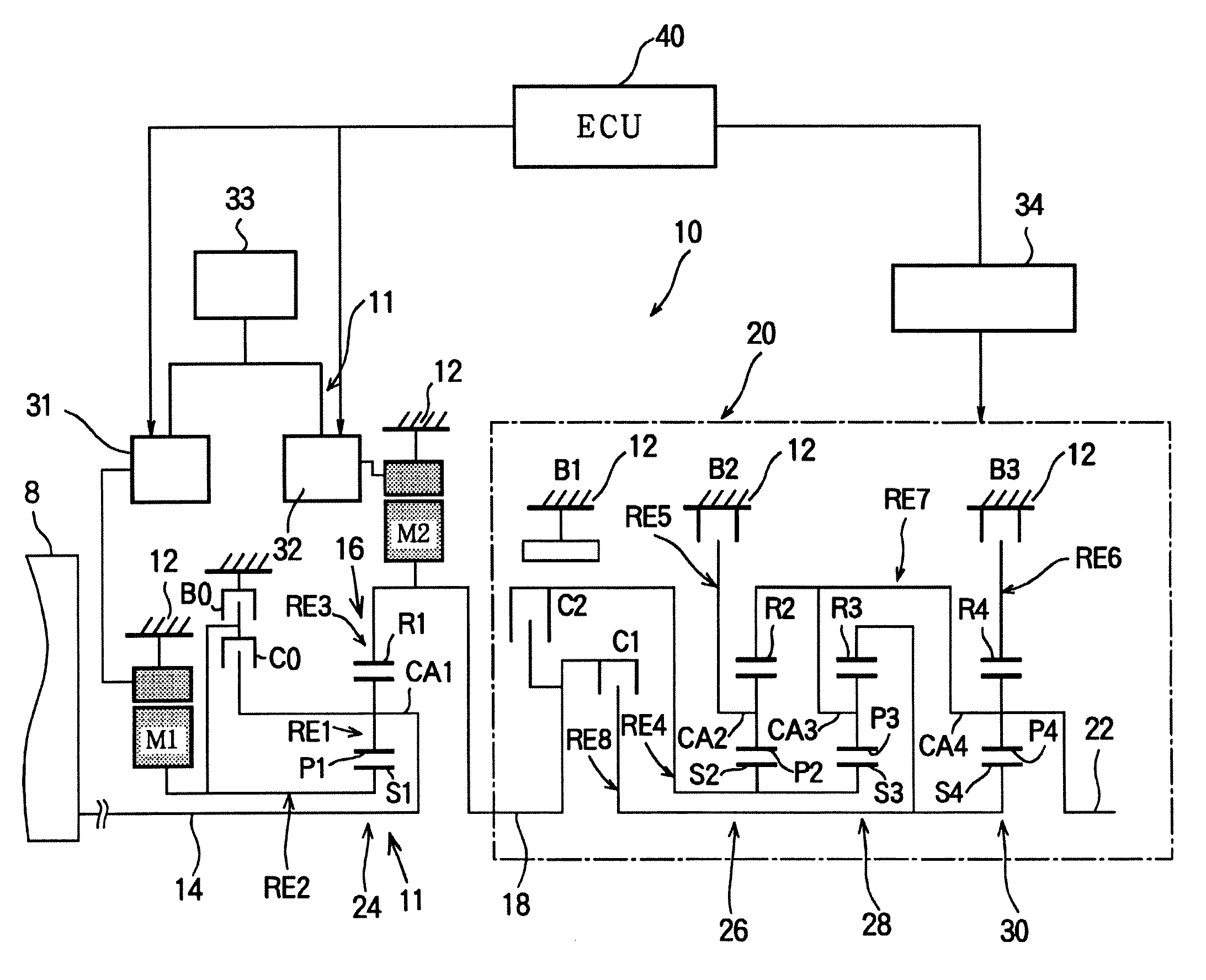

Control system for power transmission unit of vehicle

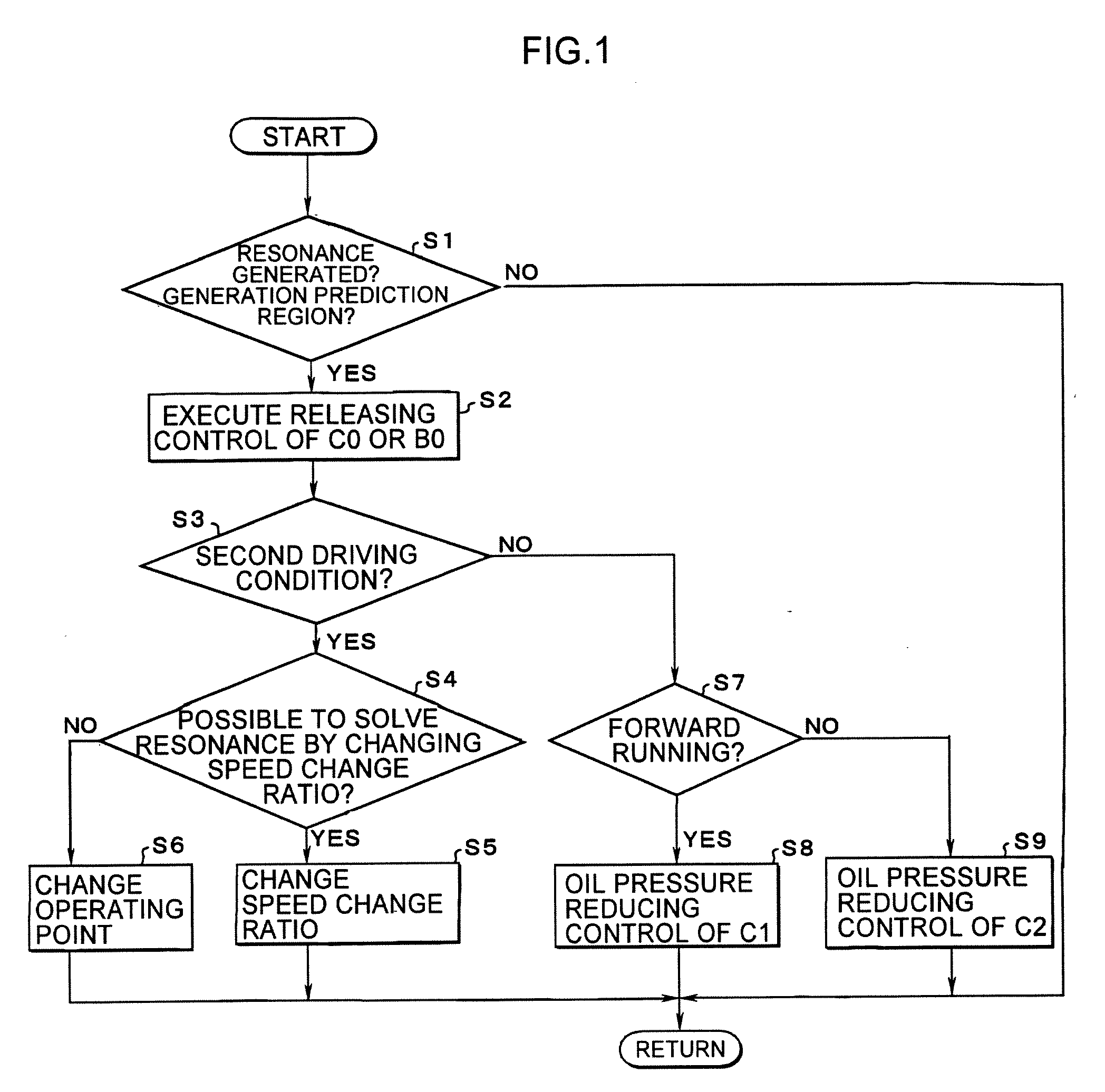

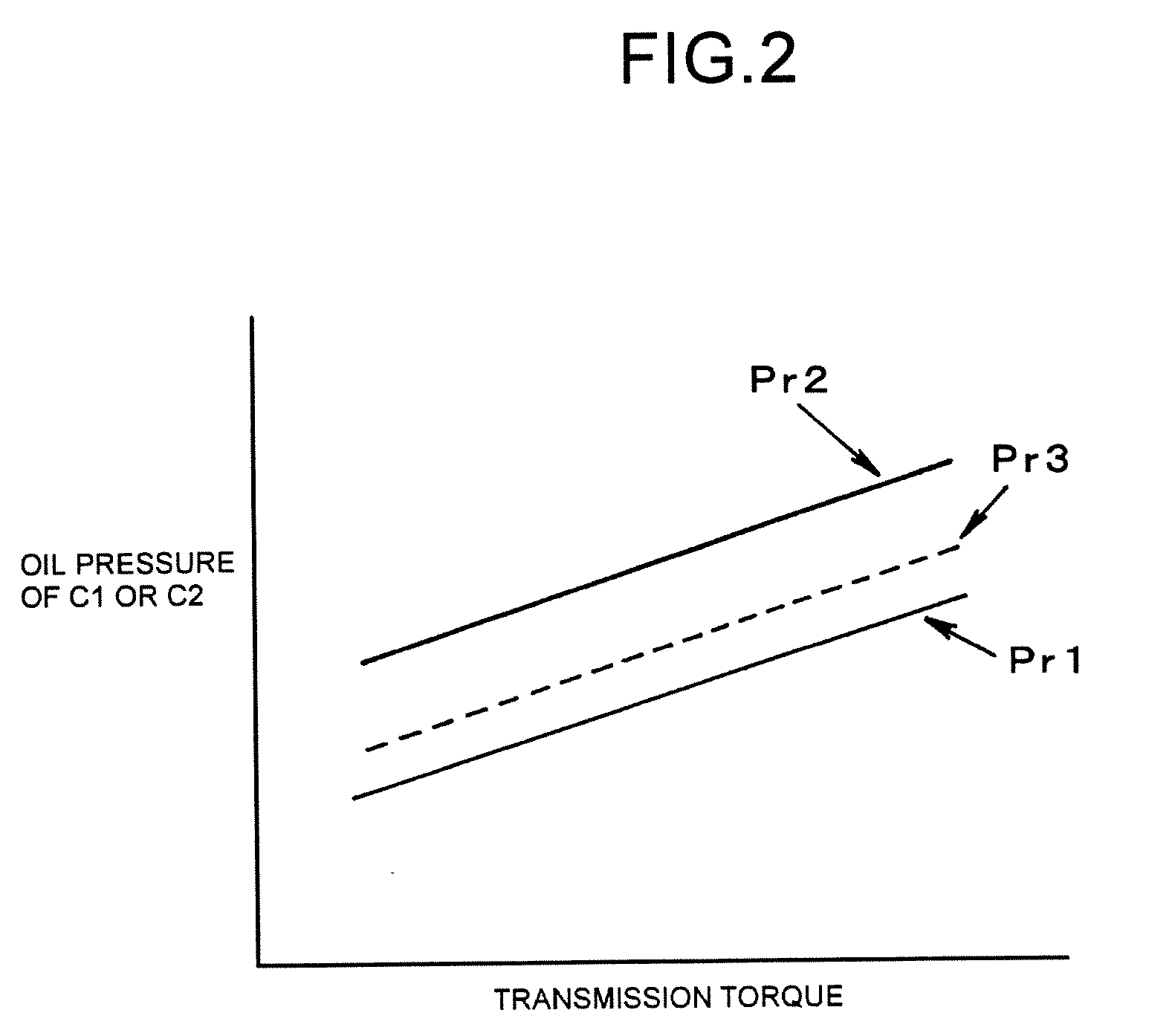

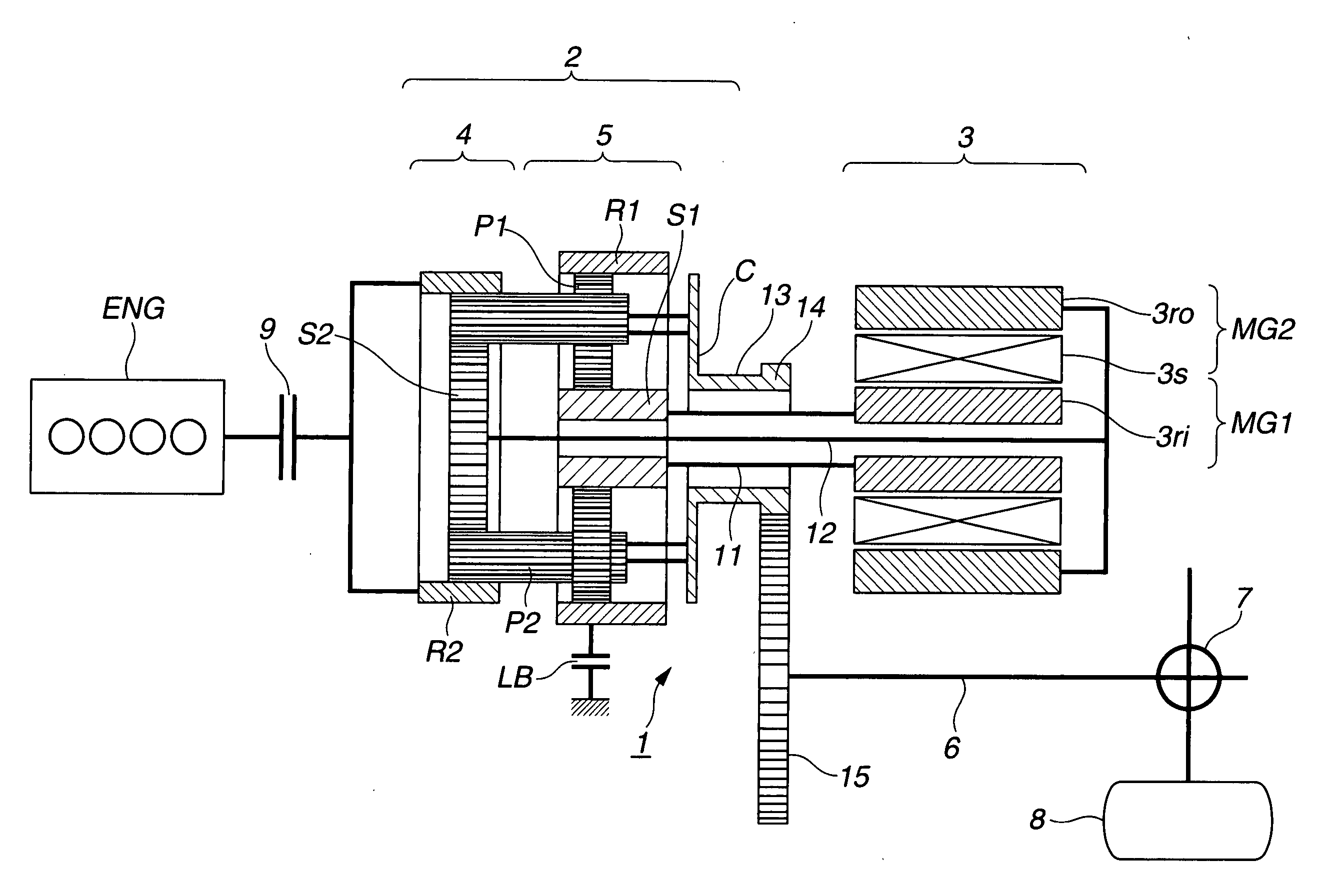

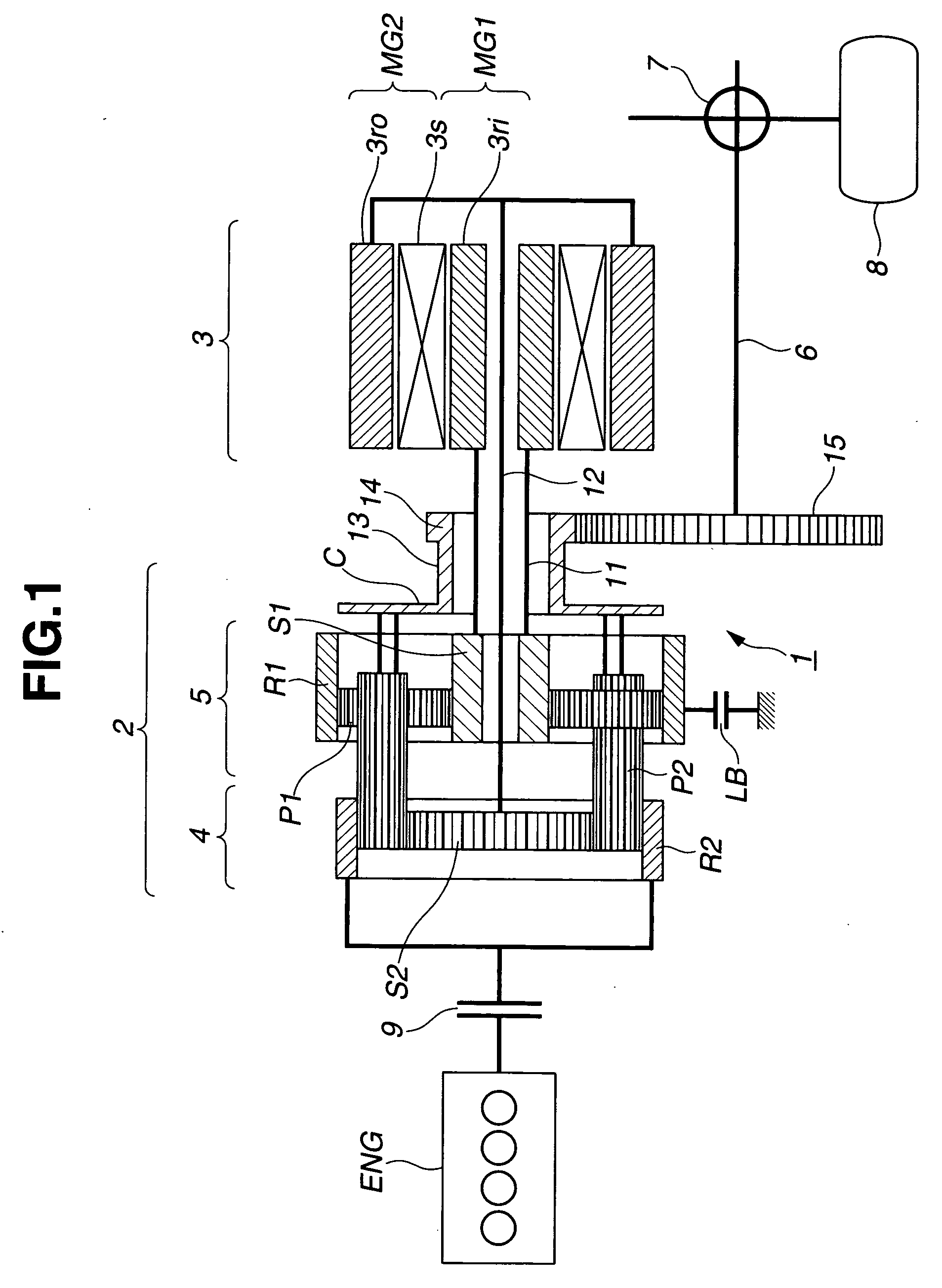

ActiveUS20070202987A1Increased durabilityReducing torque capacityClutchesGearing controlControl systemResonance

A control system for a power transmission unit of a vehicle transmitting power outputted from a prime mover, comprising: a resonance detecting / predicting device for detecting or predicting a generation of a resonance of the power transmission unit resulting from a power transmission; a driving condition detecting device for detecting a driving condition of a vehicle in case the generation of a resonance is detected or predicted by the resonance detecting / predicting device; and a resonance dampening control selecting device for changing contents of a control for dampening the detected or predicted resonance on the basis of the driving condition of the vehicle detected by the driving condition detecting device.

