Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1497 results about "Tappet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tappet is a projection that imparts a linear motion to some other component within a mechanism.

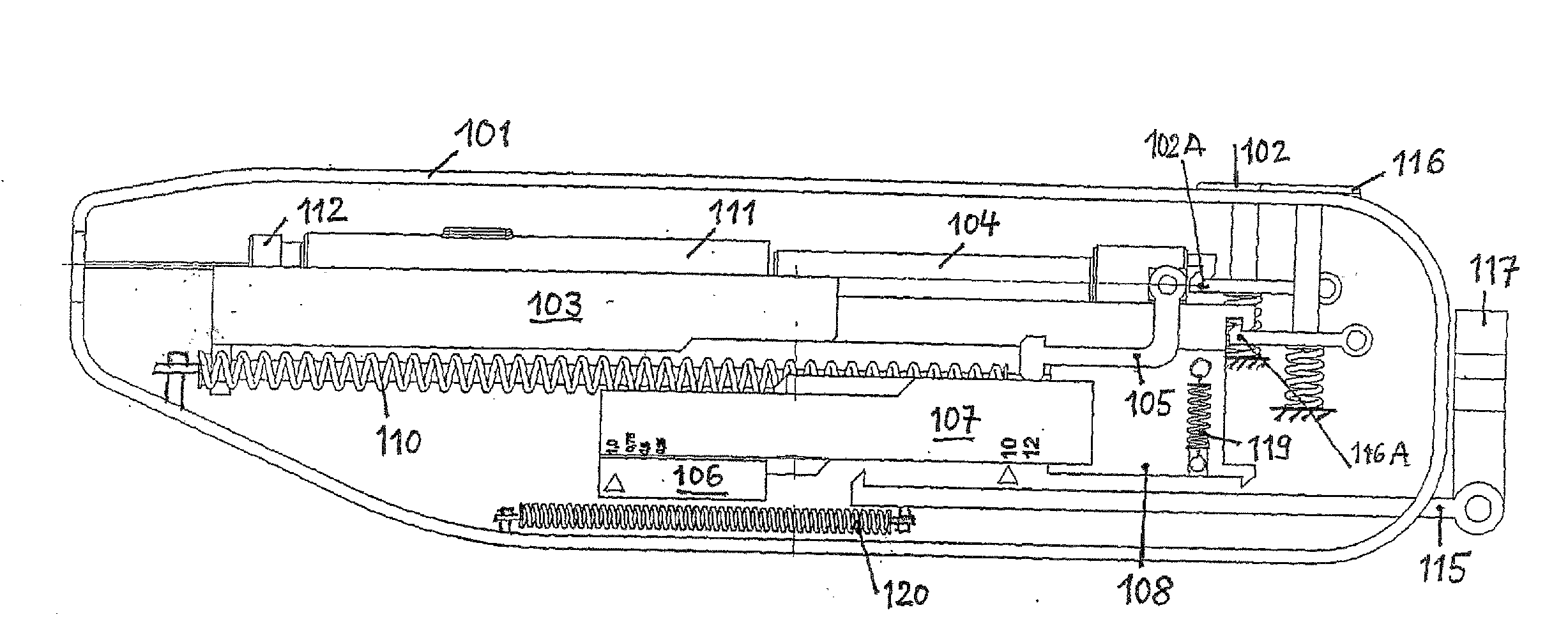

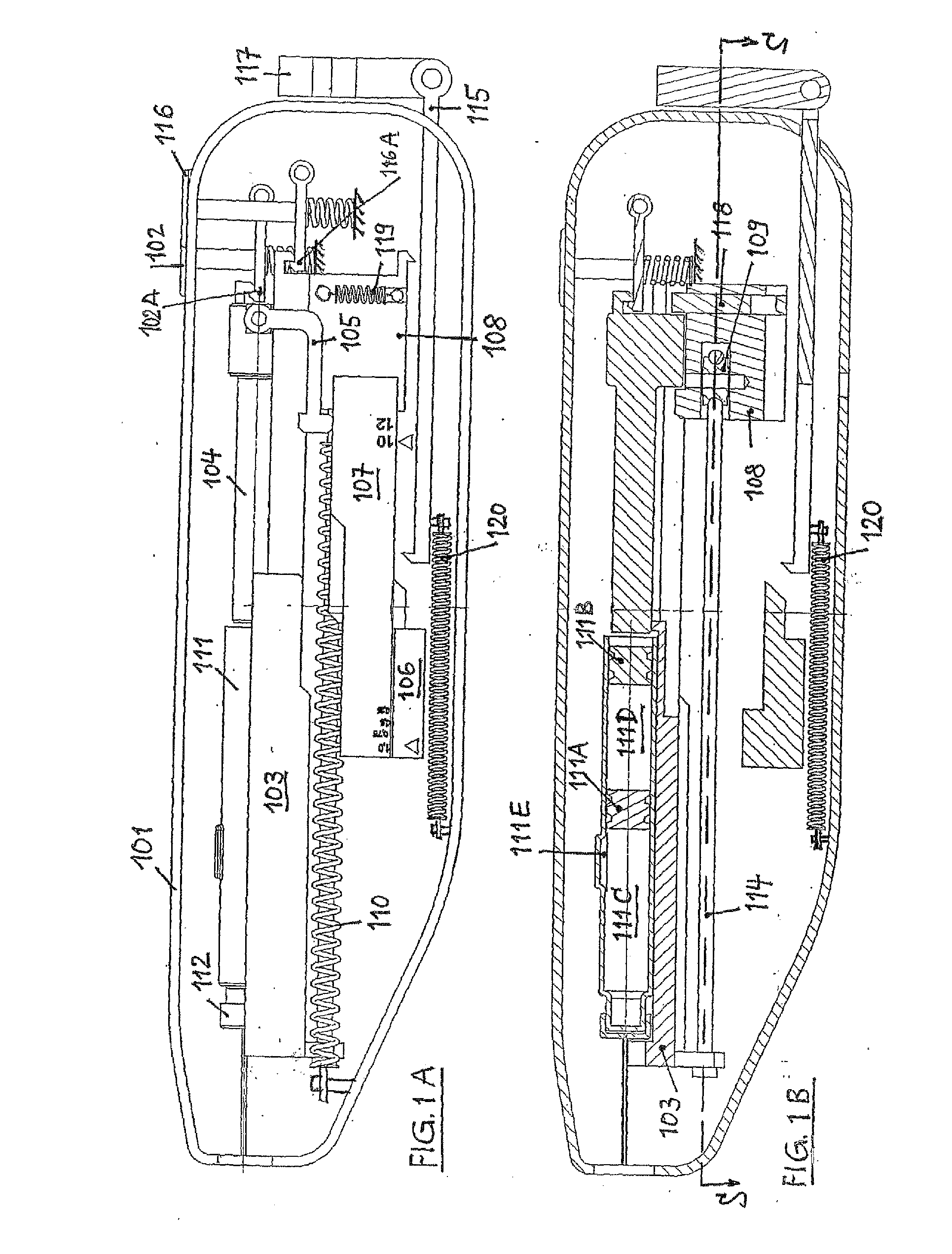

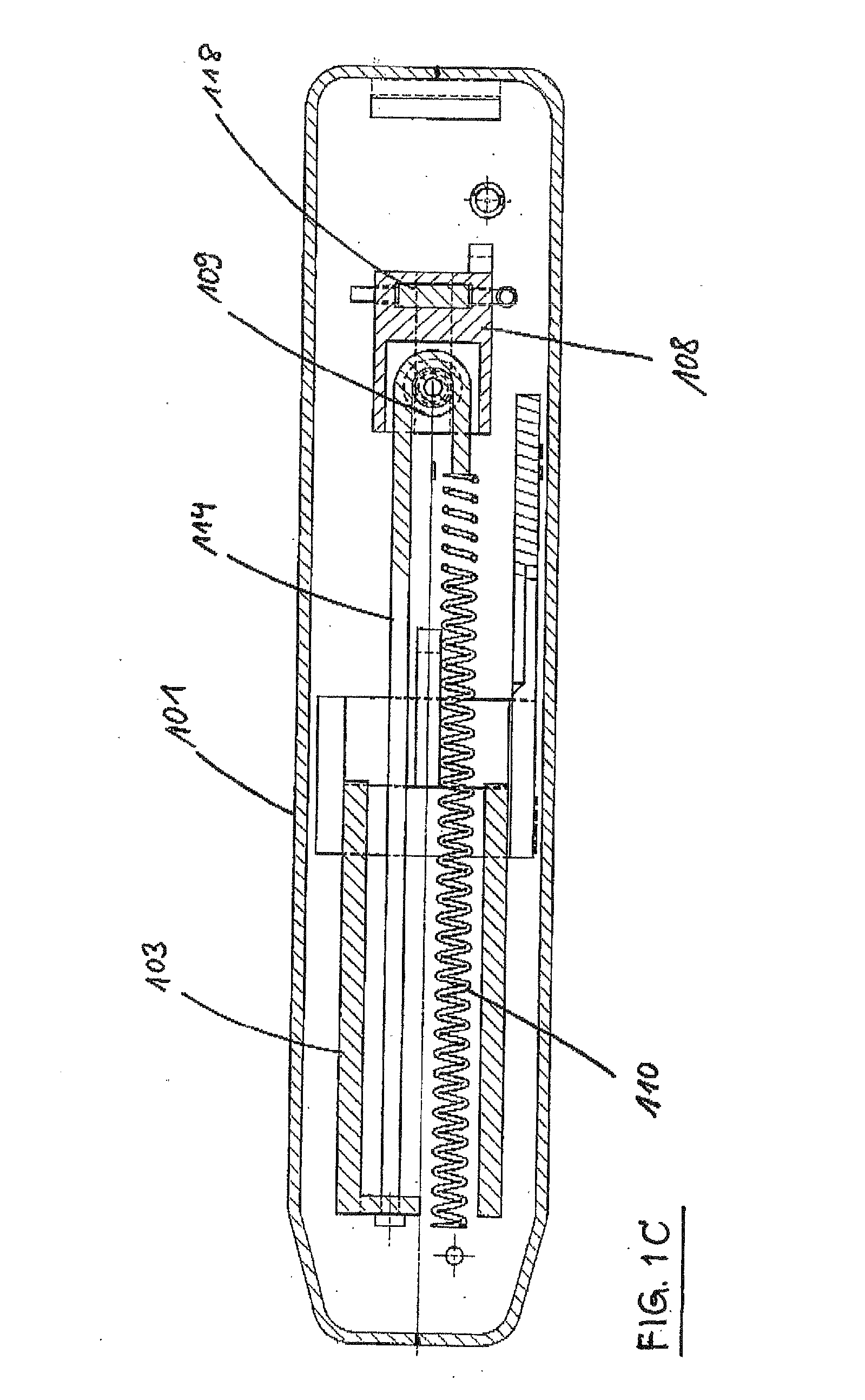

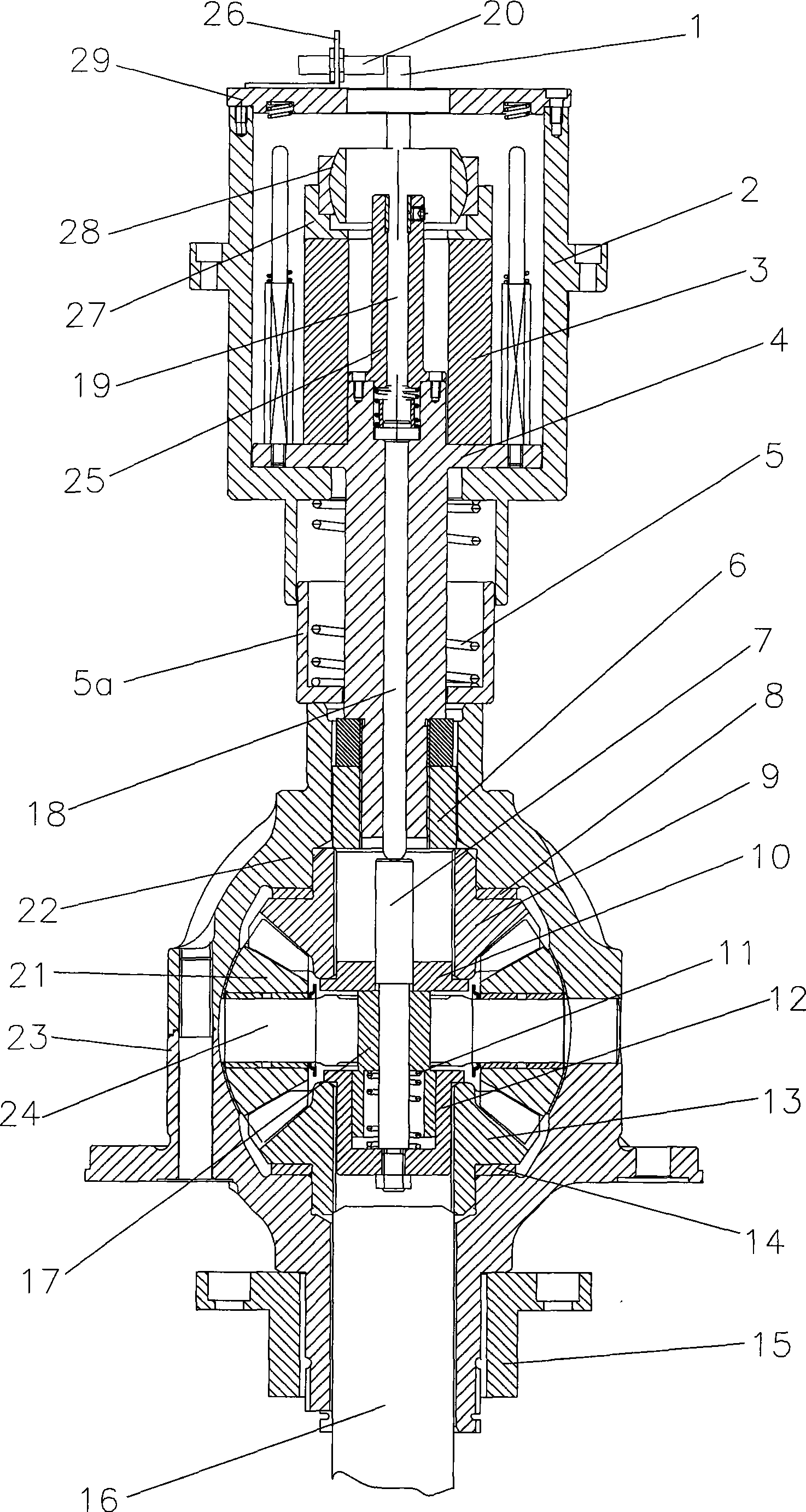

Automatic Injection Device For Two-Chamber Ampoules

ActiveUS20080188798A1Simplify mechanical designImprove handling comfortAmpoule syringesAutomatic syringesAmpullaEngineering

An injection device for holding and activating a two-chamber ampulla has components whose relative movement causes the pistons of the two-chamber ampulla to be moved in order to mix the substances, as well as devices for injecting the product which is mixed in this way. For this purpose, a receptacle (103) into which the two-chamber ampulla (111) can be inserted and secured is held in a housing (101), and the receptacle (103) can be displaced by means of a carriage (108). A tappet (104) which acts on the pistons (111A, 111B) is movably held in the receptacle (103). A traction cable (114) which is deflected by means of a roller (109) which is mounted on the carriage (108) and one of whose ends is connected to the receptacle (103) and the other end of which is connected to a tension spring (110) which is held on the housing (101) is provided in order to carry out a mixing stroke, insertion stroke, injection stroke and a return stroke. Devices which can be activated automatically and / or manually between the housing (101), receptacle (103), tappet (104) and carriage (108) control their alternating coupling to the traction cable (114) and thus the sequence of the mixing stroke, insertion stroke, injection stroke and return stroke. The invention thus provides a partially automatic injection device for two-chamber ampullas whose handling comfort and safety for the patient are substantially improved.

