Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3337 results about "Hydraulic circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydraulic circuit is a system comprising an interconnected set of discrete components that transport liquid. The purpose of this system may be to control where fluid flows (as in a network of tubes of coolant in a thermodynamic system) or to control fluid pressure (as in hydraulic amplifiers). For example, hydraulic machinery uses hydraulic circuits (in which hydraulic fluid is pushed, under pressure, through hydraulic pumps, pipes, tubes, hoses, hydraulic motors, hydraulic cylinders, and so on) to move heavy loads. The approach of describing a fluid system in terms of discrete components is inspired by the success of electrical circuit theory. Just as electric circuit theory works when elements are discrete and linear, hydraulic circuit theory works best when the elements (passive component such as pipes or transmission lines or active components such as power packs or pumps) are discrete and linear. This usually means that hydraulic circuit analysis works best for long, thin tubes with discrete pumps, as found in chemical process flow systems or microscale devices.

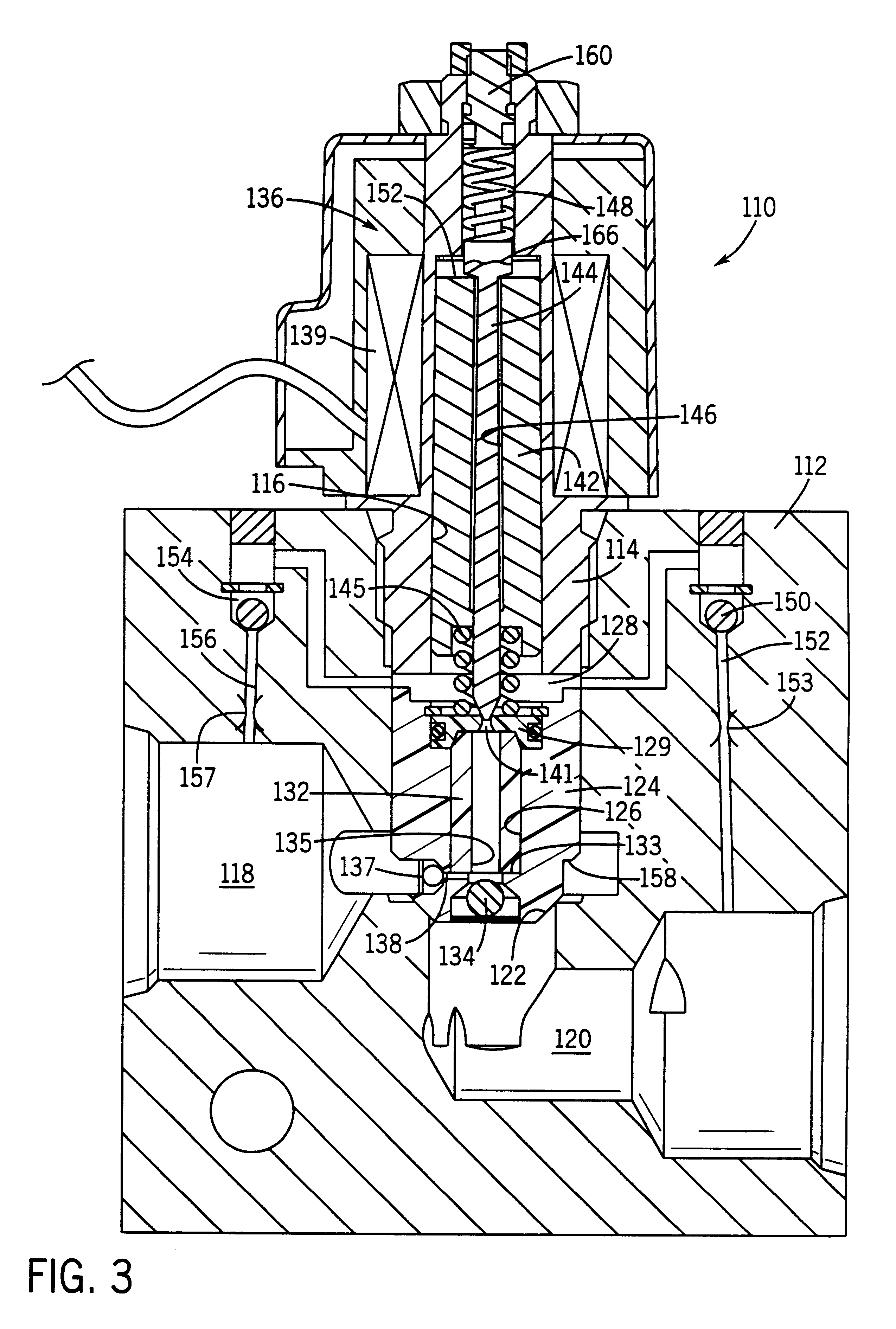

Hydraulic circuit for automatic transmission

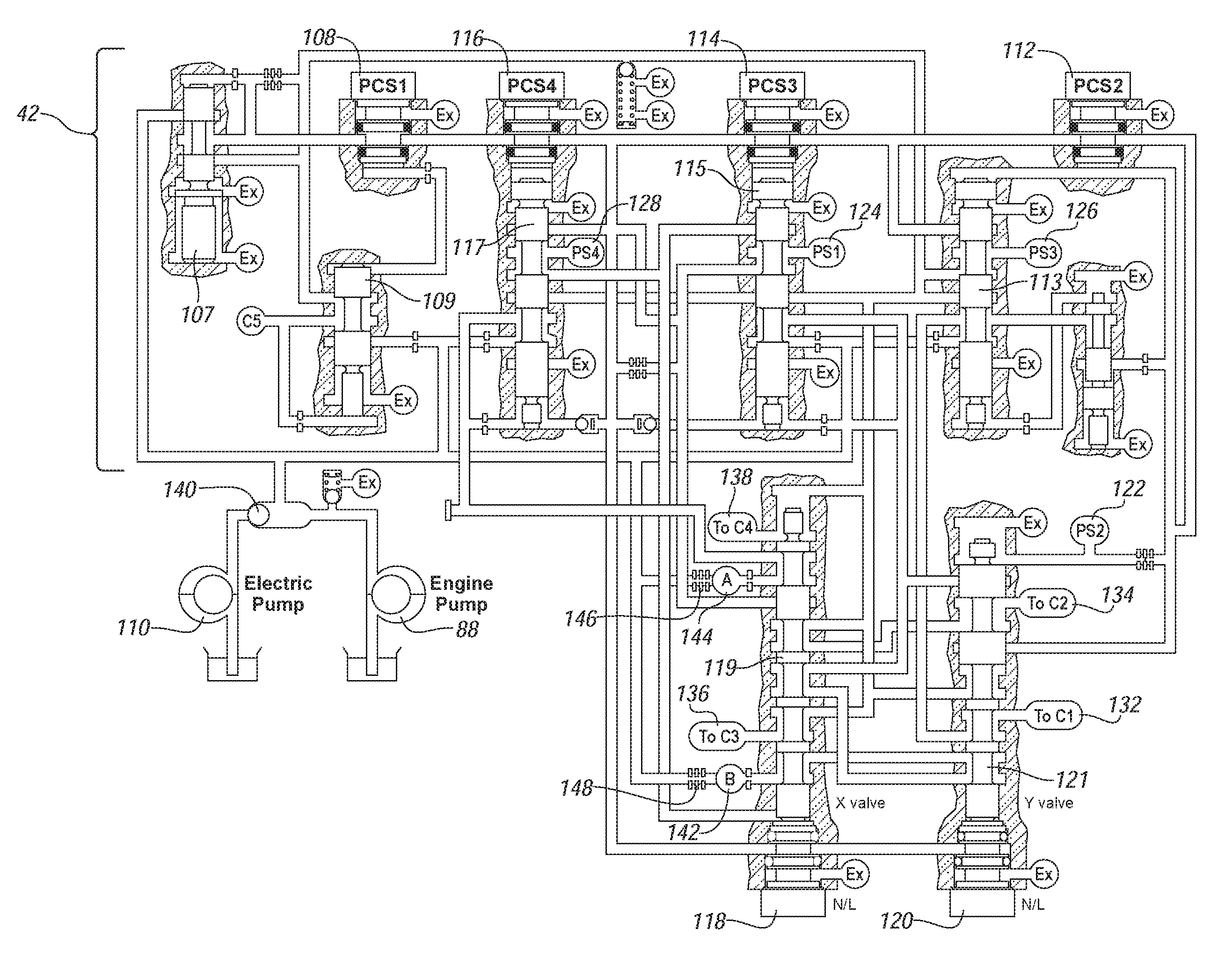

ActiveUS9488197B2Rapidly and effectively removing foreign materialFluid-pressure actuator safetyClutchesProportional controlAutomatic transmission

A hydraulic circuit may include a proportional control solenoid valve controlling hydraulic pressure such that an operating hydraulic pressure required by the friction member is supplied to the friction member; a supply hydraulic path connecting the proportional control solenoid valve with the friction member, and adapted to supply hydraulic pressure controlled by the proportional control solenoid valve to the friction member; and a switch valve disposed in the supply hydraulic path so as to selectively open / close the supply hydraulic path.

