Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1036 results about "Variable valve timing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In internal combustion engines, variable valve timing (VVT) is the process of altering the timing of a valve lift event, and is often used to improve performance, fuel economy or emissions. It is increasingly being used in combination with variable valve lift systems. There are many ways in which this can be achieved, ranging from mechanical devices to electro-hydraulic and camless systems. Increasingly strict emissions regulations are causing many automotive manufacturers to use VVT systems.

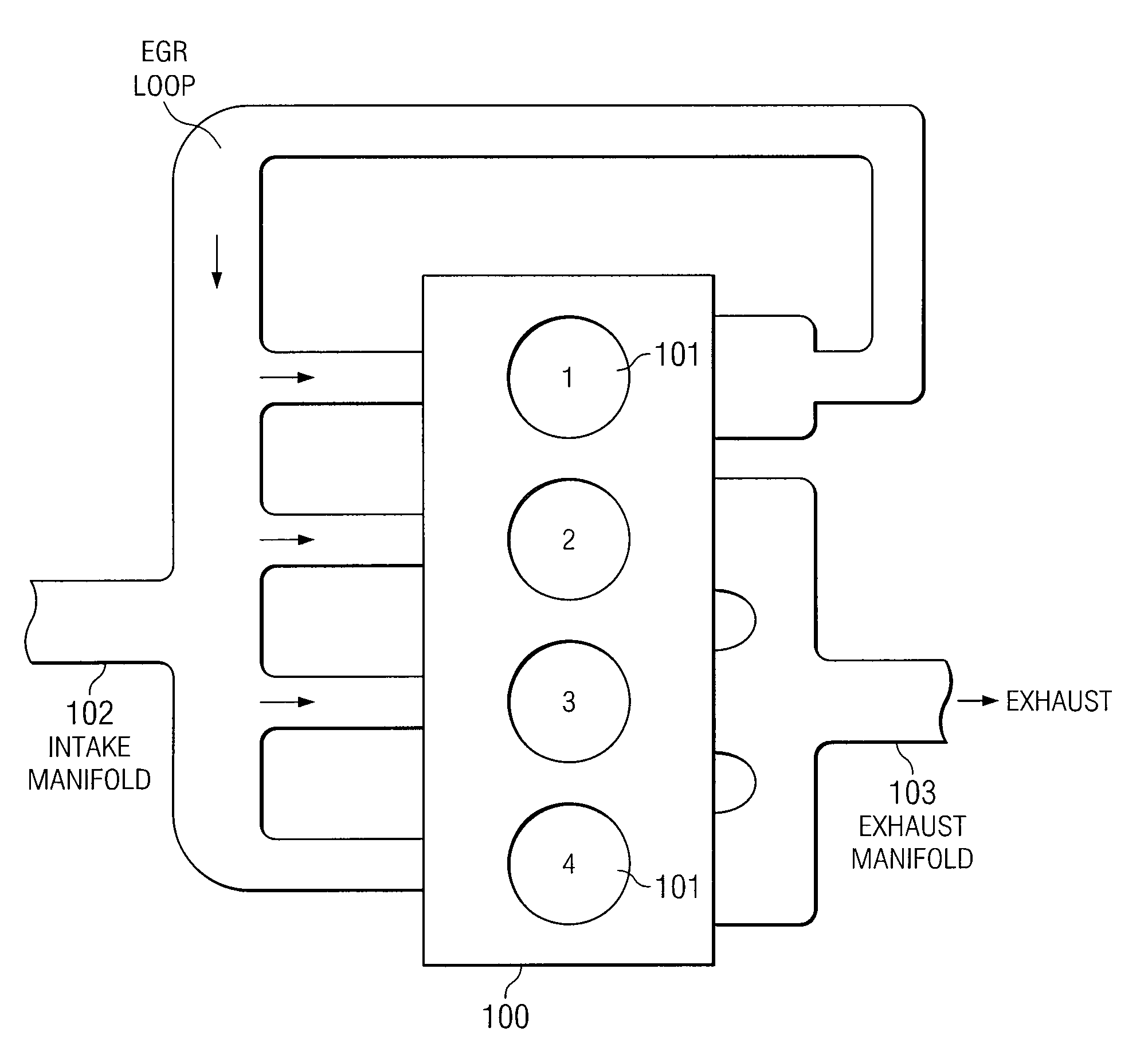

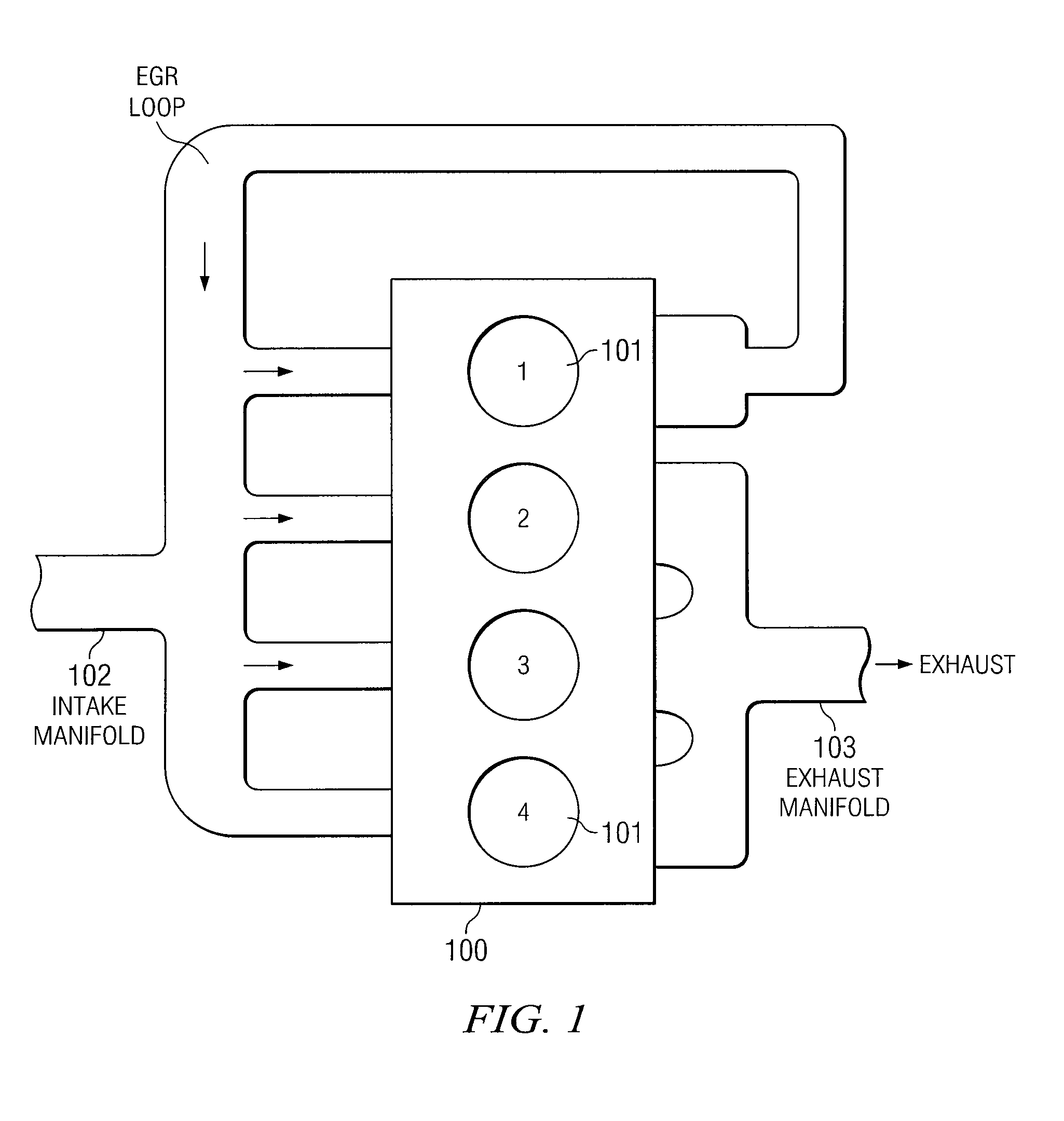

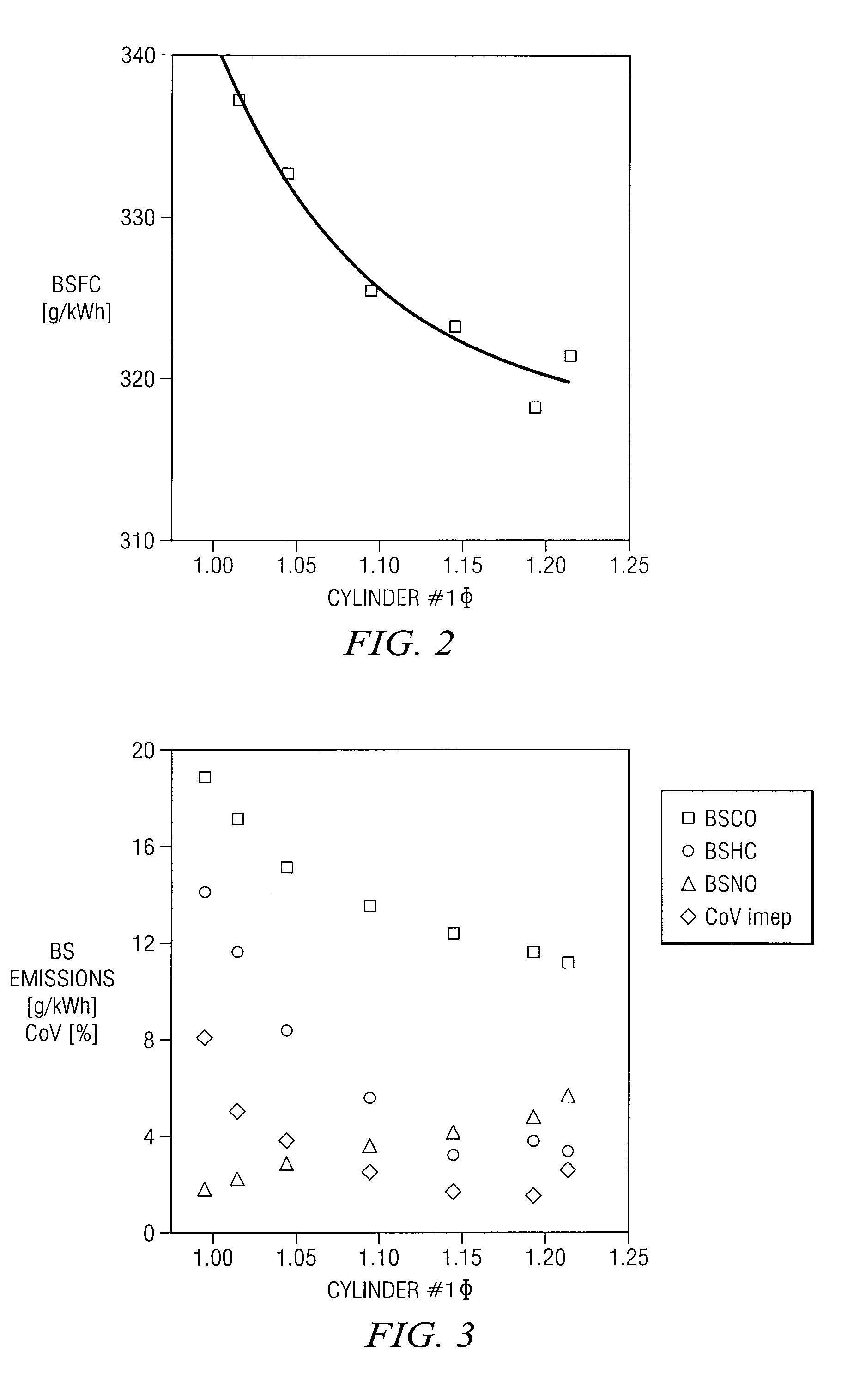

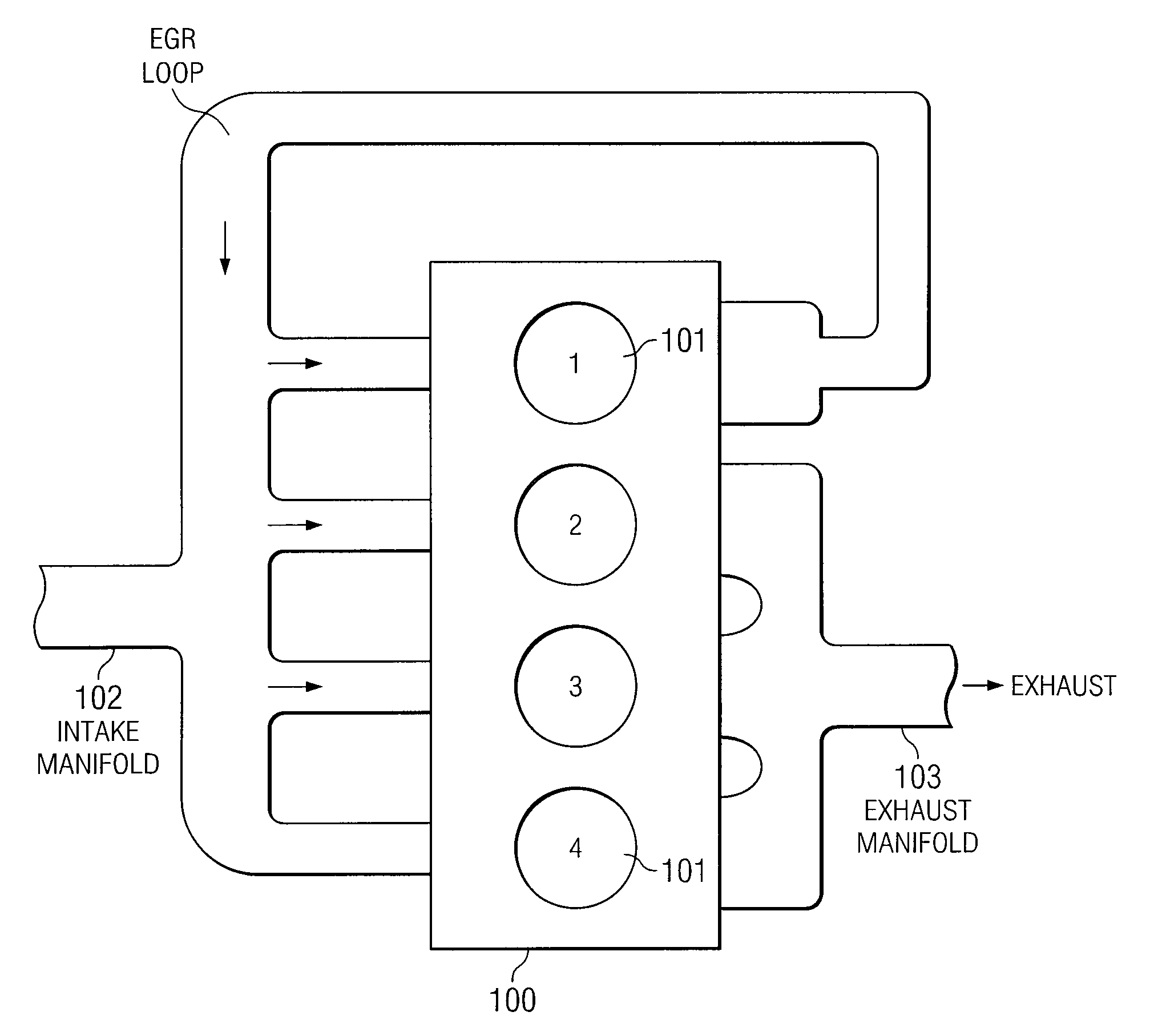

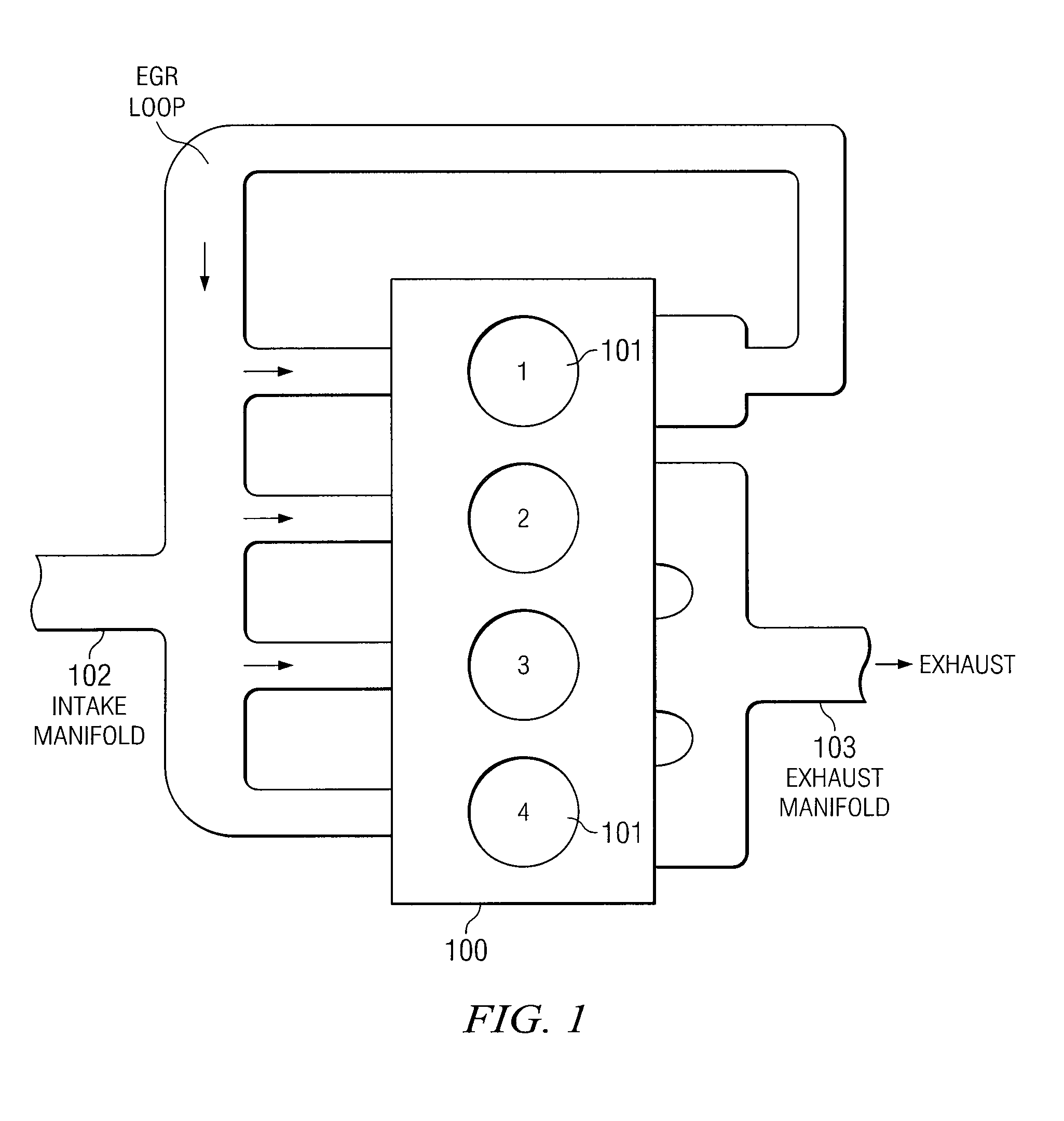

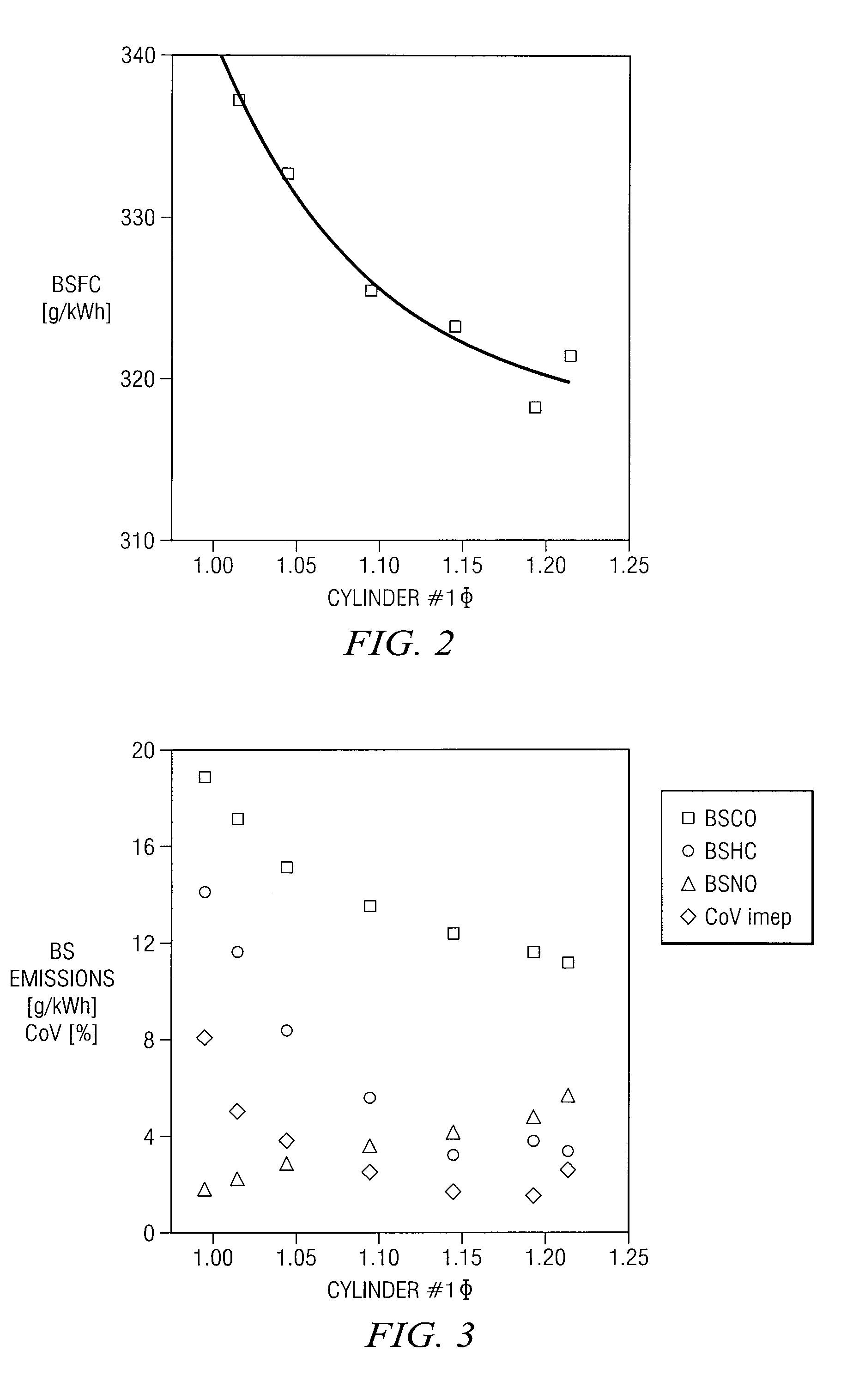

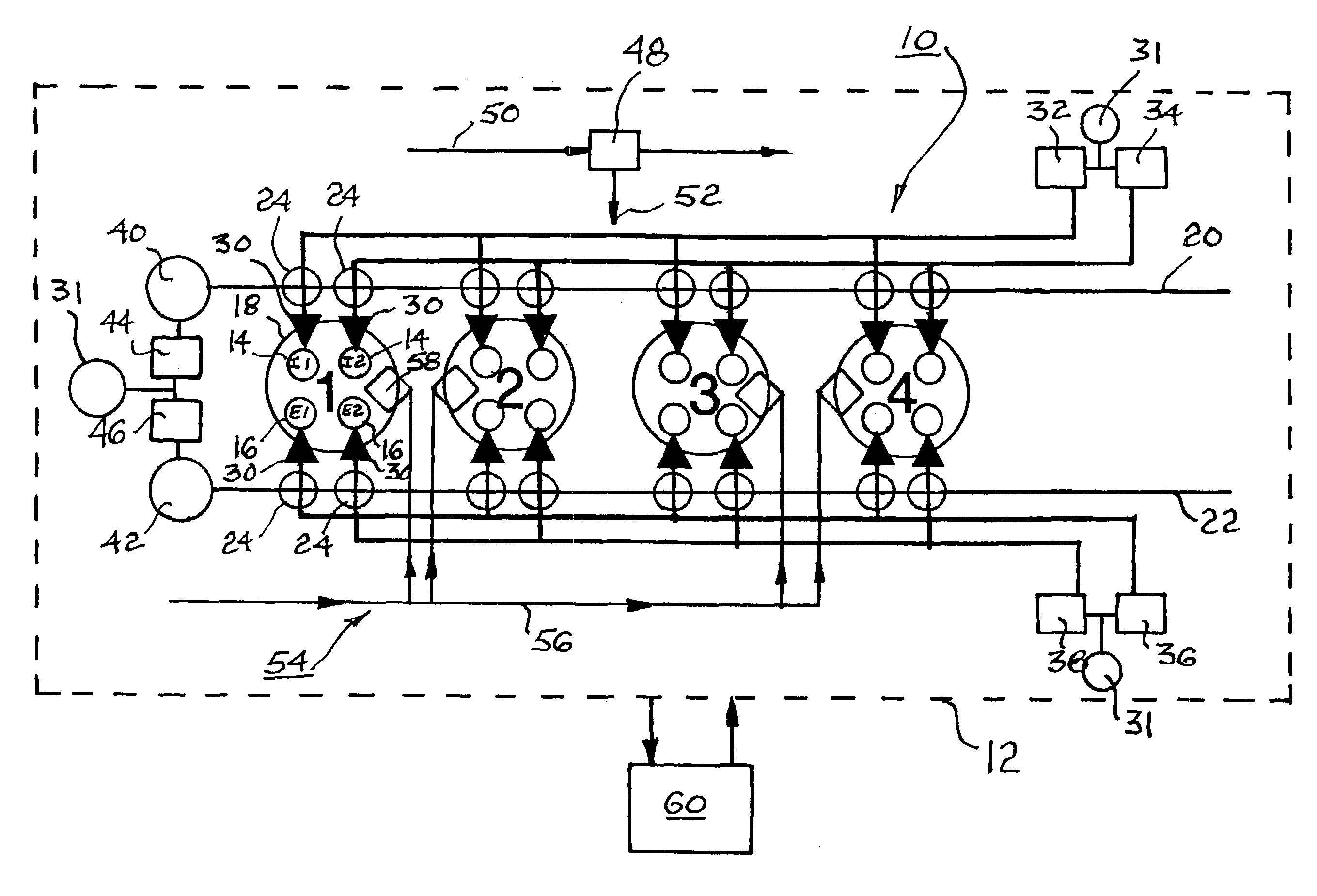

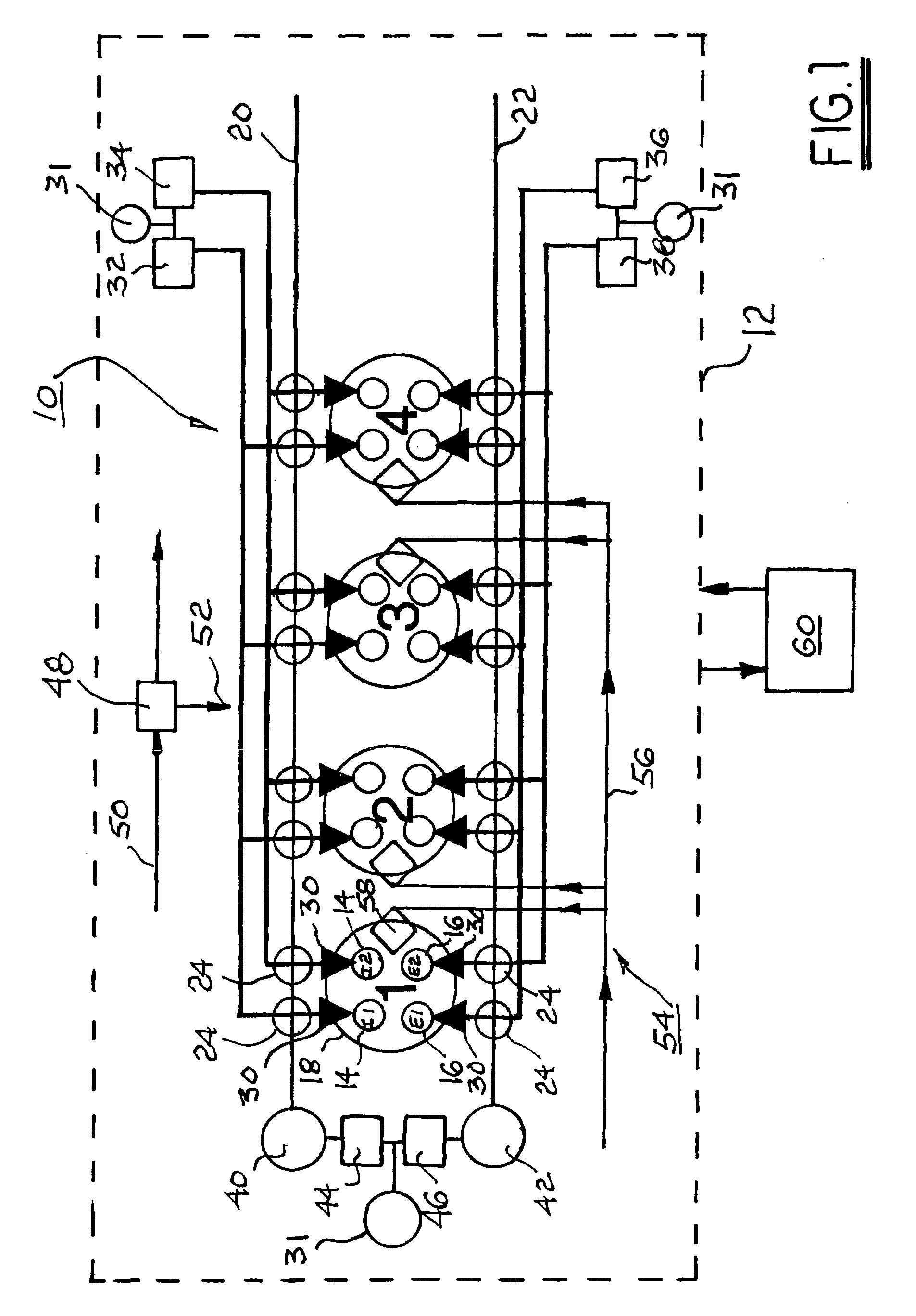

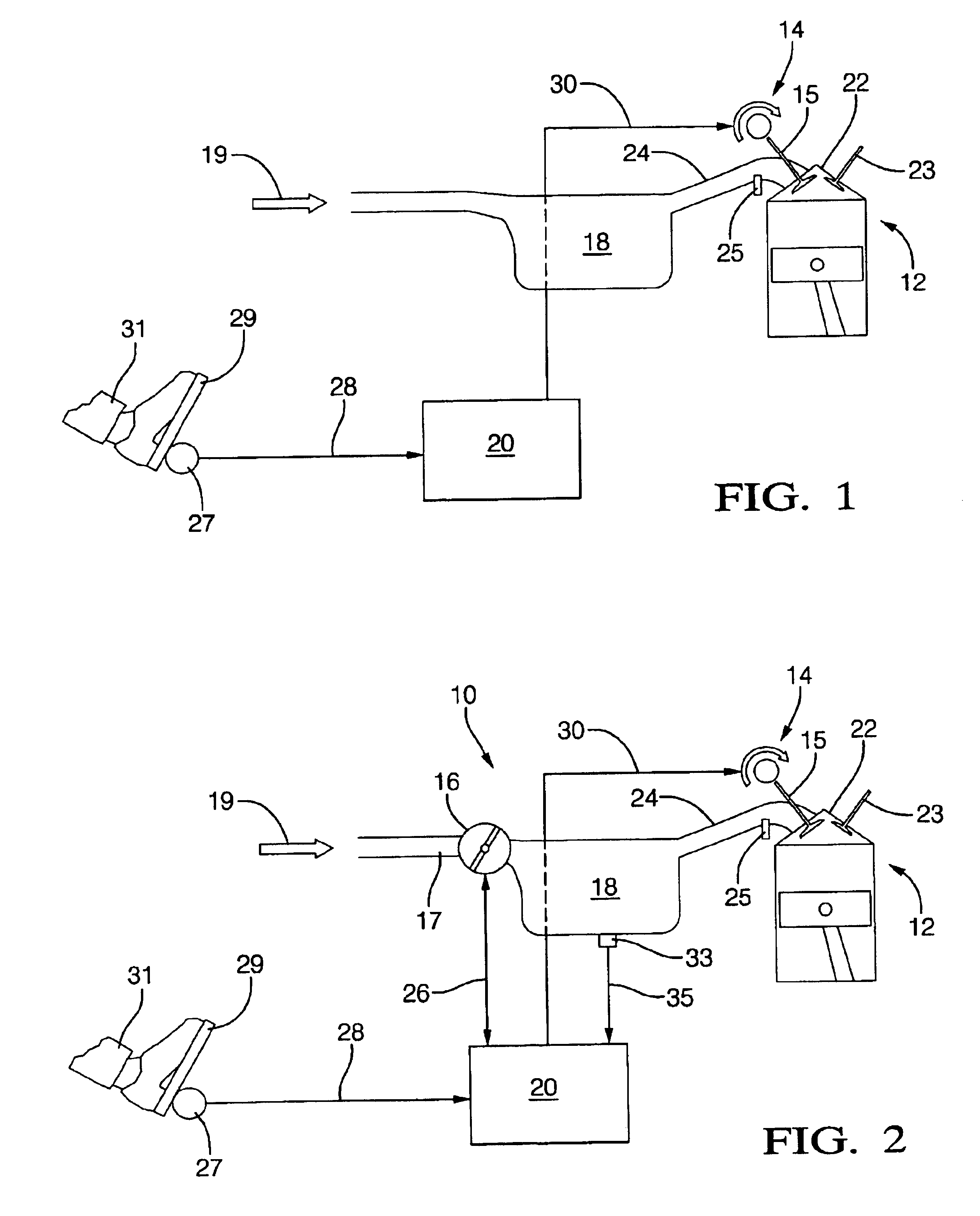

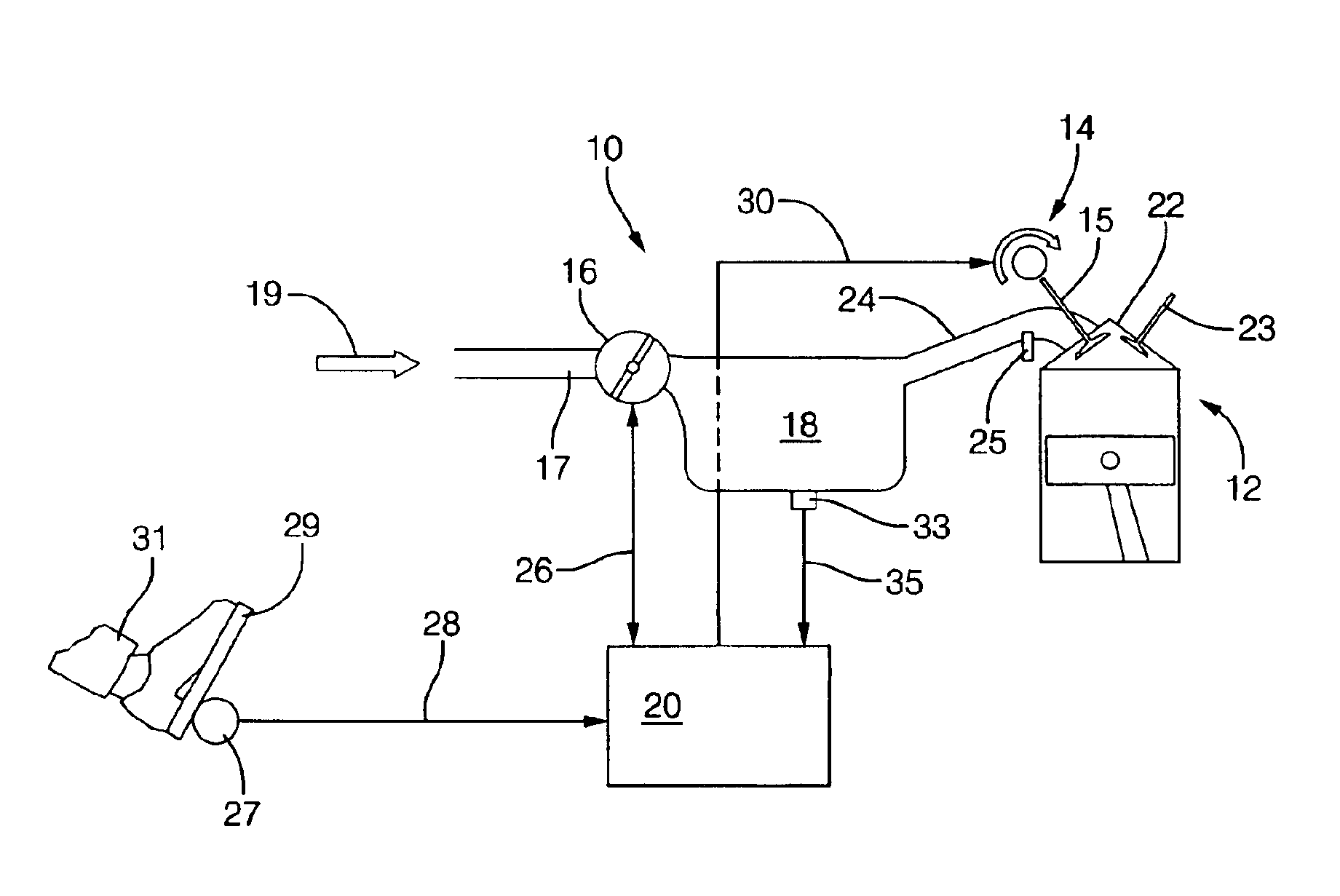

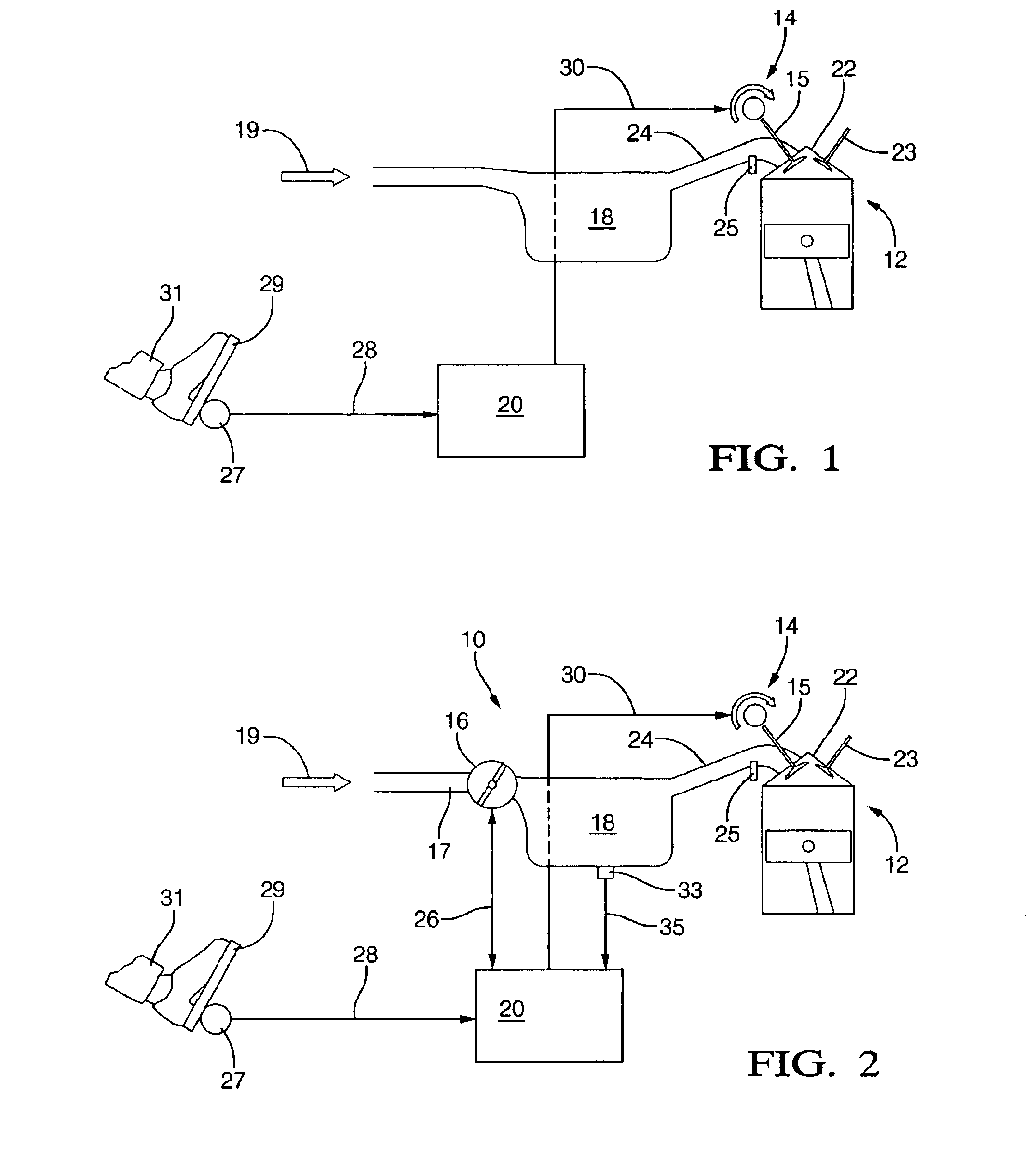

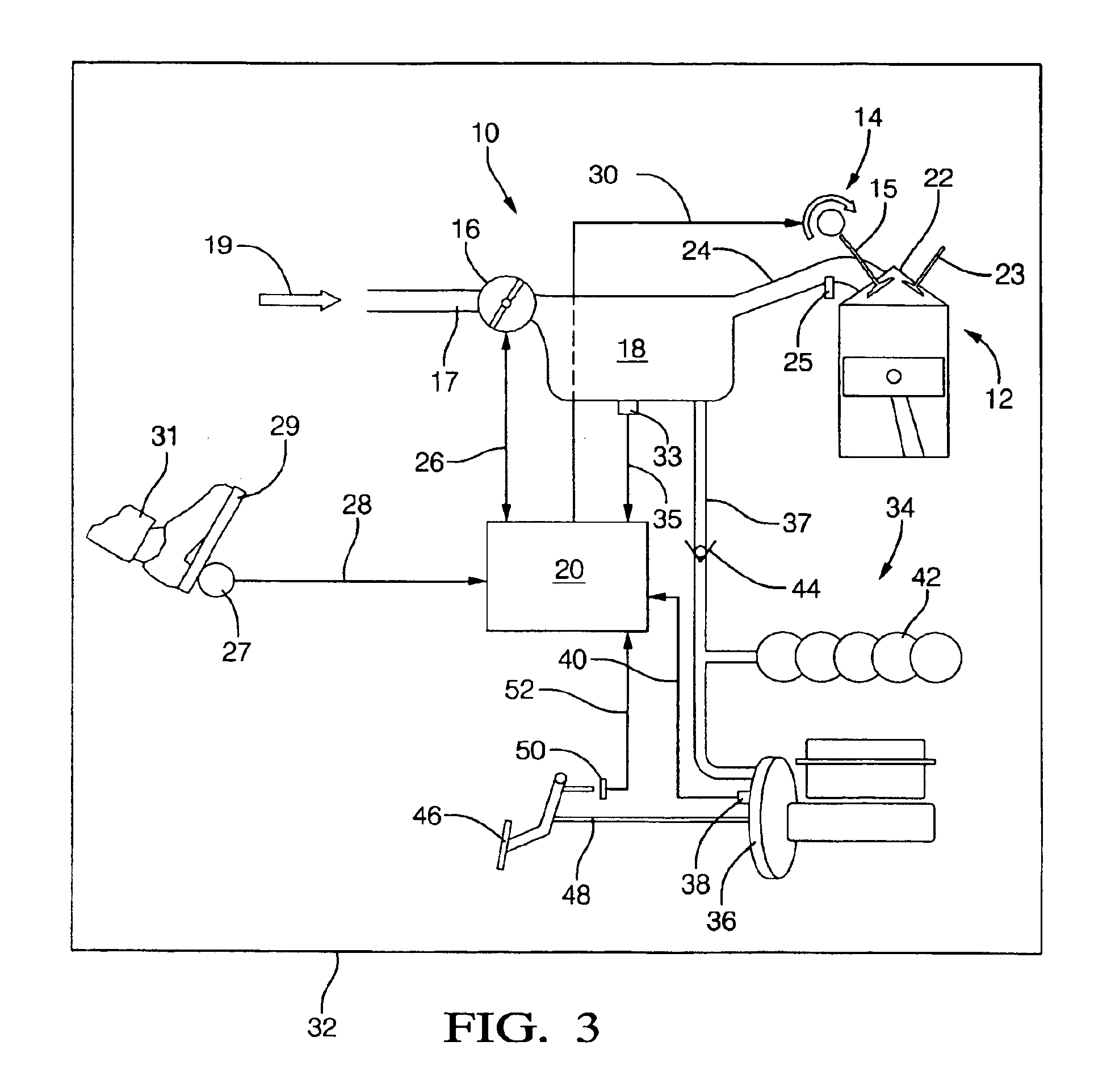

Egr system with dedicated egr cylinders

Improved exhaust gas recirculation system and methods that use one or more of the engine's cylinders as dedicated EGR cylinders. All of the exhaust from the dedicated EGR cylinders is recirculated back to the engine intake. Thus, the EGR rate is constant, but the EGR mass flow may be controlled by adjusting the air-fuel ratio of the dedicated EGR cylinders or by using various variable valve timing techniques.