Owner:BAYER INTELLECTUAL PROPERTY GMBH

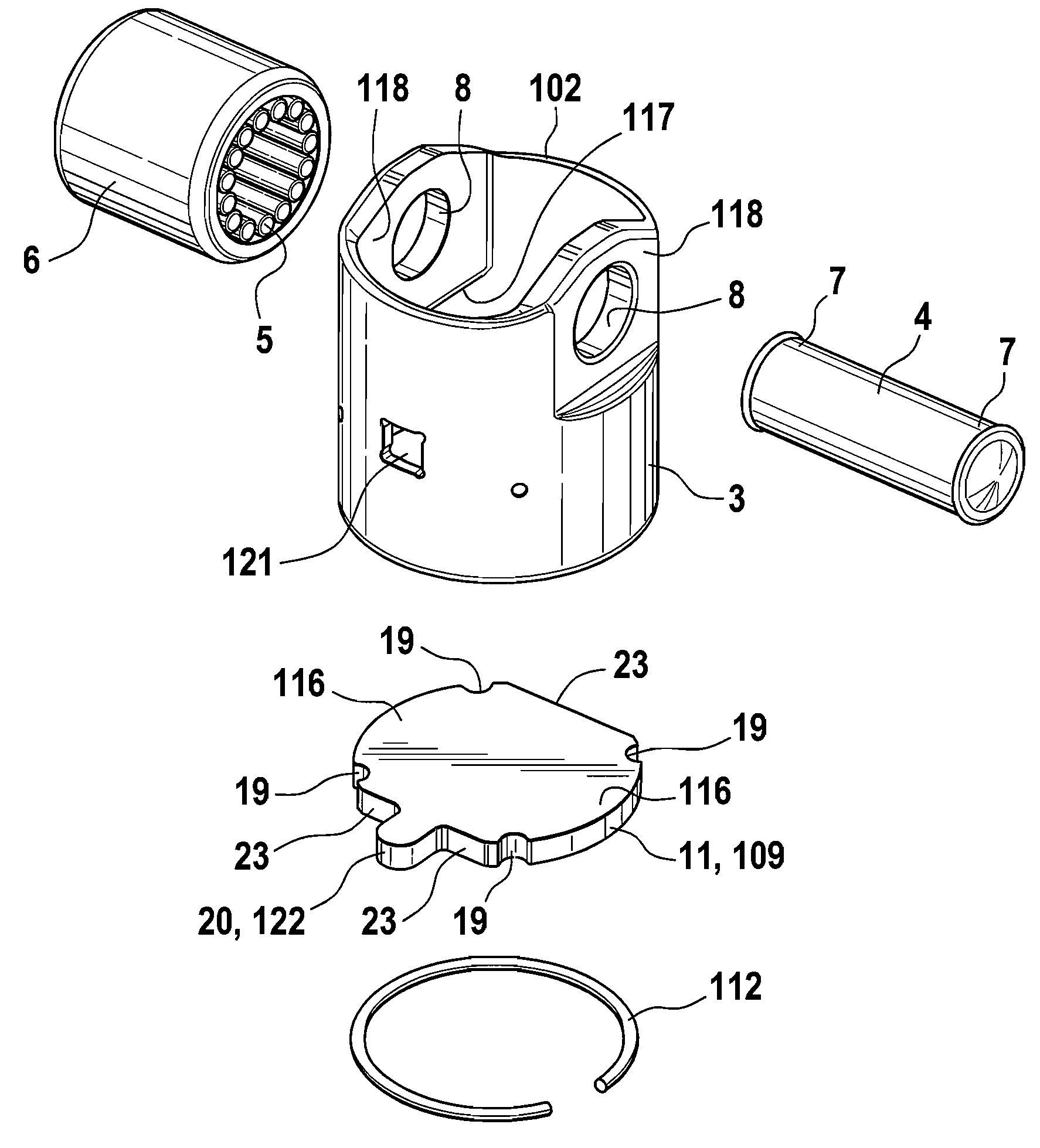

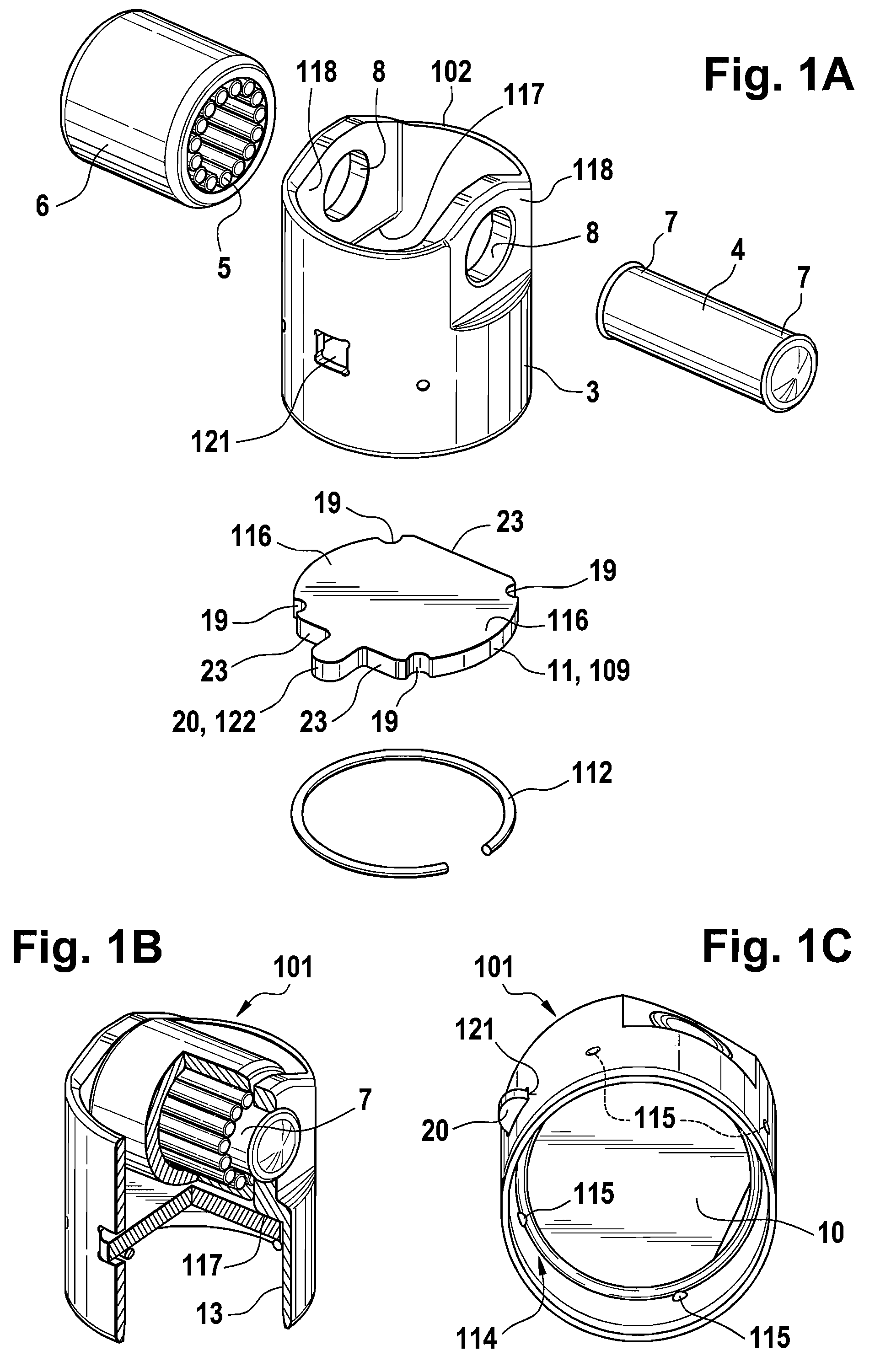

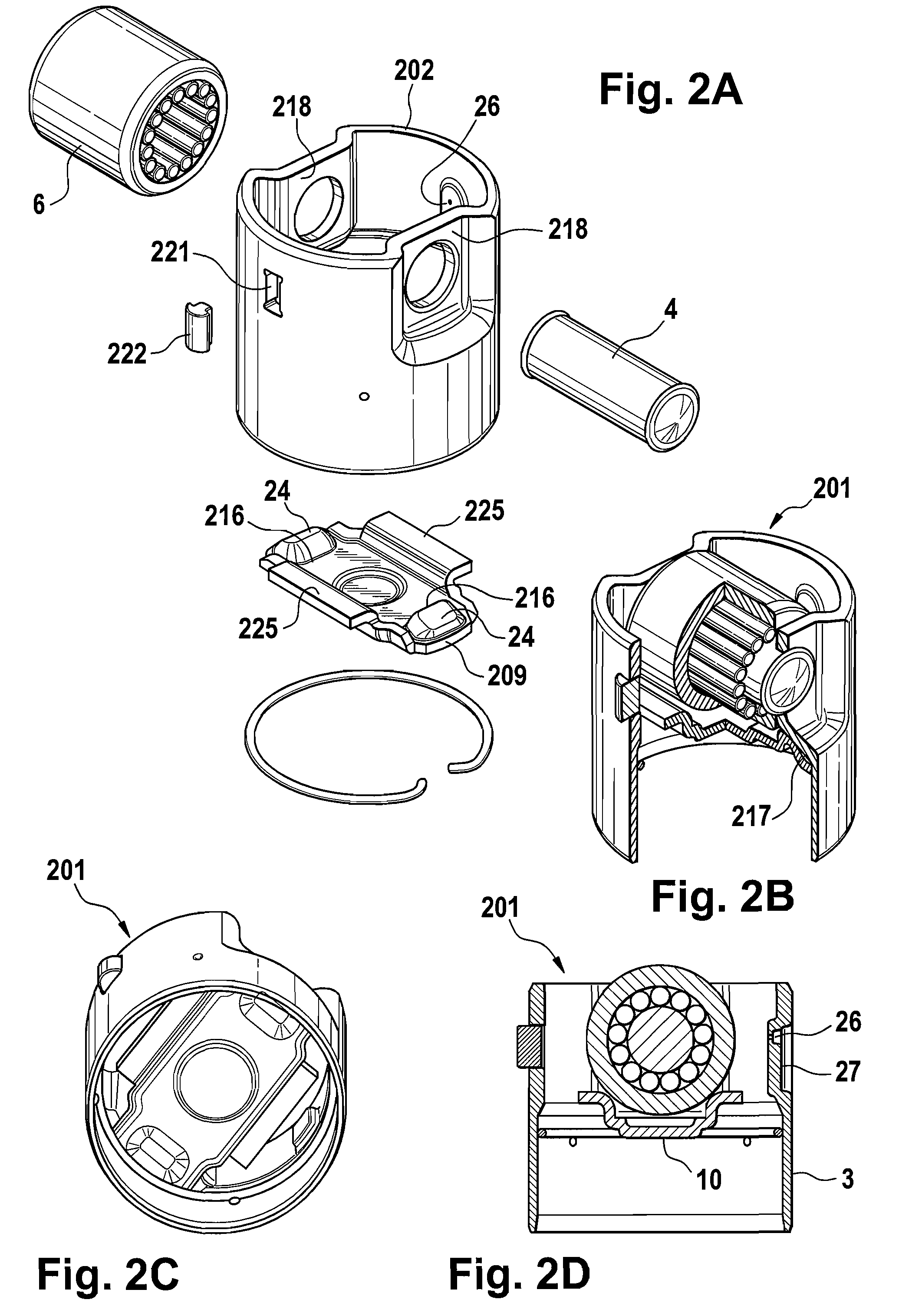

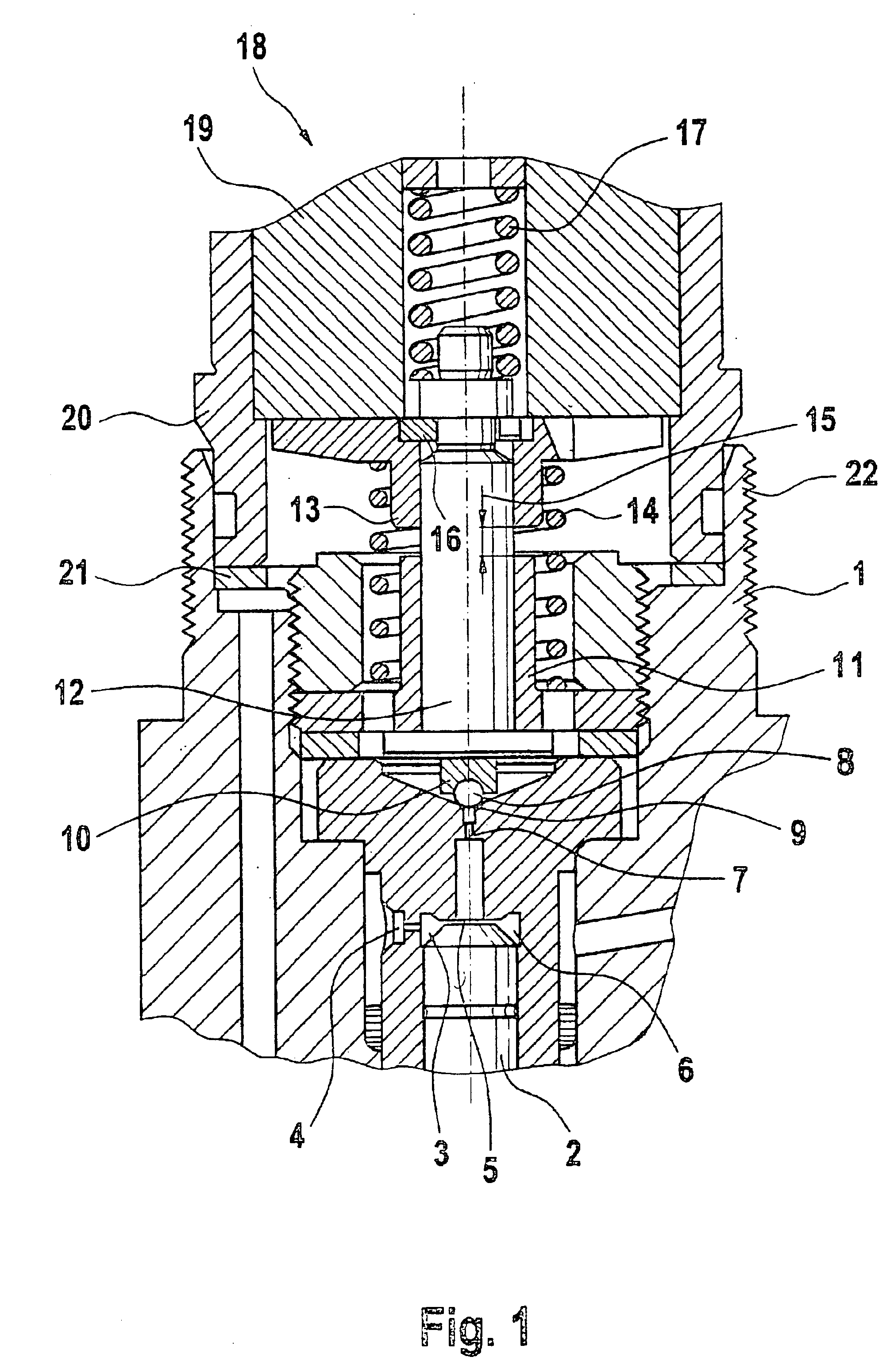

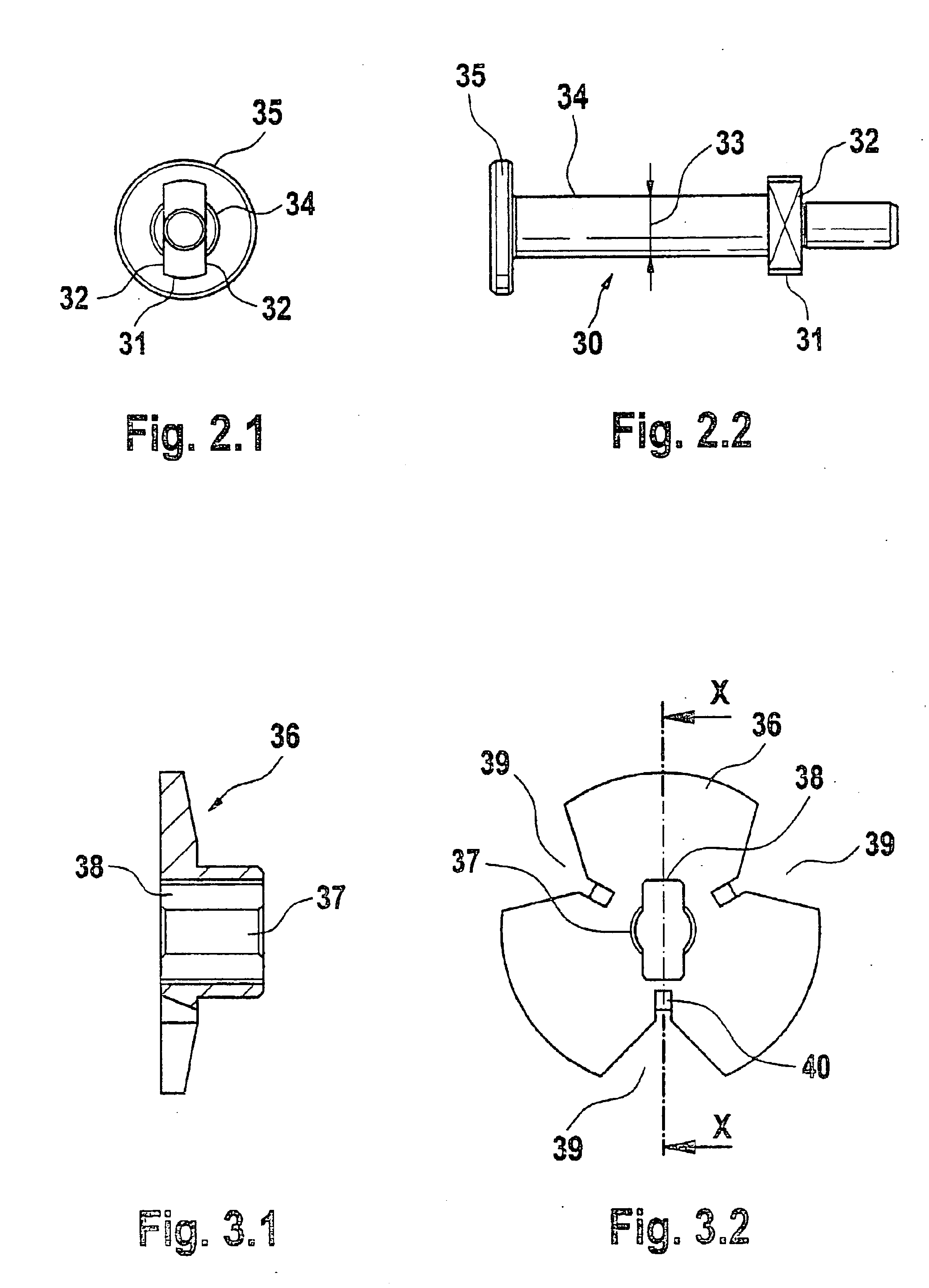

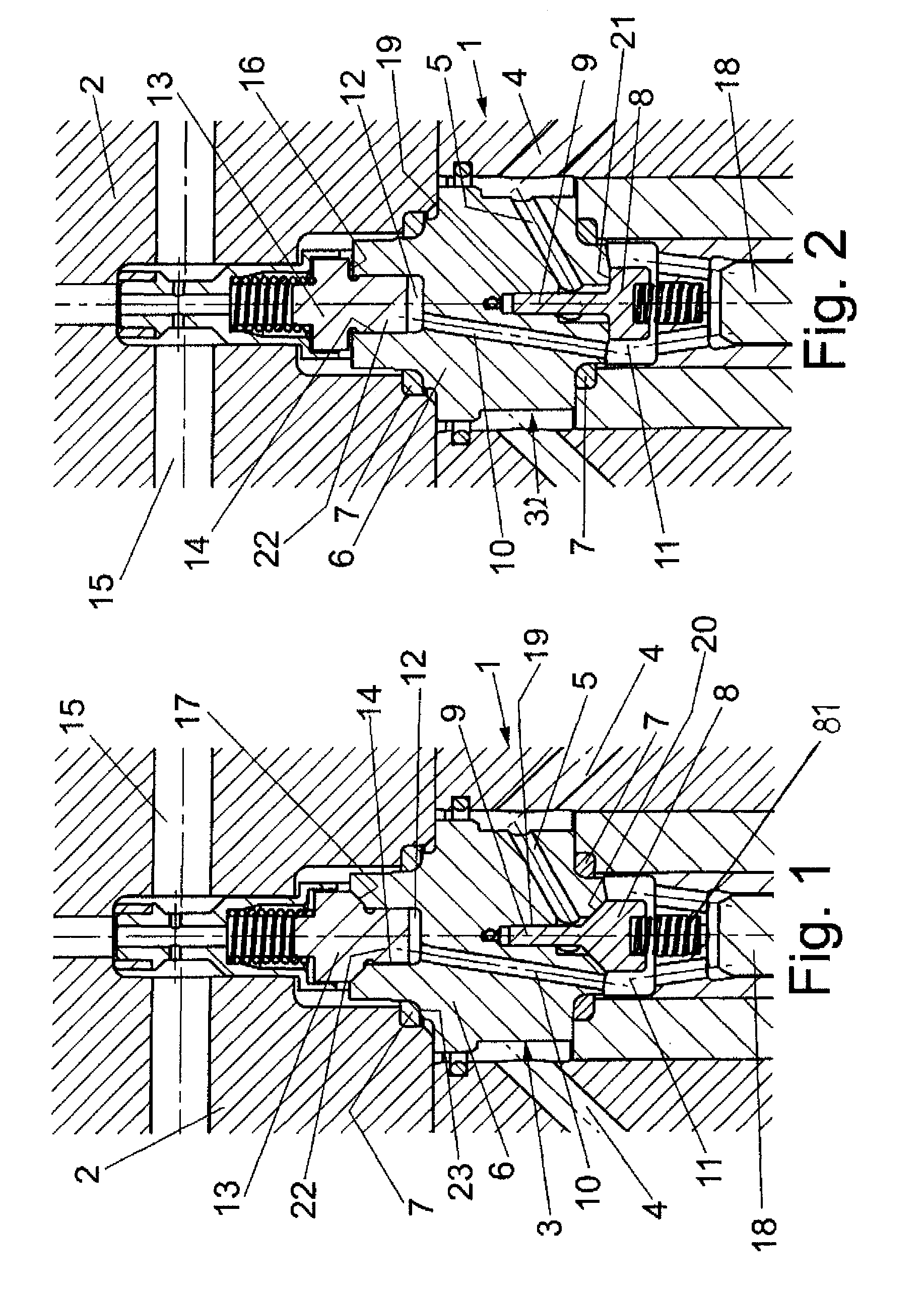

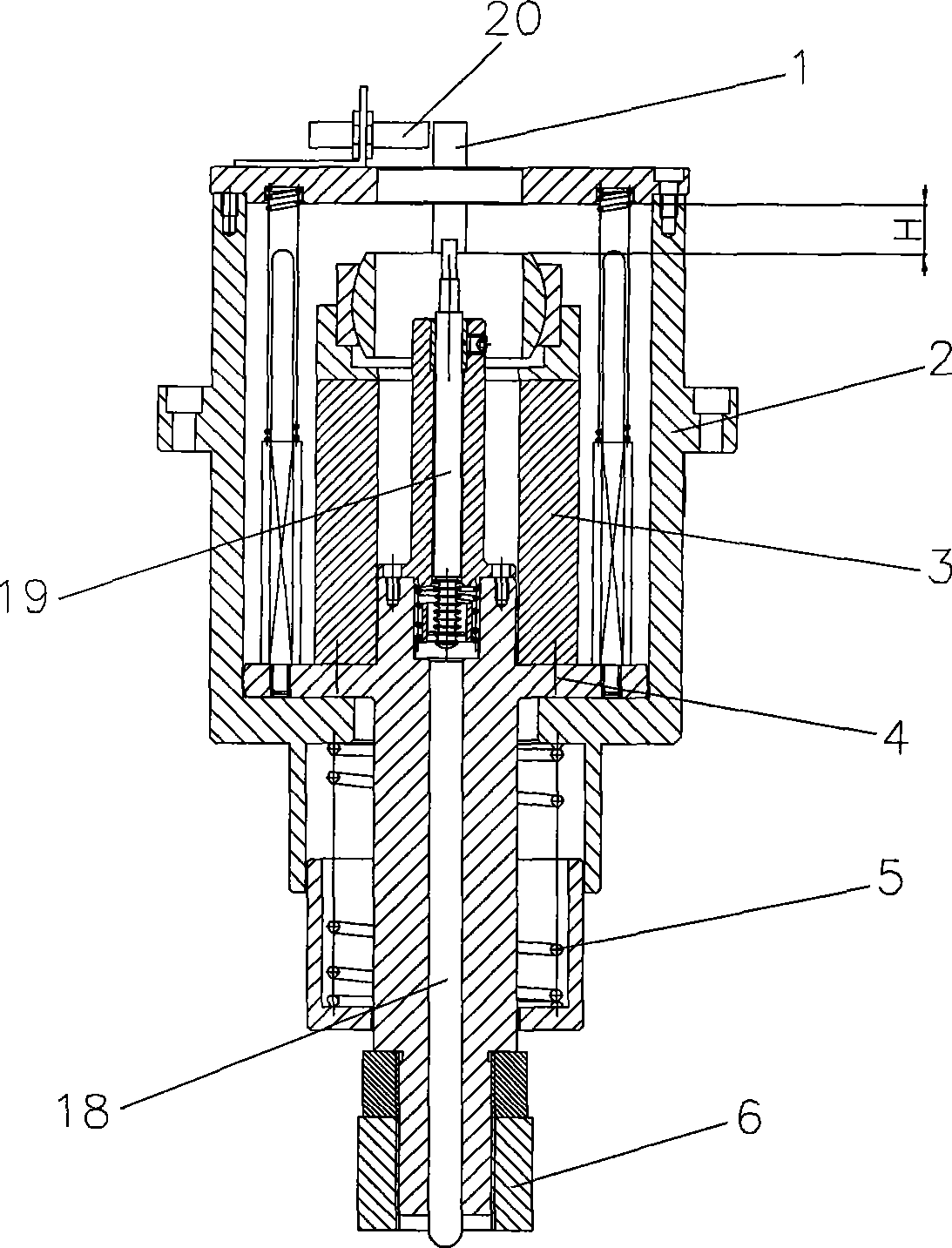

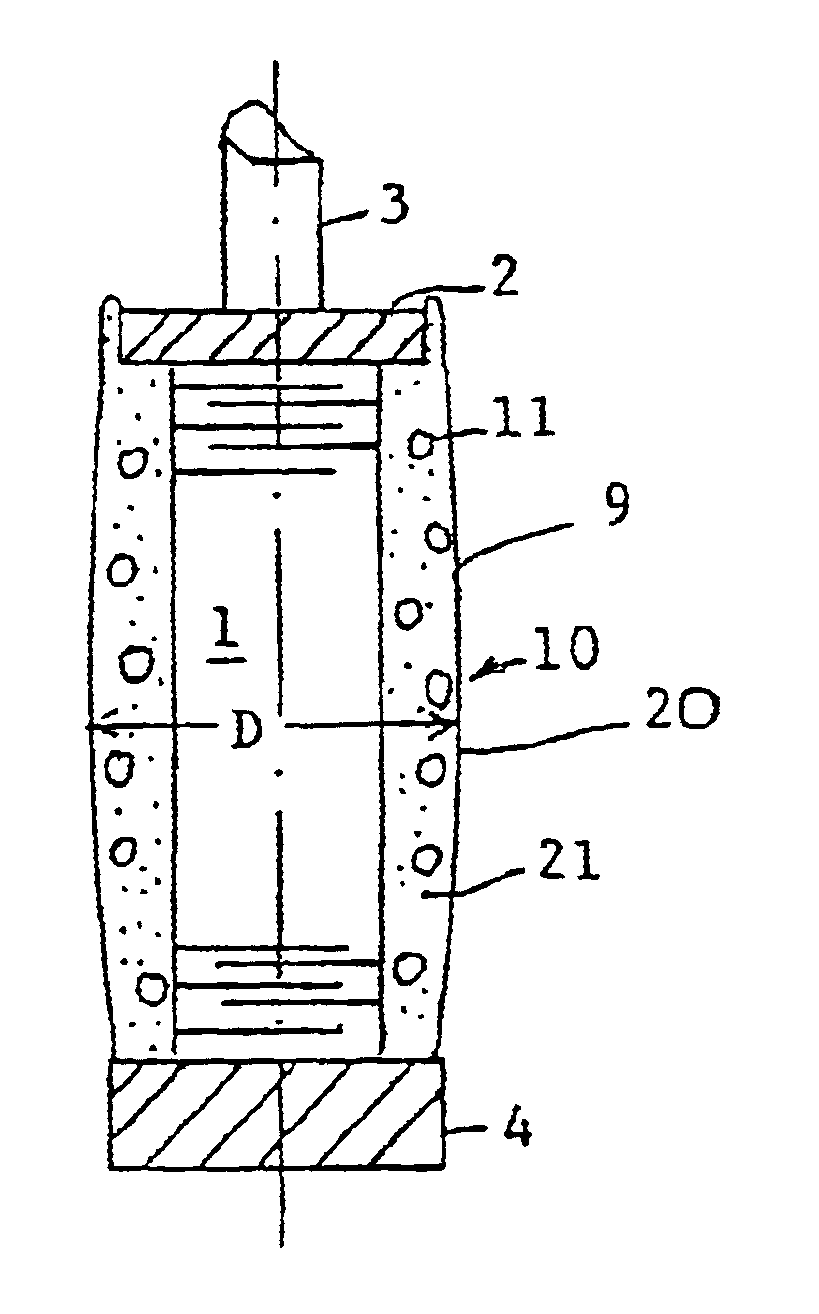

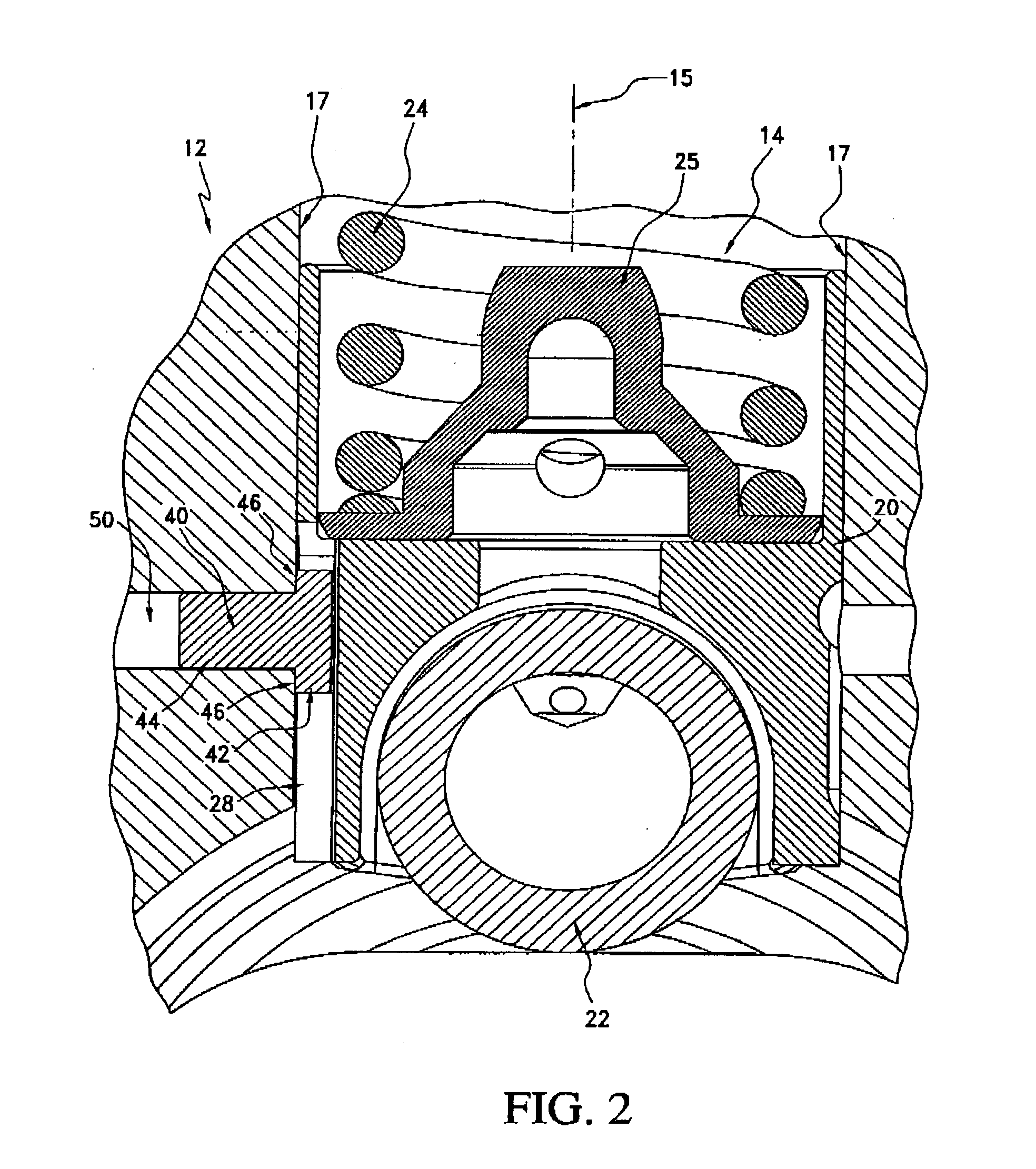

Mechanical tappet in particular for a fuel pump of an internal combustion engine

InactiveUS7793583B2High potential lightweight constructionSave on high costsValve arrangementsEngine sealsInternal combustion engineTappet

A mechanical tappet (101, 201, 301, 401, 501, 601, 701, 801, 901, 1001) is provided, in particular for actuating the lifting of a pump piston (39) of a fuel pump of an internal combustion engine, with a sleeve-shaped tappet housing (102, 202, 302, 402, 502, 602, 702, 902, 1002) constructed as a shaped sheet-metal part and with a driving roller (6) supported so that it can rotate. Here, a bolt (4) supports the driving roller so that it is centered, and end sections (7) of the bolt projecting from the driving roller are supported in bolt eyes (8) of the tappet housing.

Owner:SCHAEFFLER TECH AG & CO KG

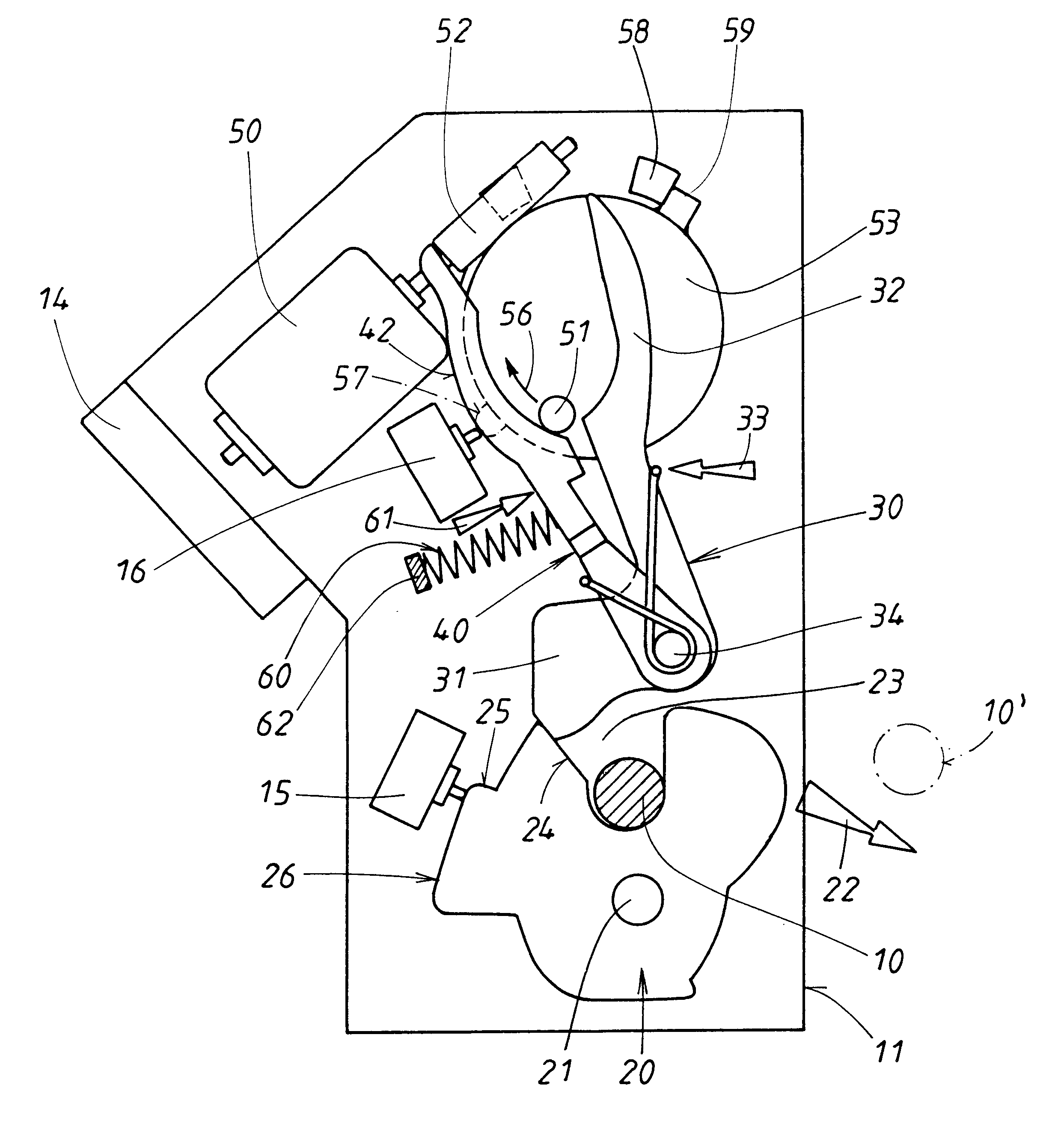

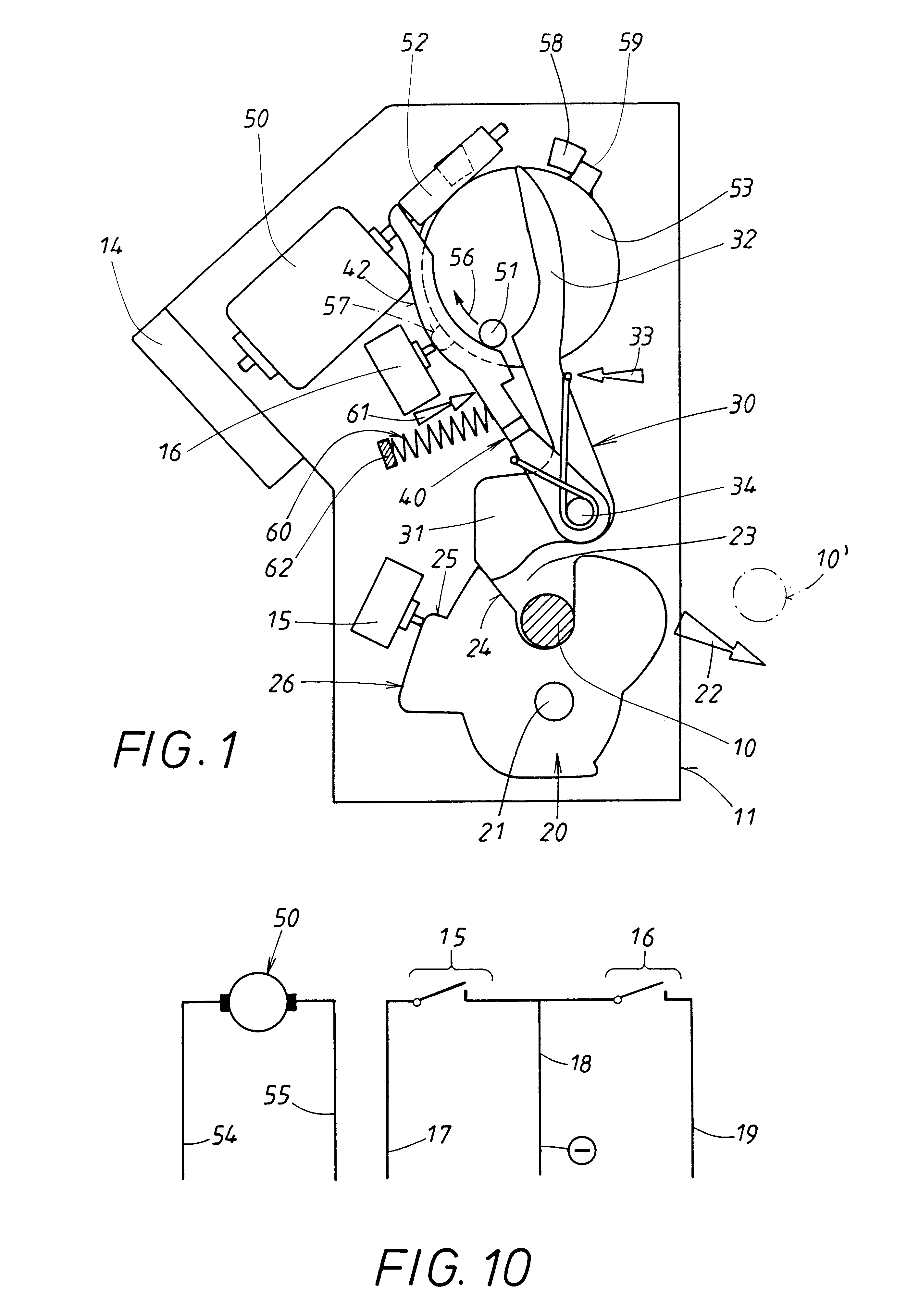

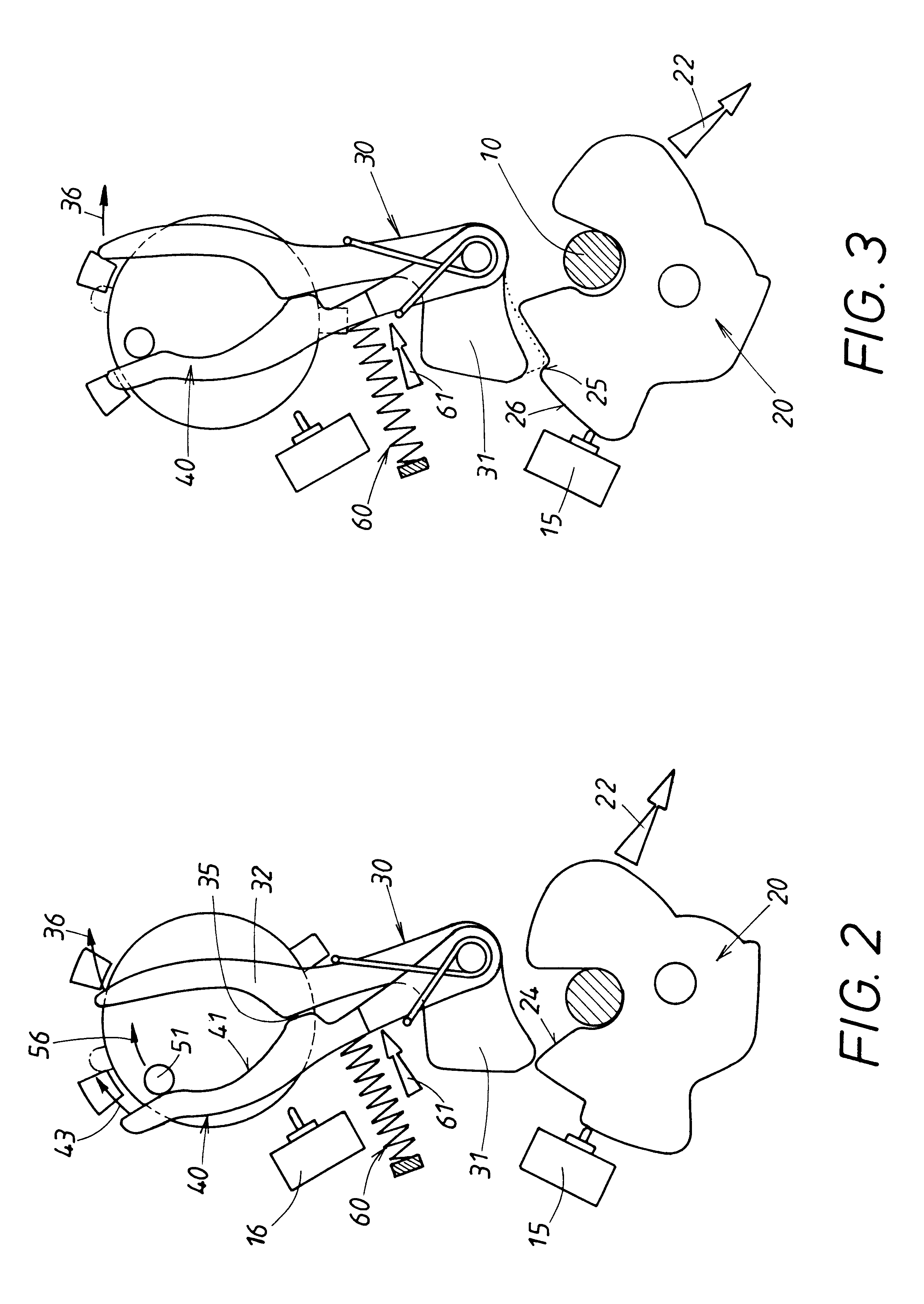

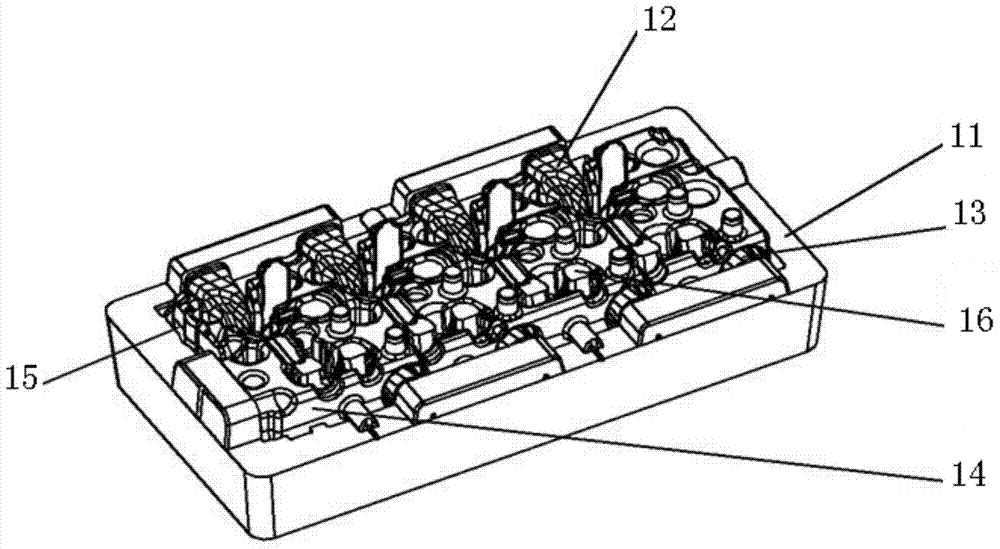

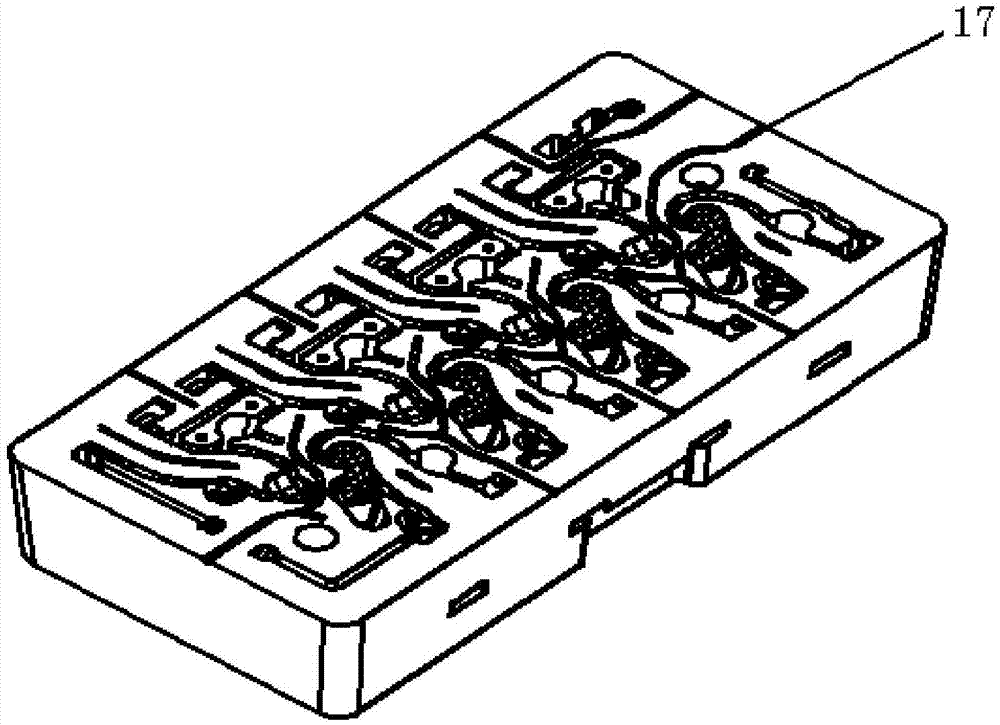

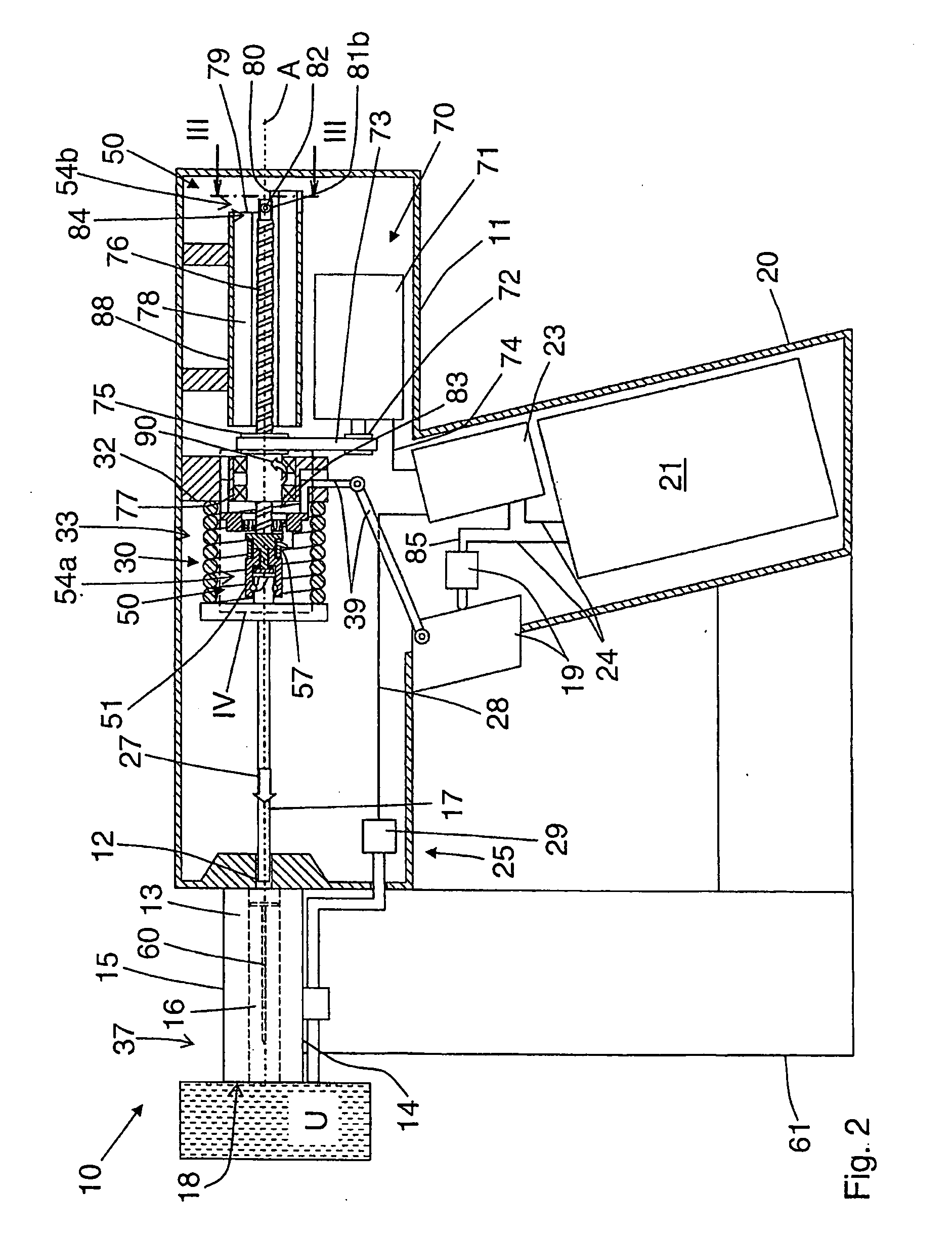

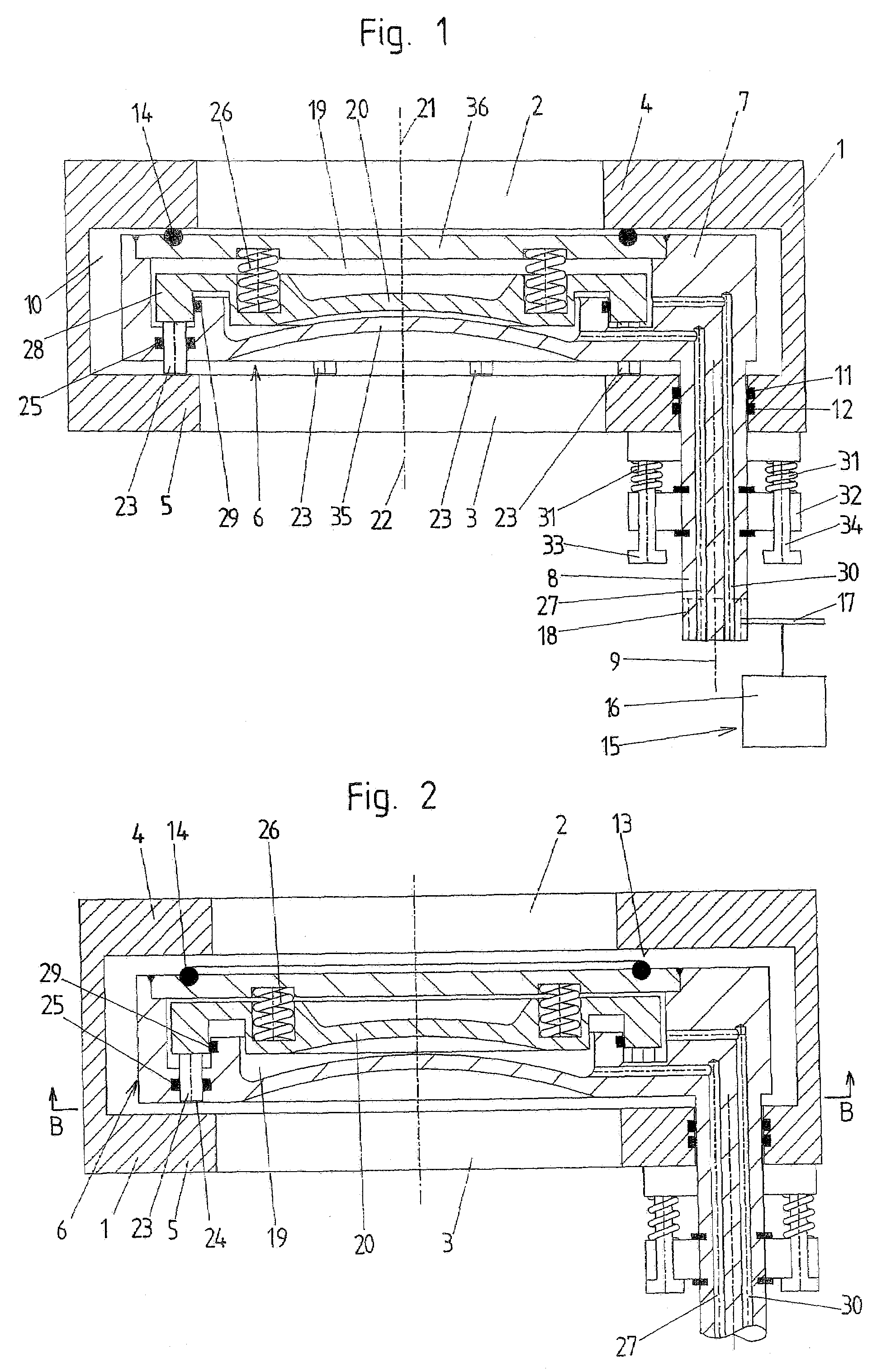

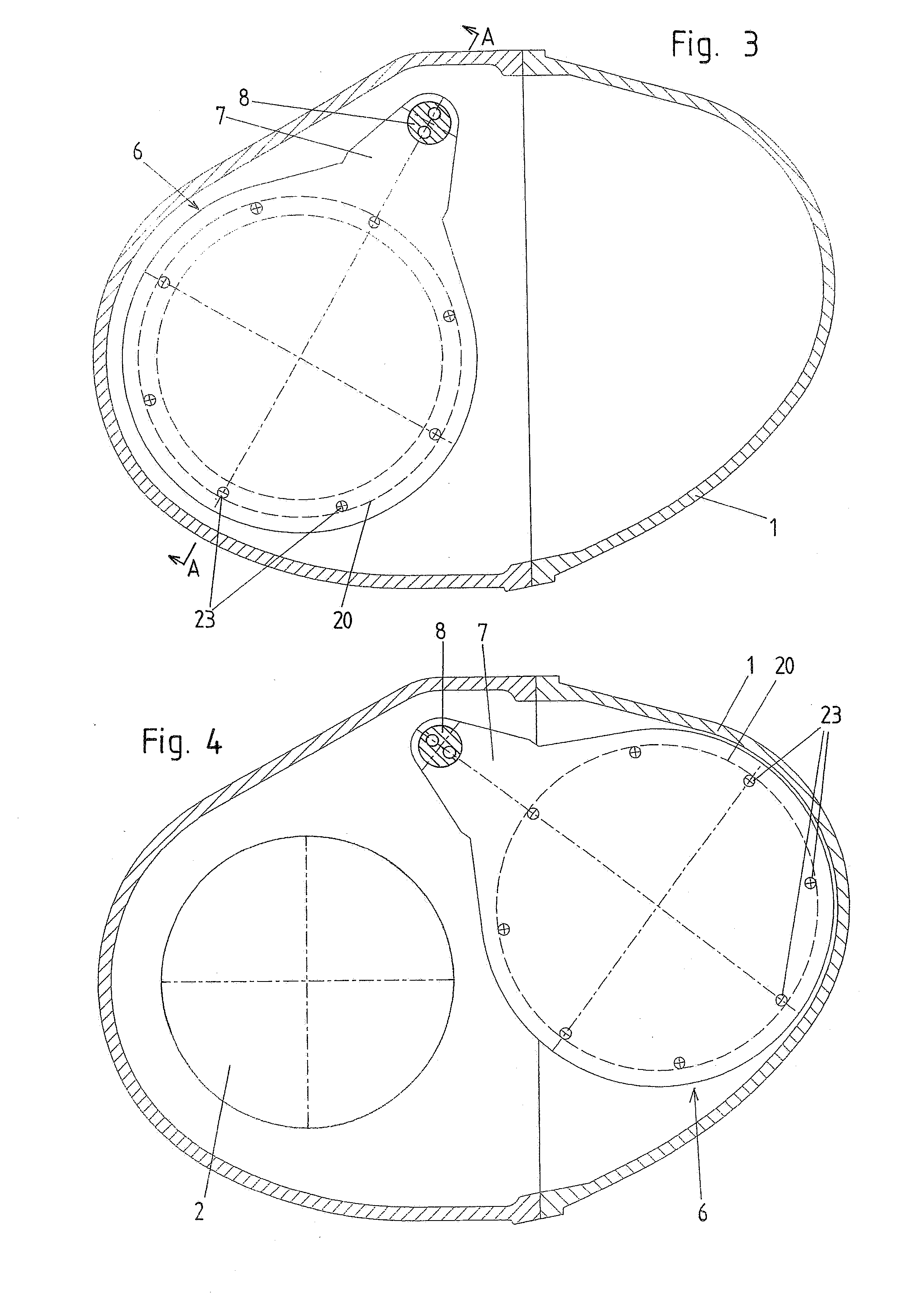

Rotating catch lock, specially for motor vehicles

The invention relates to a rotating catch lock, wherein a closing member (10) interacts with a catch (20), which can be rotated between a closing position accommodating the closing member (10) and an open position which releases said member. The catch (20) is force-loaded (22) in an open position and is held by a spring-loaded (33) rotating latch (30) in the close position. Said latch (30) is moved by a motor (50) between the locking position retaining the catch (20) and a stand-by release position in which the spring-loaded latch (30) is propped up by the catch (20) as long as it remains in an open position. In order to use small compact motors (50), the invention provides that the stored energy (61) exerted by an energy storage mechanism (60) is transmitted to the latch (30) via a storage lever (40). Normally, the latch (30) is shifted into its stand-by position by the storage lever (40). When the latch (30) is in a stand-by position, the storage lever (40) is supported on a control tappet (51) which is rotationally driven by the motor (50). The motor (50) can be driven by an electrical control logic in both a forward mode (56) unloading the energy storage (60) and a reverse mode (56') loading the energy storage (60), i.e. in opposite directions. In the reverse mode (56') the control tappet (51) releases the latch (30), moves towards the storage lever (40) and guides it back into a starting position which corresponds to the stand-by position of the latch (30).