Owner:HYUNDAI MOTOR CO LTD

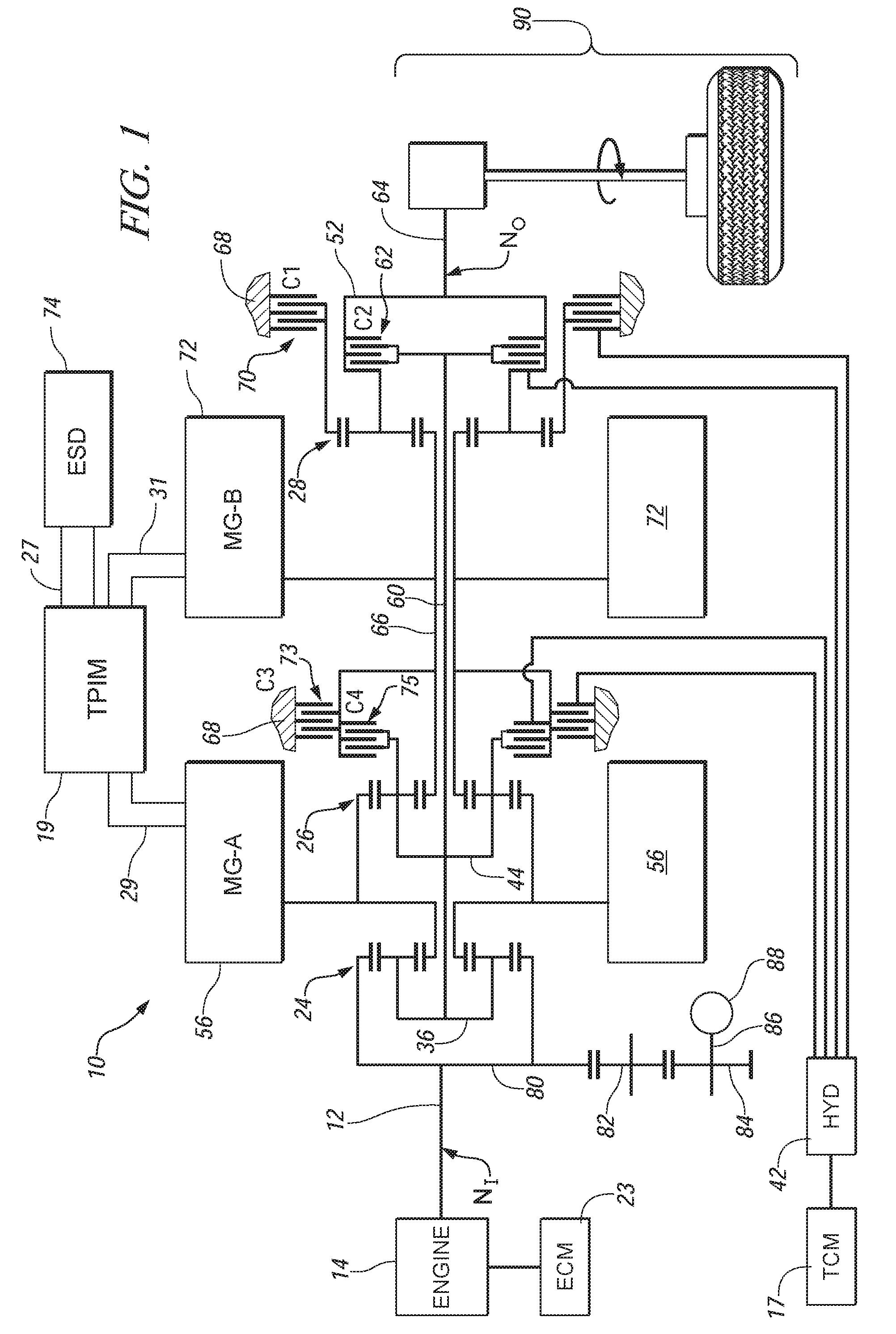

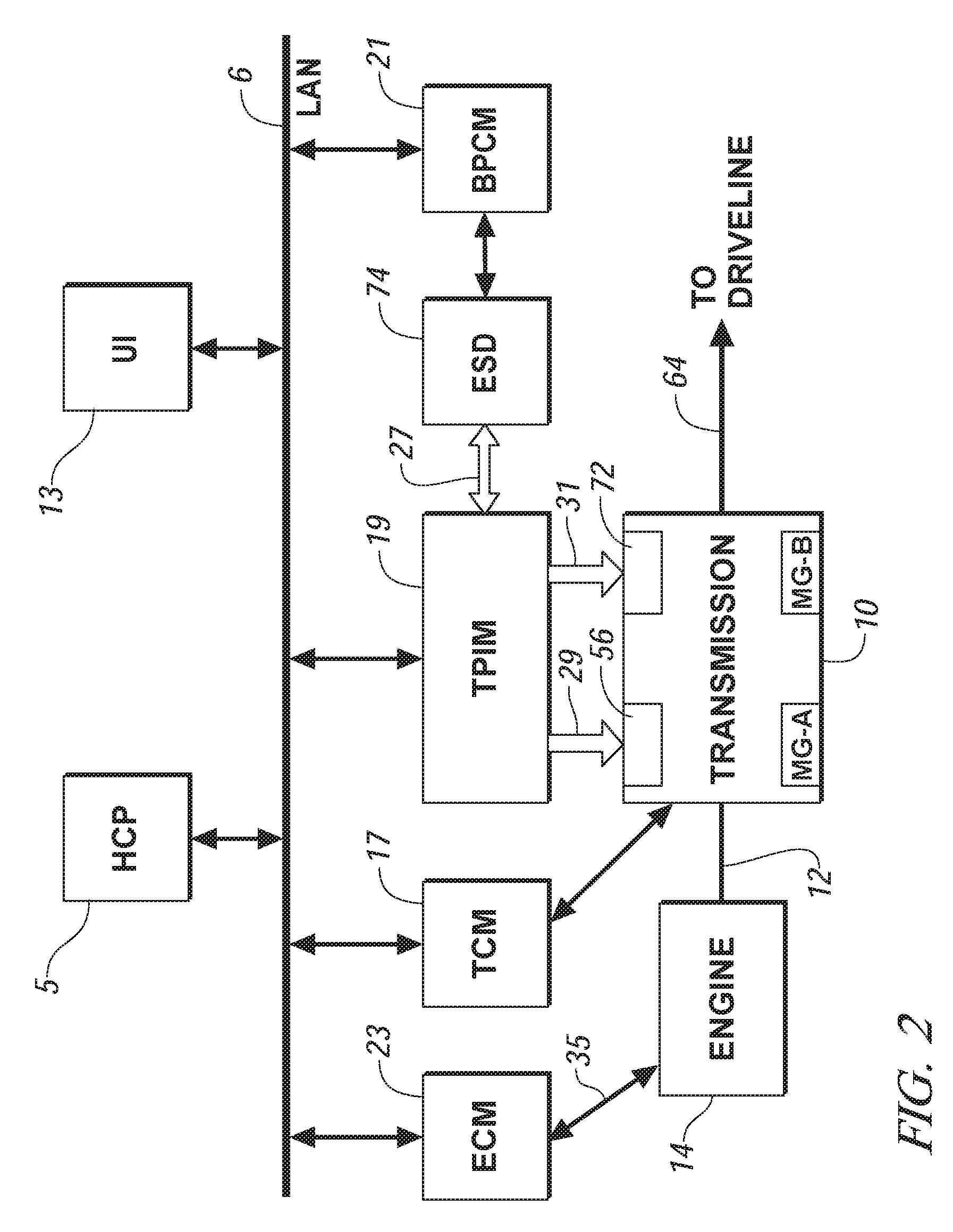

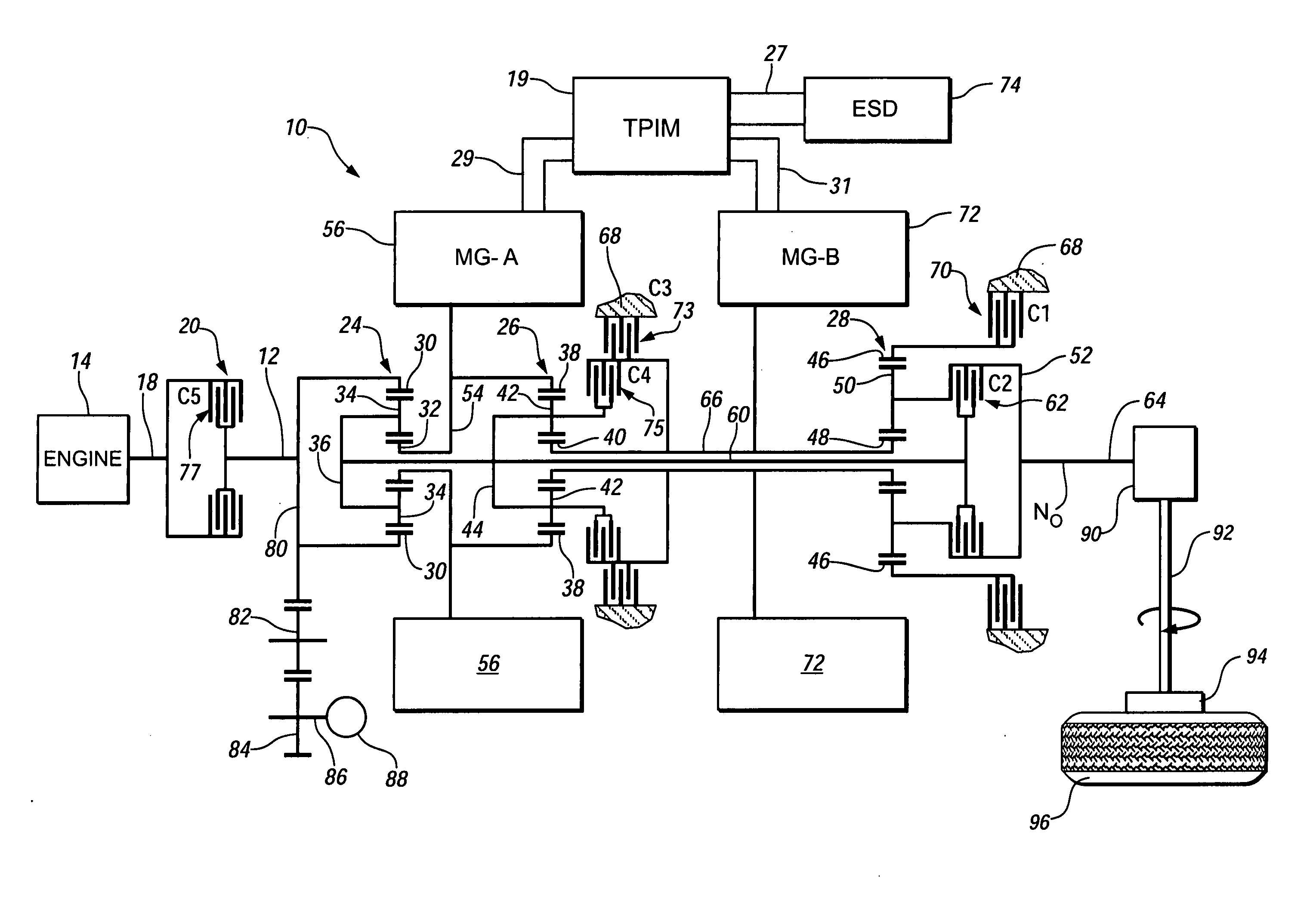

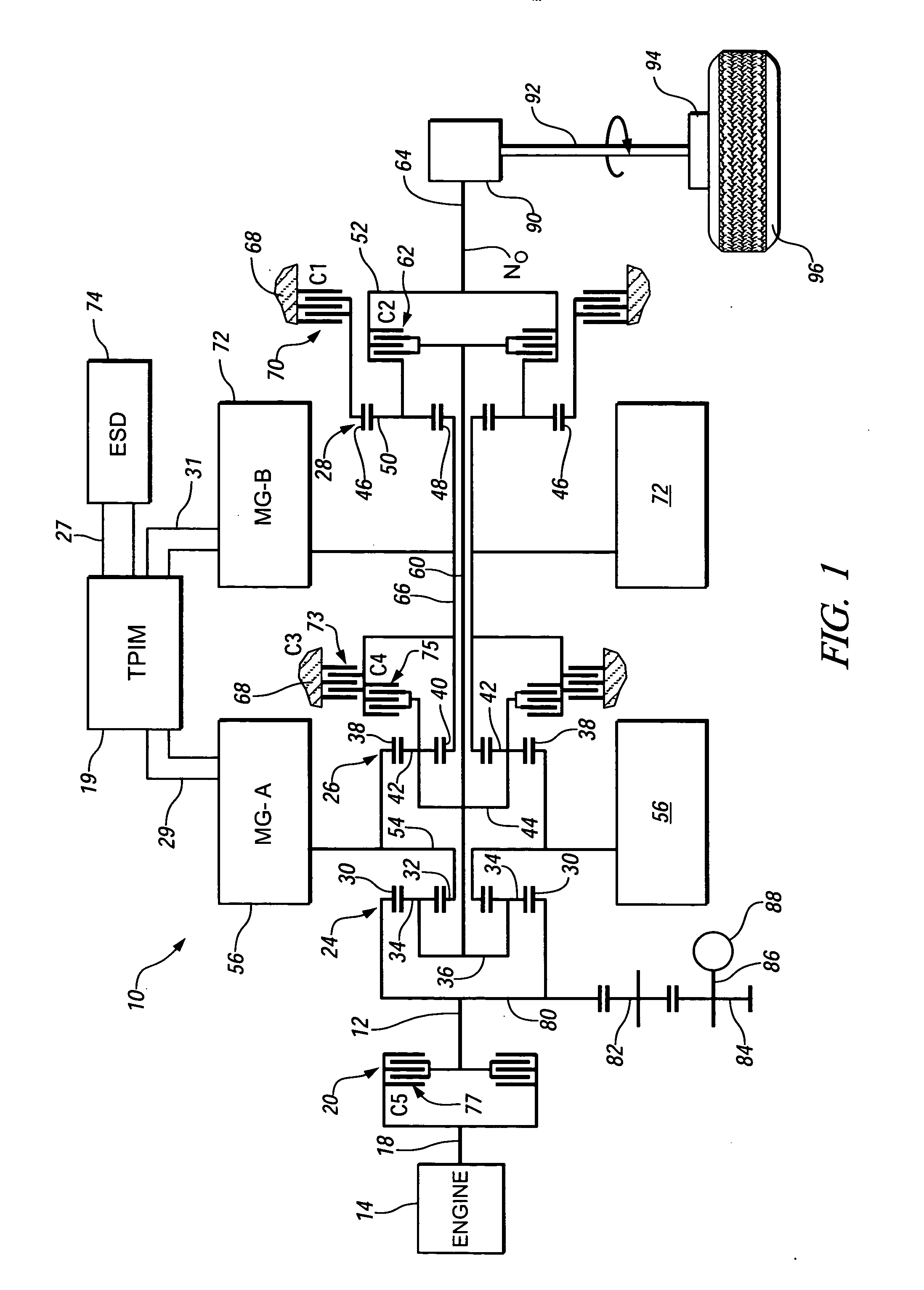

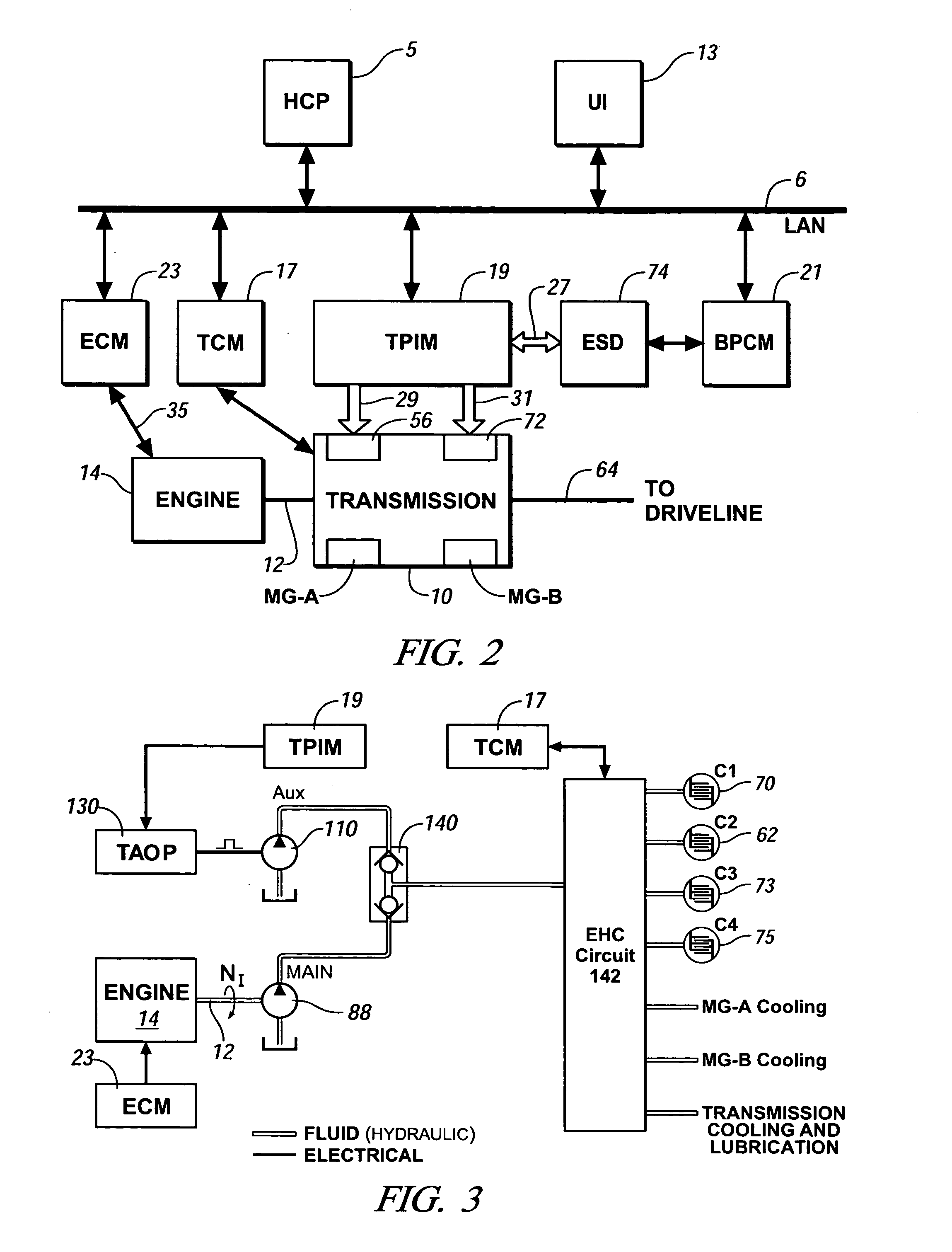

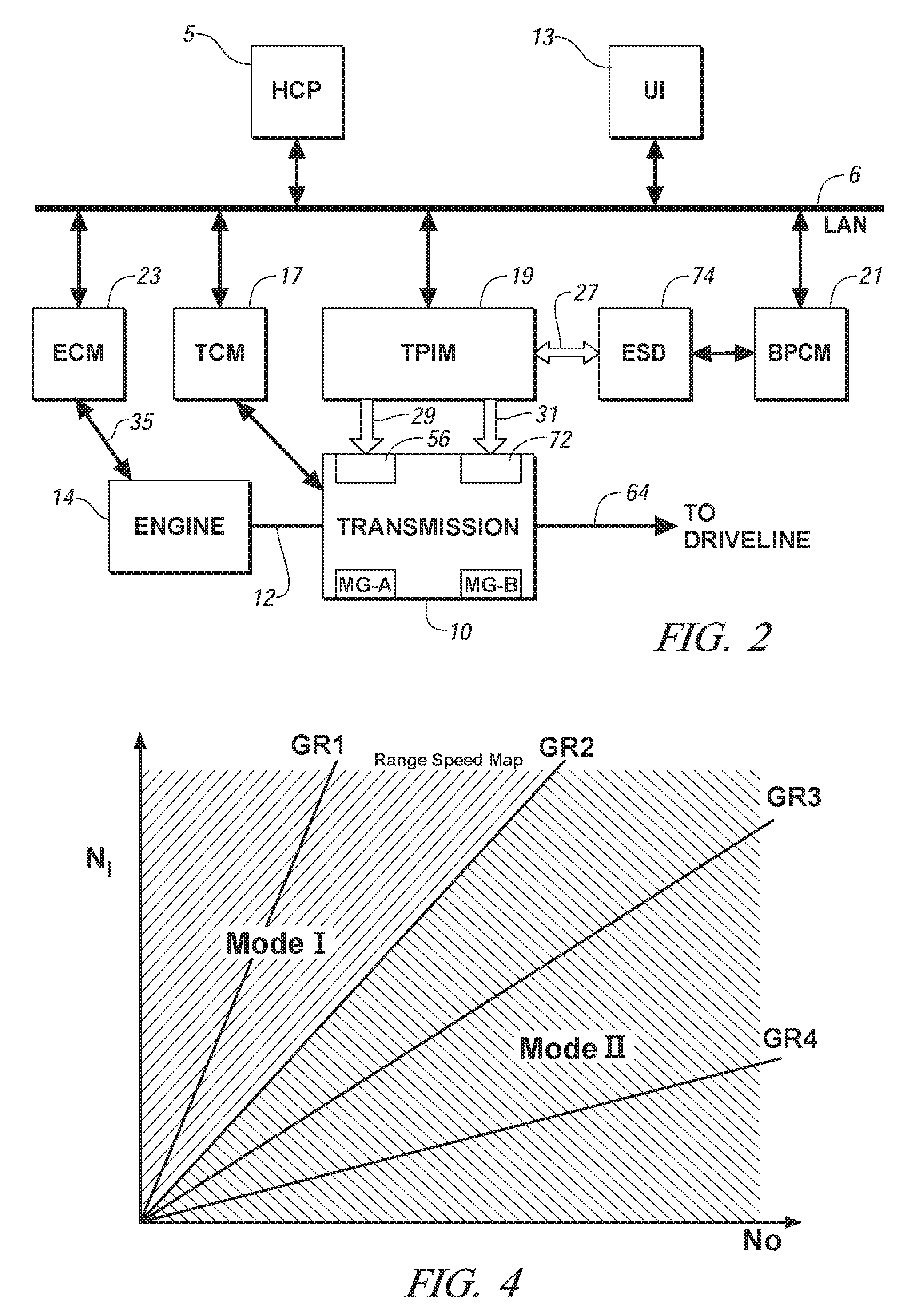

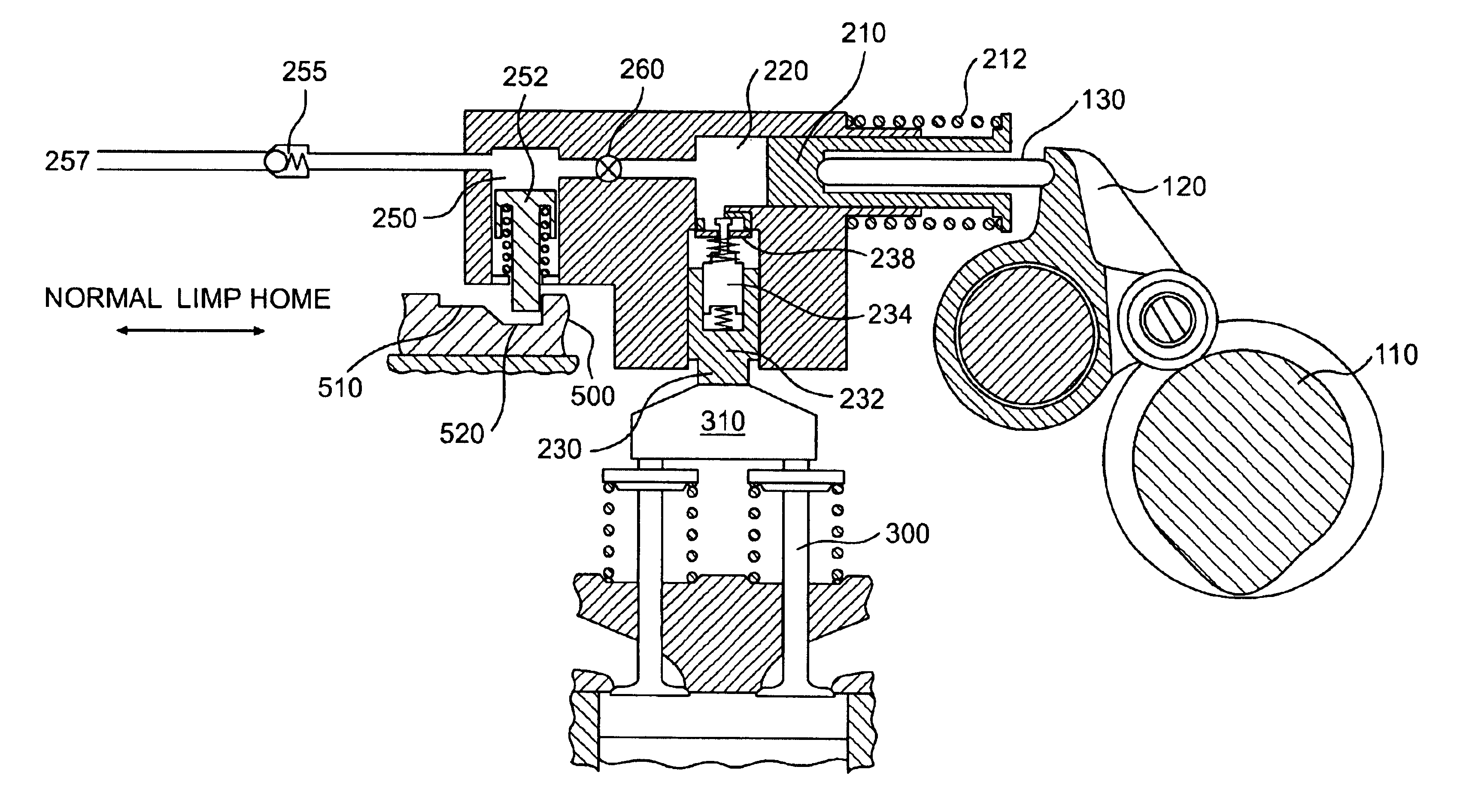

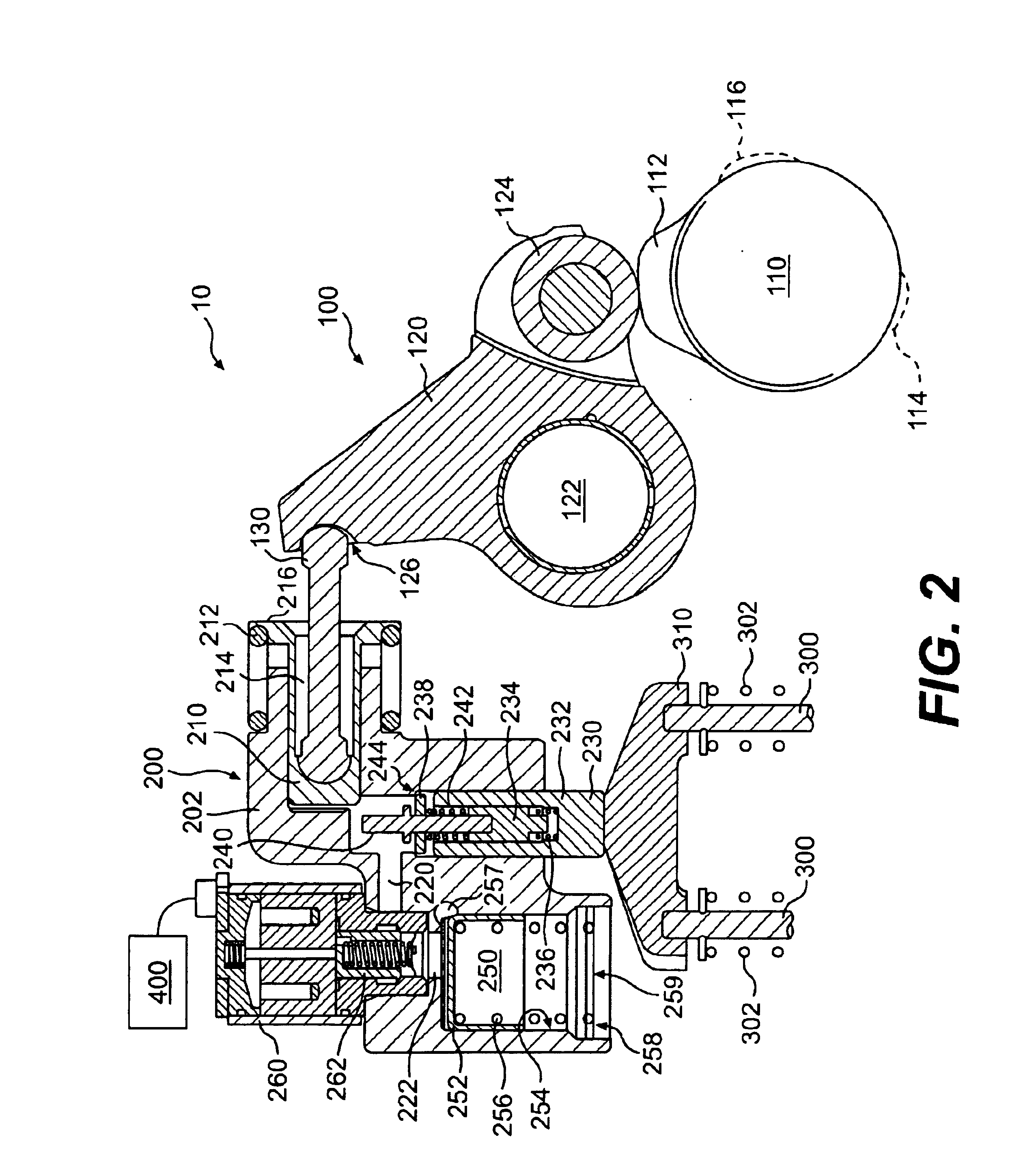

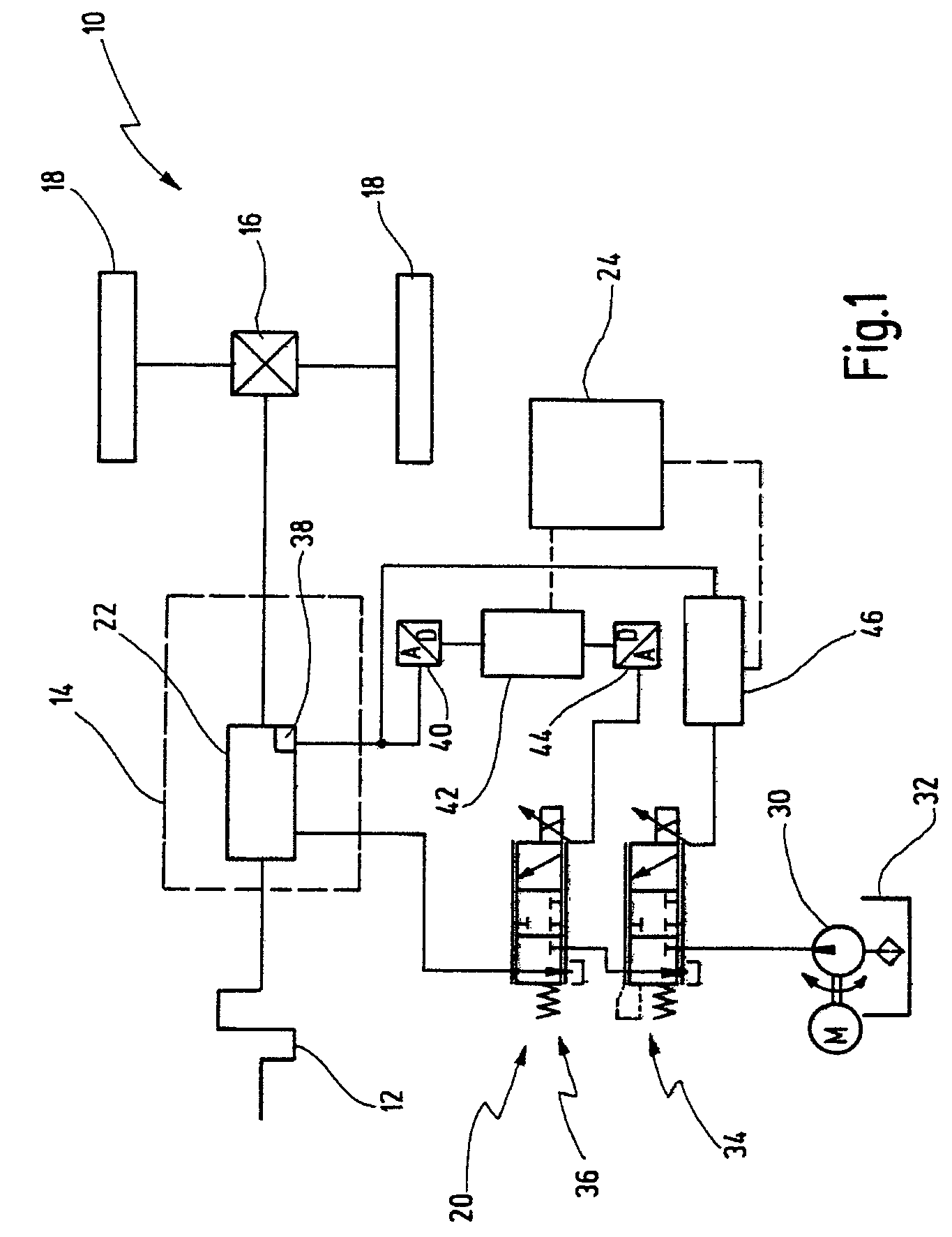

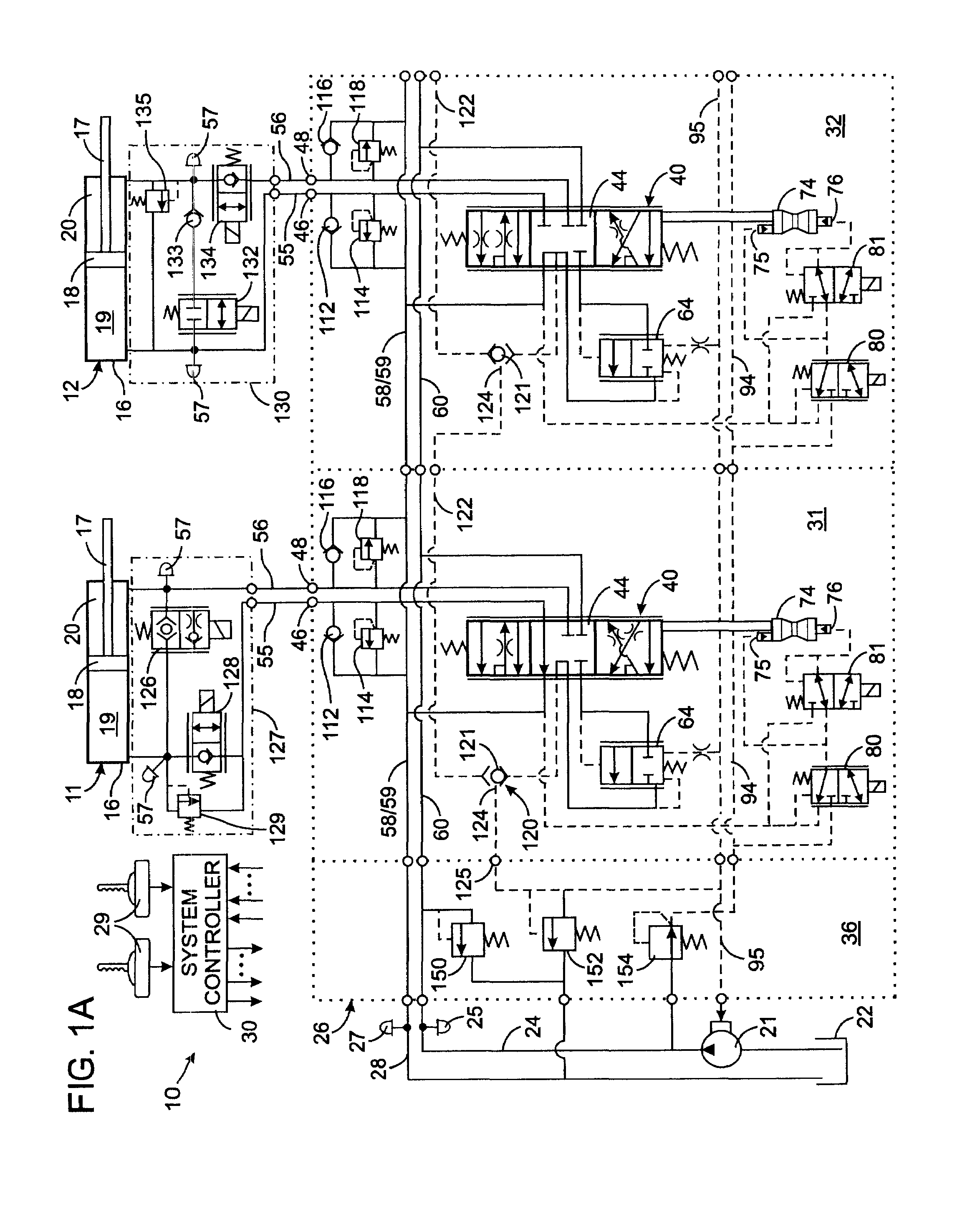

Method and apparatus to monitor devices of a hydraulic circuit of an electro-mechanical transmission

A method and an apparatus are provided to control operation of an electro-mechanical transmission device selectively operative in one of a plurality of fixed gear modes and two continuously variable modes. The method comprises controlling the flow control devices of the electro-hydraulic control circuit, and monitoring a plurality of pressure monitoring devices in the electro-hydraulic control circuit. A fault is identified in the electro-hydraulic control circuit when a signal output of one of the pressure monitoring devices does not correspond to an expected signal output for the pressure monitoring device after an elapsed time period.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method and apparatus to control hydraulic pressure in an electro-mechanical transmission

Owner:GM GLOBAL TECH OPERATIONS LLC

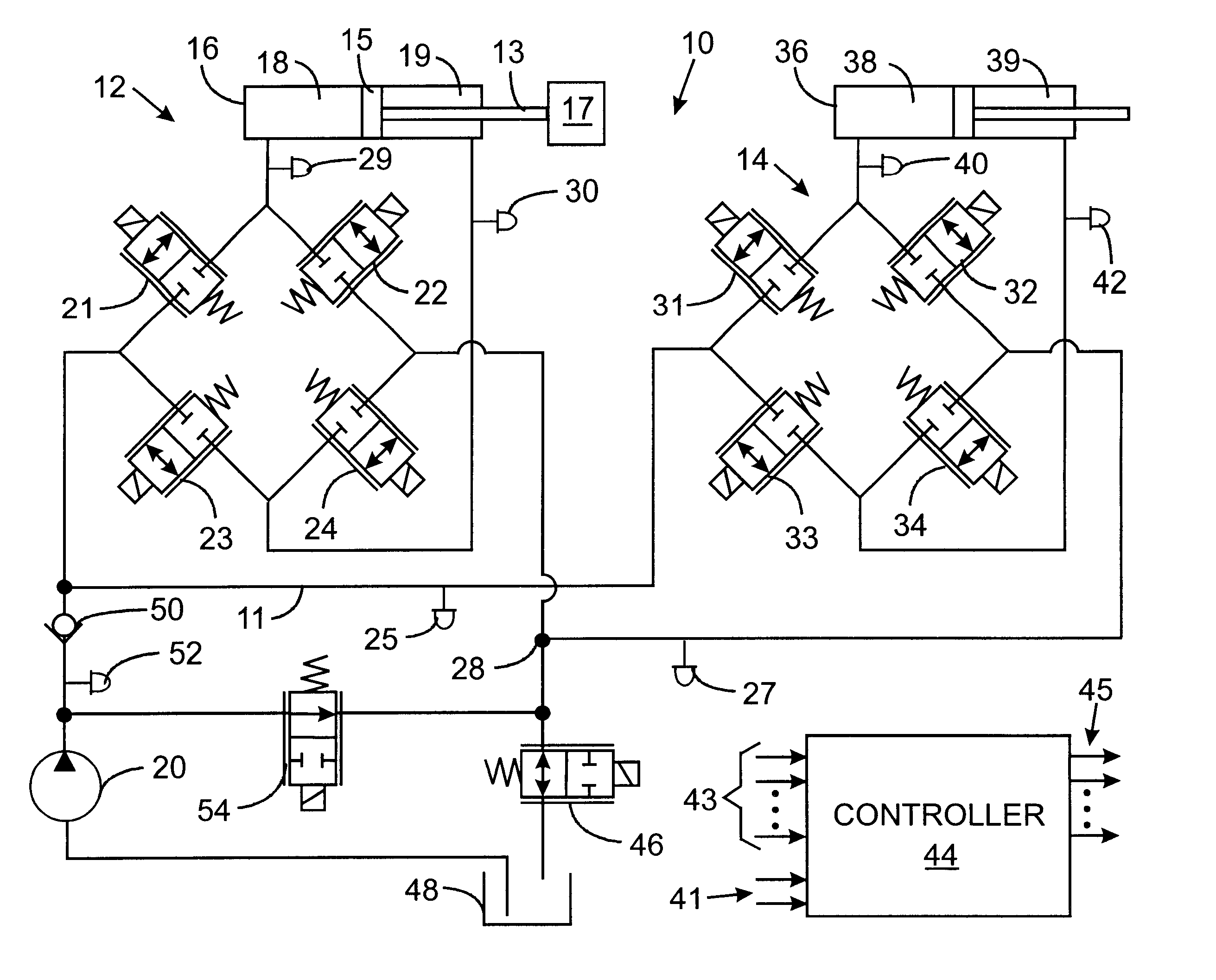

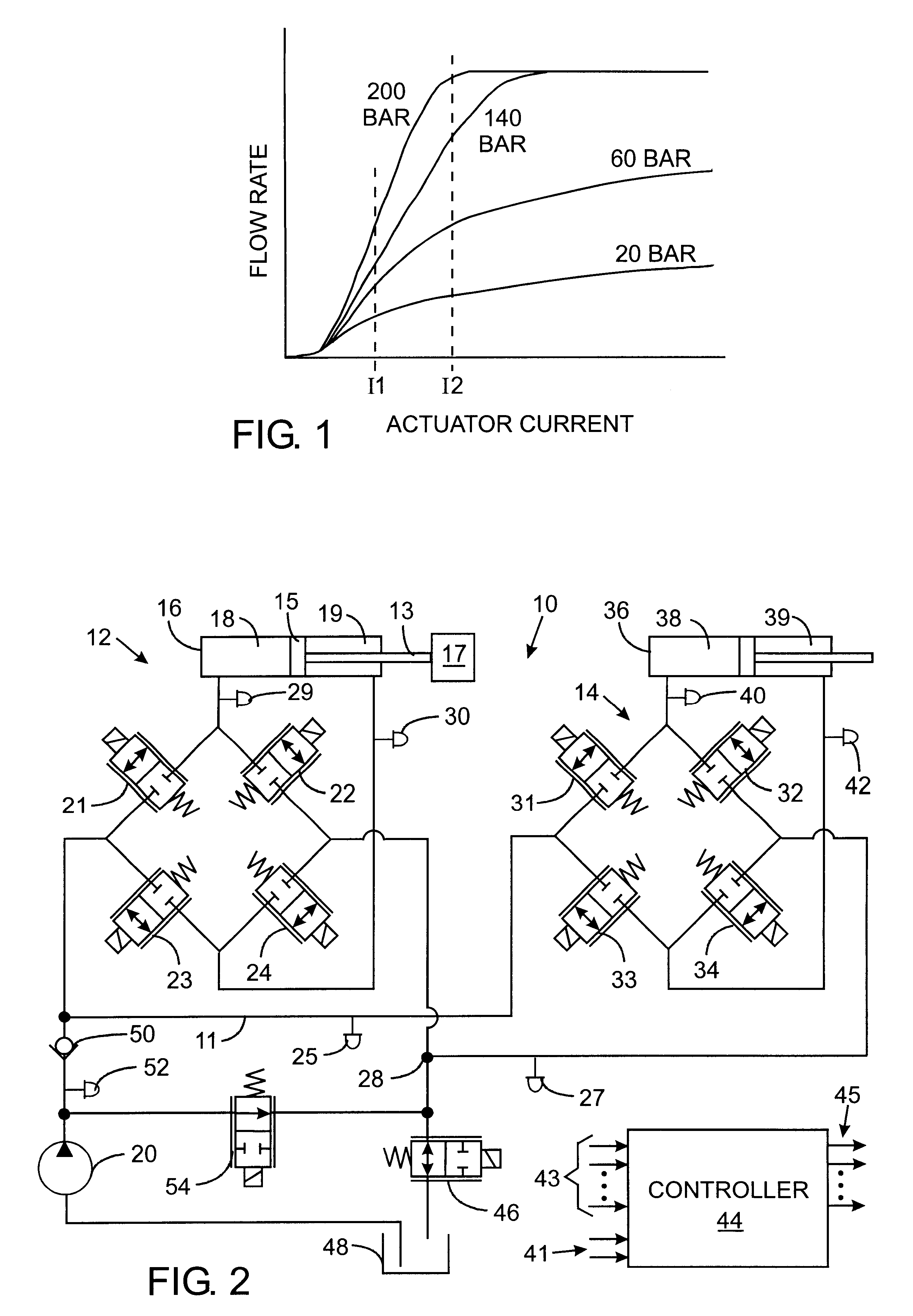

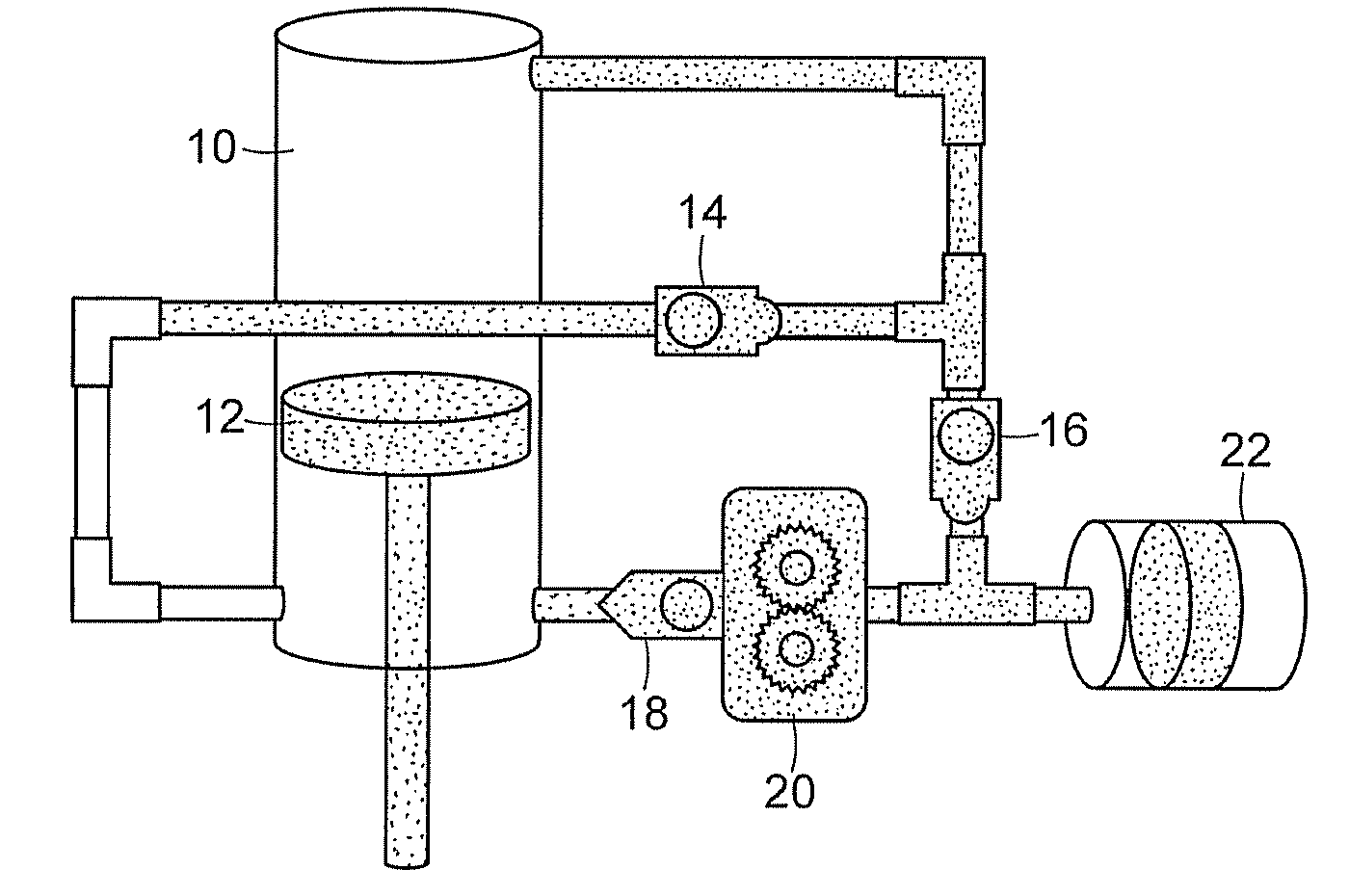

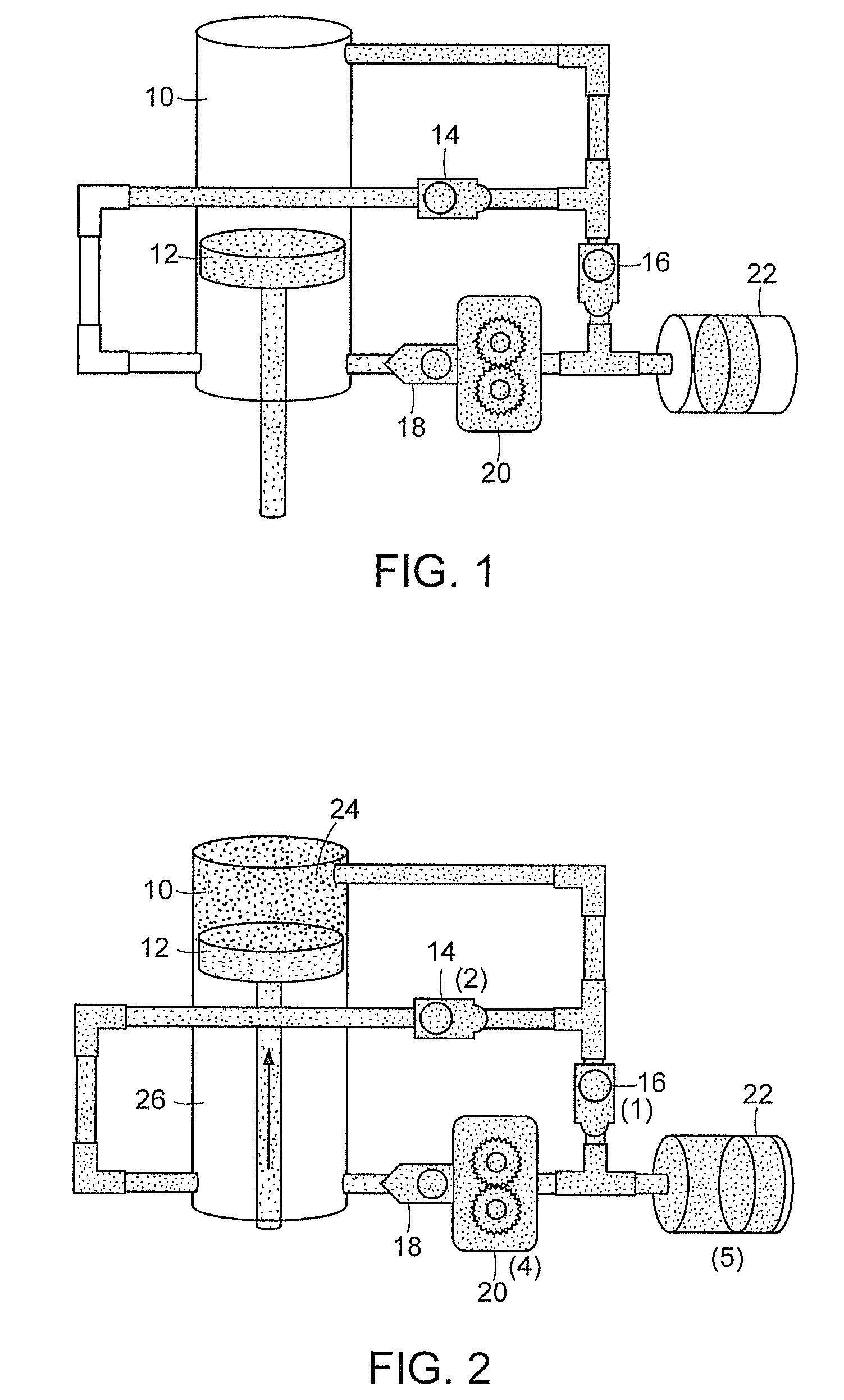

Hydraulic circuit with a return line metering valve and method of operation

A hydraulic system controls the flow of fluid to and from several functions on a machine. Each function has a valve assembly through which fluid is supplied under pressure from a source to an actuator and through which fluid returns from the actuator to a shared return line connected by a return line metering valve to the system tank. There are several regeneration modes of operation in which fluid exhausted from one port is supplied into the other port of the same actuator, which eliminates or reduces the amount of hydraulic fluid that must be supplied from the source. In some regeneration modes, input fluid for an actuator is obtained from another hydraulic function via the shared return line. In these regeneration modes an electronic controller operates the return line metering valve to restrict fluid from flowing into the tank from the shared return line, so that the fluid will be available to be supplied into an actuator port.

Owner:HUSCO INT INC

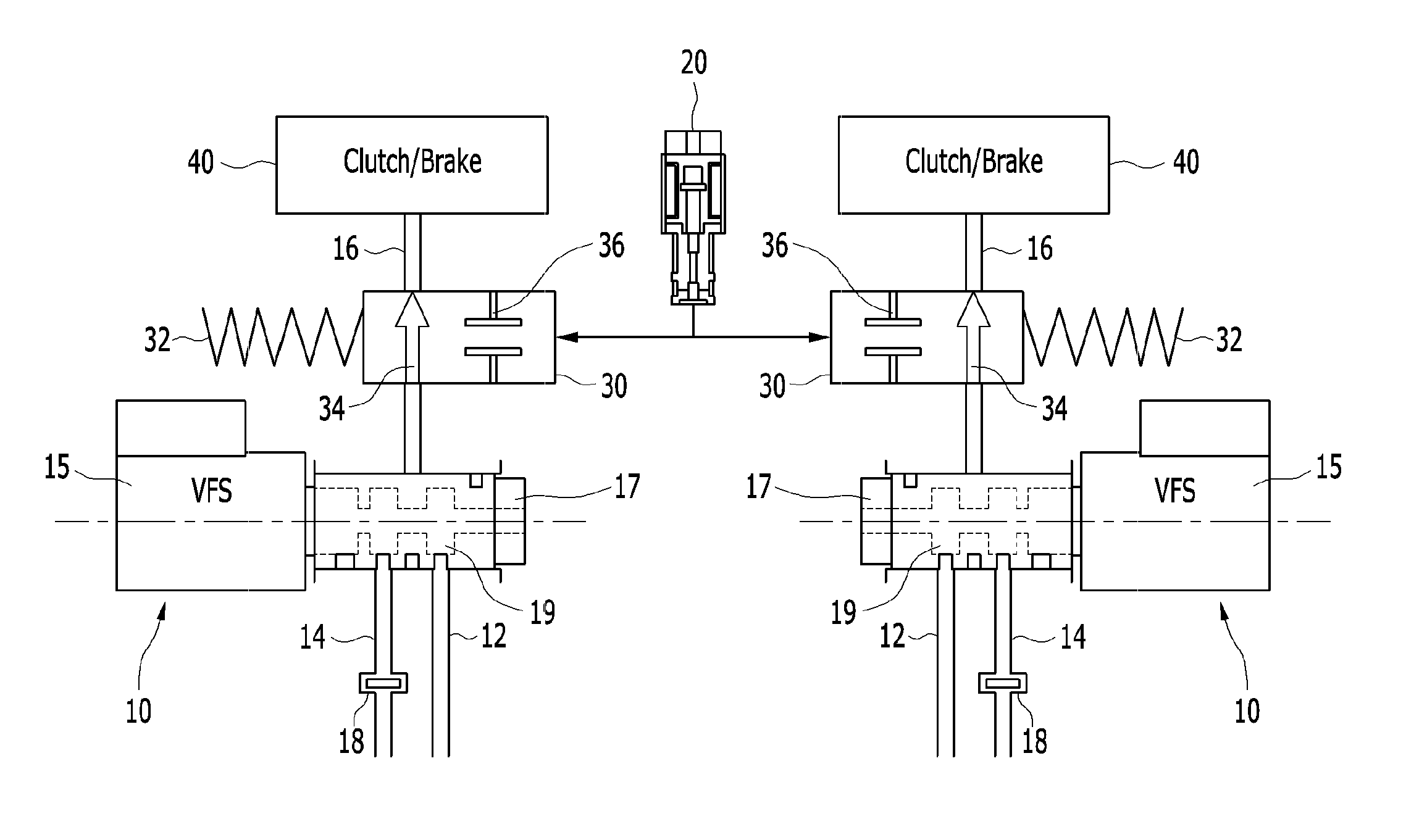

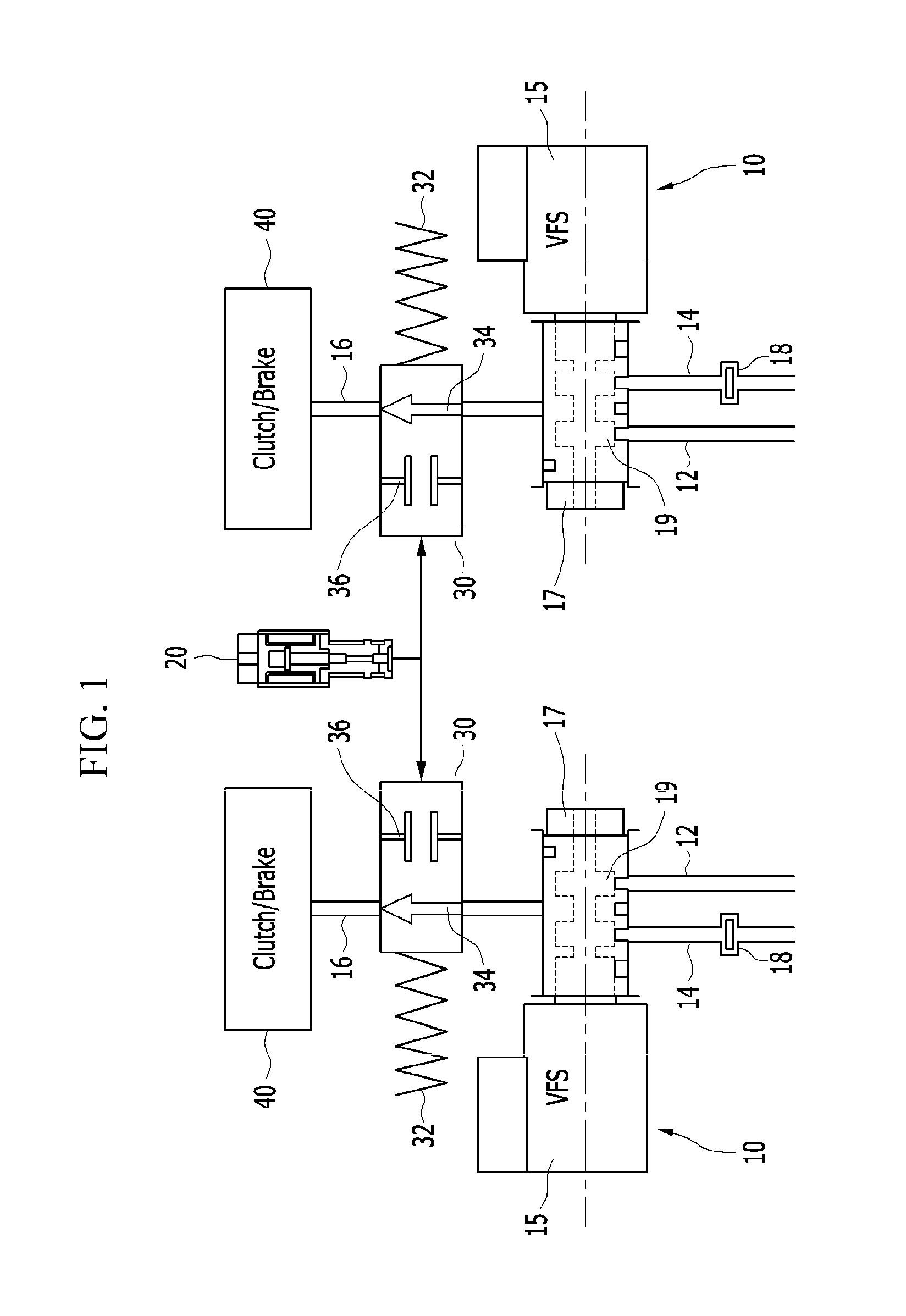

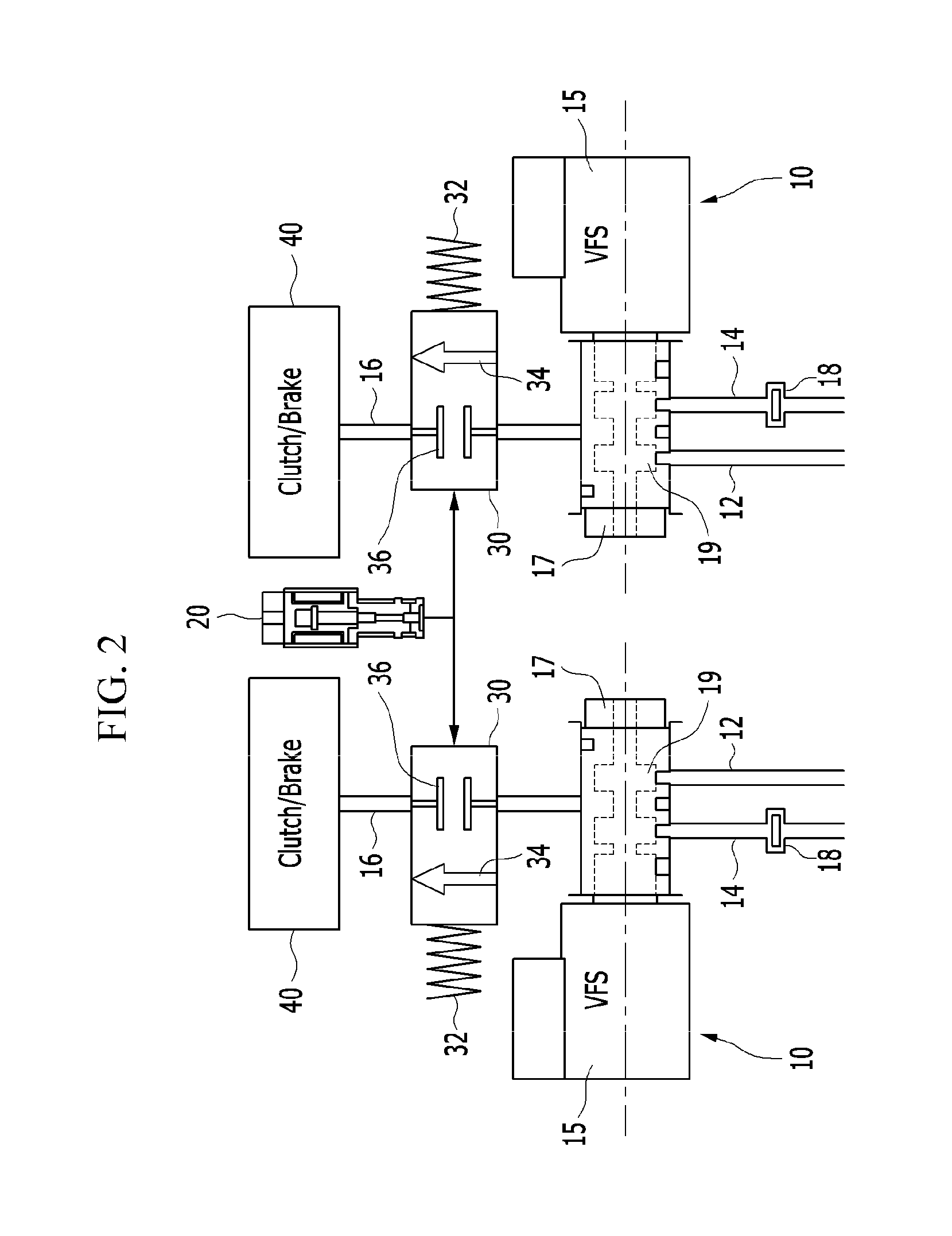

Method and apparatus to control operation of an electro-mechanical transmission

InactiveUS20080176706A1Hybrid vehiclesDigital data processing detailsTorque transmissionHydraulic circuit

A method and apparatus are provided to control operation of an electro-mechanical torque transmission device selectively operative in one of a plurality of fixed gear modes and two continuously variable modes, and operative to transmit torque input from a plurality of torque-generative devices. The transmission device includes a hydraulic circuit and is operative in one of a plurality of operating modes by selective actuation of a plurality of hydraulically-actuated torque-transfer clutches. The method comprises monitoring pressures in the hydraulic circuit, and restricting operation of the transmission when any one of the monitored hydraulic pressures does not correspond to an expected pressure thereat. Presence of a fault is verified during the restricted operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

Regenerative shock absorber

Regenerative shock absorber. A piston is disposed for reciprocating motion within a cylinder as a vehicle's suspension system deflects. Hydraulic fluid passes through an hydraulic motor to turn its shaft. The hydraulic motor shaft is connected to an electric generator to generate electricity. Flow characteristics of hydraulic circuits are selected to provide suspension system damping for appropriate wheel control.

