Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

654 results about "Aromatic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aromatic acids are a type of aromatic compound. Included in that class are substances containing an aromatic ring and an organic acid functional group.

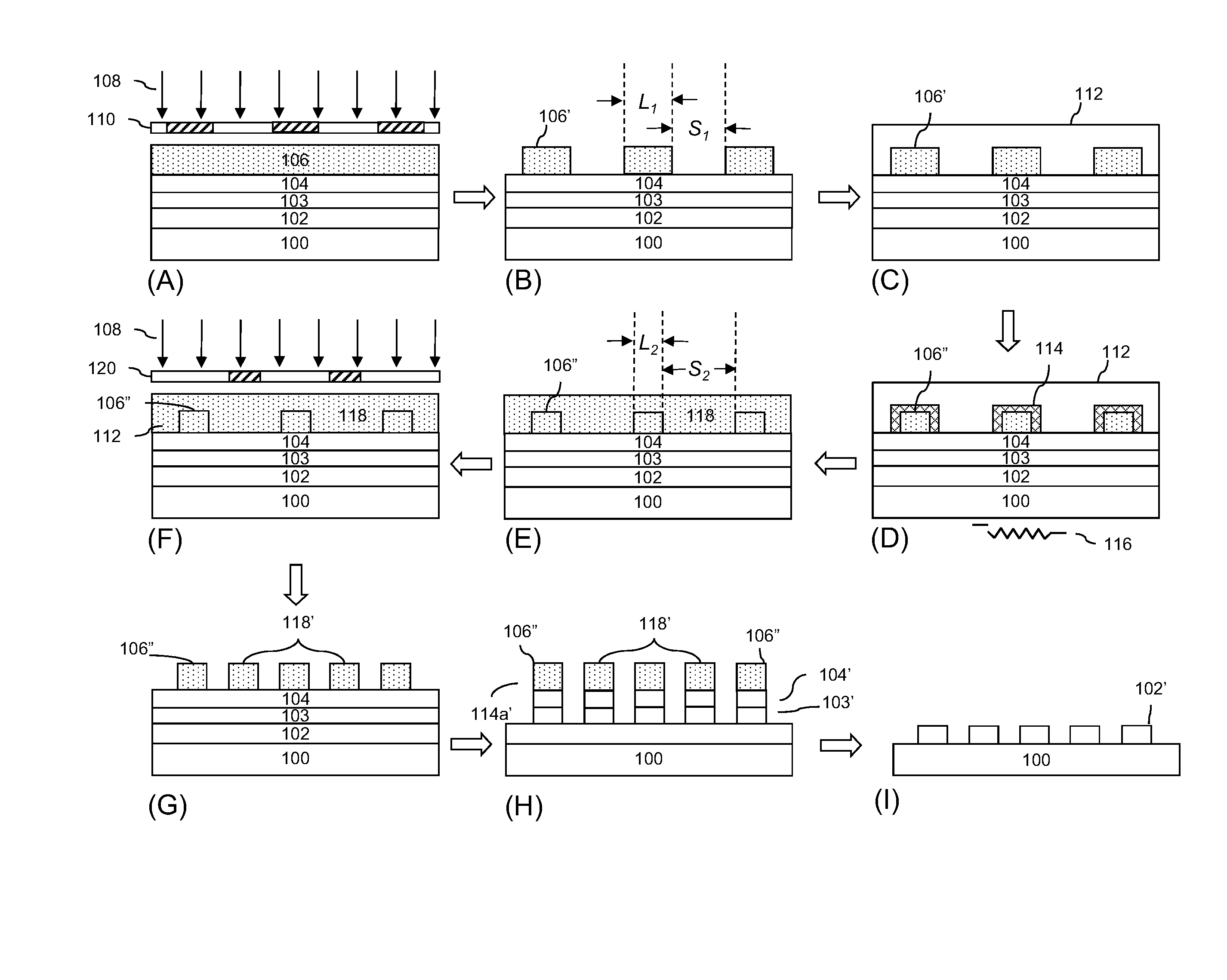

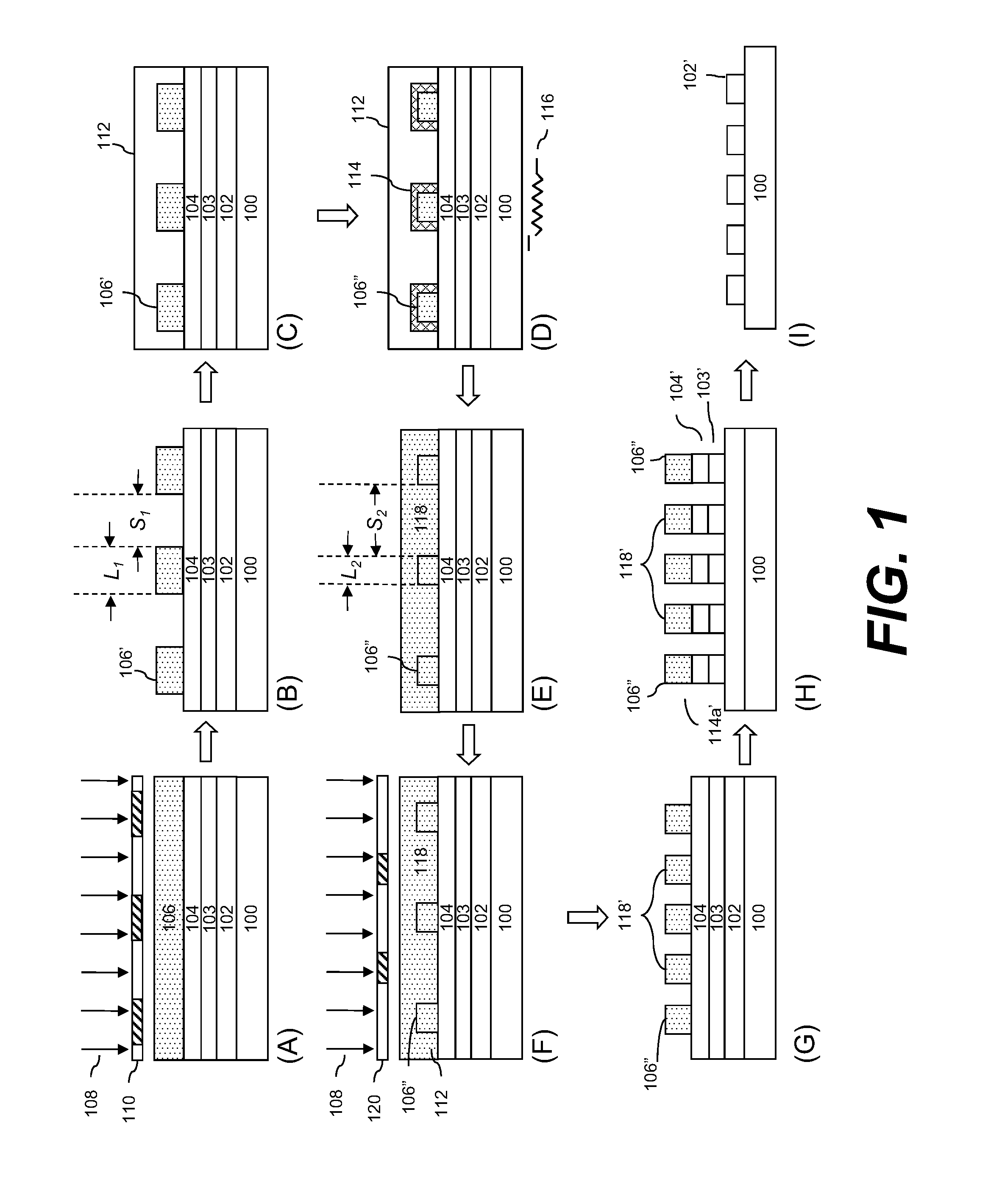

Photoresist pattern trimming methods

ActiveUS20140186772A1Increased process windowSemiconductor/solid-state device manufacturingPhotosensitive material processingResistPolymer science

Provided are methods of trimming a photoresist pattern. The methods comprise: (a) providing a semiconductor substrate; (b) forming a photoresist pattern on the substrate, wherein the photoresist pattern is formed from a chemically amplified photoresist composition comprising: a matrix polymer comprising an acid labile group; a photoacid generator; and a solvent; (c) coating a photoresist trimming composition on the substrate over the photoresist pattern, wherein the trimming composition comprises: a matrix polymer, an aromatic acid that is free of fluorine; and a solvent; (d) heating the coated substrate, thereby causing a change in polarity of the photoresist matrix polymer in a surface region of the photoresist pattern; and (e) contacting the photoresist pattern with a rinsing agent to remove the surface region of the photoresist pattern, thereby forming a trimmed photoresist pattern. The methods find particular applicability in the manufacture of semiconductor devices.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Lubricating grease and preparation method thereof

The invention relates to a lubricating grease, comprising 40-95 wt% of a lubricating base oil, 1-59 wt% of a composite zirconium based densifier and 1-59 wt% of hexapolyurea; and the composite zirconium based densifier is a compound zirconium soap generated from reaction of higher aliphatic acid, aromatic acid, water and zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the following steps: subjecting the zirconium alkoxide, higher aliphatic acid and aromatic acid to a first contact reaction in lubricating base oil at 60-120 DEG C; then subjecting the mixture obtained from the first contact reaction and water to a second contact reaction at 85-100 DEG C, and heating the products obtained from the second contact reaction for dehydration; and introducing the hexapolyurea into the obtained reaction products. The lubricating grease provided by the invention has high drop point, excellent colloidal stability, and excellent extreme pressure wear resistance and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricating grease and preparation method thereof

ActiveCN103060070ADrop point highGood colloidal stabilityLubricant compositionBall bearingBoiling point

The invention relates to lubricating grease, comprising 40-95 wt% of lubricating base oil, 1-59 wt% of a compound zirconium-based thickening agent and 1-59 wt% of a tetrapolyurea, wherein the compound zirconium-based thickening agent is a compound zirconium sceps formed by reacting a higher aliphatic acid, an aromatic acid and water with zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the steps of performing a first contact reaction on the zirconium alkoxide, the higher aliphatic acid and the aromatic acid in the lubricating base oil at a temperature of 60-120 DEG C; then performing a second reaction on the obtained mixture from the first contact reaction with water at a temperature of 85-100 DEG C; and heating the obtained product from the second reaction for dehydration; and then introducing the tetrapolyurea in the obtained reaction product. The lubricating grease has relatively high boiling point, presents excellent colloid stability and has good extreme pressure antiwear property and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Disinfecting compositions and methods of making and using same

InactiveUS20050019421A1High kill rateUse of compositionBiocidePeroxide active ingredientsSolventBiology

The present invention provides a composition, comprising: greater than about 0.1% by weight hydrogen peroxide; an aromatic acid component; surfactant; optionally, a solvent; and a carrier. The composition of the invention is useful as a disinfecting composition for killing microorganisms such as bacterium (including Mycobacterium), spores and fungi. The composition provides a pathogenic bacteria kill rate of 99.9% in about 30 seconds when bacteria are exposed to the composition and is effective in providing a Mycobacterium kill of 106 with two minutes or less. Moreover, the compositions of the invention are generally more resistant to catalase deactivation than, for example, an aqueous solution of hydrogen peroxide. The concentration of hydrogen peroxide within the composition may range from about 1% by weight to about 7% by weight and the concentration of aromatic acid component may range from about 0.1% by weight to about 5% by weight. The invention also provides a method for disinfection of a substrate utilizing the composition. The composition of the invention may be used in the foregoing method on a medical instrument, such as an endoscope or the like. Applying the compositions to a substrate may be accomplished in any of a variety of application methods such as by roll coating, dipping, spraying, or rotational tumbling. The composition may be applied to the substrate for a period of time ranging from about 30 seconds to about ten minutes. In this aspect, the invention can further comprise drying the substrate after removing the composition.

