Continuous variable air valve lift apparatus

A valve lift, variable technology, applied in the direction of valve device, internal combustion piston engine, engine components, etc., can solve the problems such as non-continuously variable, invariable valve lift, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

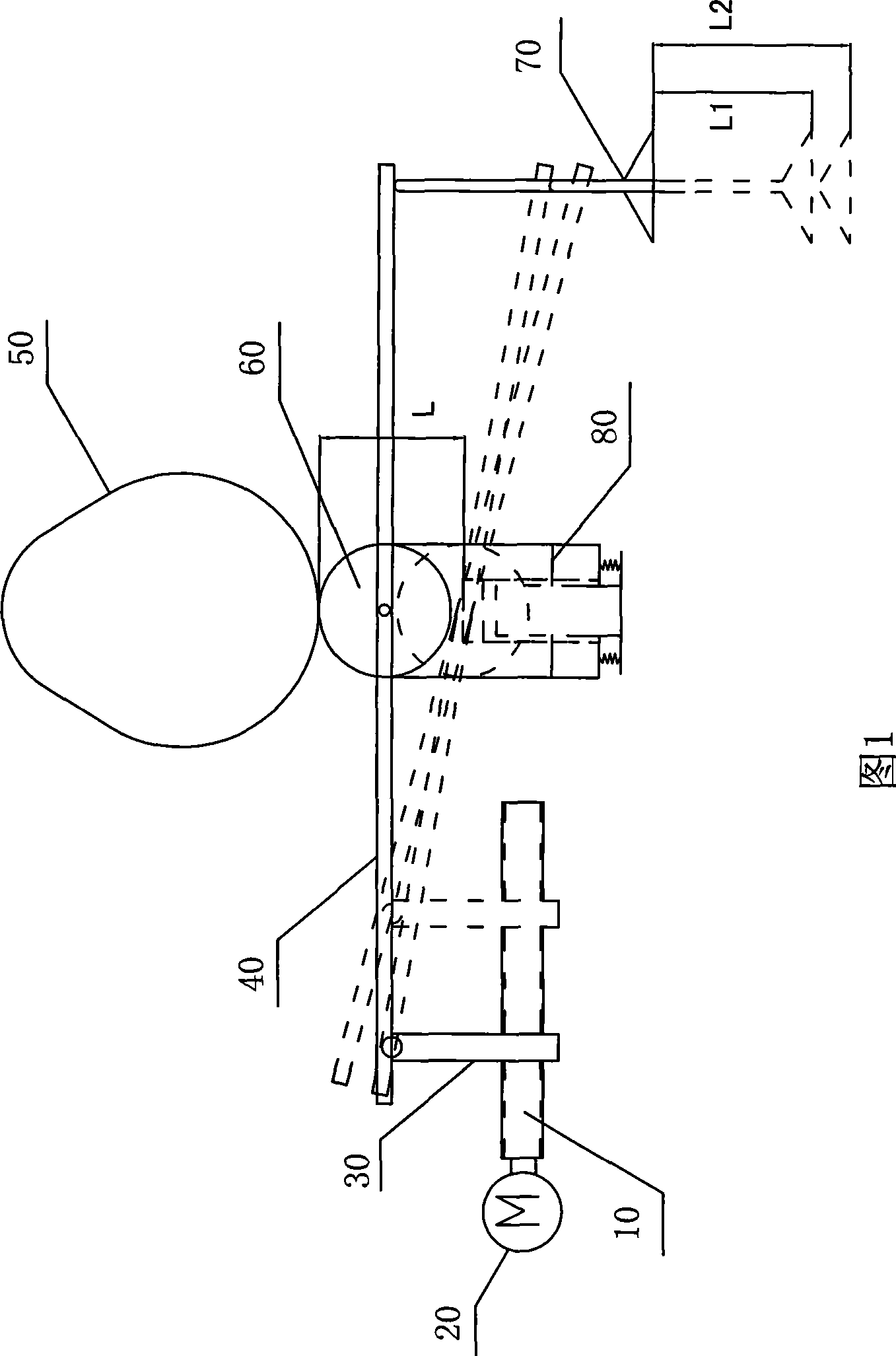

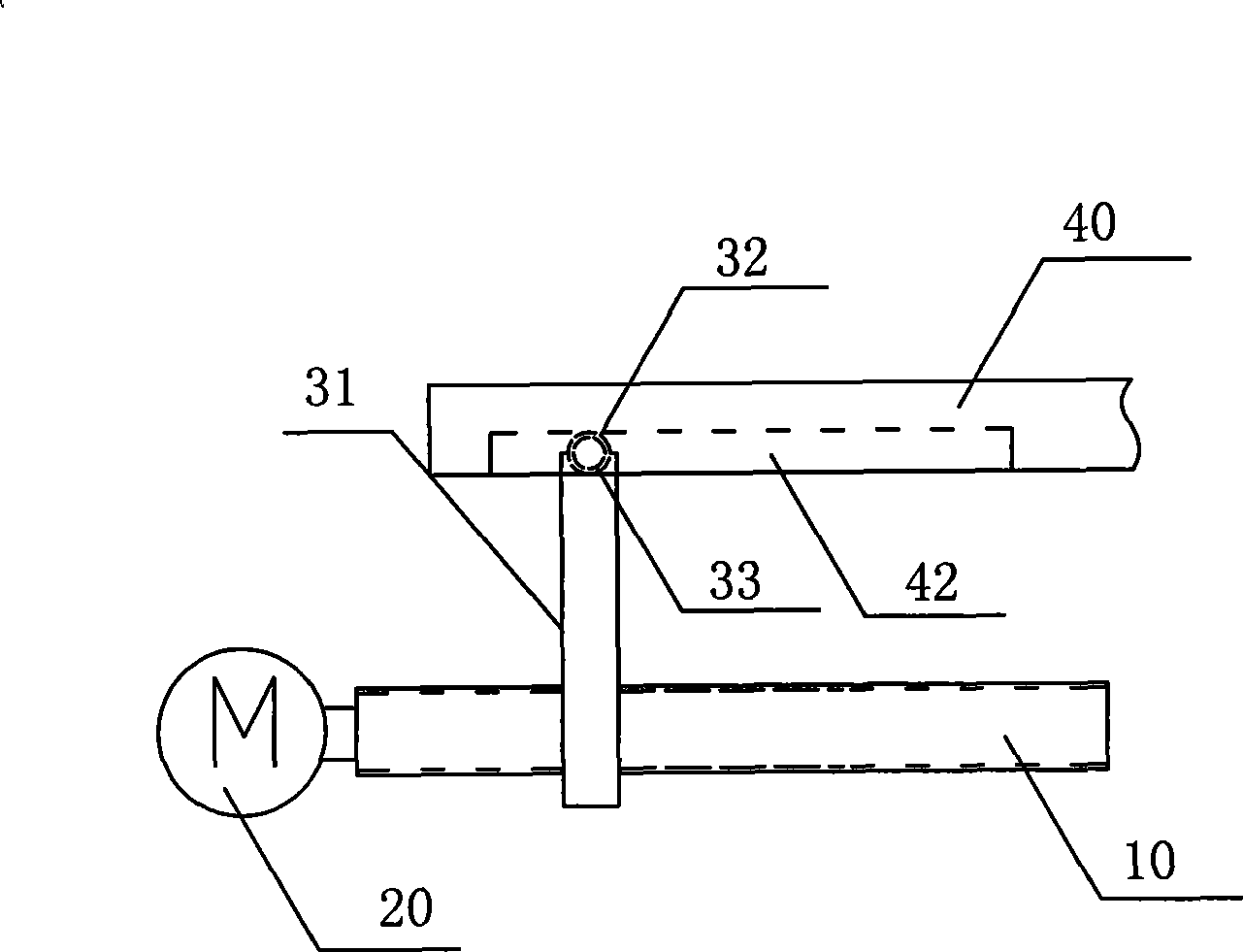

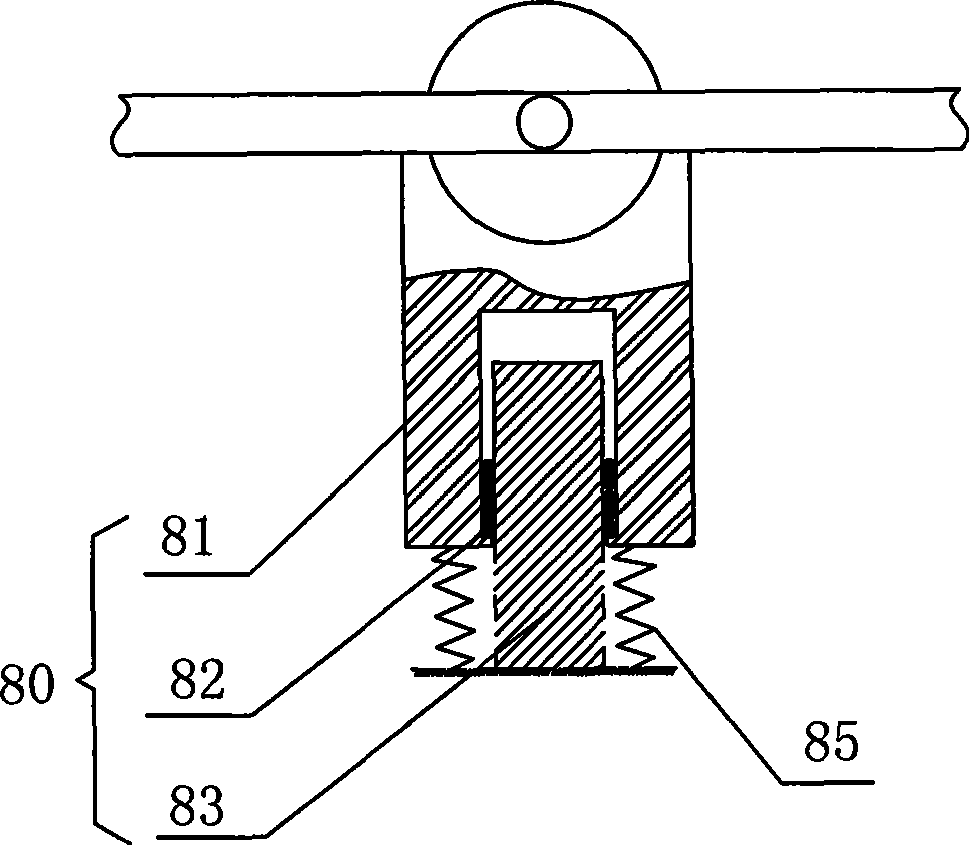

[0015] Please refer to Figure 1 together, figure 2 and image 3 As shown, the continuously variable valve lift device provided by the present invention includes a threaded rod 10, a motor 20 for driving the threaded rod 10 to rotate, a tappet 30 threaded with the threaded rod 10, and a rocker for the tappet 30 to move. The arm shaft 40, the cam 50 located above the rocker shaft 40, the rocker roller 60 interacting with the cam 50, the valve 70 driven by the rocker shaft 40, and the telescopic arm 80 connected with the rocker roller 60 .

[0016] The threaded rod 10 rotates under the drive of the motor 20, thereby driving the tappet 30 connected with the reverse thread to move laterally; wherein the connection mode between the rocker arm roller 60 and the rocker arm shaft 40 is hinged, and the rocker arm roller 60 can rotate around The center is free to rotate; the tappet 30 is slidingly connected with the chute 42 of the rocker shaft 40, and by changing the lateral position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com