Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

984results about "Commutation monitoring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

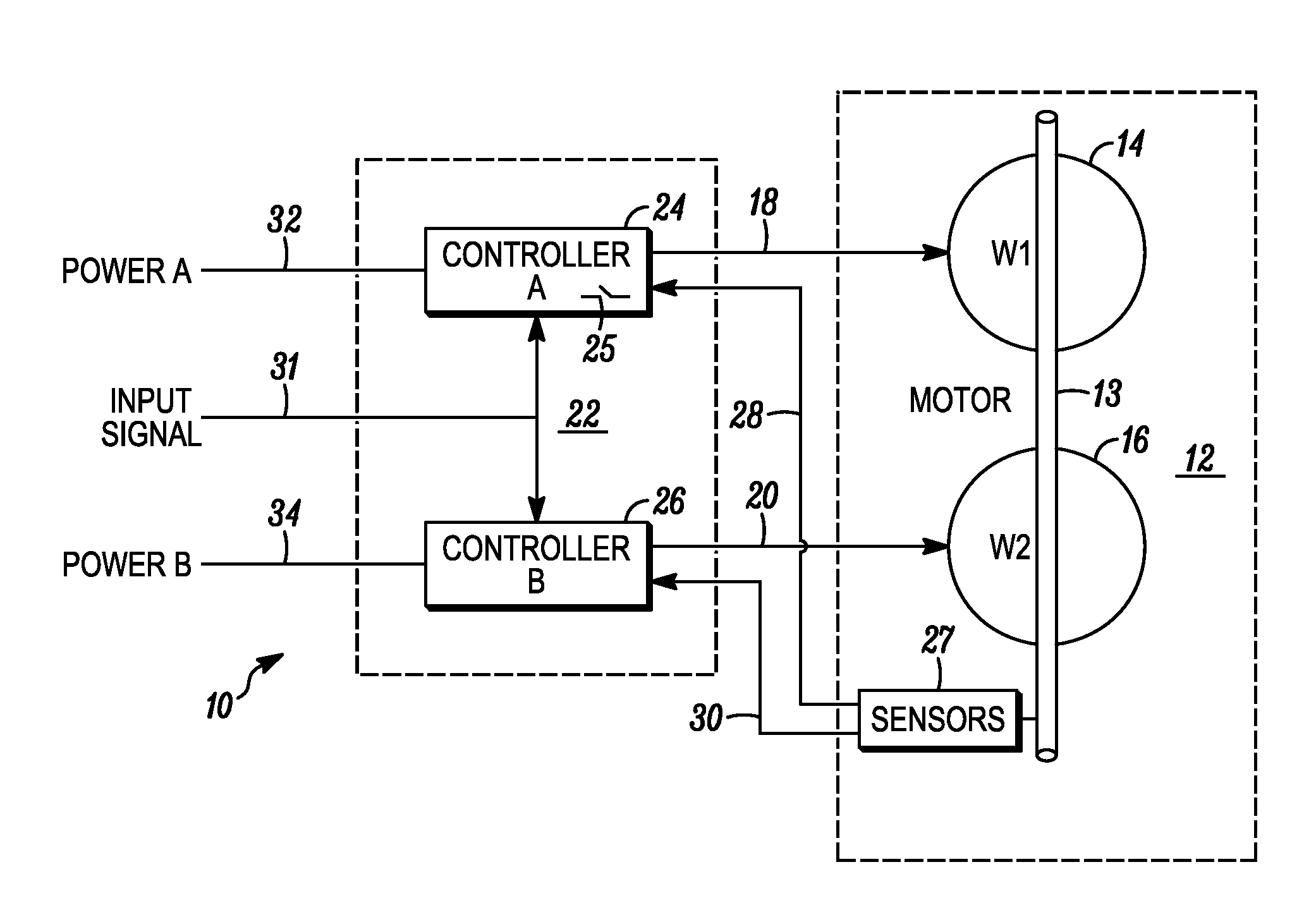

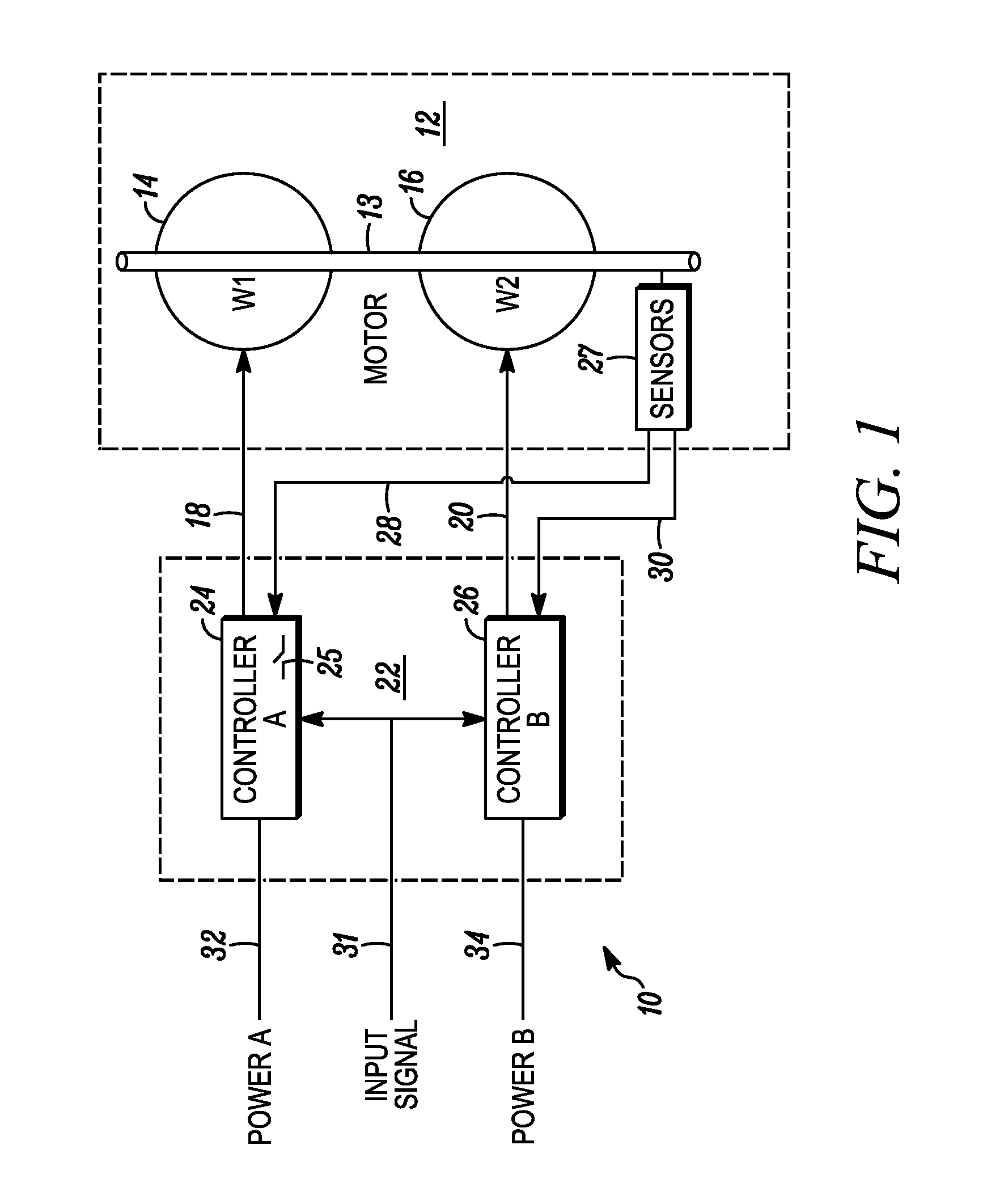

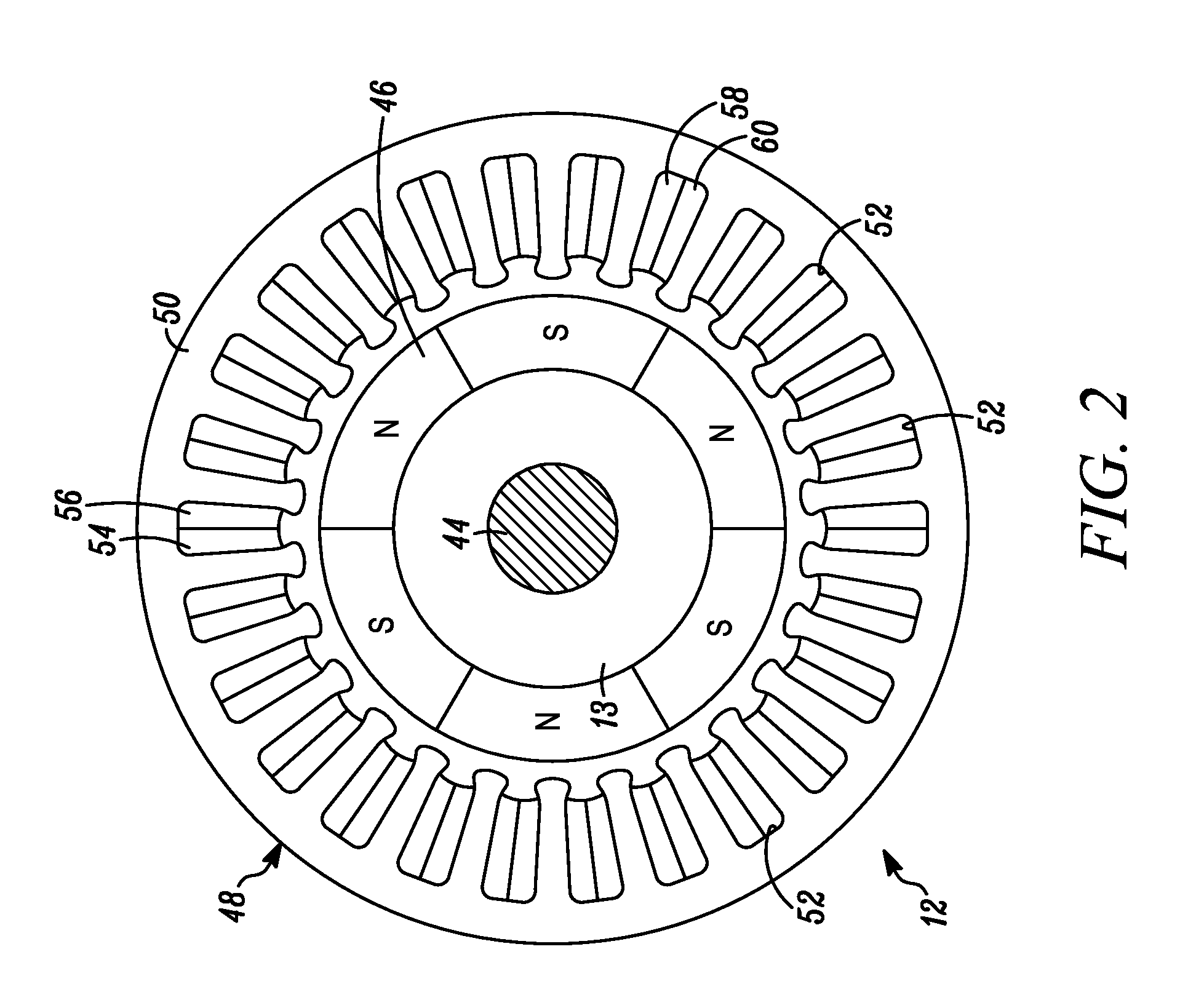

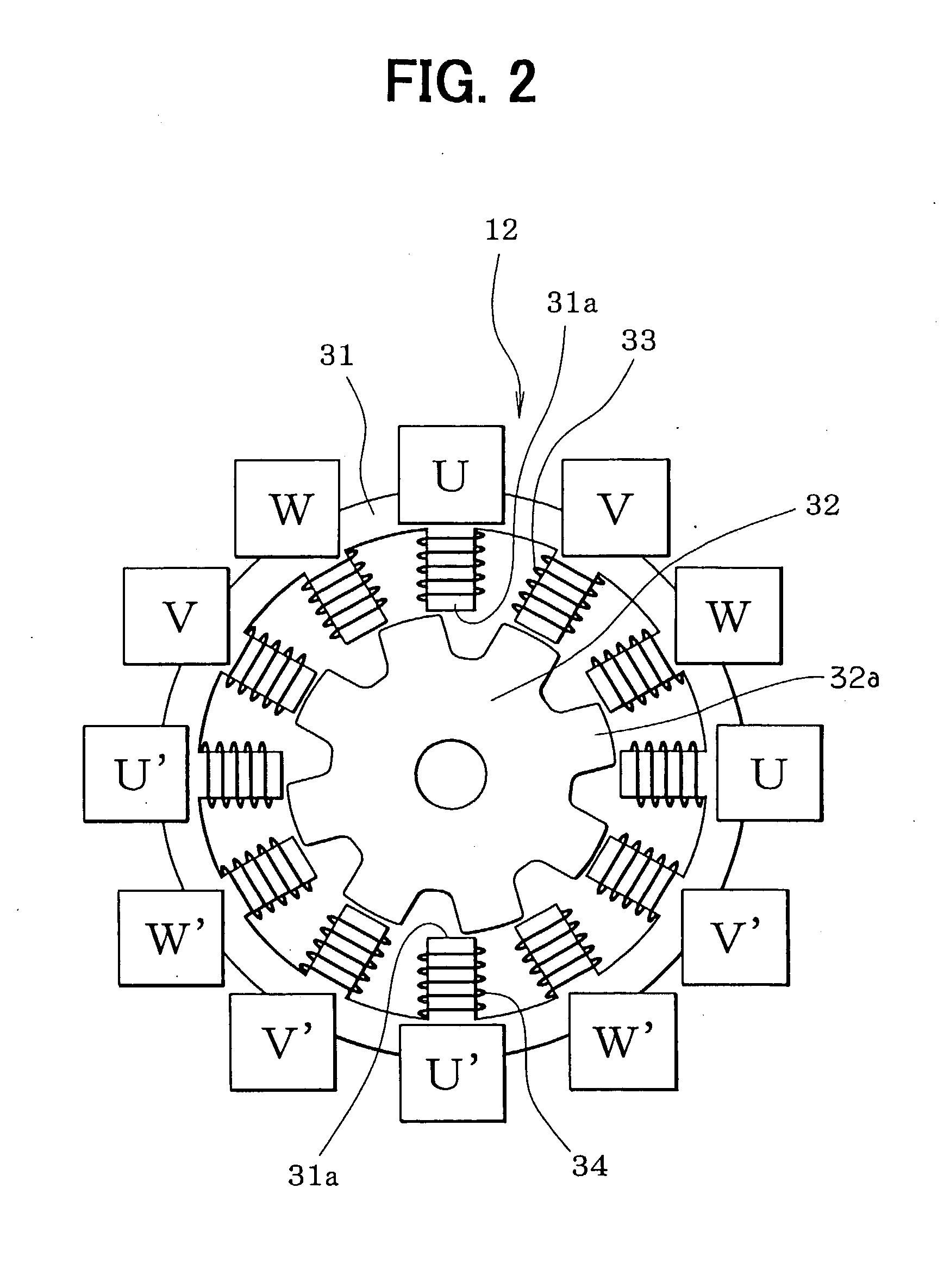

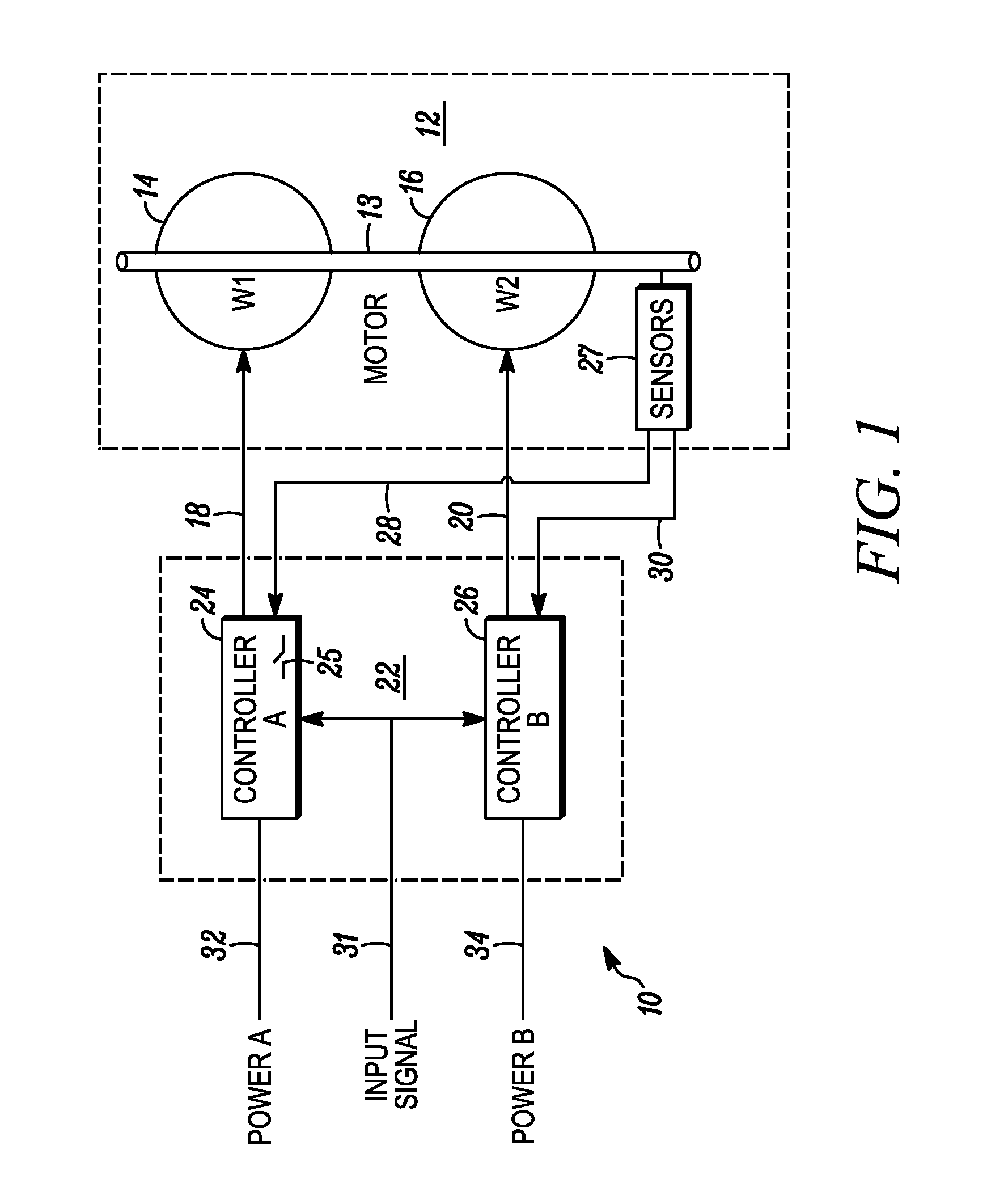

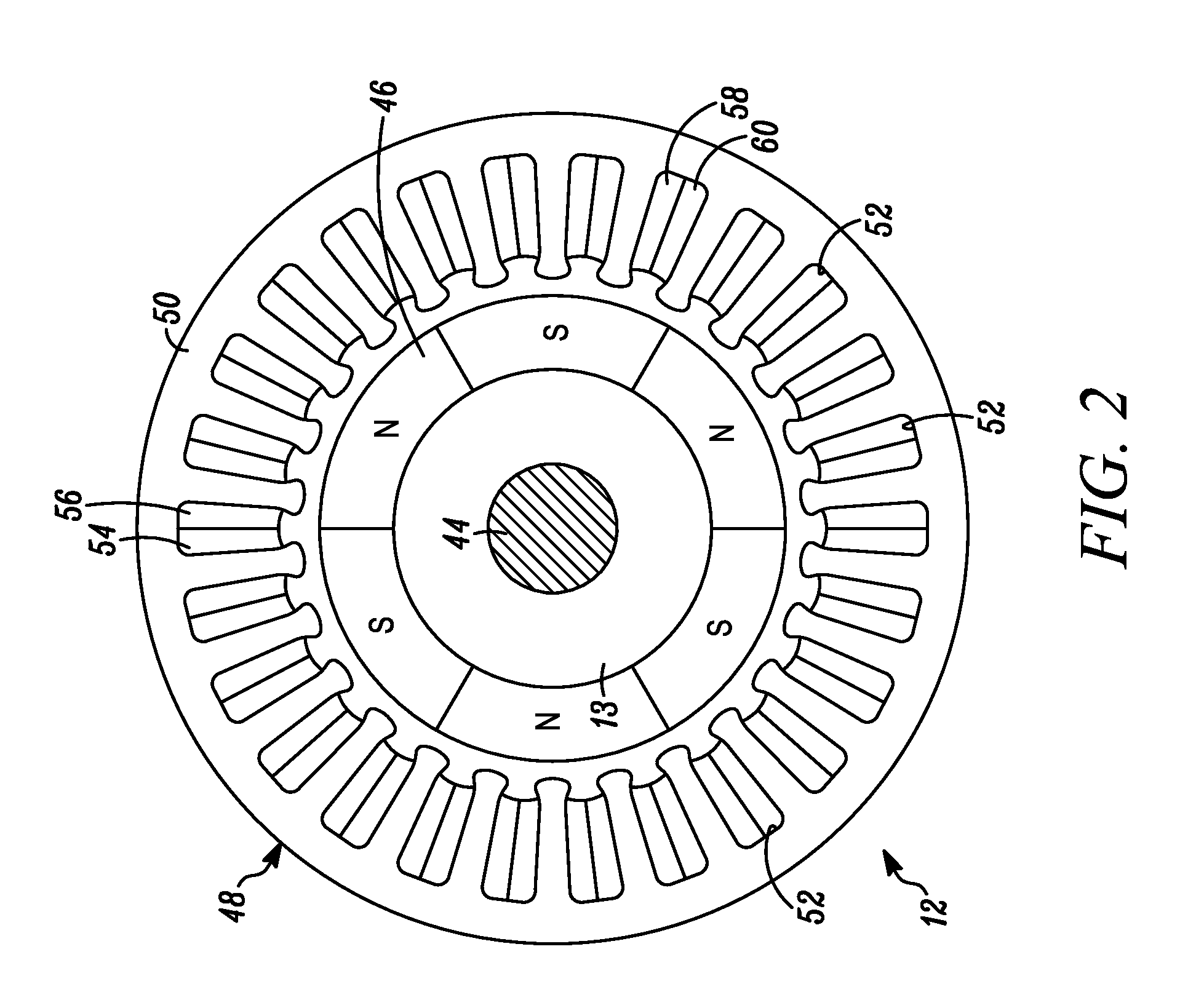

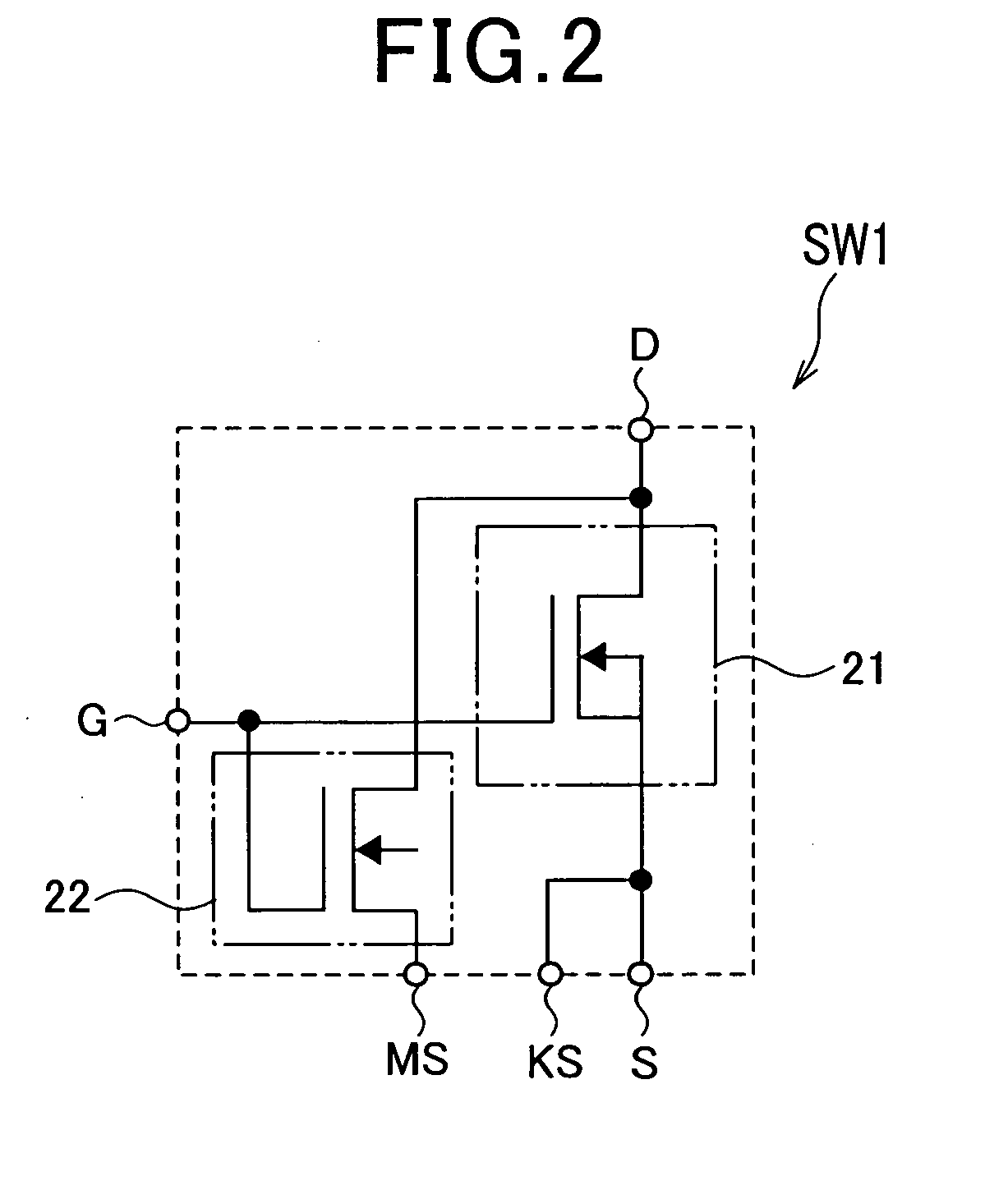

Motor having controllable torque

InactiveUS8125168B2Single-phase induction motor startersCommutation monitoringMotor controlElectric motor

A controllable motor includes a rotor. A first stator winding set is operable, upon being energized, to generate and apply a first torque to the rotor. A second stator winding set independent of the first stator winding set is operable, upon being energized, to generate and apply a second torque to the rotor. A motor control is coupled to the first and second stator winding sets. The motor control is operable to selectively energize one of the first or second stator winding sets to thereby generate and apply one of the first or second torques to the rotor, and simultaneously energize both the first and second stator winding sets to thereby generate and apply a third torque greater than the first or the second torque.

