Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4549 results about "Grease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grease is a semisolid lubricant. Grease generally consists of a soap emulsified with mineral or vegetable oil. The characteristic feature of greases is that they possess a high initial viscosity, which upon the application of shear, drops to give the effect of an oil-lubricated bearing of approximately the same viscosity as the base oil used in the grease. This change in viscosity is called shear thinning. Grease is sometimes used to describe lubricating materials that are simply soft solids or high viscosity liquids, but these materials do not exhibit the shear-thinning properties characteristic of the classical grease. For example, petroleum jellies such as Vaseline are not generally classified as greases.

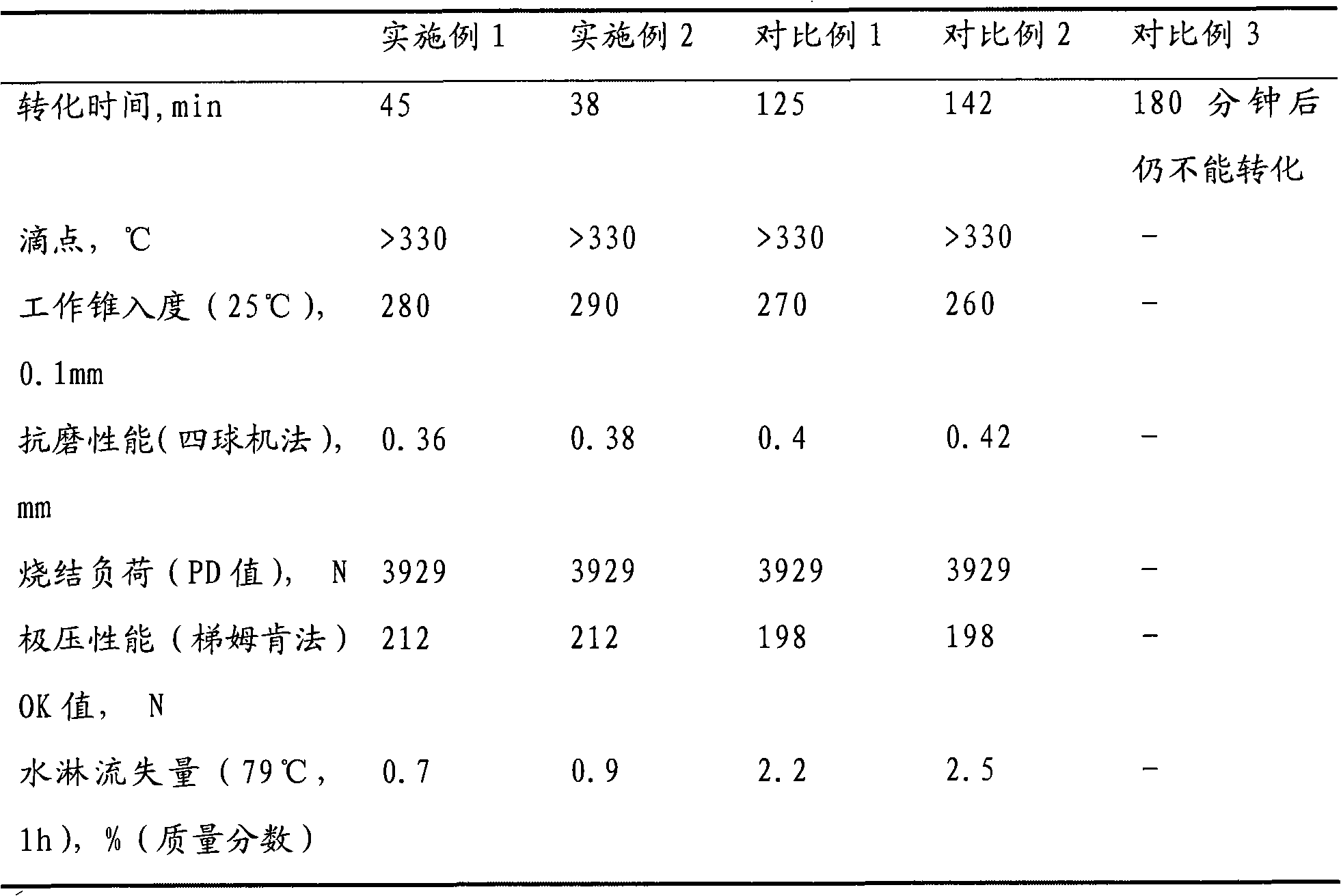

Polyurea grease composite

ActiveCN1657599AImprove extreme pressure and anti-wear performanceGood extreme pressure and anti-wear propertiesThickenersComposition BBase oil

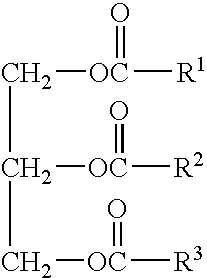

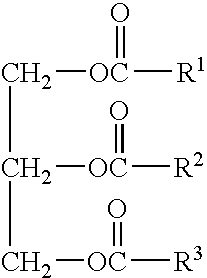

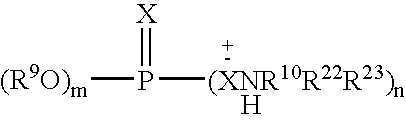

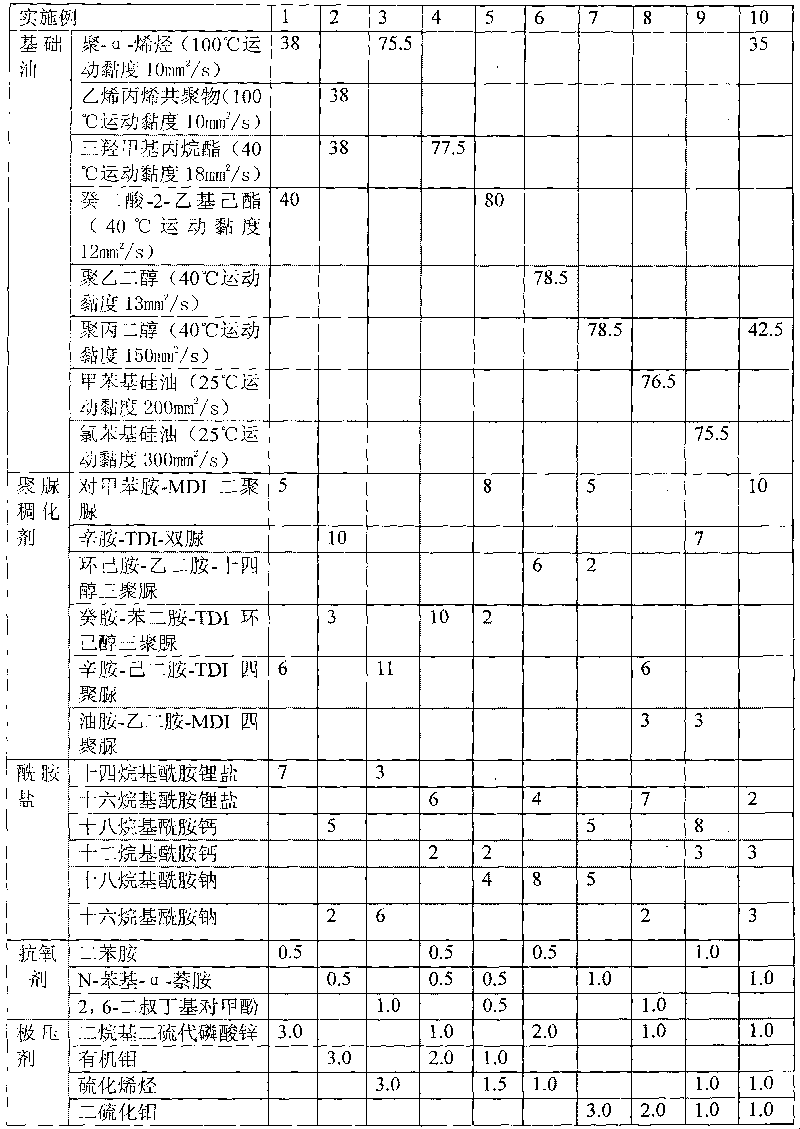

Two lubricating polyurea-ester compositions with high stability and extreme-pressure antiwear performance contain proportionally basic oil, urea-based thickening agent, Ca-based thickening agent and extreme-pressure agent for composition A, or the composition A plus inorganic Ca salt for composition B.

Owner:CHINA PETROLEUM & CHEM CORP +1

Food-grade-lubricant

InactiveUS20040241309A1Increase varietyExtend compassBase-materialsFood preparationGeneral purposePolyolefin

The present invention discloses an improved food-grade-lubricant useful as hydraulic oil, circulating oil, drip oil, general purpose oil, grease base oil, cable oil, chain oil, spindle oil, gear oil, and compressor oil for equipment in the food service industry. The lubricant comprises at least one vegetable oil, at least one polyalphaolefin, and at least one antioxidant. The lubricant has improved properties when subjected to thermal and mechanical stress.

Owner:RENEWABLE LUBRICANTS INC

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

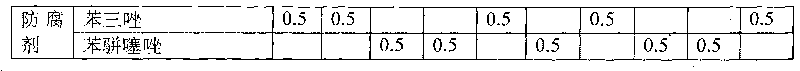

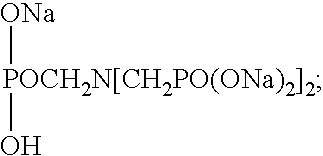

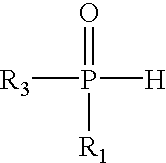

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

Detergent compositions for the removal of complex organic or greasy soils

InactiveUS6506261B1Less corrosive propertyEasy to cleanNon-ionic surface-active compoundsOrganic detergent compounding agentsHydrotropeLaundry

Organic compositions, used neat or in concentrate, are effective in removing complex organic soils from wood, metal and other hard surfaces. The compositions comprise nonionic surfactants, silicone surfactants, anionic surfactants, hydrotropes and other optional functional materials including sequestrants. Substrates such as laundry and heavily soiled hard surfaces containing a substantial proportion of organic / inorganic soils such as greases, oils and other hard to remove soil materials are readily cleaned by the cleaner compositions of the invention.

Owner:ECOLAB USA INC

Detergent compositions for the removal of complex organic or greasy soils

InactiveUS6425959B1Easy to cleanOrganic detergent compounding agentsNon-ionic surface-active compoundsHydrotropeLaundry

Organic compositions, used neat or in concentrate, are effective in removing complex organic soils from wood, metal and other hard surfaces. The compositions comprise nonionic surfactants, silicone surfactants, hydrotropes and other optional functional materials including sequestrants. Substrates such as laundry and heavily soiled hard surfaces containing a substantial proportion of organic / inorganic soils such as greases, oils and other hard to remove soil materials are readily cleaned by the cleaner compositions of the invention.

