Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17602 results about "Inlet valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

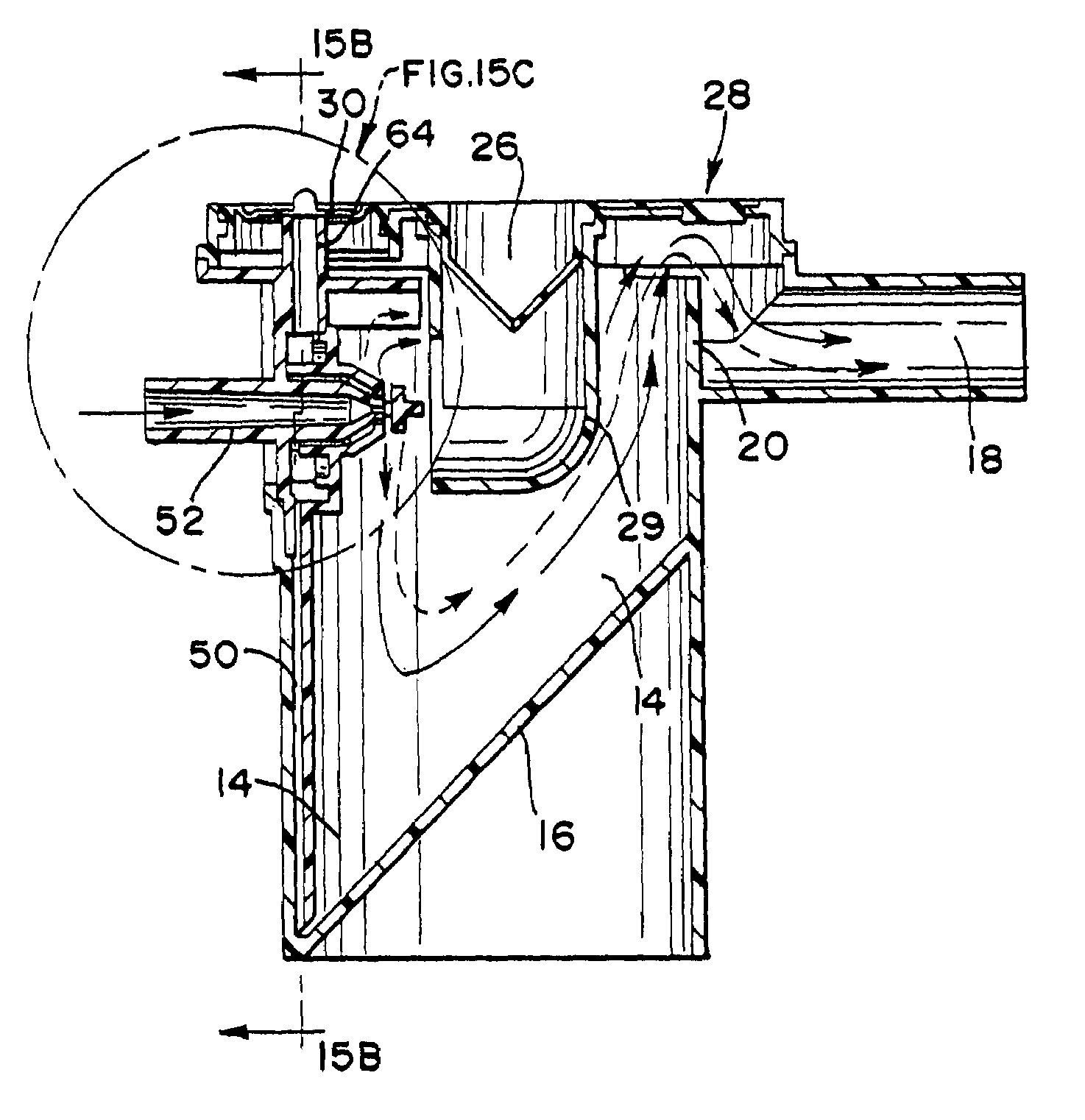

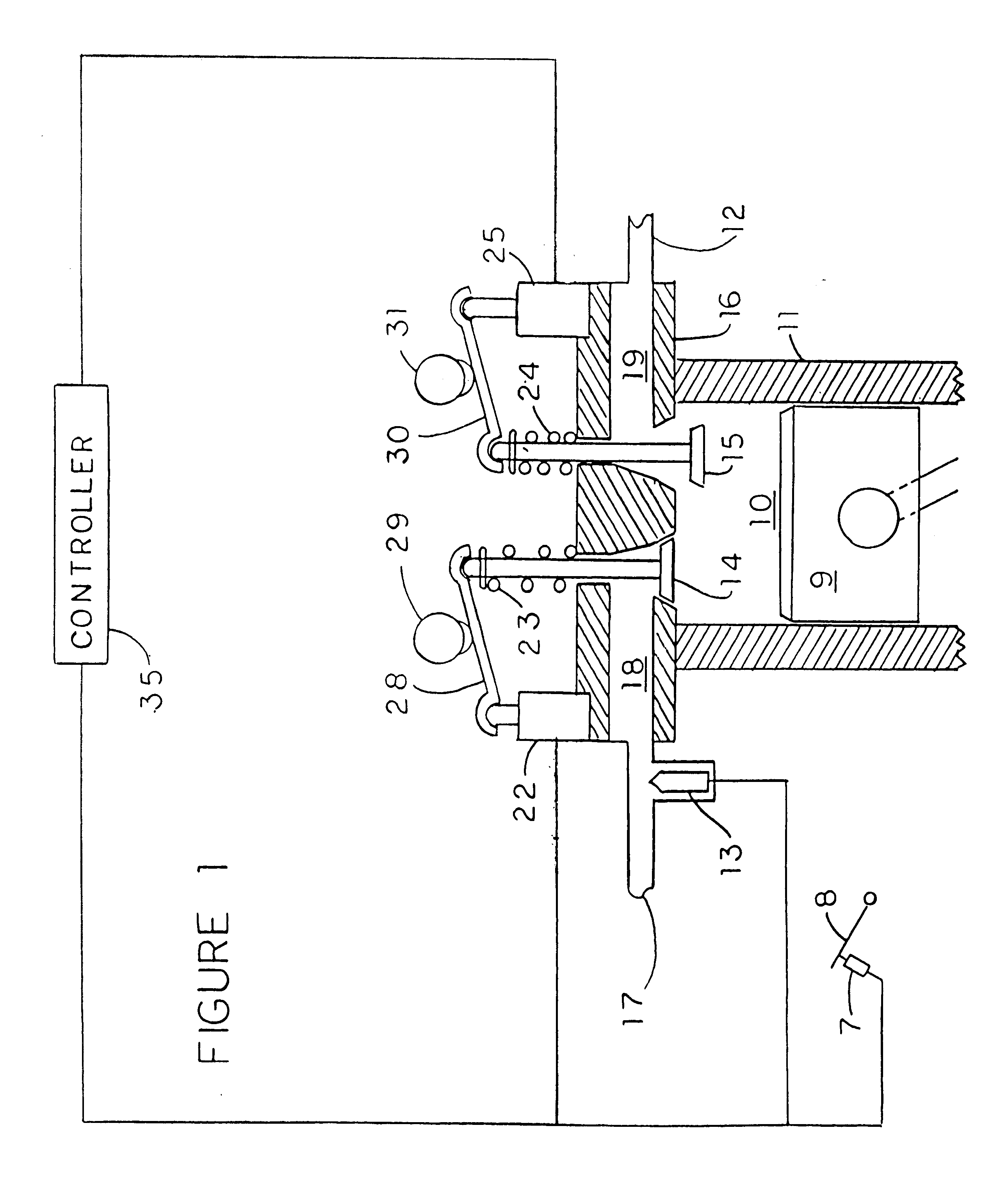

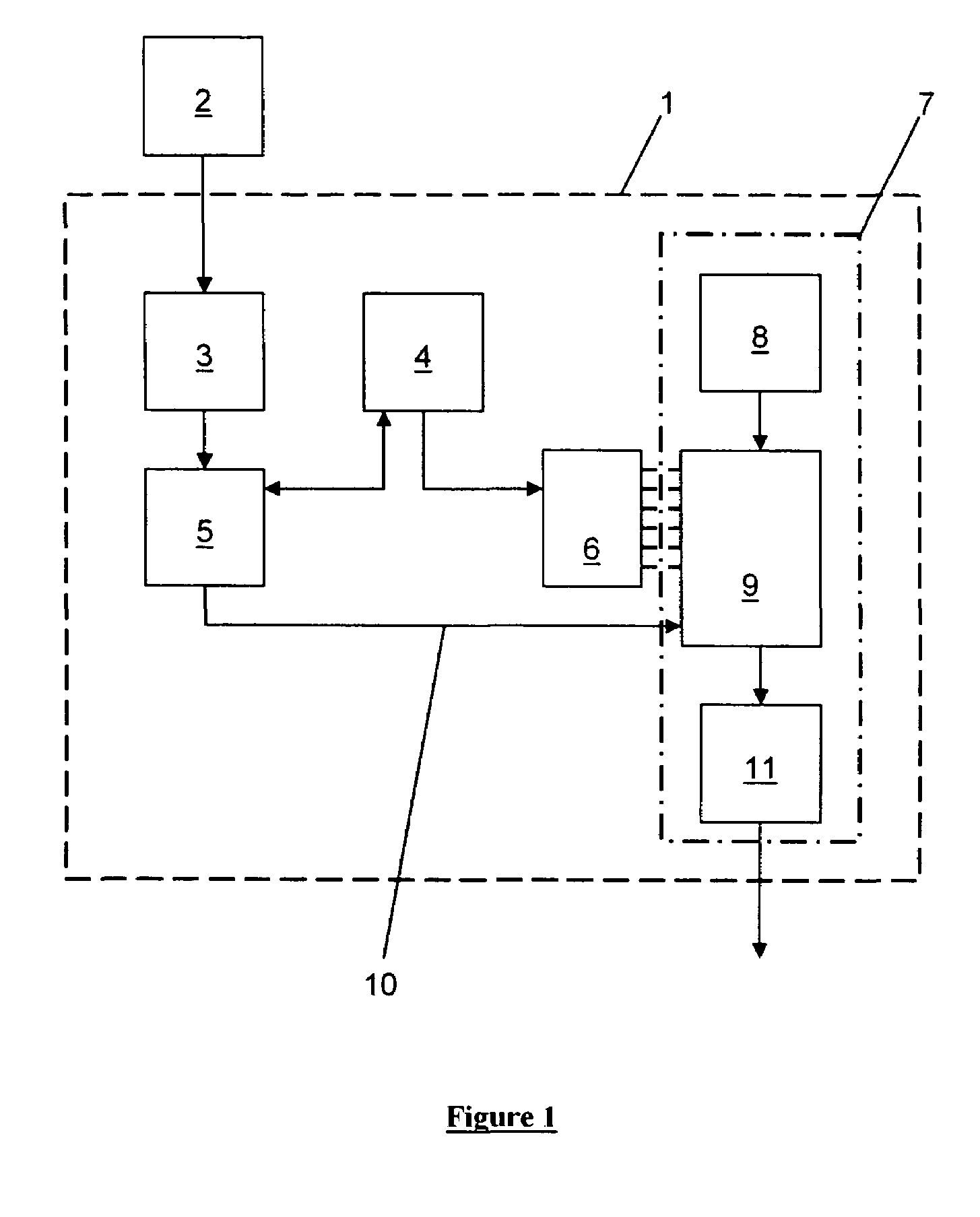

Method for wide range gas flow system with real time flow measurement and correction

InactiveUS6119710AAccurate measurementAccurate flowOperating means/releasing devices for valvesVolume/mass flow by thermal effectsDifferential pressureInlet valve

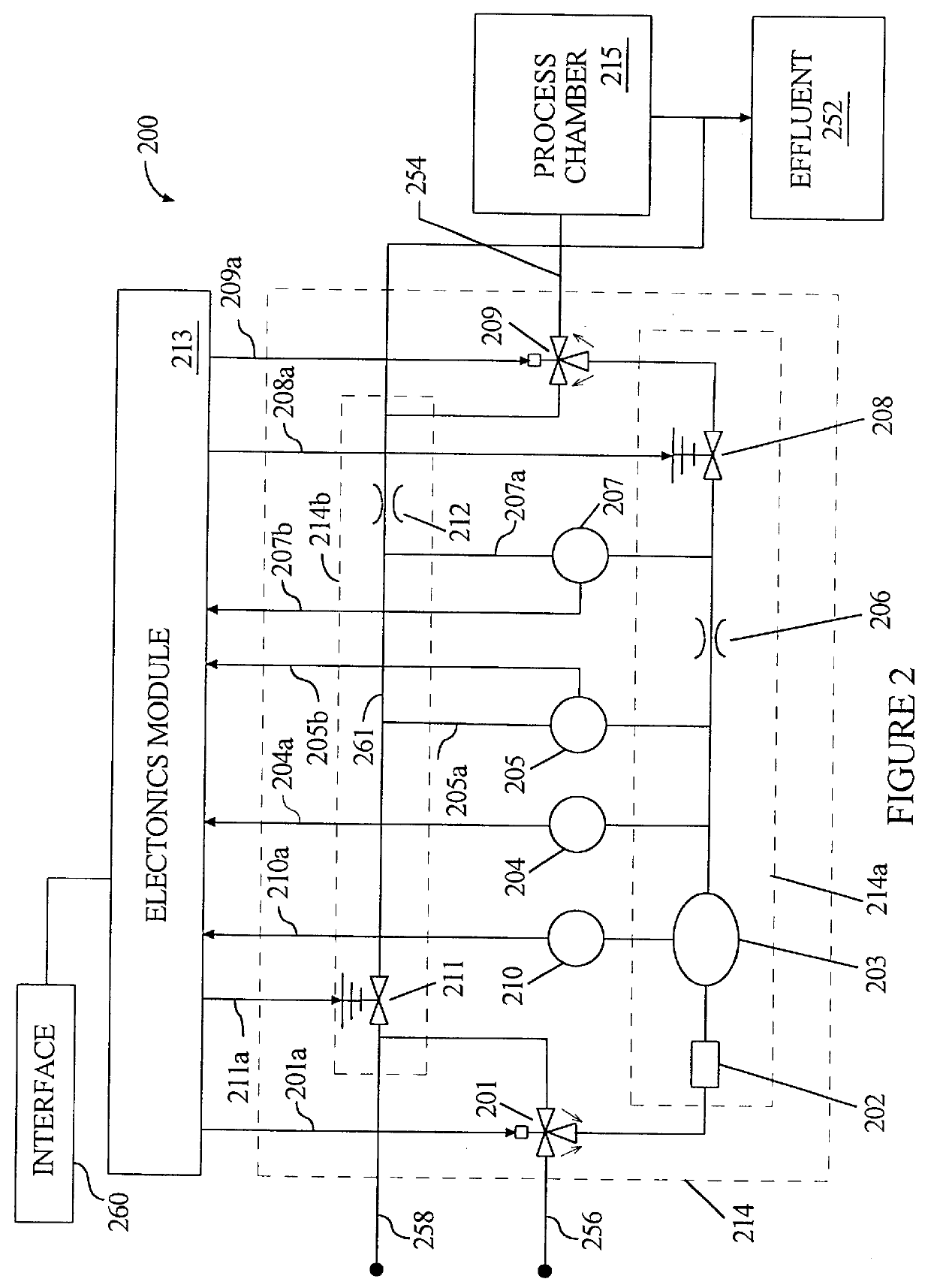

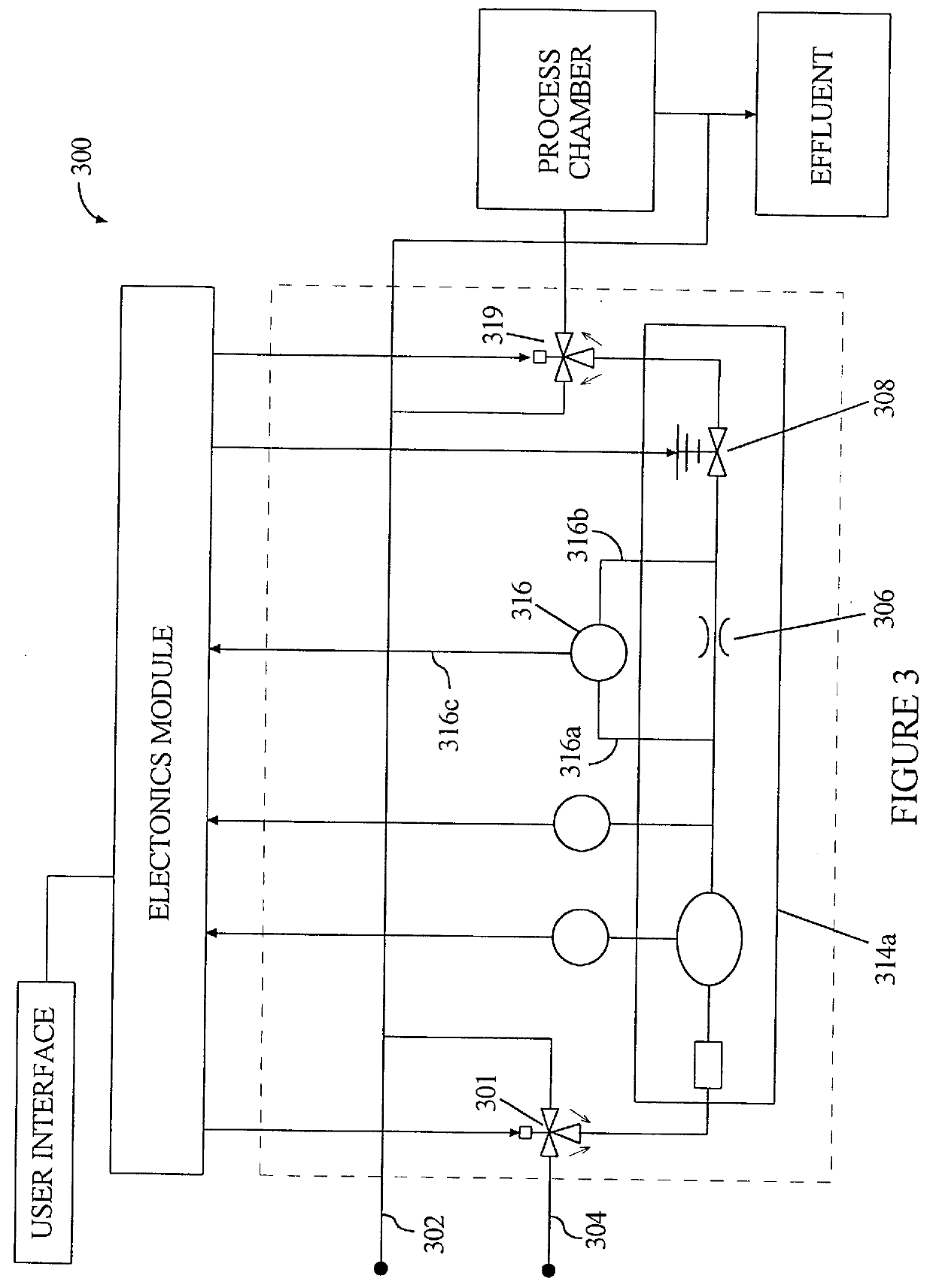

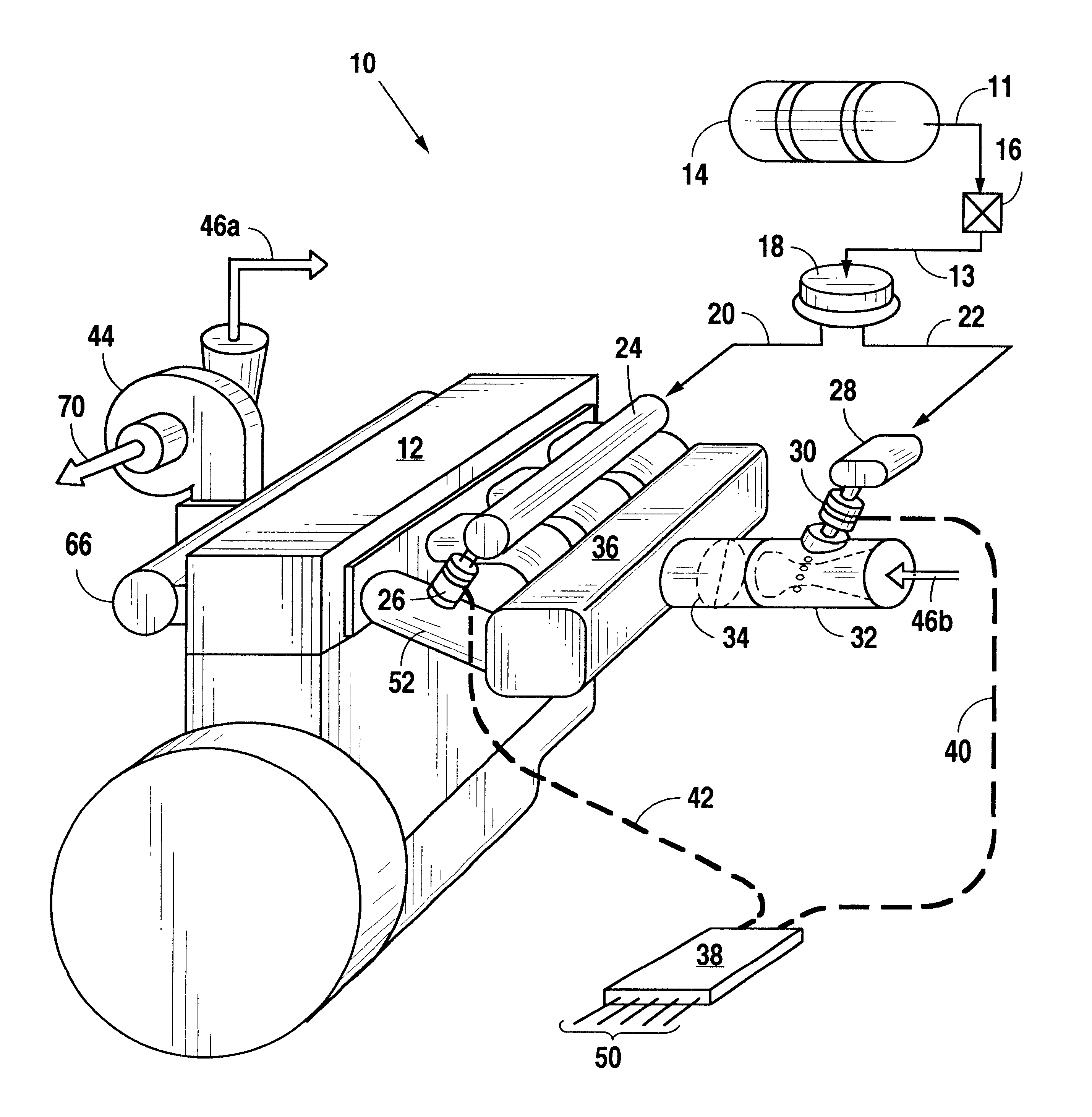

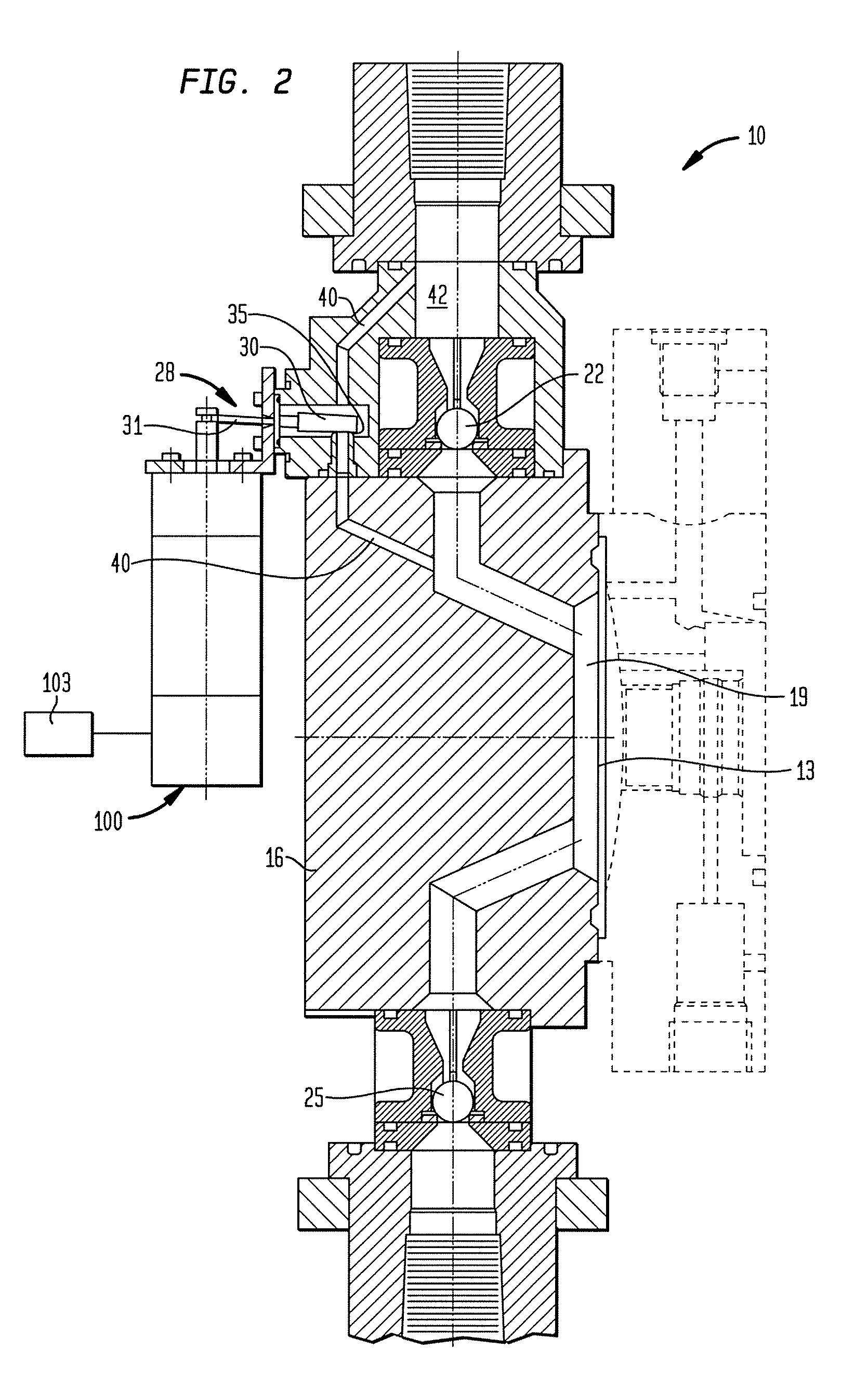

A gas delivery system accurately measures and optionally regulates mass flow rate in real time. A fluid conduit connects an inlet valve, calibration volume, flow restrictor, and outlet valve in series. Pressure and temperature sensors are coupled to the calibration volume. One or more pressure sensors may be attached across the flow restrictor. Alternatively, an absolute pressure sensor may be attached upstream of the flow restrictor. One embodiment of differential pressure sensors comprises a floating reference differential pressure sensor, including a first transducer attached to the fluid conduit upstream of the flow restrictor and a second transducer attached to the conduit downstream of the flow restrictor. In this embodiment, each transducer receives a reference pressure from a reference source, and optionally, after the calibration volume is charged, the floating reference differential pressure transducers are calibrated. When gas flow is initiated, differential and / or absolute pressure measurements are repeatedly taken, and a measured mass flow rate calculated thereon. Gas flow is adjusted until the measured mass flow rate reaches a target mass flow. Using the temperature / pressure sensors at the calibration volume, repeated calculations of actual flow rate are made to uncover any discrepancy between actual and measured mass flow rates. Whenever a discrepancy is found, the manner of calculating measured mass flow is conditioned to account for the discrepancy; thus, the measured mass flow rate more accurately represents the actual mass flow rate thereby providing an actual mass flow rate more accurately achieving the target mass flow rate.

Owner:CYBER INSTR TECH LLC AN ARIZONA LIMITED LIABILITY +1

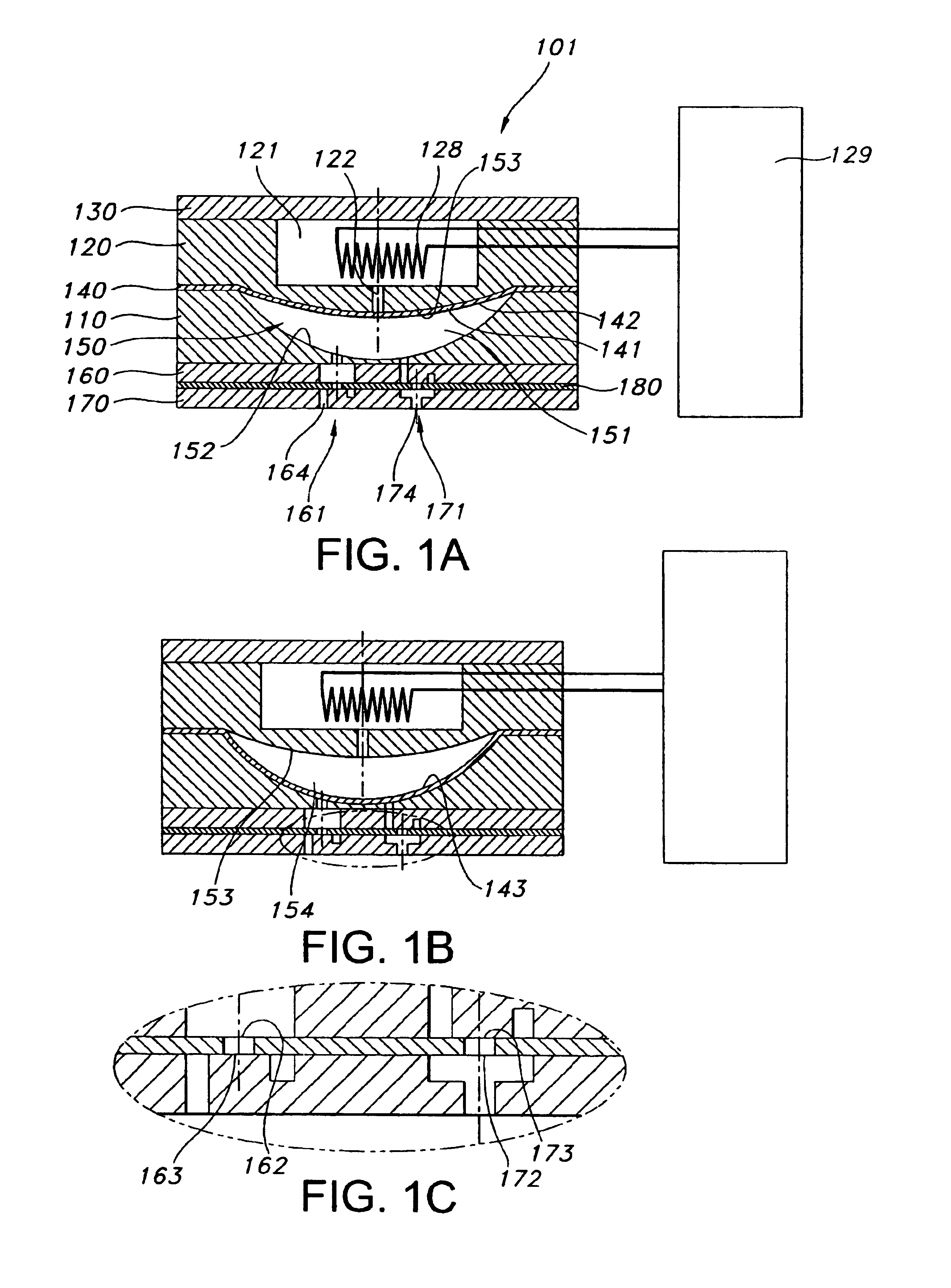

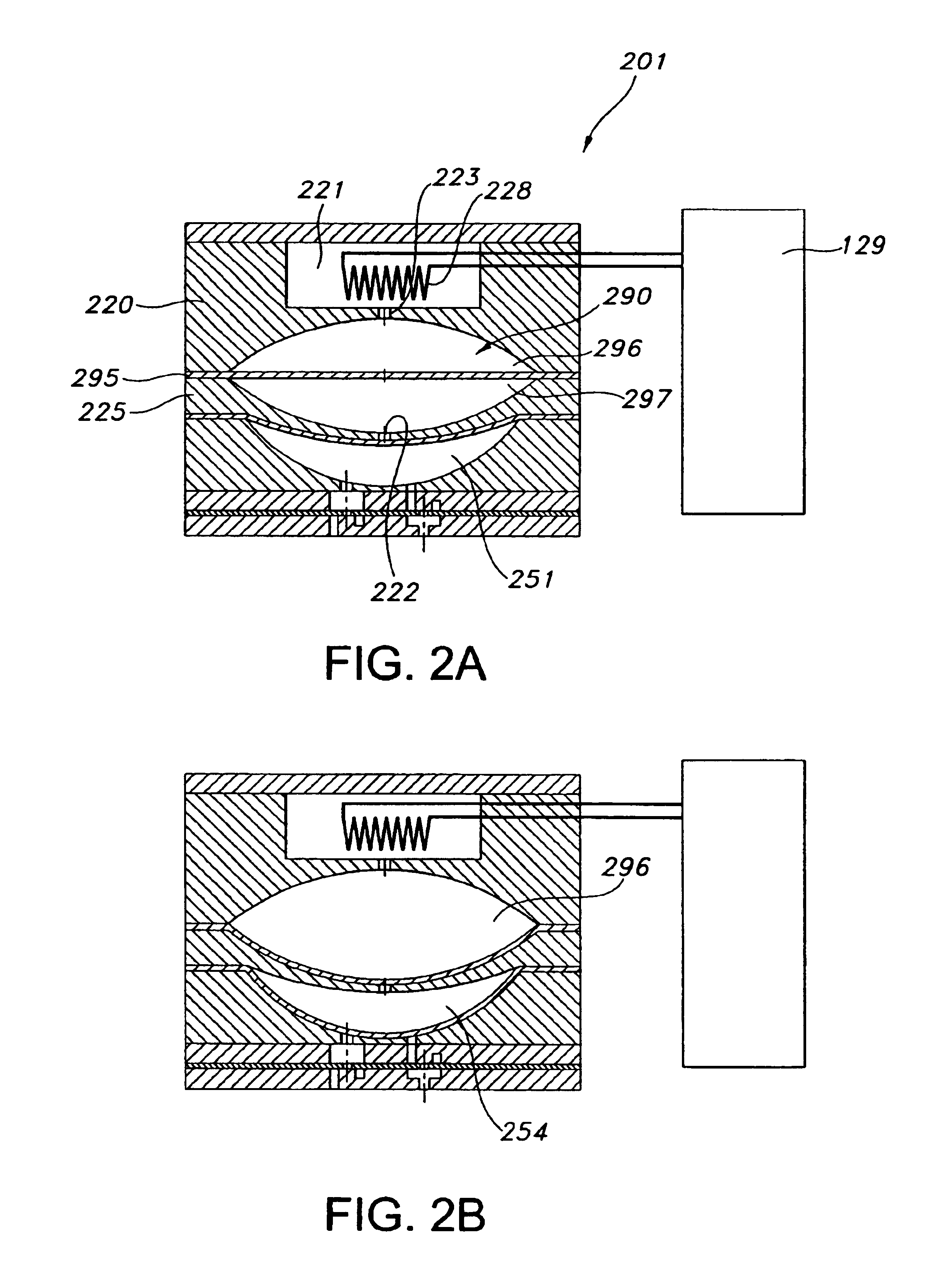

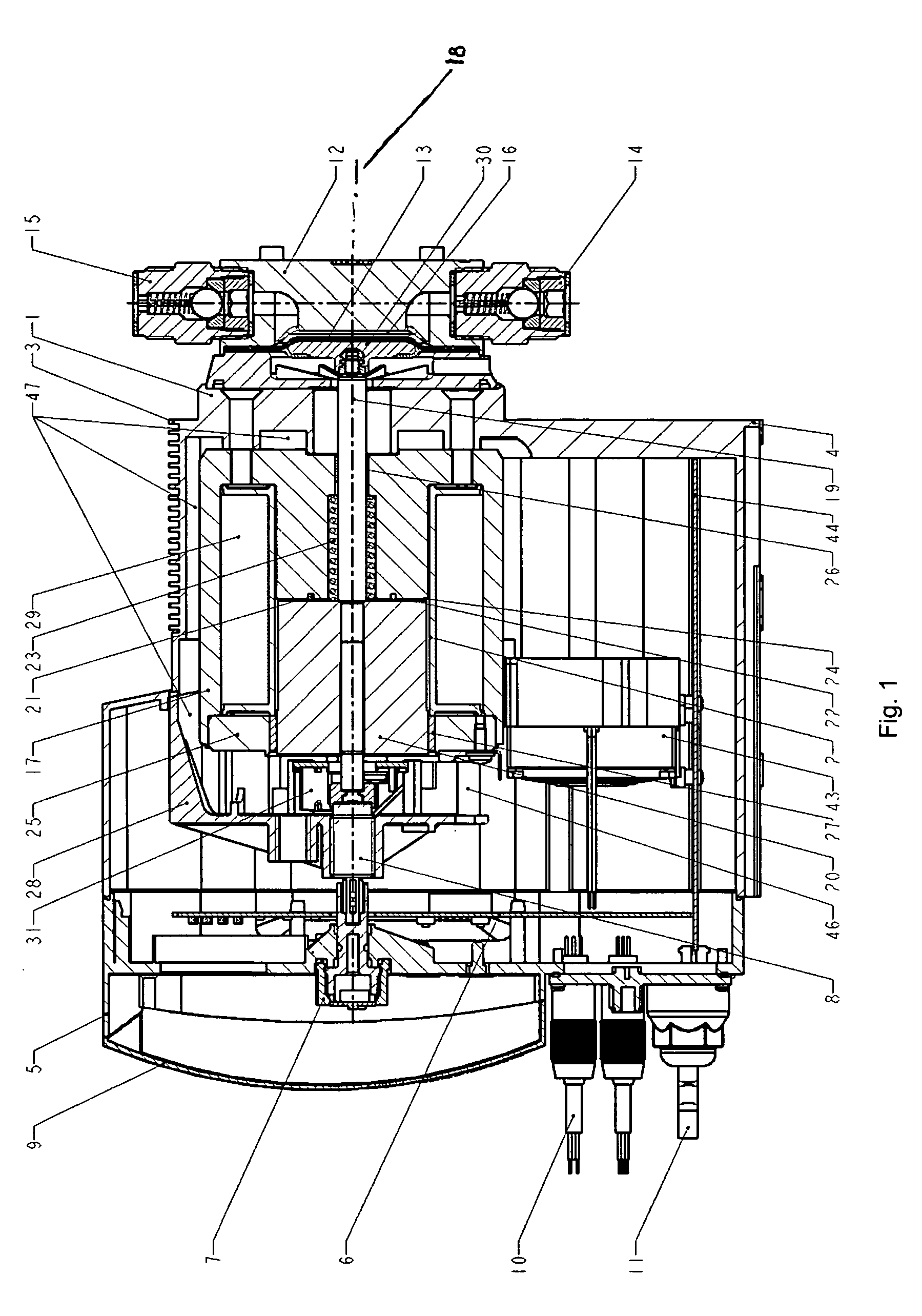

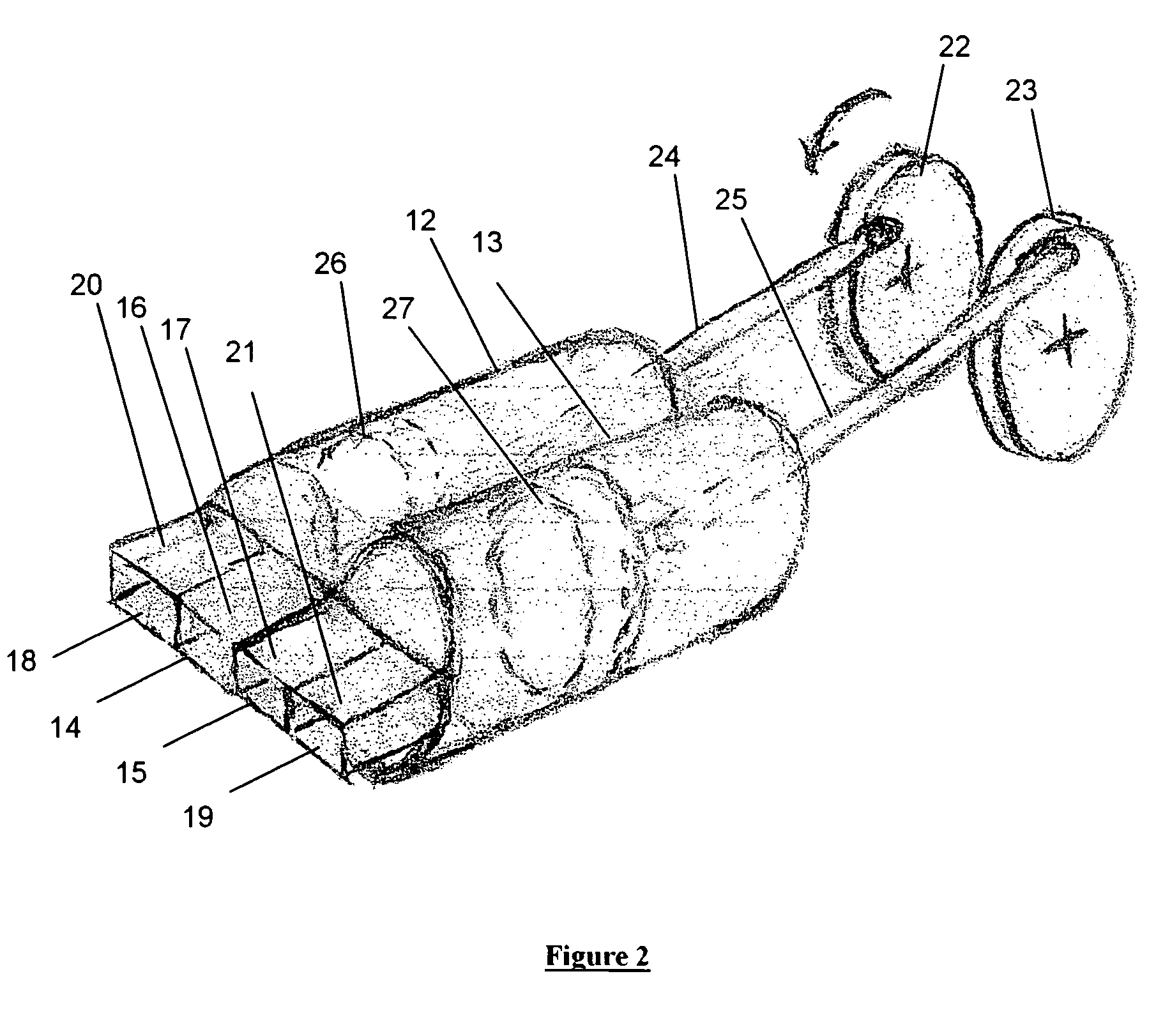

Membrane pump with stretchable pump membrane

InactiveUS6948918B2Stiff systemImprove accuracyValve arrangementsPositive displacement pump componentsPump chamberInlet valve

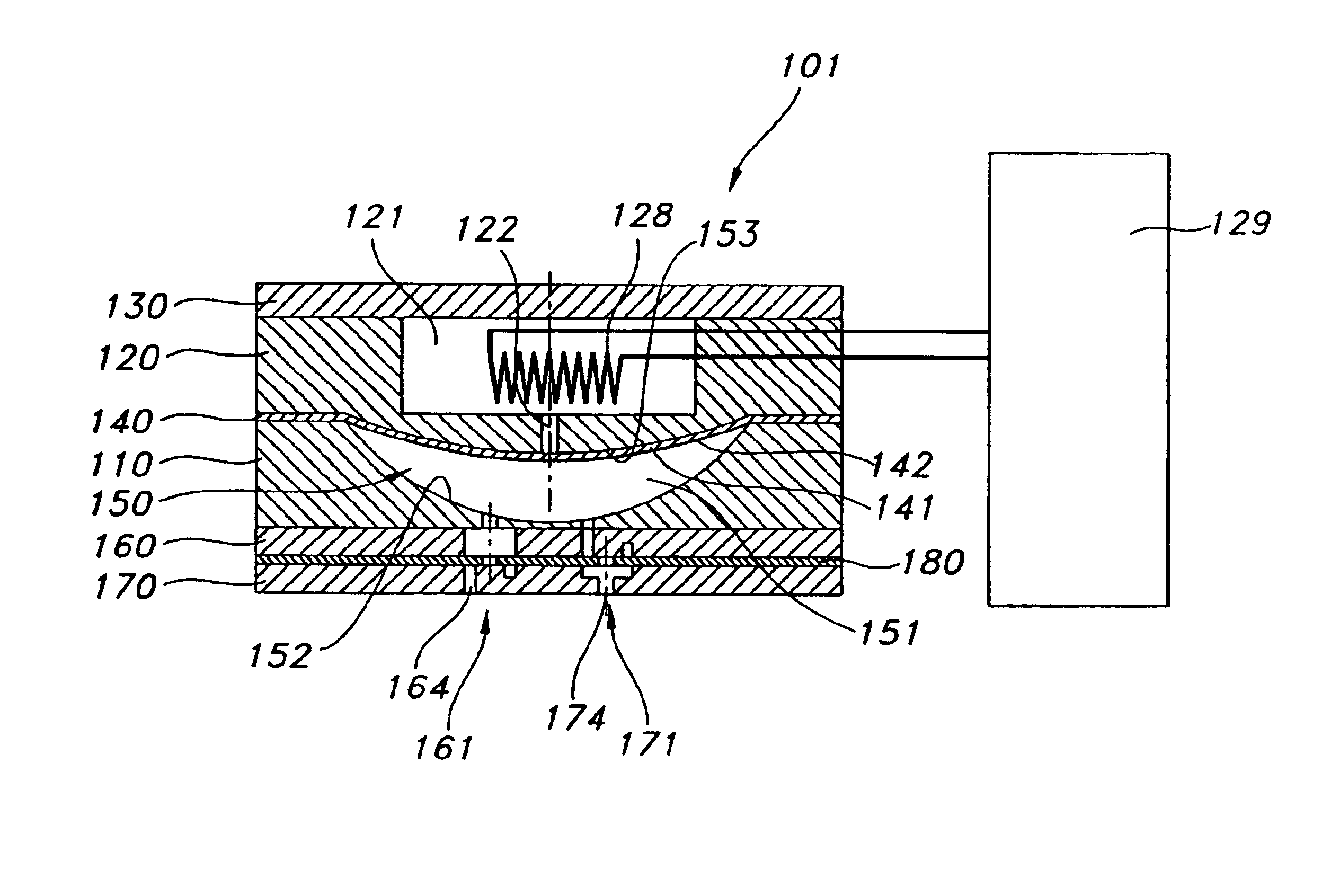

The invention relates to membrane pumps for delivering liquids. More specifically, a pump is provided having a pump housing with a pump cavity formed between first and second wall portions thereof, and an pump membrane pump membrane having first and second membrane surfaces arranged within the pump cavity, whereby a pump chamber is provided between the first wall portion and the first membrane surface, and an actuation chamber is provided between the second wall and the second membrane surface. Inlet means comprising an inlet valve in fluid communication with the pump chamber, and outlet means comprising an outlet valve in fluid communication with the pump chamber are provided. The pump membrane has a maximum volume position, and a drained volume position in which the first membrane surface in a stretched state abuts the first wall. To drive the membrane, actuating means for periodically shifting the pump membrane between the maximum volume position and the drained volume position is provided, thereby, in a situation of use, providing a flow of fluid.

