Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164results about How to "Reduce hydraulic pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

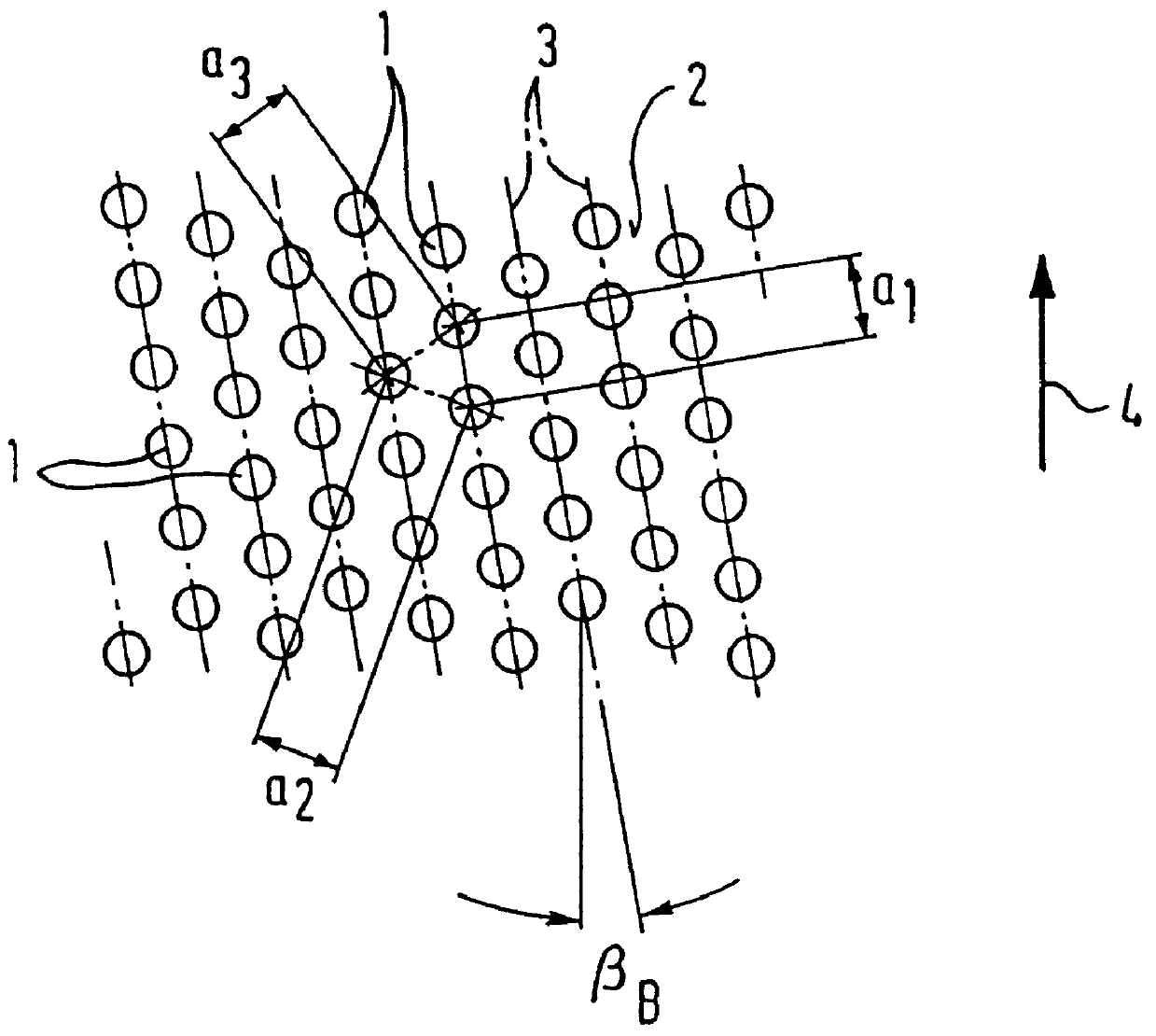

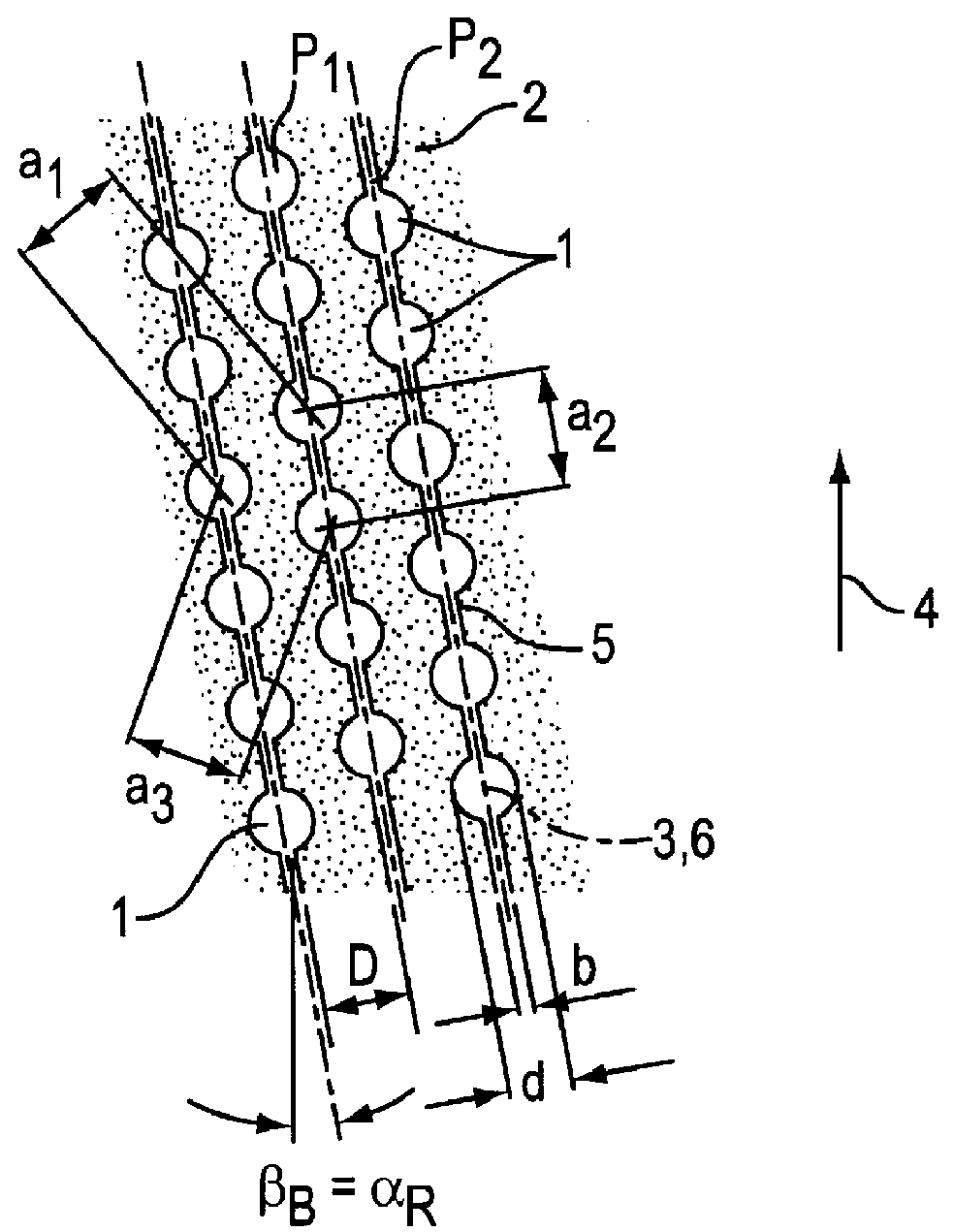

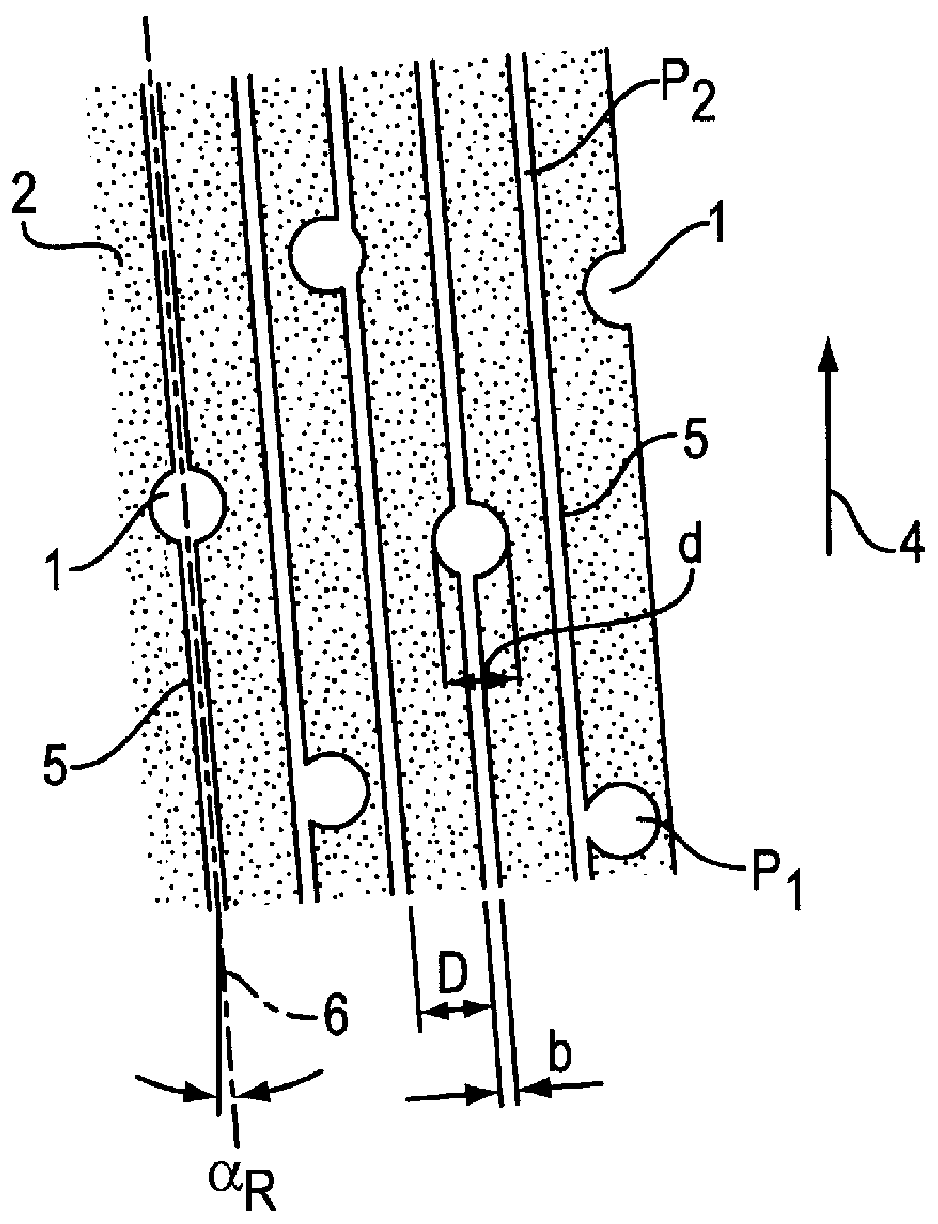

Press jacket for a press device

InactiveUS6029570APrevent buildupMeet high volumePress sectionAgricultural rollersMachine pressEngineering

Owner:VOITH SULZER PAPIERMASCHEN

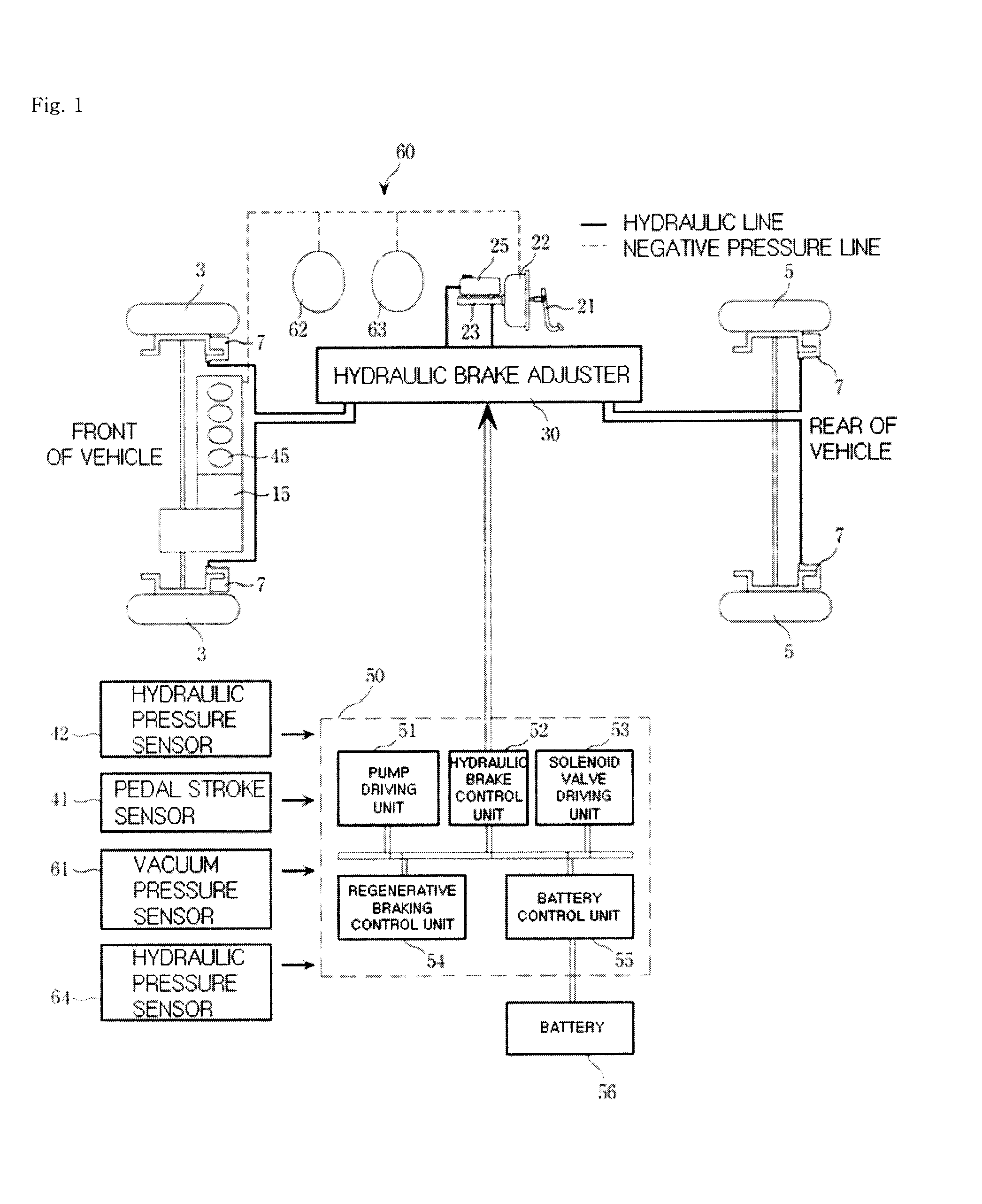

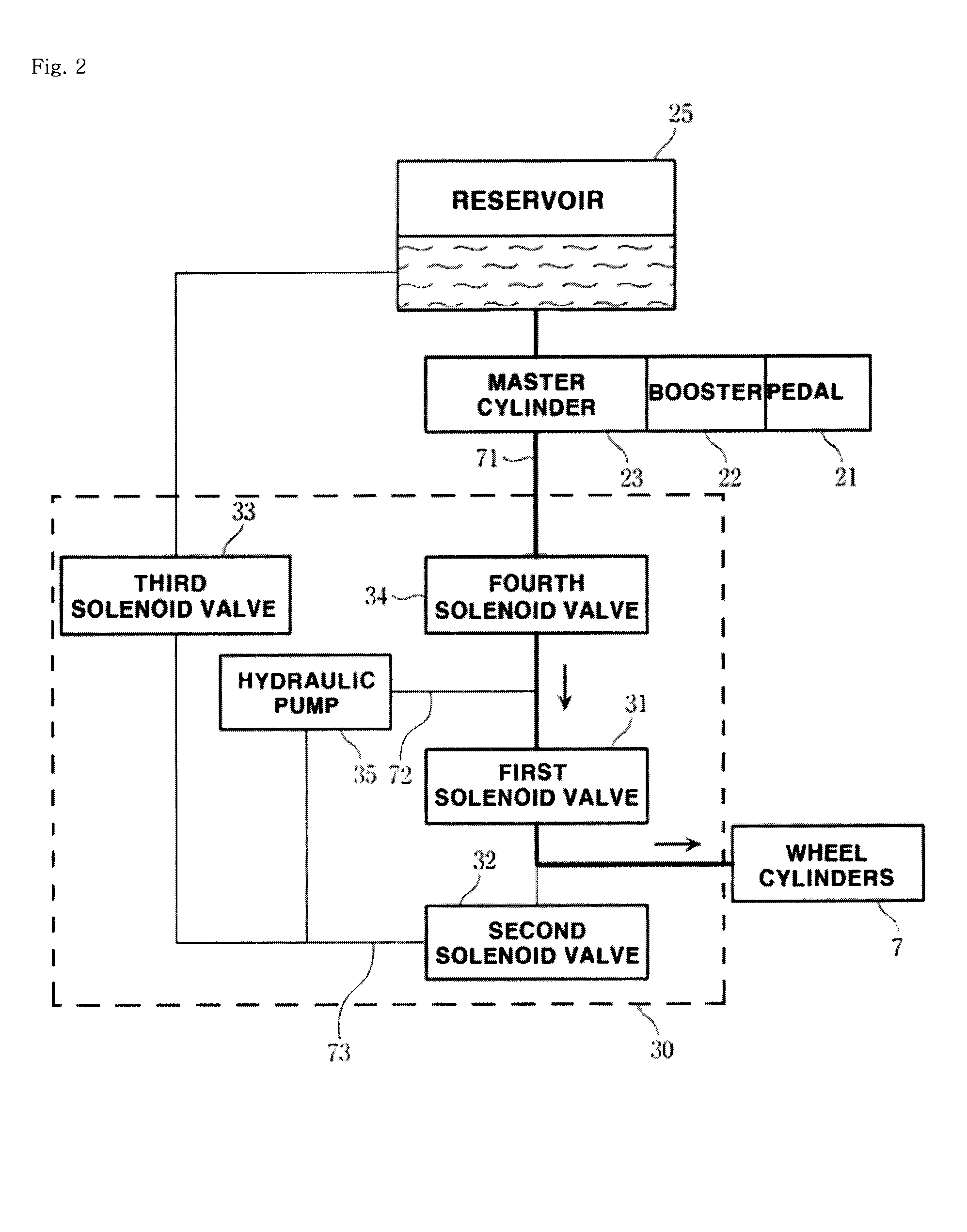

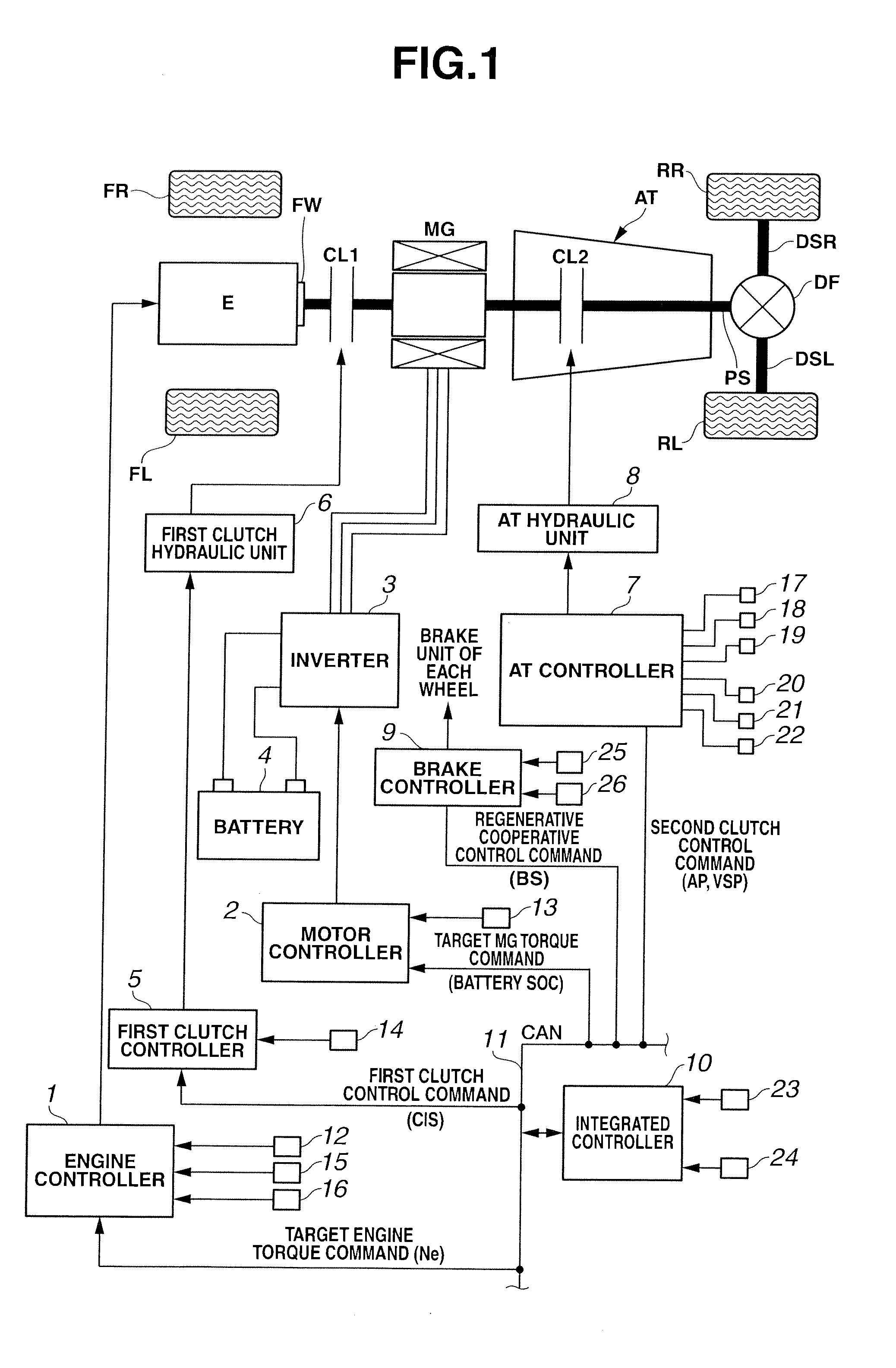

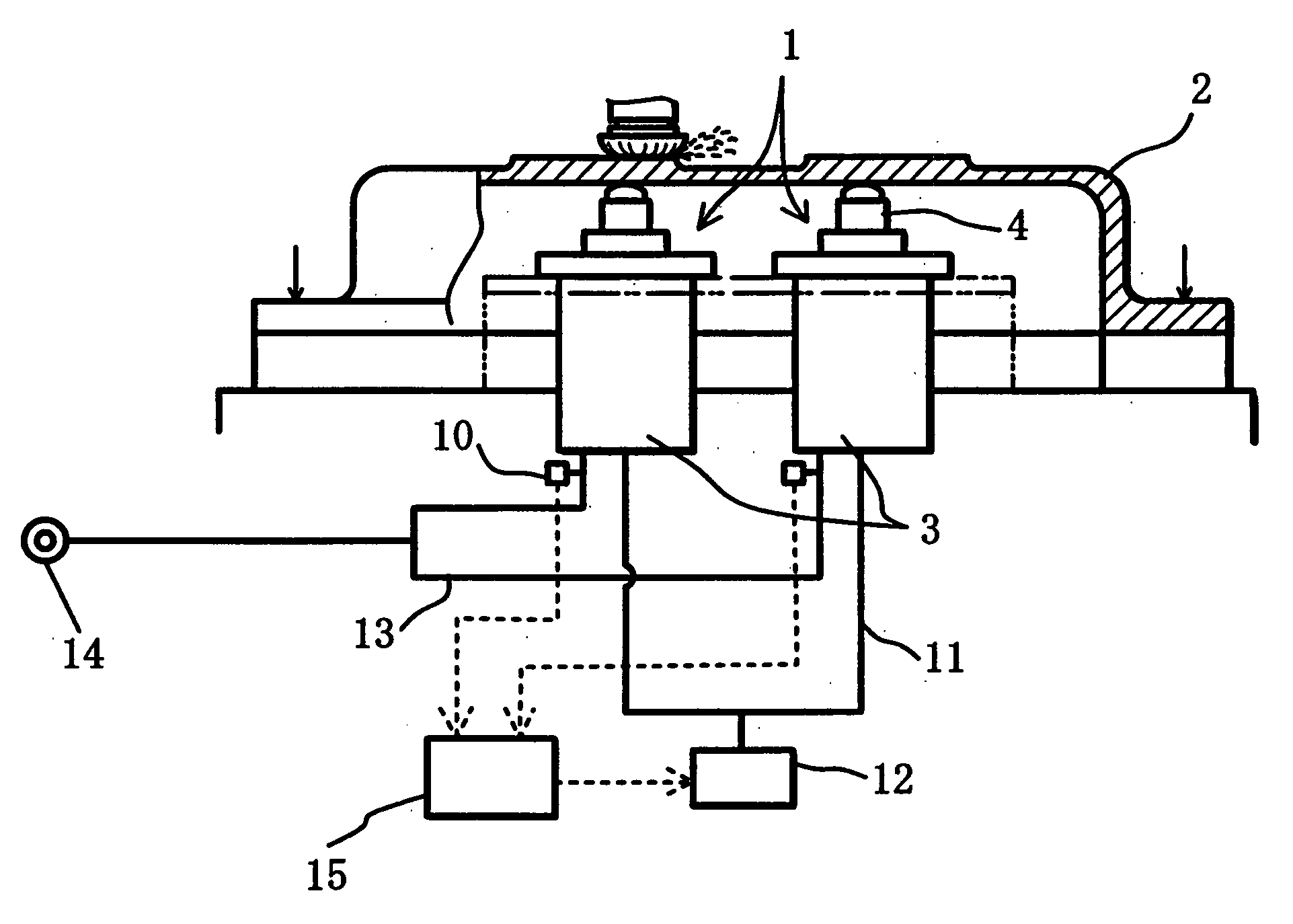

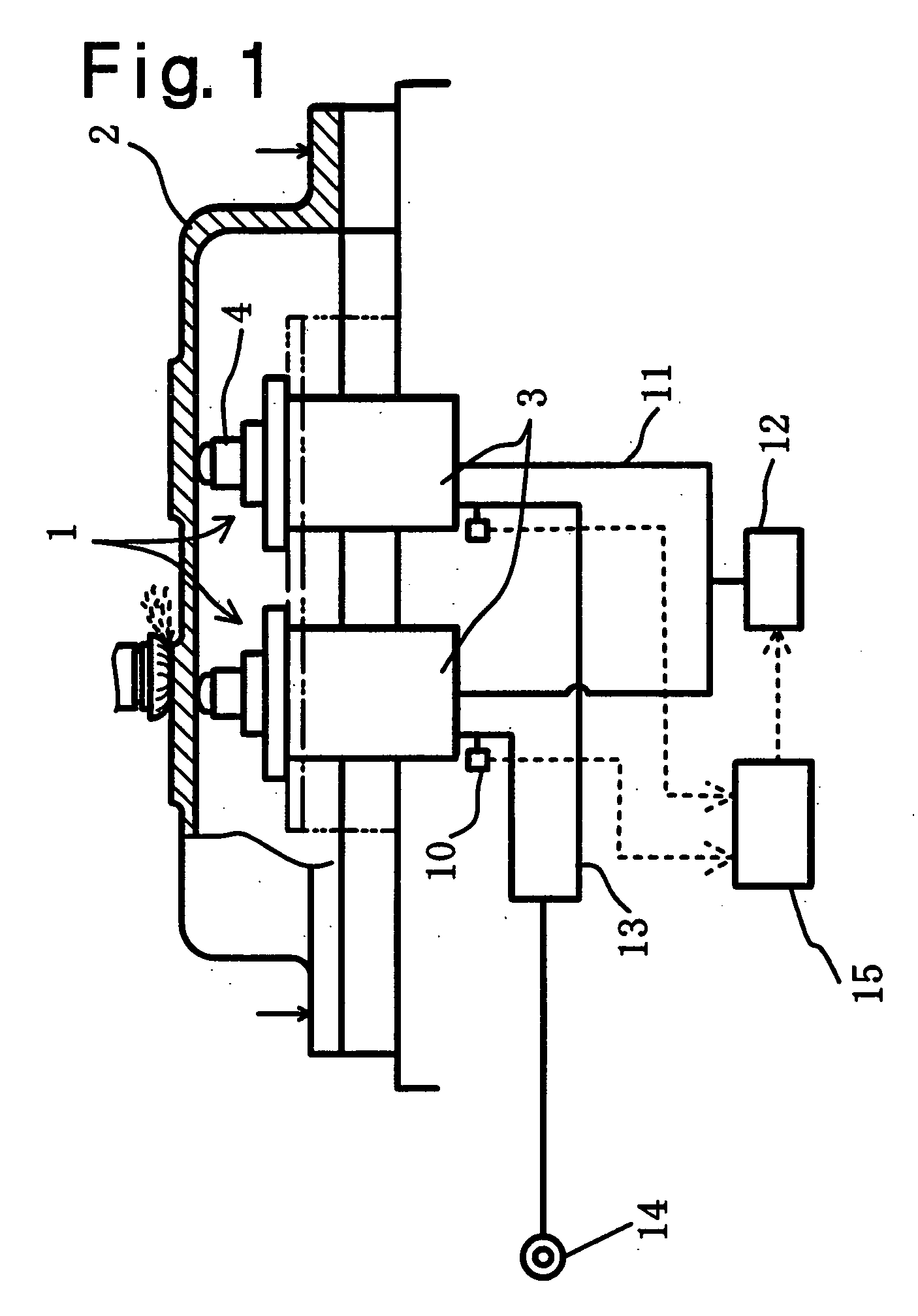

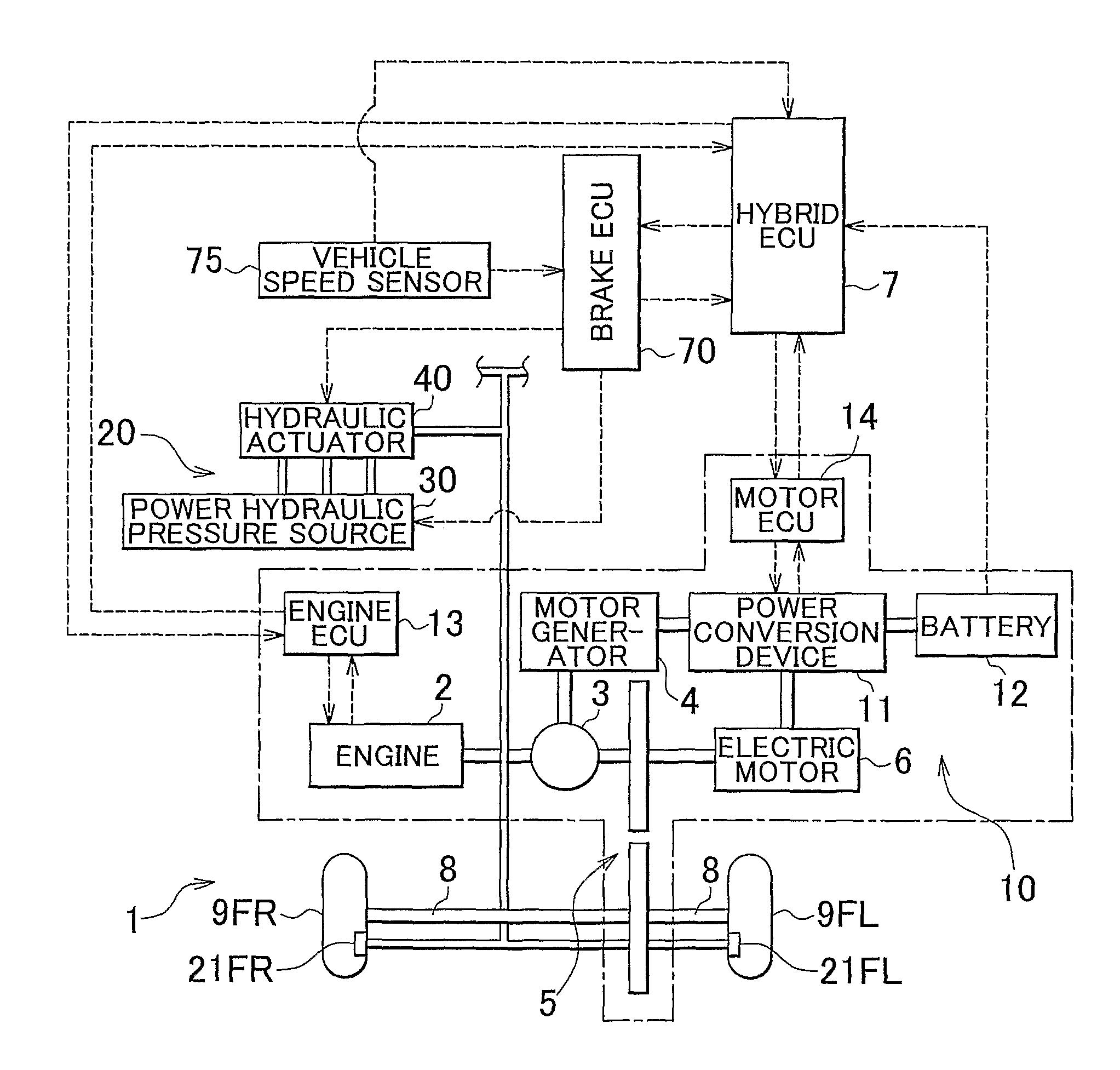

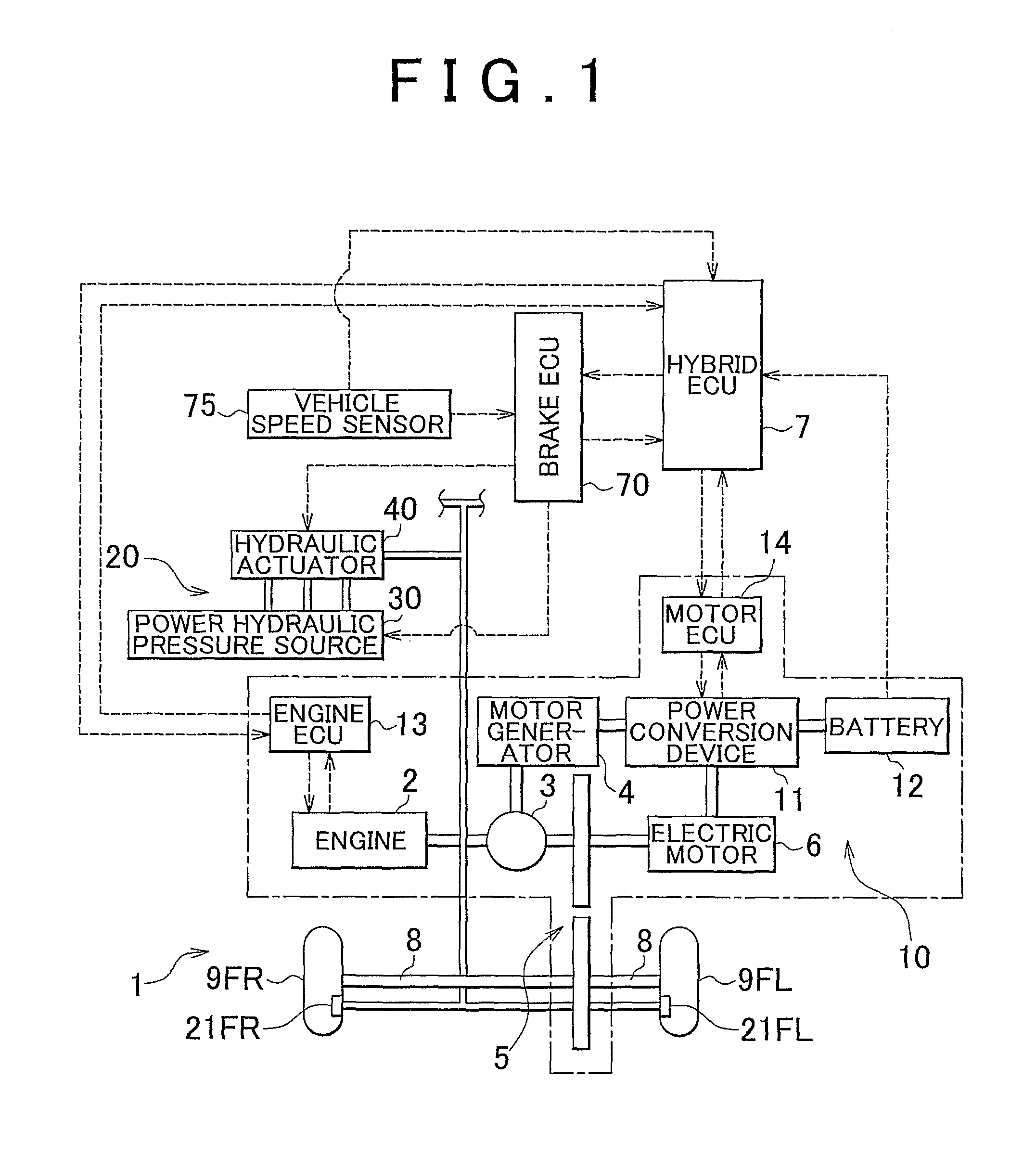

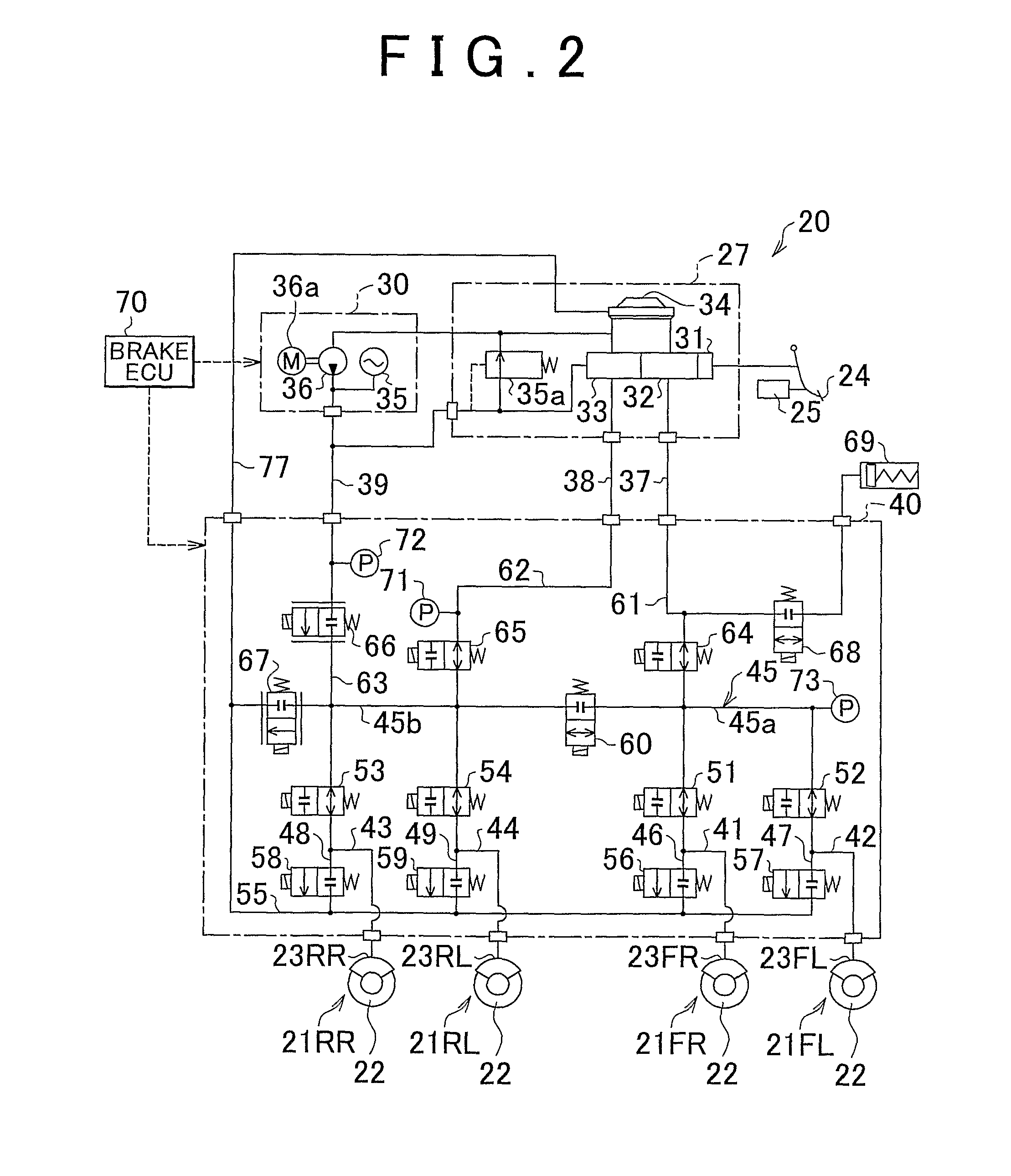

Brake system for hybrid electric vehicle and control method thereof

InactiveUS20080210497A1Reduce hydraulic pressureHybrid vehiclesMechanically actuated brakesDrive motorEngineering

The present invention provides a brake system and its control method for a hybrid electric vehicle, comprising a driving motor generating a regenerative braking torque; a hydraulic pressure supplying unit including a brake pedal, a booster and a master cylinder, a first hydraulic line, and a reservoir; a hydraulic brake adjuster for controlling a hydraulic braking pressure; a target braking force detection unit, including a pedal stroke sensor and a hydraulic pressure sensor, for detecting a target braking torque of a driver; and a control unit controlling the driving motor by calculating a maximum regenerative braking torque based on a rotational speed of the driving motor, etc. and controlling the hydraulic brake adjuster to change a hydraulic braking torque to meet the target braking torque in accordance with the thus calculated maximum regenerative braking torque by compensating an braking torque with the hydraulic braking torque.