Owner:CLEARMOTION INC

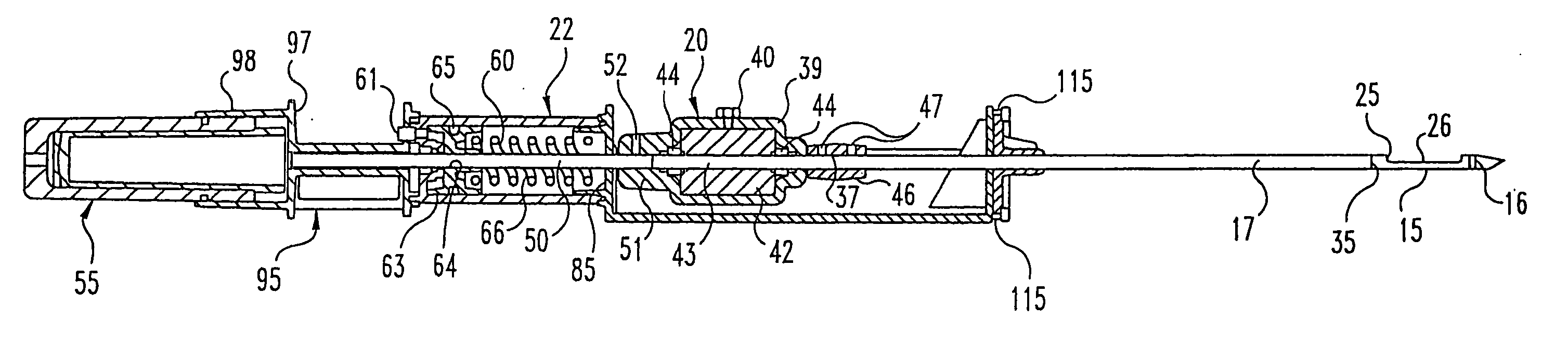

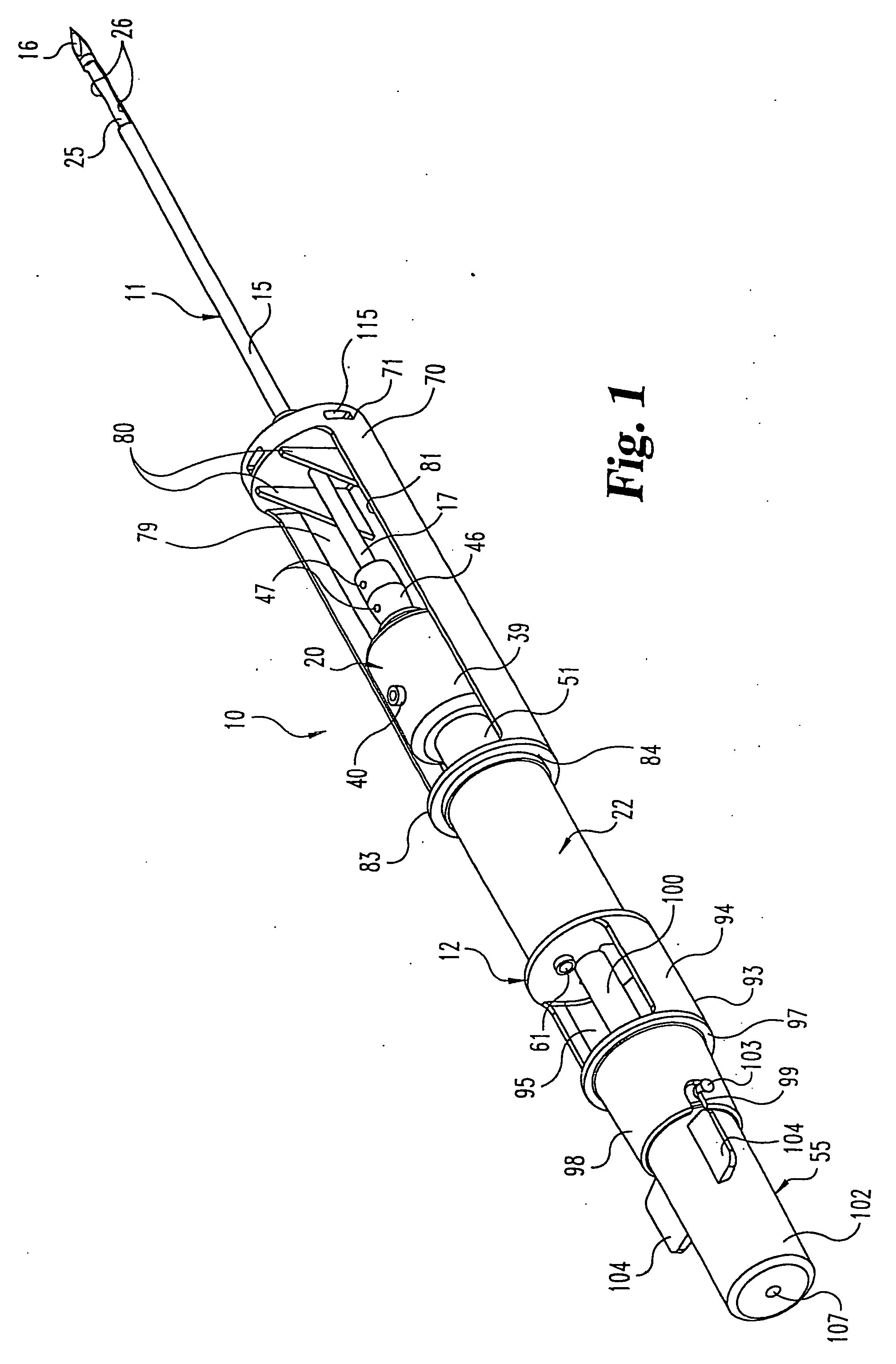

Selectively detachable outer cannula hub

InactiveUS20060155209A1Eliminate riskMaximizes length and overall size of coreSurgical needlesPerson identificationHydraulic circuitOuter Cannula

A disposable tissue removal device comprises a “tube within a tube” cutting element mounted to a handpiece. The inner cannula of the cuffing element defines an inner lumen and terminates in an inwardly beveled, razor-sharp cutting edge. The inner cannula is driven by both a rotary motor and a reciprocating motor. At the end of its stroke, the inner cannula makes contact with the cutting board to completely sever the tissue. An aspiration vacuum is applied to the inner lumen to aspirate excised tissue through the inner cannula and into a collection trap that is removably mounted to the handpiece. The rotary and reciprocating motors are hydraulically powered through a foot pedal operated hydraulic circuit. The entire biopsy device is configured to be disposable. In one embodiment, the cutting element includes a cannula hub that can be connected to a fluid source, such as a valve-controlled saline bag.

Owner:SUROS SURGICAL SYST

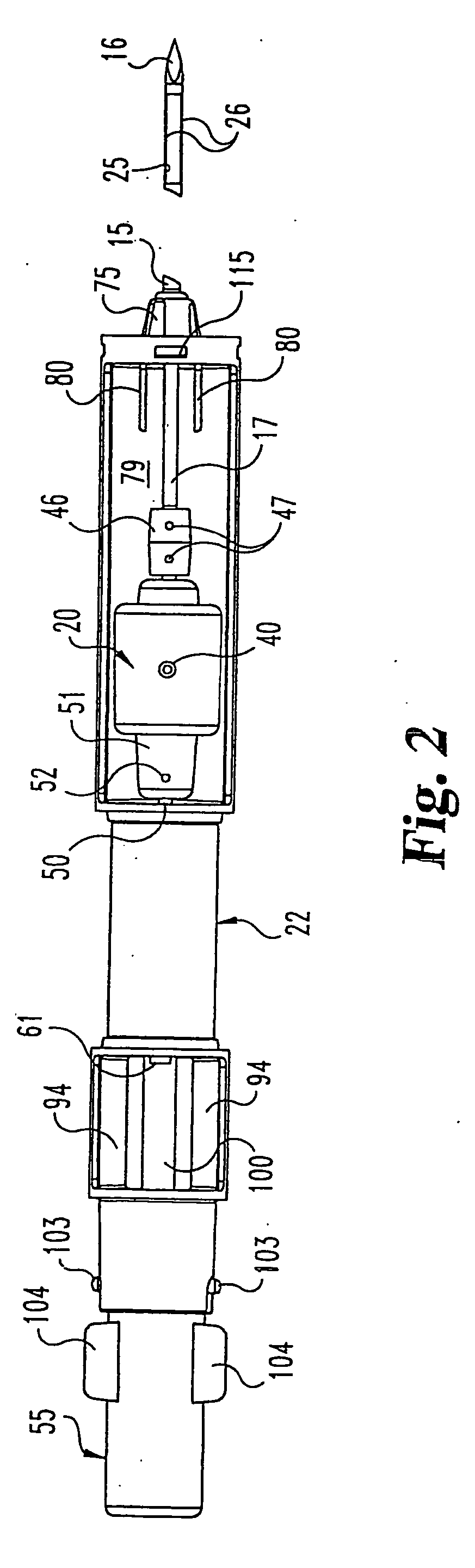

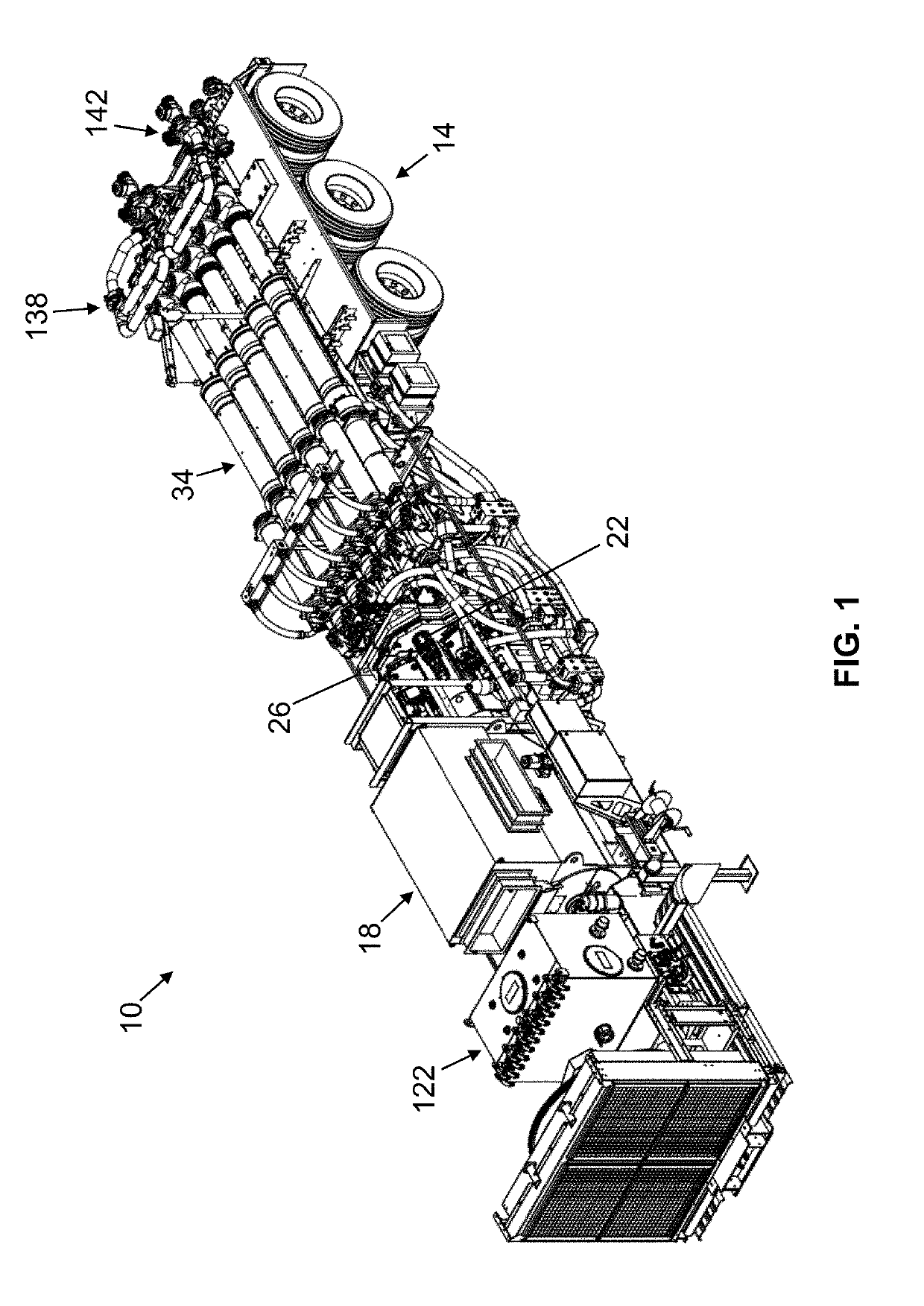

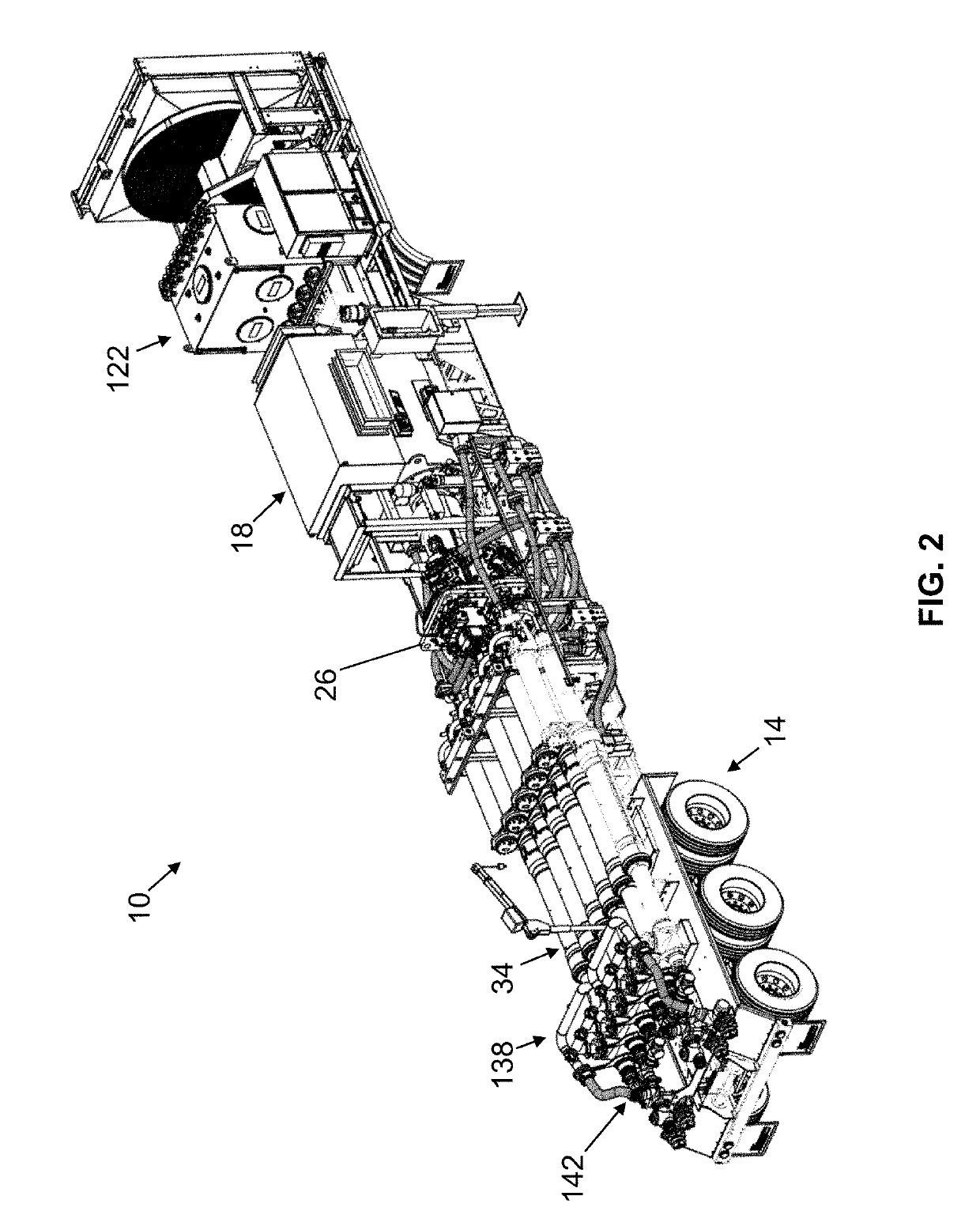

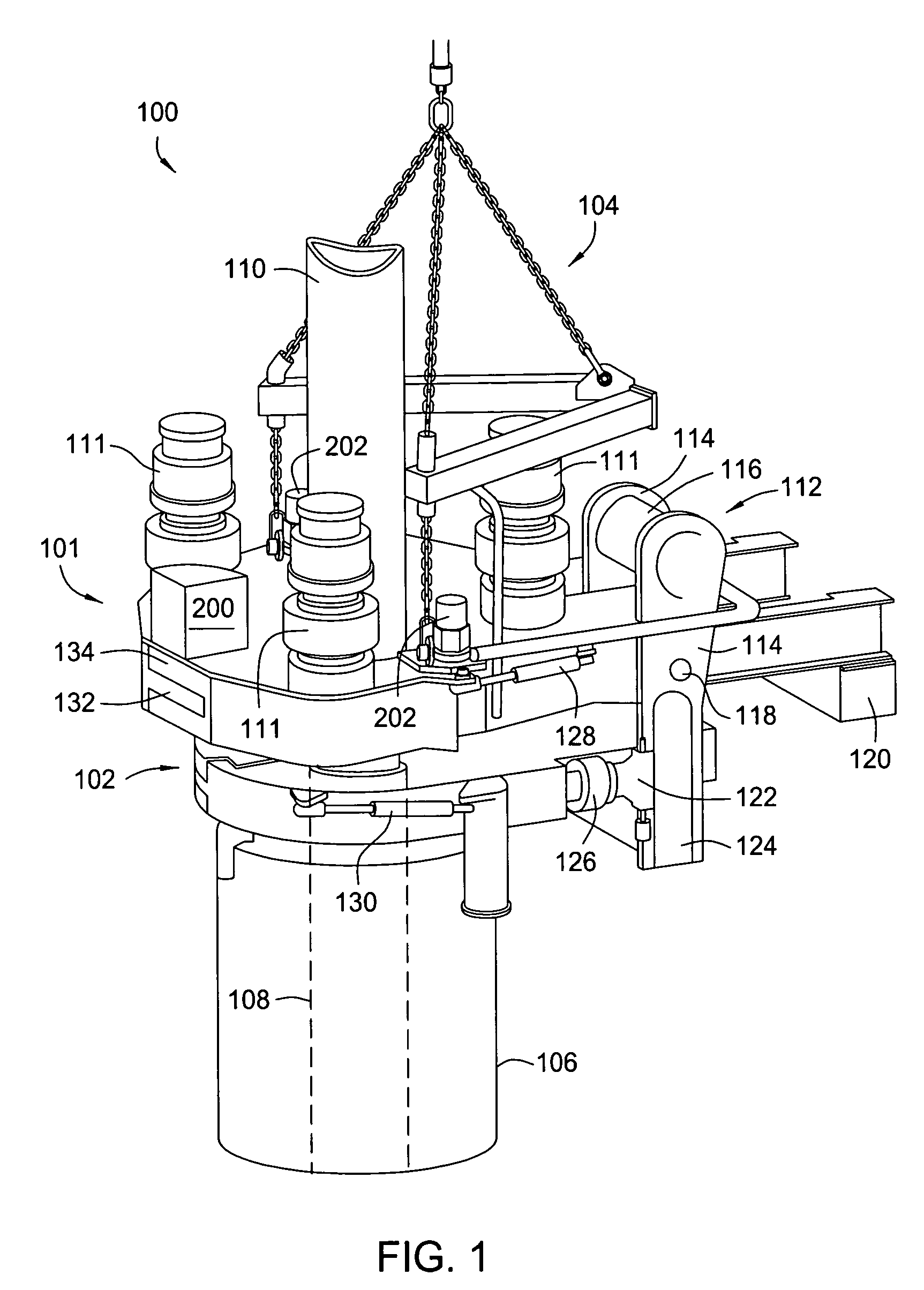

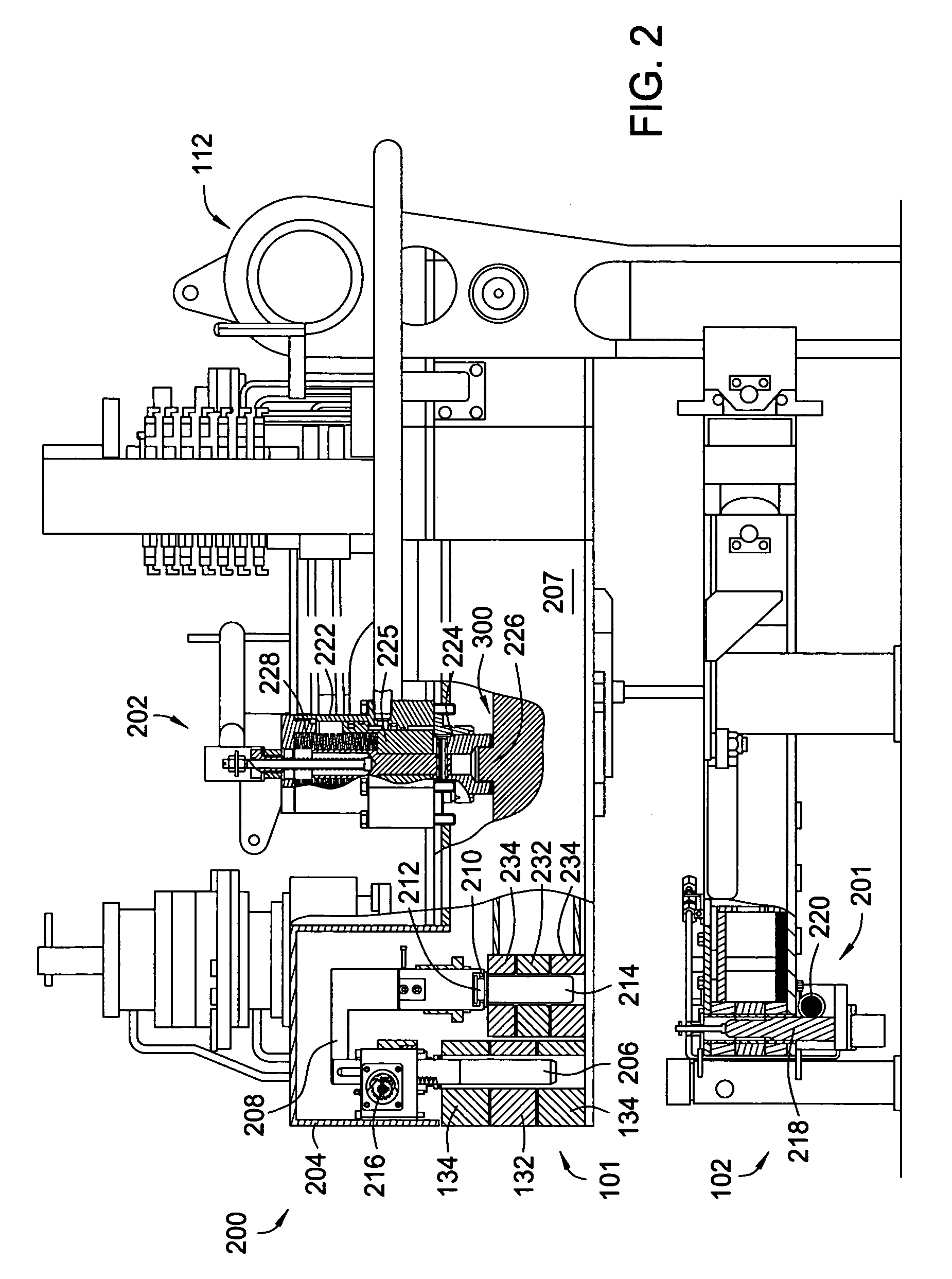

Well service pump systems and related methods

A well service pump system supplies high pressure working fluid to a well. The pump system includes a closed-loop hydraulic circuit for actuating a plurality of working pump assemblies. The pump system is powered by a motor, which transfers mechanical energy to a plurality of pumps, which, in turn, provide hydraulic fluid to operate hydraulic ram cylinders, and thereby operate the working pump assemblies. Each of the polished rods of the hydraulic ram cylinders is connected axially to a plunger rod end of the working fluid end cylinder to operate the working pump assembly.

Owner:AMERIFORGE GRP

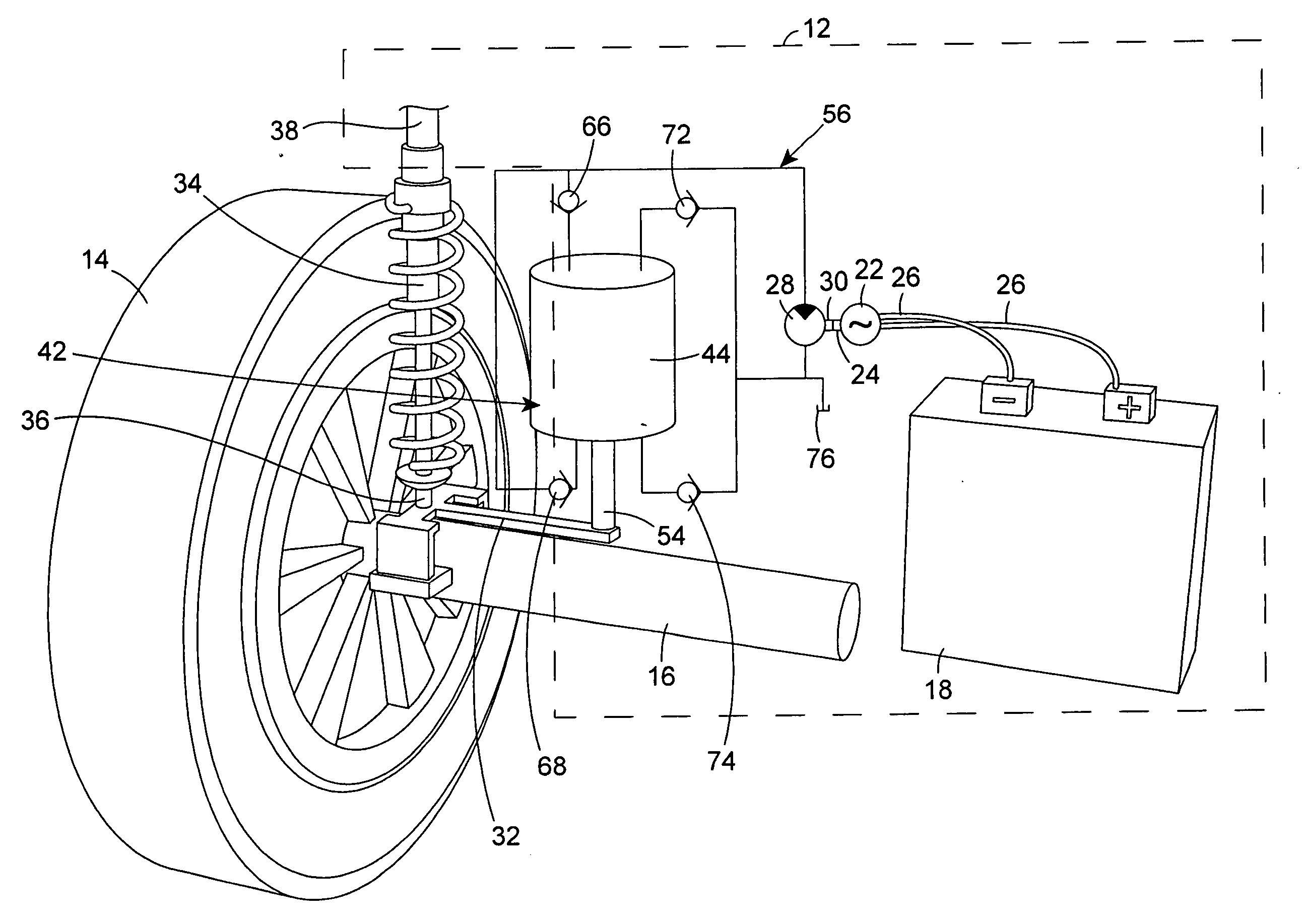

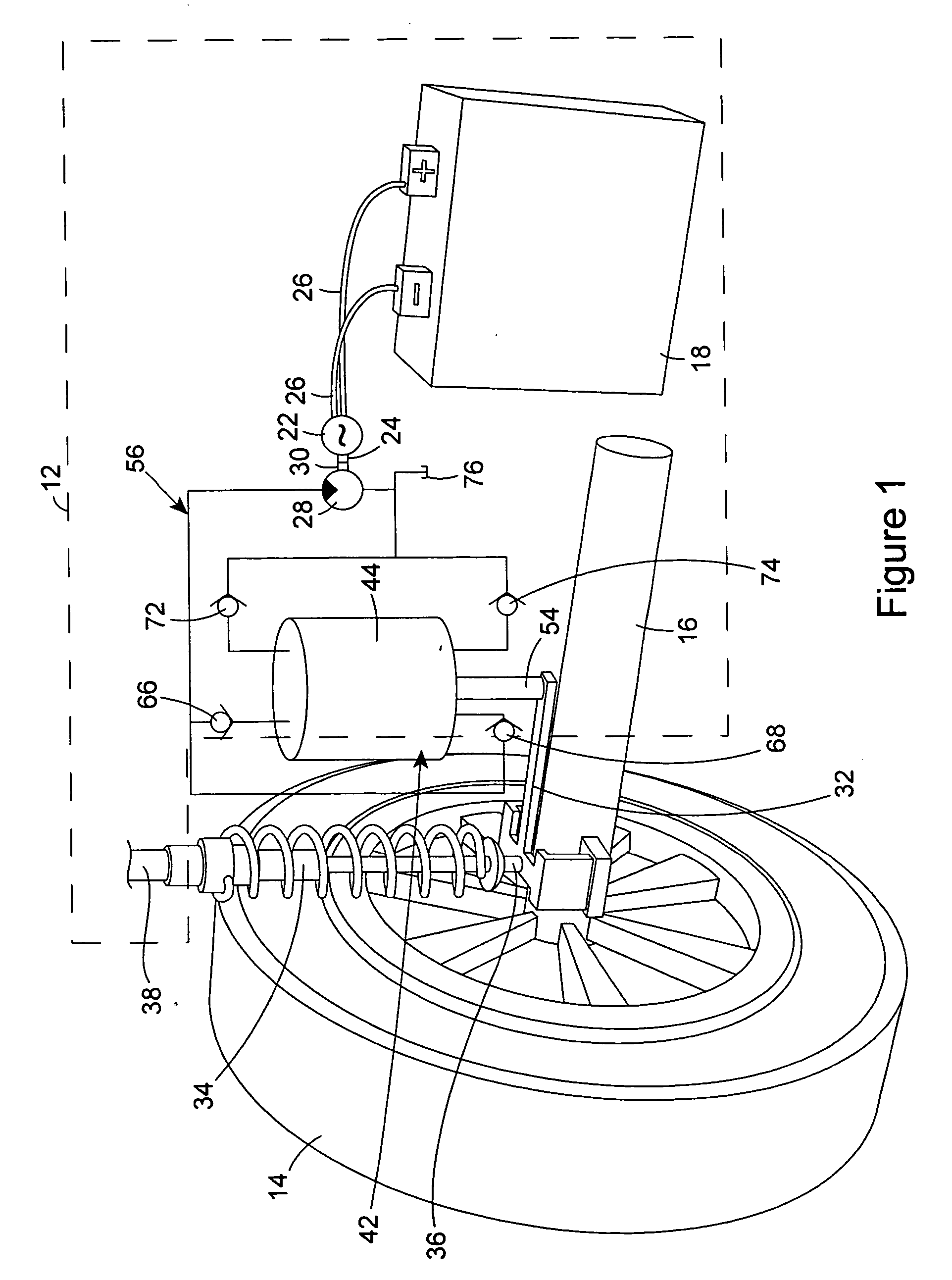

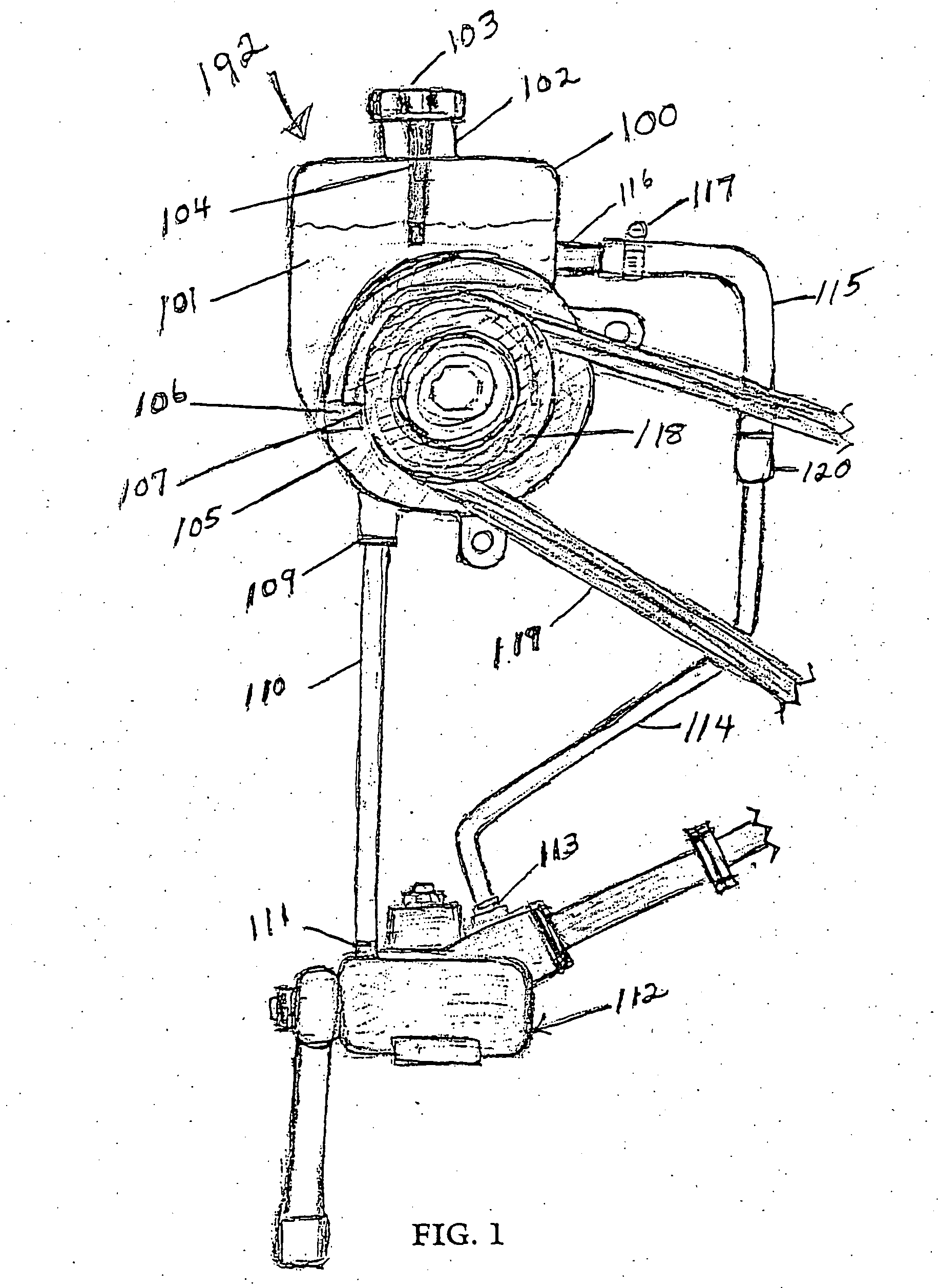

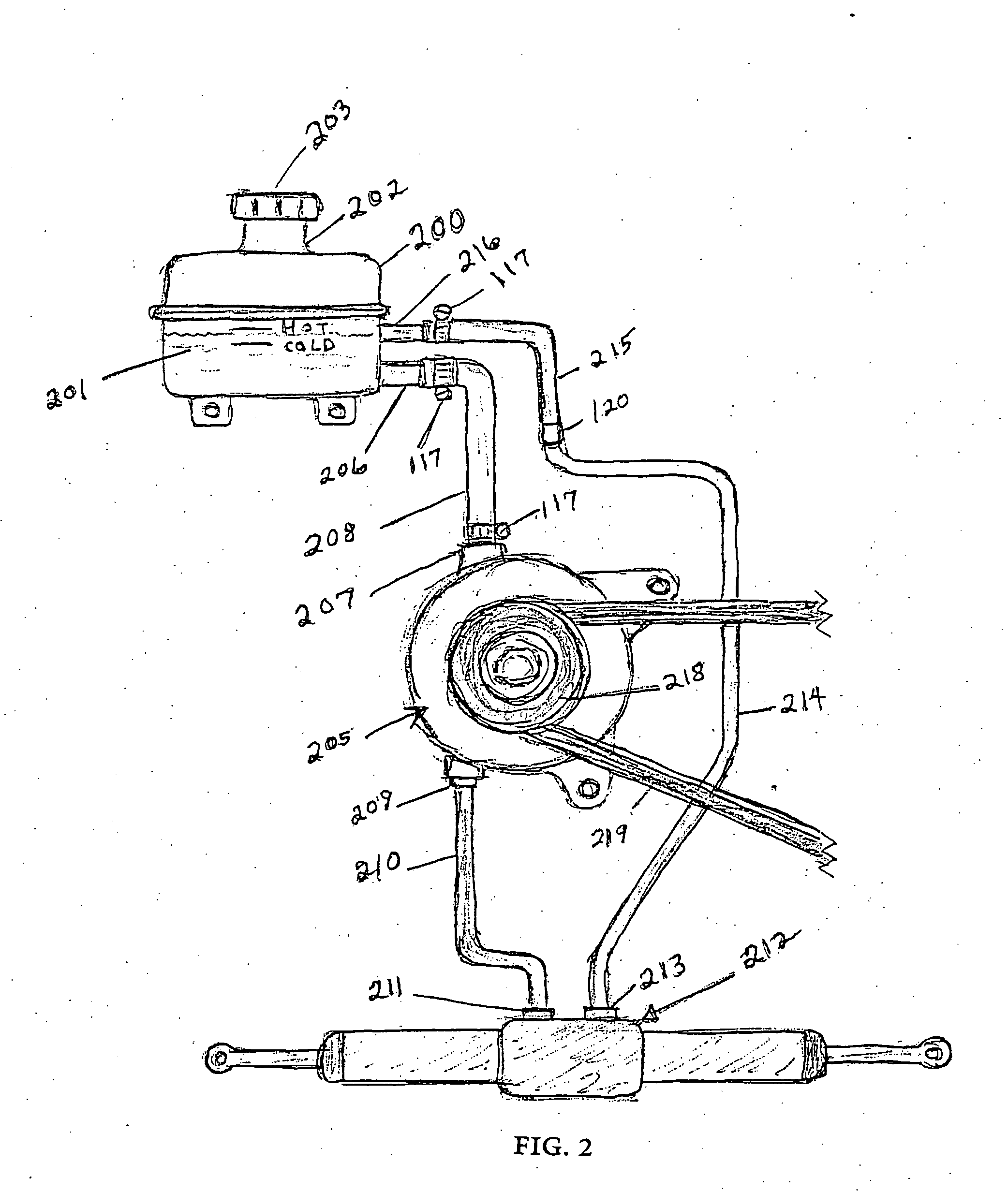

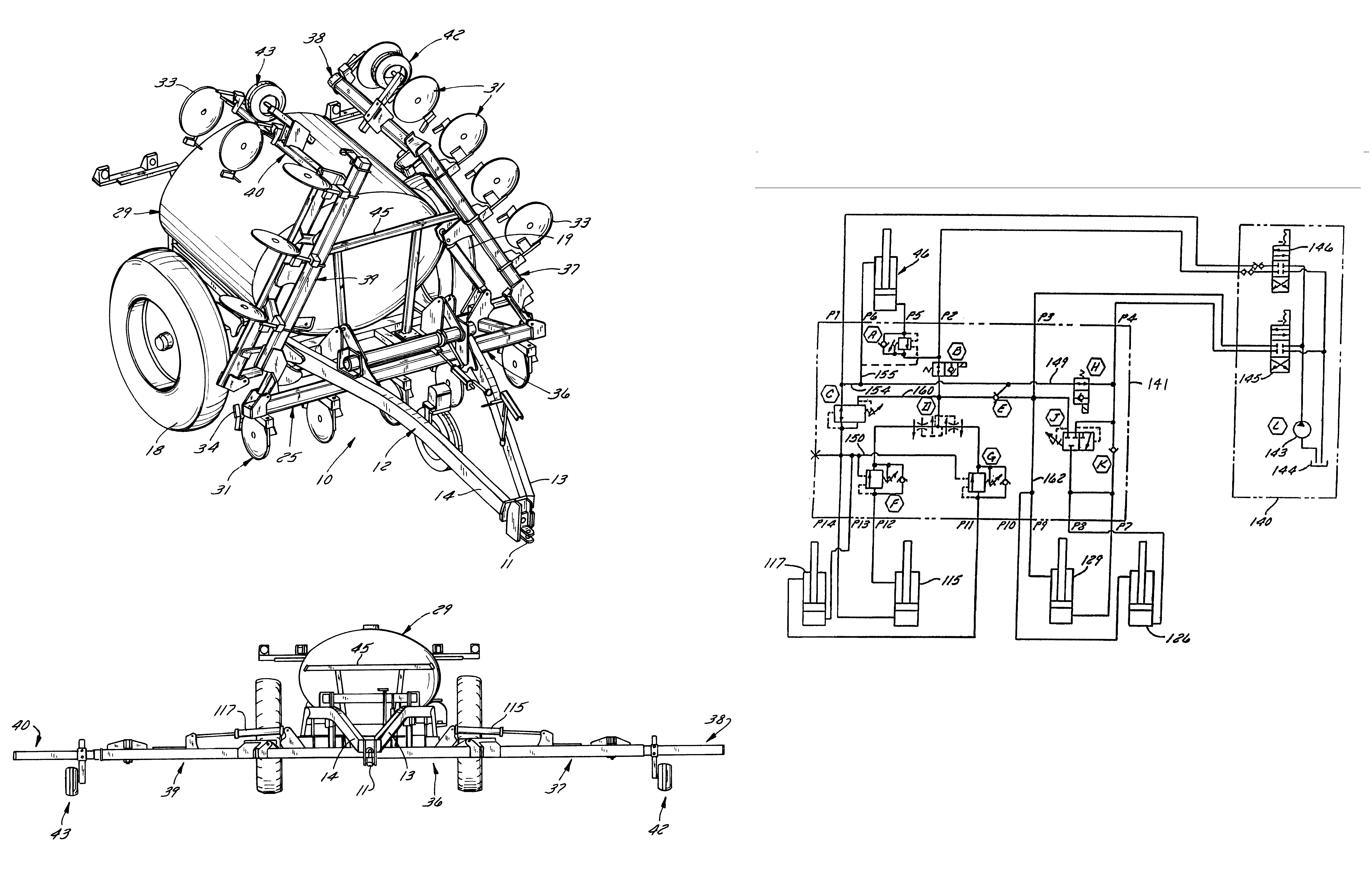

Apparatus and method for hydraulically converting movement of a vehicle wheel to electricity for charging a vehicle battery

An apparatus and its method of operation hydraulically convert the relative movements between a vehicle wheel and a body of the vehicle to electricity, and use the electricity to recharge a battery of the vehicle. A generator is provided on the vehicle and a hydraulic motor is provided on the vehicle to rotate an input shaft of the generator. A double acting piston and cylinder assembly is operatively connected to each wheel of the vehicle, and each double acting piston and cylinder assembly is connected through a hydraulic circuit to the hydraulic motor. Movements of the vehicle wheels during operation of the vehicle cause reciprocating movements of each piston in each double acting piston and cylinder assembly. The reciprocating movements of the pistons pump liquid to the hydraulic motor and draw liquid from the hydraulic motor to cause operation of the hydraulic motor. The operation of the hydraulic motor drives the generator input shaft, which in turn produces electricity that is supplied to the vehicle battery to recharge the vehicle battery.