Owner:NOVO NORDISK AS

Quaternary Ammonium Salt of a Polyalkene-Substituted Amine Compound

InactiveUS20080113890A1Organic compound preparationTransportation and packagingCompound aQuaternary ammonium cation

A quaternary ammonium salt detergent made from the reaction product of the reaction of: (a) polyalkene-substituted amine having at least one tertiary amino group; and (b) a quaternizing agent suitable for converting the tertiary amino group to a quaternary nitrogen and the use of such quaternary ammonium salt detergents in a fuel composition to reduce intake valve deposits.

Owner:THE LUBRIZOL CORP

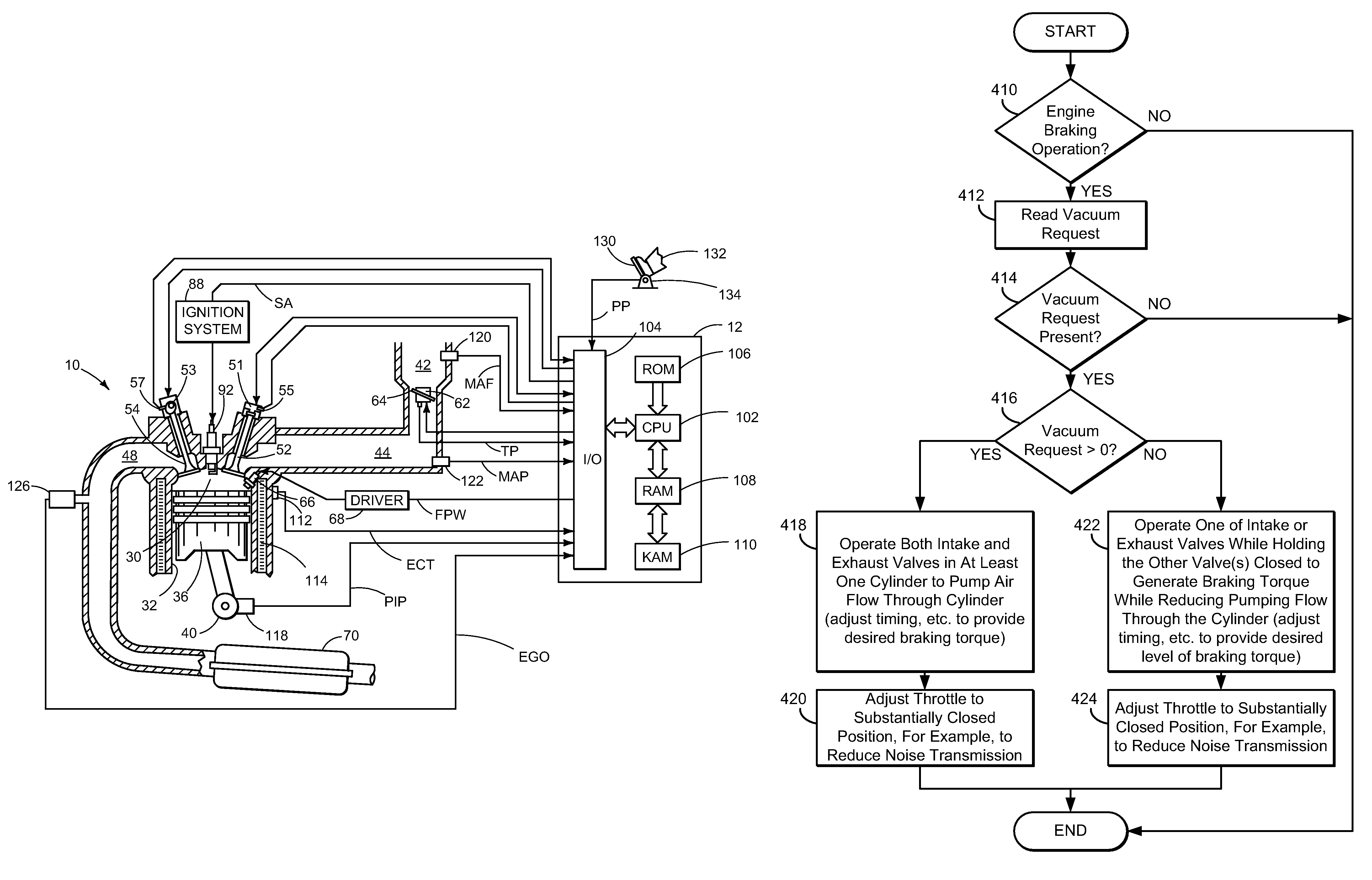

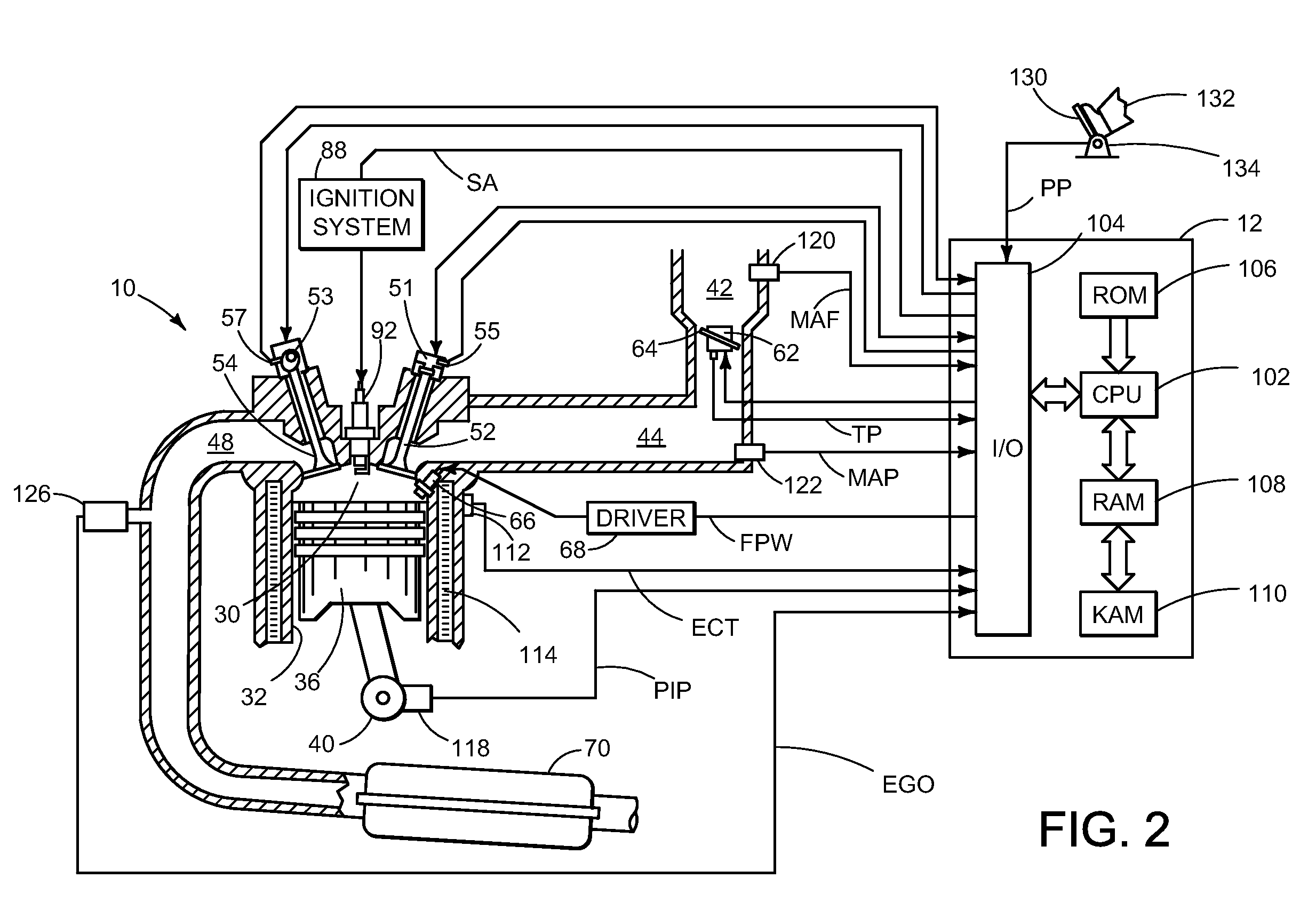

Vehicle braking control

ActiveUS7930087B2Reduced effectivenessImprove fuel economyElectrical controlInternal combustion piston enginesExhaust valveInlet valve

A method of operating an engine for a vehicle having at least a first cylinder, the method comprising of operating the first cylinder to provide at least one of compression braking and expansion braking by holding one of an intake valve and an exhaust valve of the first cylinder closed while opening, closing, and opening the other of the intake valve and the exhaust valve during a cycle of the first cylinder and during a first vacuum level of an intake manifold upstream of the first cylinder; and operating the first cylinder to provide at least one of compression braking and expansion braking by operating both the intake valve and the exhaust valve of the first cylinder during a cycle of the first cylinder to allow at least some air to flow through the first cylinder during a second vacuum level of the intake manifold.

Owner:FORD GLOBAL TECH LLC

Optimized fuel management system for direct injection ethanol enhancement of gasoline engines

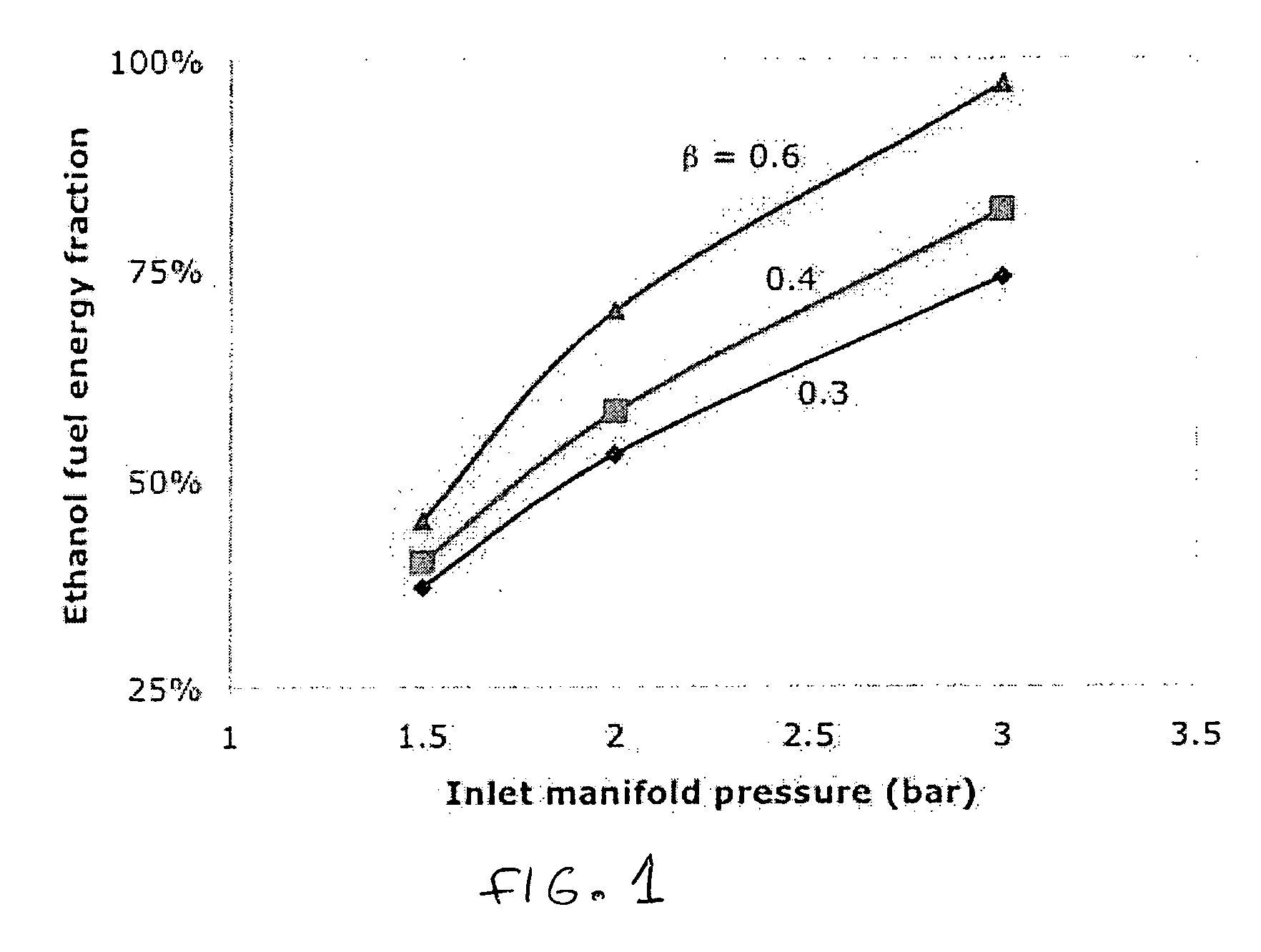

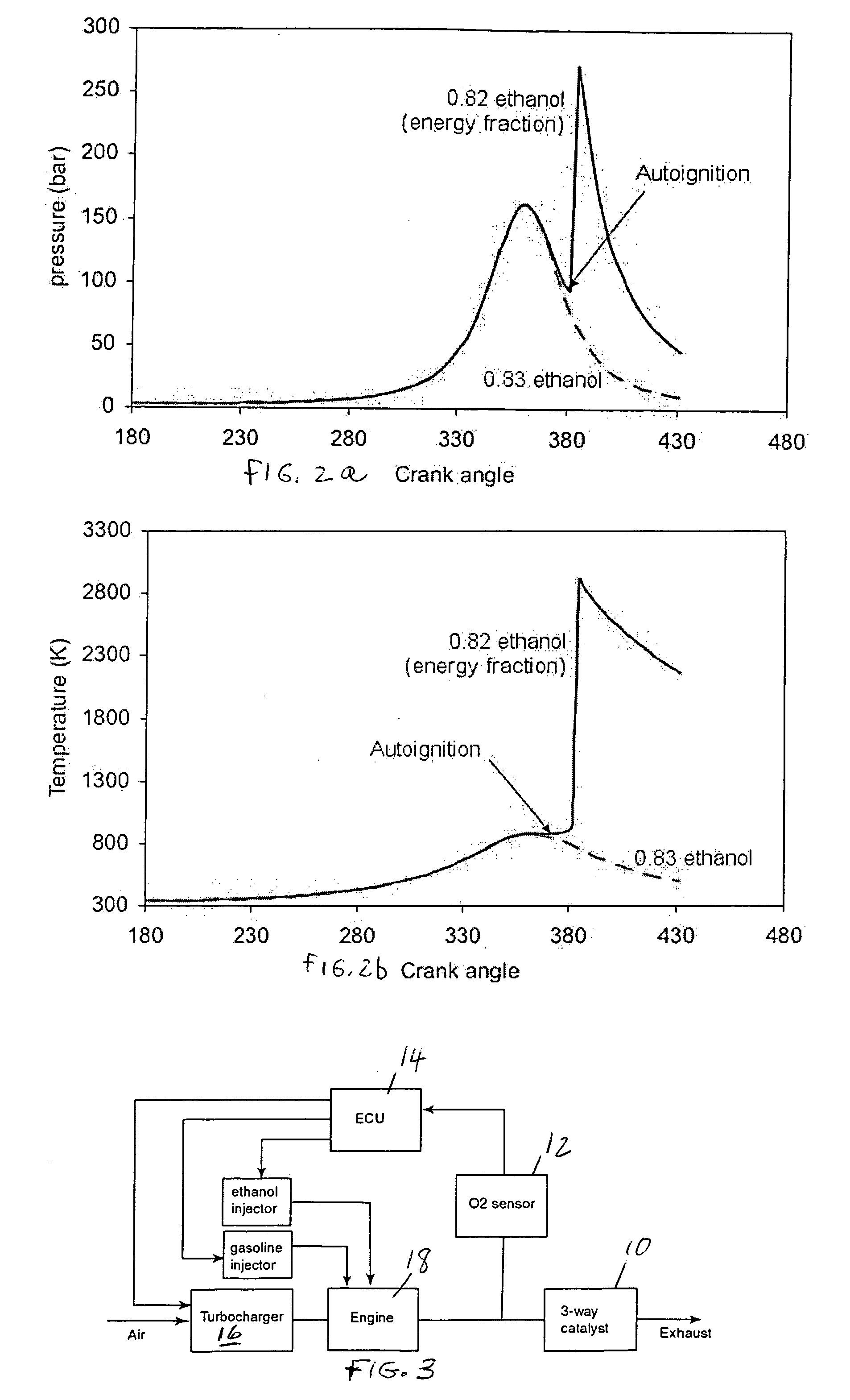

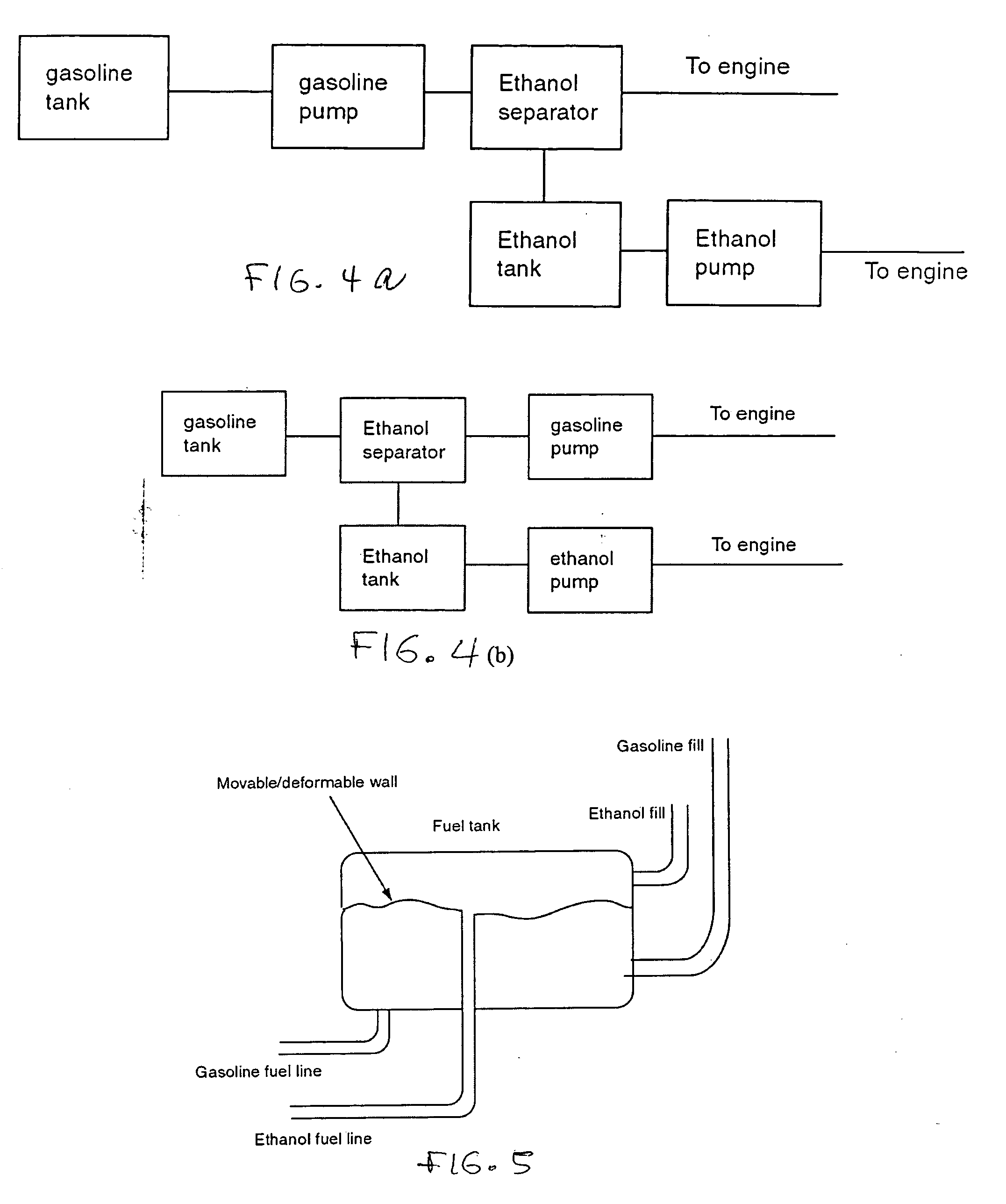

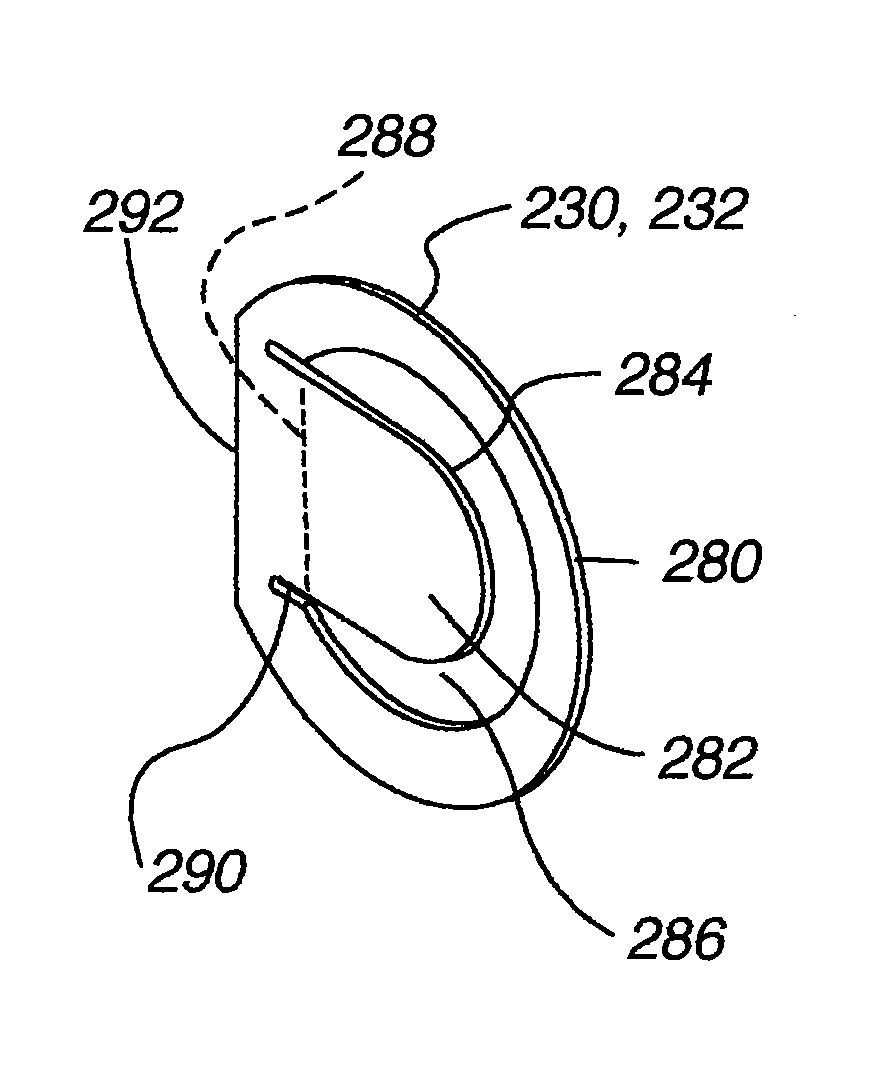

InactiveUS20060102136A1Improve engine efficiencySave gasElectrical controlNon-fuel substance addition to fuelProcess engineeringVaporization

Fuel management system for enhanced operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder. It is preferred that the direct injection occur after the inlet valve is closed. It is also preferred that stoichiometric operation with a three way catalyst be used to minimize emissions. In addition, it is also preferred that the anti-knock agents have a heat of vaporization per unit of combustion energy that is at least three times that of gasoline.

