Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8031 results about "Heat losses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat loss is a measure of the total transfer of heat through the fabric of a building from inside to the outside, either from conduction, convection, radiation, or any combination of the these. This heat loss figure is normally given in either kilowatts (kW) or British Thermal Units (BTUs) and represents the energy required to keep a room at a given temperature on the coldest days.

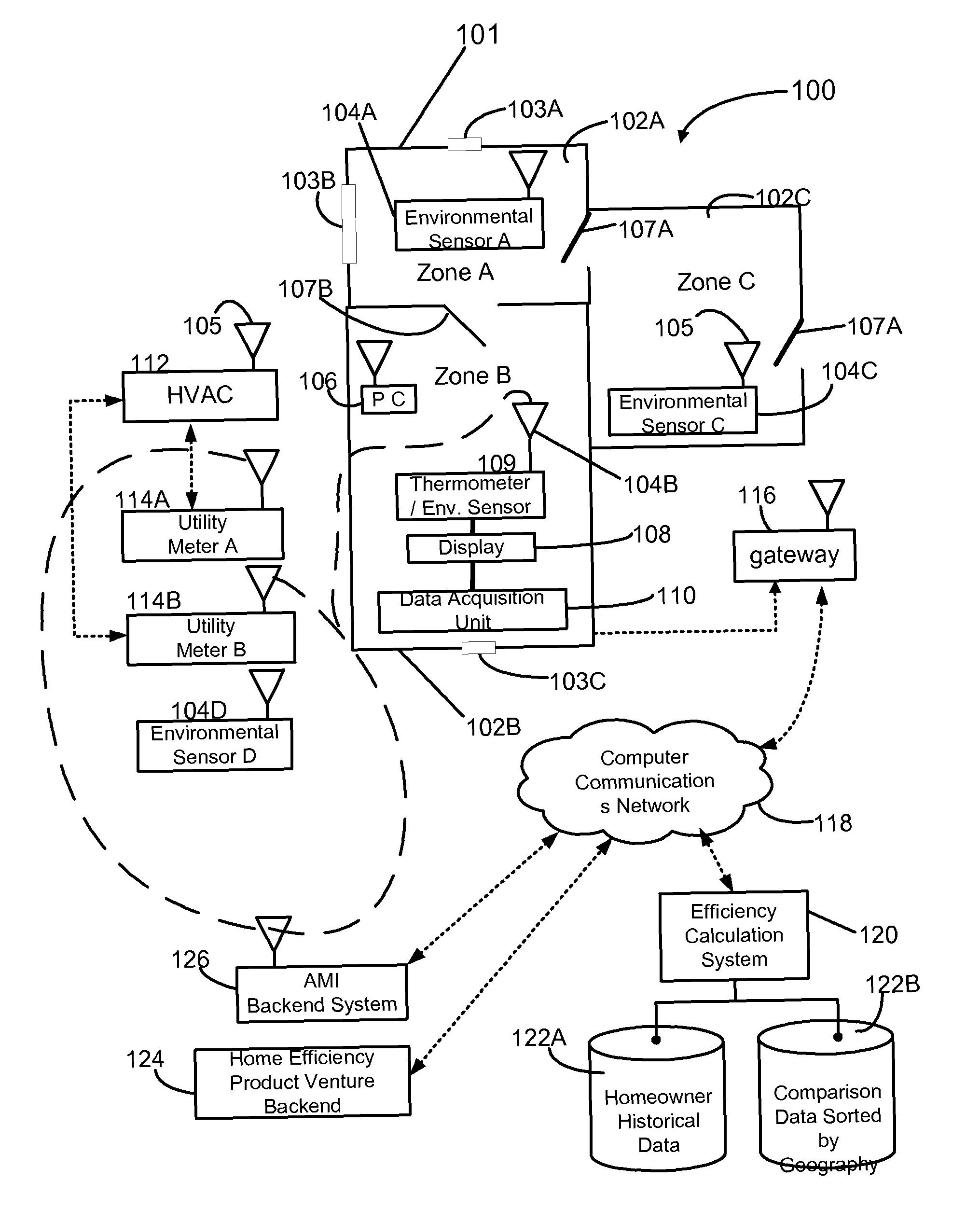

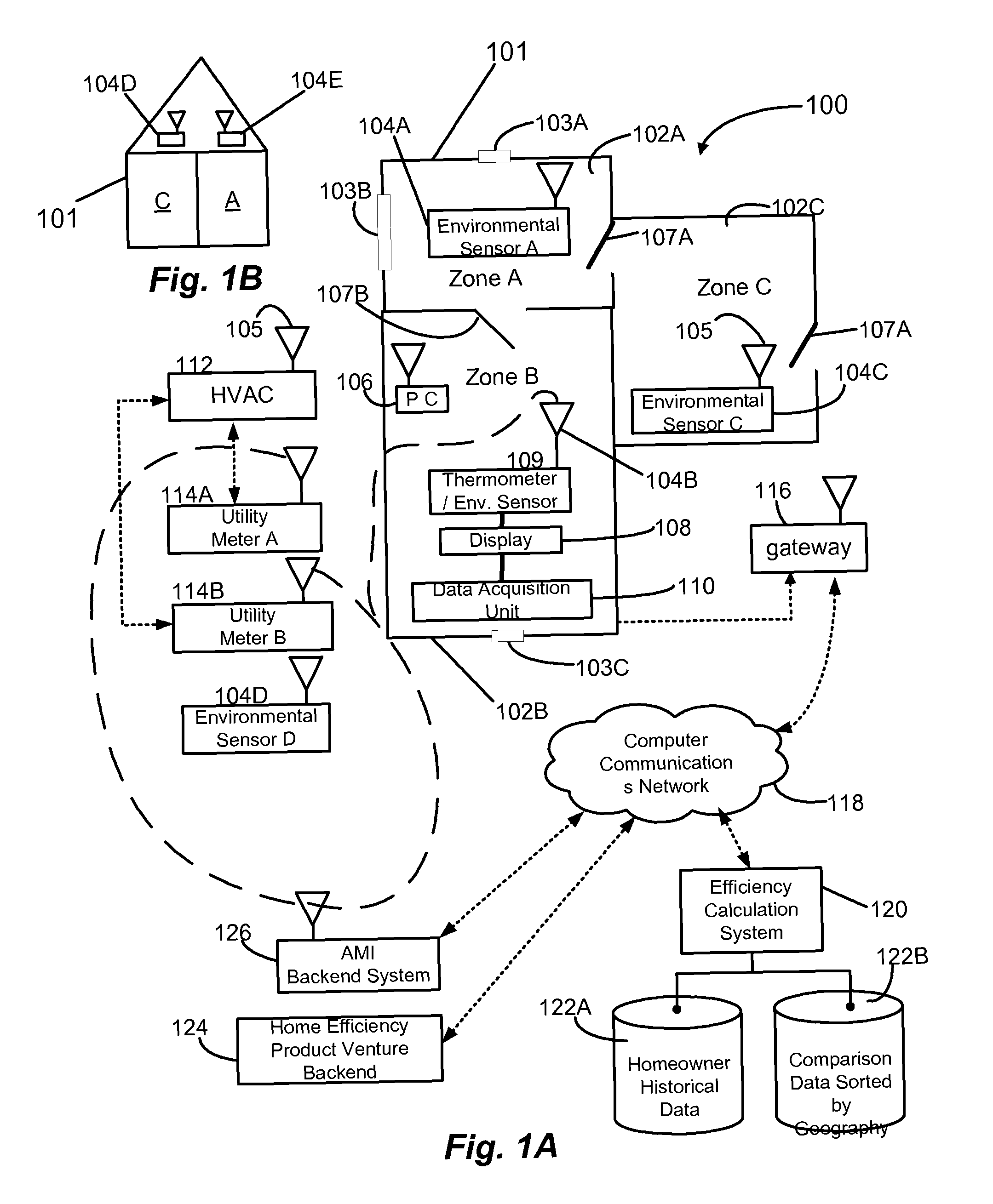

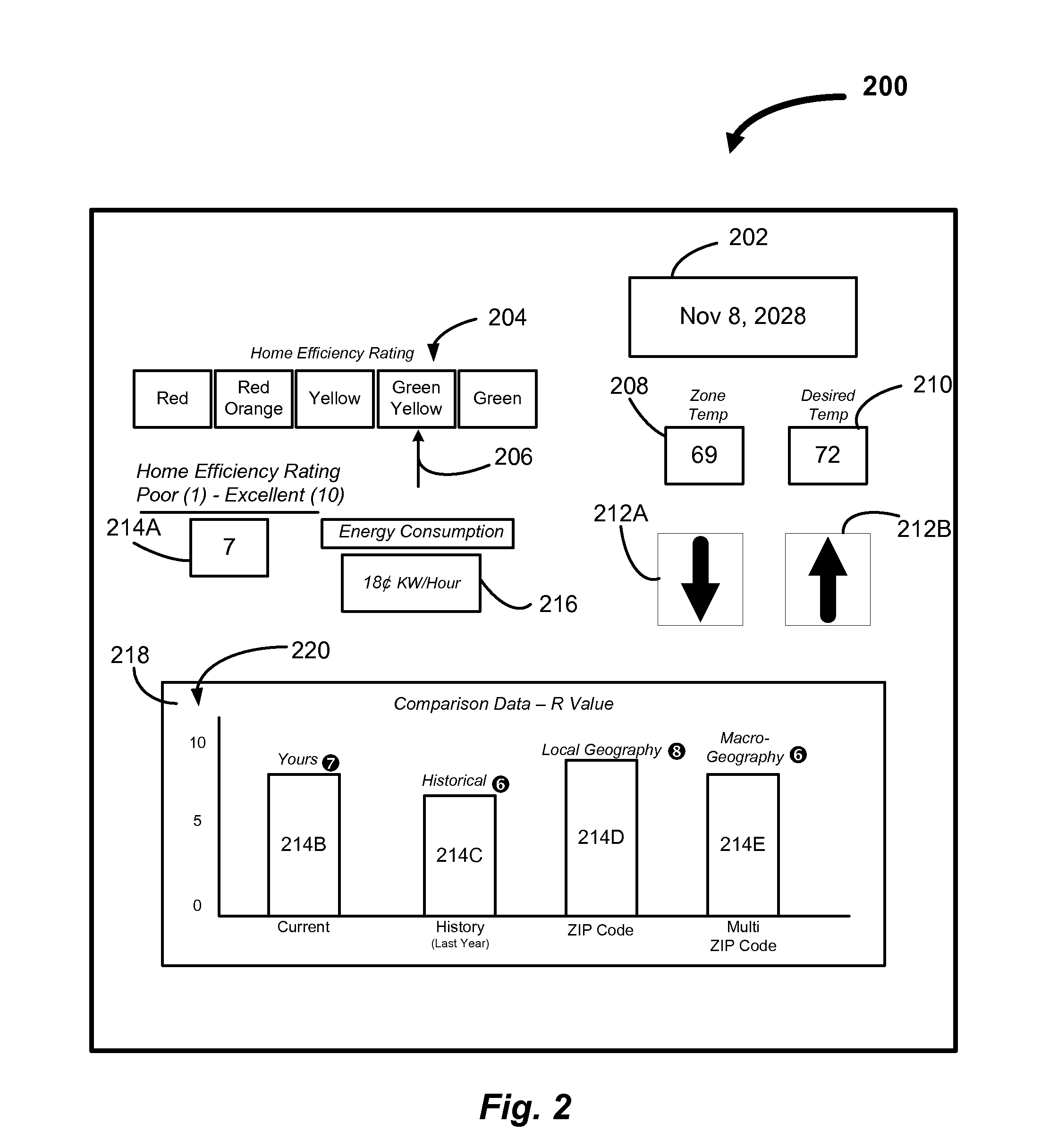

Method and system for calculating energy metrics of a building and one or more zones within the building

ActiveUS8155900B1Easy to understand visual presentationGeometric CADMechanical apparatusBusiness efficiencyBuilding energy

A method and system can provide building energy performance metrics that can help identify specific zones within a building which may have energy efficiency problems. The method and system can collect data from: indoor temperature sensors and humidity sensors present in each zone of a building; one or more temperature sensors and humidity sensors present outside of the building; one or more utility meters; and one or more HVAC devices. This data from the sensors can be aggregated and formed into a first profile. The energy efficiency calculation system can analyze the first profile to provide various energy performance metrics which can include, but are not limited to, energy efficiency ratios for air conditioners, the R-value or thermal resistance of the building, an amount of heat loss for the building, energy consumption by the building, current HVAC performance parameters, and utility usage comparisons.

Owner:ITRON

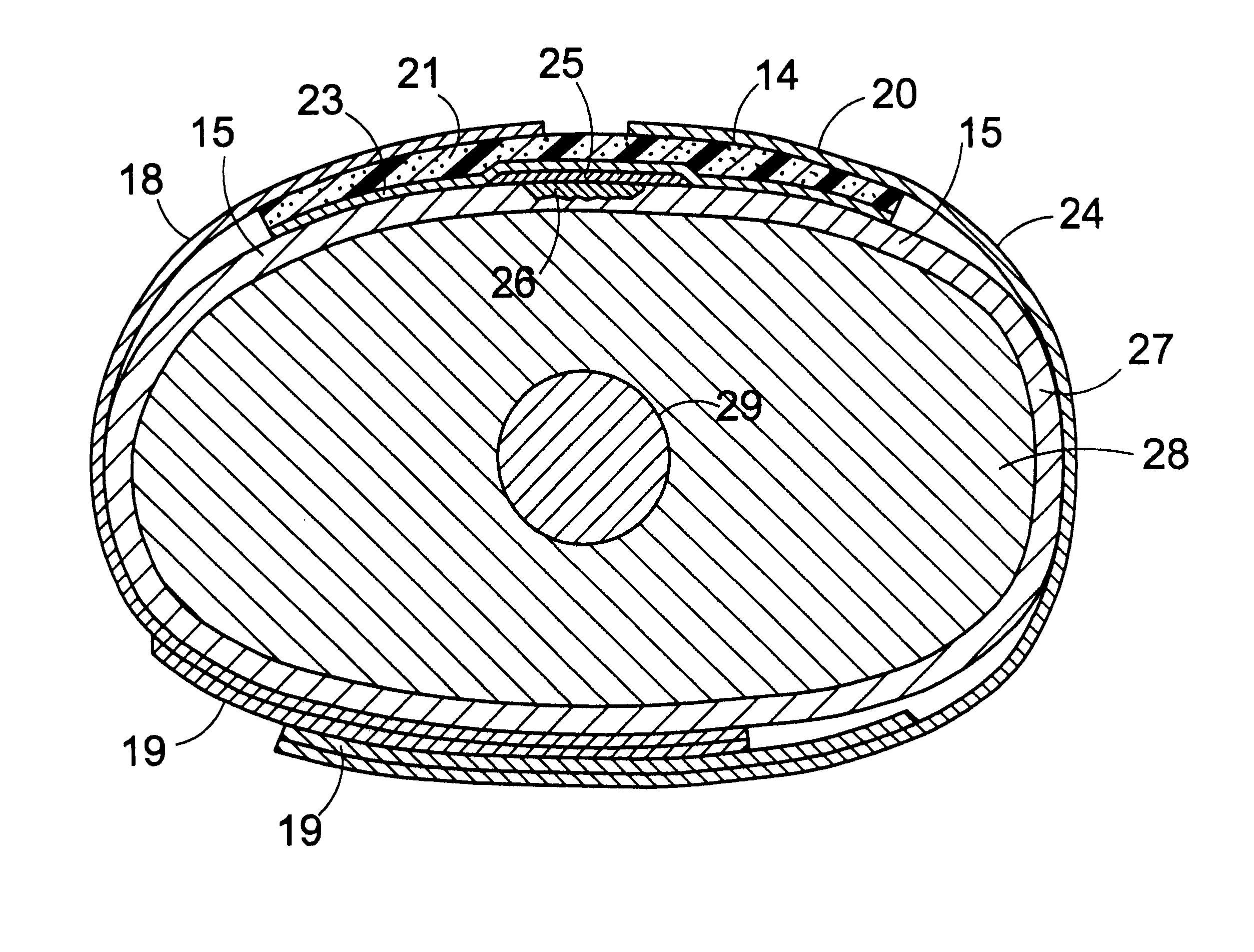

Insulator-conductor device for maintaining a wound near normal body temperature

InactiveUS6613953B1Low thermal conductivityMinimizes thermal conductionFinger bandagesPlastersHeat lossesHeat energy

A wound treatment device which fits over standard bandages and covers both the wound area itself and major portions of the surrounding area of healthy skin of an extremity such as a leg, arm, or foot. The wound treatment device maintains the wound near normal body temperature (37° C.) by conserving and redistributing the body's own heat energy using a high efficiency thermal insulator to minimize heat loss from the wound and surrounding skin area and a high efficiency thermal conductor for distributing heat from the surrounding skin to the wound area. The wound treatment device avoids potential problems associated with external heat sources and provides for an ideal physiological environment for wound healing. The wound treatment device can be worn by the patient for extended periods of time during their regular daily routine without constant medical supervision. The wound treatment device can also store extra thermal energy generated by physical activity such as walking, cleaning, or bicycling.

Owner:ALTURA DAN

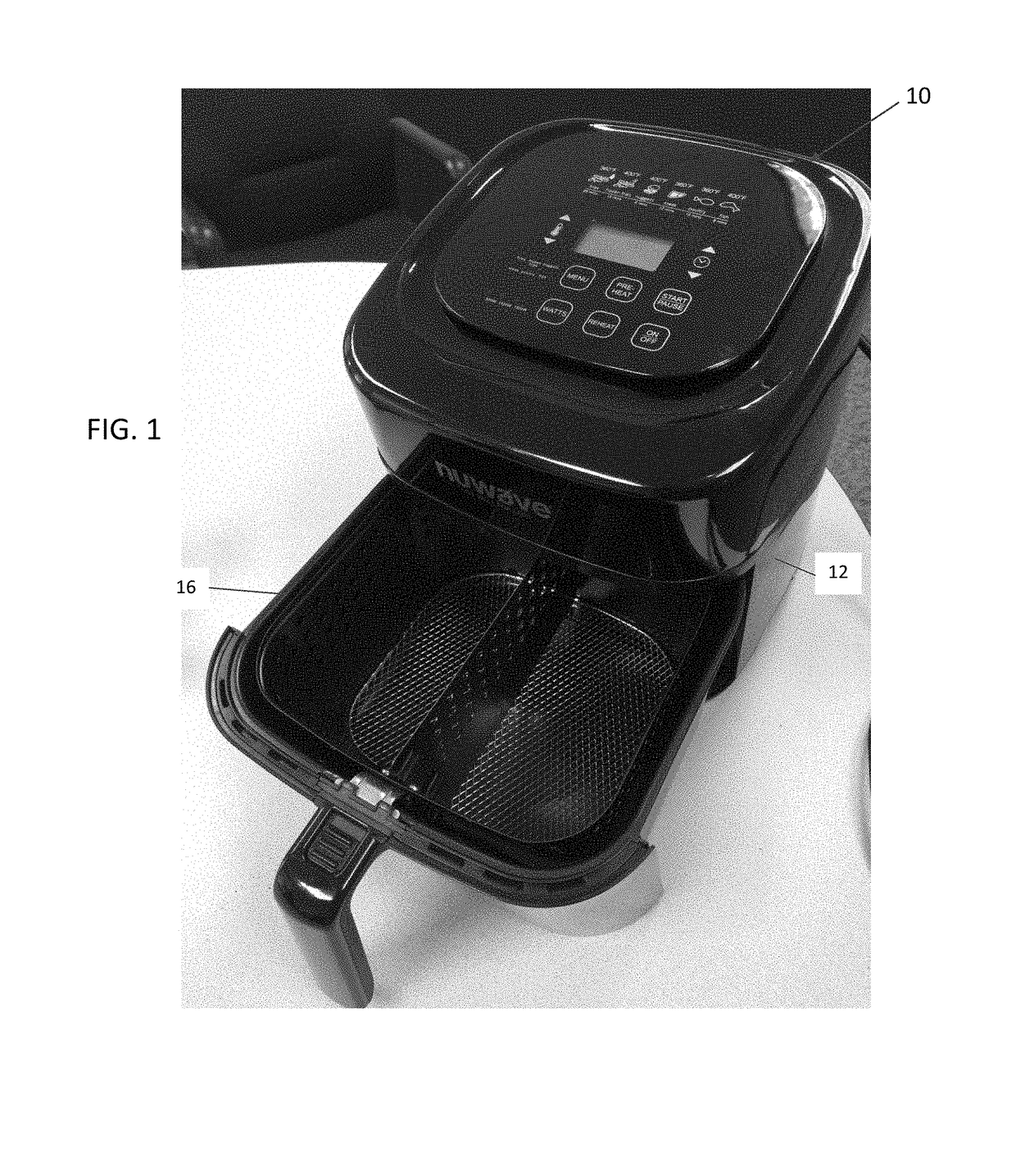

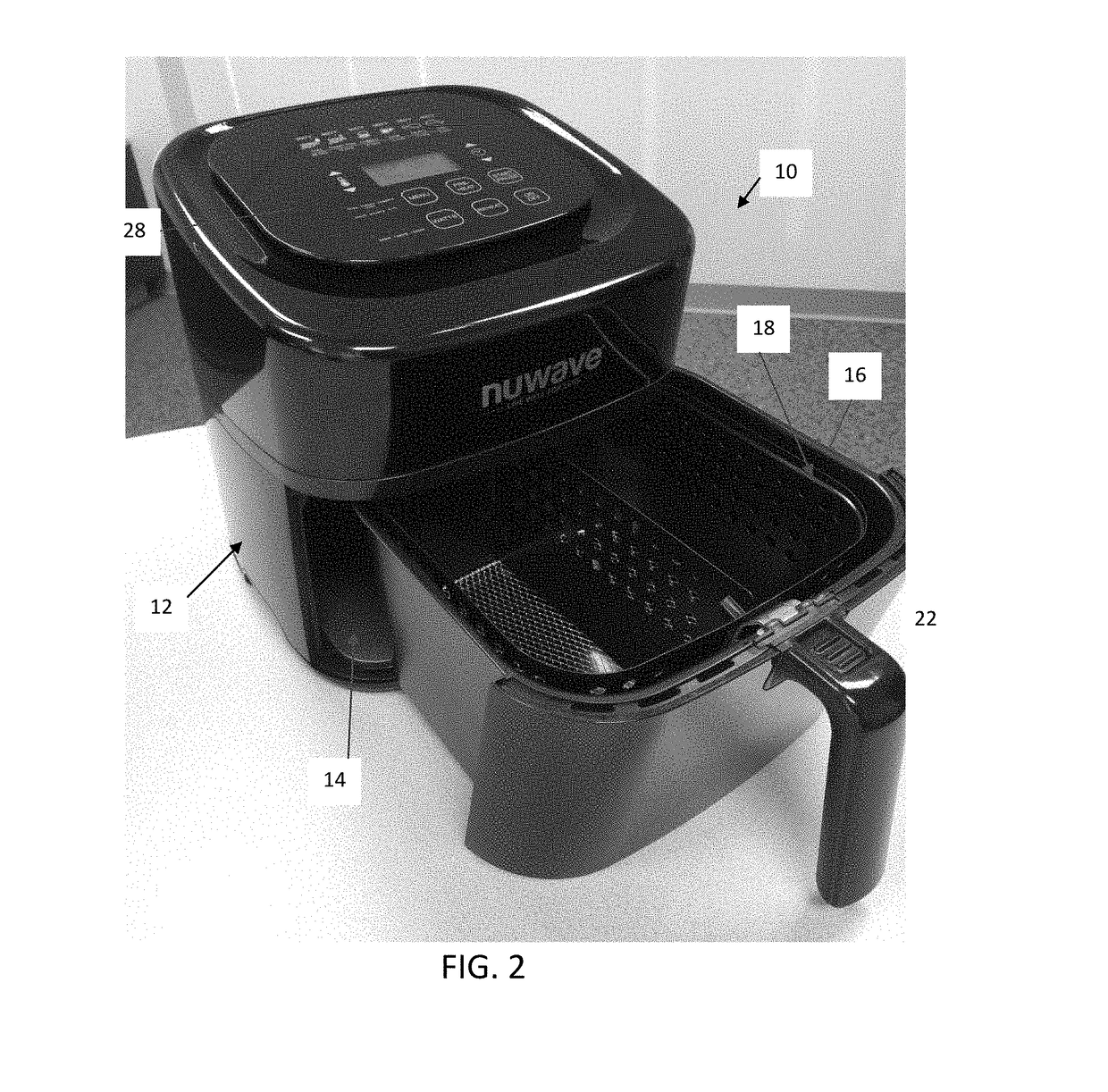

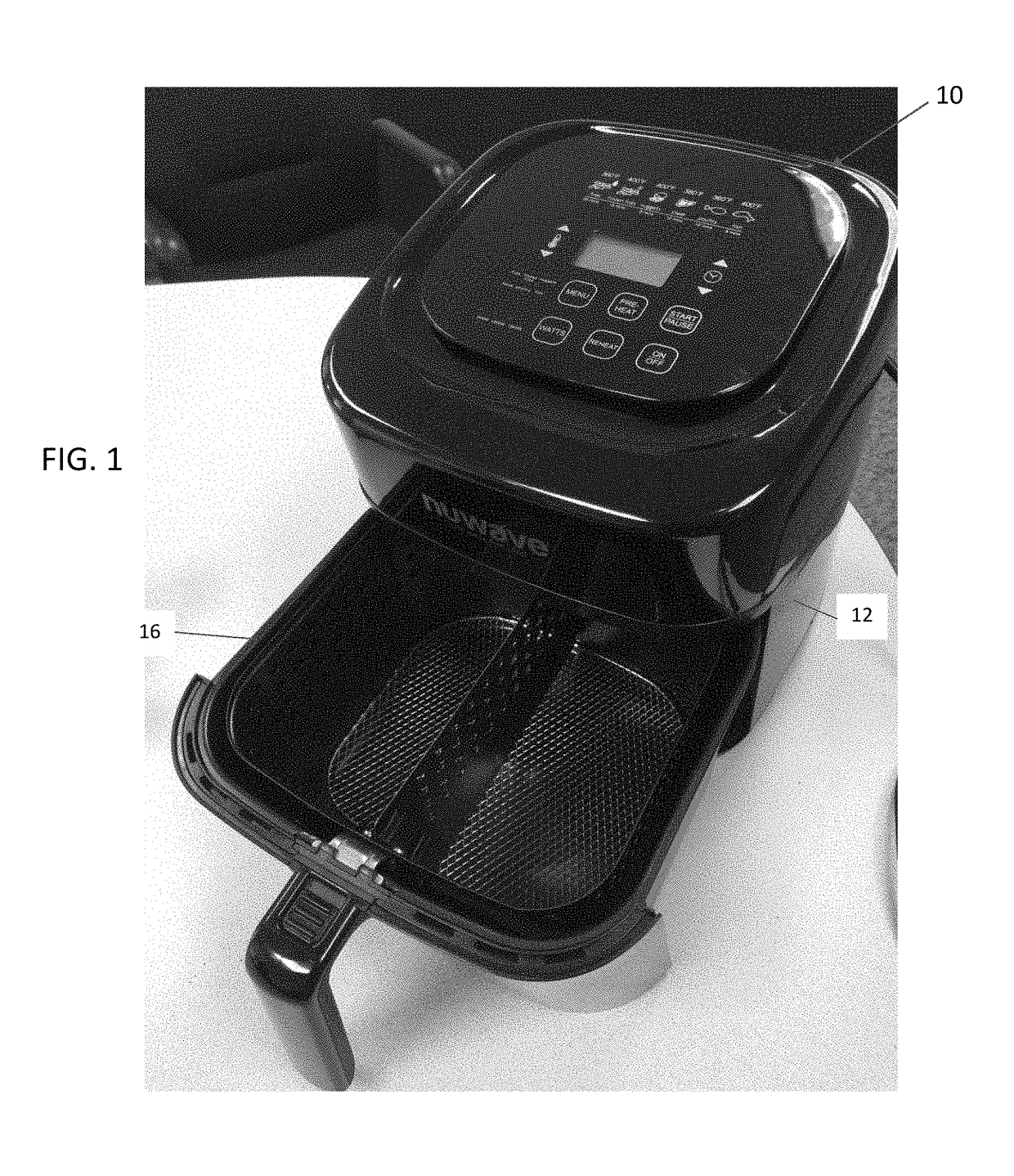

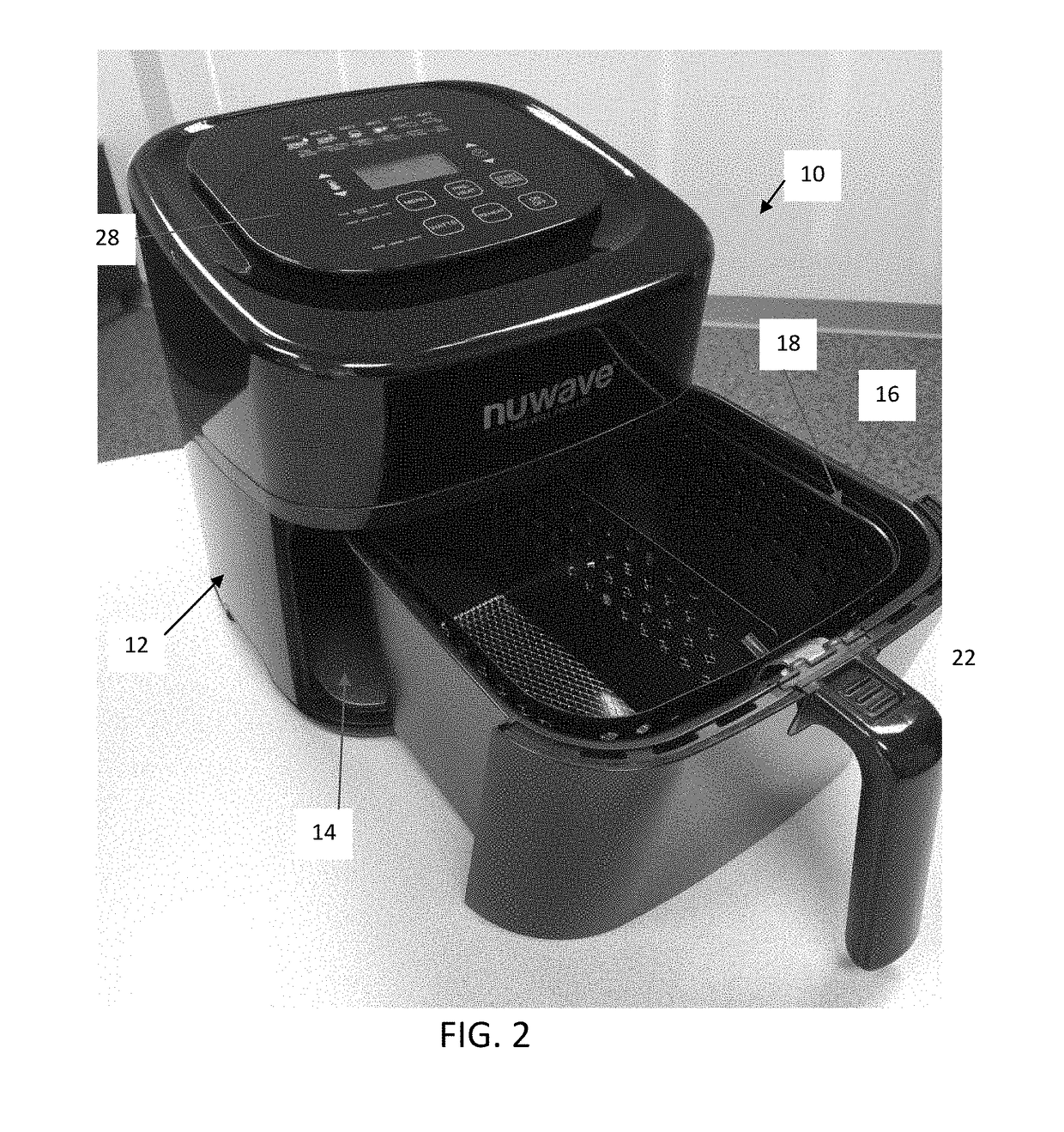

Air Fryer

InactiveUS20170231430A1Simple structureAdditional operating advantageDeep fat fryersTemperature controlHandling food

An air fryer system is disclosed which comprises a base having a heating source and an air source located therein, both sources being supplied power for operation by an AC power cord. A cooking chamber is defined within the base and a cooking drawer fits securely within the cooking chamber to substantially seal the chamber against heat loss during use. A handled food basket which detachably secures to the cooking drawer is configured to facilitate even distribution of heated air within the cooking chamber. A digital, touch screen user interface attached to a surface of the base is electronically coupled to a controller for powering on the fryer system and setting cooking conditions. The preferred system also includes infrared heating, time and temperature controls, and an automatic safety shutoff mechanism.

Owner:NUWAVE

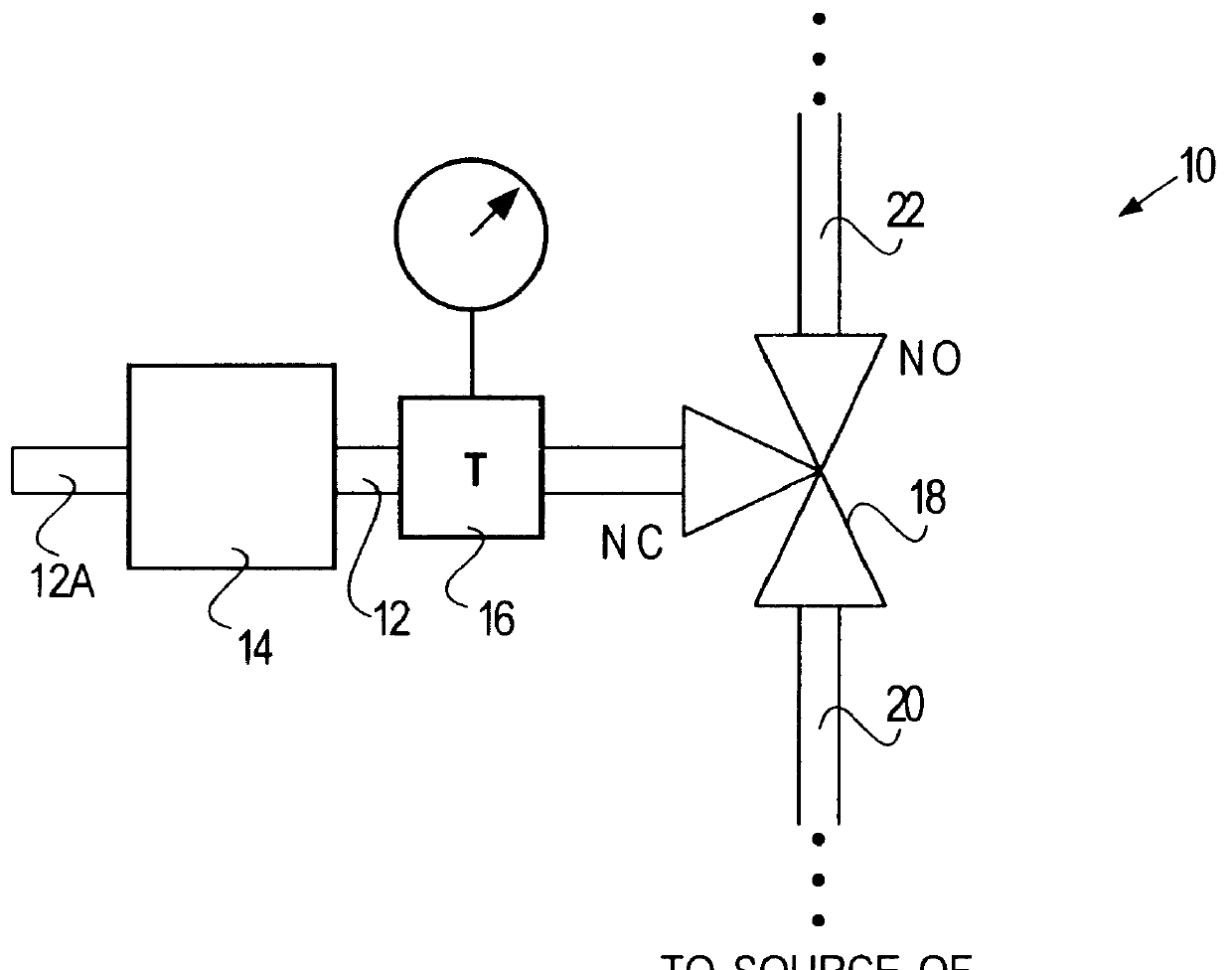

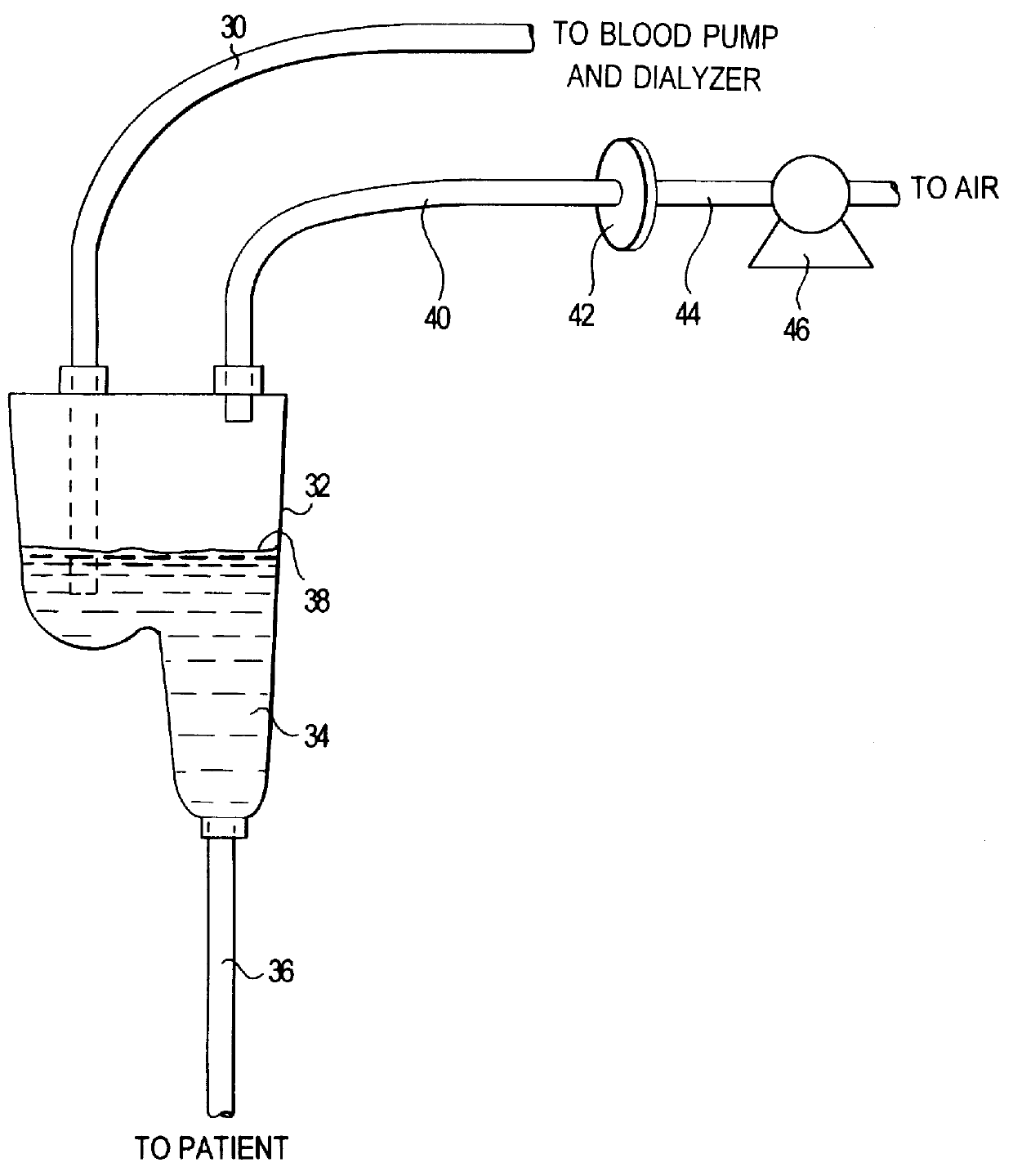

Disinfection of dead-ended lines in medical instruments

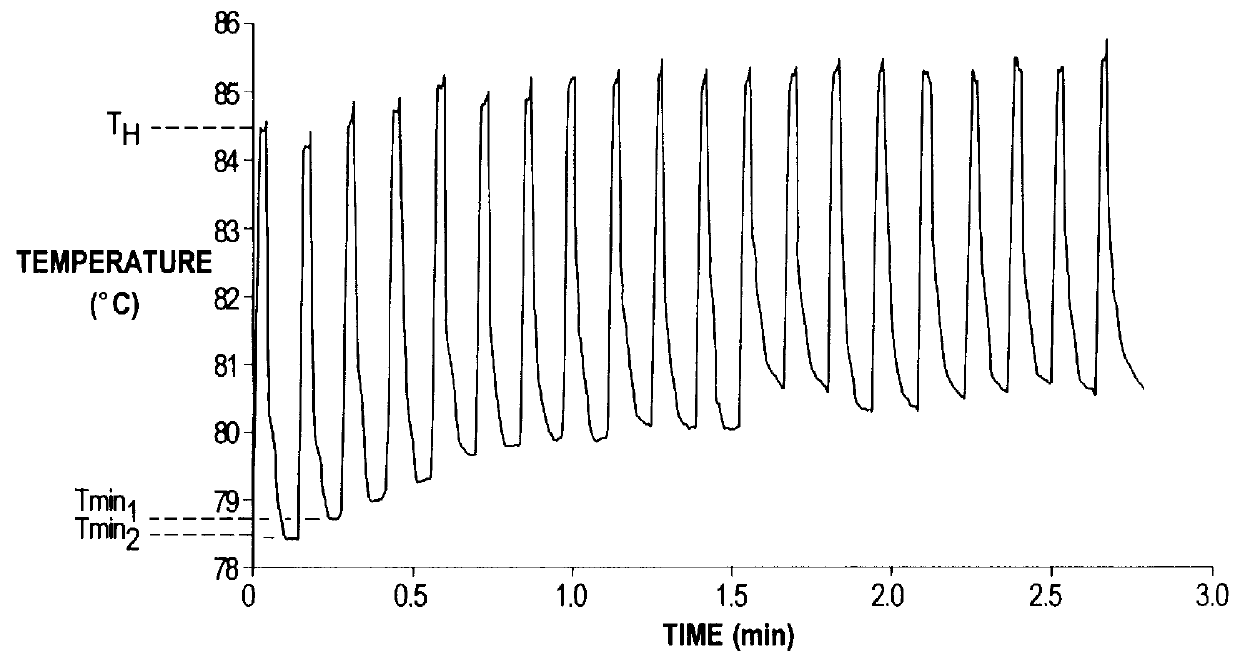

A method of disinfection of a dead-ended fluid line in a medical instrument such as a dialysis machine is described. The method comprises introducing a heated fluid into the fluid line, allowing the fluid to remain in the line for an experimentally determined optimal dwell period, removing the fluid from the fluid line, and then repeating the cycle for a time period sufficient to achieve a disinfection of the fluid line. The optimum dwell period and frequency for exchanging the heated fluid is determined so that the heated fluid is left resident in the line to exert a cidal effect but not so long that the it cools to the point of being ineffective, nor changed so frequently that that the time spent with no hot water resident in the line begins to detract (e.g., unduly prolong) the disinfection process. A representative cycle is introducing water at a temperature of about 85 degrees C, allowing it to reside in the fluid line for about 10 seconds, withdrawing the water, and then reintroducing water at 85 degrees C. The process continues for 1-2 hours. Variation from the representative cycle will be expected based on parameters such as the degree to which disinfection is to be achieved, the length and diameter of the fluid line, the temperature of the fluid, the ambient temperature, the presence of elements in the fluid line that contribute to heat loss, the material used for fluid line tubing, and whether the fluid comprises water or a disinfection solution such as a dilute citric acid solution. The optimum dwell period and frequency of the cycles can be determined experimentally from the teachings described herein.