Owner:3M INNOVATIVE PROPERTIES CO

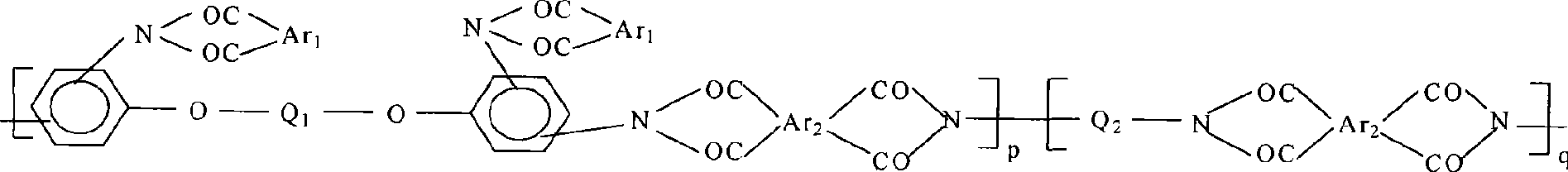

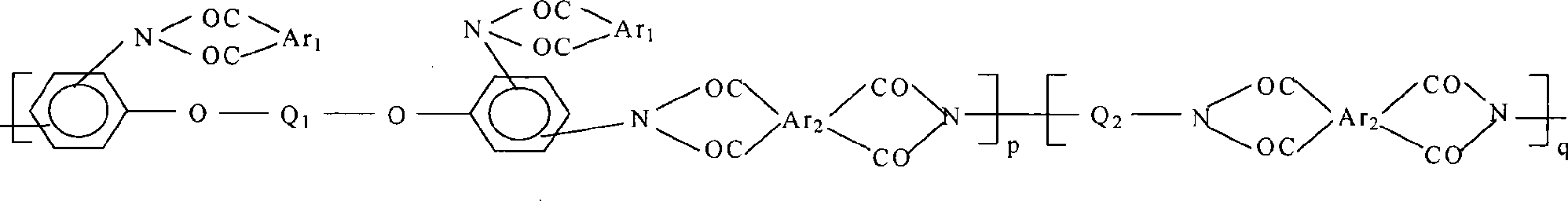

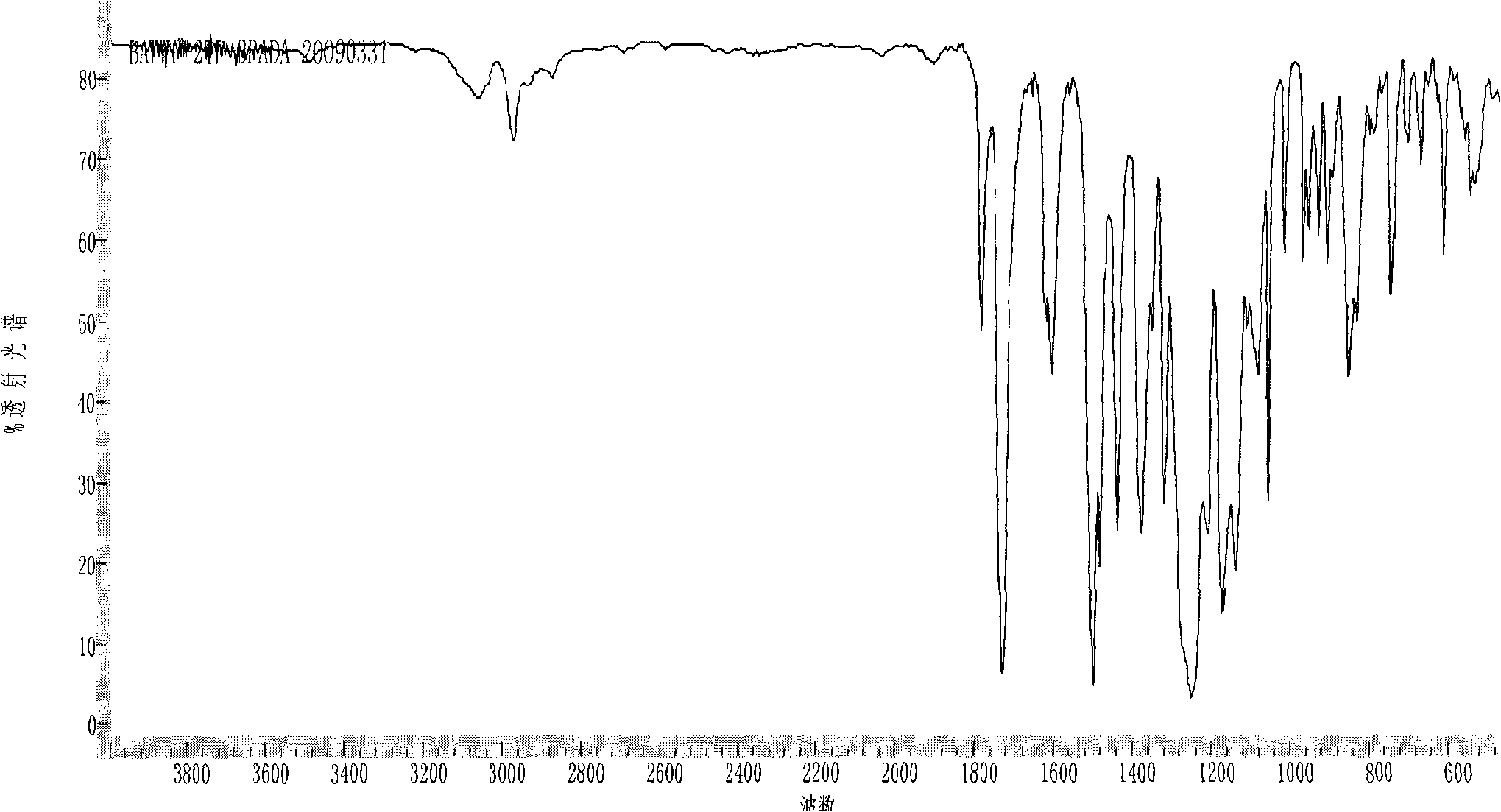

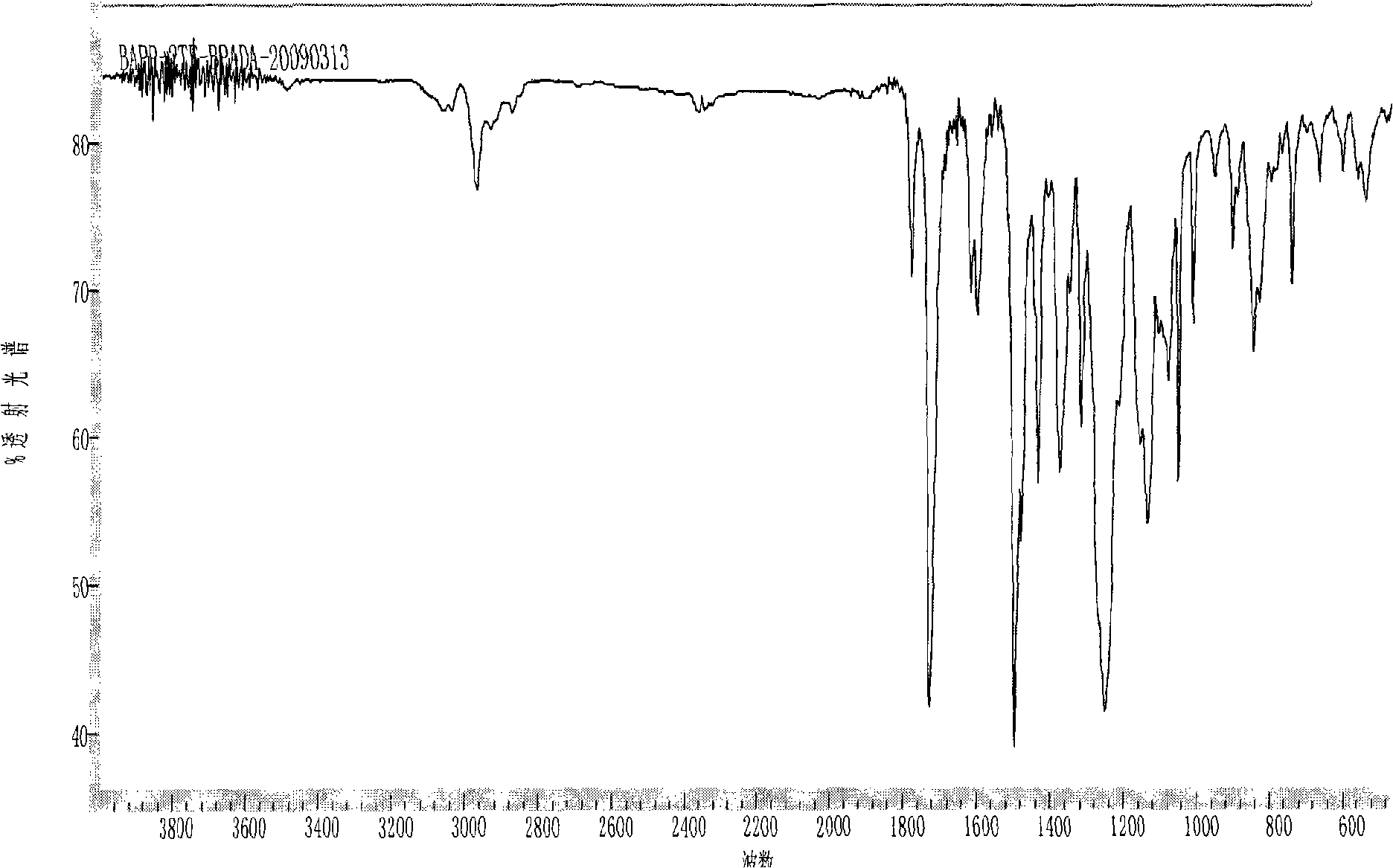

Colorless transparent aromatic polyimide film and preparation method thereof

The invention discloses a colorless and transparent aromatic polyimide film which has the general formula of molecular structure as follows; the preparation thereof includes: aromatic primary amine and aromatic acid anhydride with specific molecular structures are adopted for polymerization in a strong polar aprotic organic solvent system within the temperature range of 0 DEG C to 35 DEG C to prepare a colorless and transparent viscous polyamide acid solution with homogeneous phase. Viscosity adjustment, casting for forming the film, heating for rising temperature and solvent removal are carried out simultaneously when partial imidization reaction is carried out, and then demoulding and stretching, further deep thermal imidization and rolling are carried out to obtain the colorless and transparent aromatic polyimide film. No special production equipment is required by the invention so that production can be carried out on the conventional production line of the polyimide film and the polyimide film is applicable to industrialized production.

