Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

252 results about "Homogeneous charge compression ignition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

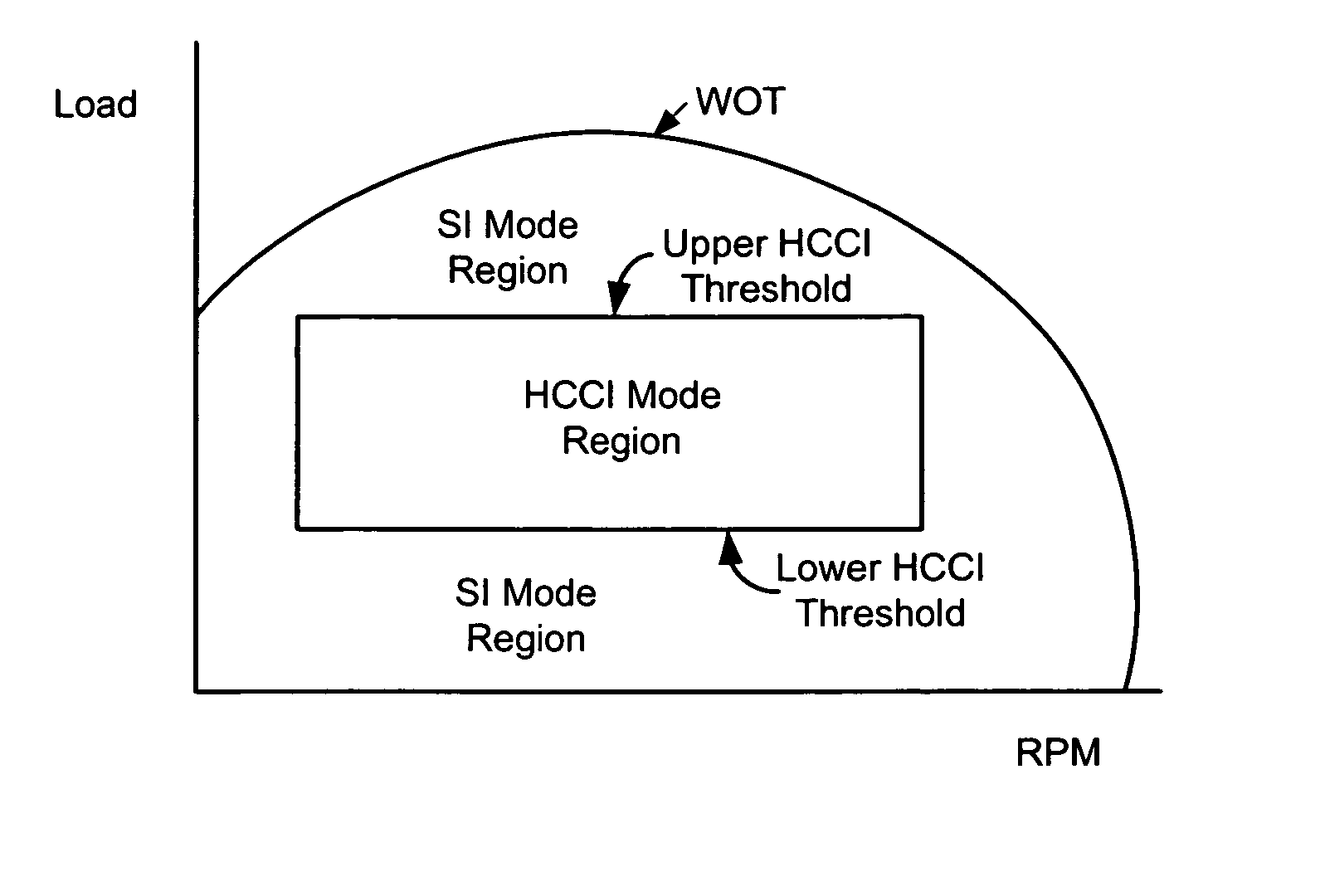

Homogeneous charge compression ignition (HCCI) is a form of internal combustion in which well-mixed fuel and oxidizer (typically air) are compressed to the point of auto-ignition. As in other forms of combustion, this exothermic reaction releases energy that can be transformed in an engine into work and heat.

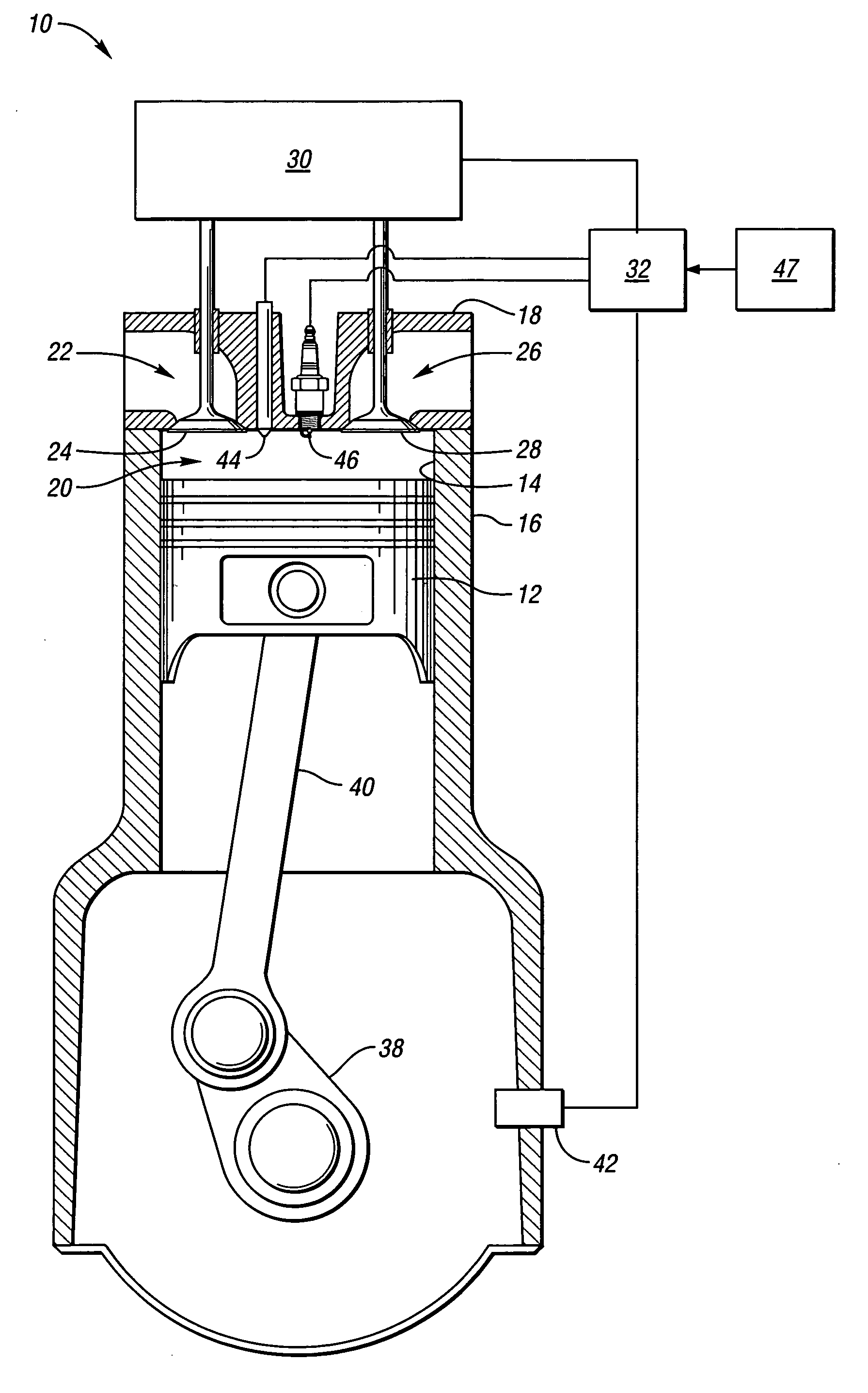

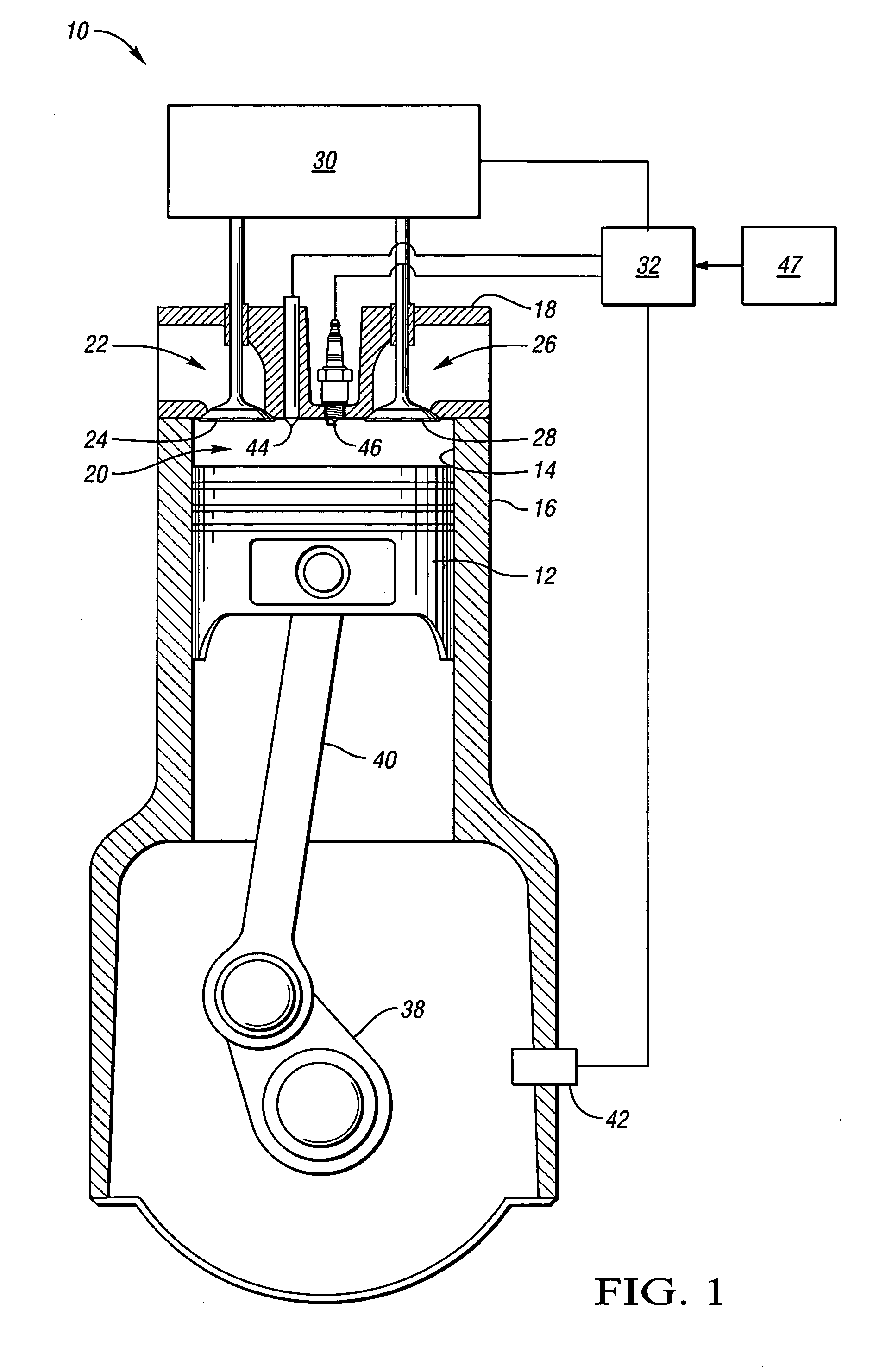

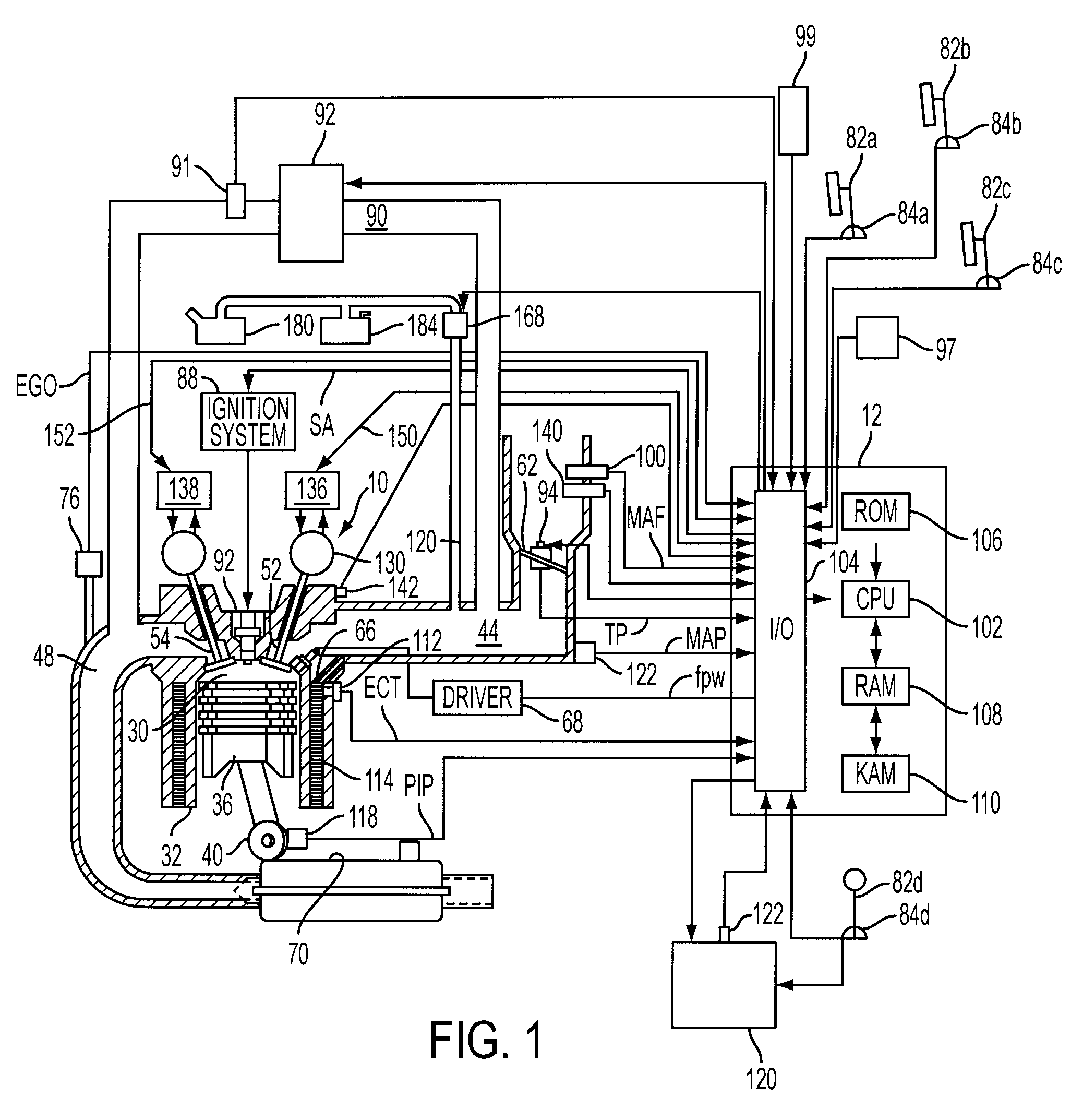

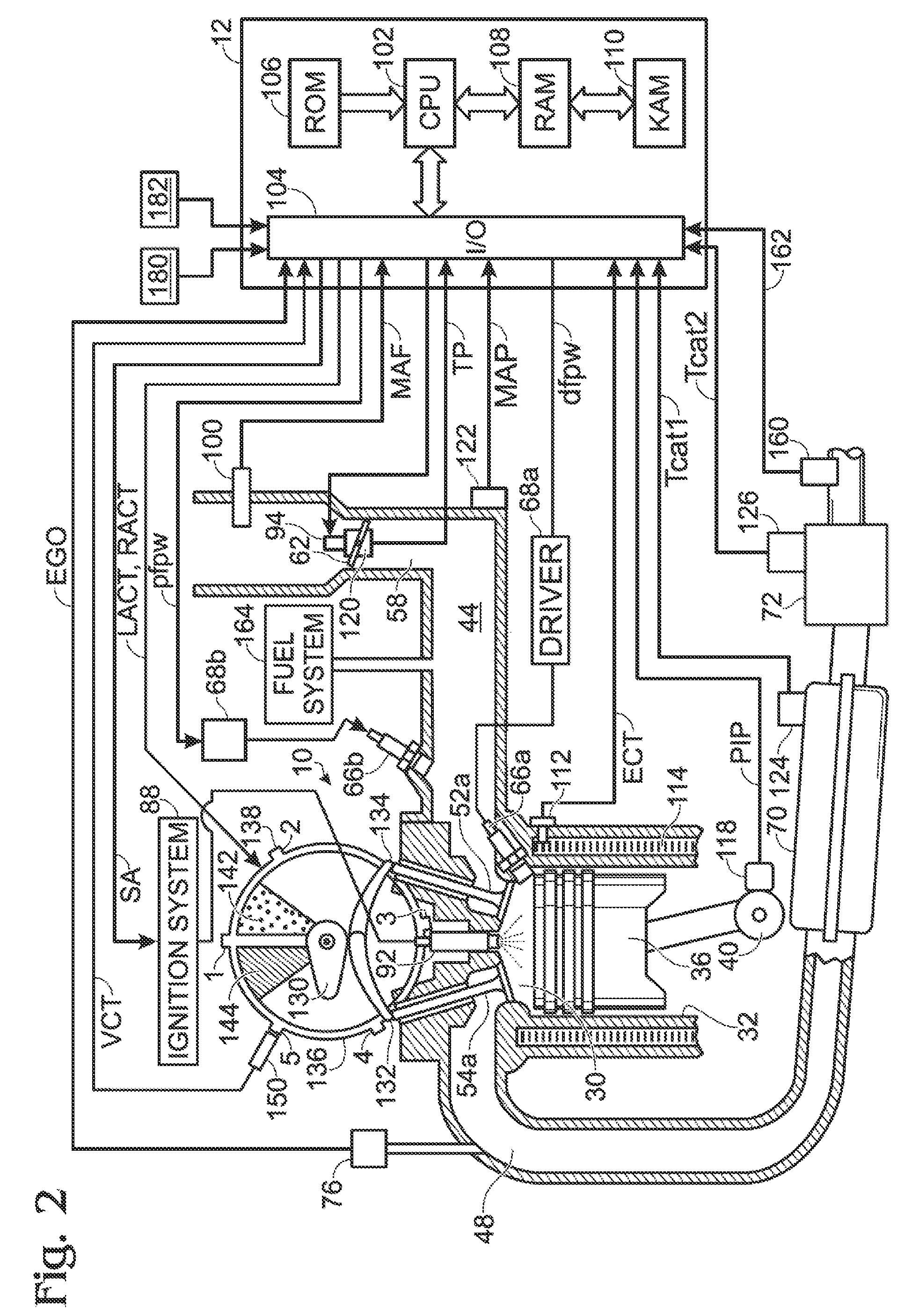

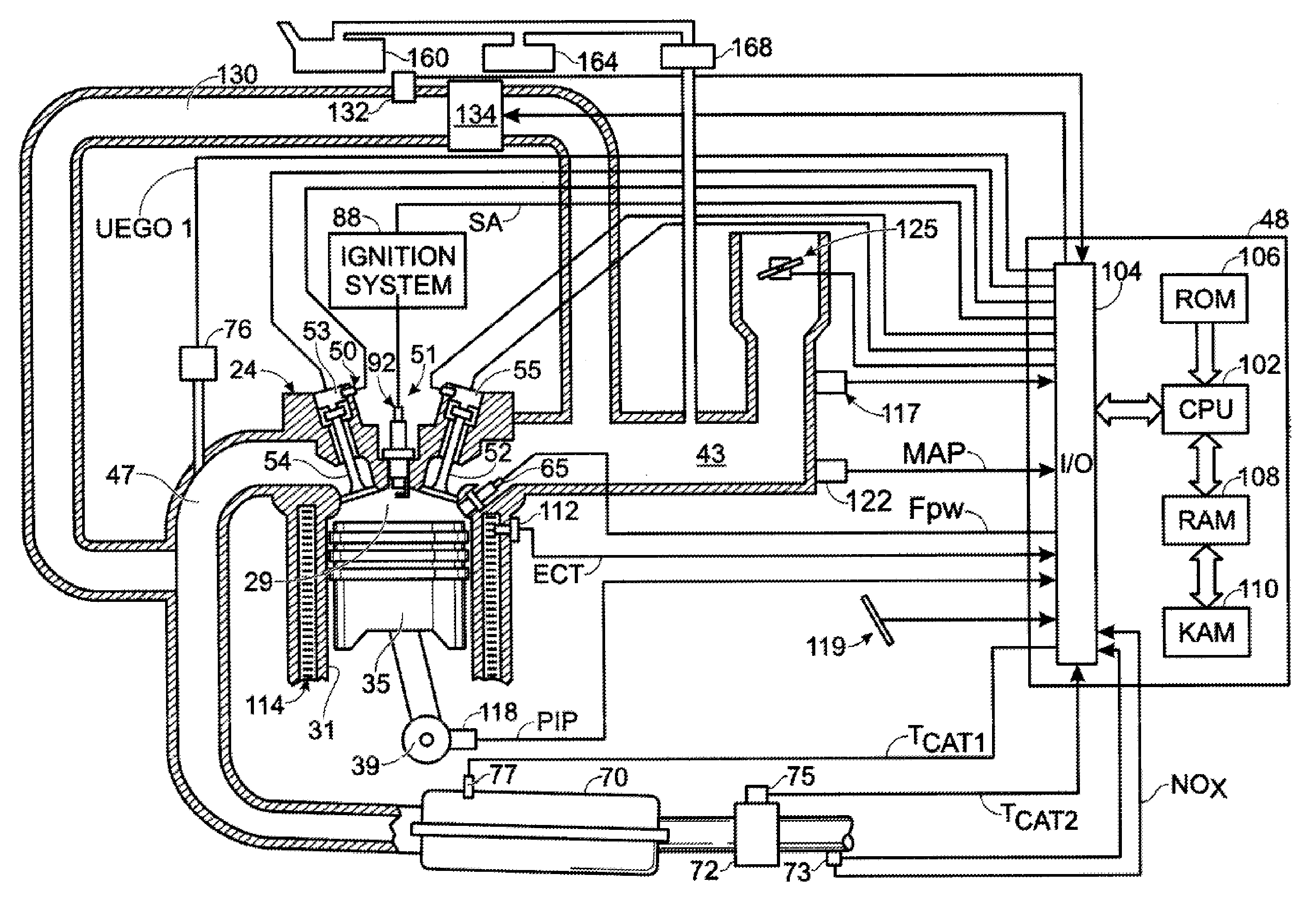

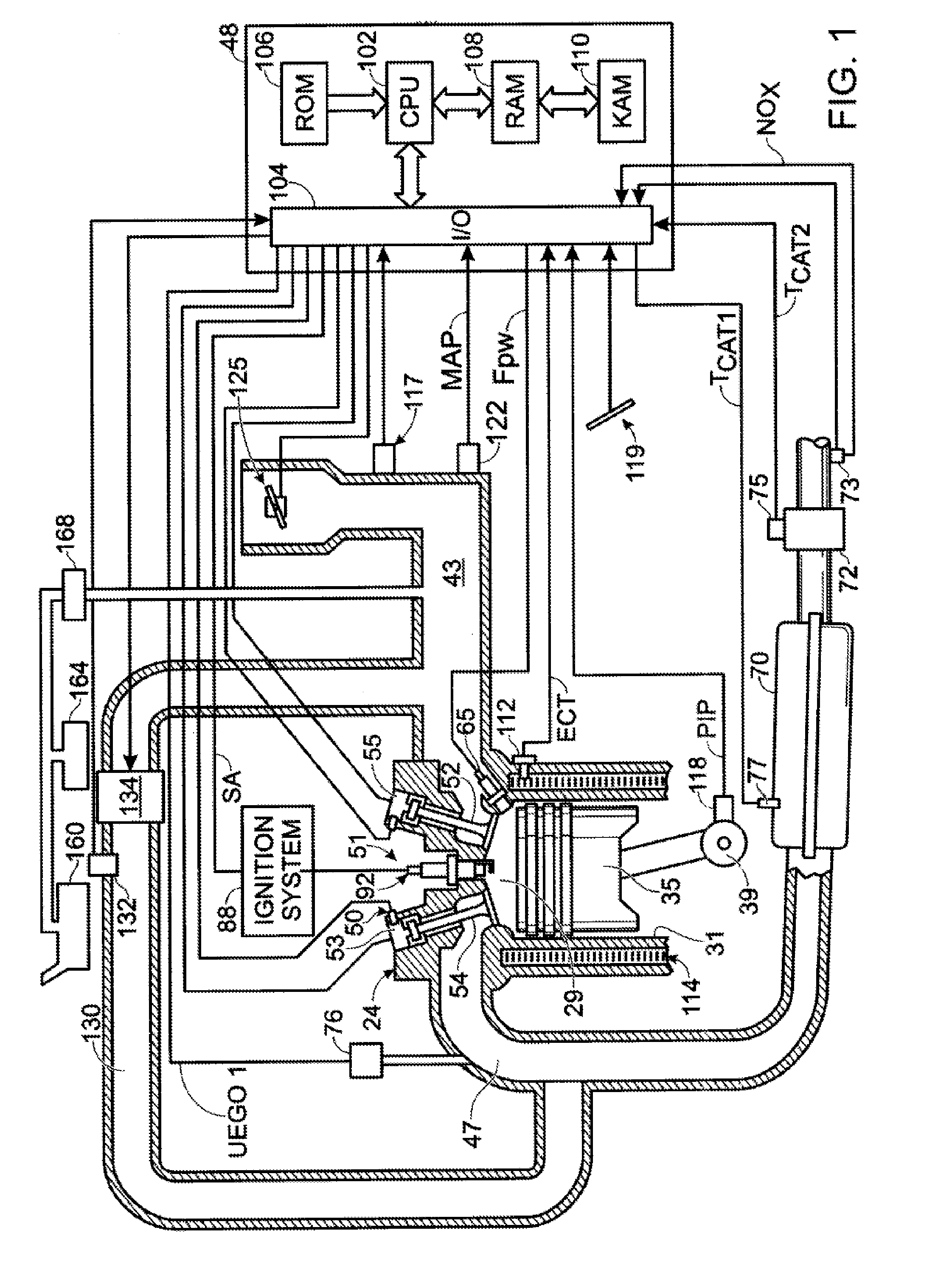

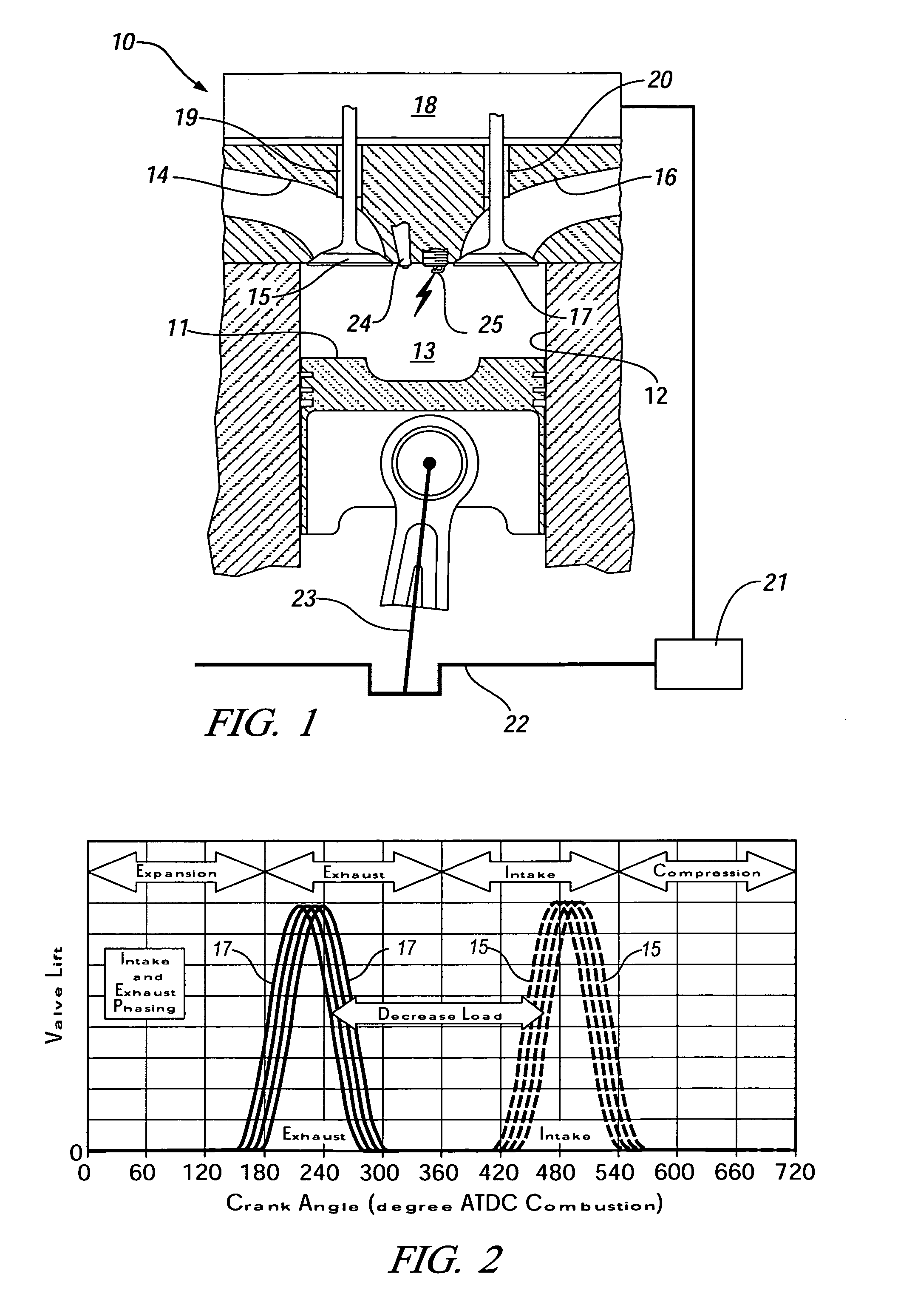

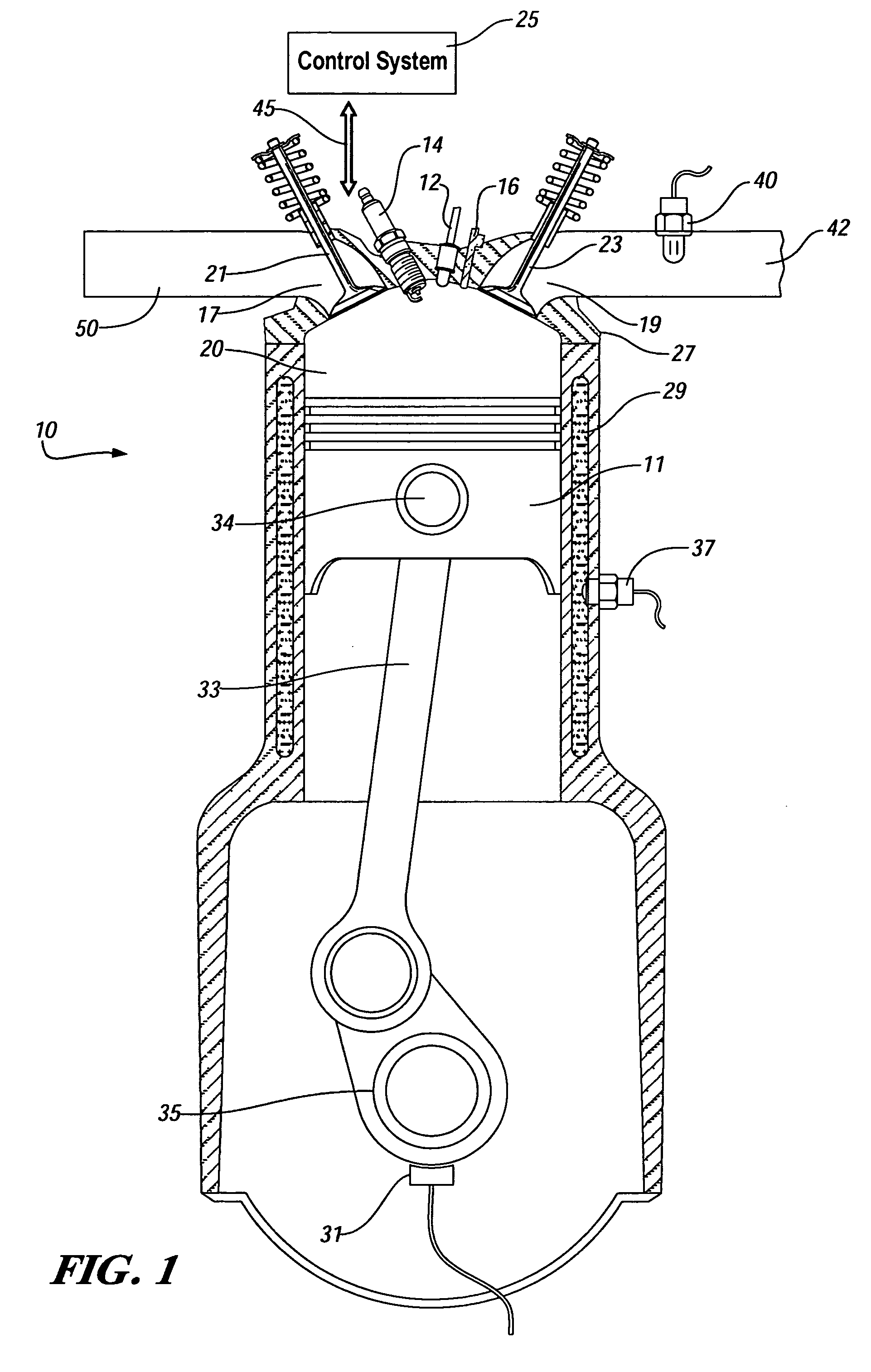

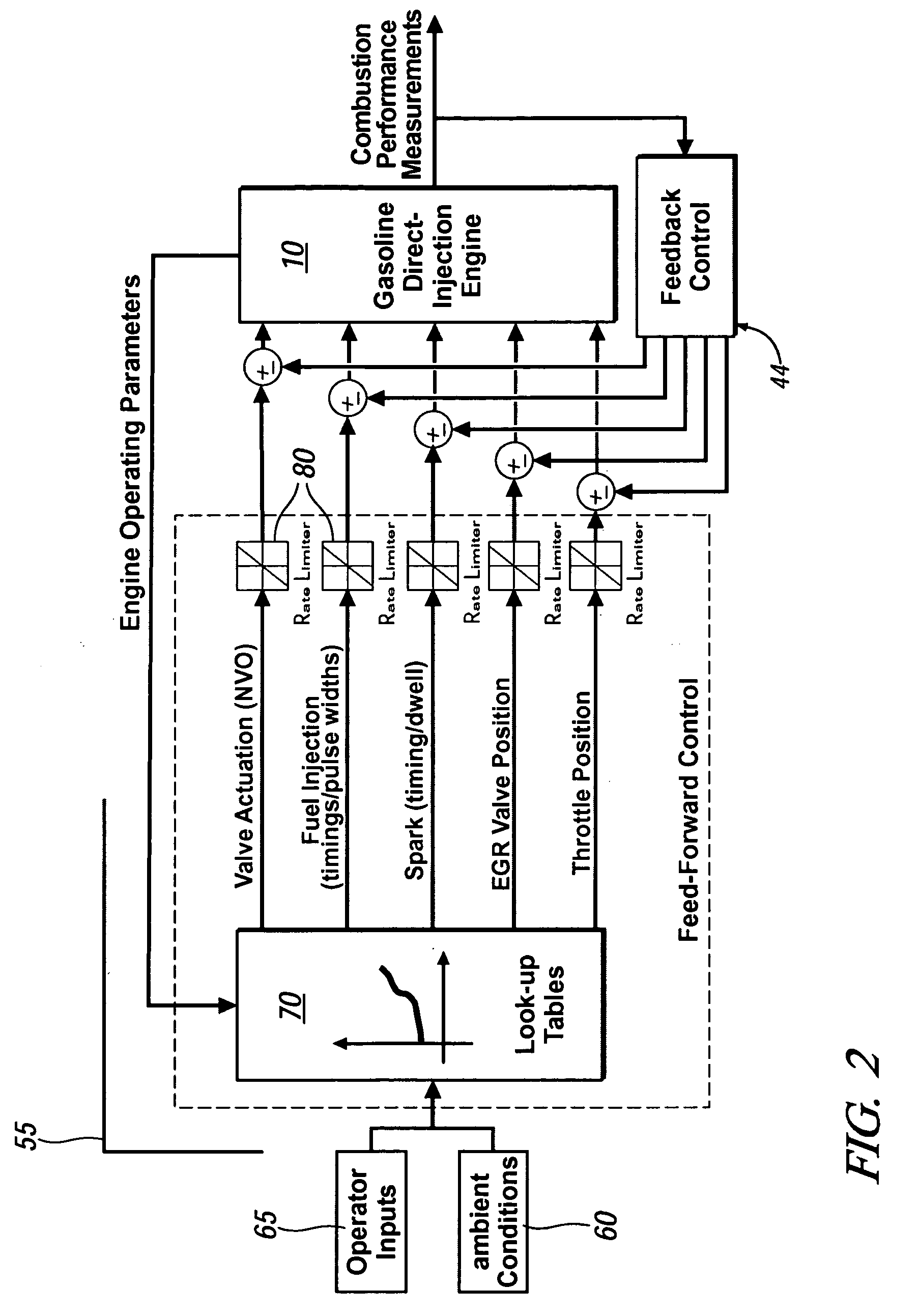

Method of HCCI and SI combustion control for a direct injection internal combustion engine

InactiveUS20060243241A1Improve fuel economyRobust controlValve arrangementsElectrical controlHomogeneous charge compression ignitionGasoline direct injection