Owner:BAXTER INT INC +2

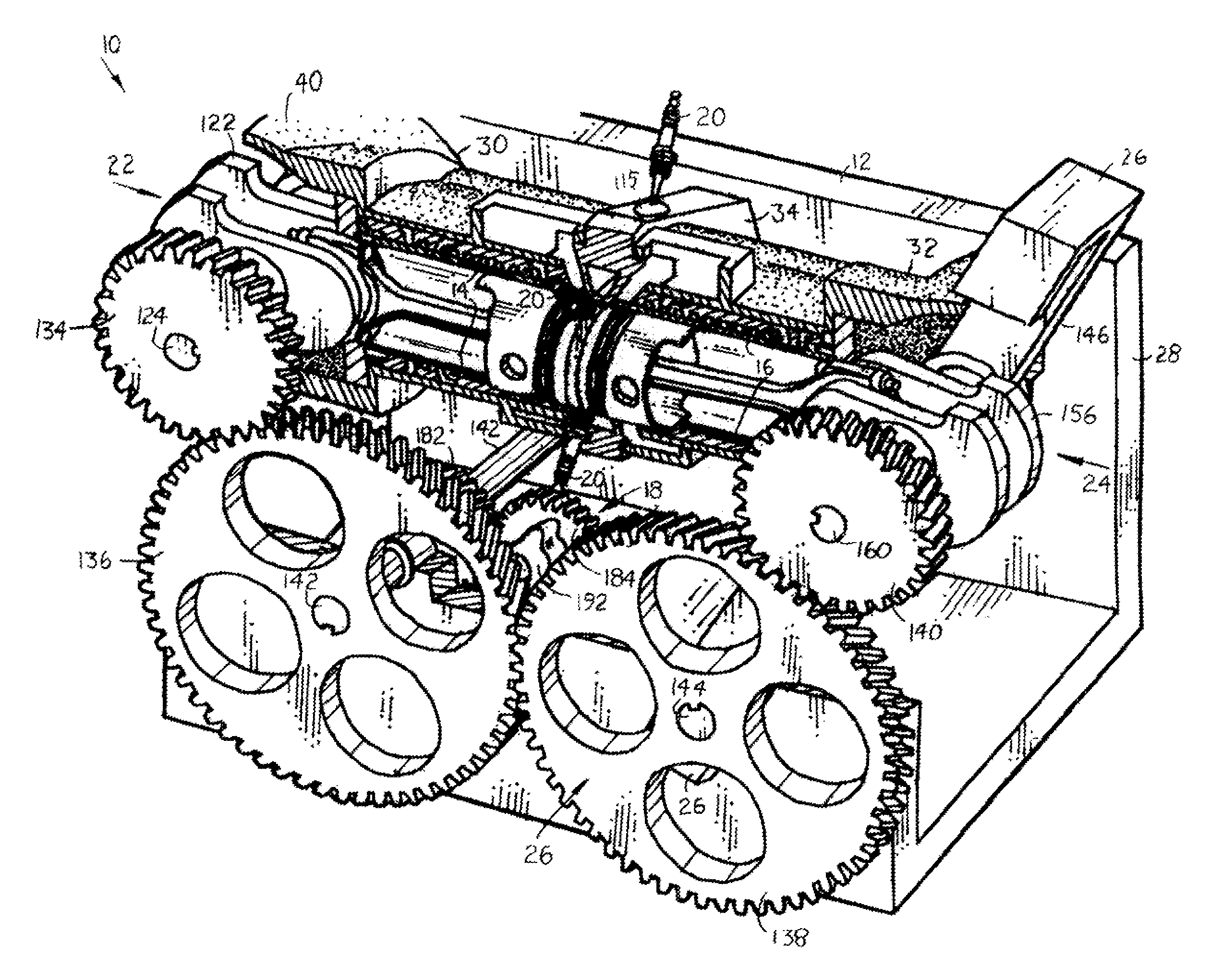

Air Fryer

InactiveUS20180255971A1Simple structureAdditional operating advantageCooking vesselsRoasters/grillsTemperature controlHandling food

An air fryer system is disclosed which comprises a base having a heating source and an air source located therein, both sources being supplied power for operation by an AC power cord. A cooking chamber is defined within the base and a cooking drawer fits securely within the cooking chamber to substantially seal the chamber against heat loss during use. A handled food basket which detachably secures to the cooking drawer is configured to facilitate even distribution of heated air within the cooking chamber. A digital, touch screen user interface attached to a surface of the base is electronically coupled to a controller for powering on the fryer system and setting cooking conditions. The preferred system also includes infrared heating, time and temperature controls, and an automatic safety shutoff mechanism.

Owner:NUWAVE

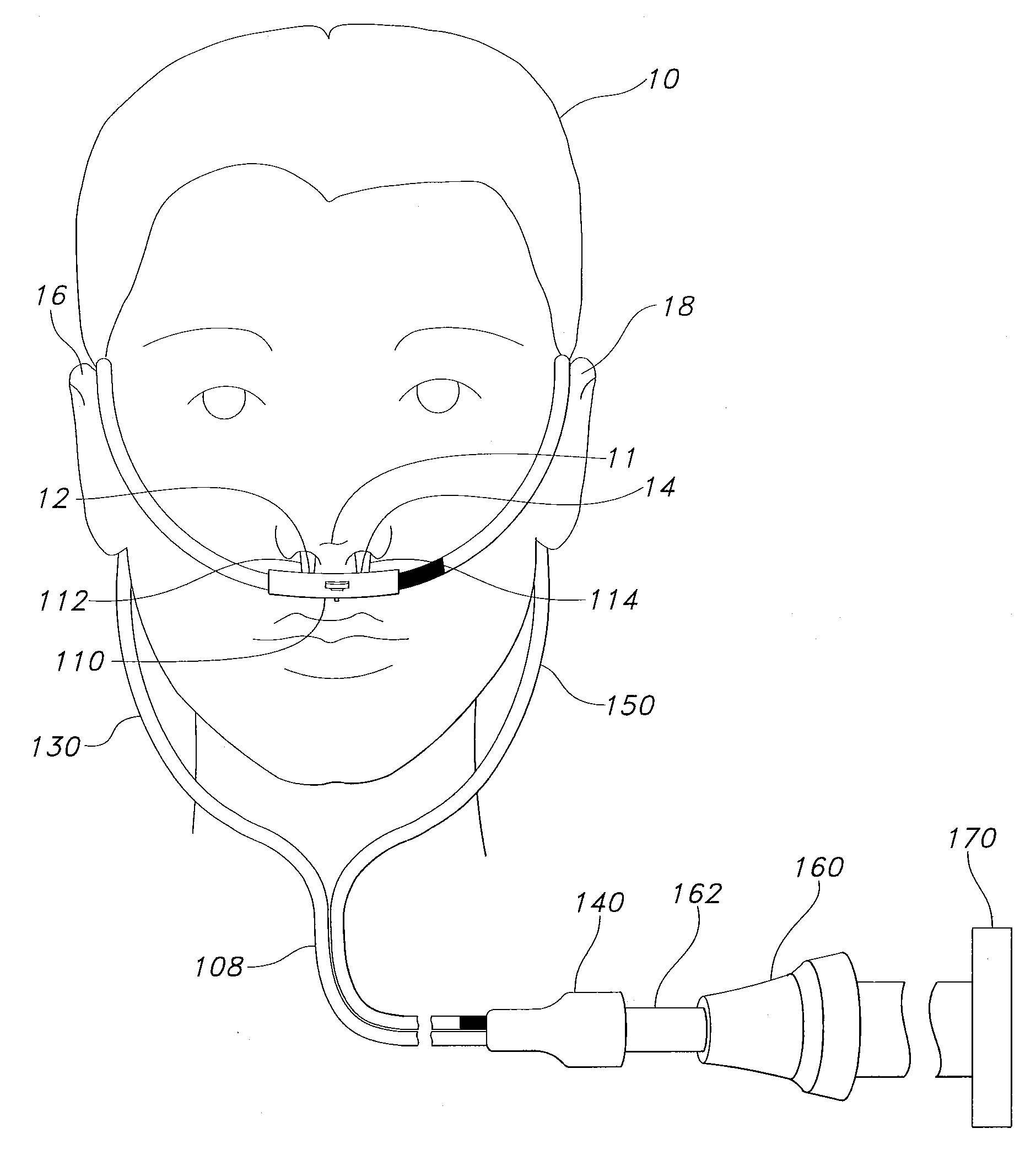

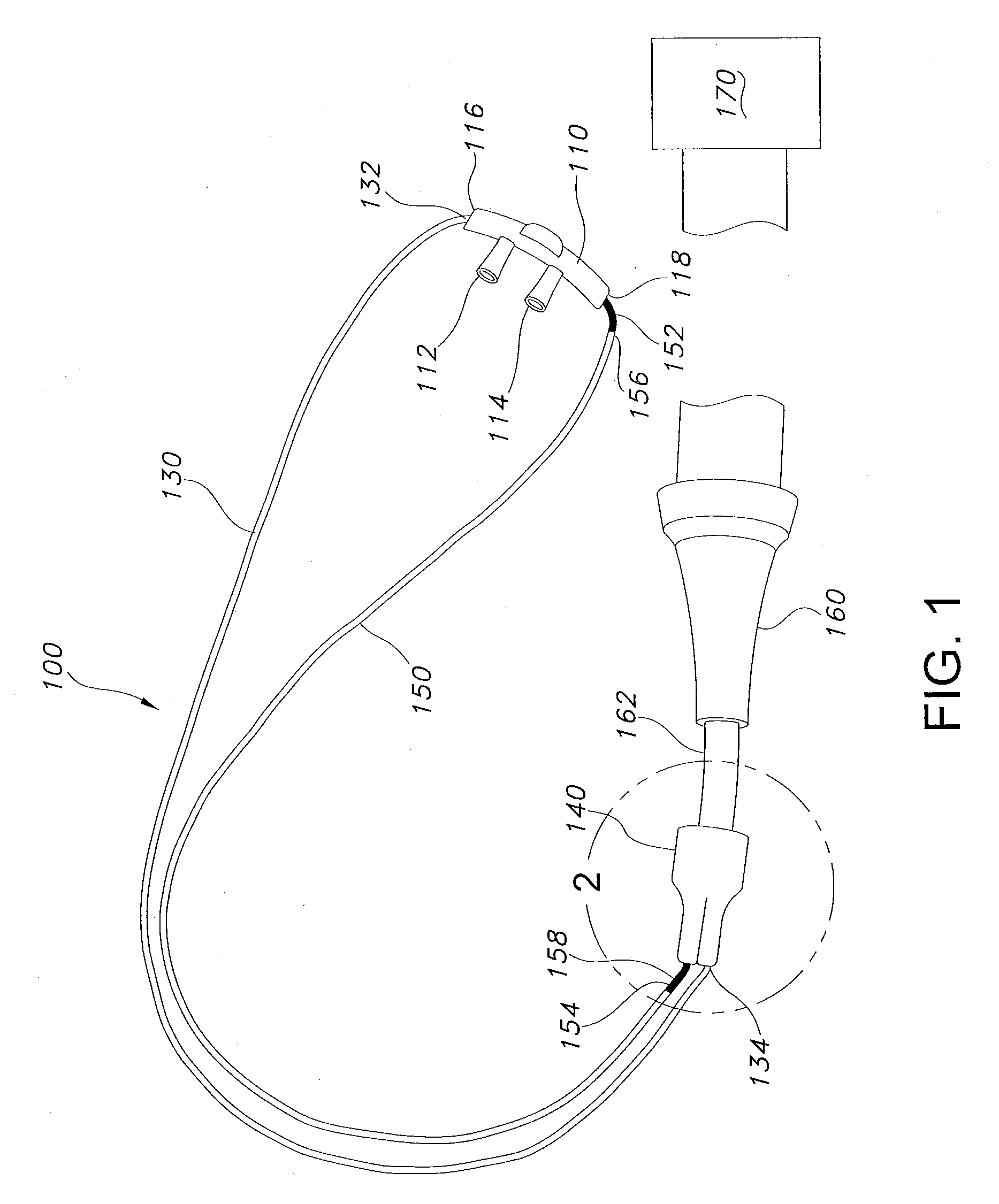

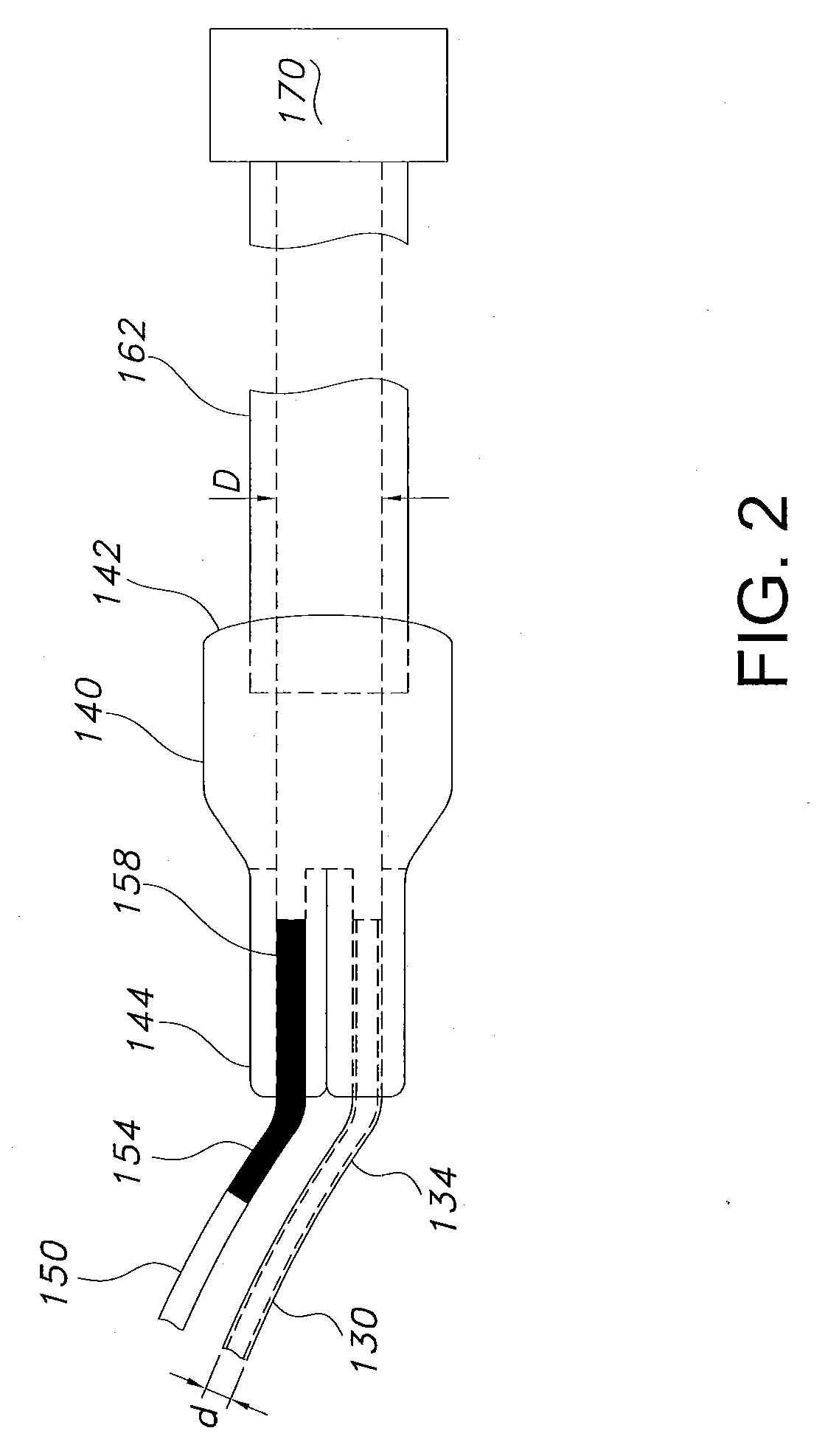

Nasal cannula with reduced heat loss to reduce rainout

ActiveUS20080121230A1Reduce gradientReducing heat loss and rainoutRespiratorsOther heat production devicesNoseCatheter

A system for delivering a humidified gas to a patient is disclosed. The system includes a supply tube having a first supply tube end and a second supply tube end. The supply tube has a first inner diameter. The system also includes an apparatus for delivering heated and humidified gas to the first end of the supply tube and a single lumen having a first lumen end and a second lumen end. The single lumen has a second inner diameter, smaller than the first diameter. The first lumen end is in fluid flow communication with the second supply tube end. The system also includes a nasal cannula in fluid flow communication with the second lumen end. A method of delivering heated and humidified gas to a patient is also disclosed.

Owner:BRIDGE BANK NAT ASSOC

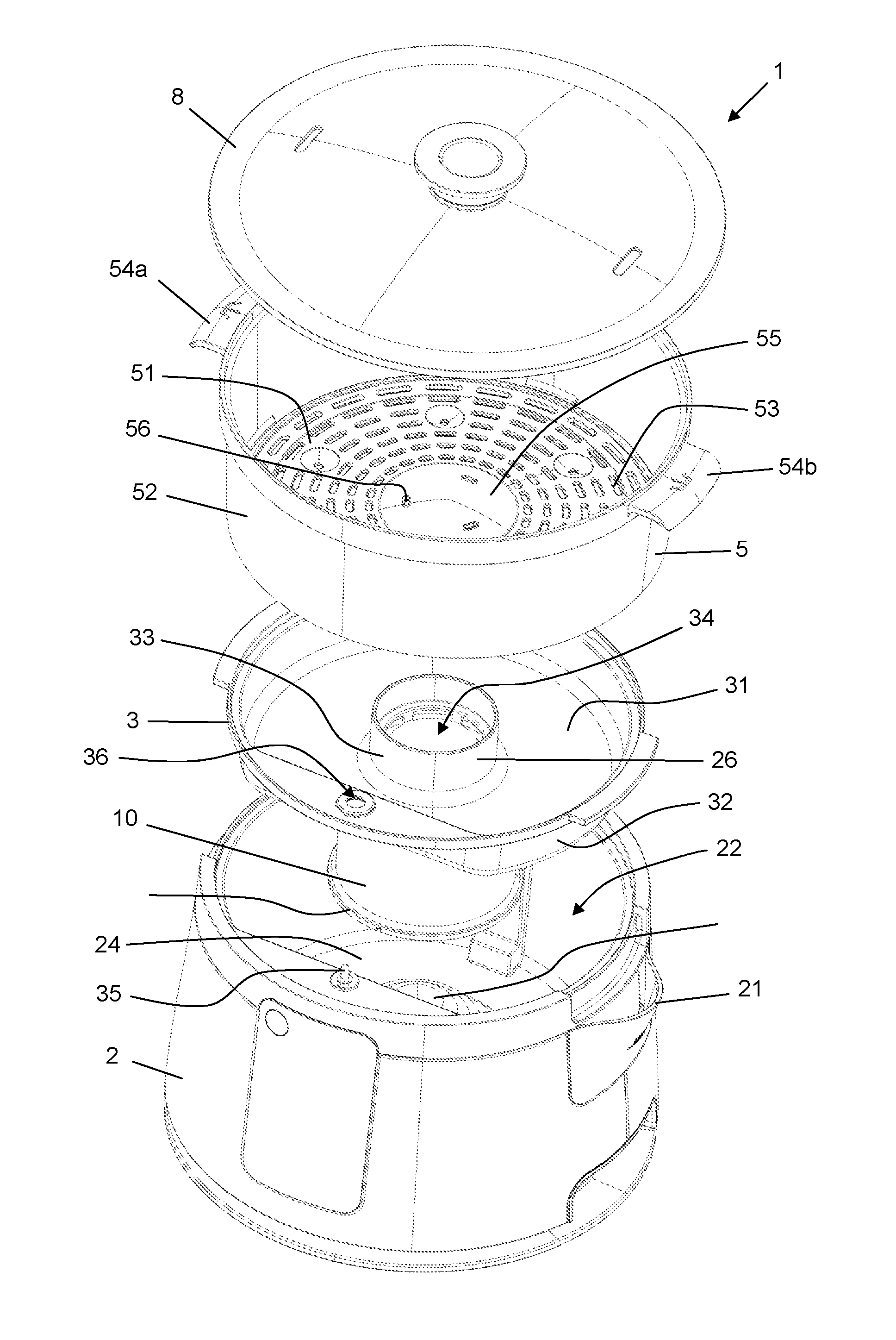

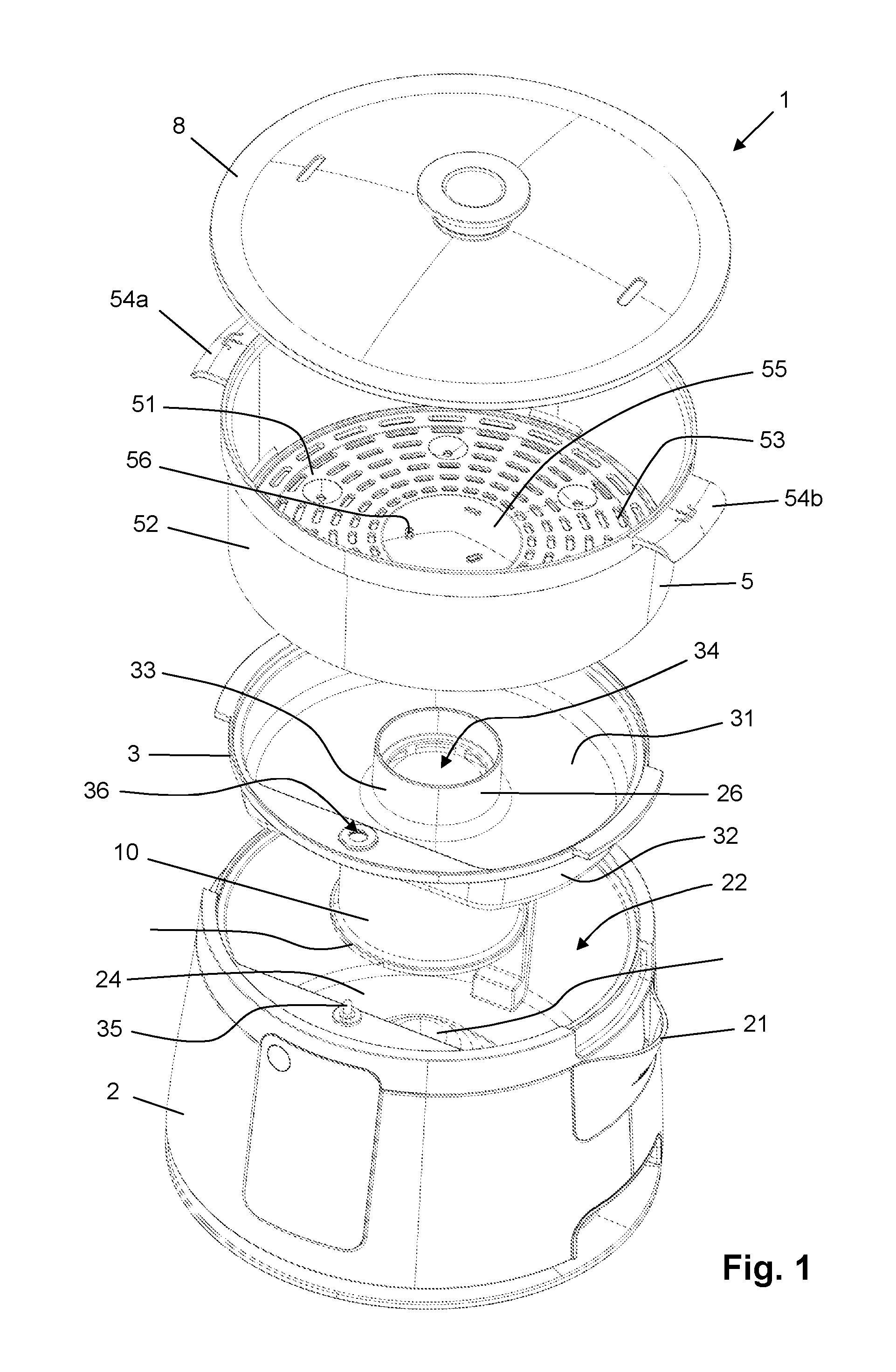

Device for steaming food

InactiveUS20150201788A1Avoid flowSufficient supplyBoiling over preventionSteam cooking vesselsEngineeringHeat losses

A device (1) for steaming food comprises a base part(2)and at least one basket (5) for containing the food to be steamed, having a bottom (51) provided with holes (53)for letting through steam to the food, wherein the at least one basket (5) is intended to be positioned above the base part (2), wherein the base part (2) comprises a steam chamber (25) for containing water to be converted into steam and heating means (23) associated with the steam chamber (25) for heating water which is inside the steam chamber (25), and wherein the device (1) is capable of producing steam at a high start-up efficiency, by minimizing heat loss from the steam chamber (25).

Owner:KONINKLJIJKE PHILIPS NV

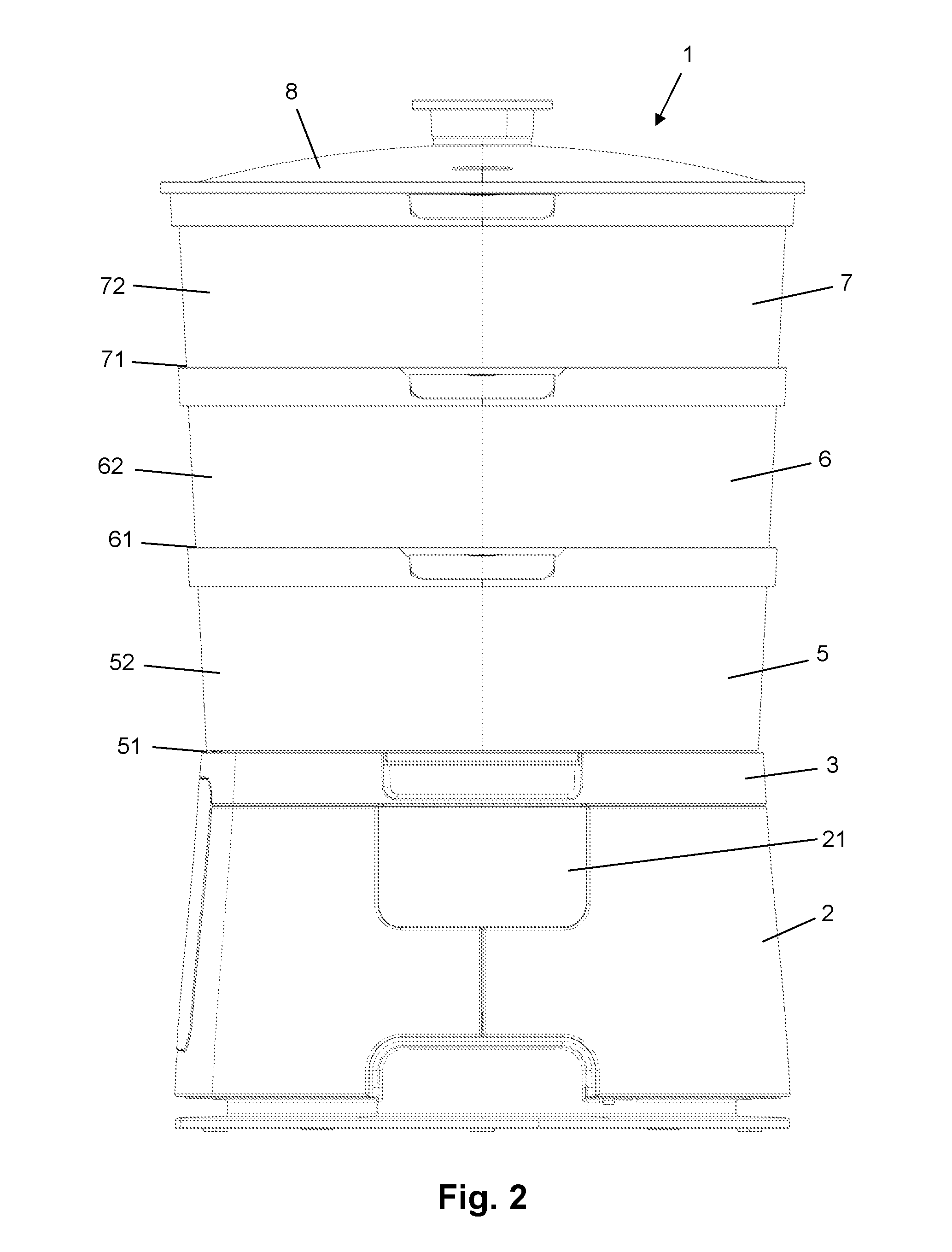

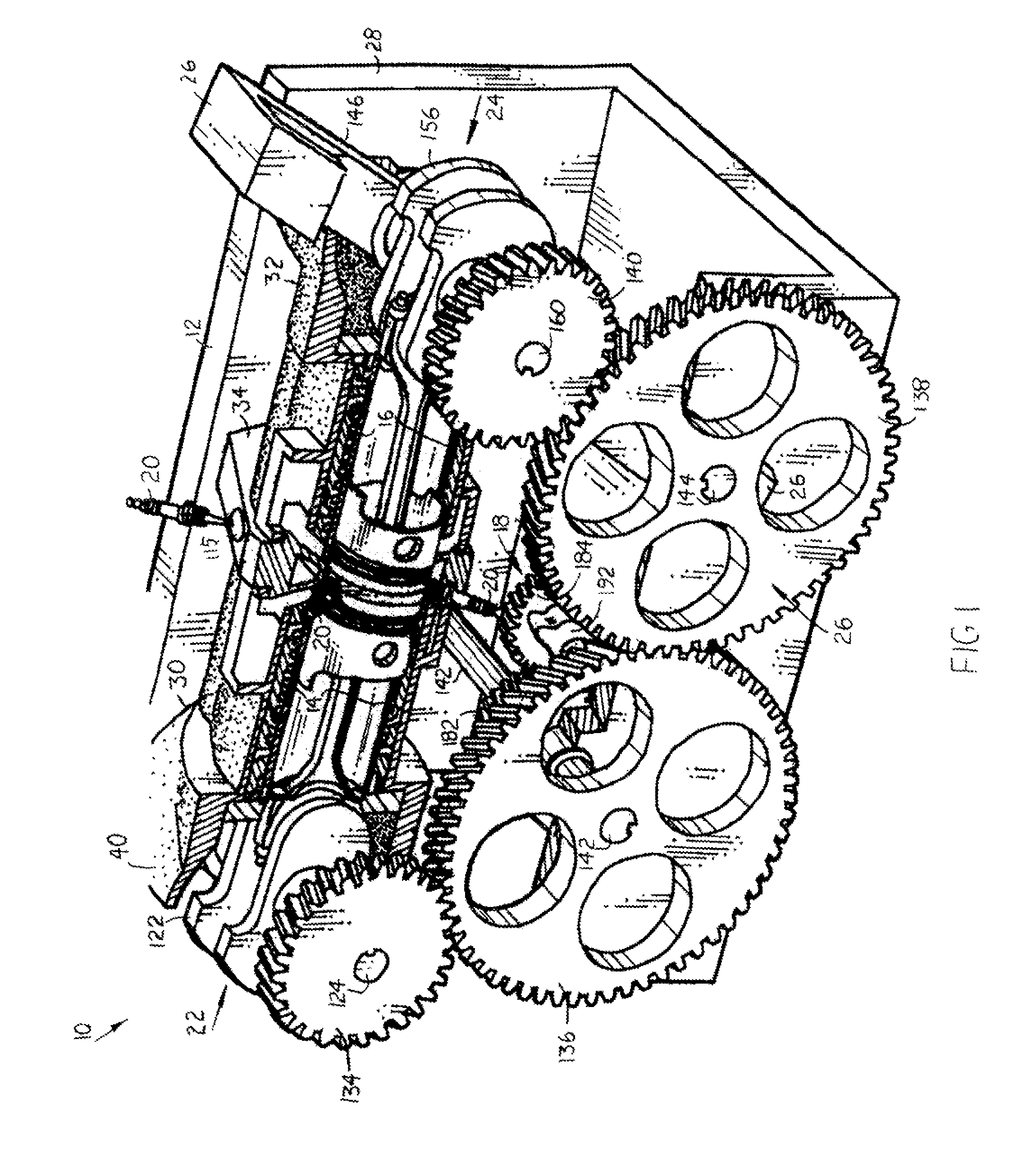

Internal combustion engine

InactiveUS7559298B2Assist in containment of heat energyReduce energy lossLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

An internal combustion engine is provided. Facing pistons eliminate a cylinder head, thereby reducing heat losses through a cylinder head. Facing pistons also halve the stroke that would be required for one piston to provide the same compression ratio, and the engine can thus be run at higher revolutions per minute and produce more power. An internal sleeve valve is provided for space and other considerations. A combustion chamber size-varying mechanism allows for adjustment of the minimum size of an internal volume to increase efficiency at partial-power operation. Variable intake valve operation is used to control engine power.