Owner:ECOLAB USA INC

Lubricating grease and preparation method thereof

ActiveCN103060070ADrop point highGood colloidal stabilityLubricant compositionBall bearingBoiling point

The invention relates to lubricating grease, comprising 40-95 wt% of lubricating base oil, 1-59 wt% of a compound zirconium-based thickening agent and 1-59 wt% of a tetrapolyurea, wherein the compound zirconium-based thickening agent is a compound zirconium sceps formed by reacting a higher aliphatic acid, an aromatic acid and water with zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the steps of performing a first contact reaction on the zirconium alkoxide, the higher aliphatic acid and the aromatic acid in the lubricating base oil at a temperature of 60-120 DEG C; then performing a second reaction on the obtained mixture from the first contact reaction with water at a temperature of 85-100 DEG C; and heating the obtained product from the second reaction for dehydration; and then introducing the tetrapolyurea in the obtained reaction product. The lubricating grease has relatively high boiling point, presents excellent colloid stability and has good extreme pressure antiwear property and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano calcium carbonate-containing calcium sulfonate complex grease and production method thereof

InactiveCN101993767AImprove thermal stabilityImprove extreme pressure and anti-wear performanceLubricant compositionMetallurgyPhysical chemistry

The invention relates to nano calcium carbonate-containing calcium sulfonate complex grease and a production method thereof. The grease comprises the following components in percentage by weight: 10 to 40 percent of high base-value calcium alkylbenzenesulfonate, 50 to 85 percent of base oil, 1 to 10 percent of nano calcium carbonate, 0.5 to 5 percent of boric acid, 0.5 to 5 percent of saturated fatty acid with 12 to 22 carbon atoms, 0.1 to 5 percent of anti-oxidant additive and 1 to 5 percent of composite transformation accelerator HBS. The grease and the production method have the advantages that: a nano calcium carbonate material is added into the formula of the calcium sulfonate complex grease for the first time, so that the thermal stability and extreme pressure wearing resistance of the ordinary calcium sulfonate complex grease are enhanced and a preparation and operation process is simplified. Simultaneously, the composite transformation accelerator is adopted, so that transformation speed and transformation rate are increased and production cost is lowered.

Owner:WUXI HUIYUAN PACKAGING TECH +1

Compositions and methods for releasing adherent deposits from surfaces and substrates

InactiveUS6929702B1Detergent solventsOrganic non-surface-active detergent compositionsWaxShoe polish

Compositions and methods for release of adherent deposits from surfaces and substrates are provided. The compositions are low volatile organic compound (low VOC) compositions, solutions or mixtures. Adherent deposits removed using the compositions include grease and oil, shoe polish, crayons, candle wax, gum, lipstick, stickers, adhesives, tape and others. The compositions may be used on any surface or substrate including carpet, fabrics, metals, painted surfaces (oil and latex), wallpapers and plastics, without harming the surface or substrate.

Owner:STONER

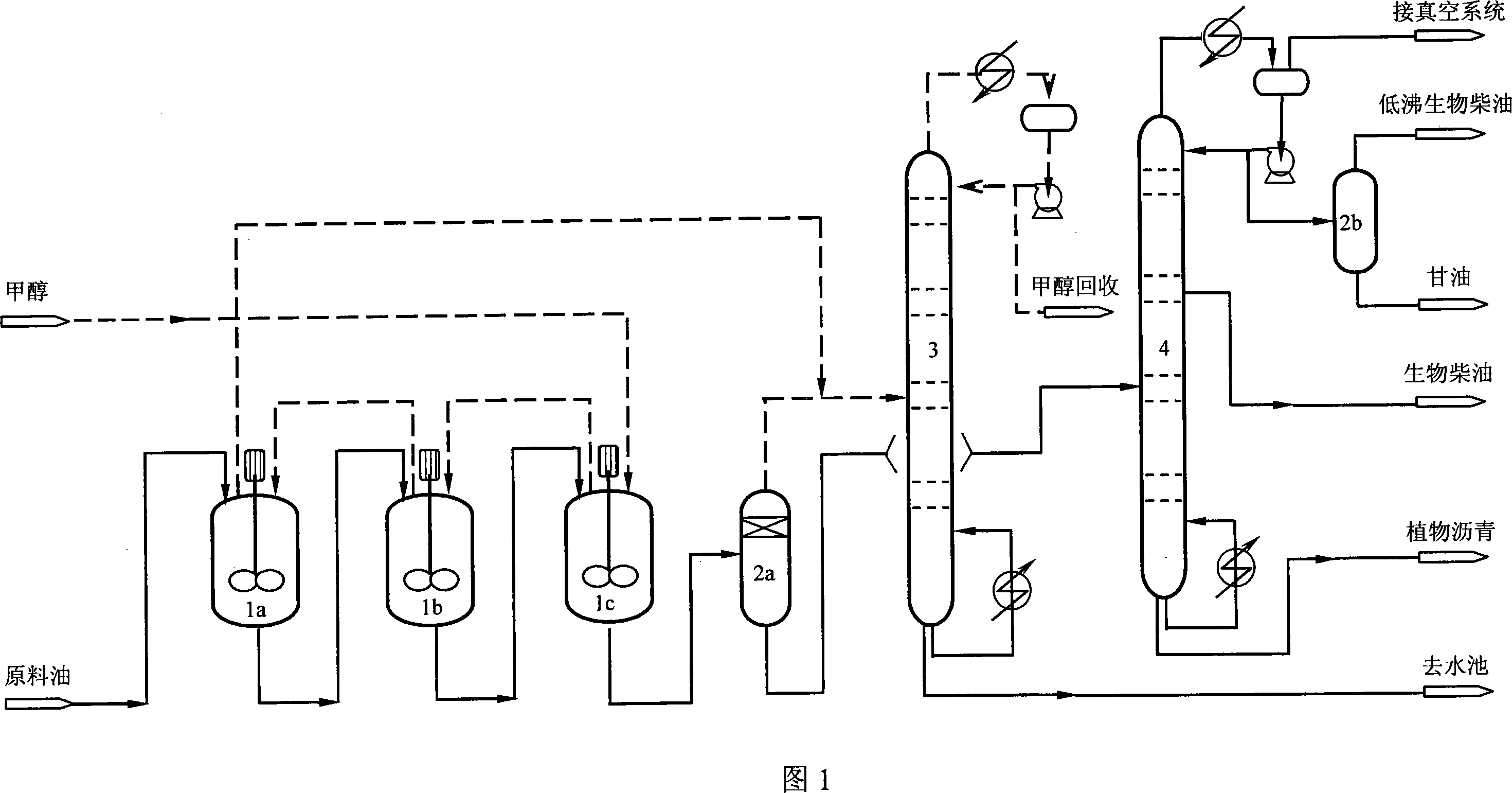

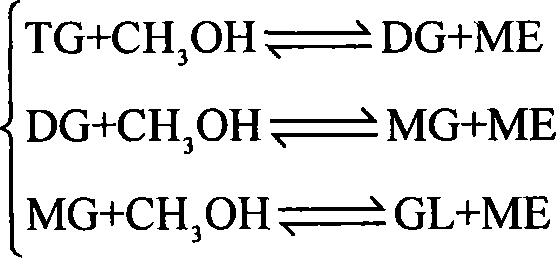

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091AHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