Owner:SOUTHWEST RES INST

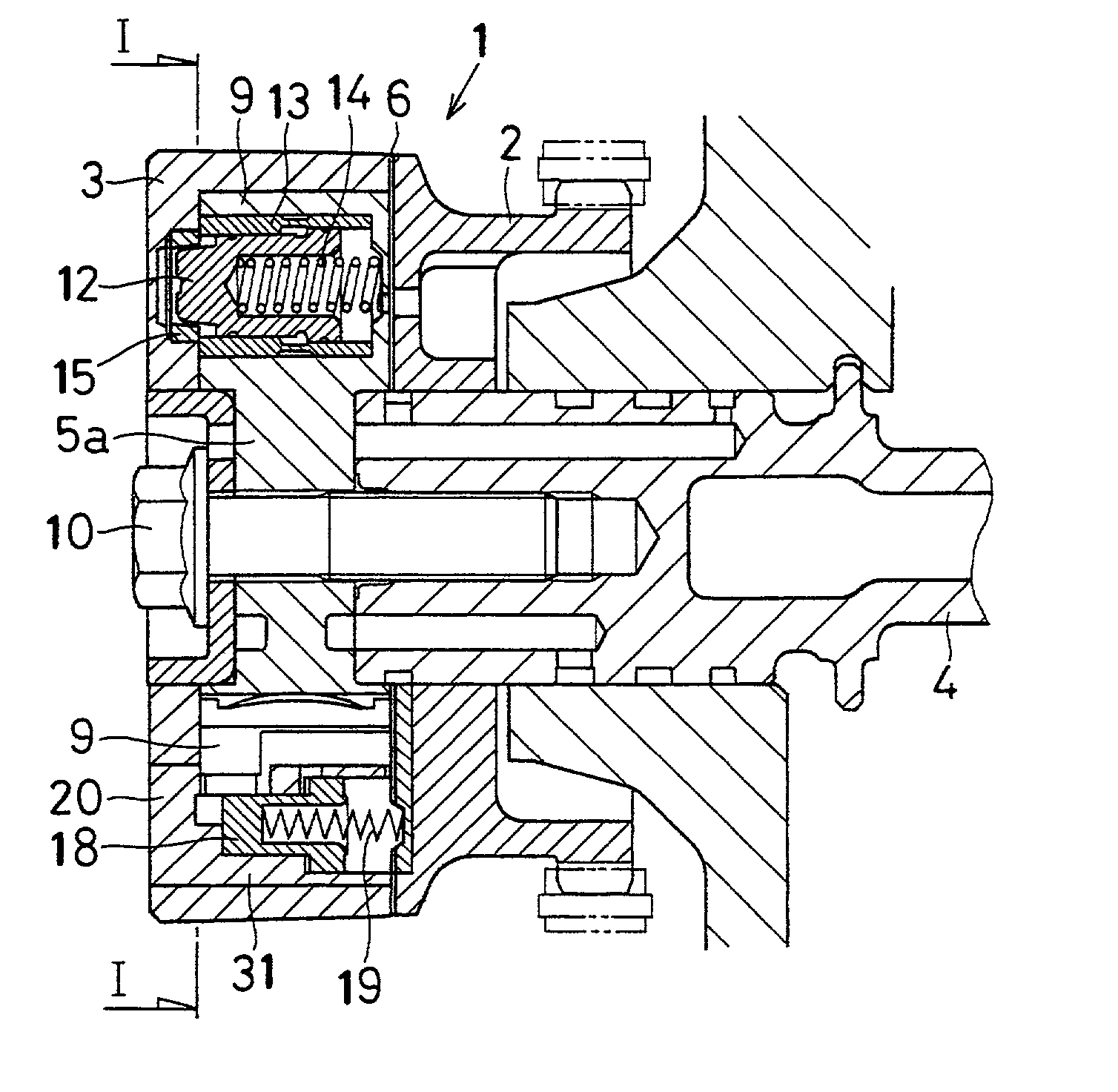

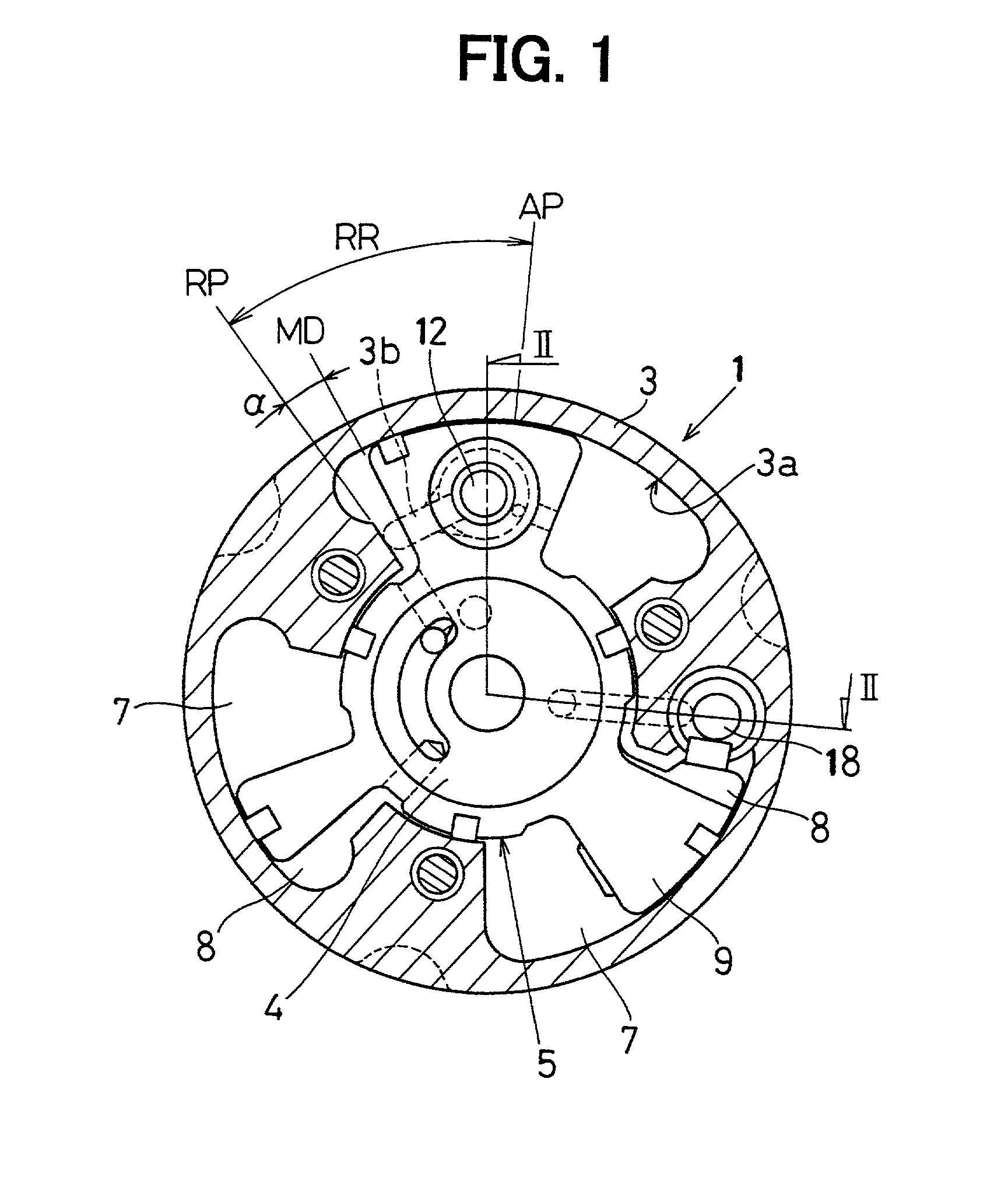

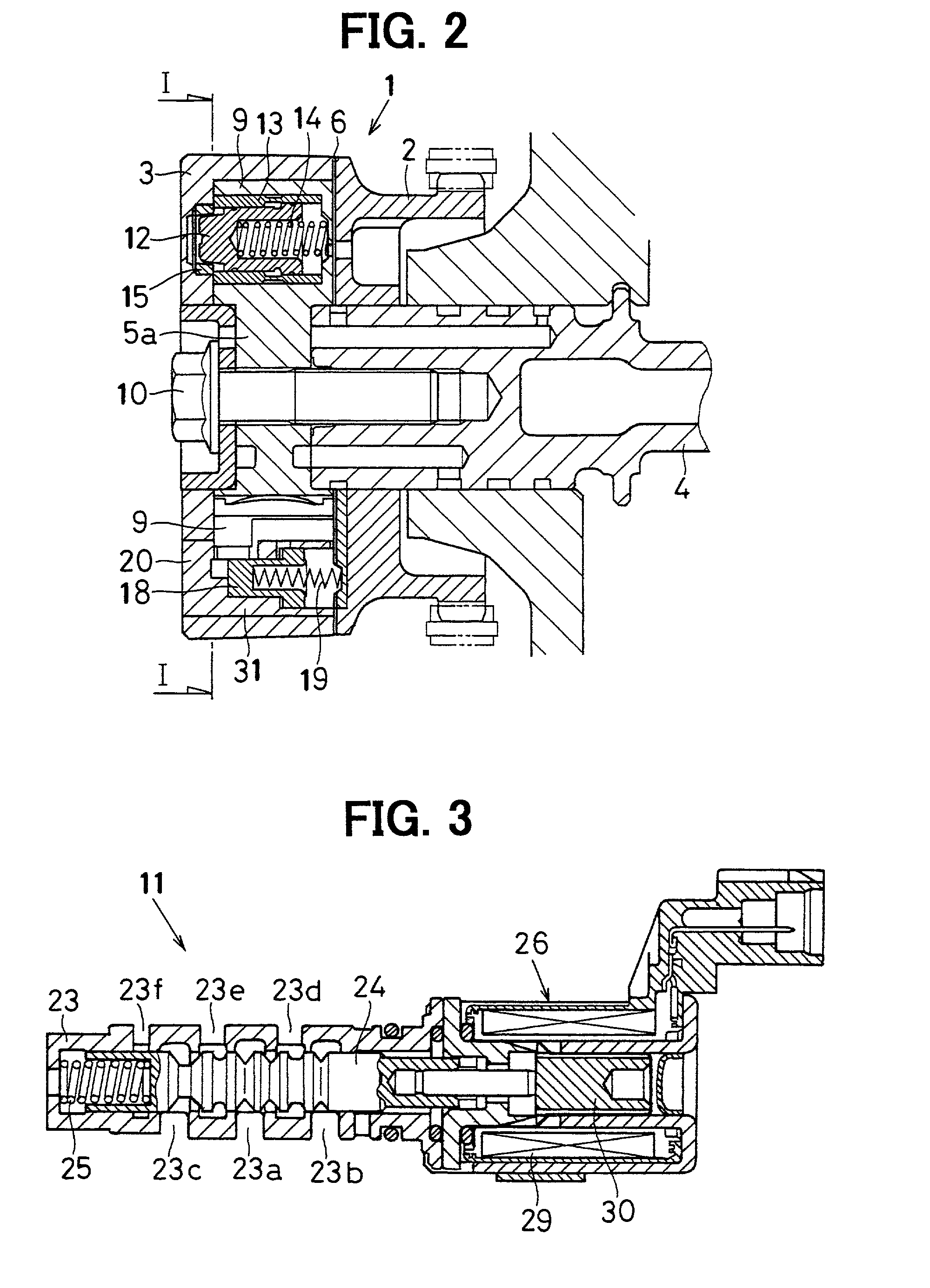

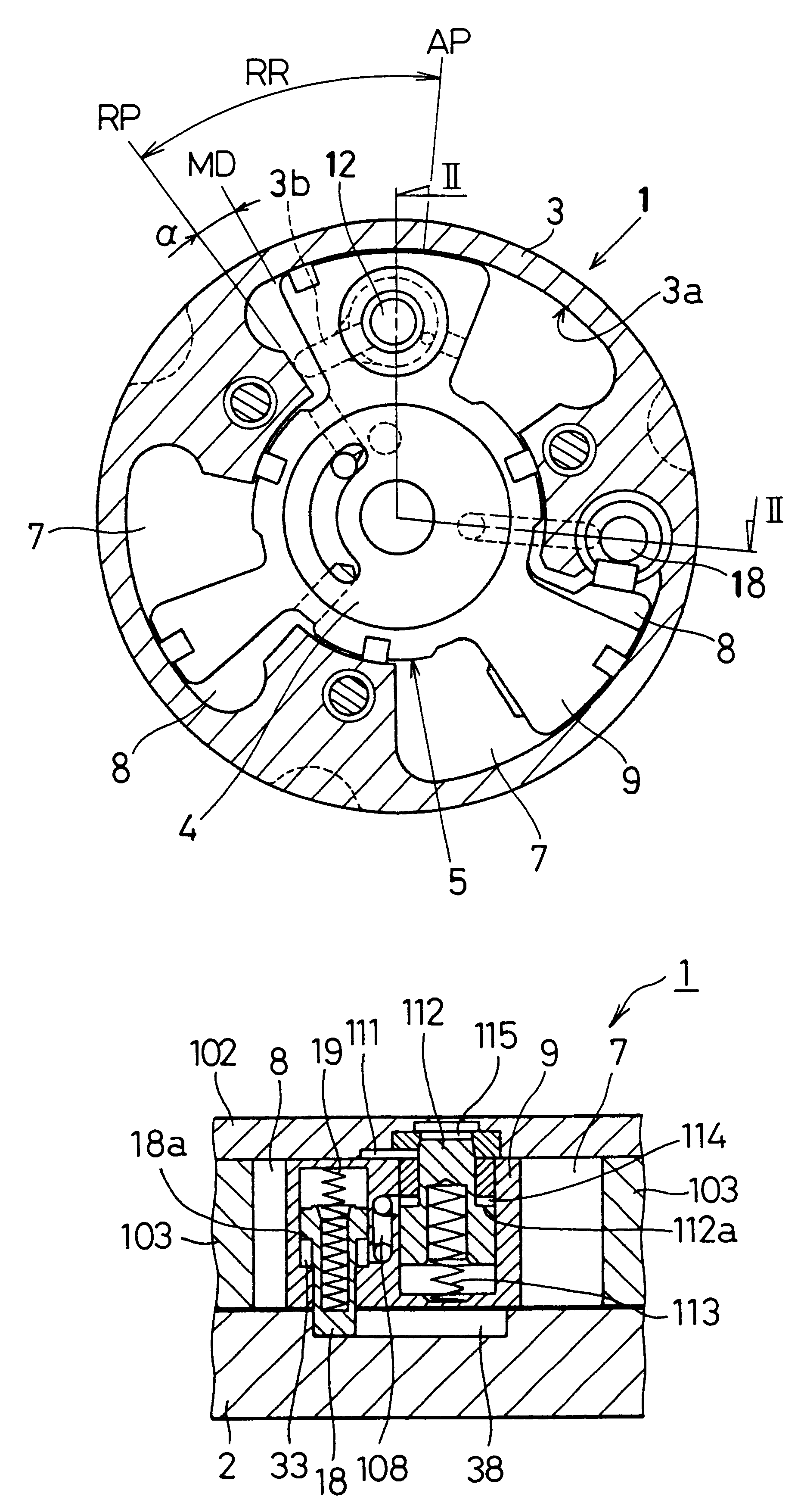

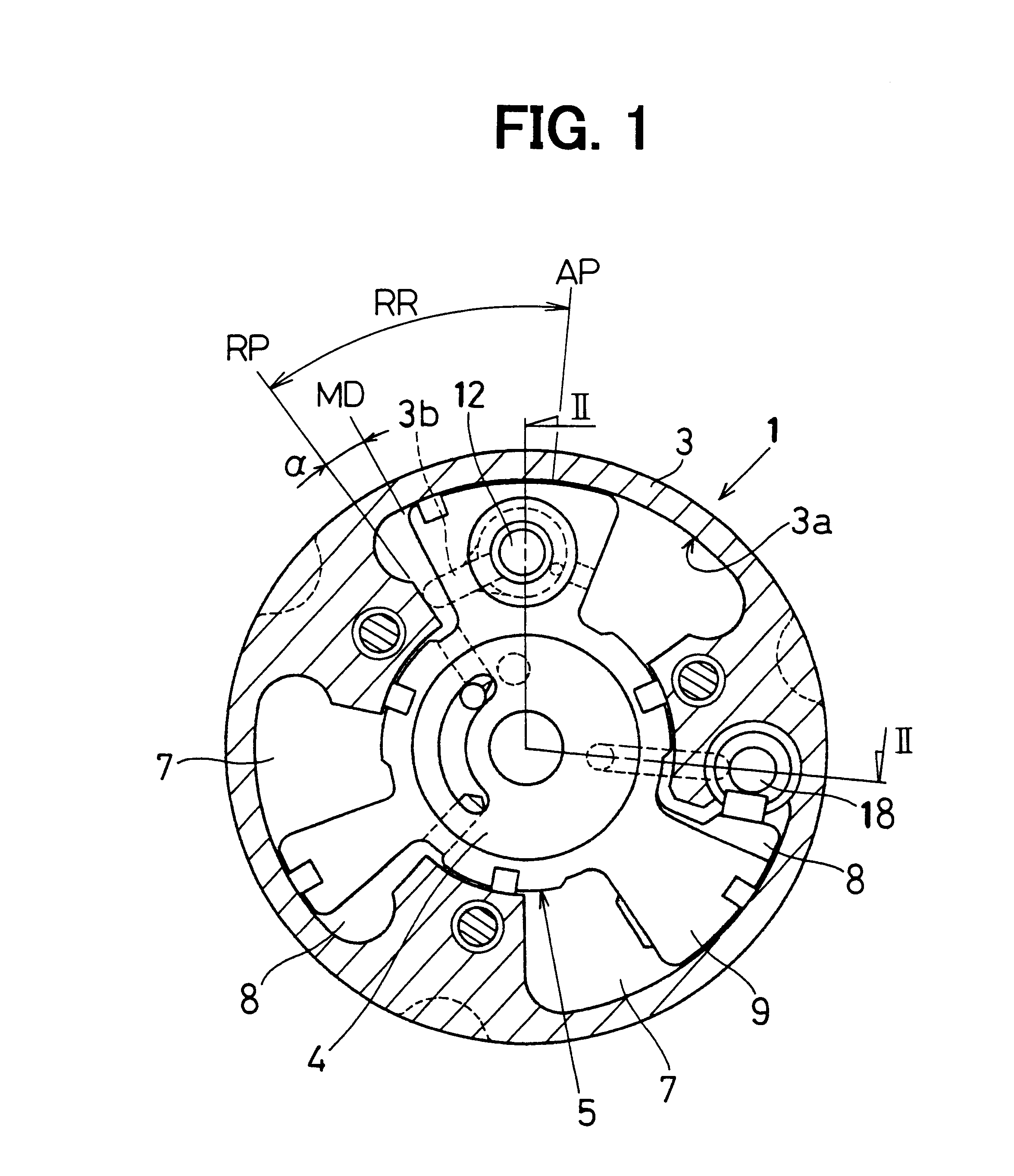

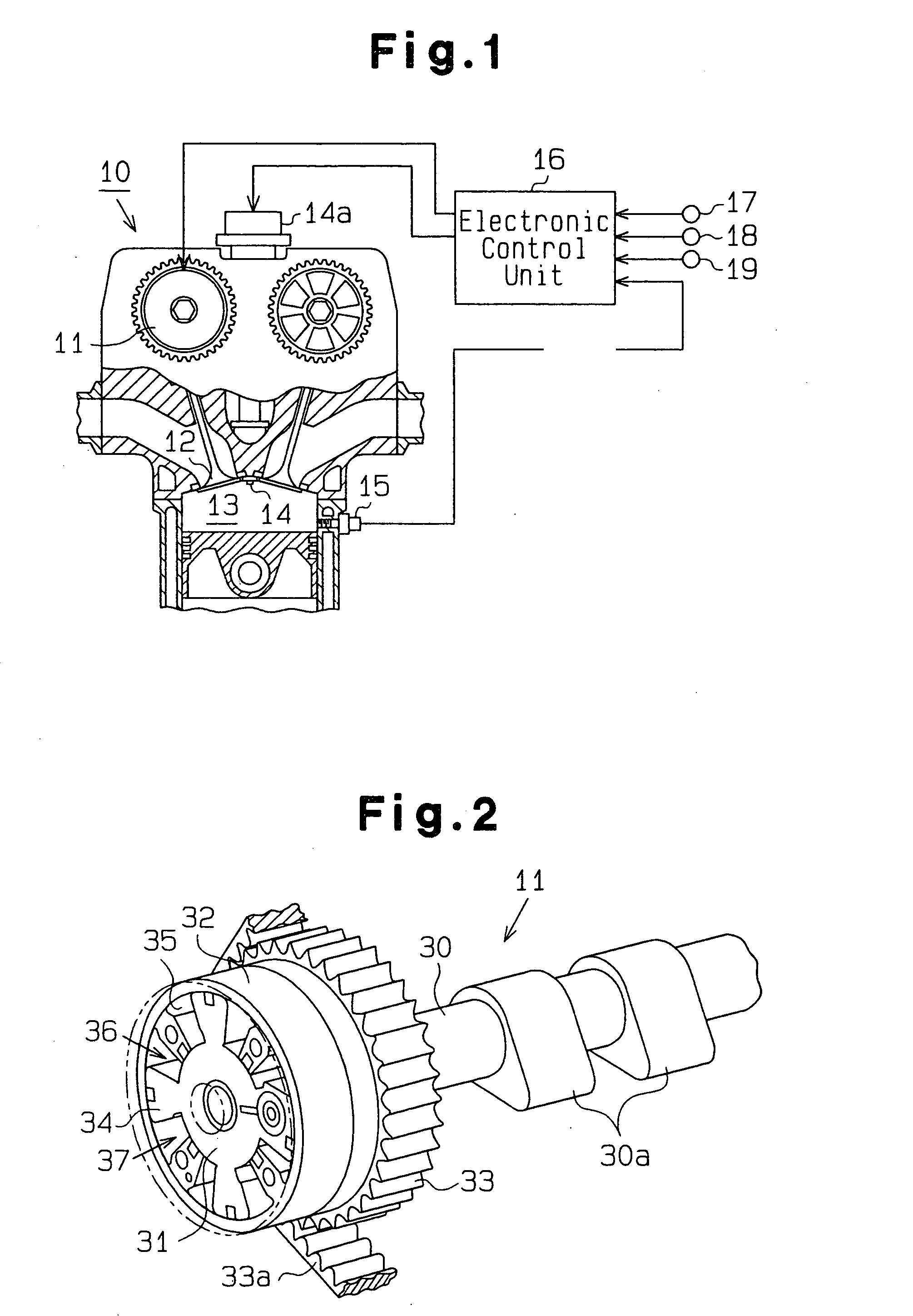

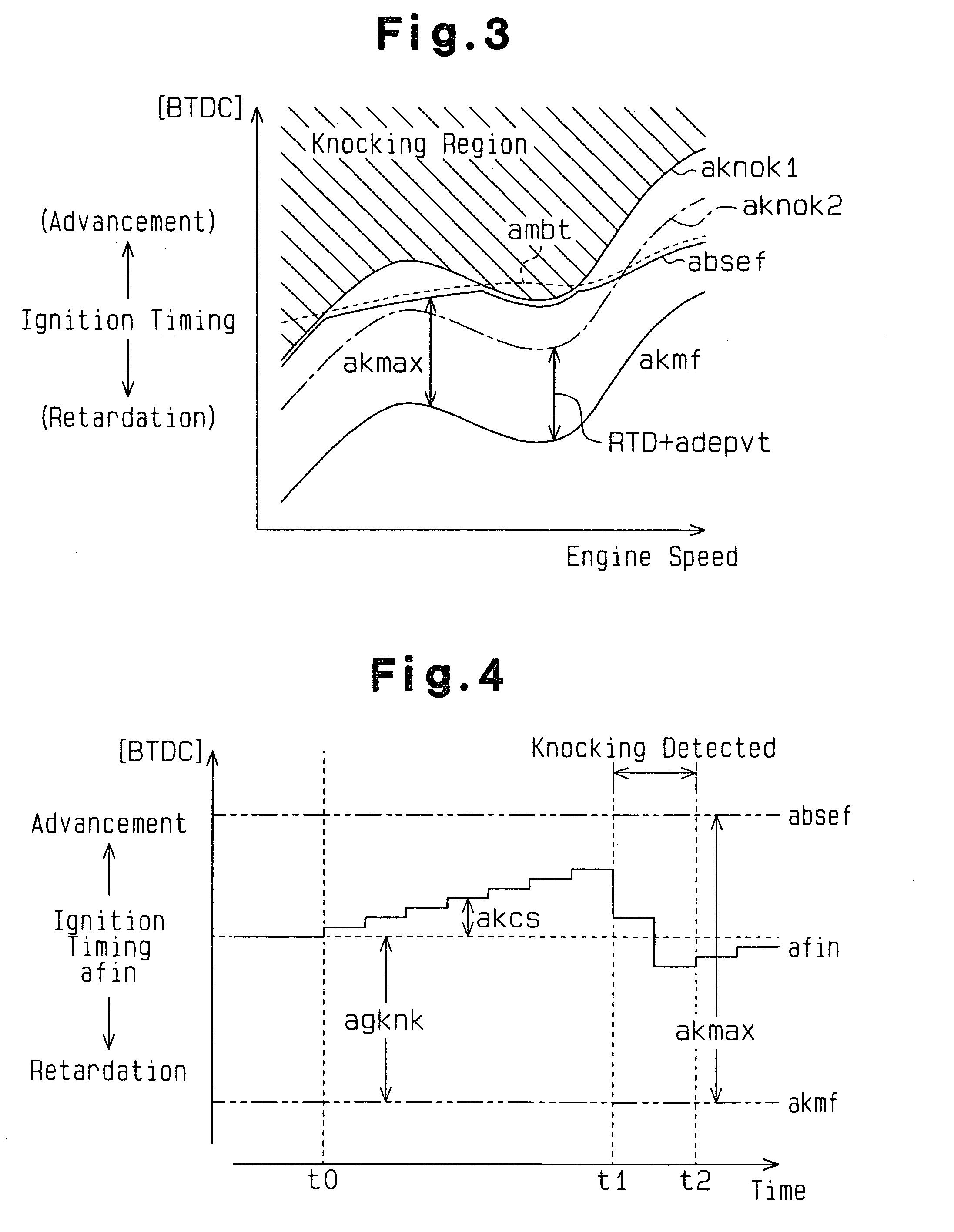

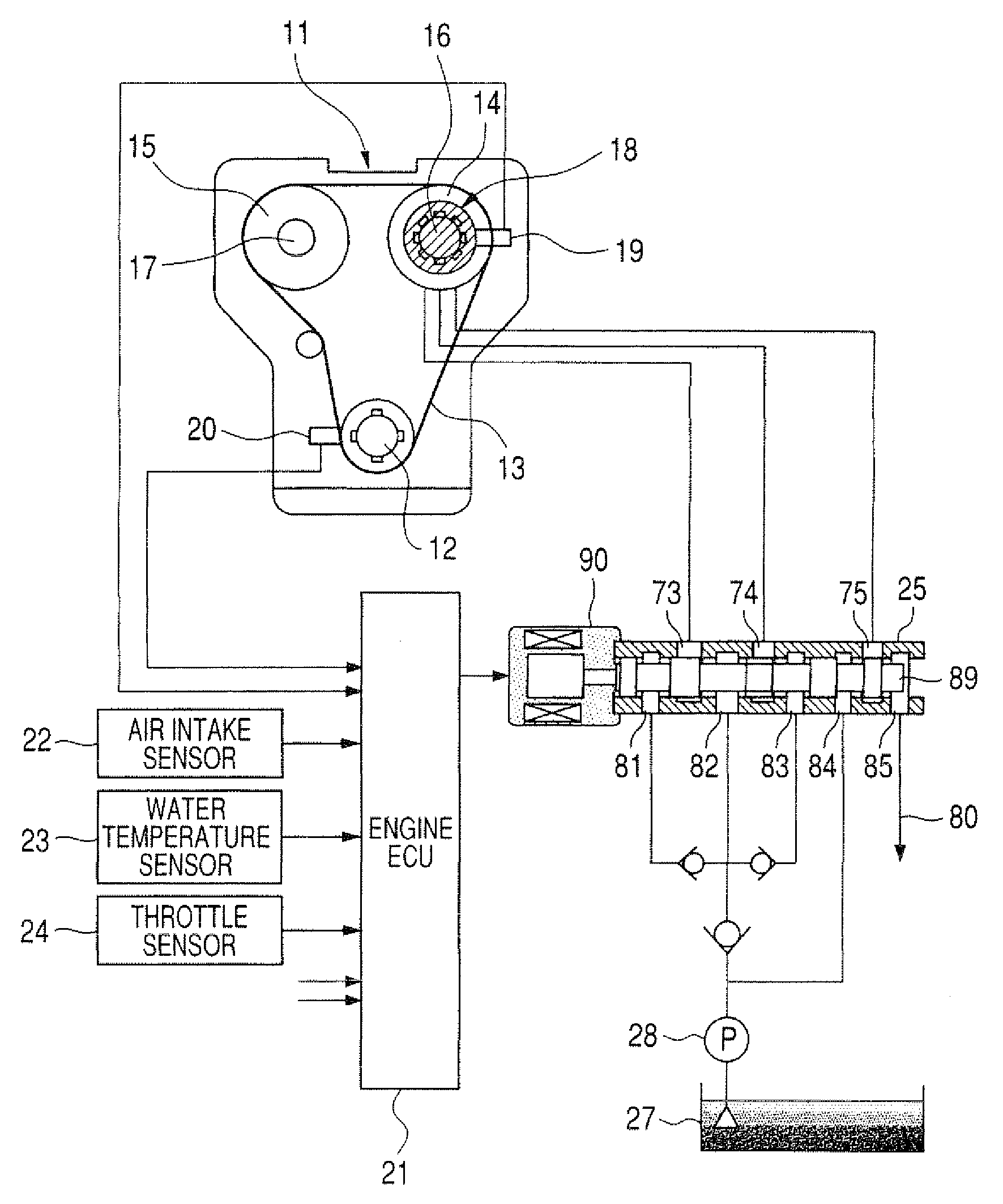

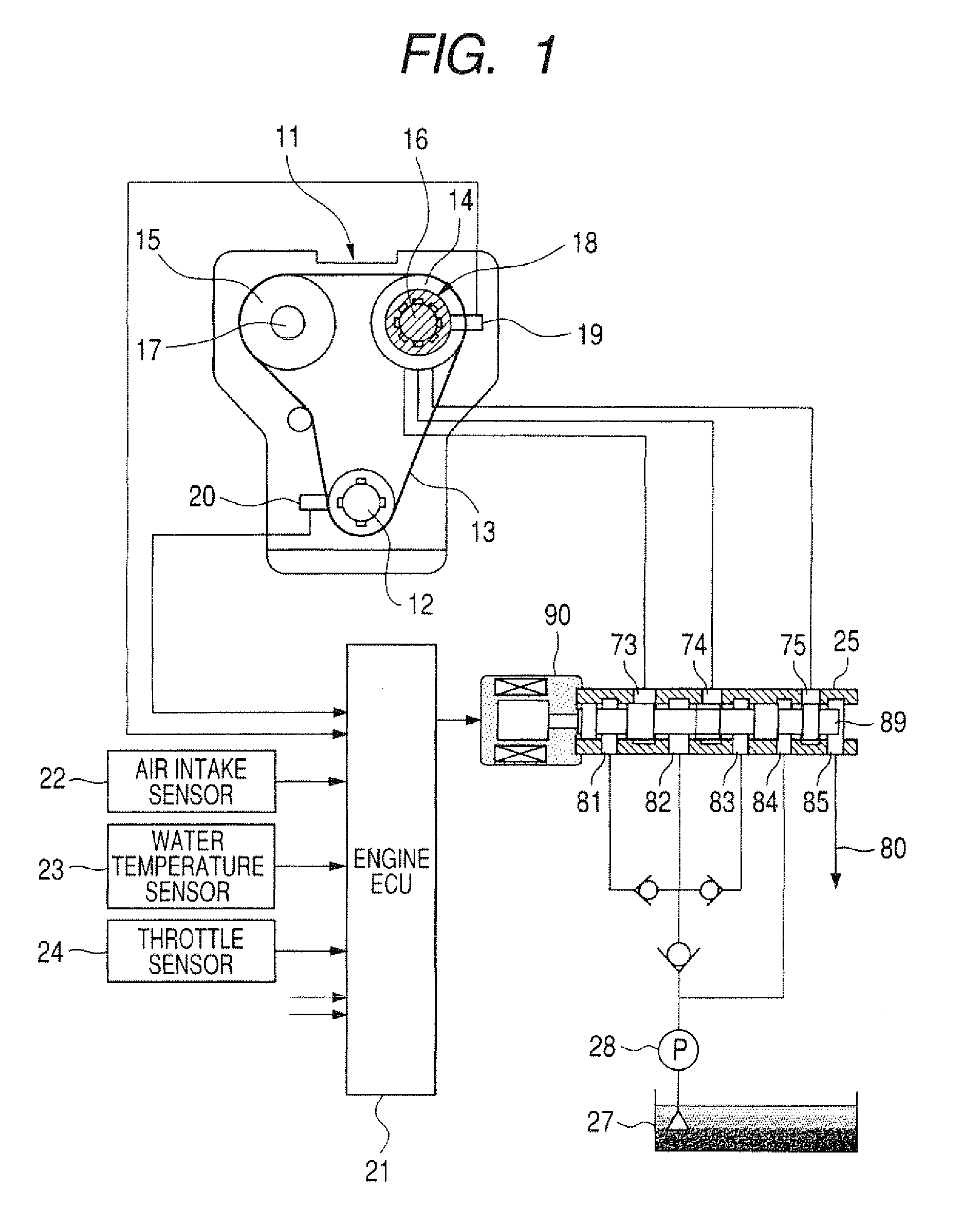

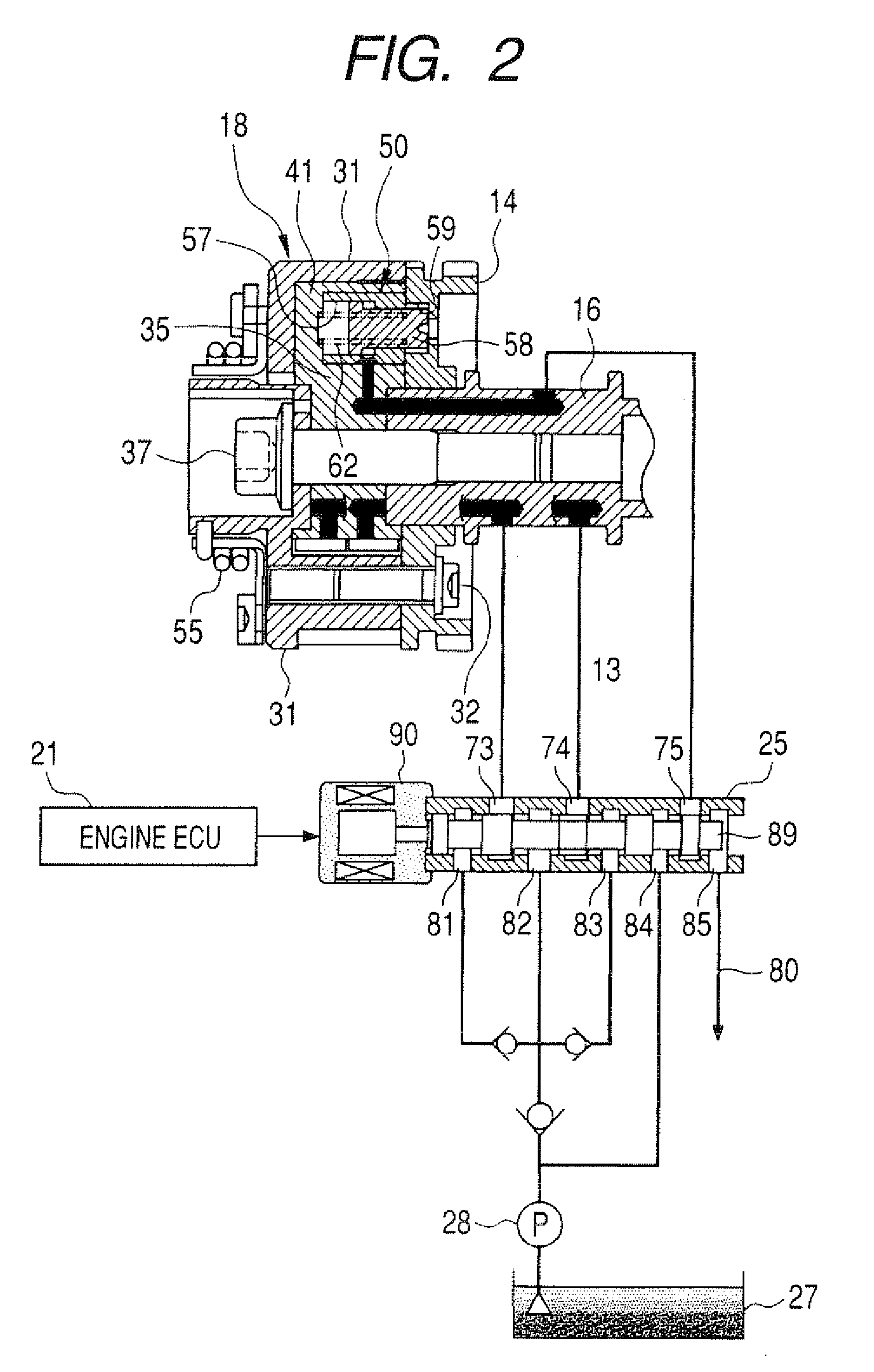

Variable valve timing apparatus

InactiveUS20020139332A1Prevent rotationPrevent the rotor from reachingValve arrangementsMachines/enginesVariable valve timingEngineering