Owner:TOYOTA JIDOSHA KK

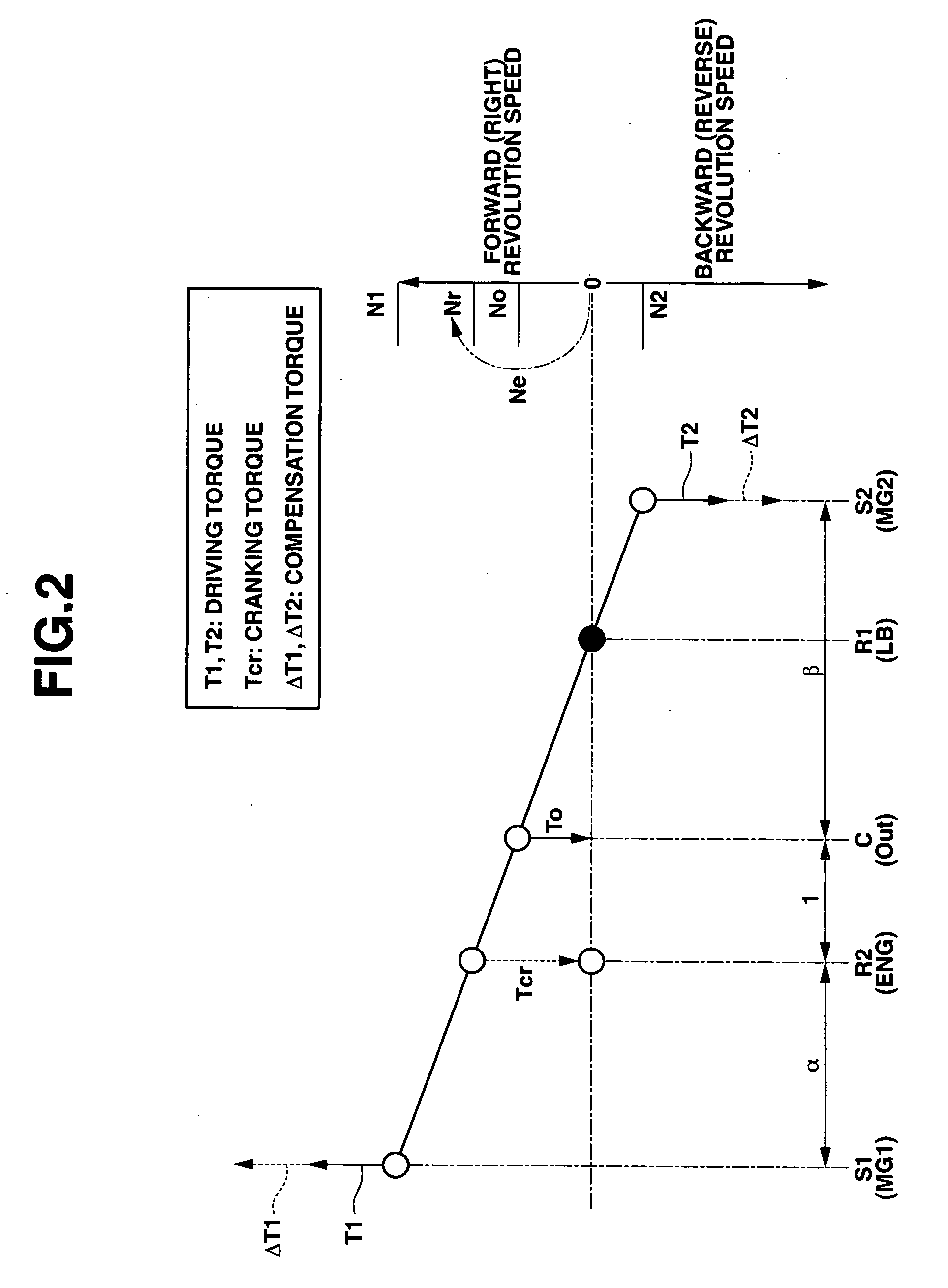

Engine starting control apparatus of hybrid drive system

InactiveUS20070087894A1Without increasing in size and weightIncreased torque transfer capabilityHybrid vehiclesClutchesTorque transmissionControl theory

An engine staring control apparatus of a hybrid drive system is arranged to increase the torque transmission capacity such that a cranking torque of an engine is compensated when the engine is started; to stop the increase of the torque transmission capacity when a revolution speed of an engine-side friction element of an engine clutch reaches a revolution speed at which the engine can start by itself; to hold a torque transmission capacity of the engine clutch after the stopping of the increase of the torque transmission capacity; and to stop the holding of the torque transmission capacity and to again increase the torque transmission capacity when the revolution speed of the engine-side friction element reaches the revolution speed of a transmission-side friction element.