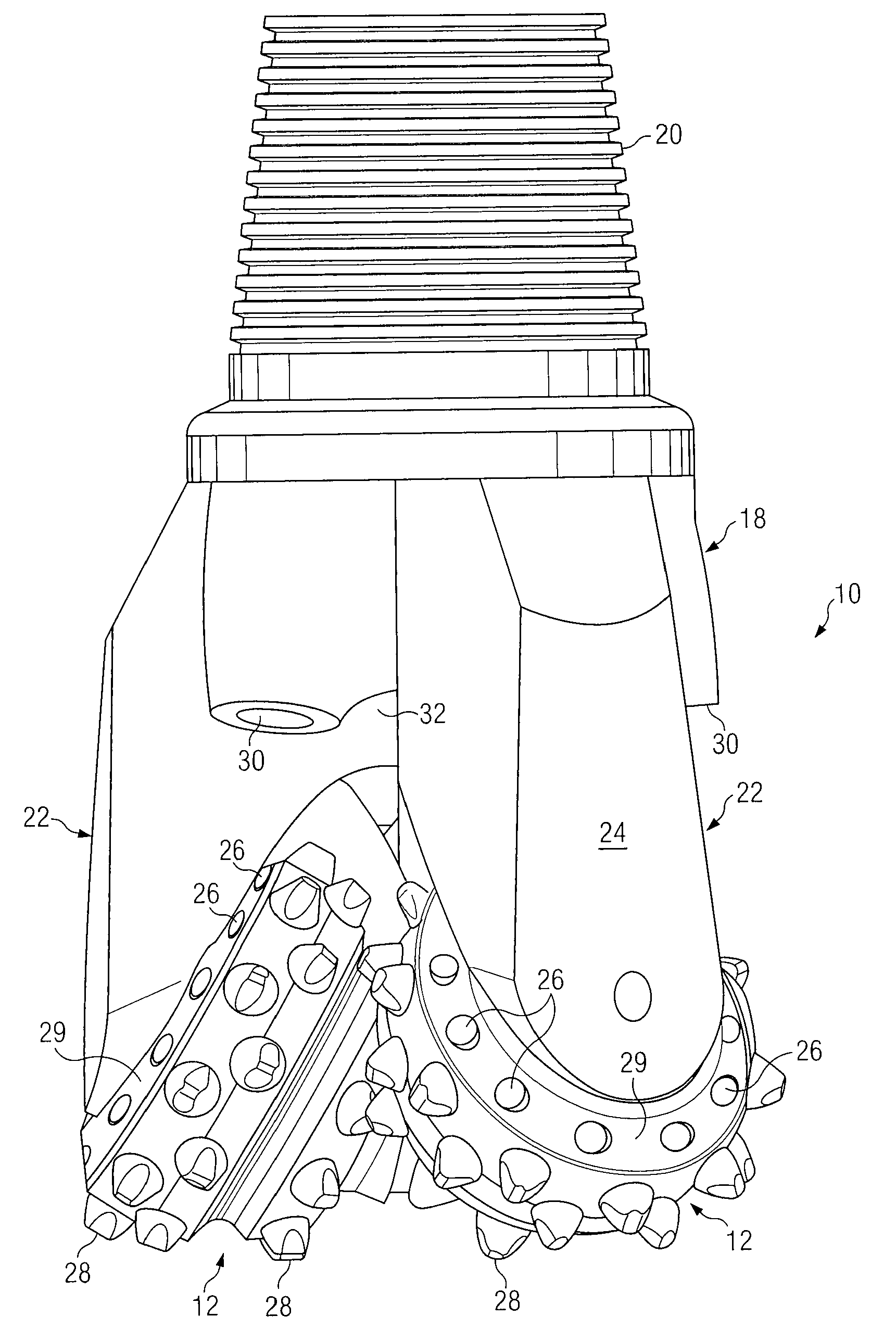

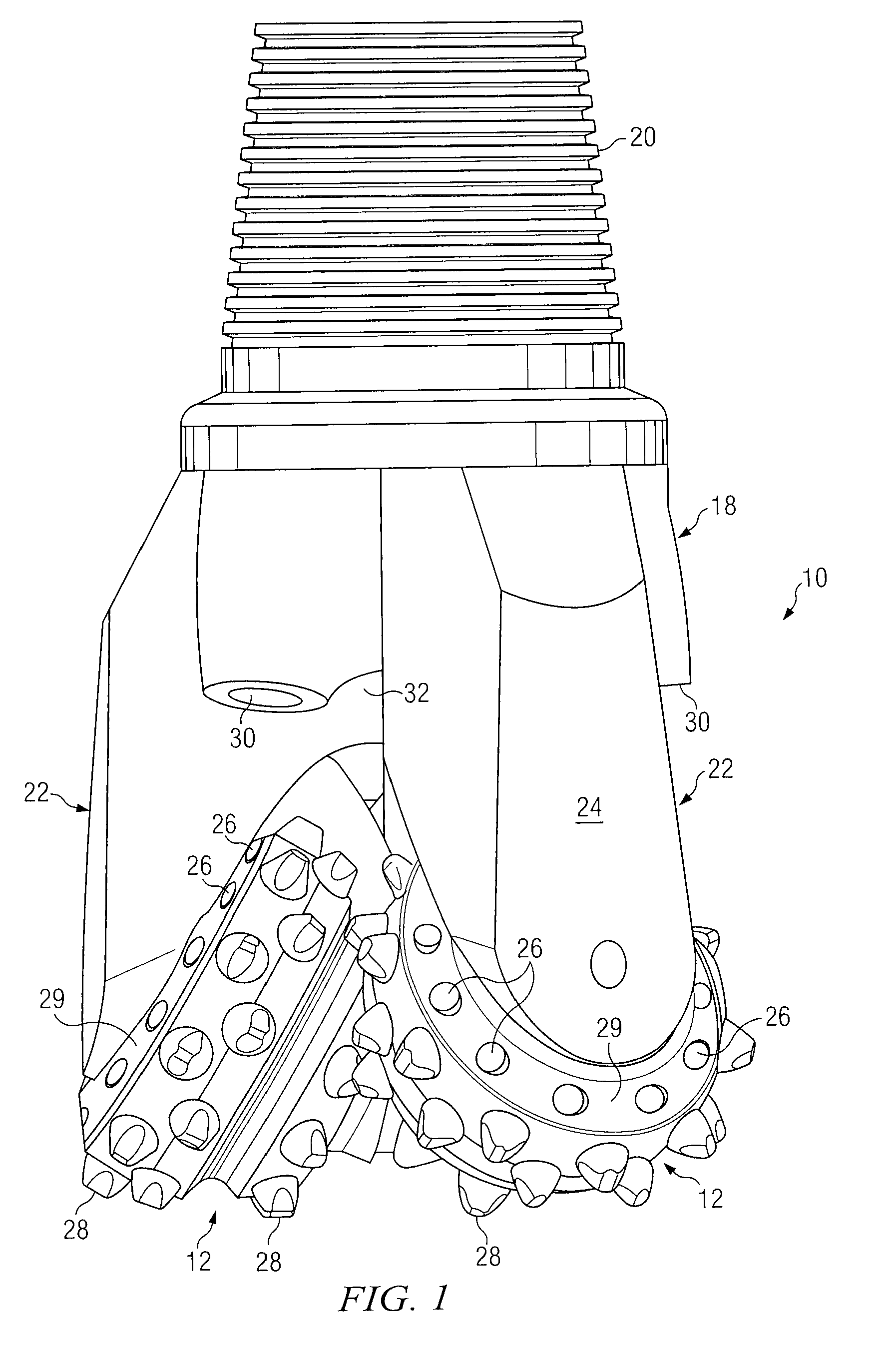

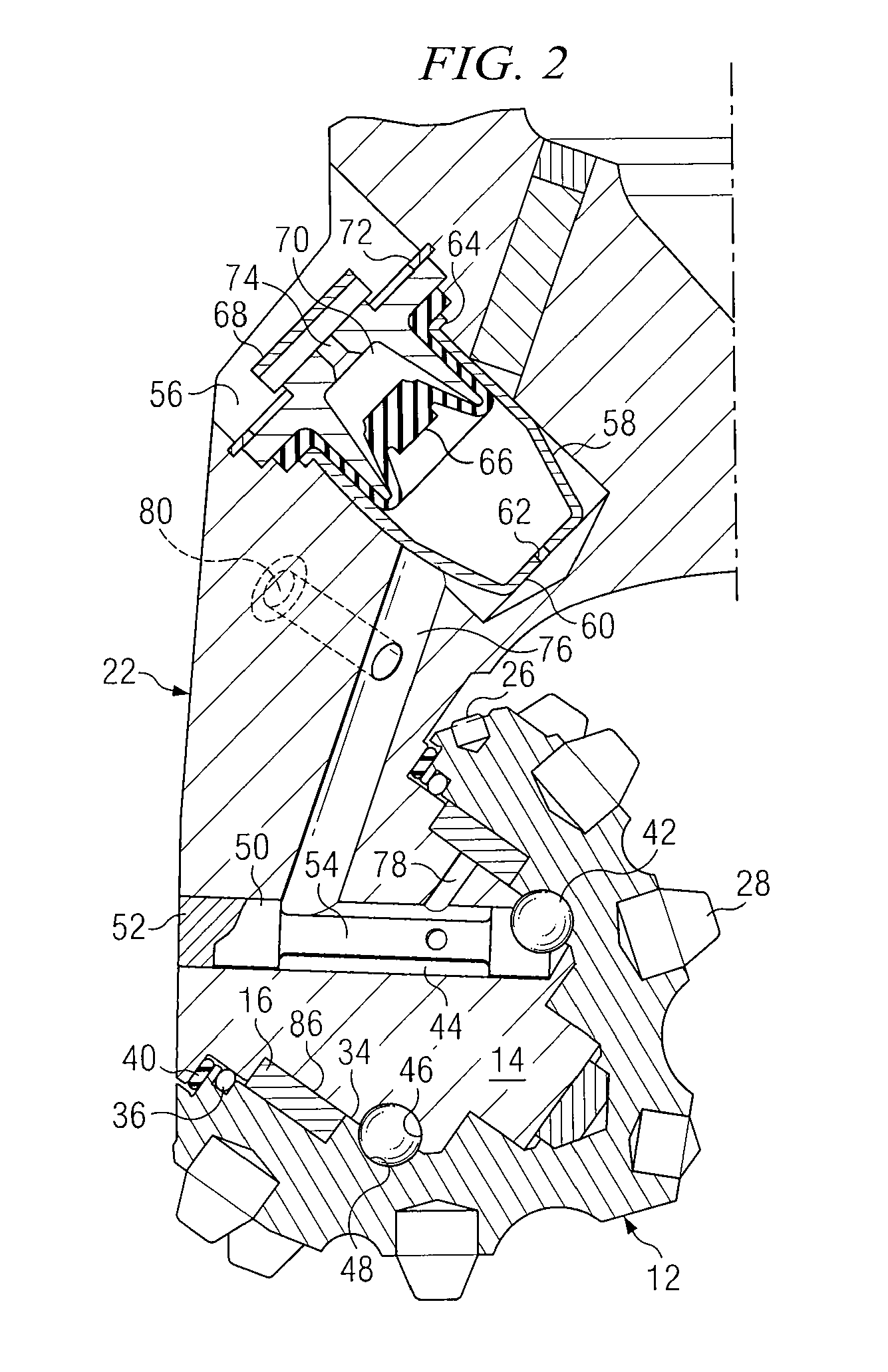

High performance rock bit grease

InactiveUS20110048809A1Improved load carryingGood for wear protectionDrill bitsAdditivesSulfonateEngineering

The present disclosure relates to greases containing metal sulfonate thickeners. In one example the thickener may be a calcium sulfonate thickener. In other examples grease may contain a combination of a metal sulfonate thickener and another thickener, such as a metal complex soap grease, detergent, or non-soap thickener. The grease may be formulated to meet specific performance criteria relevant to lubrication of a roller cone drill bit in downhole conditions. The disclosure also relates to a roller cone drill bit containing a grease of the disclosure.

Owner:HALLIBURTON ENERGY SERVICES INC

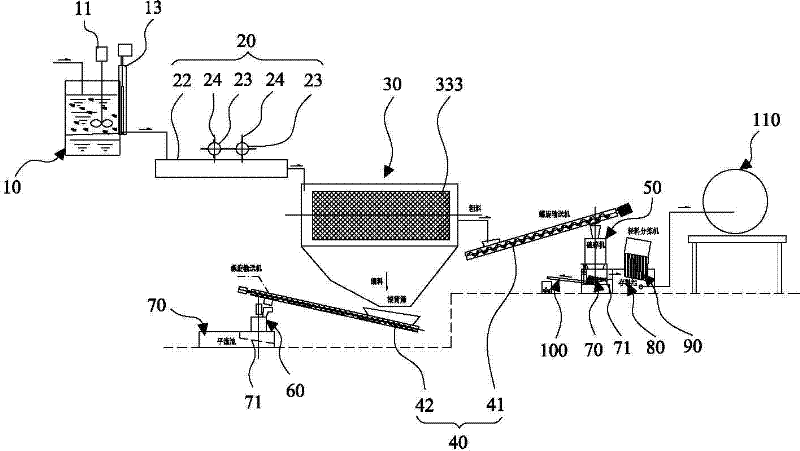

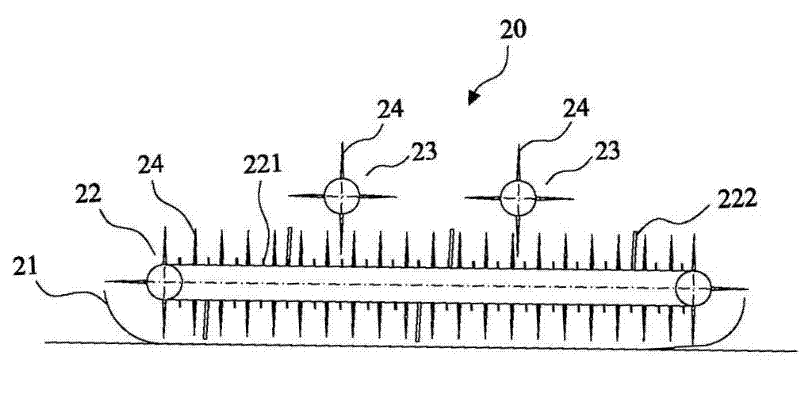

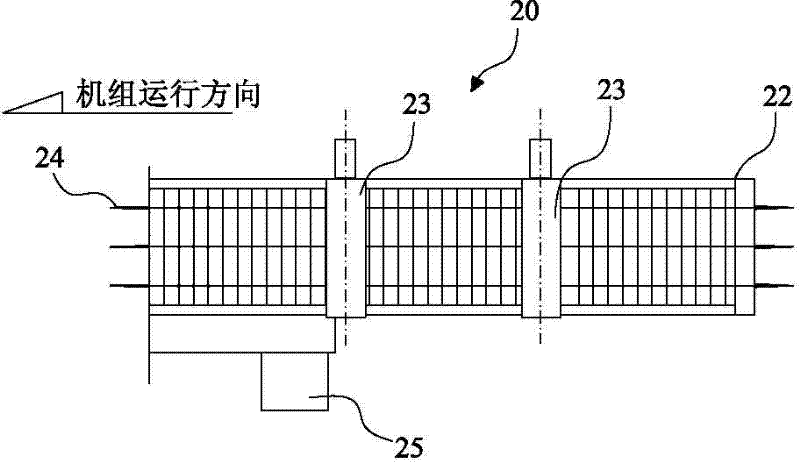

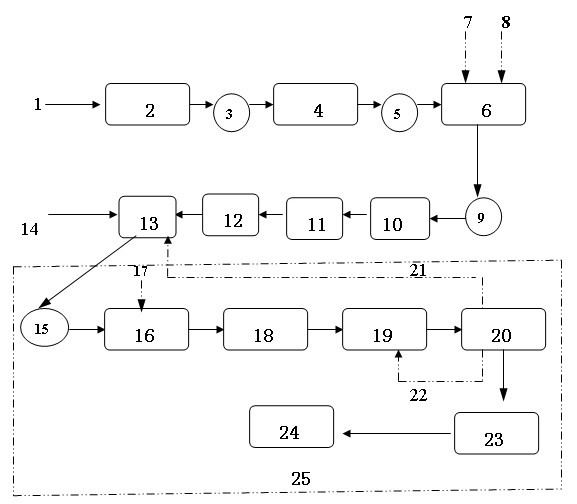

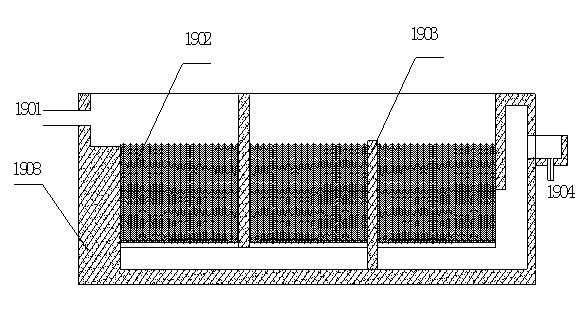

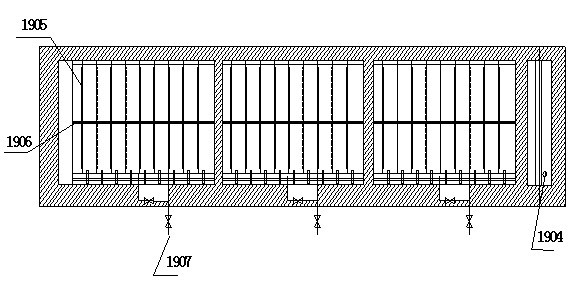

Restaurant-kitchen garbage sorting system

InactiveCN102327890AImprove processing efficiencyAccurate classificationSievingScreeningPlastic packagingProcess engineering