Owner:DONGHUA UNIV +3

Lubricating grease and preparation method thereof

The invention relates to a lubricating grease, comprising 40-95 wt% of a lubricating base oil, 1-59 wt% of a composite zirconium based densifier and 1-59 wt% of octapolyurea; and the composite zirconium based densifier is a compound zirconium soap generated from reaction of higher aliphatic acid, aromatic acid, water and zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the following steps: subjecting the zirconium alkoxide, higher aliphatic acid and aromatic acid to a first contact reaction in lubricating base oil at 60-120 DEG C; then subjecting the mixture obtained from the first contact reaction and water to a second contact reaction at 85-100 DEG C, and heating the products obtained from the second contact reaction for dehydration; and introducing the octapolyurea into the obtained reaction products. The lubricating grease provided by the invention has high drop point, excellent colloidal stability, and excellent extreme pressure wear resistance and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

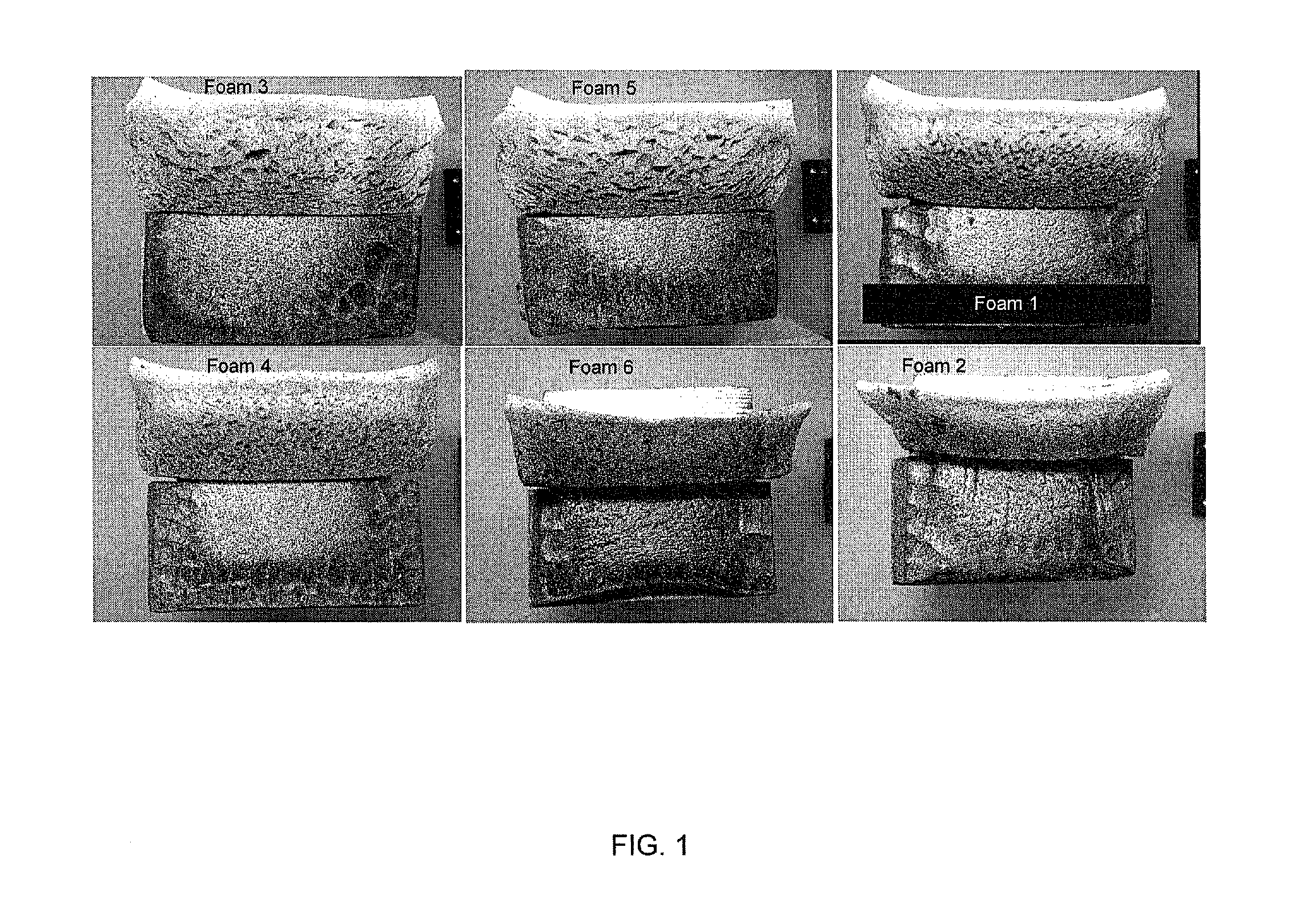

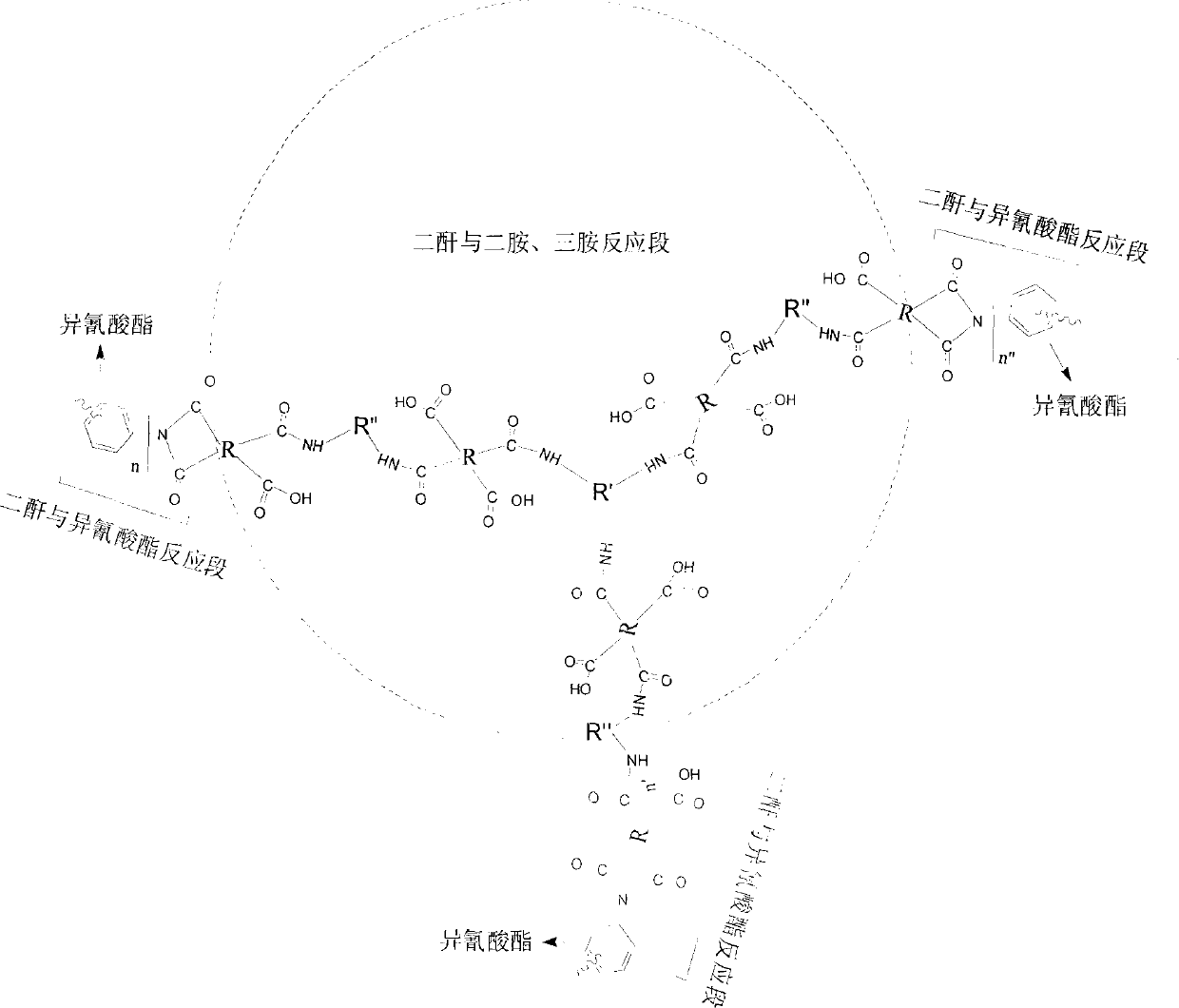

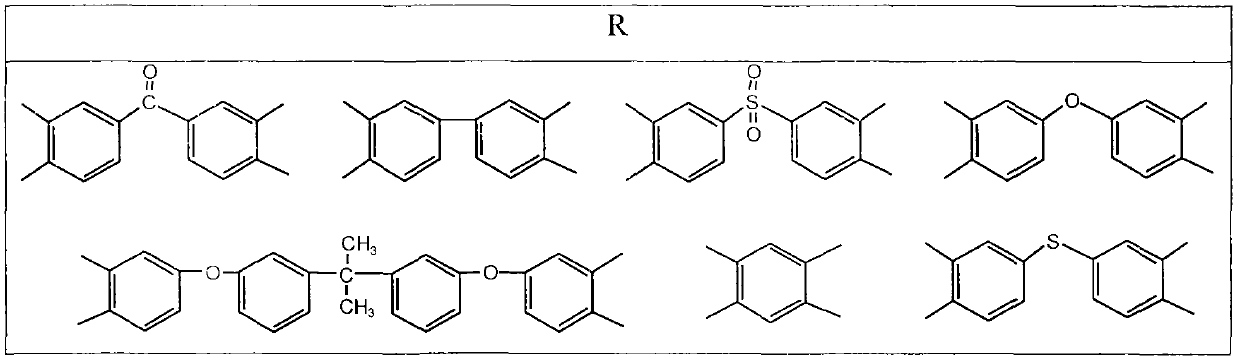

Polyimide foam and method of producing the same

The invention discloses polyimide foam and a preparation method thereof. Aromatic dianhydride and / or aromatic acid ester, alcohol with low molecular, a catalyst and a surface active agent are mixed proportionally in a polar solvent and react so as to form foam precursor solution. The foam precursor solution and isocyanate react in a mould and freely foam into a foam intermediate. The intermediate is solidified by microwave radiation or / and oven heating to obtain solid polyimide foam. The preparation process has short path, simple technology, good stability for storage of the foam precursor solution, adaptation to processing technologies of pouring, spray coating, extrusion, and the like, no occurrence of defects of cracked foam, foam combination, subsidence and incomplete amination, low preparation cost as well as uniform hold diameter and stable performance of the solid polyimide form, and is convenient for popularization and application.