Owner:CLEEVES ENGINES

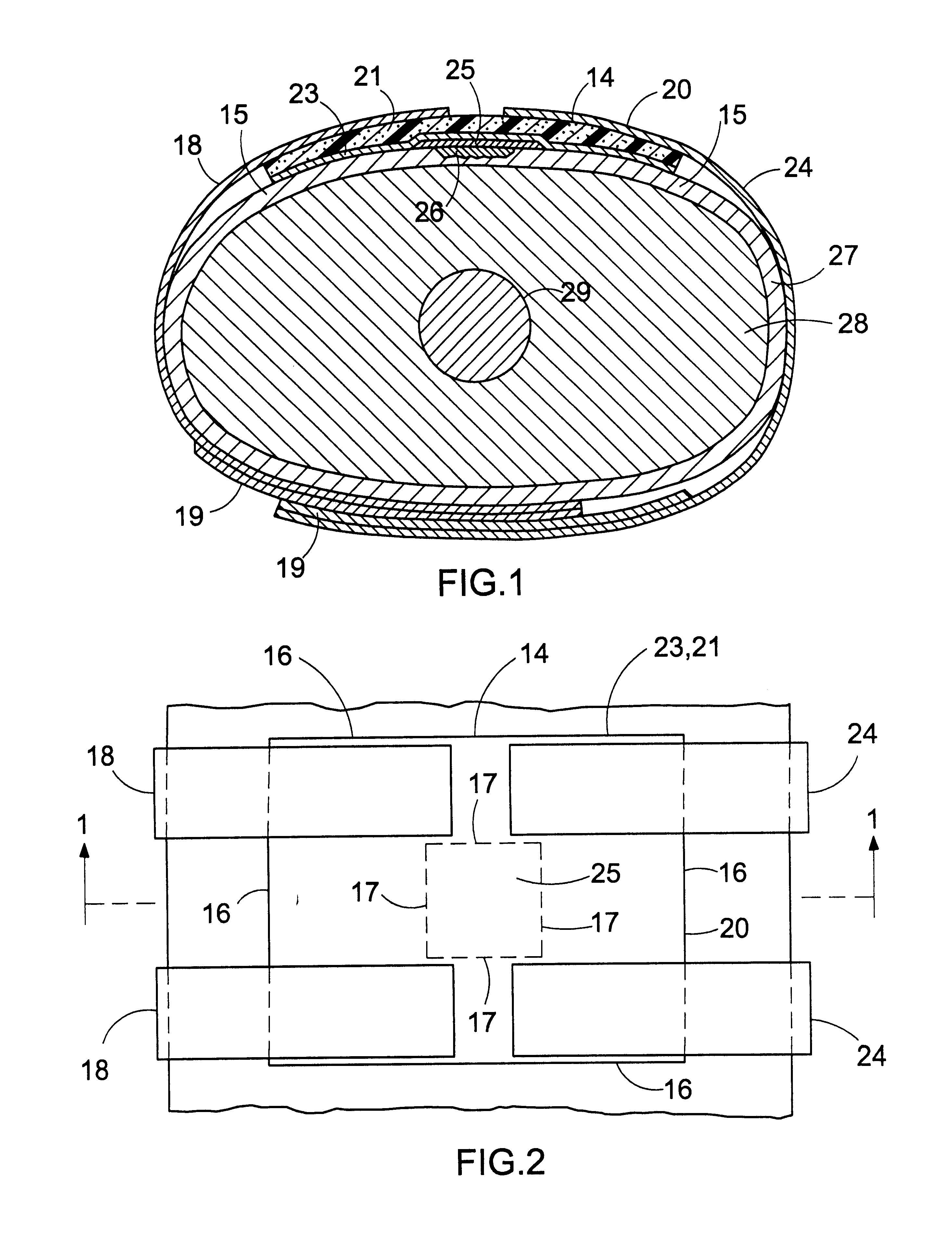

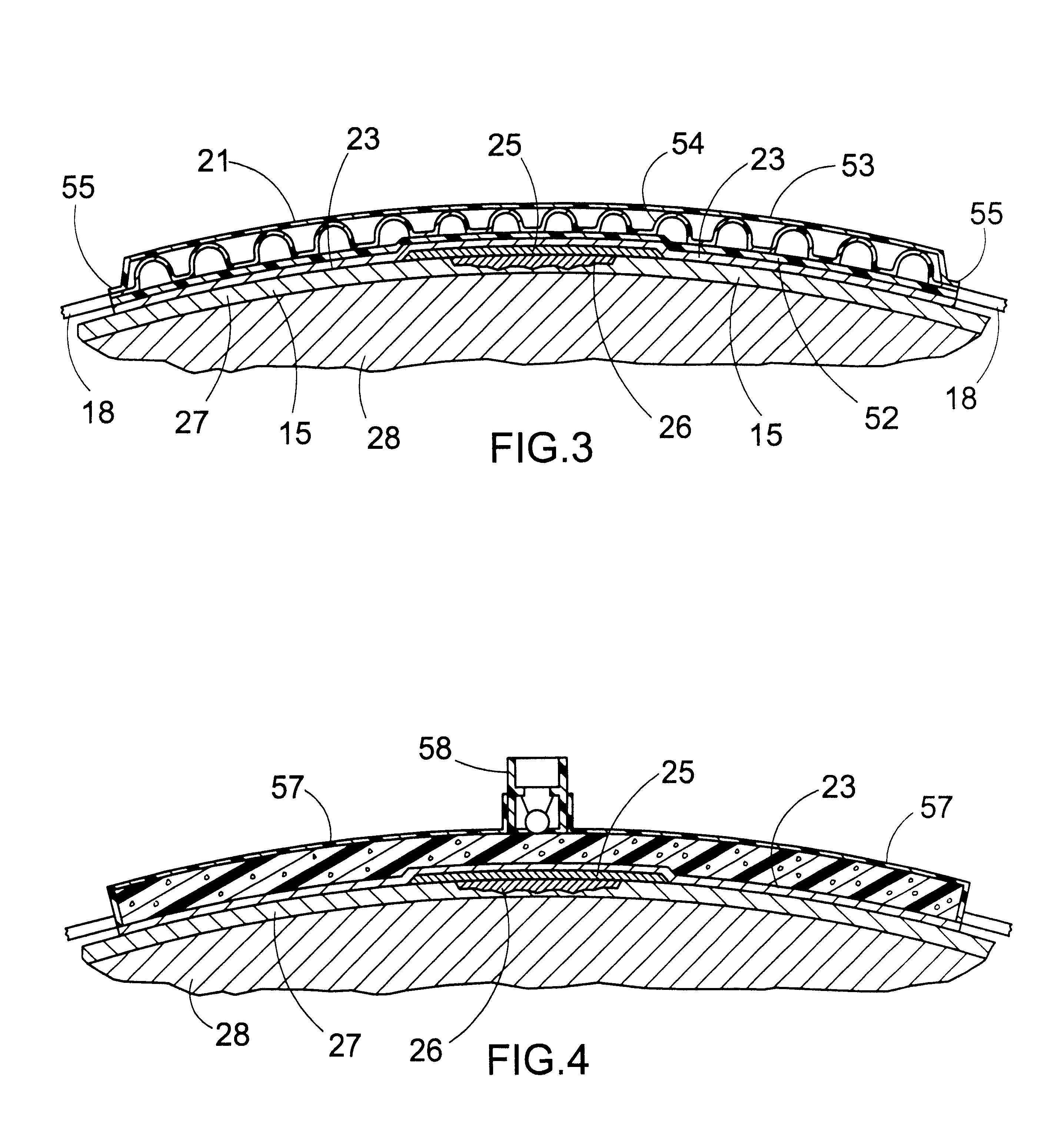

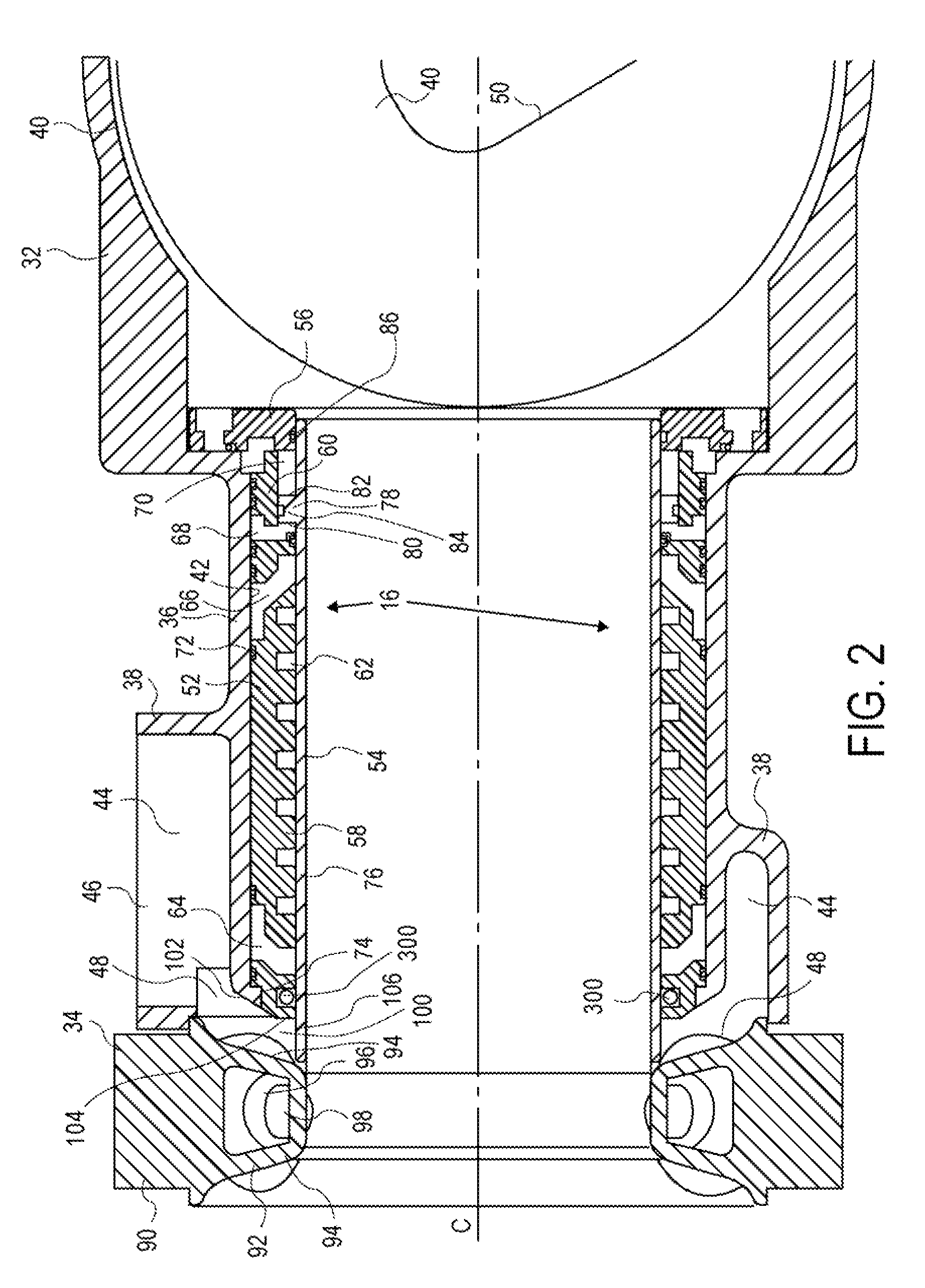

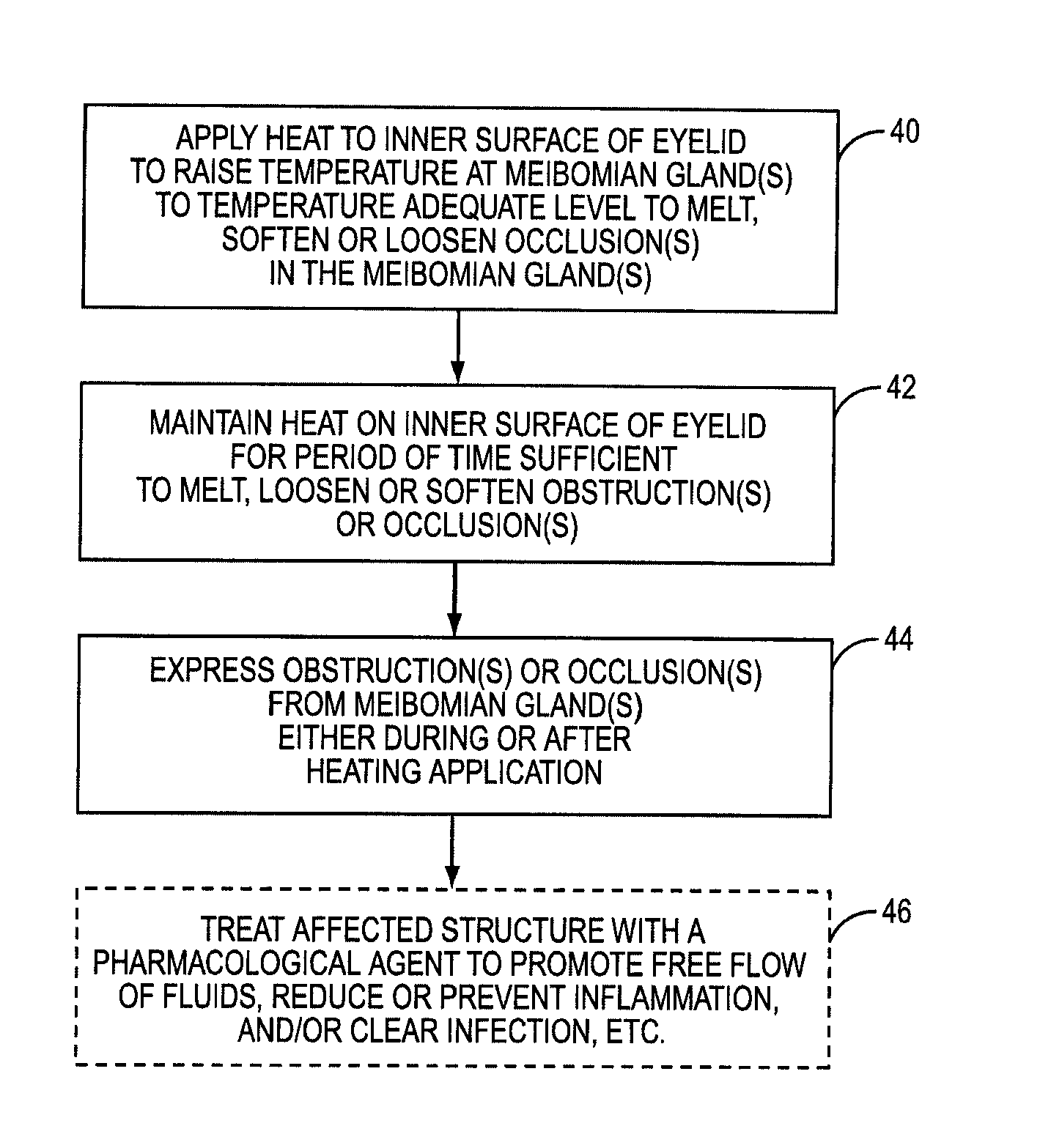

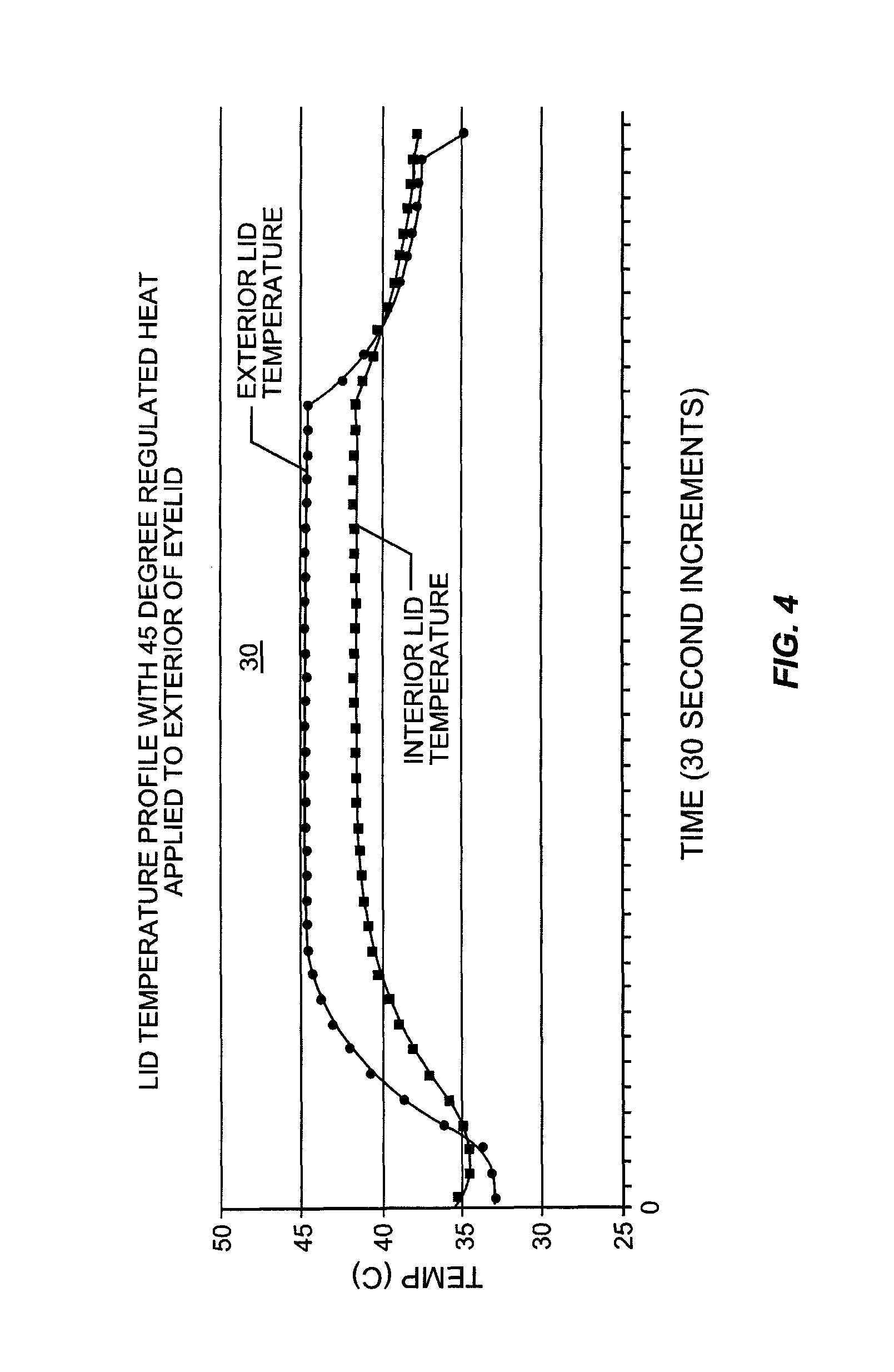

Inner eyelid heat and pressure treatment for treating meibomian gland dysfunction

ActiveUS7976573B2Effectively and efficiently raiseImprove sebum flowUltrasound therapyEye surgeryMedicineThermal compression

A method of treating meibomian gland dysfunction. Heat is applied to the inside of the eyelid to provide conductive heat transfer to the meibomian glands. The application of heat assists in the expression of obstructions or occlusions in the meibomian glands to restore sufficient sebum flow to the lipid layer to treat dry eye. Temperatures at the meibomian glands reach desired levels more quickly and efficiently when heating the inside of the eyelid. Reaching such higher temperature levels may be instrumental in removing obstructions in the meibomian glands. Less time may also be required to reach desired temperature levels when applying heat to the inside of the eyelid. A force may also be applied to the inside of the patient's eyelid to improve conductive heat transfer and reduce blood flow in the eyelid that causes convective heat loss. Thus, the application of force can further increase the temperature level and / or reduce the time to reach desired temperature levels for removing obstructions.

Owner:TEARSCIENCE INC

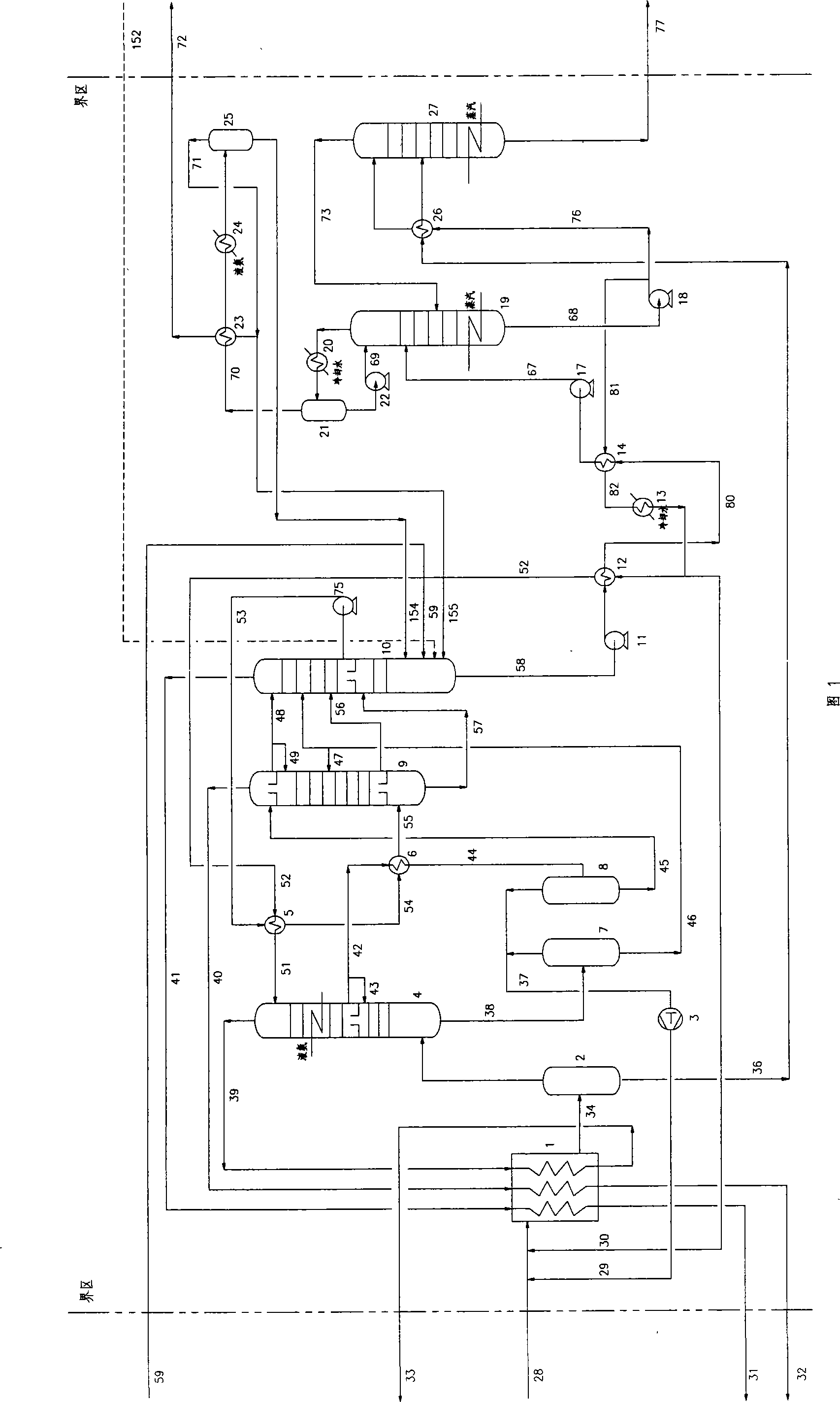

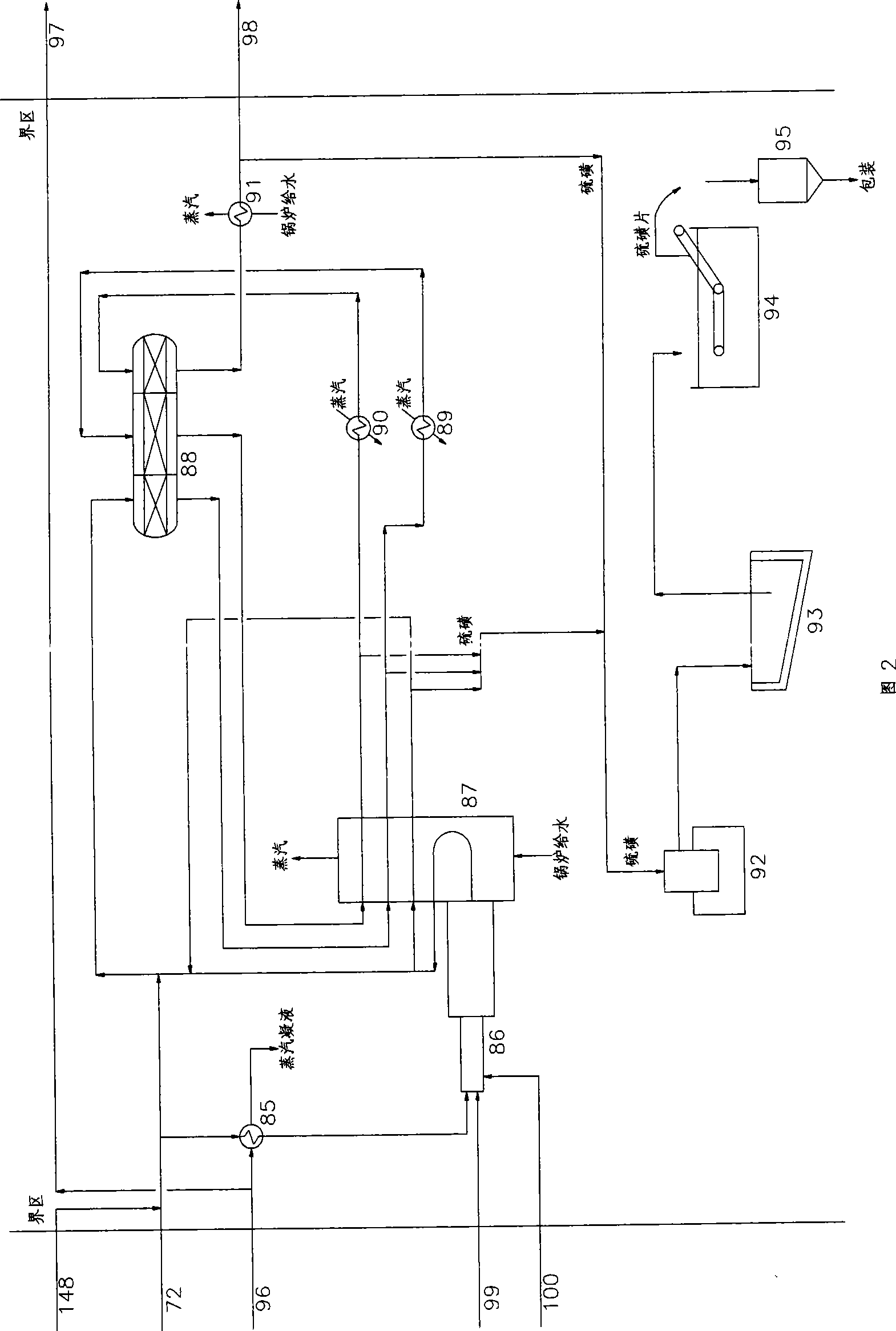

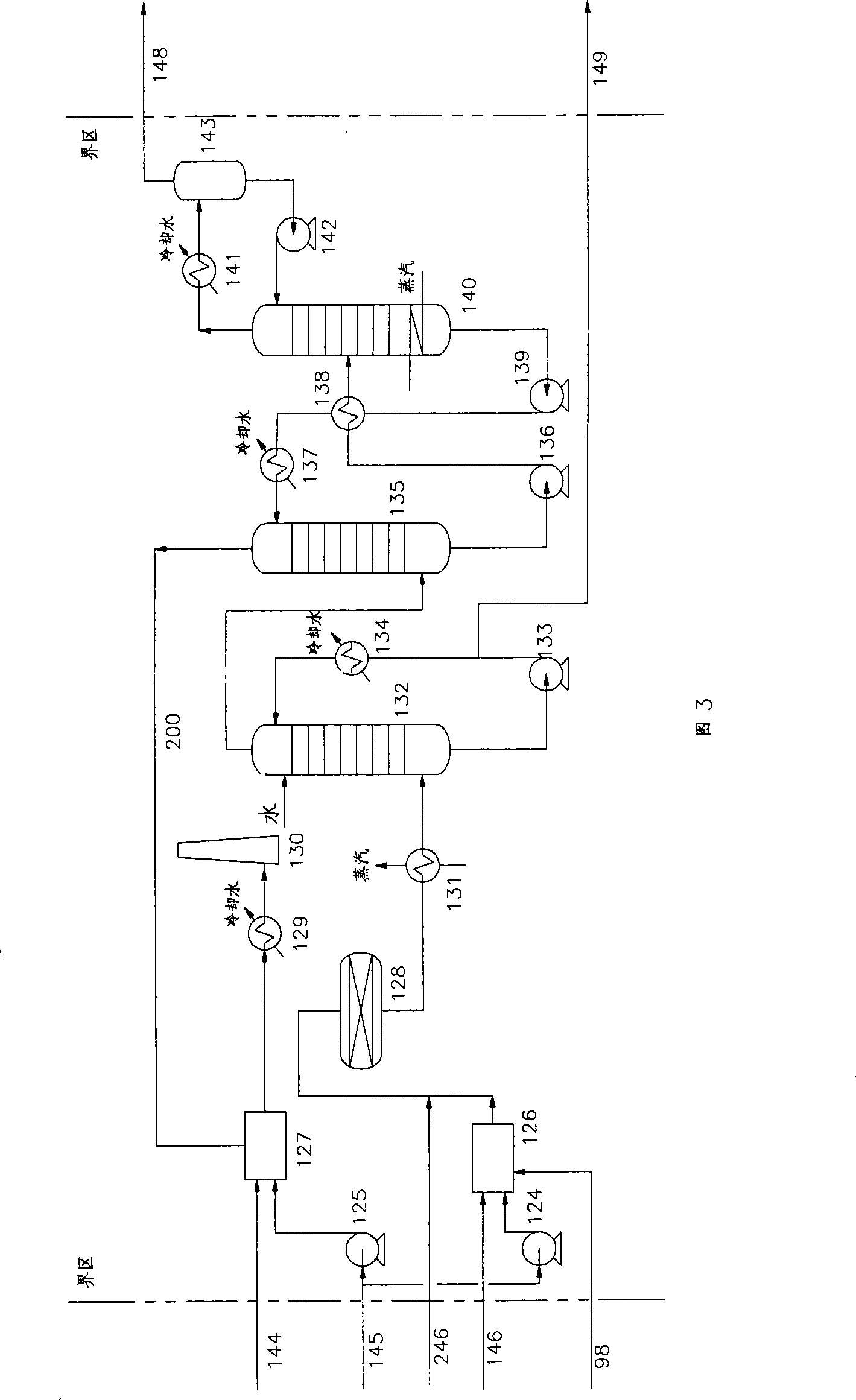

Low temperature methanol washing integrated Claus sulfur recovery system and process

ActiveCN101418246AFlexible processing capacityLow investment costProductsReagentsSulfurHydrogenation reaction

The invention relates to a reclaiming system and a process for low-temperature methanol washing integrated Claus sulfur of coal gas and natural gas. The system is additionally provided with a Claus tail gas washing tower and uses sulfur-free methanol saturated by CO2 from a CO2 product tower as a washing agent, and the washed liquid returns to an H2S concentrating tower; through combination of heating, gas stripping and pressure adjustment, concentration of H2S in acid gas washed by methanol is adjusted flexibly; at the same time, the system is additionally provided with a tail gas pre-heater before hydrogenation reaction to compensate heat loss of a hydrogenation reaction system. The process mainly comprises the following steps: removing H2S-CO2 gas, condensing H2S, reclaiming Claus sulfur, hydrogenising and reducing the gas, selectively absorbing and desulfurizing saturated cold methanol. The process has the advantages that the process can efficiently, flexibly, safely and energy-conservatively treat carbonyl gas with different pressures, temperatures, water content and sulfur concentration; and total sulfur reclamation ratio can reach more than 99.9 percent. The concentration of the H2S in emptied tail gas is below 25 mg / Nm3, so the H2S gas can meet the requirement of environmental protection, and can be exhausted directly without being burnt.

Owner:HUALU ENG & TECH

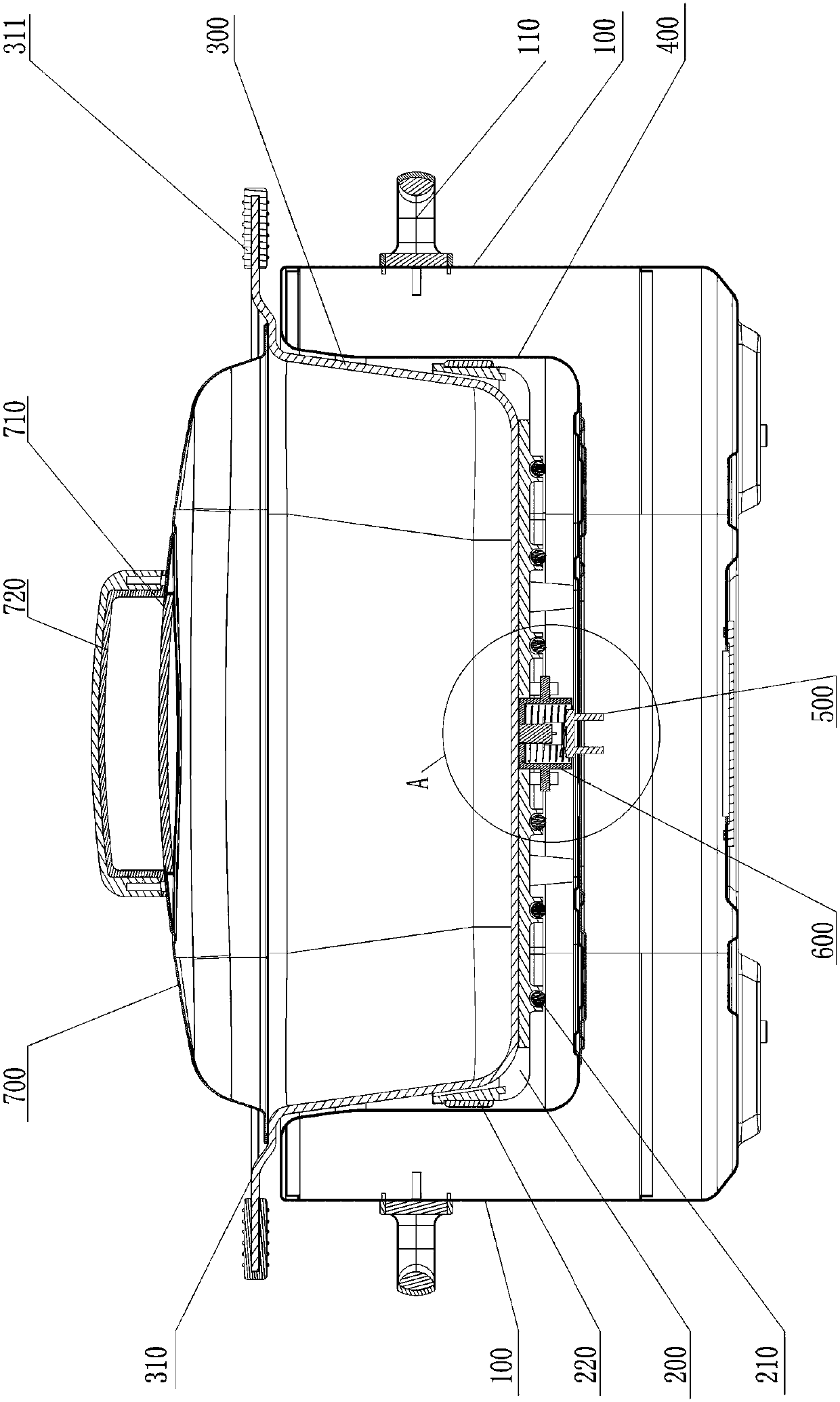

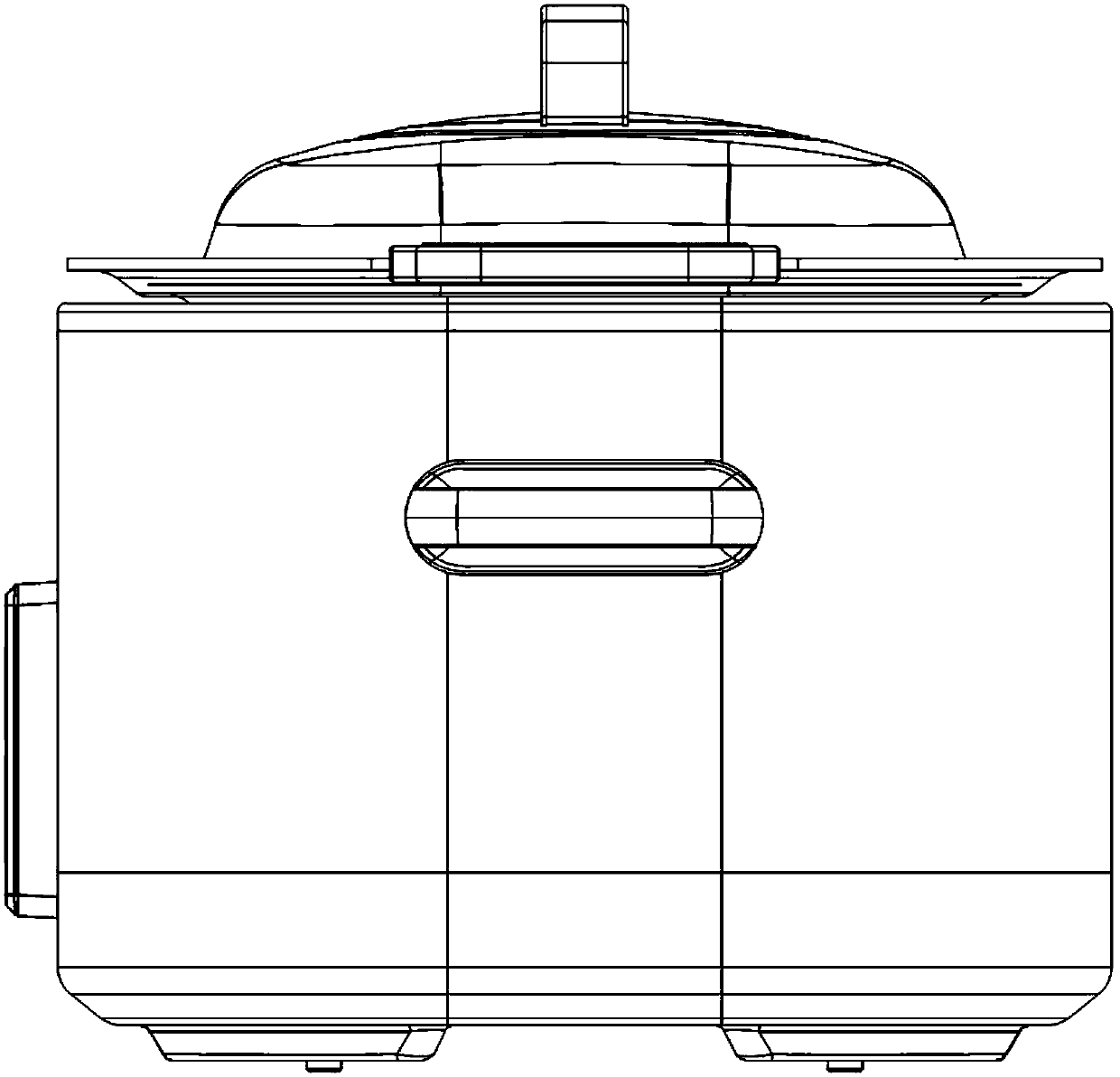

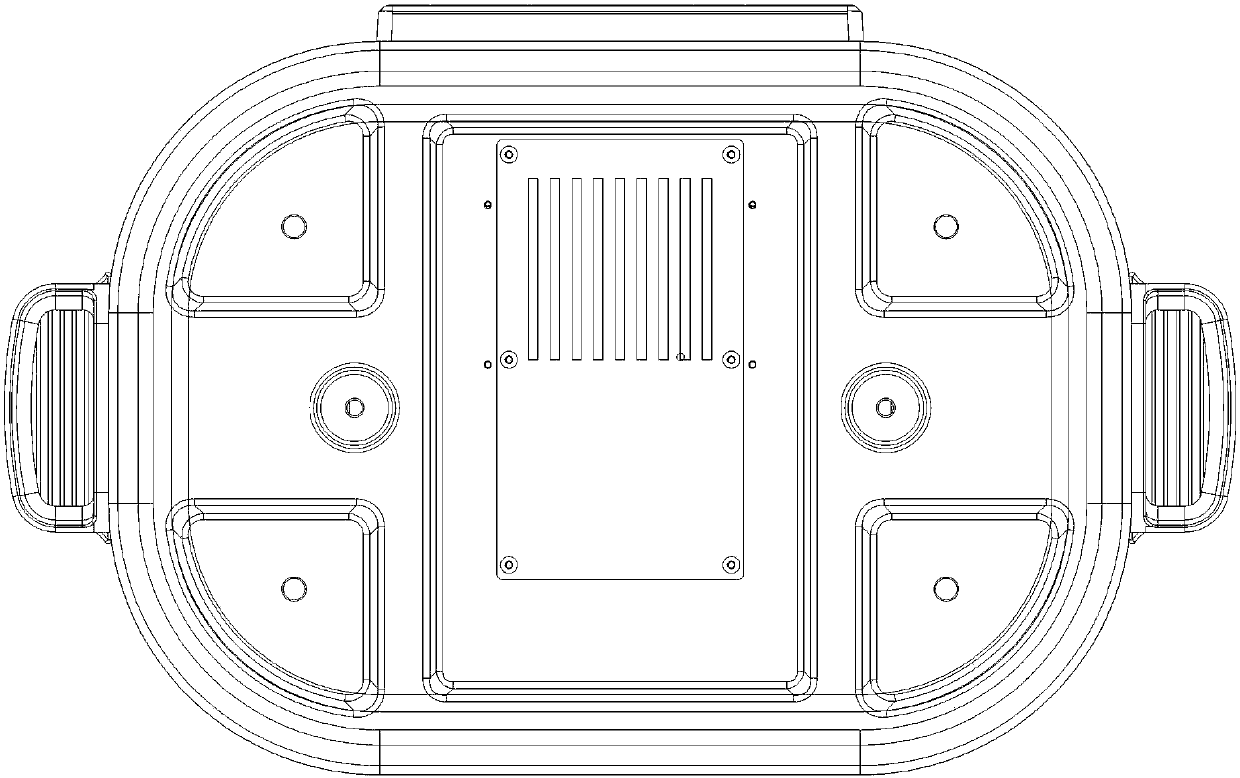

Multifunctional pot

PendingCN107836981AEvenly heatedAvoid uneven heatingHot plates heating arrangementsWarming devicesEngineeringHeat losses

The invention discloses a multifunctional pot. The pot includes a housing, a heating element heat conduction disk and a pot body, a liner is arranged in the housing, and the upper end of the housing is connected with the upper end of the liner; the heating element heat conduction disk is arranged in the liner, the height of the heating element heat conduction disk is lower than the depth of the liner, a bottom heating element is arranged at the outer bottom of the heating element heat conduction disk, an annular heating element is arranged on the outer side wall of the heating element heat conduction disk, and the bottom heating element and the annular heating element are in series connection and are electrically connected to a working circuit of the multifunctional pot; the pot body is arranged on the heating element heat conduction disk, the inner wall of the heating element heat conduction disk is in contact with the outer wall of the pot body, and the height of the pot body is larger than the depth of the heating element heat conduction disk. The heating element heat conduction disk of the multifunctional pot directly heats the pot body evenly, the inner wall of the heating element heat conduction disk can be in close contact with the outer wall of the pot body, hence, most of heat can be transmitted to the pot body, the liner can effectively keep the heating element from transmitting heat to the outside world, the heat loss is small, and the energy utilization rate is high.