Owner:MASSACHUSETTS INST OF TECH

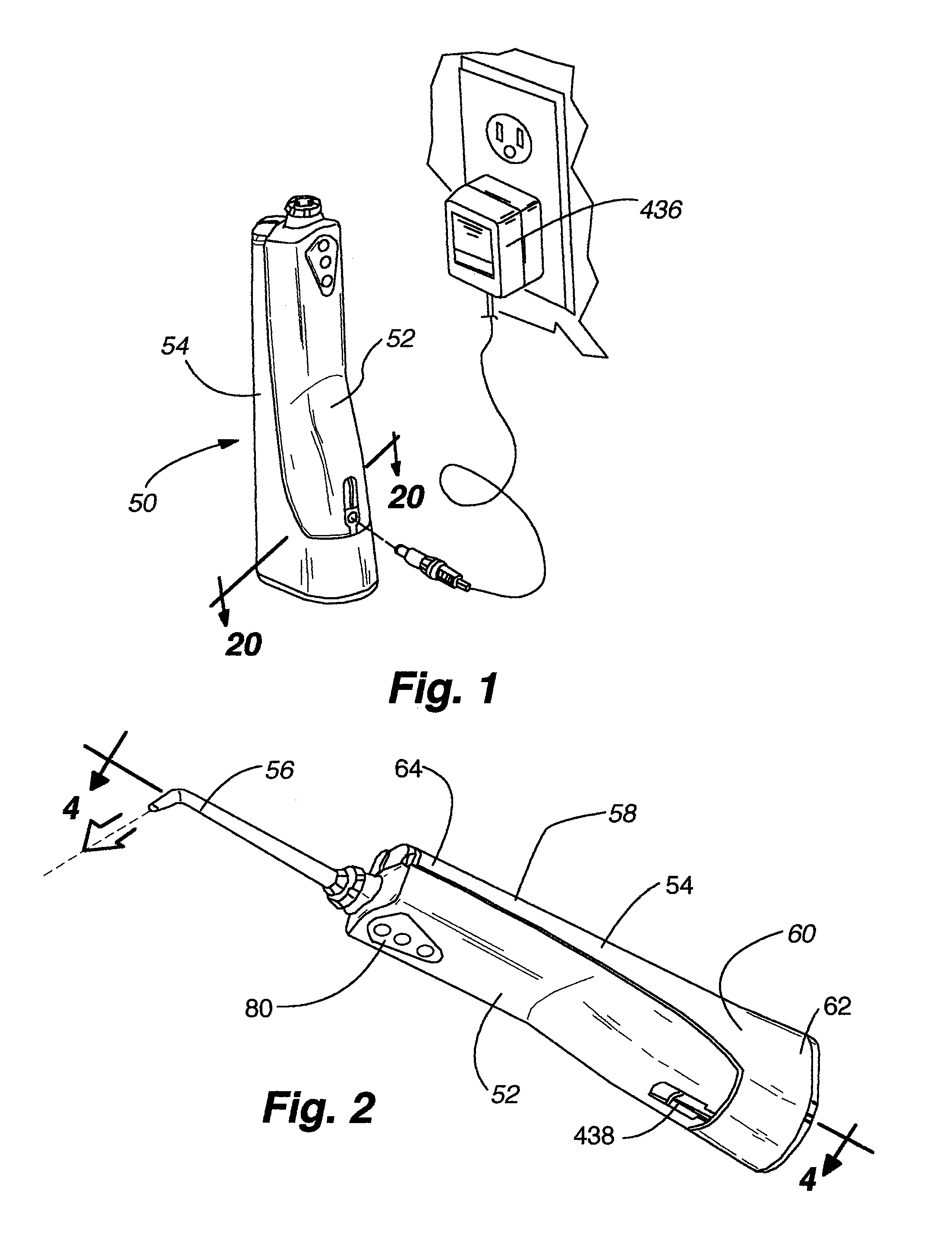

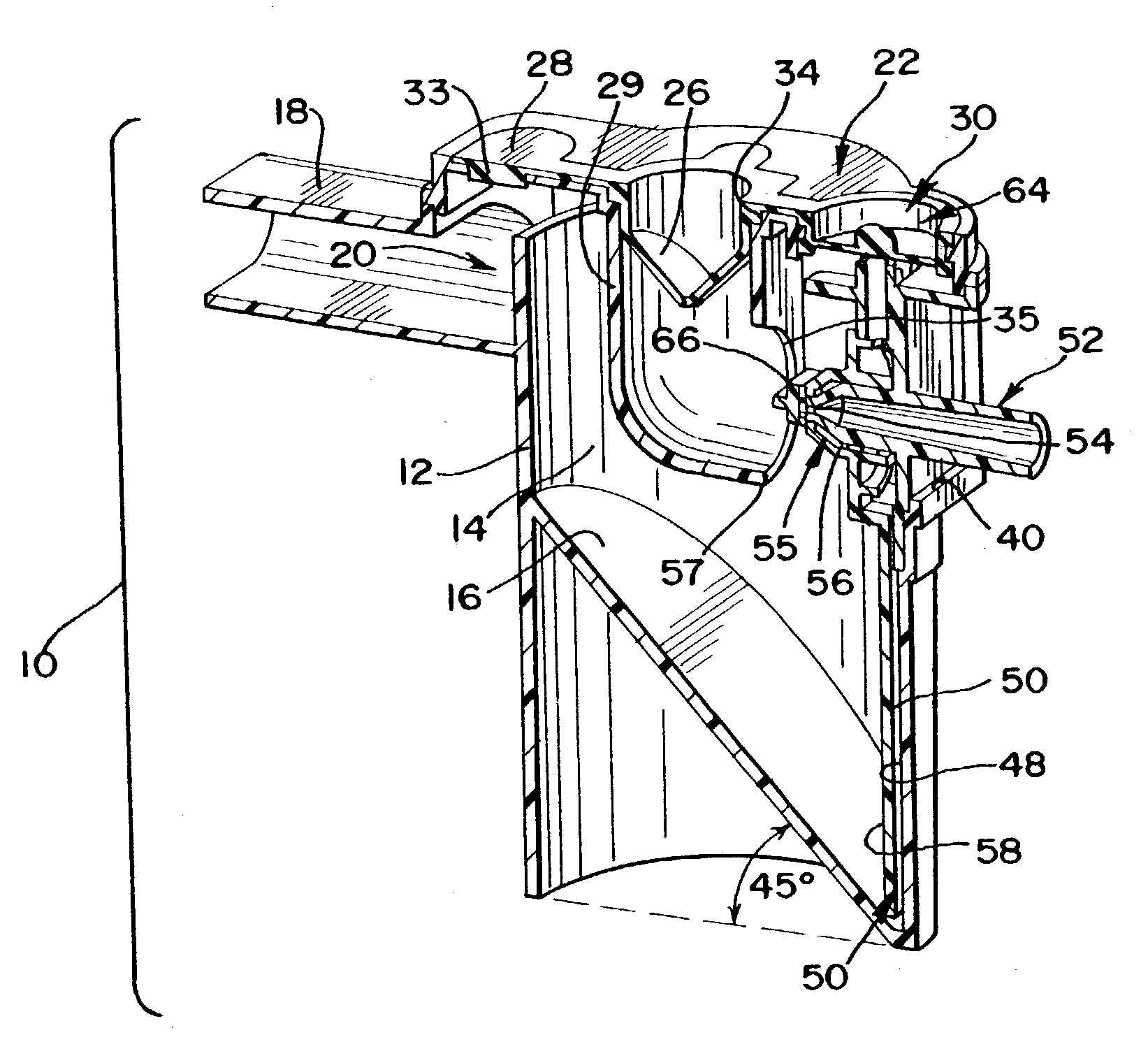

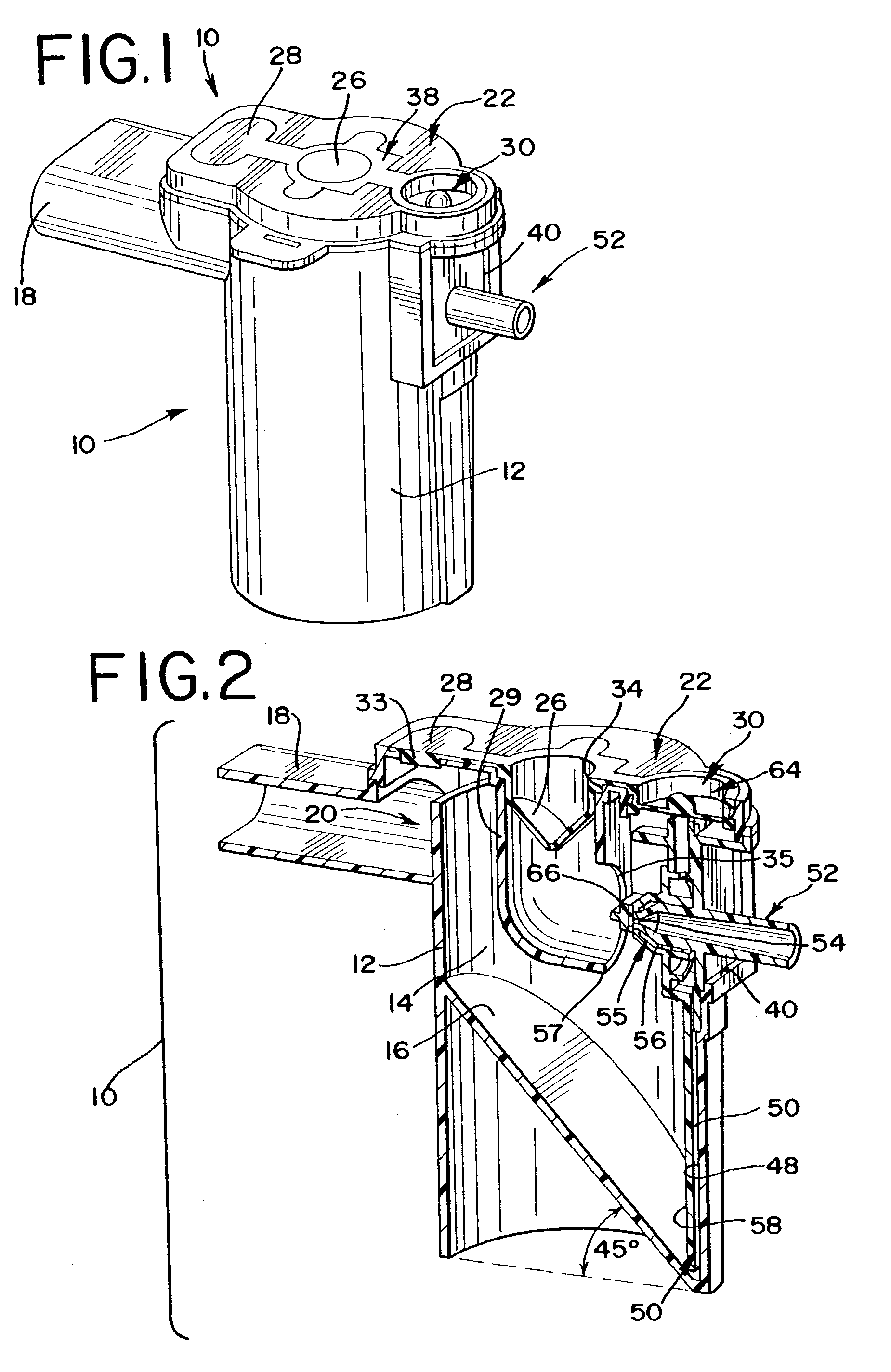

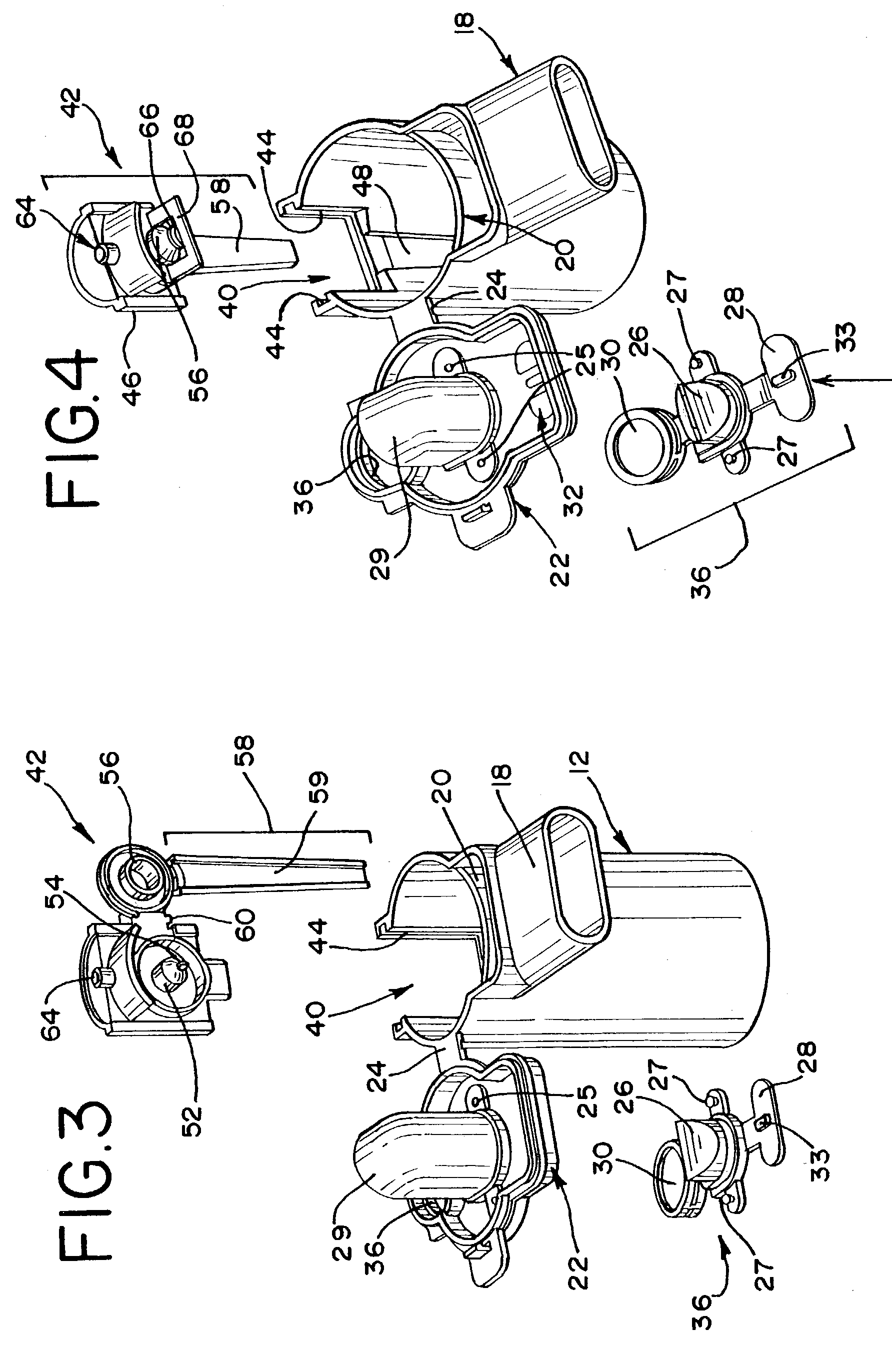

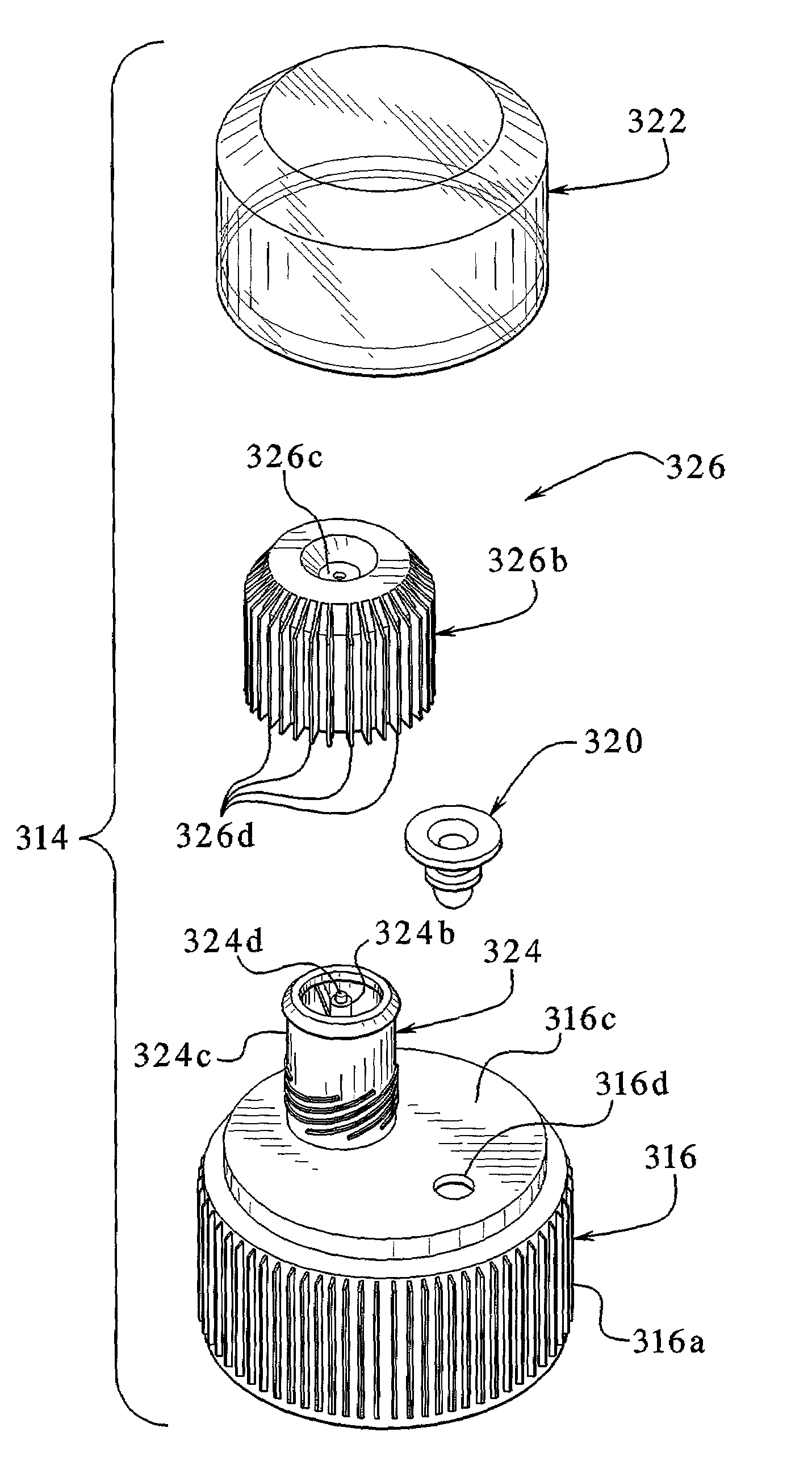

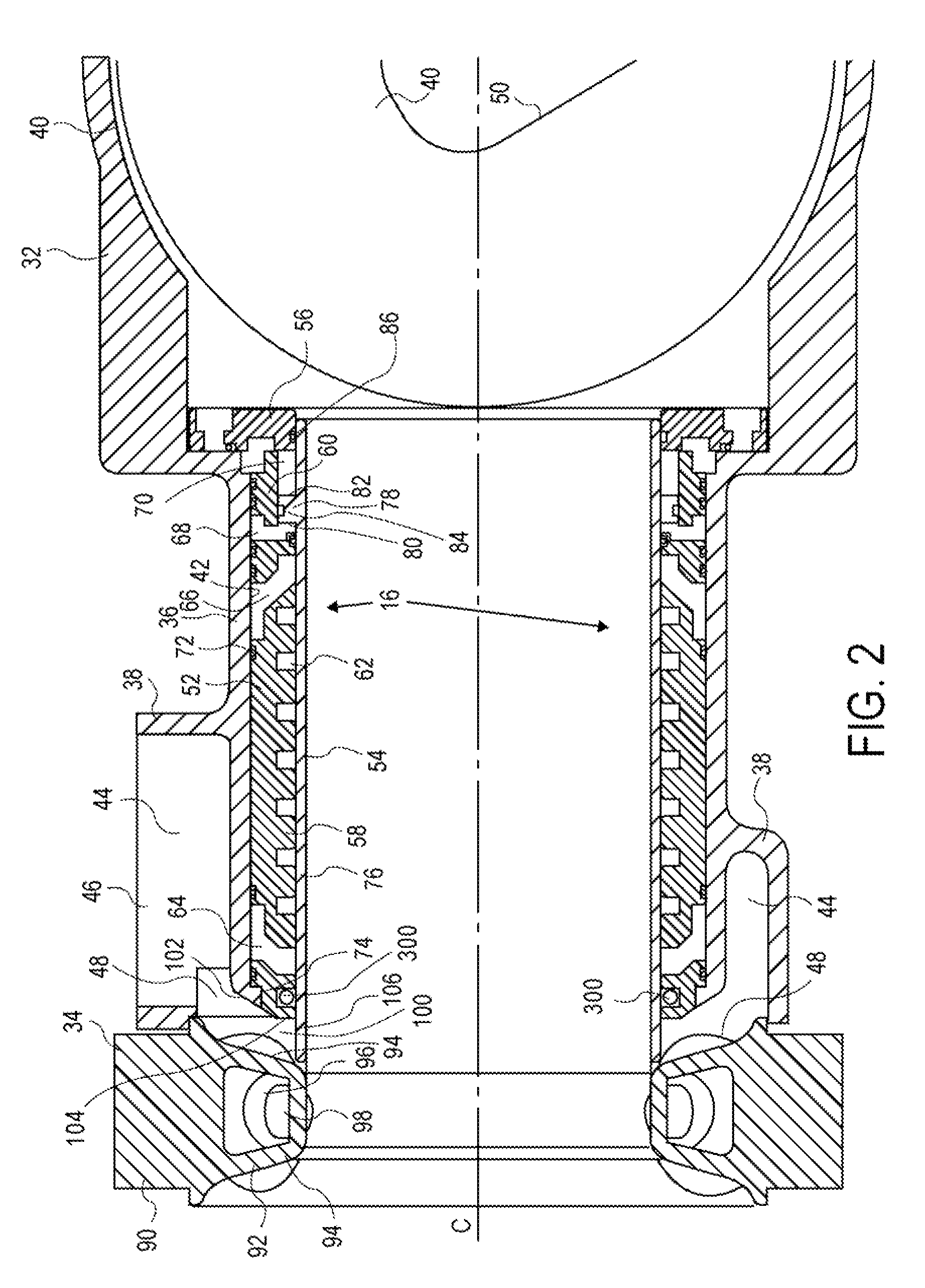

Hand held oral irrigator

According to one broad aspect of one embodiment of the present invention, disclosed herein is a hand held oral irrigation device having a tip for dispensing fluids. In one example, an oral irrigation device includes a body portion, and a reservoir for storing fluids, wherein the body and / or the reservoir define a first major diameter at a lower end of the oral irrigation device, and define a second major diameter at an upper end of the oral irrigation device, the first major diameter being larger than the second major diameter. In this example, by providing such a geometry for the device, a user can grasp the device with one hand about the second major diameter during use. In another example, the body includes a pump for pumping fluids from the reservoir to the tip, wherein the pump includes an inlet valve and an outlet valve, the inlet valve including a reed valve made of flexible fabric material. The outlet valve may also include a reed valve made of flexible fabric material.

Owner:WATER PIK INC

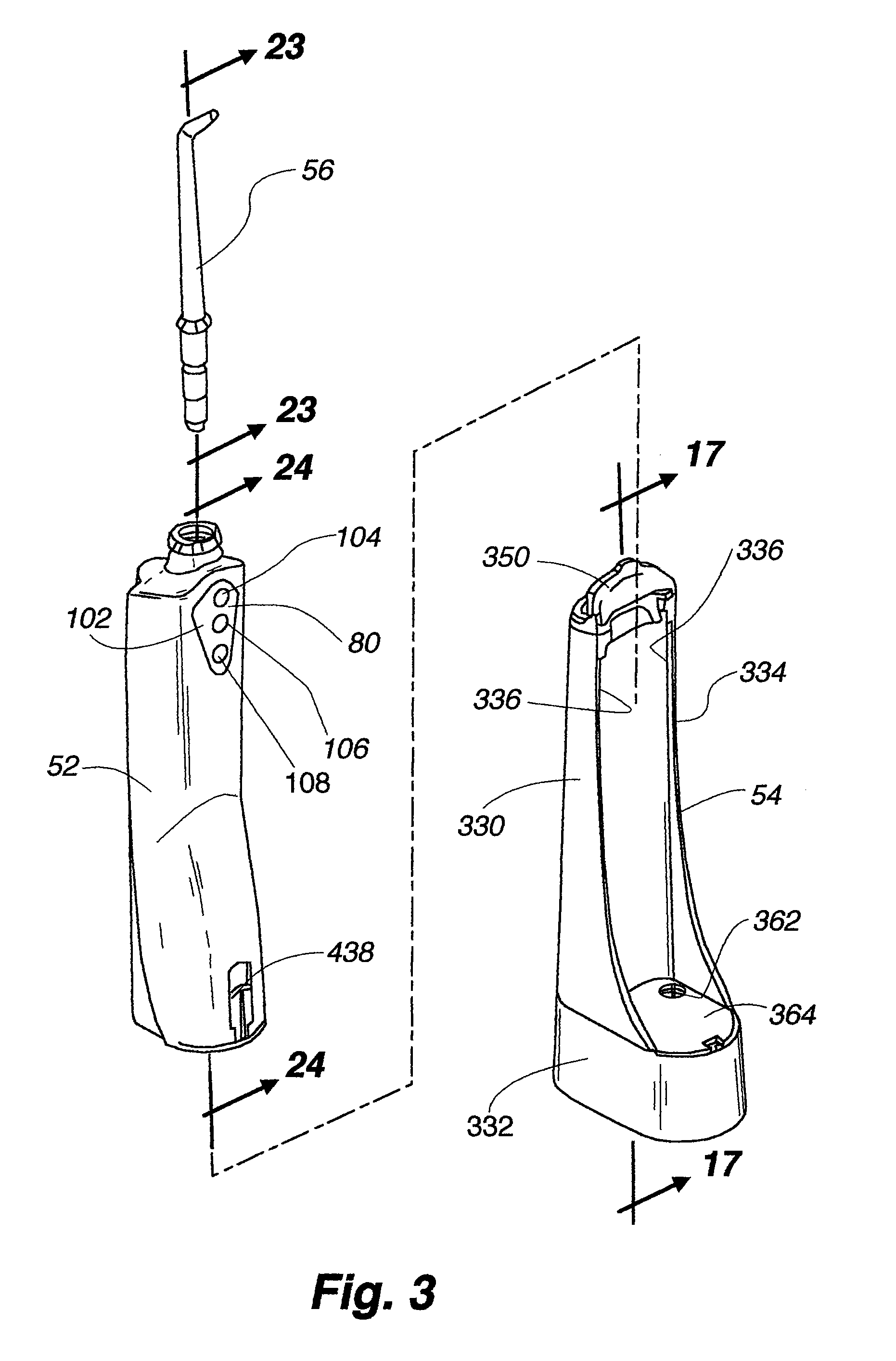

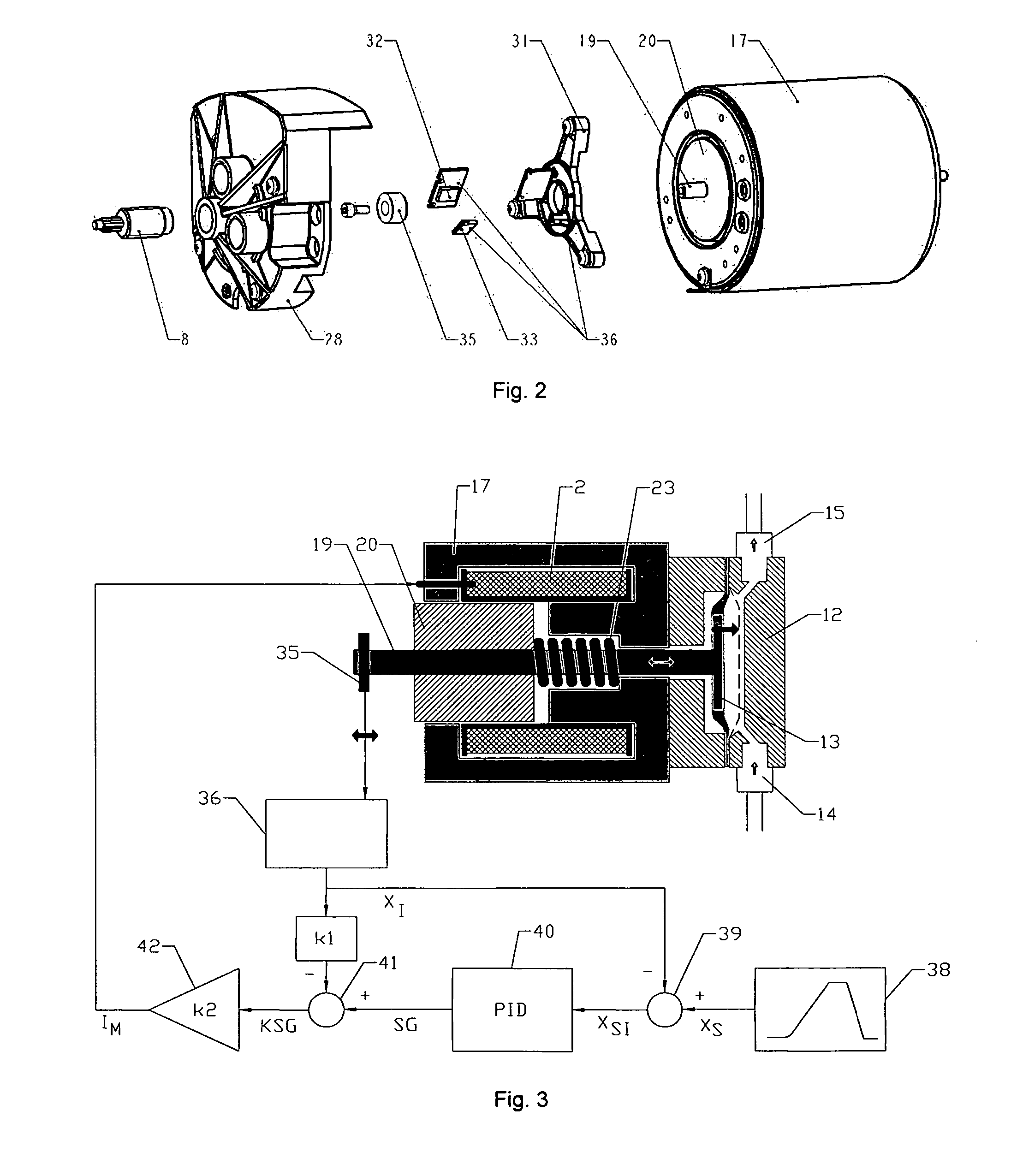

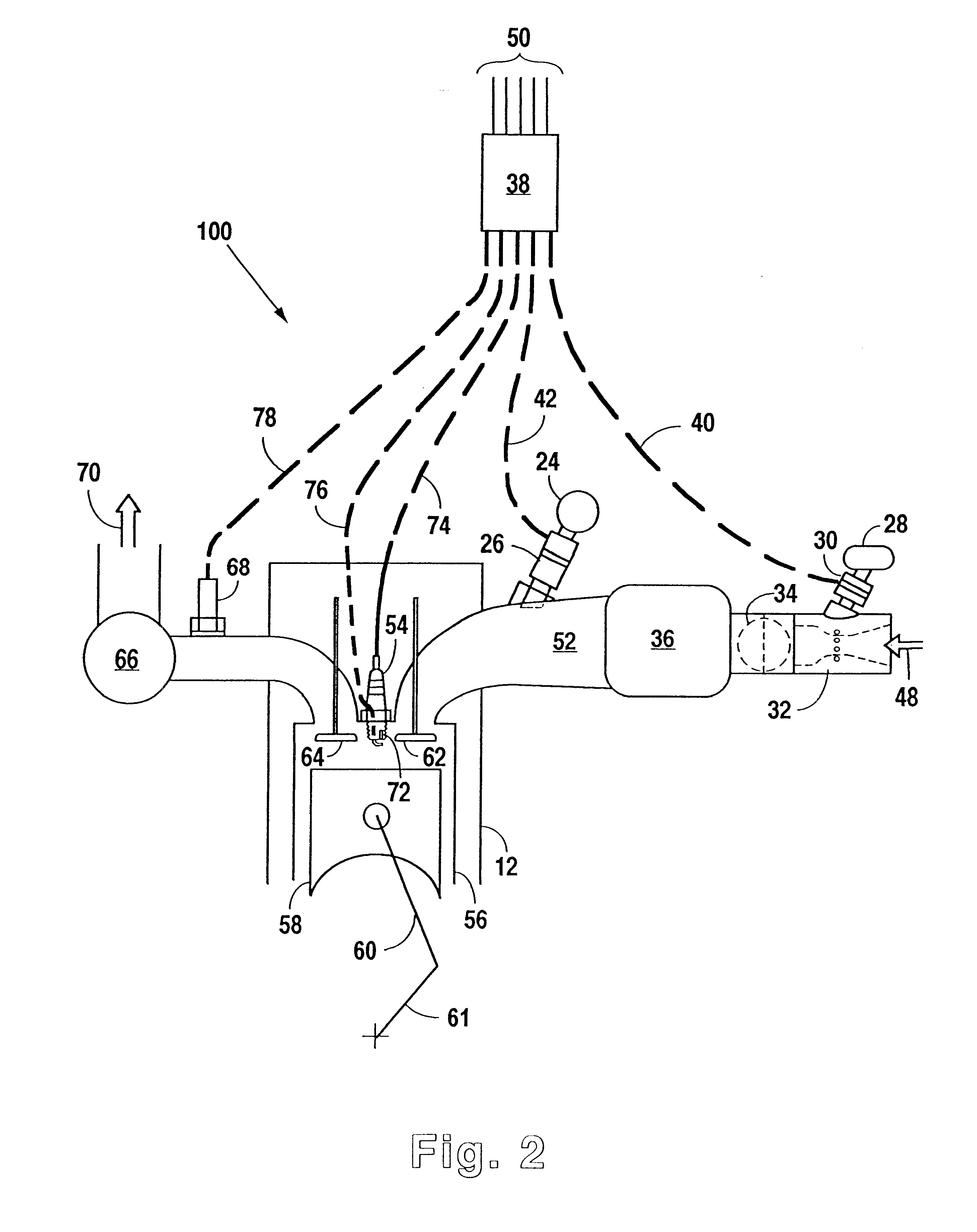

Magnetic drive metering pump

ActiveUS20070040454A1Motor/generator/converter stoppersDC motor speed/torque controlMagnetic tension forceInlet valve

A magnetic drive metering pump in which a movable thrust member fixed to a connecting rod is axially movable in a longitudinal axis in a magnet shroud anchored in a pump housing so that the thrust member with the connecting rod, on electrically driving (actuating) the magnetizing coil, is drawn into the magnet shroud against the force of a recuperating spring, reducing an air gap between the thrust member and an inner face of magnetic shroud, into a bore in the magnet shroud and after deactivating the magnet the thrust member is returned to the starting position by the recuperating spring so that the thrust member and an elastic displacement member actuated thereby on carries out an oscillating motion continued activation and deactivation of the magnetizing coil, which diaphragm cooperates alternately with an outlet and an inlet valve to produce a pump stroke (pressure stroke) and a priming stroke in a metering head arranged in the longitudinal axis. In such a magnetic drive metering pump, a reference element is associated with the module constituted by the thrust member and connecting rod, the position of which reference element is detected by a positional sensor, wherein the positional sensor provides an actual signal which is in a fixed relationship to the position of the reference element, and in that the motion of the unit formed by the thrust member and the connecting rod is influenced as regards control accuracy via a control circuit so that it follows a predetermined nominal profile.

Owner:PROMINENT

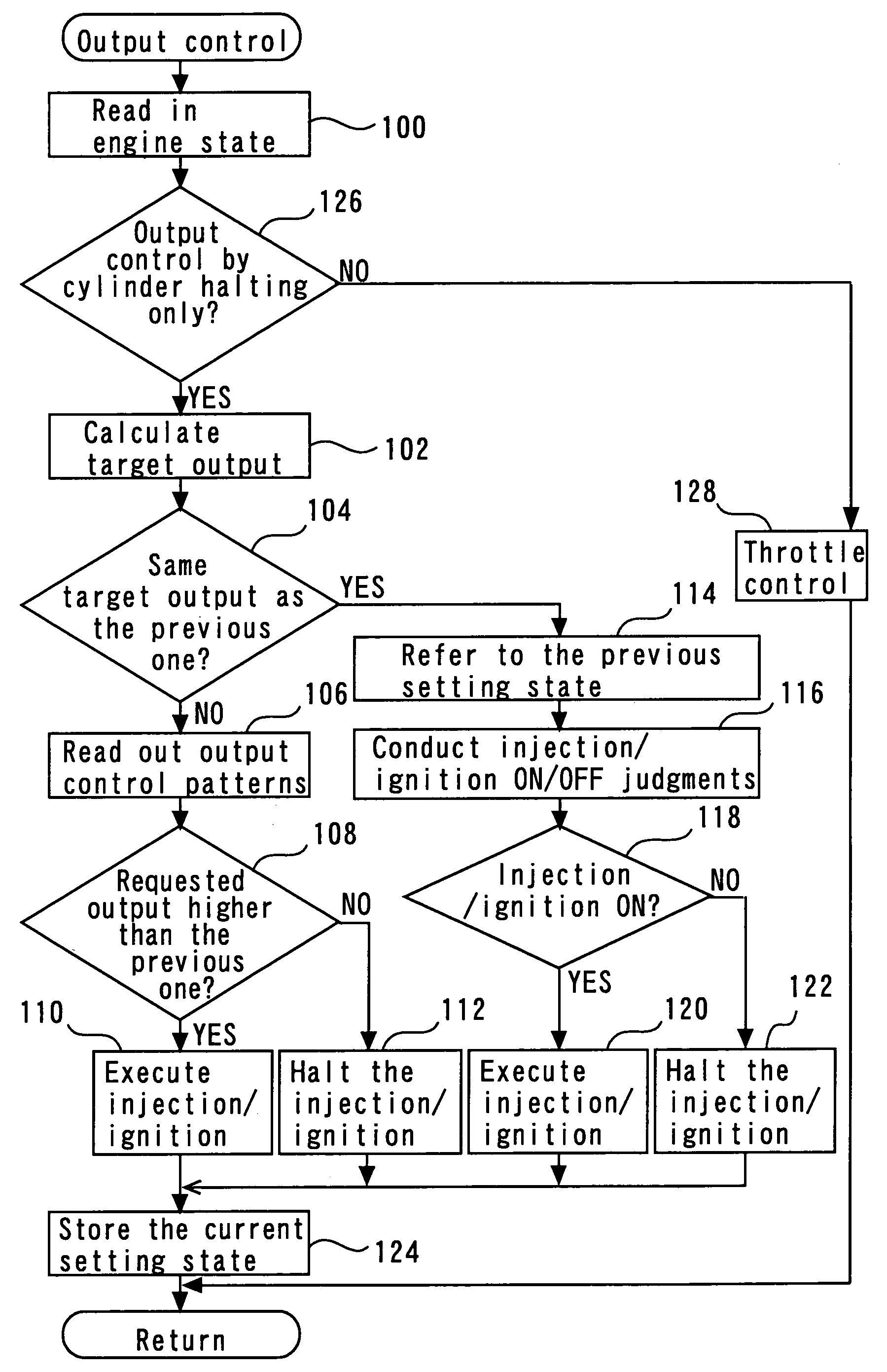

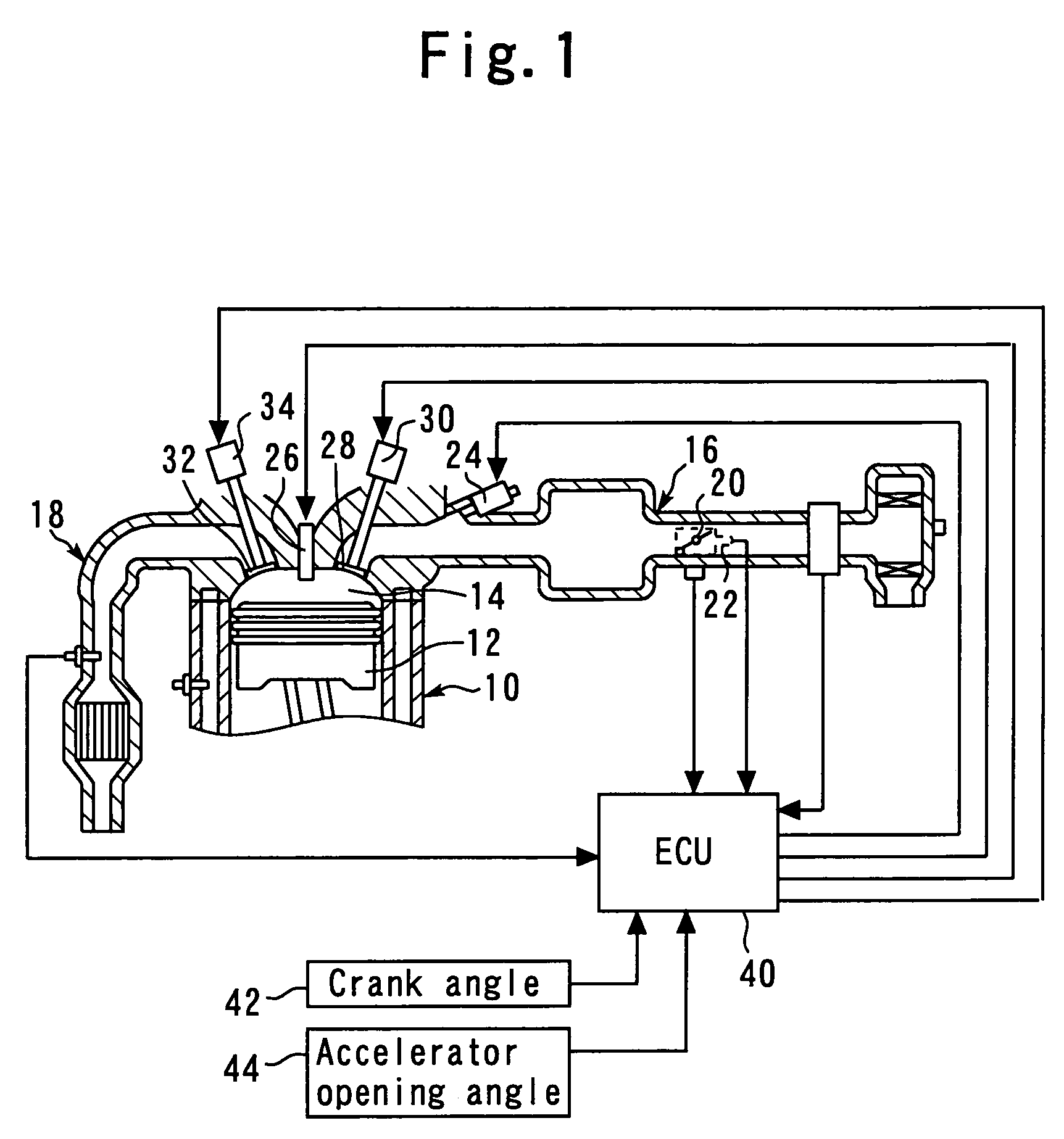

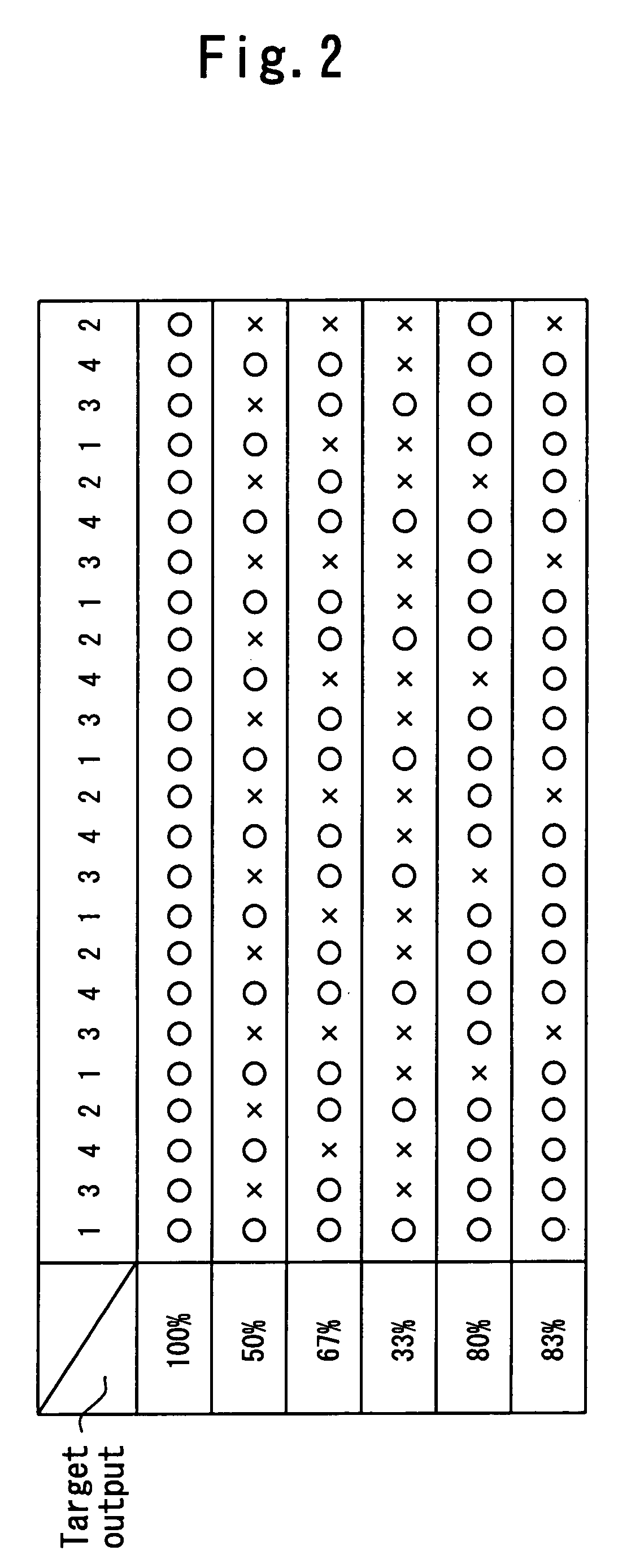

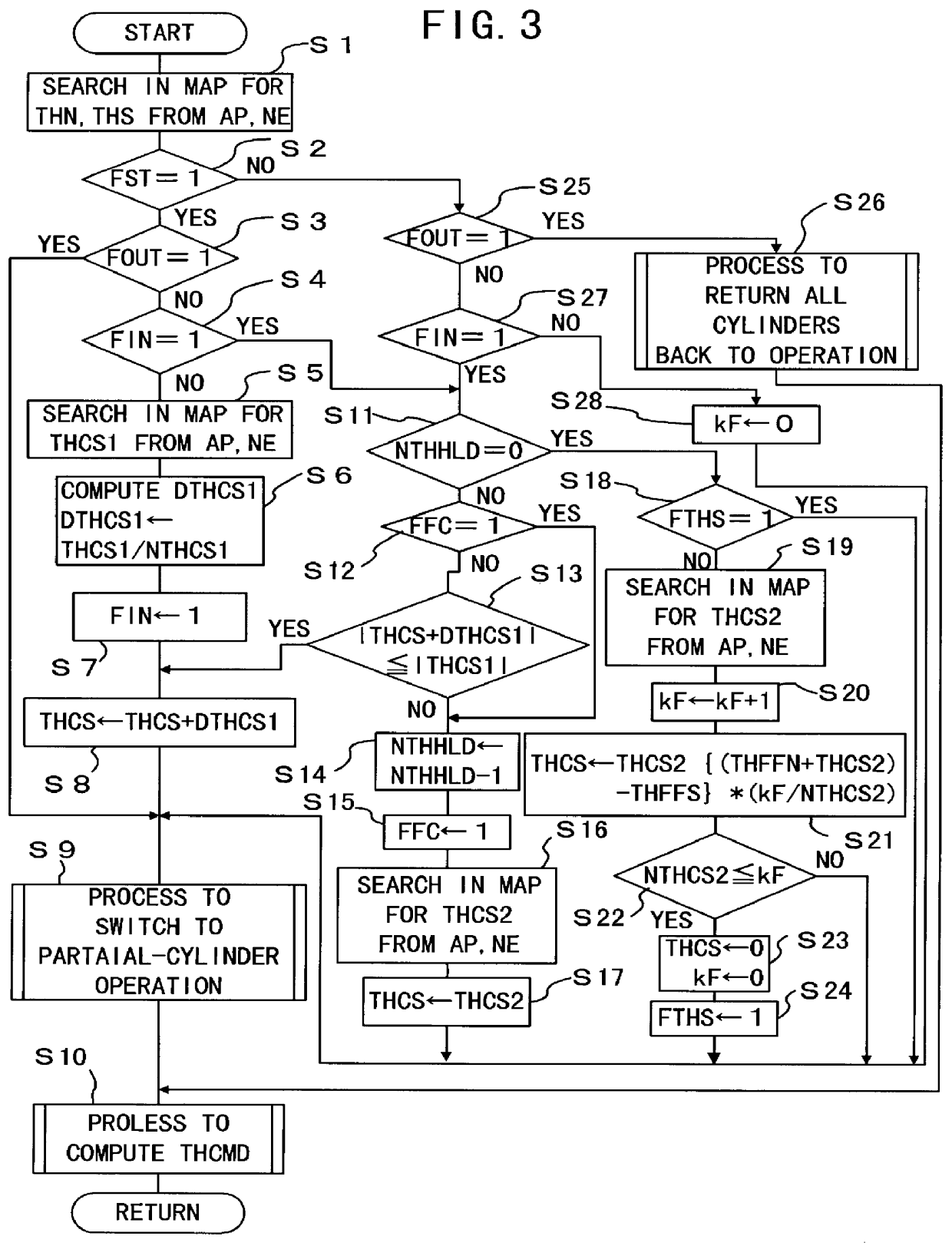

Output control system for internal combustion engine

InactiveUS7066136B2Easy to controlElectrical controlInternal combustion piston enginesCombustionExhaust valve

An intake electromagnetic driving valve and an exhaust electromagnetic driving valve are provided which use electromagnetic force to drive an intake valve and an exhaust valve, respectively. In step 102, the ratio between the number of combustion execution cycles and the number of combustion halts is set to obtain a desired target output value. Output control patterns that each consist of combustion execution timing equivalent to the required number of combustion execution cycles, and combustion halt timing equivalent to the required number of combustion halts are set in step 106, 114. In steps 108 to 112, or 118 to 122, in accordance with the output control patterns, whether combustion is to be executed is set with respect to the explosion timing that arrives in each cylinder in order.

