Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

450 results about "Valvetrain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A valvetrain or valve train is a mechanical system that controls operation of the valves in an internal combustion engine, whereby a sequence of components transmits motion throughout the assembly. A conventional reciprocating internal combustion engine uses valves to control the flow of the air/fuel admix into and out of the combustion chamber.

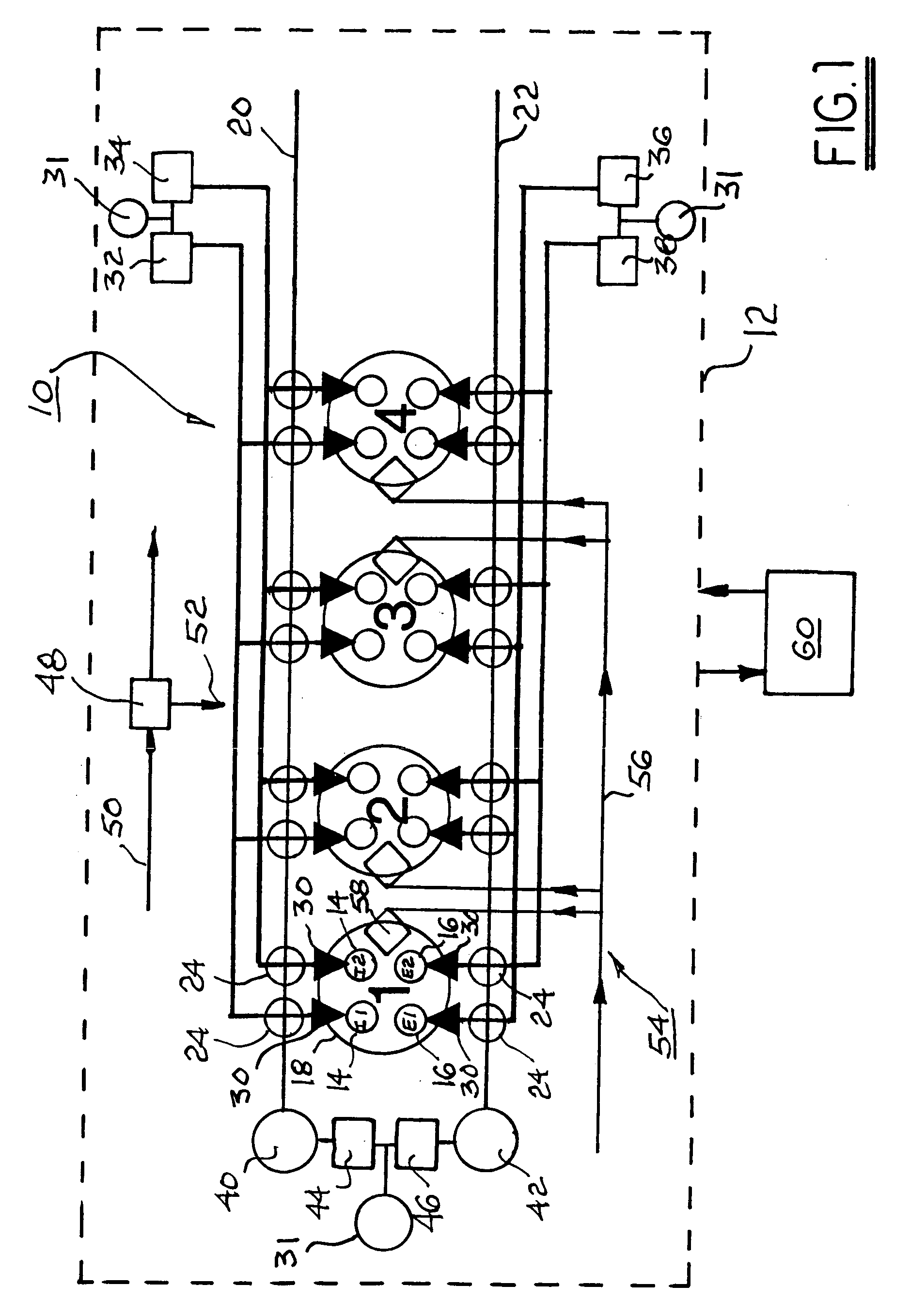

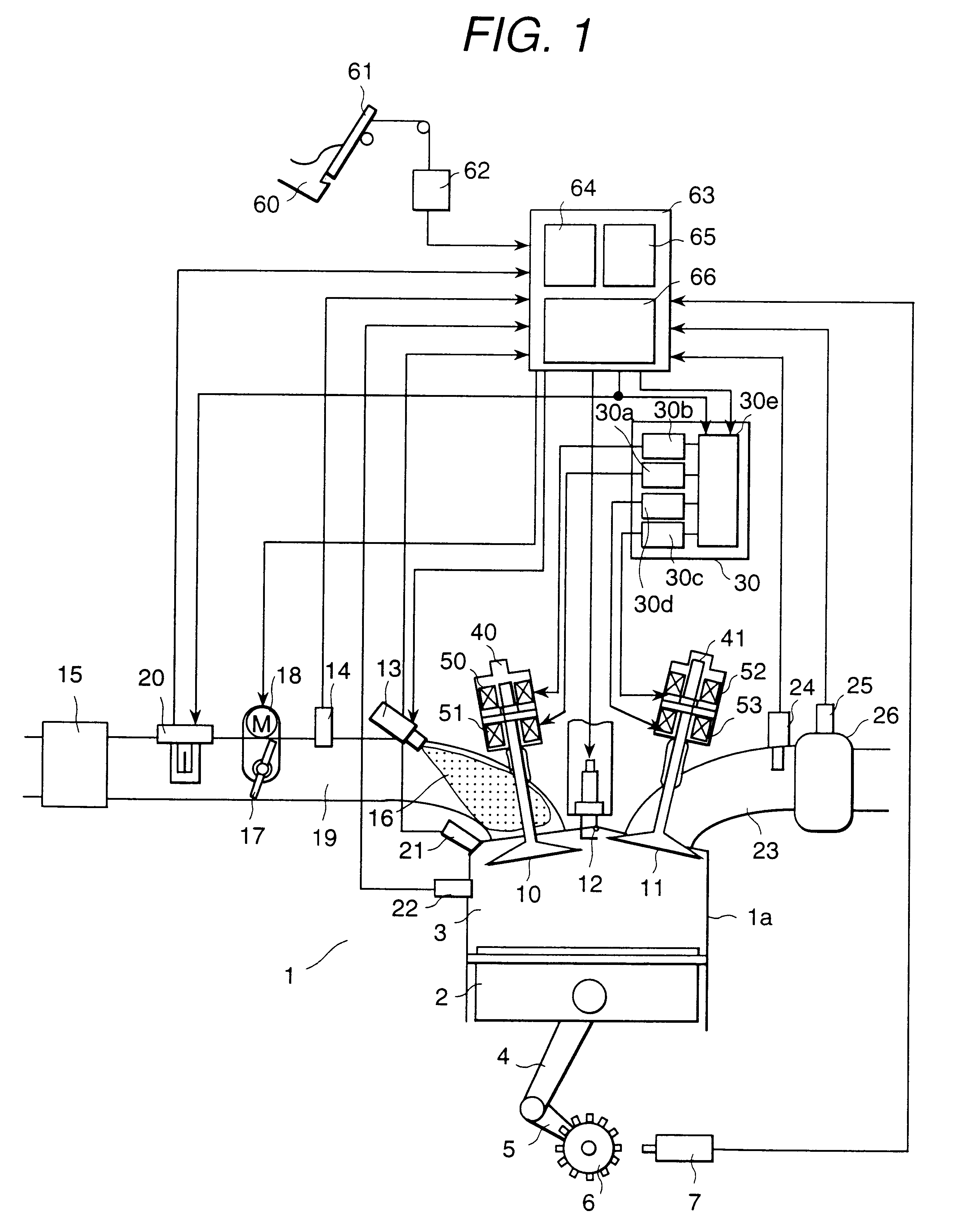

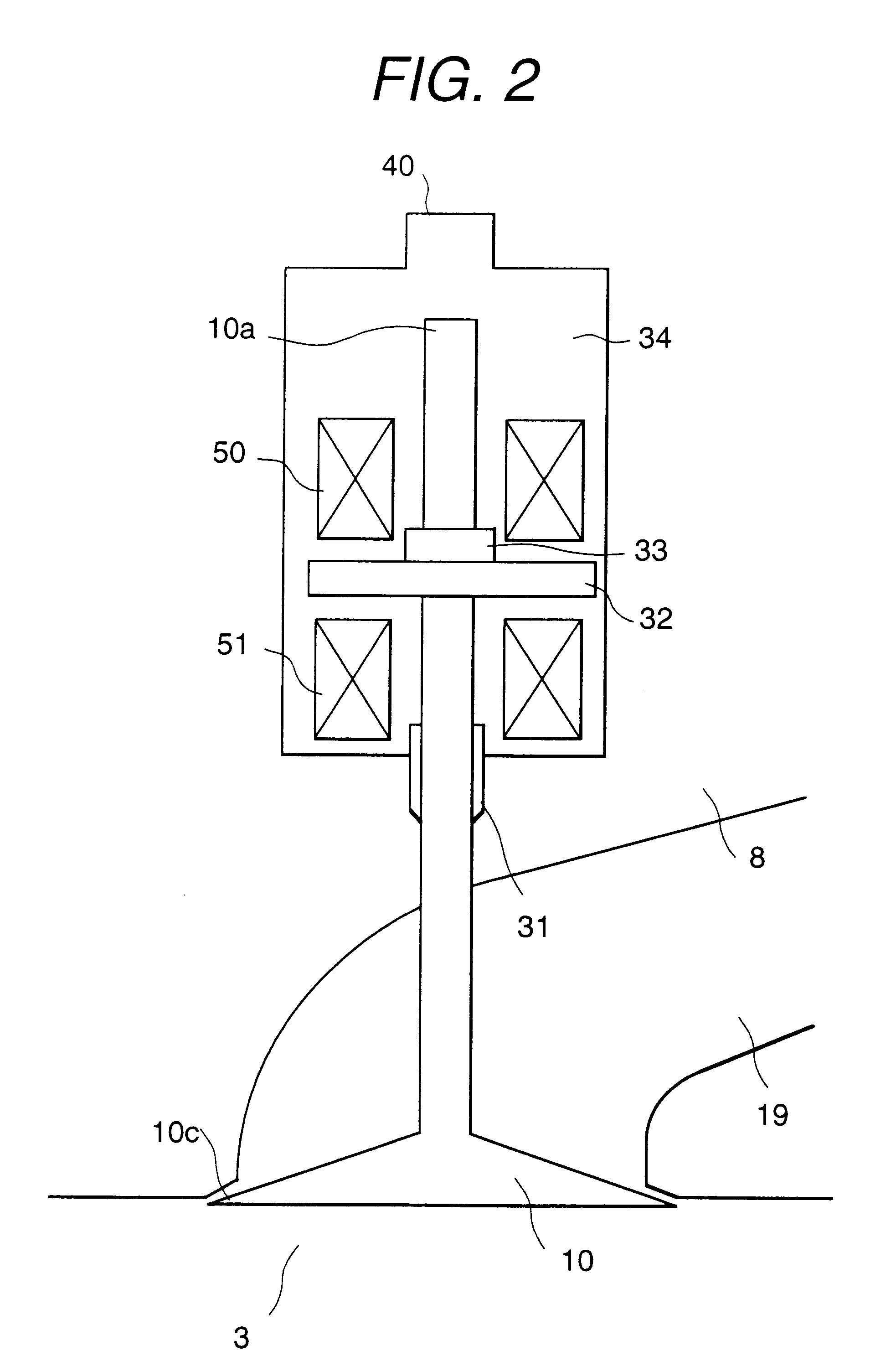

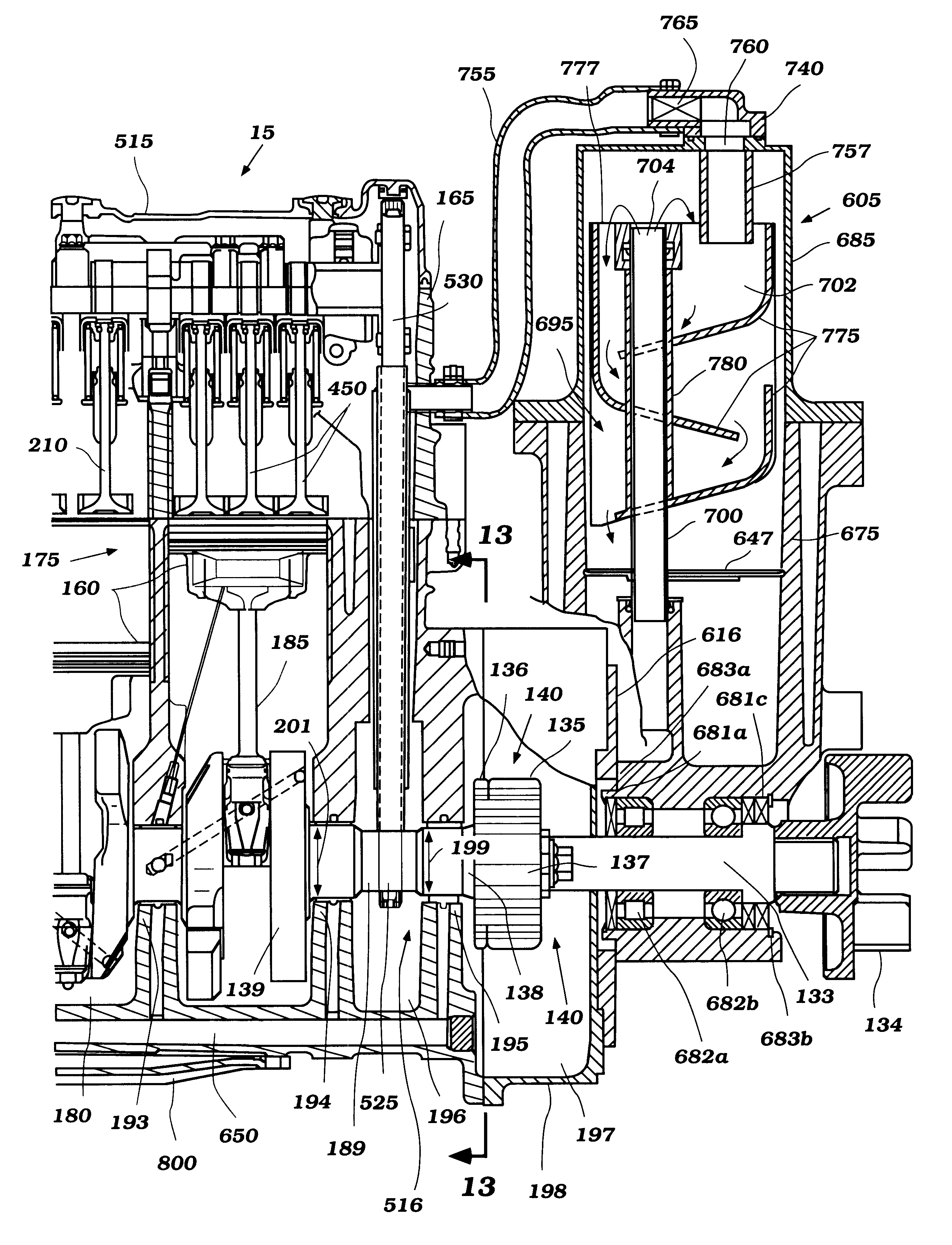

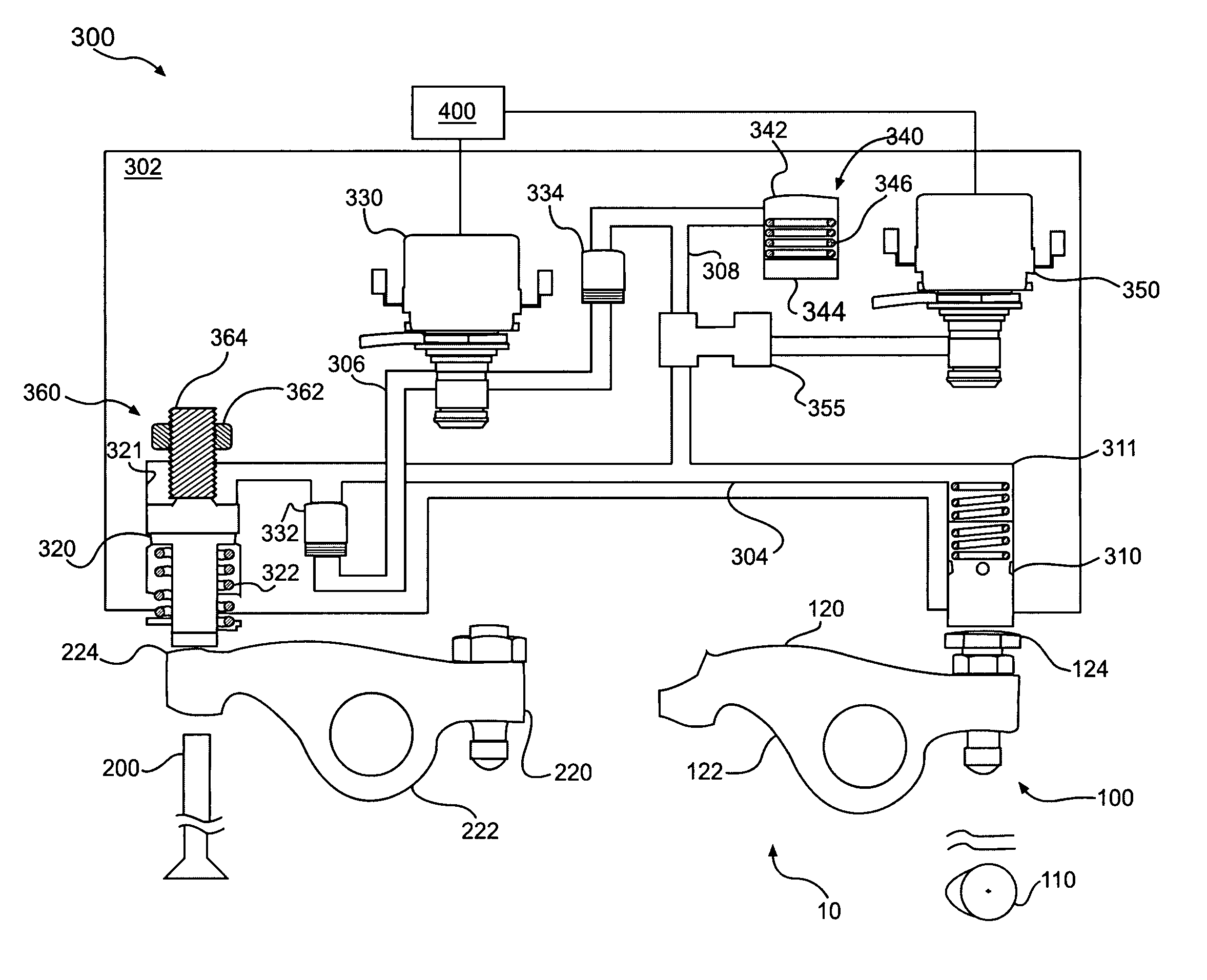

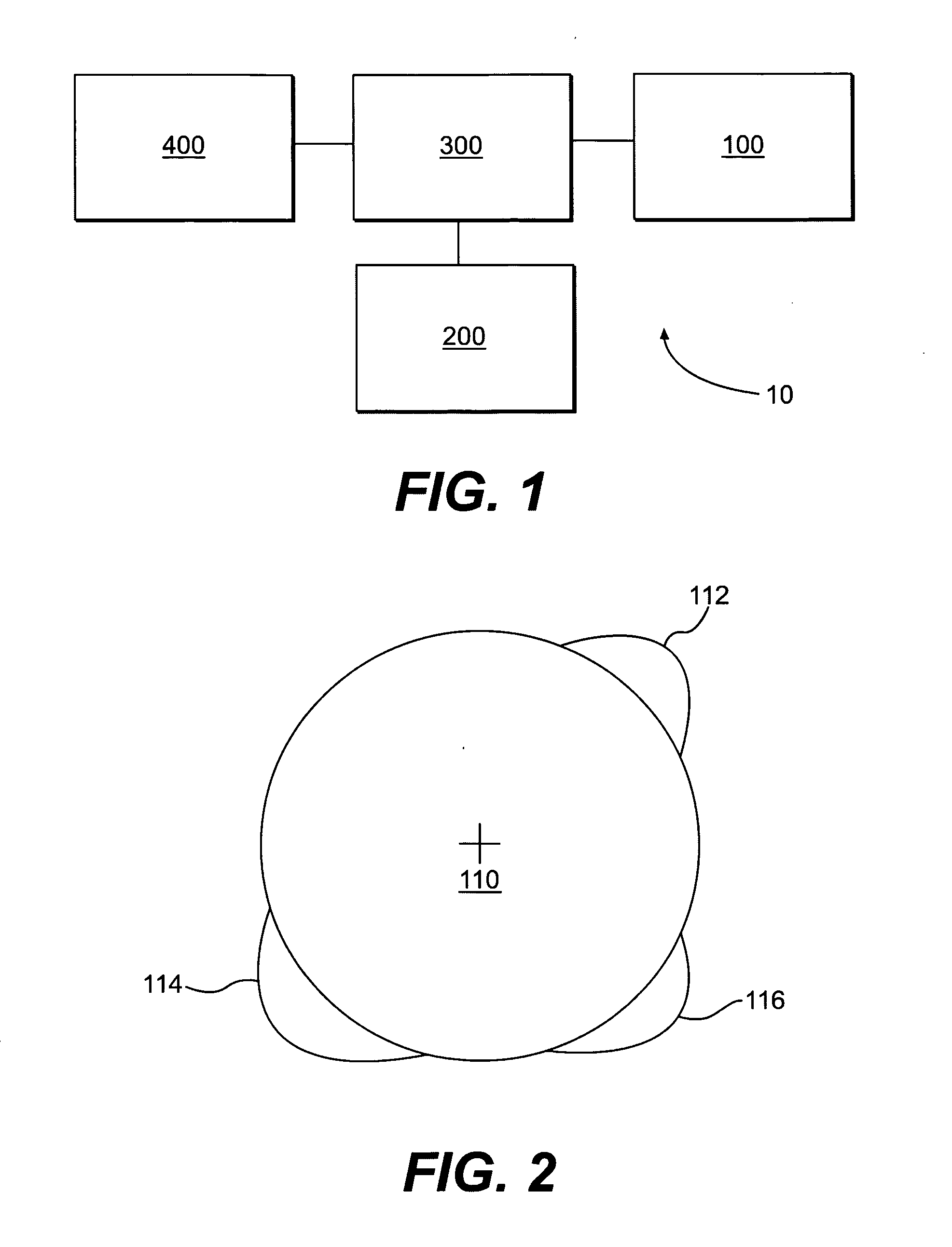

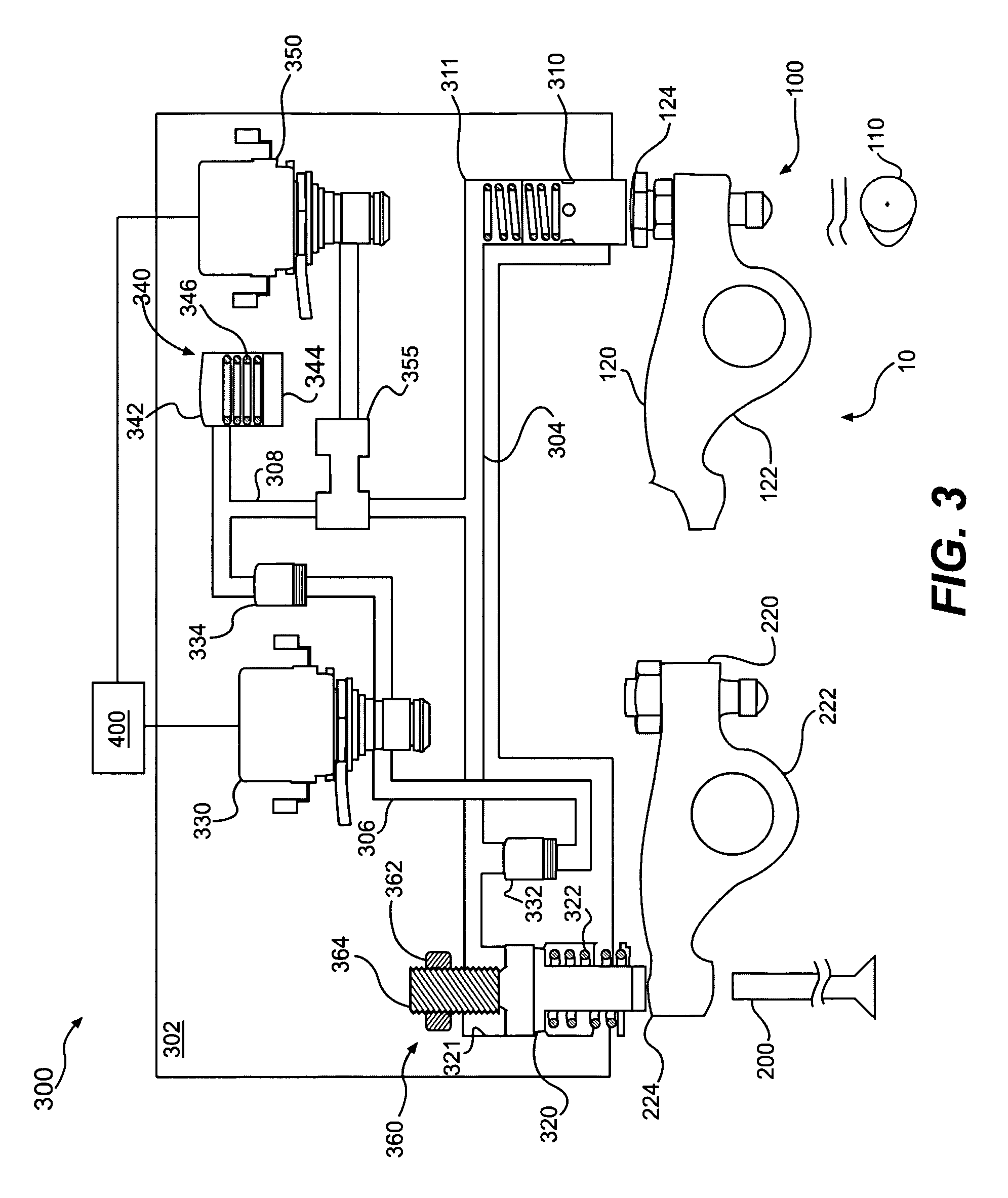

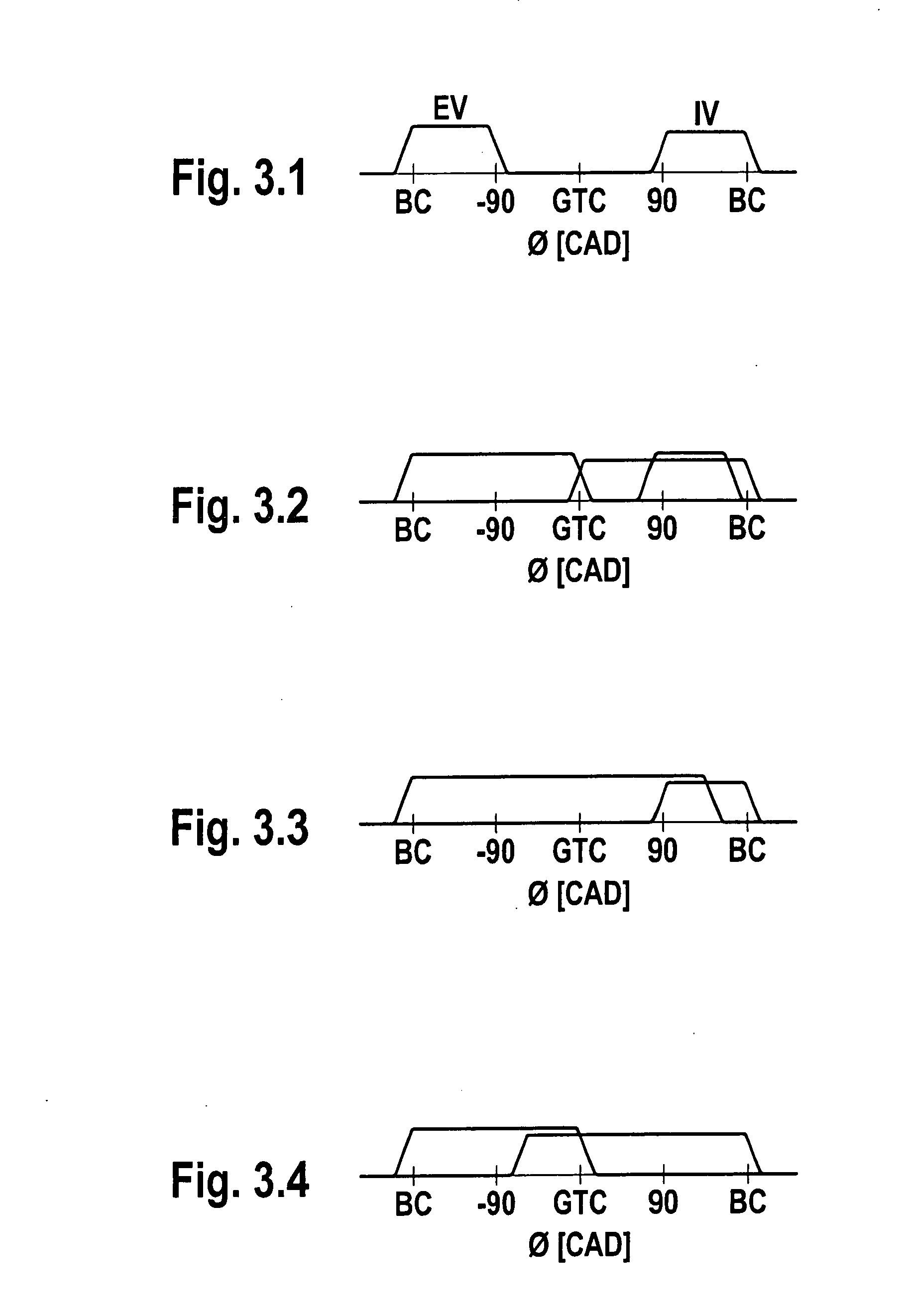

Method and apparatus for optimized combustion in an internal combustion engine utilizing homogeneous charge compression ignition and variable valve actuation

InactiveUS20060144356A1Electrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