Owner:NINGBO JINYU ELECTRIC APPLIANCE

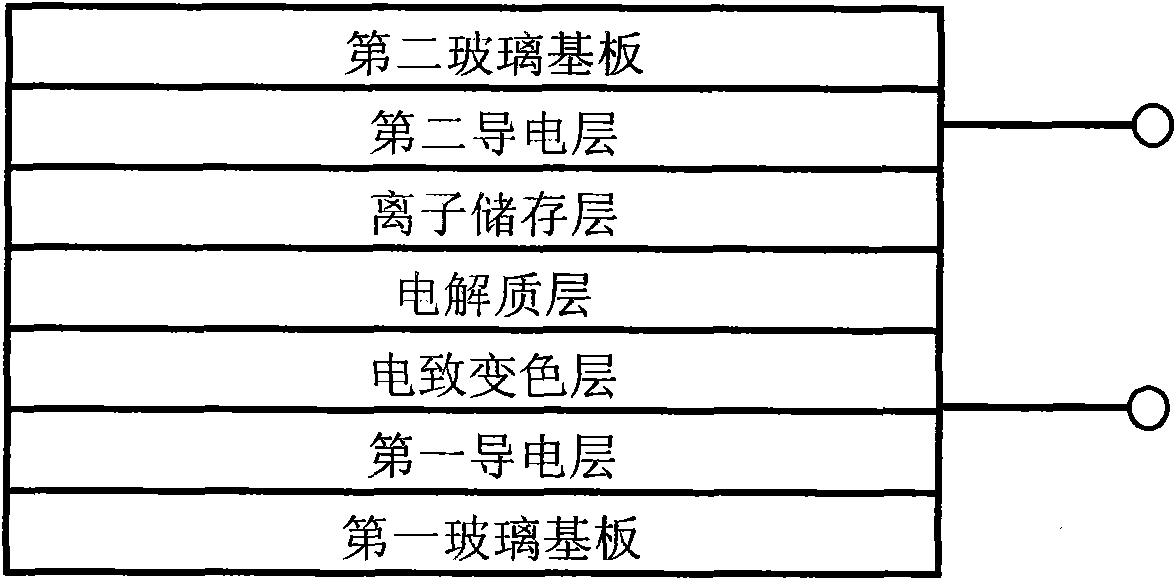

Intelligent dimming glass

InactiveCN101833211AHigh electrochromic efficiencyLow external voltageNon-linear opticsOptical elementsFiberOptoelectronics

The invention discloses intelligent dimming glass comprises a first glass base plate and a second glass base plate which are stacked at the top and the bottom, a first conductive layer, an electrochromic layer, an electrolyte layer, an iron storage layer and a second conductive layer are sequentially arranged between the first glass base plate and the second glass base plate; one ends of the first conductive layer and the second conductive layer are respectively connected with an anode and a cathode; and the first conductive layer and the second conductive layer are conductive films having infrared reflection performance, and the surfaces of the conductive films are coated with active carbon fibers. Compared with the prior art, the intelligent dimming glass has the characteristics of infrared reflection effect, high electrochromic efficiency, lower required external voltage and the like, can not only reduce indoor heat losses and realize the purpose of saving energy sources, but also prolong the service life of the intelligent dimming glass, thereby meeting the requirements of daily life and architectural decoration of people.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Temperature regulation device for a fluid-containing receptacle and use thereof

InactiveUS20060248902A1Machines using electric/magnetic effectsCooling fluid circulationEngineeringHeat losses

Owner:HUNNELL ADAM

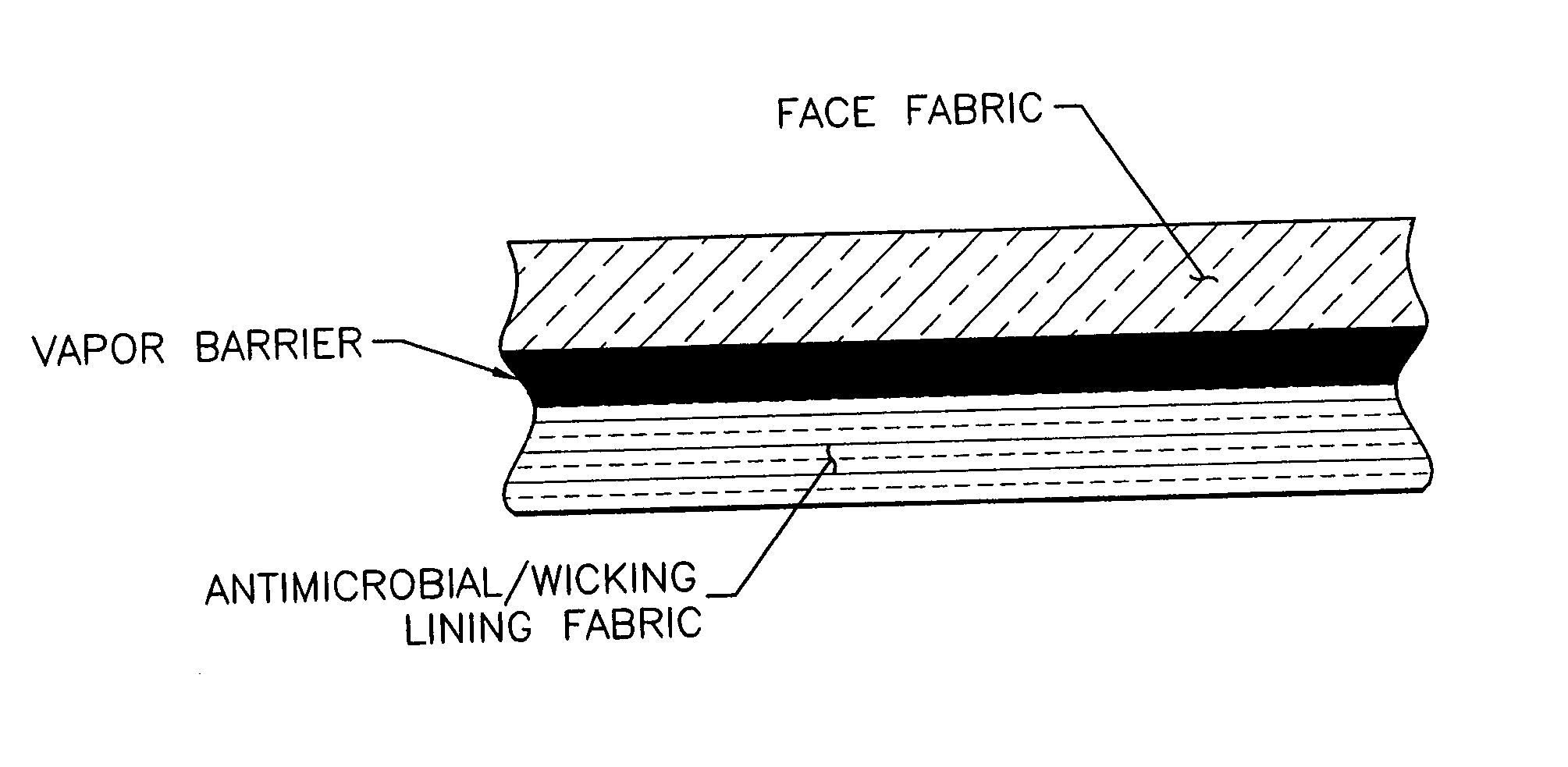

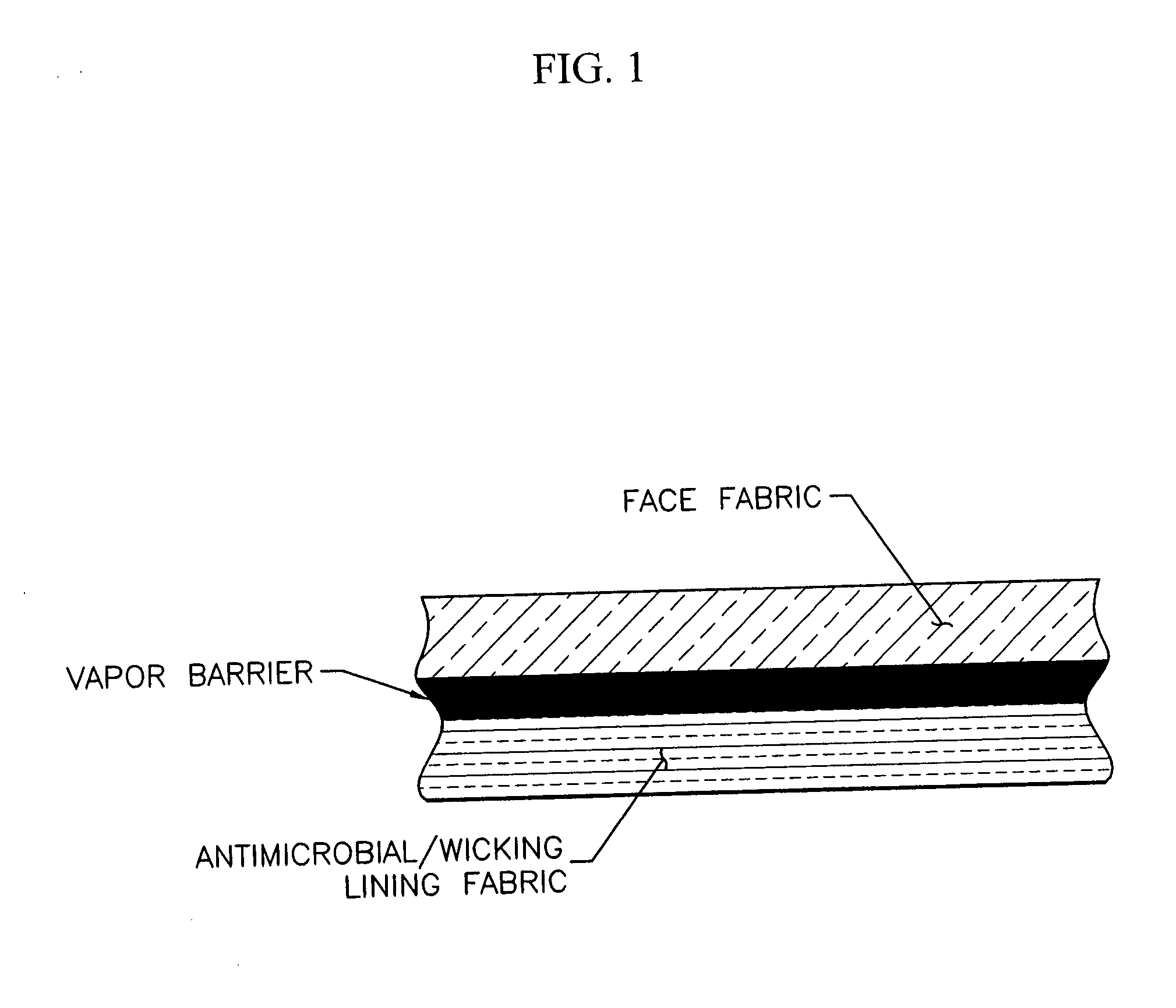

Multifunctional composite vapor barrier textile

InactiveUS20070166503A1Relieve overheatingAdd to comfort and aesthetic propertyGarment special featuresSynthetic resin layered productsVapor barrierAdhesive

The present invention is directed to a multifunctional waterproof / vapor barrier fabric for use in industrial, medical, outdoor apparel (hunting, fishing, skiing, mountaineering, etc.) and military applications. The invention combines functional elements that are especially suited for the above applications. The fabric comprises a lining with wicking and antimicrobial properties, a vapor barrier film or coating with low Moisture Vapor Transmission Rate (M.V.T.R.), and a woven or knit face fabric enhanced with a hydrophobic face coating. The fabric performs admirably in various uses due in part to the use of hydrophobic adhesive, film and coatings, which renders the fabric subject to negligible moisture gain. The durability and water proof properties of the fabric are enhanced due to the impermeable low M.V.T.R design. The fabric of the present invention incorporates a unique combination of properties that addresses issues commonly associated with vapor barrier fabrics. The invention provides a waterproof / barrier fabric that is desirable to wear in direct contact with the skin to prevent evaporative heat loss in cool or cold conditions. The fabric is also effective when worn over one or more layers of other clothing. The fabric is particularly effective because it is capable of use as a base layer and waterproof shell, which helps to minimize the number of layers of clothing needed in cold weather.

Owner:HANNIGAN RYAN B

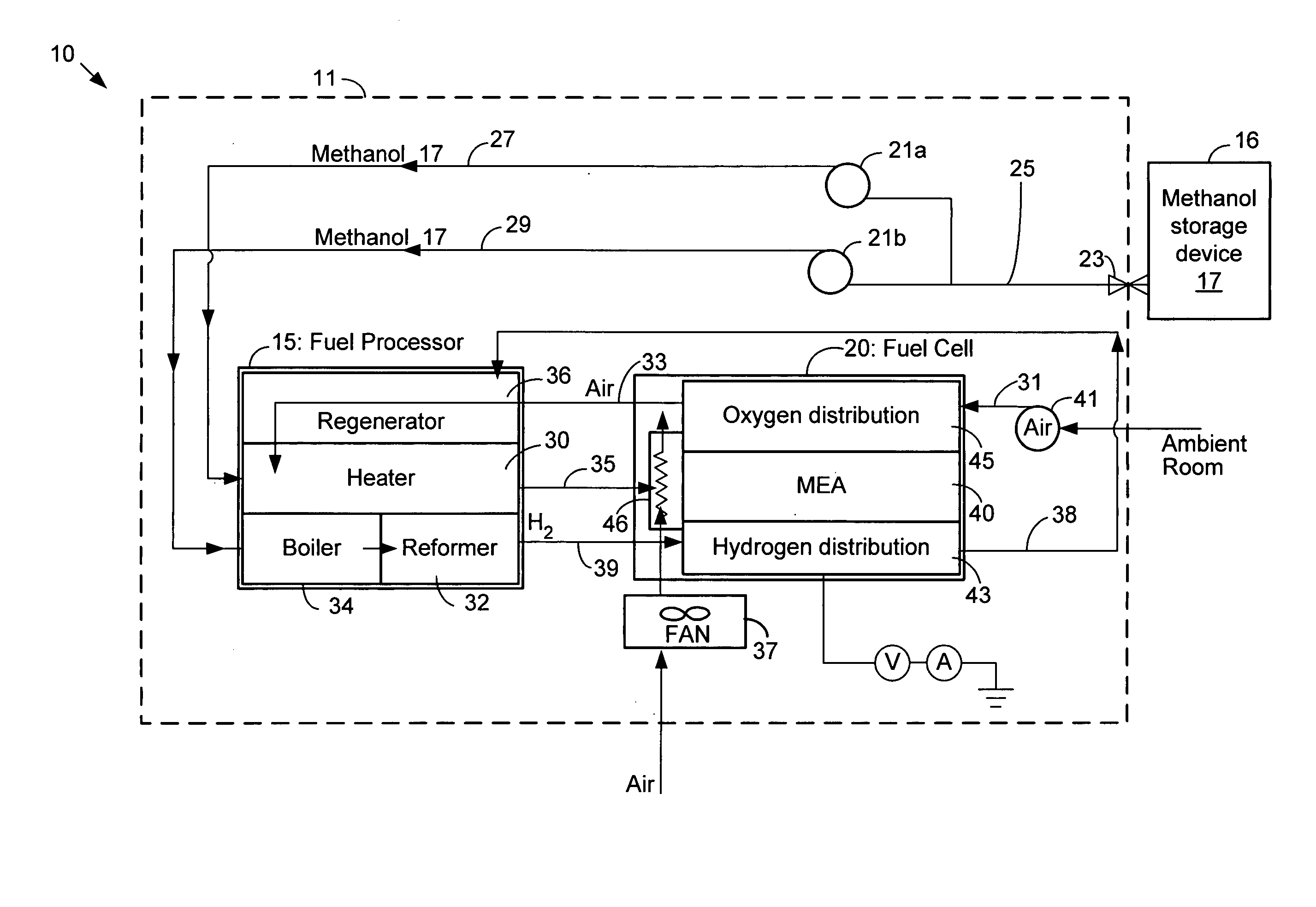

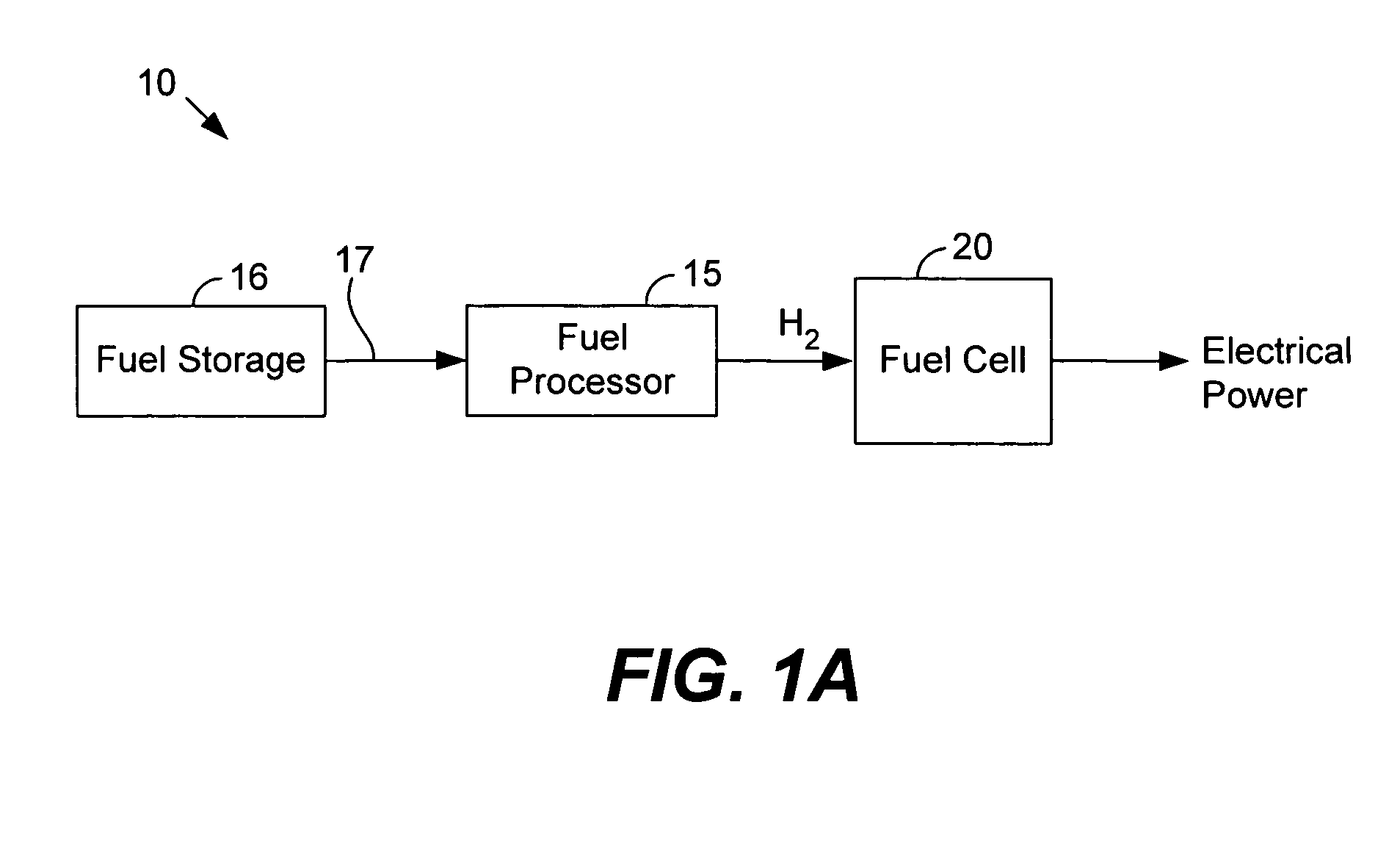

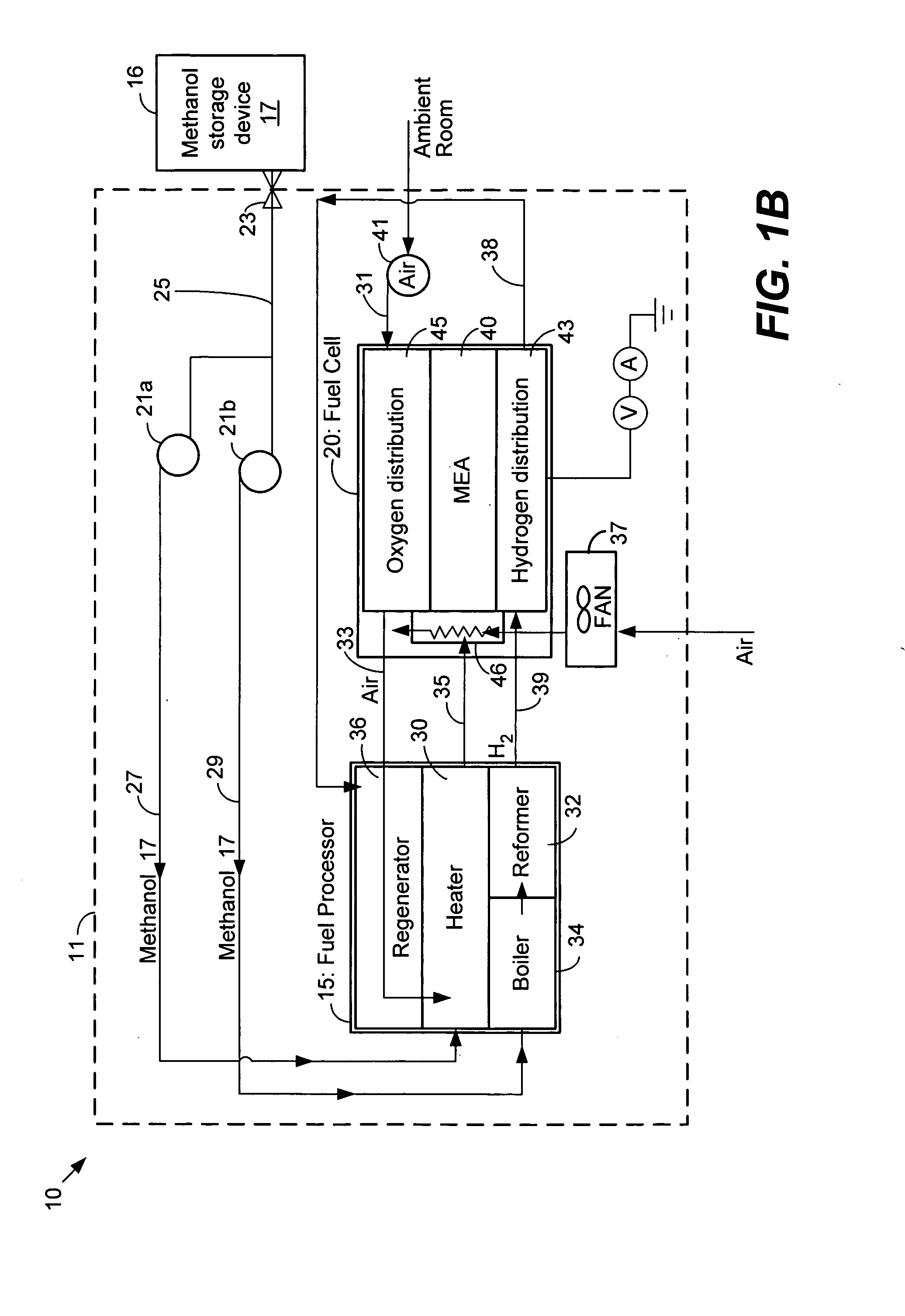

Heat efficient portable fuel cell systems

ActiveUS20060127719A1Reduce heat lossImprove thermal efficiencyHydrogenFuel cells groupingFuel cellsHydrogen

The invention relates to fuel cell systems with improved thermal efficiency. The systems include a fuel cell that generates electrical energy using hydrogen and a fuel processor that produces hydrogen from a fuel. Some heat efficient systems described herein include a thermal catalyst that generates heat when the catalyst interacts with a heating medium. The heat is used to heat the fuel cell. The thermal catalyst may be disposed in, proximity to the fuel cell, or remote from the fuel cell and a heat transfer pipe conducts heat from the catalyst to the fuel cell. Another thermally efficient embodiment uses a recuperator to transfer heat generated in the fuel cell system to incoming fuel. A fuel cell package may also include a multi-layer insulation arrangement to decrease heat loss from the fuel cell and fuel processor, which both typically operate at elevated temperatures.

Owner:ADVENT TECH LLC

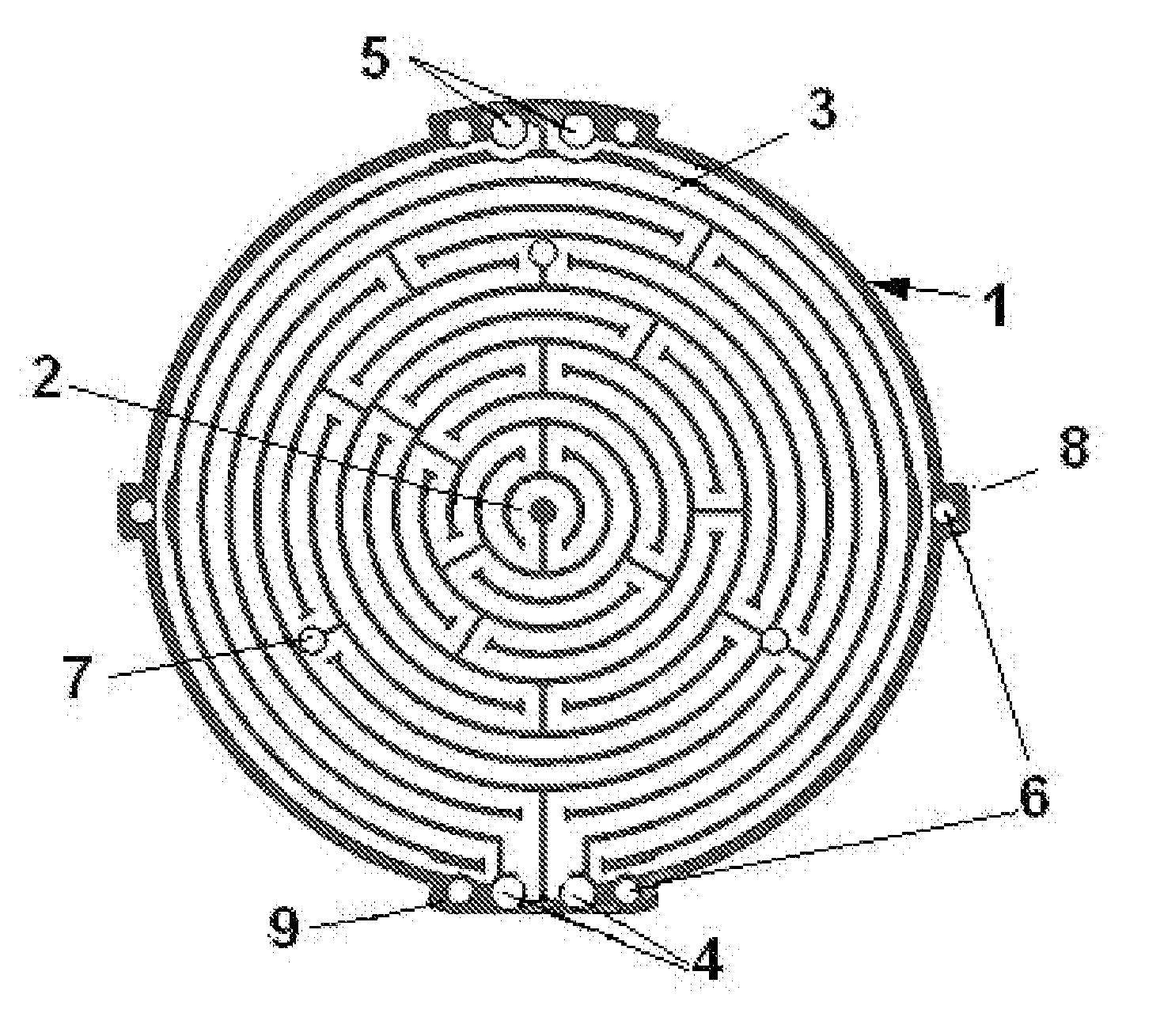

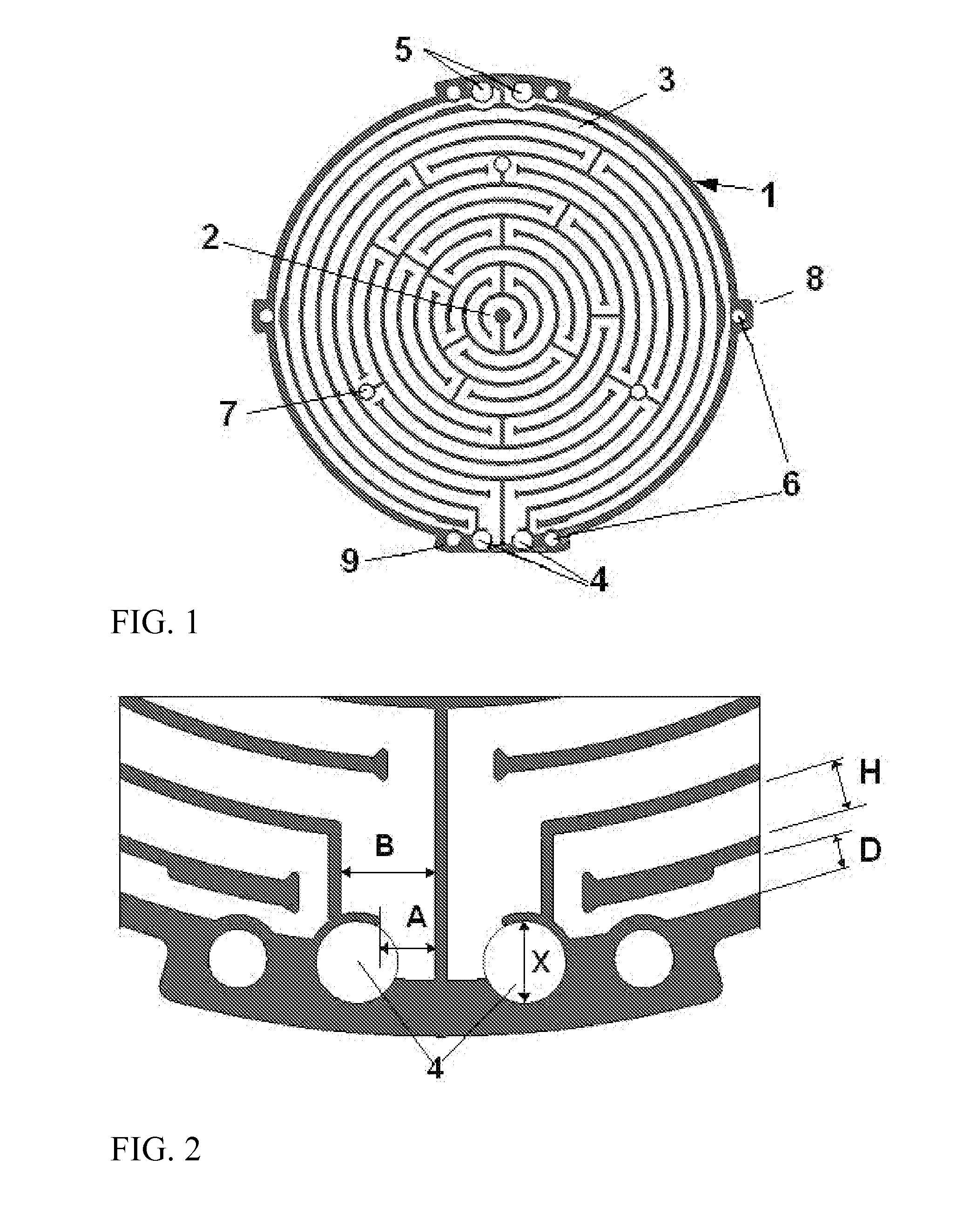

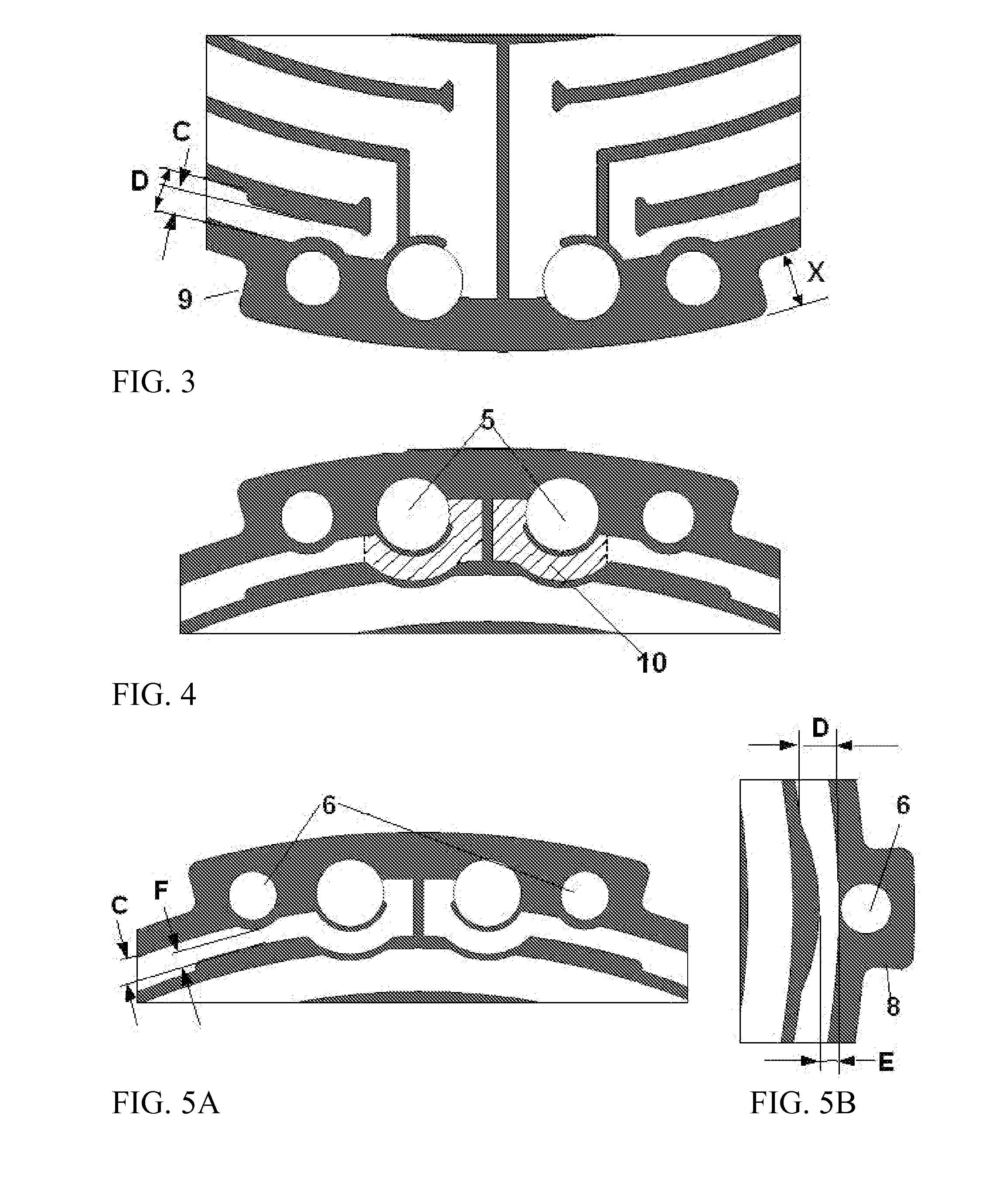

Electrode Pattern For Resistance Heating Element and Wafer processing Apparatus

ActiveUS20080029195A1Uniform temperature distributionImprove heat lossWorkpiece holdersCellsElectrical resistance and conductanceElectrical connection

There is disclosed a wafer processing apparatus having optimized electrode patterns for its resistive heating element. The optimized electrode pattern is designed to compensate for the heat loss around contact areas, electrical connections, and through-holes, etc., by generating more heat near or around those areas, providing maximum temperature uniformity. In another embodiment of the optimized design of the invention, the resistance of heating element closely matches the impedance of the power supply for higher efficiency, especially when higher operating temperature or higher electrical power is required.

