Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1639 results about "Cold weather" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

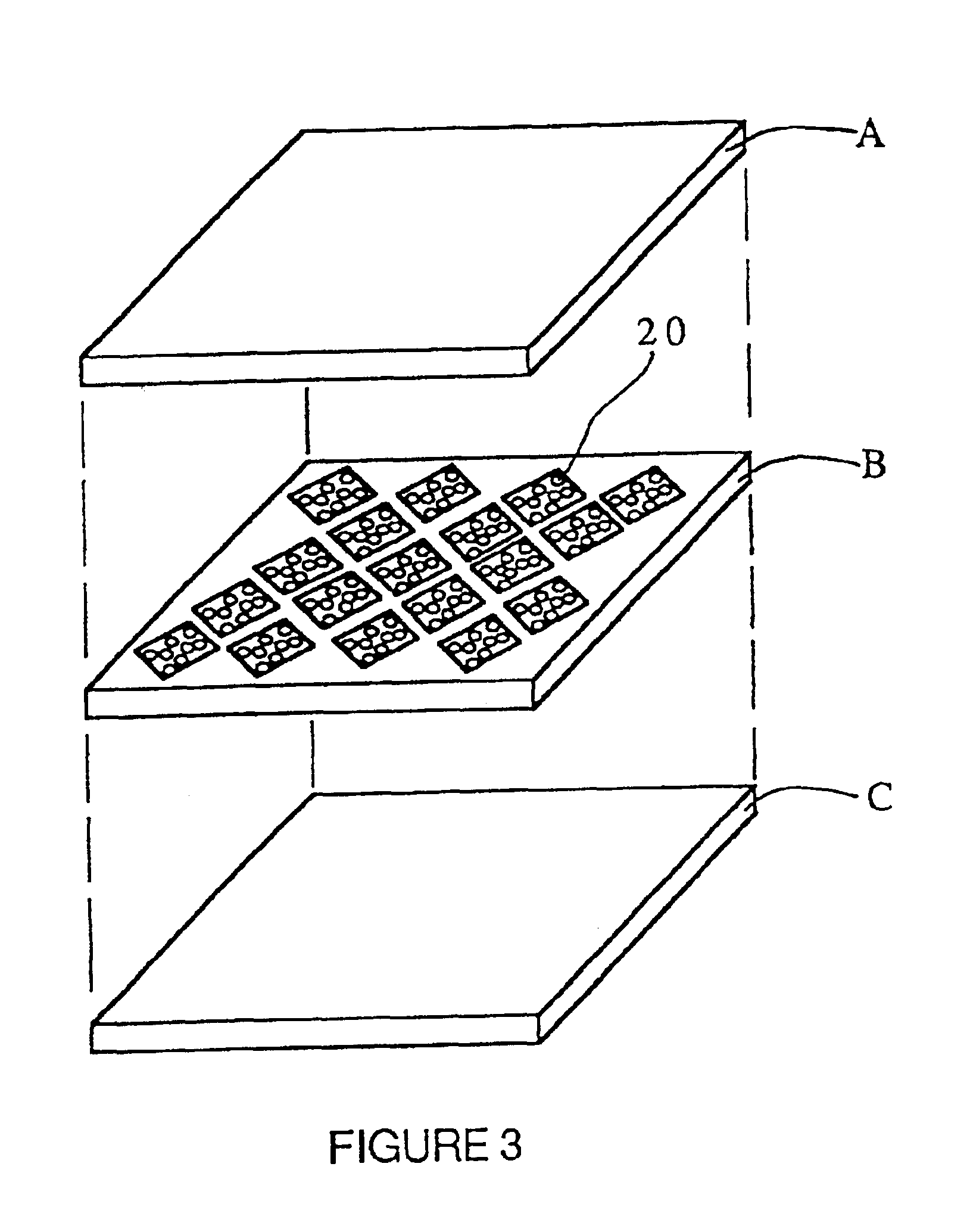

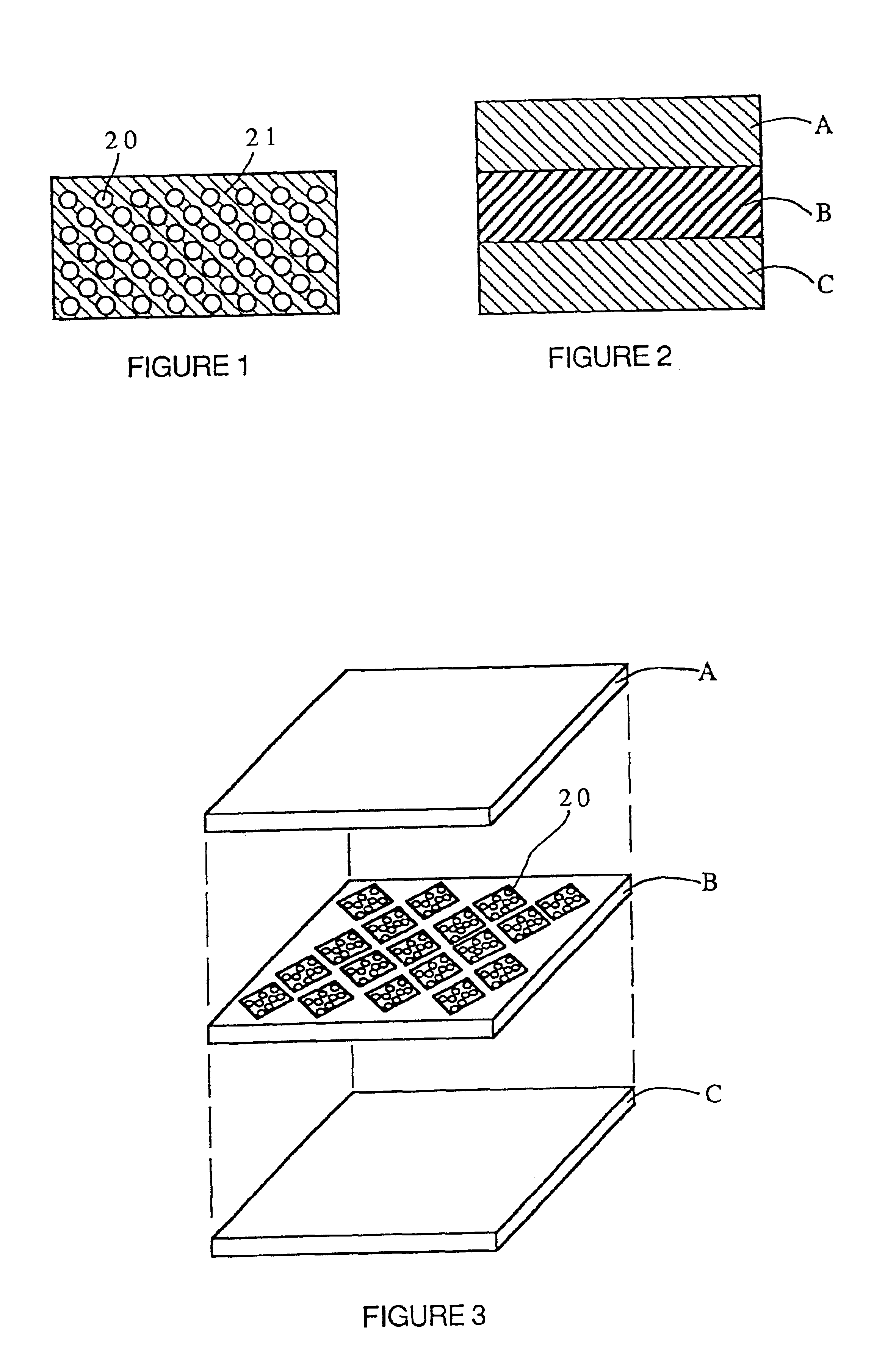

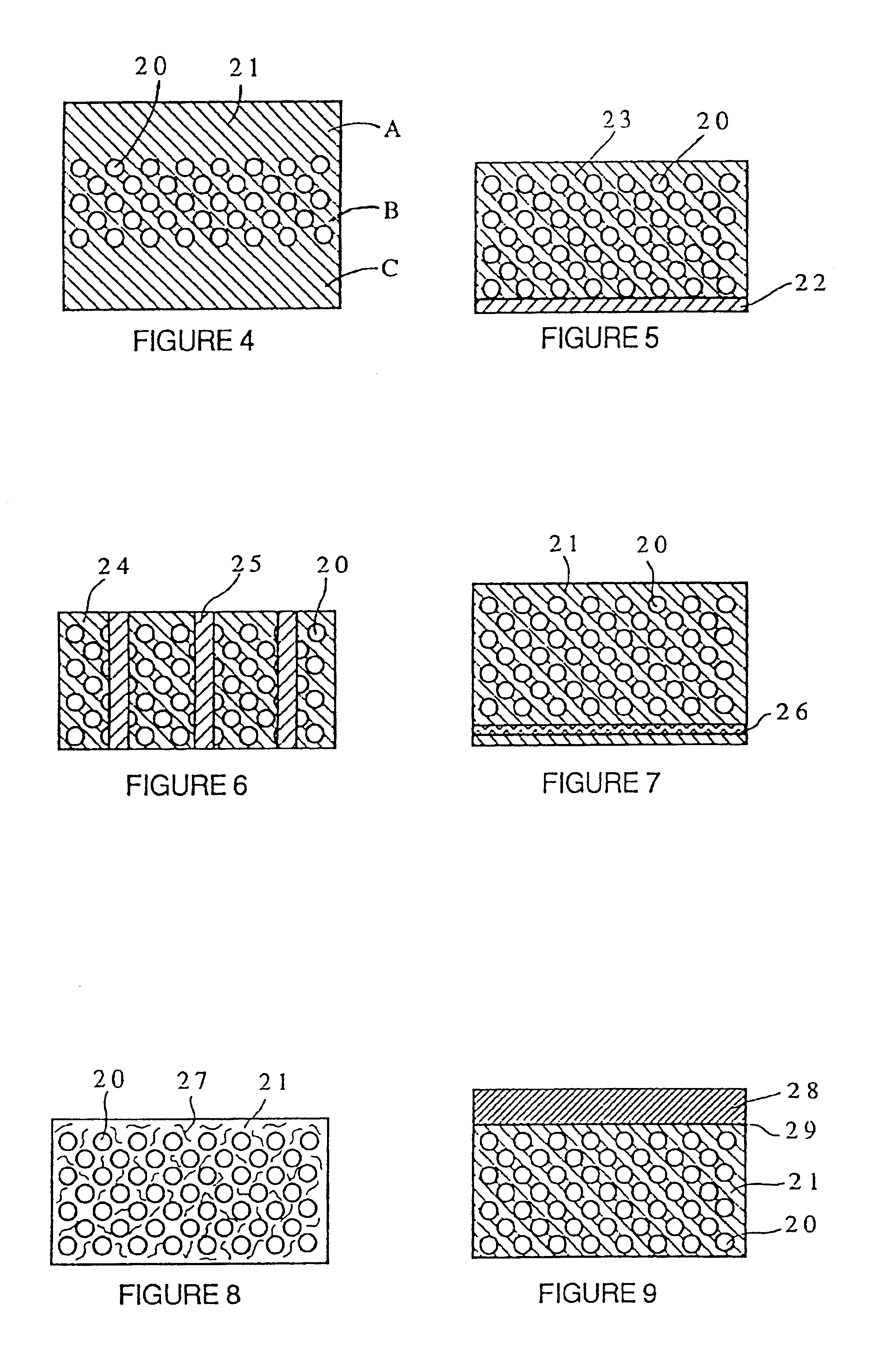

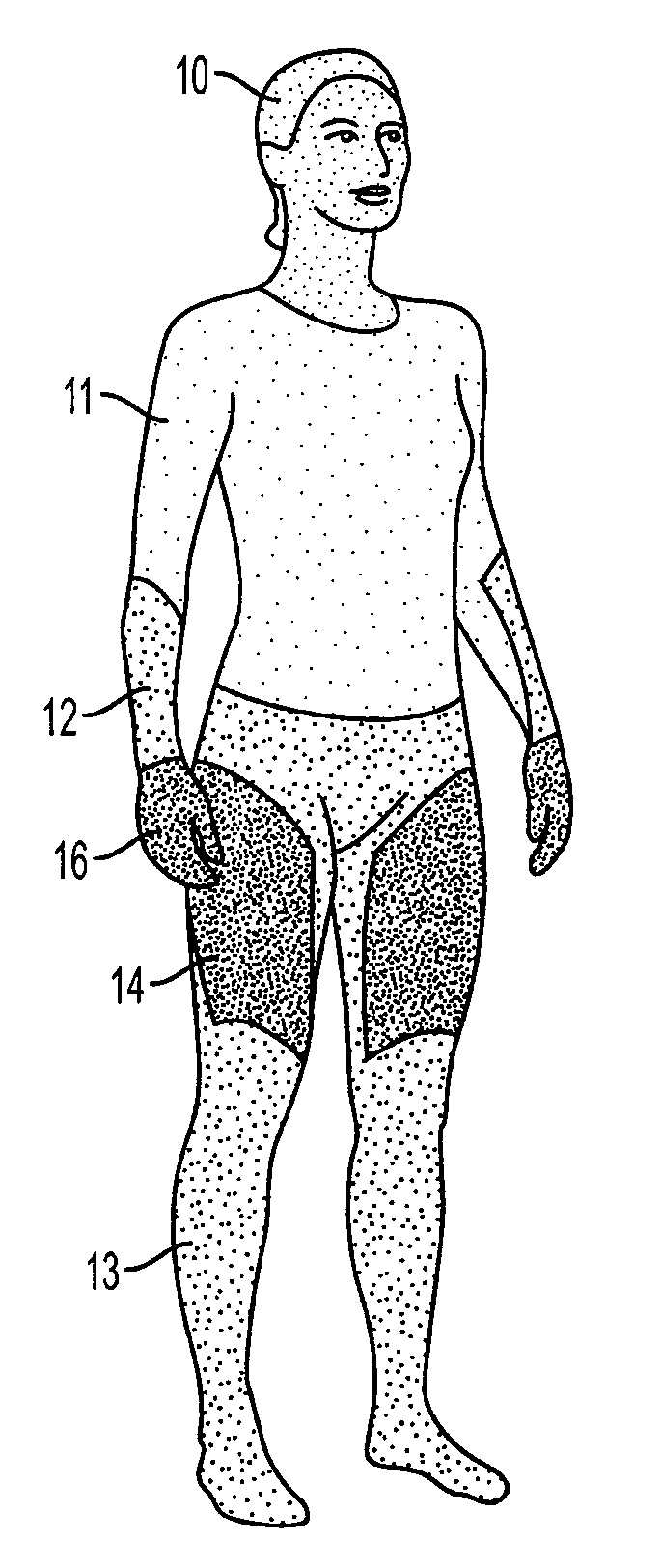

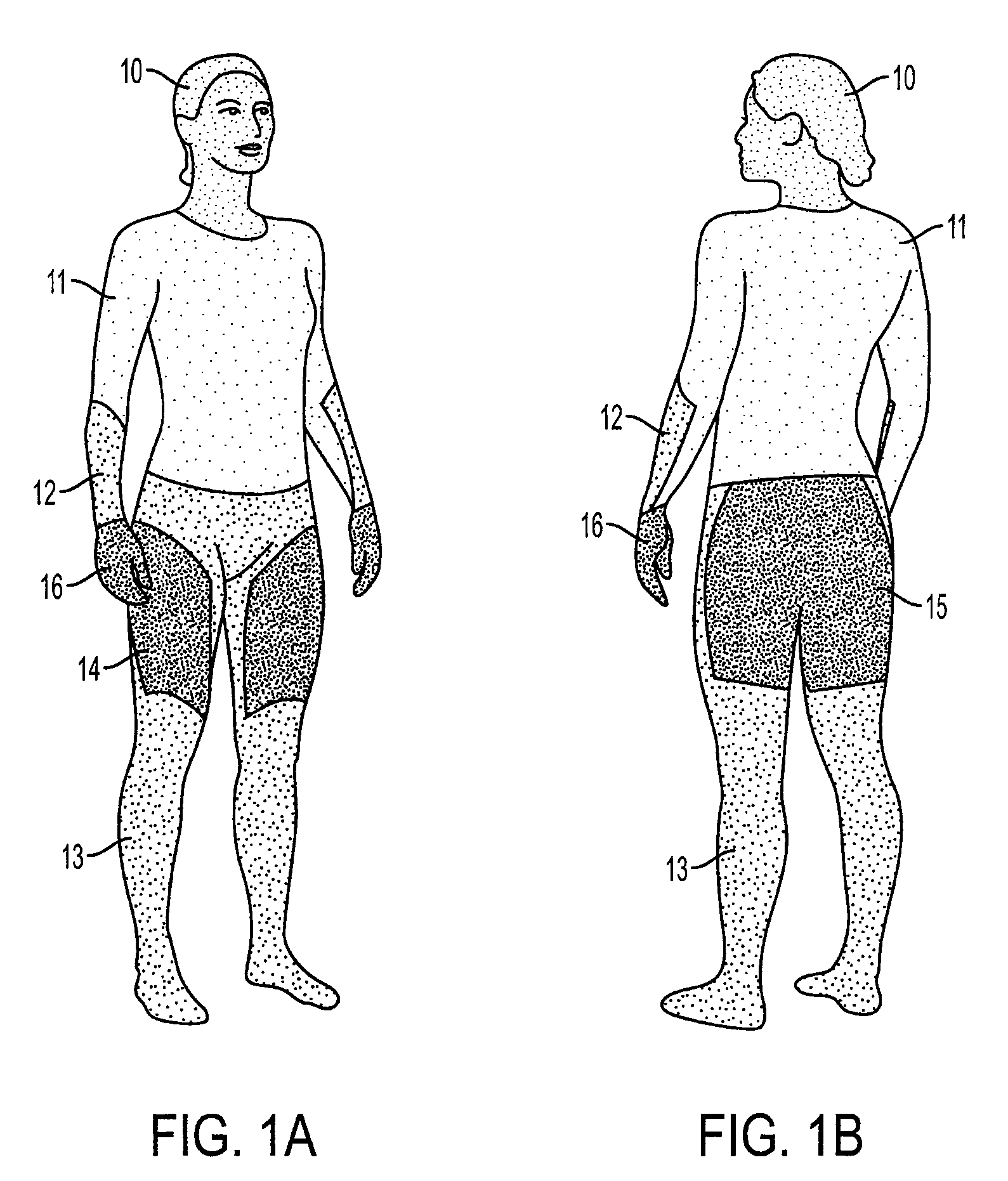

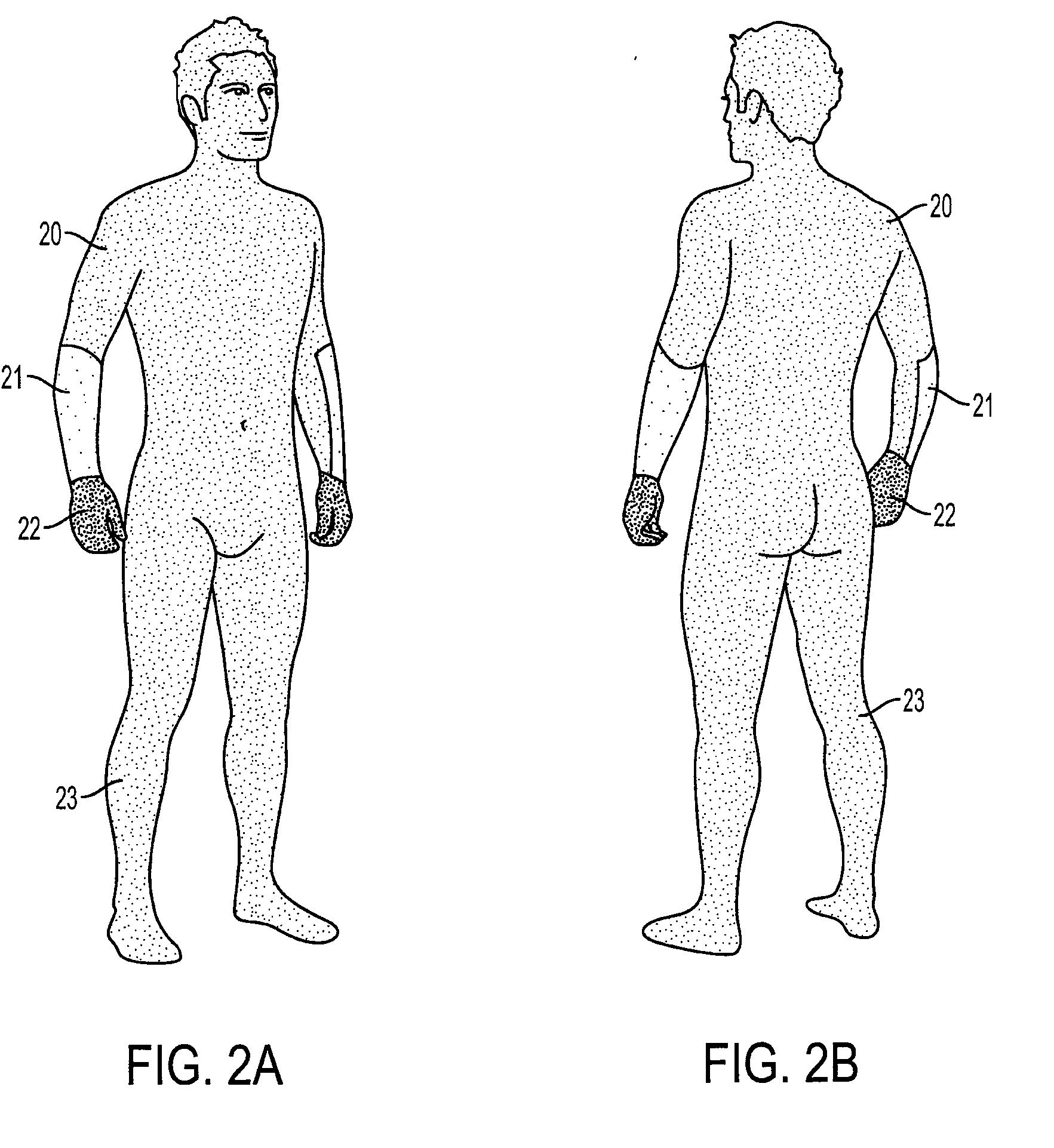

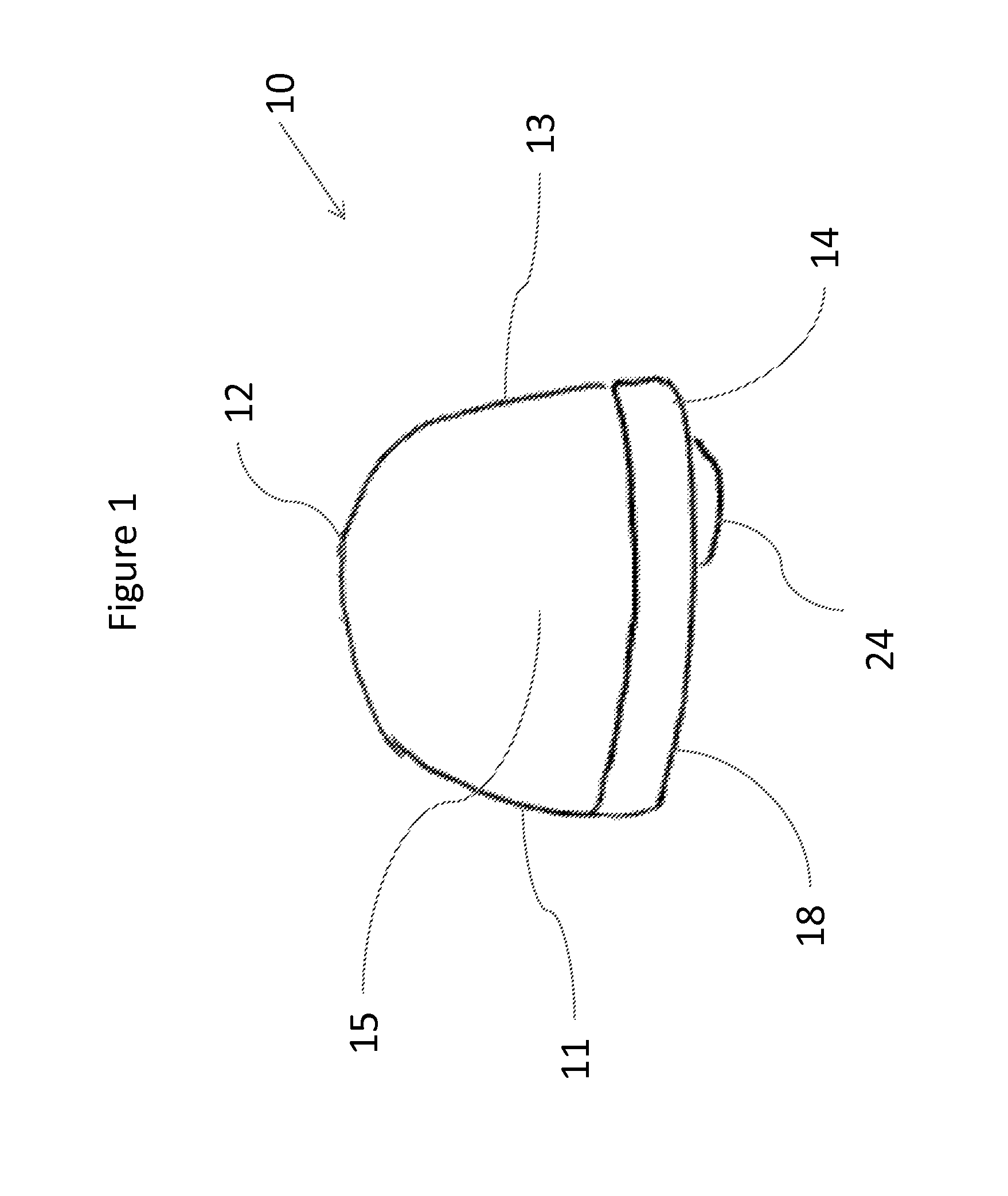

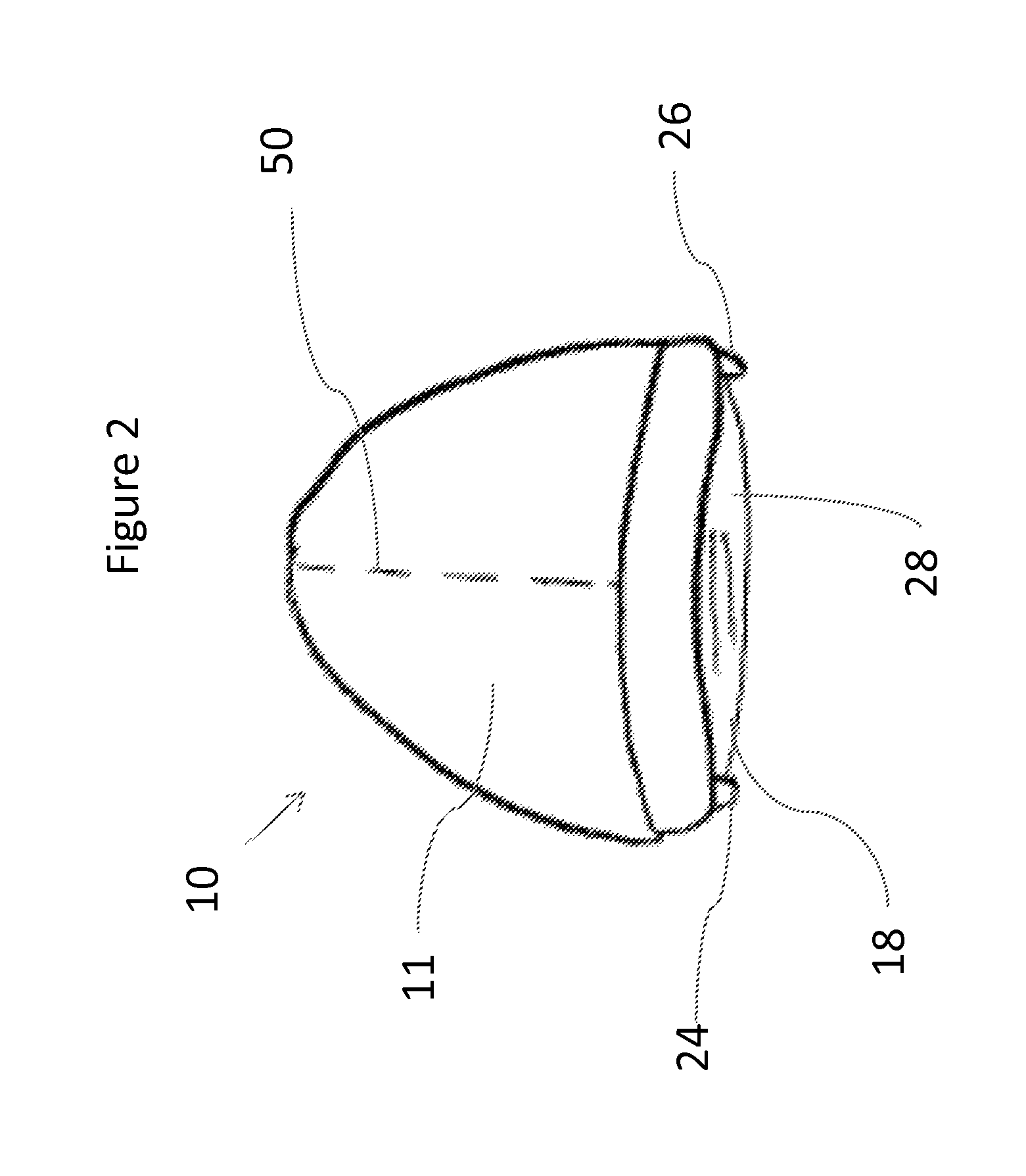

Phase change material thermal capacitor clothing

InactiveUS6855410B2Good thermal controlFast regenerationExothermal chemical reaction heat productionNatural cellulose pulp/paperSOCKSThermal insulation

An apparatus and method for metabolic cooling and insulation of a user in a cold environment. In its preferred embodiment the apparatus is a highly flexible composite material having a flexible matrix containing a phase change thermal storage material. The apparatus can be made to heat or cool the body or to act as a thermal buffer to protect the wearer from changing environmental conditions. The apparatus may also include an external thermal insulation layer and / or an internal thermal control layer to regulate the rate of heat exchange between the composite and the skin of the wearer. Other embodiments of the apparatus also provide 1) a path for evaporation or direct absorption of perspiration from the skin of the wearer for improved comfort and thermal control, 2) heat conductive pathways within the material for thermal equalization, 3) surface treatments for improved absorption or rejection of heat by the material, and 4) means for quickly regenerating the thermal storage capacity for reuse of the material. Applications of the composite materials are also described which take advantage of the composite's thermal characteristics. The examples described include a diver's wet suit, ski boot liners, thermal socks, gloves and a face mask for cold weather activities, and a metabolic heating or cooling blanket useful for treating hypothermia or fever patients in a medical setting and therapeutic heating or cooling orthopedic joint supports.