Owner:HONEYWELL INT INC

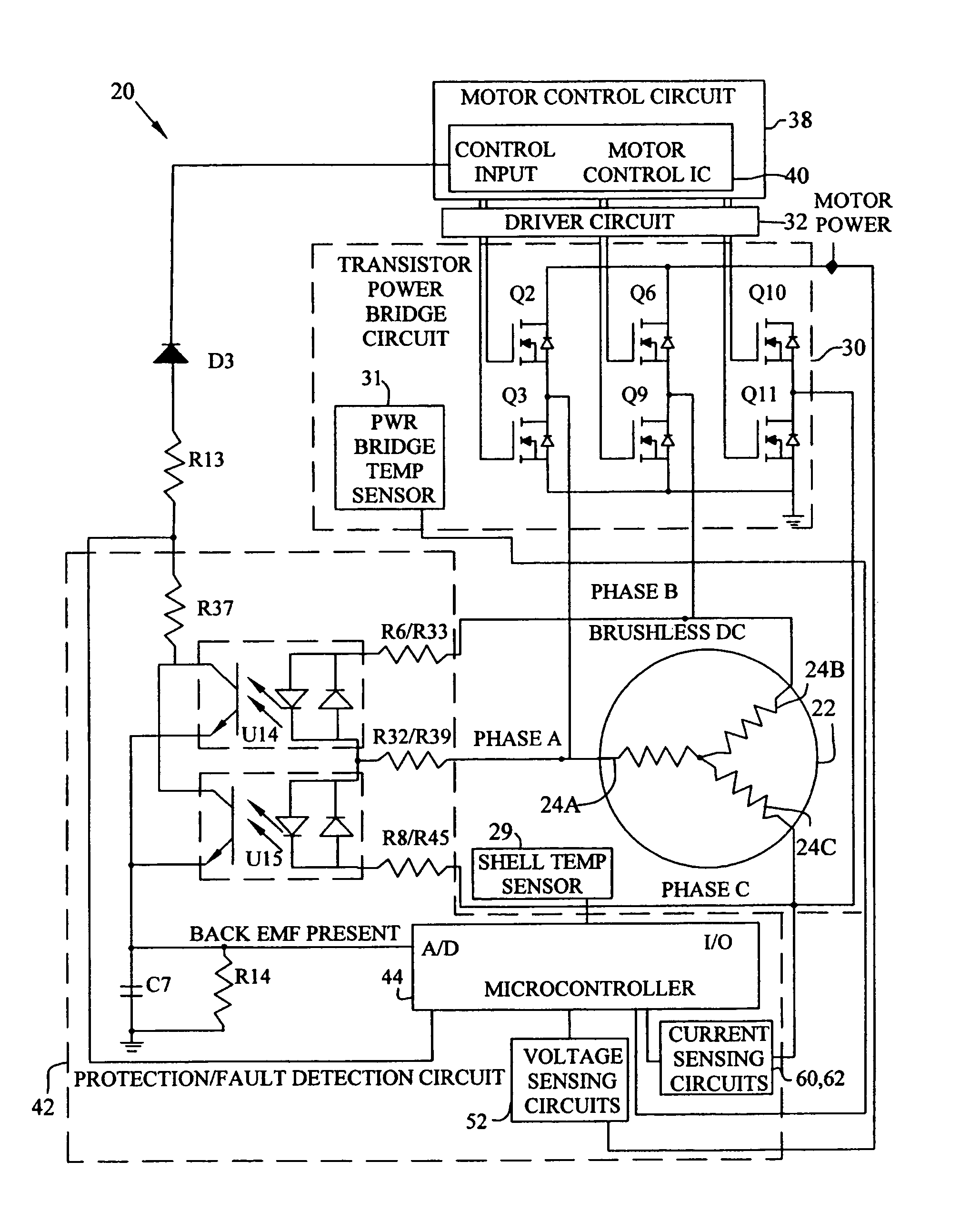

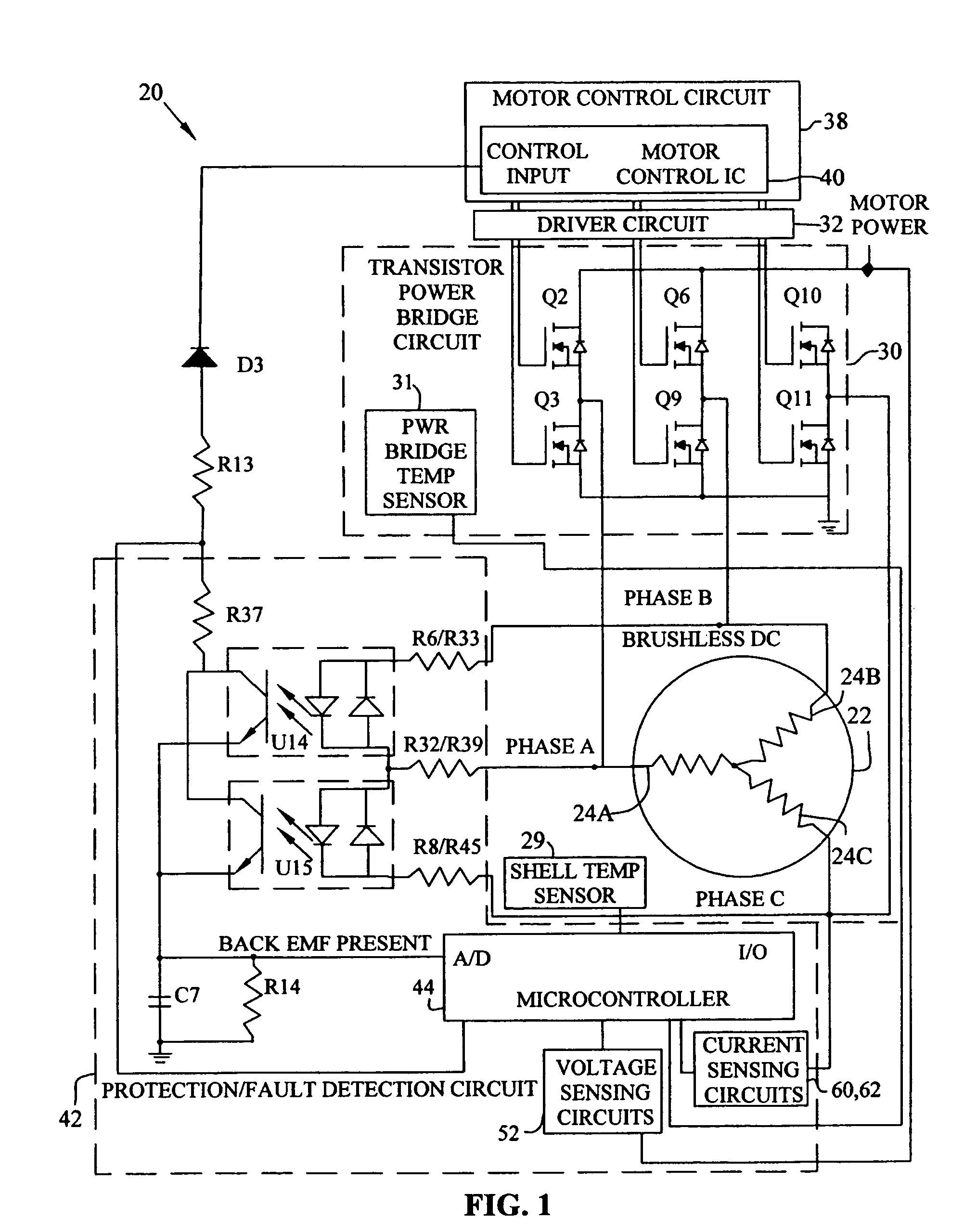

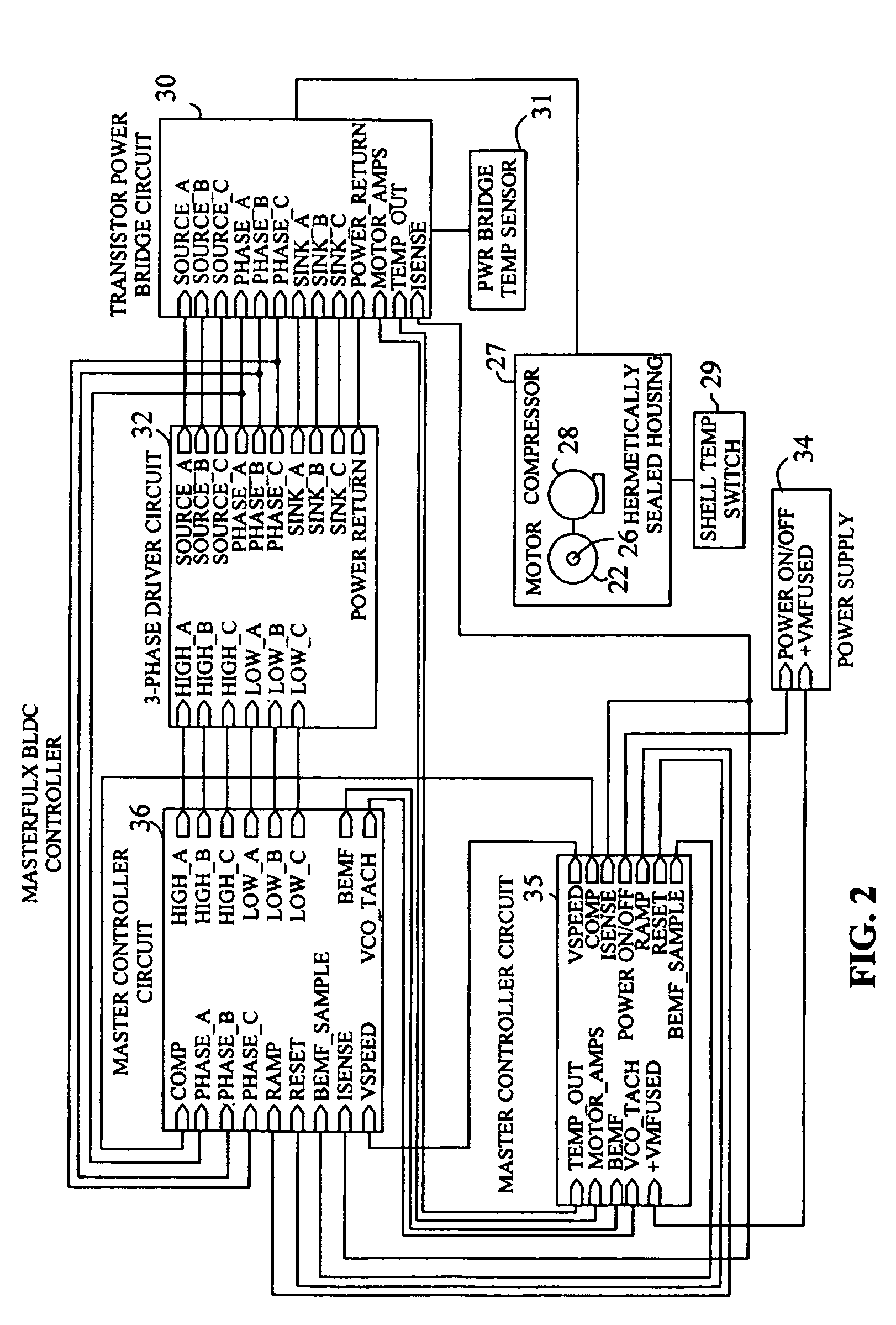

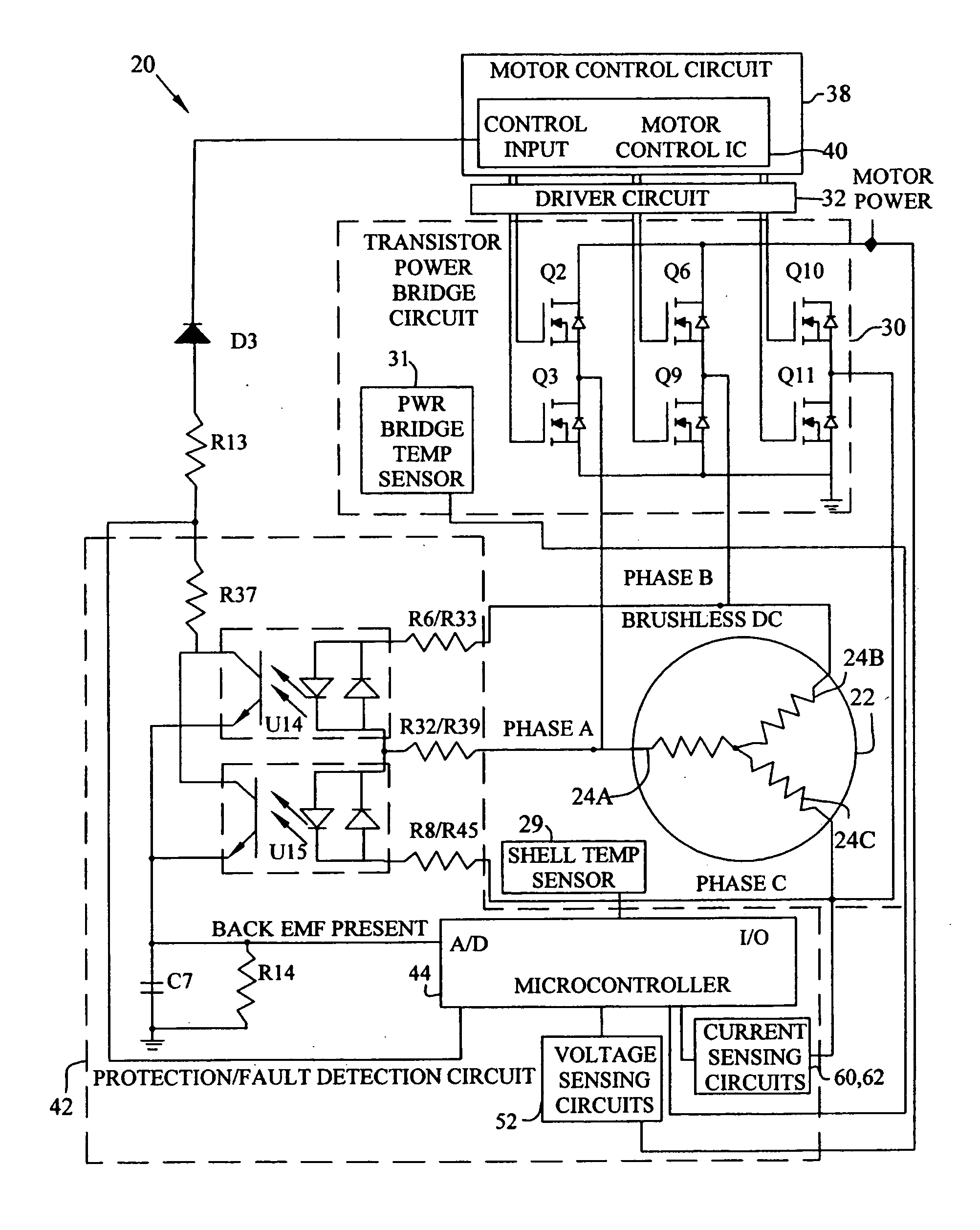

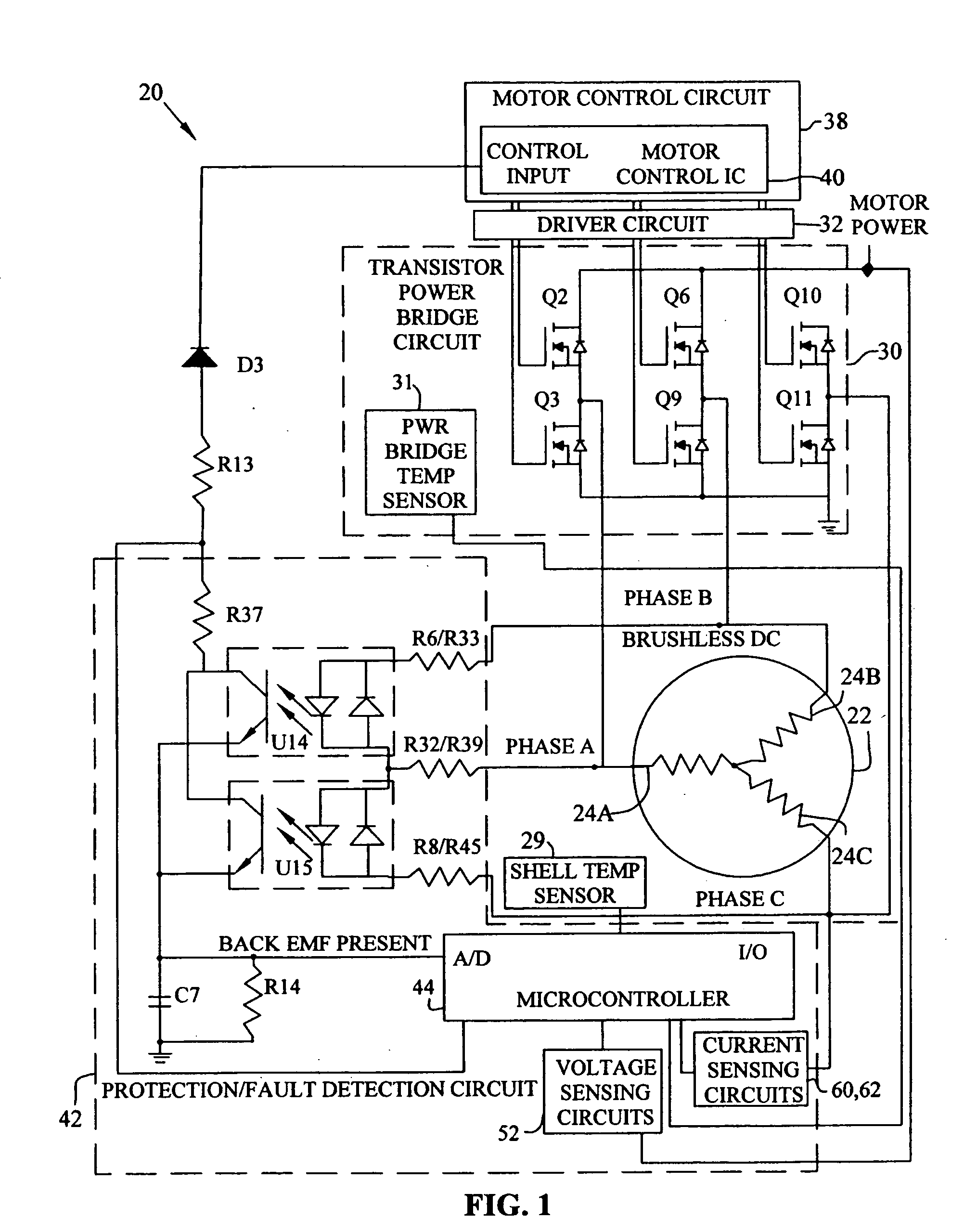

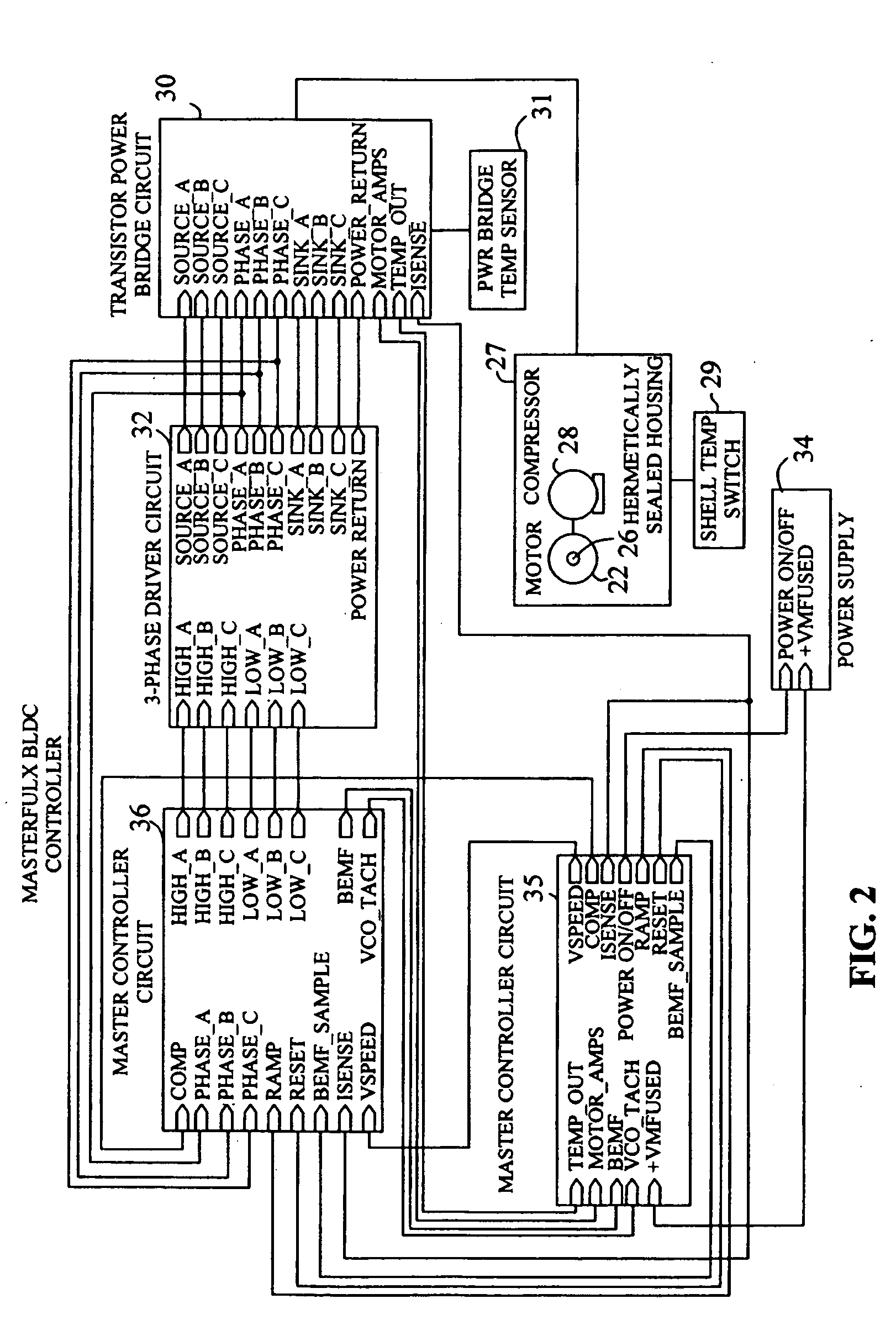

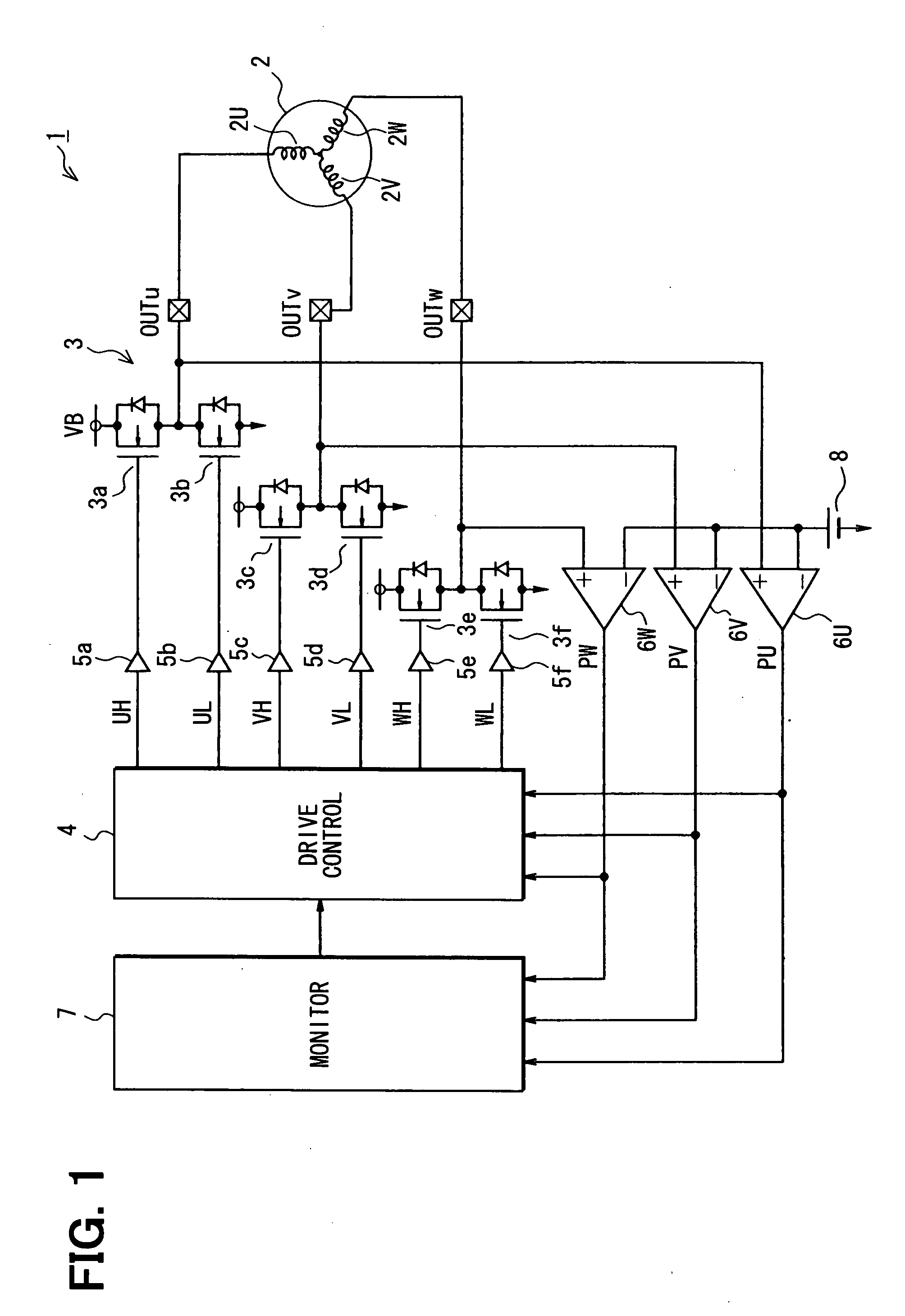

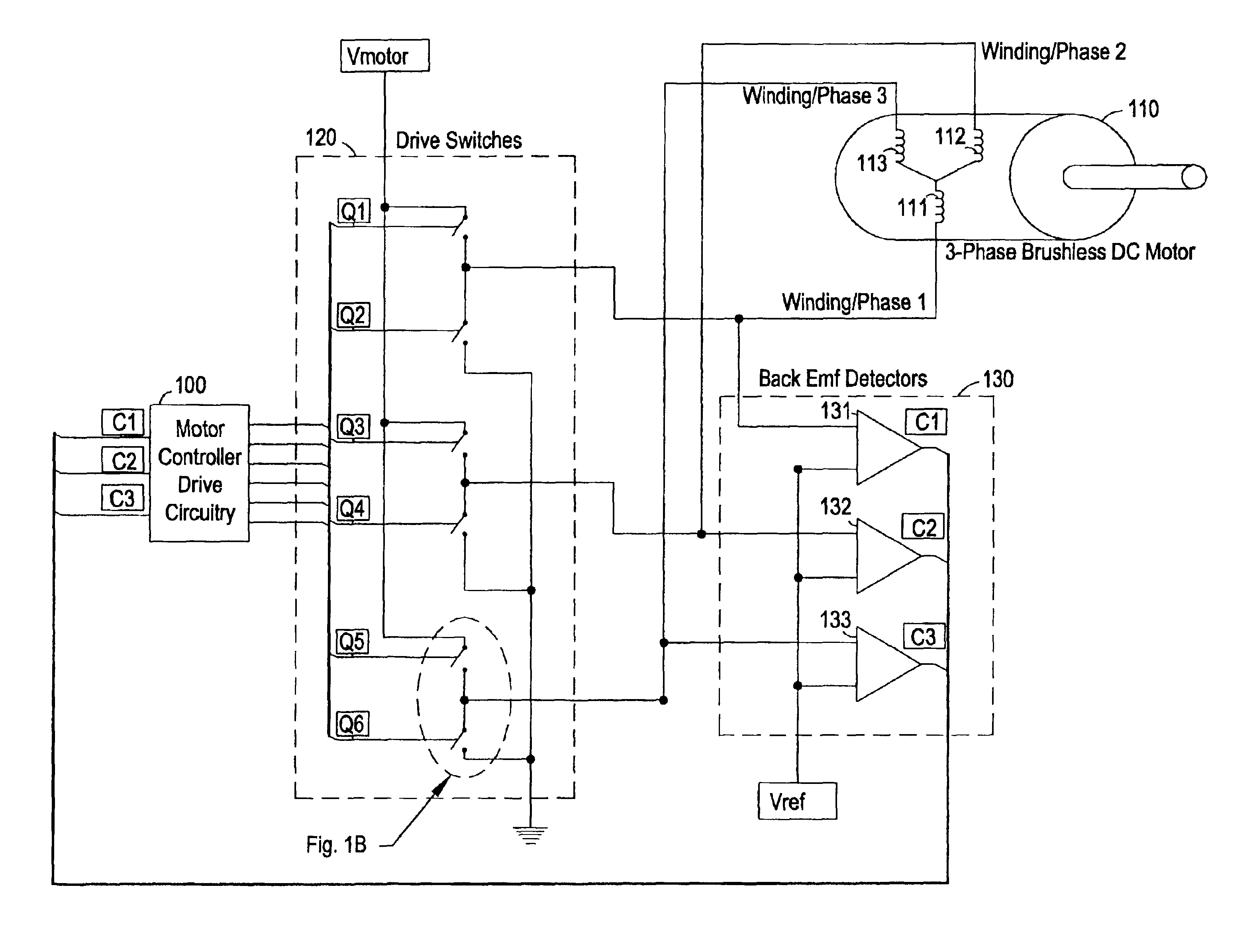

Brushless and sensorless DC motor control system with locked and stopped rotor detection

ActiveUS7042180B2Simple control methodEasily interfaceCommutation monitoringAC motor controlMotor speedDc motor control

A motor control system for a brushless and sensorless DC motor for driving a compressor, pump or other application, includes a protection and fault detection circuit for detecting a locked rotor and a rotor which has stopped because of lost rotor phase lock. The motor control system also includes an off-the-shelf motor control integrated circuit having an input for disabling power outputs to the motor phase coils. The protection and fault detection circuit uses a back EMF sampling circuit coupled to the motor phase coils and momentarily disables power to the motor phase coils, via the motor control integrated circuit input, to determine if the motor rotor is rotating. The system also monitors supply voltage, supply current, temperature, and motor speed limits to detect faults and protect system components.

Owner:REGAL BELOIT AMERICA

Brushless and sensorless DC motor control system with locked and stopped rotor detection

ActiveUS20050029976A1Easy to modifyEasily interfaceCommutation monitoringDC motor speed/torque controlMotor speedDc motor control

A motor control system for a brushless and sensorless DC motor for driving a compressor, pump or other application, includes a protection and fault detection circuit for detecting a locked rotor and a rotor which has stopped because of lost rotor phase lock. The motor control system also includes an off-the-shelf motor control integrated circuit having an input for disabling power outputs to the motor phase coils. The protection and fault detection circuit uses a back EMF sampling circuit coupled to the motor phase coils and momentarily disables power to the motor phase coils, via the motor control integrated circuit input, to determine if the motor rotor is rotating. The system also monitors supply voltage, supply current, temperature, and motor speed limits to detect faults and protect system components.