Owner:TOWERTECH RES GROUP

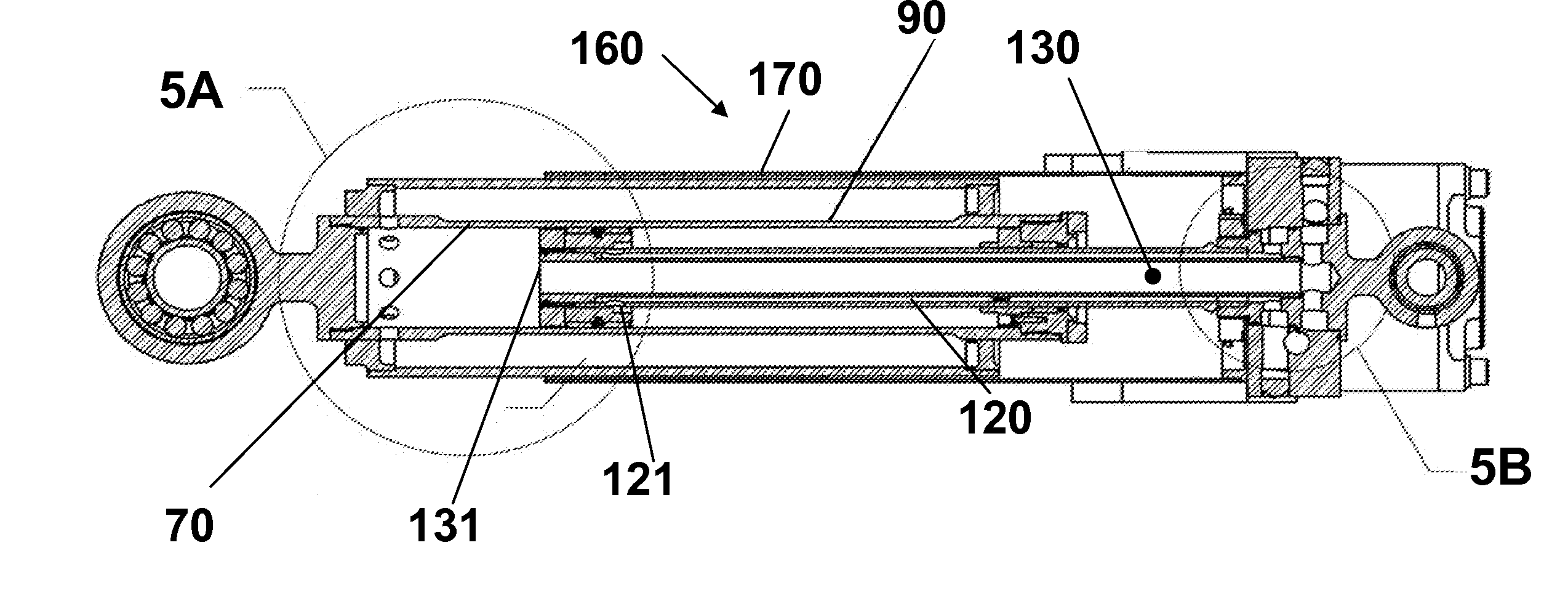

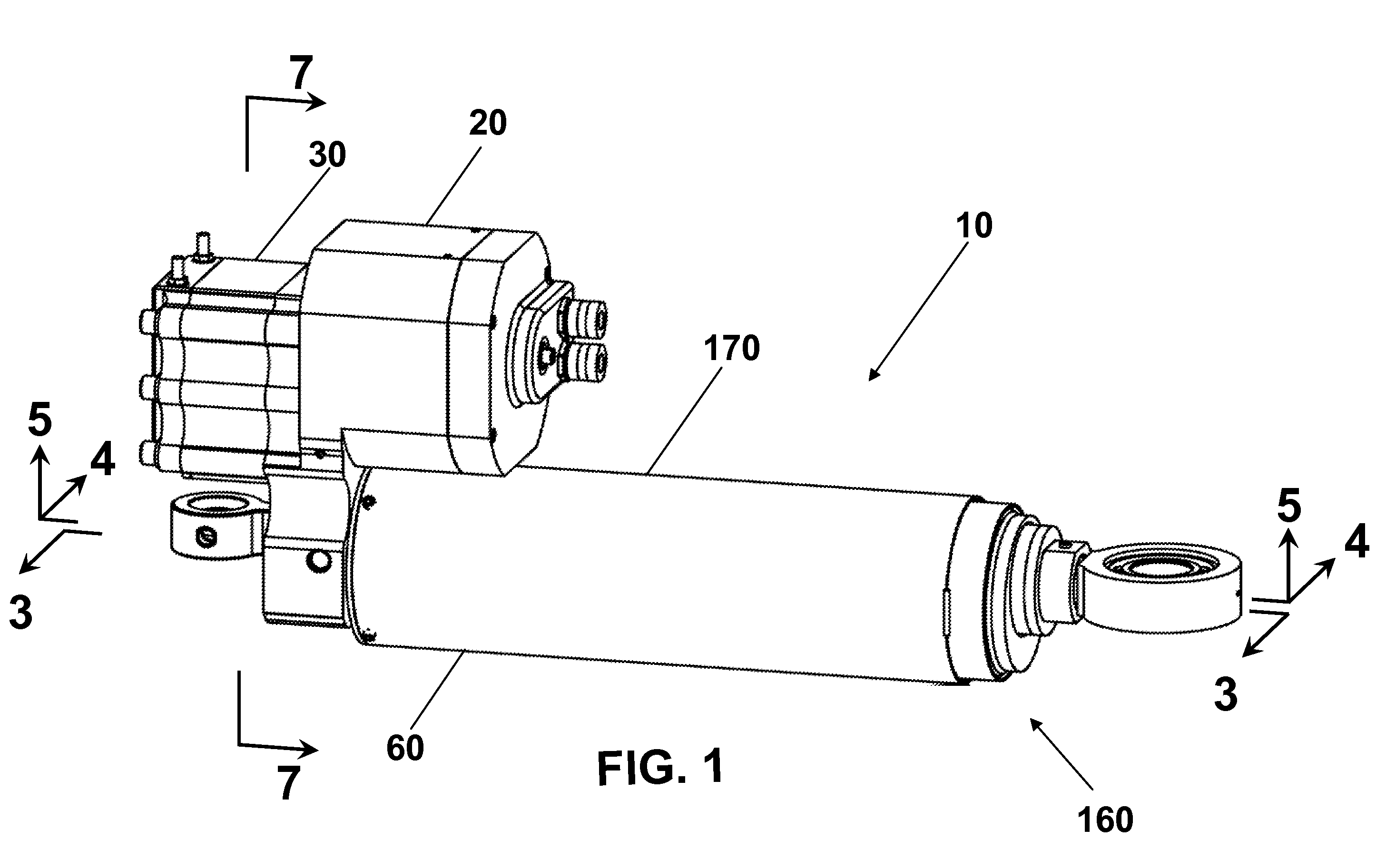

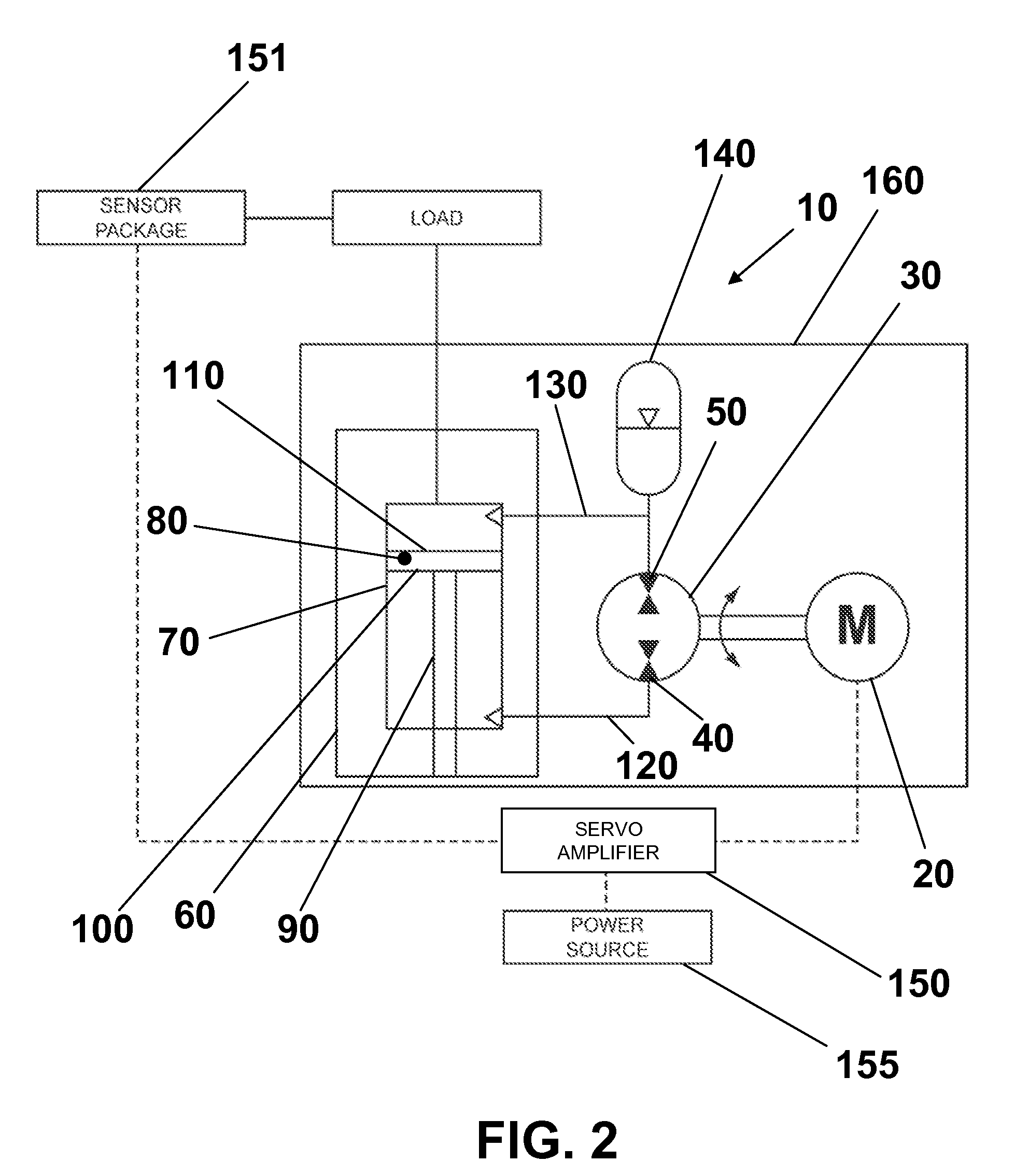

Actuators

Actuators suited for use with, for example, vehicular suspension systems. In some embodiments, the present actuators include a reversible hydraulic pump configured to produce variable hydraulic pressure; a hydraulic cylinder assembly having a cylinder bore, and a piston positioned within the cylinder bore that is axially movable relative to the cylinder bore; and a hydraulic circuit hydraulically coupling the reversible hydraulic pump to the hydraulic cylinder assembly. In these embodiments, actuated axial motion of the piston relative to the cylinder bore is accomplished without the use of check valves, pressure regulating valves, or actively controlled valves.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

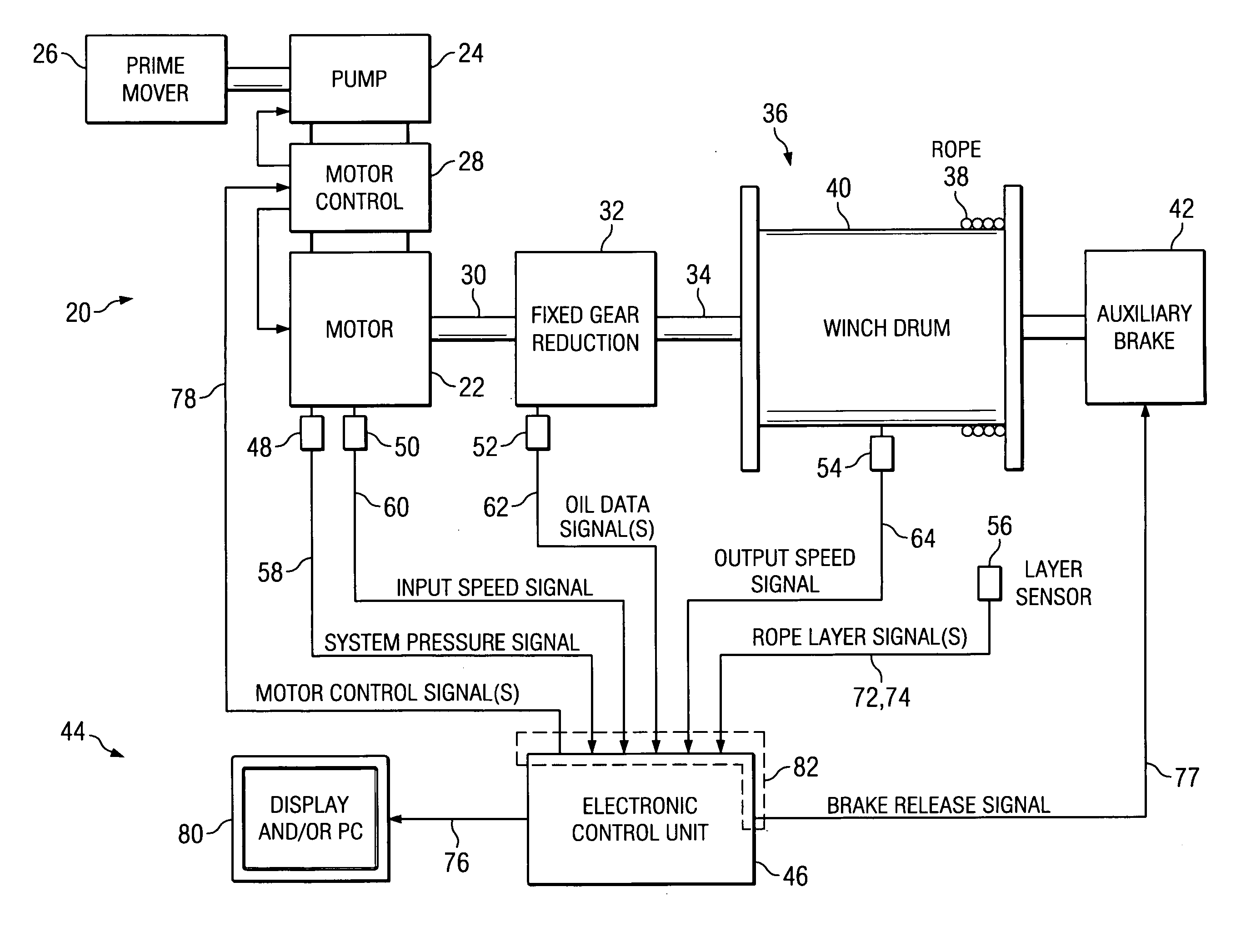

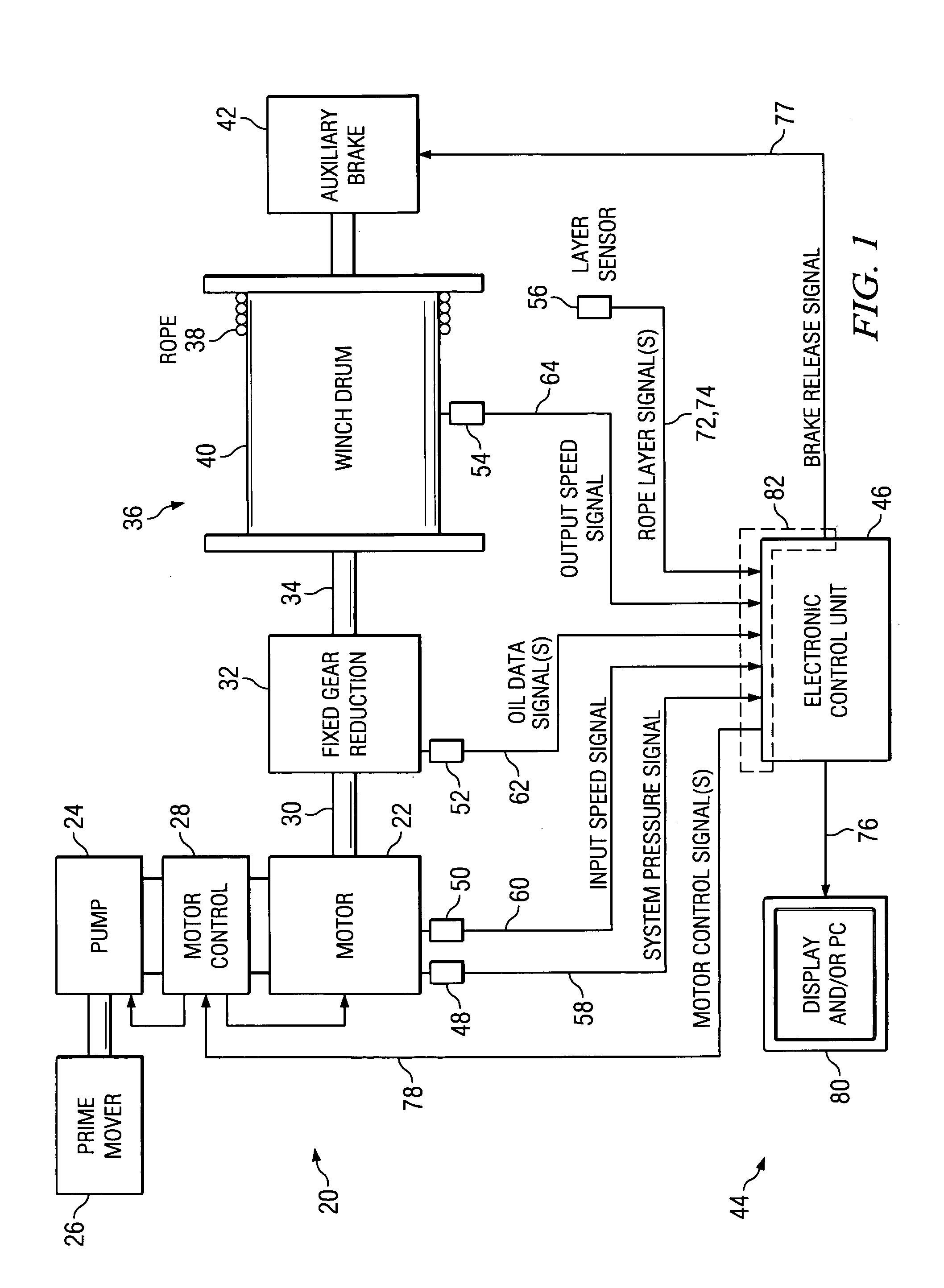

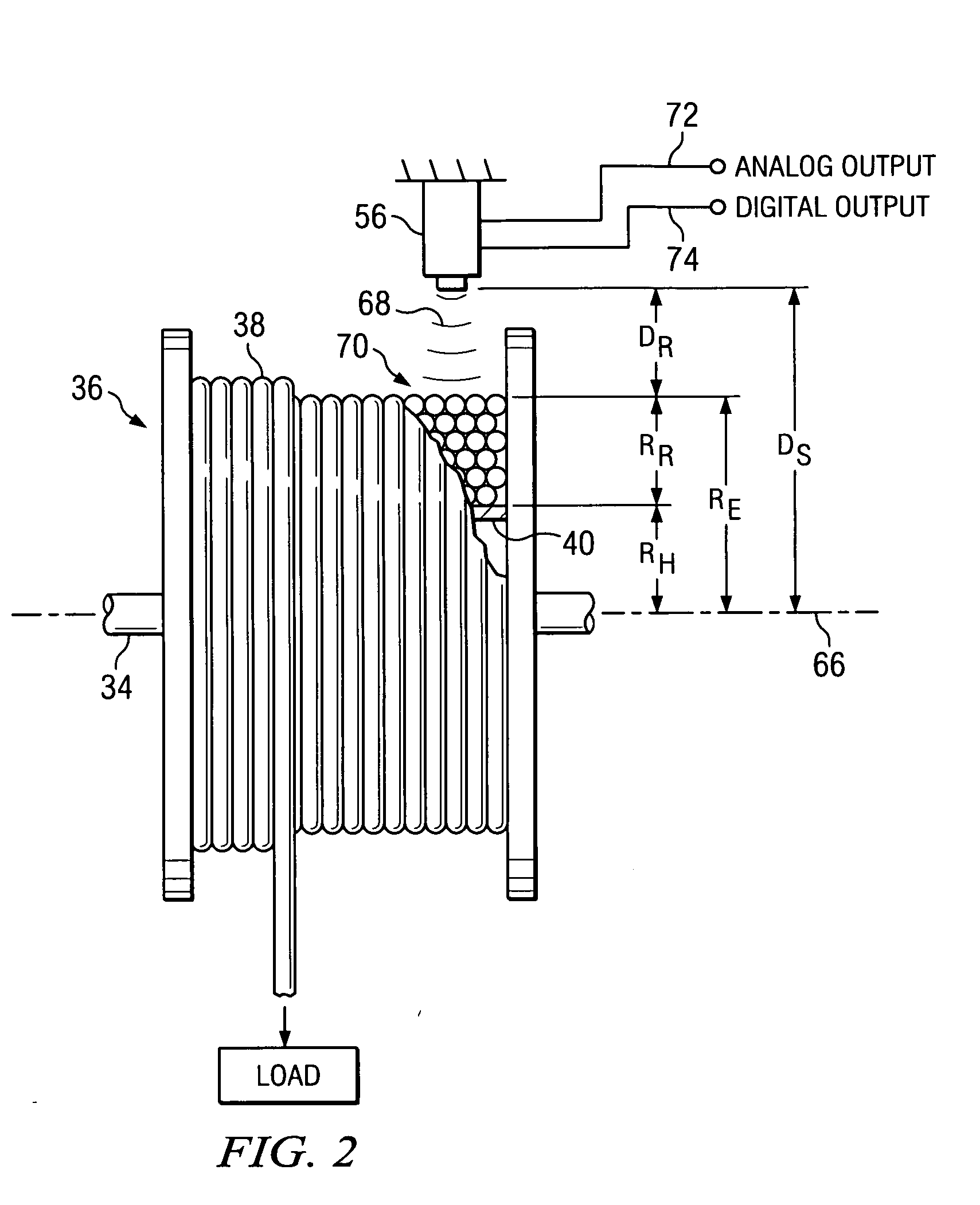

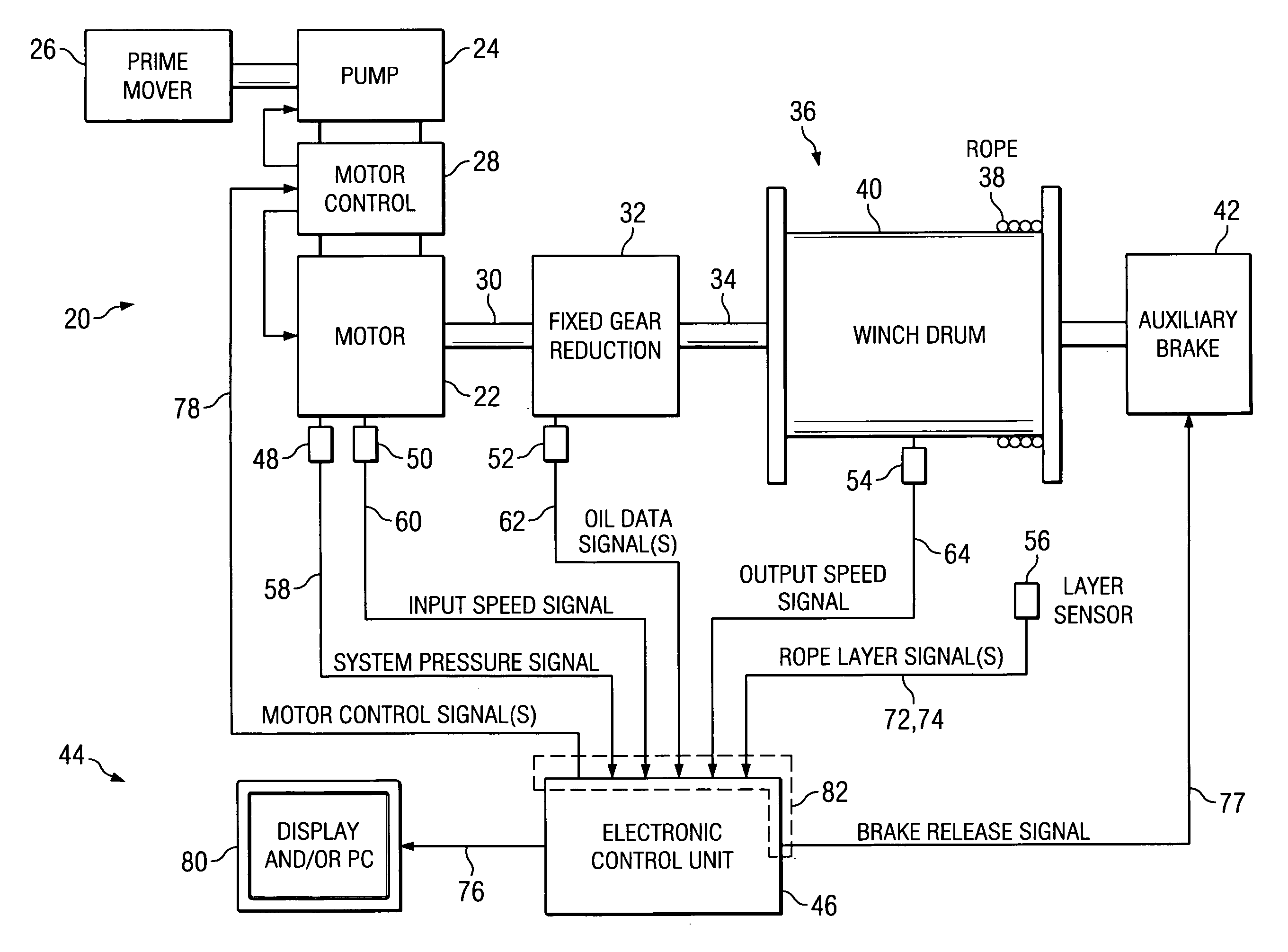

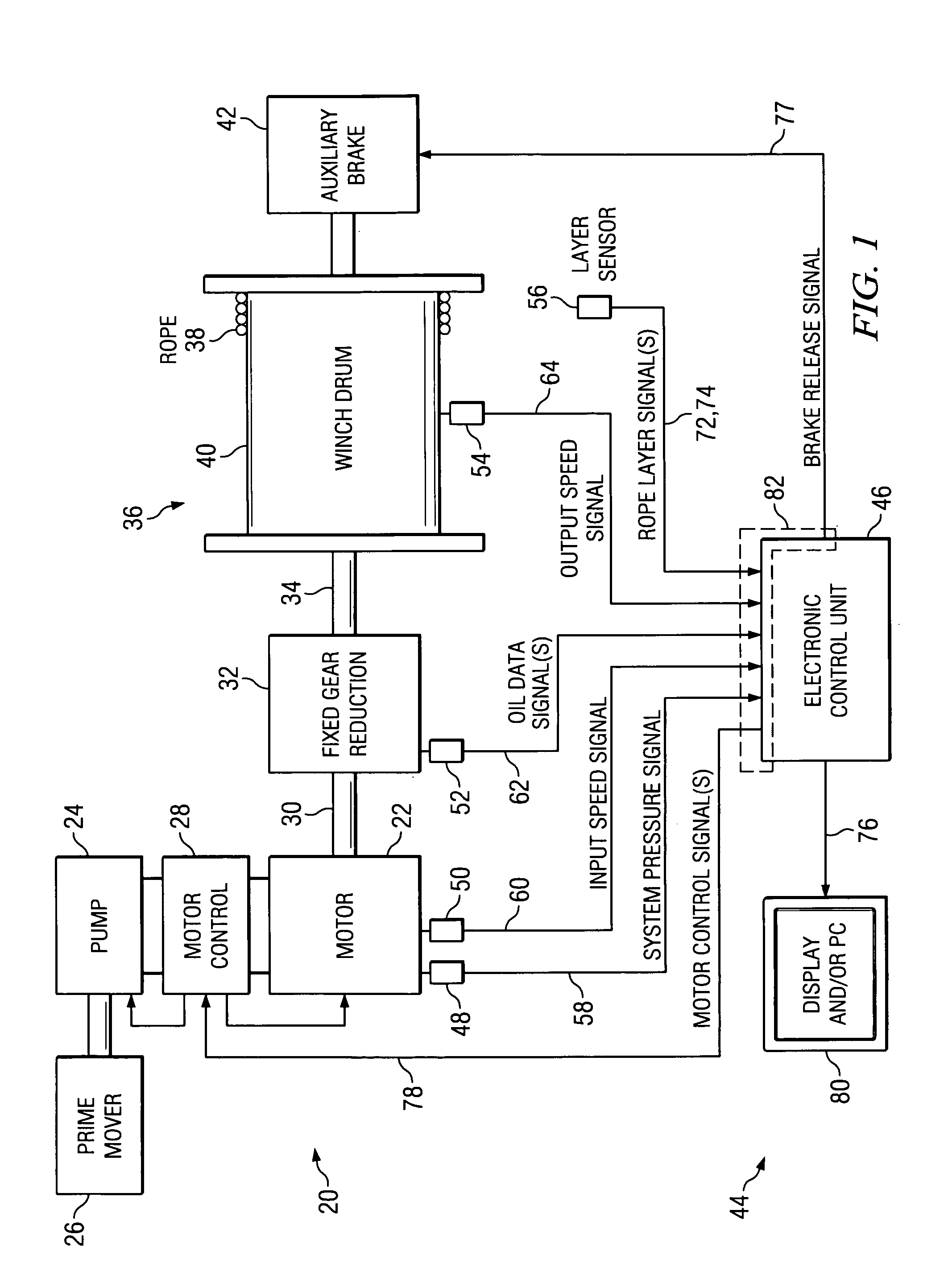

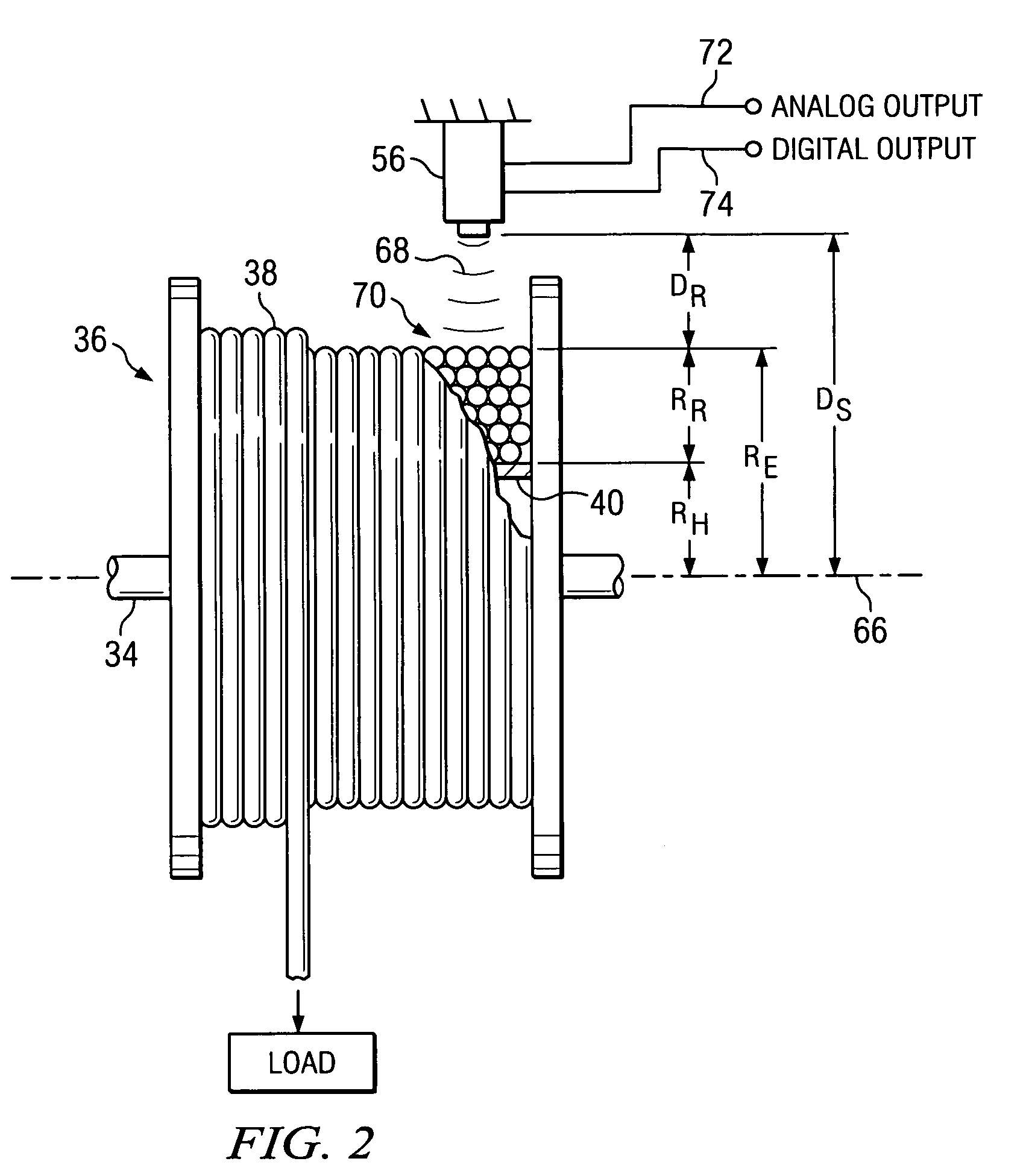

Electronic winch monitoring system

ActiveUS20050072965A1Reduce pressureReduce hydraulic pressureWinding mechanismsFixed ratioTime profile

An electronic winch monitoring system for a winch having a fixed-ratio gearbox with input and output shafts, a winch drum connected to the output shaft, and an auxiliary brake connected to the output shaft activated by reducing the pressure in a brake release hydraulic circuit. The system comprises an input shaft speed sensor, an output shaft speed sensor, and an electronic control unit having a monitoring section and a brake control section. The monitoring section receives the speed signals, processes them to produce a calculated ratio of actual input to output shaft speeds, and produces a fault indication signal when the value of the difference between the calculated speed ratio and the fixed ratio exceeds a predetermined value. The brake control section, upon receiving the fault signal, reduces the hydraulic pressure in the brake circuit using a nonlinear pressure-time profile to engage the auxiliary brake and stop the winch drum.