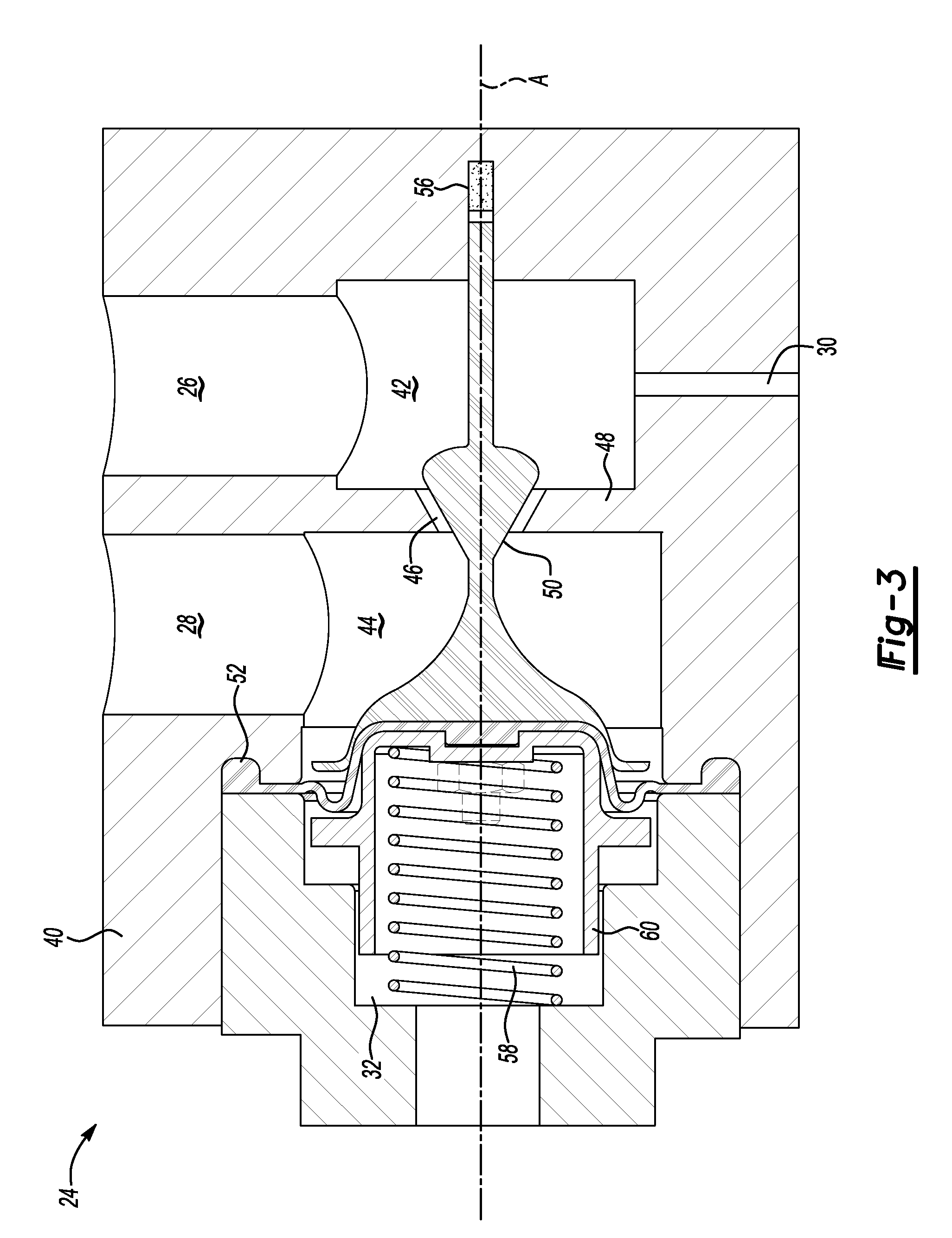

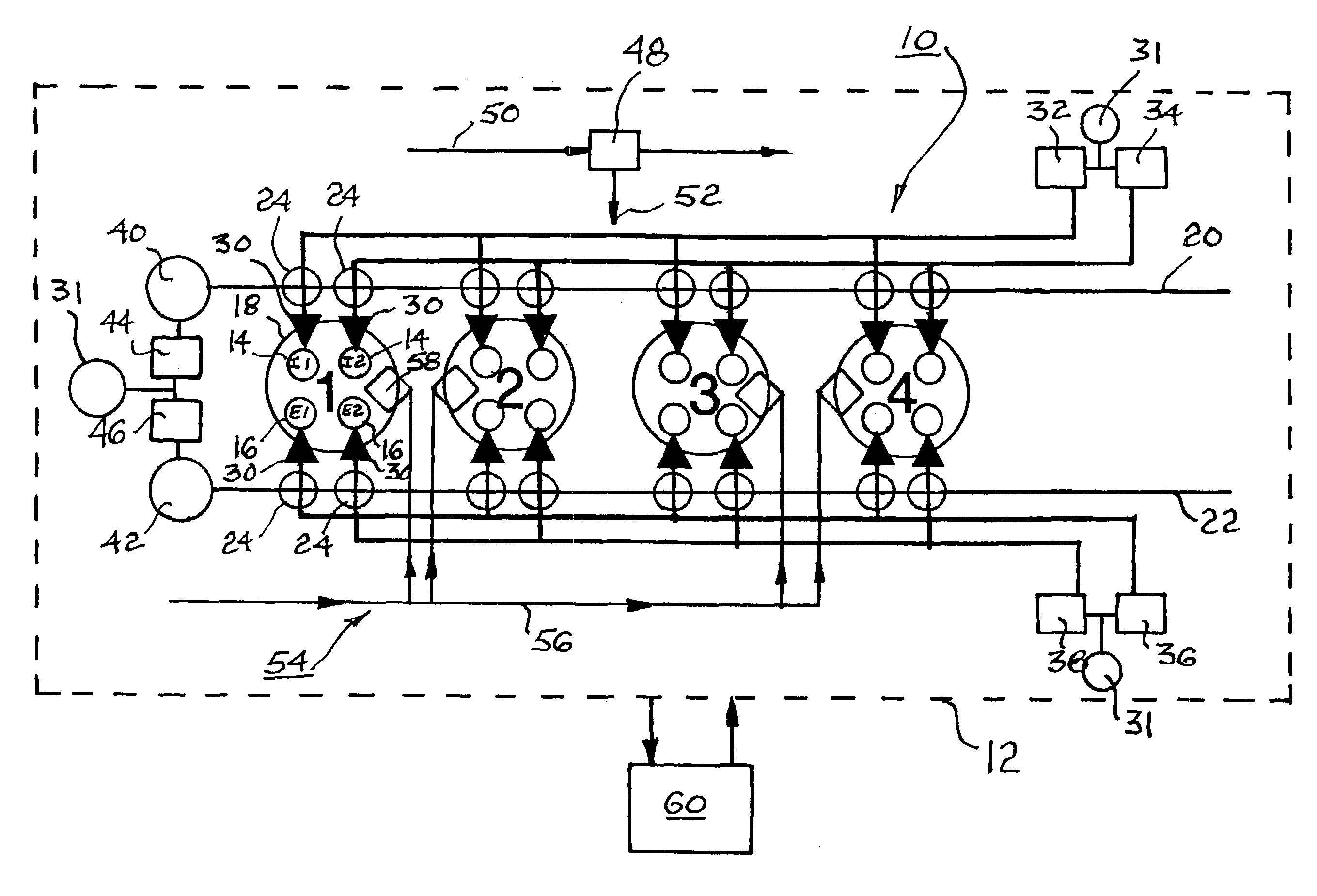

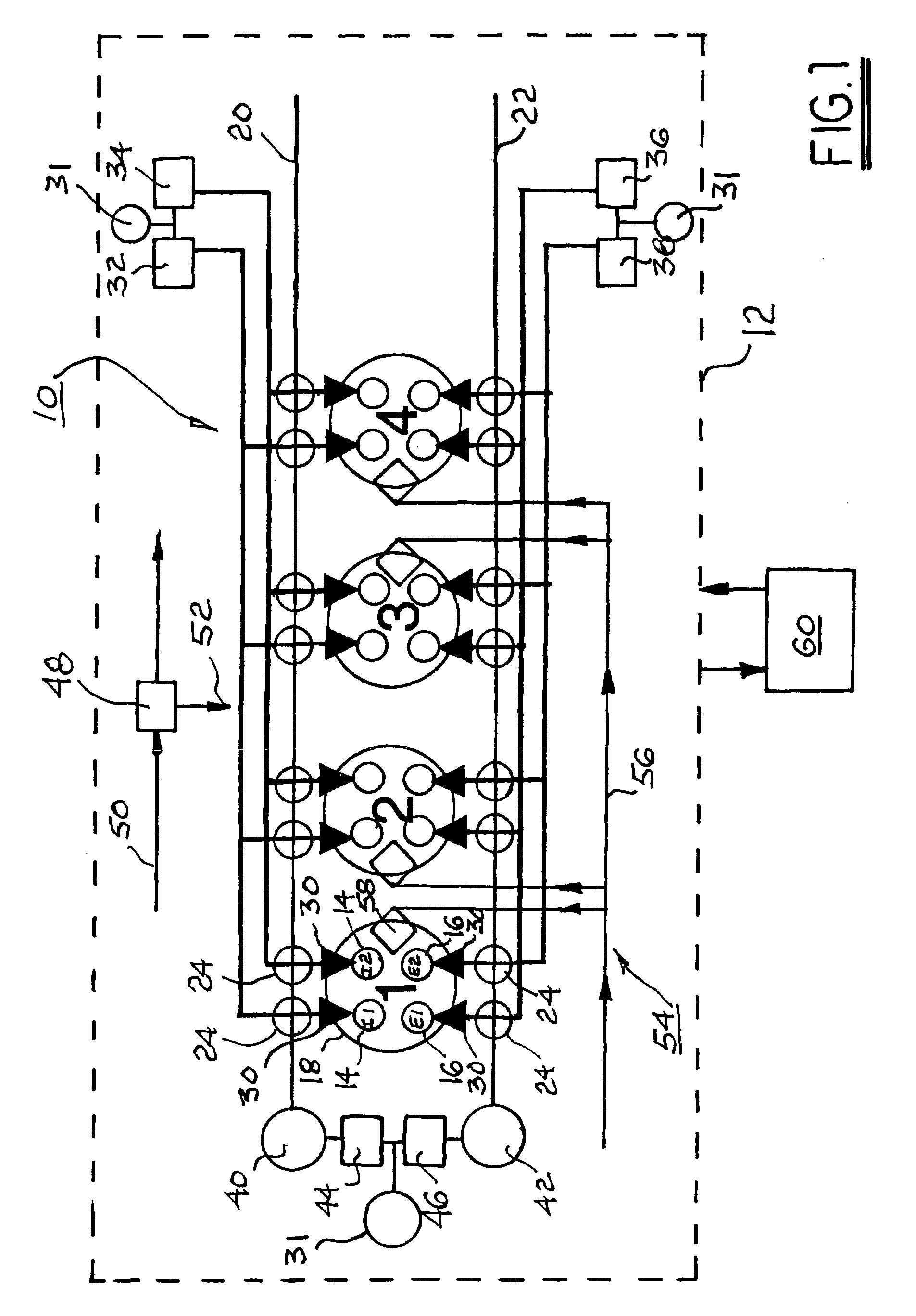

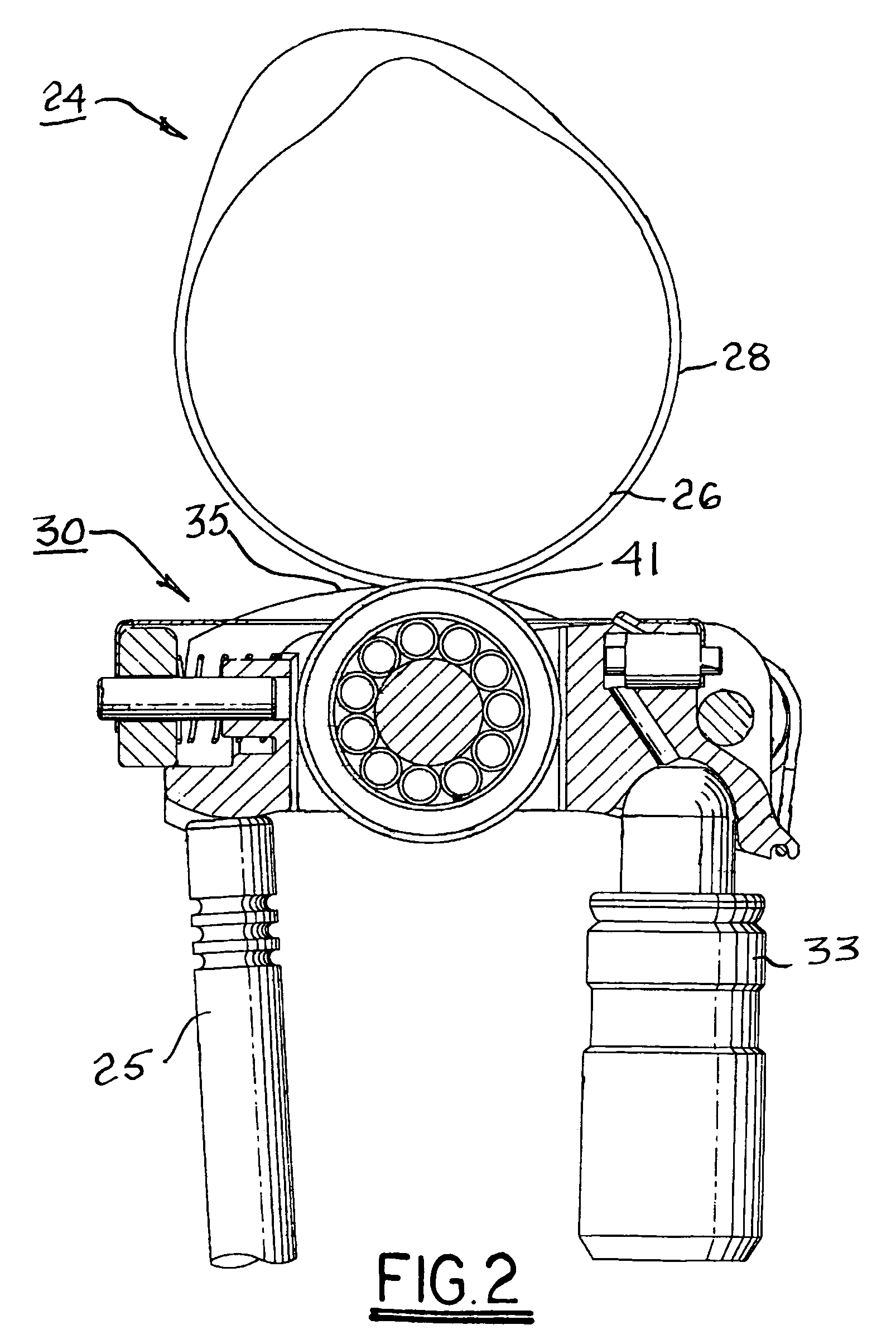

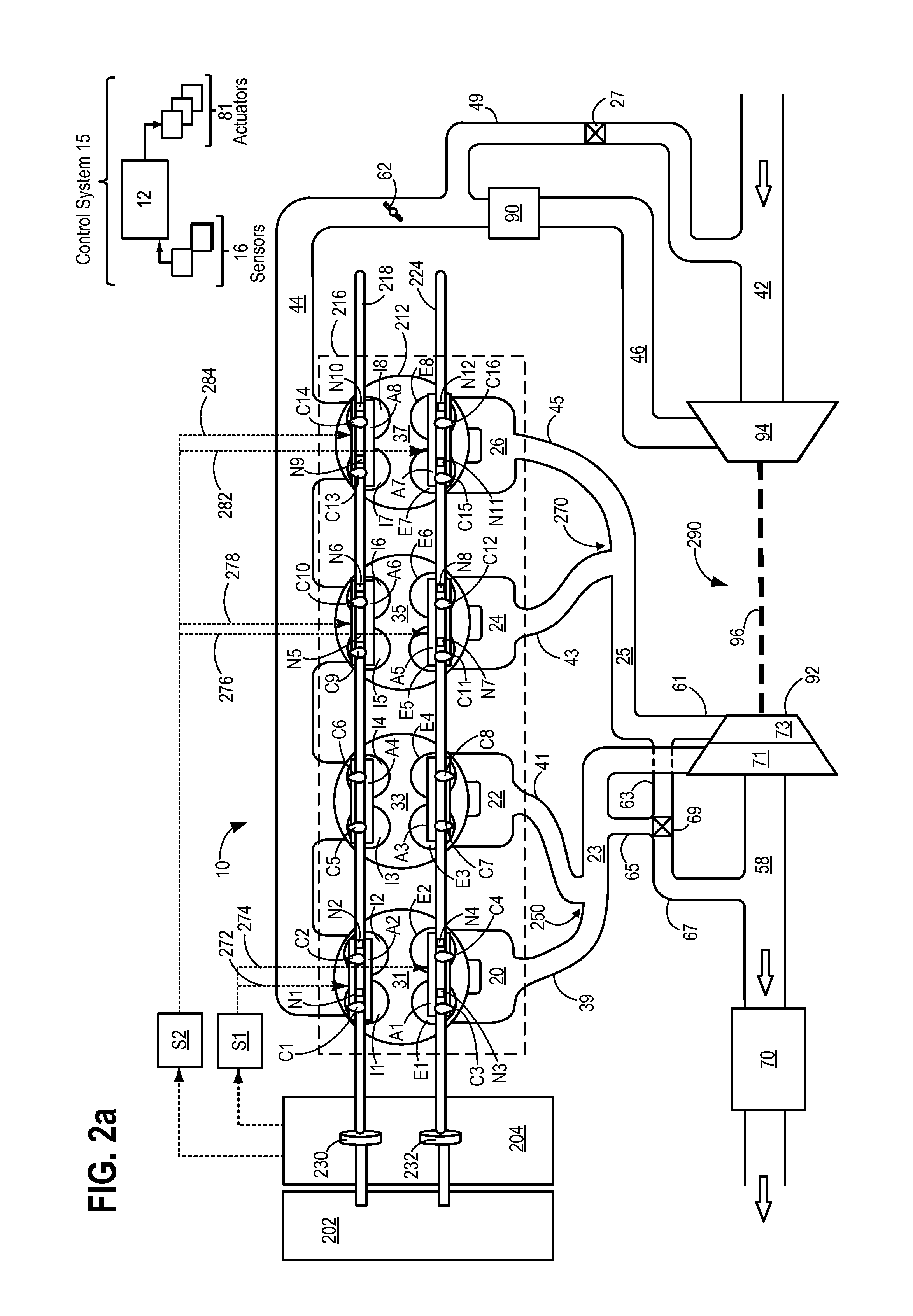

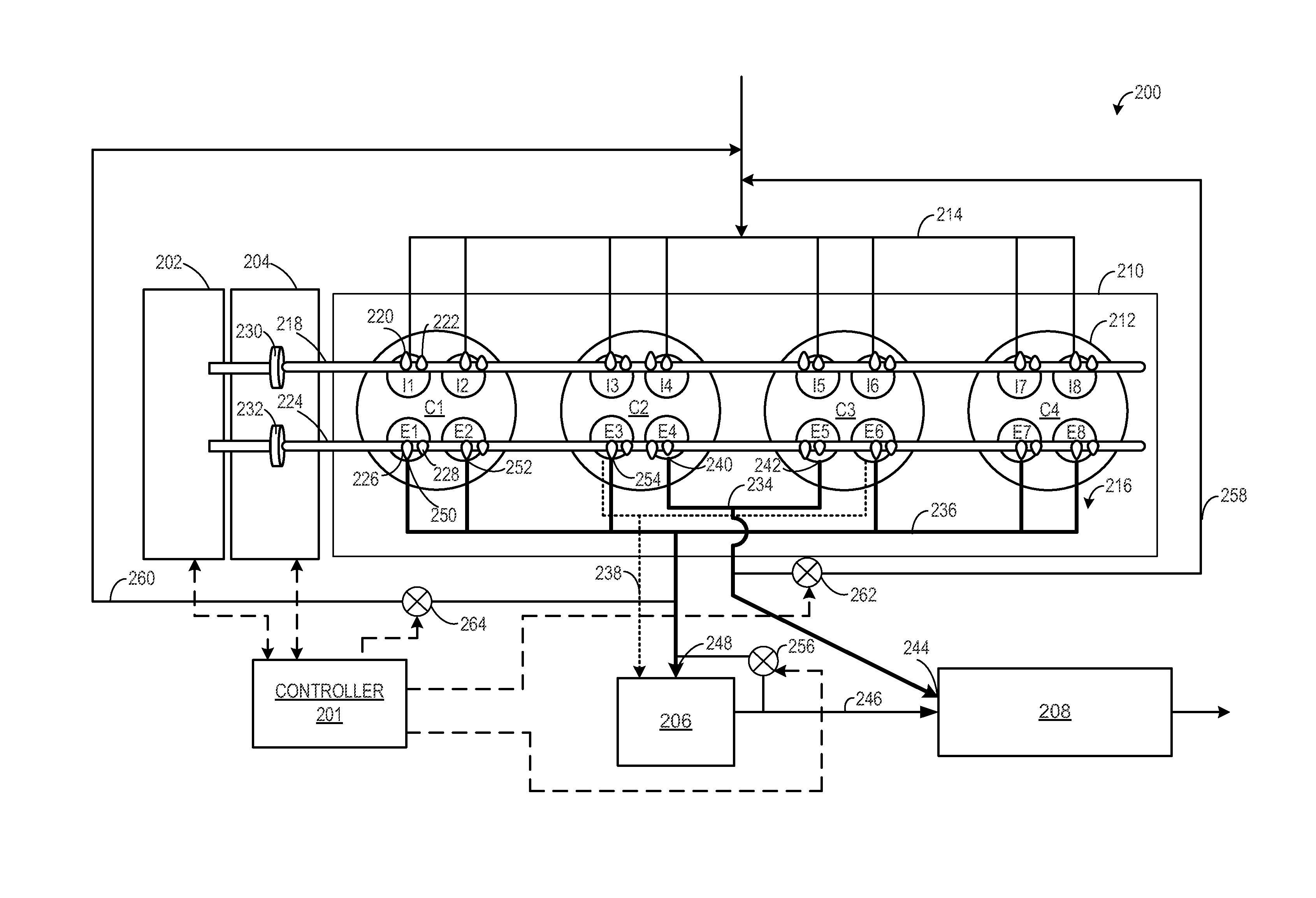

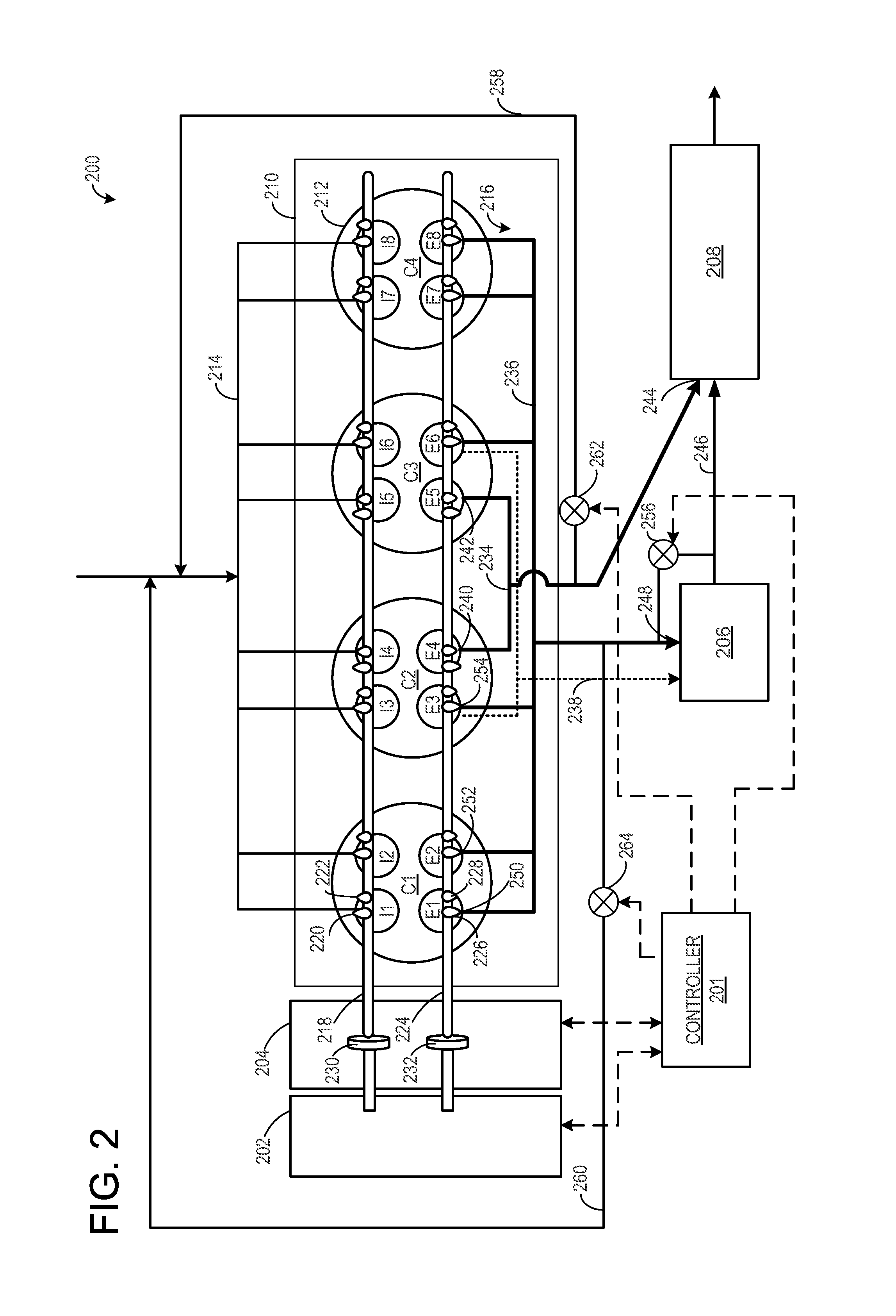

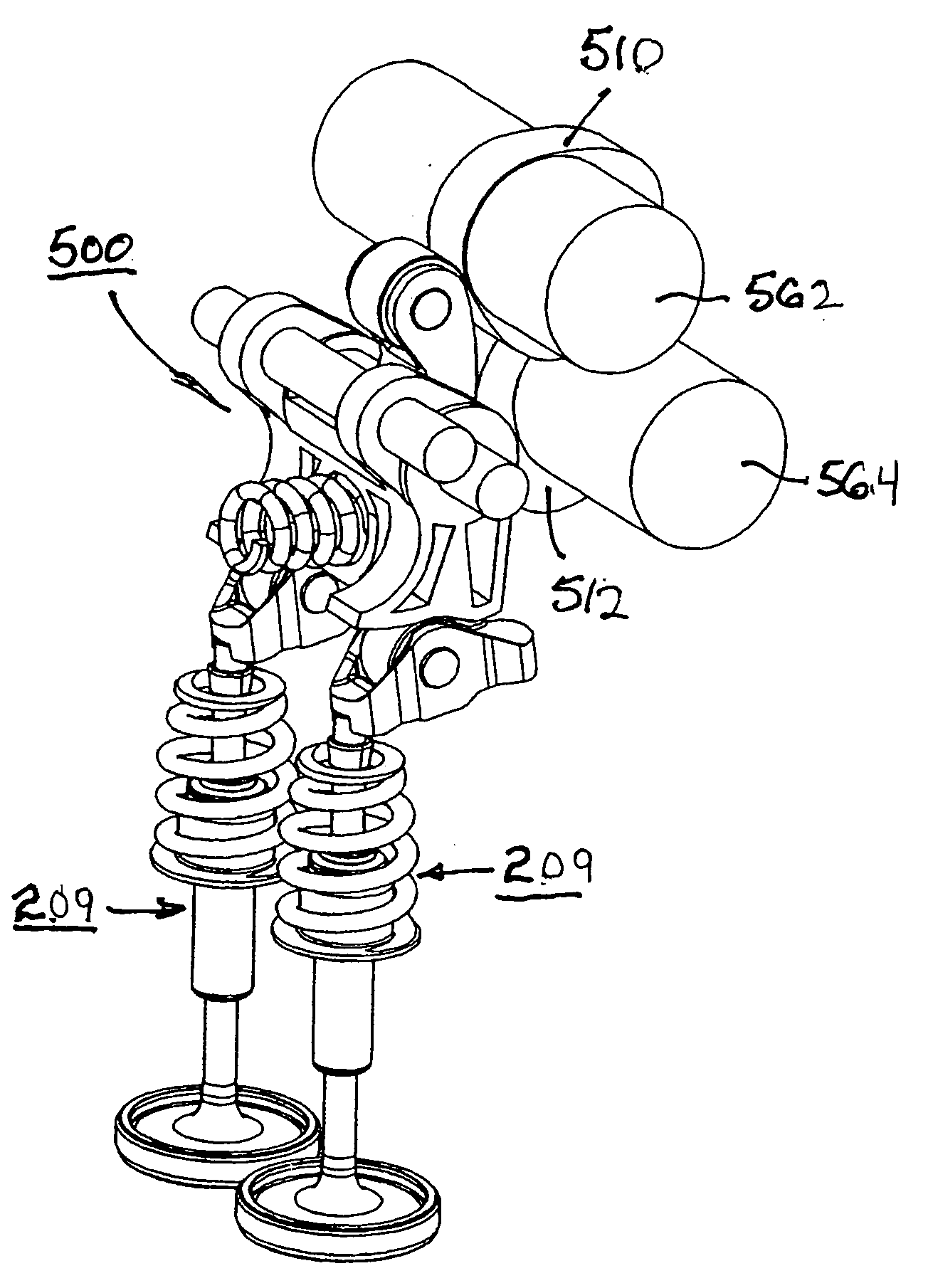

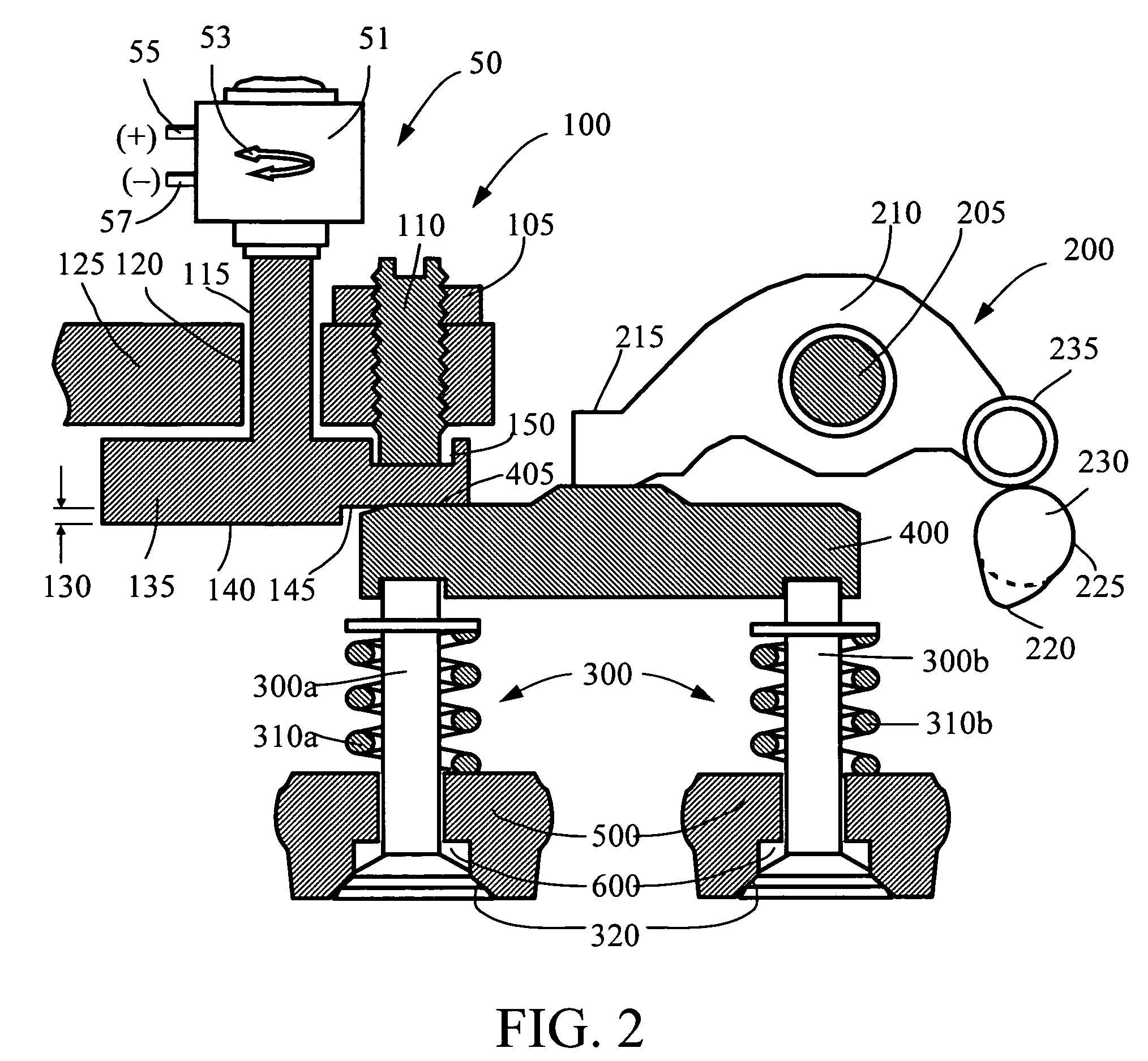

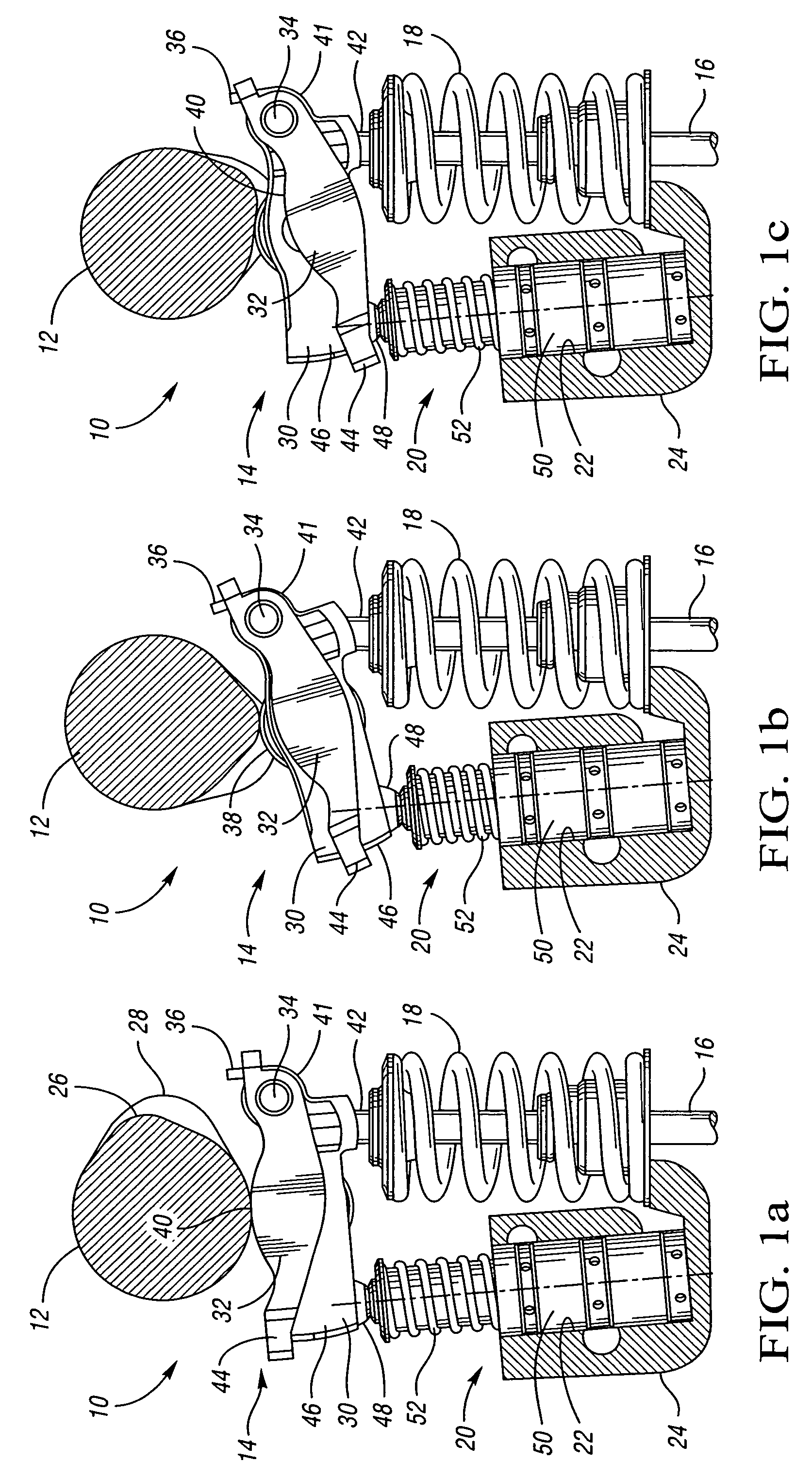

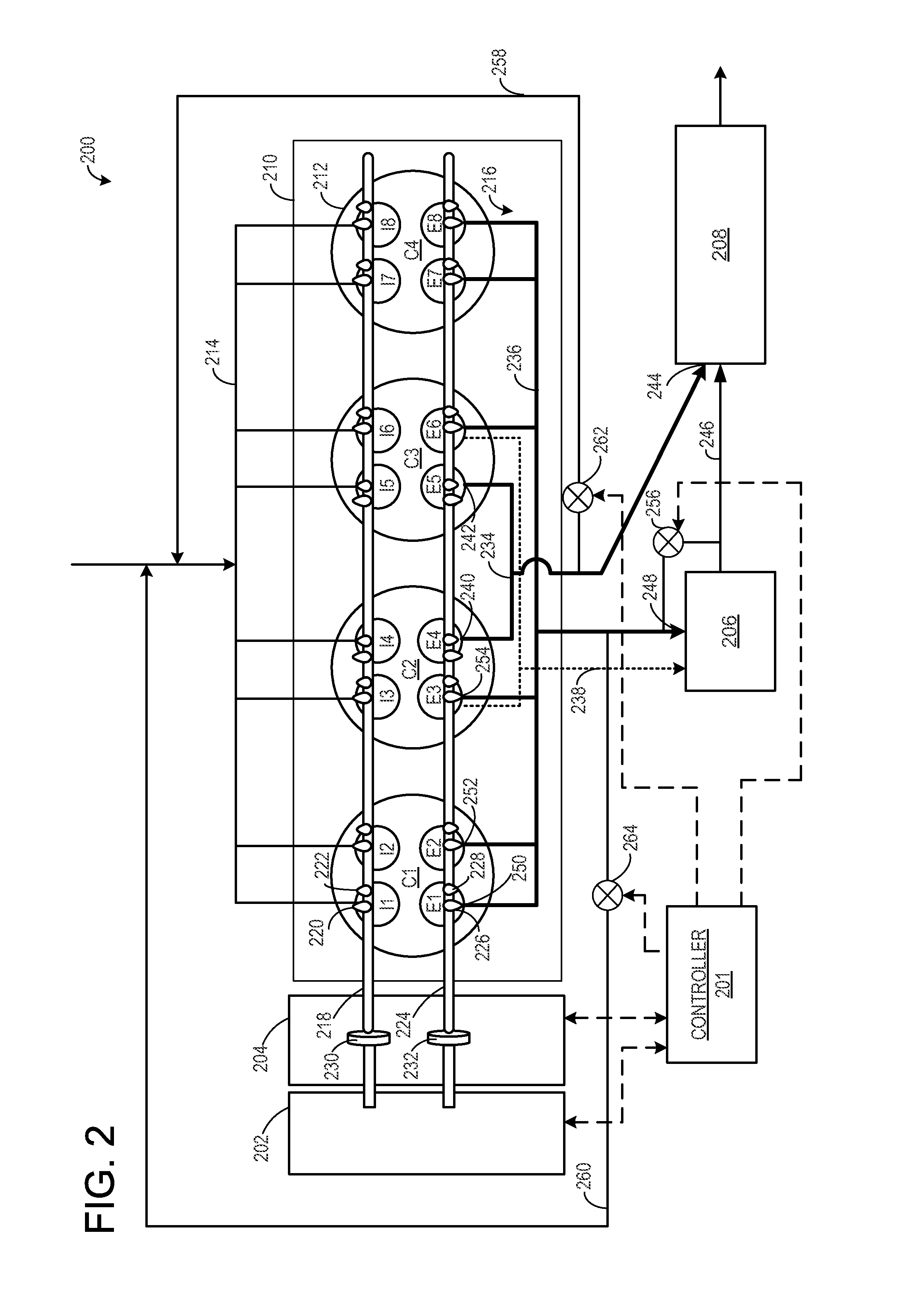

A valvetrain system mechanization for an internal combustion engine using compression ignition, including homogeneous charge compression ignition, having two intake and one or more exhaust valves per cylinder. The valves are operated by dual overhead camshafts having two-step cams. The intake and exhaust camshafts are provided with phasers for varying the opening and closing of the intake and exhaust valves. A two-step roller finger follower is disposed for each valve between the cam lobes and the valve stem. The two sets of intake and exhaust valves are controlled by separate oil control valves. Swirl of gases may be introduced by mismatching the lifts of the valves. The valve opening times, closing times, lifts, fuel injection, compression ratio, and exhaust gas recirculation may be varied to optimize combustion conditions for a range of engine operating modes.