Owner:BEIJING RADIATION APPL RES CENT

Non-halide cleaning-free welding flux for leadless solder

InactiveCN101062536AImprove solderabilityHigh insulation resistanceWelding/cutting media/materialsSoldering mediaSurface-active agentsAmino acid

The invention relates to a lead free soldering clean free soldering flux with the mass percentage of organic acid activating agent 1. 5-3. 5%, surface active agent 0. 04-0. 6%, organic amine and derivant 2. 0-5. 0%, with the rest being film forming matter. The said organic acid could be one or more of the aliphatic acid mono acid or bi-acid, aromatic acid, or amino acid. The said surface active agent is one or more of the nonion surface active agent, and the said organic amine and the derivant being ethanediamine, tetramethylenediamine, diethyl ethanolamine and so on, with the said film forming material being diethyl ethanolamine or resin. The soldering flux does not have halogen, being environmental protective, good in welding, welding spot being full and luminous, without residue, no corrosion, high in isolation resistance.

Owner:CENT SOUTH UNIV

Methods and compositions for controlling a pest population

InactiveUS6124275ALow toxicityPrevent intrusionSalicyclic acid active ingredientsBiocideMammalPest control

The invention is directed to a method for controlling a pest population using a composition comprising a benzyl ester of an aromatic acid or aliphatic acid or a salicylate. Methods and compositions for controlling a pest population are provided. The compositions comprise a benzyl ester of an aromatic acid or aliphatic acid or a salicylate. The composition can include at least one fatty-acid ester to increase the pesticidal activity. The subject method controls the population of pests such as plant pests or pests infesting a mammal by contacting the pests with the composition. The subject method reduces the environmental and health hazards in pest control by minimizing the toxicity of the subject composition.

Owner:SUMMUS GROUP

Hard polyimide foaming structural material and preparation method thereof

The invention discloses a hard polyimide foaming structural material and a preparation method thereof. The method comprises the following steps of: mixing aromatic dianhydride and / or aromatic acid ester, high molecular alcohol, low molecular alcohol, a catalyst and a surfactant according to a ratio into a polar solvent and reacting to form polyimide foam precursor solution; reacting the precursor solution with isocyanate in a die; pressurizing and foaming to form a polyimide foam intermediate; and performing microwave radiation or / and performing heat curing by using an oven to obtain the hard polyimide foaming structural material. The preparation process route is short and the process is simple; the storage stability of the foam precursor solution is high; and the prepared hard polyimide foaming structural material has uniform aperture, hard quality, high strength, low density and high temperature resistance, is non-toxic and environmentally-friendly in the foaming process and easy to industrialize, and can be applied in the fields of electron, carrier rockets, aviation, ships, railway locomotives and the like.

Owner:BEIJING RADIATION APPL RES CENT

Lubricating grease and preparation method thereof

The invention relates to a lubricating grease, comprising 40-95 wt% of a lubricating base oil, 1-59 wt% of a composite zirconium based densifier and 1-59 wt% of bipolyurea; and the composite zirconium based densifier is a compound zirconium soap generated from reaction of higher aliphatic acid, aromatic acid, water and zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the following steps: subjecting the zirconium alkoxide, higher aliphatic acid and aromatic acid to a first contact reaction in lubricating base oil at 60-120 DEG C; then subjecting the mixture obtained from the first contact reaction and water to a second contact reaction at 85-100 DEG C, and heating the products obtained from the second contact reaction for dehydration; and introducing the bipolyurea into the obtained reaction products. The lubricating grease provided by the invention has high drop point, excellent colloidal stability, and excellent extreme pressure wear resistance and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas delivery pipeline drag reducer and preparation thereof

The invention relates to a gas conveying pipeline drag reducer used in gas and particularly natural gas conveying pipeline drag reduction and a preparation method thereof, relating to a macromolecular compound composition and the pipeline system technical field. The gas conveying pipeline drag reducer is characterized in that: the drag reducer consists of pyridine, secondary amine, formaldehyde or acetaldehyde, aromatic acid and deionized water; when total weight is counted as 100 percent, the compositions in percentage by weight are: 10 to 20 percent of the pyridine, 20.4 to 28.4 percent of the secondary amine, 7.6 to 8.4 percent of the formaldehyde or the acetaldehyde, 37 to 38.4 percent of the aromatic acid and 13 to 15 percent of the deionized water. The preparation method comprises the following steps that: the pyridine and the secondary amine in proportional quantities are added in a container and are mixed evenly; the formaldehyde or the acetaldehyde in proportional quantity is dripped to carry out reaction; the aromatic acid in proportional quantity is added, and the deionized water in proportional quantity is dripped so as to carry out reaction continuously; and finally, redundant water is removed, and a target product is obtained after purification. The gas conveying pipeline drag reducer has direct source of raw materials; moreover, the preparation method has simple process, convenient operation and moderate reaction conditions, and a product prepared by the method has excellent drag reduction effect.

Owner:PIPECHINA SOUTH CHINA CO

Rejuvenation of reclaimed asphalt

ActiveUS20140338565A1Low cloud and pour pointImprove thermal stabilityIn situ pavingsSolid waste managementCrack resistanceFatty acid

Asphalt compositions comprising reclaimed asphalt and a rejuvenating agent are disclosed. The reclaimed asphalt comprises aggregate and an aged binder. The rejuvenating agent, which has a cyclic content of at least 5 wt. %, comprises an ester or ester blend derived from an acid selected from aromatic acids, fatty acids, fatty acid monomers, fatty acid dimers, fatty acid trimers, rosin acids, rosin acid dimers, and mixtures thereof. The rejuvenating agent revitalizes the aged bitumen binder of reclaimed asphalt and restores its physical properties to those of the original performance-grade bitumen. Improvements include desirable softening, low-temperature cracking resistance, better fatigue cracking resistance, good elevated temperature performance, improved miscibility, and restored temperature sensitivity. The rejuvenating agents enable the use of higher levels of recovered asphalt, particularly RAP, in asphalt mixtures, reduce binder and aggregate costs, and help the road construction industry reduce its reliance on virgin, non-renewable materials.