Owner:HYUNDAI MOTOR CO LTD

Hydraulic controller for hydraulic actuator

ActiveUS20050143224A1Prevent excessive increase in frequencyReduce energy consumptionFluid couplingsPropulsion using engine-driven generatorsEngineeringEnergy expenditure

A hydraulic controller for a hydraulic actuator (6) incorporated in a power transmission mechanism, wherein an accumulator (16) is connected to an oil supply passage (14) for the hydraulic actuator (6) for supplying oil from a pump (10) via a regulator (11) and a one-way valve (12) and a lubricating oil passage (20) for the power transmission mechanism is connected to the regulator 11 in the drain side thereof, by which energy consumption can be reduced maximally even if the pump (10) is regularly driven for lubrication. It is provided with a hydraulic pressure switching means (19) capable of freely switching a setting pressure of the regulator (11) between a high pressure and a low pressure. While the hydraulic pressure of the oil supply passage (14) is higher than or equal to a pressure at which the hydraulic actuator (6) can be operated, the controller maintains the setting pressure of the regulator (11) at the low pressure to reduce a work load of the pump 10.

Owner:HONDA MOTOR CO LTD

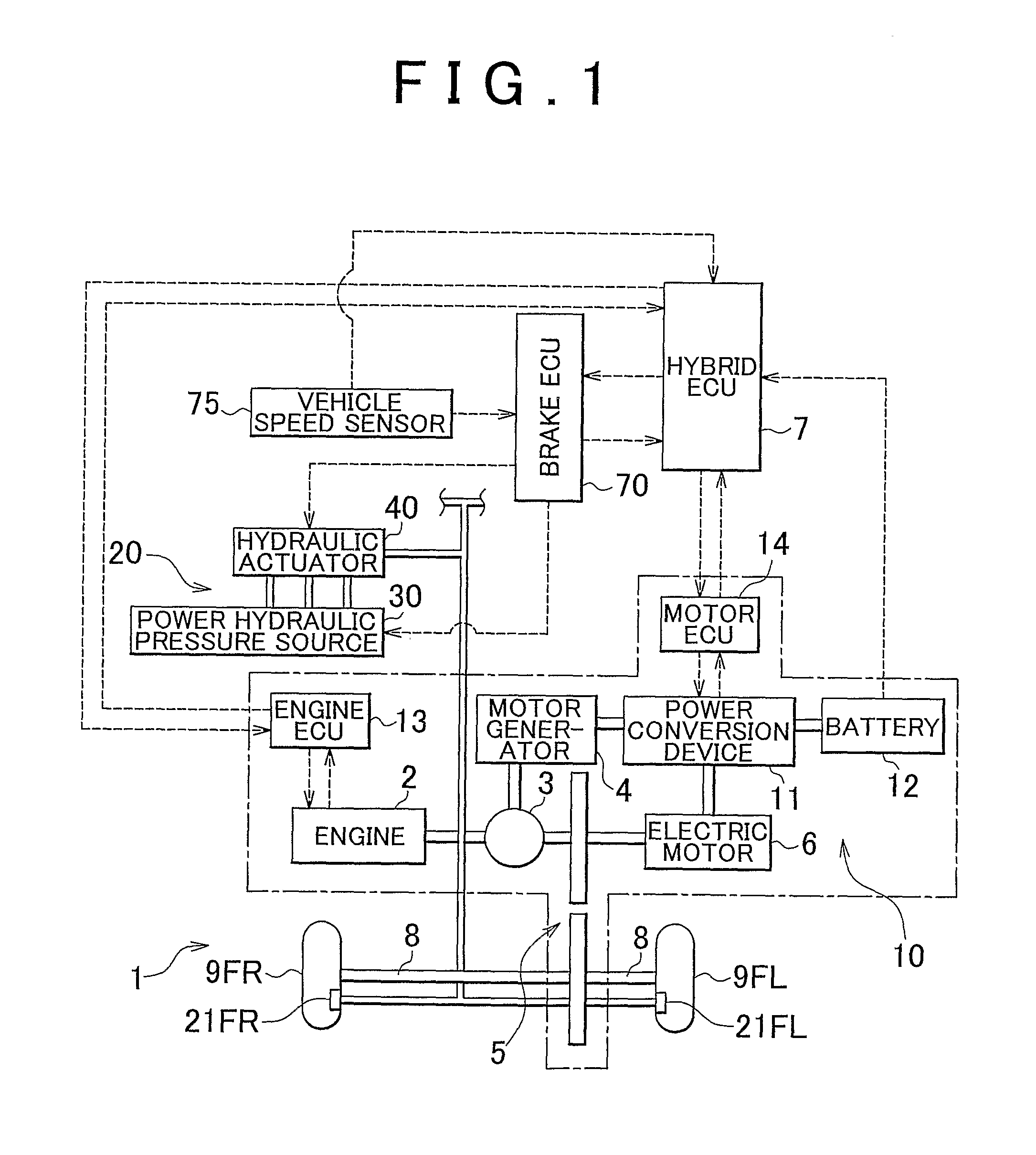

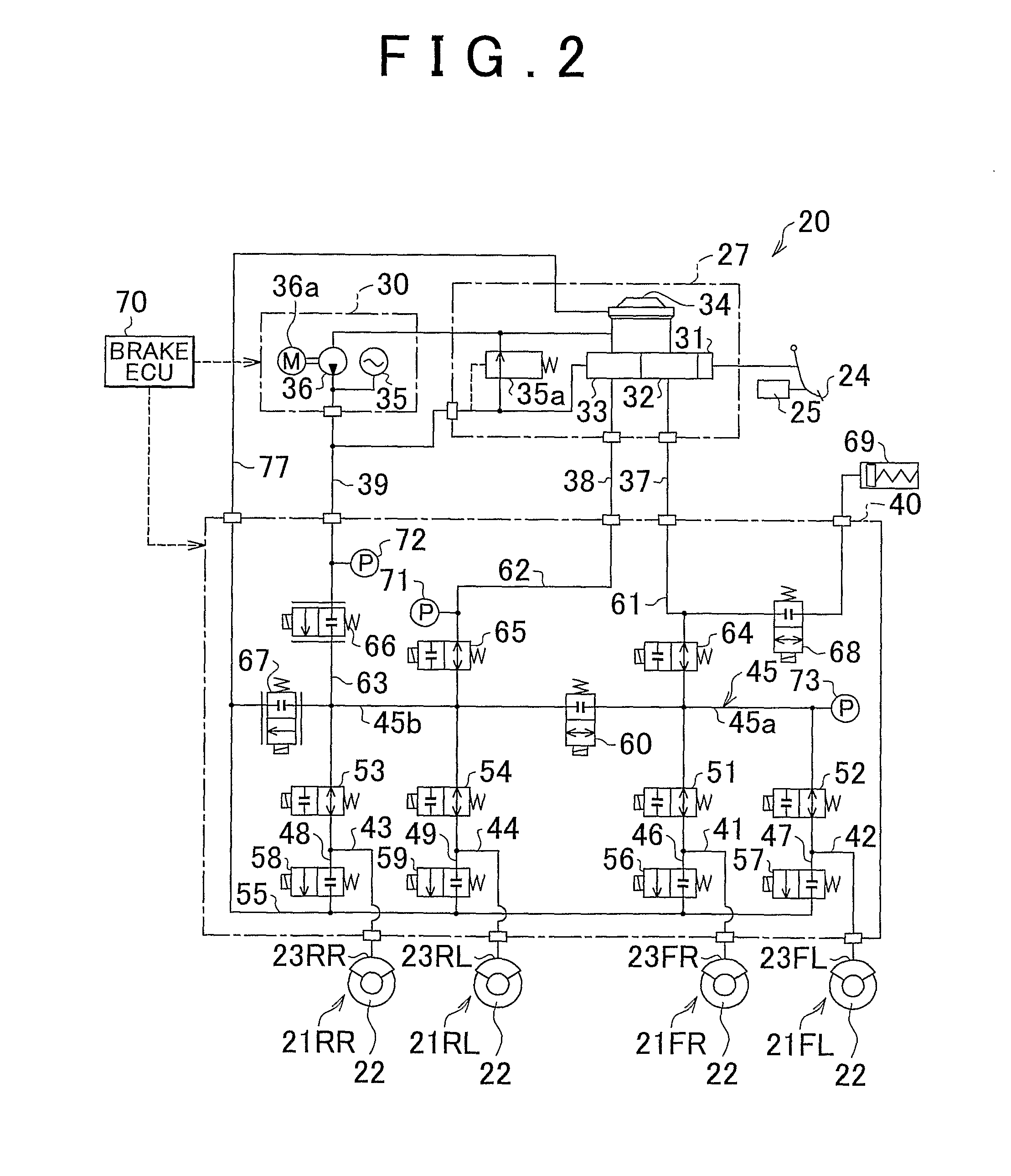

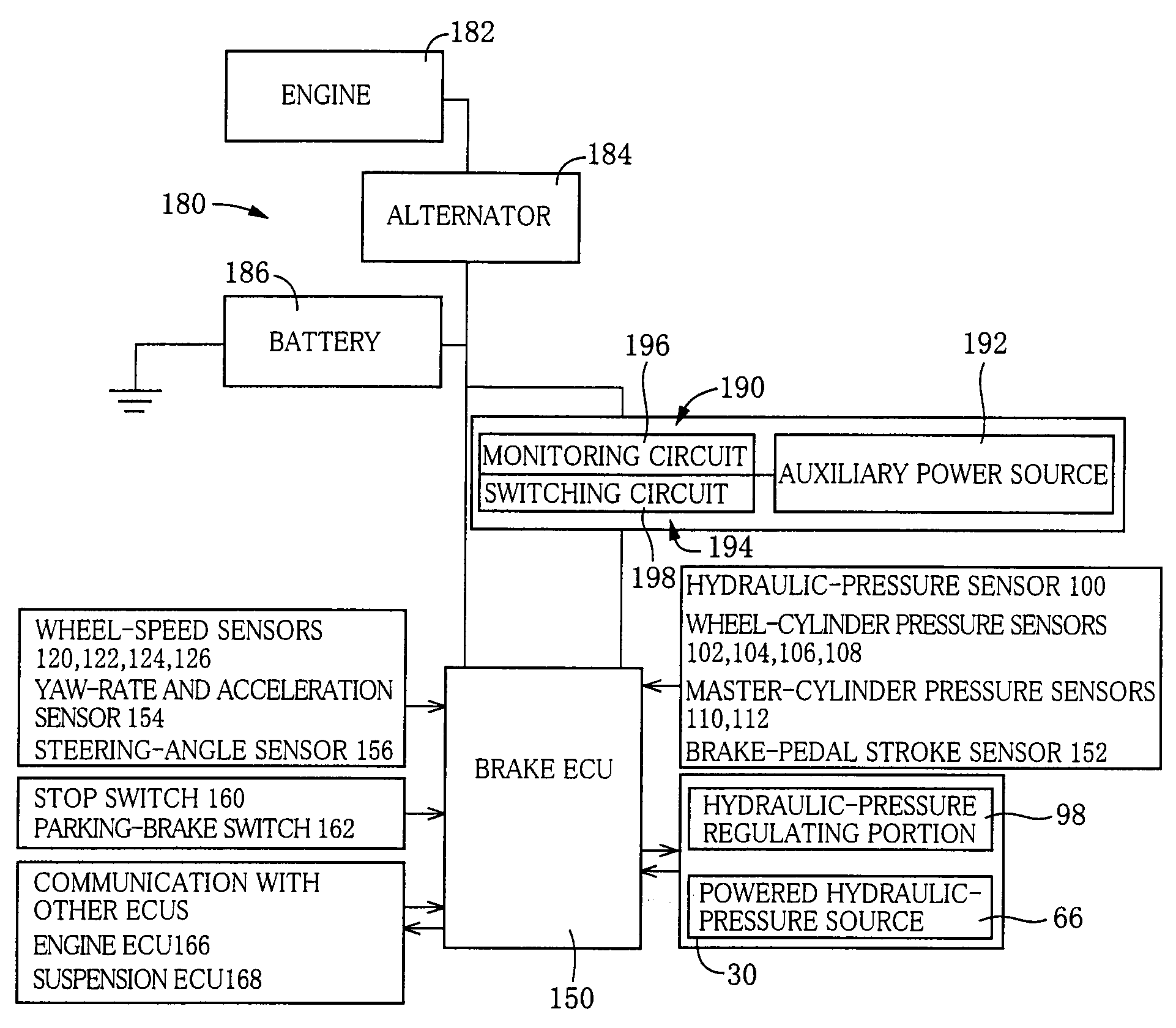

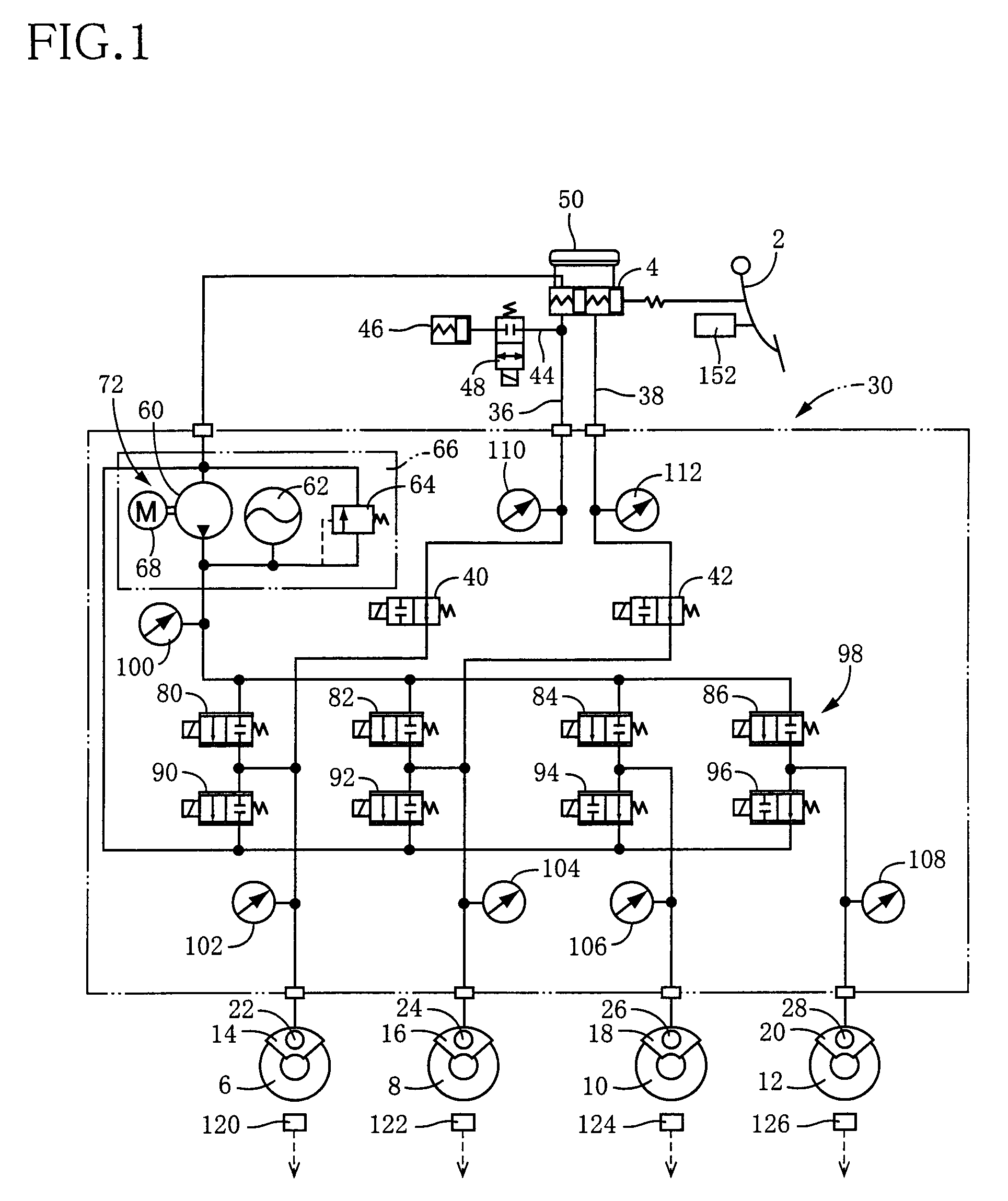

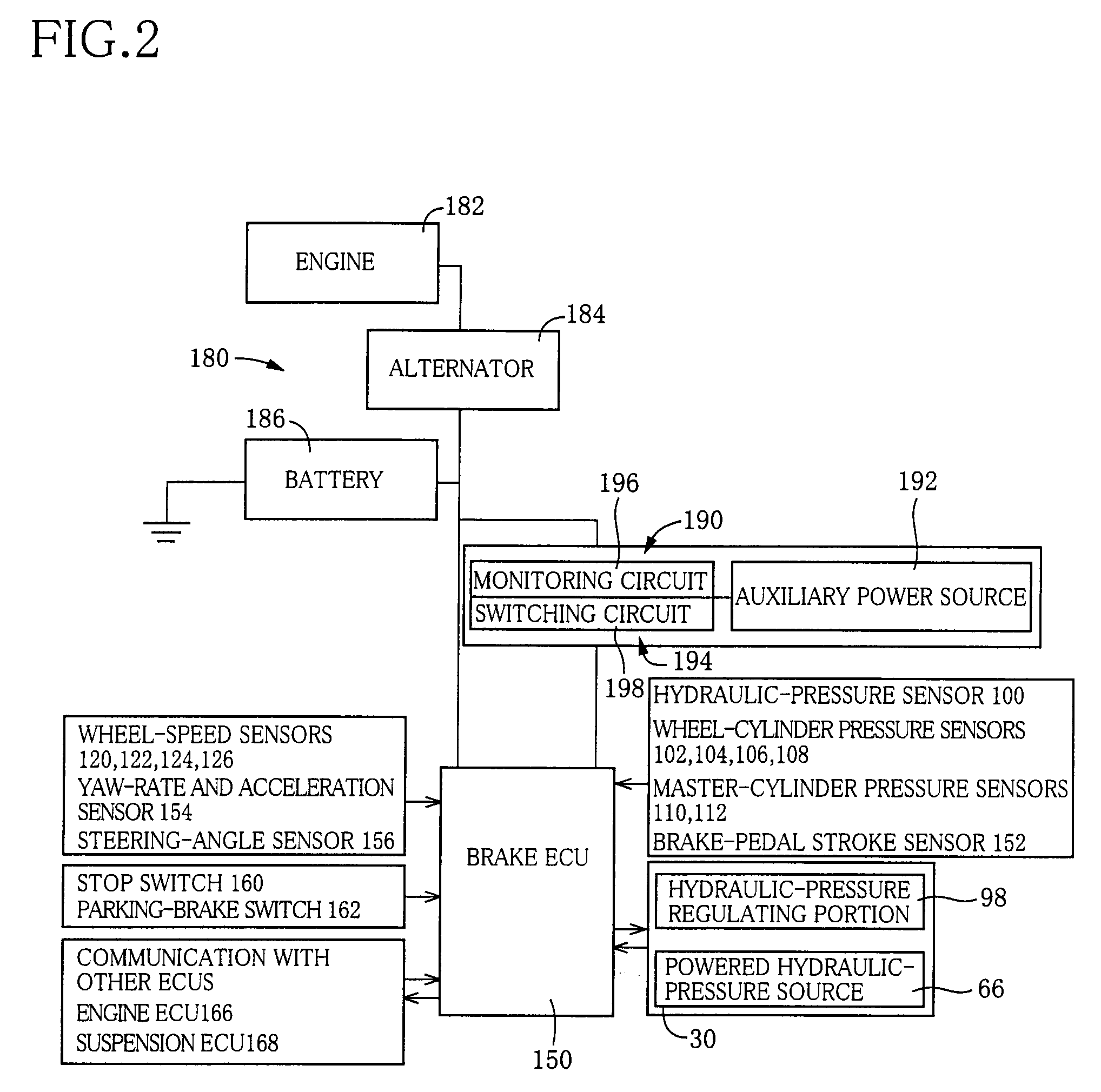

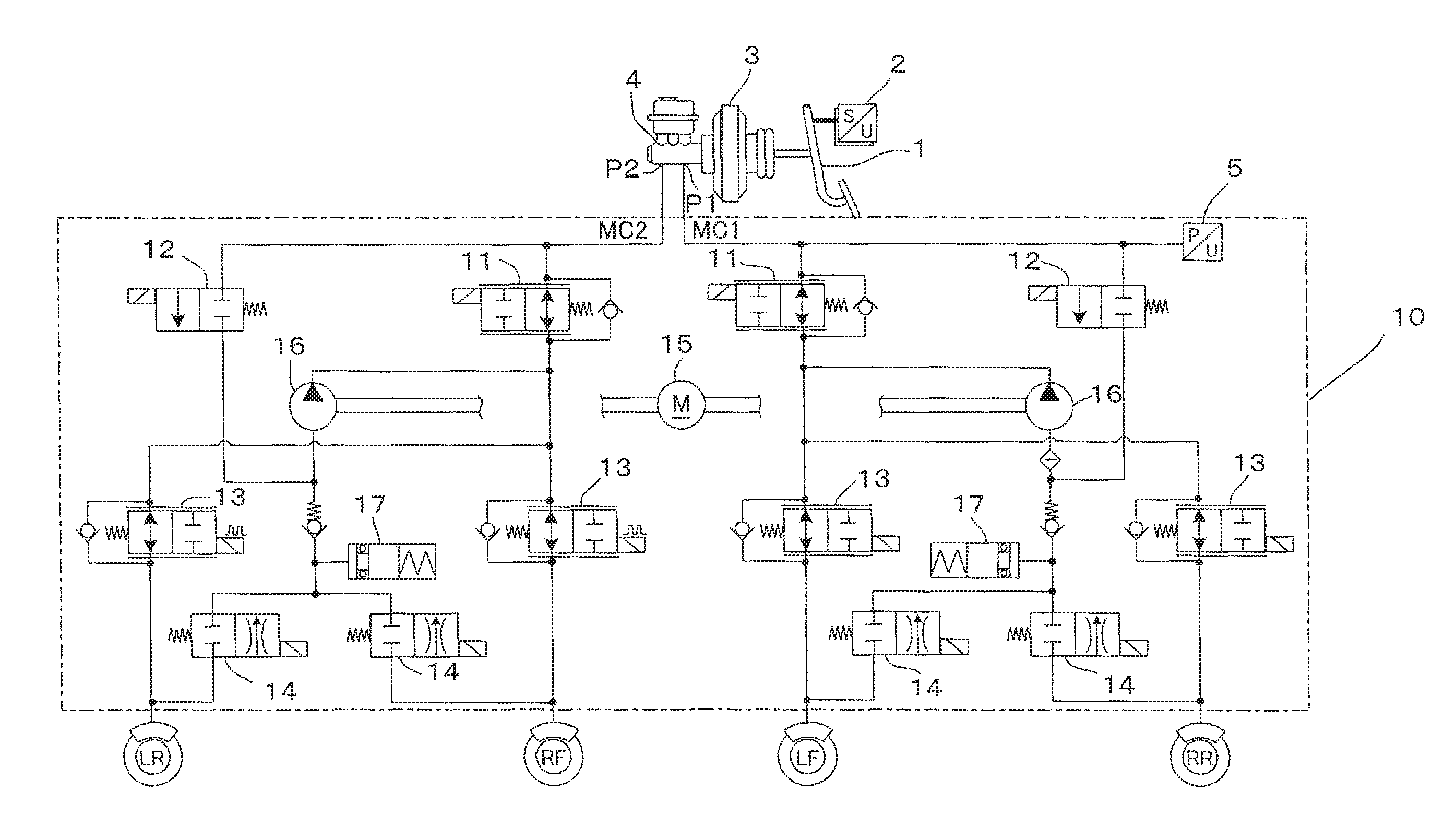

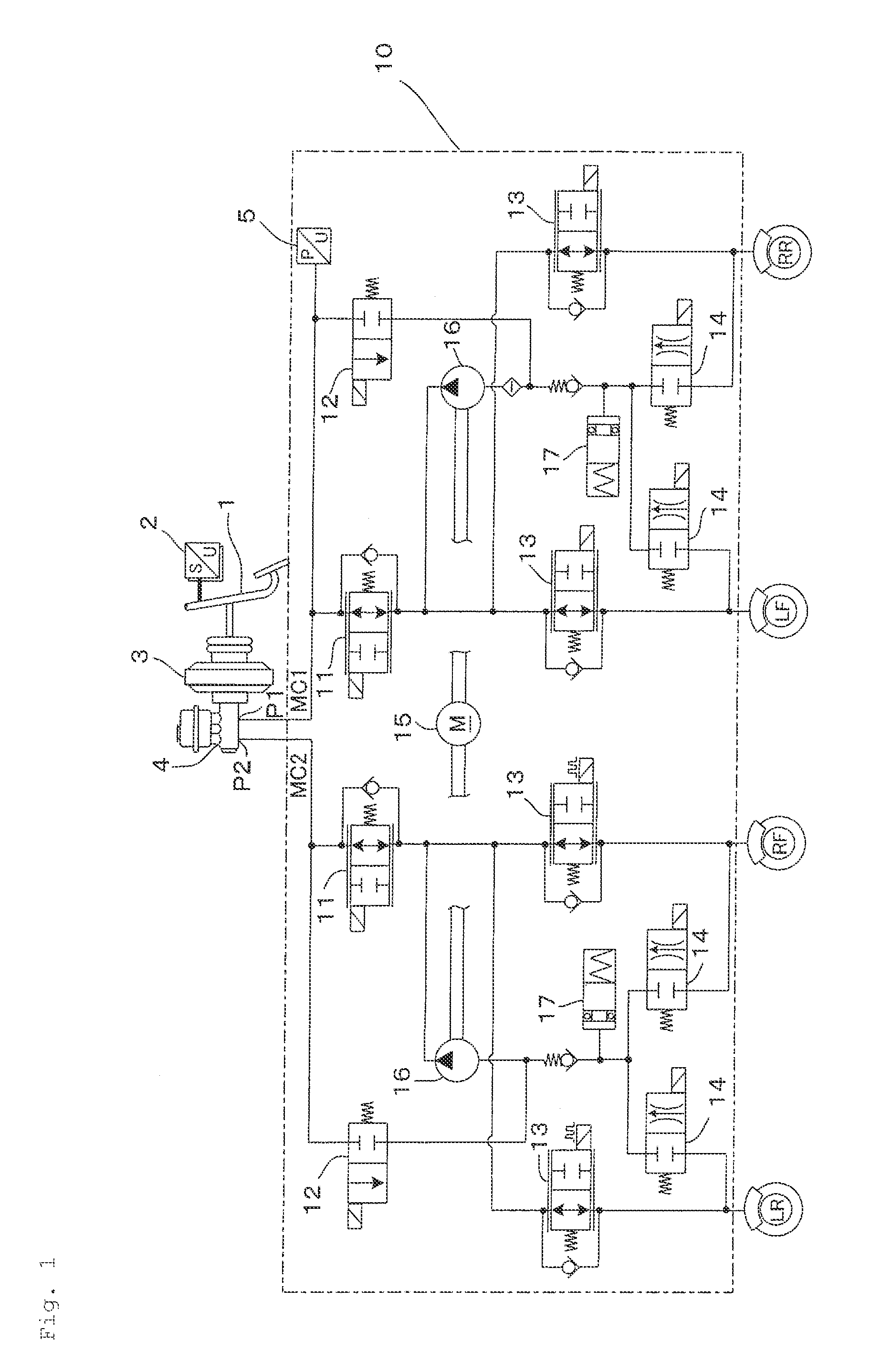

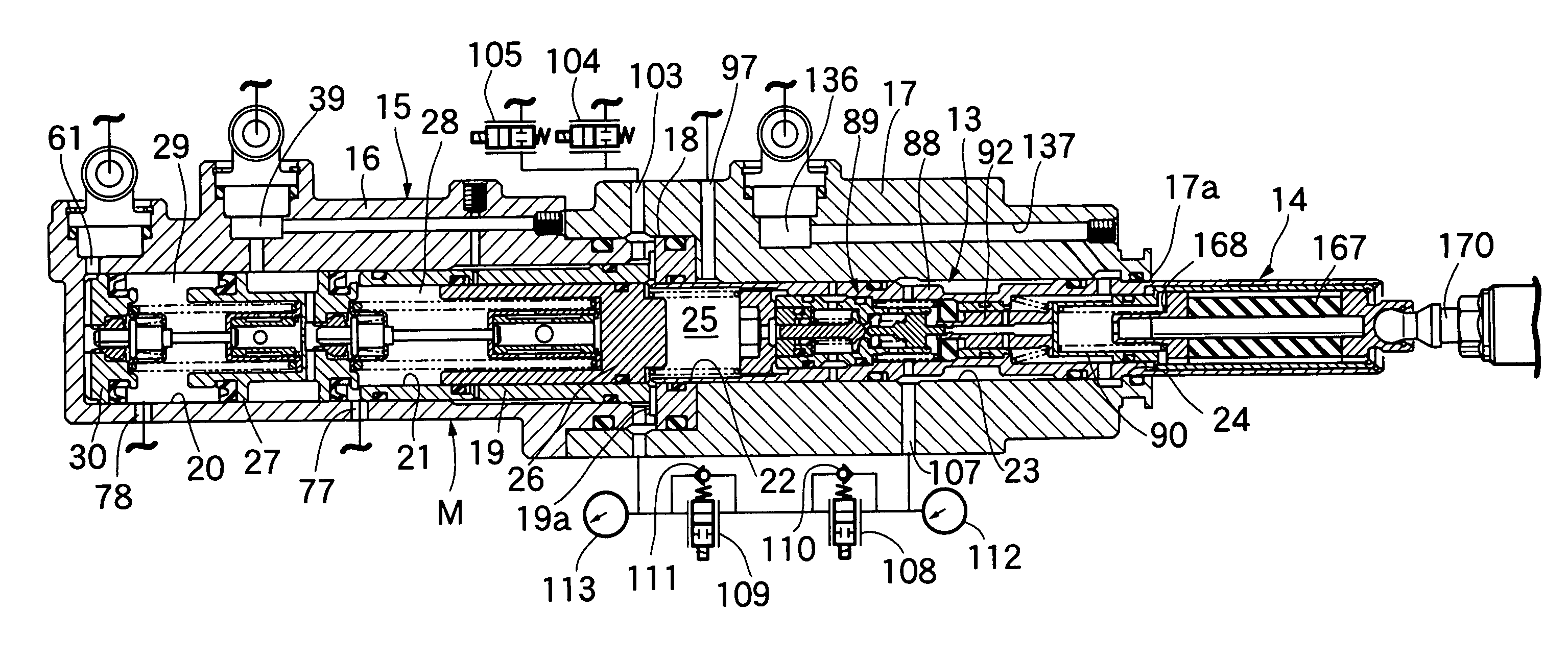

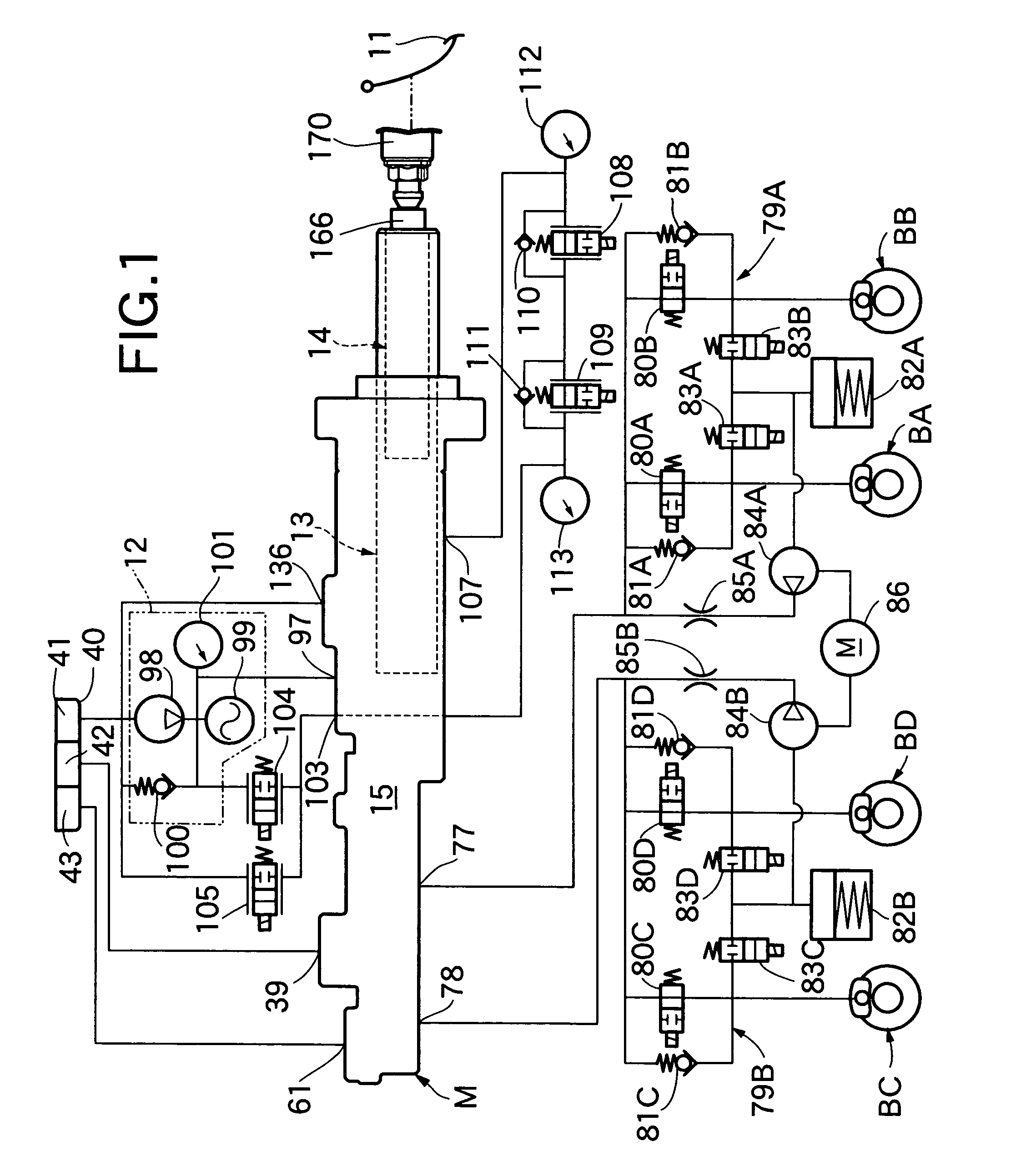

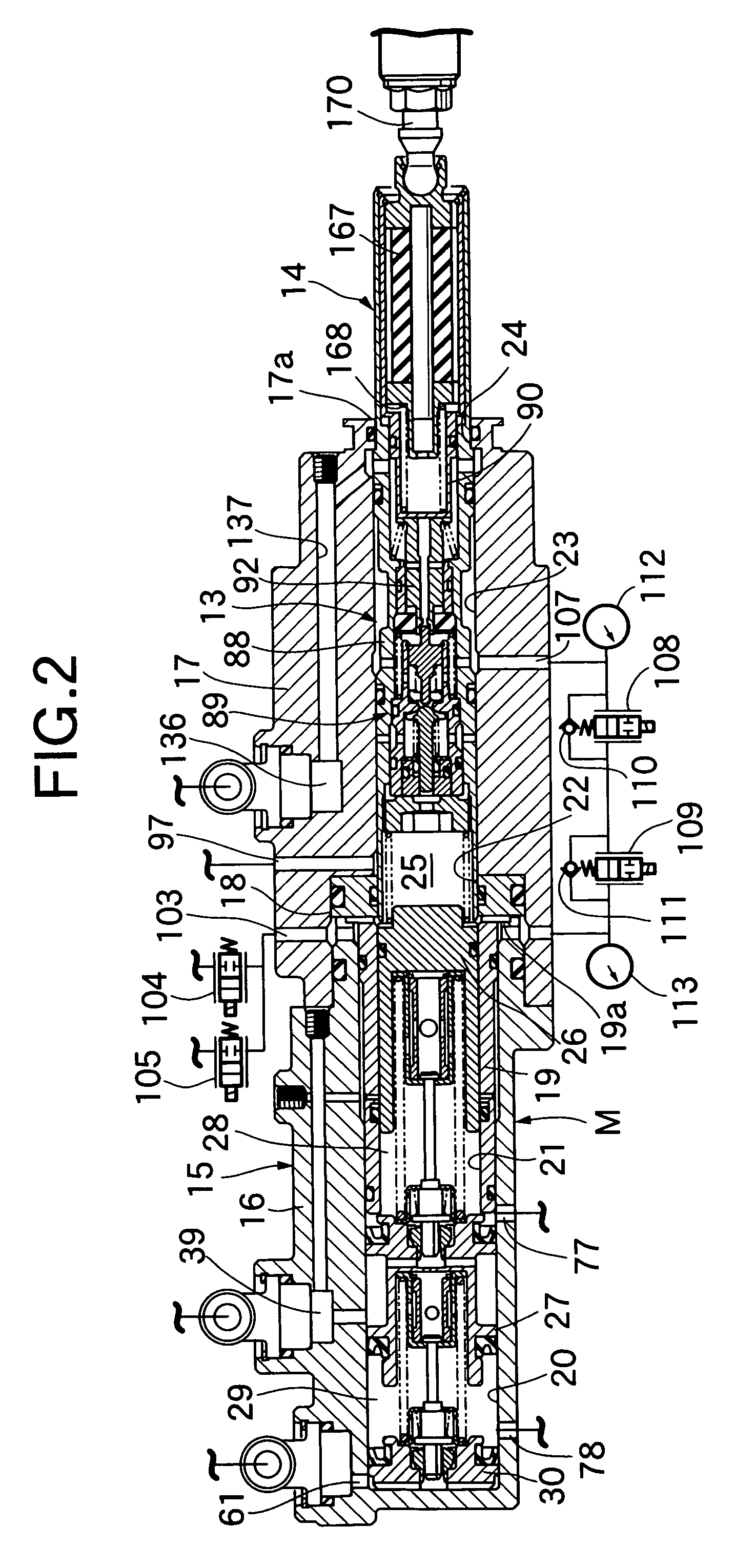

Brake apparatus, brake control unit, and brake control method

ActiveUS20110285198A1InhibitionReduce hydraulic pressureHybrid vehiclesBraking element arrangementsEngineeringBrake control

There is provide a brake control technology according to which a target hydraulic pressure is reliably achieved when a hydraulic pressure is decreased during hydraulic control and brake drag does not occur even when the target hydraulic pressure is zero. In a brake apparatus, a dead-band region is set for the target hydraulic pressure that is used in the hydraulic control. When braking control is switched from the hydraulic control to regenerative control in cooperative braking control, residual pressure reduction control is executed. In the residual pressure reduction control, the target hydraulic pressure is set to a value that is lower than zero to which the hydraulic pressure should be brought.