Owner:GENERAL ELECTRIC CO

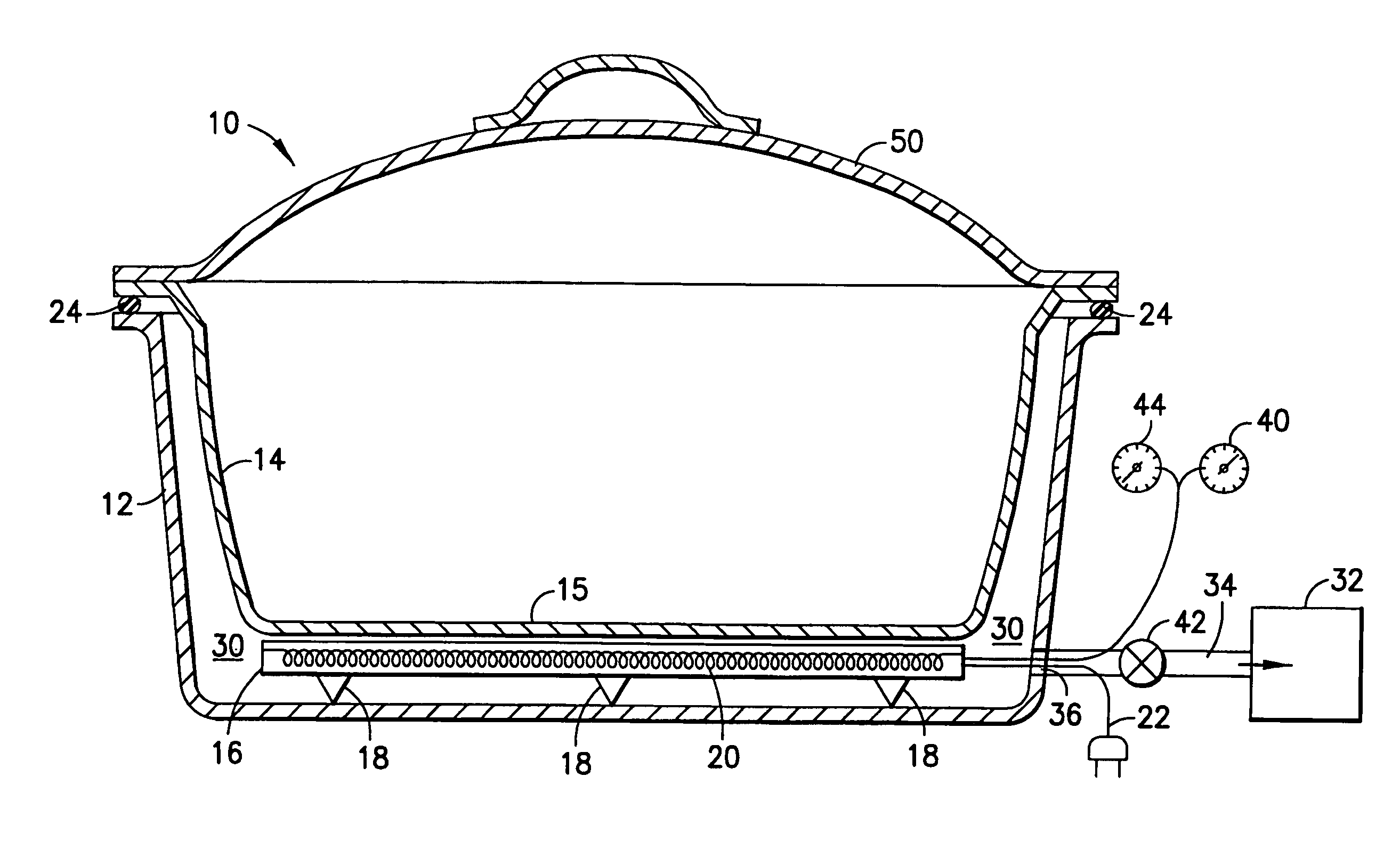

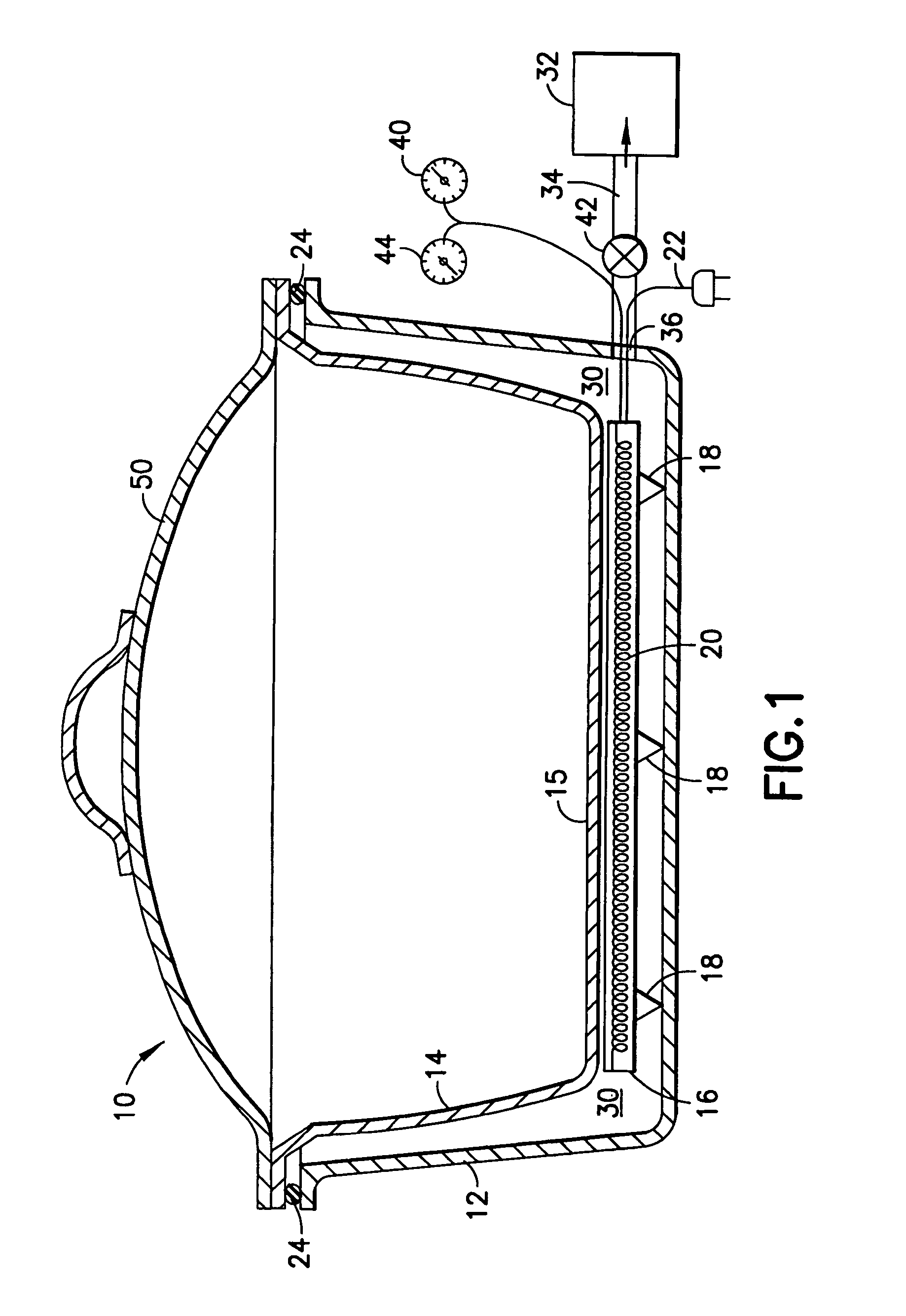

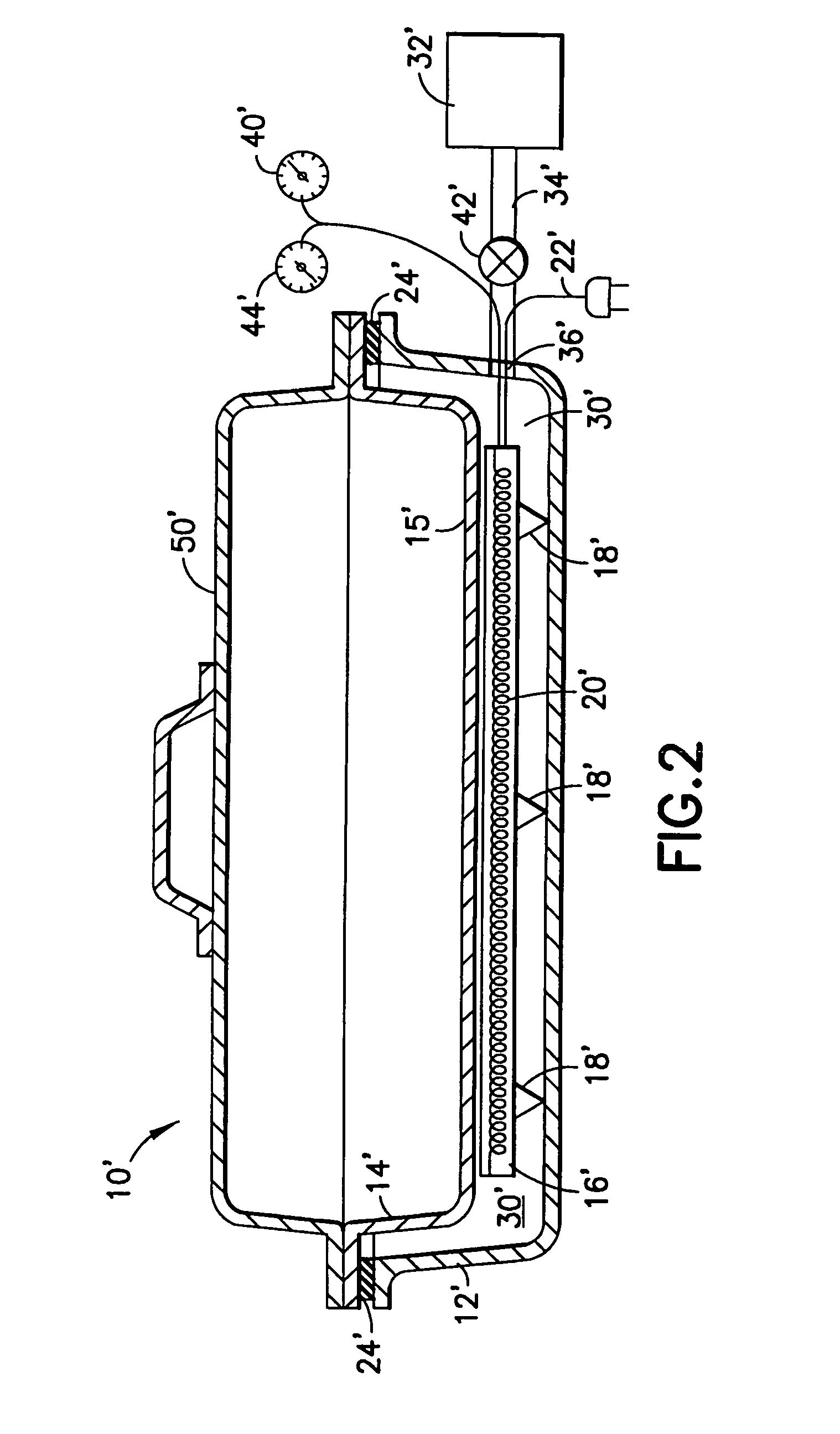

Vacuum cooking or warming appliance

Owner:CLAD METALS

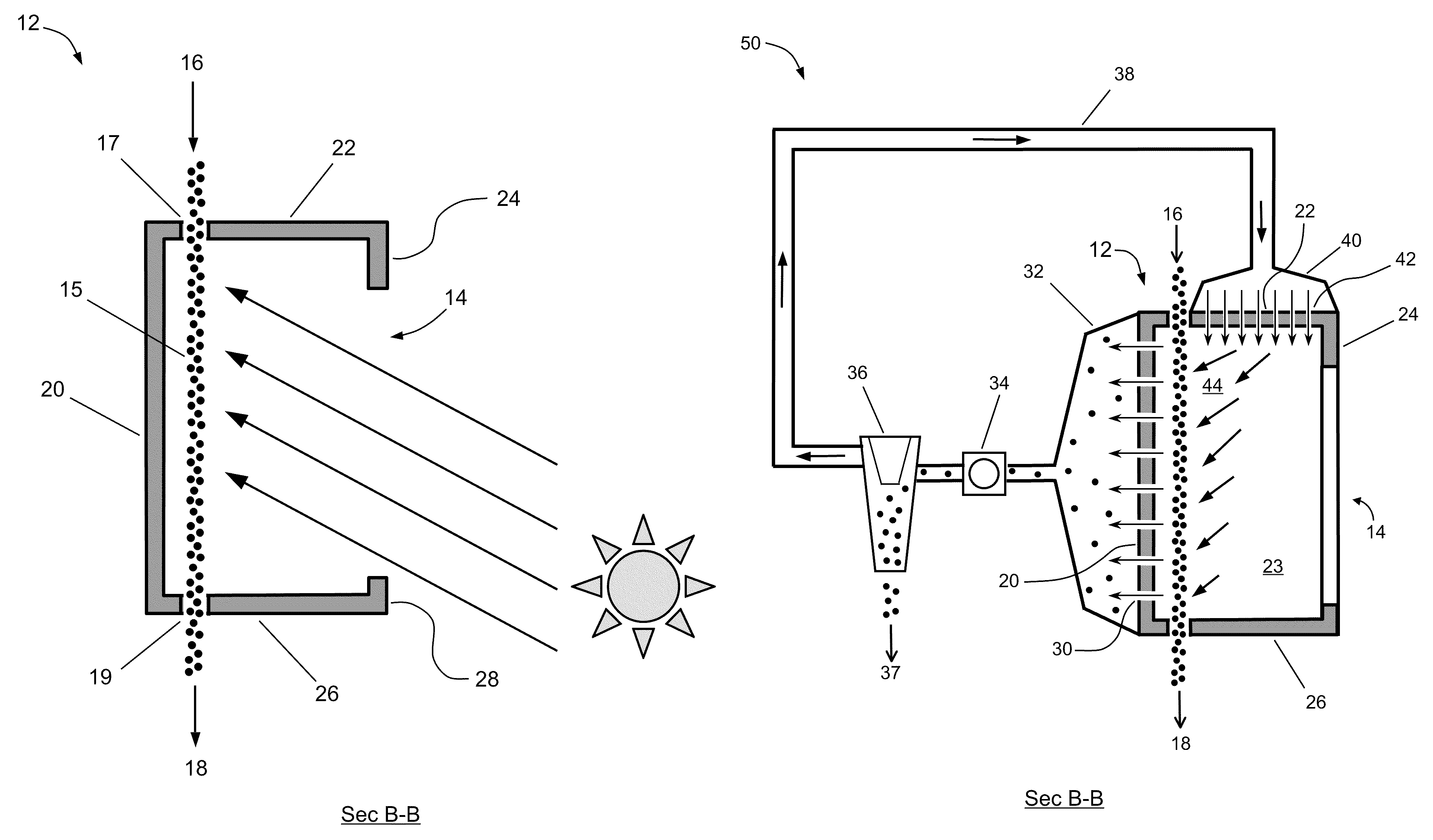

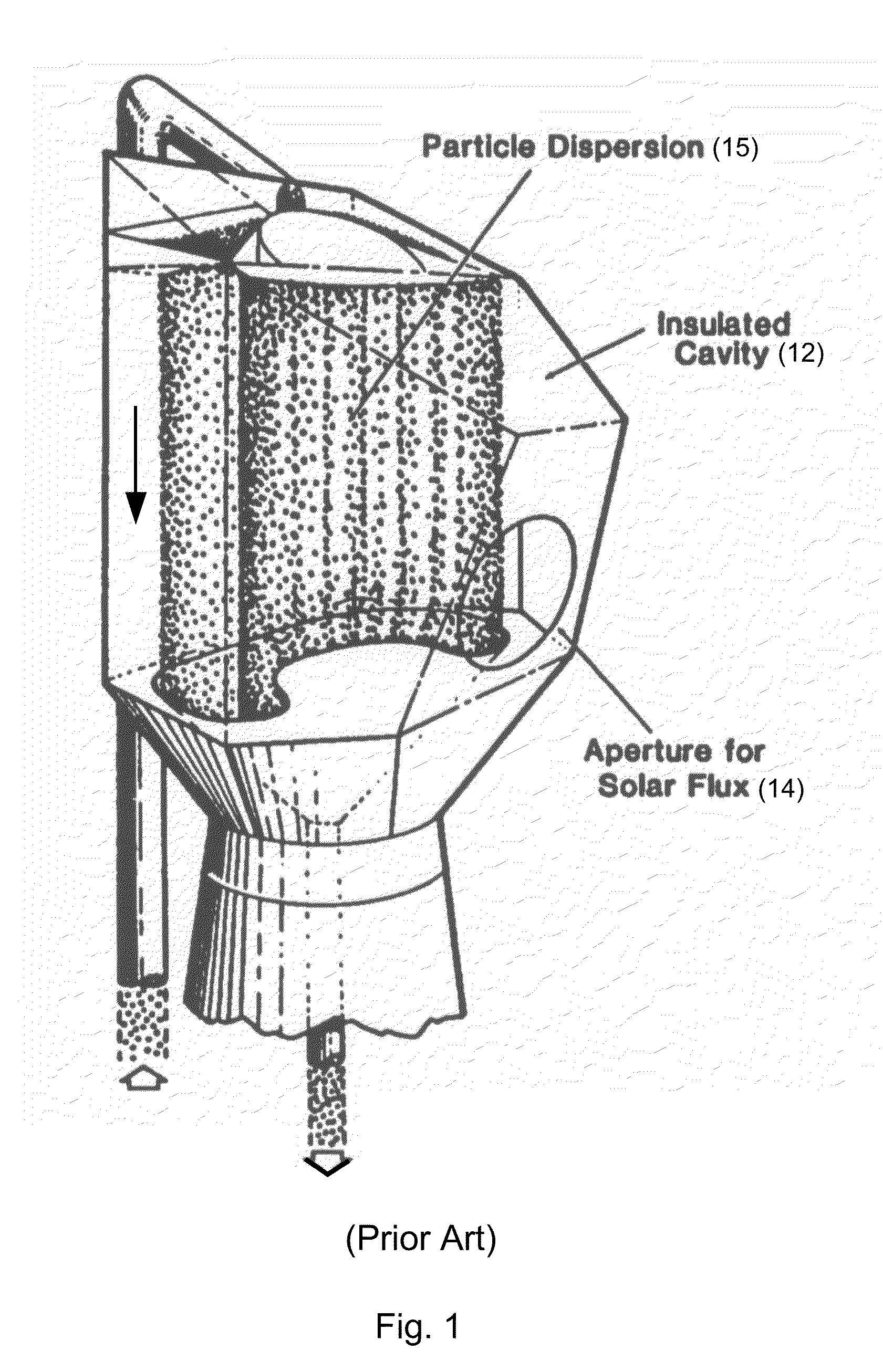

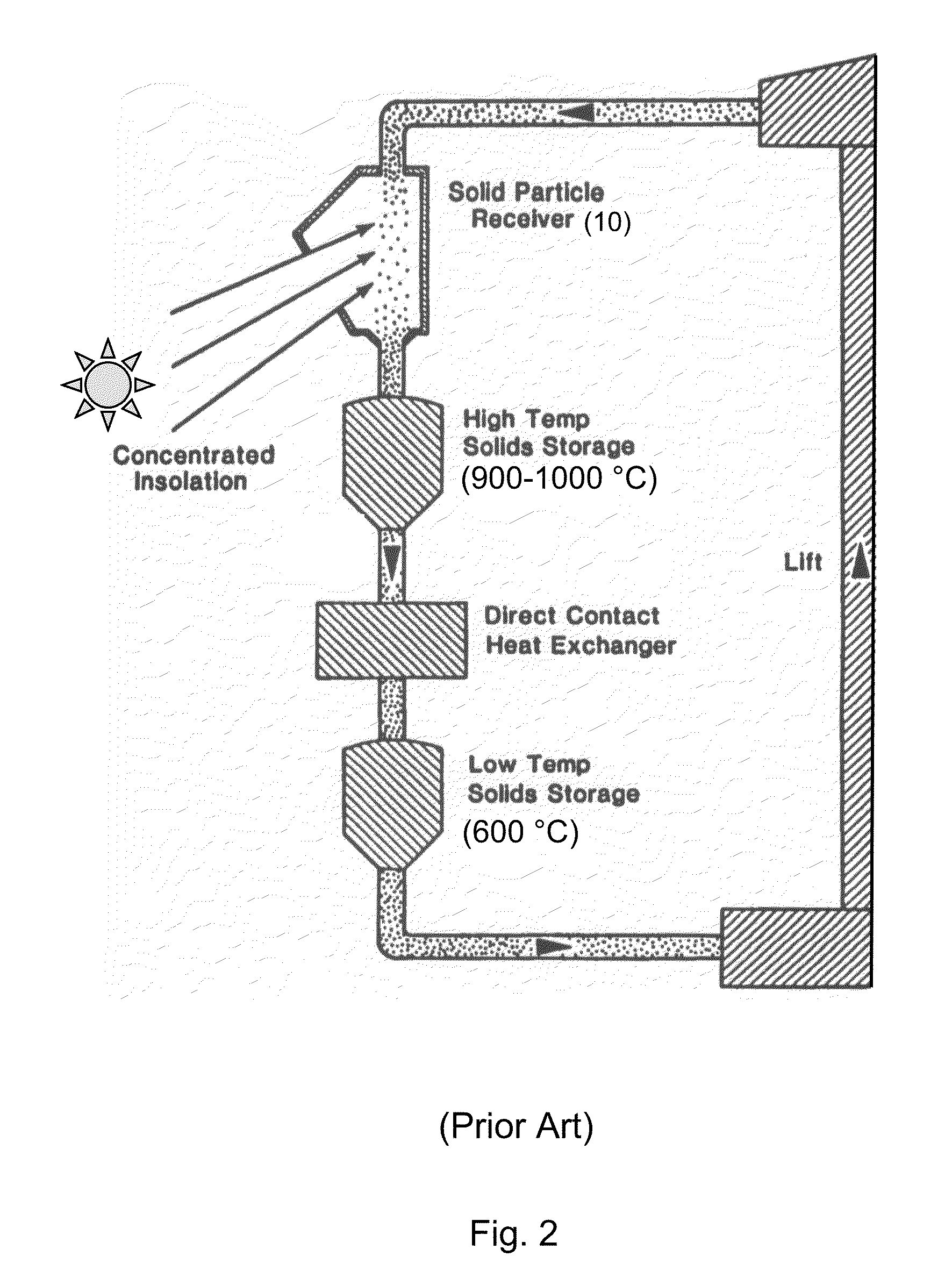

Suction-recirculation device for stabilizing particle flows within a solar powered solid particle receiver

ActiveUS8109265B1Reduce heat lossImprove efficiencySolar heating energySolar heat devicesCycloneSolar power tower

A suction-recirculation device for stabilizing the flow of a curtain of blackened heat absorption particles falling inside of a solar receiver with an open aperture. The curtain of particles absorbs the concentrated heat from a solar mirror array reflected up to the receiver on a solar power tower. External winds entering the receiver at an oblique angle can destabilize the particle curtain and eject particles. A fan and ductwork is located behind the back wall of the receiver and sucks air out through an array of small holes in the back wall. Any entrained particles are separated out by a conventional cyclone device. Then, the air is recirculated back to the top of the receiver by injecting the recycled air through an array of small holes in the receiver's ceiling and upper aperture front wall. Since internal air is recirculated, heat losses are minimized and high receiver efficiency is maintained. Suction-recirculation velocities in the range of 1-5 m / s are sufficient to stabilize the particle curtain against external wind speeds in excess of 10 m / s.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

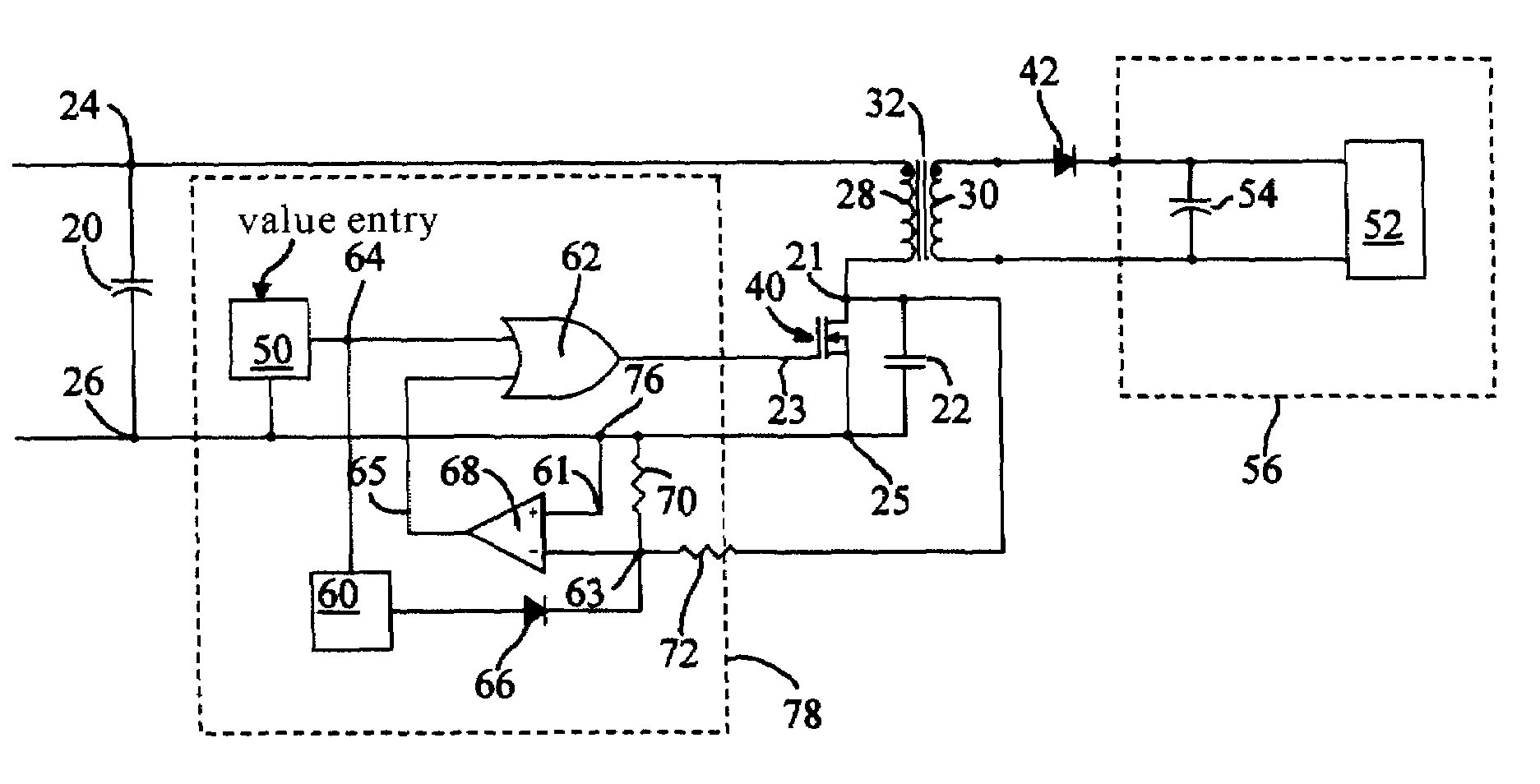

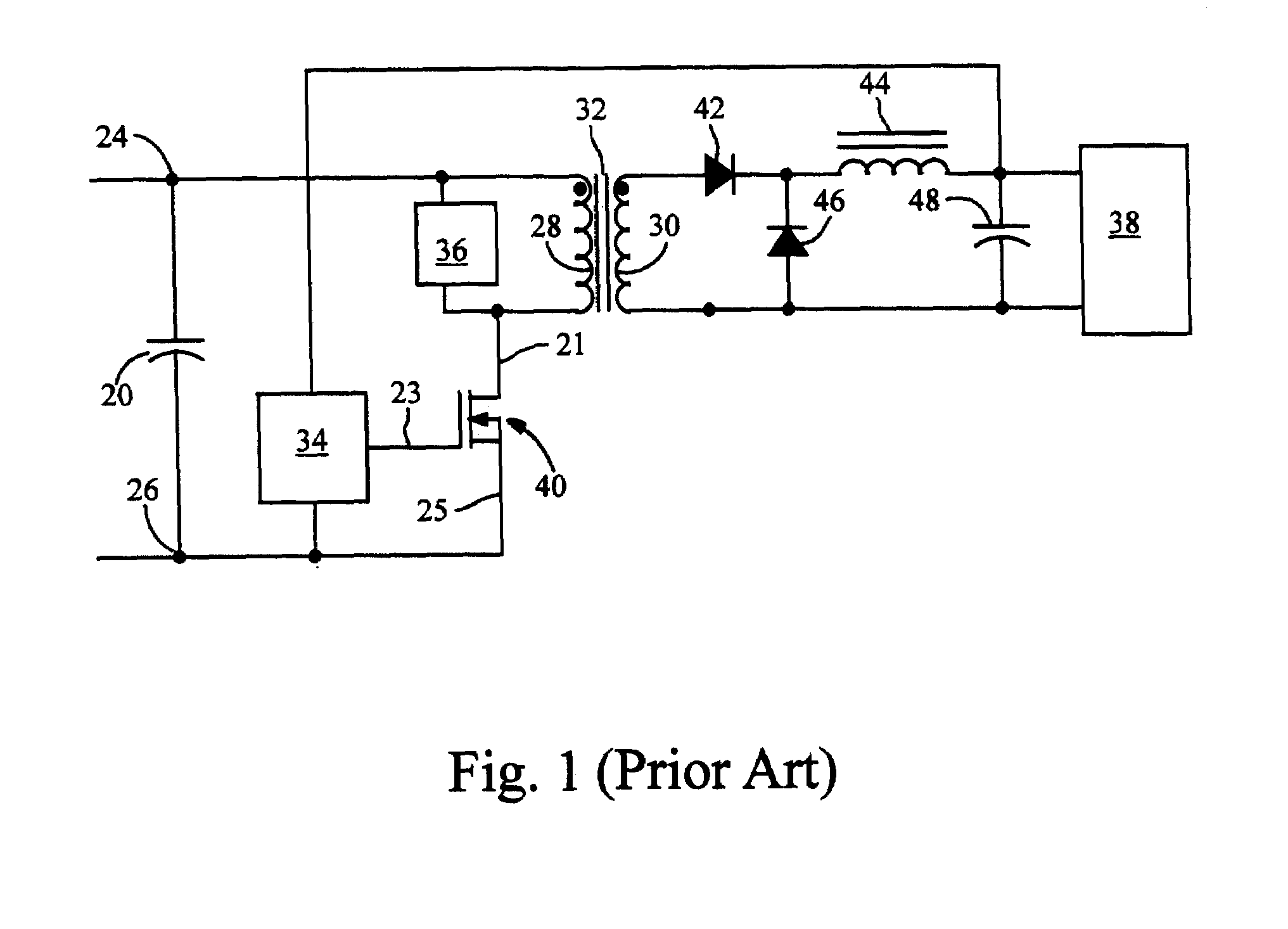

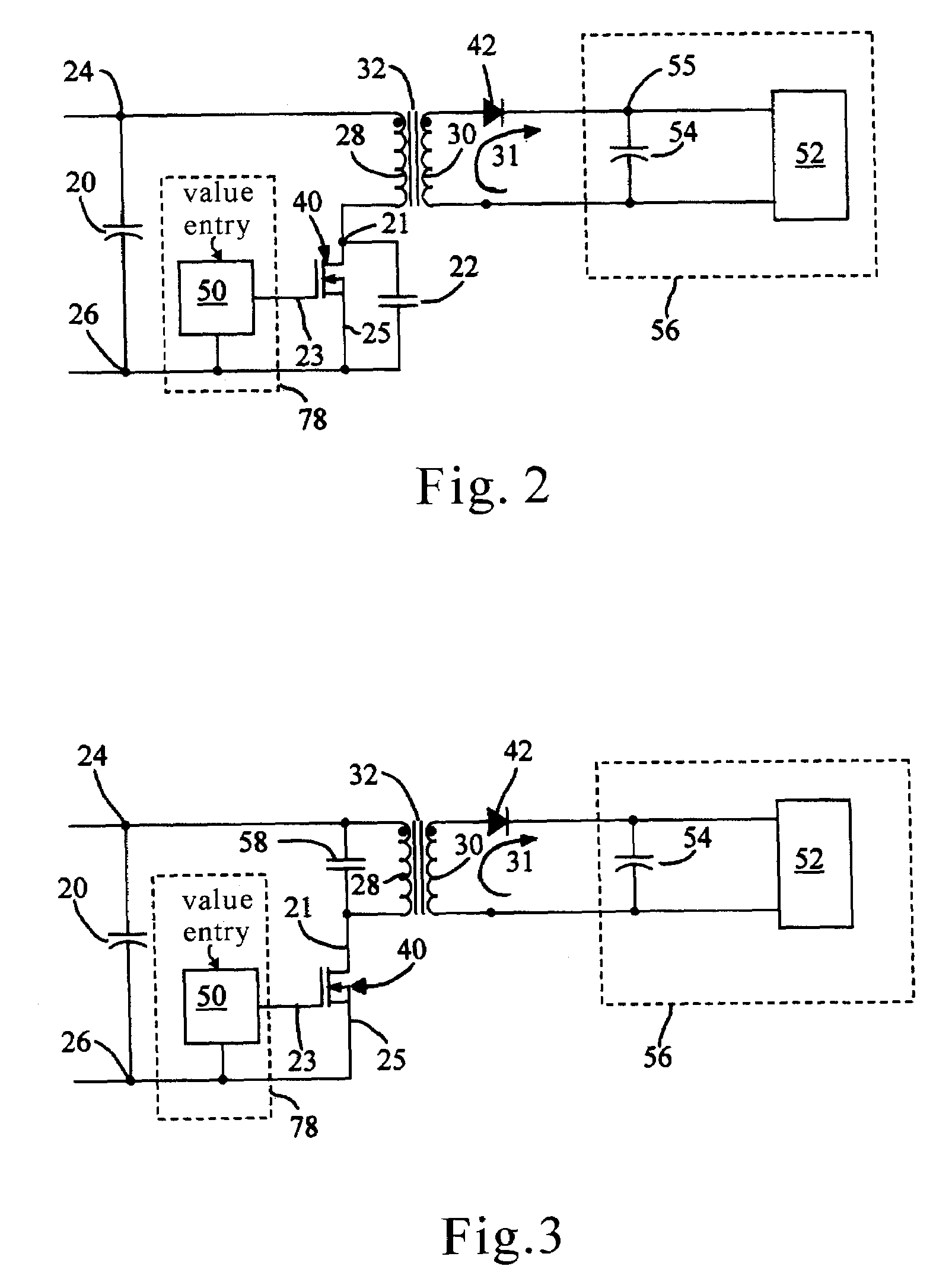

Switching-type power converter

An apparatus for increasing efficiency and reducing heat dissipation in power converters is disclosed. Zero-voltage-switching (ZVS) can reduce switching loss of power converters but it often results in a very complicated design and only works well under constant output current. In order to allow the ZVS to work over a wide loading range, the transformer secondary current is blocked when the primary starts to resonate. Hence, the resonant voltage waveform across the switch will not change even when the loading current is changing. Such a resonant voltage waveform is obtained with the aid of the transformer primary inductance and capacitor(s). Also provided is a novel driving circuit which controls the switching. Alternatives and variations of this apparatus can be made to satisfy different applications such as power conversion and power inversion. The subject power converter significantly lowers the heat loss and achieves higher efficiency for very wide loading ranges.