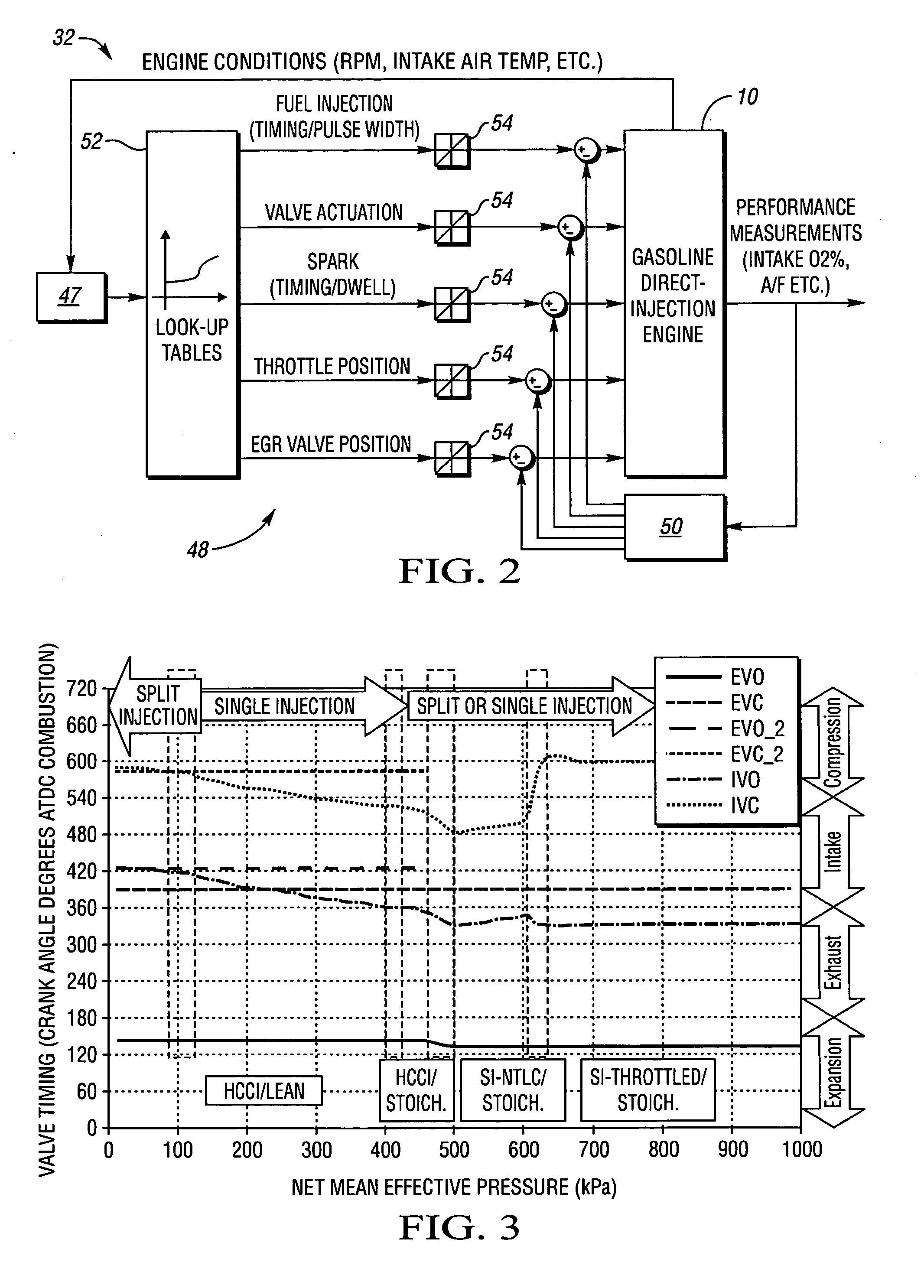

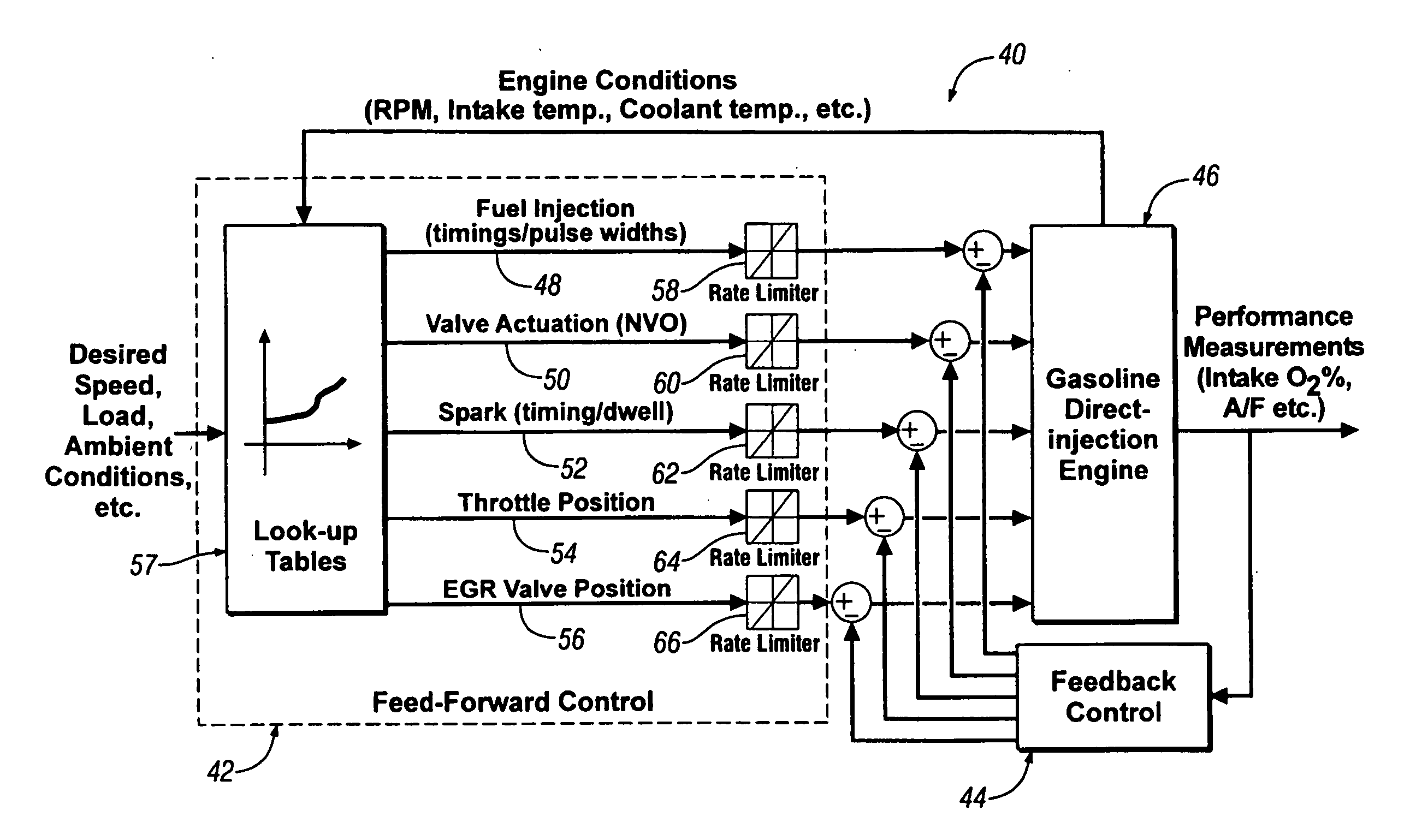

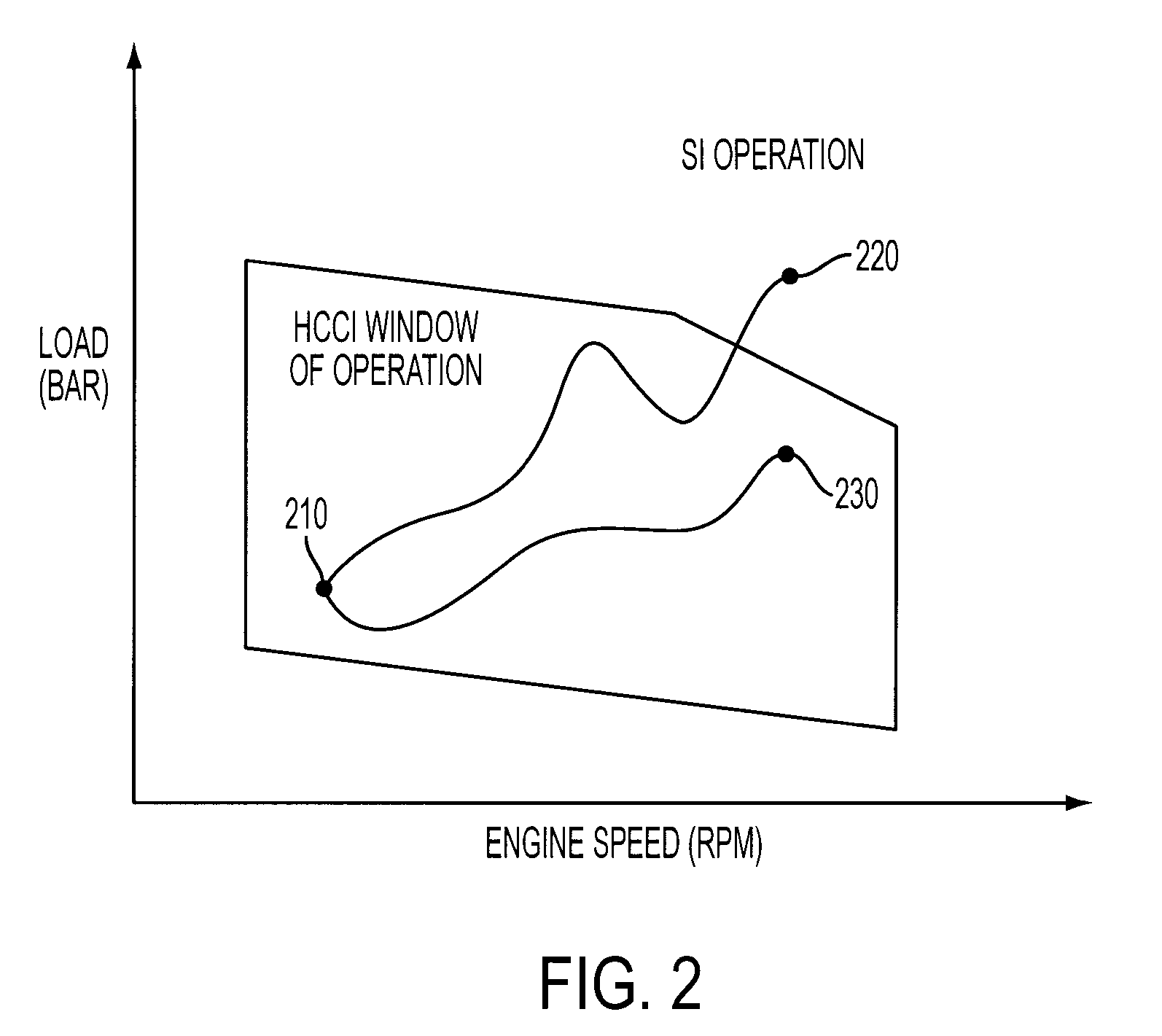

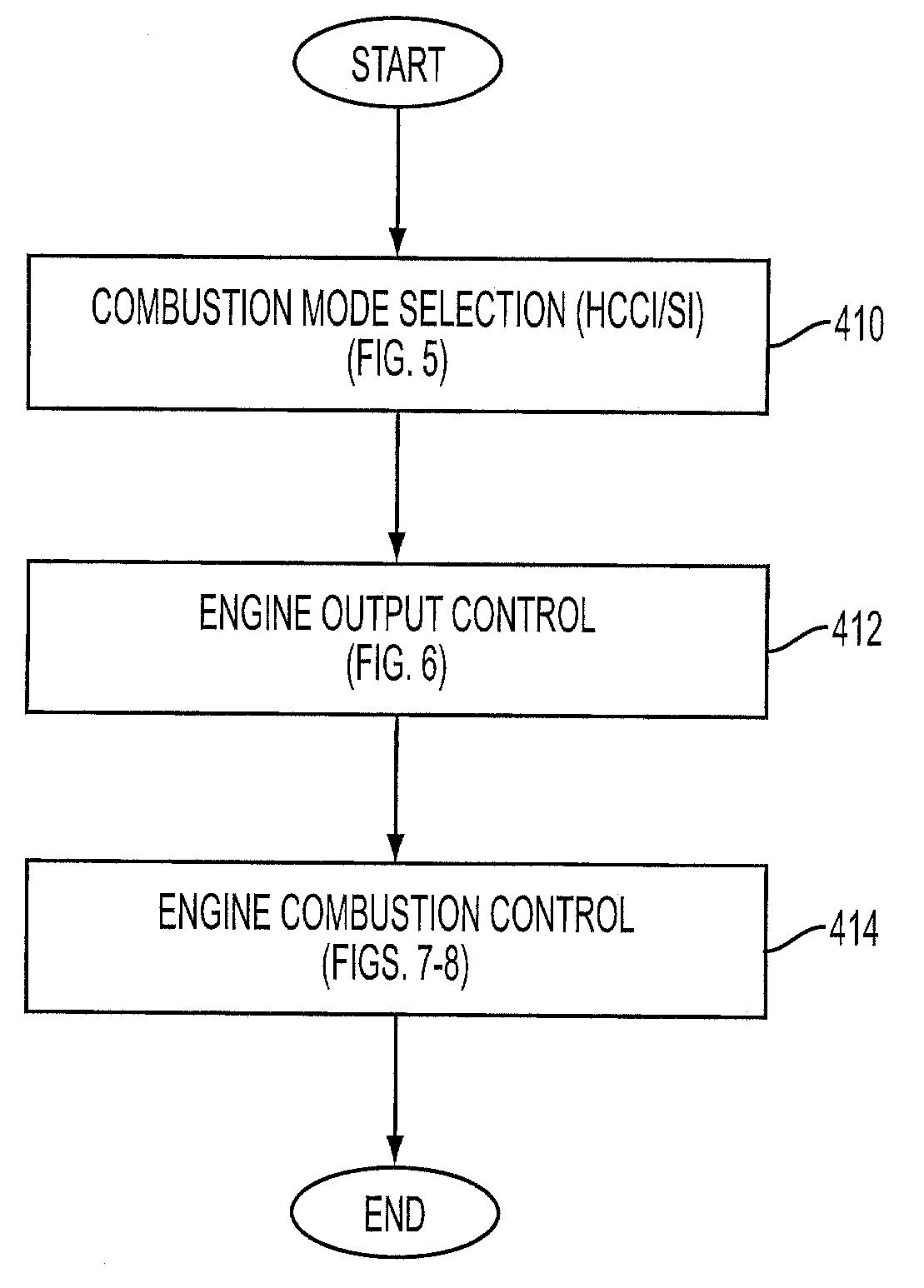

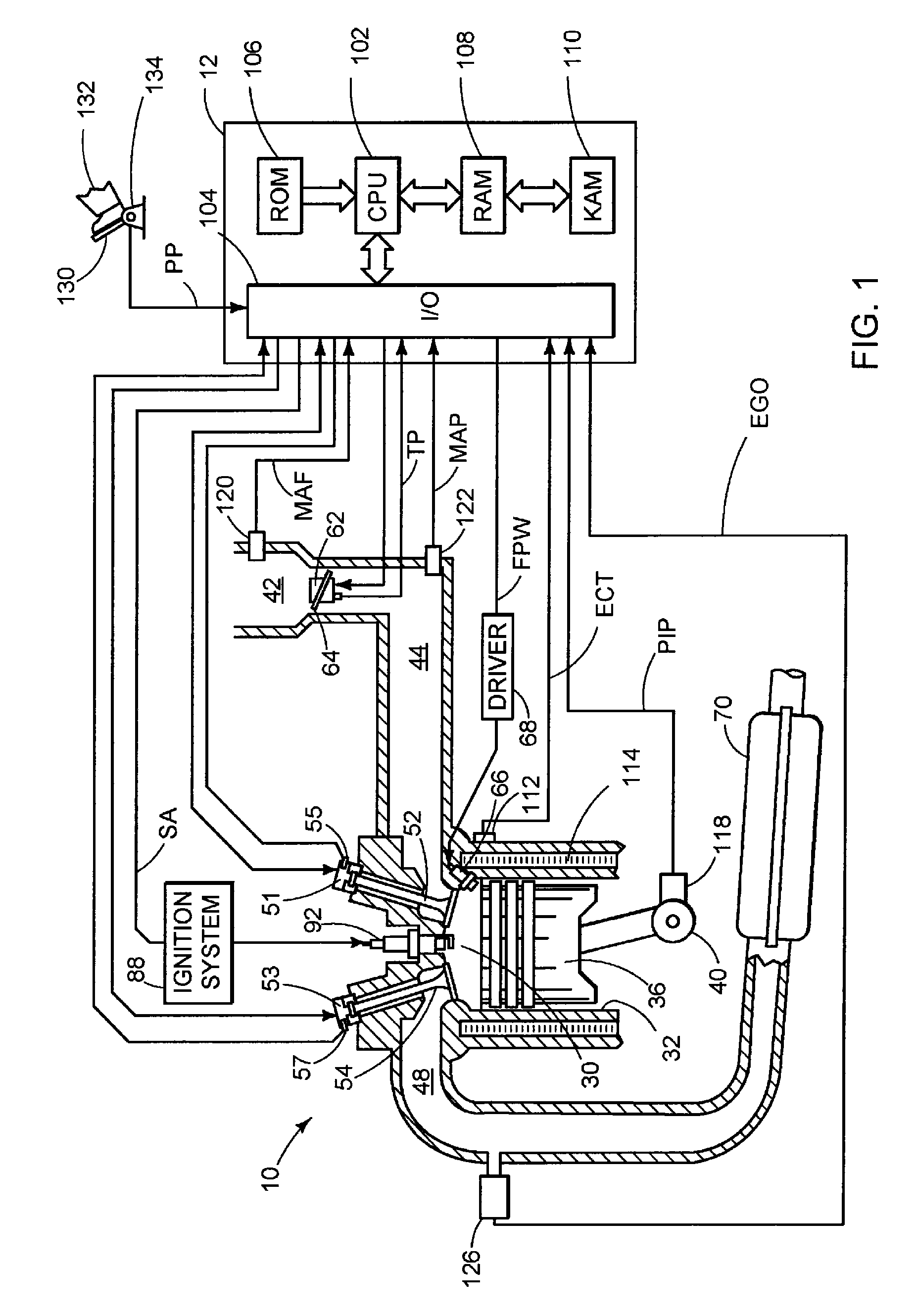

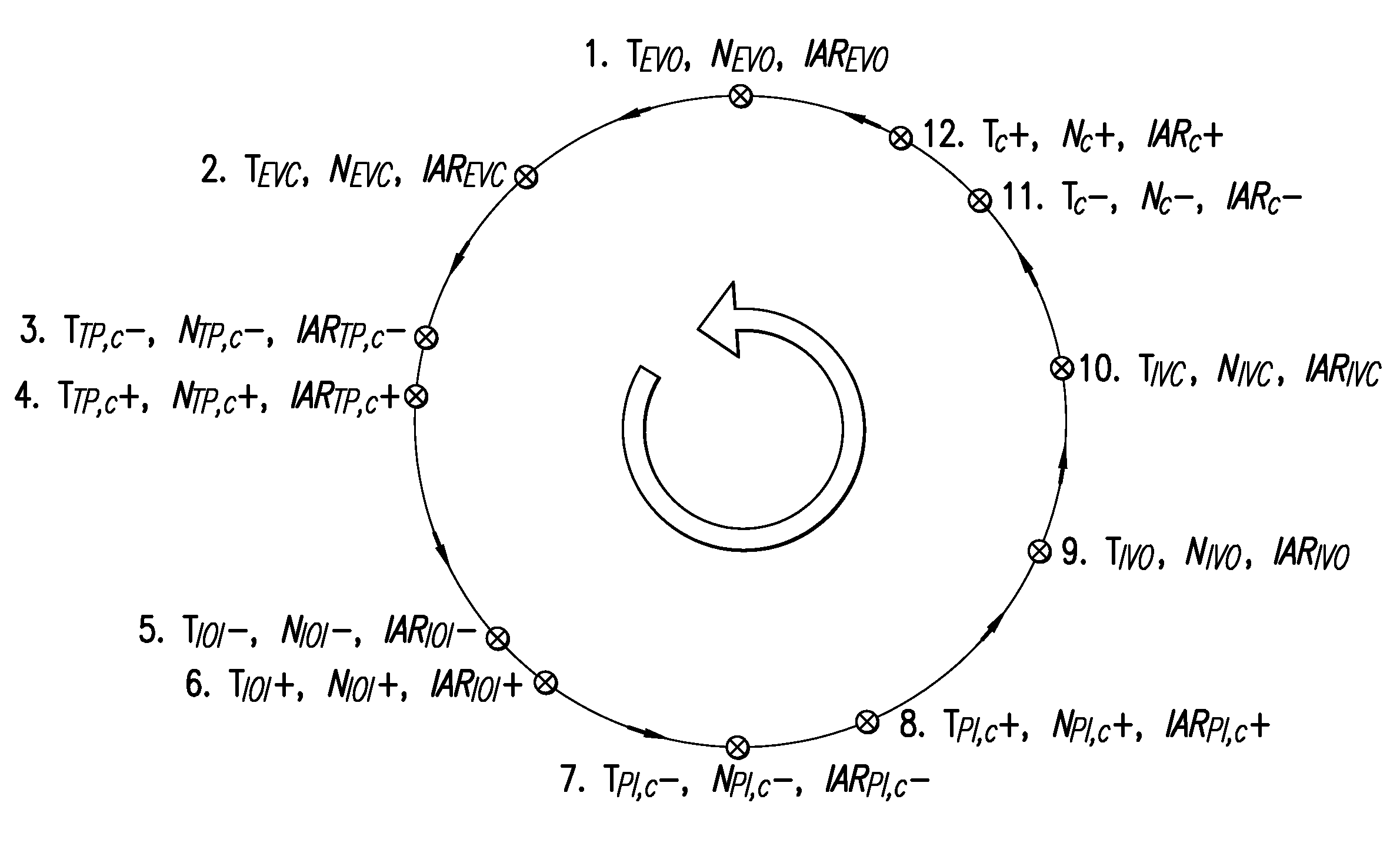

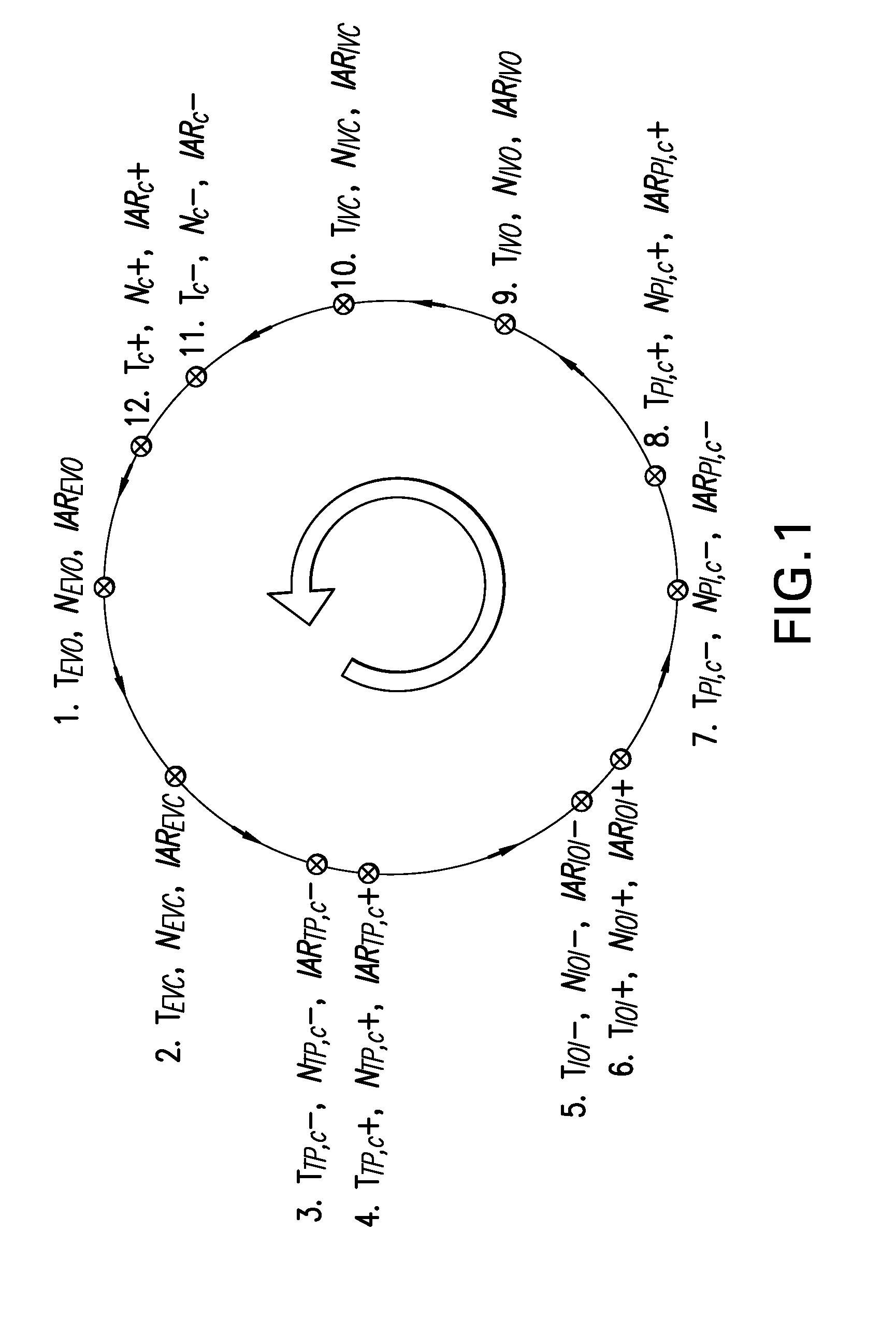

The present invention relates to methods for robust controlled auto-ignition and spark ignited combustion controls in gasoline direct-injection engines, including transients, using either exhaust re-breathing or a combination of exhaust re-compression and re-breathing valve strategy. These methods are capable of enabling engine operation with either lean of stoichiometric or stoichiometric air / fuel ratio for oxides of nitrogen (NOx) control, with varying exhaust gas recirculation (EGR) rates and throttle valve positions for knock control, and with a combination of homogeneous charge compression ignition (HCCI) and spark ignition (SI) combustion modes to optimize fuel economy over a wide range of engine operating conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

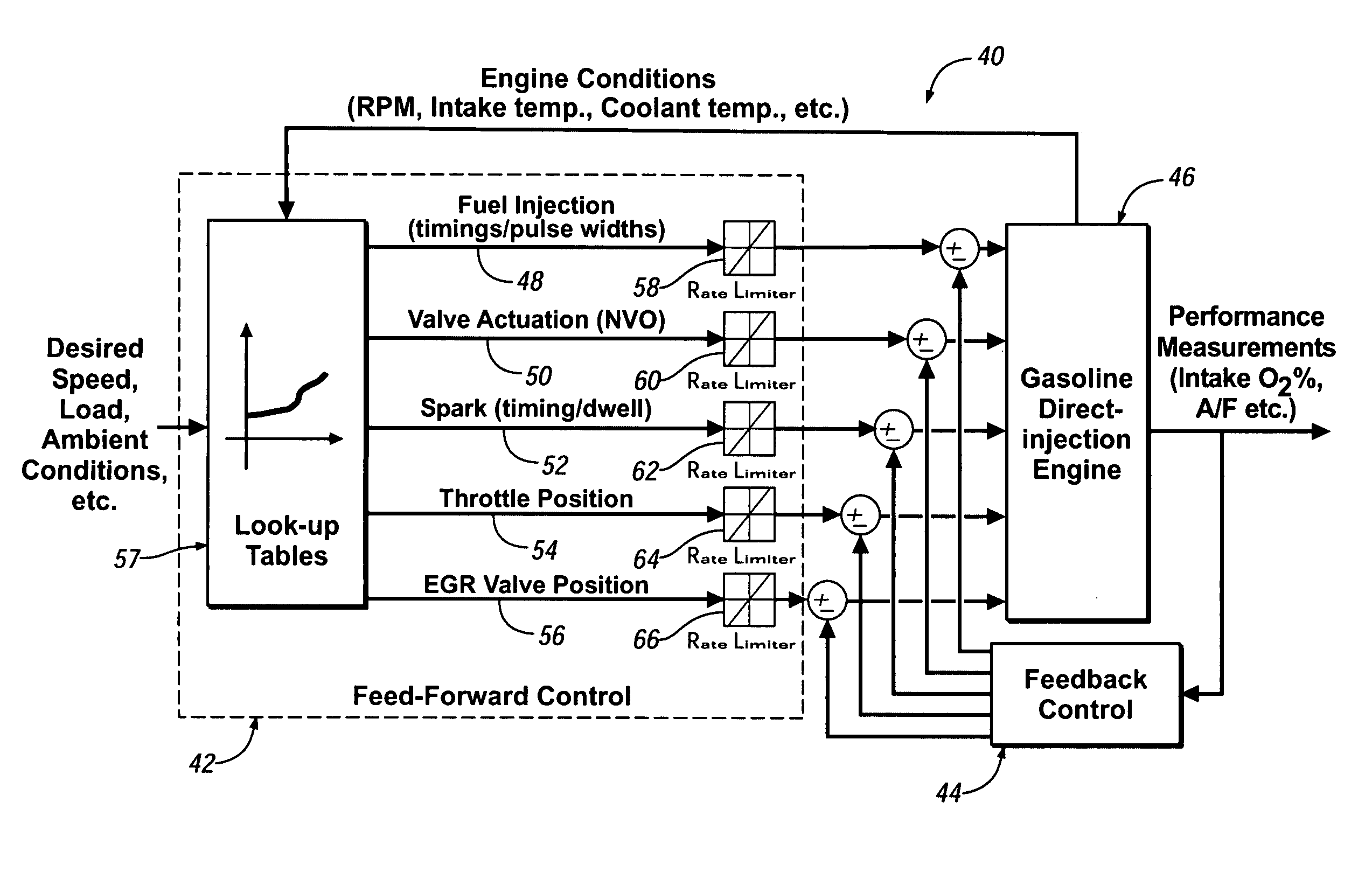

Method for load transient control between lean and stoichiometric combustion modes of direct-injection engines with controlled auto-ignition combustion

InactiveUS20060196469A1Electrical controlNon-fuel substance addition to fuelStable stateHomogeneous charge compression ignition

A method is provided for control of a direct-injection engine operated with controlled auto-ignition (HCCI) during load transient operations between modes of lean combustion low load (HCCI / Lean) and stiochiometric combustion medium load (HCCI / Stoich.). The method includes 1) operating the engine at steady state, within a homogeneous charge compression-ignition (HCCI) load range, with fuel-air-exhaust gas mixtures at predetermined conditions, for each speed and load, and controlling the engine during changes of operating mode between one to another of the HCCI / Stoich. medium load mode and the HCCI / Lean lower load mode by synchronizing change rates of predetermined controlled inputs to the current engine fueling change rate.

Owner:GM GLOBAL TECH OPERATIONS LLC

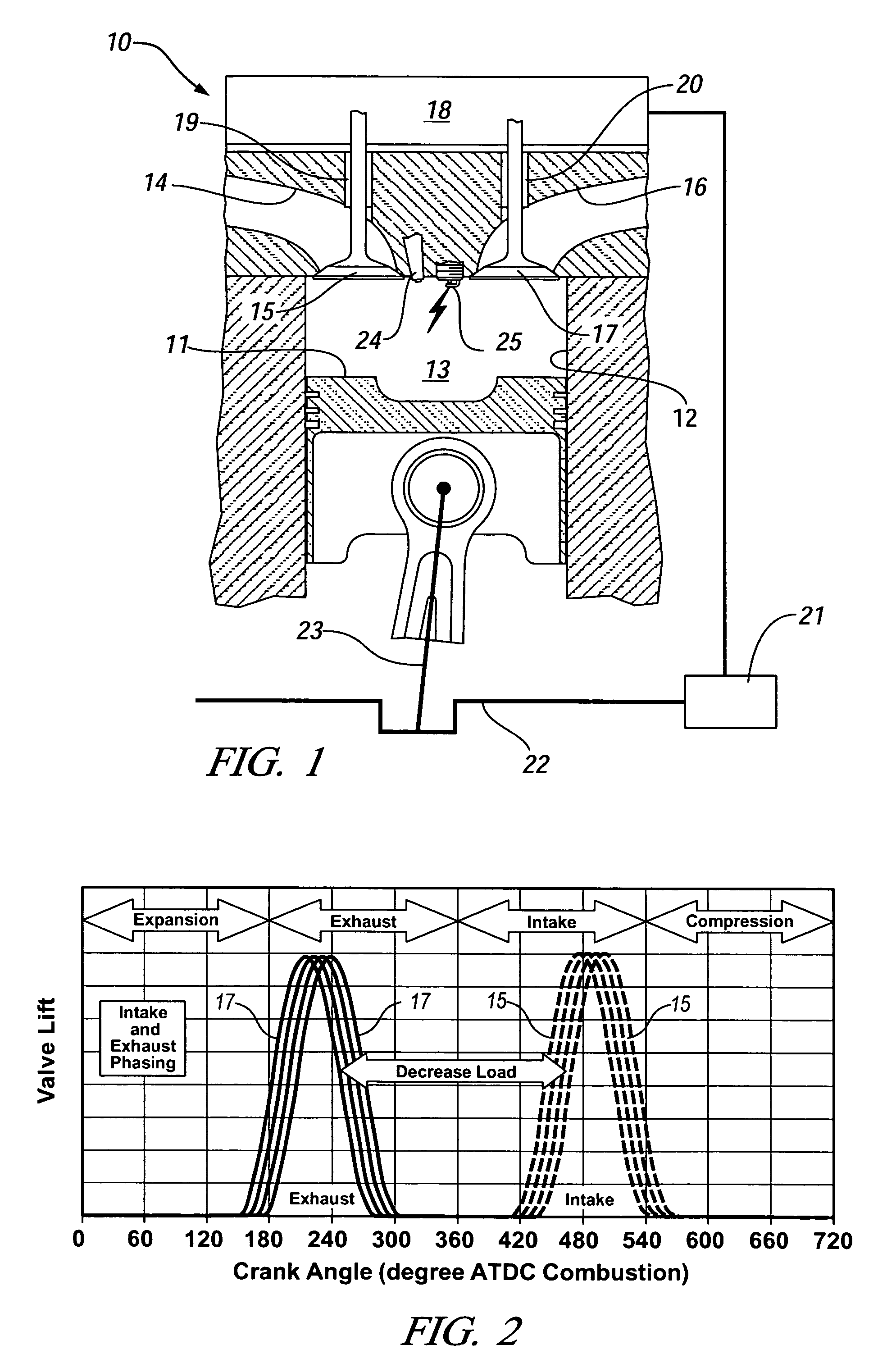

Method for transition between controlled auto-ignition and spark ignition modes in direct fuel injection engines

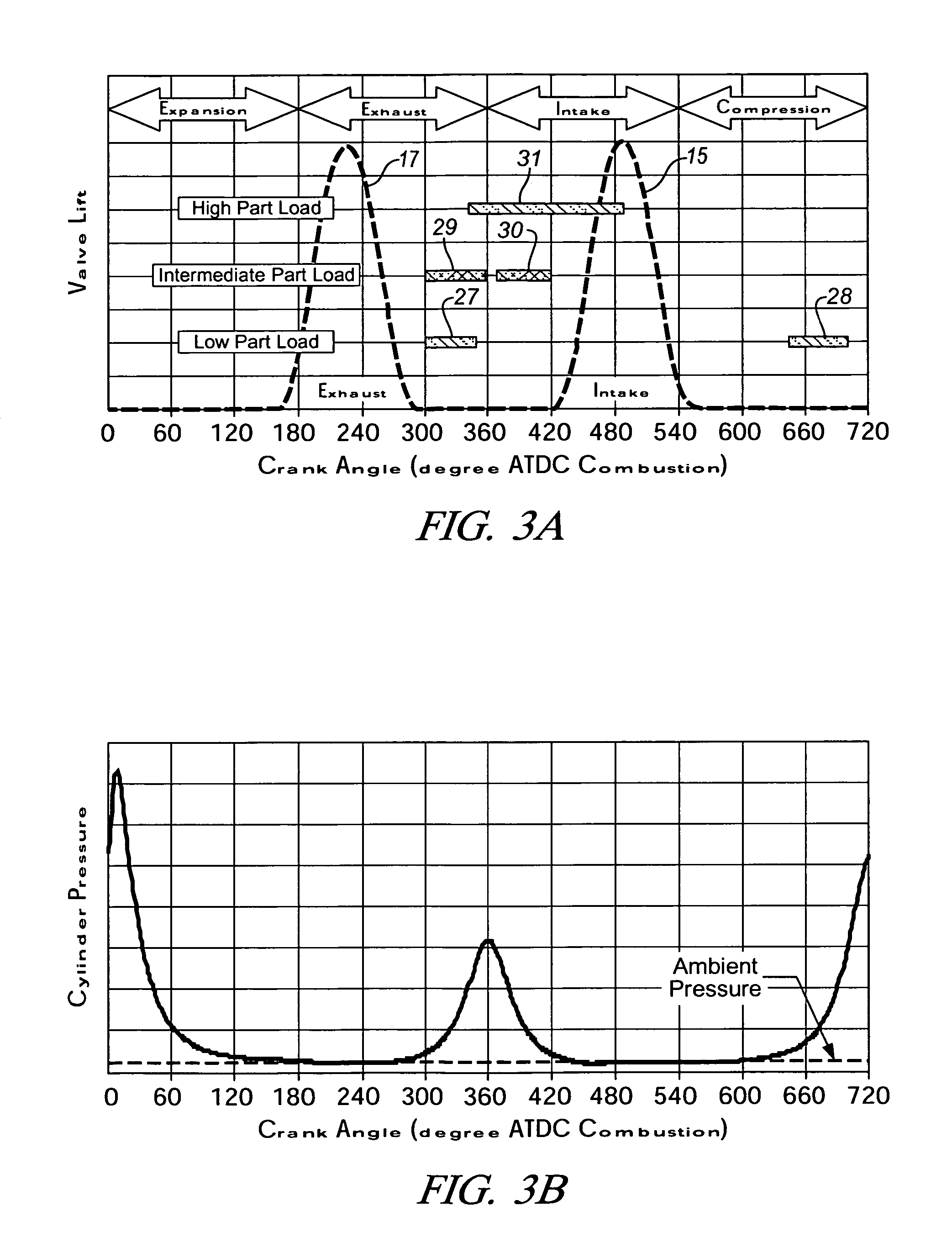

InactiveUS20060196466A1Eliminate misfiringEliminate partial burnValve arrangementsElectrical controlHomogeneous charge compression ignitionExhaust valve