Owner:TOYOTA JIDOSHA KK

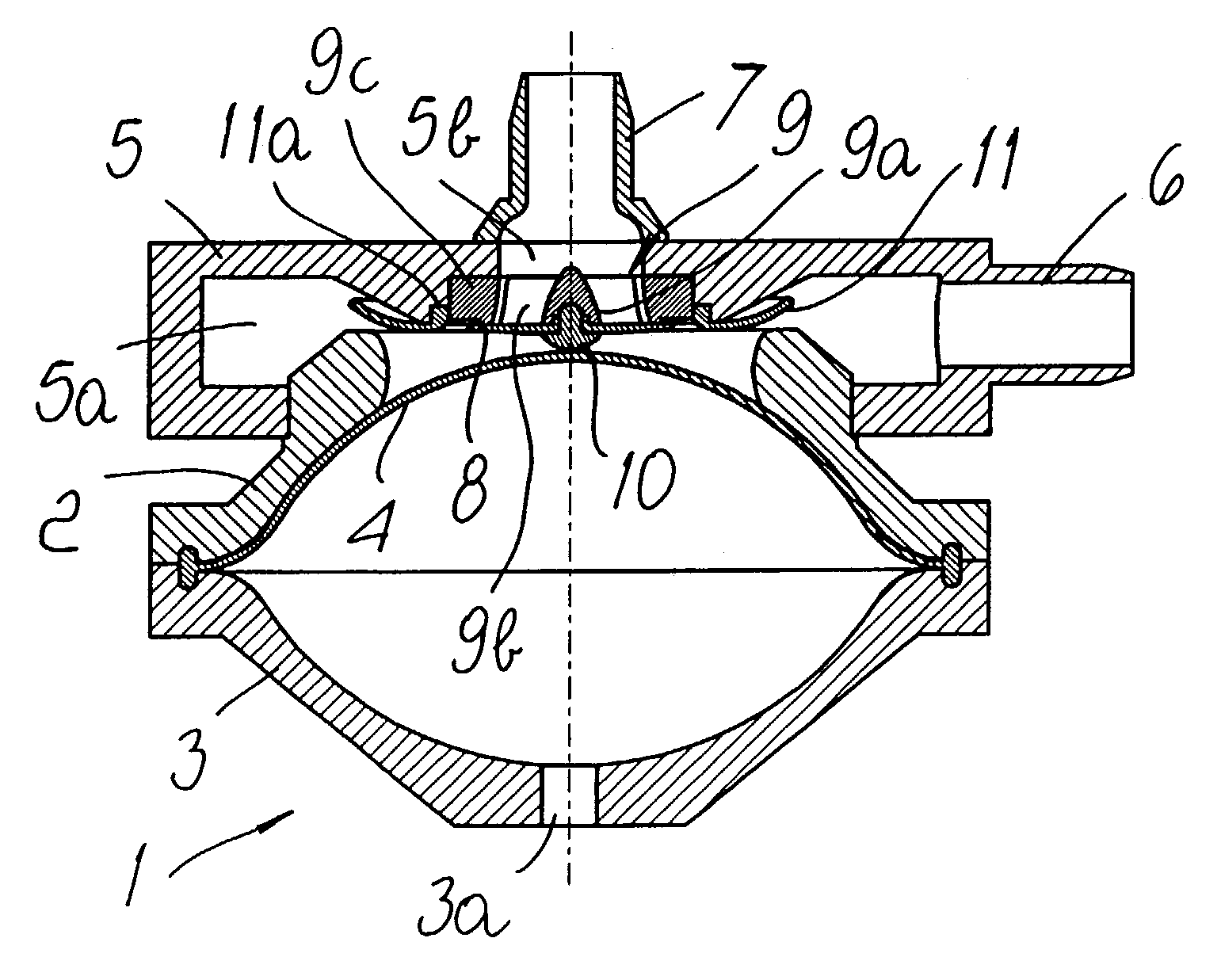

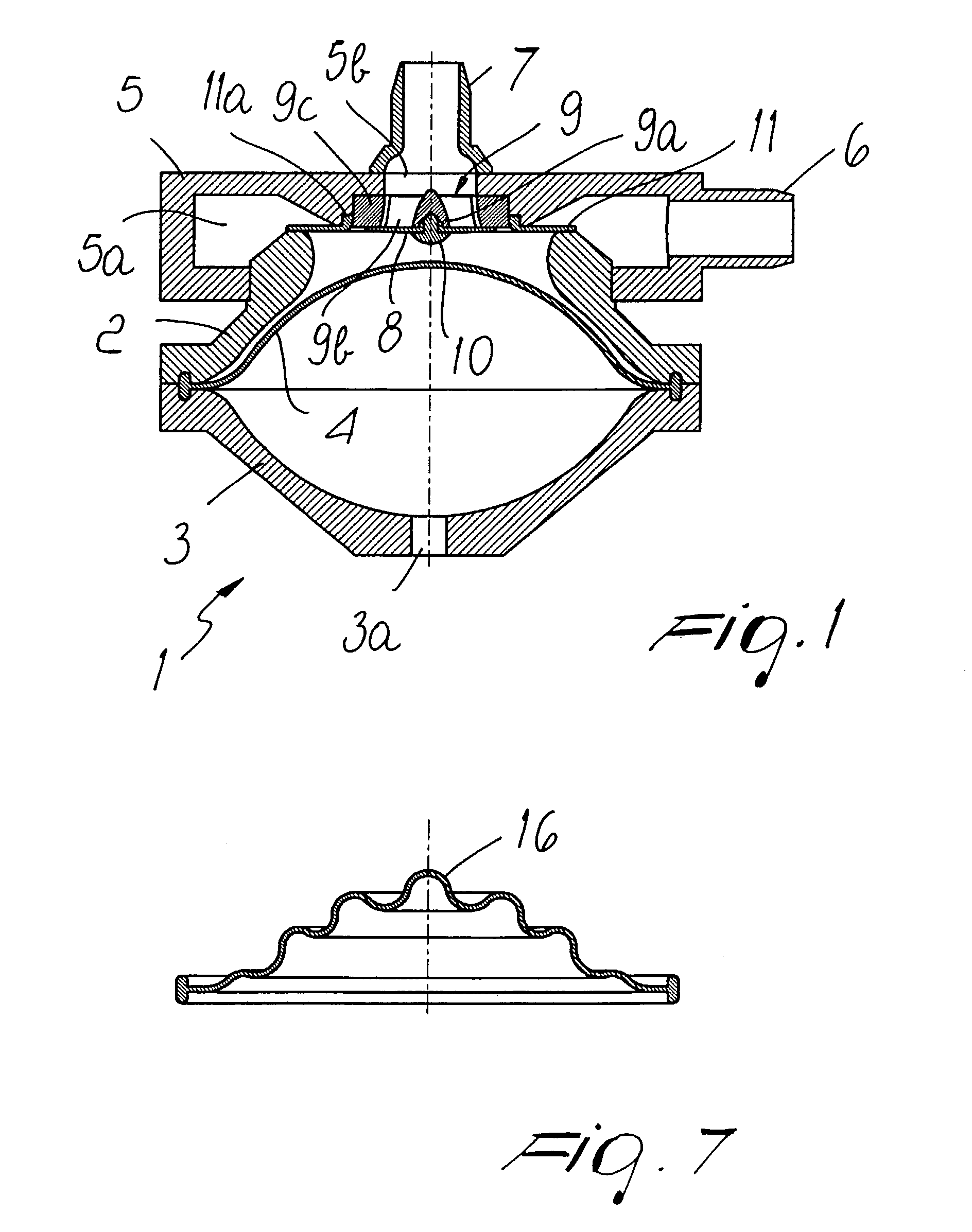

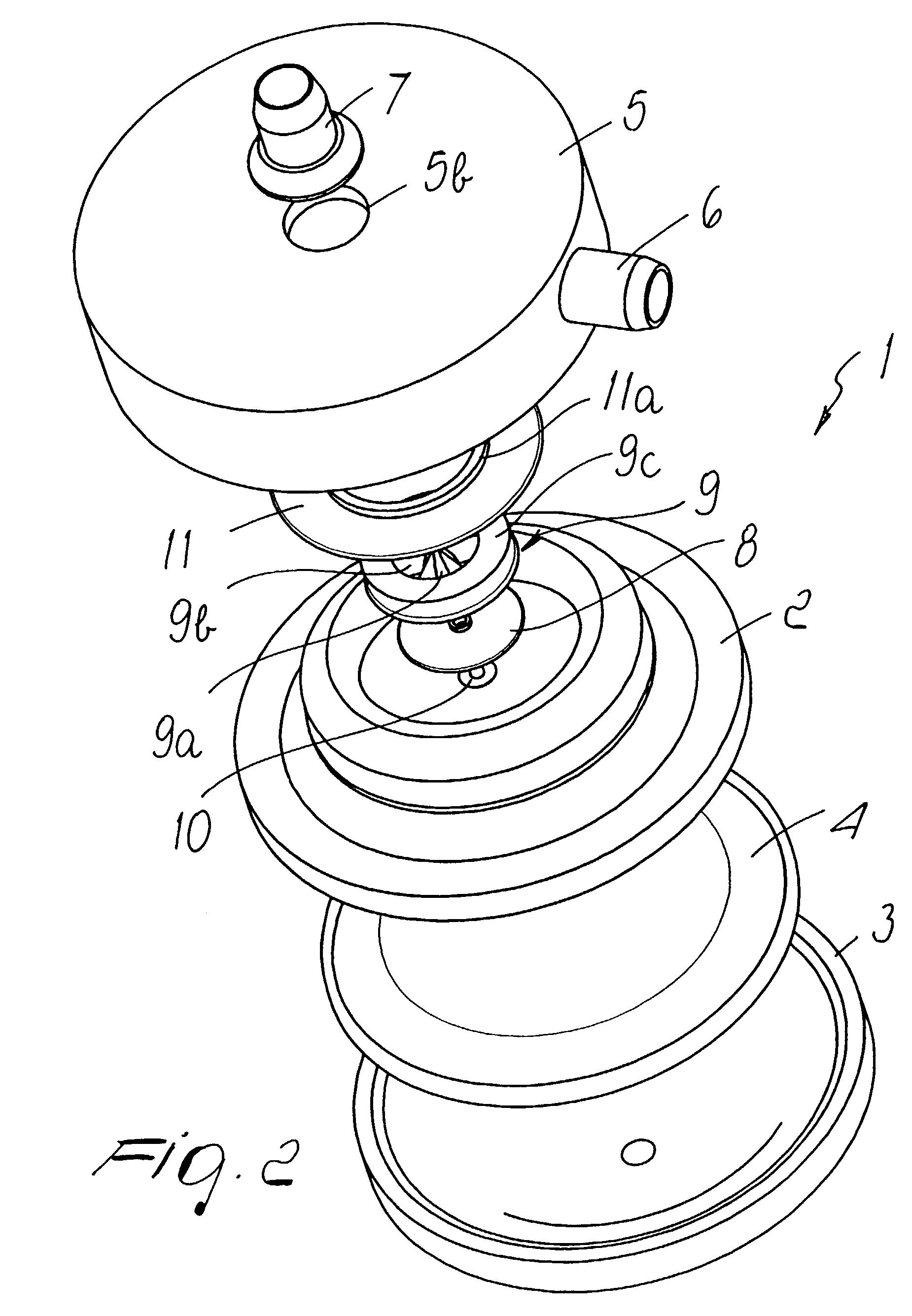

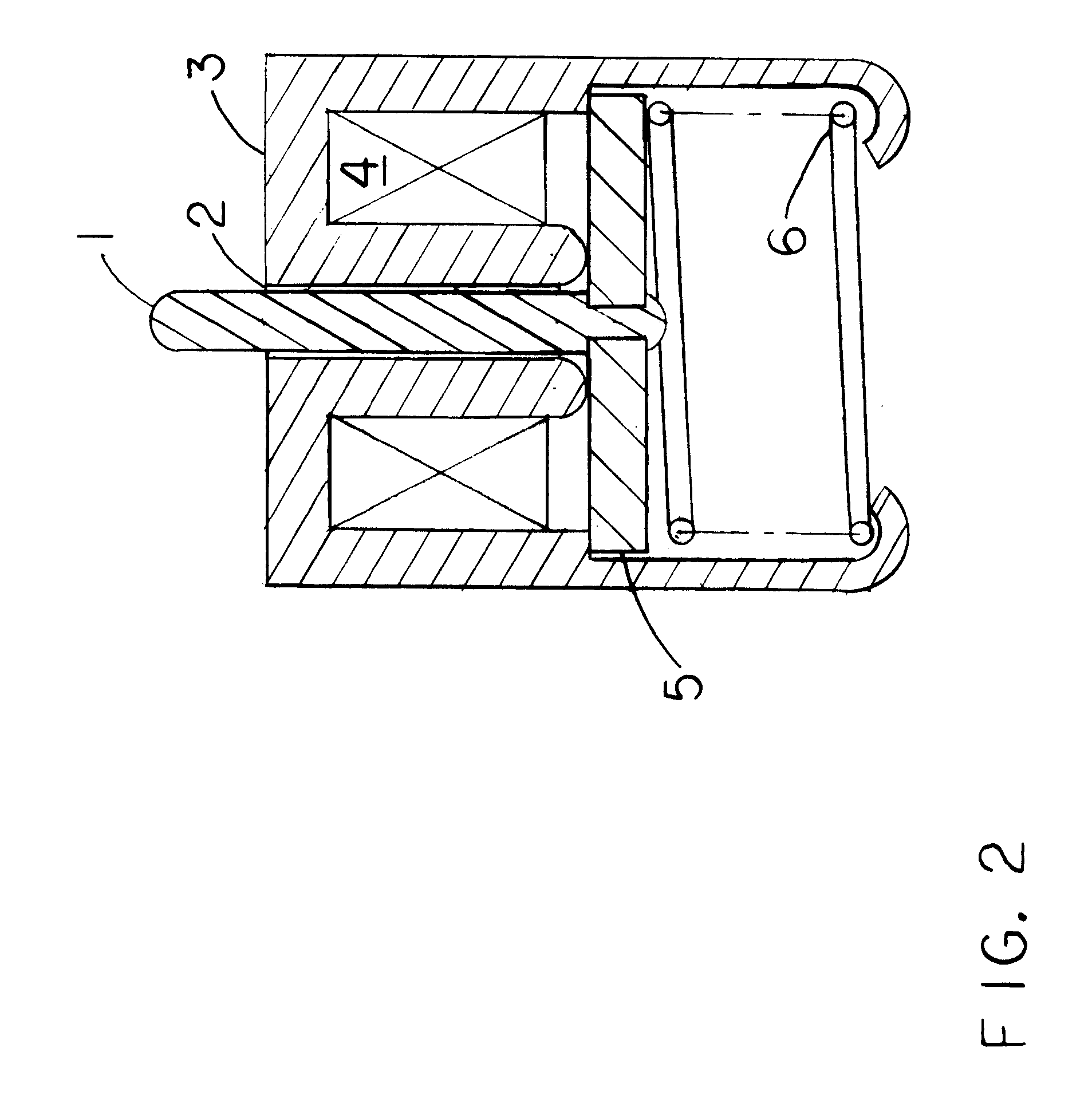

Blood pumping unit, with a coplanar disk inlet valve and an annular outlet valve

InactiveUS7029245B2Maximum of constructive simplicityLow costFlexible member pumpsDialysis systemsWorking fluidInlet valve

A unit for pumping fluid, particularly blood, is provided with an enclosure that has two half-shells and an elastic membrane fixed perimetrically to the enclosure in order to divide its space into two parts. One of the half-shells is provided with valves that are located at the opening of two connecting ducts for the intake and delivery of the fluid, and the other half-shell is connected to a line of working fluid that is alternately pressurized and depressurized. The first valve is a disk-shaped sheet made of elastic material. The first valve is in a central position with a support that is fixed to the opening of the first duct for connection to the outside and is suitable to rest at its peripheral region on the support. A second valve is a sheet of elastic material located at the peripheral region of the disk at the opening of the second duct for connection to the outside which lies at the peripheral region of the opening of the first duct.

Owner:SORIN GRP ITAL SRL

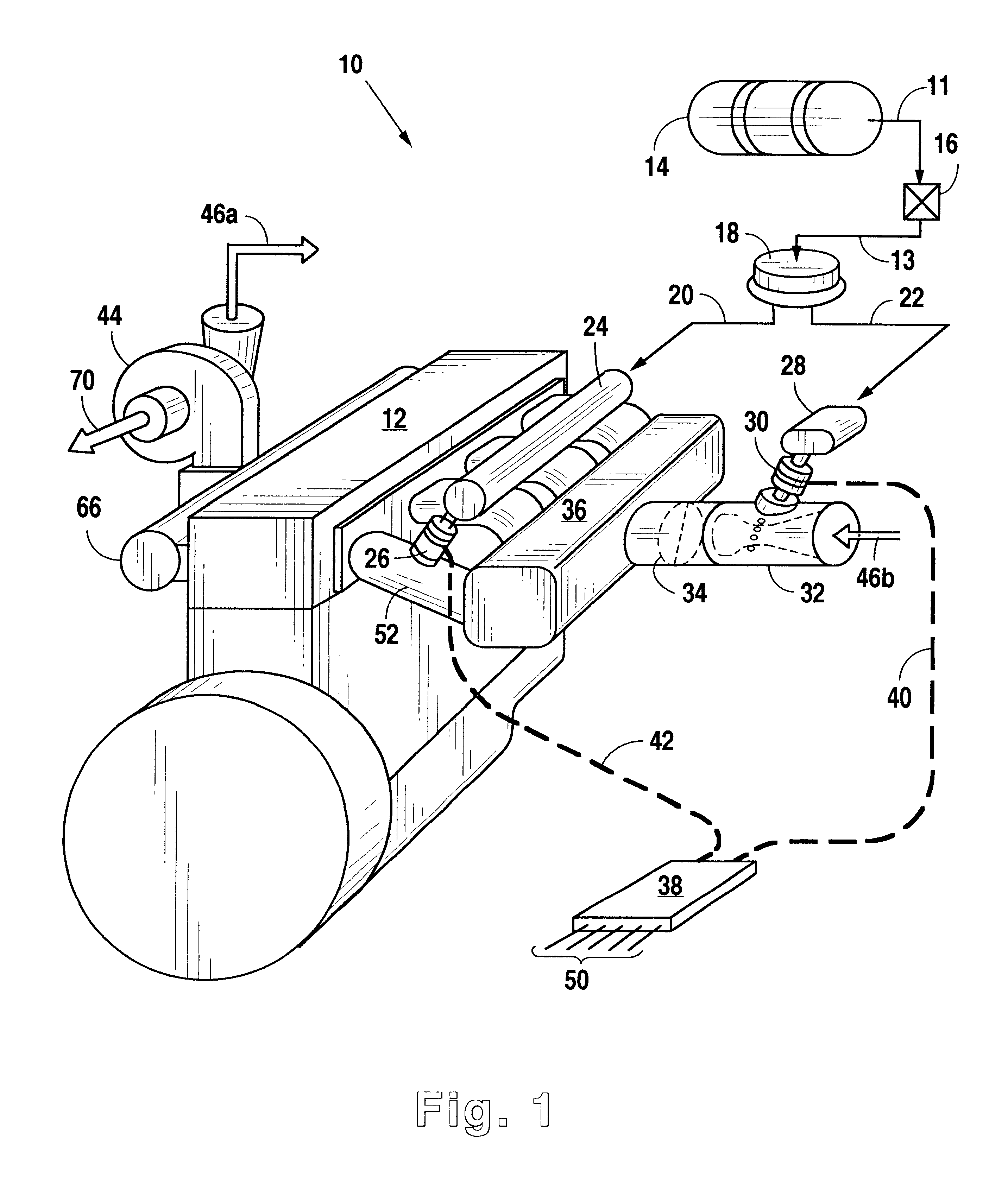

Nebulizer apparatus and method

InactiveUS6994083B2Reduce effortContinuous nebulizationSpray nozzlesMedical atomisersNebulizerInhalation

A nebulizer for efficiently and reliably delivering aerosolized fluid to an inhaling patient is disclosed. The nebulizer includes a fluid channel air inlet and fluid channel air inlet valve responsive to either a manual force external of the nebulizer, or a patient's breathing, to begin the nebulization process. Also provided is a method of providing nebulization including the steps of moving a fluid channel air inlet valve against a fluid channel air inlet so that a negative pressure may build up over the fluid in the fluid channel to draw fluid from the fluid reservoir and begin nebulization during inhalation.

Owner:TRUDELL MEDICAL INT INC

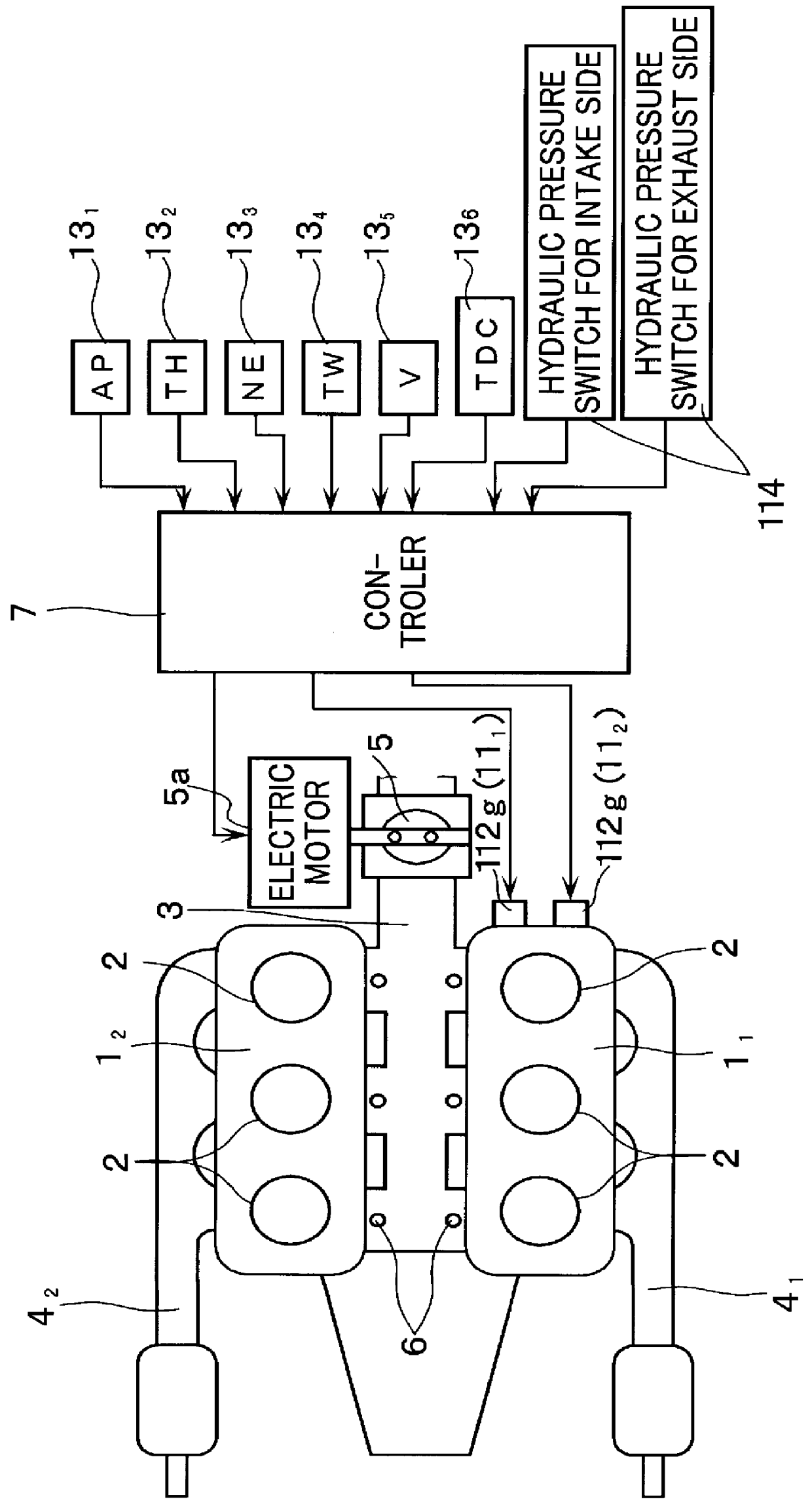

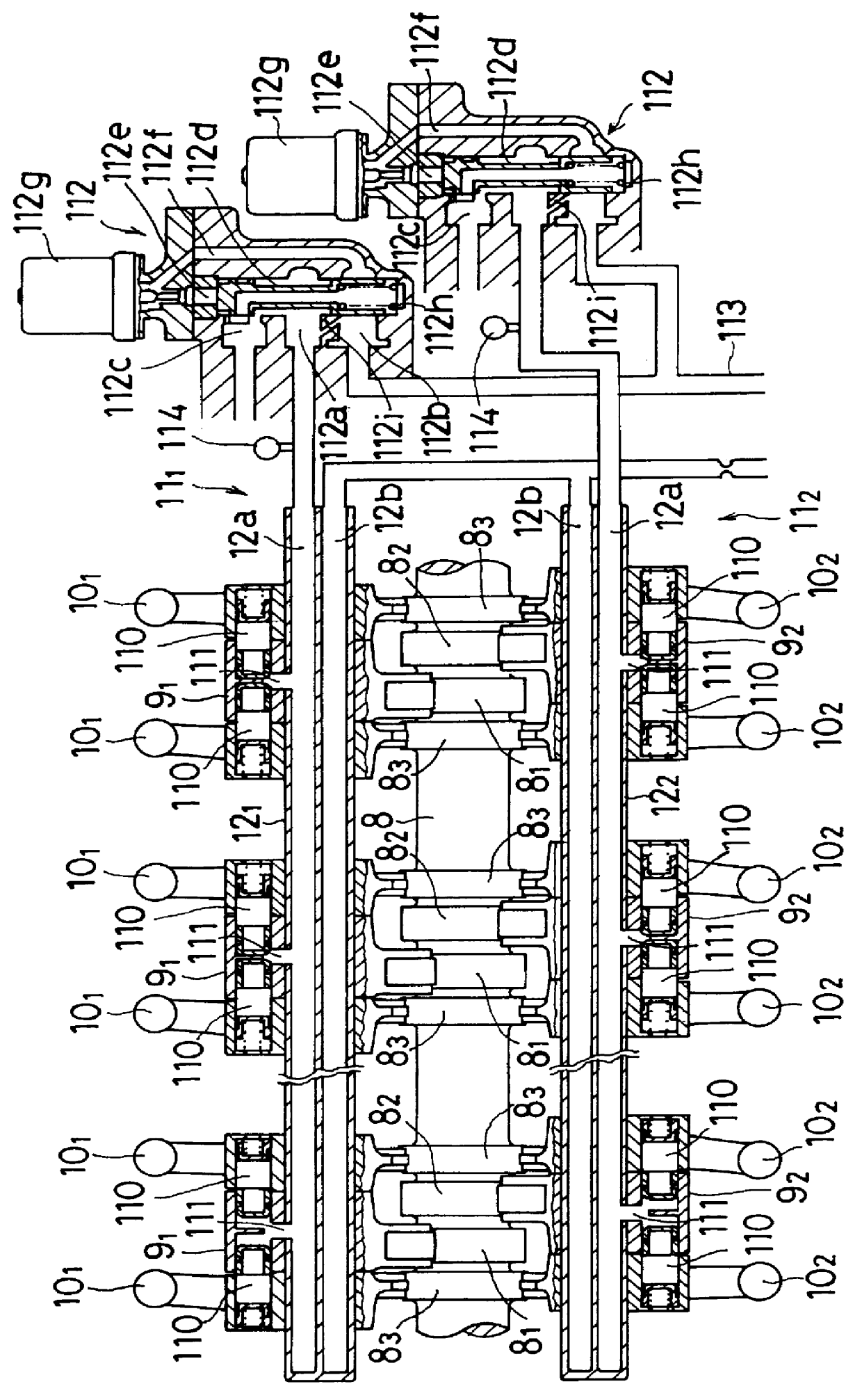

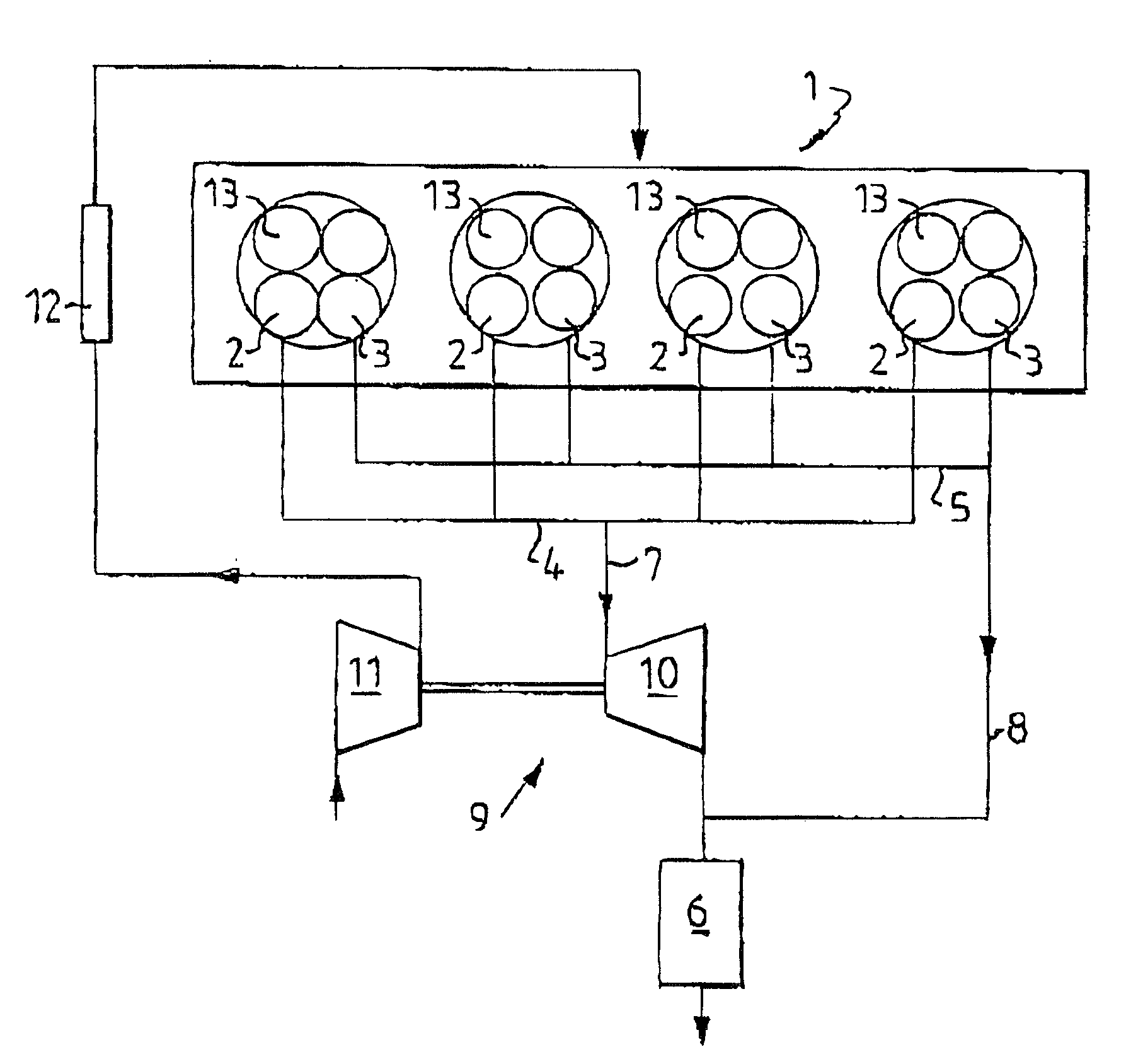

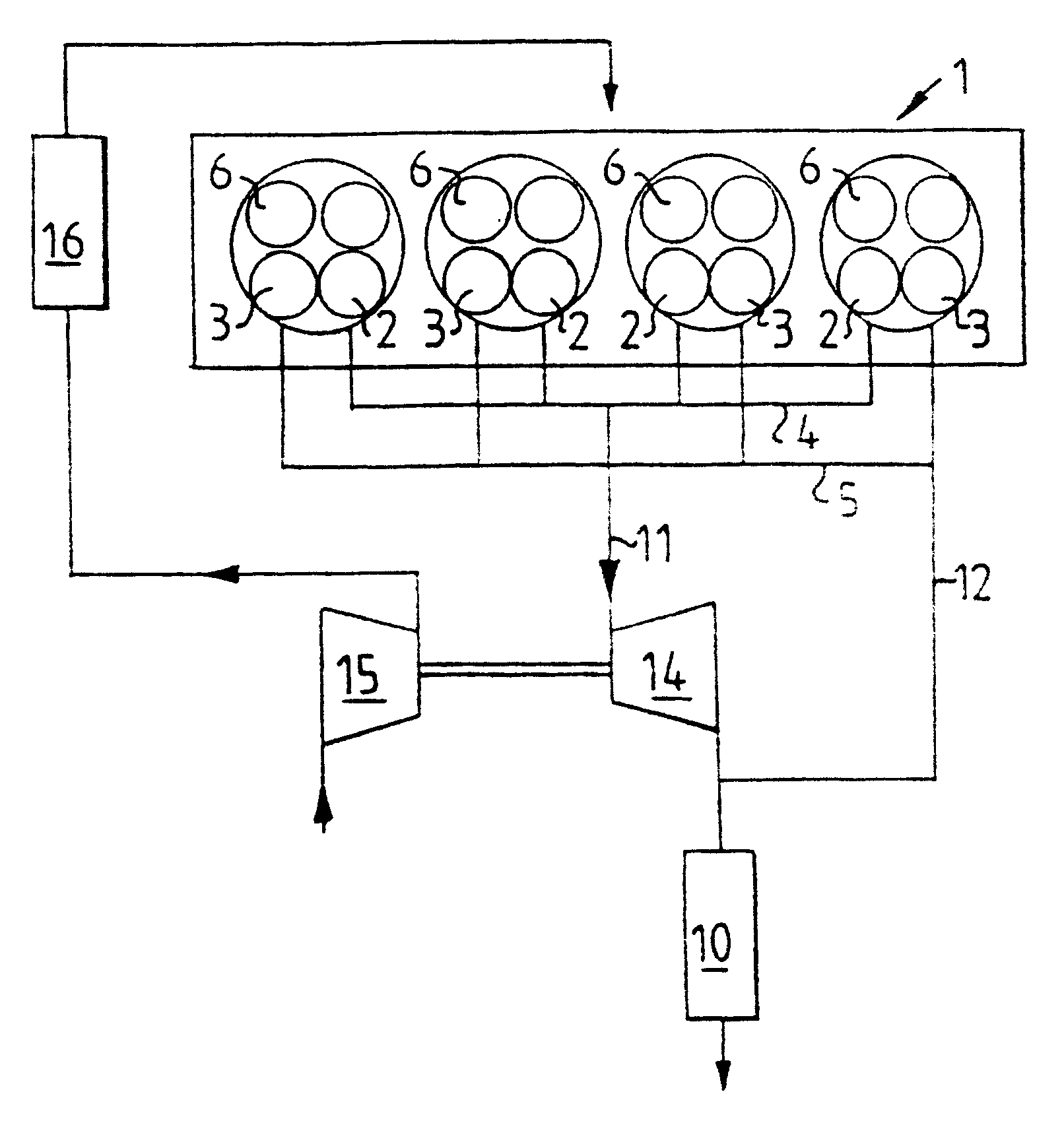

Apparatus for controlling multi-cylinder internal combustion engine with partial cylinder switching-off mechanism

In an apparatus for controlling a multi-cylinder internal combustion engine with partial cylinder switch-off mechanism which is switchable between an all-cylinder operation mode in which all cylinders are operated and a partial-cylinder operation mode in which operation of partial cylinders is suspended, the operation of intake valves and exhaust valves is suspended or resumed in a predetermined order with respect to all of the suspended cylinders irrespective of a rotational frequency of the engine. There are provided a solenoid valve on an intake side and a solenoid valve on an exhaust side for switching input hydraulic pressures for hydraulically operated switching devices respectively on the intake side and on the exhaust side between the driving state and the drive-free state. At the time of switching the operation, one of the solenoid valves on the intake side and the exhaust side is driven in advance. The subsequent number of rotations of a crankshaft is counted. When the number of this counting has reached a predetermined value, the solenoid valve on the other side is driven.