Owner:FUNG SZE WEI +1

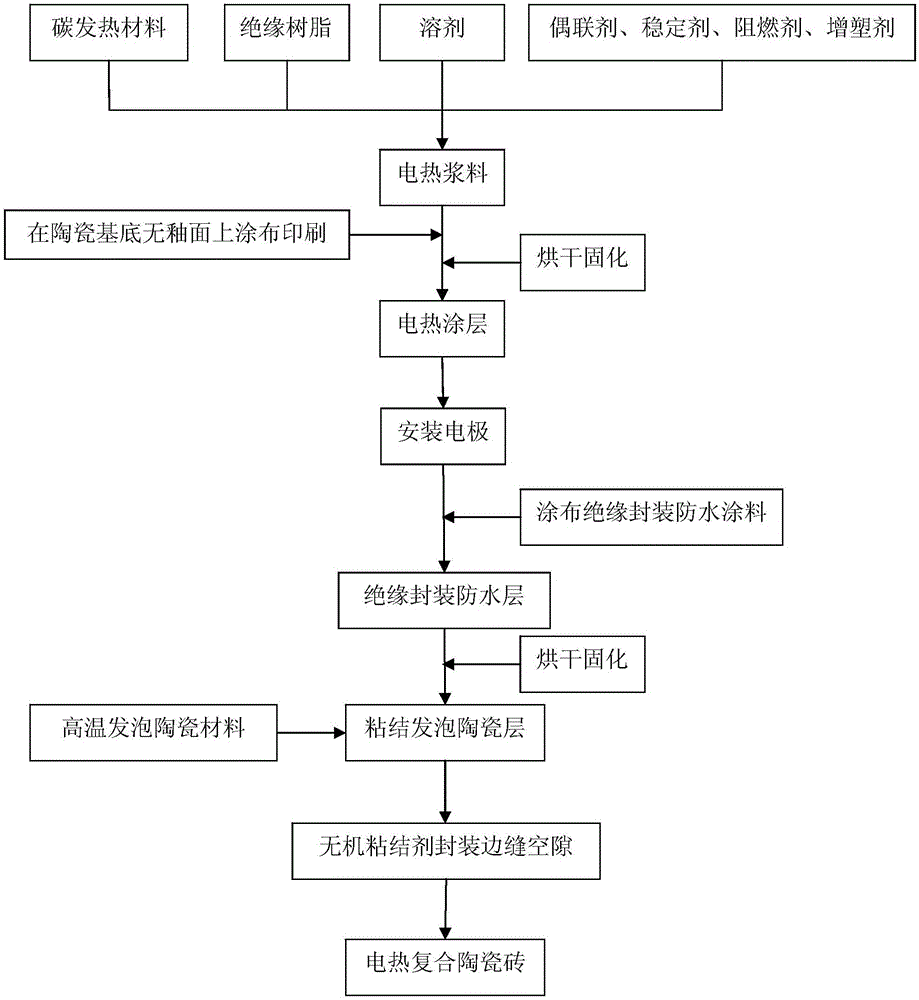

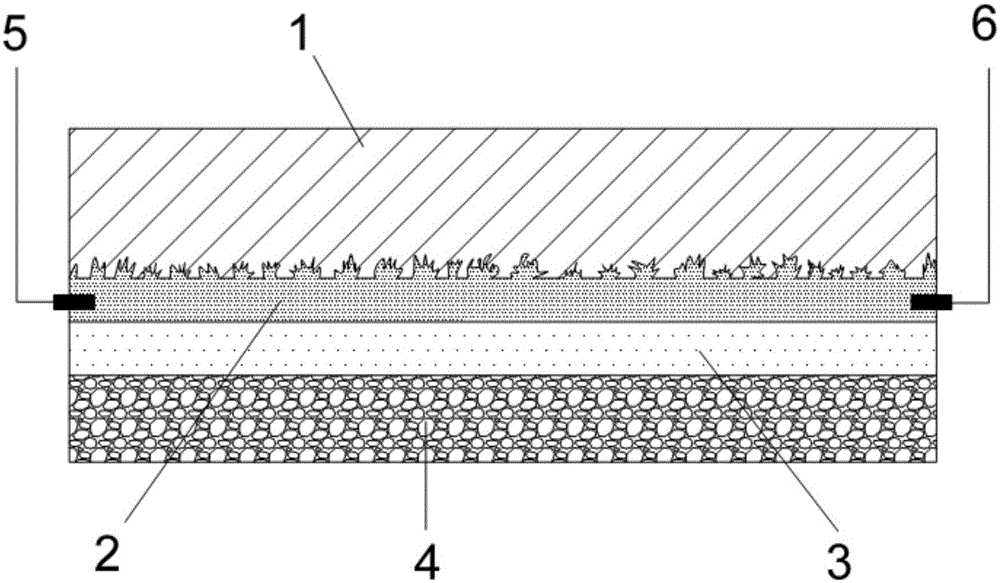

Electrothermal composite ceramic brick and preparation method thereof

The invention discloses an electrothermal composite ceramic brick and a preparation method thereof. An electrothermal coating layer, a guiding-out wiring electrode, a coating insulation packaging waterproof layer and an application foaming ceramic layer coat an unglazed surface of a ceramics substrate in order. The electrothermal coating layer coats the unglazed surface of the ceramics substrate in an electrothermal slurry form, the electrothermal slurry permeates the green body of the ceramics substrate, and the penetration depth is less than the thickness of the ceramics substrate and more than 0.5mm. Because of the penetration, the electrothermal coating layer of the electrothermal composite ceramic brick is combined with the ceramics substrate tightly, a surface heating mode is achieved, the thermal efficiency is high, normal and safe usage can be achieved under a voltage of 24-380V, the heating power is 90-120w / m<2>, and the temperature of the ceramics substrate can reach 18-50 DEG C through a temperature control device. The insulation packaging waterproof layer and the foaming ceramic layer outside the electrothermal coating layer can prevent heat from outward transmission effectively, heat loss is lowered, and the whole safety and reliability of the ceramic brick are raised.

Owner:GUANGDONG TIANBI CERAMICS

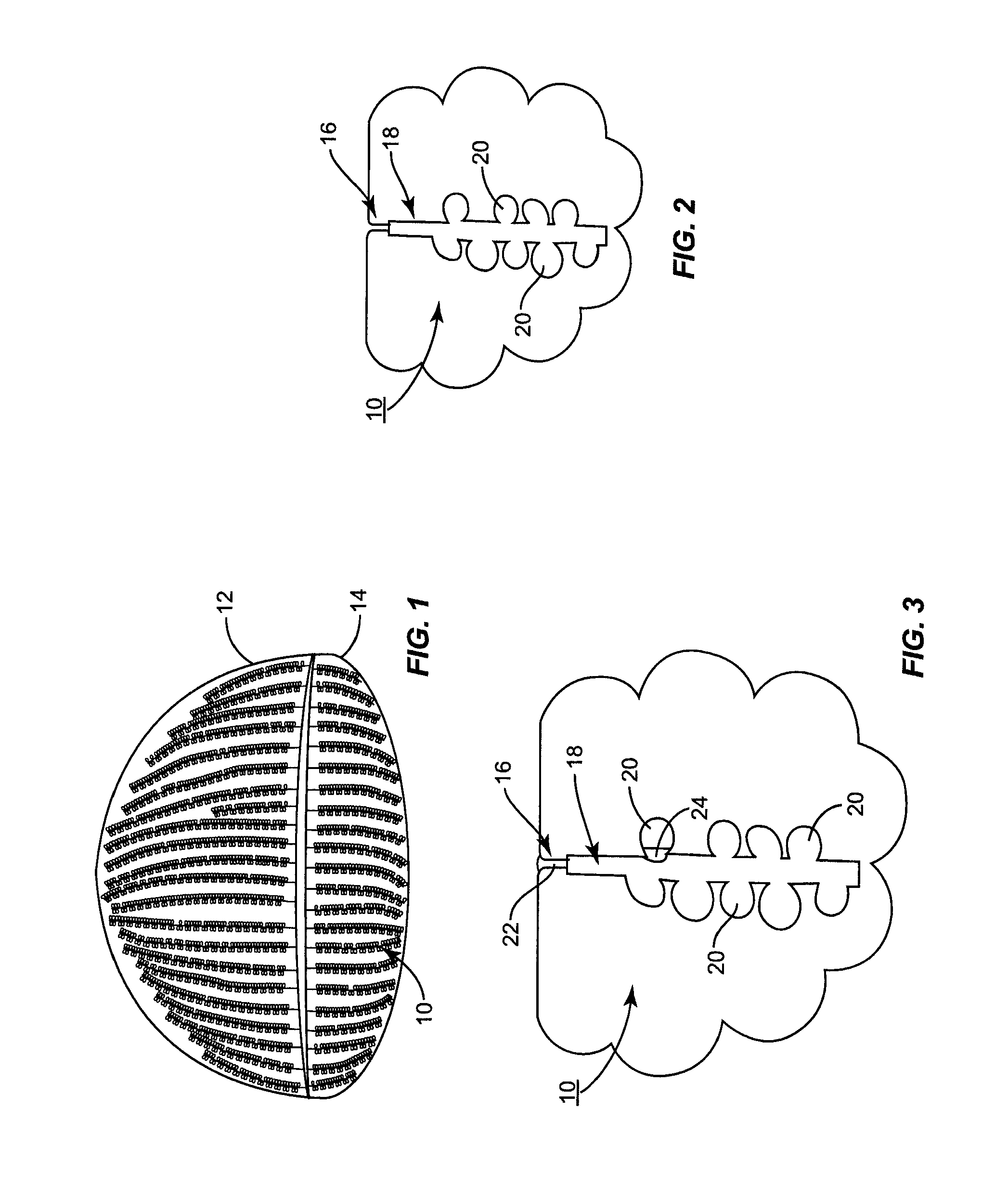

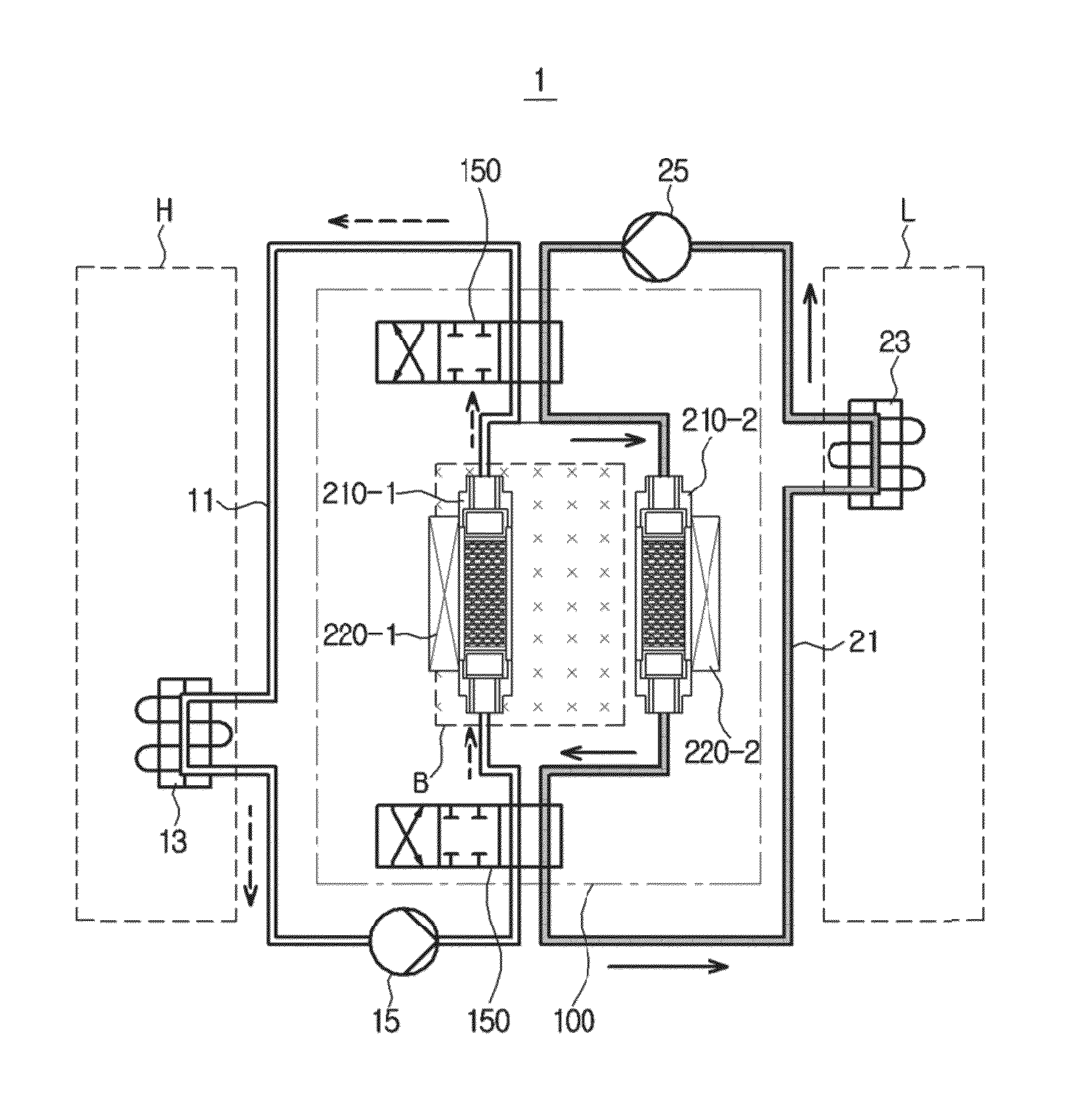

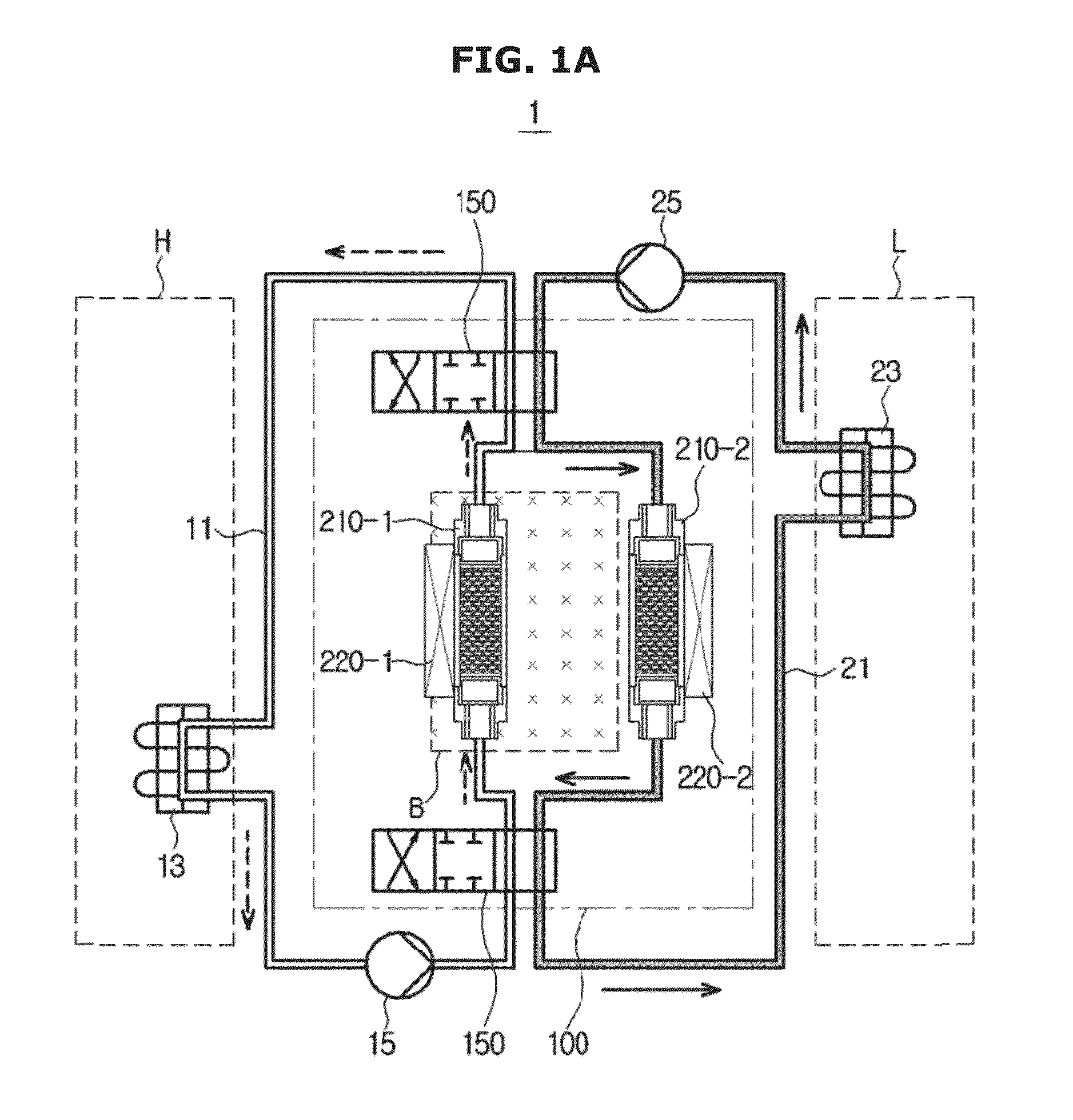

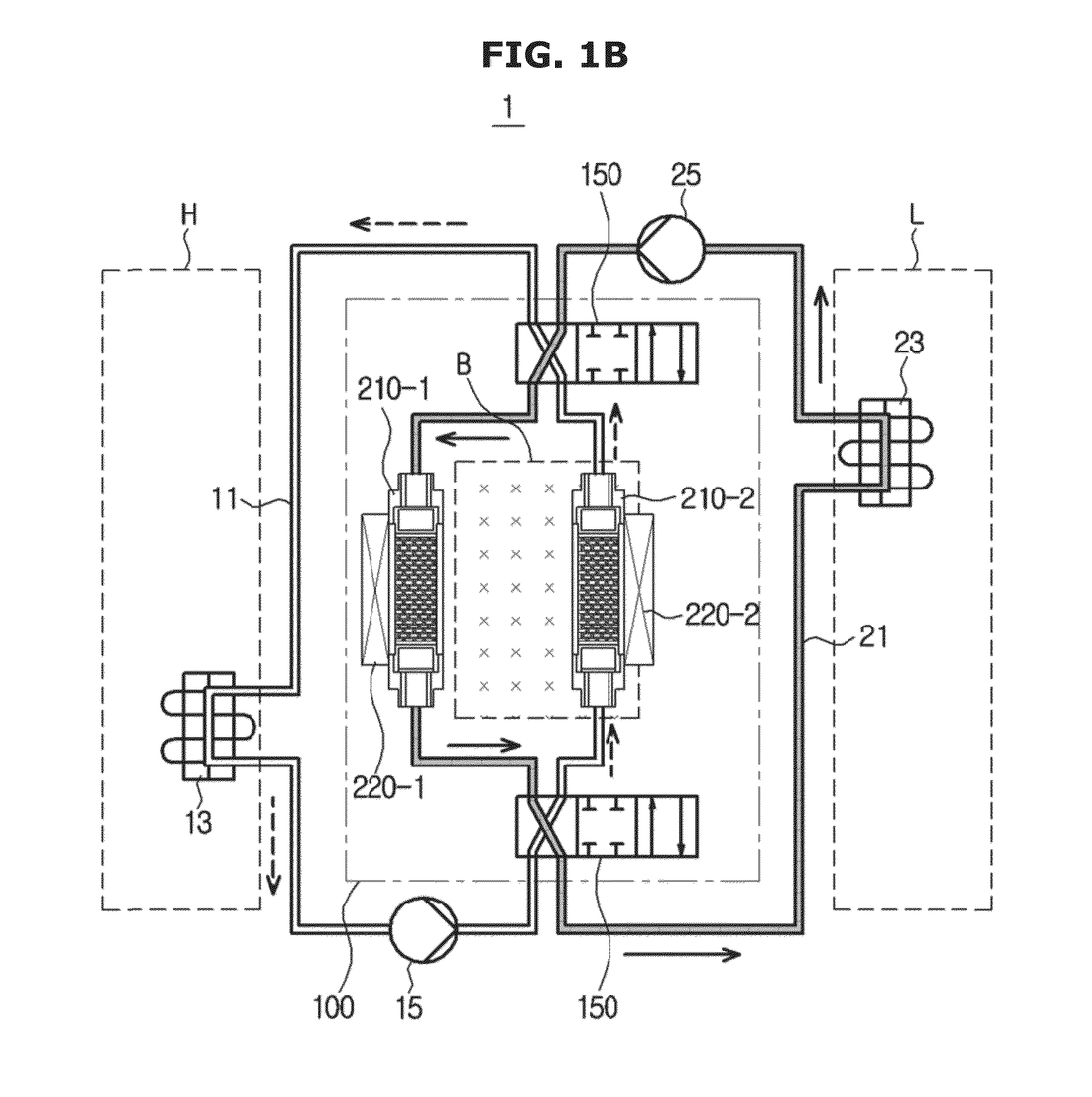

Magnetic cooling apparatus

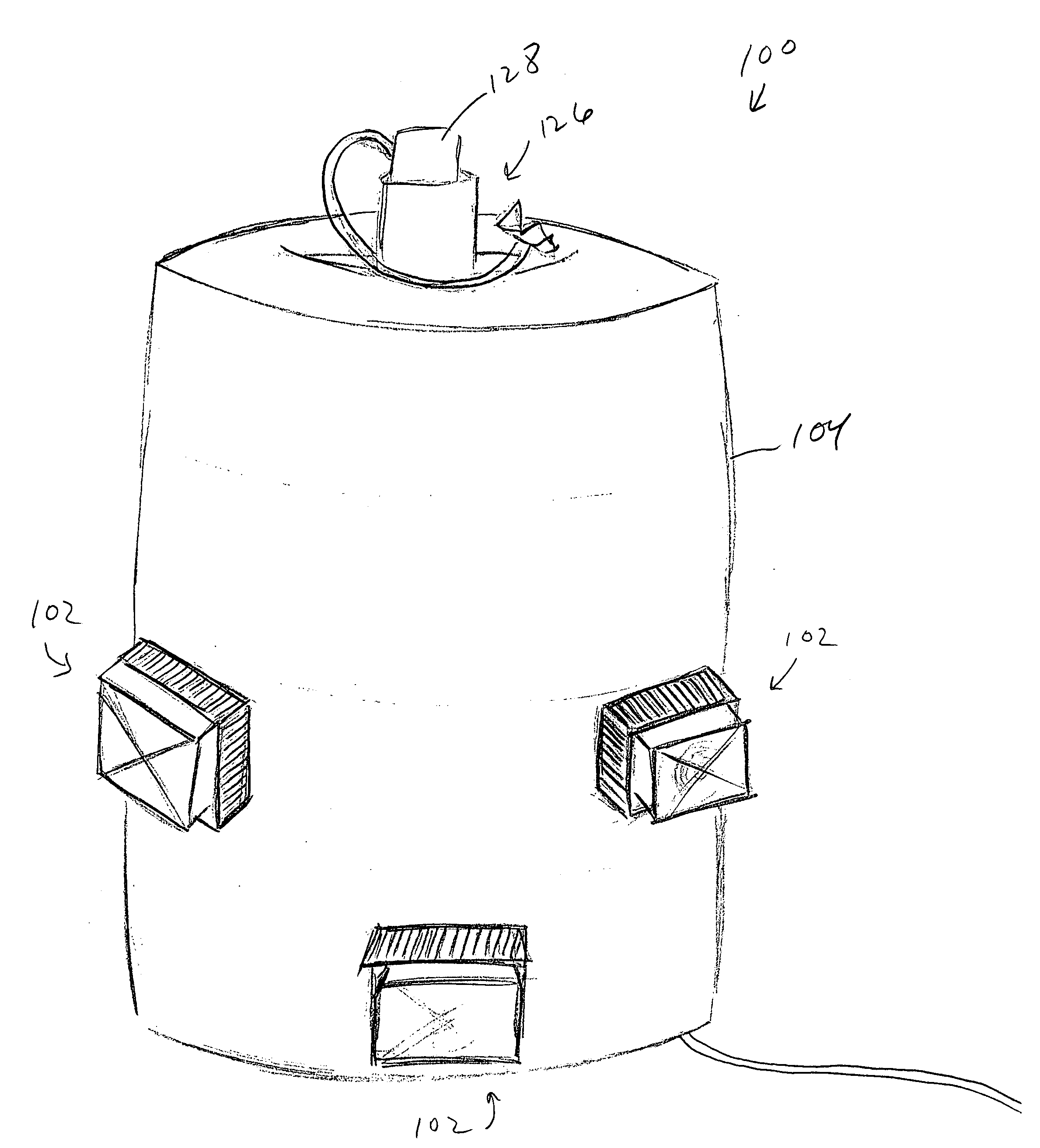

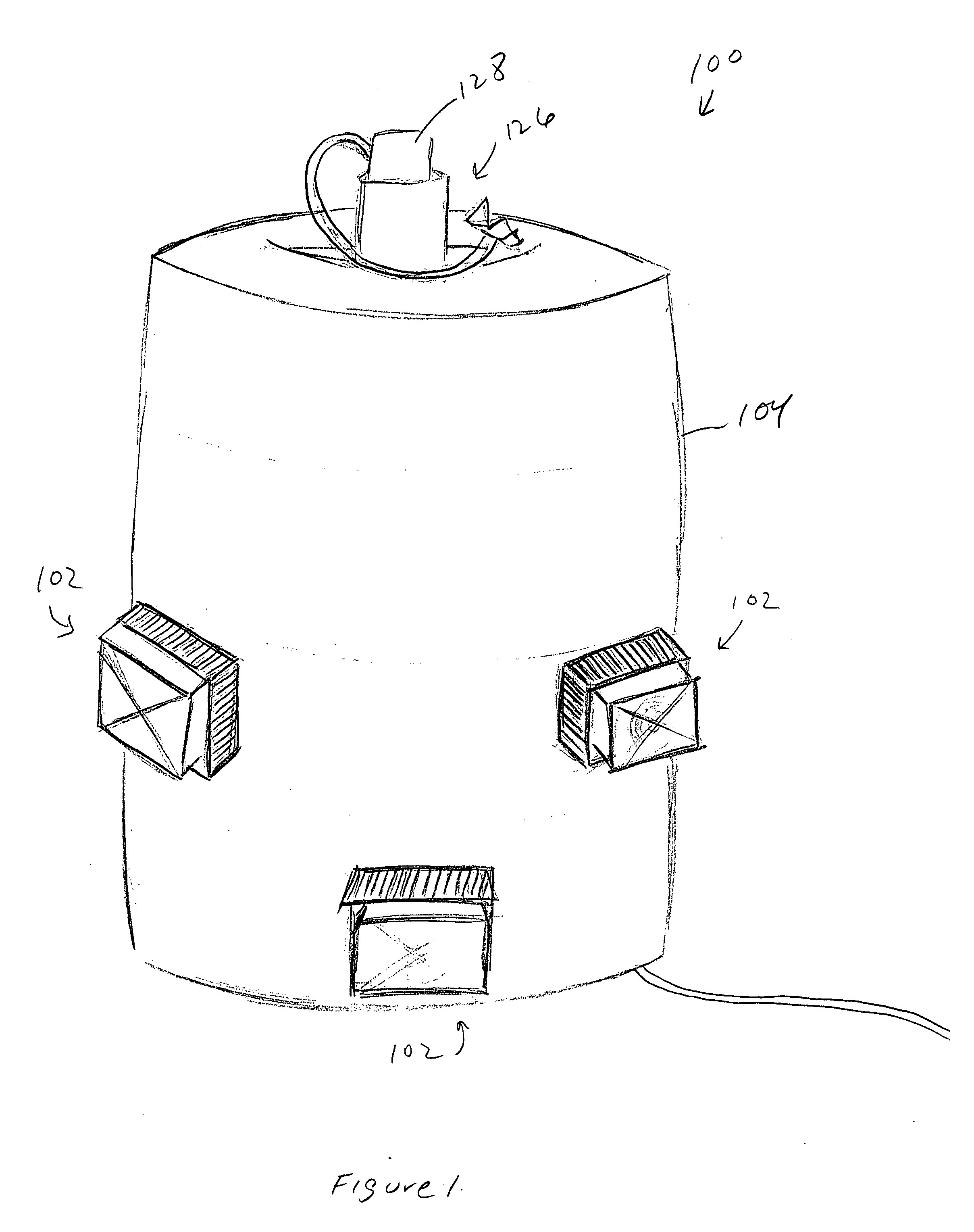

ActiveUS20150007582A1Reduce heat lossHeat loss is generatedMachines using electric/magnetic effectsSustainable buildingsReciprocating motionEngineering

A magnetic cooling apparatus including a plurality of magnetic regenerators including a plurality of magnetocaloric materials to emit heat when magnetized and to absorb heat when demagnetized. The magnetic regenerators are rotatably disposed on a circumference having a predetermined radius, at least one coil is disposed on the circumference and coupled to the magnetic regenerators, and a plurality of permanent magnets is provided inside and outside the circumference to generate a magnetic field to magnetize or demagnetize the magnetic regenerators. The at least one coil interacts with the magnetic field generated by the permanent magnets to rotate the magnetic regenerators. The coil interacting with the magnetic field to magnetize or demagnetize the magnetic regenerators is coupled to the magnetic regenerators such that the magnetic regenerators reciprocate or rotate, thereby minimizing a size of the magnetic cooling apparatus, relative to the use of a motor. In addition, a member to switch a channel of a heat transfer fluid directly performs heat transfer between the heat transfer fluid and an external fluid, thereby minimizing heat loss.

Owner:SAMSUNG ELECTRONICS CO LTD

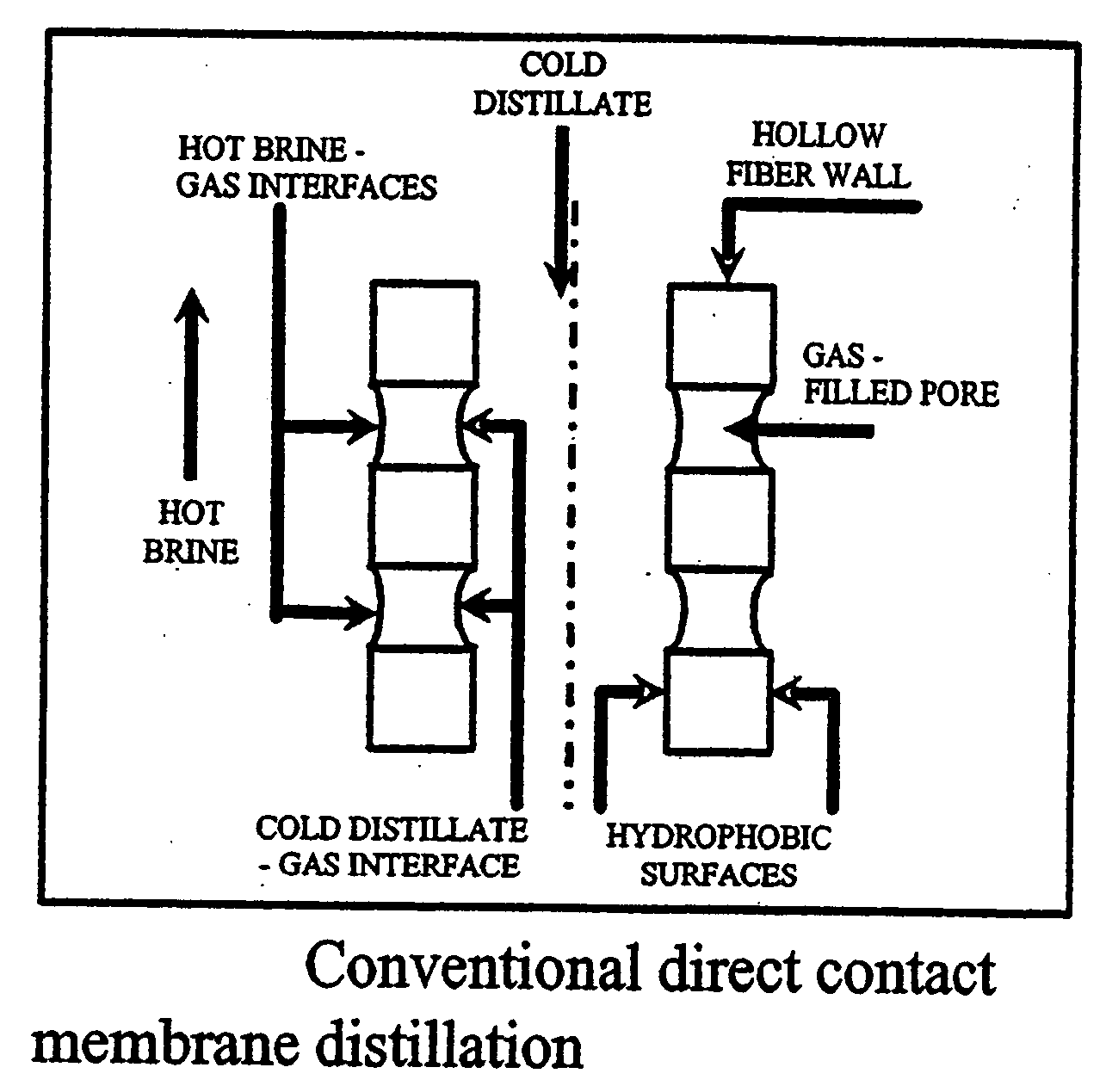

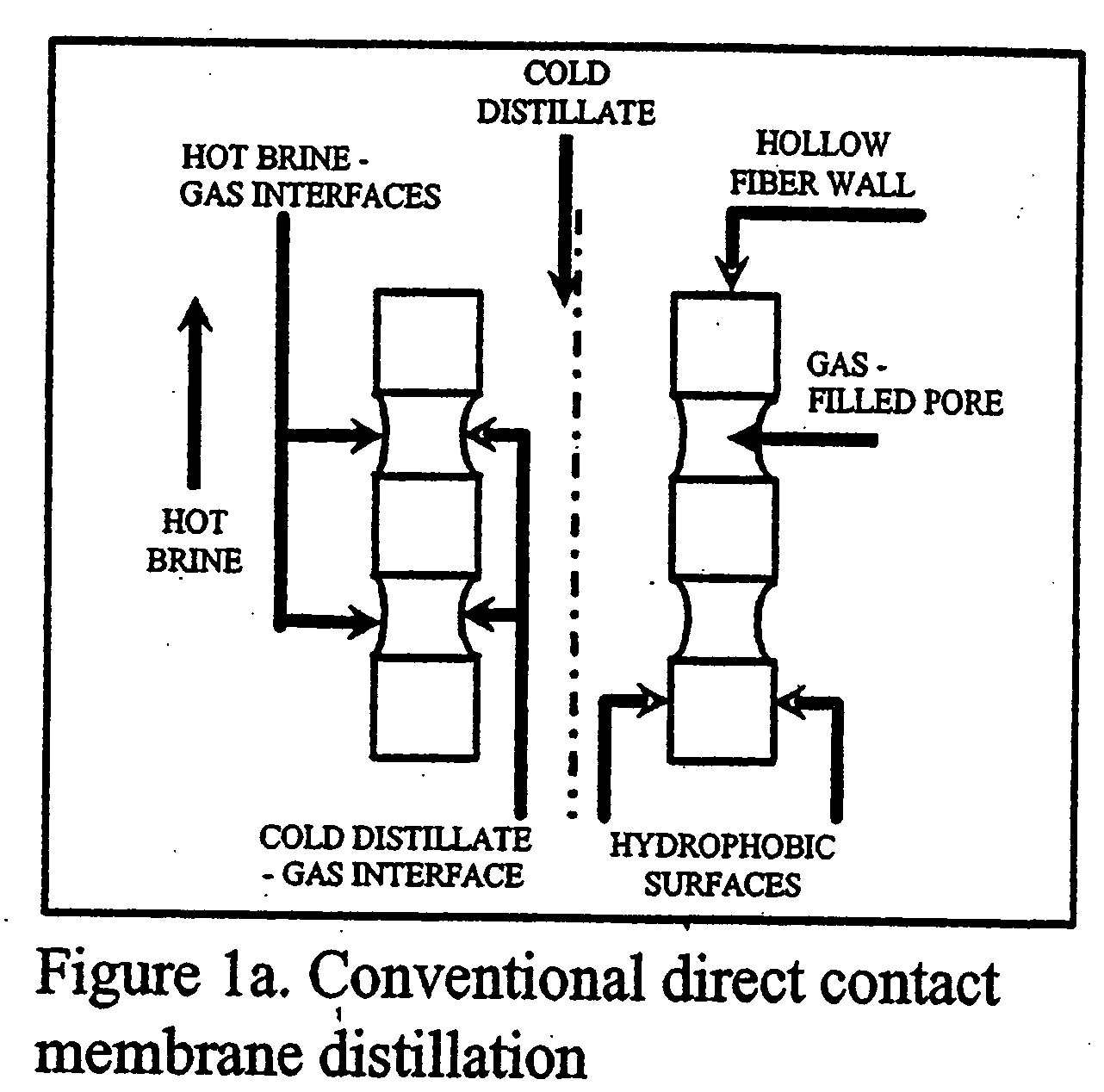

Devices and methods using direct contact membrane distillation and vacuum membrane distillation

ActiveUS20060076294A1Eliminate pore wettingReduce lossesGeneral water supply conservationSolid sorbent liquid separationFiberHollow fibre membrane

DCMD and VMD systems and methods for use in desalination applications are provided. The DCMD and VMD systems employ coated porous hydrophobic hollow fiber membranes. The coatings advantageously function to essentially eliminate pore wetting of the membrane, while permitting substantially unimpeded water vapor permeance through the fiber walls. The DCMD and VMD membranes are characterized by larger fiber bore diameters and wall thicknesses. The membranes substantially reduce the loss of brine sensible heat, e.g., heat loss via conductive heat flux through the membrane wall and the vapor space and, in exemplary embodiments, the brine-side heat transfer coefficient is dramatically enhanced by horizontal / vertical cross flow of brine over the outside surface of the coated fibers. Superior water vapor fluxes are achieved with the systems and methods.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