Owner:DELPHI TECH INC

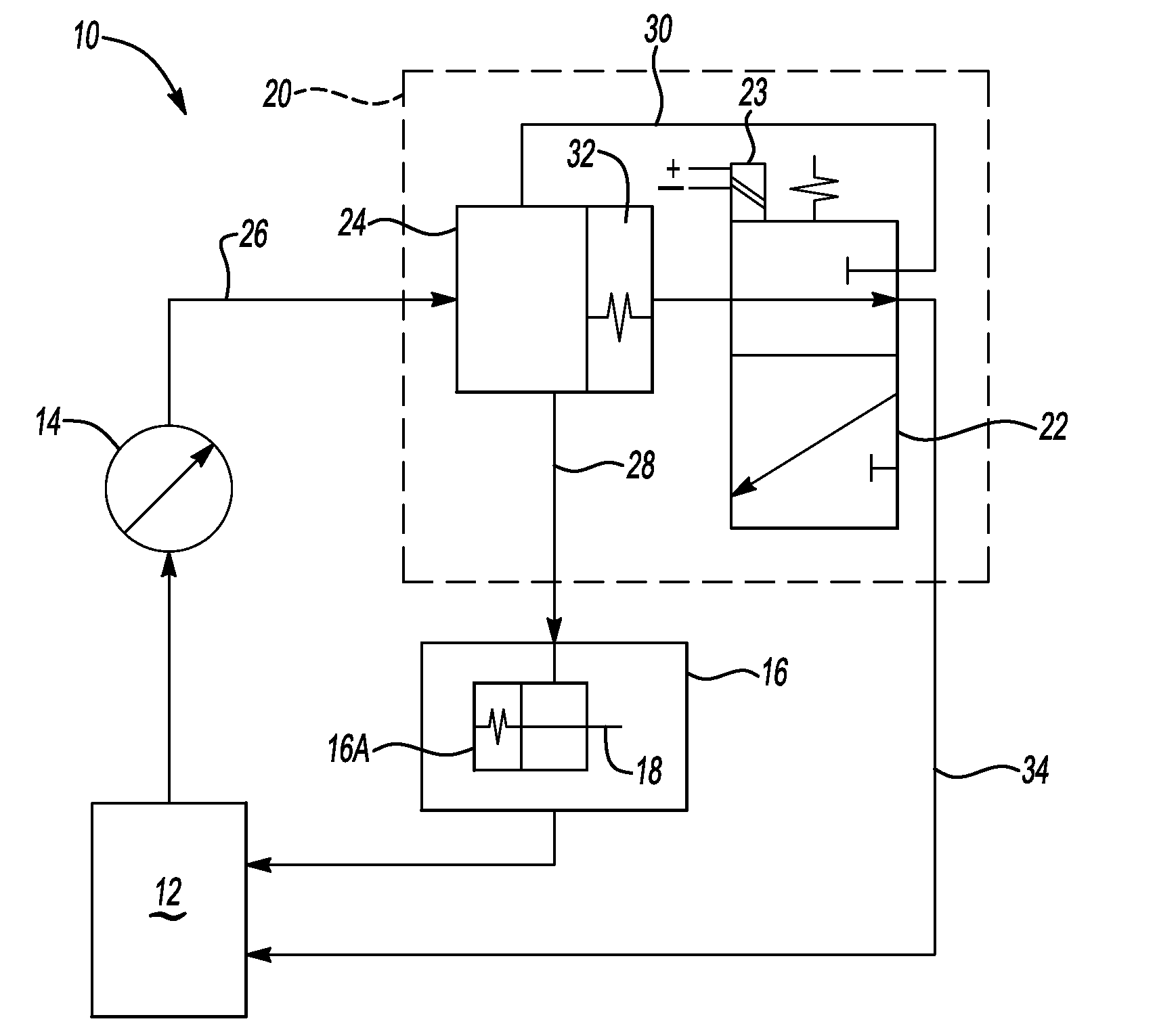

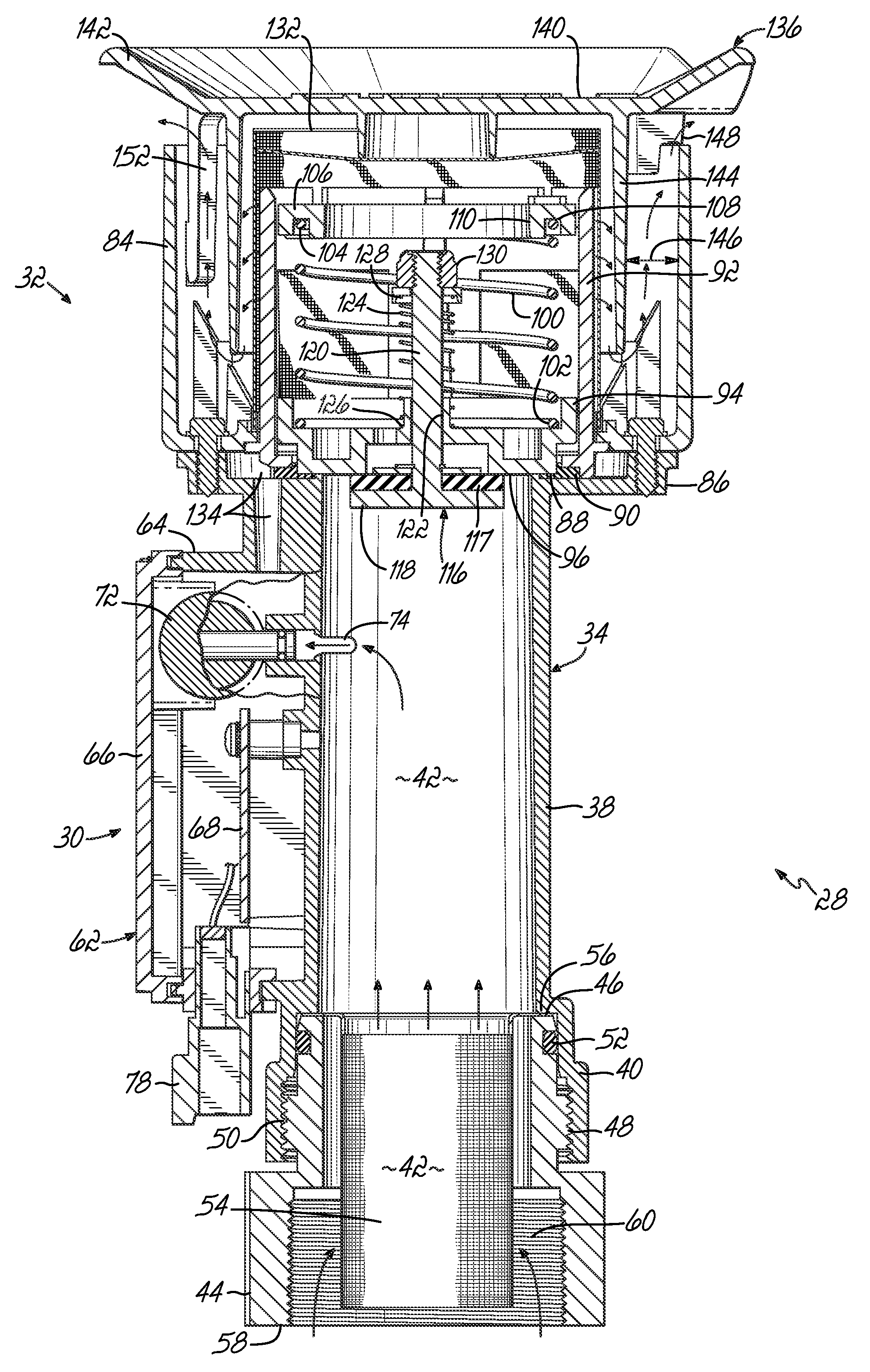

Valvetrain oil control system and oil control valve

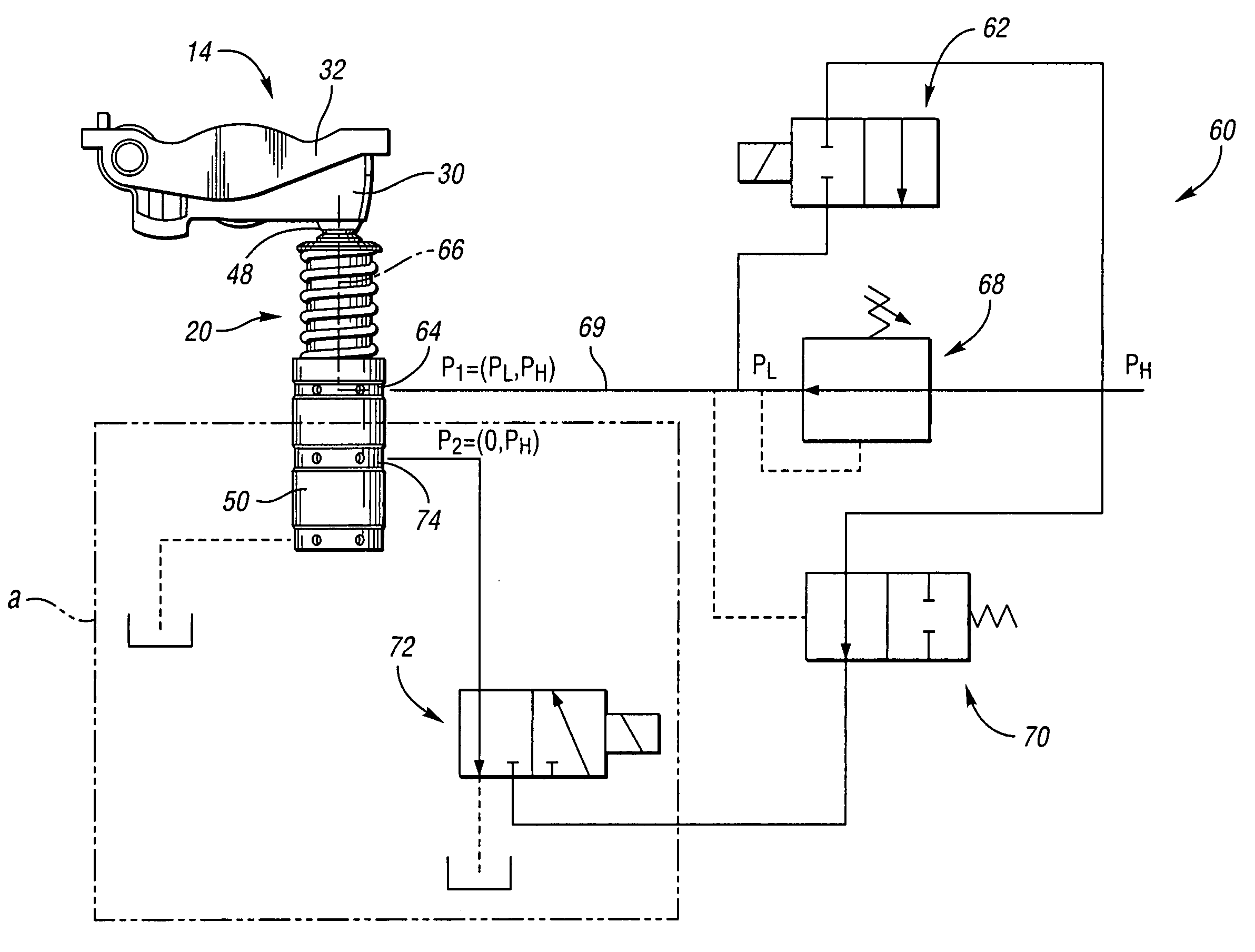

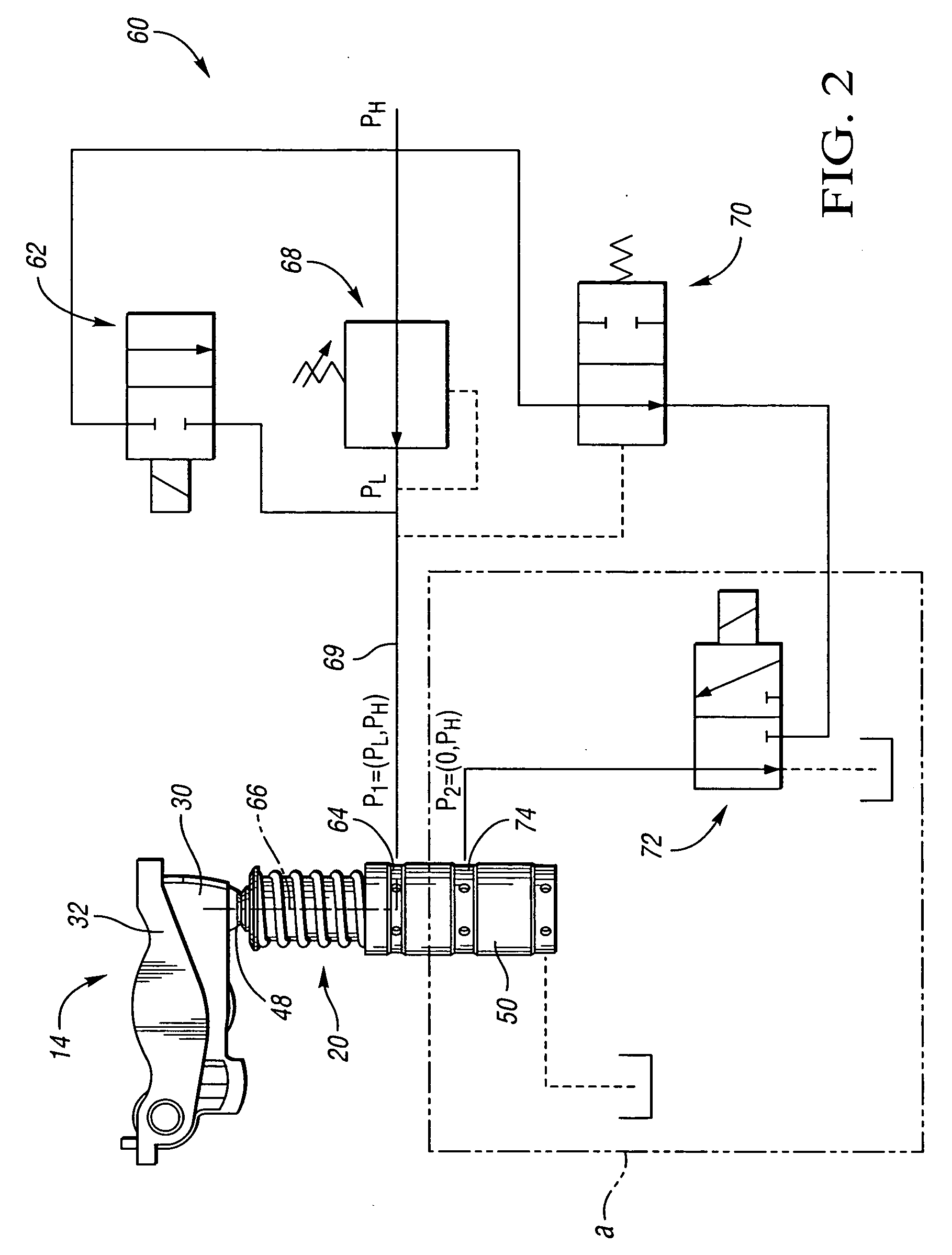

InactiveUS20100018482A1Reduce fuel consumptionOperating means/releasing devices for valvesPipeline systemsControl systemEngineering

A hydraulic control system includes an oil control valve to control oil flow within a valvetrain. The control valve varies the flow rate to actuate an engine component from a first position to a second position based upon fluid pressure from the control valve. Varying the flow rate through the control valve includes increasing the flow rate through the control valve to increase the pressure to a first level to actuate the engine component to the first position. After the engine component is actuated, the flow rate through the control valve is maintained at a level sufficient to maintain the engine component in the first position. To actuate the engine component to the second position the flow rate through the control valve is then decreased. The fluid flow rate through the control valve is then maintained at a level sufficient to maintain the engine component in the second position.

Owner:EATON CORP

Method and apparatus for optimized combustion in an internal combustion engine utilizing homogeneous charge compression ignition and variable valve actuation

InactiveUS7308872B2Electrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

A valvetrain system mechanization for an internal combustion engine using compression ignition, including homogeneous charge compression ignition, having two intake and one or more exhaust valves per cylinder. The valves are operated by dual overhead camshafts having two-step cams. The intake and exhaust camshafts are provided with phasers for varying the opening and closing of the intake and exhaust valves. A two-step roller finger follower is disposed for each valve between the cam lobes and the valve stem. The two sets of intake and exhaust valves are controlled by separate oil control valves. Swirl of gases may be introduced by mismatching the lifts of the valves. The valve opening times, closing times, lifts, fuel injection, compression ratio, and exhaust gas recirculation may be varied to optimize combustion conditions for a range of engine operating modes.

Owner:DELPHI TECH INC

Valvetrain oil control system and oil control valve

InactiveUS8327750B2Reduce fuel consumptionOperating means/releasing devices for valvesServomotor componentsControl systemEngineering

A hydraulic control system includes an oil control valve to control oil flow within a valvetrain. The control valve varies the flow rate to actuate an engine component from a first position to a second position based upon fluid pressure from the control valve. Varying the flow rate through the control valve includes increasing the flow rate through the control valve to increase the pressure to a first level to actuate the engine component to the first position. After the engine component is actuated, the flow rate through the control valve is maintained at a level sufficient to maintain the engine component in the first position. To actuate the engine component to the second position the flow rate through the control valve is then decreased. The fluid flow rate through the control valve is then maintained at a level sufficient to maintain the engine component in the second position.

Owner:EATON CORP

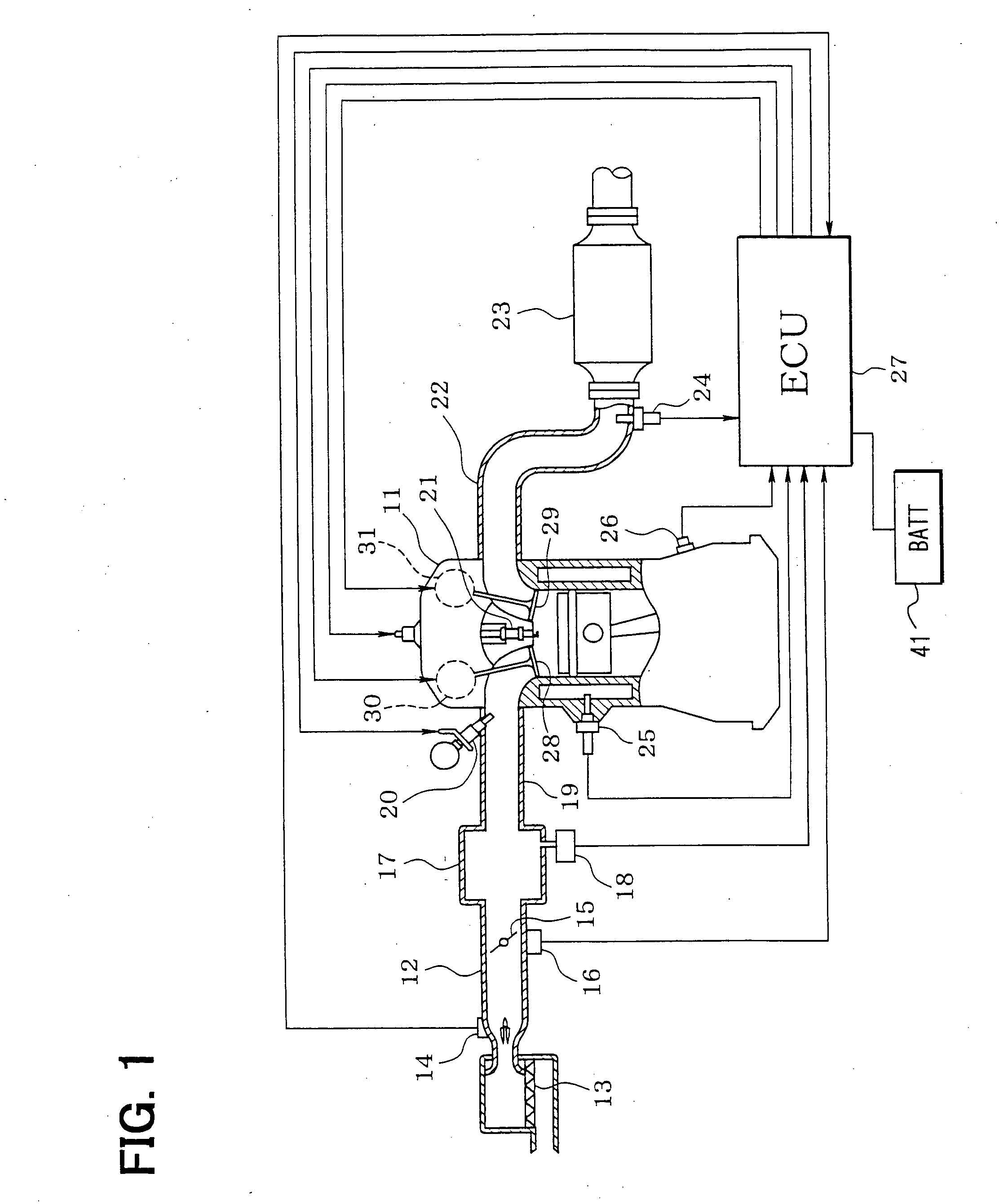

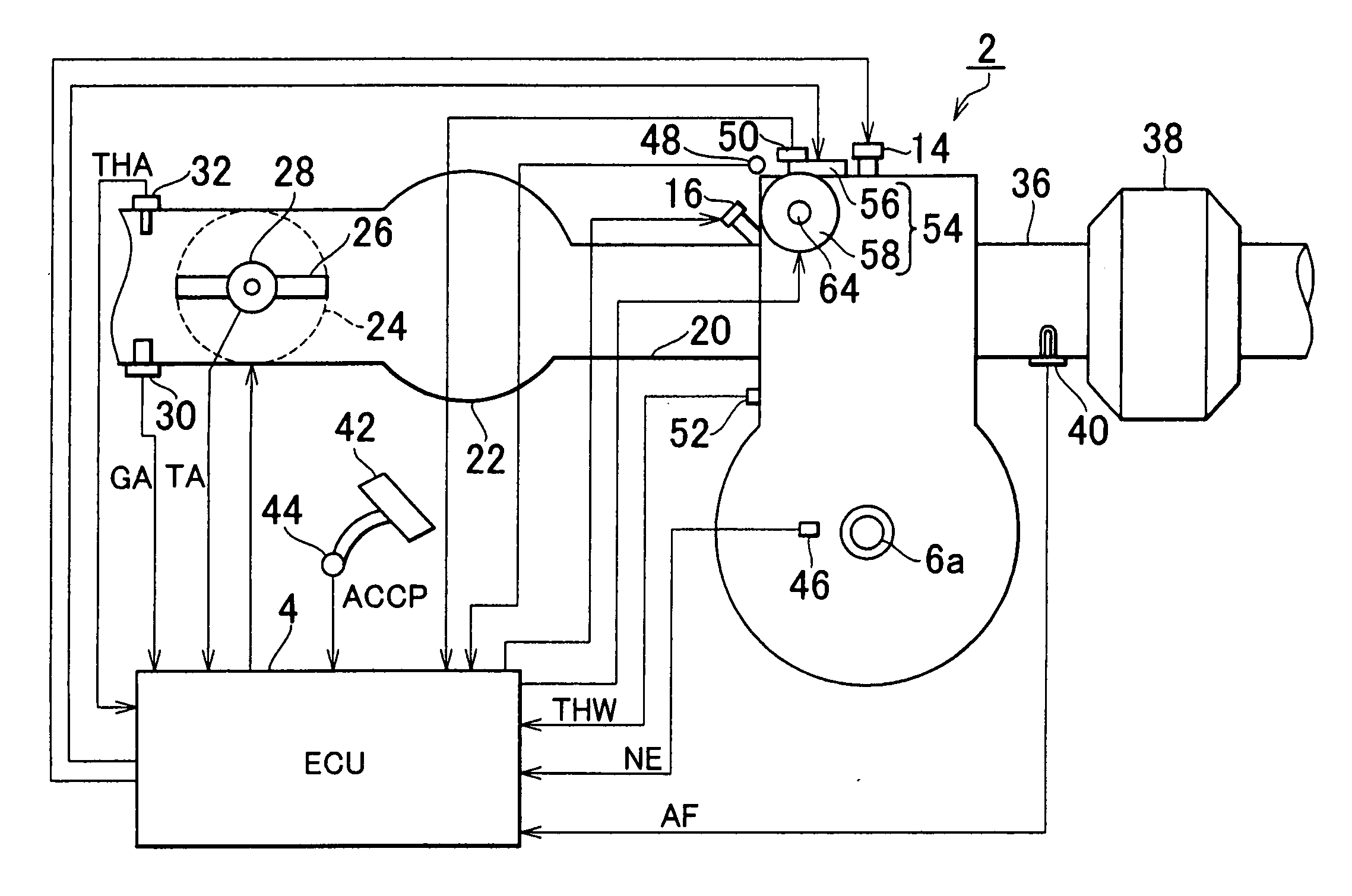

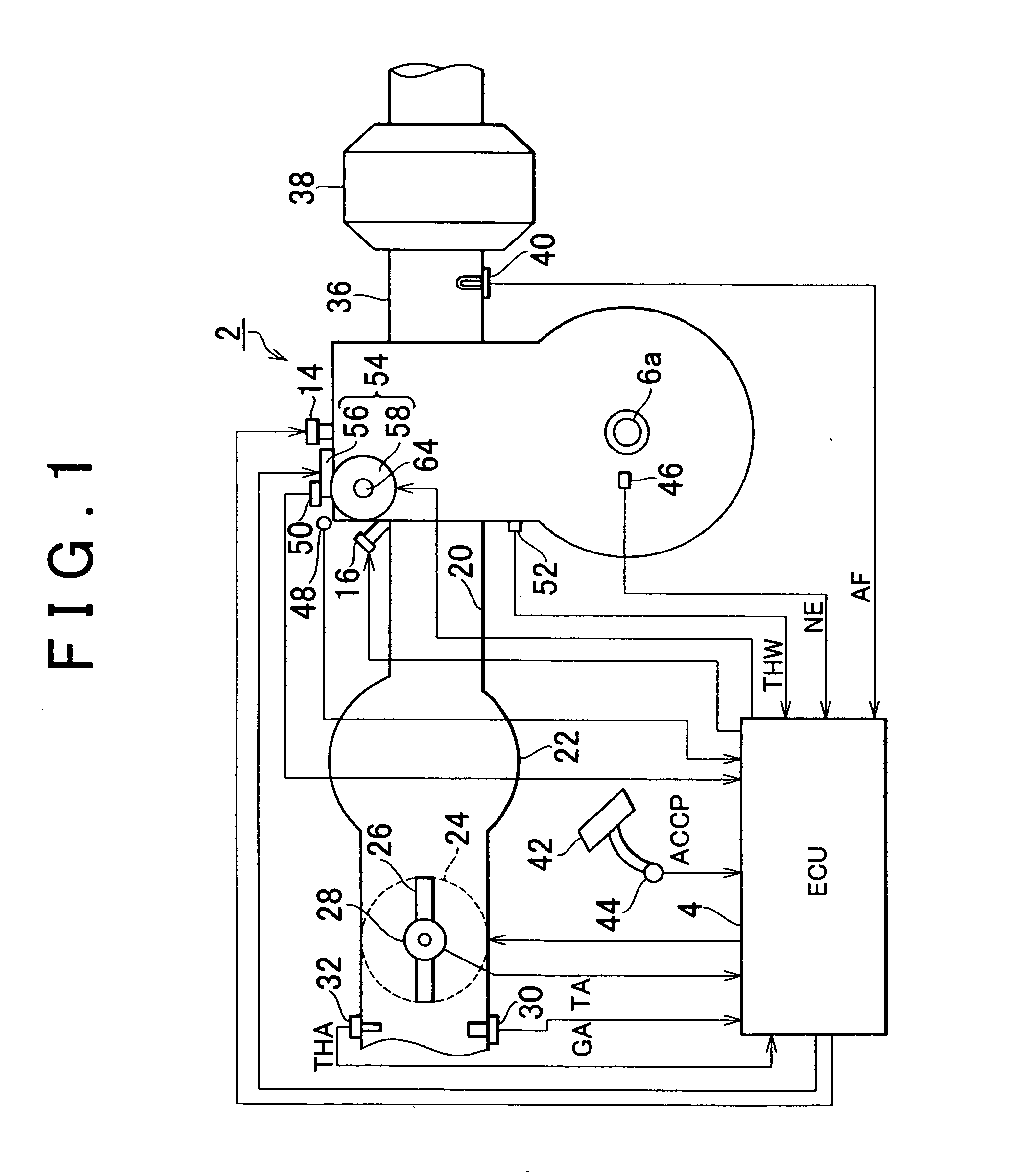

Apparatus of diagnosing an internal combustion engine and a method of diagnosing of an internal combustion engine

InactiveUS6457353B1Assurance controlEnsure reliabilityElectrical controlInternal combustion piston enginesExhaust valveExternal combustion engine

By employing command value signals for controlling the opening timing of an exhaust valve or an intake valve and means for measuring flow rates of an intake air of a flow direction which flows through an intake manifold of an internal combustion engine, an air flow rate corresponding to the command value signal is measured. A valve mechanism includes the intake valve and the exhaust valve for each cylinder of the internal combustion engine and is controlled by a valve control means for controlling the valve mechanism. A failure diagnosis of an operating status of the valve mechanism can be performed.

Owner:HITACHI LTD

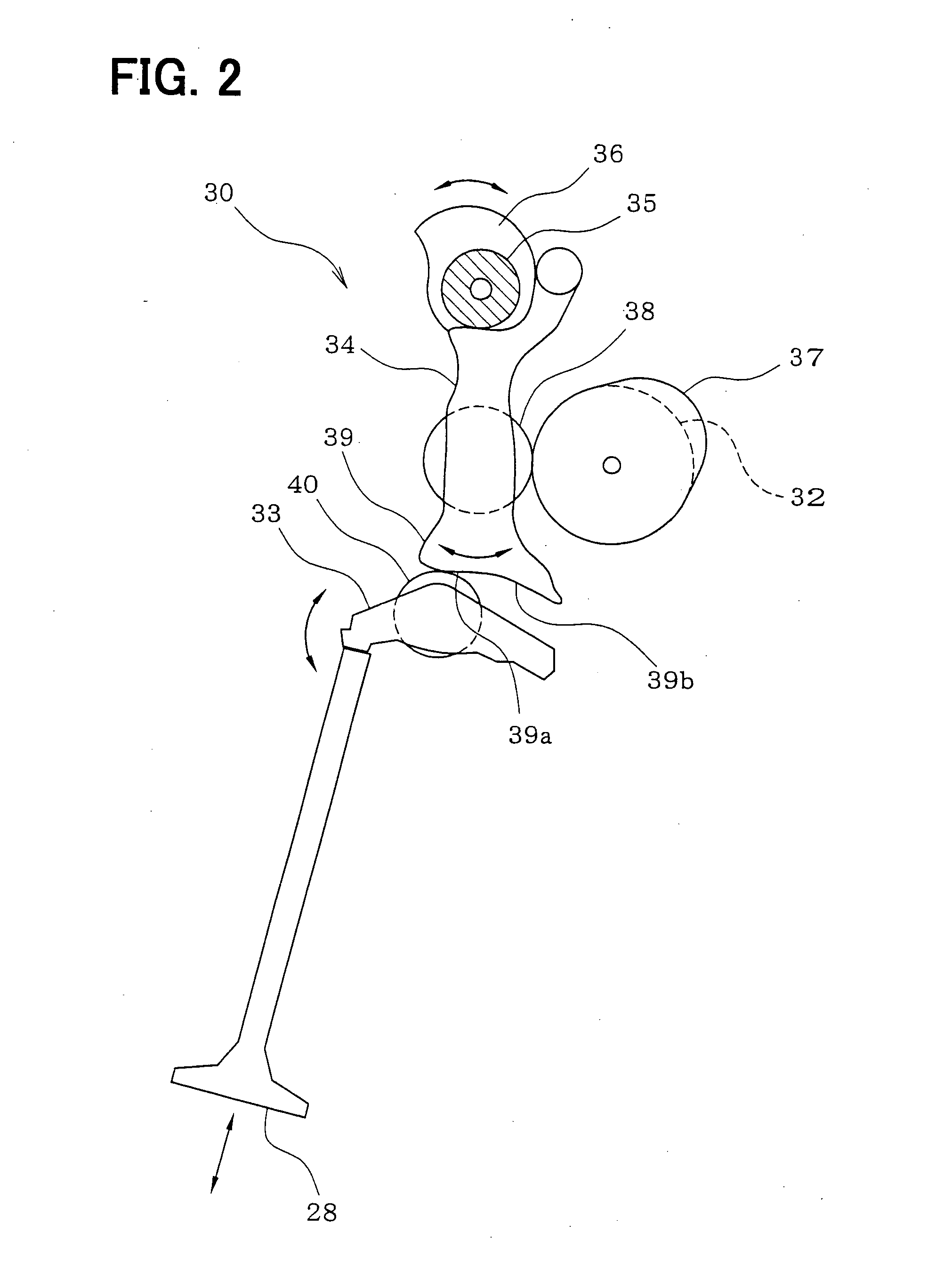

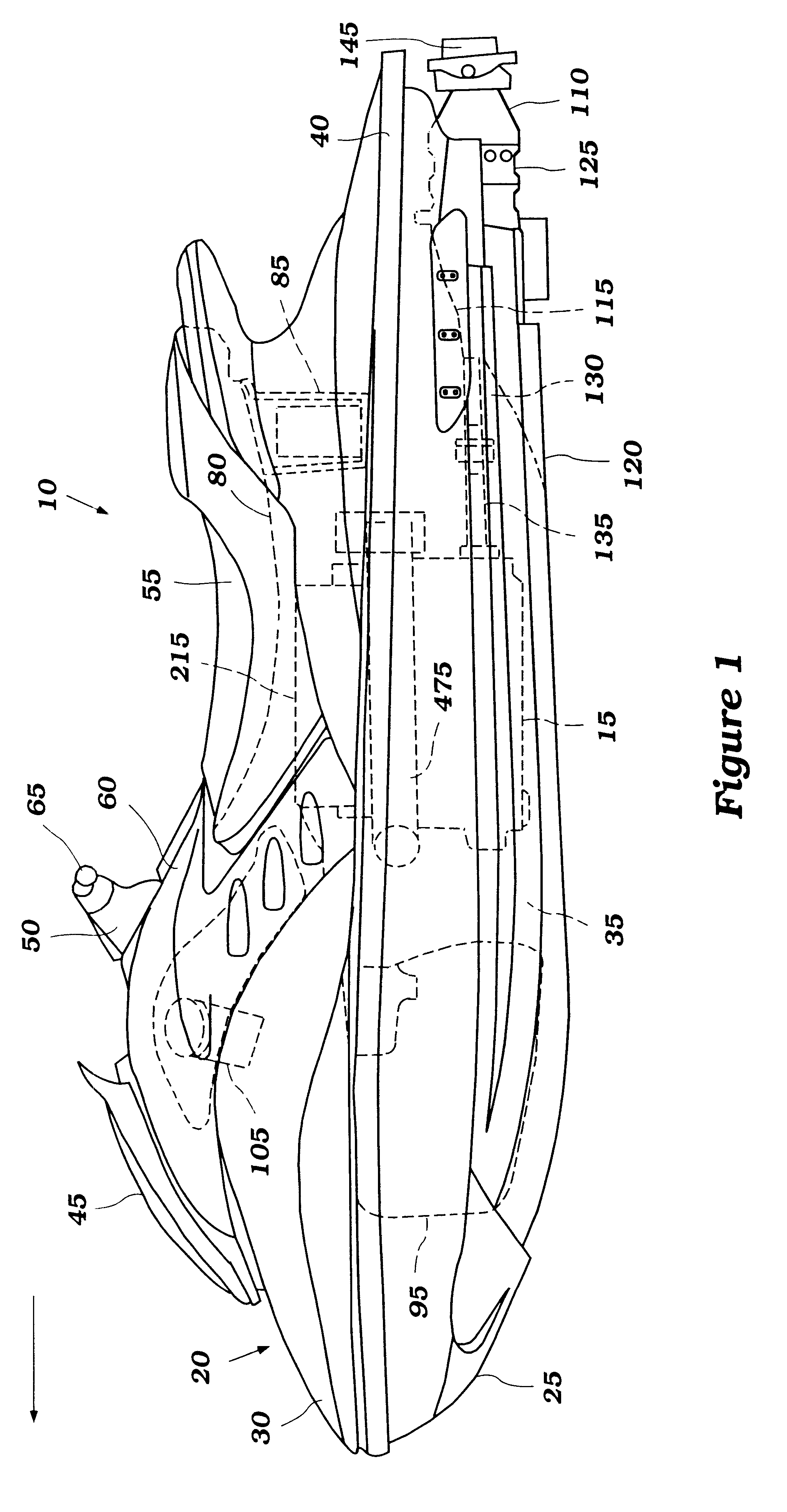

System for variable valvetrain actuation

InactiveUS20070125329A1Simple taskReduce in quantityValve drivesMachines/enginesCylinder headGasoline

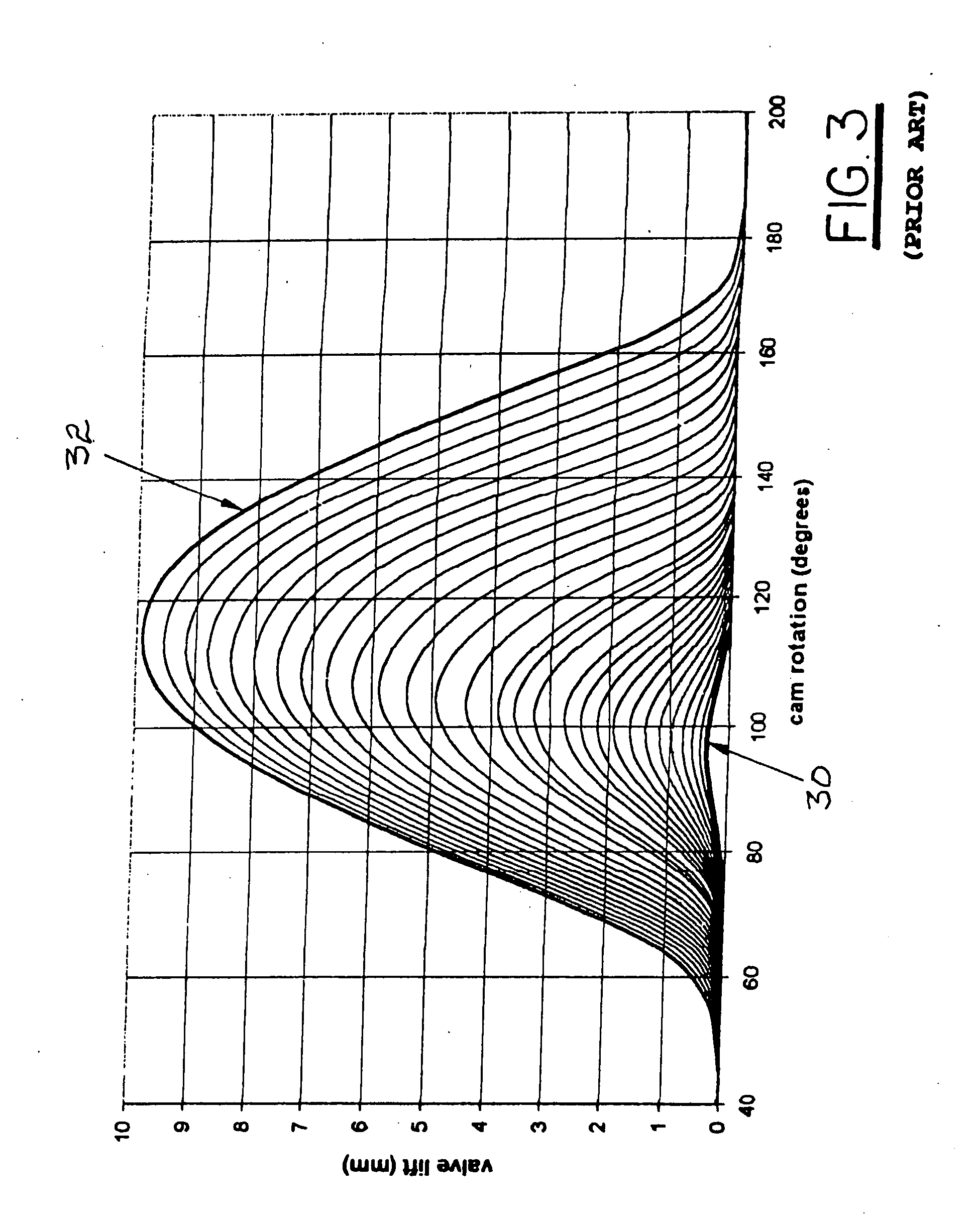

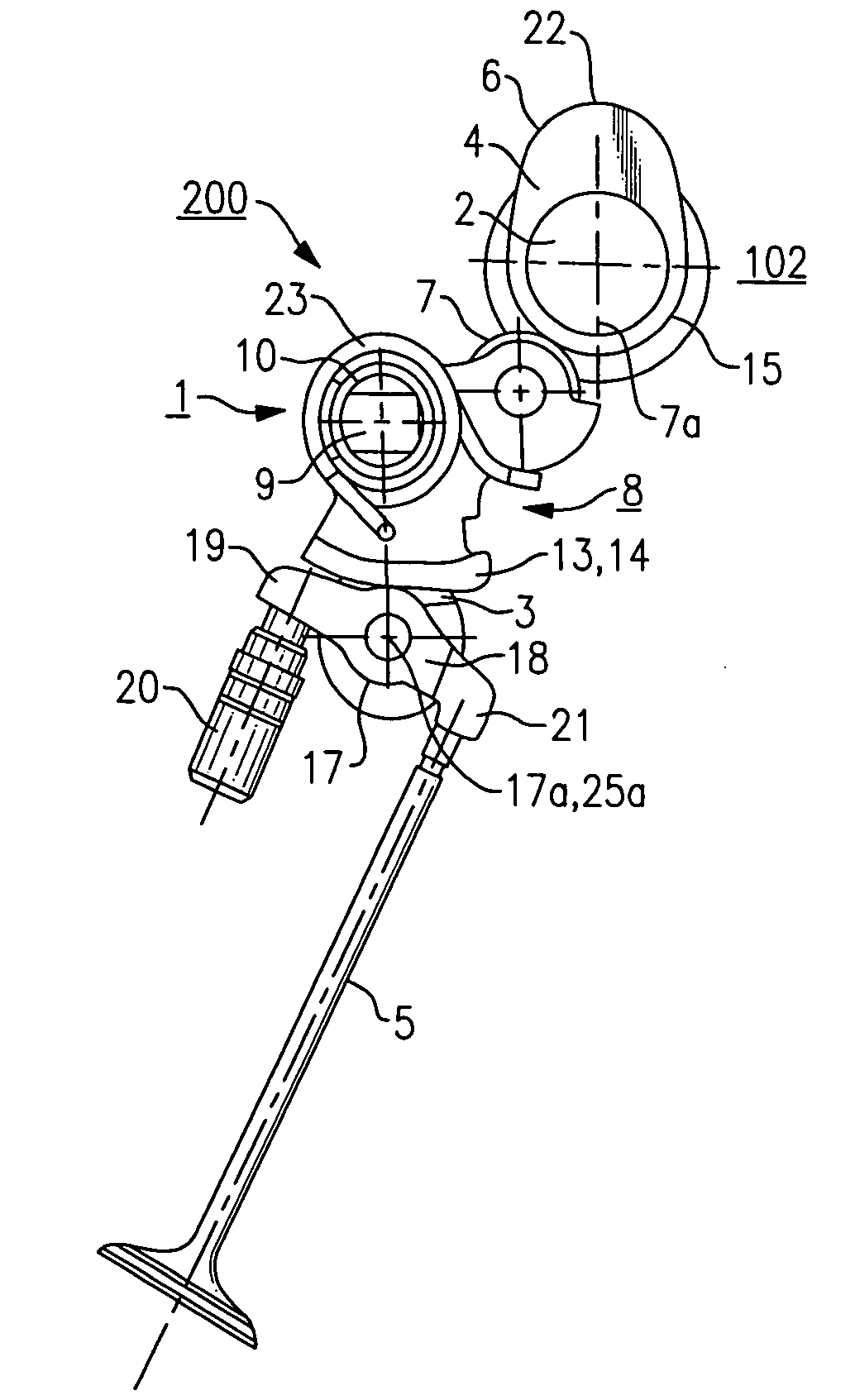

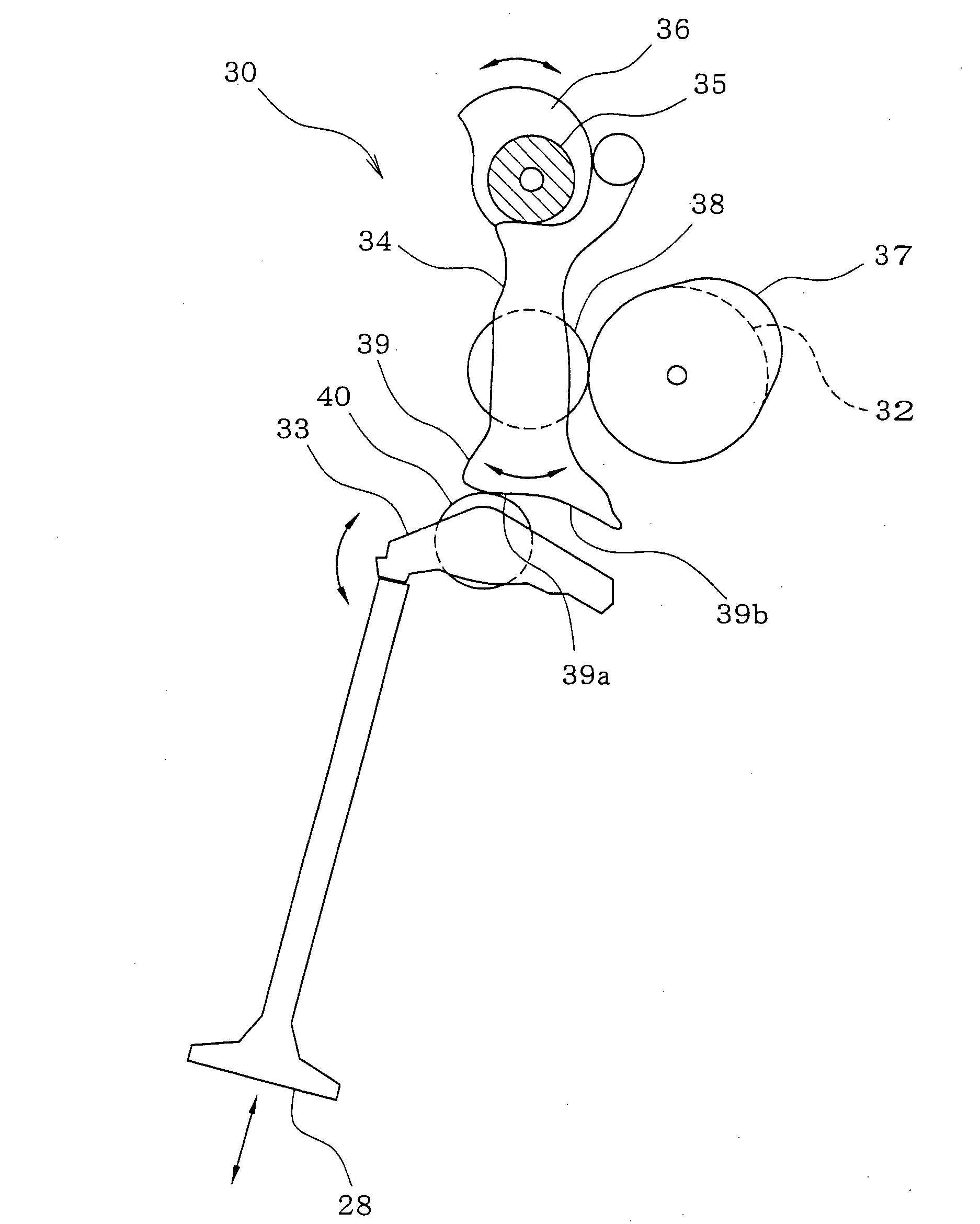

An electromechanical VVA system for controlling the poppet valves in the cylinder head of an internal combustion engine. The system varies valve lift, duration, and phasing in a dependent manner for one or more banks of engine valves. A rocker subassembly for each valve or valve pair is pivotably disposed on a control shaft between the camshaft and the roller finger follower. The control shaft may be displaced about a pivot axis outside the control shaft to change the angular relationship of the rocker subassembly to the camshaft, thus changing the valve opening, closing, and lift. A plurality of control shafts for controlling all valvetrains in an engine bank defines a control shaft assembly. The angular positions of the individual control shafts may be tuned to optimize the valve timing of each cylinder. The system is applicable to the intake and exhaust camshafts of diesel and gasoline engines.