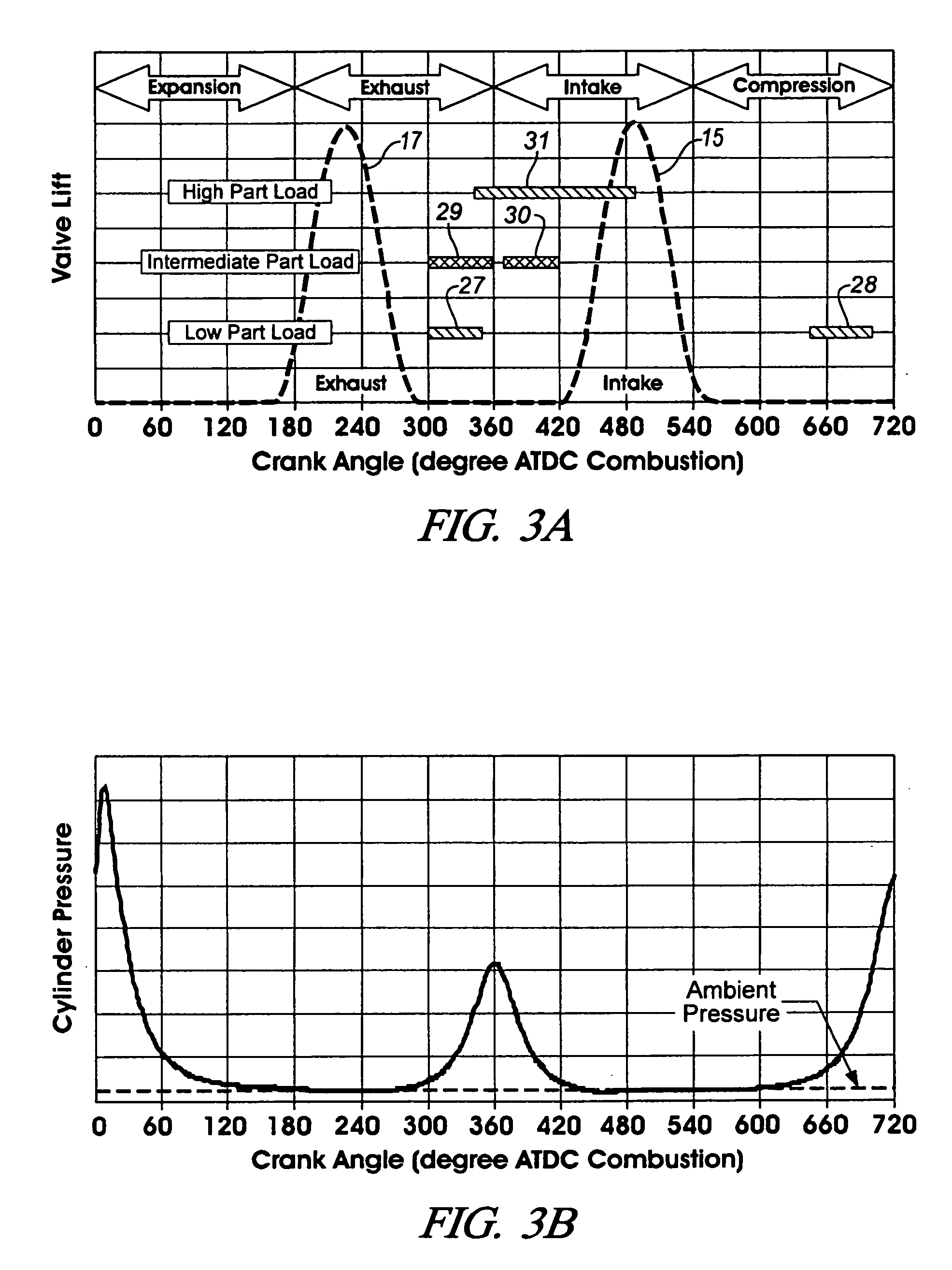

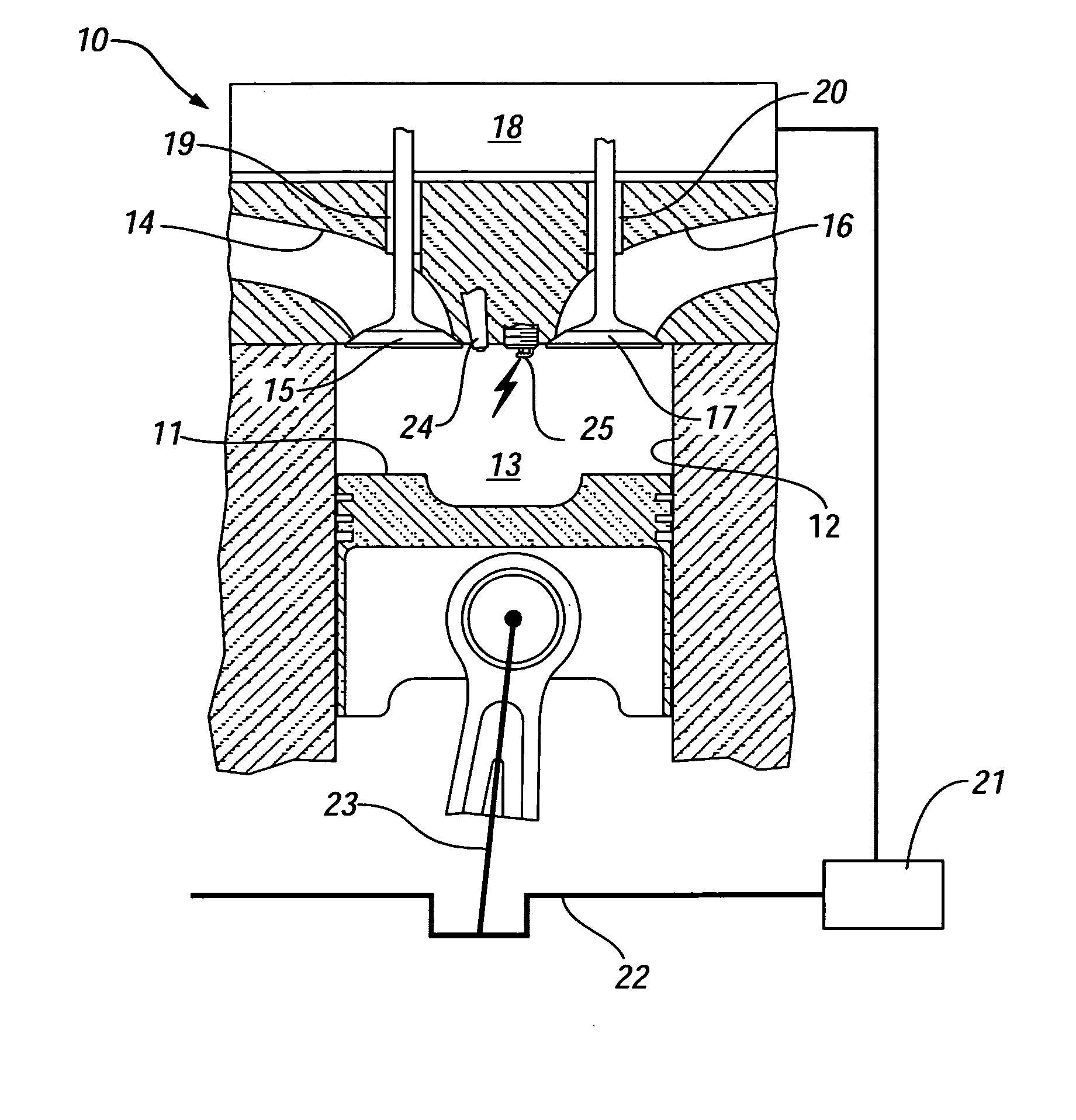

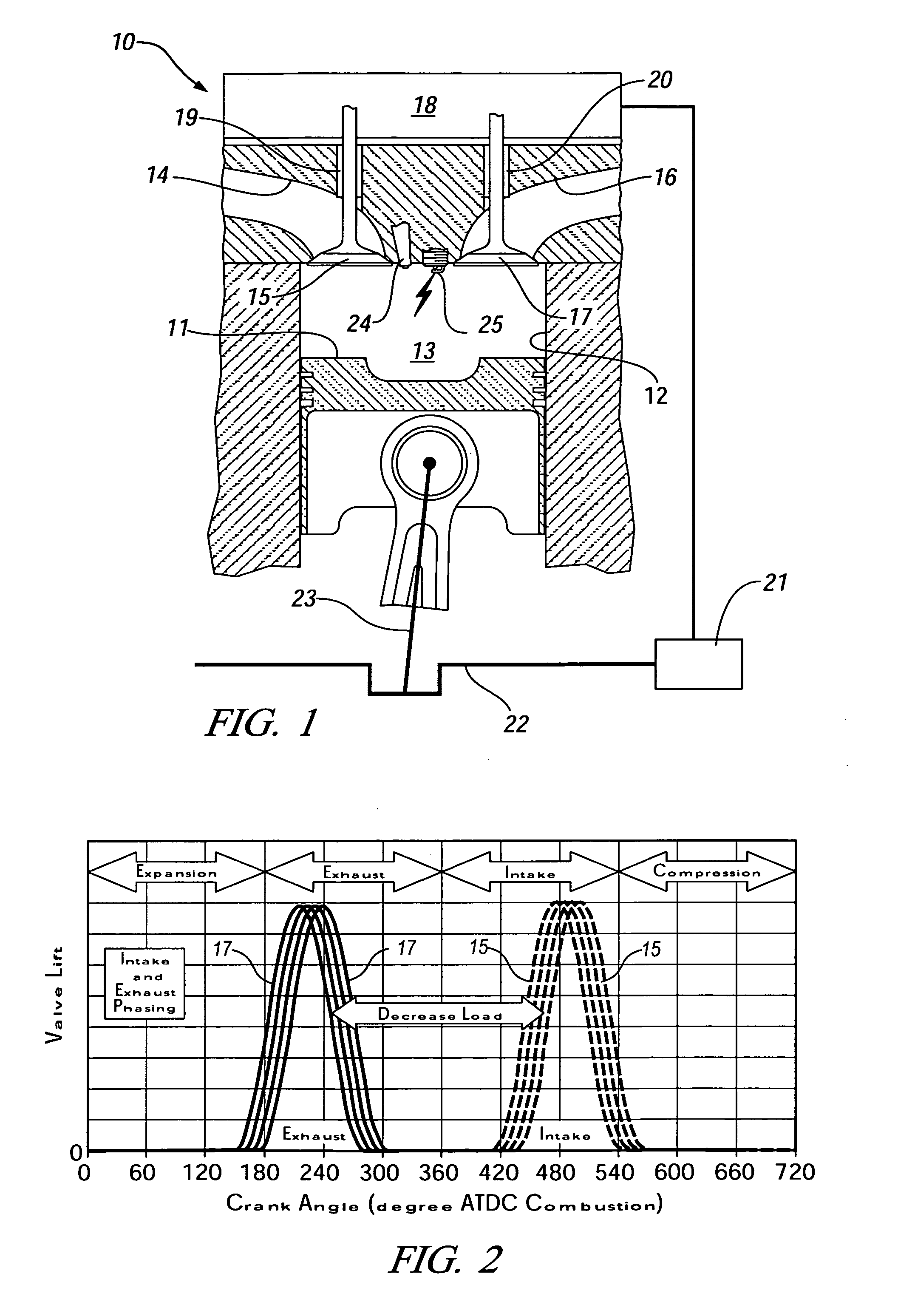

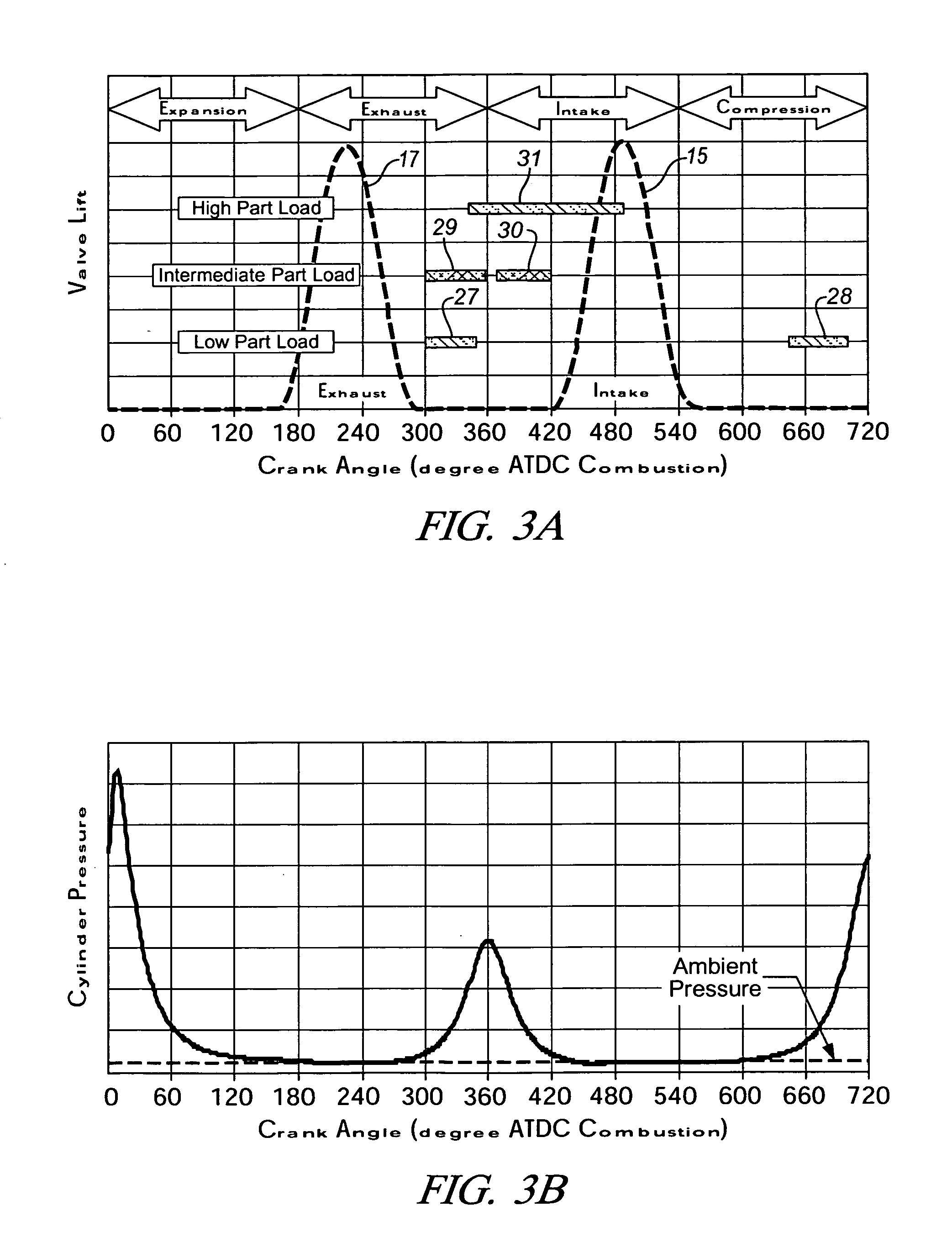

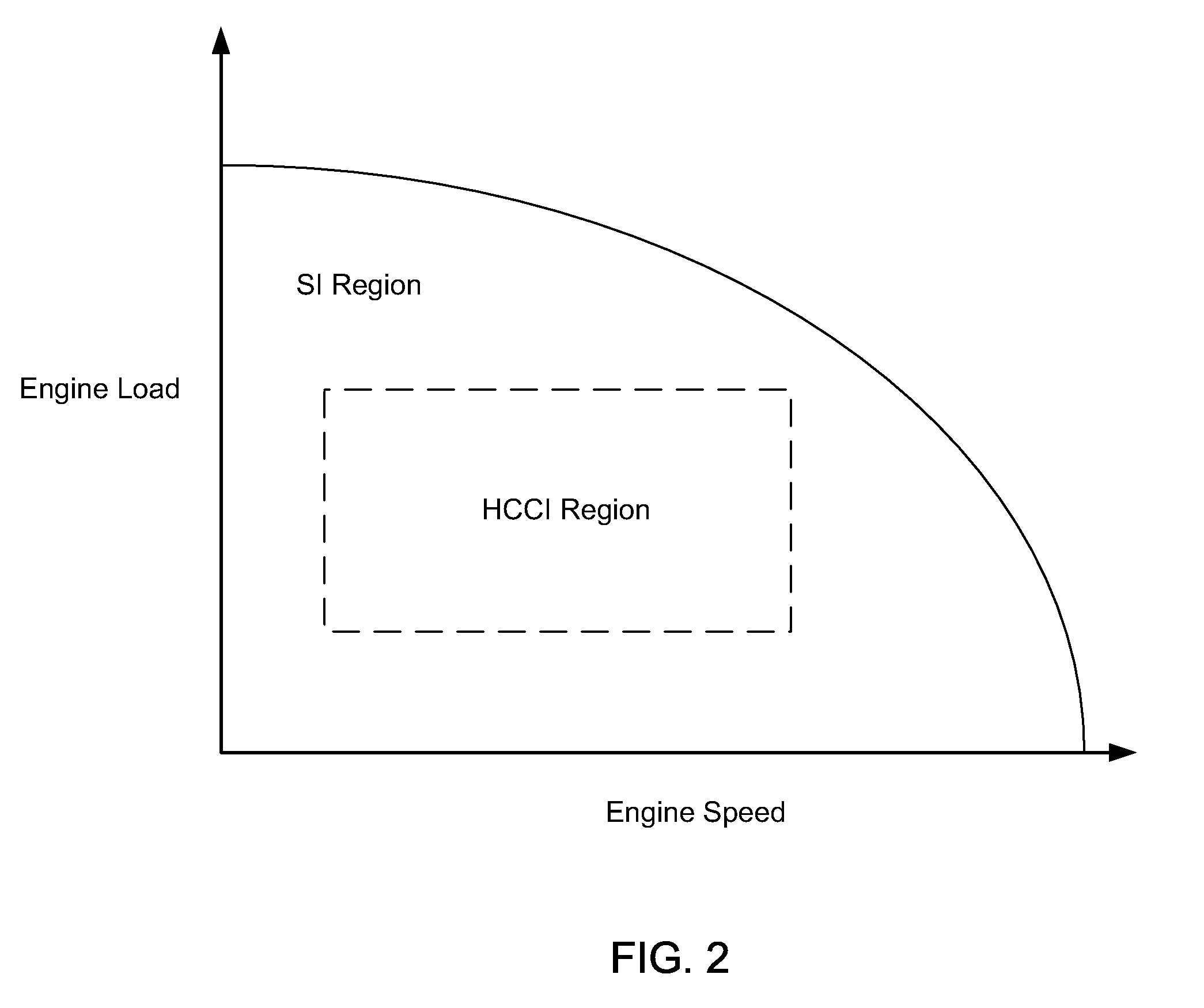

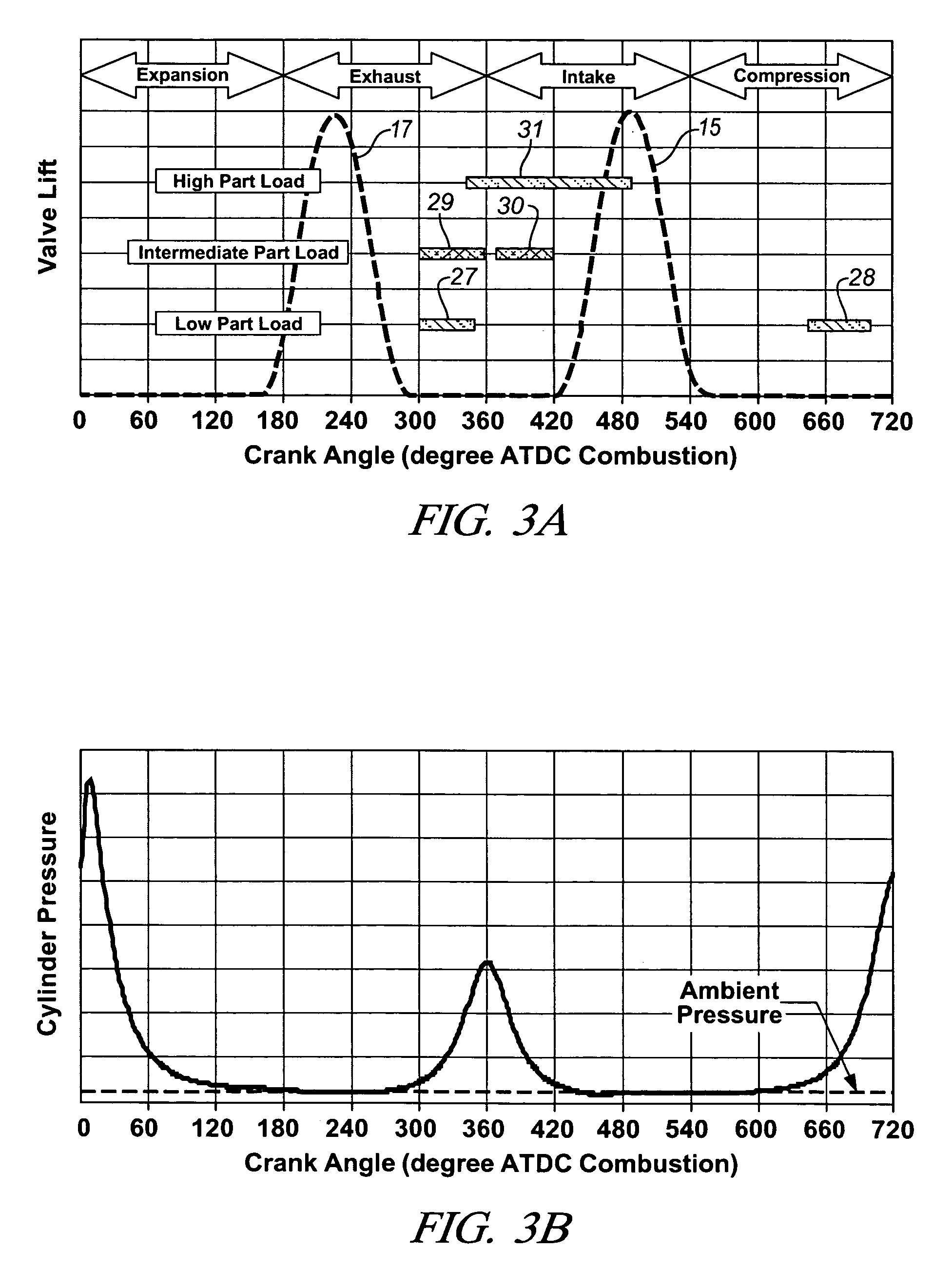

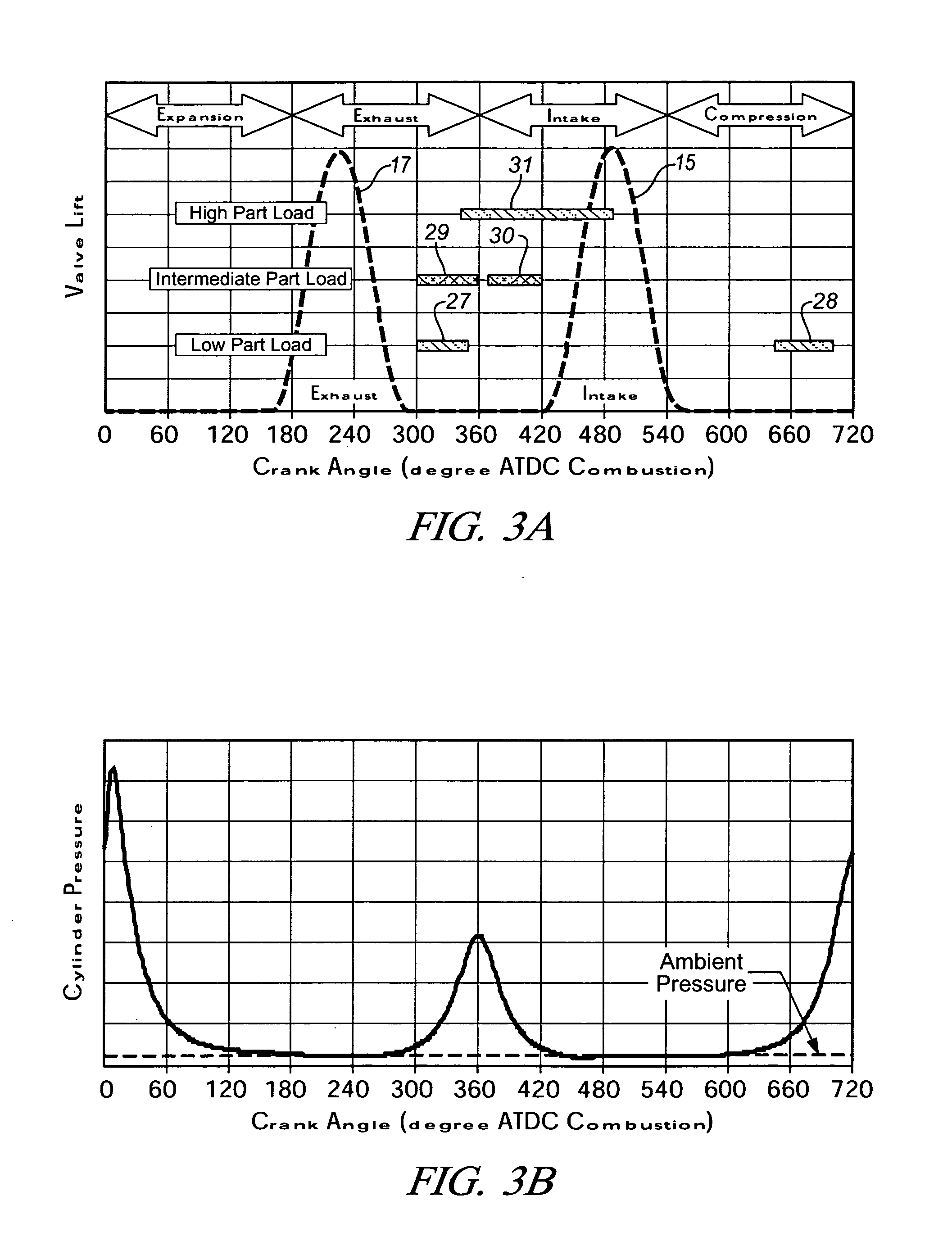

A method is provided for control of transition between combustion modes of a direct-injection engine operable in a homogeneous charge compression ignition (HCCI) mode at lower loads and a spark ignition flame propagation (SI) mode at higher loads. The engine includes a variable valve actuation system including two-step high and low lift valve actuation and separate cam phasing for both intake and exhaust valves. The method includes operating the engine at steady state, with fuel-air-exhaust gas mixtures at predetermined conditions, for each speed and load, and controlling the engine during mode changes between the HCCI mode and the SI mode by switching the exhaust and intake valves between low lift for HCCI operation and high lift for SI operation. High load may be an SI throttled mode with an intermediate unthrottled mode (SI / NTLC} in which transition between HCCI and SI / NTLC modes requires switching only the exhaust valve lift and transition between SI / NTLC and SI throttled modes requires switching only the intake valve lift, with predetermined phase adjustments in the valve timing phasing.

Owner:GM GLOBAL TECH OPERATIONS LLC

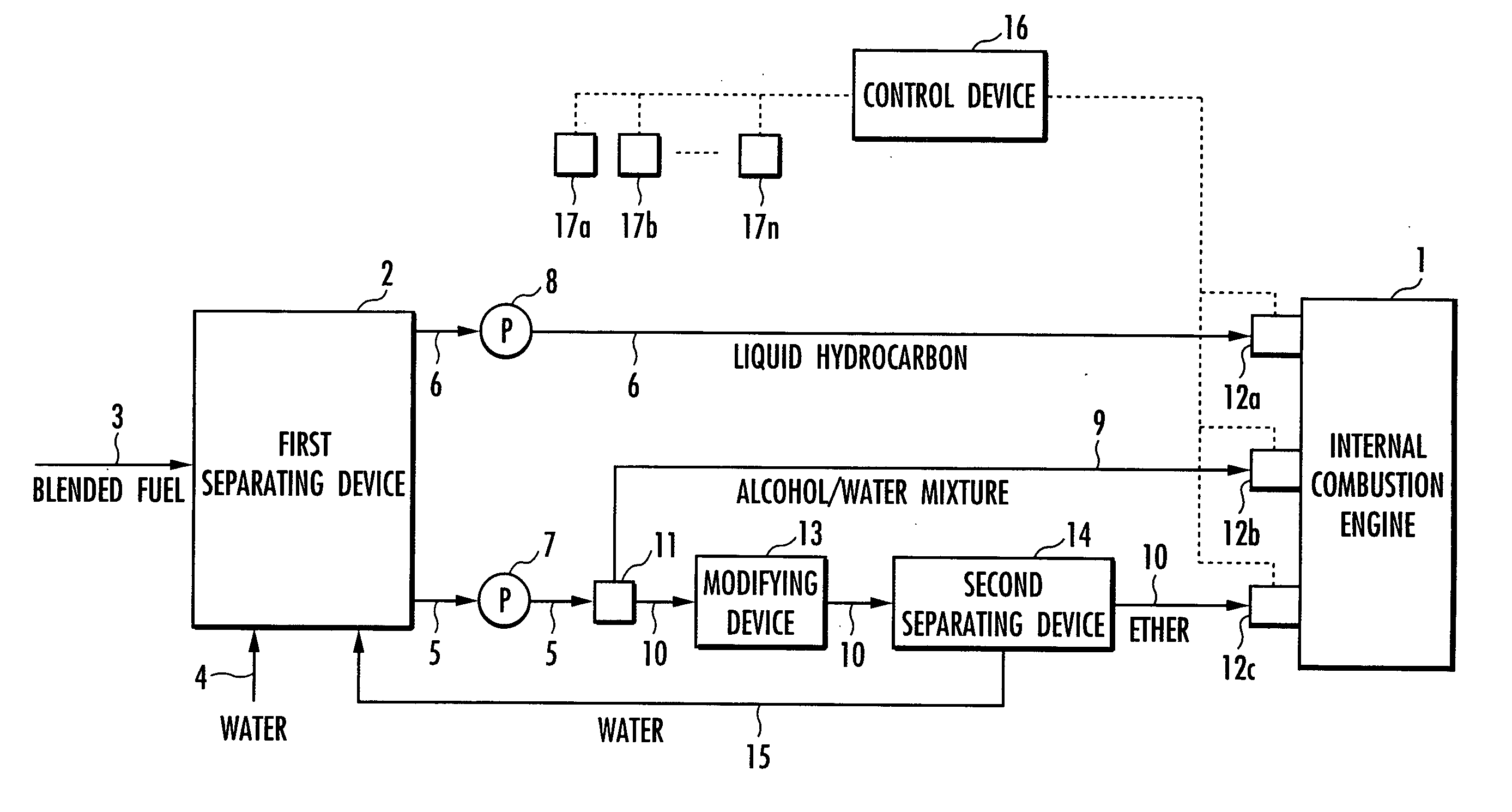

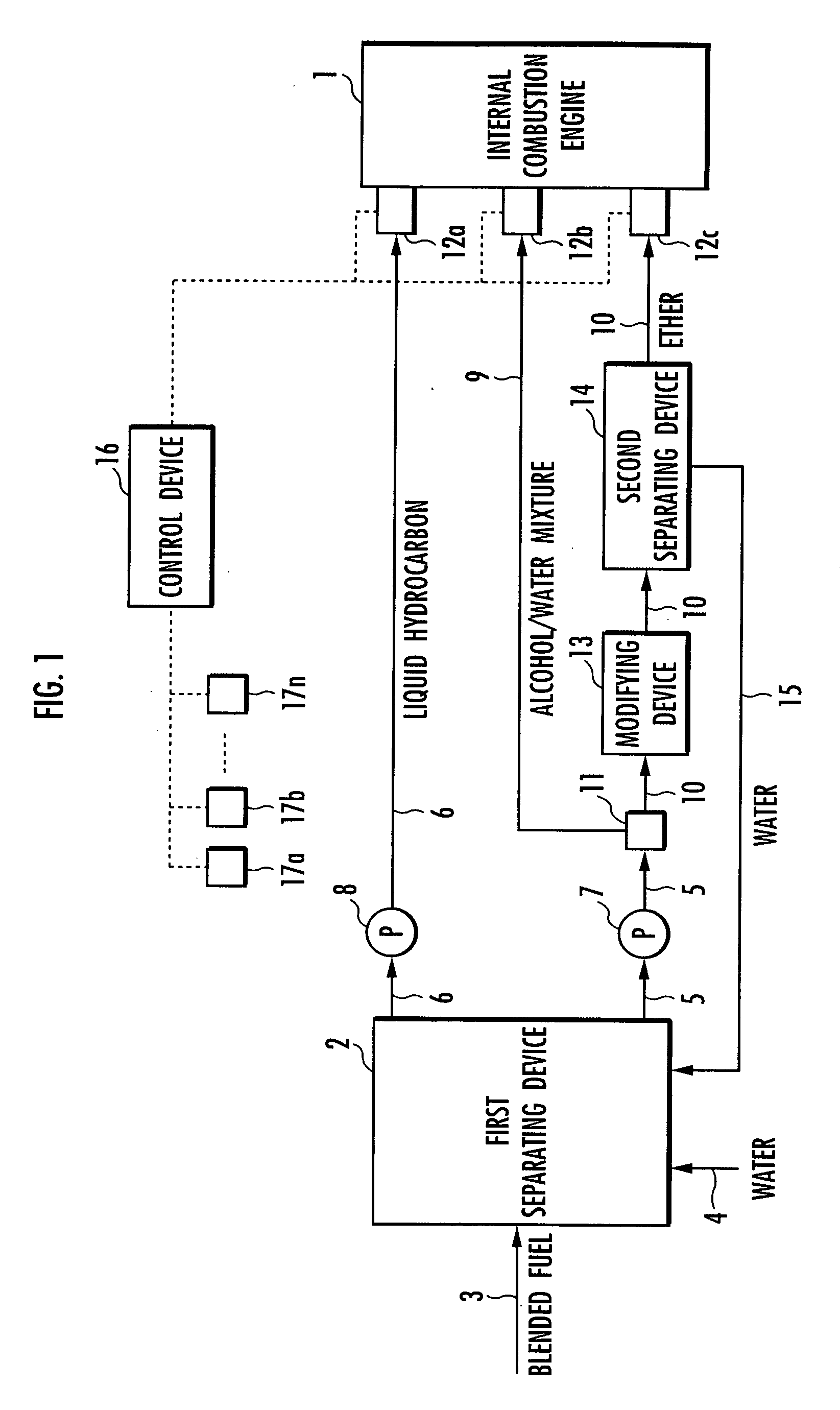

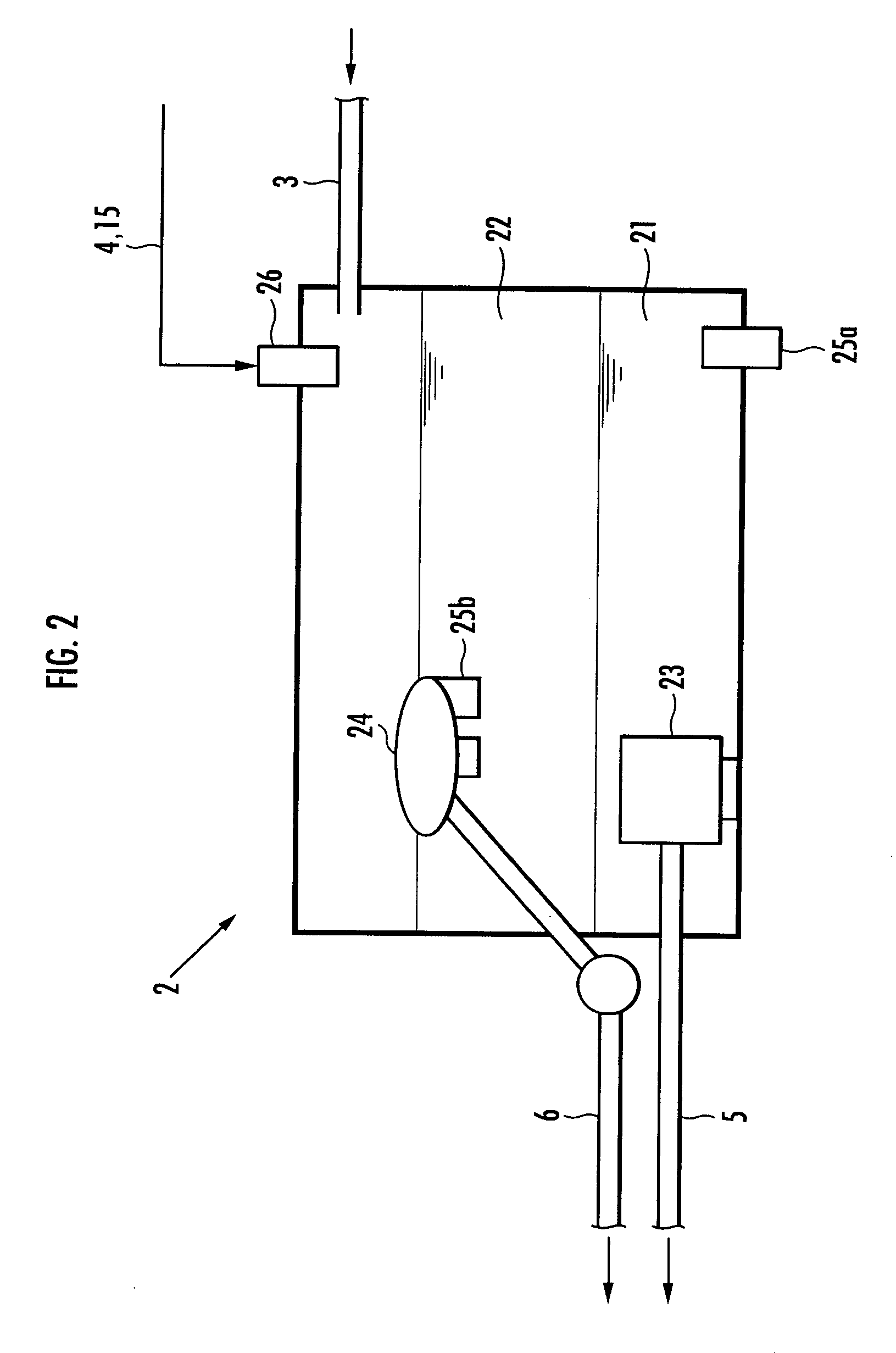

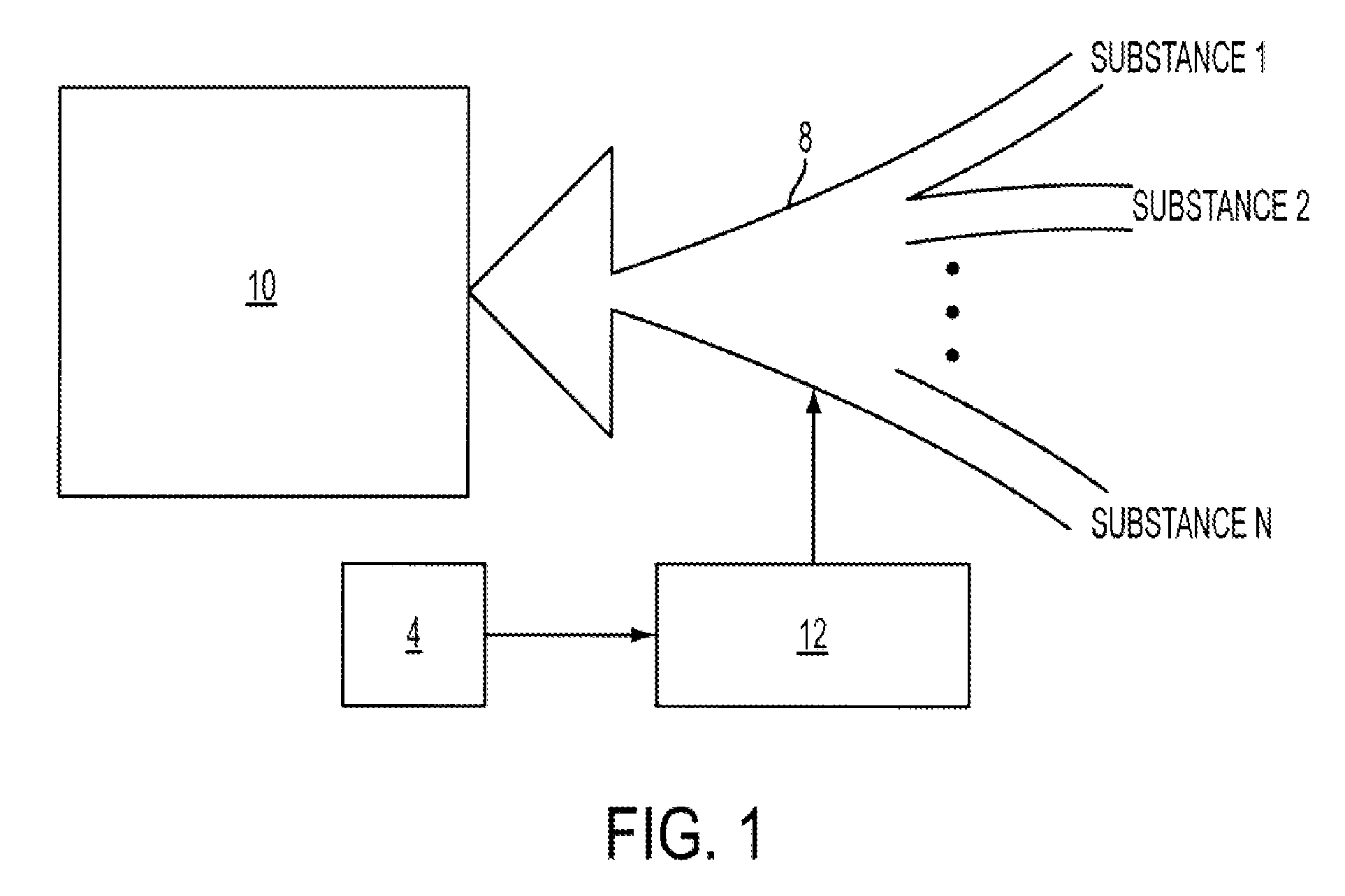

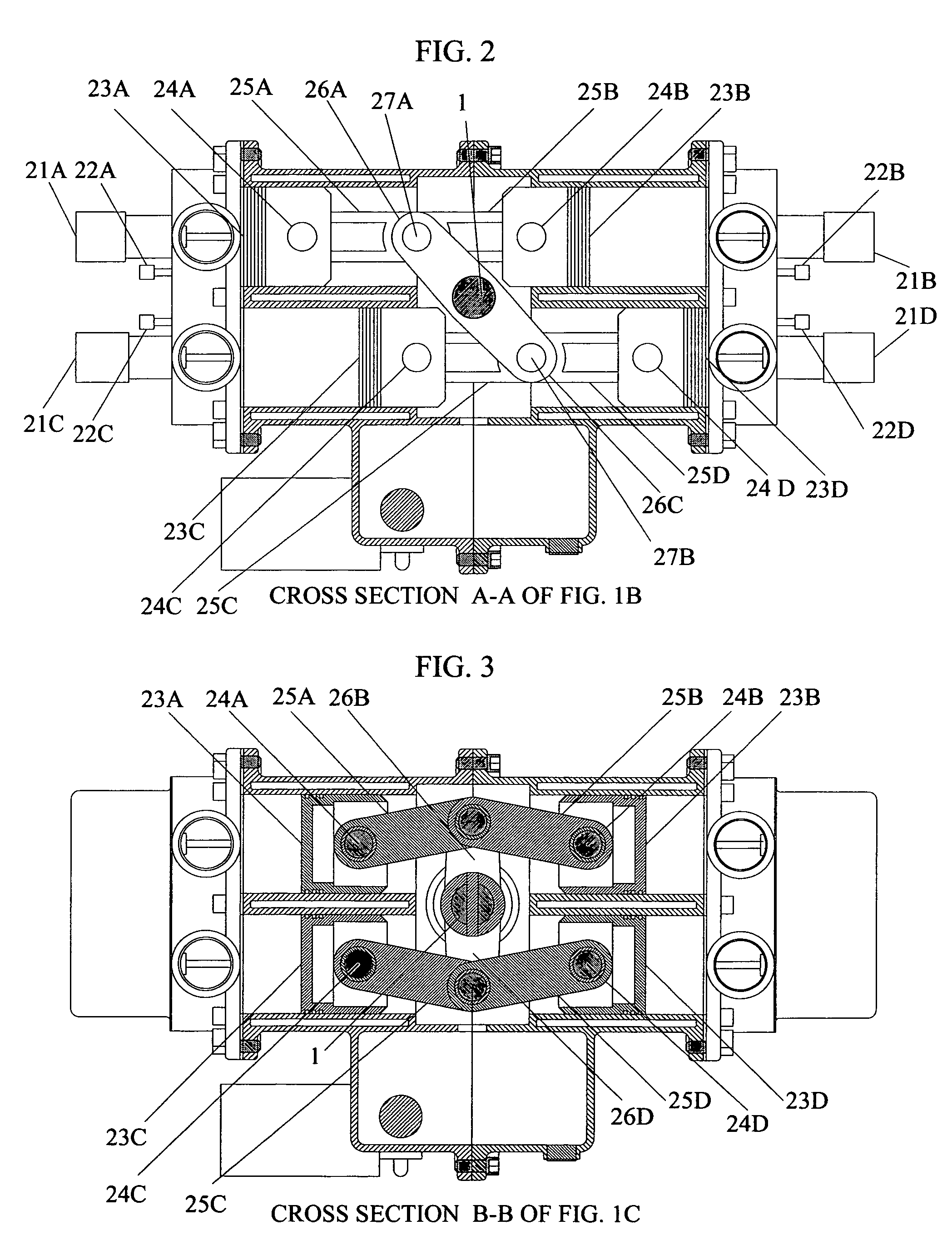

Internal combustion engine system

InactiveUS20070028861A1Easy to operateInternal combustion piston enginesNon-fuel substance addition to fuelHomogeneous charge compression ignitionAlcohol

The invention provides an internal combustion engine system that uses a blended fuel consisting of hydrocarbon and alcohol, and can efficiently operate relative to a wide range of required load. The internal combustion engine system includes: an internal combustion engine 1; a first separating means 2 for separating the blended fuel into an alcohol / water mixture 21 and liquid hydrocarbon 22; a reforming means 13 for reforming the alcohol / water mixture to an ether / water mixture; a second separating means 14 for separating the ether / water mixture into the ether and the water; and control means 16 that controls the ratios of the liquid hydrocarbon 22, the alcohol / water mixture 21, and the ether. The internal combustion engine 1 is a homogeneous charge compression ignition internal combustion engine. The internal combustion engine system further includes: a first injector 12a that supplies the liquid hydrocarbon 22; a second injector 12b that supplies the alcohol / water mixture 21; and a third injector 12c that supplies the ether. The control means 16 increases the alcohol / water mixture 21 with increasing required load, and increases the ether with decreasing required load.