Owner:BUCKLEY THERESA M

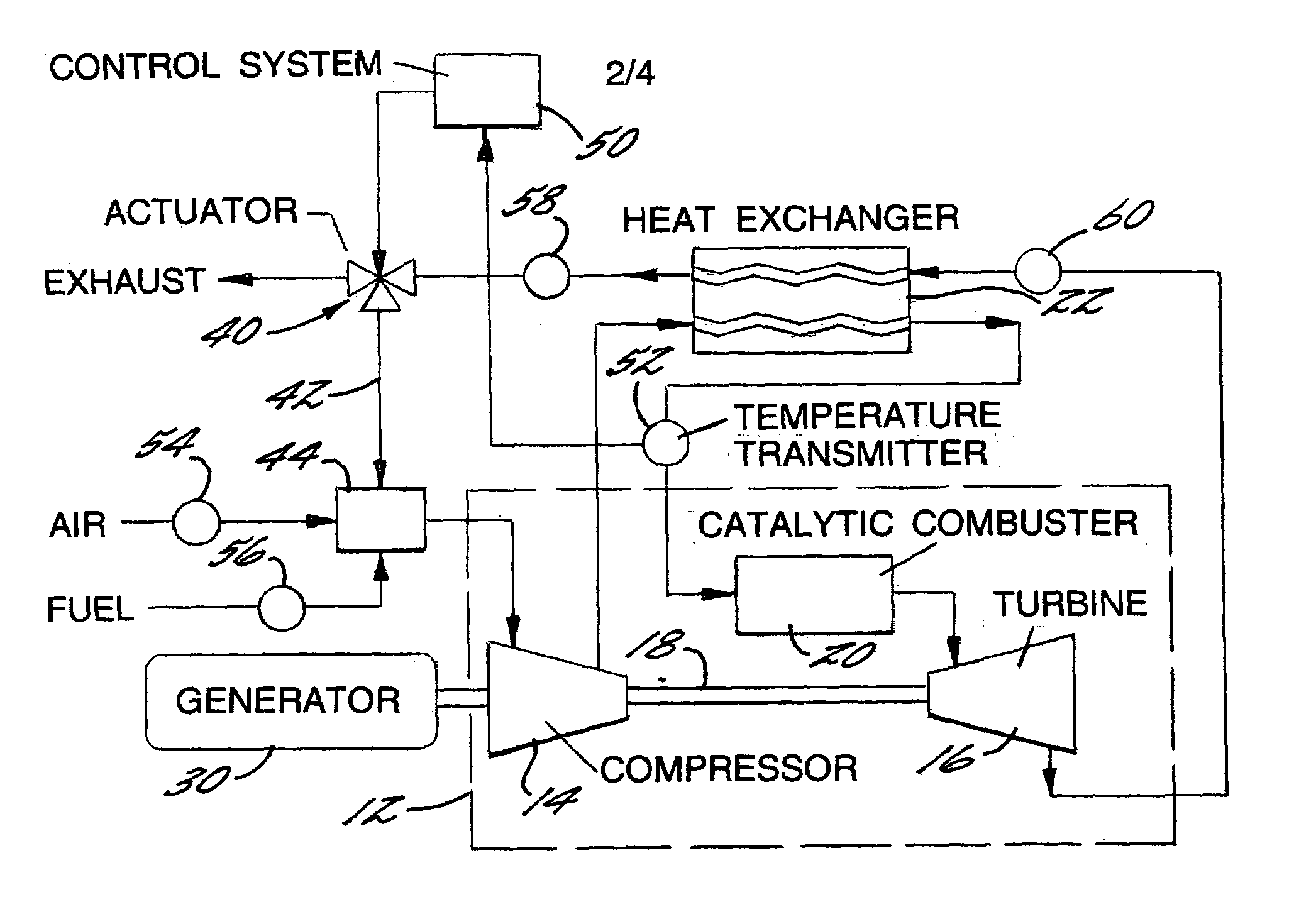

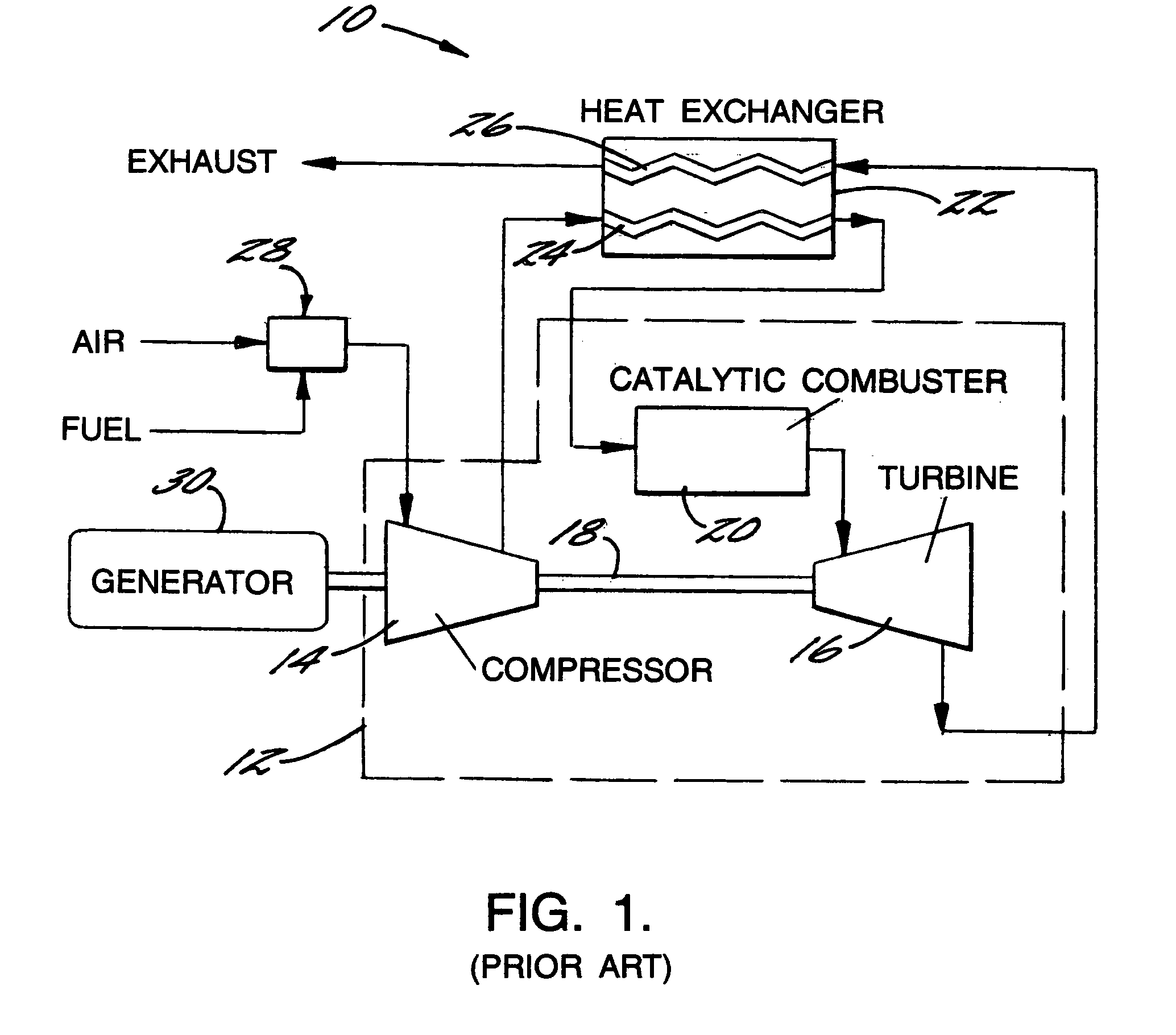

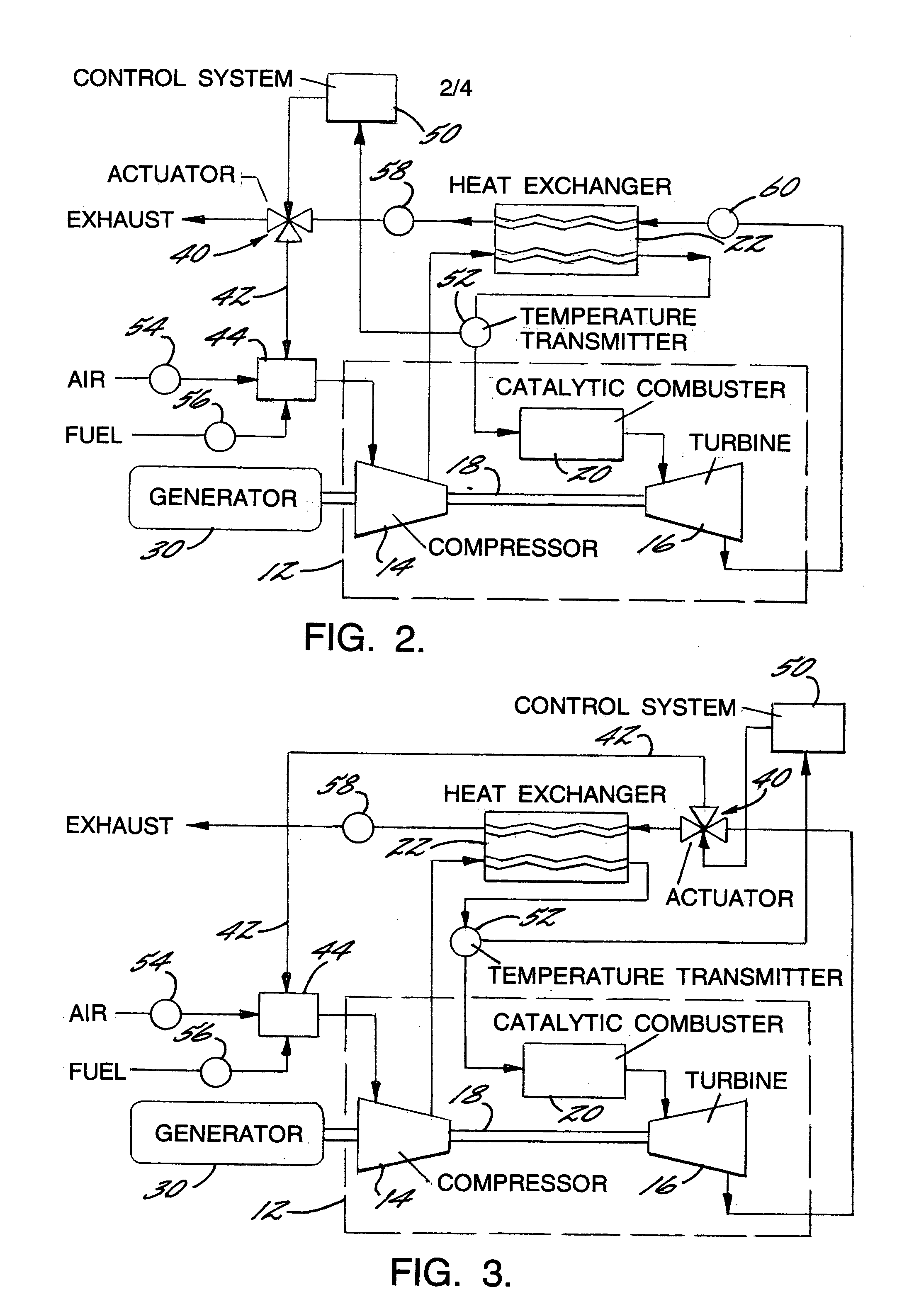

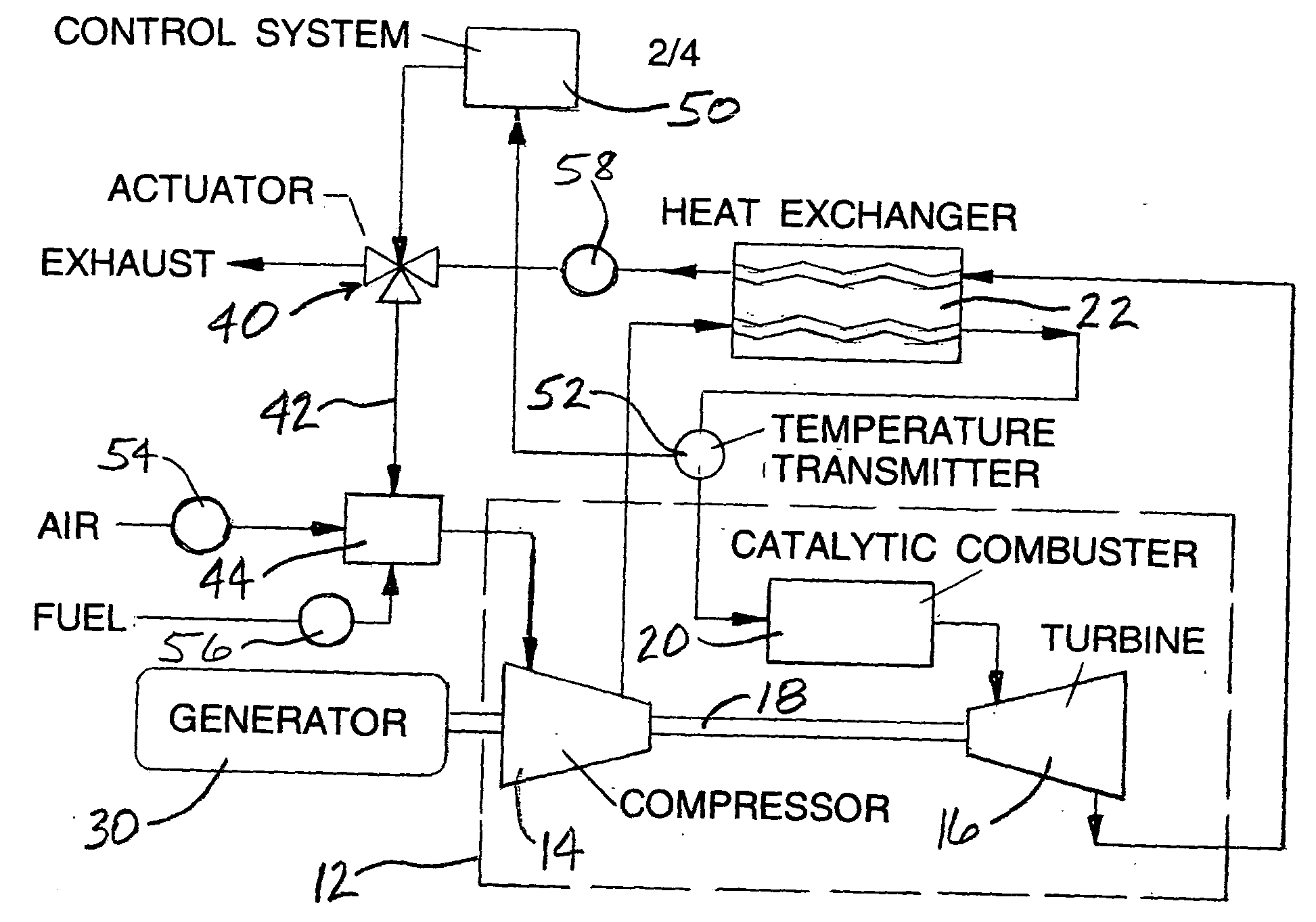

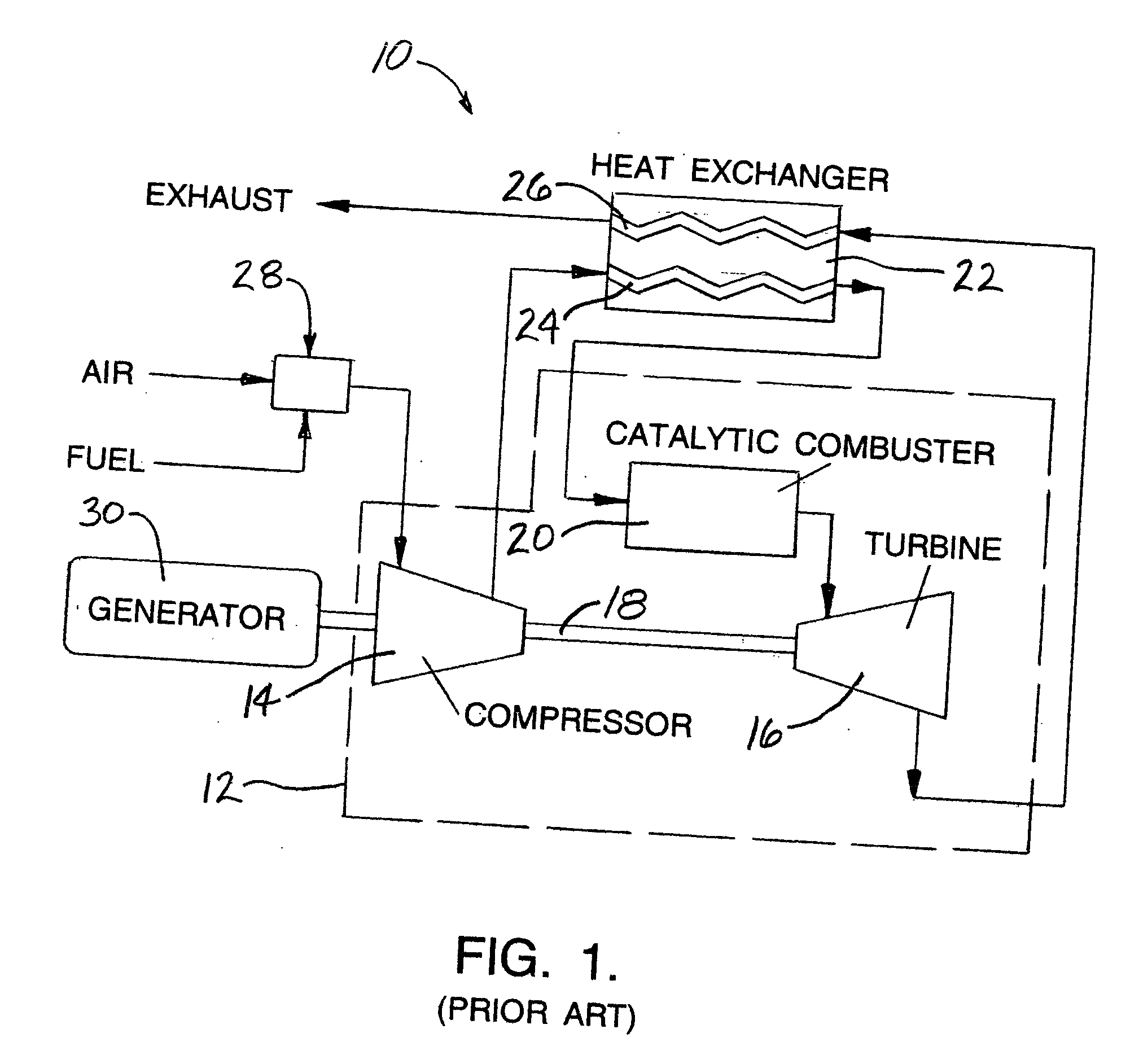

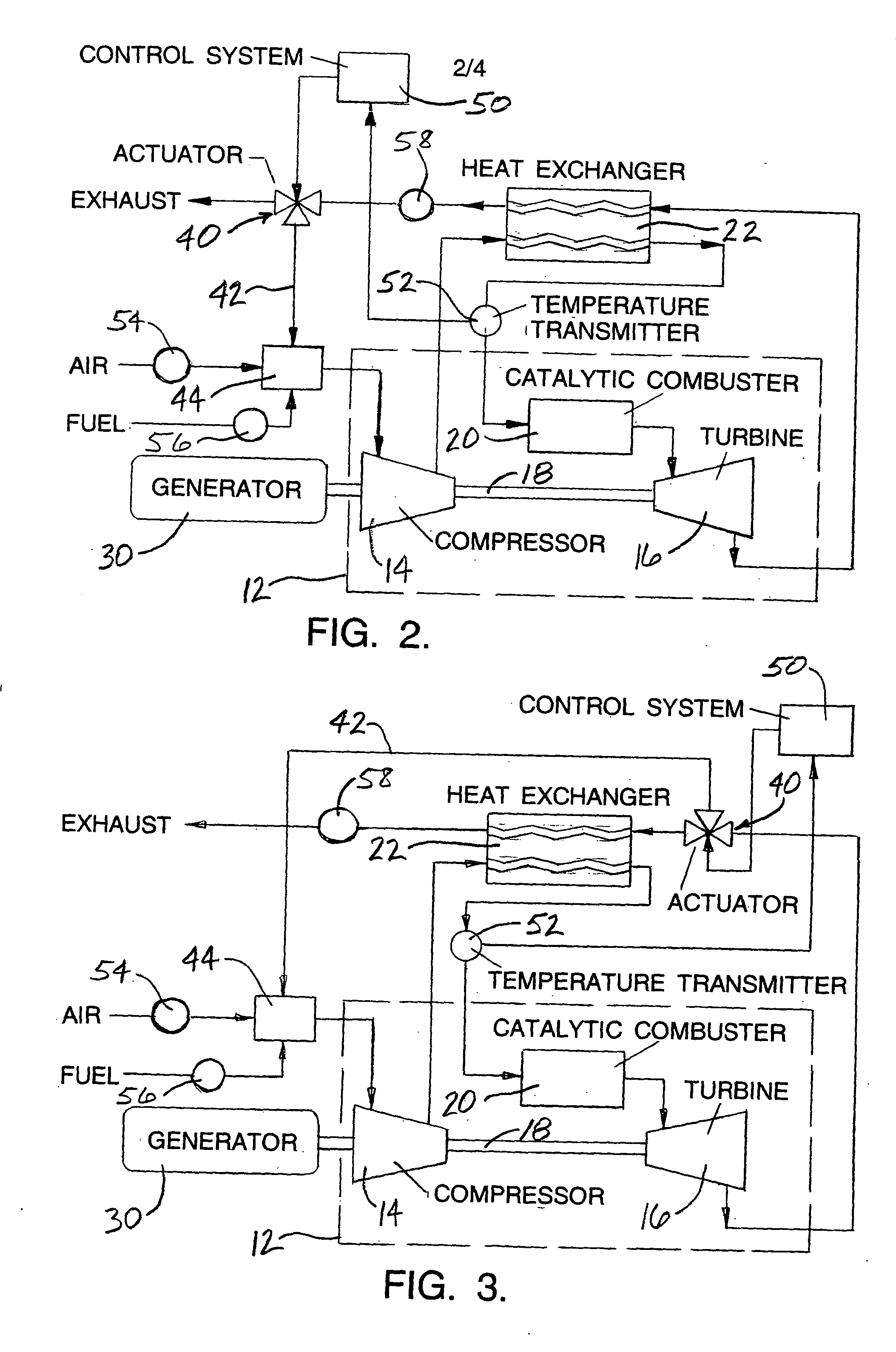

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS7007487B2Maximize efficiencyReduce air pollutionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

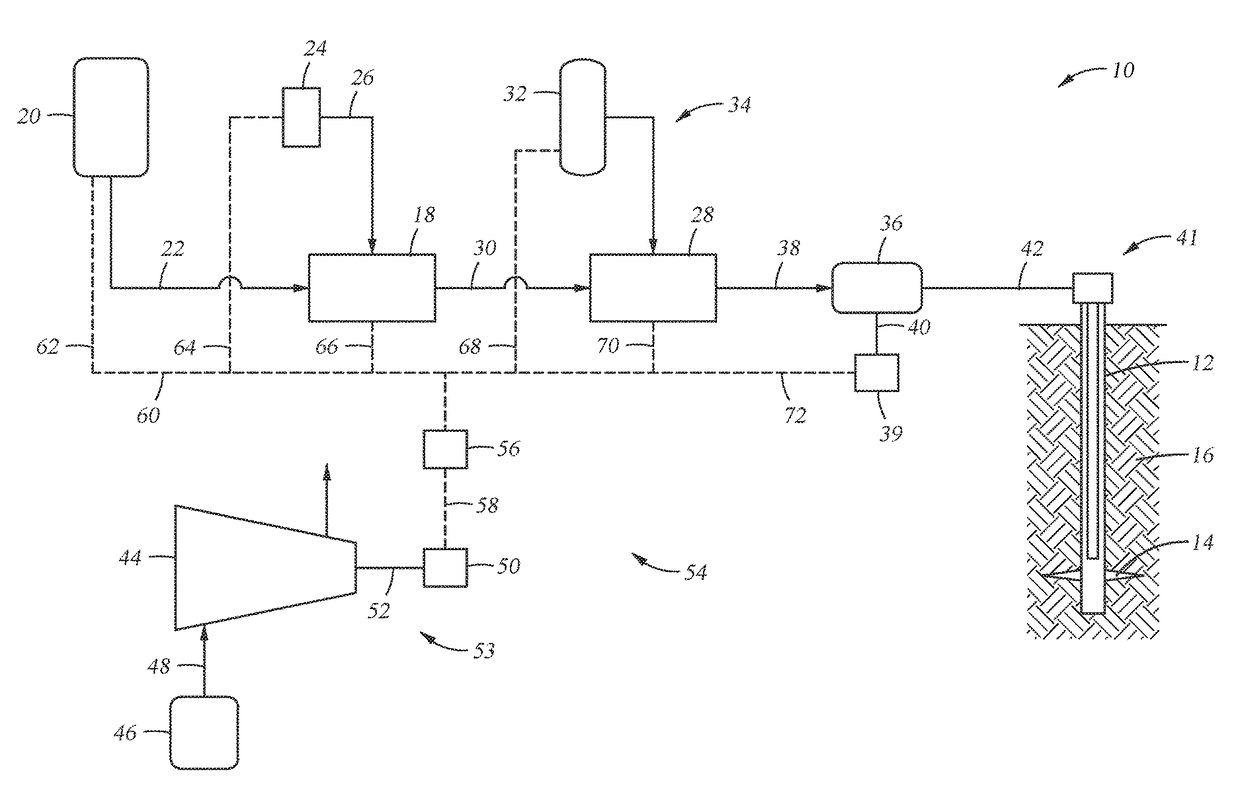

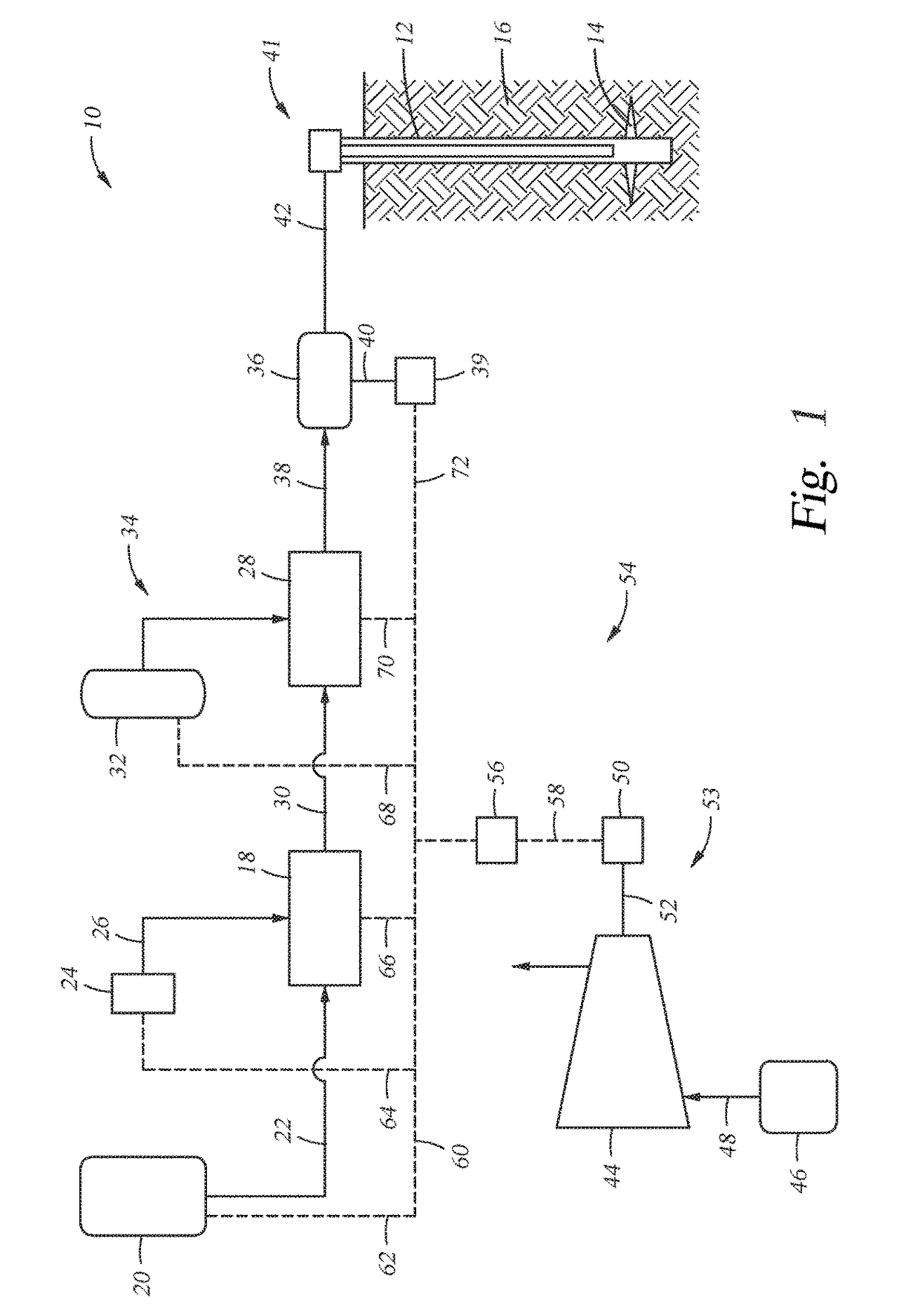

Cold weather package for oil field hydraulics

A hydraulic fracturing system includes an electrically powered pump that pressurizes fluid, which is piped into a wellbore to fracture a subterranean formation. System components include a fluid source, an additive source, a hydration unit, a blending unit, a proppant source, and a fracturing pump. The system includes heaters for warming hydraulic fluid and / or lube oil. The hydraulic fluid is used for operating devices on the blending and hydration units. The lube oil lubricates and cools various moving parts on the fracturing pump.