Owner:TOYOTA JIDOSHA KK

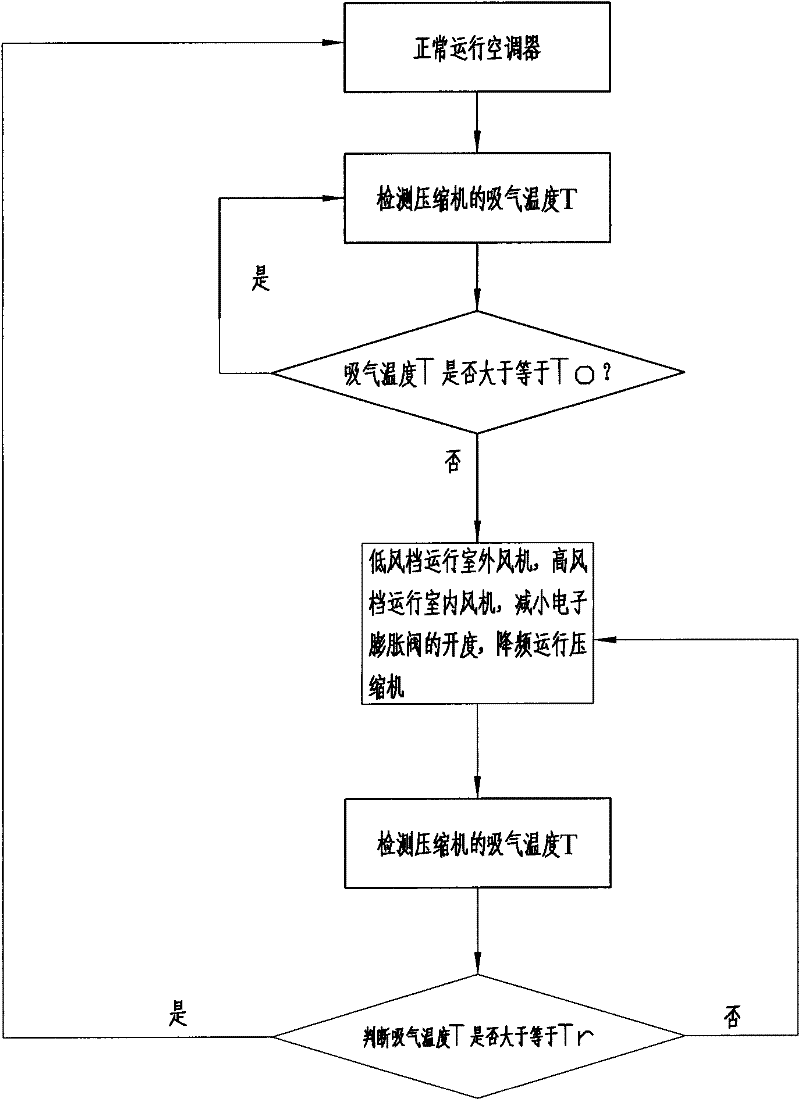

Control method for protection of compressor during refrigeration cycle of direct-current frequency-conversion air conditioner

InactiveCN102331067AReduce condensationGaseousSpace heating and ventilation safety systemsLighting and heating apparatusFrequency conversionRefrigeration

The invention discloses a control method for the protection of a compressor during the refrigeration cycle of a direct-current frequency-conversion air conditioner, comprising the following steps of: a, normally running the air conditioner; b, detecting a suction temperature T of a suction inlet of the compressor; c, judging whether the suction temperature T is equal to or greater than To; if so, returning to the step b; and if not, turning to the next step; d, running an outdoor fan in a low wind shift, running an indoor fan in a high wind shift, reducing the opening degree of an electronic expansion valve, and running the compressor with a reduced frequency; e, repeating the step b; and f, judging whether the suction temperature T is equal to or greater than Tr; if so, returning to the step a; and if not, returning to the step d. Through the control method, the compressor can be prevented from being slugged at low temperature.

Owner:NINGBO AUX ELECTRIC

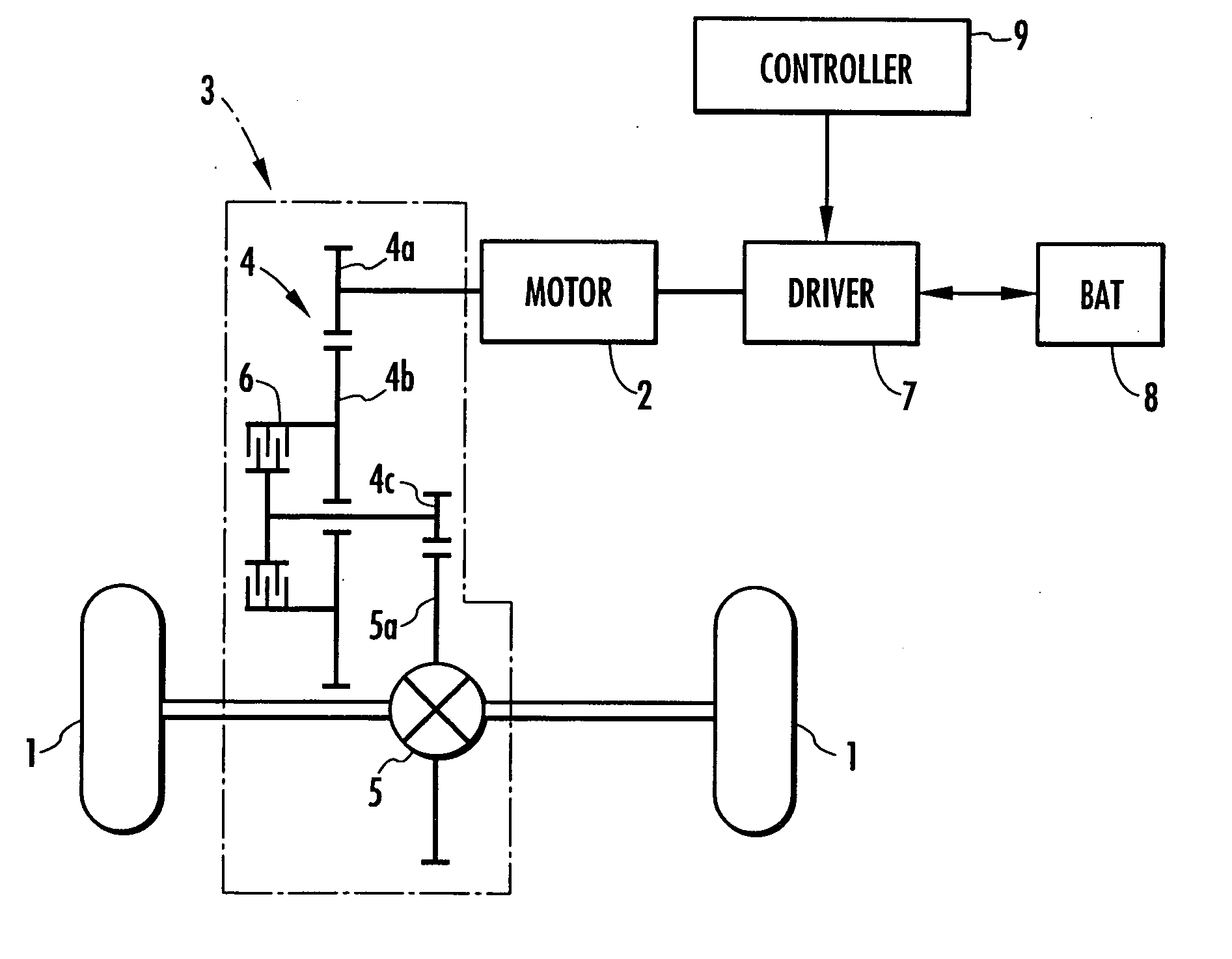

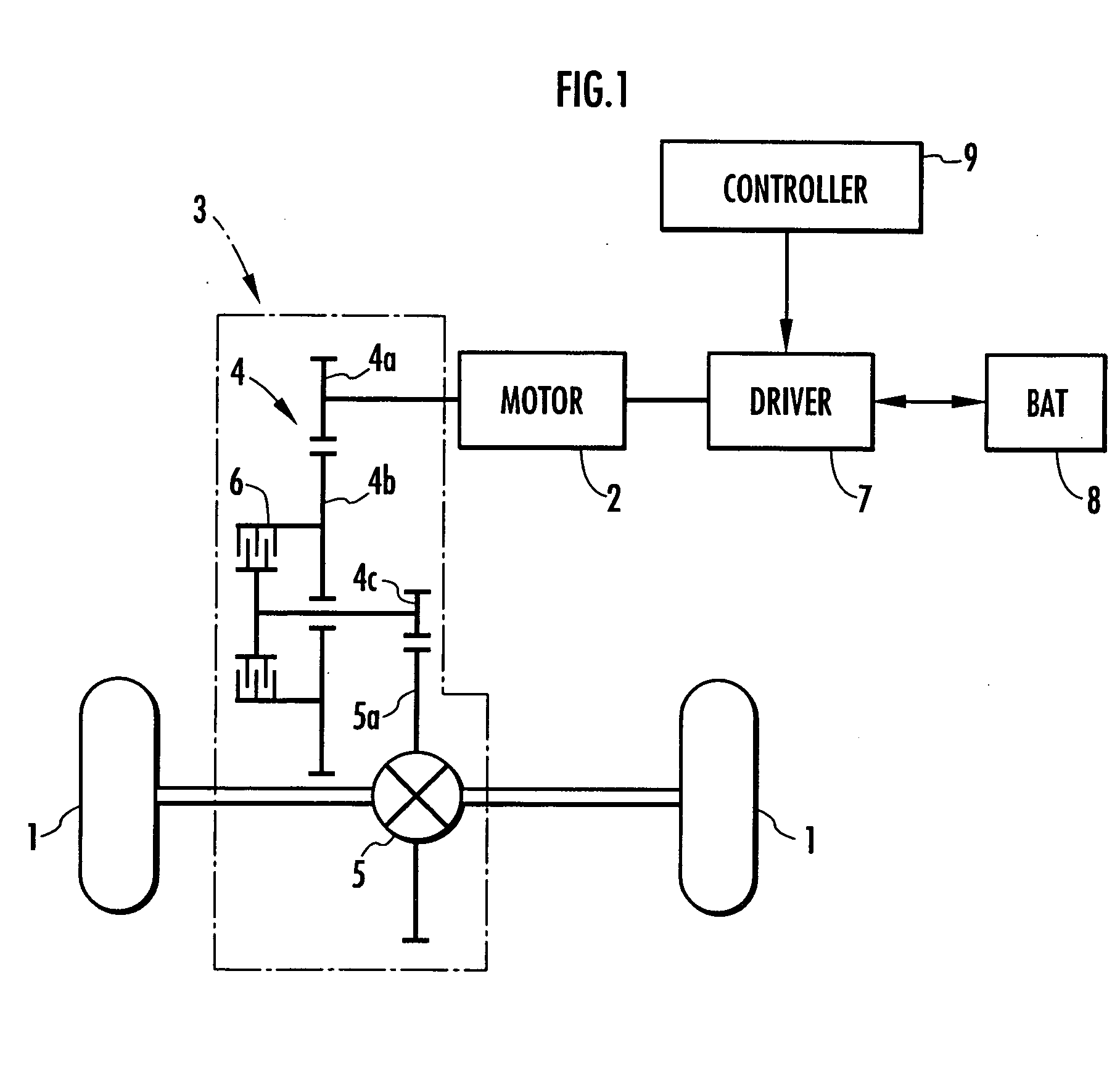

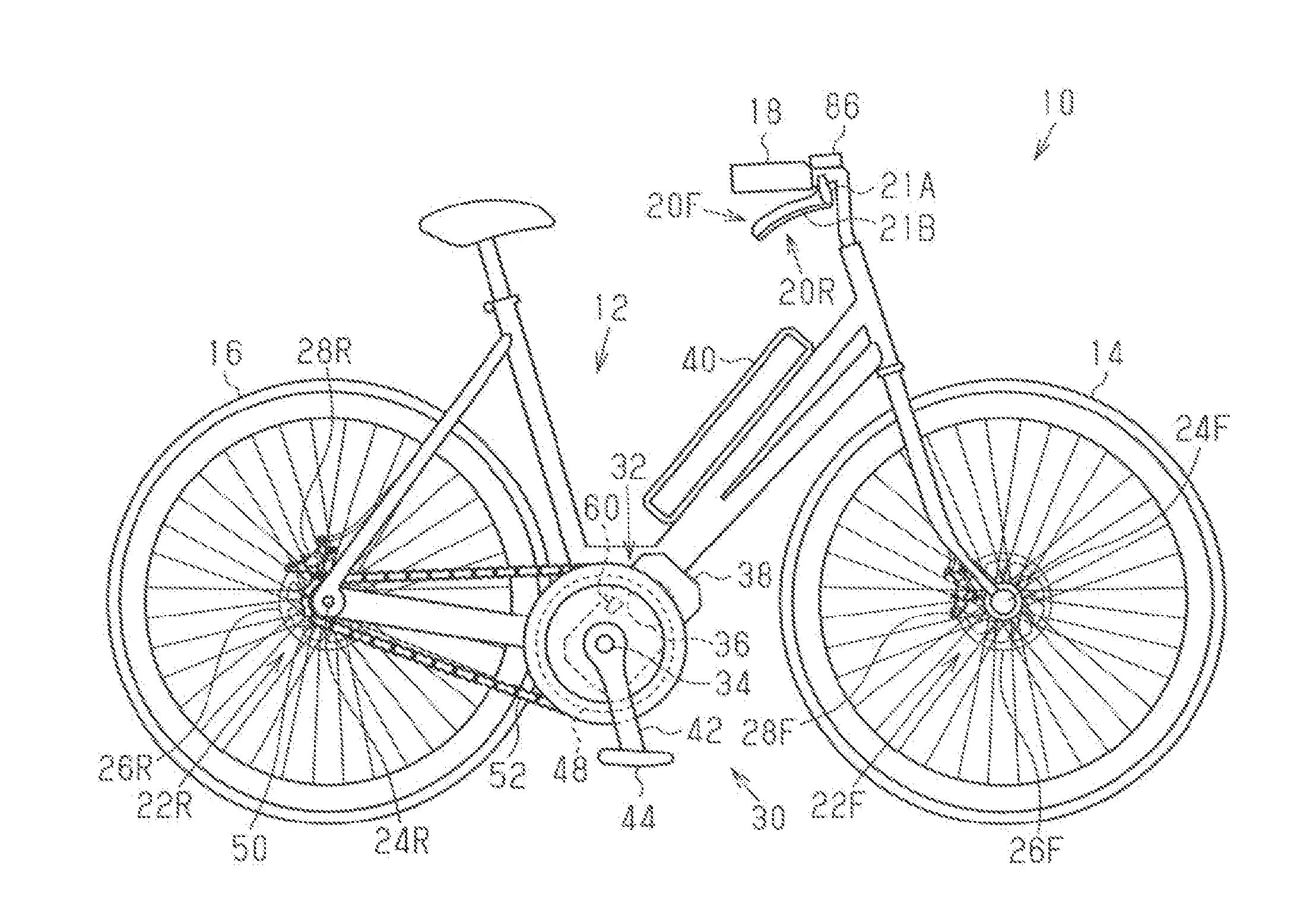

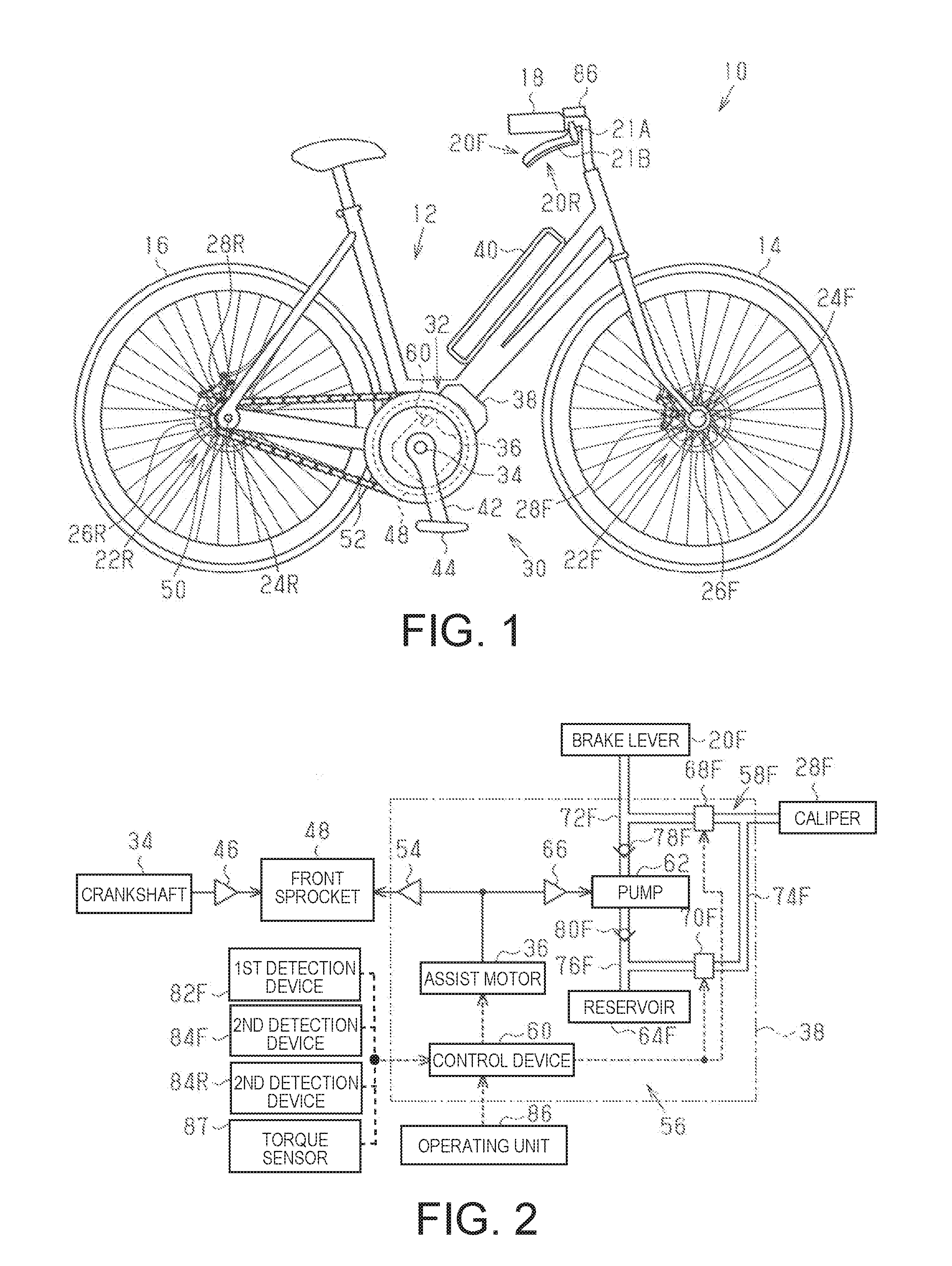

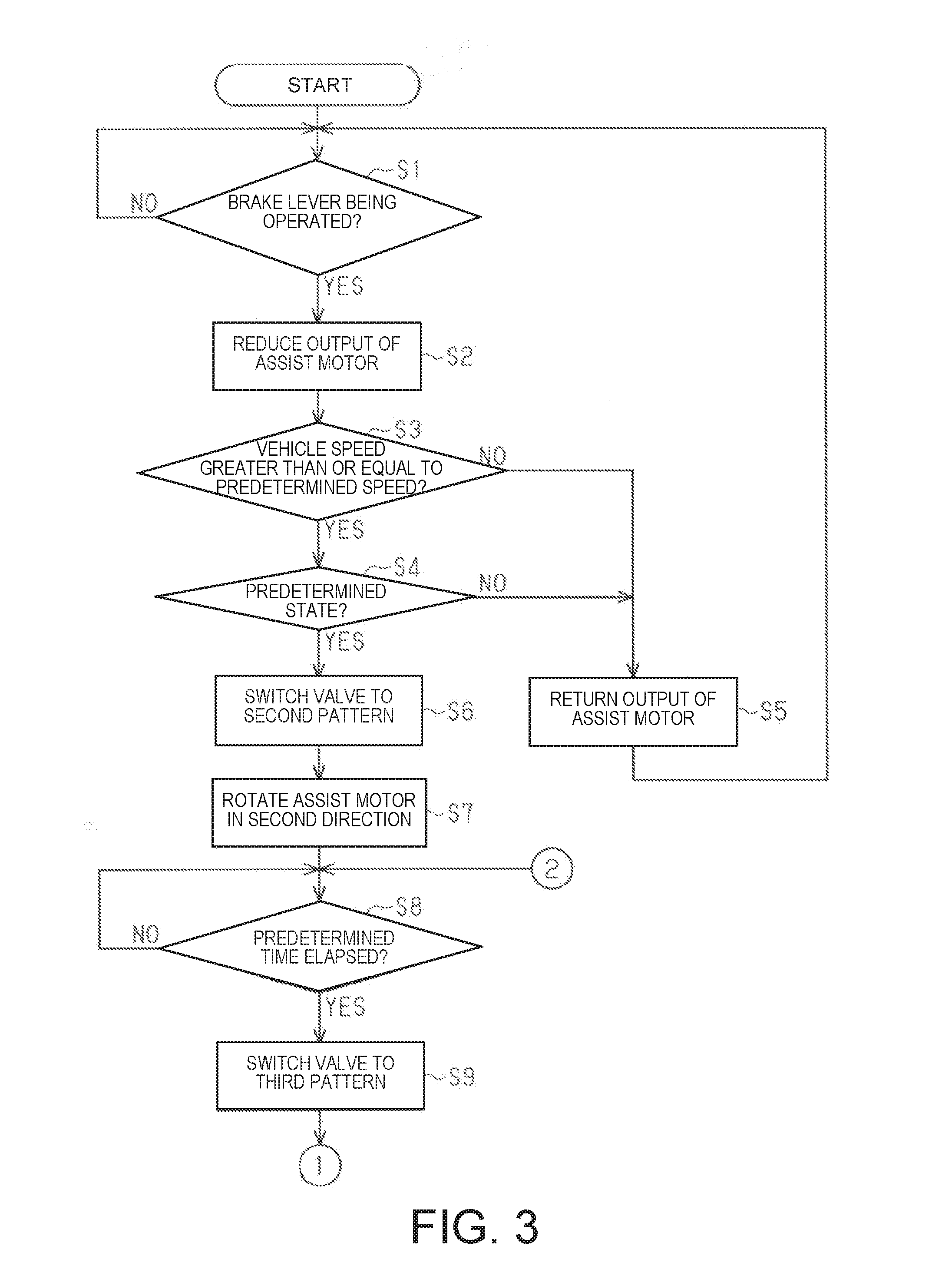

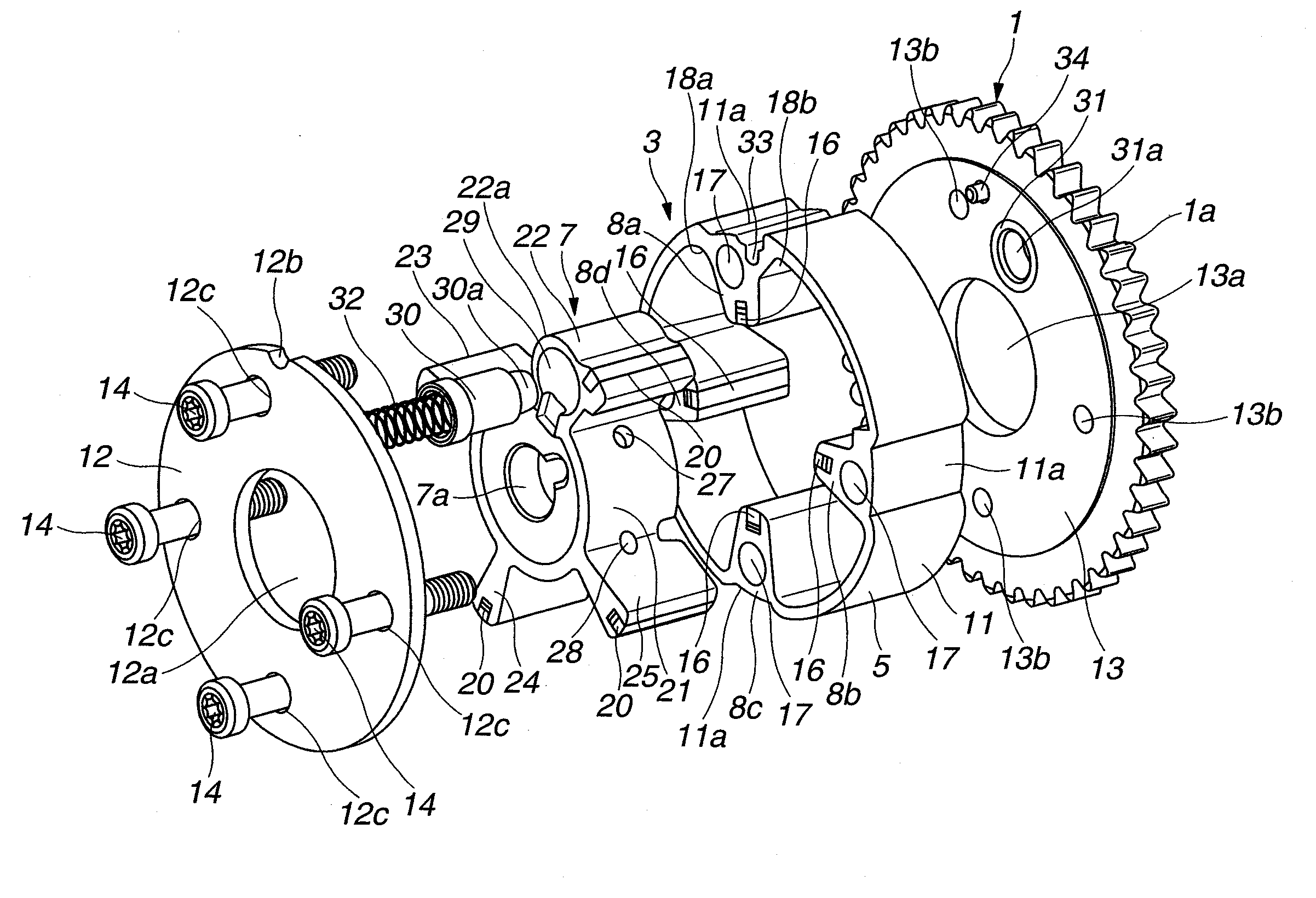

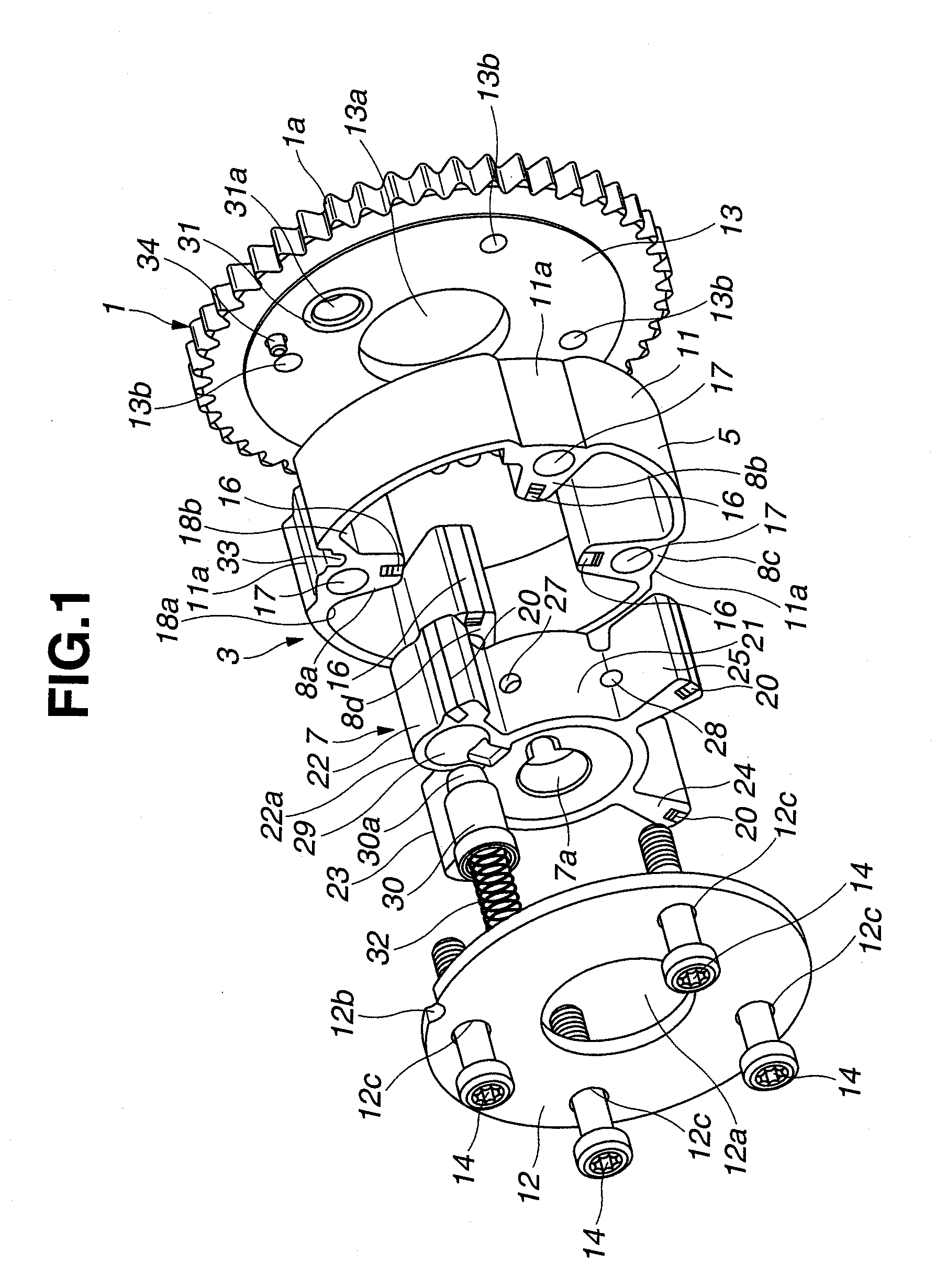

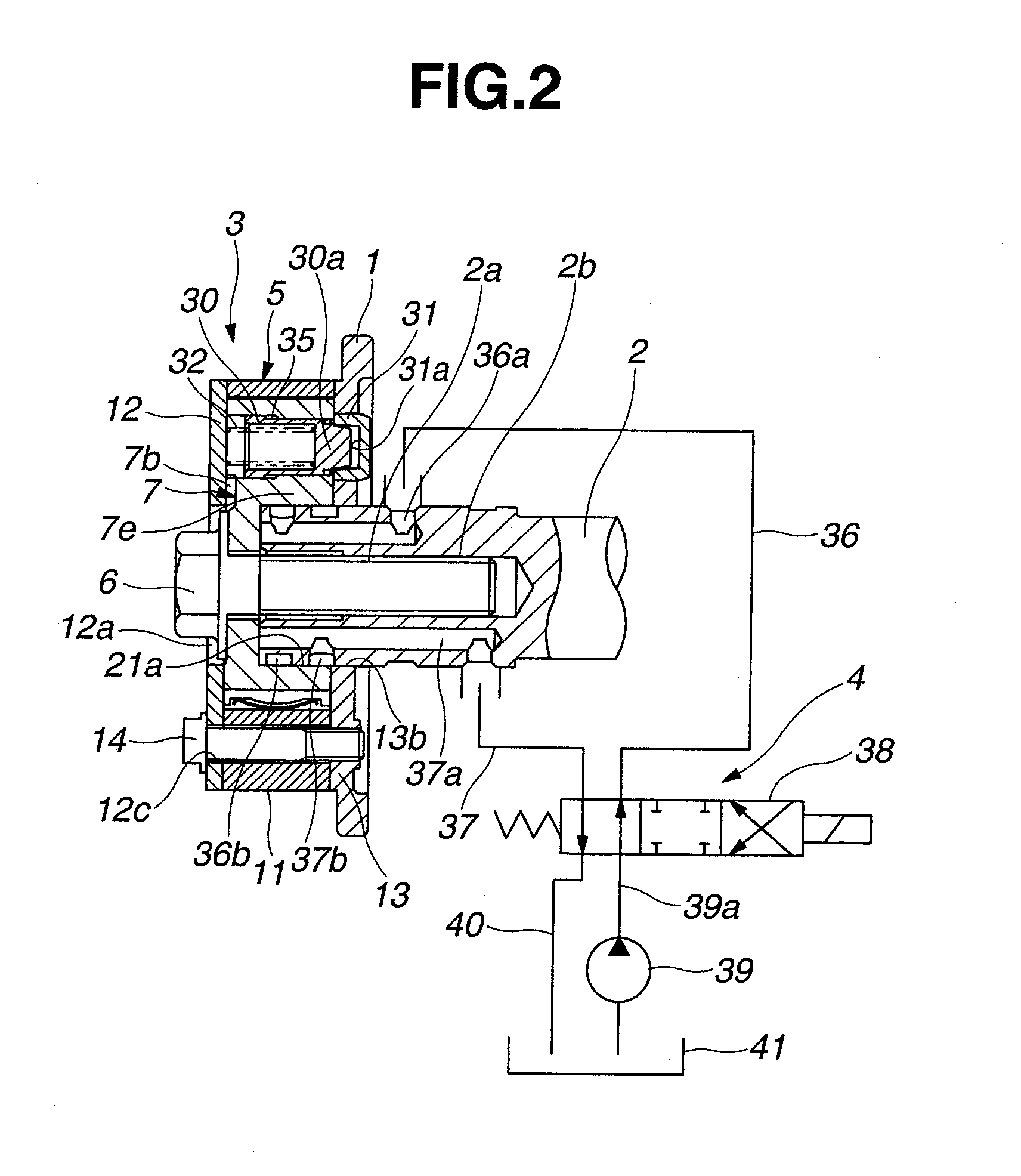

Bicycle apparatus

ActiveUS20160318575A1Reduce outputReduce hydraulic pressureCycle brakesElectric energy managementEngineeringCrankshaft

A bicycle apparatus is basically provided with an ABS unit which is driven by an assist motor which adds an assisting force to a manual drive force inputted from a crankshaft of a bicycle, and which controls a braking force that is applied to a wheel of the bicycle.