Owner:REGAL BELOIT AMERICA

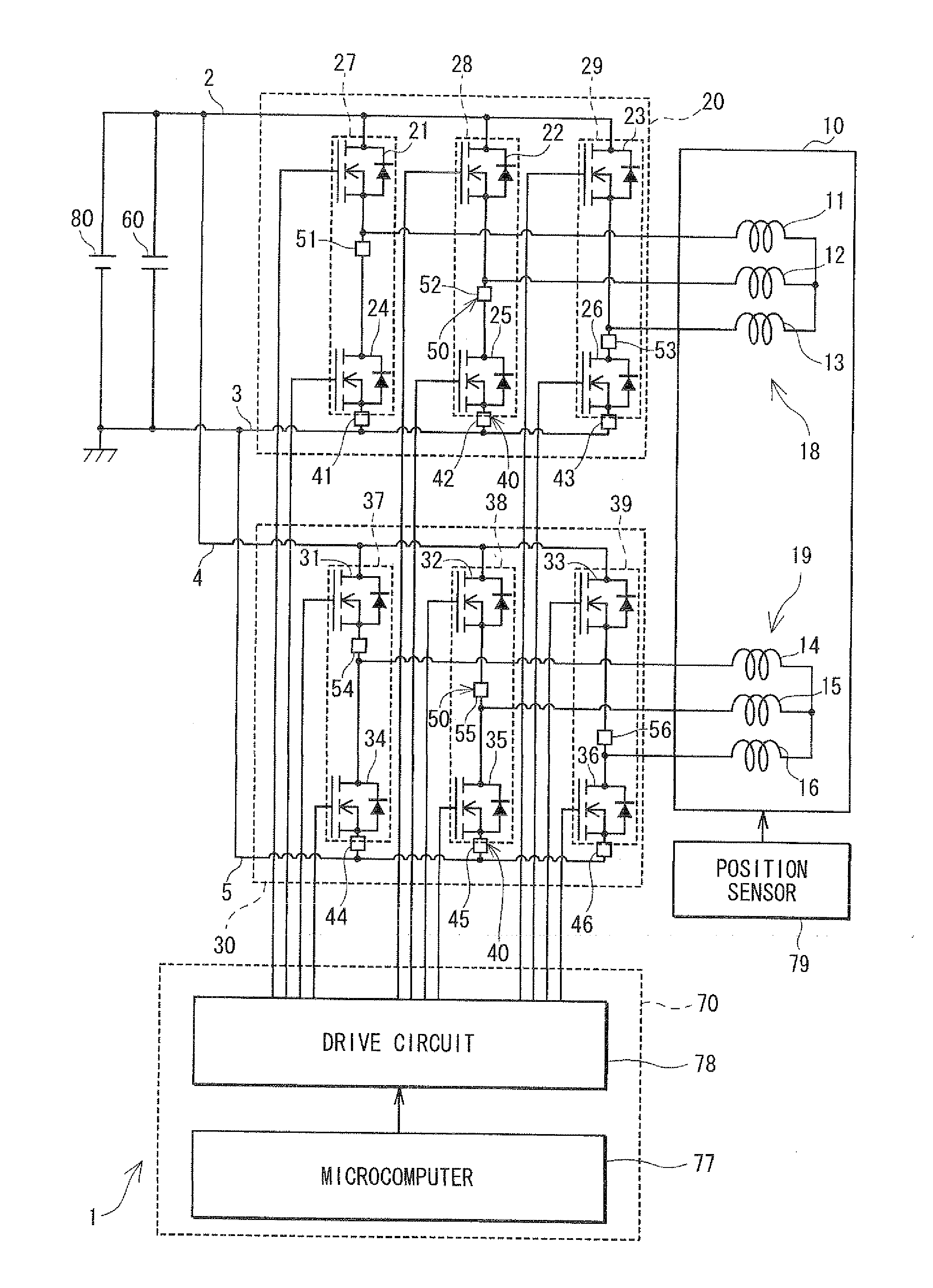

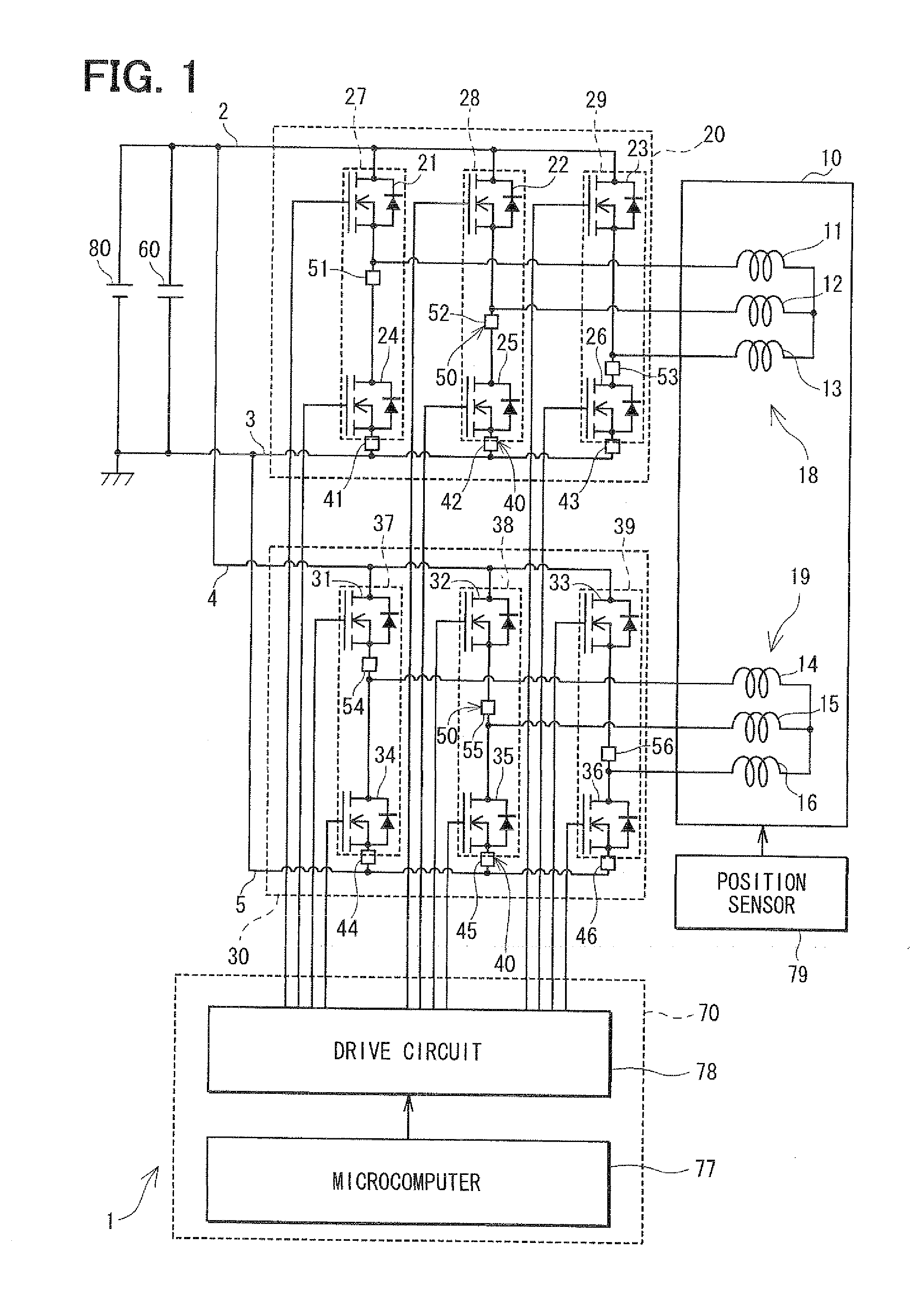

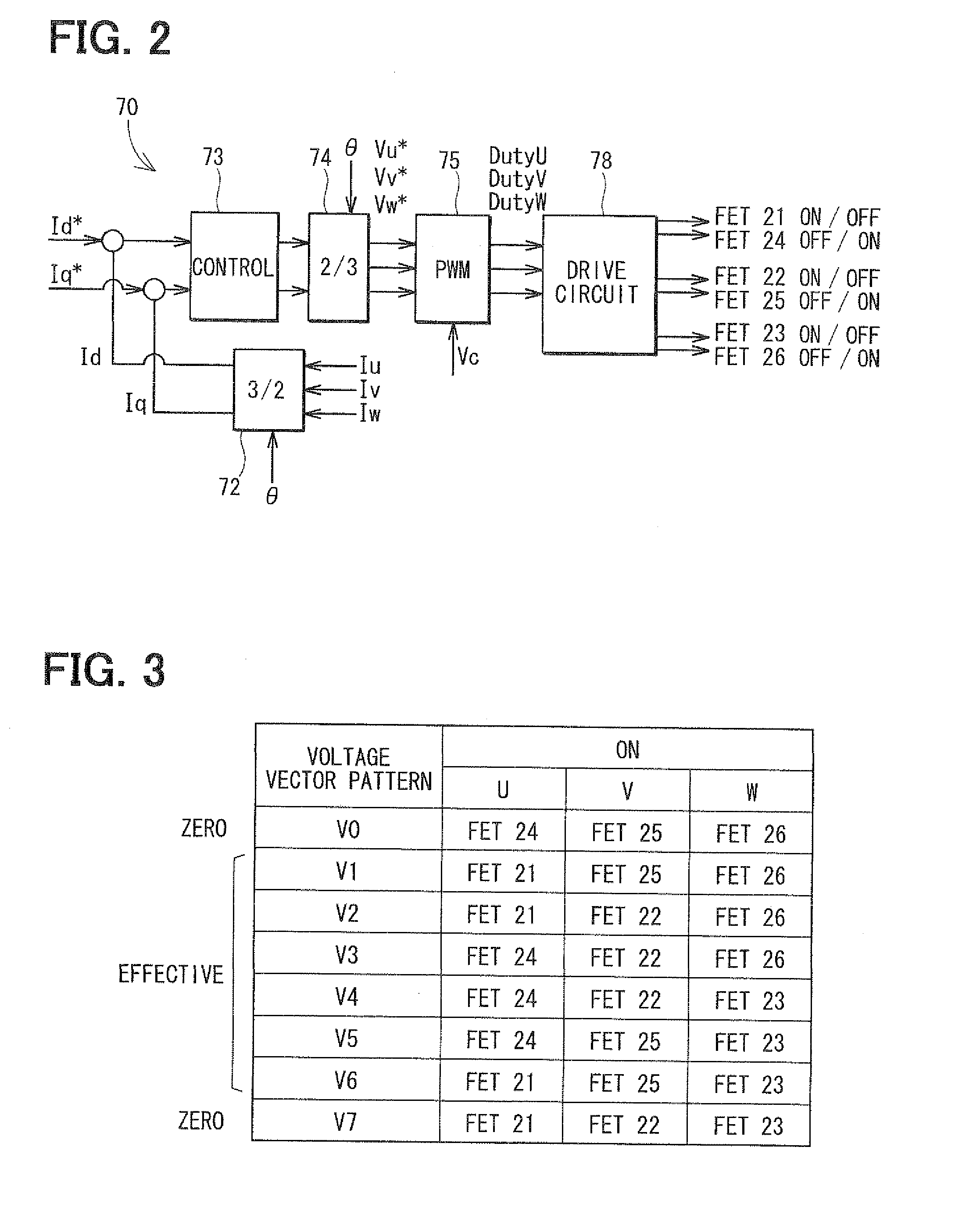

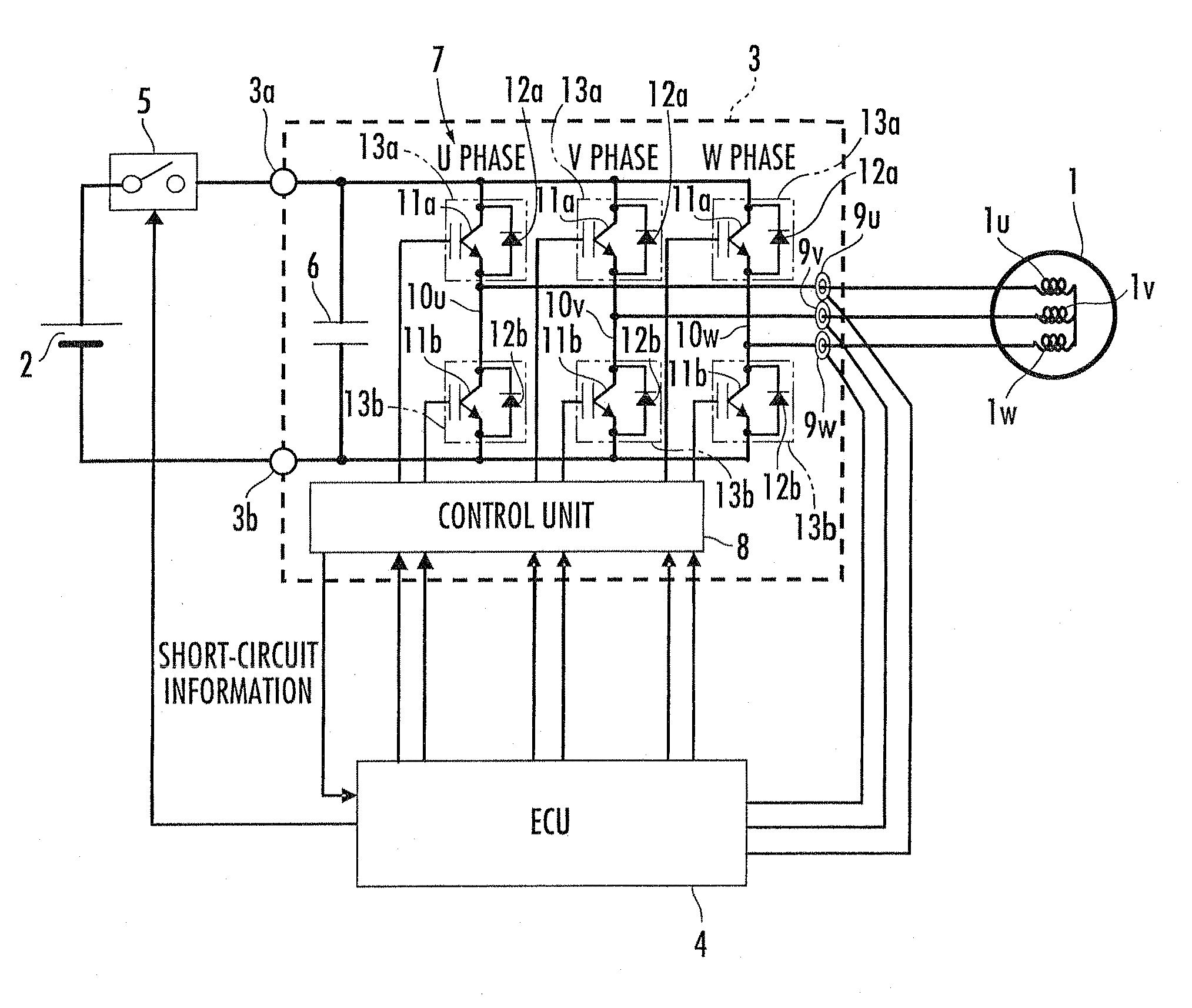

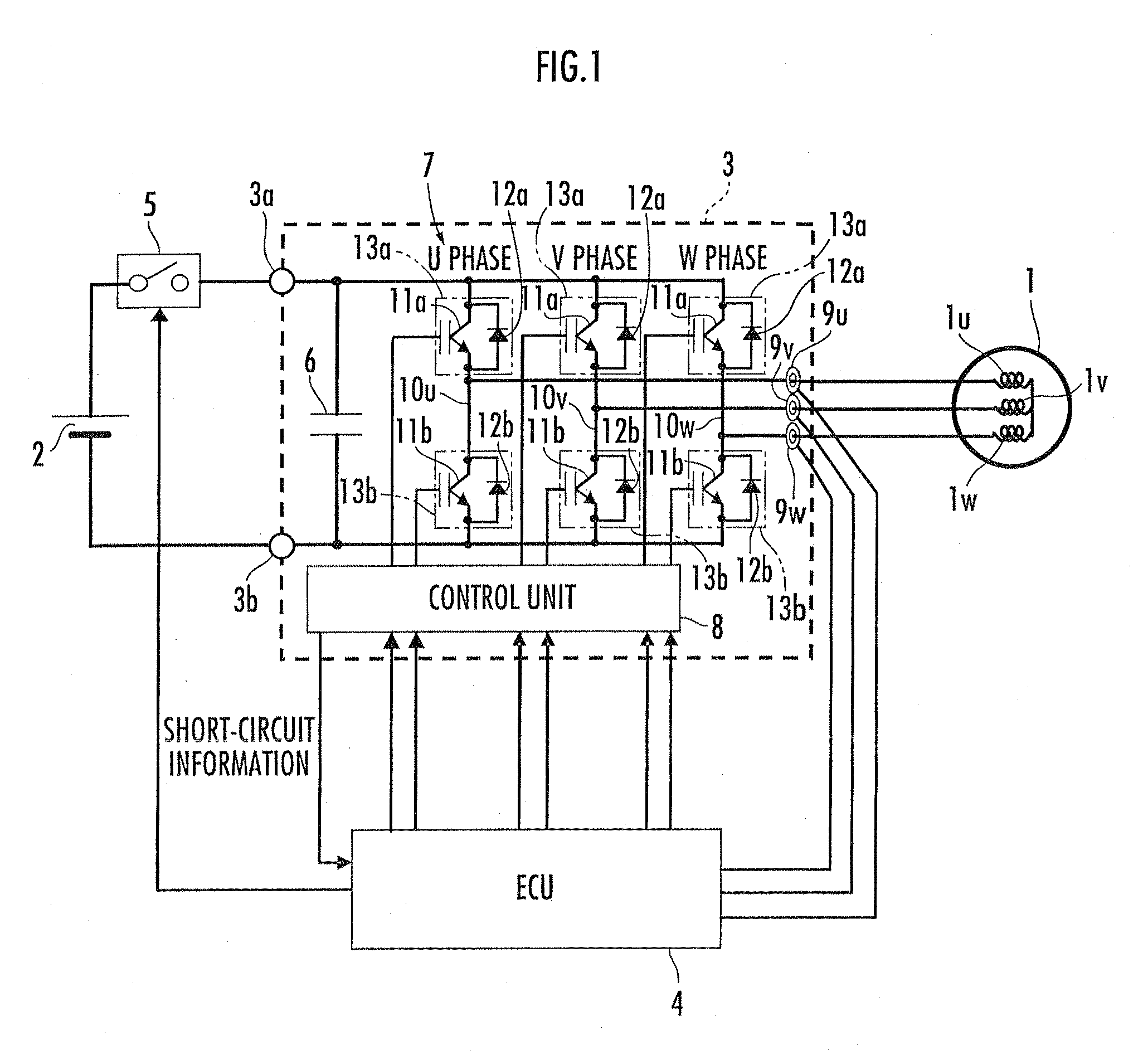

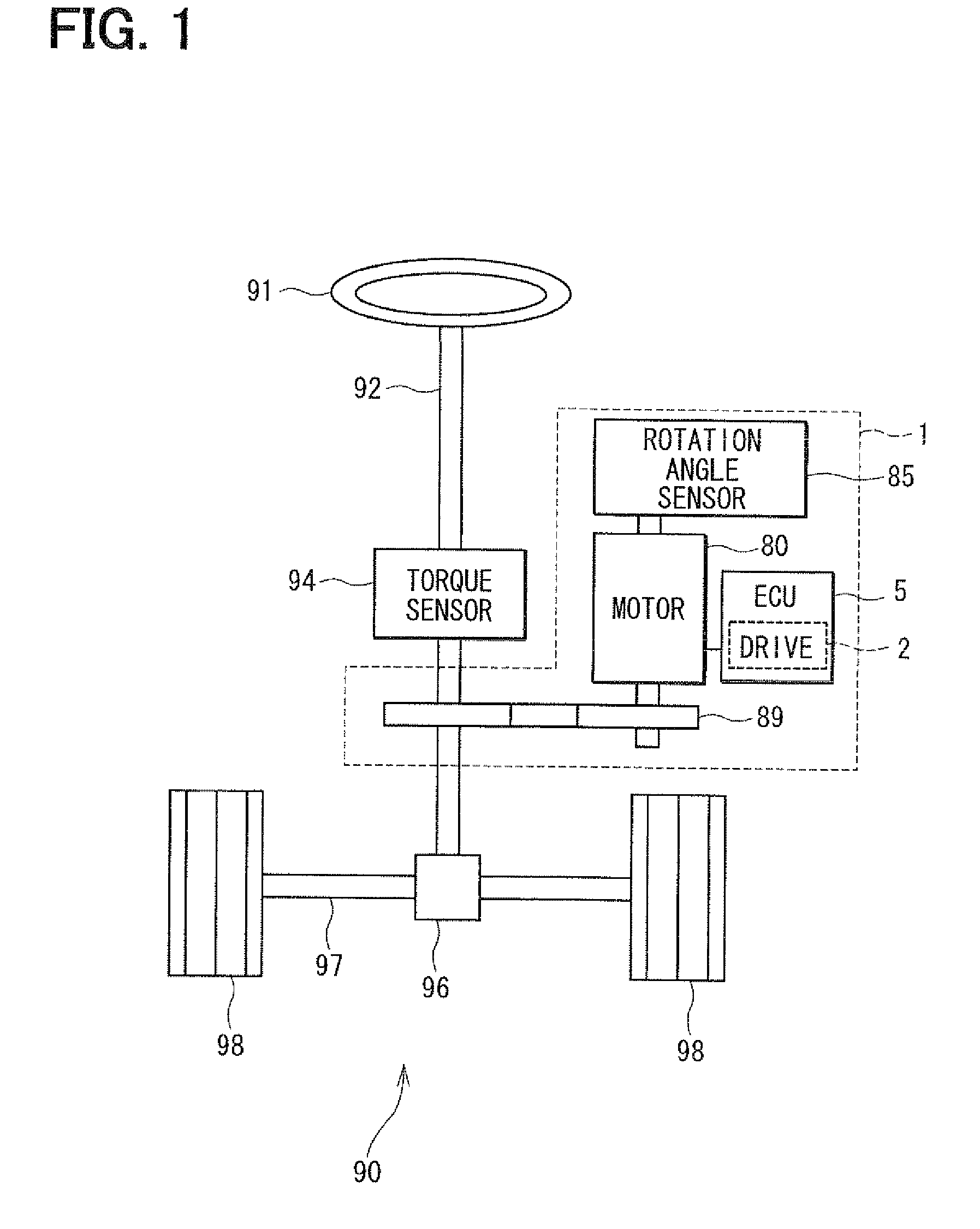

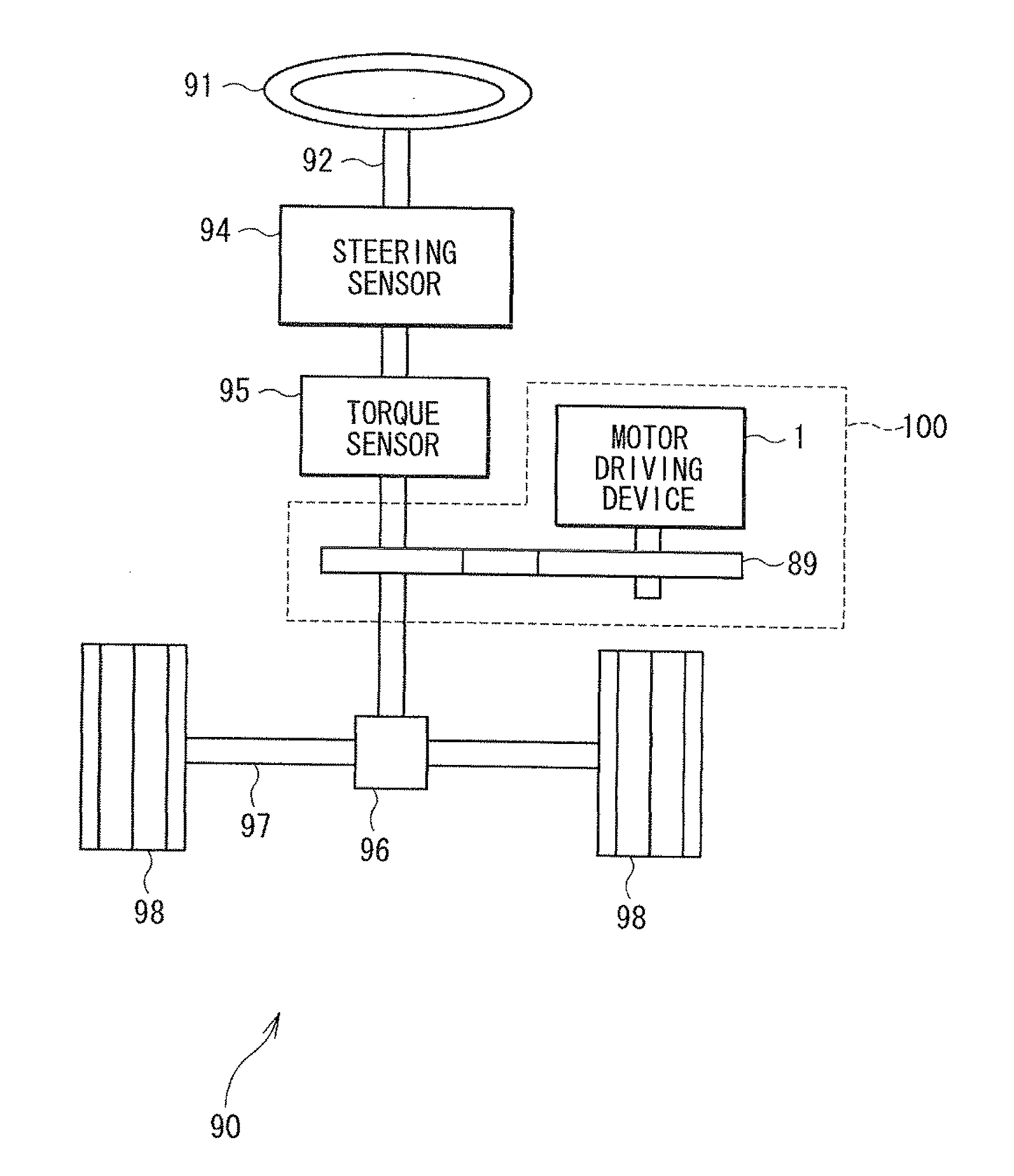

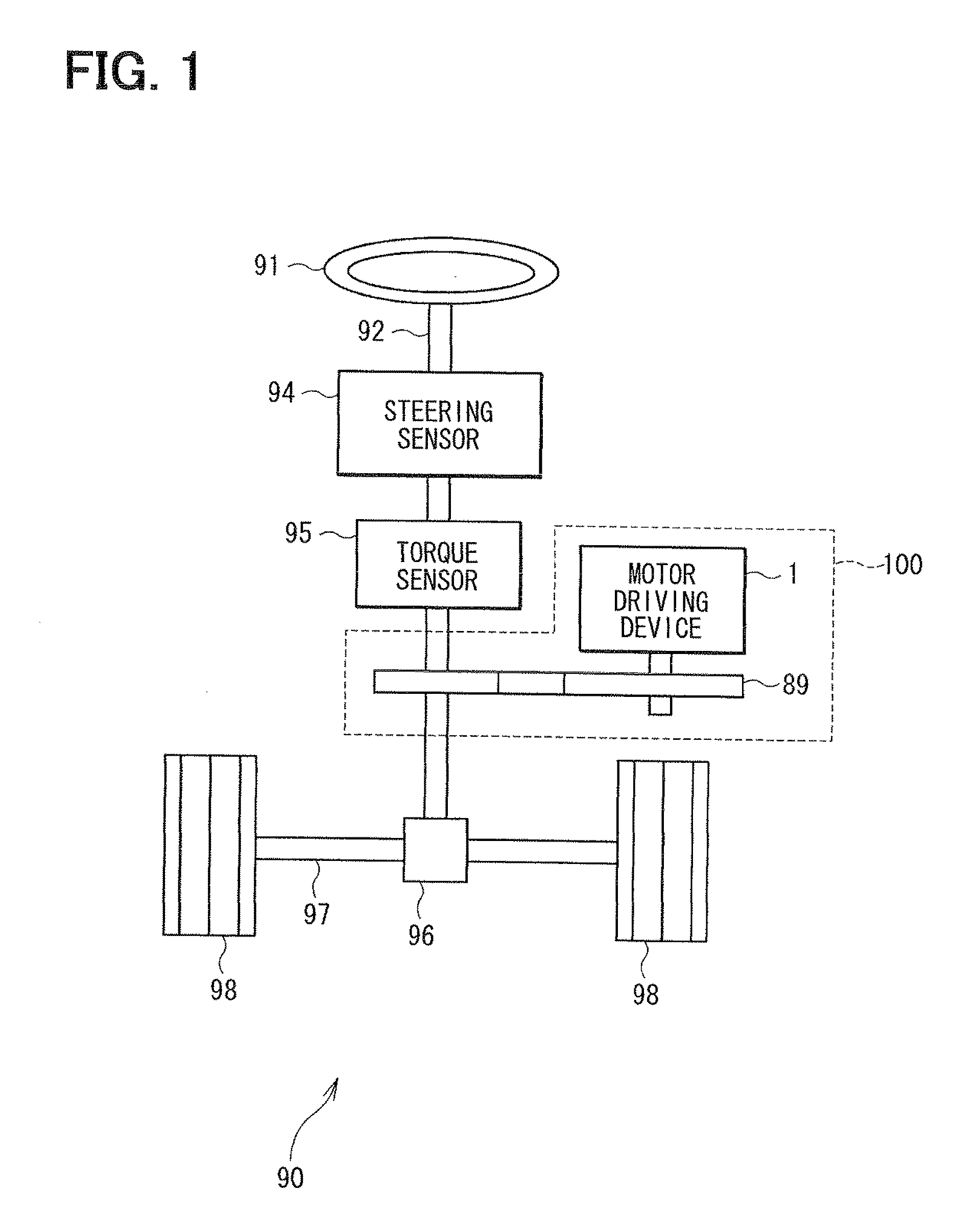

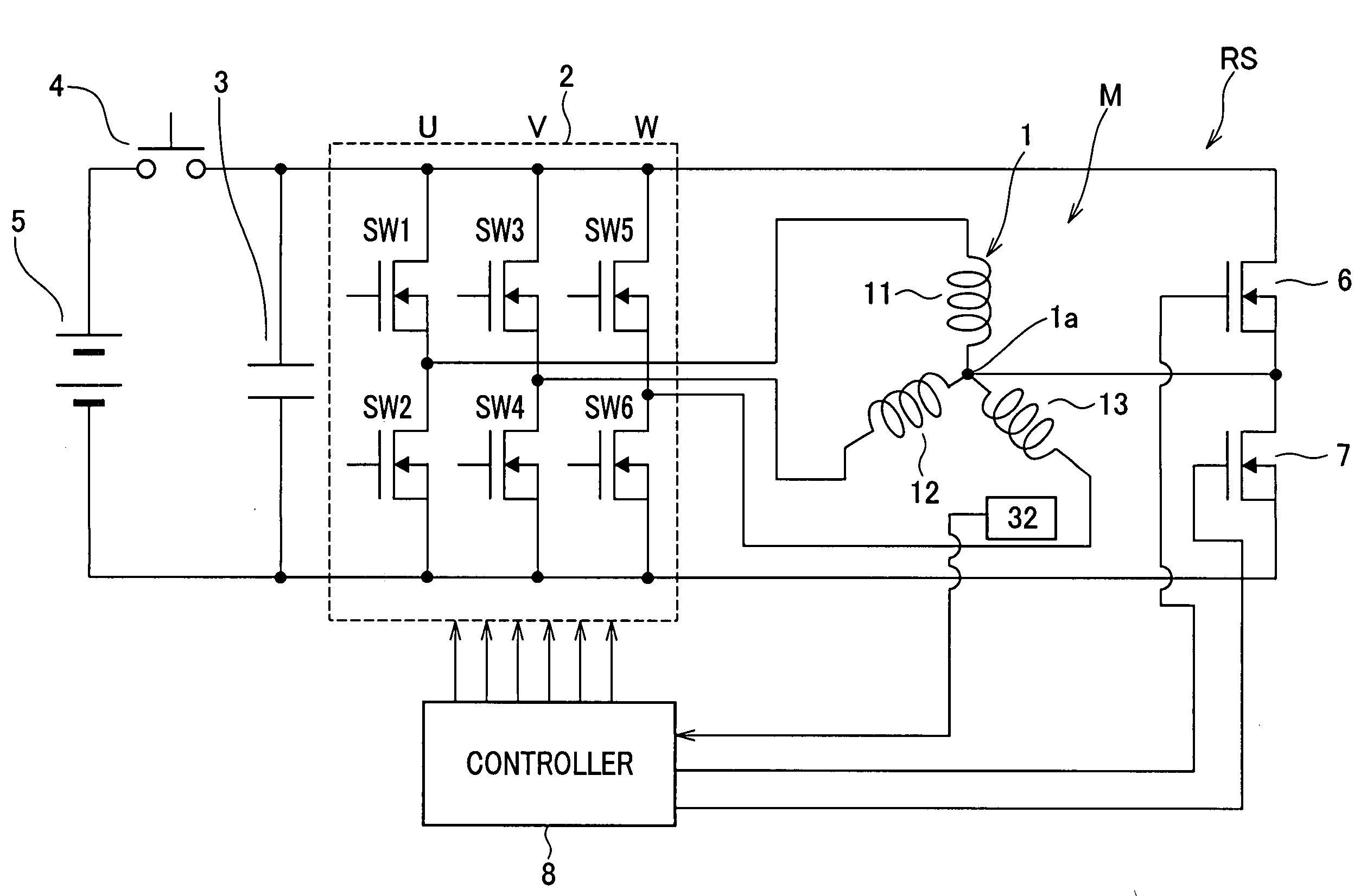

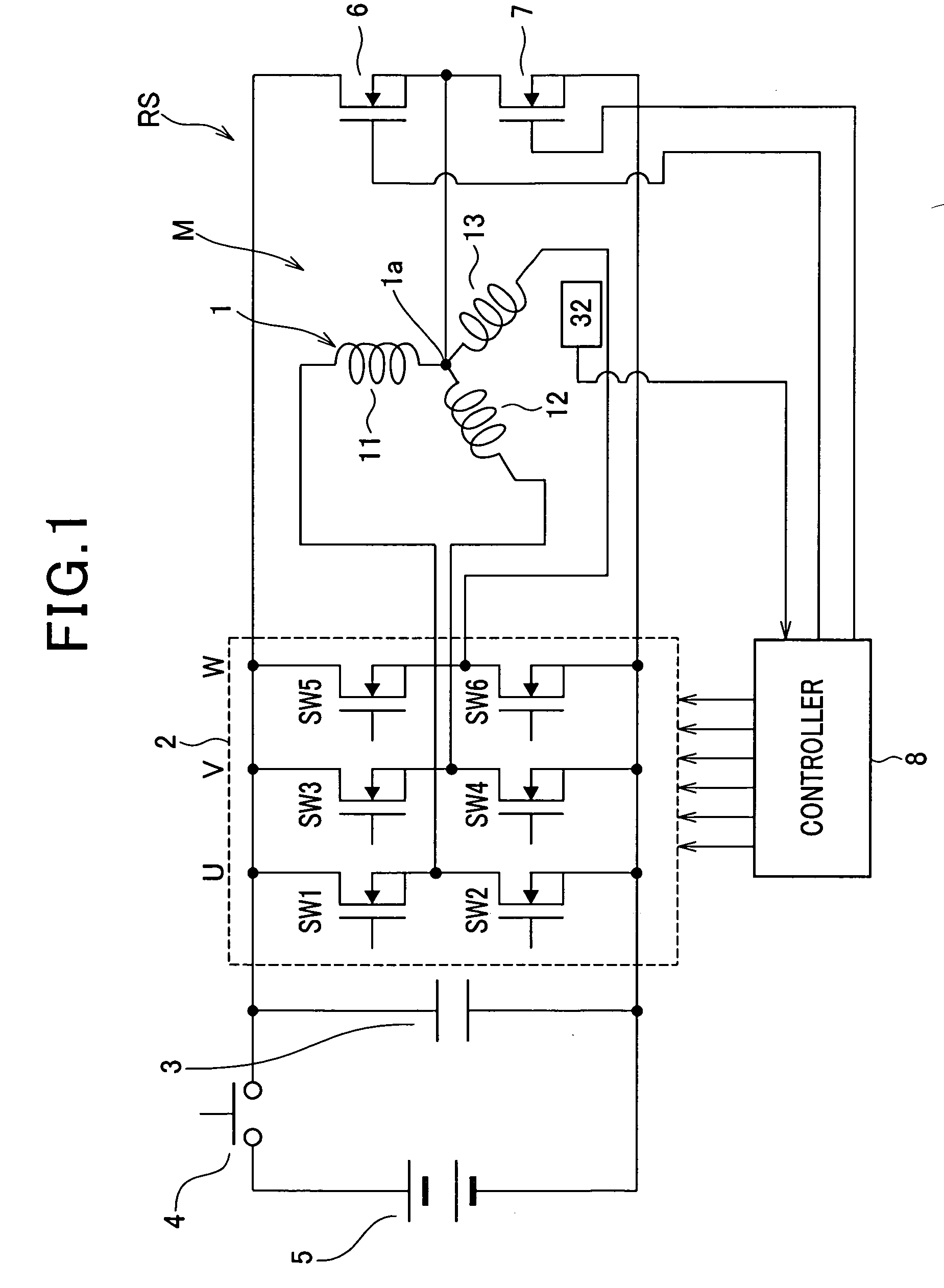

Control apparatus for multi-phase rotary machine and electric power steering system

ActiveUS20110074333A1Smooth rideInhibition effectCommutation monitoringDC motor speed/torque controlBrake torqueElectric power steering

A control apparatus for a multi-phase rotary machine includes a control unit and a plurality of power supply systems including respective inverter units. When a short-circuiting failure occurs in one of the systems due to an ON-failure in any one of FETs in an inverter unit of the failure system, the control unit stops driving of the rotary machine by bringing all the FETs in the failure system into the OFF state. The control unit controls FETs of the non-failure system such that a brake torque generated in the failure system is cancelled or the influence of the brake torque exerted on the driving of the motor is reduced.

Owner:DENSO CORP

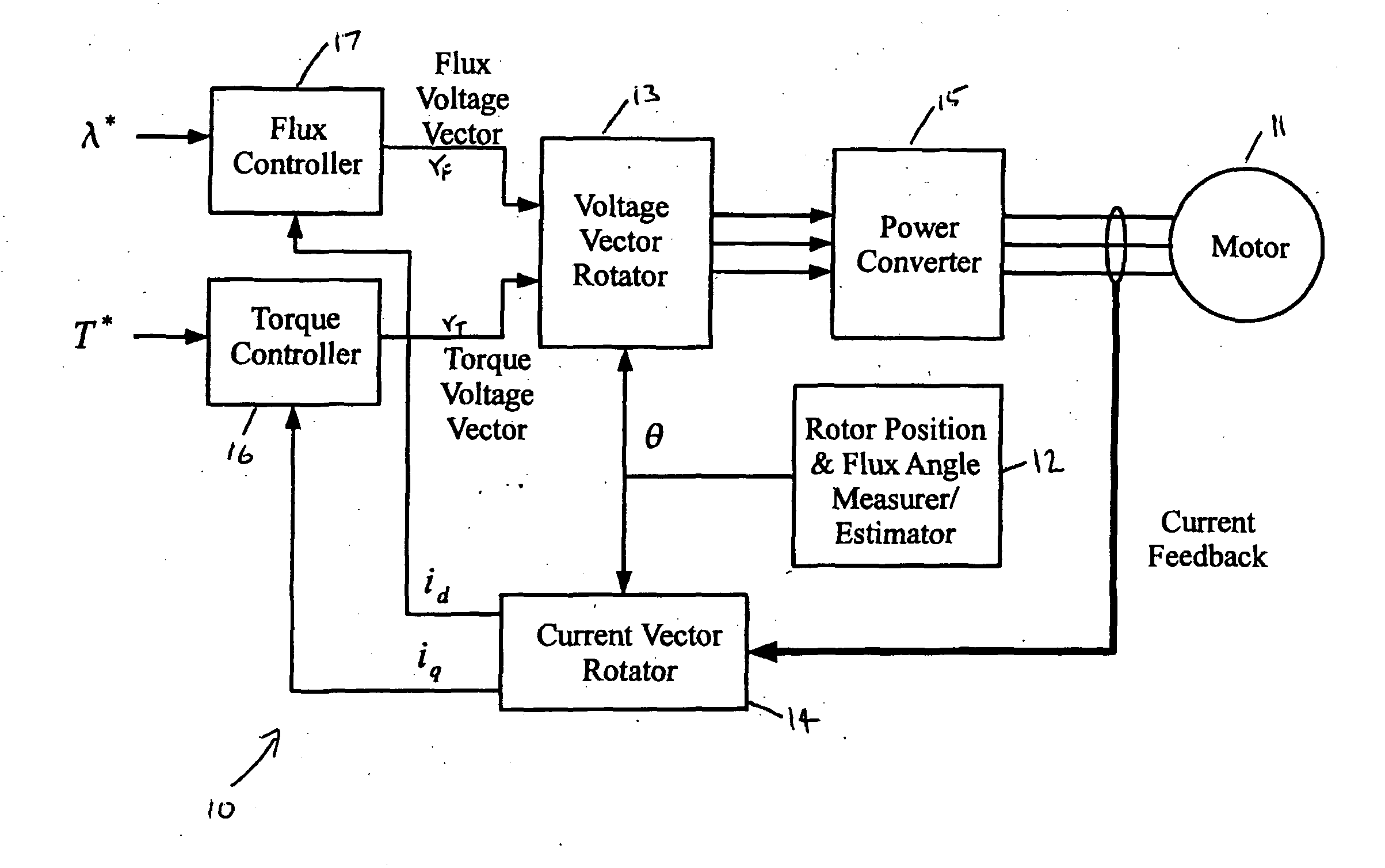

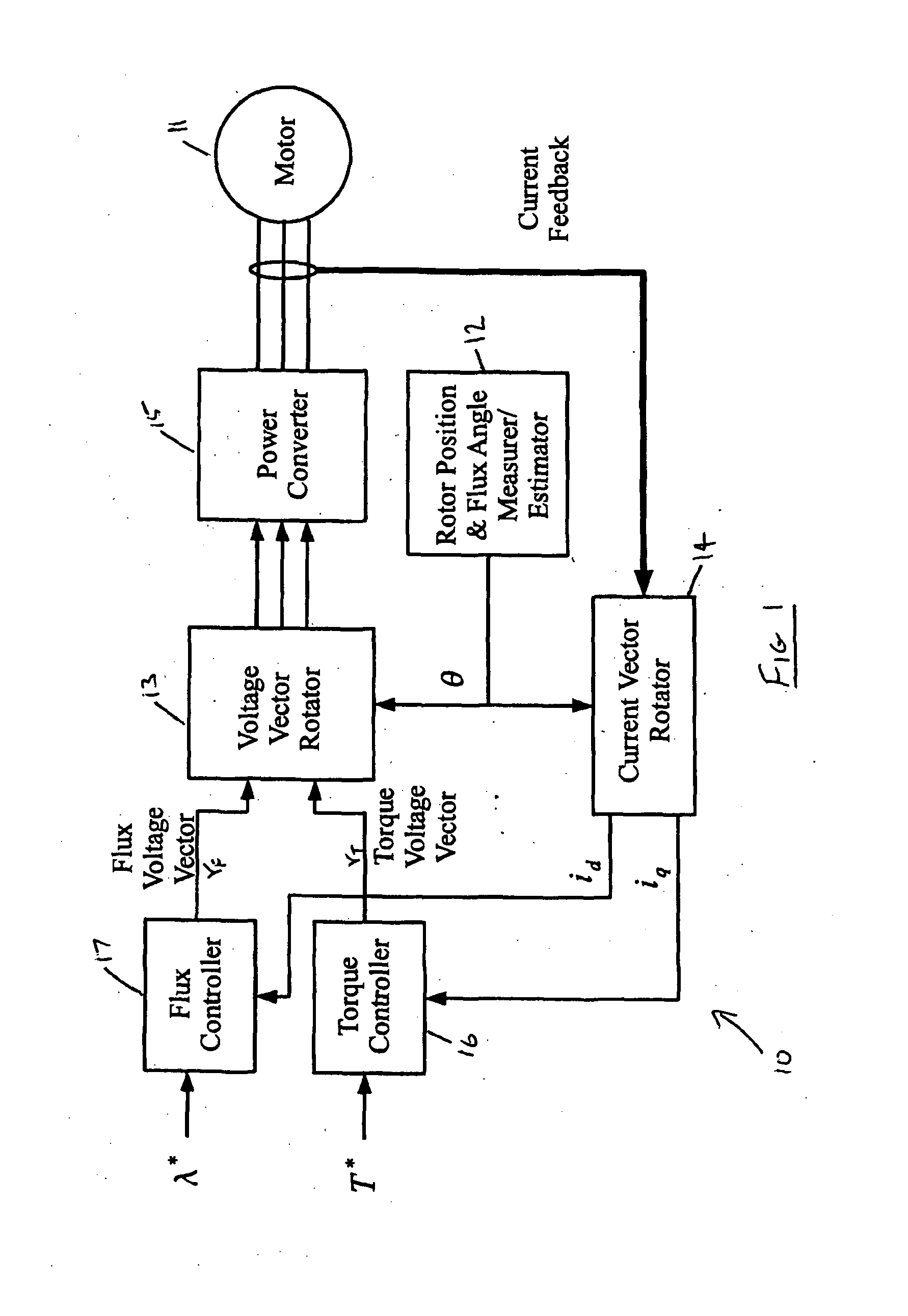

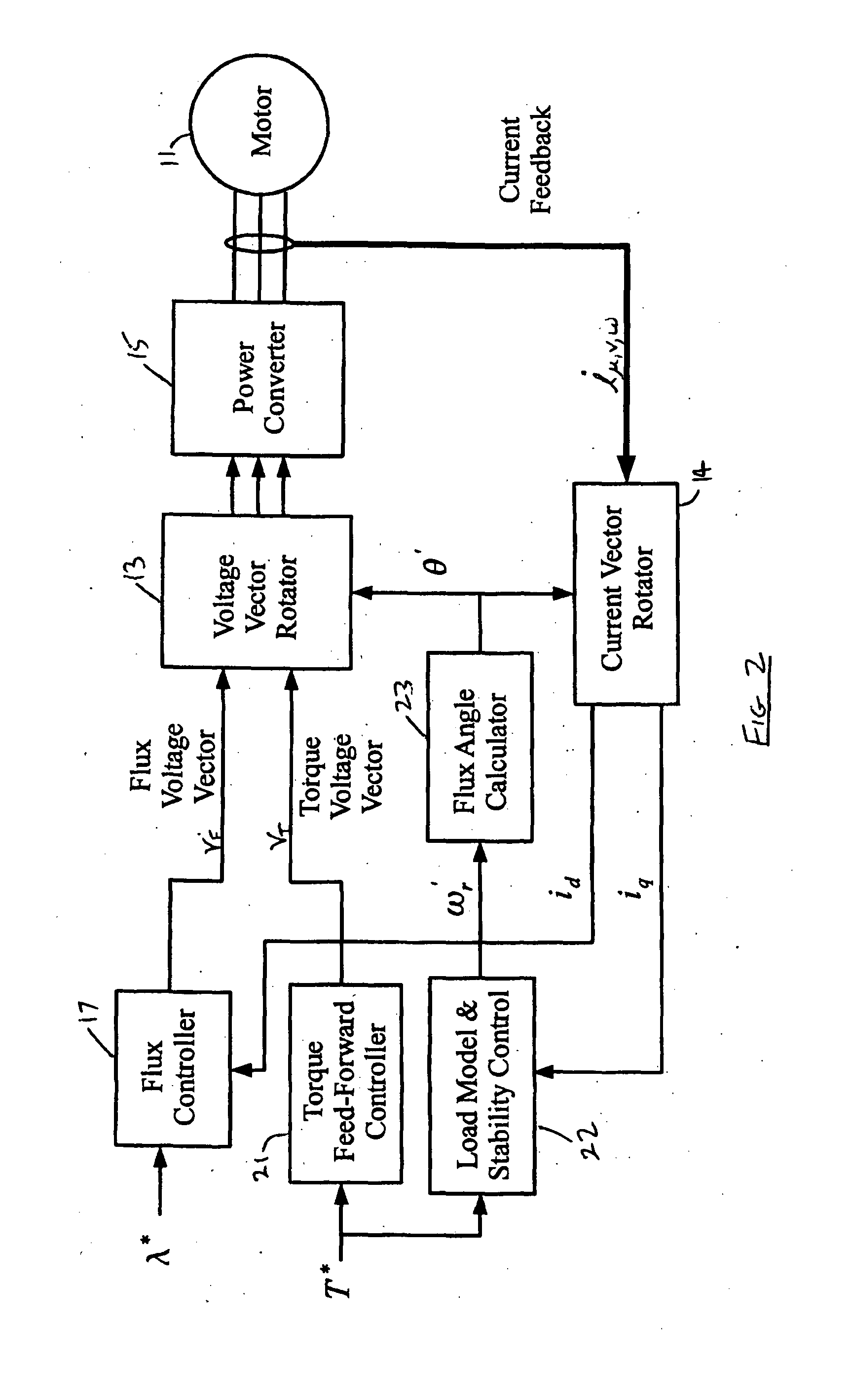

Sensorless ac motor controller

ActiveUS20130221885A1Control changesImprove stabilityCommutation monitoringMotor/generator/converter stoppersMotor speedVoltage vector

A controller for an AC electric motor, includes a Feed Forward Torque Controller and a load model. The Torque controller directly derives a torque related component of applied motor voltages from a signal representing a torque command input T* and at least one motor parameter. The load model derives a motor speed value including a model of motor speed behaviour of the AC electric motor to provide an output signal which represents the motor speed of the AC electric motor. This motor speed output signal is used in determining a frequency of rotation of an applied motor voltage vector. Where an input to the load model is the signal representing the torque command input T*, the load model uses the signal representing the torque command T*, at least over a part of an operating speed range of the AC motor which includes zero speed, to determine the motor speed output signal.

Owner:HUNTER GREGORY PETER

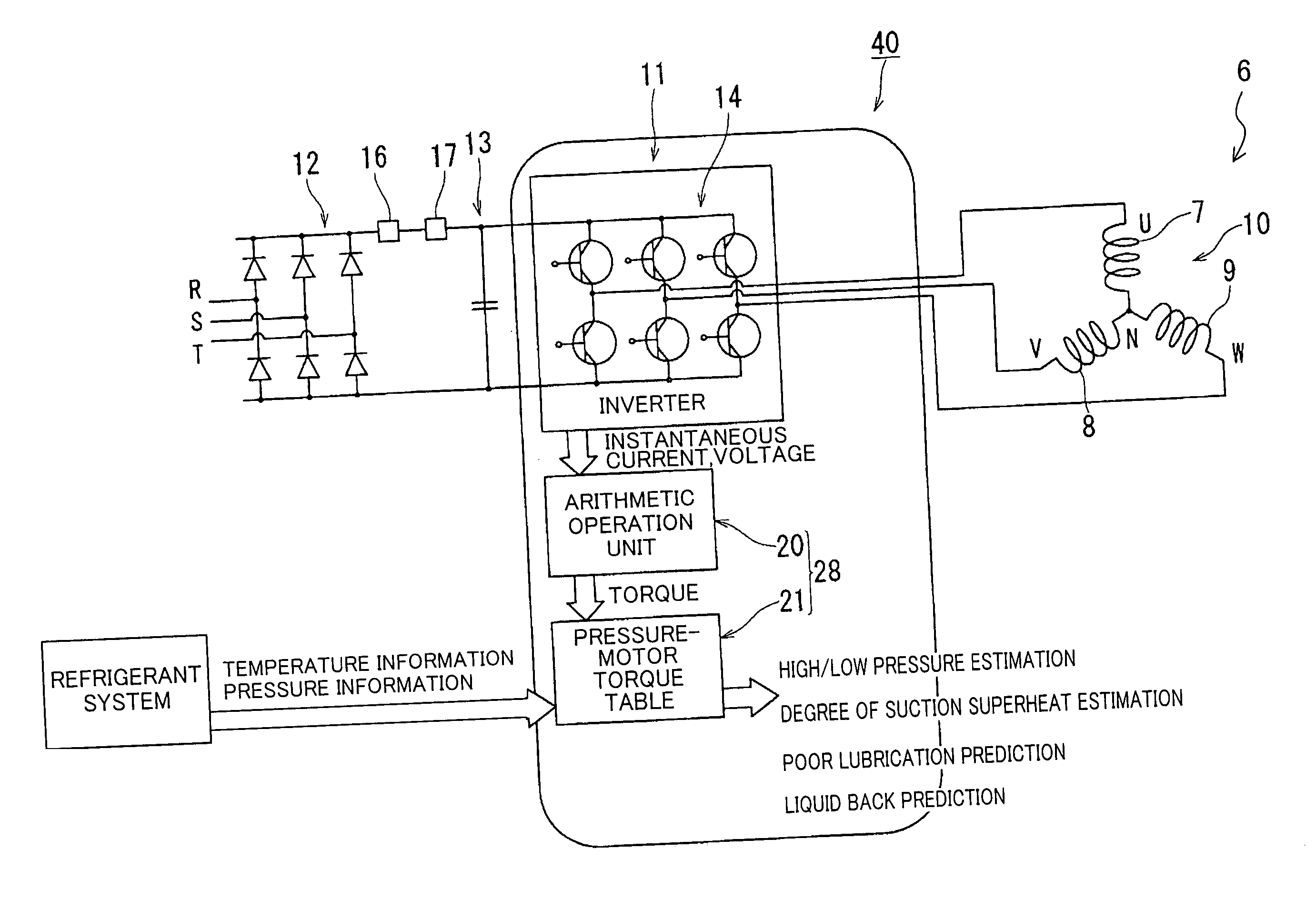

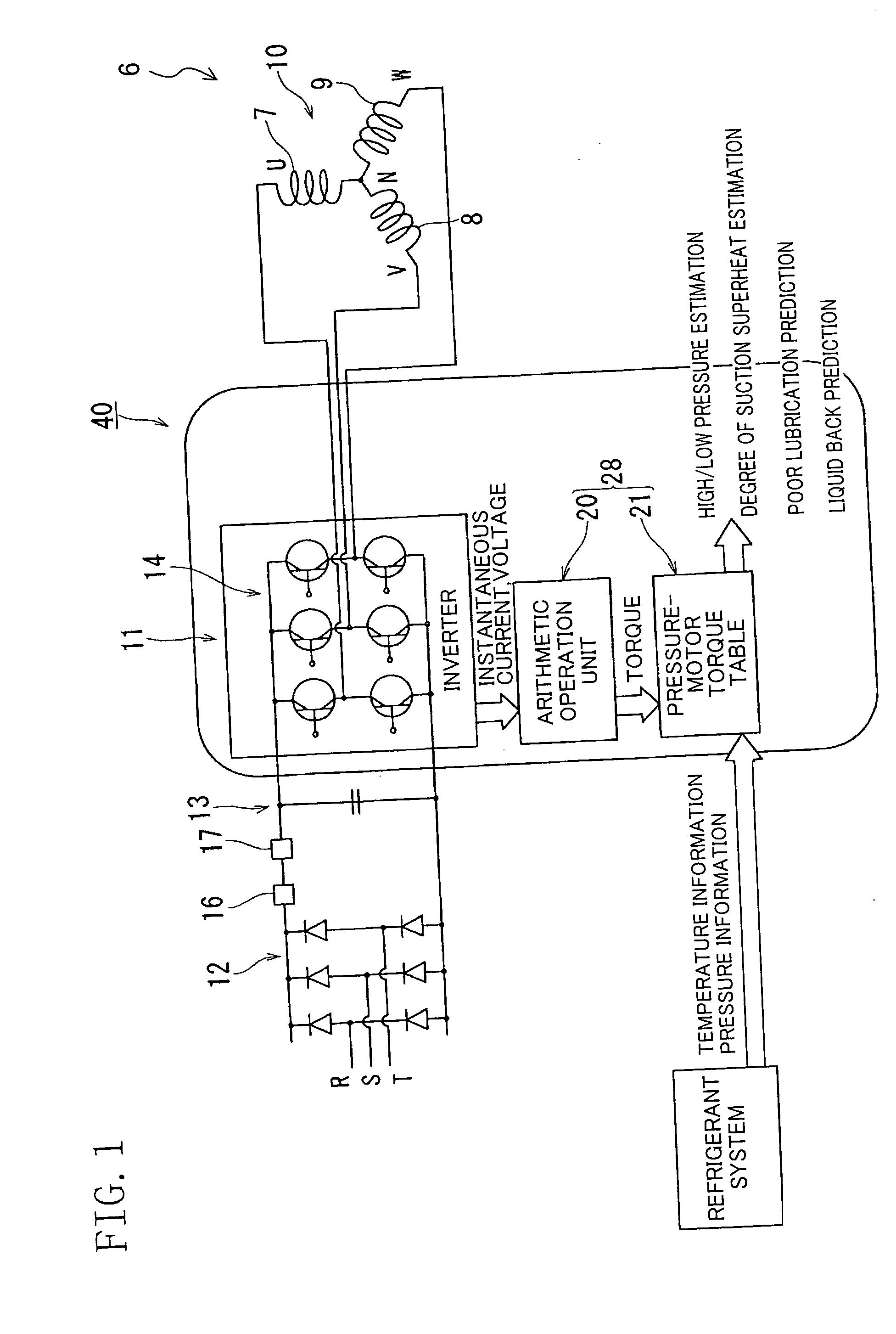

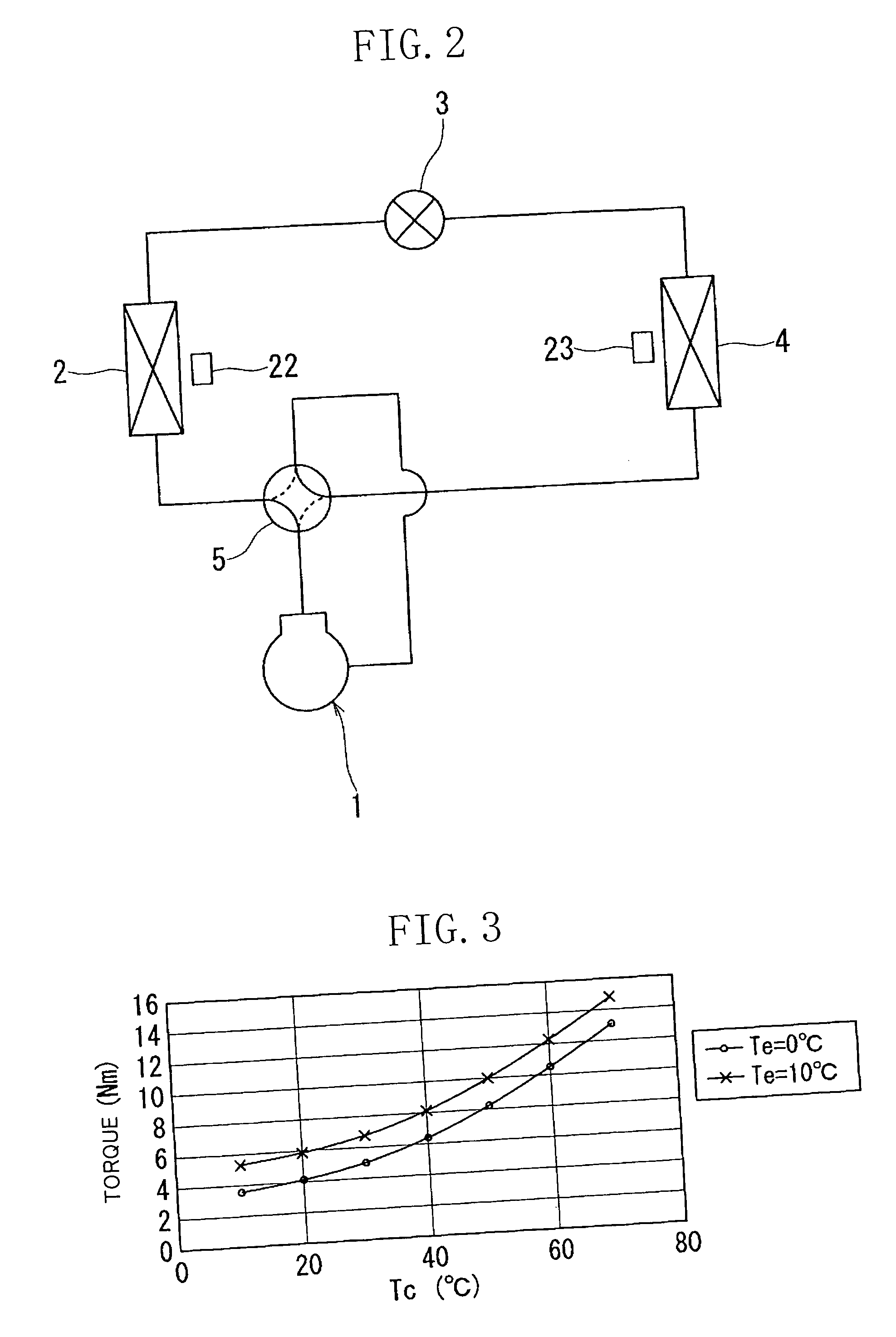

Driver of compressor and refrigerator

ActiveUS20050247073A1Easy to operateOperating frequency of the compressor <b>1Commutation monitoringSpace heating and ventilationPower flowMotor drive

An instantaneous current and instantaneous voltage of a three-phase coil of a brushless DC motor are detected, and the internal condition of a compressor is predicted from these detection values. The prediction about the internal condition of the compressor is made in such a way that motor driving torque which is a parameter of a motor model is identified and poor lubrication, liquid compression or the like is predicted from this identified motor driving torque. This enables it to make, in real time, a failure forecast, failure diagnosis etc. on the compressor.

Owner:DAIKIN IND LTD

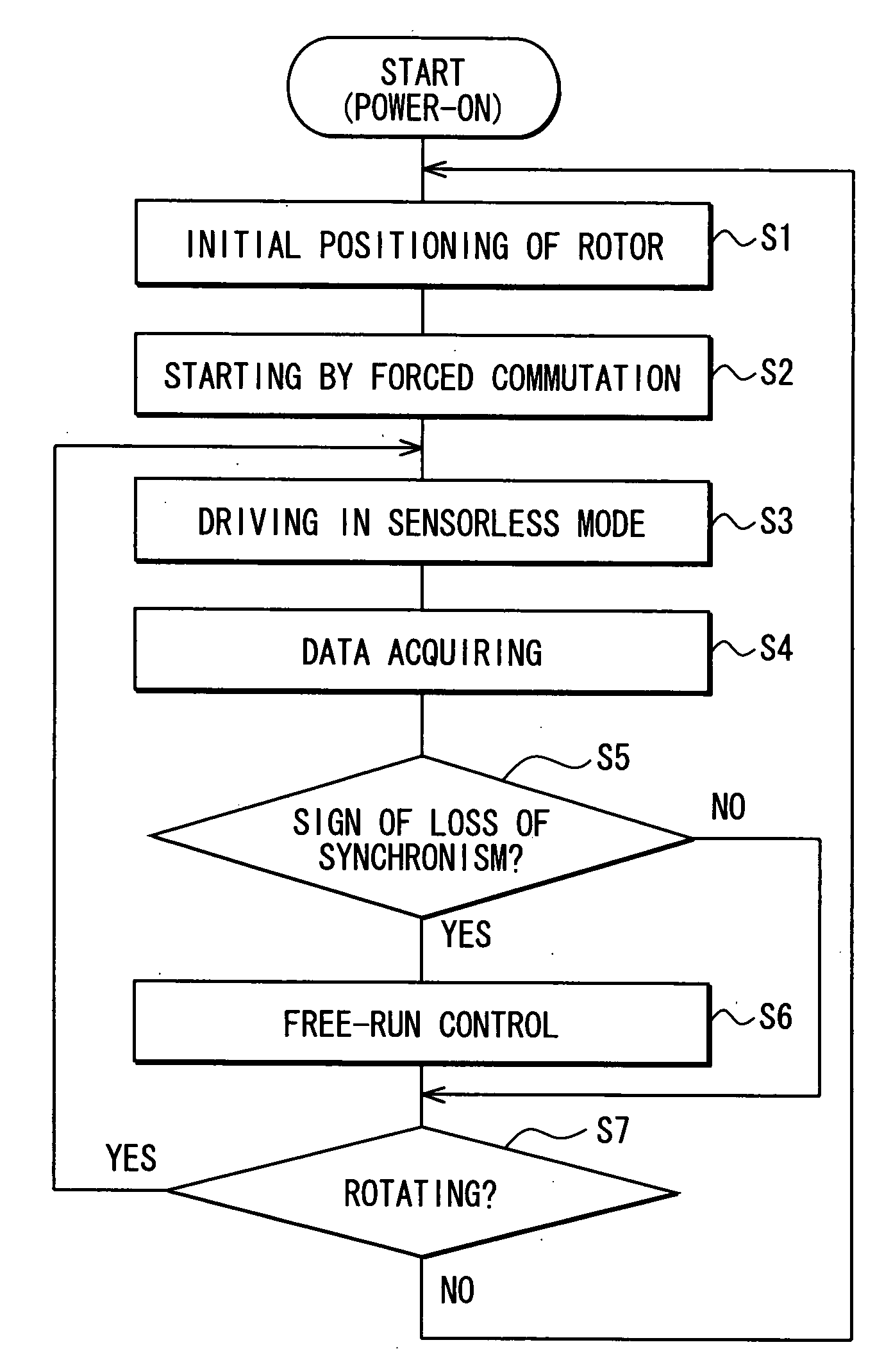

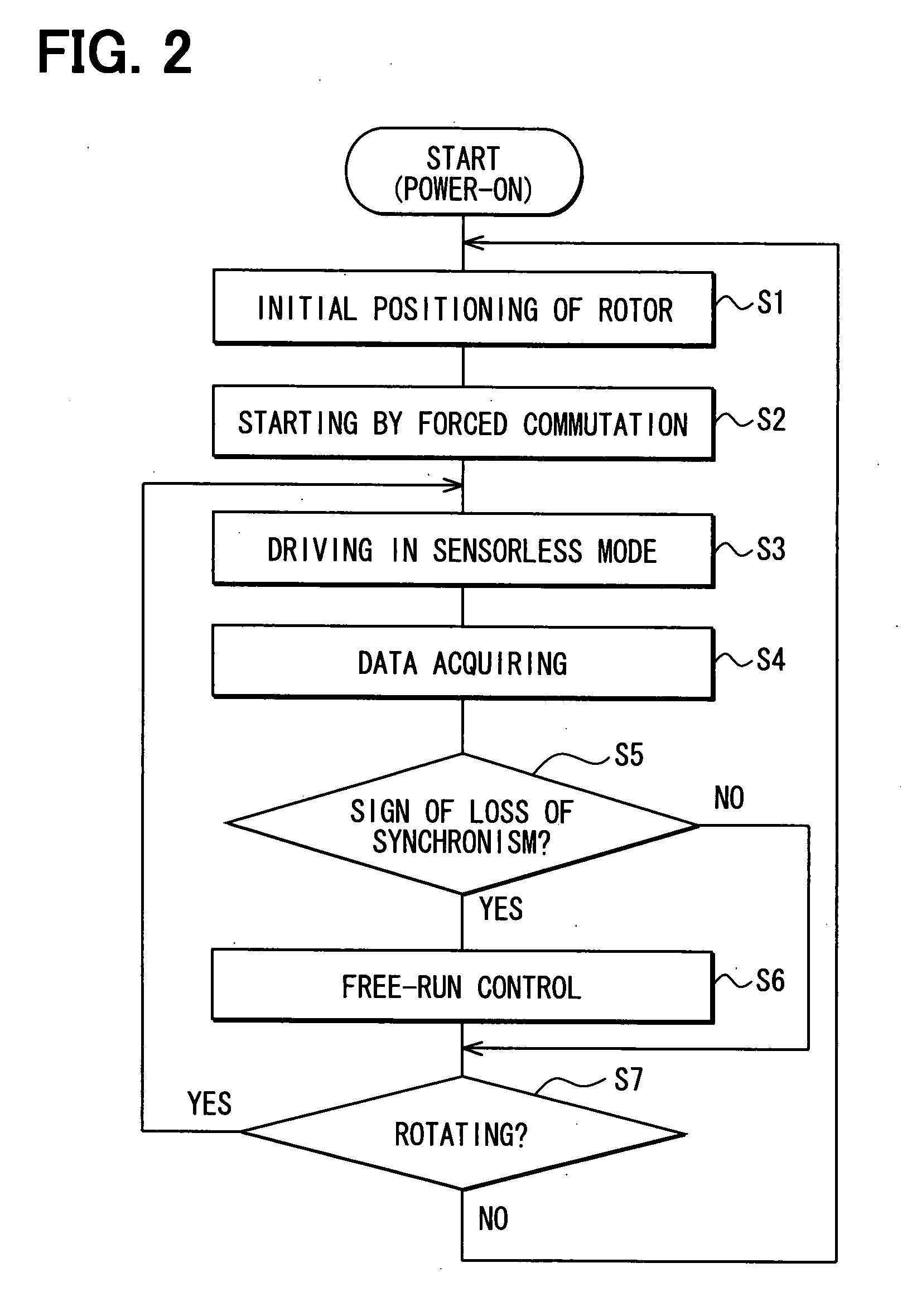

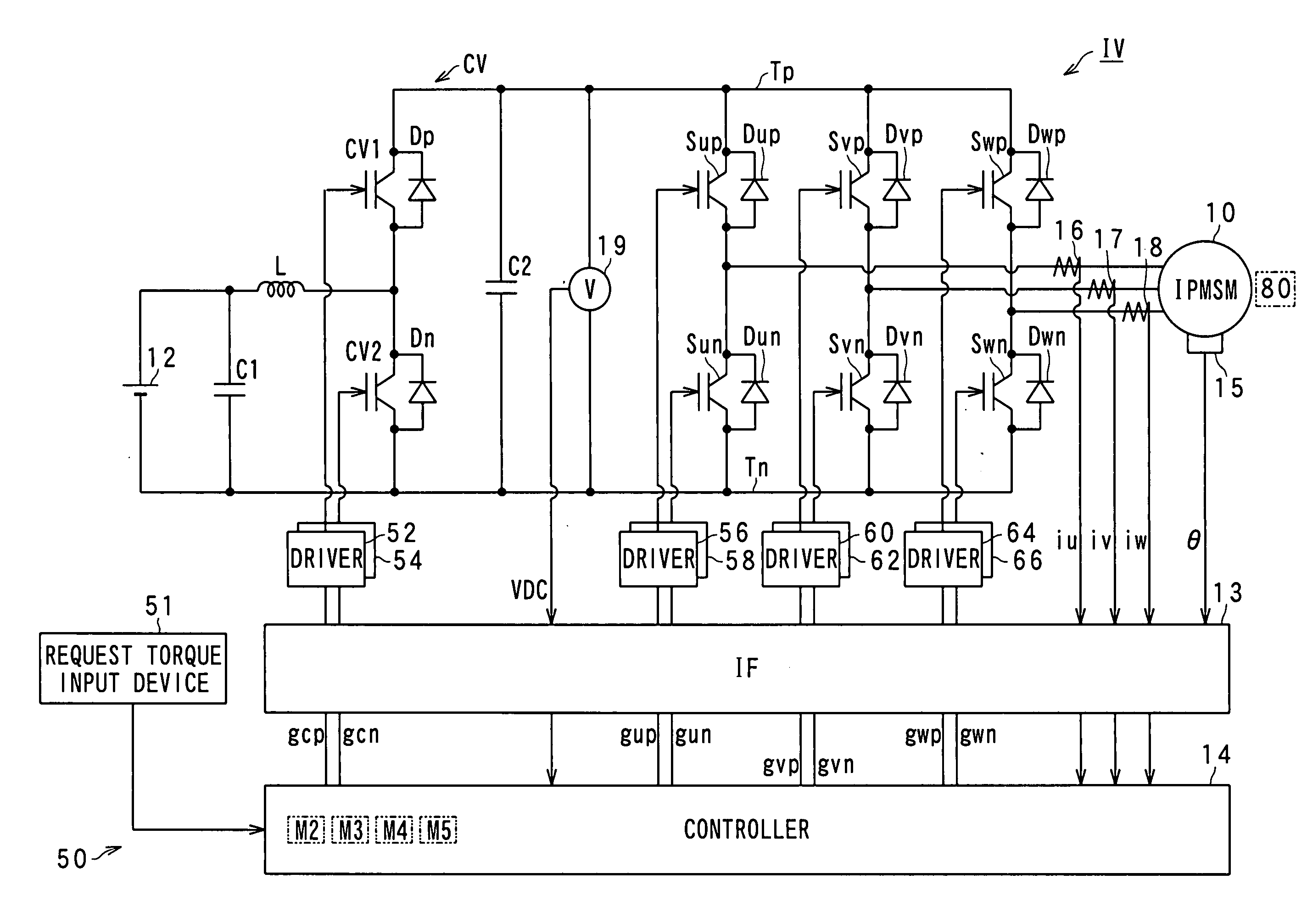

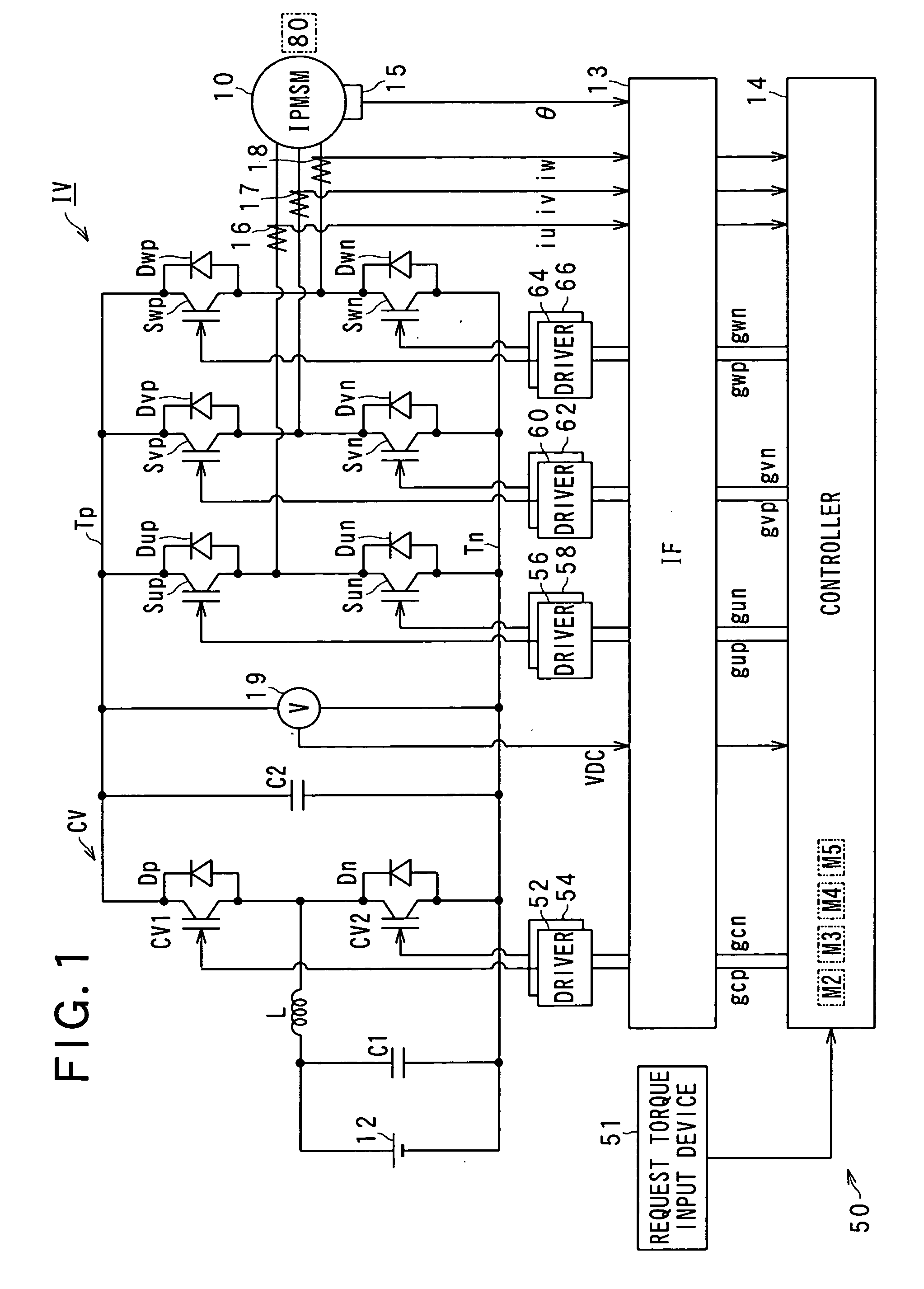

Apparatus and method for driving rotary machine

InactiveUS20080252242A1Loss of stateShort timeMotor/generator/converter stoppersCommutation monitoringRotary machineSynchronism

A motor driving apparatus has a loss-of-synchronism monitoring circuit that monitors the rotation of a rotary machine such as a brushless DC motor to detect a sign of transition to a state of loss of synchronism. When the sign is detected, an energization control circuit temporarily stops driving of the rotary machine to bring it into a free running state, and thereafter carries out control so as to resume driving of the rotary machine. Further, the motor driving apparatus has an inverter and a drive control circuit that controls switching operation of the inverter based on rotation of the rotary machine.