Owner:HONDA MOTOR CO LTD

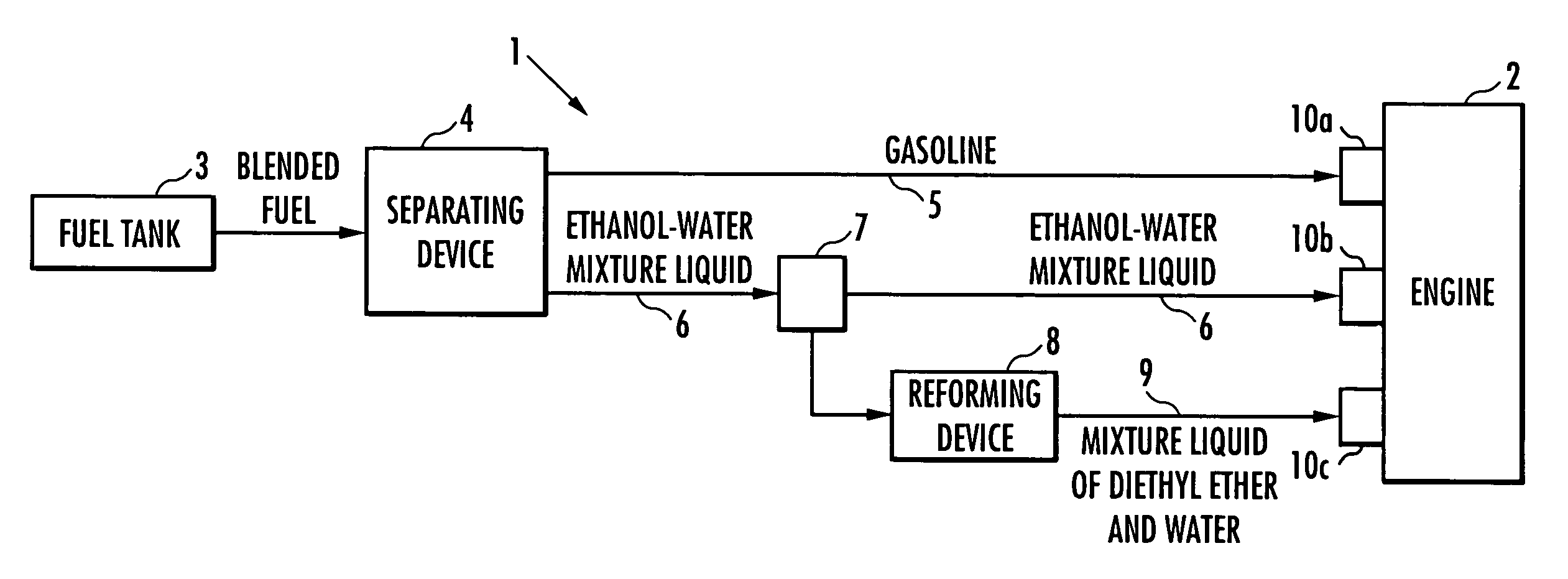

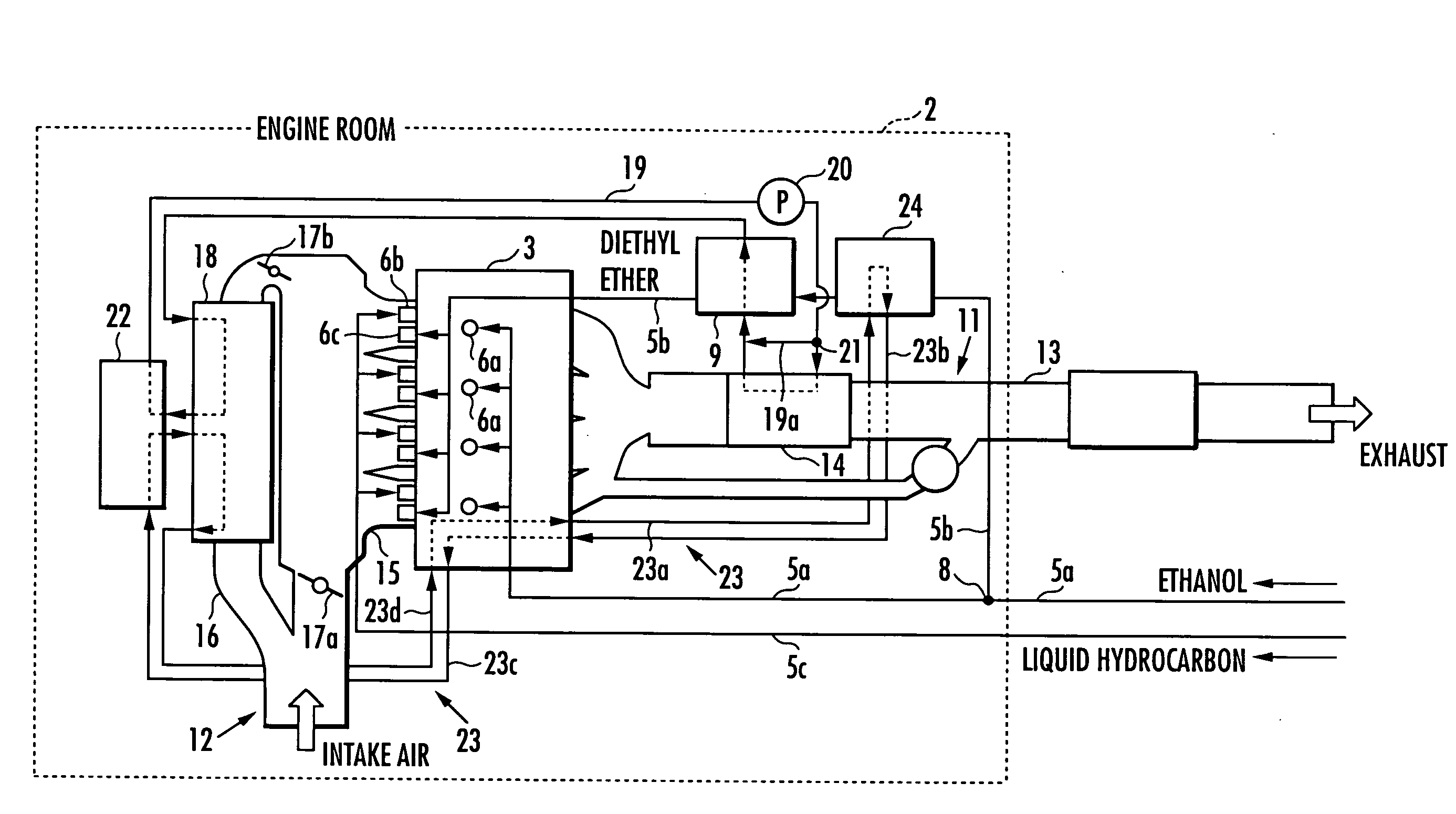

Internal combustion engine system

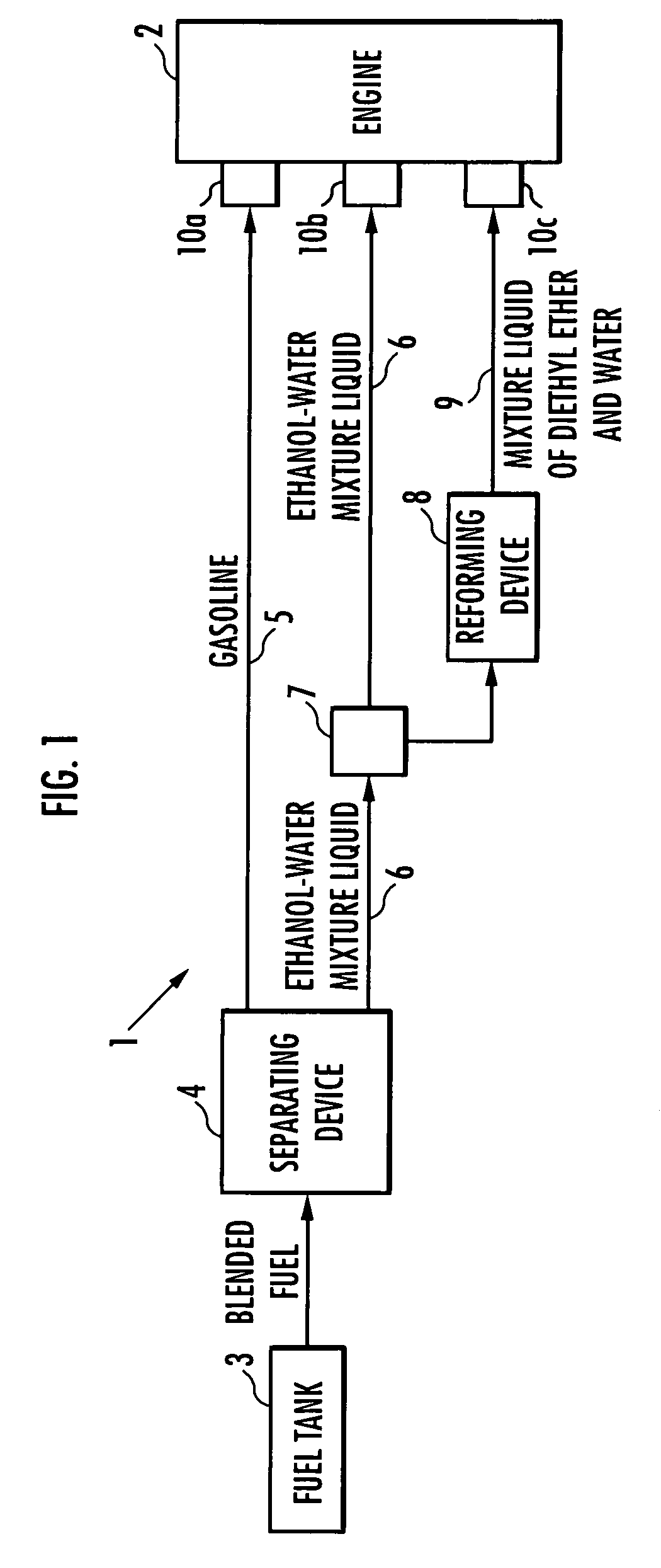

InactiveUS20070221163A1Improve efficiencyEmission reductionNon-fuel substance addition to fuelInternal combustion piston enginesHomogeneous charge compression ignitionFuel tank

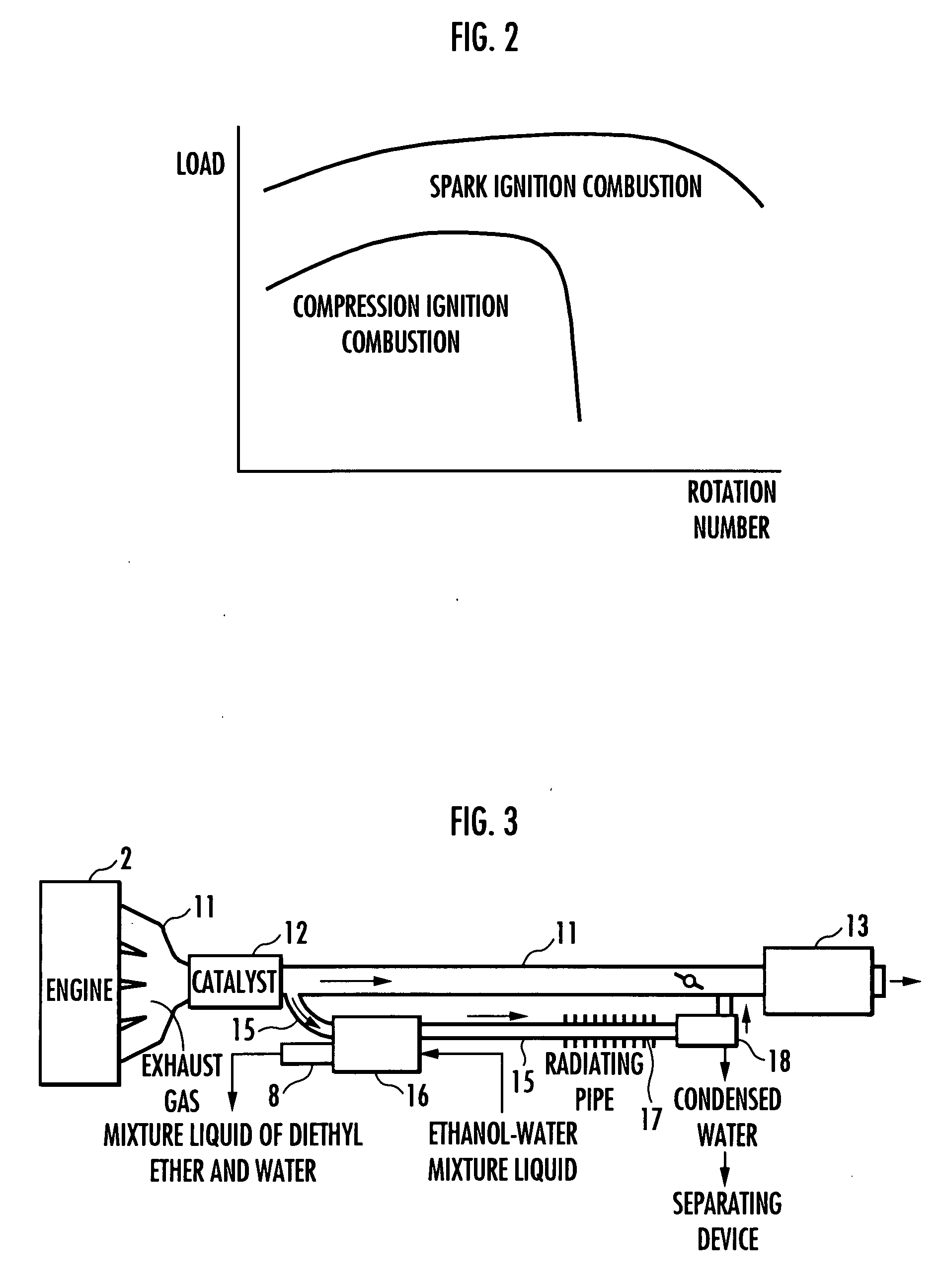

The present invention provides an internal combustion engine system which uses a blended fuel of gasoline and ethanol, operates with high efficiency, and can inhibit nitrogen oxide and the like from being discharged. The internal combustion engine system comprises: a fuel tank 3 that accommodates a blended fuel having an octane number of 80 to 100, which has been prepared by blending gasoline having the octane number of 30 to 85 and ethanol into a weight ratio between 9:1 and 6:4; separating means 4 for adding water to the blended fuel to separate the blended fuel into the gasoline and an ethanol-water mixture liquid; reforming means 8 for reforming one part of the ethanol-water mixture liquid to produce a mixture liquid of diethyl ether and water; and fuel injectors 10a, 10b and 10c which independently inject each of the gasoline, the ethanol-water mixture liquid and the mixture liquid of diethyl ether and water. The internal combustion engine system conducts spark ignition combustion when a load is high, and conducts homogeneous charge compression ignition combustion when the load is low.

Owner:HONDA MOTOR CO LTD

Homogeneous charge compression ignition internal combustion engine

InactiveUS6260520B1Emission reductionShorten the construction periodElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionCylinder head

A HCCI engine includes a cylinder block with a cylinder head closing off a cylinder, a power piston slidably contained within the cylinder, and a boost piston for initiating timed combustion of fuel within a combustion chamber. The boost piston is housed within a wall of the combustion chamber such that when the boost piston moves from a base position to an extended position, the heat increase within the combustion chamber is sufficient to cause fuel within the combustion chamber to ignite.

Owner:FORD GLOBAL TECH LLC

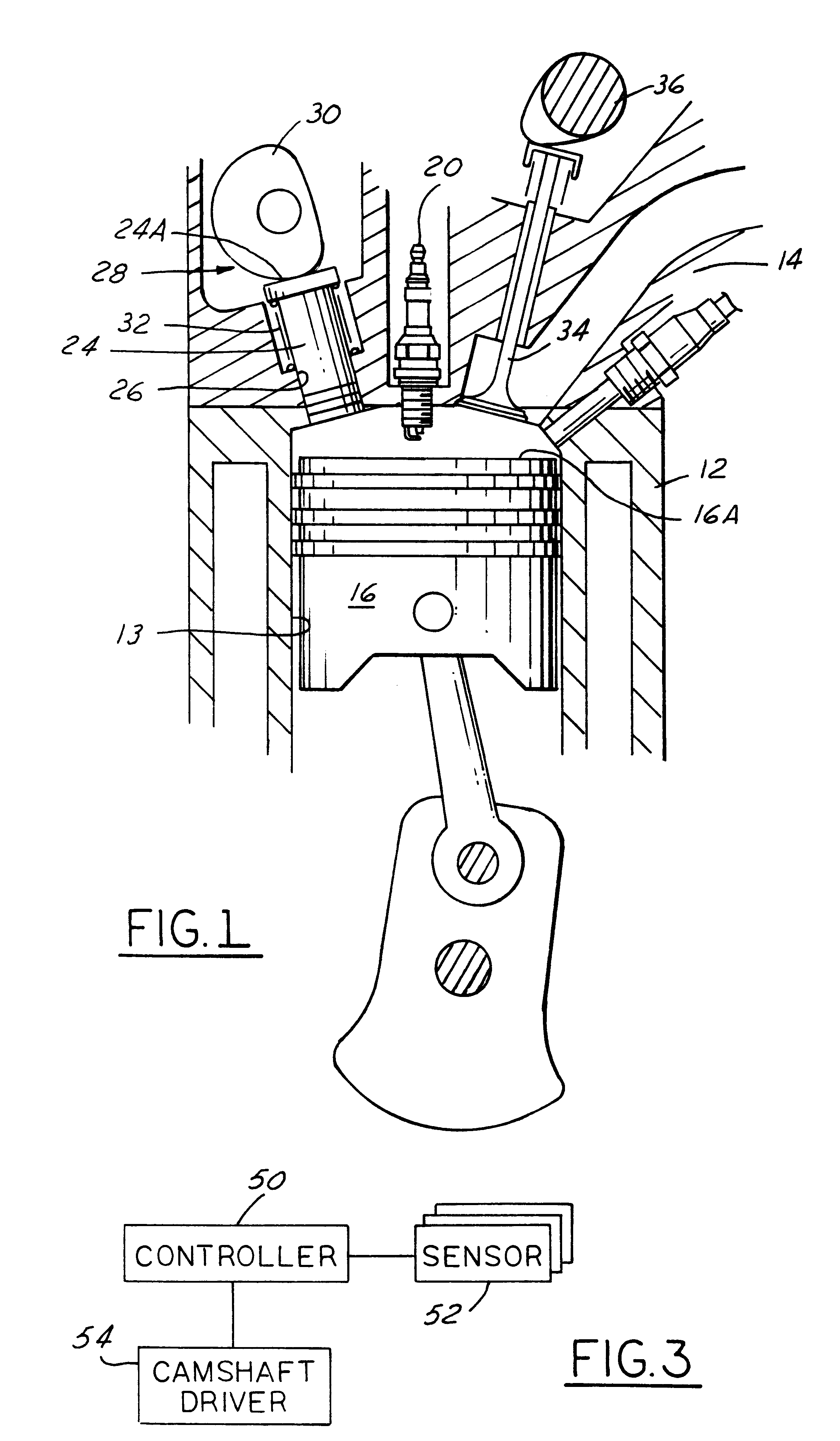

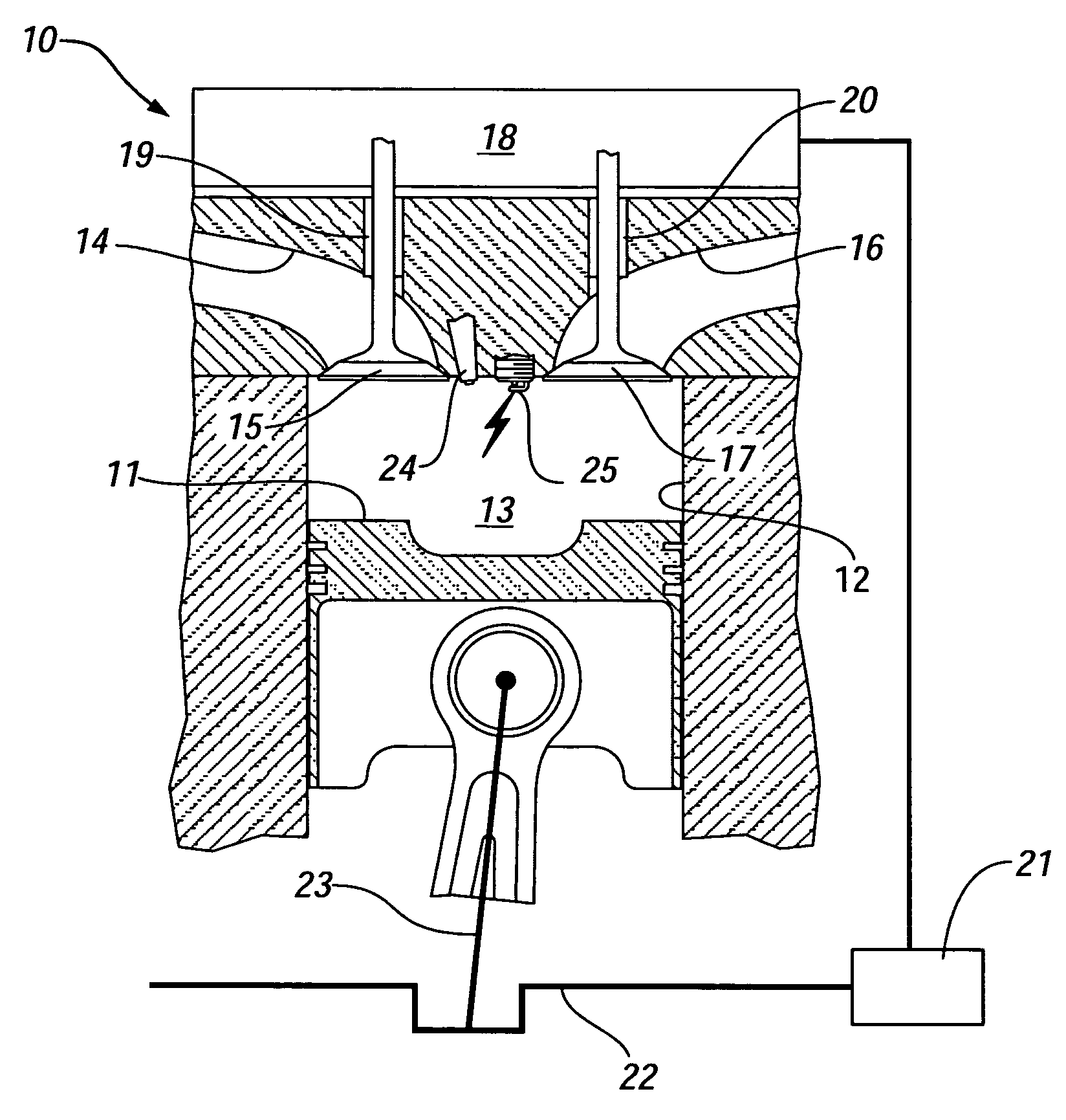

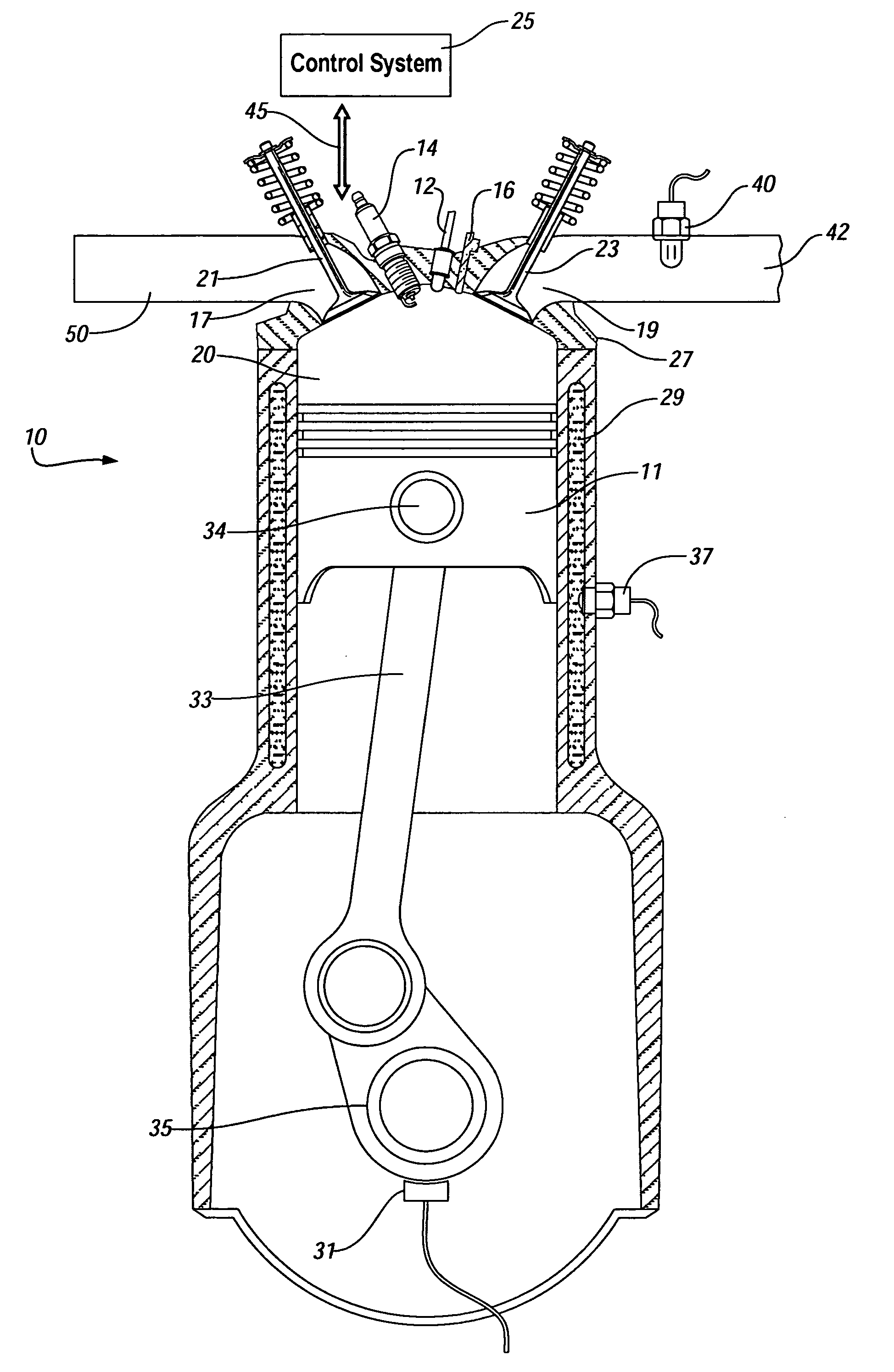

Method and apparatus for optimized combustion in an internal combustion engine utilizing homogeneous charge compression ignition and variable valve actuation

InactiveUS20060144356A1Electrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