Owner:HUF HULSBECK & FURST GMBH & CO KG

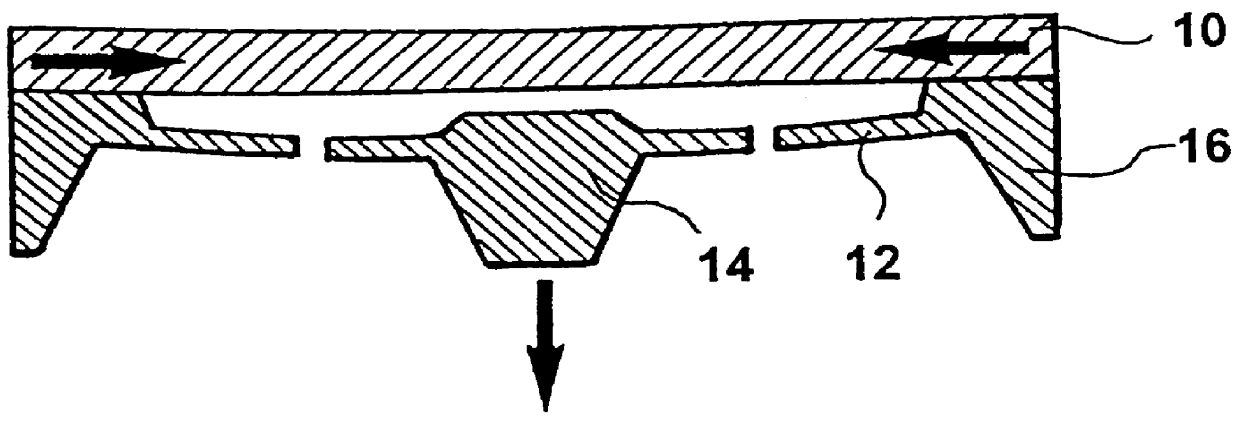

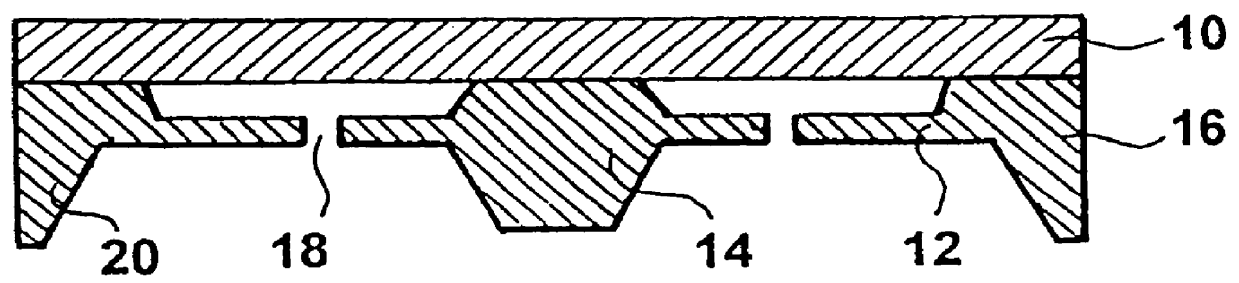

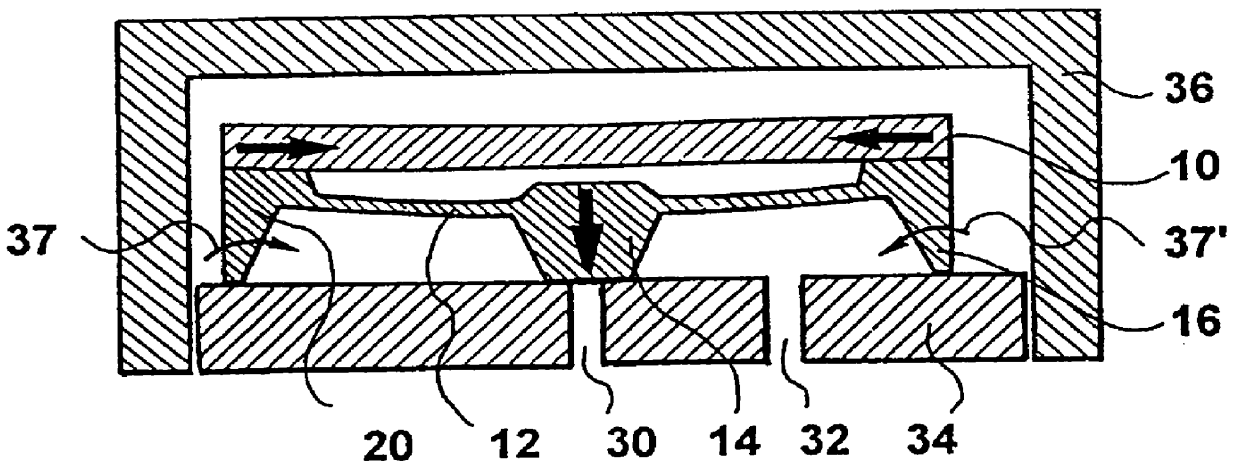

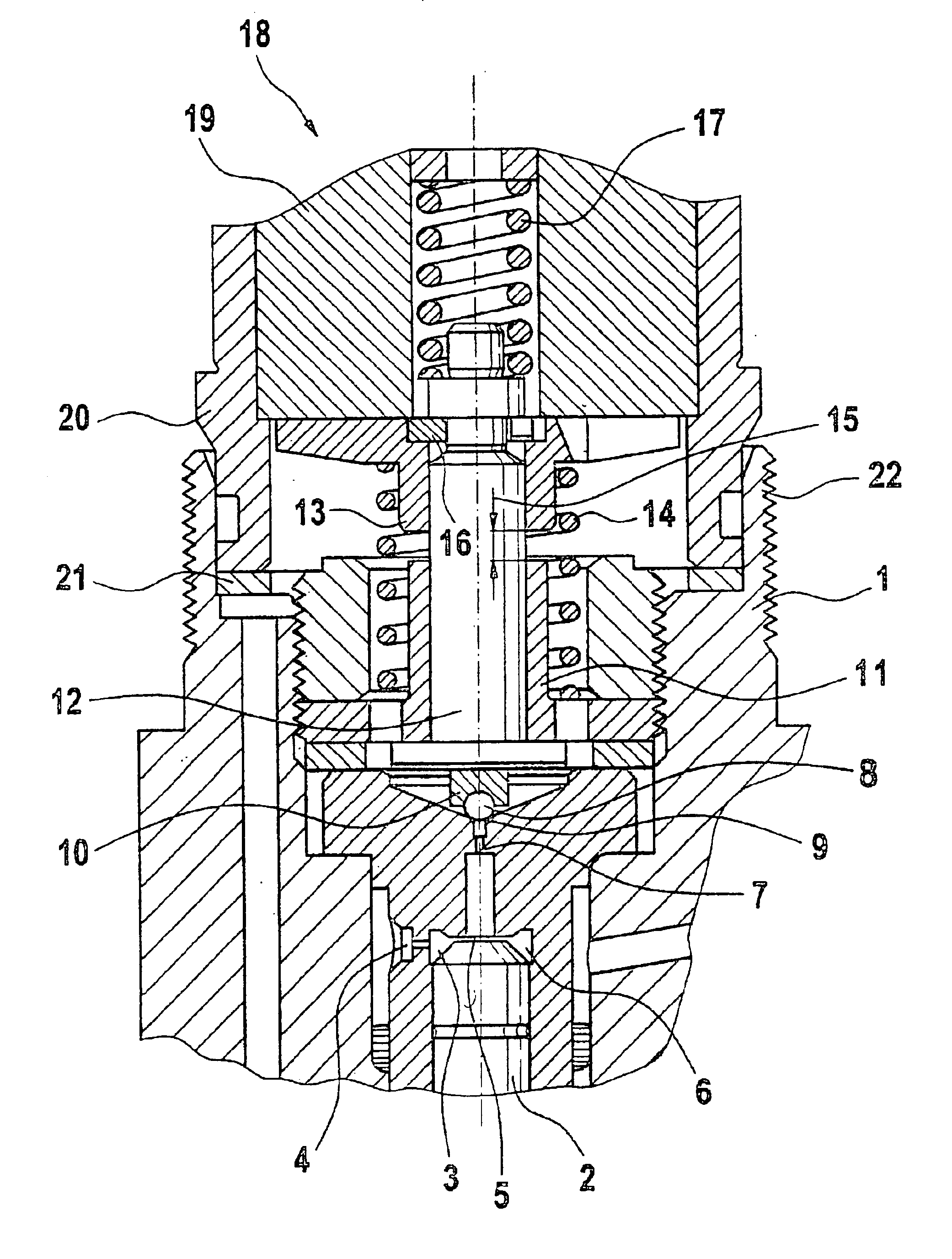

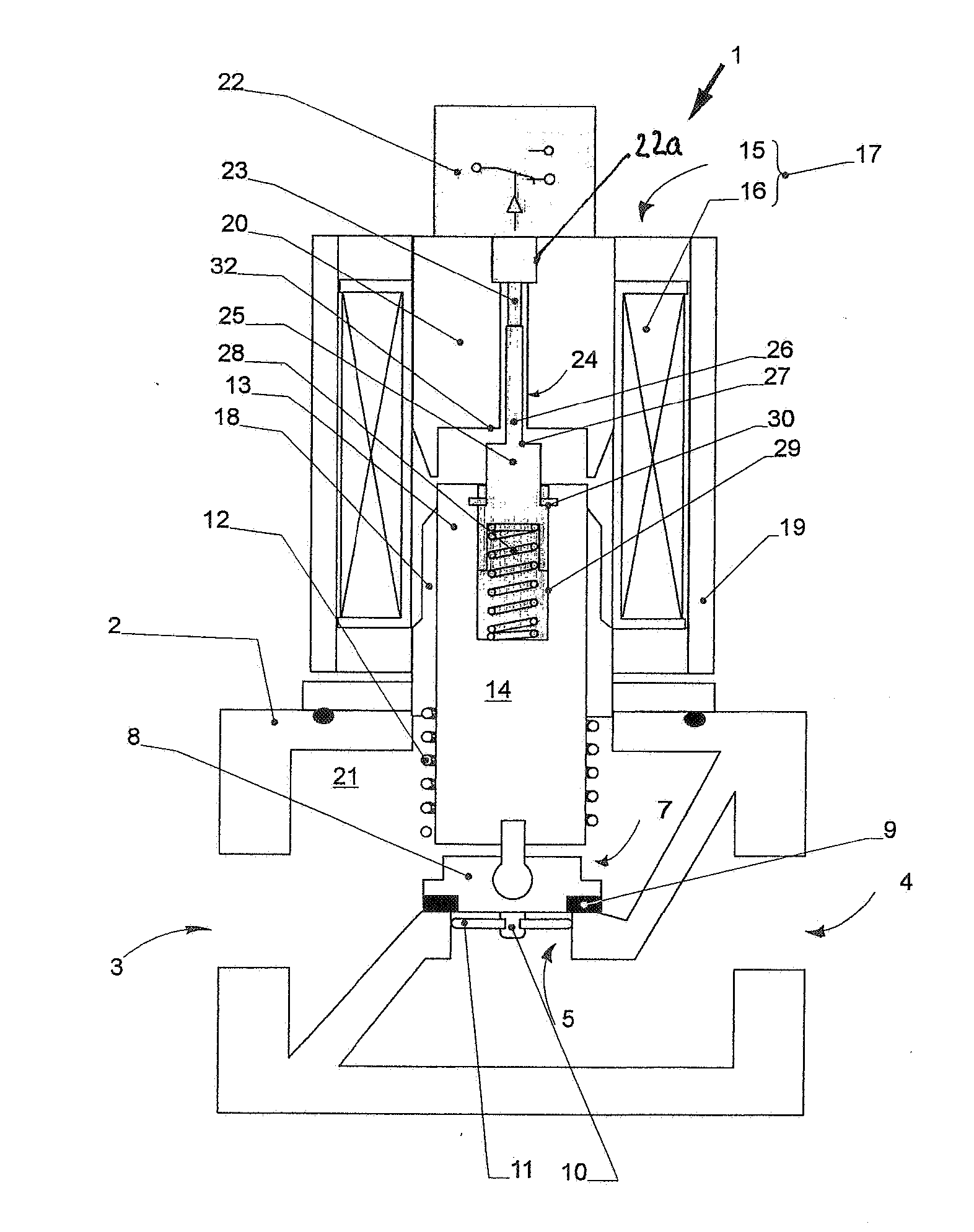

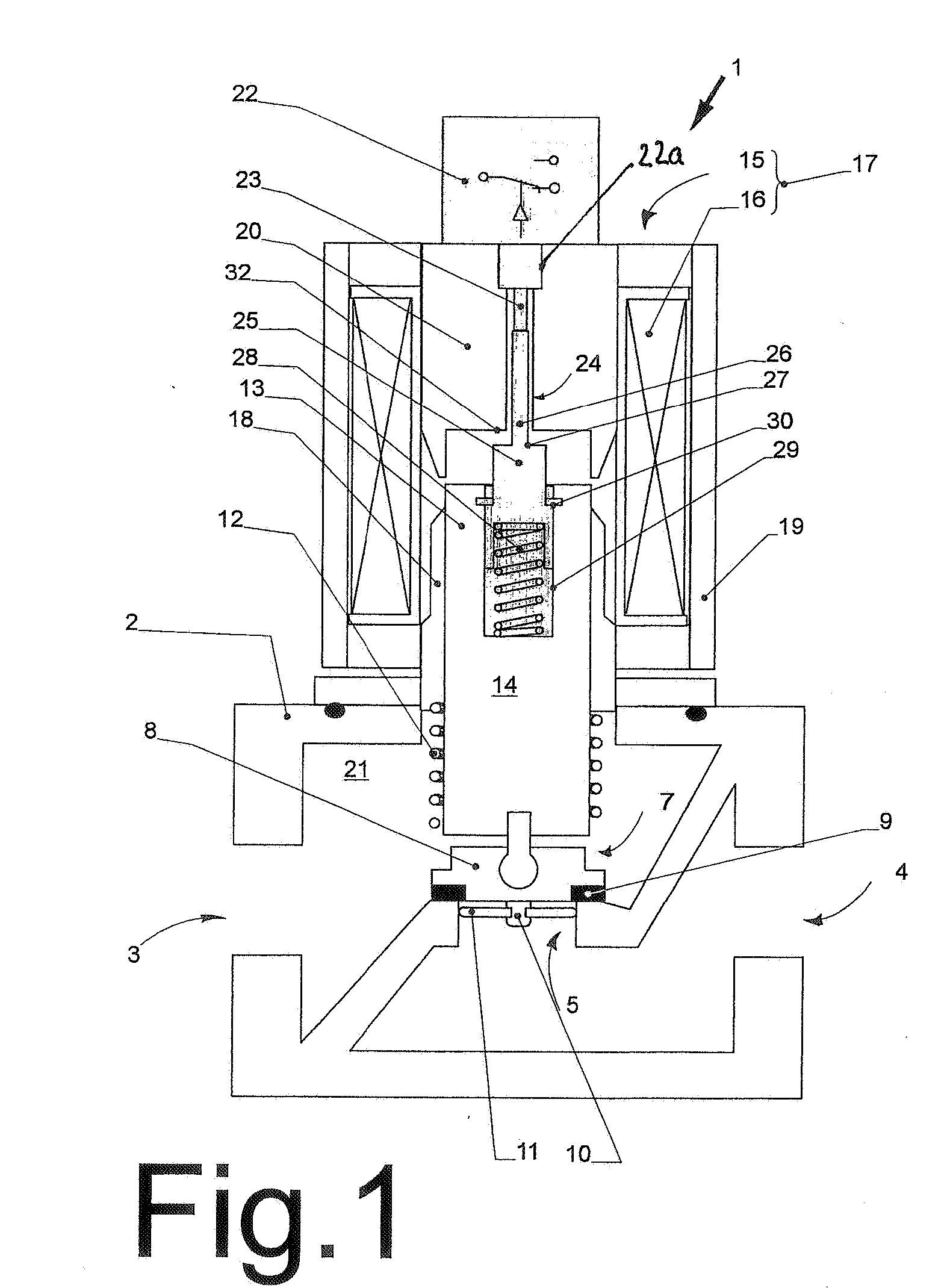

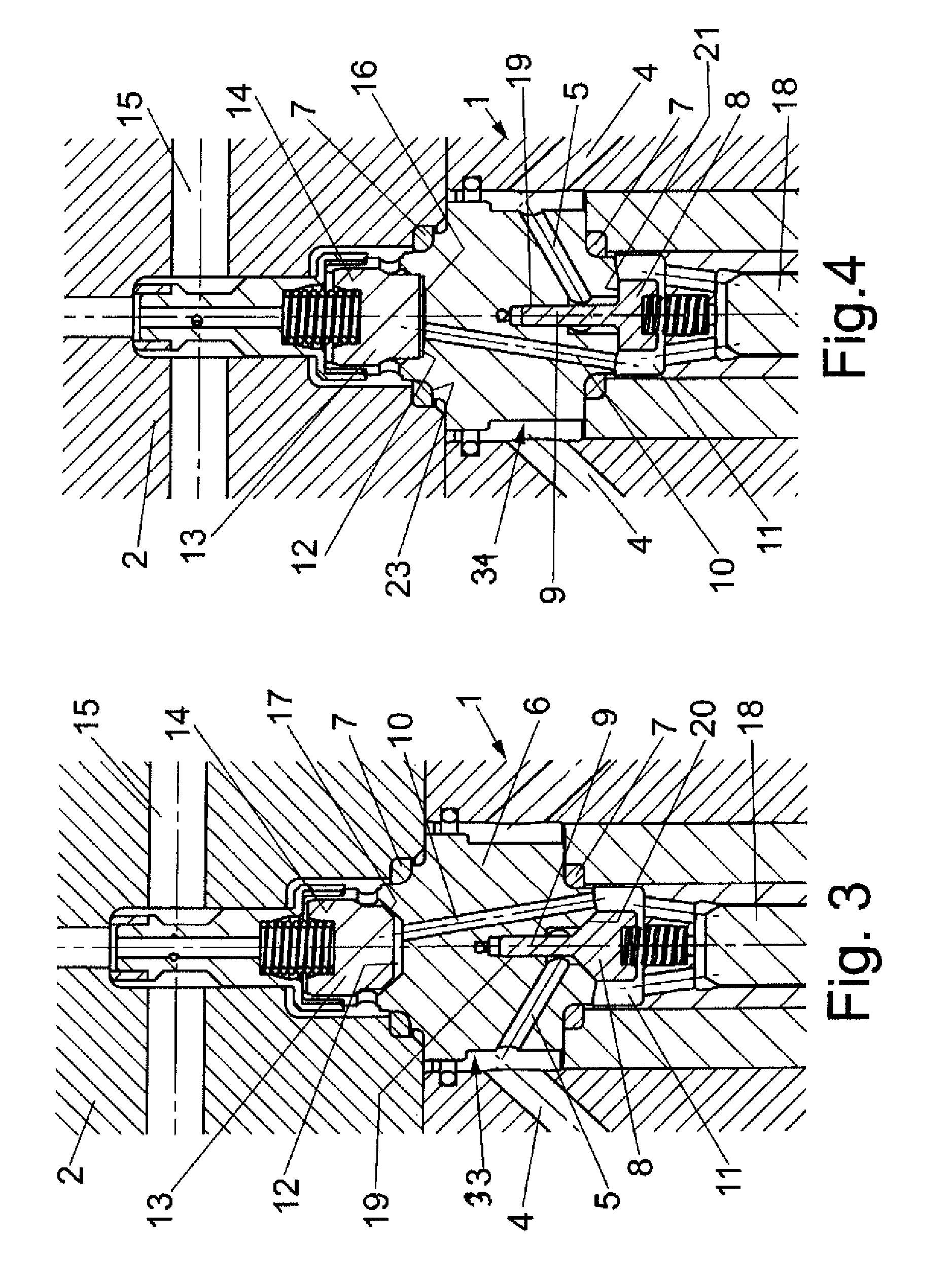

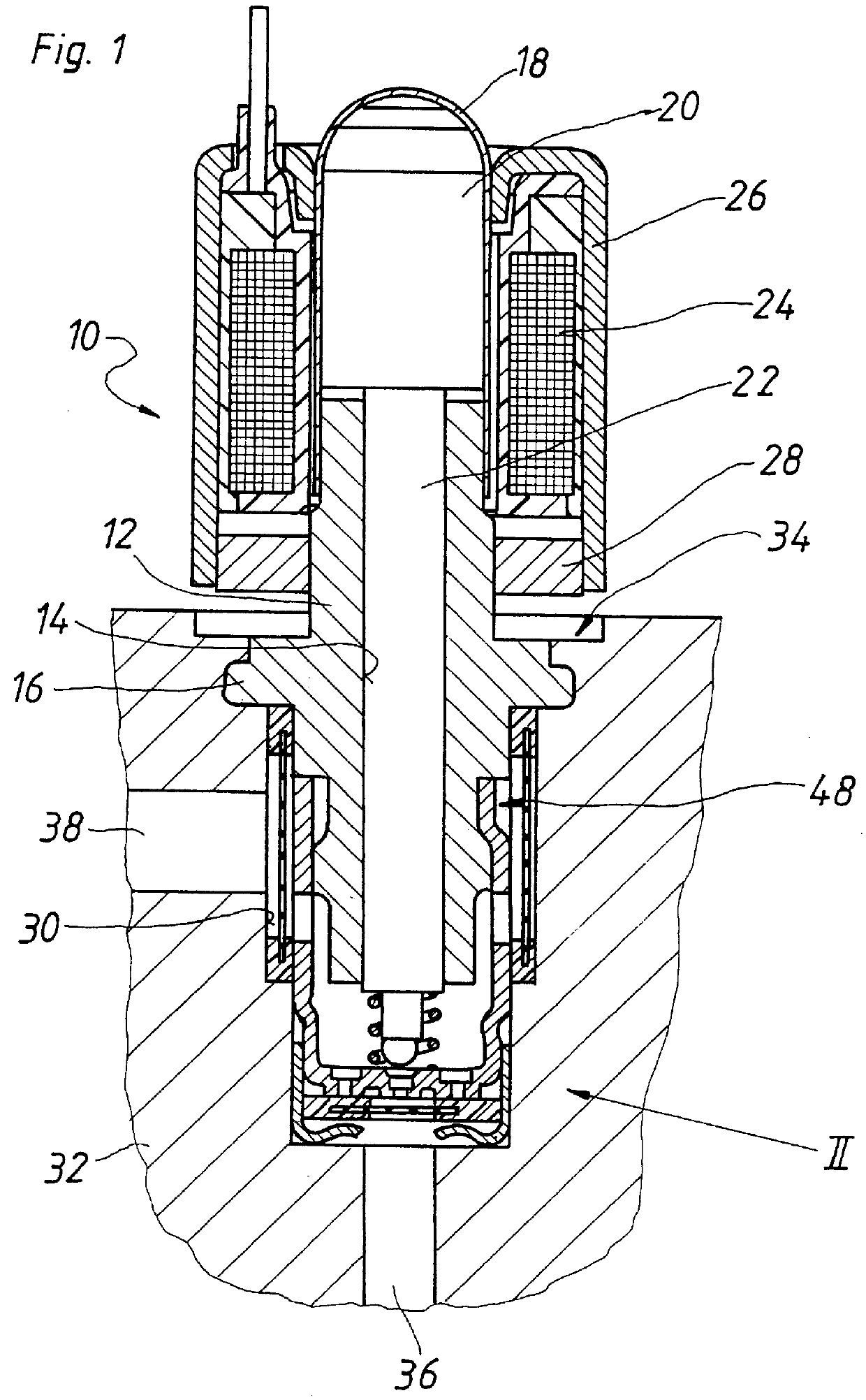

Piezoelectrically actuated microvalve

InactiveUS6131879ALarge opening widthReduce constructionOperating means/releasing devices for valvesCircuit elementsElectricityPiezoelectric actuators

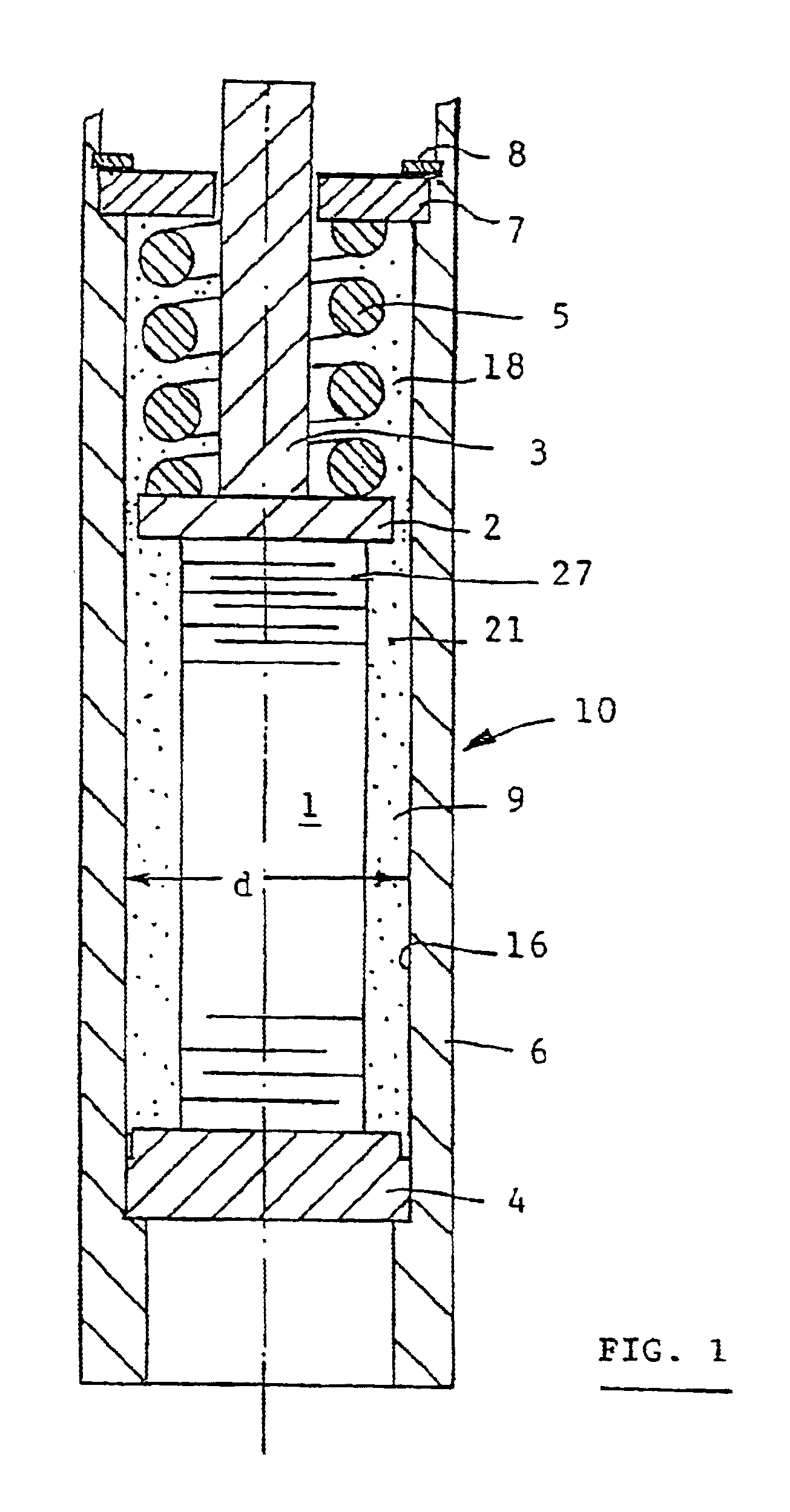

PCT No. PCT / EP97 / 06344 Sec. 371 Date May 20, 1999 Sec. 102(e) Date May 20, 1999 PCT Filed Nov. 13, 1997 PCT Pub. No. WO98 / 23868 PCT Pub. Date Jun. 4, 1998A microvalve has a base element provided with a passage opening, a tappet, a suspension device for guiding the tappet, and a piezoelectric actuator for actuating the tappet. The suspension device guides the tappet relative to the base element in such a way that the passage opening can be closed or opened by the tappet. The longitudinal dimensions of the piezoelectric actuator can be changed by the application of an electric voltage. Longitudinally spaced ends of the piezoelectric actuator are connected to longitudinally spaced ends of the suspension device in such a way that the suspension device provides a way for mechanical translation between the actuator and the tappet. A change in the longitudinal dimensions of the piezoelectric actuator caused by the application of an electric voltage to the piezoelectric actuator is mechanically translated by the suspension device into a movement of the tappet essentially at right angles to the longitudinal direction so that the passage opening will be opened or closed. In addition, the suspension device is secured to the base element with the aid of a hinge-like element. At least two spaced points are used to secure the suspension device to the base element.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

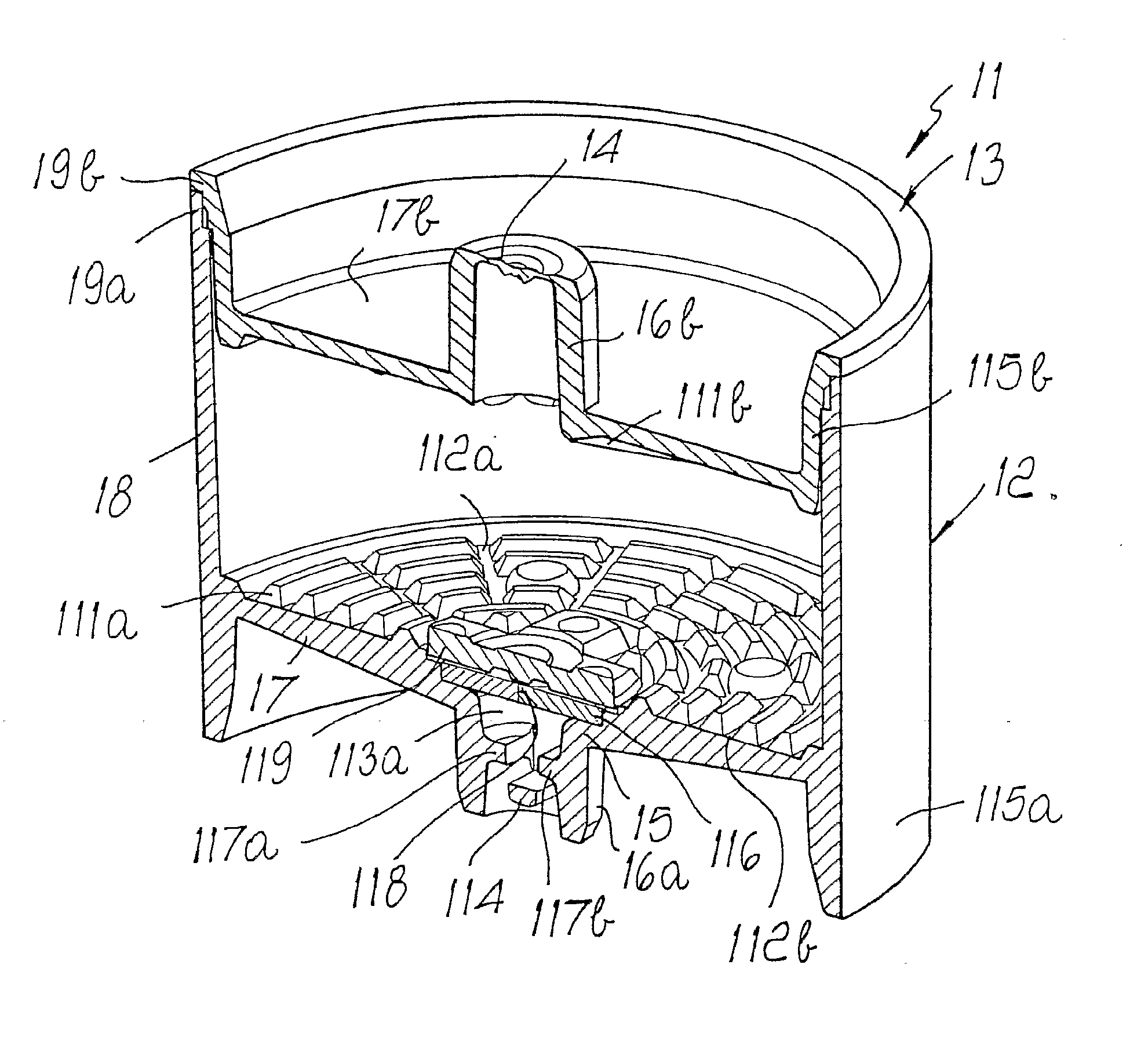

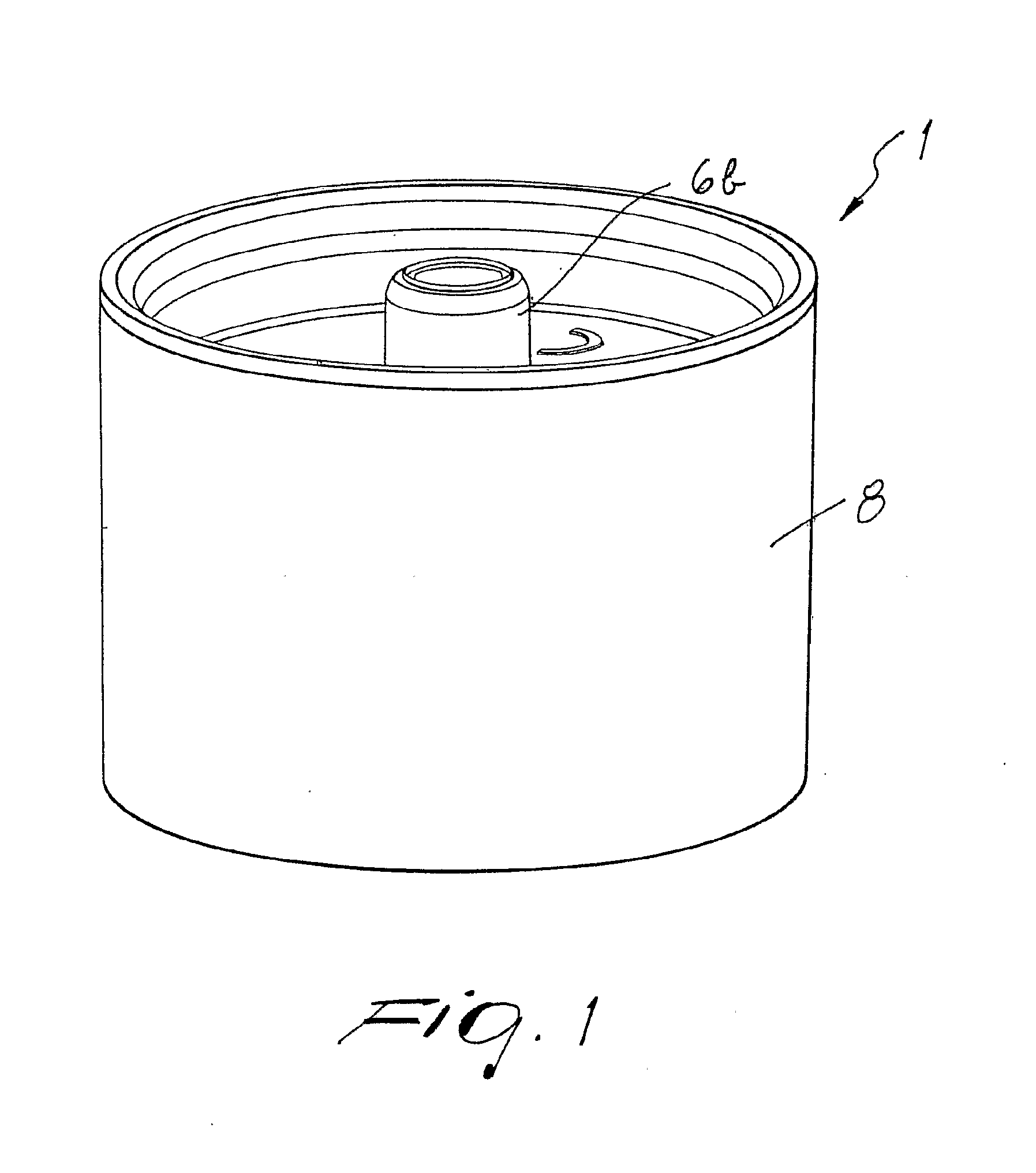

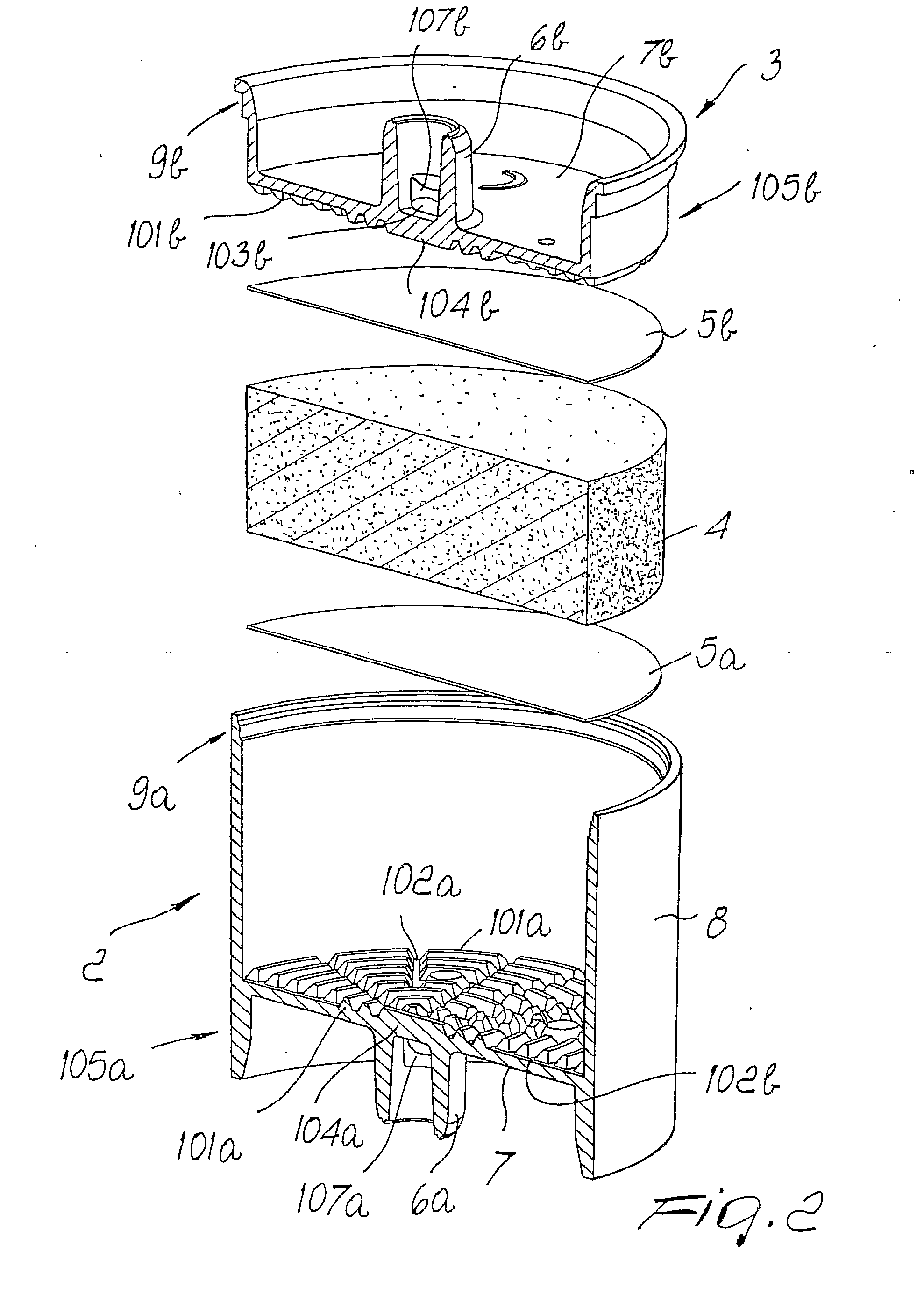

Integrated cartridge for extracting a beverage from a particulate substance

InactiveUS20100043646A1Improve sensory qualityQuality improvementSmall article dispensingReady-for-oven doughsEspresso coffeeFluid - substance

A cartridge, particularly for espresso coffee machines, for extracting a beverage from a particulate substance contained therein by means of water under pressure is provided. The cartridge comprises a main body with a cup portion and a lid portion. The cup portion comprises a base, a sidewall and a rim opposed to the base, while the lid portion is fixedly attached to the rim of the cup portion so as to define an internal volume of the cartridge. The internal volume of the cartridge houses the particulate substance comprised within filtering means for retaining the particulate substance and for percolating fluid substances therethrough. The lid portion comprises a normally closed lid port defining a first passage for percolation fluid substances when it is opened. The cartridge further comprises a tappet arranged inside the internal volume so as to pierce the base when a pressure is applied to the base towards the internal volume, thus opening a normally closed cup port.