Owner:KRATON CHEM LLC

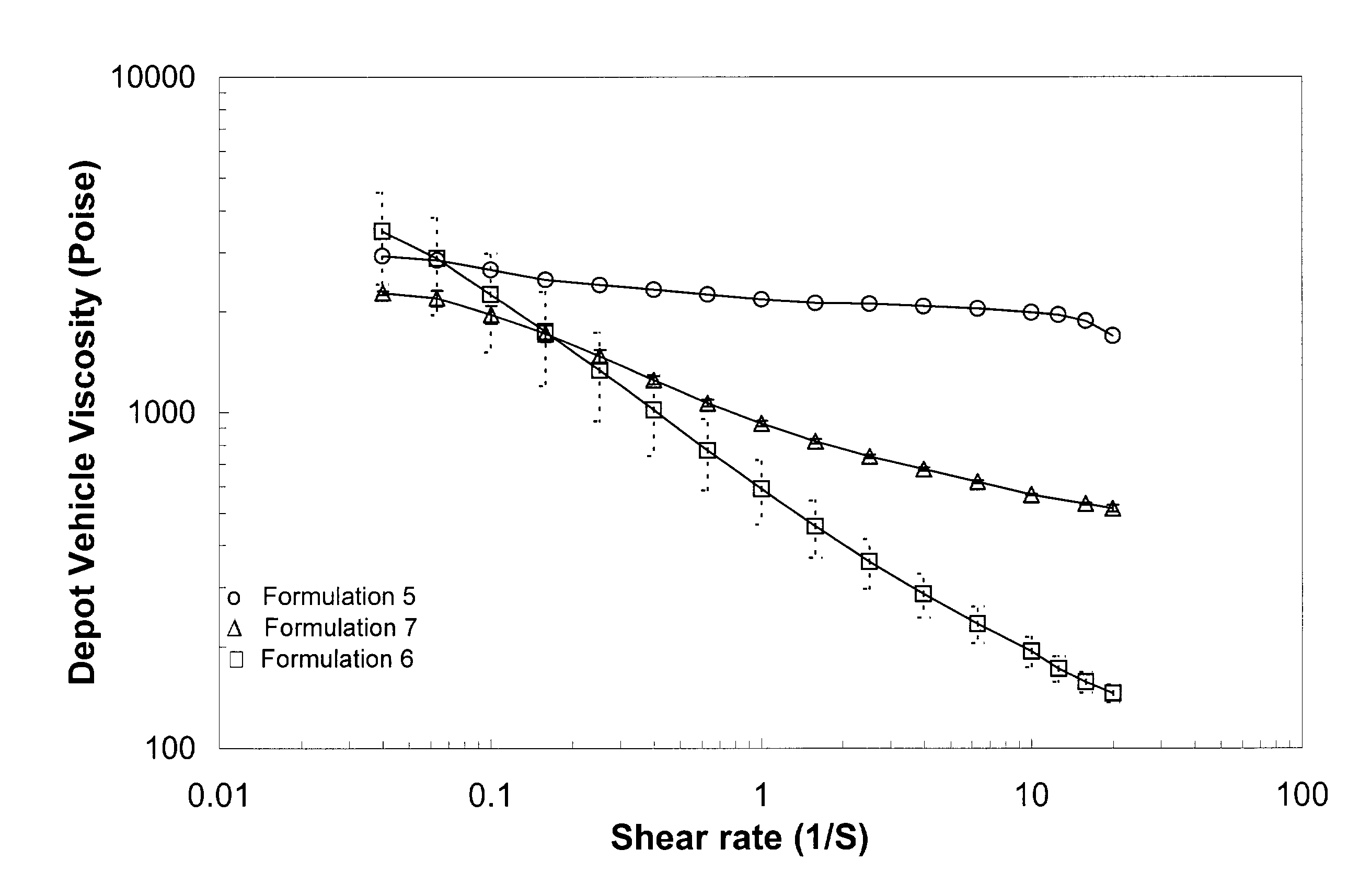

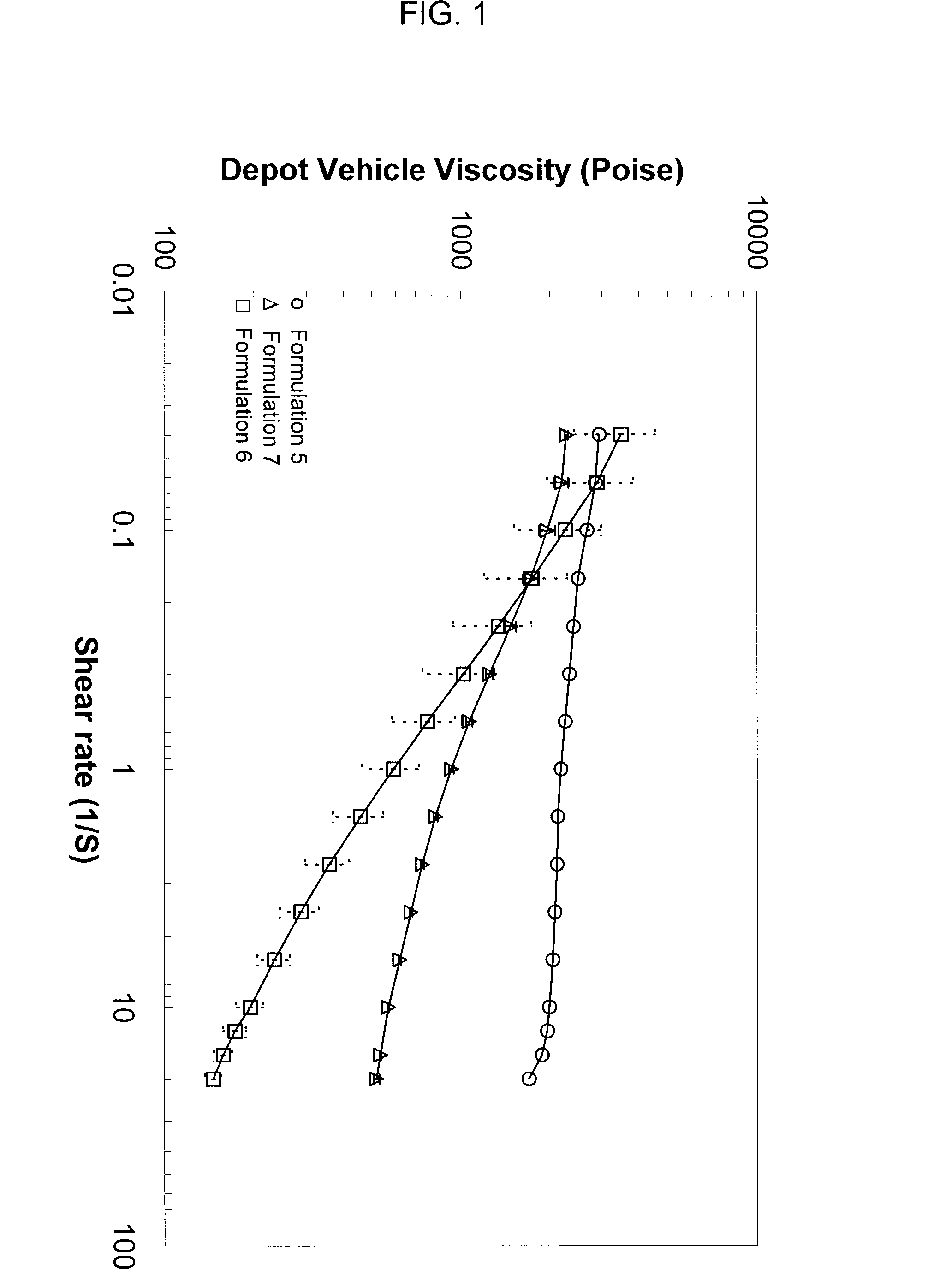

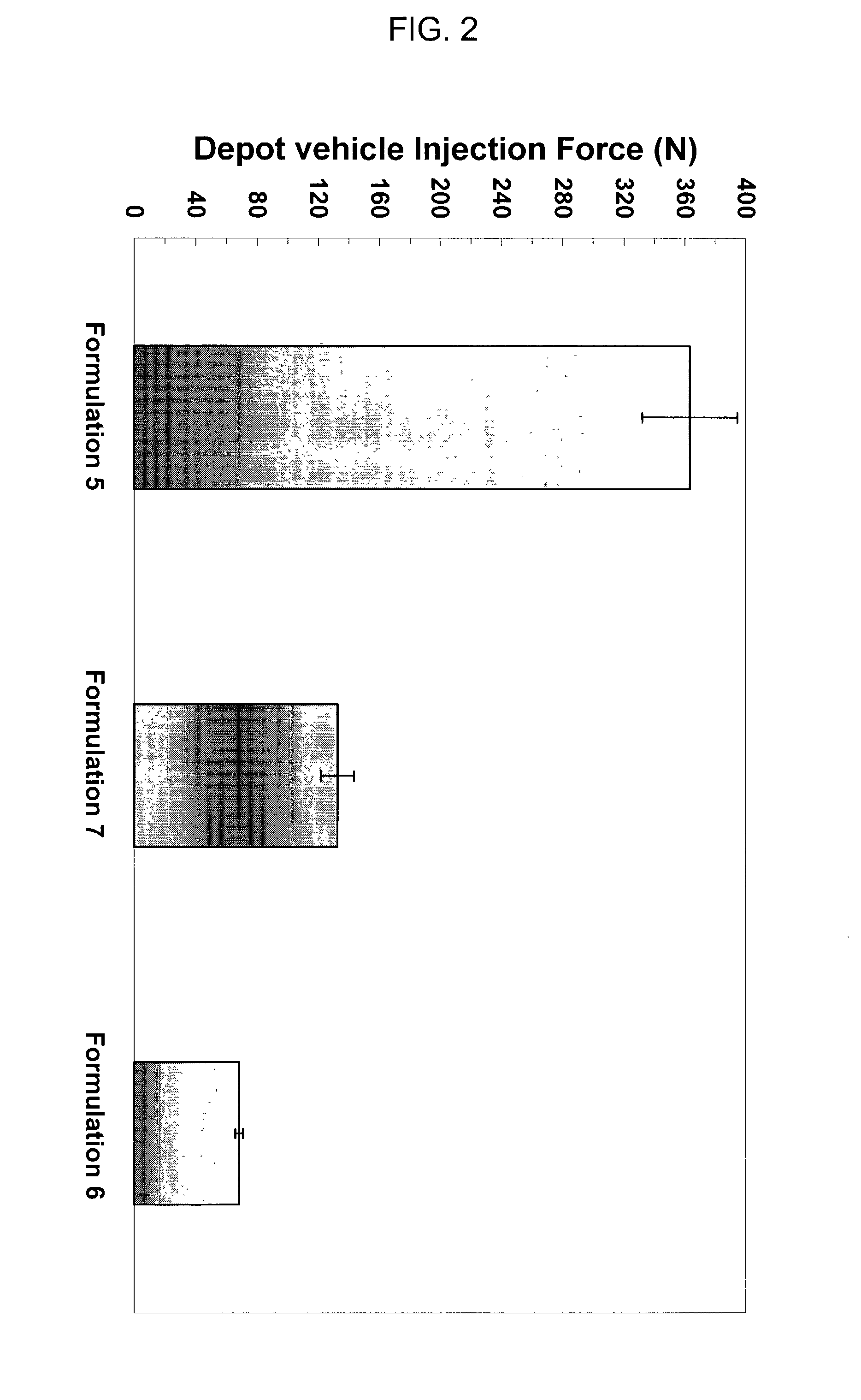

Catheter injectable depot compositions and uses thereof

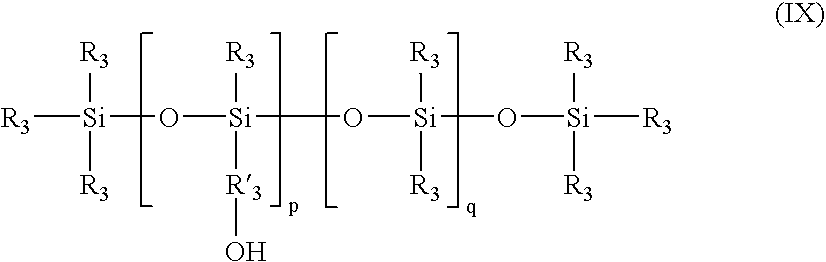

InactiveUS7829109B2Improved shear thinning behaviorReduce injection forcePowder deliverySenses disorderMedicineAromatic alcohol

Catheter injectable depot compositions are provided that include a bioerodible, biocompatible polymer, a solvent having miscibility in water of less than or equal to 7 wt. % at 25° C., in an amount effective to plasticize the polymer and form a gel therewith, a thixotropic agent, and a beneficial agent. The solvent comprises an aromatic alcohol, an ester of an aromatic acid, an aromatic ketone, or mixtures thereof. The compositions have substantially improved shear thinning behavior and reduced injection force, rendering the compositions readily implanted beneath a patient's body surface by injection.