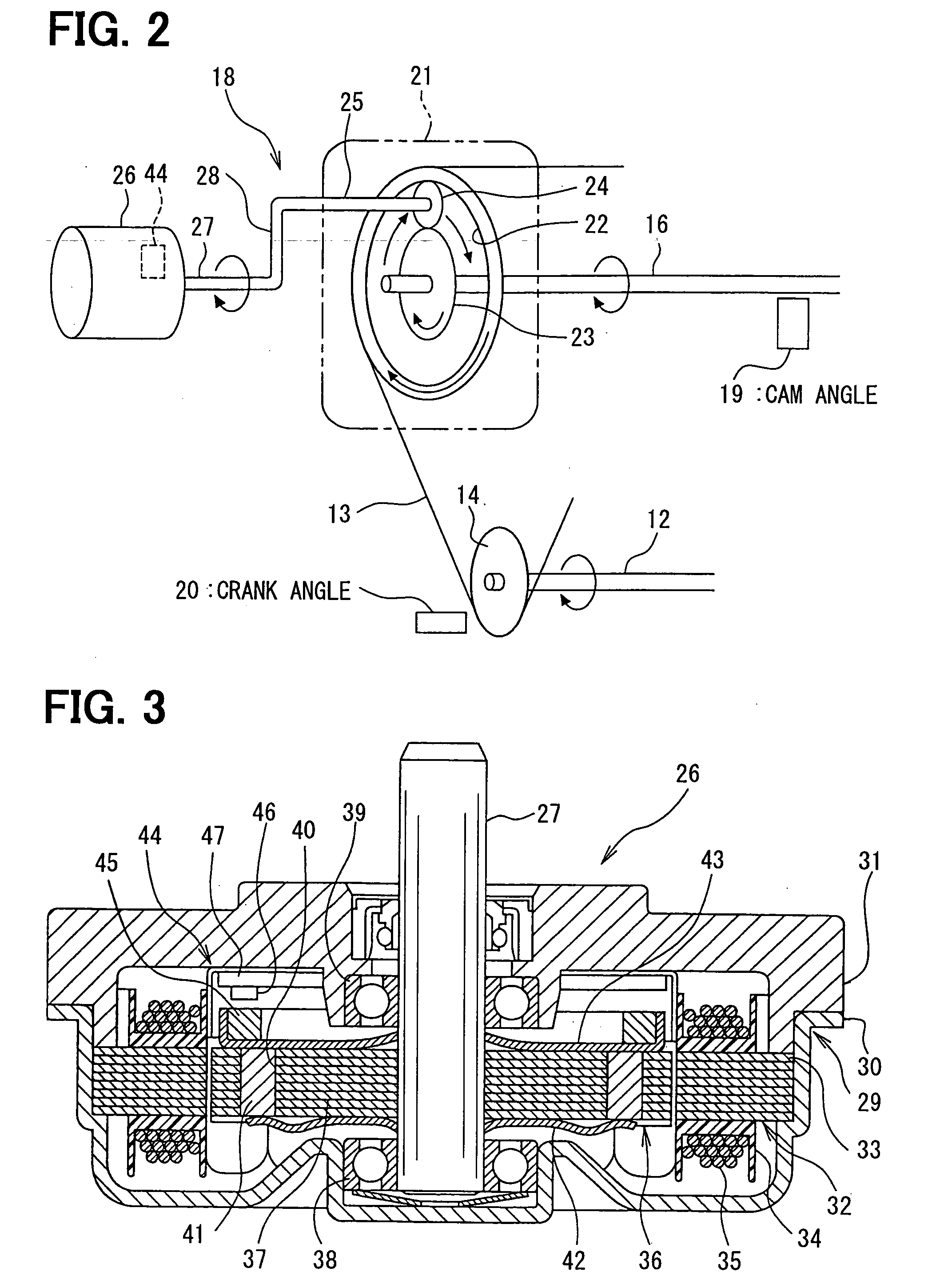

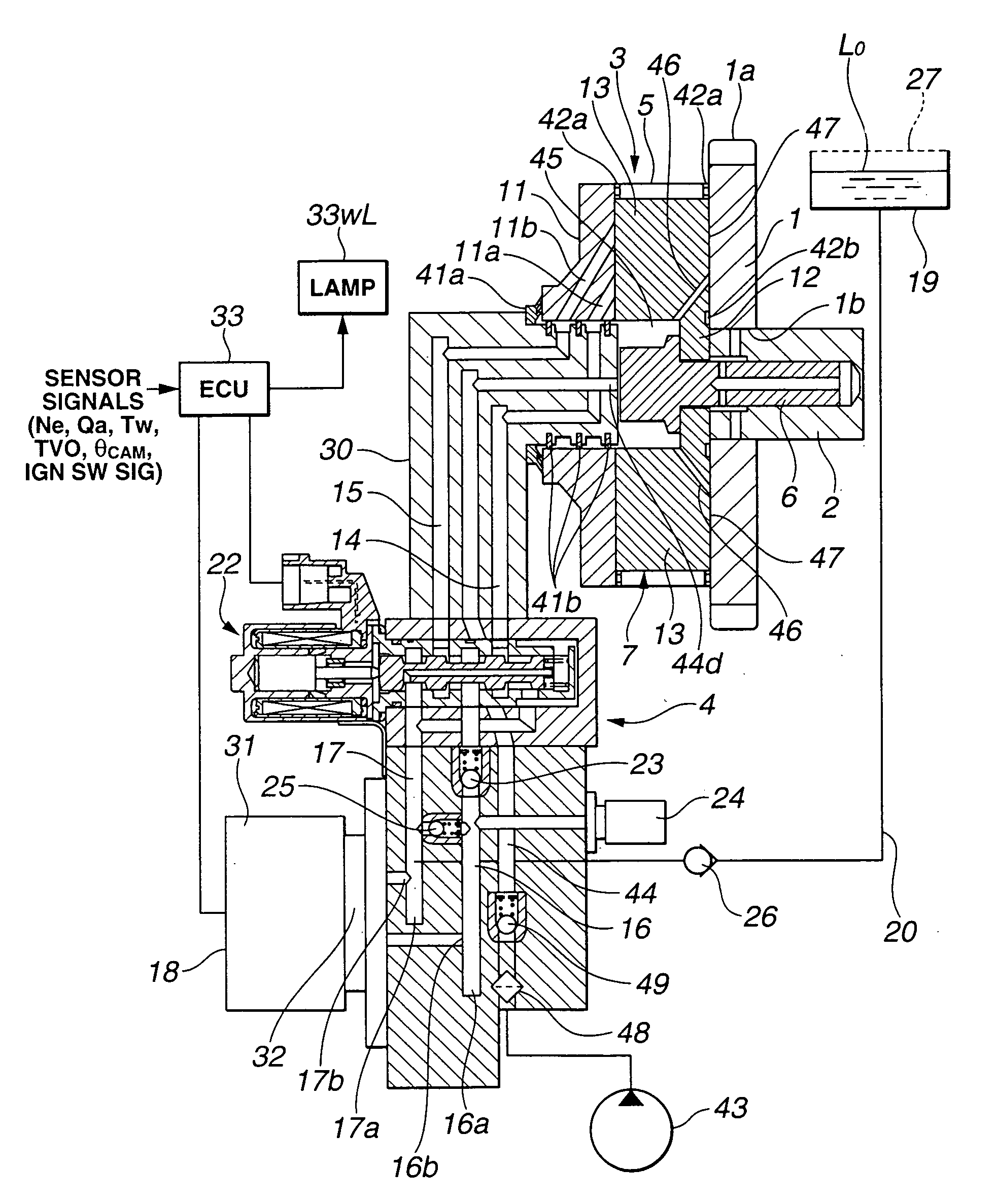

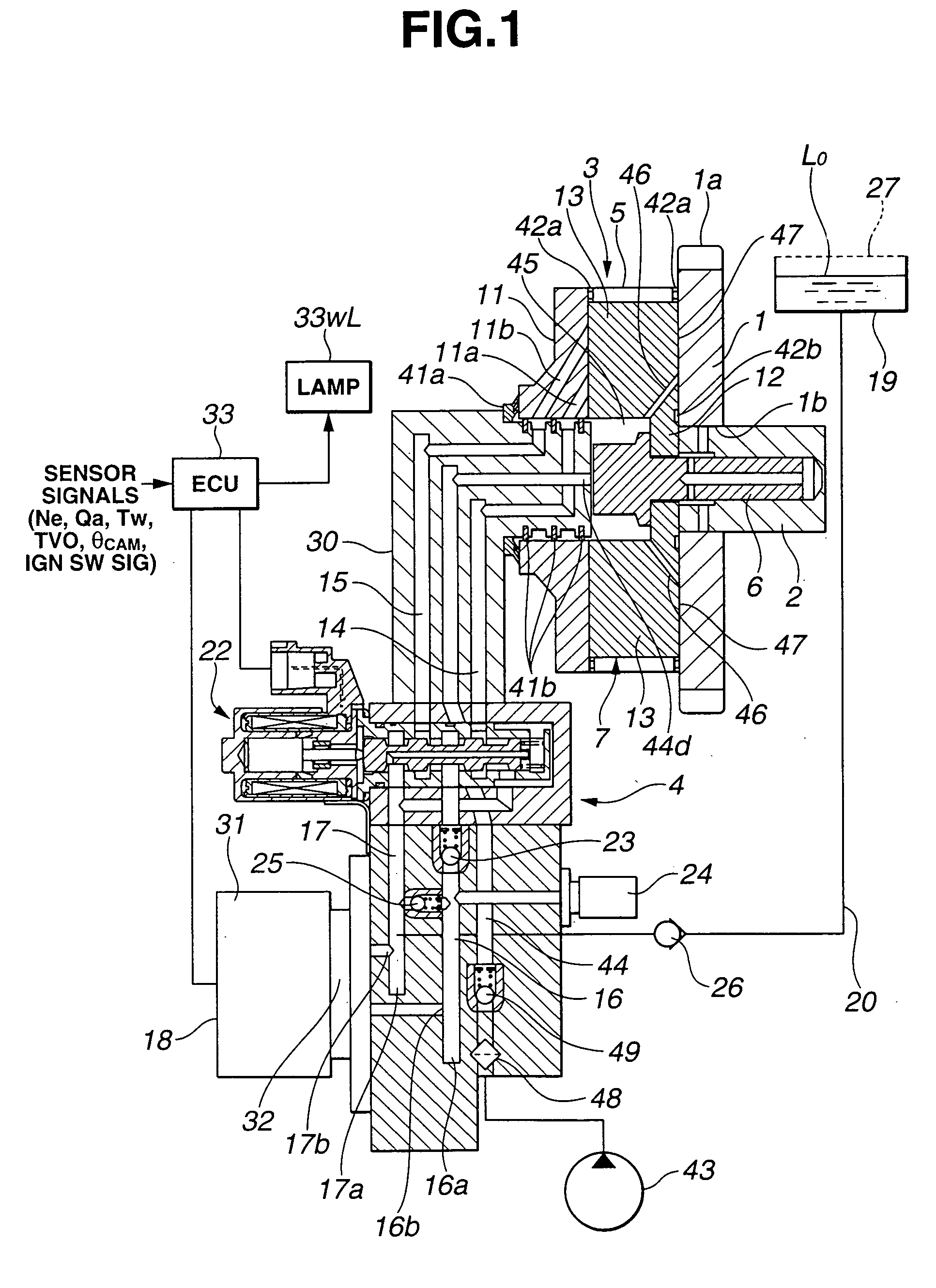

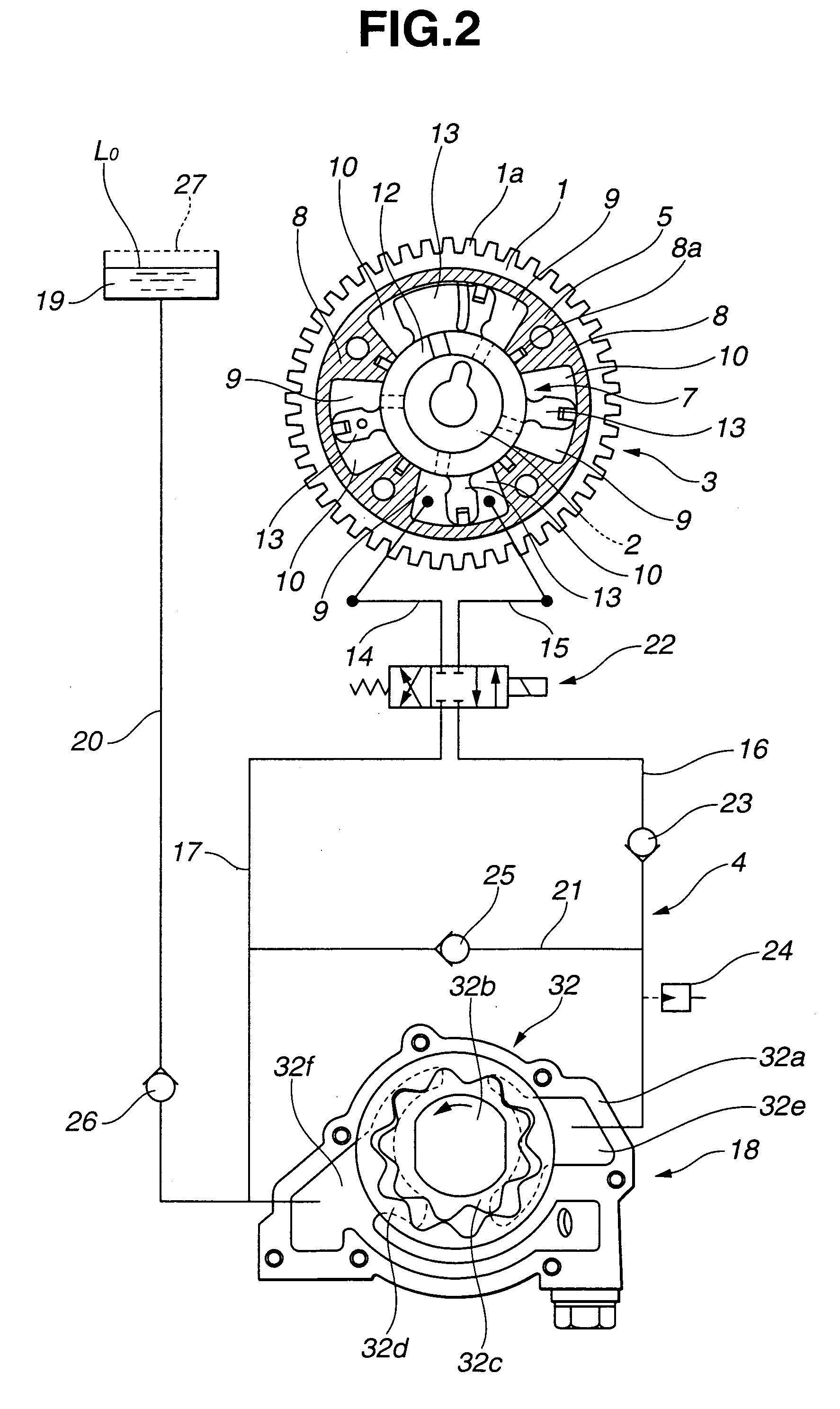

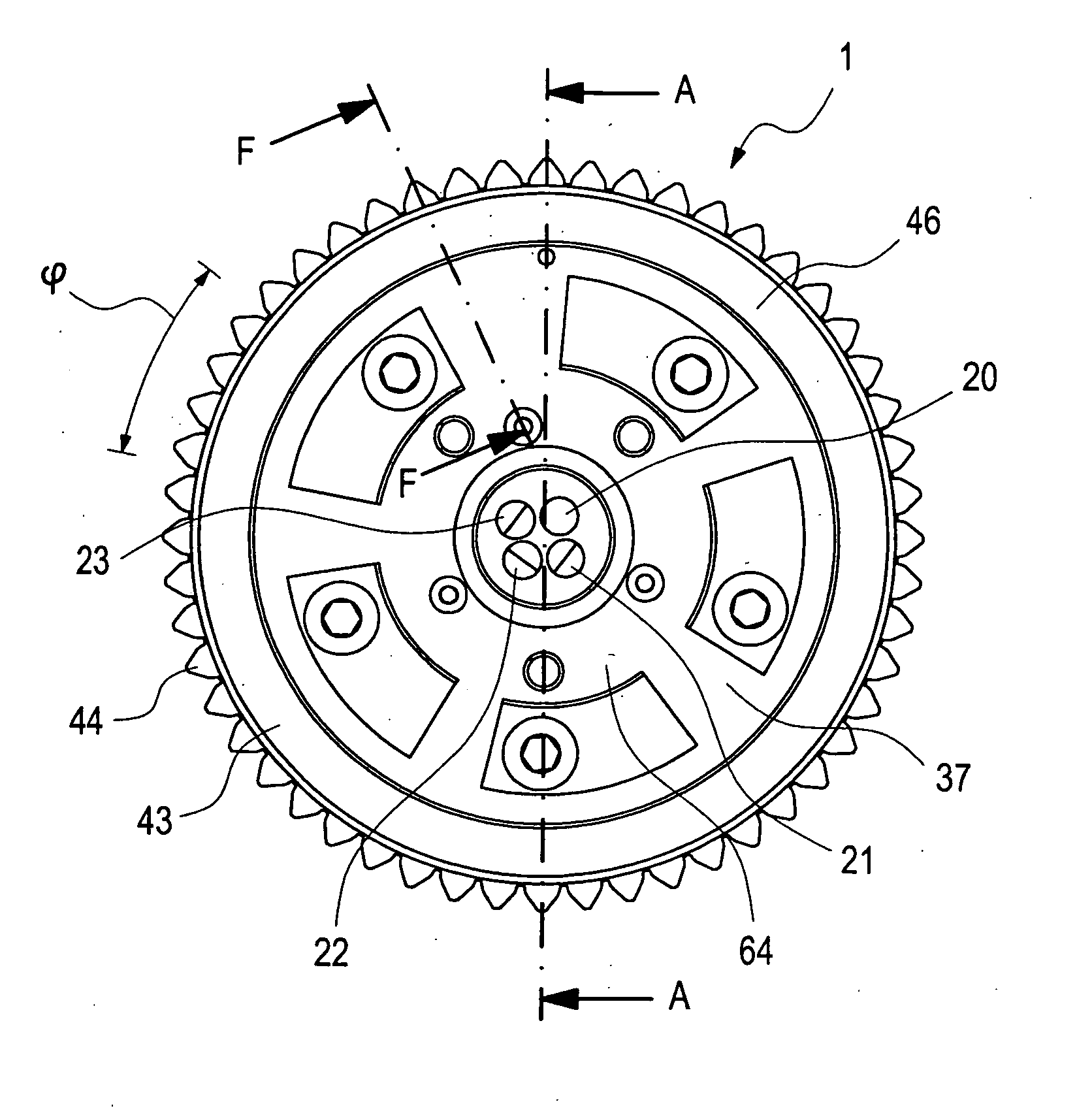

A variable valve timing apparatus rotatably receives a rotor in a housing. The rotor can rotate within a predetermined angular range. In some cases, the rotor is locked by a lock pin at an intermediate position within the angular range. In this manner, it is possible to realize a suitable valve timing even when an engine is restarted after it is stopped. In some case, the rotor is prevented from moving to the largest delay angle position by a restricting pin. In this manner, it is possible to prevent the rotor from reaching the largest delay angle position before the engine is stopped. On the other hand, while the engine is operated, it is possible to rotate the rotor to the largest delay angle position and to realize a valve timing responsive to the state of operation.

Owner:DENSO CORP

EGR system with dedicated EGR cylinders

Improved exhaust gas recirculation system and methods that use one or more of the engine's cylinders as dedicated EGR cylinders. All of the exhaust from the dedicated EGR cylinders is recirculated back to the engine intake. Thus, the EGR rate is constant, but the EGR mass flow may be controlled by adjusting the air-fuel ratio of the dedicated EGR cylinders or by using various variable valve timing techniques.

Owner:SOUTHWEST RES INST

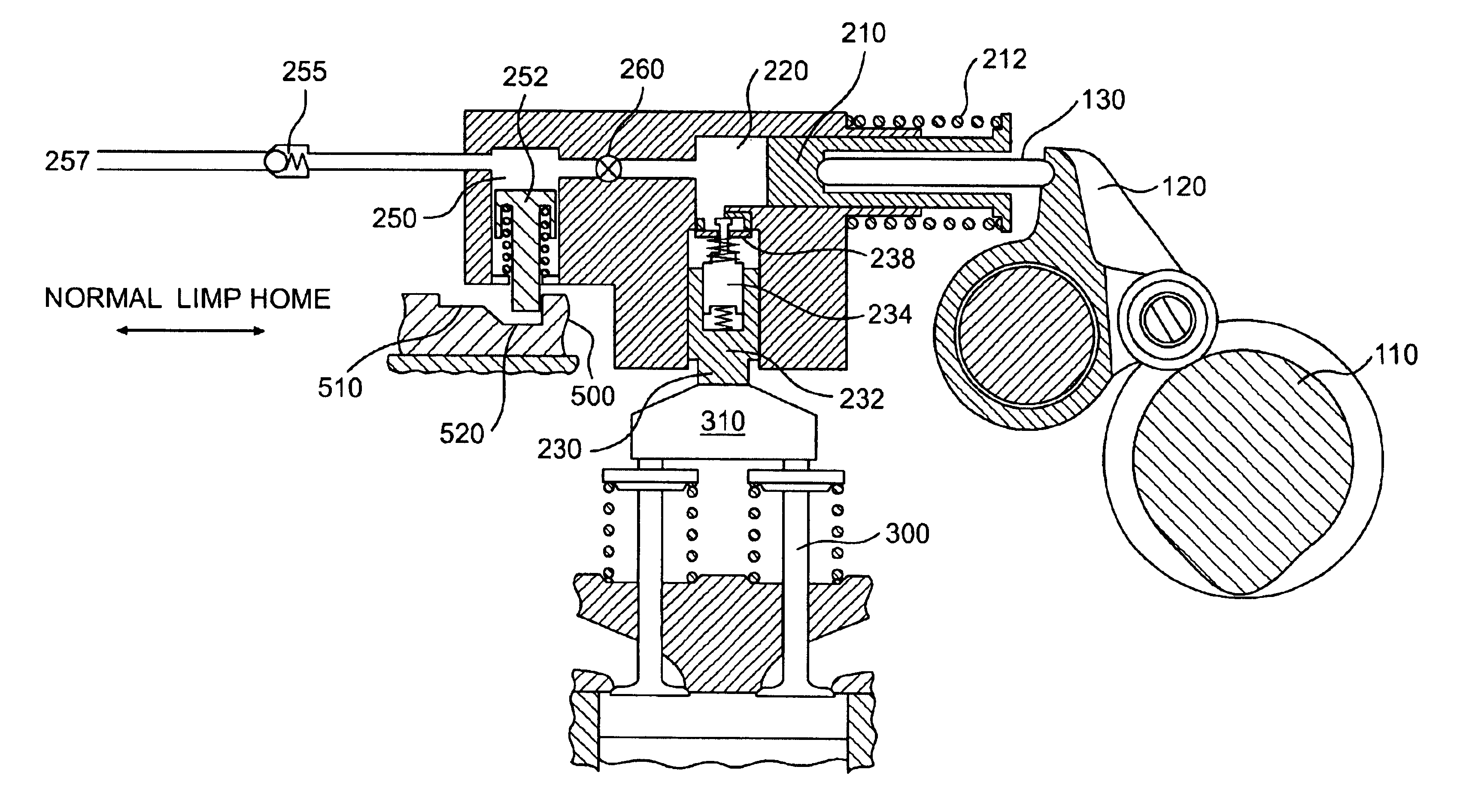

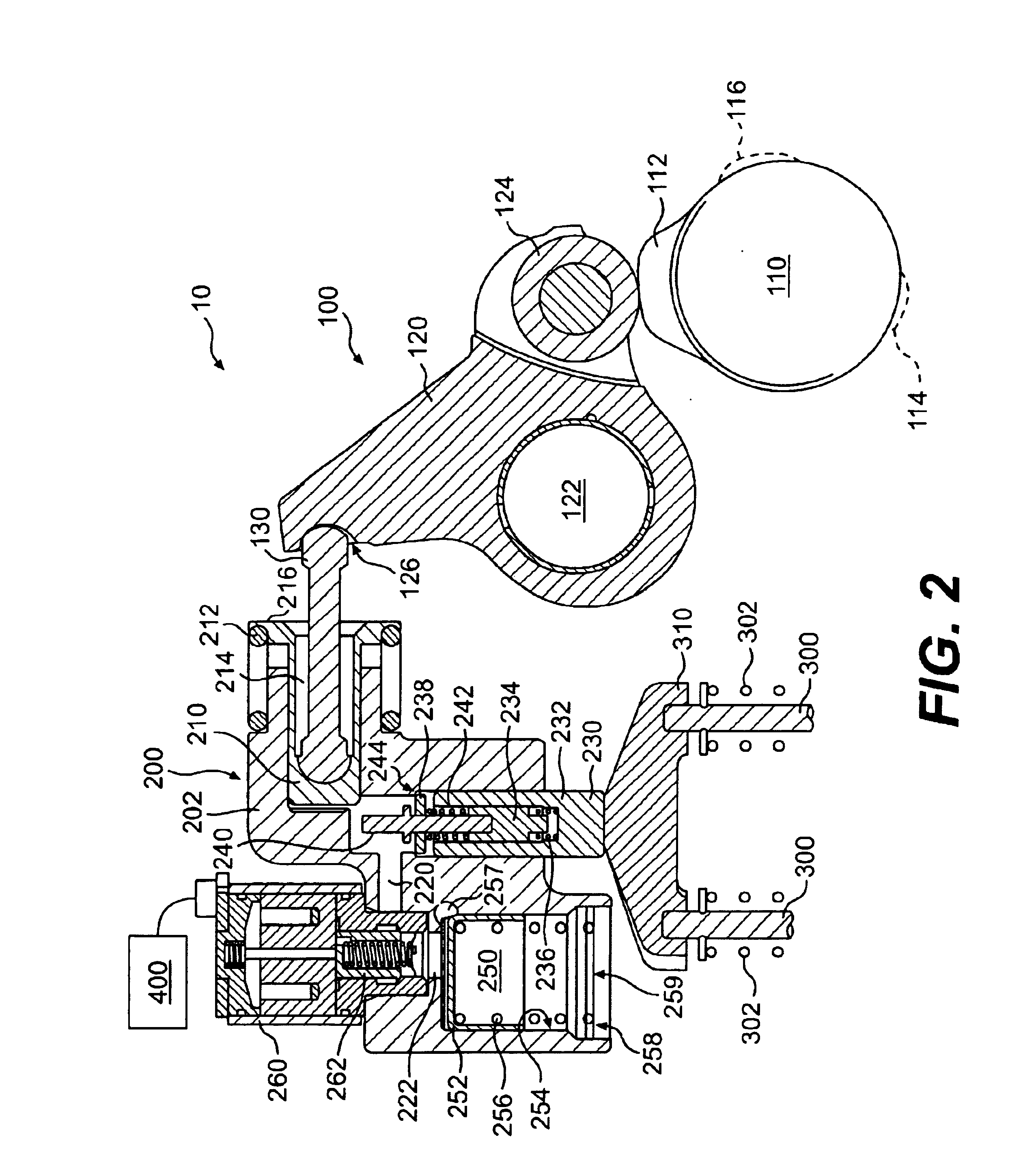

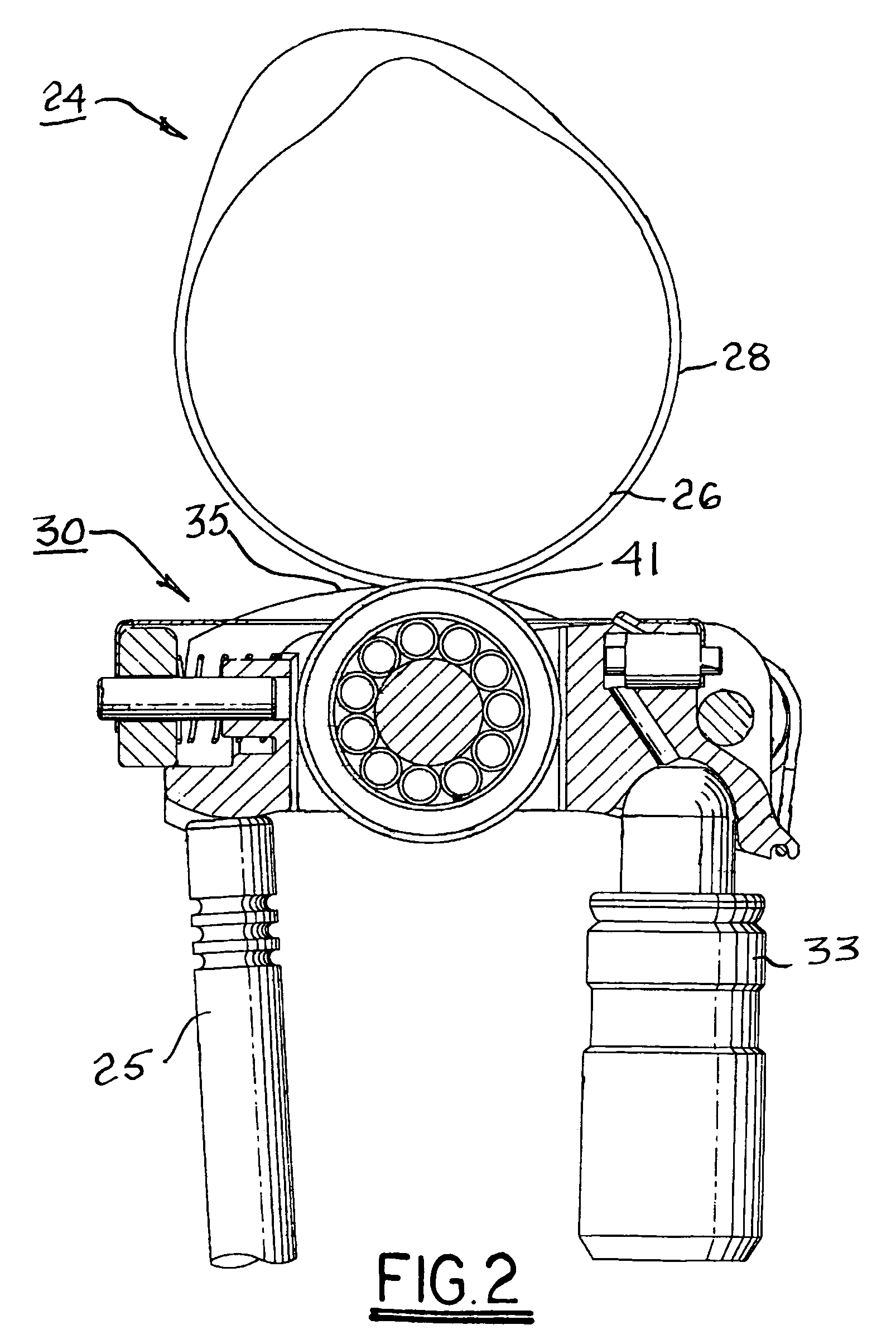

Compact lost motion system for variable valve actuation

InactiveUS6883492B2Wide rangeNon-fuel substance addition to fuelInternal combustion piston enginesVariable valve timingHydraulic circuit

Lost motion systems and methods for providing engine valves with variable valve actuation for engine valve events are disclosed. The system may include a master piston hydraulically linked to a slave piston, and a dedicated cam operatively connected to the master piston. The slave piston may be disposed substantially perpendicular to the master piston in a common housing. The slave piston is adapted to actuate one or more engine valves. The slave piston may incorporate an optional valve seating assembly into its upper end. A trigger valve may be operatively connected to the master-slave hydraulic circuit to selectively release and add hydraulic fluid to the circuit.

Owner:JACOBS VEHICLE SYST

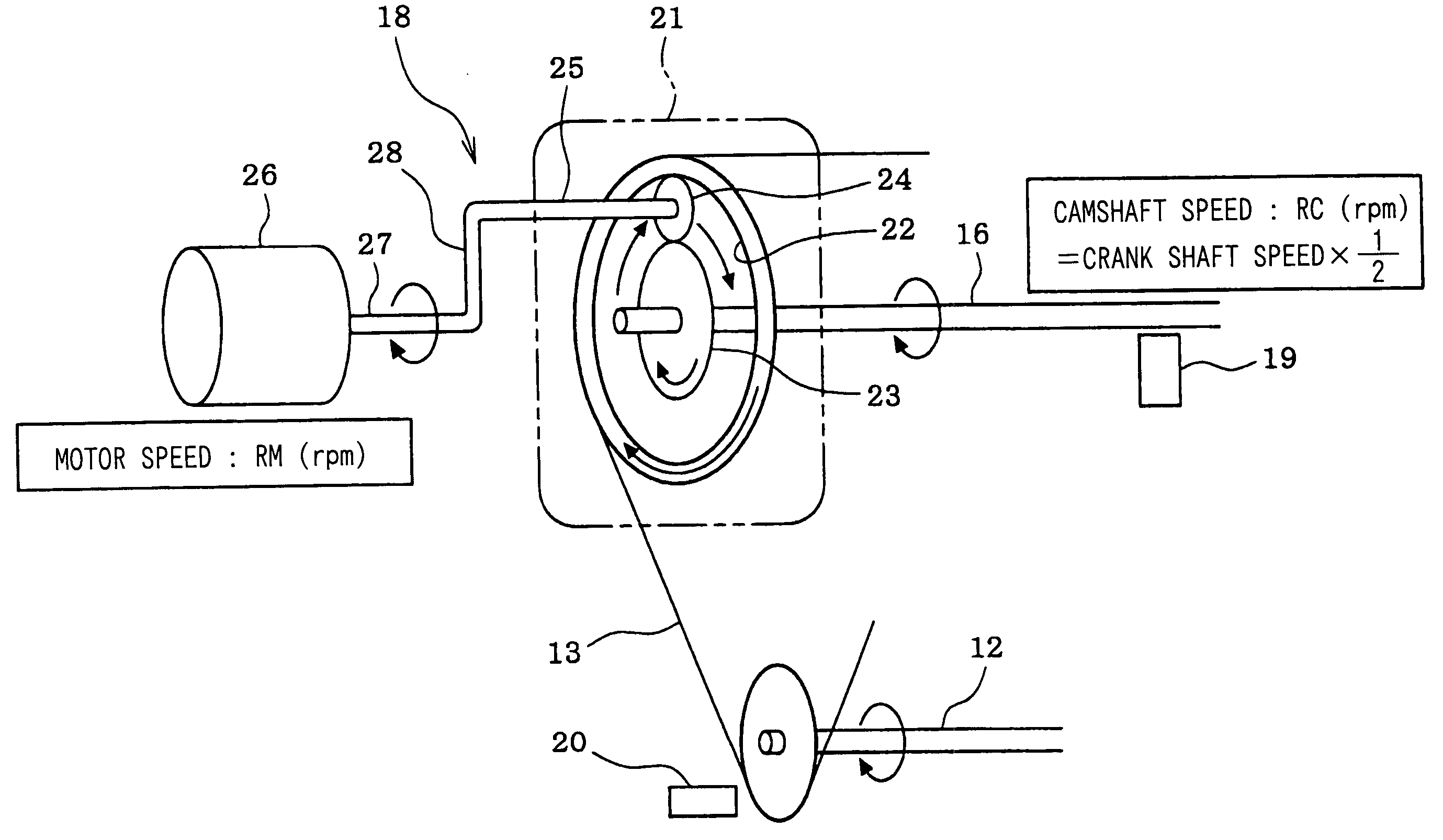

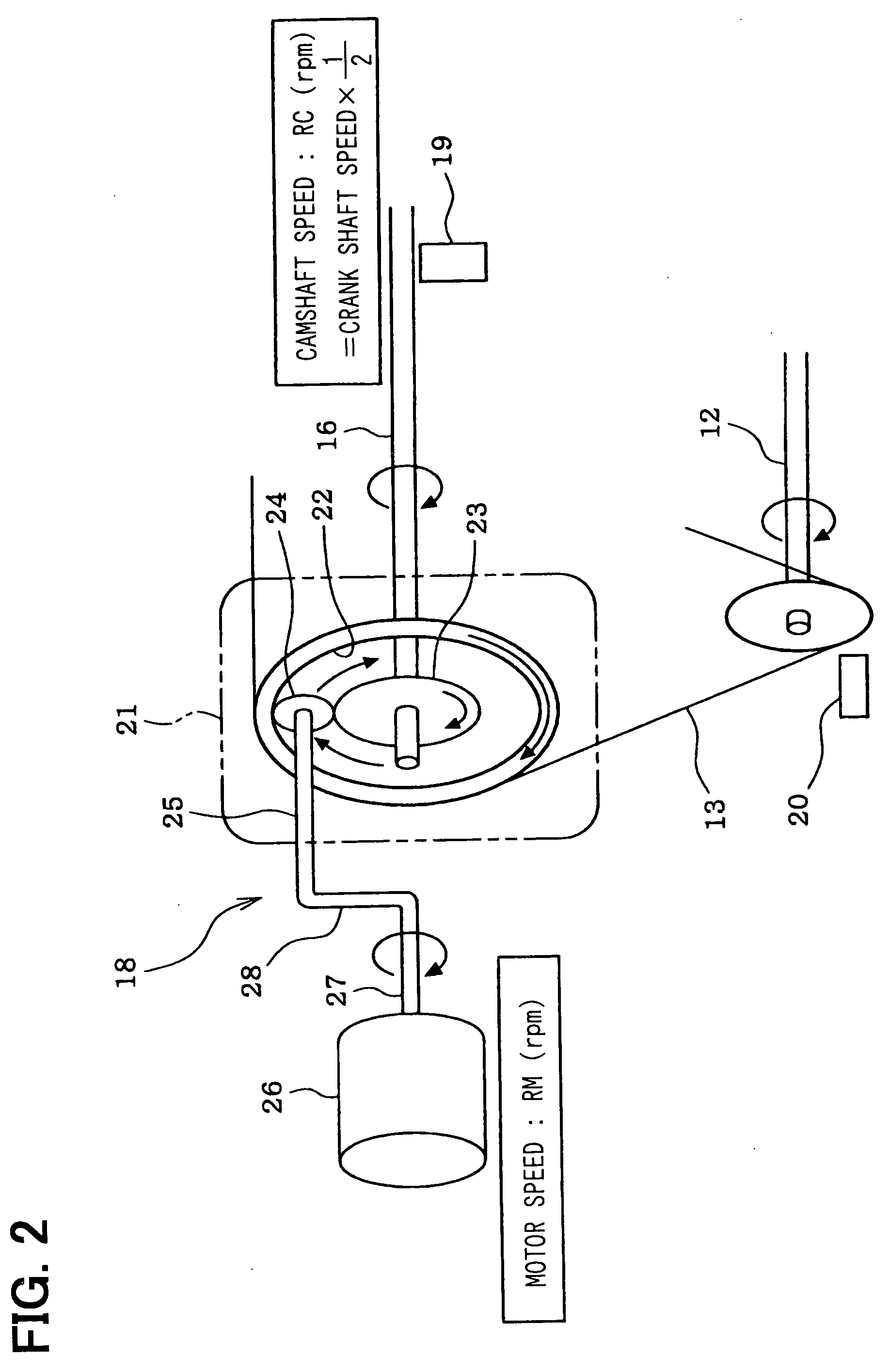

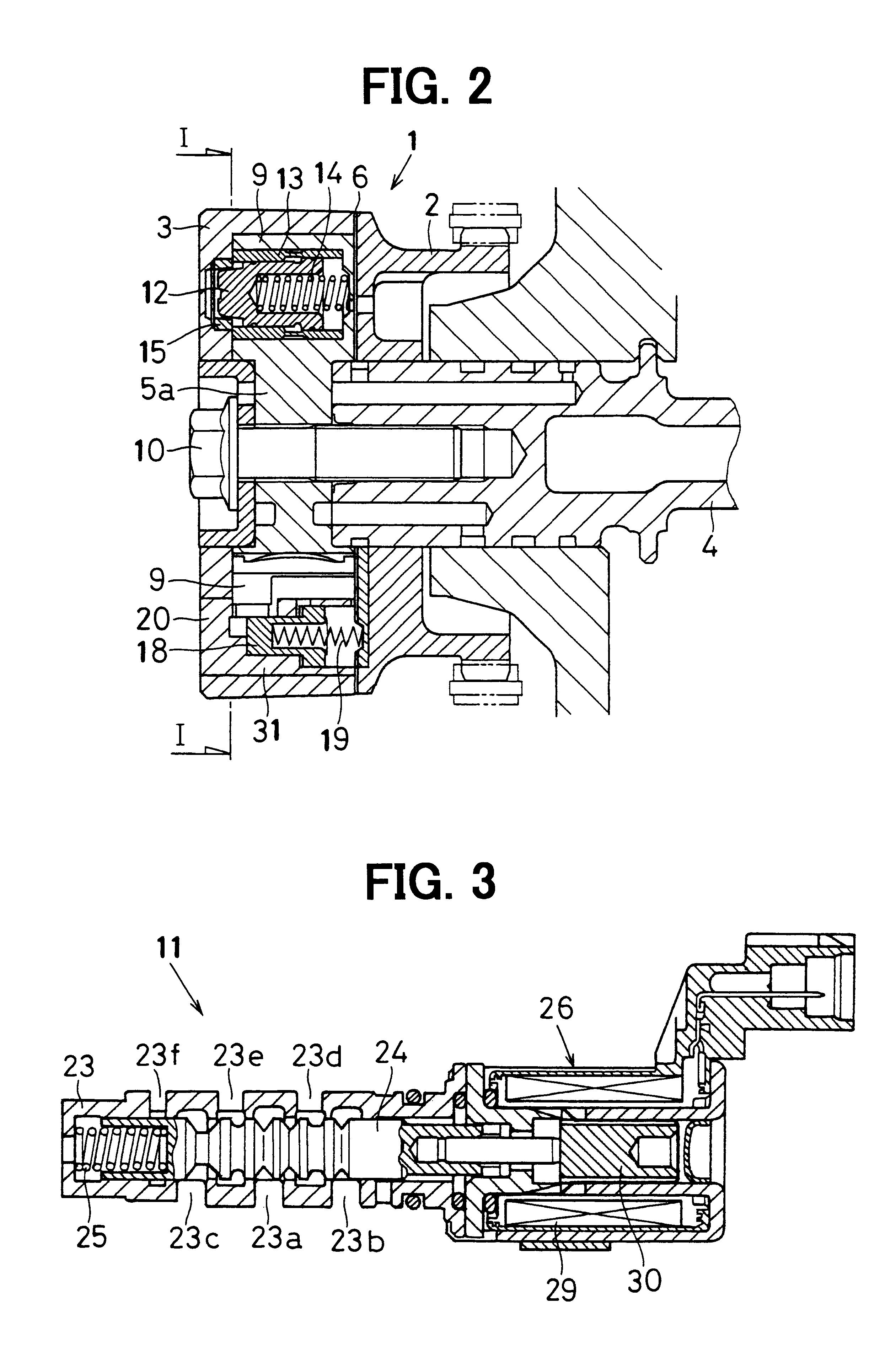

Variable valve timing control device of internal combustion engine

A required valve timing change rate Vreq is calculated so as to make a deviation D between a target valve timing VTtg and an actual valve timing VT small and then a required speed difference DMCRreq between a motor 26 and a camshaft 16 is calculated on a basis of the required valve timing change rate Vreq. When the deviation D is larger than a predetermined value, a required motor speed Rmreq is calculated by adding the required speed difference DMCRreq to a camshaft speed RC and a motor control value is calculated so as to control the motor speed RM to the required motor speed Rmreq. When the deviation D is not larger than the predetermined value, the camshaft speed RC is set as the required motor speed Rmreq and the motor control value is calculated so as to control the motor speed RM to the camshaft speed RC.