The invention discloses a restaurant-kitchen garbage sorting system. The system orderly comprises a scrubbing oil groove for separating grease from residues, a bag breaking conveyor for tearing a plastic package and a drum screening machine for screening the residues into coarse material and fine material, and a coarse material outlet and a fine material outlet are arranged on the drum screening machine, a coarse material spiral conveyor and a fine material spiral conveyor are respectively arranged corresponding to the coarse material outlet and the fine material outlet, a crusher is arranged at an outlet of the coarse material spiral conveyor, a pulping machine is arranged at an outlet of the fine material spiral conveyor, and a horizontal flow pool for dividing the pulp from the crusher and the pulping machine into light material and heavy material. Therefore, the restaurant-kitchen garbage sorting system can effectively treat the bagged garage without manual operation, and improve the garage processing efficiency; and the garage can be classified so as to be convenient for recycle.

Owner:DONGGUAN CAMDA GENERATOR WORK

Lubricating grease composition and preparation

A grease composition is prepared from an isomerized base oil having consecutive numbers of carbon atoms and less than 10 wt % naphthenic carbon by n-d-M; a kinematic viscosity at 100° C. of less than 10 mm2 / s, and a cloud point—pour point spread of less than 25° C. The grease composition in one embodiment, exhibits improved service life, i.e., capable of performing for longer period of time of at least 50% at high temperatures / speeds and in an oxidizing environment as compared to greases containing Group II or POA base oils in the prior art.

Owner:CHEVROU USA INC

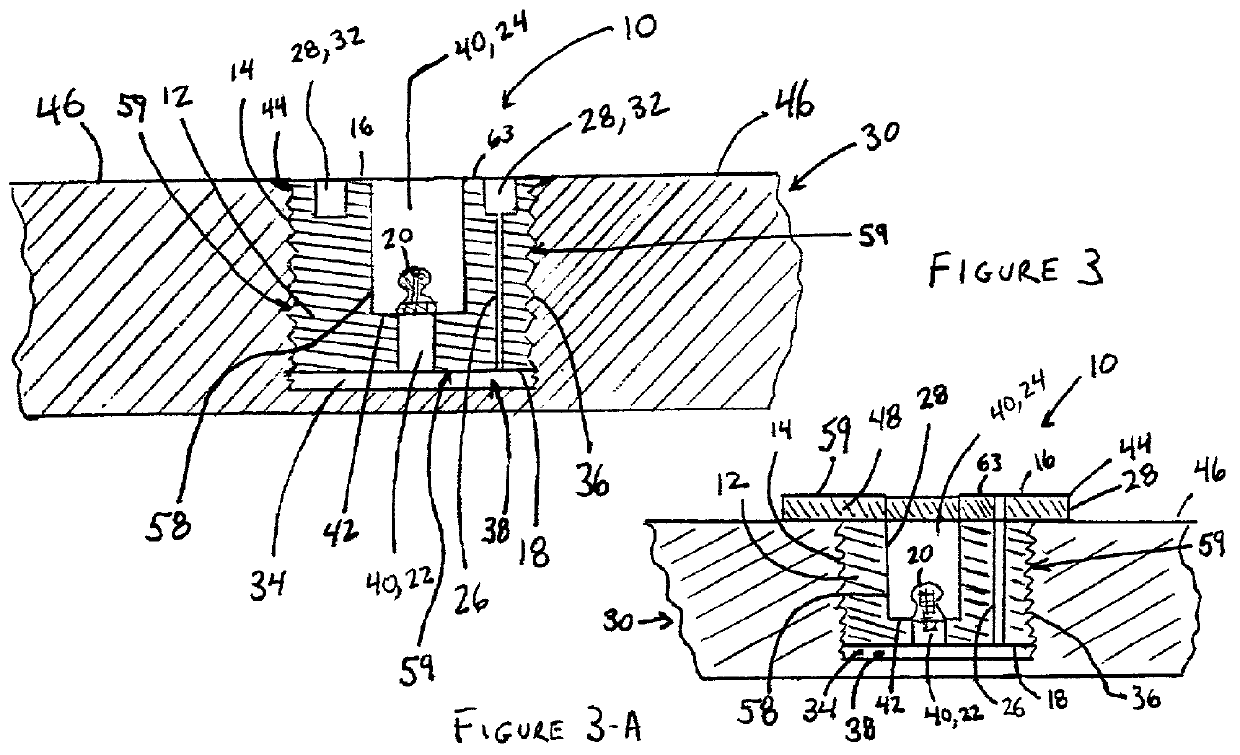

Protection plug

InactiveUS20010052438A1Avoid damageMachines/enginesLubricating pumpsMechanical engineeringLubrication

A plug for protecting the interior of a recessed area of a component during storage is disclosed herein. The plug includes a lubrication fitting positioned thereon to flow a protective material, such as grease, into the cavity between the lower end of the plug and the recessed area and any remaining voids between the walls of the plug and the walls of the recessed area. The plug may also include an engagement surface to assist in the insertion and removal of the plug into and out of recessed areas of a component.

Owner:TUCKER ROBERT C

Composite calcium-base lubricating grease and its prepn

ActiveCN1888036ASmall change in surface hardening valueImprove extreme pressure performanceAdditivesPolymer scienceOxidation stability

The present invention relates to one kind of composite calcium-base lubricating grease, which consists of base oil in 68-95 wt%, composite calcium-base thickener 4-30 wt% and titania 0.1-8 wt%, and the titania in the lubricant grease is preferably nanometer level particles. The present invention also provides three kinds of preparation process of the lubricant grease. The composite calcium-base lubricating grease of the present invention has the features of high oxidation stability, small surface hardening value change, high dropping point and high extreme pressure wear resistance, and may be used for lubricating at relatively high temperature and humidity condition and heavy load.

Owner:CHINA PETROLEUM & CHEM CORP +1

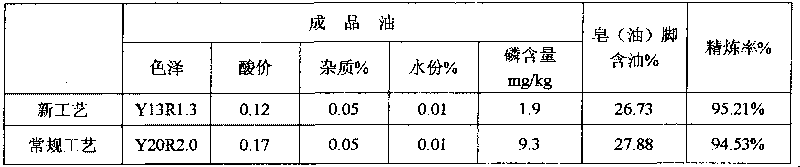

Novel process for refining oil-tea camellia seed crude oil

ActiveCN101735886AReduce side effectsLow reaction temperatureFatty-oils/fats refiningOil and greaseVegetable oil

The invention discloses a novel process for refining oil-tea camellia seed crude oil, which belongs to the technical field of grease refining in the fine and further processing of farm and sideline products. A process flow comprises the following steps: filtering the oil-tea camellia seed crude oil to eliminate impurities; performing a first low temperature acid reaction; performing low temperature alkali refining; removing soap; performing water washing after first acid adding; performing second water washing; and de-coloring and deodorizing the obtained product to obtain first-level oil-tea camellia seed oil. The novel process is characterized by improving the oil obtaining rate of refining, lowering production cost, improving product quality and stability and the like, and is used for refining the oil-tea camellia seed crude oil and refining rap oil, peanut oil and other vegetable oil.

Owner:HUNAN XINJINHAO TEA OIL

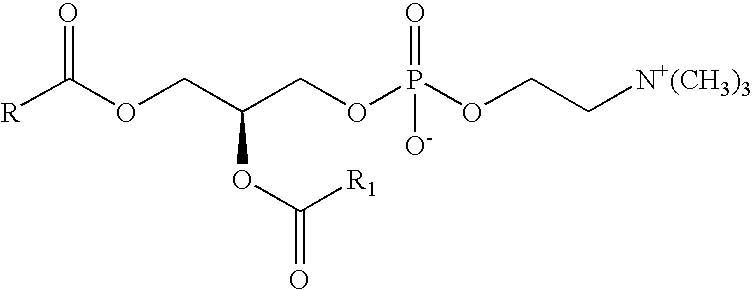

Environmentally friendly grease composition

InactiveUS20050197260A1Group 5/15 element organic compoundsAdditivesEnvironmentally friendlyGlycerol

An environmentally friendly grease composition is provided comprising (a) a vegetable oil and (b) a cellulose fiber. The grease may further comprise glycerin; a rust inhibitor; and / or a fatty acid ester, lecithin, phosphatidyl choline, or a combination thereof.

Owner:MONTANA STATE UNIVERSITY

Method for preparing calcium sulfonate with high base number

The invention relates to a method for preparing calcium sulfonate with high base number. In the method, alkyl benzene sulfonic acid and / or petroleum sulfonic acid serve as raw materials, low molecular alcohol serves as accelerating agent, calcium oxide and / or calcium hydroxide serve as calcifying agent; firstly, neutralization reaction is carried out to generate calcium sulfonate; then carbonation reaction is carried out for twice, post-treating agent is added for reaction; finally, alcohol, water, solvent and solid residue are removed to obtain the calcium sulfonate with high base number. The product of the invention is especially suitable for preparing lubricating grease, can shorten conversion time of calcium sulfonate crystal form, improve high-temperature bproperty and anti-moisture performance of the lubricating grease and satisfy the demands of high-performance lubricating grease.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid-liquid phase composite lubricating grease and preparation method thereof

InactiveCN101880583AImprove process efficiencyLubricant compositionOperating temperature rangeBase oil

The invention belongs to the field of lubricant and preparation methods thereof, particularly relates to a solid-liquid phase composite lubricating grease and a preparation method thereof. According to the theory of solid-liquid phase composite lubrication technology, and aimed at the requirements of a bearing on lubrication in different application cases and operating temperature ranges, the invention provides a technical scheme for the solid-liquid phase composite lubricating grease composition and the preparation method thereof. The components of the additive include solid-liquid phase composite additive, base oil and more than two types of mono-soap greases and composite soap greases, which are prepared into the solid-liquid phase composite lubricating grease with a uniform dispersion system by shearing dispersion. The solid-liquid phase composite lubricating grease produced by the invention can enhance and improve the structure form of the common lubricating grease, in the aspects of use temperature, lubricating mode and lubricating effect, during a lubrication process from an initial stage below 60DEG C, to a later stage of a mesotherm 60-120 DEG C, a high temperature 80-180 DEG C till an extra-high temperature more than 350 DEG C, each effective component in the solid-liquid phase composite lubricating grease plays respective lubrication action in different lubrication temperature stages, realizes zero blind spot lubrication in each lubrication temperature stage, obtains the effects of decreasing friction, reducing attrition, saving energy, protecting and prolonging the device use lift, and opens a new path for saving energy.