Owner:DURECT CORP

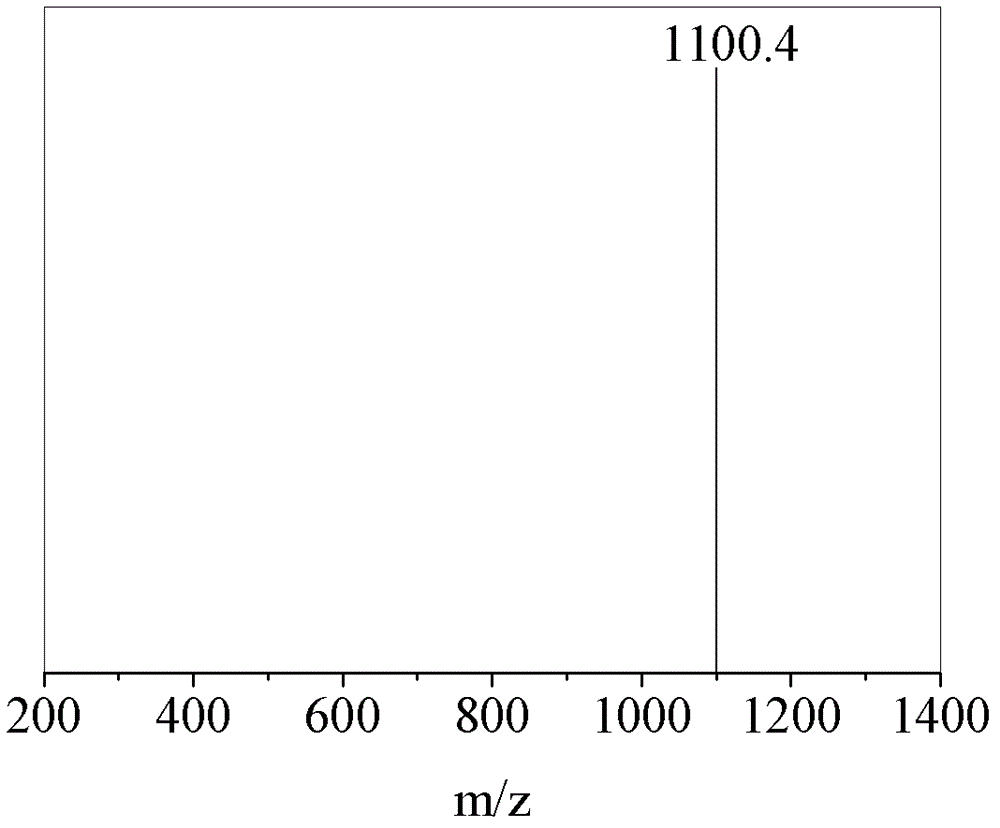

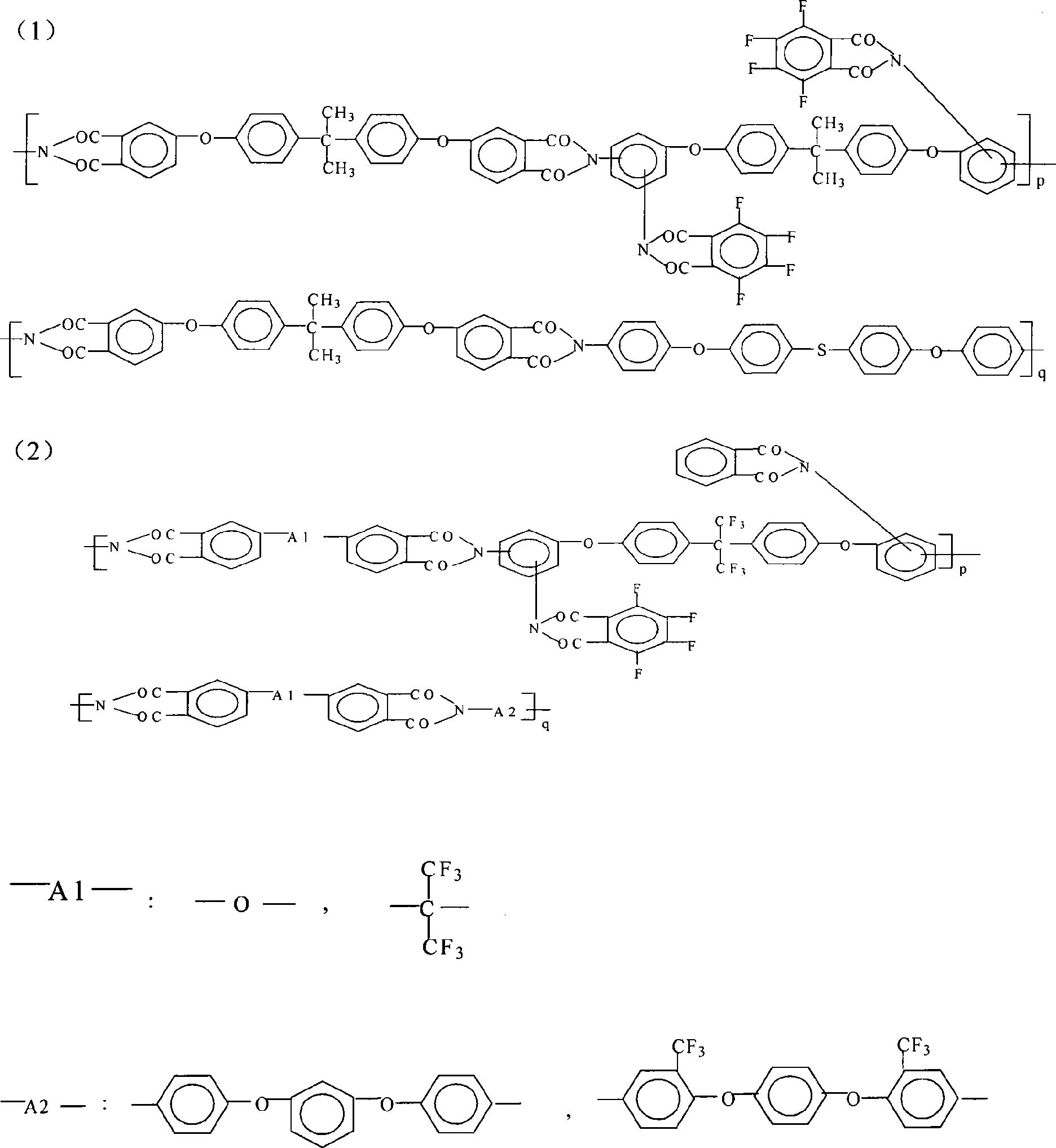

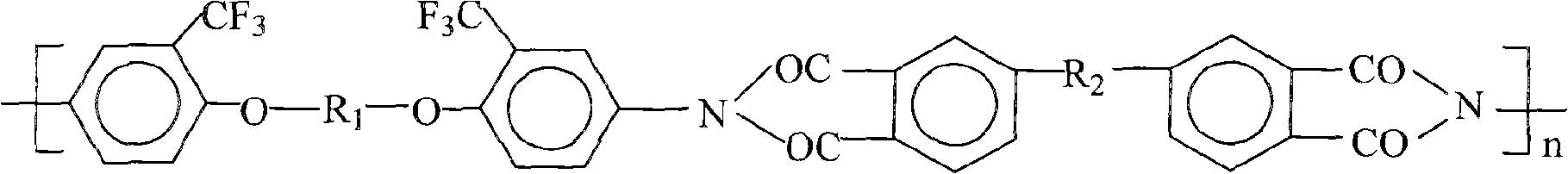

Thermoplastic fluorine-containing fully aromatic polyimide powder and preparation method thereof

The invention relates to thermoplastic fluorine-containing fully aromatic polyimide powder, which has a general molecular structural formula shown above, wherein -R1 is a divalent linking group of fluorine-containing aromatic primary diamine; and -R2 is a divalent linking group of a molecule of aromatic acid dianhydride. The method comprises the following steps: reacting the fluorine-containing aromatic primary diamine with the aromatic acid dianhydride in a phenol solvent in the presence of a catalyst for 5 to 10 hours; pouring the hot solution in a precipitator with high-speed stirring to precipitate solid powder; and obtaining the thermoplastic fluorine-containing fully aromatic polyimide powder after filtration, washing, soaking, filtration and drying. The thermoplastic fluorine-containing fully aromatic polyimide powder has good solubility, is a high-performance heat-resistance toughness modifier for epoxy resin, unsaturated polyimide resin, unsaturated polyester resin and other thermosetting resins, and is good in application prospect, simple in operation, low in cost, environmentally-friendly, and suitable for industrial production.