Owner:SHIMANO INC

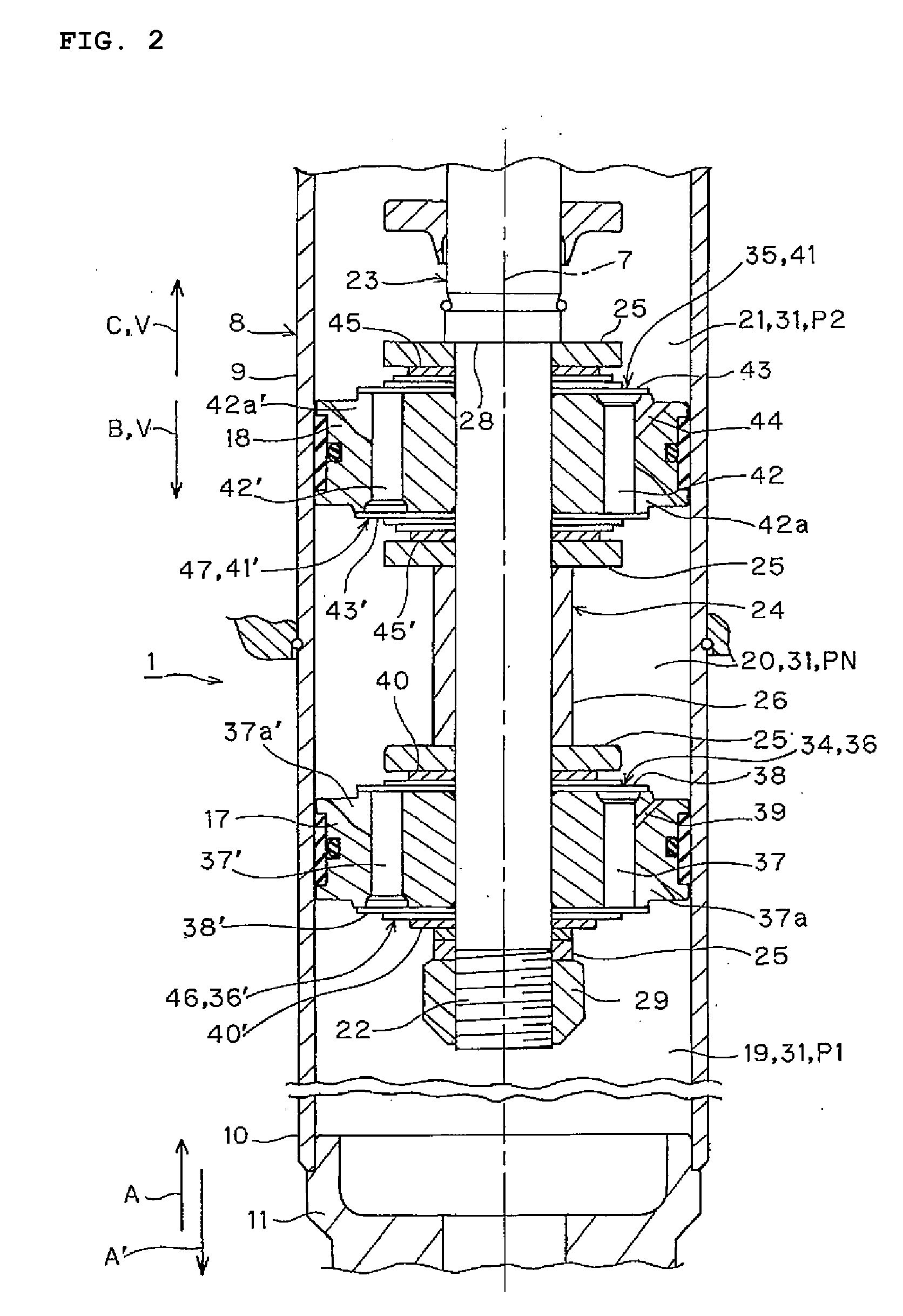

Variable valve timing control apparatus of internal combustion engine

InactiveUS20120285407A1Increase the number ofReduce hydraulic pressureValve arrangementsMachines/enginesWorking fluidVariable valve timing

A variable valve timing control apparatus of an internal combustion engine, has a housing having a plurality of shoes and a vane member having a plurality of vanes dividing each working fluid chamber formed between adjacent two shoes into advance and retard oil chambers. The vane member rotates to an advanced angle side and to a retarded angle side relative to the housing by selectively supplying or exhausting hydraulic pressure in or from the advance oil chamber and the retard oil chamber. A most-advanced angle position and a most-retarded angle position are limited by the fact that one vane touches one shoe from a circumferential direction. Radius of curvature of one of both corners of a base part of the one shoe, which is a corner located at a side where the one vane does not touch, is set to be greater than those of corners of the other shoes.

Owner:HITACHI AUTOMOTIVE SYST LTD

Brake control apparatus

ActiveUS20080036294A1Operation force is not rapidlyAvoid rapid changesBraking action transmissionDigital data processing detailsWheel speed sensorEngineering

A brake control apparatus for controlling brakes of a vehicle having wheels, the apparatus including a stopped-state detecting portion which detects, based on a speed of at least one of the wheels detected by at least one wheel-speed sensor, a stopped state of the vehicle; an operation-force limiting portion which limits, based on a detection of the stopped state of the vehicle by the stopped-state detecting portion, an operation force of at least one of the brakes, such that an upper limit of the operation force is an intermediate level of an operation-force range used when the stopped state is not detected; a sensor ignoring portion which ignores, when an electric voltage supplied from a power source to the at least one wheel-speed sensor is not higher than a reference value, the at least one wheel-speed sensor; a limitation canceling portion which cancels, when the sensor ignoring portion ignores the at least one wheel-speed sensor, a limitation of the operation force by the operation-force limiting portion; and a rapid-change restraining portion which restrains a rapid change of the operation force caused by a cancellation of the limitation of the operation force by the limitation canceling portion.

Owner:TOYOTA JIDOSHA KK

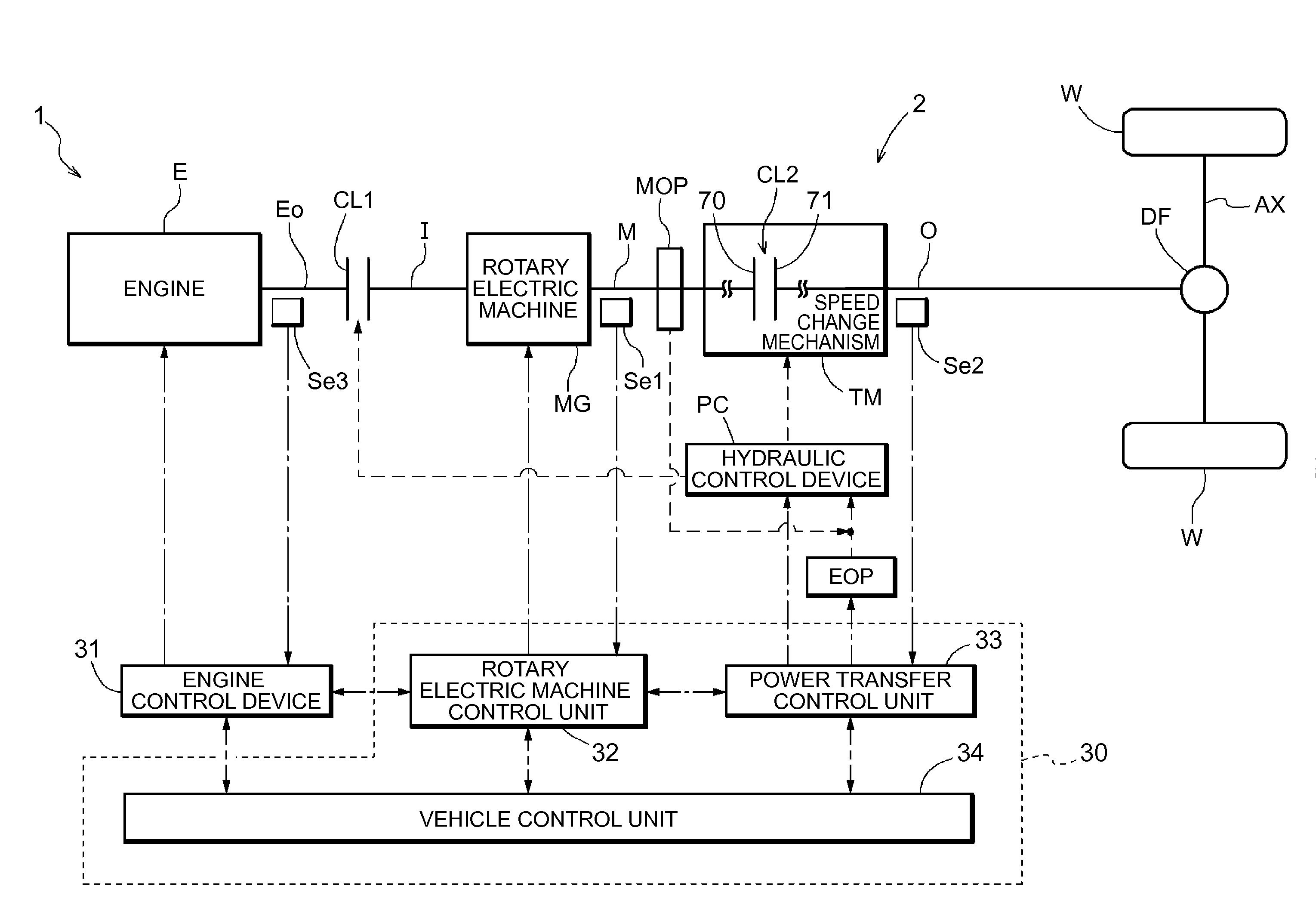

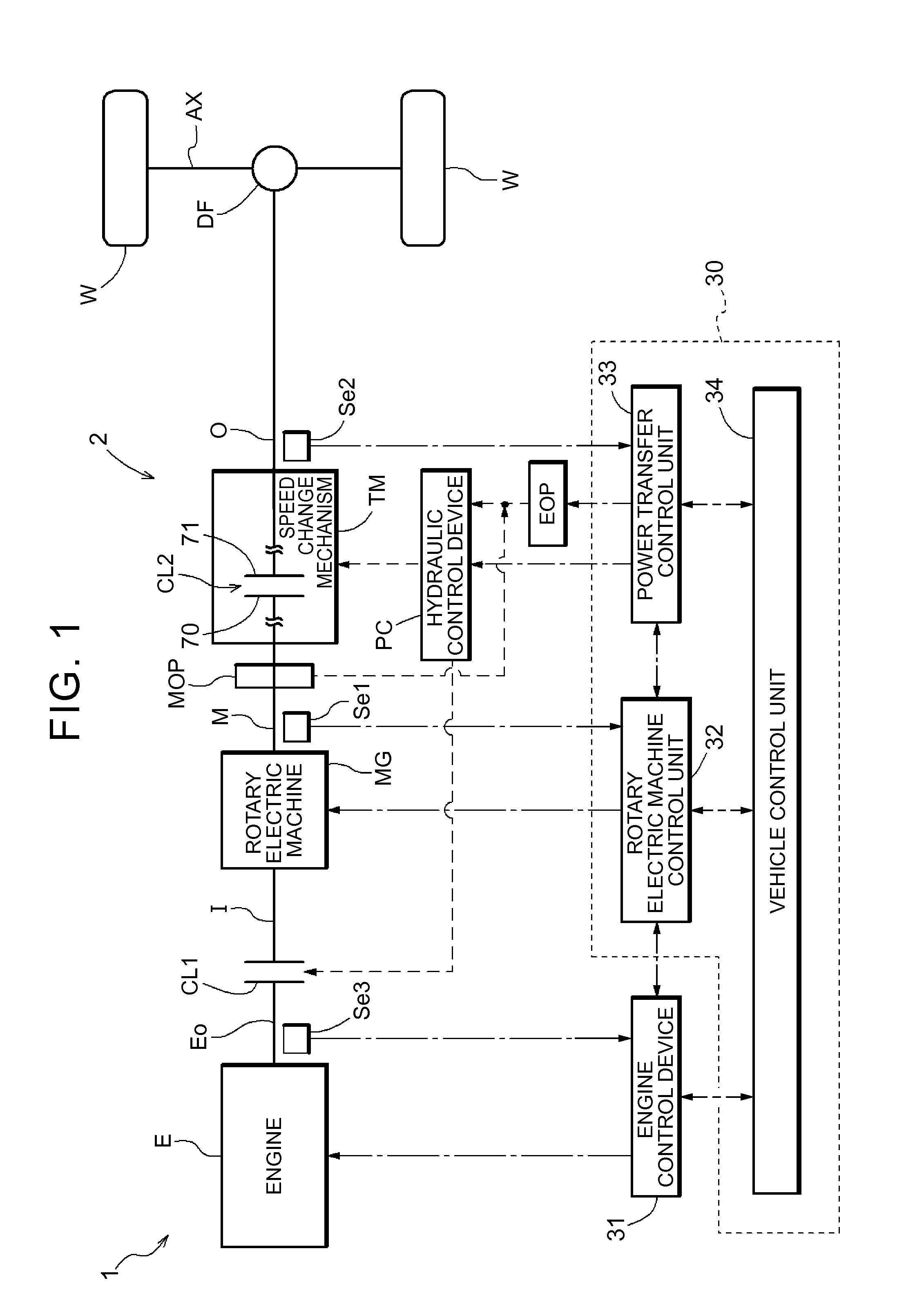

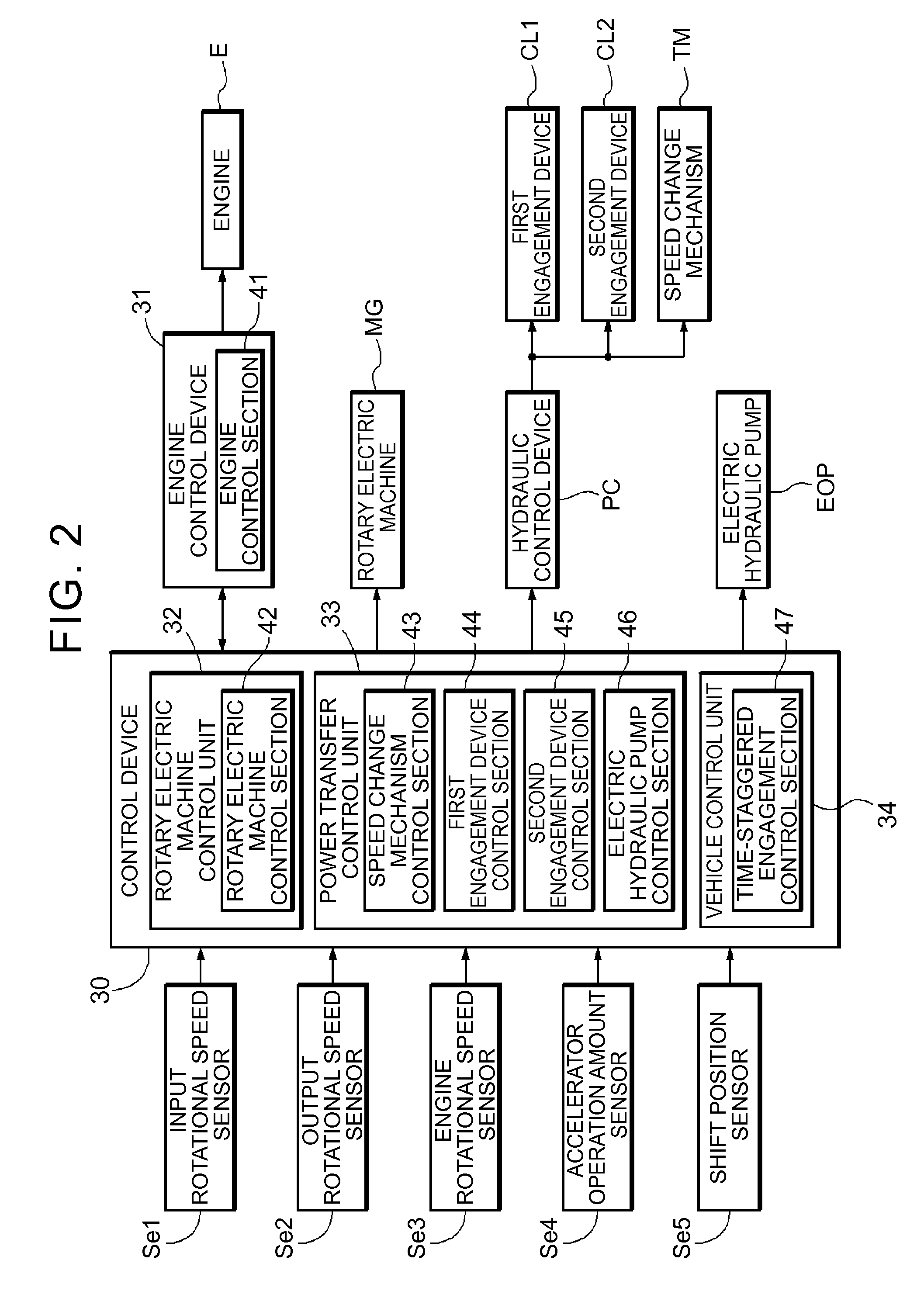

Control device for vehicle drive device

ActiveUS20140288754A1Reduced durabilityAmount of supply of working oil shorterClutchesDigital data processing detailsElectric machineEngineering

A control device that controls a vehicle drive device in which a rotary electric machine is provided in a power transfer path that connects between an internal combustion engine and wheels. Engagement of a second engagement device is started when a change in shift range from a stop range to a running range is detected when output torque of the rotary electric machine is zero with the internal combustion engine rotating and with both the first engagement device and the second engagement device disengaged. Engagement of a first engagement device is started after engagement of the second engagement device is started, and the output torque of the rotary electric machine is increased from zero at the same time as engagement of the first engagement device is started or before engagement of the first engagement device is started.

Owner:AISIN AW CO LTD

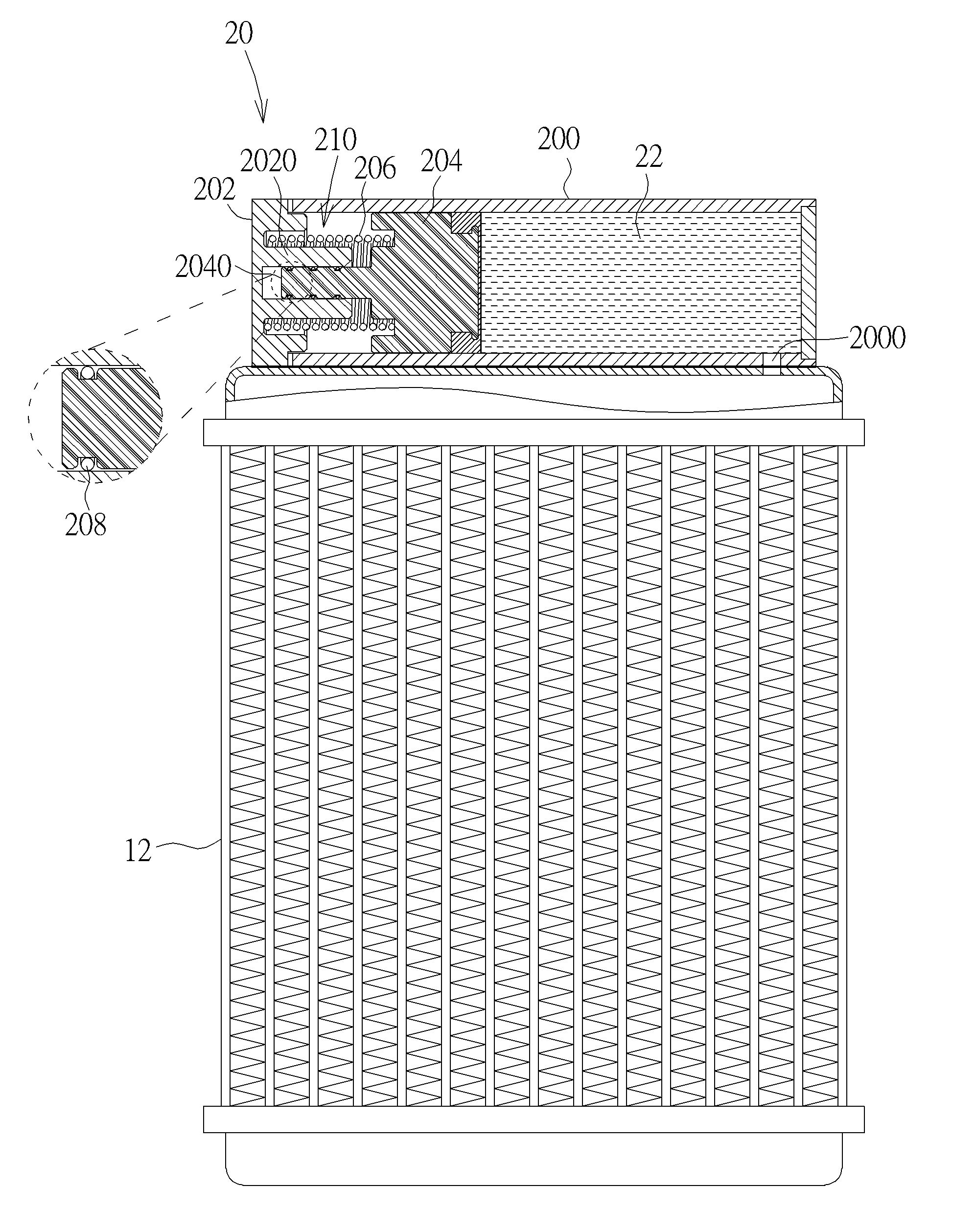

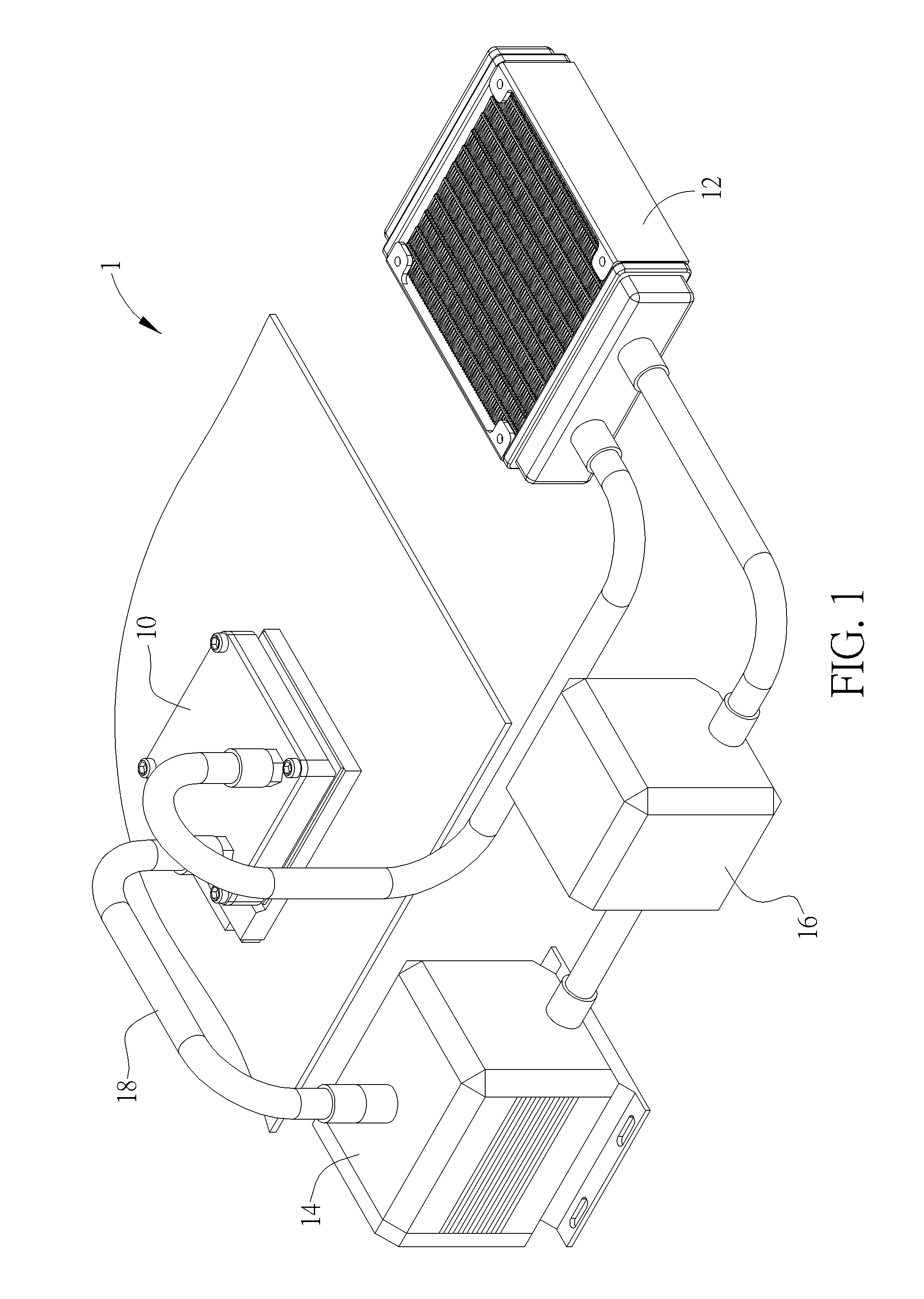

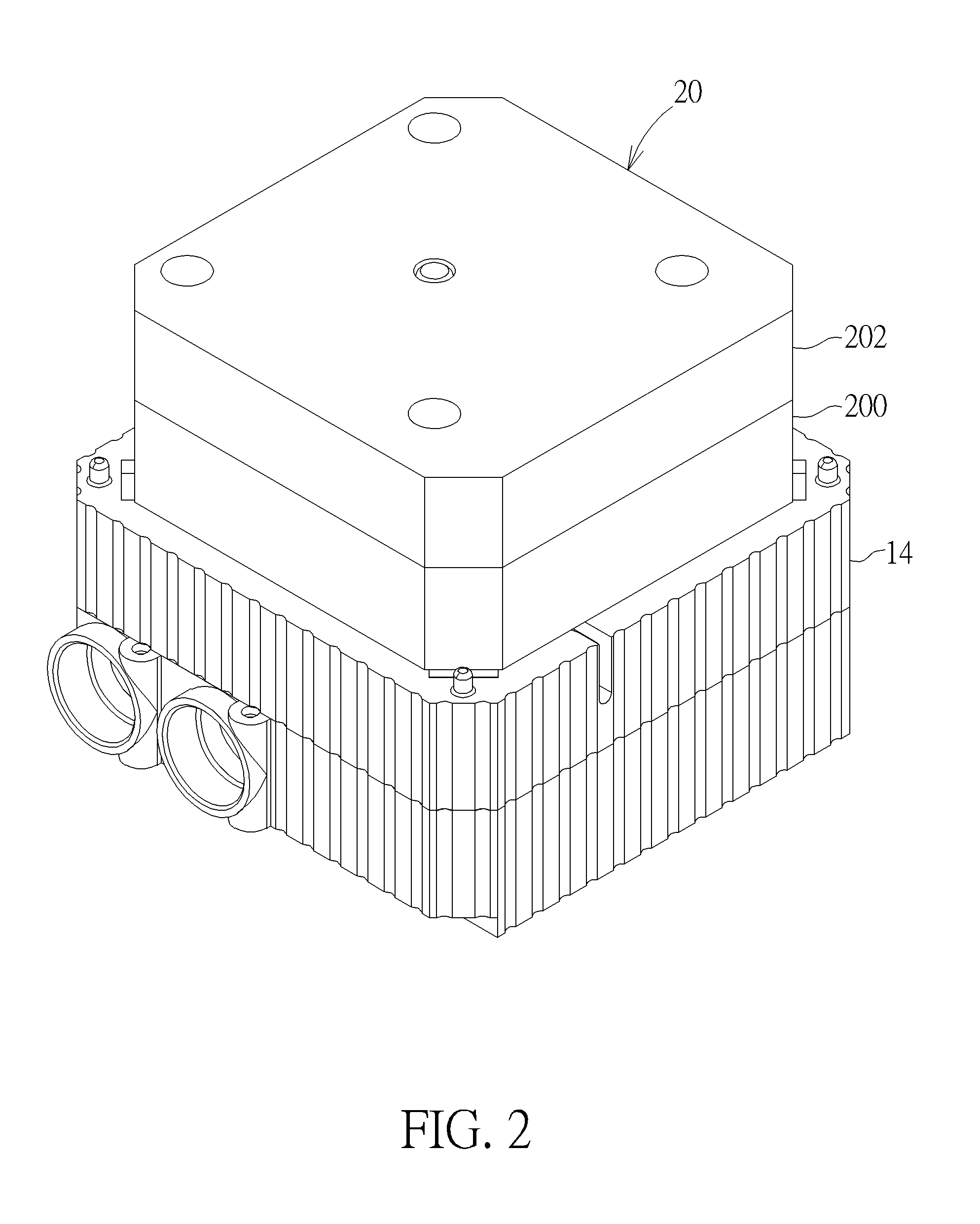

Liquid supply mechanism and liquid cooling system

ActiveUS20160366788A1Increase hydraulic pressureReduce thrustSemiconductor/solid-state device detailsLiquid transferring devicesLiquid cooling systemEngineering

A liquid supply mechanism includes a lower cover, an upper cover, a plunger, at least one resilient member and at least one damping member. The lower cover has a liquid outlet and the upper cover is connected to the lower cover. A chamber is formed between the lower cover and the upper cover. The chamber communicates with the liquid outlet and contains a cooling liquid. The upper cover has an axial hole. The plunger is movably disposed in the chamber. The plunger has an axial rod and the axial rod is inserted into the axial hole. The resilient member is disposed in the chamber. Opposite ends of the resilient member abut against the upper cover and the plunger. The damping member is disposed on the axial rod and abuts against an inner wall of the axial hole.