Owner:NISSAN MOTOR CO LTD

Control apparatus for hybrid vehicle

InactiveUS20100286858A1Suppress noiseSuppresses occurrenceAnalogue computers for vehiclesClutchesDrive wheelAutomatic transmission

A hybrid vehicle control apparatus is provided with an engine, an electric motor, a holding element, an automatic transmission, a range position detecting device and a controller. The holding element is arranged between the engine and the electric motor to selectively connect and disconnect the engine and the electric motor to and from each other. The automatic transmission is arranged between the electric motor and a drive wheel. The range position detecting device detects a range position of the automatic transmission selected by a driver. The controller executes a control operation serving to stop the engine while also executing a slip control serving to lower a torque transfer capacity of the holding element upon a determination that a request to stop the engine has occurred while the engine is operating, the holding element is engaged, and the automatic transmission is detected in a non-driving range.

Owner:NISSAN MOTOR CO LTD

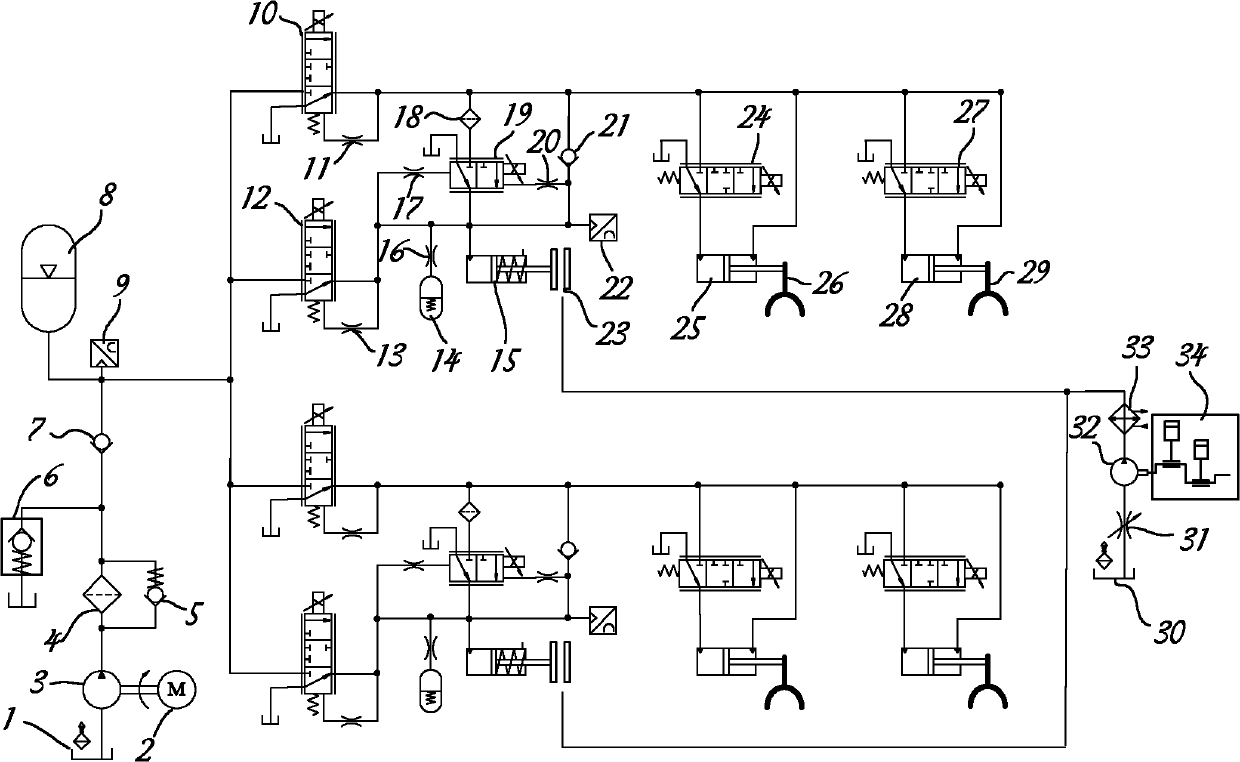

Hydraulic control system for wet-type double-clutch automatic transmission

ActiveCN102168754AReduce displacementLow powerClutchesGear lubrication/coolingAutomatic transmissionControl signal

The invention belongs to automobile transmissions, in particular to a hydraulic control system for a wet-type double-clutch automatic transmission. The hydraulic control system consists of two separate subsystems, wherein one subsystem is a clutch and gearshift mechanism hydraulic control subsystem which is mainly used for operating an odd number gear clutch and an even number gear clutch to separate and combine according to a control signal transmitted by an electronic control unit as well as operating a gear-shift mechanism control oil cylinder to finish switching of each gear synchronizer; and the other subsystem is a clutch cooling and lubricating subsystem. By adopting a more scientific and reasonable hydraulic control system, the efficiency of the hydraulic control system for the wet-type double-clutch automatic transmission is improved, the fuel consumption is reduced, the effects of saving energy and reducing emission are achieved, and the reliability of the system work and the compactness of the structure are enhanced.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

An engine start control device for a hybrid vehicle

InactiveCN1944134AAvoid disappearingAvoid shockClutchesInternal combustion piston enginesControl theoryHybrid vehicle

The present invention makes it possible to start the engine when switching from the electric driving (EV) mode to the hybrid (HEV) mode without feeling of torque loss and with low impact. At t1 when the EV→HEV mode switching request increases with the acceleration, the control is started using the mode 2301b, and the transmission torque capacity tTc1 of the first clutch for HEV is increased for driving force control. Before the second clutch for EV&HEV starts to slip, The PTO shaft of the engine is started to rotate by the drag of the first clutch. In the mode 2301b, the second clutch transmission torque capacity tTc2 is maintained at the maximum driving force evTmax in the EV mode. Switch to mode 2303 at t2 when the second clutch starts to slip, and determine tTc2 so that the second clutch slips and start the engine caused by the drag of the first clutch, and tTc1 is determined to maintain the increase in driving force and the stability of the second clutch slide.