Owner:北京德润同创科技有限公司

Grease composition, viscous agent, and mechanical element

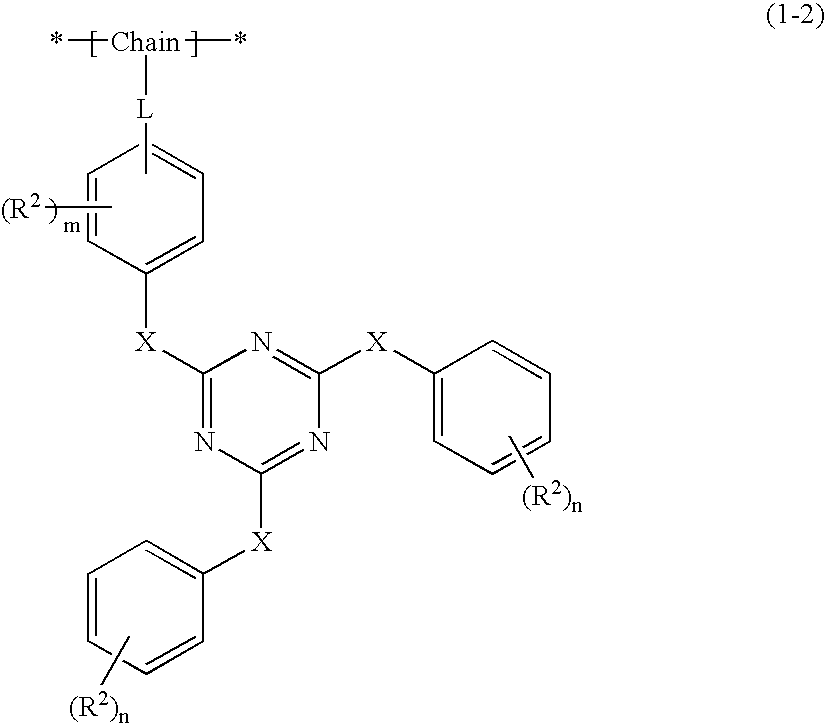

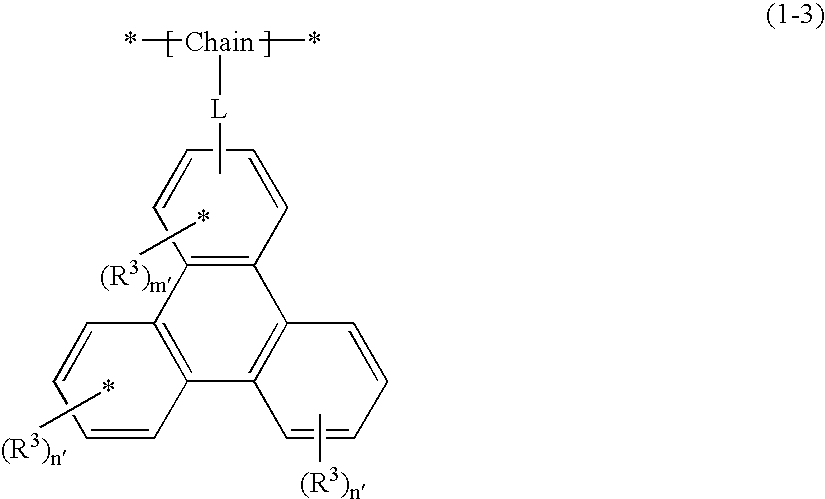

InactiveUS20080194441A1Reduce performanceReduce wearLiquid crystal compositionsOrganic chemistryPolymer scienceBackbone chain

A grease composition comprising at least one polymer having a mesogen structure in the principal chain or in the side chain(s) thereof, and at least one viscous agent is disclosed. A viscous agent which is a discotic compound having, in the molecule thereof, a discotic core and three or more side chain groups radially extended from said discotic core is also disclosed. The discotic core and / or said side chain groups has at least one tautomeric group therein, and at least one side chain group of said three or more side chains has, at the end portion thereof, a long chain group in which 20 or more atoms selected from the group consisting of oxygen, carbon, nitrogen, silicon and sulfur atoms are linked in a straight-chain-like manner or in a branched manner.

Owner:FUJIFILM CORP

Aluminum nitride composition

An aluminum nitride composition including an aluminum nitride powder and an aromatic amine-based condensate is provided. In the composition, the aluminum nitride may hardly undergo decomposition even under severe conditions of high temperature and high humidity, and the electrical insulating properties and high thermal conductivity inherent in aluminum nitride powder can be maintained under such severe conditions. Accordingly, this composition is useful as a durable heat-dissipating composition, in particular, as a heat-dissipating coating material, grease or sheet.

Owner:SHIN ETSU CHEM IND CO LTD

Double-layer cleansing lotion and preparation method thereof

ActiveCN103202775AEasy to cleanGood removal effectCosmetic preparationsMake-upInorganic saltsEmulsion

The invention discloses a double-layer cleansing lotion and a preparation method thereof. The double-layer cleansing lotion comprises a water-phase layer and an oil-phase layer. The water-phase layer comprises water soluble preservatives, water soluble grease, inorganic salt electrolyte, moisturizing agent and water. The oil-phase layer comprises water-insoluble grease, oil soluble preservatives and oil soluble pigment. The preparation method includes: sequentially adding water soluble preservatives, water soluble grease, inorganic salt electrolyte and moisturizing agent into water, well mixing to obtain water-phase layer components, sequentially adding oil soluble preservatives and oil soluble pigment in water-insoluble grease, well mixing to obtain oil-phase layer components, and mixing the water-phase layer components and the oil-phase layer components to obtain the double-layer cleansing lotion. During use, the double-layer cleansing lotion can be emulsified by shaking to form emulsion, and instant deemulsification occurs to form double-layer structure with clearly-separated oil and water when the double-layer cleansing lotion stands still. The double-layer cleansing lotion is mild in cleansing, instant in emulsification, fast in deemulsification, clear in boundary and the like.

Owner:FOSHAN WIN COSMETIC

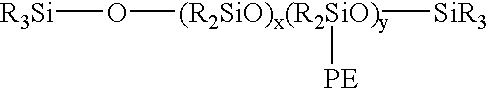

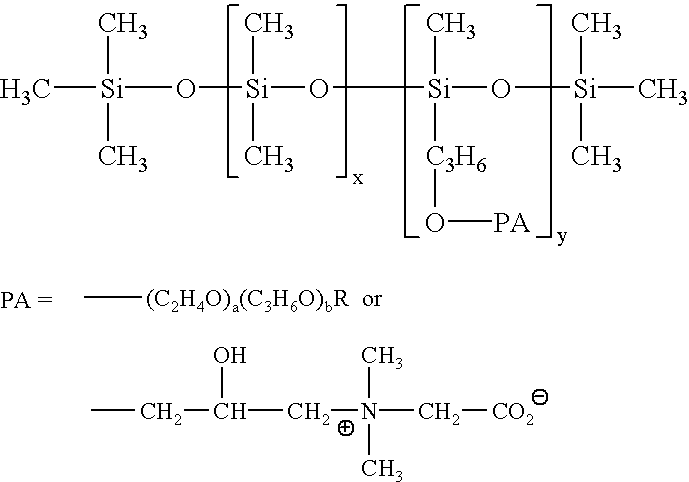

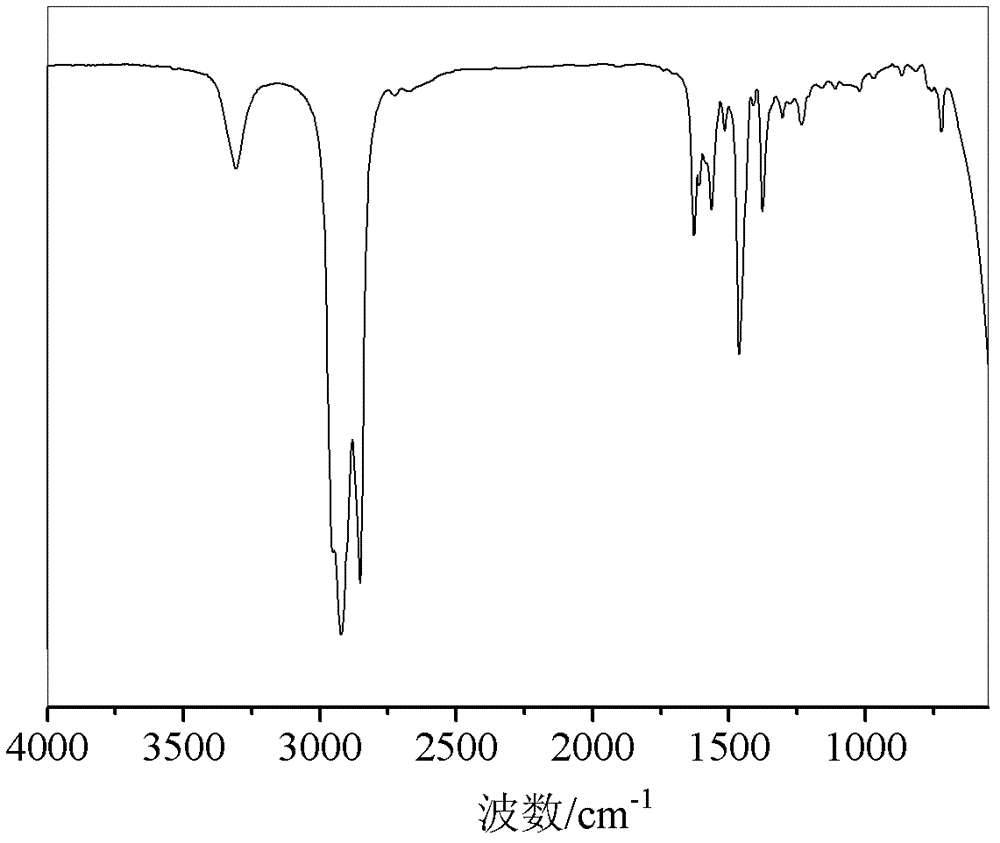

Silicone defoaming agent for papermaking and pulping and preparation method thereof

InactiveCN101798781ANovel production formulaRaw materials are easy to getDefoamers additionCoatingsEmulsionPapermaking

The invention provides a silicone defomaing agent for papermaking and pulping and a preparation method thereof, which belong to the papermaking chemicals, and mainly comprise silicon grease mixture, silicon oil mixture, emulsifier, thickener and water. In the defoaming agent emulsion, silicon grease mixture and silicon oil mixture account for 70 to 90 percent of the active matter content, wherein total active matter content accounts for 5 to 30 percent of total content of emulsion, and the rest medium is water. The anti-foaming performance is improved through the silicon grease mixture, the defoaming performance is improved through the silicon oil mixture, the viscosity of the silicon grease is reduced by adding the emulsifier, and the emulsion effect is improved. The silicone defoaming agent has novel formula composition and good defoaming and anti-foaming performance, and has excellent performance in the papermaking pulping work procedure and partial water systems.