Owner:DENSO CORP

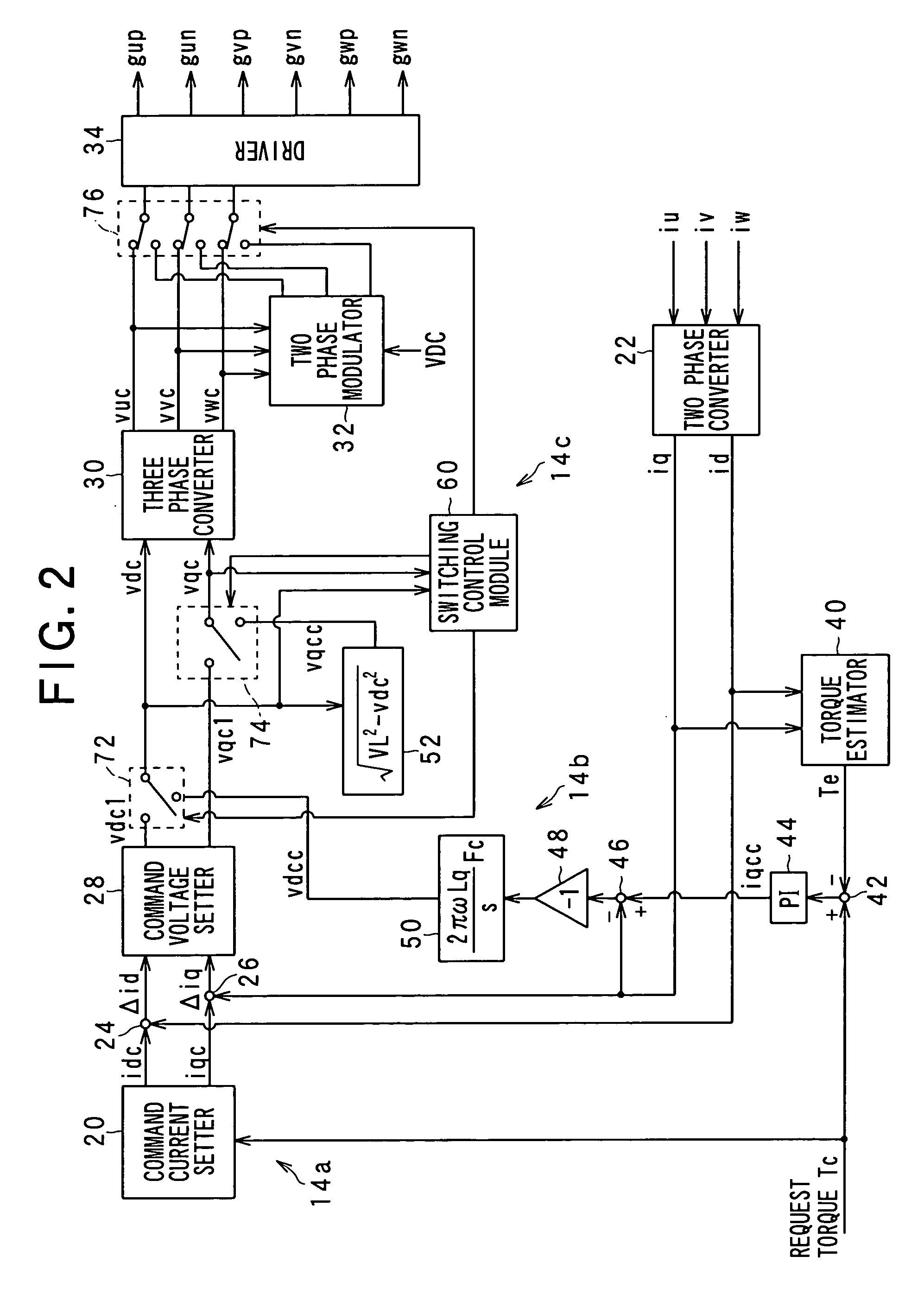

Apparatus for carrying out improved control of rotary machine

ActiveUS20090322264A1Easy maintenanceHigh levelCommutation monitoringDC motor speed/torque controlControl variableVoltage

In an apparatus, a first drive unit drives, in a first range of a voltage utilization factor, a switching member to thereby control an output voltage of the power converter to be matched with a command voltage. A second drive unit drives, in a second range of the voltage utilization factor, the switching member to thereby generate a value of a controlled variable of a rotary machine. The second range of the voltage utilization factor is higher than the first range thereof. An estimating unit estimates, during the switching member being driven by the second drive unit, a value of a parameter associated with the output voltage of the power converter. The estimated value is required for the first drive unit to generate the value of the controlled variable generated by the second drive unit.

Owner:DENSO CORP

Controller for motor, and vehicle

InactiveUS20100036555A1More currentHigh currentCommutation monitoringSingle motor speed/torque controlElectrical polarityEngineering

When a short-circuit failure of any of switch portions (13) including switch elements (11) and parallel-connected feedback diodes (12) of an inverter circuit (7) is detected during the operation of a motor (1), a switch portion (13) where the short-circuit failure has occurred is checked for whether it is on the positive polarity side or the negative polarity side. The switch elements (11) are so controlled that all the switch portions (13) on the same polarity side as where the short-circuit has occurred are brought into a conducted state and all the others disconnected. This prevents a large electric current from flowing into each switch portion of the inverter circuit without requiring any switch to block the power distribution between a motor and the inverter circuit when a short-circuit failure of the switch portion of the inverter circuit occurs.

Owner:HONDA MOTOR CO LTD

Motor drive and electric power steering apparatus using the same

ActiveUS20110156627A1Reduces change in operationReduce stepsCommutation monitoringDC motor speed/torque controlPower inverterElectric power steering

In a multi-system motor drive apparatus, a power supply relay is interrupted when a first power supply system fails at time t0. A power control unit doubles a current supplied to an inverter of a second power supply system thereby to supplement the electric power, which has been supplied by an inverter of the first power supply system. The total output of inverters is thus maintained before and after the failure. After an elapse of a predetermined period, the electric power supplied by the second power supply system is reduced gradually so that the inverter of the second power supply system will not be operated to supply the doubled power for a long period.

Owner:DENSO CORP

Motor control apparatus

ActiveUS20040008002A1Small sizeReliability of motor controlProgramme controlMotor/generator/converter stoppersLoop controlControl system

Presence / absence of a failure in a feedback control system of a motor is monitored. When a failure is detected in the feedback control system, the motor is driven by switching to an open-loop control. During the open-loop control, the motor is rotated by sequentially switching the motor current supply phase without feeding back encoder count information. The position count is incremented or decremented every time the current supply phase is switched. When the position count has reached a target count, it is determined that the rotor has reached a target position, whereupon the open-loop control is finished.

Owner:DENSO CORP

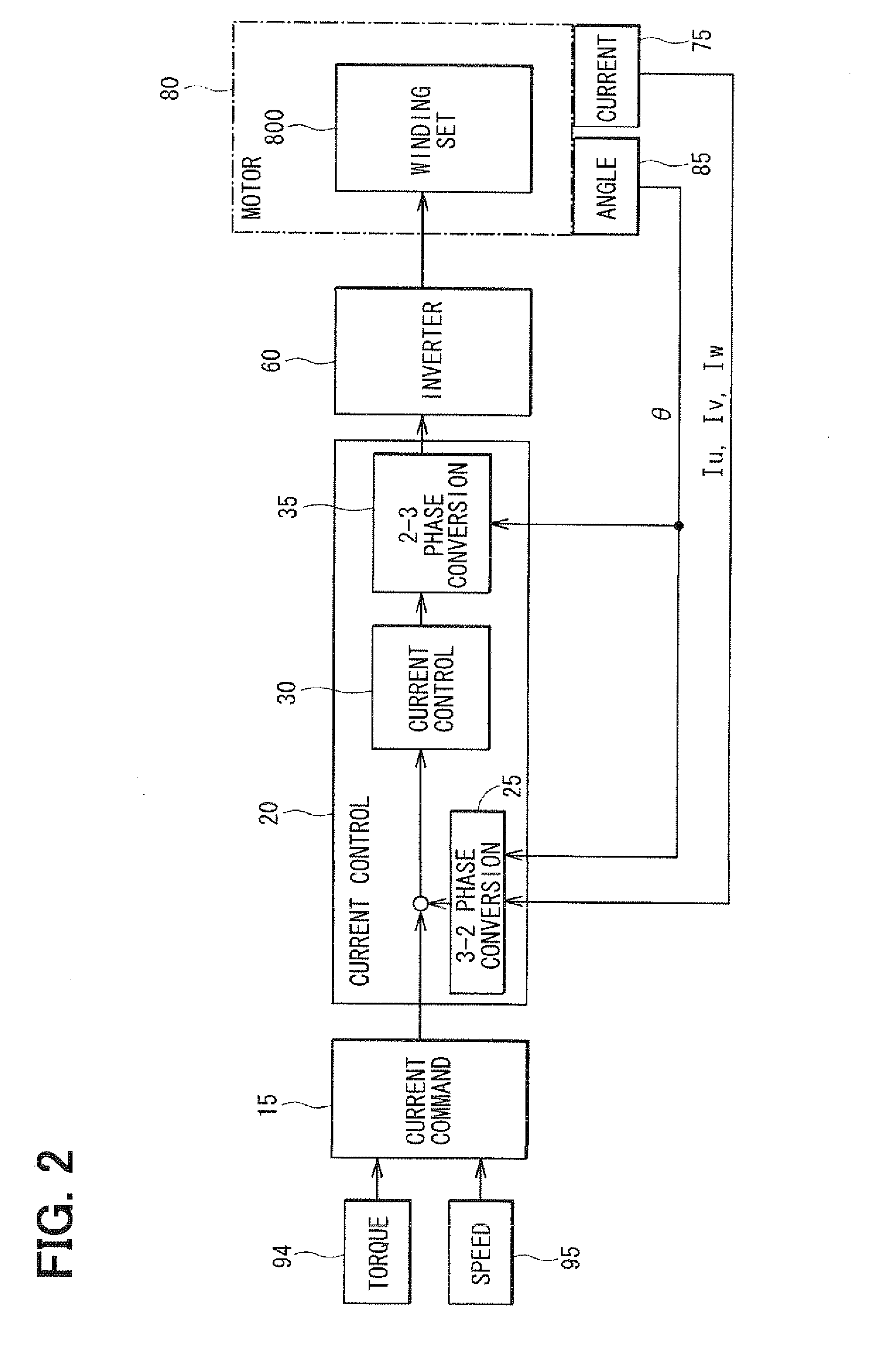

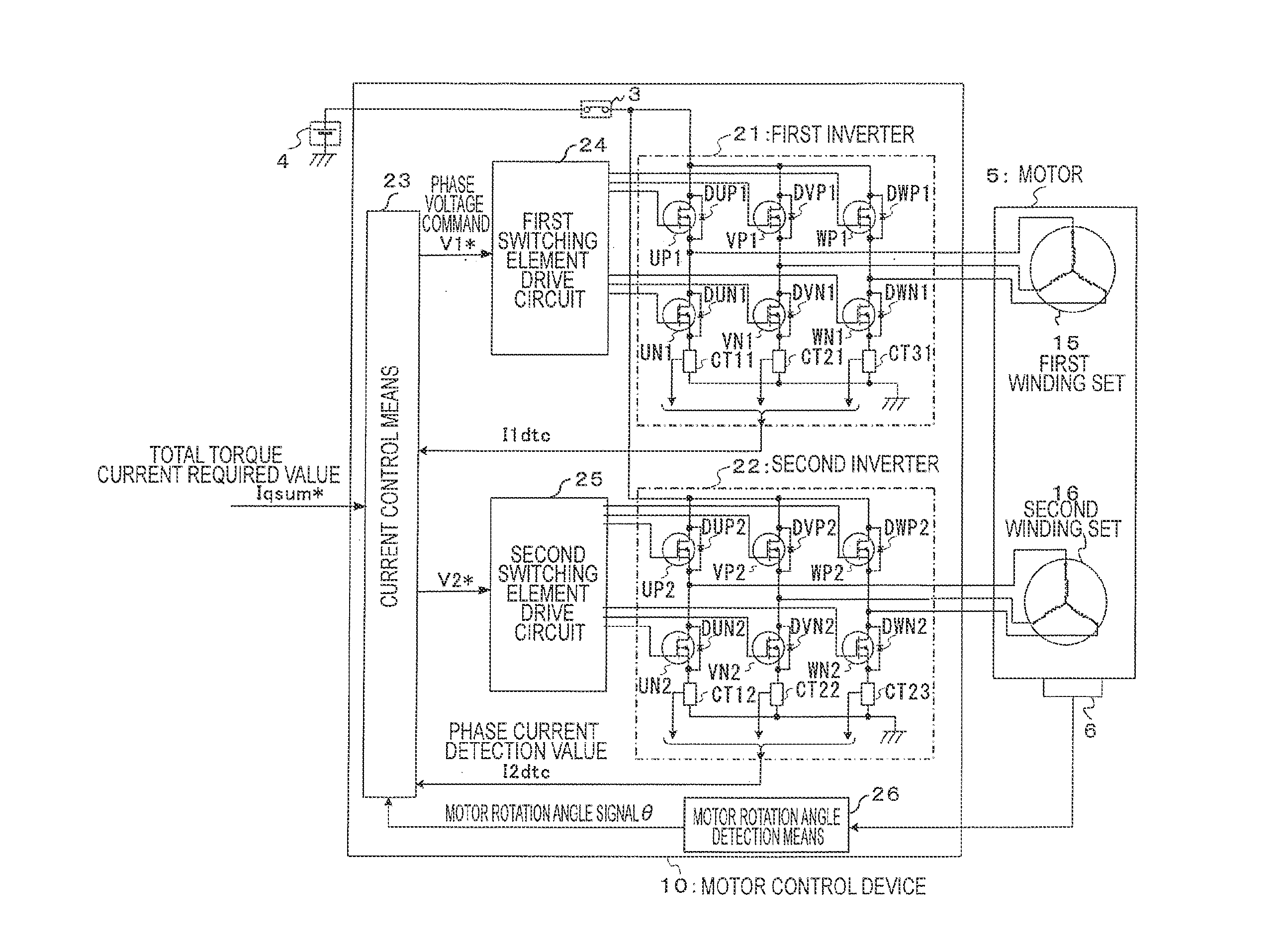

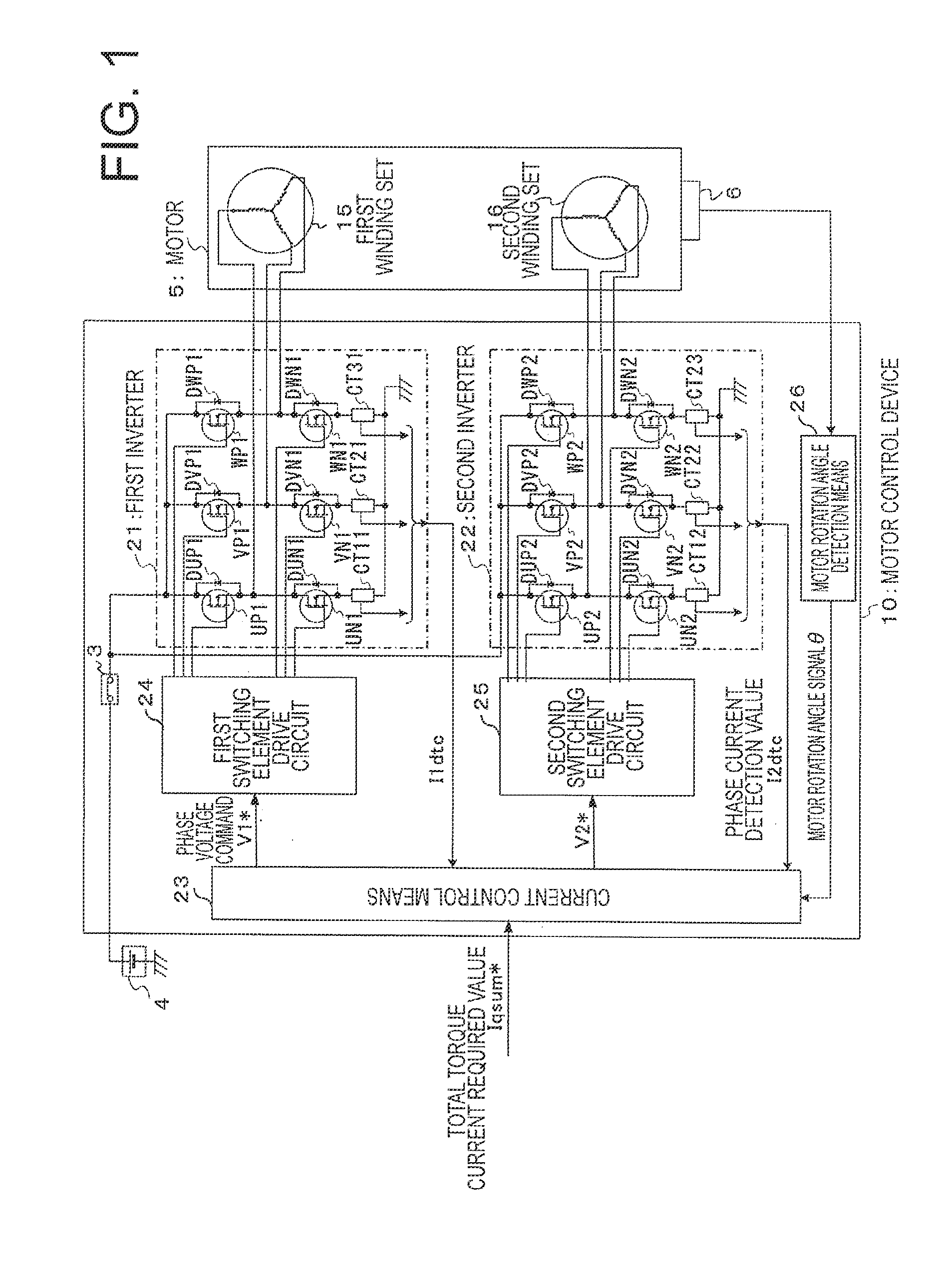

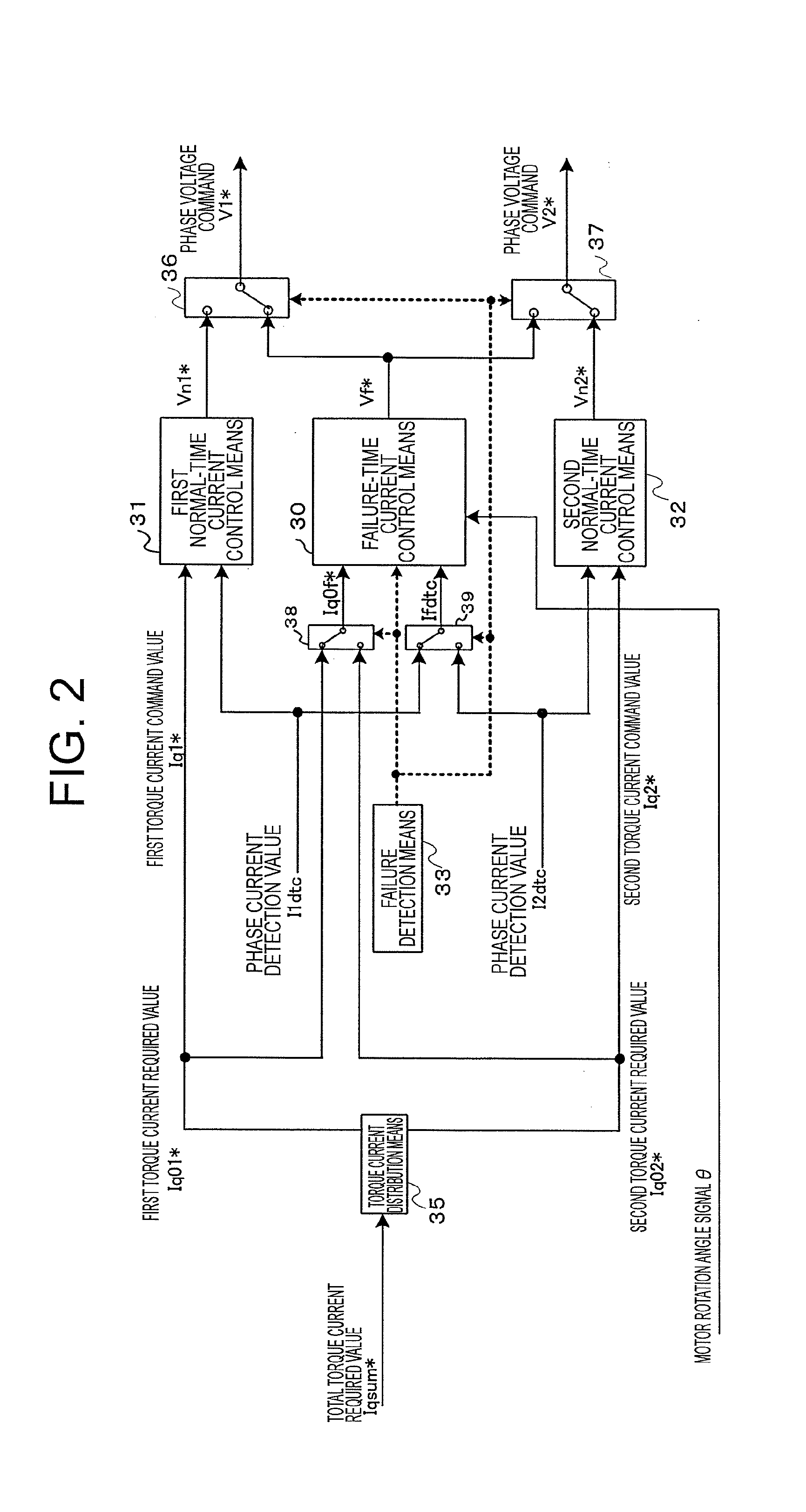

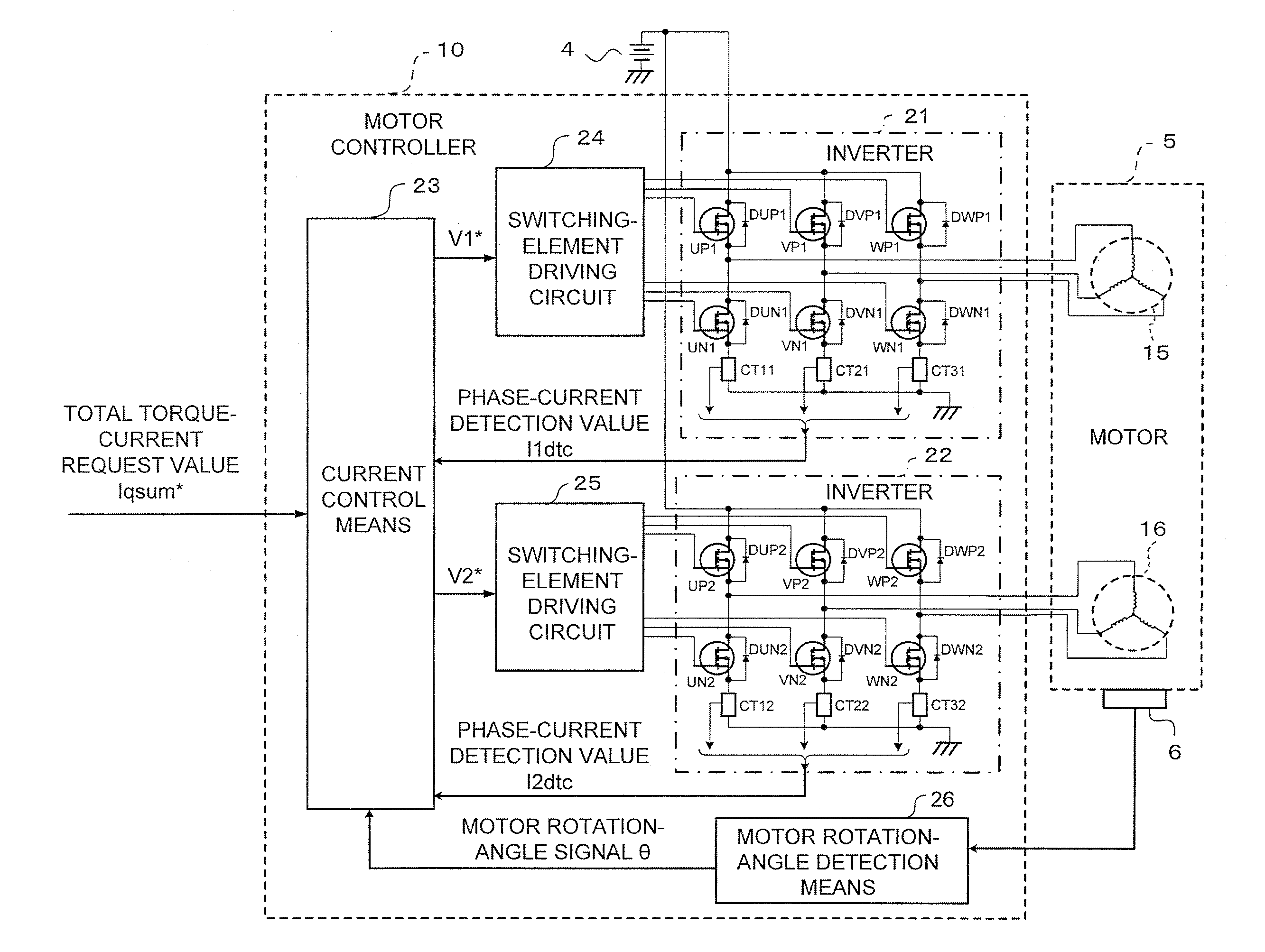

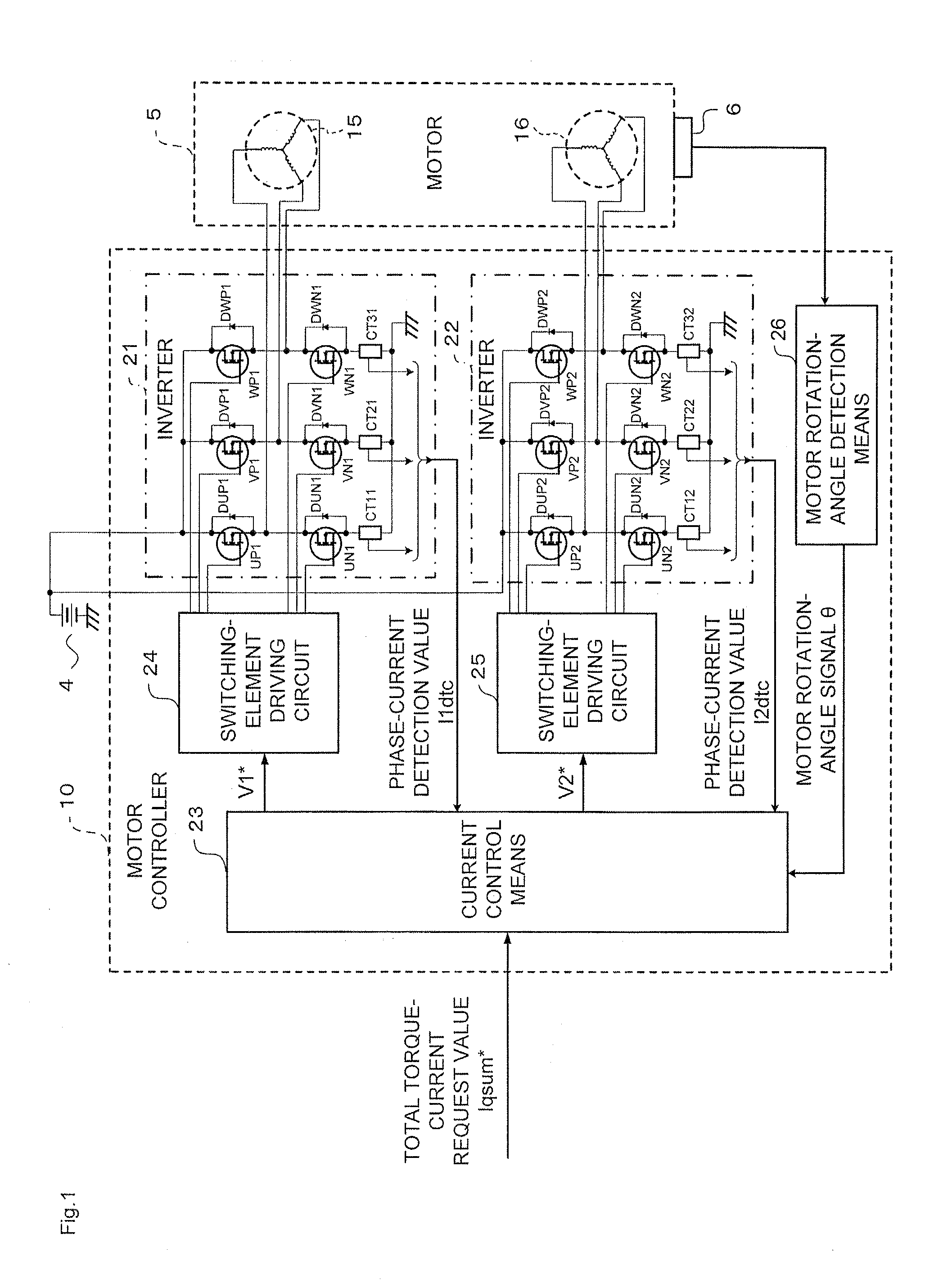

Motor control device, current control method applied to motor control device, and electric power steering device using motor control device

ActiveUS20130200827A1Low costSufficient output torqueMotor/generator/converter stoppersCommutation monitoringElectric power steeringPower flow

Provided is a motor control device (10) for controlling a motor (5) provided with a plurality of sets of windings, in which, when a current control unit (23) detects a short-circuit failure as a primary failure, the current control unit (23) continues the control, and, further, when the current control unit (23) detects a secondary failure, the current control unit (23) provides control of opening a power supply relay (3). Accordingly, in a case where a failure of a winding of a motor or an inverter occurs, a torque pulsation is restrained and a sufficient output torque is provided, and further, in a case where a secondary failure occurs, excessive heat generation and current consumption are prevented and the cost of the device is reduced.

Owner:MITSUBISHI ELECTRIC CORP

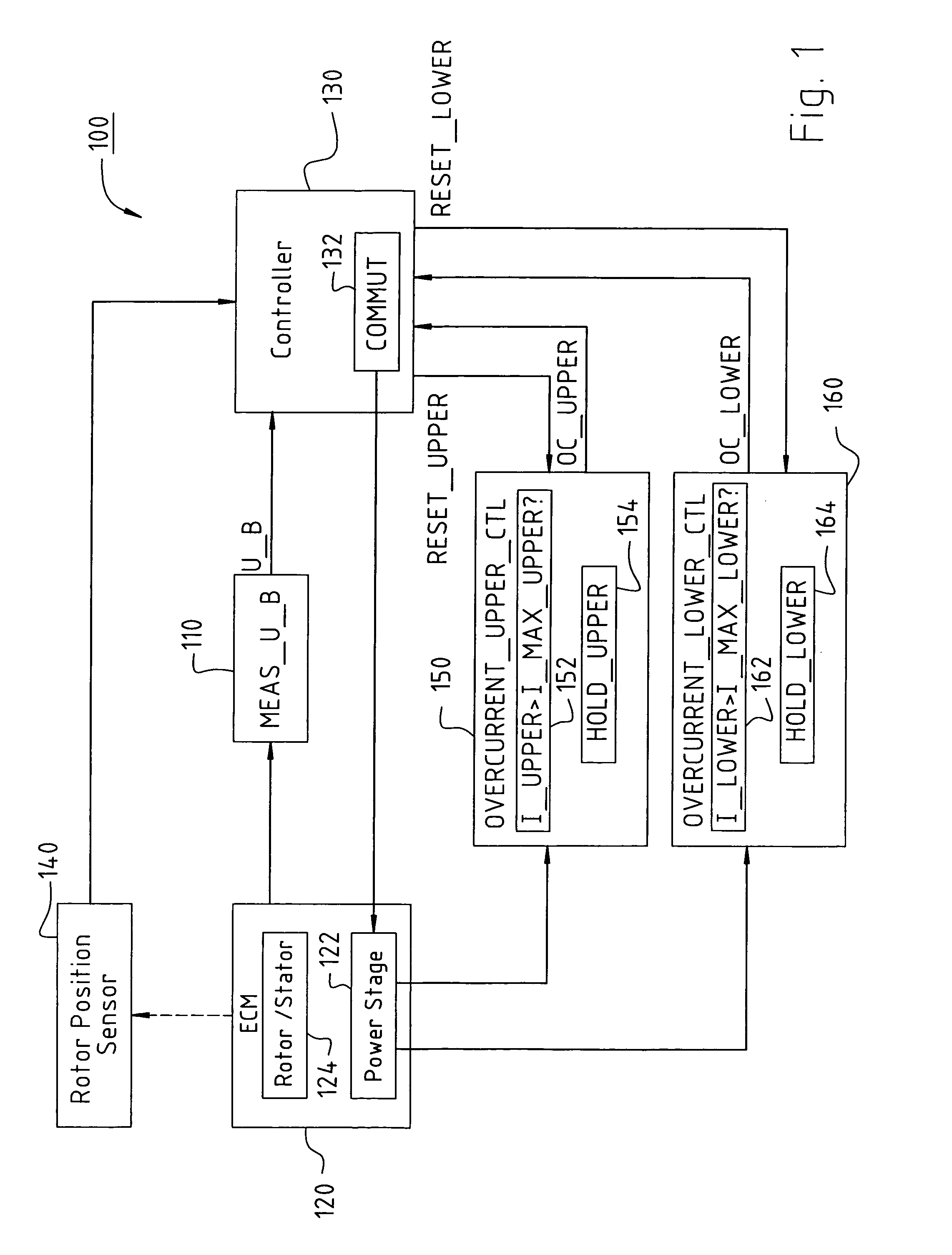

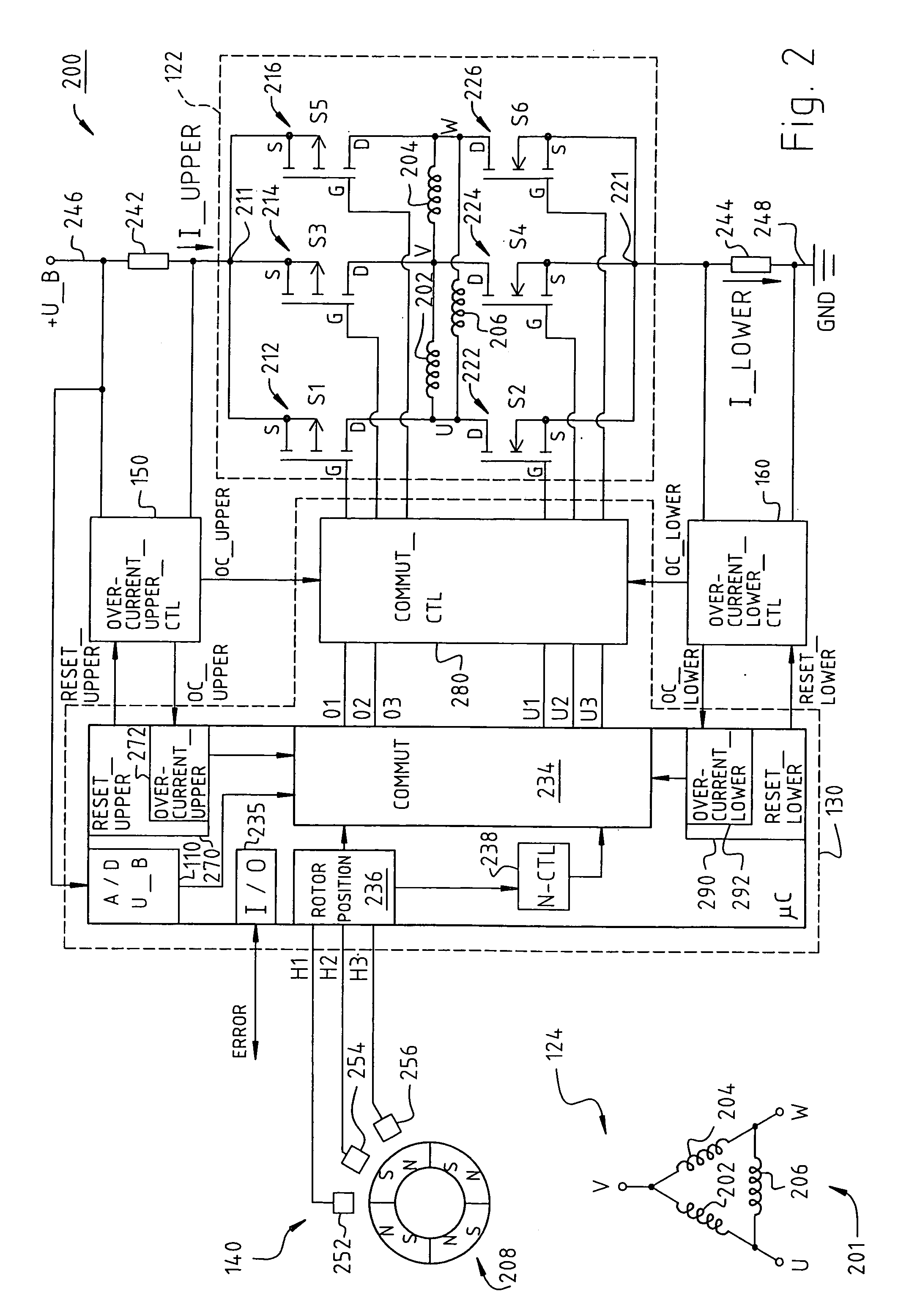

Electronically commutated motor (ECM) and method of controlling an ecm

InactiveUS20070024225A1Protection from damageProtection from destructionCommutation monitoringMotor/generator/converter stoppersEngineeringLimit value

An electronically commutated motor comprises a rotor (208); a stator (201) electromagnetically interacting with the rotor (208), which stator is formed with a stator winding (202, 204, 206); a power stage (122) controlling the currents flowing in the stator winding (202, 204, 206) during operation; at least one current measuring element (242, 244) for sensing a measured value for the currents (I_UPPER, I_LOWER) flowing in the power stage, and an overcurrent measuring element (152, 162) for evaluating an associated measured value and for sensing a current whose absolute value exceeds a predetermined limit value (I_MAX_UPPER, I_MAX_LOWER); a holding element (154, 164) associated with the overcurrent measuring element (152, 162), configured, when an overcurrent occurs in the associated current measuring element (242, 244), to generate an overcurrent signal (OC_UPPER, OC_LOWER), to store the signal, and to deliver a signal to the power stage (122).