Owner:NISSAN MOTOR CO LTD

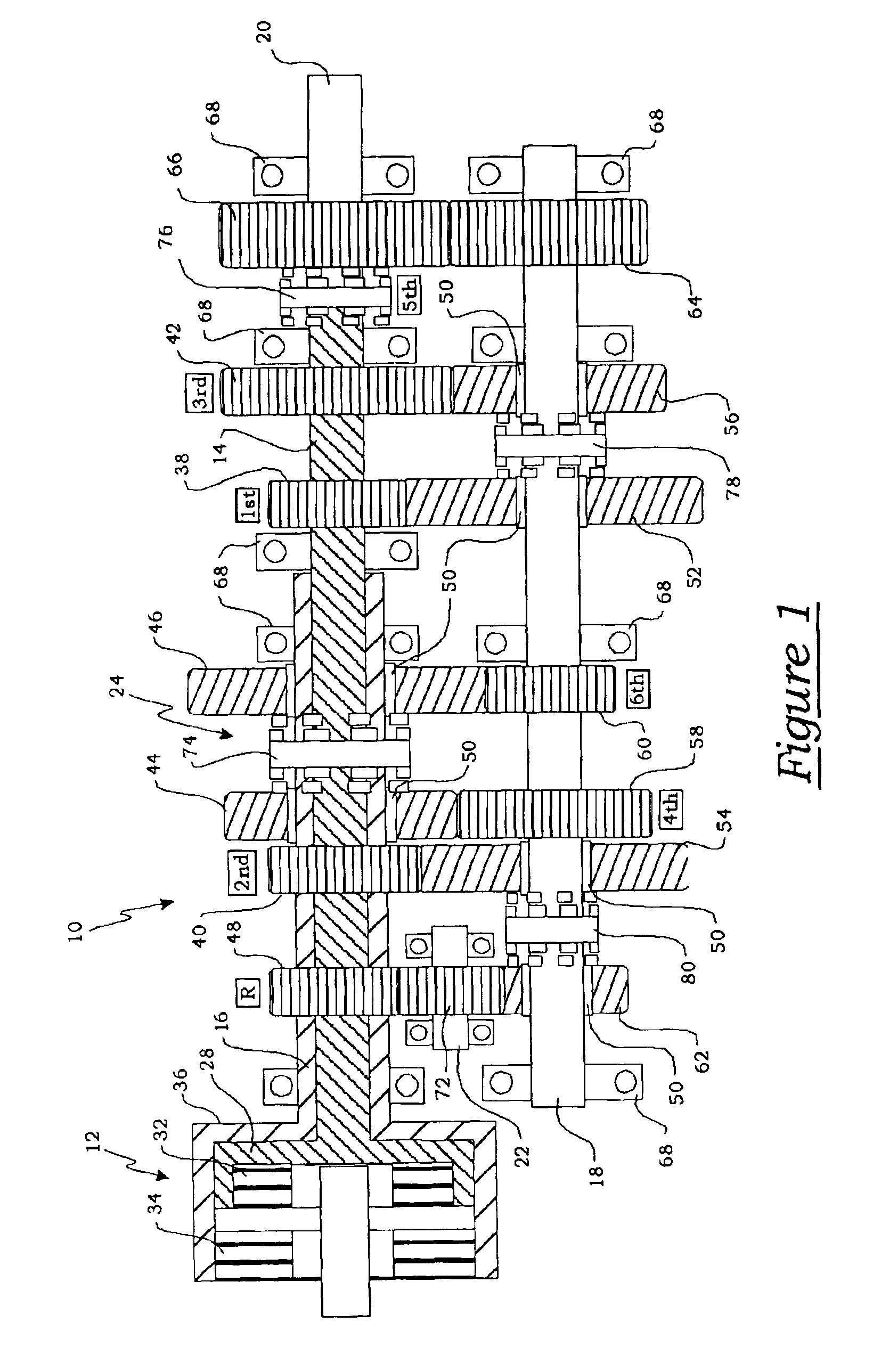

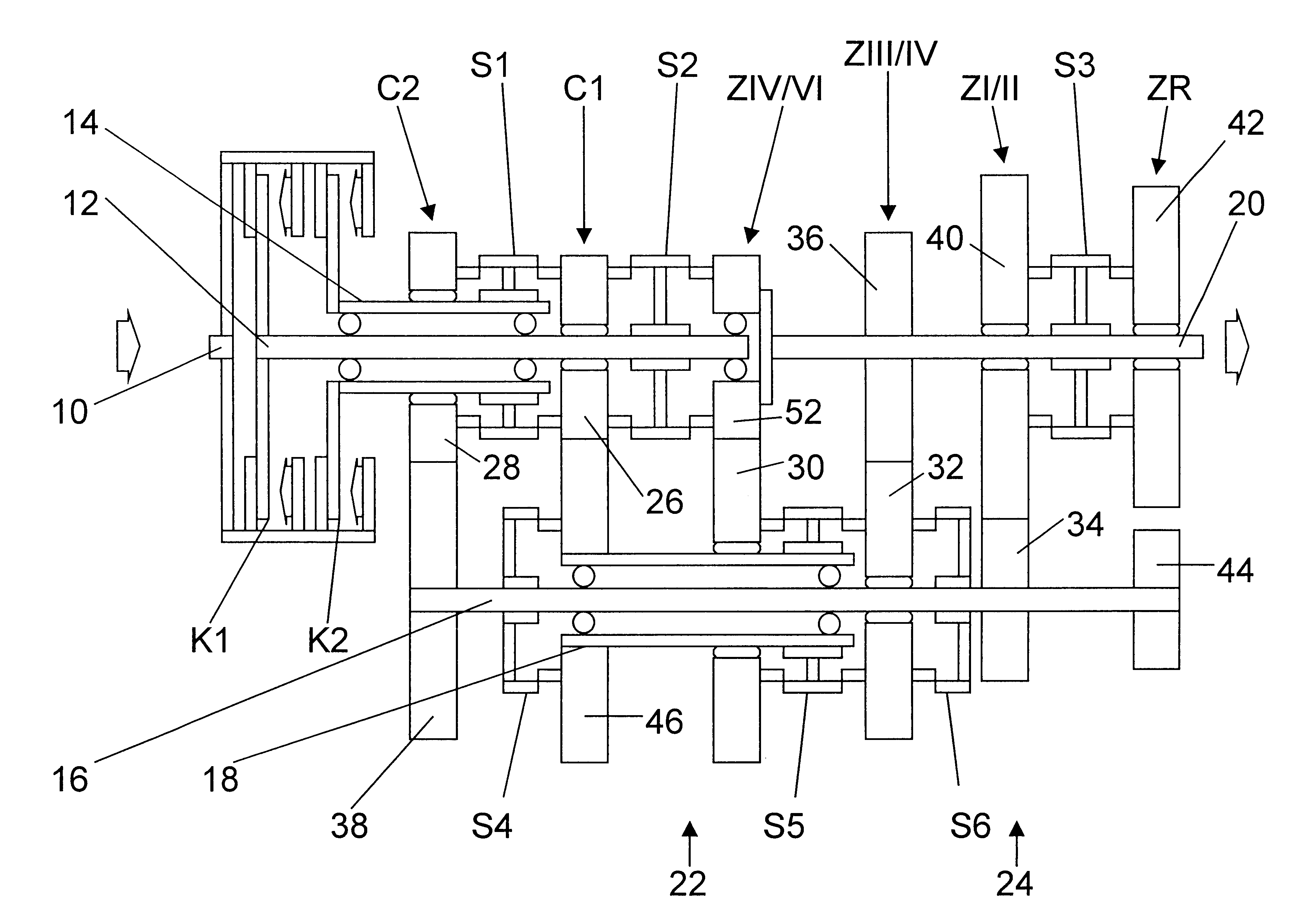

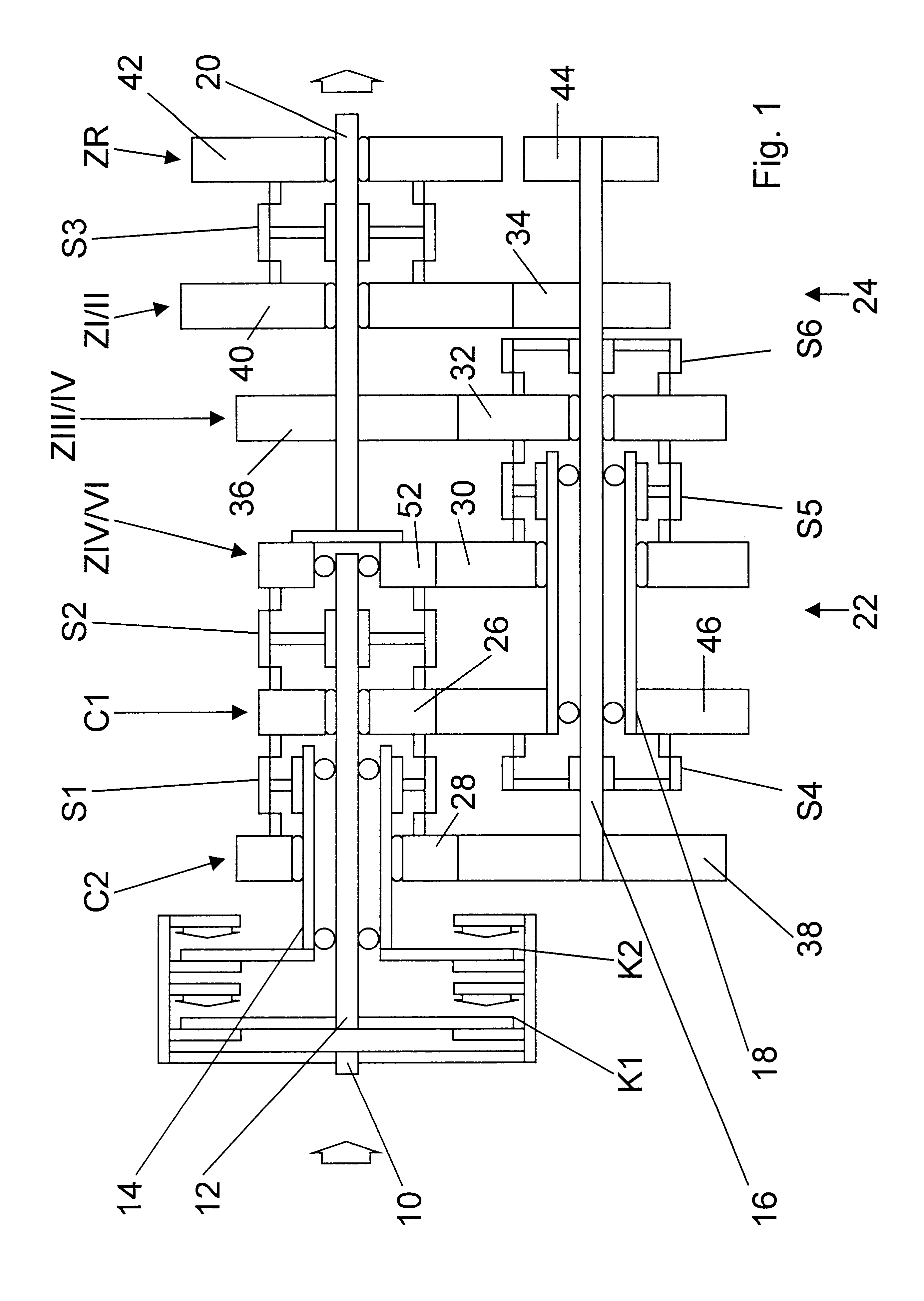

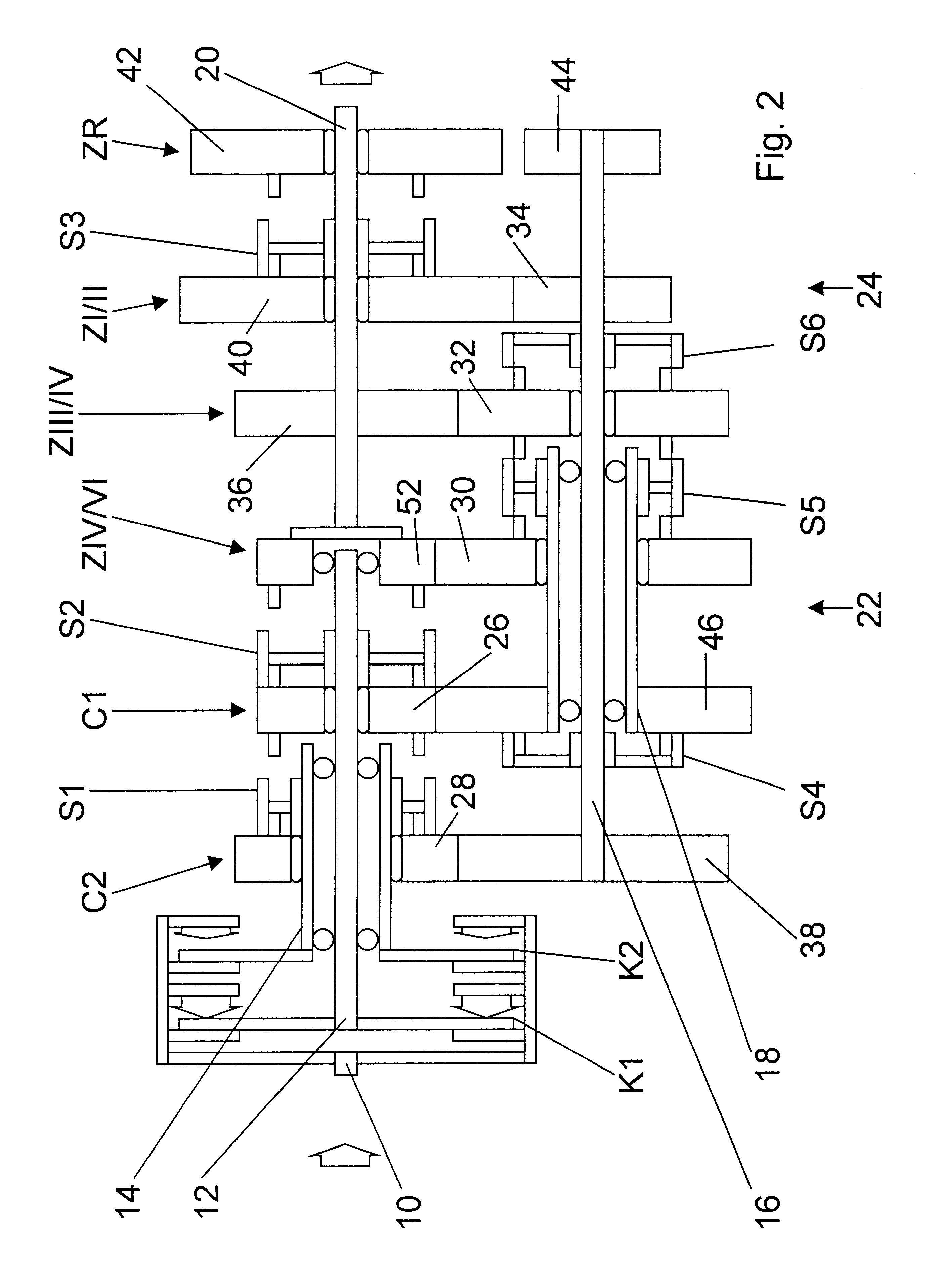

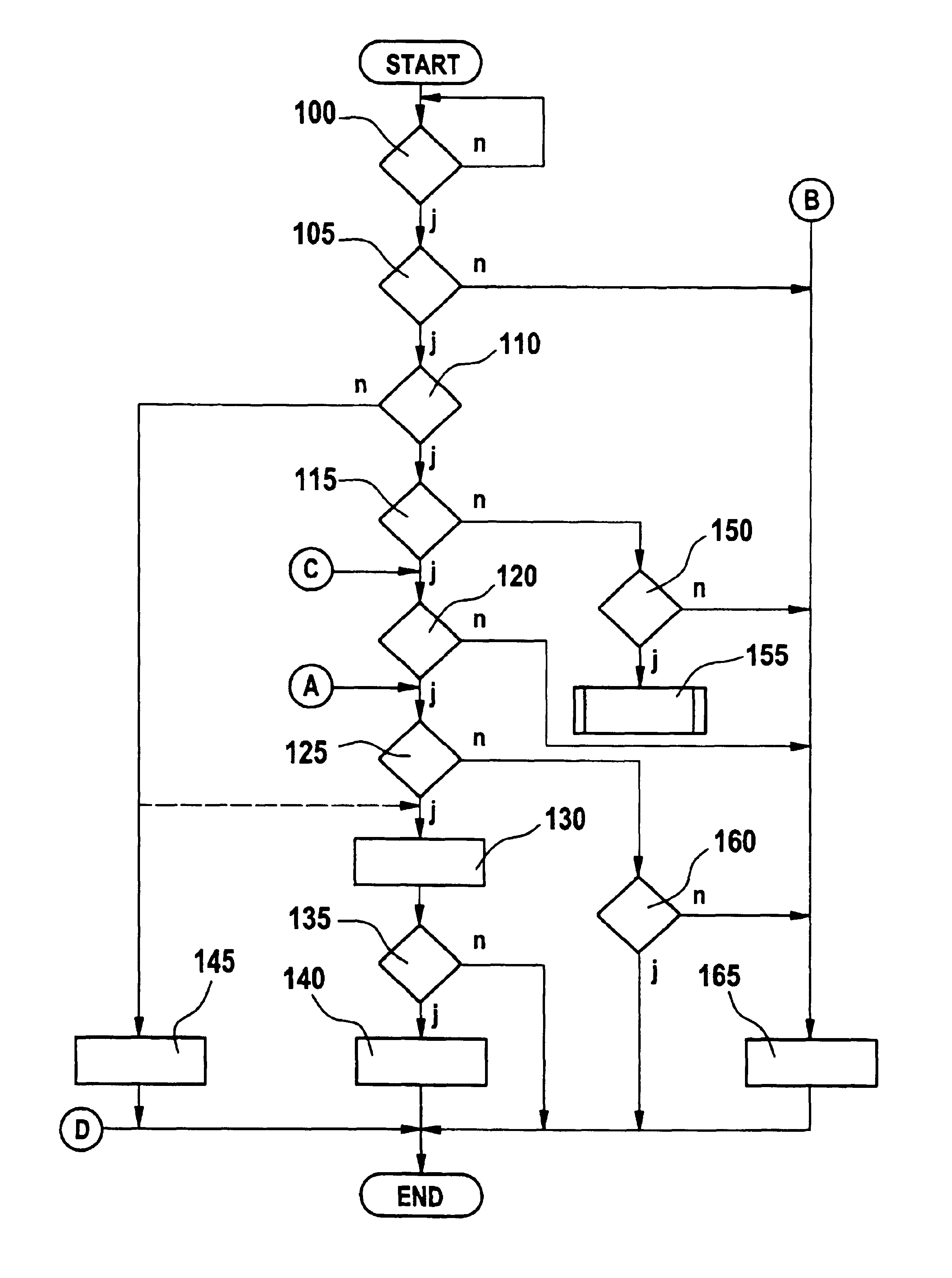

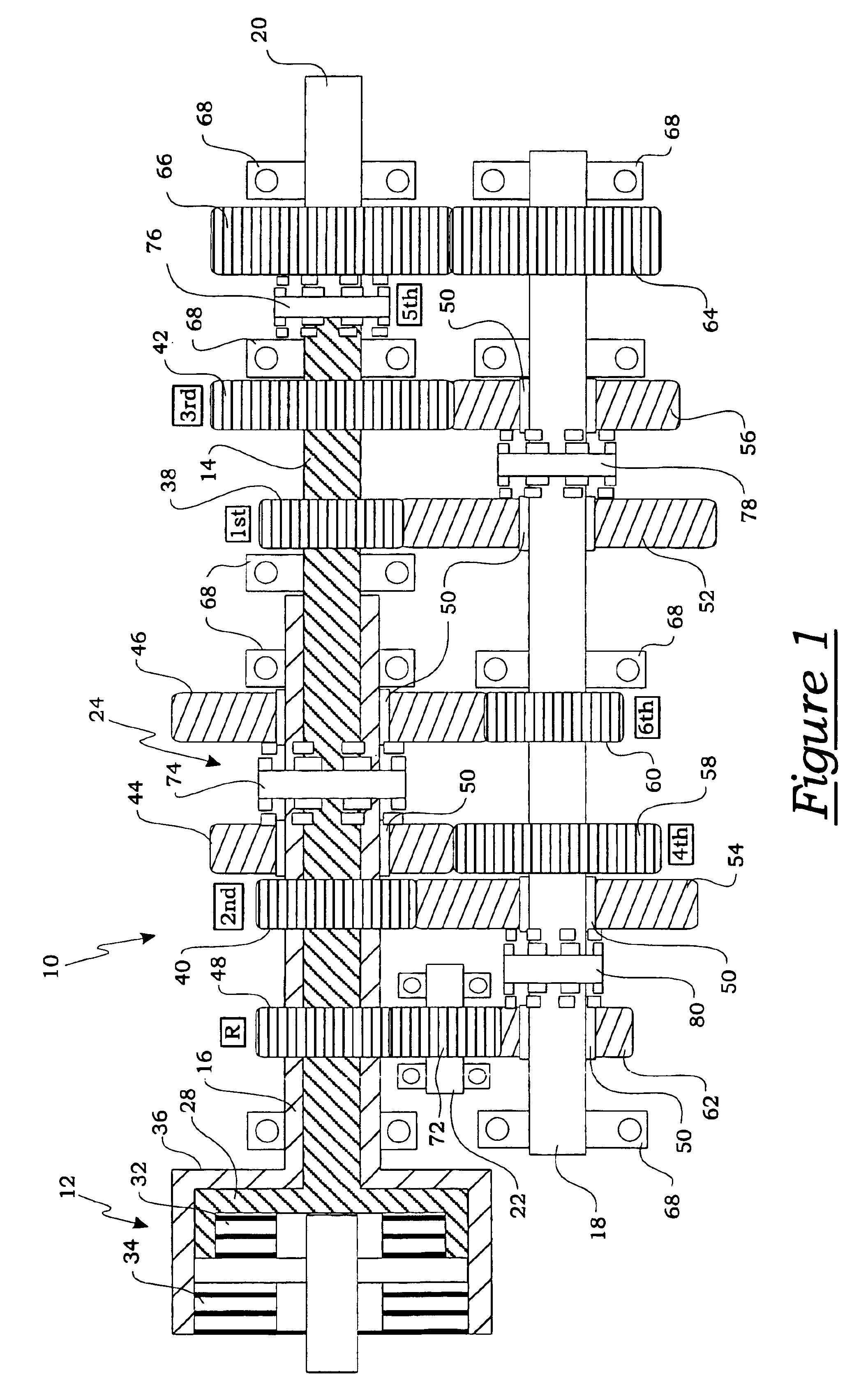

Toothed gear transmission having two partial transmissions disposed parallel to each other in the power flow

InactiveUS6209406B1Long maintenance intervalsAvoid excessive wearClutchesToothed gearingsPower flowEngineering

The invention is based on a toothed gear transmission in which an input shaft is connected to an output shaft by a first and a second partial transmission, which are disposed parallel to each other in the power flow and which both have a frictionally engaged load shifting clutch and an intermediate shaft, in which each of the intermediate shafts can be effectively connected to the input shaft through the load shifting clutch, and with at least one first transmission constant. It is proposed that for starting, the first load shifting clutch can be placed in effective connection with the output shaft through a transmission constant and the second load shifting clutch can be placed in effective connection with the output shaft through a transmission constant, each at a gear ratio of the lowest gear speed.

Owner:INTELLECTUAL VENTURES II

Method and device for controlling the drive unit of a vehicle

A method for controlling the drive unit of a vehicle in which an extended overrun mode having reduced fuel consumption and reduced pollutant emission is possible. A free-wheel mode in which the vehicle operates with the clutch disengaged is set as a function of a driving situation or an operating state of the drive unit. An output variable of the drive unit, such as torque or vehicle speed, is set to a constant value during the transition between an engaged-clutch travel mode and a free-wheel mode.

Owner:ROBERT BOSCH GMBH