Owner:XIAN SUNY FINE CHEM

Method for treatment of waste emulsion

InactiveCN101792239AEasy to separateSimple processWaste water treatment from metallurgical processMultistage water/sewage treatmentElectrolysisWaste oil

The invention discloses a method for the treatment of waste emulsion, more particularly a method for the treatment of waste emulsion generated in the machining processes such as cutting, grinding and the like. The method comprises the following steps: separation of stored emulsion breakers, mechanical air flotation, ion-carbon electrolysis, coagulating sedimentation, oil separation with inclined plate, microorganism purification, sedimentation, sand filtering, etc.; the method has the advantages of simple technology and standard-reaching wastewater, and devices for the implementation of the method have small floor area, little investment, low running cost, low energy consumption, maximal recycling of waste oil resource and prominent operability and is widely suitable for machining and the treatment of waste emulsion in other industries. The waste oil recycled according to the method is completely capable of being used for the production of patented product, the protective grease, thus idealized application of resources is achieved.

Owner:成都蜀光石油化学有限公司

Preparation method and application of environment-friendly type shield tail sealing grease

The invention discloses a preparation method and an application of environment-friendly type shield tail sealing grease. The shield tail sealing grease mainly comprises the following components: 14-30% of lubricating oil, 7-22% of oil plasticizer, 3-15% of thickening agent, 3-12% of lubricating grease, 3-8% of natural degradable fiber, 35-60% of filling granular material, 1-3% of coloring agent and 0.1-2% of preservative. The environment-friendly type shield tail sealing grease prepared by using the method is used for sealing a shield tail of a shield tunneling machine in tunnel engineering, and has the advantages of good water pressure sealing performance, excellent pumping performance, high adhesivity, good lubrication, stable properties, no corrosion, antioxidation, wide raw material resources, environment-friendliness and simple preparation process.

Owner:东莞市明洁隧道建设材料有限公司

Ester type fire-resistant hydraulic fluid and preparation method thereof

InactiveCN103013635AInhibition of catalytic oxidationImprove stabilityLubricant compositionPhosphoric acidTriazole derivatives

The invention relates to an ester type fire-resistant hydraulic fluid. The hydraulic fluid comprises the following raw materials by weight percent: 95-99% of base oil, 1.0-5.0% of diphenol propane, 0.005% of dimethylsilicone fluid or dimethylsilicone grease, 0.05% of tricresyl phosphate, 0.1% of benzotriazole, 100 parts per million (PPM) demulsifying agent T1001 or LZ5957 and 0.2-0.3% of triazole derivative, thiadiazole derivative, N-salicylidene ethylamine, N, N'-bis(salicylidene)ethylenediamine, N, N'-bis(salicylidene)propylene diamine or ethylenediamine tetraacetic acid. A preparation method of the ester type fire-resistant hydraulic fluid comprises the following steps of sufficiently and evenly stirring various materials at room temperature according to a formula, and then filtering. The ester type fire-resistant hydraulic fluid has the beneficial effects that the high temperature use performance of the product is greatly improved, the service life of a hydraulic system and the oil changing period of oils are prolonged, and the ester type fire-resistant hydraulic fluid has a good flame-retardant effect and is safe to use. The preparation method has the advantages that operation is convenient, technology and equipment are simple, energy consumption is low, cost is low, and the like.

Owner:ANLU AOSEN PETROCHEM

Functionalized polymer composition for grease

A grease composition containing: (a) the reaction product of: (i) a calcium containing overbased organic acid; and (ii) at least one acid producing compound or derivatives thereof selected from the group consisting of: (1) a non-polymeric hydrocarbyl substituted dicarbonyl derivative selected from the group consisting of an acid, an ester, a salt, an anhydride, ester-acid, acid-salt and mixtures thereof; (2) a copolymer derived from monomers containing (1) an olefin; and (2) an unsaturated dicarboxylic acid anhydride or derivatives thereof; and (3) an inorganic acid containing about 2 or more acidic hydrogens; and (b) an oil of lubricating viscosity, wherein the overbased calcium sulphonate contains colloidally dispersed calcium carbonate is selected from the group consisting of calcite, vaterite and mixtures thereof. The invention further relates to the process to make the composition and its use in greases to increase water resistance.