Owner:PACCAR INC

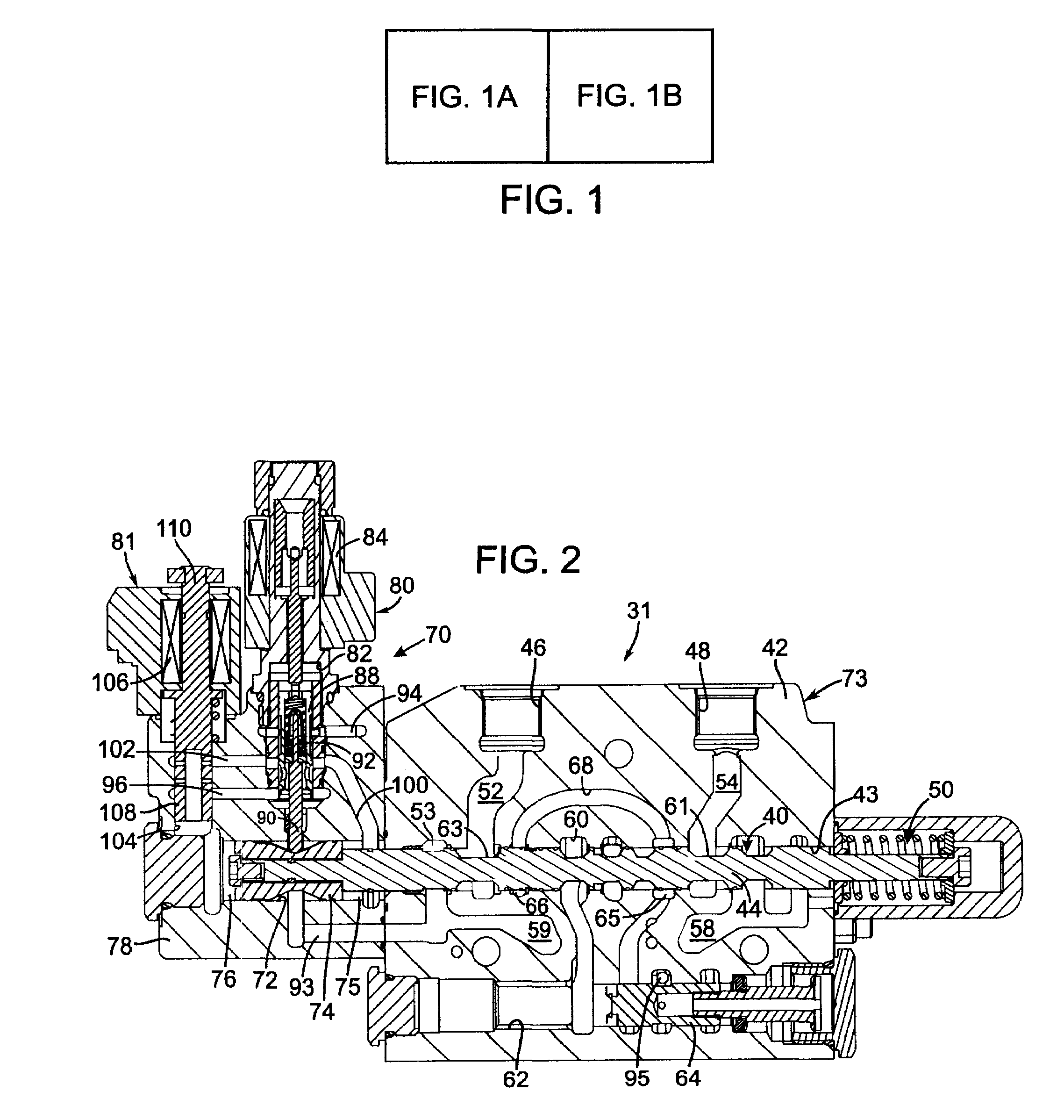

Compact lost motion system for variable valve actuation

InactiveUS6883492B2Wide rangeNon-fuel substance addition to fuelInternal combustion piston enginesVariable valve timingHydraulic circuit

Lost motion systems and methods for providing engine valves with variable valve actuation for engine valve events are disclosed. The system may include a master piston hydraulically linked to a slave piston, and a dedicated cam operatively connected to the master piston. The slave piston may be disposed substantially perpendicular to the master piston in a common housing. The slave piston is adapted to actuate one or more engine valves. The slave piston may incorporate an optional valve seating assembly into its upper end. A trigger valve may be operatively connected to the master-slave hydraulic circuit to selectively release and add hydraulic fluid to the circuit.

Owner:JACOBS VEHICLE SYST

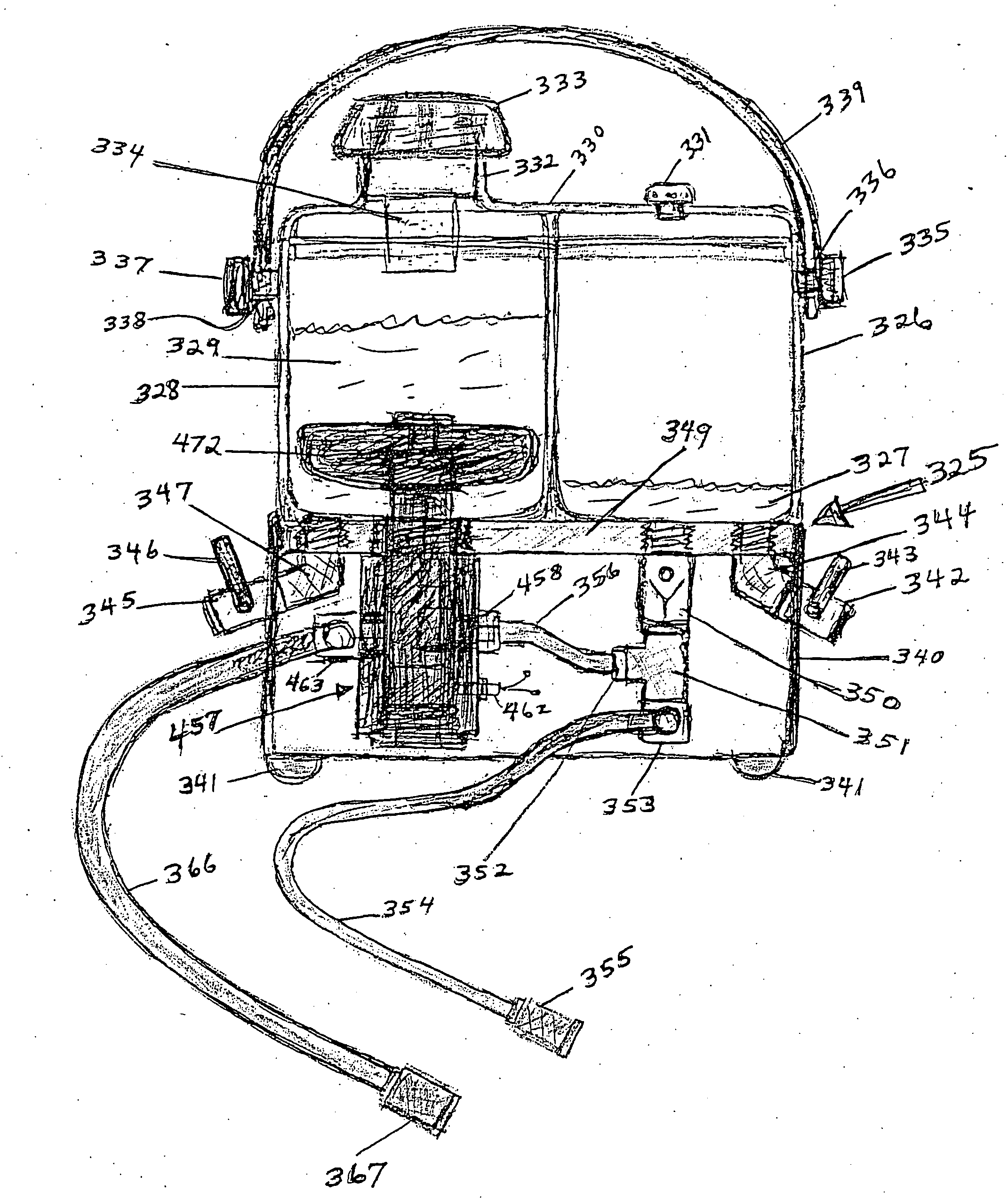

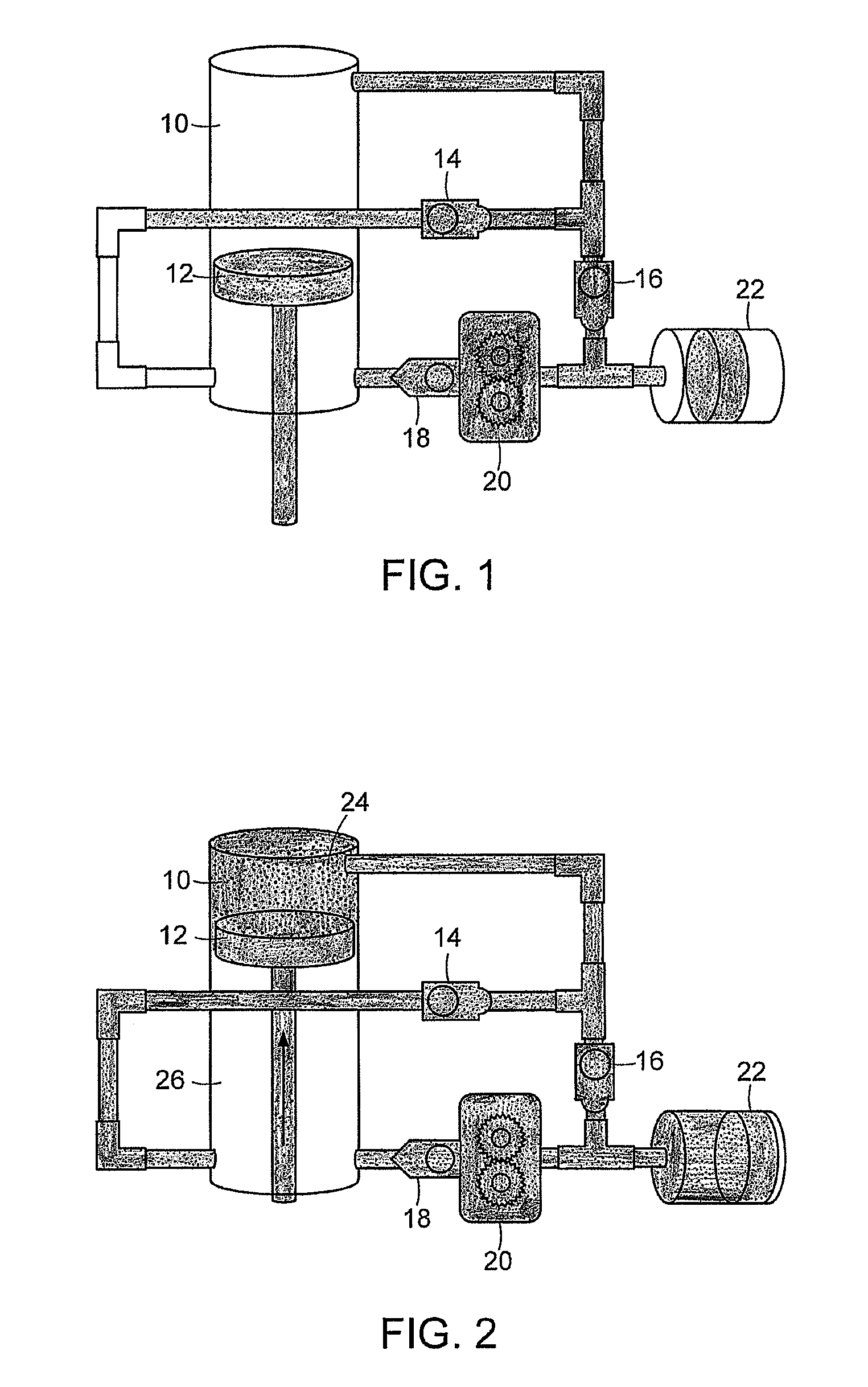

Automatic fluid exchanger

InactiveUS20050166993A1Preventing air infusionEffective blockingLiquid fillingPackaging by pressurising/gasifyingFluid controlPositive pressure

A fluid exchanger for servicing the fluid circuits of vehicular power steering systems and other fluid circulating or hydraulic circuits. The fluid exchanger uses a float operated fluid control valve to harness fluid pressure provided by a pump of an accessed hydraulic circuit. The fluid control valve uses both negative and positive pressure of the circuit's pump to control fluid flow patterns. The float and fluid control valve are matched to be either mechanical / hydraulic or electrical / hydraulic in design. If the exchanger is provided with a mechanically operated fluid control valve, a mechanical float is provided in the exchanger's fresh fluid reservoir and is directly connected to the valve slide of the fluid control valve. If the exchanger is provided with an electric solenoid operated fluid control valve, a float operated electrical switch is provided in the exchanger's fresh fluid reservoir and is wired to control the solenoid of the valve.

Owner:VIKEN JAMES P +1

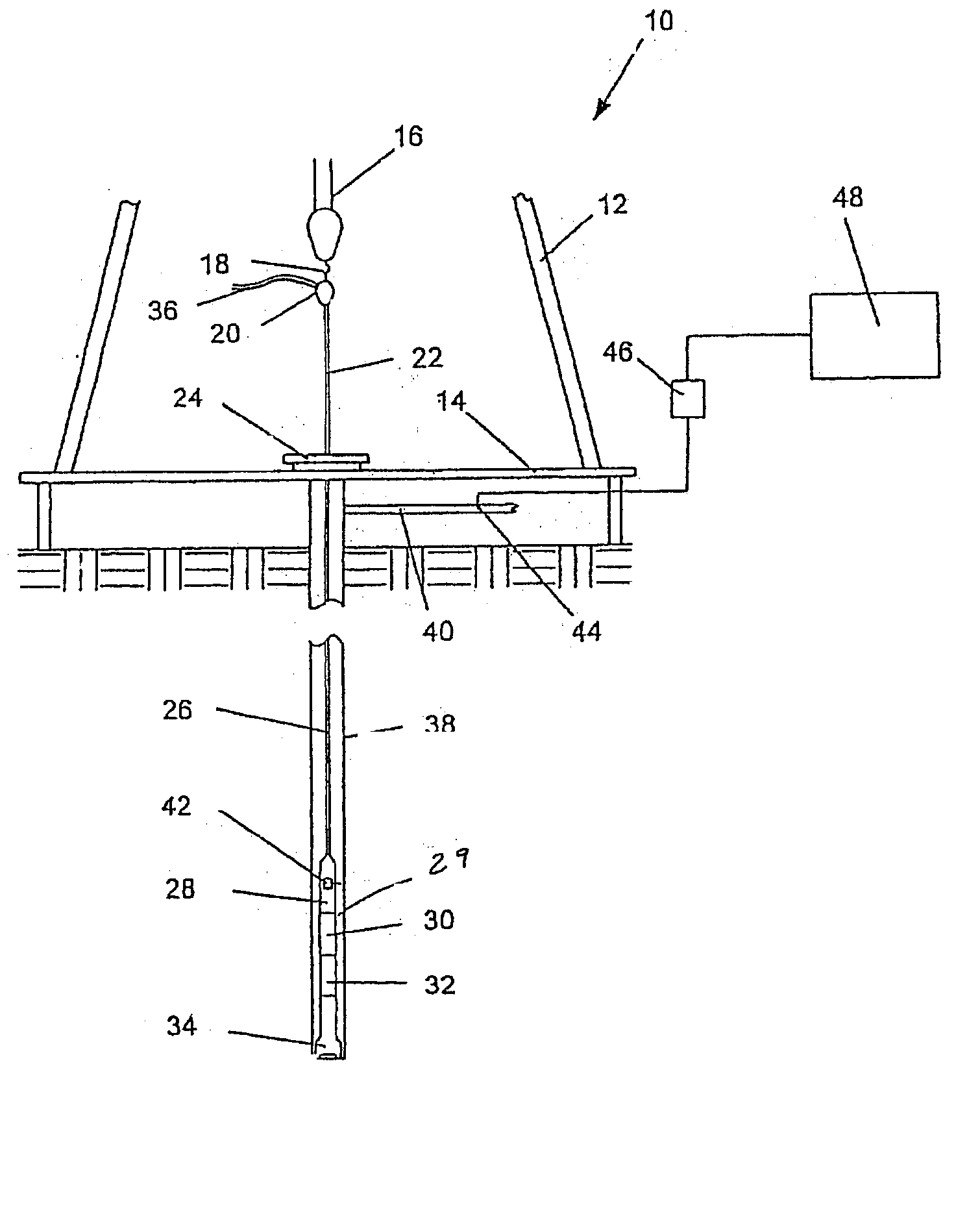

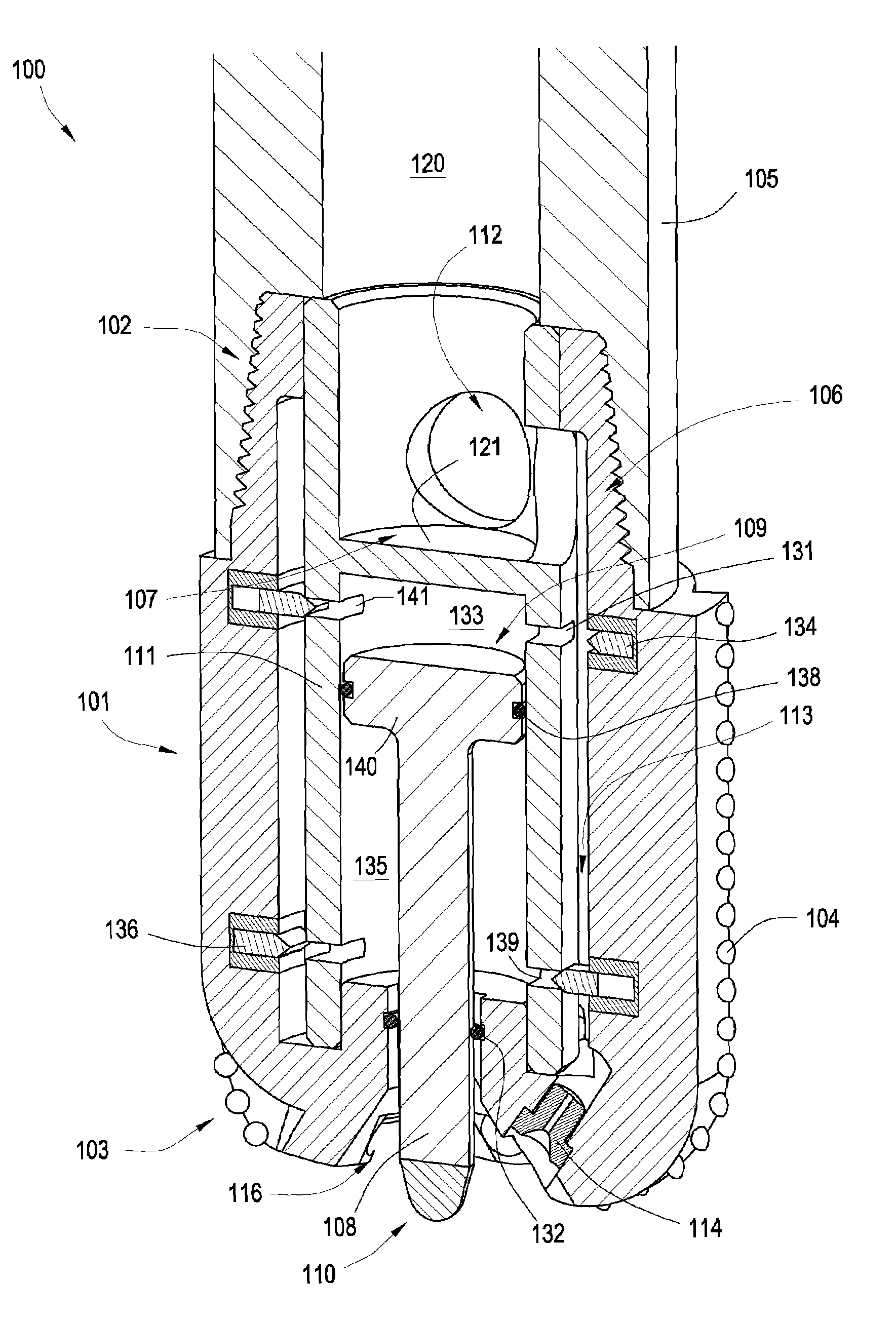

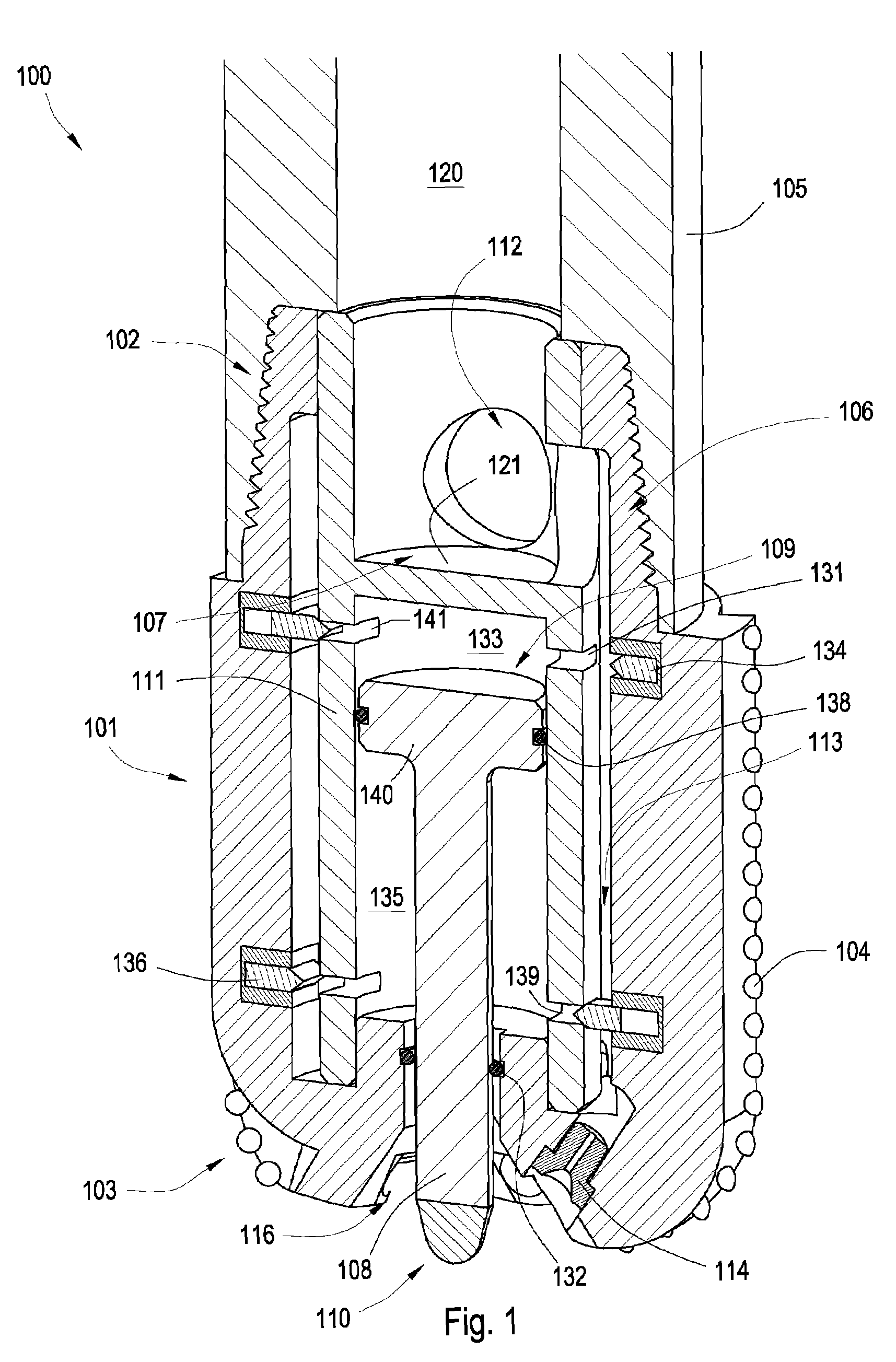

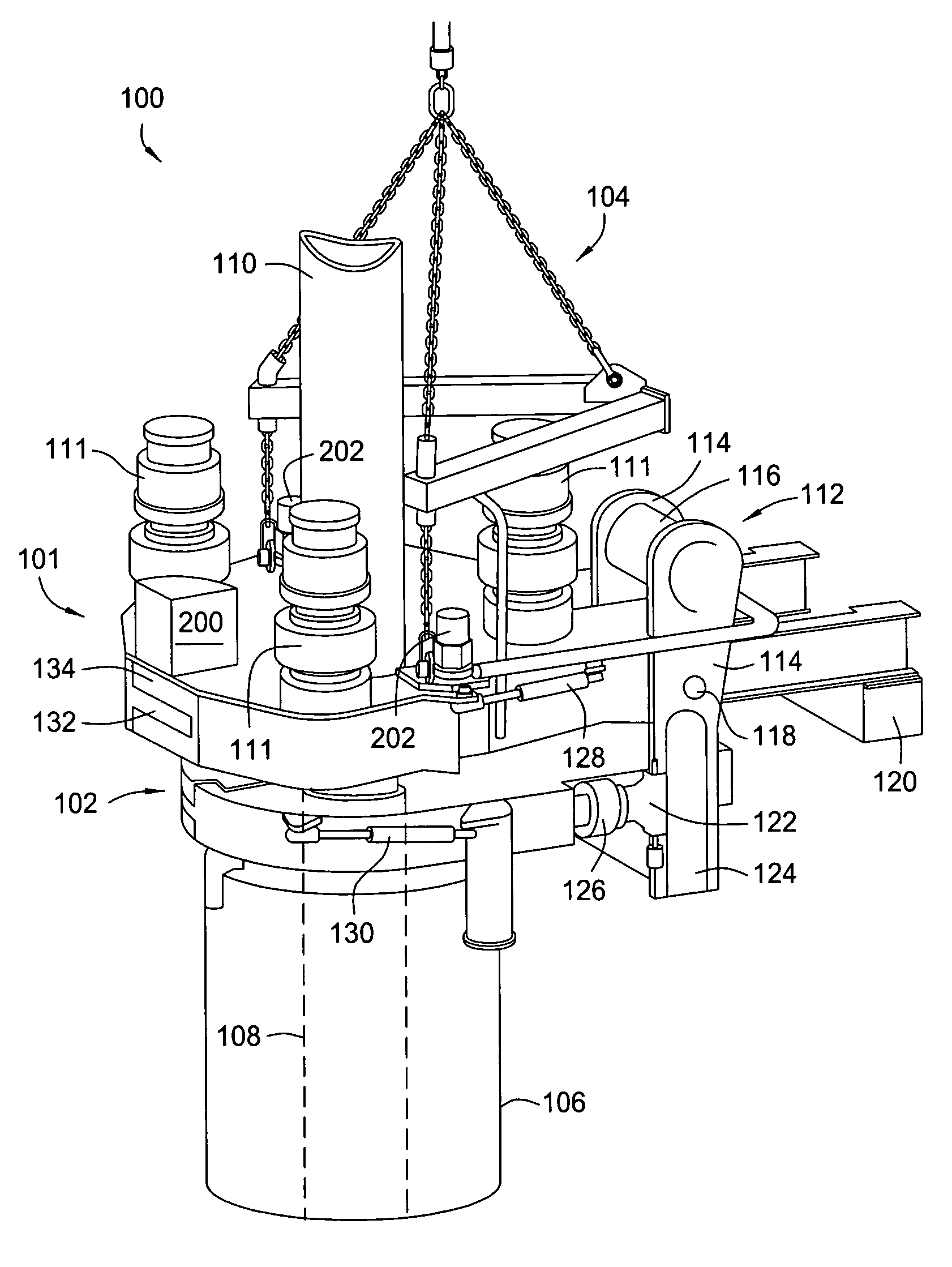

Method and apparatus for MWD formation testing

A method and apparatus for formation testing is disclosed. In a preferred embodiment, a formation testing tool includes a longitudinal body with a flowbore; a plurality of extendable centralizing pistons coupled to the body; an extendable sample device coupled to the body; and a centralizing hydraulic circuit configured to cause each of the plurality of centralizing pistons to extend at substantially the same rate. The centralizing hydraulic circuit includes a series of flow control and pressure-determining valves configured to extend the centralizing pistons at substantially the same rate, and to help maintain stability in the hydraulic circuit in response to external pressures. In some embodiments, the extendable sample device is preferably configured to be recessed beneath a surface of the body in a first position and to extend beyond the surface in a second position. The extendable sample device is preferably extended to contact the borehole wall substantially normal to the wall, protecting the sample device from excessive bending moments and other excessive forces.

Owner:HALLIBURTON ENERGY SERVICES INC

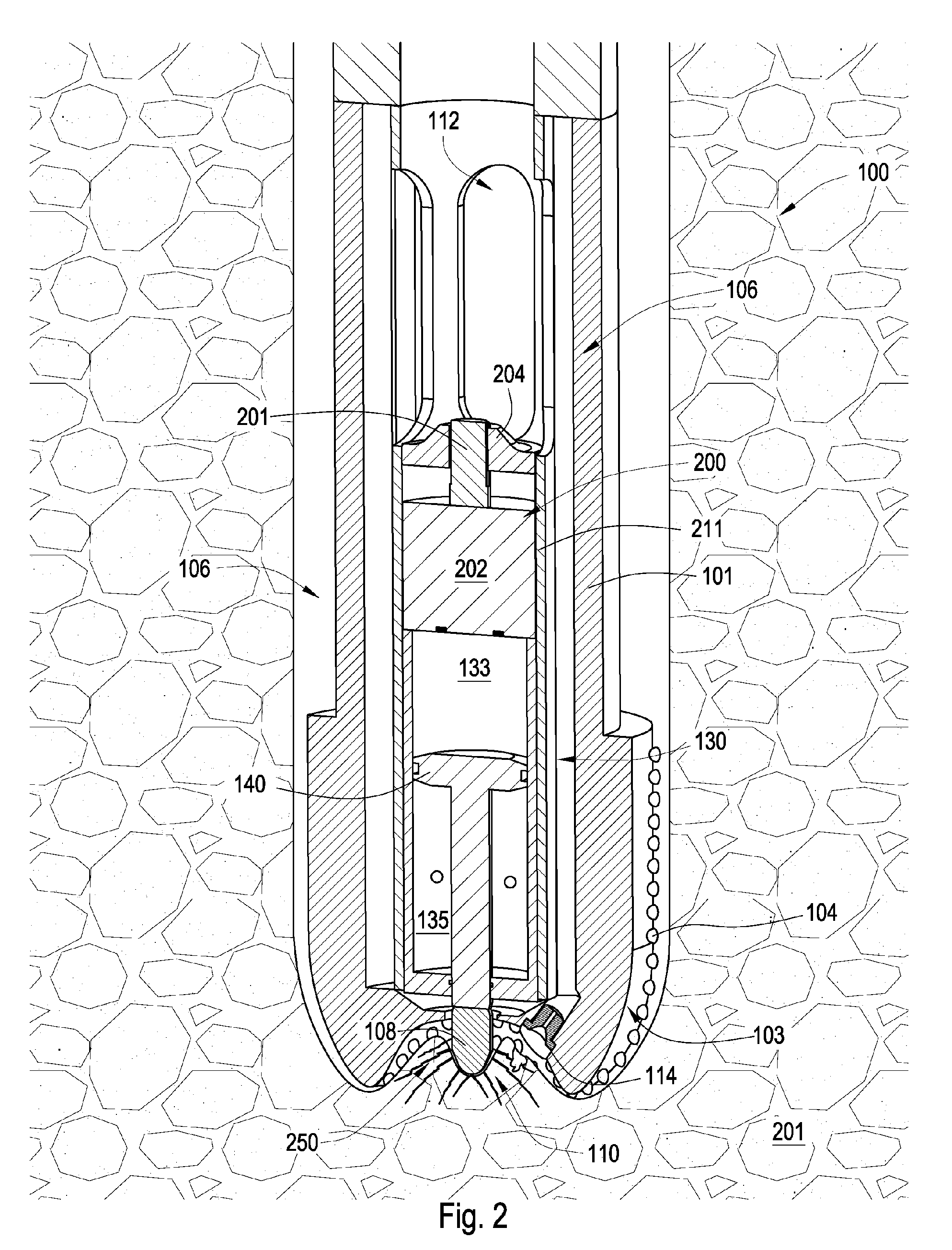

Hydraulic drill bit assembly

In one aspect of the present invention a drill bit assembly has a body portion intermediate a shank portion and a working portion. The working portion has at least one cutting element and the body portion has at least a portion of a jackleg apparatus. The jackleg apparatus has at least a portion of a shaft disposed within a chamber; the shaft has a distal end. The jackleg apparatus has a hydraulic compartment adapted to displace the distal end of the shaft relative to the working portion. The chamber also has an opening proximate the working portion of the assembly. The hydraulic compartment may be part of a hydraulic circuit which has a pump. The pump may have a first section with is rotationally fixed to the body portion and a second section rotationally isolated from the body portion.

Owner:SCHLUMBERGER TECH CORP

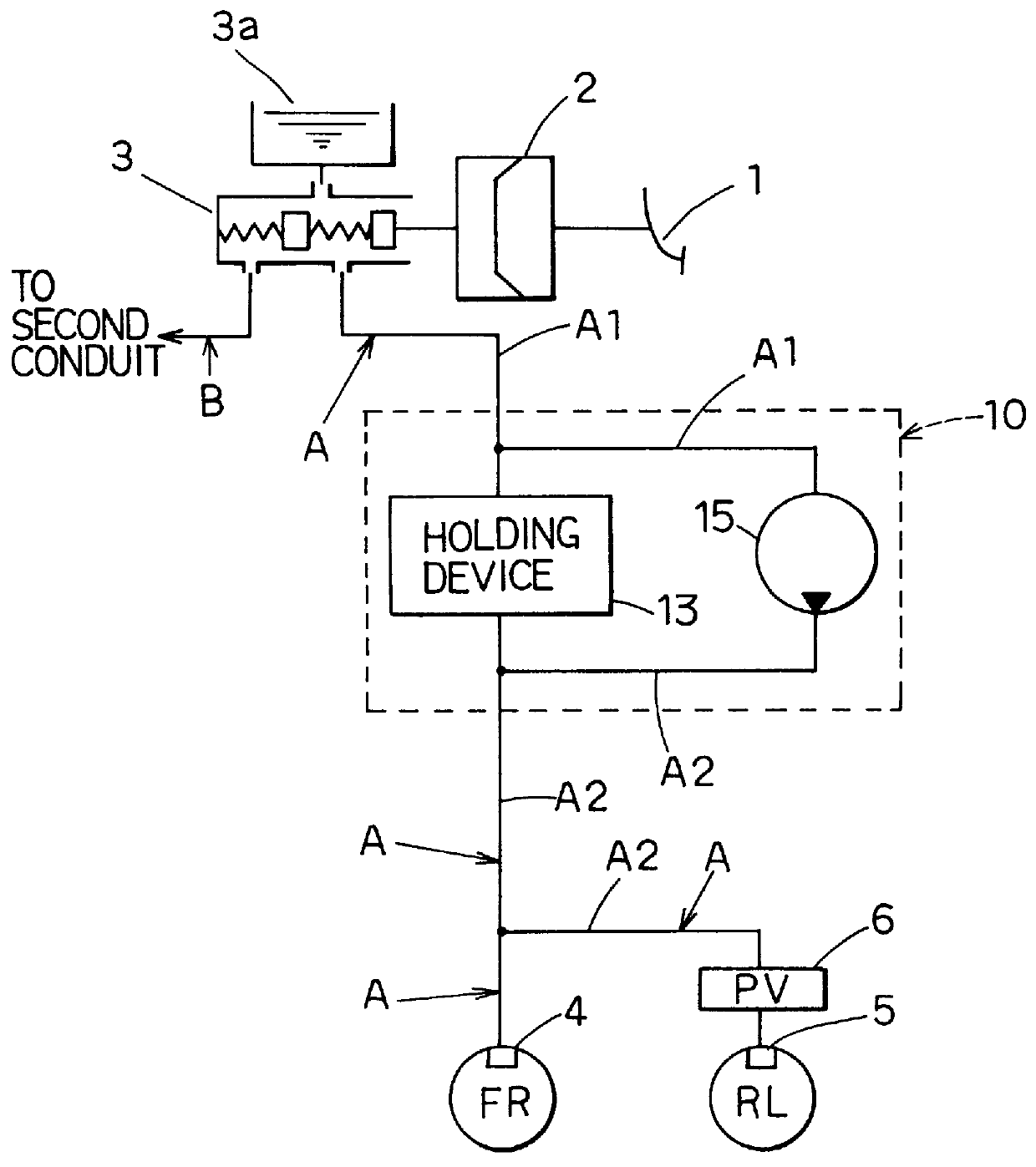

Hydraulic circuit having a rotary type pump and brake apparatus for a vehicle provided with the same

InactiveUS6142581APrevent leakagePrevent liquid leakageBraking action transmissionAutomatic initiationsRotary pumpDrive shaft

A hydraulic circuit has a rotary type pump comprising a rotor rotating with a driving shaft and a casing which holds the rotor and the driving shaft. The casing further comprises an inlet port through which fluid is introduced to spaces formed by the rotor, an outlet port through which fluid is discharged from the spaces, and a hydraulic path for leading fluid from clearance around said driving shaft to the outside of the casing. A reservoir is provided to store fluid coming through the hydraulic path. A return conduit is disposed between the reservoir and an upstream side conduit connected to the inlet port in order that fluid stored in the reservoir is returned to the upstream side conduit. In the return conduit, a check valve is disposed to prevent the reverse flow of fluid from the upstream side conduit to the reservoir.