Owner:COOLER MASTER CO LTD

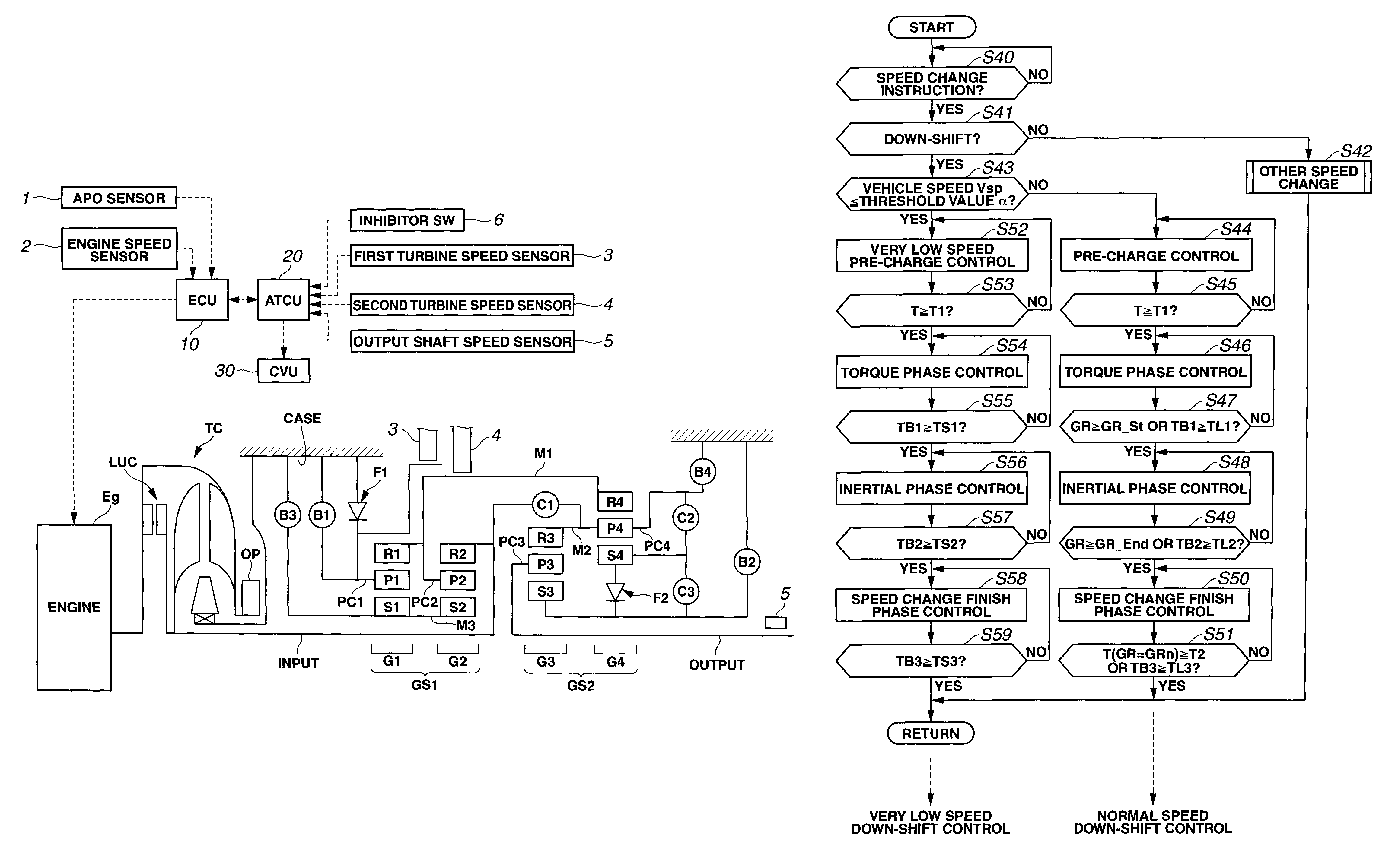

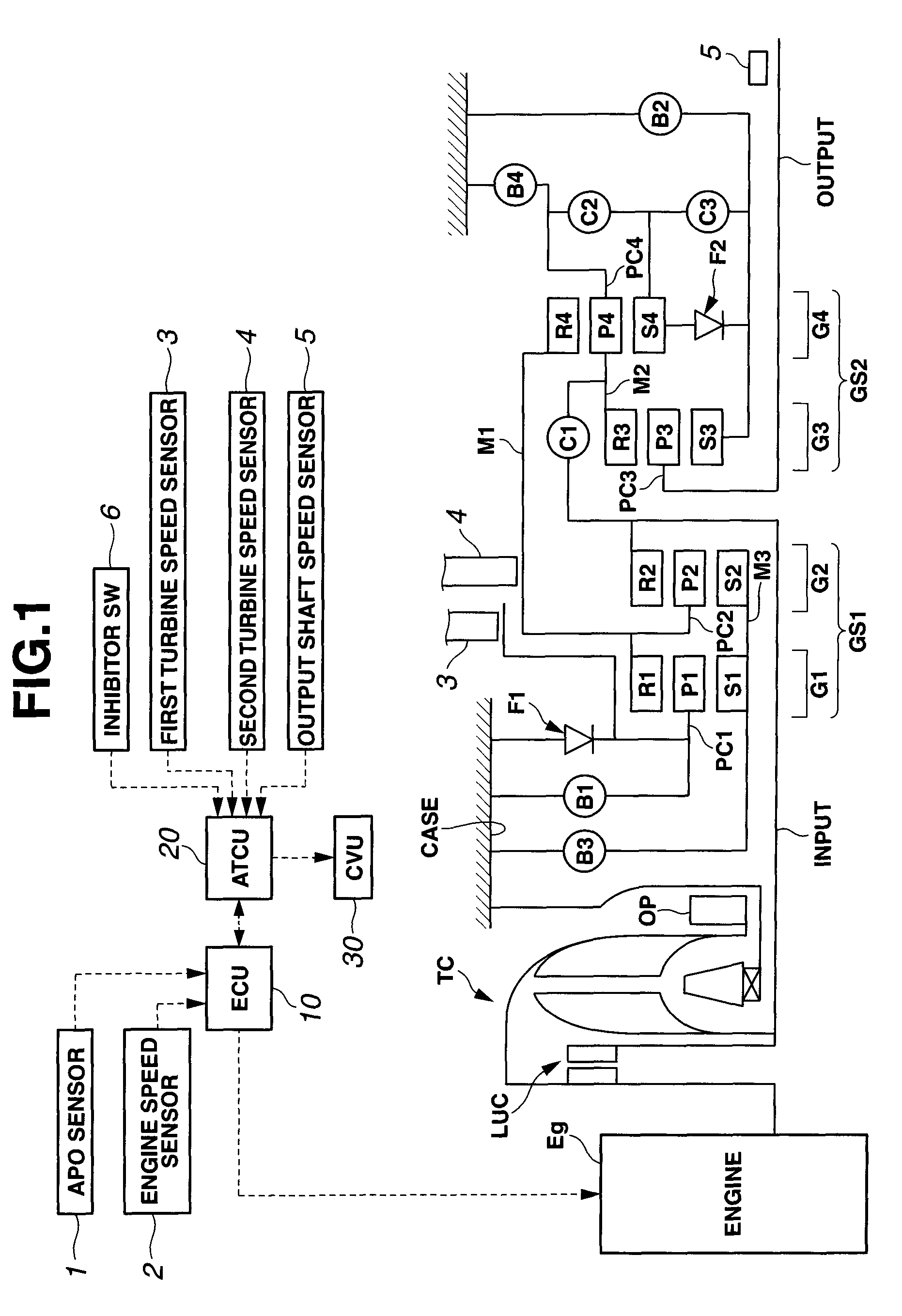

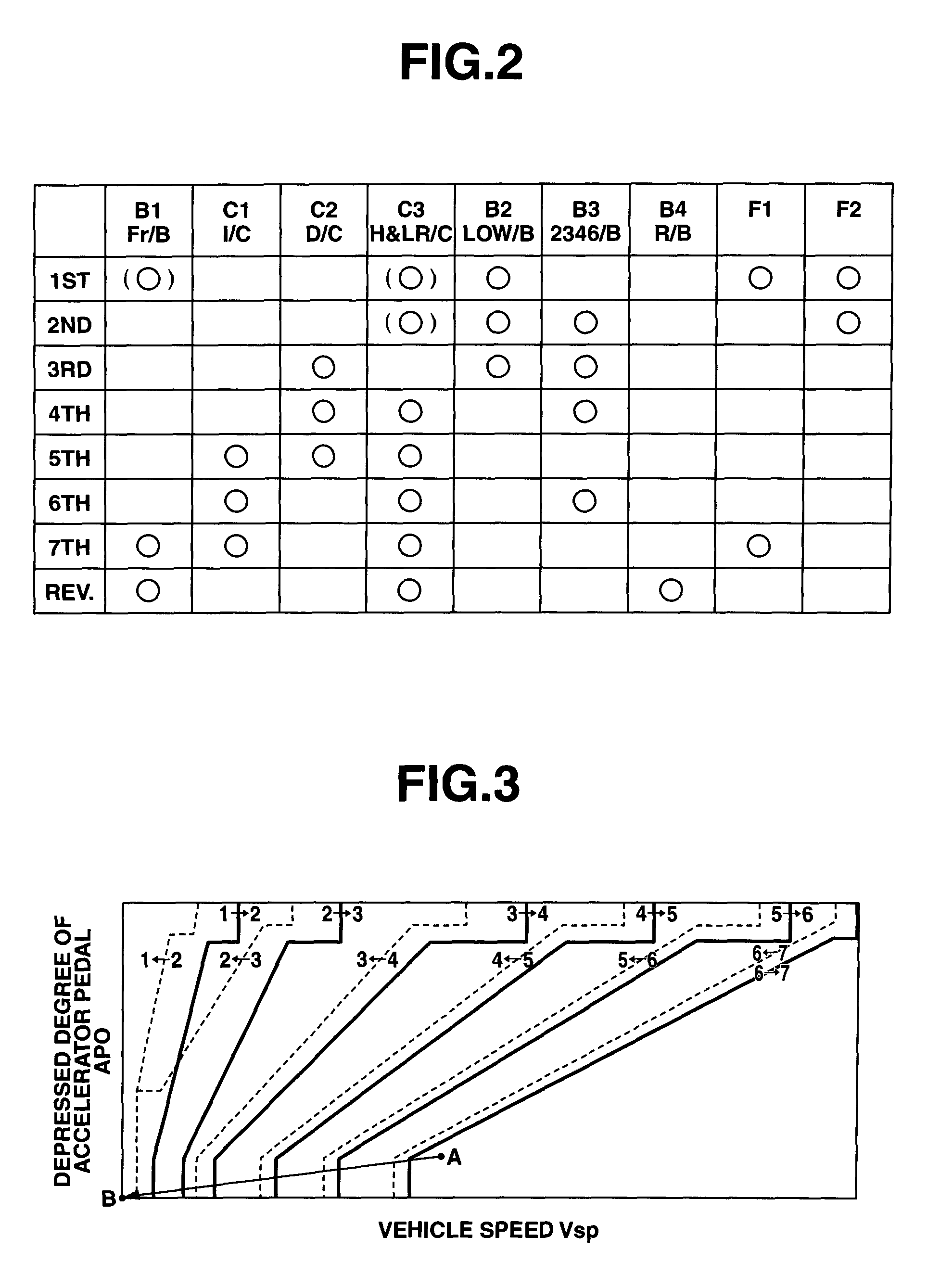

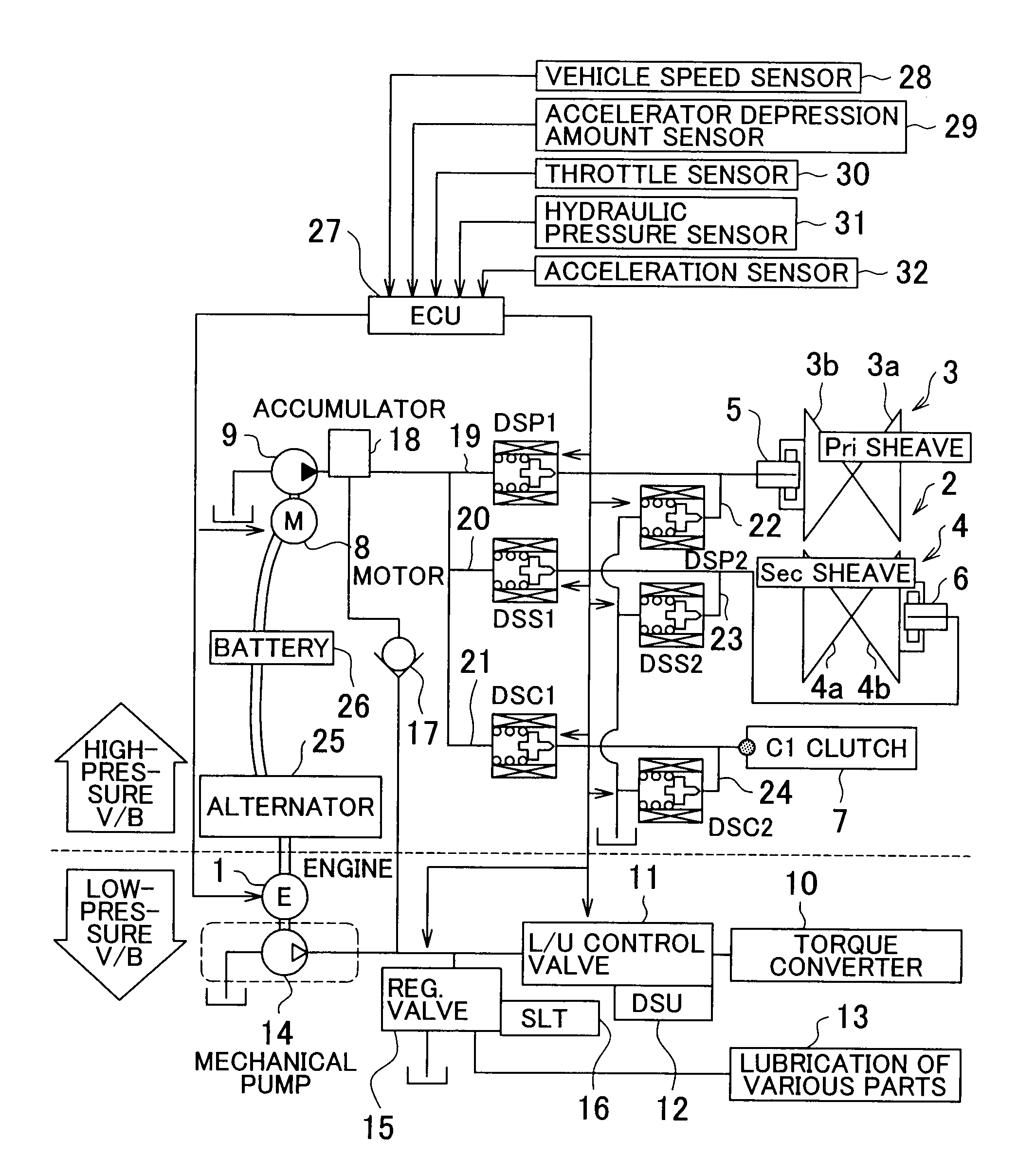

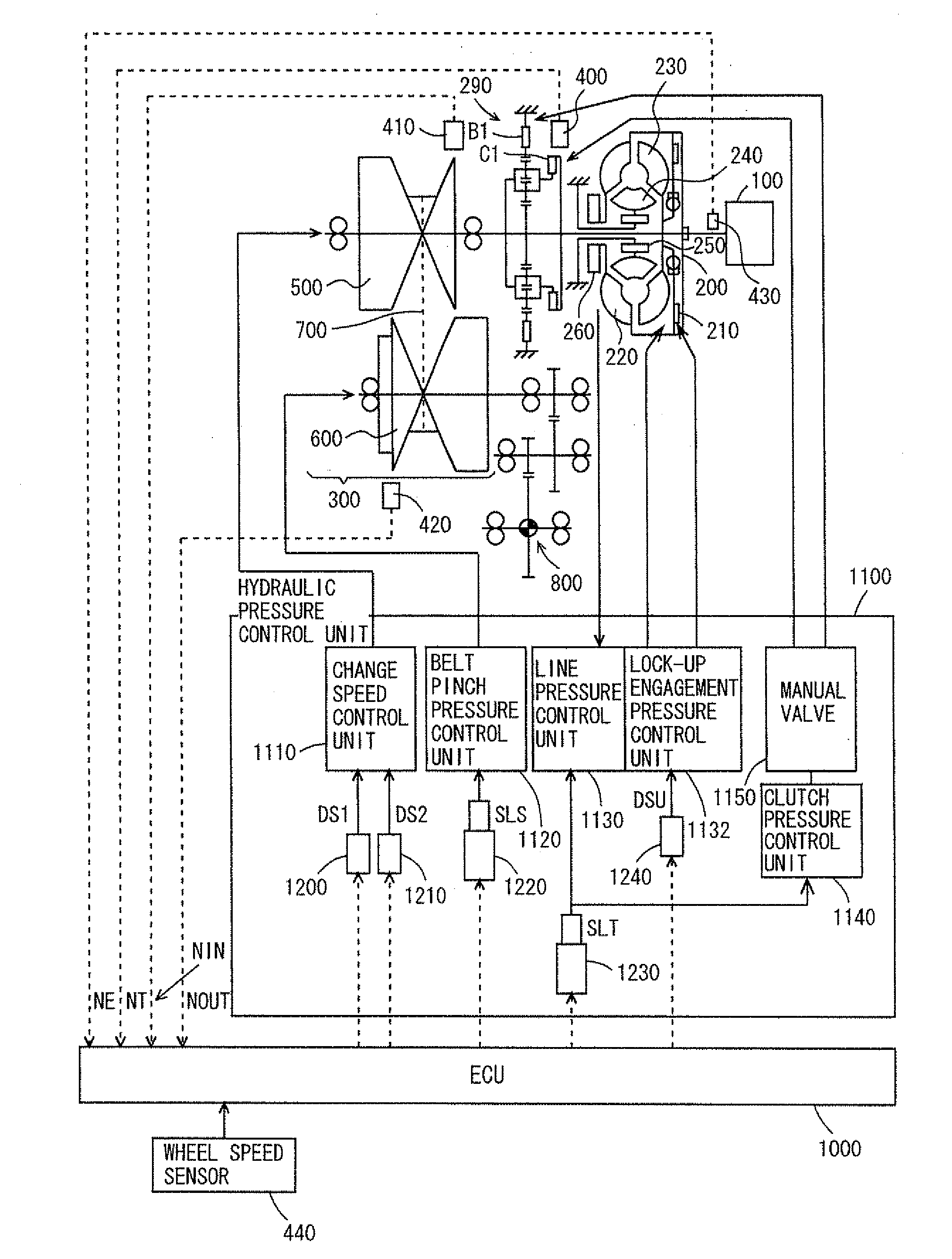

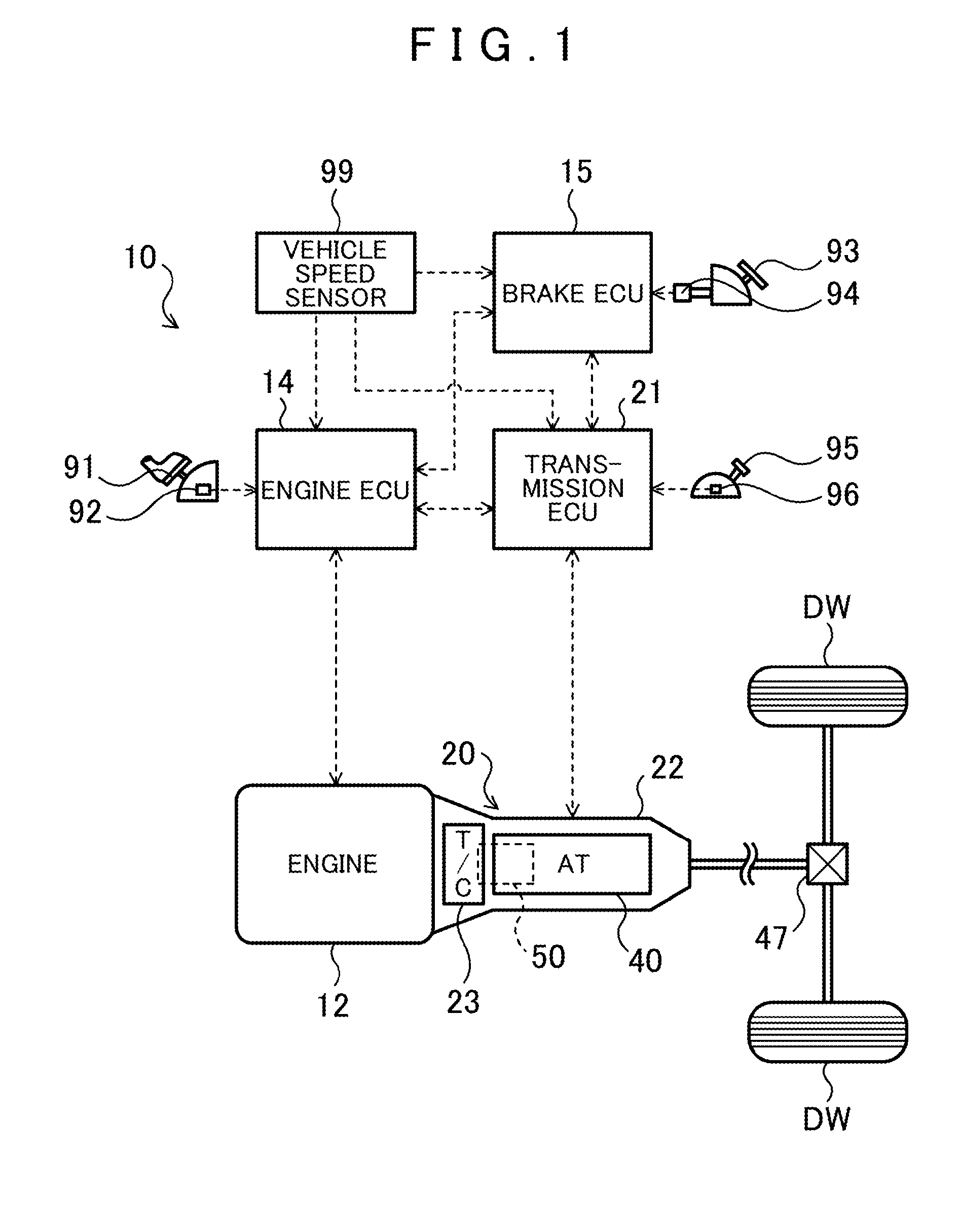

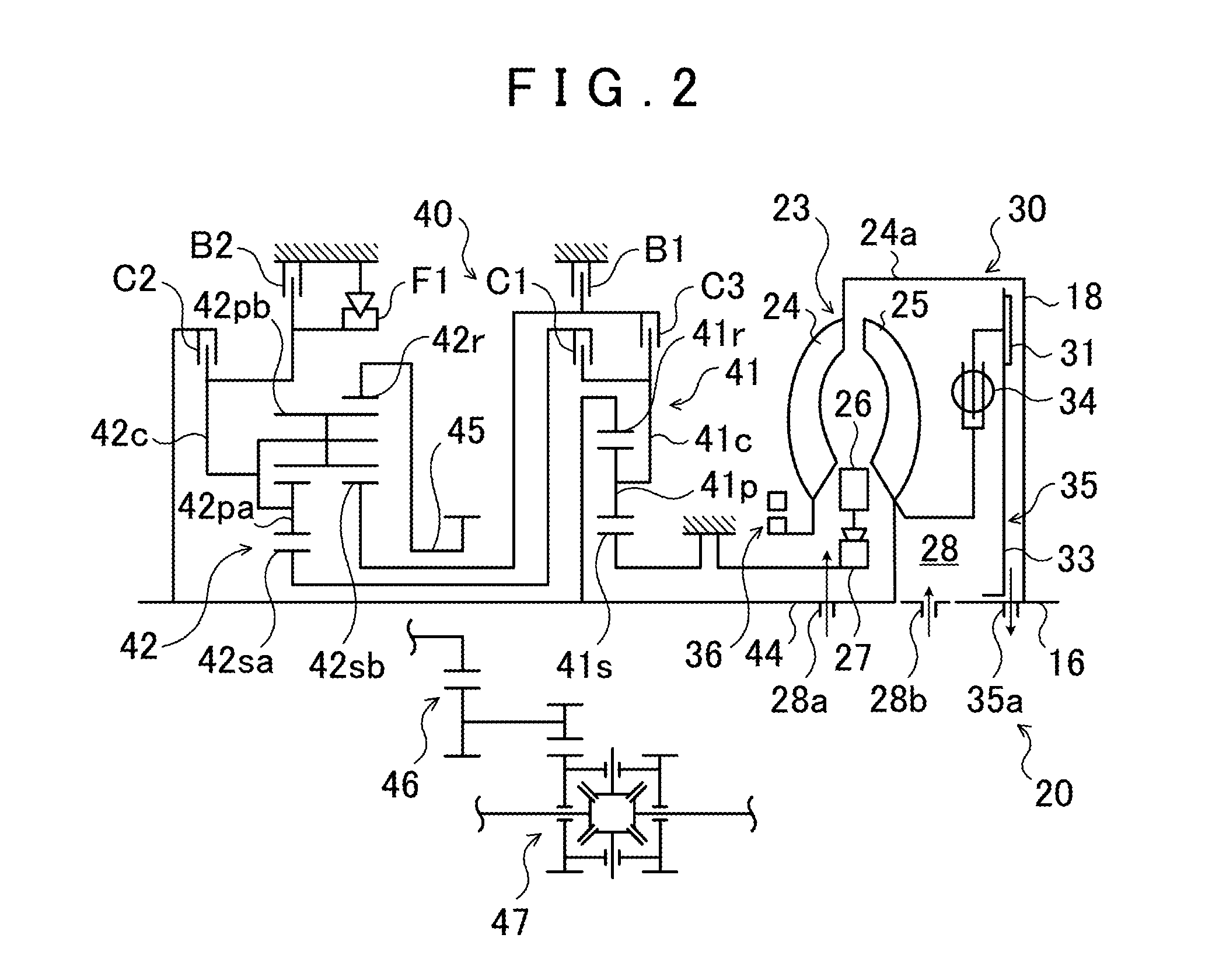

Speed change control system of automatic transmission

ActiveUS8131436B2Increase hydraulic pressureReduce hydraulic pressureClutchesDigital data processing detailsAutomatic transmissionControl system

When it is judged that a vehicle speed detected by a vehicle speed sensor is equal to or lower than a predetermined very low value, that is, for example, 5 km / h, the hydraulic pressure applied to an engaging-side frictional element is sharply increased, sharply reduced and then held higher than a given value capable of effecting a piston stroke of a corresponding piston unit until a time when the piston stroke is completed. Upon completion of the piston stroke, the hydraulic pressure is increased to a maximum value in a time that is smaller or shorter than that set when the detected vehicle speed is higher than the predetermined very low value.

Owner:JATCO LTD +1

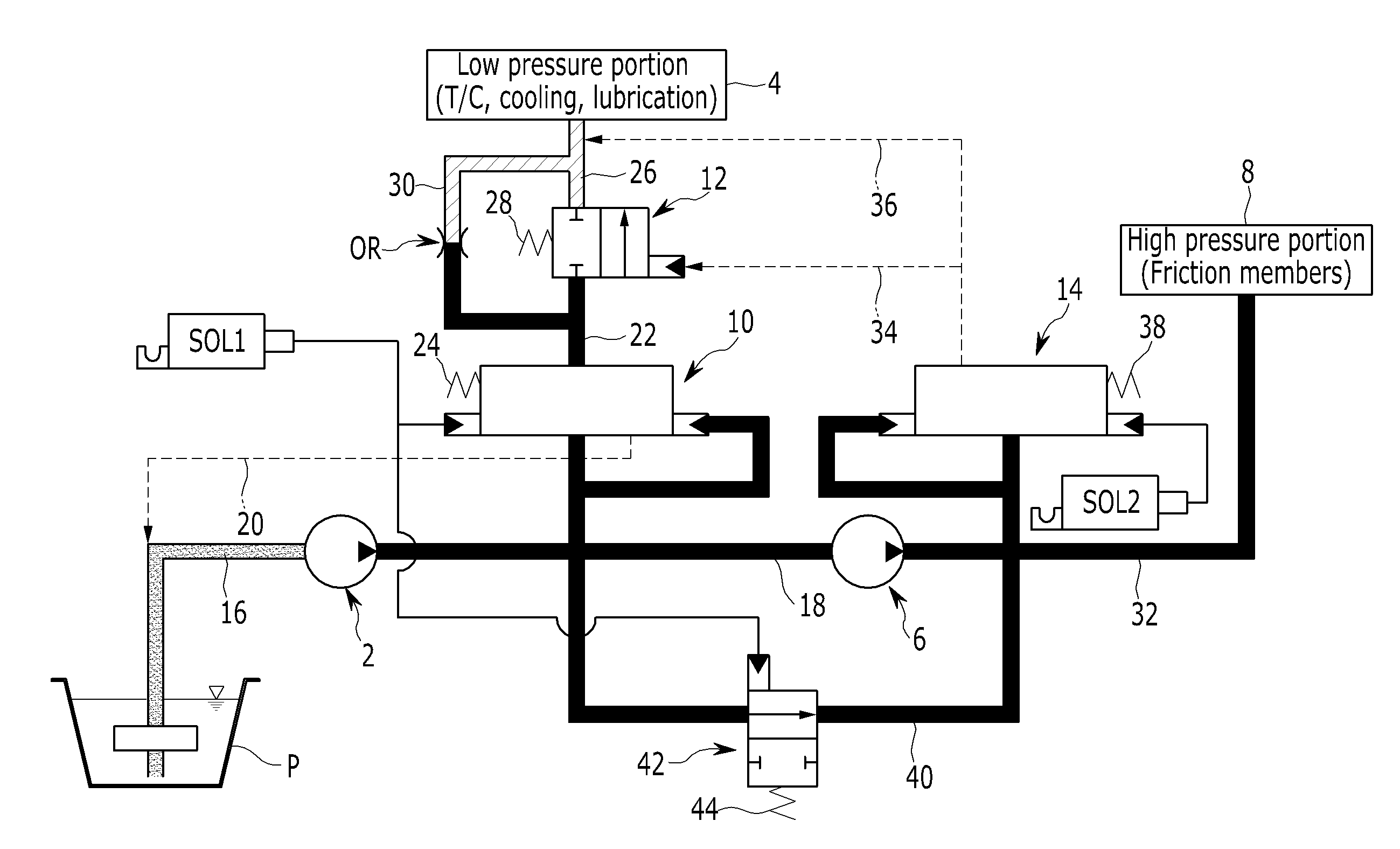

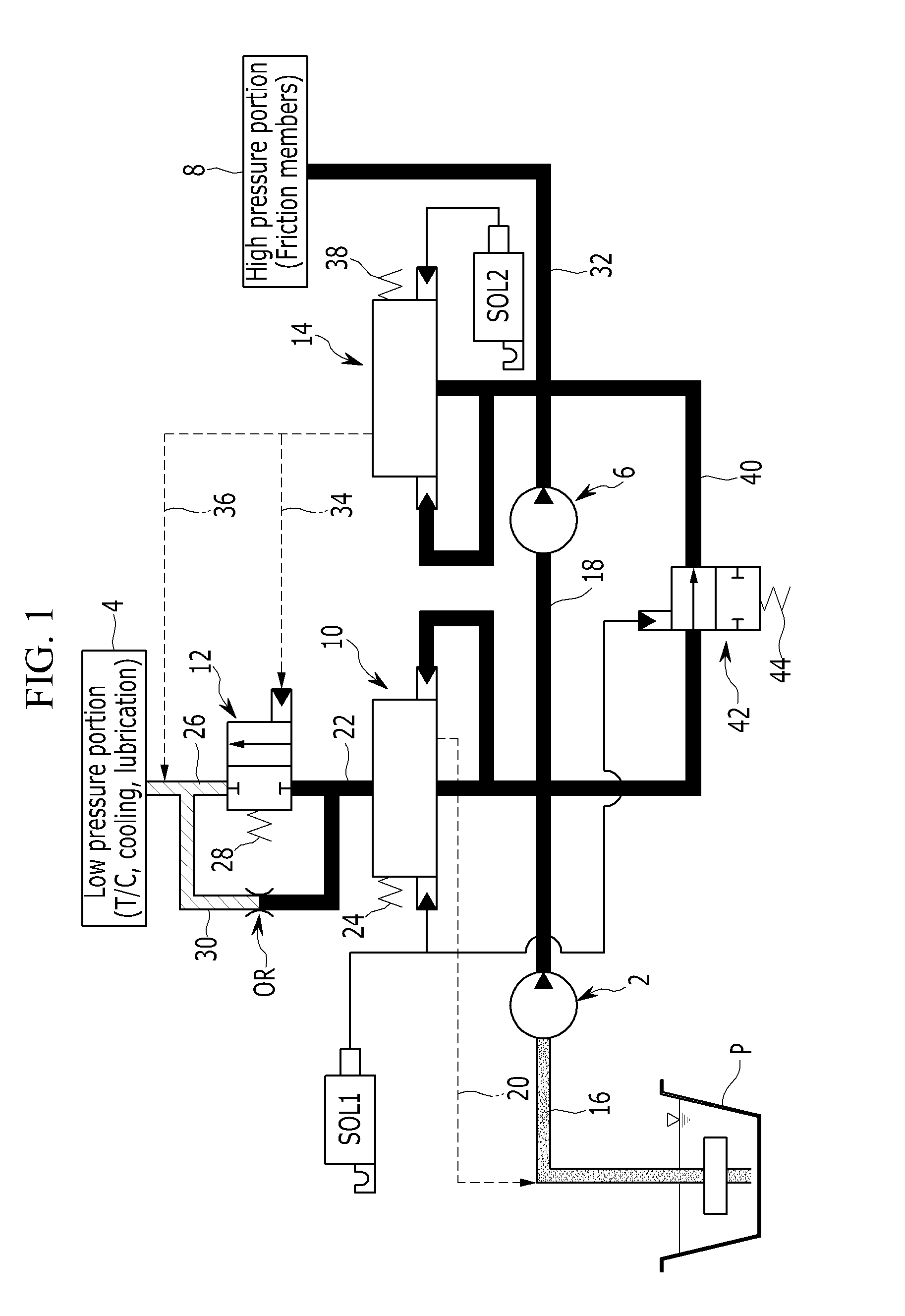

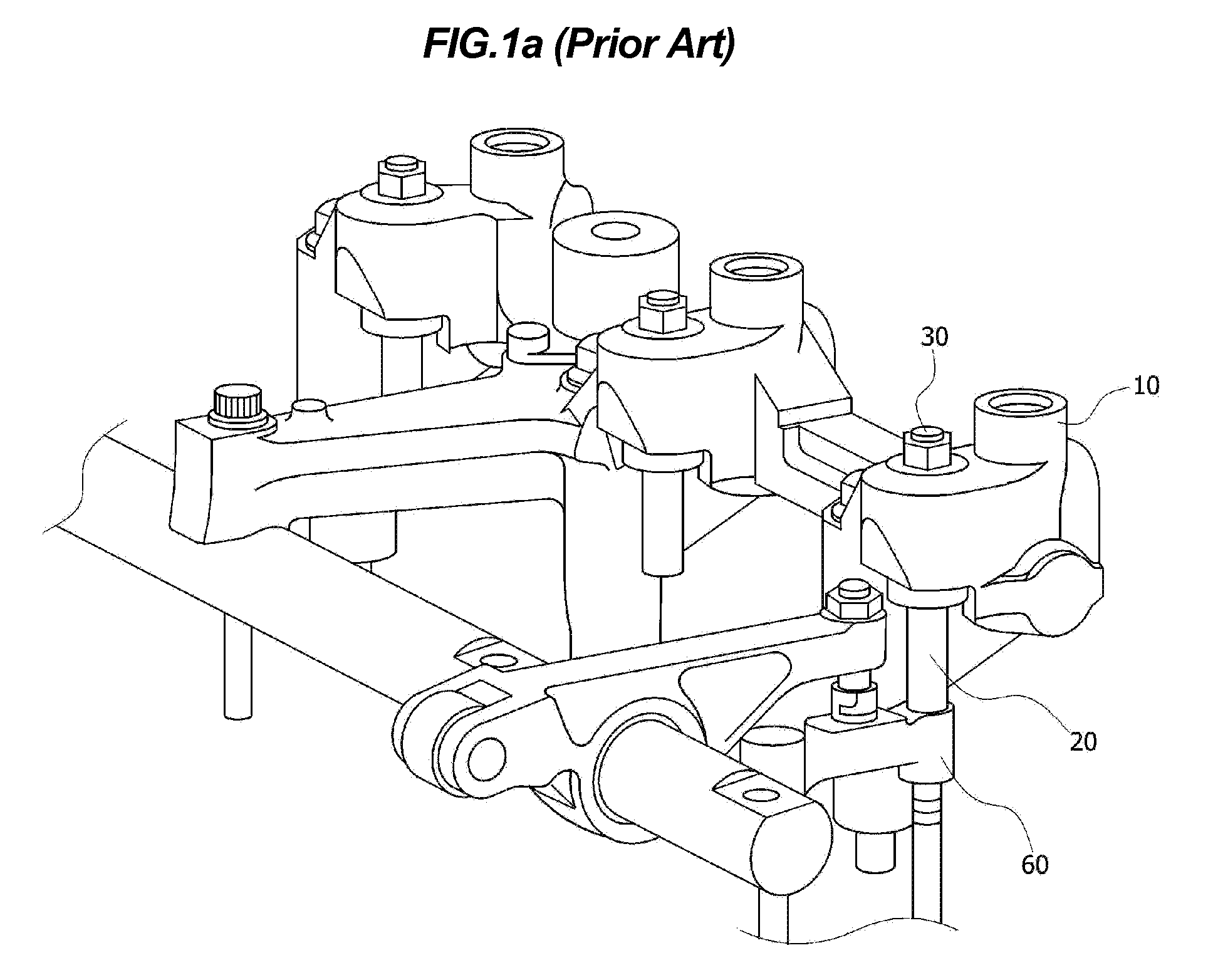

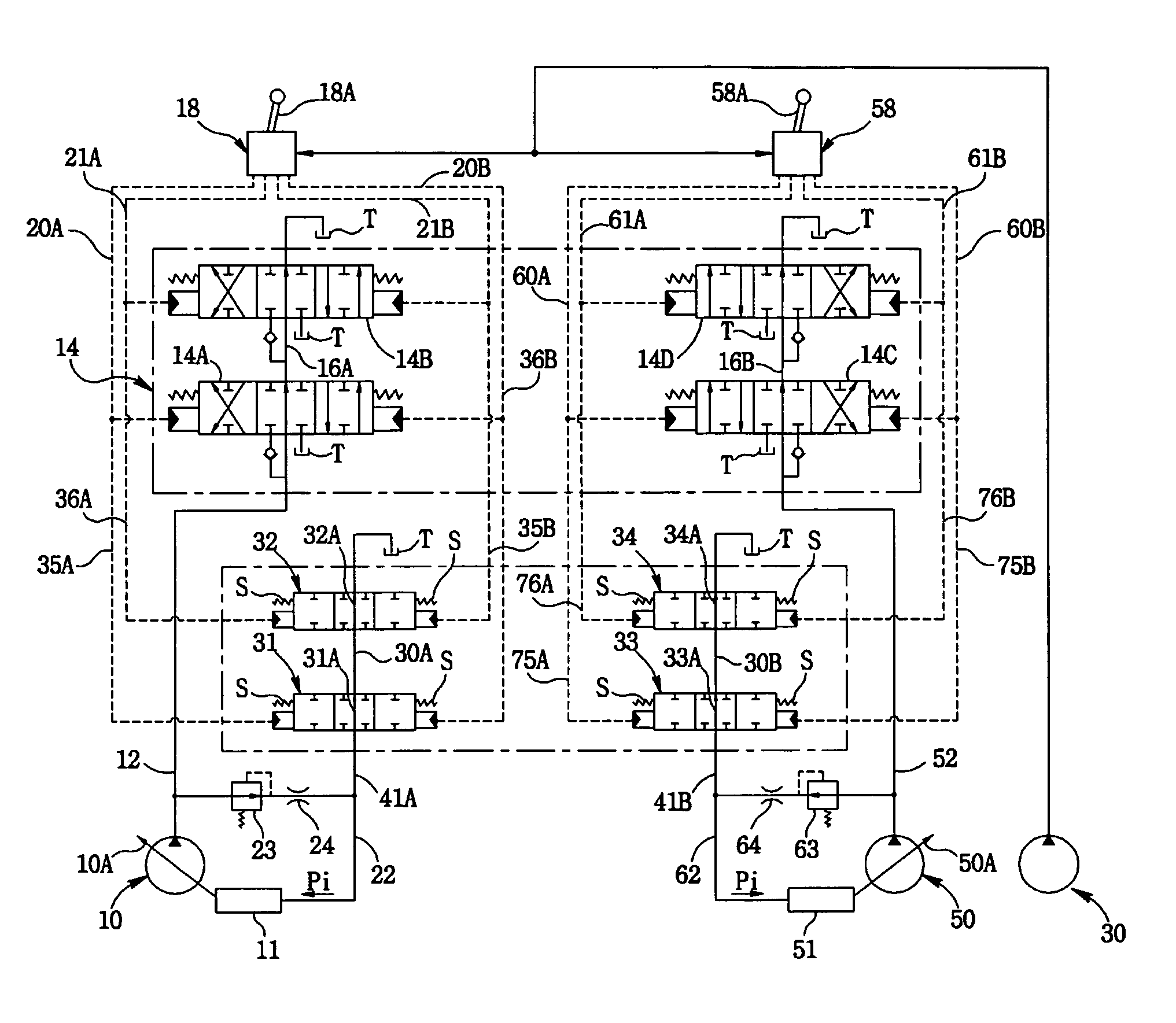

Hydraulic pressure supply system of automatic transmission for vehicle

ActiveUS20150027570A1Improve responsivenessImprove stabilityServomotorsGear lubrication/coolingAutomatic transmissionHydraulic pump

A hydraulic pressure supply system may supply low hydraulic pressure generated at a low-pressure hydraulic pump to a low pressure portion through a low-pressure regulator valve, may supply a portion of the low hydraulic pressure to a high-pressure hydraulic pump, and may supply high hydraulic pressure generated at the high-pressure hydraulic pump to a high pressure portion through a high-pressure regulator valve.