Owner:ILLYCAFFE SPA

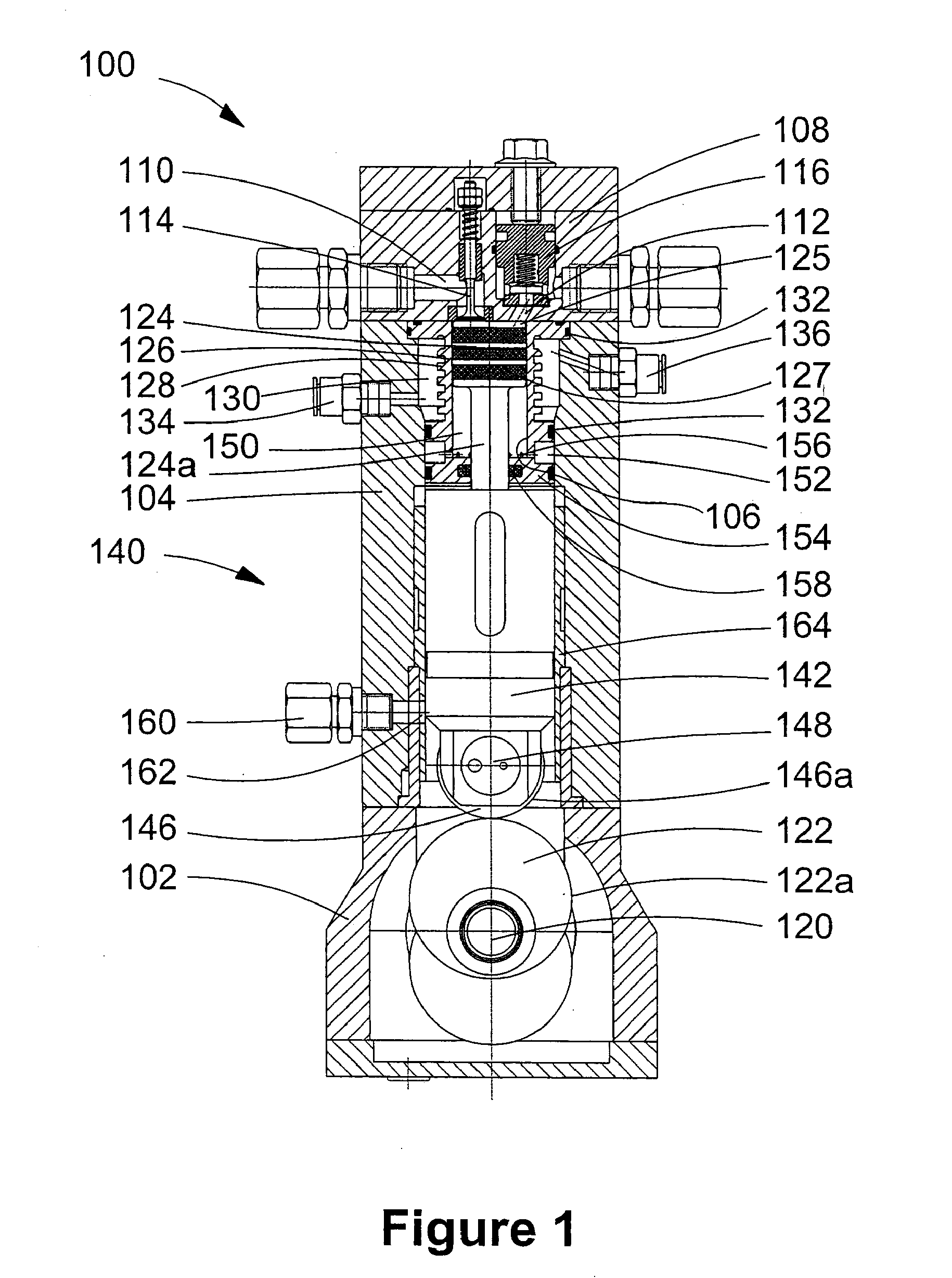

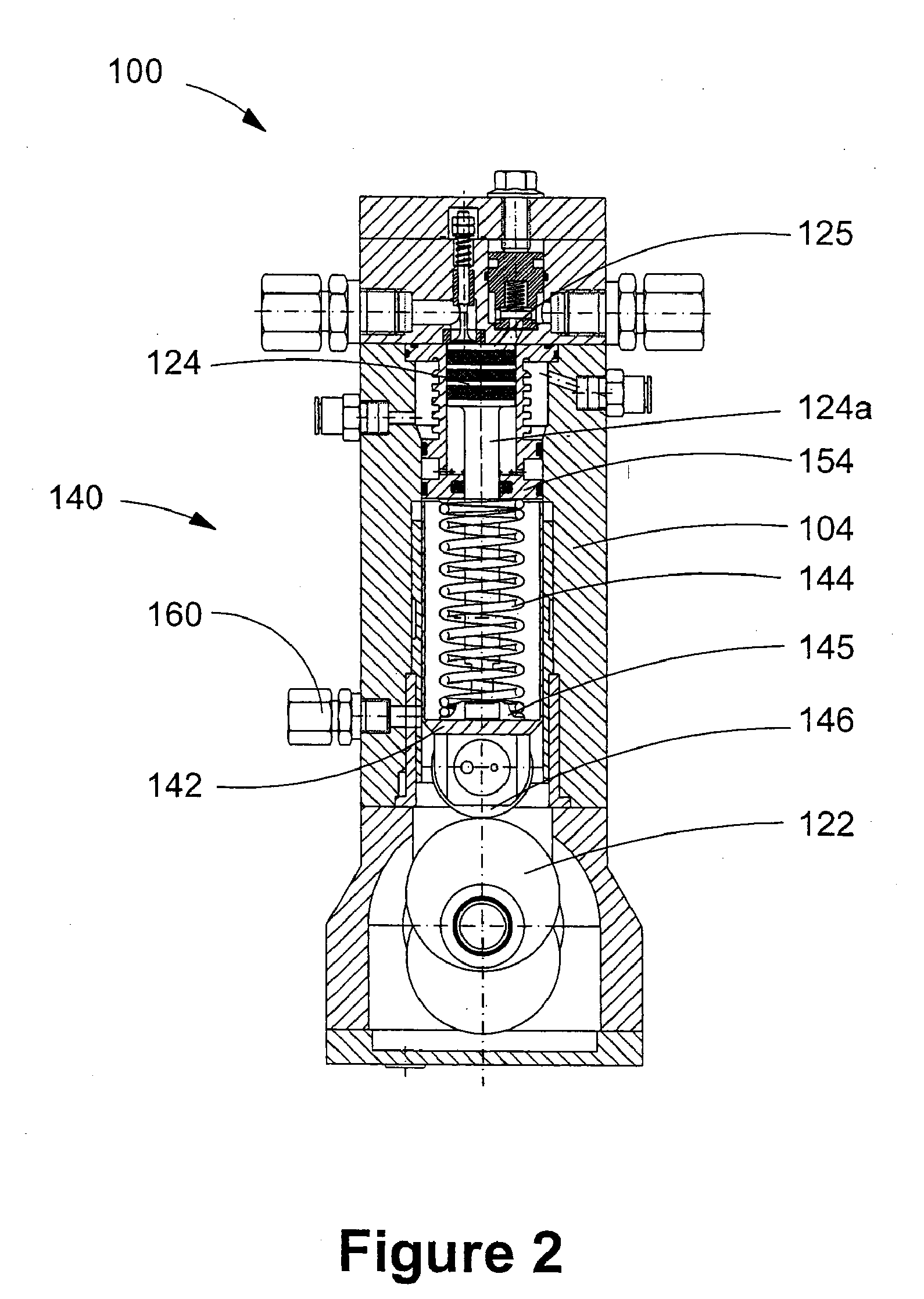

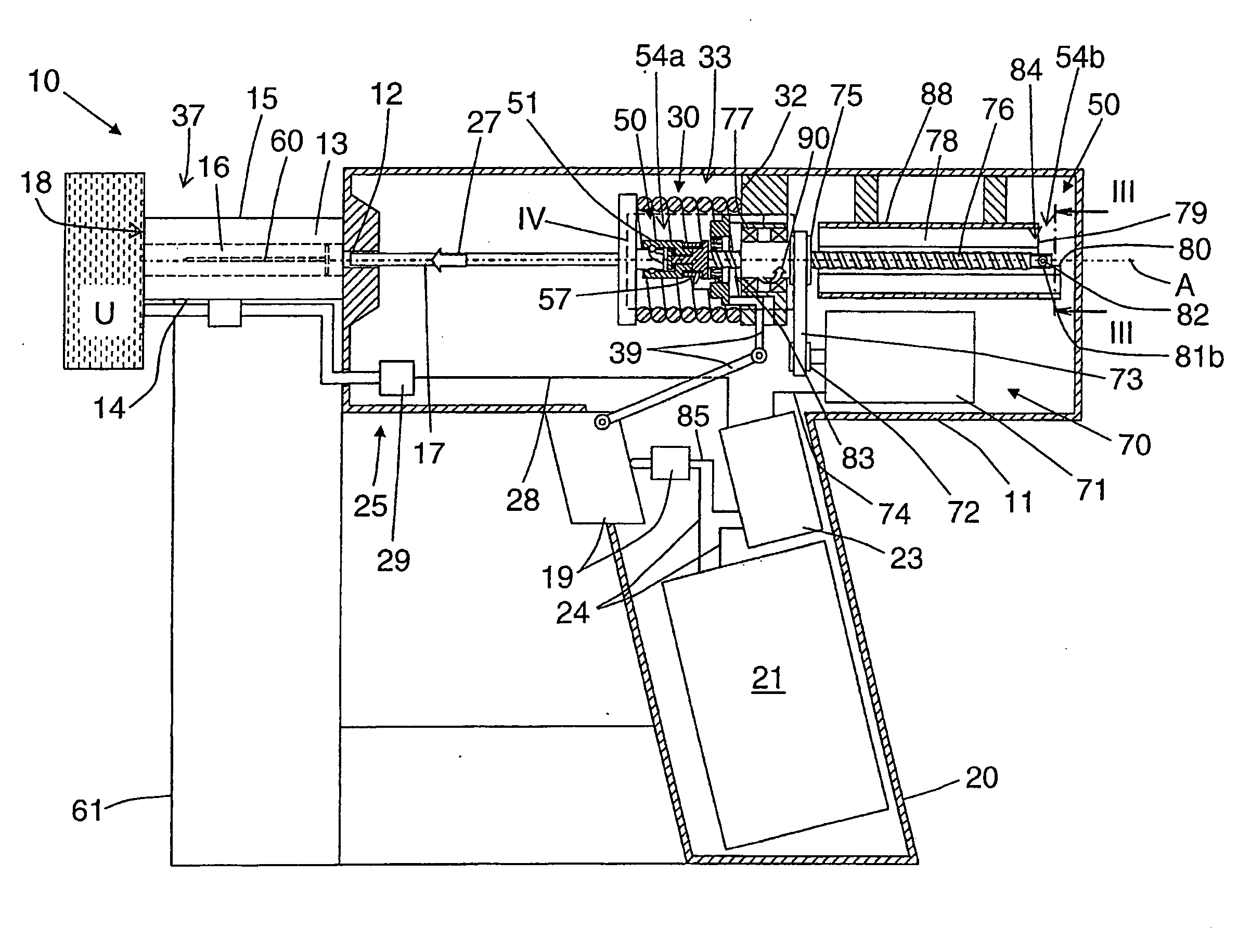

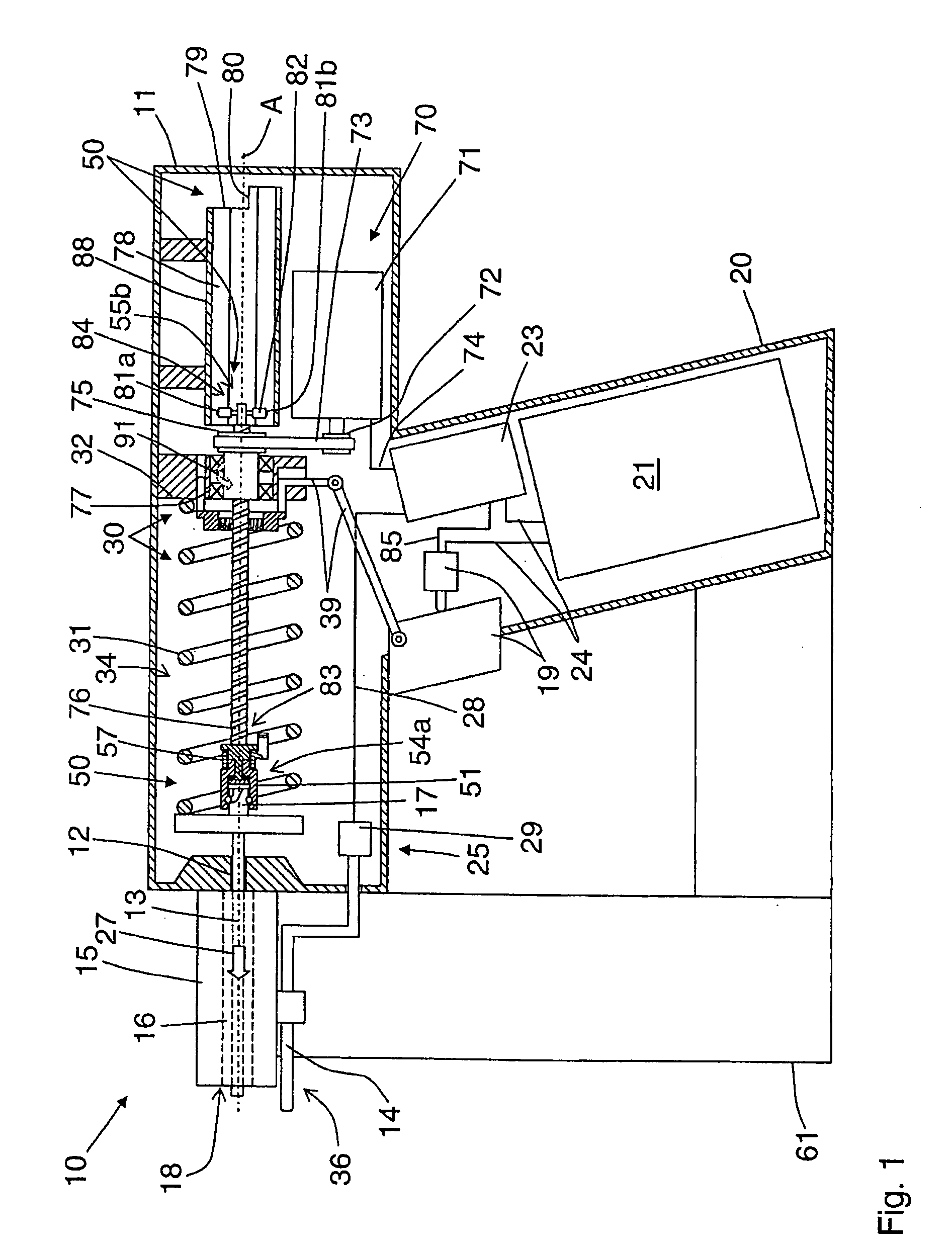

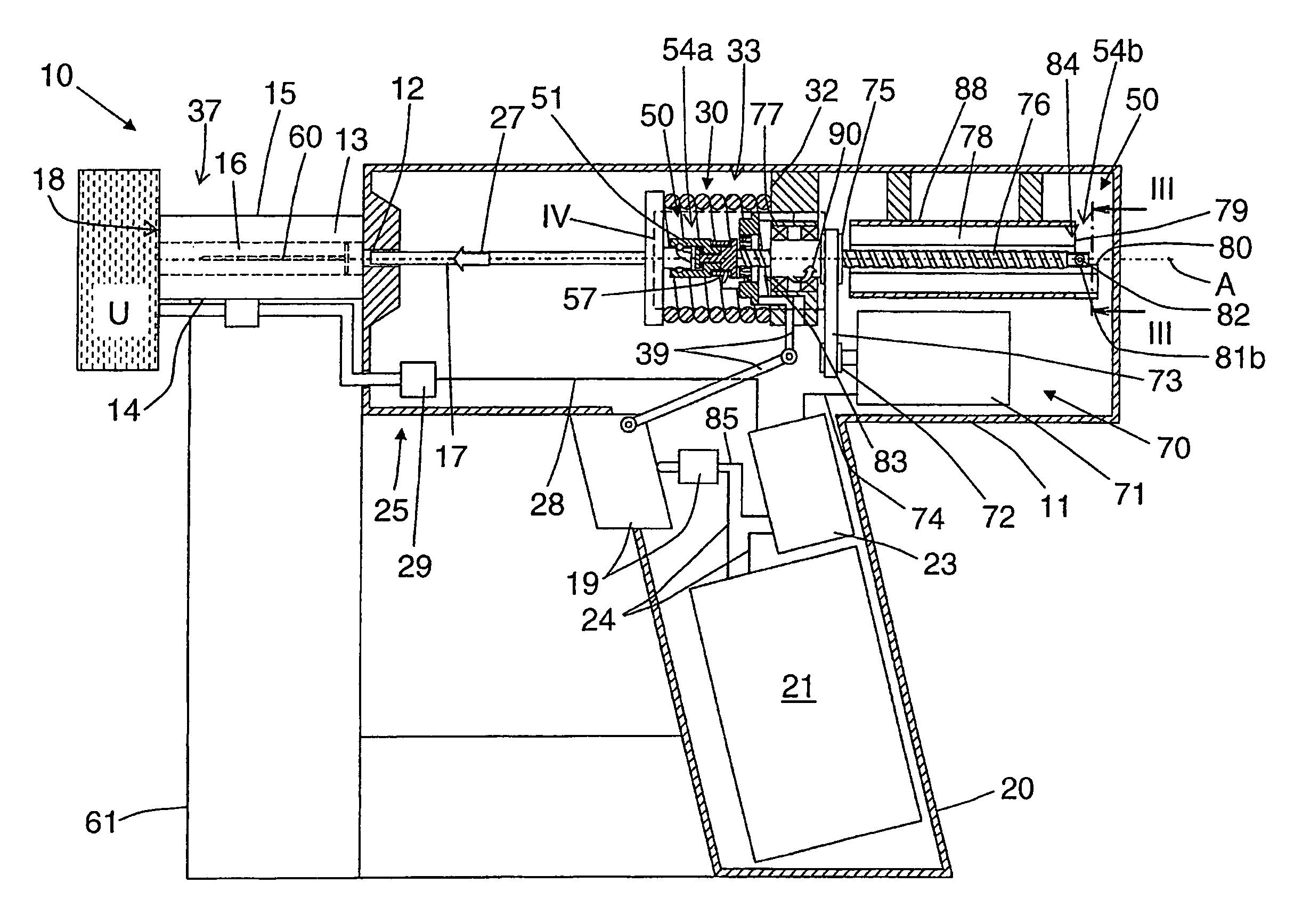

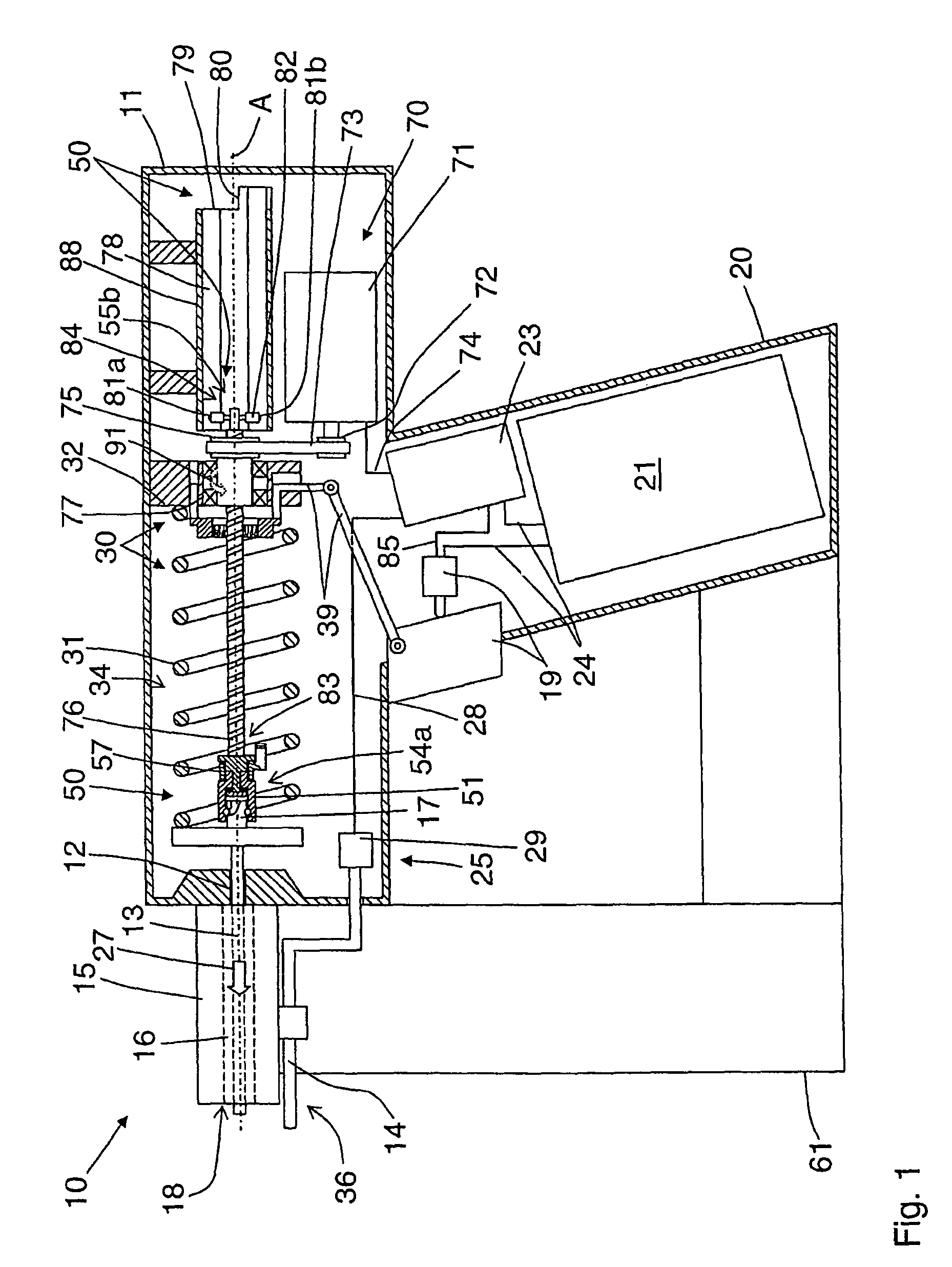

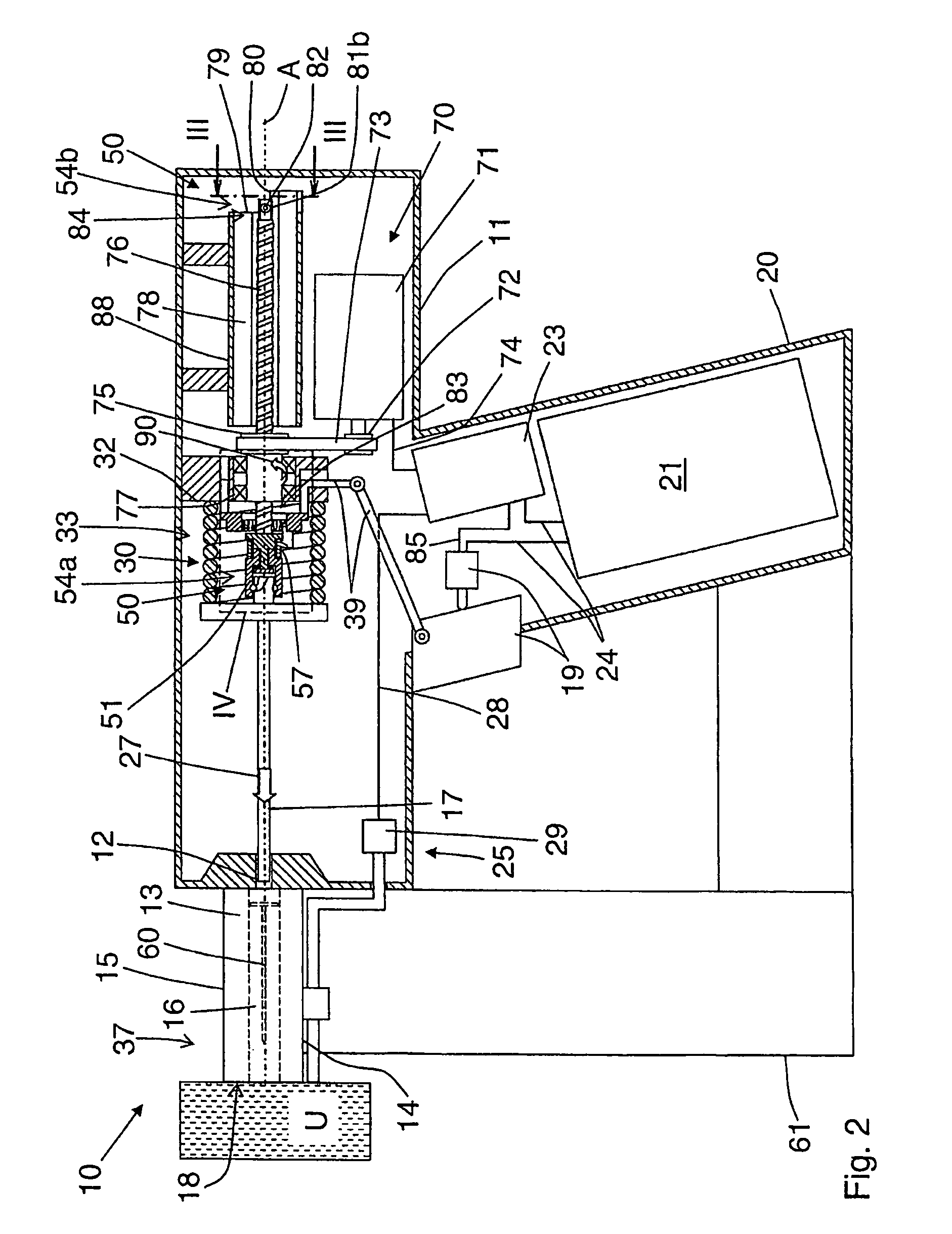

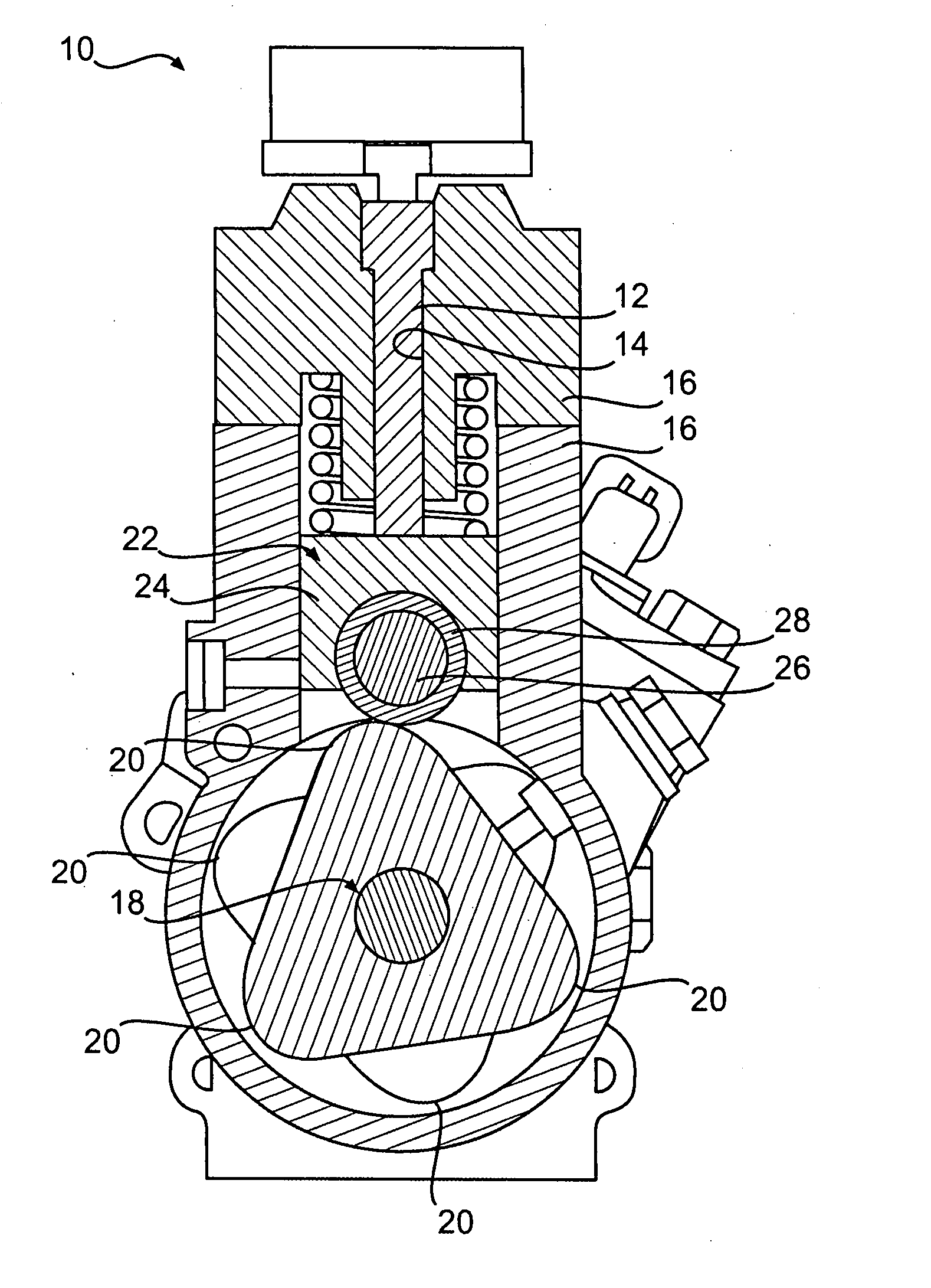

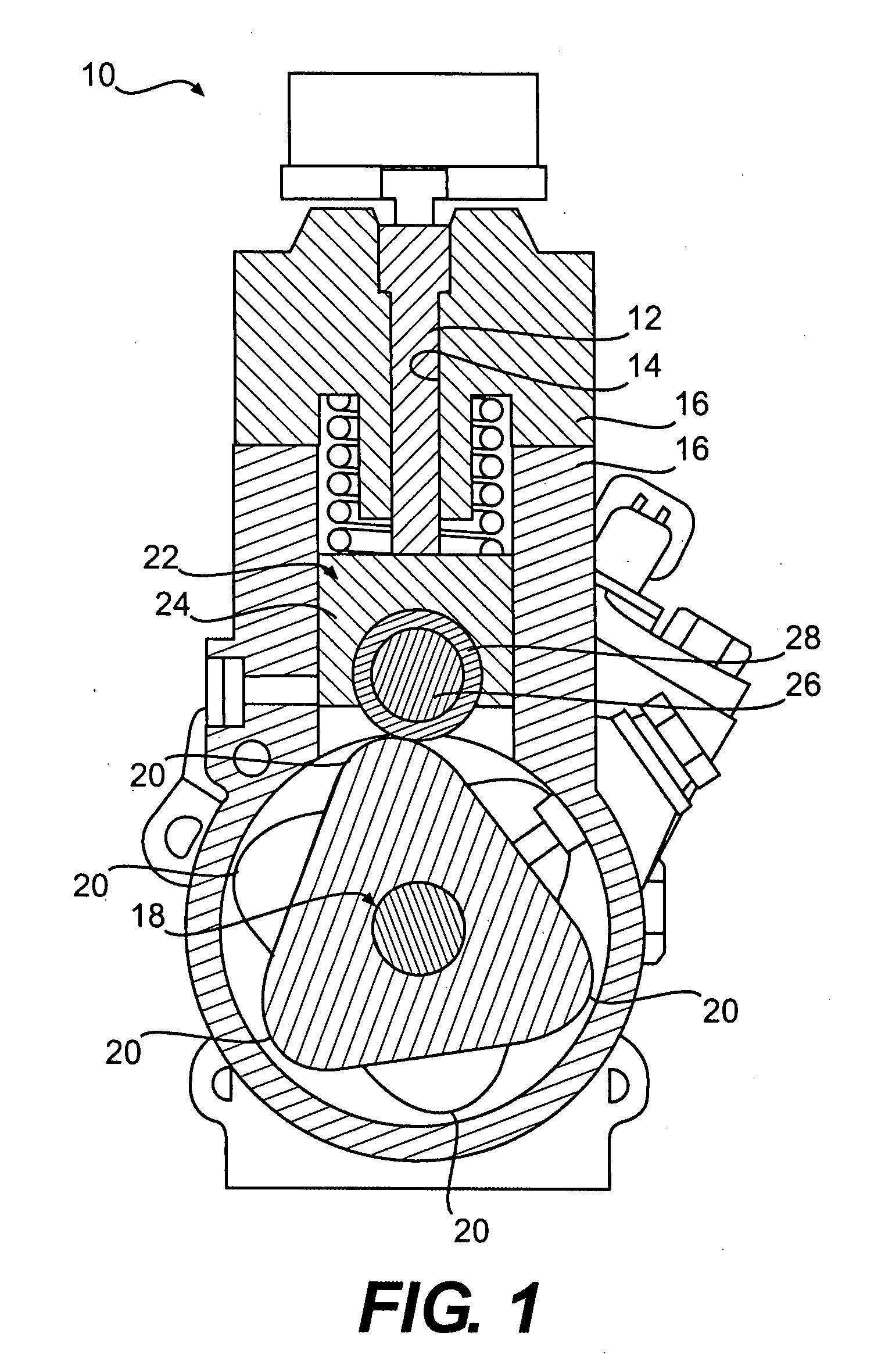

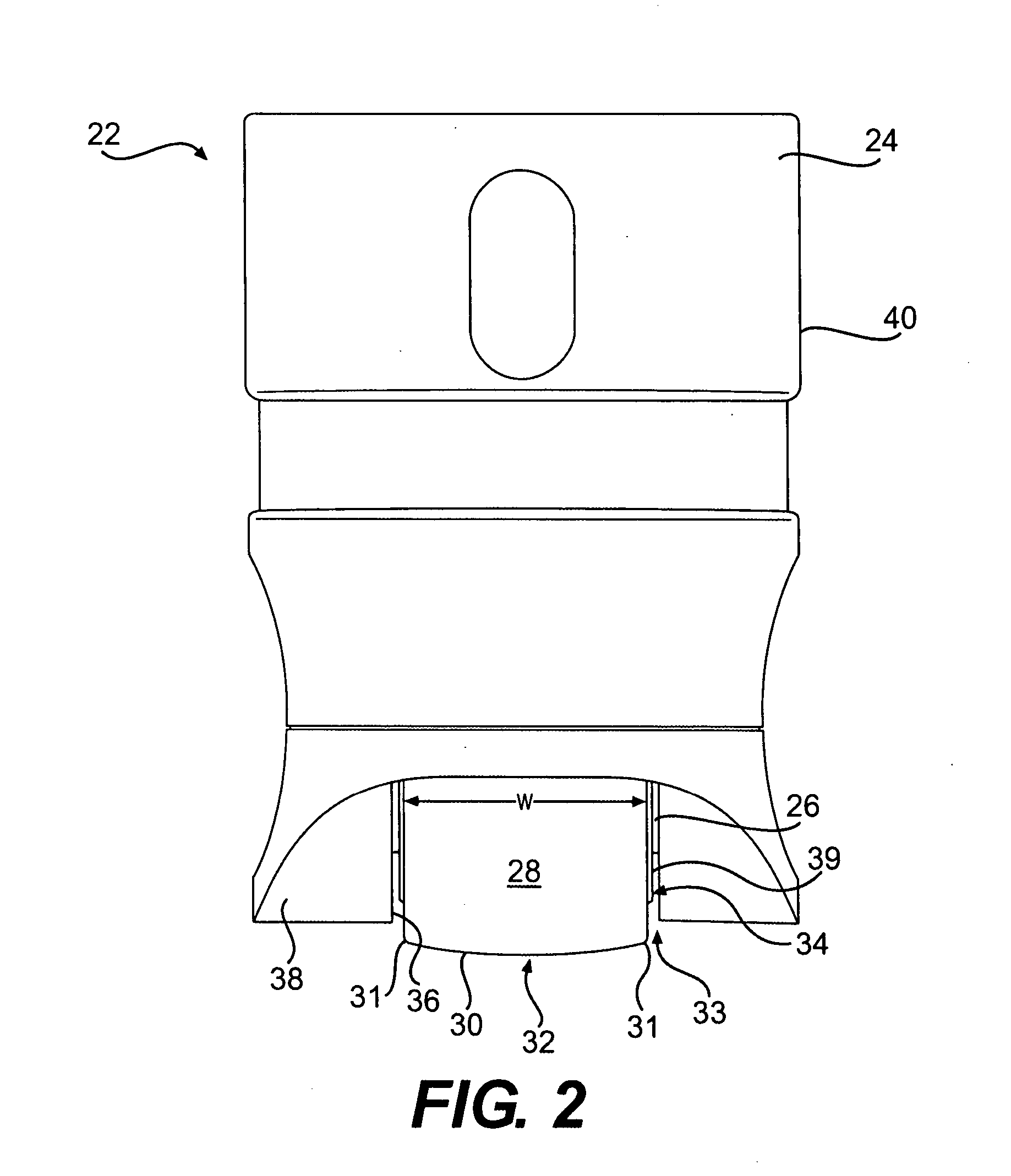

High-Pressure Gas Compressor And Method Of Operating A High-Pressure Gas Compressor

ActiveUS20080213115A1Reduce in quantitySimple manufacturing processPositive displacement pump componentsFlexible member pumpsFriction reductionInlet valve