Owner:HONDA MOTOR CO LTD

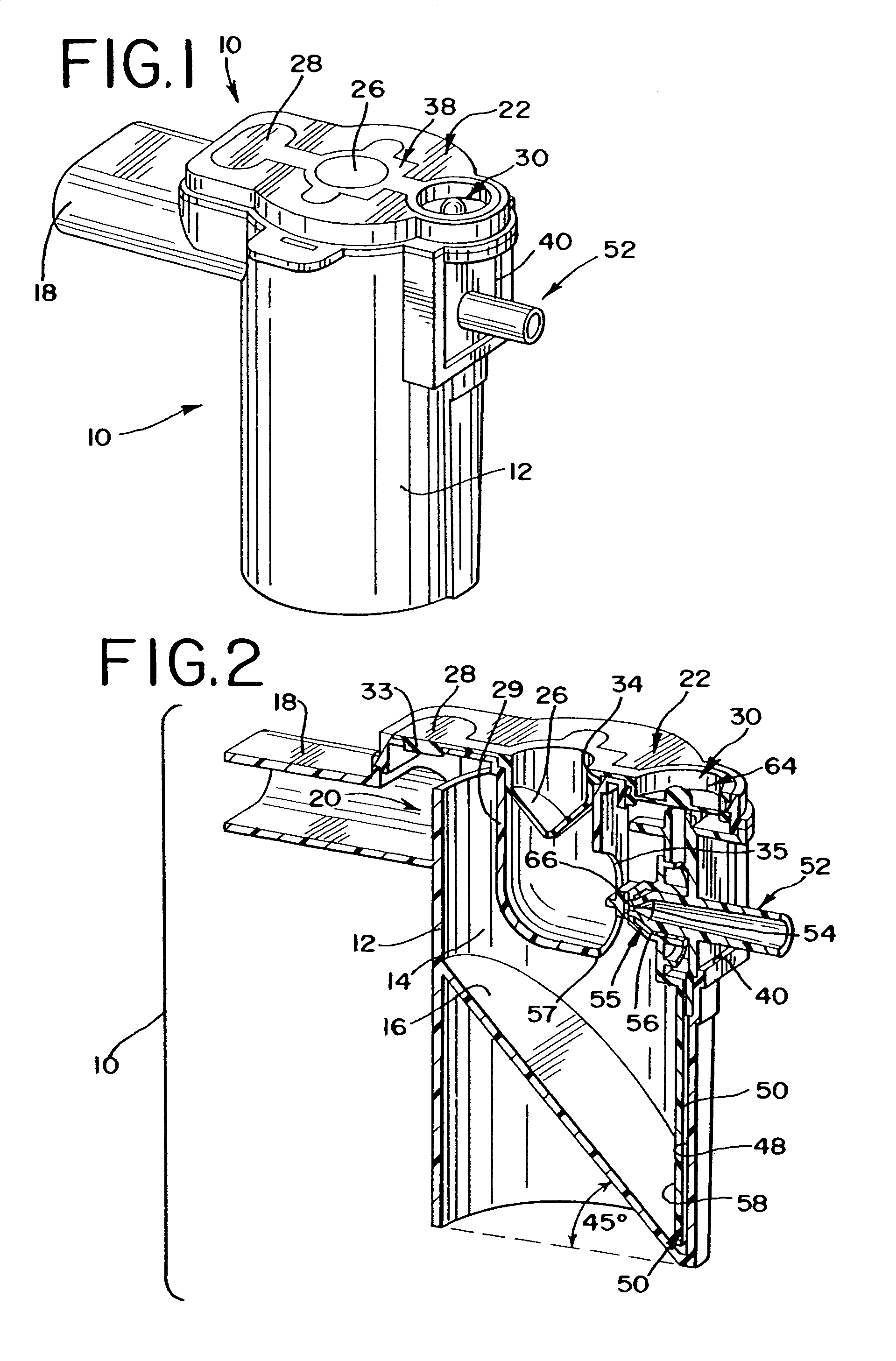

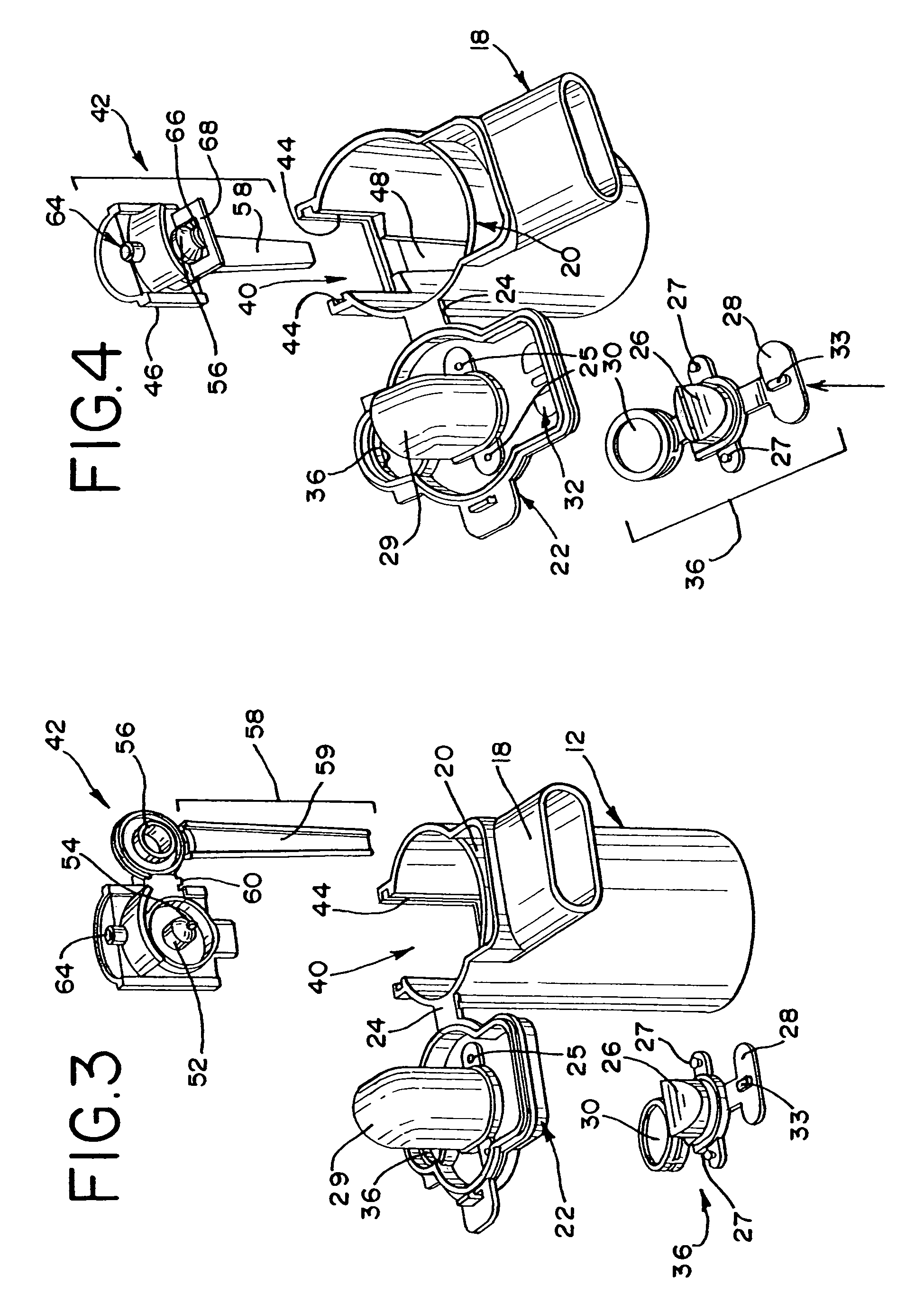

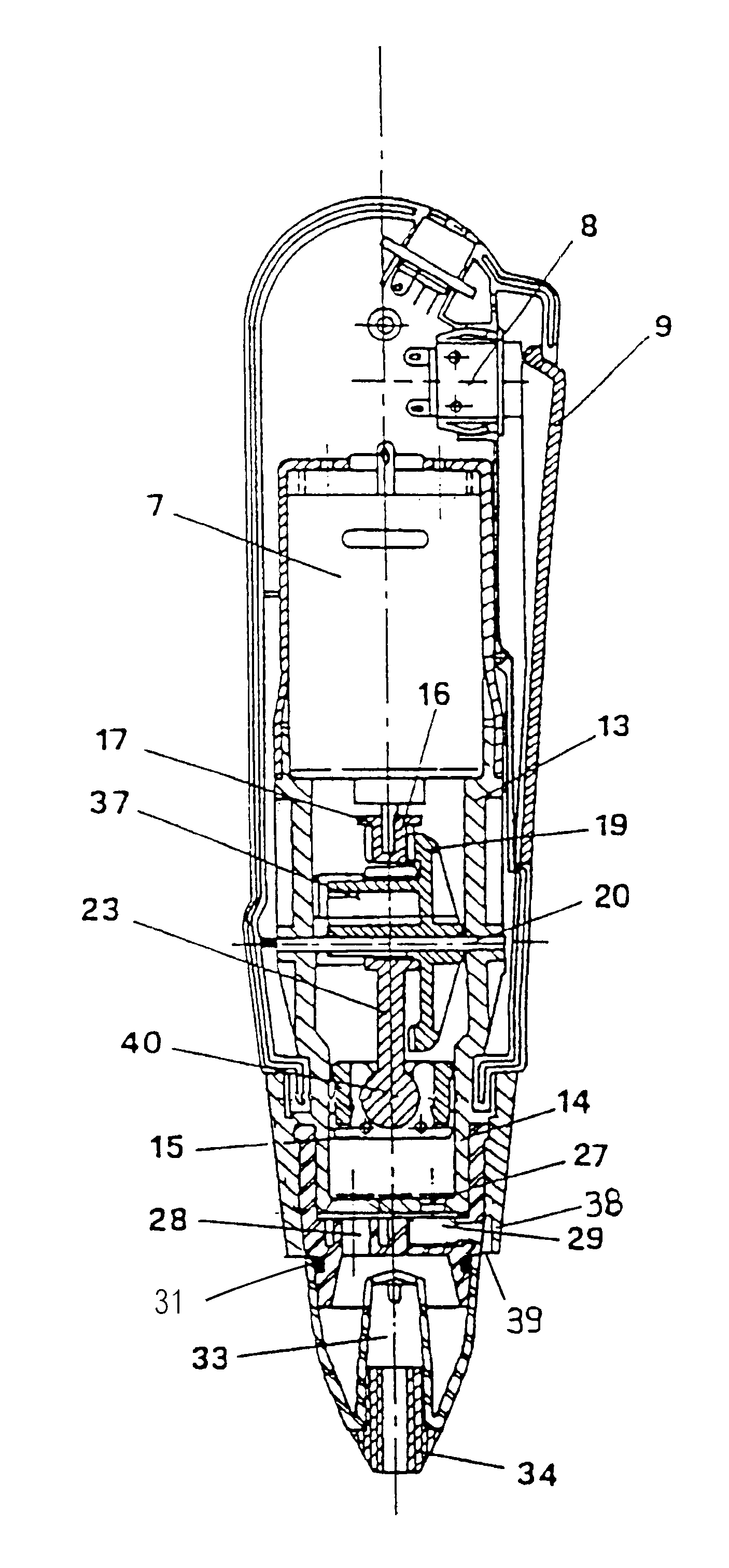

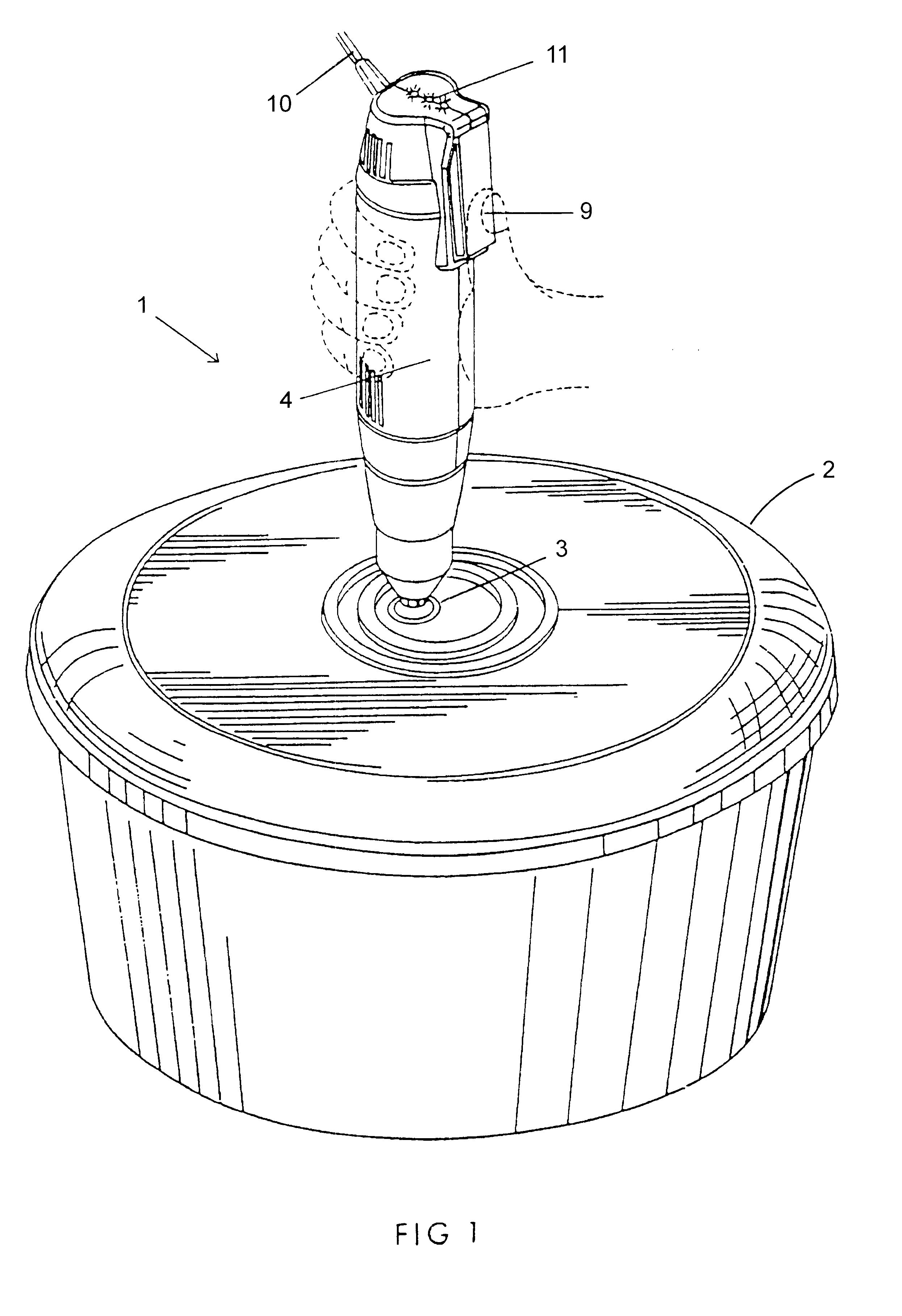

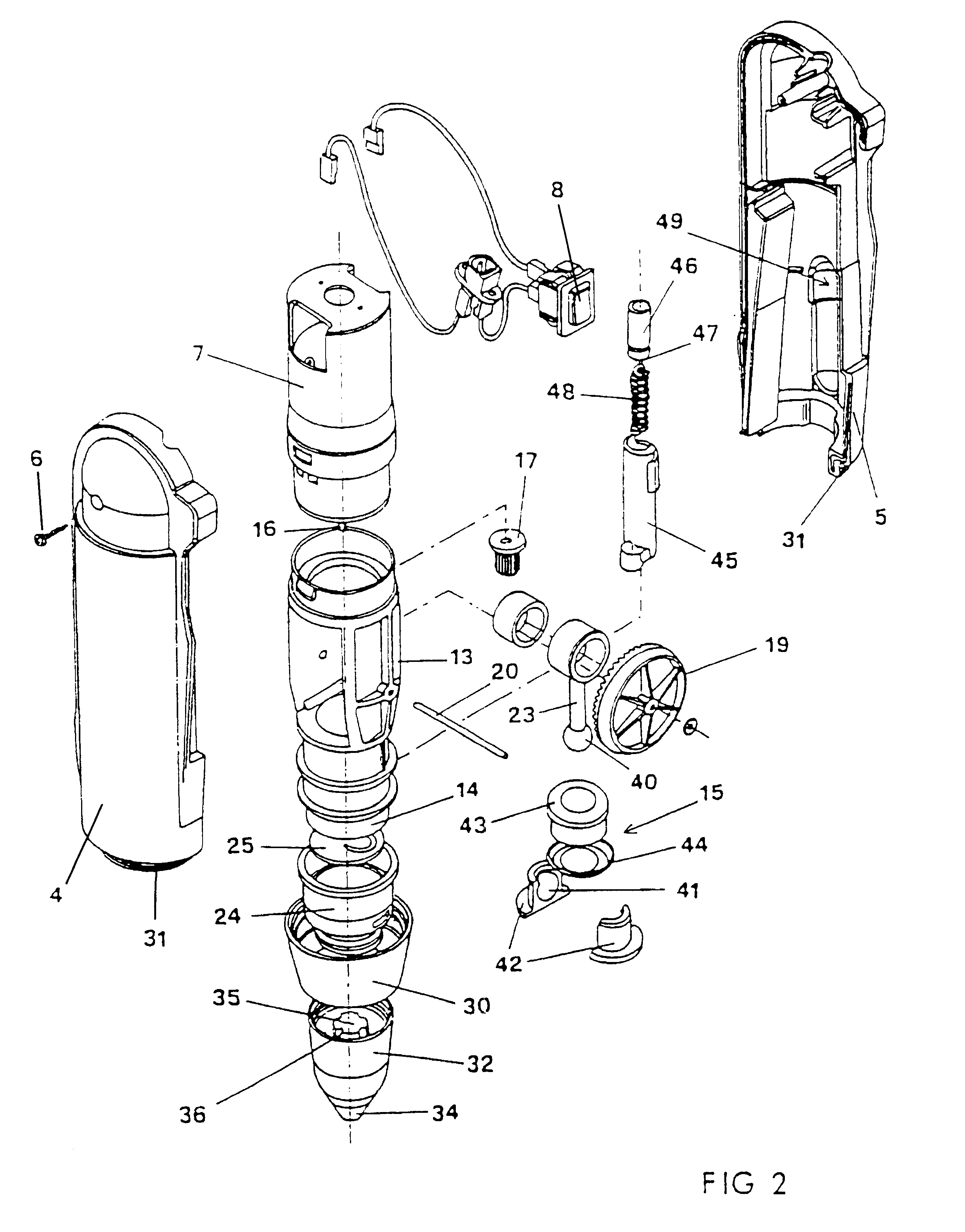

Hand-held suction pump

A hand-held suction pump for creating a vacuum in a container (2) provided with a suction valve (3), comprising an elongated outer casing in which an electric motor (7) and a piston pump (14, 15) driven by the motor (7) are accommodated, wherein the pump chamber (14) of the piston pump is connected by an inlet valve and a suction duct (28) to a hollow tip (34) at the free end of the casing for direct coupling with the suction valve of the container, the pump chamber being further connected by an outlet valve to an exhaust duct (29) having a duct opening on the outer surface of the wall of the outer casing for porting an exhaust flow to the exterior of the outer casing. In order to reduce noise caused by the exhaust flow, the duct opening of the exhaust duct (29) is overlapped by a baffle (38) which is separated by a gapped distance from the outer surface of the wall of the outer casing so as to deflect the exhaust flow exiting the duct opening by a substantial angle.

Owner:ARACARIA

Nebulizer apparatus and method

InactiveUS20030136399A1Alleviate inhalation effortContinuous nebulizationSpray nozzlesMedical atomisersNebulizerInhalation

A nebulizer for efficiently and reliably delivering aerosolized fluid to an inhaling patient is disclosed. The nebulizer includes a fluid channel air inlet and fluid channel air inlet valve responsive to either a manual force external of the nebulizer, or a patient's breathing, to begin the nebulization process. Also provided is a method of providing nebulization including the steps of moving a fluid channel air inlet valve against a fluid channel air inlet so that a negative pressure may build up over the fluid in the fluid channel to draw fluid from the fluid reservoir and begin nebulization during inhalation.

Owner:TRUDELL MEDICAL INT INC

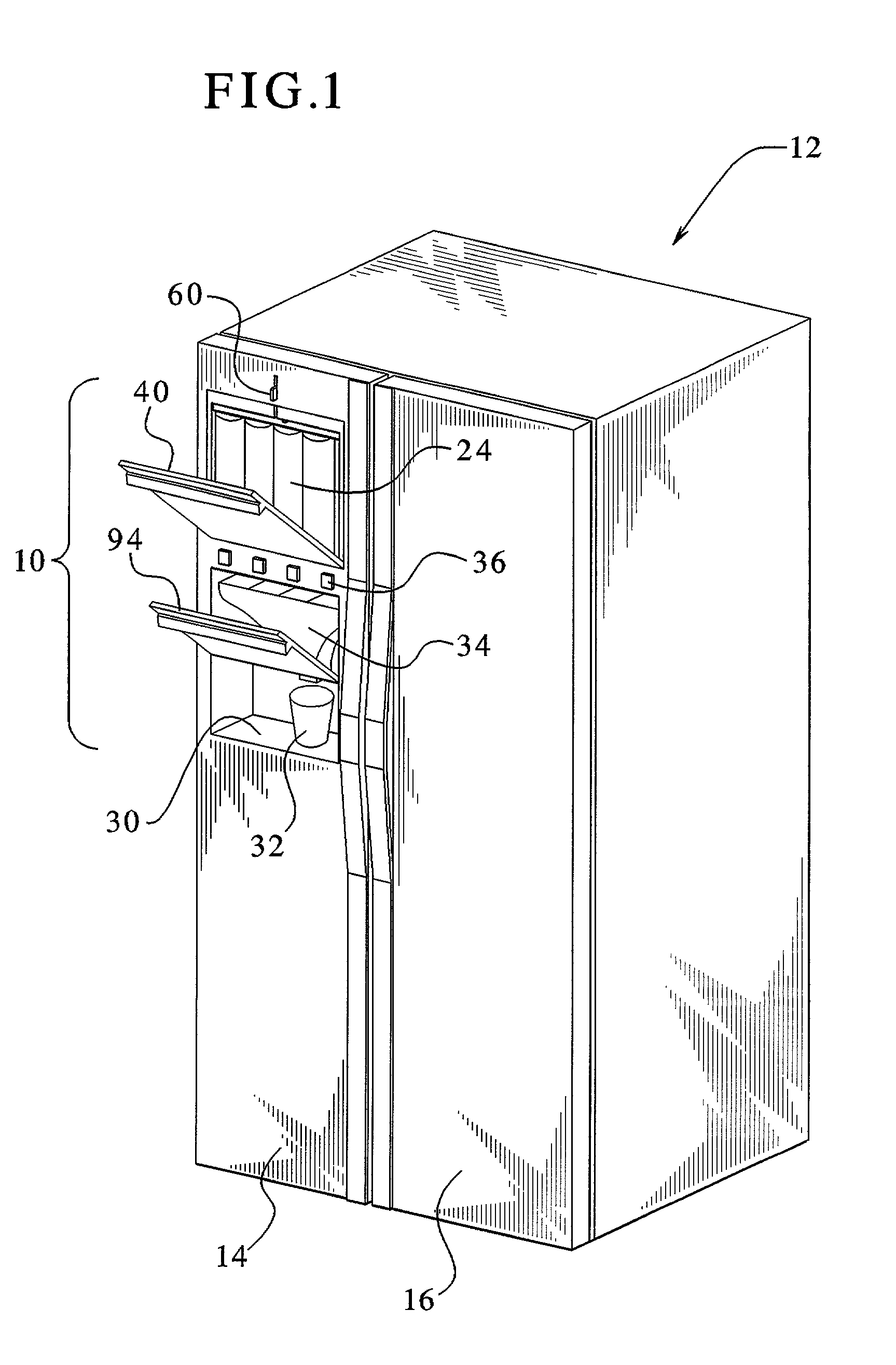

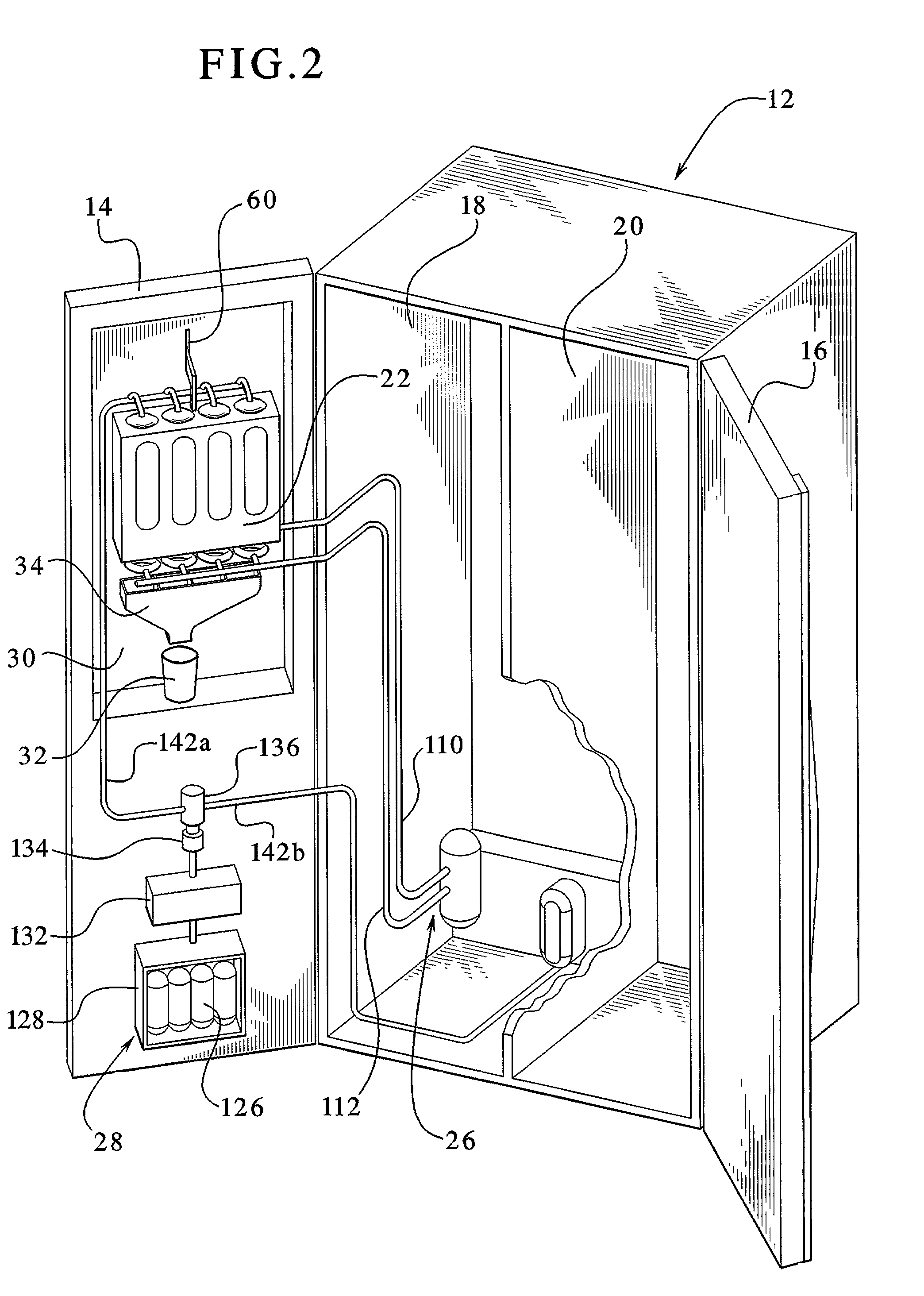

Drink supply canister for beverage dispensing apparatus

InactiveUS7083071B1Reliable consistent controlEasy to controlPlug valvesDomestic cooling apparatusInlet valveEngineering

A drink supply canister for a beverage dispensing apparatus. The drink supply canister includes a removable valve assembly member having a drink supply outlet valve and a gas inlet valve. The beverage dispensing apparatus pressurizes the drink supply canister by supplying gas to the gas inlet valve. The beverage dispensing apparatus includes a drink supply canister holder for holding a plurality of such drink supply canisters. The beverage dispensing apparatus directs a supply of water and gas to the drink supply canister holder for producing carbonated and non-carbonated beverages.

Owner:BEVERAGE WORKS

Internal combustion engine

InactiveUS6595183B1Increase mass flowIncrease torqueValve arrangementsElectrical controlExhaust valveTop dead center

A multicylinder internal combustion engine with an exhaust-driven turbocompressor and with a divided exhaust flow has at least two exhaust valves and one intake valve per cylinder. A first exhaust valve is connected to a first exhaust manifold which leads to the turbine of the compressor, while a second exhaust valve is connected to a second exhaust manifold which opens downstream of the turbine. In the top dead center position of the piston, the second exhaust valve and the intake valve are open at the same time for a period. The synchronization between these valves is such that the length of the period during which they are open together increases with the engine speed when the engine is driven at high load. In this way, the possibilities are improved of the engine providing good torque over a wide engine speed range.

Owner:SAAB AUTOMOBILE AB

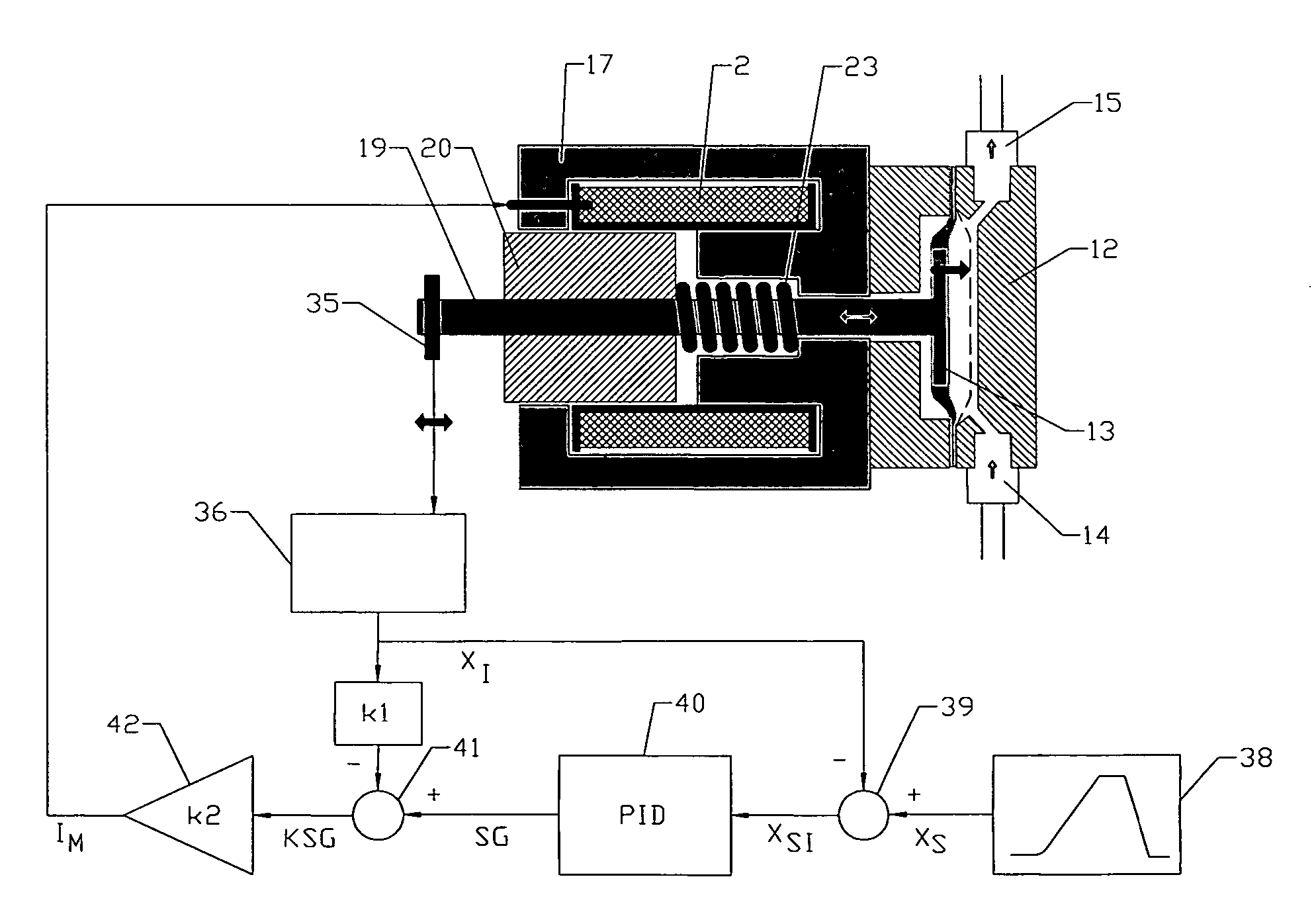

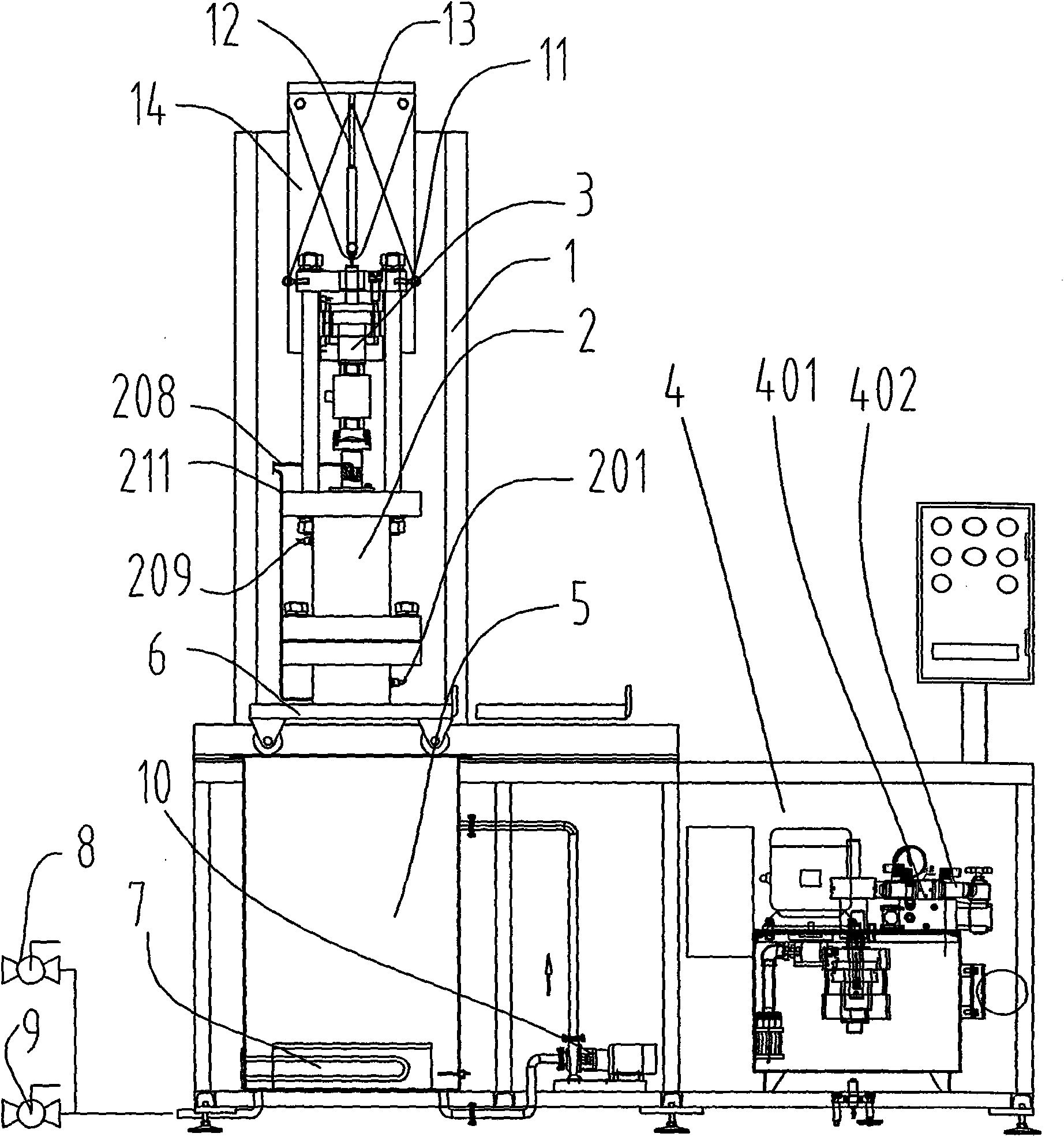

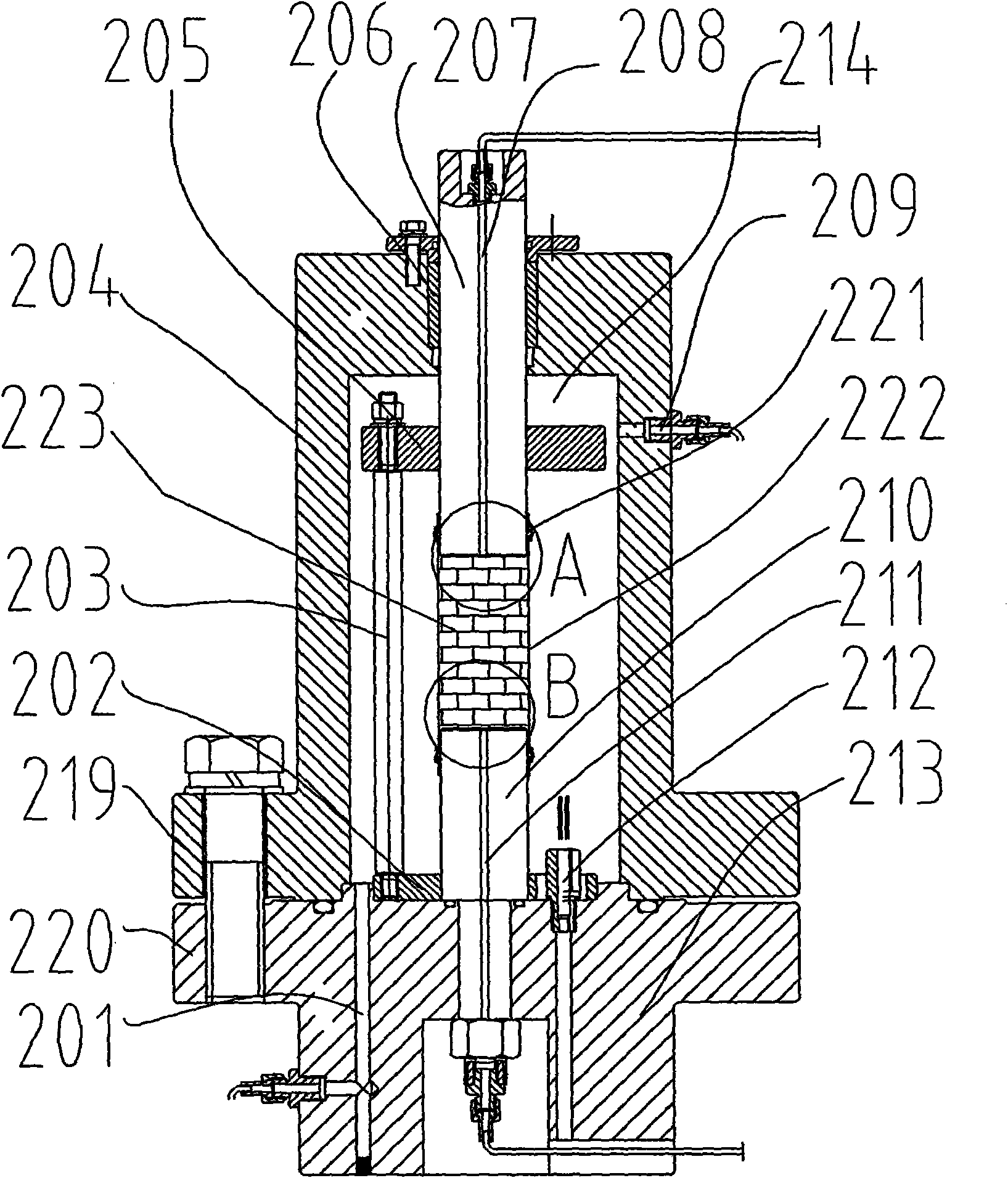

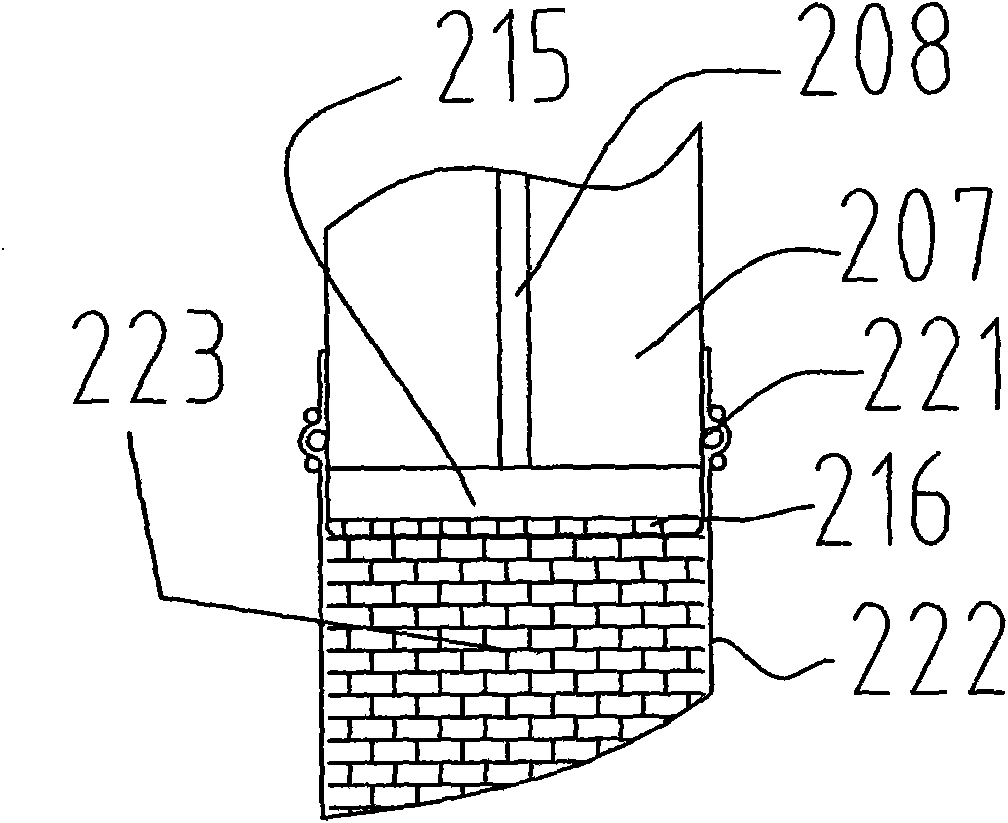

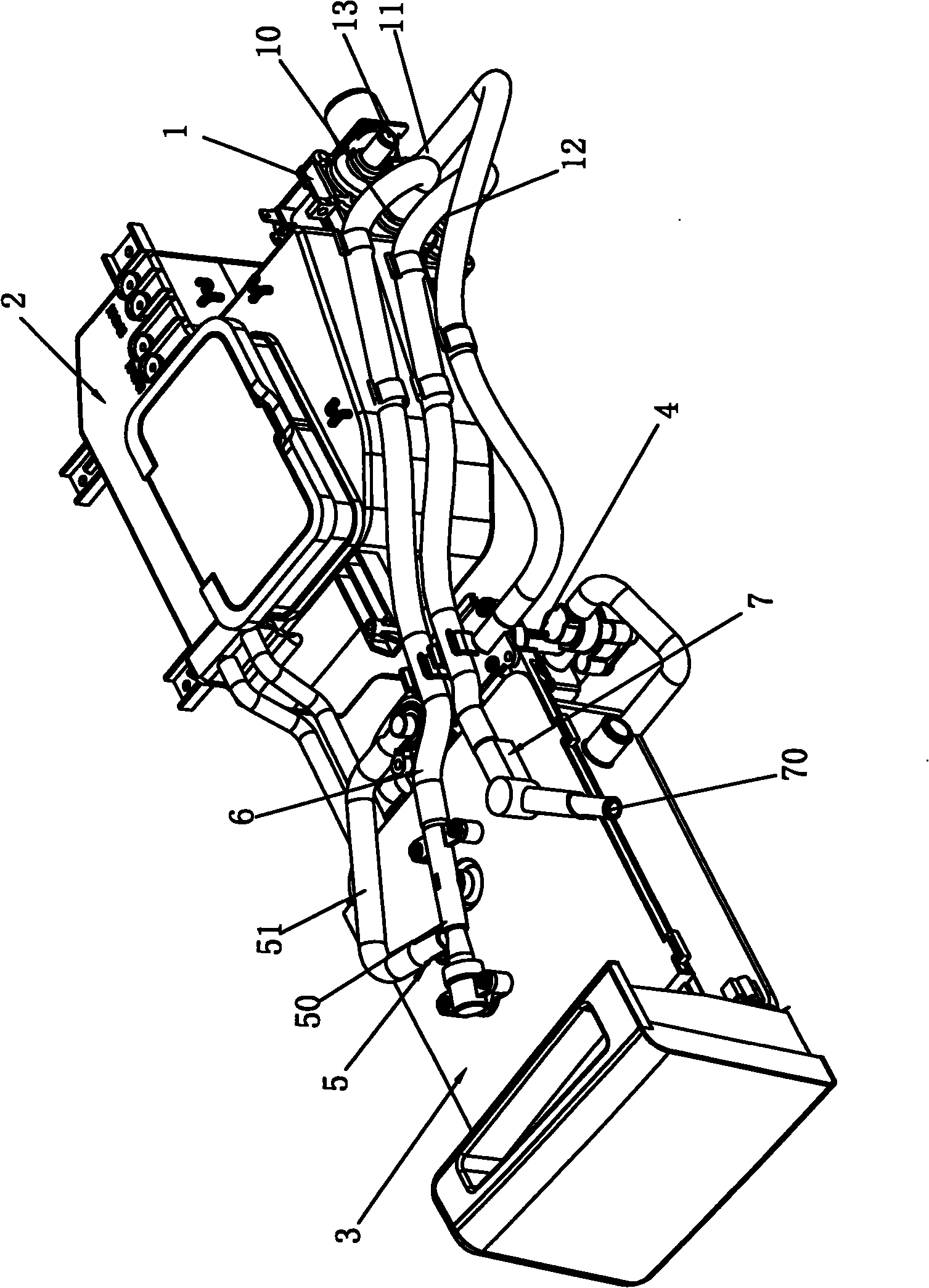

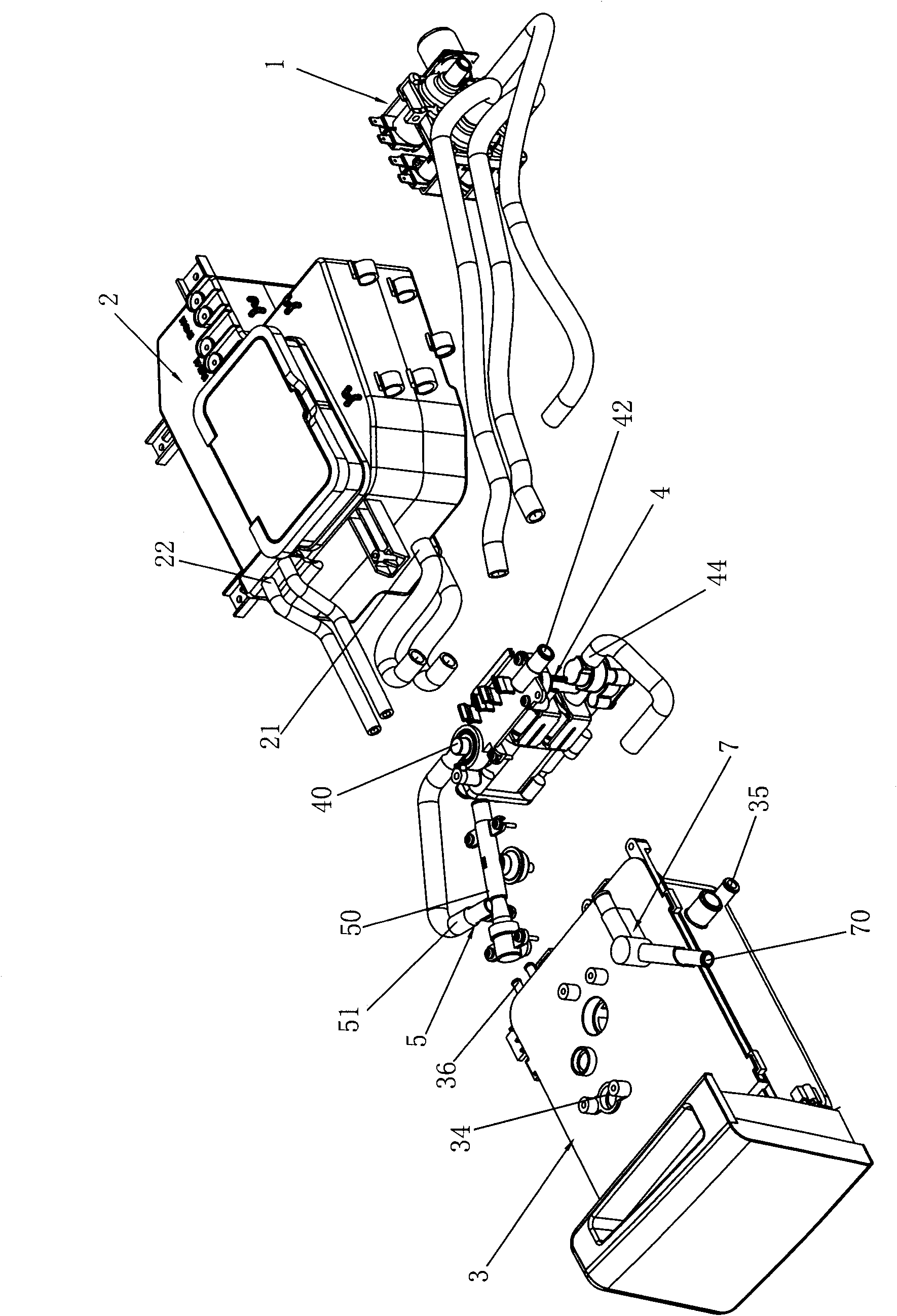

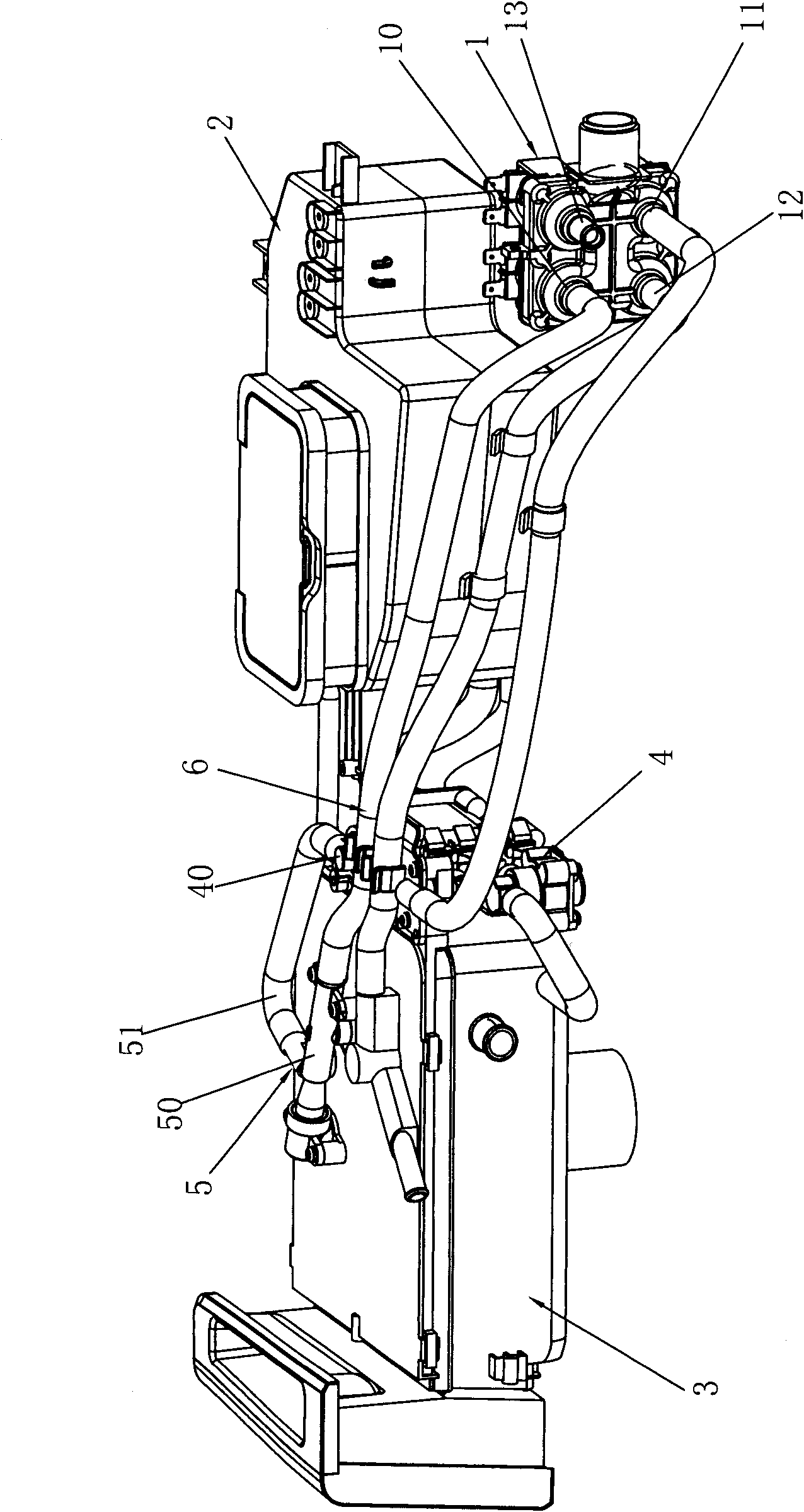

Fluid-solid-heat coupling triaxial servo percolation device for gas-contained coal

InactiveCN101634621APrecise permeability measurementImprove breathabilitySurface/boundary effectMaterial strength using tensile/compressive forcesWater bathsAxial compression

The invention discloses a fluid-solid-heat coupling triaxial servo percolation device for gas-contained coal, comprising a lifting stand, a hydraulic servo control system, an axial loading device mounted at the top of the lifting stand and a triaxial pressure chamber connected with the lower end of the axial loading device. A thermostatic water tank is arranged below the triaxial pressure chamber; a movable worktable is arranged above the thermostatic water tank; the lower end of the triaxial pressure chamber is arranged on the movable worktable; heating tubes are arranged in the thermostatic water tank; and a water inlet valve, a water drain valve and a water-bath circulating water pump are arranged outside the thermostatic water tank and are communicated with the thermostatic water tank. In the hydraulic servo control system, an axial compression loading oil pump is communicated with an oil inlet and an oil outlet by a pipeline, and a peripheral compression loading oil pump is communicated with an oil intake / drain hole by a pipeline. The fluid-solid-heat coupling triaxial servo percolation device for gas-contained coal can carry out the research of gas-contained coal percolation tests in states, such as different terrestrial stresses, different gas pressures, different temperatures, and the like and the distortion and failure characteristics of the gas-contained coal in a percolation process.