Owner:US WELL SERVICS LLC

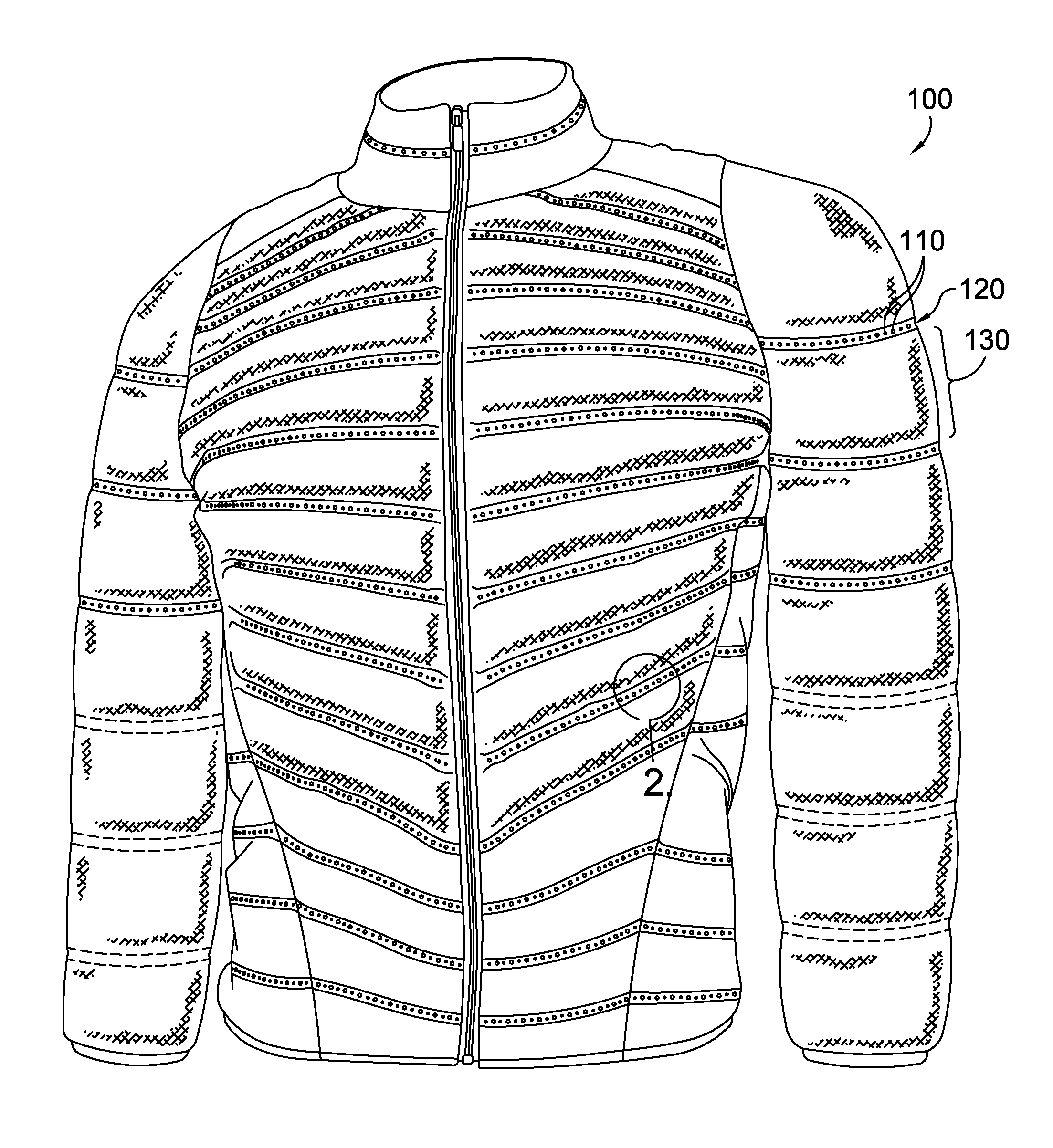

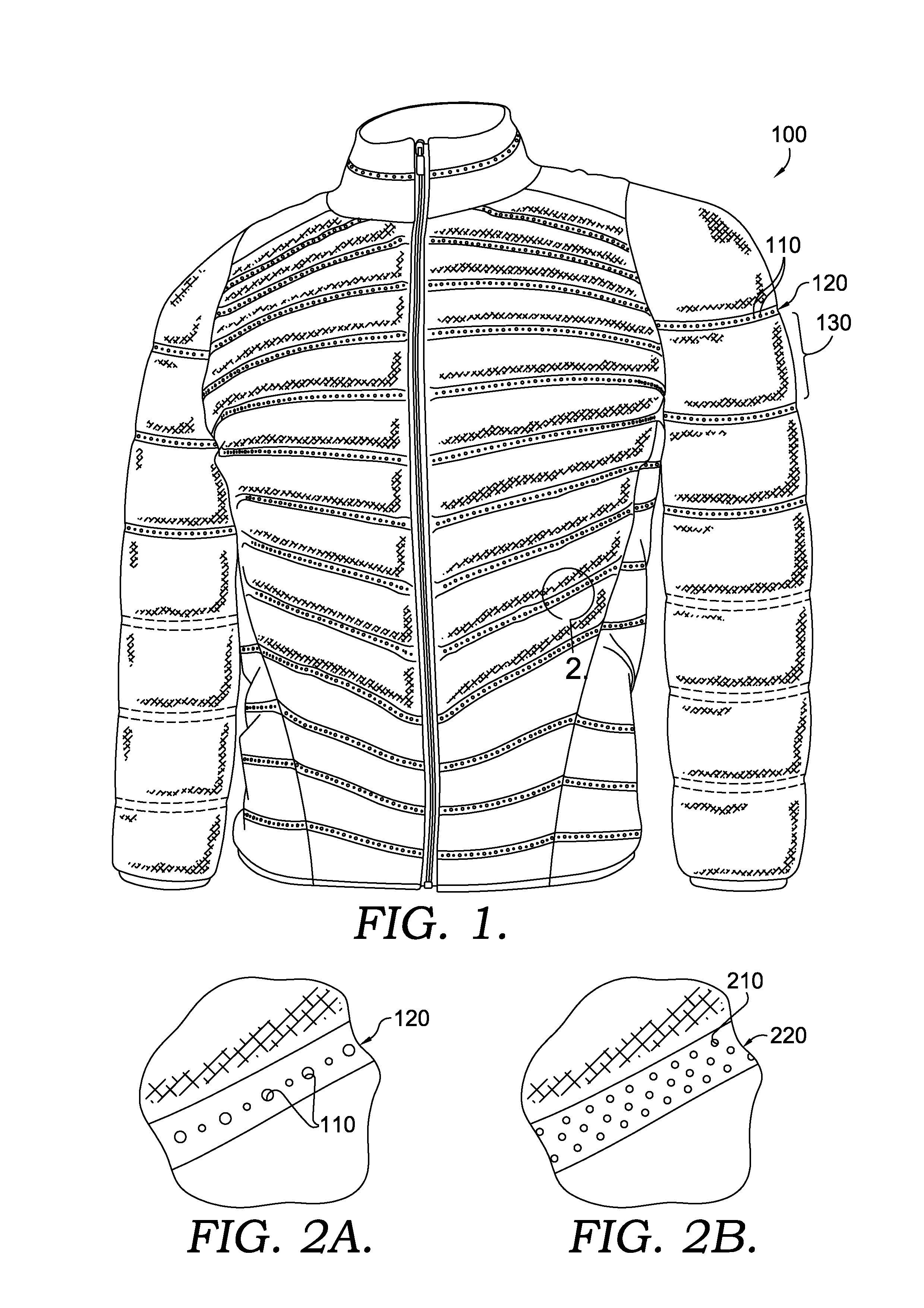

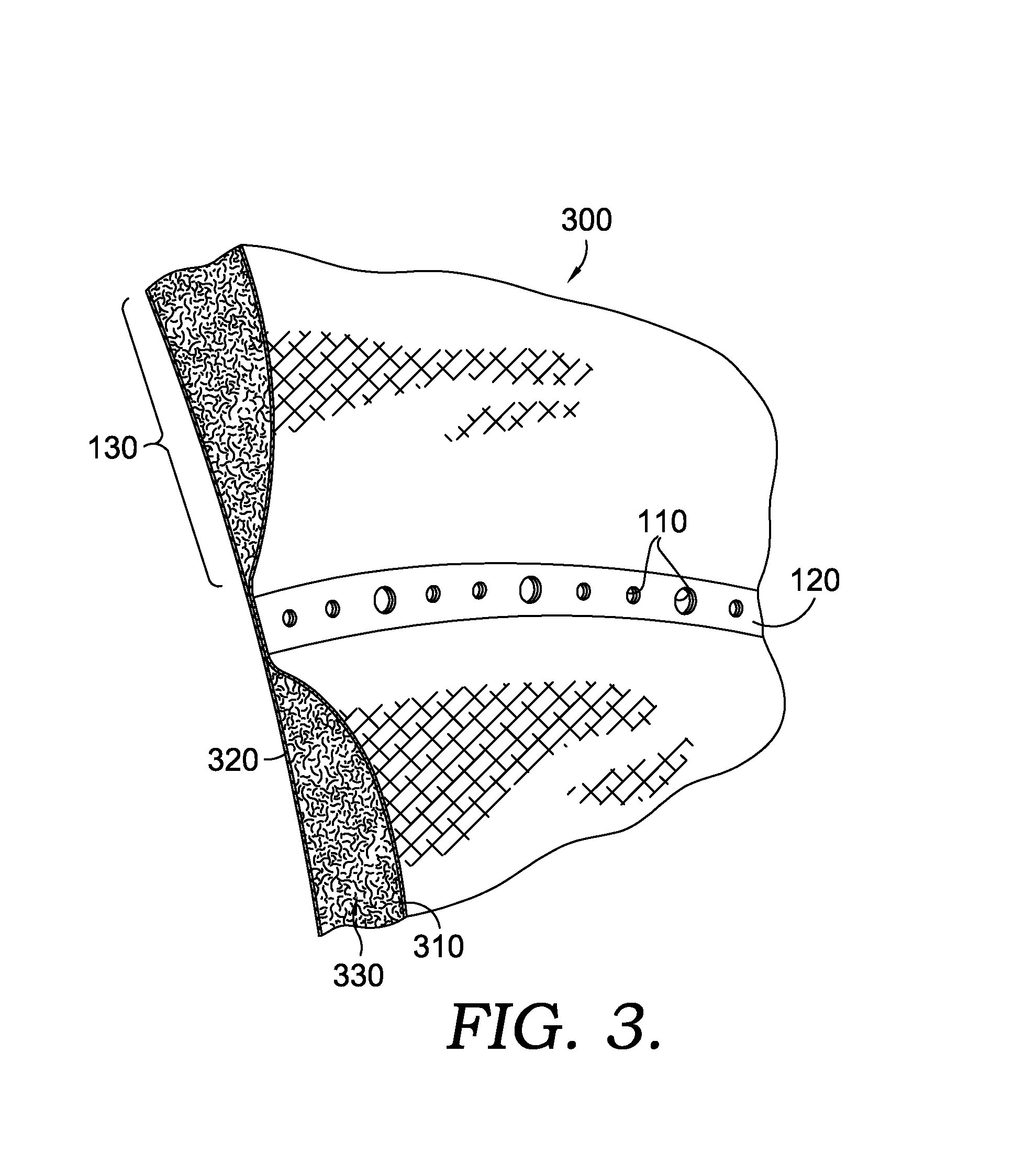

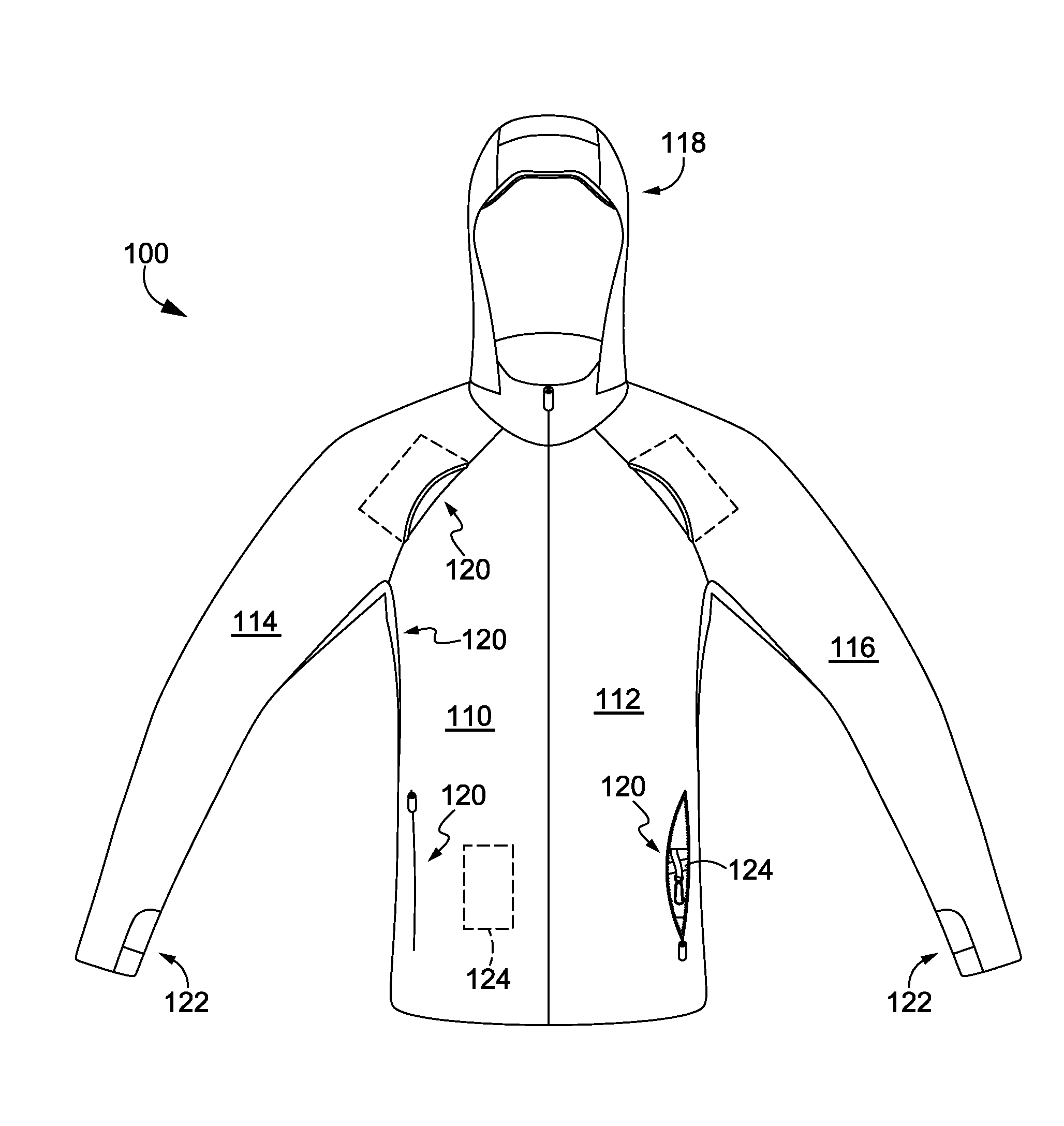

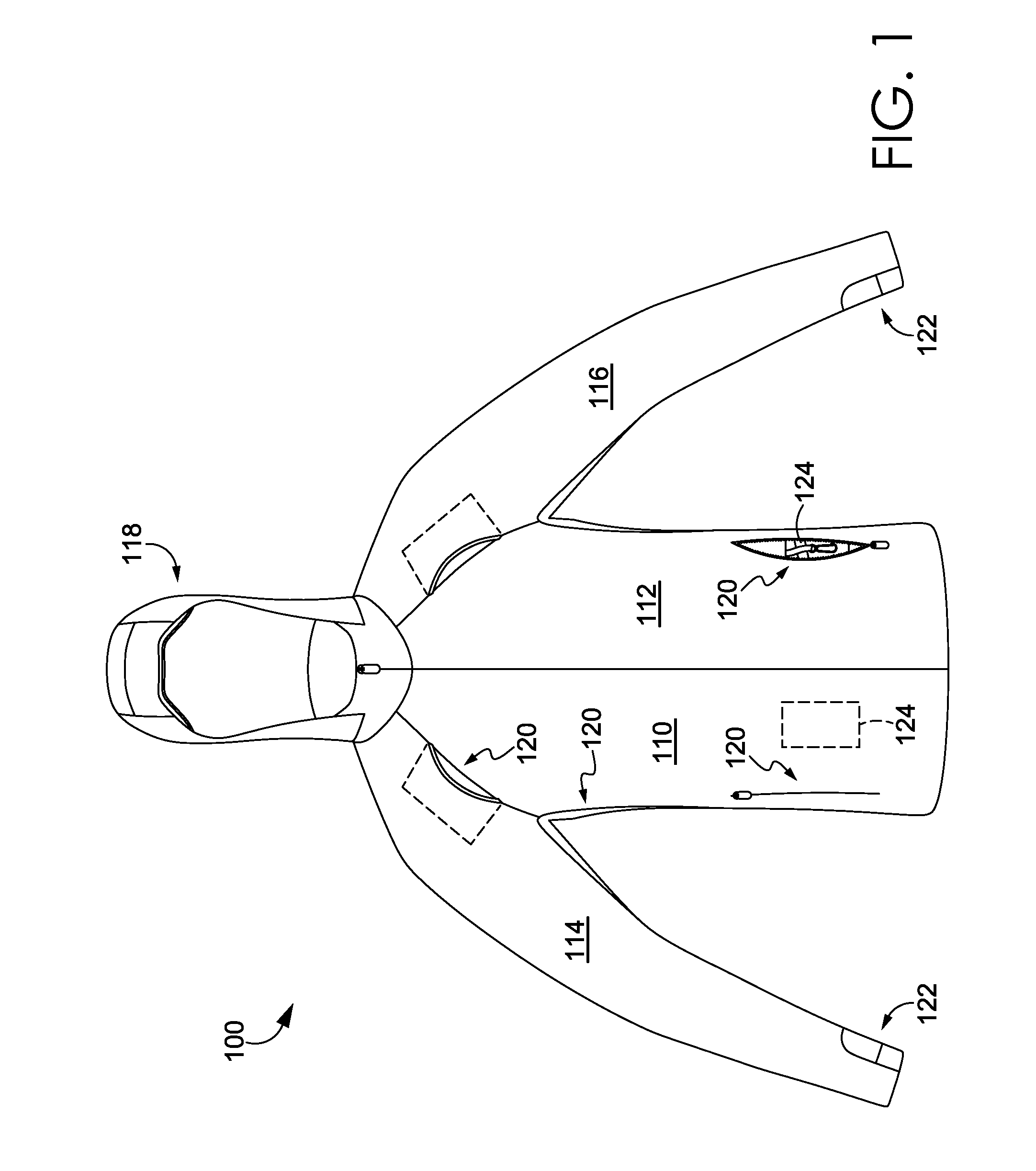

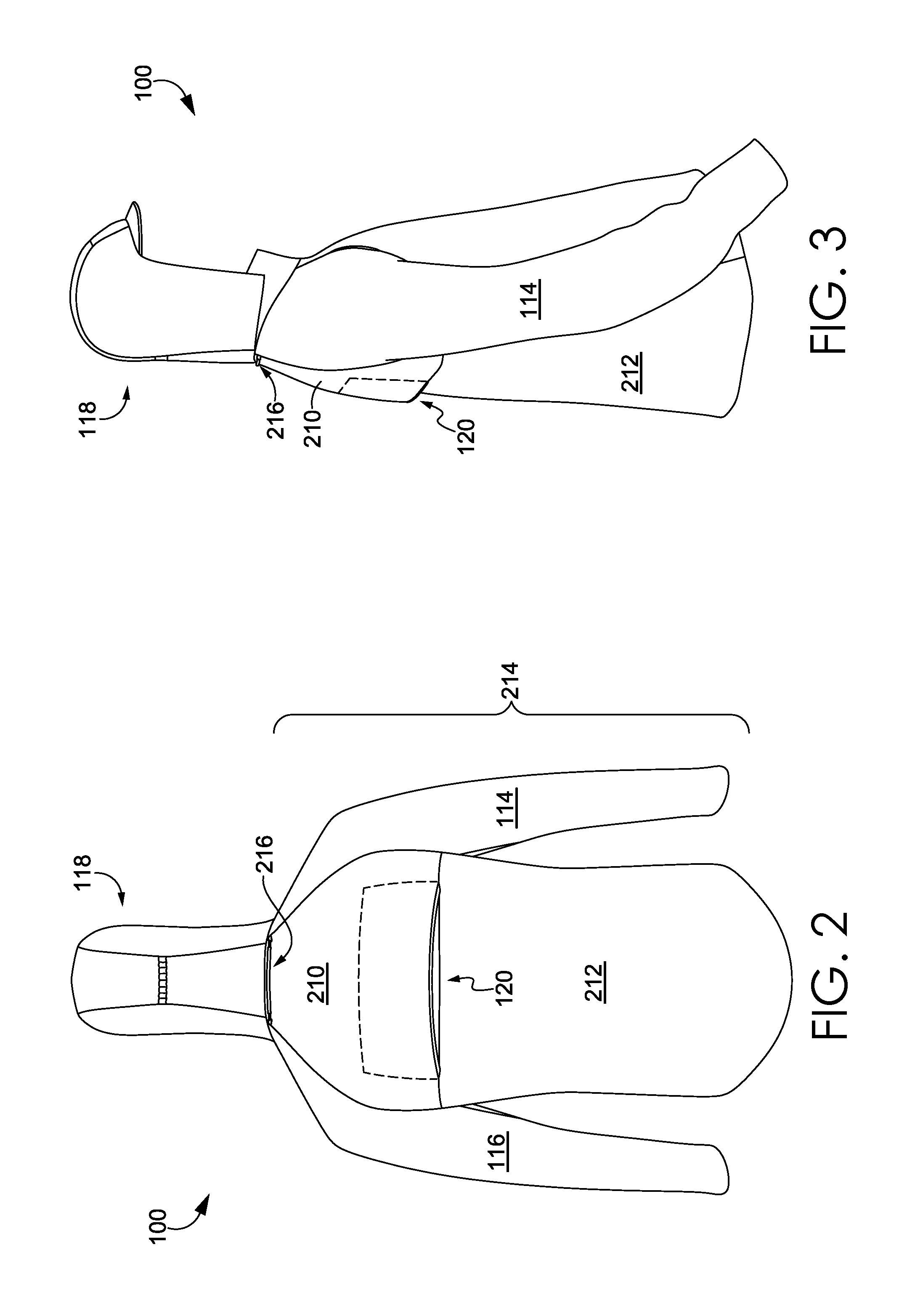

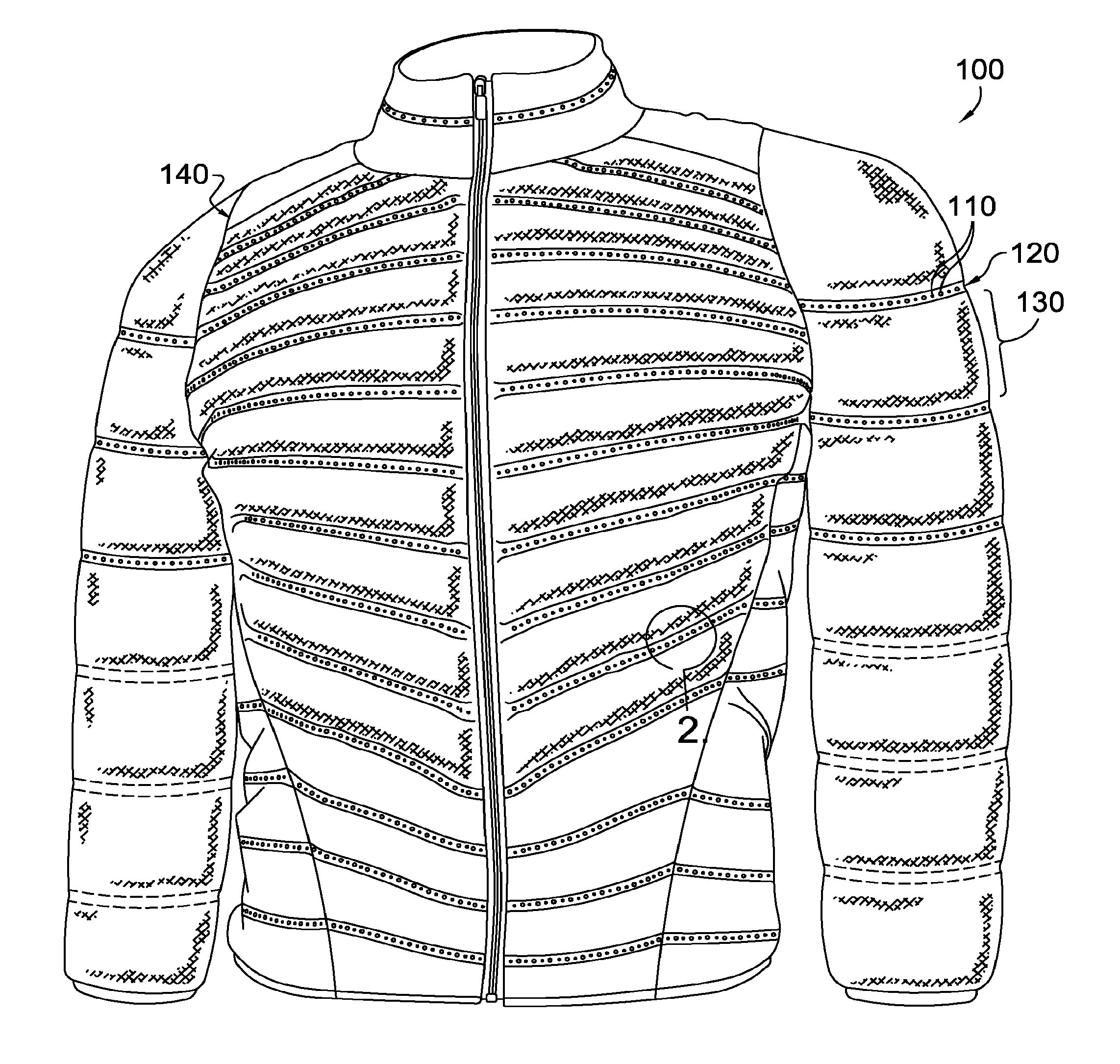

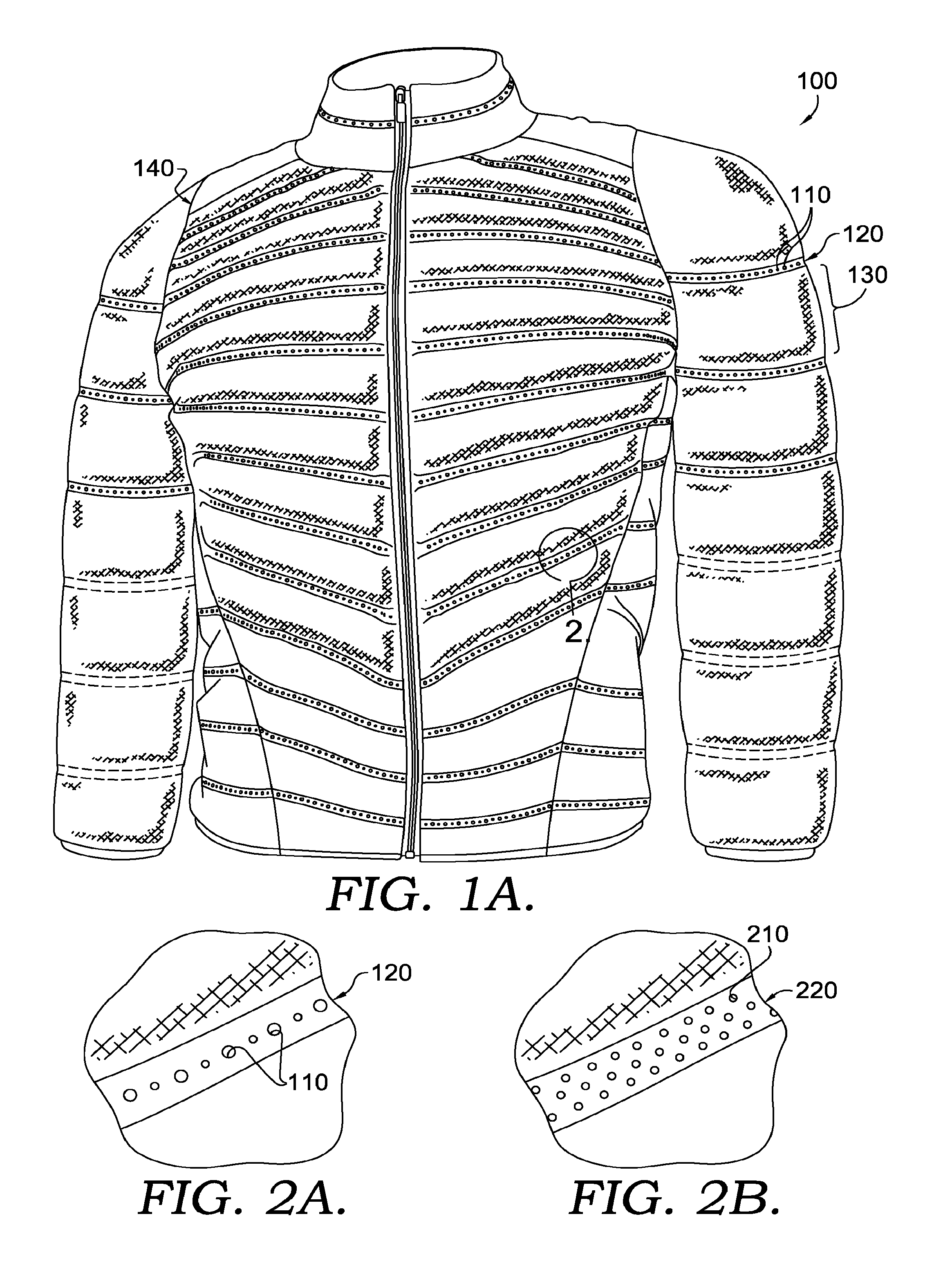

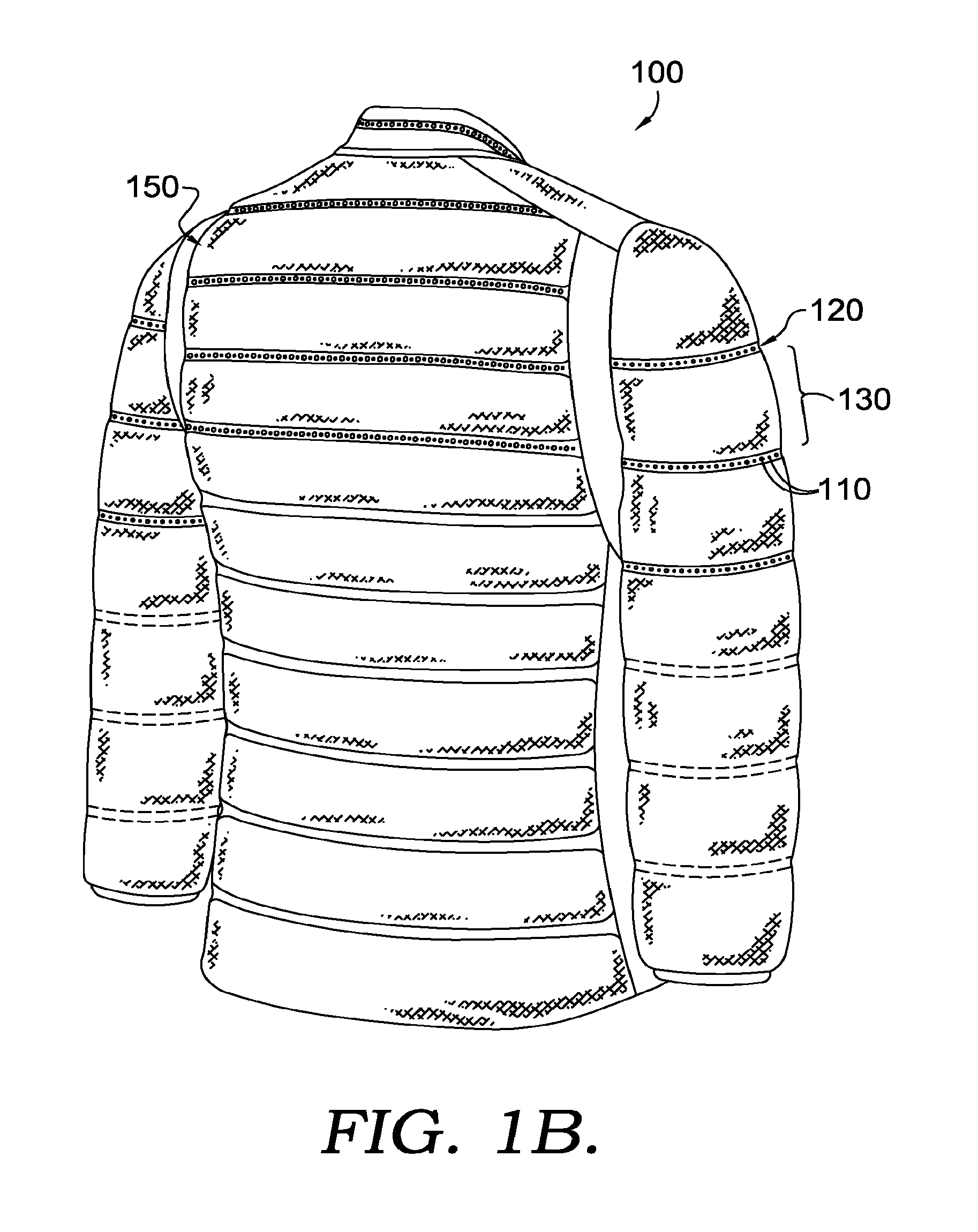

Cold Weather Vented Garment

ActiveUS20130276201A1Challenging to containKeep it lightweightGarment special featuresOvergarmentsFilling materialsEngineering

The present invention relates to breathable, vented, and insulating cold weather garments. More particularly, the present invention relates to garments with chambers to retain an insulating fill material. Perforations along the seams between the insulating chambers may achieve optimal evaporative moisture transfer from the inside (proximal to the body of a wearer) of the garment to the outside environment.

Owner:NIKE INC

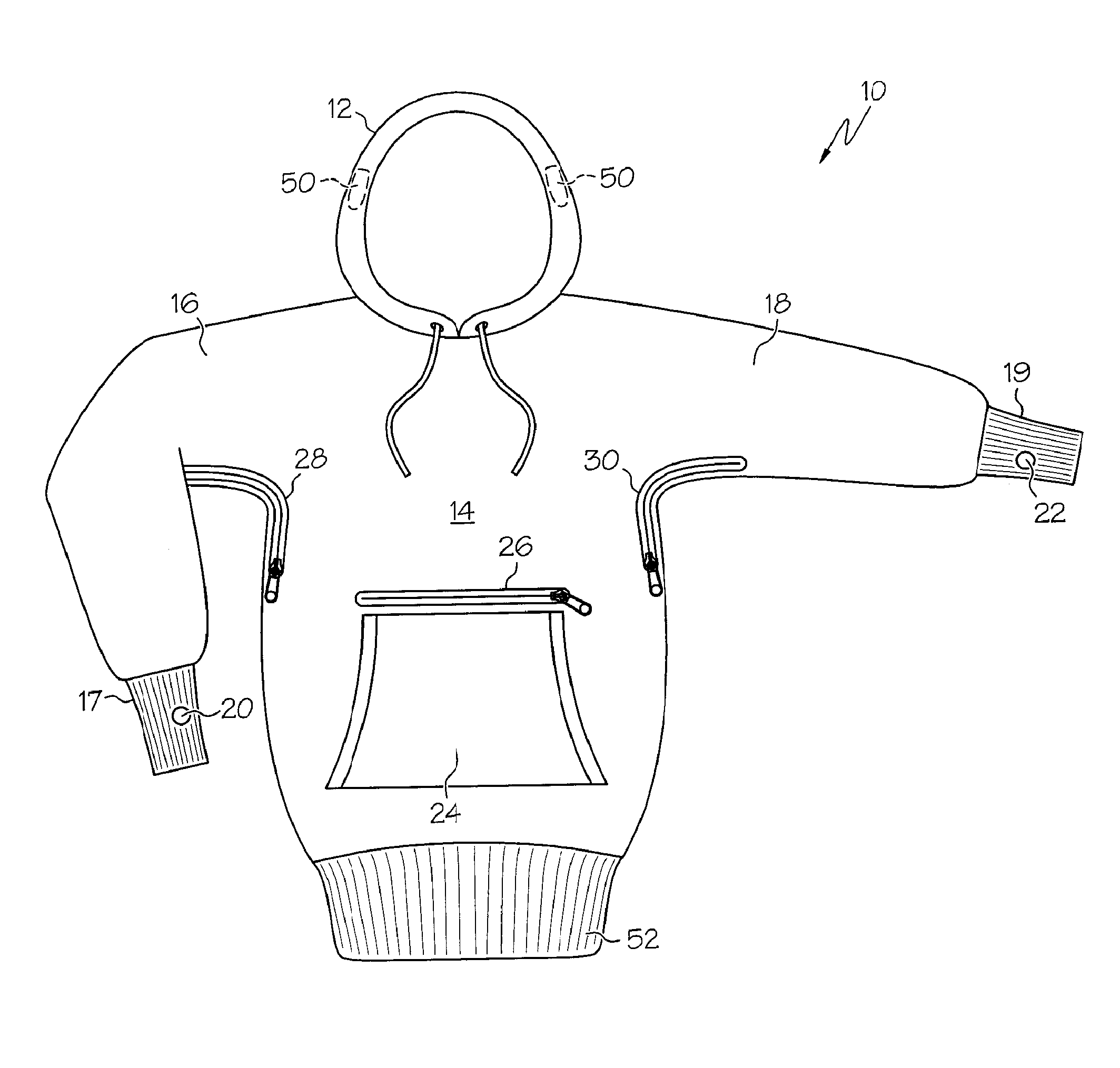

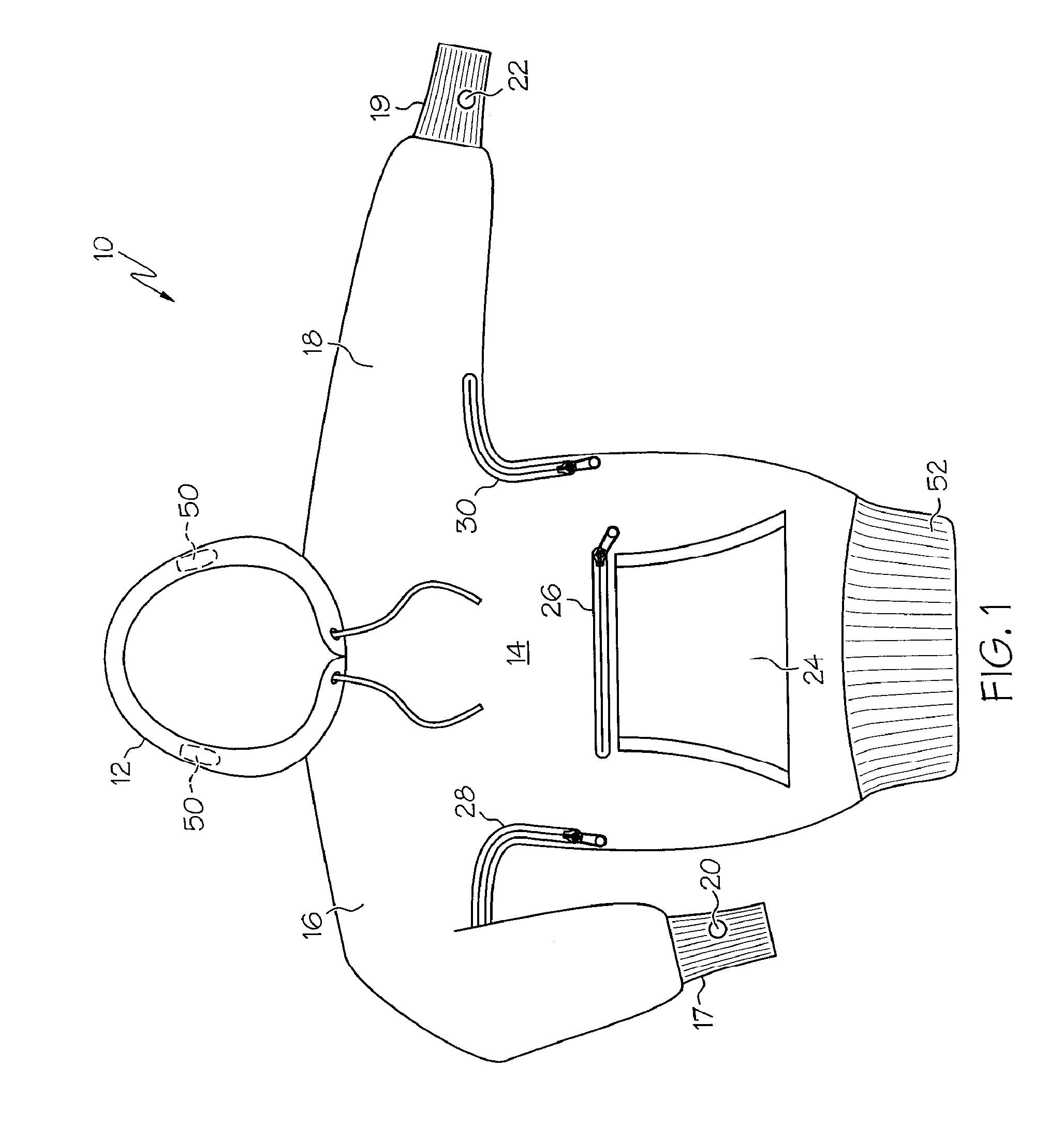

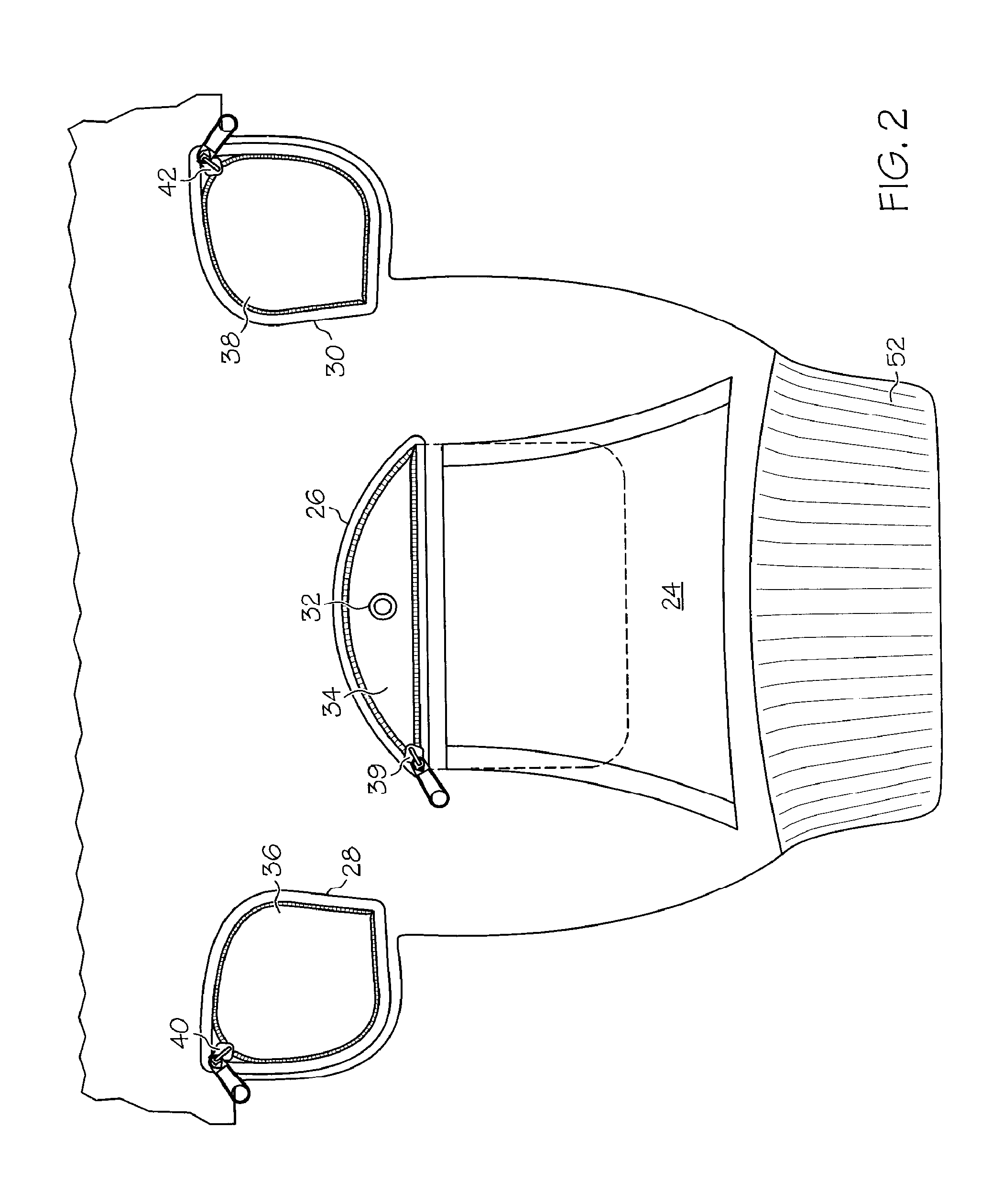

Thermoregulated Recreational Garment

A thermoregulated recreational garment includes a front pouch with side entry openings for warming or resting the hands therein during periods of inactivity, a front pocket located behind the front pouch, and two side ventilation openings. The two side ventilation openings are adapted for quick venting and cooling of the body, typically after periods of strenuous activity when a lot of body heat is built up inside the garment. The torso section also can include long sleeves with extended cuffs and thumb holes to allow the user to slide their thumbs therethrough so that the cuffs cover the user's wrists during cold weather outdoor activities. The front pocket is adapted to hold an audio device, and typically an opening such as a grommet or eyelet is fitted through the back wall of the front pocket to provide access for headphone wires. The front pocket is sized adequately so excess wire length can be carried within it, thereby avoiding tangling, even during periods of heavy exercise and rapid arm movements, such as during skiing or snowboarding.

Owner:MAYERSON ADAM +1

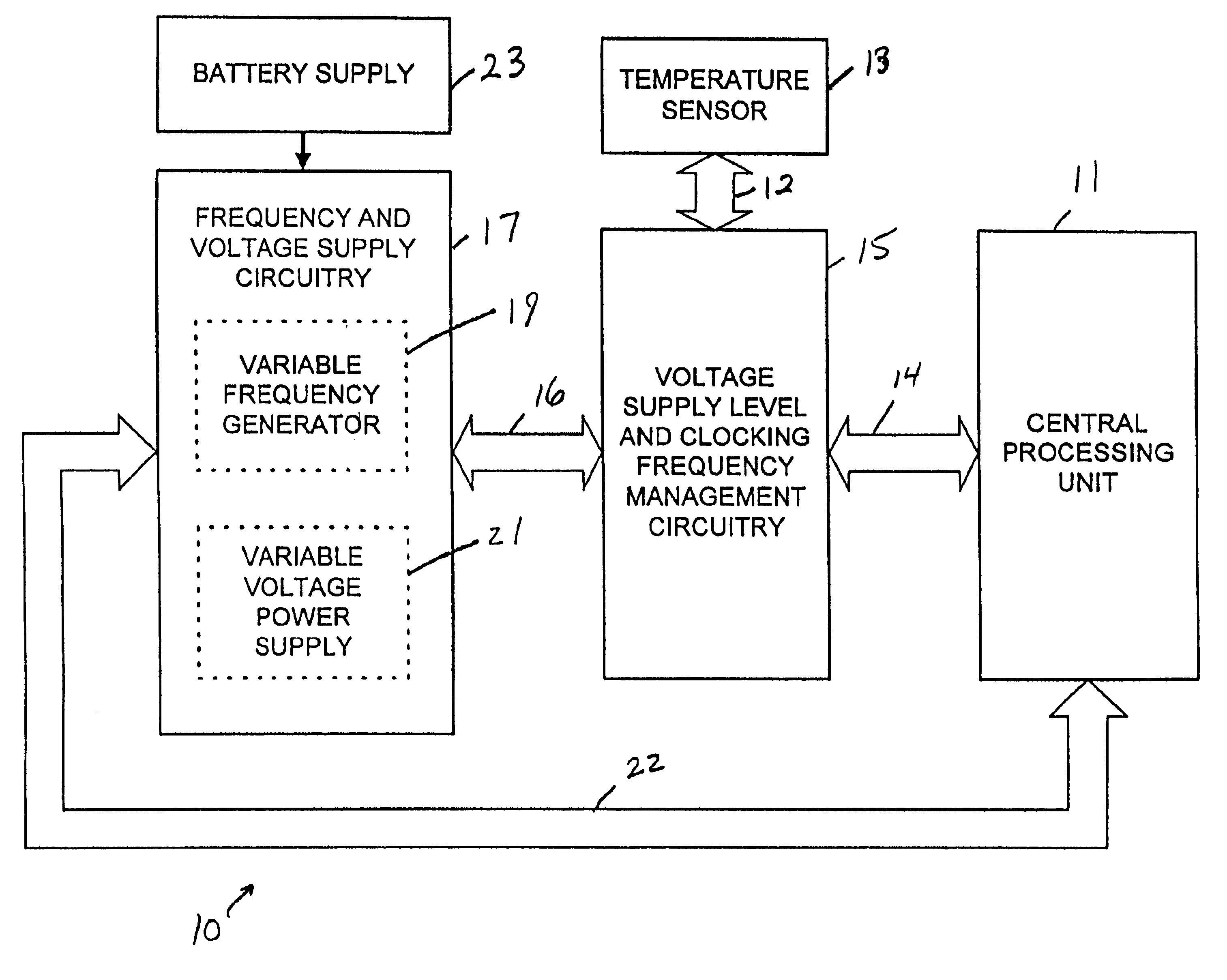

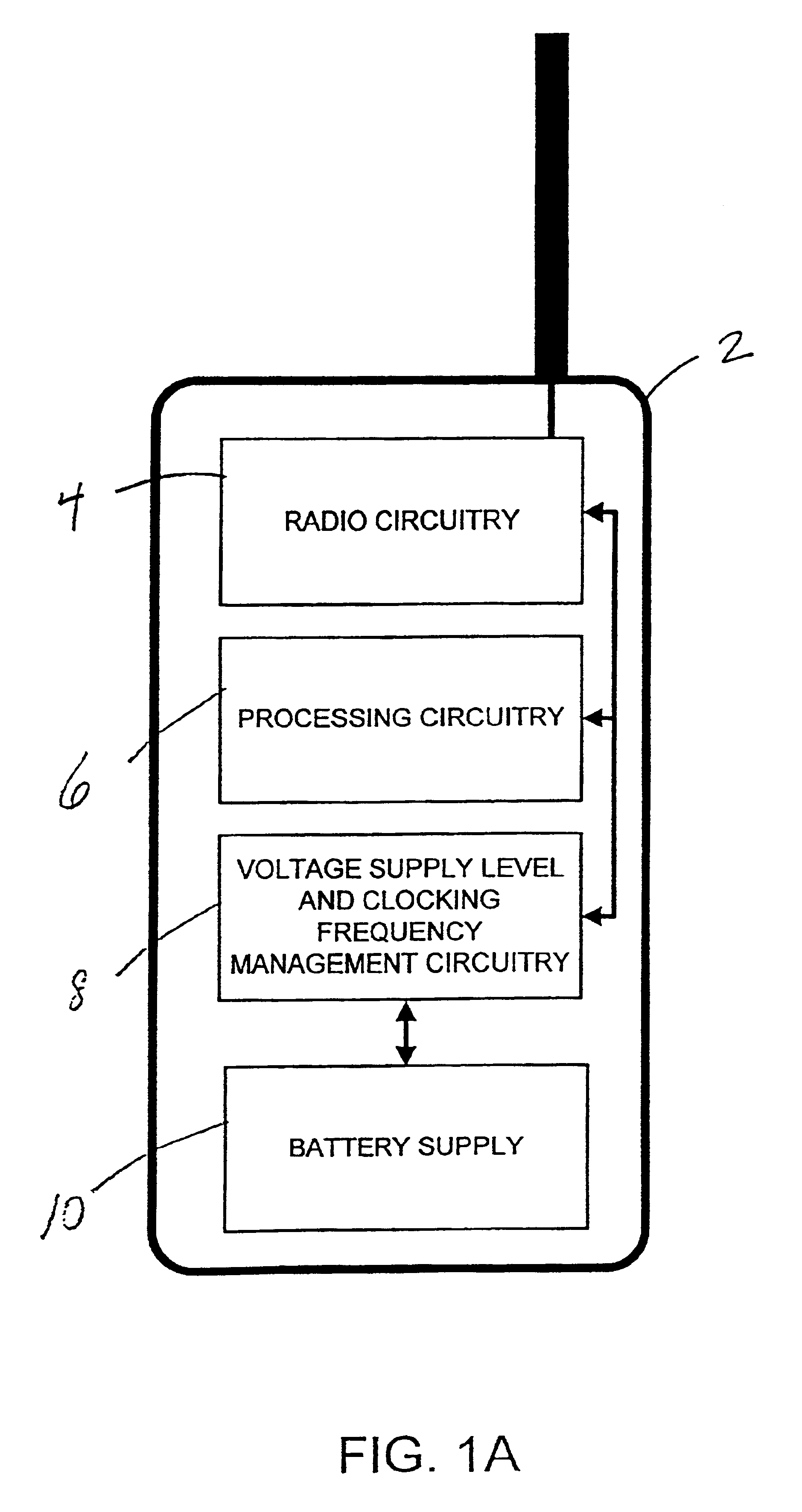

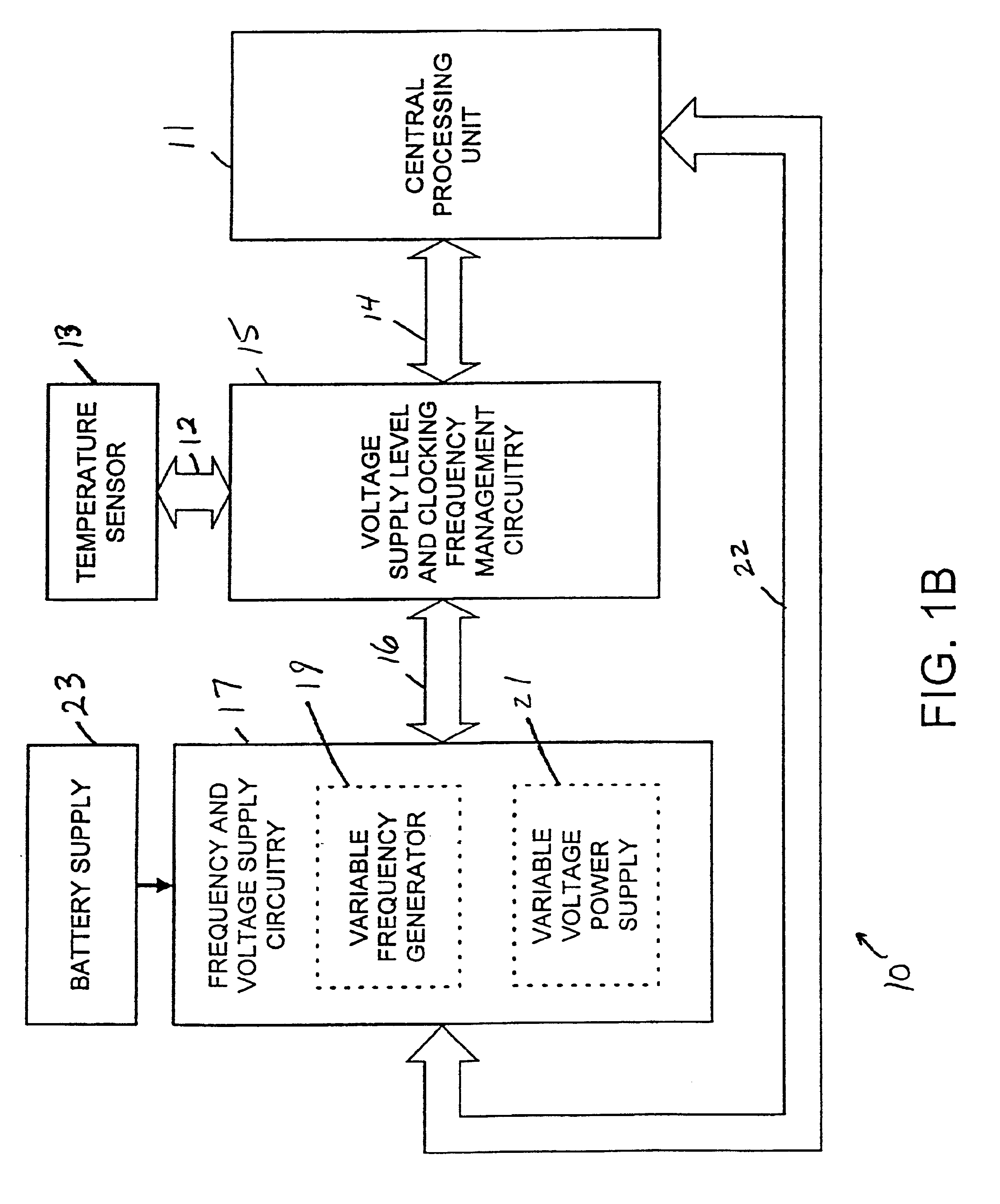

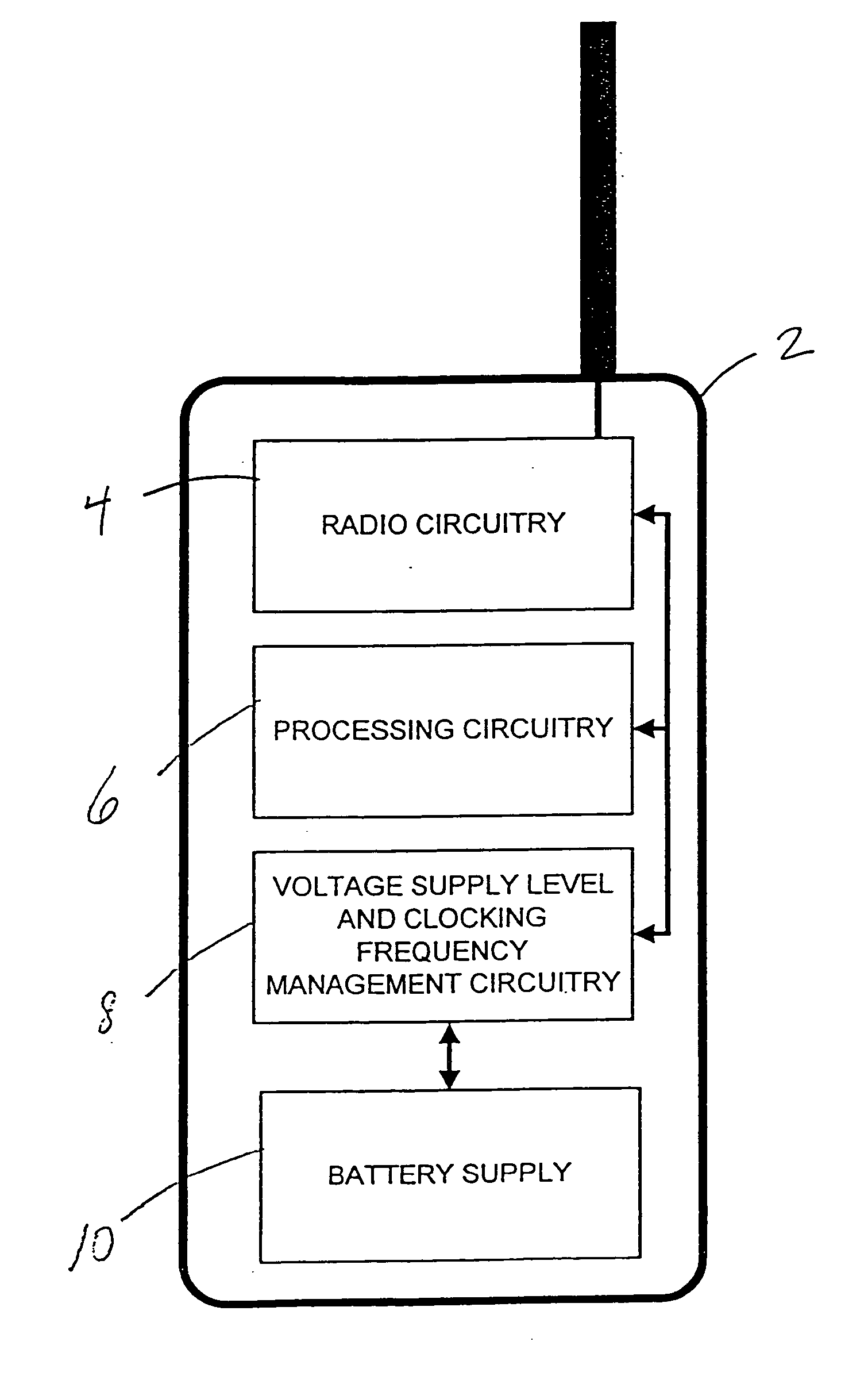

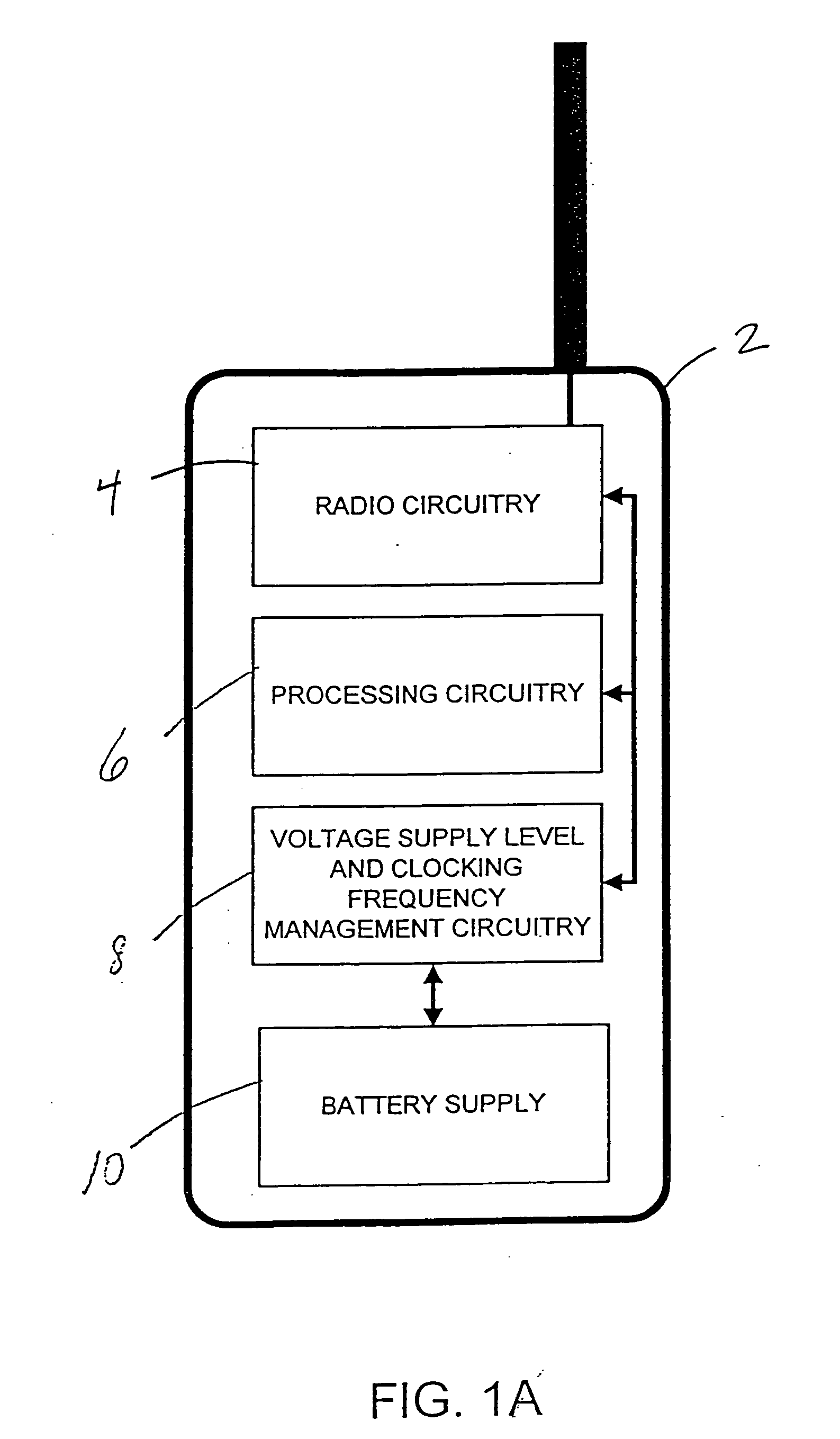

Battery powered device with dynamic power and performance management

A computing device operates over a range of voltages and frequencies and over a range of processor usage levels. The computing device includes at least a variable frequency generator, a variable voltage power supply and voltage supply level and clocking frequency management circuitry. The variable frequency generator is coupled to the processor and delivers a clock signal to the processor. The variable voltage power supply is coupled to the processor and delivers voltage to the processor. The voltage supply level and clocking frequency management circuitry adjust both the voltage provided by the variable voltage power supply and the frequency of the signal provided by the variable frequency generator. The computing device includes a temperature sensor that provides signals indicative of the temperature of the processor and the voltage supply level and clocking frequency management circuitry adjusts the voltage and / or the clocking frequency provided by the variable voltage power supply. The computing device may also include a fan controlled by the voltage supply level and clocking frequency management circuitry, the fan adjusting the temperature of the processor when activated. In cold weather applications, the computing device may further include a heater controlled by the voltage supply level and clocking frequency management circuitry that raises the temperature of the processor when activated.