Owner:DENSO CORP

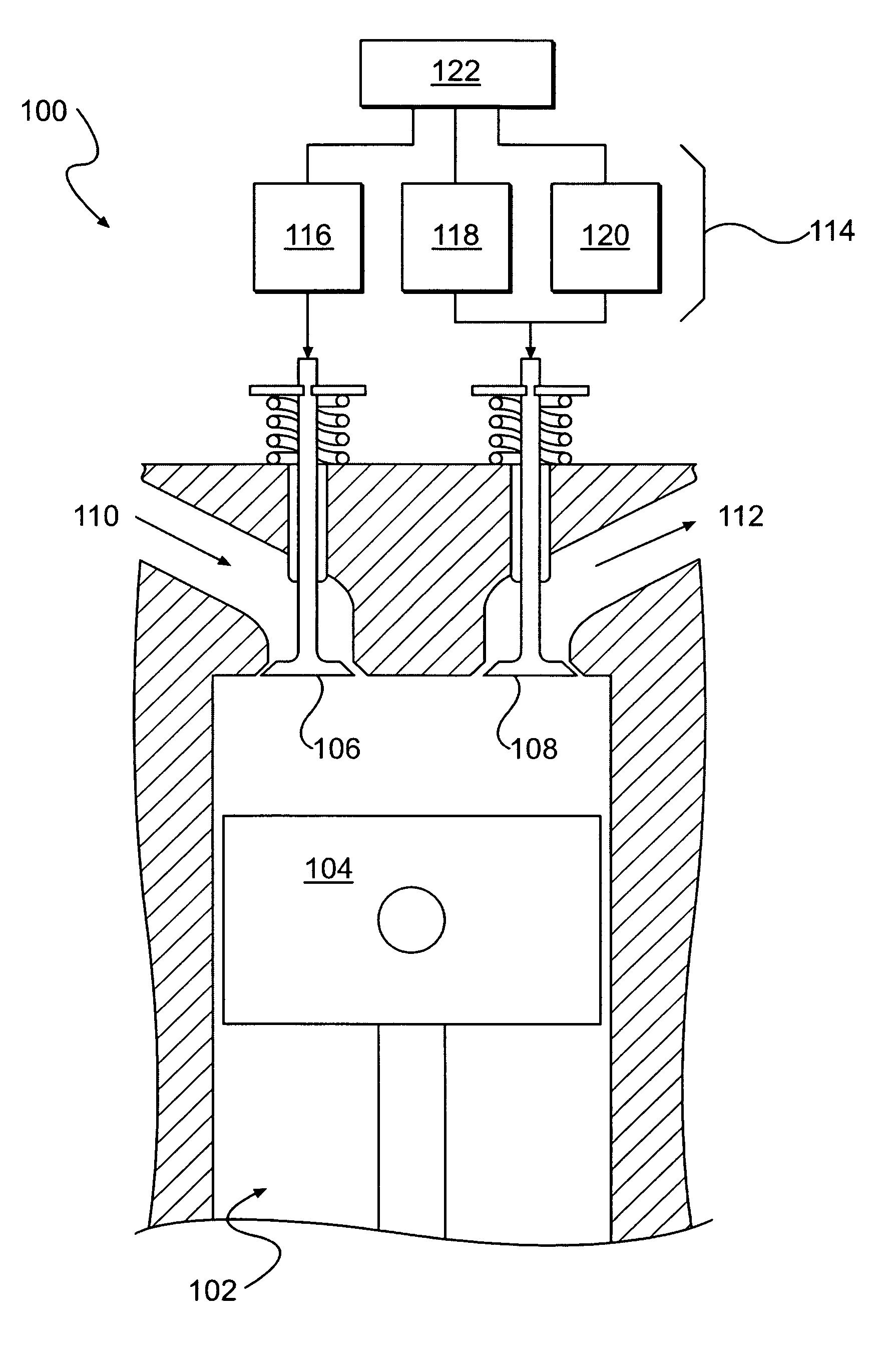

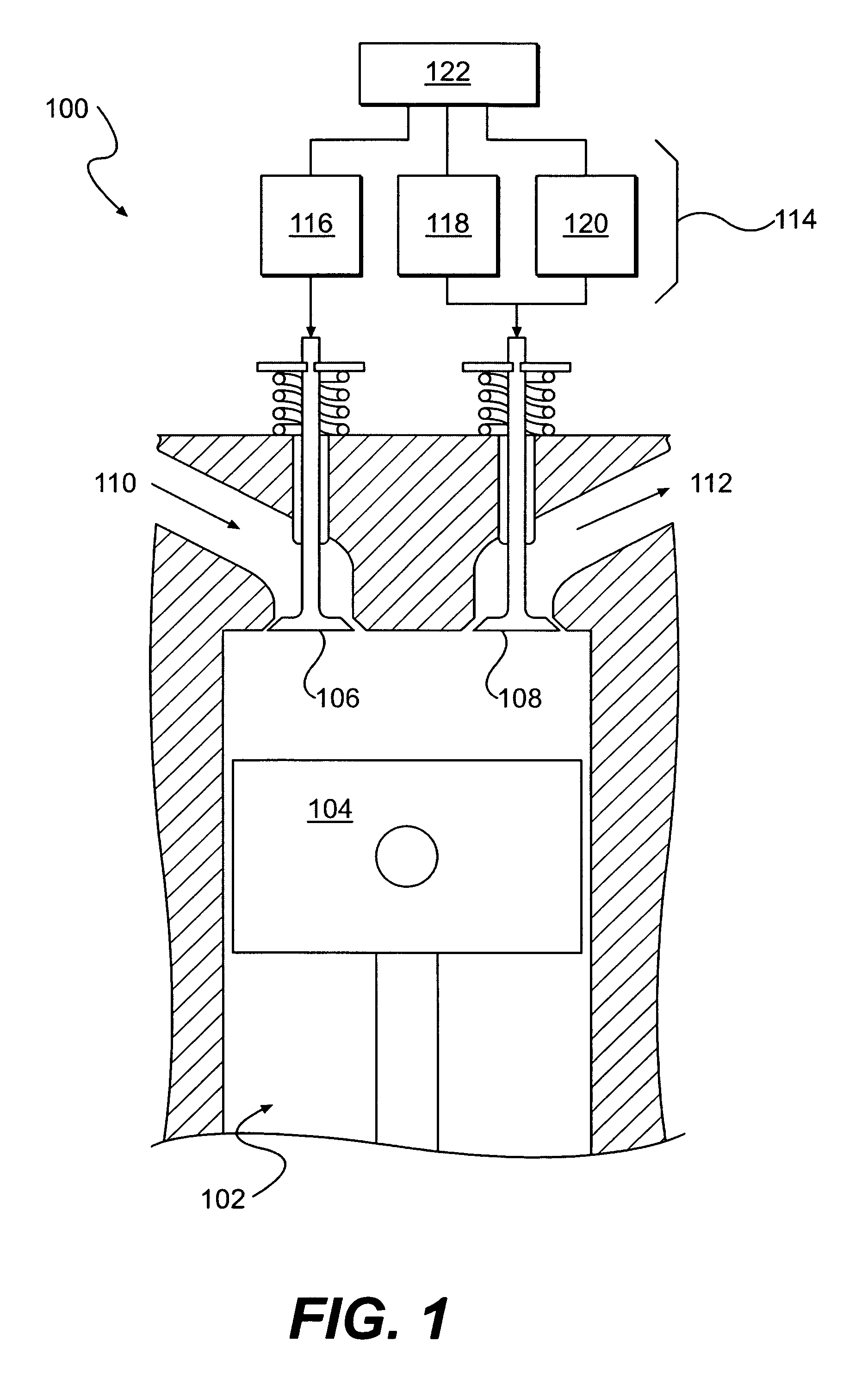

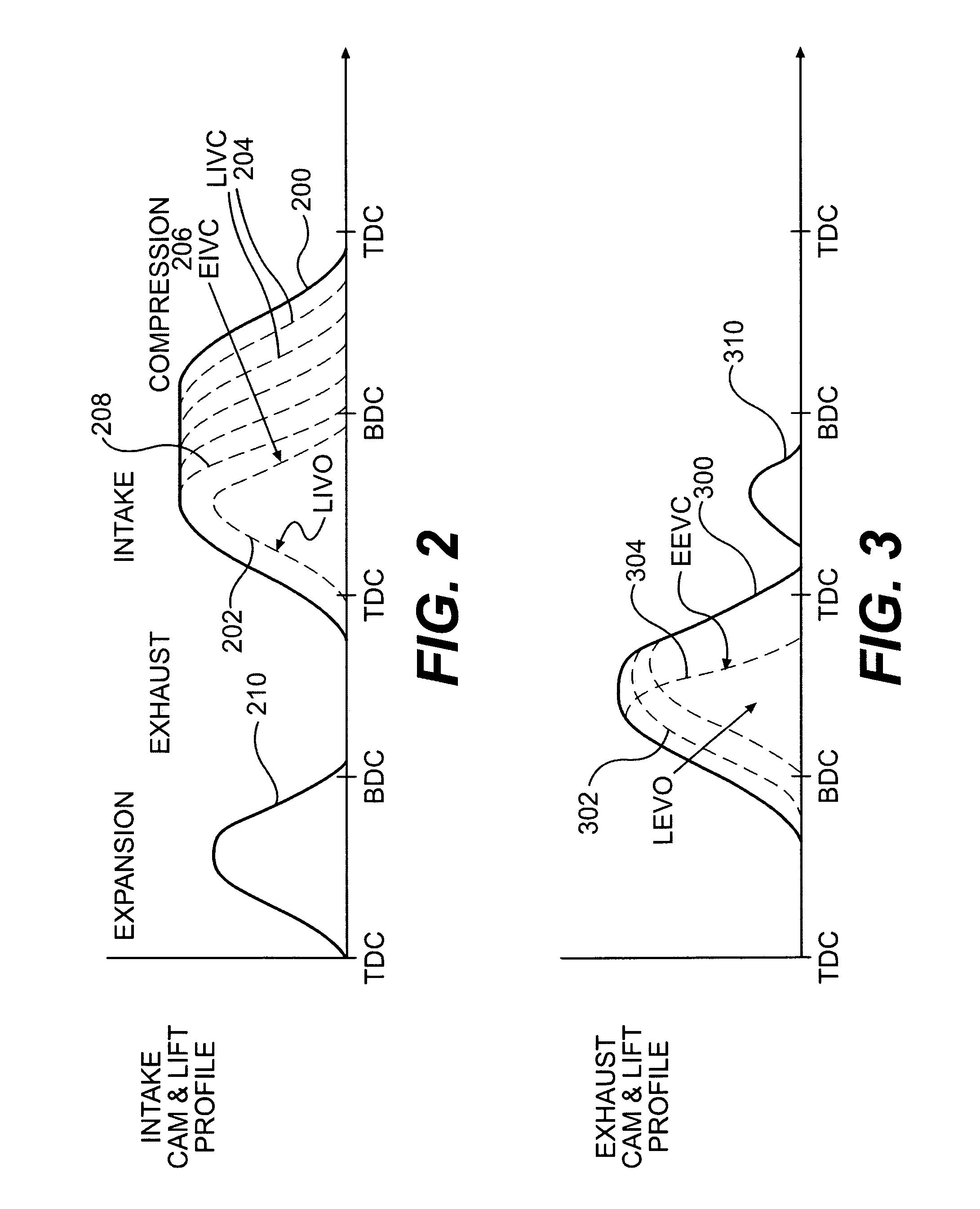

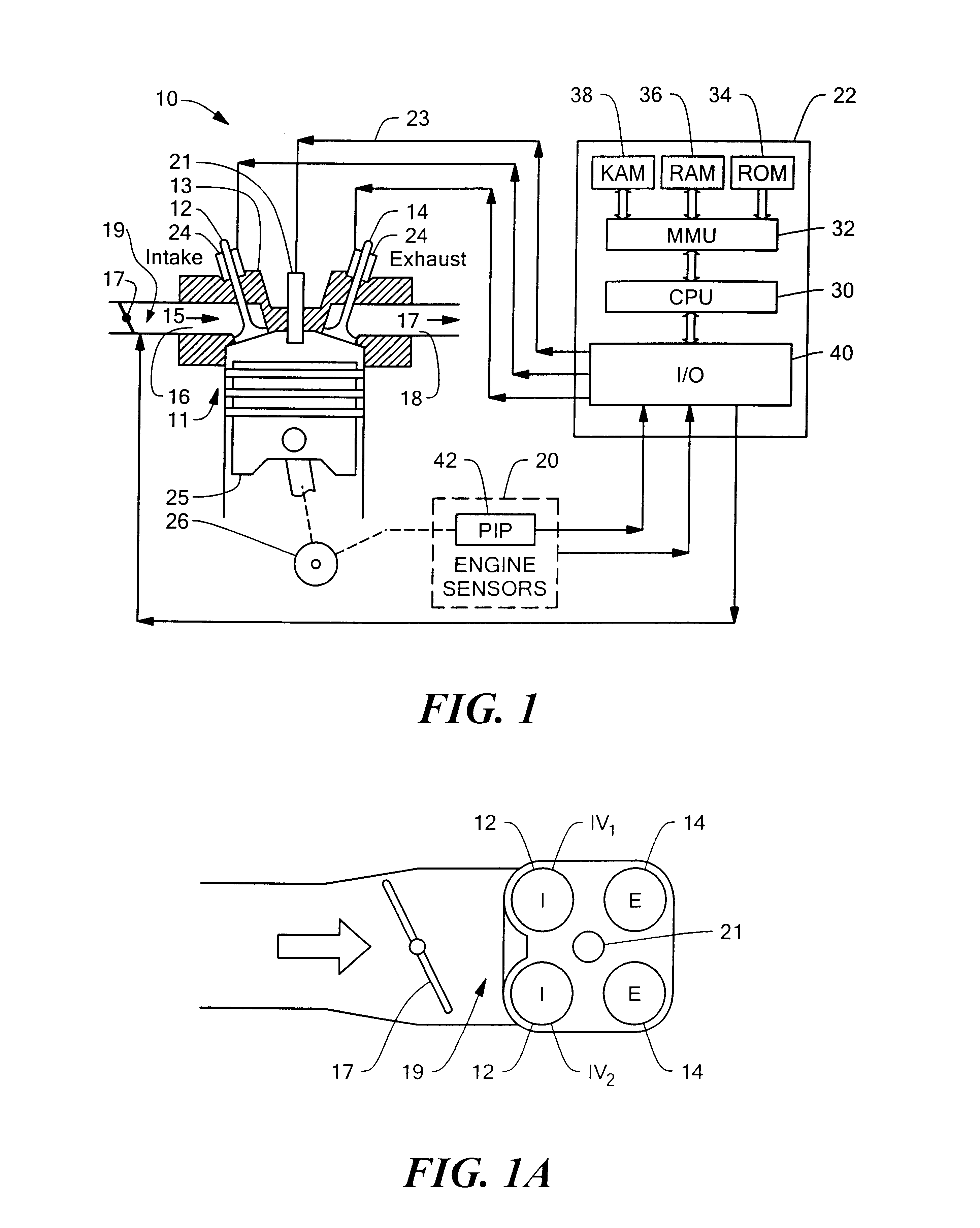

Method and apparatus for optimized combustion in an internal combustion engine utilizing homogeneous charge compression ignition and variable valve actuation

InactiveUS7308872B2Electrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

A valvetrain system mechanization for an internal combustion engine using compression ignition, including homogeneous charge compression ignition, having two intake and one or more exhaust valves per cylinder. The valves are operated by dual overhead camshafts having two-step cams. The intake and exhaust camshafts are provided with phasers for varying the opening and closing of the intake and exhaust valves. A two-step roller finger follower is disposed for each valve between the cam lobes and the valve stem. The two sets of intake and exhaust valves are controlled by separate oil control valves. Swirl of gases may be introduced by mismatching the lifts of the valves. The valve opening times, closing times, lifts, fuel injection, compression ratio, and exhaust gas recirculation may be varied to optimize combustion conditions for a range of engine operating modes.