Owner:CHONGQING UNIV

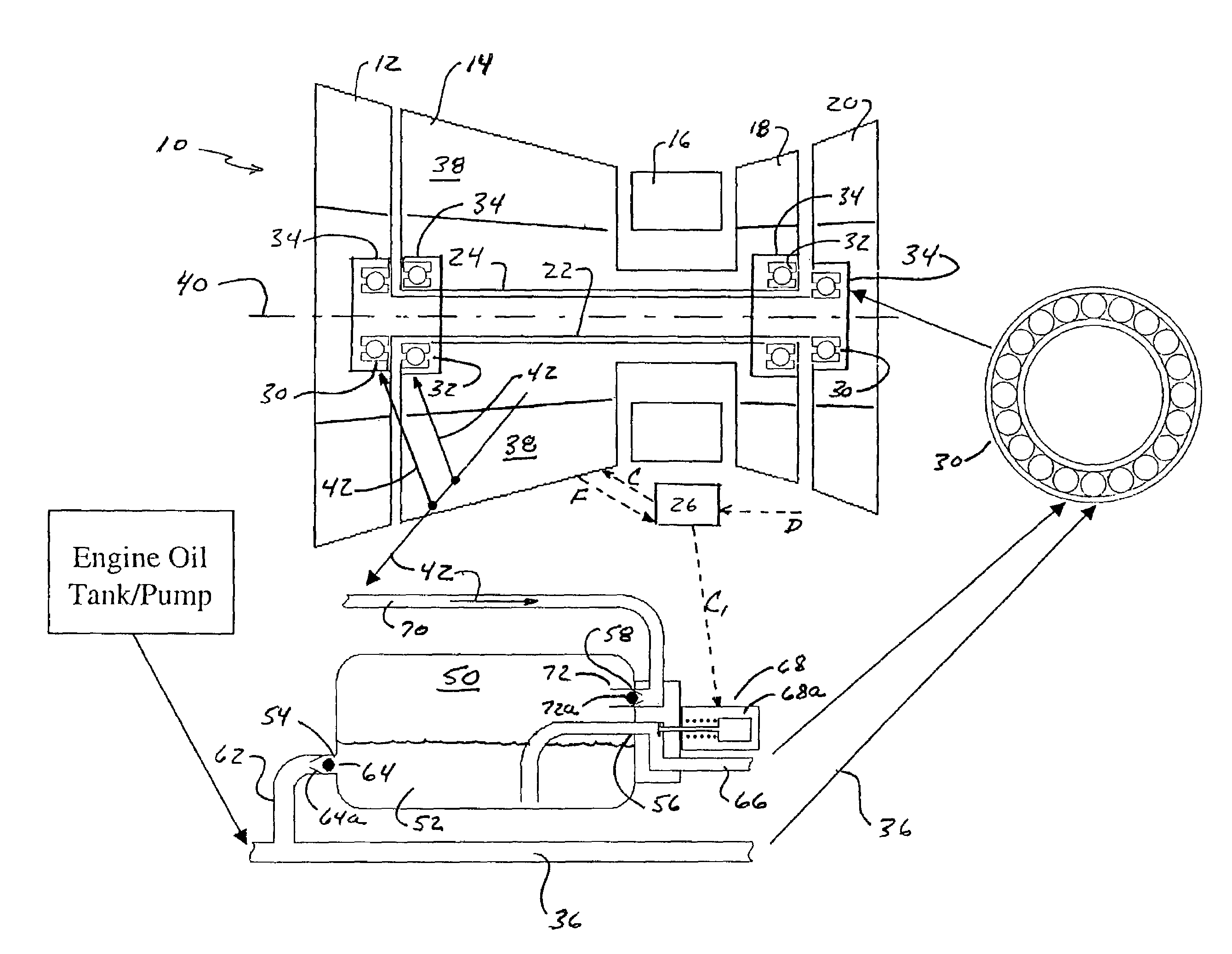

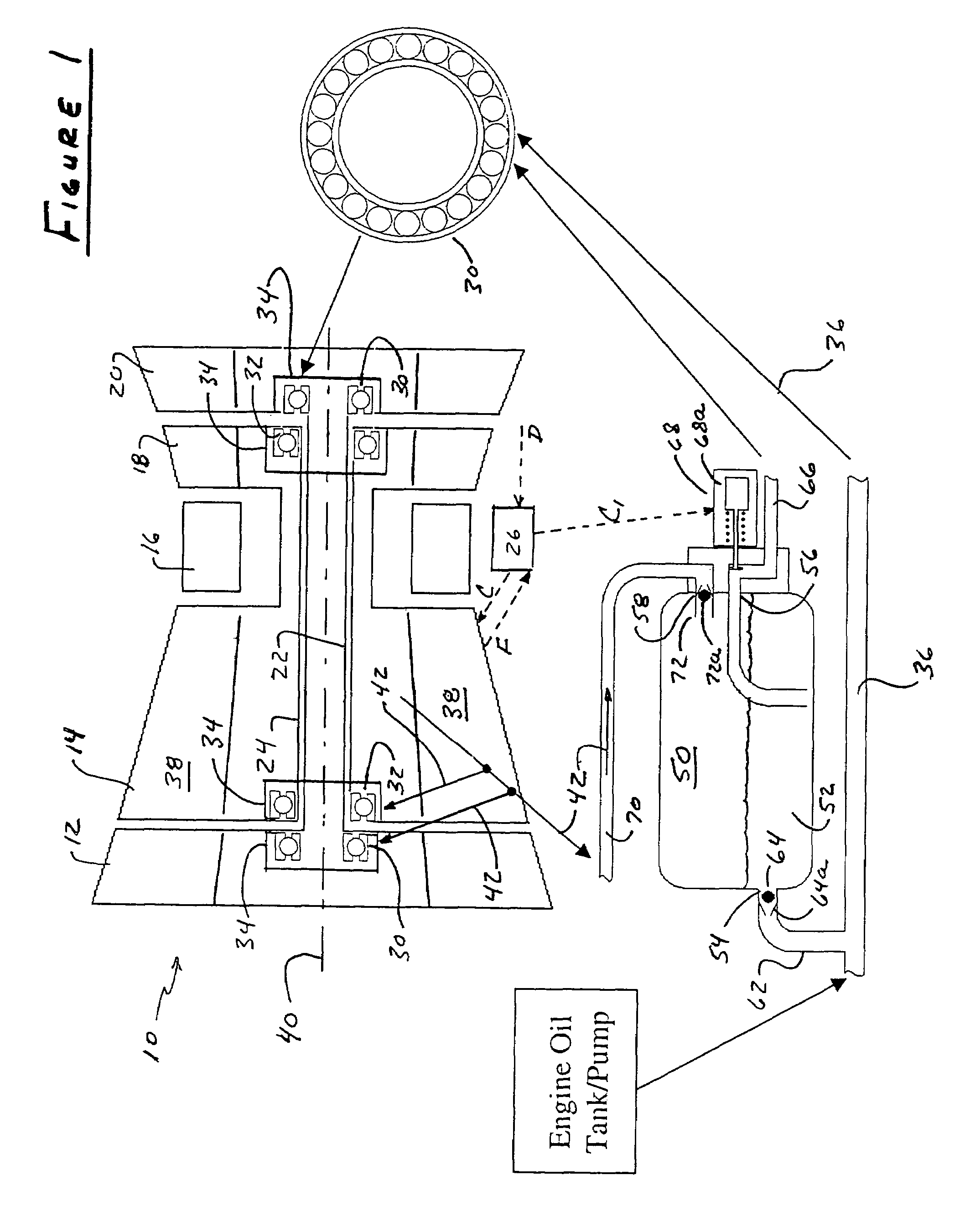

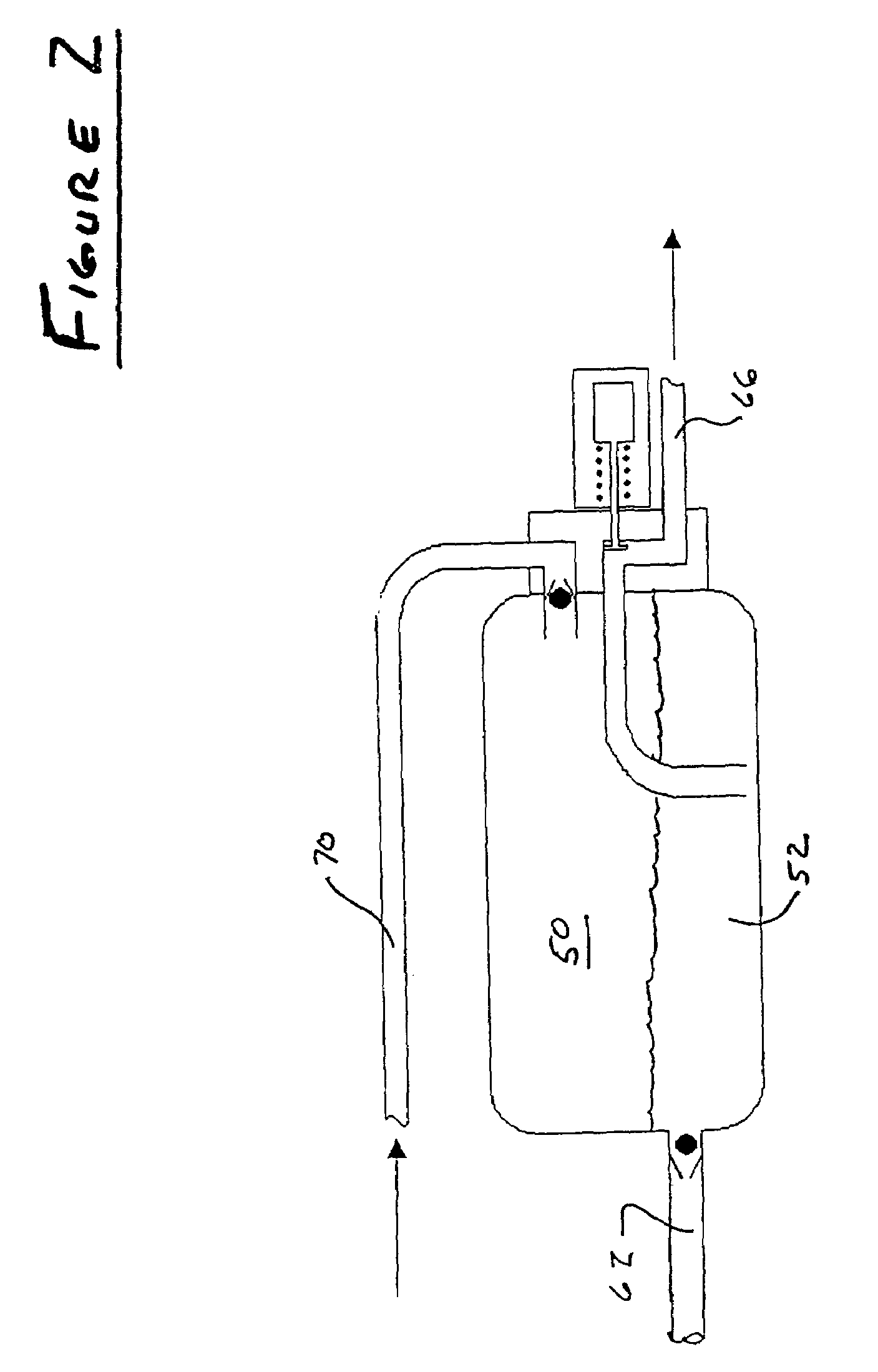

Emergency lubrication system

ActiveUS7387189B2Extended time intervalLight weightEfficient propulsion technologiesMachines/enginesNormal rateInlet valve

An emergency lubrication system for a turbine engine includes a reservoir 50 containing a reserve quantity of lubricant 52 and having a lubricant inlet 54 and a lubricant outlet 56. A lubricant supply line 62 and a lubricant outlet line 66 each have a respective valves 64, 68 for regulating lubricant flow into and out of the reservoir. A fluid supply line 70 includes a valve 72 for selectively establishing communication between the reserve quantity of lubricant and a source of pressurized fluid. During normal operation the lubricant outlet valve continuously releases lubricant at a normal rate to the component requiring lubrication while the lubricant inlet valve concurrently admits fresh lubricant into the reservoir. During abnormal operation, the lubricant inlet valve closes in response to abnormally low lubricant pressure outside the reservoir thereby preventing backflow of reserve lubricant out of the reservoir. The fluid inlet valve opens to admit pressurized fluid into the reservoir thus pressurizing the reserve lubricant. The lubricant outlet valve opens or cycles open and closed in response to a command from a controller 26 so that the pressurized fluid forces lubricant through the outlet 56 as a subnormal rate, which persists until the lubricant reserve is substantially depleted. The subnormal rate is ideally achieved by intermittently releasing lubricant from the reservoir, but may also be achieved by releasing a continuous stream of lubricant at a rate less than the normal rate of release.

Owner:RTX CORP

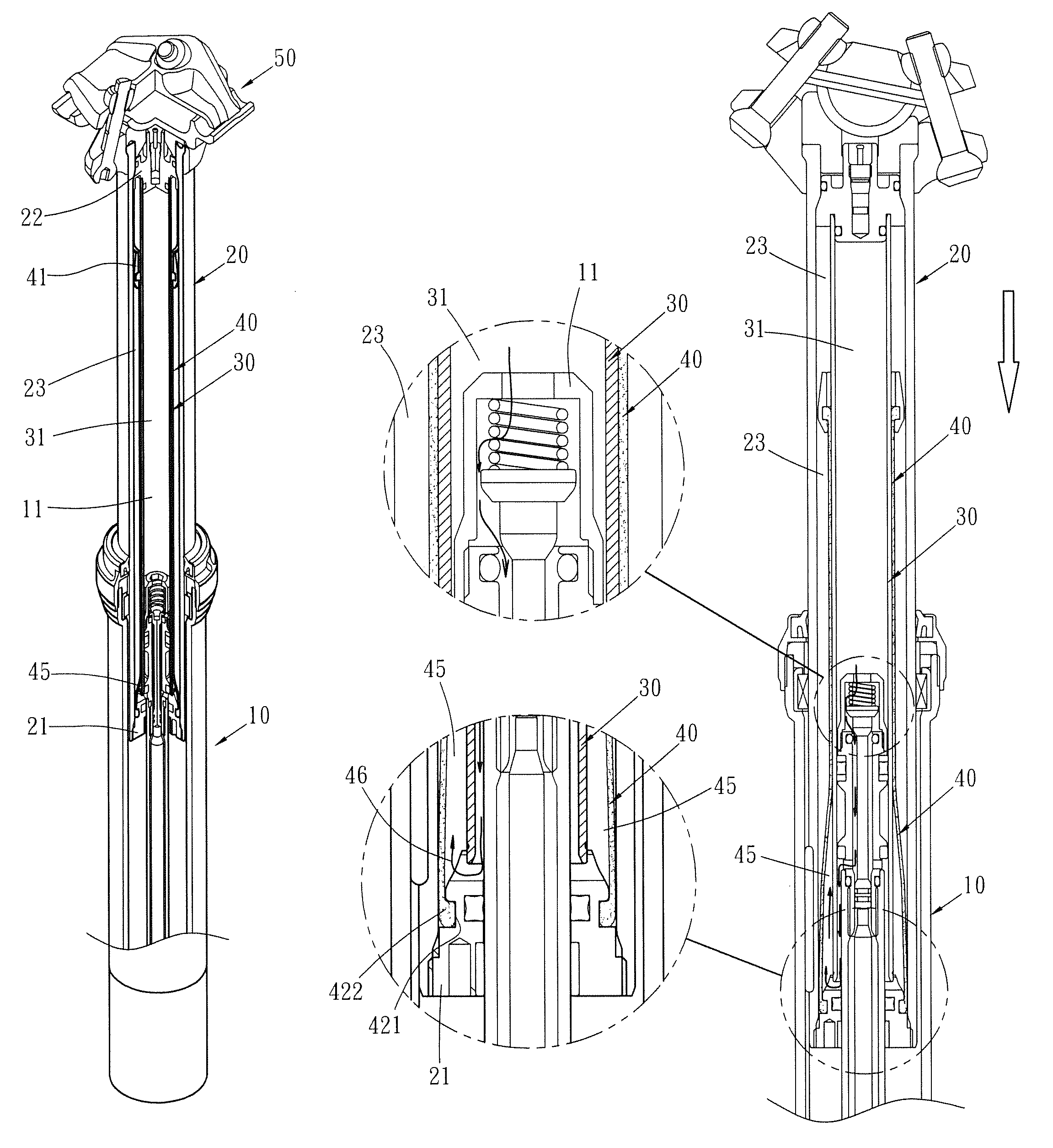

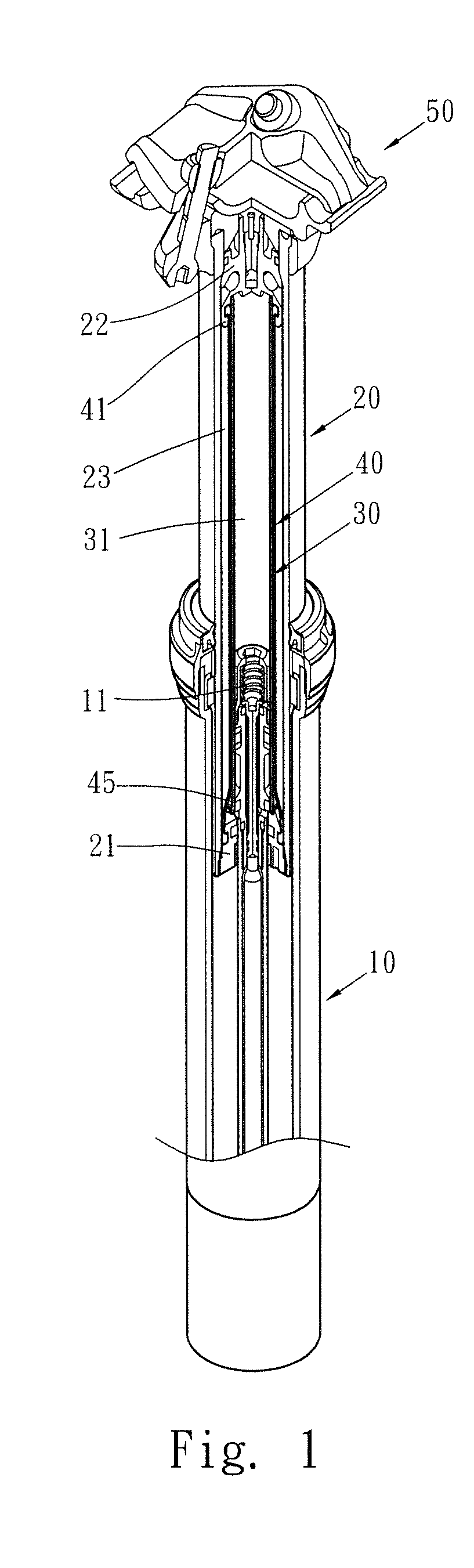

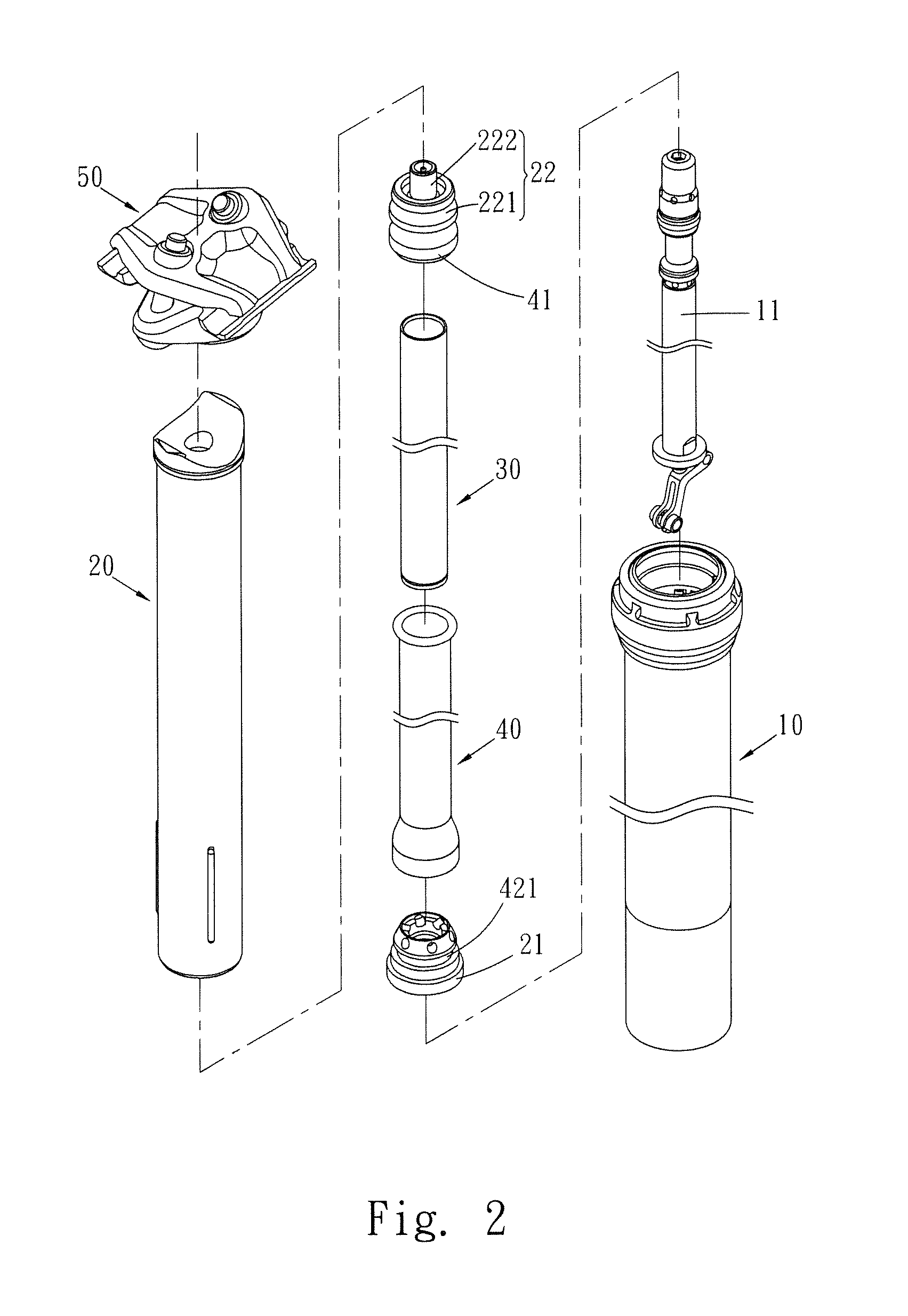

Height adjustable seat tube with oil storage unit

A height adjustable seat tube includes an outer tube and an inner tube is inserted into the outer tube. An end cap is fixed to the inner tube and a valve unit in the inner tube extends through the end cap and co-movable linearly with the inner tube. An inlet valve is connected to the inner tube. An oil tube is connected between the inlet valve and the valve unit. A first oil room is defined between the oil tube and the valve unit. An oil storage member is connected between a connection member and the end cap. A first air room is defined between the inlet valve, the oil storage member and the inner tube. A second oil room is defined between the oil tube, the oil storage member and the end cap. An oil path is in communication between the first and second oil rooms.

Owner:HSU JUNG YU

Engine valve disabler

A method for improving efficiency and reducing emissions of an internal combustion engine. Variable displacement engine capabilities are achieved by disabling engine valves during load changes and constant load operations. Active cylinders may be operated at minimum BSFC by intermittently disabling other cylinders to provide the desired net torque. Disabling is begun by early closing of the intake valve to provide a vacuum at BDC which will result in no net gas flow across the piston rings, and minimum loss of compression energy in the disabled cylinder; this saving in engine friction losses is significant with multiple disablements.

Owner:MOYER DAVID F

Detergent for washing machine and automatic disinfectant adding device

ActiveCN101956311AReduce pollutionFully automatedOther washing machinesTextiles and paperDisinfectantInlet valve

The invention discloses a detergent for a washing machine and an automatic disinfectant adding device. The automatic adding device comprises a washing machine water inlet valve, a solvent box and a washing machine sink component; the automatic adding device also comprises an automatic adding precise control device which is connected with the washing machine water inlet valve, the solvent box and the washing machine sink component through connecting pipelines respectively; the automatic adding precise control device is provided with a negative pressure suction port and a constant volume container; and a solvent in the solvent box is pumped into the constant volume container by negative pressure generated by inlet water of the washing machine sink component, and the quantitative solvent is flushed into the washing machine sink component by the inlet water of the automatic adding precise control device and further flows to a washing drum. The automatic adding device makes great contribution on the aspect of adding the detergent to the washing machine, can precisely add different detergents, can fully realize automatic addition by using the negative pressure generated by the inlet water, has a simple structure, realizes automation of the washing process, and improves the washing efficiency.

Owner:HAIER GRP CORP +2

Fuel system with dual fuel injectors for internal combustion engines

InactiveUS6371092B1Reduce startup timeElectrical controlInternal combustion piston enginesCombustionInlet valve

This invention is directed to an apparatus and method for providing improved control of fuel, preferably gaseous fuel, to an internal combustion engine such that each cylinder of the engine will operate within a predetermined tolerance off of its lean misfire limit. The disclosed system introduces fuel to the engine at two locations: (1) upstream of the intake manifold to provide premixing of a majority of the fuel with air, and (2) near the intake valve of each cylinder for tailoring the fuel flow to each cylinder to achieve that fuel-to-air ratio which is necessary to maintain each cylinder at the desired tolerance from the lean misfire limit. Several calibration and control methods are described to maximize performance of the fuel system, including the use of a misfire detection technique to determine the lean misfire limit of each cylinder to allow the respective port fuel injector to provide a specified margin from lean misfire. The present invention enhances engine performance and driveability while reducing exhaust emissions.

Owner:ECONTROLS LLC

Beverage dispenser

Apparatus for dispensing a post-mix beverage is characterized by a beverage concentrate metering system comprising a reservoir of beverage concentrate, a disposable pump unit containing a pair of piston pumps and inlet and outlet valves from each piston pump. The inlet valves are coupled to the reservoir of beverage concentrate and the outlet valves are coupled to a mixer. A control valve introduces diluent to the concentrate intermediate the outlet valves and mixer and a reusable pump drive operates the piston pumps. The control valve and pump drive are operated by a control system in a manner such that a predetermined ratio of diluent to concentrate is delivered to the mixer. Downstream from the mixture the admixture of diluent and concentrate is dispensed as a beverage into a cup.

Owner:IMI VISION LTD

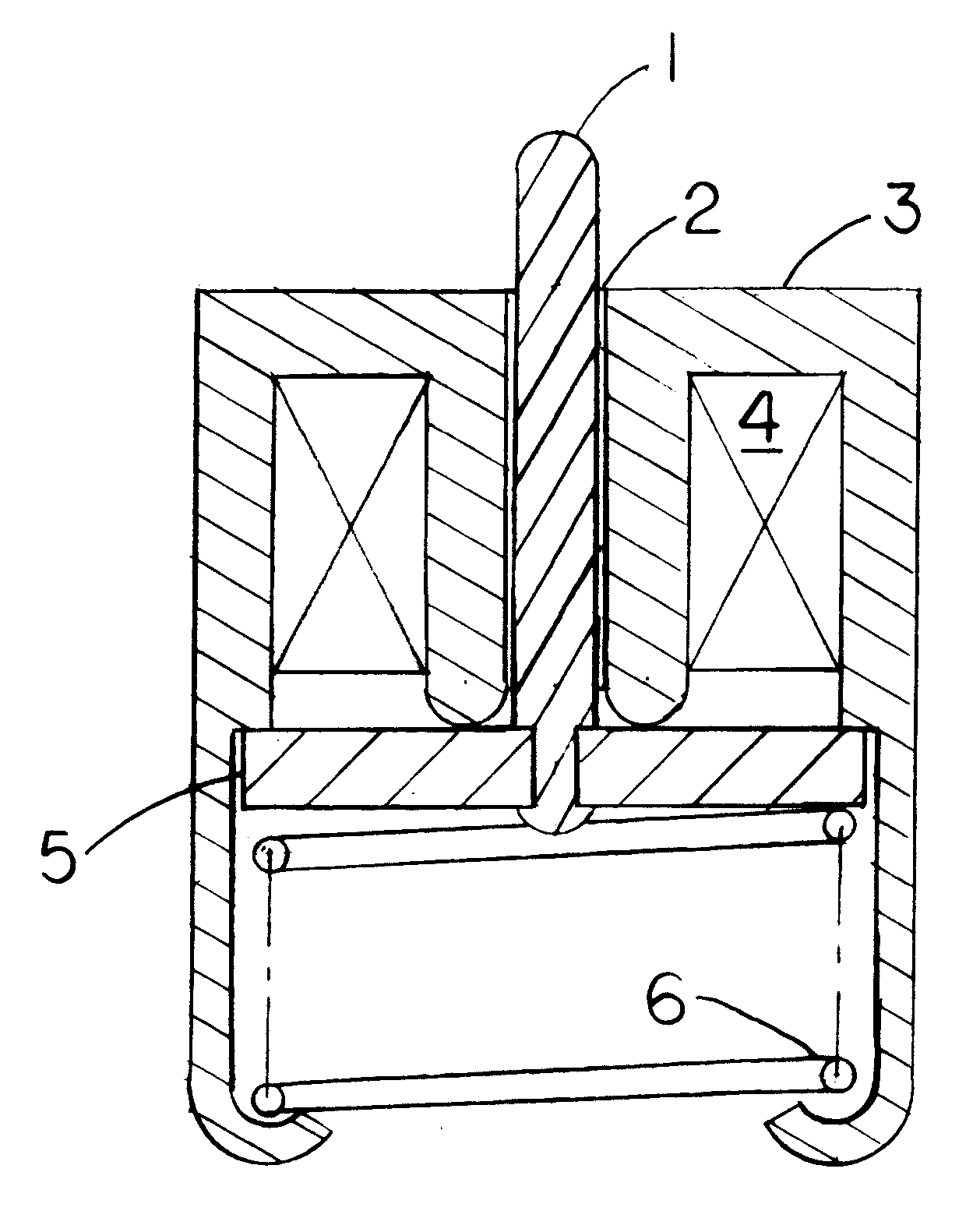

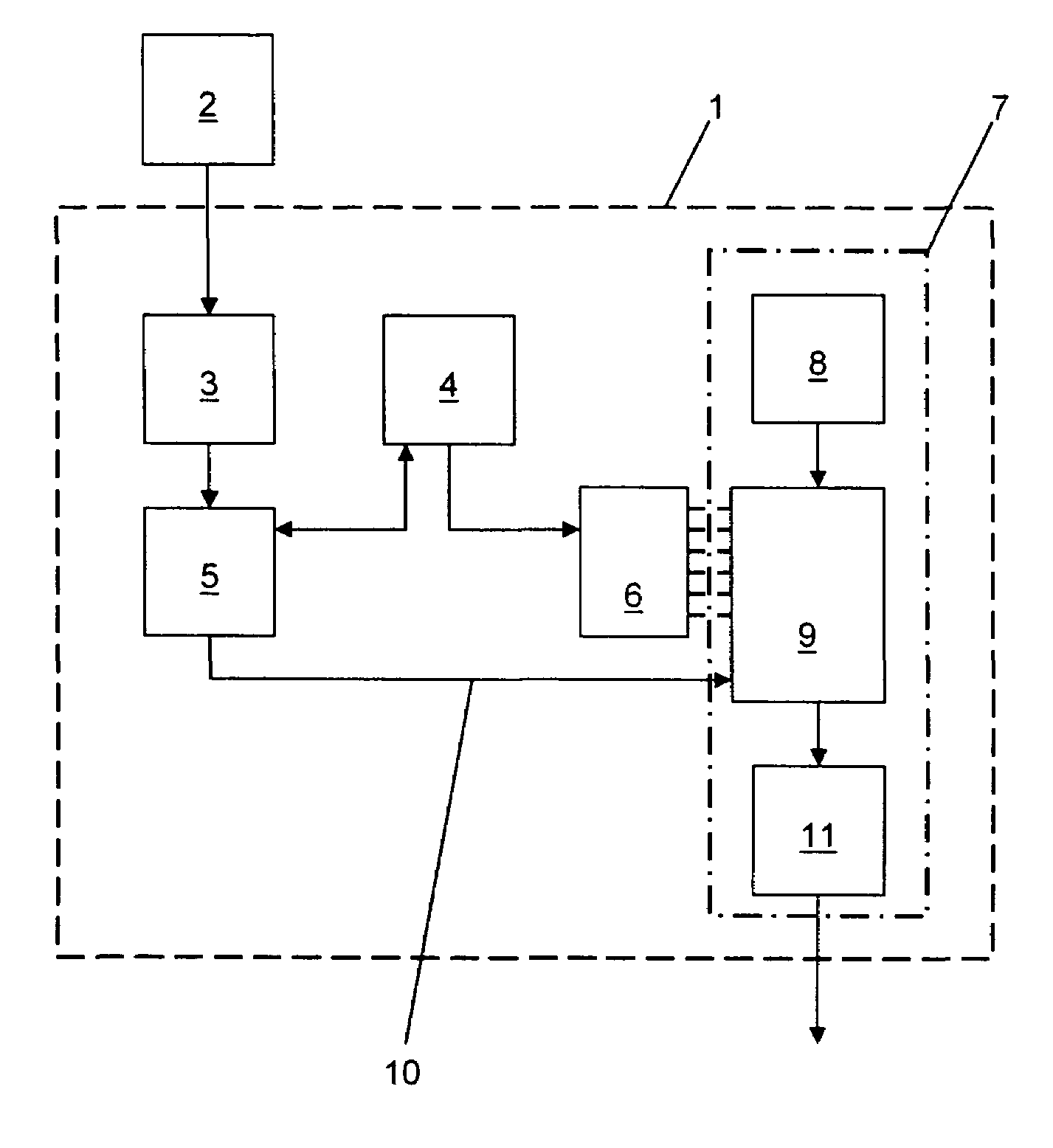

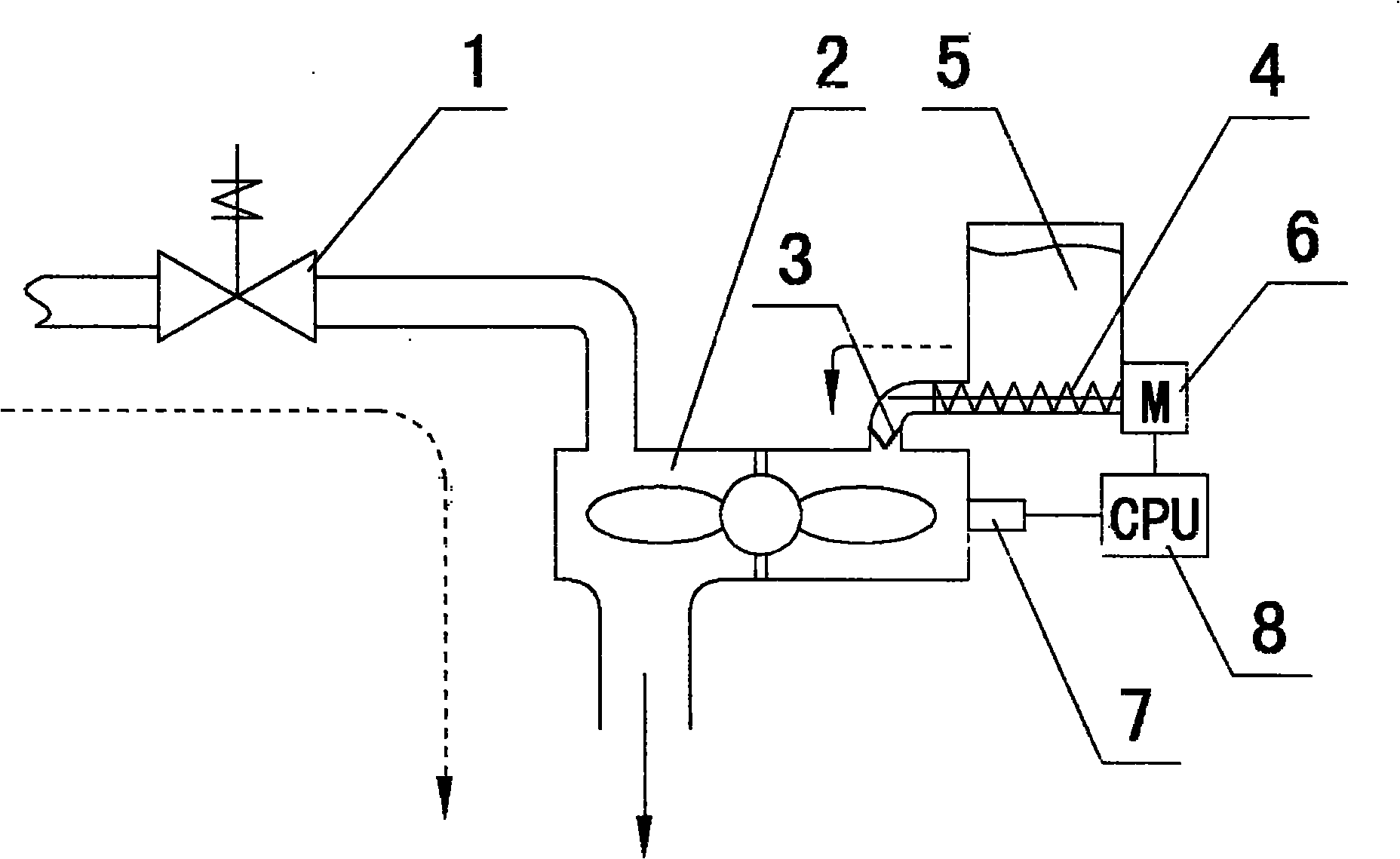

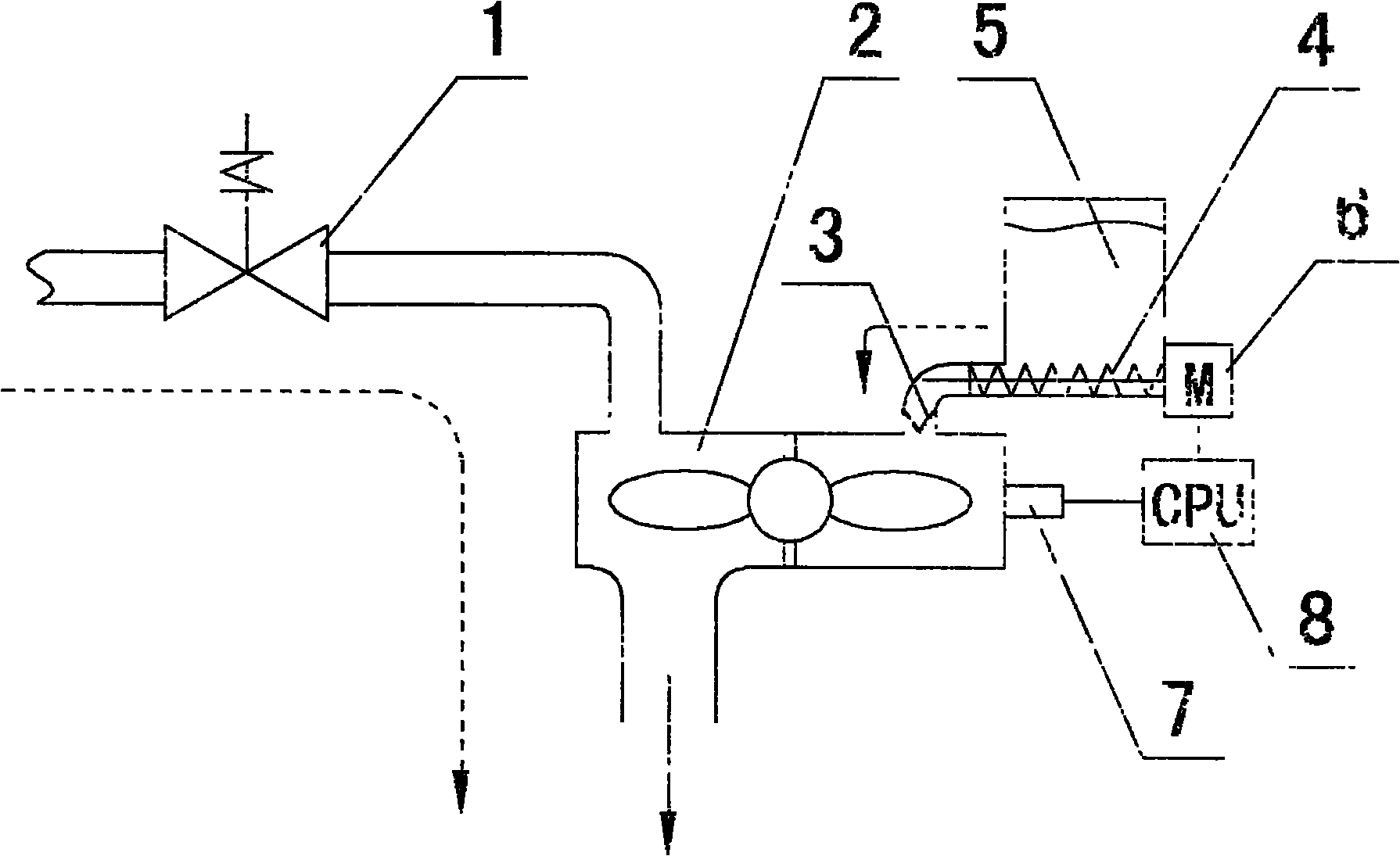

Detergent pouring and mixing device

InactiveCN102182049AWell mixedModerate concentrationOther washing machinesControl devices for washing apparatusInlet valveEngineering

The invention provides a detergent pouring and mixing device. The device comprises an inlet valve 1, a turbine agitator 2, a discharge mouth 3, a screw pump 4, a charge basket 5, a motor 6, an inductor 7 and a controller 8, wherein the duckbilled discharge mouth 3 is arranged in the discharge hole of the charge basket 5; and the screw pump 4 driven by the motor 6 is arranged at the bottom of the charge basket 5. The device has the following beneficial effects: after being arranged on the washing machine, the device can automatically pour the detergent according to the required proportion and can fully mix the detergent with the inlet water to ensure the detergent entering into the washing basket to have an appropriate and uniform concentration.