Hybrid vehicle drive control system

ActiveUS20070114082A1Eliminates lackAvoid it happening againClutchesGearing controlElectricityDrive wheel

A hybrid vehicle drive control system has a first clutch interposed between an engine and a motor / generator, a transmission including several gear position clutches arranged between the motor / generator and a drive wheel, and a controller. The controller selectively starts the engine using torque from the first clutch during a drive mode change from an electric drive mode to a hybrid drive mode. When an engine start command and a gear shifting operation occur during a drive mode change, the controller selects the gear position clutch that is a common engaged clutch from among the engaged gear position clutches constituting the vehicle running gears occurring from immediately before starting the engine until immediately after starting the engine as a second clutch to be controlled. Then, the controller executes a slip control of the second clutch when the first clutch is being connected to start the engine during the drive mode change.

Owner:NISSAN MOTOR CO LTD

Method of controlling a dual clutch transmission

InactiveUS6909955B2Improving overall drivability and comfortClutchesDigital data processing detailsEngineeringClutch

A method of controlling the timing of the shift events of a dual clutch transmission that includes the steps of sensing the current output speed of the transmission, determining the time required to complete each possible shift event within the transmission, and determining an output speed modification value for each possible shift event. The method also includes the steps of determining a modified shift point output speed for each possible shift event by summing the determined output speed modification value with a predetermined shift pattern output speed, and commanding the shift when the current output speed reaches the determined modified shift point output speed.