Owner:HYUNDAI MOTOR CO LTD

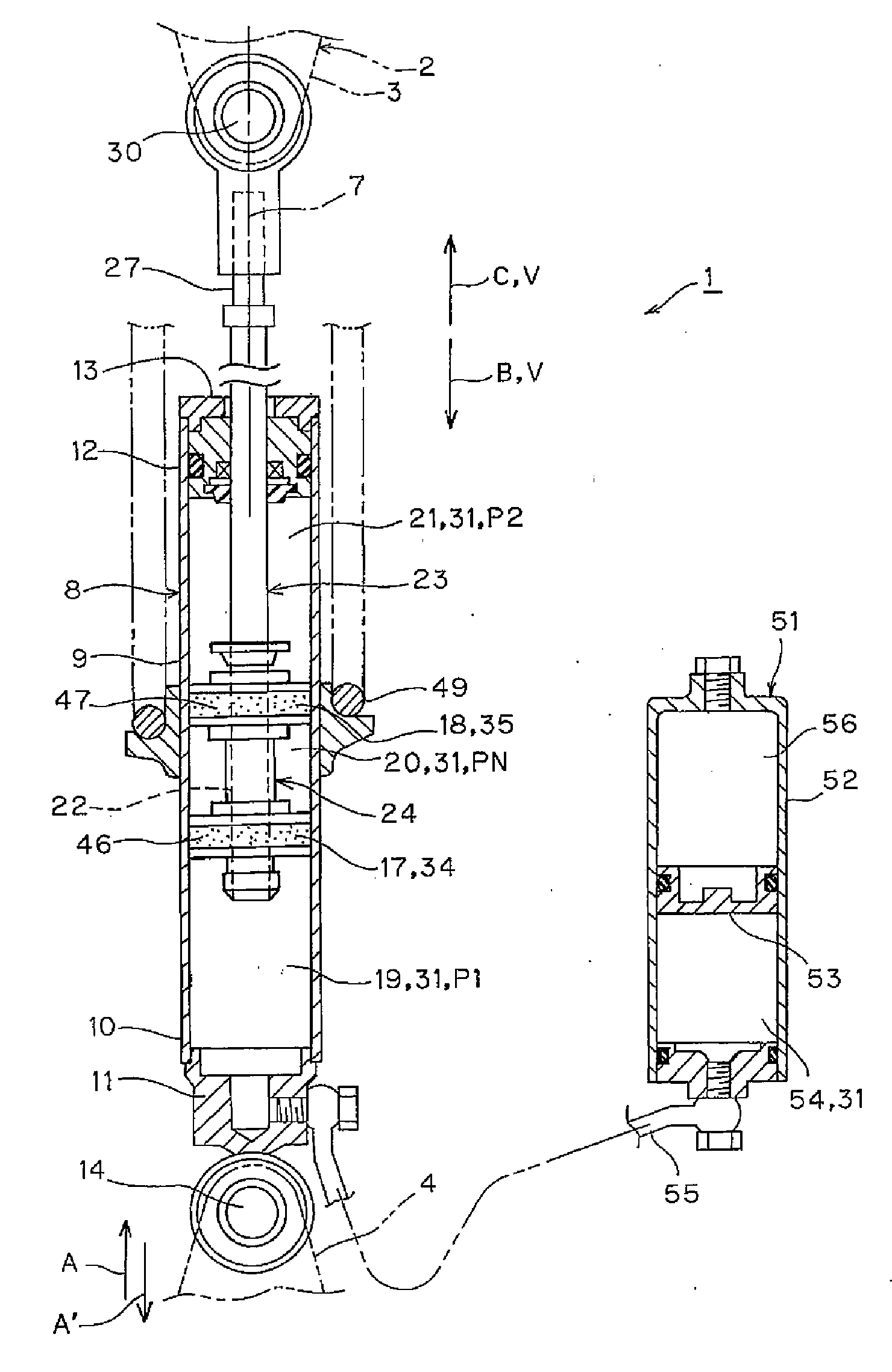

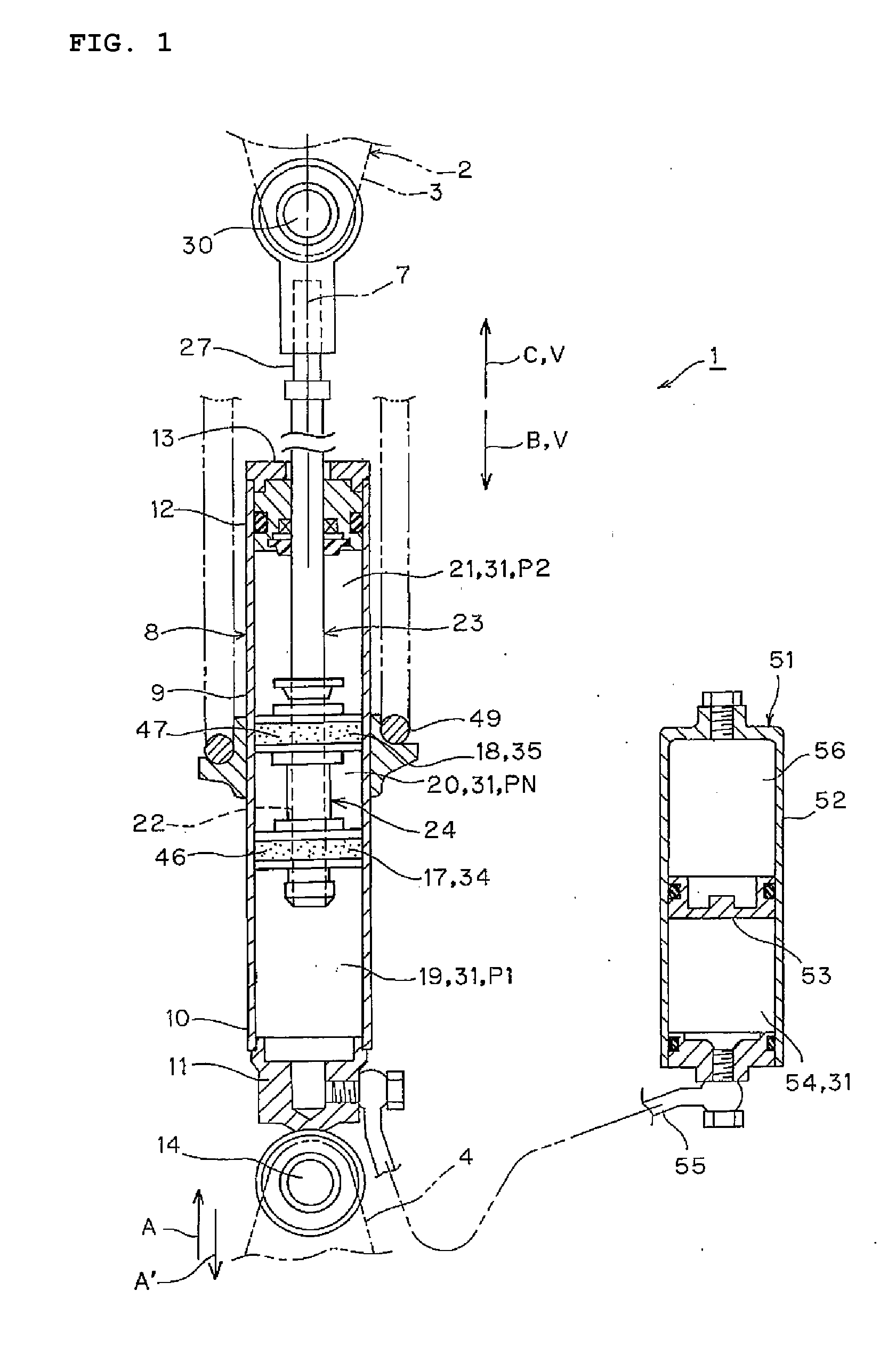

Hydraulic shock absorber

ActiveUS20090101459A1Increase hydraulic pressureHigh responseSpringsSprings/dampers design characteristicsMoving speedEngineering

In a shock absorber of a vehicle, when a moving speed of a piston rod in relation to a cylinder tube is slow and first and second input forces are externally applied to the shock absorber, damping forces of pressure side and extension side first damping force generating devices are larger than that of pressure side and extension side second damping force generating devices. On the other hand, when the moving speed is fast, the damping forces of the pressure side and the extension side second damping force generating devices are larger than that of the pressure side and the extension side first damping force generating devices. A gas enclosure chamber filled with gas is connected to a first chamber through a free piston.

Owner:YAMAHA MOTOR CO LTD

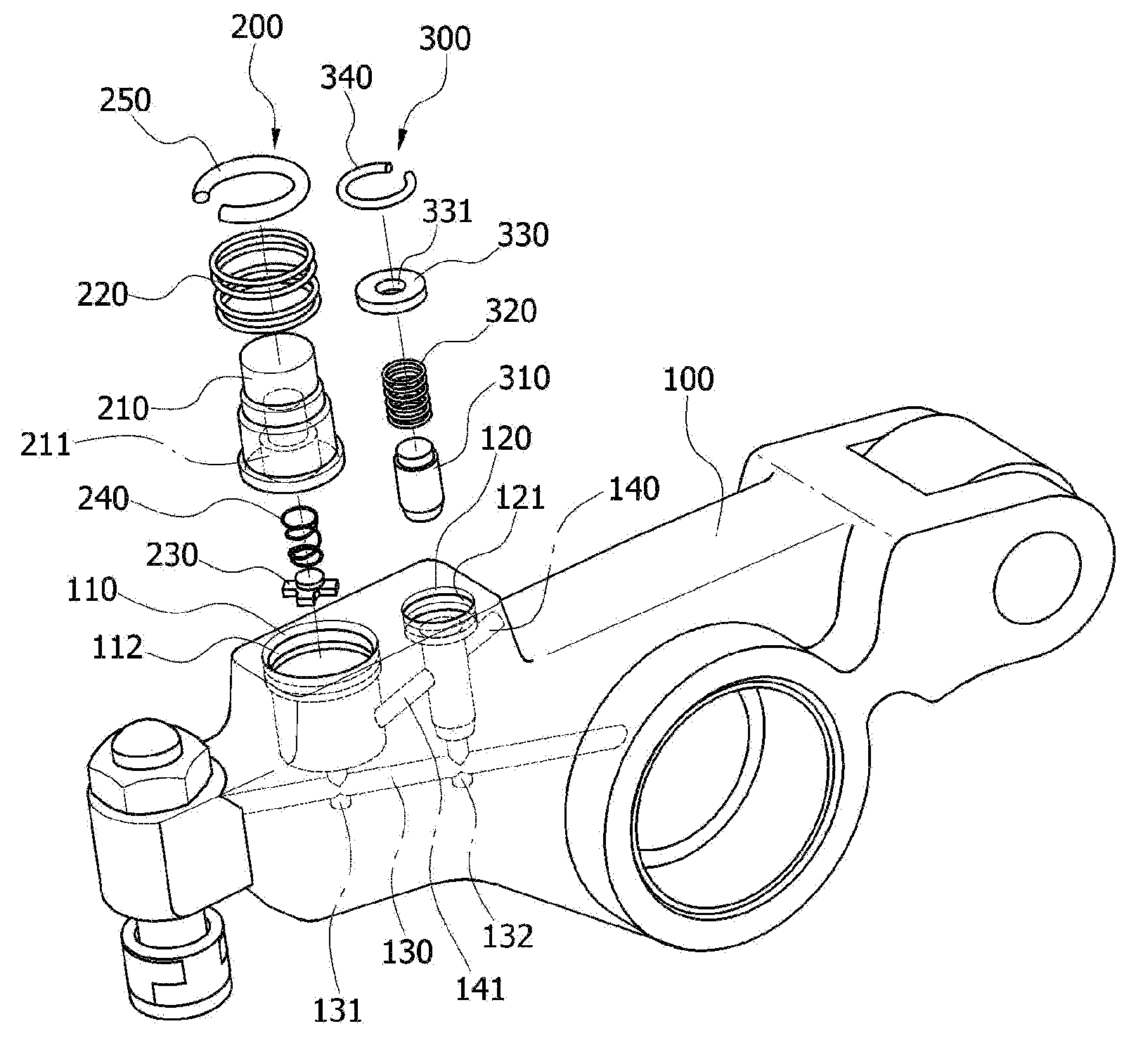

Engine brake unit

ActiveUS20110023821A1Reduce manufacturing costLow weight costValve arrangementsOutput powerEngineeringActuator

An engine brake unit may include a rocker arm having a first space defined in a valve-pressing portion thereof, wherein the first space communicates with a supply passage, through which engine brake oil is introduced, a stopper fixedly provided above the first space of the rocker arm in a predetermined distance, an actuator located inside the first space and having a pressure piston, wherein the pressure piston is selectively raised by hydraulic pressure of the engine brake oil to butt against the stopper, thereby pressing a portion of the rocker arm downwards.

Owner:HYUNDAI MOTOR CO LTD +1

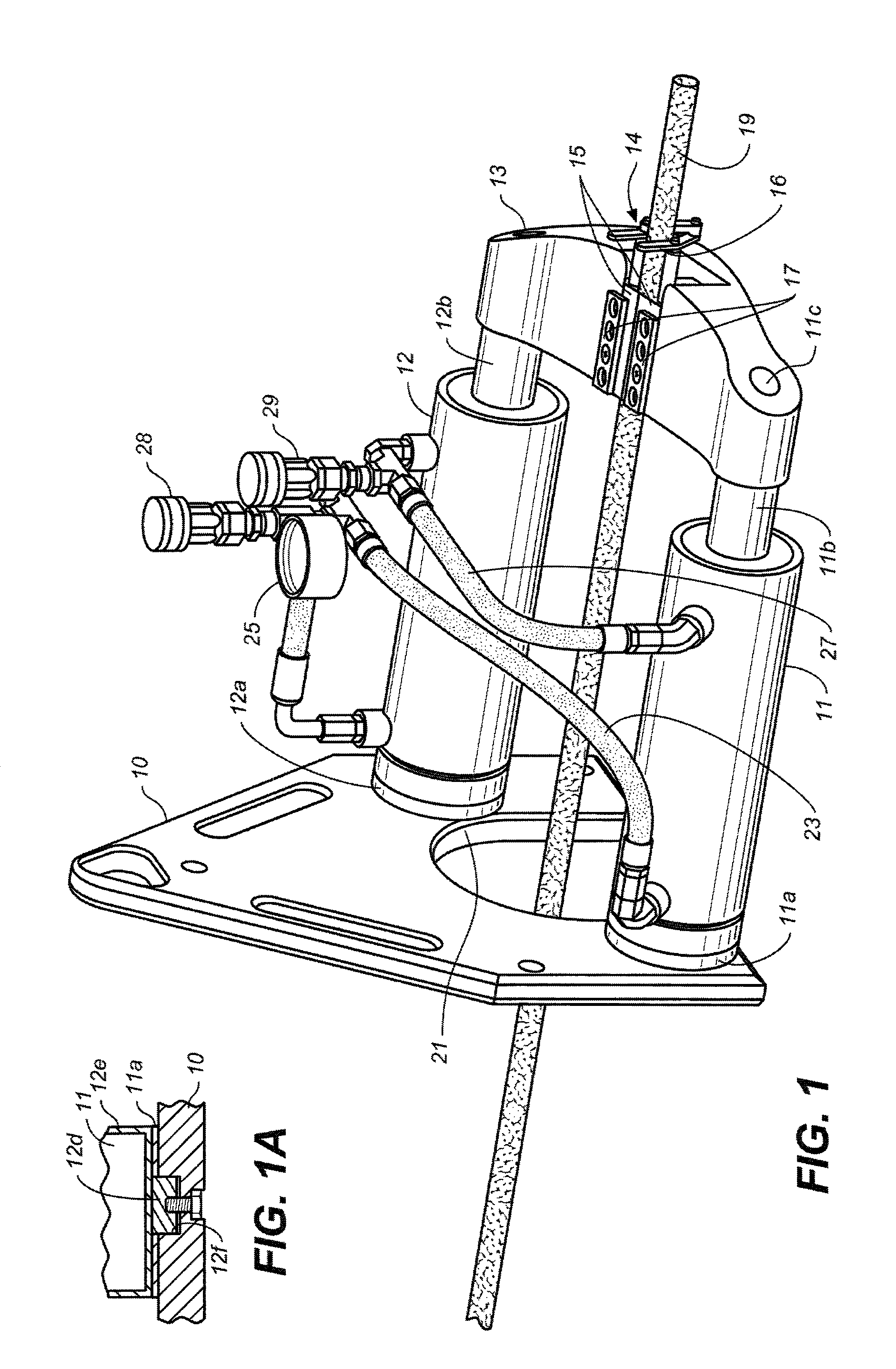

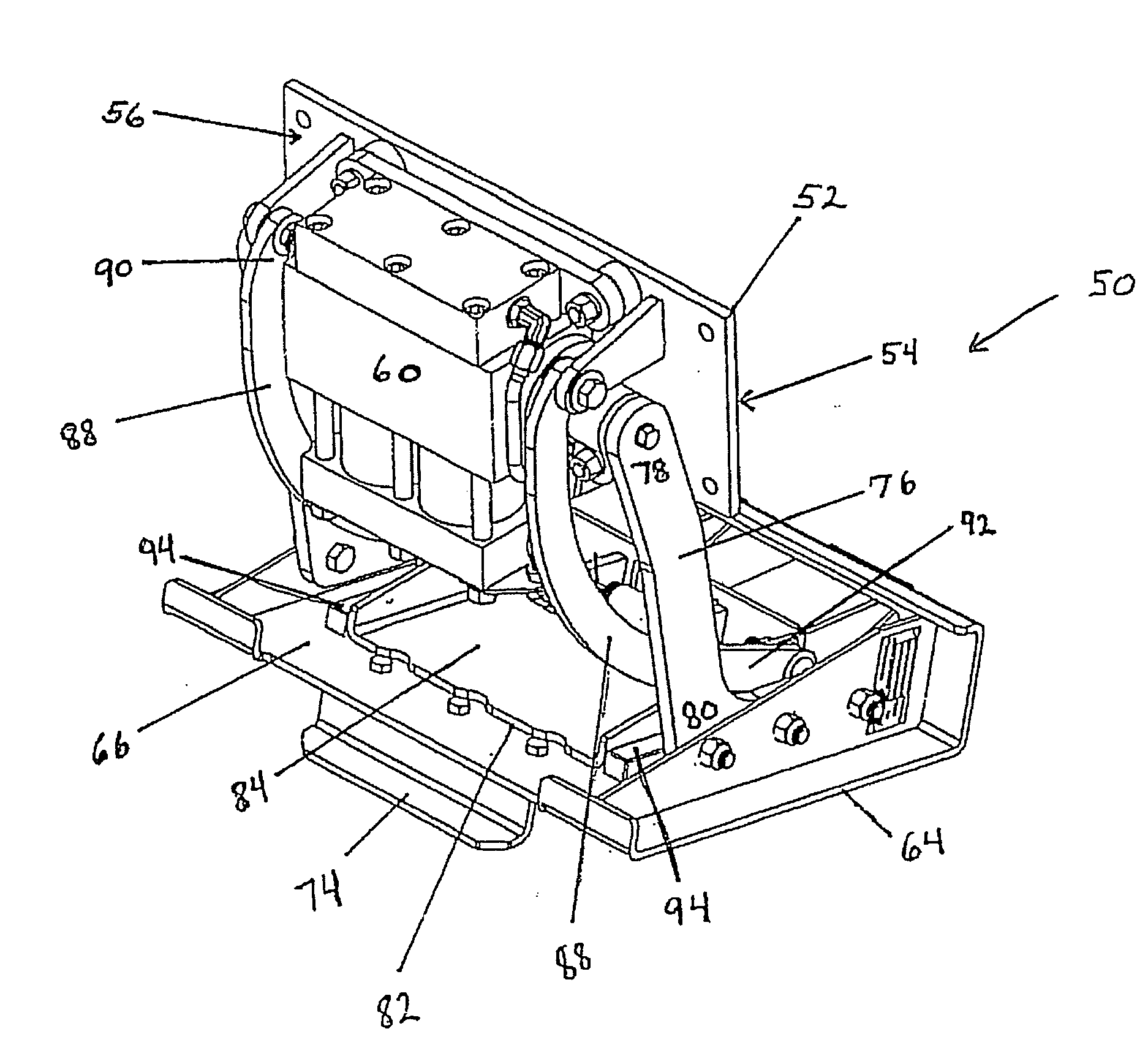

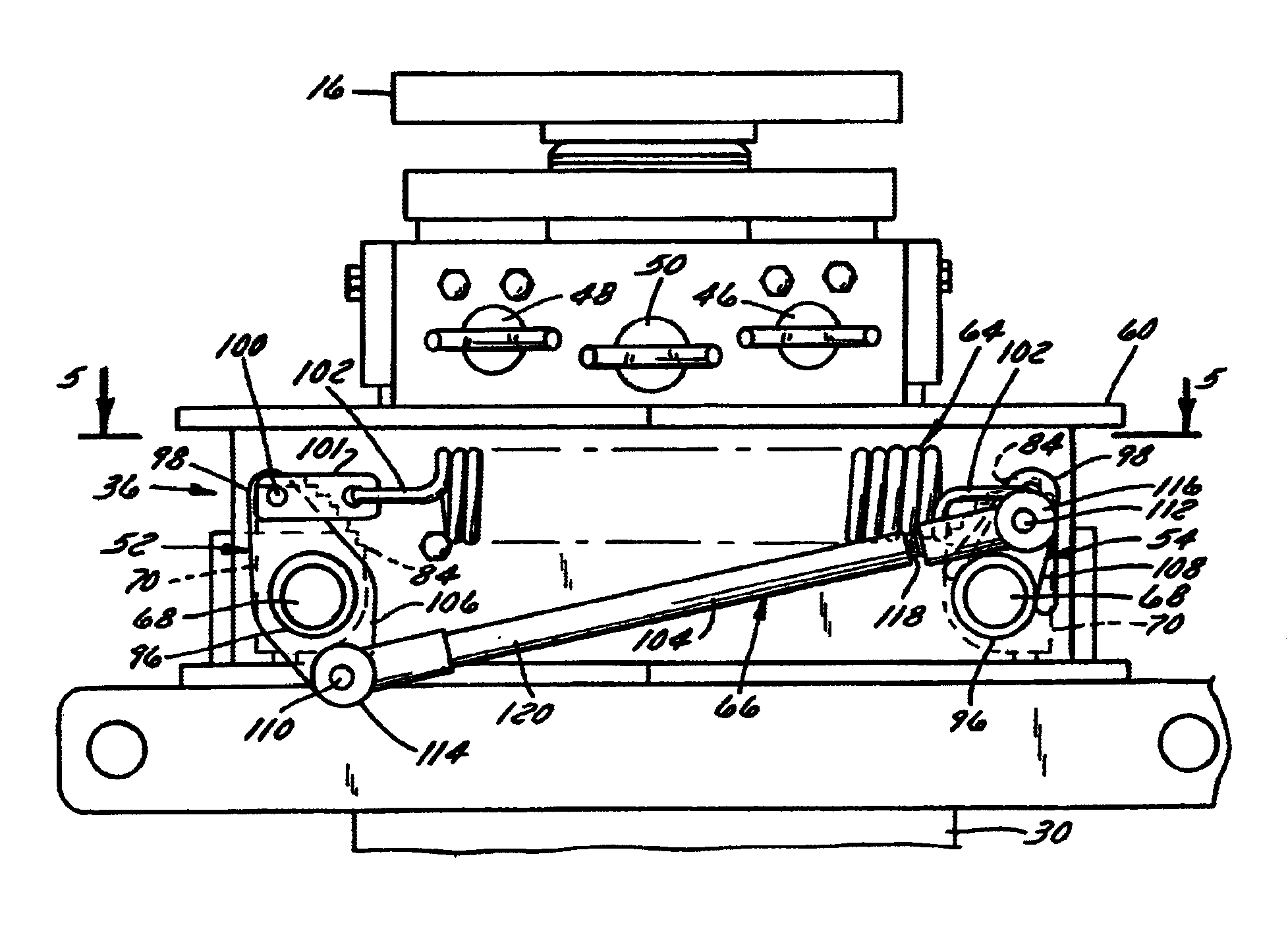

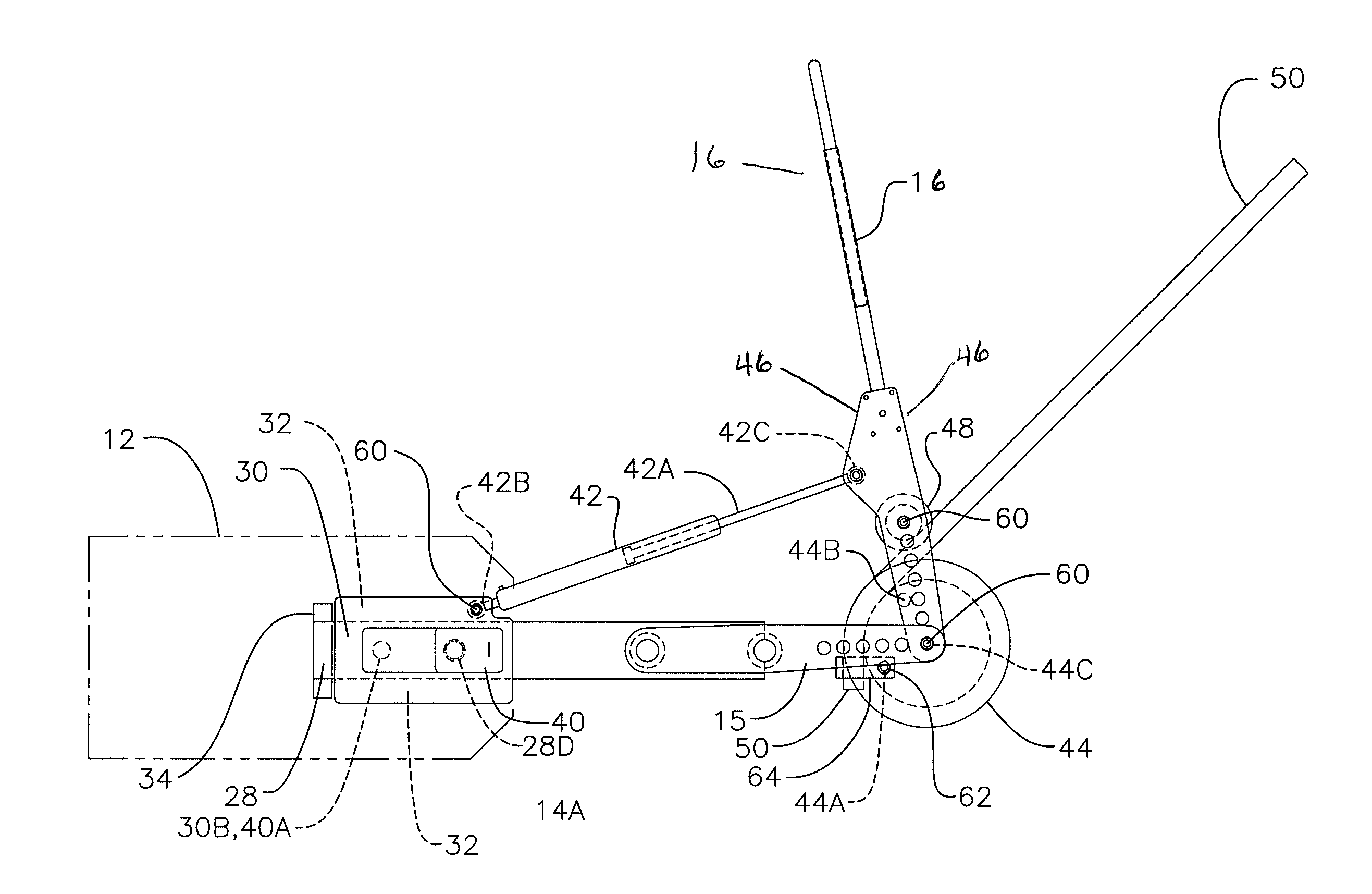

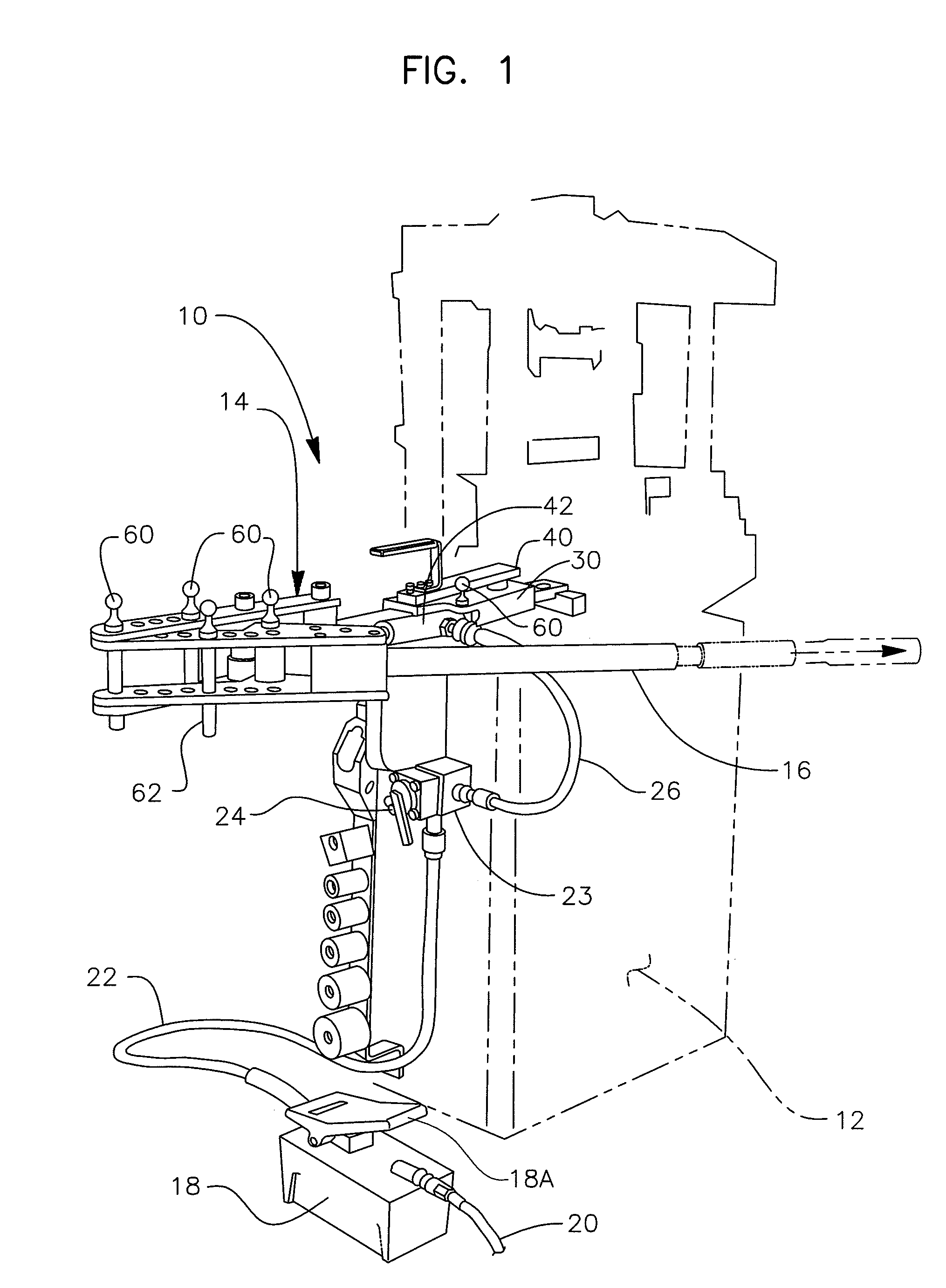

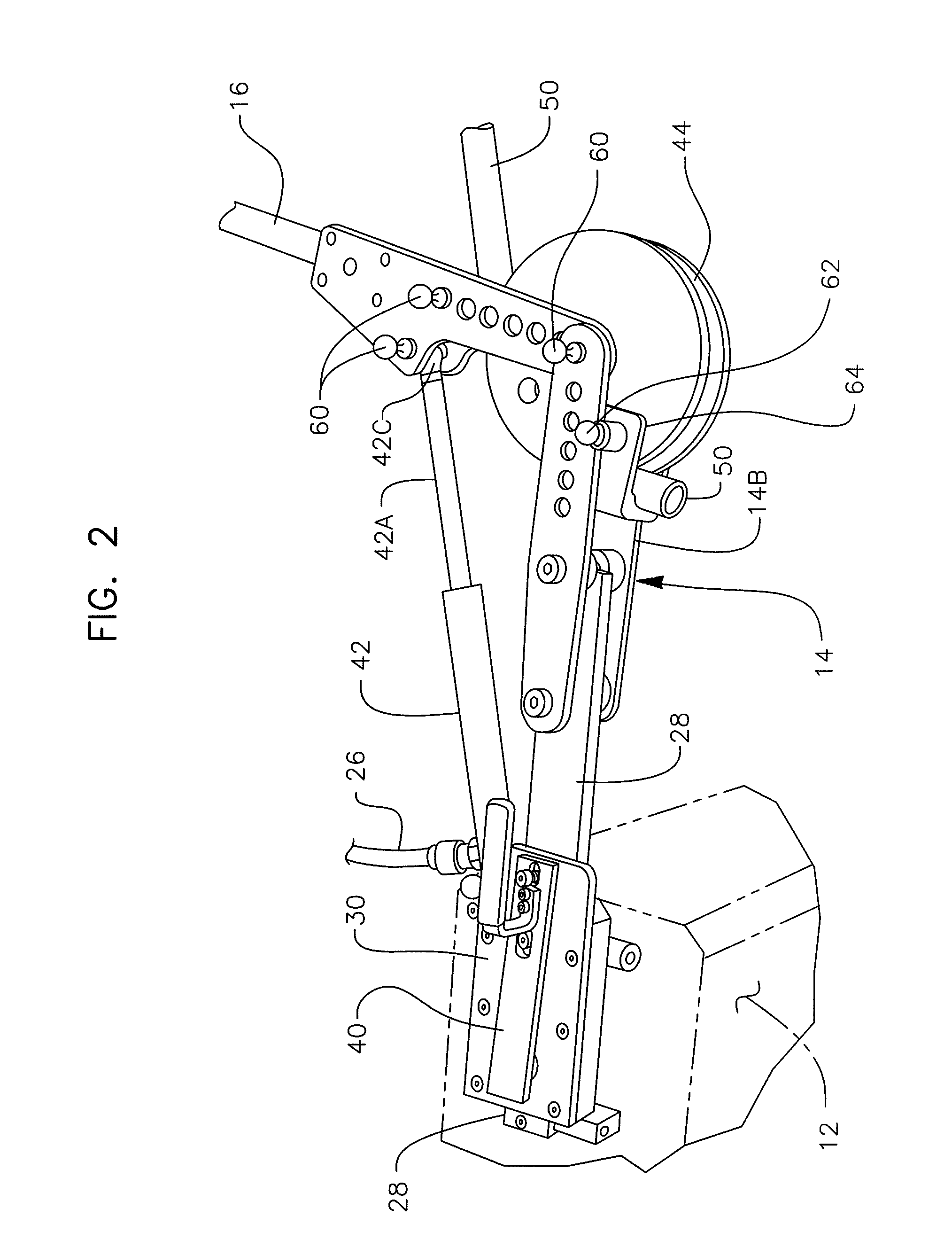

Pipe bursting apparatus

ActiveUS8702349B2Light weightLow costPipe laying and repairSoil-shifting machines/dredgersHydraulic cylinderPipe bursting