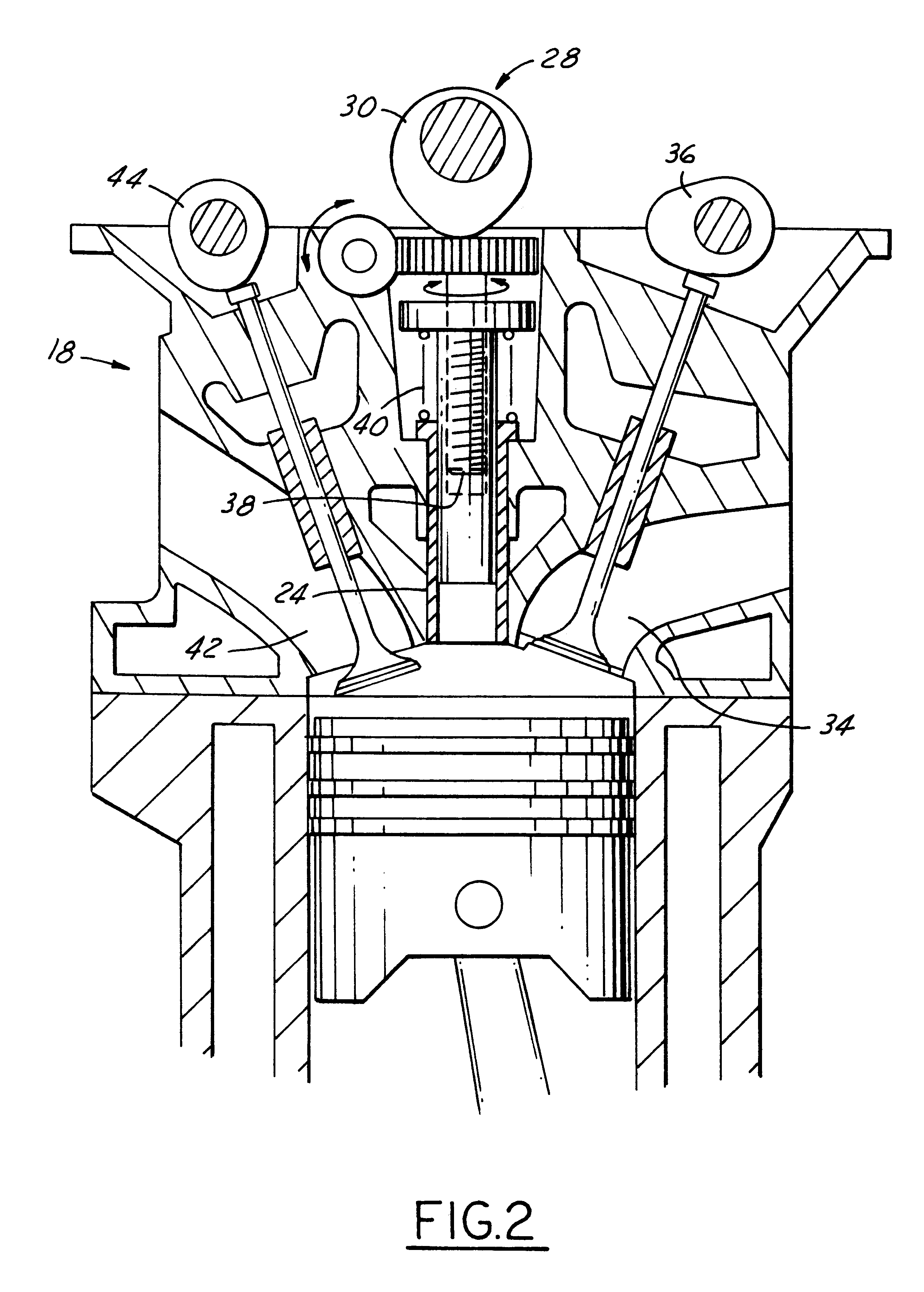

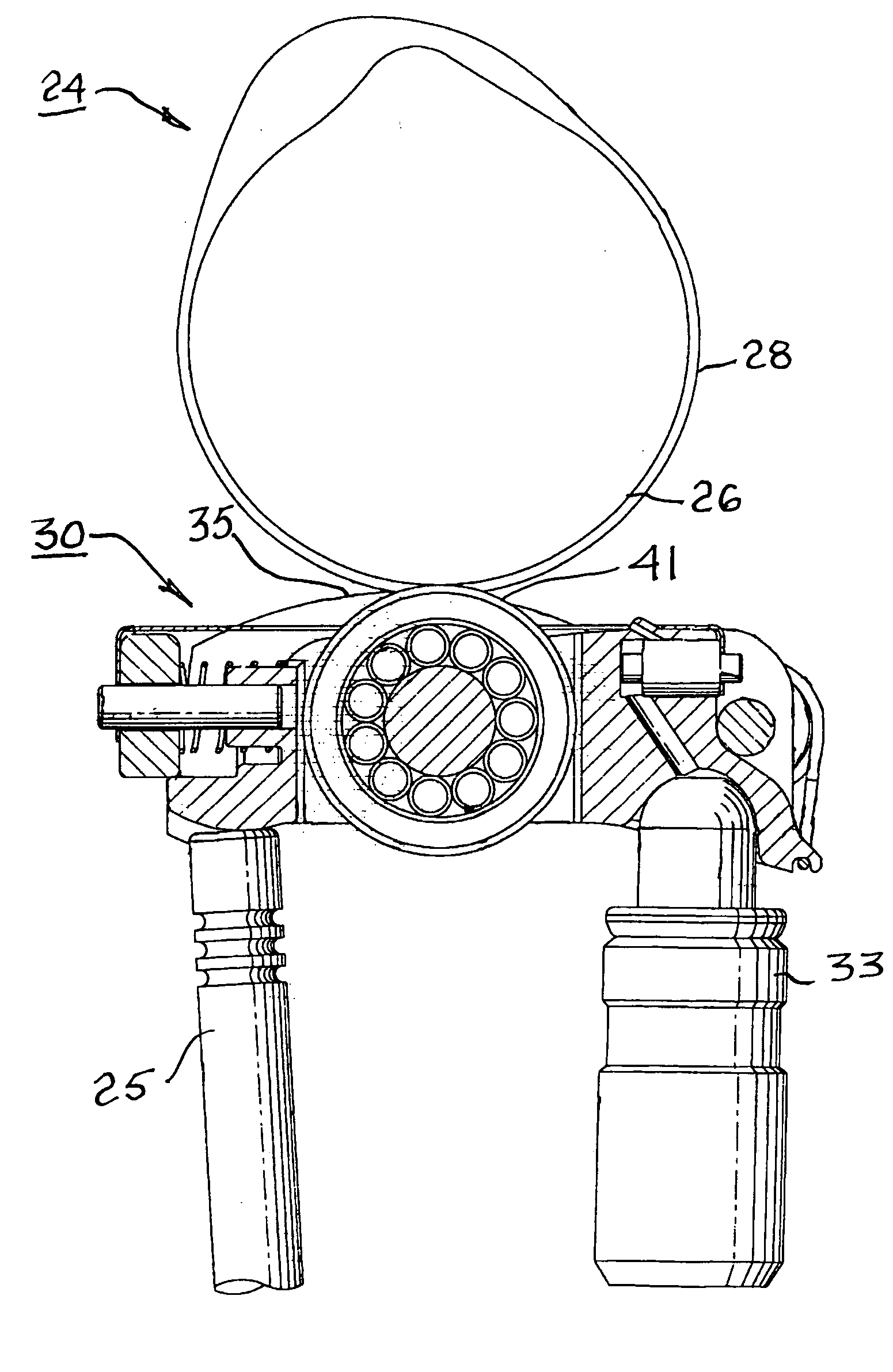

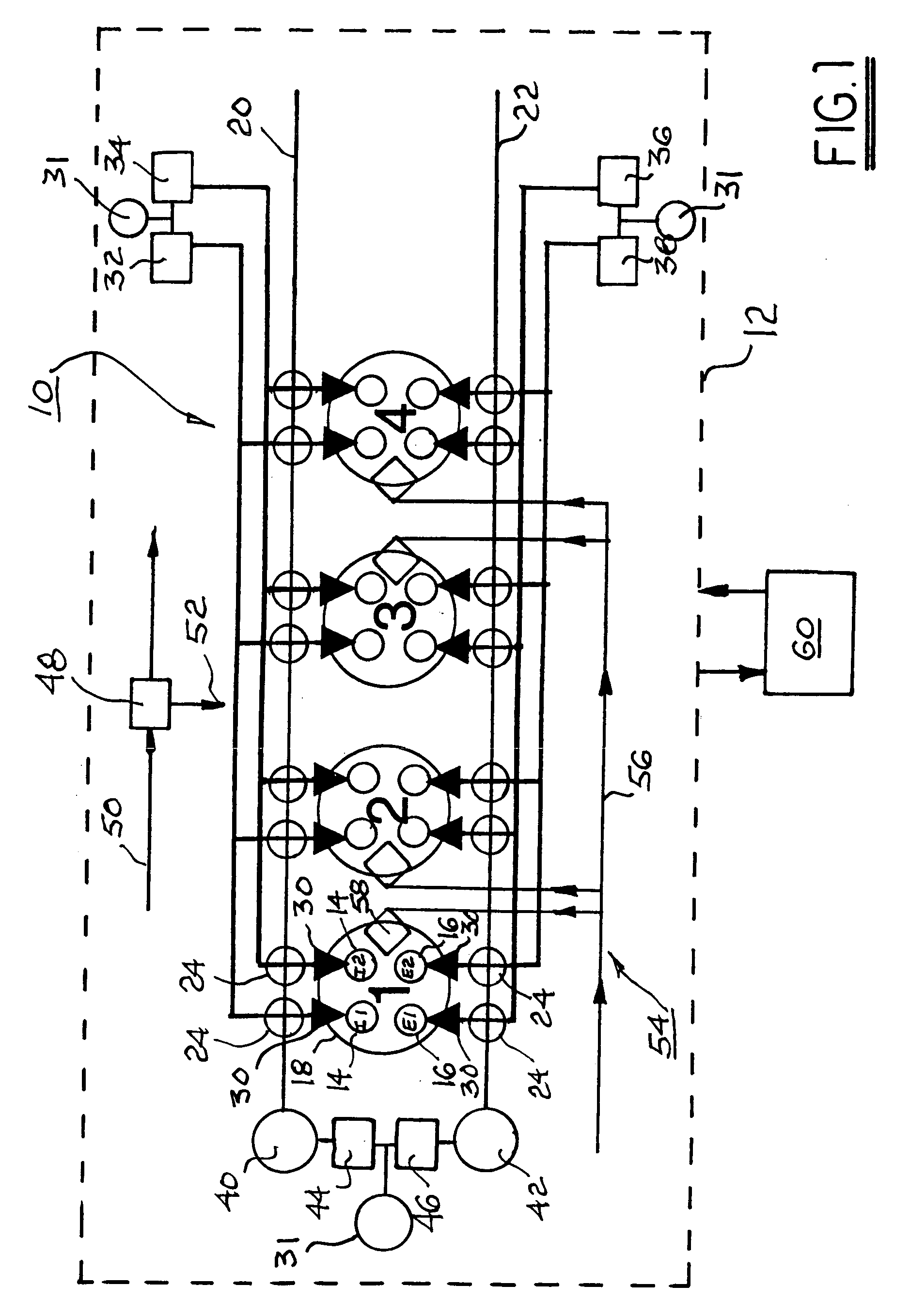

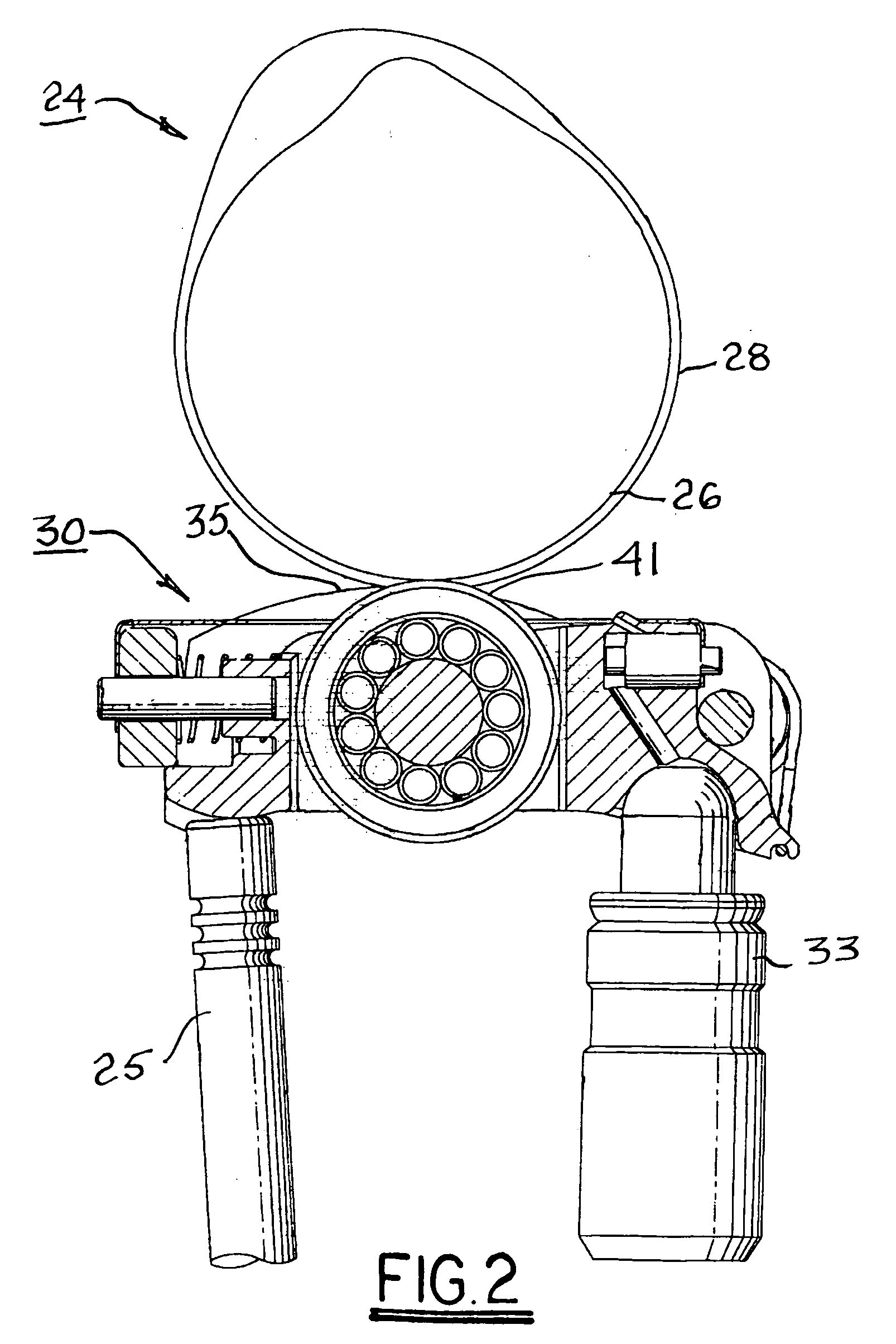

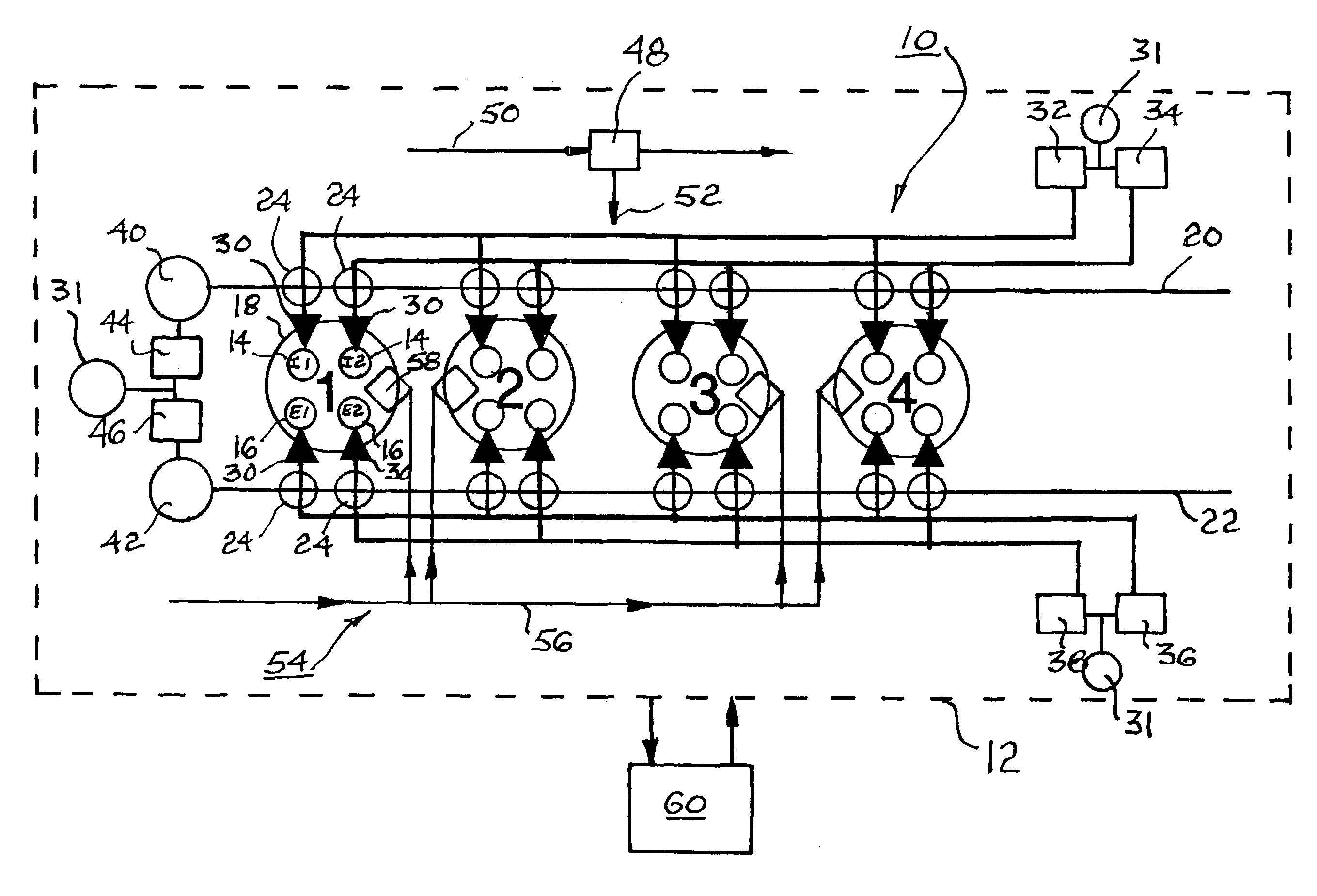

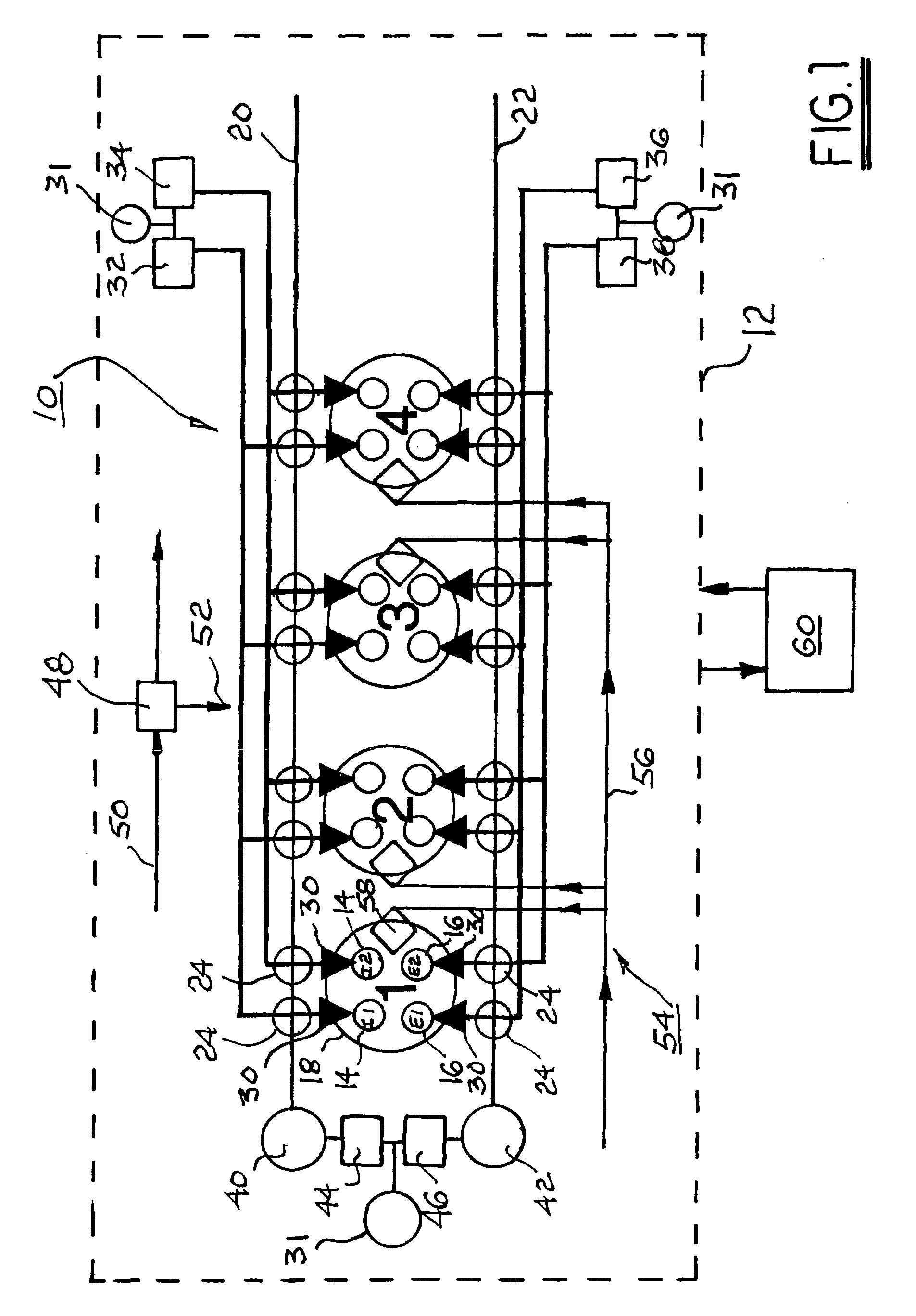

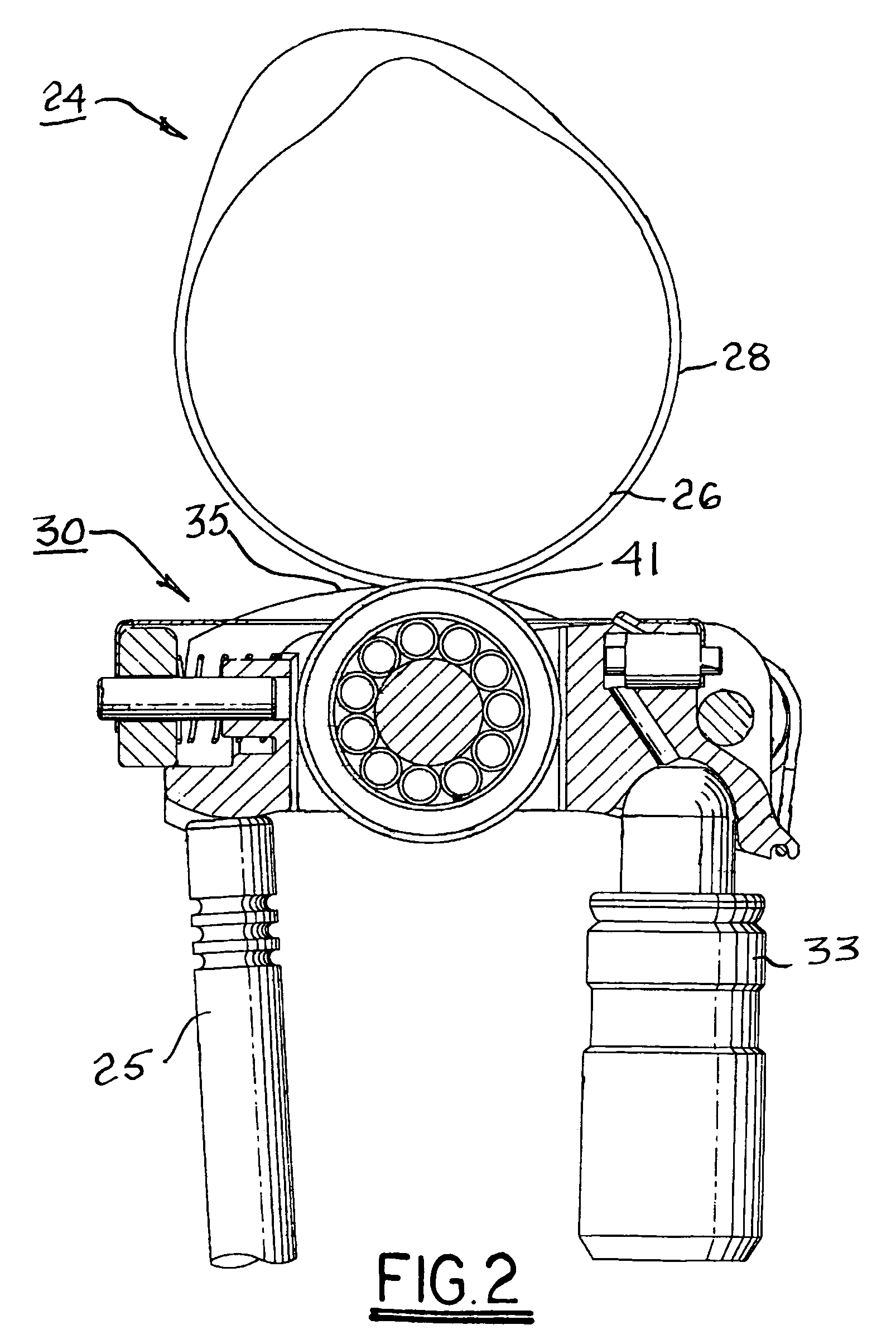

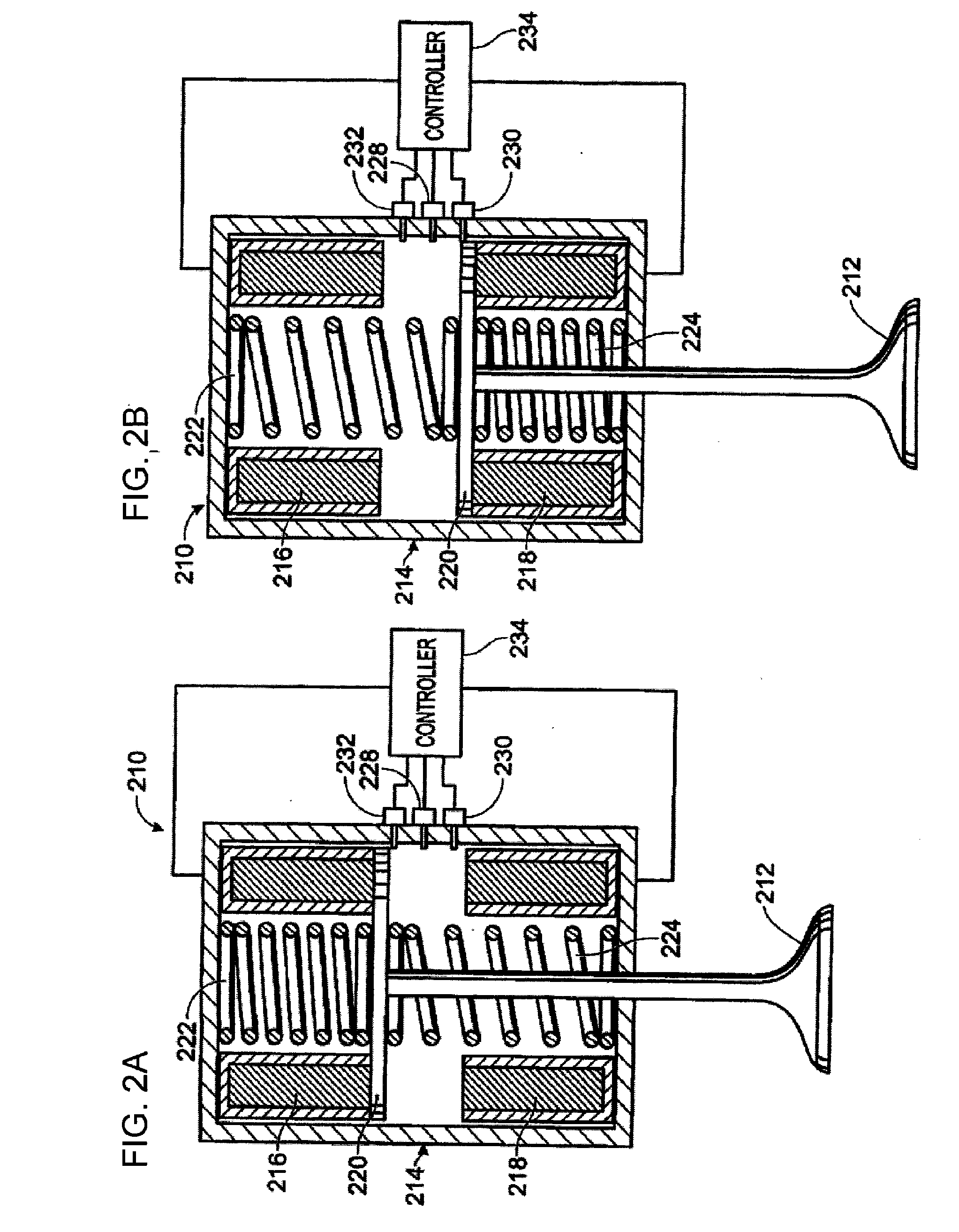

A valvetrain system mechanization for an internal combustion engine using compression ignition, including homogeneous charge compression ignition, having two intake and one or more exhaust valves per cylinder. The valves are operated by dual overhead camshafts having two-step cams. The intake and exhaust camshafts are provided with phasers for varying the opening and closing of the intake and exhaust valves. A two-step roller finger follower is disposed for each valve between the cam lobes and the valve stem. The two sets of intake and exhaust valves are controlled by separate oil control valves. Swirl of gases may be introduced by mismatching the lifts of the valves. The valve opening times, closing times, lifts, fuel injection, compression ratio, and exhaust gas recirculation may be varied to optimize combustion conditions for a range of engine operating modes.

Owner:DELPHI TECH INC

Method of controlling combustion in a homogeneous charge compression ignition engine

InactiveUS6953024B2Improved combustion controlNeed for goodElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionCombustion

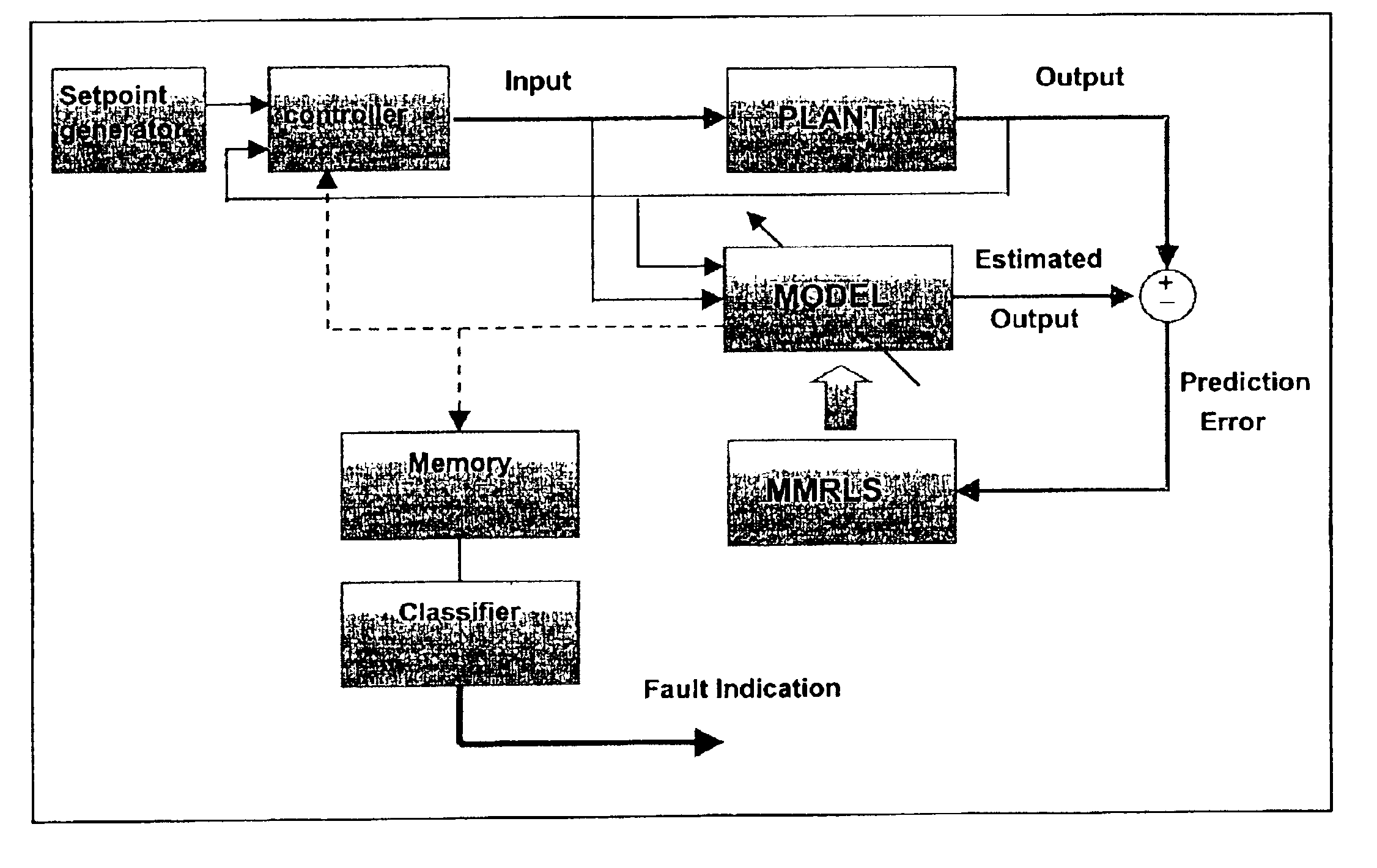

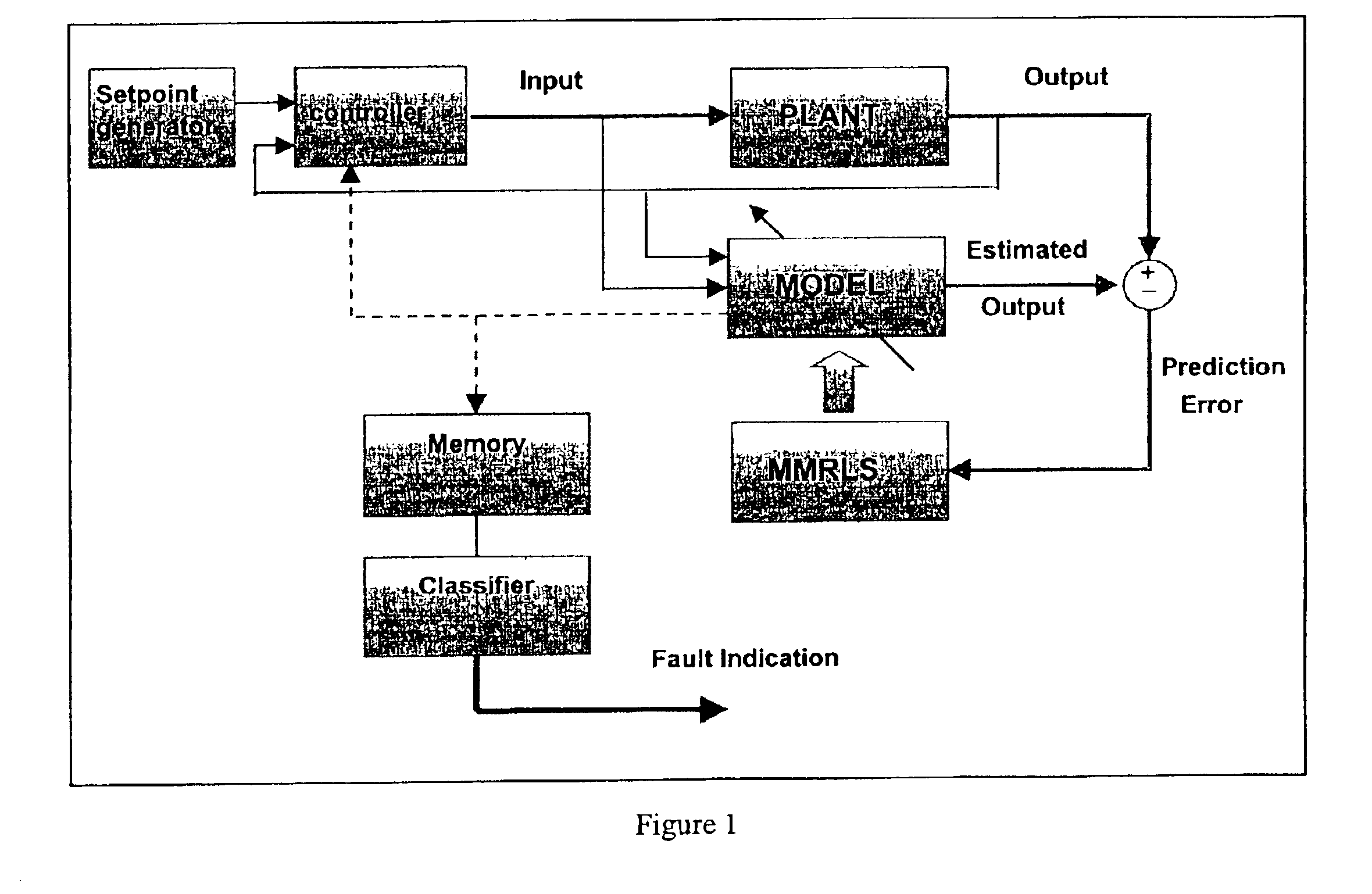

A method of controlling combustion in an homogenous charge compression ignition engine through indirect mechanisms. The method utilizes a predictive model so that combustion can be controlled over a wide range of operating conditions while maintaining optimum operation with respect to efficiency and emissions. The methods include an adaptive aspect, which allows the predictive model to be updated if deemed necessary. Furthermore, the methods include a model with a plurality of control modes. A control mode can be chosen to optimize the engine for one of a plurality of output characteristics, including response time, efficiency, or emissions characteristics.

Owner:TIAX LLC

Vehicle engine system having predictive control function

ActiveUS7274986B1Delay transitionReduce transportationAnalogue computers for vehiclesElectrical controlHomogeneous charge compression ignitionControl system

An engine system for a vehicle, comprising at least one cylinder configured to vary operation between a spark ignition mode and a homogeneous charge compression ignition mode; a navigation system configured to receive navigation information and / or one or more human / machine interface (HMI) sensors; a control system for varying operation of the engine between the spark ignition mode and the homogeneous charge compression ignition mode responsive at least to one of the navigation information and HMI sensor information, where the information is used by the control system to affect transitions into the homogeneous charge compression ignition mode differently than transitions out of homogeneous charge compression ignition mode is provided.

Owner:FORD GLOBAL TECH LLC

Multiple combustion mode engine using direct alcohol injection

ActiveUS7461628B2Improve efficiencyReduce the production of nitrogen oxidesAnalogue computers for vehiclesElectrical controlHomogeneous charge compression ignitionAlcohol

A method of operating an engine, comprising of performing homogeneous charge compression ignition combustion during a first operating condition, and performing spark ignition combustion during a second operating condition, where an amount of directly injected alcohol in at least one of said homogeneous charge compression ignition combustion and said spark ignition combustion is varied in response to at least an operating parameter.