Owner:BORGWARNER INC

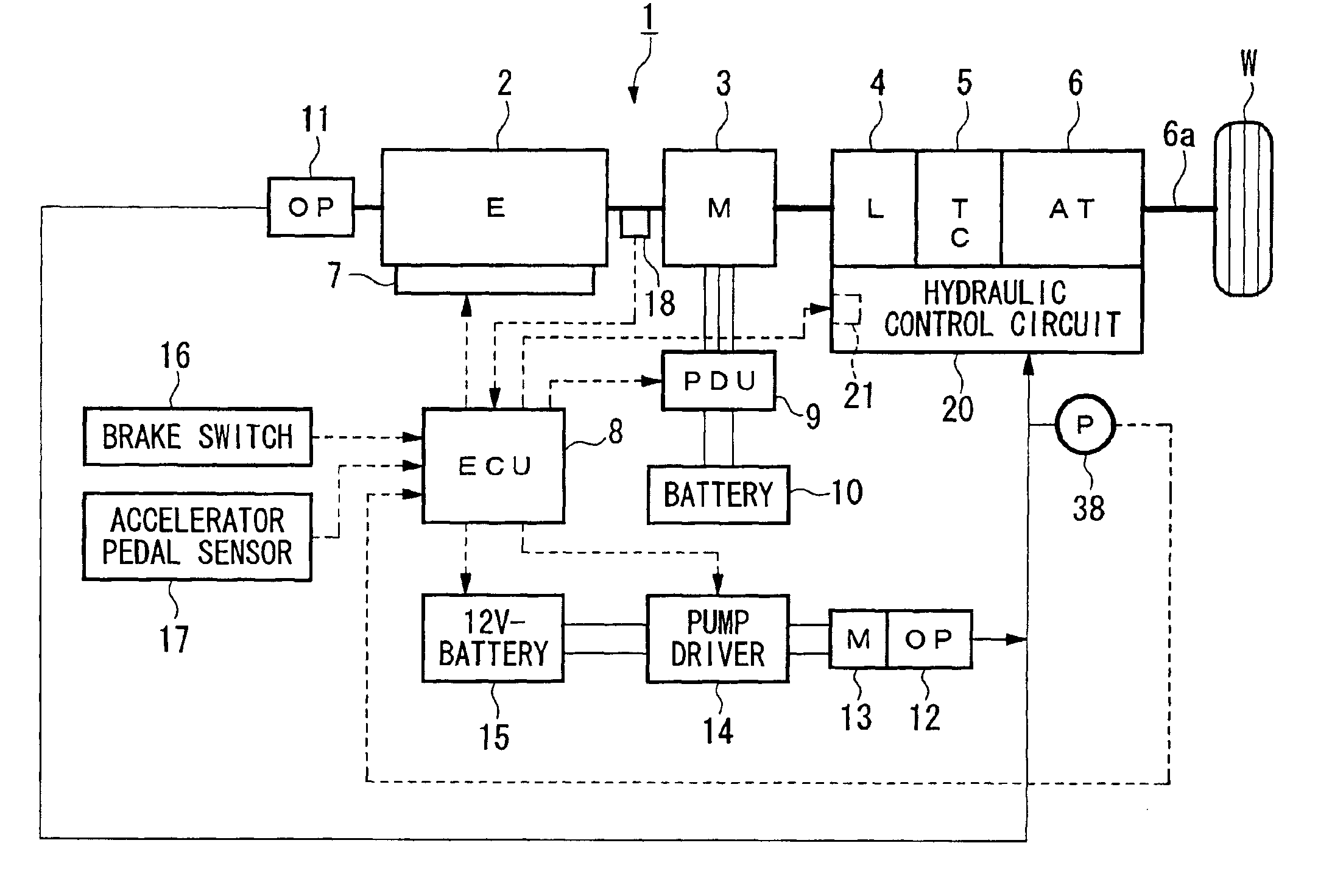

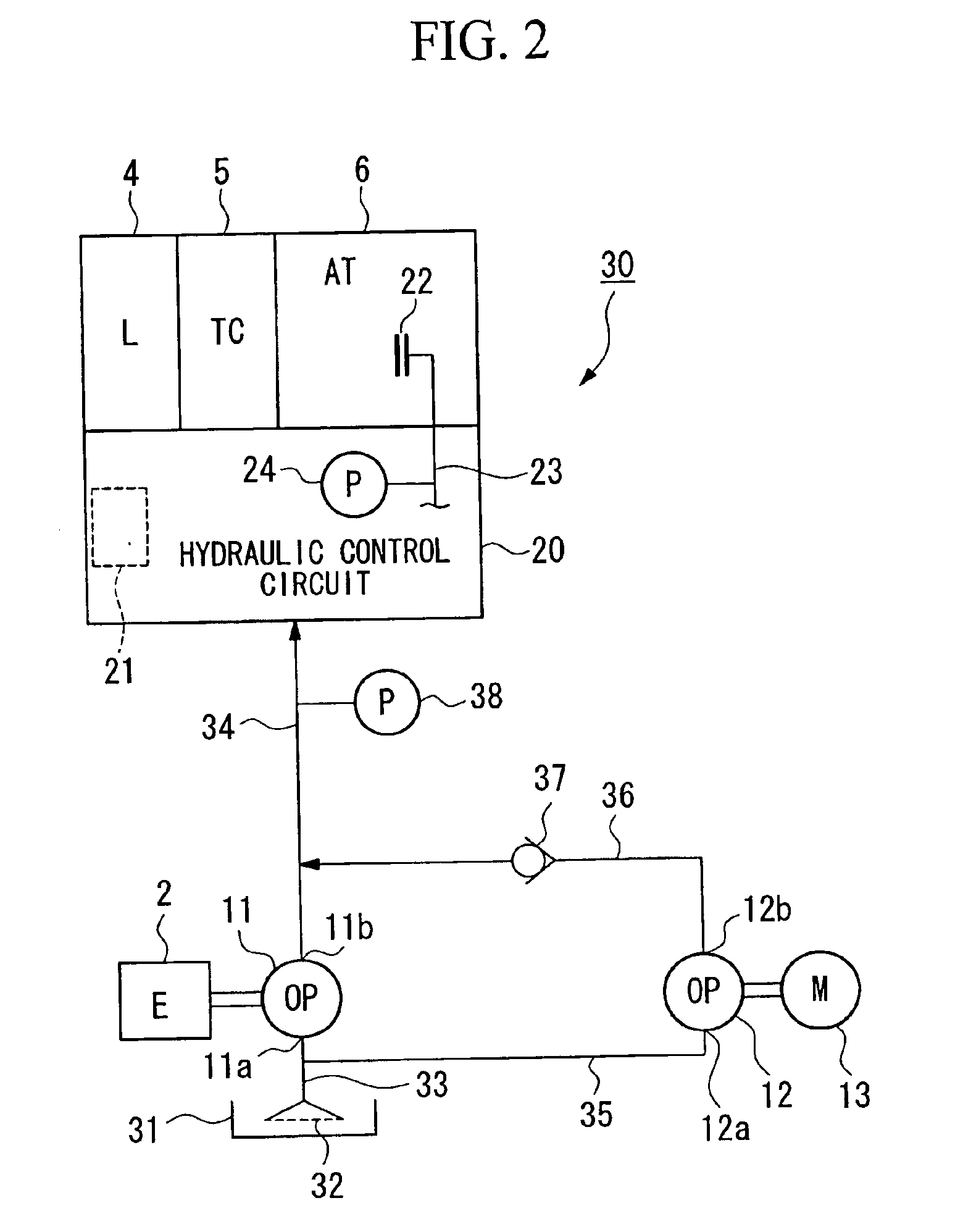

Hydraulic control apparatus for hybrid vehicle

InactiveUS7041030B2Smooth transmissionClutchesInternal combustion piston enginesMotor driveTorque transmission

A hydraulic control apparatus for a hybrid vehicle, which enables a smooth torque transmission when an engine of the vehicle is started from an idling stop state. The hydraulic control apparatus includes an engine and a motor as power sources, a transmission having a torque converter, a clutch for a starting gear, an engine automatic stop and start device which is associated with the engine, a motor-driven oil pump for supplying oil pressure to the transmission, a brake pedal sensor, an accelerator pedal sensor, an engine revolution rate sensor. The oil pressure applied to the clutch is controlled to a level corresponding to a creeping torque when the engine is automatically stopped. When the brake pedal is released, the engine is automatically started, the accelerator pedal is not depressed, and the engine revolution rate is less than an idling revolution rate, the oil pressure applied to the clutch is maintained to the level corresponding to the creeping torque.