Owner:DELPHI TECH INC

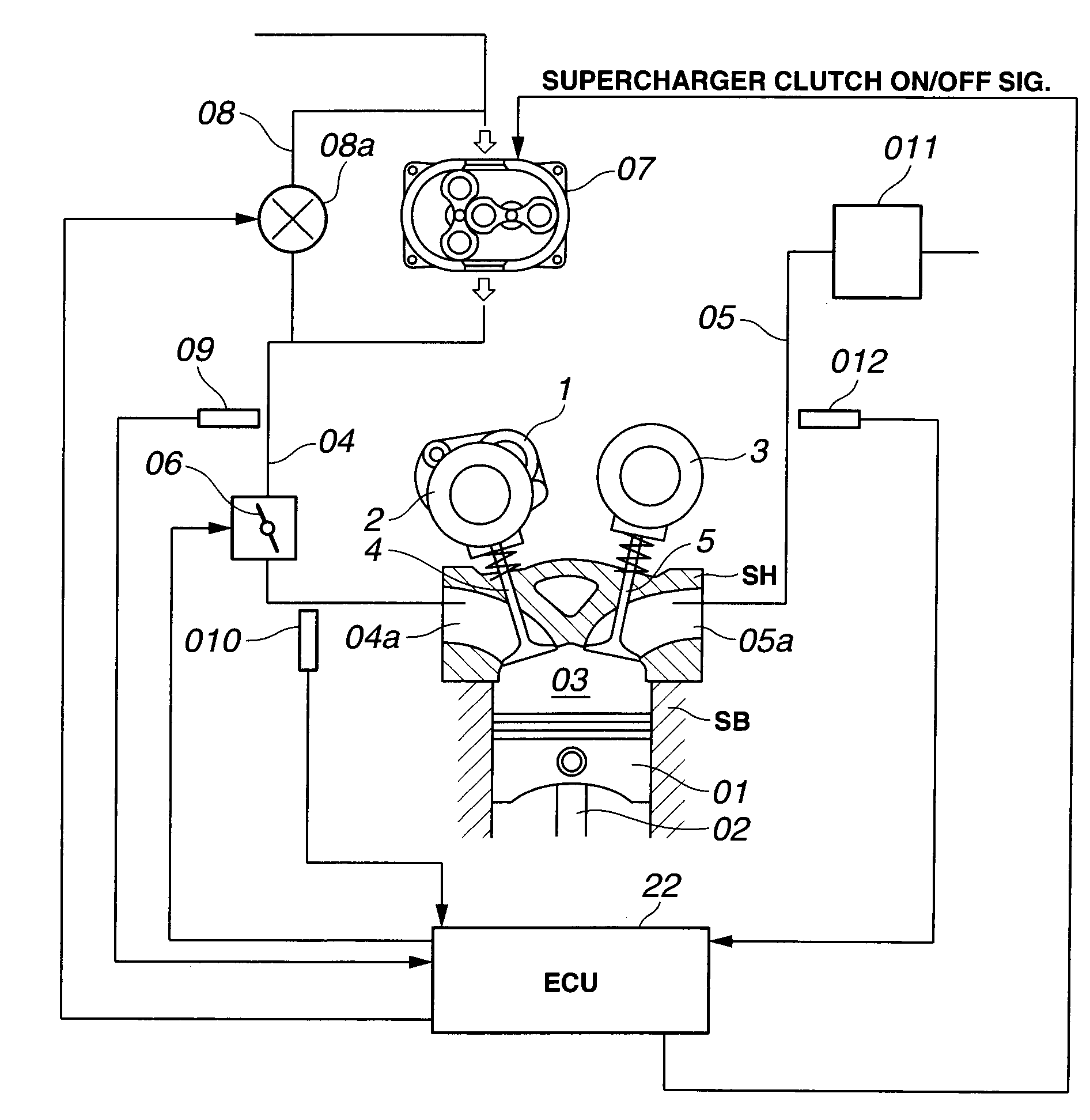

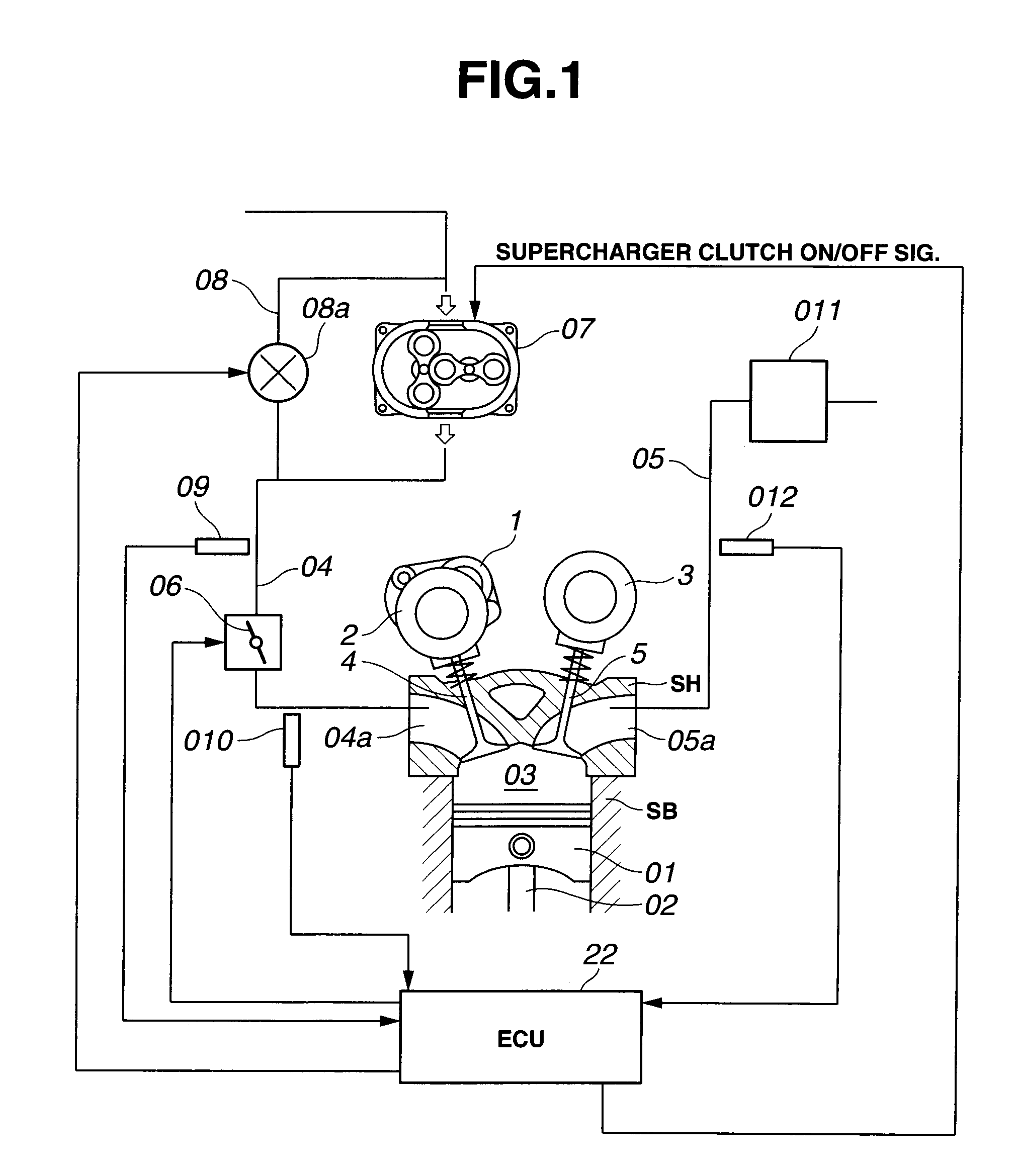

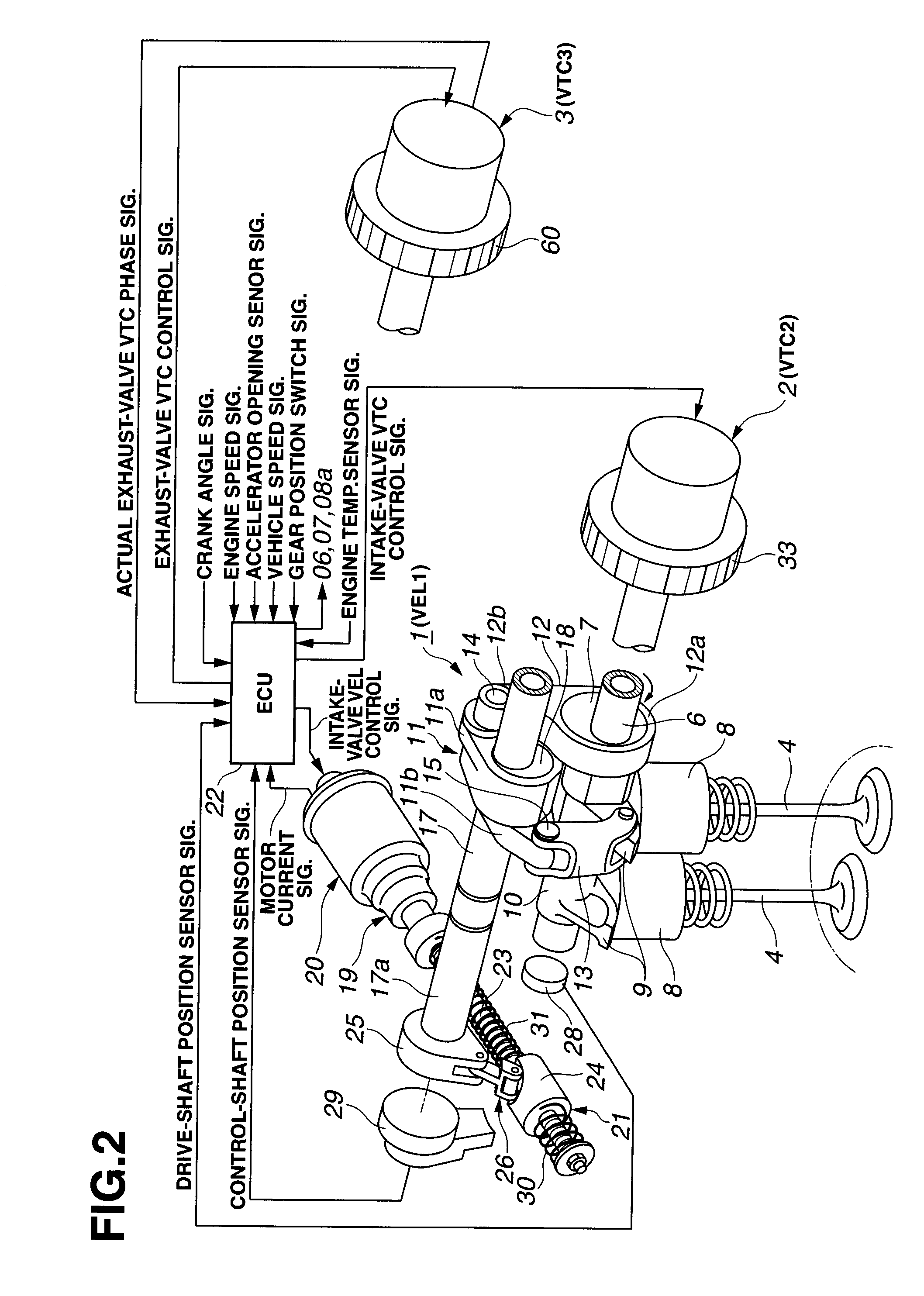

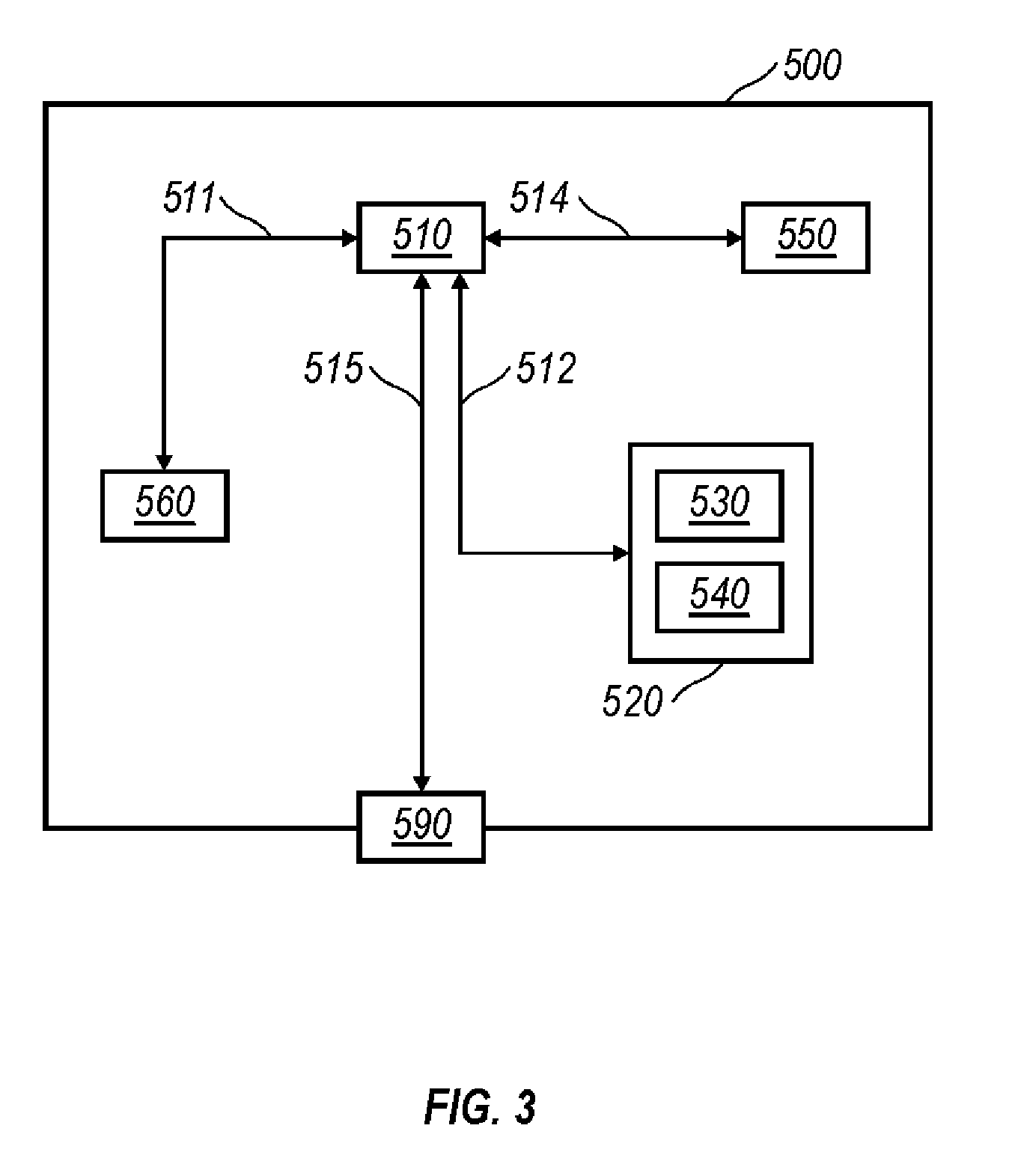

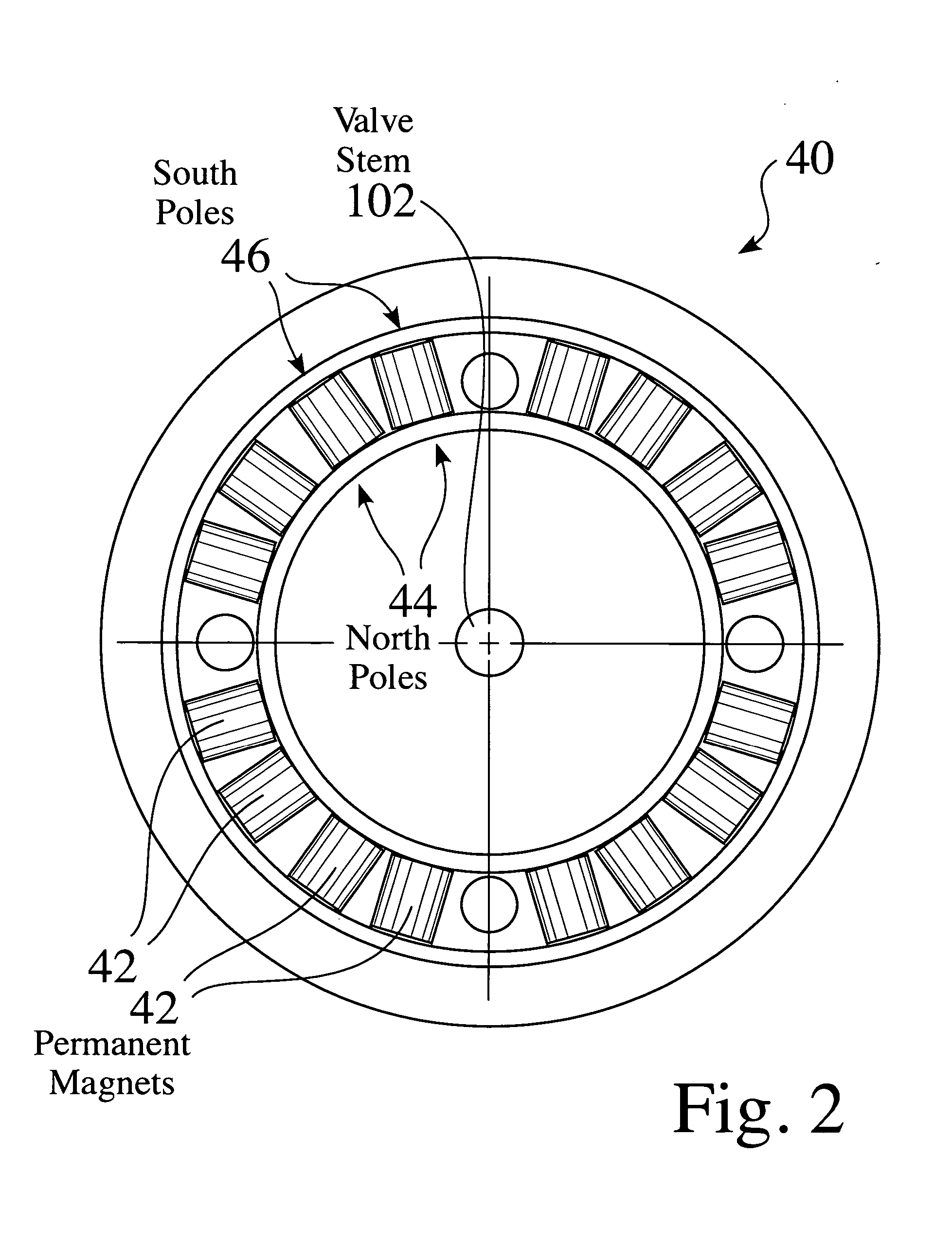

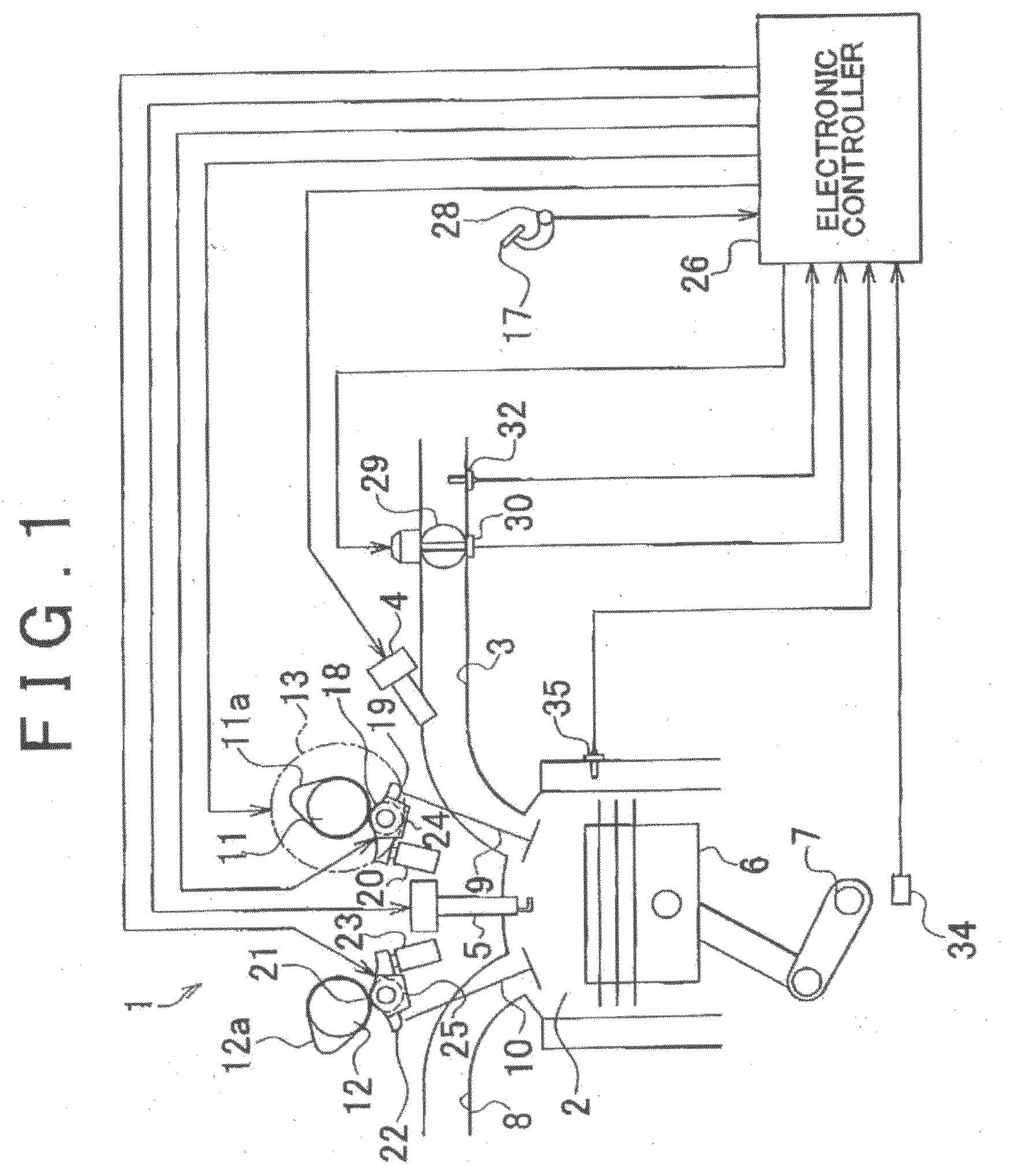

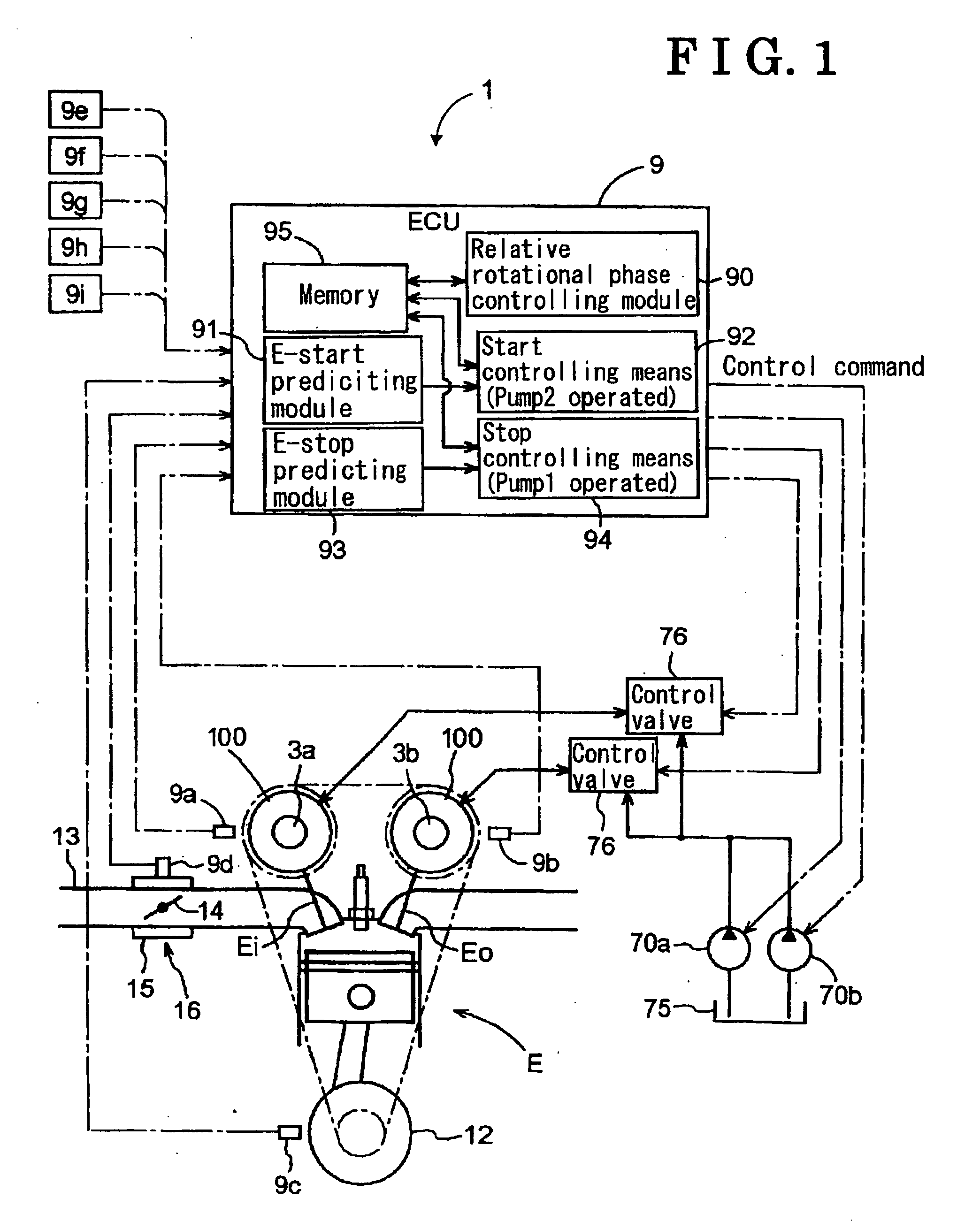

Variable valve actuation system of internal combustion engine and control apparatus of internal combustion engine

ActiveUS20090228187A1Improve responsivenessEngine-torque-increase responsivenessAnalogue computers for vehiclesValve arrangementsExhaust valvePhase shifted

In a control apparatus of a supercharged internal combustion engine, a variable valve actuation system interacts with an engine control system. A controller is configured or programmed to increase an intake-valve lift by a variable valve lift mechanism, which is provided for variably controlling at least the intake-valve lift of engine valves, when starting from a vehicle stand-still state or when accelerating from an idling state or a light load state. The controller is further configured or programmed to increase a valve overlap of intake and exhaust valves by a variable phase control mechanism, which is provided for variably phase-shifting a central phase angle of a valve lift characteristic curve of at least one of the intake and exhaust valves, while increasing a boost pressure of intake air introduced into an engine cylinder by a supercharging device, after the intake-valve lift has been increased.

Owner:HITACHI ASTEMO LTD

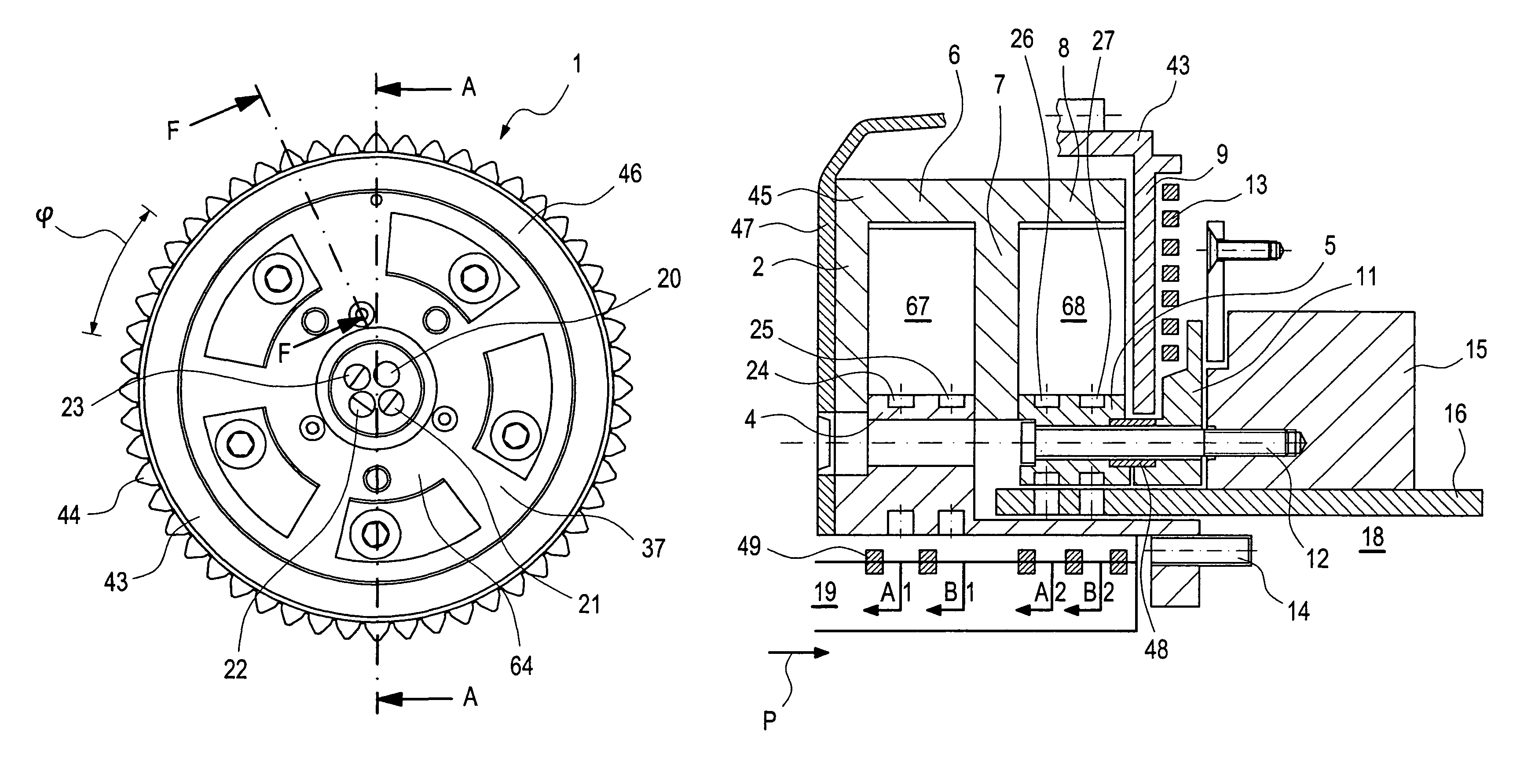

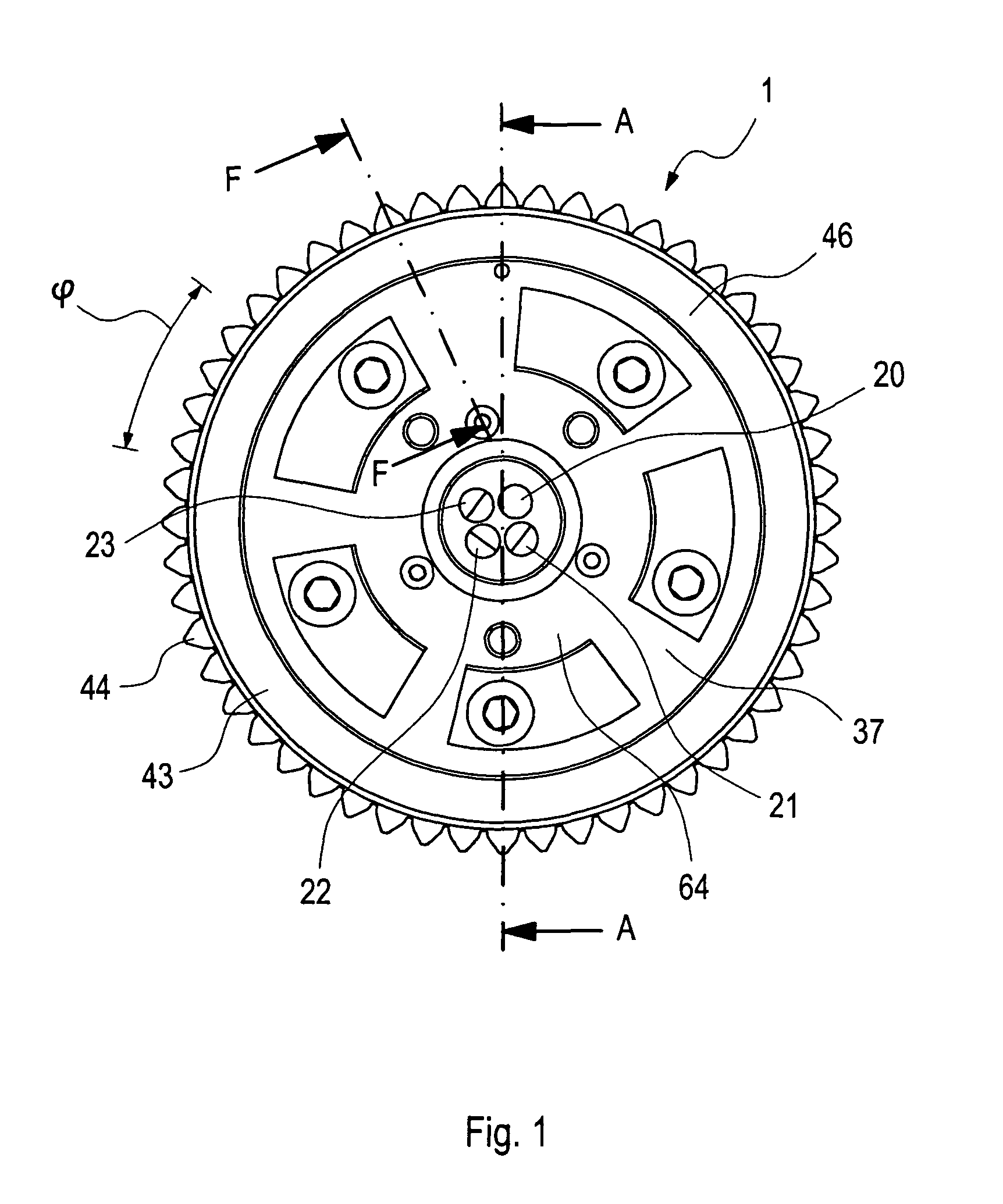

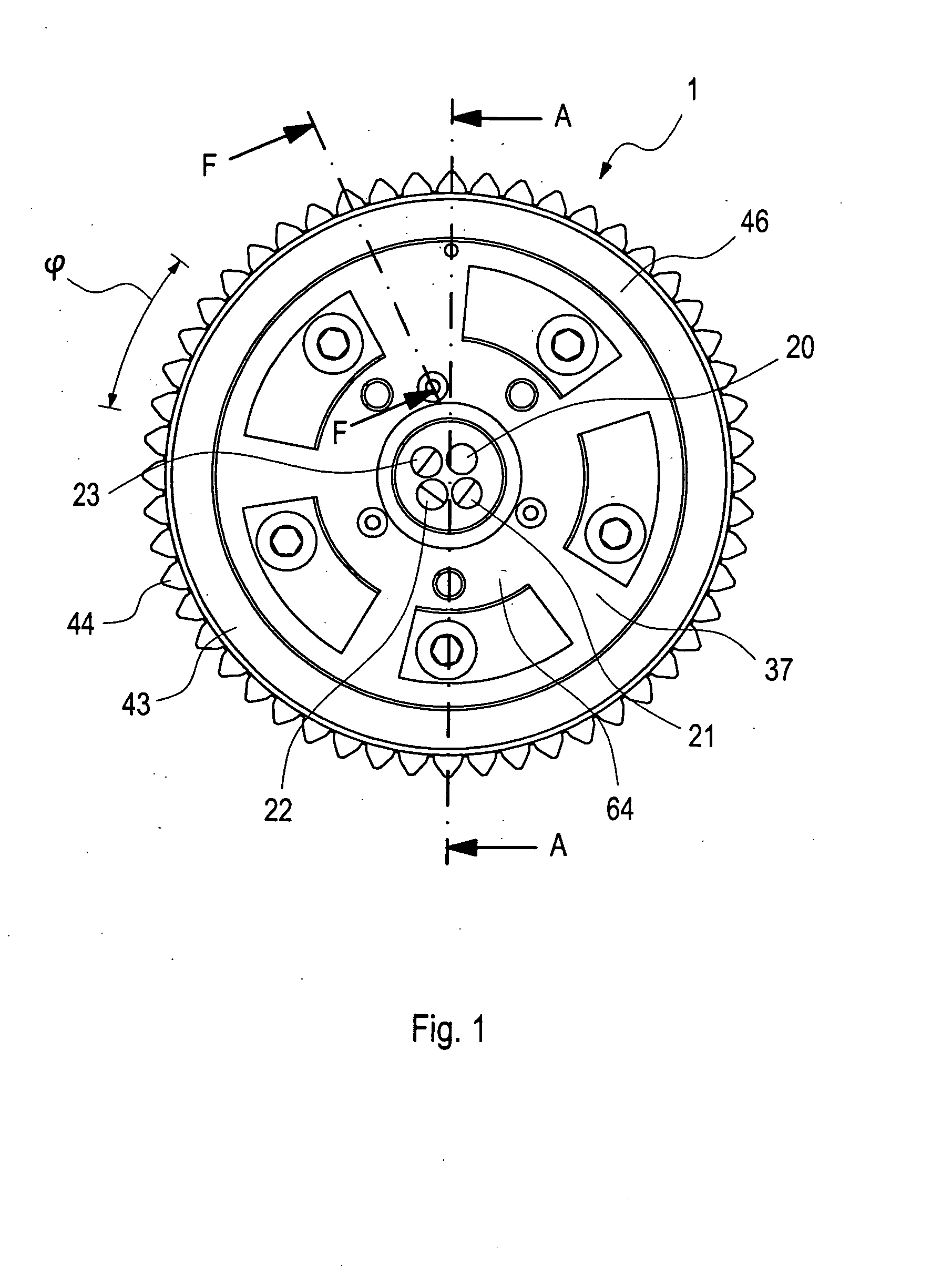

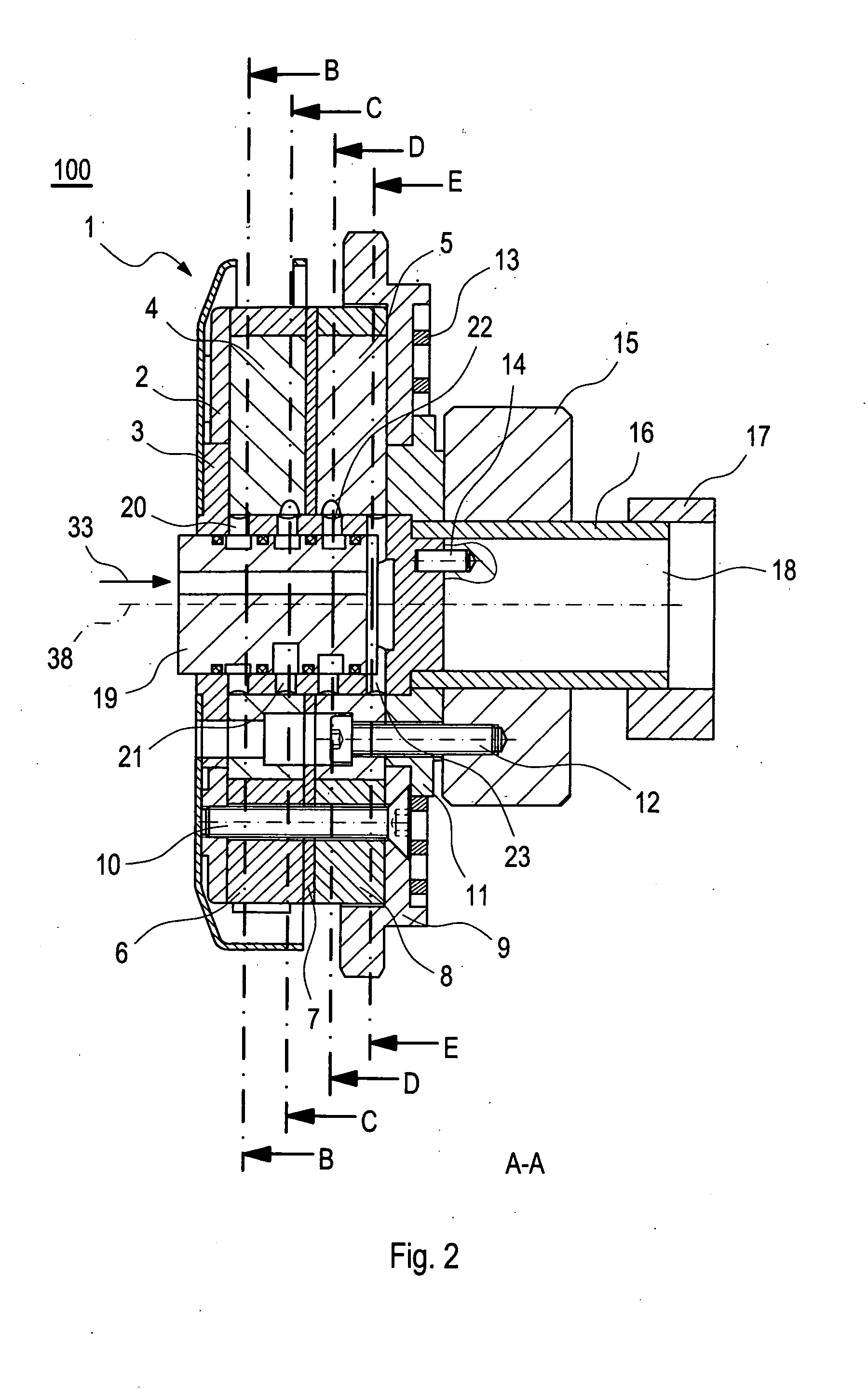

Variable valve timing device

InactiveUS7841311B2Rapid responsePromote densificationValve arrangementsYielding couplingVariable valve timingEngineering

The present invention provides a variable valve timing device for an internal combustion engine having a double camshaft. A gas exchange valve control shaft is provided which has first and second concentrically arranged cam shafts that are adjustable in a rotatable manner with respect to each other, by which a cam of the first cam shaft is adjusted in terms of its angle towards a cam of the second cam shaft. A cam phasing device is provided which operates by rotatable vanes provoking a swivelling relative movement between a driven member and an output member. The cam phasing device comprises at least two pivotable vane adjusters. Each pivotable vane adjuster is assigned to one of the two cam shafts. The pivotable vane adjusters are arranged axially one after the other in a direction of a valve control shaft. Each pivotable vane adjuster may be designed as a rotor-type vane adjuster.

Owner:HILITE INT INC

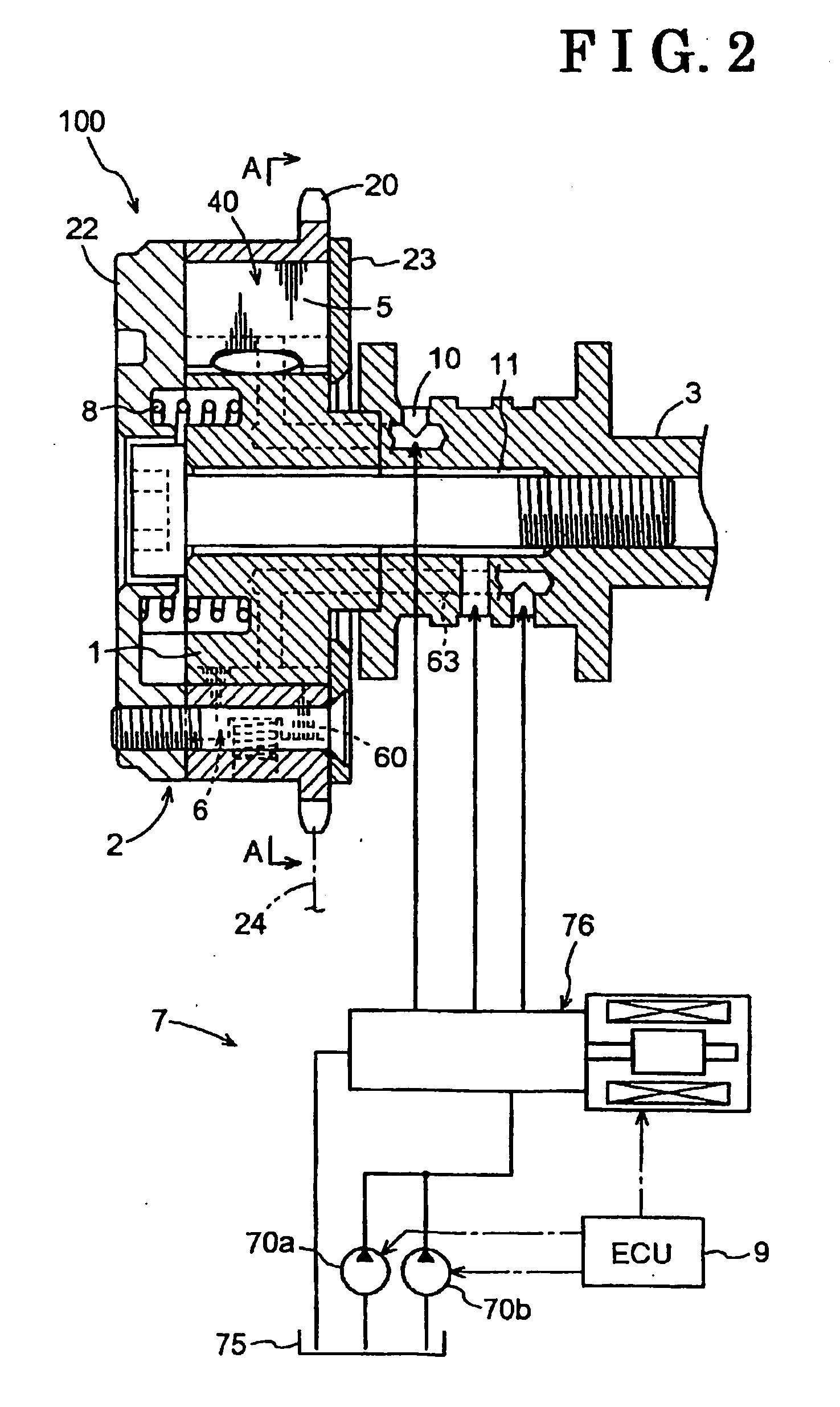

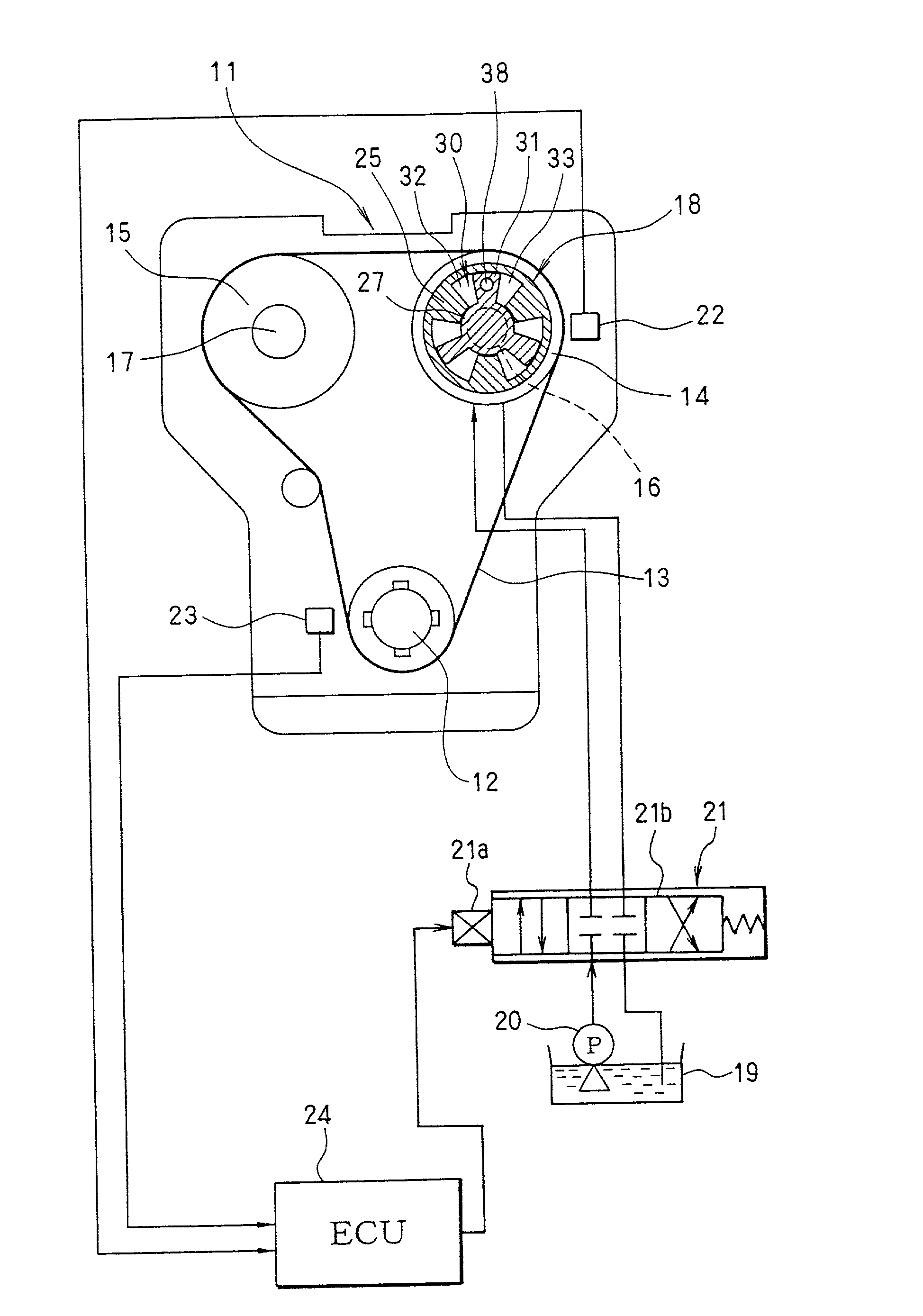

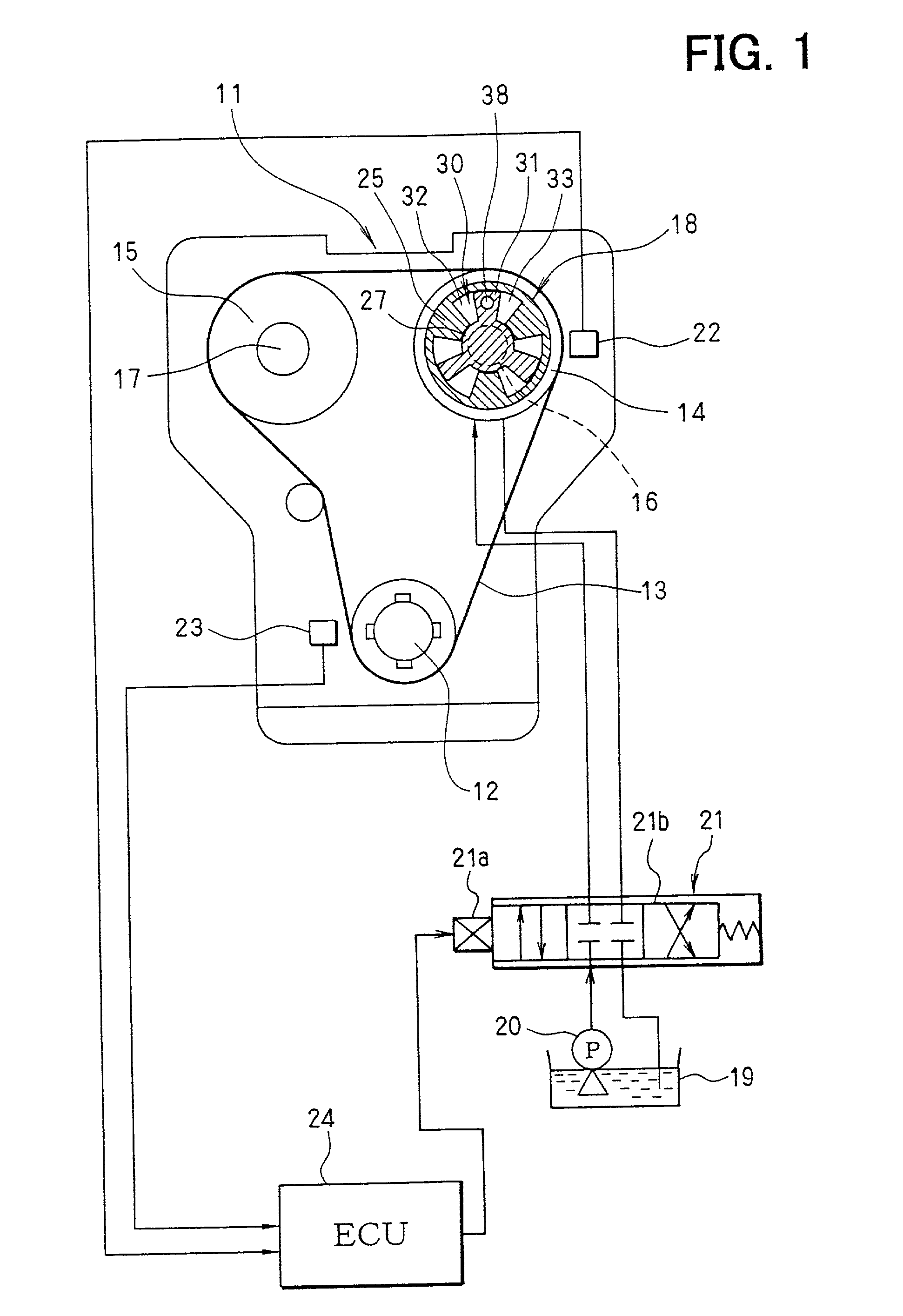

Variable valve timing apparatus

InactiveUS6779499B2Prevent rotationPrevent the rotor from reachingValve arrangementsMachines/enginesVariable valve timingEngineering

A variable valve timing apparatus rotatably receives a rotor in a housing. The rotor can rotate within a predetermined angular range. In some cases, the rotor is locked by a lock pin at an intermediate position within the angular range. In this manner, it is possible to realize a suitable valve timing even when an engine is restarted after it is stopped. In some case, the rotor is prevented from moving to the largest delay angle position by a restricting pin. In this manner, it is possible to prevent the rotor from reaching the largest delay angle position before the engine is stopped. On the other hand, while the engine is operated, it is possible to rotate the rotor to the largest delay angle position and to realize a valve timing responsive to the state of operation.

Owner:DENSO CORP

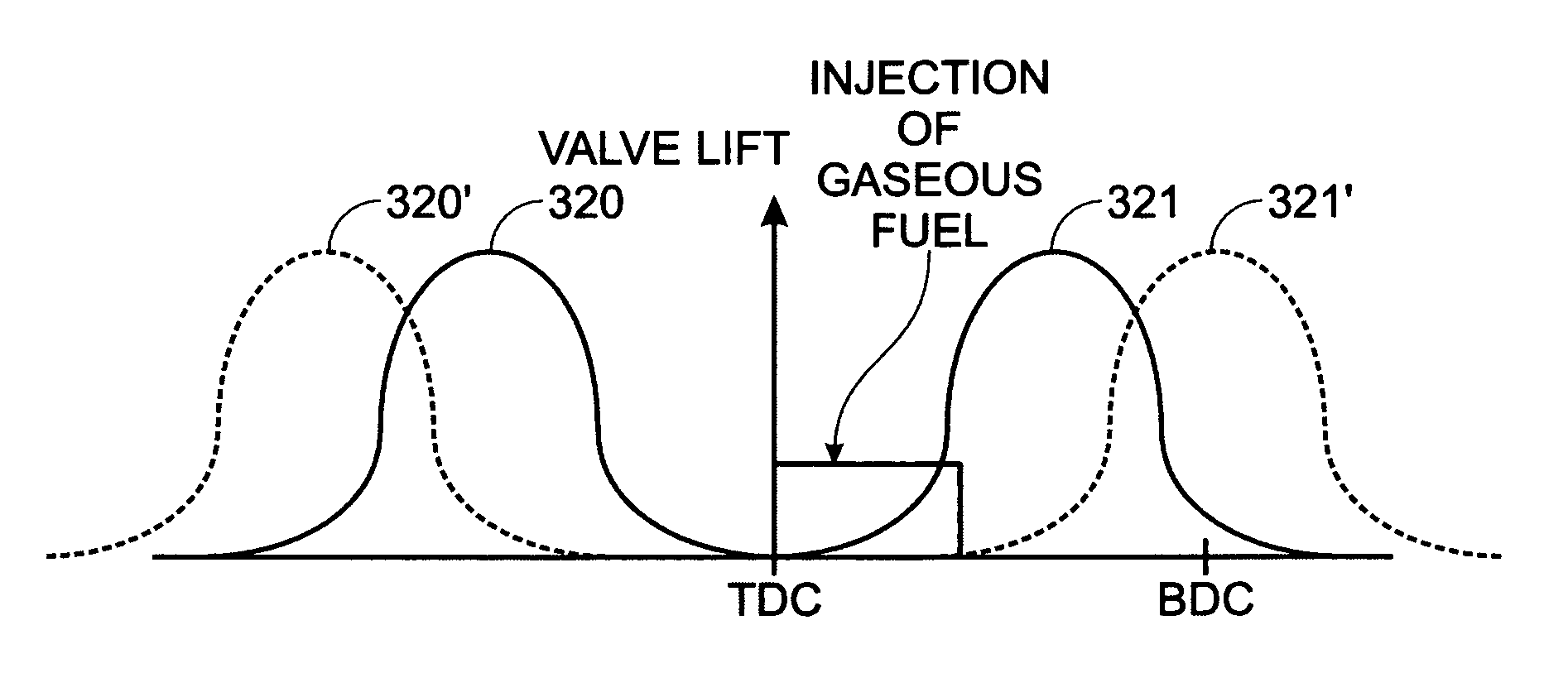

Control apparatus for internal combustion engine

ActiveUS20050005908A1Efficient solutionValve arrangementsElectrical controlVariable valve timingIgnition timing

Based on results of a knock control for adjusting ignition timing in accordance with the occurrence of knocking, an electronic control unit computes deposit required ignition timing akgrg, which is ignition timing determined by taking adhesion of deposits in an internal combustion engine into consideration. Based on the deposit required ignition timing akgrg, the electronic control unit reduces a vvt allowable variable range of a target VVT advancement amount, which is a control target value of a variable valve timing mechanism. The electronic control unit corrects a required ignition timing based on the actual VVT advancement amount vt, which is chanted according to the reduction of the allowable variable range of the target VVT advancement amount. As a result, problems resulting from the adhesion of deposits are effectively avoided.