Owner:AVAGO TECH INT SALES PTE LTD

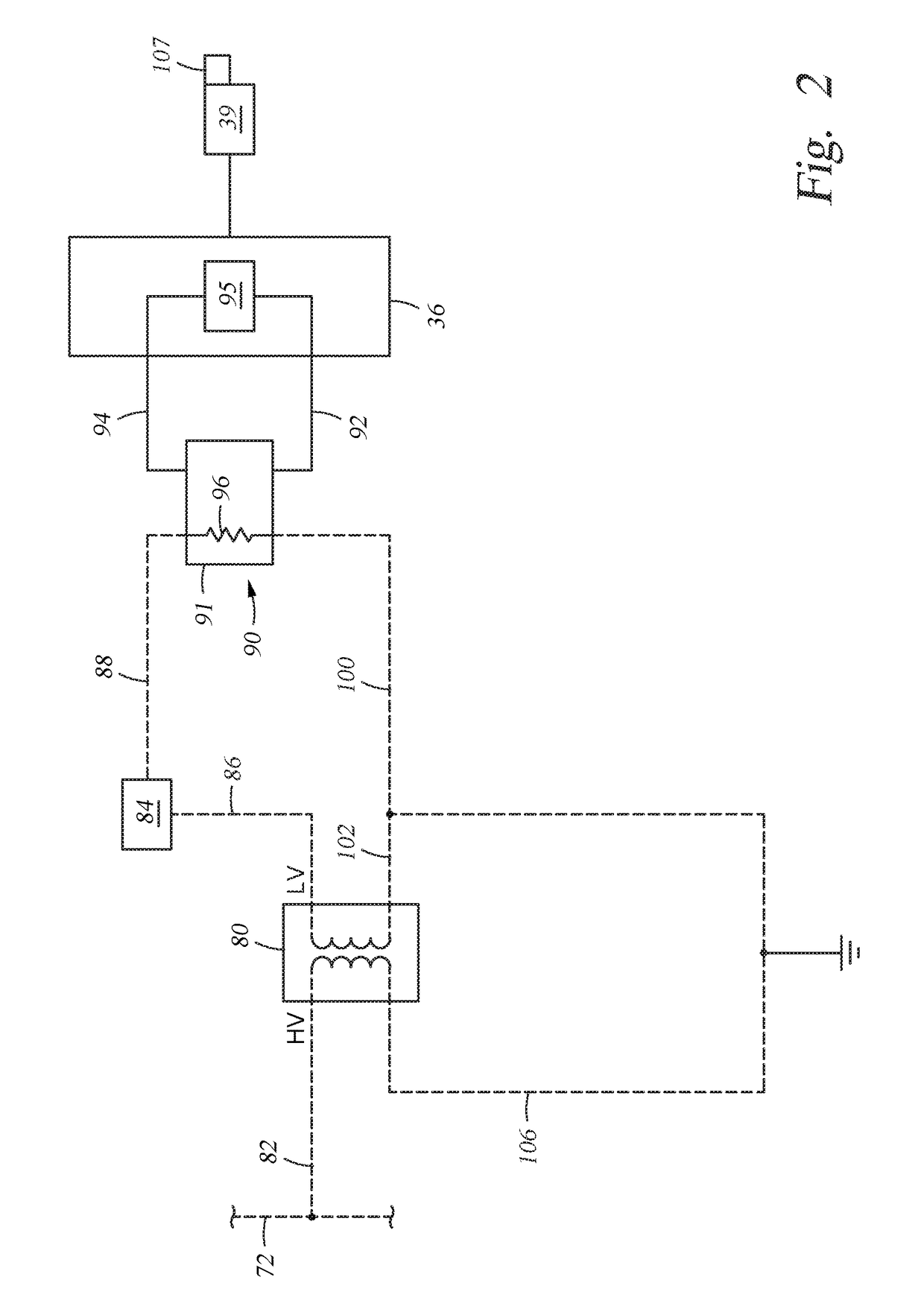

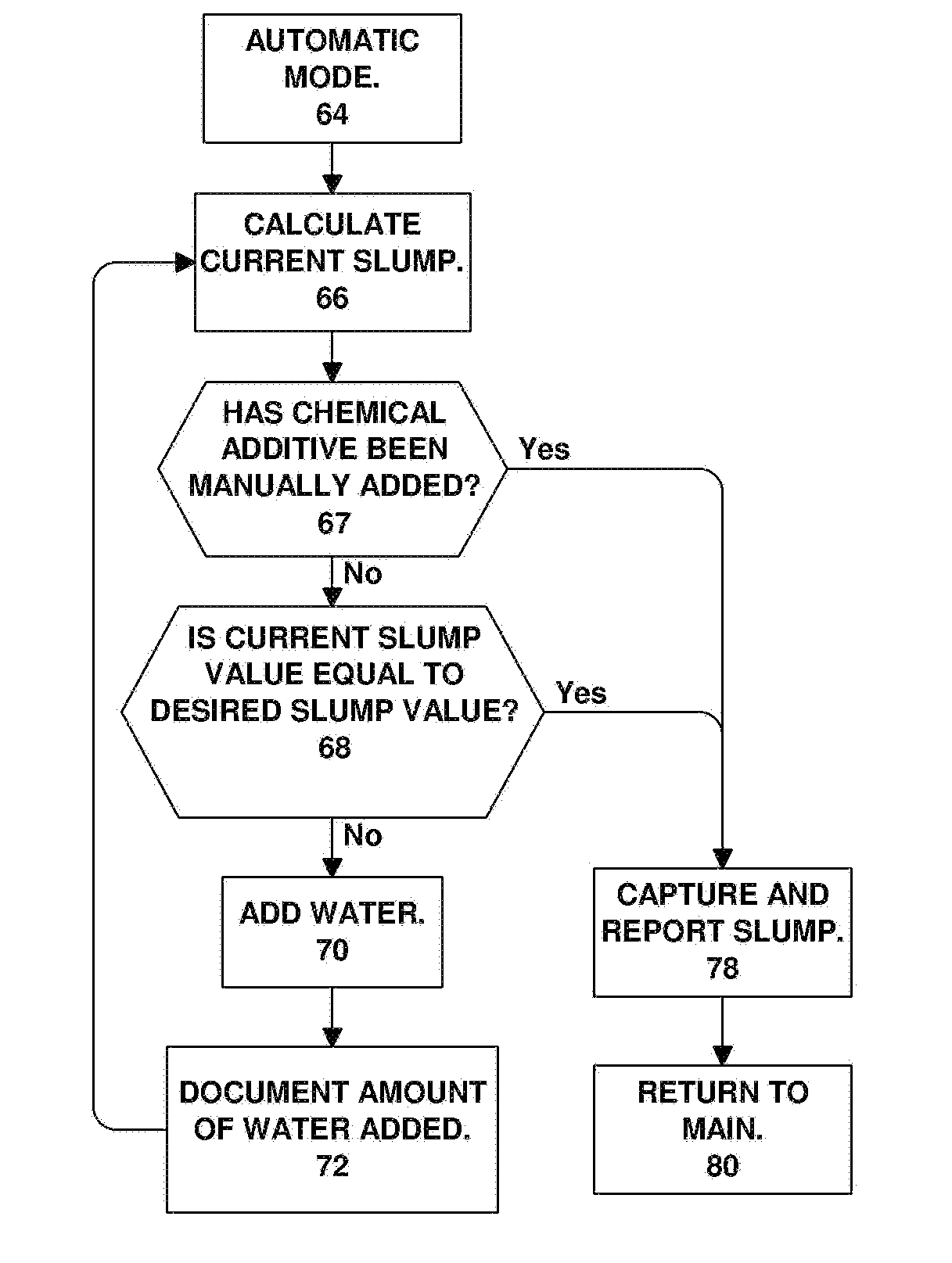

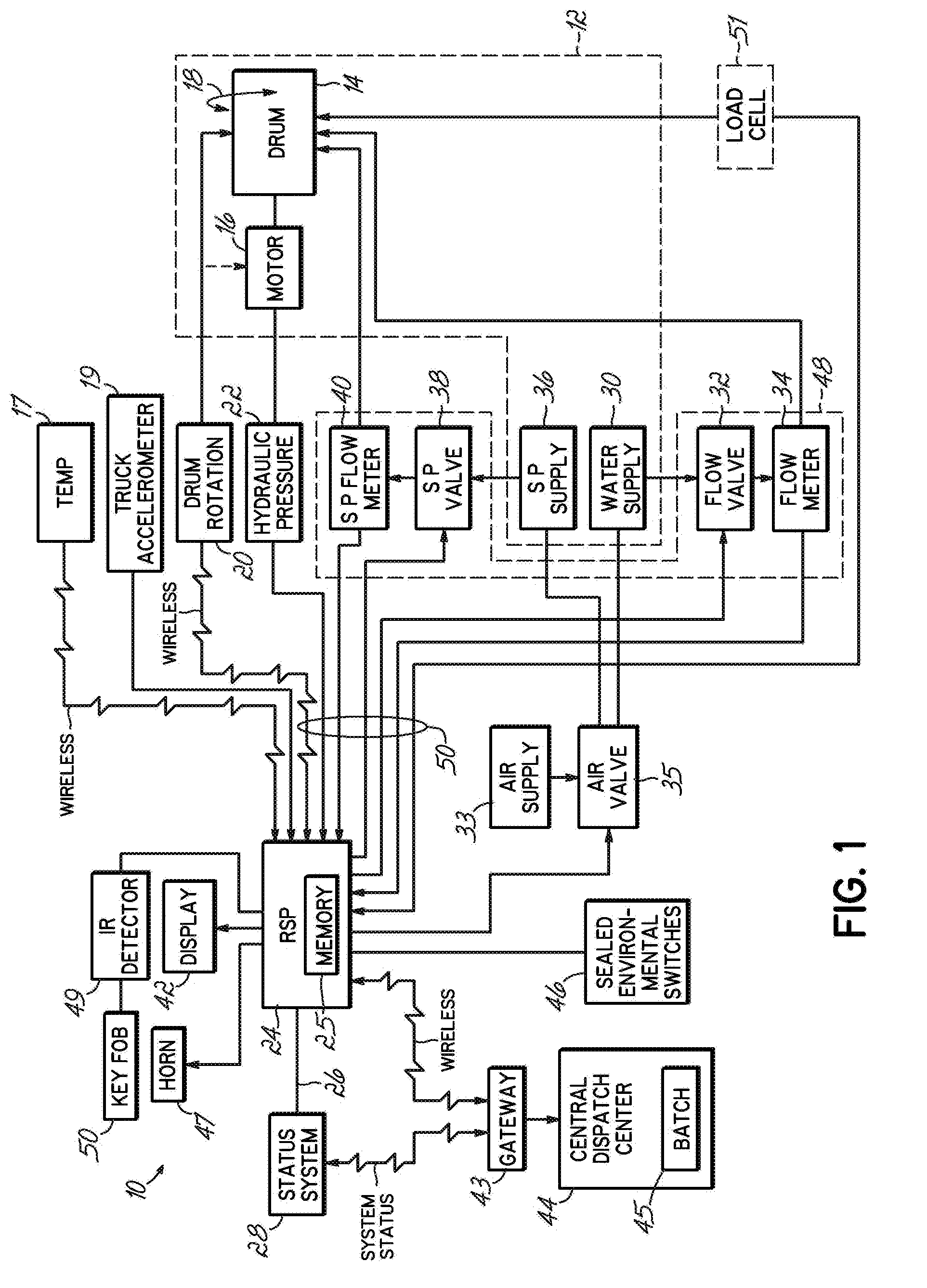

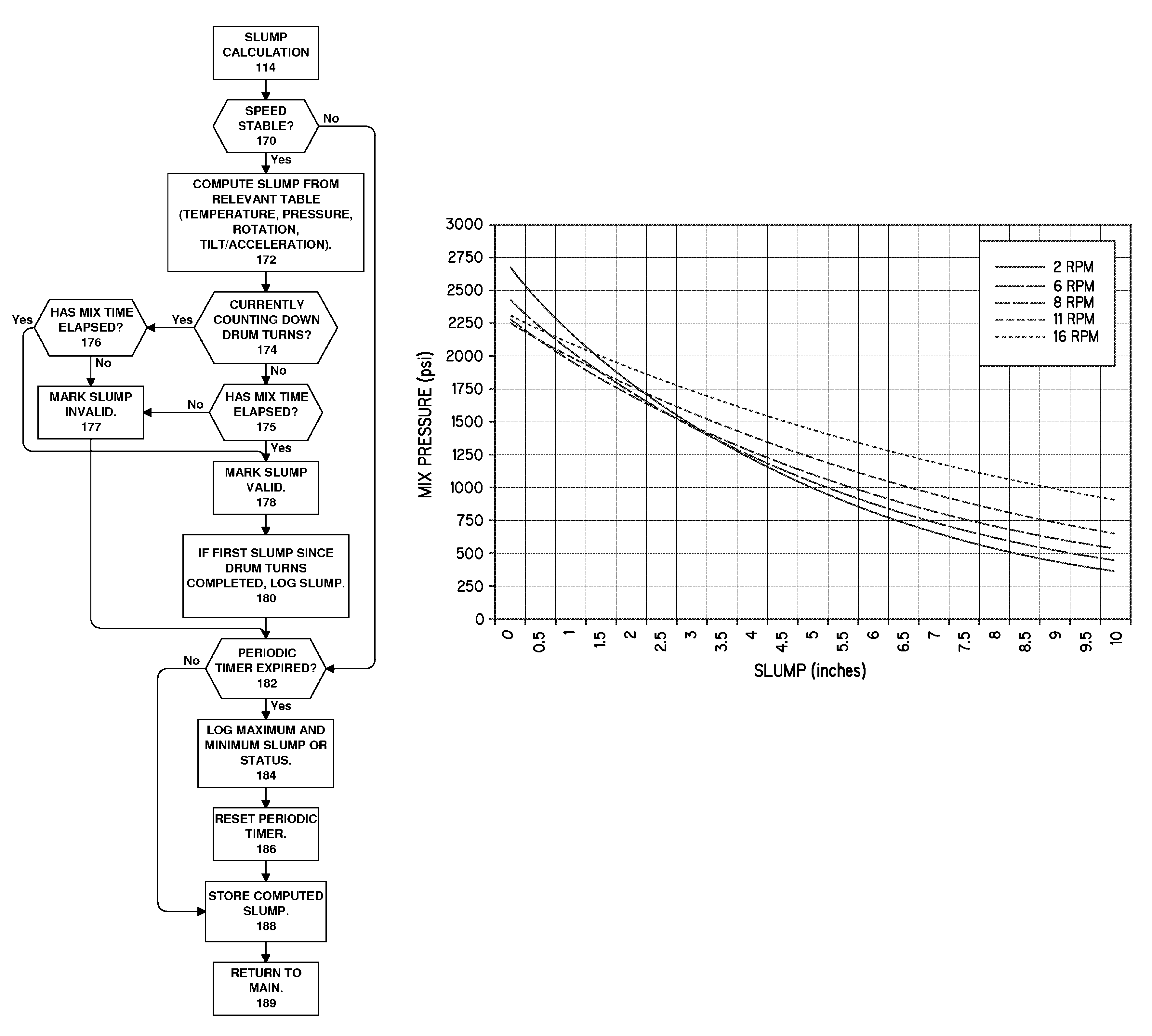

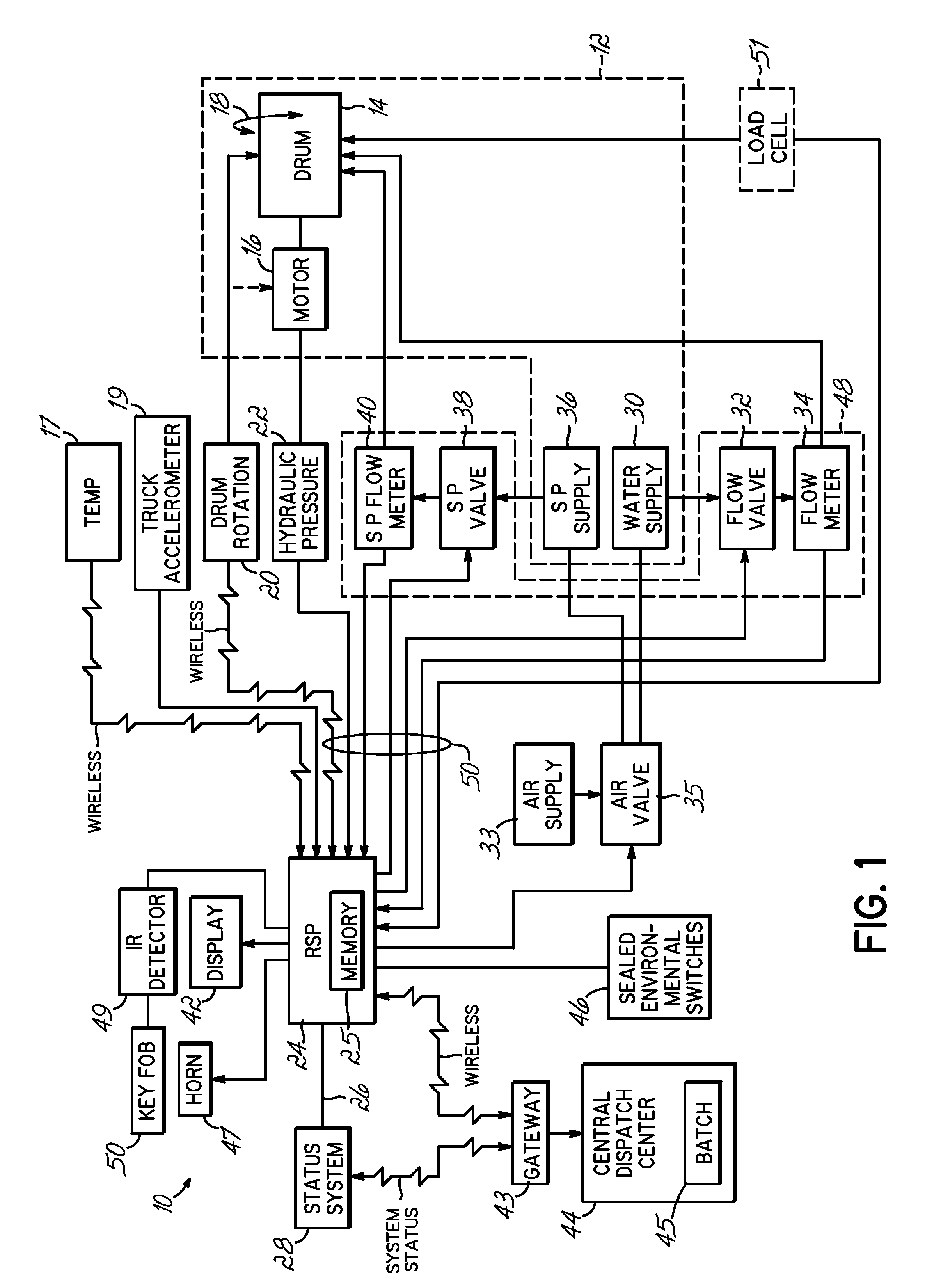

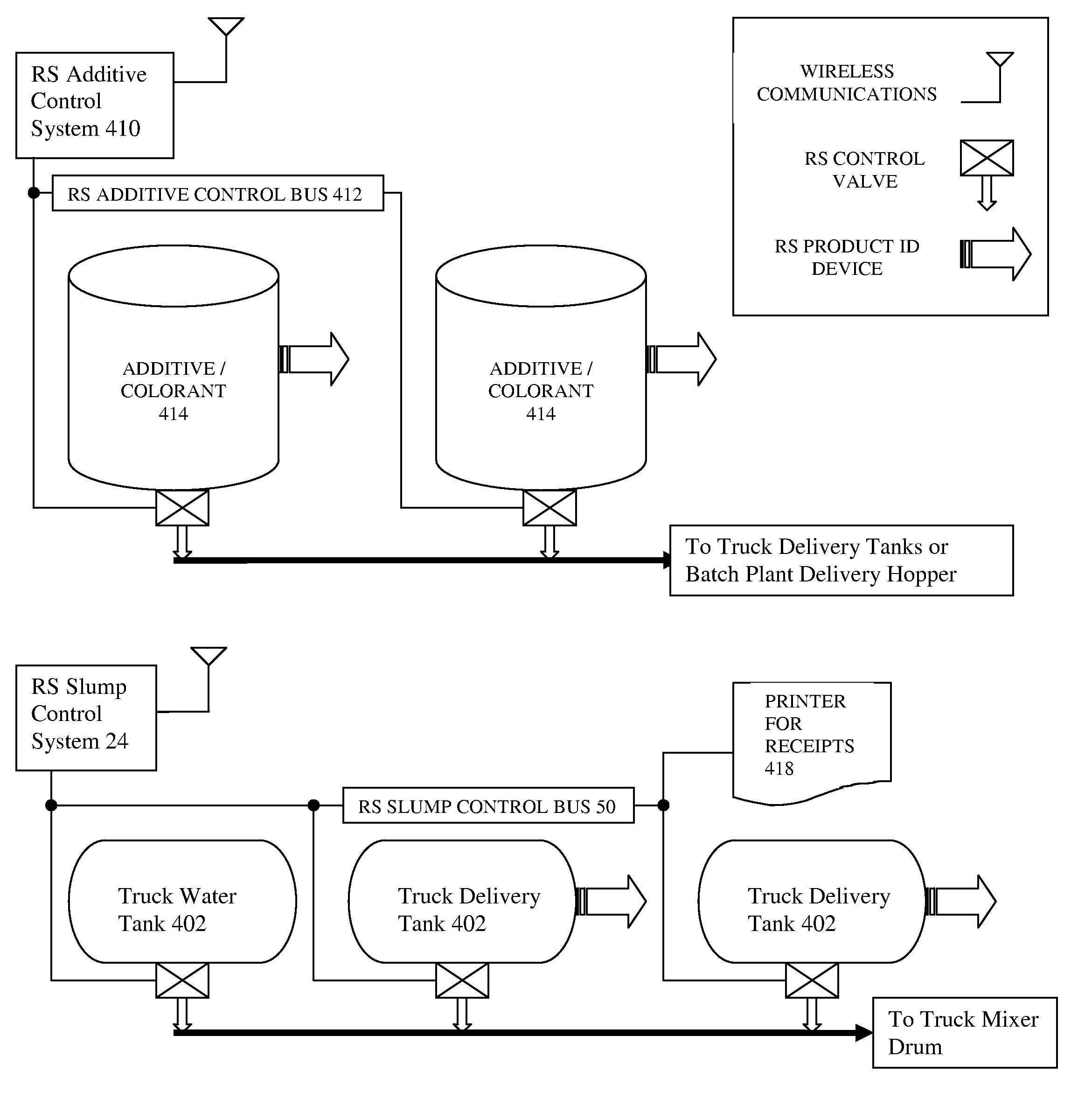

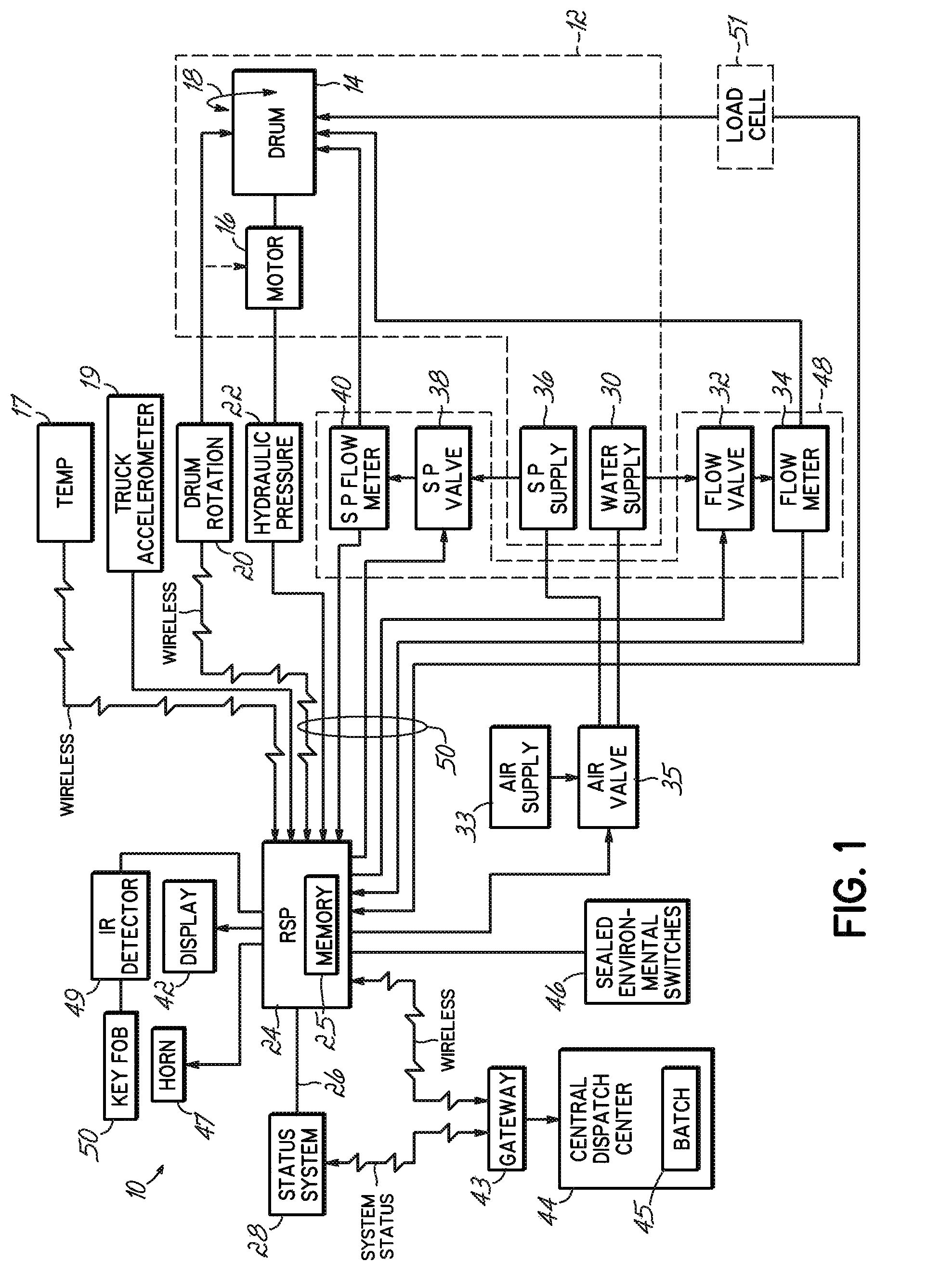

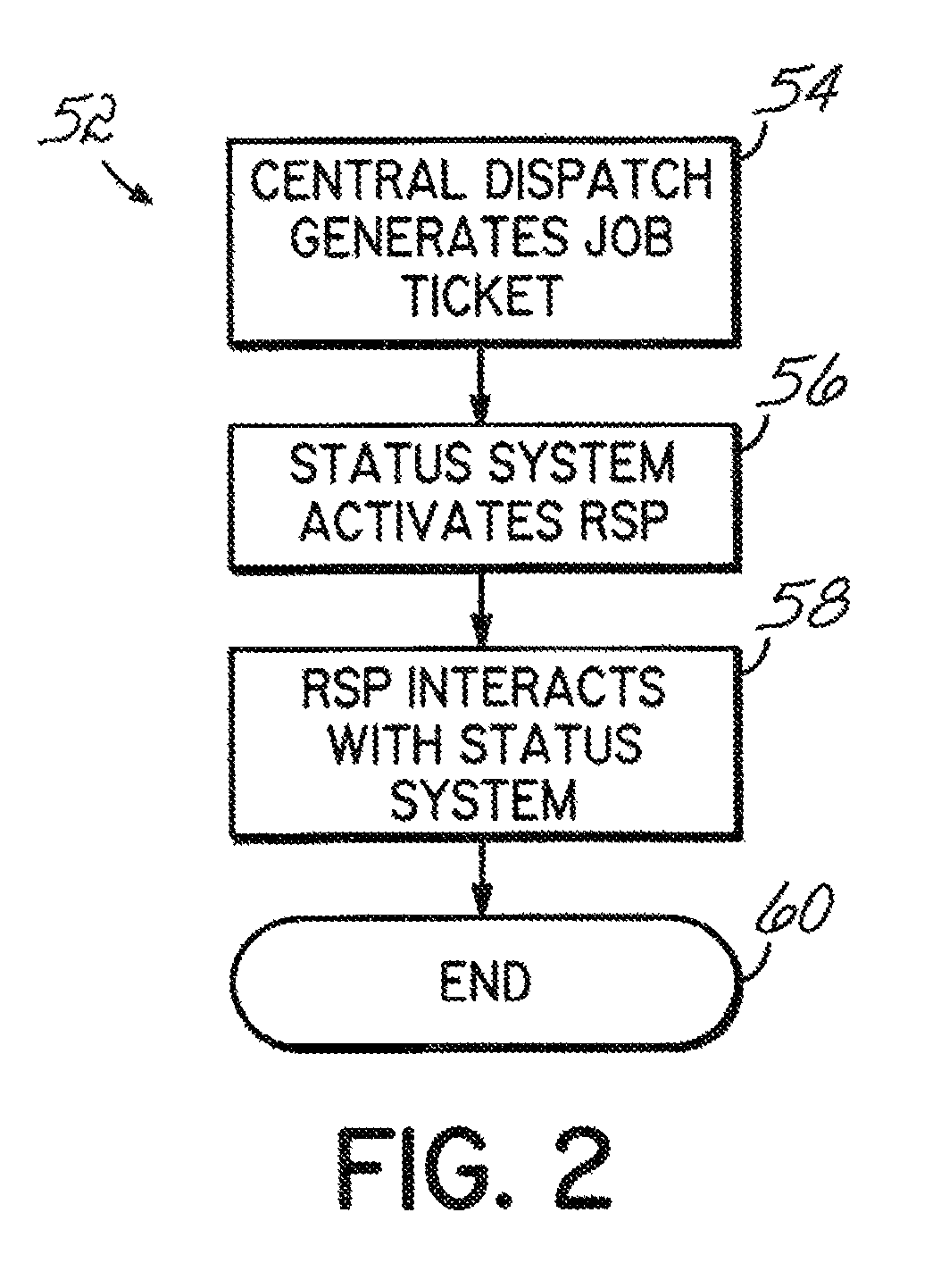

Method and System for Calculating and Reporting Slump in Delivery Vehicles

ActiveUS20090037026A1Easy to useThermometer detailsSampled-variable control systemsDelivery vehicleCold weather

A system for managing a concrete delivery vehicle having a mixing drum 14 and hydraulic drive 16 for rotating the mixing drum, including a rotational sensor 20 configured to sense a rotational speed of the mixing drum, a hydraulic sensor 22 coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, a temperature sensor for sensing temperature of the drum, and a communications port 26 configured to communicate a slump calculation to a status system 28 commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum. Temperature readings are further used to qualify or evaluate a load. Also, water purge connections facilitate cold weather operation.

Owner:VERIFI

Method and system for calculating and reporting slump in delivery vehicles

A system for managing a concrete delivery vehicle having a mixing drum 14 and hydraulic drive 16 for rotating the mixing drum, including a rotational sensor 20 configured to sense a rotational speed of the mixing drum, a hydraulic sensor 22 coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, a temperature sensor for sensing temperature of the drum, and a communications port 26 configured to communicate a slump calculation to a status system 28 commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum. Temperature readings are further used to qualify or evaluate a load. Also, water purge connections facilitate cold weather operation.

Owner:VERIFI INC

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS20050022499A1Increase flow rateReduce the temperatureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