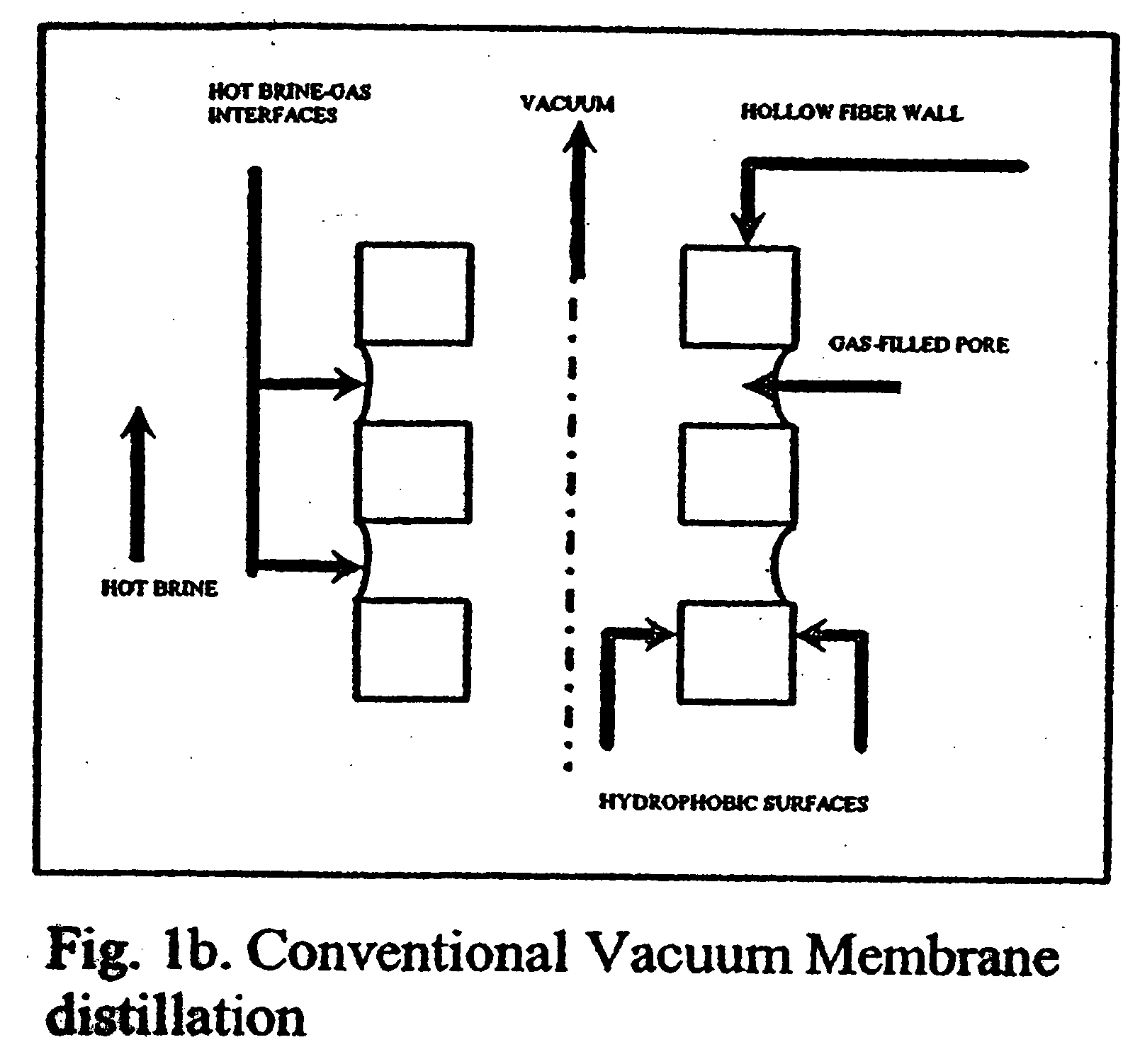

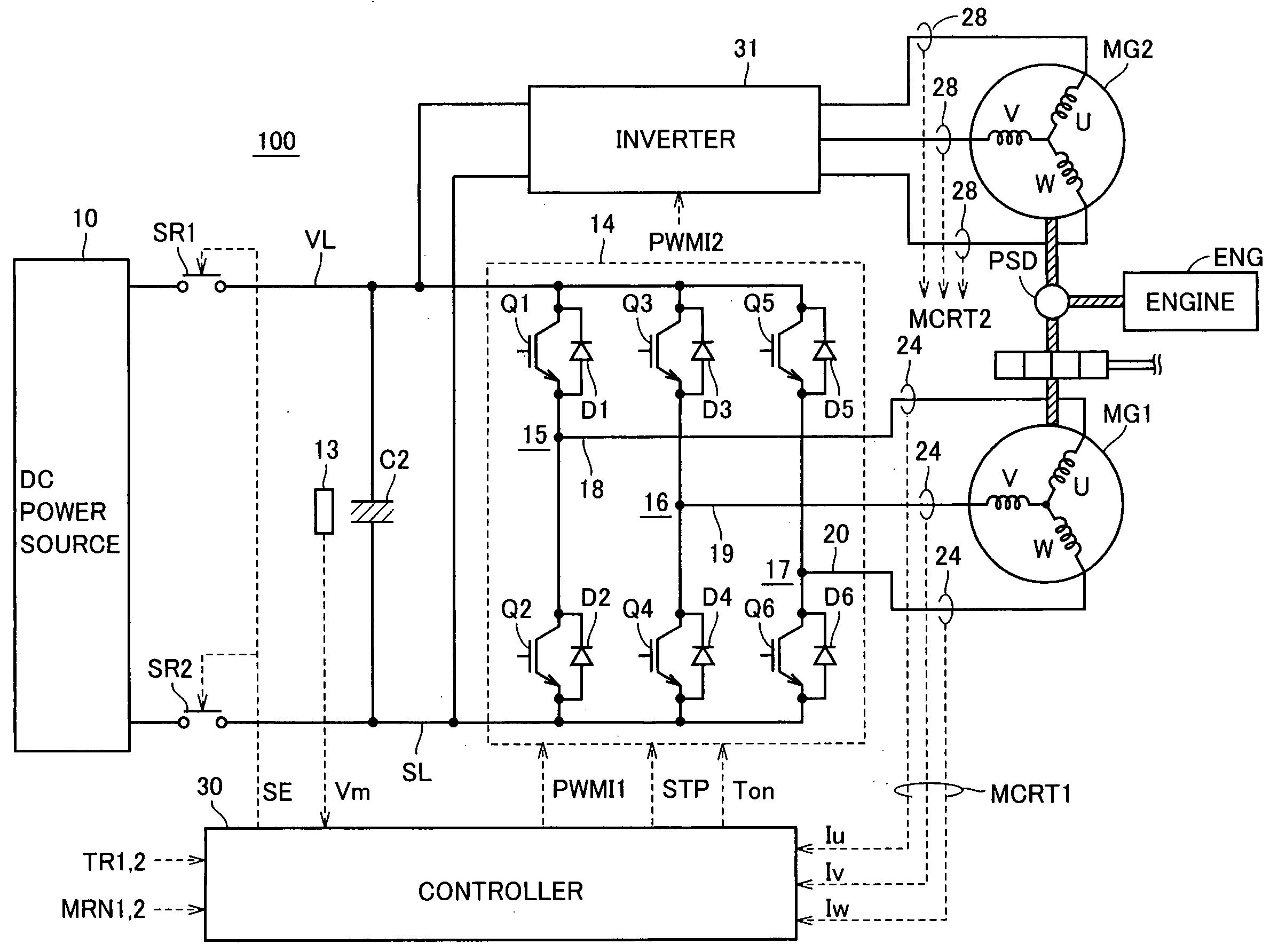

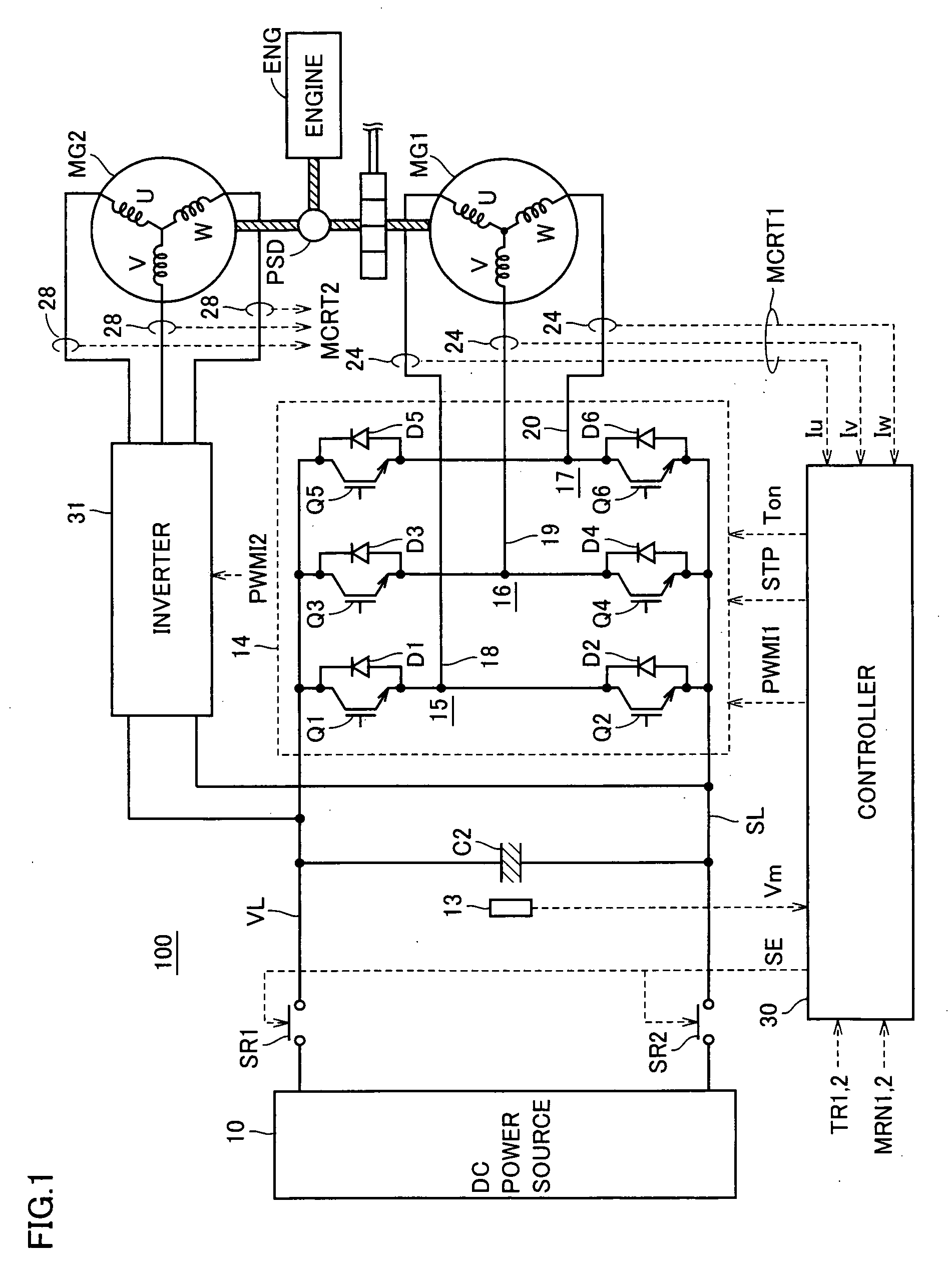

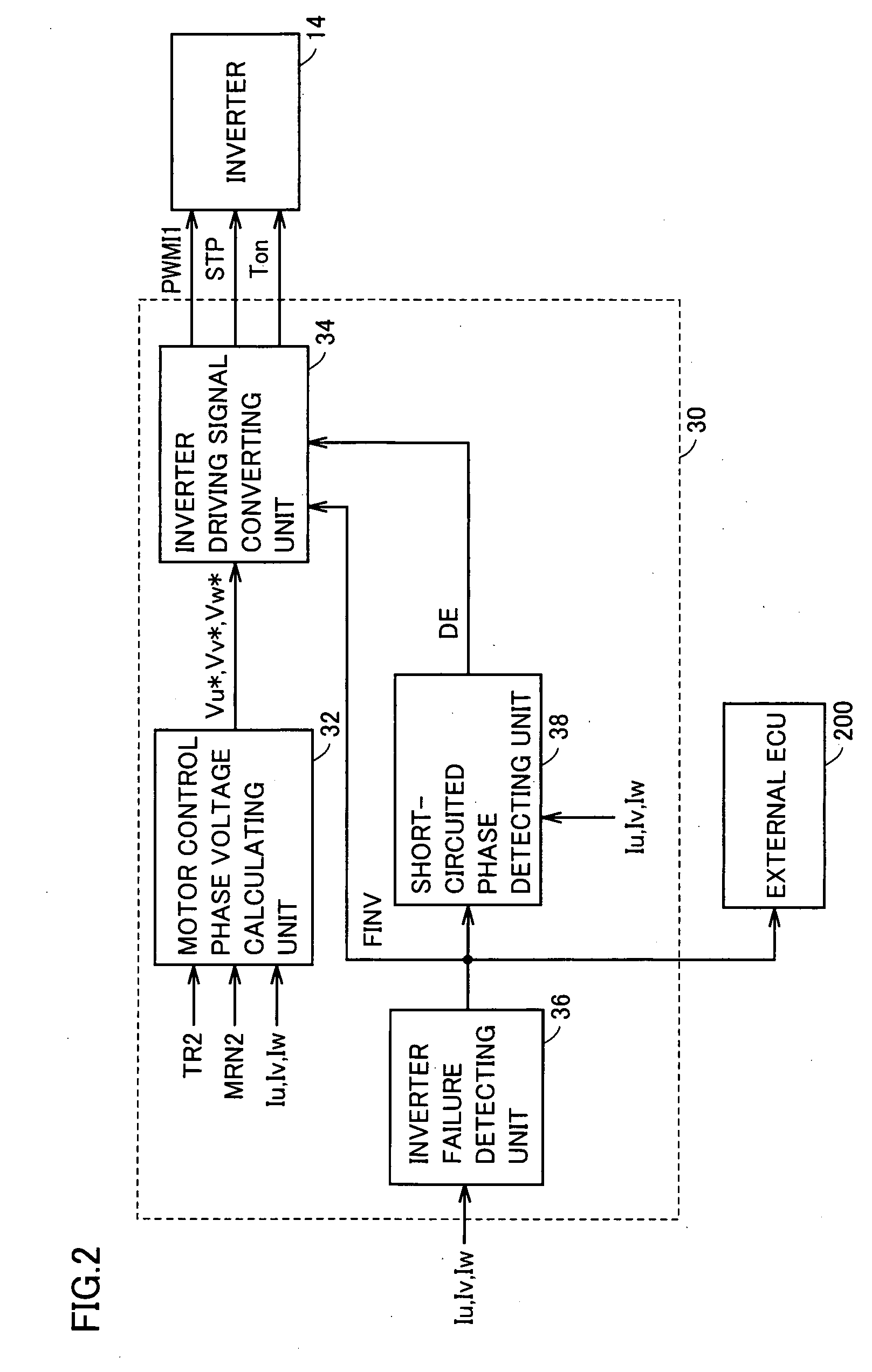

Motor drive device

InactiveUS20090195199A1More currentHybrid vehiclesElectronic commutation motor controlMotor driveCurrent sensor

A controller (30) determines a failure of an inverter (14) in response to detection of an excessive current in any one of IGBT elements of the inverter (14) during driving of a motor generator (MG1). The controller (30) sets the inverter (14) to a suspended state in response to the determination of the failure, and identifies a short-circuited phase based on a motor current (MCRT1) from a current sensor (24). The controller (30) simultaneously turns on two IGBT elements forming upper and lower arms of the short-circuited phase in a discharge process of a capacitor (C2) performed during stop control of a vehicle. Thus, the two IGBT elements are short-circuited because of a rapid increase in heat loss caused by an excessive short-circuit current. As a result, an excessive current at the inverter and power supply lines caused by a back electromotive force generated at the motor generator (MG1) when the vehicle is towed is suppressed.

Owner:TOYOTA JIDOSHA KK

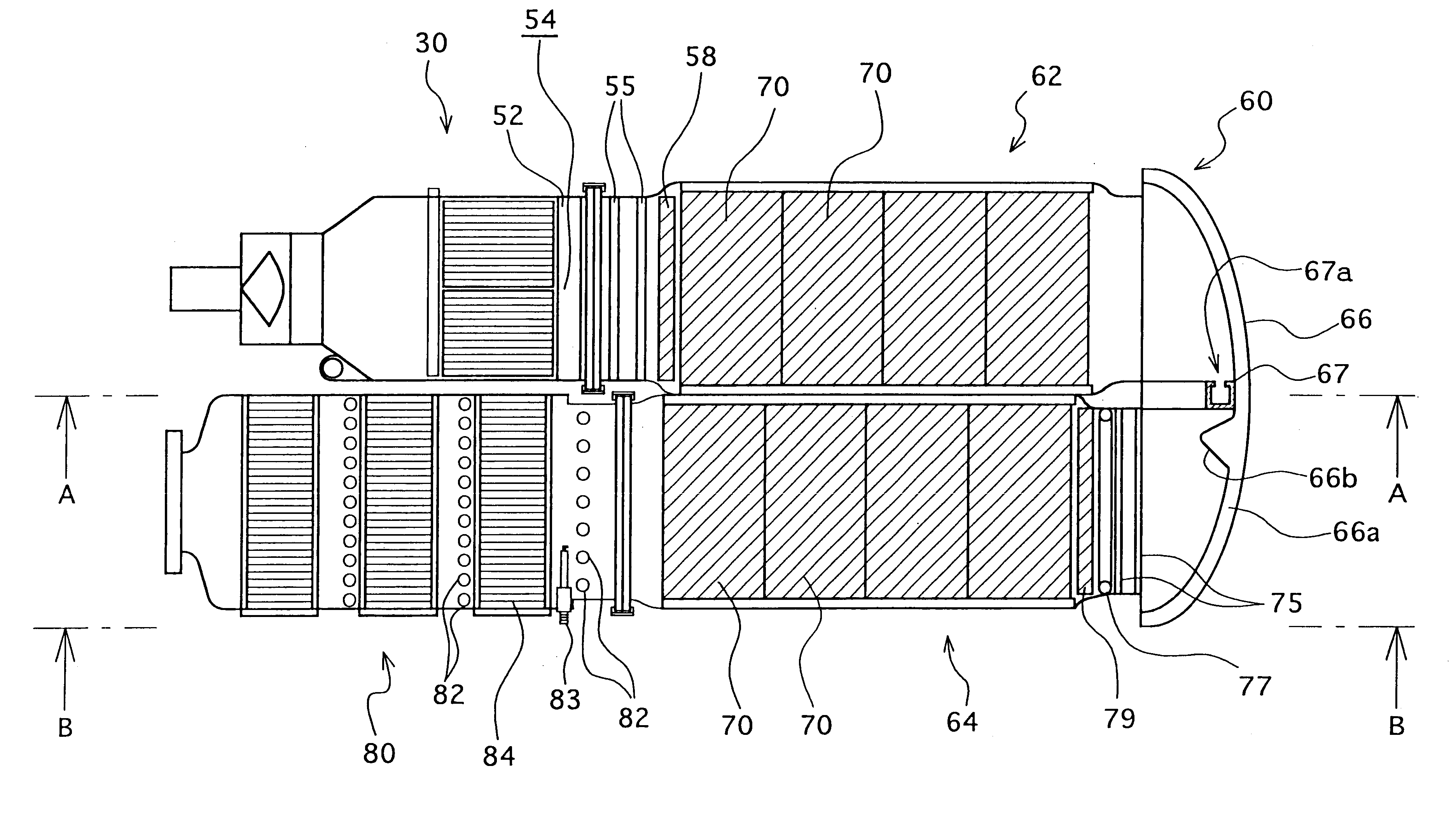

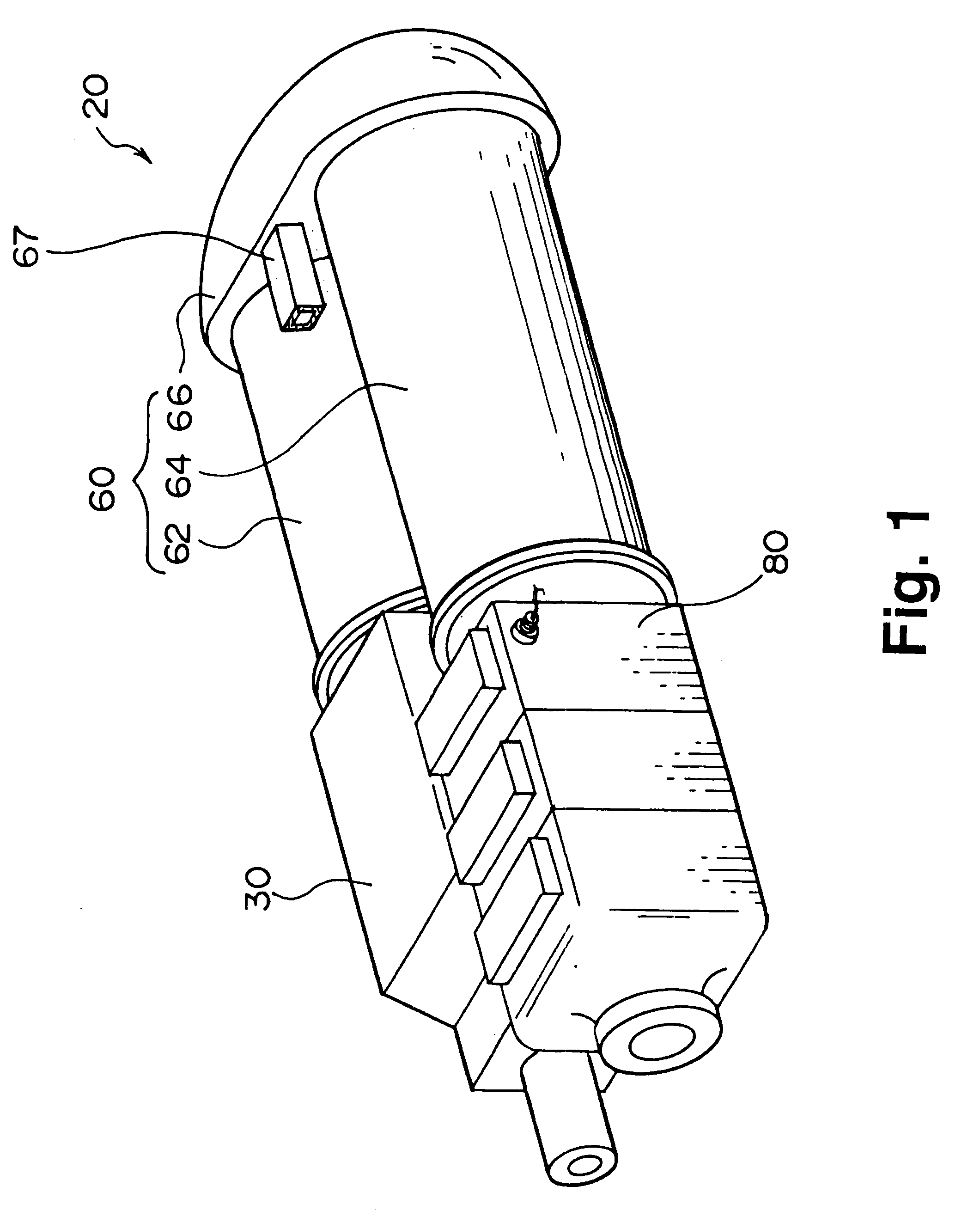

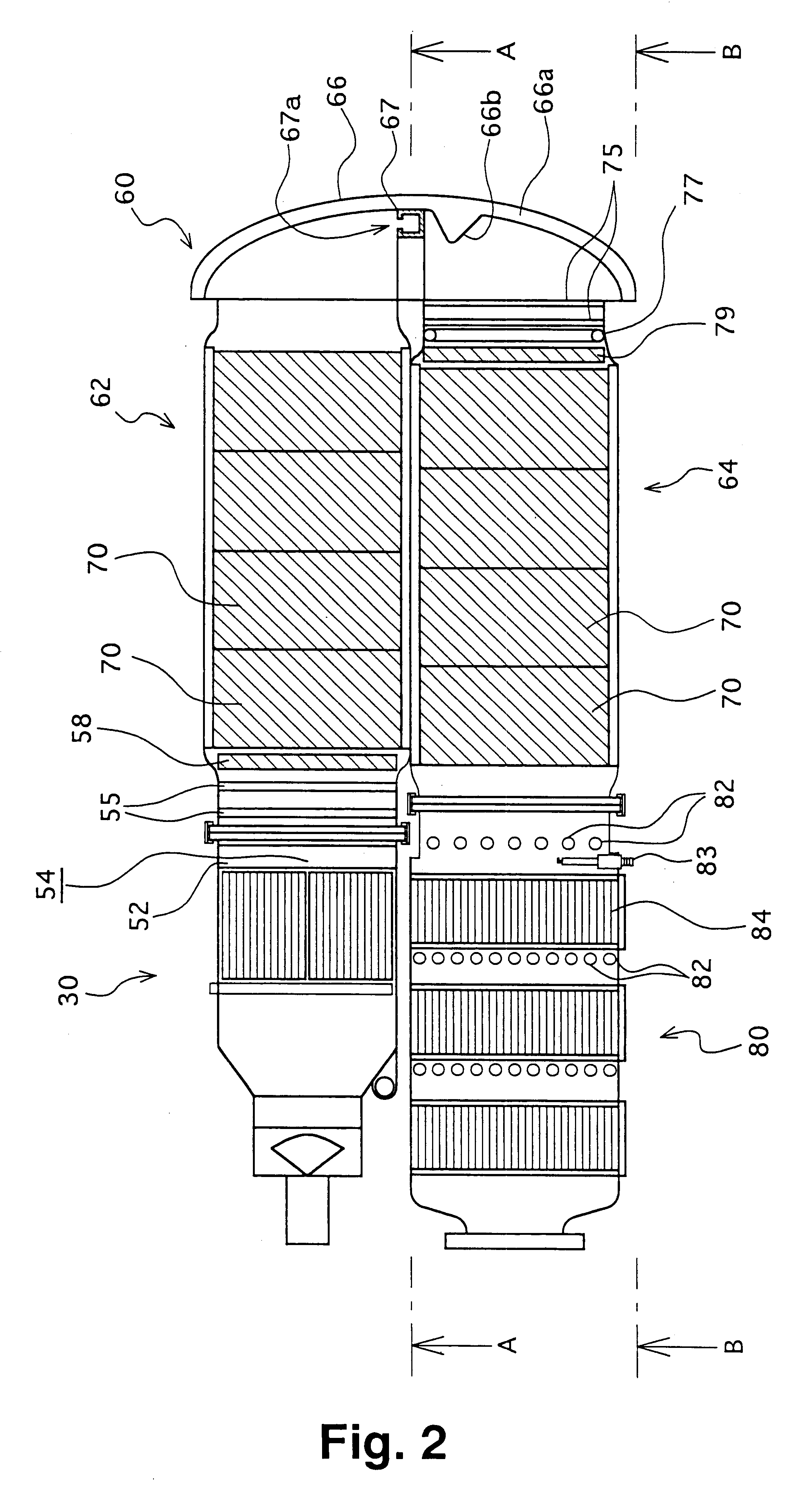

Fuel reformer for mounting on a vehicle

InactiveUS6390030B1Keep for a long timeImprove fuel performanceHydrogen separation using solid contactChemical industryContact timeVaporization

A fuel reformer suited for mounting on a vehicle is provided. A raw material gas containing methanol and water is vaporized at a vaporization section 30. The vaporized gas flows horizontally to a reforming section 60 with monolithic catalyst 70. The reforming section is divided into two sides, a front side 62 and a rear side 64, with an interconnecting pipe 66 bent at 180 degrees, for connecting the front and rear sides. By making the material gas flow horizontally, even when the reformer is mounted to a vehicle which has a larger space in its horizontal direction than in its vertical direction, especially a small passenger car, the contact time period between gas and catalyst can be extended. By bending the reforming section by 180 degrees, the size of the reformer can be reduced so that the reformer is suited for mounting on a vehicle having limited space. Because the vaporization section 30 and the CO reducing section 80 can be placed adjacent to each other, by using heat generated at the CO reducing section, the heat loss during pre-heating of the methanol and water can be reduced.

Owner:TOYOTA JIDOSHA KK

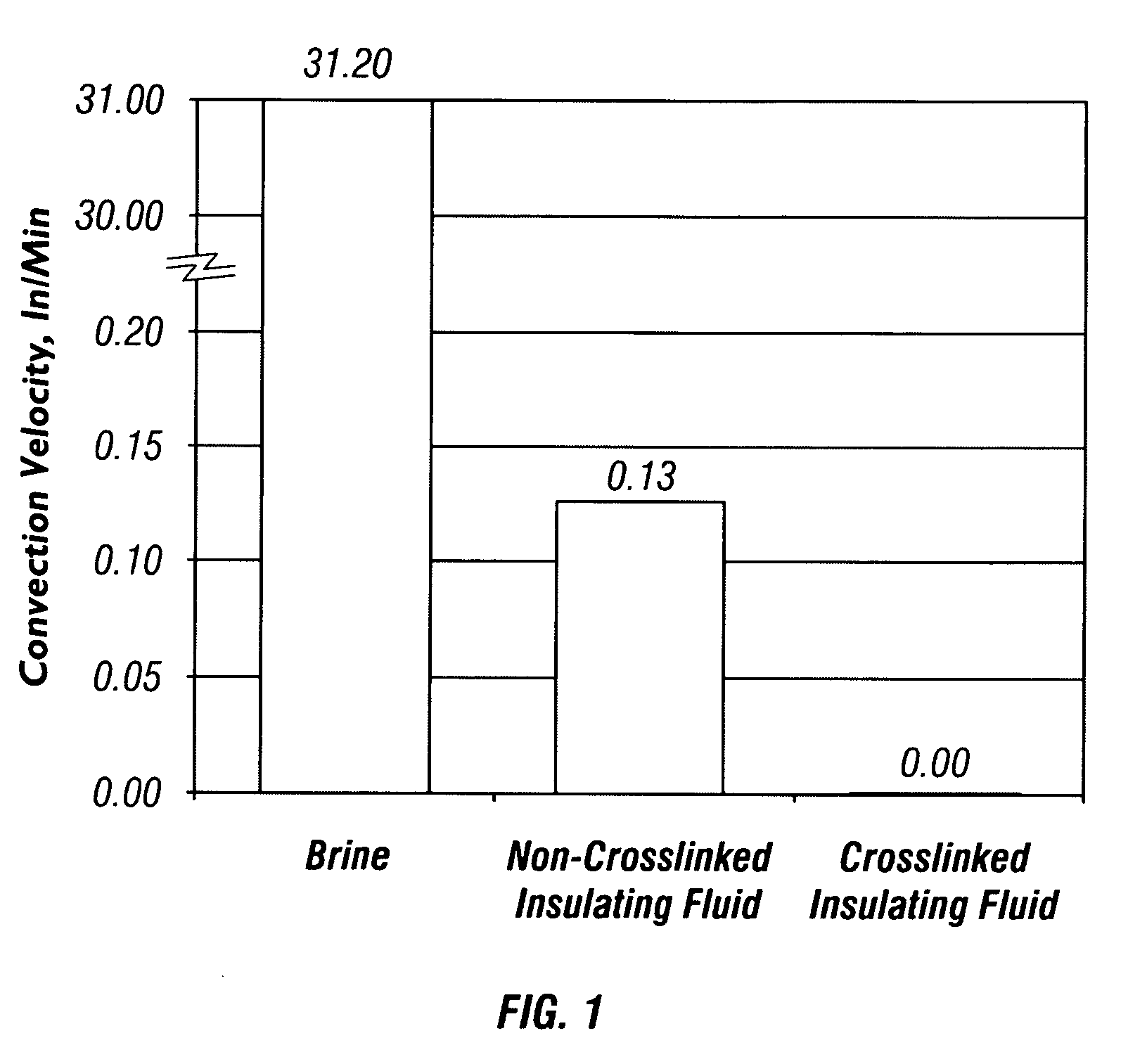

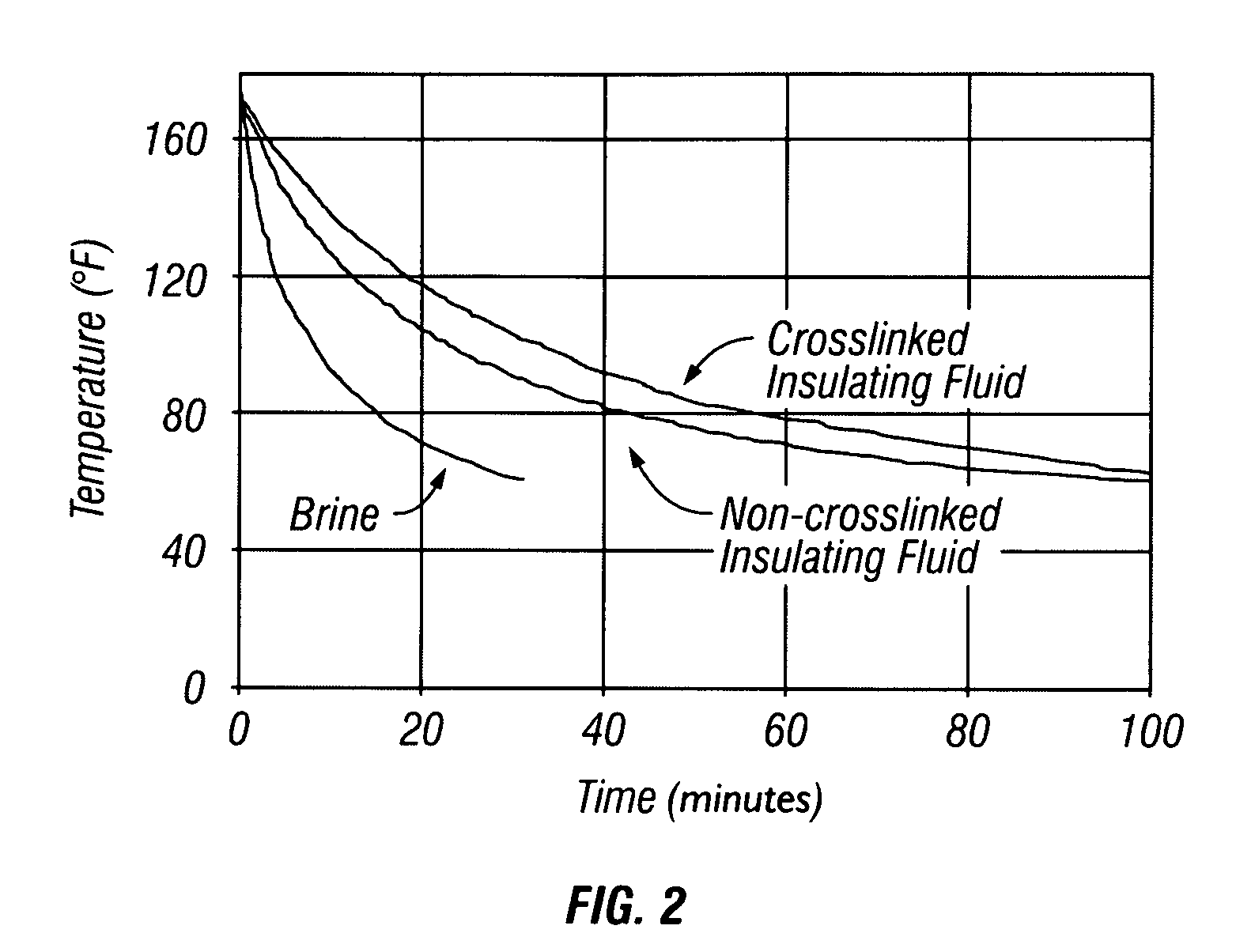

Methods of using crosslinkable compositions

InactiveUS7306039B2Improve the level ofFacilitate cross-linkingCosmetic preparationsDrilling rodsHeat lossesProduction tubing

A thermal insulating packer fluid contains water and / or brine, a crosslinkable viscosifying polymer, a crosslinking agent and an optional set retarder. The composition is capable of inhibiting unwanted heat loss from production tubing or uncontrolled heat transfer to outer annuli. The viscosity of the composition is such as to reduce the convection flow velocity within the annulus.