Owner:DONGHUA UNIV

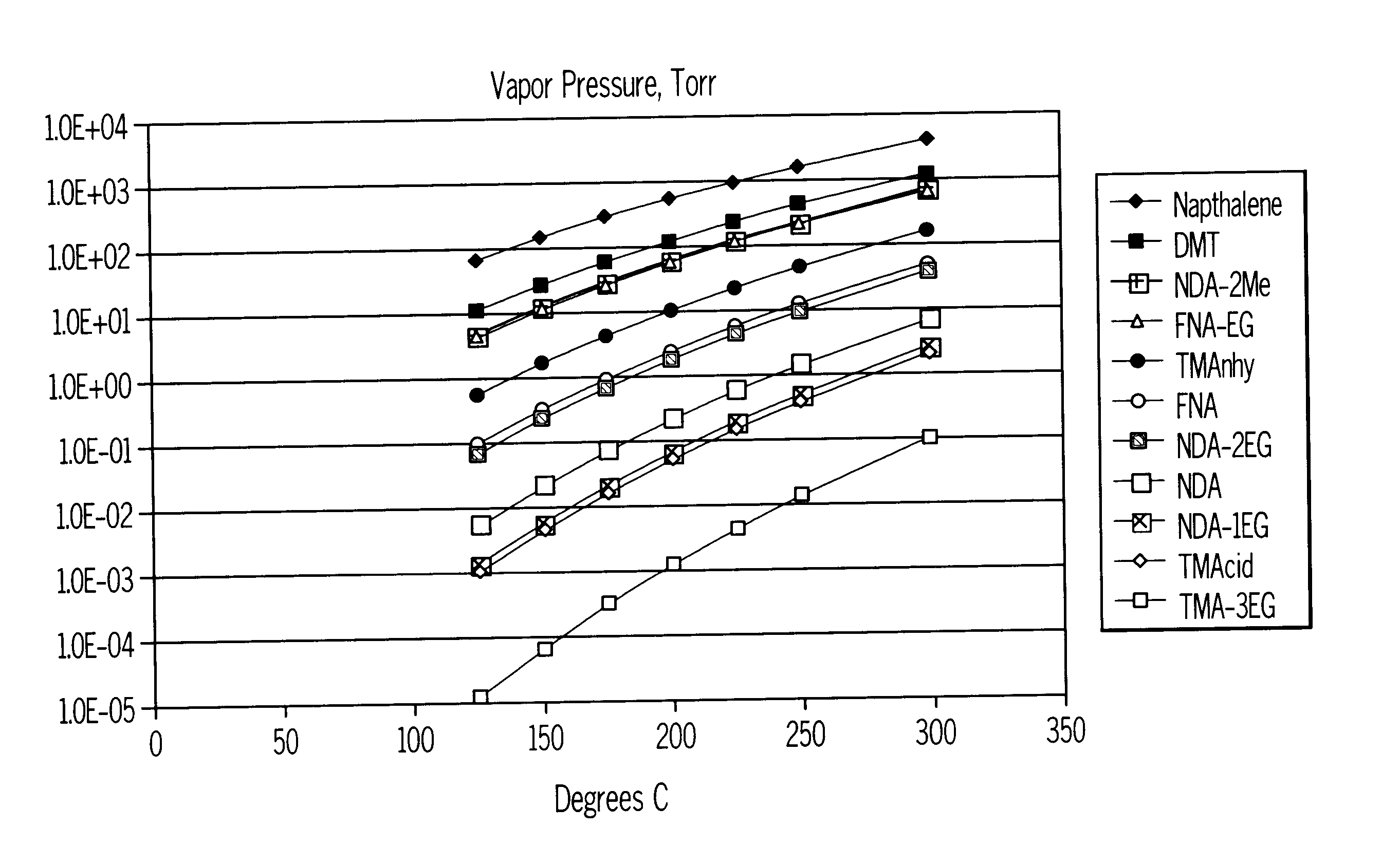

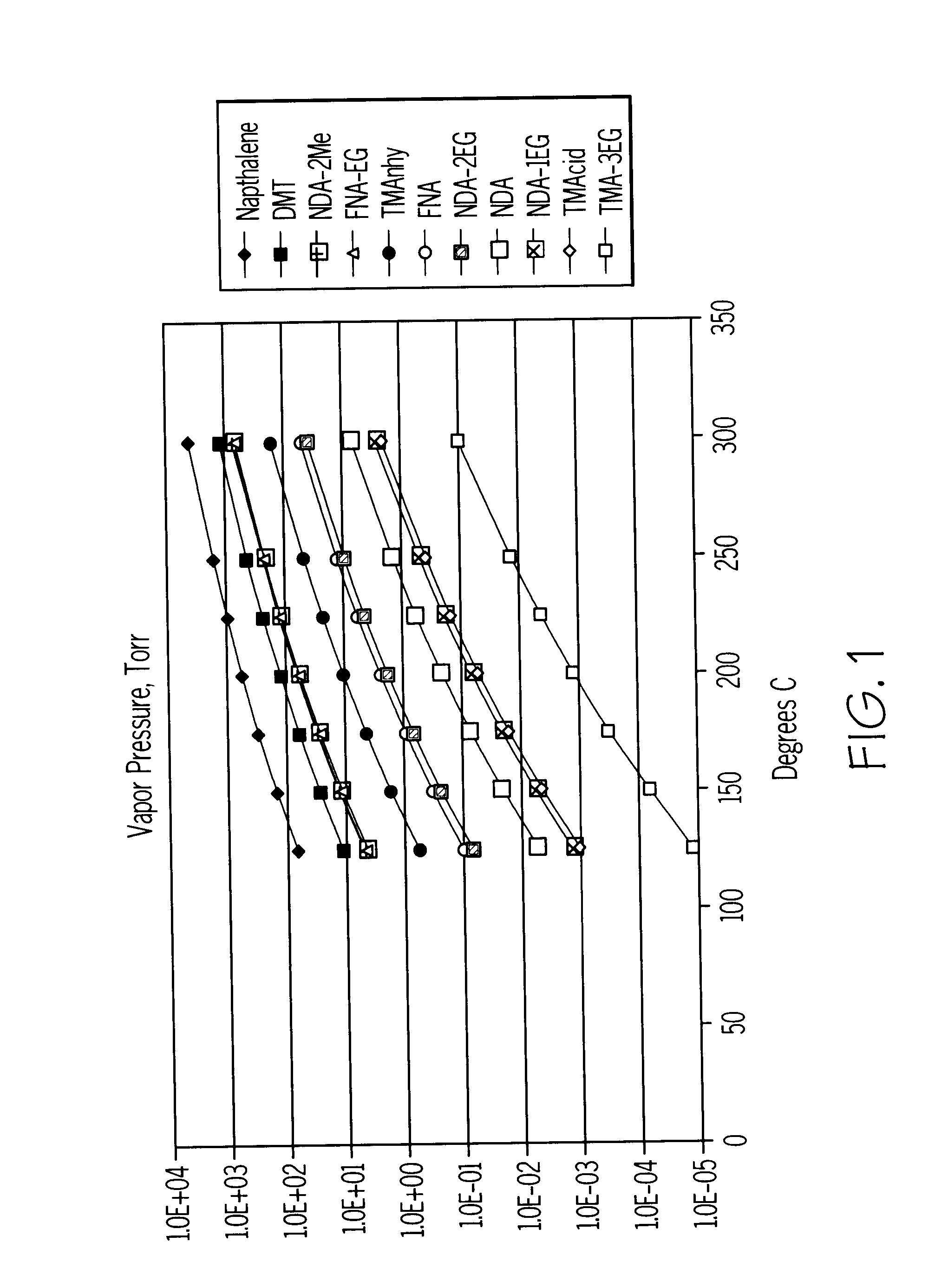

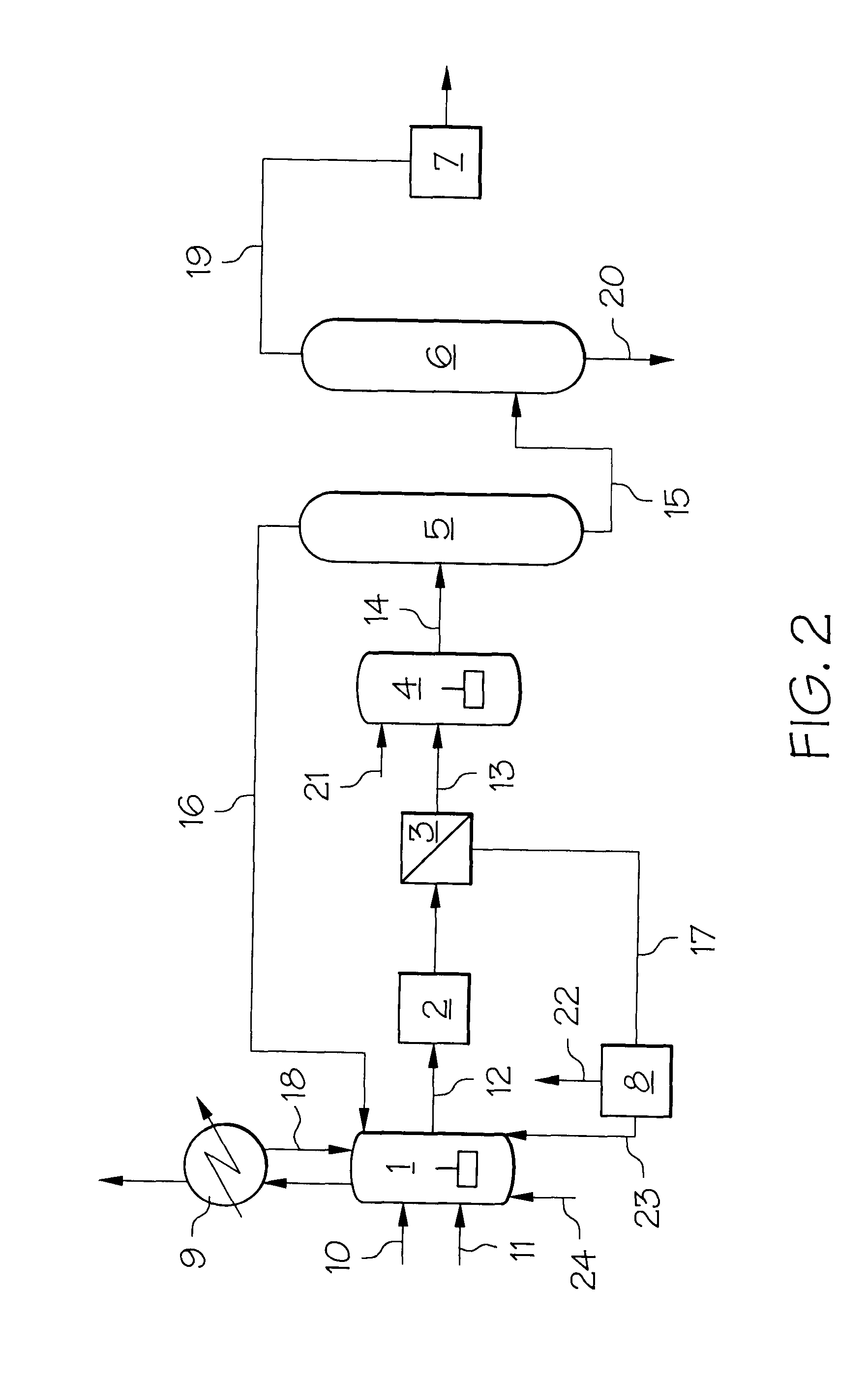

Production, purification and polymerization of aromatic dicarboxylic acids

InactiveUS6642407B2Reduce pressureOrganic compound preparationCarboxylic acid esters separation/purificationPolyesterPartial oxidation

This invention provides a process for purifying the crude aromatic dicarboxylic acids produced by oxidation of dialkyl aromatic hydrocarbons and for using the purified acids in the preparation of polyethylene terephthalate, polyethylene naphthalate and other polyesters. The invention simplifies the manufacturing process by converting the crude aromatic acids into bis-glycol esters in an esterification reactor 4, from which the esterified partial oxidation impurities present in the oxidation product are removed by distillation in distillation tower 5. After removal of the volatile impurities, the dicarboxylic acid esters can separated by distillation in distillation tower 6 or by crystallization and converted to polyesters by polycondensation. The volatile impurities removed as overhead from tower 5 can be recycled as stream 16 to the oxidation reactor where they act as oxidation promoters thereby optionally allowing for a bromine-free oxidation process for dialkyl aromatic hydrocarbons.

Owner:EXXONMOBIL CHEM PAT INC

Fuel oil additive and fuel oil products containing the fuel oil additive

InactiveUS20040065002A1Improve performanceBoost octaneLiquid carbonaceous fuelsFuel additivesAlkaline earth metalKerosene

The present invention provides a fuel oil additive capable of effectively improving the quality of fuel oils, which comprises an oil-soluble metal salt of organic acid having the general formula MR, where R is an organic acid radical and the corresponding organic acid is a C1-C40 saturated or unsaturated fatty acid, naphthenic acid, aromatic acid or alkylphenol, M is a metal cation and the corresponding metal is an alkali metal, alkali-earth metal, rare-earth metal, transition metal, or the like. The present invention also provides fuel oil products added to the fuel oil additive, including gasoline, diesel oil, kerosene, heavy oil, resid, or the like. The present invention especially provides a gasoline antiknock agent and a gasoline having excellent antiknock property, and this kind of gasoline antiknock agent is characteristic of effectiveness, economy, safety, no environmental pollution, no toxicity to human body, no adverse effect on parts of automobile engine, use convenience, and the like.