Owner:HONDA MOTOR CO LTD +1

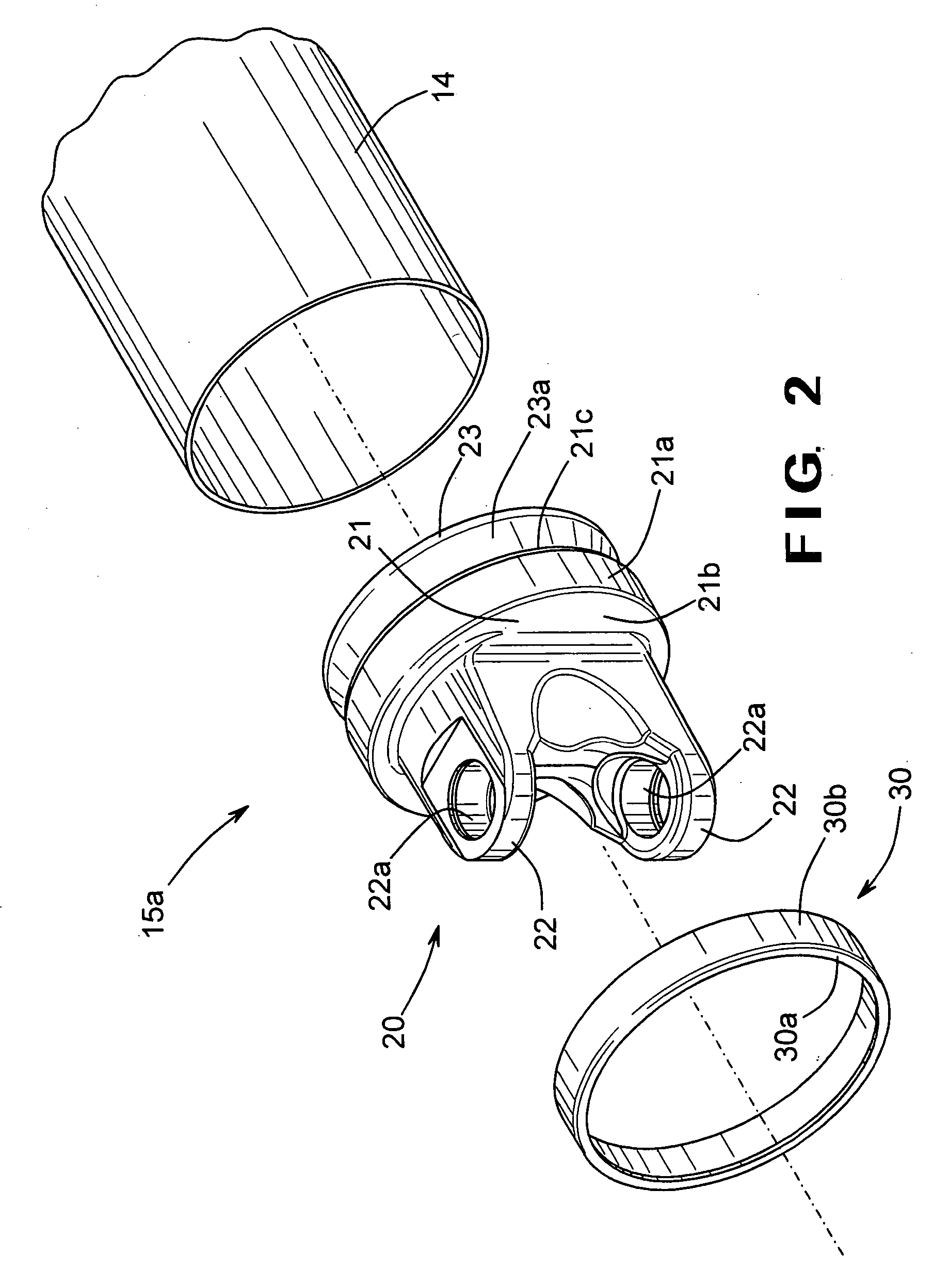

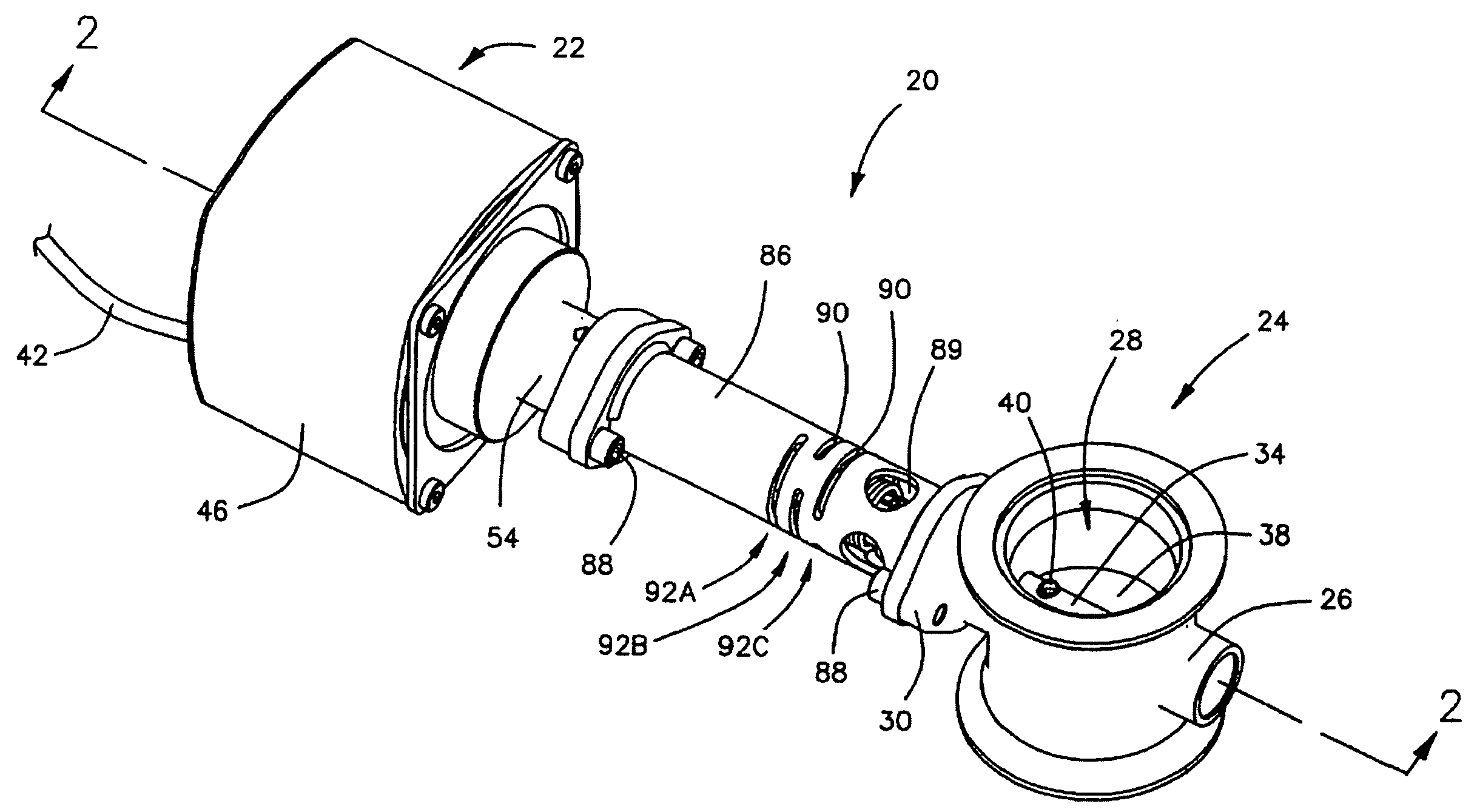

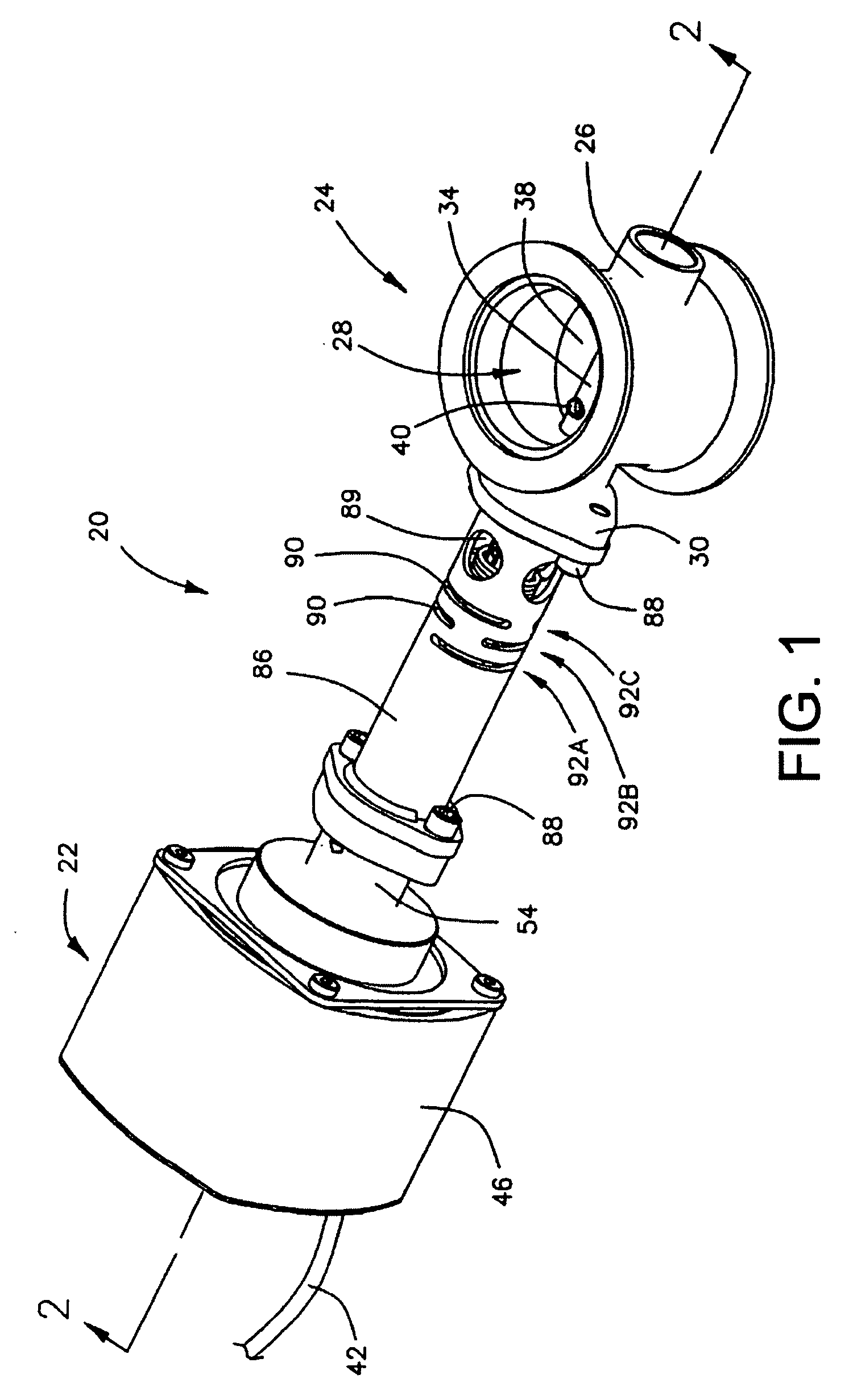

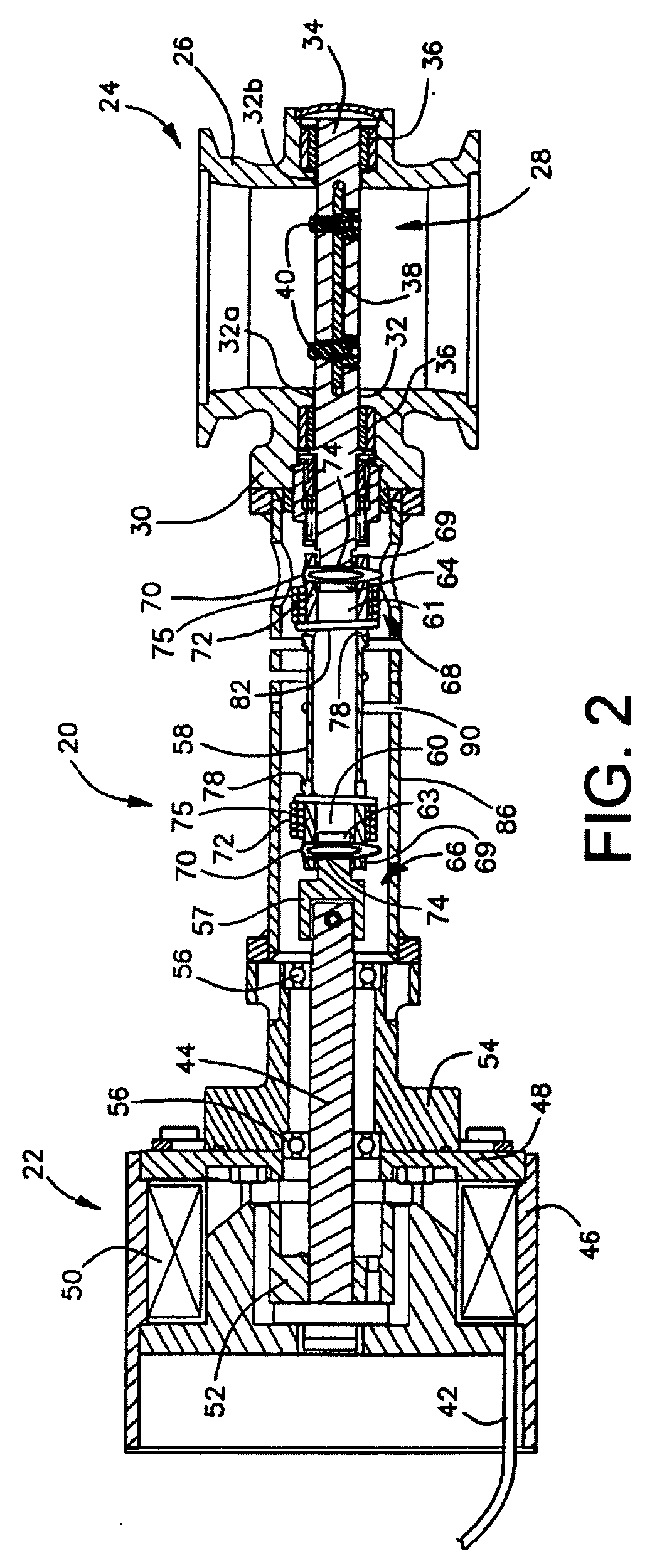

Tortionally Stiff, Thermally Isolating Shaft Coupling with Multiple Degrees of Freedom to Accommodate Misalignment

ActiveUS20090293654A1Easy to controlPrevent heat transferClutchesOperating means/releasing devices for valvesHysteresisCoupling

A coupling arrangement coupling and thermally isolating a continuously variable electrical actuator rotationally coupled to and from a butterfly valve is provided. The valve may be used to modulate high temperature exhaust gas flow through an engine turbocharger. The actuator provides a continuously variable control of the valve. The coupling arrangement provides a thermal block to reduce heat transfer and vibration insulation between the actuator and the valve. The coupling arrangement generally includes a coupling shaft rotationally coupled at opposite ends to the input and output shafts by torsion spring mechanisms. The torsion spring mechanisms include yokes rotationally locking the coupling shaft to the input and output shafts. The torsion spring mechanisms allow a limited range of axial and pivotal translation between the coupling shaft and the input and output shafts and are preloaded to prevent rotational hysteresis in the valve.