Owner:DELPHI TECH IP LTD

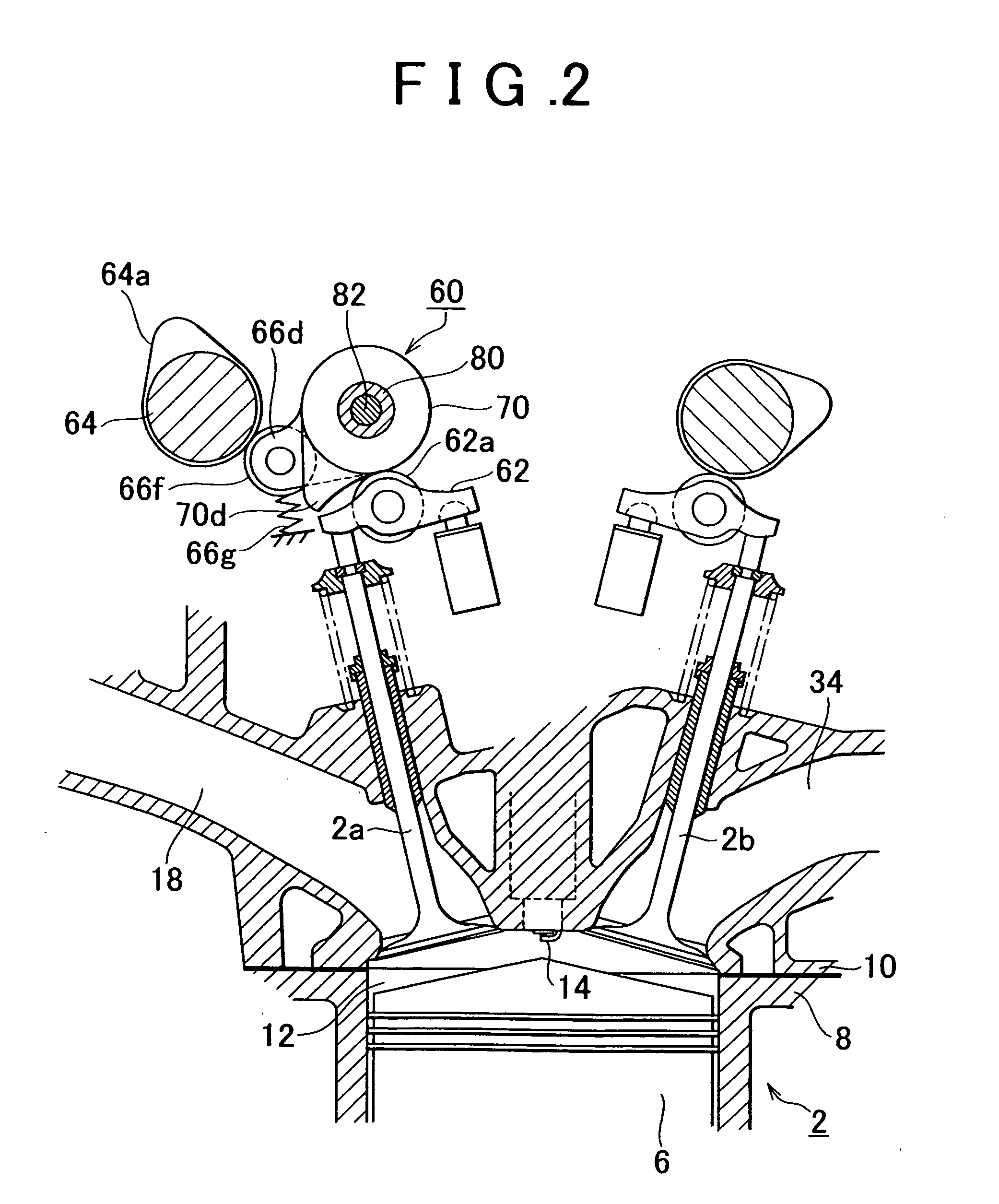

Valve train for internal combustion engine

InactiveUS20050056241A1Excellent low friction propertiesHigh wear resistanceValve drivesLiquid carbonaceous fuelsCarbon filmHydrogen

A valve train for an internal combustion engine is comprised of a lubricating oil, and a camshaft which is made of an iron-based material and comprises a cam lobe and a camshaft journal. The camshaft slidingly moves on a counterpart thereof through the lubricating oil. A hard carbon film is formed on at least one of a sliding portion of the camshaft and the counterpart made of an iron-based material. A hydrogen amount of the hard carbon film is 10 atomic percent or less.

Owner:NISSAN MOTOR CO LTD

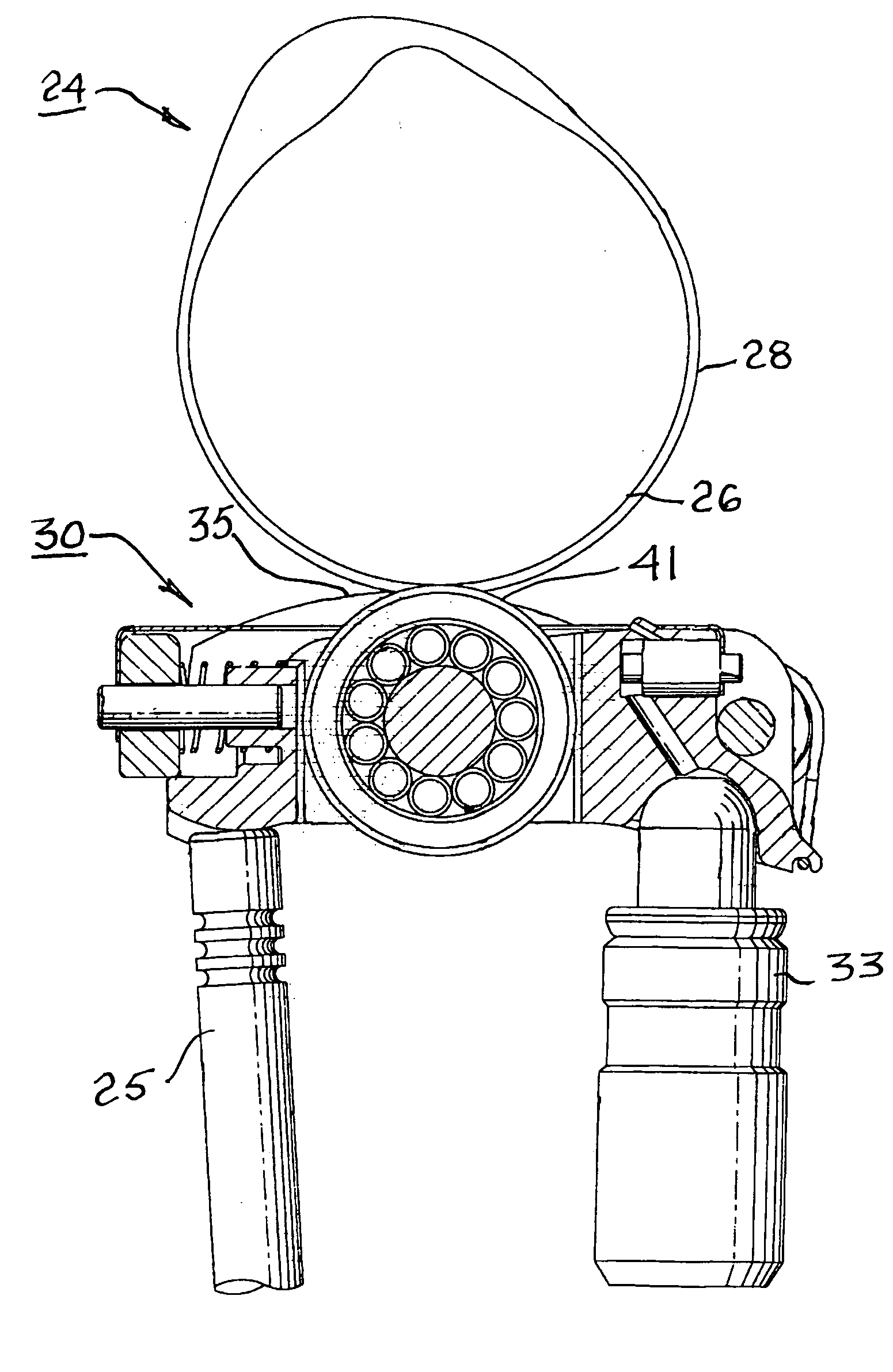

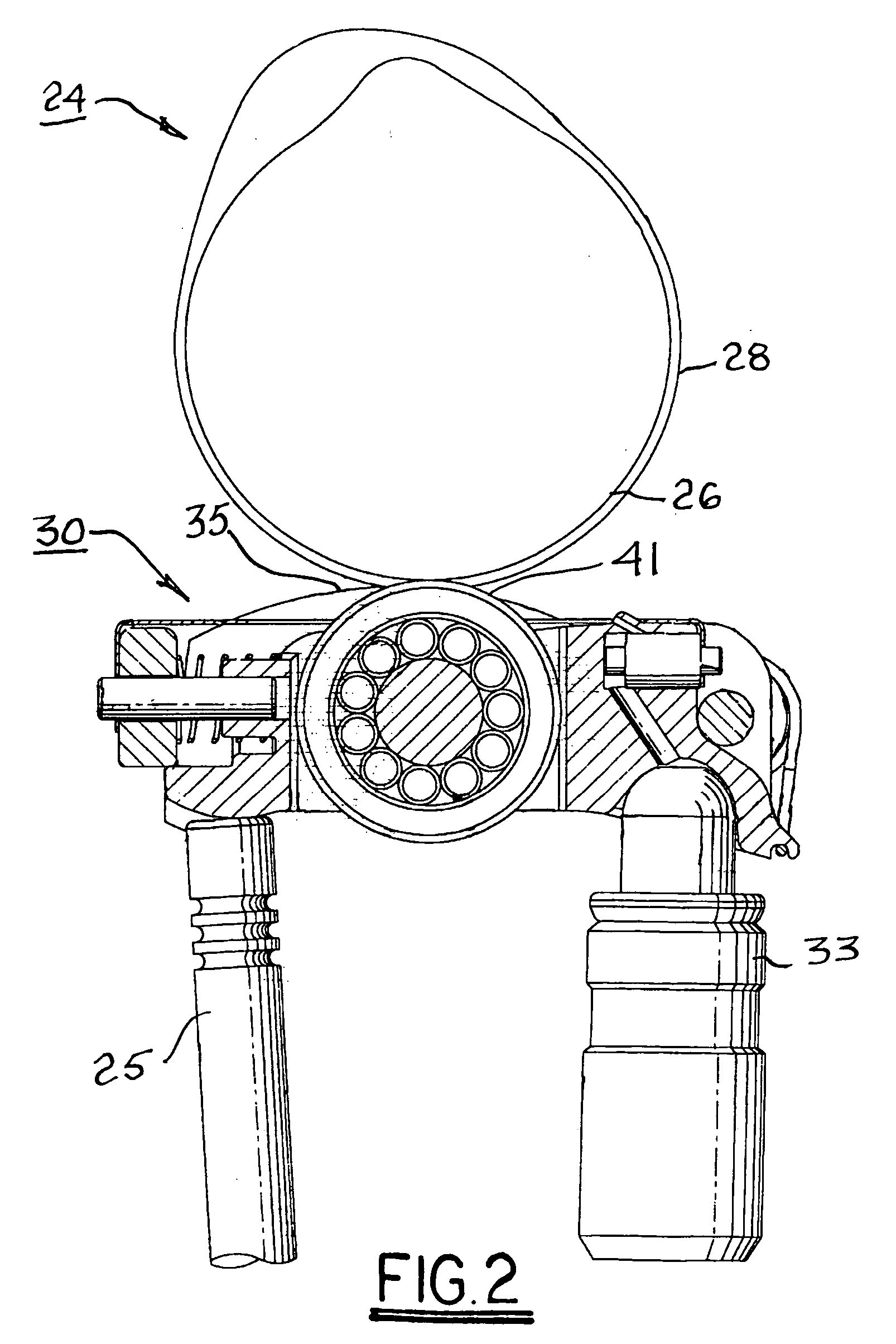

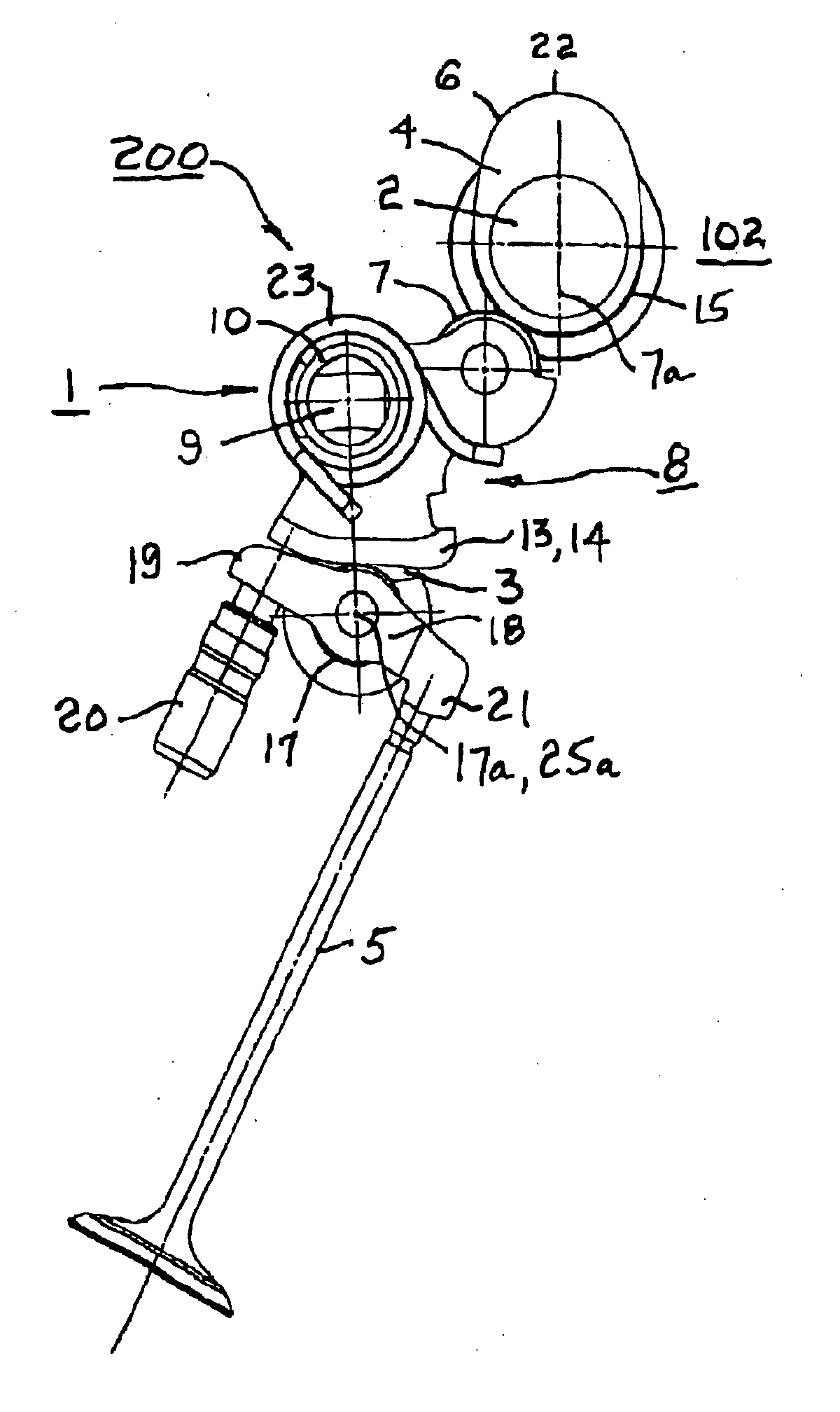

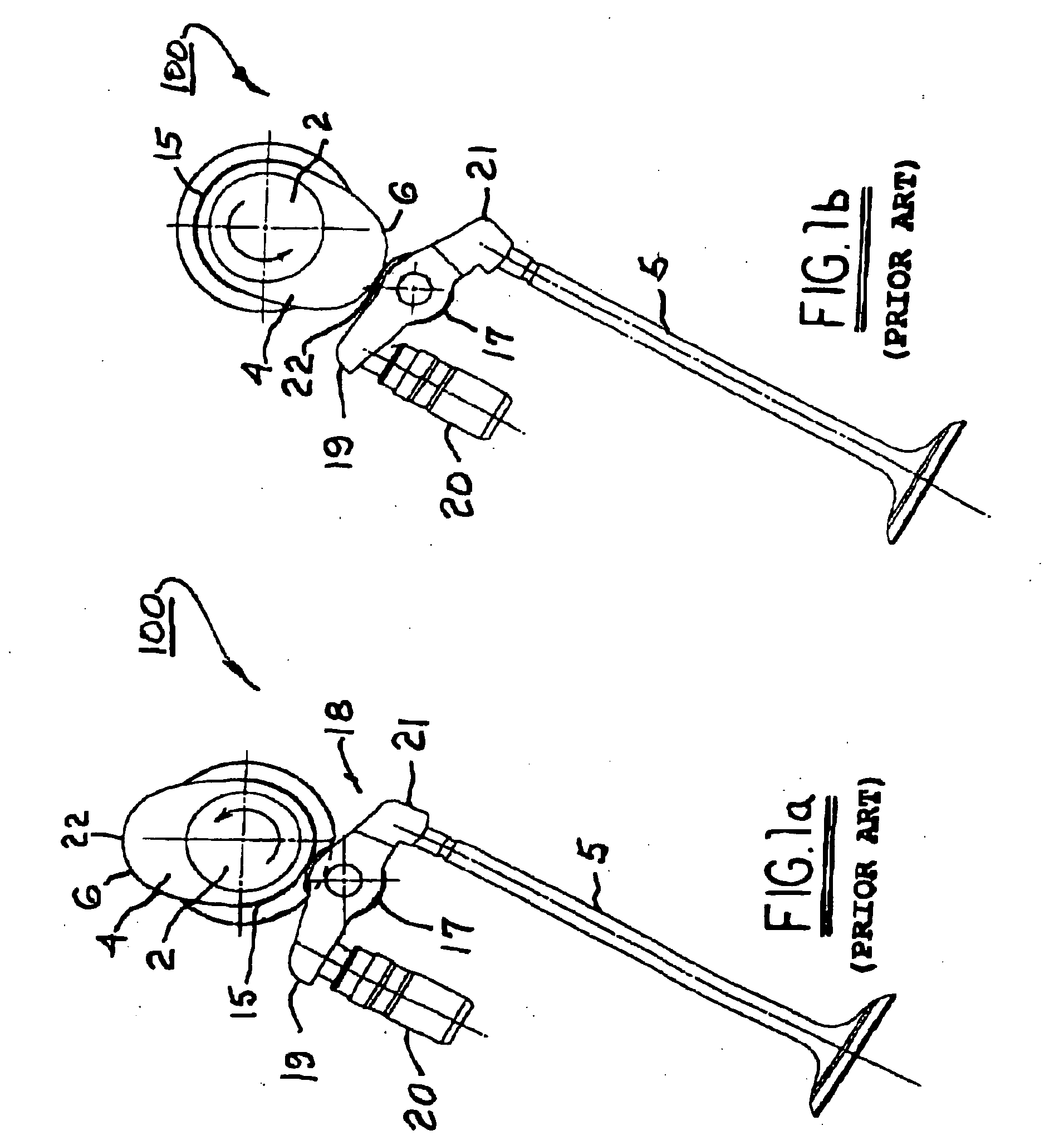

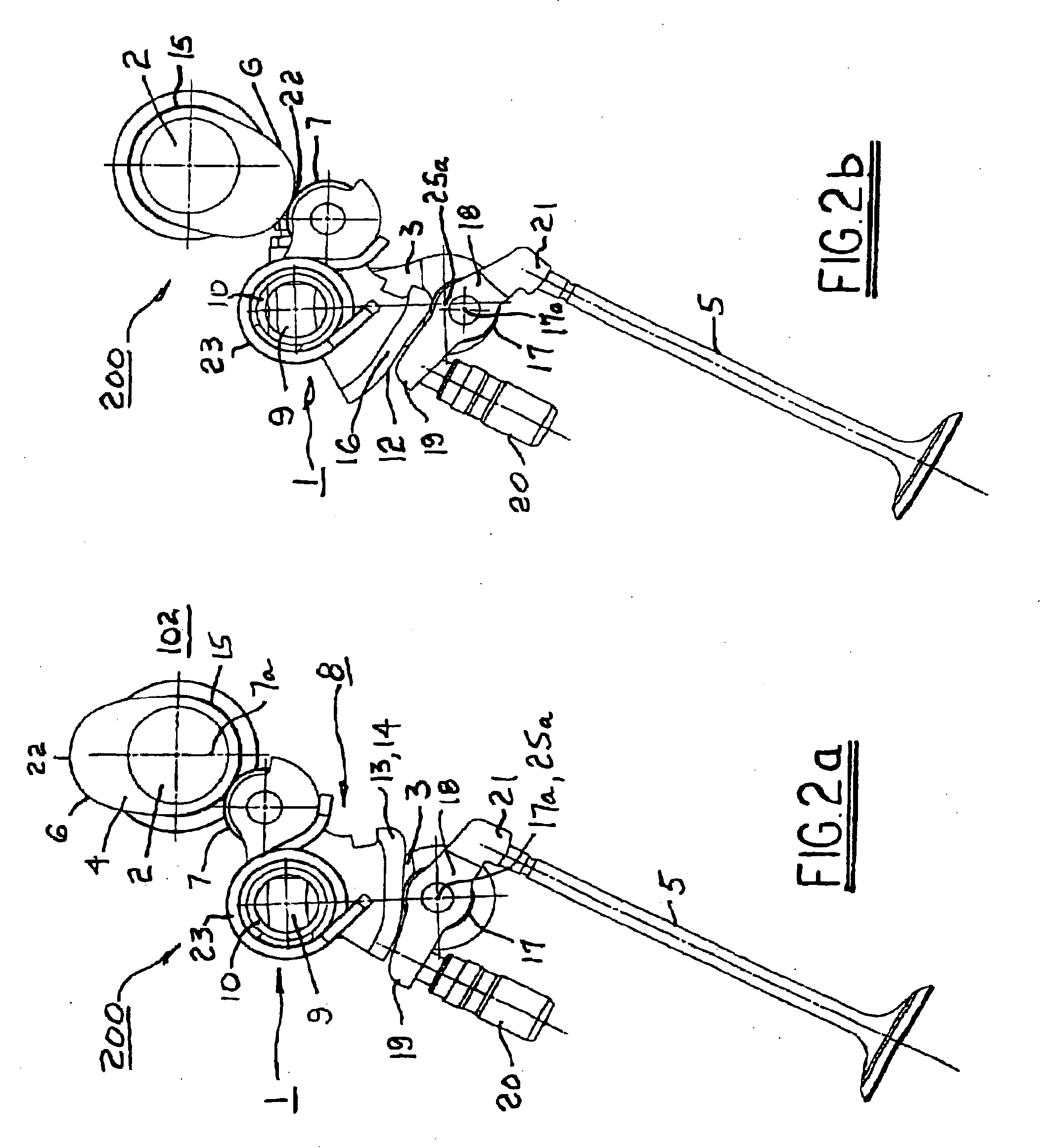

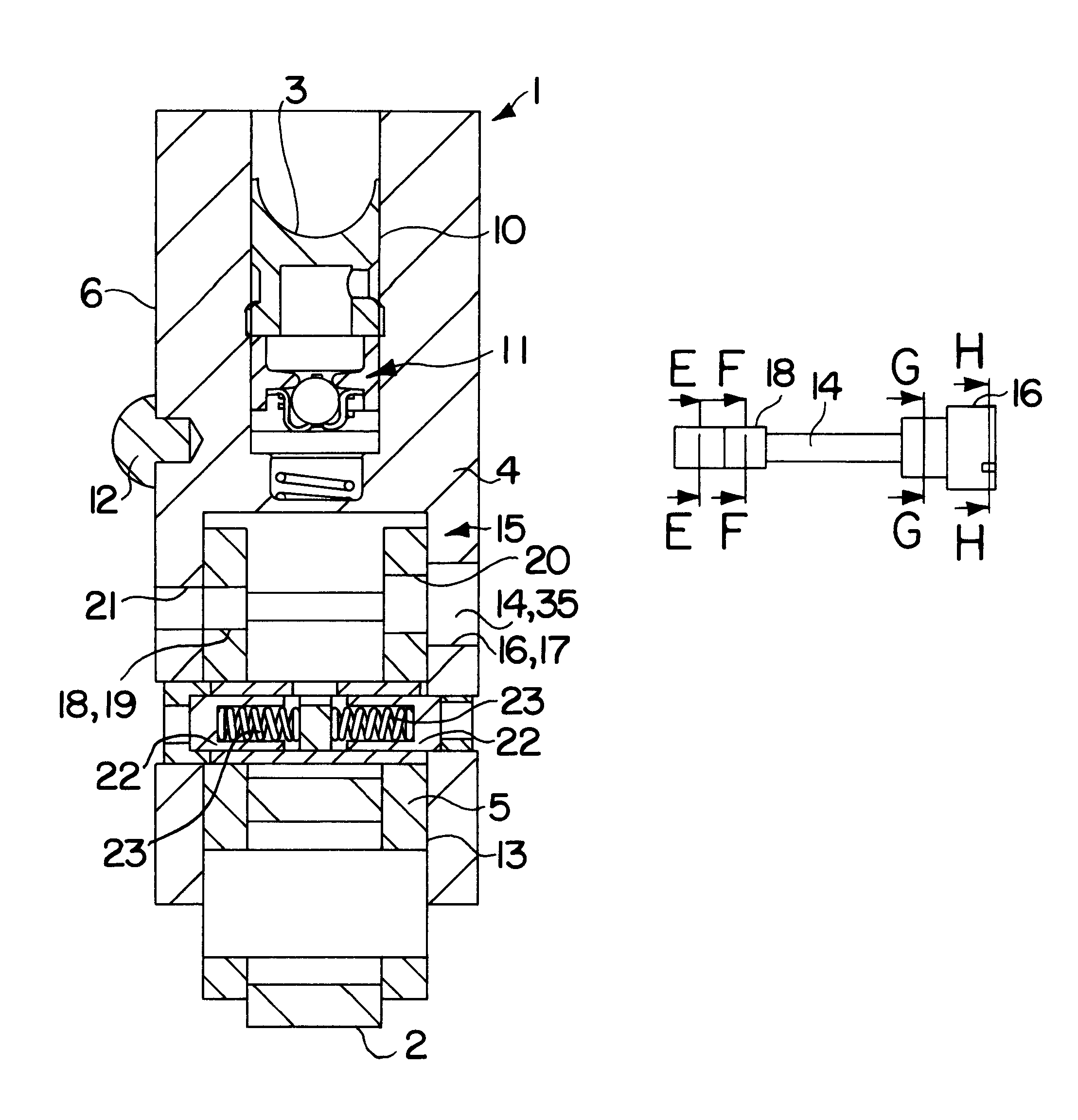

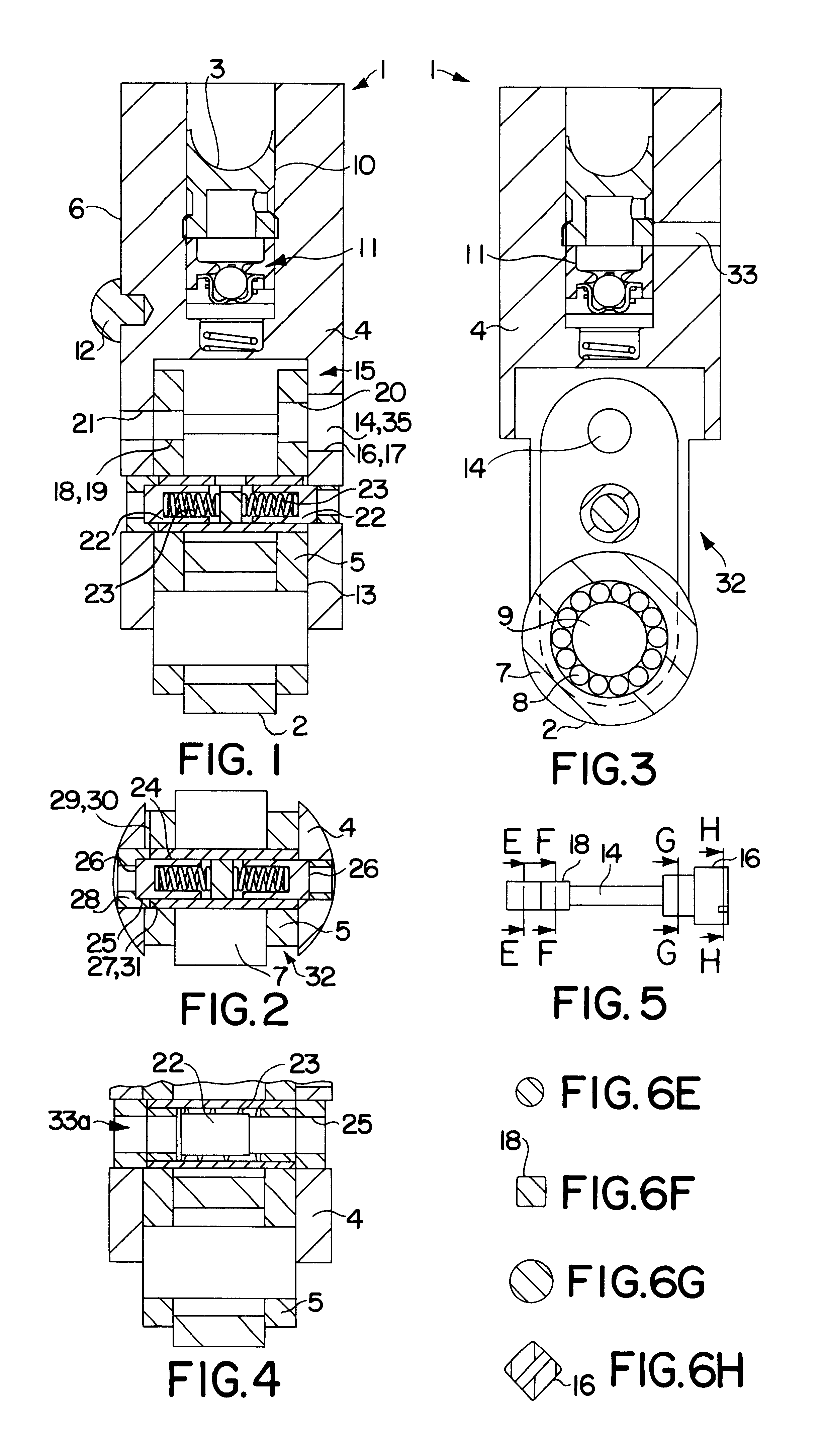

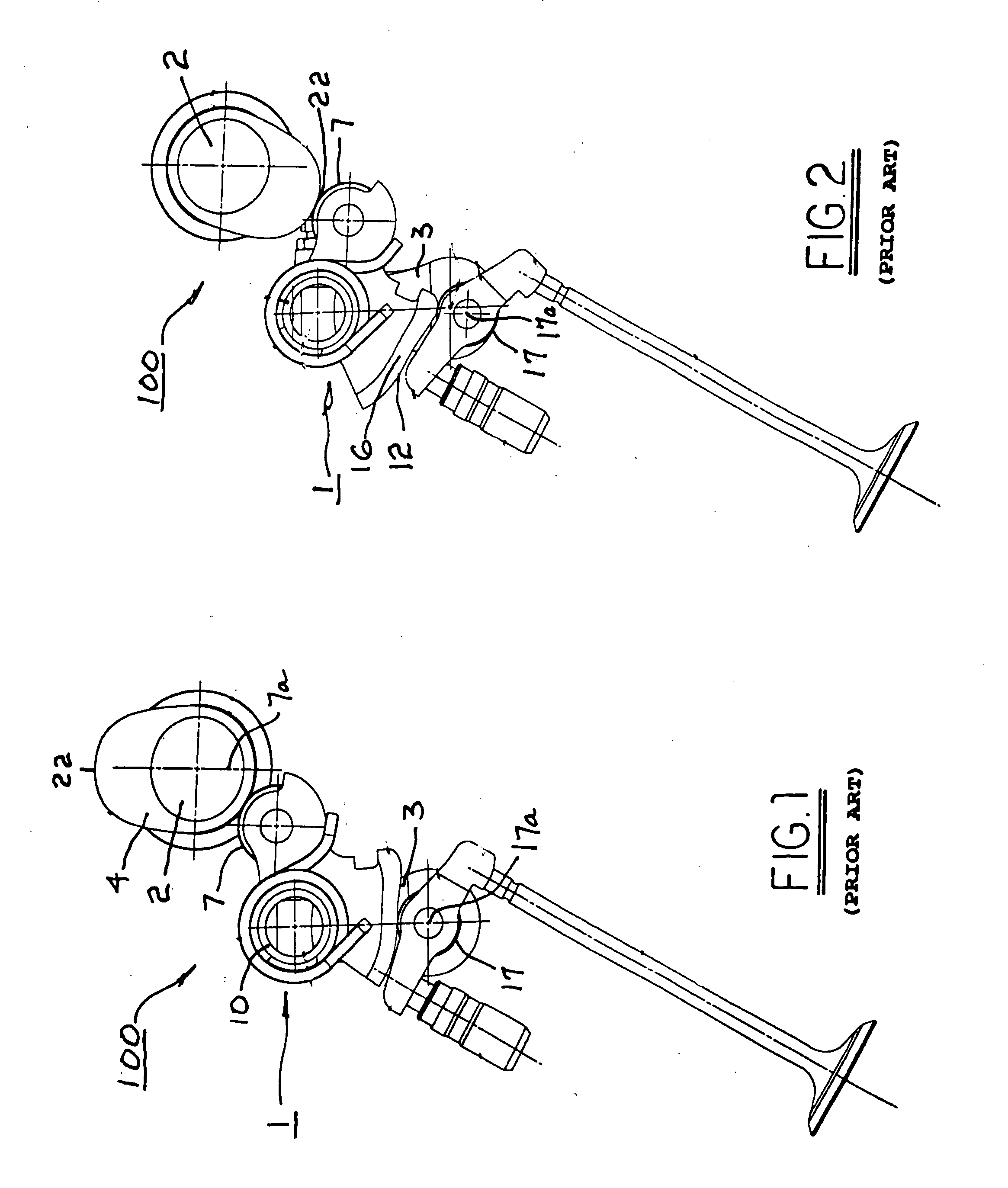

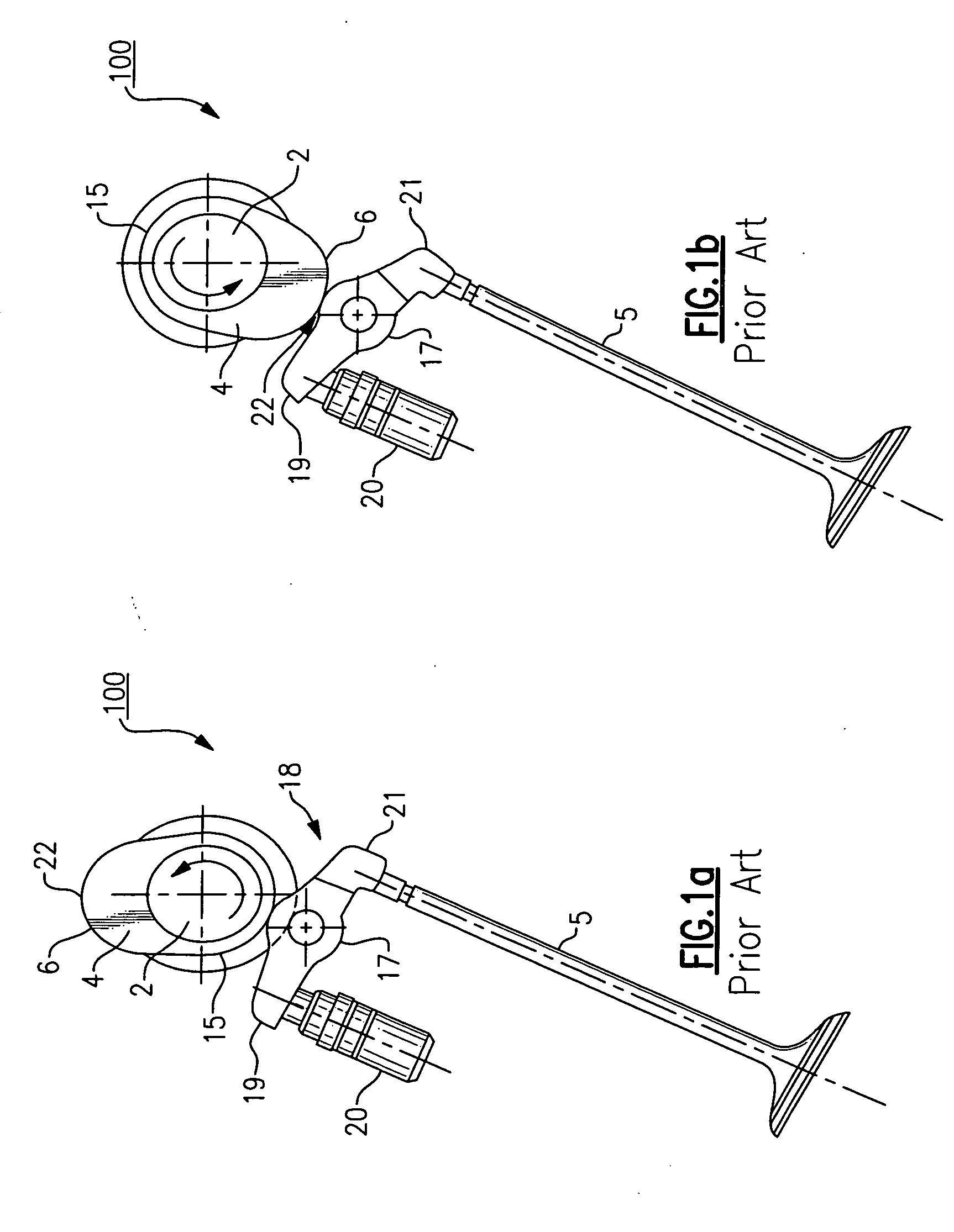

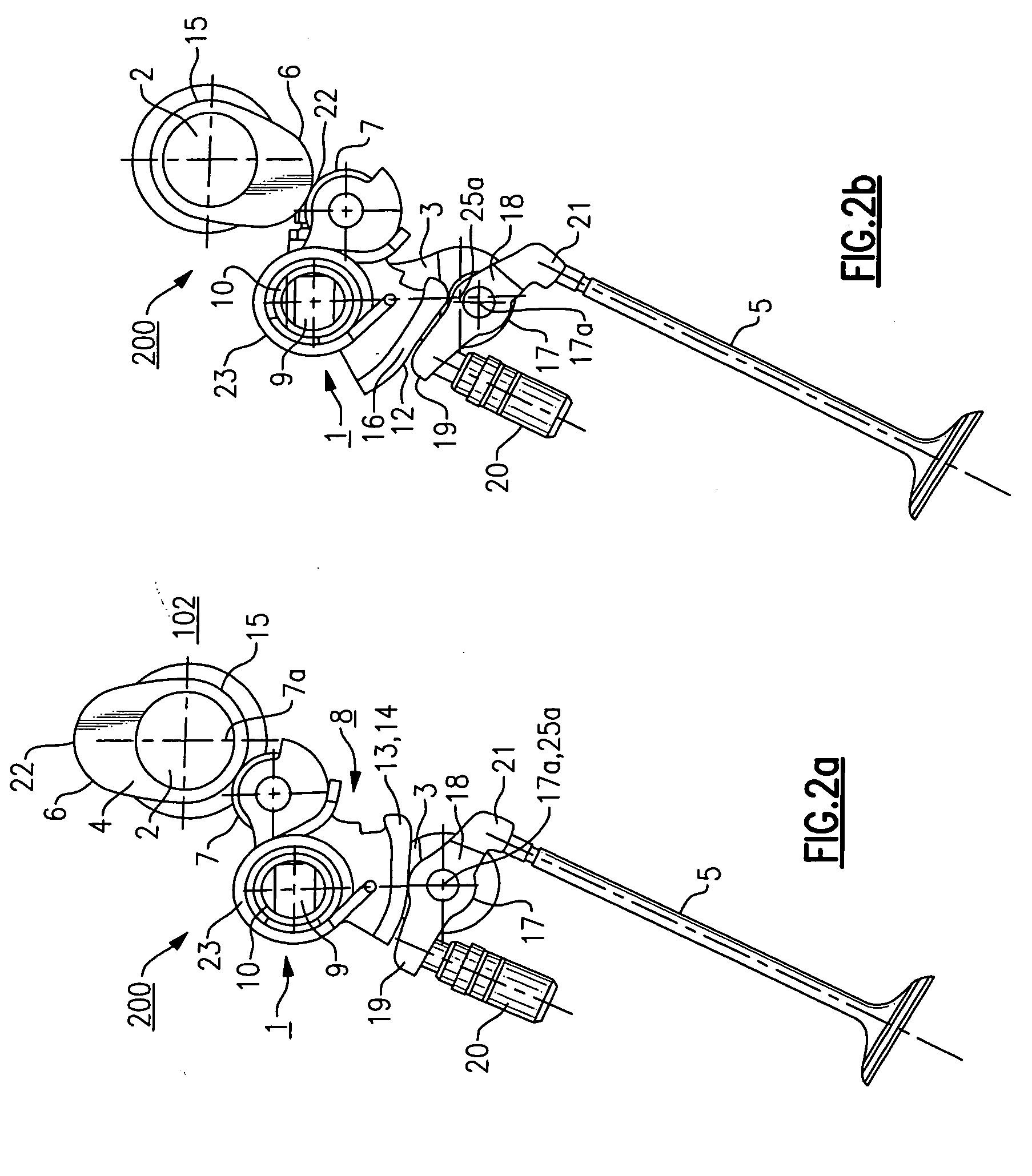

Switchable cam follower

A switchable cam follower (1) for a valve train of an internal combustion engine, which valve train can be actuated indirectly by tappet push rods, the cam follower comprises an outer and an inner section (4,5) end for switching-off the cam follower (1) from the cam lift, the inner section (5) is pivotable relative to the outer section (4) during a valve lift phase of the cam.