Owner:TRIC TOOLS INC

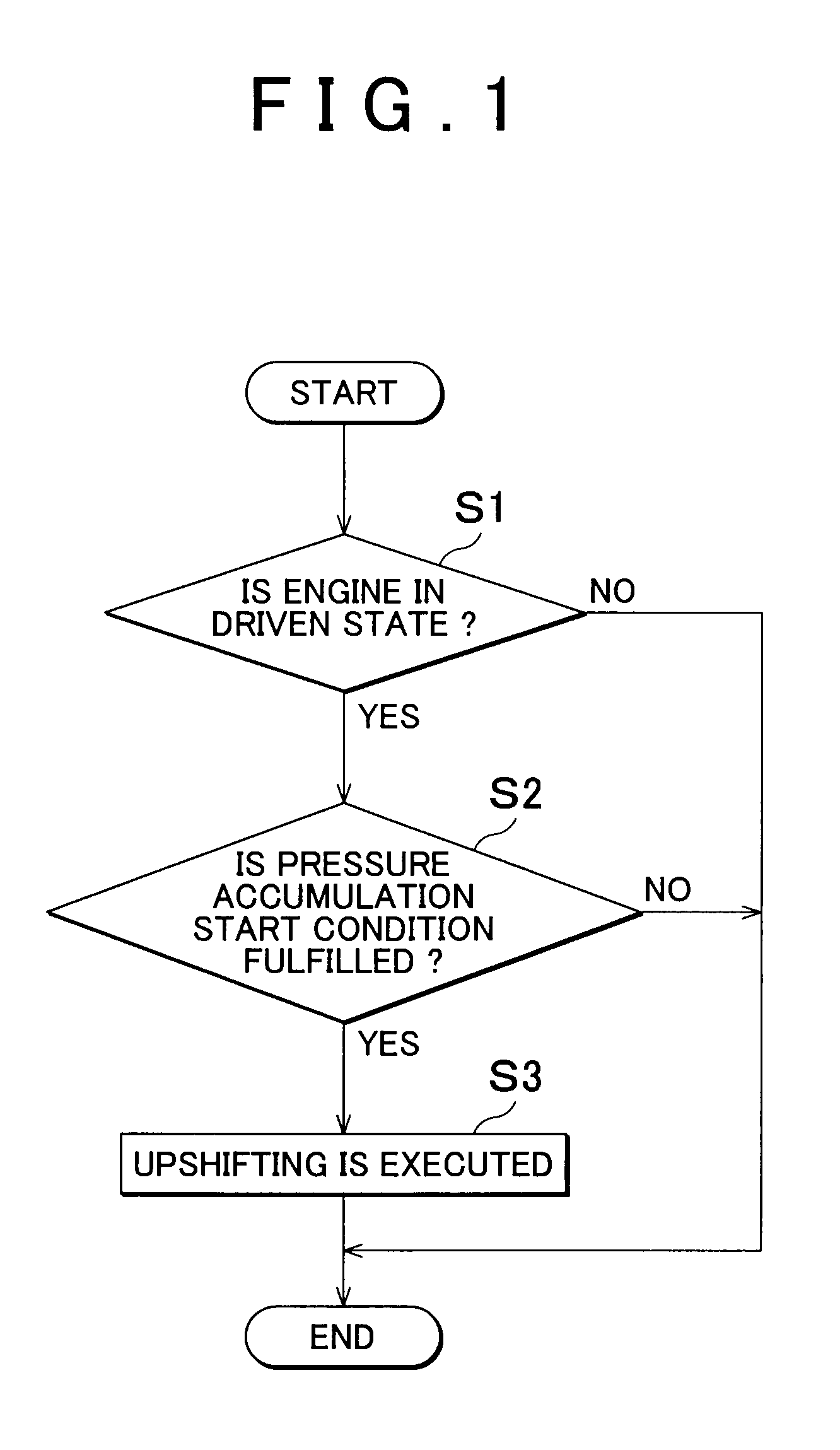

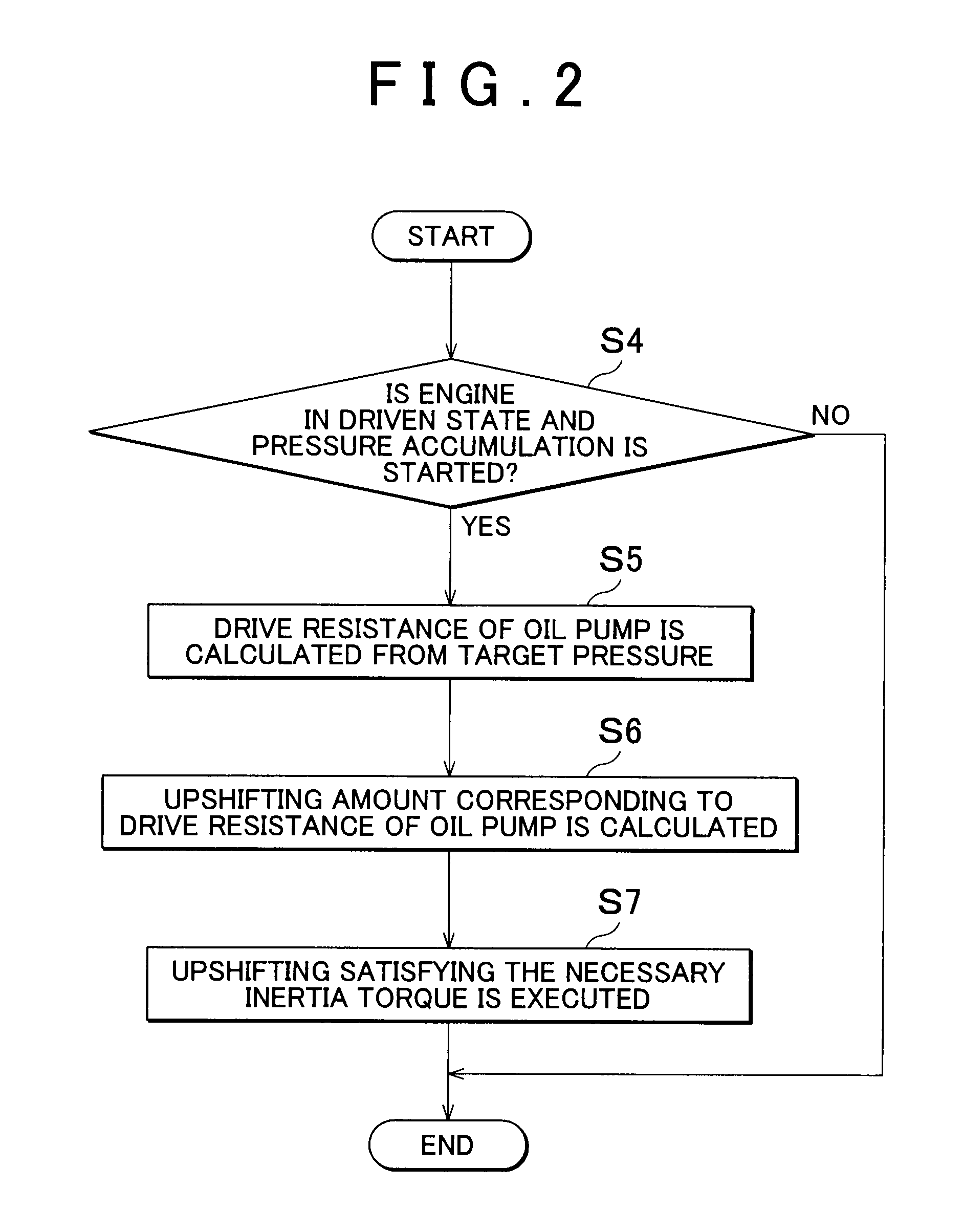

Shift controller and shift control method for automatic transmission mechanism

InactiveUS20100210413A1Reduce gear ratioReduce hydraulic pressureFluid couplingsRoad transportAutomatic transmissionHydraulic pump

A shift controller for an automatic transmission mechanism is configured such that when the engine is in a driven state in which the engine is driven by a travel inertia force or the like and an accumulated pressure amount of the accumulator is equal to or less than a predetermined threshold, the excessive engine brake force, which is generated due to the accumulation of at least a portion of the hydraulic pressure generated from the mechanical hydraulic pump in the accumulator, is inhibited or reduced by conducting upshifting that relatively decreases the gear ratio of the automatic transmission mechanism. Therefore, the generation of the excessive engine brake force can be inhibited or reduced even when the engine is in the driven state and pressure accumulation is performed.

Owner:TOYOTA JIDOSHA KK

Vehicle brake device and method of controlling vehicle brake device

ActiveUS20130134767A1Good pedal feelingAvoid reactionBraking element arrangementsPower to auxillary motorsRegenerative brakeWheel cylinder

There is provided a vehicle brake device that includes hydraulic brake means for generating a hydraulic brake force and regenerative brake means for generating a regenerative brake force and distributes the hydraulic brake force and the regenerative brake force for a driver-requested brake force. The hydraulic brake means includes a pressure reducing valve that reduces hydraulic pressure of wheel cylinders. The vehicle brake device includes hydraulic brake control means for maintaining the pressure reducing valve open while the driver-requested brake force is covered by only the regenerative brake force. The hydraulic brake control means does not open the pressure reducing valve when hydraulic pressure is present in the wheel cylinders.

Owner:BOSCH CORP

Hydraulic control apparatus for vehicle

ActiveUS20120109478A1Suppress feverReduce transmissionHybrid vehiclesDigital data processing detailsTarget engagementDrive wheel

The hydraulic control apparatus calculates a target engagement hydraulic pressure of a frictional engagement element, controls the frictional engagement element so that a revolution speed at a driving source side of the frictional engagement element is higher than a revolution speed at a driving wheel side of the frictional engagement element, outputs a command current to a solenoid valve on the basis of a map having a relationship between the target engagement hydraulic pressure and the command current, and decreases the engagement hydraulic pressure when a vehicle speed is equal to or less than a predetermined vehicle speed at which the vehicle is judged to be vehicle stop during execution of the slip control. Further, the hydraulic control apparatus corrects the map so that a variation of the command current with respect to a variation of the target engagement hydraulic pressure is small when decreasing the engagement hydraulic pressure.

Owner:JATCO LTD +1

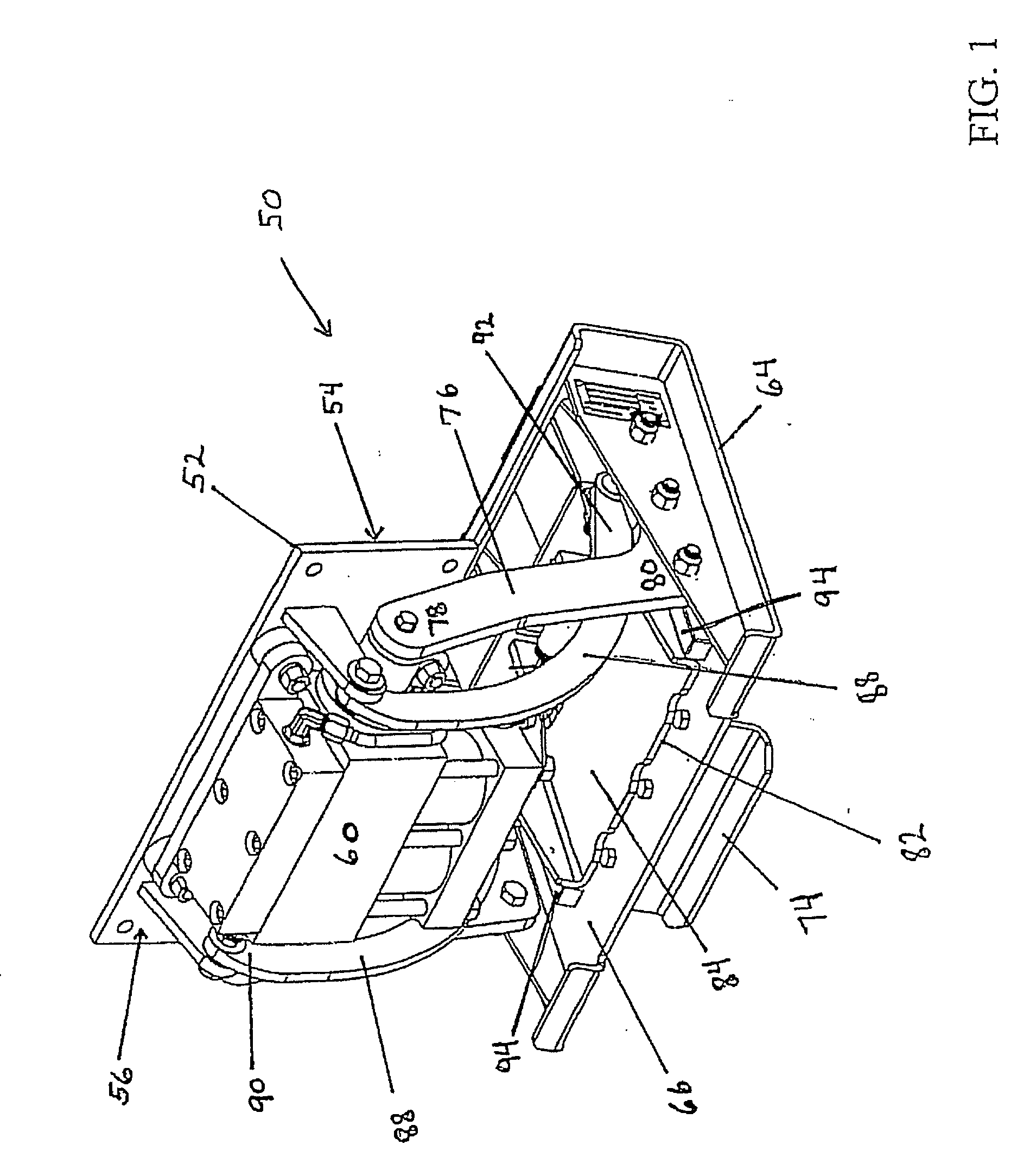

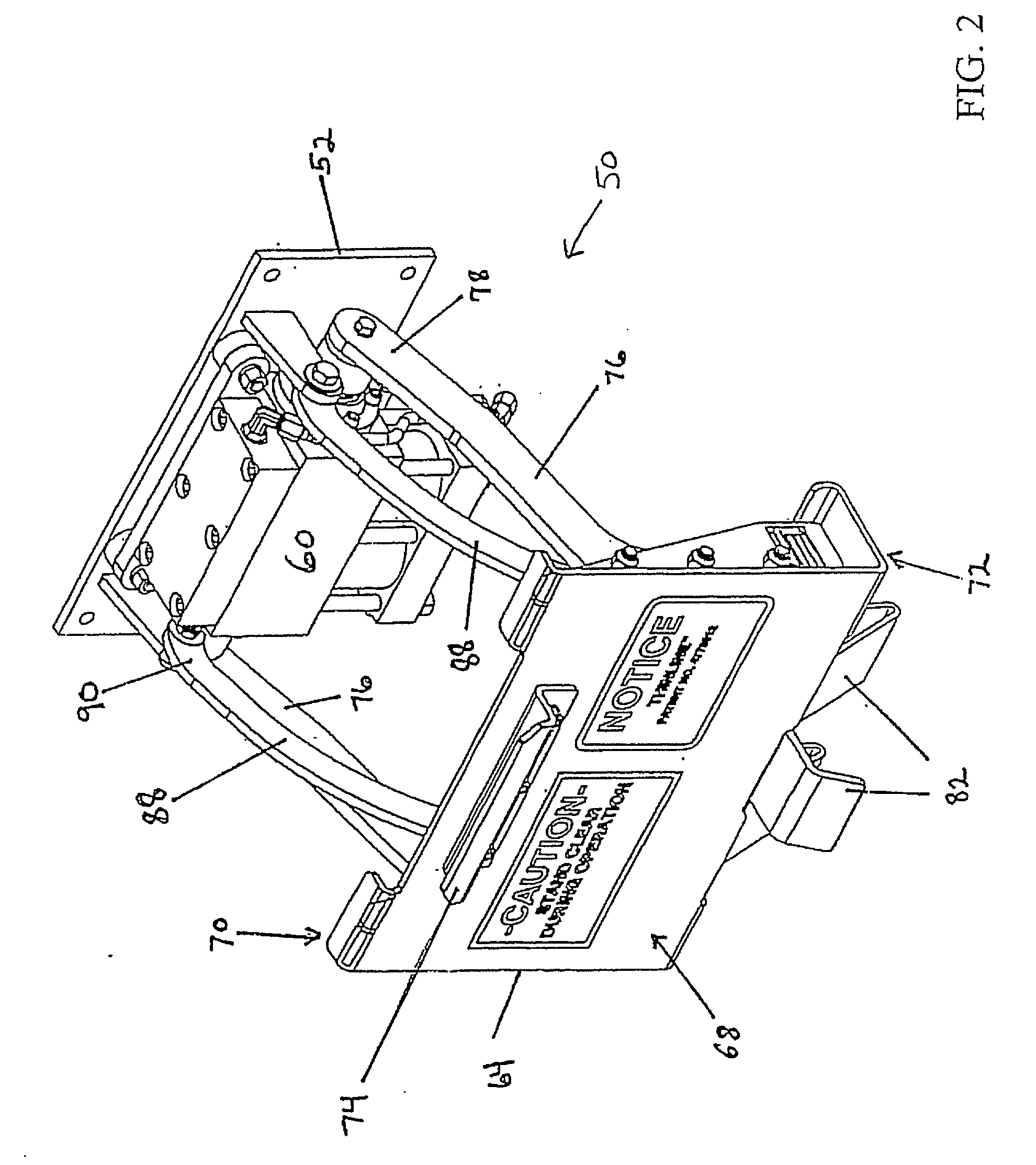

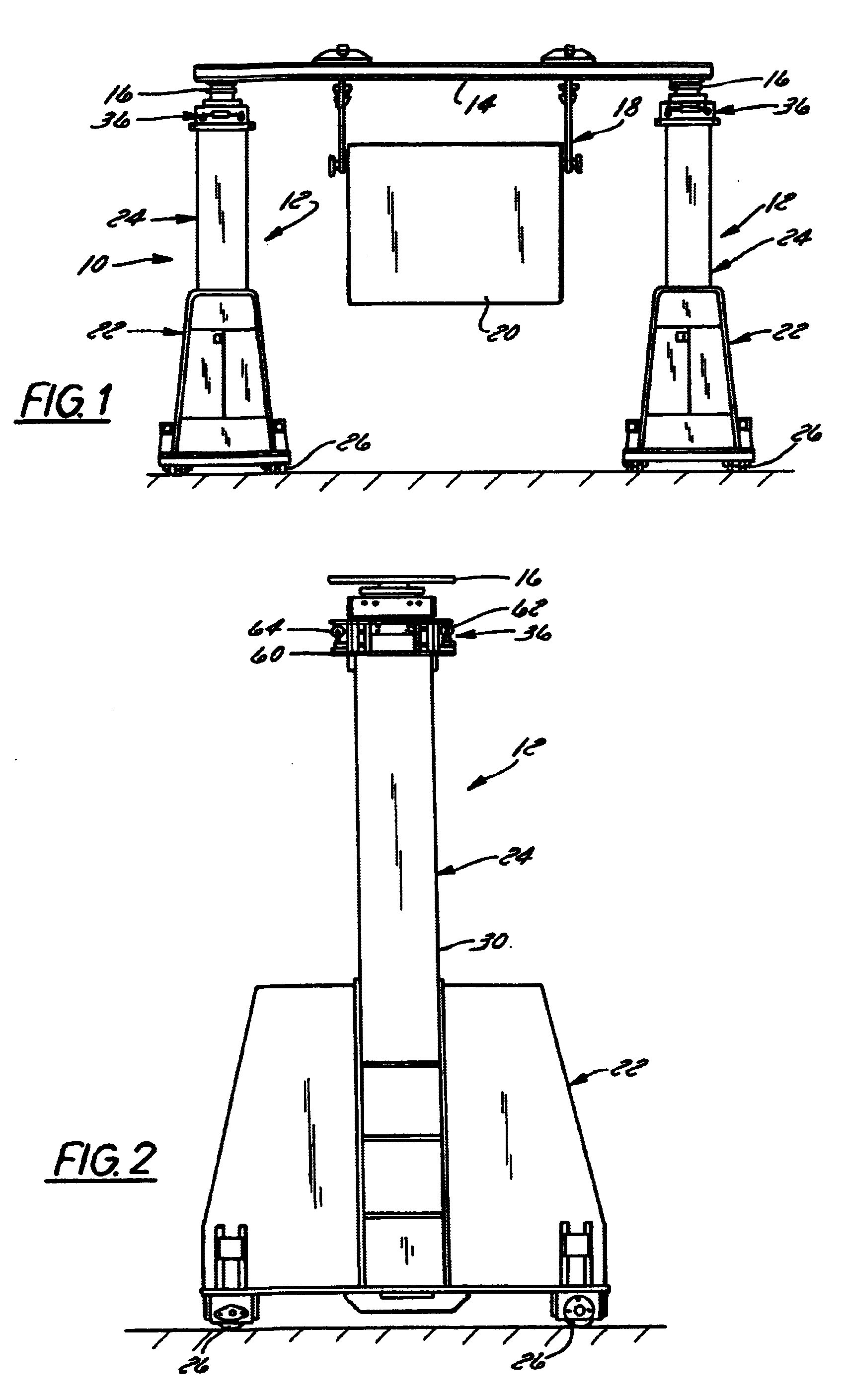

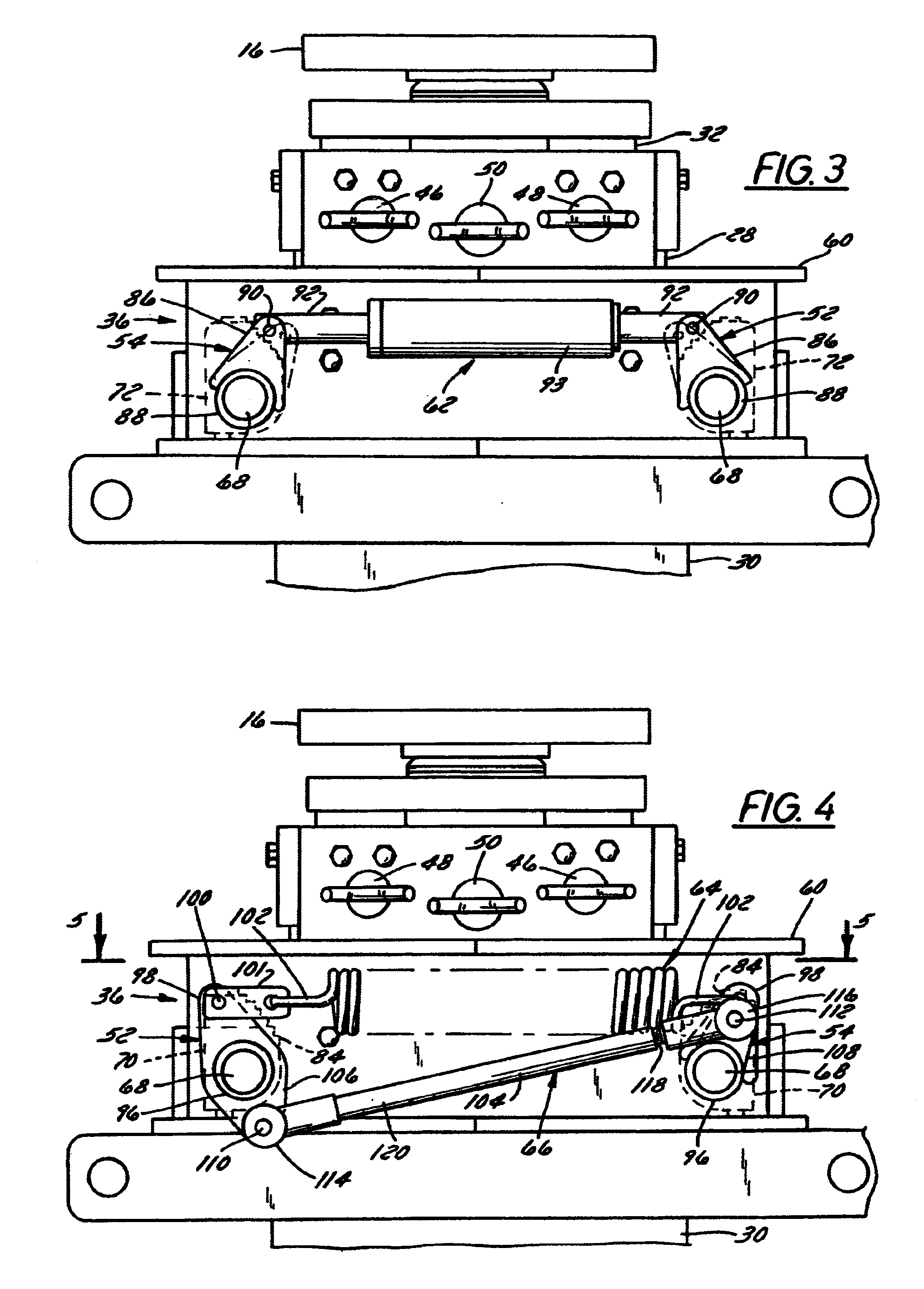

Refuse cart lifter with an improved range of rotation

InactiveUS20060045681A1Extended operating rangeImprove efficiencyArticle unpackingLoading/unloadingRefuse collectionElectric machinery

A lifter is disclosed which allows for an improved operating envelope of the faceplate. The lifter utilizes a motor having 210 degrees of rotation and lifting arms of a unique geometry to rotate a faceplate from a retracted position below and substantially behind the lifter baseplate to a dumping position above and substantially behind a lower hopper edge for the purpose of dumping refuse carts into a refuse collection vehicle. This dumps refuse further into the vehicle hopper, which minimizes the number of packing cycles required on a collection route. A faceplate is attached to the motor using two lifting arms. The faceplate has a fixed upper hook and may be configured with a sliding, retractable lower hooking mechanism or a spring loaded, cam actuated rotating hook mechanism. The faceplate may include multiple sets of attachment points for attaching the lifting arms to facilitate the mounting of the lifter on a refuse collection vehicle over a range of heights without necessitating replacement of the lifting arms.

Owner:BAYNE MACHINE WORKS

Work support

InactiveUS20040130086A1Reduce the overall diameterPrevent ejectionSleeve/socket jointsPrecision positioning equipmentHydraulic cylinderAbutment

The abutment of the rod to the work piece is accomplished in a stable manner by providing an air passage in the inside of the work support for supplying pressurized air for detecting the abutment between the rod and the work piece. Work support is equipped with case, rod, sleeve that elastically deforms to reduce its diameter, hydraulic cylinder for driving rod in an advancing direction, spring for elastically energizing rod in advancing direction, detection nozzle for ejecting pressurized air, air passage connected to detection nozzle, sensor for detecting abutment between the tip of rod and work piece based on air pressure, and a control unit. Work piece is supported by the tip of rod abutting work piece while ejecting pressurized air from detection nozzle, and locks rod by elastically deforming sleeve to reduce its diameter after detecting the abutment of rod by a pressure sensor and control unit.

Owner:PASCAL ENG

Extendible boom with locking mechanism having equalizer arrangement

InactiveUS6685038B1Avoids bind and bend loadAvoids binding and bending loadBase supporting structuresBraking devices for hoisting equipmentsCamEngineering

A extendible boom incorporates a locking mechanism that mechanically engages an extended boom section in response to the loss of hydraulic fluid pressure to the lift cylinder for that boom section so as to prevent unintended boom lowering. The locking mechanism includes locking devices, such as toothed cams, that are located on opposite sides of the boom and that are configured to move, 1) from a disengaged position permitting unobstructed movement of the extended section relative to the adjacent section, 2) to an engaged position in which the locking devices engage opposite sides of the extended section to prevent unintended boom lowering. In order to prevent the imposition of unequal locking forces that could occur if only the locking device on one side of the extended boom section were to engage that section, an equalizer arrangement mechanically couples the locking devices on opposite sides of the extended boom section to one another so that both locking devices always move through essentially the same stroke at essentially the same time. The equalizer arrangement preferably comprises an equalizer bar that mechanically couples pivot shafts of the two locking devices together so that rotation of one pivot shaft drives the other pivot shaft to simultaneously rotate through a pivot stroke that at least substantially equals a pivot stroke of the one shaft.

Owner:J&R ENG

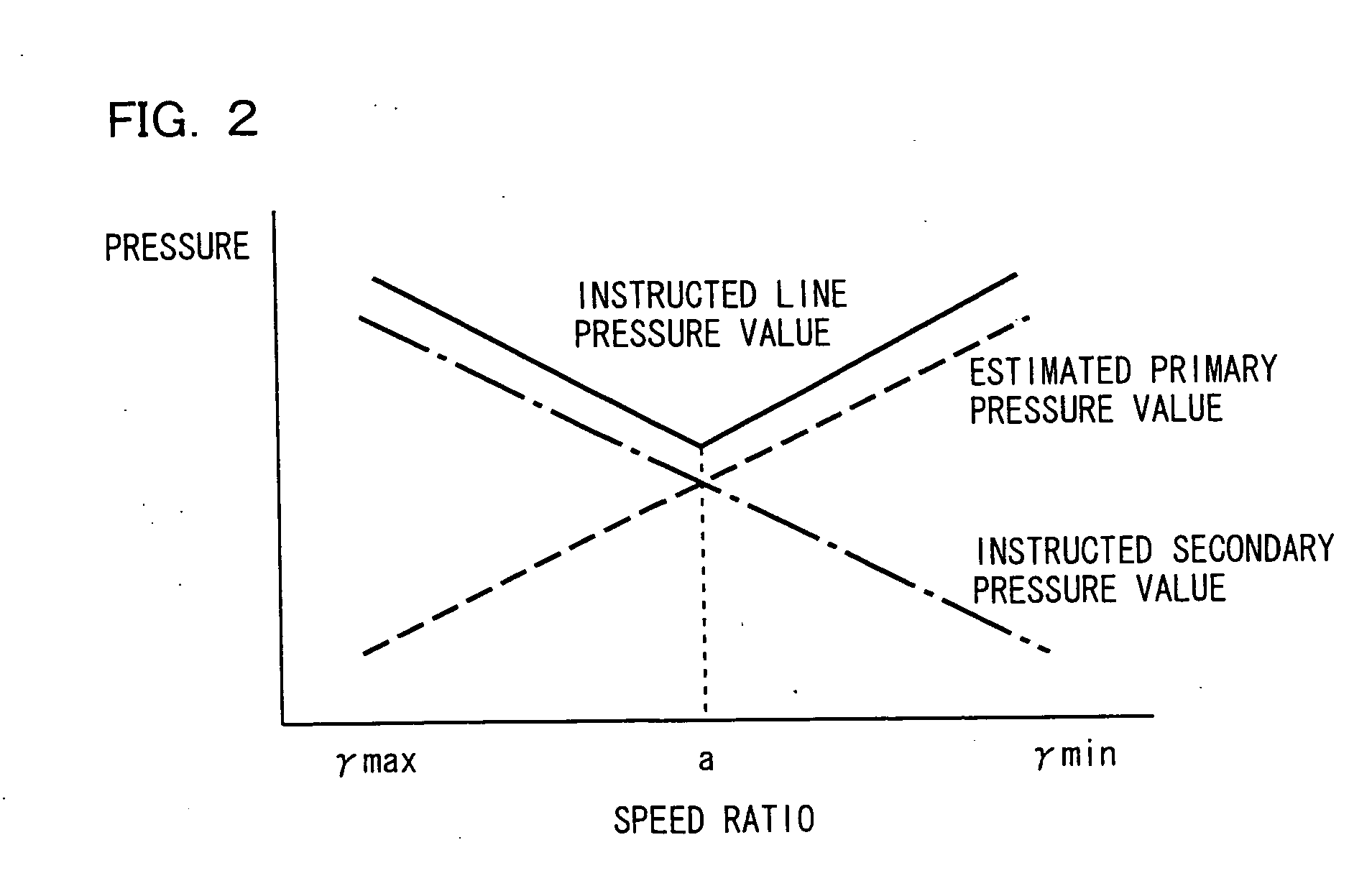

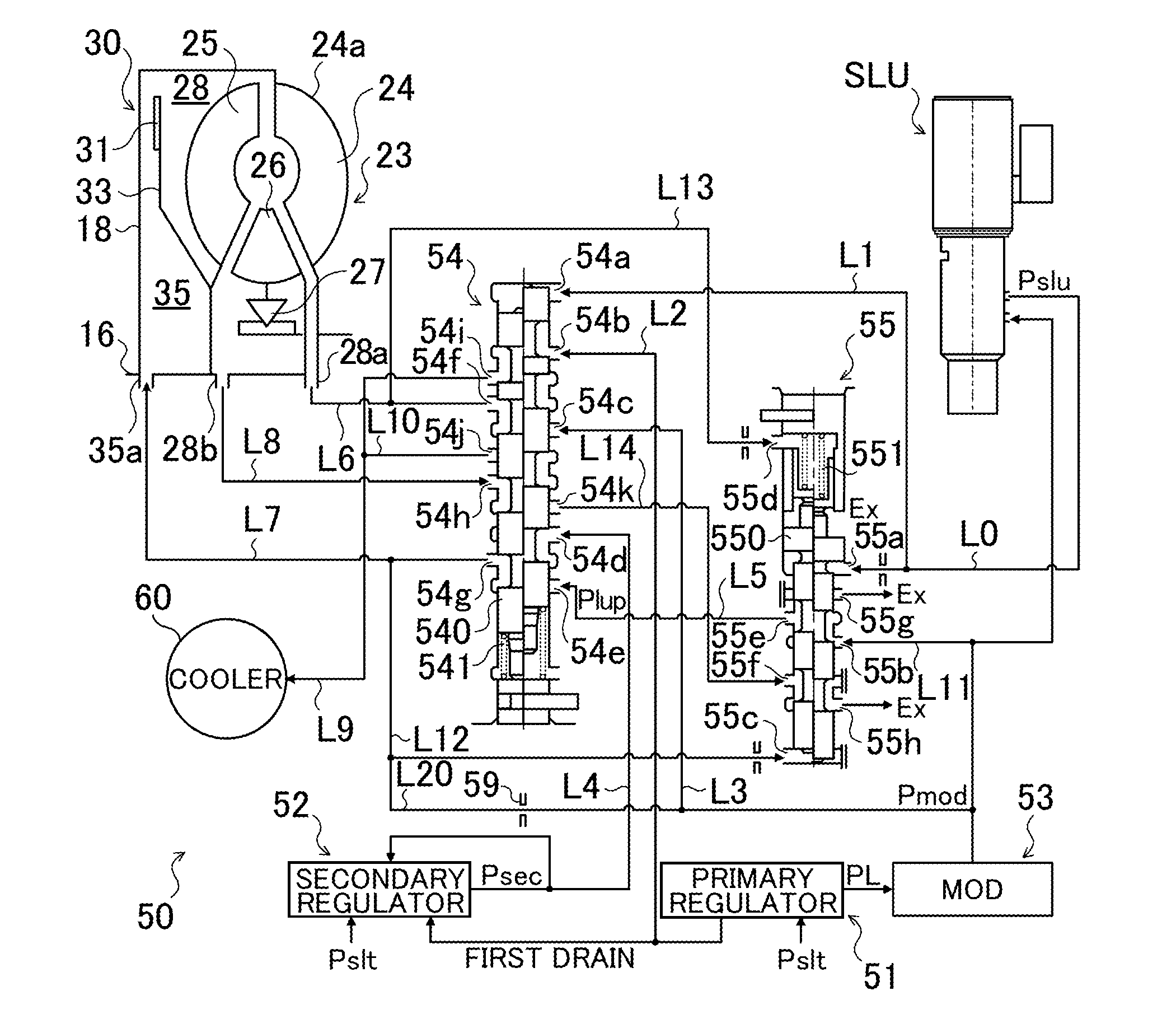

Failure determining device and failure determining method of continuously variable transmission

ActiveUS20100191407A1Reduce hydraulic pressureReduce the degree of variationVehicle testingRegistering/indicating working of vehiclesControl theoryVariator

Owner:TOYOTA JIDOSHA KK

Brake control system and brake control method

InactiveCN101720288AReduce hydraulic pressureLow costElectric devicesElectrodynamic brake systemsControl systemState of charge

Owner:TOYOTA JIDOSHA KK

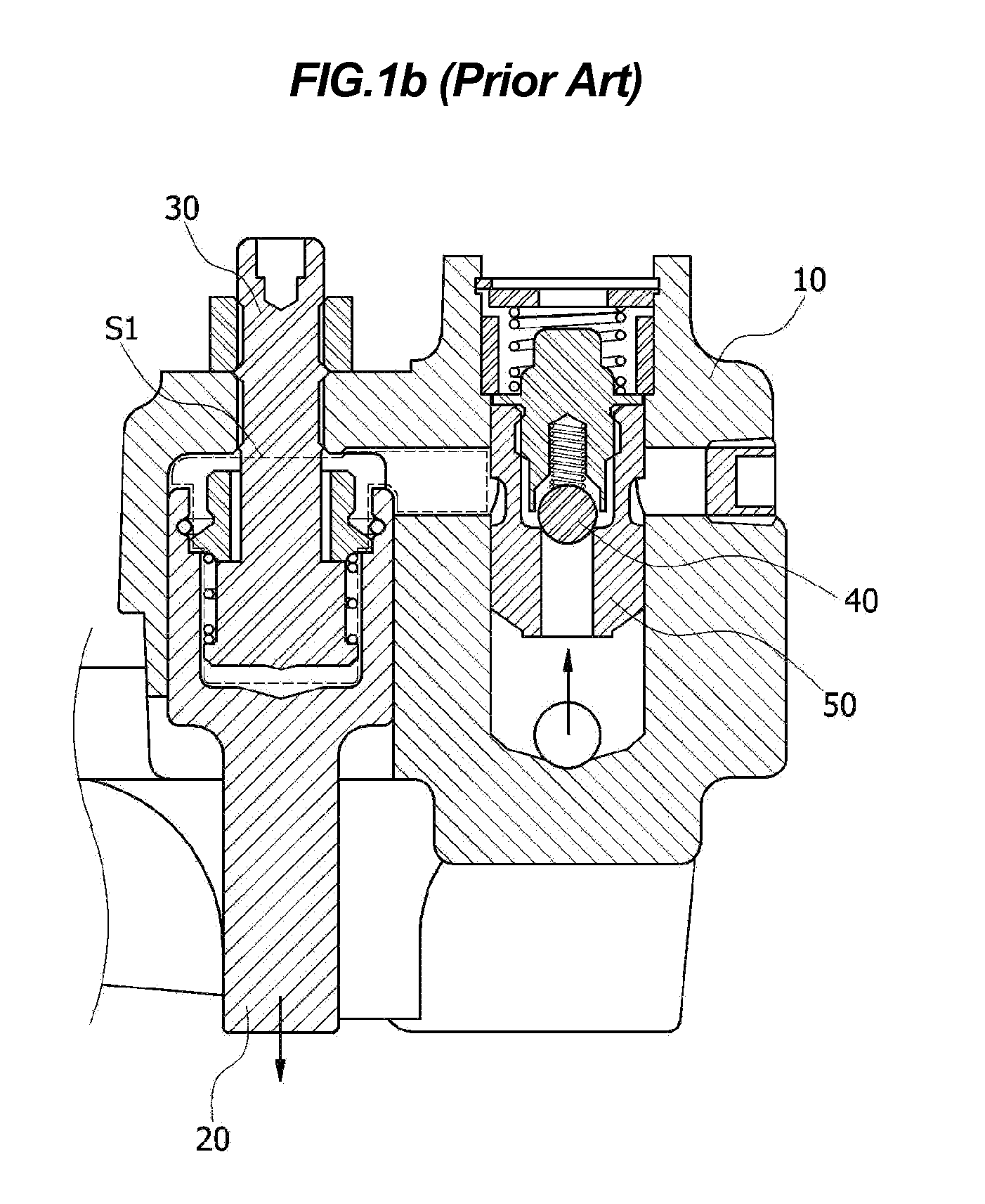

Hydraulic pressure control device

InactiveUS20120000740A1Quick engagementSuppress reduction in hydraulic pressureRotary clutchesFluid actuated clutchesClutch controlDifferential pressure

A hydraulic pressure control device including a first oil passage connected to an engagement side oil chamber defined on one side of a piston included in a clutch, an engagement pressure generating valve generating an engagement pressure supplied to the engagement side oil chamber via the first oil passage; a second oil passage connected to a back-pressure side oil chamber defined on the other side of the piston, and a clutch control pressure generating valve generating a clutch control pressure supplied to the back-pressure side oil chamber via the second oil passage and operates to lower the clutch control pressure as hydraulic pressure supplied as a feedback pressure from the back-pressure-side oil chamber side becomes higher. The hydraulic pressure control device controls a differential pressure between the engagement side oil chamber and the back-pressure side oil chamber, and the first oil passage and the second oil passage are communicated with each other via a bypass oil passage having an orifice in a midway position thereof.