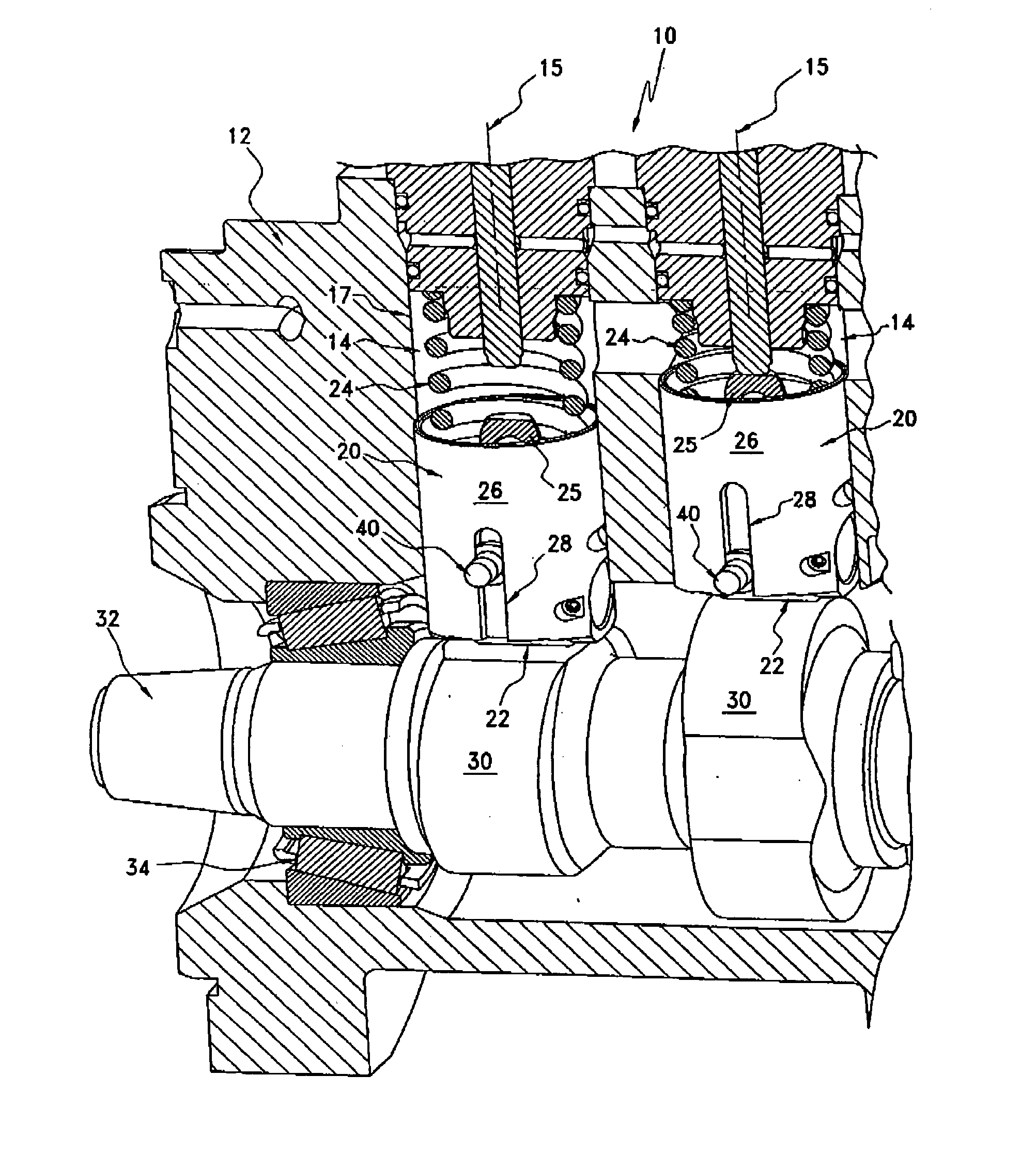

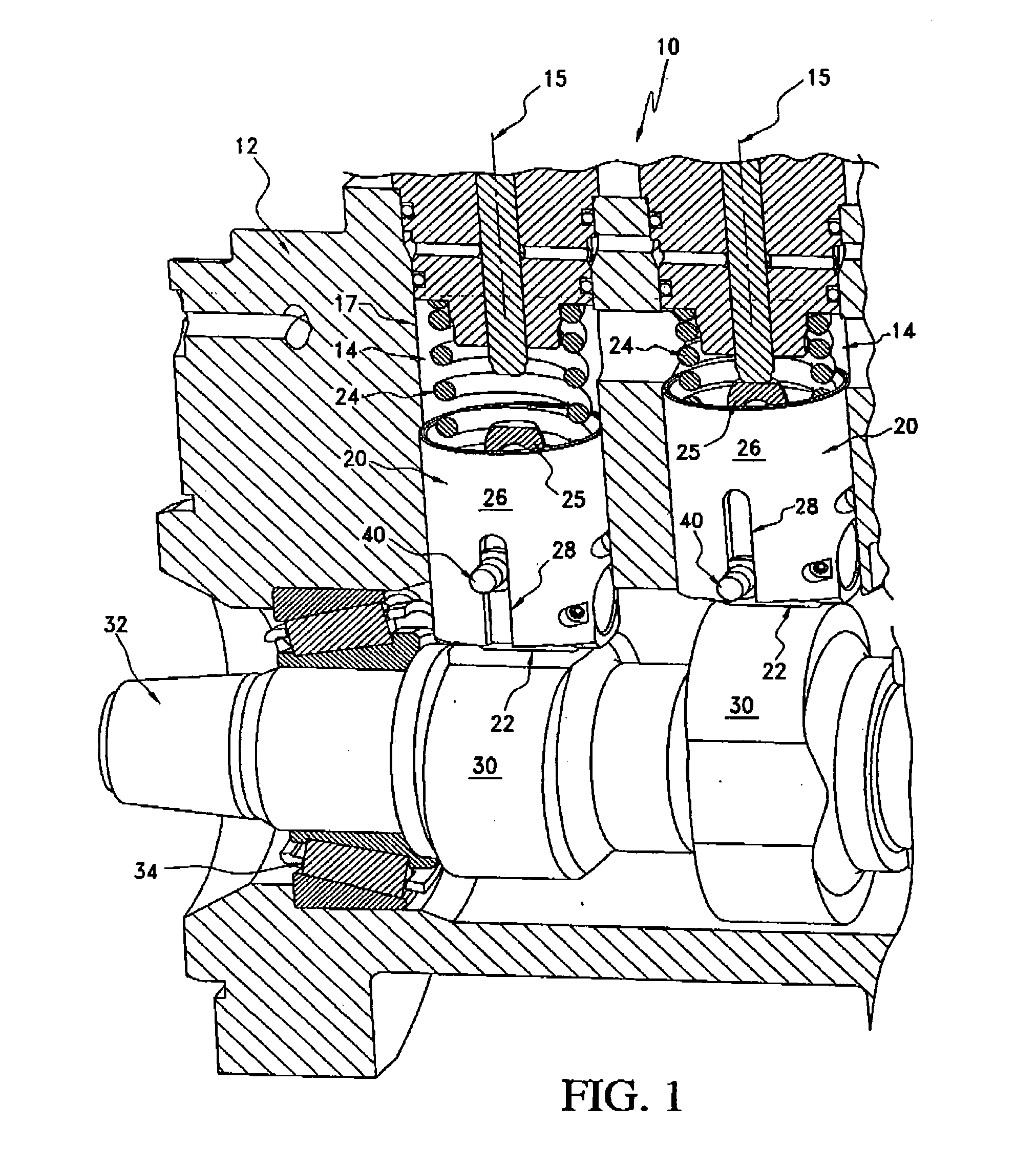

A high-pressure gas compressor comprises a single-acting cam driven piston with a pressure compensation chamber disposed between the piston and the cam. A roller tappet assembly transmits reciprocating motion from the cam to the piston. A pressurized gas directed to the pressure compensation chamber offsets forces acting on the piston from the compression chamber gas pressure, thereby reducing Hertzian pressure between the tappet roller and the cam. Overall efficiency and durability can be improved by reducing friction between compressor components, for example by employing thin film coatings to reduce friction, pressurized oil lubrication systems and higher cylinder bore diameter to piston stroke ratios. The service life of gas seals and compression efficiency can be improved by thermal management strategies, including liquid-cooled compressor cylinder liners and intercoolers between compression stages. Employing a poppet-style intake valve and reducing parasitic volume in the compression chamber can improve compressor volumetric efficiency.

Owner:WESTPORT FUEL SYST CANADA INC

Solenoid valve comprising a plug-in/rotative connection

InactiveUS6874706B2Good guidance precisionEasy to adjustOperating means/releasing devices for valvesSpray nozzlesCombustion chamberSolenoid valve

A solenoid valve for a fuel injector for injecting fuel into the combustion chamber of an internal combustion engine having an injector body which includes an electromagnet. An armature group of the solenoid valve may be actuated by this electromagnet to relieve the pressure in a control chamber, so that a nozzle needle / tappet assembly in the injector body implements an opening / closing movement. The armature group includes a first and a second armature part. The first armature part and the second armature part are joined to one another by an insert-and-twist connection, one of the armature parts being enclosed by an armature guide which includes anti-rotation elements.

Owner:ROBERT BOSCH GMBH

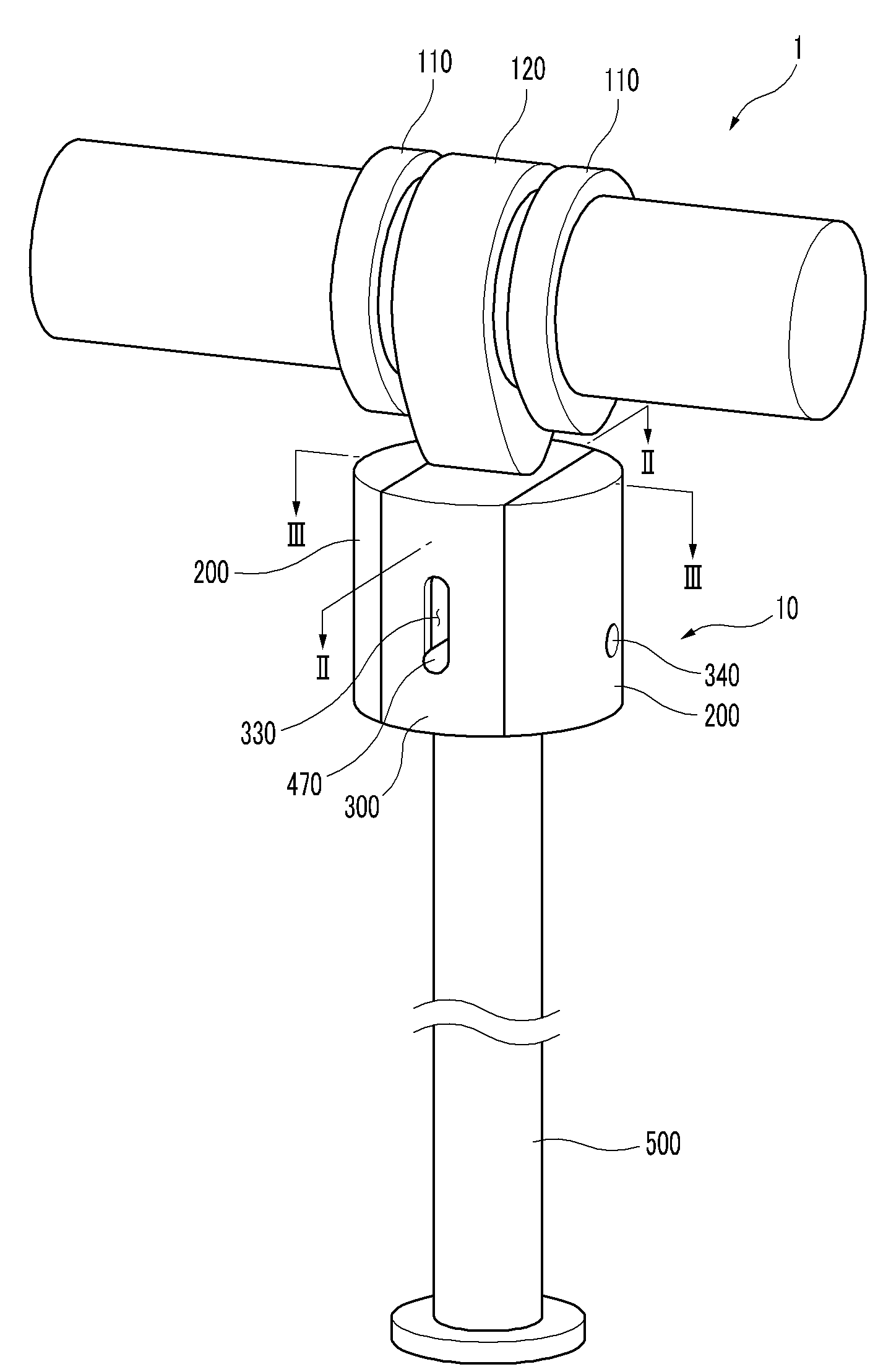

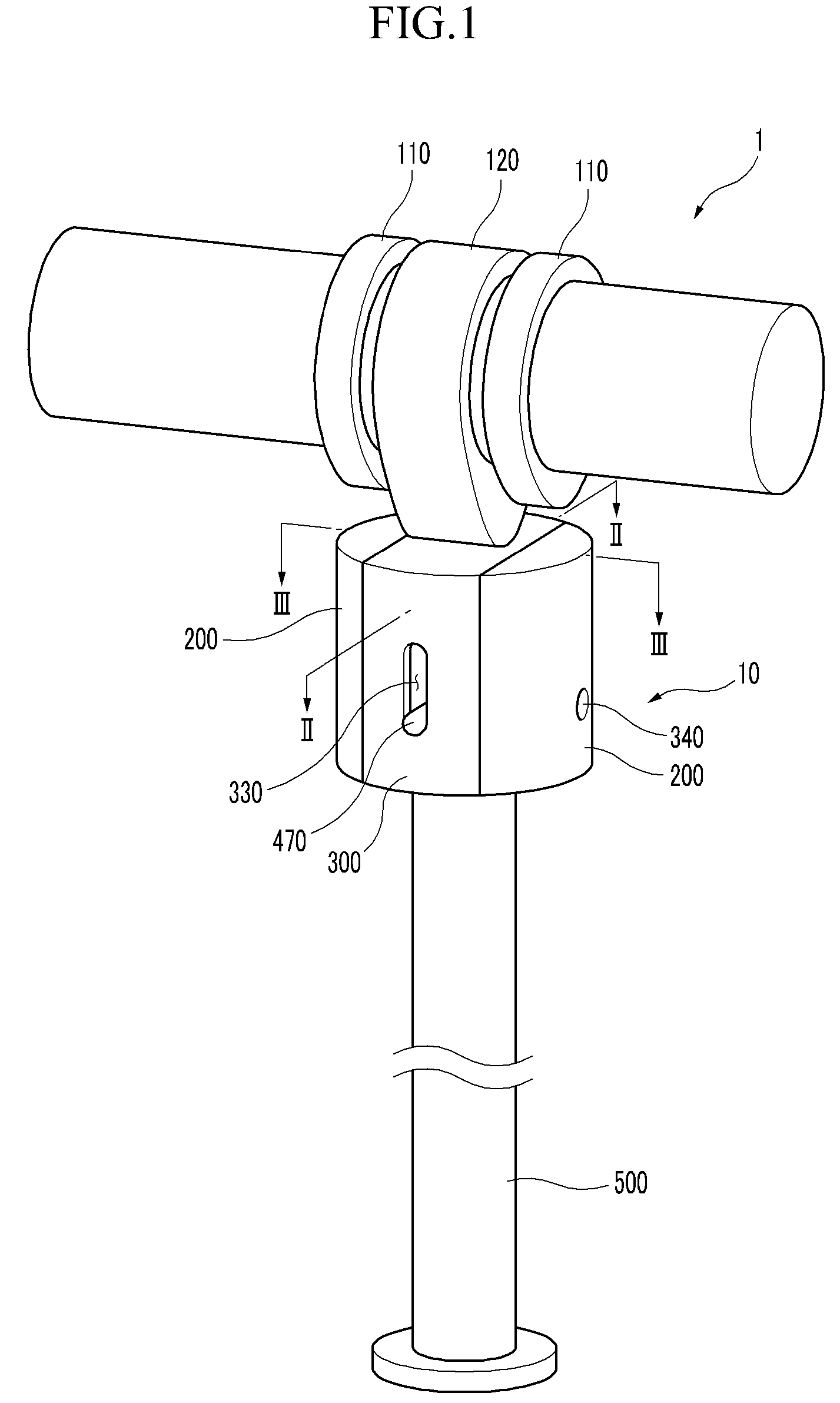

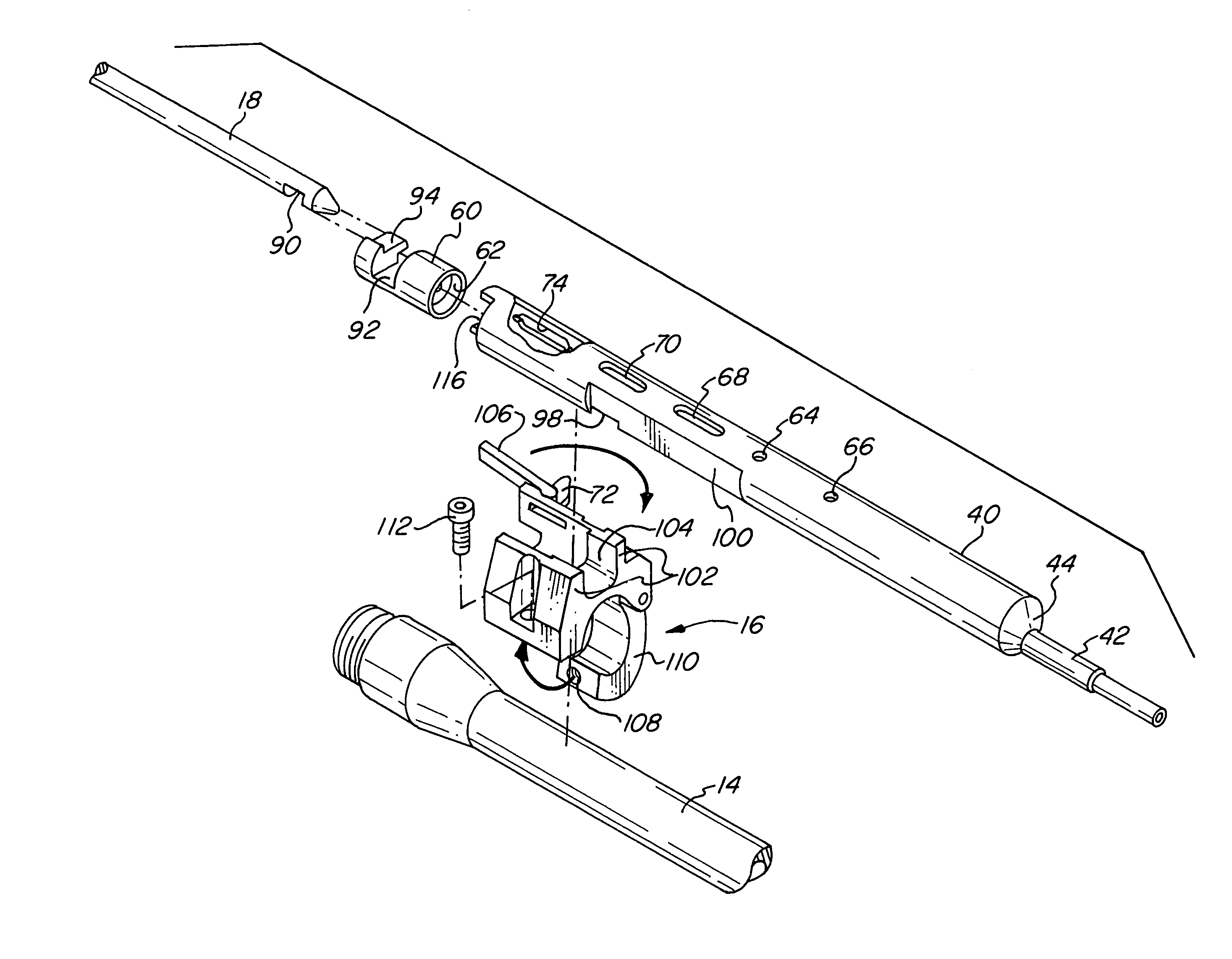

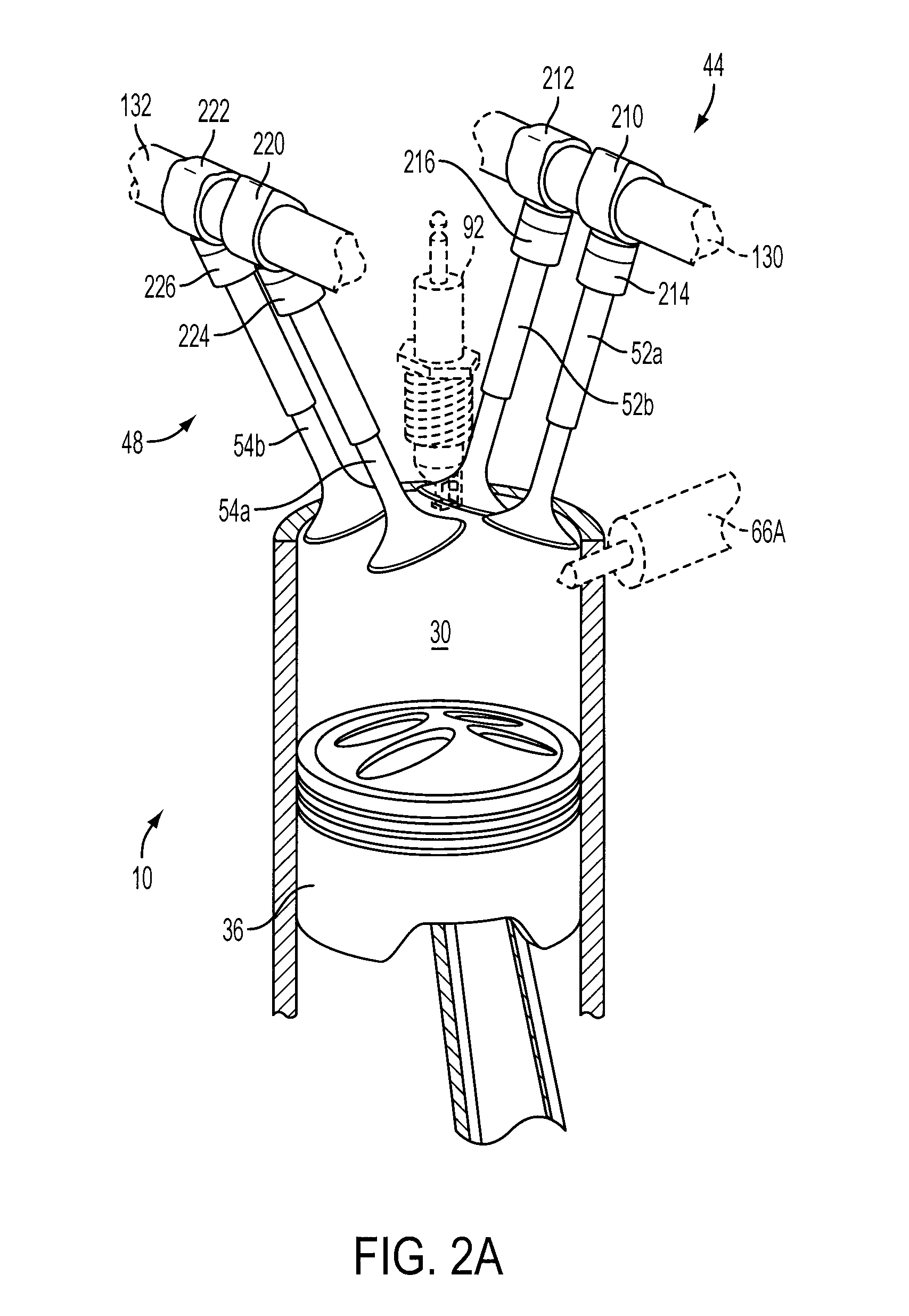

Variable valve lift apparatus

InactiveUS7987826B2Reduce manufacturing costSimple structureValve drivesMachines/enginesHigh liftEngineering

A variable valve lift apparatus according to an exemplary embodiment of the present invention includes a low lift cam, a high lift cam in parallel with the low lift cam, a low lift tappet body that selectively contacts the low lift cam, a high lift tappet body disposed within the low lift tappet body and constantly contacting the high lift cam, a guide portion that is connected with a valve and selectively connects the low lift tappet body and the high lift tappet body, and a lost motion spring that is disposed between the guide portion and the low lift tappet body and supplies restoring force to the low lift tappet body.

Owner:HYUNDAI MOTOR CO LTD

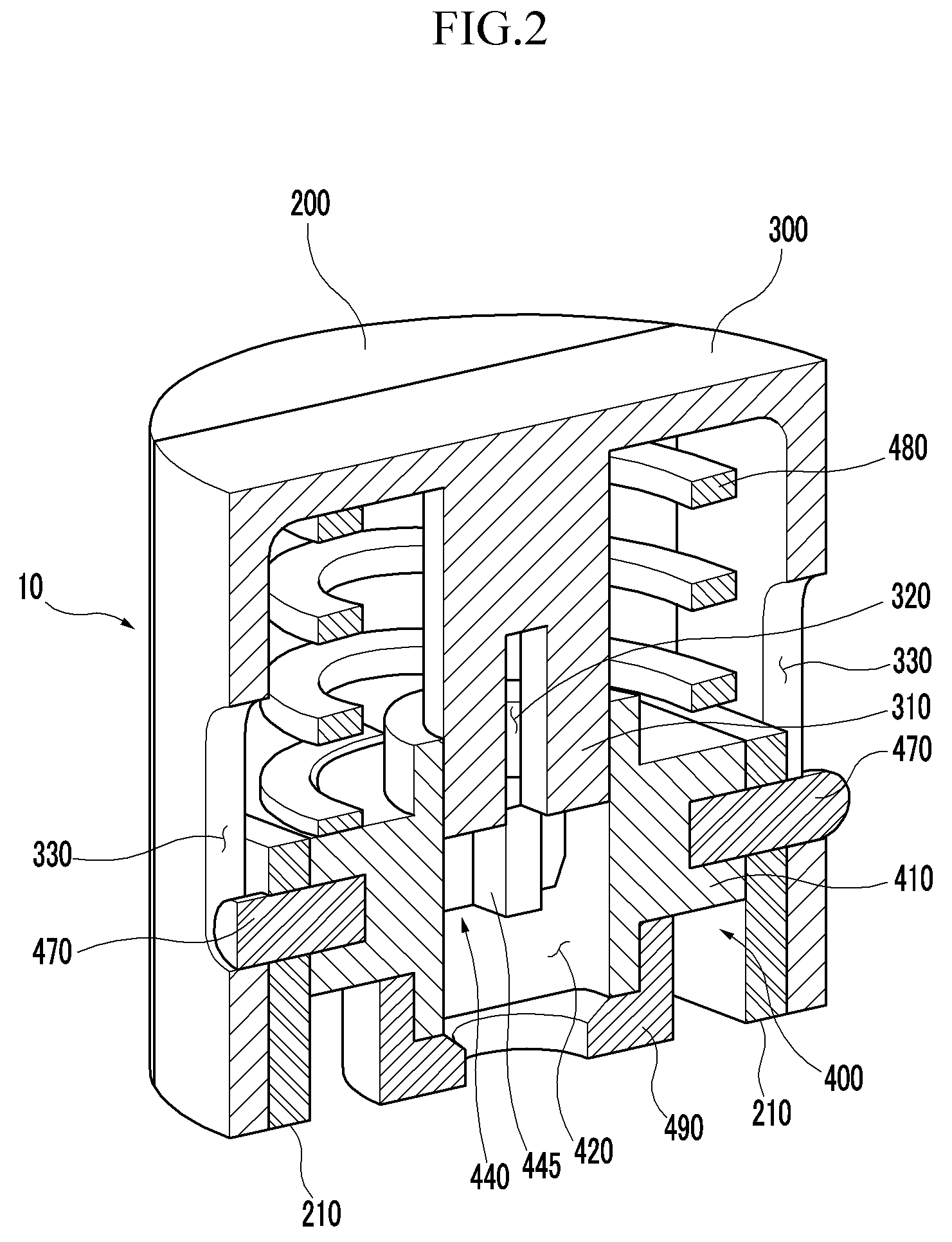

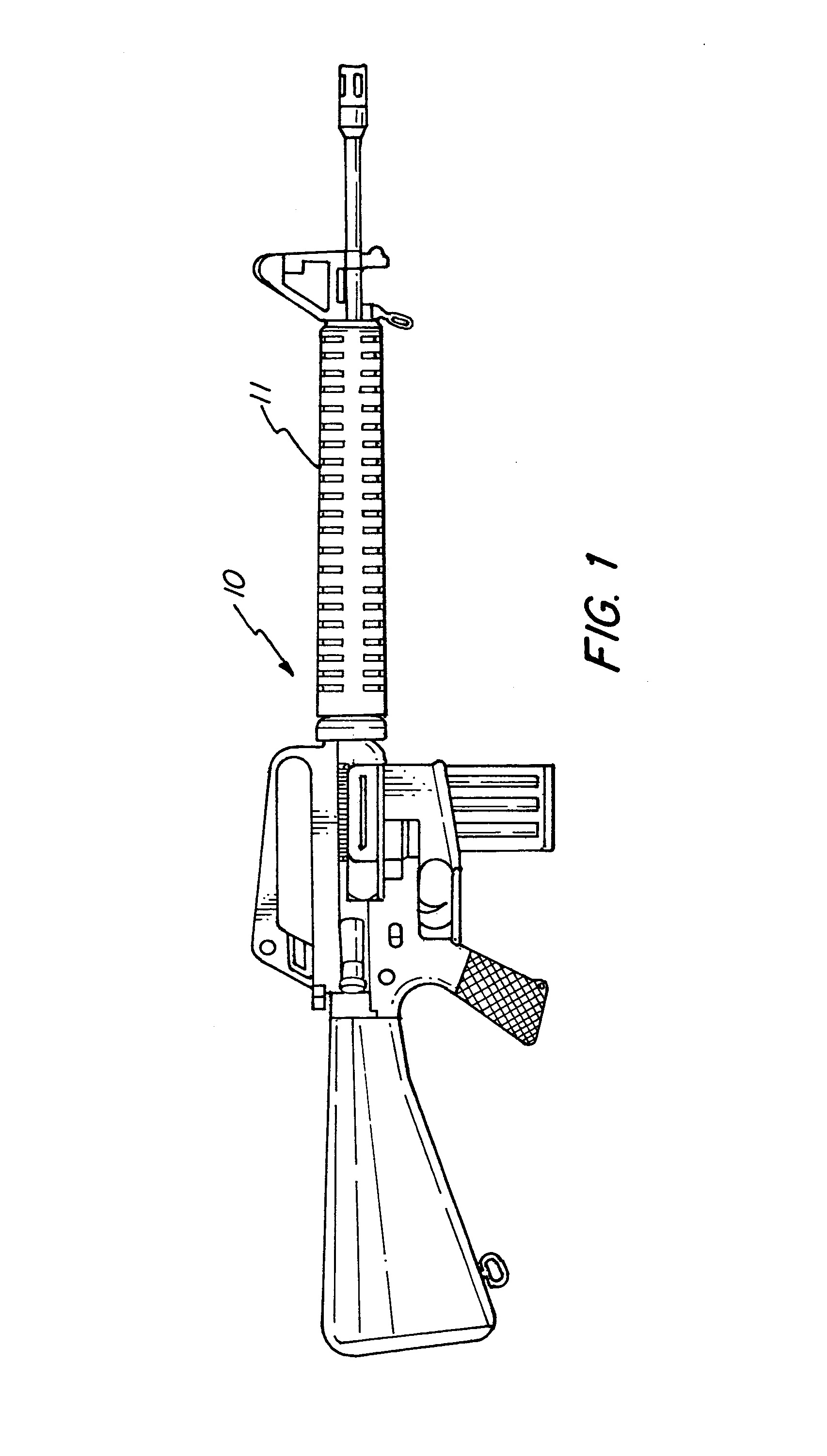

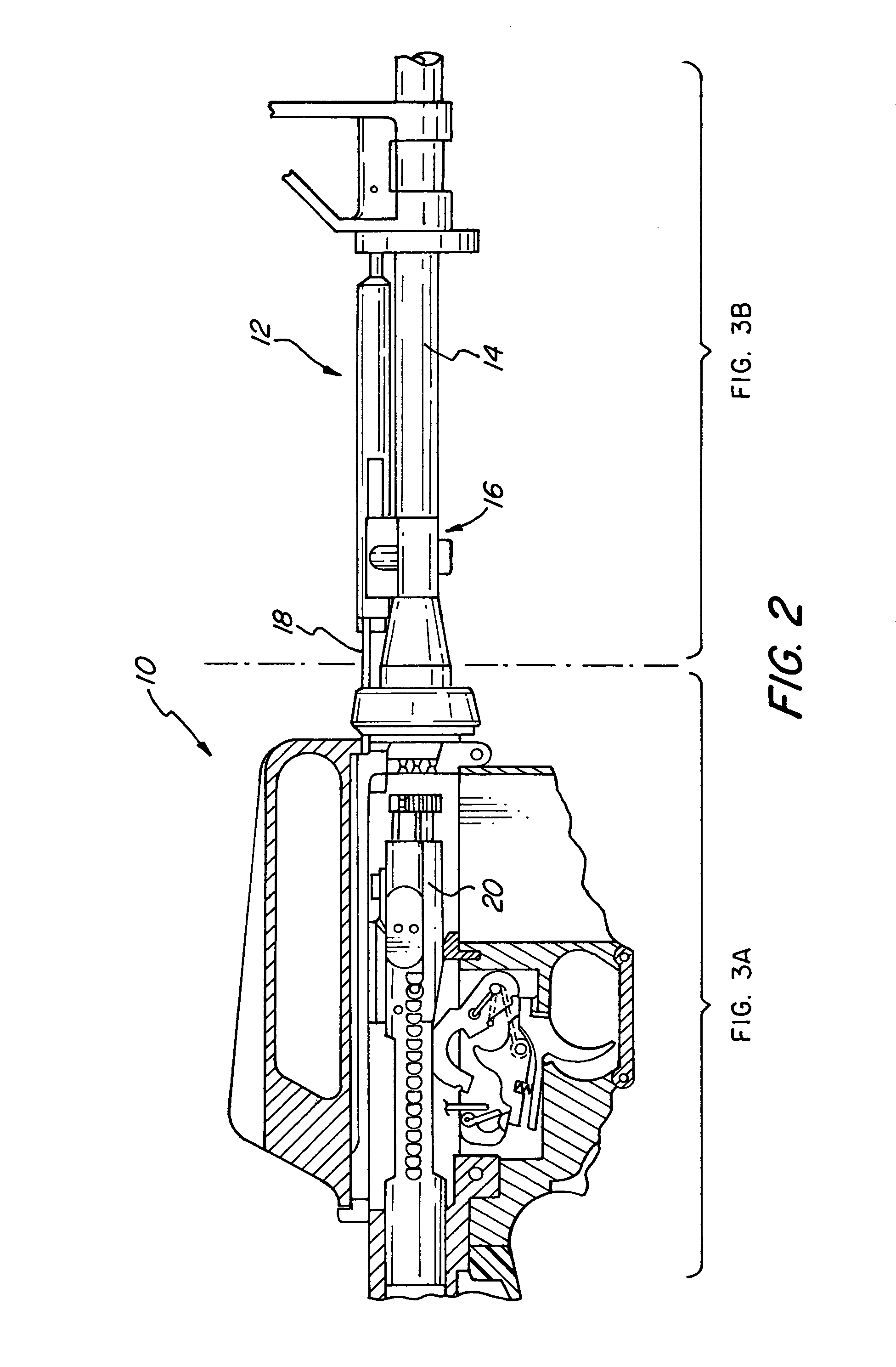

Gas tappet system for a rifle

ActiveUS8181563B1Gentler power strokeReduce impulse forceWeapon assembly/disassemblyCombustionSemi automatic

A gas tappet system for use in an M16, M4, or AR-15 type rifle having a detachable piston eccentrically connected to an operating rod. A piston having a plenum therein and a releasably attached operating rod uses combustion or propellant gasses to move the piston in a long stroke, preventing damaging impulses to the bolt carrier and cycling rounds for automatic or semi-automatic fire. The operating rod, piston, cylinder, and mounting clamp permit easy installation on the rifle without any modification and can easily be removed for reinstallation of the original direct gas impingement system.