Owner:INA WALZLAGER SCHAEFFLER KG

Method for controlling vibrations during transitions in a variable displacement engine

InactiveUS20160102620A1Improve fuel economyReduce displacementValve arrangementsElectrical controlVibration controlSolenoid valve

Methods and systems are provided for controlling vibrations during transitions between engine operating modes in a four-cylinder engine. One method includes timing a transition in engine operation between two-cylinder, three-cylinder, and four-cylinder modes with a sequence of firing events such that successive firing events are separated by at least 120 crank angle degree intervals. Vibrations resulting from transitions may be countered by adjusting active mounts, the active mounts being adjusted in synchronization with a valvetrain switching solenoid.

Owner:FORD GLOBAL TECH LLC

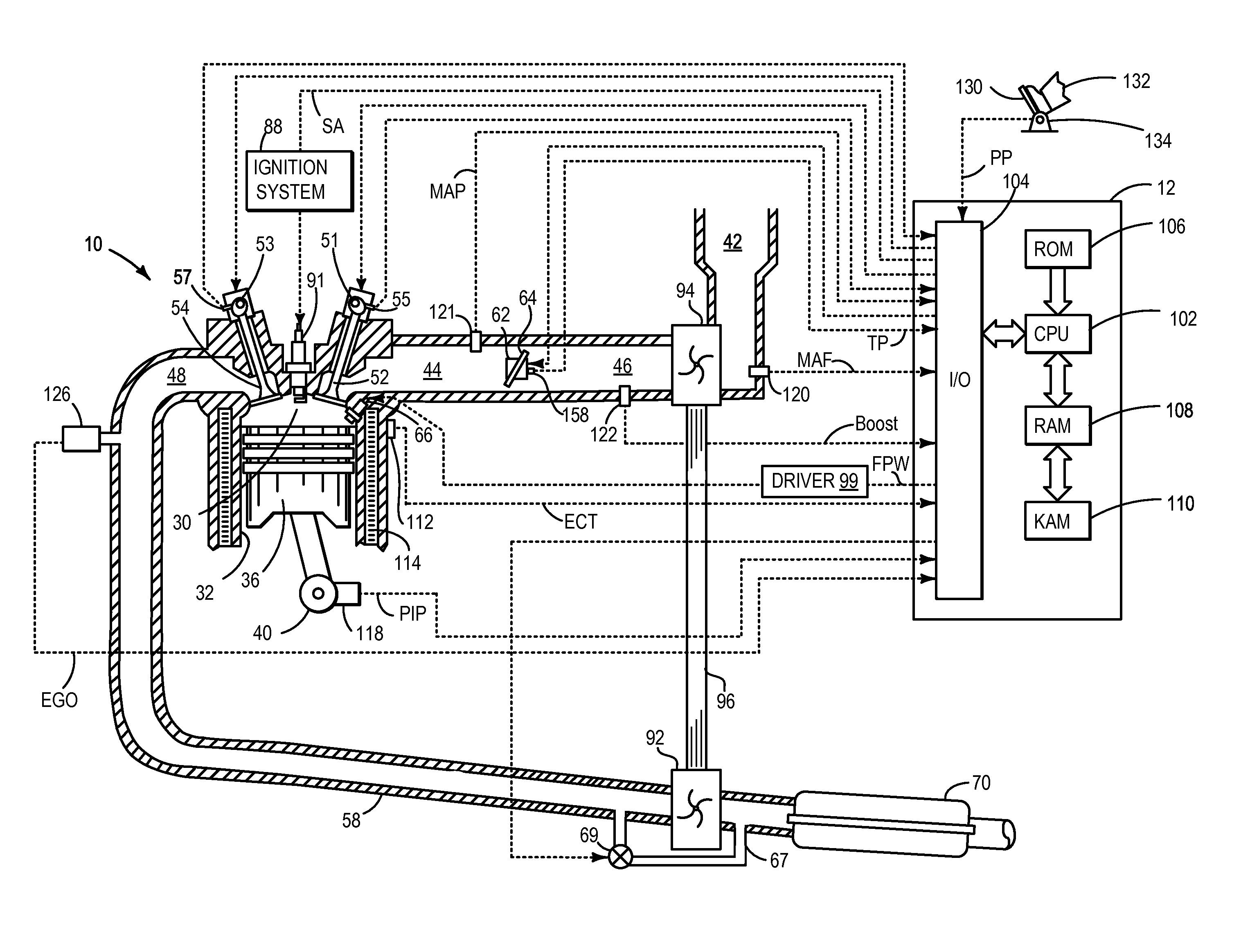

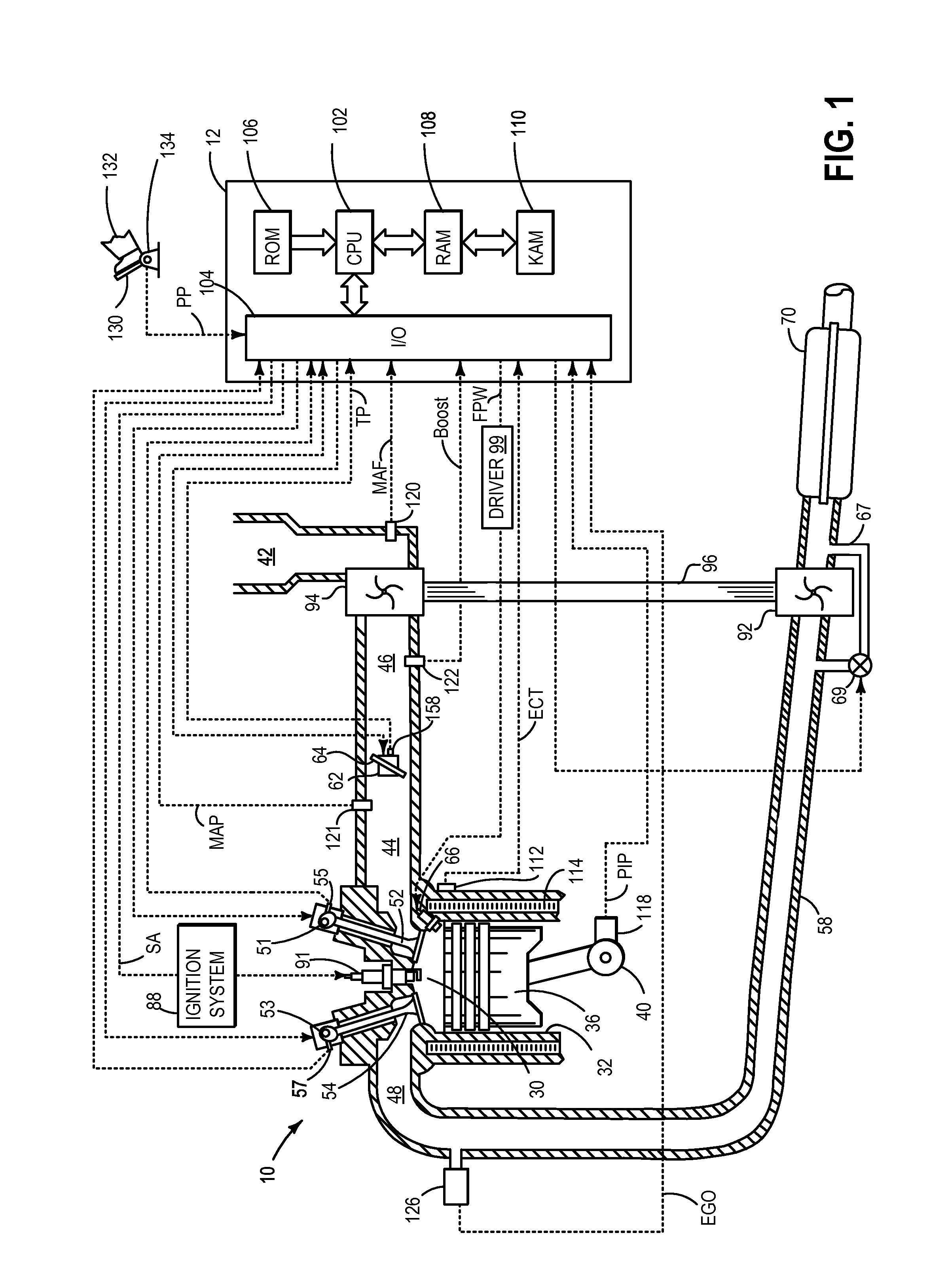

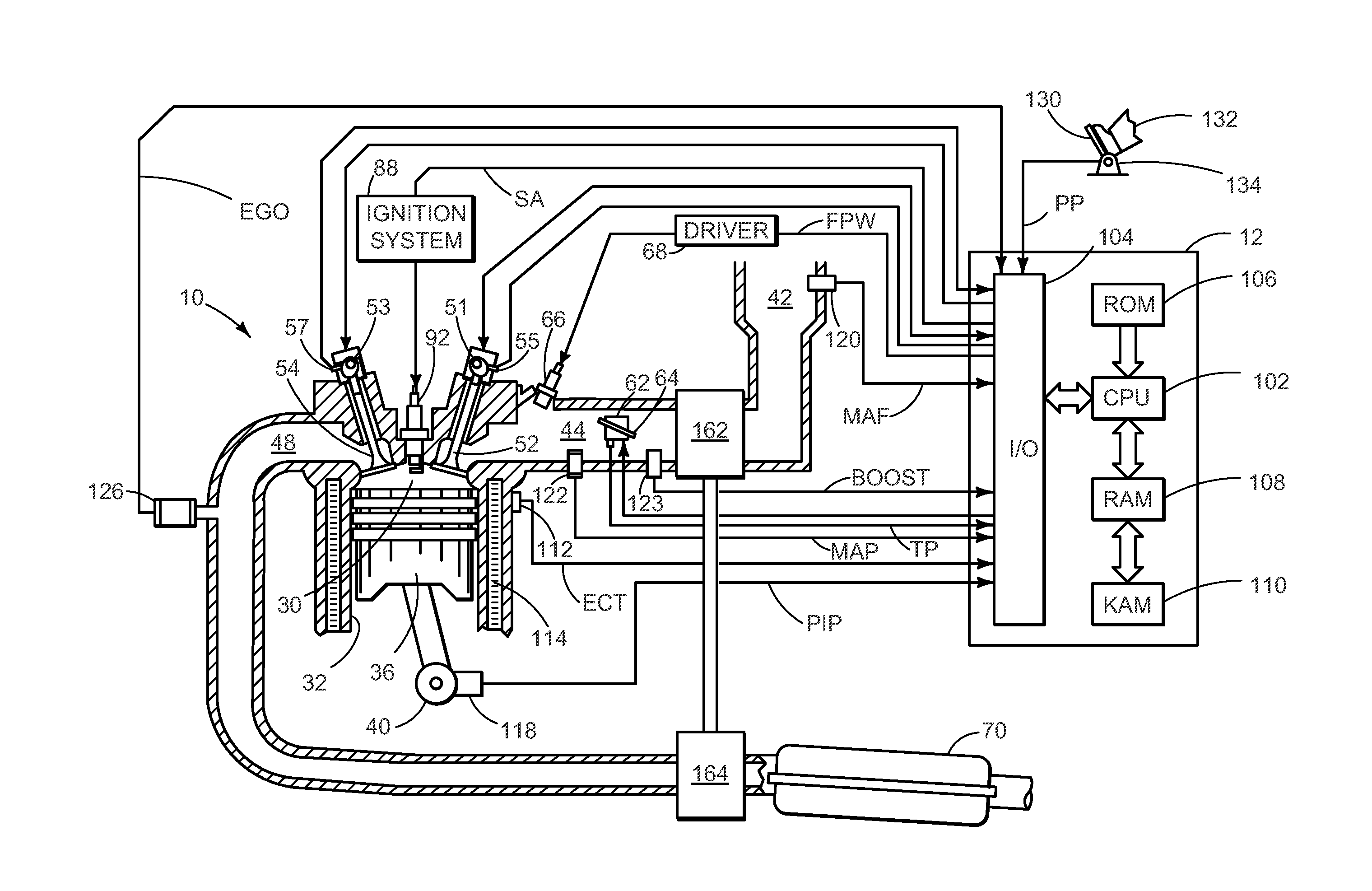

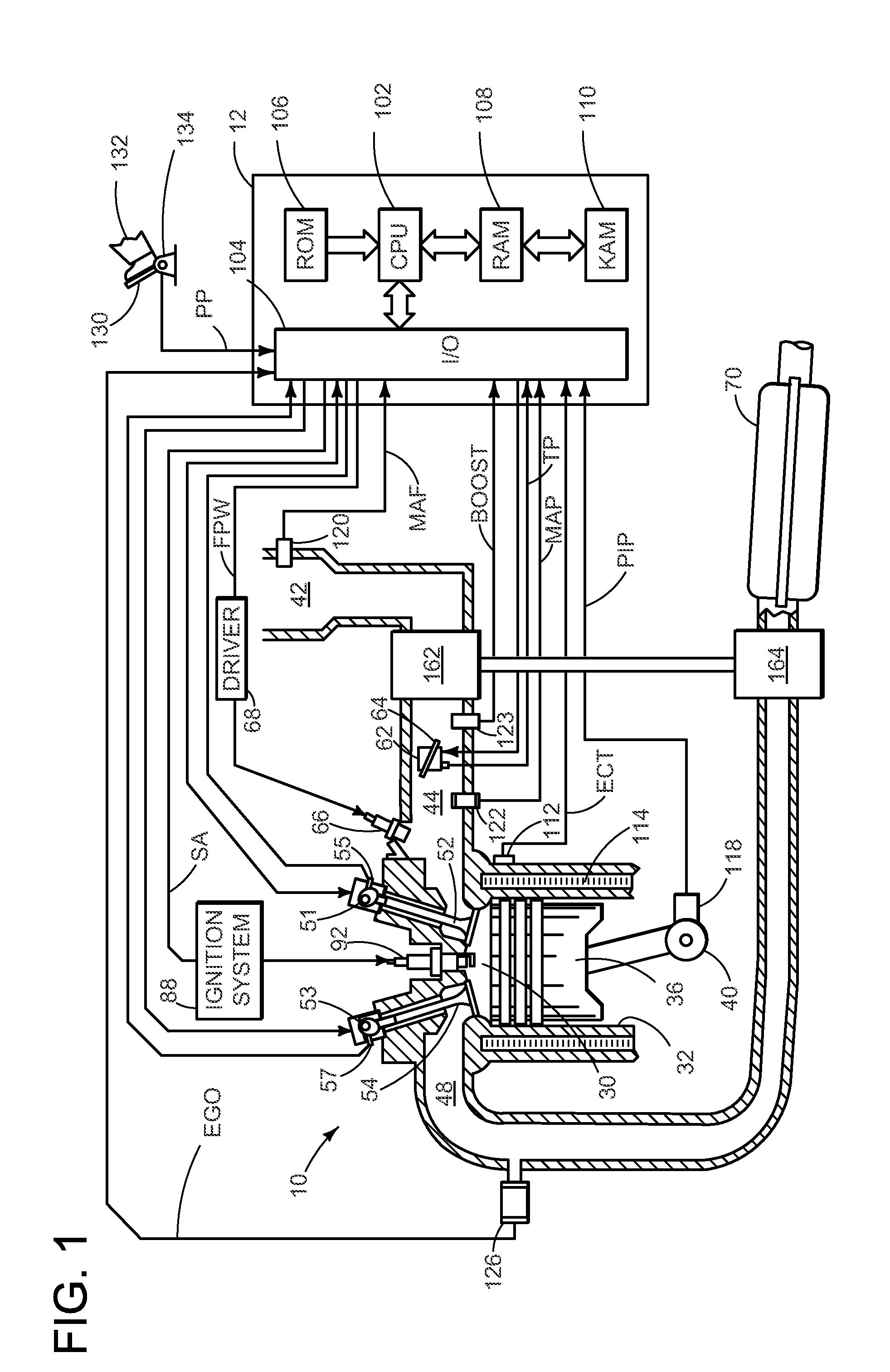

Variable valvetrain turbocharged engine

ActiveUS8833058B2Expand business scopeLower inlet temperatureElectrical controlNon-fuel substance addition to fuelTurbochargerValvetrain

Owner:FORD GLOBAL TECH LLC

Phaser-actuated continuously variable valve actuation system with lost motion capability

A system for continuously varying actuation of a valve in an internal combustion engine including a first cam for opening the valve, a second cam for closing the valve, and an oscillating rocker arm continuously engaging each of the first cam, the second cam, and the valvetrain, with the aid of a lost motion spring. The cams are disposed on first and second camshafts that are geared together. The first camshaft gear is driven by the engine crankshaft and thus is phase-invariant. The second camshaft gear is rotationally mounted on the second camshaft and supports the stator of a camshaft phaser. The phaser rotor is mounted to the second camshaft. Varying the rotor position varies the phase of the second cam and thus varies lift and closing timing of the valve. The system is useful in improving the performance of both spark-ignited and compression-ignited engines.

Owner:DELPHI TECH INC

System for variable valvetrain actuation

InactiveUS20070125330A1Simplifies taskReduce in quantityCam-followersValve drivesGear driveCylinder head

An electromechanical VVA system for controlling the poppet valves in the cylinder head of an internal combustion engine. The system varies valve lift, duration, and phasing in a dependent manner for one or more banks of engine valves. A rocker subassembly for each valve is pivotably disposed in roller bearings on a rocker pivot shaft between the camshaft and a roller follower. A control shaft supports the rocker pivot shaft for controlling a plurality of rocker subassemblies mounted in roller bearings for a plurality of engine cylinders. The control shaft rotates about its axis to displace the rocker pivot shaft and change the angular relationship of the rocker subassembly to the camshaft, thus changing the valve opening, closing, lift and duration. An actuator attached to the control shaft includes a worm gear drive for positively rotating the control shaft.

Owner:DELPHI TECH INC

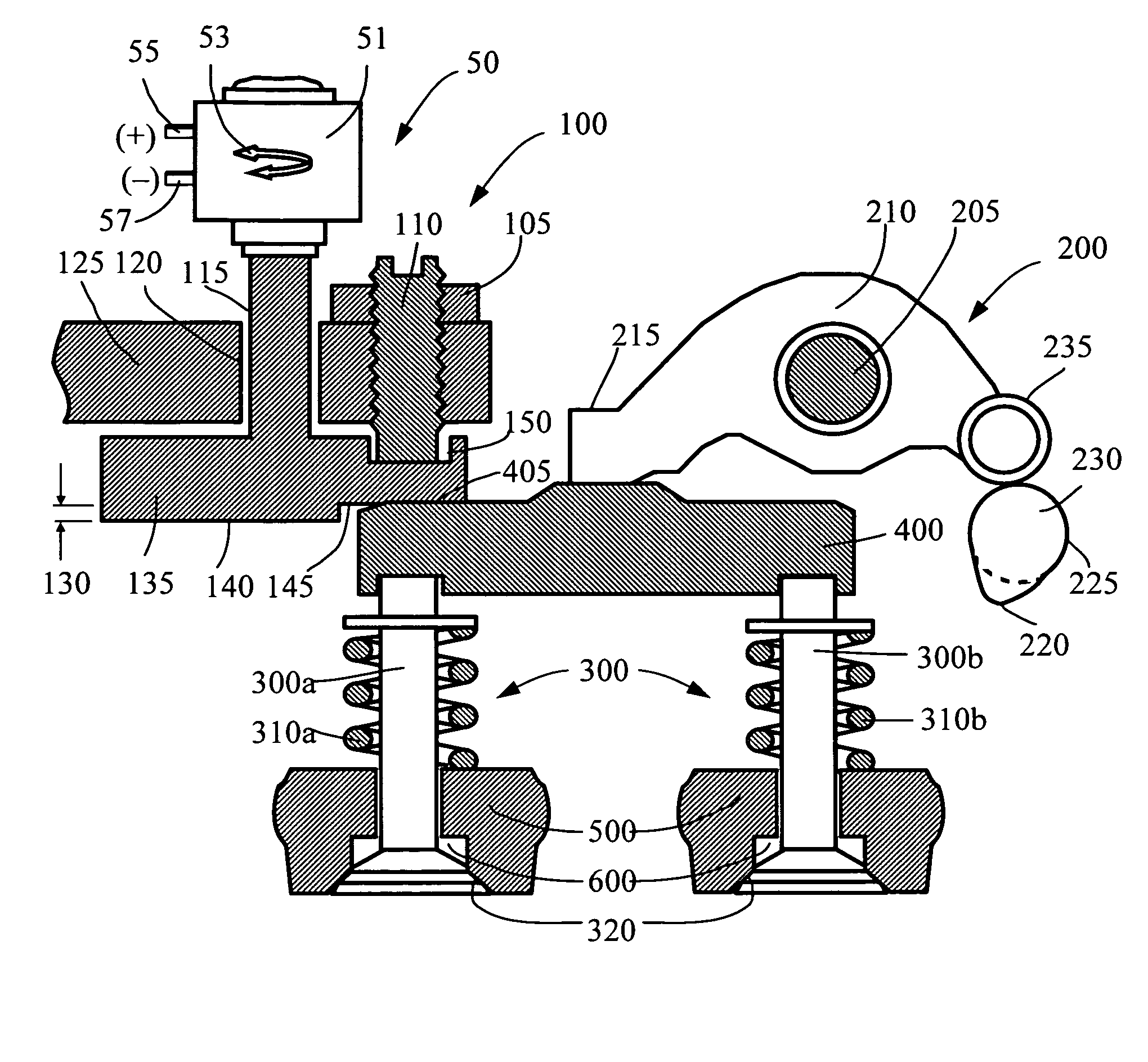

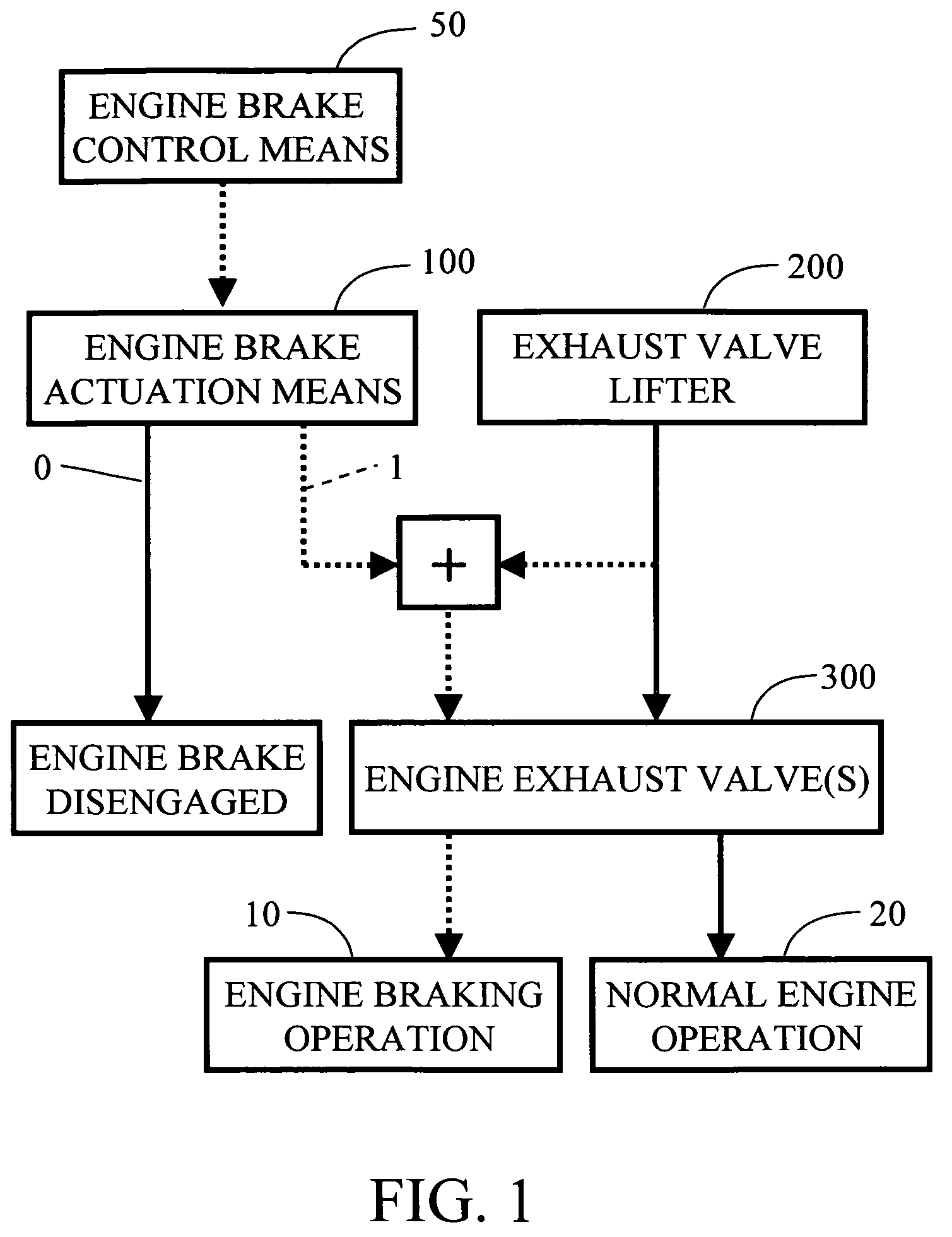

Engine braking apparatus with mechanical linkage and lash adjustment

ActiveUS7789065B2Less componentsReduce complexityValve arrangementsNon-fuel substance addition to fuelExhaust valveEngineering

An apparatus for modifying engine valve lift to produce an engine valve event in an internal combustion engine comprises actuation device for operating at least one exhaust valve, and control device for moving the actuation device between its inoperative position and operative position. In the inoperative position, the actuation device is disengaged from the at least one exhaust valve, and in the operative position, the actuation device holds open the at least one exhaust valve to produce the modified engine valve lift for the engine valve event, which includes an engine braking event. The actuation device includes a motion limiting apparatus for controlling movement of the actuation device. The actuation device can be integrated into a valve bridge and other valve train components, such as a rocker arm, wherein a plunger is slidably disposed between the inoperative position and the operative position.

Owner:JACOBS VEHICLE SYST

Active compression ratio modulation through intake valve phasing and knock sensor feedback

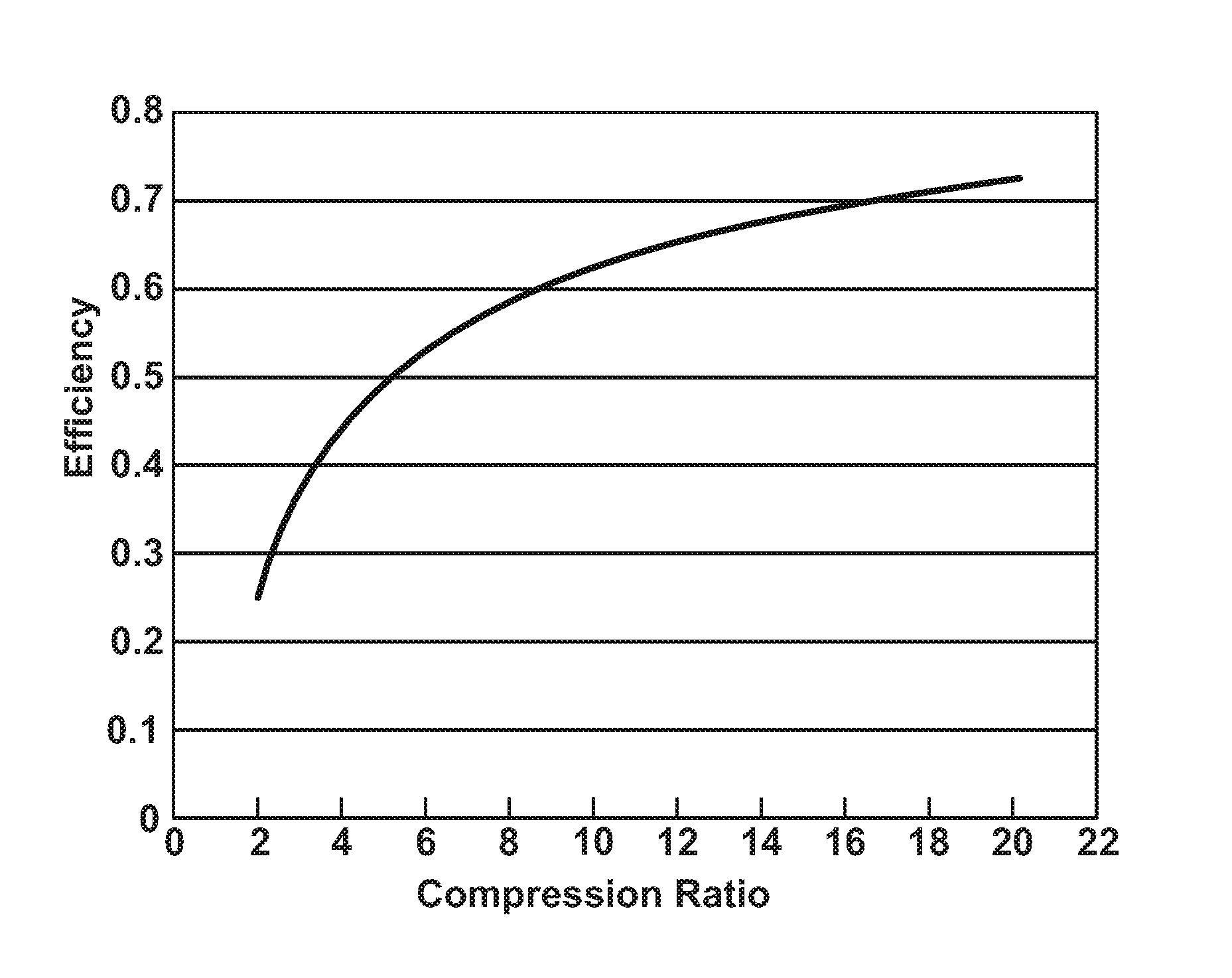

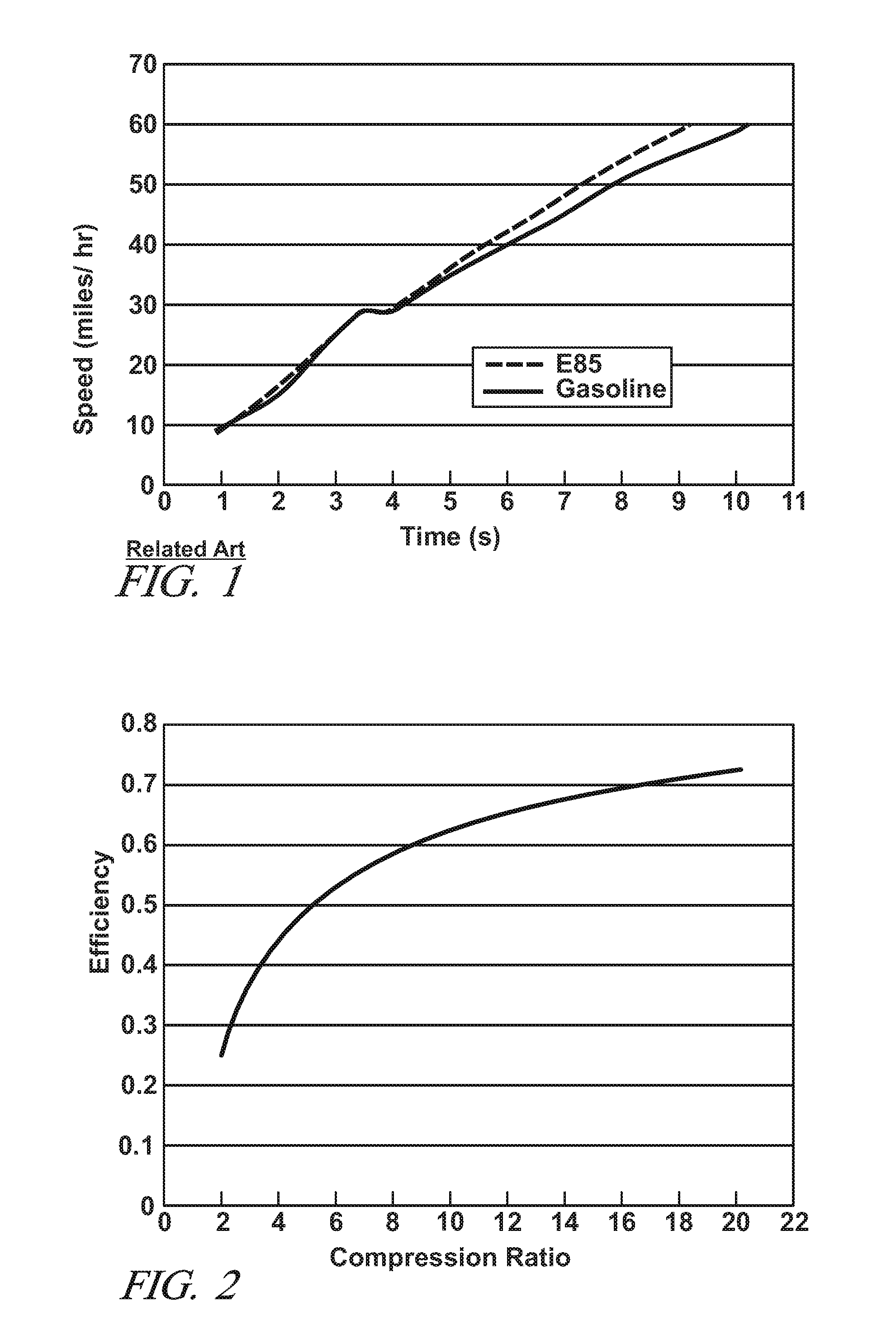

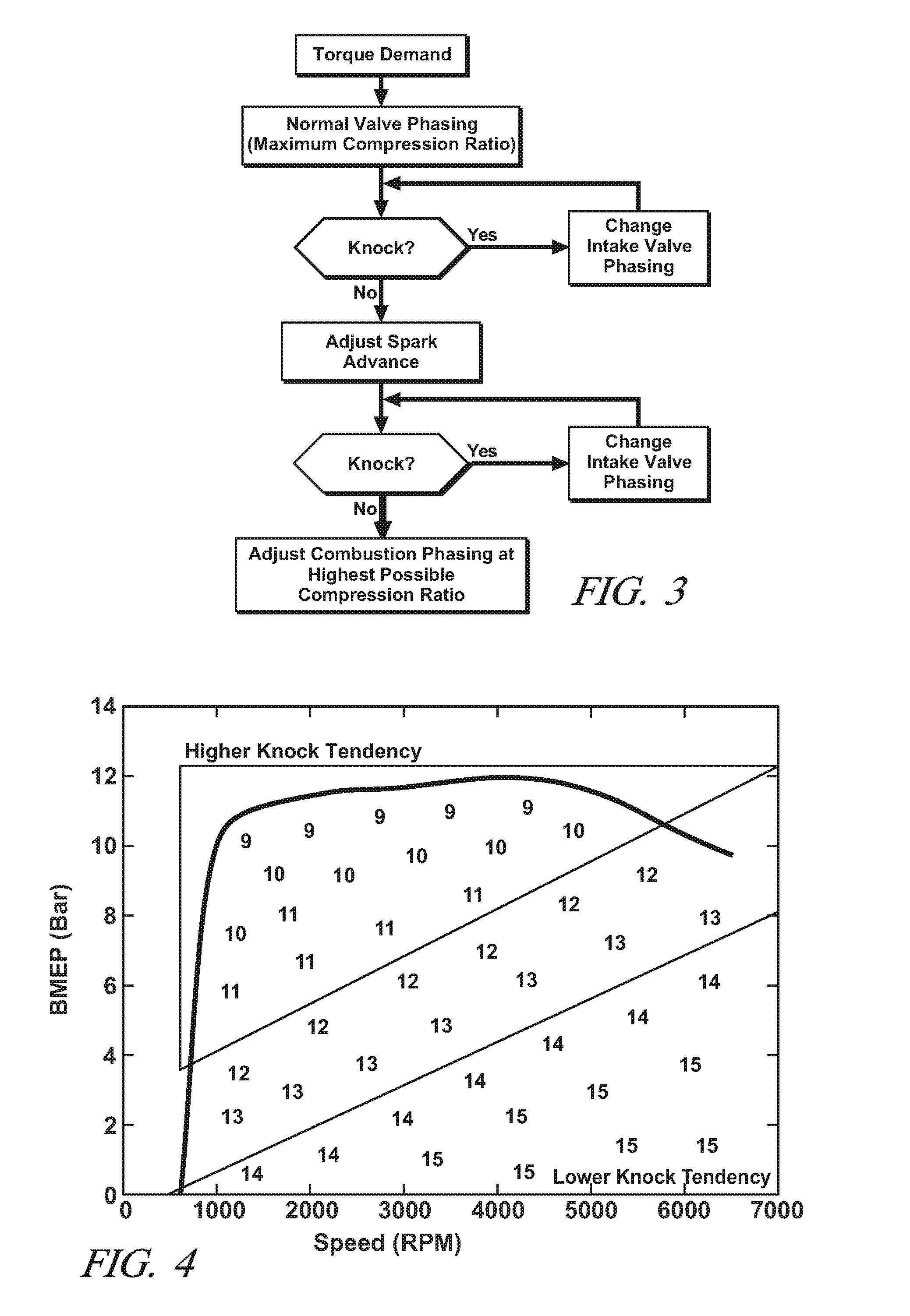

InactiveUS20100049420A1Analogue computers for vehiclesElectrical controlReciprocating motionExternal combustion engine

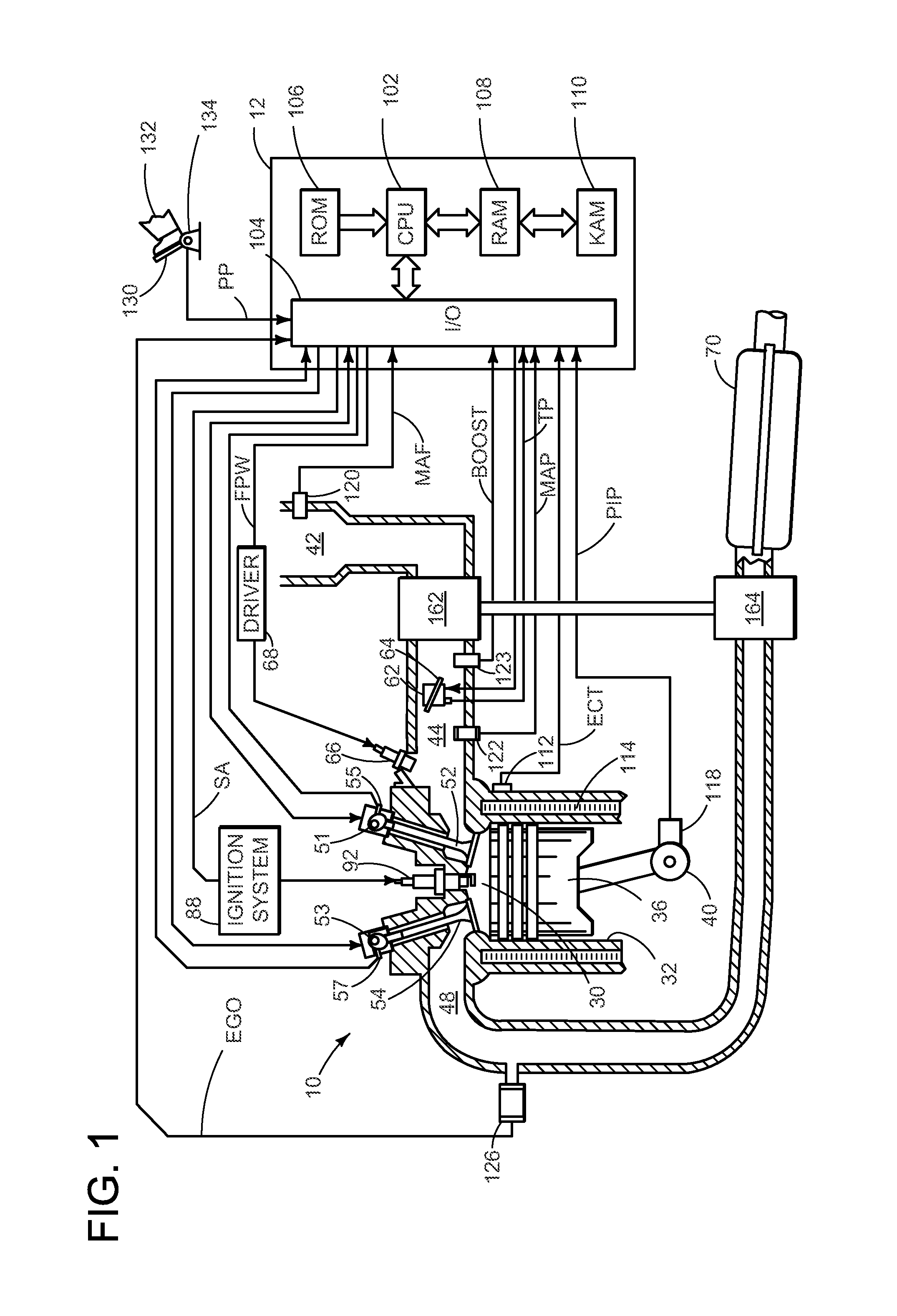

An internal combustion engine includes a piston reciprocable within a cylinder, a phase controllable valvetrain configured to alter the effective compression ratio of the engine, and a knock sensor. A method for controlling the engine includes controlling the valvetrain to a first effective compression ratio whereat knock is detectable by the knock sensor and thereafter controlling the valvetrain to reduce the effective compression ratio to a point whereat knock is no longer detectable.