Owner:TOYOTA JIDOSHA KK

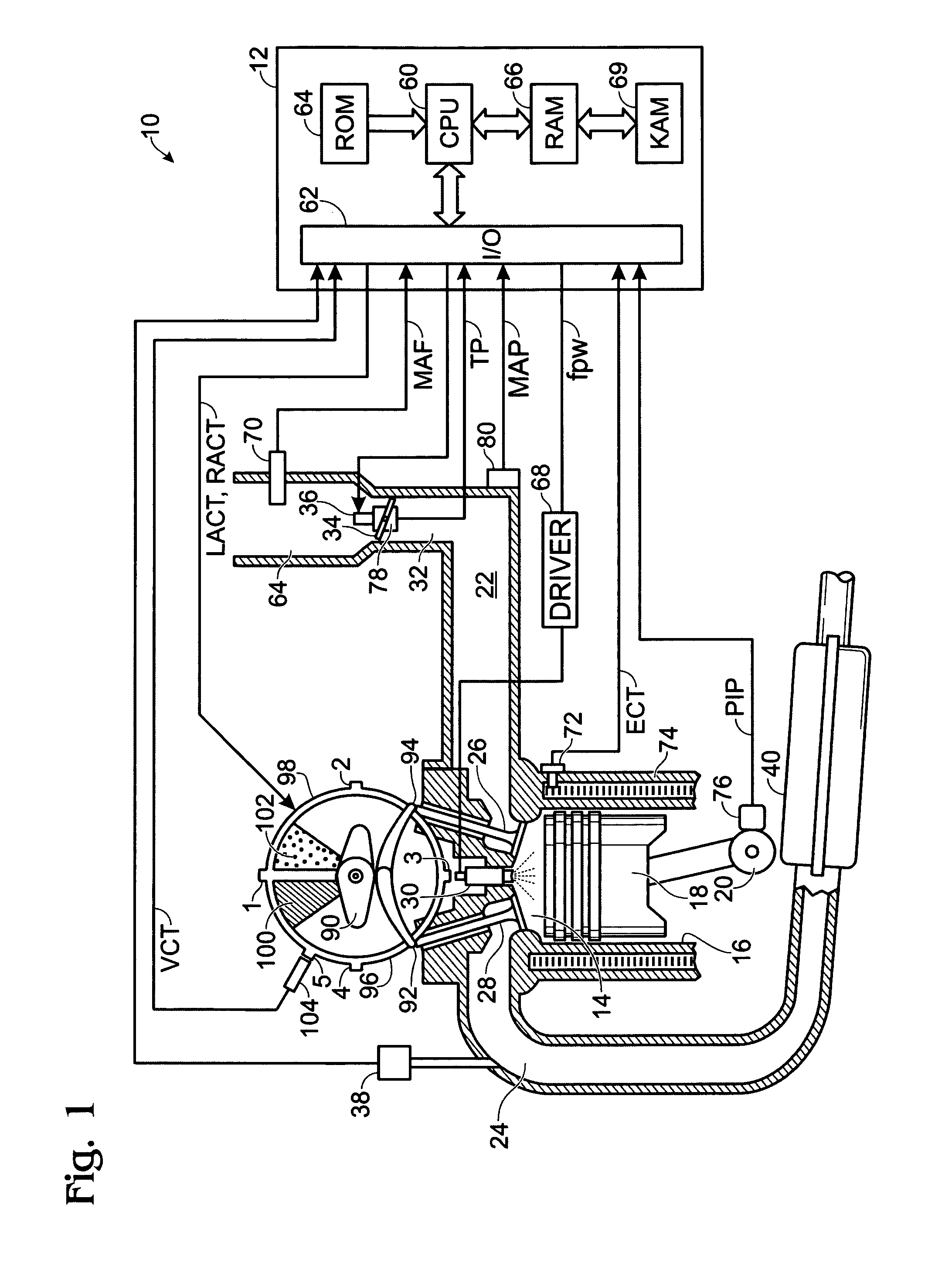

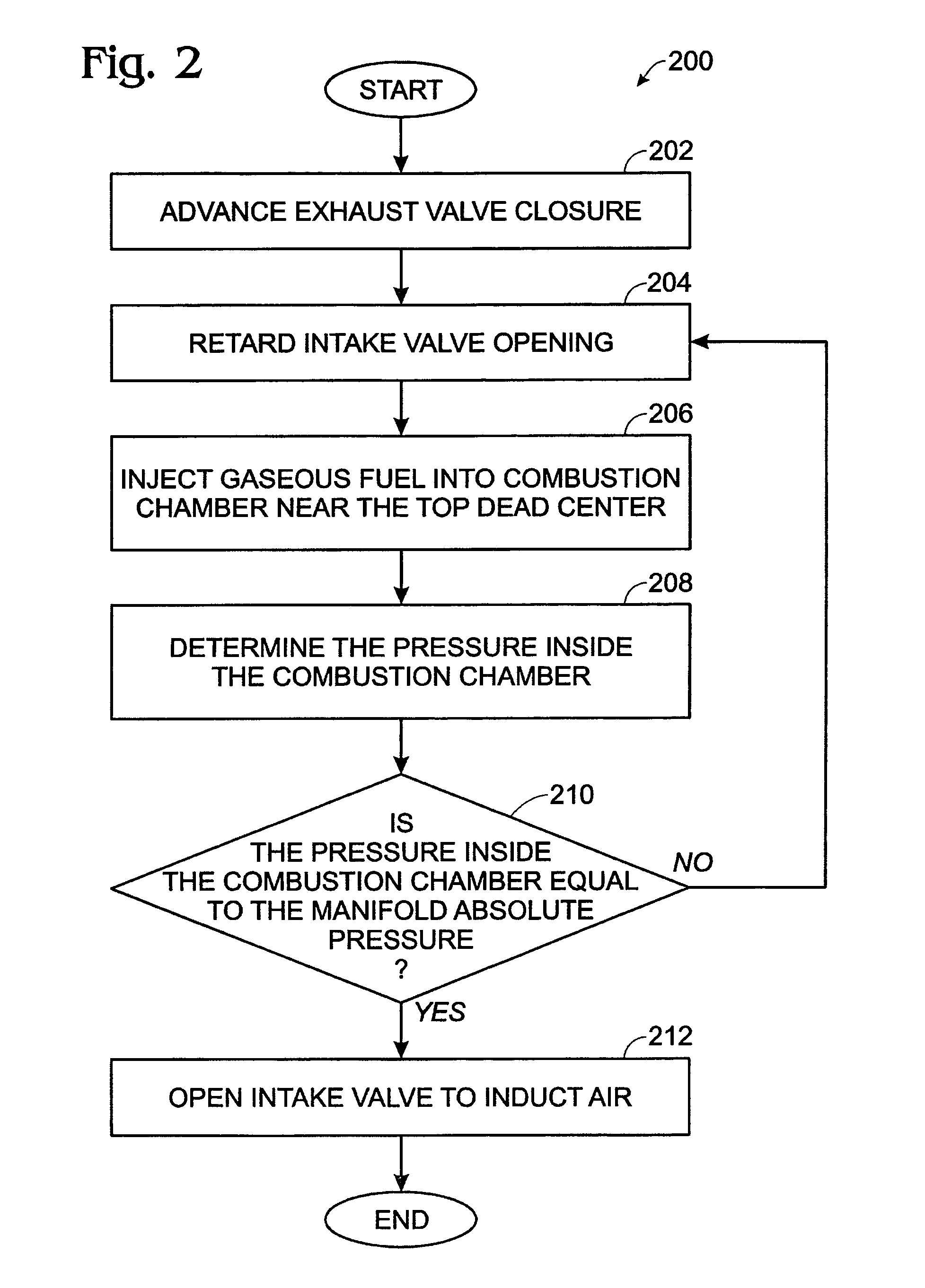

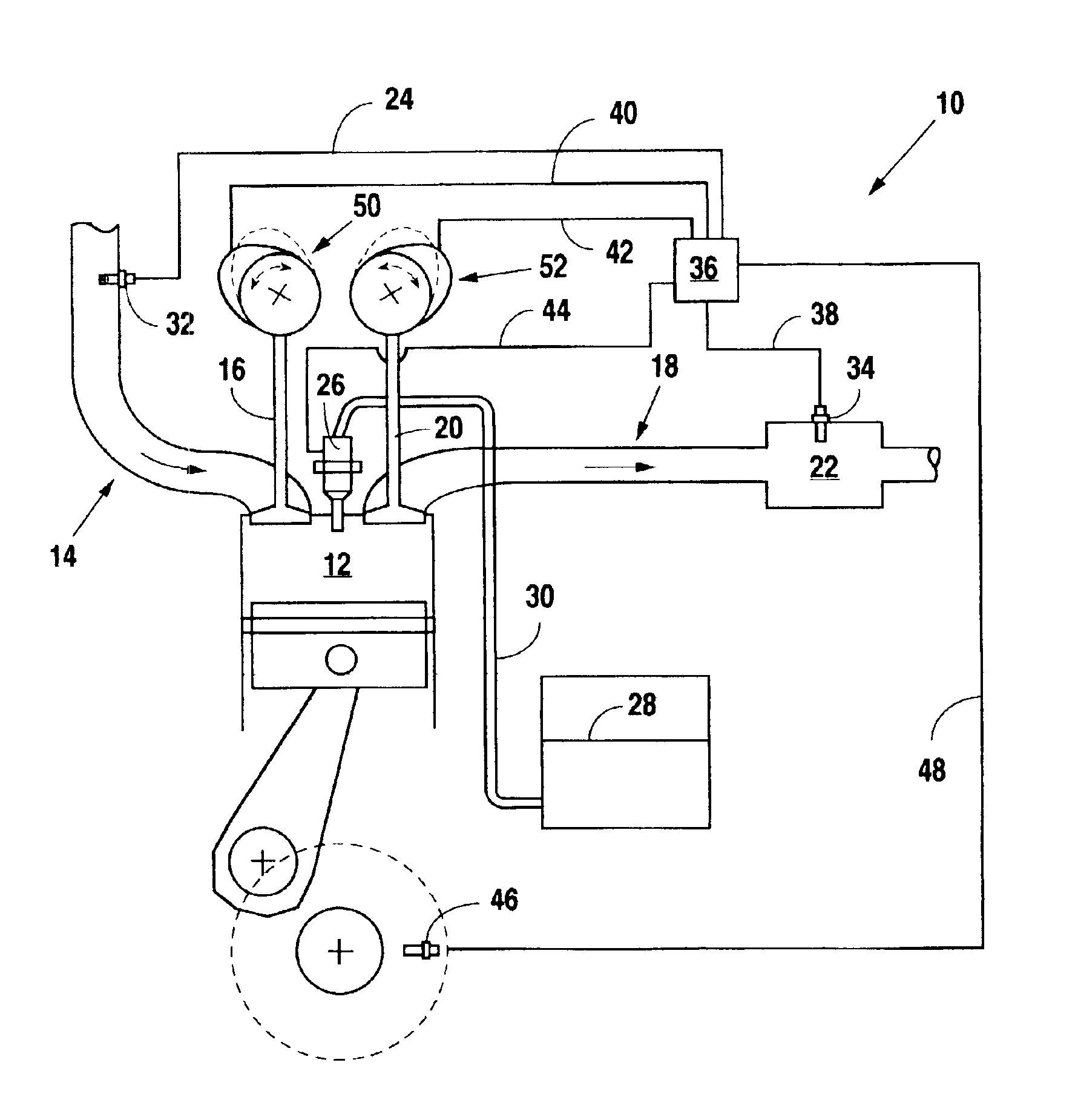

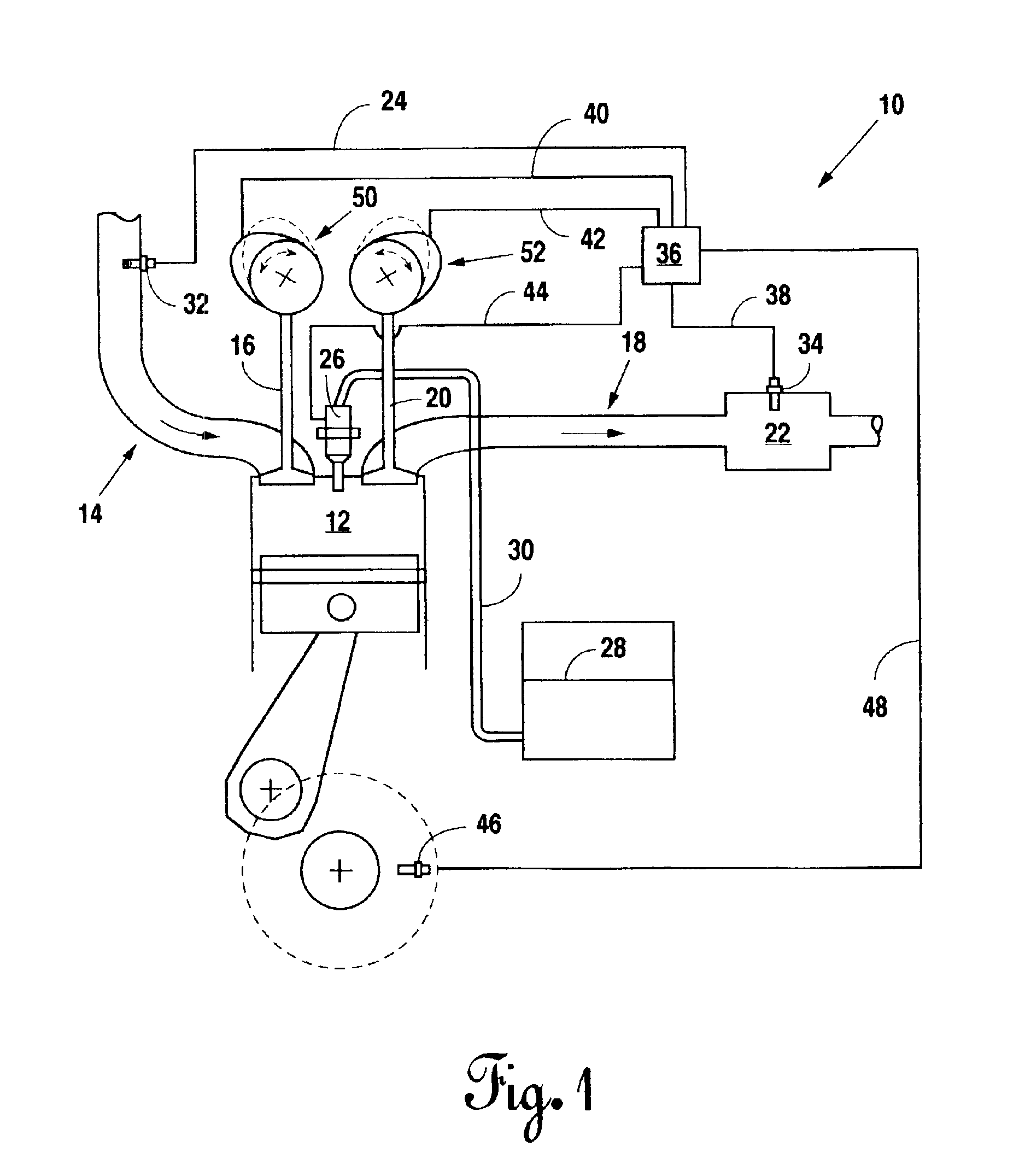

System and method for direct injection of gaseous fuel into internal combustion engine

InactiveUS7117830B1Reduce exhaustReduce volumeValve arrangementsElectrical controlExhaust valveTop dead center

A method for an engine capable of burning gaseous fuel, the engine also including a combustion chamber, at least one intake valve, and at least one exhaust valve, an injector to directly inject pressurized gaseous fuel into the combustion chamber, and a variable valve timing system coupled to the intake valves and exhaust valves, the method comprising closing the exhaust valve before top dead center of piston position to increase combustion chamber pressure achieved at top dead center and to trap exhaust gas in the cylinder; and starting injection of a gaseous fuel directly into the combustion chamber after the exhaust valve is closed and before the intake valve is opened.

Owner:FORD GLOBAL TECH LLC

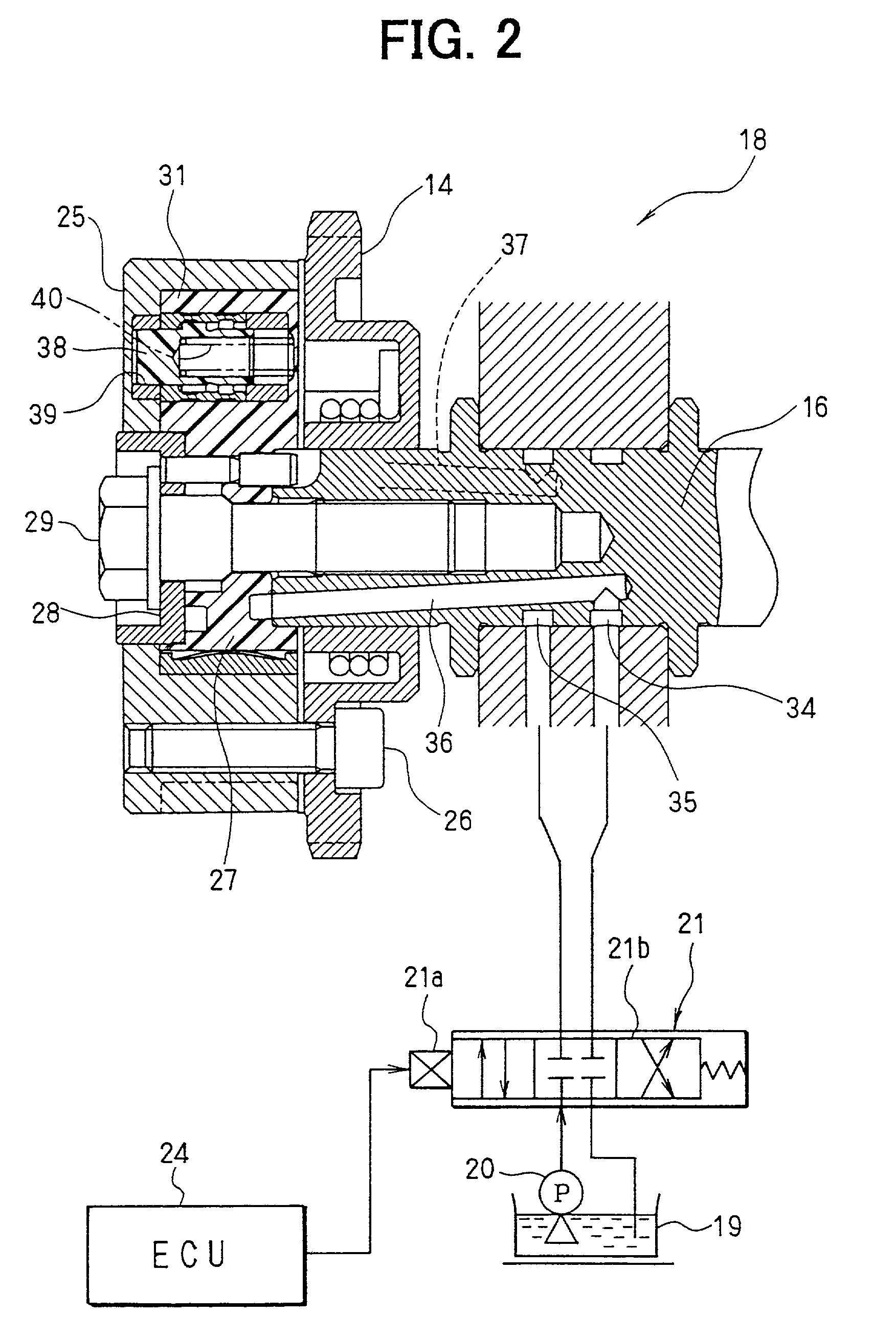

Method for variable valve actuation to provide positive power and engine braking

A control method for transitioning from positive power to engine braking (and vice-versa) is disclosed. This transition may be made using variable valve actuation and two-stroke braking. The process may involve three engine operation modes: positive power (i.e., firing or non-braking), engine braking, and transition between engine braking and positive power. The intake and exhaust valve actuations provided for each of the different modes of operation may be different from each other.

Owner:JACOBS VEHICLE SYST

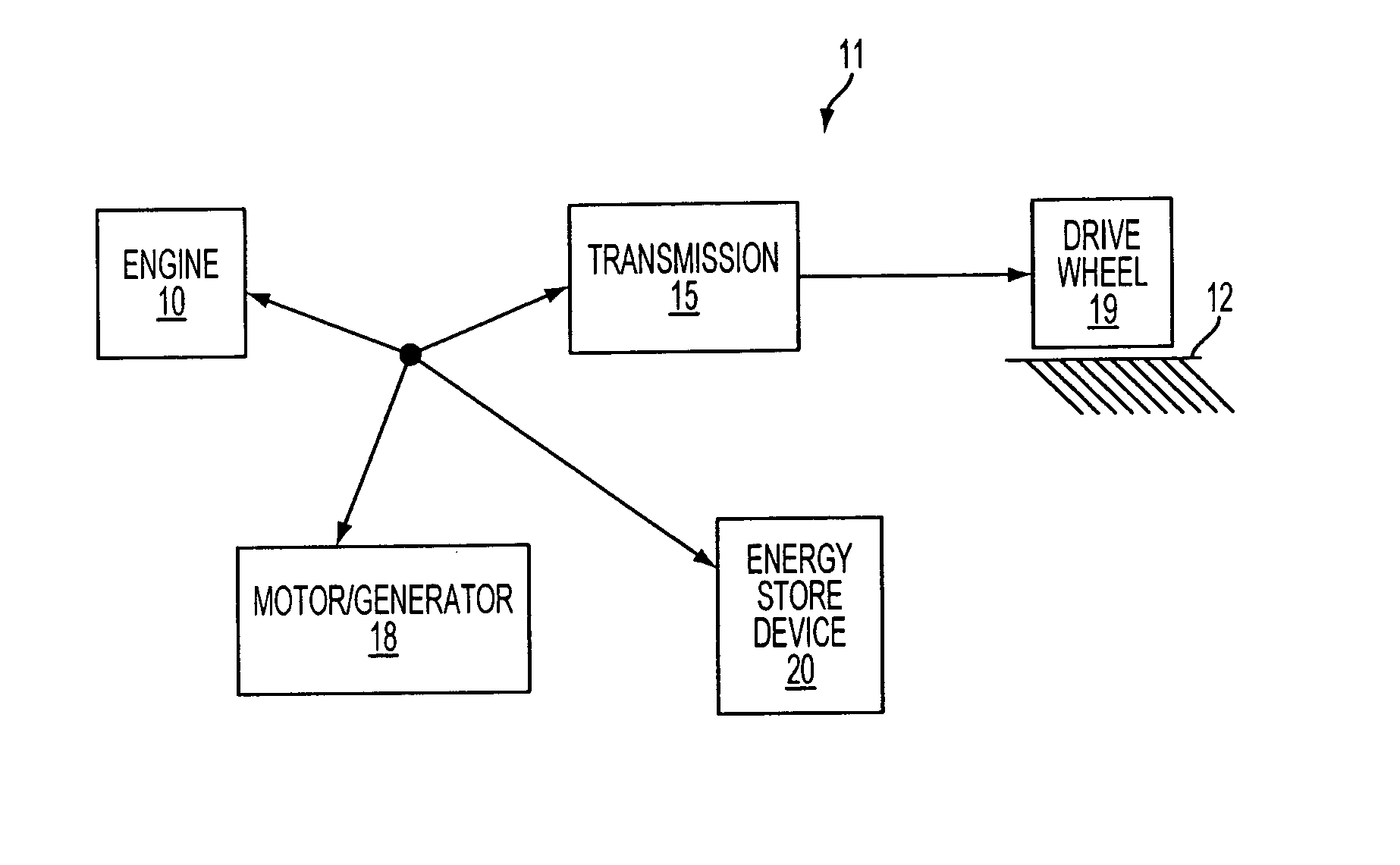

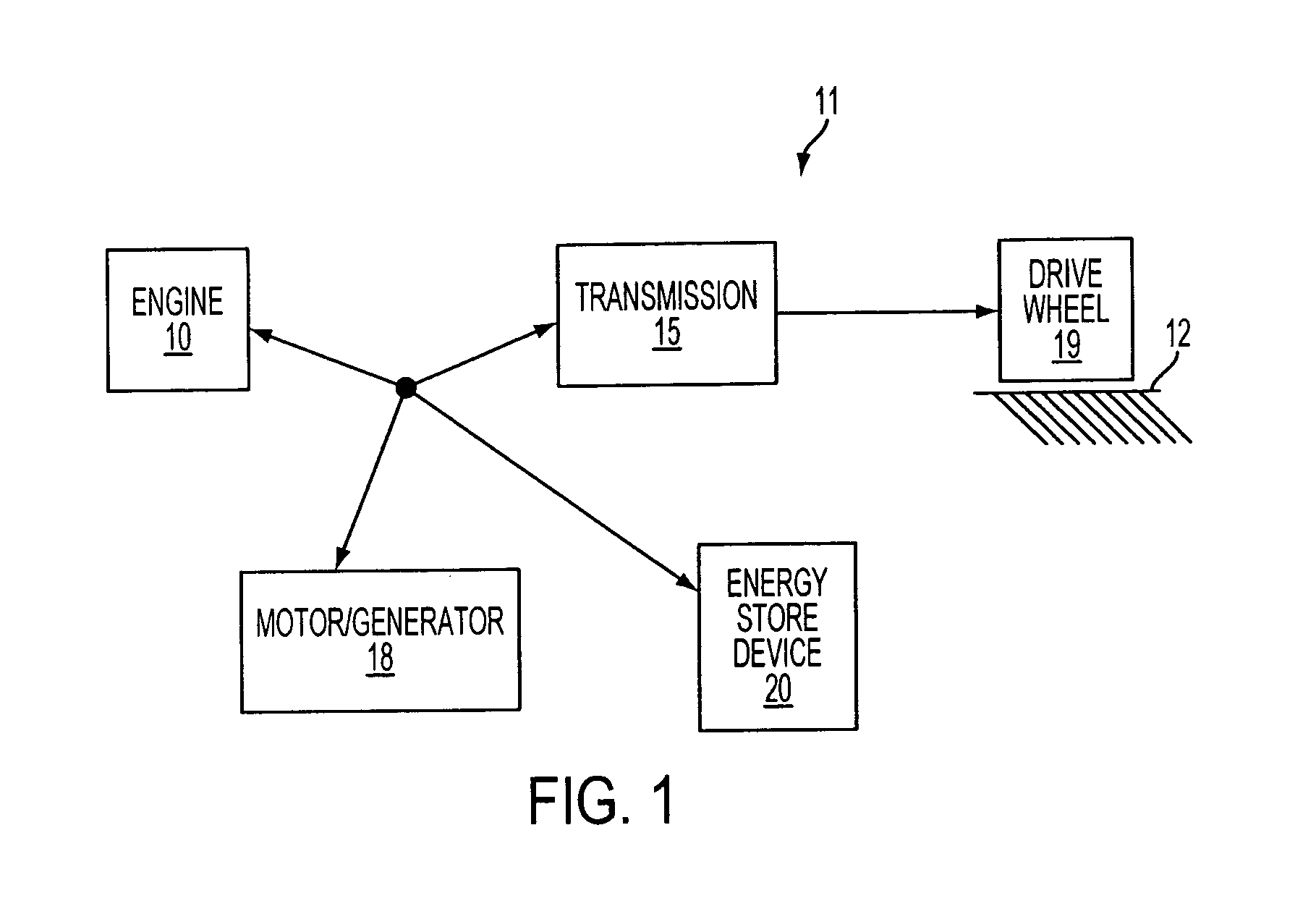

Hybrid vehicle system having engine with variable valve operation

ActiveUS20070209618A1Efficient and stable utilization operationEasy to operateElectrical controlInternal combustion piston enginesExhaust valveVariable valve timing

A system for a vehicle with an engine having at least one cylinder with at least an intake valve and an exhaust valve, comprising of a hydraulic variable valve actuator system configured to vary a timing of the intake valve in a first range and a timing of the exhaust valve in a second range, said actuator system configured to have a default intake valve timing to which intake valve timing is held when insufficient hydraulic pressure is available to move intake valve timing, and a default exhaust valve timing to which exhaust valve timing is held when insufficient hydraulic pressure is available to move exhaust valve timing, where said default intake valve timing is in a retarded portion of said first range and said default exhaust valve timing is in a retarded portion of said second range, and a hybrid propulsion system coupled to the engine.

Owner:FORD GLOBAL TECH LLC

Variable valve timing control apparatus for internal combustion engine

ActiveUS20100269772A1Rapidly and smoothly accomplishedAvoid lostValve arrangementsMachines/enginesVariable valve timingEngineering

Owner:DENSO CORP

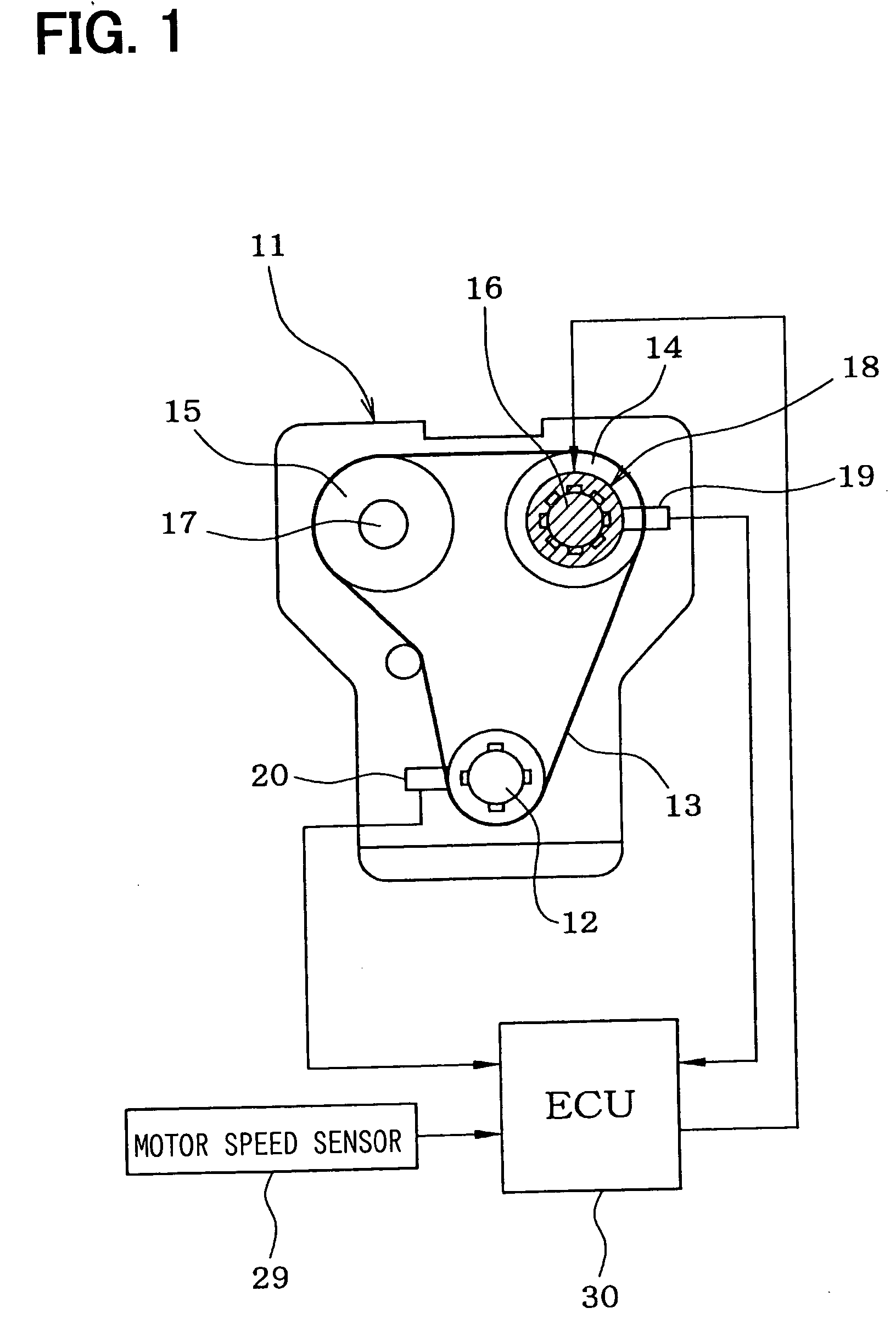

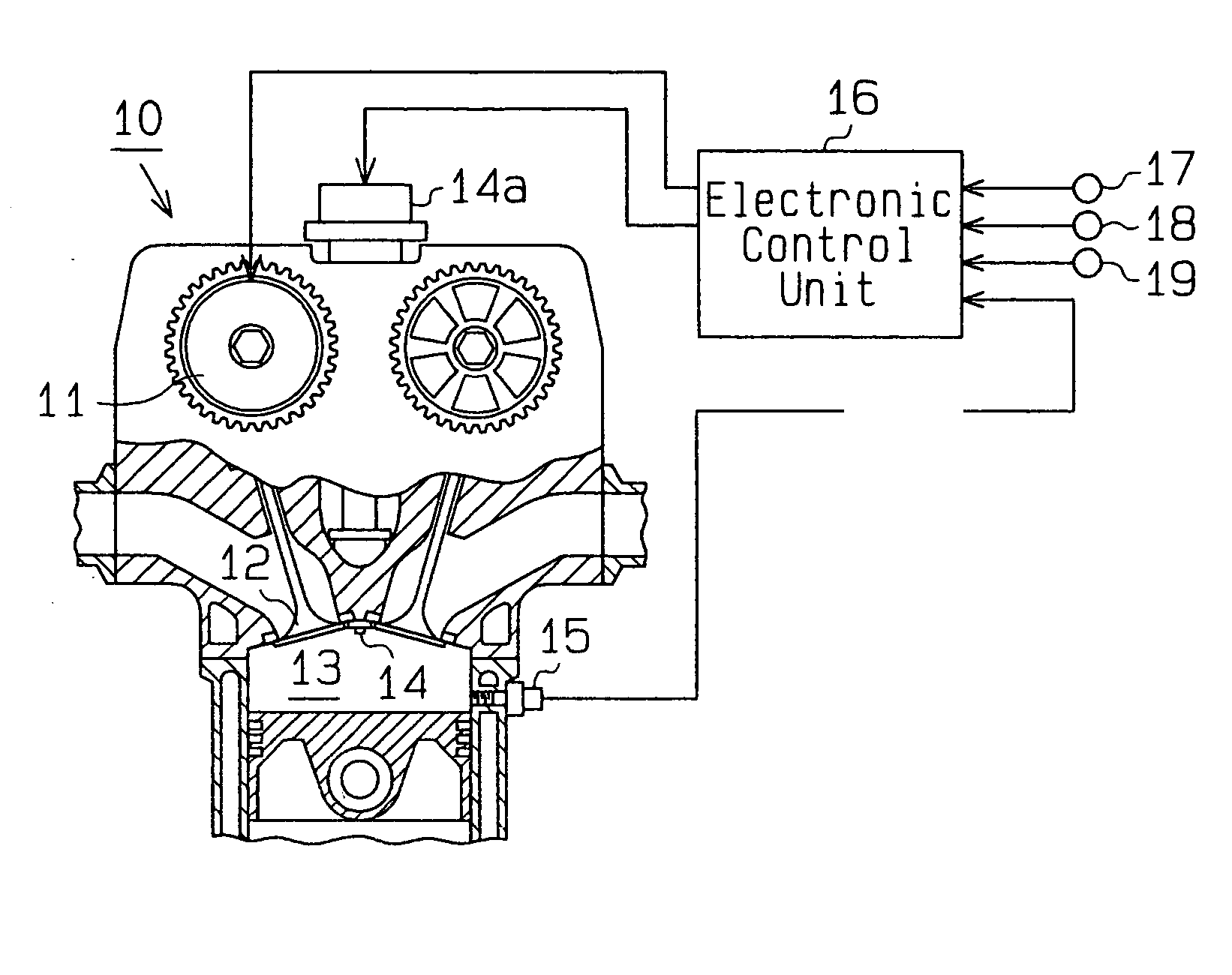

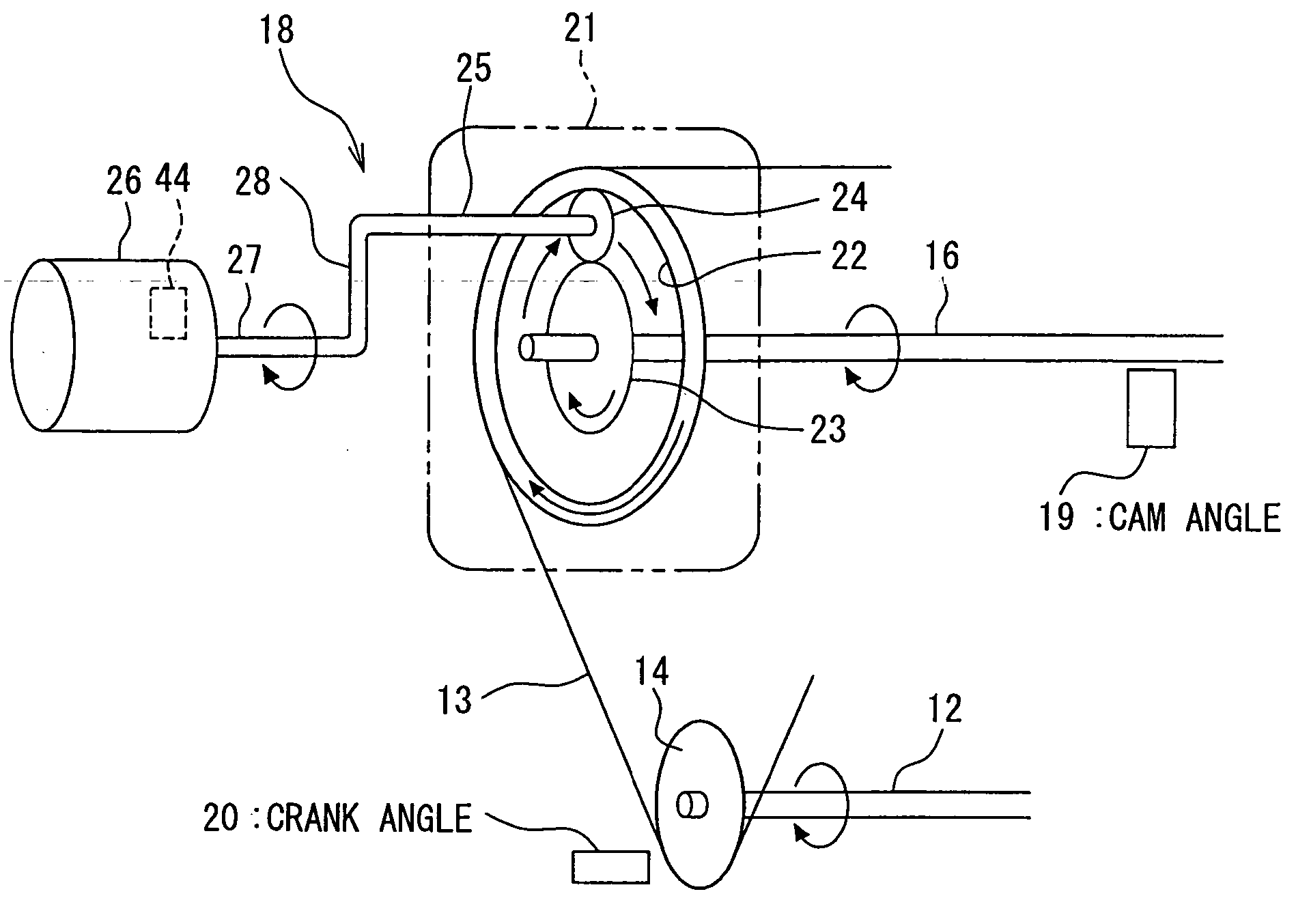

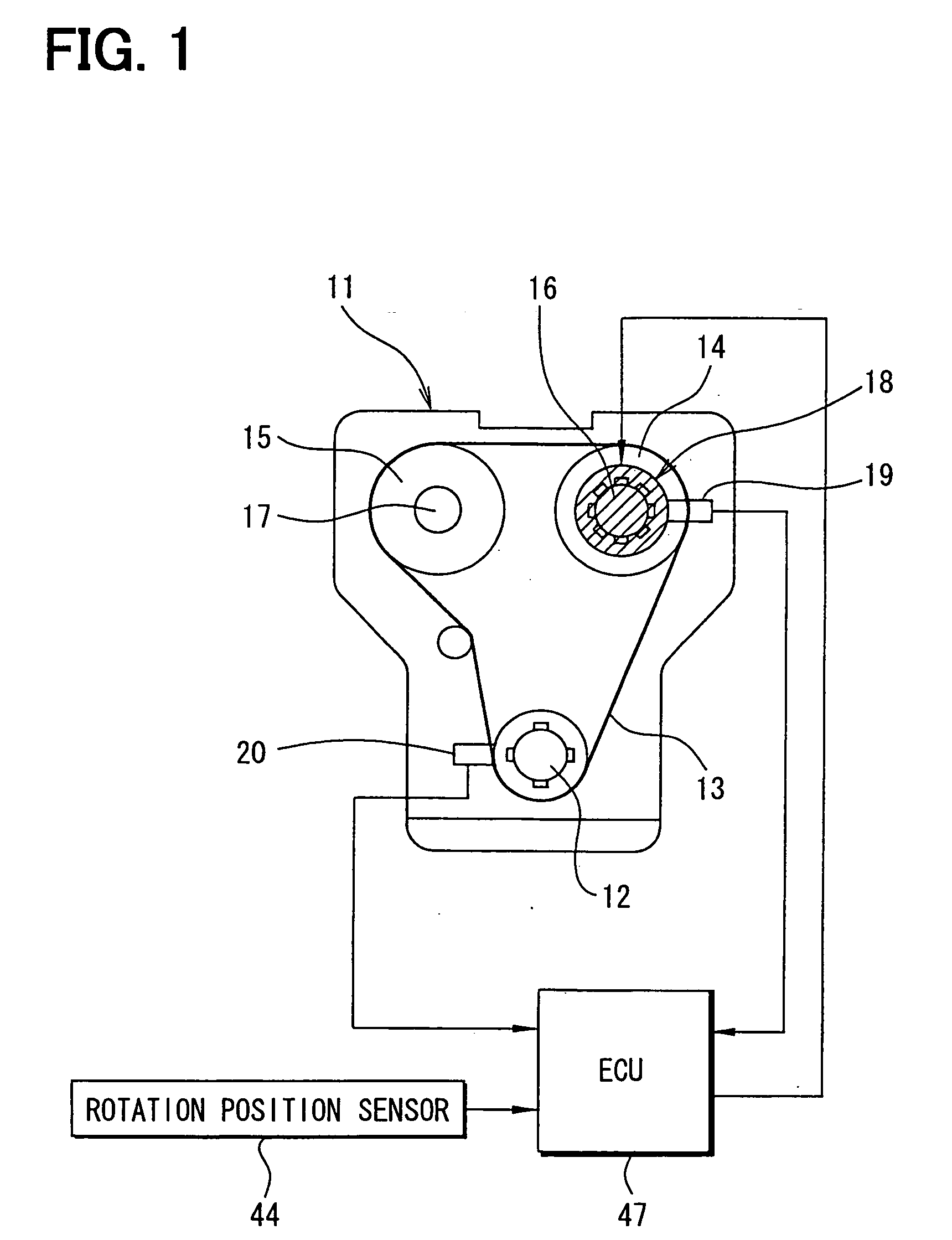

Engine rotation condition detecting system and engine control method

InactiveUS20060042578A1Accurate detectionLow costValve drivesMachines/enginesVariable valve timingRotation velocity

An internal combustion engine has a variable valve timing apparatus including a driving motor between a crankshaft and a camshaft. The driving motor rotates synchronously with the camshaft when the valve timing apparatus is not in operation. A motor rotation sensor produces a motor rotation signal. When the engine rotation speed is below a reference speed, the driving motor is not energized. Under this condition, the rotation speed and the rotation direction of the engine are calculated based on the motor rotation signal in place of a crank rotation signal produced by a crank angle sensor. Further, the rotation stop position of the engine is calculated based on the motor rotation signal when the engine is stopped.