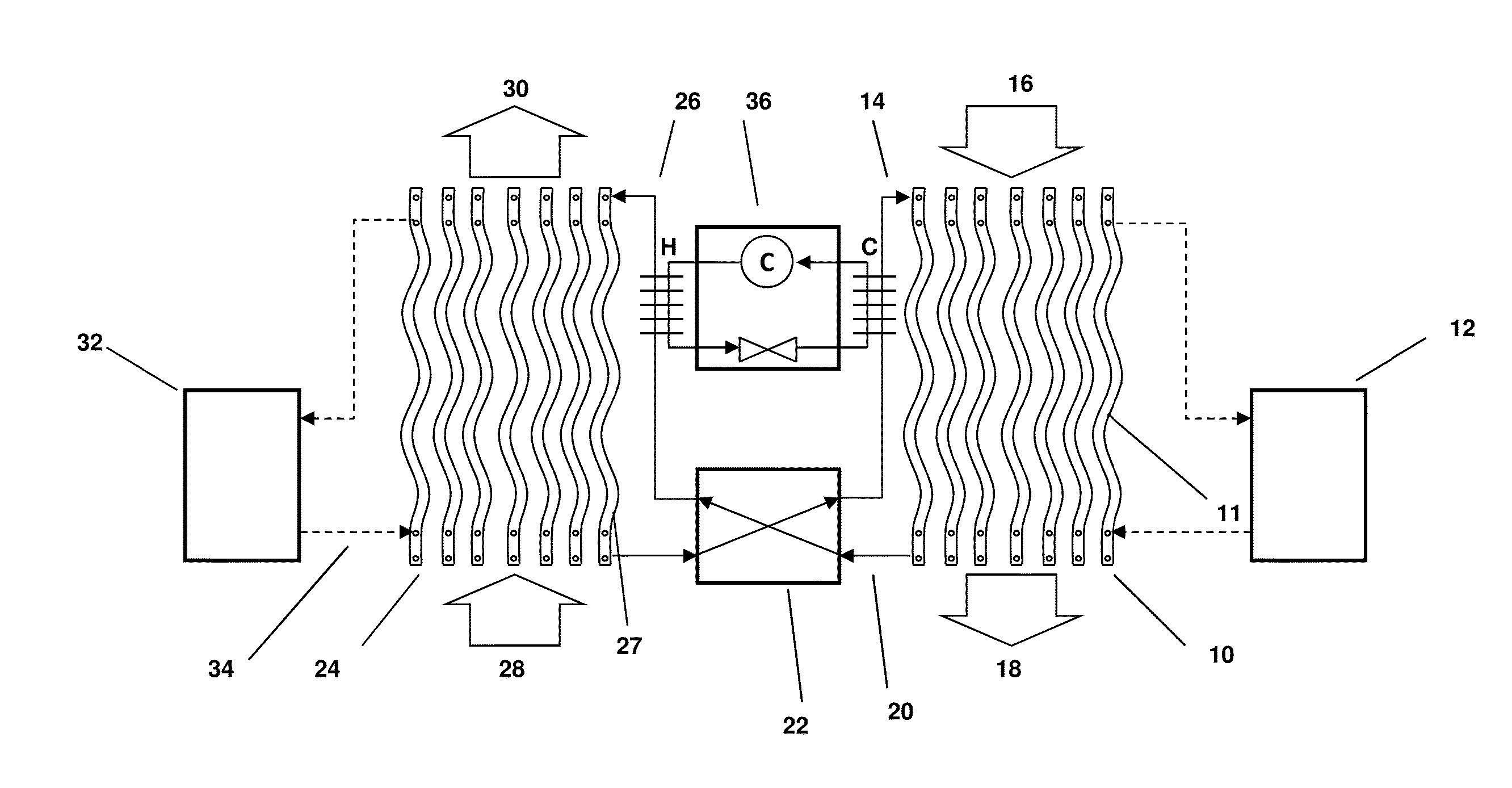

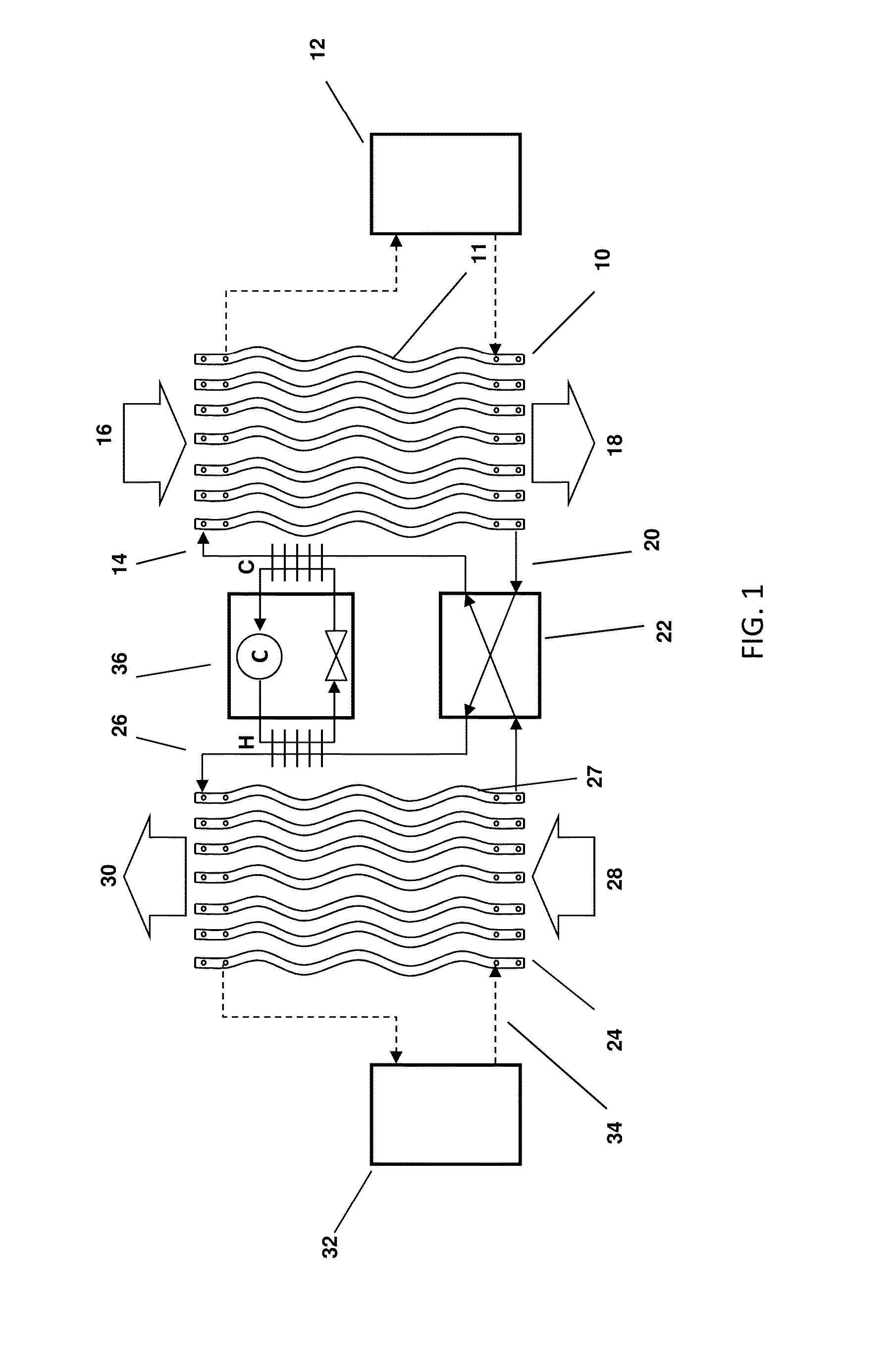

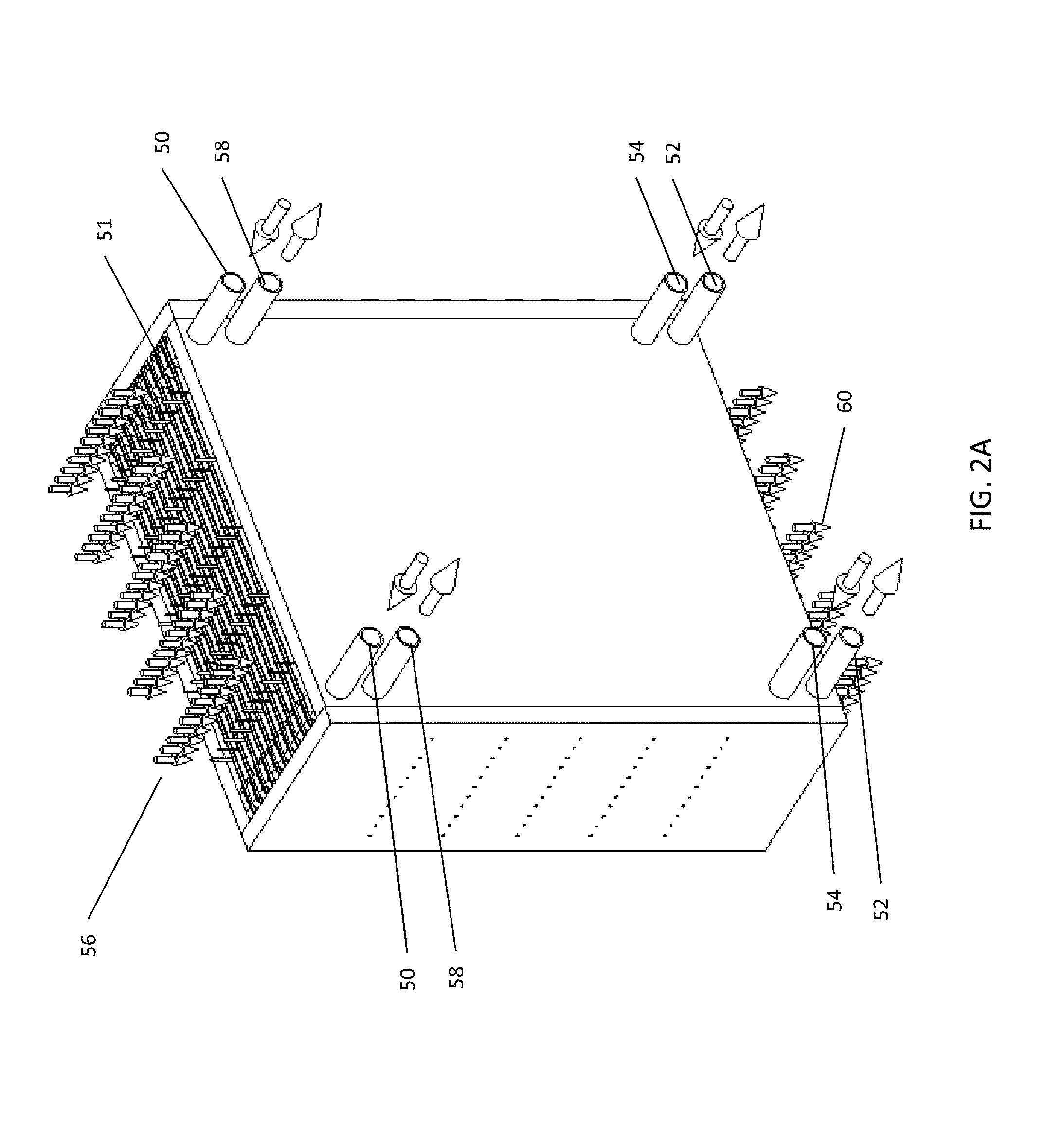

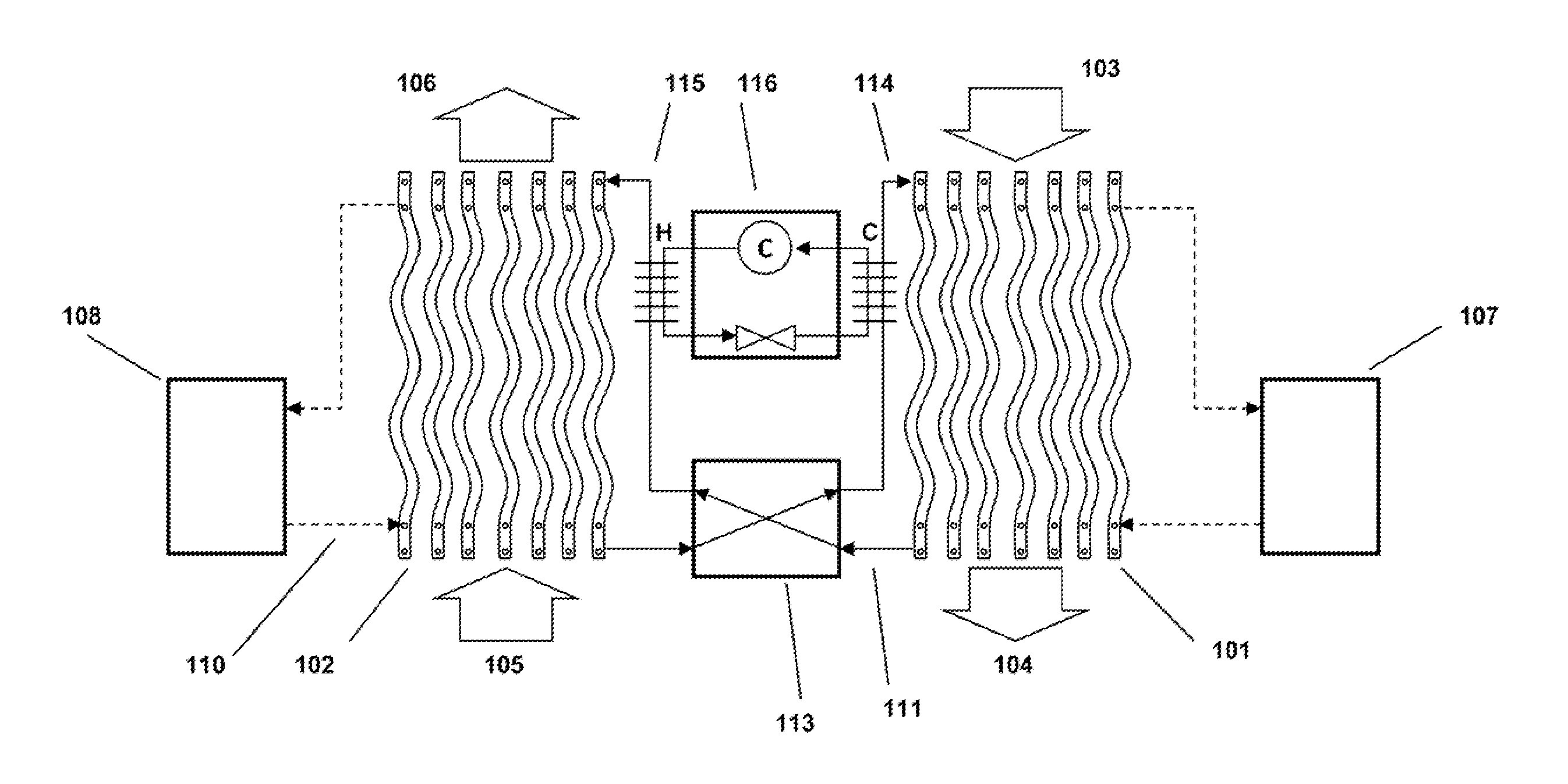

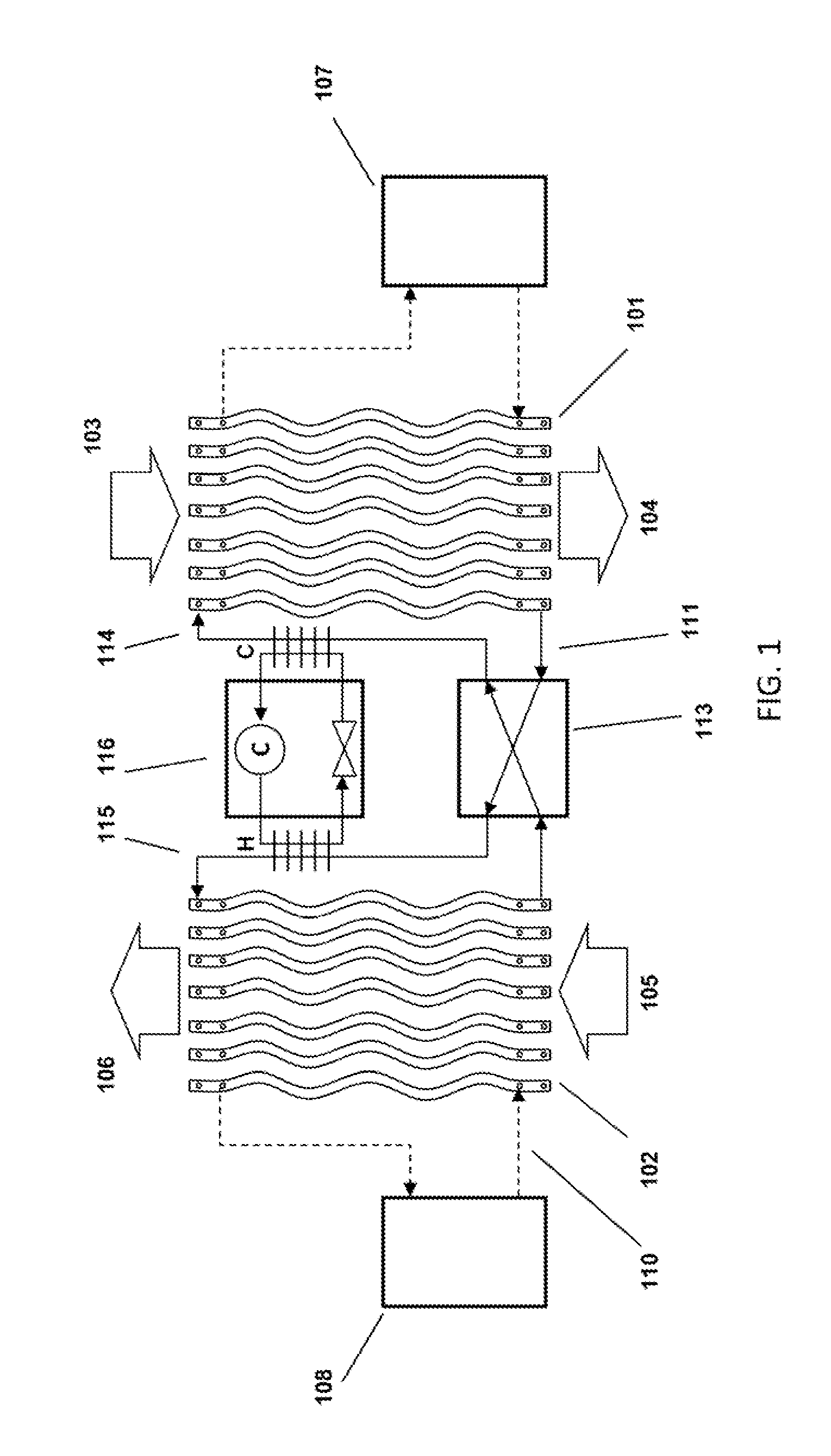

Desiccant air conditioning methods and systems

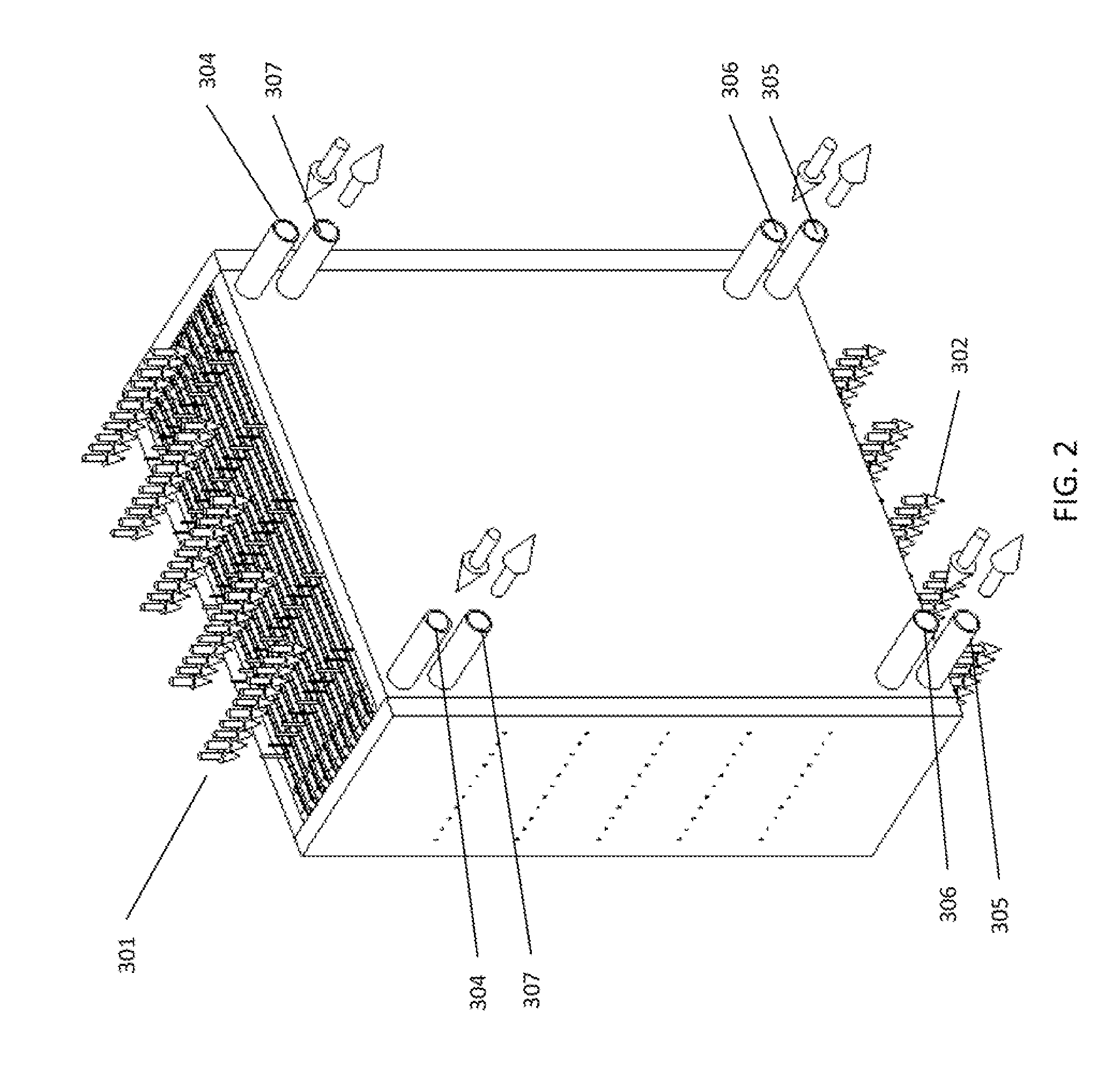

ActiveUS20140245769A1Efficient dehumidificationEfficient workEnergy recovery in ventilation and heatingMechanical apparatusDesiccantOperation mode

A desiccant air conditioning system for treating an air stream entering a building space, including a conditioner configured to expose the air stream to a liquid desiccant such that the liquid desiccant dehumidifies the air stream in the warm weather operation mode and humidifies the air stream in the cold weather operation mode. The conditioner includes multiple plate structures arranged in a vertical orientation and spaced apart to permit the air stream to flow between the plate structures. Each plate structure includes a passage through which a heat transfer fluid can flow. Each plate structure also has at least one surface across which the liquid desiccant can flow. The system includes a regenerator connected to the conditioner for causing the liquid desiccant to desorb water in the warm weather operation mode and to absorb water in the cold weather operation mode from a return air stream.

Owner:COPELAND LP

Methods and systems for mini-split liquid desiccant air conditioning

InactiveUS20140260399A1Effective coolingEfficient dehumidificationDomestic cooling apparatusLighting and heating apparatusEngineeringCold weather

A split liquid desiccant air conditioning system is disclosed for treating an air stream flowing into a space in a building. The split liquid desiccant air-conditioning system is switchable between operating in a warm weather operation mode and a cold weather operation mode.

Owner:7AC TECH

Image intensifier and LWIR fusion/combination system

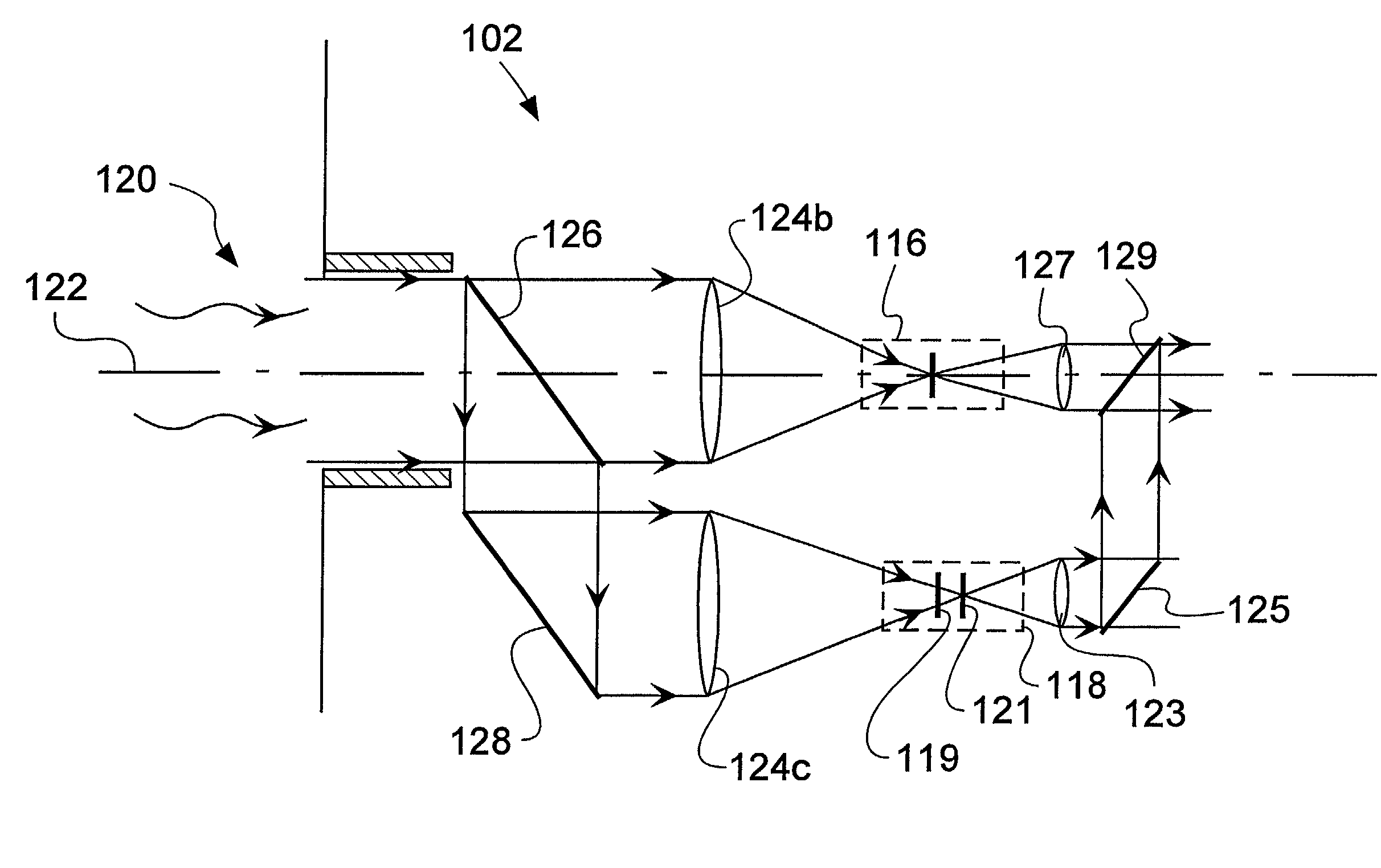

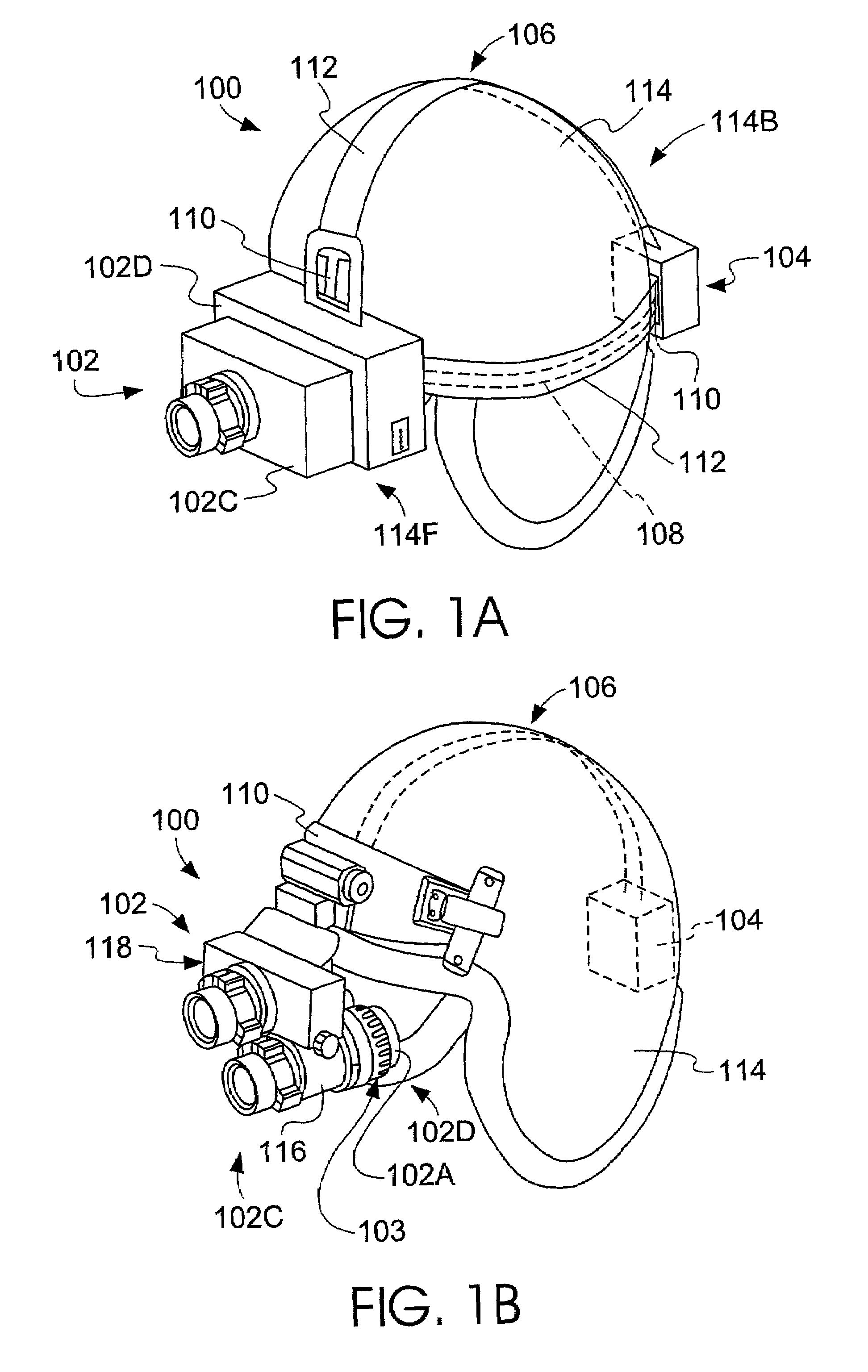

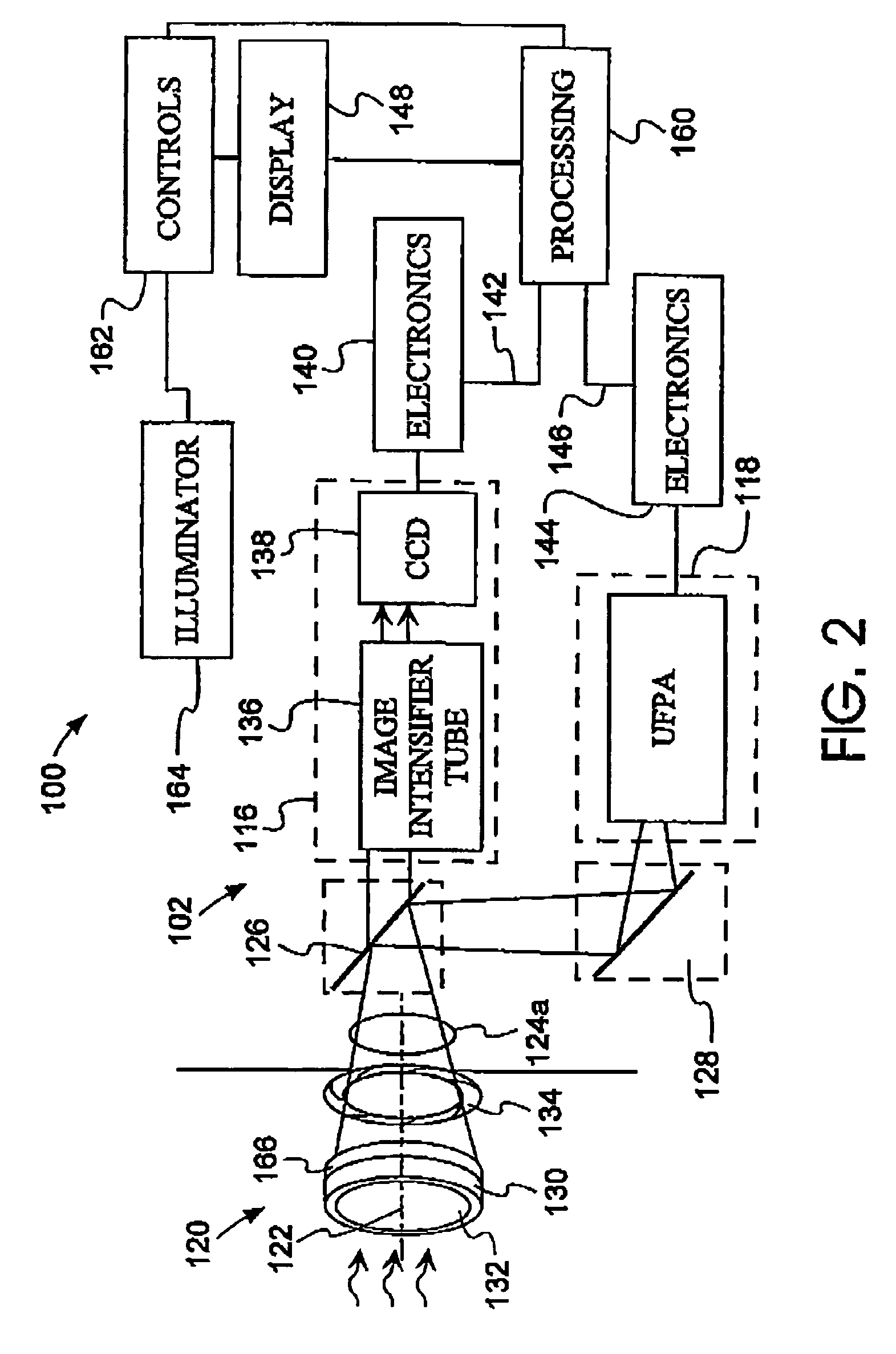

InactiveUS7345277B2Remove parallaxOvercome disadvantagesTelevision system detailsRadiation pyrometryWireless transceiverTransceiver

An infrared imaging device combines two sensors, each sensor sensitive to a different spectral range of infrared radiation. Both sensors are combined in a single camera sharing one of three common optical apertures, thus parallax is eliminated between the sensors. Further, a display device is aligned along an optical axis in common with the camera eliminating parallax between the display and camera. Images from the first sensor, the second sensor, or both sensors may be viewed optically and / or electronically. The device is handheld, or mountable on a headgear such as a helmet. When mounted on headgear, the display is viewable by directing the operator's gaze upward, thus the display does not interfere with an operator's straight and downward sight. The image can be sent to a remote display by a wireless transceiver, and waterproof, fireproof, vibration / impact resistance, and hot / cold weather resistance are achieved using a high strength plastic enclosure with foam insert.

Owner:ZHANG EVAN

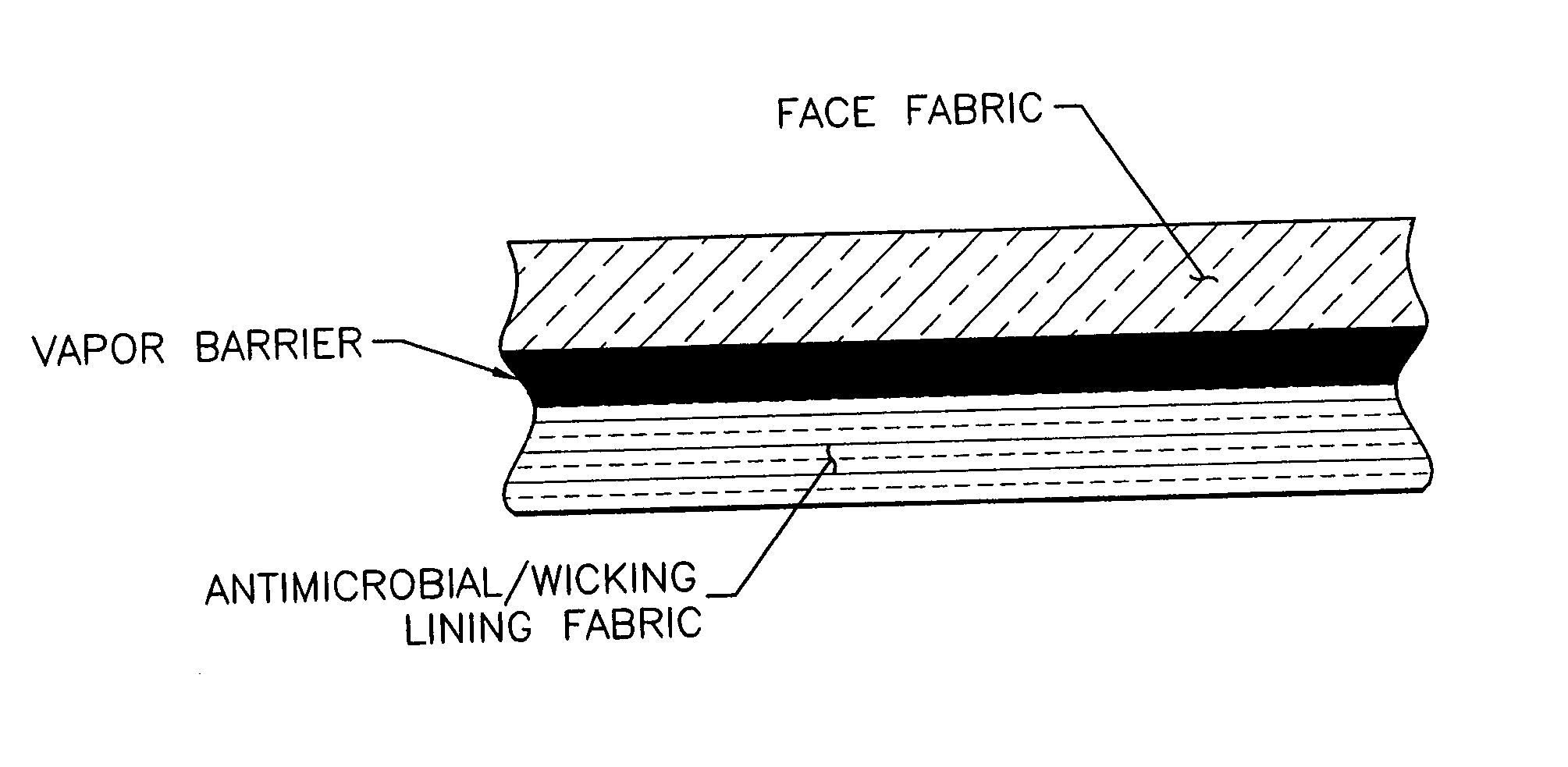

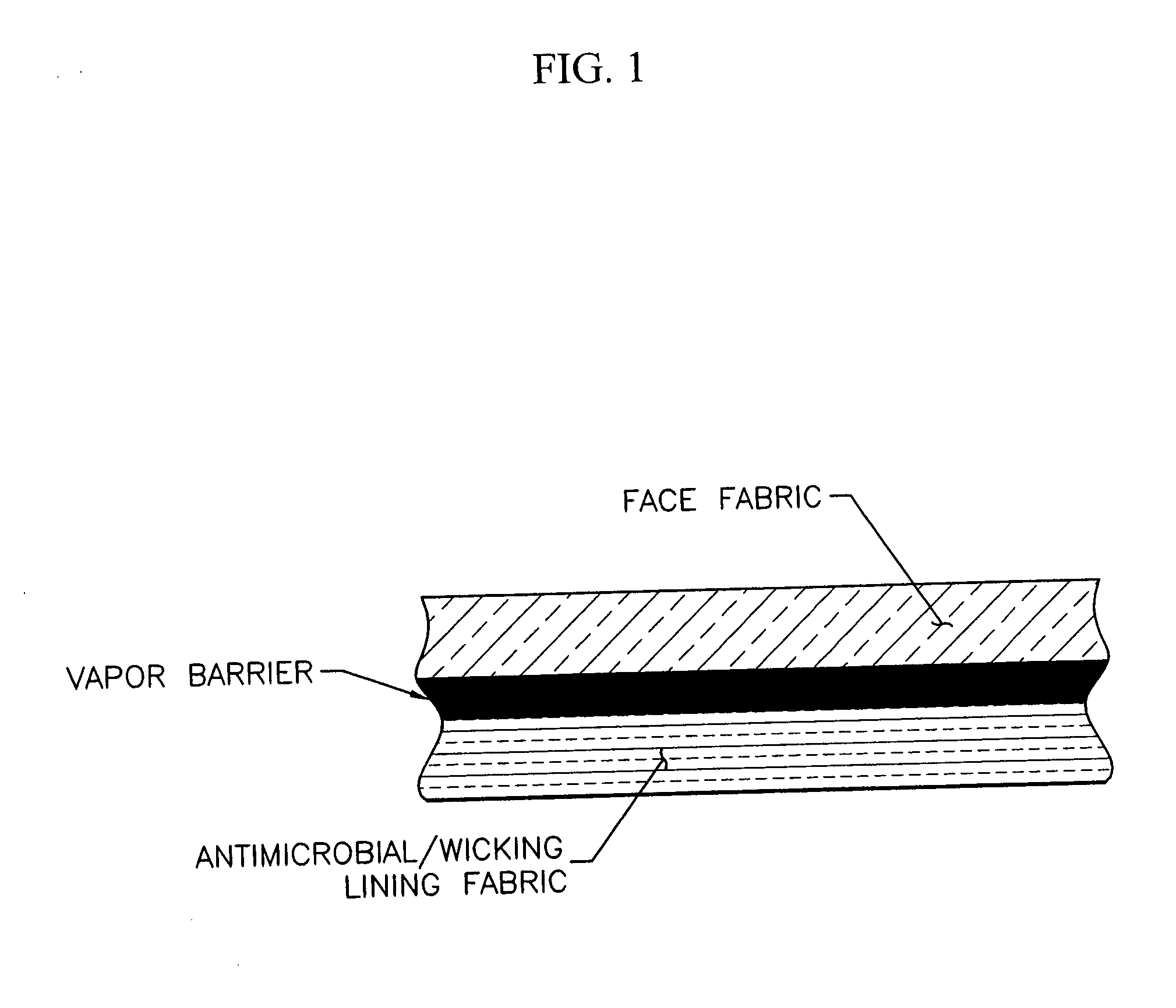

Multifunctional composite vapor barrier textile

InactiveUS20070166503A1Relieve overheatingAdd to comfort and aesthetic propertyGarment special featuresSynthetic resin layered productsVapor barrierAdhesive

The present invention is directed to a multifunctional waterproof / vapor barrier fabric for use in industrial, medical, outdoor apparel (hunting, fishing, skiing, mountaineering, etc.) and military applications. The invention combines functional elements that are especially suited for the above applications. The fabric comprises a lining with wicking and antimicrobial properties, a vapor barrier film or coating with low Moisture Vapor Transmission Rate (M.V.T.R.), and a woven or knit face fabric enhanced with a hydrophobic face coating. The fabric performs admirably in various uses due in part to the use of hydrophobic adhesive, film and coatings, which renders the fabric subject to negligible moisture gain. The durability and water proof properties of the fabric are enhanced due to the impermeable low M.V.T.R design. The fabric of the present invention incorporates a unique combination of properties that addresses issues commonly associated with vapor barrier fabrics. The invention provides a waterproof / barrier fabric that is desirable to wear in direct contact with the skin to prevent evaporative heat loss in cool or cold conditions. The fabric is also effective when worn over one or more layers of other clothing. The fabric is particularly effective because it is capable of use as a base layer and waterproof shell, which helps to minimize the number of layers of clothing needed in cold weather.

Owner:HANNIGAN RYAN B

Method and system for calculating and reporting slump in delivery vehicles

ActiveUS8989905B2Easy to useThermometer detailsTransportation and packagingDelivery vehicleCold weather

A system for managing a concrete delivery vehicle having a mixing drum 14 and hydraulic drive 16 for rotating the mixing drum, including a rotational sensor 20 configured to sense a rotational speed of the mixing drum, a hydraulic sensor 22 coupled to the hydraulic drive and configured to sense a hydraulic pressure required to turn the mixing drum, a temperature sensor for sensing temperature of the drum, and a communications port 26 configured to communicate a slump calculation to a status system 28 commonly used in the concrete industry, wherein the sensing of the rotational speed of the mixing drum is used to qualify a calculation of current slump based on the hydraulic pressure required to turn the mixing drum. Temperature readings are further used to qualify or evaluate a load. Also, water purge connections facilitate cold weather operation.