Owner:FORD GLOBAL TECH LLC +1

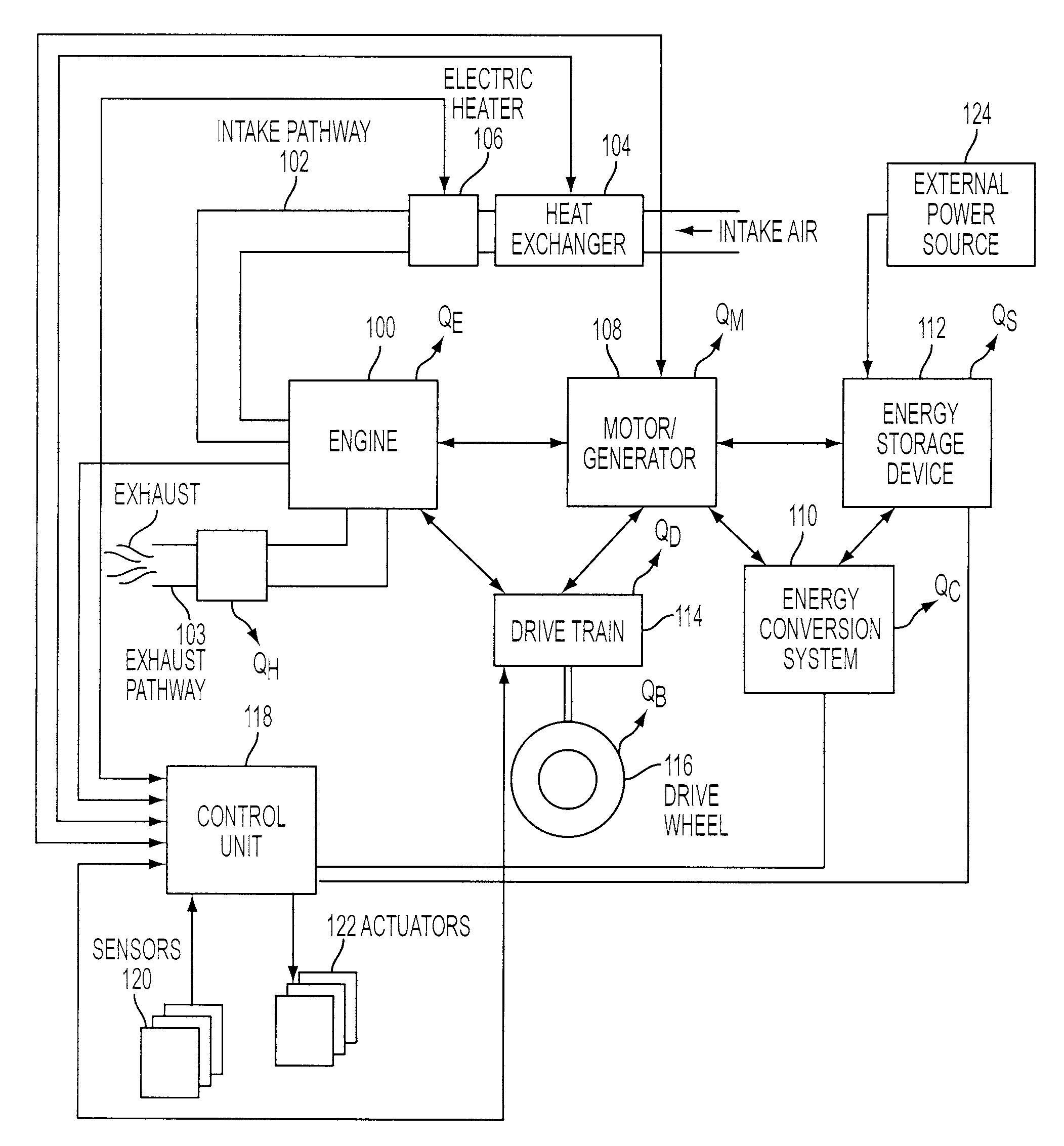

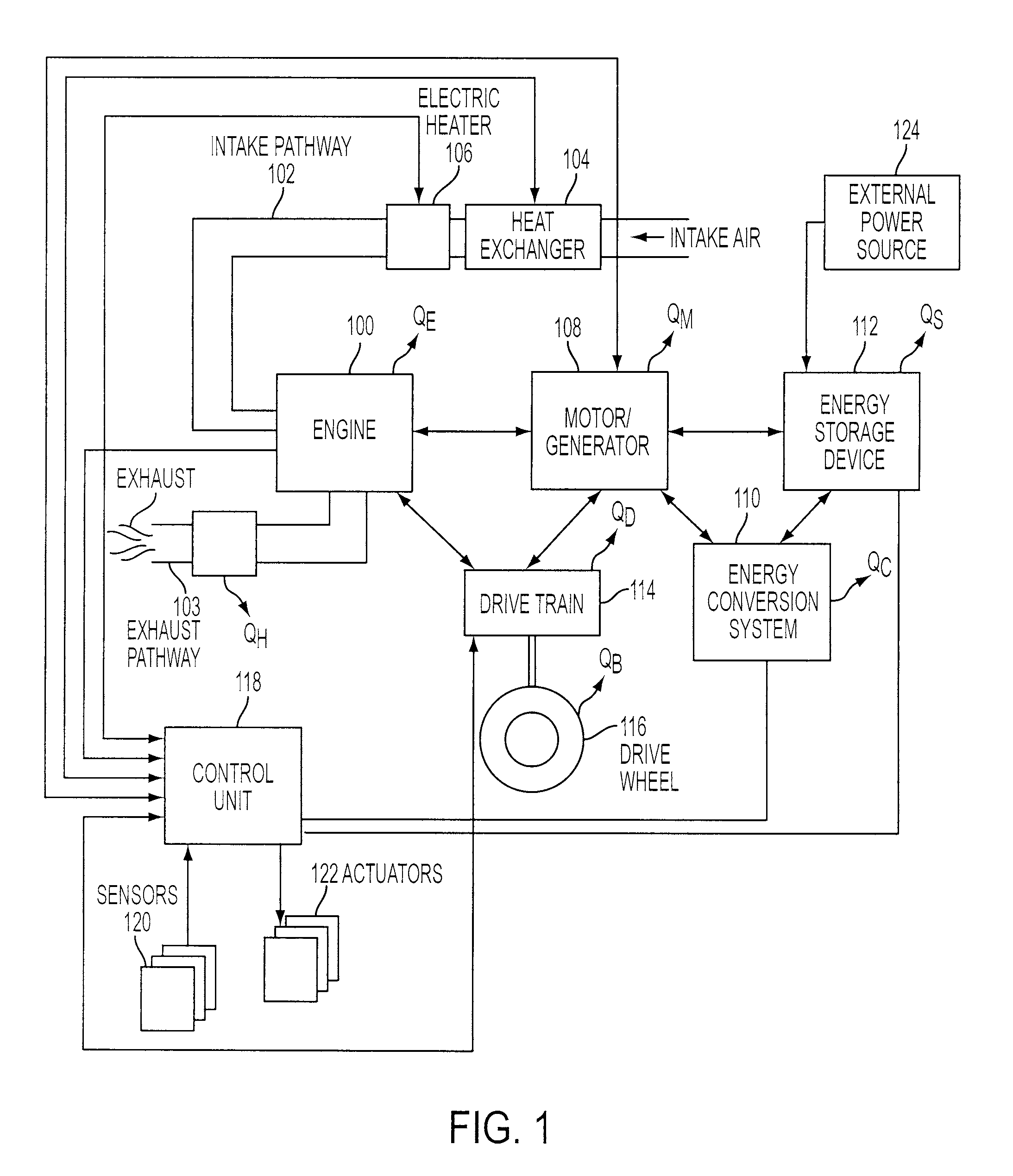

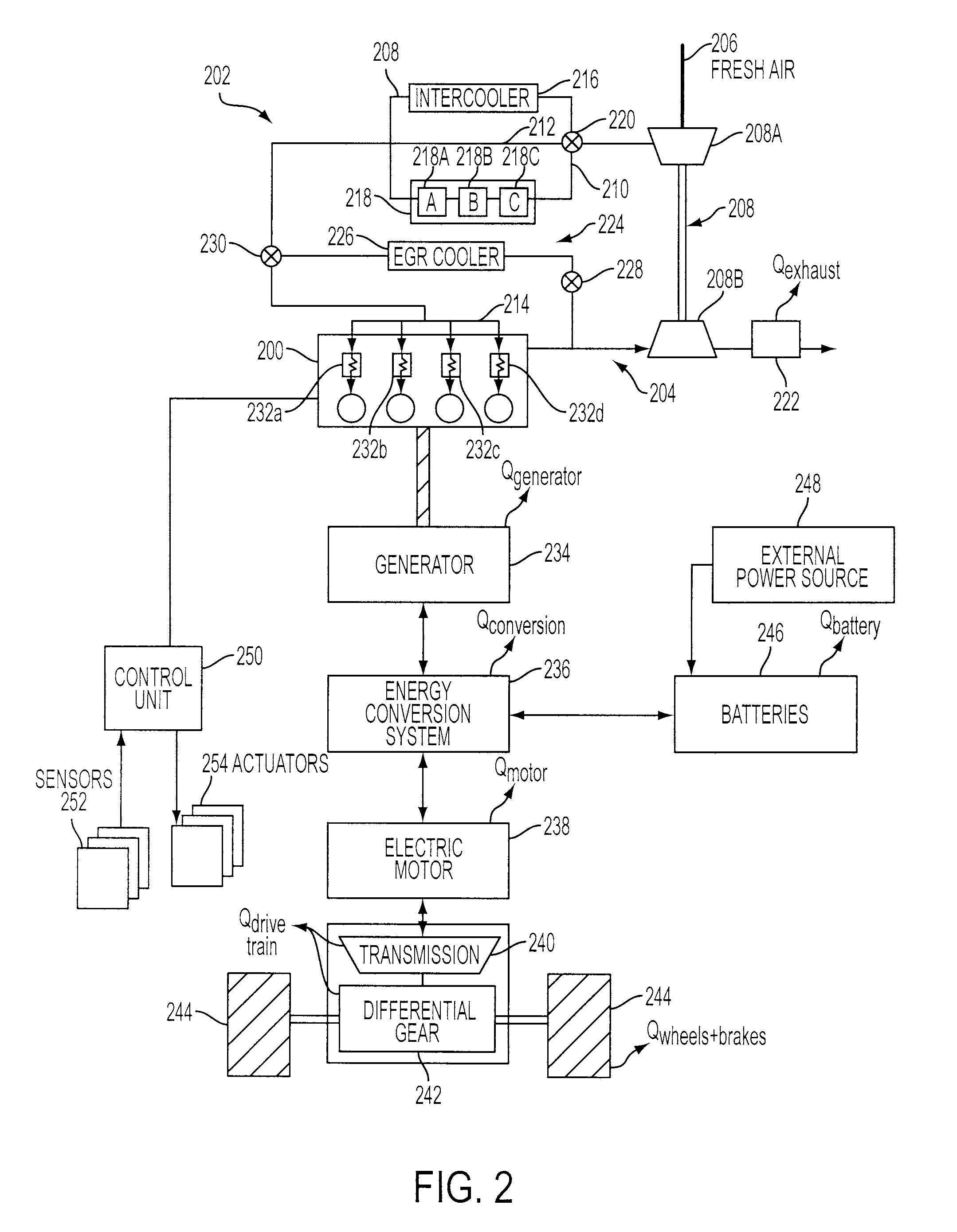

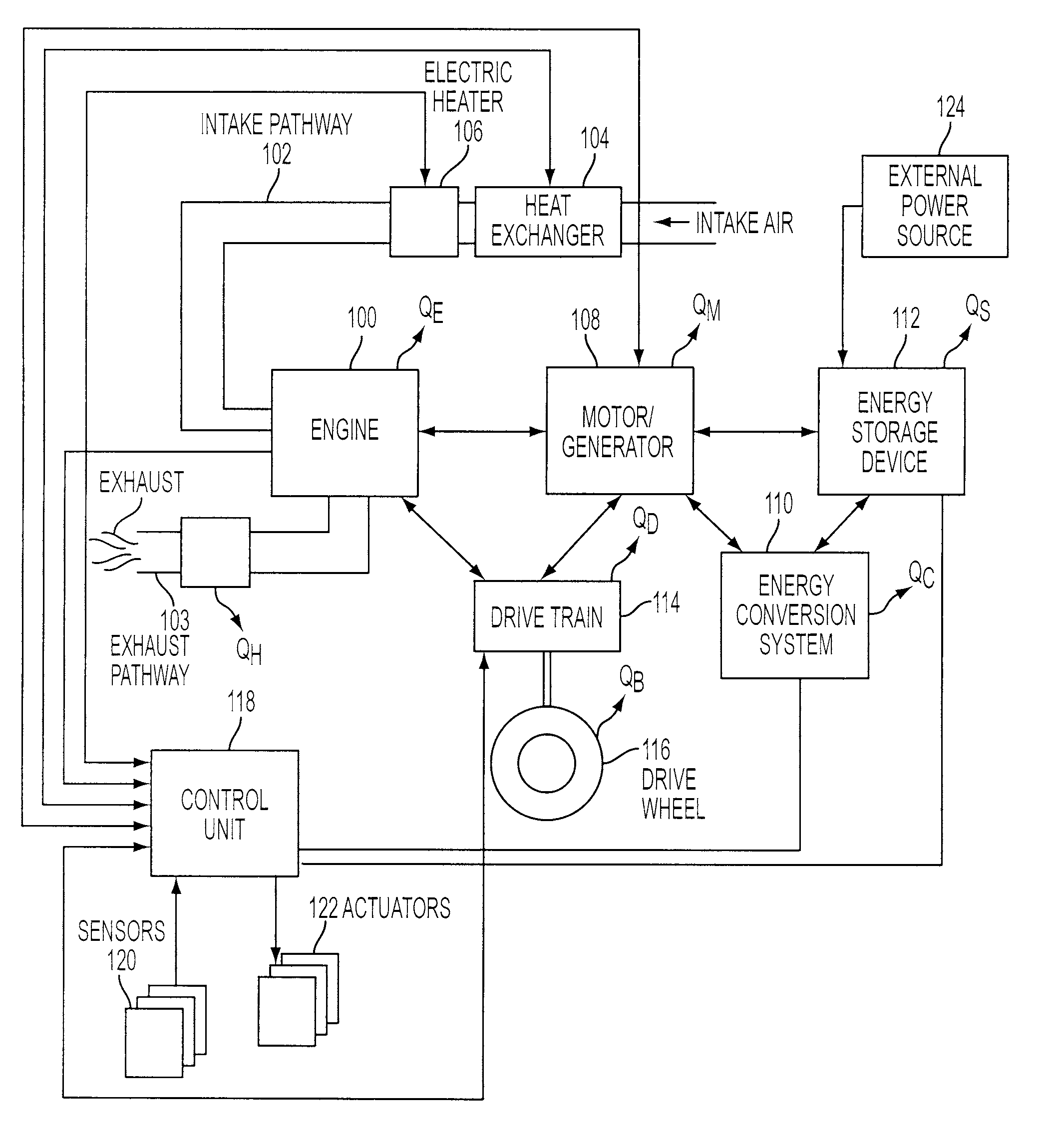

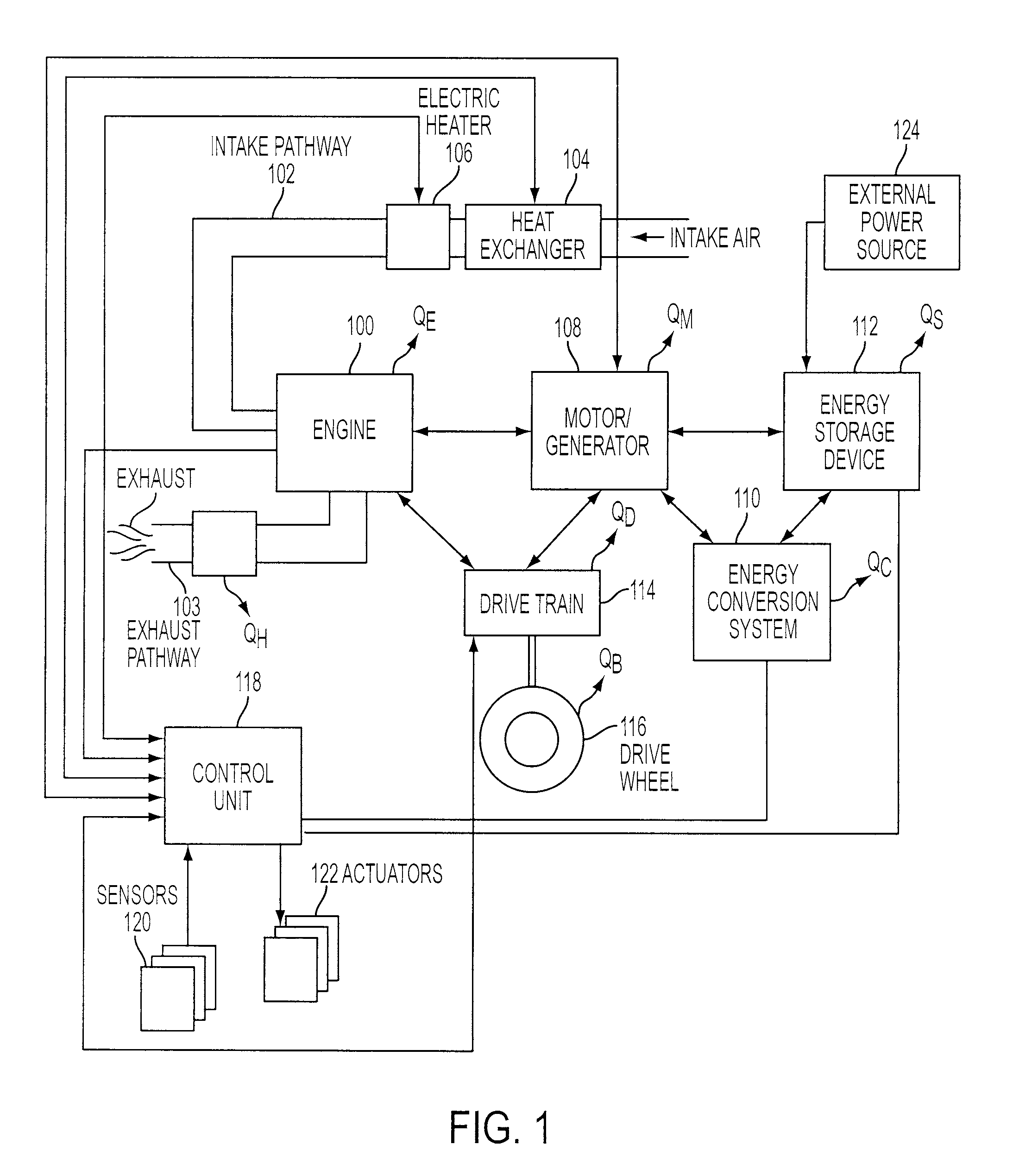

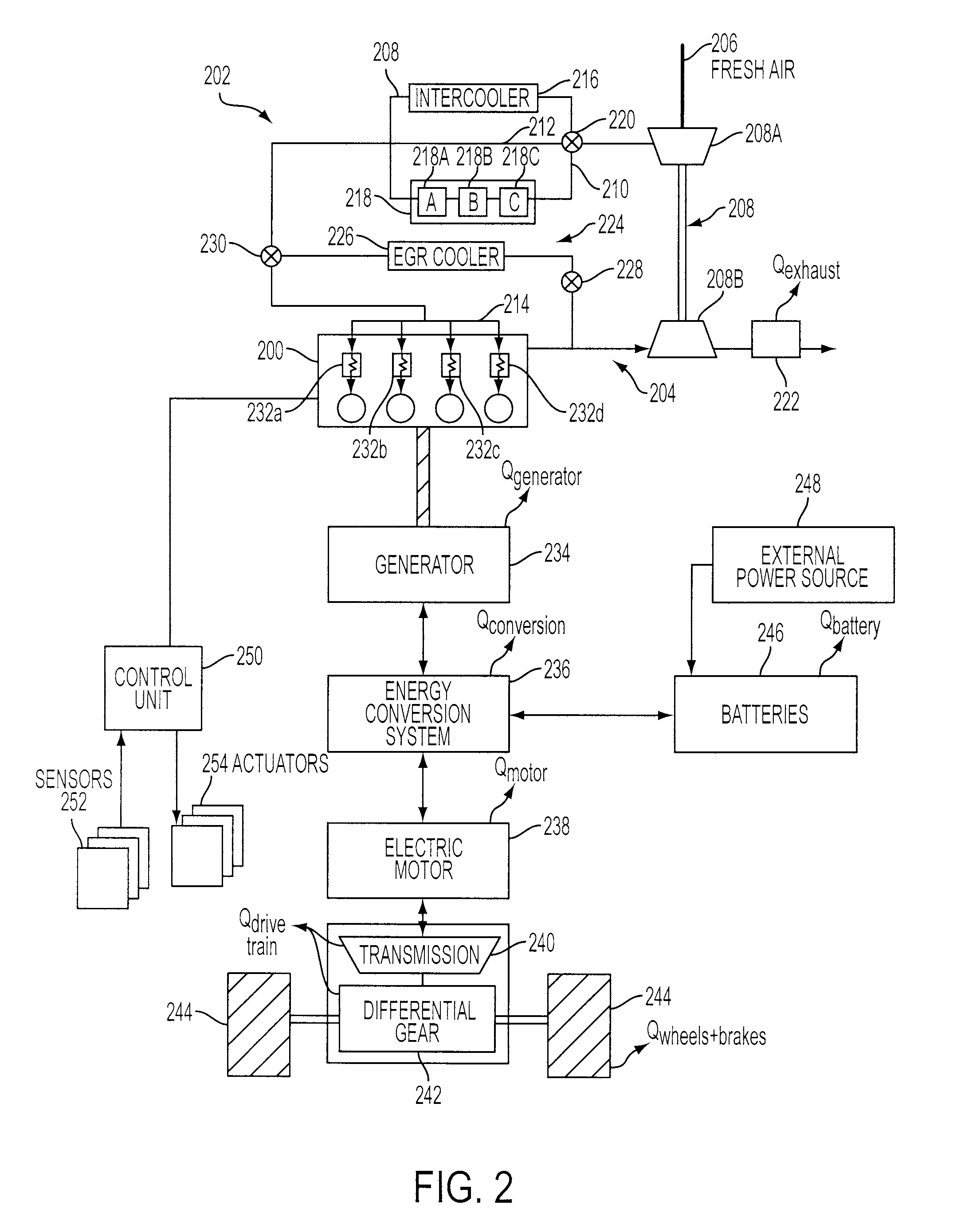

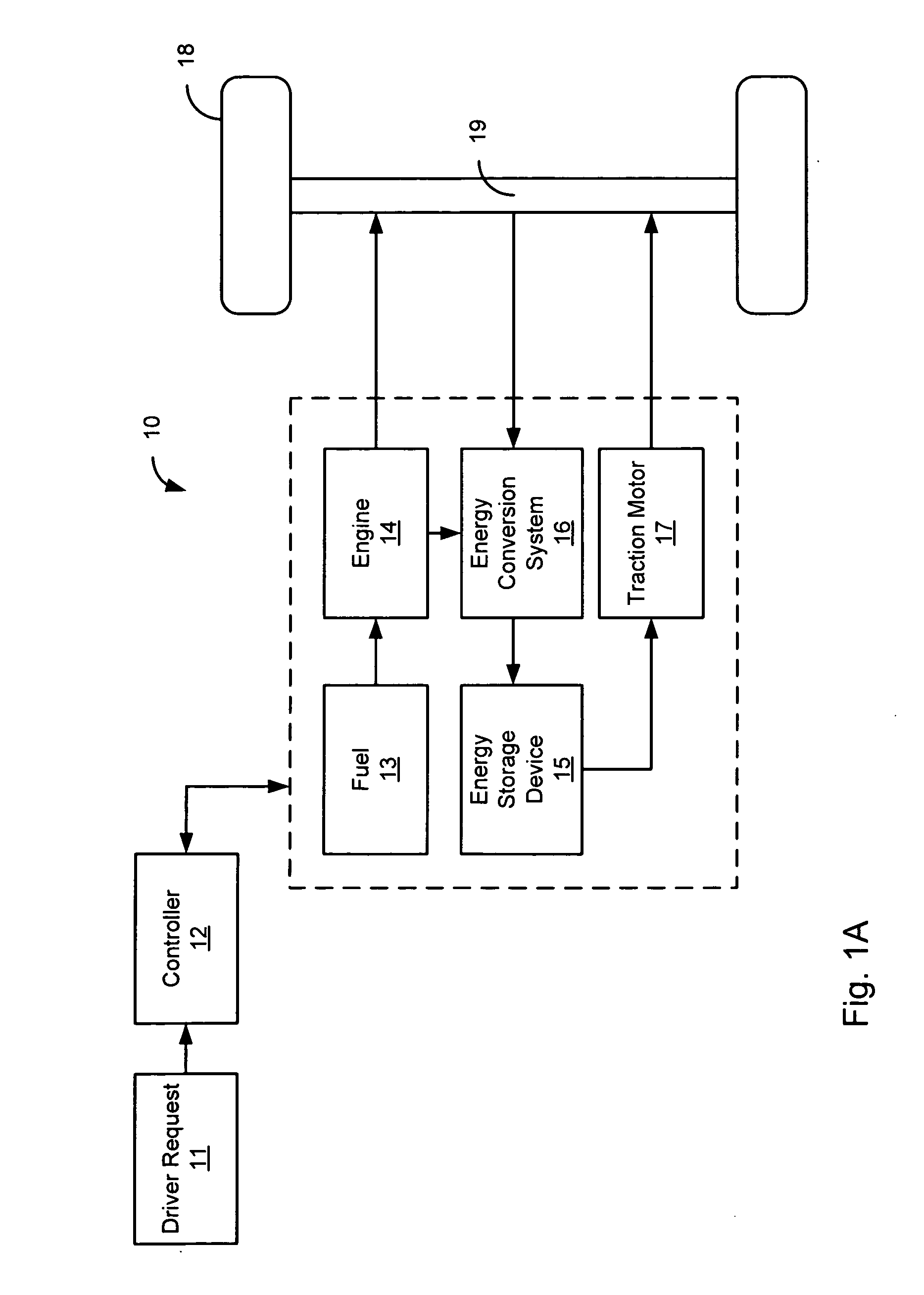

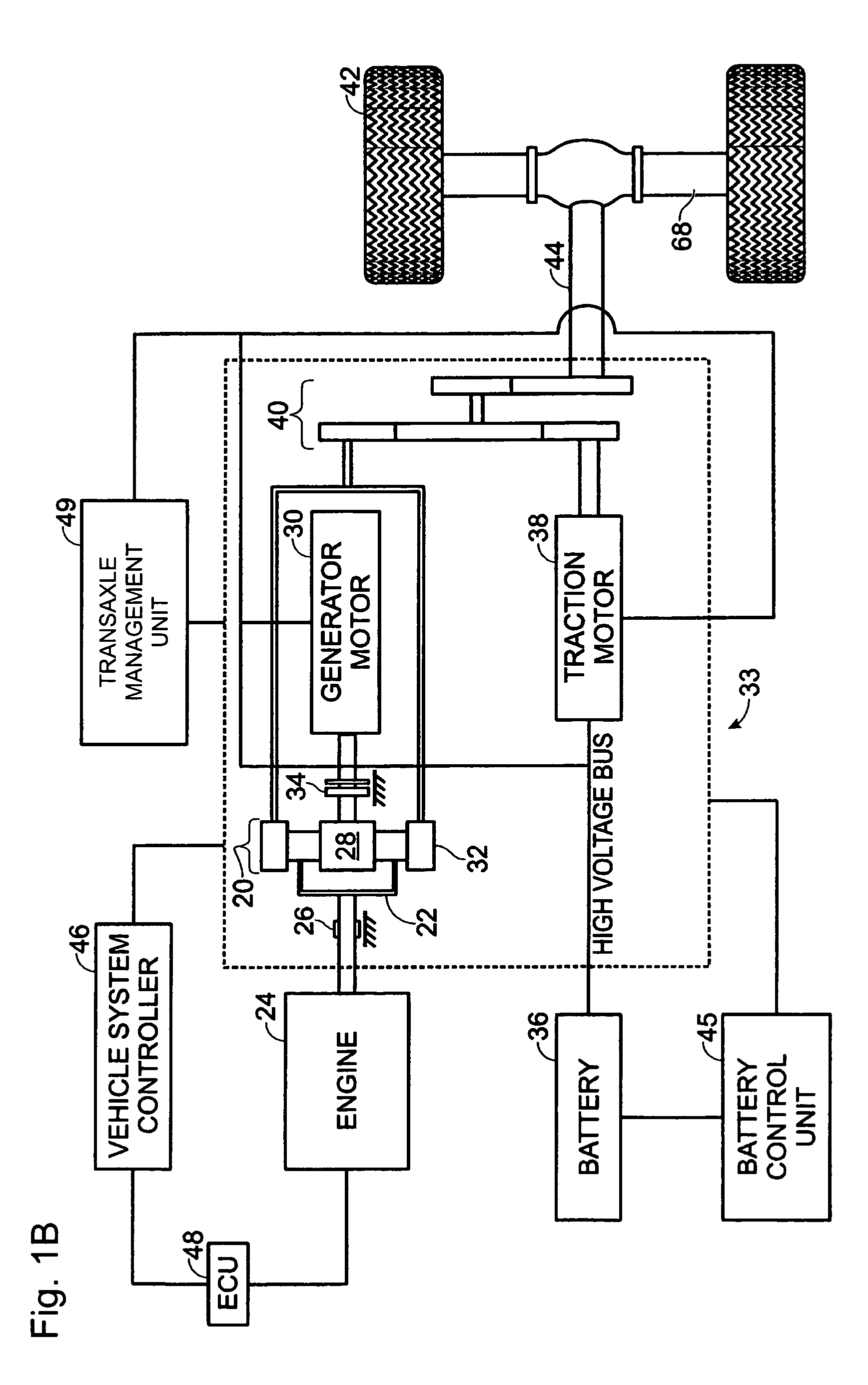

Hybrid Thermal Energy Conversion for HCCI Heated Intake Charge System

InactiveUS20080276913A1Accurate intake charge temperature controlReduce the impactElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionThermal energy

A method of operating an internal combustion engine coupled in a hybrid powertrain, the method comprising of extracting waste energy from a component of an electrical power system of the hybrid powertrain, and adjusting intake air temperature during homogeneous charge compression ignition operation of the engine by using said extracted waste energy.

Owner:FORD GLOBAL TECH LLC

Approach for Facilitating Engine Mode Transitions

ActiveUS20080066713A1Increasing negative overlapElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

A method of transitioning a cylinder of an engine from a spark ignition mode to a homogeneous charge compression ignition mode, the cylinder having at least one electrically actuated intake valve and at least one exhaust valve, the method comprising of before a transition, operating the cylinder with at least some overlap between an opening event of the intake valve and an opening event of the exhaust valve in the spark ignition mode; in response to a transition request, operating the cylinder with at least some negative overlap between an opening event of the intake valve and an opening event of the exhaust valve, retarding the intake valve opening and closing timing by different amounts and retarding ignition timing; and further increasing negative overlap and performing the homogeneous charge compression ignition mode.

Owner:FORD GLOBAL TECH LLC

Hybrid thermal energy conversion for HCCI heated intake charge system

InactiveUS7621262B2Consume electricityLow efficiencyHybrid vehiclesElectrical controlHomogeneous charge compression ignitionThermal energy

Owner:FORD GLOBAL TECH LLC

Load transient control methods for direct-injection engines with controlled auto-ignition combustion

InactiveUS20060196467A1Electrical controlNon-fuel substance addition to fuelHomogeneous charge compression ignitionLow load

A direct injection controlled auto-ignition engine is operated at steady state, within a homogeneous charge compression-ignition (HCCI) load range and with fuel-air-diluent mixtures at predetermined conditions, for each speed and load, of engine control inputs, including at least fueling mass flow rate, injection timing (FI), spark timing (SI) and exhaust recompression obtained by negative valve overlap (NVO). During load change rates below a predetermined threshold, SI, FI and NVO change rates are synchronized to current changes in the fueling mass flow rate. For fast load increases above the threshold, the cylinder charge is temporarily enriched by increasing the percentage of residual gas or reducing the percentage of fresh air mass in the charge sufficiently to maintain auto-ignition temperature during the load change. This may be done by delaying NVO action for a predetermined speed-dependent number of engine cycles. At very low loads, stable fuel rate reduction may require an alternate method involving deceleration fuel cut-off followed by a step change during refire.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method and apparatus for optimized combustion in an internal combustion engine utilizing homogeneous charge compression ignition and variable valve actuation

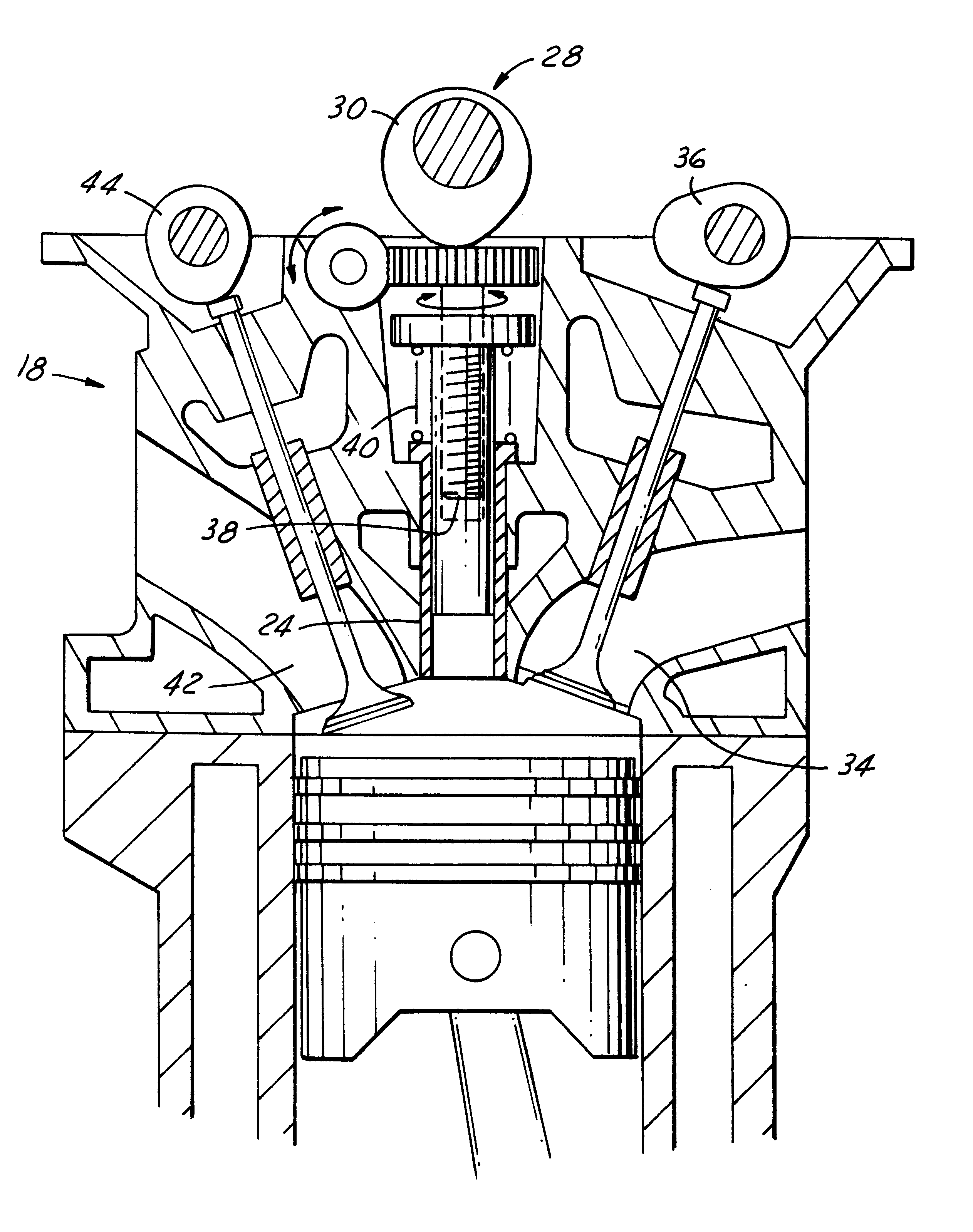

InactiveUS7308872B2Electrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

A valvetrain system mechanization for an internal combustion engine using compression ignition, including homogeneous charge compression ignition, having two intake and one or more exhaust valves per cylinder. The valves are operated by dual overhead camshafts having two-step cams. The intake and exhaust camshafts are provided with phasers for varying the opening and closing of the intake and exhaust valves. A two-step roller finger follower is disposed for each valve between the cam lobes and the valve stem. The two sets of intake and exhaust valves are controlled by separate oil control valves. Swirl of gases may be introduced by mismatching the lifts of the valves. The valve opening times, closing times, lifts, fuel injection, compression ratio, and exhaust gas recirculation may be varied to optimize combustion conditions for a range of engine operating modes.

Owner:DELPHI TECH INC

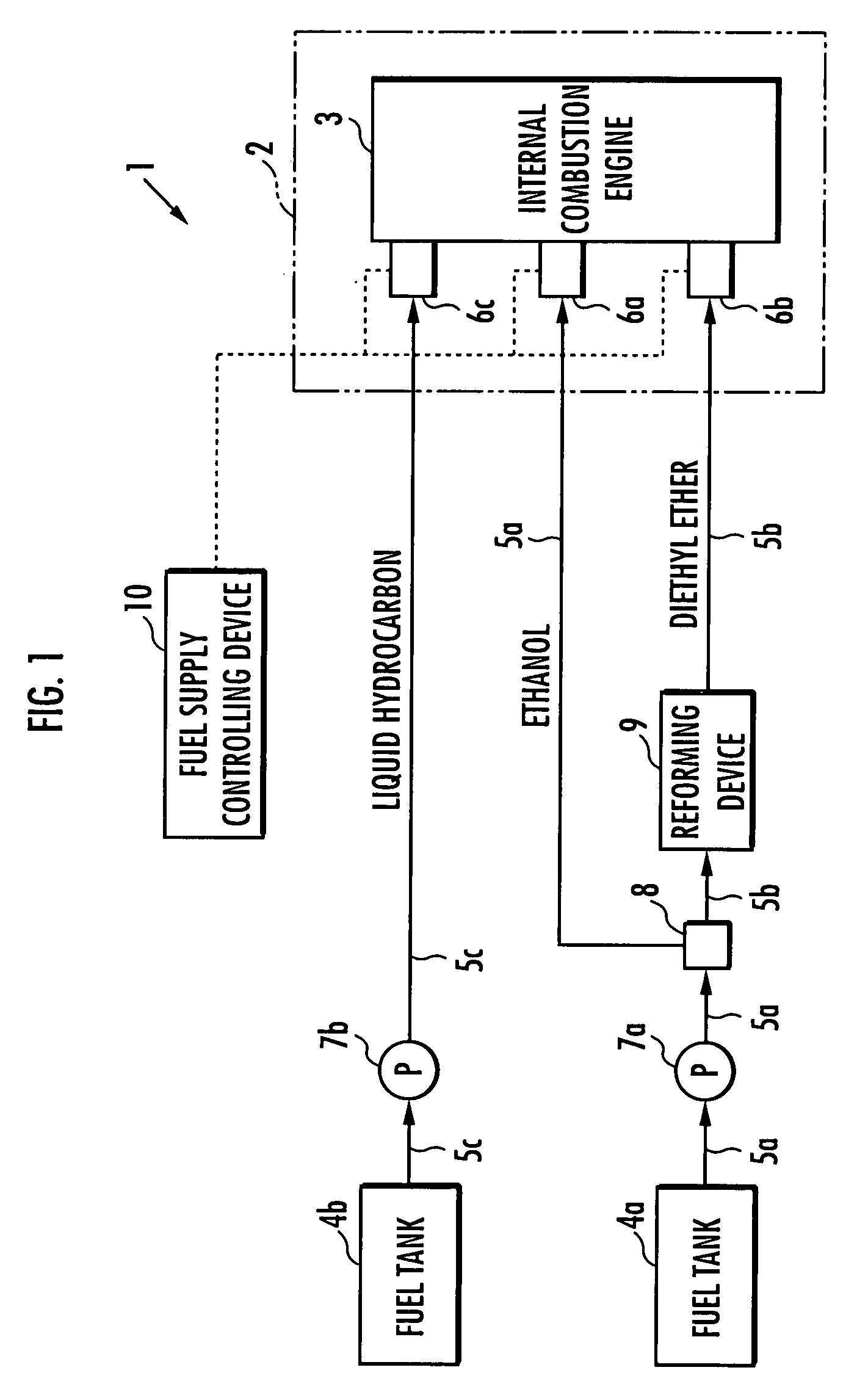

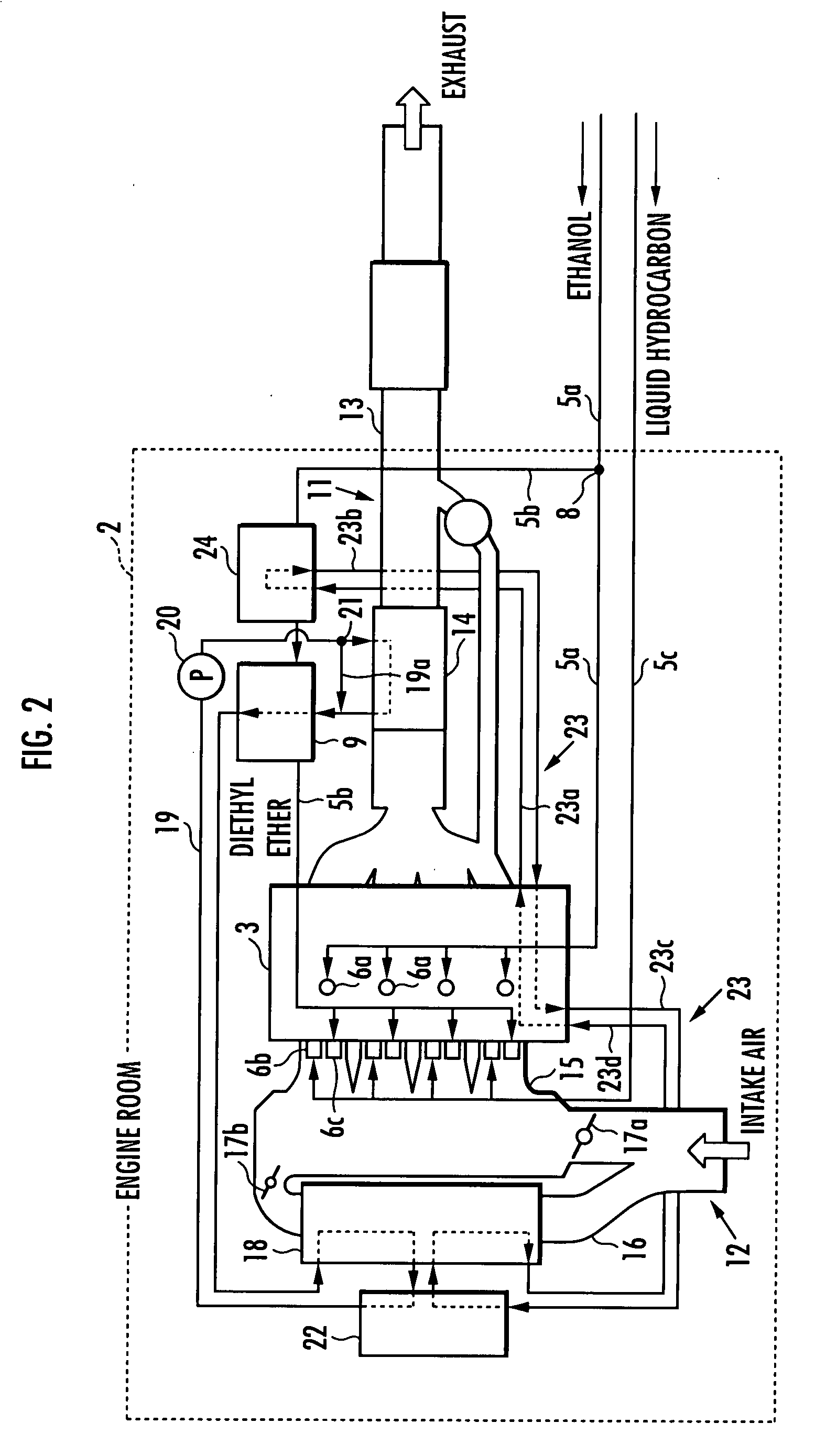

Internal combustion engine system

InactiveUS20080098985A1Accurate timingElectrical controlNon-fuel substance addition to fuelHomogeneous charge compression ignitionNaphtha

The present invention provides an internal combustion engine system that can precisely control ignition timing on homogeneous charge compression ignition. The internal combustion engine system includes a fuel tank 4a containing ethanol, a fuel tank 4b containing at least one of gasoline and GTL naphtha, a reforming device 9 for reforming ethanol to obtain diethyl ether, a heat exchange device 14 for heating a heating medium, an ethanol heater 9b for heating ethanol with the heating medium, and a fuel supply controlling device 10 for controlling a mixture ratio of the fuel. The internal combustion engine system further includes an intake air heater 18 for heating intake air with the heating medium. The internal combustion engine system further comprises an adiabatic storage container 29 for storing the heating medium during a halt of an internal combustion engine 3. The internal combustion engine system further comprises a flow controlling device 27 for flowing the heating medium to the adiabatic storage container 29 only when a temperature detected by a thermal detector 30a is higher than a temperature detected by a thermal detector 30b during an operation of the internal combustion engine 3. The internal combustion engine system further comprises a fuel tank 42 containing a mixed fuel, and a separating device 43 for separating the mixed fuel into an ethanol-water mixture, gasoline and GTL naphtha by adding water to the mixed fuel.