Owner:THE LUBRIZOL CORP

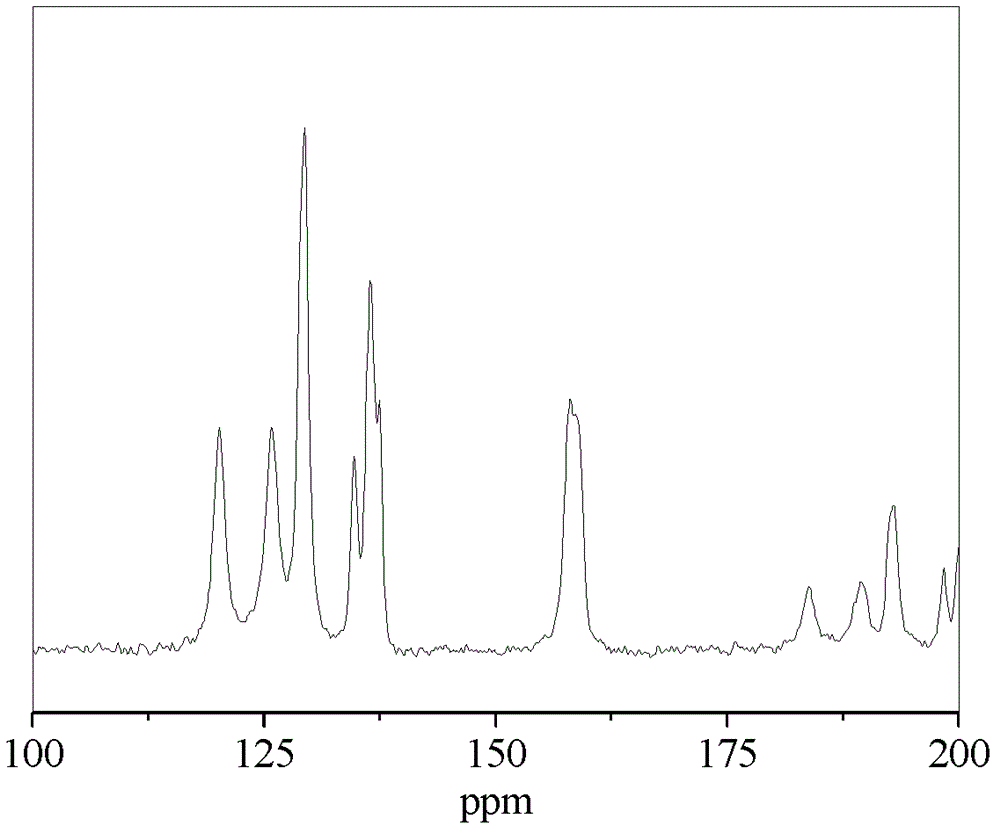

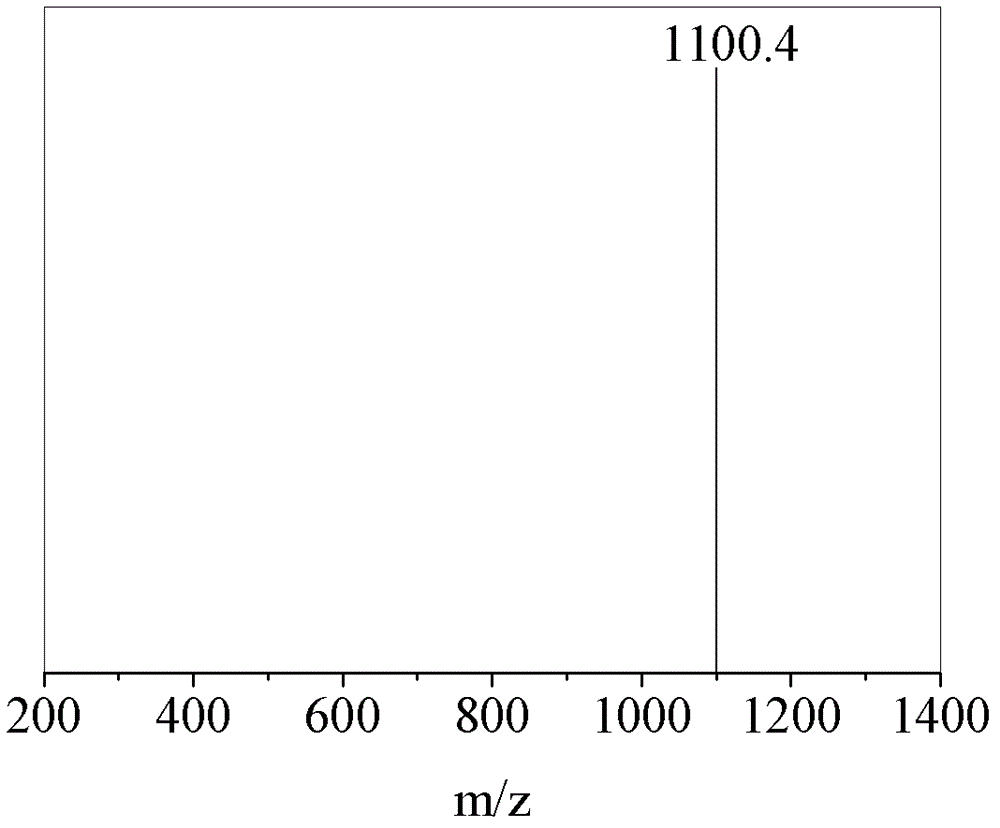

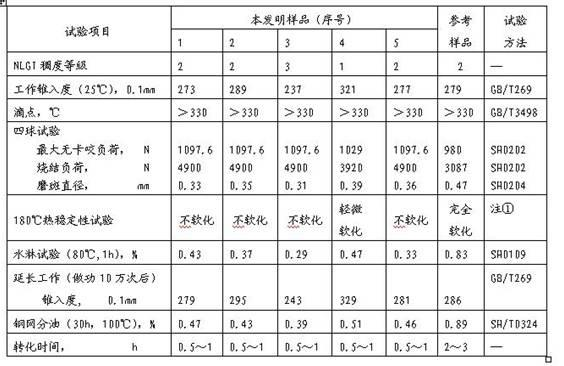

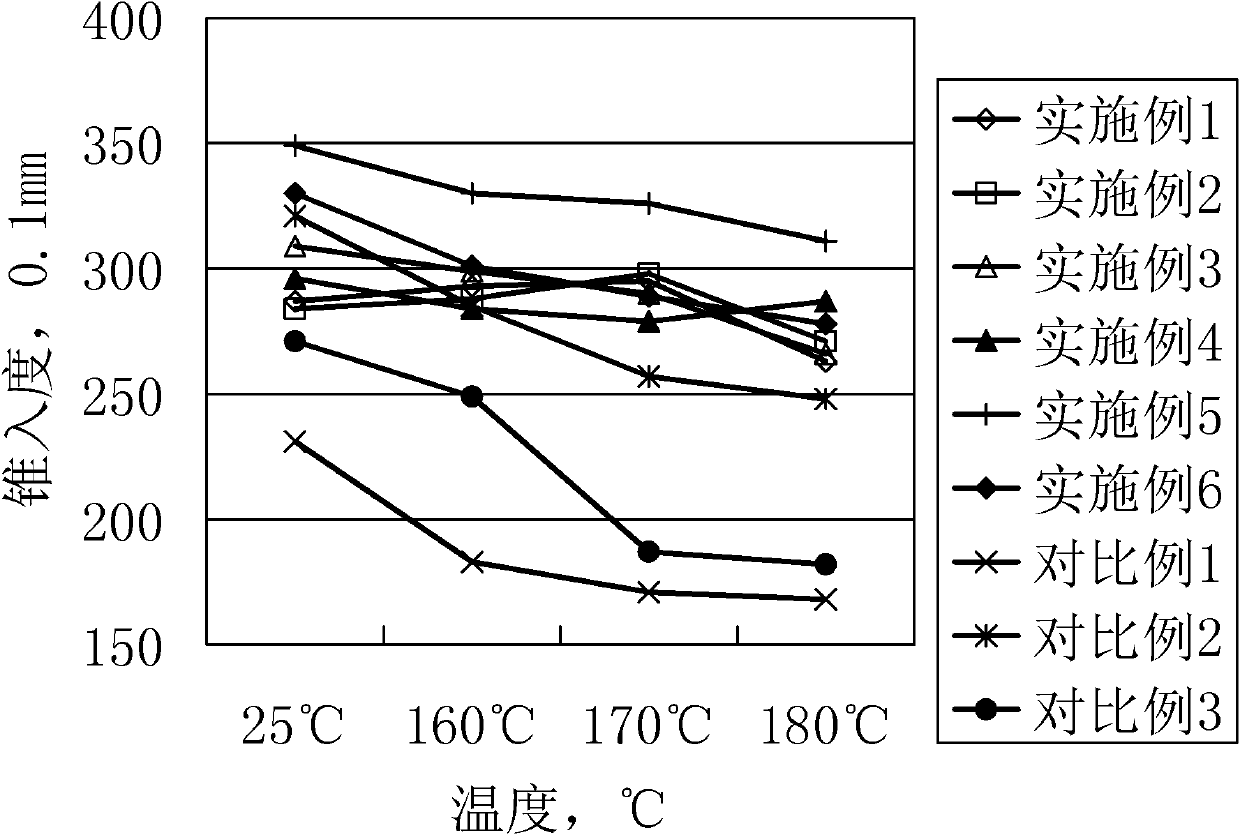

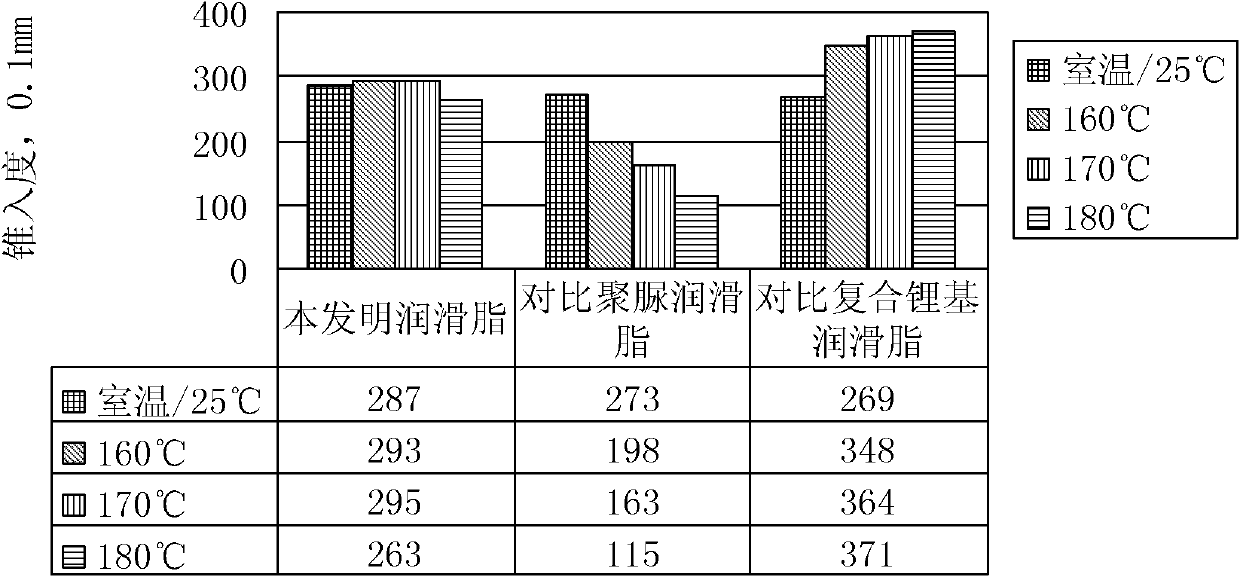

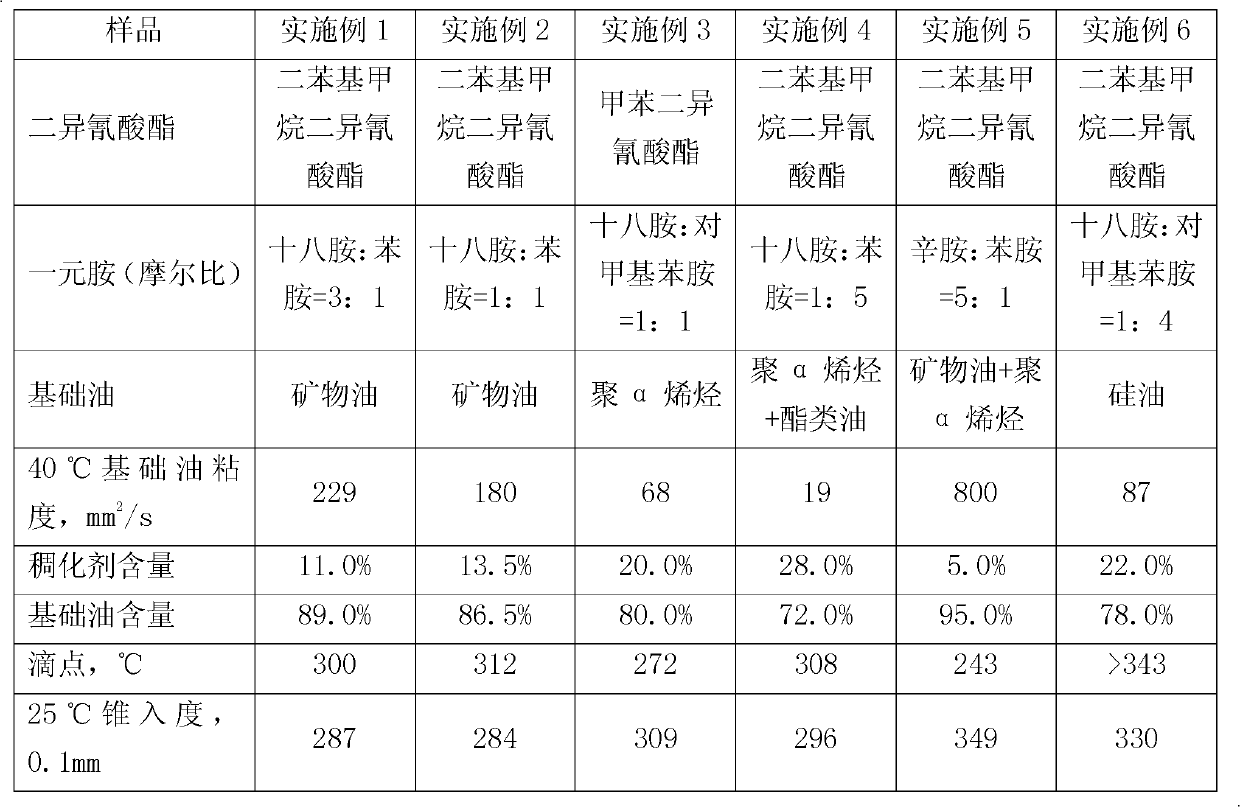

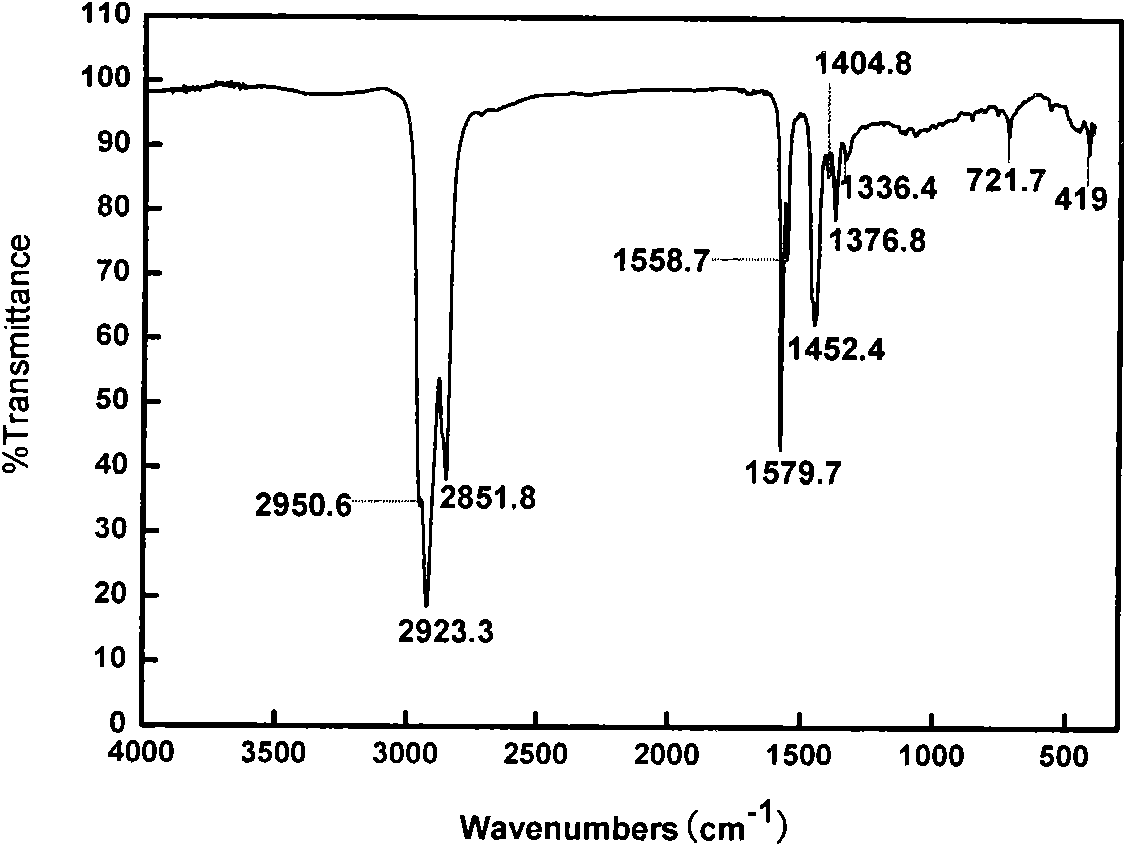

Polyurea lubricating grease composition

InactiveCN102002414AThere is no special requirement for the amount addedSolve the problem of hardening at high temperatureThickenersPolymer scienceFatty amine

The invention relates to a polyurea lubricating grease composition. The lubricating grease composition contains 72 to 95 weight percent of base oil and 5 to 28 weight percent, preferably 7 to 20 weight percent of diurea thickening agent; and the diurea thickening agent is prepared by reaction of monoamine and diisocyanate, the monoamine is a mixture of fatty amine and aromatic amine, and the molar ratio of the fatty amine to the aromatic amine is 5:1-1:5. The lubricating grease composition is polyurea lubricating grease, and has excellent high temperature resistance; and the lubricating grease composition has the characteristics that: the penetration value of the composition after being baked at a high temperature for long time is changed little compared with the composition baked at room temperature, namely the consistency of the composition is changed little, and the composition does not obviously become hard to affect the lubricating effect or become soft to cause high-temperature loss. The room-temperature and high-temperature penetration changes of the lubricating grease composition and the common high-temperature lubricating grease are shown as a table 1, and the constant temperature time of the lubricating grease composition at the high temperature is 24 hours.