Owner:VERIFI INC

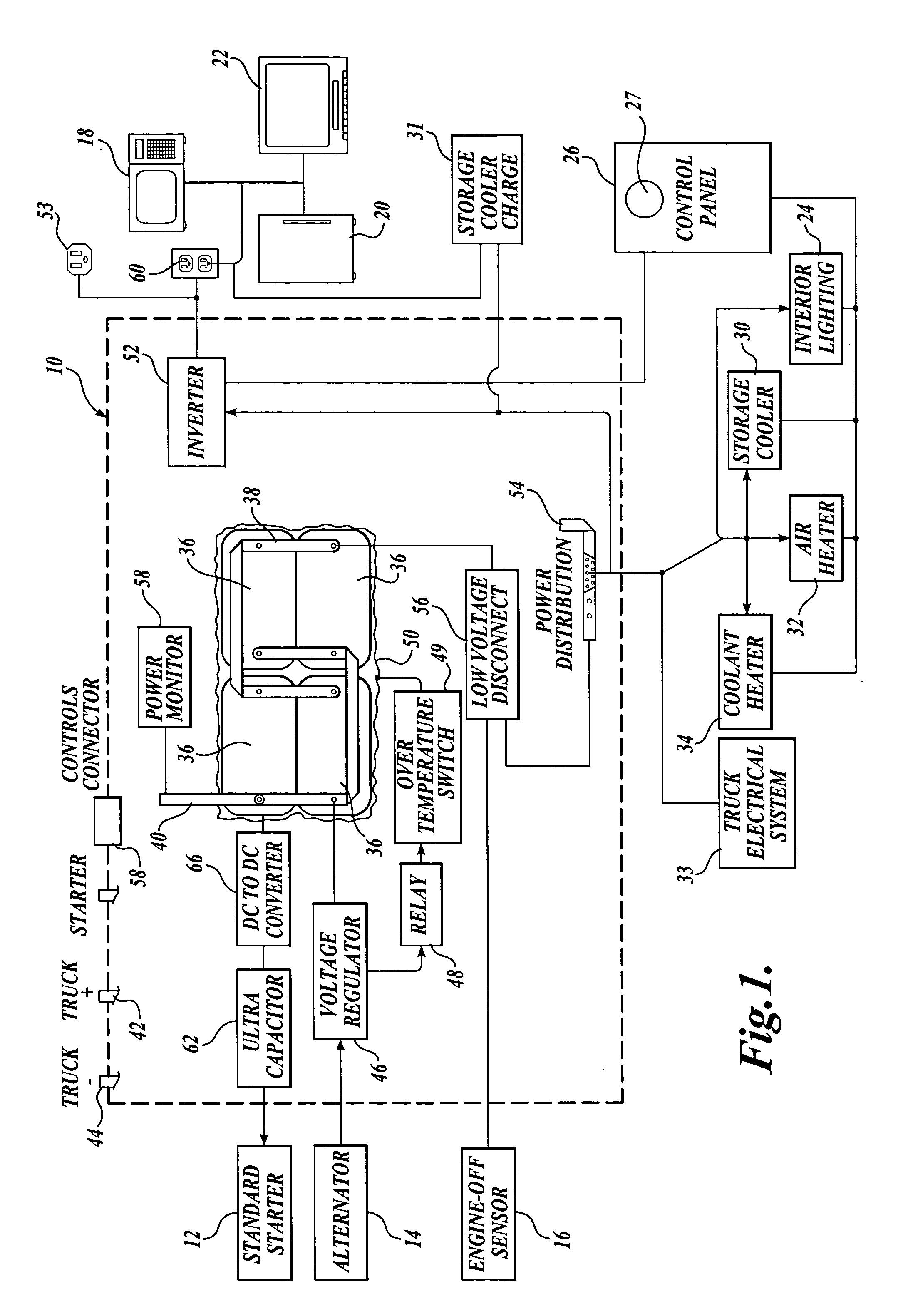

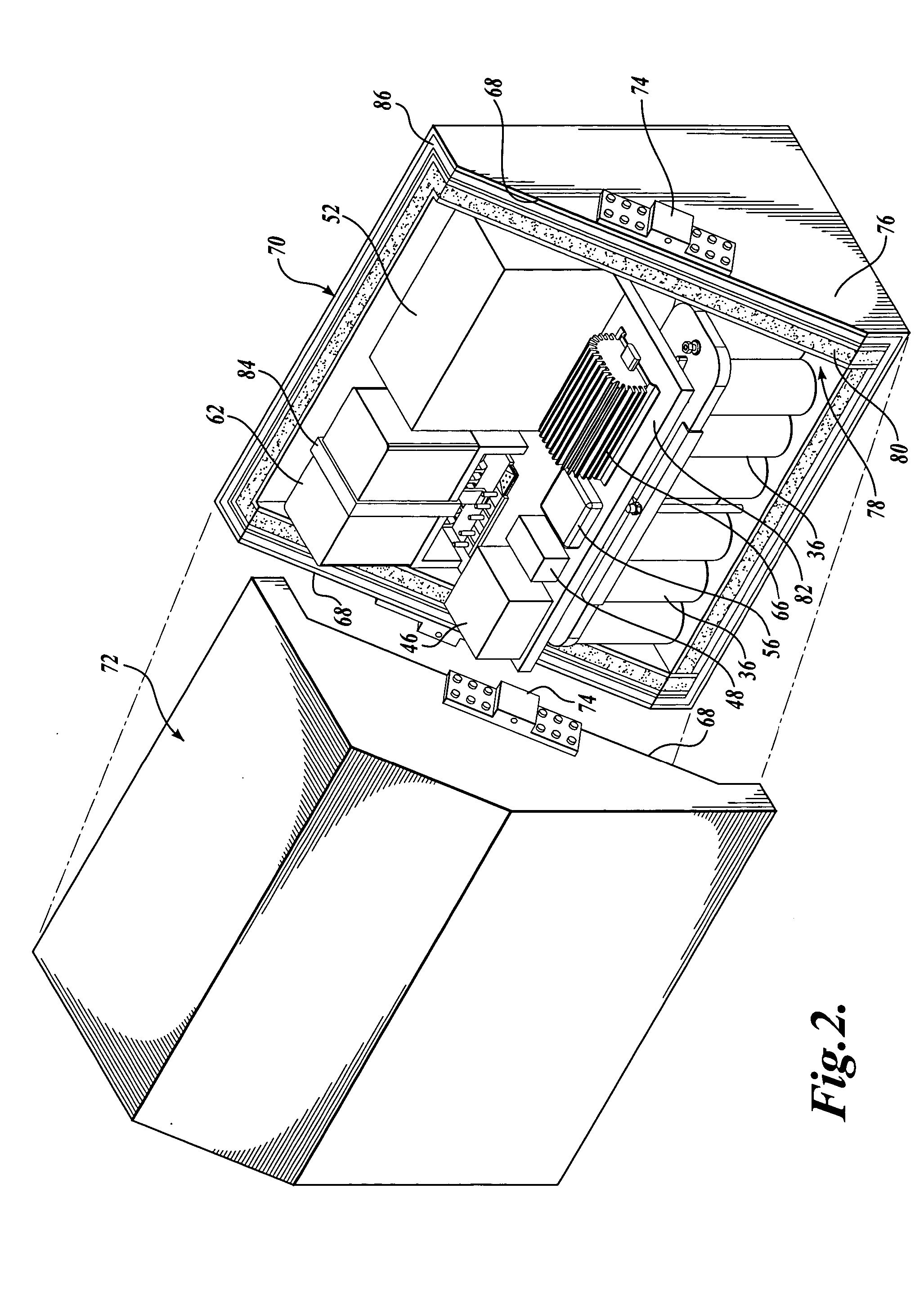

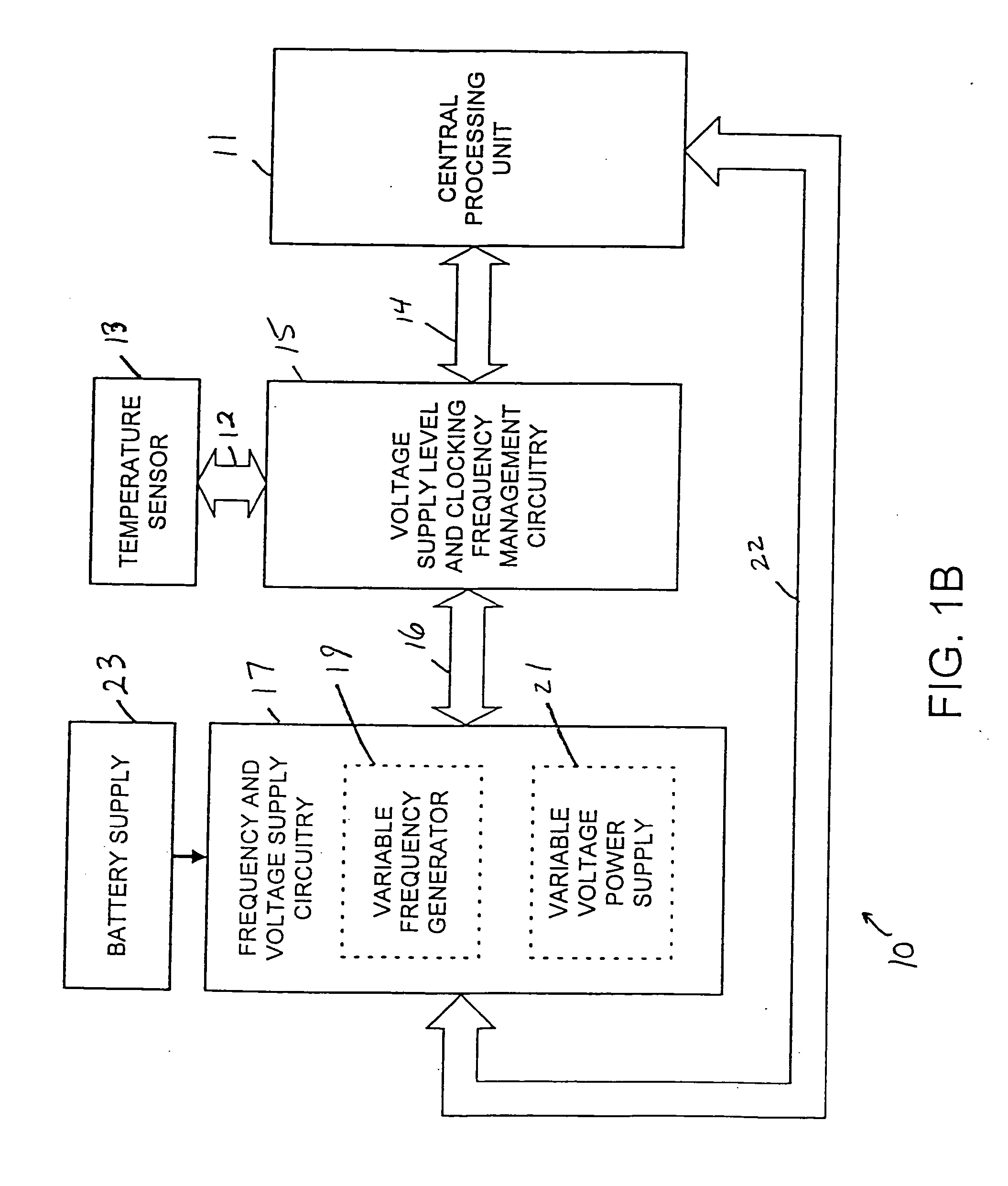

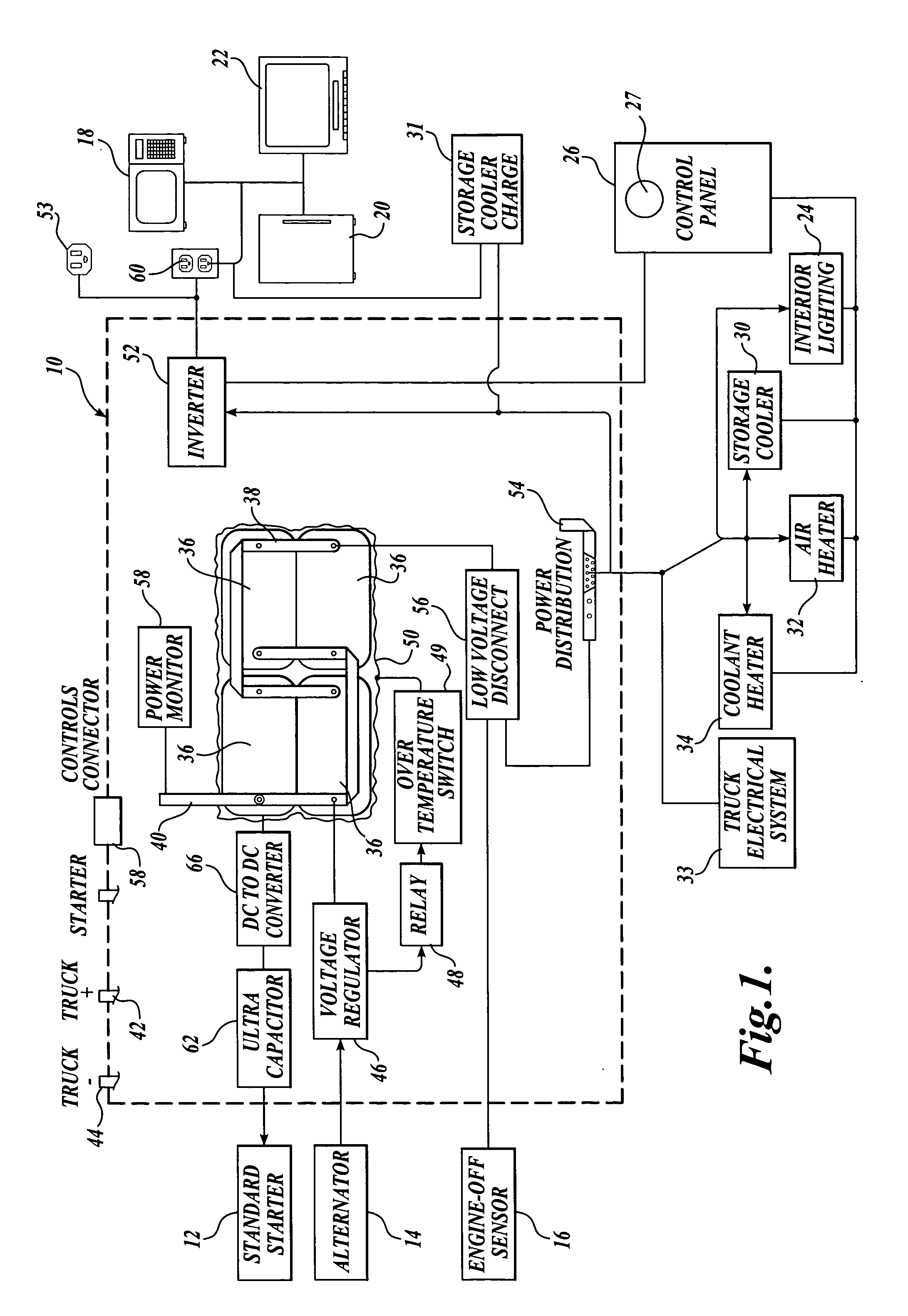

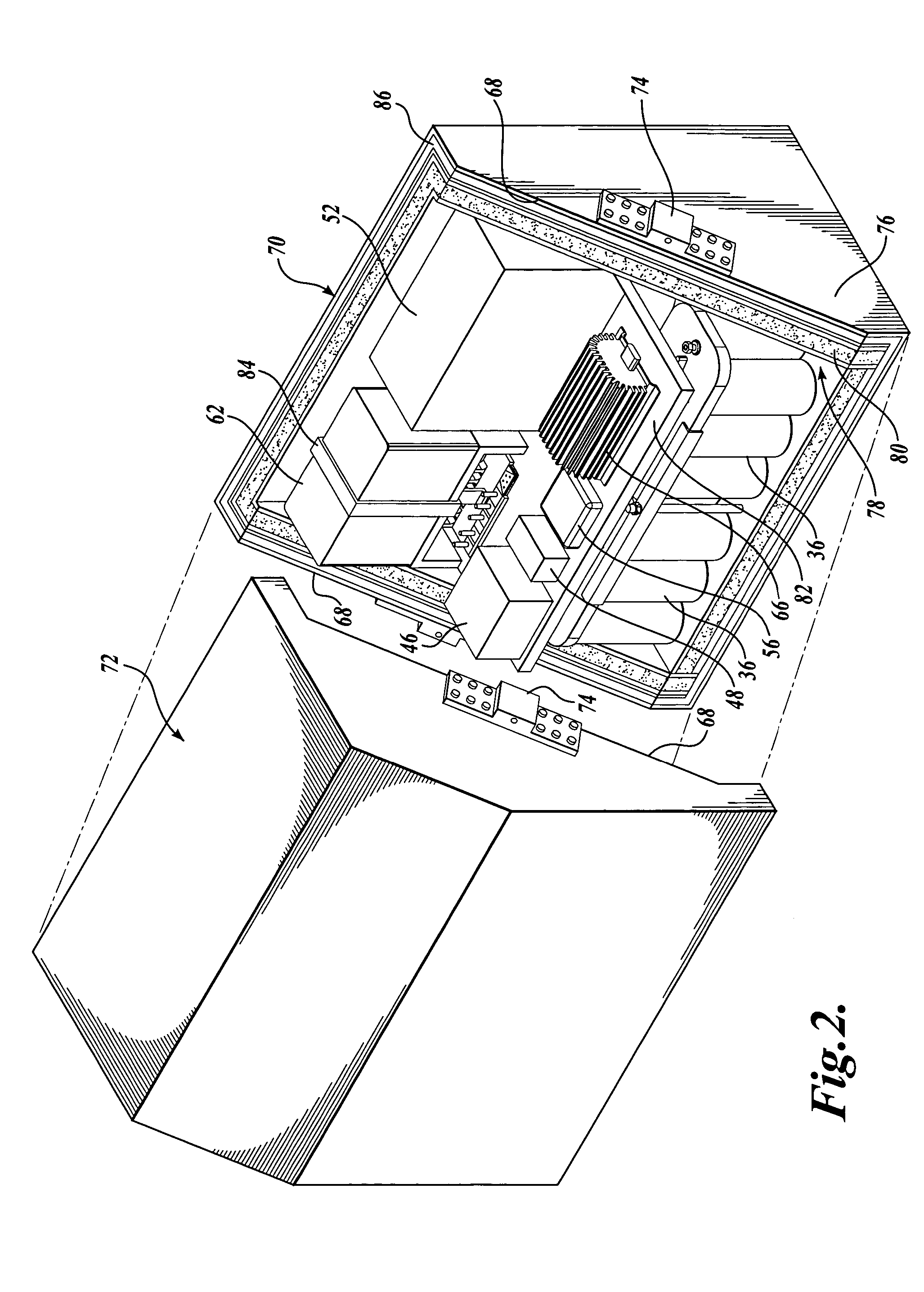

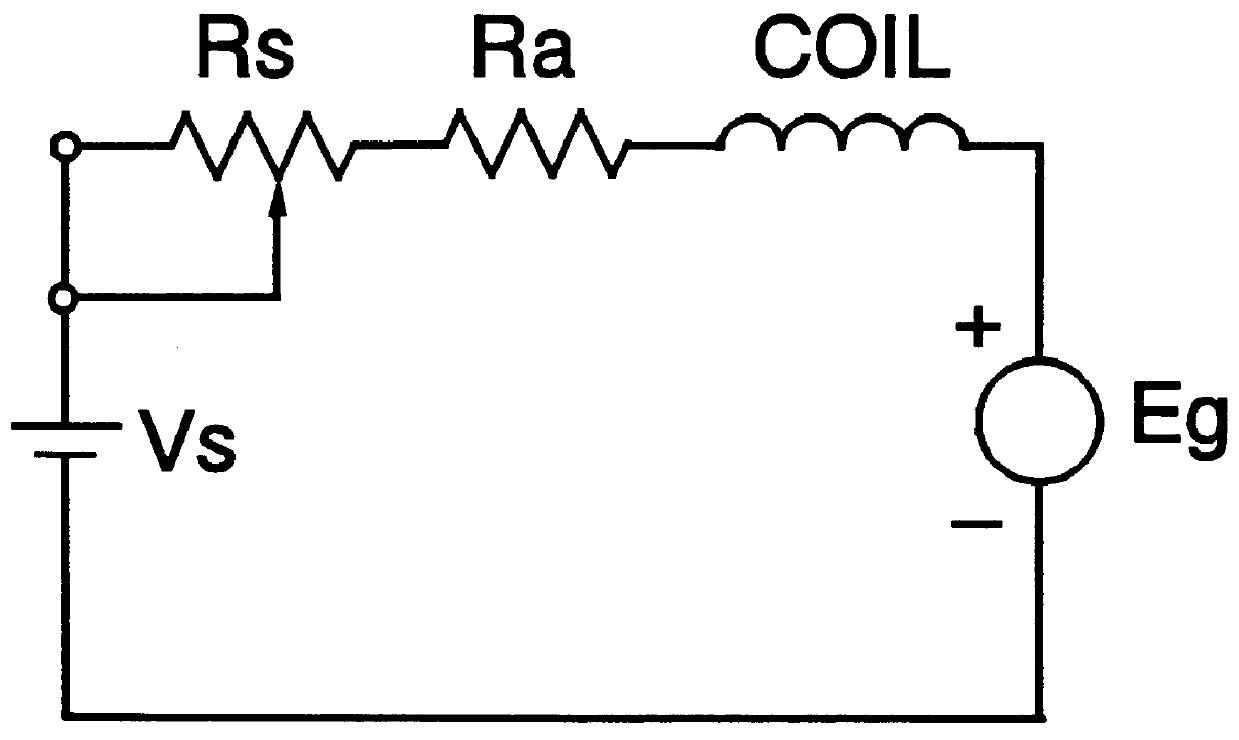

Electrical power system for vehicles requiring electrical power while the vehicle engine is not in operation

ActiveUS20060023480A1Increased power capacityReduce capacityConverter typesVehicle heating/cooling devicesCharge currentLow voltage

A system for supplying electrical power for use when the vehicle engine is shut down and configurations of long-haul trucks employing the system are disclosed. The power system is a battery bank contained within an insulated enclosure. The batteries are heated when the truck is in operation with the insulated enclosure maintaining battery temperature sufficient to provide high battery power capacity for an extended period after the vehicle is shut down. A large capacitor, rather than the batteries, provides current for starting the vehicle engine. A dc-to-dc converter controls the fully charged capacitor voltage and provides capacitor charging current even when the batteries have been discharged to a low-voltage condition. The disclosed long-haul truck configurations include a storage cooler that employs a phase-change medium that is thermally charged to a low temperature while the truck is in operation and is used to provide sleeper unit cooling air. Additional provision is made for heating the sleeper unit and for powering a coolant heater that can warm the truck engine block and truck fuel when the engine is shut down during cold weather.

Owner:PACCAR INC

Battery powered device with dynamic power and performance management

Owner:AVAGO TECH INT SALES PTE LTD

Electrical power system for vehicles requiring electrical power while the vehicle engine is not in operation

ActiveUS7145788B2Reduce capacitySave energyConverter typesVehicle heating/cooling devicesCapacitor voltageLow voltage

A system for supplying electrical power for use when the vehicle engine is shut down and configurations of long-haul trucks employing the system are disclosed. The power system is a battery bank contained within an insulated enclosure. The batteries are heated when the truck is in operation with the insulated enclosure maintaining battery temperature sufficient to provide high battery power capacity for an extended period after the vehicle is shut down. A large capacitor, rather than the batteries, provides current for starting the vehicle engine. A dc-to-dc converter controls the fully charged capacitor voltage and provides capacitor charging current even when the batteries have been discharged to a low-voltage condition. The disclosed long-haul truck configurations include a storage cooler that employs a phase-change medium that is thermally charged to a low temperature while the truck is in operation and is used to provide sleeper unit cooling air. Additional provision is made for heating the sleeper unit and for powering a coolant heater that can warm the truck engine block and truck fuel when the engine is shut down during cold weather.

Owner:PACCAR INC

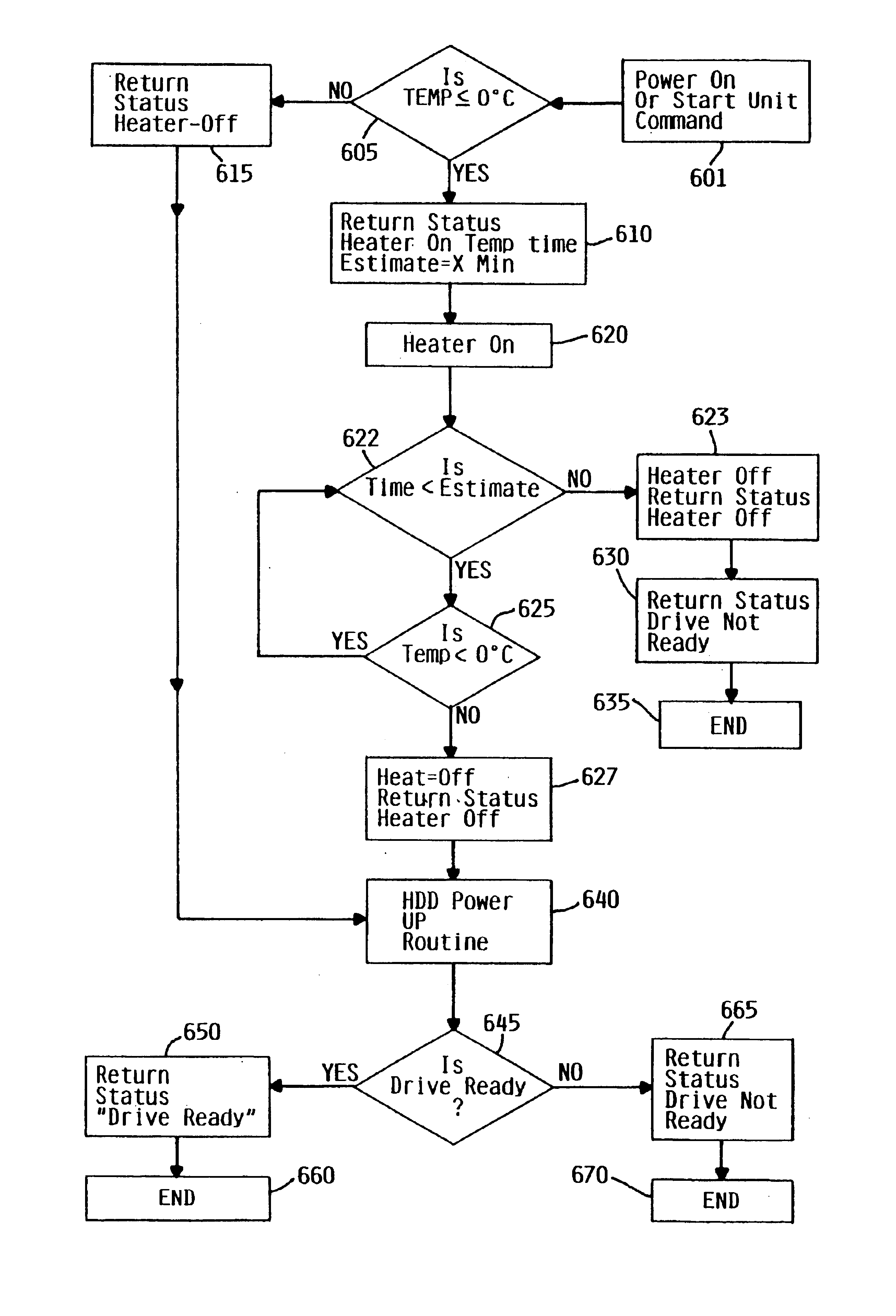

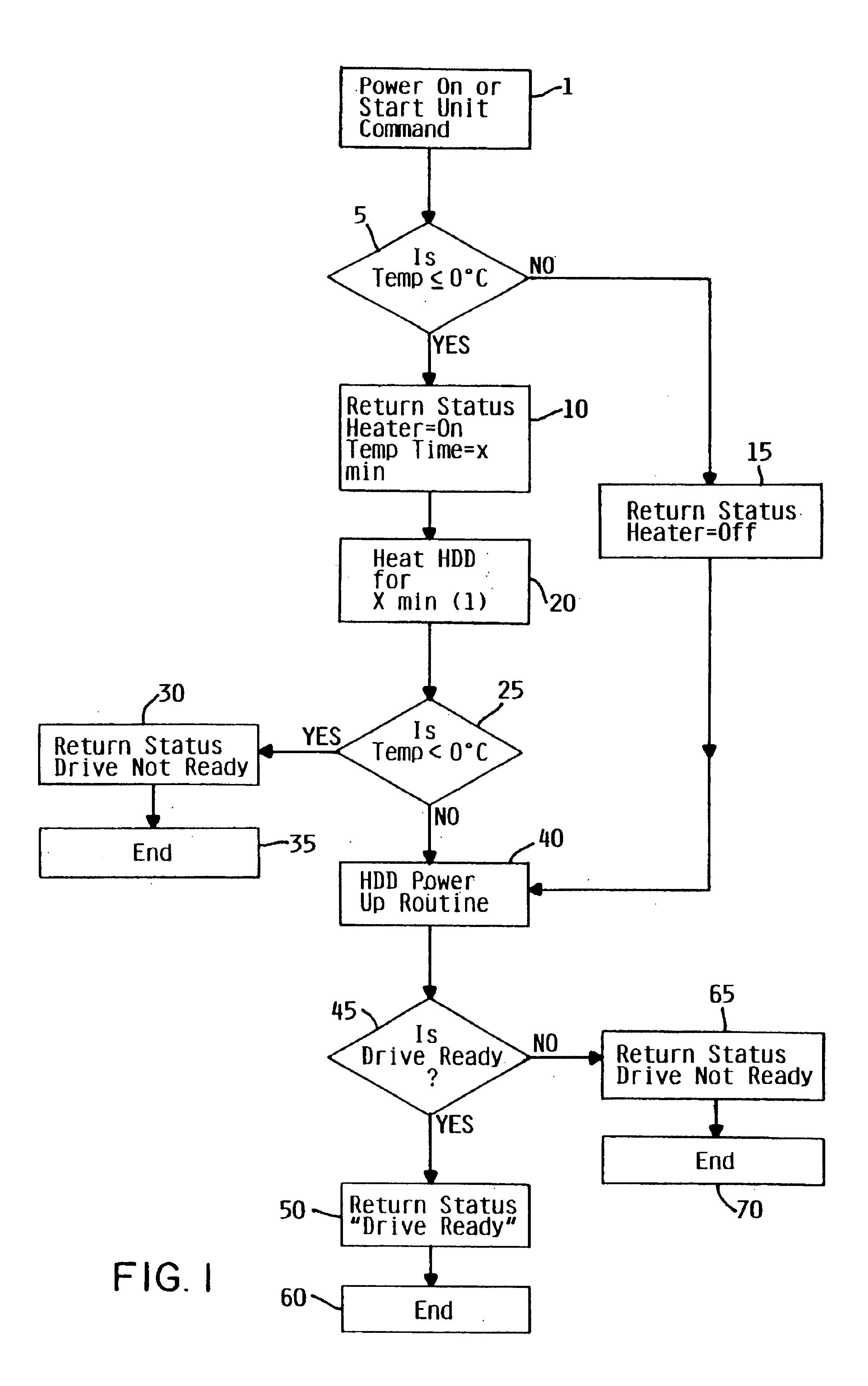

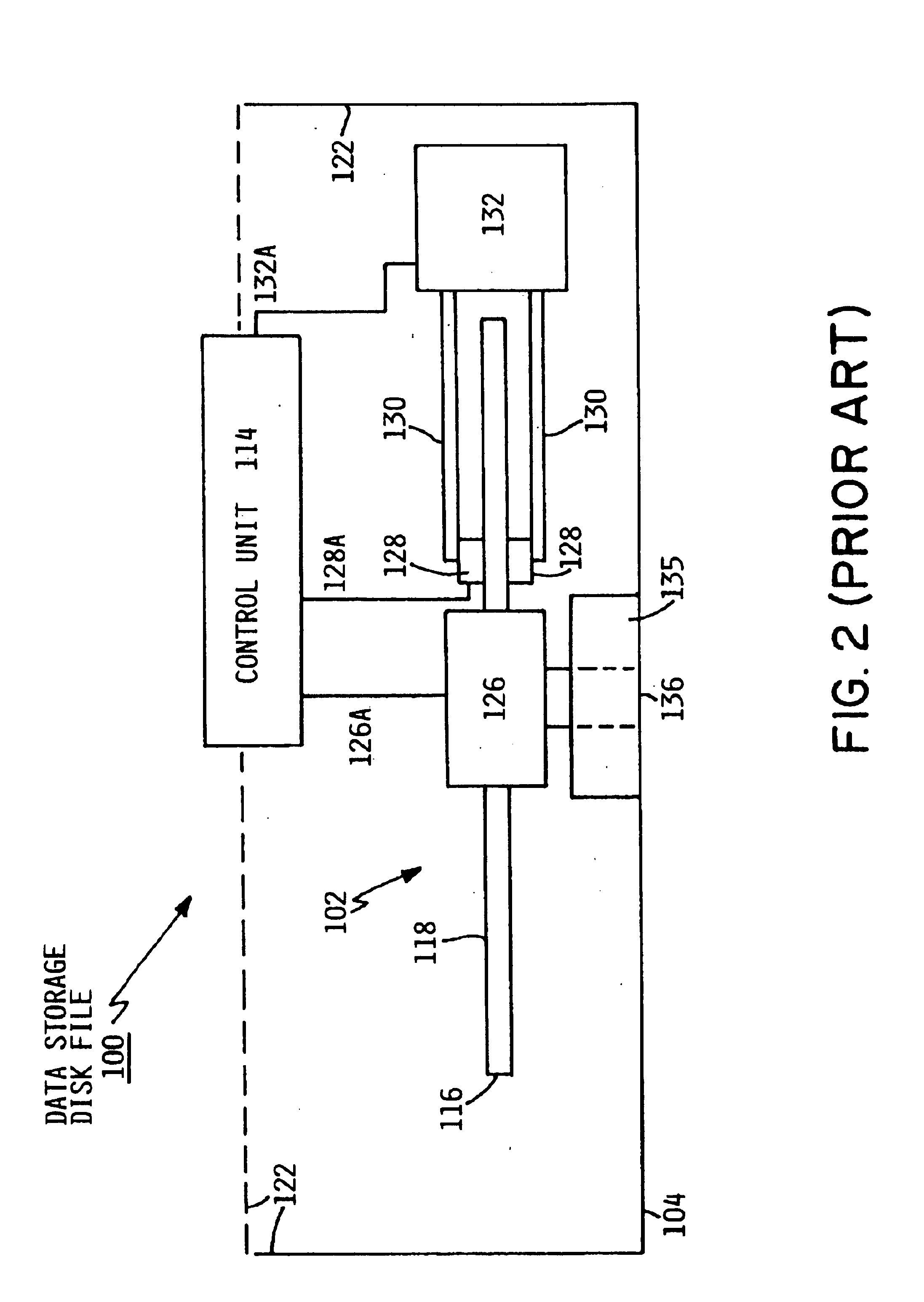

Method and apparatus for enabling cold temperature performance of a disk

InactiveUS6735035B1High torqueHigh viscosityCommutation monitoringApparatus for flat record carriersDirect-access storage deviceEngineering

In cold weather, the higher torque required for normal spinning operation of a spindle motor assembly in a direct access storage device due to the increased viscosity of the grease, is overcome by localizing the heating to the spindle motor assembly to reduce the viscosity of the grease, and then let a disk driven self heat during and after spin-up of the spindle motor assembly.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

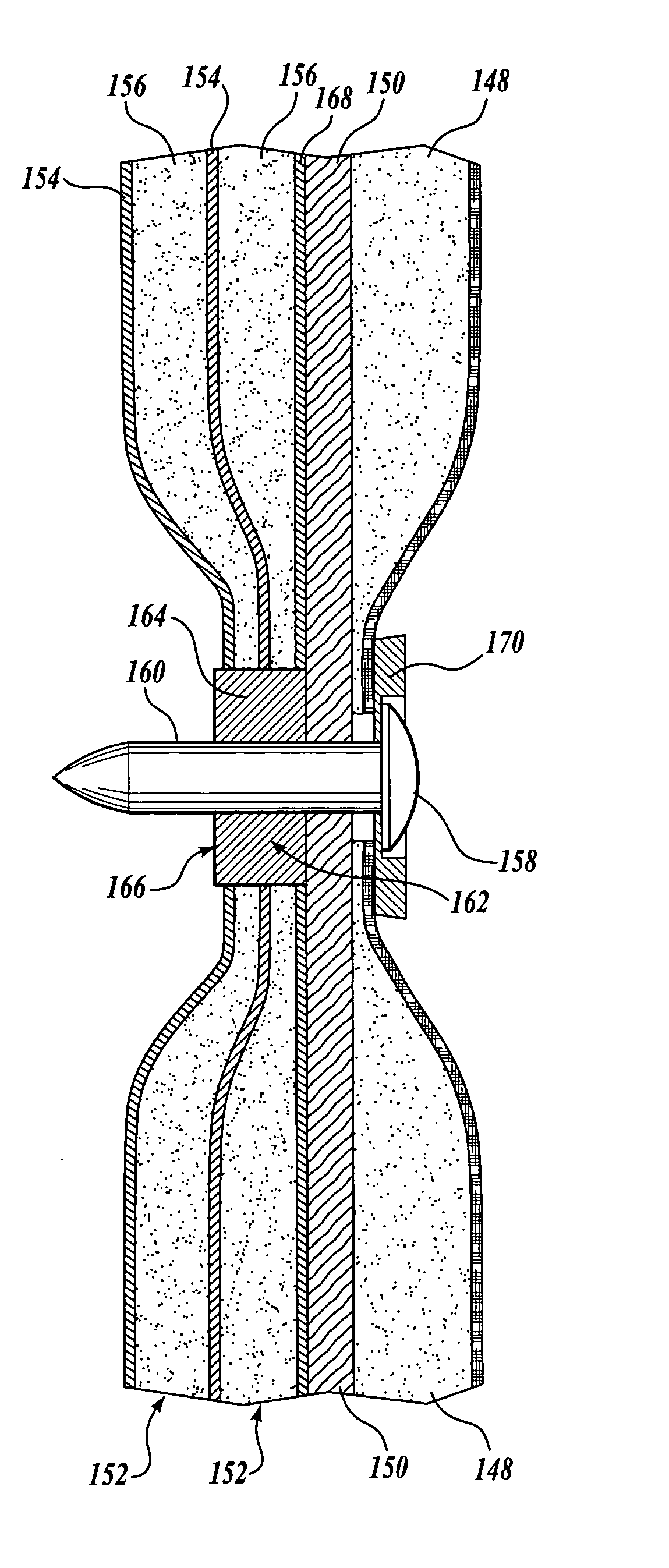

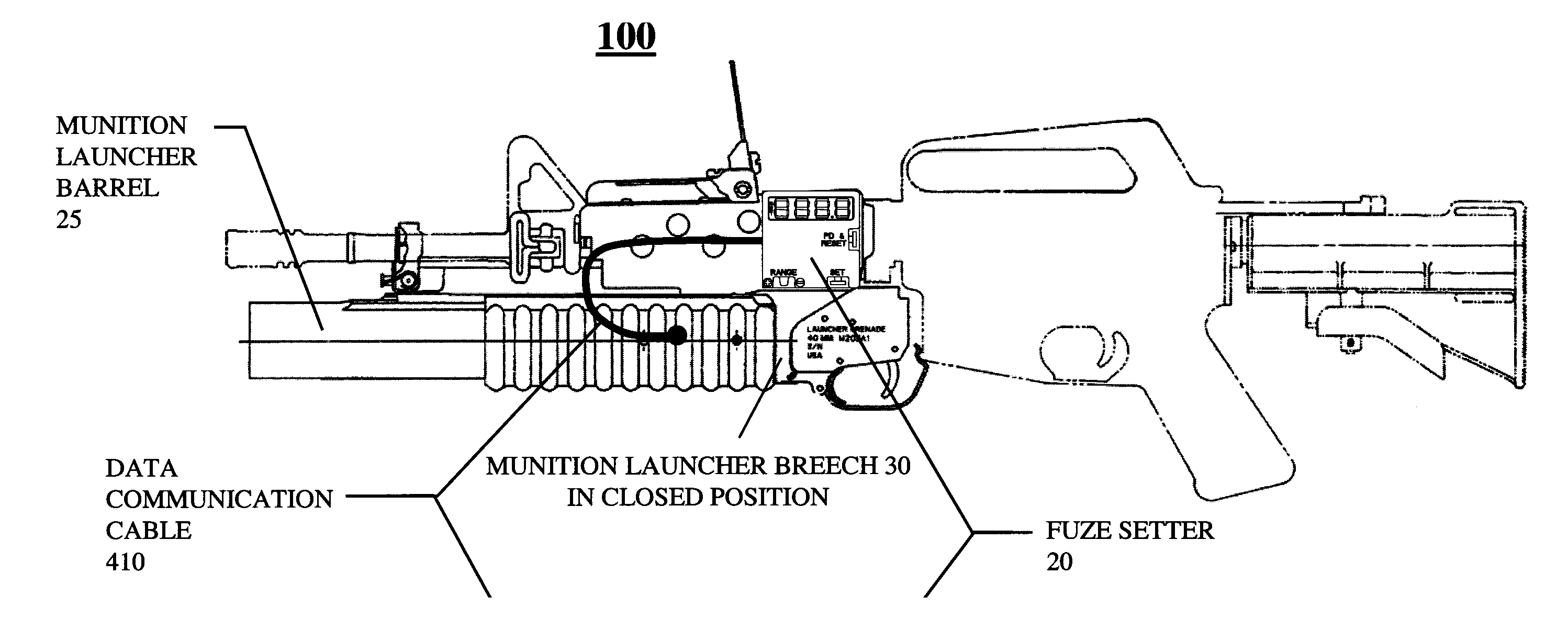

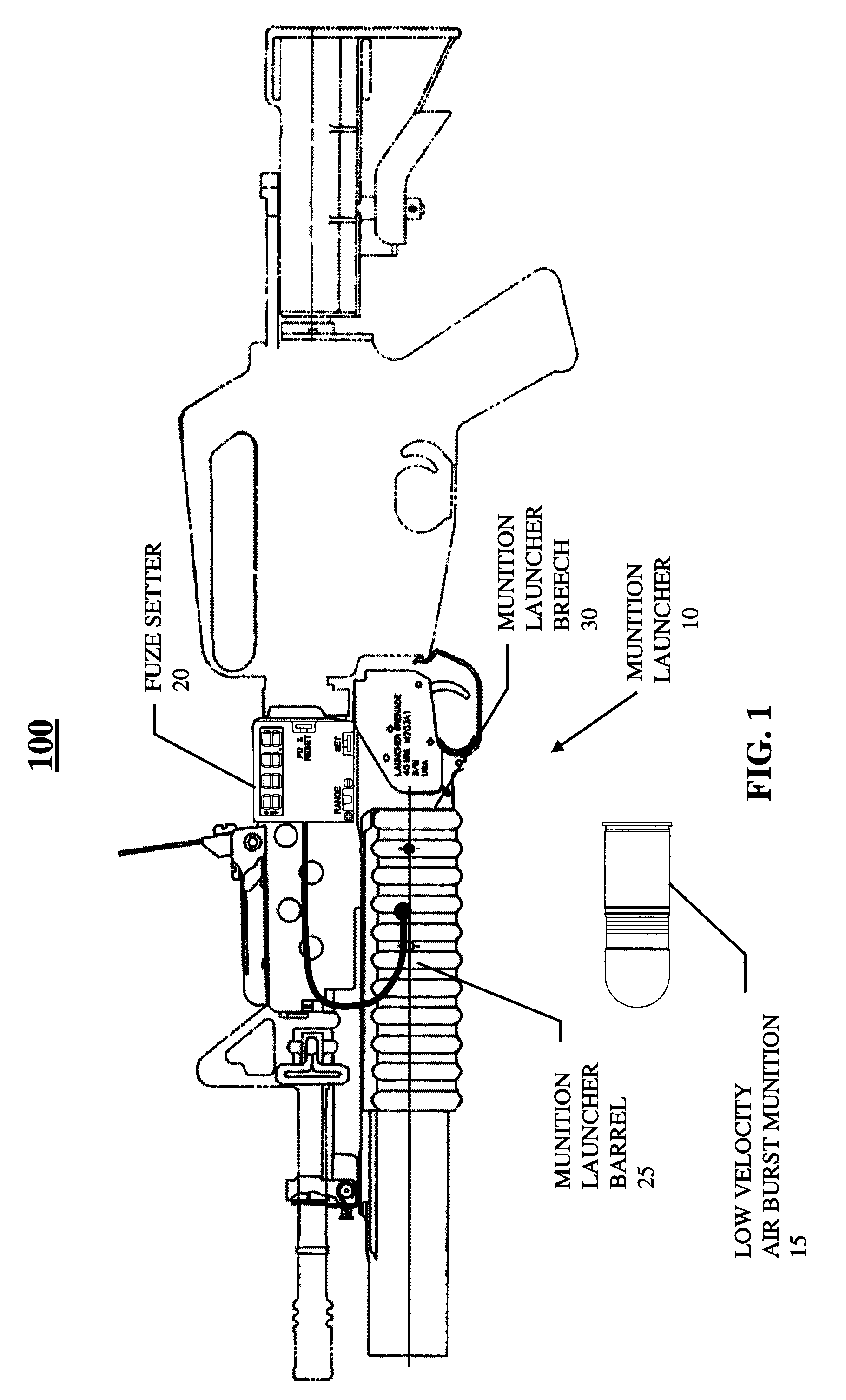

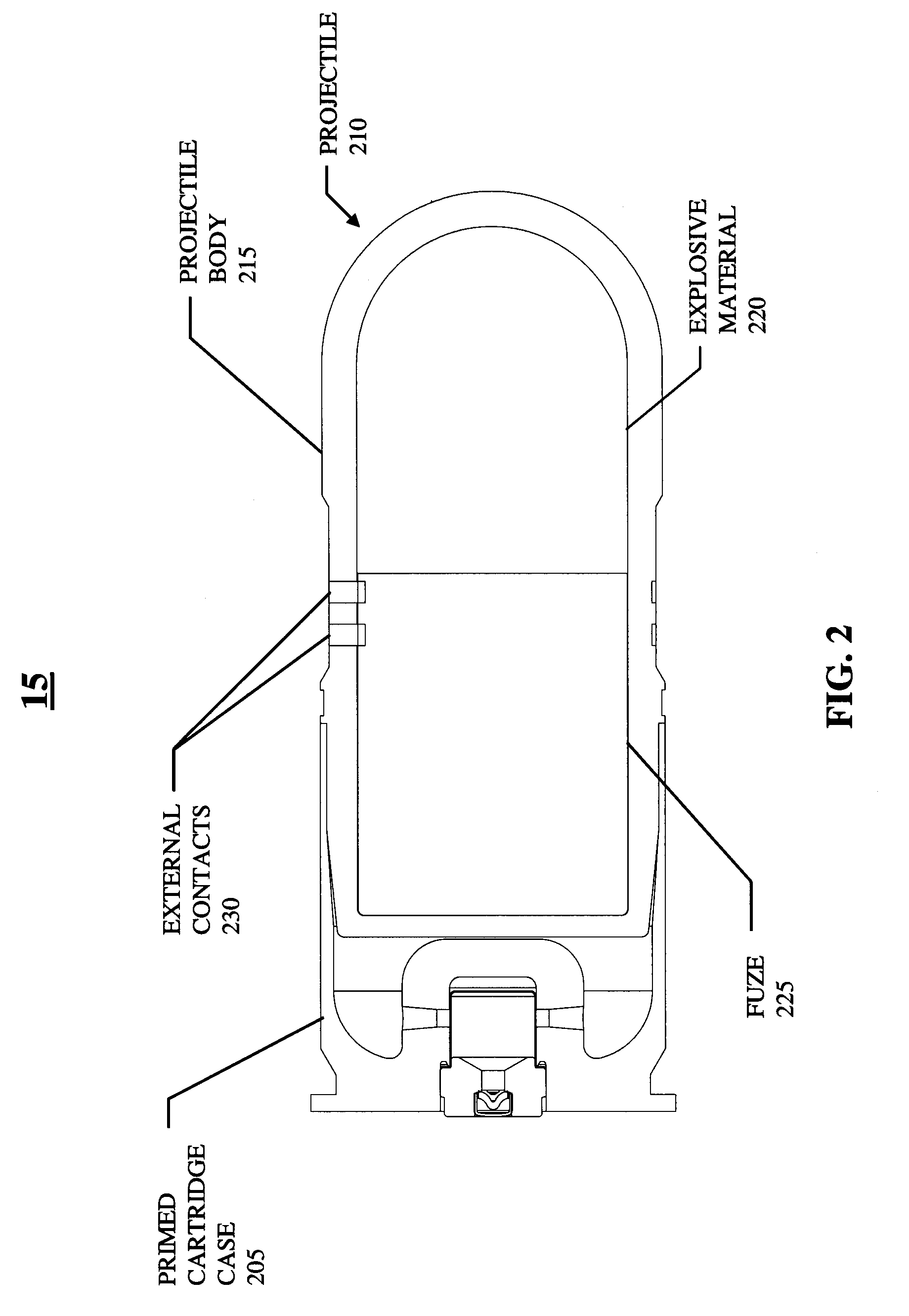

Low velocity air burst munition and launcher system implemented on an existing weapon