Owner:GM GLOBAL TECH OPERATIONS LLC

Valvetrain with two-step switchable rocker and deactivating stationary lash adjuster

ActiveUS20060102119A1Easy to controlImproved lost-motion controlValve arrangementsMachines/enginesHydraulic circuitActuator

The invention provides a valvetrain configuration in an internal combustion engine in which a plurality of two-step rockers enable the engine poppet valves to switch between two lift profiles. In addition, a lost-motion stationary lash adjuster enables the deactivation of the engine poppet valve. The integration of a two-step rocker with a deactivating stationary lash adjuster yields a better control of the combustion process, under different engine operating conditions than what is achievable with either one of these actuators acting alone. Preferably, the locking and unlocking of the two-step rocker arm and deactivating stationary lash adjuster is controlled by two on / off hydraulic valves in a hydraulic circuit, and a piloted check valve prevents hard landings between stationary and moving components within the stationary hydraulic lash adjuster.

Owner:GM GLOBAL TECH OPERATIONS LLC

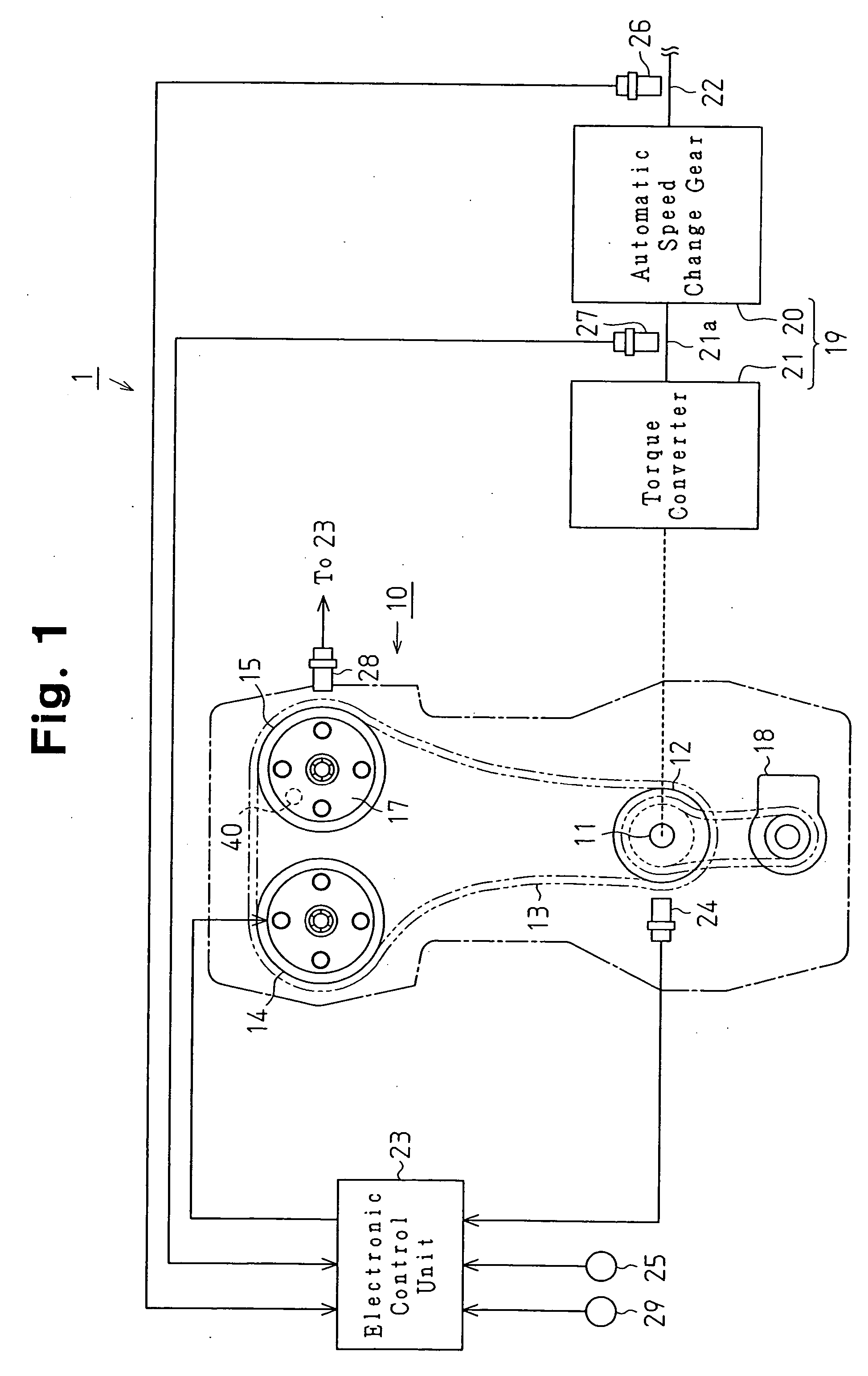

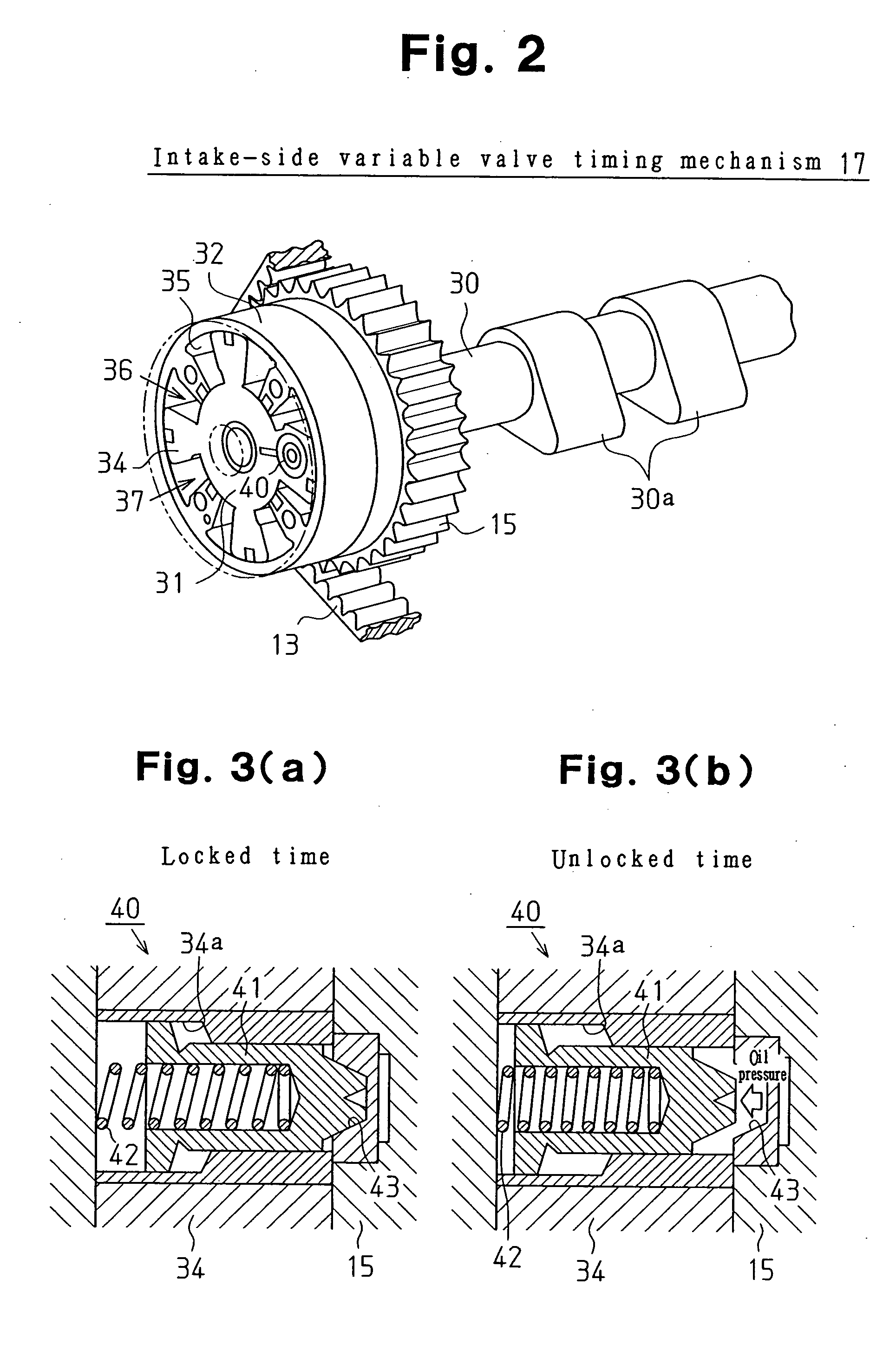

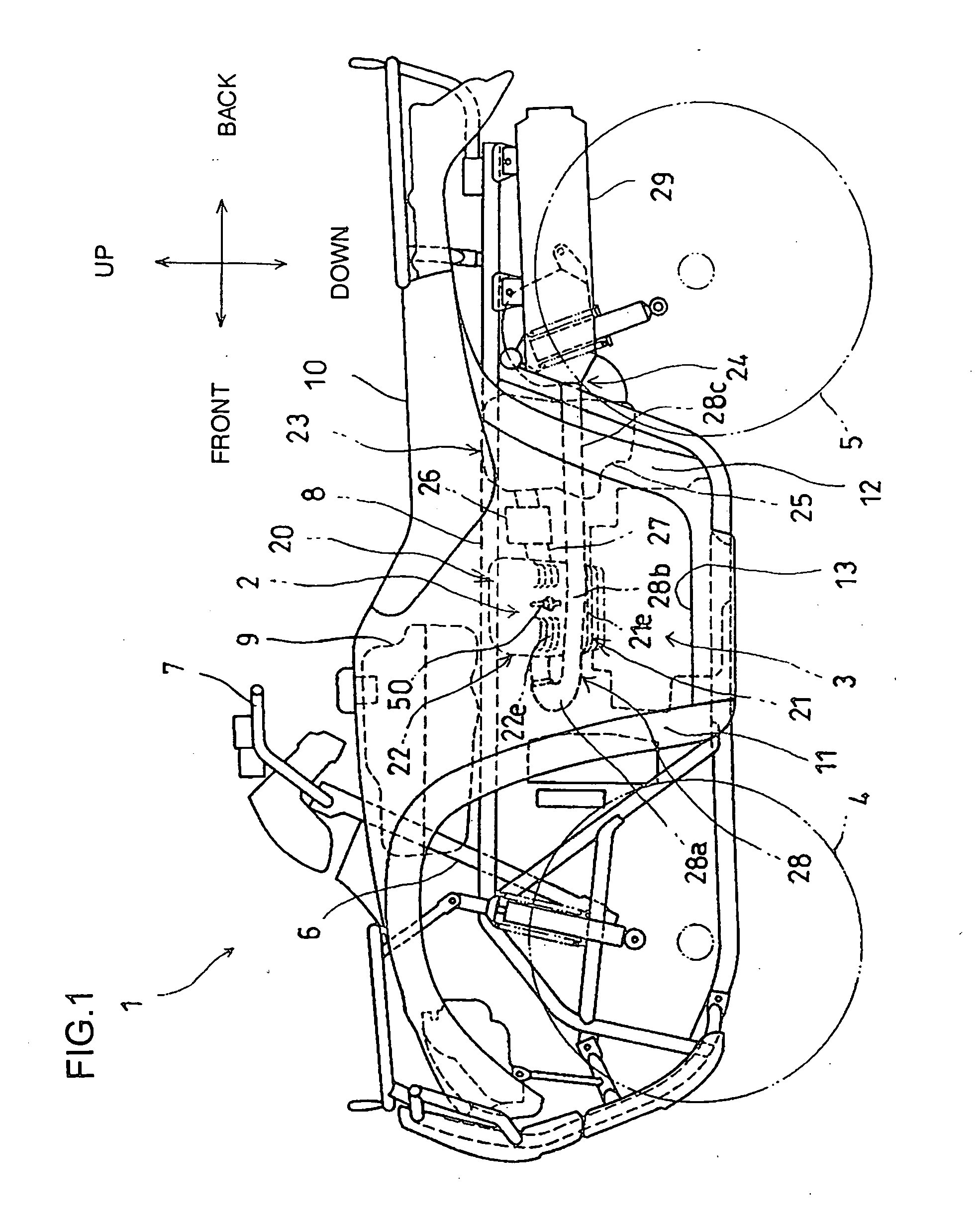

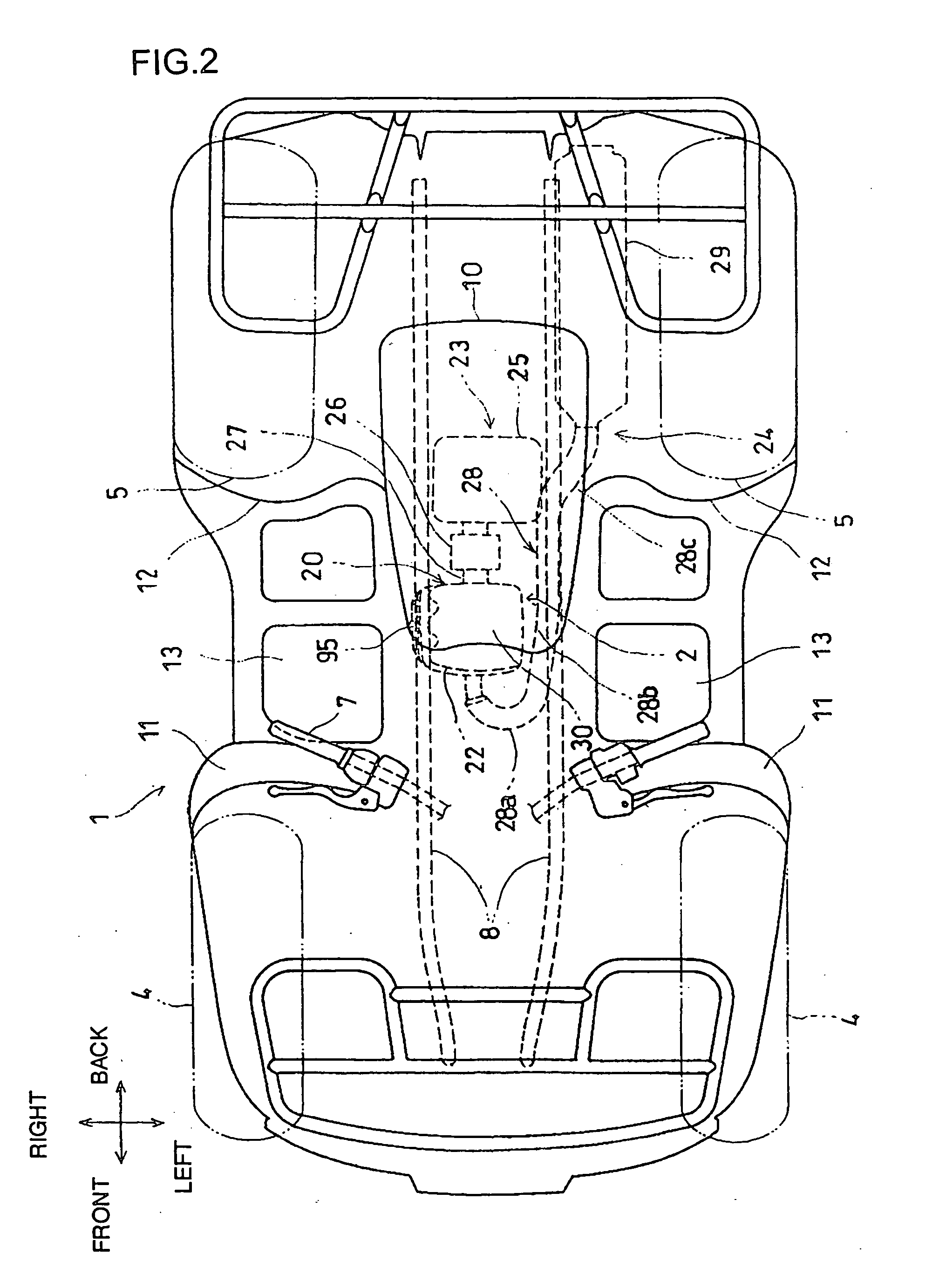

Apparatus for controlling engine

InactiveUS20070017480A1Easy to controlSmooth startValve arrangementsElectrical controlControl systemValvetrain

An engine has variable-valve mechanisms. An engine control system has an engine control unit for executing automatic stop and start control. At an automatic-stop, the variable-valve mechanisms are controlled to obtain a valve operation characteristic suitable for a restart of the engine. When a catalyst is in an inactivated state, the variable-valve mechanisms are controlled to reduce the amount of residual gas leaking out from cylinders. At an automatic-start, the control of the variable-valve mechanism is prohibited and an intake air is adjusted by using a throttle valve. At an automatic-stop, the engine speed is abruptly reduced so that the engine speed passes through a resonant revolution speed area in a short period of time. When the voltage of a battery is low, the control of the variable-valve mechanism may be prohibited.

Owner:DENSO CORP

Variable valvetrain turbocharged engine

ActiveUS20130269315A1Expand business scopeLower inlet temperatureElectrical controlInternal combustion piston enginesTurbochargerValvetrain

Embodiments for routing exhaust in an engine are provided. In one example, an engine method comprises, during a first condition, firing a subset of cylinders and routing all exhaust from the subset of cylinders through a first exhaust manifold coupled directly to a catalyst and not a turbocharger, and during a second condition, firing all cylinders, routing a first portion of exhaust through a second exhaust manifold coupled to the turbocharger, and routing a second portion of exhaust through the first exhaust manifold. In this way, exhaust can be directly routed to a catalyst under some conditions.

Owner:FORD GLOBAL TECH LLC

Exhaust gas recirculation

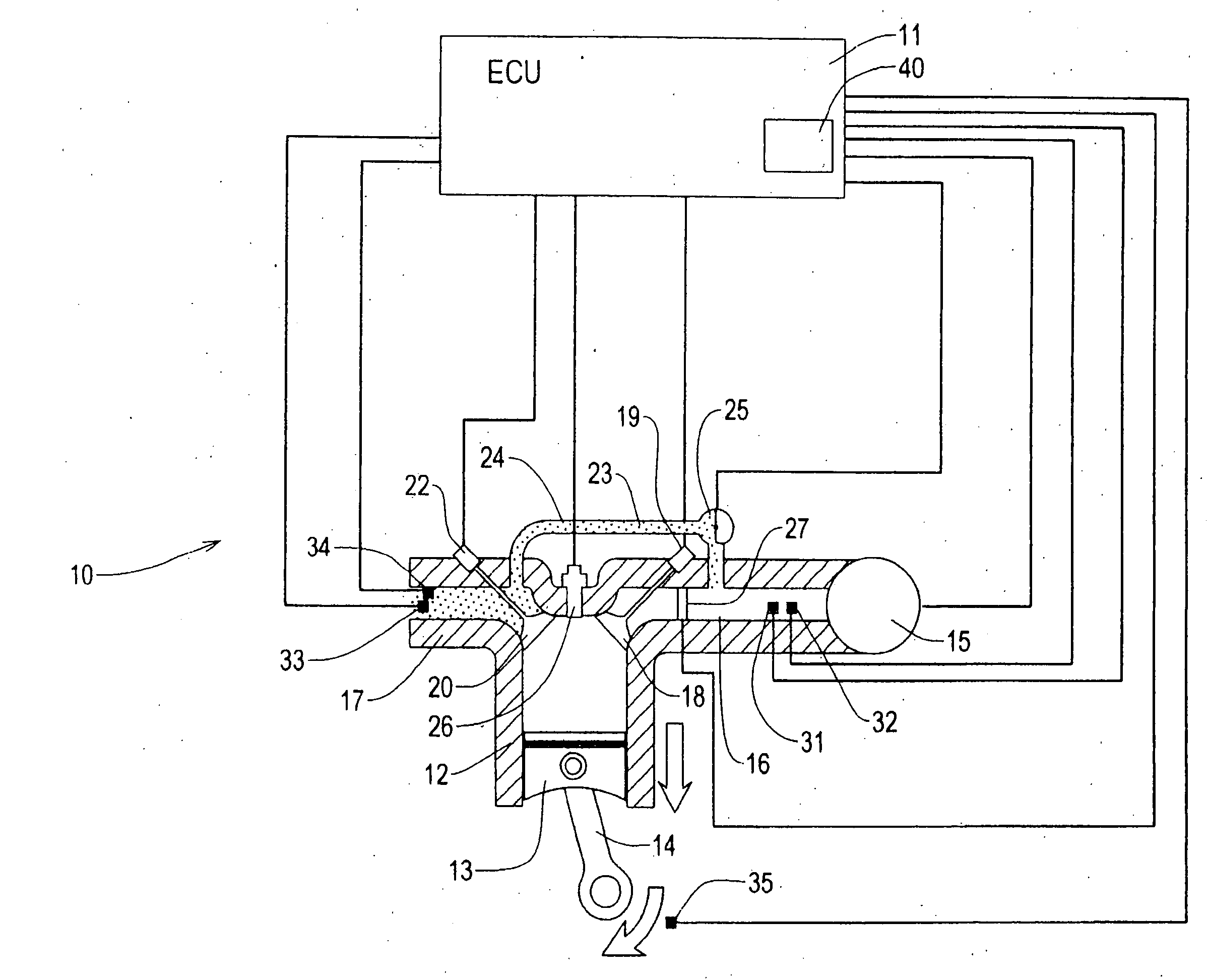

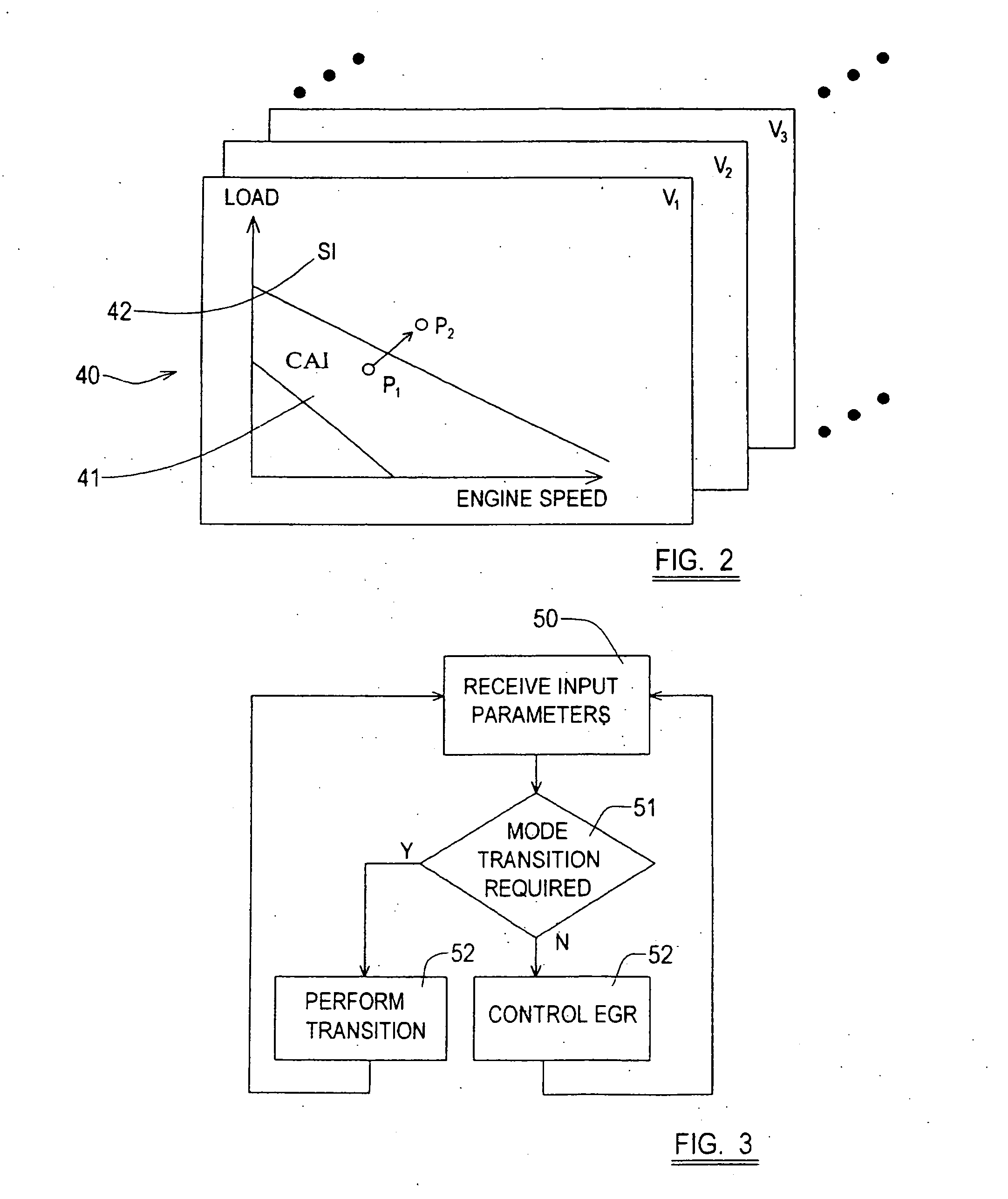

InactiveUS20060102158A1Easy to operateReduce the compression ratioValve arrangementsElectrical controlCombustion chamberGasoline

An internal combustion engine comprising, an engine management unit, a combustion chamber having an inlet port and an outlet port, a fuel supply mechanism to supply gasoline to the engine, a valve train mechanism to permit introduction of air to the inlet port of the combustion chamber and release exhaust gases from the outlet port of the combustion chamber, and an external recirculating system whereby exhaust gases from the outlet port may be passed to the inlet port, wherein, the engine management unit is operable to, control the valve train mechanism to retain and / or rebreathe exhaust gases within the combustion chamber to cause the engine to operate in a controlled auto ignition combustion mode, and control the external recycling system to supply exhaust gases to the inlet port in the controlled auto ignition combustion mode, such that self-ignition occurs in the combustion chamber.