Owner:EBM PAPST ST GEORGEN & -

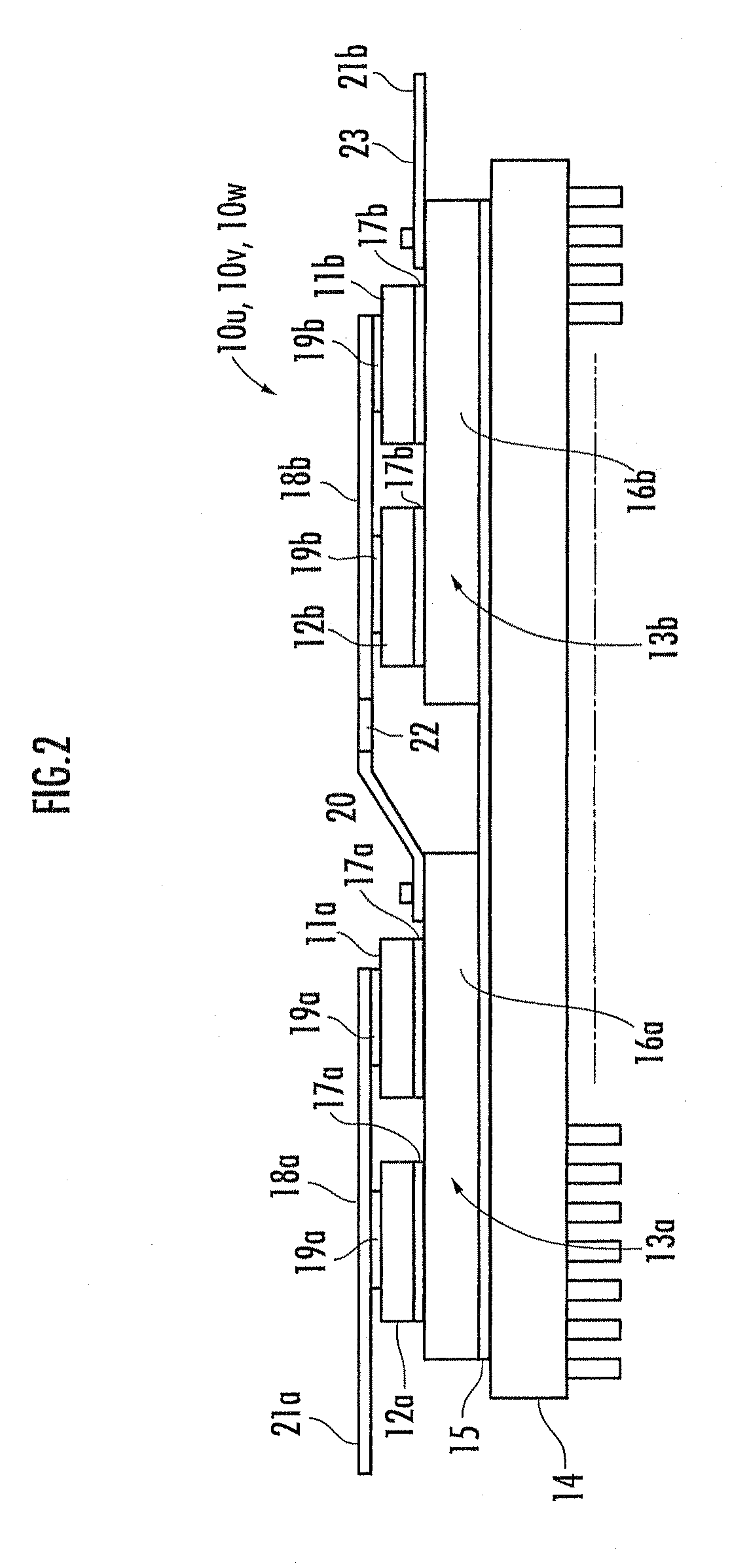

Motor driving device, electric power steering device using the same and method for detecting failure in the same

ActiveUS20110156626A1Commutation monitoringDigital data processing detailsPower inverterElectric power steering

A voltage application unit applies voltage to windings of a motor without passing though an inverter unit. A first detection unit detects a short circuit failure in switching elements of the inverter unit based on a terminal voltage between each of the switching elements and a corresponding winding and a power voltage of a power supply. Before rotation of the motor, when no short circuit failure is detected and when a switching unit switches at least one of the high and low potential-side switching elements of the inverter unit on and subsequently switches all the switching elements off, a second failure detection unit determines whether the switching unit is incapable of rendering the switching element non-conductive based on the terminal voltage and the power voltage.

Owner:DENSO CORP

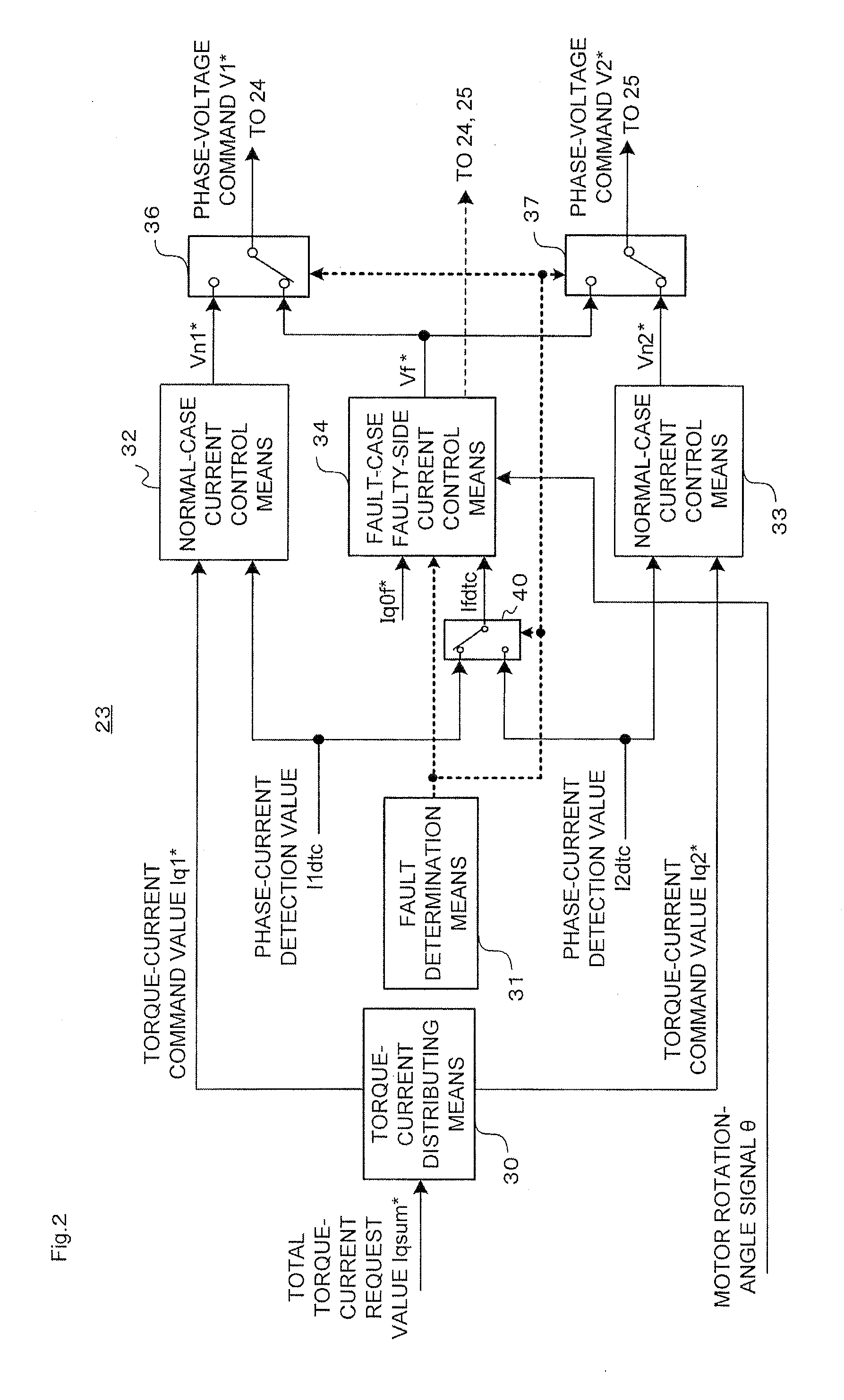

Motor controller and electric power steering device using the same

ActiveUS20130299271A1Low costSmall sizeCommutation monitoringMotor/generator/converter stoppersElectric power steeringMotor controller

Provided are a motor controller for suppressing a torque pulsation with a simple configuration and obtaining a sufficient output torque in the case of an open-type fault occurring in any one of windings of a motor and inverters, and an electric power steering device using the motor controller. In the motor controller for controlling a current supplied from and a voltage applied from a power source with respect to the motor including winding sets of a plurality of systems, when a fault determination unit (31) determines the occurrence of the open-type fault, the supply of the currents to the windings of one of the systems in which the fault has occurred is stopped by control performed on switching elements included in the inverter of the faulty system, whereas the supply of the currents to the windings of the normal system in which the fault has not occurred is continued.

Owner:MITSUBISHI ELECTRIC CORP

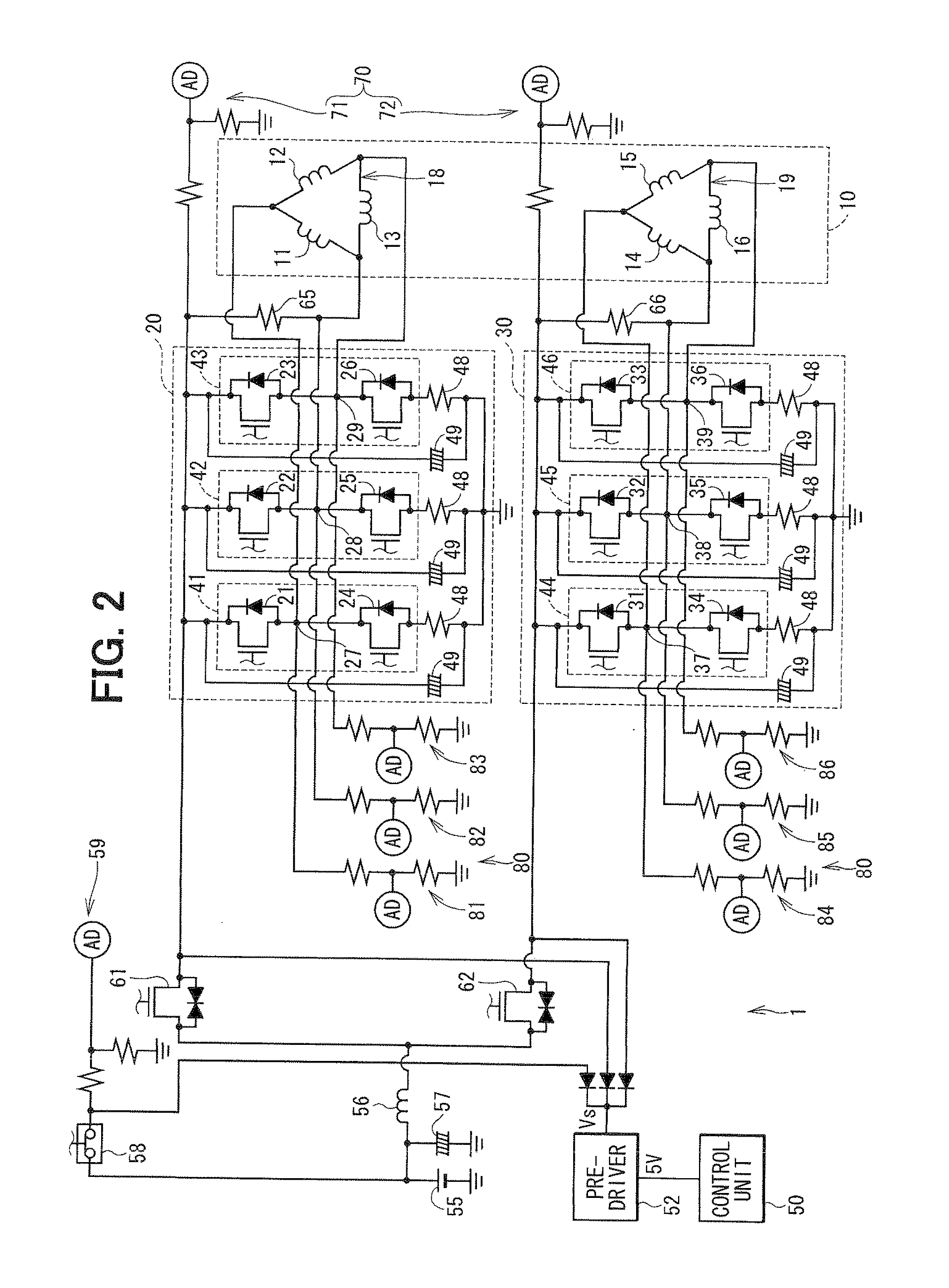

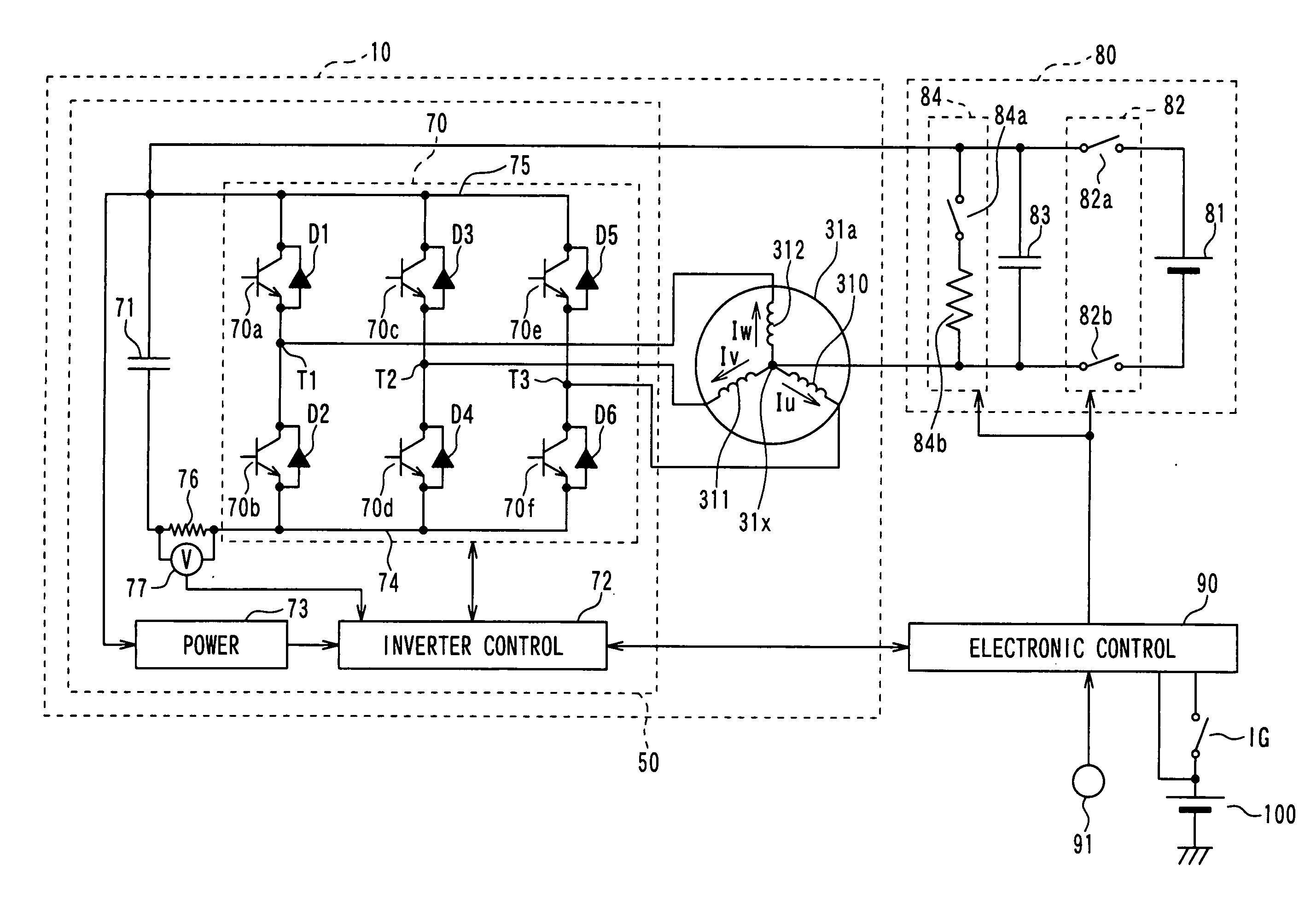

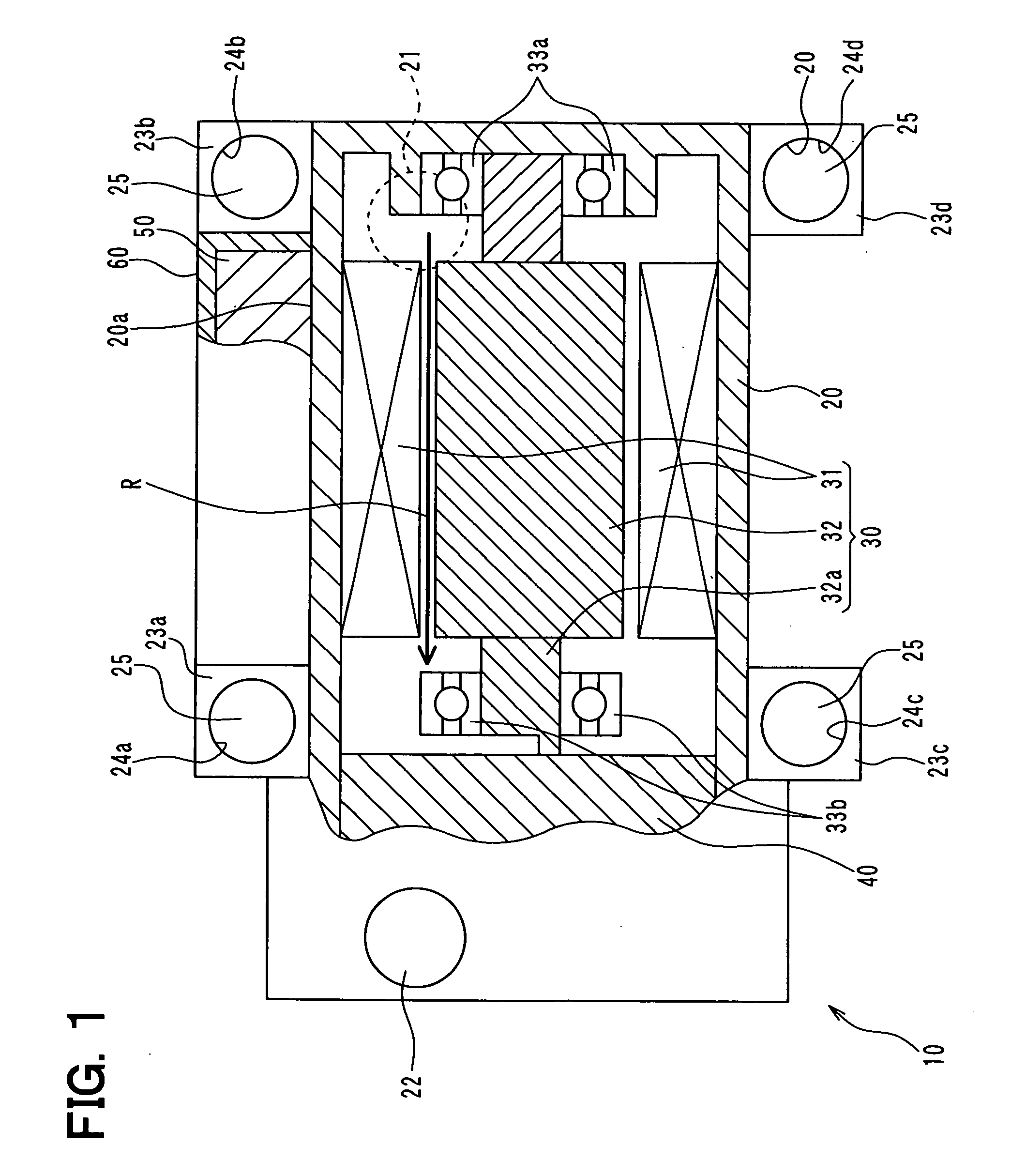

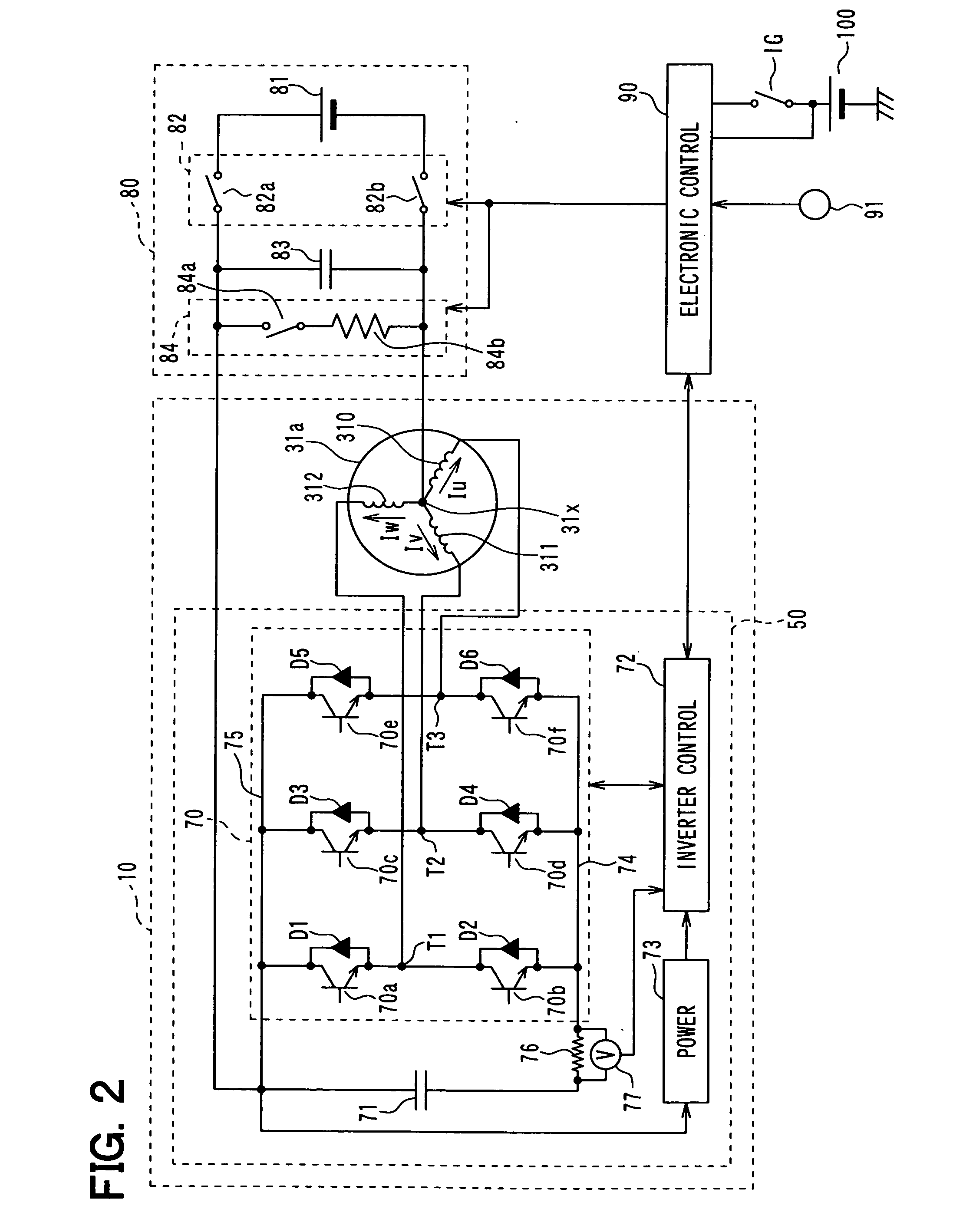

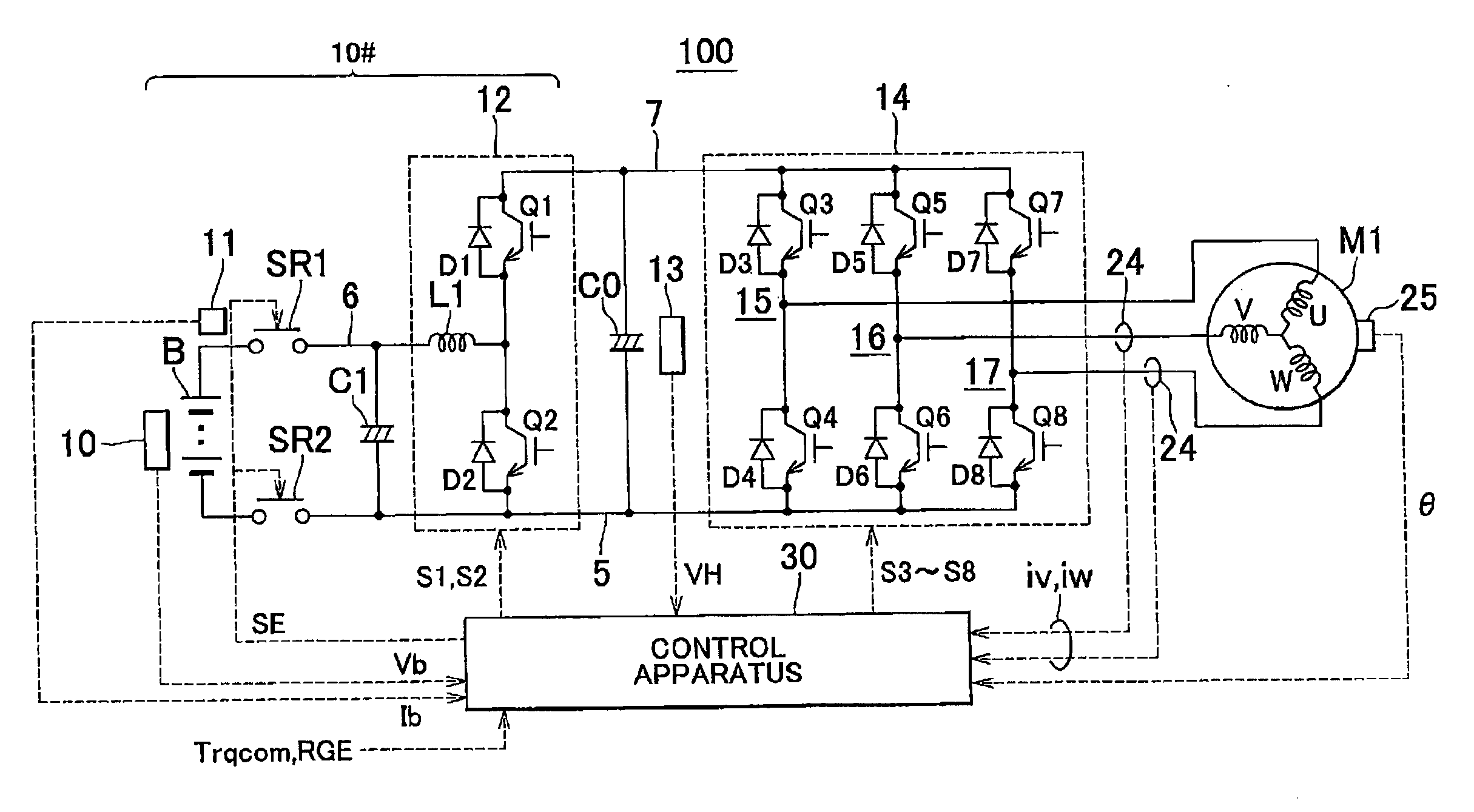

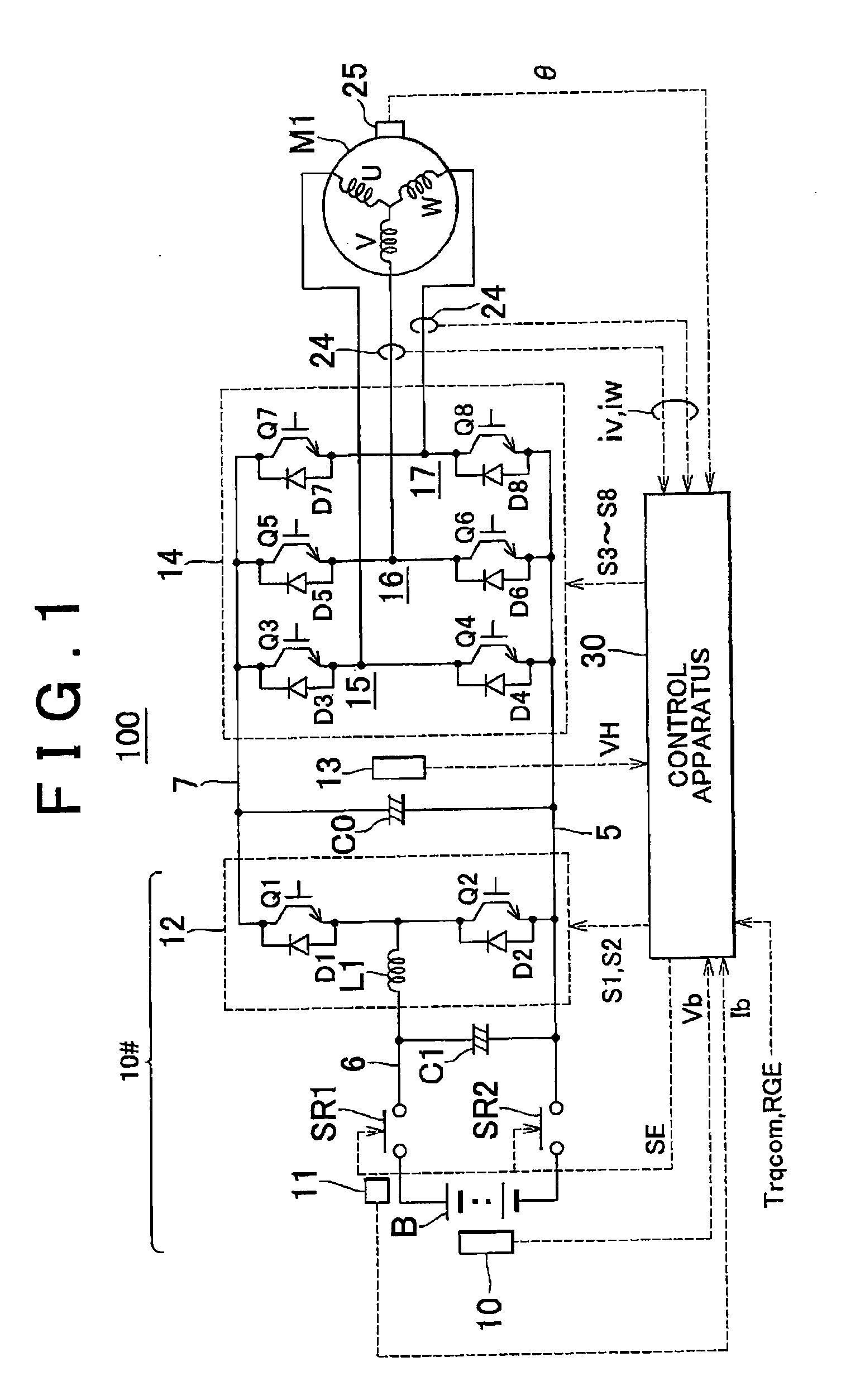

Driving apparatus for a vehicle-mounted electric motor

An inverter circuit for a motor outputs three-phase AC currents, which are outputted from common connection points to stator coils, based on output voltage of a DC power source and a power supply capacitor by a switching operation of transistors. An inverter control circuit determines that a system main relay is turned off, upon receiving a main relay-off signal from an electronic control unit. The inverter control circuit turns on the low-side transistors, while turning off the high-side transistors. A discharge current flows from the positive electrode to the negative electrode of the power supply capacitor through the stator coil and the low-side transistors, so that electric charge stored in the power supply capacitor is discharged.

Owner:DENSO CORP

Motor having controllable torque

InactiveUS20090128084A1Increase in sizeSingle-phase induction motor startersCommutation monitoringEngineeringControl theory

A controllable motor includes a rotor. A first stator winding set is operable, upon being energized, to generate and apply a first torque to the rotor. A second stator winding set independent of the first stator winding set is operable, upon being energized, to generate and apply a second torque to the rotor. A motor control is coupled to the first and second stator winding sets. The motor control is operable to selectively energize one of the first or second stator winding sets to thereby generate and apply one of the first or second torques to the rotor, and simultaneously energize both the first and second stator winding sets to thereby generate and apply a third torque greater than the first or the second torque.

Owner:HONEYWELL INT INC

Rotary electric system with star-connected multiphase stator windings

ActiveUS20090096394A1Continuous rotationReliably addressingCommutation monitoringDC motor speed/torque controlFull waveConductor Coil

In a rotary electric system, a switch member includes at least one of a first switch and a second switch. The first switch is connected between a neutral point of multiphase stator windings and a high-side electrode of a direct current power source. The second switch is connected between the neutral point and a low-side electrode of the direct current power source. A controller works to turn the switch member off and on thereby switching control of the multiphase inverter between full-wave driving mode and half-wave driving mode. The full-wave driving mode allows the controller to drive all of the high-side and low-side switching elements per phase of the multiphase stator windings. The half-wave driving mode allows the controller to drive any one of the high-side switching element and the low-side switching element per phase of the multiphase stator windings.