Owner:HONDA MOTOR CO LTD

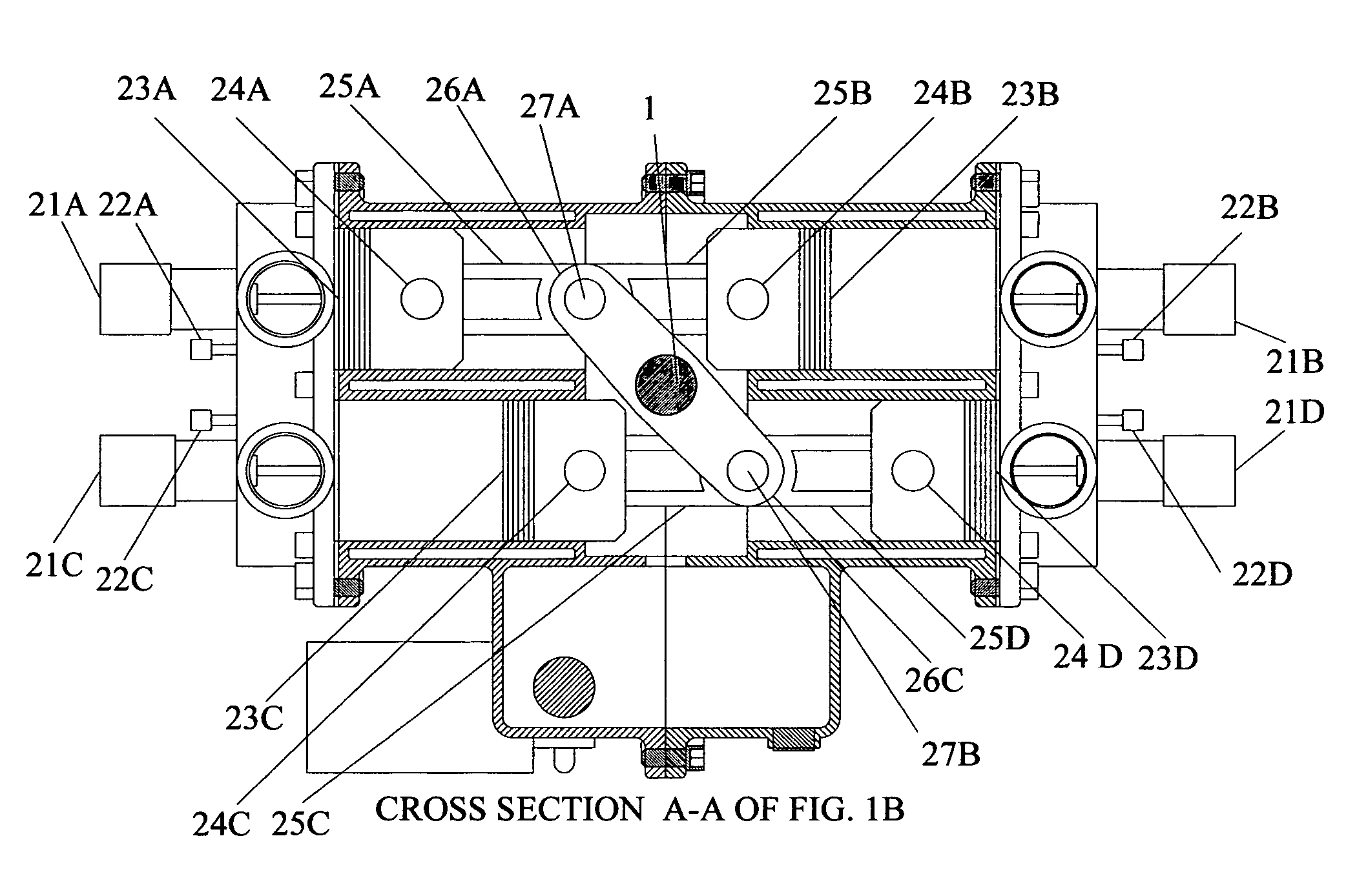

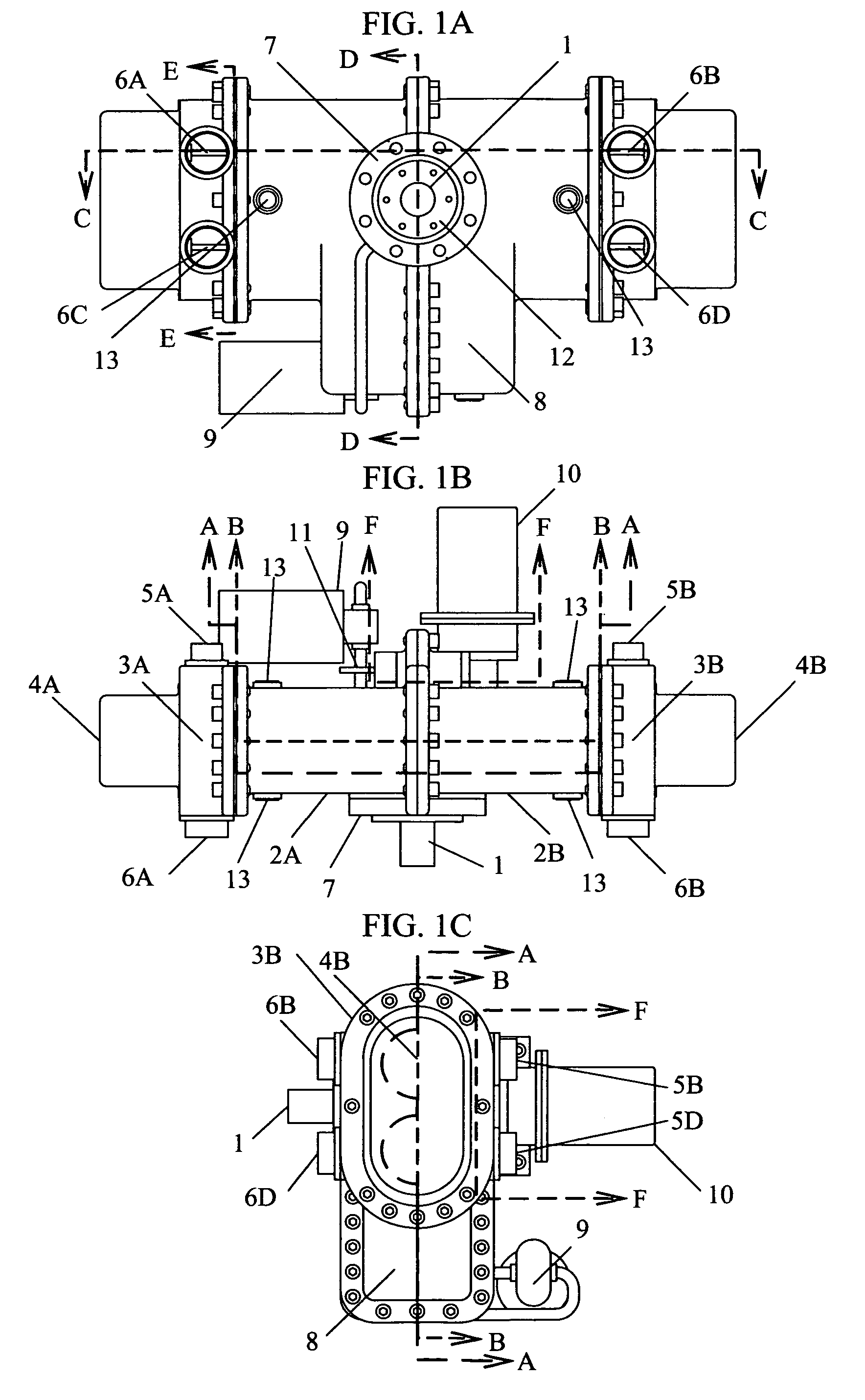

Homogeneous charge compression ignition and barrel engines

InactiveUS20060037567A1Rapidly raise compression levelRapidly increase compression levelInternal combustion piston enginesEngine componentsHomogeneous charge compression ignitionReciprocating motion

A homogenous charge compression ignition barrel engine includes an engine housing with a first and second end. An elongated power shaft is longitudinally disposed in the engine housing and defines a longitudinal axis of the engine. A plurality of cylinders surround the longitudinal axis with each cylinder having a closed end and an open end. Each cylinder has a central axis. The open ends of the cylinders are each generally directed toward the first end of the housing. An intake system is operable to introduce a combustible mixture of air and fuel into each of the cylinders. A track is disposed between the first end of the housing and the open ends of the cylinders such that a portion of the track is disposed generally in alignment with the central axis of each of the cylinders. The track has a cam surface that longitudinally undulates with respect to the open ends of the cylinders. A portion of the cam surface is disposed generally in alignment with the central axis of each of the cylinders. The track and the cylinders are rotatable with respect to each other such that the undulating cam surface moves with respect to the open ends of the cylinders. A piston is moveably disposed in each of the cylinders such that a combustion chamber is defined between the piston and the closed end of the cylinder. Each piston is in mechanical communication with the cam surface of the track such that as the cylinders and the track move with respect to each other, the pistons reciprocate within the cylinders. Each cylinder is operable to compress a combustible mixture until the mixture auto ignites, without the introduction of a spark.

Owner:THOMAS ENGINE CO LLC

Method for transition between controlled auto-ignition and spark ignition modes in direct fuel injection engines

InactiveUS7370616B2Eliminate misfiring and partial burnsValve arrangementsElectrical controlHomogeneous charge compression ignitionExhaust valve

A method is provided for control of transition between combustion modes of a direct-injection engine operable in a homogeneous charge compression ignition (HCCI) mode at lower loads and a spark ignition flame propagation (SI) mode at higher loads. The engine includes a variable valve actuation system including two-step high and low lift valve actuation and separate cam phasing for both intake and exhaust valves. The method includes operating the engine at steady state, with fuel-air-exhaust gas mixtures at predetermined conditions, for each speed and load, and controlling the engine during mode changes between the HCCI mode and the SI mode by switching the exhaust and intake valves between low lift for HCCI operation and high lift for SI operation. High load may be an SI throttled mode with an intermediate unthrottled mode (SI / NTLC} in which transition between HCCI and SI / NTLC modes requires switching only the exhaust valve lift and transition between SI / NTLC and SI throttled modes requires switching only the intake valve lift, with predetermined phase adjustments in the valve timing phasing.

Owner:GM GLOBAL TECH OPERATIONS LLC

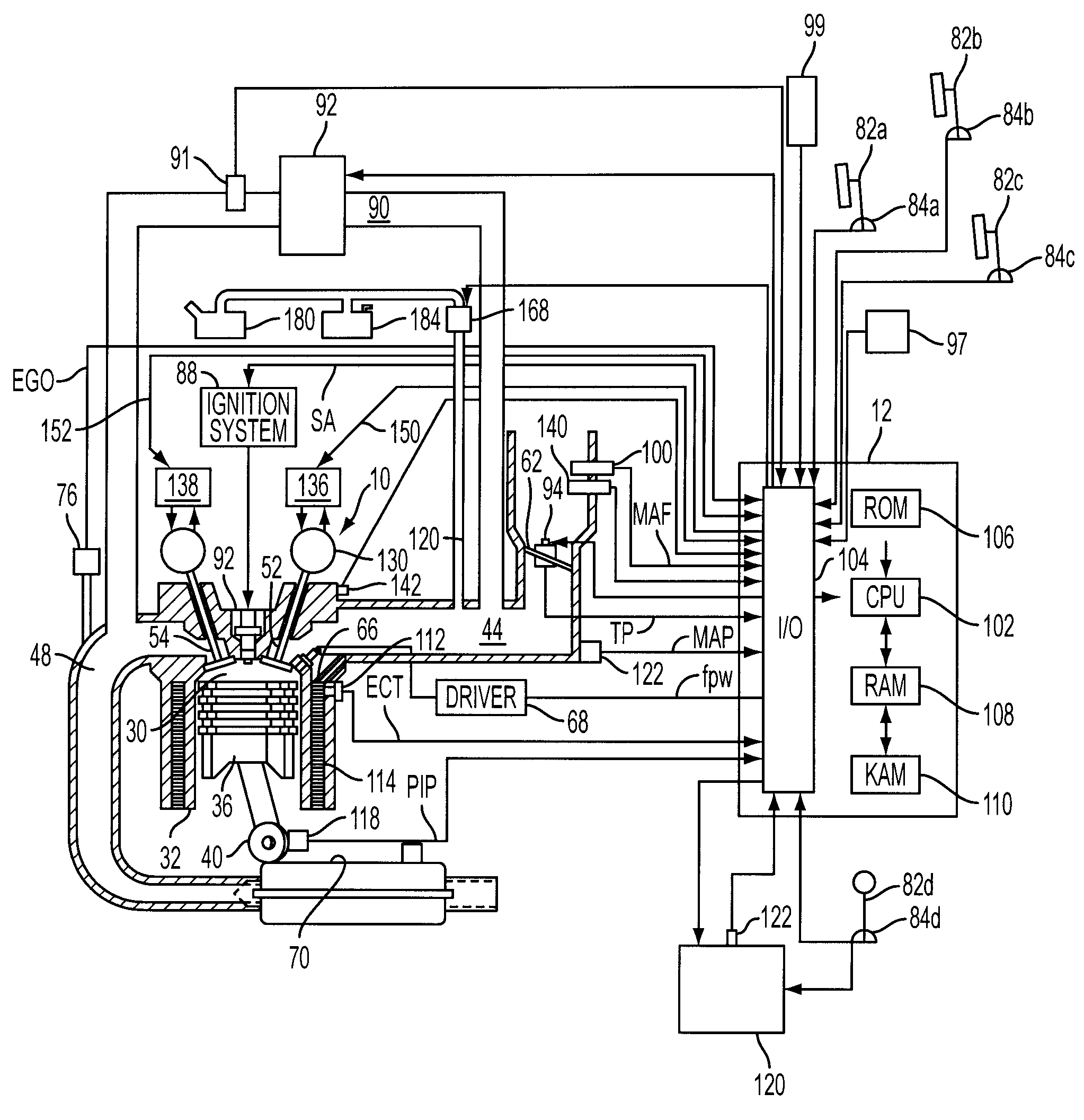

Method and apparatus to control operation of a homogeneous charge compression-ignition engine

InactiveUS7360523B2Weakening rangeReduce environmental stressValve arrangementsElectrical controlHomogeneous charge compression ignitionAmbient pressure

The invention provides a method for operating a multi-cylinder, spark-ignition, direct-injection, four-stroke internal-combustion engine adapted to operate in a controlled auto-ignition mode selectively operative at stoichiometry and lean of stoichiometry. The method comprises adapting an engine valve actuation system to control engine valve opening and closing, and monitoring engine operating conditions and ambient barometric pressure. The engine is operated unthrottled and the engine valve actuation system is controlled to effect a negative valve overlap period when the engine operating conditions are within predetermined ranges. A mass of fuel is injected during the negative valve overlap period. The magnitude of the negative valve overlap period is decreased with decreasing ambient pressure and increased with increasing ambient pressure.

Owner:GM GLOBAL TECH OPERATIONS LLC

Speed transient control methods for direct-injection engines with controlled auto-ignition combustion

InactiveUS20060196468A1Robust auto-ignition combustion controlSmooth transitionValve arrangementsElectrical controlHomogeneous charge compression ignitionDiluent

A direct injection controlled auto-ignition engine is operated at steady state, within a homogeneous charge compression-ignition (HCCI) load range and with fuel-air-diluent mixtures at predetermined conditions, for each speed and load, of engine control inputs, including at least injection timing (FI), spark timing (SI), throttle position, exhaust gas recirculation (EGR) valve setting and exhaust recompression obtained by negative valve overlap (NVO). During engine speed transients, the control inputs are synchronized to changes in the current engine speed, and also with any concurrent changes in the engine fueling rate. Inputs that are inactive during all or part of a speed change have a zero change rate while inactive. The method maintains robust auto-ignition combustion during speed transients with constant or variable fueling rates and with or without load changes.

Owner:GM GLOBAL TECH OPERATIONS LLC

Engine Dynamic Load Leveling

ActiveUS20080135021A1Challenge and limitationLower efficiency benefitElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionControl theory

A method for controlling an internal combustion engine having a plurality of cylinders using electronic valve actuation, including operating a first portion of the cylinders in a homogeneous charge compression ignition (HCCI) mode, operating a second portion of the cylinders in a non-HCCI mode, and adjusting the valve timing of the second portion of cylinders to dynamically load level the engine in response to a transient torque demand. A system for controlling a multiple cylinder internal combustion engine, including a first group of cylinders to operate in an HCCI mode, a second group of cylinders to operate in a non-HCCI mode, and an engine controller operably coupled to the first and second groups of cylinders, said controller to adjust the valve timing of the second group of cylinders to dynamically load level the engine in response to a transient torque demand.

Owner:FORD GLOBAL TECH LLC

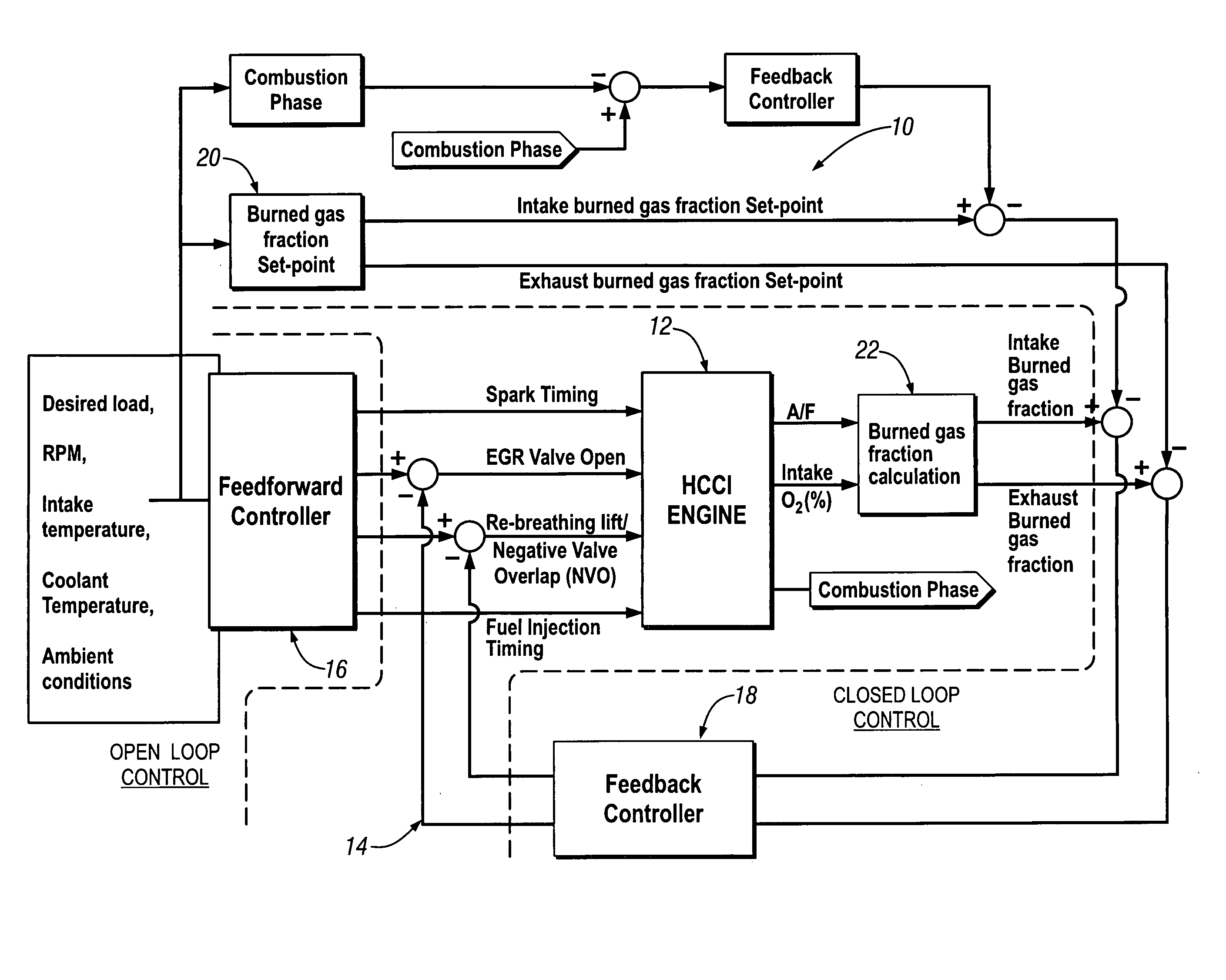

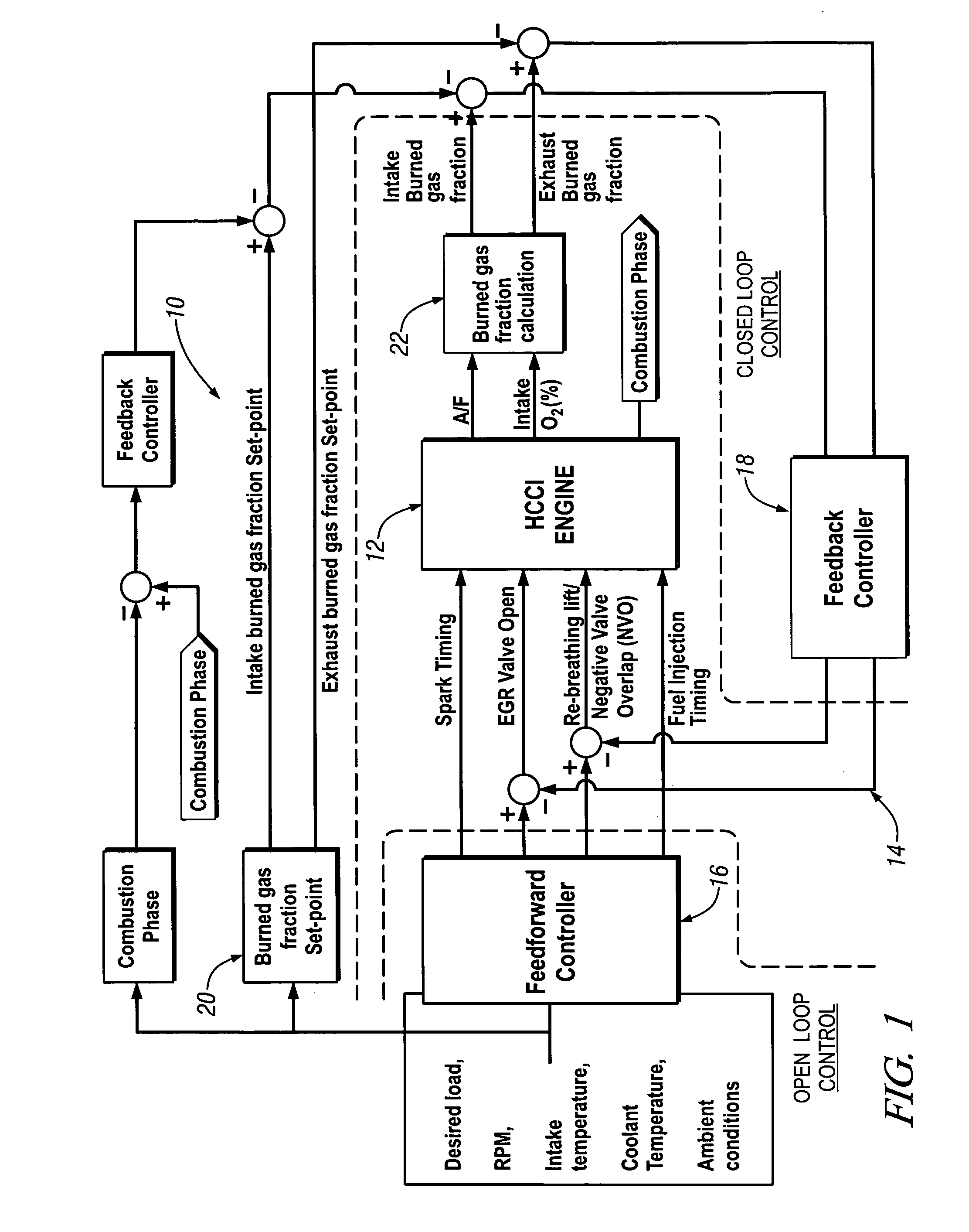

HCCI engine combustion control

ActiveUS20060016438A1Reduce the differenceElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionCombustion

An exemplary method of controlling a gasoline engine operating unthrottled with homogeneous charge compression ignition (HCCI) combustion includes operating the engine with predetermined values of external EGR and internal EGR settings, and burned gas fraction set points for intake and exhaust gases. Repeated adjustments are made to the external EGR and internal EGR settings to move the exhaust and intake gases burned gas fractions toward their state set points. Effects of disturbances in actual operating conditions are thereby minimized.

Owner:GM GLOBAL TECH OPERATIONS LLC

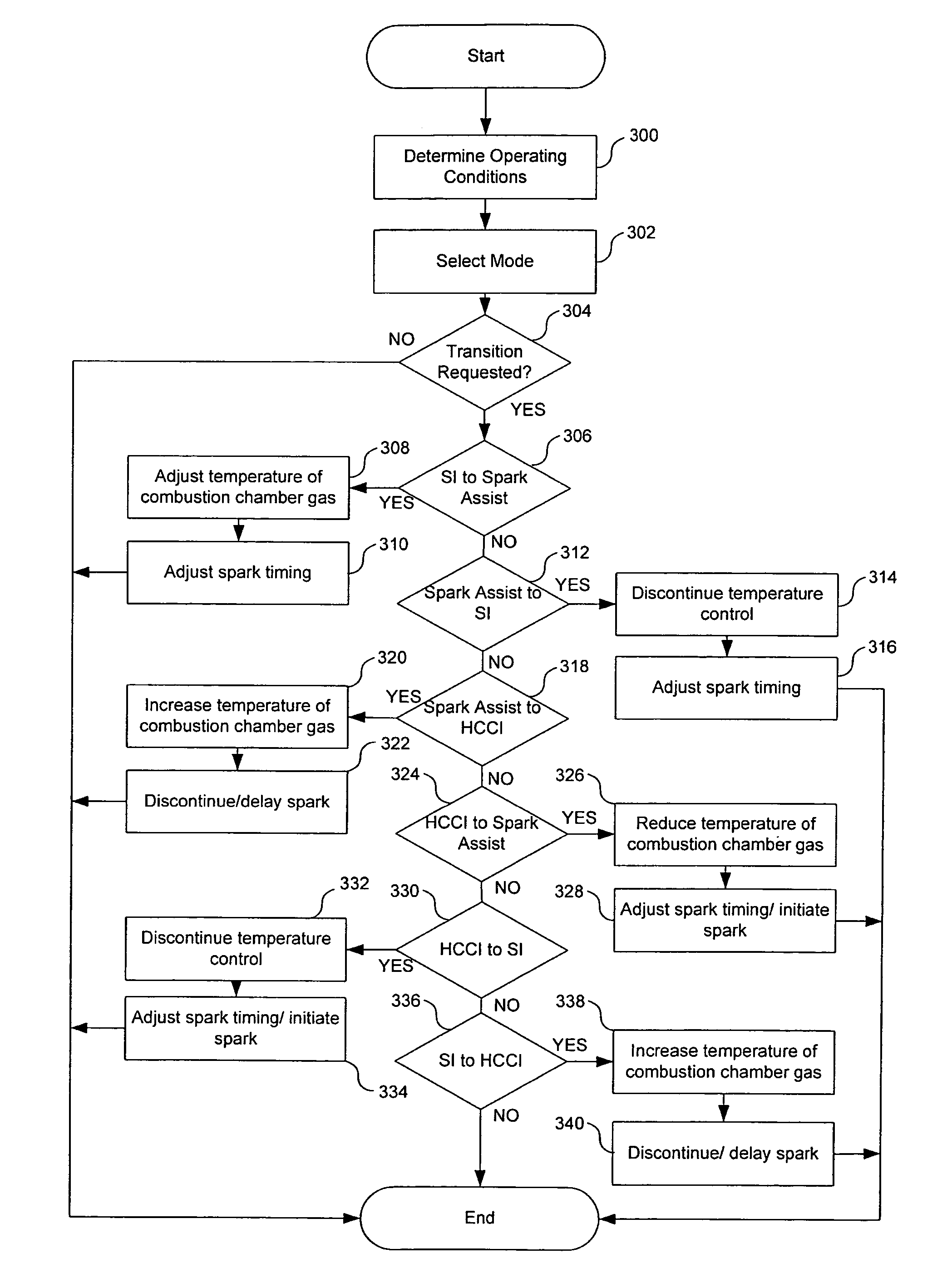

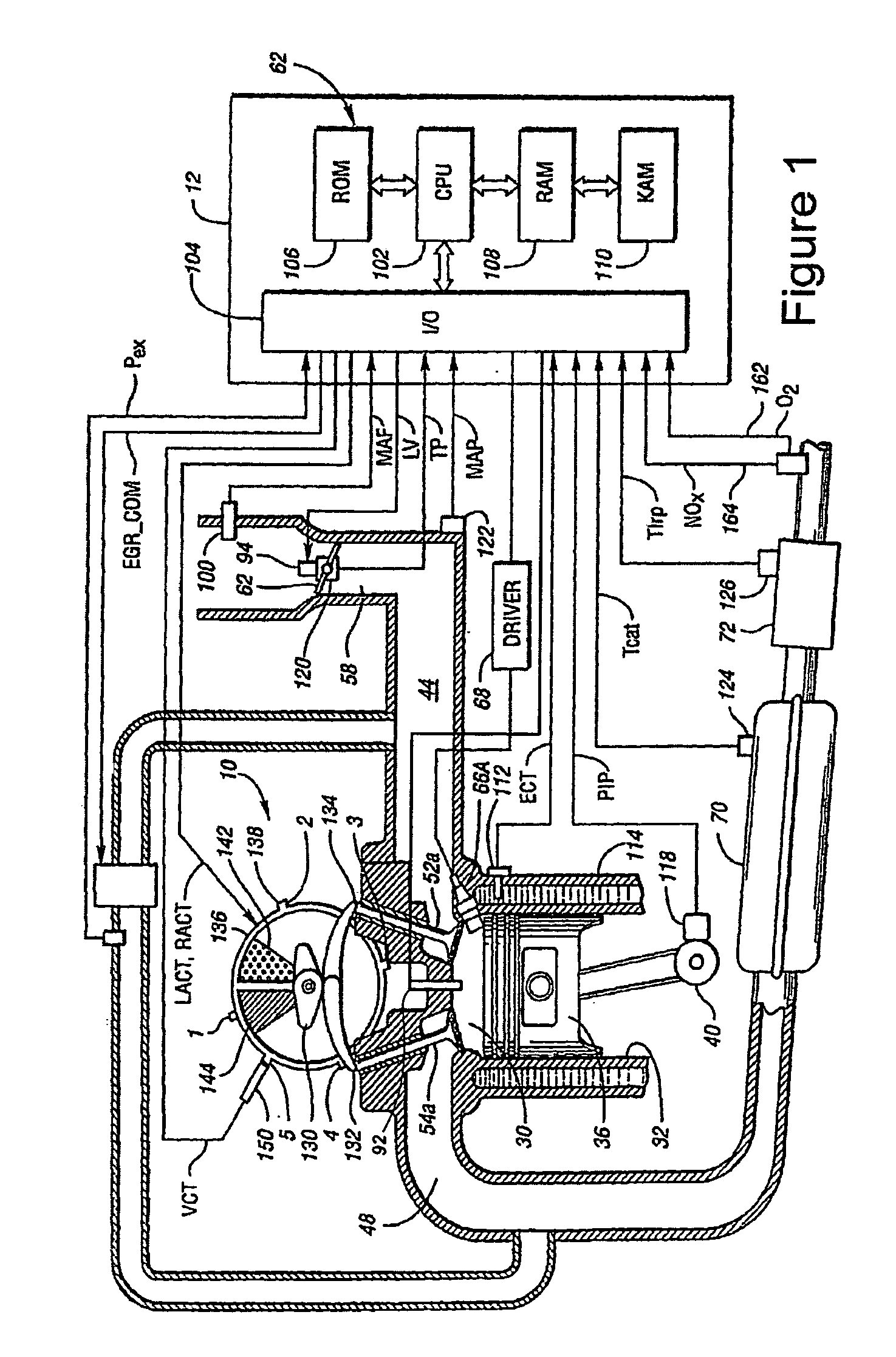

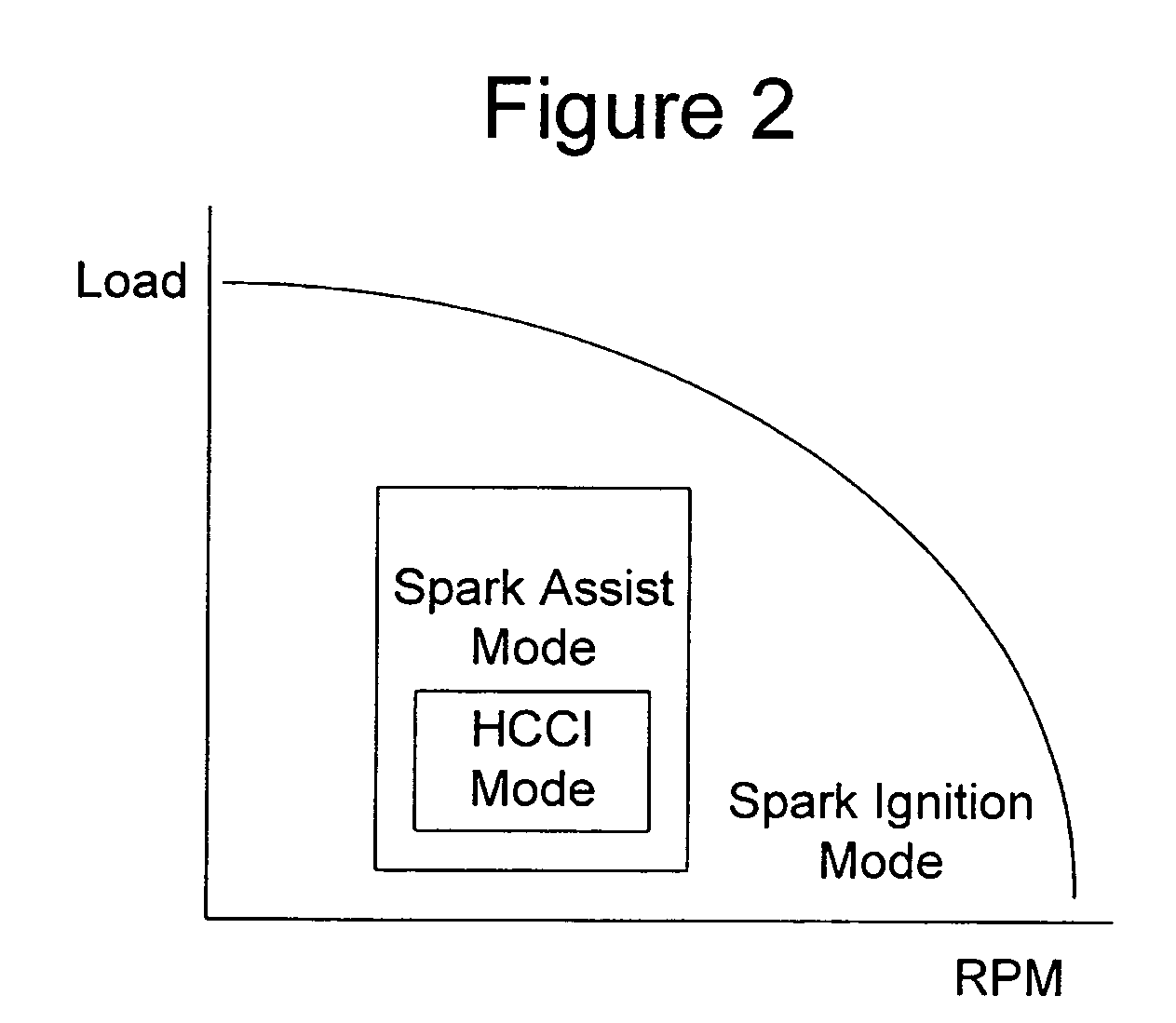

Transition strategy for engine operation with spark ignition and homogeneous charge compression ignition modes

ActiveUS7240659B2Improve efficiencyReduce the production of nitrogen oxidesElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExternal combustion engine

A method of operating an internal combustion engine having a combustion chamber with a piston and a spark plug, when transitioning between spark ignition combustion and autoignition combustion, creating a first mixture of air and fuel, adjusting an operating condition of the engine so that said first mixture of air and fuel in the combustion chamber approaches, but does not achieve, the autoignition temperature, and performing a spark from the spark plug so that at least a portion of said first mixture combusts to raise a remaining portion of said first mixture to said autoignition temperature.

Owner:FORD GLOBAL TECH LLC

System and method for operation of an engine having multiple combustion modes and cylinder deactivation

InactiveUS20070204830A1Reduce engine efficiencyReduce drive feelHybrid vehiclesElectrical controlHomogeneous charge compression ignitionAutomotive engineering

A method of operating an engine having a plurality of combustion cylinders configured to produce an engine output, comprising of adjusting a condition of the engine to achieve combustion by each of spark ignition and homogeneous charge compression ignition, and varying the engine output by at least varying a number of cylinders carrying out combustion.

Owner:FORD GLOBAL TECH LLC

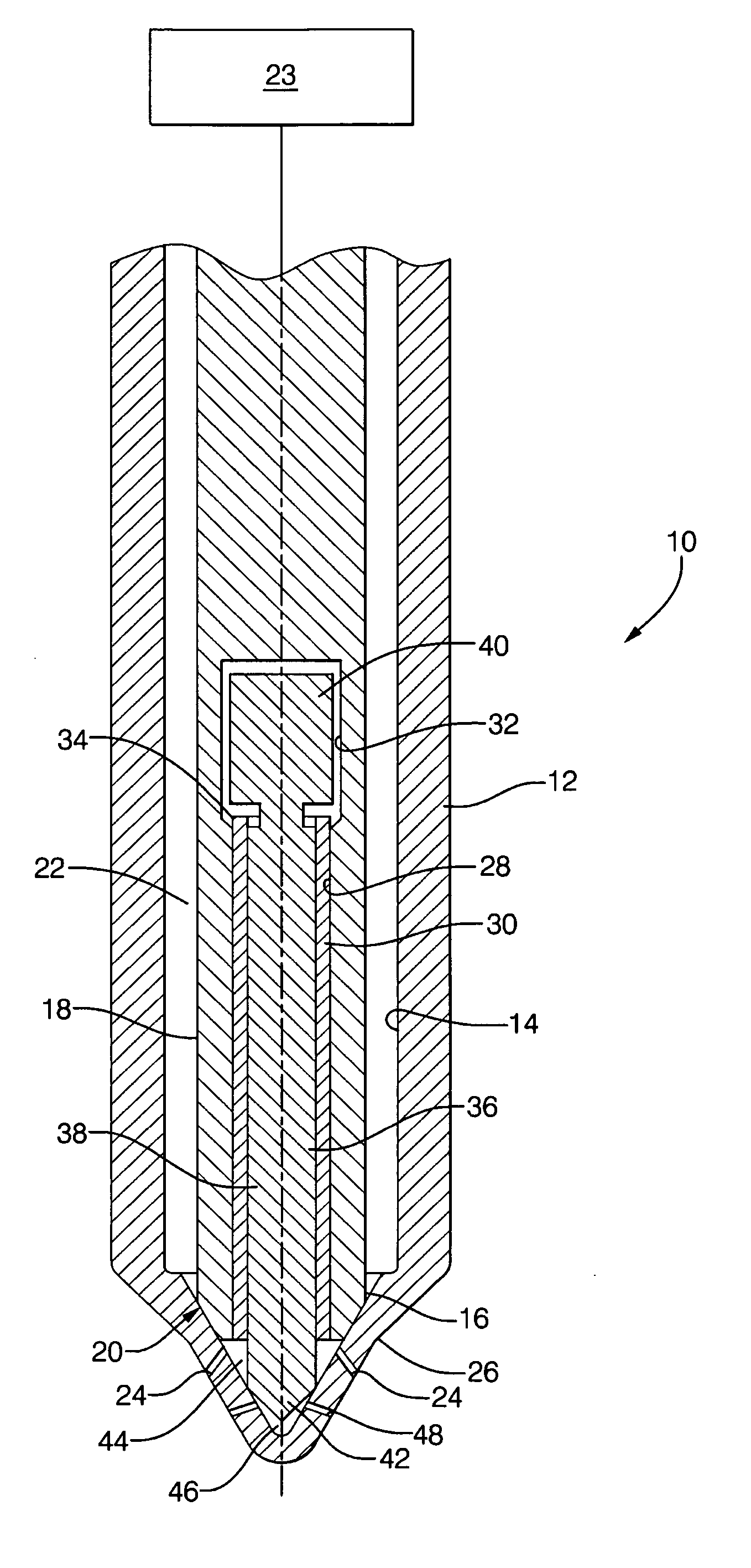

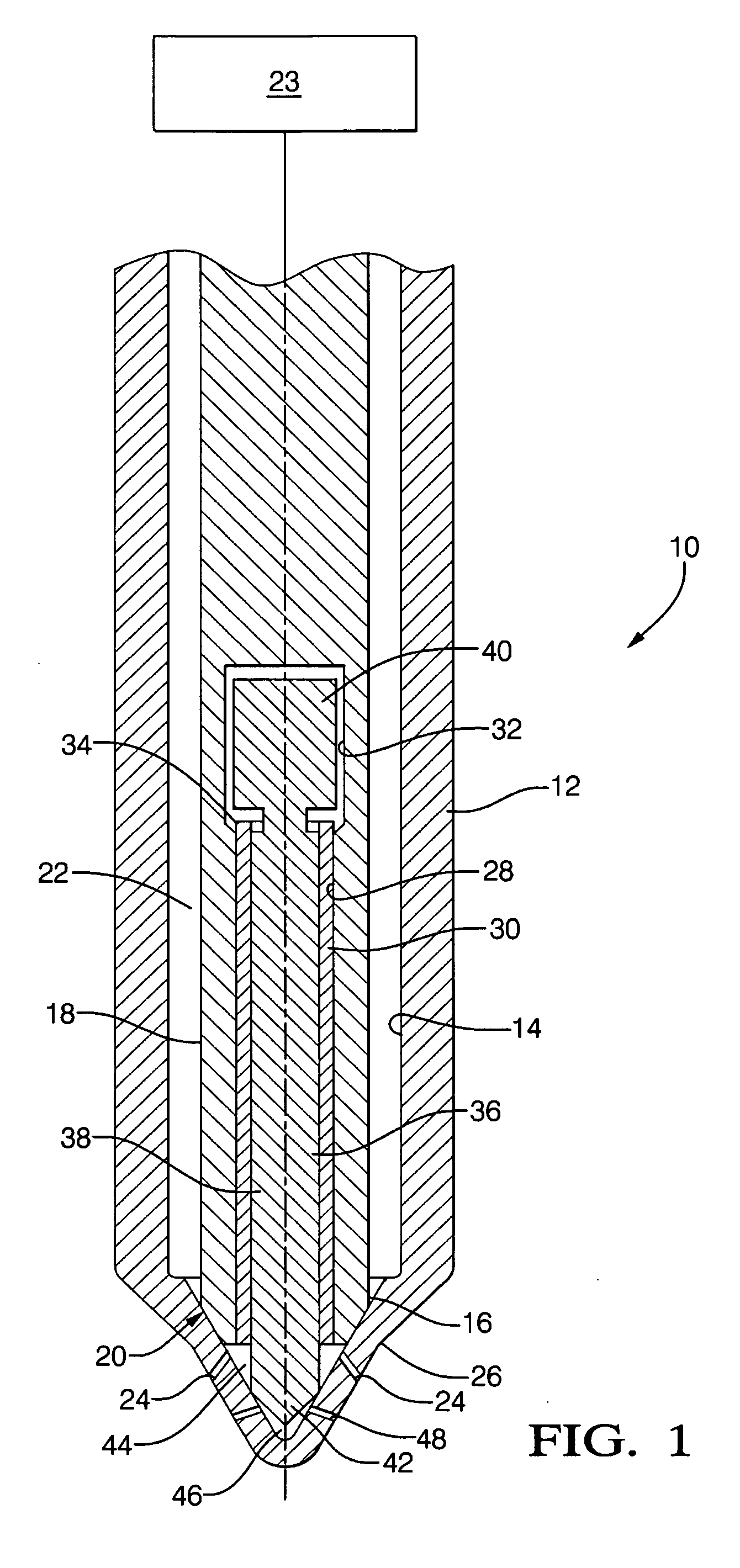

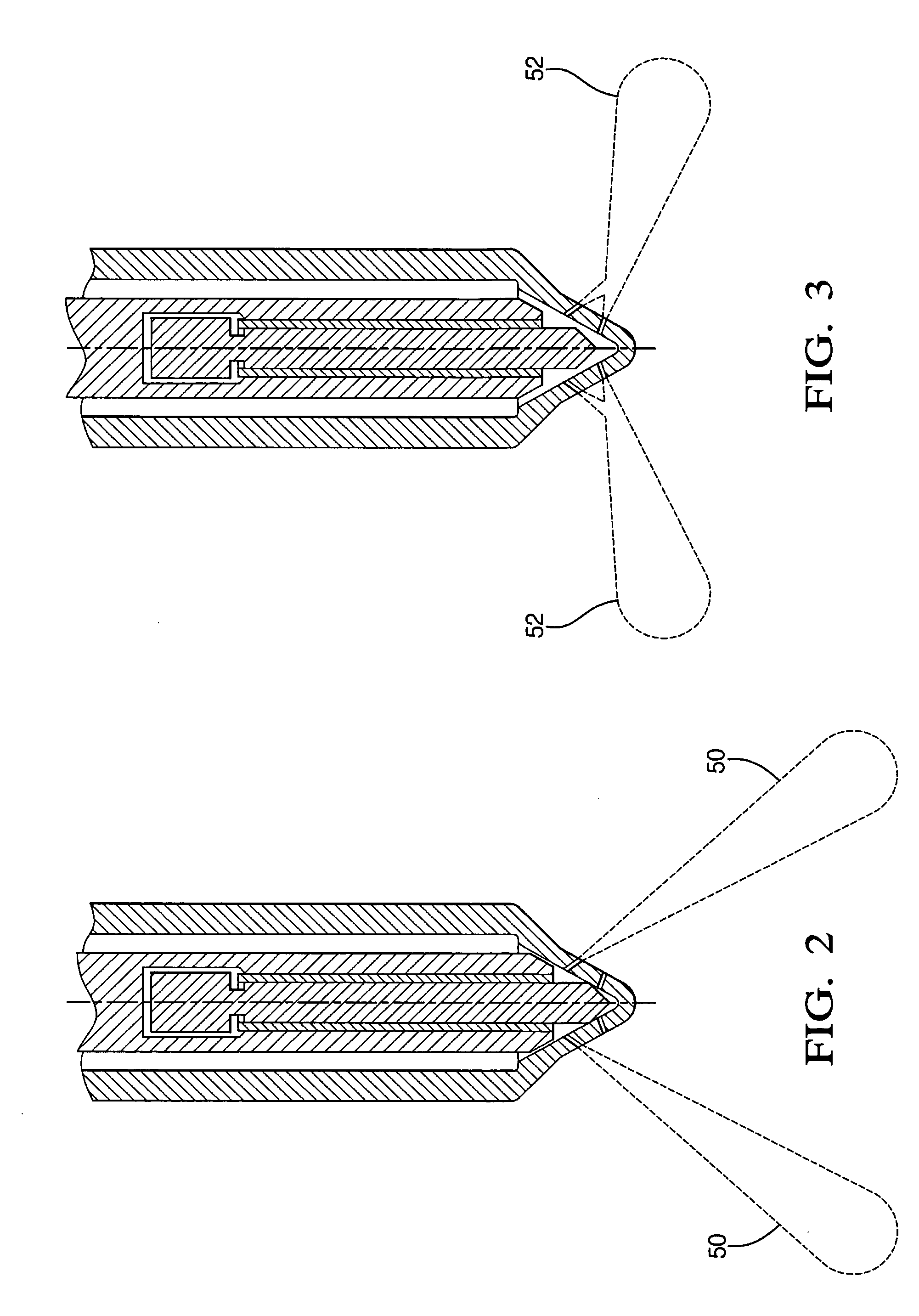

Apparatus and method for mode-switching fuel injector nozzle

InactiveUS20050224605A1Prevent penetrationInternal combustion piston enginesSpray nozzlesHomogeneous charge compression ignitionCombustion

A fuel injector nozzle for dispersing fuel during a normal combustion operation and a supplemental combustion operation, the fuel injector nozzle comprising: a plurality of first outlet openings configured to disperse fuel during homogeneous charge compression ignition and non-homogeneous charge compression ignition; and a plurality of second outlet openings configured to disperse fuel only during non-homogeneous charge compression ignition, wherein fuel dispersed from the plurality of second outlet openings collides with and subsumes fuel dispersed from the plurality of first outlet openings.