Owner:AISIN AW CO LTD

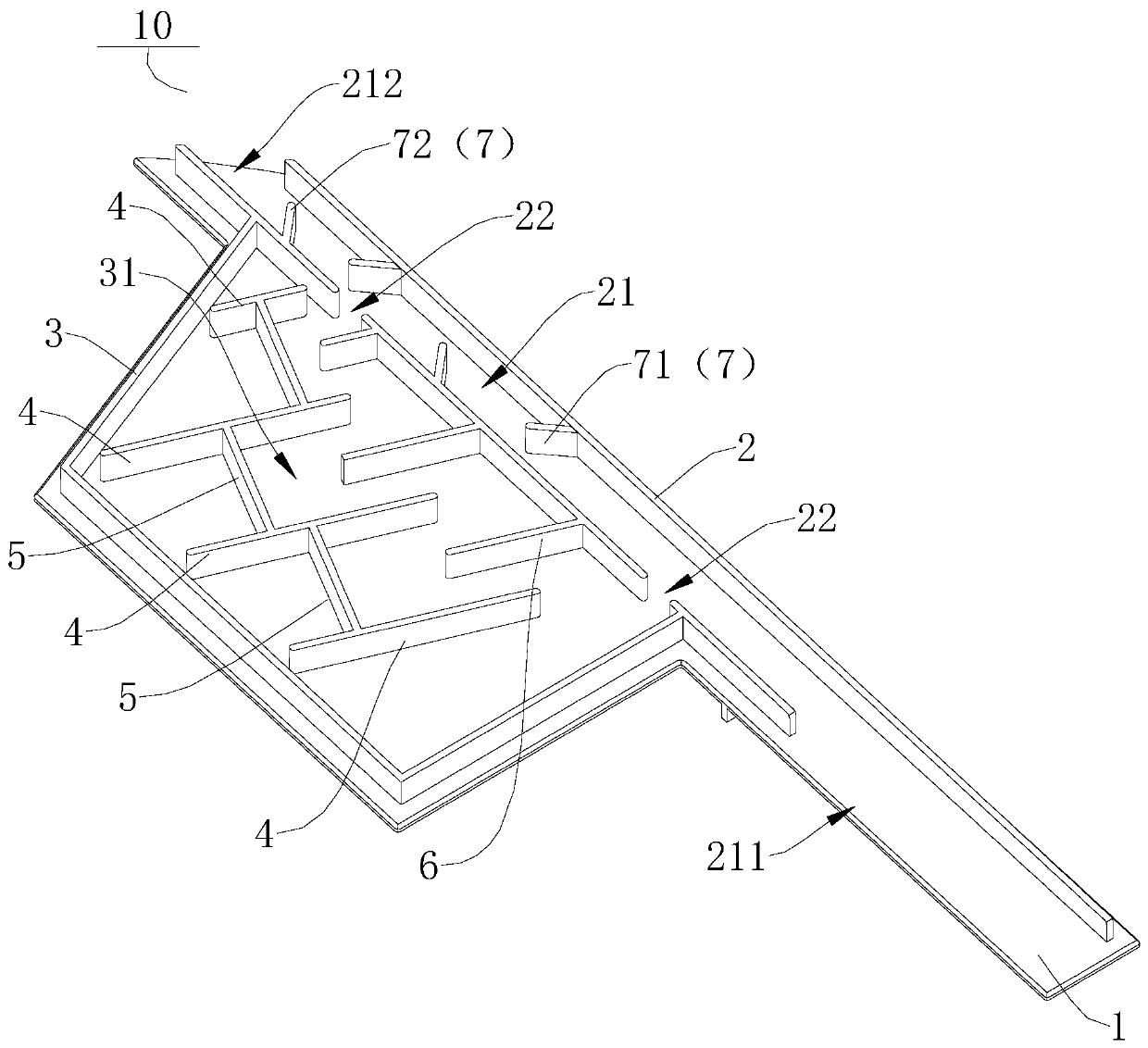

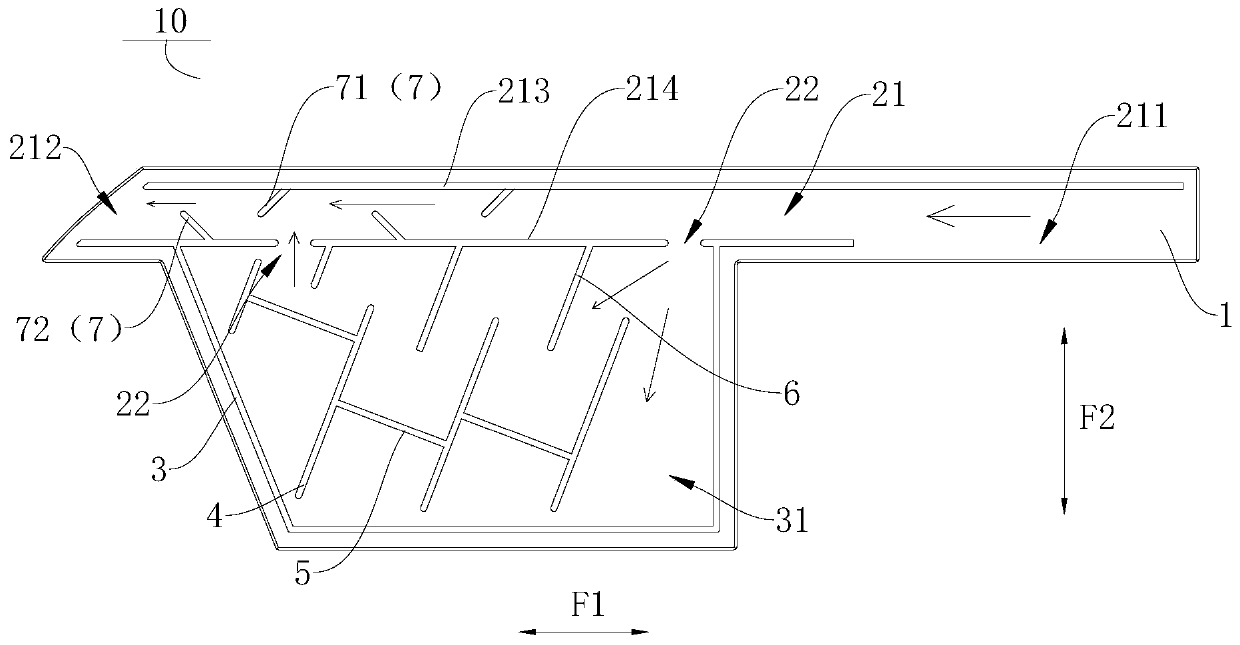

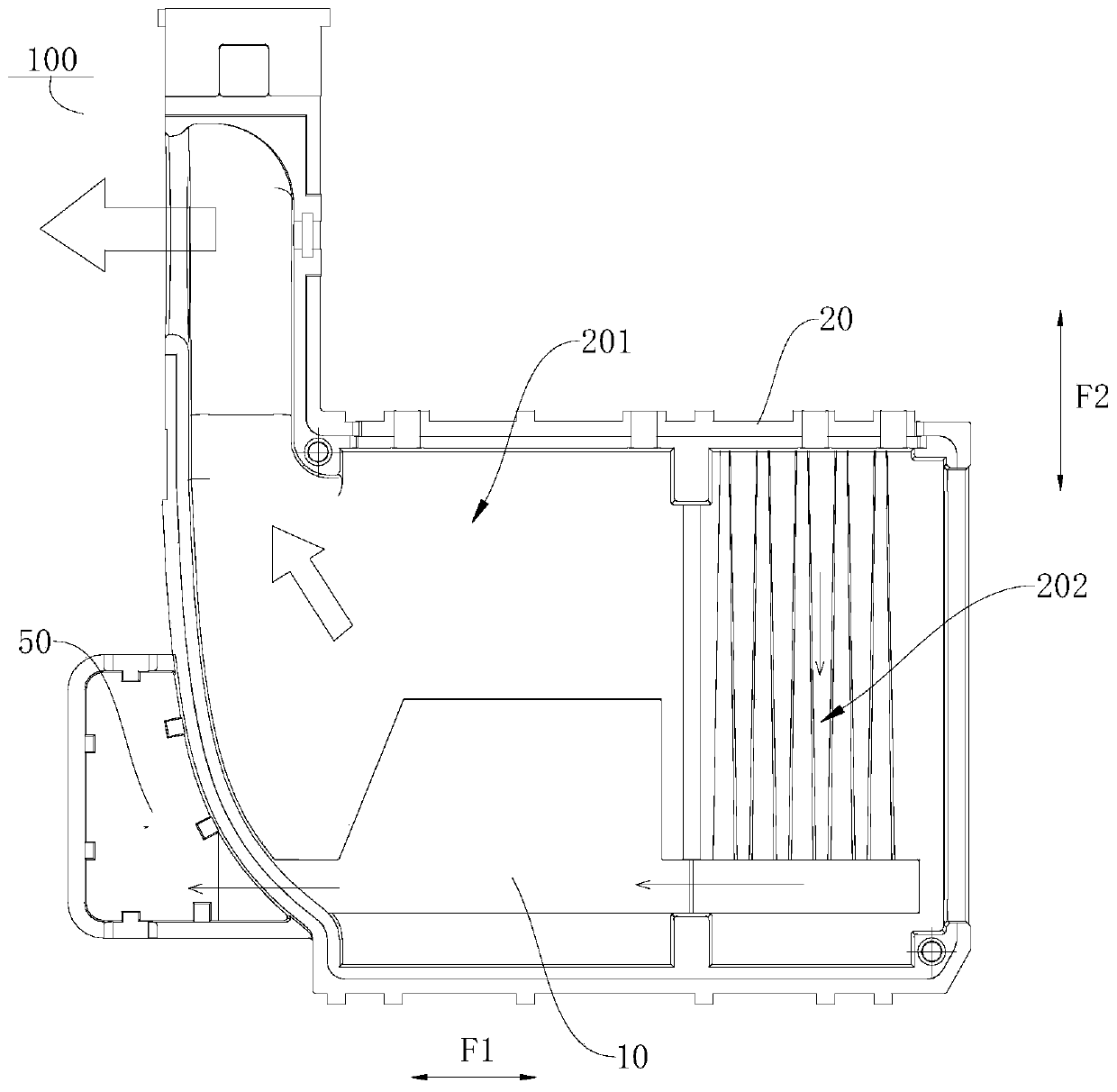

Liquid discharging partition plate for clothes dryer and clothes dryer

ActiveCN111364220APrevent backflowIncrease the return pathTextiles and paperLaundry driersEngineeringStructural engineering

The invention discloses a liquid discharging partition plate for a clothes dryer and the clothes dryer. The liquid discharging partition plate is provided with a liquid guiding groove, an inlet of theliquid guiding groove and an outlet of the liquid guiding groove are located at the two ends of the liquid guiding groove in the length direction correspondingly, the liquid discharging partition plate is further provided with a flow dividing groove, the flow dividing groove is located in at least one side of the liquid guiding groove in the width direction, and the flow dividing groove communicates with the liquid guiding groove through a liquid passing opening. According to the liquid discharging partition plate, when negative pressure is generated in an air duct, flowed-back condensate atthe outlet of the liquid guiding groove can flow to the liquid guiding groove and the flow dividing groove correspondingly so that on one hand, the flow dividing effect can be achieved, hydraulic pressure is reduced, on the other hand, condensate flowing back paths are increased, and therefore the condensate can be prevented from flowing back into the air duct.

Owner:WUXI FILIN ELECTRONICS CO LTD

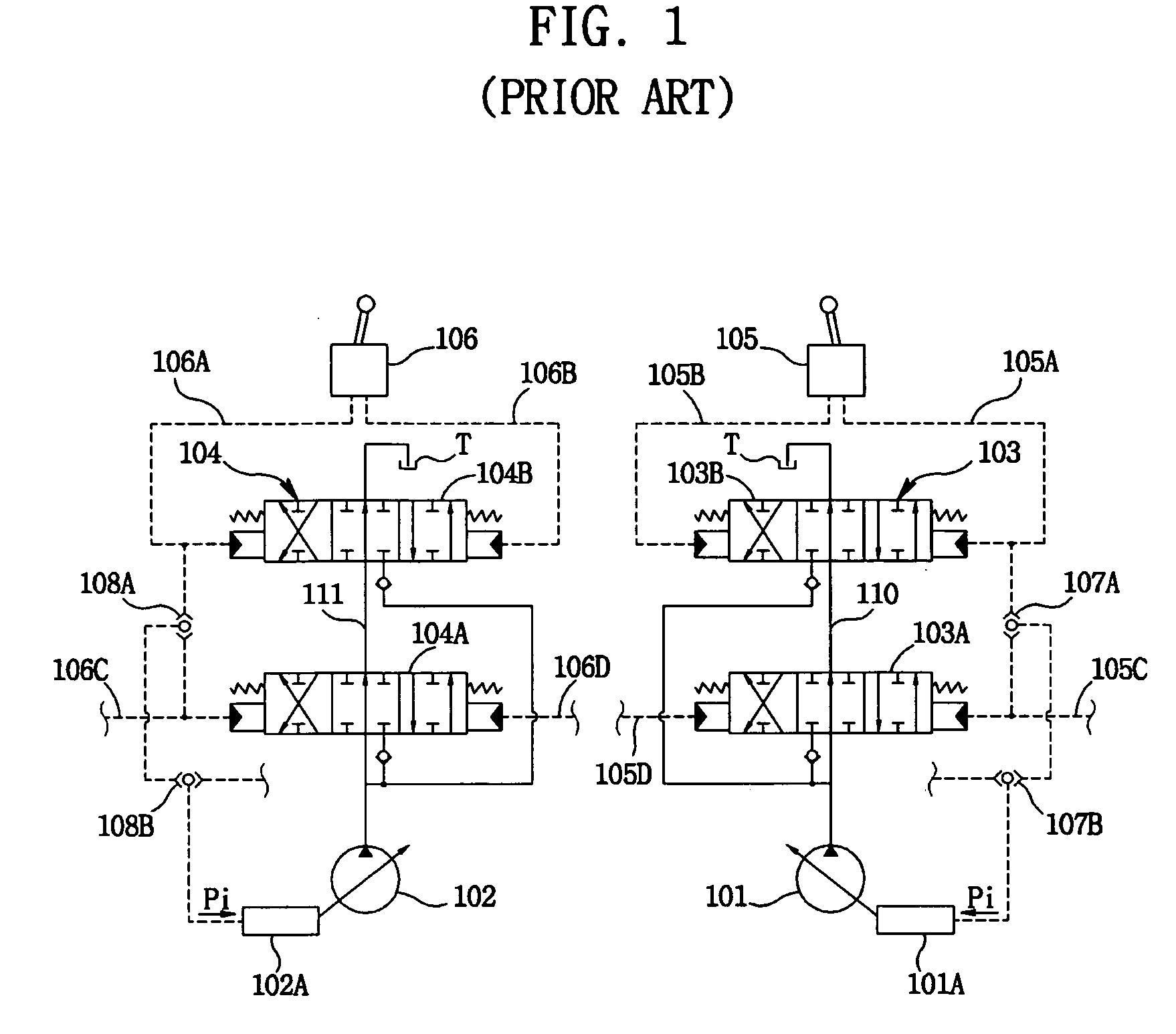

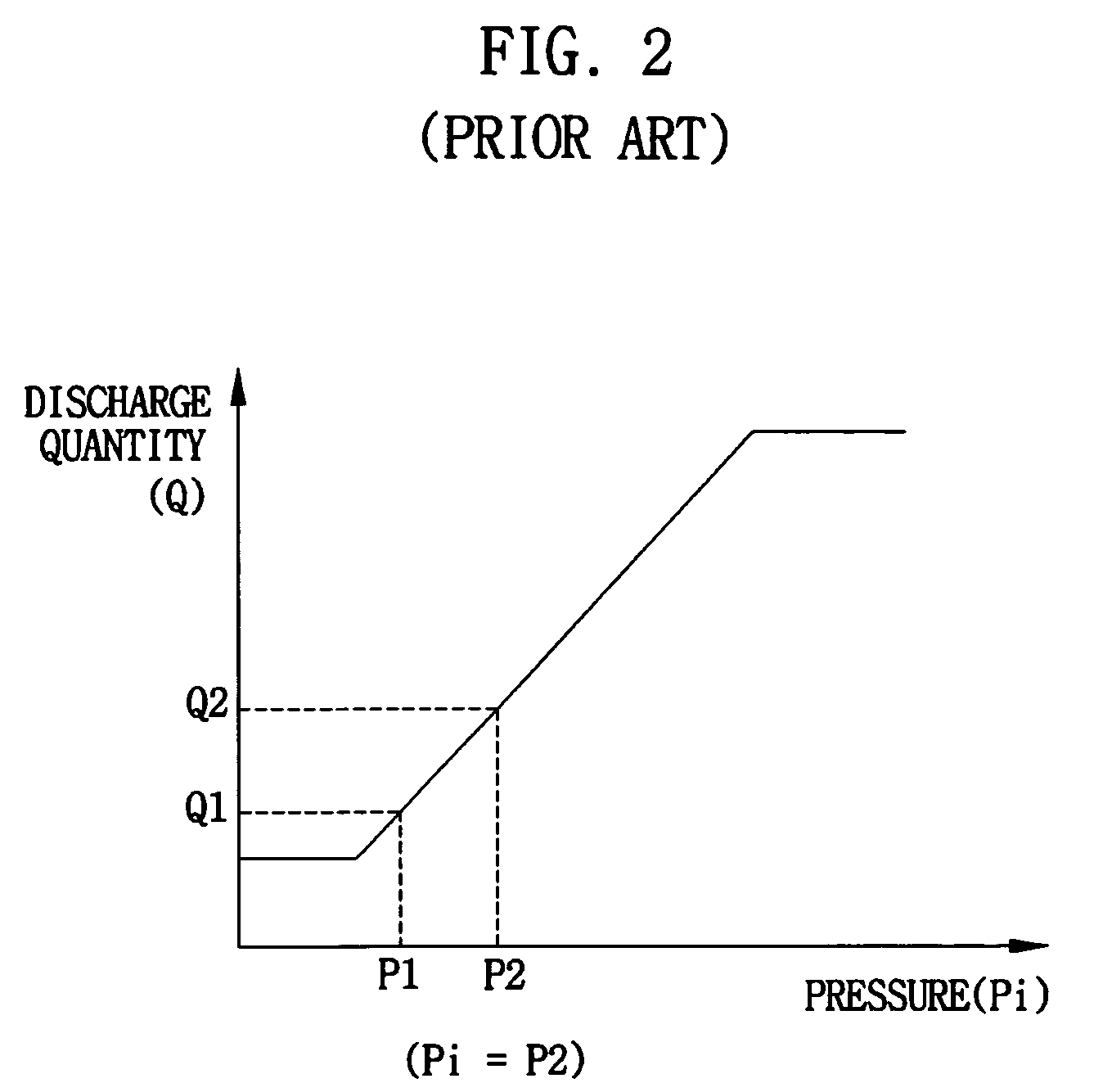

Fluid pump control system for excavators

InactiveUS20060147315A1Improve excavator 's performanceReduce hydraulic pressureFluid couplingsSoil-shifting machines/dredgersVariable displacementControl line

A fluid pump control system for excavators enables fluid pumps to produce hydraulic flows of a quantity great enough to actuate hydraulic actuators for smooth composite operations. The system includes variable displacement fluid pumps, fluid quantity control mechanisms for controlling the discharge quantity of the respective fluid pumps, fluid quantity control signal lines respectively connected to the fluid quantity control mechanisms, signal pressure control lines for bringing the fluid quantity control signal lines into connection with a fluid tank to drop the fluid quantity control signal pressures within the fluid quantity control signal lines, and a plurality of cutoff valves attached to the signal pressure control lines in tandem and shiftable in concert with the shifting movement of spools of a control valve for increasing the fluid quantity control signal pressures within the signal pressure control lines in proportion to the shifting amounts of the cutoff valves.

Owner:DOOSAN INFRACORE CO LTD

Brake apparatus, brake control unit, and brake control method

ActiveUS8303046B2InhibitionReduce hydraulic pressureHybrid vehiclesBraking element arrangementsEngineeringControl theory

There is provide a brake control technology according to which a target hydraulic pressure is reliably achieved when a hydraulic pressure is decreased during hydraulic control and brake drag does not occur even when the target hydraulic pressure is zero. In a brake apparatus, a dead-band region is set for the target hydraulic pressure that is used in the hydraulic control. When braking control is switched from the hydraulic control to regenerative control in cooperative braking control, residual pressure reduction control is executed. In the residual pressure reduction control, the target hydraulic pressure is set to a value that is lower than zero to which the hydraulic pressure should be brought.

Owner:TOYOTA JIDOSHA KK

Vehicle braking system

InactiveUS7104058B2Reduce in quantitySimple configurationServomotor componentsRotary clutchesEngineeringMechanical engineering

In a vehicle braking system, a backup piston pushes a master piston directly from behind when hydraulic pressure of a boosted hydraulic pressure chamber decreases. The backup piston has a piston body which is slidably fitted in a casing, and a pusher which is slidably fitted in the casing with a seal diameter smaller than seal diameters of the master piston and the piston body and which extends to the front end of the piston body, to push the master piston from behind. An annular input chamber communicated with a hydraulic power source is formed between the backup piston and the casing. When the pusher pushes the master piston forward, amount of volume increased in the boosted hydraulic pressure chamber is set to be substantially equal to amount of volume decreased in the input chamber. Thus, it is possible to avoid increase in the hydraulic pressure of the boosted hydraulic pressure chamber during forward movement of the backup piston, using a simple configuration with a reduced number of parts.

Owner:AUTOLIV NISSIN BRAKE SYST JAPAN CO LTD +1

Acute angle metal stock bender

ActiveUS7536890B2Eliminate useReduce hydraulic pressureForging/hammering/pressing machinesHydraulic cylinderAcute angle

Apparatus for bending stock to an acute angle. A hydraulic cylinder with a ram extendable under hydraulic pressure provides the bending power. The ram automatically retracts from an extended position when hydraulic pressure is removed. One end of an apparatus supporting arm consists of a slide bar. The slide bar end of the arm is secured to a support with the opposite end pivotably mounting a forming die and a lever. The lever pivotably mounts a forming roller. The lever carries the forming roller around the die and bend stock secured to the die around the die. A slide is slideably attached to the slide bar. The cylinder and ram are pivotably attached extending between the slide and the lever. With this arrangement providing hydraulic pressure to extend the ram will rotate the lever and forming roller around the die and bend secured stock around the die, then removing pressure will retract the ram and move the slide with the attached cylinder and ram towards the die where the slide is automatically locked in place. This permits making an acute angle bend by successive bends with the cylinder and ram at two different locations with respect to the die.

Owner:BULLE MARSHALL R

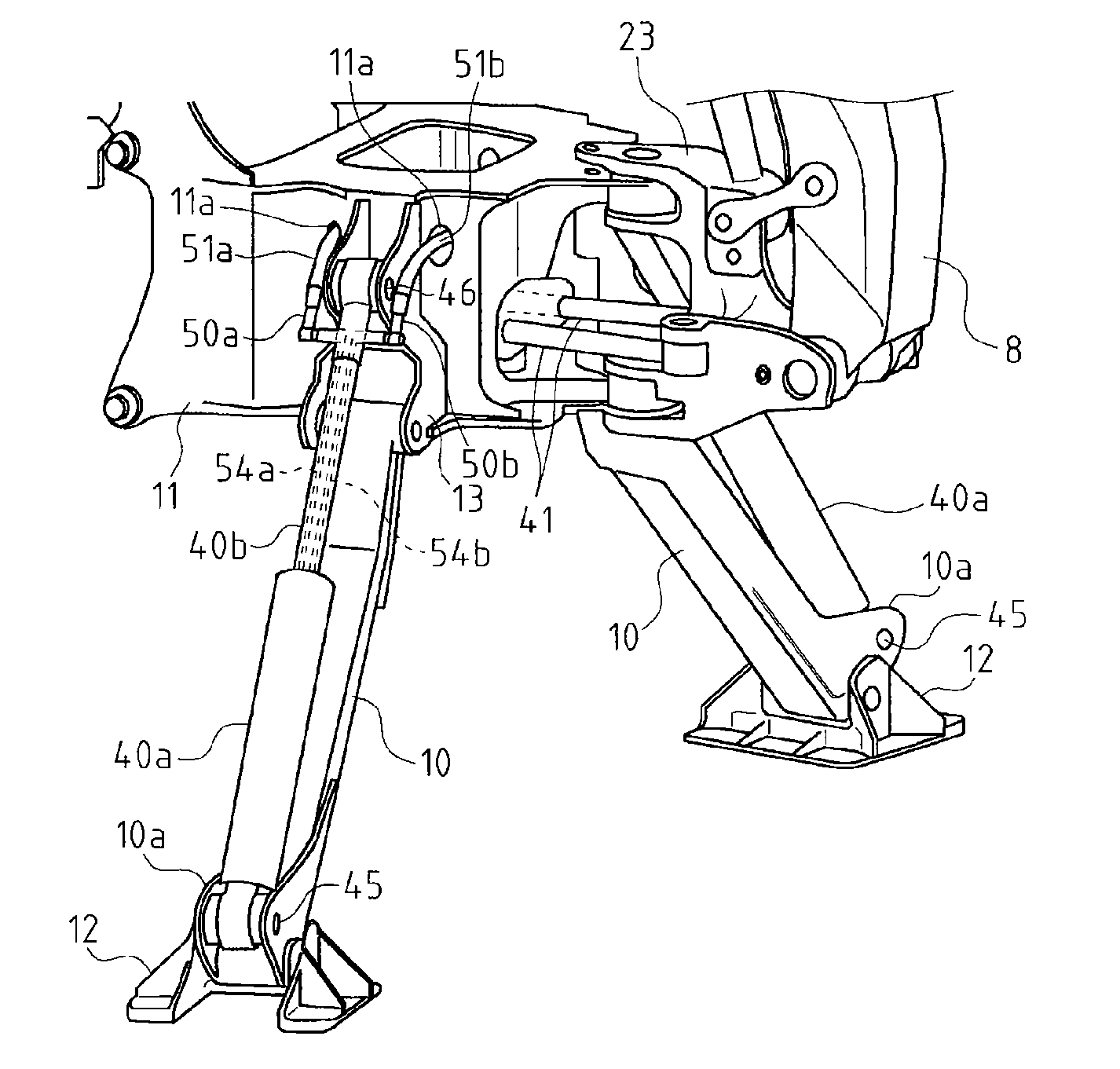

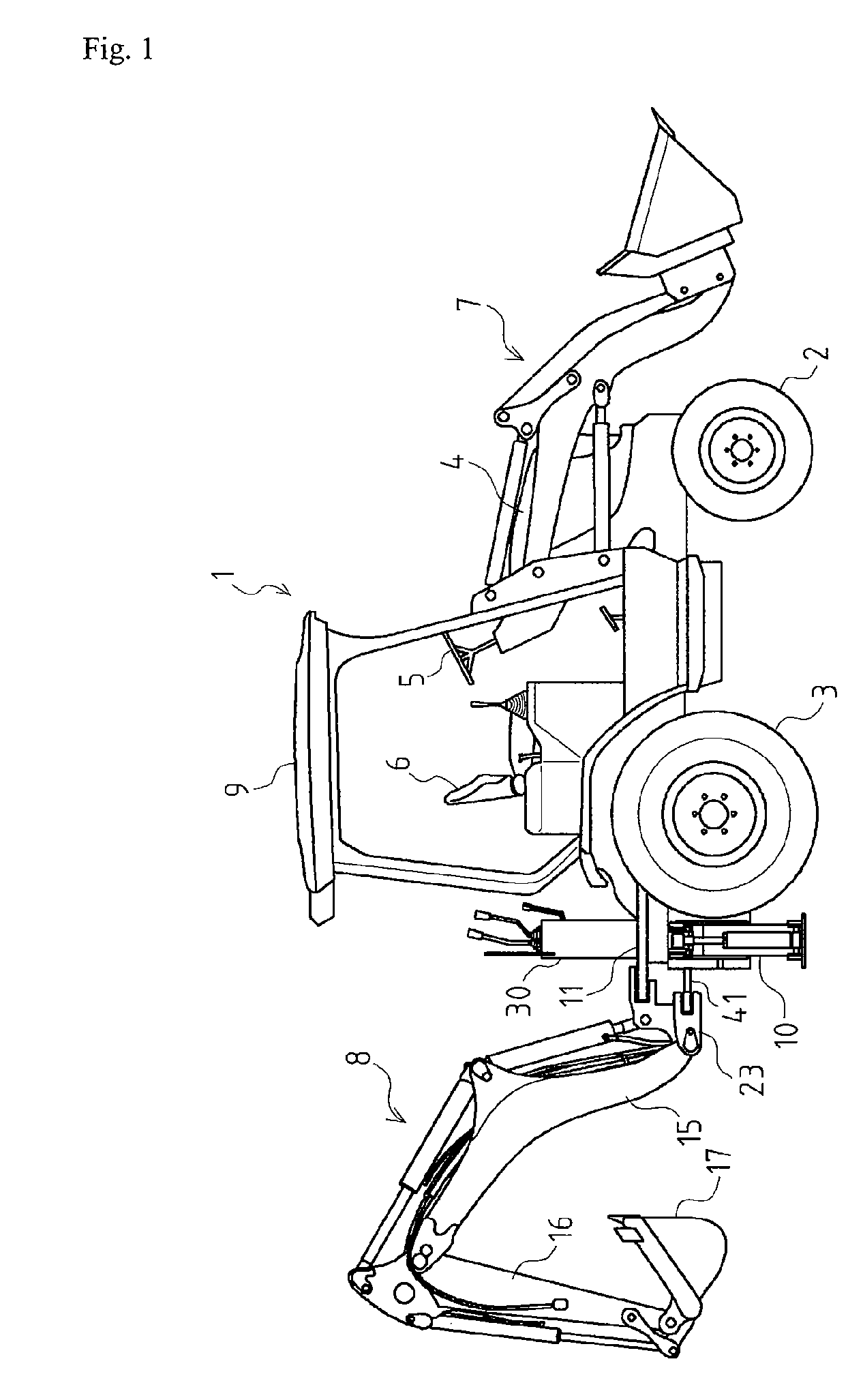

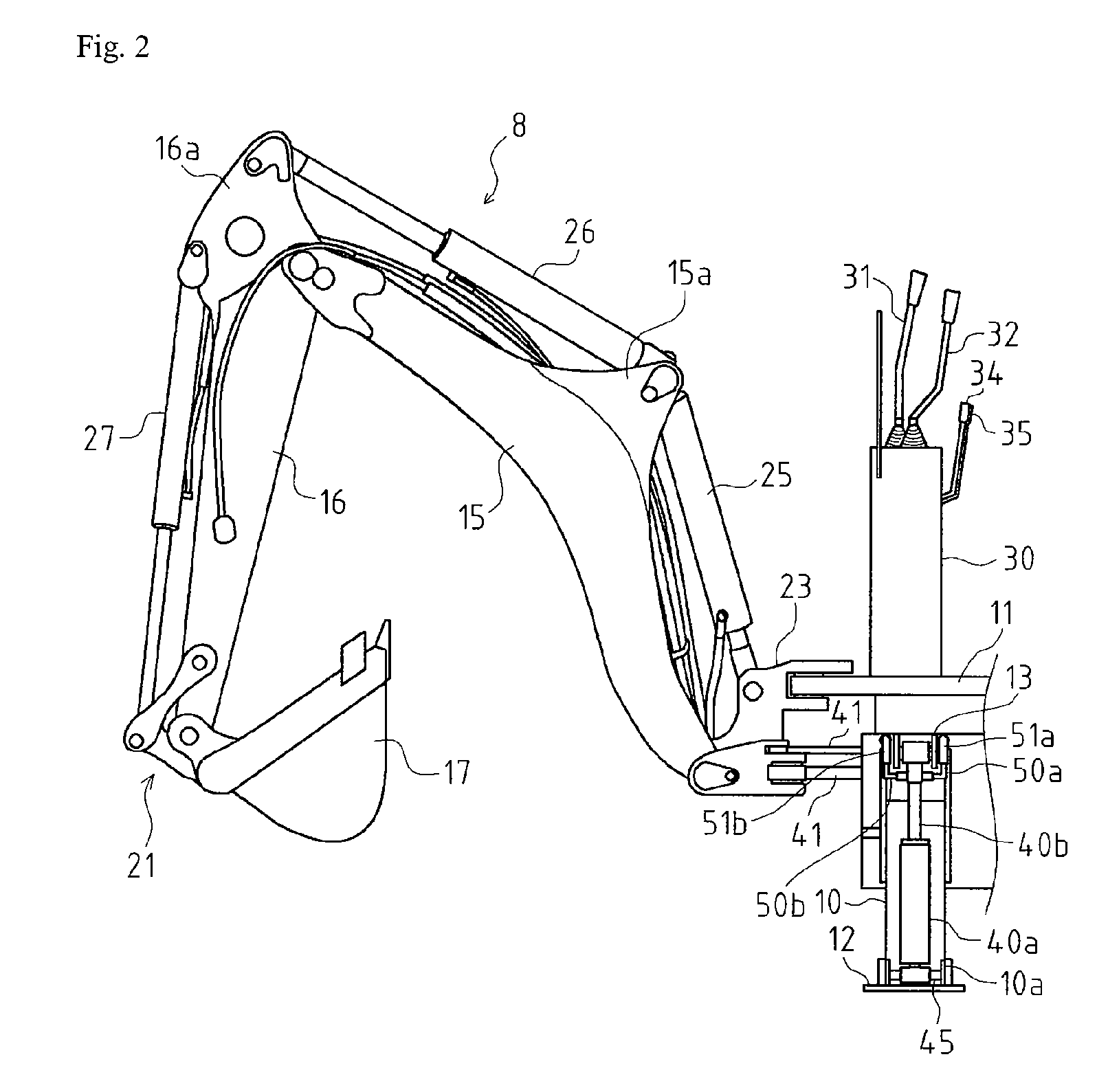

Hydraulic Cylinder of Outrigger

InactiveUS20070289439A1Reduce hydraulic pressureAvoid damageCylindersSoil-shifting machines/dredgersHydraulic cylinderMechanical engineering

A structure of a hydraulic cylinder of an outrigger should be improved to prevent a hydraulic pressure hose from being damaged, and an arrangement of the hydraulic cylinder should be improved to prevent a rod part of the hydraulic cylinder from being damaged. A cylinder (40) is interposed between a machine frame and each of outriggers (10), which are vertically swingably disposed at opposite sides of the machine frame, so as to lift up and down the outrigger. Fluid passages (54a and 54b) are formed in a rod part (40b) of the hydraulic cylinder (40). Connection portions of fluid suction and delivery ports of the respective fluid passages (54a and 54b) to be connected to the respective hydraulic pressure hoses (51a and 52b) are disposed adjacent to a pivot of the hydraulic cylinder (40).

Owner:YANMAR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com