Owner:刘立杰

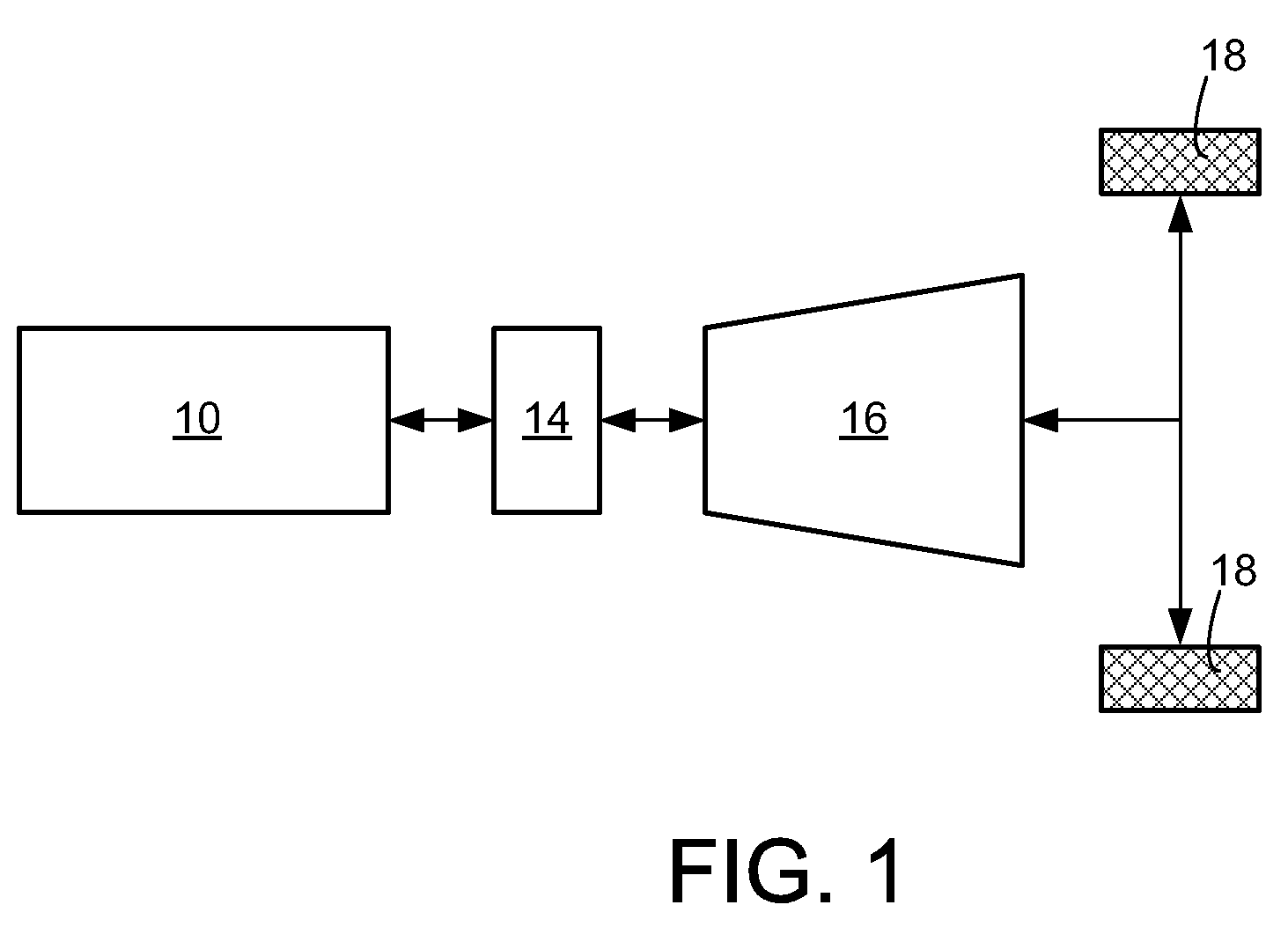

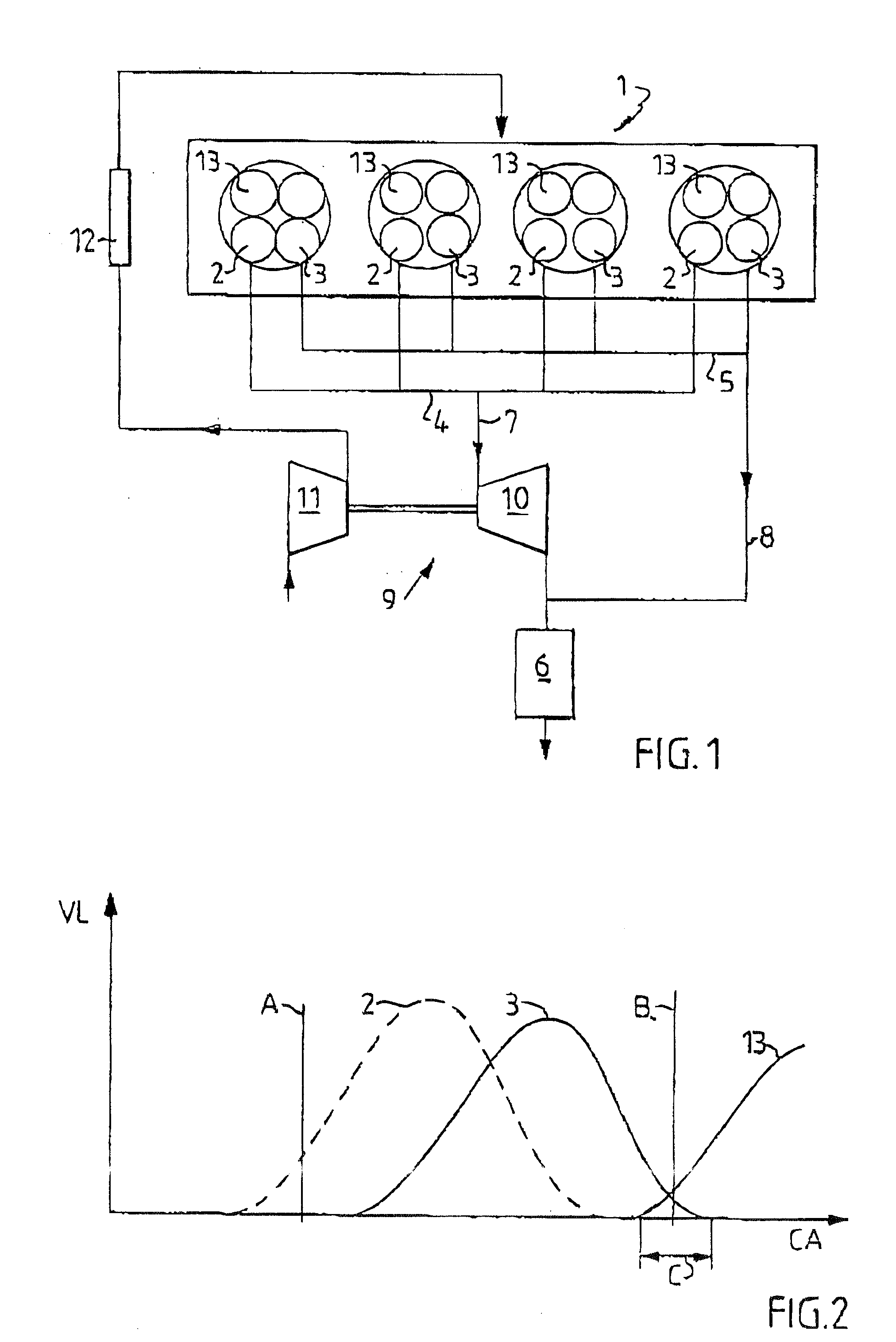

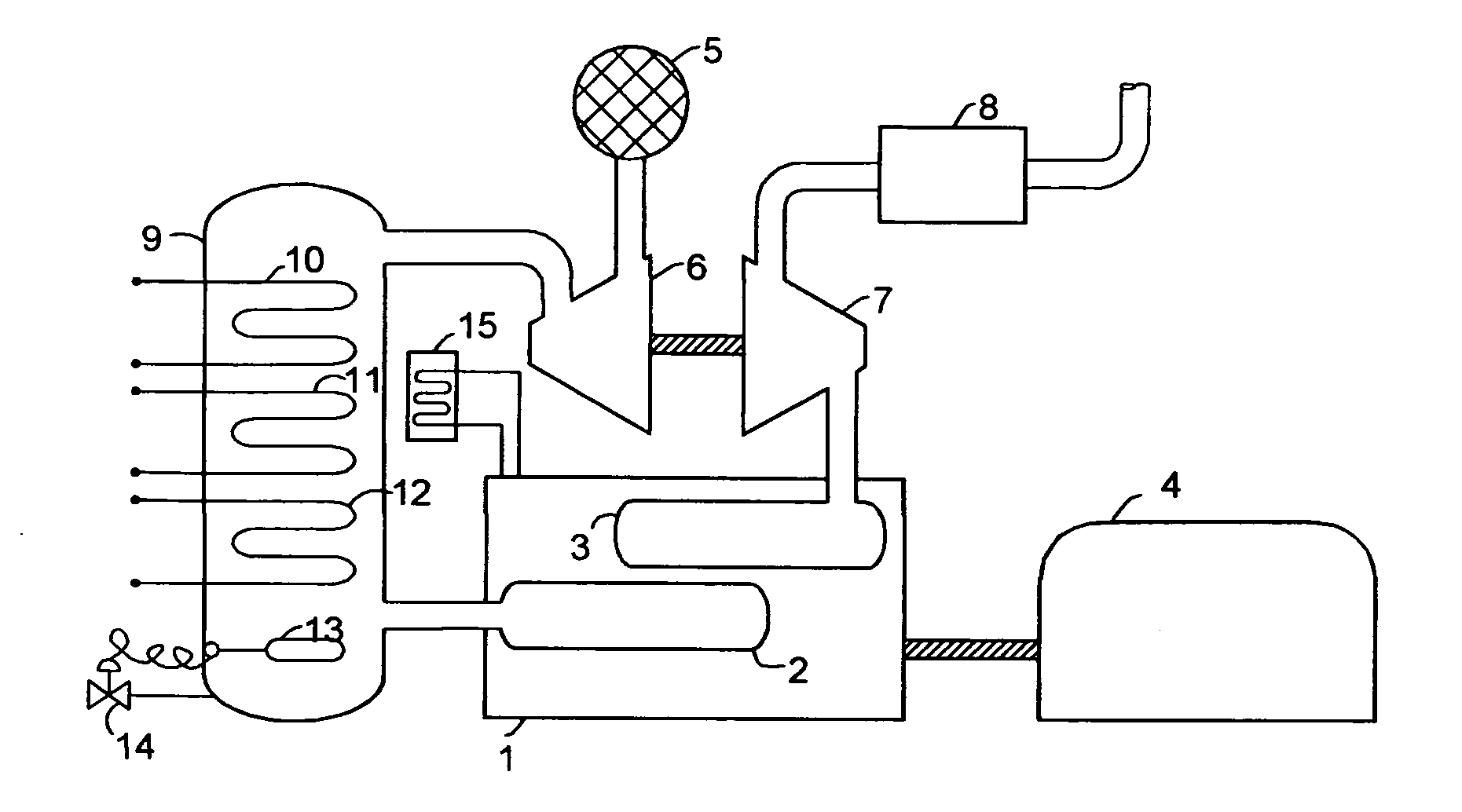

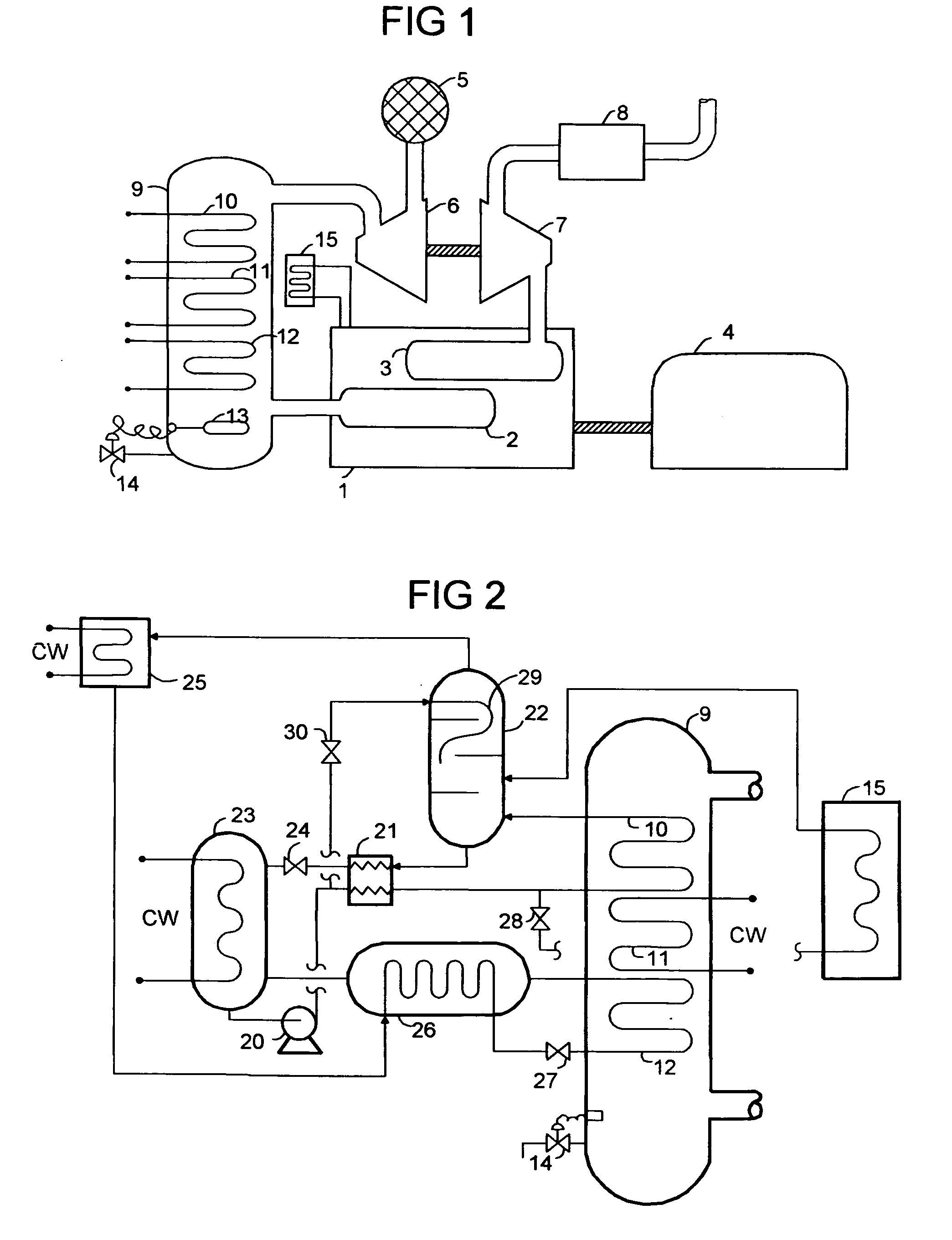

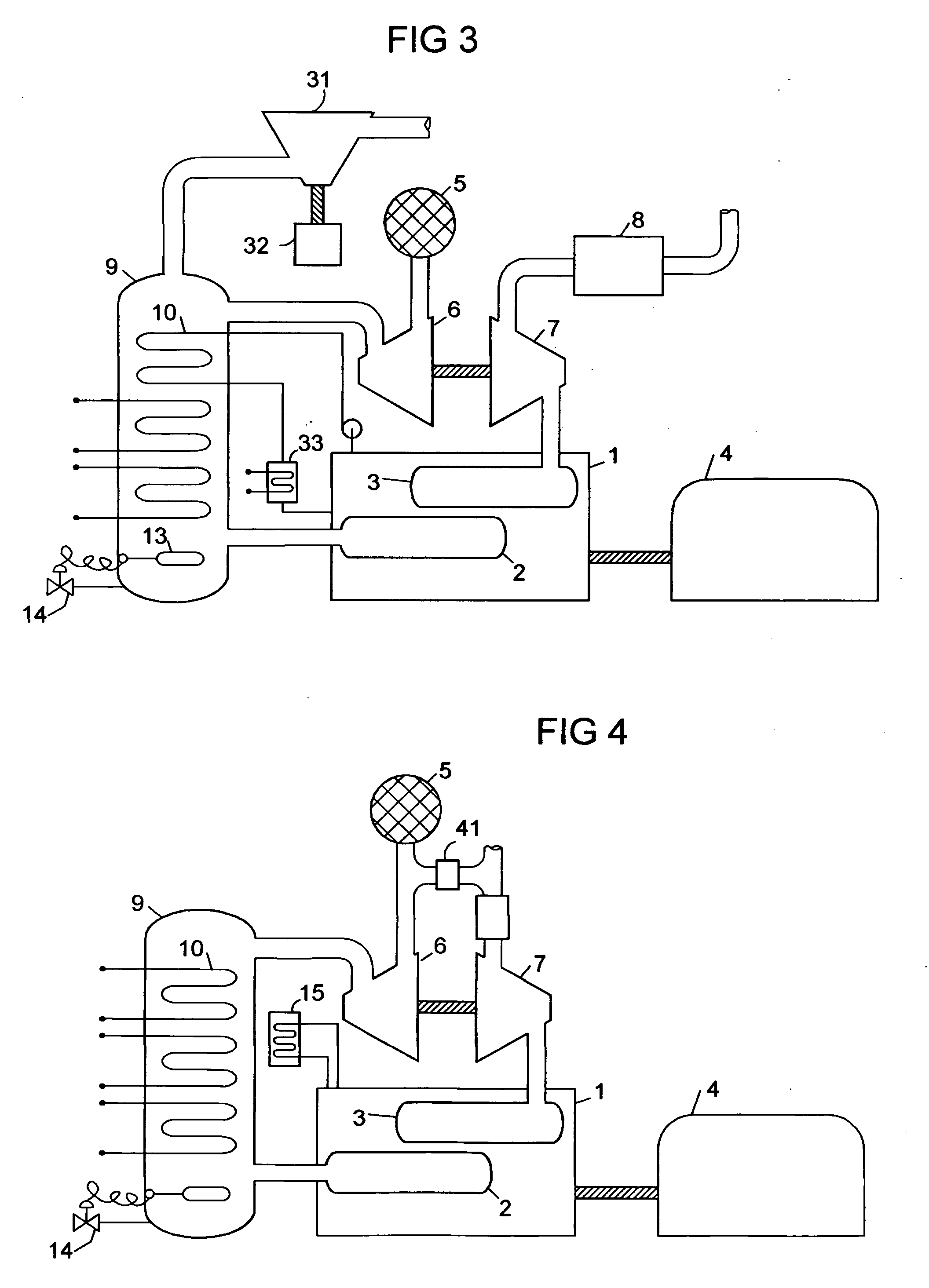

Charge air chiller

InactiveUS20090031999A1Maximum increase in energy efficiencyIncrease boost pressureInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerInlet valve

A system for chilling the pressurized charge air to a reciprocating engine is disclosed wherein the chilling is provided by a thermally activated refrigeration cycle powered by waste heat from the engine system. This reduces the required compression power, and also retards knock, making higher compression ratios possible. The chilling system is designed to minimize the amount of chilling required, and also to enable use of compression heat to power the chiller. The disclosed improvement also accommodates exhaust gas recirculation, plus providing activation heat from the exhaust gas, plus Miller cycle timing of the intake valves. Referring to FIG. 1, the charge air from turbocharger 5 is cooled in three stages: heat recovery stage 10; ambient-cooled stage 11; and chilling stage 12. Condensed moisture is removed from the charge air by valve 14 before the charge is supplied to inlet manifold 2.

Owner:ERICKSON DONALD CHARLES

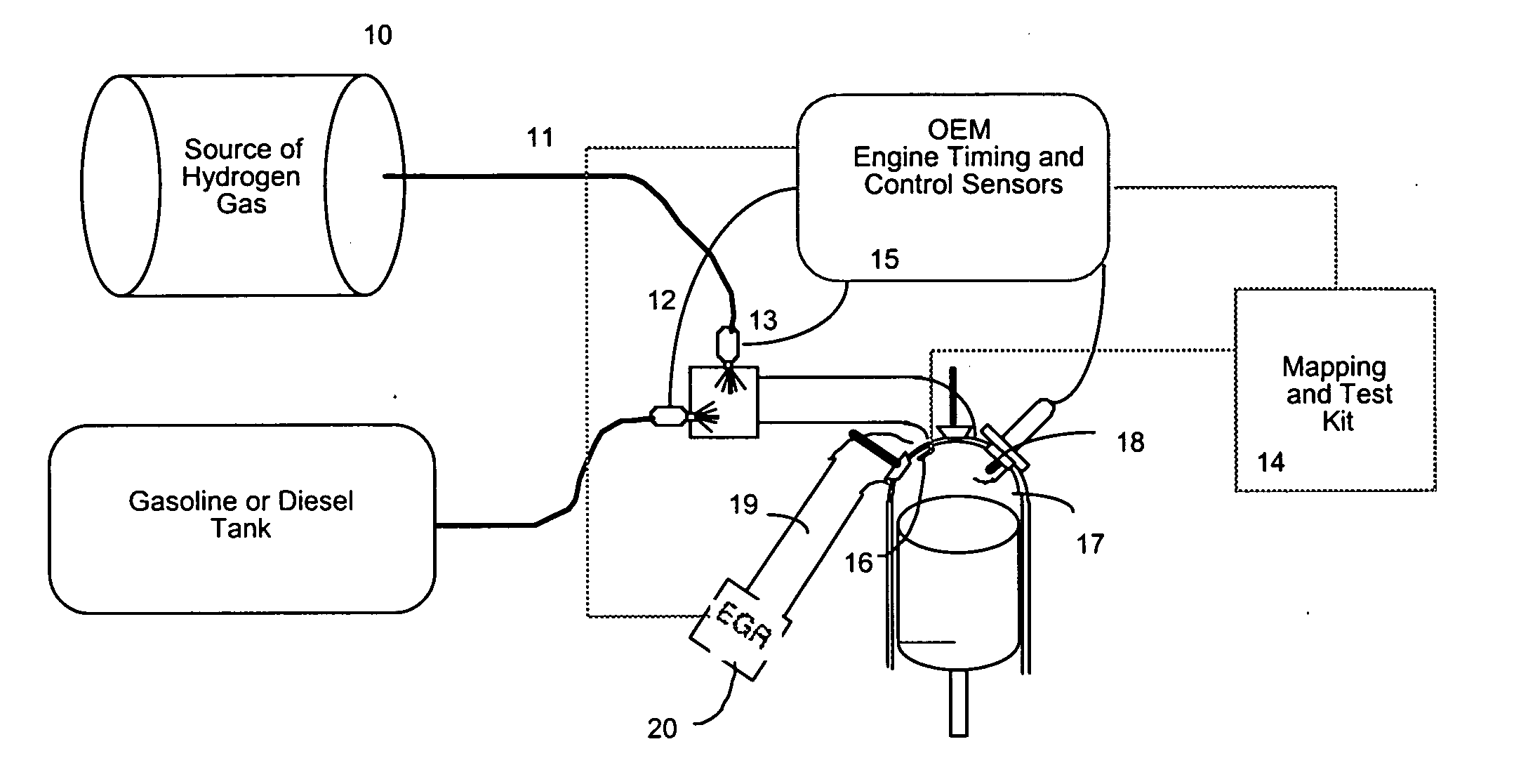

System and method for operating an internal combustion engine with hydrogen blended with conventional fossil fuels

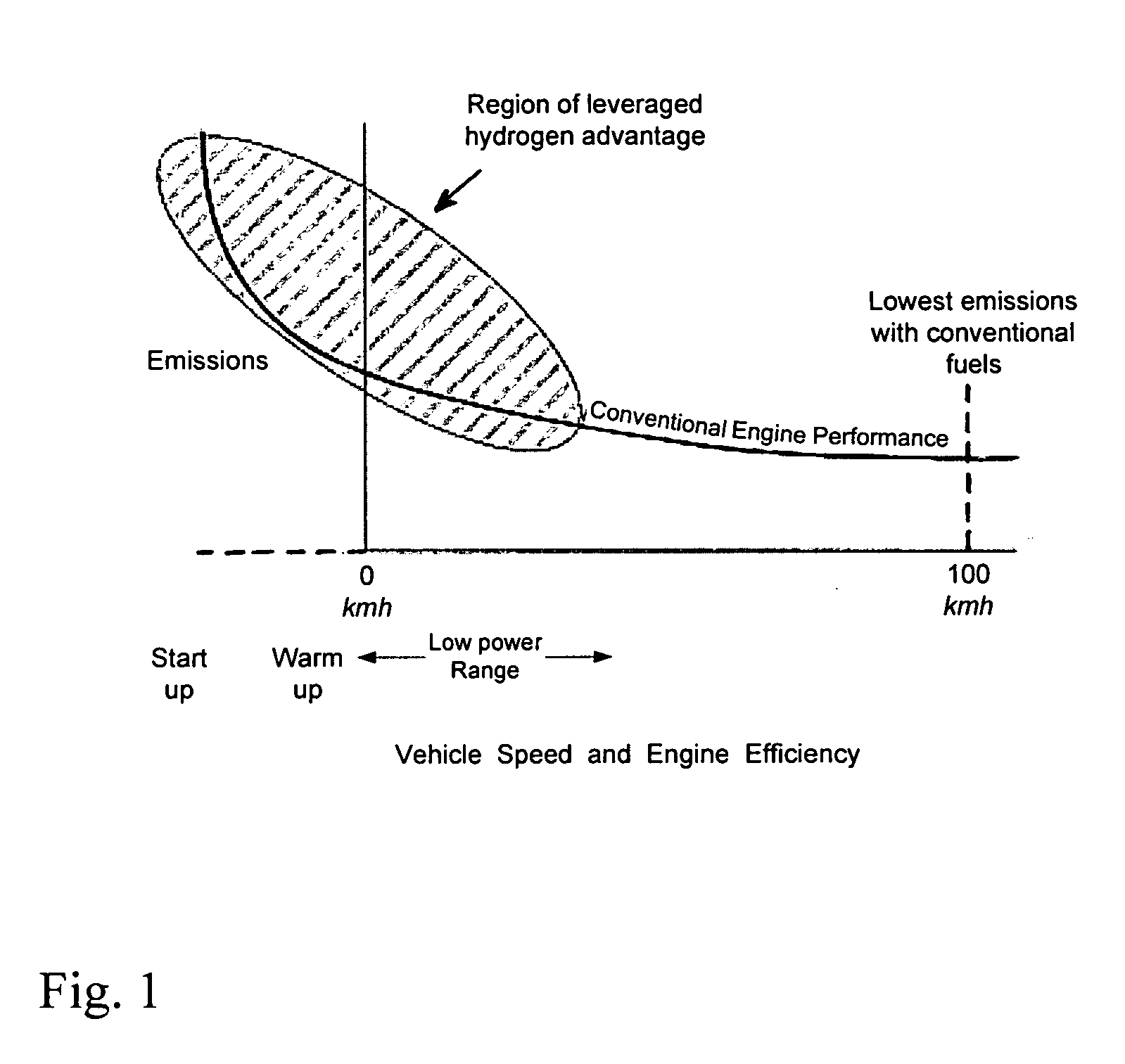

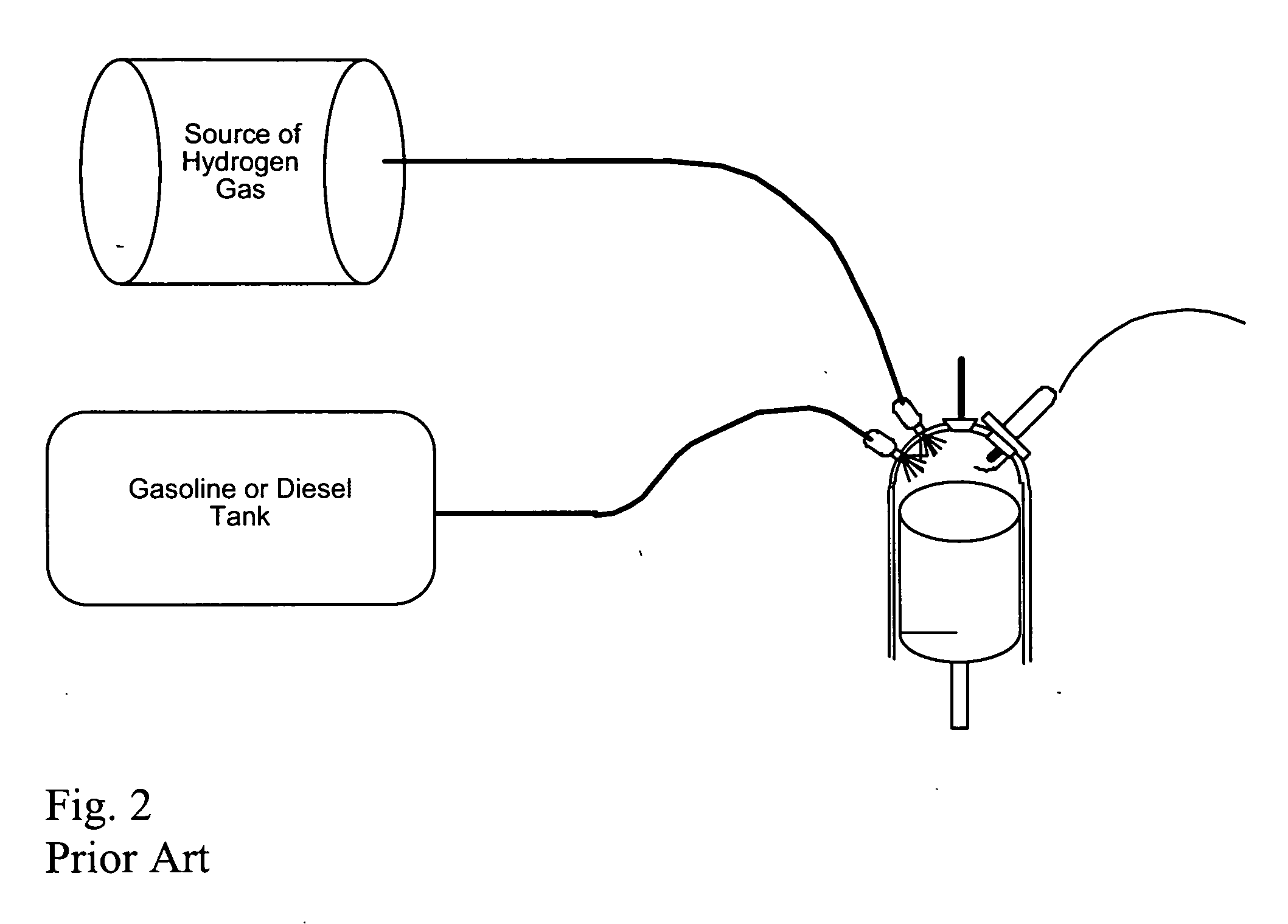

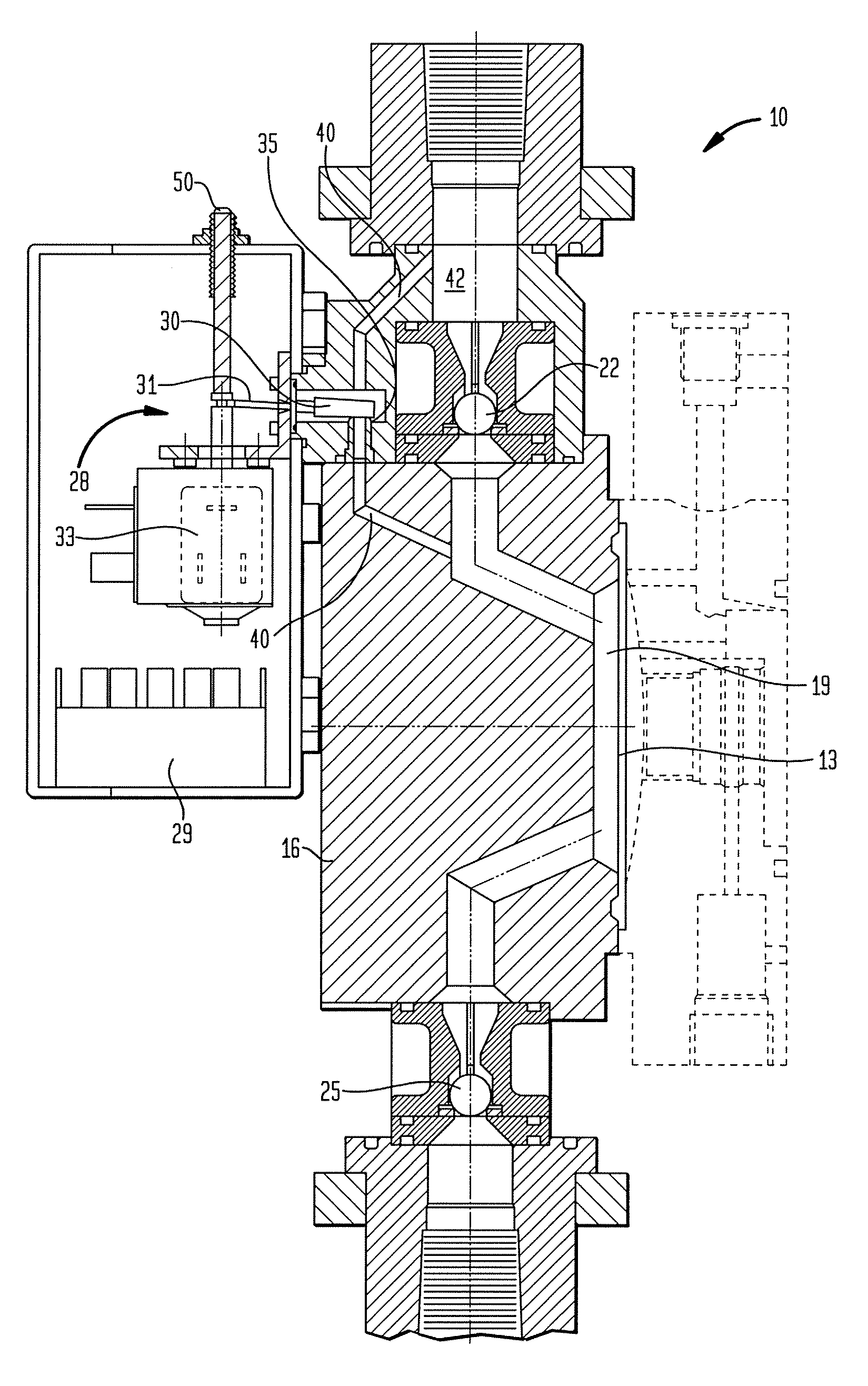

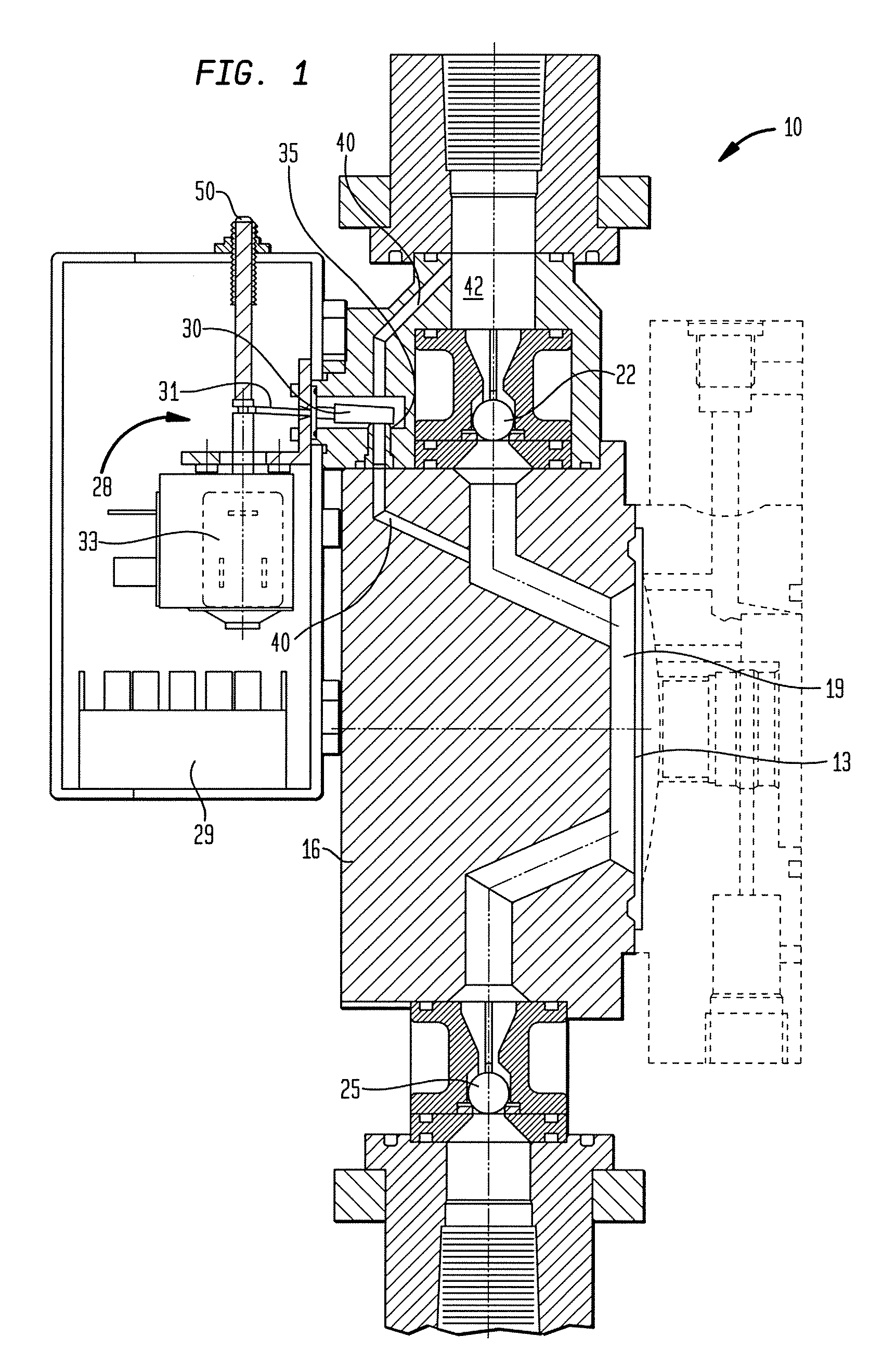

ActiveUS20050229872A1Inexpensively repAccelerate emissionsHydrogenElectrical controlHydrogenExternal combustion engine

A system for retrofitting an internal combustion engine to use a proportion of hydrogen gas and existing fossil fuel is disclosed. The system is comprised of a source of hydrogen gas and means for delivering hydrogen gas to the combustion chamber of the engine. The engine operating parameters are adjusted and the delivery of hydrogen is controlled to provide selective introduction of hydrogen gas throughout the engine's operating cycle. The source of hydrogen gas can comprise an onboard hydrogen reformer, or hydrogen and carbon monoxide can be reformed inside the cylinder from an on board carrier of hydrogen. A single point injector placed at the intake manifold in close proximity to the engine intake valve can be used to mix the hydrogen gas to the air / fossil fuel mixture or sequential injectors can deliver hydrogen in close proximity to each engine intake valve, or directly into each cylinder.