Owner:DENSO CORP

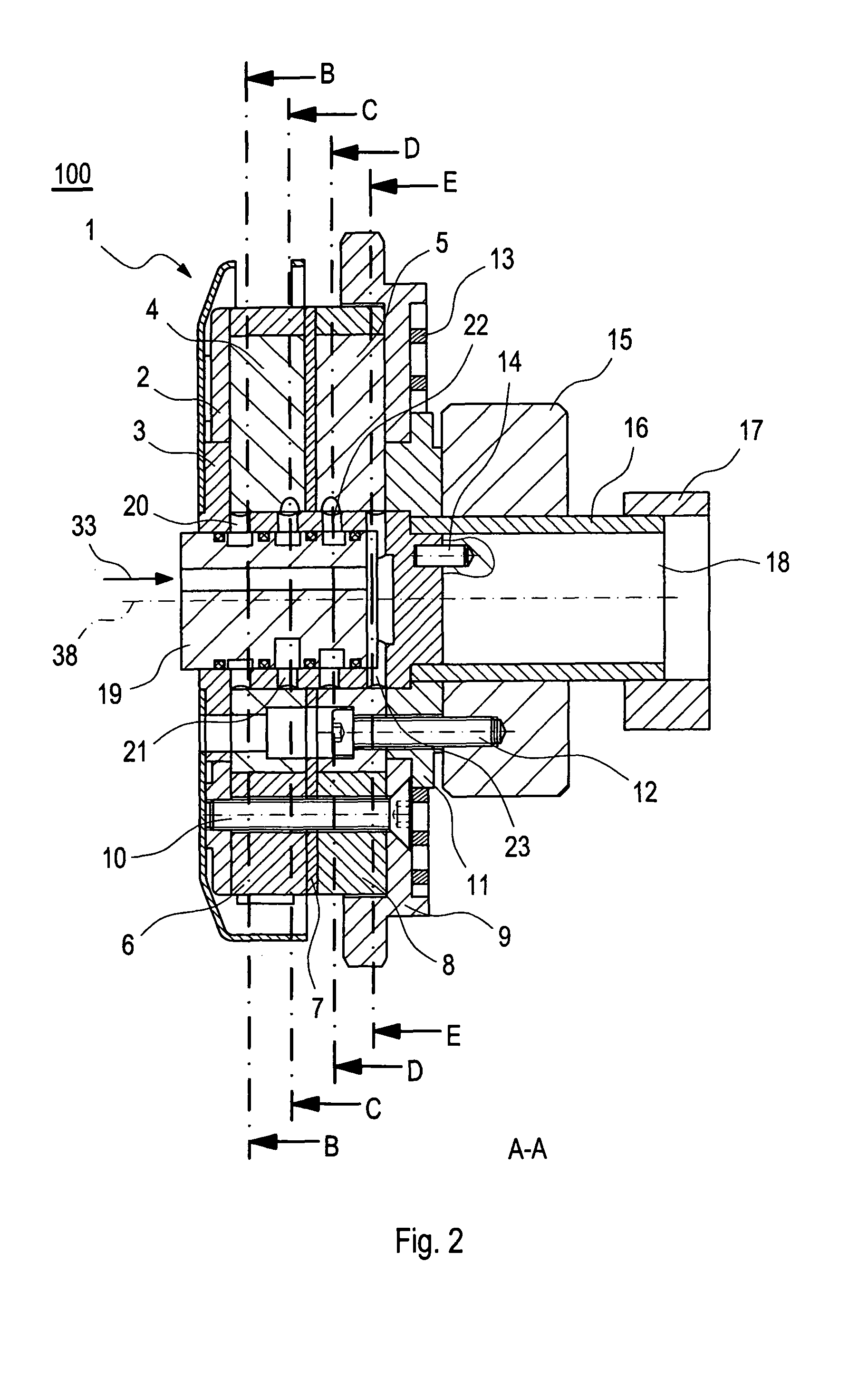

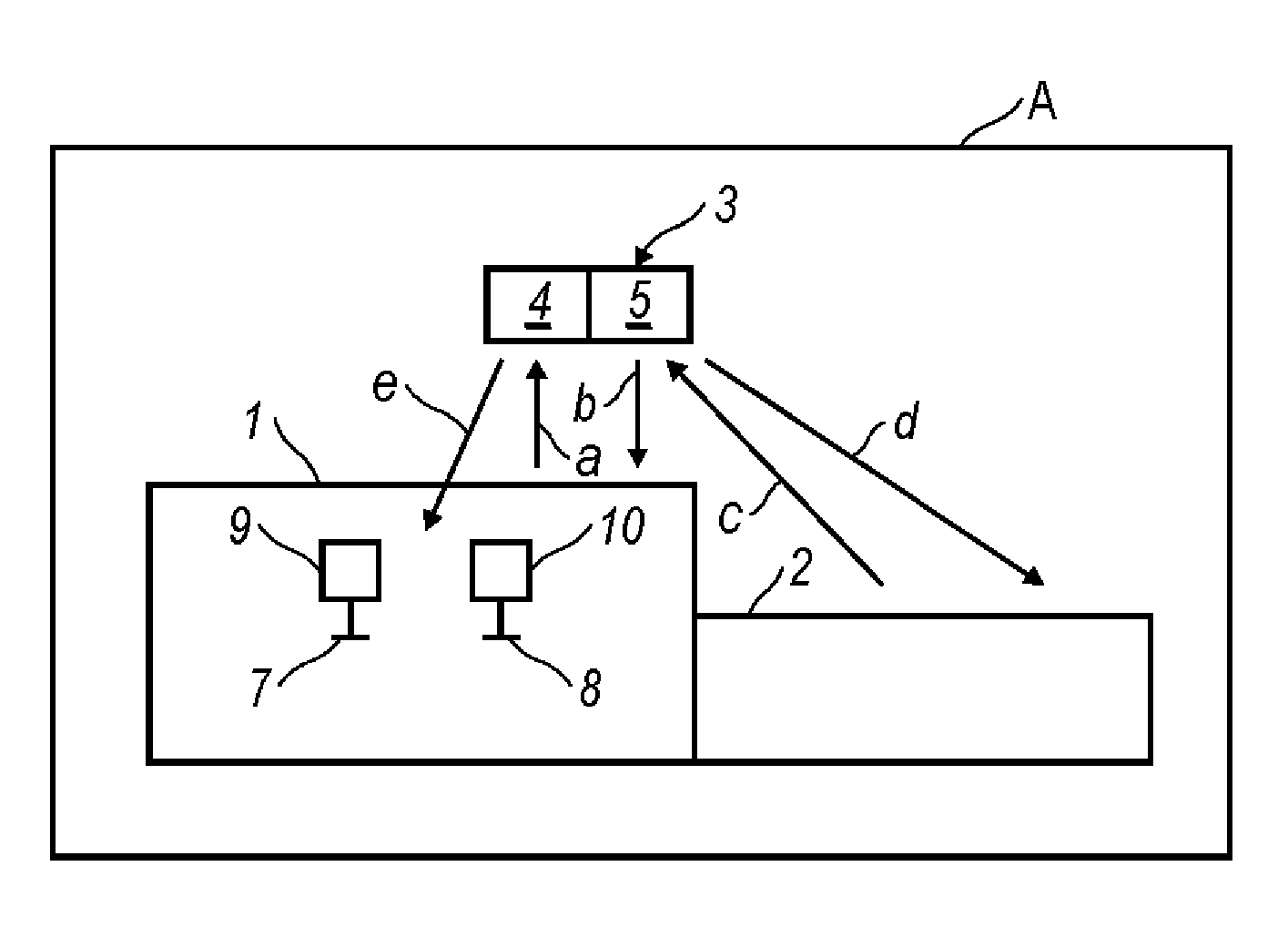

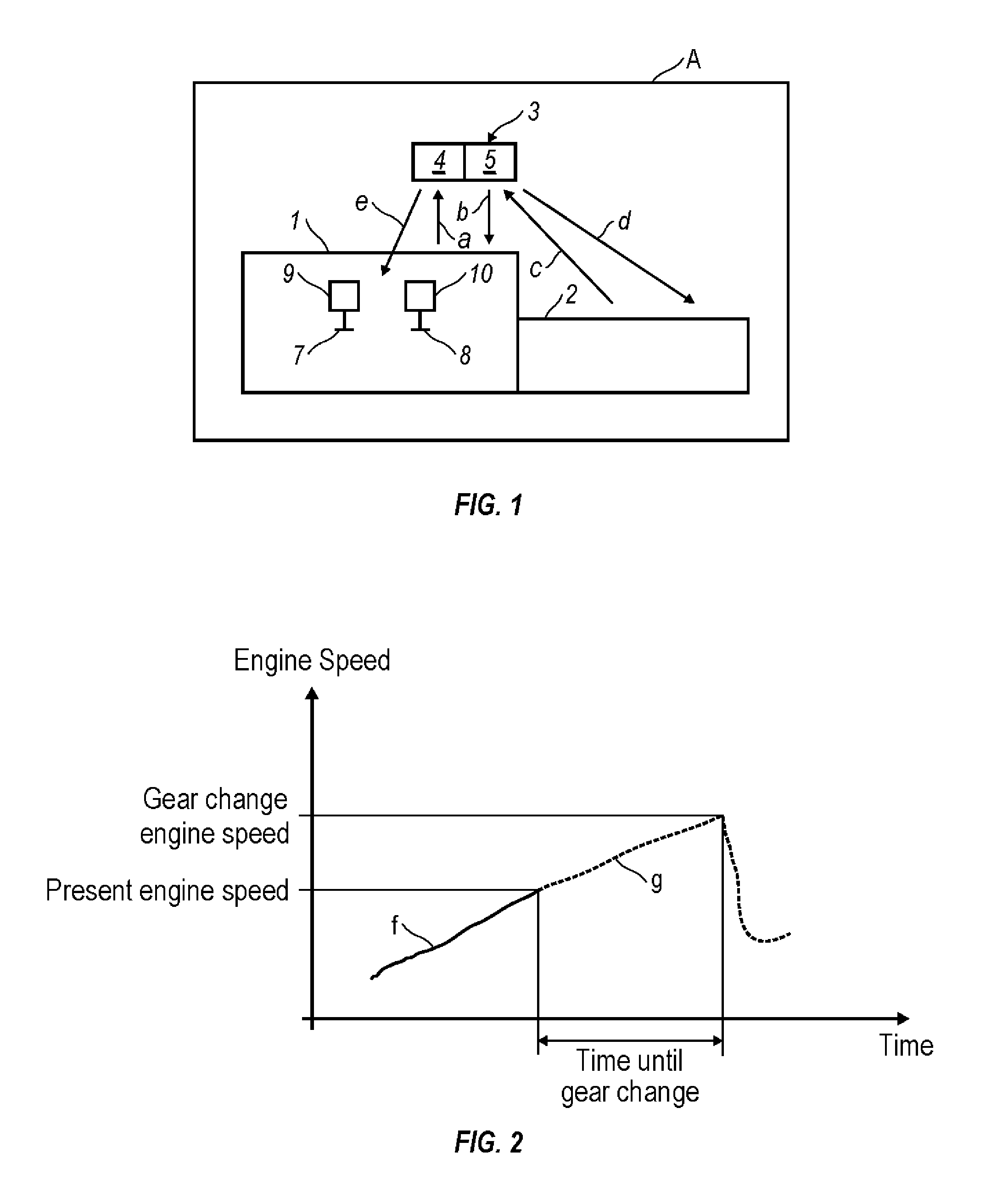

Method for controlling the adjustment of the valves in a combustion engine with variable valves and a vehicle with such an engine with electronic controlling device for the valve control

InactiveUS20060199699A1Improve responseReduce stepsElectrical controlInternal combustion piston enginesVariable valve timingGear wheel

Method and arrangement for providing a vehicle having a combustion engine (1) with valves (7, 8) adapted to have variable valve timing and / or valve lift height. The valves are provided with operating devices (9,10) that are controlled by electronic controlling devices (3), which are arranged, while the vehicle is being driven, with the aid of entered information about at least the gradient of the road and the throttle position, to calculate future resistance to forward motion and the period of time to a future transient in the engine's operating condition, for example in association with a future change of engine operating mode and / or a future gear change in a gearbox (2) connected to the engine. The controlling devices are arranged to control valve timing and / or the valve lift height during the period of time for optimization of the engine's performance, once the transient has arisen.

Owner:VOLVO LASTVAGNAR AB

Variable valve timing control system of internal combustion engine

InactiveUS20050257762A1Tendency increaseIncrease system costValve drivesMachines/enginesWorking fluidVariable valve timing

A variable valve timing control system of an internal combustion engine includes a hydraulically-operated phase converter disposed between a sprocket and a camshaft, and having a phase-advance hydraulic chamber and a phase-retard hydraulic chamber for changing an angular phase of the camshaft relative to the sprocket. An electric pump is provided to supply working fluid selectively to one of the hydraulic chambers via a directional control valve. Also provided is a check valve disposed in a discharge line of the pump for permitting flow in a direction that the working fluid flows from the pump to the directional control valve and preventing any flow in the opposite direction, so as to prevent a pulse pressure arising from alternating torque exerted on the camshaft from being transmitted from either one of the hydraulic chambers via the discharge line to a discharge port of the pump.

Owner:HITACHI LTD

Variable valve timing device

InactiveUS20090173297A1Rapid responsePromote densificationValve arrangementsYielding couplingVariable valve timingEngineering

The present invention provides a variable valve timing device for an internal combustion engine having a double camshaft. A gas exchange valve control shaft is provided which has first and second concentrically arranged cam shafts that are adjustable in a rotatable manner with respect to each other, by which a cam of the first cam shaft is adjusted in terms of its angle towards a cam of the second cam shaft. A cam phasing device is provided which operates by rotatable vanes provoking a swivelling relative movement between a driven member and an output member. The cam phasing device comprises at least two pivotable vane adjusters. Each pivotable vane adjuster is assigned to one of the two cam shafts. The pivotable vane adjusters are arranged axially one after the other in a direction of a valve control shaft. Each pivotable vane adjuster may be designed as a rotor-type vane adjuster.

Owner:HILITE INT INC

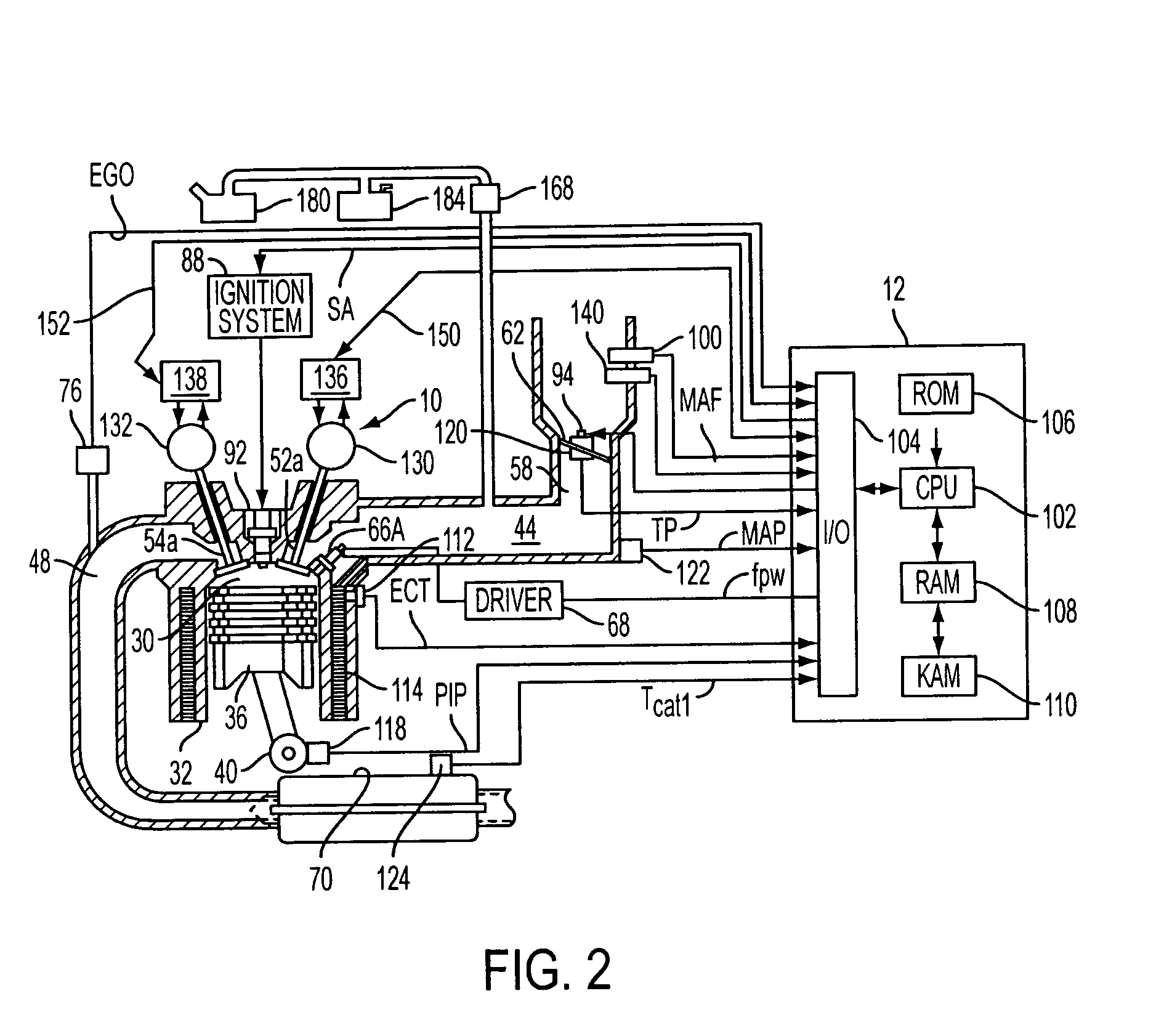

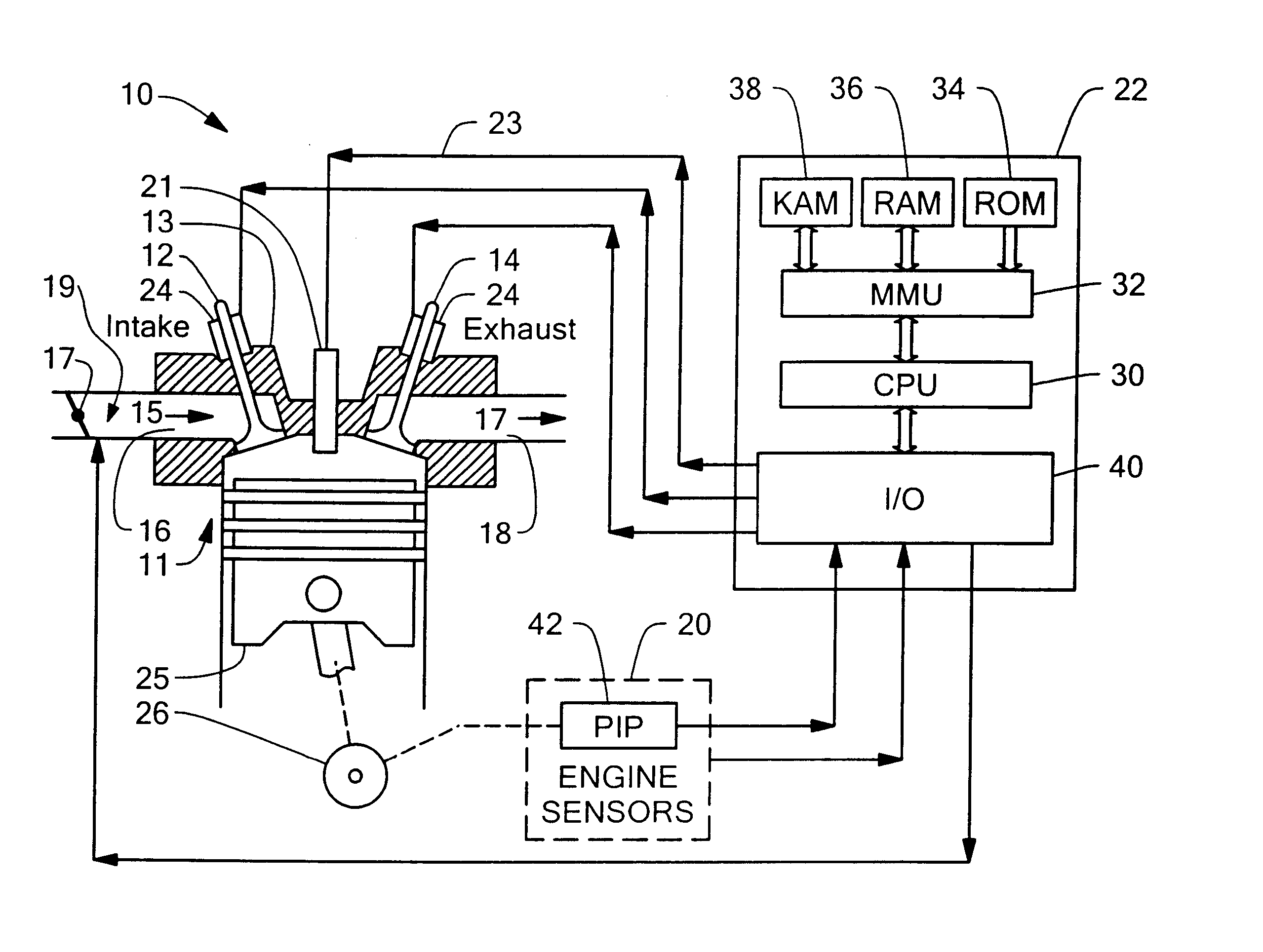

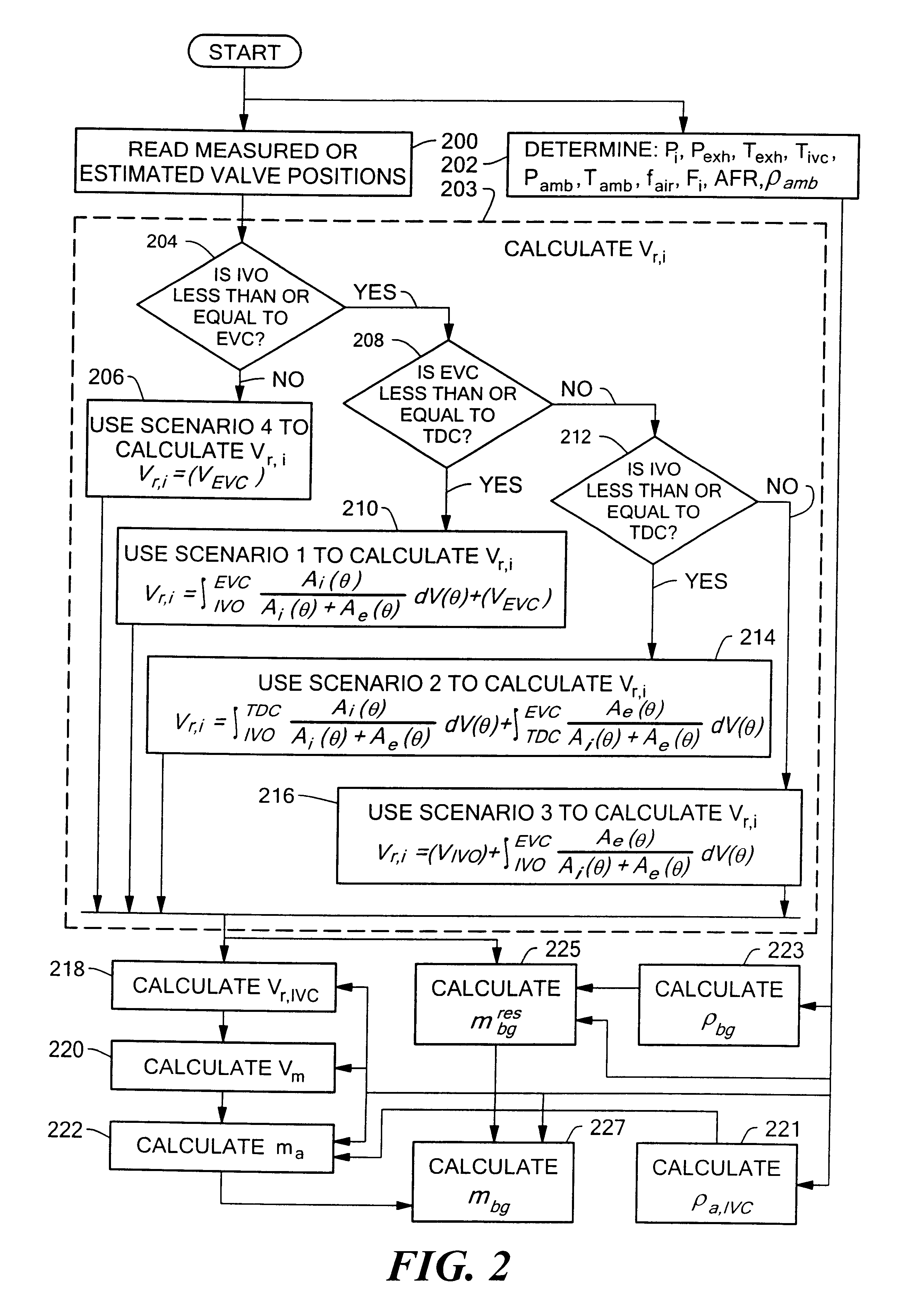

Method and system for estimating cylinder charge for internal combustion engines having variable valve timing

A method for determining cylinder air charge and / or cylinder burned gas for an internal combustion engine system. The engine system includes cylinders, each one of such cylinders having at least one intake valve and at least one exhaust valve in communication with such cylinder. The method determines one of a plurality of different scenarios, each one of the scenarios representing a geometrical relationship between opening and closing of the intake valve relative to closing of the exhaust valve. The cylinder air charge and / or cylinder burned gas is calculated in accordance with the determined one of the plurality of scenarios. In one embodiment, the engine system stores a plurality of different software modules. The method selects one of the plurality of software modules in accordance with the determined one of the plurality of scenarios. The cylinder air charge and / or cylinder burned gas calculation comprises executing the selected one of the modules. In one embodiment, a memory stores a relationship between volume occupied by residual gas in the at least one cylinders at a predetermined position of the at least one cylinder in the engine during the cycle determined in accordance with each one of the plurality of scenarios for each of a plurality of different intake valve opening and exhaust valve closing conditions. The method includes: determining from the memory the volume occupied by residual gas in the at least one cylinders at a predetermined position of the at least one cylinder in the engine during the cycle for the intake valve opening and exhaust valve closing conditions; and, determining from volume occupied by residual gas in the at least one cylinders at a predetermined position of the at least one cylinder in the engine during the cycle the cylinder air charge and / or cylinder burned gas.

Owner:FORD GLOBAL TECH LLC

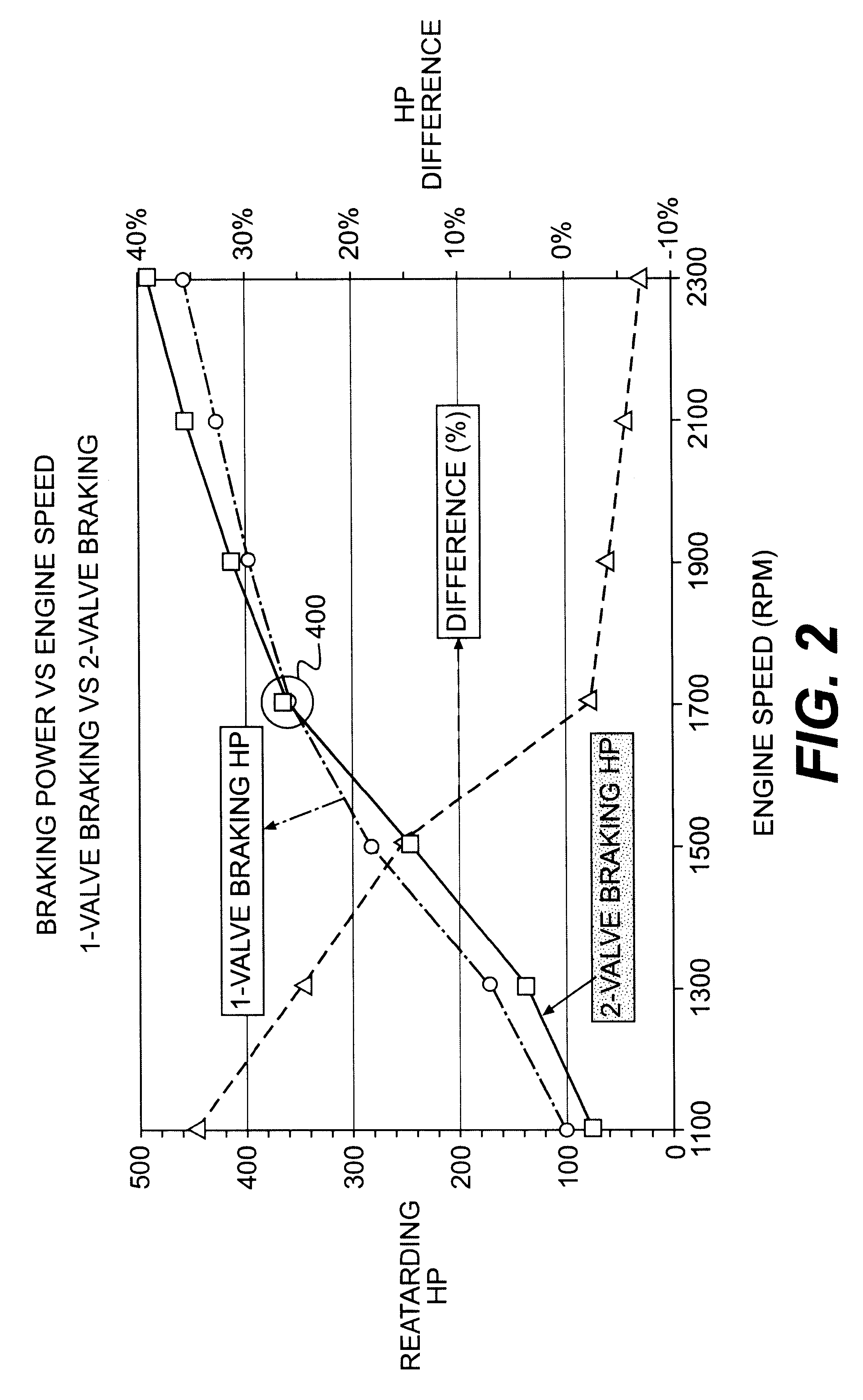

Method and system of improving engine braking by variable valve actuation

InactiveUS6647954B2Improving engine brakingConvenient amountElectrical controlValve drivesLow speedVariable valve timing

The present invention relates to methods of improving engine braking of a reciprocating piston internal combustion engine by variable valve actuation. One embodiment of the present invention enables independent two-valve actuation for each cylinder, and engine braking horsepower can be optimized using two-valve braking at high engine speeds and one-valve braking at low speeds. Another embodiment of the present invention enables better a sequential valve actuation to reduce engine braking load and compliance. Another embodiment of the present invention enables better engine starting and warming up by controlling timing and lift of each valve.

Owner:DIESEL ENGINE RETARDERS

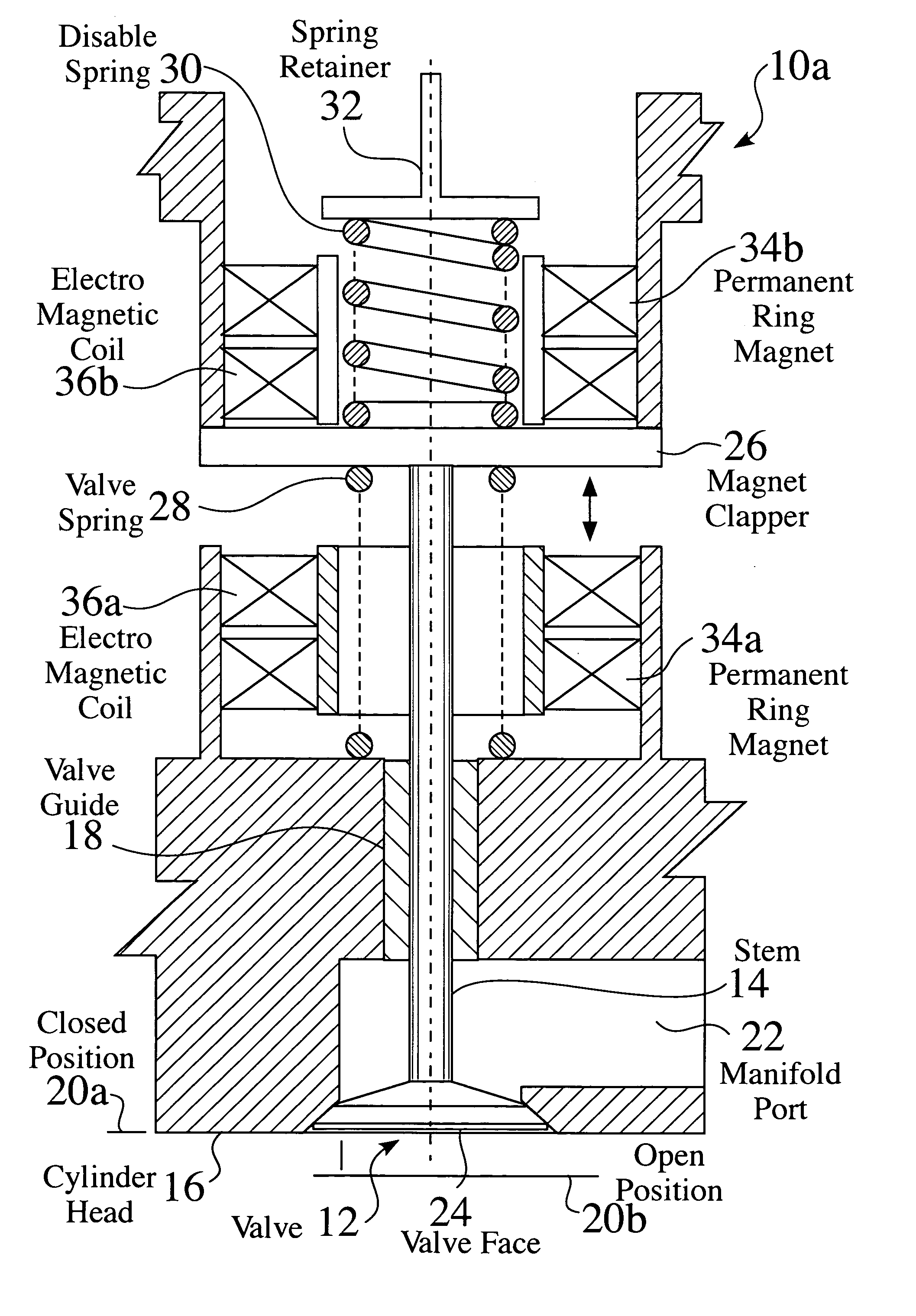

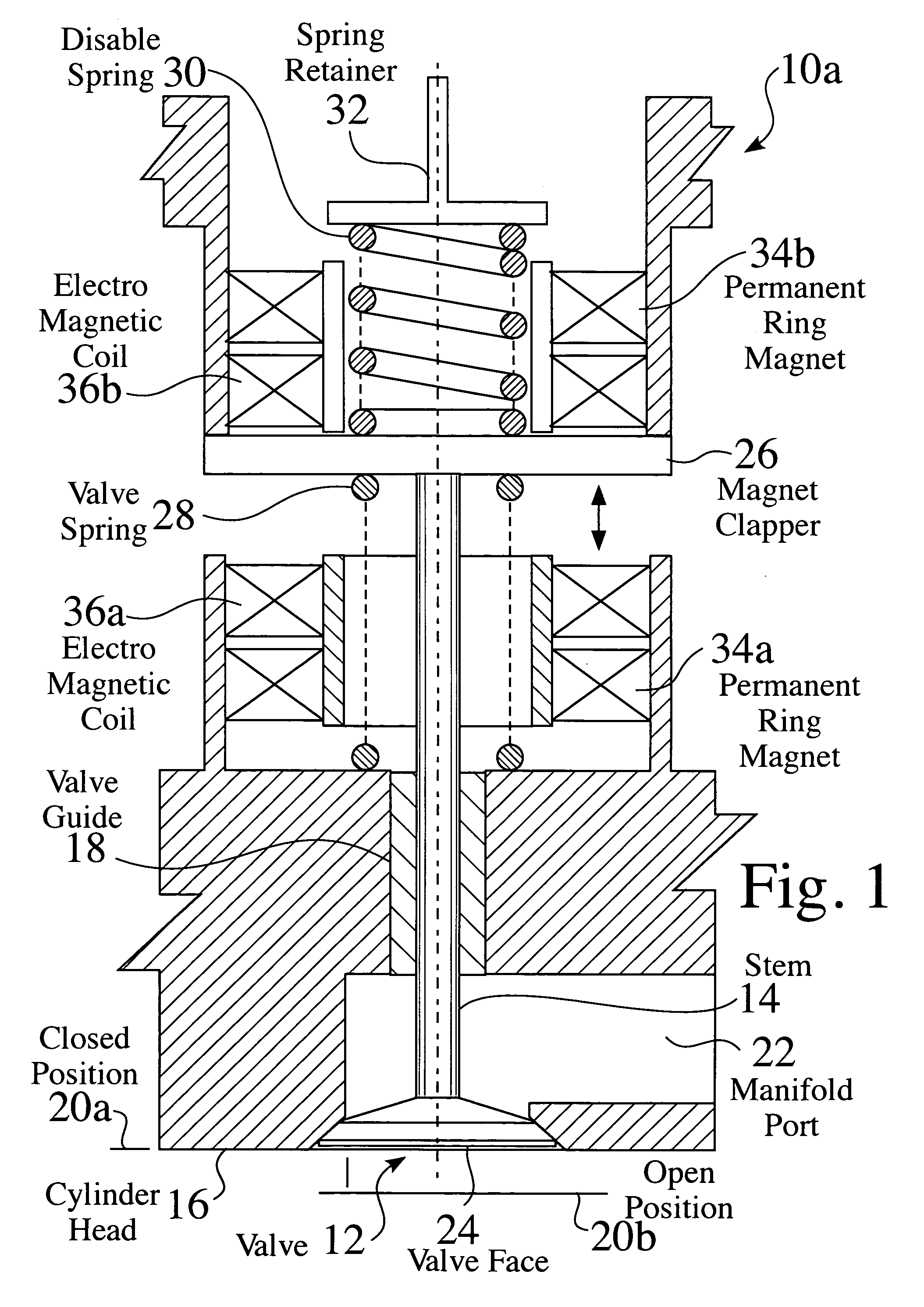

Electromagnetic valve system

InactiveUS20050046531A1Easy to moveIncrease and decrease local magnetic fluxOperating means/releasing devices for valvesMultiple way valvesSolenoid valveVariable valve timing

Systems are provided for electromagnetic actuation of a valve mechanism. A valve is linearly moveable between a first closed position and a second open position. A first spring is compressed when the valve is in the first closed position, and a second valve spring is compressed when the valve is in the second open position. An electromagnetic actuation assembly and a permanent magnet is combined with the valve, such that the valve is latchable in either a closed or open position, and is readily movable between positions through application of energy to the electromagnetic circuitry. The electromagnetic circuitry is controllable to increase or decrease the local magnetic flux, such as to promote movement of the valve, or to provide a soft landing of the valve at either end of movement. Some system embodiments provide energy recovery, feed back, and / or feed forward sensing and control. The electromagnetic valve system can be implemented for a wide variety of engines, valves and actuators, such as for variable valve timing, valve disablement, and / or hybrid engine and energy storage applications.