Owner:DENSO CORP

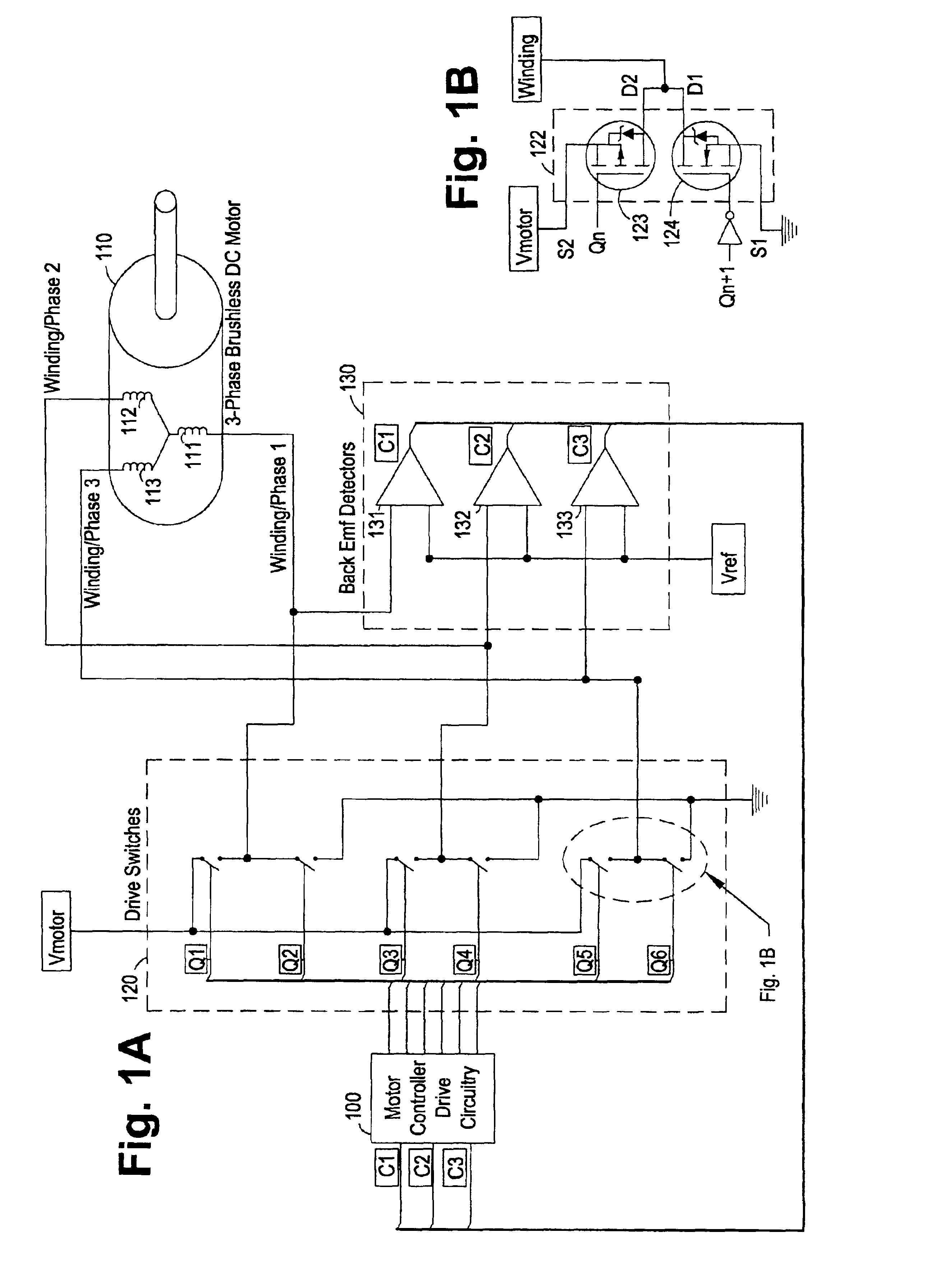

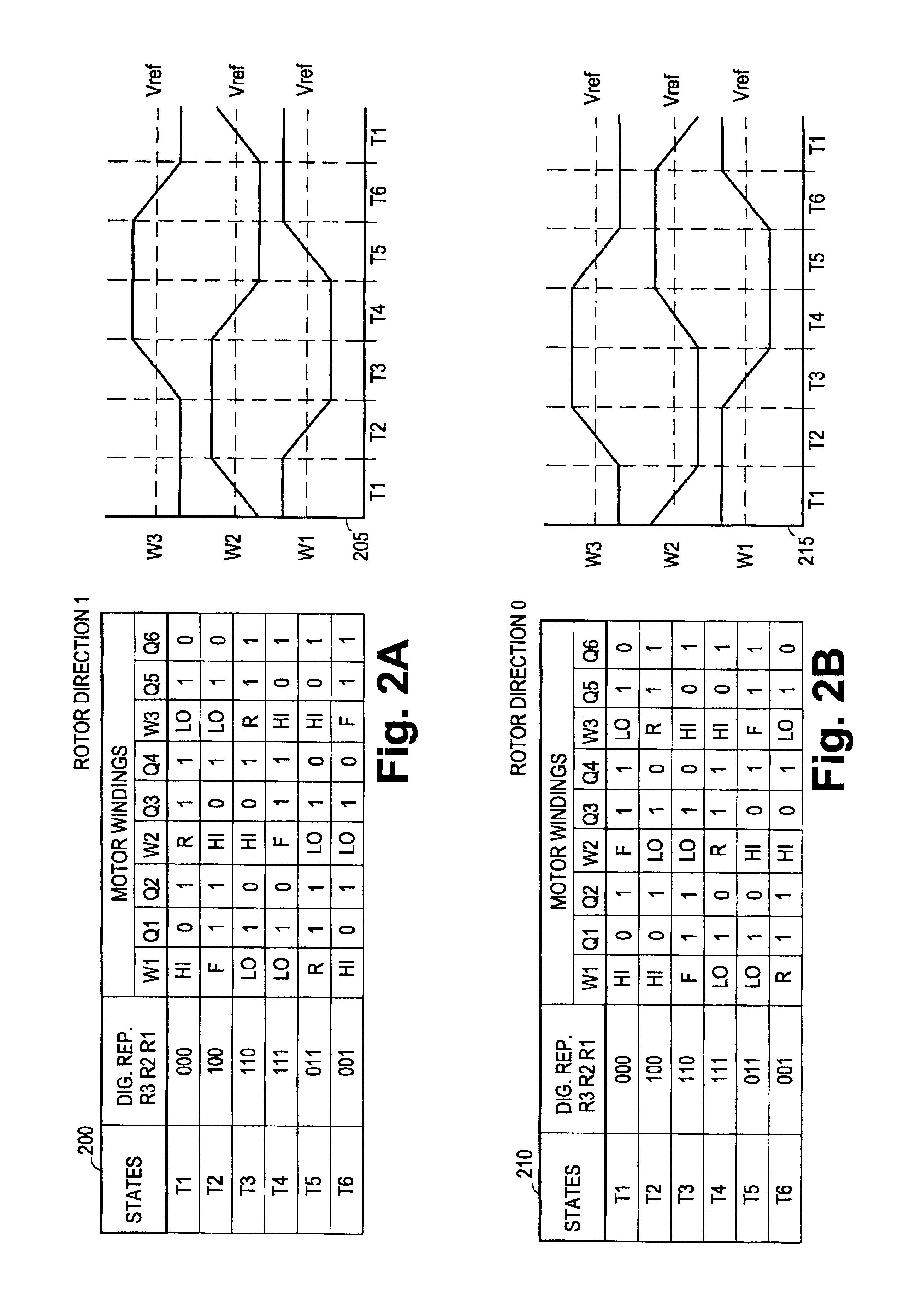

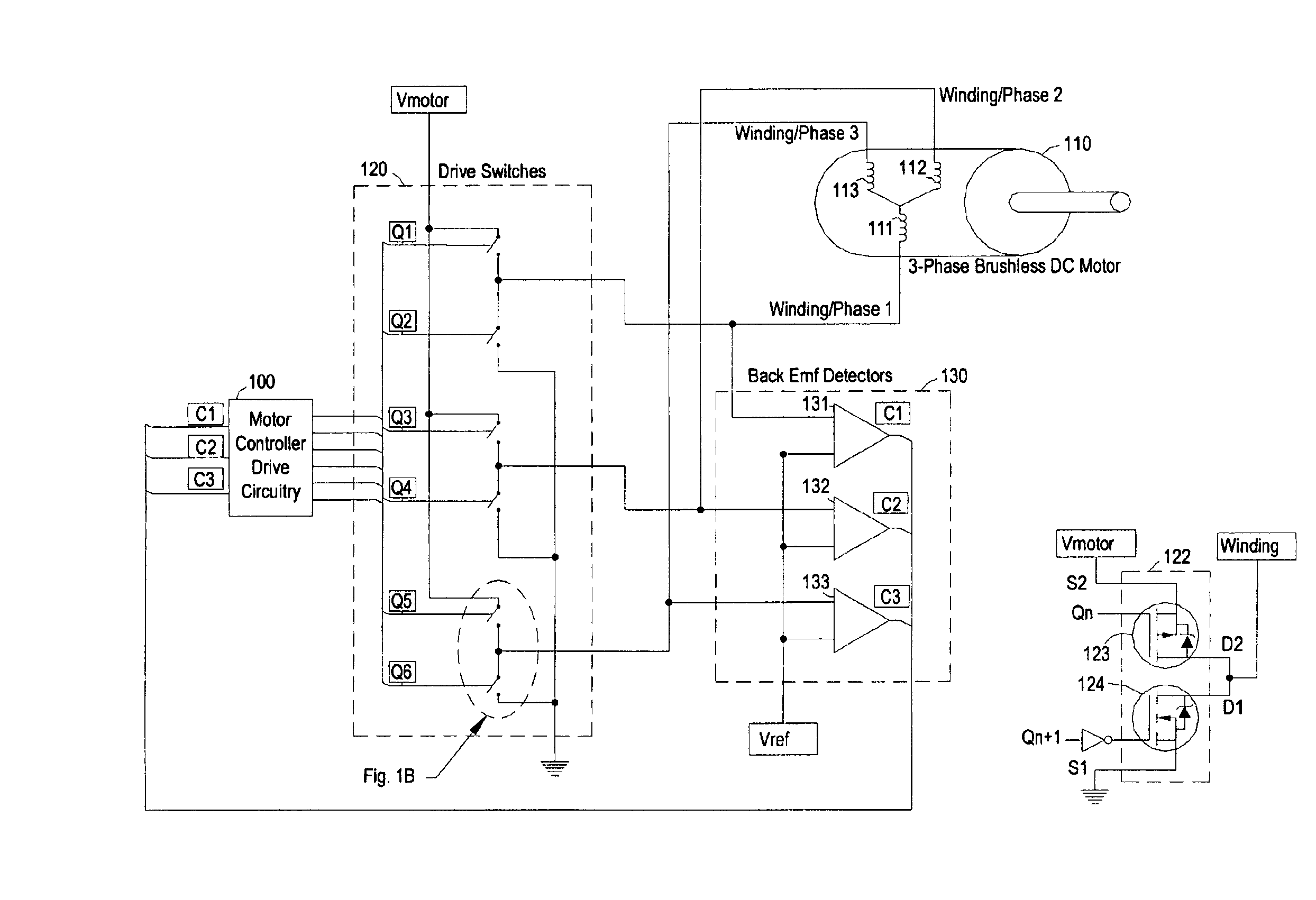

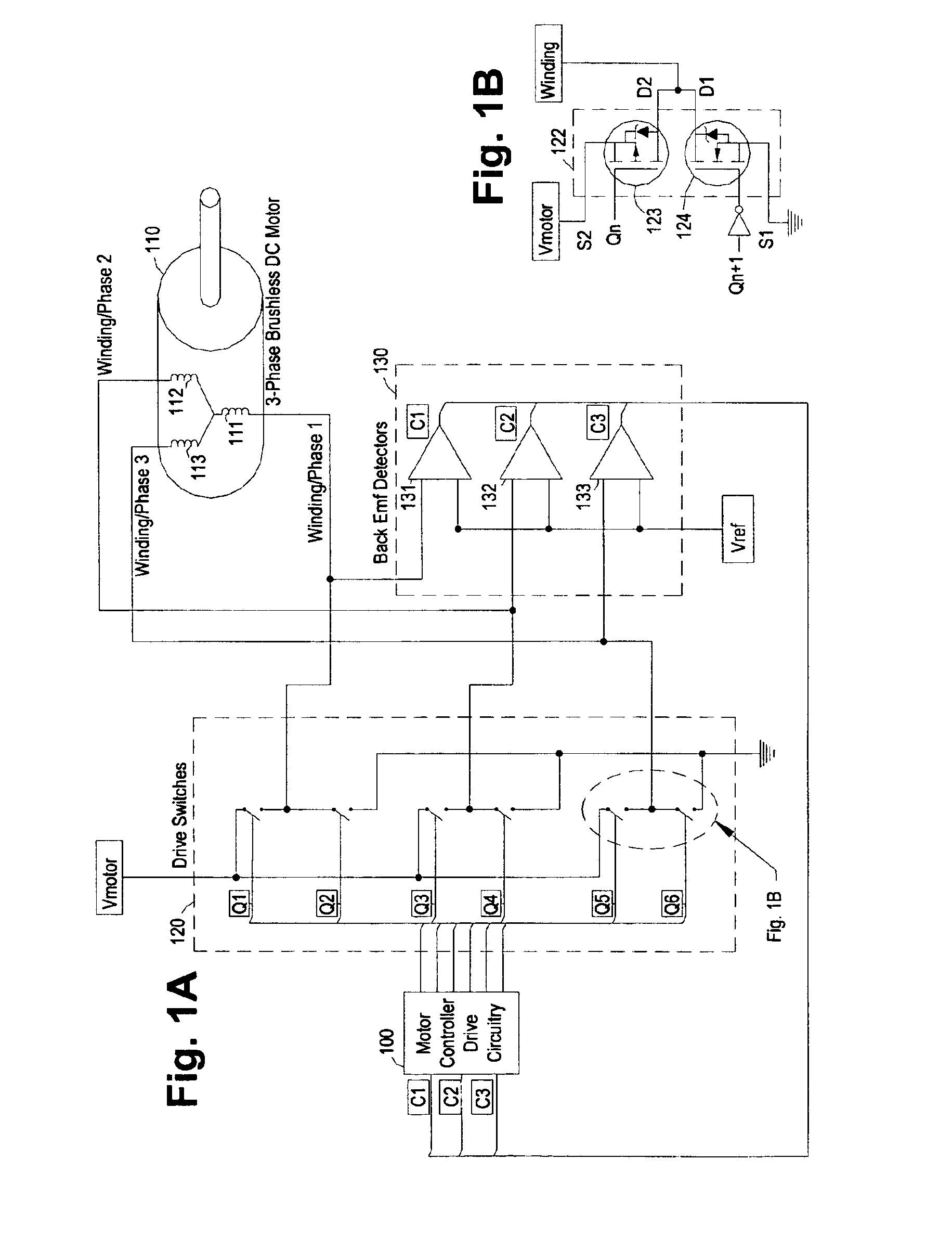

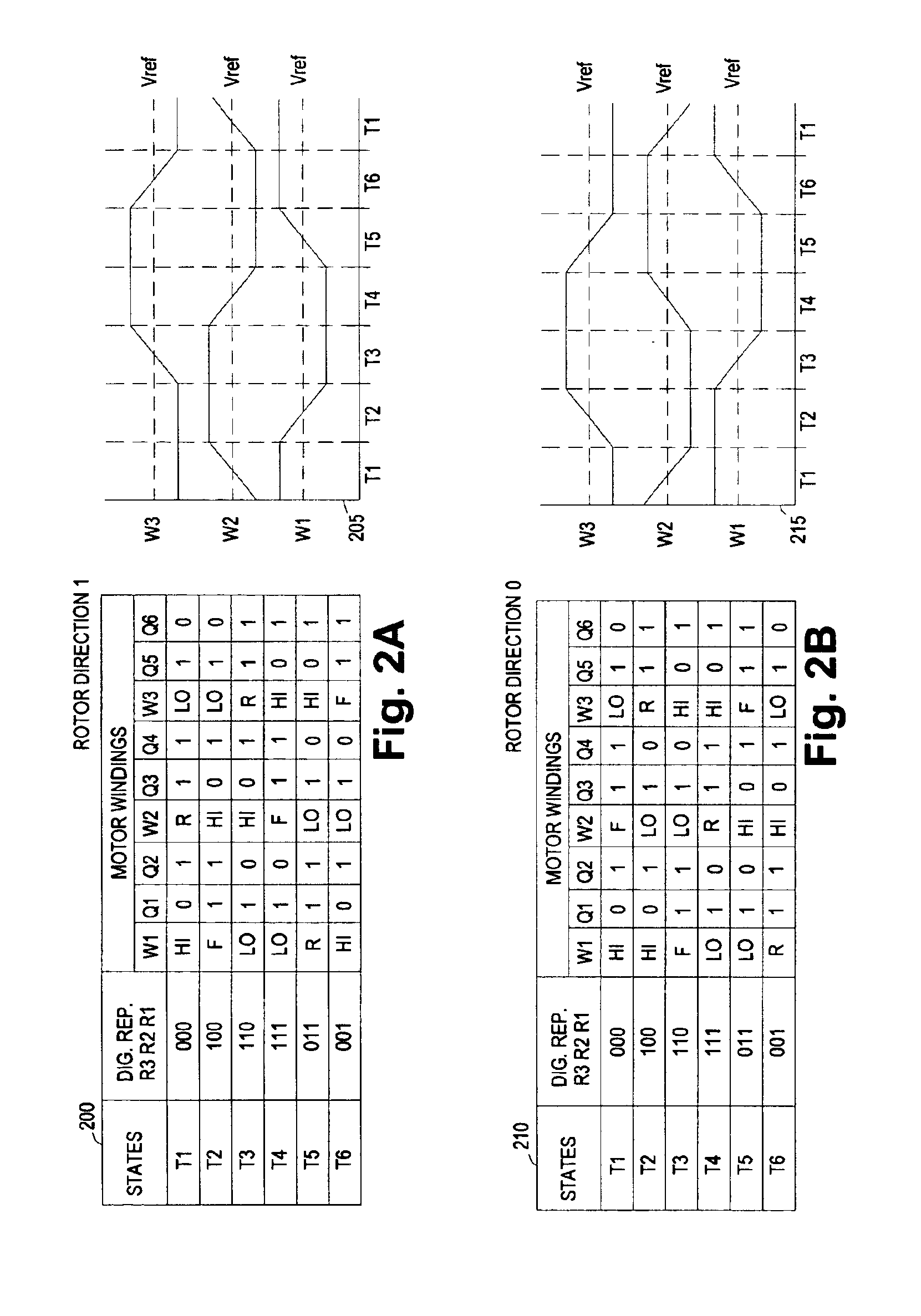

Digital adaptive sensorless commutational drive controller for a brushless DC motor

InactiveUS6901212B2Efficient startMotor/generator/converter stoppersCommutation monitoringControl signalProgrammable logic device

A digitally adaptive controller circuit for commutating a brushless, sensorless, DC motor in either of two directions adapted to receive digital back electromotive force (BEMF) detector signals. The digital circuit is driven by an input clock that is adjustable to configure the motor controller for use with a broad range of DC motors. The circuit includes commutational logic that decodes a current commutational state and a user-definable binary direction input into logic levels for digital control signals for controlling motor drive switches. The circuit also includes a signature analyzer to compare logic levels in the BEMF detector signals with expected logic levels based on an expected rotor position and direction of rotation. The digital circuit commutates the motor if the logic levels in the BEMF detector signals are at the expected logic levels. The digital circuit is compact and simple enough to be deployed onto a single programmable logic device.

Owner:HALLIBURTON ENERGY SERVICES INC

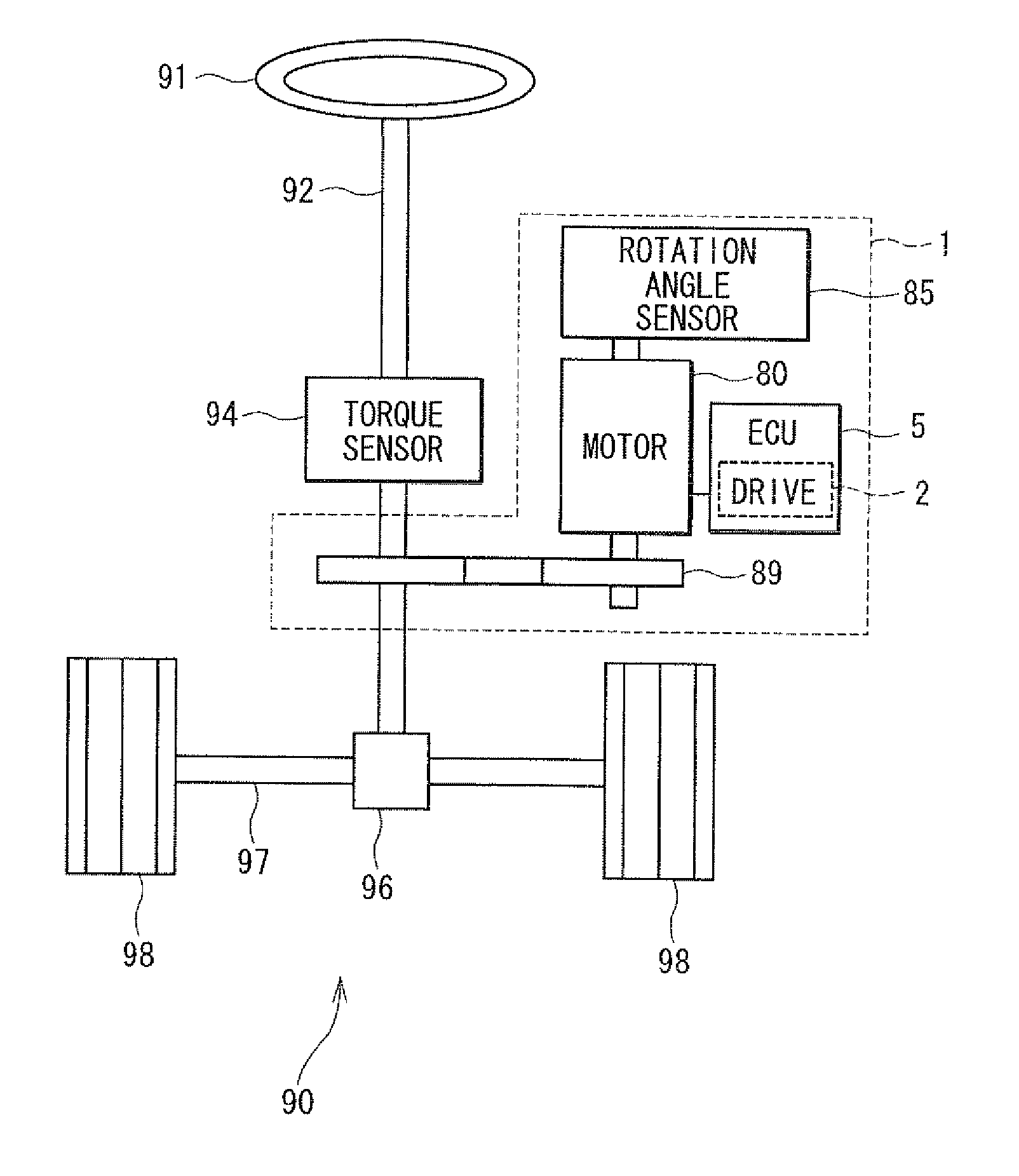

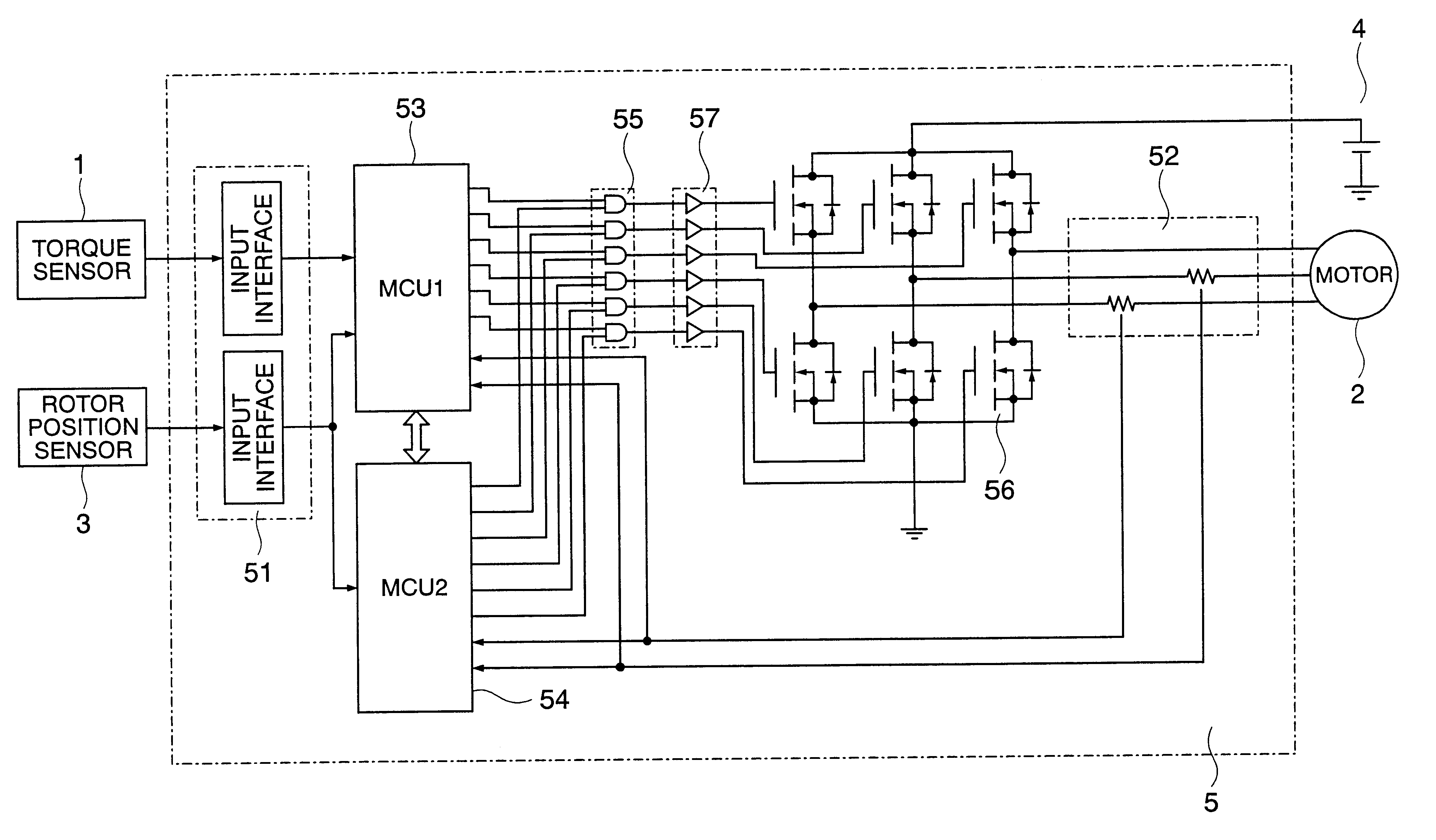

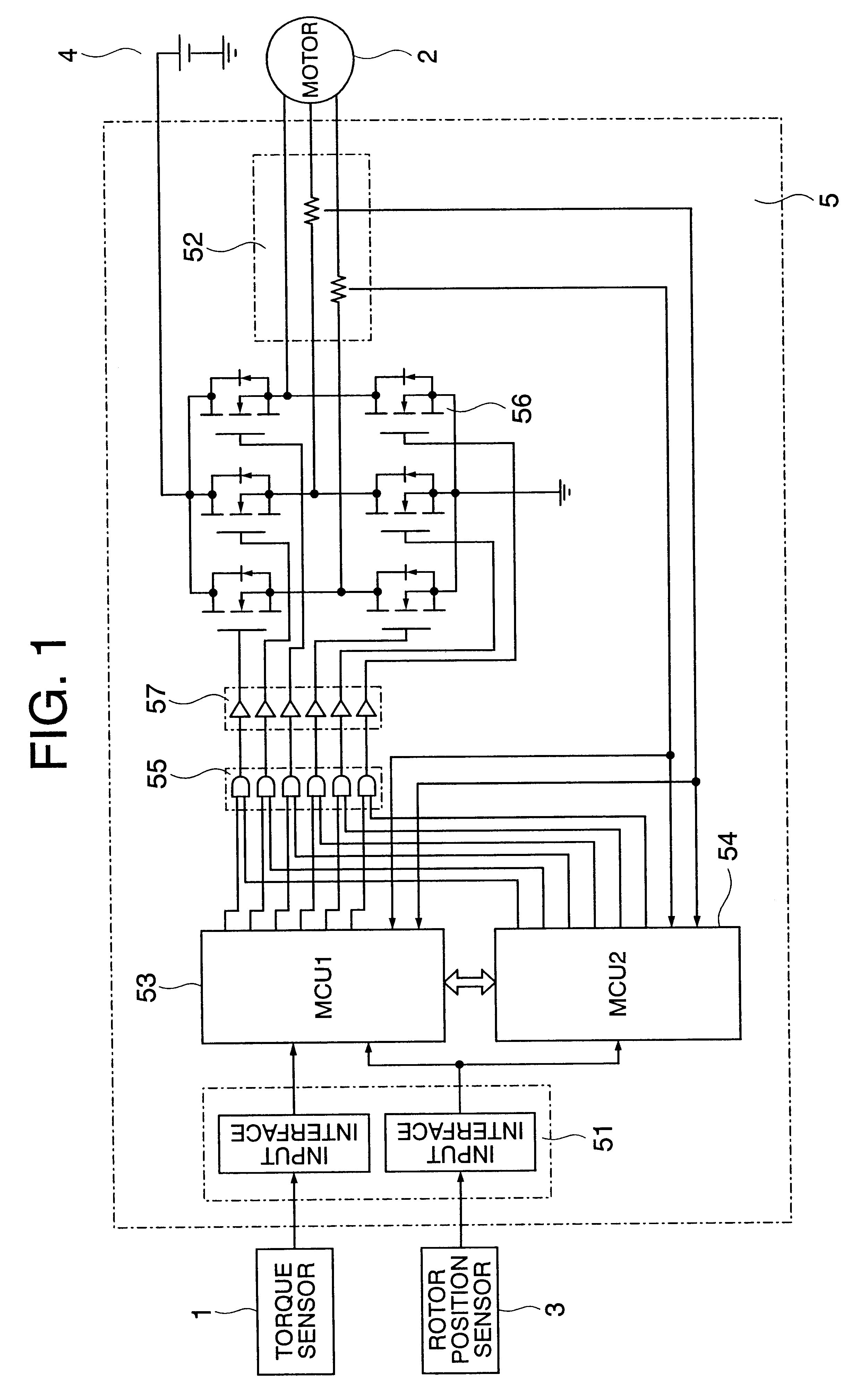

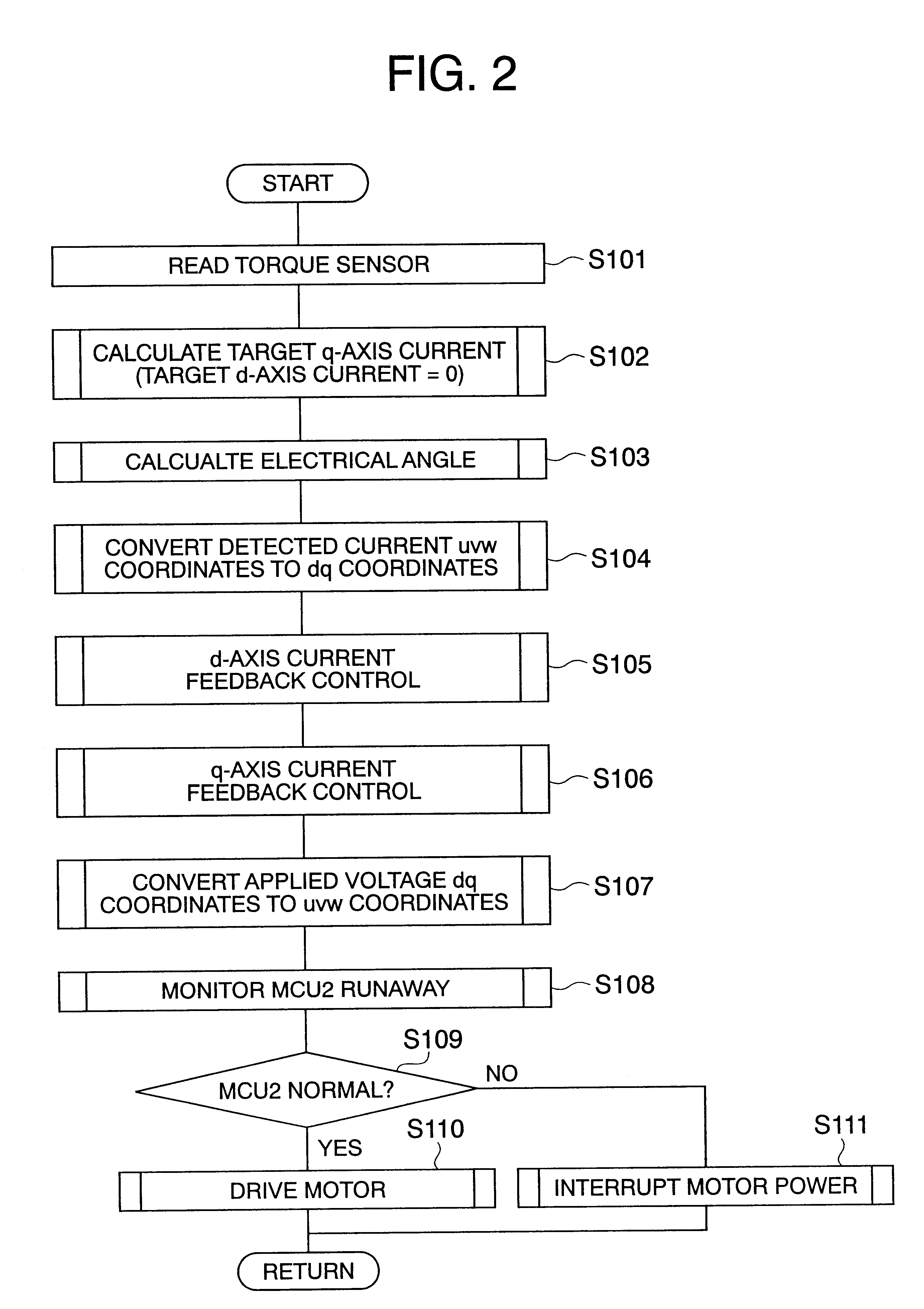

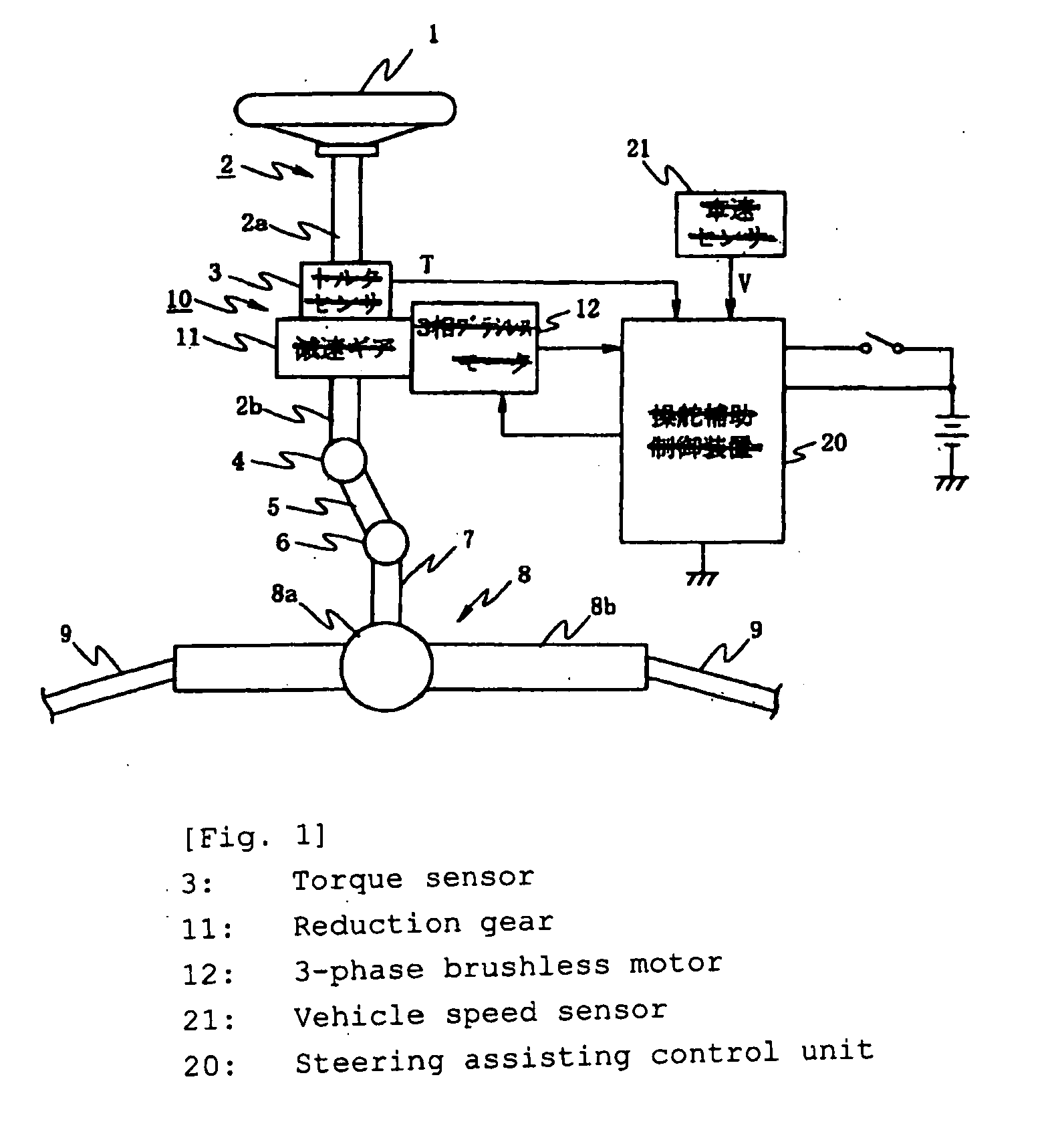

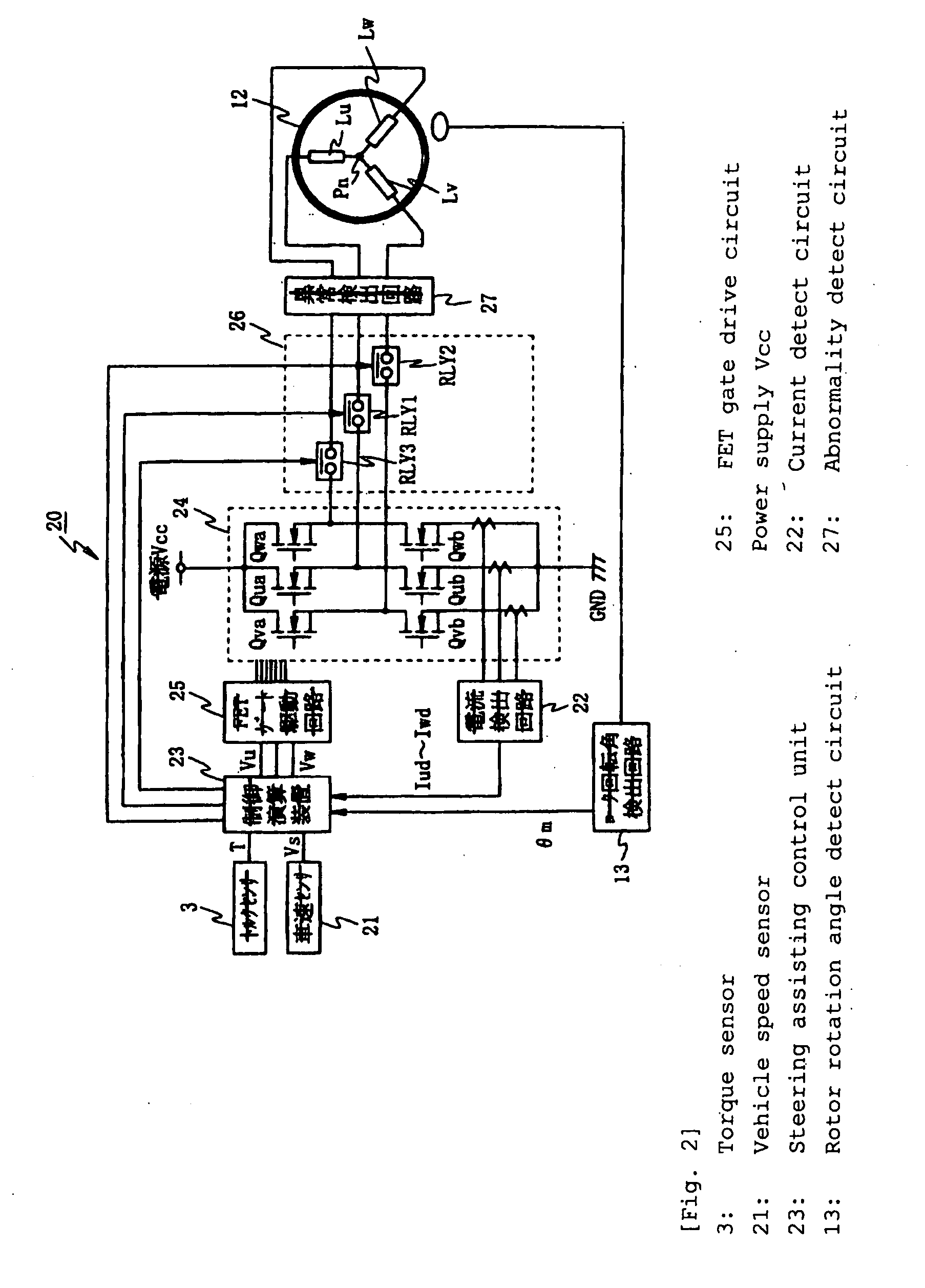

Electric power steering apparatus

InactiveUS6687590B2Commutation monitoringDigital data processing detailsElectric power steeringMicrocontroller

The present invention is an electric power steering apparatus which includes a multi-phase motor that assists steering effort of a driver, a motor drive circuit provided with at least an upper switching element that connects or disconnects the winding of each phase of the multi-phase motor and a power supply, and a lower switching element that connects or disconnects the winding of each phase of the multi-phase motor and grounding, a logic circuit that determines ON / OFF of the upper switching element and the lower switching element, and first and second microcontrollers that control the motor drive circuit via this logic circuit, in which the logic circuit determines ON / OFF of the upper switching element and the lower switching element so that the power to the winding of the each phase of the multi-phase motor is stopped according to the instruction of either the first microcontroller or the second microcontroller.

Owner:MITSUBISHI ELECTRIC CORP

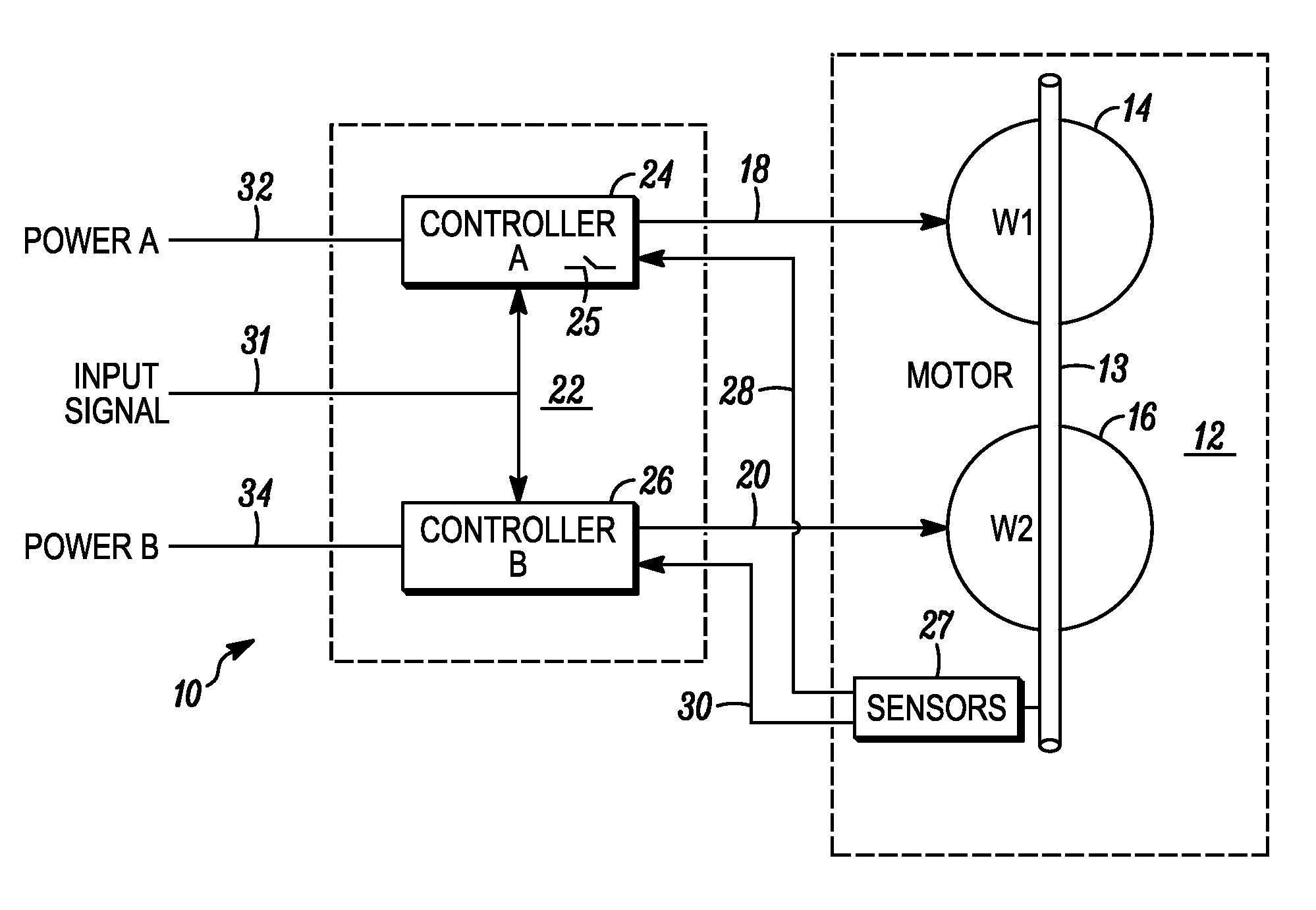

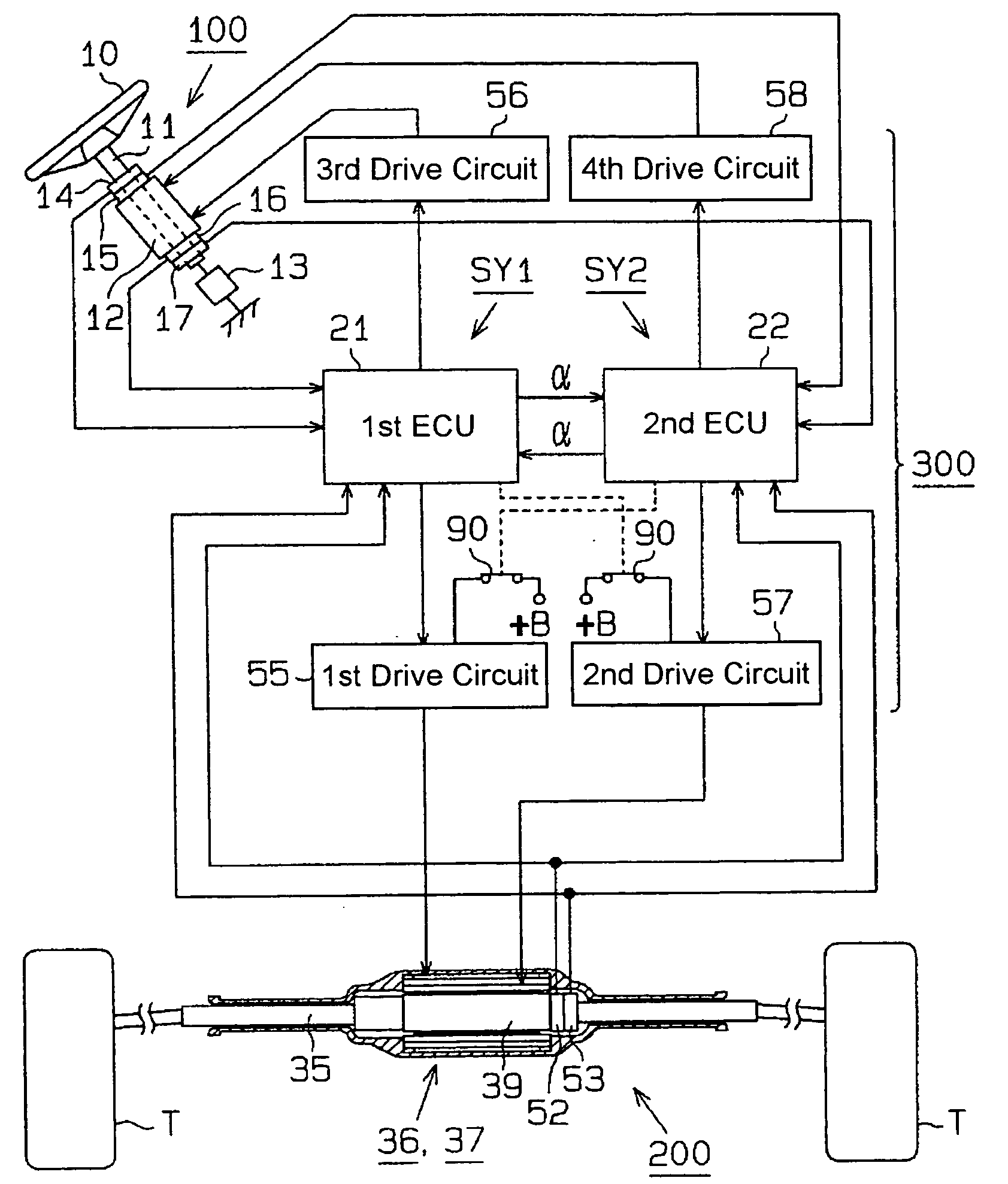

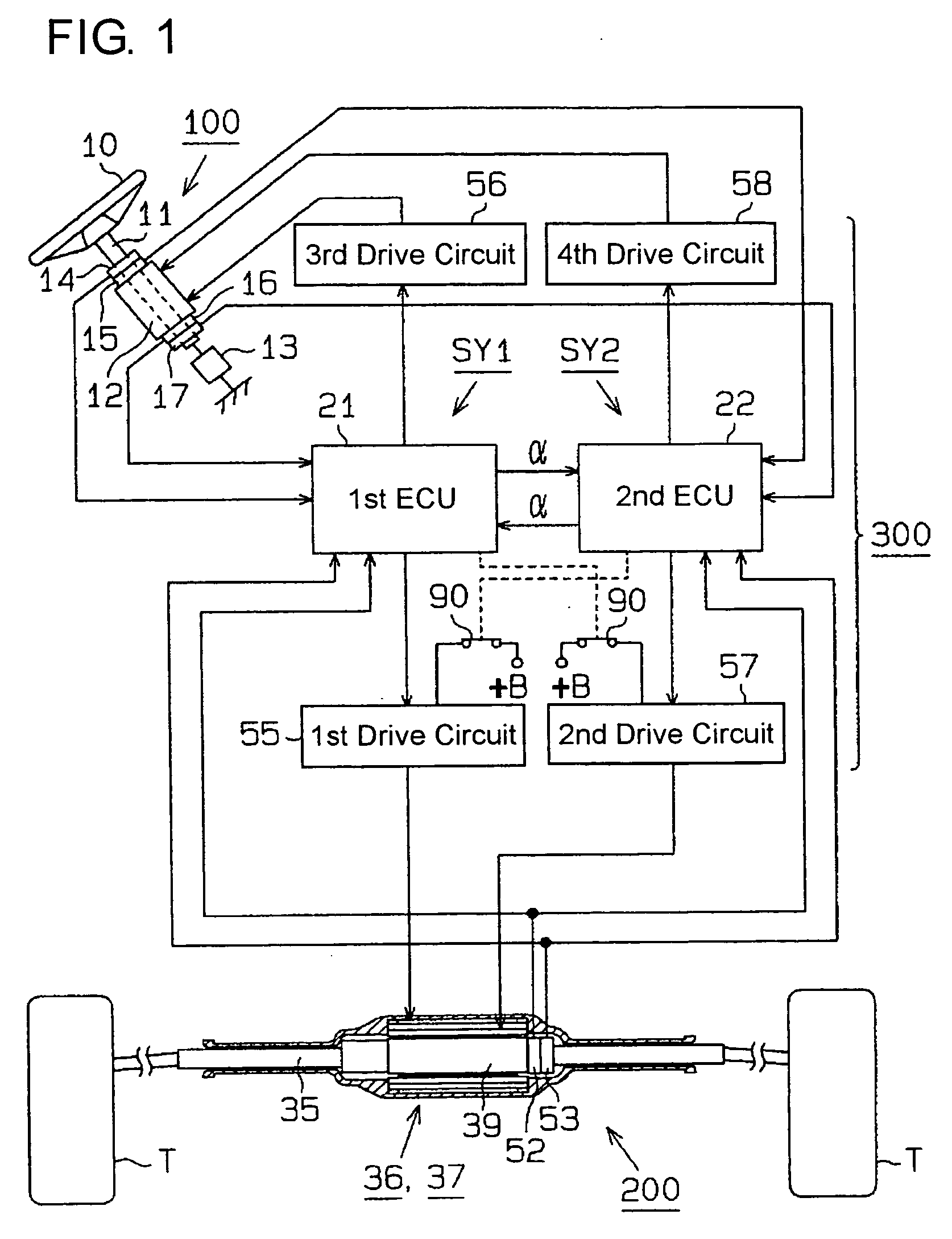

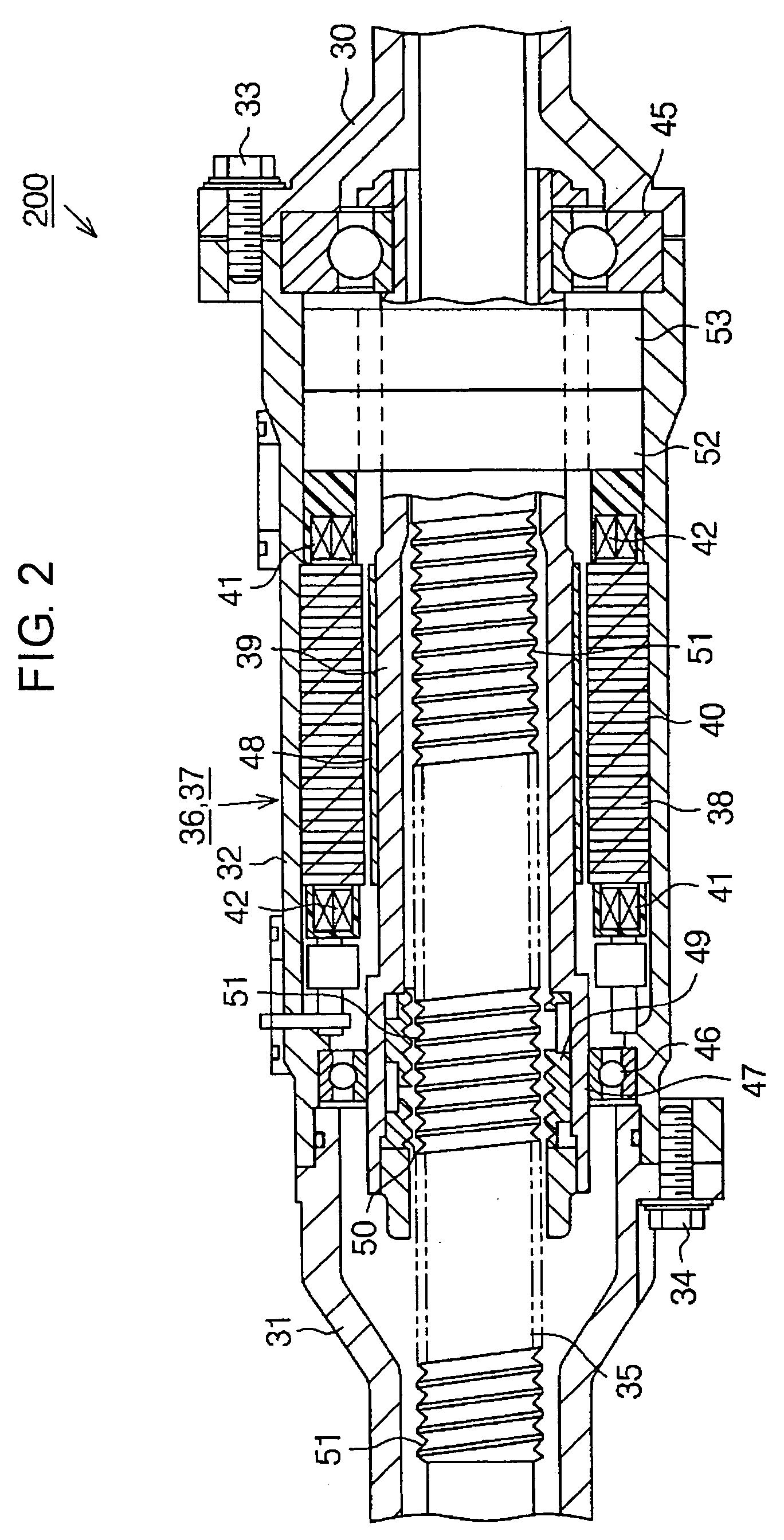

Steering control device and steering control method of motor vehicle

ActiveUS20050159866A1Low costOutput specificationVehicle testingCommutation monitoringSteering wheelMonitoring system

A first system and a second system include a first motor and a second motor for driving a steering mechanism in dependence on the rotational manipulation of a steering wheel. A first ECU and a second ECU mutually monitor abnormalities of the systems each to stop an abnormal system. When the respective systems are normal, the first ECU and the second ECU drivingly control the first motor and the second motor of their own systems to drive the steering mechanism by cooperation of the respective motors. When either one of the both systems is abnormal, the ECU of the other system solely drivingly controls the motor of its own system thereby to drive the steering mechanism. Thus, it can be realized to make the systems low in cost irrespective of the provision of the plural systems.