Owner:MAHLE POWERTRAIN

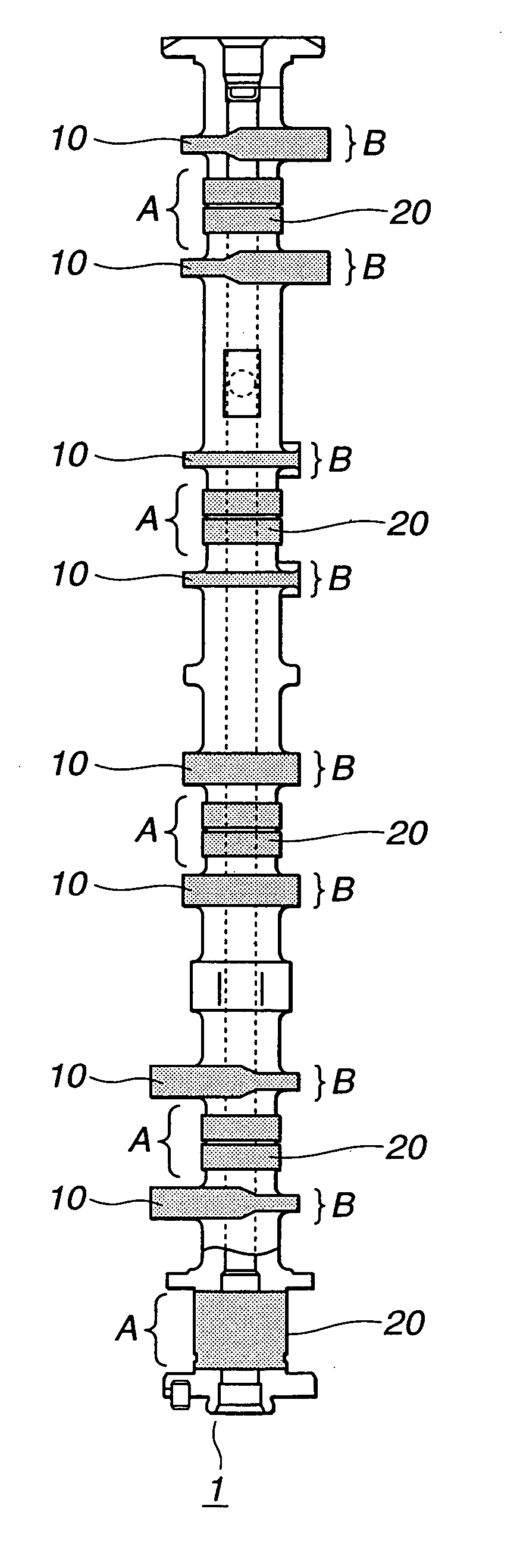

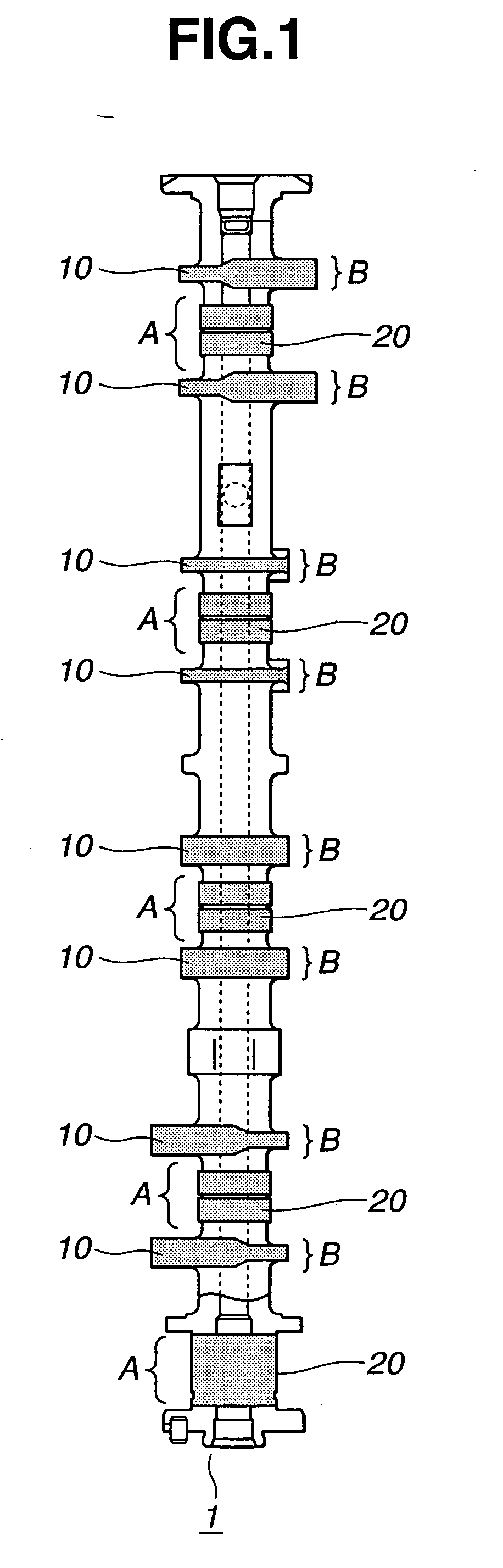

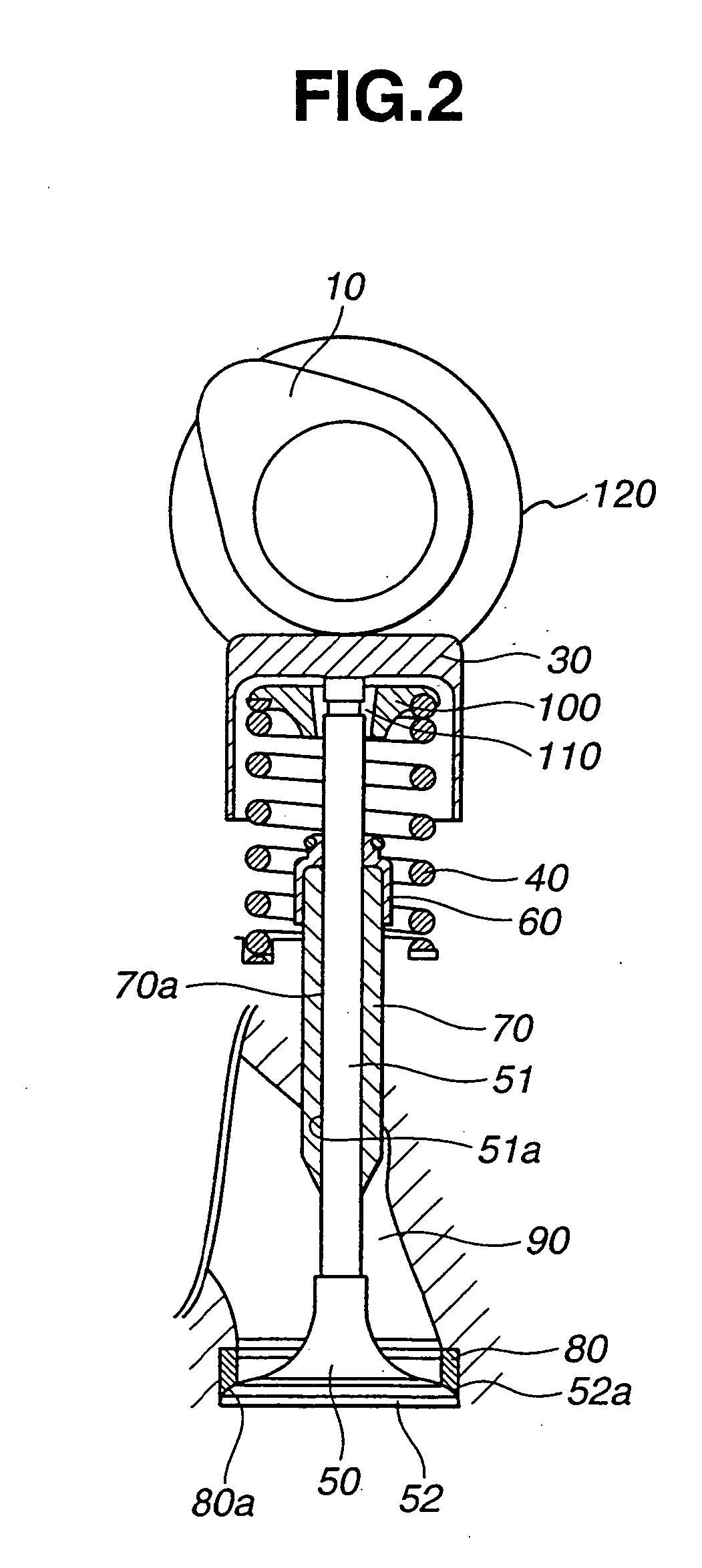

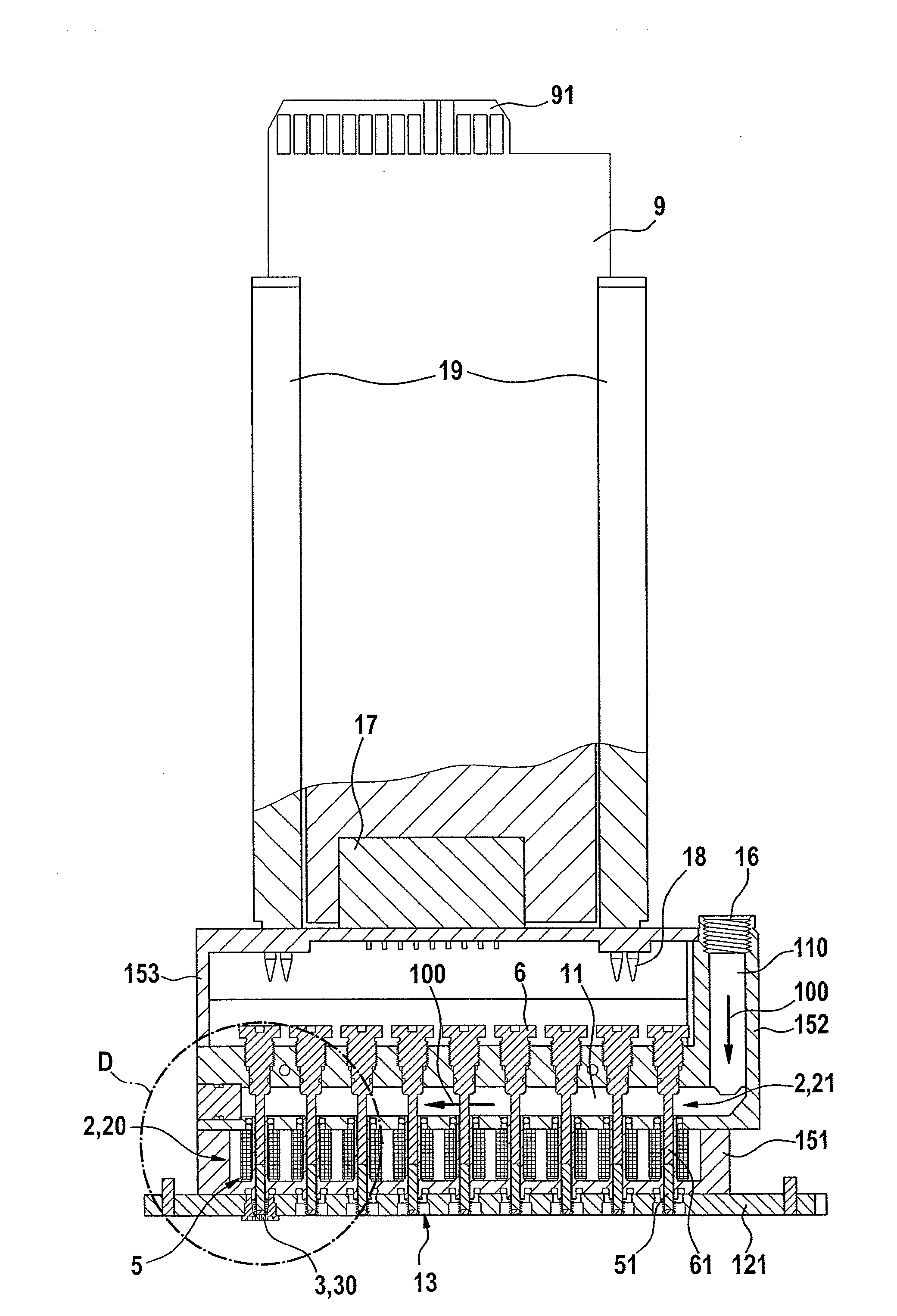

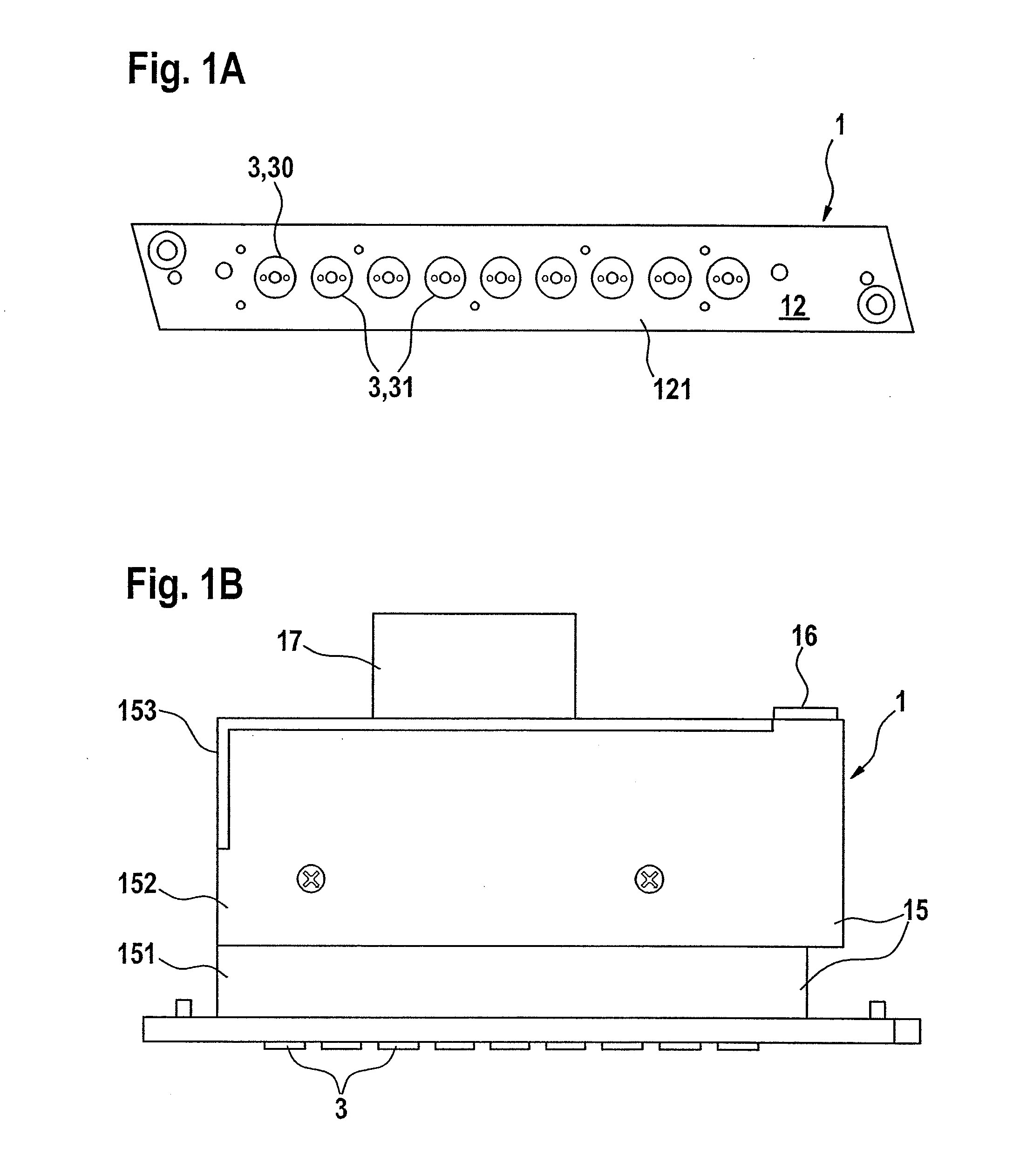

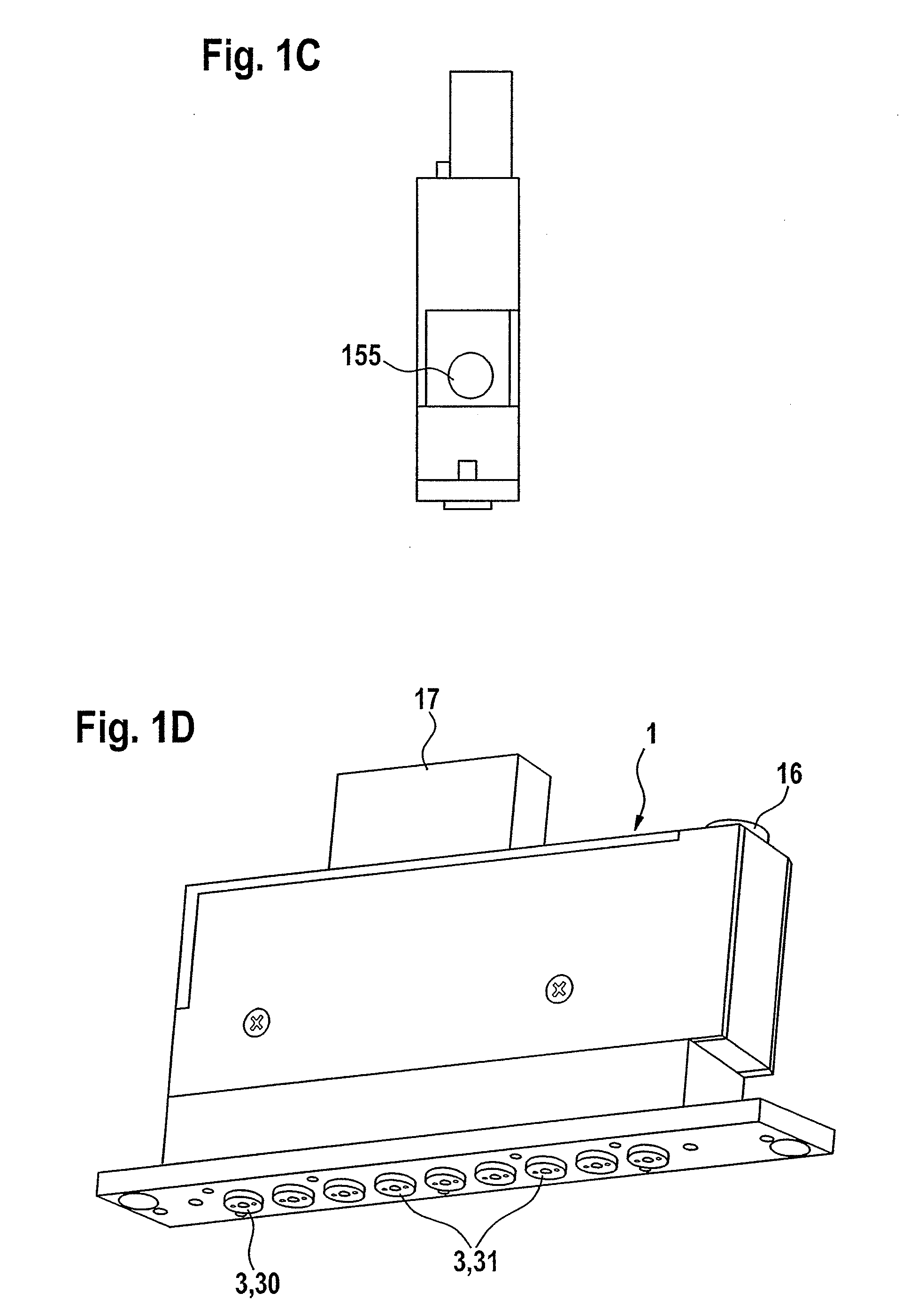

Applicator for applying fluid to a substrate, comprising valve mechanisms, method for cleaning said applicator, and valve mechanisms for said applicator

InactiveUS20100132612A1Easy to removeSensitive to damageLiquid surface applicatorsSpray nozzlesFluid intakeMedicine

Disclosed is an applicator (1) for applying fluid to a substrate, comprising valve mechanisms (21) which are arranged in a row and are each equipped with an application valve nozzle (31), and a distributing fluid chamber (11) that has a fluid intake duct (110). A cleaning valve mechanism (21) which is incorporated into the row of application valve mechanisms (21) and is fitted with a cleaning valve nozzle (30) is associated with the fluid intake duct (110). A flow path (100) for cleaning the fluid chamber (11) is formed between the fluid intake duct (110) and the cleaning valve mechanism (20) in the distributing fluid chamber (11), said flow path (100) being effective when the cleaning valve nozzle (30) is open. Also disclosed is a method for cleaning said applicator (1). In said method, pressurized cleaning fluid is applied to the distributing fluid chamber (11), the application valve mechanisms (21) are kept closed while the cleaning valve nozzle (30) is opened, and the cleaning valve nozzle (30) is then closed while the application valve mechanisms are opened when the pressurized cleaning fluid is applied to the distributing fluid chamber (11). A valve mechanism (2) of the applicator (1) encompasses a detachably mounted nozzle diaphragm (3, 4) which unblocks a valve piston (51) in the removed state. The valve mechanism (2) further encompasses a straight fluid duct that remains free of flow corners. A setting piston (61) is movably mounted for adjusting and setting the stroke of the valve piston (51).

Owner:J ZIMMER MASCHENBAU GES

Apparatus and method for controlling internal combustion engine

InactiveUS20050051122A1Restraining decrease in follow-up performanceLower performance requirementsElectrical controlInternal combustion piston enginesControl theoryValvetrain

A controller restricts an operation amount of the variable valve actuation mechanism of a fluid pressure operated type such that increase in the valve overlap amount of an engine is restrained when the engine is in a transient operation state in which the output of the engine increases. When the controller determines that the variable valve actuation mechanism is in the locked state, the controller relaxes the restriction imposed on the operation amount of the variable valve actuation mechanism. Hence, a decrease in follow-up performance of valve properties to desired properties is restrained while restraining temporary stagnation of increase in engine rotational speed caused by vehicle acceleration.

Owner:TOYOTA JIDOSHA KK

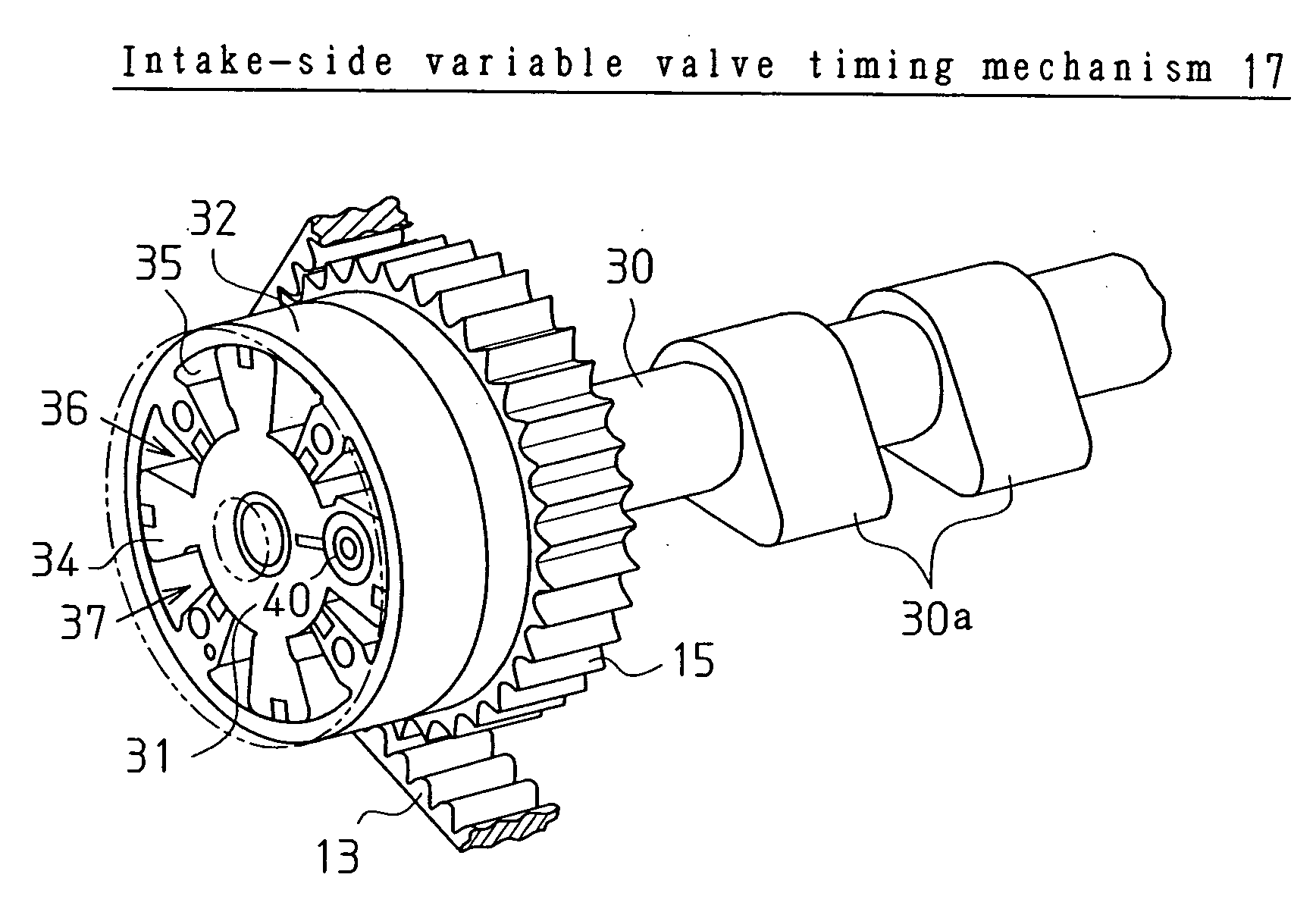

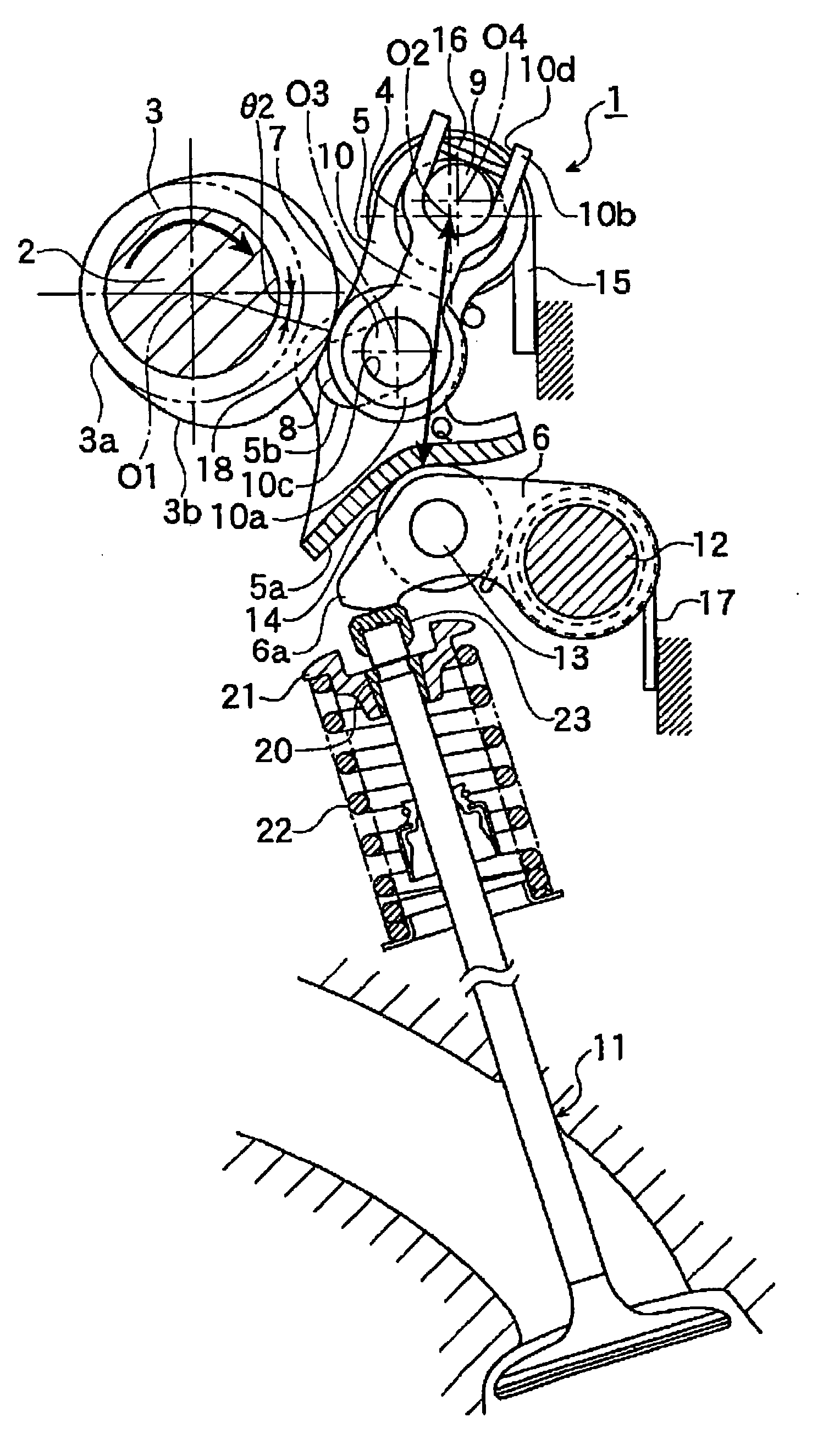

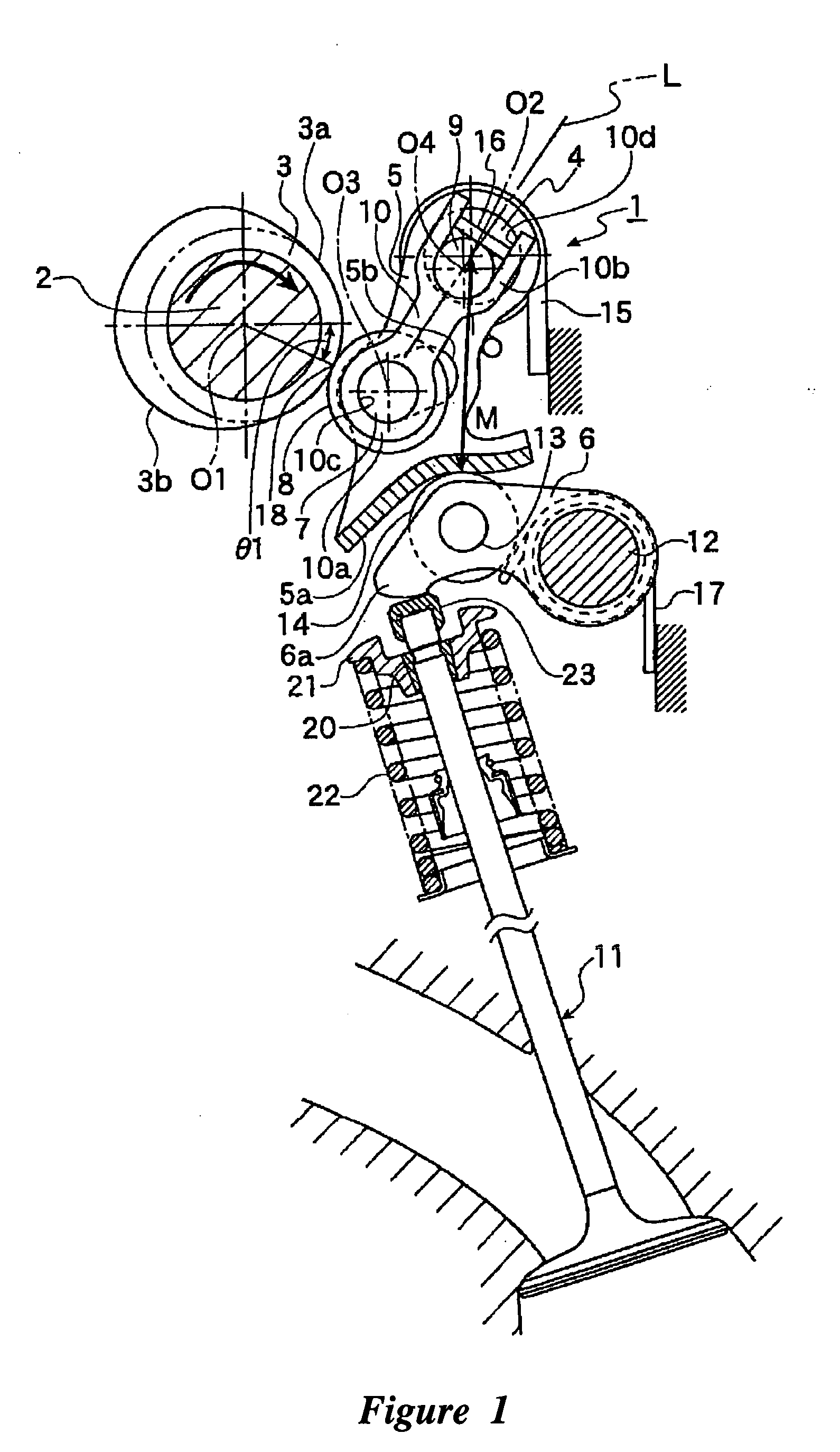

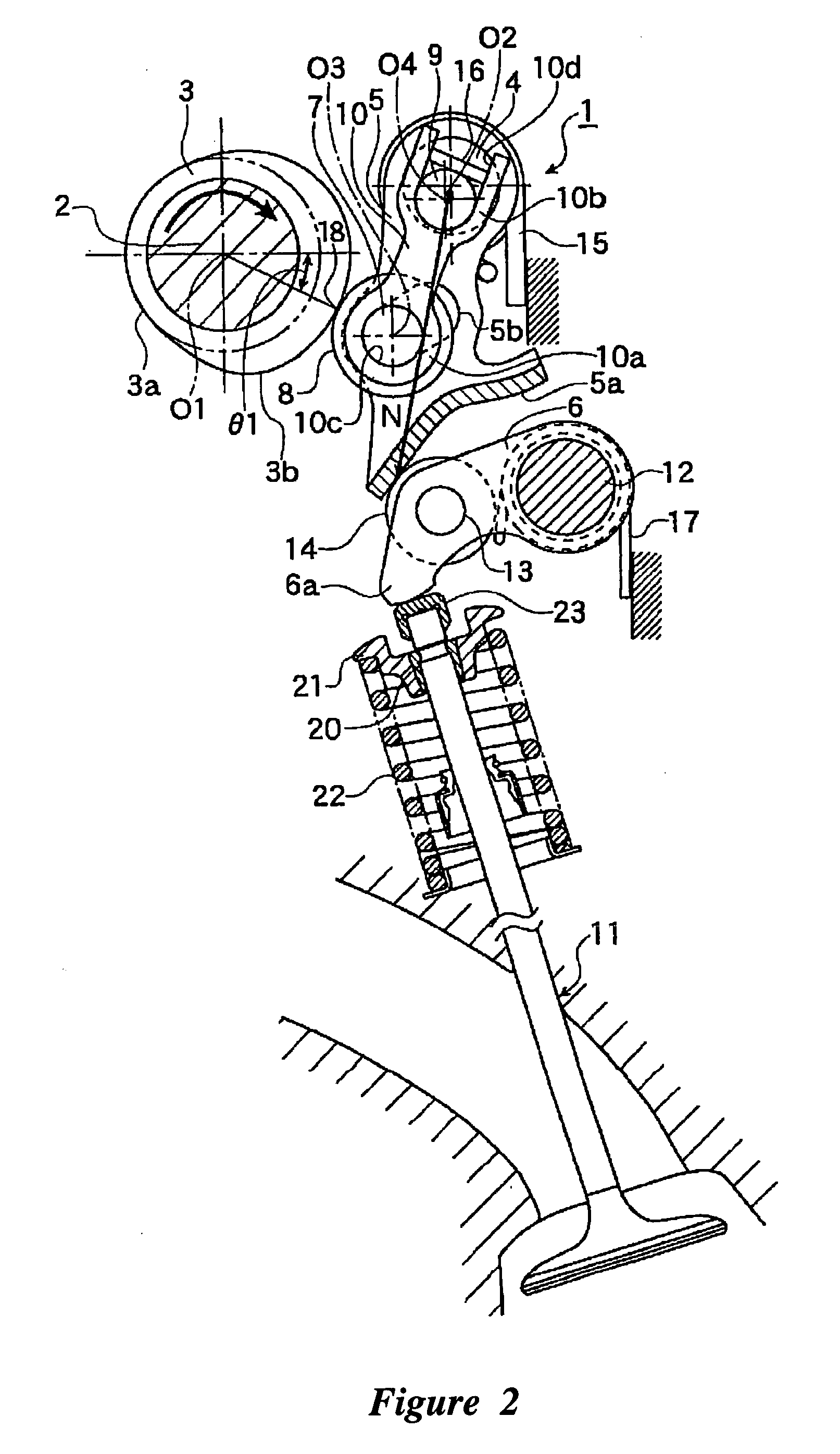

Variable valve train mechanism of internal combustion engine

A rotational cam can be disposed on a camshaft rotationally driven by a crankshaft of an internal combustion engine. A swing cam can be swingable through the rotational cam. The swing cam has a rotational cam abutment portion which contacts the rotational cam and transmits driving force from the rotational cam to the swing cam. An abutment portion displacing mechanism can be provided for displacing the rotational cam abutment portion to change a relative distance between the rotational cam abutment portion and a center axis of the swing shaft. Changing the relative distance allows changing a lift and the like of a valve.

Owner:YAMAHA MOTOR CO LTD

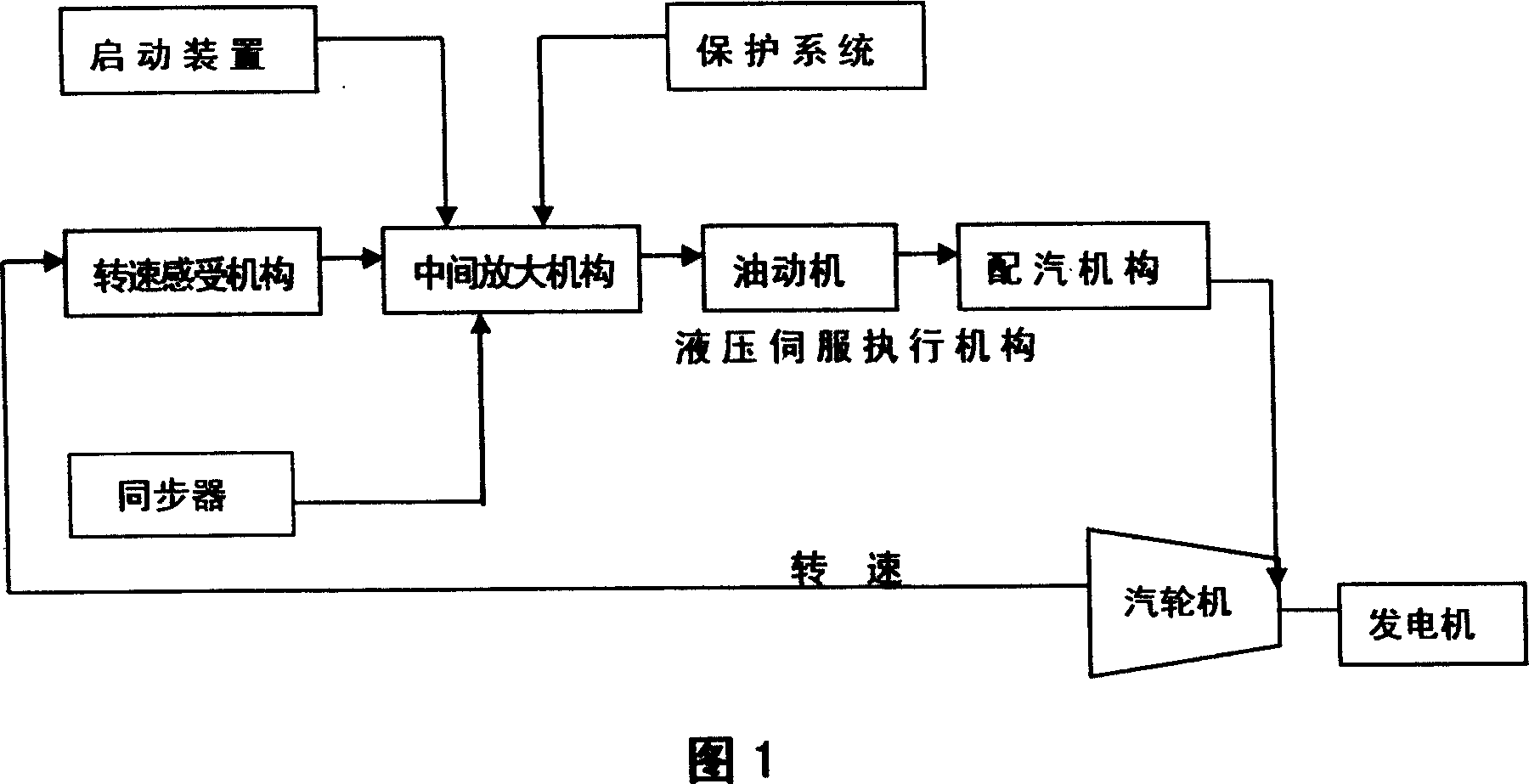

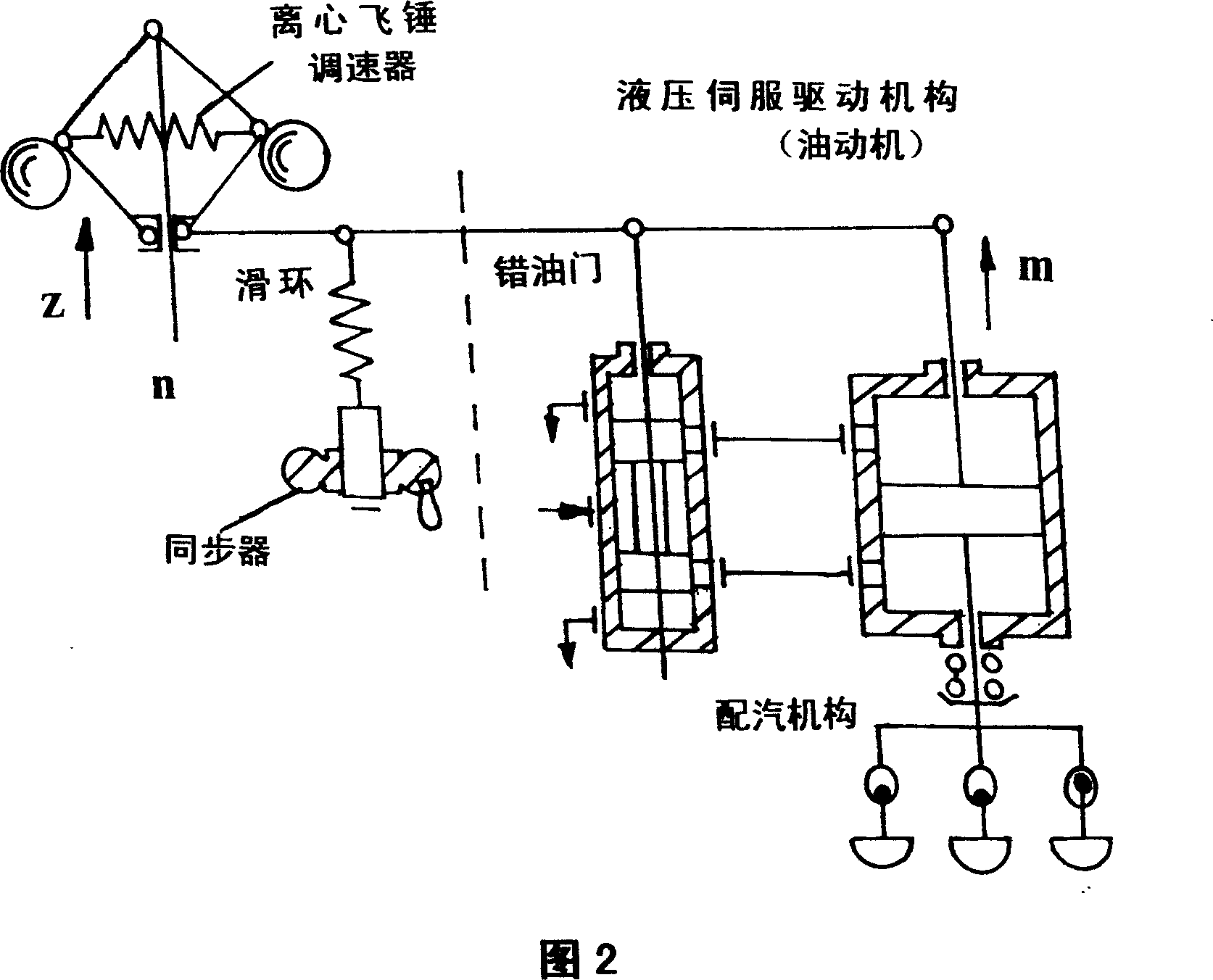

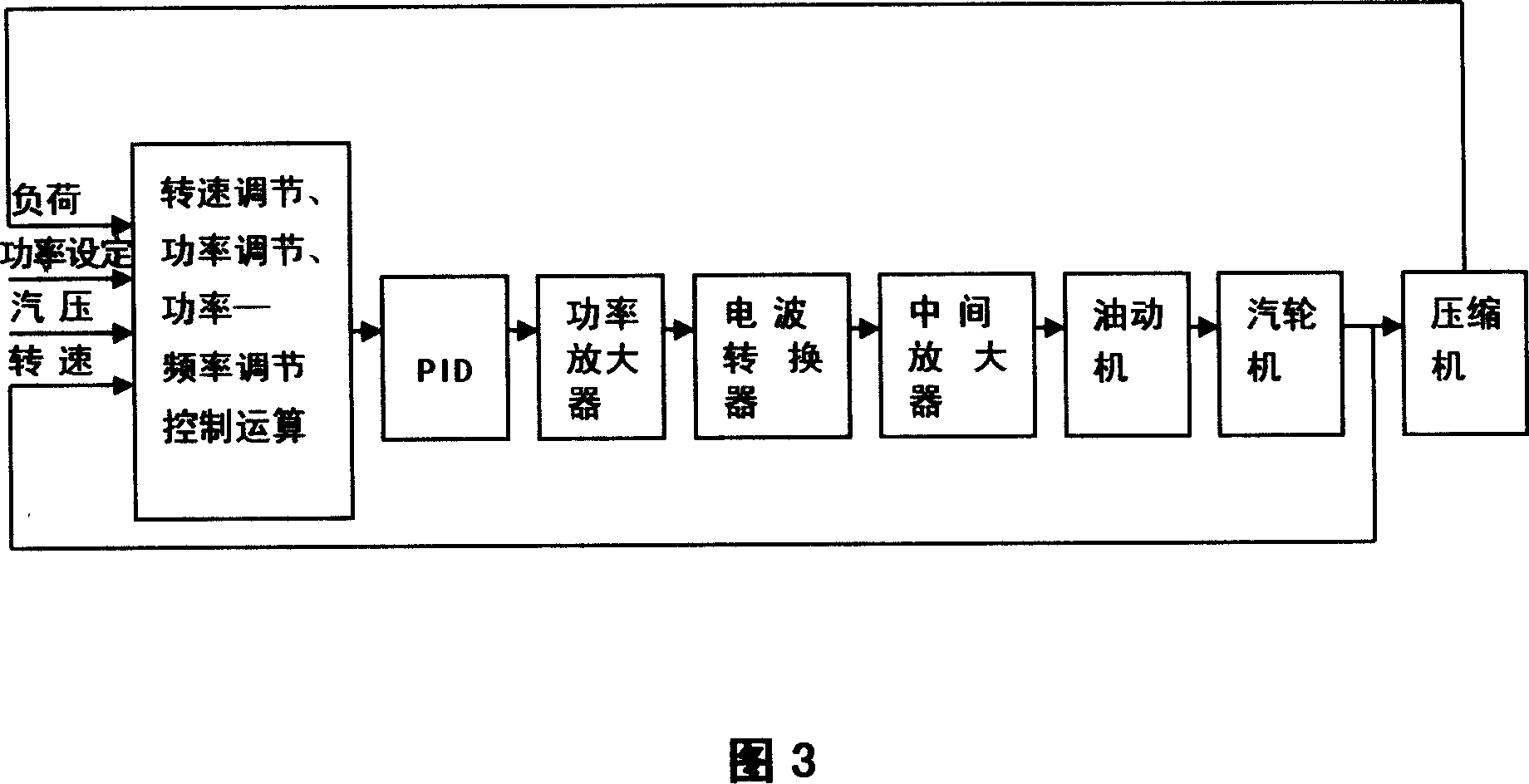

Speed adjustment control system of steam turbine

InactiveCN1959067AImprove responsivenessQuick responseMachines/enginesEngine componentsSpeed control systemControl signal

A speed controlling device of steam turbine consists of rotation speed sensing mechanism, intermediate amplifying mechanism, synchronizer, start-up unit, oil supplier and valve actuating mechanism. It is featured as calibrating relation of air intake flow on steam turbine to stroke of oil supplier to be approximately linear relation, utilizing synchronizer to act on intermediate amplifier to generate control signal for controlling stroke of oil supplier so as to change rotary speed of steam turbine.