Owner:OREILLY HUGH

Effervescent gas bleeder apparatus

InactiveUS7175397B2Positive displacement pump componentsFlexible member pumpsReciprocating motionInlet valve

A diaphragm metering pump suitable for metering an effervescent gas. The pump has a pump head with a product chamber having an inlet end with a one-way inlet valve and an outlet end with a one-way outlet valve. A displaceable diaphragm member defines a boundary of the product chamber. The diaphragm member is capable of being reciprocated to cause pumping displacements. A discharge side is disposed downstream from the outlet valve. A passageway is disposed in fluid communication between the discharge side and the product chamber. A valve is disposed in the passageway. The valve is opened intermittently to allow liquid to re-enter the product chamber in an amount effective to purge gas from the product chamber to prevent loss of prime.

Owner:PULSAFEEDER

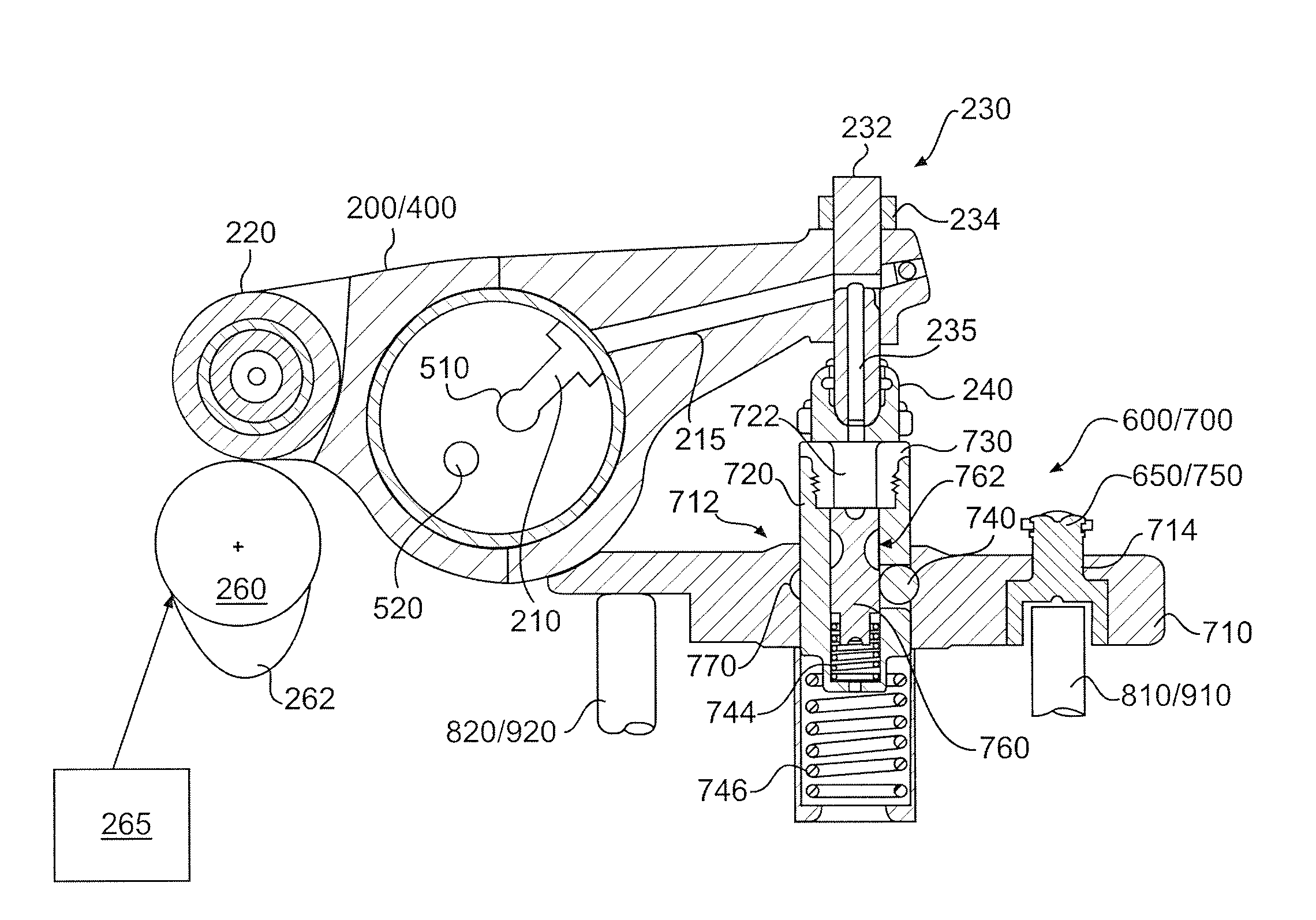

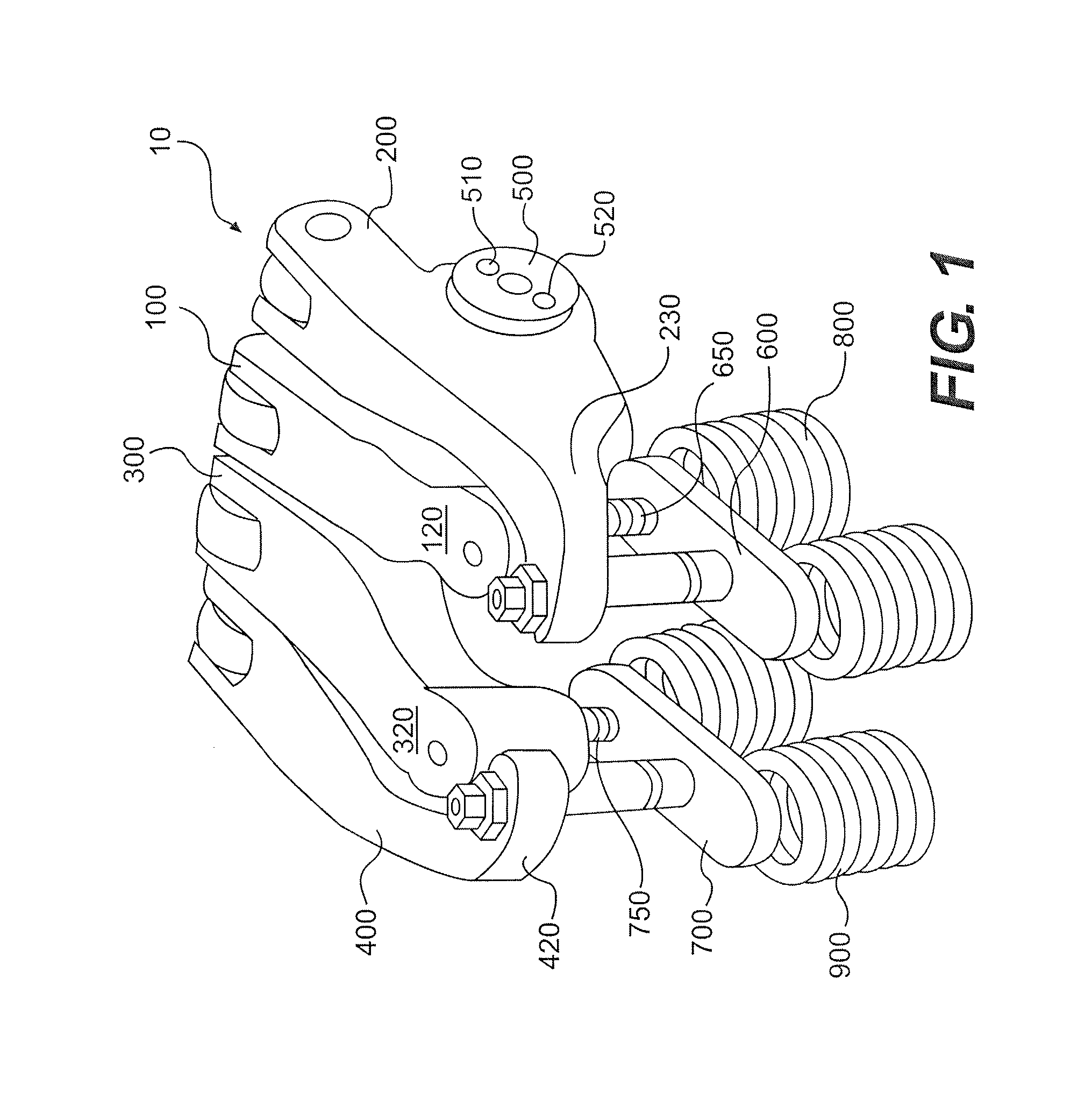

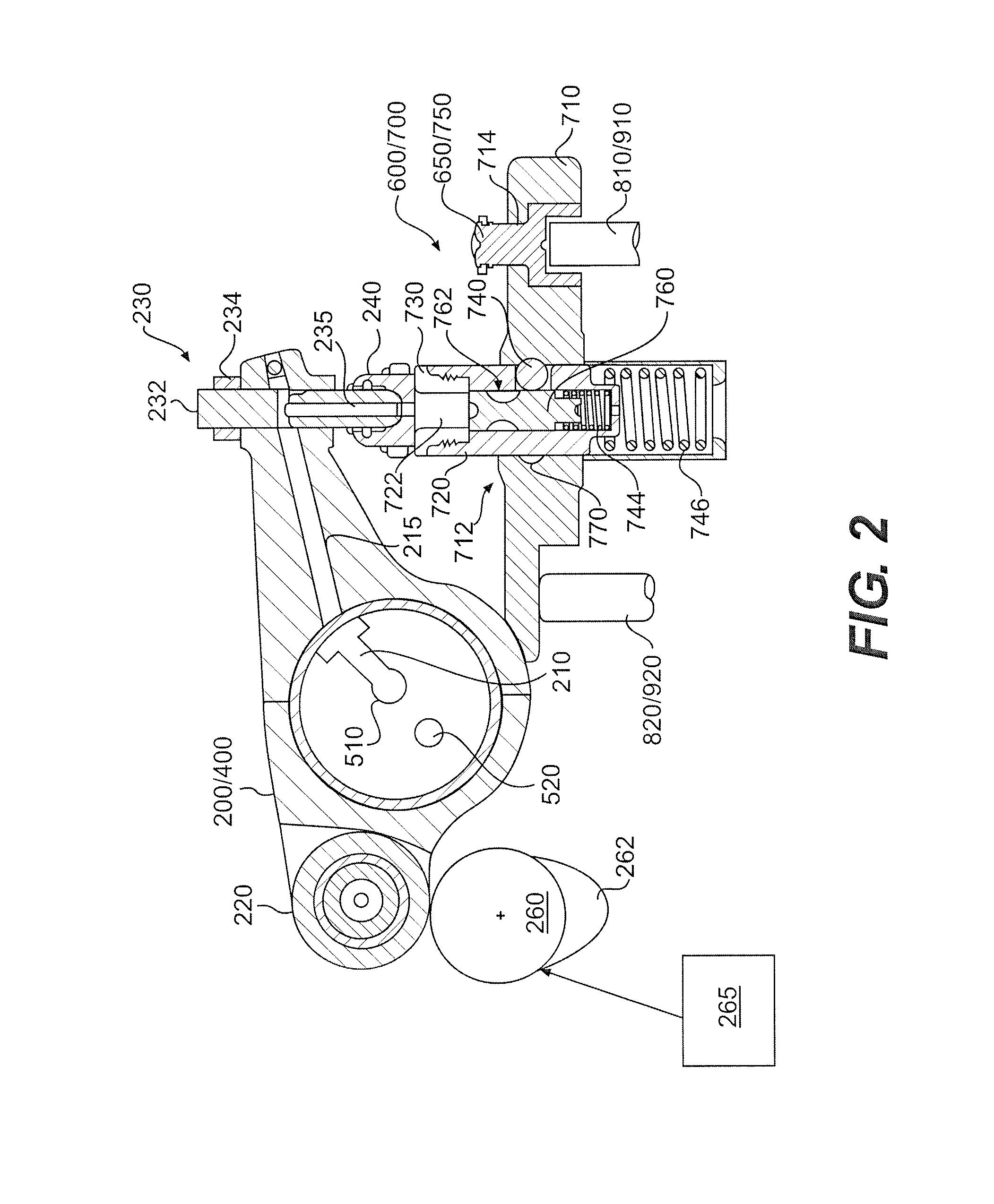

Combined engine braking and positive power engine lost motion valve actuation system

A system for actuating one or more engine valves for positive power operation and engine braking operation is disclosed. In a preferred embodiment, an exhaust valve bridge and intake valve bridge each receive valve actuations from two sets of rocker arms. Each valve bridge includes a sliding pin for actuating a single engine valve and an outer plunger disposed in the center of the valve bridge to actuate two engine valves through the bridge. The outer plunger of each valve bridge may be selectively locked to its valve bridge to provide positive power valve actuation. During engine braking, application of hydraulic pressure to the outer plungers may cause the respective valve bridges and outer plungers to unlock so that all engine braking valve actuations are provided from a rocker arm acting on one engine valve through the sliding pin.

Owner:JACOBS VEHICLE SYST

Combustion engine

InactiveUS6460337B1Improve performanceReduce the temperatureValve arrangementsInternal combustion piston enginesExhaust valveCombustion

A turbo-fed internal combustion engine has a first and a second exhaust-gas valve per cylinder, these exhaust-gas valves each being connected to their respective exhaust manifold. One exhaust manifold conducts exhaust gases to an exhaust-gas turbine and the other exhaust manifold conducts subsequent exhaust gases past this exhaust-gas turbine which drives a compressor for charge air. The intake valve of the cylinder is arranged so as, as the engine speed increases, to close either earlier, before the piston reaches its bottom dead center, or later, after the piston has passed its bottom dead center. In this way, the temperature increase resulting from compression in the cylinder is reduced. Cooled air from the compressor can be taken in so as to obtain an adequate degree of filling in the cylinder, with a lower final temperature.

Owner:SAAB AUTOMOBILE AB

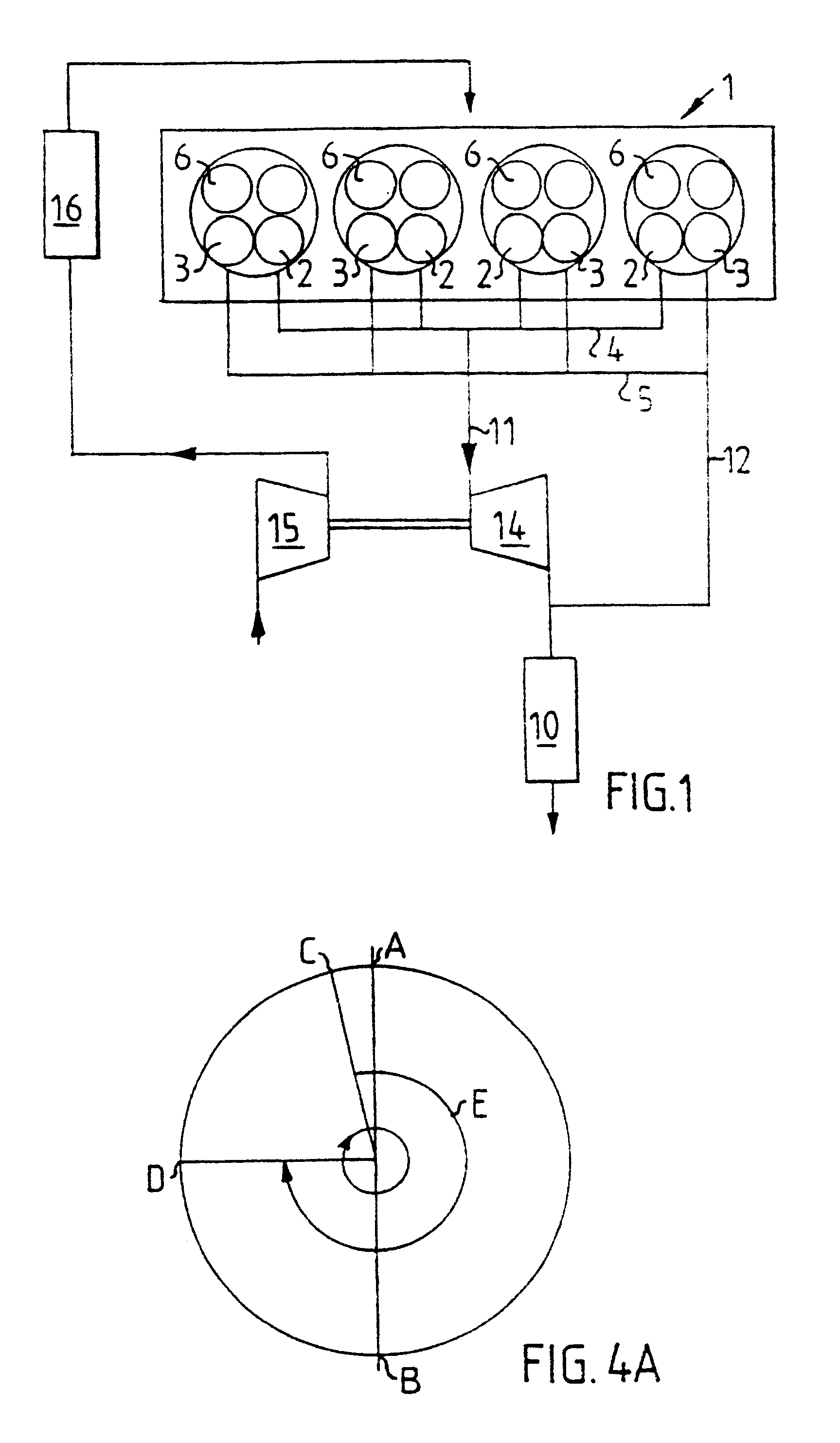

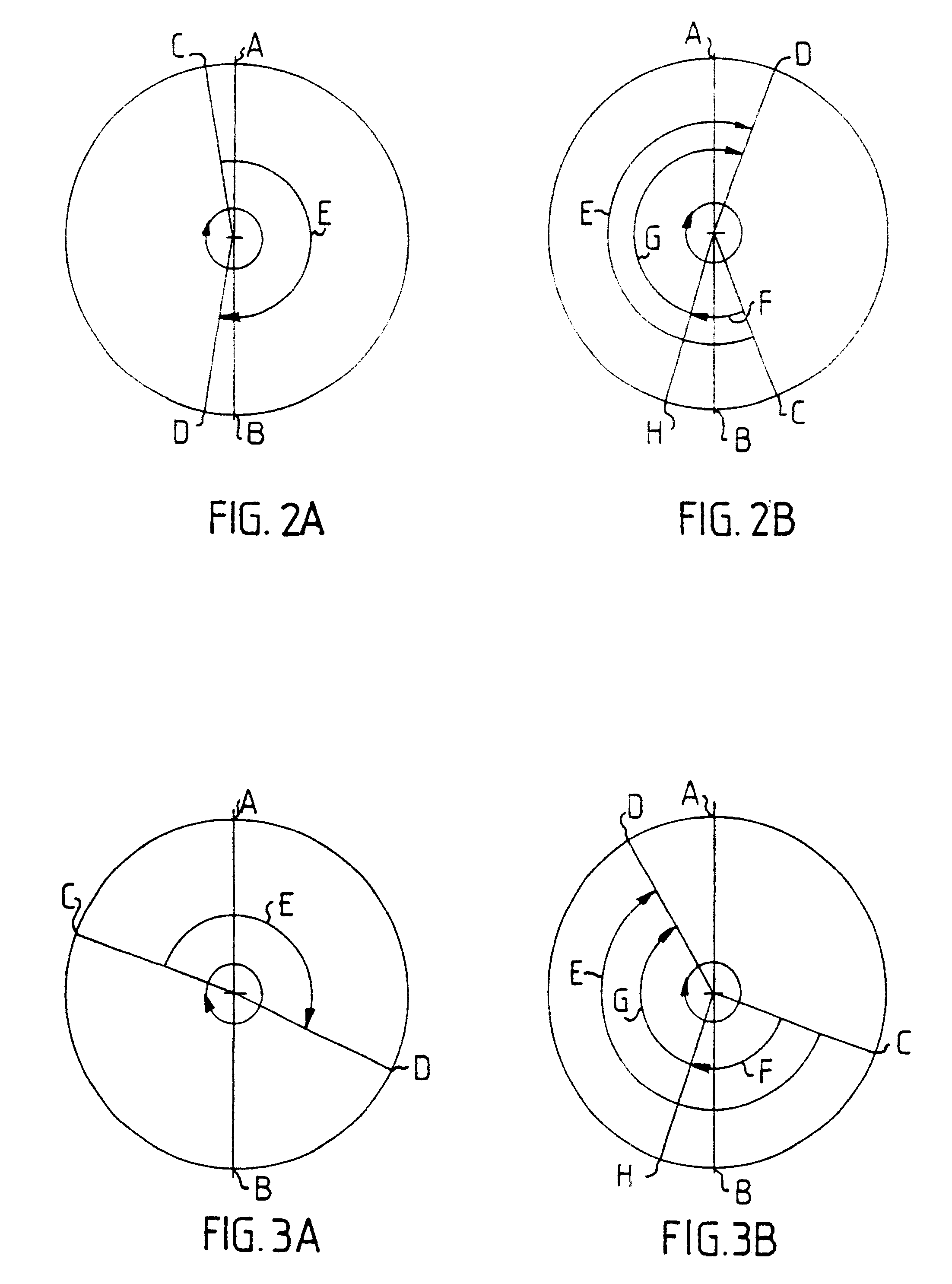

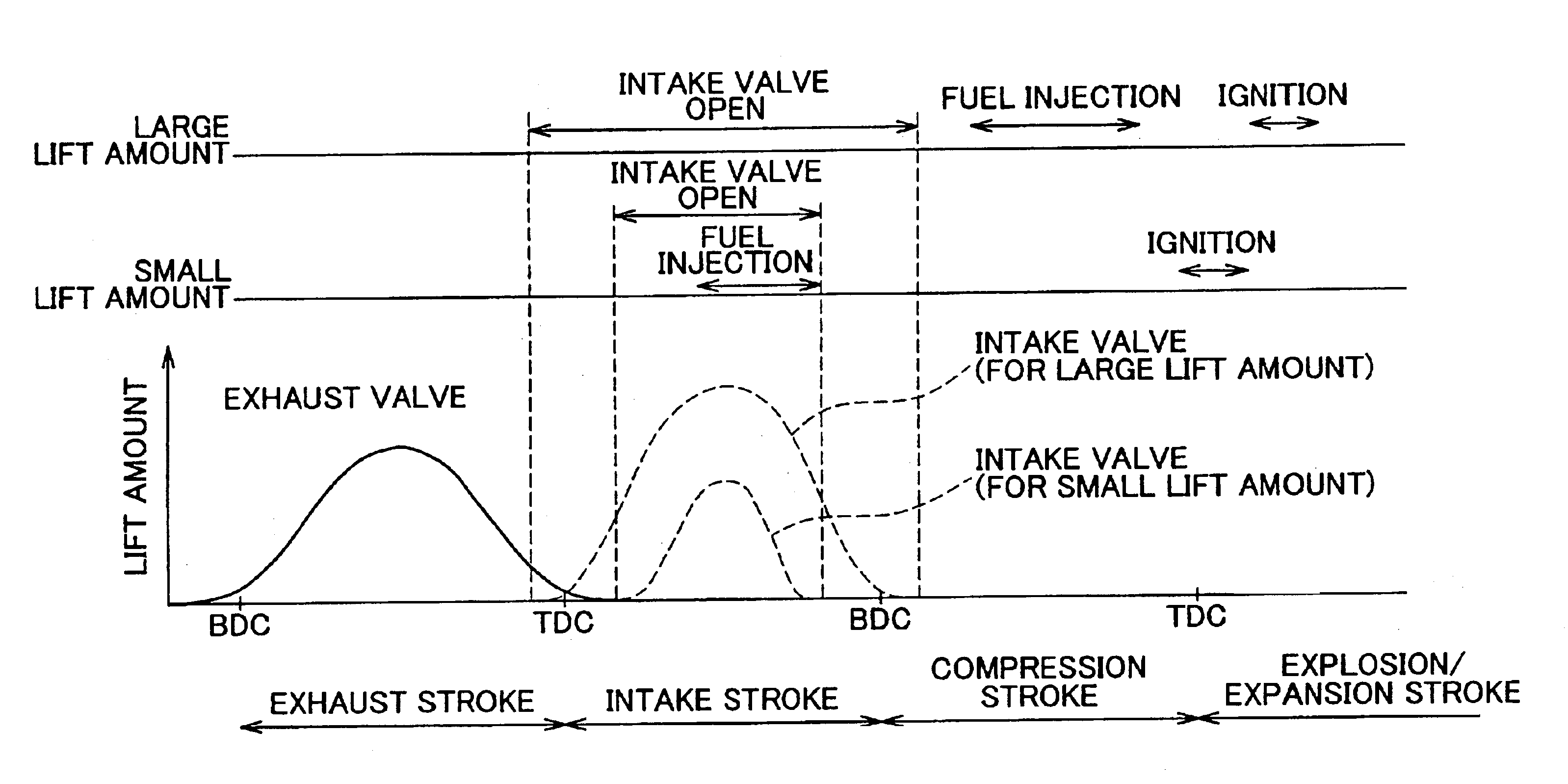

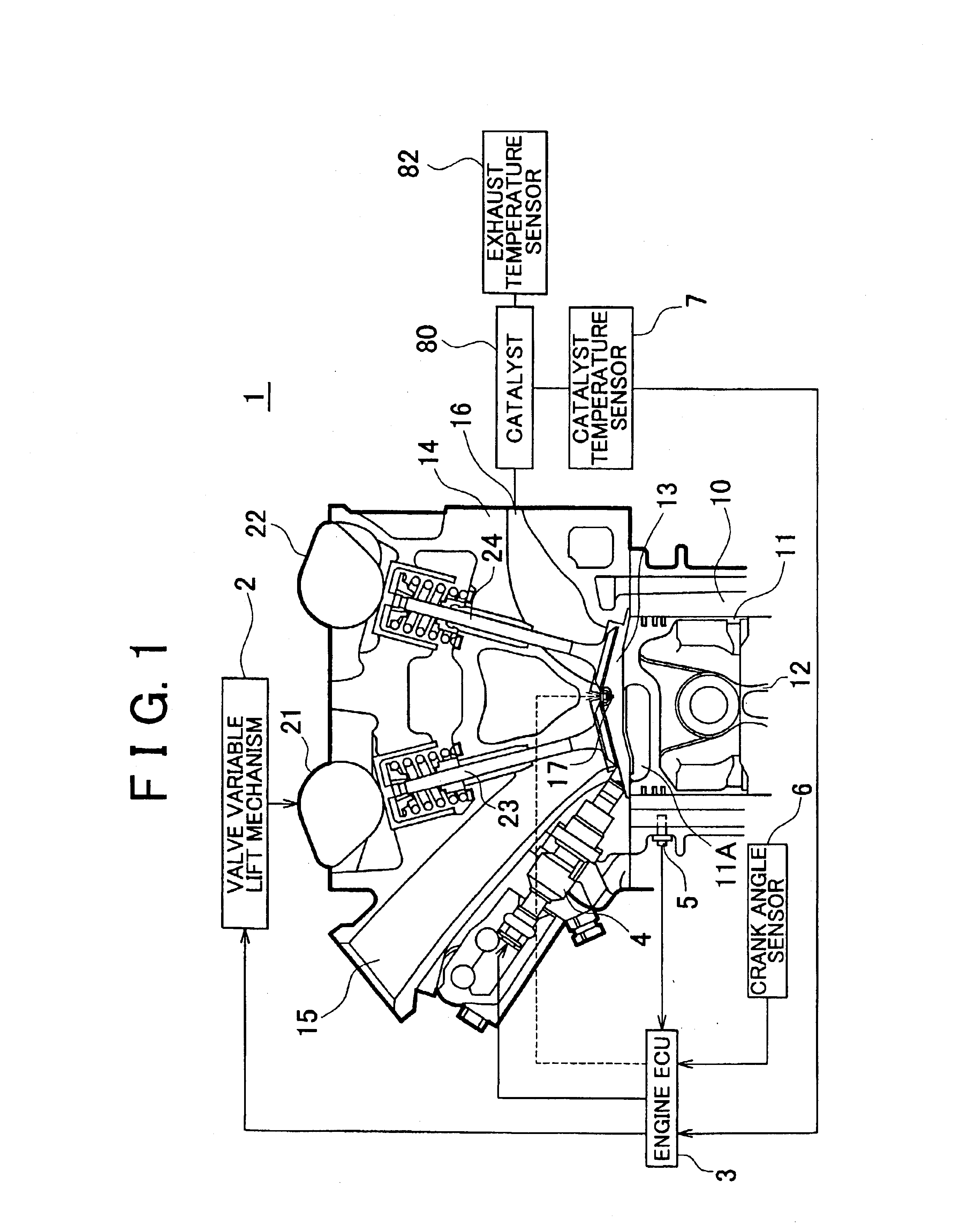

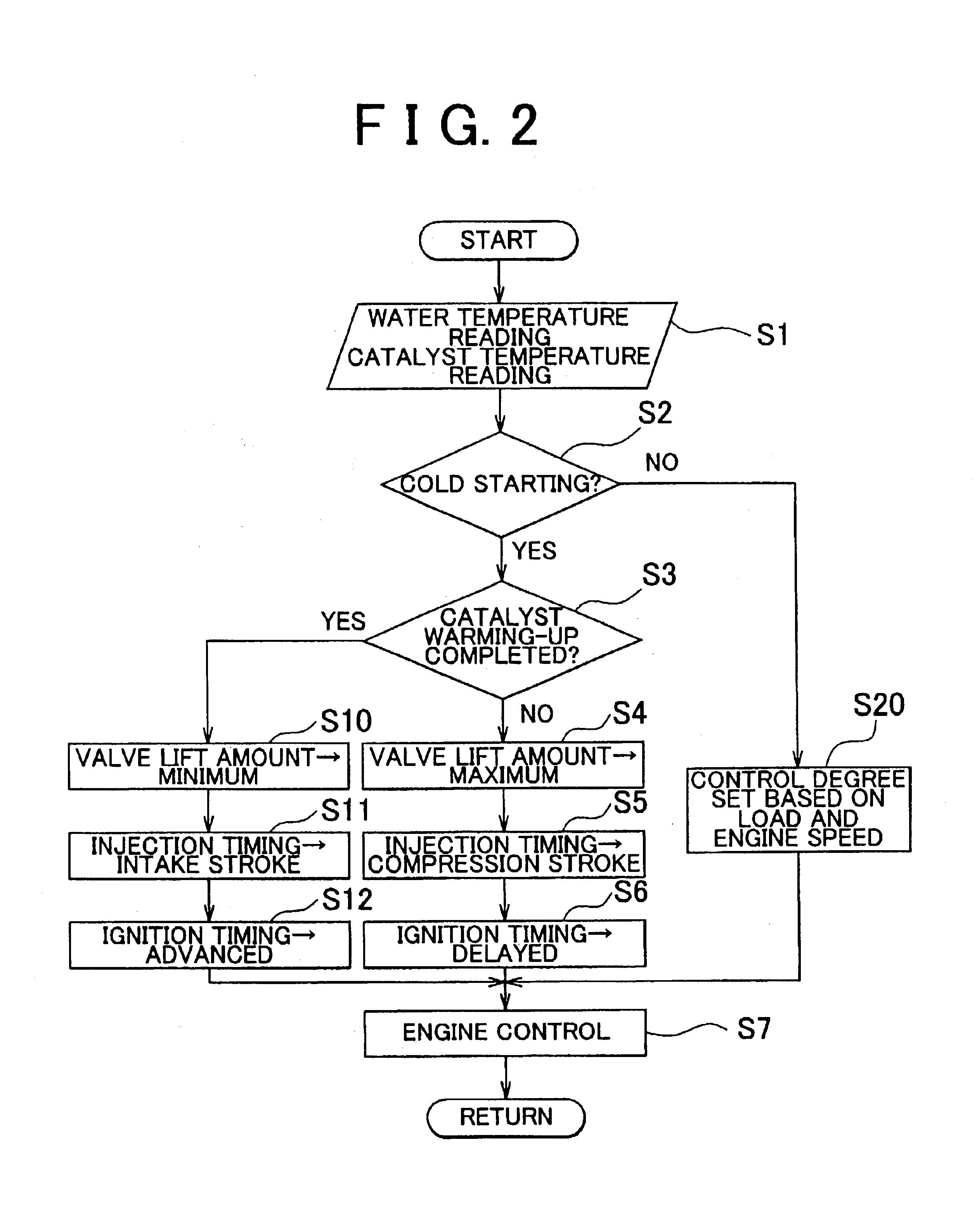

In-cylinder injection type spark-ignition internal combustion engine and control method thereof

InactiveUS6837040B2Improve fuel efficiencyValve arrangementsElectrical controlInlet valveIgnition timing

An in-cylinder injection type spark-ignition internal combustion engine and a control method thereof realize a stabilized stratified-charge combustion by setting a large lift amount to an intake valve when the engine is cold-started and by executing a compression stroke injection. At this time, warming-up capability of a catalyst is improved by delaying an ignition timing.

Owner:TOYOTA JIDOSHA KK

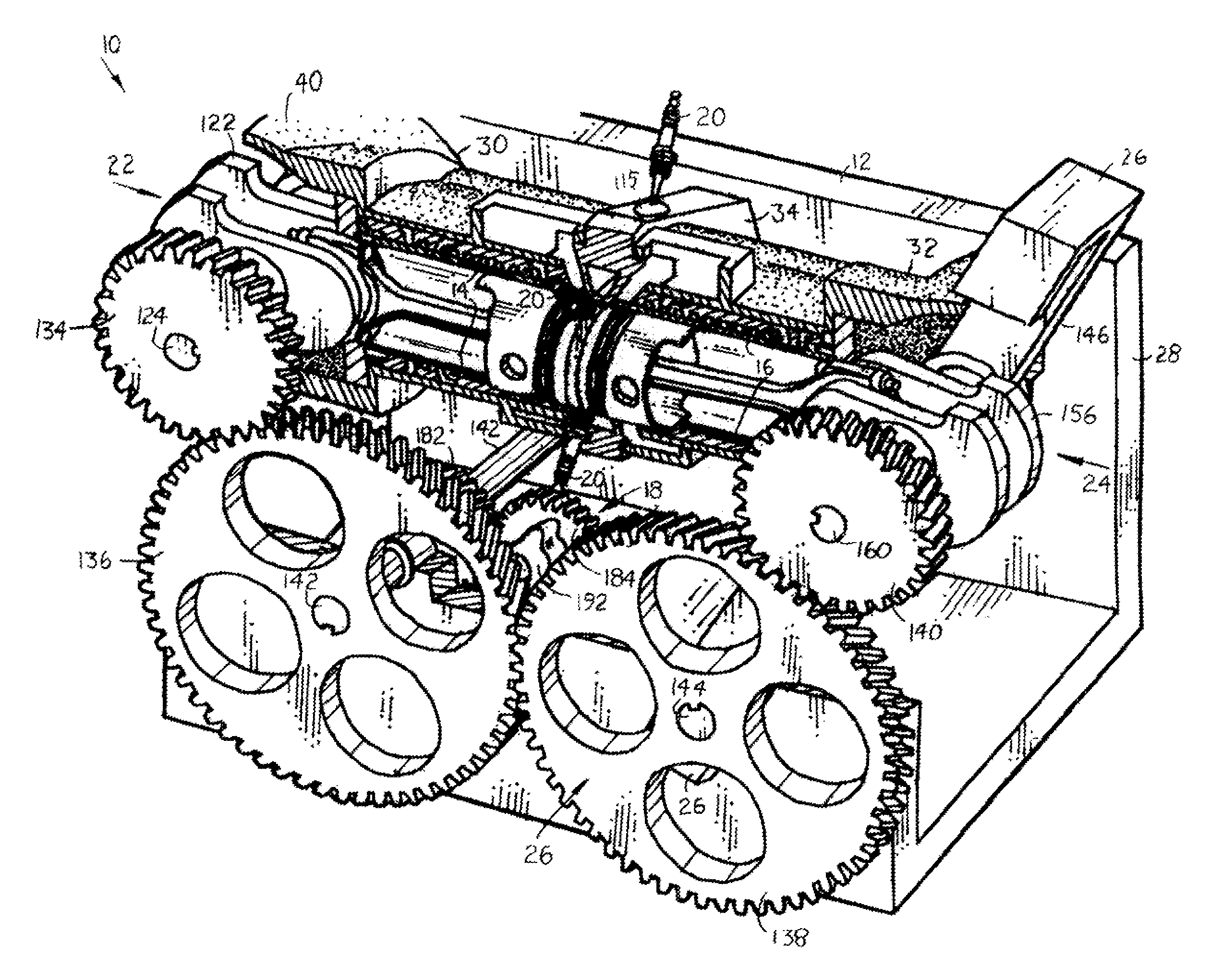

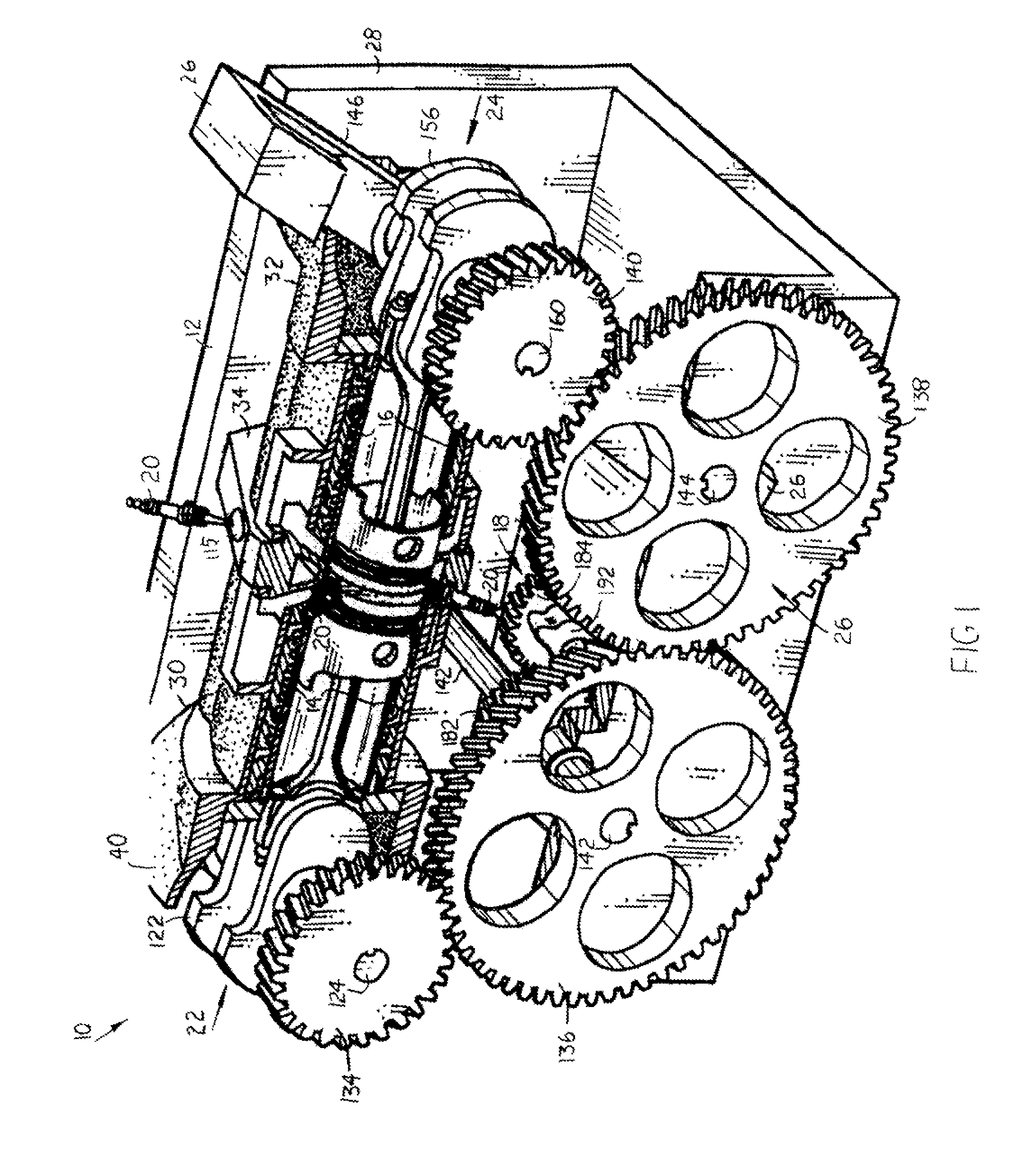

Internal combustion engine

InactiveUS7559298B2Assist in containment of heat energyReduce energy lossLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

An internal combustion engine is provided. Facing pistons eliminate a cylinder head, thereby reducing heat losses through a cylinder head. Facing pistons also halve the stroke that would be required for one piston to provide the same compression ratio, and the engine can thus be run at higher revolutions per minute and produce more power. An internal sleeve valve is provided for space and other considerations. A combustion chamber size-varying mechanism allows for adjustment of the minimum size of an internal volume to increase efficiency at partial-power operation. Variable intake valve operation is used to control engine power.

Owner:CLEEVES ENGINES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com