Owner:SOCIAL PROFIT NETWORK

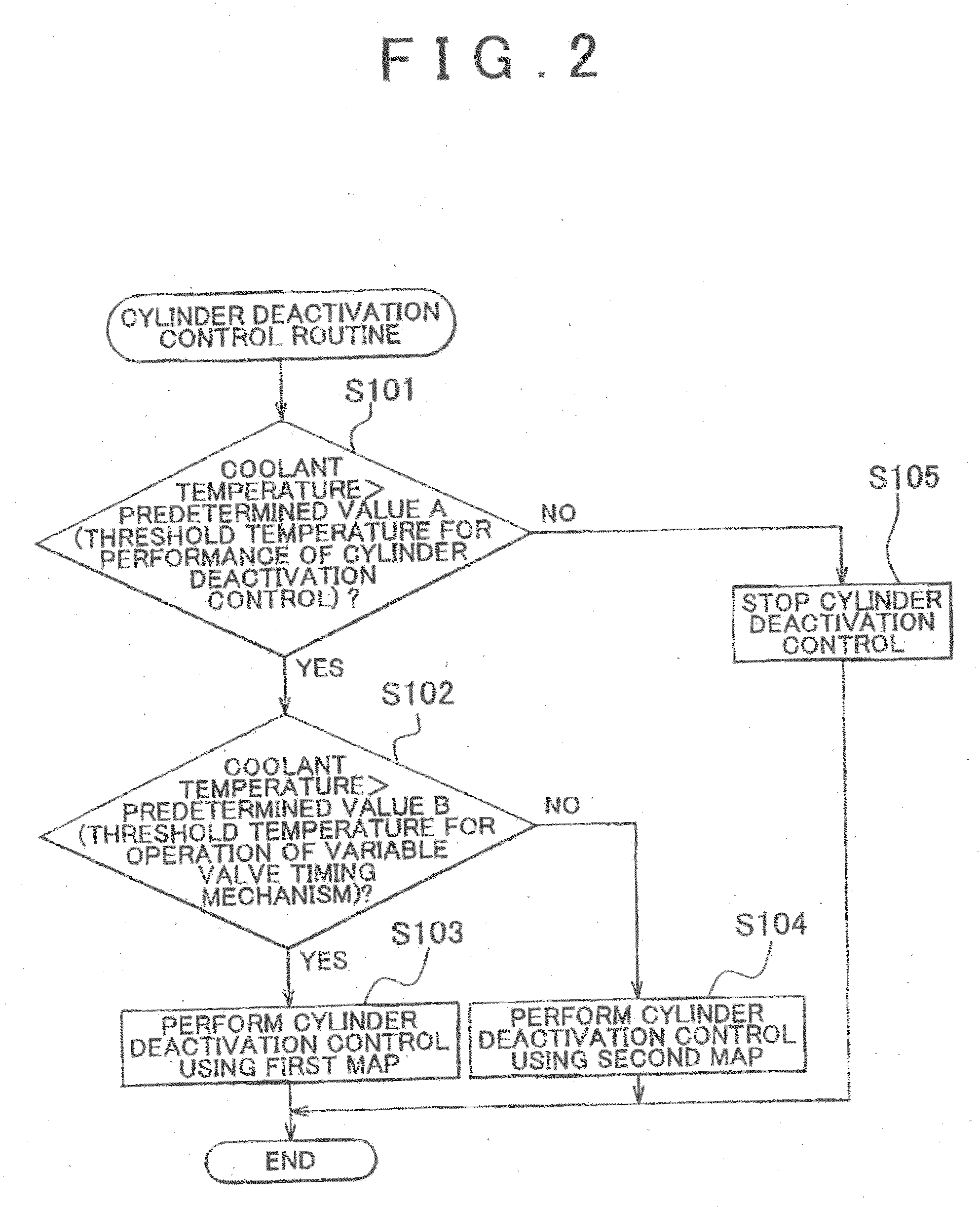

Controller for internal combustion engine

ActiveUS20090204312A1Improve fuel economySuppress deterioration of combustion conditionValve arrangementsElectrical controlVariable valve timingInlet valve

Owner:TOYOTA JIDOSHA KK

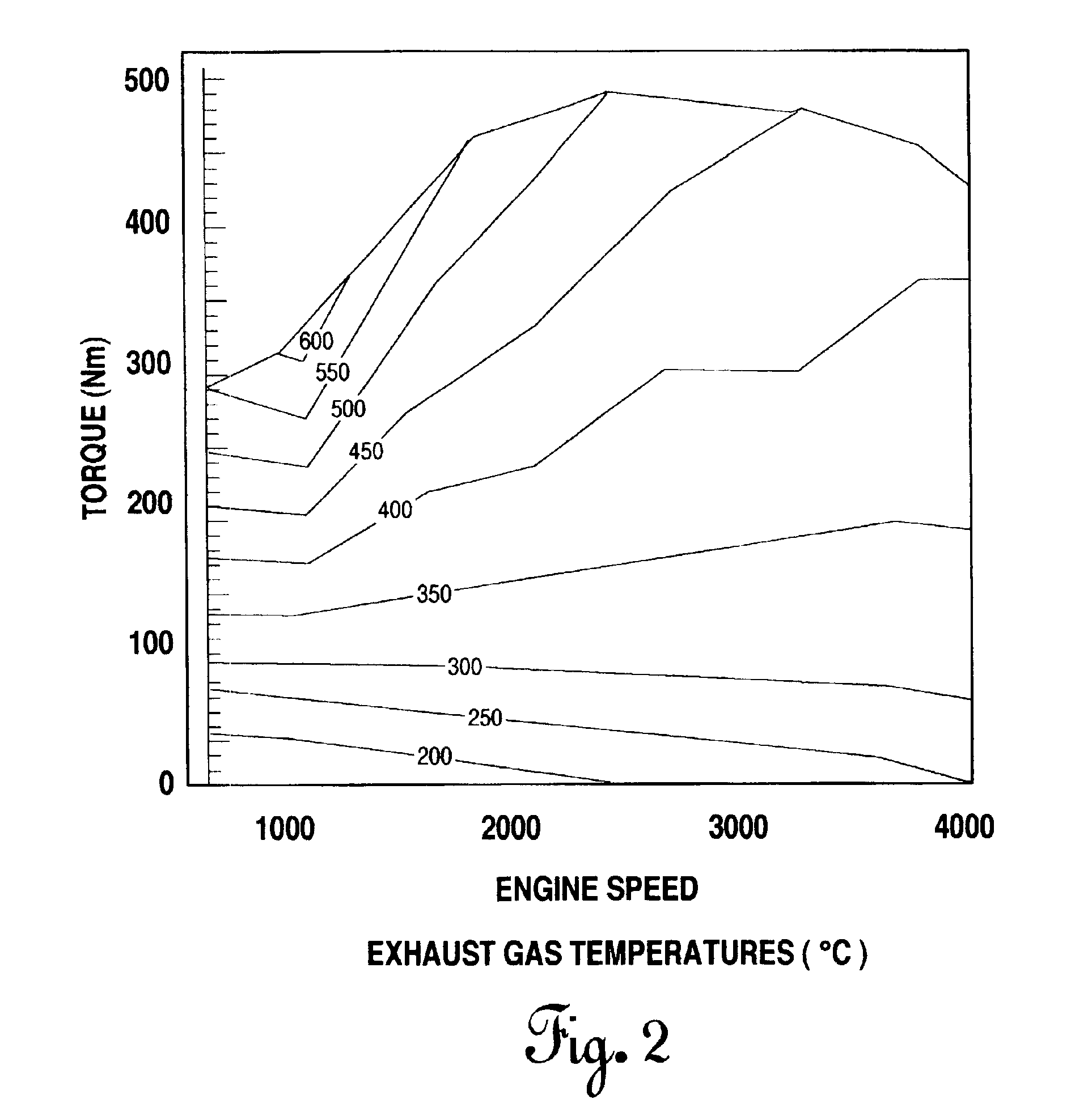

Use of a variable valve actuation system to control the exhaust gas temperature and space velocity of aftertreatment system feedgas

InactiveUS6948310B2Maintain temperatureValve arrangementsElectrical controlExhaust valveVariable valve timing

A method for controlling the temperature and / or space velocity of exhaust gas passing through an aftertreatment device disposed in the exhaust system of a diesel engine provides an optimal environment for efficient conversion of NOx and undesirable emissions during transient and steady state engine operation. The method includes controlling intake and / or exhaust valve timing, either singly or in combination with fuel injection timing and selective individual cylinder cutout, in response to sensed engine operating parameters.

Owner:SOUTHWEST RES INST

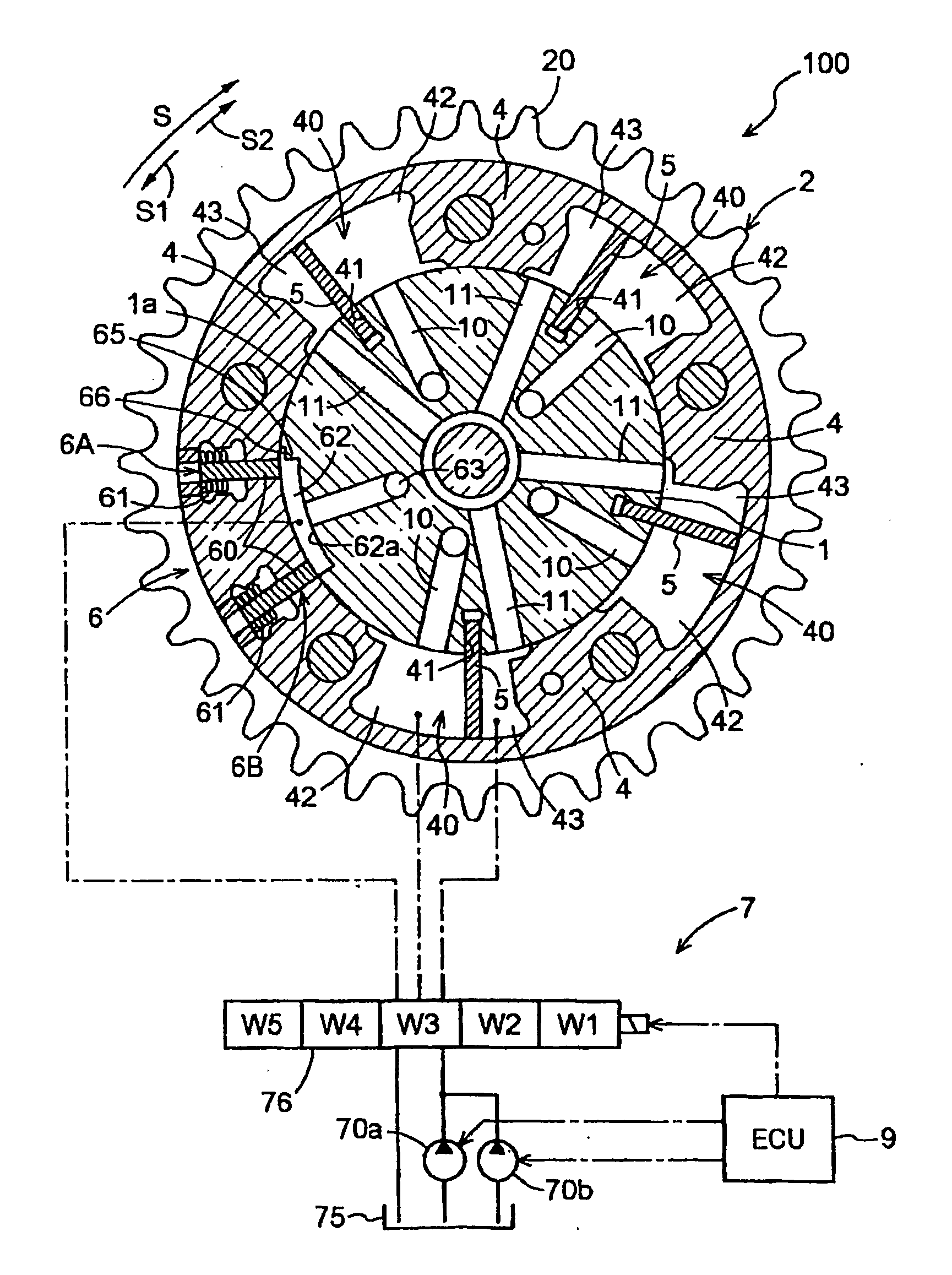

Variable valve timing control apparatus with supplementary oil pump

InactiveUS20090025668A1Power operated startersValve arrangementsVariable valve timingLocking mechanism

A variable valve timing control apparatus includes: a relative rotational phase adjusting mechanism capable of adjusting a relative rotational phase between a drive-side rotational member and a driven-side rotational member between the most advanced angle phase and the most retarded angle phase; and a lock mechanism capable of locking the relative rotational phase at an intermediate phase between the most advanced angle phase and the most retarded angle phase; a first pump operated by a driving force of an engine; and an electrically driven second pump operated as an electrically driven pump. Hydraulic fluid is supplied from at least one of the first pump and the second pump, and the second pump is capable of operating even if the first pump is inoperative when the engine is not running.

Owner:AISIN SEIKI KK

Control apparatus for device having dead band, and variable valve system

InactiveUS20030000489A1Valve arrangementsPiezoelectric/electrostriction/magnetostriction machinesVariable valve timingControl signal

A control unit employed in a variable valve timing apparatus vibrates a control signal for controlling an oil-pressure control valve. If the vibration center of the duty value of the control signal for driving the oil-pressure control valve lies in a dead band, the vibration takes the duty value to the outside of the dead center temporarily. Thus, even if the center value of the control signal lies in the dead band, the valve timing of the oil-pressure control valve changes with variations in control signal. As a result, the width of the dead band appears small or to have a value of zero. Accordingly, the response characteristic of variations in valve timing to the variations in control signal is improved. The vibration of the control signal is also effective for detection of a width of the dead band.

Owner:DENSO CORP

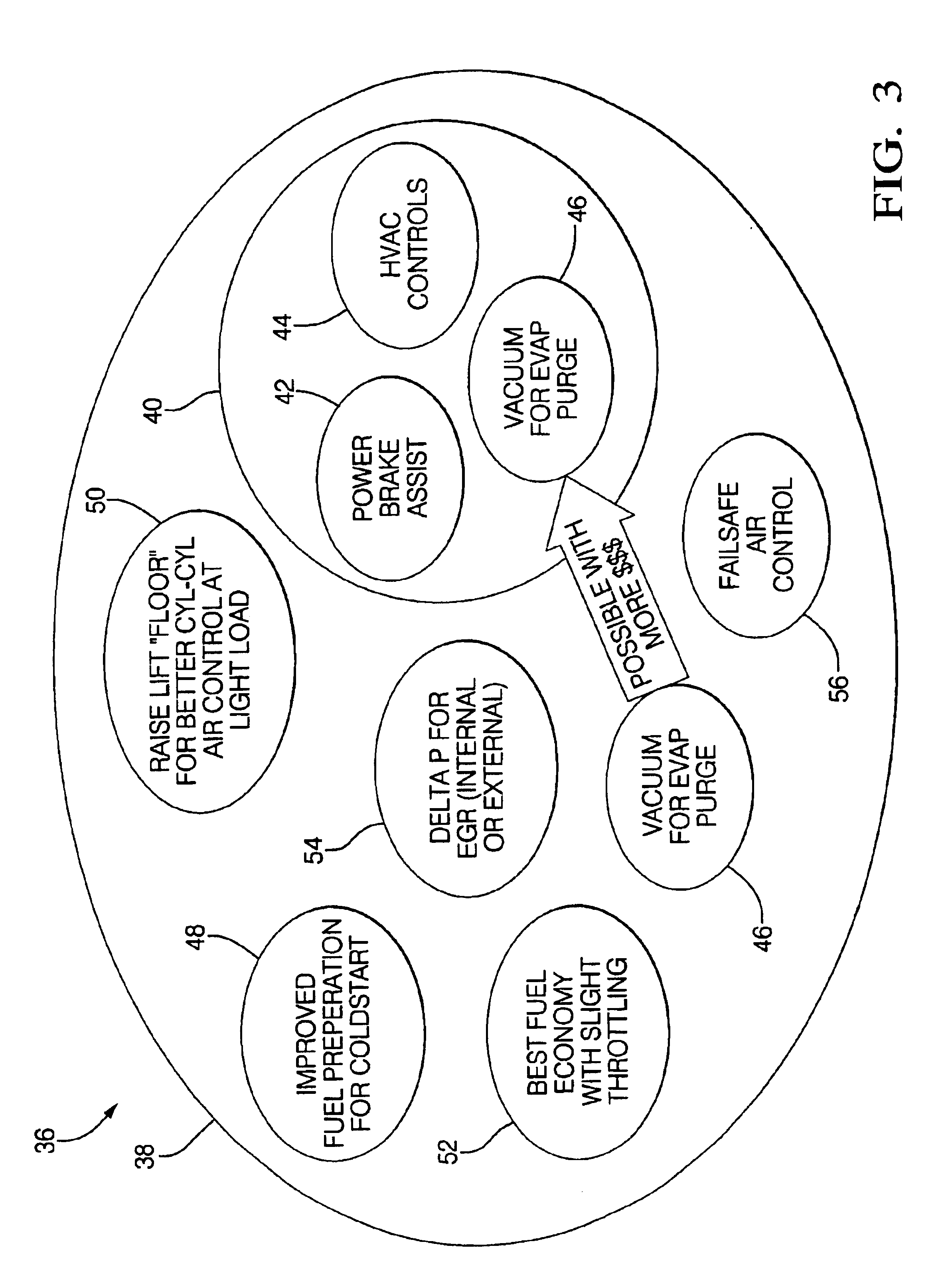

Vacuum management system for engine with variable valve lift

InactiveUS6866020B2Improve fuel economyNon-fuel substance addition to fuelInternal combustion piston enginesVacuum assistedVariable valve timing

A vacuum management system for an engine with variable valve lift includes a vacuum control valve at the entrance to the intake manifold to increase vacuum within the manifold as needed and preferably only when it can be done without impairing fuel economy or engine performance. Vacuum may then be used for any of various vacuum-assisted devices and functions, for example, boosting a vehicle braking system. The numerical relationships among important operating parameters are determined in a laboratory, and a programmable engine control module (ECM} is provided with algorithms and tables of such values by which the ECM is able to vary valve lift and vacuum control valve position to provide optimum flow across the intake valves and optimum manifold vacuum under all engine operating conditions.

Owner:DELPHI TECH INC

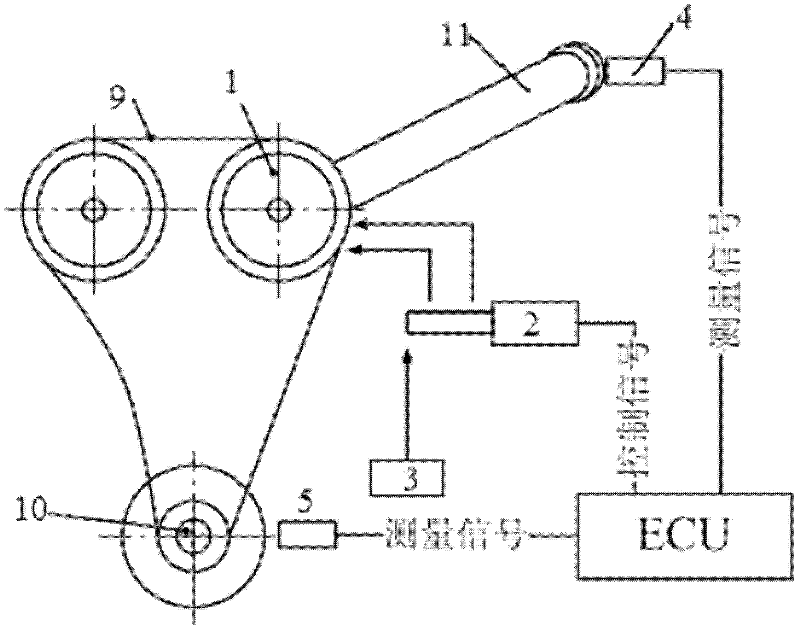

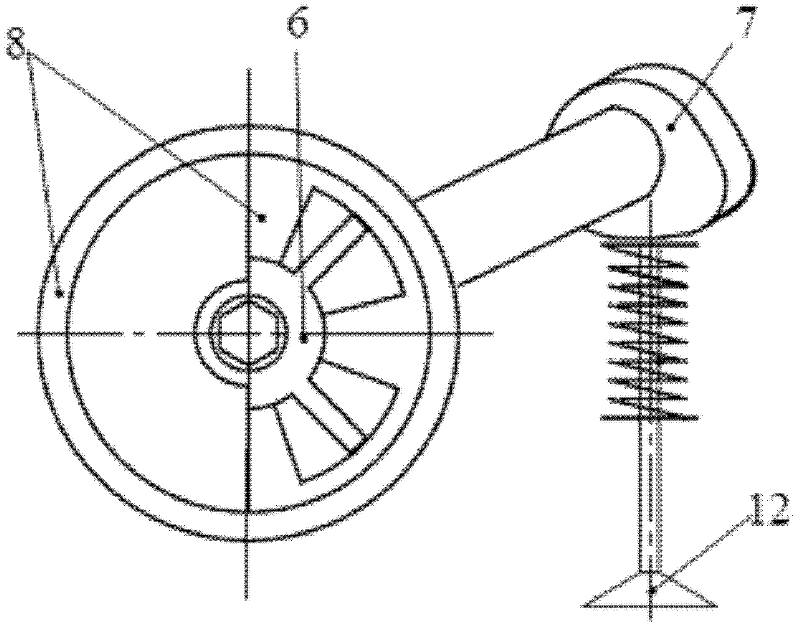

VVT (Variable Valve Timing) control method capable of combining self-learning feed-forward and active anti-interference feedback

ActiveCN102374038AHigh control precisionImprove response speedInternal combustion piston enginesOutput powerVariable valve timingControl signal

The invention discloses a VVT (Variable Valve Timing) control method capable of combining self-learning feed-forward and active anti-interference feedback, which can improve the response speed of a VVT phase control, reduce the energy consumption of a regulating process and increase the adaptability to the operating environment change and the state change of an engine. The control method disclosed by the invention comprises the following steps of: carrying out a feed-forward control, an active anti-interference feedback control and a self-learning correction; regulating a hydraulic oil demandvolume of a solenoid valve and a demand current I of a VVT solenoid valve through the feed-forward control; and obtaining a control signal It of a VVT system through the active anti-interference feedback control. The self-learning correction comprises the steps of concluding and calculating a characteristic parameter of the VVT system according to a VVT control quantity (a duty ratio of a PWM (Pulse Width Modulation) wave) and a response characteristic yr of the VVT system during the regulation of the VVT system so as to correct a calculating coefficient in a feed-forward controller model, thereby continuously increasing the calculation accuracy of the feed-forward control, improving the control capability of the feed-forward control, reducing the dependence on the feedback control and effectively improving the response speed and the accuracy of the control of the VVT system.

Owner:TIANJIN UNIV

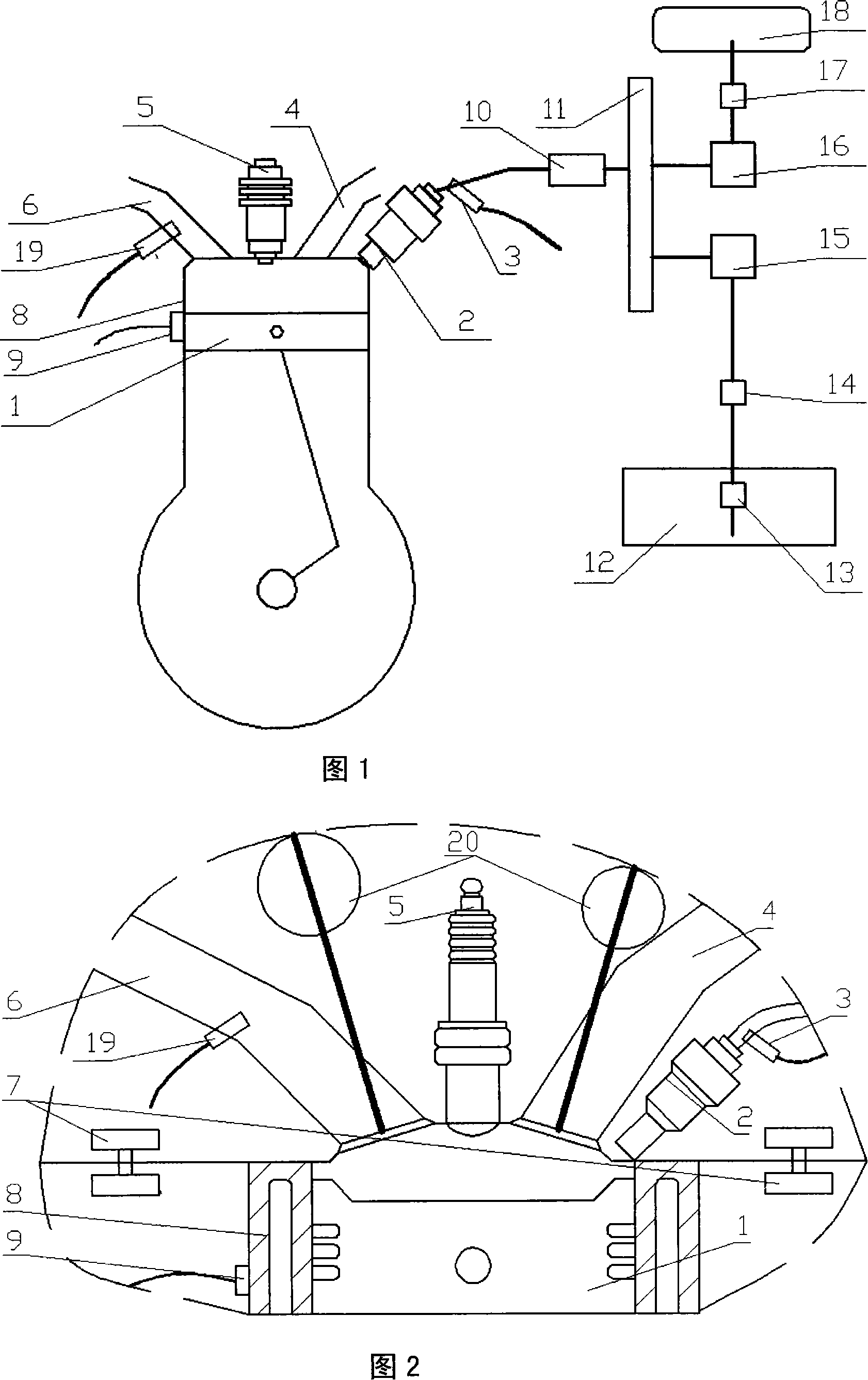

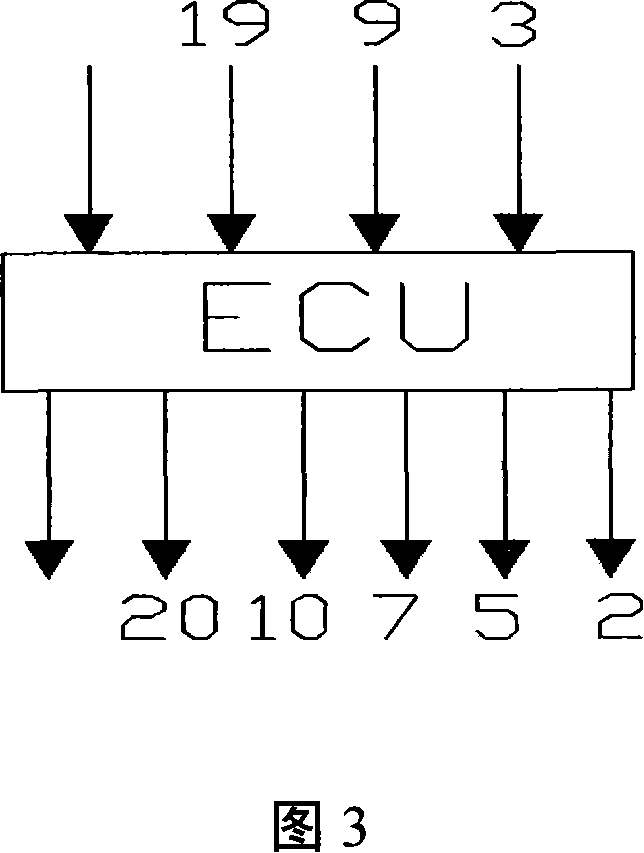

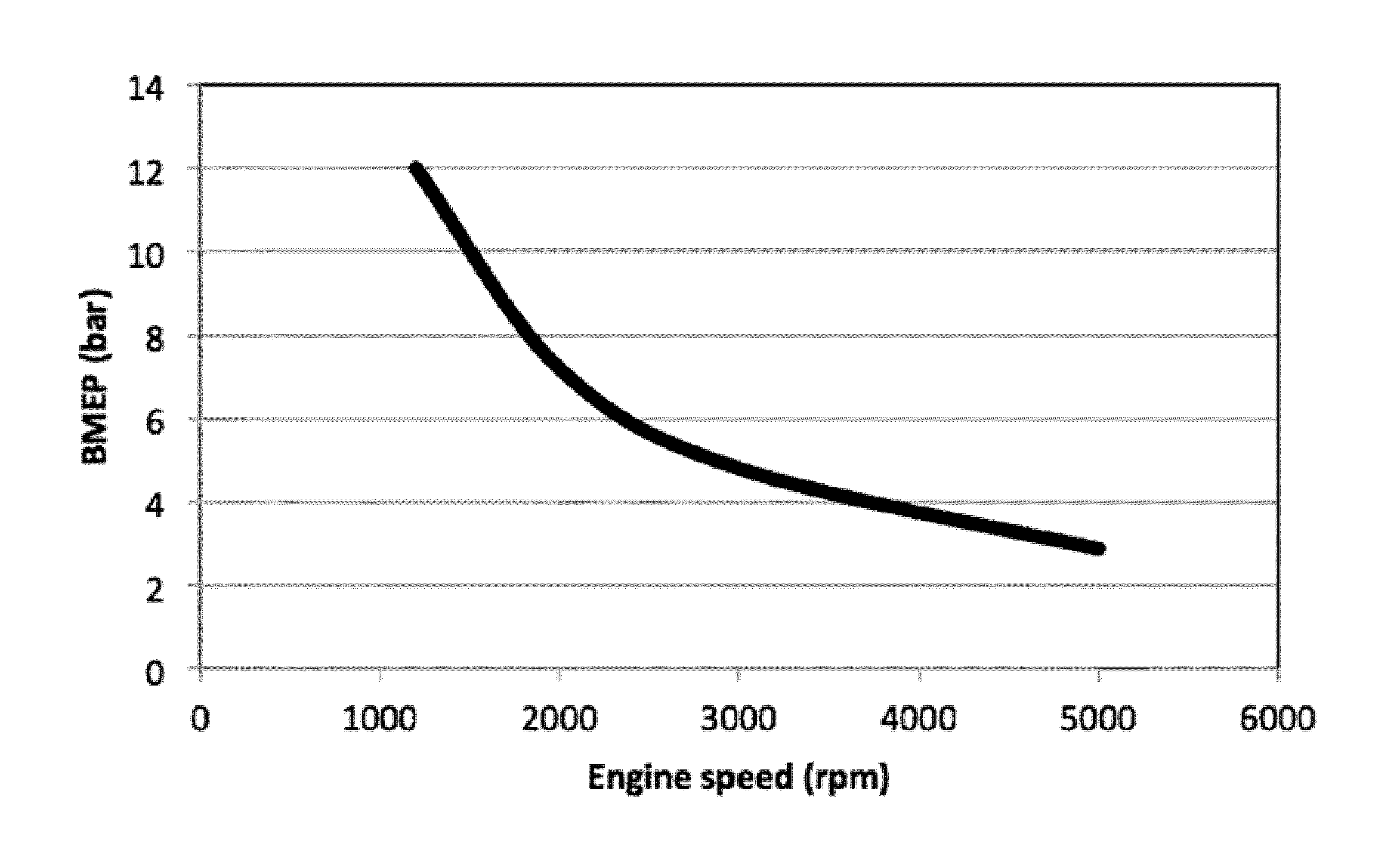

Flexible fuel engine with alterable compression ratio and control method thereof

InactiveCN101131126AValve arrangementsInternal combustion piston enginesCombustion systemVariable valve timing

The present invention discloses one kind of engine with changeable compression ratio and changeable fuel and its control method. The engine includes one combustion system, one fuel pressure regulating system, one liquid fuel providing system, one gas fuel providing system, one changeable gas valve timing mechanism, one electronic control unit and one sensor module. According to the acquired signal, the electronic control unit determines the current fuel type, regulates the compression ratio, combustion controlling strategy and gas distribution phase of the engine and regulates the pressure of the fuel injector, so as to fit the fuel. The engine of the present invention can burn gas fuel, liquid fuel and mixed fuel, and has compression ratio adjustable in 8-18 and high dynamic performance and economic performance in burning different types of fuel.

Owner:CHERY AUTOMOBILE CO LTD

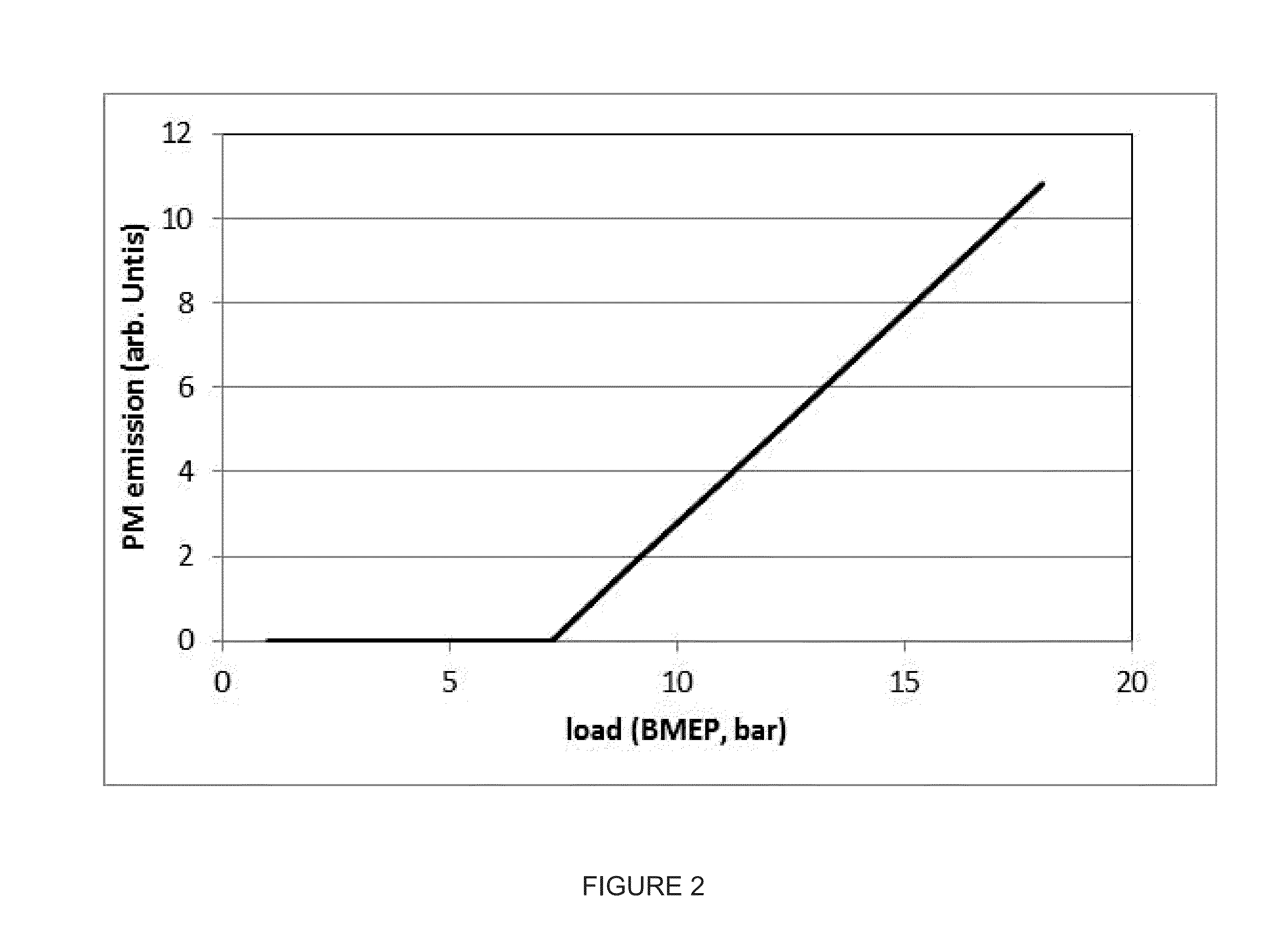

Gasoline Particulate Reduction Using Optimized Port and Direct Injection

ActiveUS20150369162A1Reduce particulate emissionsEmission reductionElectrical controlInternal combustion piston enginesParticulatesVariable valve timing

Additional approaches for the reduction of particulate emissions in gasoline engines using optimized port+direct injection are described. These embodiments include control of the amount of directly injected fuel so as to avoid a threshold increase in particulates due to piston wetting and reduction of cold start emissions by use of air preheating using variable valve timing.

Owner:ETHANOL BOOSTING SYST LLC

Vacuum system for engine with variable valve lift

InactiveUS6863048B2Improve fuel economyElectrical controlInternal combustion piston enginesVariable valve timingInlet valve

A vacuum system for an engine with variable valve lift includes a controllable vacuum-forming valve at the entrance to the intake manifold and a programmable engine control module (ECM) to increase vacuum as desired within the manifold by modulating the valve as needed to optimize fuel economy. To provide vacuum brake assist, a brake booster diaphragm is connected conventionally to the manifold and a vacuum storage tank and check valve are disposed between the booster diaphragm and the manifold. During periods of vehicle deceleration, when engine load is low, the ECM may switch the VVL-controlled intake valves to a higher lift to increase the pumping capacity of the engine, while simultaneously partially closing the vacuum-forming valve to create vacuum in the intake manifold, the brake booster, and the vacuum storage tank at little or no expense to engine performance.

Owner:DELPHI TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com