InactiveUS7021187B1Simple designReduce power consumptionAmmunition projectilesAmmunition fuzesElectricityAir burst

A low velocity air burst munition and launcher system allows the user to program the munition to detonate in the air at a specified range from the muzzle. The system further allows the munition to detonate upon impact or self-destruct if the target is missed. The system allows the user to program and reset the munition multiple times, and allows the user to perform this operation at night in cold weather conditions. The system requires the user to manually input the range into a fuze programming device prior to projectile launch. The fuze programming device is capable of direct interface with electronic range determining devices. The system employs electrical contacts in the chamber of the munition launcher barrel and on the projectile body to complete the circuit used for programming. Furthermore, this system is capable of integrating a magnetic induction method of programming.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

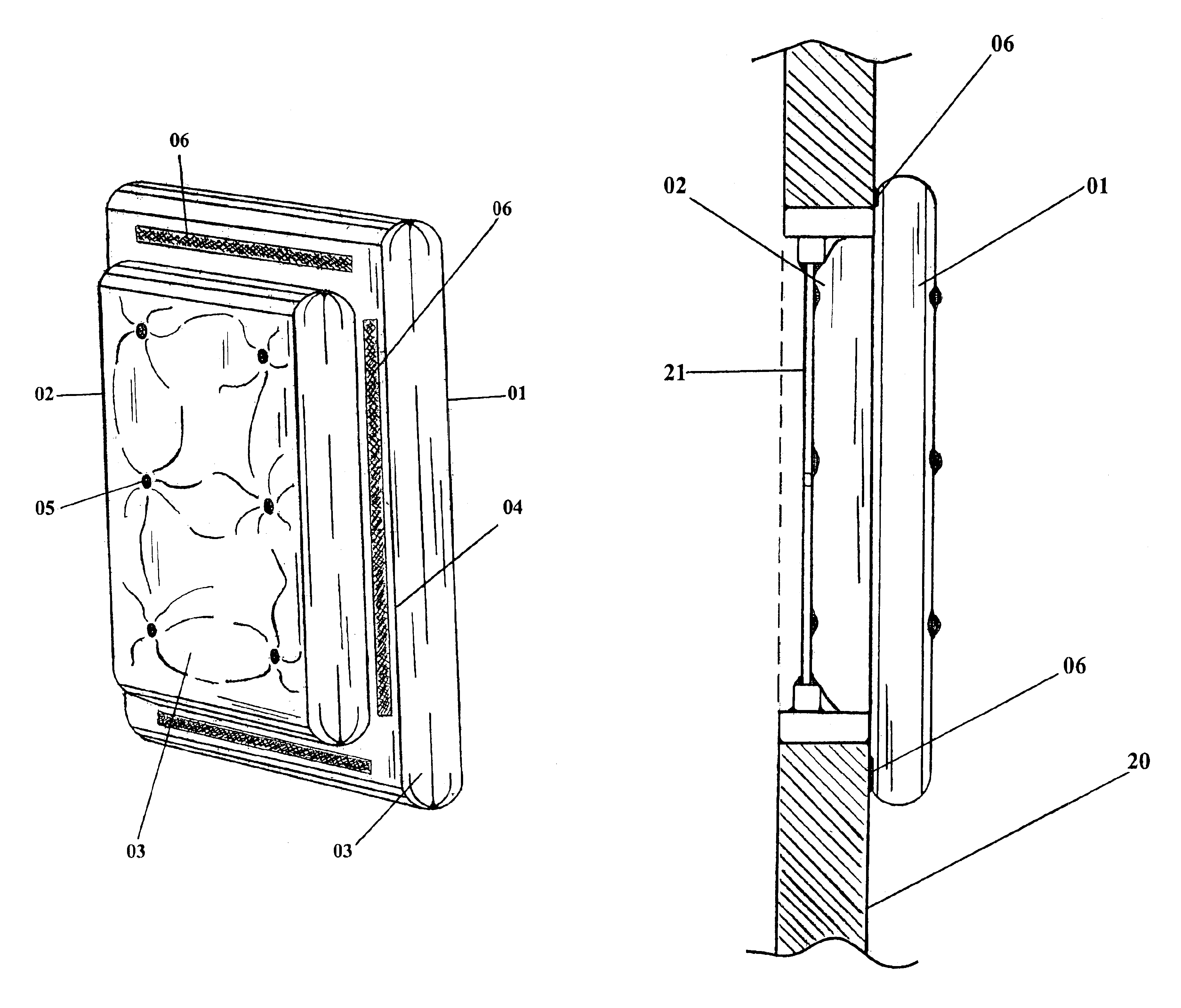

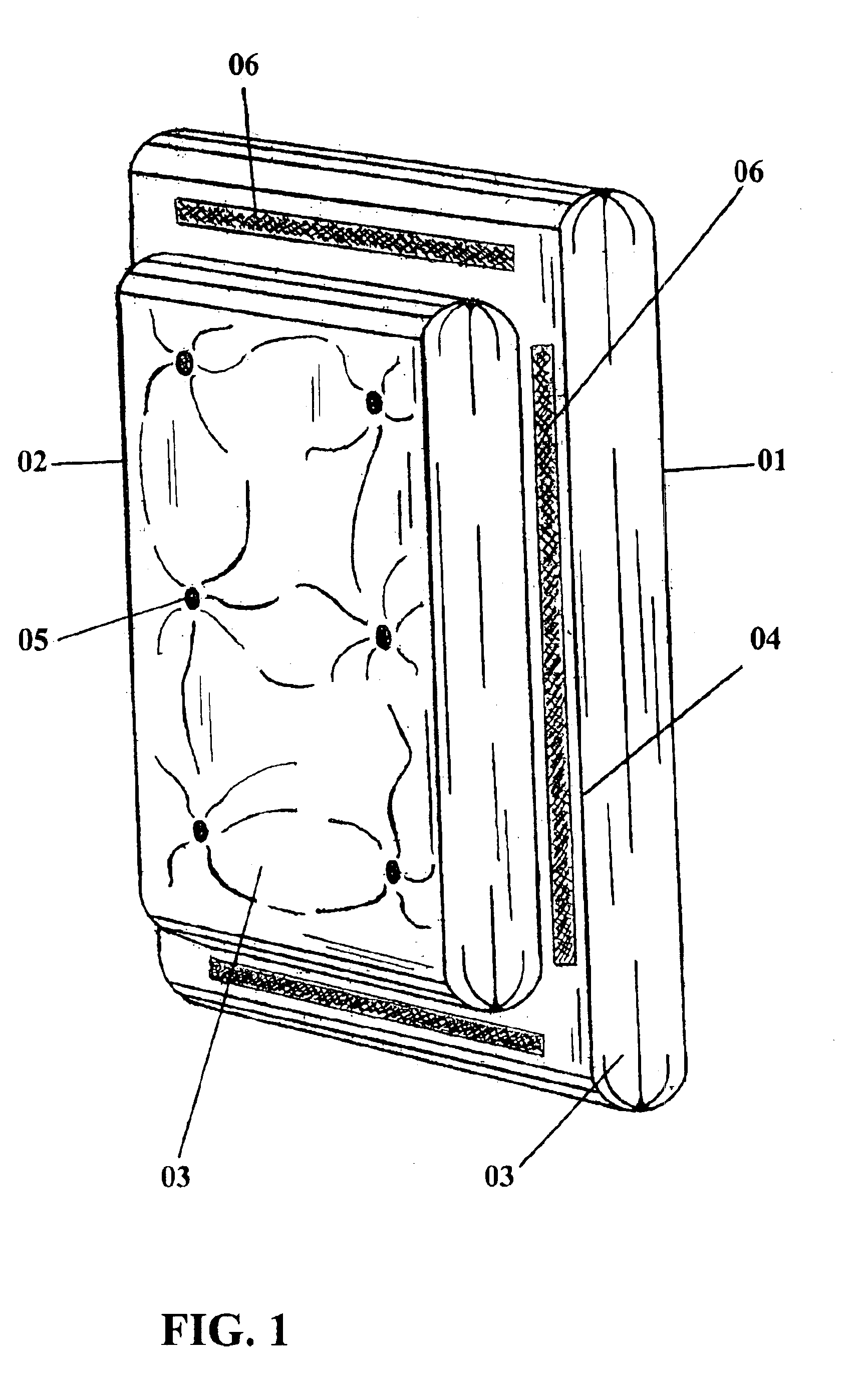

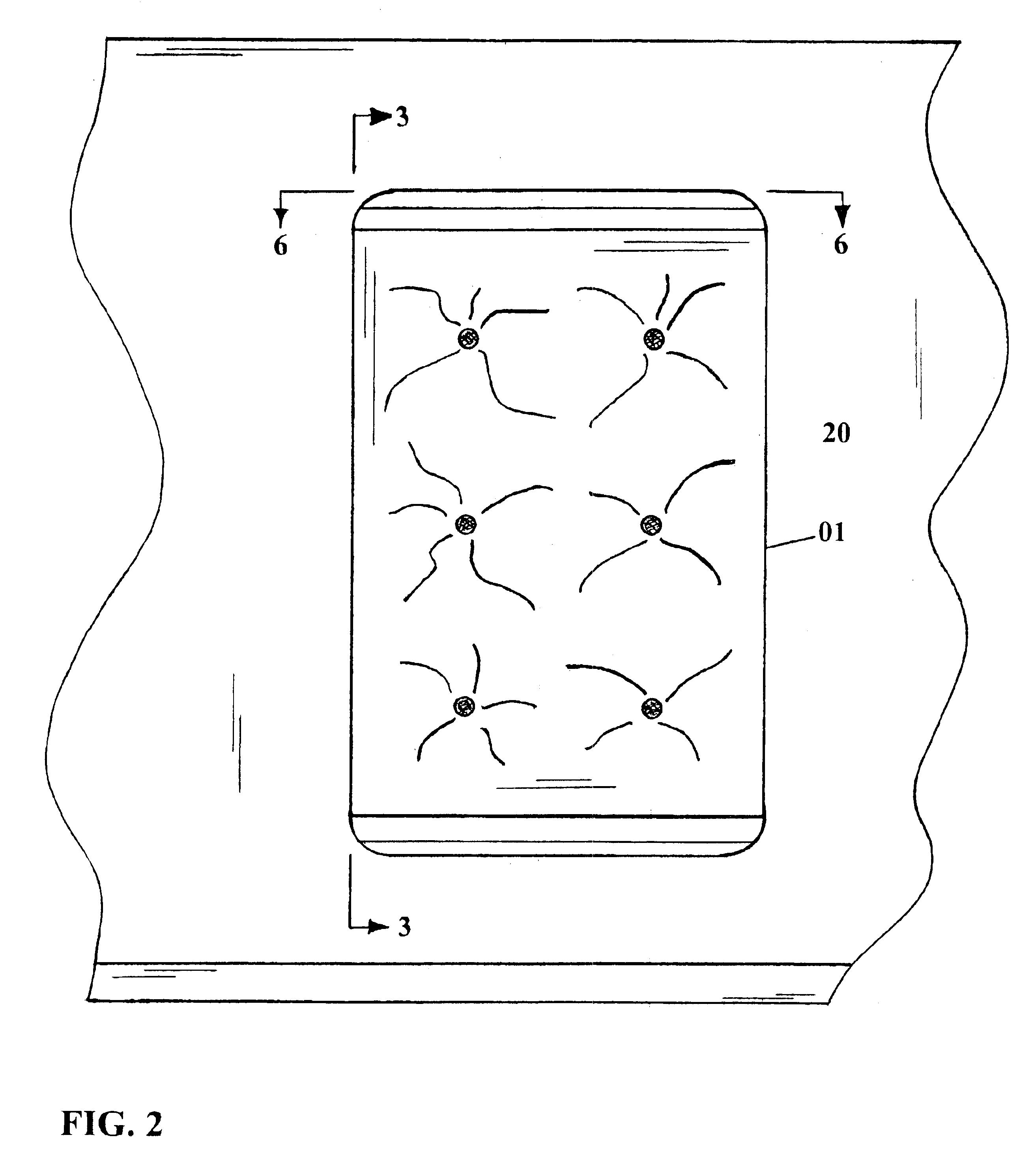

Thermal insulating window and entrance portable cover/pad

InactiveUS6848492B2Simple and cost-effective to installScreensLight protection screensElectricityCold weather

An inexpensive, lightweight, reusable and detachable or removable insulation device for residential and commercial dwellings and similar heated structures. The device has an inner-portion insulating pad adapted to fit inside of a typical entrance or window unit framing. The device further has an outer-portion insulating pad adapted to overlap the window or entrance framing. The outer-portion insulating pad is provided fasteners so as to be secured to the building wall structure outside of the framing and surrounding the window or entrance framing by. During cold weather months, the present invention will greatly restrict warm air from escaping between small crevices in inept window systems by fitting firmly into window framing using a insulating material, thus creating a thermal barrier and improving the efficiency of the furnace by reducing the demand for electricity or fuel consumption.

Owner:THOMAS DONALD LEE

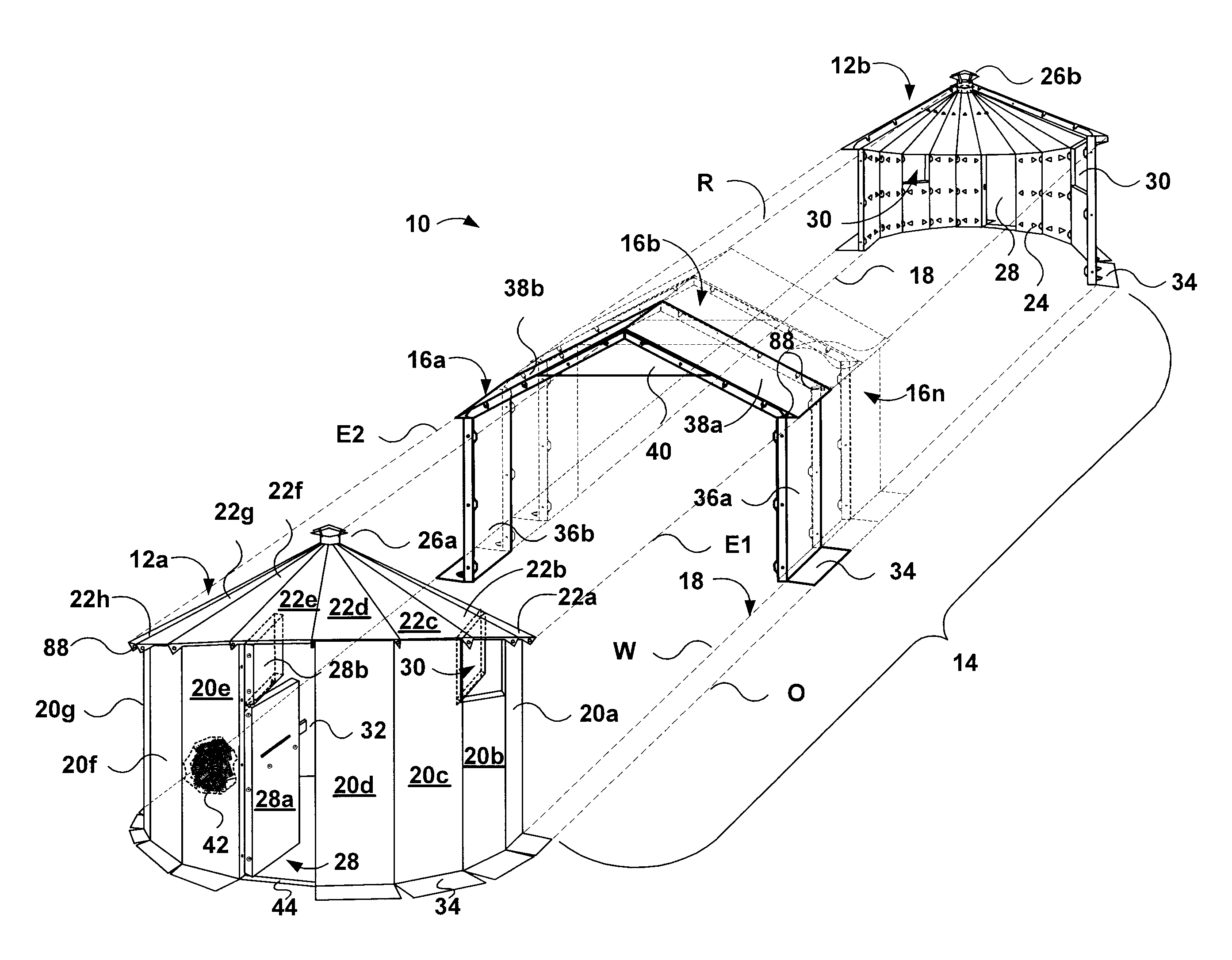

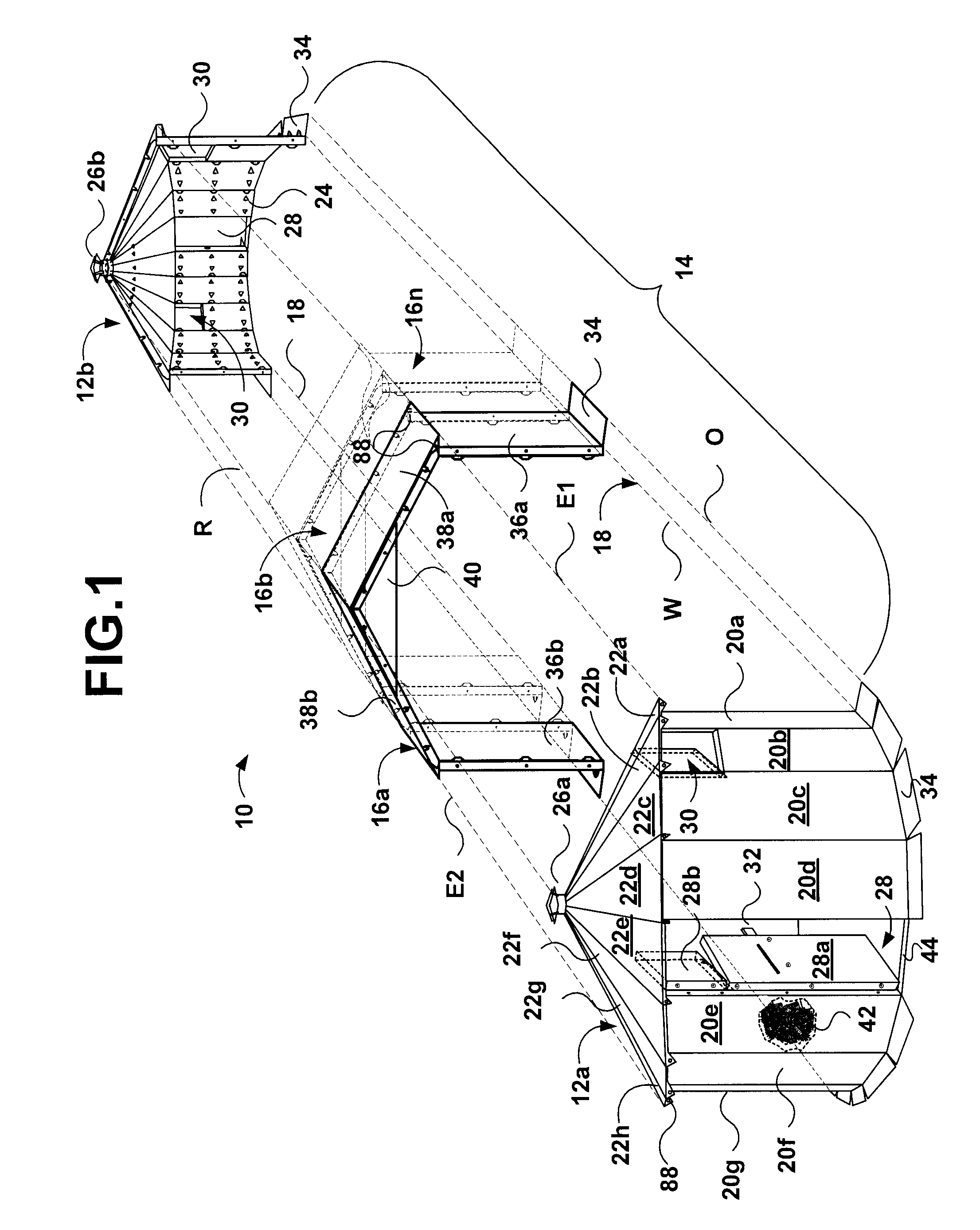

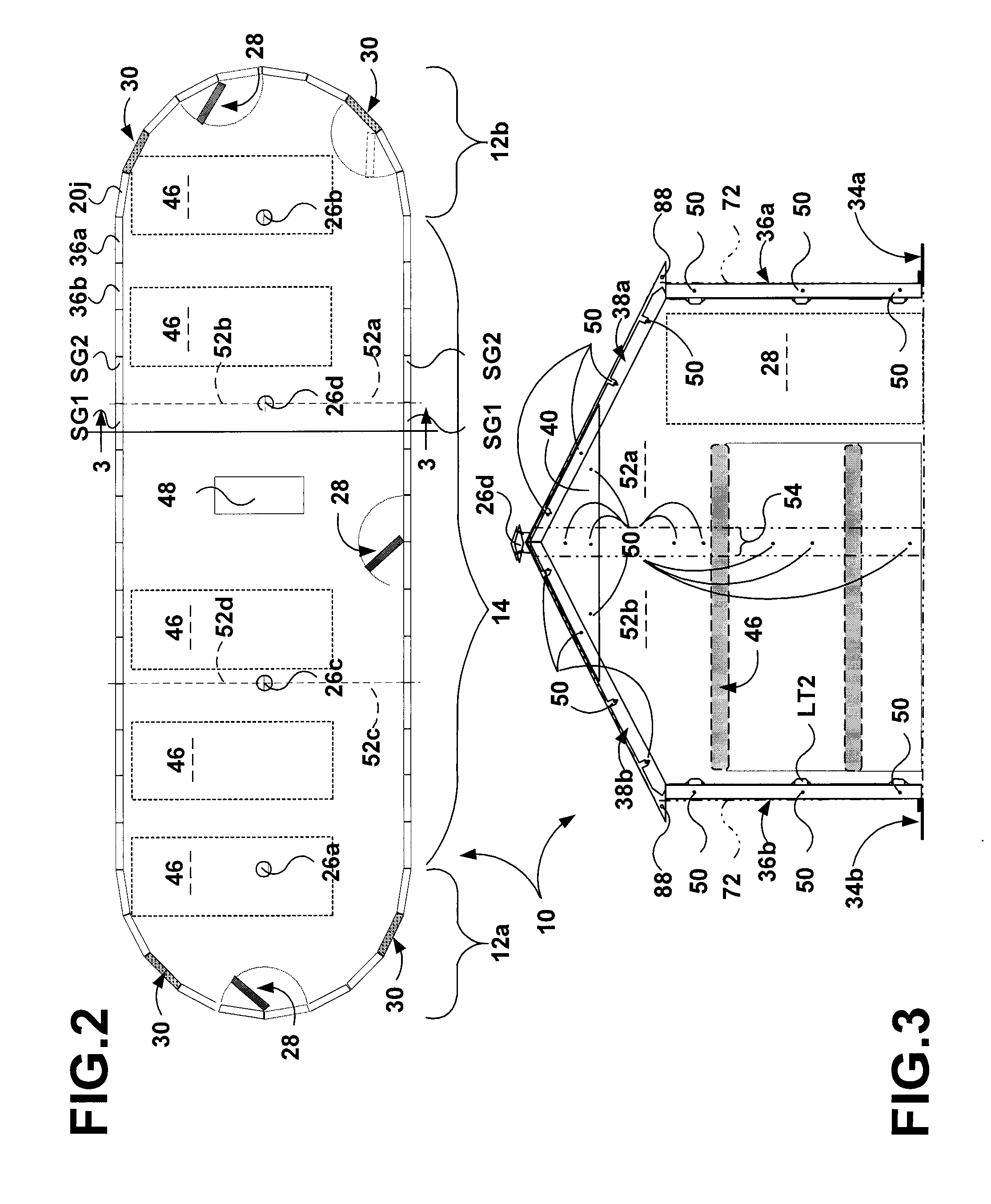

Segmented, elongated, expandable, 4-season, double-walled, low-cost, rigid extruded plastic panel structures

InactiveUS8381454B1Easy to die cutImprove structural stabilityTents/canopiesHospitalsDouble wallRigid wall

Low-cost, semi-permanent rigid-wall modular longhouse-type, peaked-roof structures, stadium-shaped (in plan view), made of light-weight, water-proof cellular extruded plastic sheet material die cut into blanks that are easily portable, quickly field erectable and dismountable by unskilled workers for a wide variety of uses. Two semi-circular end portions are spaced apart and joined by multiple segments of straight wall and roof modules, the length depending only on the number of intermediate segments. Blanks are easily folded on site into double-walled, bolt-together, modular wall and roof panels. Only four basic panel configurations are needed to form all structural elements. Multiple modular structures may be grouped to form larger compound structures with individual ones assigned to individual persons or dedicated work space usages: disaster shelters, sleeping, gathering, storage, hygiene, medical treatment, schooling, entertainment, goods manufacture, cooking, eating, herding, etc. Double-wall modules provide inter-stitial space for cold-weather insulation and passive ventilation in hot environments.

Owner:INNOVATION LAW GROUP

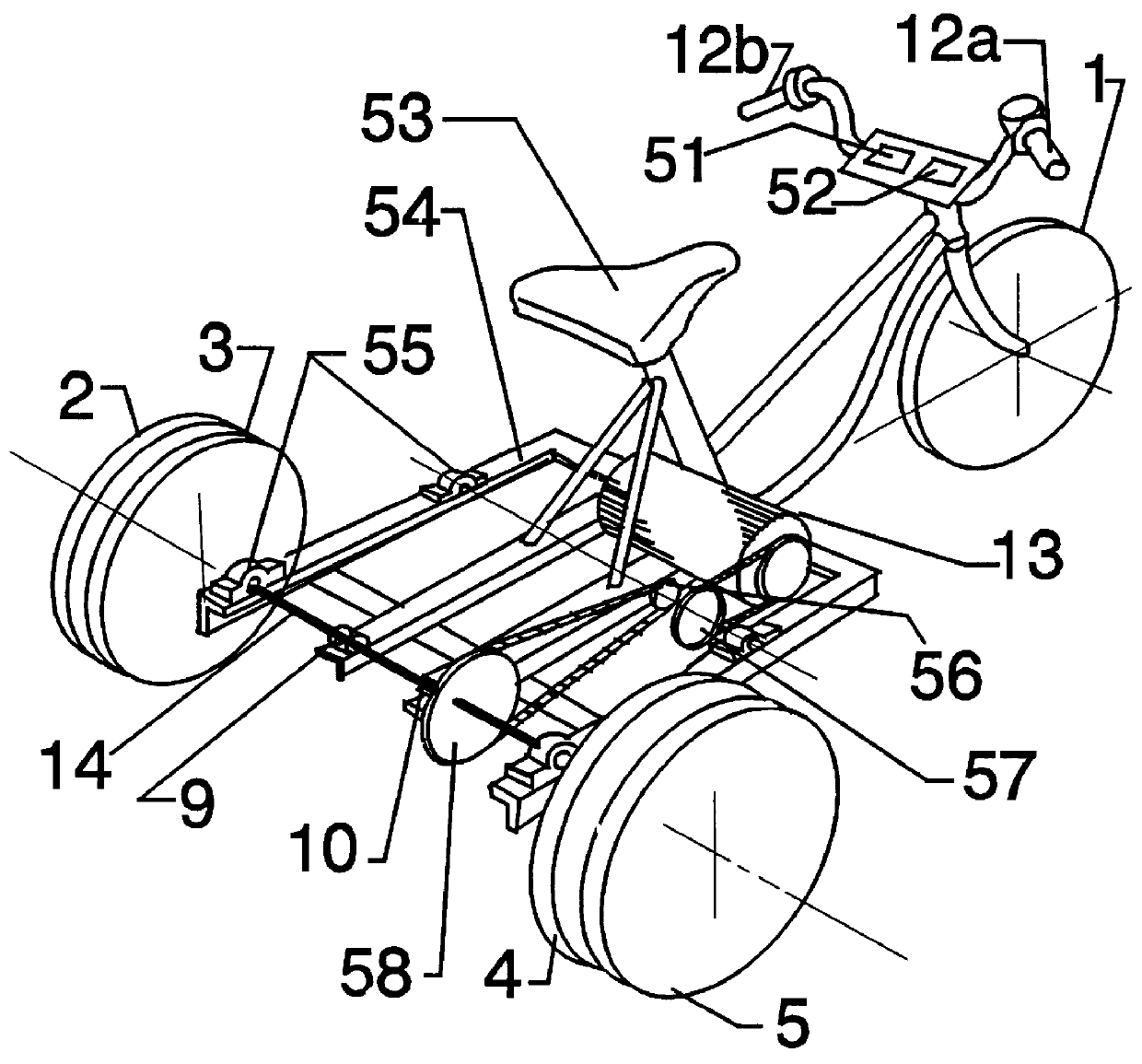

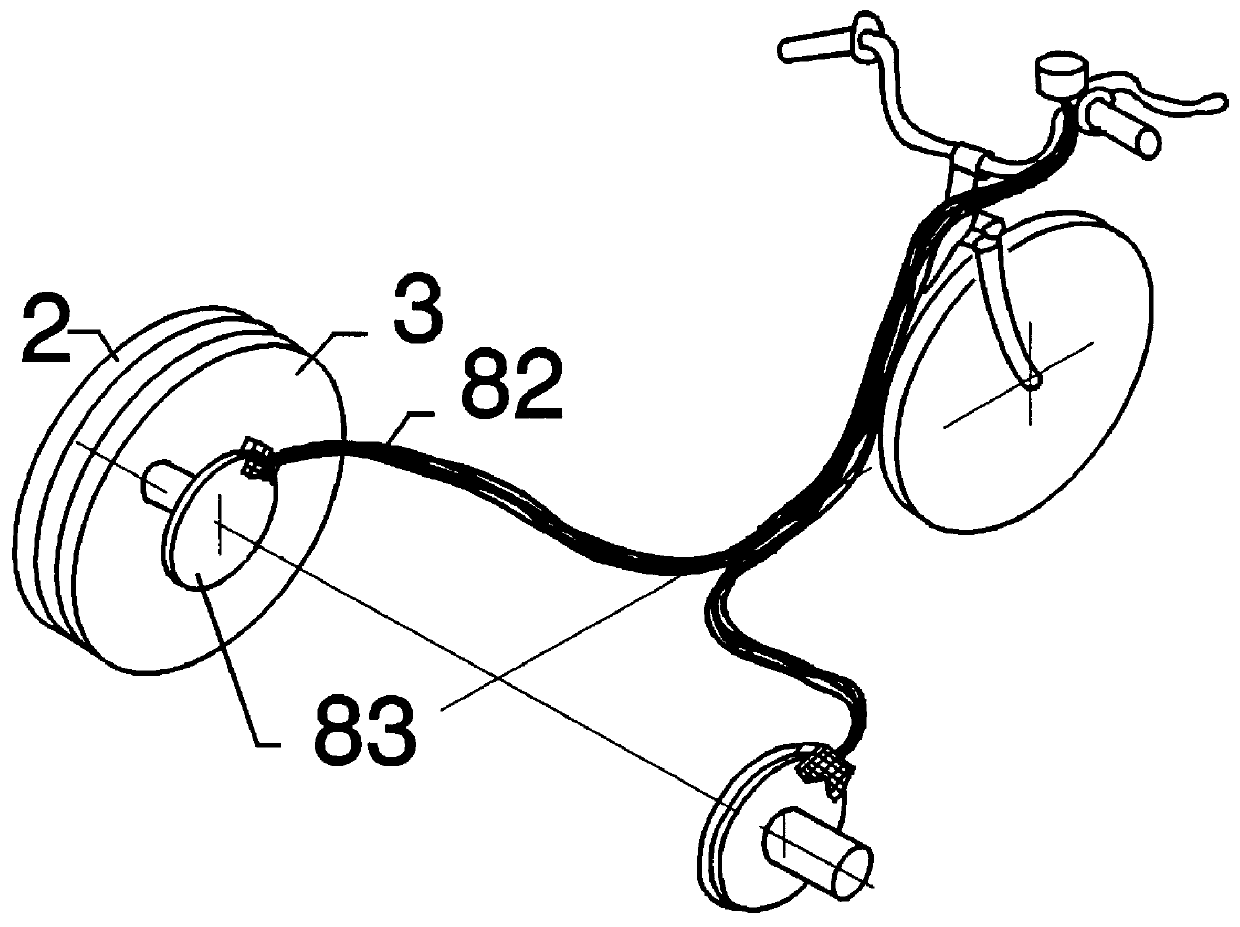

Solar energy powered electric vehicle

InactiveUS6021862AEasy to switchIncrease supplyPropulsion by humans/animalsVehicle transmissionElectrical batteryCold weather

A tricycle is driven by an electric motor supplied by batteries recharged by solar panels. Electric braking is used. The batteries and a battery charger are enclosed in a thermally insulated compartment and the batteries are kept warm in cold weather by the heat produced by the battery charger and by electric braking. The solar panels are mounted on the roof of the passenger cabin and / or on the insulated compartment and are oriented towards the sun by a stepper motor.

Owner:SHARAN ANAND M

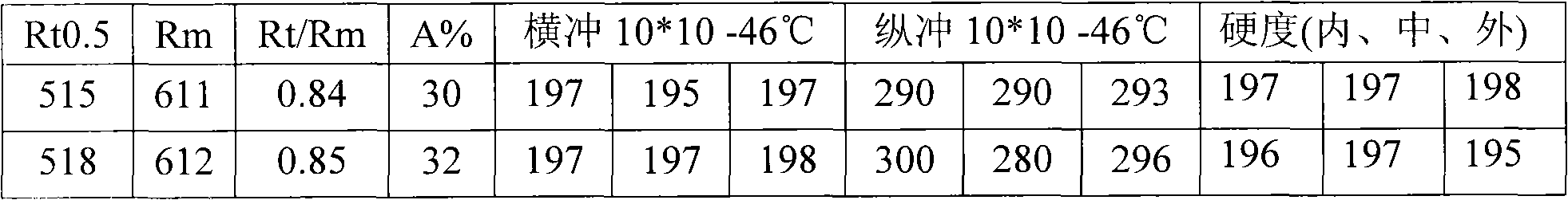

High-strength high-ductility X70 thick-wall seamless pipeline steel and manufacturing method

ActiveCN101343715AImprove hardenabilityFulfil requirementsFurnace typesHeat treatment furnacesCold weatherThick wall

The invention provides a high-intensity and high-toughness X70 thick-walled seamless pipeline steel. The steel comprises the following elements, in weight percentage: 0.04 to 0.12 percent of C, 0.17 to 0.35 percent of Si, 1.20 to 1.60 percent of Mn, 0.015 percent or less than 0.015 percent of P, 0.010 percent or less than 0.010 percent of S, 0.10 to 0.30 percent or less than 0.10 to 0.30 percent of Mo, 0.005 to 0.045 percent of Al, 0.02 to 0.06 percent of Nb, 0.02 to 0.10 percent of V, 0.10 to 0.25 percent of Cu, 0.10 to 0.30 percent of Ni, 0.010 to 0.030 percent of Ti, 0.20 percent or less than 0.20 percent of Cr, 0.43 percent or less than 0.43 percent of CE, 0.22 percent or less than 0.22 percent of Pcm, balance iron and trace impurity element. The invention also provides a seamless pipeline steel rolling and manufacturing method. The invention has the advantages that micro-alloy steel is adopted, the seamless pipeline steel is suitable for the production of the thick-walled pipeline with the wall thickness of less than 36 mm, the overall structure of the pipe adopts an even Bainite structure, the carbon equivalent is low, the welding performance is good, the impact performance at low temperature is good, the requirements of the thick-walled pipeline used in deep sea and under other cold weather are satisfied, the mechanical property of the pipeline is enhanced, the steel hardness penetration when in water quenching is improved, and the difficult problem of thick-walled pipe machining by a chamfering machine is solved.