Owner:DENSO CORP

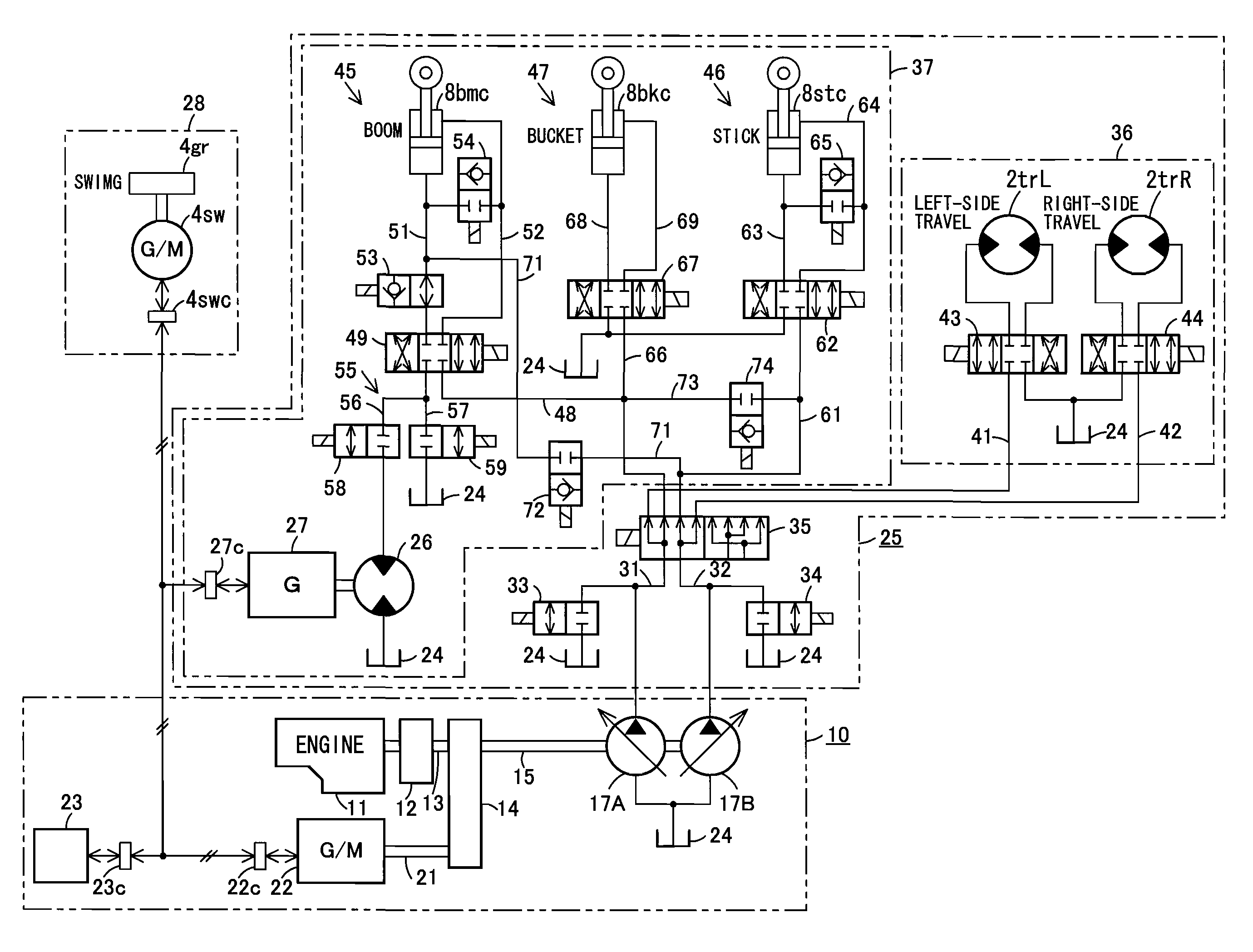

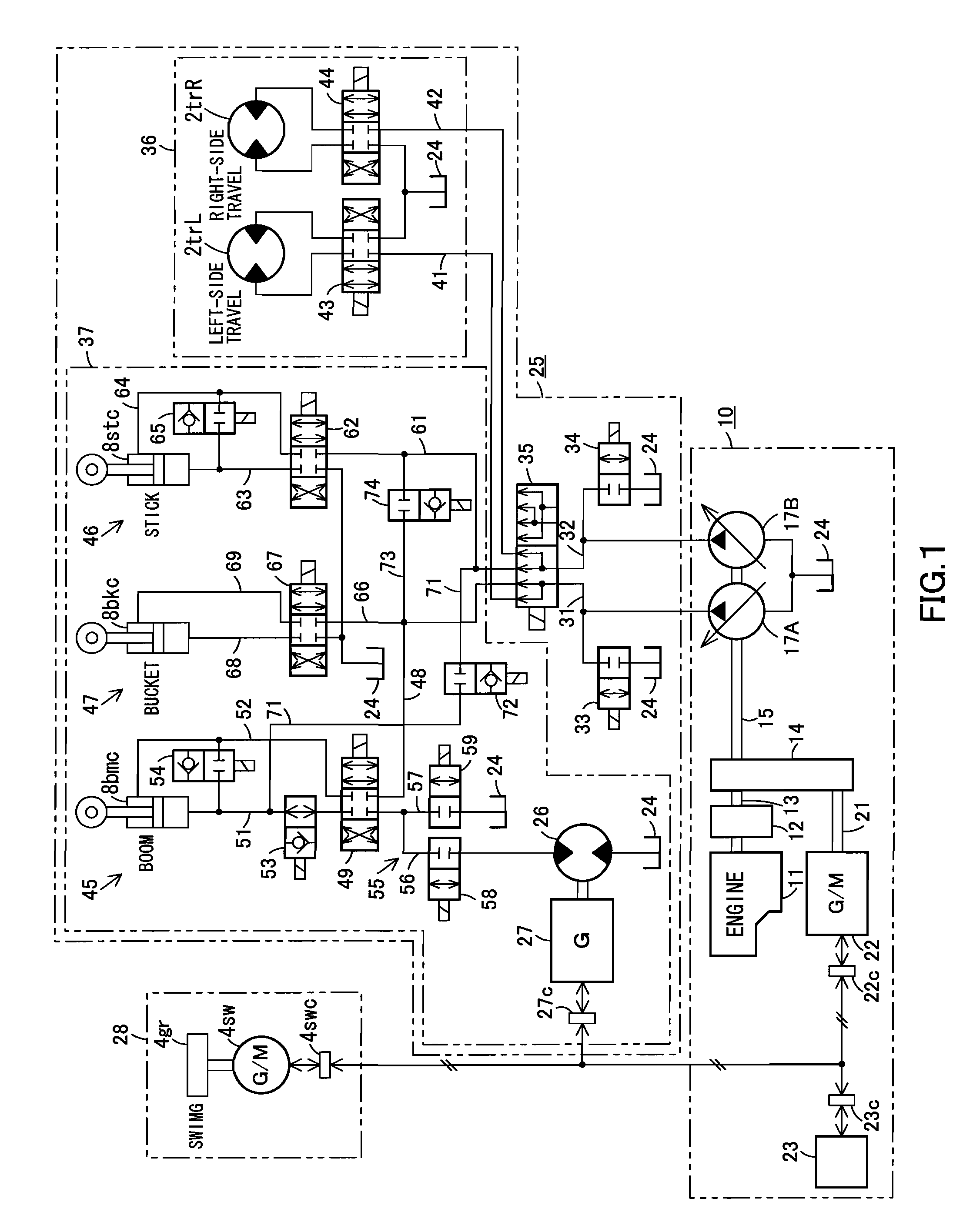

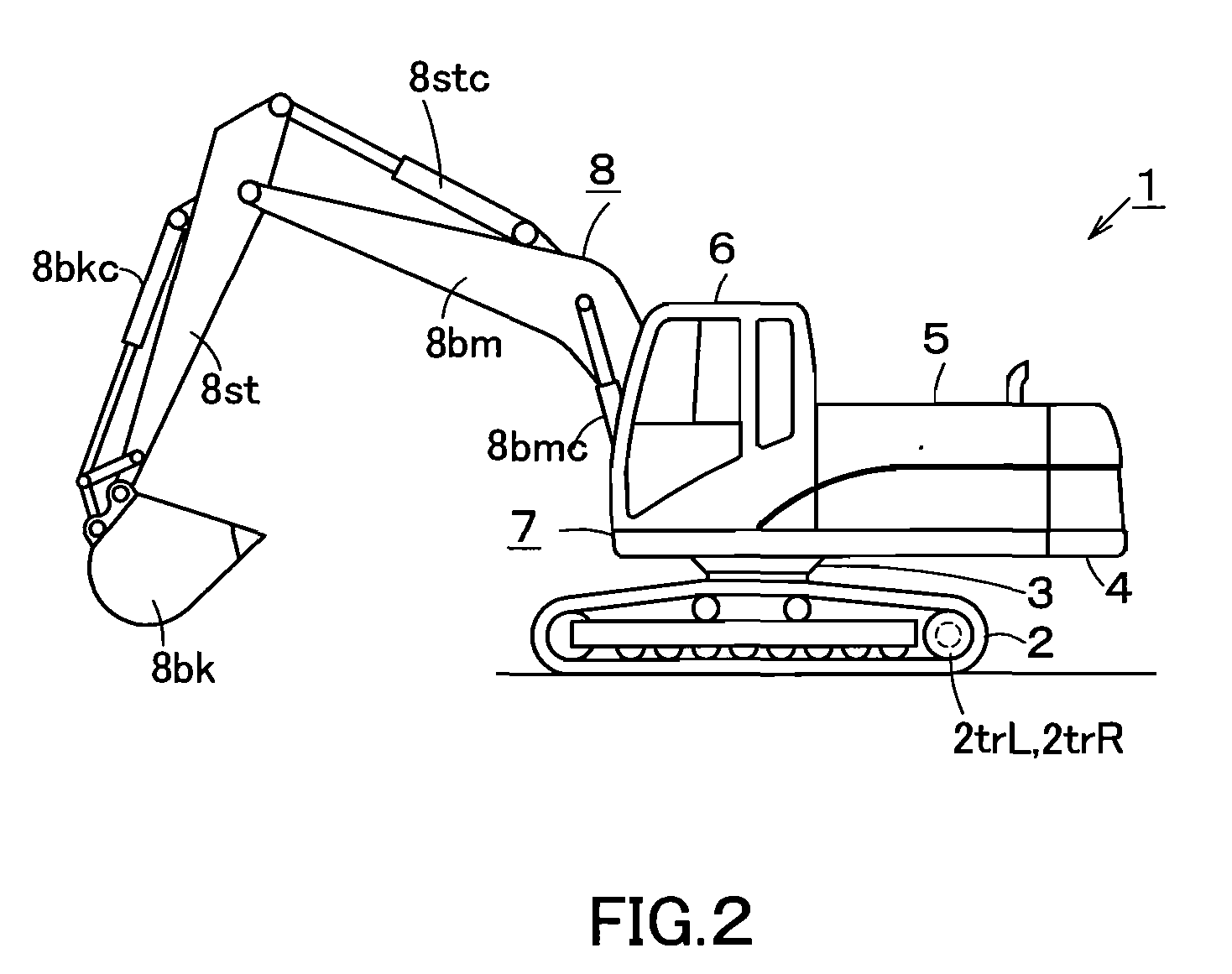

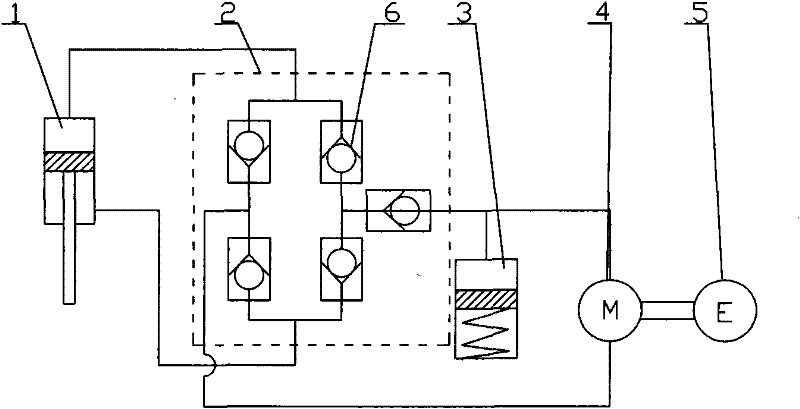

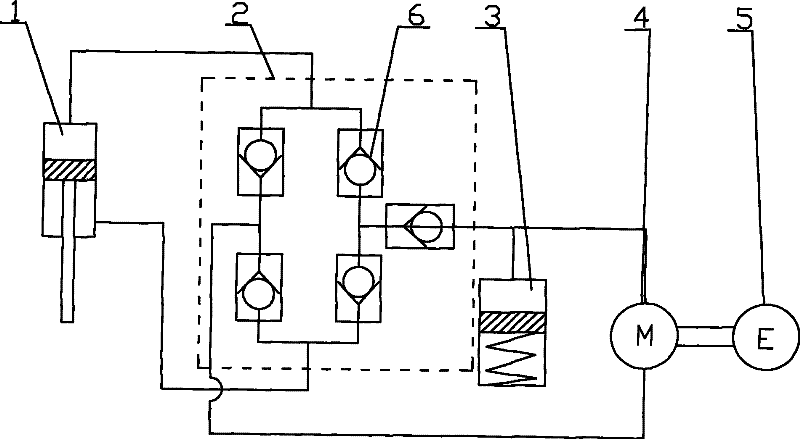

Hydraulic circuit, energy recovery device, and hydraulic circuit for work machine

InactiveUS20090288408A1Increase speedImprove work efficiencyFluid couplingsServomotor componentsSolenoid valveHydraulic circuit

A hydraulic circuit that enables smooth absorption of the energy of a return fluid from a hydraulic actuator by means of an energy recovery motor. A return fluid passage to which the fluid discharged from a boom cylinder is branched is provided at the tank passage side of a solenoid valve of a boom control circuit. The return fluid passage comprises two return passages, which are provided with a flow rate ratio control valve for controlling a ratio of fluid that branches off into the return passages. The flow rate ratio control valve is comprised of a solenoid valve disposed in the return passage, which is provided with an energy recovery motor, and a solenoid valve disposed in the return passage, which branches off the upstream side of the solenoid valve.