Owner:PETERKEN WILLIAM

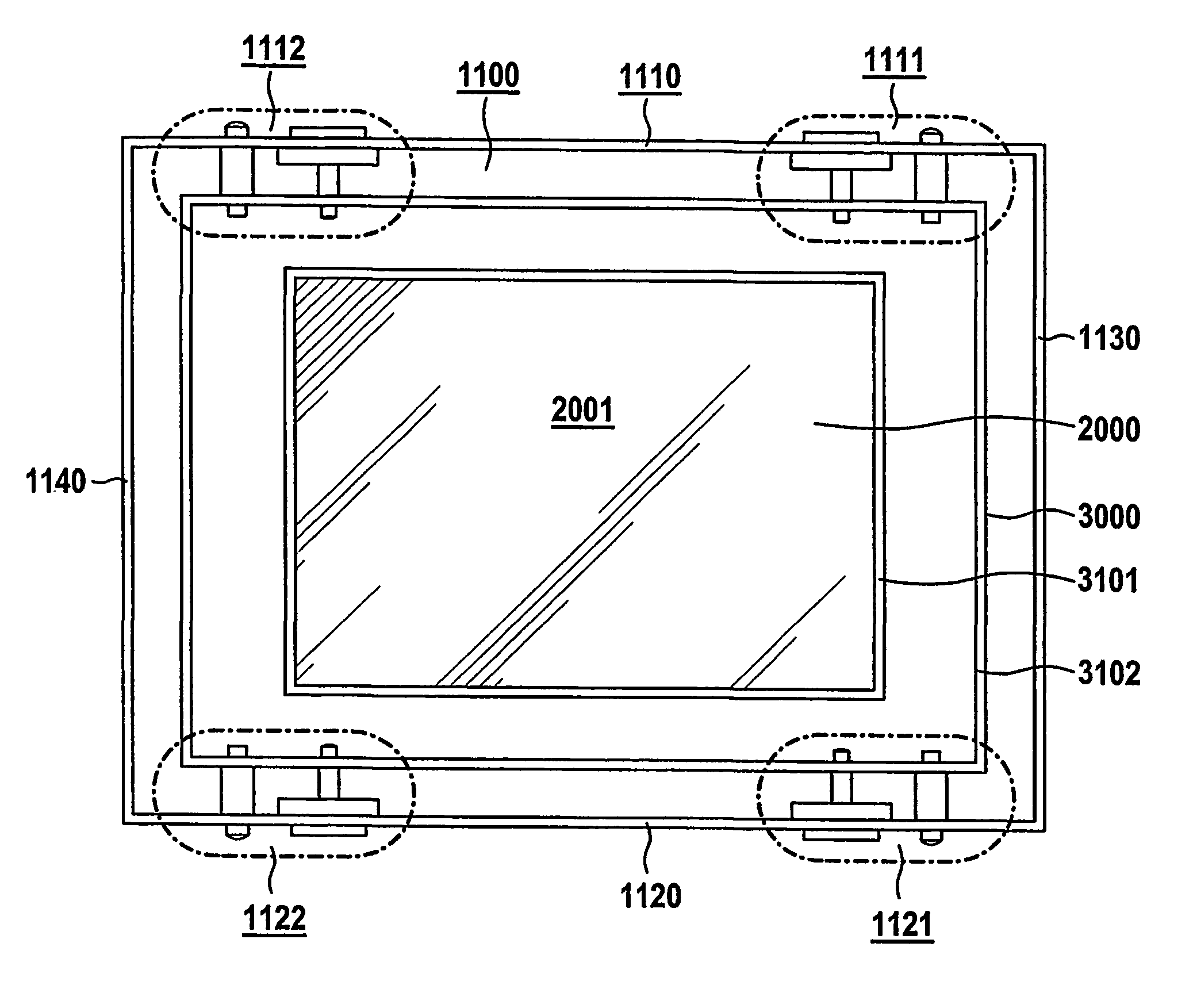

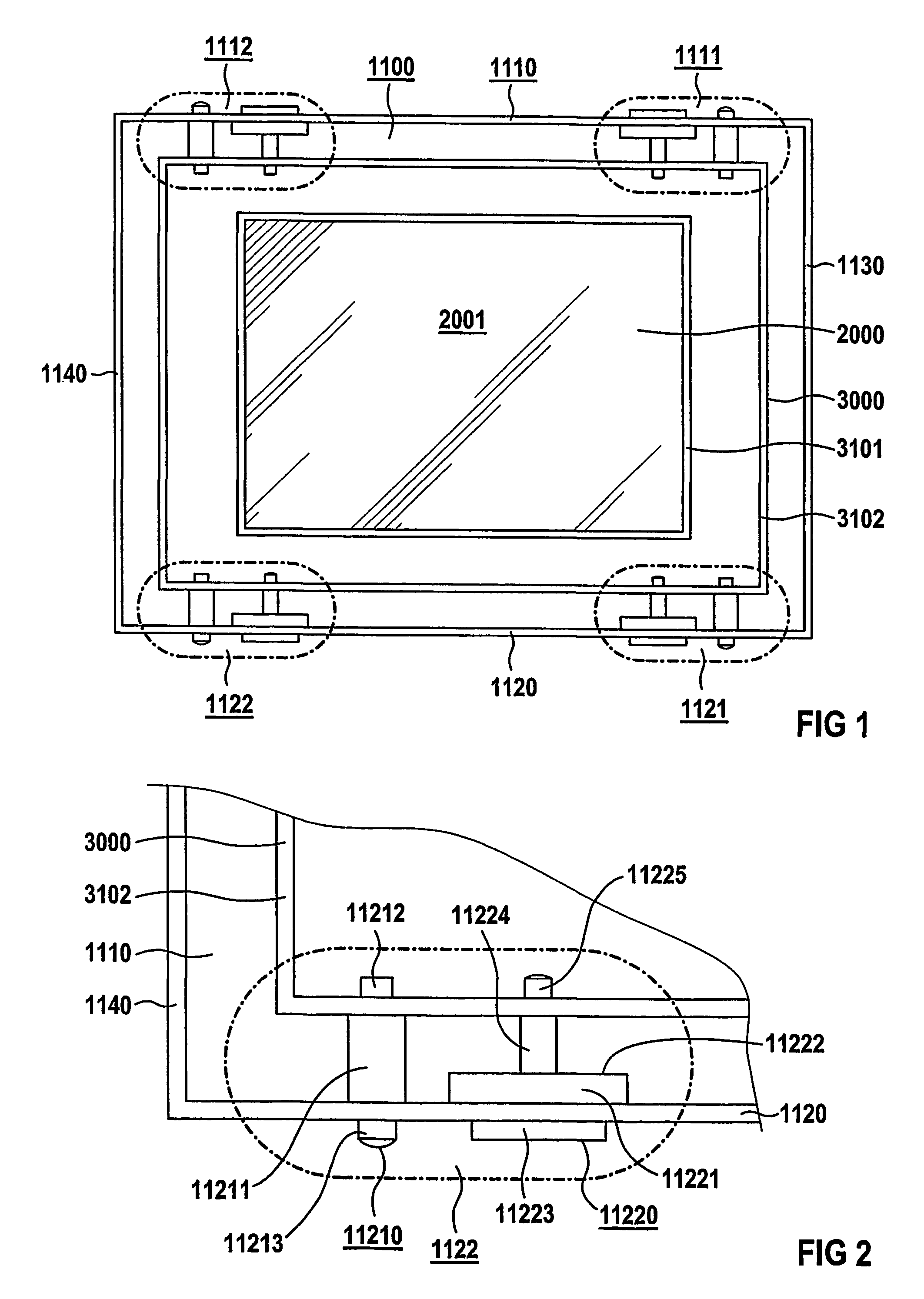

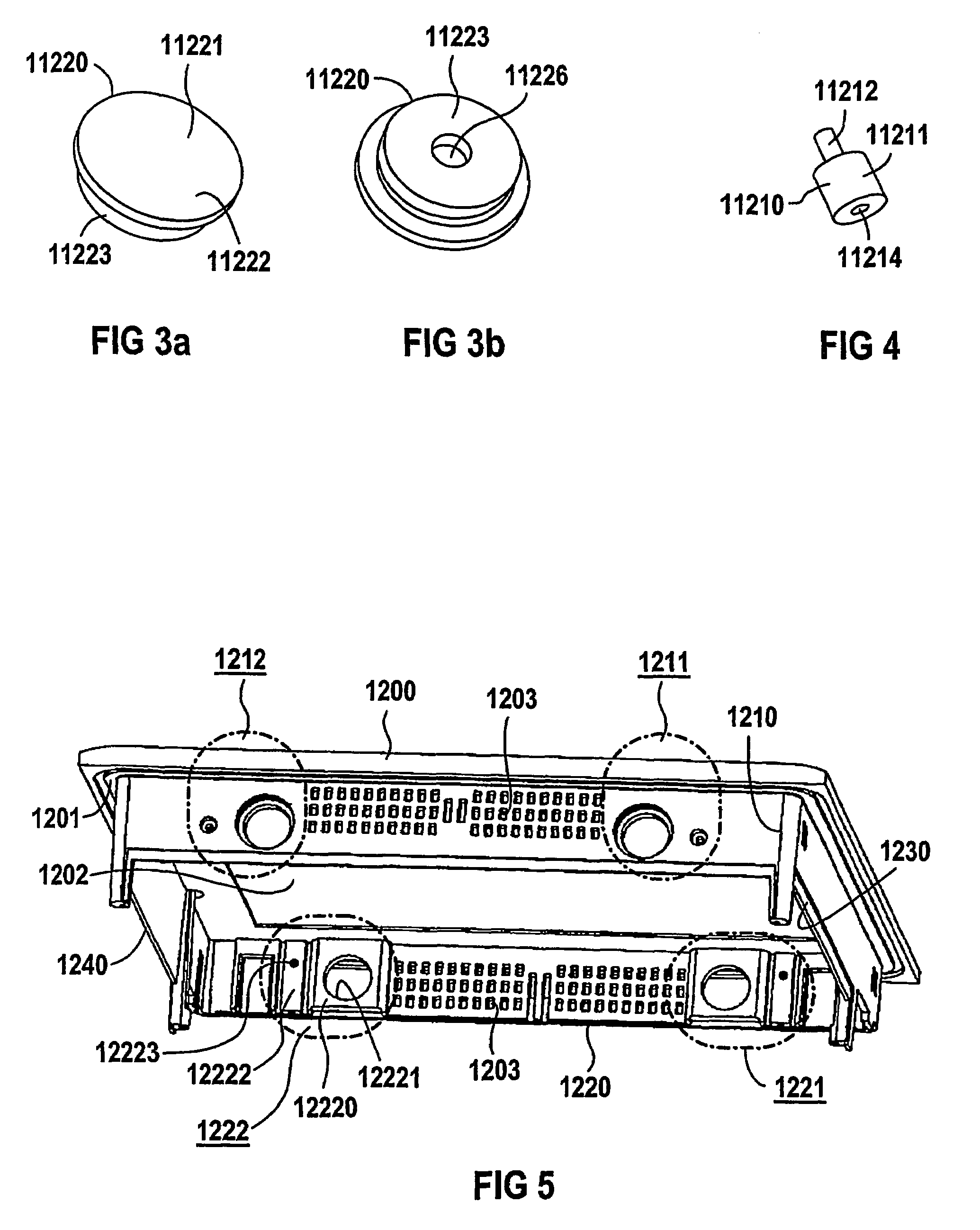

Retaining device for the floating mounting of a flat screen and electronic display device comprising a flat screen and a retaining device

InactiveUS7267313B2Effective shockEffective vibration dampingDigital data processing detailsStands/trestlesDisplay deviceEngineering

A retaining device includes bearing units (1111, 1112, 1121 1122) that float-mount a flat screen (2000) and that are preferably each provided with at least one elastic-positioning element (11210) and a vibration damping element (11220). The elastic-positioning element preferably includes a cylinder-shaped hard rubber spacer element (11211). The vibration-damping element (11220) preferably includes a damper with an annular plate-shaped housing and a gel filling (11221). Vibrations and shocks are introduced substantially centrally into the vibration-damping element via a tappet (11224). The retaining device is advantageously used in an electronic display device to float-mount a flat screen, configured e.g. as an LCD display unit, in combination with a touch screen as a contact-sensitive unit.

Owner:SIEMENS AG

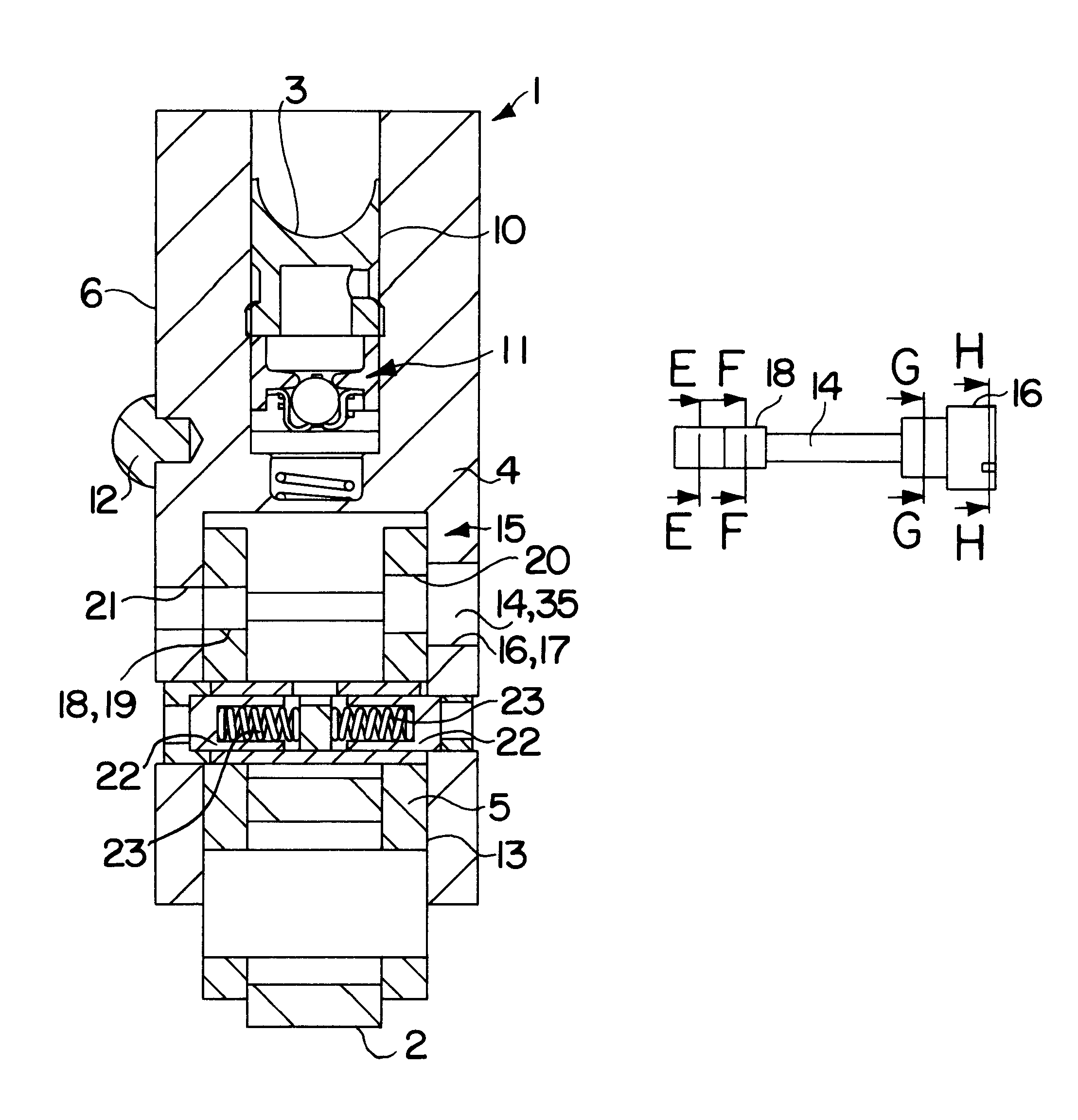

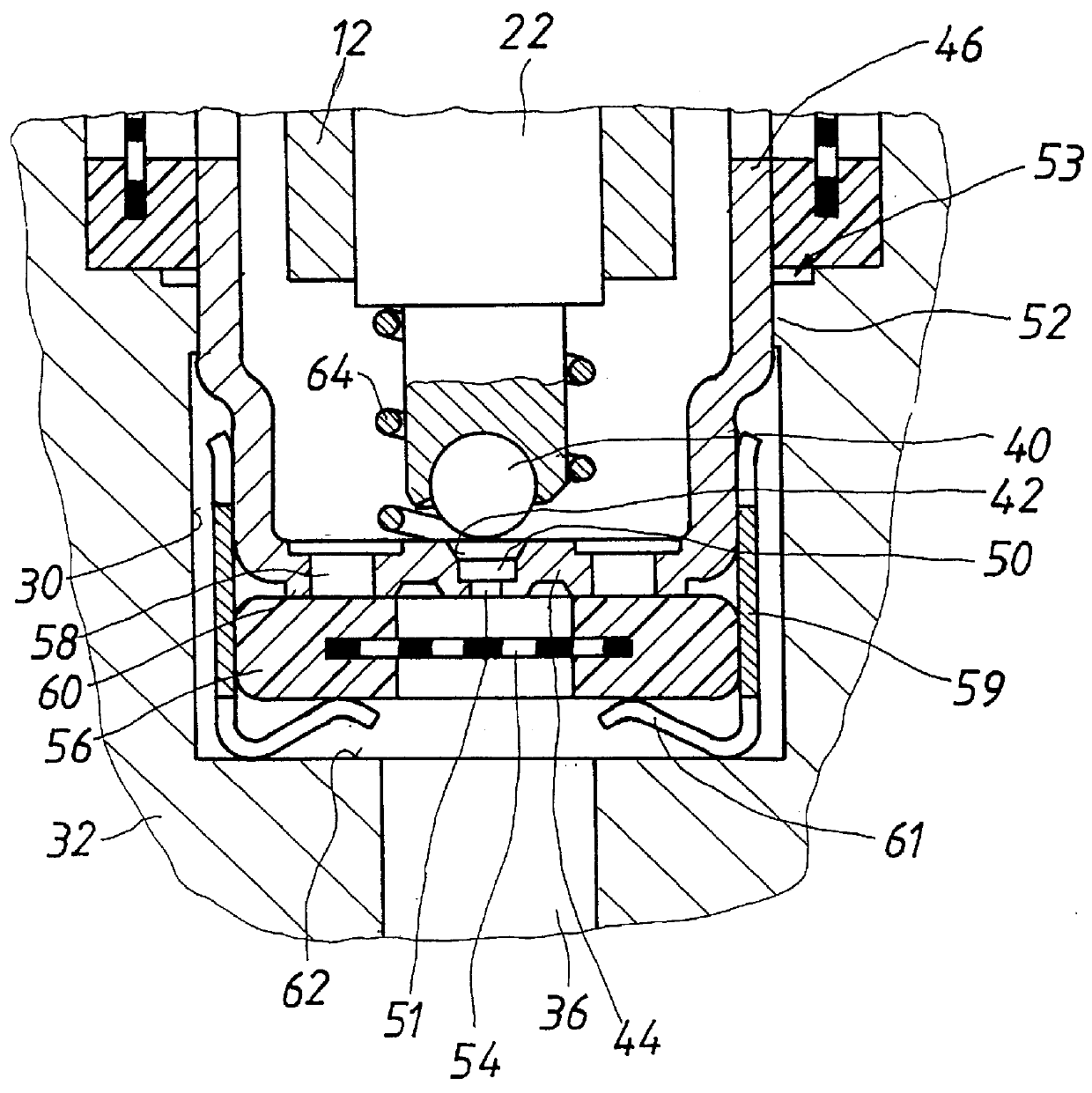

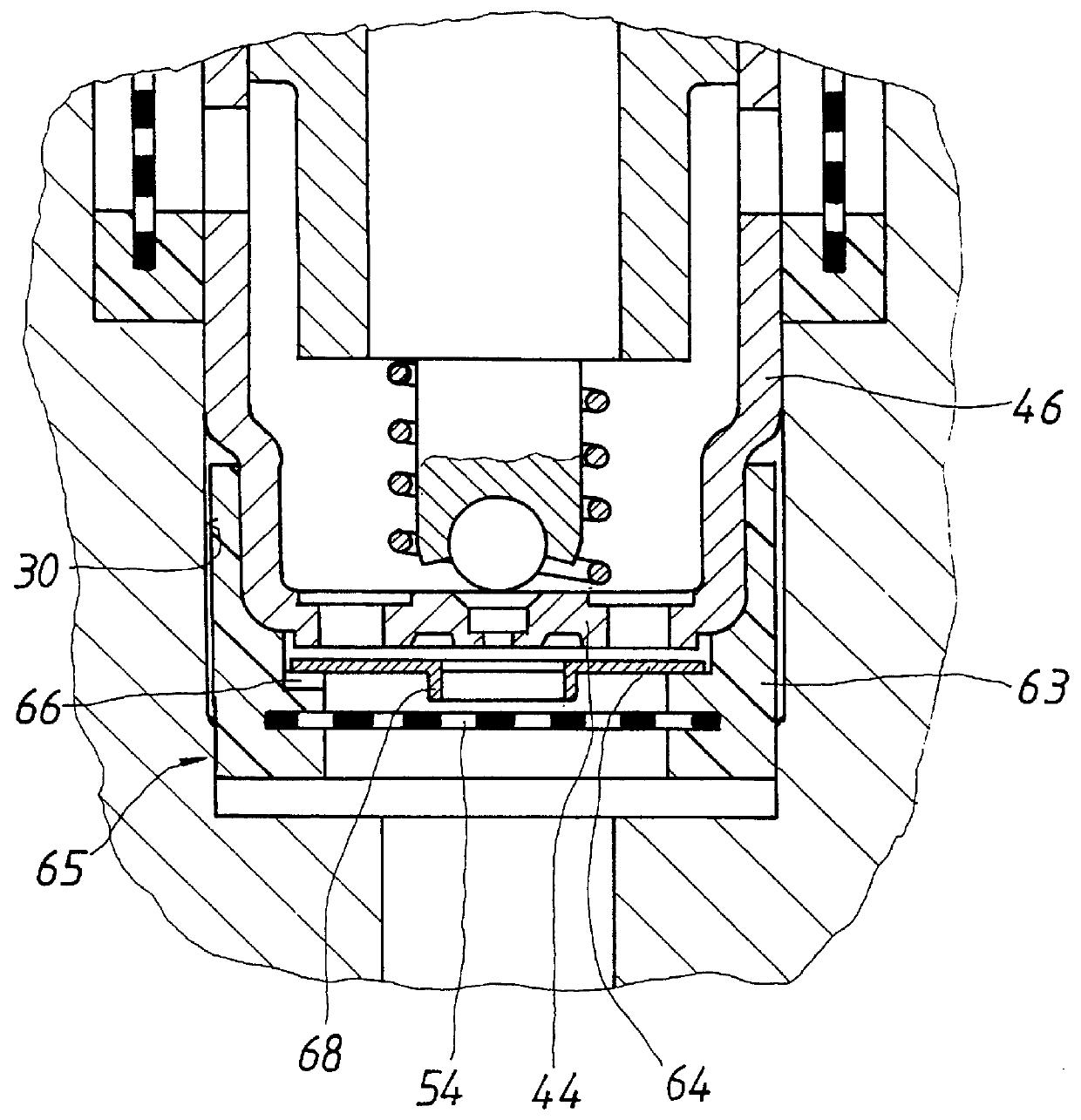

Switchable cam follower

A switchable cam follower (1) for a valve train of an internal combustion engine, which valve train can be actuated indirectly by tappet push rods, the cam follower comprises an outer and an inner section (4,5) end for switching-off the cam follower (1) from the cam lift, the inner section (5) is pivotable relative to the outer section (4) during a valve lift phase of the cam.

Owner:INA WALZLAGER SCHAEFFLER KG

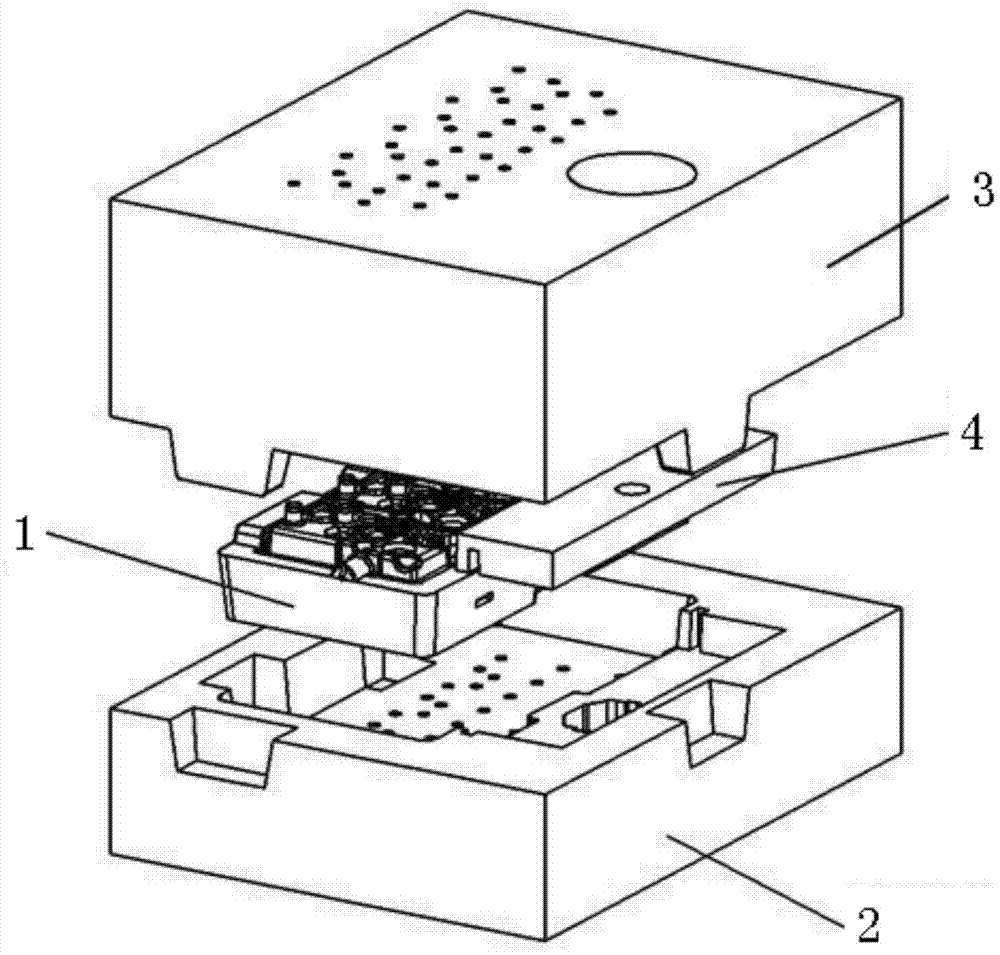

Cast sand core for cylinder cover of diesel engine

ActiveCN104707939AUniform wall thicknessNo input requiredFoundry mouldsFoundry coresInlet channelDiesel engine

The invention discloses a cast sand core for a cylinder cover of a diesel engine. The cast sand core comprises a composite overall sand core, a base plate core, an upper cover plate core and a casting auxiliary core, wherein the composite overall sand core comprises a base plate part, an air inlet channel part, an exhaust channel part, an upper water sleeve part, a lower water sleeve part, a tappet hole part and an exhaust system channel; the exhaust system channel is formed in the composite overall sand core; a sand removal window is formed in the bottom of the composite overall sand core; the base plate core comprises a core assembly frame position, a core assembly abdicating position, a sand core exhaust channel and a casting position; the core assembly frame position is used for accommodating the composite overall sand core; the sand core exhaust channel is communicated with the exhaust system channel; a first sprue is formed in the upper cover plate core; and the casting auxiliary core comprises a second sprue and a first cross gate. According to a casting method for the cylinder cover of the diesel engine by employing the composite overall sand core, the cylinder cover with an accurate shape and a uniform wall thickness can be obtained; and according to the cylinder cover of the diesel engine, the floating core phenomenon in casting of the air inlet cannel, the exhaust channel, the upper water sleeve and the lower water sleeve is avoided, a cylinder cover water cavity is free of a joint surface, a product casting is free of a water sleeve burr, and the water cavity is high in cleanliness.

Owner:GUANGXI YUCHAI MASCH CO LTD

Hand-held fastener driver

ActiveUS20100089963A1Easy constructionAvoid disadvantagesStapling toolsNailing toolsLocking mechanismHand held

Owner:HILTI AG

Valve with end position switching

InactiveUS20060272712A1Avoid destructionImprove sealingOperating means/releasing devices for valvesPipeline systemsEngineeringTappet

For detecting closing or opening of a valve activated preferably by a solenoid actuator, a switch activated by a tappet spring mounted on an armature of the actuator is provided. A stop and an associated surface limit the stroke of the tappet with reference to the switch. Preferably, a valve closing element opens the gas flow only when the armature has already executed a part of its opening stroke. The trigger point of the switch is set in this first part of the opening stroke of the armature, in which the valve closing element has not yet opened. The stroke limiting of the tappet for activating the switch is also preferably set in this region of the opening stroke of the armature. However, the stop limits the stroke of the tappet independent of the opening stroke size of the armature, so that the same switch can be used for different valves with different nominal diameters and opening strokes.