Owner:BAKER HUGHES INC

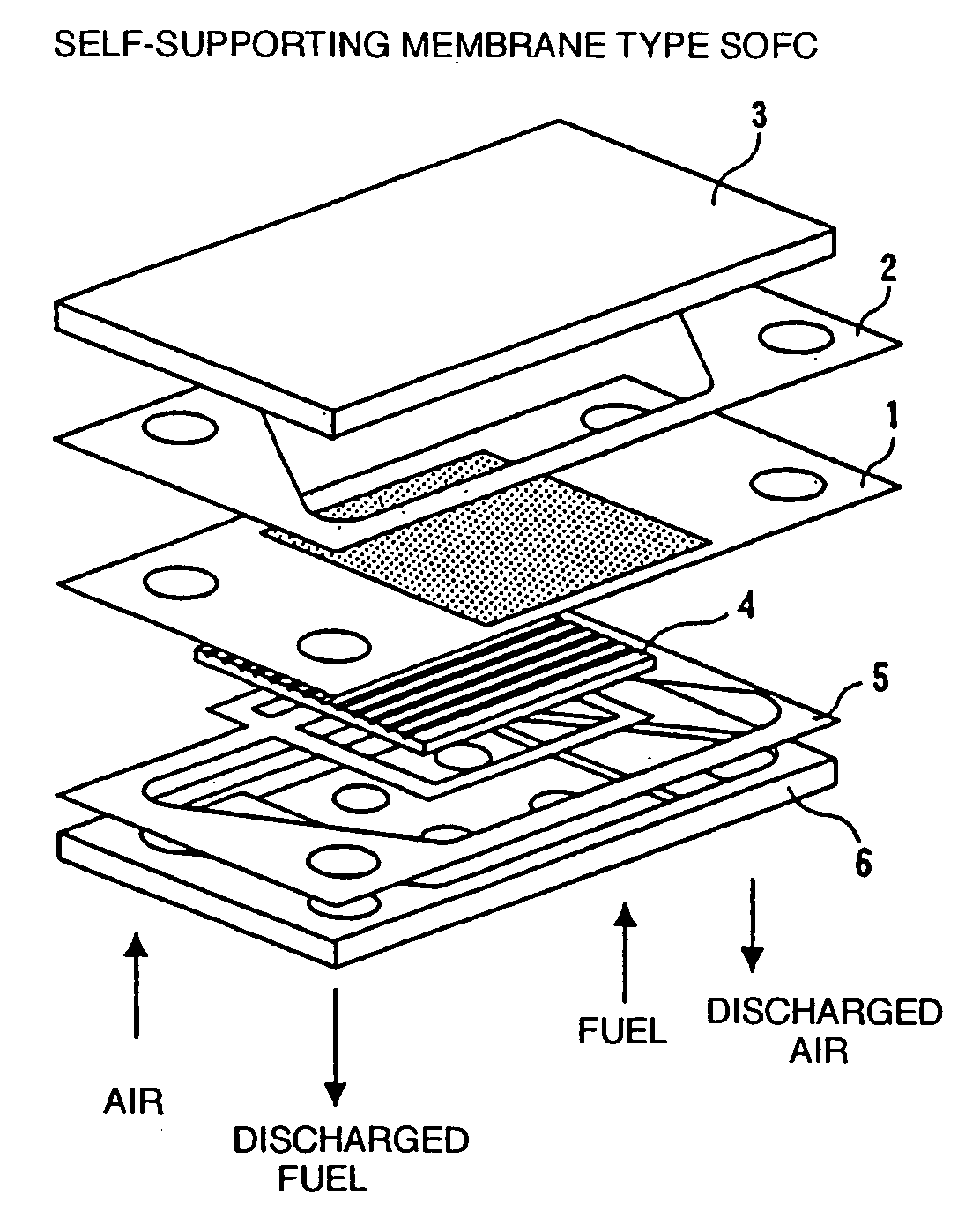

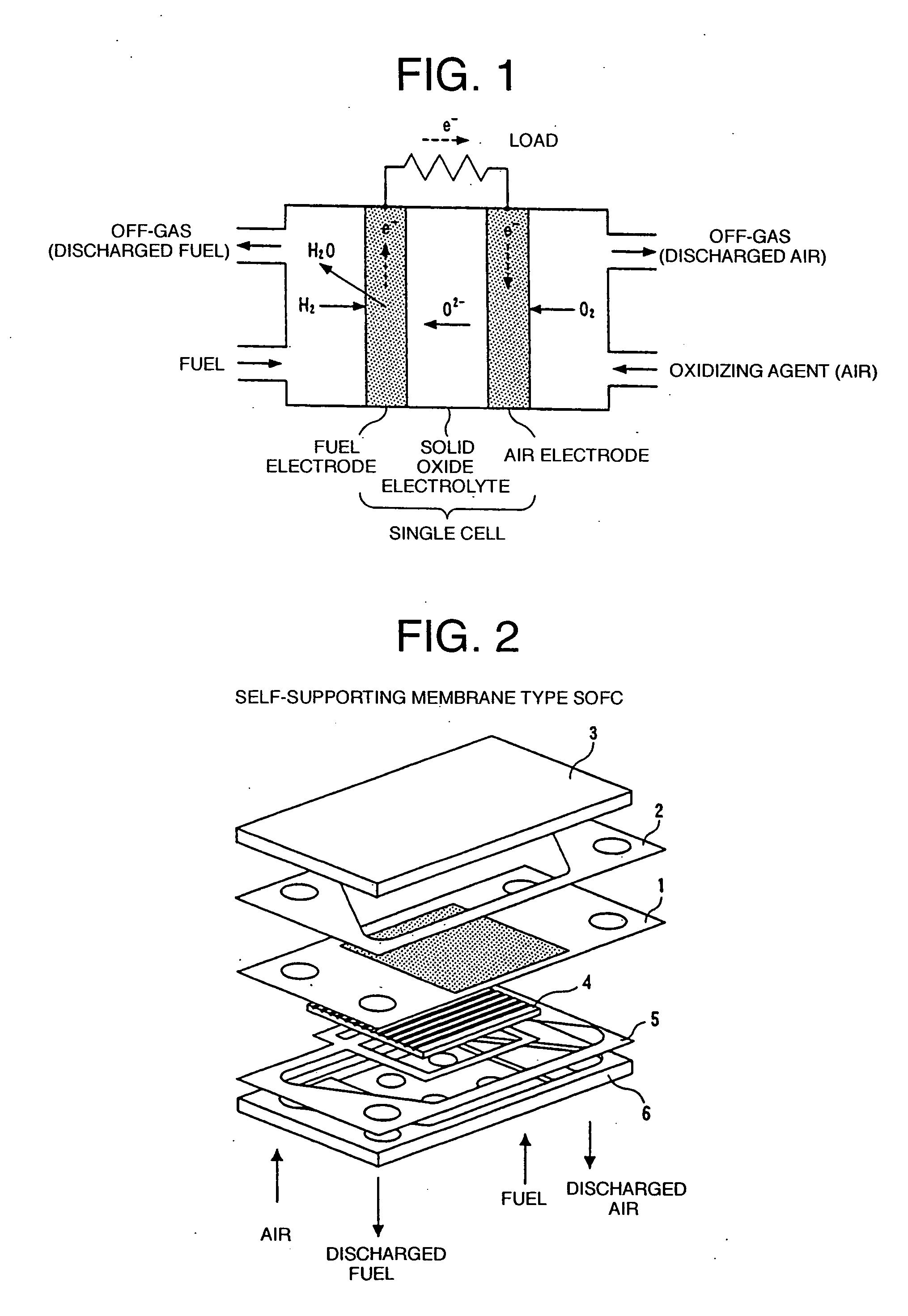

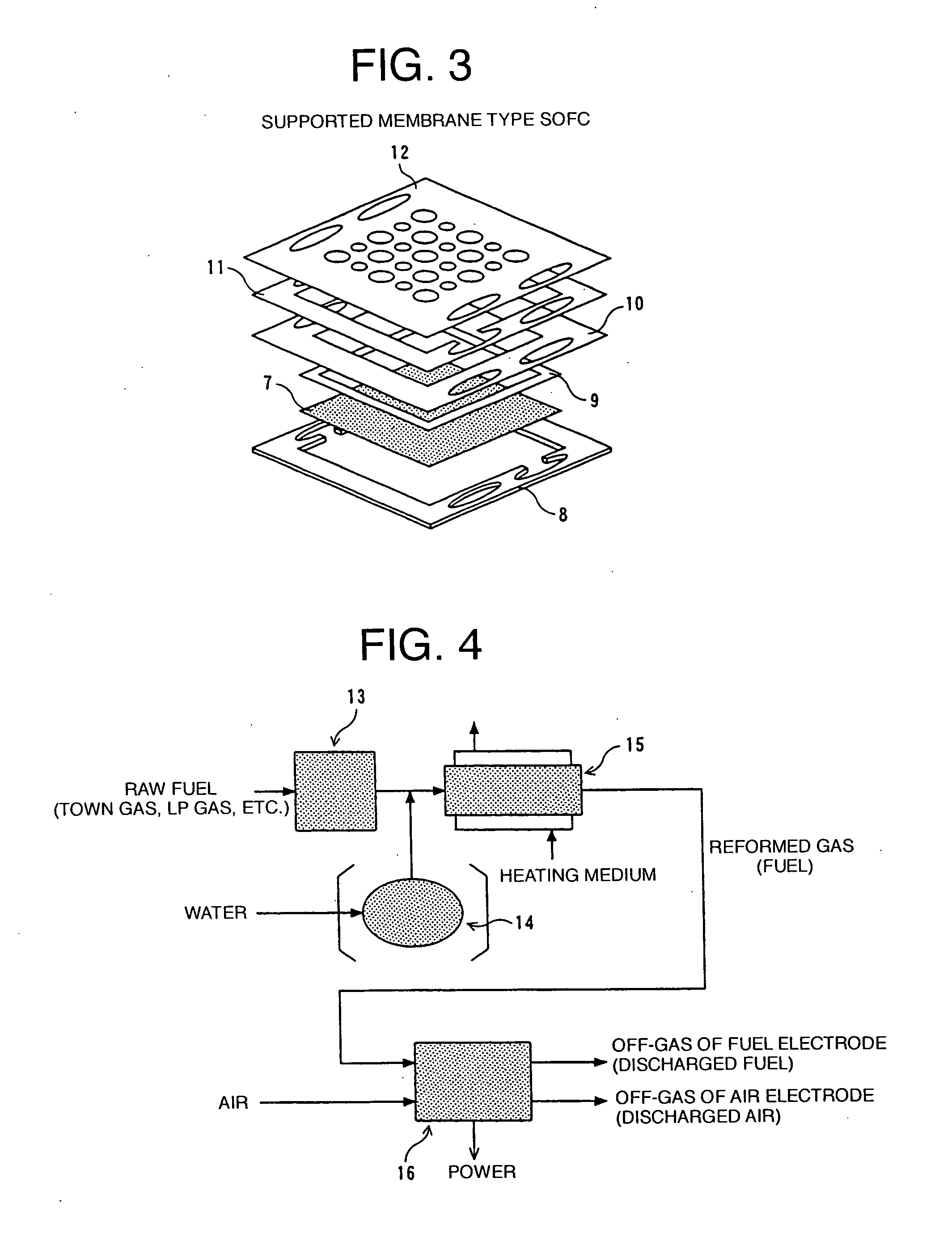

Solid oxide fuel cell system

There are provided a solid oxide fuel cell system comprising (a) a solid oxide fuel cell stack, (b) a preliminary reformer for removing hydrocarbons having two or more carbon atoms from a hydrocarbon fuel by converting the hydrocarbons having two or more carbon atoms into methane, hydrogen, and carbon monoxide, and (c) an integrated heat exchanger for catalytic combustion for heating either air or fuel, or both the air and fuel, to be guided to the solid oxide fuel cell stack, by use of a combustion gas formed by combusting discharged fuel with the use of discharged air, wherein component equipment described above are disposed in an adiabatic vessel and the integrated heat exchanger for catalytic combustion for use in the solid oxide fuel cell system. With the invention, an advantage of the preliminary reformer in combination with that of the integrated heat exchanger for catalytic combustion can be obtained, and heat loss of the SOFC system is eliminated or reduced as much as possible. In addition, with the integrated heat exchanger for catalytic combustion according to the invention, since air and / or fuel, to be fed to the SOFC stack, can be heated by controlling the maximum temperature achieved thereof, it is quite useful as an heat exchanger for an SOFC with operation temperature on the order of 850° C. or lower, particularly, for a supported membrane type SOFC, and further, the same is quite useful in making up an SOFC system because an inexpensive material can be used as a constituent material of a component equipment of the system, the system in whole can be reduced in size, and so forth.

Owner:TOKYO GAS CO LTD

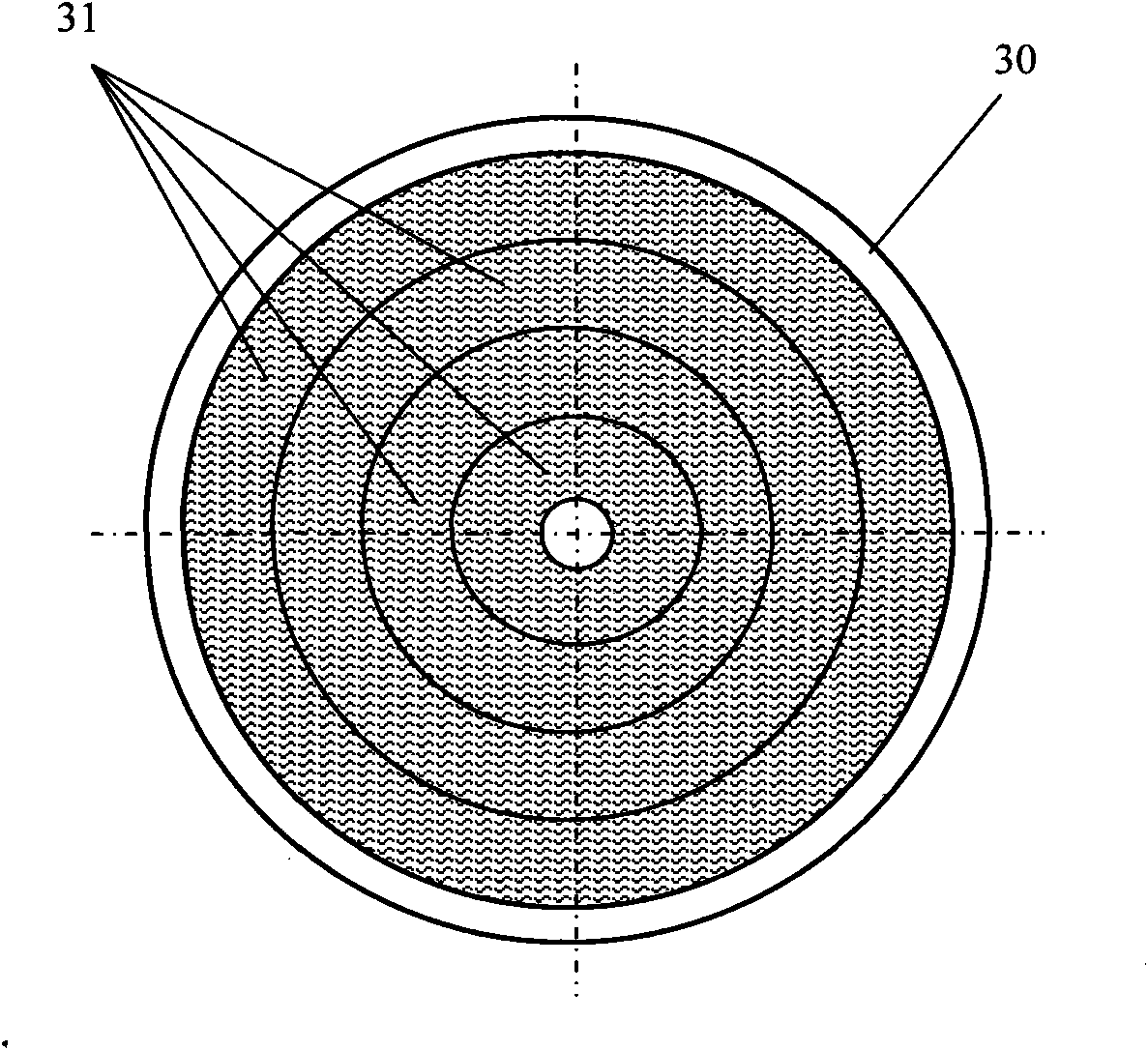

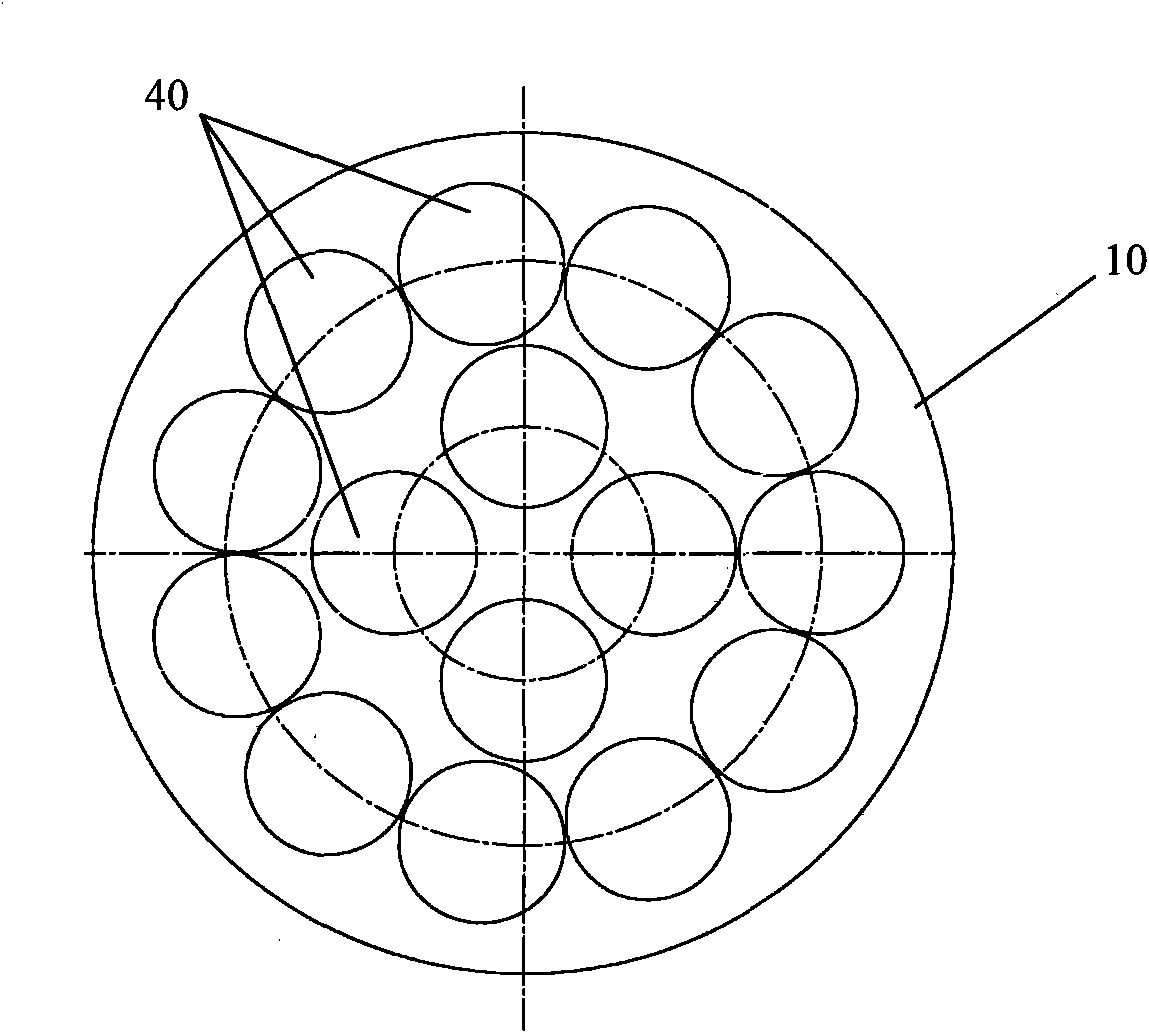

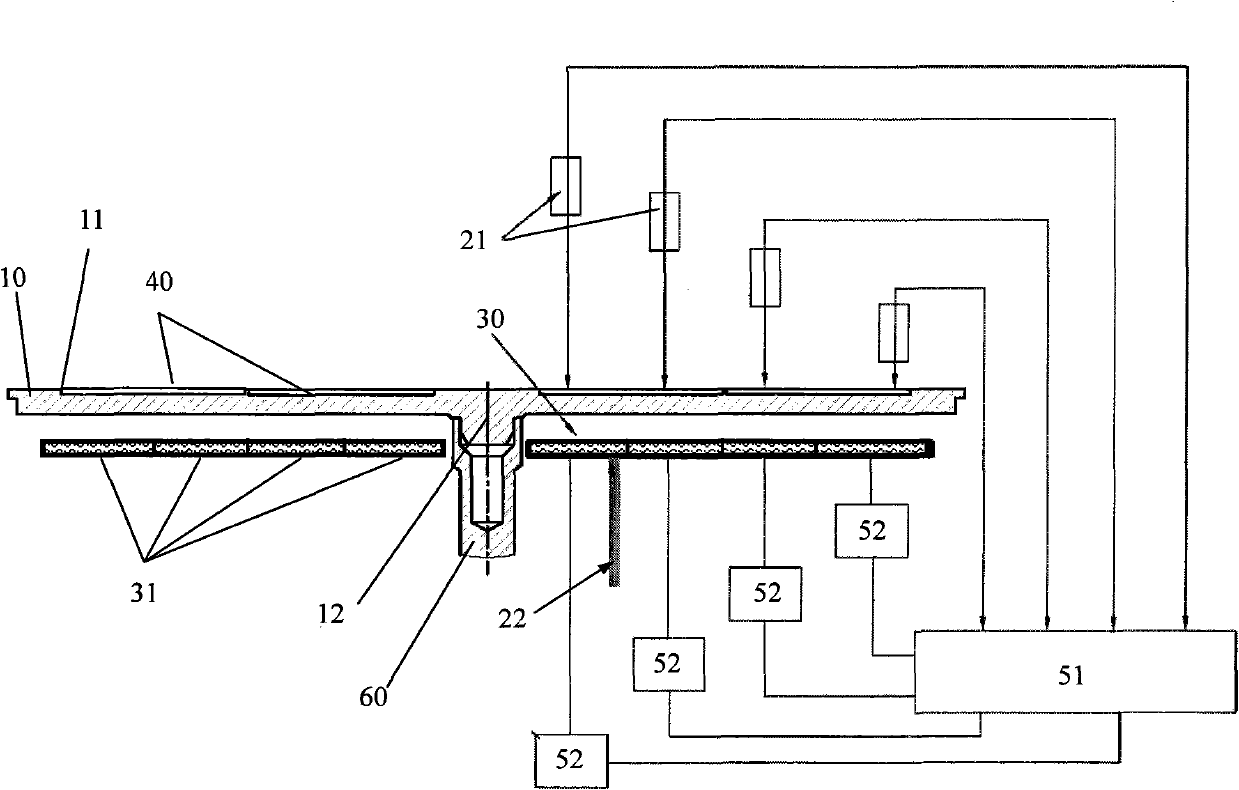

Device and method for controlling temperature and uniformity of epitaxial wafers in MOCVD system

ActiveCN101906622AGuaranteed accuracyAccurate measurementChemical vapor deposition coatingTemperature controlHeat losses

The invention discloses a device for controlling temperature and uniformity of epitaxial wafers in an MOCVD (metal organometallic chemistry vapor deposition) system. A group of non-contact optical thermometers is arranged above a tray along the radial direction to feed back the temperature of single or a plurality of epitaxial wafers in a plurality of annular areas. A temperature controller independently controls the power output of a plurality of heating elements below the tray by using difference minimization of a statistical average value of the temperatures of the epitaxial wafers and an epitaxial process specified temperature as a target. The plurality of epitaxial wafers in each annular area are correspondingly heated by using one or more lower adjacent heating elements which are arranged annularly and have small radial coverage area so as to effectively balance the radial heat loss of the epitaxial wafers and the tray under the process condition of different temperatures and realize accurate and stable control of the temperature and the uniformly between the single epitaxial wafers and the adjacent epitaxial wafers. The device is also provided with a contact thermocouple thermometer for measuring a heater temperature serving as a reference point of the epitaxial process specified temperature and meanwhile monitoring whether the heater works normally.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

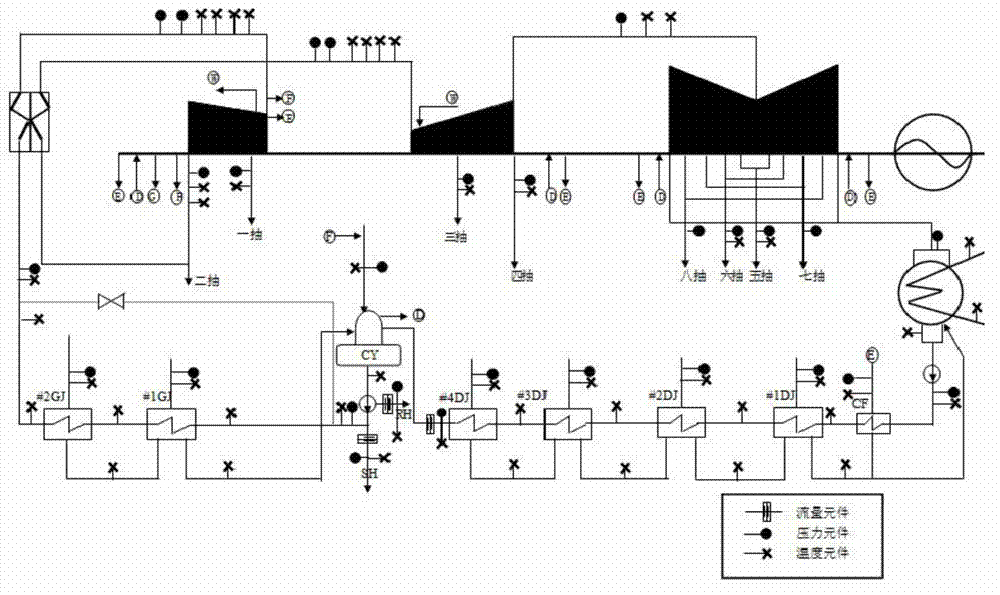

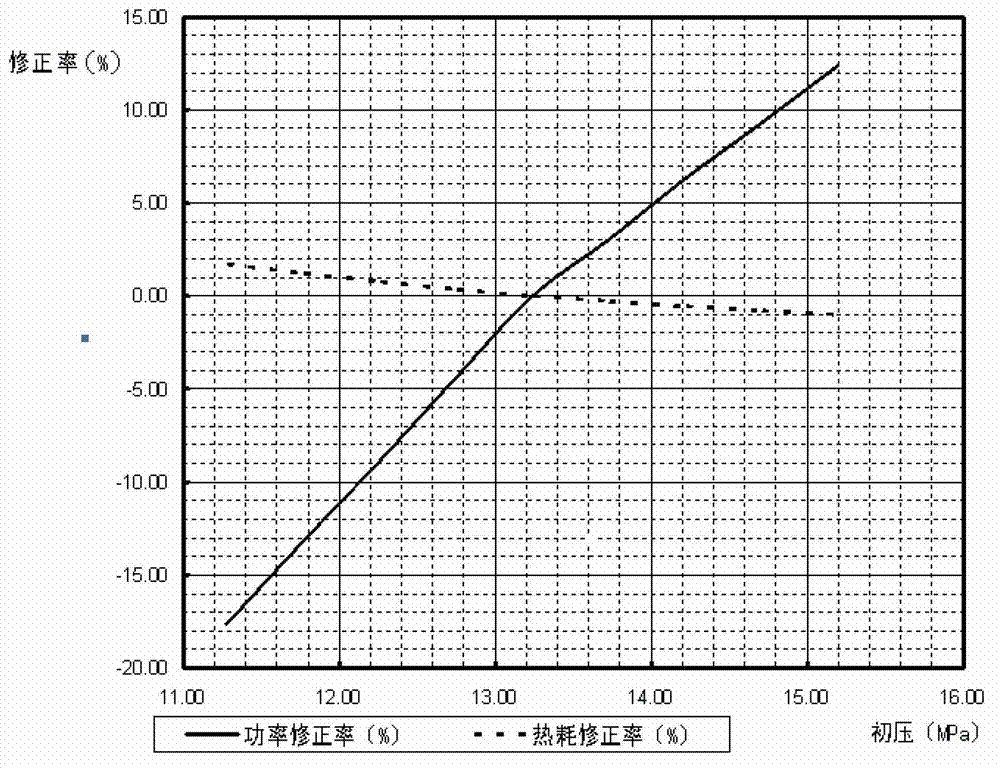

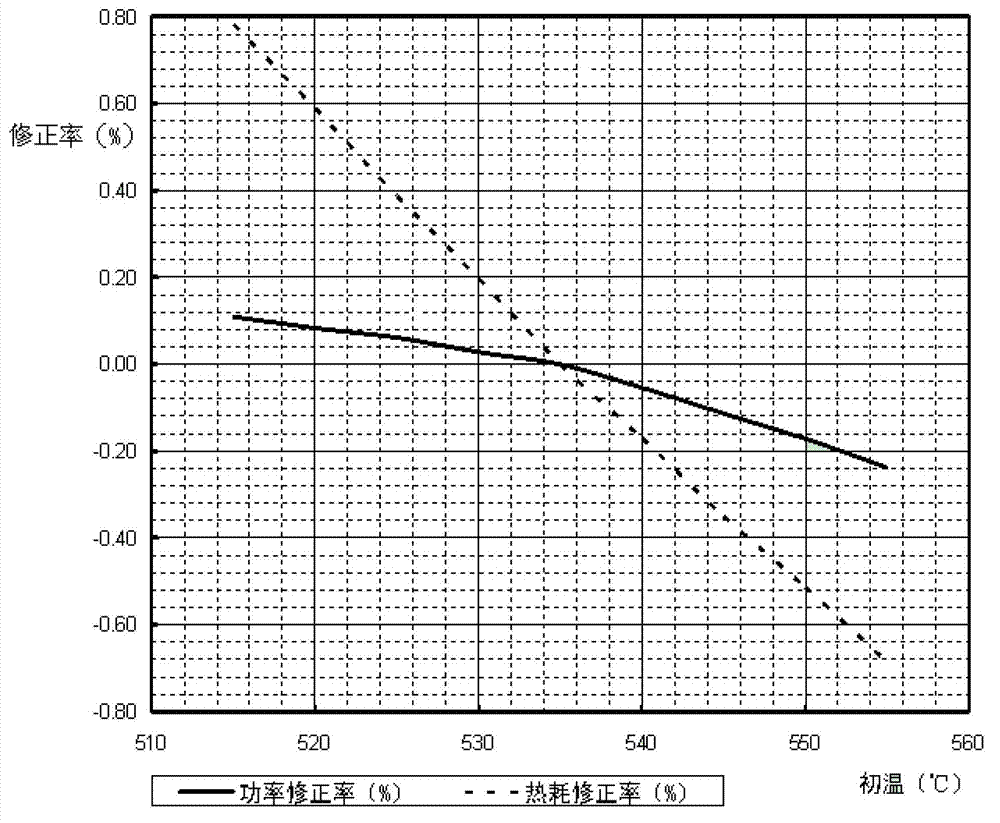

Method for evaluating performances of condensing steam turbine after high back pressure improvement

The invention discloses a method for evaluating performances of a condensing steam turbine after high back pressure improvement. The method comprises the following steps: distributing sufficient pressure, temperature, flow and electric power test points on a thermodynamic system of a turbine unit; stopping heating steam extraction on a low pressure cylinder gap bridge pipe; calculating the main steam flow, the cold reheat steam flow and the reheat steam flow; calculating the low pressure cylinder efficiency of a unit; taking a high back pressure heat supply unit as a pure condensing unit running under a high back pressure working condition, calculating the heat loss efficiency of the unit, and performing the second-type correction on the heat rate; and comparing the heat rate and the lower pressure cylinder efficiency with design values of a manufacture plant, and evaluating the lower pressure cylinder improvement technology and the unit improvement effect. The method disclosed by the invention is easy and feasible.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

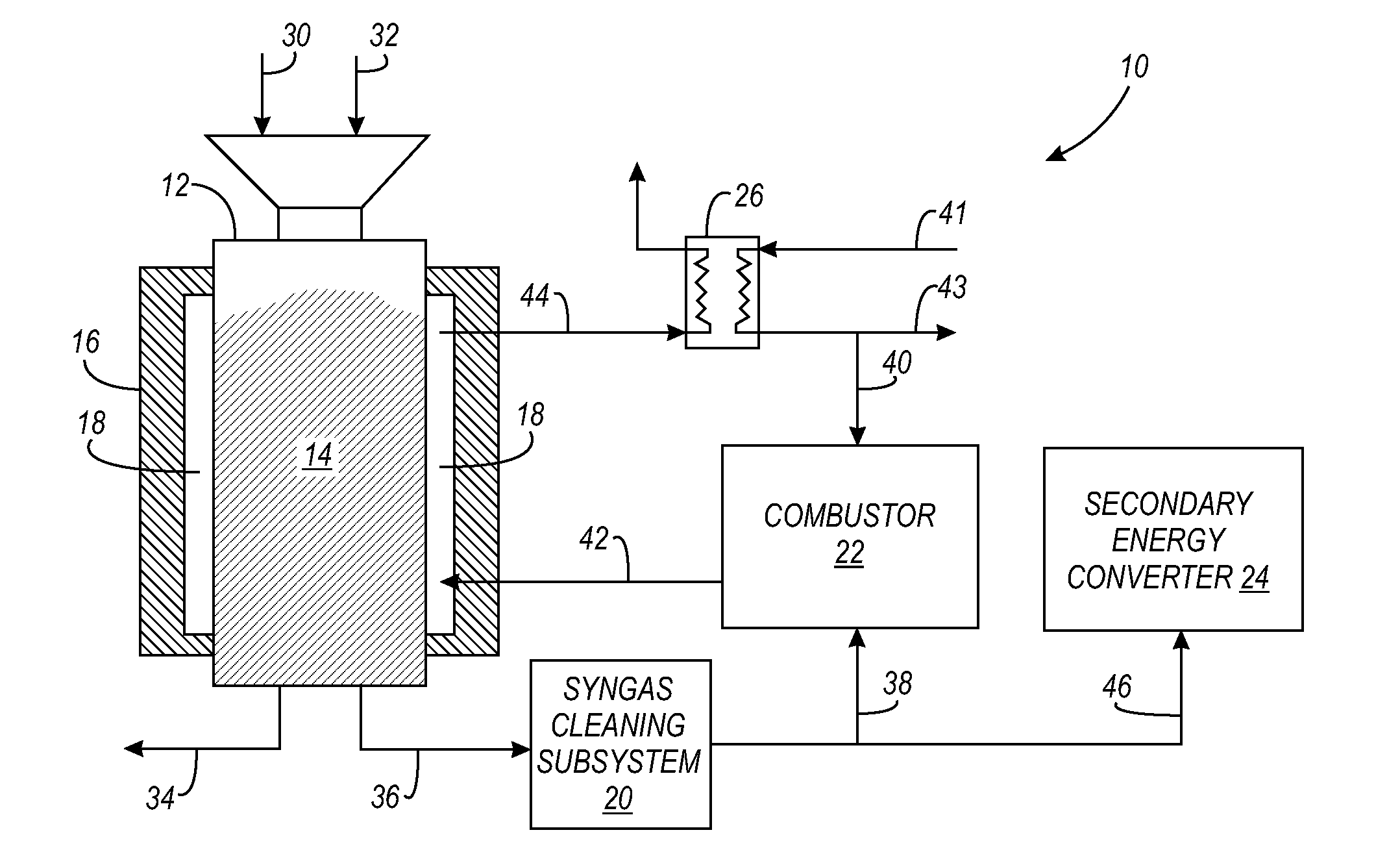

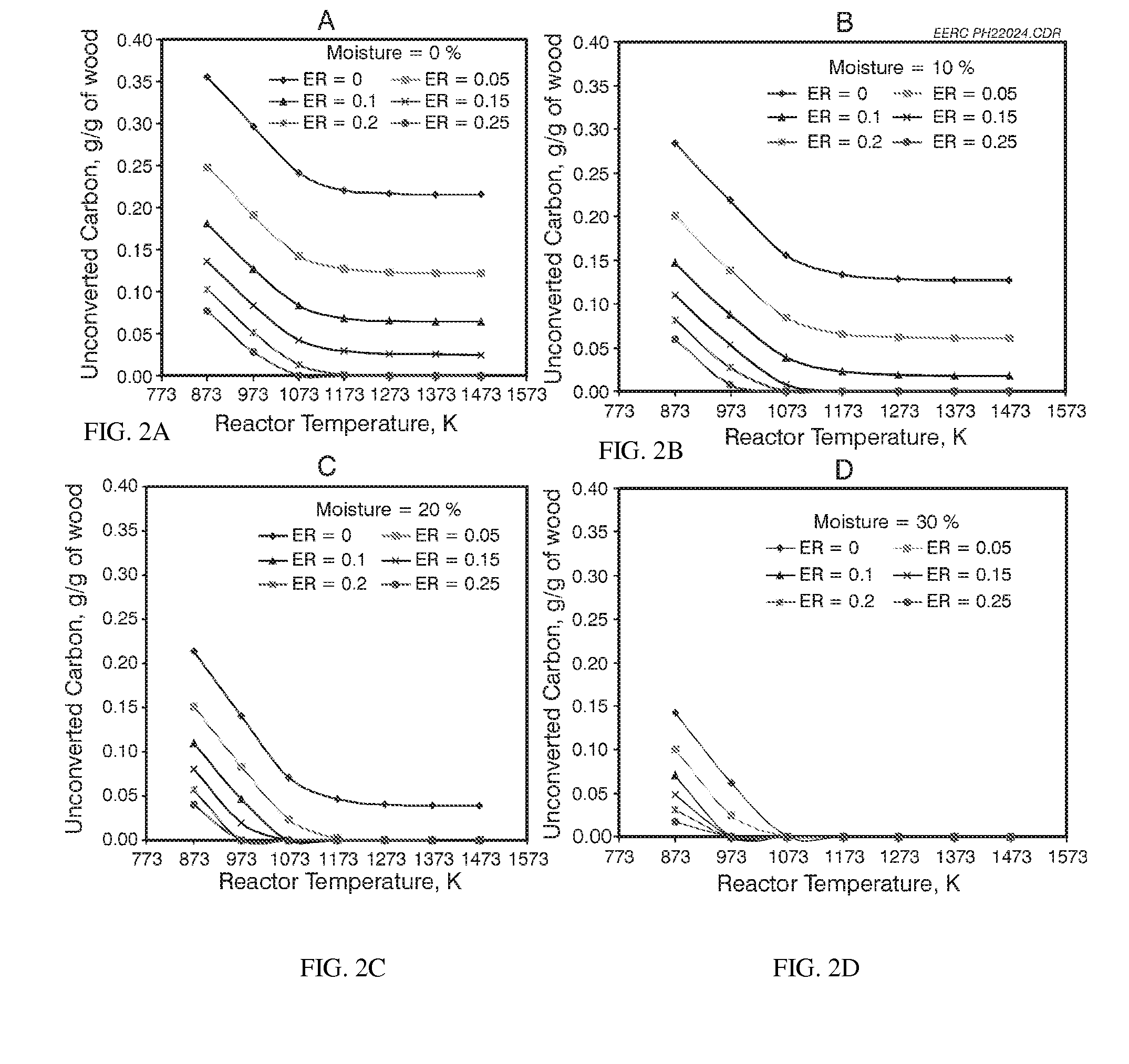

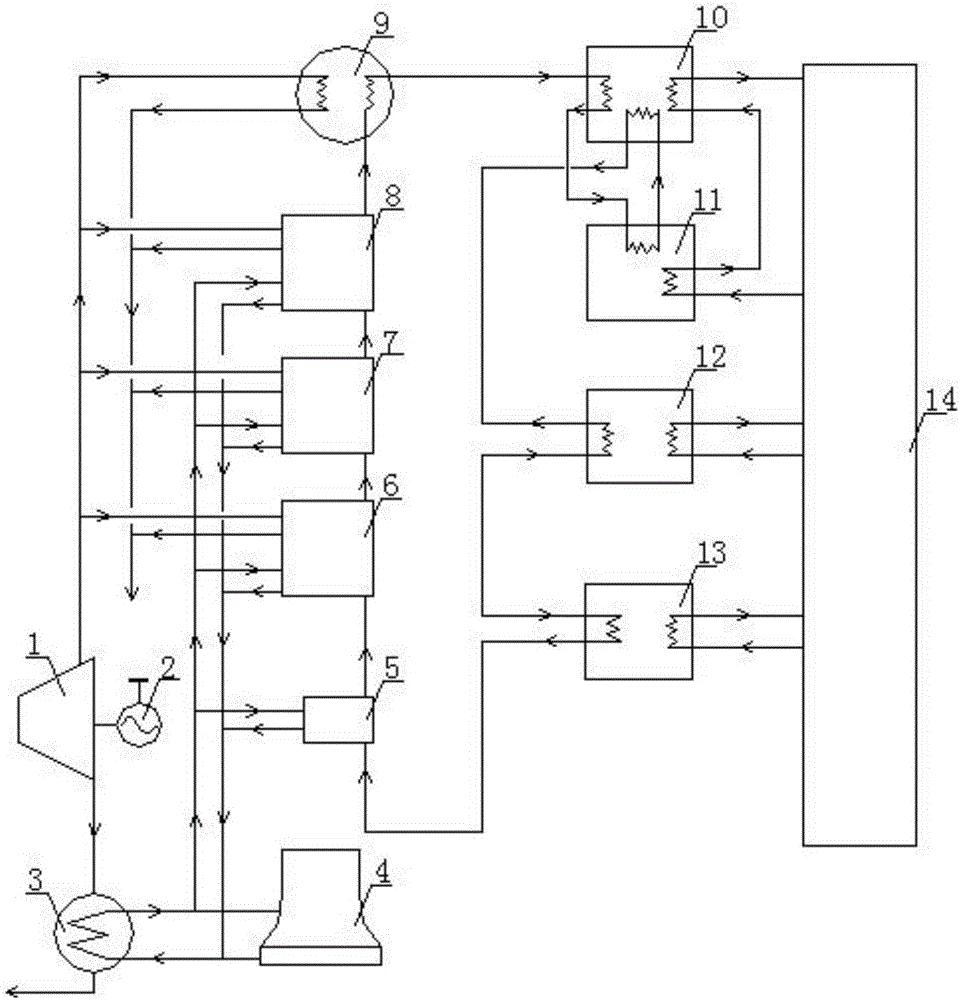

Thermally stable cocurrent gasification system and associated methods

InactiveUS20080196308A1Reduce solid wasteGasification processes detailsCarburetting by solid carbonaceous material pyrolysisOperational costsHigh energy

A method and apparatus, in one example, relates to a system and method for the generation of very low-tar, high-energy synthesis gas from a large variety of carbonaceous feedstock, including those with higher moisture levels than conventional gasifiers. The system comprises a gasification reactor wherein a portion of the energy of the output syngas of the reactor is used to heat the gasification zone of the reactor via an annular space surrounding the gasification zone of the gasifier, to maintain a temperature condition above 800° C. The maintenance of a long, quasi-uniform high-temperature gasification zone reduces the amount of input air or oxygen, reduces bridging within the gasifier, cracks pyrolysis oils, increases the conversion of char, minimizes heat losses from the bed, and converts moisture within the packed bed into a gasification medium. This results in a very low tar synthesis gas with less nitrogen dilution and higher energy content than conventional gasifiers. The reduction in bridging reduces operating costs.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

Energy-saving heat supply system with function of reducing temperature of heat supply return water

InactiveCN106705185AIncrease profitReduce circulating water flowLighting and heating apparatusSteam useCooling towerTemperature difference

The invention discloses an energy-saving heat supply system with a function of reducing the temperature of heat supply return water, and belongs to the field of improvement of energy utilization efficiency. Heat exchange can be repeatedly carried out on heat sources by multistage heat exchangers, multistage absorption heat exchange units, multistage compression heat pumps and an ice making type refrigerator, accordingly, the heat supply areas can be enlarged, and the energy utilization efficiency can be improved. The energy-saving heat supply system has the advantages that the temperature of the return water of heat supply primary pipe networks can be reduced and reach 0 DEG C, the return water contains 10% of ice particles, accordingly, route heat loss of the return water of the heat supply primary pipe networks can be reduced, the temperature difference of the return water of the heat supply primary pipe networks can be increased and reaches 118 DEG C from the original 60 DEG C, the flow rate of circulating water of the heat supply primary pipe networks can be lowered, energy consumption of circulating pumps can be reduced, heat supply flow rates of a user side can be greatly increased, the delivery efficiency of the pipe networks can be improved, the heat supply scale can be expanded, waste heat of a cooling tower can be recycled, and the like.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com