Owner:CATEPILLAR SARL

Regenerative shock absorber

Owner:CLEARMOTION INC

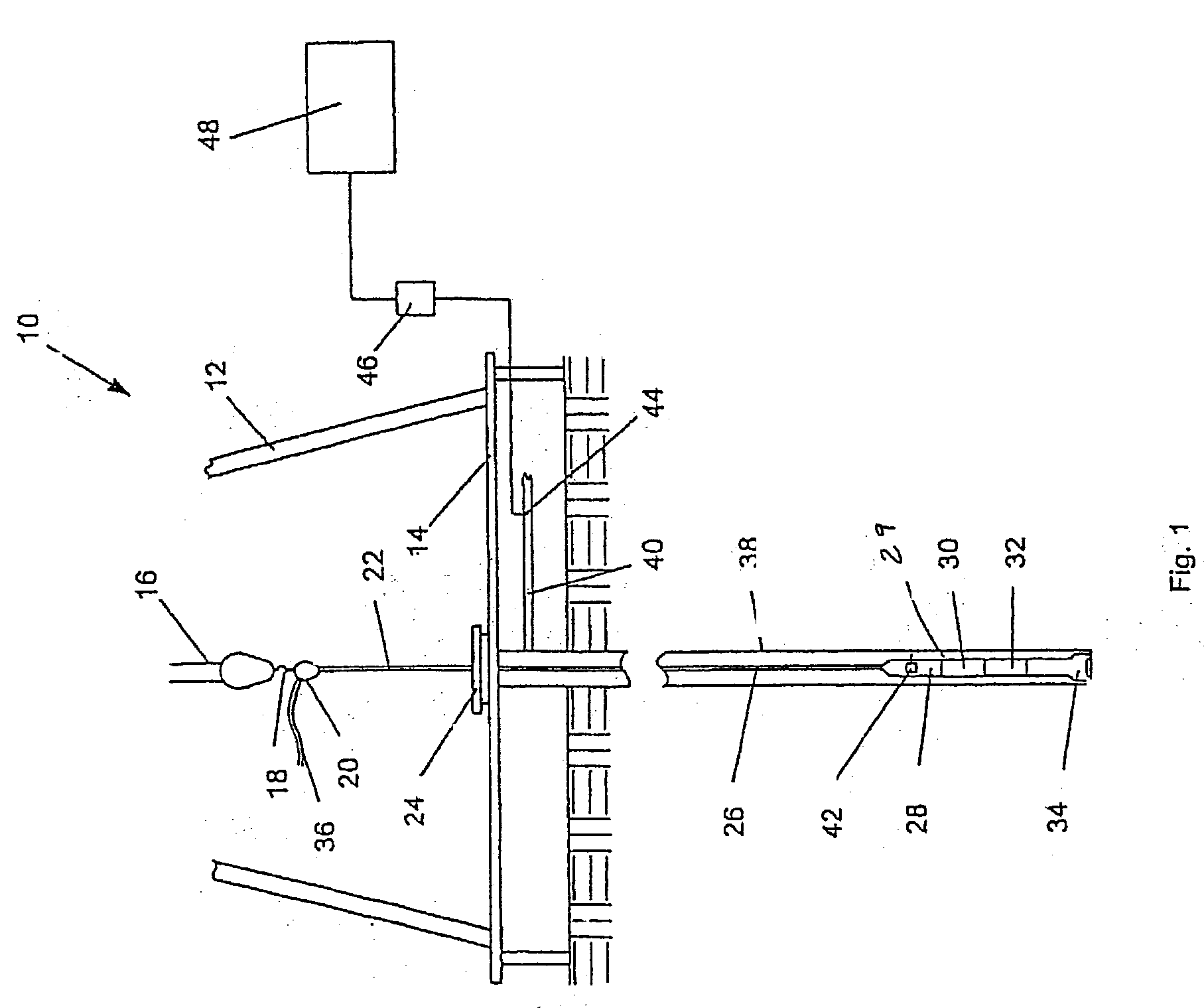

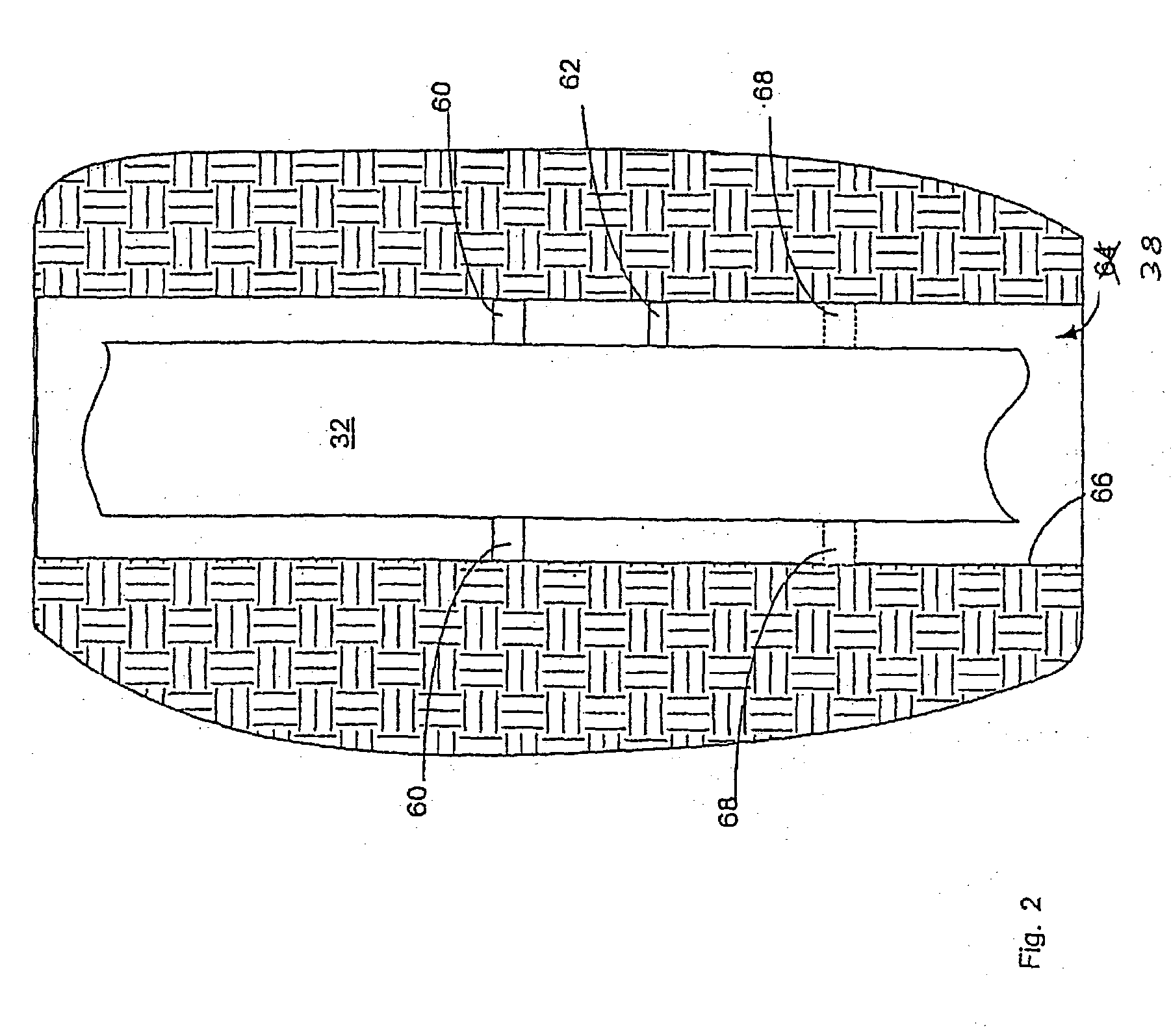

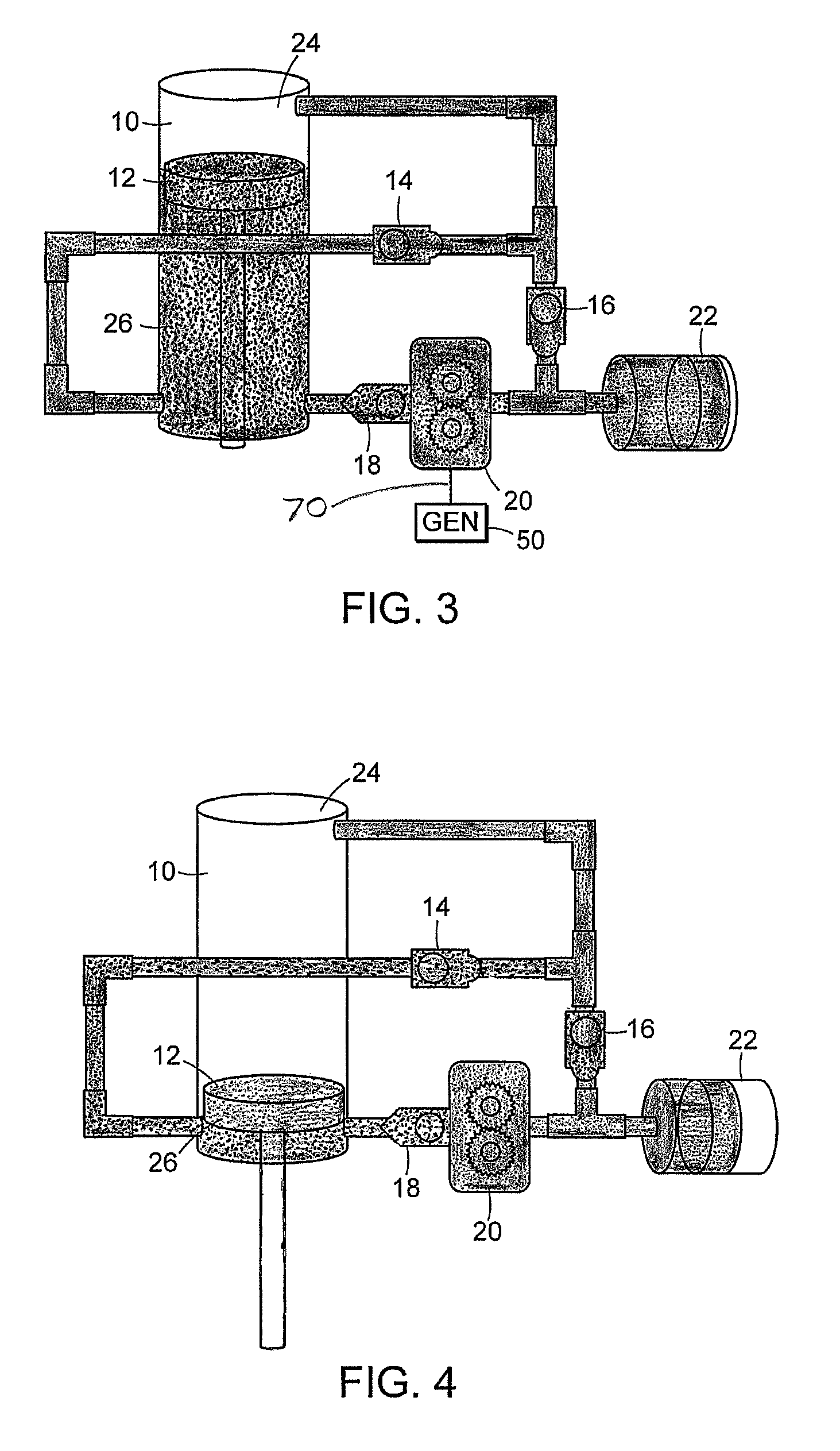

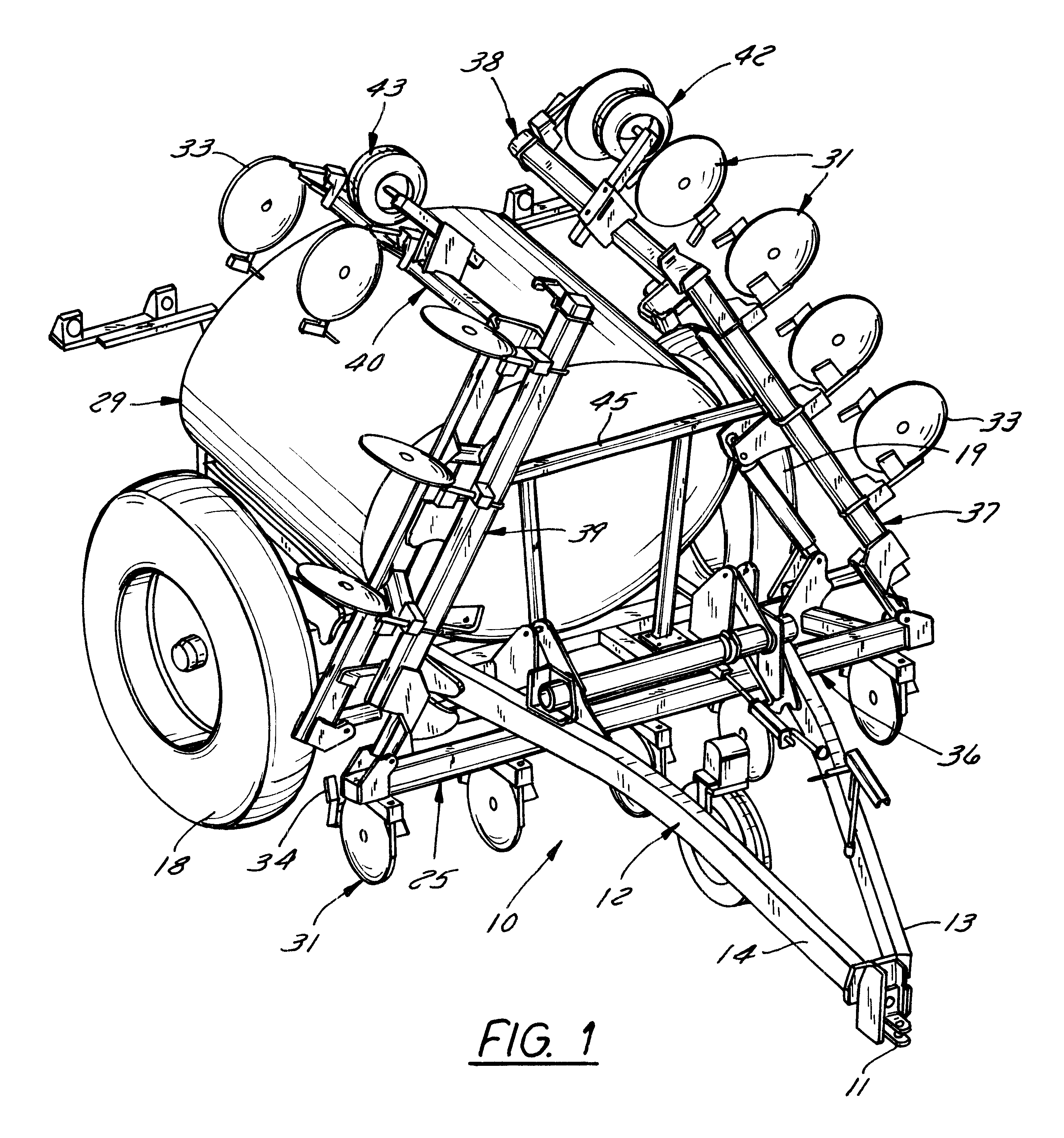

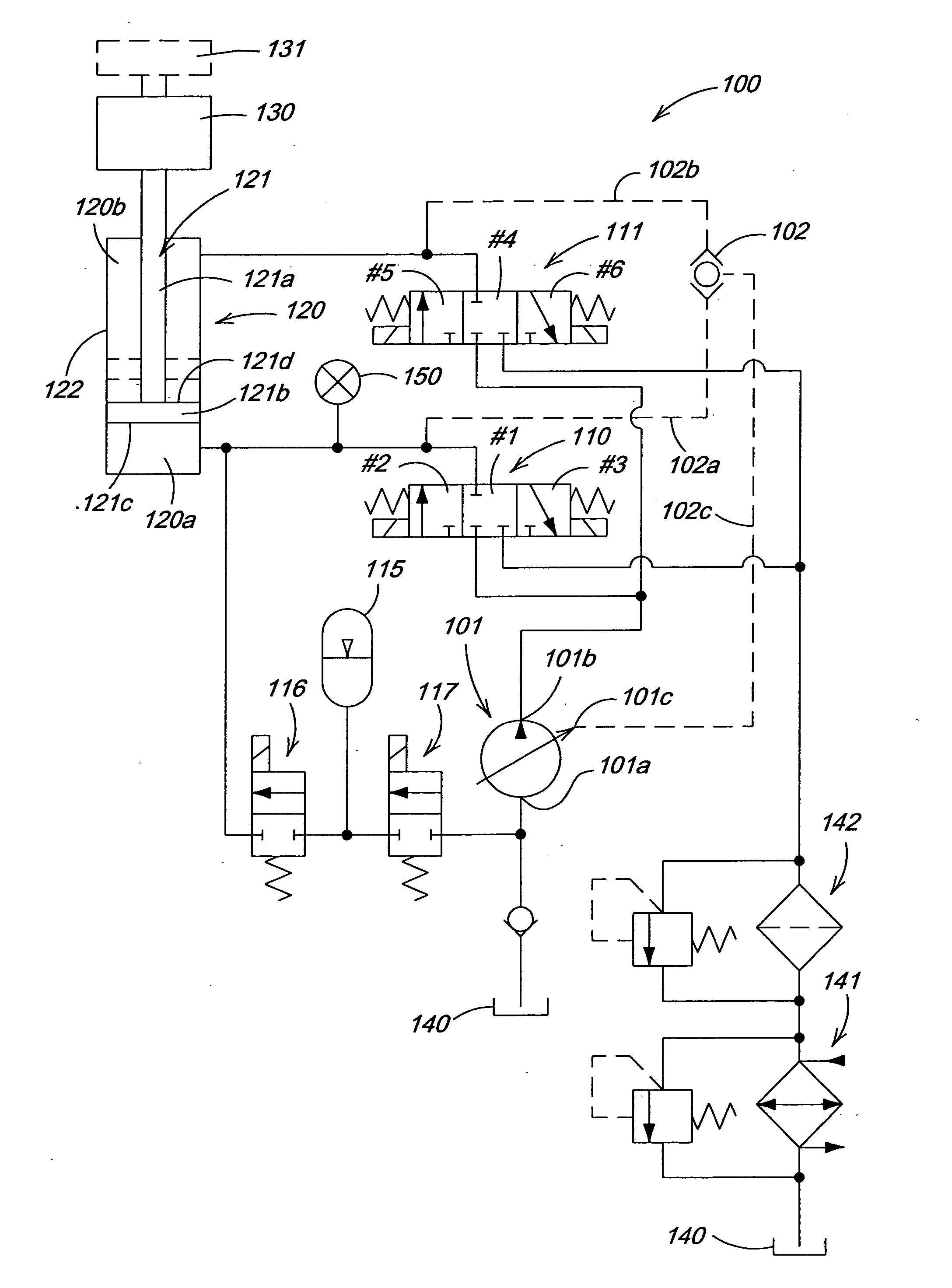

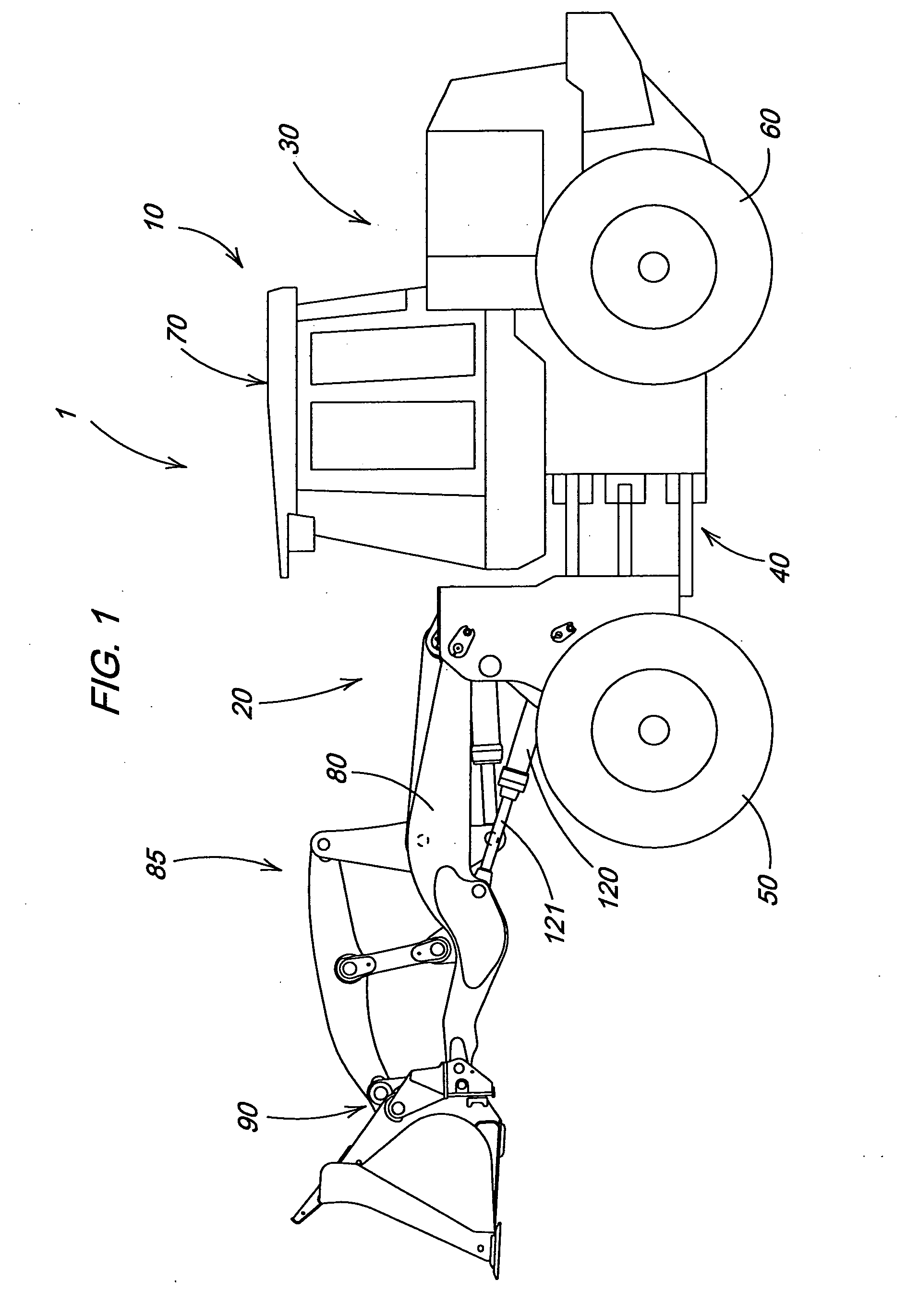

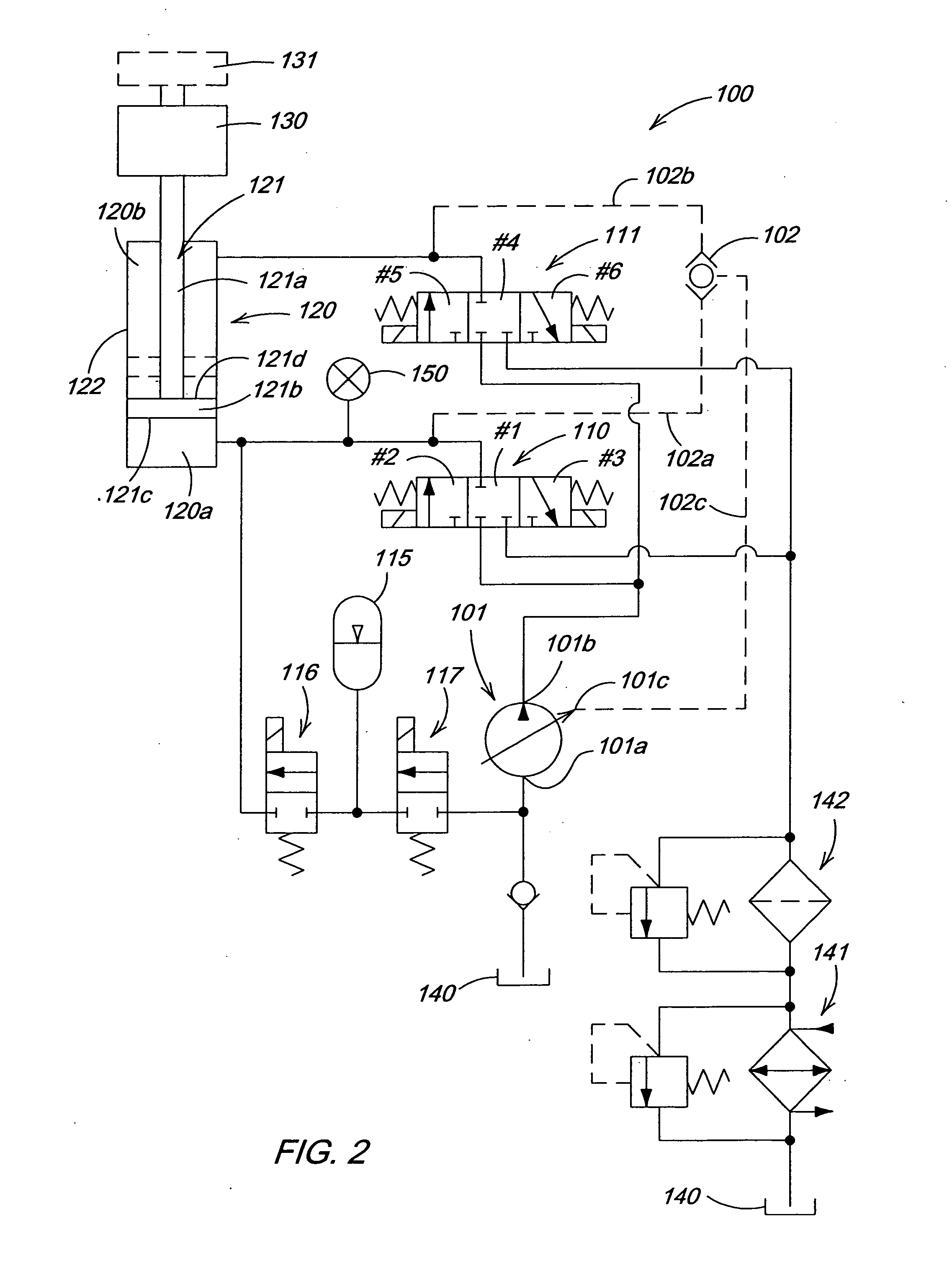

Flexible toolbar and operating hydraulic circuit

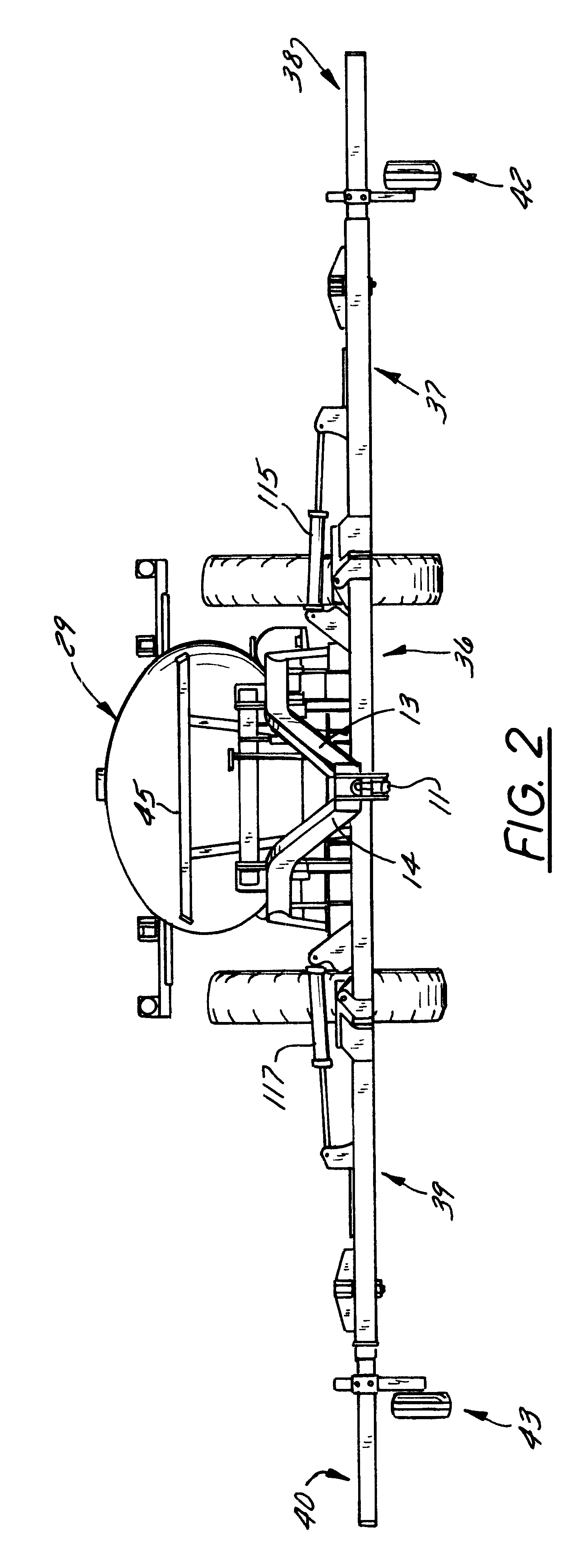

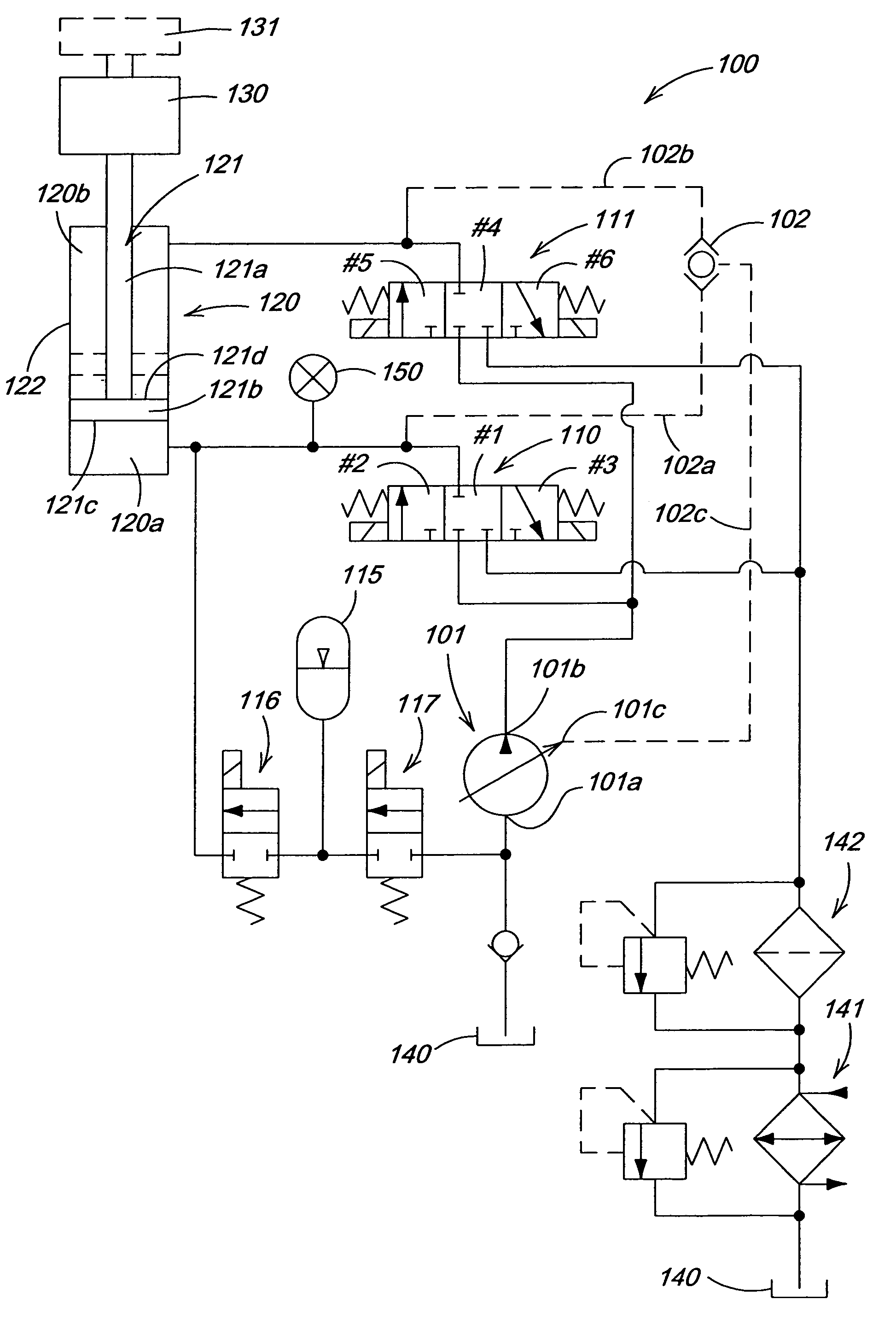

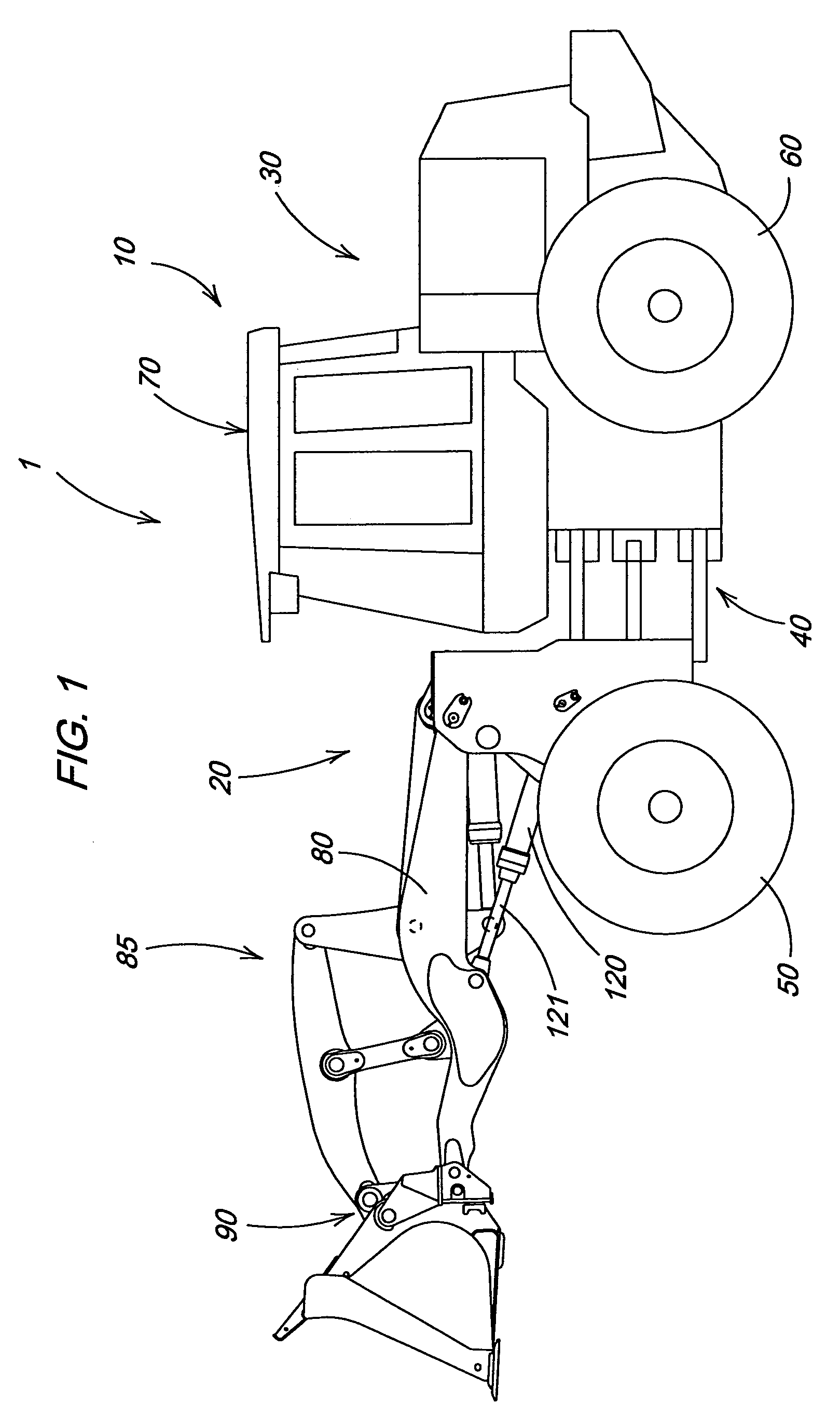

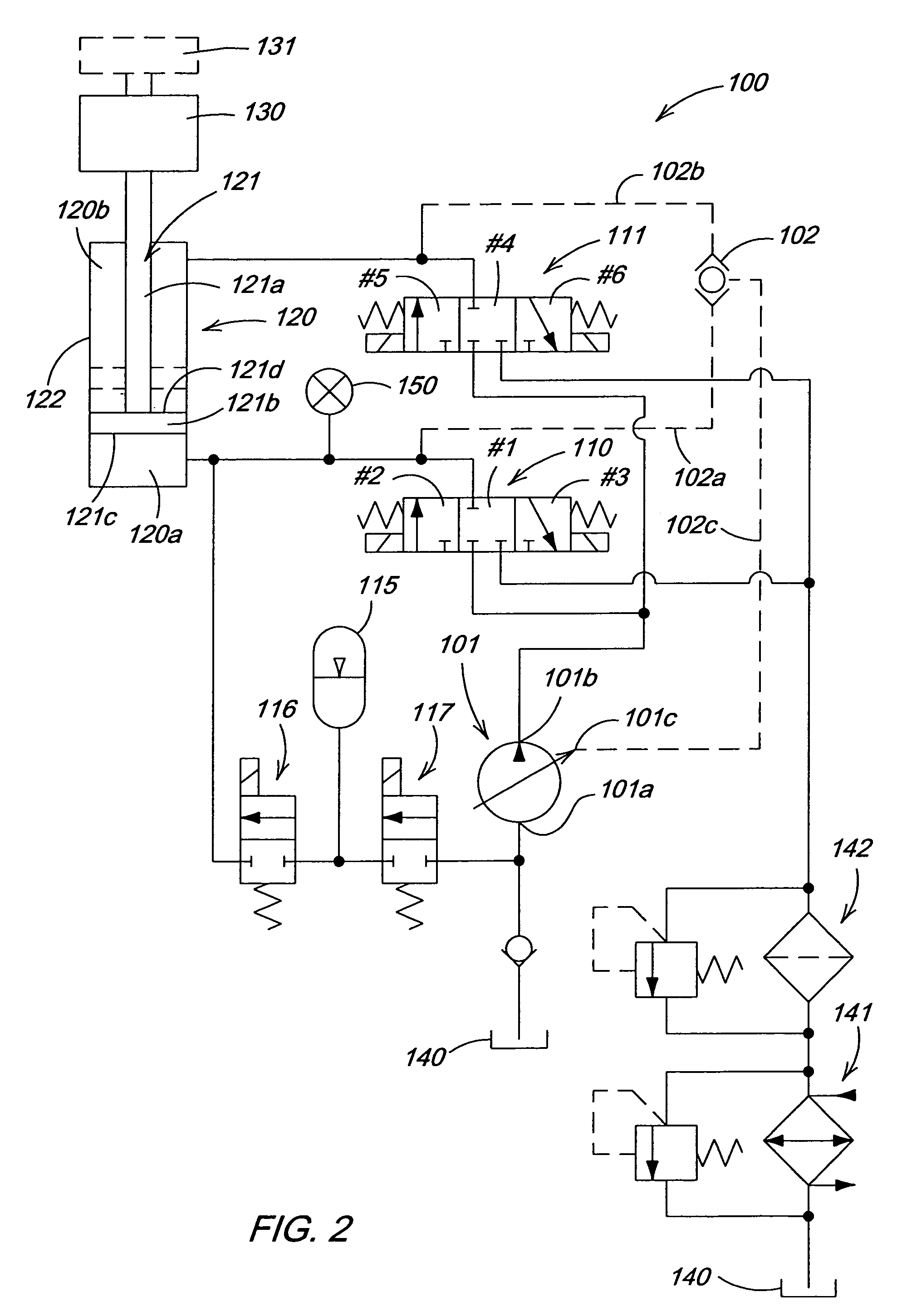

InactiveUS6675907B2Reduce the overall heightImprove securitySpadesAgricultural machinesHydraulic circuitEngineering

A winged implement includes an hydraulic control circuit having two operator-controlled valves, including a work valve and a transport valve. Using only these controls, and without leaving the tractor cab, the operator can (1) fold the implement for transport; (2) unfold the wings; (3) place the implement in the field use position with substantial constant down pressure on the wings; and (4) raise the wings and center section to an intermediate position with the wings inclined upwardly for end row turns.

Owner:CNH IND AMERICA LLC +1

Hydraulic energy intensifier

InactiveUS7124576B2Reduce energy loadHigh energyFluid couplingsAccumulator installationsHydraulic cylinderStored energy

Hydraulic circuits used to manipulate tools in, for example construction equipment, uses less power for a retraction of a hydraulic cylinder than for an extension of that cylinder. Provided is a hydraulic circuit that uses the stored energy from the low energy phase to lower the energy load on the hydraulic pump during the high energy phase. Energy from the hydraulic pump is increased during the low energy phase to increase the amount of stored hydraulic energy. The increased amount of stored energy is then used to intensify or add to the energy generated by the hydraulic pump for the high energy phase.

Owner:DEERE & CO

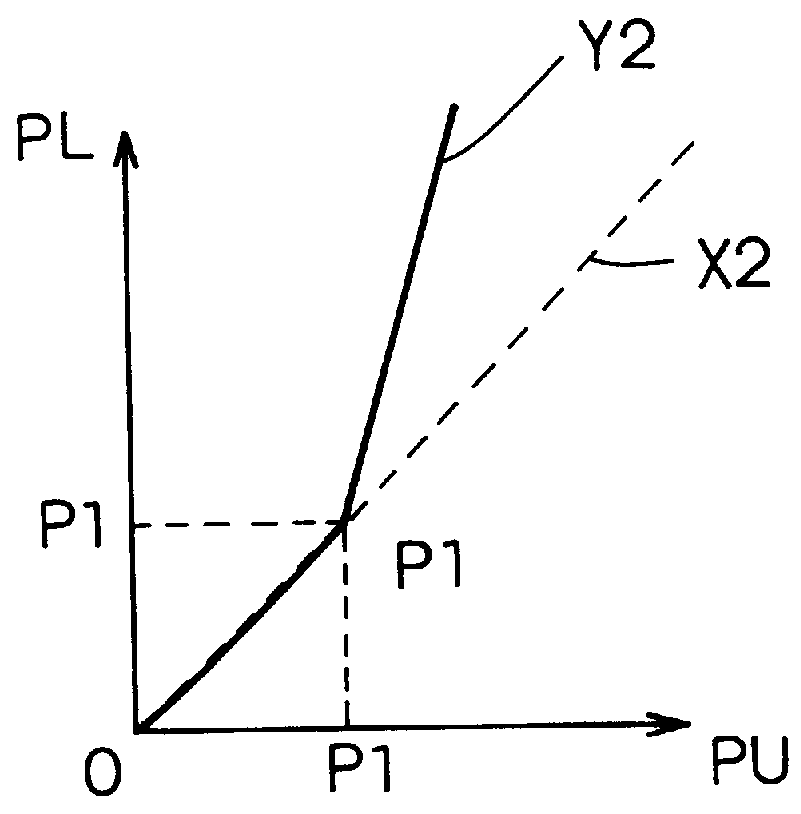

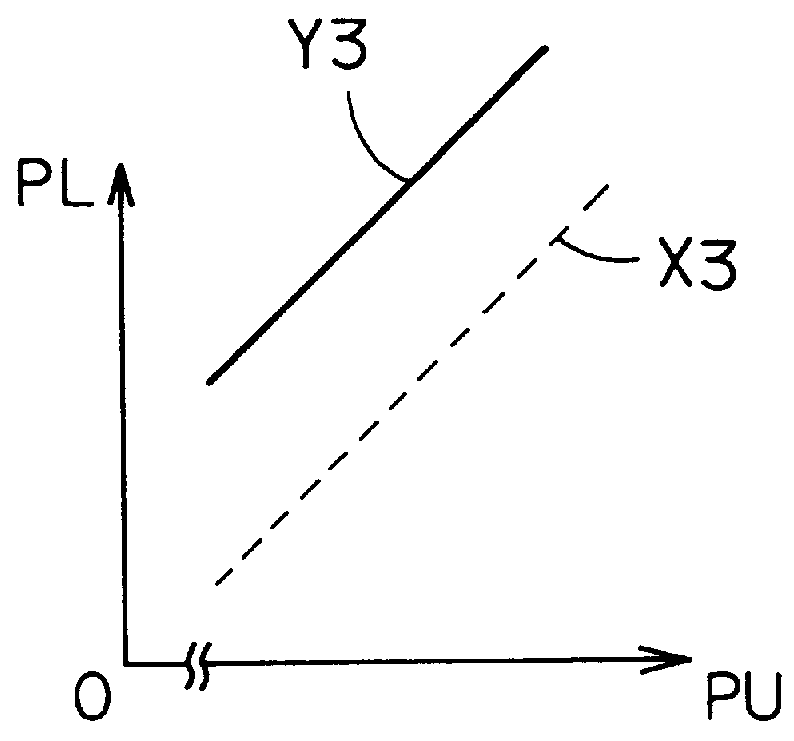

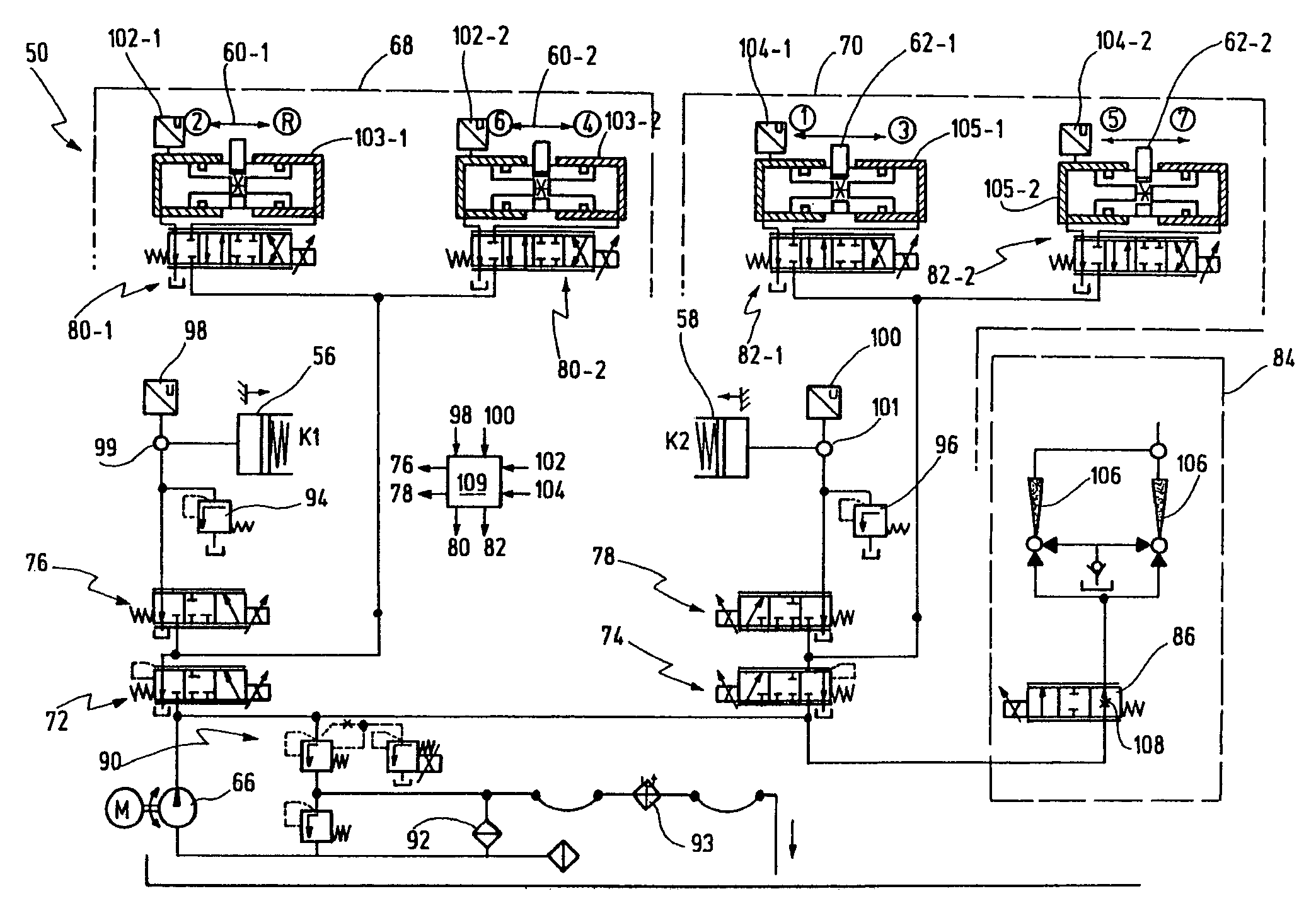

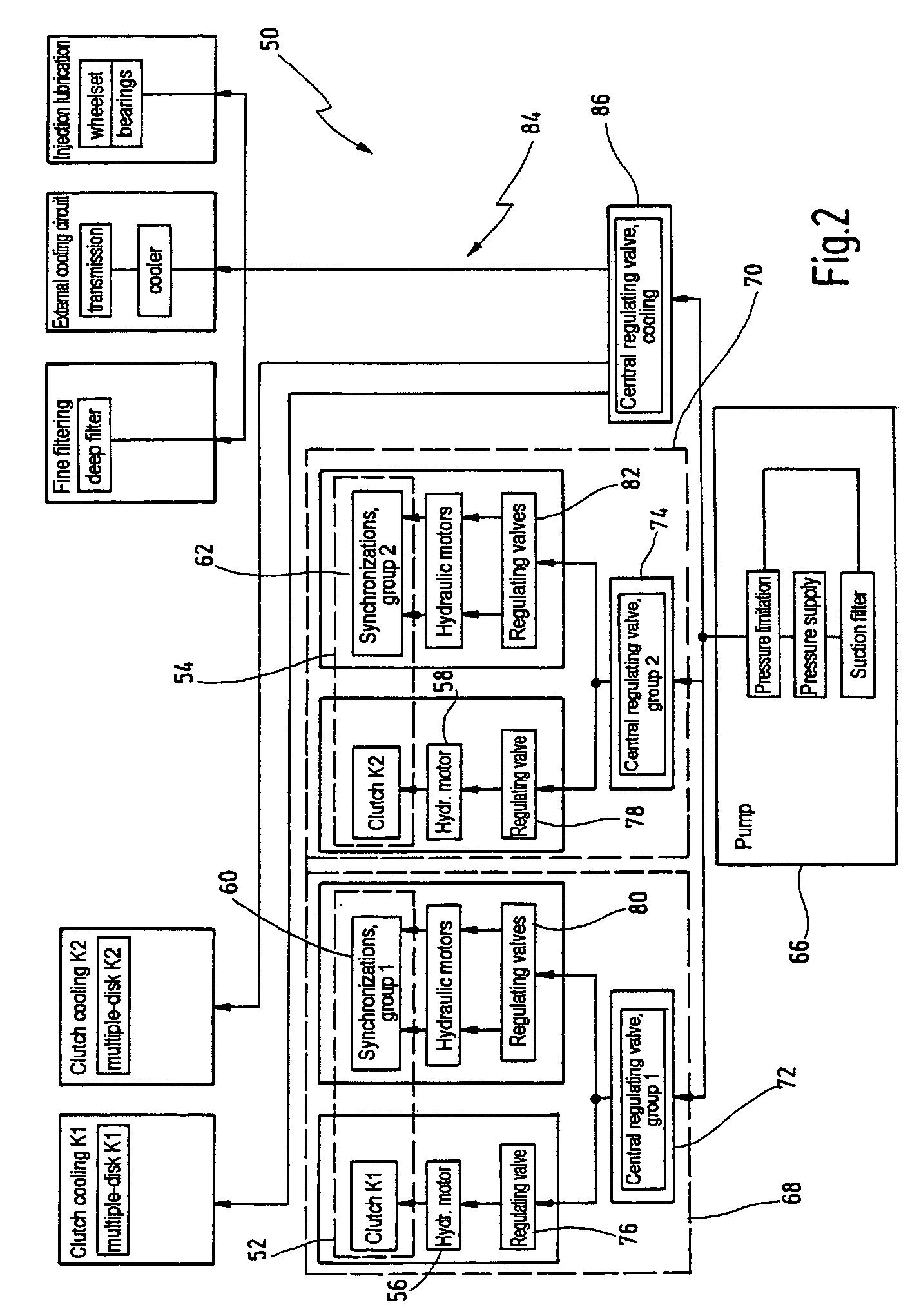

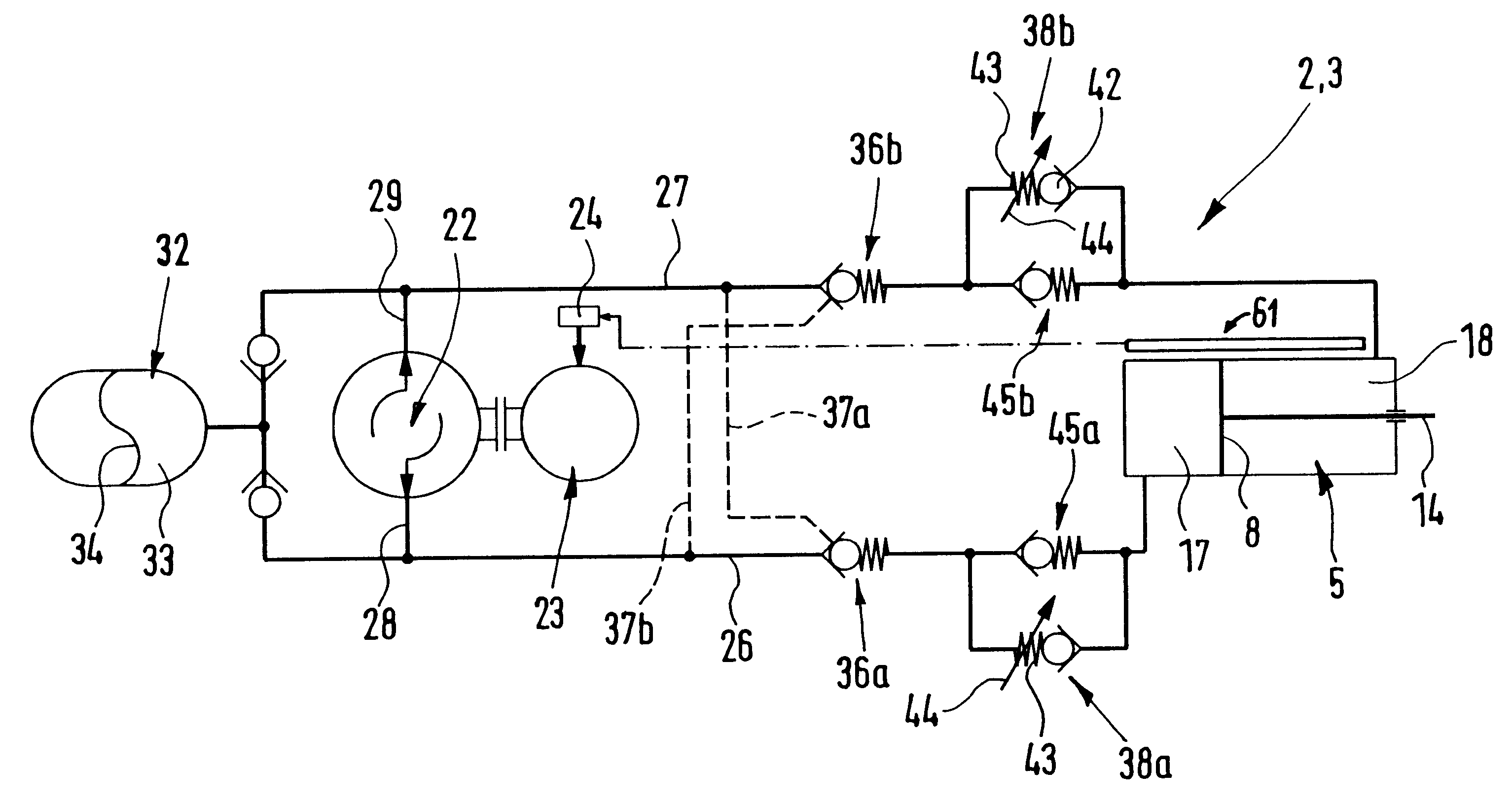

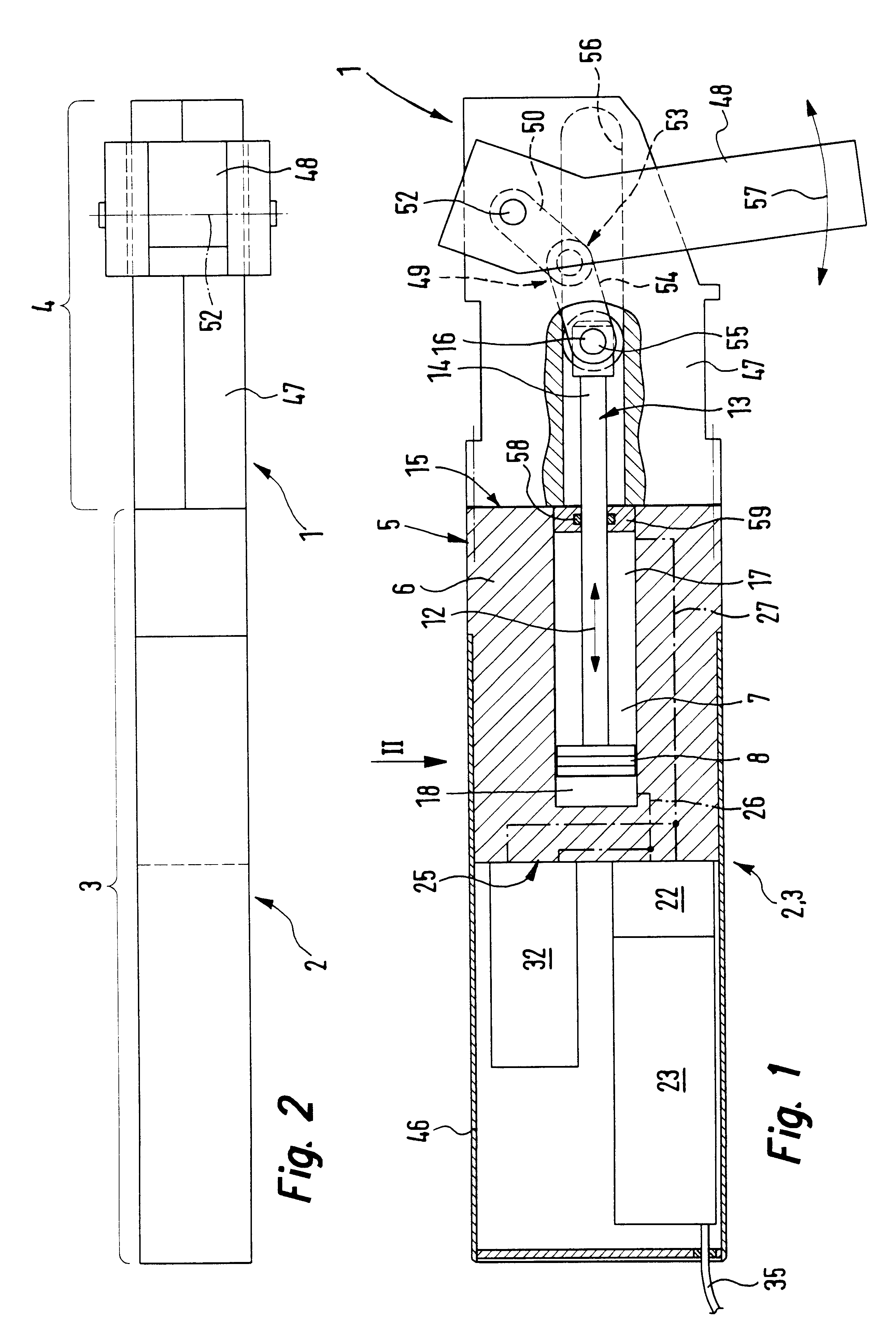

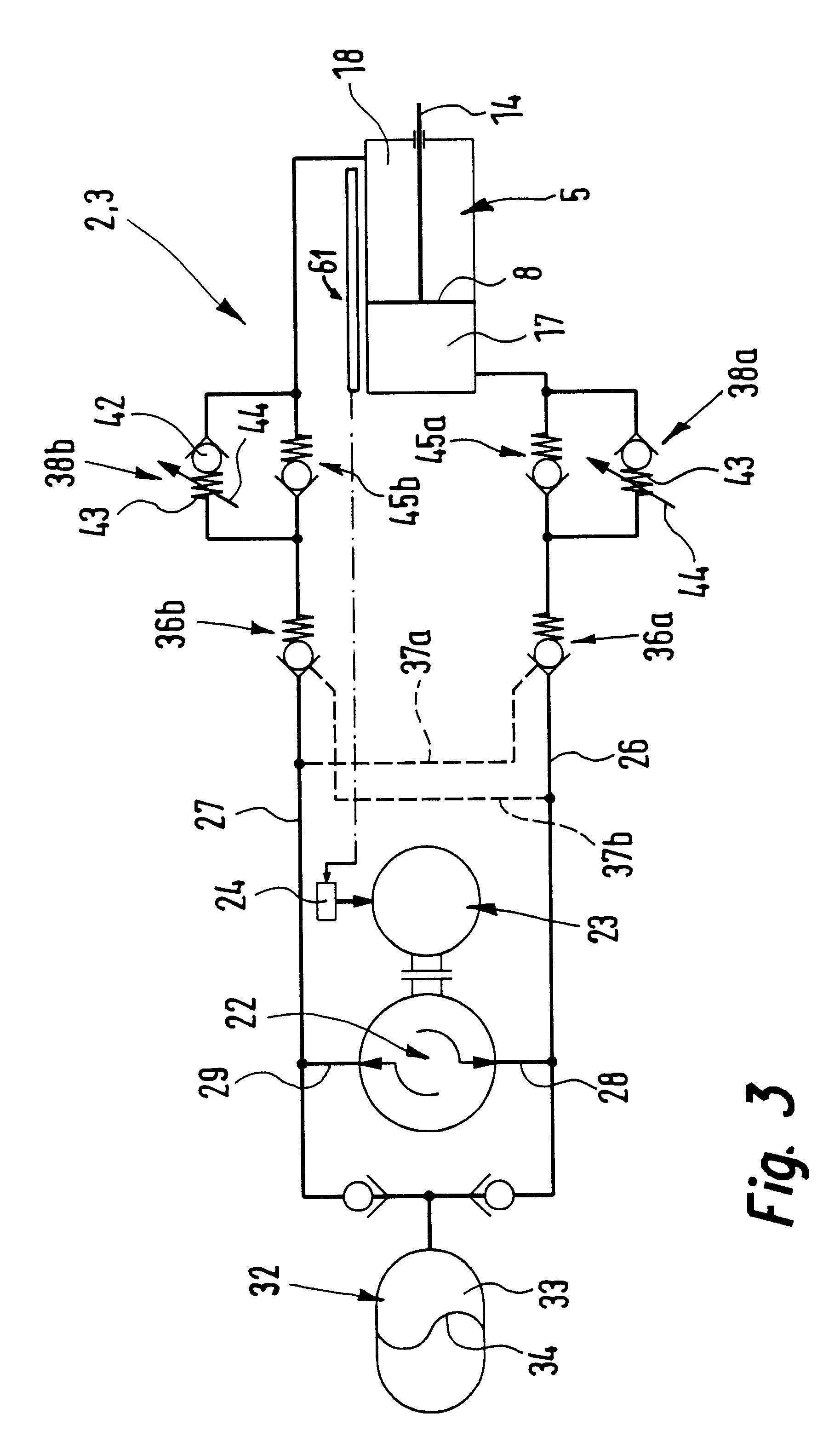

Hydraulic circuit for the control of a drive train

A hydraulic circuit for the control of a double clutch transmission which has two transmission groups, each with an isolating clutch and with a plurality of shift clutches for the engagement and disengagement of gear steps, the hydraulic circuit having for each transmission group a specific hydraulic branch connected to a pump in each case via a safety valve, and each hydraulic branch having in each case a clutch control valve for controlling the assigned isolating clutch and at least one shift control valve for controlling the assigned shift clutches. Here, the safety valves are designed in each case as proportional pressure regulating valves.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

Tong

Methods and apparatus for making and breaking tubular connections within a tubular string are disclosed. In certain aspects, a tong assembly includes gated power and back up tongs coupled to a torque bar. Jaws of the tongs may be arranged circumferentially with support members disposed between adjacent jaws to substantially complete a 360° closed circle. A hydraulic circuit may equally distribute fluid and pressure to actuate the jaws. The power tong may include a gated rotor driven by at least three drive motors. The rotor may be selectively physically locked from rotation or movement by one or more rotor locks. Further, the tong assembly may include an interlock that prevents activation of the drive motors until the rotor locks actuate to unlock the rotor. Additionally, gate locks may secure the tongs and rotor when closed, and a releasable coupling arrangement may aid engagement of a motor to a rotor pump.