Owner:TIANJIN PIPE GROUP CORP

Cold-weather apparel item

ActiveUS20160242474A1Effective air flow patternEasy to exportGarment special featuresGarment hoodsDistractionCold weather

A cold-weather apparel item configured to promote breathability, provide warmth, and minimize distractions is provided herein. The cold-weather apparel item is formed from a composite fabric that is breathable and repels water. The cold-weather apparel item further comprises at least a hood lock cord system that maintains the hood of the apparel item in a secure position while not being used, inflow air ducts and outflow air ducts to provide ventilation, and a layered thumbhole assembly with overlapping panels that fits snugly around a wearer's thumbs when used.

Owner:NIKE INC

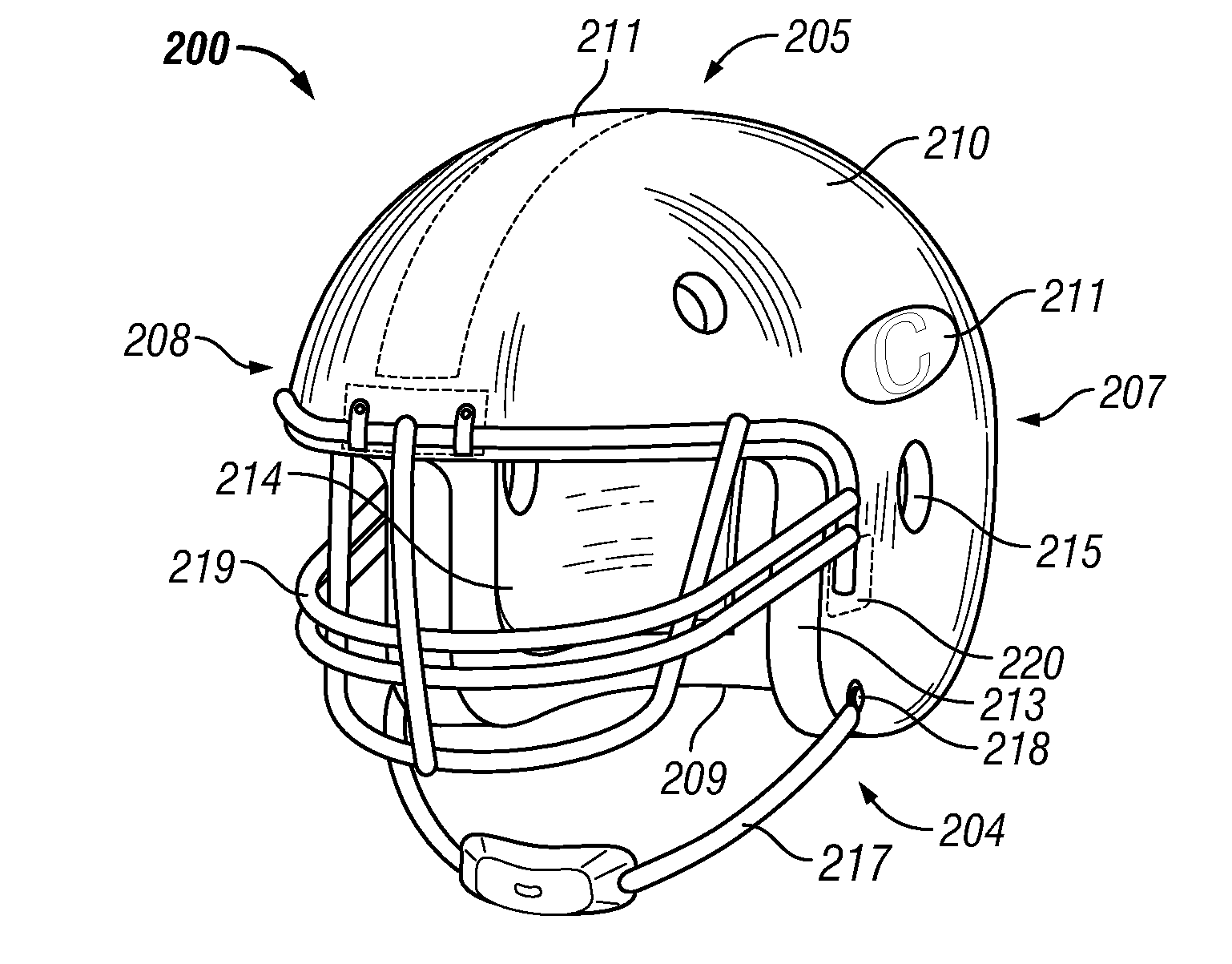

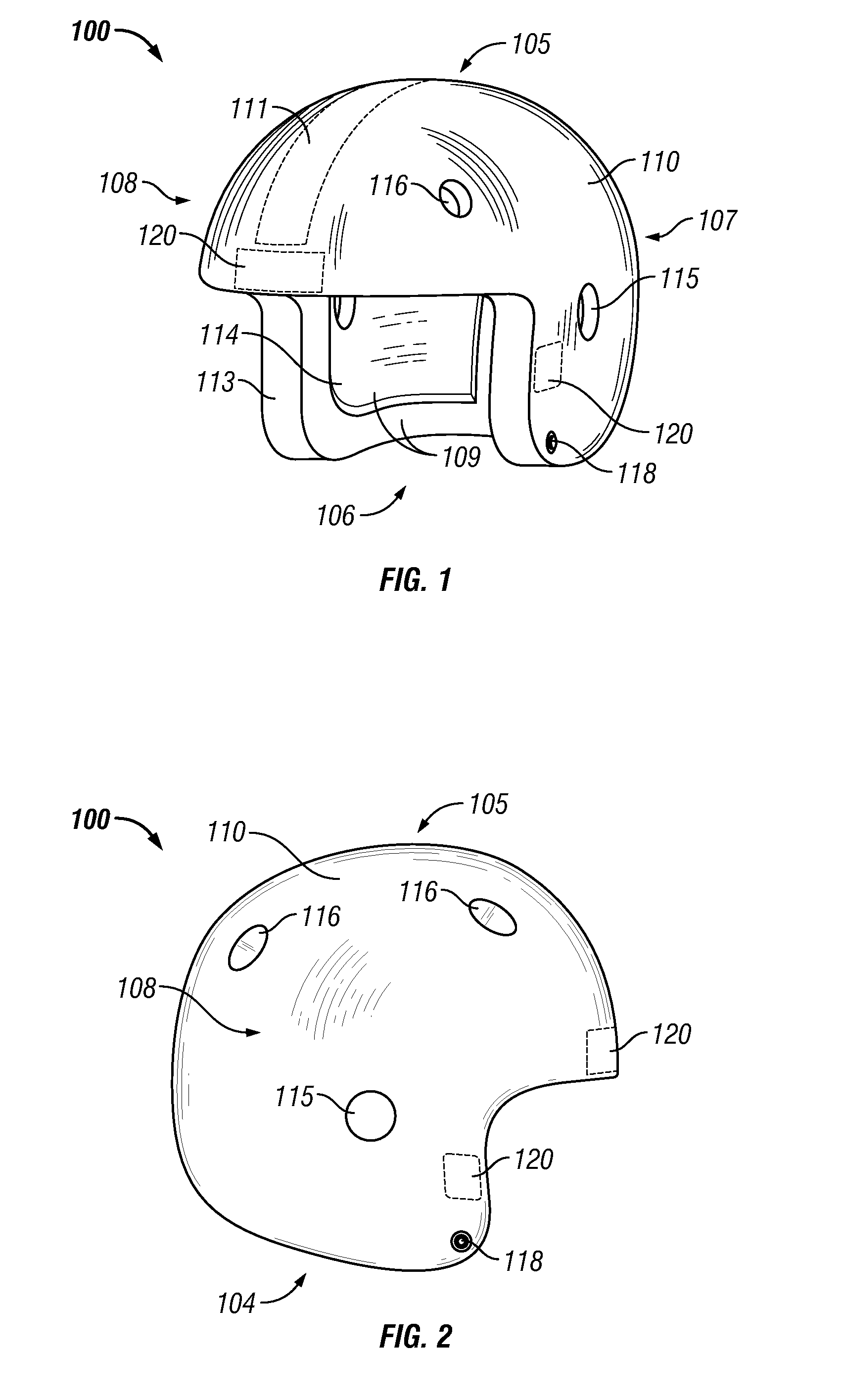

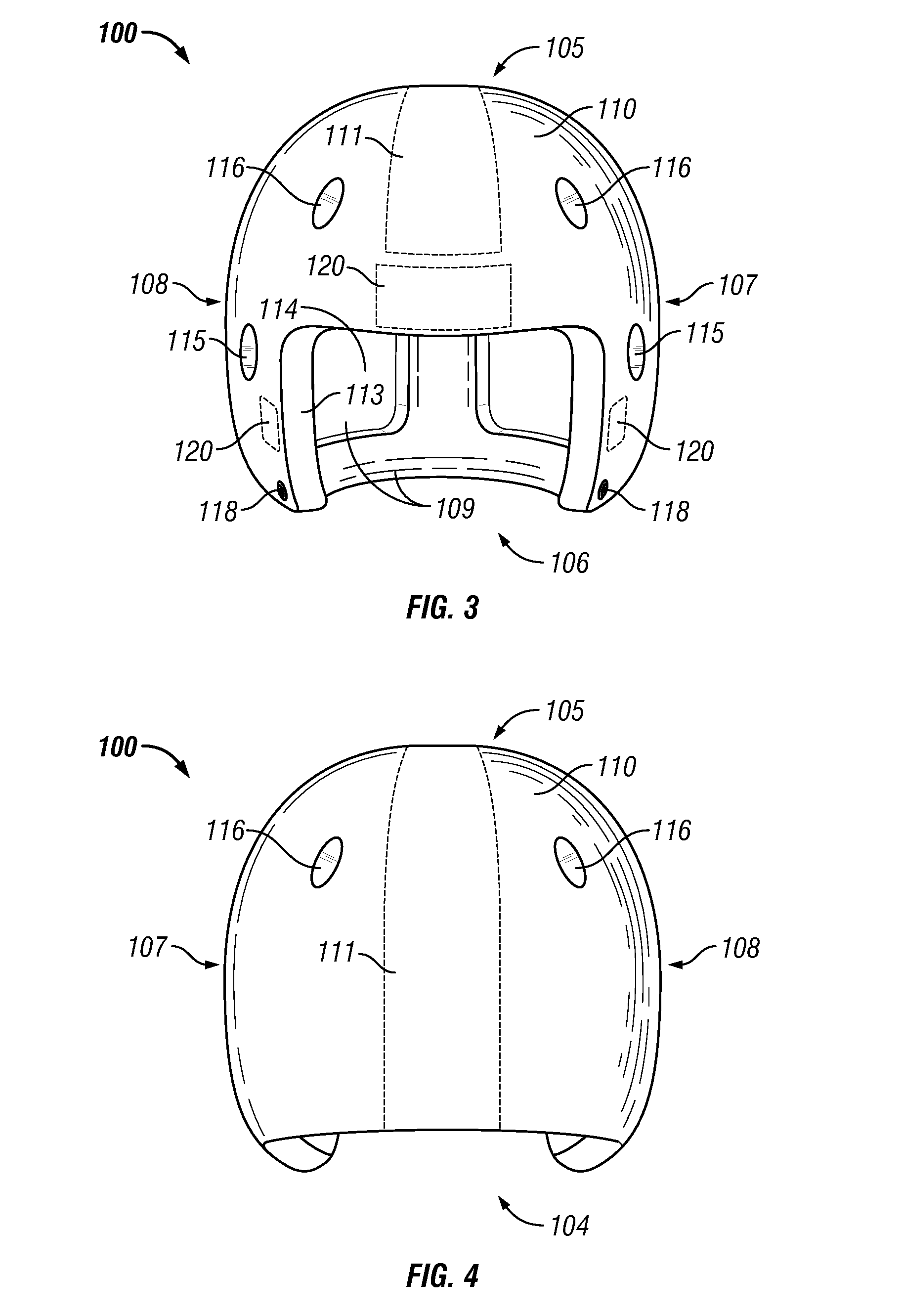

Hybrid Head Covering

A versatile protective headgear which is a close replica of a football helmet, fabricated from a lightweight, suitable foam material that is conformable and resilient, capable of absorbing energy and protecting the wearer from lacerations and / or contusions from incidental contact in outdoor sporting activities. The headgear provides warmth and protection from moisture in cold weather, but the internal design also provides sufficient ventilation for year around use. The foam material can be produced in a variety of colors and has a smooth external surface that will accept paint and decals for authentic team identification. The headgear may be held in place by a standard football chin strap and is designed to have a removable face mask. The authentic appearance and cold weather protection it provides makes it an effective and desirable head covering for all cold weather recreational and work activities, including attendance at football games. Its flexibility permits packing for travel and storage. The simple construction from one piece of material makes is easy and economical to manufacture.

Owner:PYE BRIAN

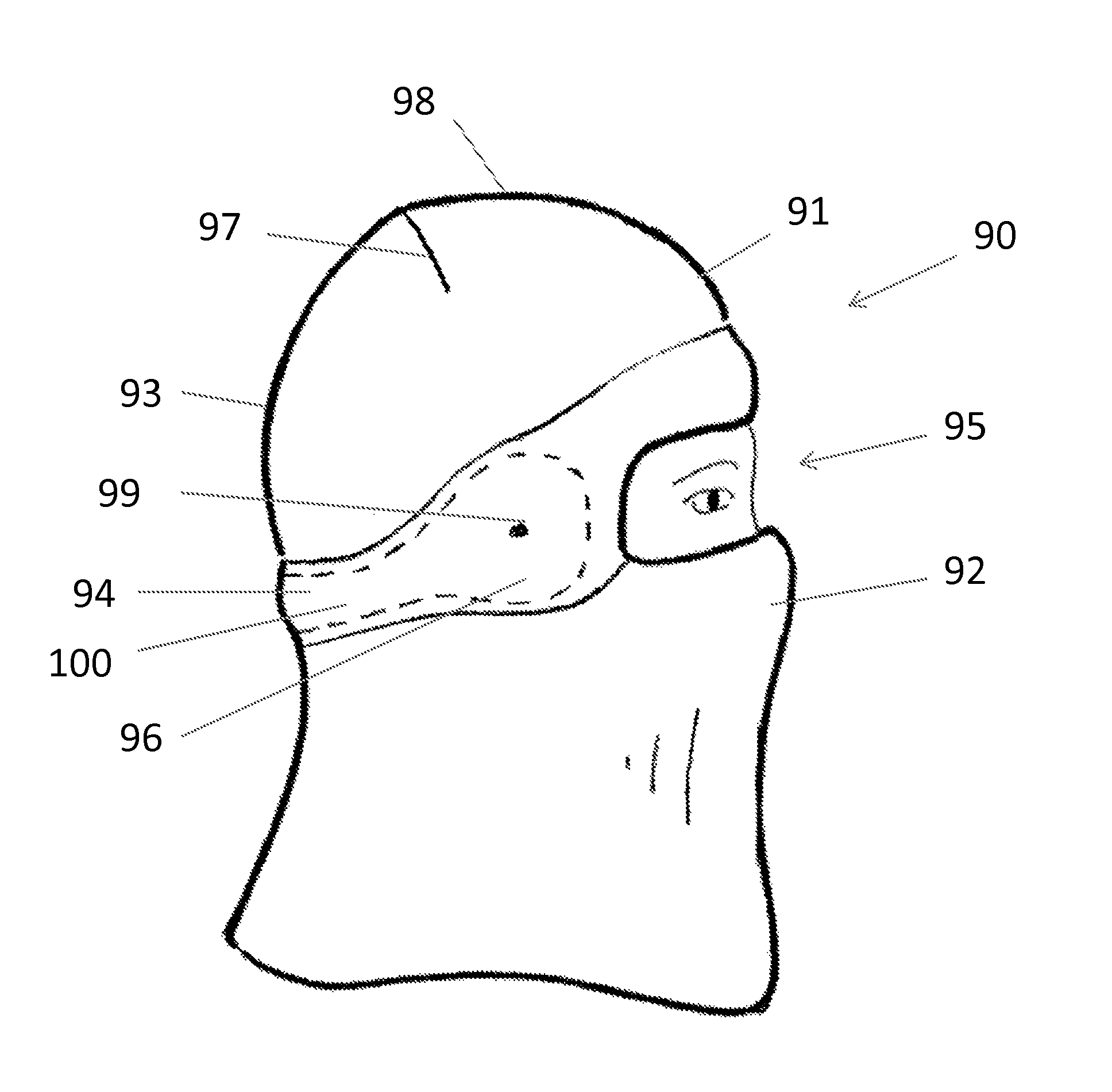

Hat and face mask with ear warmer

Headwear suitable for wearing in cold weather, such as a hat or a face mask, that has ear warmers secured on the inside of the hat or face mask which have a frame with a band and a first and second ear portion. The hat is provided with a shape suitable for securing the hat around a person's head so as to conform to the contours of the head to substantially minimize gaps between the hat and the head. Unexpectedly, the band of the ear warmer within the sleeve of the hat provides tension to the hat that causes it to hug the back of the head. At the same time, the first and second ear portions keep the ears of the wearer securely covered.

Owner:ILLORETTA +1

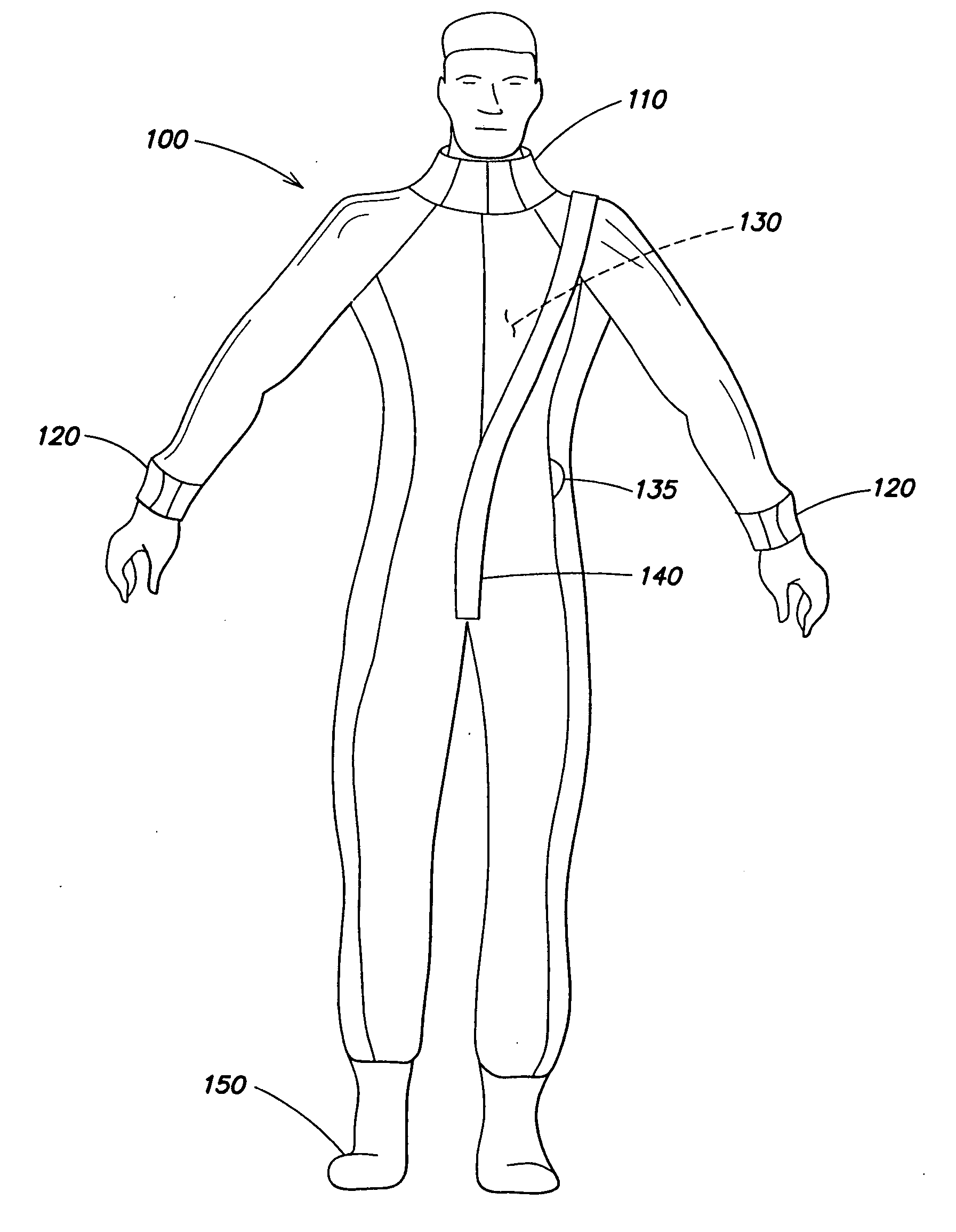

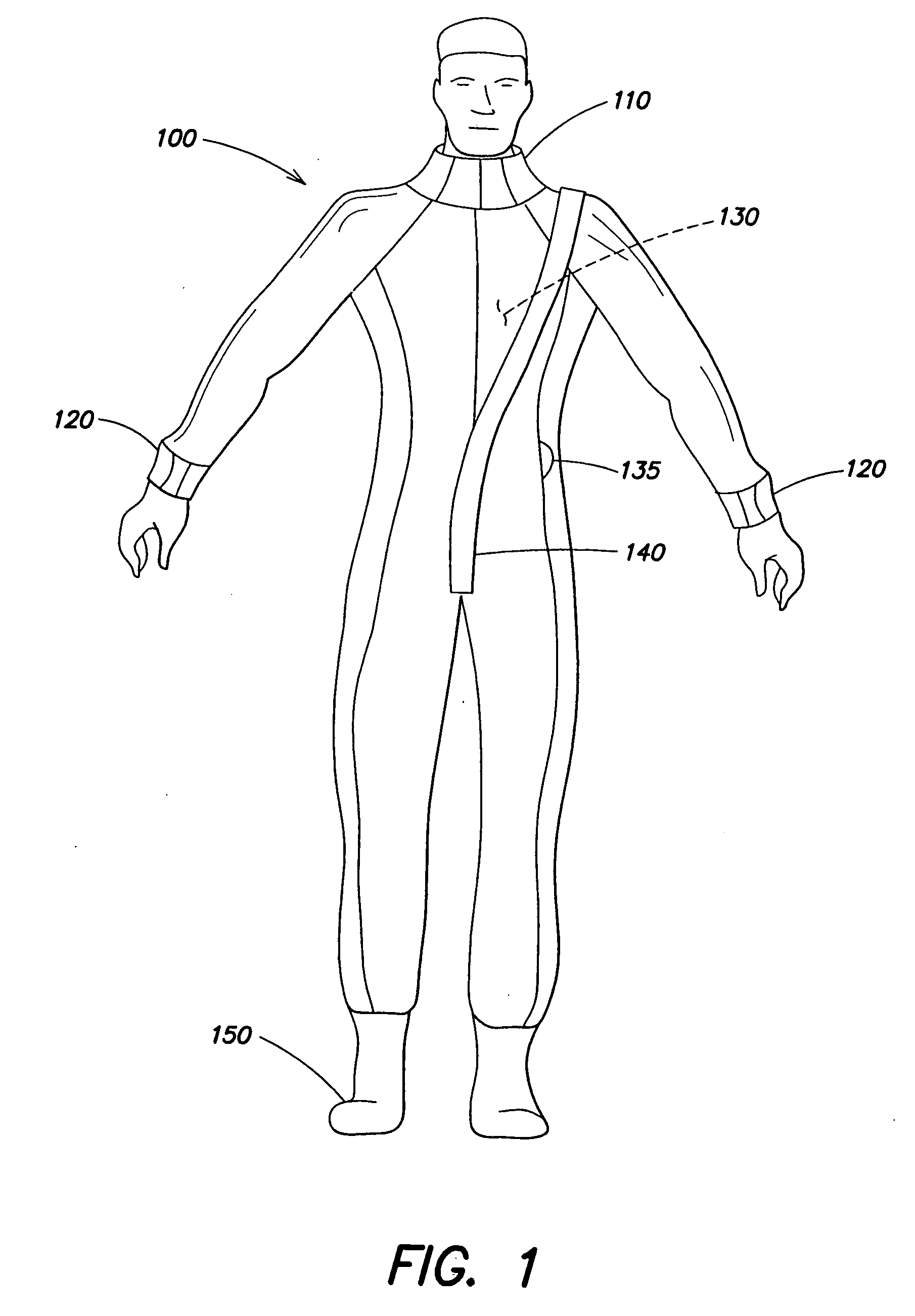

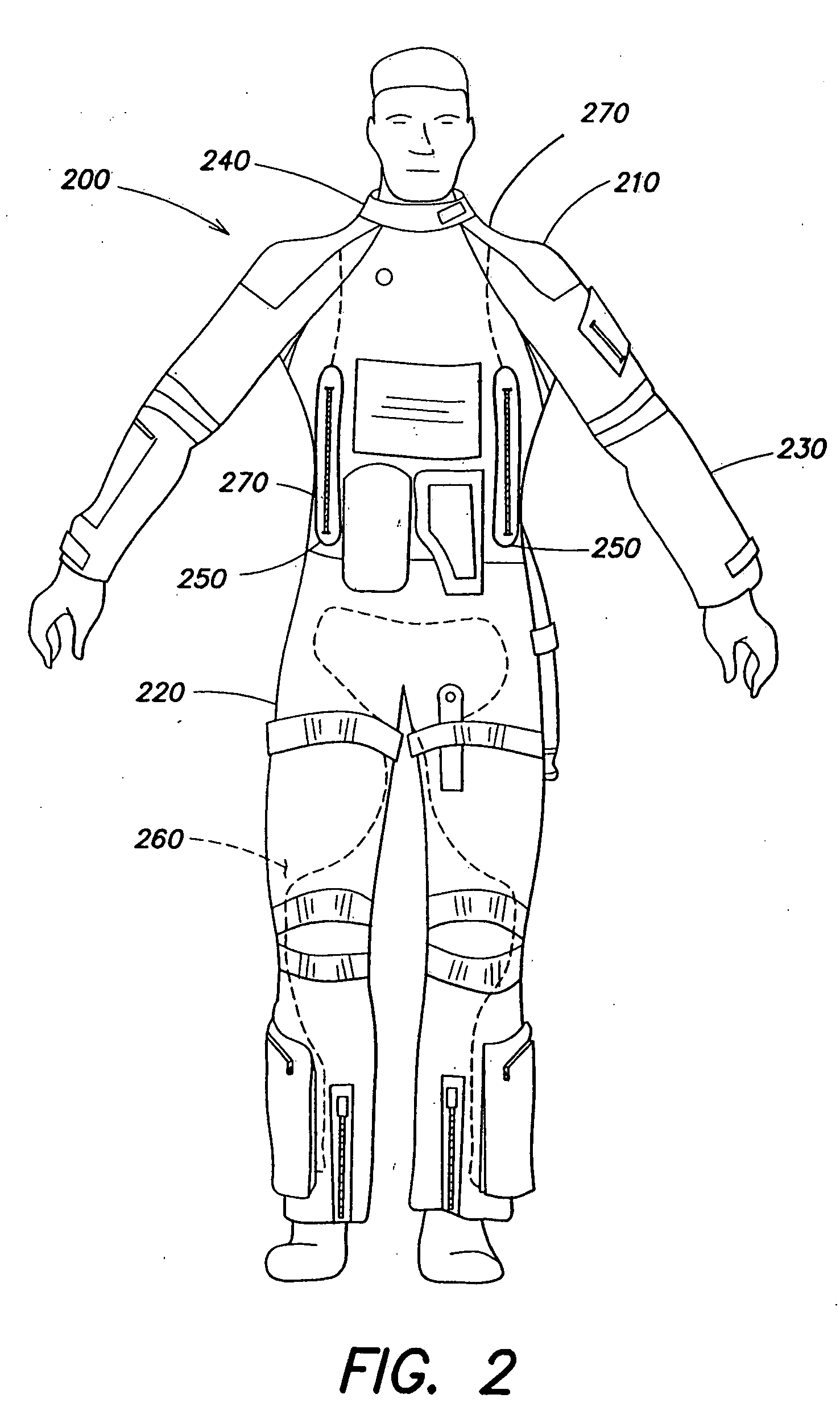

Integrated protective ensemble

An integrated ensemble for personal protection and comfort. The integrated ensemble may generally include one or more multifunctional layers. Each layer may include functionality directed to provision of specific types of protection and / or personal comfort. A liner may be generally capable of providing immersion protection, cooling, and cold weather protection. A shell may be designed for wear in cooperation with the liner. The shell may be capable of providing protection against flame, acceleration, and other environmental factors, as well as providing cooling and gear carriage. The disclosed integrated ensembles are generally low-bulk to facilitate movement.

Owner:TIAX LLC

Cold weather vented garment

ActiveUS9392825B2Challenging to containKeep it lightweightGarment special featuresOvergarmentsFilling materialsEngineering

The present invention relates to breathable, vented, and insulating cold weather garments. More particularly, the present invention relates to garments with chambers to retain an insulating fill material. Perforations along the seams between the insulating chambers may achieve optimal evaporative moisture transfer from the inside (proximal to the body of a wearer) of the garment to the outside environment.

Owner:NIKE INC

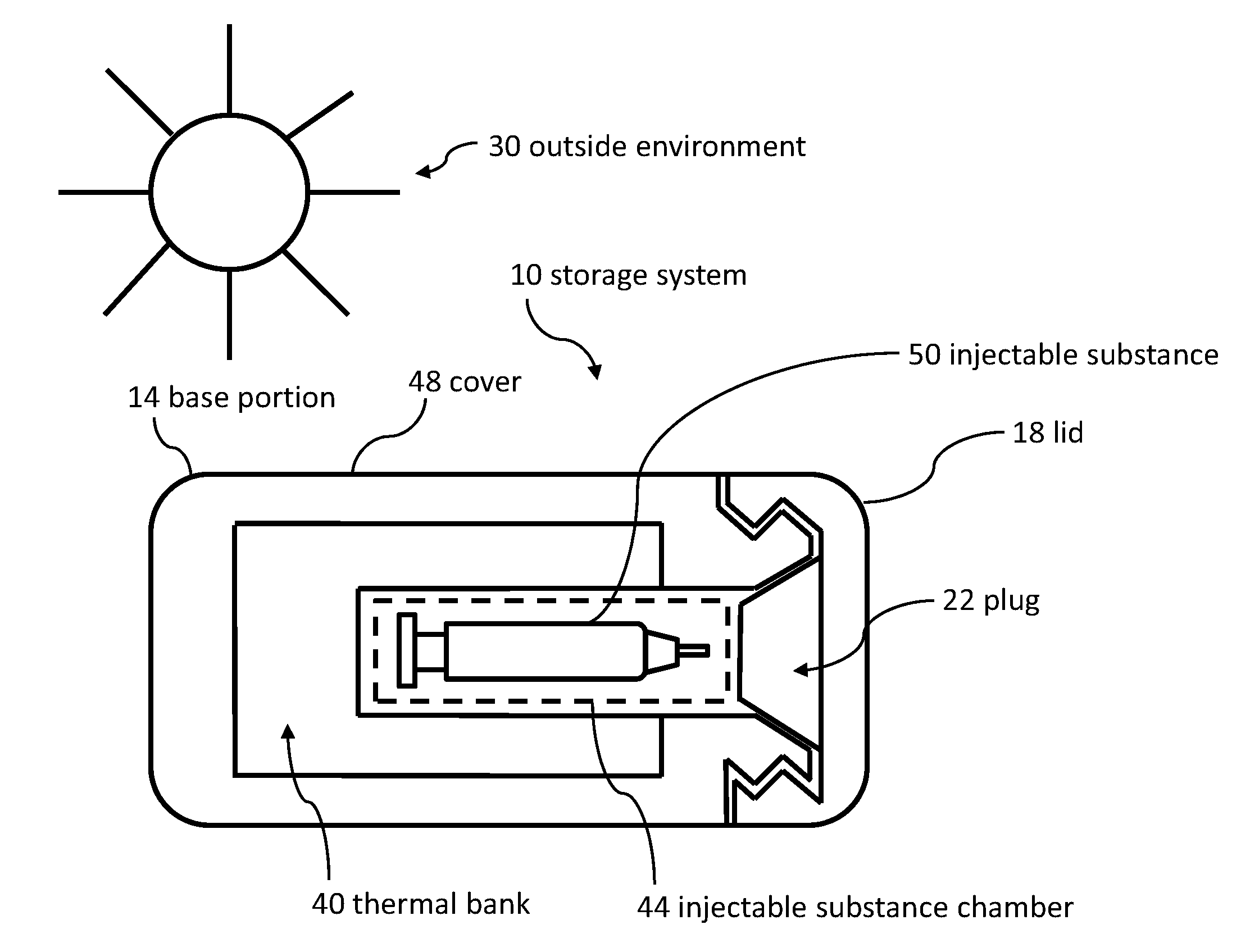

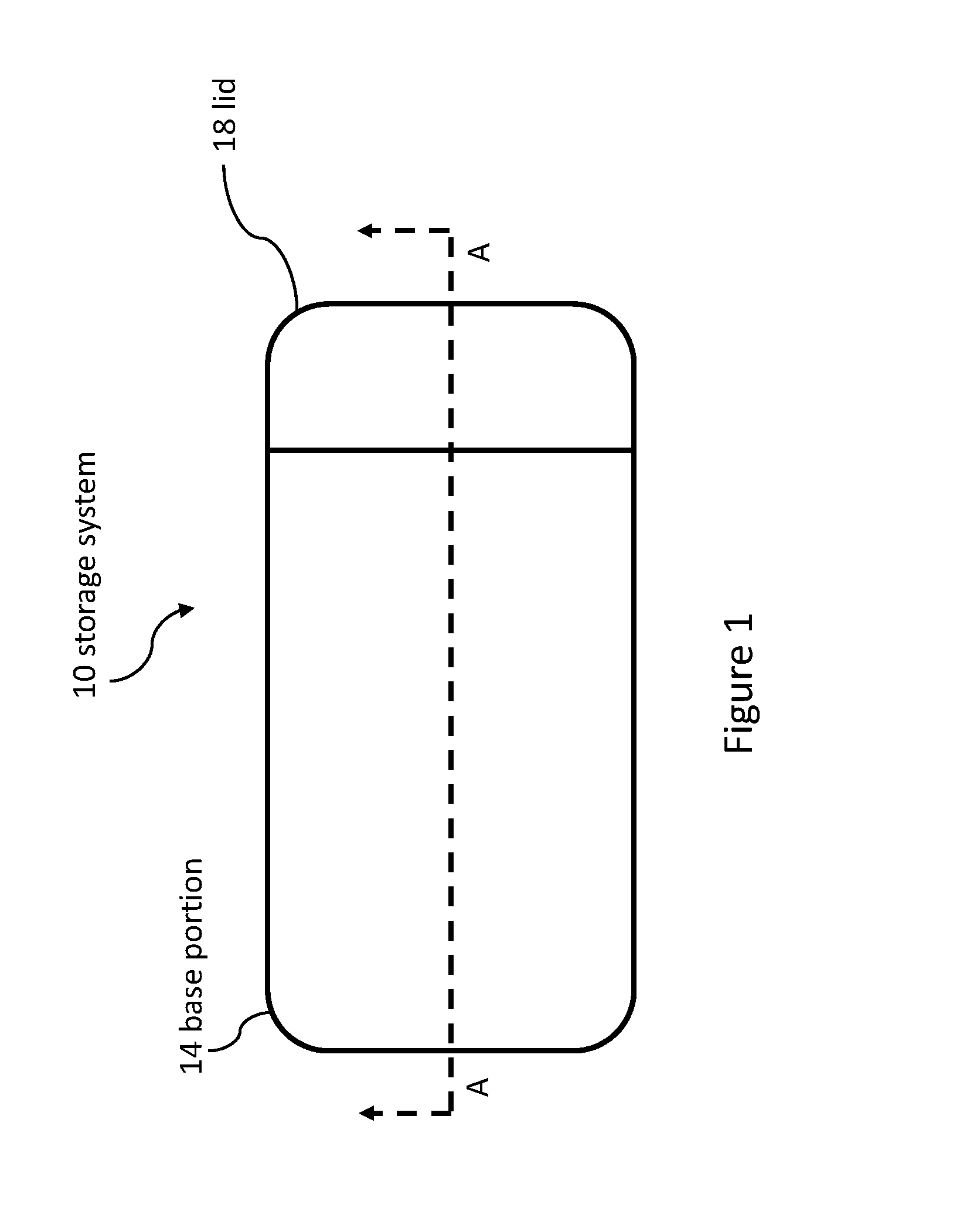

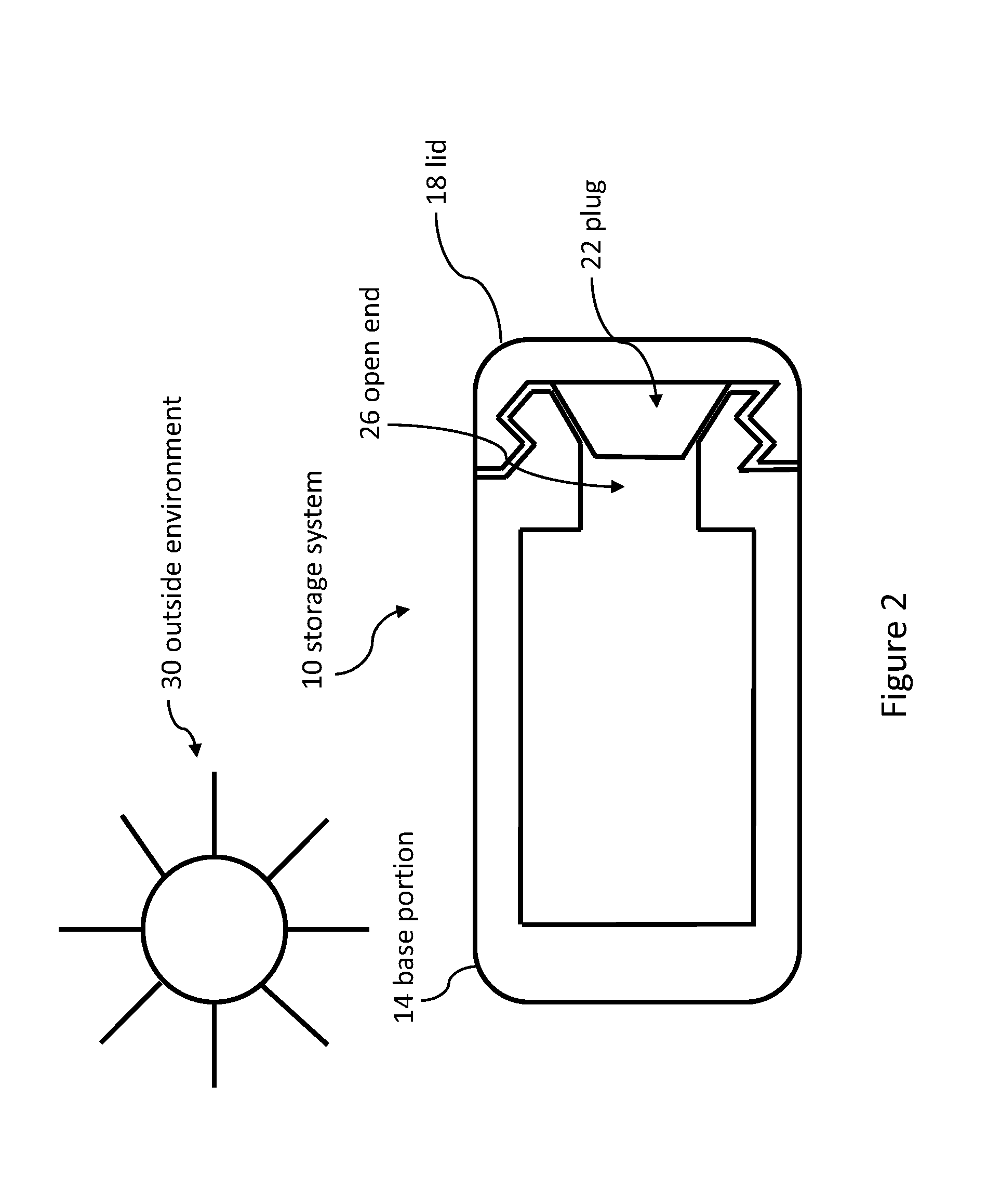

Storage systems and methods for medicines

ActiveUS20150151893A1Reduce volumeReduce weightMedical devicesIndirect heat exchangersElectricityEngineering

People can damage their medicines by taking them outside in hot or cold weather. On the other hand, some people need to carry their medicines with them wherever they go (even if the weather is extremely hot or cold). Specially constructed storage systems can protect medicines from damage due to hot and cold weather without requiring bulky structures or expensive components that consume electricity to regulate temperature.

Owner:WENGREEN SANDY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com