Owner:JTEKT CORP

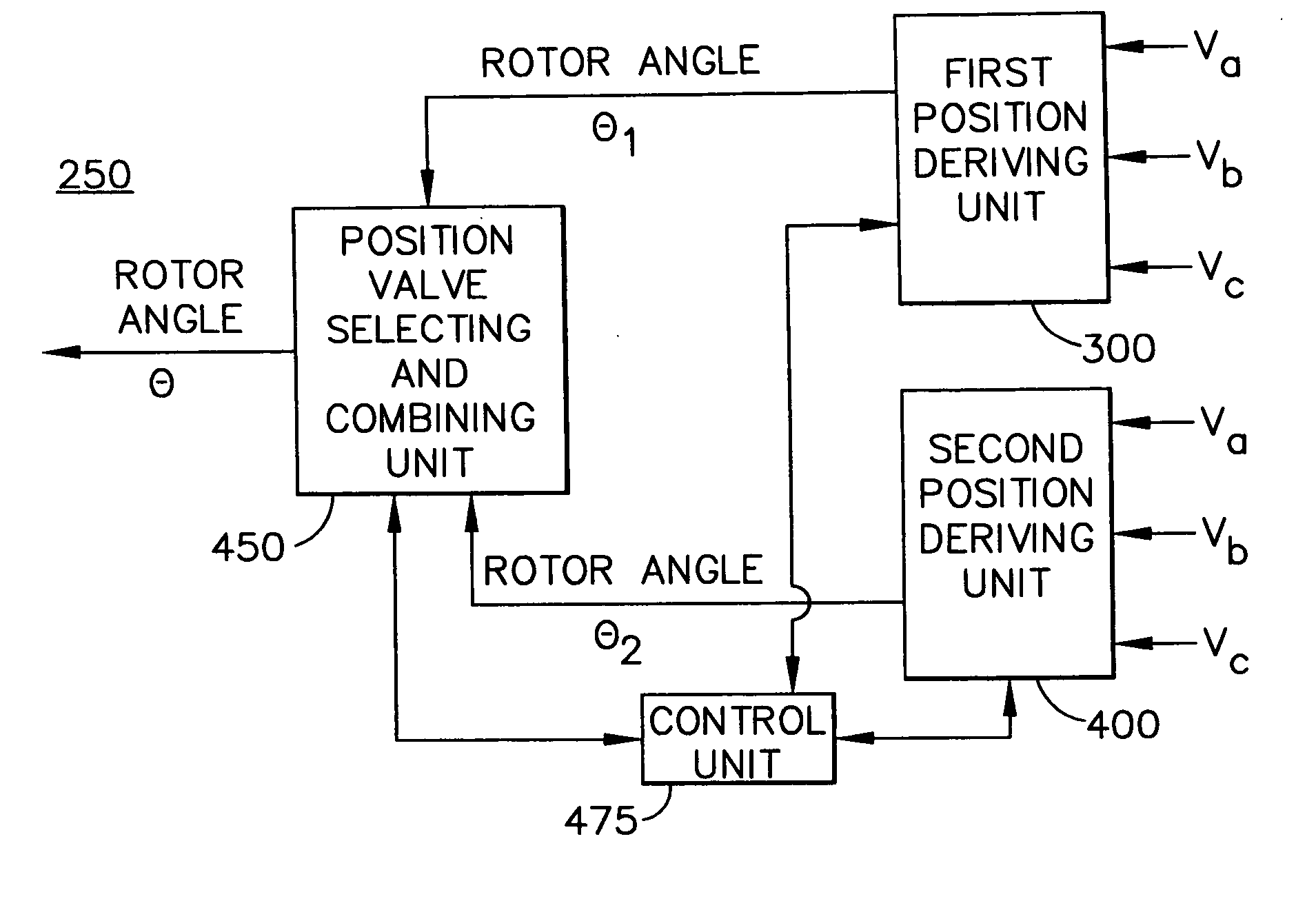

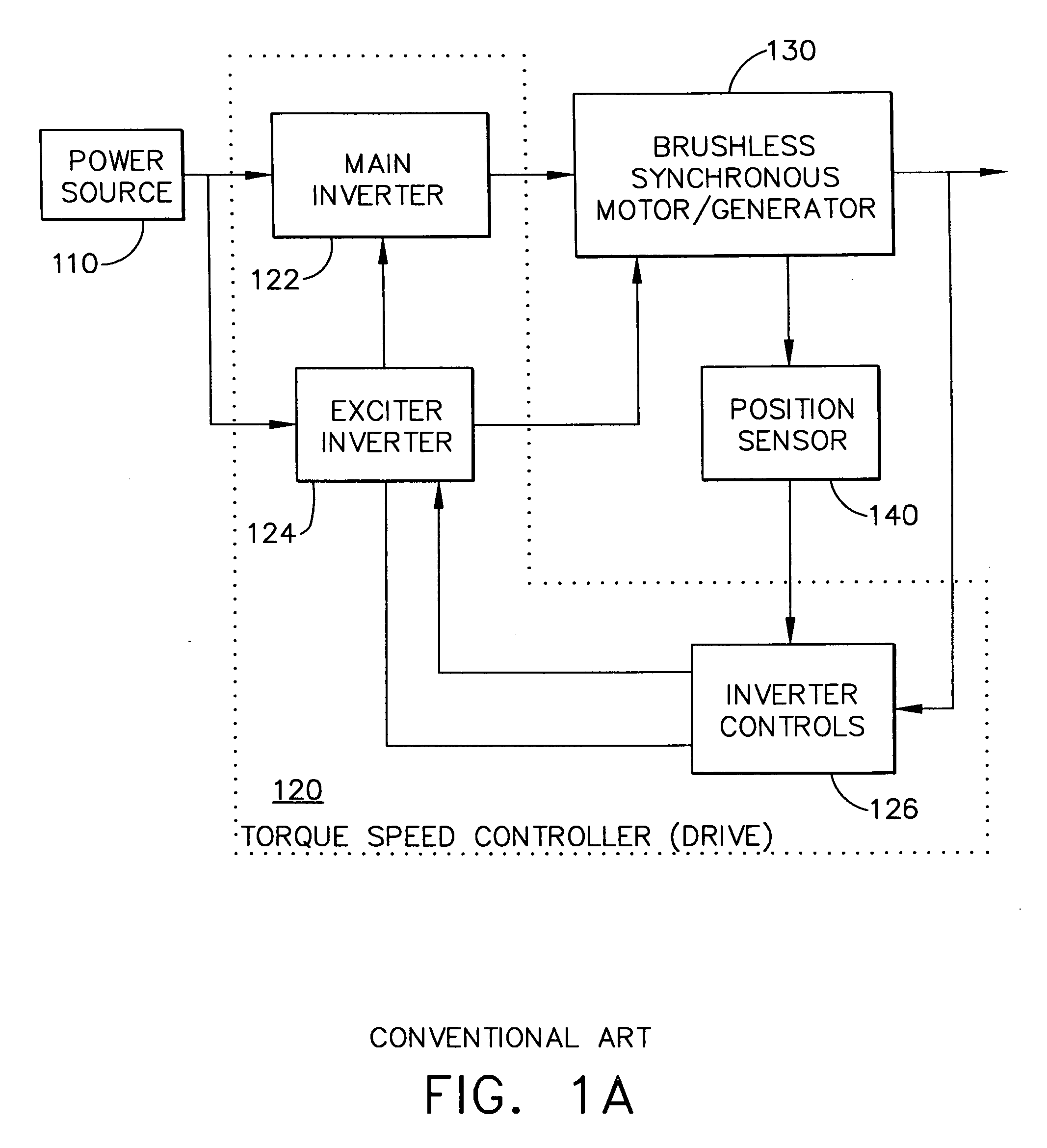

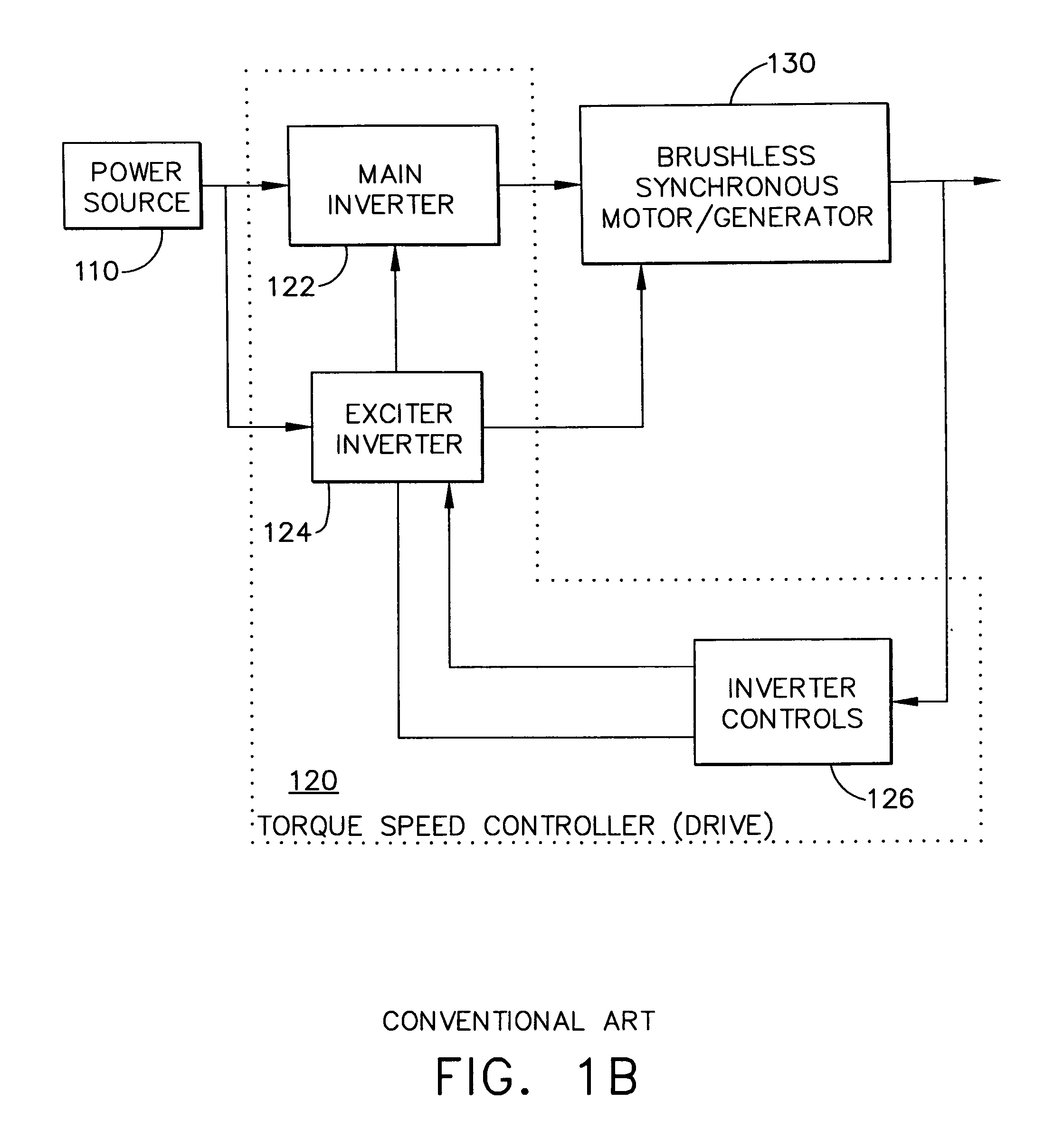

Adaptive position sensing method and apparatus for synchronous motor generator system

An adaptive, sensorless position sensing apparatus (250) derives rotor position of a synchronous machine (200). The apparatus (250) comprises a first rotor position deriving unit (300) for generating first rotor position values by applying a first sensorless rotor position calculation technique, which emulates a resolver; a second rotor position deriving unit (400) for generating second rotor position values by applying a second sensorless rotor position calculation technique; and a rotor position result output unit (450) for outputting rotor position results over a range of rotor speeds as a function of the first rotor position values, the second rotor position values, and rotor speed.

Owner:HONEYWELL INT INC

Digital adaptive sensorless commutational drive controller for a brushless DC motor

InactiveUS7030582B2Commutation monitoringSynchronous motors startersVoltage polarityElectrical polarity

Devices and methods for controlling brushless, sensorless DC motors are disclosed. In one embodiment, an electrical motor is provided with a rotor, a stator, and a semiconductor on insulator (SOI) application-specific integrated circuit (ASIC). The ASIC is configured to energize stator windings in a commutational sequence to drive the rotor. A motor controller embodiment is provided with a set of comparators and a clocked digital circuit. Each comparator determines a voltage polarity on a respective stator winding. The clocked digital circuit receives polarity signals from the comparators and detects zero crossings having an expected crossing direction, which are then used to determine a commutational sequence for energizing stator windings. A method embodiment is provided for driving DC motor windings. One method embodiment includes: receiving polarity signals, measuring intervals, and advancing a commutation state.

Owner:HALLIBURTON ENERGY SERVICES INC

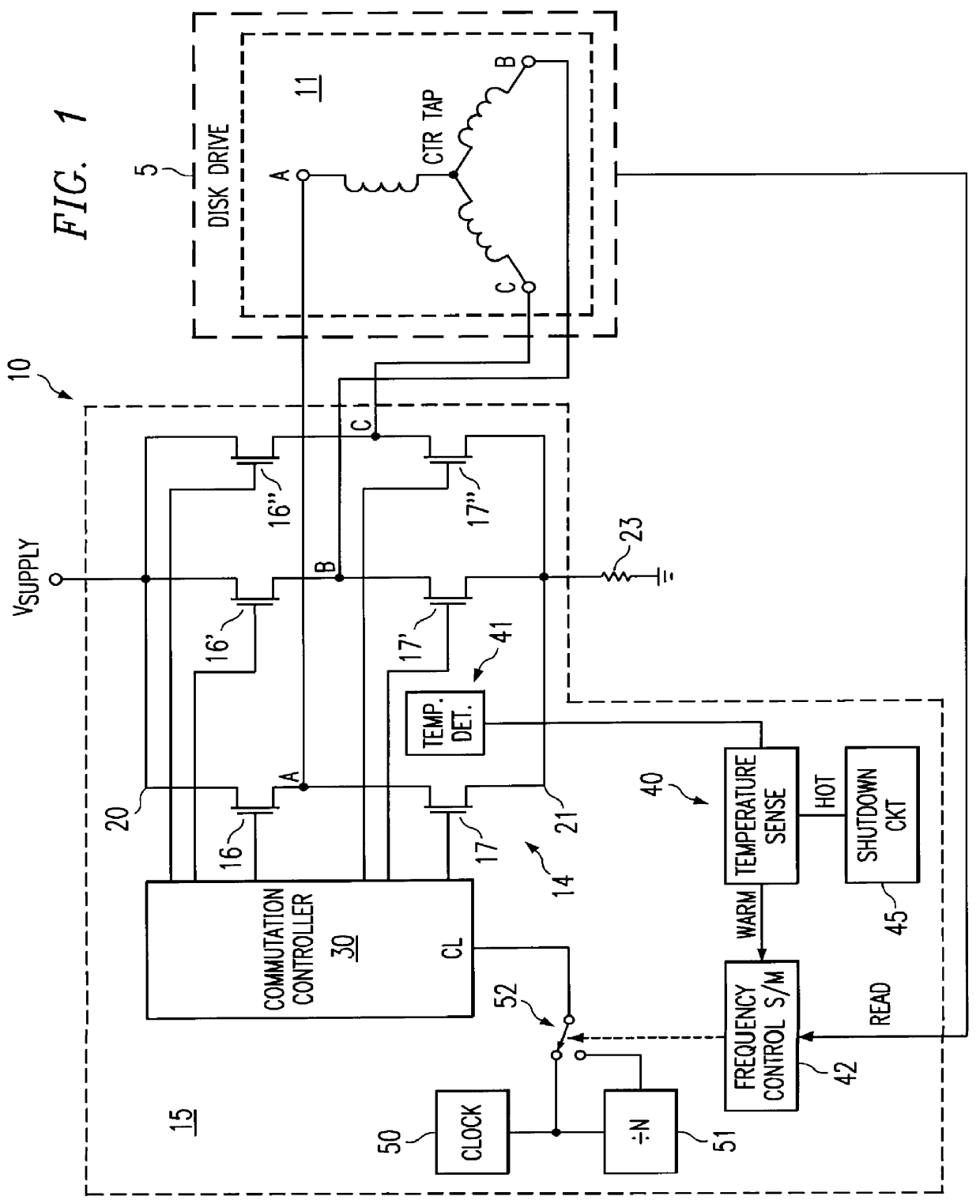

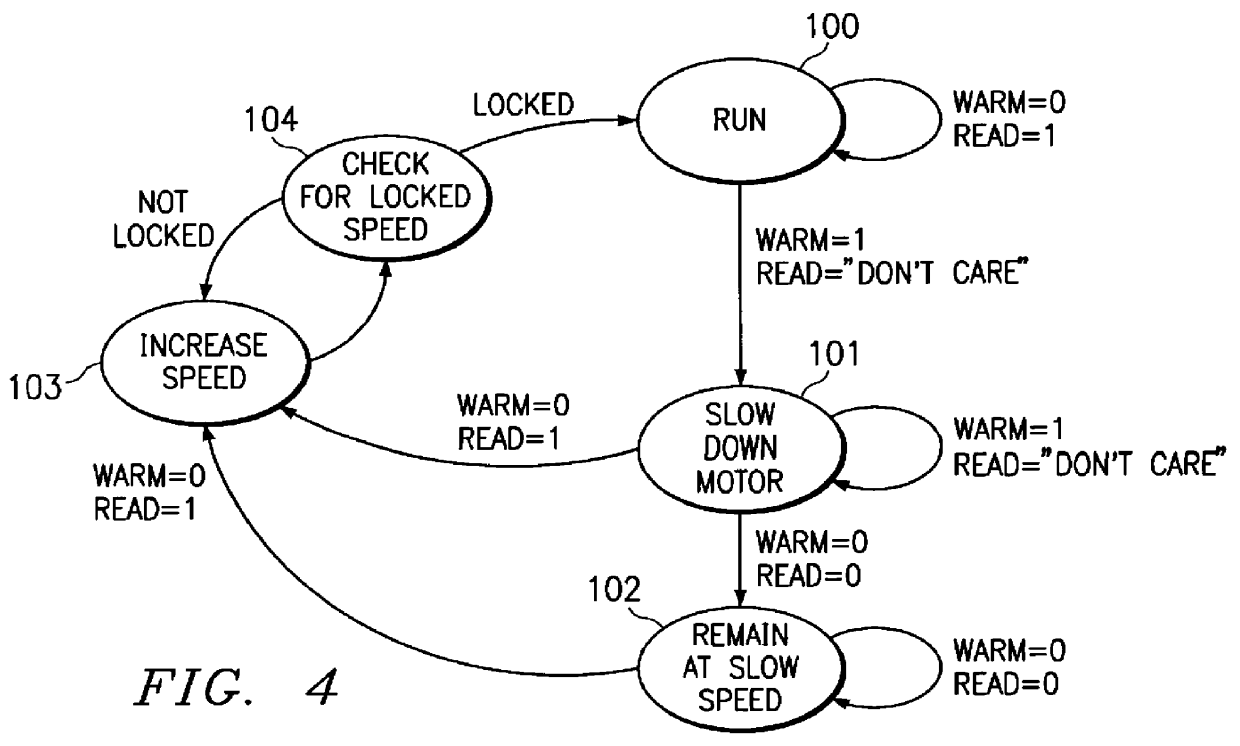

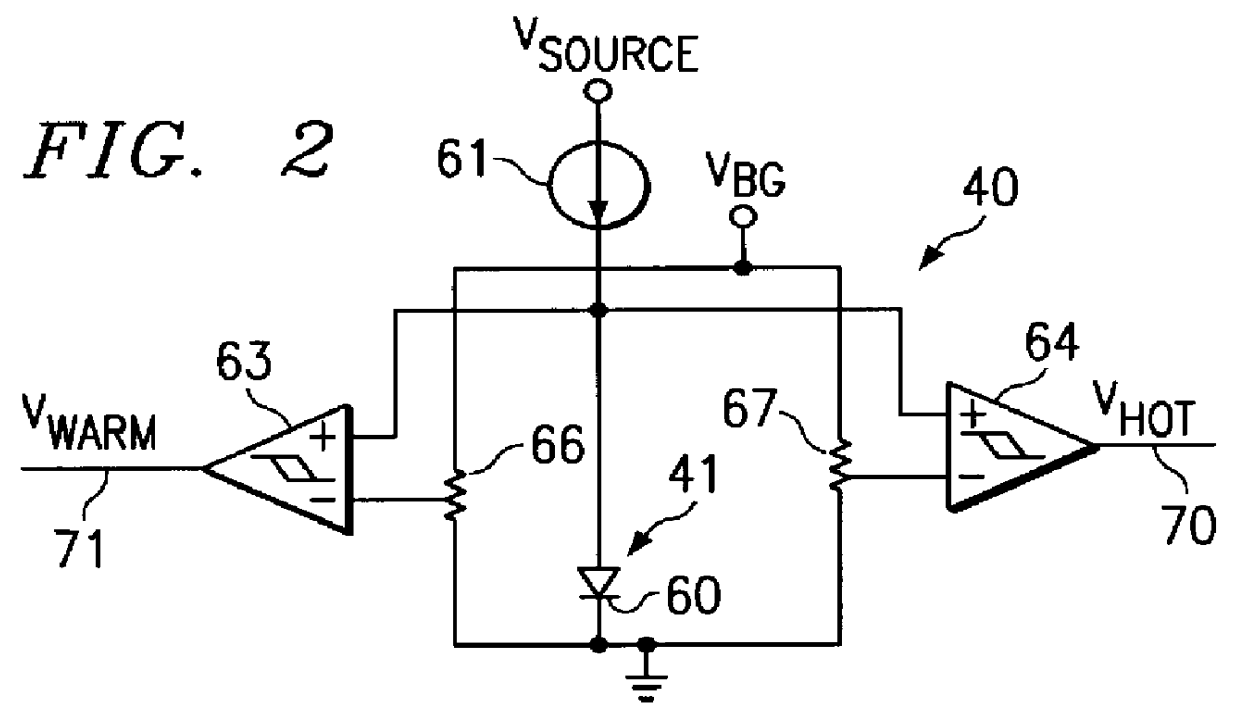

Overtemperature warning cycle in operation of polyphase DC motors

A method and integrated circuit for providing drive signals to a polyphase dc motor. The integrated circuit is fabricated on a semiconductor substrate for providing drive signals to a polyphase dc motor. The circuit includes a coil drive circuit for connection to drive coils of the motor to selectively supply drive currents thereto in a predetermined sequence. A sequencer circuit commutatively selects the drive coils to which the drive currents are selectively supplied, and a motor, speed controlling circuit controls the speed of the motor by controlling the speed of commutation. A temperature sensing element, such as a diode, is fabricated in the substrate to indicate the temperature of the substrate, and a temperature measuring circuit is connected to the temperature sensing element and to the motor speed controlling circuit to operate the motor speed controlling circuit to slow the speed of the motor when the temperature of the substrate exceeds a first predetermined temperature. If desired, temperature measuring circuit can include a circuit for measuring a second temperature higher than the first predetermined temperature to operate a shut down circuit to turn off the motor if the substrate temperature is too high.

Owner:STMICROELECTRONICS SRL

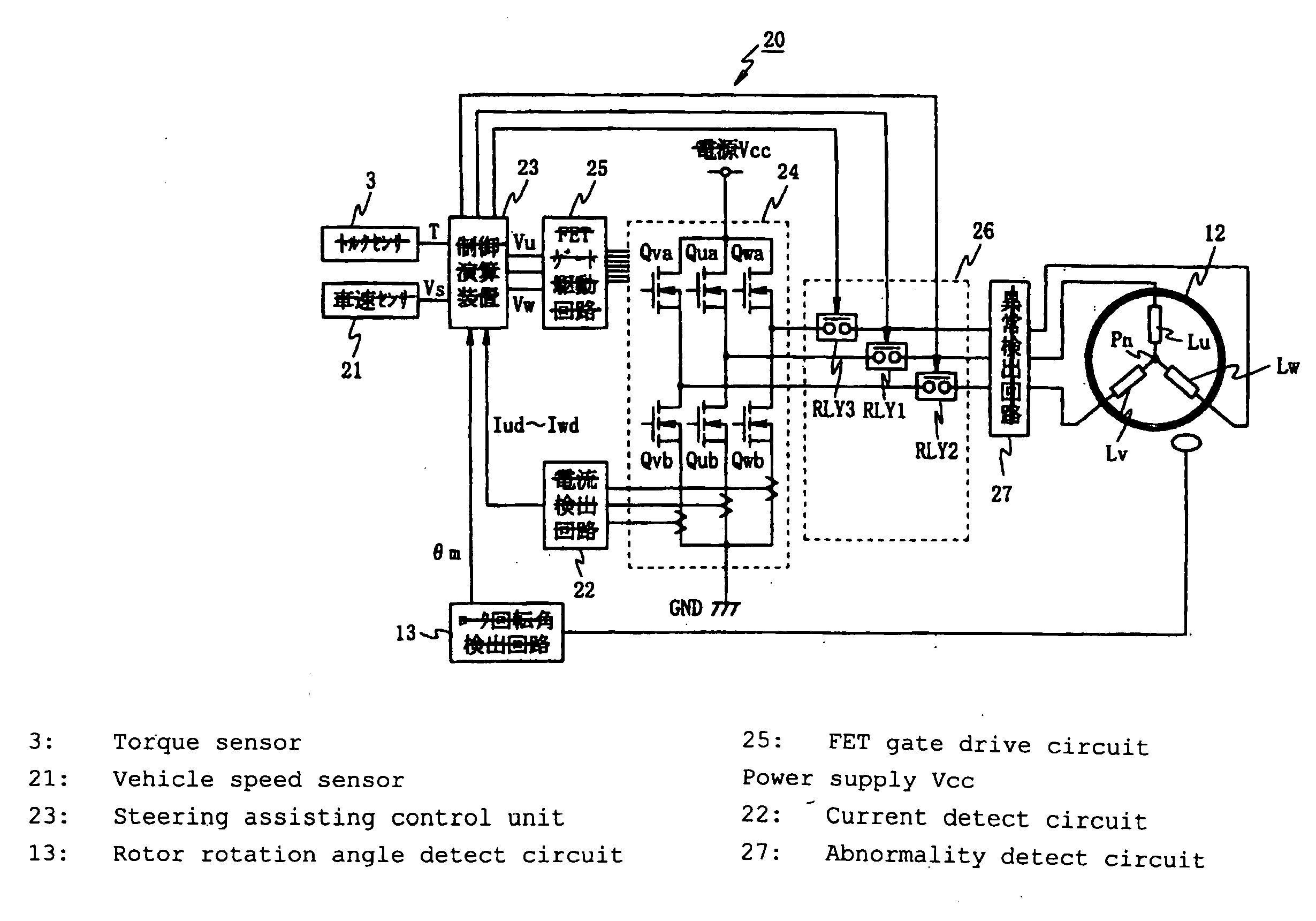

Electric power steering apparatus

InactiveUS20100017063A1Reduce loadCommutation monitoringDigital data processing detailsPhase currentsElectric power steering

An electric power steering apparatus in which the intensity and directions of drive currents flowing in remaining phases continues motor rotation driving. An abnormality detect unit (27) detects a conduction abnormality in drive systems for the respective phase coils of the 3-phase brushless motor (12). A steering assisting current command value calculating unit (31) calculates a steering assisting current command value. A normal time motor command value calculating unit (33) calculates three phase current command values according to the steering assisting current command value. An abnormal time motor command value calculating unit (34) calculates two phase current command values for using the two remaining phase coils. A command value select portion (35) selects the phase current command values calculated by the normal or abnormal time motor command value calculating unit. A motor control unit (36) drives the electric motor (12) according to the selected phase current command value.

Owner:NSK LTD

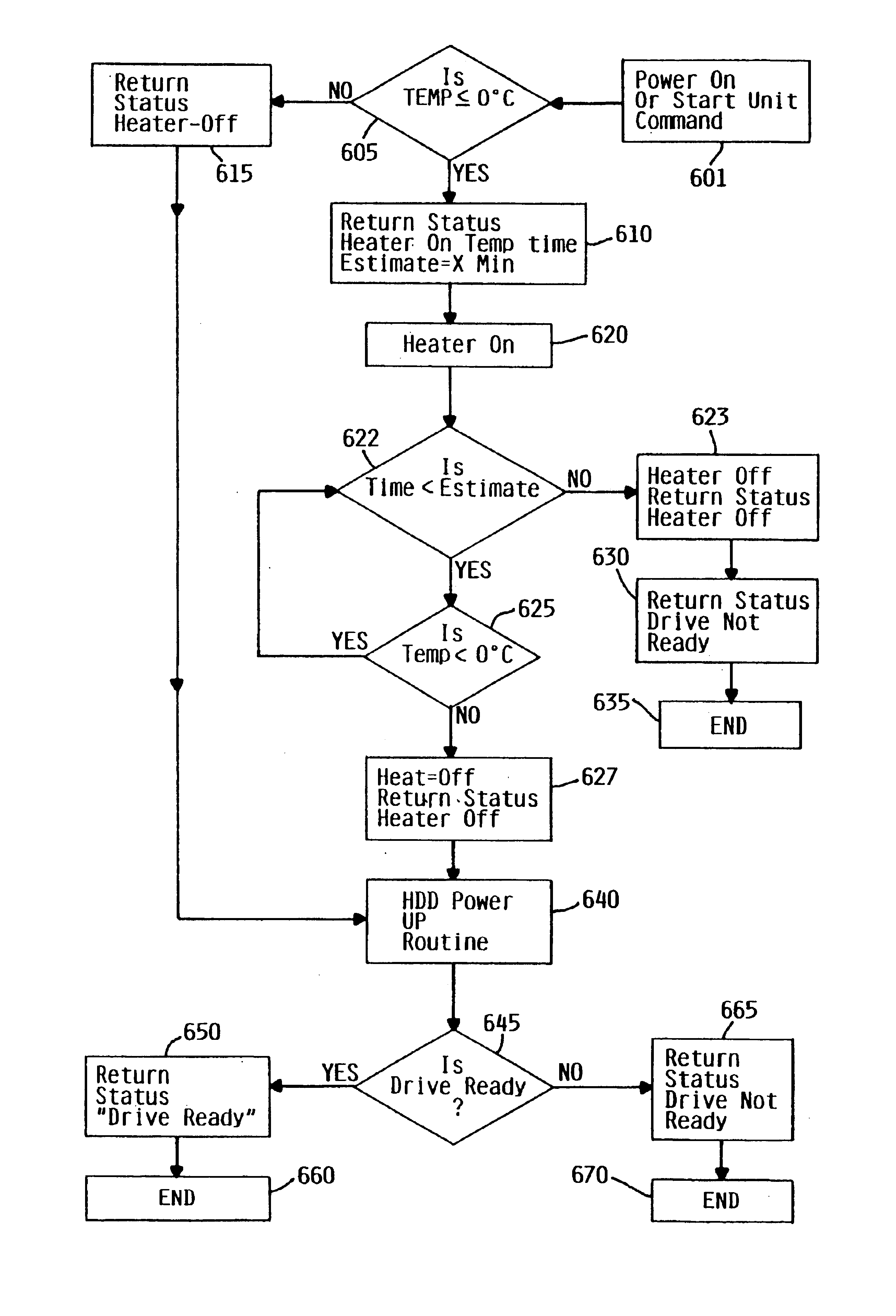

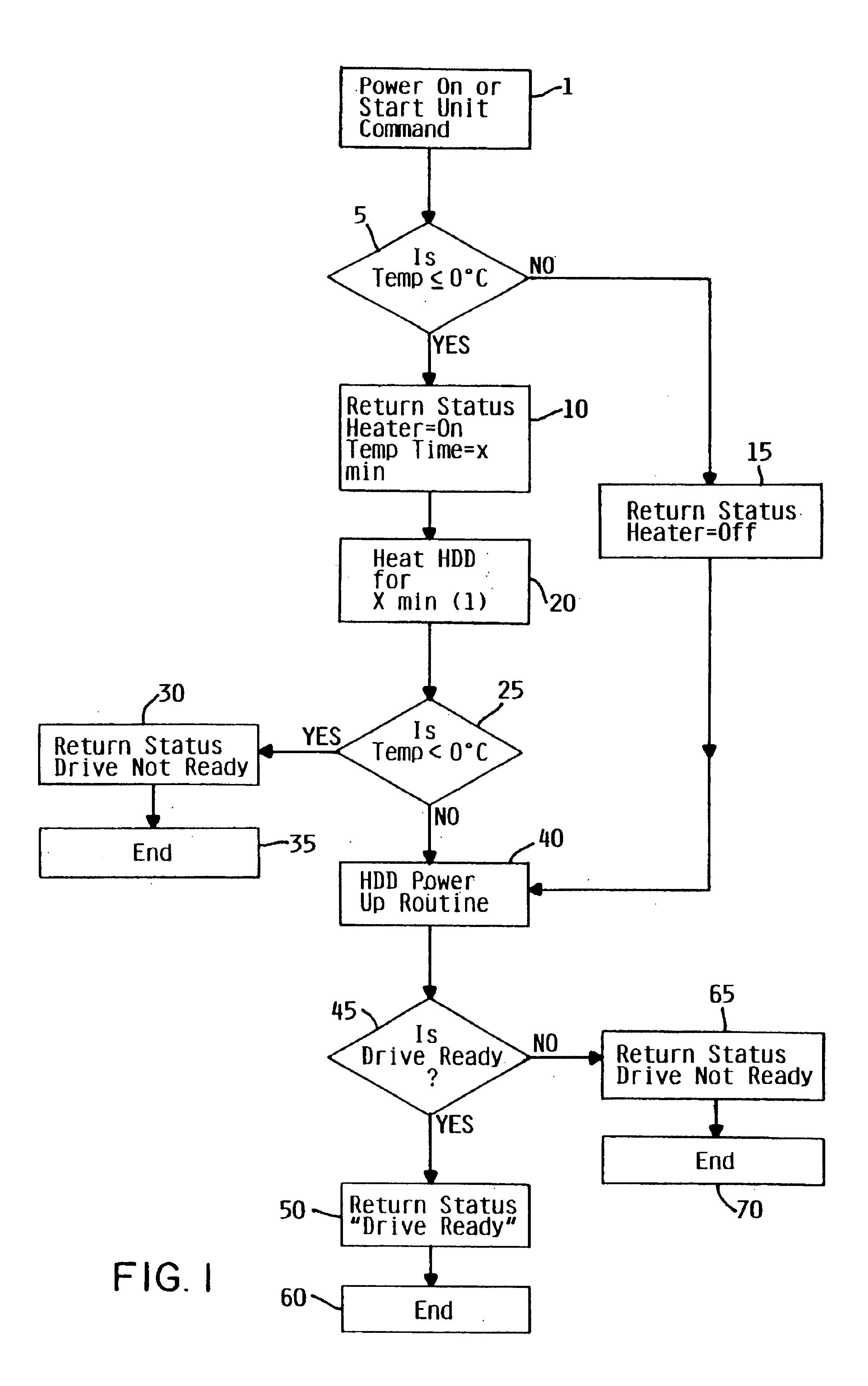

Method and apparatus for enabling cold temperature performance of a disk

InactiveUS6735035B1High torqueHigh viscosityCommutation monitoringApparatus for flat record carriersDirect-access storage deviceEngineering

In cold weather, the higher torque required for normal spinning operation of a spindle motor assembly in a direct access storage device due to the increased viscosity of the grease, is overcome by localizing the heating to the spindle motor assembly to reduce the viscosity of the grease, and then let a disk driven self heat during and after spin-up of the spindle motor assembly.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