Owner:KARL DUNGS

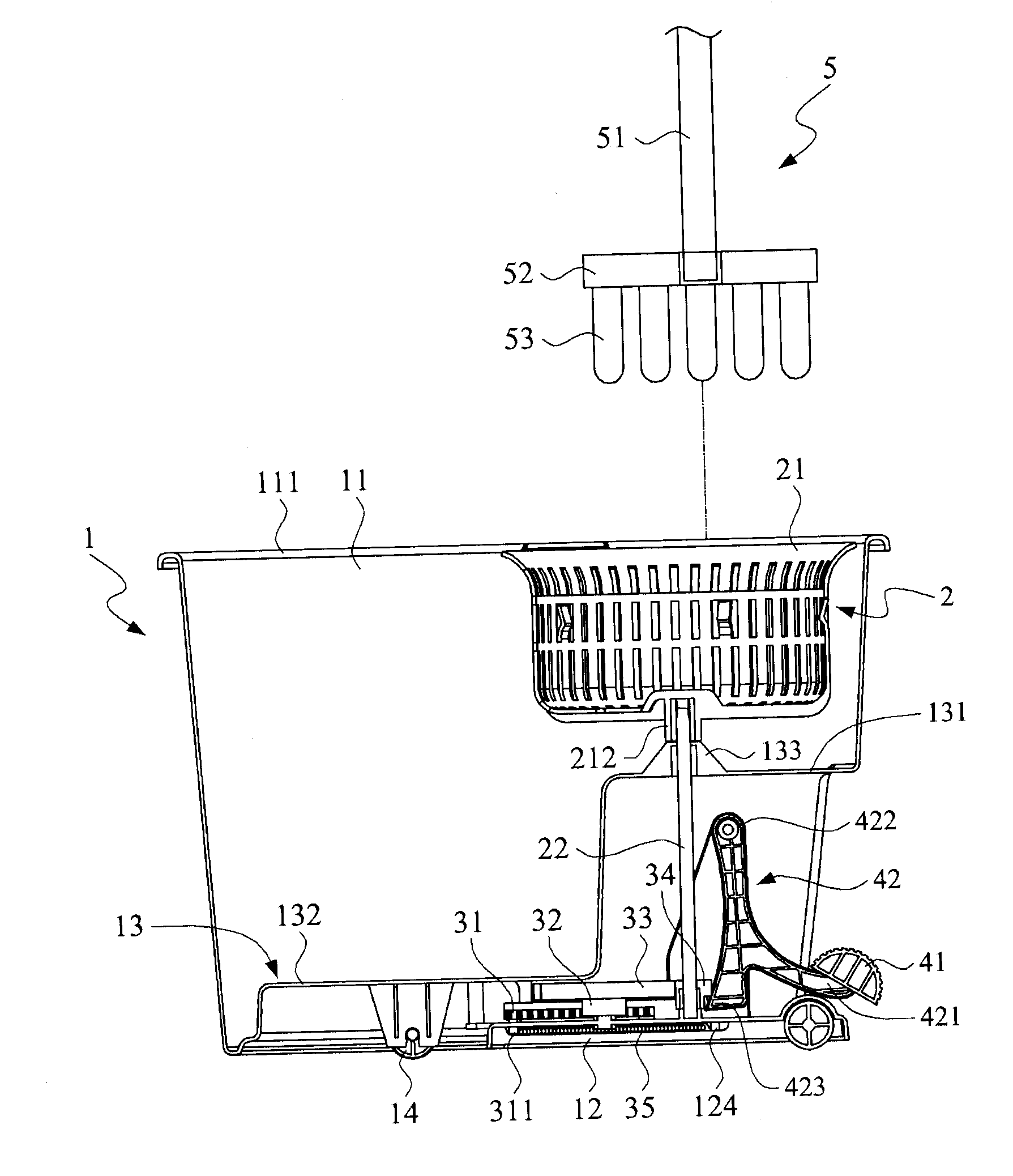

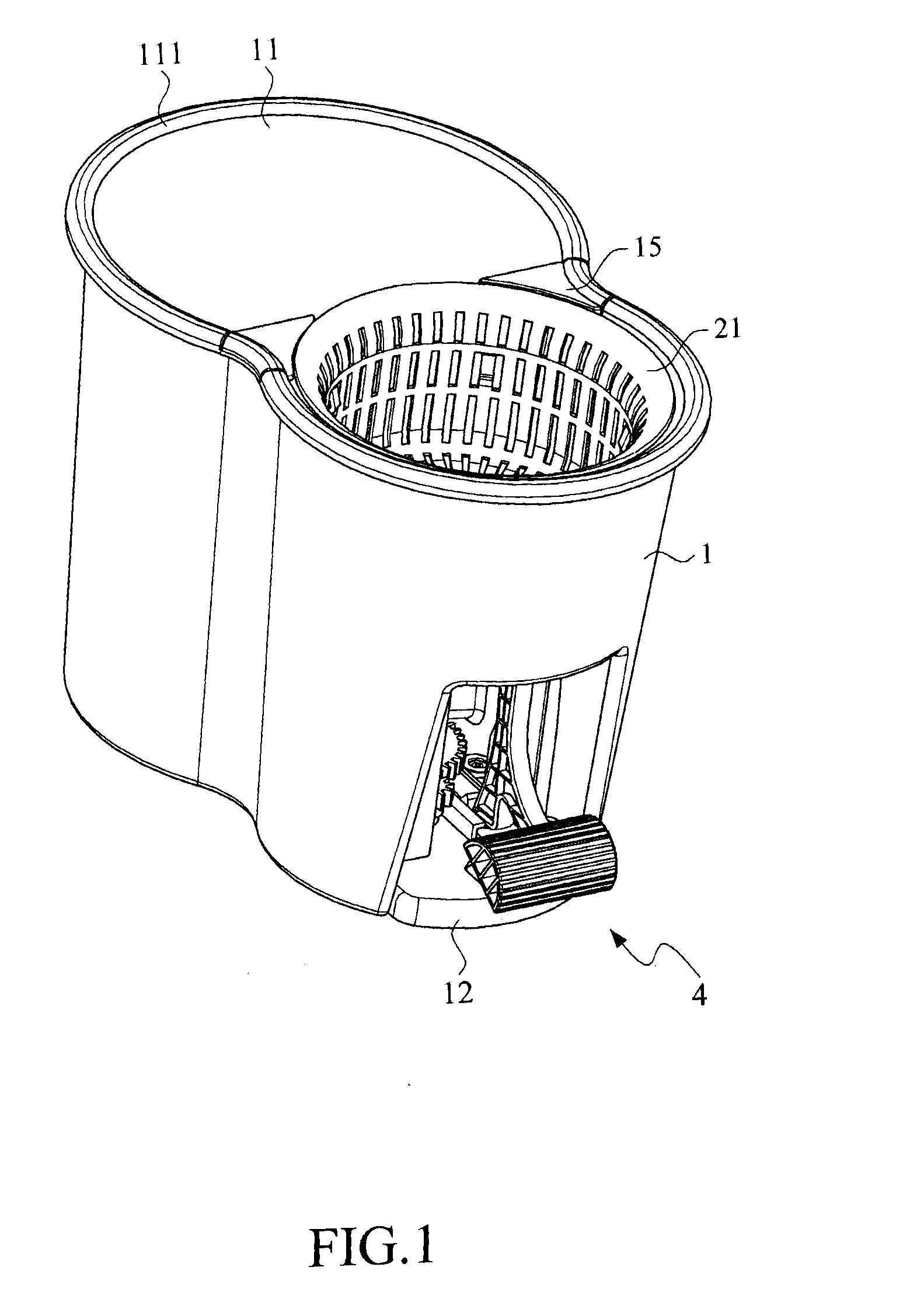

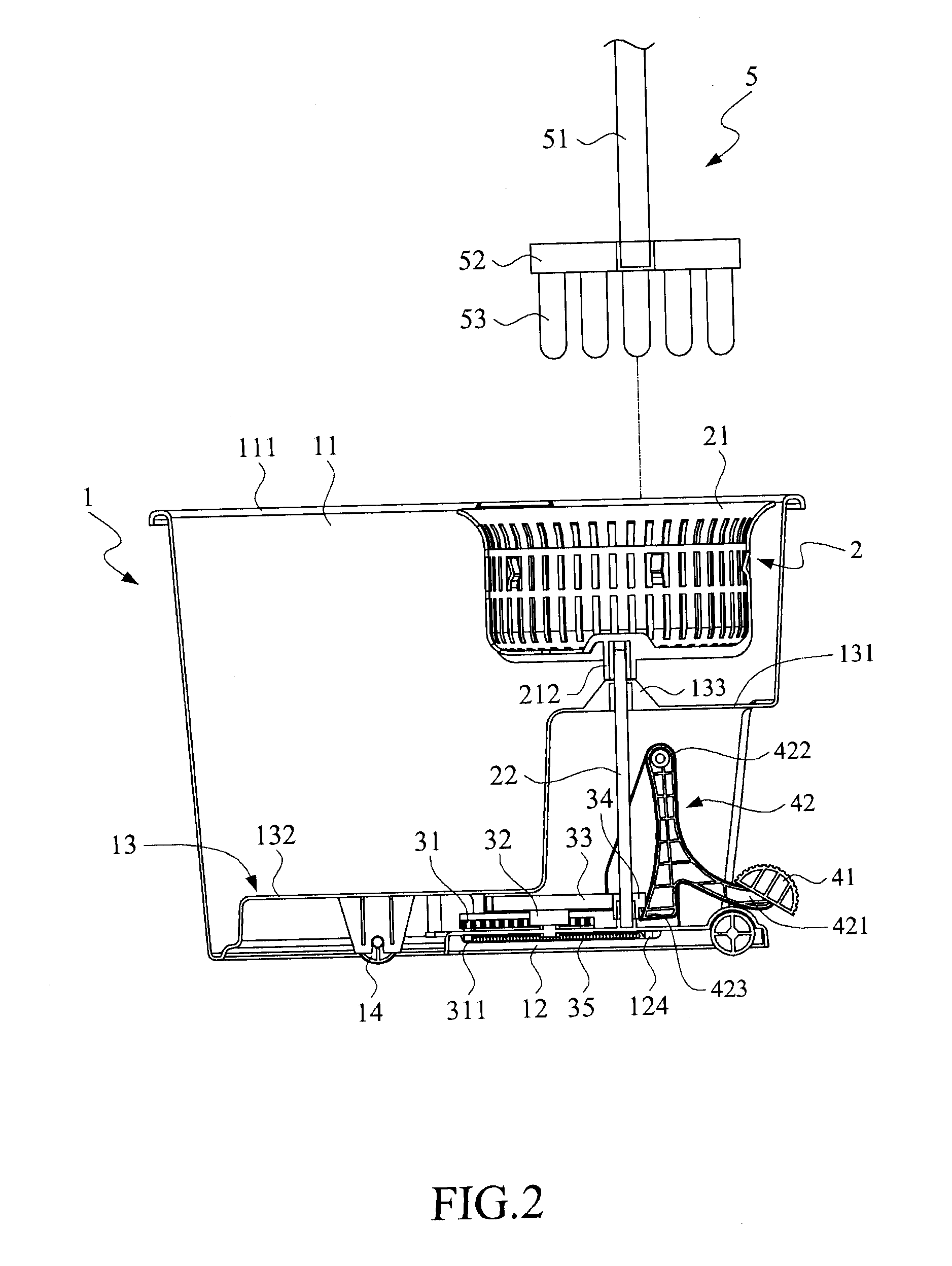

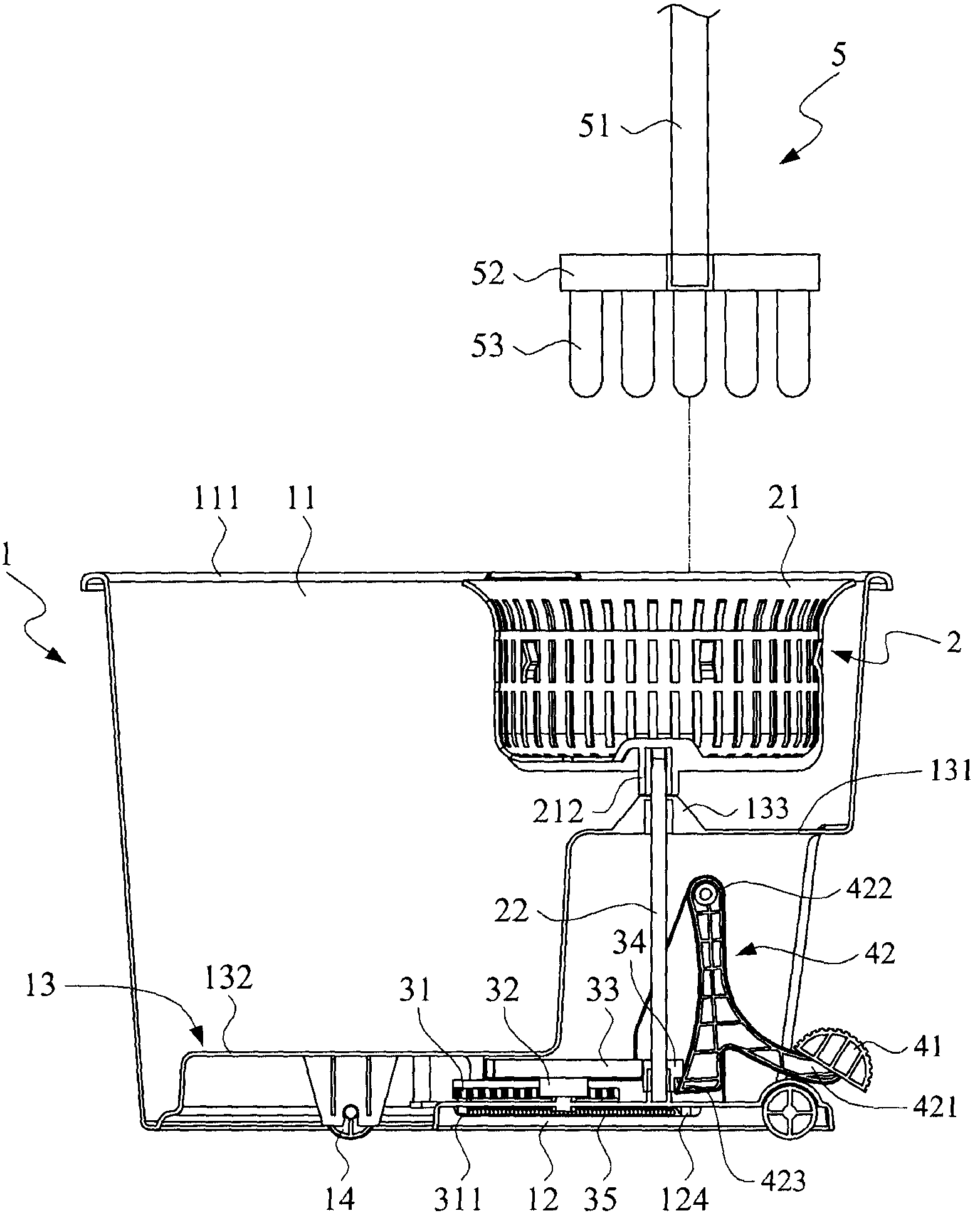

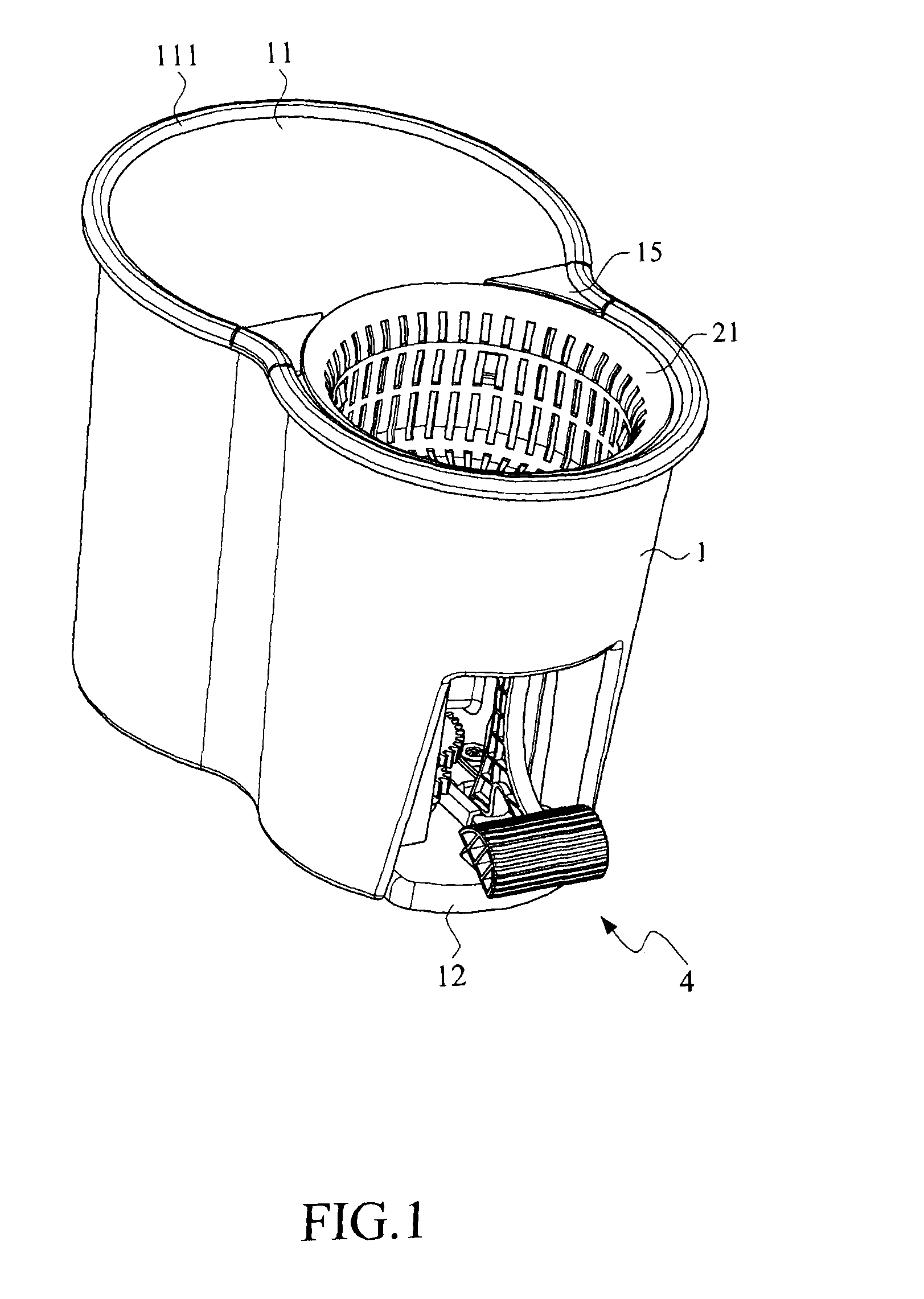

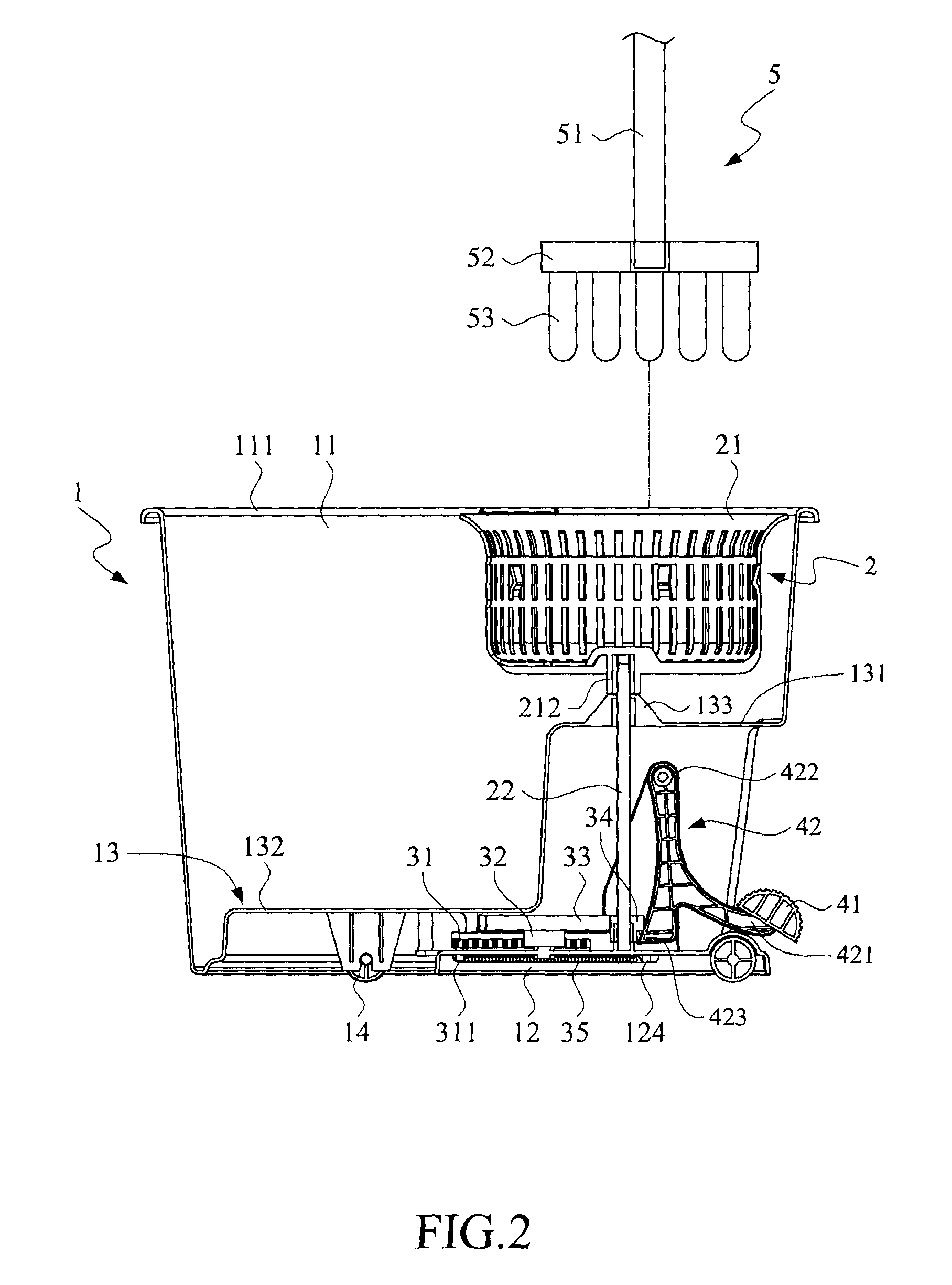

Dehydrating device

InactiveUS20090151399A1Fast spinEasily handling tappet unitWringing machinesCarpet cleanersDrive shaftTappet

A dehydrating device comprises a tappet unit, a transmission unit and a rotation unit, wherein the rotation unit comprises a bearing member and a transmission shaft. A aquiferous member is disposed in the bearing member, and then the operation of the tappet unit is beginning. The tappet unit then mechanically drives the transmission unit and the rotation unit so as to dewater the aquiferous member.

Owner:DIKAI INT ENTERPRISE

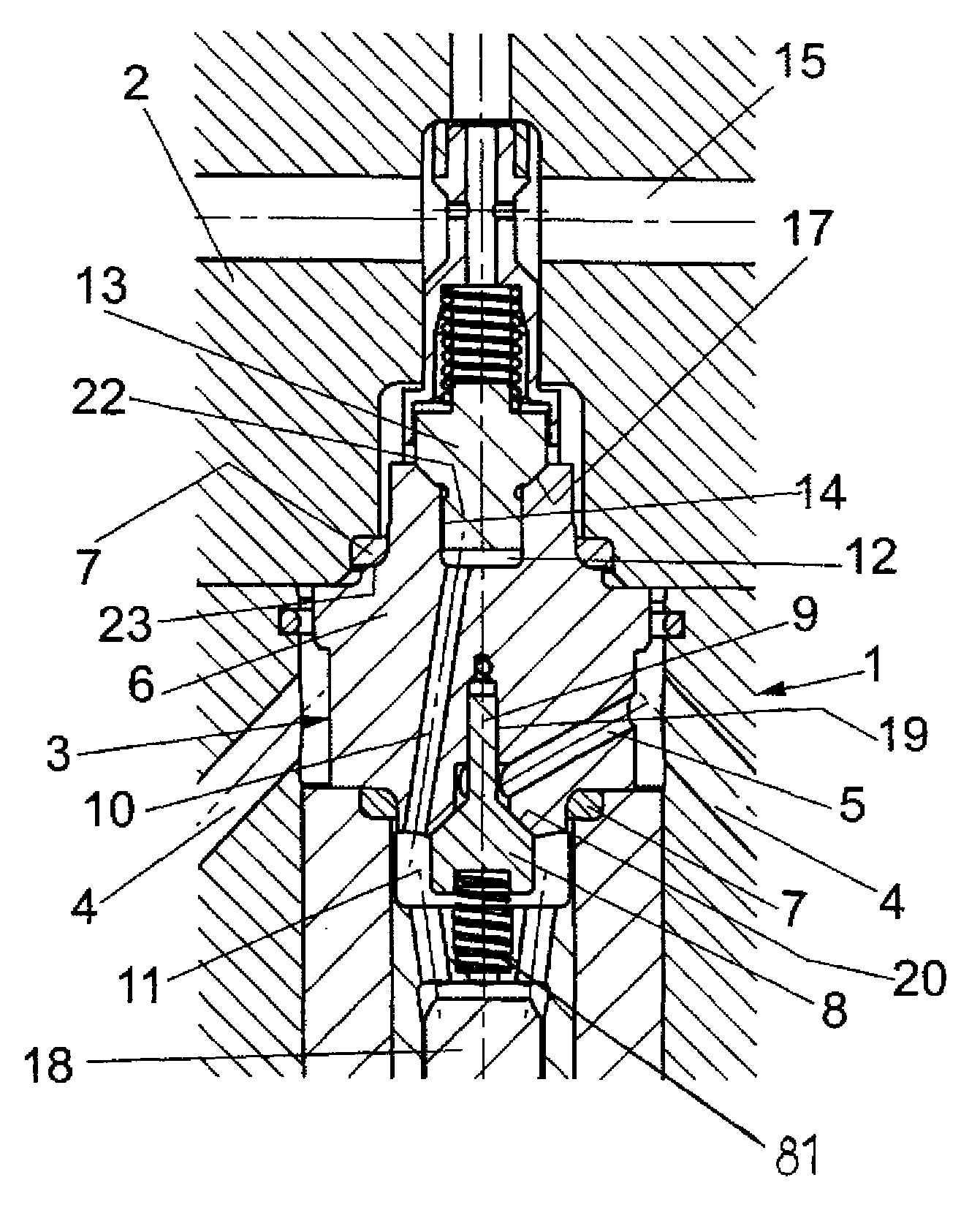

High-pressure valve assembly

ActiveUS8240634B2Stress minimizationImprove versatilityOperating means/releasing devices for valvesPositive displacement pump componentsEngineeringHigh pressure

A high-pressure valve assembly includes a flange defining an axis. Projecting into the flange is a valve body which is sealed against the flange by a static ring seal. Provided on one side of the valve body is a spring-loaded closure member which is supported for movement in a direction of the axis to form a suction valve, and on another side of the valve body in opposition to the one side is a spring-loaded tappet which is supported for movement in the direction of the axis to form a pressure valve. A channel connects the suction valve with the pressure valve and has one end porting into a pressure chamber of the valve body adjacent to the pressure valve. The pressure chamber extends in axial direction of the tappet and is sized to extend substantially above a bottom edge of the ring seal.

Owner:HAMMELMANN MASCHFAB

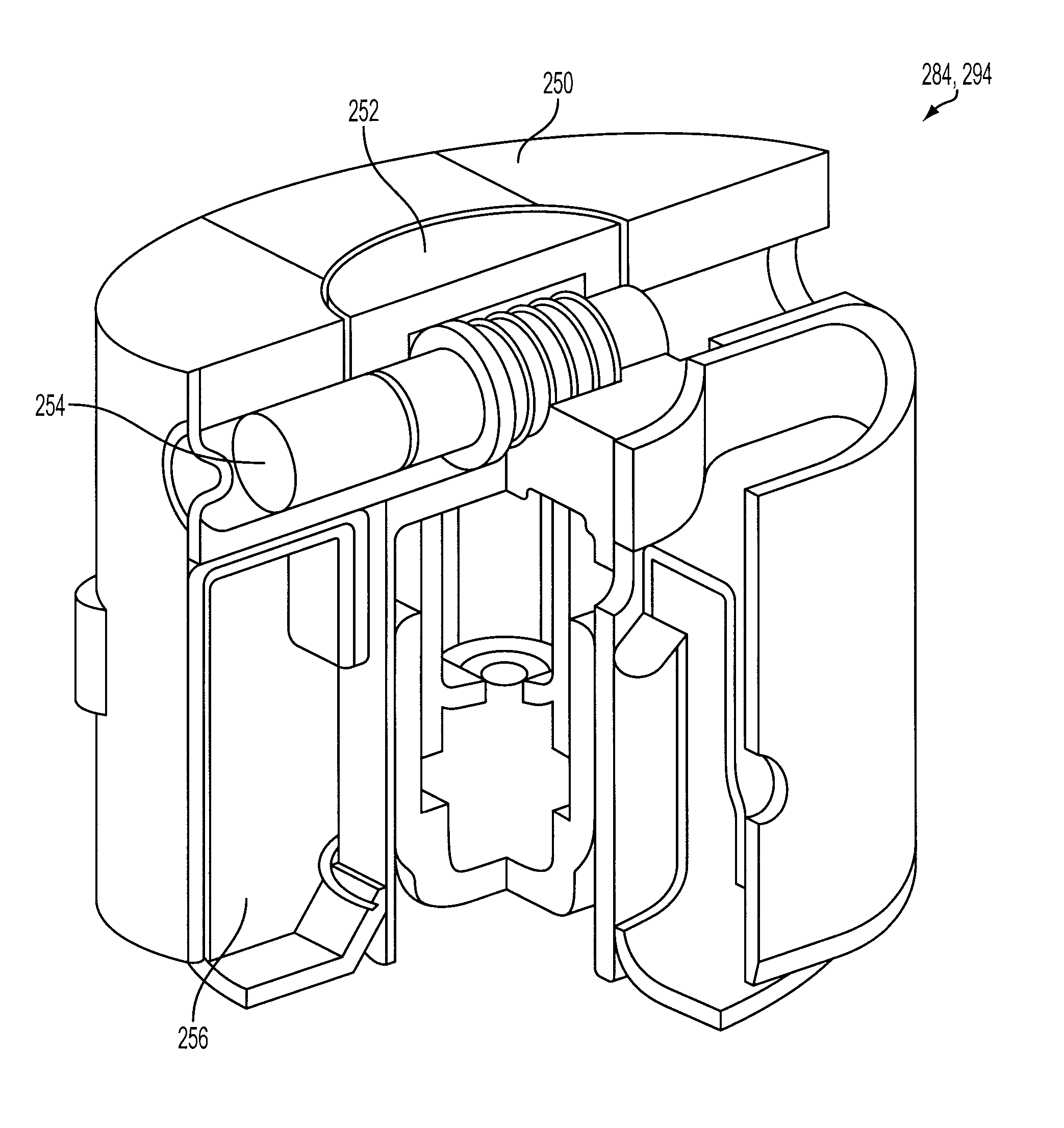

System and method for adaptive control of variable valve lift tappet switching

ActiveUS20070240653A1Reduce torque fluctuationReducing emission spikeValve arrangementsElectrical controlEngineeringCylinder Valve

A method of controlling cylinder valve switching between a first valve condition and a second valve condition for transitioning between combustion modes of an engine comprises adjusting timing of a signal to switch between said valve conditions in response to information from a combustion sensor, wherein said combustion modes include spark ignition and homogeneous compression ignition.

Owner:FORD GLOBAL TECH LLC

Magnet valve with integrated check valve

InactiveUS6084493AMade especially economicallyReduction in the wheel brake pressure at the end of the braking operation is speeded upOperating means/releasing devices for valvesApplication and release valvesSolenoid valveEngineering

PCT No. PCT / DE97 / 02698 Sec. 371 Date Sep. 13, 1999 Sec. 102(e) Date Sep. 13, 1999 PCT Filed Nov. 17, 1997 PCT Pub. No. WO98 / 40258 PCT Pub. Date Sep. 17, 1998A magnet valve having a rod-like base body for insertion into a stepped bore of a hydraulic block through which a valve tappet reaches a valve closing ball and on whose face end remote to an armature a cup-shaped sleeve is mounted. A valve seat of the magnet valve is embodied on the bottom of the cup-shaped sleeve. In order to make a large flow cross section available for a flow through the magnet valve in one flow direction, a check valve is integrated with the magnet valve and that to this end flow openings are disposed on an imaginary circle in the bottom of the cup-shaped sleeve. The openings are closed by an annular valve closing body of the check valve. The magnet valve of the invention is intended particularly for use as a brake pressure buildup valve for a wheel brake cylinder of a slip-controlled vehicle brake system.

Owner:ROBERT BOSCH GMBH

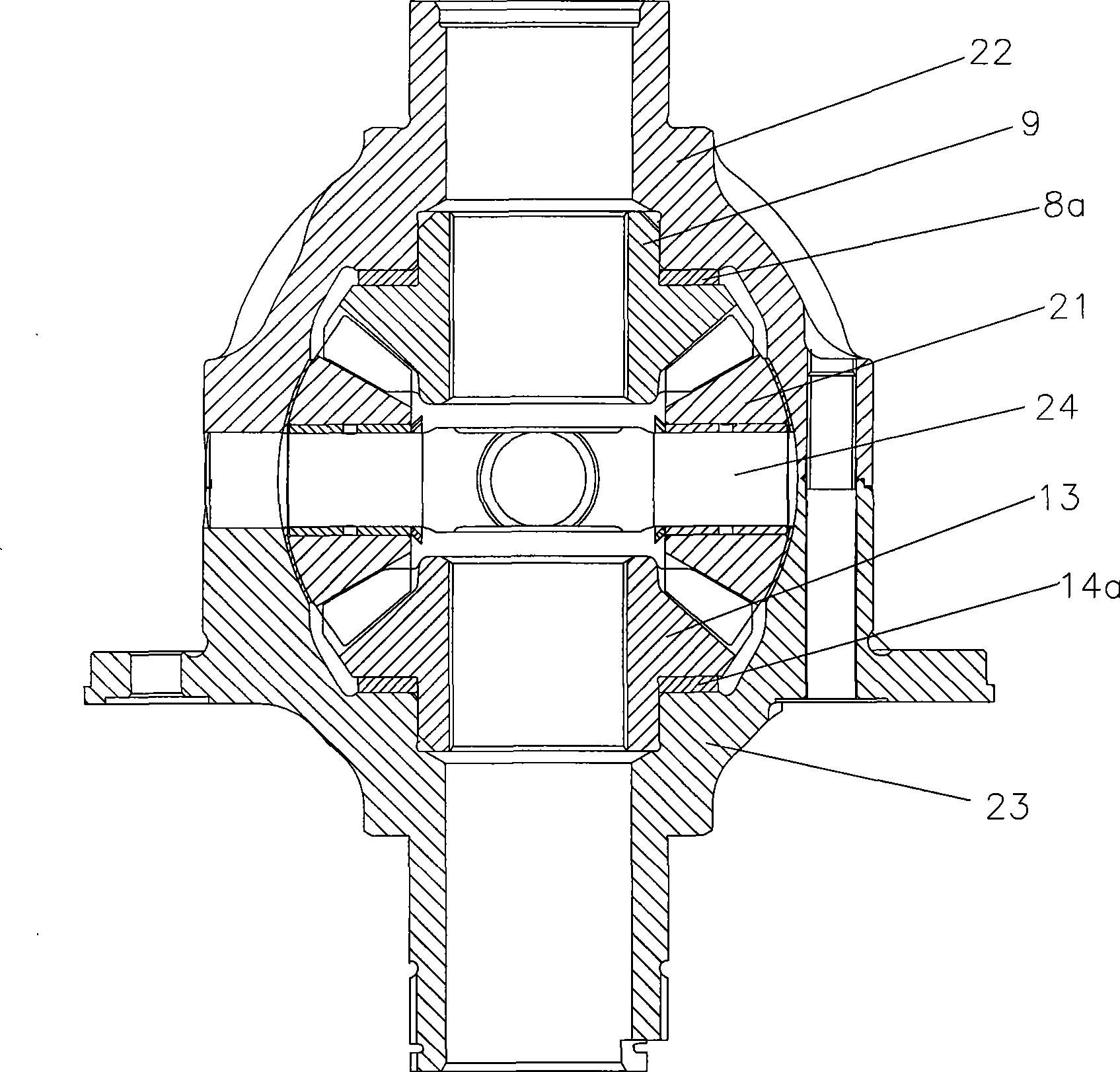

Vacuum valve

InactiveUS7413162B2Enhanced closing forceSimple wayOperating means/releasing devices for valvesSlide valveInterior spaceAxial displacement

A vacuum valve comprises a valve housing which has an inlet opening and an outlet opening, a valve disk which is located in the interior space of the valve housing and which is arranged at a carrying arm that is rigidly connected to a shaft which, for purposes of opening and closing the vacuum valve, is rotatable around its longitudinal axis and displaceable in axial direction, and a driving device for opening and closing the vacuum valve. The driving device comprises a rotary drive for rotating the shaft. The driving device further comprises a driving piston which is arranged in an inner cavity of the valve disk and which has, at least over portions of its circumference, a radial extension which is larger than the outlet opening with respect to the center longitudinal axis of the outlet opening and at which tappets are arranged on the side facing the outlet opening. The tappets are guided out of the inner cavity of the valve disk and are supported in the closed position of the valve disk at the valve housing in the area next to the outlet opening and press the valve disk against the valve seat and can be lifted from the valve housing for displacing the valve disk from its closed position into its intermediate position by means of a displacement of the driving piston. At least one spring element displaces the valve disk into its intermediate position by an axial displacement of the shaft.

Owner:VAT HLDG AG

Hand-held fastener driver

ActiveUS7992756B2Easy constructionAvoid disadvantagesStapling toolsNailing toolsLocking mechanismHand held

A hand-held fastener driver for fastening elements, having a driving tappet that is movably mounted in a tappet guide and that can be driven using at least one drive spring element is disclosed, having a tensioner for the drive spring element, and having a locking mechanism. In a locked position of the locking mechanism, the drive spring element can be locked in its tensioned position, whereby the tensioner has a tensioning element that is provided with a profile, and said tensioning element can be axially moved along a longitudinal axis of motion using a rotatable counter-element that is engaged with the profile and that can be driven by a motor.

Owner:HILTI AG

Vacuum valve

InactiveUS20070228314A1Enhanced closing forceSimple wayOperating means/releasing devices for valvesSlide valveAxial displacementInterior space

A vacuum valve comprises a valve housing which has an inlet opening and an outlet opening, a valve disk which is located in the interior space of the valve housing and which is arranged at a carrying arm that is rigidly connected to a shaft which, for purposes of opening and closing the vacuum valve, is rotatable around its longitudinal axis and displaceable in axial direction, and a driving device for opening and closing the vacuum valve. The driving device comprises a rotary drive for rotating the shaft. The driving device further comprises a driving piston which is arranged in an inner cavity of the valve disk and which has, at least over portions of its circumference, a radial extension which is larger than the outlet opening with respect to the center longitudinal axis of the outlet opening and at which tappets are arranged on the side facing the outlet opening. The tappets are guided out of the inner cavity of the valve disk and are supported in the closed position of the valve disk at the valve housing in the area next to the outlet opening and press the valve disk against the valve seat and can be lifted from the valve housing for displacing the valve disk from its closed position into its intermediate position by means of a displacement of the driving piston. At least one spring element displaces the valve disk into its intermediate position by an axial displacement of the shaft.

Owner:VAT HLDG AG

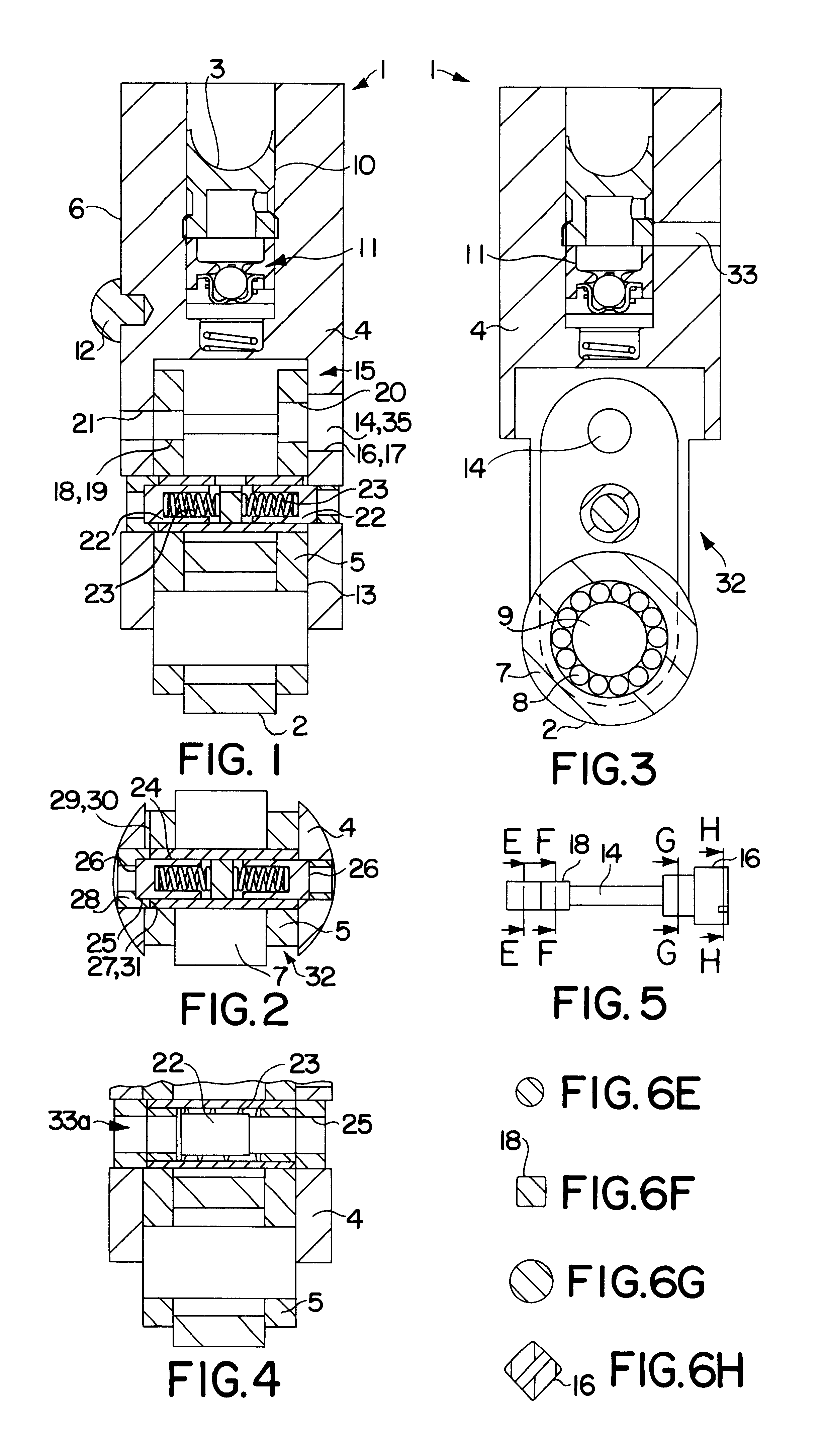

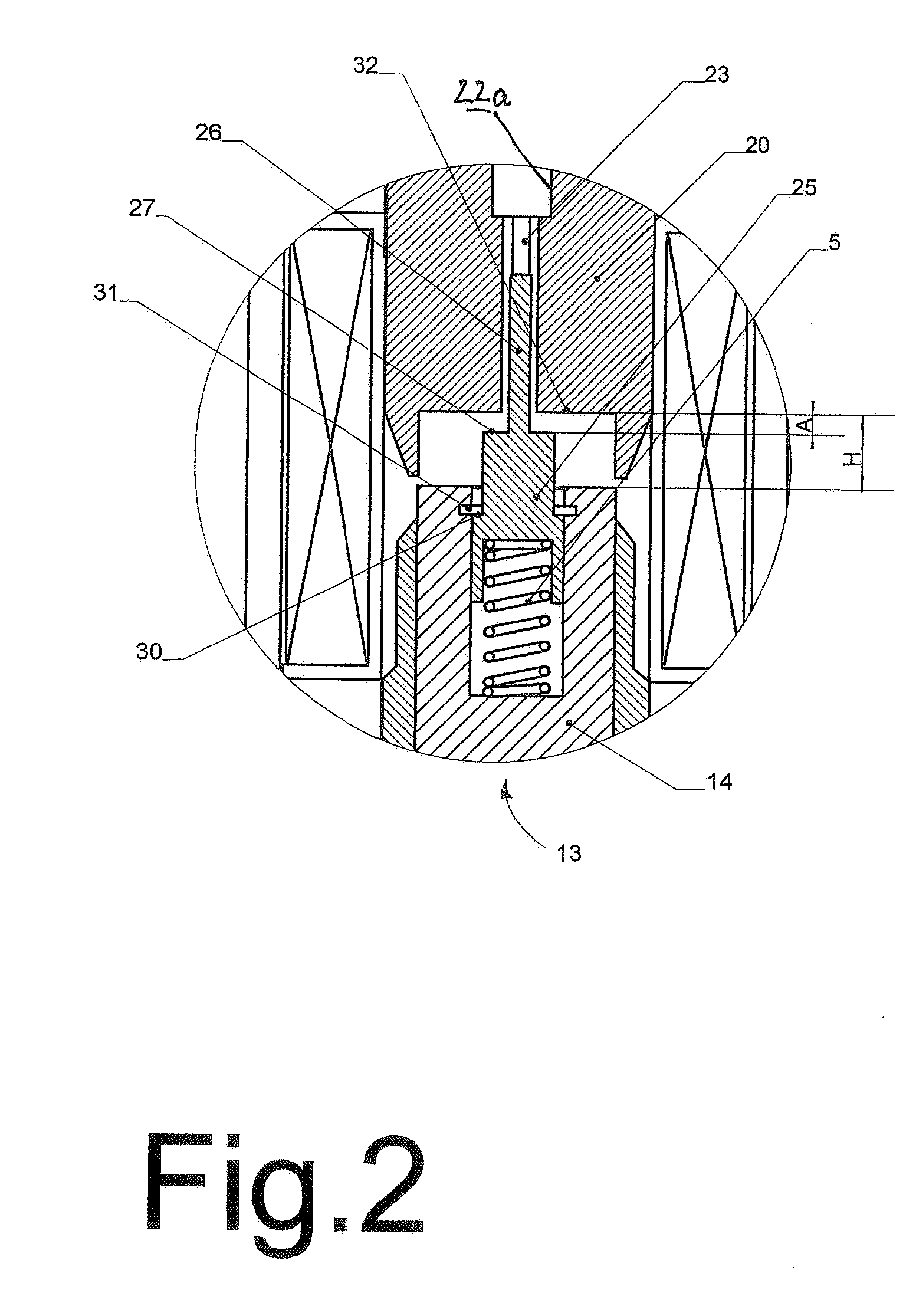

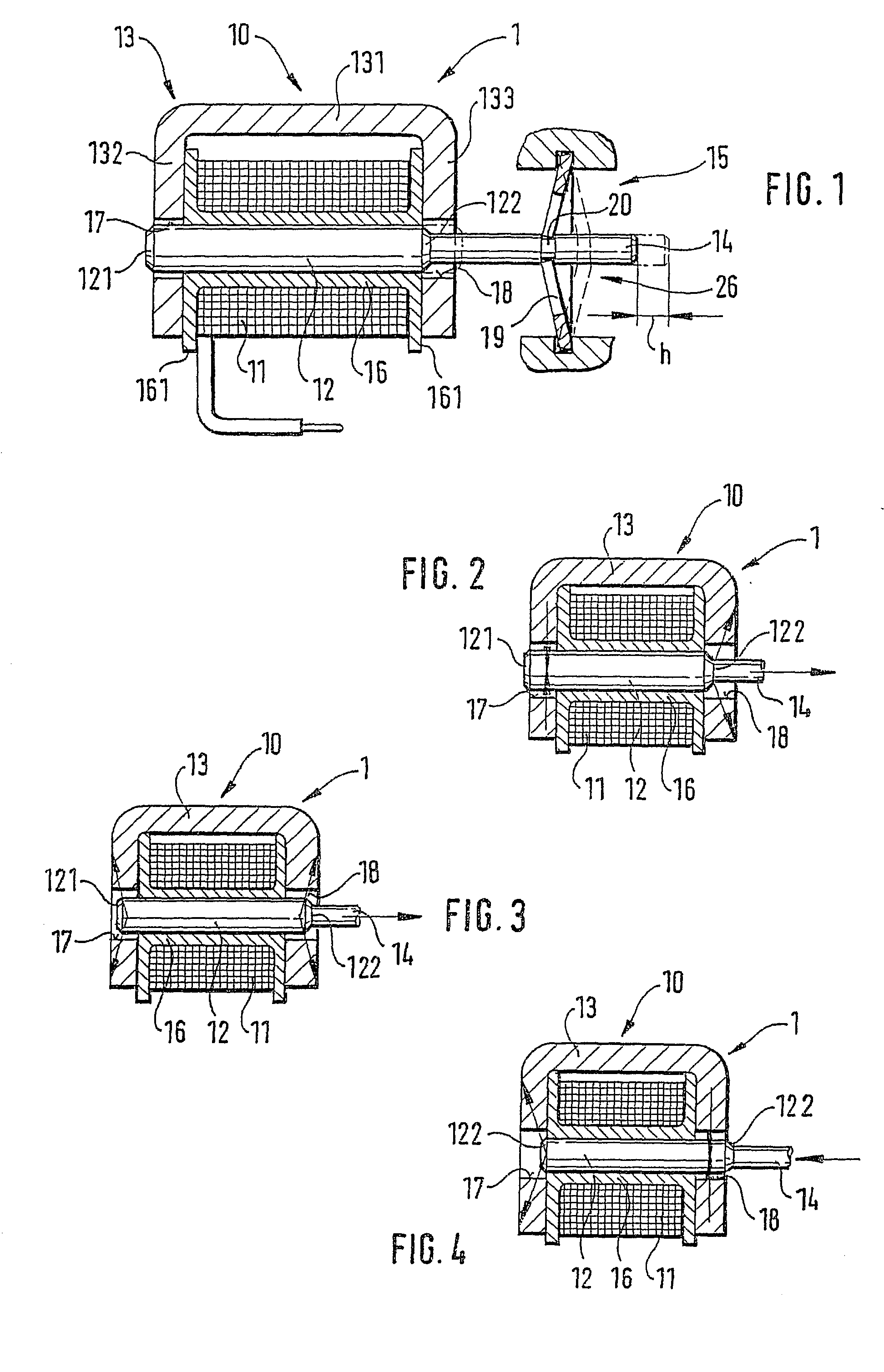

Actuator, in particular for valves, relays or similar

InactiveUS20020149456A1Non-polarised relaysElectromagnets with armaturesLocking mechanismEngineering

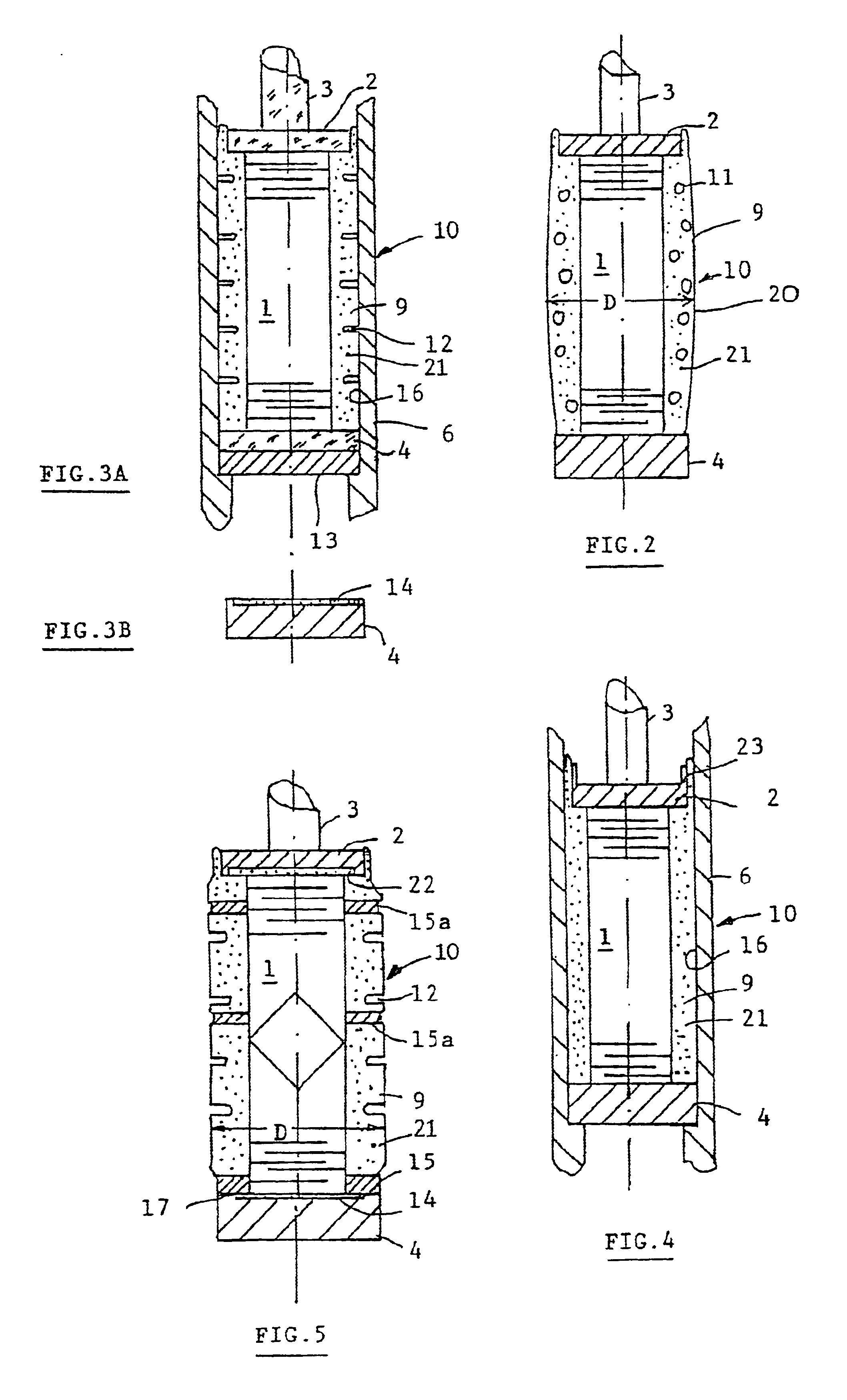

An actuator, in particular for valves, relays, or the like, is disclosed, which has an electromagnet (10) with a magnet coil (11), a magnet armature (12) that can be slid between two end positions, and a magnet yoke (13), and has an actuation tappet (14) driven by the magnet armature (12). In order to produce a bistable actuator with a low power consumption and a low heating of current-carrying components-particularly when long switching times in both switch positions are required, on the one hand, the electromagnet (10) is embodied so that its magnet armature (12) has a stable middle position that is disposed between its two end positions, which are determined by the two switch positions of the actuator, and that can be approached from both end positions by supplying current to the magnet coil (11), and on the other hand, a bistable mechanical locking mechanism (15) is provided, which acts on the magnet armature (12) or on the actuation tappet (14) and comes into play in the end positions of the magnet armature (12) (FIG. 1).