Owner:WEATHERFORD TECH HLDG LLC

Hydraulic valve assembly with a pressure compensated directional spool valve and a regeneration shunt valve

A hydraulic circuit controls flow of fluid between first and second ports of a hydraulic actuator, such as a cylinder / piston arrangement and each of a supply conduit and a tank return conduit. The hydraulic circuit operates in standard powered operating modes as well as powered and unpowered regeneration modes. In a powered operating mode, a conventional pressure compensated spool valve determines the velocity of the hydraulic actuator. A workport blocking valve connects one workport of the spool valve to the first port and the other workport is connected to the second port. A regeneration shunt valve is directly connected between the first and second ports of the hydraulic actuator. In a regeneration operating mode or a mix of powered and regeneration modes, a combination of the spool valve, the workport blocking valve, and the regeneration shunt valve determines the velocity of the hydraulic actuator.

Owner:HUSCO INT INC

Drive device

InactiveUS6543223B2Easy to driveReduce needFluid couplingsServomotor componentsHydraulic pumpHydraulic circuit

A drive device comprising a closed hydraulic circuit which has a hydraulic drive adapted to be actuated by hydraulic medium and has a hydraulic pump responsible for the supply and removal of the hydraulic medium to and from the hydraulic drive. For the operation of the hydraulic pump an electric motor is provided. The activation of the hydraulic drive is controlled by the operational state of the hydraulic pump.

Owner:FESTO AG & CO KG

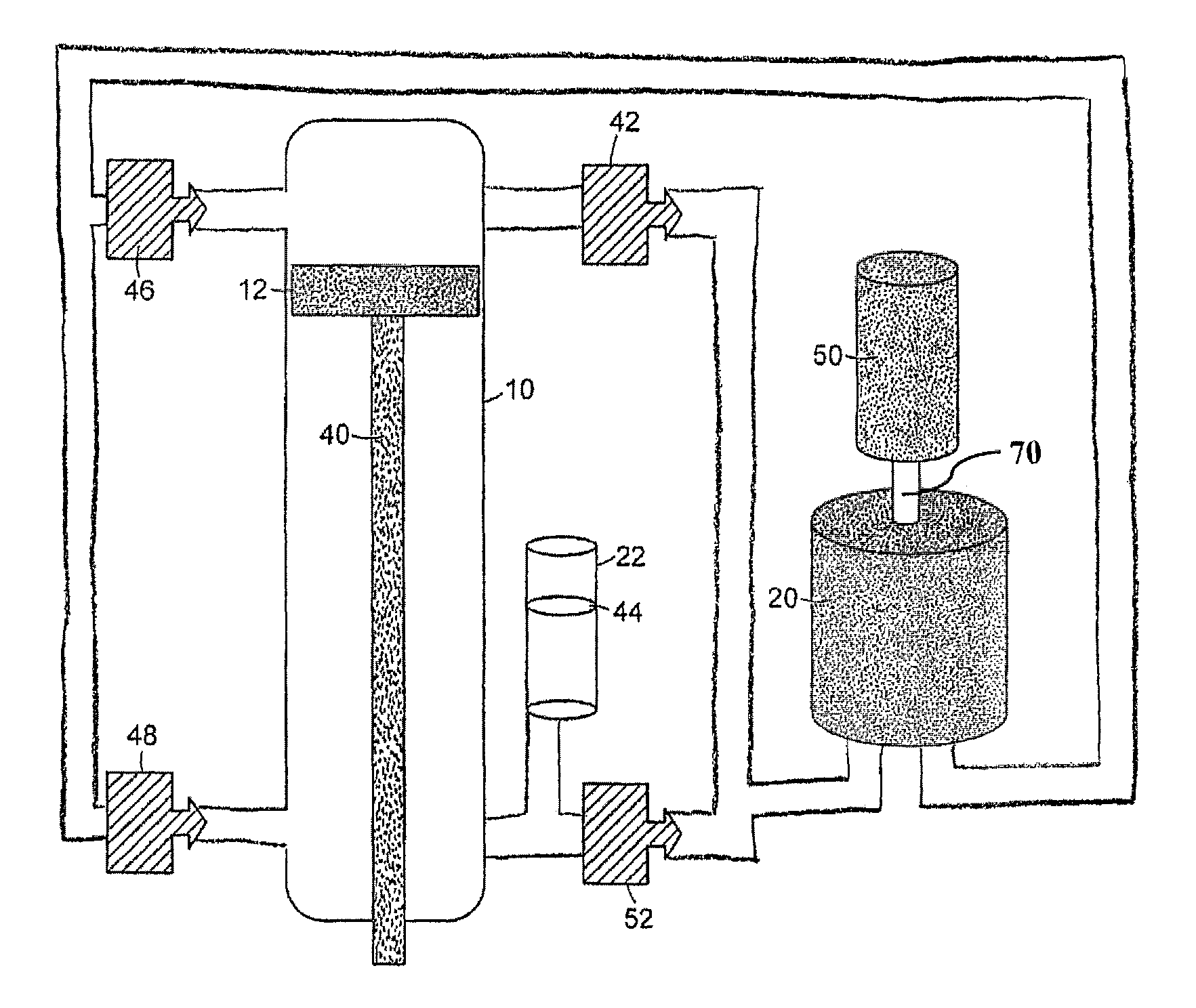

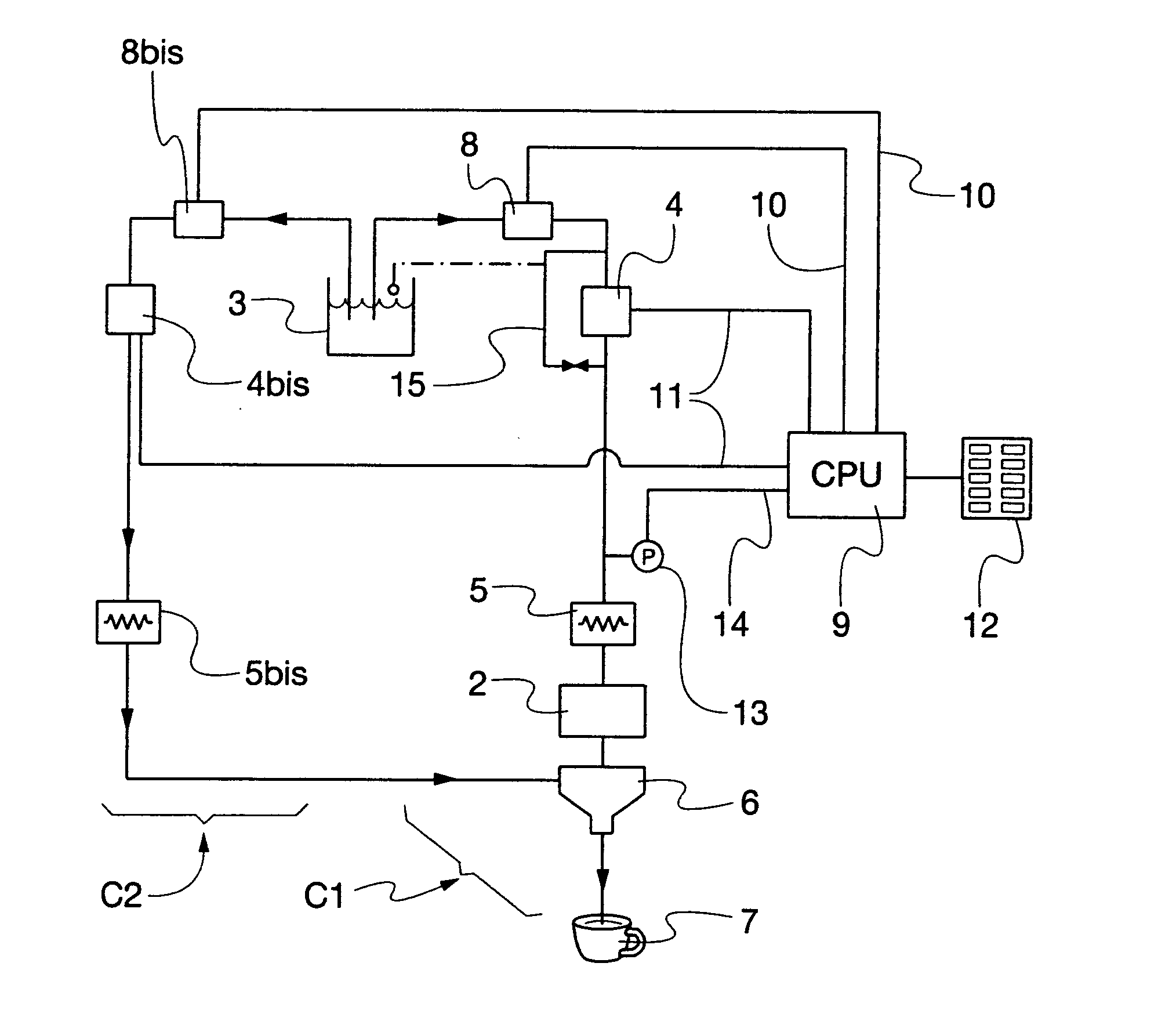

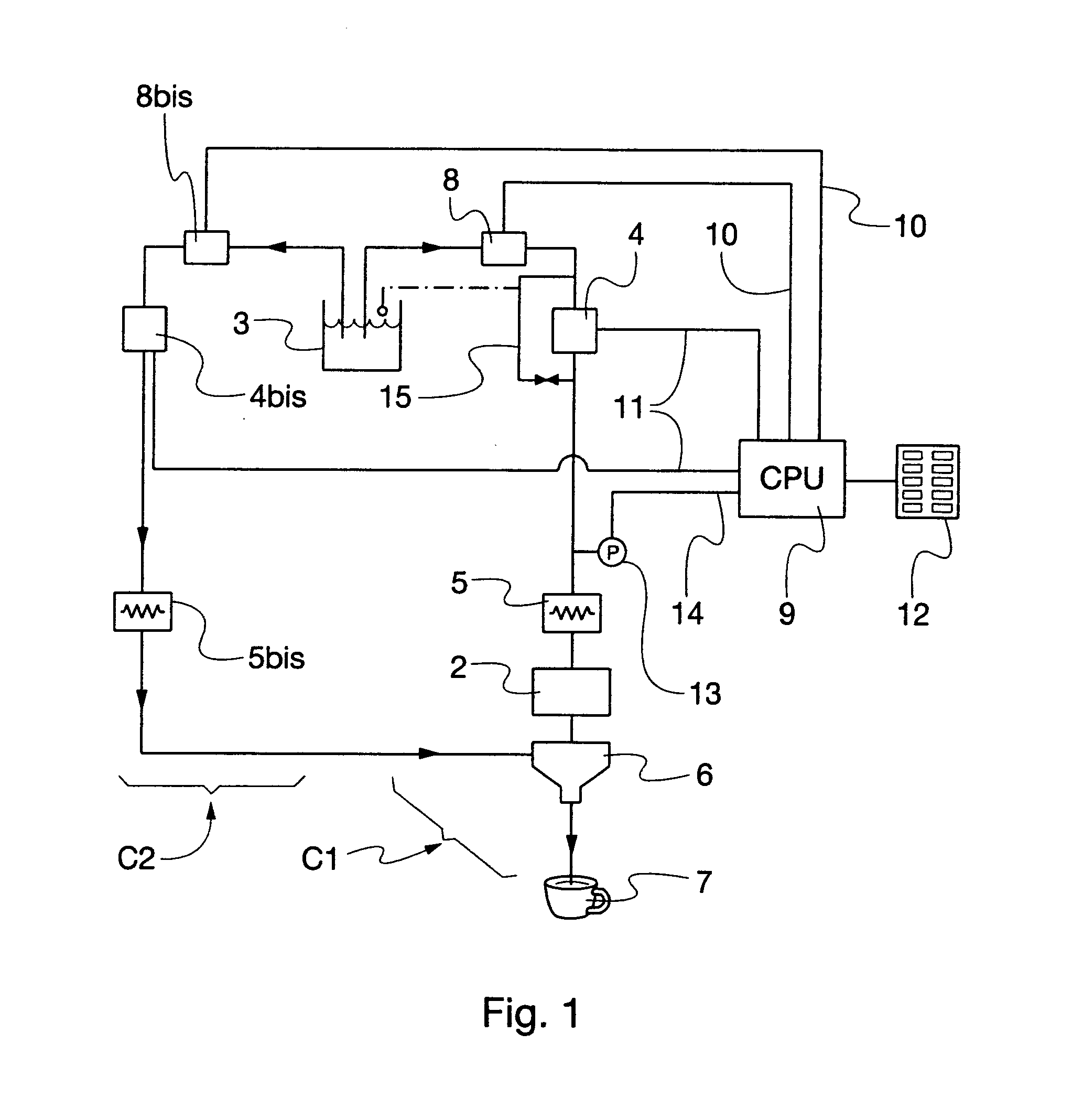

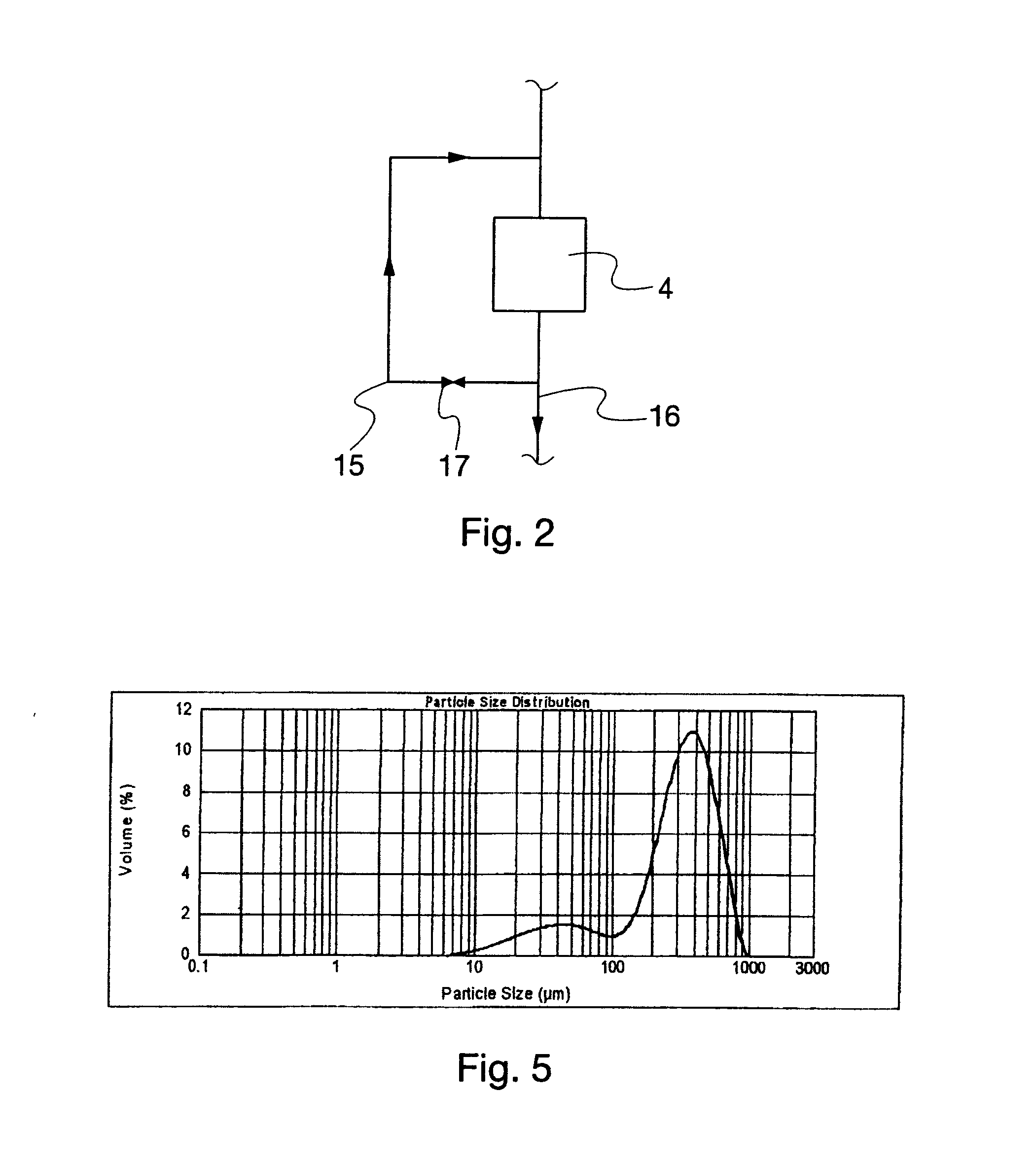

Device and method for preparation of beverages with differing tastes

ActiveUS20130129885A1Promote wettingEasy extractionBeverage vesselsFood preparationWater sourceWater flow

A beverage dispensing machine includes: a first hydraulic circuit including a water source, a pump, a water heater, a brewing device selected from a brewing chamber and a capsule, the brewing device including an inlet and outlet, a beverage collector collecting brewed beverage leaving the brewing device and for dispensing the beverage to a container; and a second hydraulic circuit that includes a second pump and second water heater, the outlet of the second water heater being connected to the first circuit at a location that is downstream to the brewing device with respect to the water flow in the first circuit. The first circuit can maintain in the brewing device a pressure substantially constant for a pre-set time, the pressure being less that an opening pressure for the brewing device.

Owner:TUTTOESPRESSO SRL

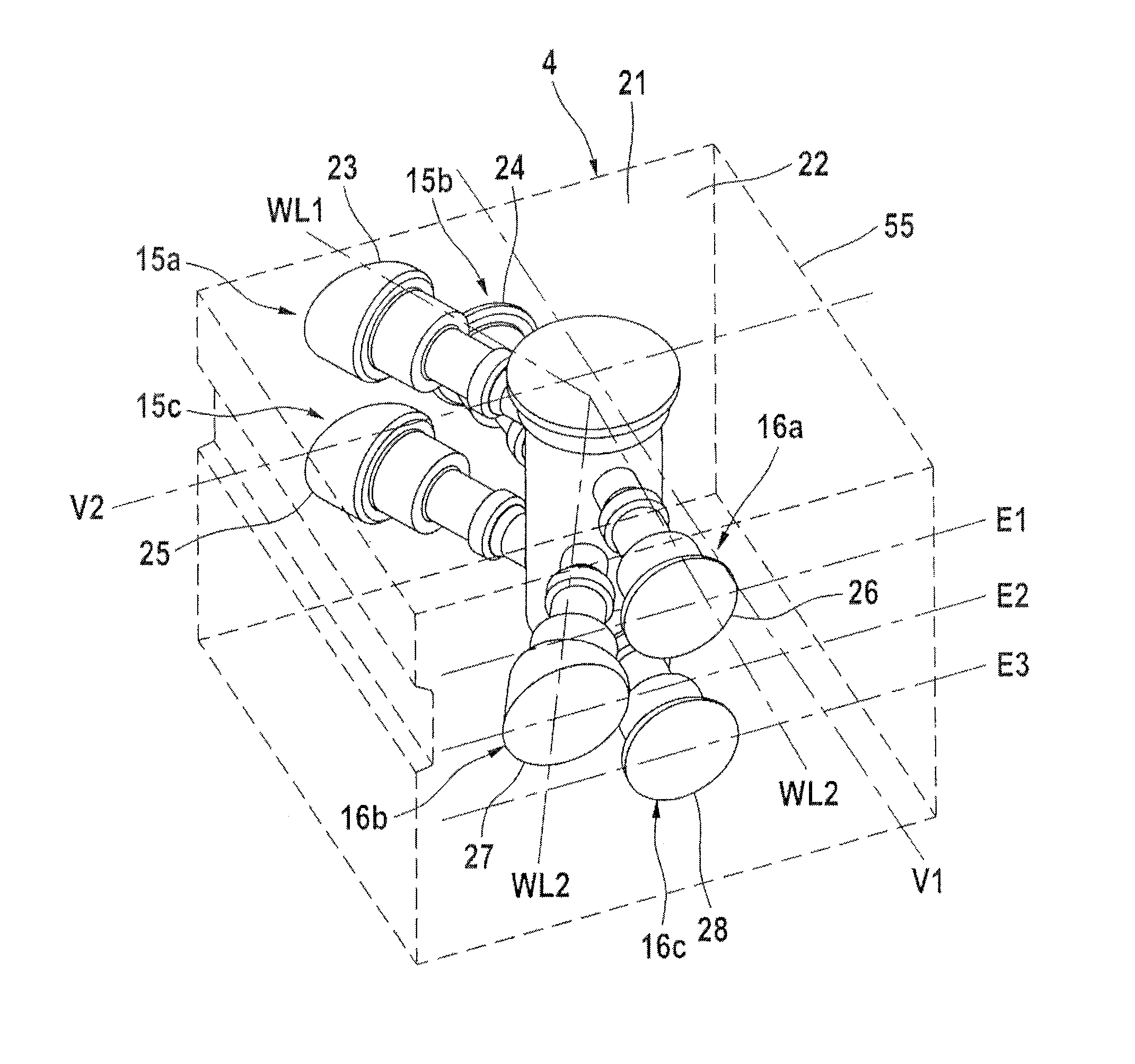

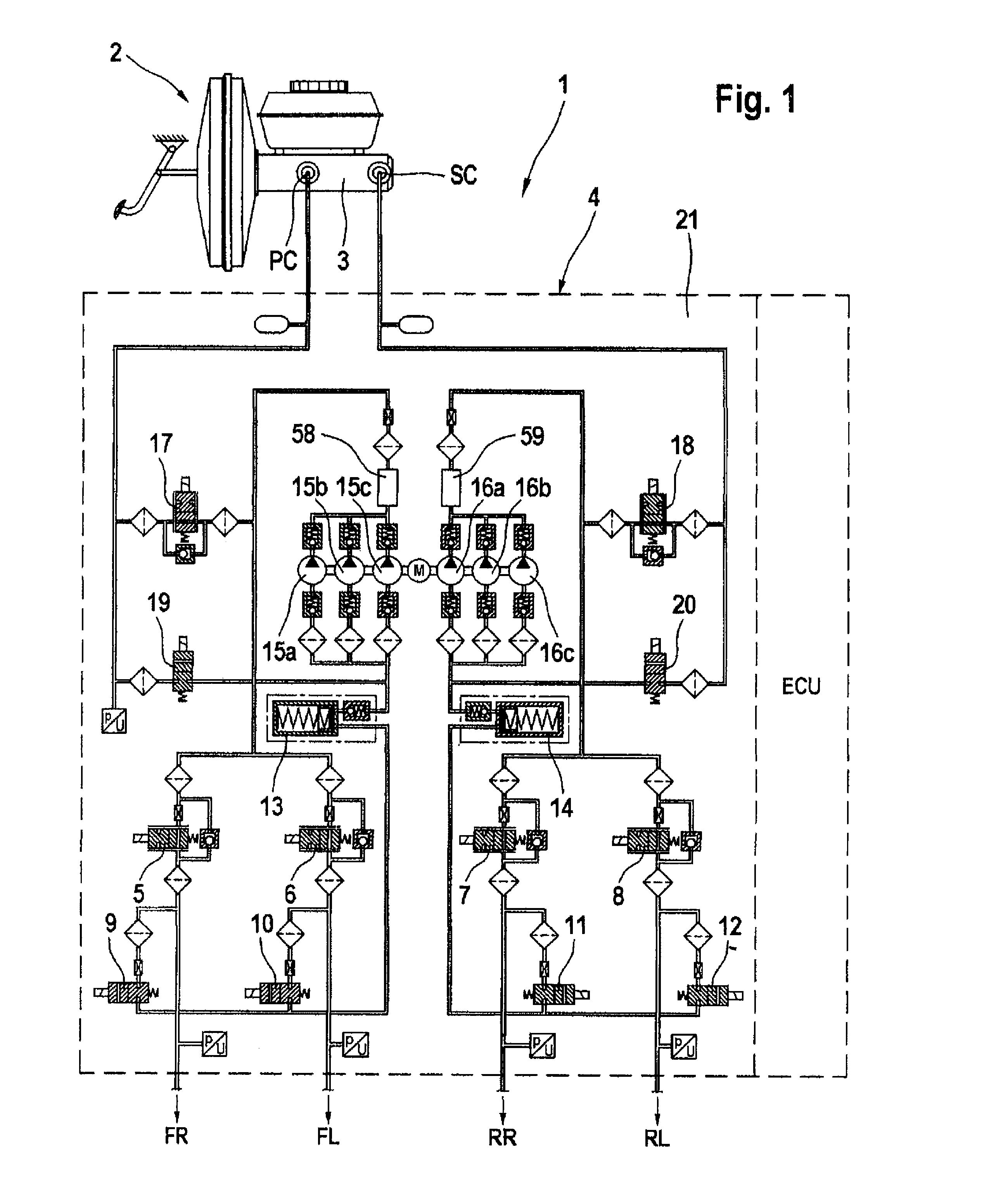

Hydraulic unit for slip-controlled braking systems

ActiveUS8500215B2Improve compromiseAvoid disadvantagesPositive displacement pump componentsBraking action transmissionDrive shaftHydraulic circuit

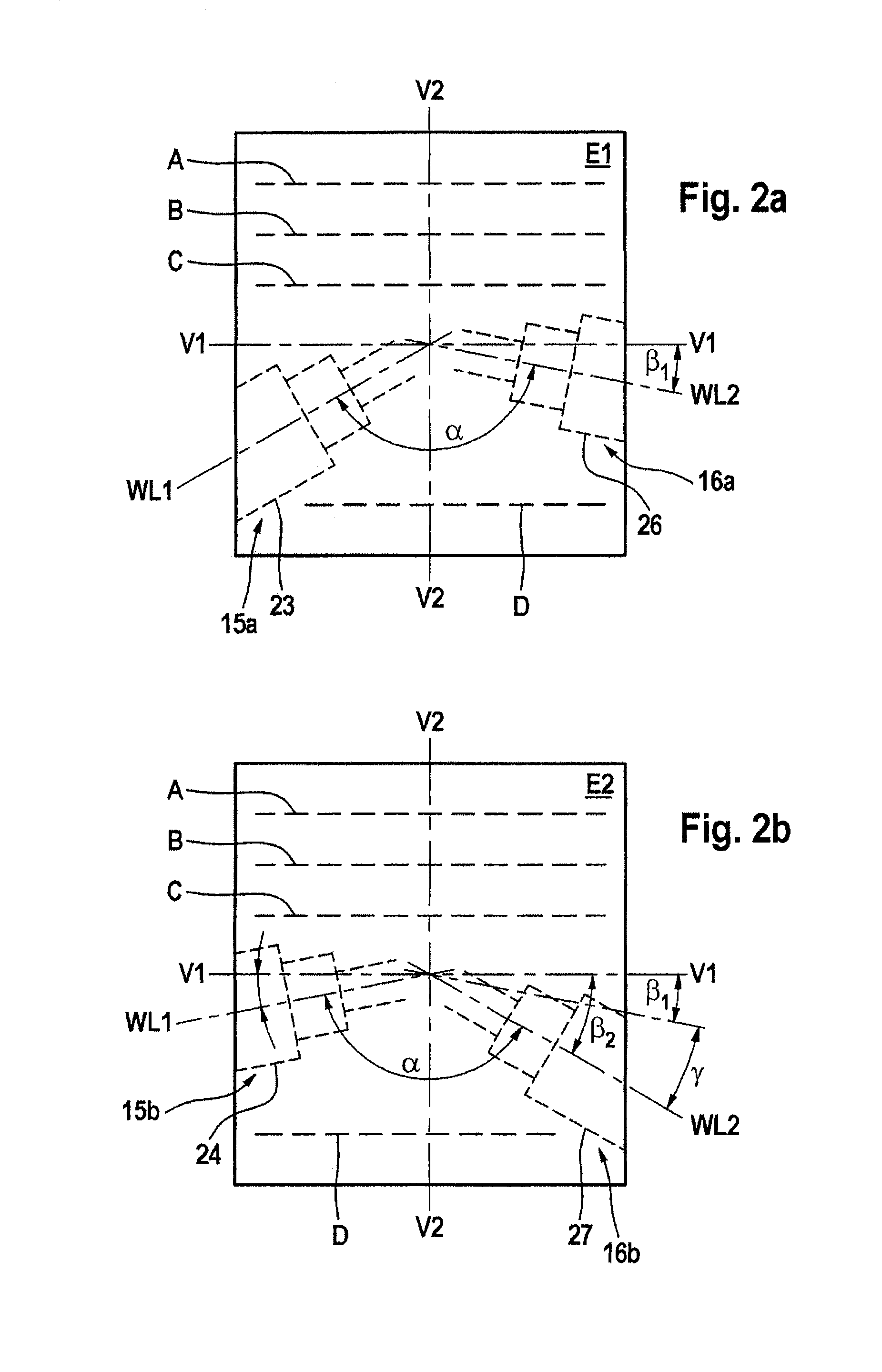

A hydraulic unit for slip-controlled braking systems has a plurality of receiving holes for transport devices associated with a plurality of hydraulic circuits bundled into groups, wherein the receiving holes are disposed at a distance from each in parallel with the upper side and a drive shaft having eccentrics located at the plane spacing for driving the transport devices. In order to provide a compromise optimized for manufacturing a small, convenient hydraulic unit, it is proposed that three theoretical planes (E1, E2, E3) are arranged in parallel to the upper side, each receiving two V-shaped receiving holes for transport devices disposed at an angle to each other, and that the drive shaft includes three separate eccentrics for driving the transport devices.

Owner:CONTINENTAL TEVES AG & CO OHG

Electronic winch monitoring system

An electronic winch monitoring system for a winch having a fixed-ratio gearbox with input and output shafts, a winch drum connected to the output shaft, and an auxiliary brake connected to the output shaft activated by reducing the pressure in a brake release hydraulic circuit. The system comprises an input shaft speed sensor, an output shaft speed sensor, and an electronic control unit having a monitoring section and a brake control section. The monitoring section receives the speed signals, processes them to produce a calculated ratio of actual input to output shaft speeds, and produces a fault indication signal when the value of the difference between the calculated speed ratio and the fixed ratio exceeds a predetermined value. The brake control section, upon receiving the fault signal, reduces the hydraulic pressure in the brake circuit using a nonlinear pressure-time profile to engage the auxiliary brake and stop the winch drum.

Owner:PACCAR INC

Hydraulic energy intensifier

InactiveUS20060075749A1Reduce energy loadHigh energyFluid couplingsAccumulator installationsHydraulic cylinderStored energy

Hydraulic circuits used to manipulate tools in, for example construction equipment, uses less power for a retraction of a hydraulic cylinder than for an extension of that cylinder. Provided is a hydraulic circuit that uses the stored energy from the low energy phase to lower the energy load on the hydraulic pump during the high energy phase. Energy from the hydraulic pump is increased during the low energy phase to increase the amount of stored hydraulic energy. The increased amount of stored energy is then used to intensify or add to the energy generated by the hydraulic pump for the high energy phase.

Owner:DEERE & CO

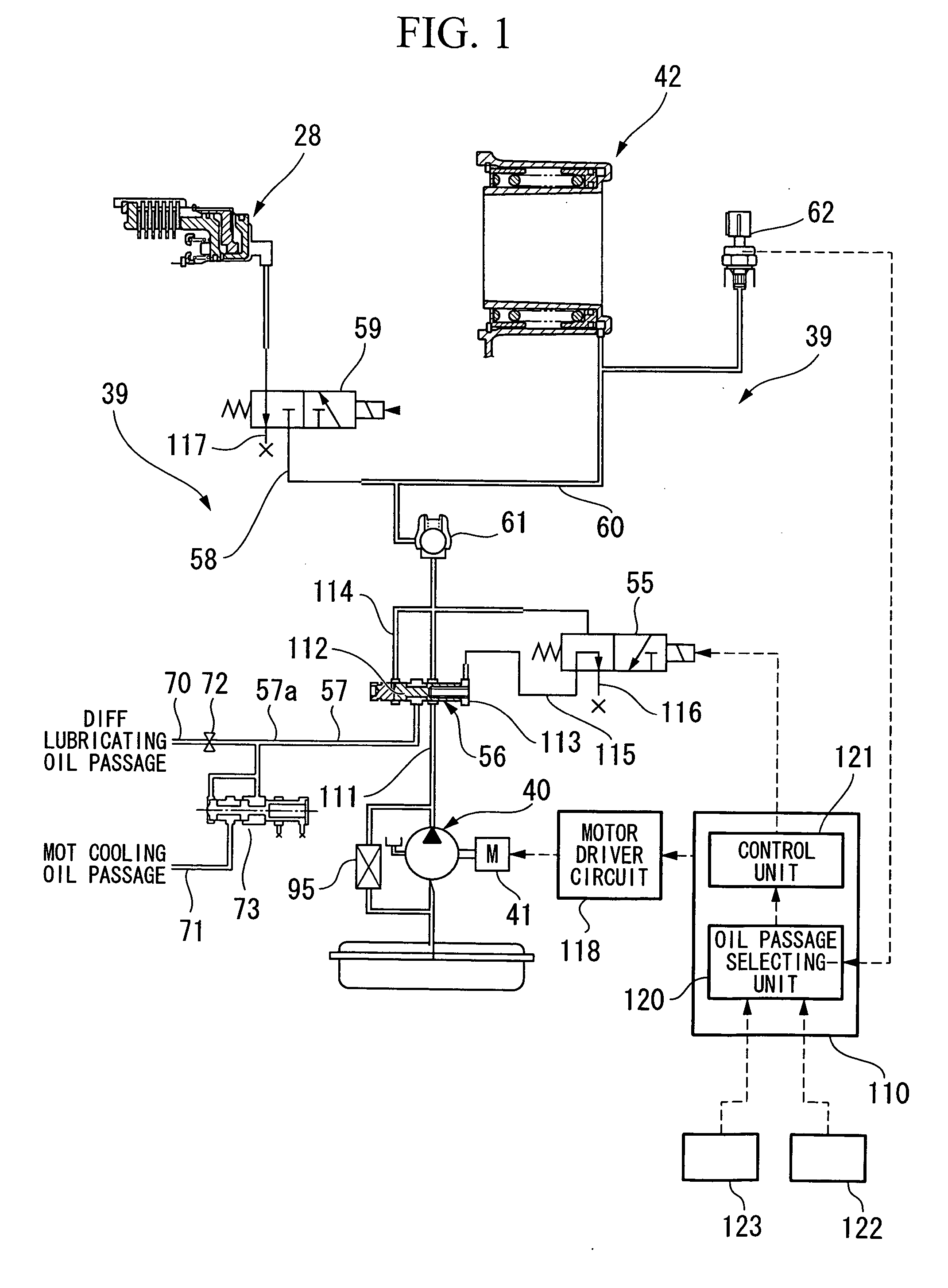

Hydraulic circuit control device

InactiveUS20060223670A1Reduce stressIncrease heightServomotorsGear lubrication/coolingHydraulic circuitControl mode

A hydraulic circuit control device that selectively supplies oil to a first oil passage and a second oil passage by an oil pump, the control device includes: an oil passage switching unit adapted to connect the oil pump to either the first oil passage or the second oil passage; a control mode switching unit adapted to switch the control mode of the electric motor to either a torque control mode or a speed control mode; an oil passage selecting unit adapted to select whether to connect the oil pump to the first oil passage or the second oil passage; and a control unit adapted to perform control so that the control mode switching unit switches the control mode to the torque control mode when the first oil passage has been selected, and perform control so that the control mode switching unit switches the control mode to the speed control mode when the second oil passage has been selected.

Owner:HONDA MOTOR CO LTD

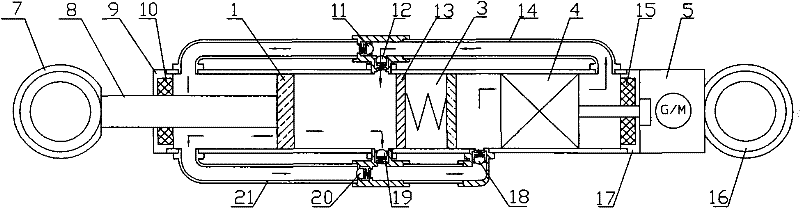

Electrohydraulic energy-regenerative type shock absorber

ActiveCN101749353APrevent reversalExtend your lifeLiquid based dampersMechanical energy handlingHydraulic motorDrive shaft

The invention relates to an electrohydraulic energy-regenerative type shock absorber, which comprises a hydraulic circuit, a working chamber and a piston, wherein the working chamber is divided into a piston working cavity and an accumulating power-generating cavity by a partition plate (13), and the piston is positioned in the piston working cavity and is connected with an external upper mounting base (7) through a piston push rod (8); a hydraulic motor (4) is positioned in the energy storage power-generating cavity and is connected with an external rotary generator (5) through a driving shaft, and an accumulator (3) is positioned in the accumulating power-generating cavity and is positioned below the partition plate (13); and the hydraulic circuit and a plurality of one-way valves (6) form a hydraulic rectifier bridge, and the hydraulic circuit adopts the method that an external pipeline is arranged outside the piston or the piston is designed to form internal and external cavities. The invention has simple structure, fewer components and small volume, can allow the energy generated by vehicle vibration to be fully used for doing work, can effectively recover vibration energy, has better shock absorbing effect than the existing shock absorber, and also prolongs the service life of the generator.

Owner:武汉经开科创运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com