Owner:WOODWARD GOVERNOR CO

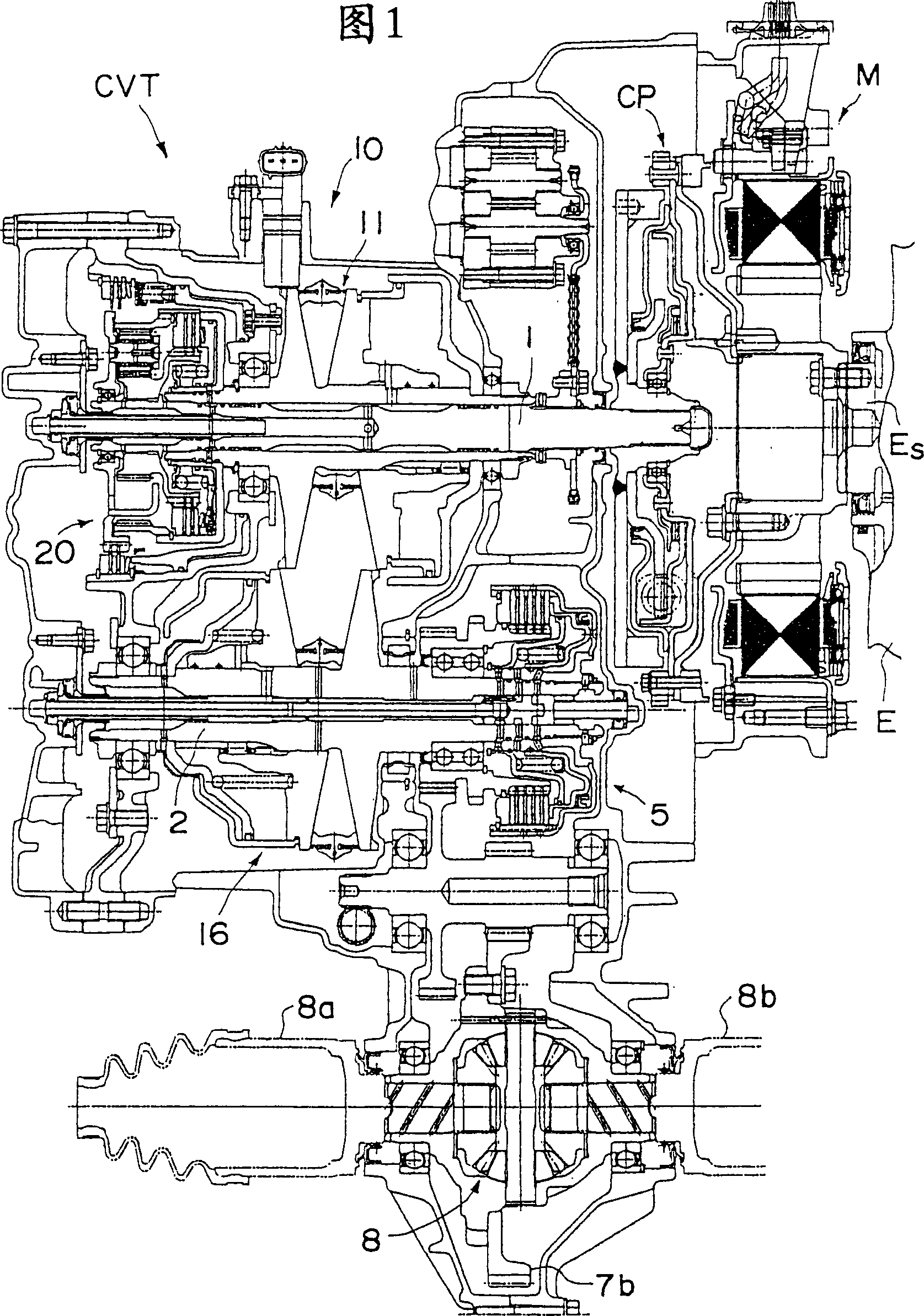

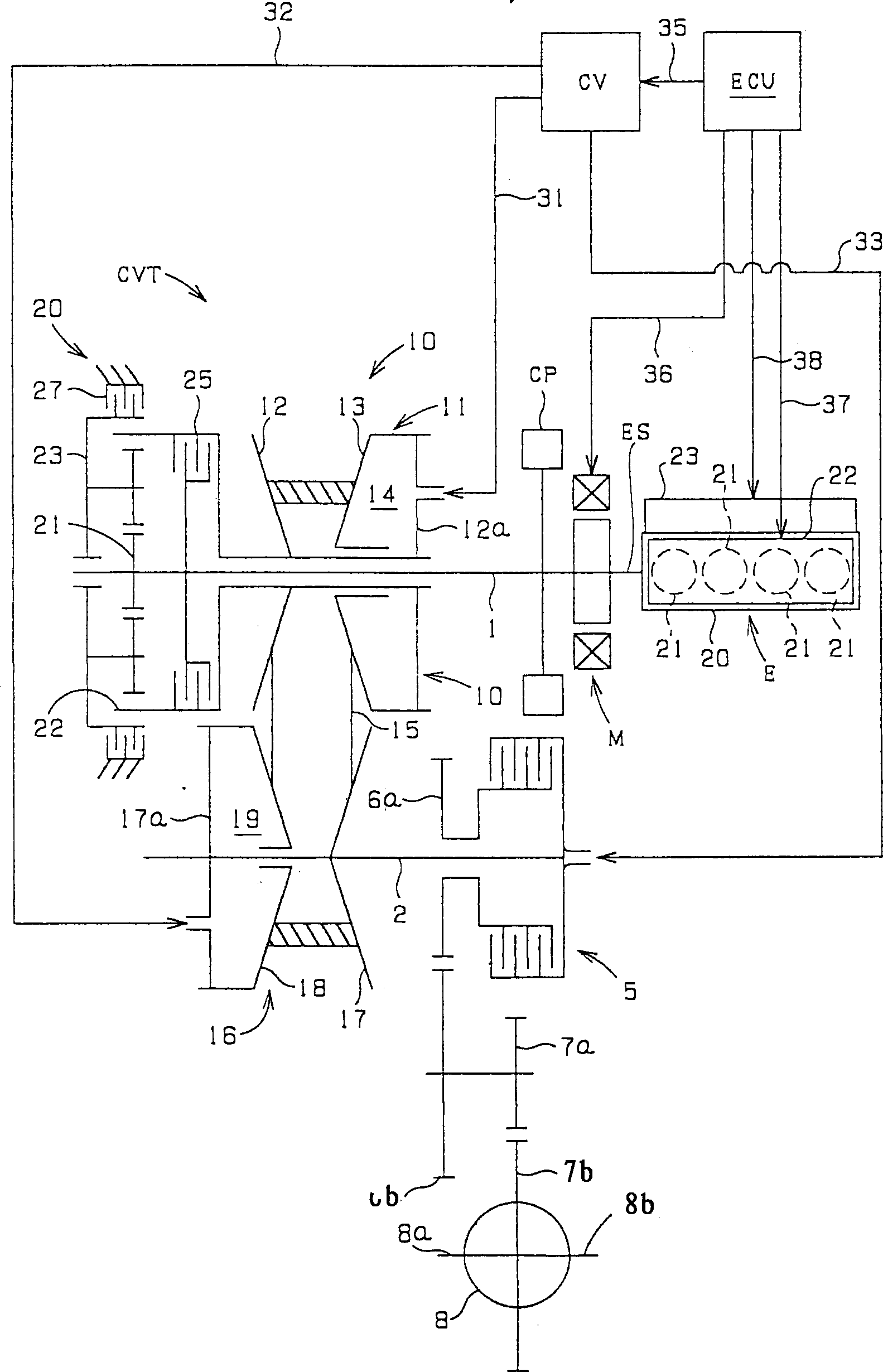

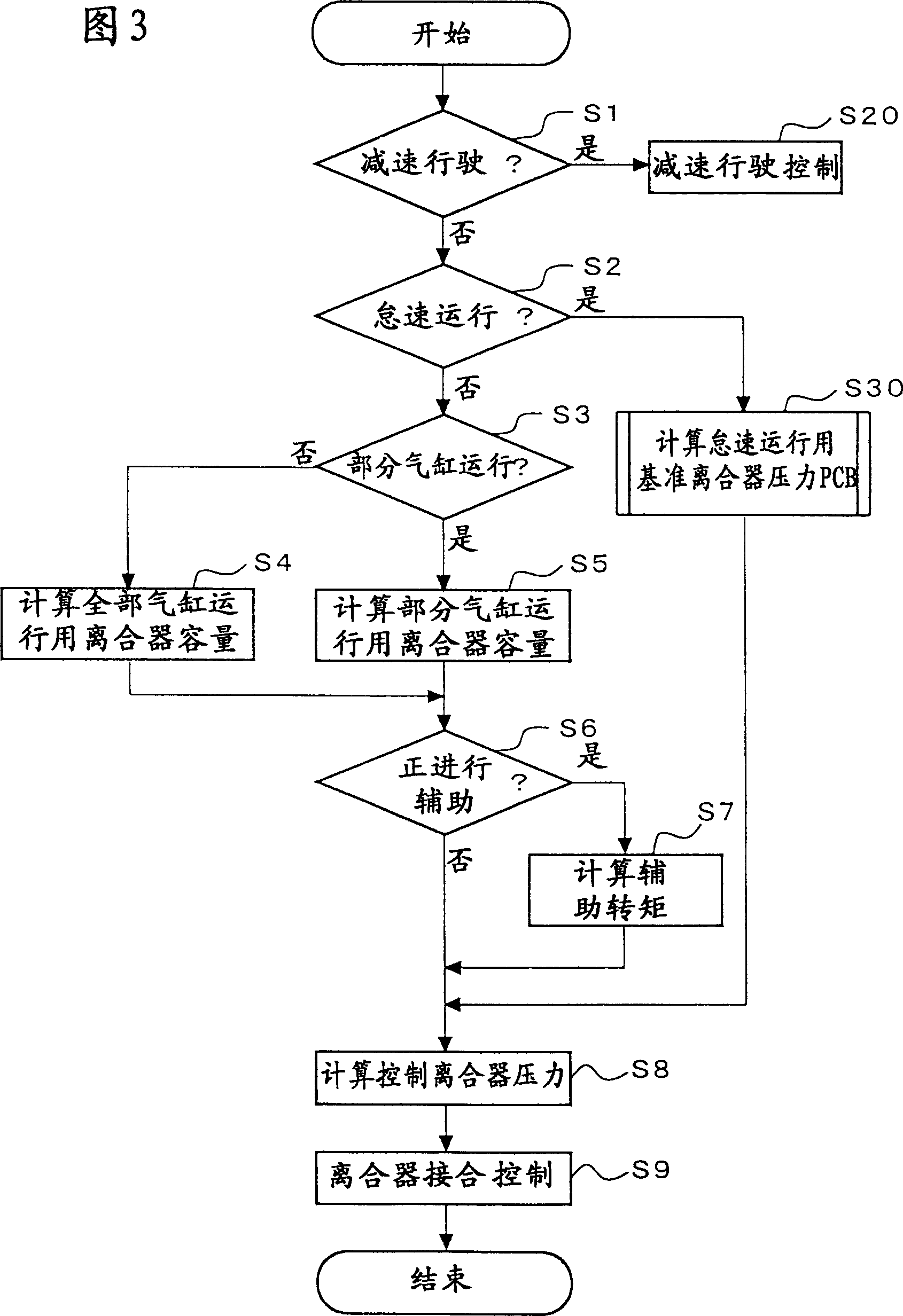

Power transmitting device

A power transmission comprises a continuously variable transmission CVT, which transmits a rotational driving force from an engine E, a starting clutch 5, which variably sets the transmission capacity for the continuously variable transmission CVT, and a control valve CV, which controls the engagement operation of the starting clutch 5. While the engine E is in a partial cylinder operation mode, the control valve CV controls the engagement operation of the starting clutch 5 to attain a predetermined transmission capacity at a rotational speed of the engine that is higher than for a case of the engine in an all cylinder operation mode.

Owner:HONDA MOTOR CO LTD

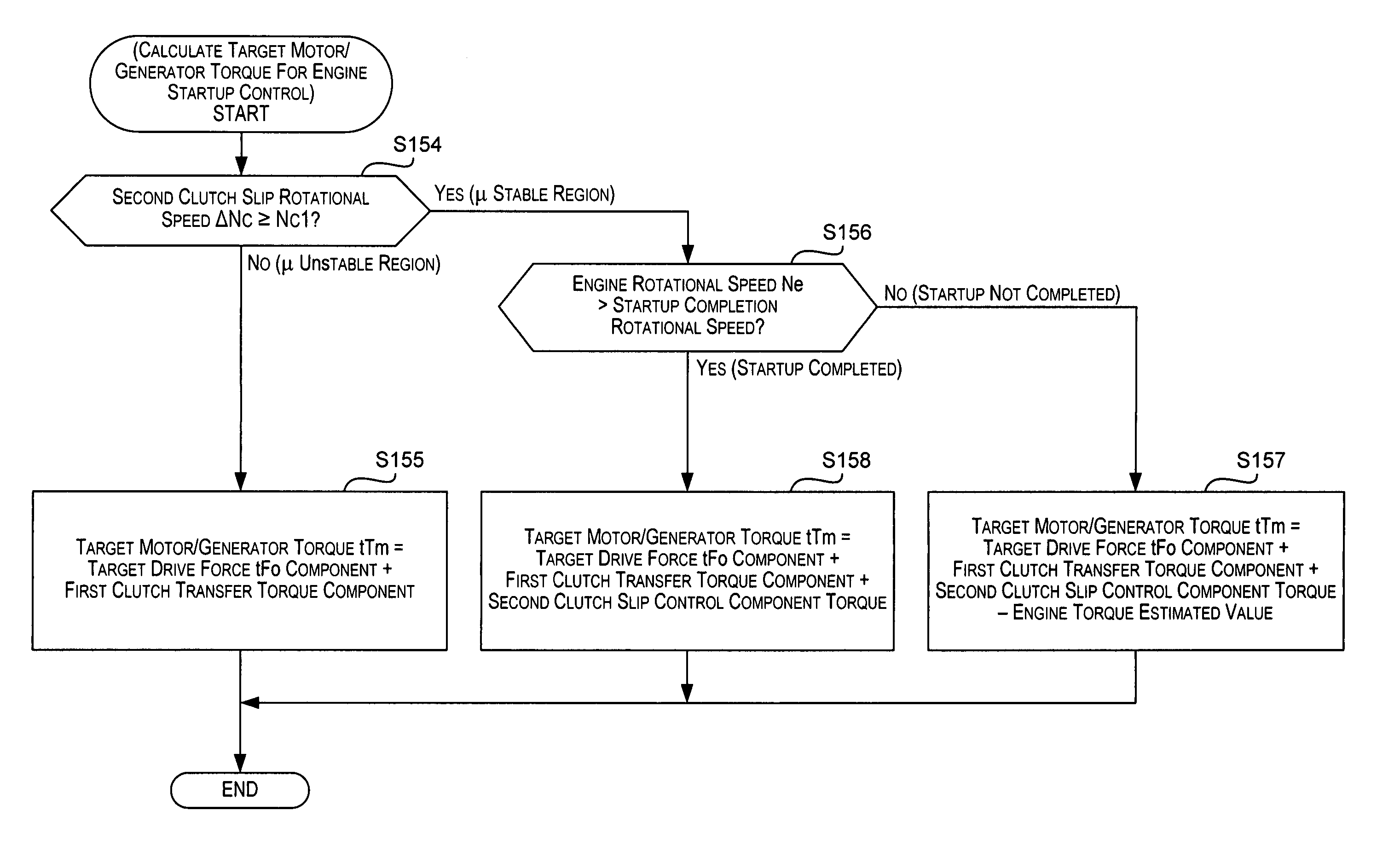

Hybrid vehicle drive control system

A hybrid vehicle drive control system is configured to perform engine startup when switching from an electric drive mode to a hybrid drive mode, without creating a sense of output torque loss. In particular, a controller selectively controls a first clutch disposed between the engine and the motor / generator and a second clutch disposed between the motor / generator and a drive wheel to switch between an electric drive mode in which the first clutch is released and the second clutch is engaged, and a hybrid drive mode in which both the first and second clutches are engaged. The controller sets the second torque transfer capacity to a value that is more than zero and less than the target motor / generator torque of the motor / generator when switching from the electric drive mode to the hybrid drive mode and when starting the engine.

Owner:NISSAN MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com