Owner:DELPHI TECH HLDG S A R L

Four-cylinder, four-cycle, free piston, premixed charge compression ignition, internal combustion reciprocating piston engine with a variable piston stroke

ActiveUS7258086B2Increase the compression ratioImprove engine efficiencyElectrical controlInternal combustion piston enginesFree-piston engineHomogeneous charge compression ignition

A four-cycle, four-cylinder, premixed charge compression ignition internal combustion reciprocating free piston engine with a variable piston stroke and a compression ratio that varies as needed to provide charge ignition, to offer the potential of higher efficiency, lower emissions, and multi-fuel operation. The engine does not have a crankshaft, and therefore does not provide direct rotary output. Instead its free pistons oscillate, in a manner similar to a two cycle free piston engine. For many applications, such as piston pumps and compressors, the engine provides an output directly driven by the oscillating pistons. In other applications, such as but not limited to use as a gas generator for a power turbine, the engine provides an indirect means of producing rotary power. When the engine is used with high-speed power turbines, the power turbine may be directly coupled to a high-speed alternator for electrical power output.

Owner:SUSTAINABLE ENERGY TECH DEV TRUST

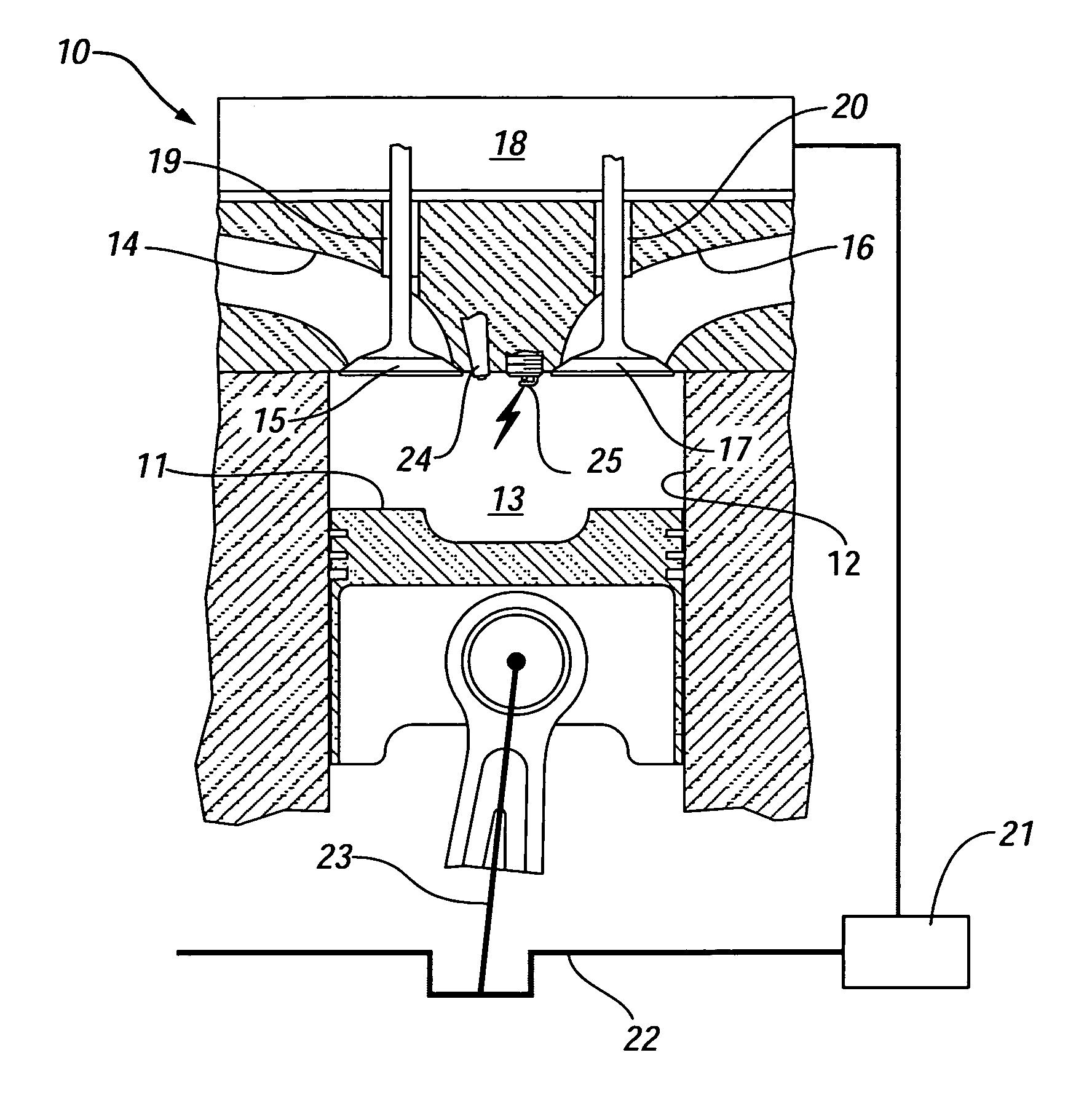

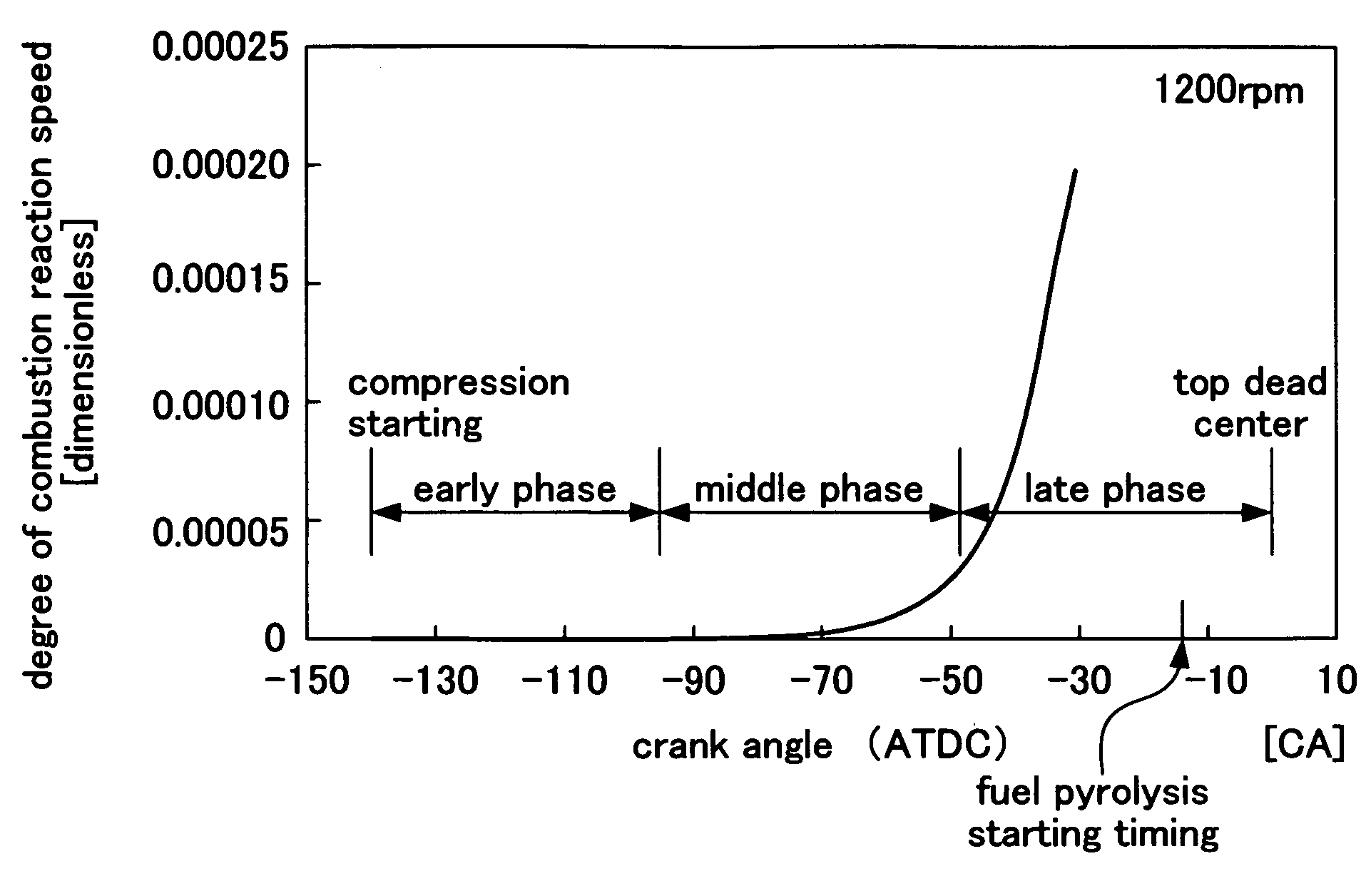

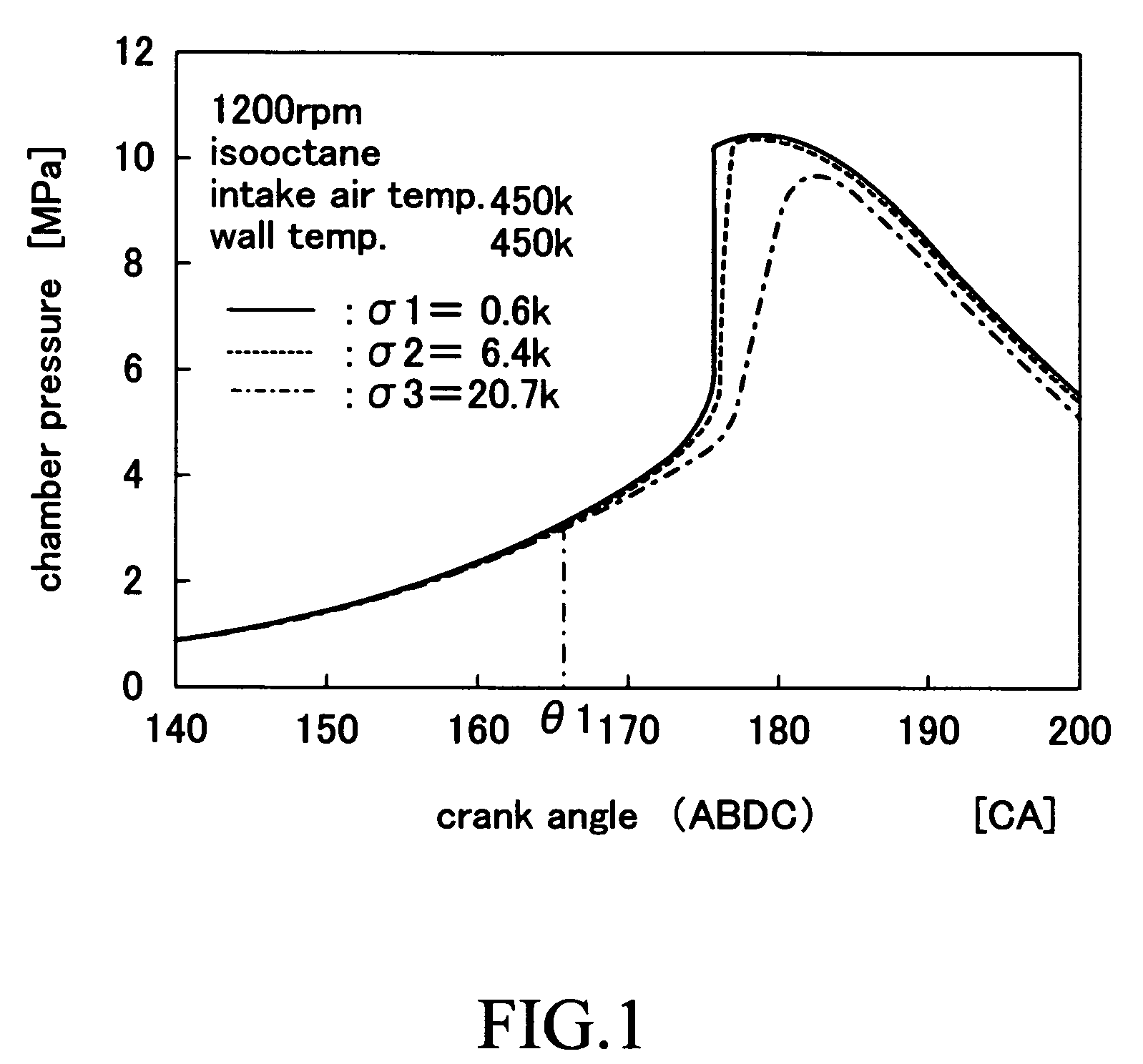

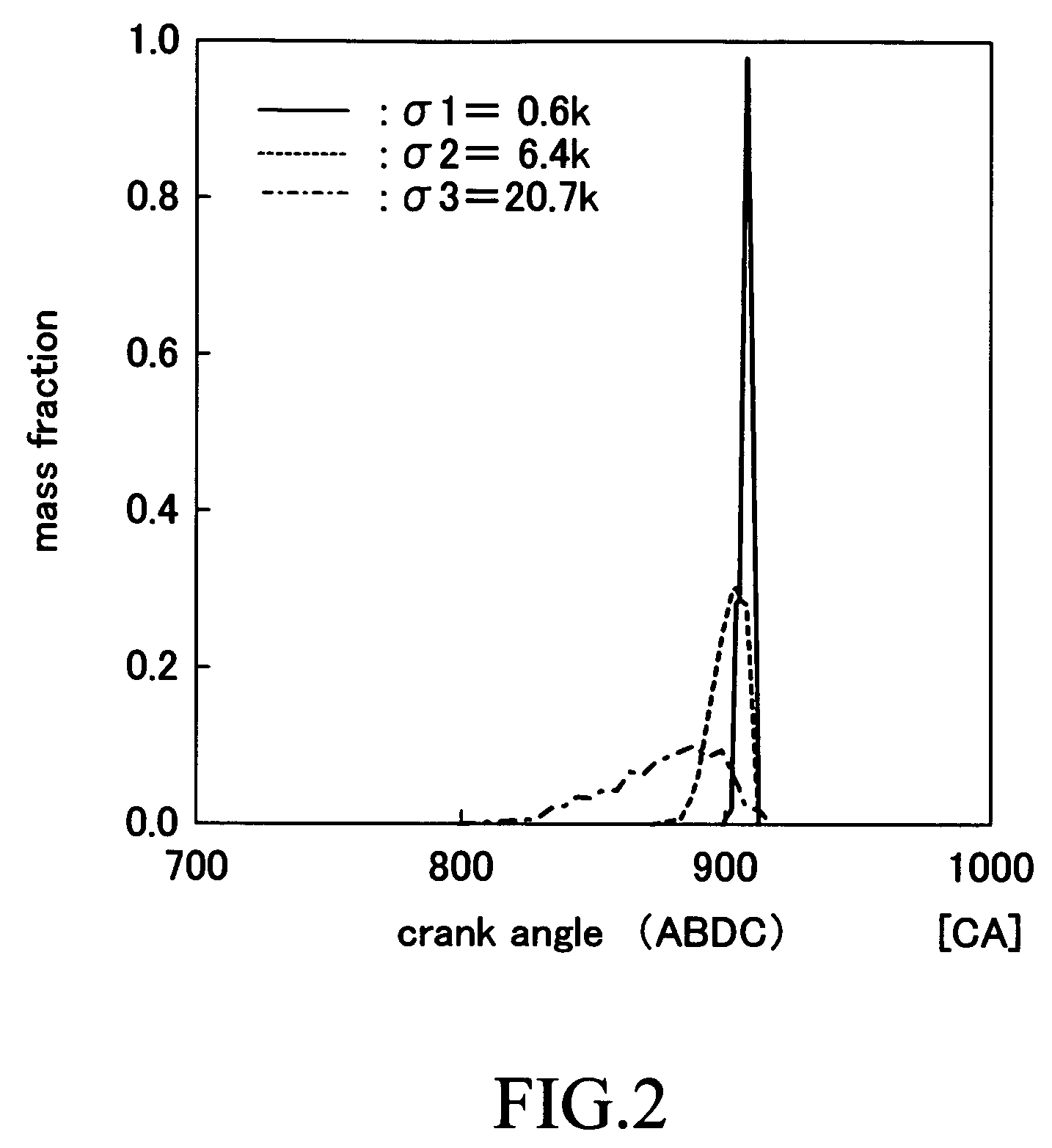

Control apparatus for an internal combustion engine capable of pre-mixed charge compression ignition

InactiveUS7421999B2Increase temperatureSystem can be simplified and lightenedElectrical controlNon-fuel substance addition to fuelHomogeneous charge compression ignitionCombustion noise

An electric control device 70 is applied to an internal combustion engine 10 capable of a pre-mixed charge compression ignition combustion in which air-fuel mixture gas including air and fuel injected from an injector 37 is formed in a combustion chamber 25, and the air-fuel mixture gas is self-ignited to be combusted by compressing the air-fuel mixture gas during a compression stroke. The electric control device injects high pressure fluid such as air from the air injection valve 38 into the air-fuel mixture gas at a predetermined acting timing within a compression stroke prior to fuel pyrolysis starting timing to enhance the temperature un-uniformity of the air-fuel mixture gas. This enables the temperature un-uniformity of the air-fuel mixture gas at the fuel pyrolysis starting timing to become larger than the temperature un-uniformity of the air-fuel mixture gas at the fuel pyrolysis starting timing obtained only by simply compressing the air-fuel mixture gas during the compression stroke. As a result, the combustion is moderated and the combustion noise is reduced.

Owner:TOYOTA JIDOSHA KK

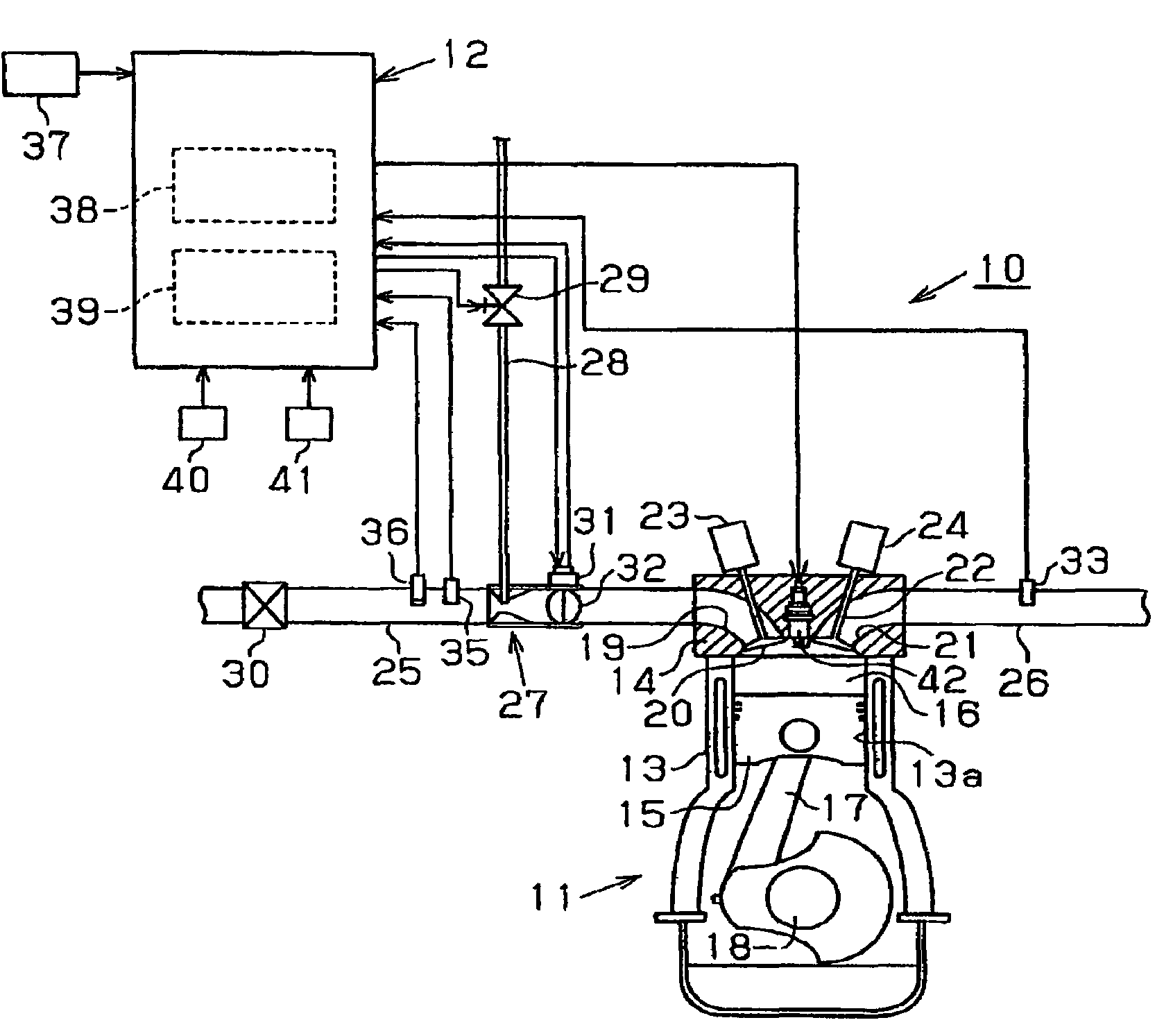

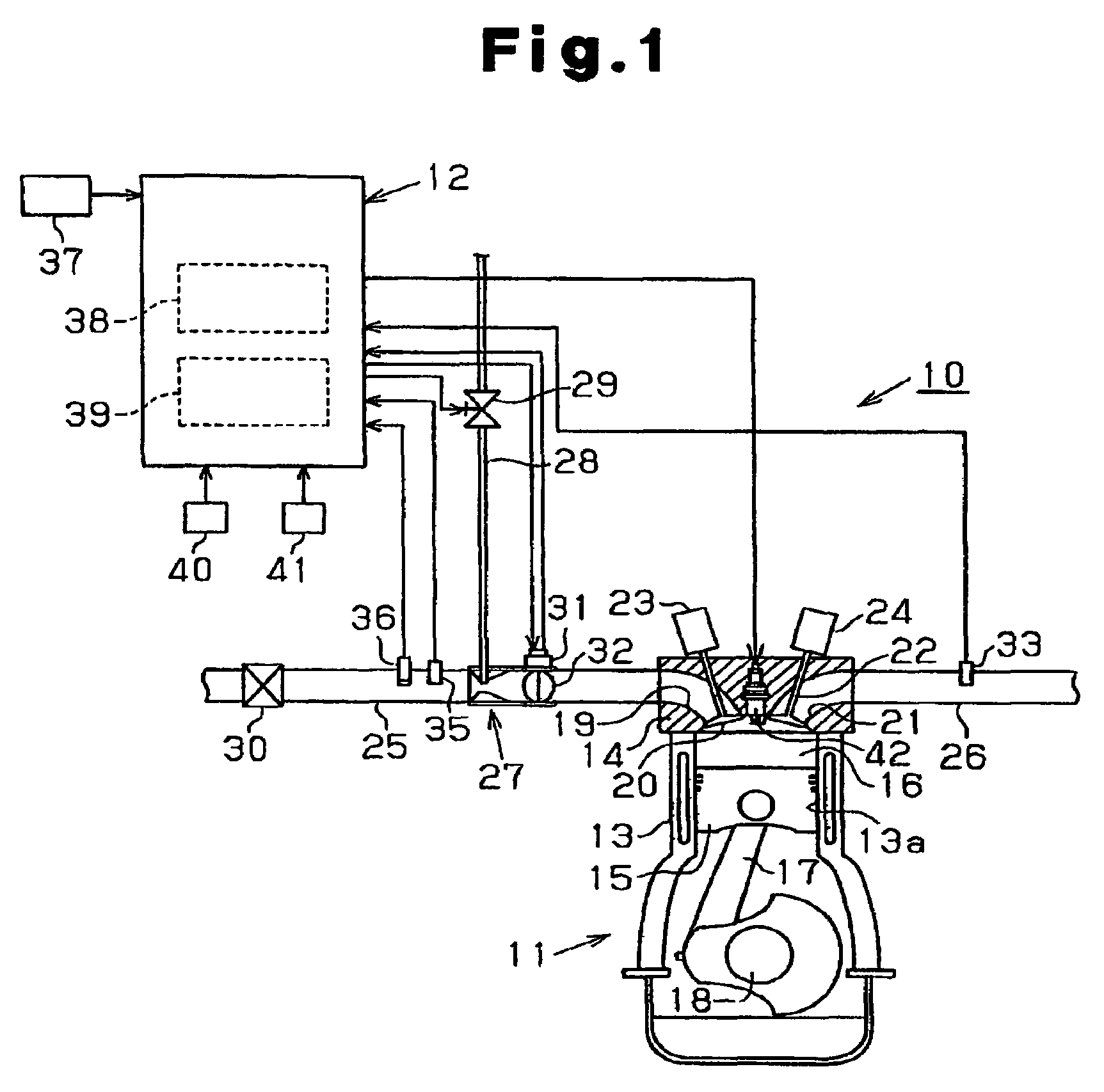

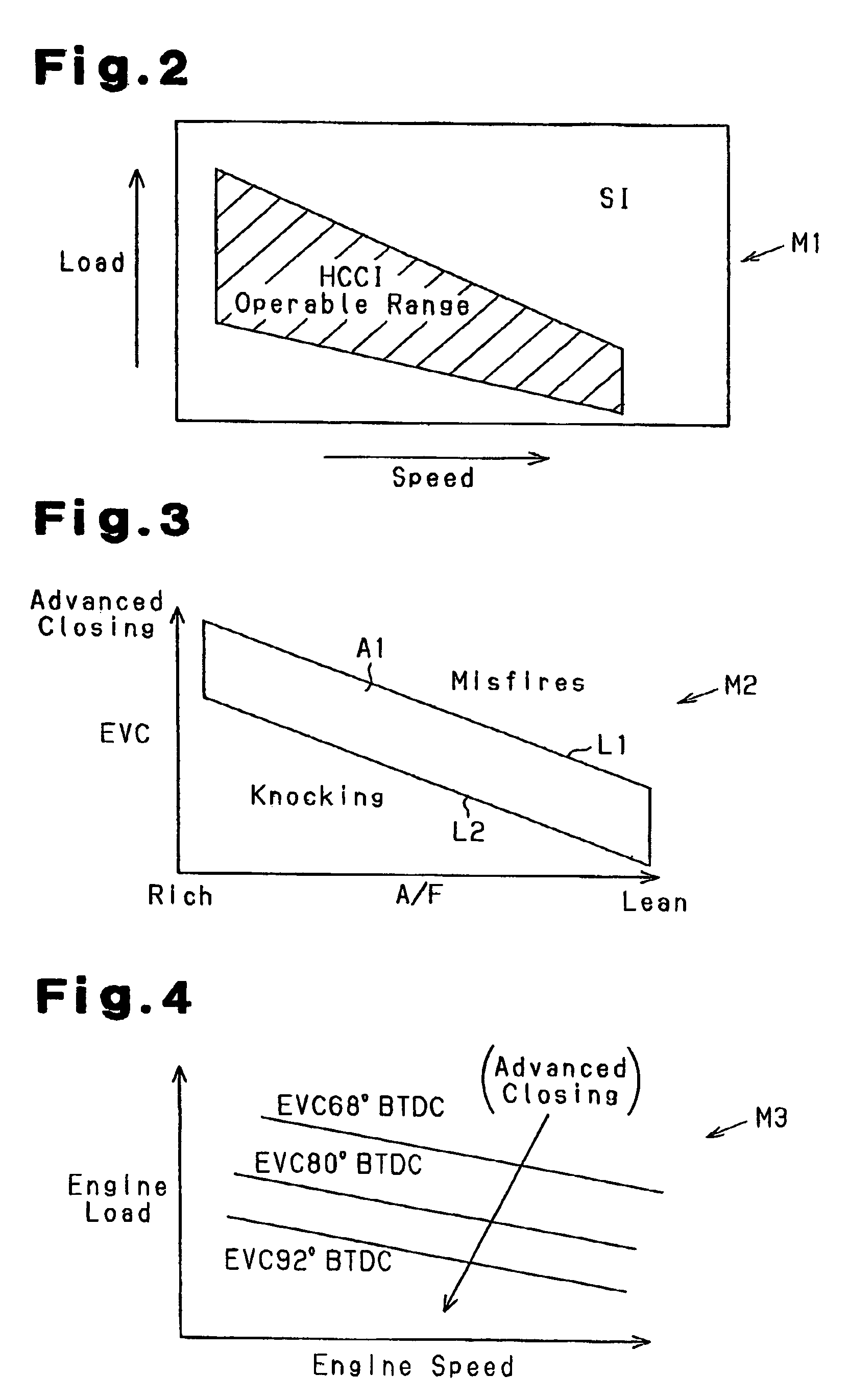

Homogeneous charge compression ignition engine and method for operating homogeneous charge compression ignition engine

InactiveUS6978771B2Avoid it happening againElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

A homogeneous charge compression ignition engine for preventing knocking or misfires even if the air-fuel ratio deviates from a target value. The controller determines the possibility of misfires occurring due to changes in the air-fuel ratio based on a map showing the relationship of the air-fuel ratio and the timing at which the exhaust valve closes (EVC) when stable homogeneous charge compression ignition is enabled. When there is a possibility of misfires occurring, the controller retards the EVC. When there is a possibility of knocking occurring due to changes in the air-fuel ratio, the controller uses a map to advance the EVC.

Owner:TOYOTA IND CORP

Method and apparatus to operate a homogeneous charge compression-ignition engine

ActiveUS20070107692A1Low variabilityElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionCoolant temperature

A method and apparatus for controlling engine operation to compensate for effects of combustion chamber deposits (CCDs) on combustion in a controlled auto-ignition engine is presented. Control methodologies comprise operation of variable valve actuation, fuel injection, spark timing, and intake air and coolant temperature to dynamically compensate for the effect of CCDs. A sensitivity to core gas temperature and chamber wall thermal conditions is shown, which is correlatable to in-cylinder CCD formation. Intake charge or coolant temperature control can be used to compensate for CCD effects. An engine control scheme relies upon a parametric input that quantifies instantaneous CCD formation in the combustion chamber. The result is further applicable to control pre-ignition in a conventional spark-ignition engine.

Owner:GM GLOBAL TECH OPERATIONS LLC

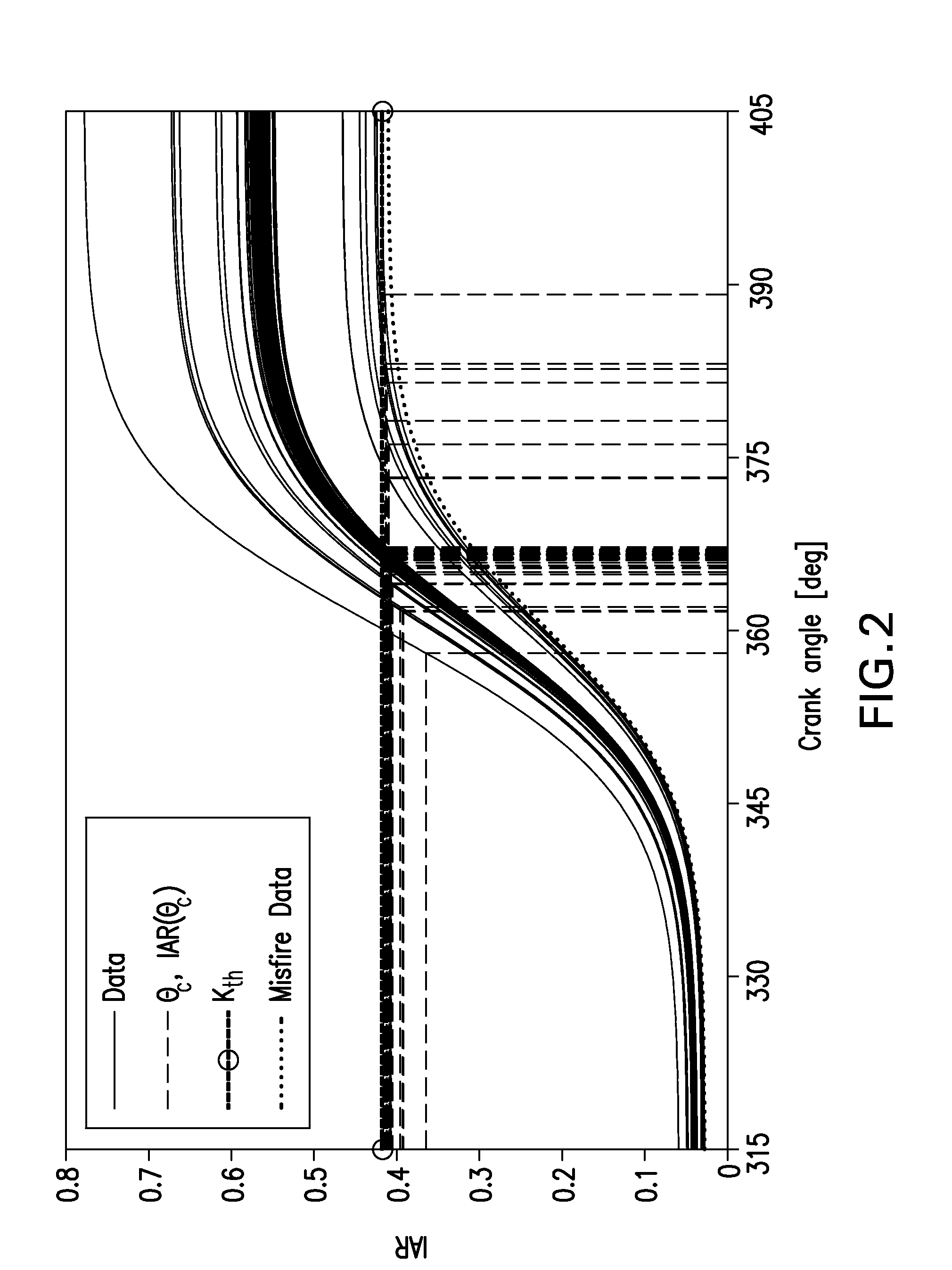

Prediction and estimation of the states related to misfire in an HCCI engine

InactiveUS20110270505A1Guaranteed uptimeInternal-combustion engine testingAnalogue computers for vehiclesHomogeneous charge compression ignitionExhaust valve

A method for predicting and correcting an impending misfire in a homogeneous charge compression ignition (HCCI) engine includes: modeling HCCI engine operation in a nominal, steady-state operating region and in unstable operating regions bordering the steady-state operating region, using a zero-dimensional model; predicting an occurrence of an engine misfire based on the modeling of the HCCI engine operation; and providing a remedial corrective measure when an engine misfire is predicted. The remedial corrective measure includes one of: (a) late injection to avoid full combustion during a trapping cycle, and a reduction in amount of injected fuel to account for residual fuel of the previous cycle; or (b) earlier exhaust valve closing to trigger combustion of residual fuel within the trapping cycle, and a later injection and reduction of injected fuel to account for residual fuel of the previous cycle.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com