Owner:ROBERT BOSCH GMBH

Differential gear pad-choosing measuring system and measuring method

ActiveCN101441071AImprove work efficiencyAchieve high-precision assemblyMachine gearing/transmission testingPressure.driveTappet

The invention relates to a differential pad-selection measurement system and method, which are characterized in that: a differential left shell is arranged on a positioning bench, a lower simulation pad is arranged between the differential left shell and a lower semiaxis gear; planetary gears are sleeved on four ends of a cross axle of member to be measured and are arranged in a shaft hole of the differential left shell; a lower puller sleeve arranged in a shaft hole of the lower semiaxis gear is hung on the lower semiaxis gear through an upper edge shoulder of the lower puller sleeve, a measurement tappet is fixedly connected with the lower puller sleeve, a puller spring is arranged between the measurement tappet and the lower puller sleeve, a spring guide sleeve sleeves on the measurement tappet and is supported by the puller spring; an upper top board is arranged on the spring guide sleeve by press mounting manner; and a displacement sensor, a pressure sensor and a proximity switch are respectively arranged in a pressure driving body. The invention can automatically complete accurate measurement of thickness of the differential pad, and can increase product quality and production efficiency.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Dehydrating device

InactiveUS7743528B2Fast spinEasily handling tappet unitCarpet cleanersFloor cleanersDrive shaftTappet

A dehydrating device comprises a tappet unit, a transmission unit and a rotation unit, wherein the rotation unit comprises a bearing member and a transmission shaft. A aquiferous member is disposed in the bearing member, and then the operation of the tappet unit is beginning. The tappet unit then mechanically drives the transmission unit and the rotation unit so as to dewater the aquiferous member.

Owner:DIKAI INT ENTERPRISE

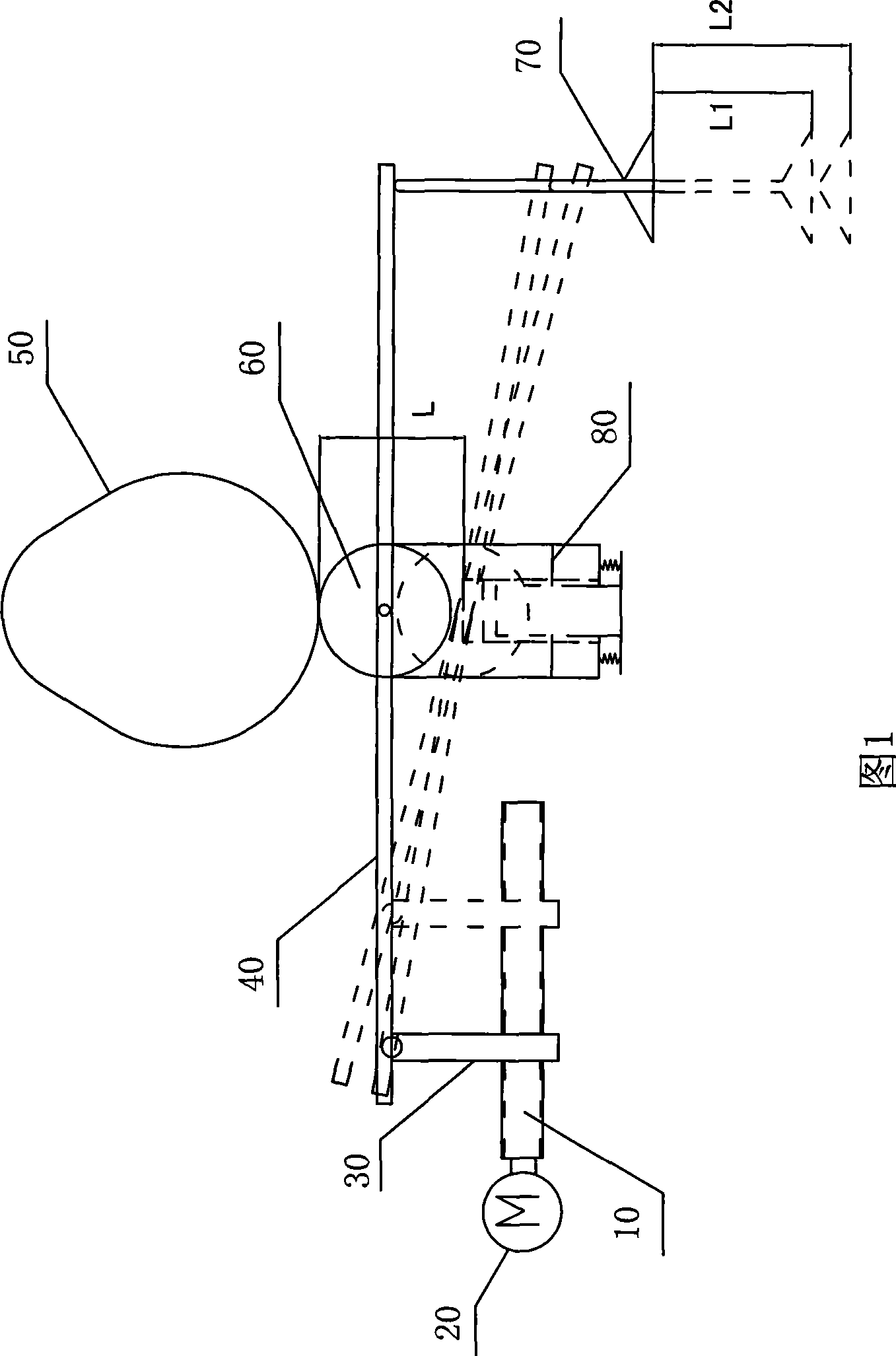

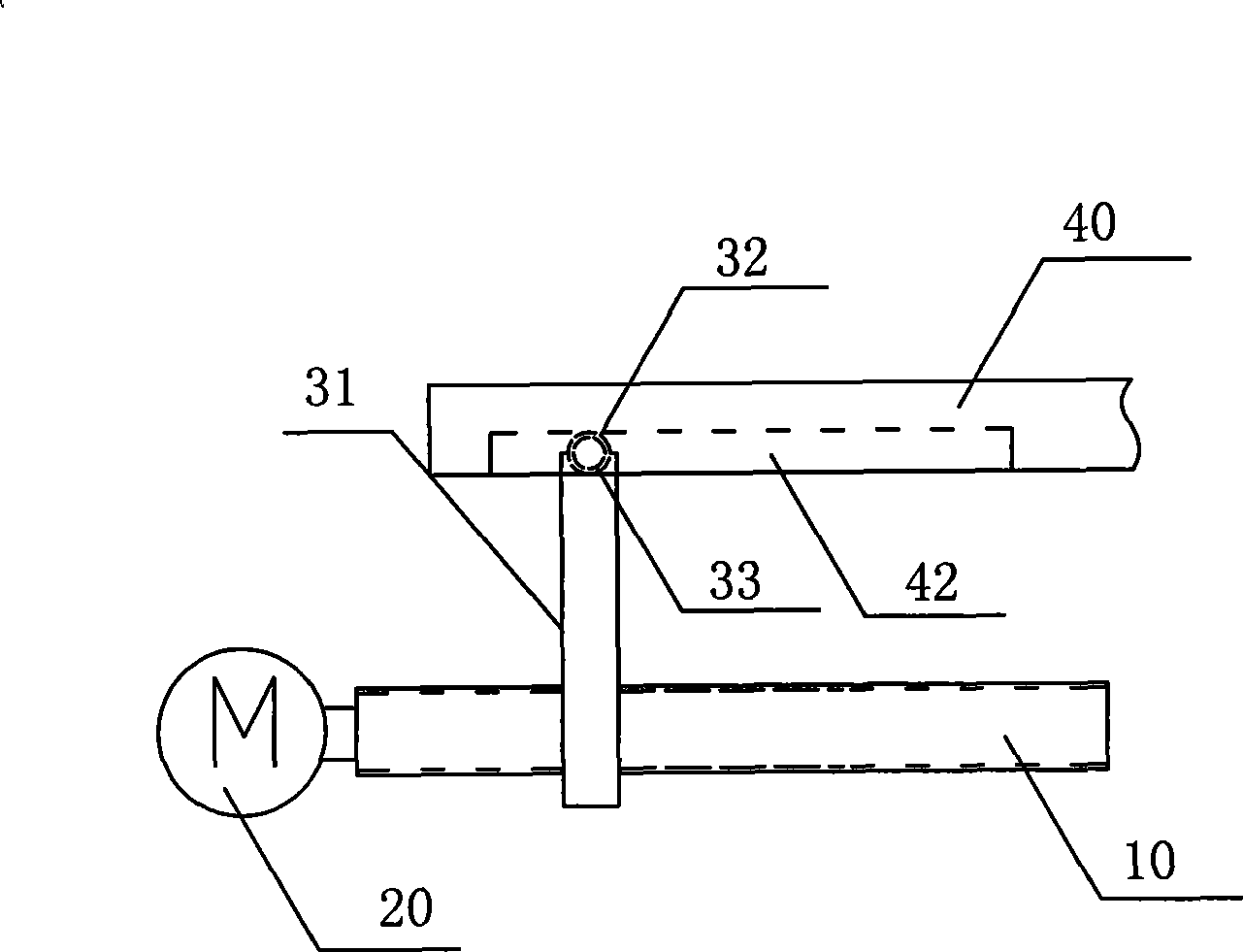

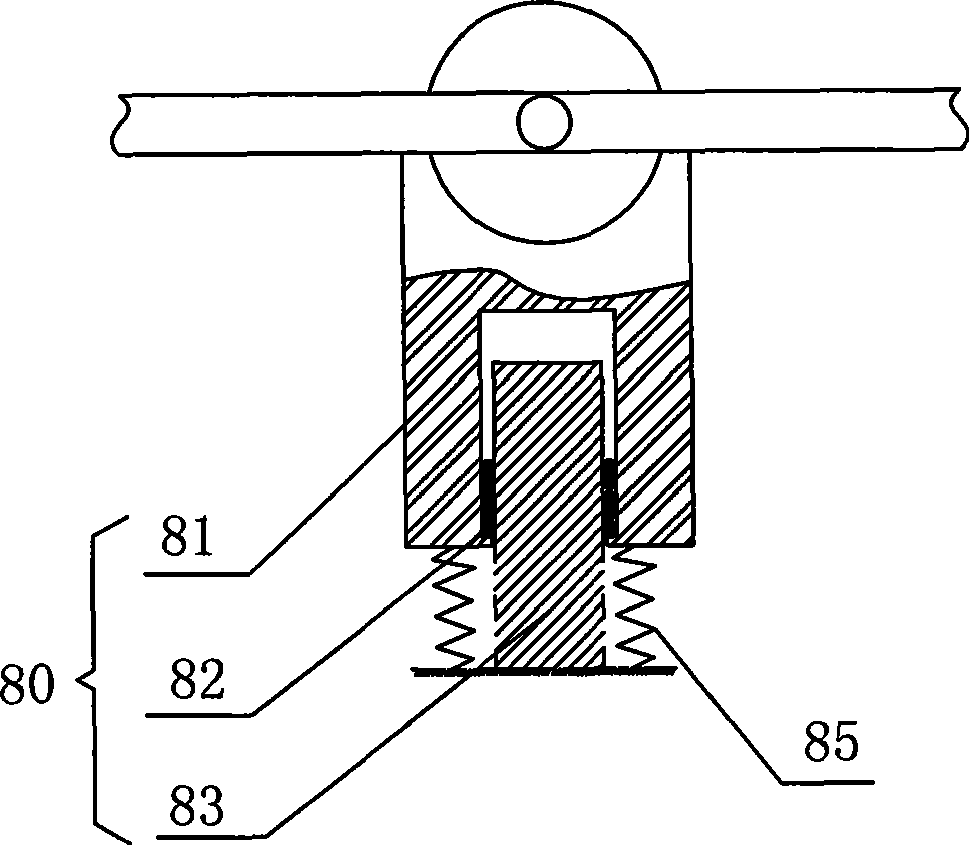

Continuous variable air valve lift apparatus

ActiveCN101429882AContinuously variable liftChange leverage ratioValve arrangementsInternal combustion piston enginesMotor driveElectric machine

The invention relates to a constant variable valve lift device. The device comprises a threaded rod, a motor driving the threaded rod to do rotational movement, a tappet connected with the threaded rod by threads, a rocker shaft movably connected with the tappet, a cam arranged above the rocker shaft, a rocker roller which interacts with the cam and is hinged with the rocker shaft, a valve driven by the rocker shaft and a telescopic arm connected with the rocker roller, wherein the rocker shaft is provided with a slideway which is movably connected with the top of the tappet, and the tappet moves in the slideway. The constant variable valve lift device solves the problem of inconstant variation of the valve lift by making a lever ratio change with the position of a fulcrum of the rocker shaft according to the lever principle.

Owner:CHERY AUTOMOBILE CO LTD

Piezoelectric actuator

InactiveUS6700308B2Easy to centerImprove heat transfer performanceOperating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesElastomerMobile vehicle

The invention relates to a piezoelectric actuator, in particular for actuating control valves or injection valves in motor vehicles, having an actuator body in the form of a multilayered laminate made up of stacked layers of piezoelectric material with intervening metallic or electrically conductive layers that function as electrodes, and the end faces of this actuator body are respectively contacted by a top plate oriented toward the valve having an axially protruding valve tappet and a bottom plate at the opposite end, wherein the actuator rests in an axial bore of a valve housing and is prestressed at the ends in the axial direction between the top plate and the bottom plate by means of a spring element. According to the invention, the actuator-at least including the top plate-is enclosed by an electrically insulating elastomer sleeve so that when installed, the actuator with the elastomer sleeve rests snugly against the inner wall of the axial bore of the valve housing in the vicinity of the actuator.

Owner:ROBERT BOSCH GMBH

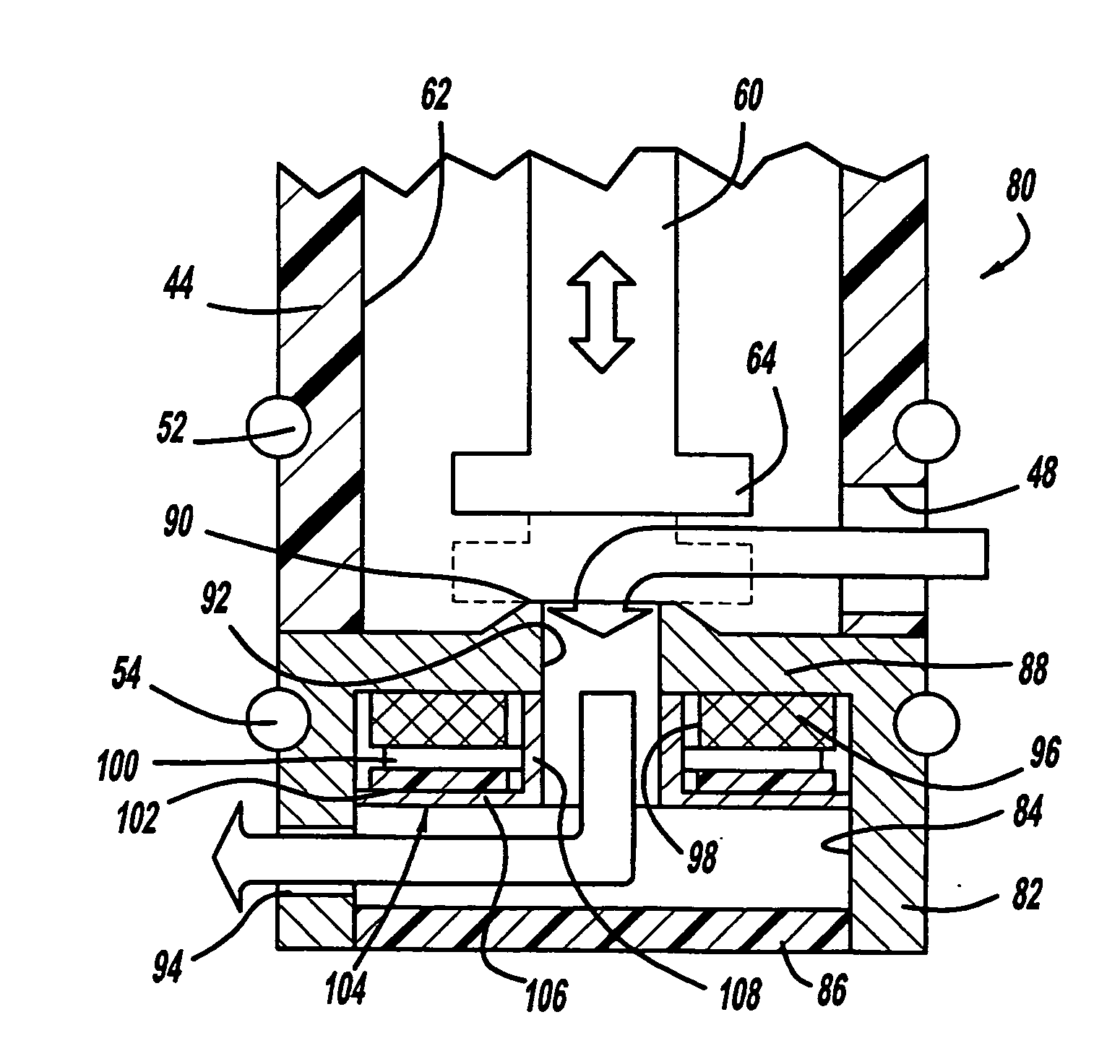

Fuel pump with a guided tappet assembly and methods for guiding and assembly

ActiveUS7311087B2Reduce contact stressImprove reliability and durabilityFuel injecting pumpsSpecial fuel injection apparatusInternal combustion engineTappet

A fuel pump for an internal combustion engine including a fuel pump housing, a cylindrical bore having a central axis and being defined by a bore wall surface, a receiving hole formed in the housing, and a tappet assembly received in the cylinder bore. The tappet assembly includes an outer peripheral surface with an elongated key slot longitudinally extending parallel to the central axis. A guide key partially received in the receiving hole is provided, the guide key including a head that extends into the cylindrical bore to engage the elongated key slot of the tappet assembly. The head has an outer dimension that is larger than a dimension of the receiving hole along the central axis. Methods for guiding a reciprocating tappet assembly in a fuel pump and assembling a fuel pump are also provided.

Owner:CUMMINS INC

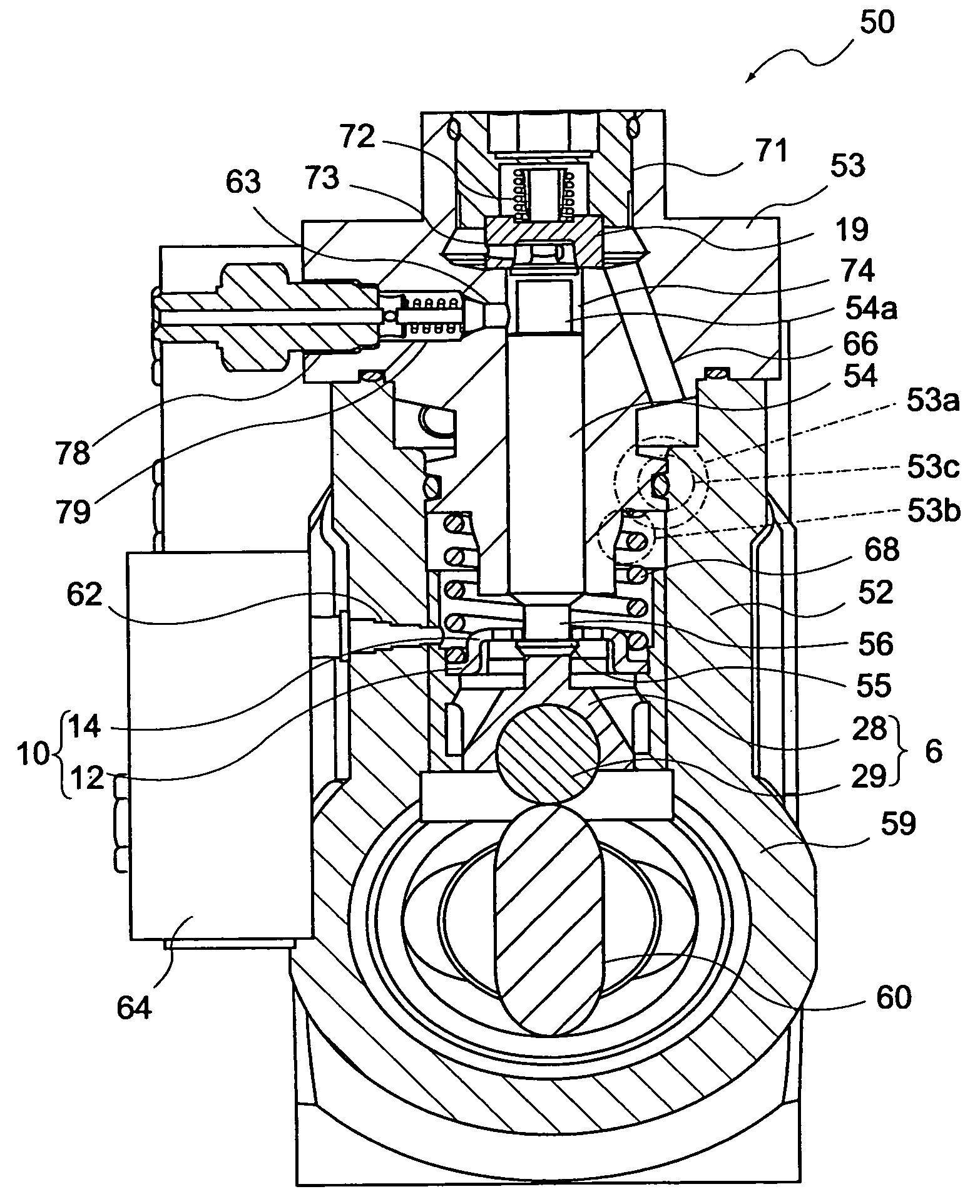

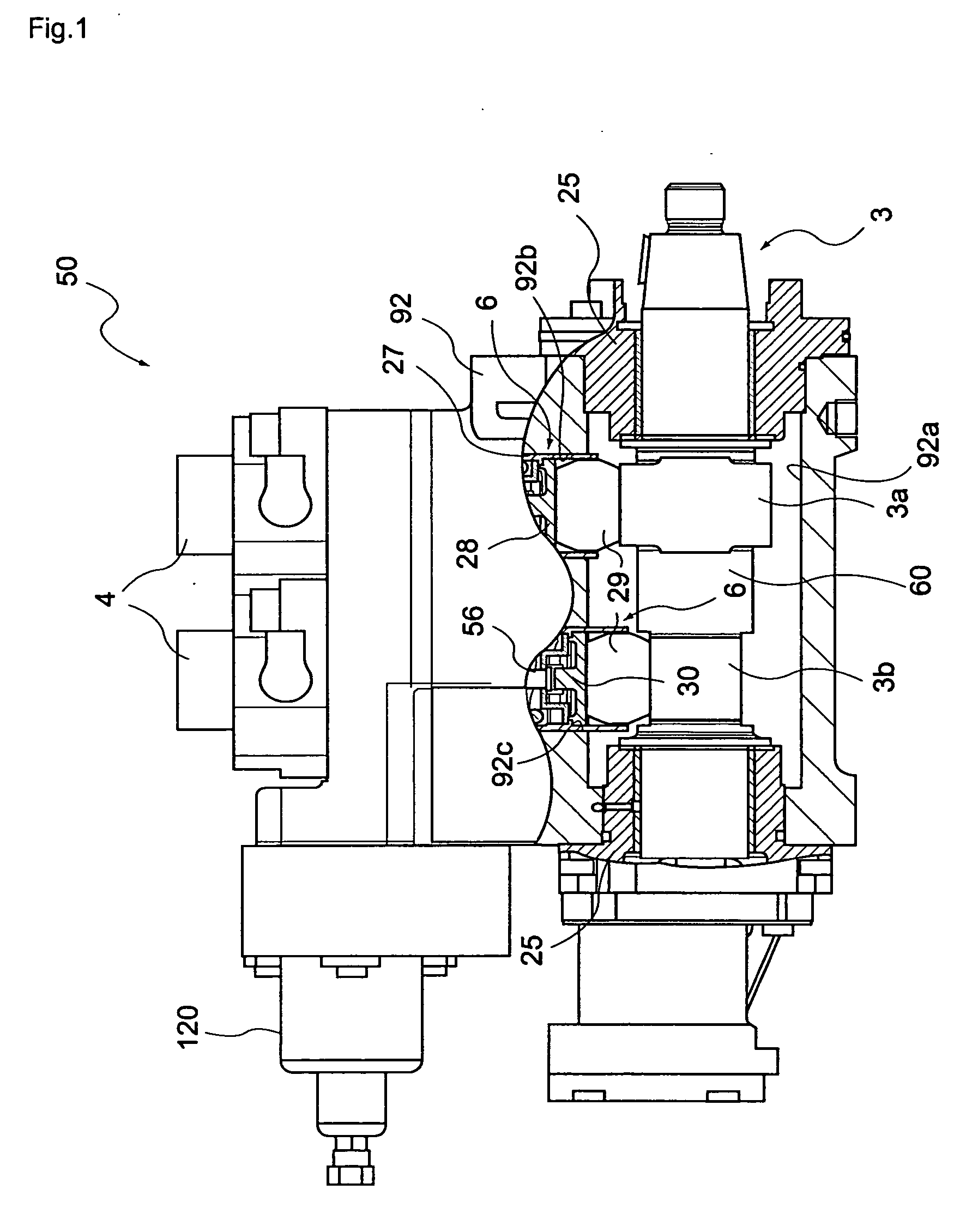

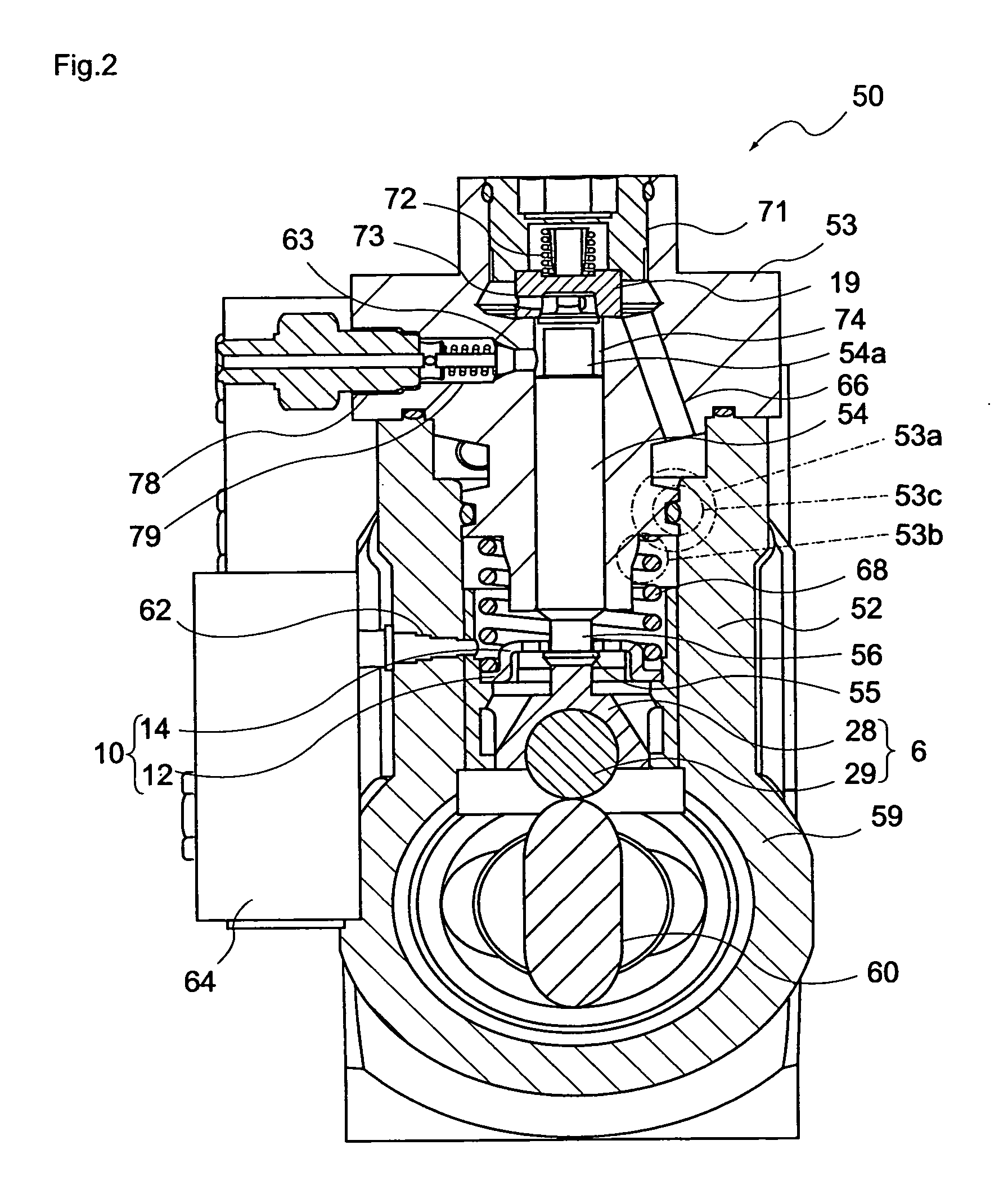

Fuel supply pump

InactiveUS20050100466A1Easy constructionEasy to producePositive displacement pump componentsFuel injecting pumpsEngineeringCam

A fuel supply pump, which is simple in construction and easy to produce and is capable of efficiently pressurizing a high flow rate of fuel, is provided. The fuel supply pump (50) includes a housing (52), a plunger barrel (53), a plunger (54) for pressurizing fuel, which is installed in the plunger barrel (53) so as to be allowed to move up and down, a cam (60) installed in rotation way below the plunger (54), a tappet structure body (6) installed between the cam (60) and the plunger (54) to transmitting the turning force, serving as a lifting force, from the cam shaft (3) to the plunger (54), a tappet structure body (6) installed between the cam (60) and the plunger (54) and provided for transmitting a upward or downward movement of the cam (60) caused by the rotation of the camshaft (3) to the plunger (54); and a return spring (68) for setting lowering force to the plunger (54), which is installed between the tappet structure body (6) and the plunger barrel (53).

Owner:DIESEL KIKI CO LTD

Tappet assembly

In one aspect, the present disclosure is directed to a tappet assembly for a machine. The assembly may include a tappet body, a pin fixedly mounted in the tappet body, and a substantially cylindrical roller mounted about the pin. The roller may have a substantially cylindrical outer surface with a circumferential dimension and a width dimension, the width dimension being defined by two lateral edges. The roller may be configured to provide rolling contact between the outer surface of the roller and a cam lobe. The outer surface of the roller may be crowned such that at maximum operational loading conditions of the machine a footprint of contact pressure from the cam lobe is spread substantially the full width of outer cylindrical surface of the roller.

Owner:CATERPILLAR INC

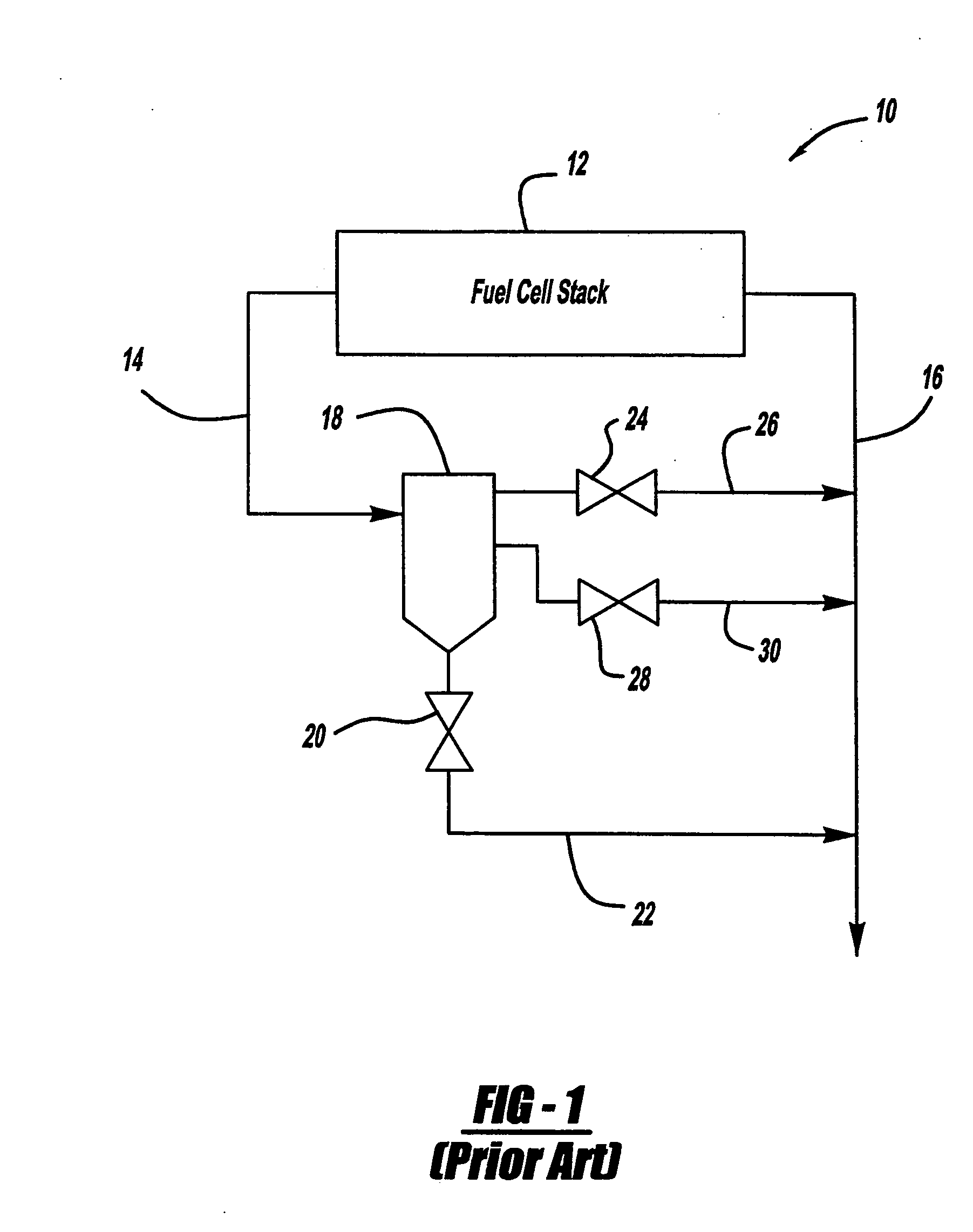

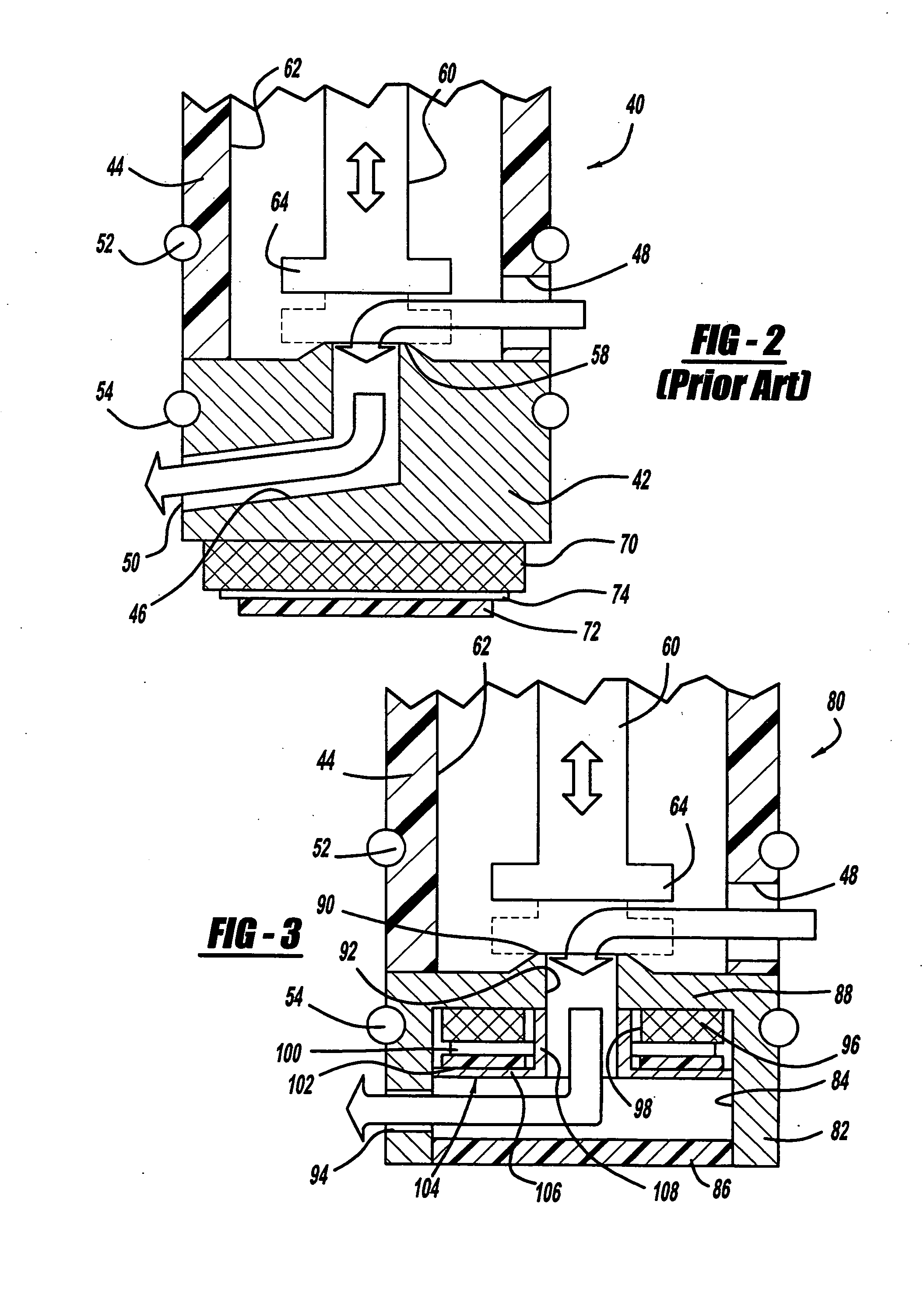

Cartridge valve with integrated ceramic ring heater

InactiveUS20080105843A1Operating means/releasing devices for valvesValve members for heating/coolingFuel cellsTappet

A valve including an integrated heater that has particular application for one or more of a bleed valve, a drain valve and a pressure release valve in an anode outlet unit of a fuel cell system. The valve includes a valve body having a valve body chamber defining a valve seat. A valve tappet seats against the valve seat to close a flow channel in the valve through which a fluid flows. A ring heater is mounted within the chamber so that the fluid flows through a central opening in the ring heater, where the ring heater is in close proximity to the valve seat.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com