Owner:沈阳创思达自动化系统有限公司

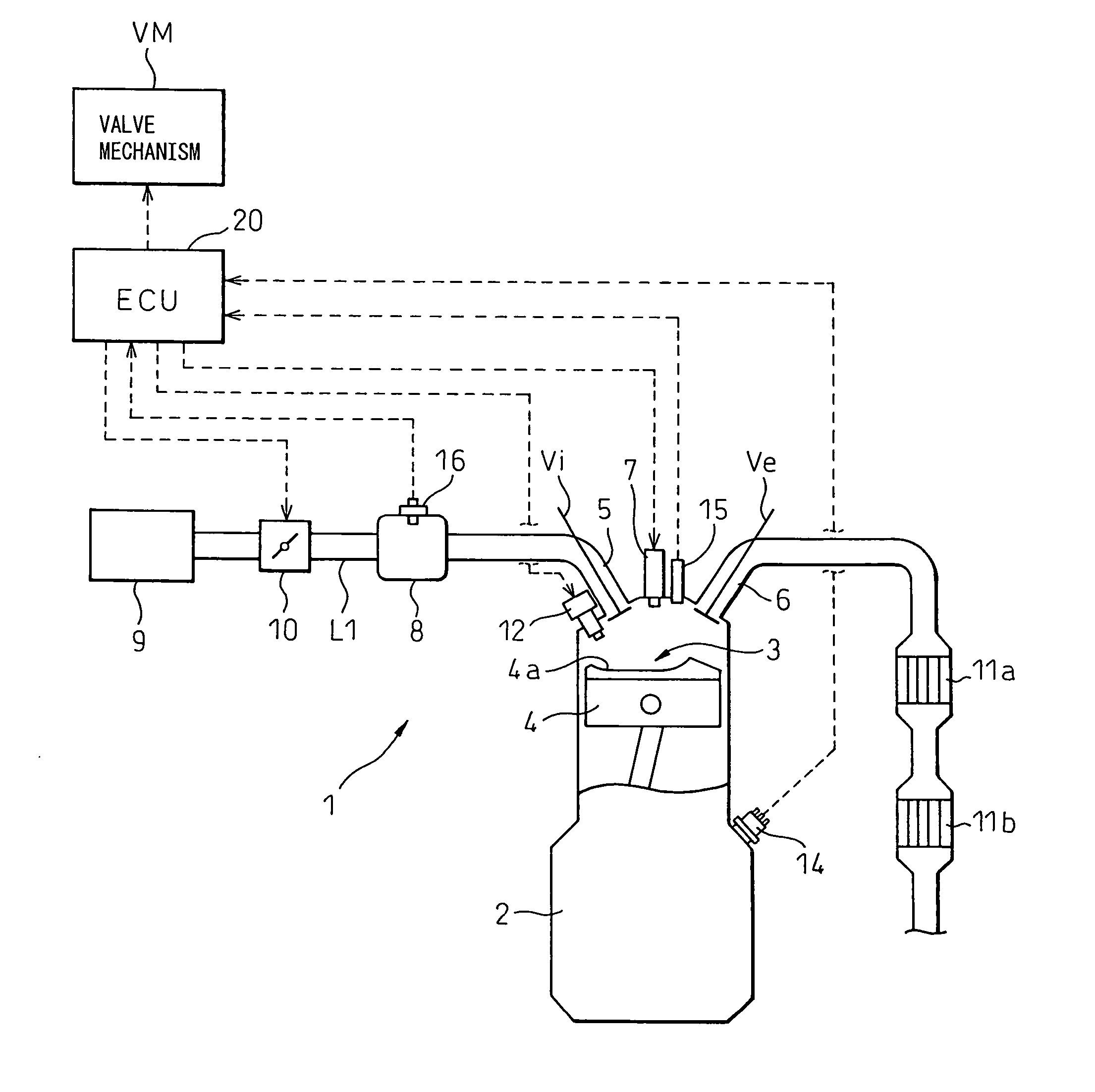

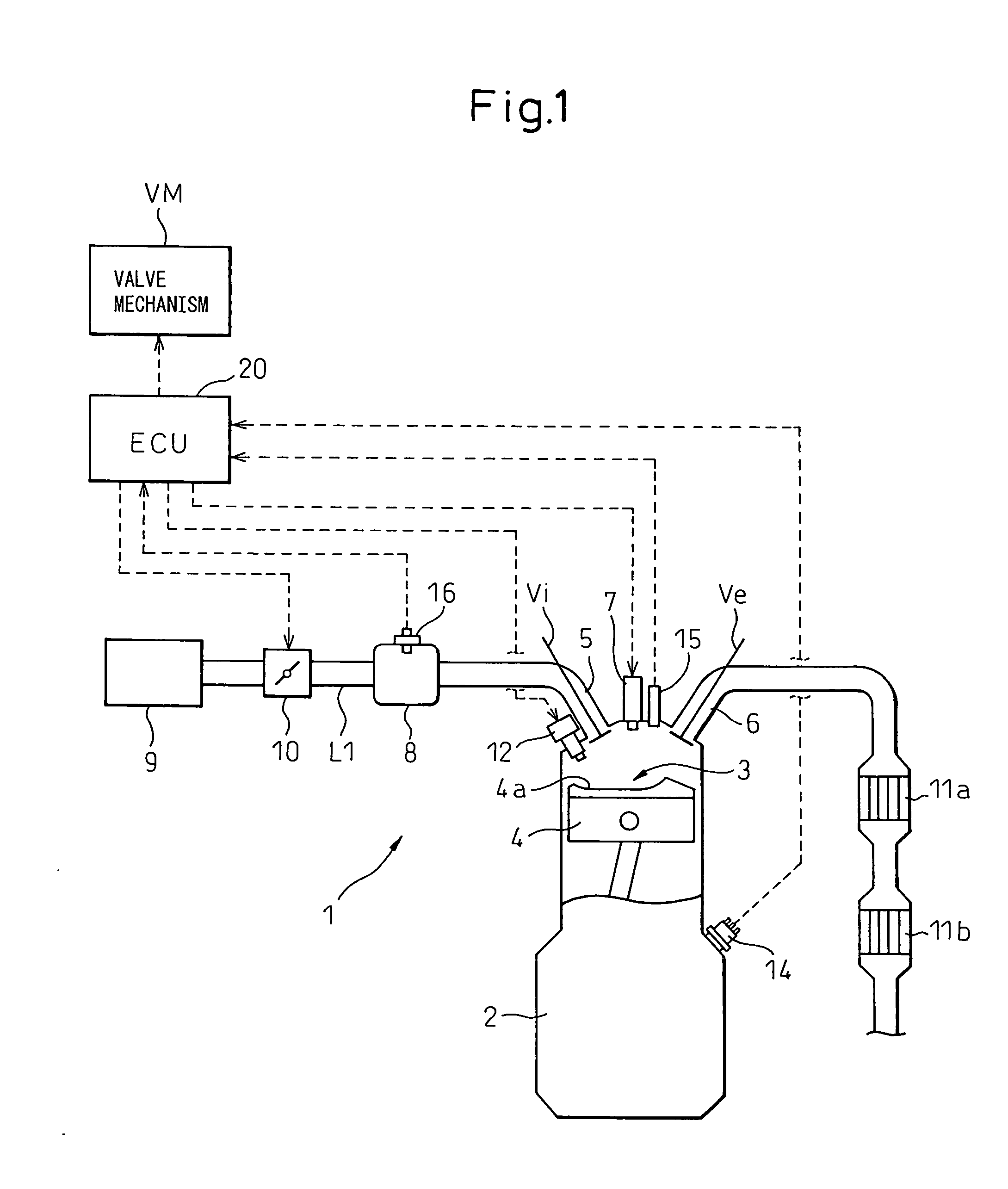

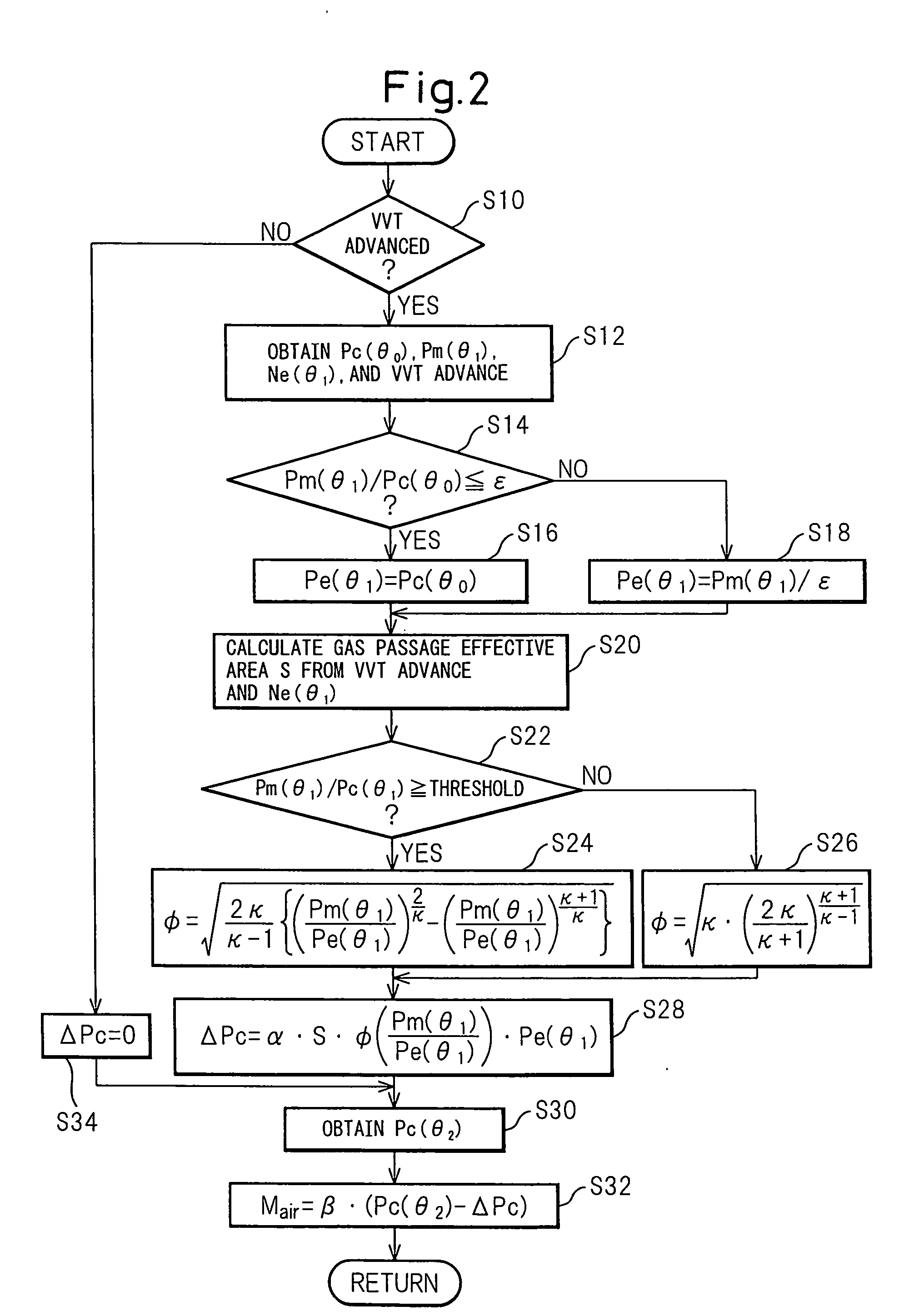

Control system and control method of internal combustion engine

An internal combustion engine (1) provided with a valve mechanism (VM) able to change a valve opening characteristic of at least one of an intake valve (Vi) and exhaust valve (Ve), a cylinder pressure sensor (15) for detecting a cylinder pressure in a combustion chamber (3), and an ECU (20), wherein the ECU (20) calculates the amount of air sucked into the combustion chamber (3) based on an intake air pressure during valve overlap between the intake valve (Vi) and the exhaust valve (Ve), the exhaust gas pressure during valve overlap, a cylinder pressure during the compression stroke detected by a cylinder sensor (15), and a gas passage effective area during valve overlap.

Owner:TOYOTA JIDOSHA KK

Oil pump construction for watercraft engine

A lubrication system for an internal combustion engine includes an oil pump assembly driven by the crankshaft. The oil pump can be mounted in various positions for maintaining a low center of gravity of the engine. Optionally, or in addition, the engine can include a bearing disposed between a valvetrain drive gear and an output drive gear.

Owner:SANSHIN KOGYO CO LTD

System and method for multi-lift valve actuation

ActiveUS20050188966A1Internal combustion piston enginesNon-fuel substance addition to fuelHigh pressureEngine valve

A system and method for actuating one or more engine valves to produce an engine valve event is disclosed. The system may comprise: a housing; an accumulator disposed in the housing having a first open end and a second open end; a master piston slidably disposed in a first bore formed in the housing; a valve train element(s) for imparting motion to the master piston; and a slave piston slidably disposed in a second bore formed in the housing, the slave piston in fluid communication with the master piston through a high pressure hydraulic passage, wherein the first open end and the second open end of the accumulator are in communication with the high pressure hydraulic passage to selectively modify the imparted motion.

Owner:JACOBS VEHICLE SYST

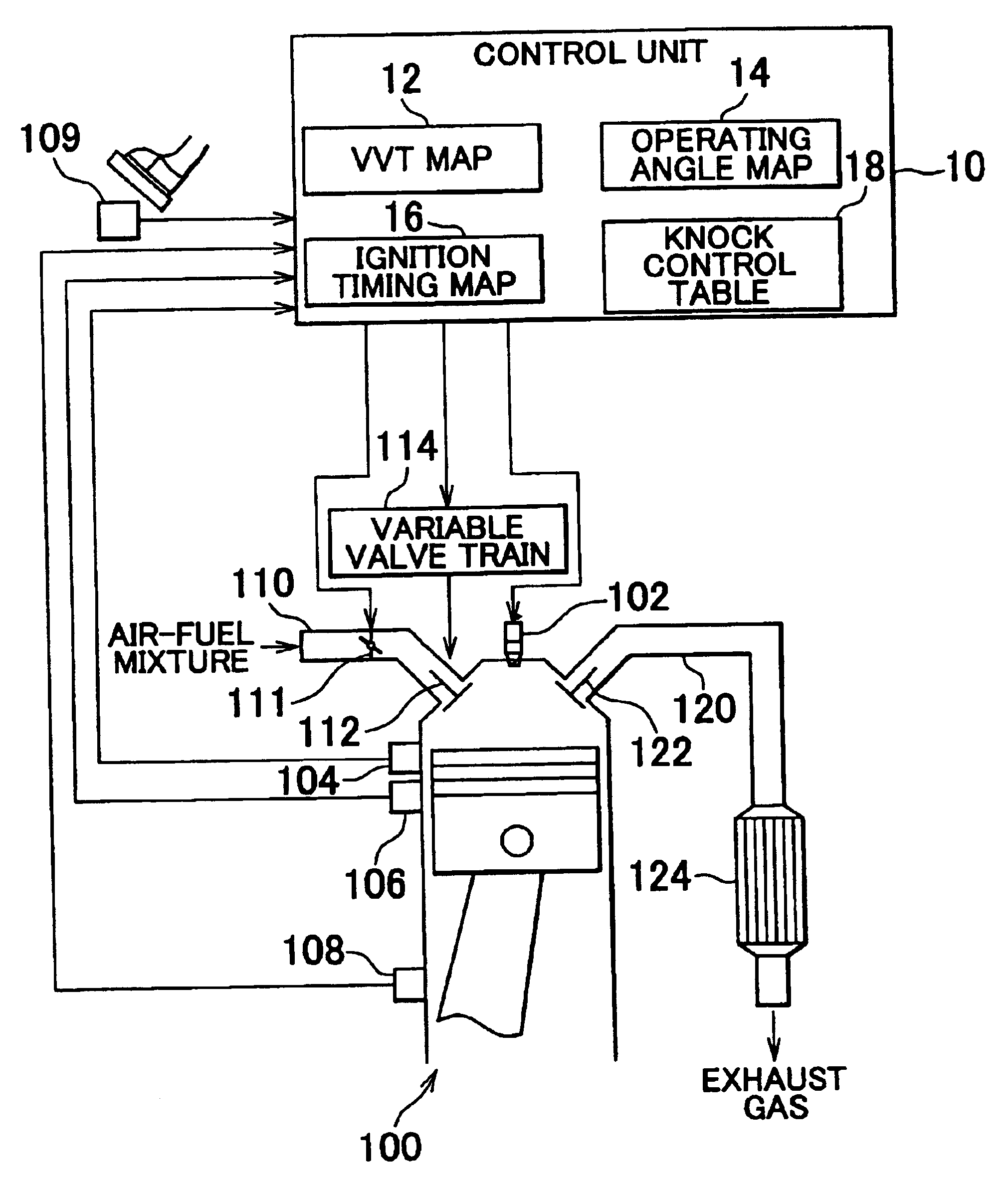

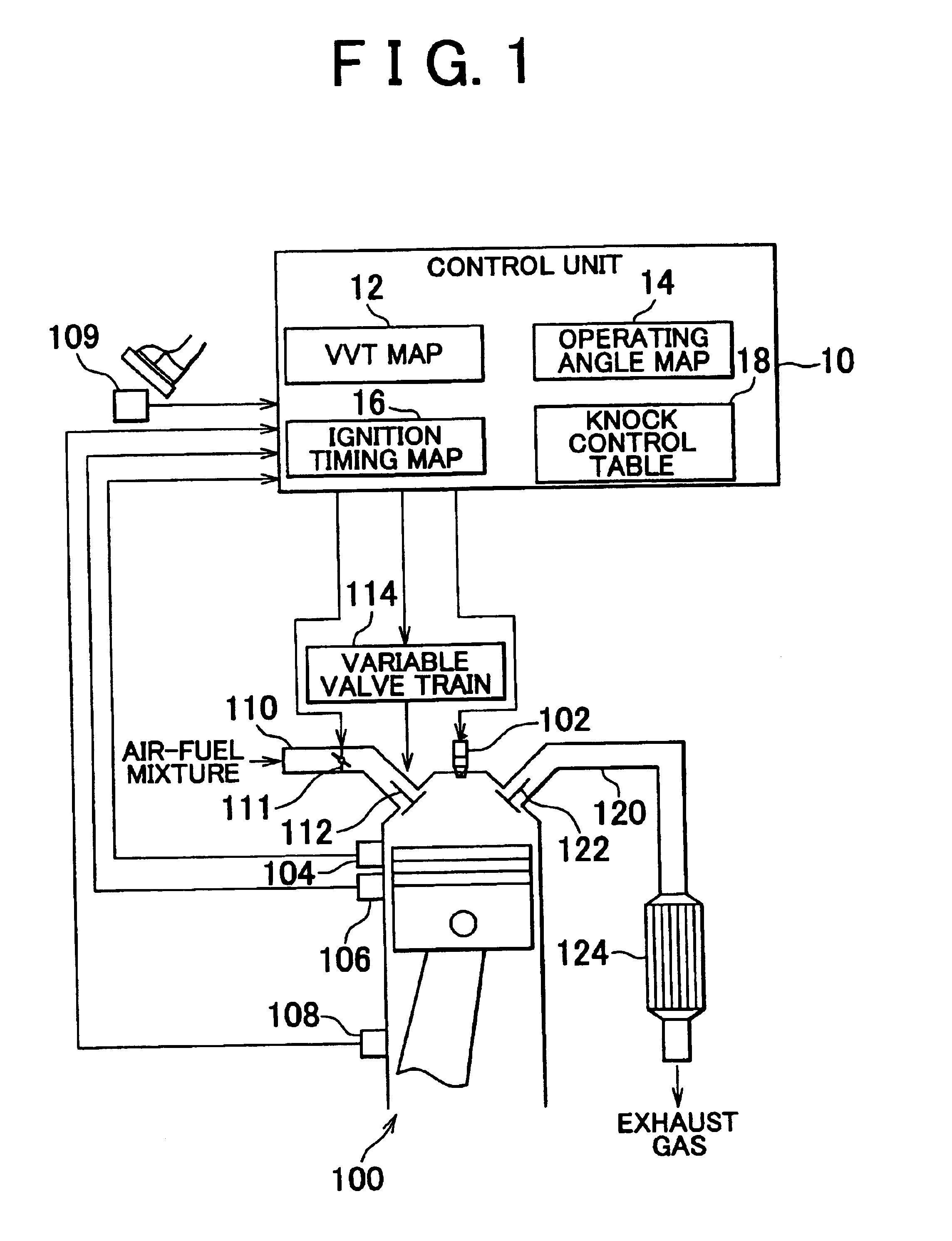

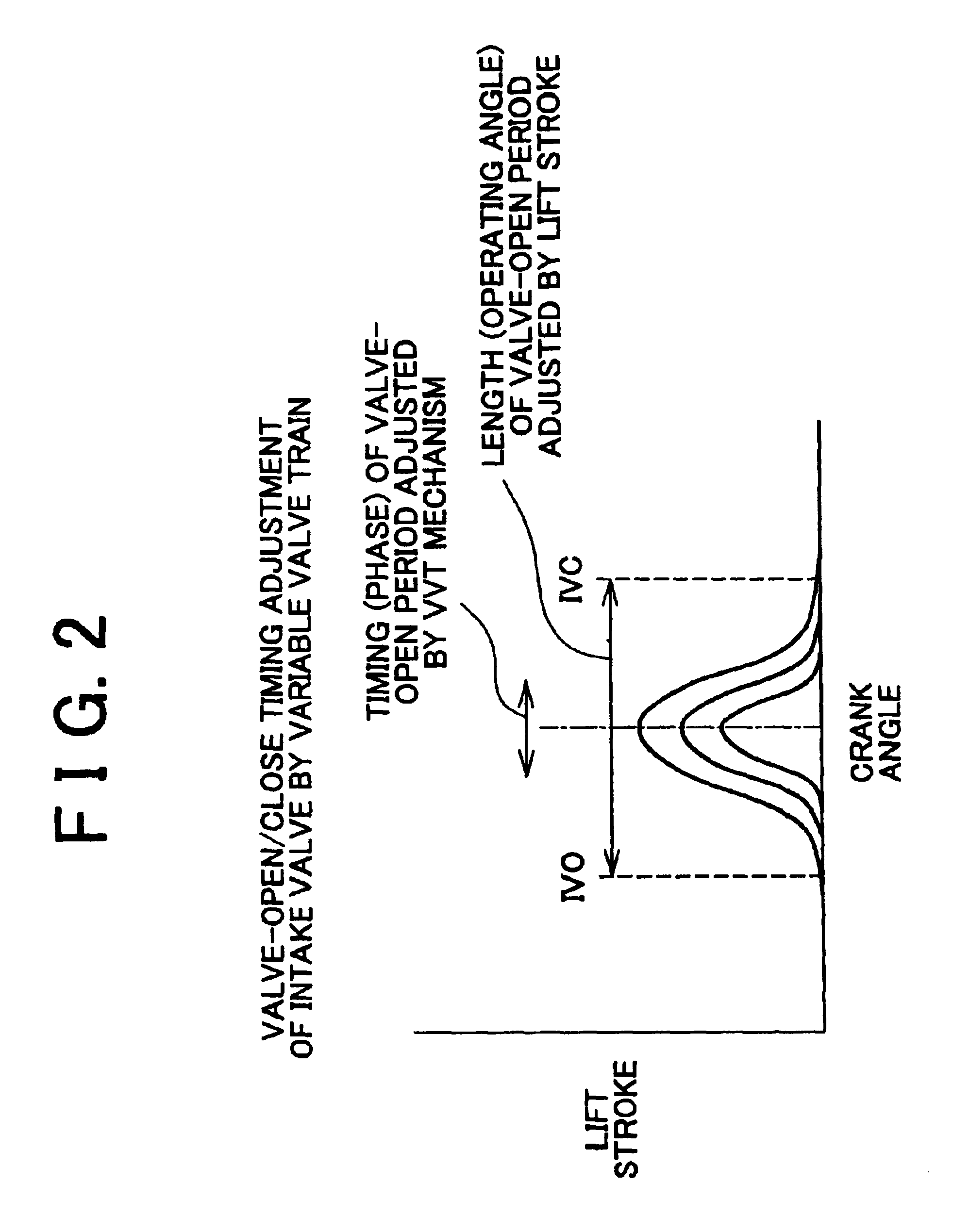

Control system and method for internal combustion engine with variable valve mechanism

InactiveUS6848422B2Improve reliabilityKnock suppressionValve arrangementsElectrical controlTop dead centerControl system

An engine is provided with a variable valve mechanism capable of changing a degree of an operating angle and a phase of a valve-open period of an intake valve. A controller selectively executes at least one of a plurality of knock controls including a phase adjustment of the valve-open period of the intake valve when a knocking is detected by a knock sensor. When the operating angle of the intake valve is smaller than 180 degrees, a knock control is selected and executed such that a valve-open timing IVO of the intake valve does not exceed a predetermined timing (TDC+α) retarded from a top dead center TDC by a predetermined angle α. Specifically, for example, when the operating angle is smaller than 180 degrees and the valve-open timing IVO of the intake valve is after the top dead center TDC, the valve-open timing IVO is advanced.

Owner:TOYOTA JIDOSHA KK

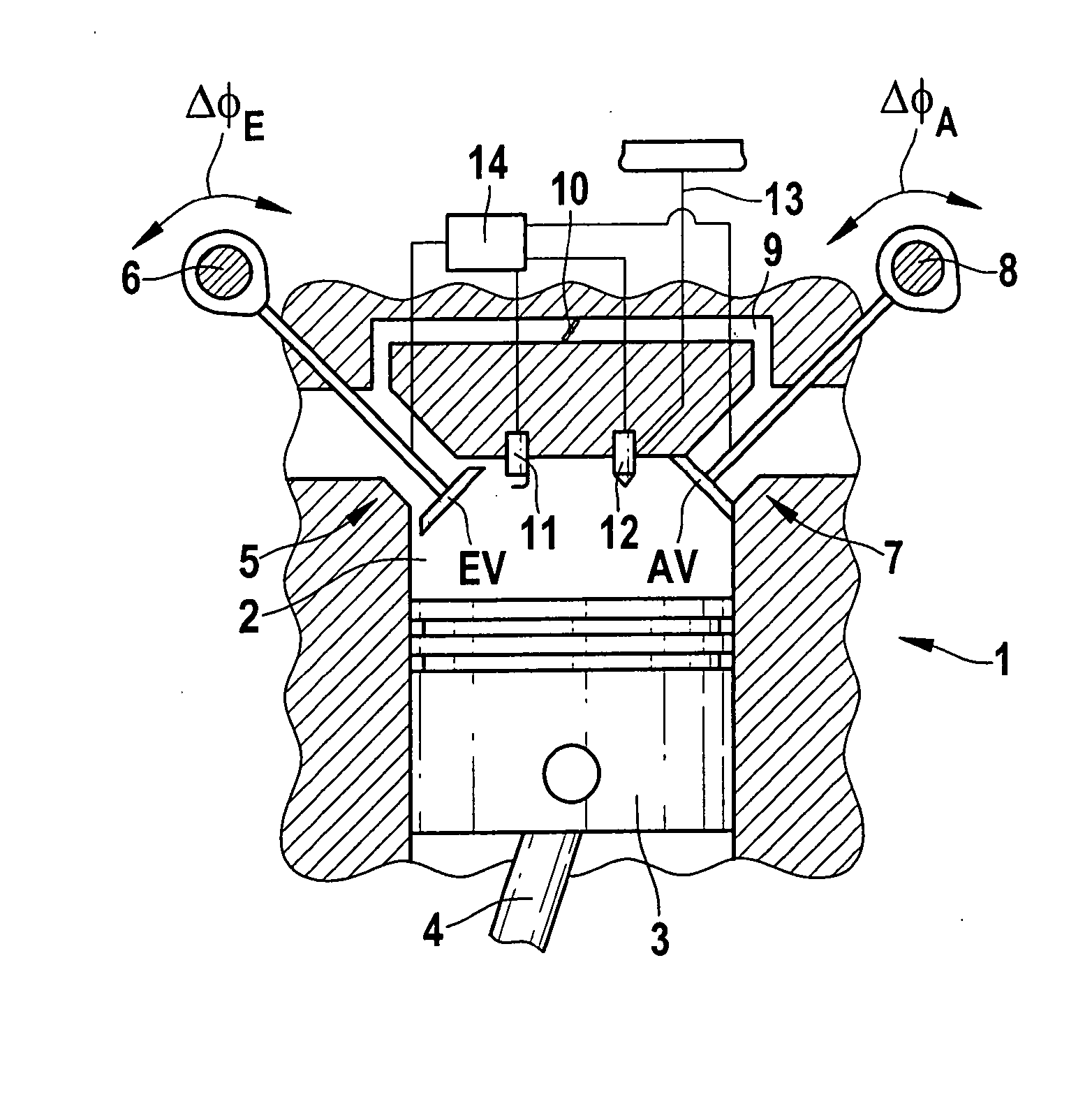

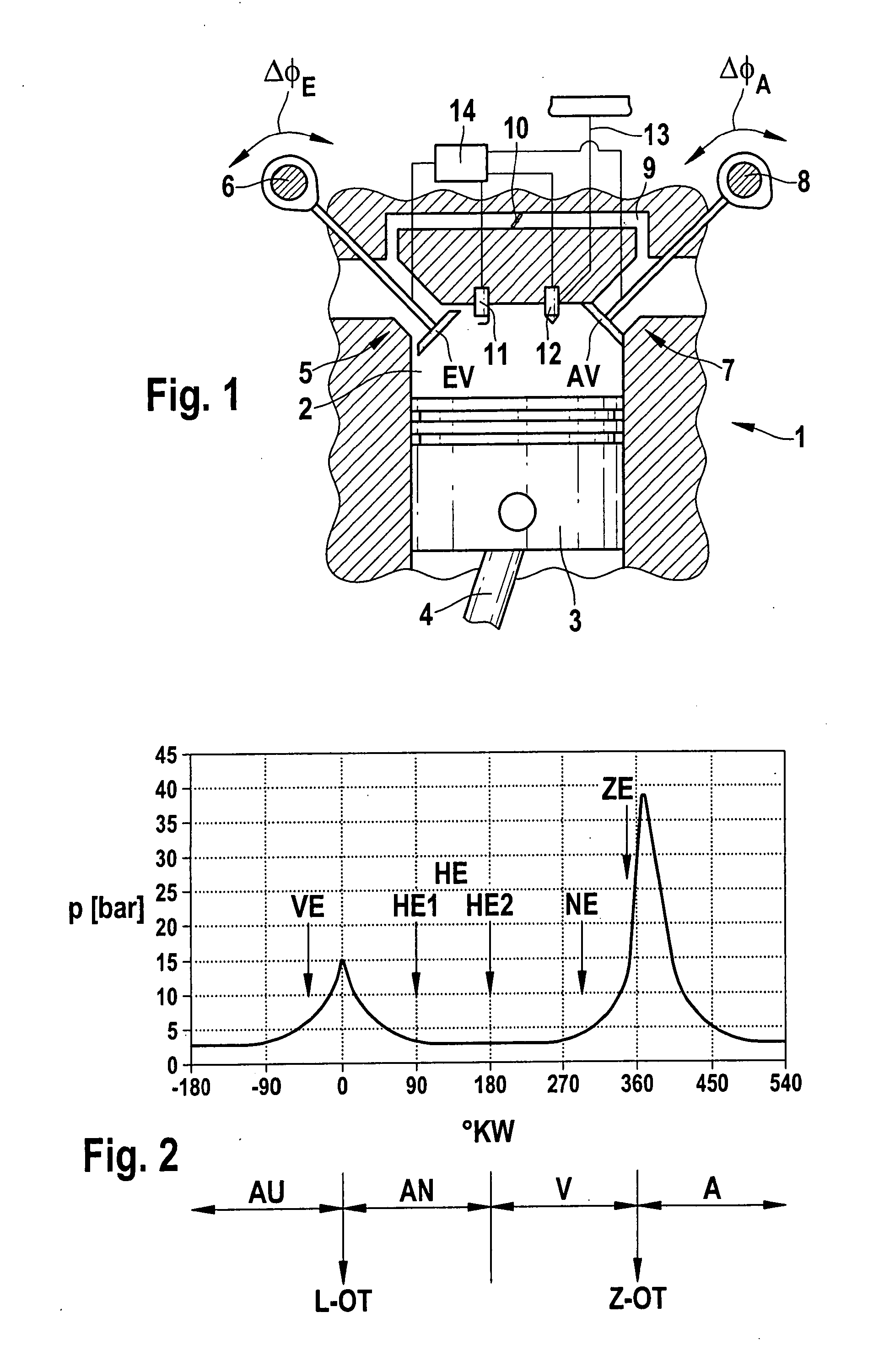

Procedure for the operation of an internal combustion engine

InactiveUS20080071462A1Reduce frequencyAvoid fireAnalogue computers for vehiclesElectrical controlLoop controlNuclear engineering

Procedure for the transition of an internal combustion engine, particularly a gasoline engine with direct gasoline injection and with a partially variable valve-train assembly, from an initial mode of operation into a target mode of operation, whereby the initial mode of operation and the target mode of operation are either a mode of operation with an externally-supplied ignition or one with self-ignition. The procedure comprises the procedural steps: Adaptation of the operating parameters of the initial mode of operation to the required values for the target mode of operation in a map-based pilot control phase Changeover of the mode of operation after the map-based pilot control phase Closed-loop control of the operating parameters after the changeover.

Owner:ROBERT BOSCH GMBH

Internal combustion engine with oil temperature sensor

InactiveUS20050092283A1Reduce the heating effectAccurate temperatureExhaust apparatusCylinder headsDegrees of freedomCylinder block

The invention relates to an engine arrangement that increases the degree of freedom of the engine state sensor while decreasing the size of the engine body. More specifically, the engine is formed with a chamber for housing a valve train and serving dually as a return oil path of the lubricating oil after having lubricated the valve train. The engine includes an oil temperature sensor partially exposed on one side of a cylinder block and an exhaust pipe partially exposed on the opposite side of the cylinder block.

Owner:HONDA MOTOR CO LTD

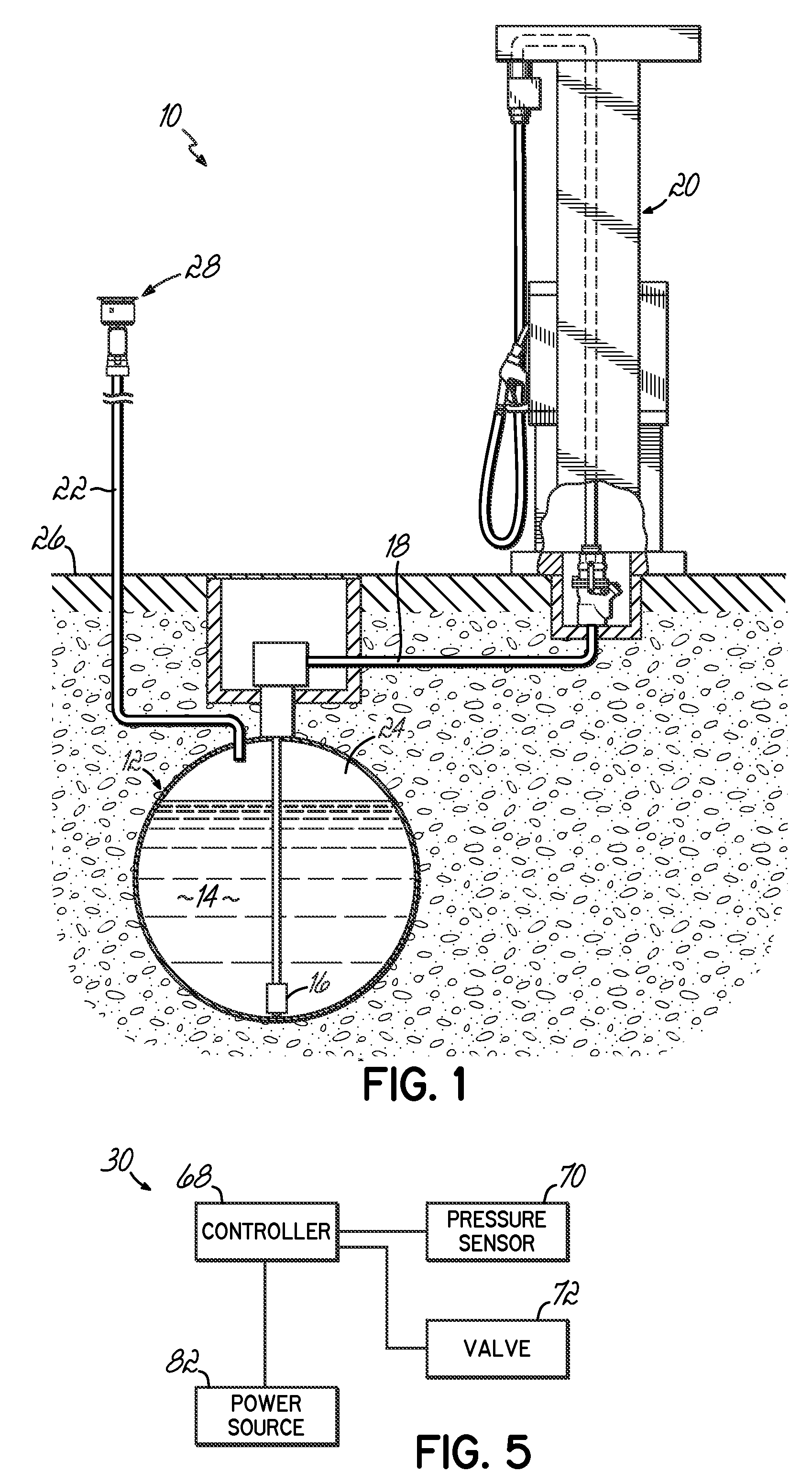

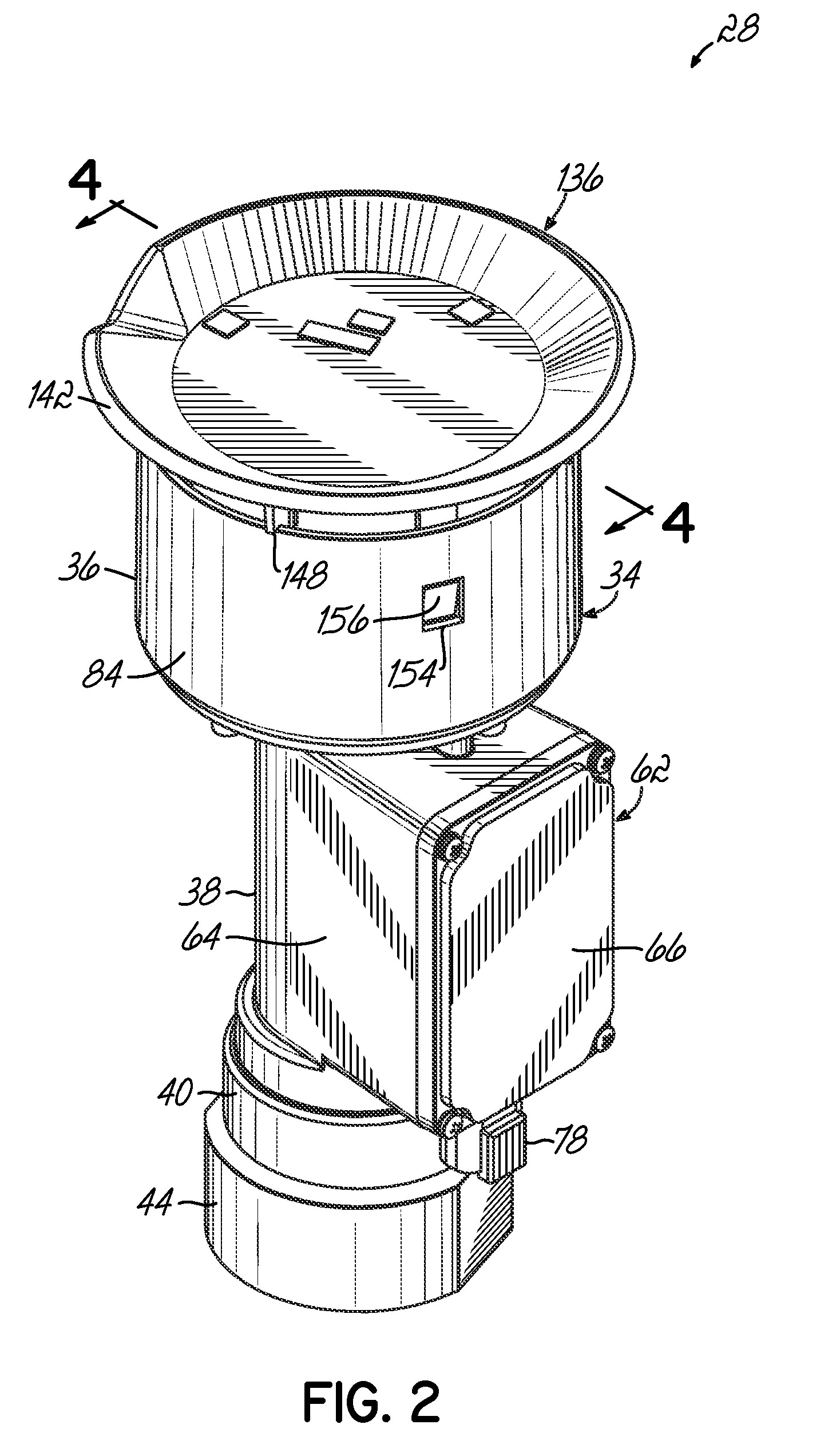

Underground fuel tank vent valve

InactiveUS20070131281A1Eliminate functional mechanical structureOperating means/releasing devices for valvesFlow control using electric meansFuel tankAtmospheric pressure

A vent valve for a fuel tank includes a valve housing having a first valve mechanism movable between an open and closed position and a second valve mechanism movable between an open and closed position. The first valve mechanism opens to vent the tank at a first design pressure differential between the tank pressure and atmospheric pressure and the second valve mechanism opens to vent the tank at a second design pressure differential that is greater than the first design pressure differential. The first valve mechanism is an electronic valve mechanism and the second valve mechanism is a mechanical valve mechanism. A method of venting a fuel tank includes opening the first valve mechanism to establish fluid communication between the tank and atmosphere at the first design pressure differential and opening the second valve mechanism to establish fluid communication between the tank and atmosphere at the second design pressure differential.

Owner:OPW FUELING CONTAINMENT SYST INC

Failure diagnostic apparatus for variable valve mechanism of internal combustion engine and failure diagnostic method for variable valve mechanism

InactiveUS20050154522A1Improve reliabilityLower performance requirementsAnalogue computers for vehiclesDigital data processing detailsEngineeringCam

A failure diagnosis for a slide sensor of a variable valve mechanism is performed when a valve working angle is at a value in the initial state. The initial state is set to a valve characteristic state where the valve working angle is at the maximum value. The maximum valve working angle corresponds to the refuge running performable region in which an engine can be started and refuge running can be performed. Therefore, even when it is difficult to adjust the valve working angle using rotation of a spiral cam due to a failure in the slide sensor, the refuge running can be performed only by maintaining the initial state by maintaining control. It is thus possible to increase reliability of the refuge running in the case where a failure has occurred in the variable valve mechanism.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com