Owner:CHINA PETROLEUM & CHEM CORP

Thermoplastic film with good interply adhesion

A multilayer film including an outer layer that includes a homo- or interpolymer of propylene and, directly adhered to the outer layer, a layer that includes a homogeneous ethylene / alpha-olefin interpolymer having a density of no more than about 0.91 g / cm3 exhibits good seal strength and good adhesion between the two layers, even in areas where the film is sealed, even after the film is oriented, even when the film is subjected to the elevated temperatures involved in cook-in procedures, and even where the film is subjected to, e.g., grease from fatty foods. The film also can include one or more, for example, bulk layers, O2-barrier layers, and / or abuse layers.

Owner:CRYOVAC ILLC

Complex lithium grease and preparation method thereof

The invention provides complex lithium grease and a preparation method thereof. The complex lithium grease comprises grease base oil, complex lithium thickening agents and surfactants with mass part ratio of (290-1450):(50.4-251.3):(2-10), wherein the grease base oil is at least one of vacuum second line base oil, vacuum third line base oil and vacuum fourth line base oil; the complex lithium thickening agents are formed by C12-C24 fatty acid lithium and auxiliary acid lithium with mass part ratio of (34-70):(16.4-81.3); and the auxiliary acid lithium is any two of C1-C22 fatty acid lithium, lithium borate, lithium phosphate, aromatic acid lithium, lithium naphthenate, dicarboxylic acid lithium and polybasic acid lithium. The invention also provides the preparation method of the complex lithium grease. The surfactants are added to the complex lithium grease to have synergistic effect with soap molecules of the complex lithium grease and further improve the arrangement of the soap molecules and the capability of curing the base oil, thus increasing the dropping point of the grease.

Owner:CHINA NAT OFFSHORE OIL CORP +2

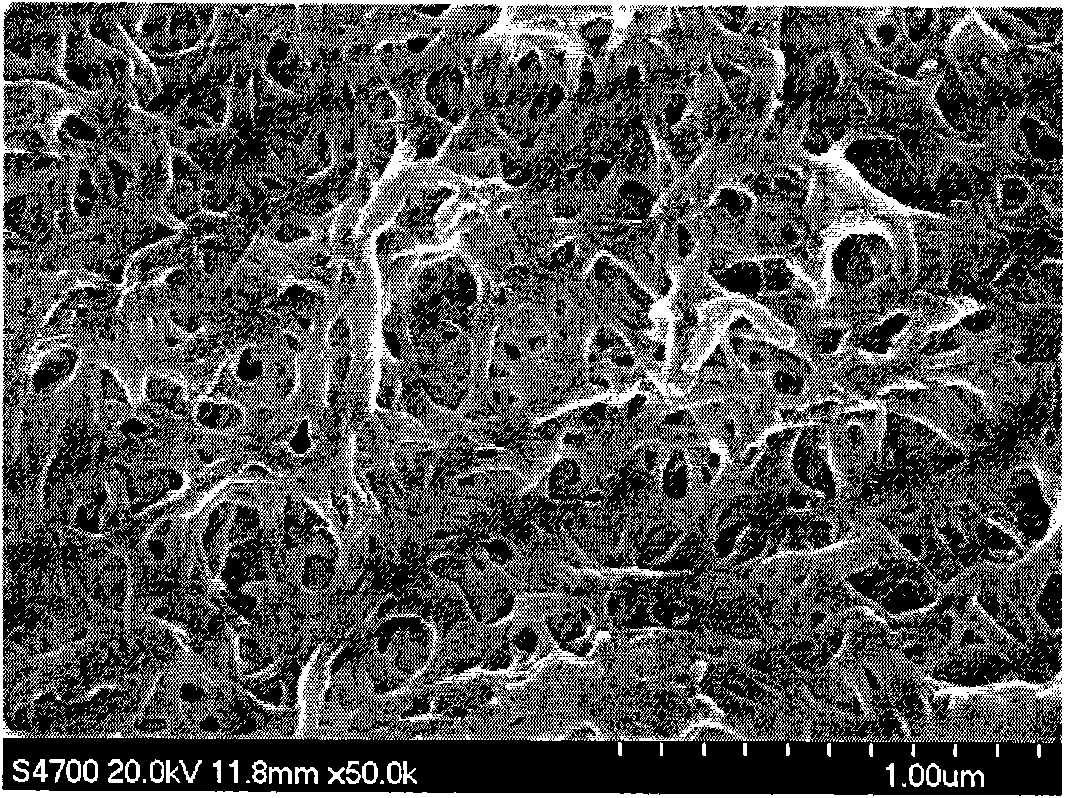

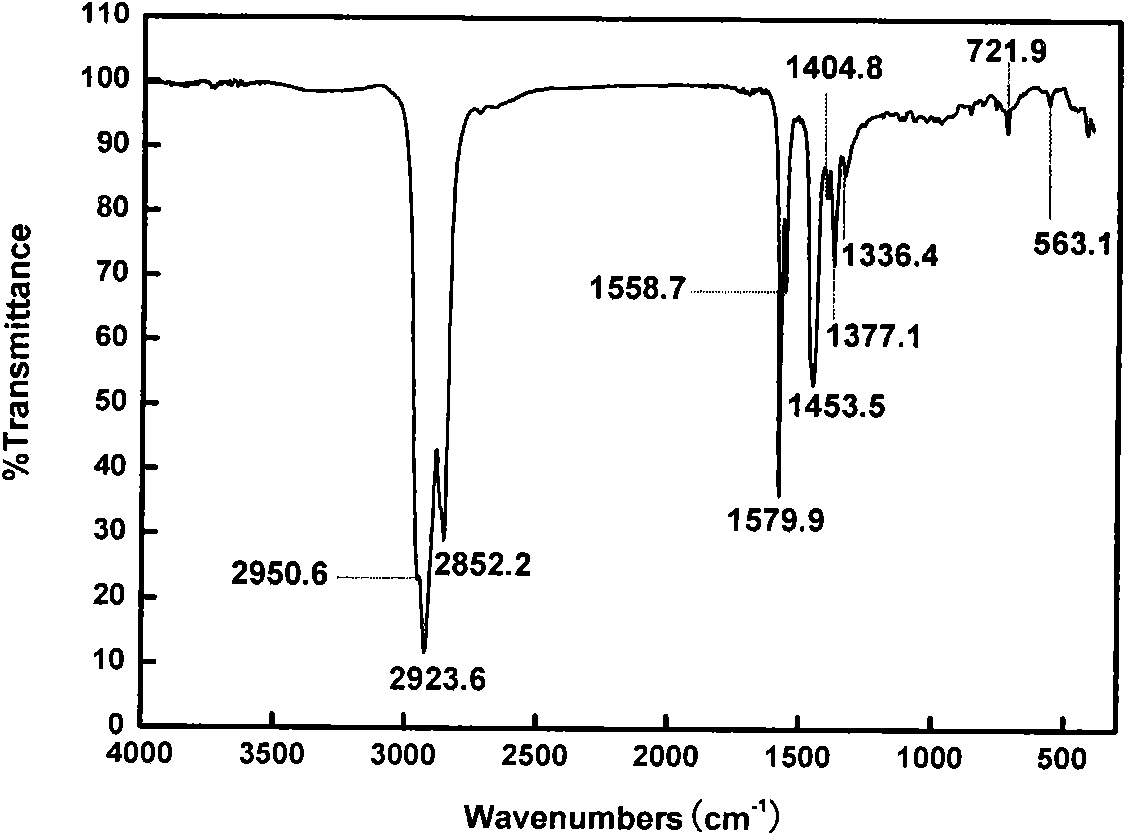

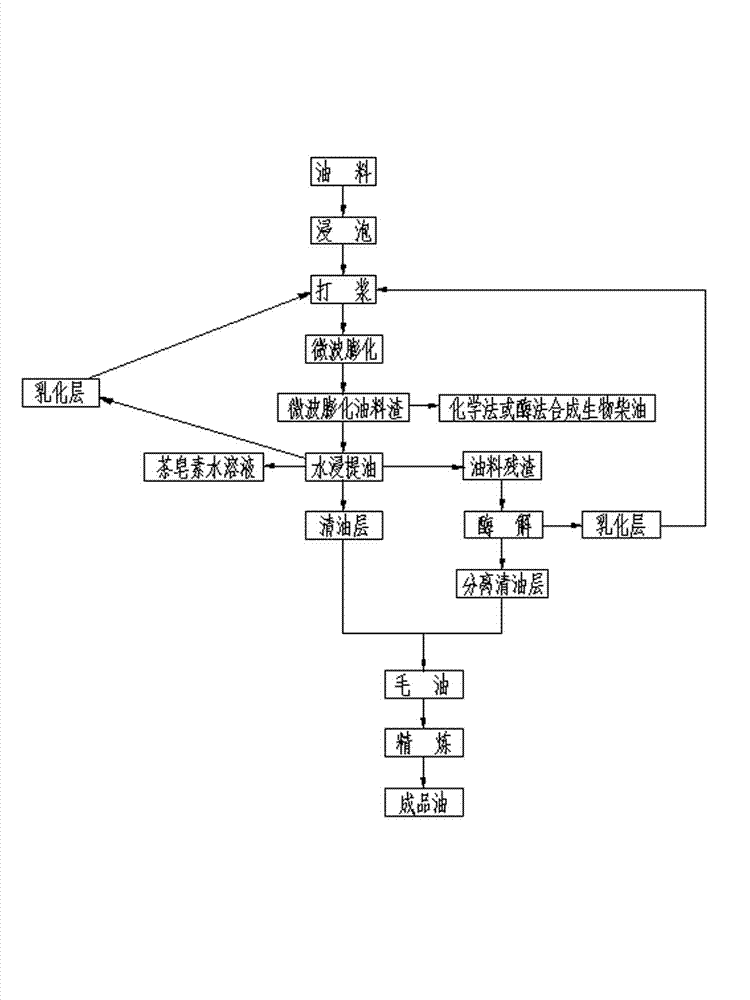

Method for digesting grease through microwave pretreatment and aqueous enzymatic method

InactiveCN102816632AFully destroyedImprove oil yieldFatty-oils/fats productionCamellia oleiferaPhosphatidase

The invention relates to a method for digesting grease through microwave pretreatment and an aqueous enzymatic method. The method includes soaking raw materials, performing microwave puffing treatment on camellia oleifera seed slurry, digesting grease with water, performing physical refining on the obtained grease after degumming through a phosphatidase enzymatic method, or directly performing rough filtration, refined filtration and nanofiltration, and then performing vacuum dehydration and drying to obtain grease products and a by-product of wet meal. According to the method, the microwave puffing treatment is adopted on raw materials such as camellia oleifera seeds, cell structures of the raw materials can be fully destroyed, and the oil yield of the following water immersion method can be improved; grease digestion through water after microwave pretreatment for materials belongs to an environment-friendly and safe production process; and the method has the advantages of being simple and environment-friendly in process, high in oil yield, low in investment and prone to industrial production.

Owner:SHAOGUAN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com