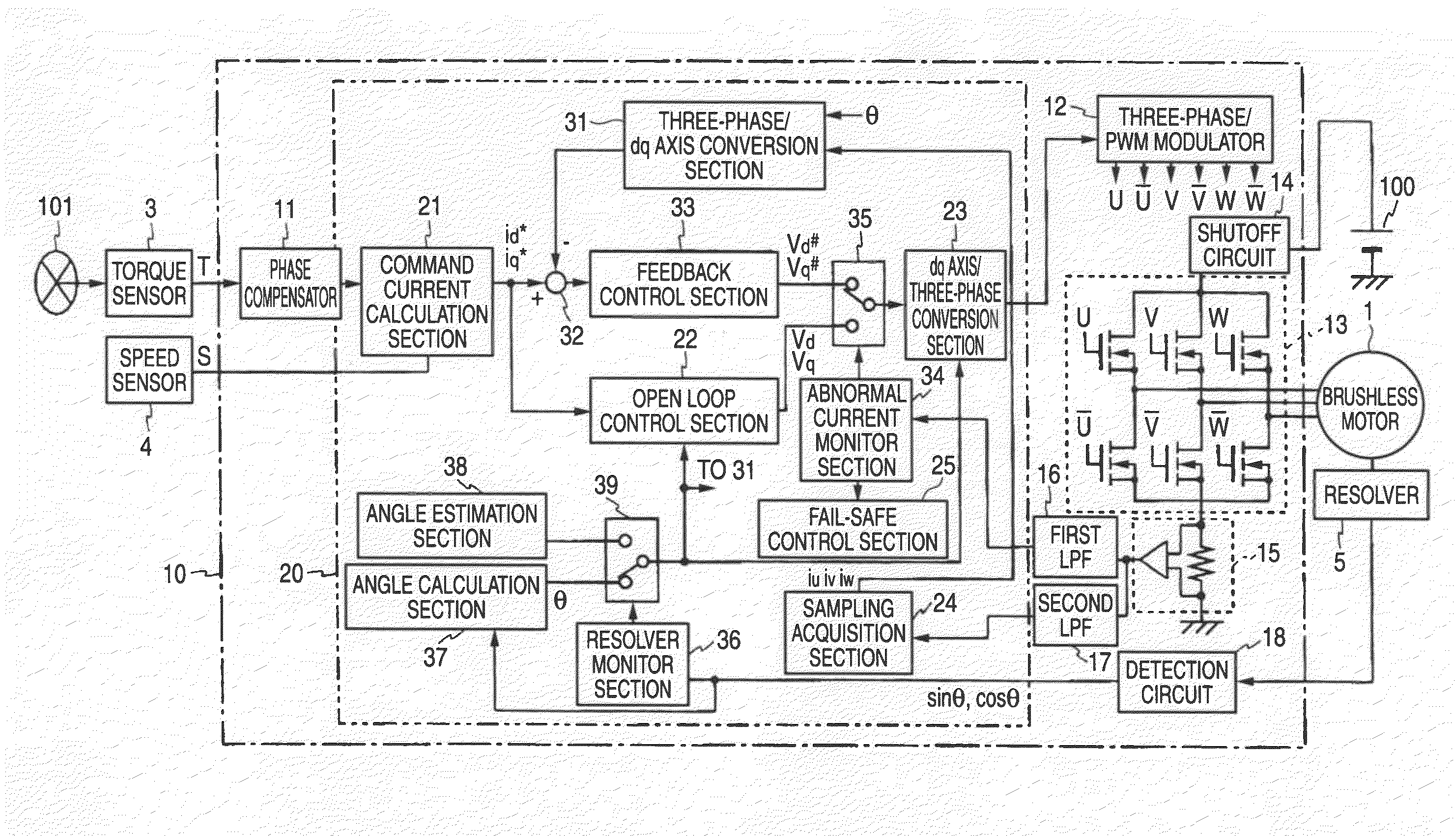

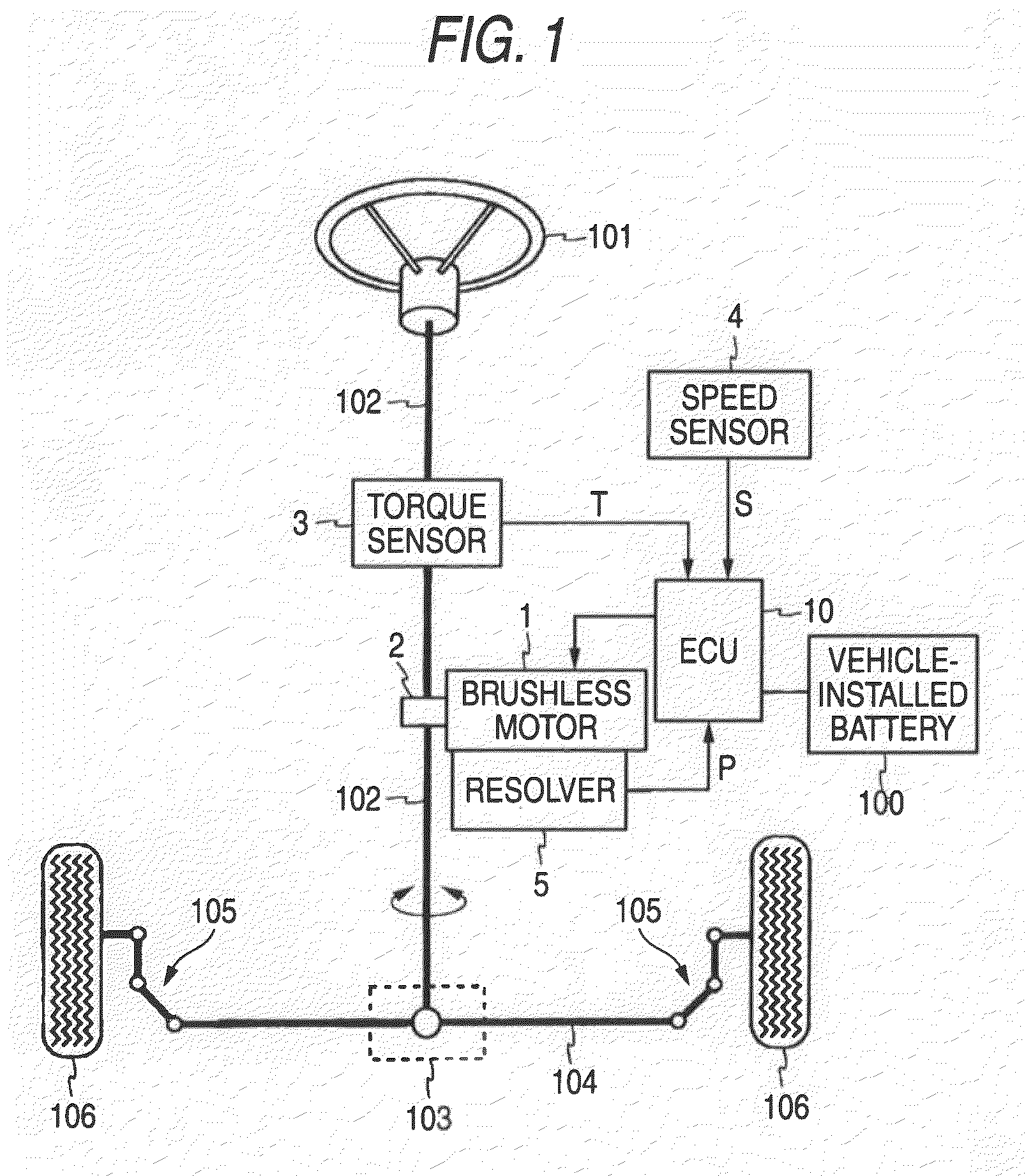

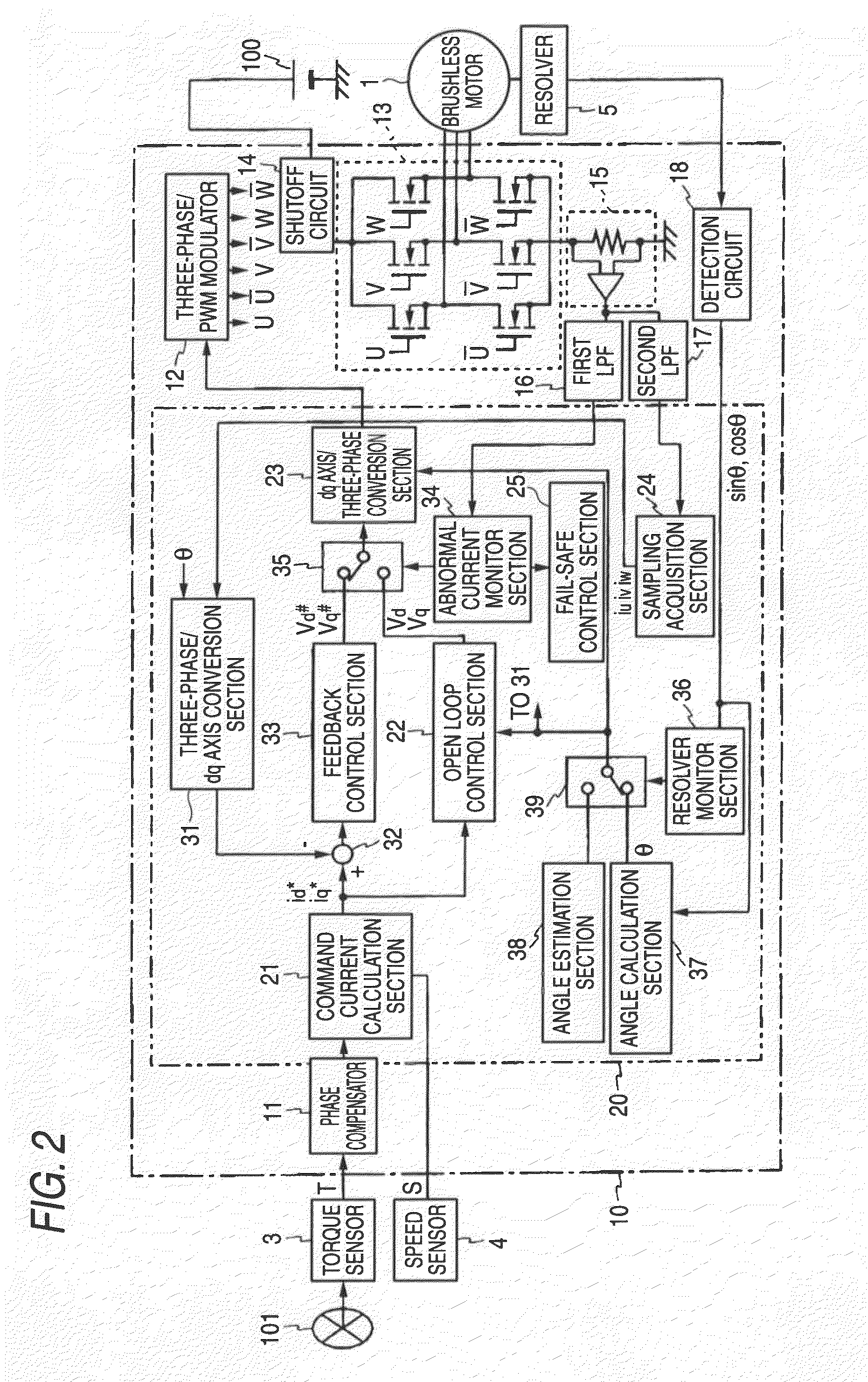

Motor controller and electric power steering system

InactiveUS20090079373A1Lower cutoff frequencySafe steering assistingCommutation monitoringAC motor controlElectric power steeringMicrocomputer

A current sensor of a motor controller detects the current applied to a motor drive circuit and thus a phase where a failure cannot be detected would occur without taking any measures. However, an abnormal current monitor section contained in a microcomputer receives a voltage signal of an average value of the currents detected in the current sensor by allowing a signal to pass through a first LPF having a cutoff frequency sufficiently lower than the frequency of a PWM signal. Therefore, whether or not the value is within a predetermined normal range is checked, whereby whether or not some failure containing a failure of the current sensor occurs can be easily determined about every phase.

Owner:JTEKT CORP

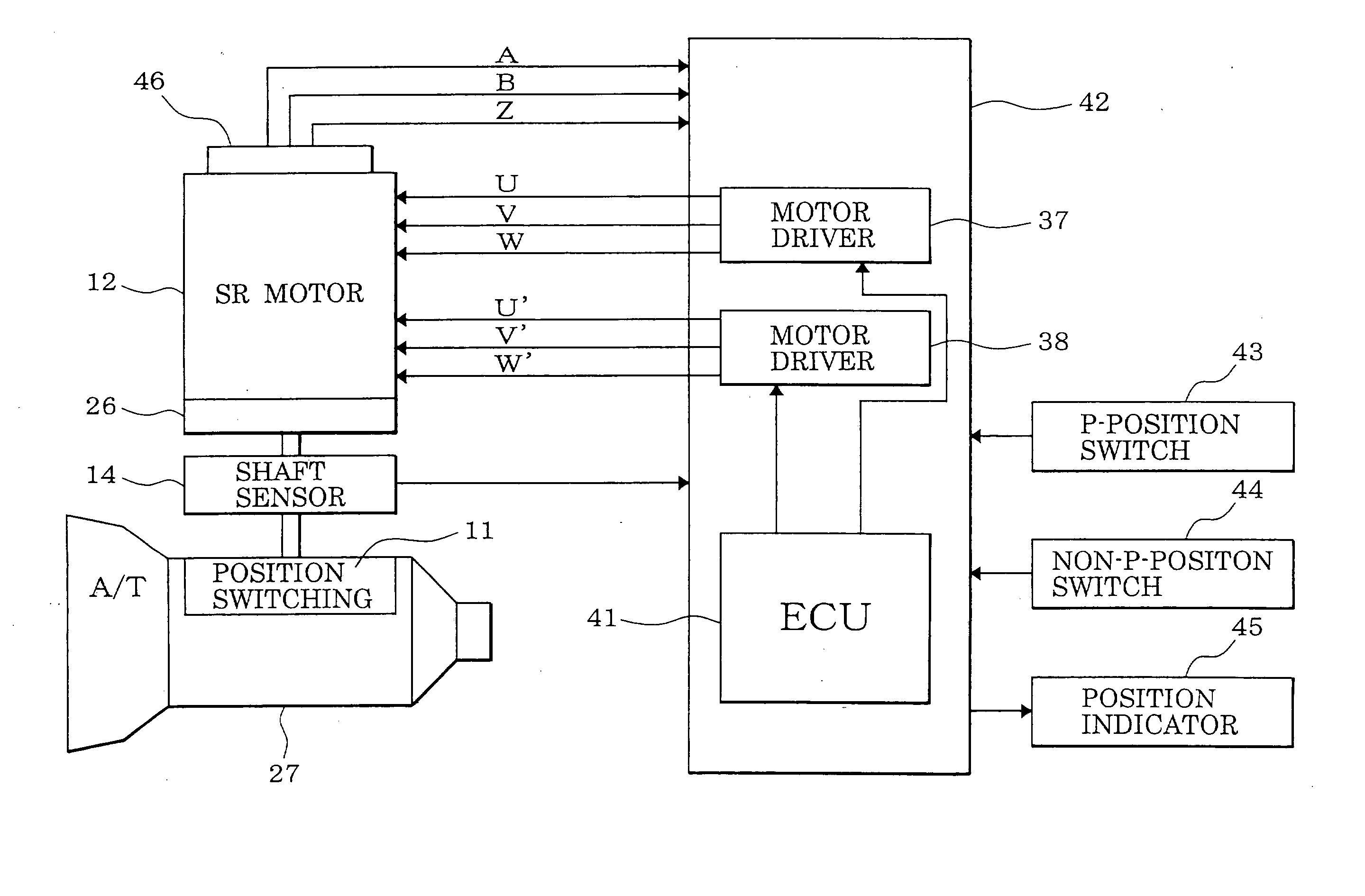

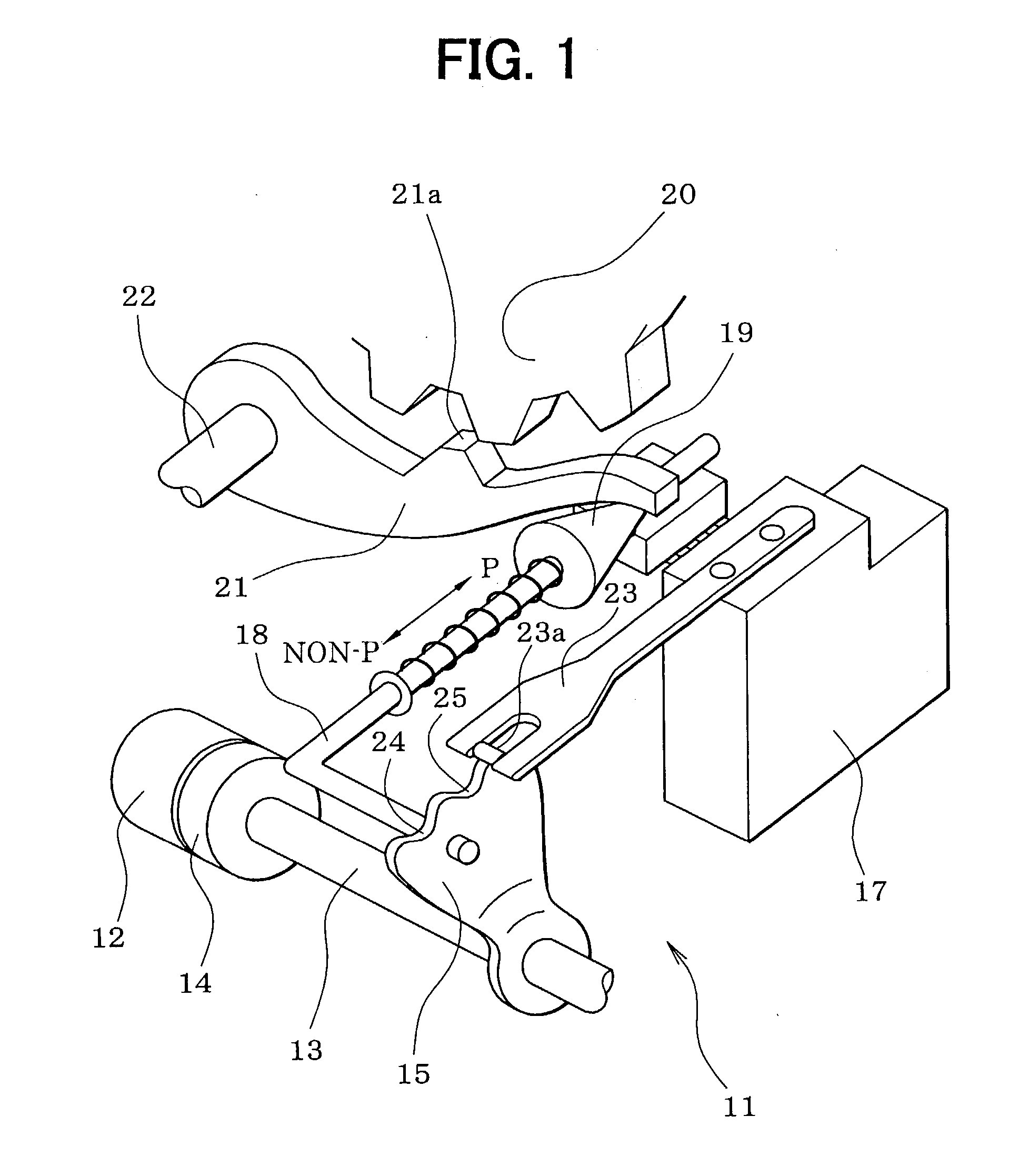

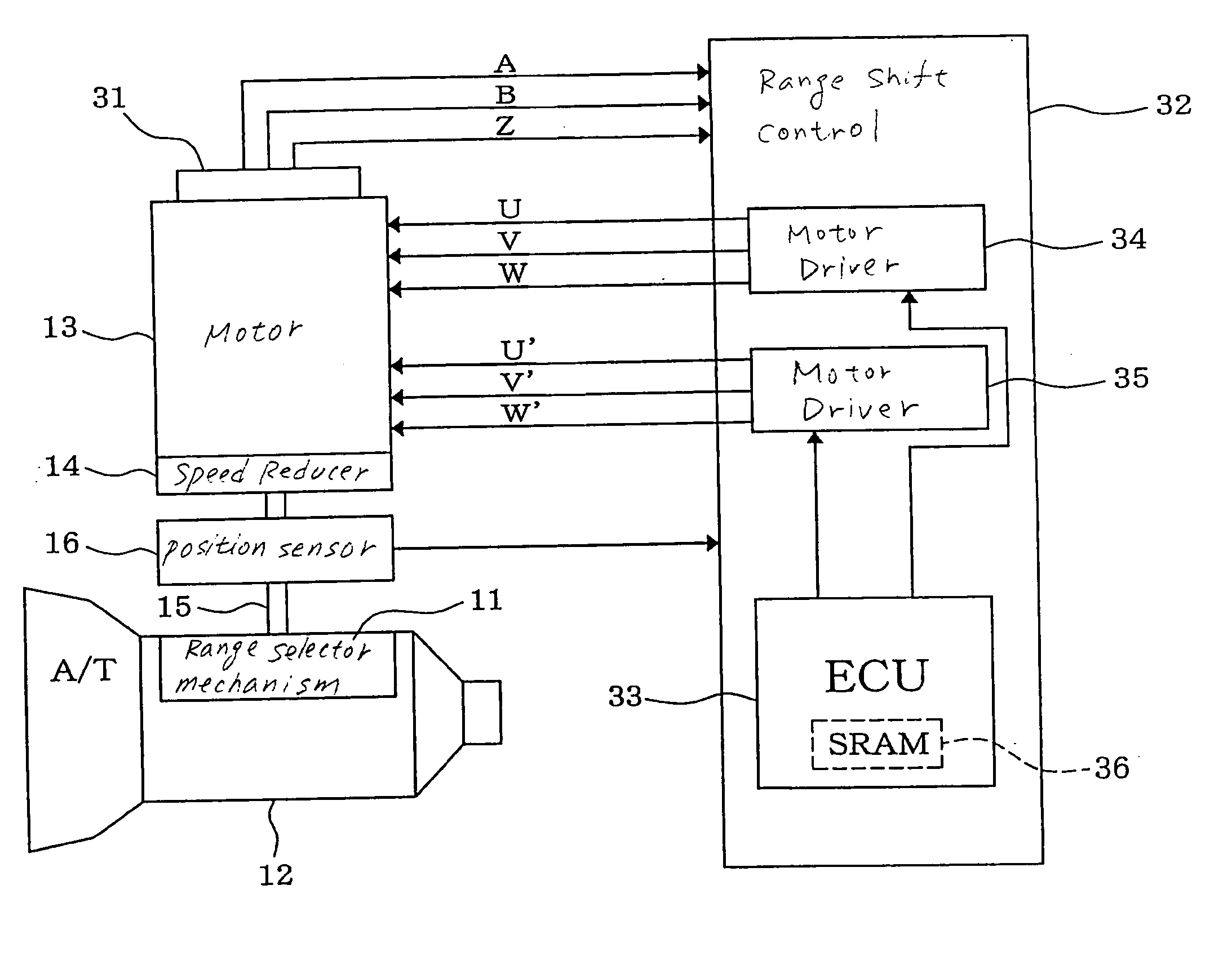

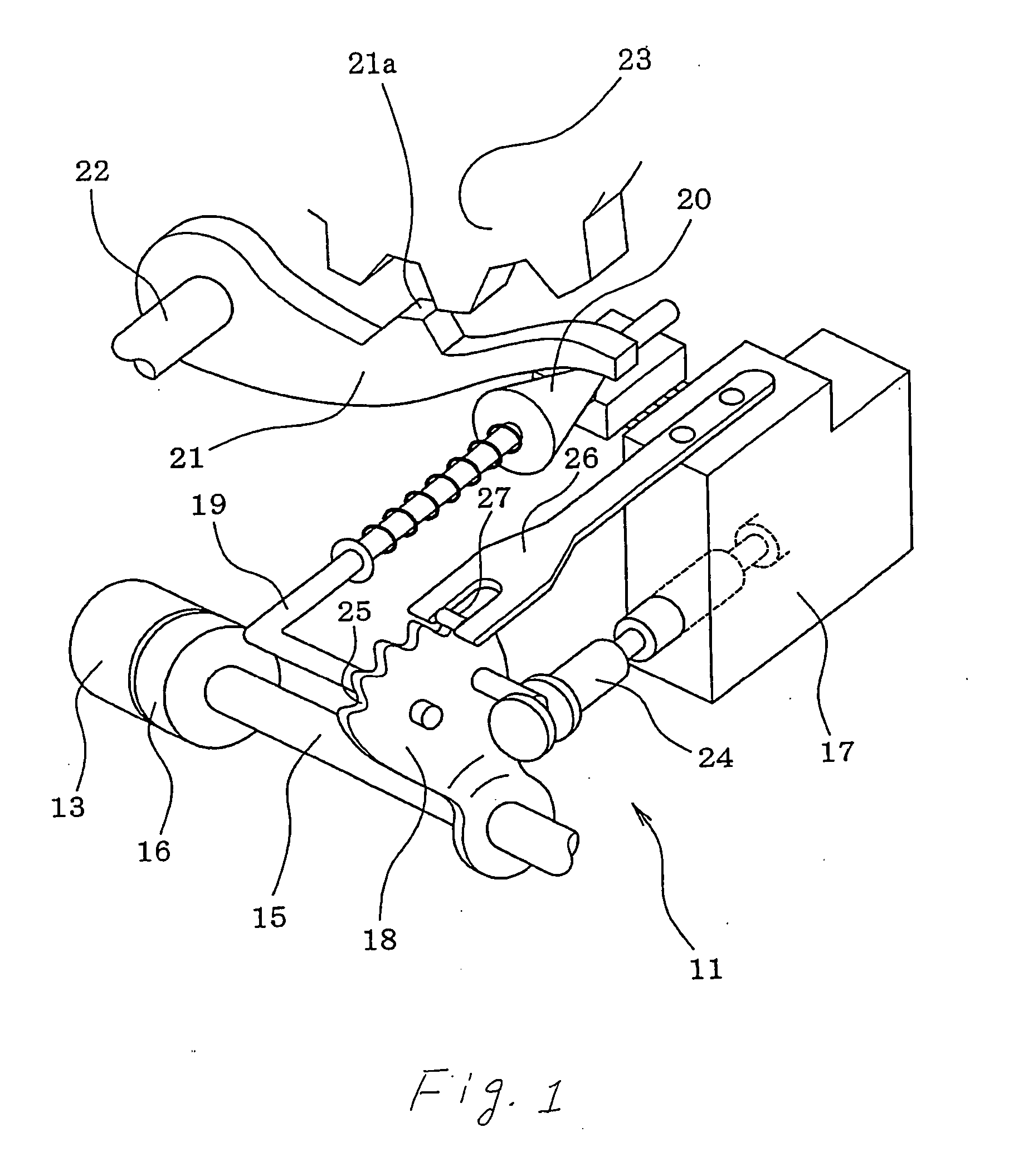

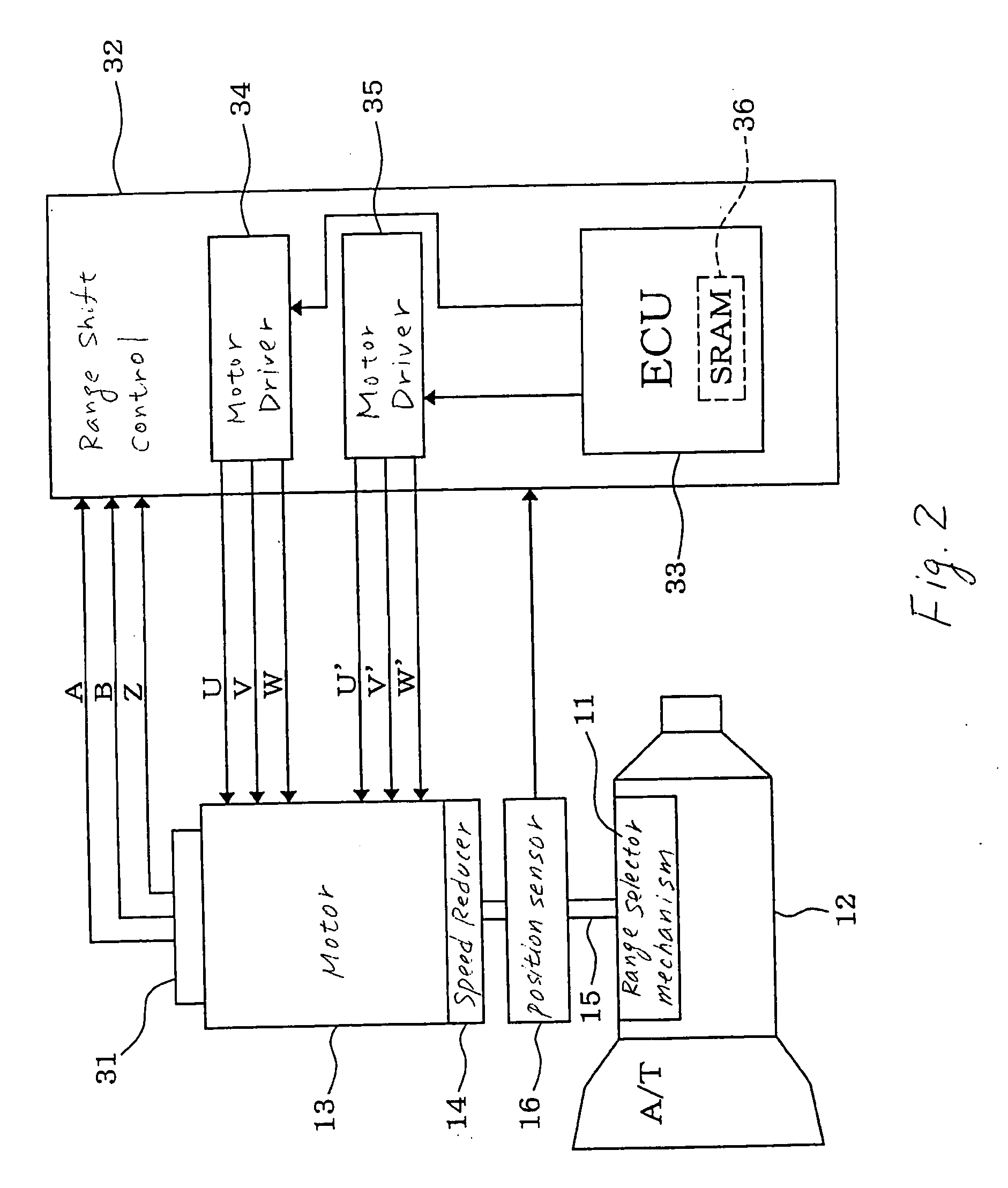

Failure monitor for motor drive control system

ActiveUS20050156550A1Avoid disadvantagesCommutation monitoringDigital data processing detailsAxis–angle representationMotor drive

A failure monitor designed to monitor a failure in operation of a motor drive control system. The system works to drive a motor-driven member through an output shaft and an electric motor and includes an output shaft angular position sensor for determining an angular position of the output shaft and an encoder for determining an angular position of the motor for use in controlling the motor. The system works to discriminate among failures in operation of the output shaft angular position sensor and the encoder and another type of a failure using outputs of the sensors.

Owner:DENSO CORP

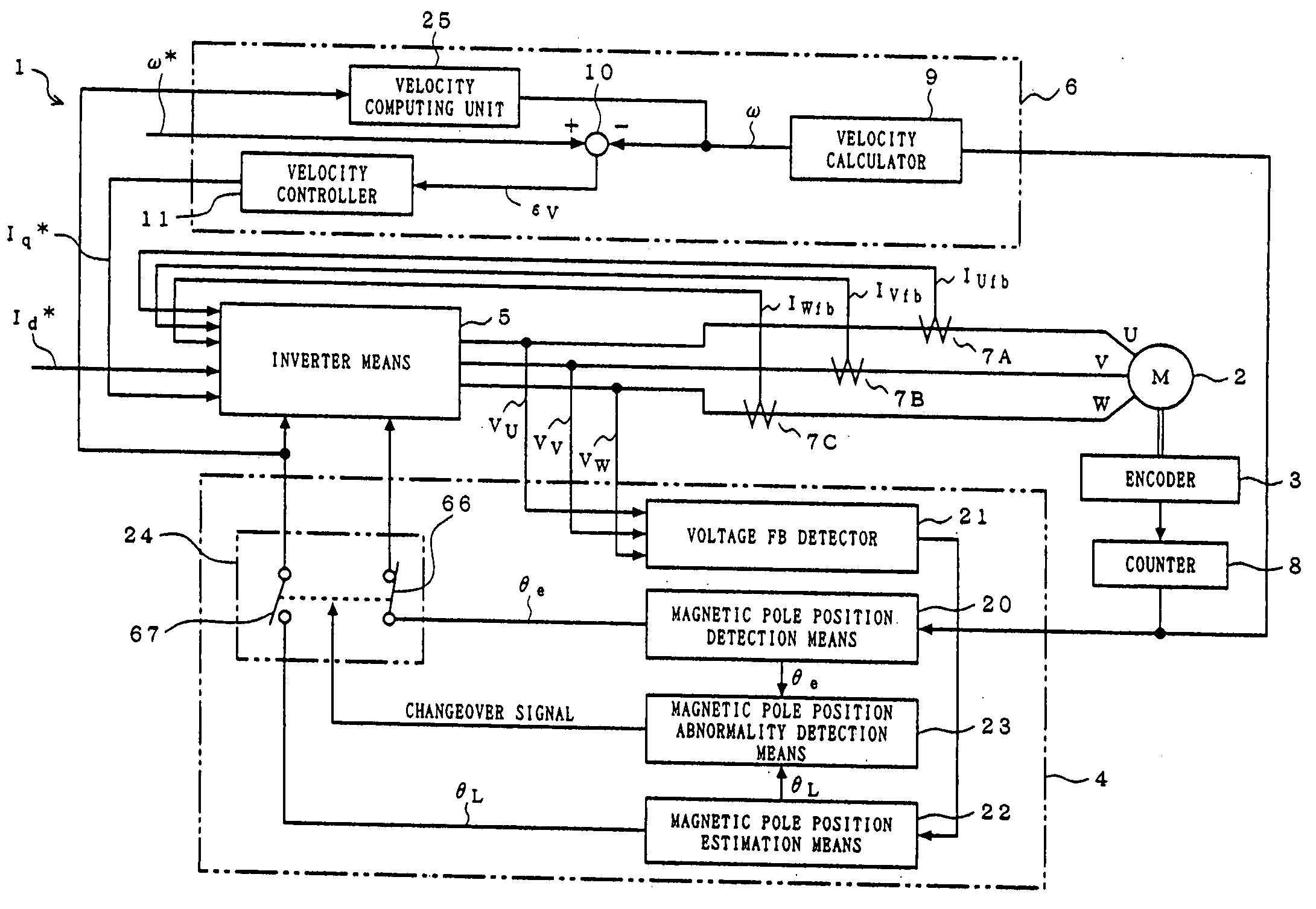

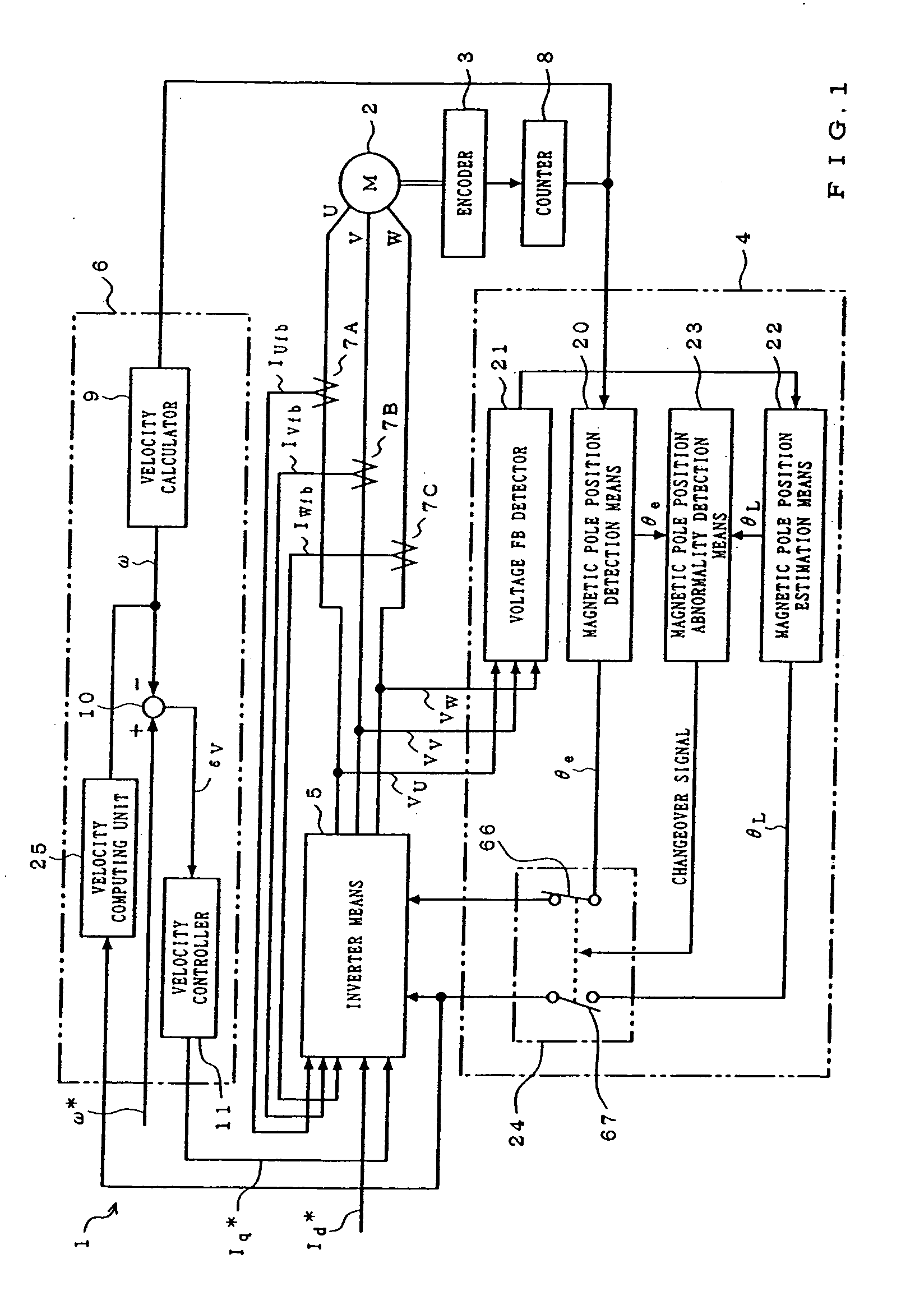

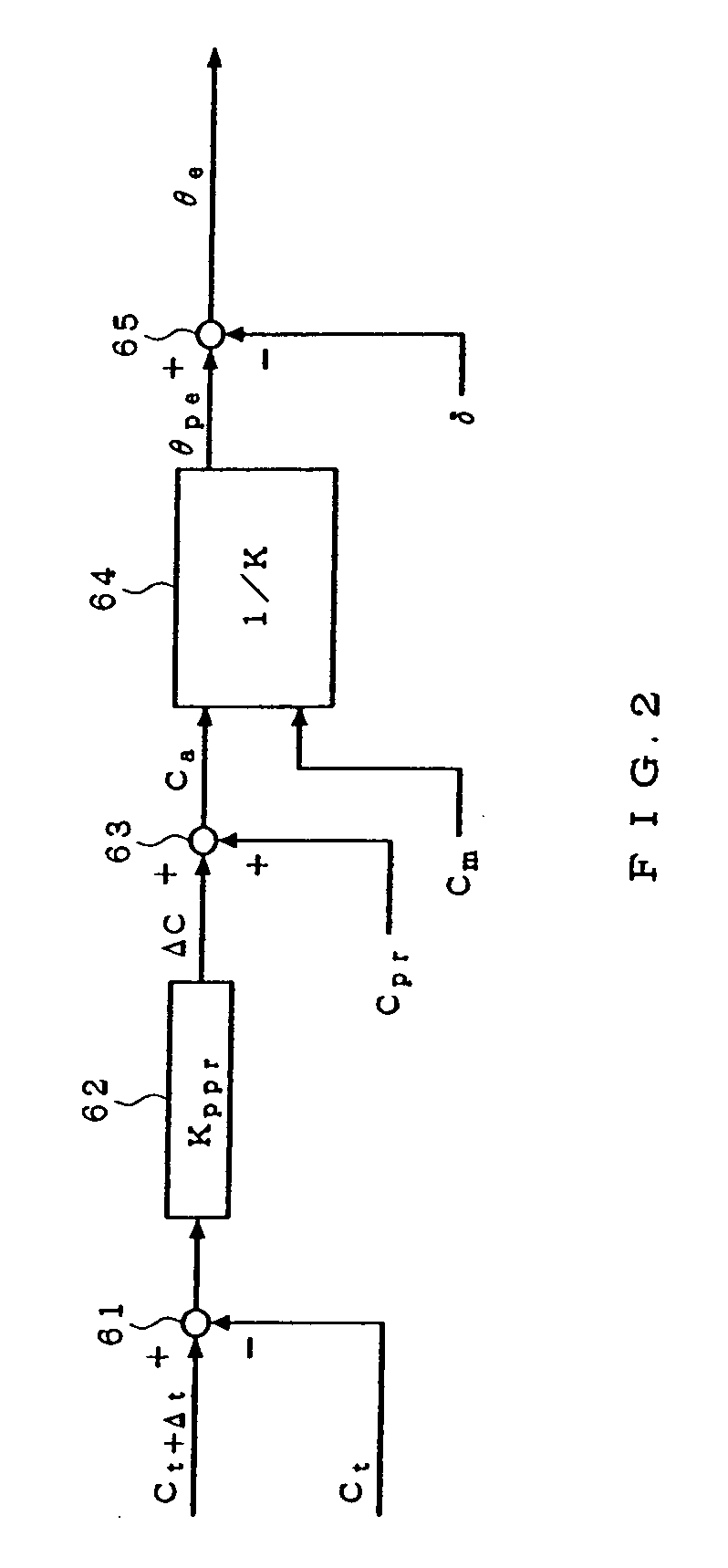

Motor Controller

InactiveUS20040257027A1Commutation monitoringSynchronous motors startersSynchronous motorMagnetic poles

A motor controller is provided. This motor controller comprises, a synchronous motor, a feed back detector which is mounted on the synchronous motor and detects the position and velocity of the rotor of the synchronous motor, magnetic pole position detection means for detecting an magnetic pole position of the rotor of the synchronous motor, inverter means for controlling an electric power to be supplied to the synchronous motor according to the magnetic pole position detected by the magnetic pole position detection means, magnetic pole position estimation means for estimating the magnetic pole position of the rotor of the synchronous motor from the induced voltage of the stator windings of the synchronous motor, and magnetic pole position abnormality detection means for detecting the abnormality of the feed back detector by always comparing the magnetic pole position detected by the magnetic pole position detection means and the estimated magnetic pole position estimated by the magnetic pole position estimation means.

Owner:ROCKWELL AUTOMATION TECH +1

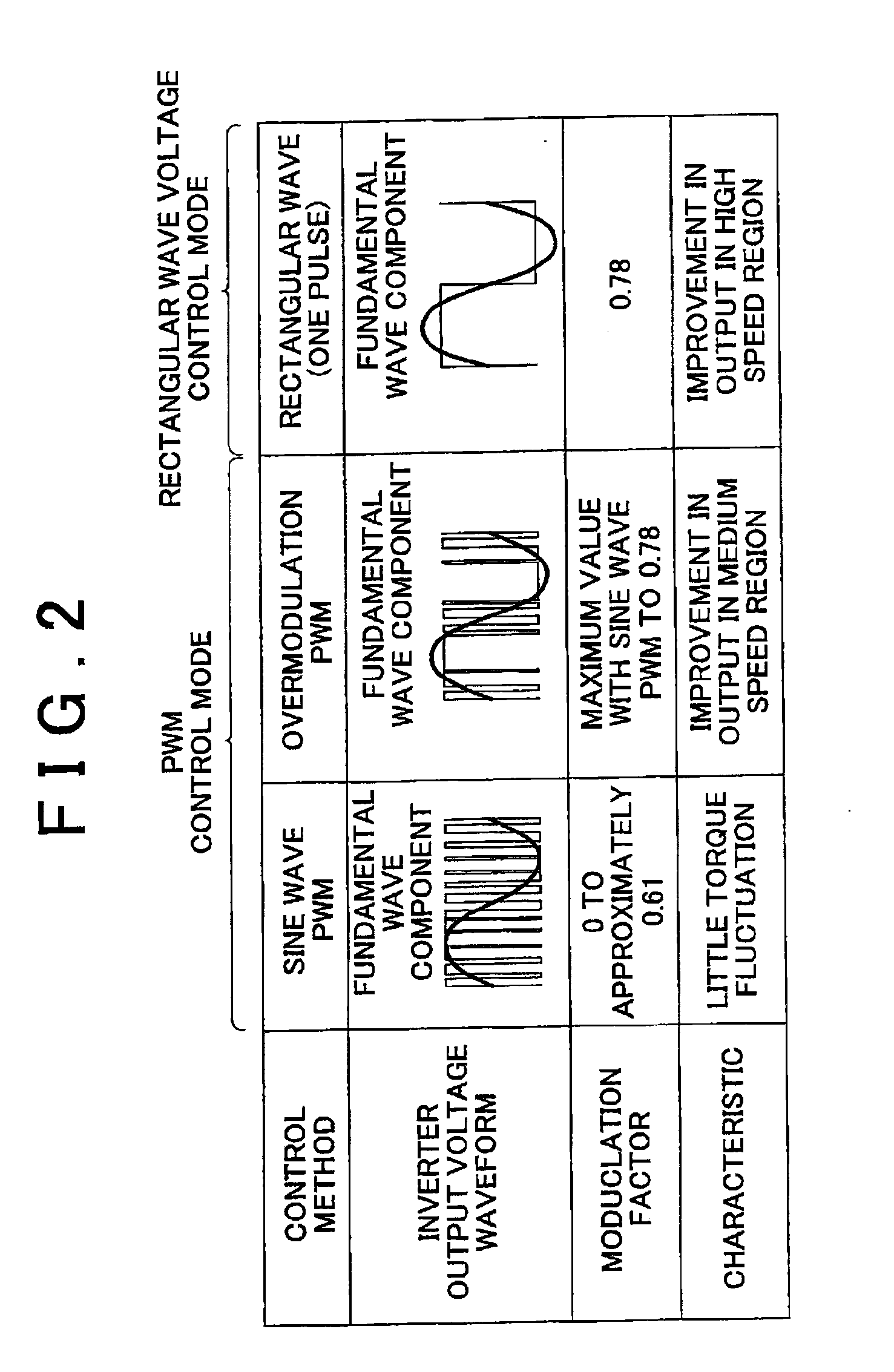

Alternating-current motor control apparatus

ActiveUS20100123418A1Simple structureImprove responsivenessVehicle testingTorque ripple controlPhase currentsCurrent meter

When a rectangular wave voltage control mode is selected, a control apparatus estimates the output torque of an alternating-current motor based on the outputs of a current sensor and a rotation angle sensor, and executes torque feedback control by adjusting the phase of rectangular wave voltage based on the difference between the torque estimated value and a torque command value. The control apparatus executes a switching interruption that outputs a control command to a switching element of an inverter every 60 degrees of electrical angle, and executes an angle interruption that samples the phase currents of the alternating-current motor based on the output of the current sensor and converts those phase currents into a d-axis current and a q-axis current every predetermined electrical angle that is set beforehand. The control apparatus for the alternating-current motor then sets the predetermined electrical angle such that the number of angle interruptions between switching interruptions varies according to the rotation speed of the alternating-current motor.

Owner:TOYOTA JIDOSHA KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com