Owner:HU SHIBIN

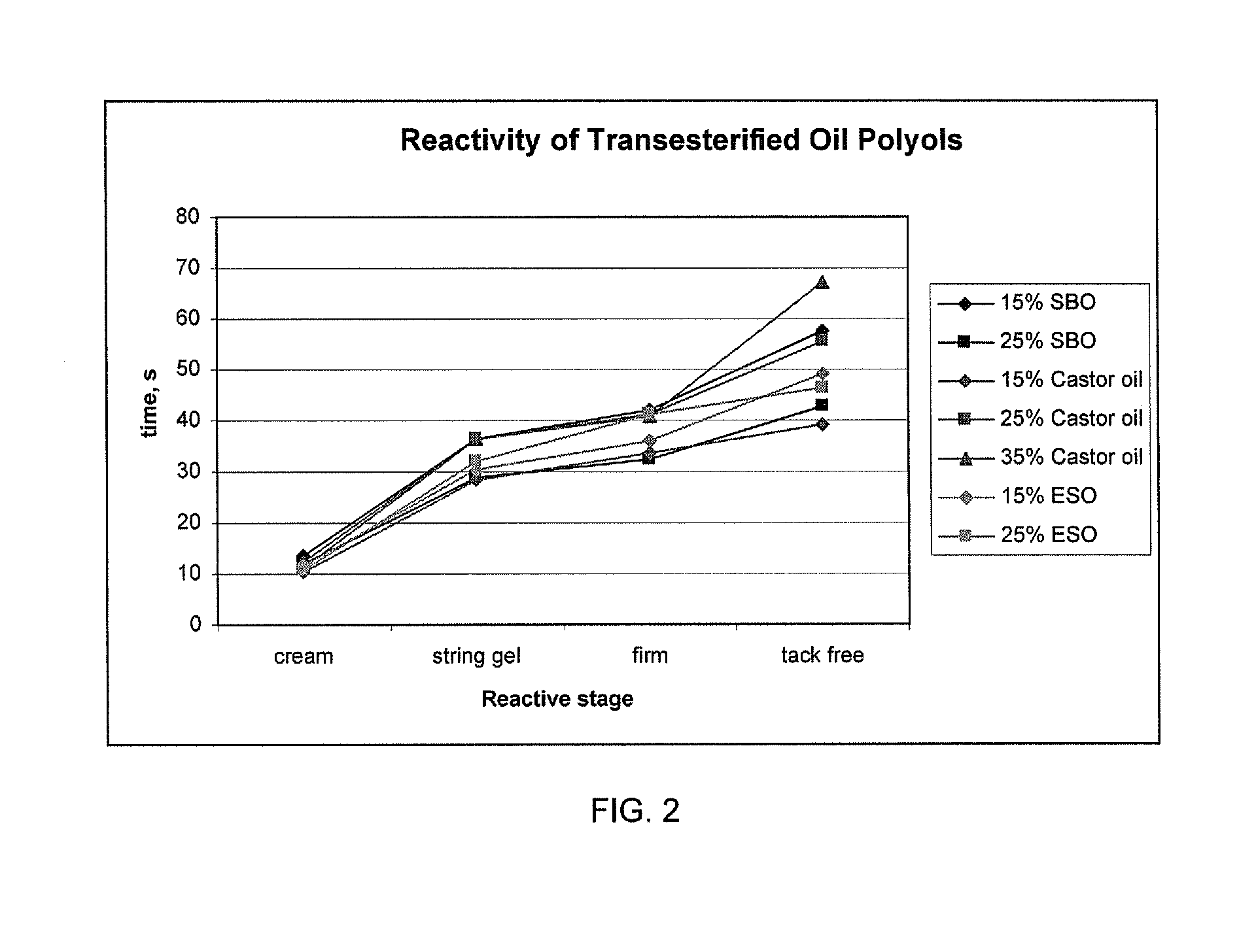

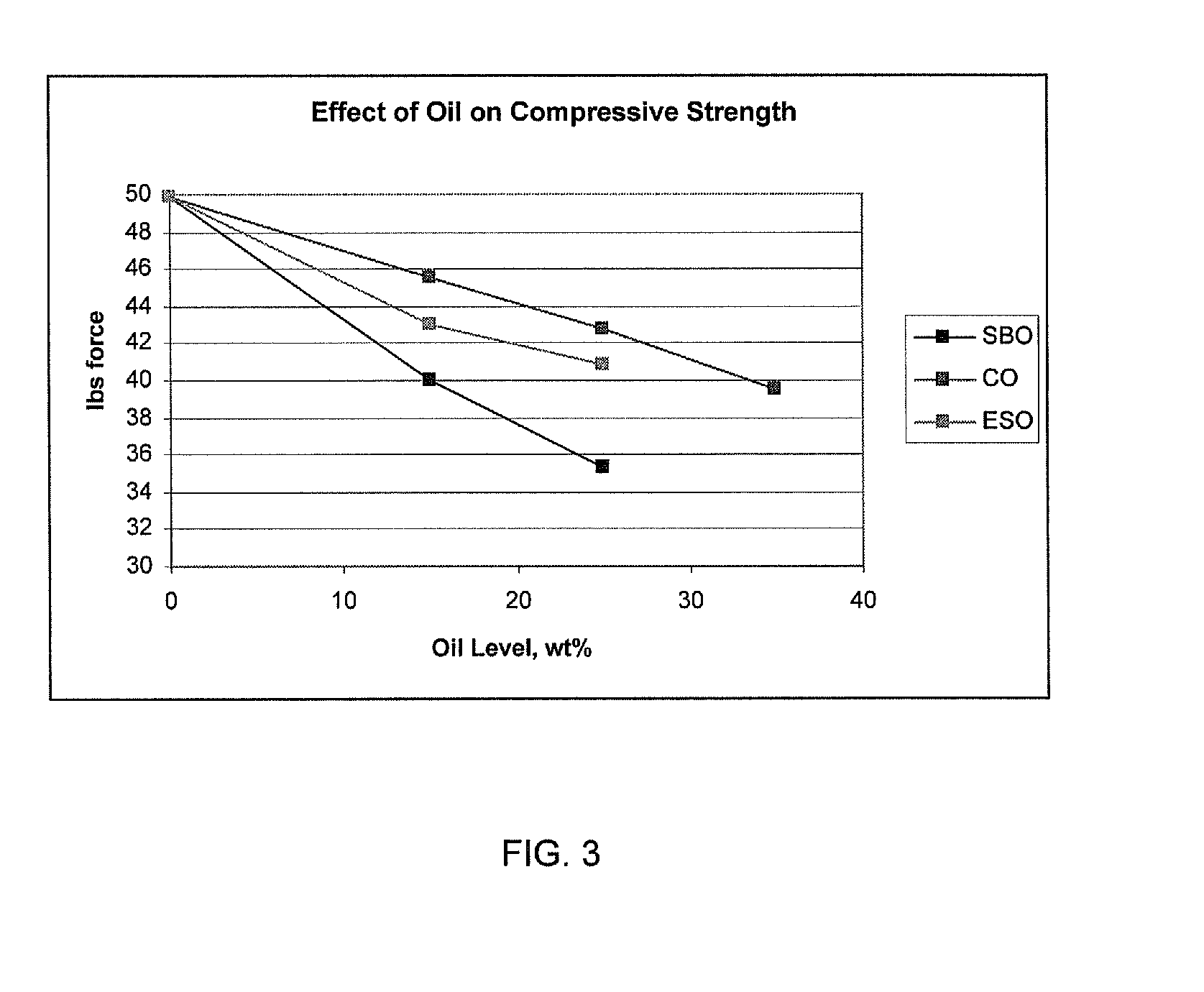

Aromatic Polyester Polyols and Aromatic Polyester Polyol Blends Containing Biorenewable Components and Methods of Making

There are provided aromatic polyester polyol compositions comprising: (i) at least one aromatic acid component; (ii) at least one hydroxylated component; (iii) at least one functionalized natural oil component; and (iv) optionally at least one catalyst component for use in preparing foams. The aromatic polyester polyol compositions can be formed by esterification and / or transesterification. The present technology also provides a polyol blend for use in preparing foams wherein the polyol blend comprises (a) an aromatic polyester polyol formed by an interesterification reaction between (i) a phthalic acid based material; (ii) a hydroxylated material; and (iii) a hydrophobic material, wherein the hydrophobic material is present in an amount of from about 1% to about 50% by weight of the aromatic polyester polyol; and (b) a natural oil based polyol, wherein the hydrophobic material in the aromatic polyester polyol compatibilizes the natural oil based polyol to form a phase stable polyol blend.

Owner:STEPAN COMPANY

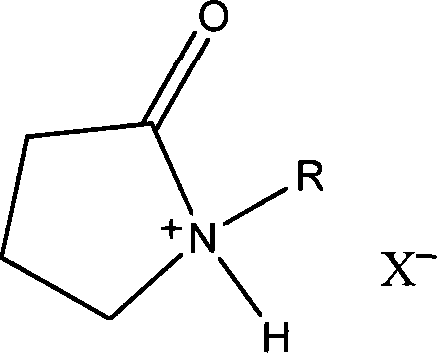

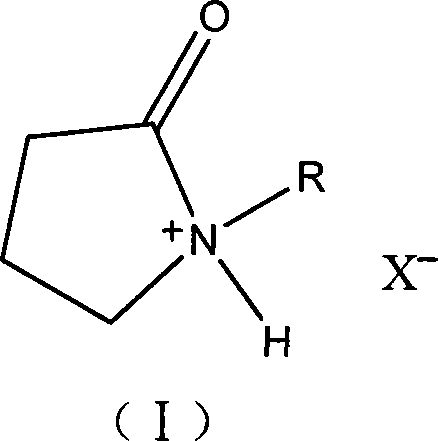

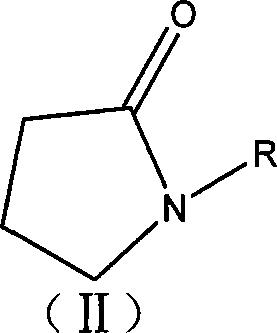

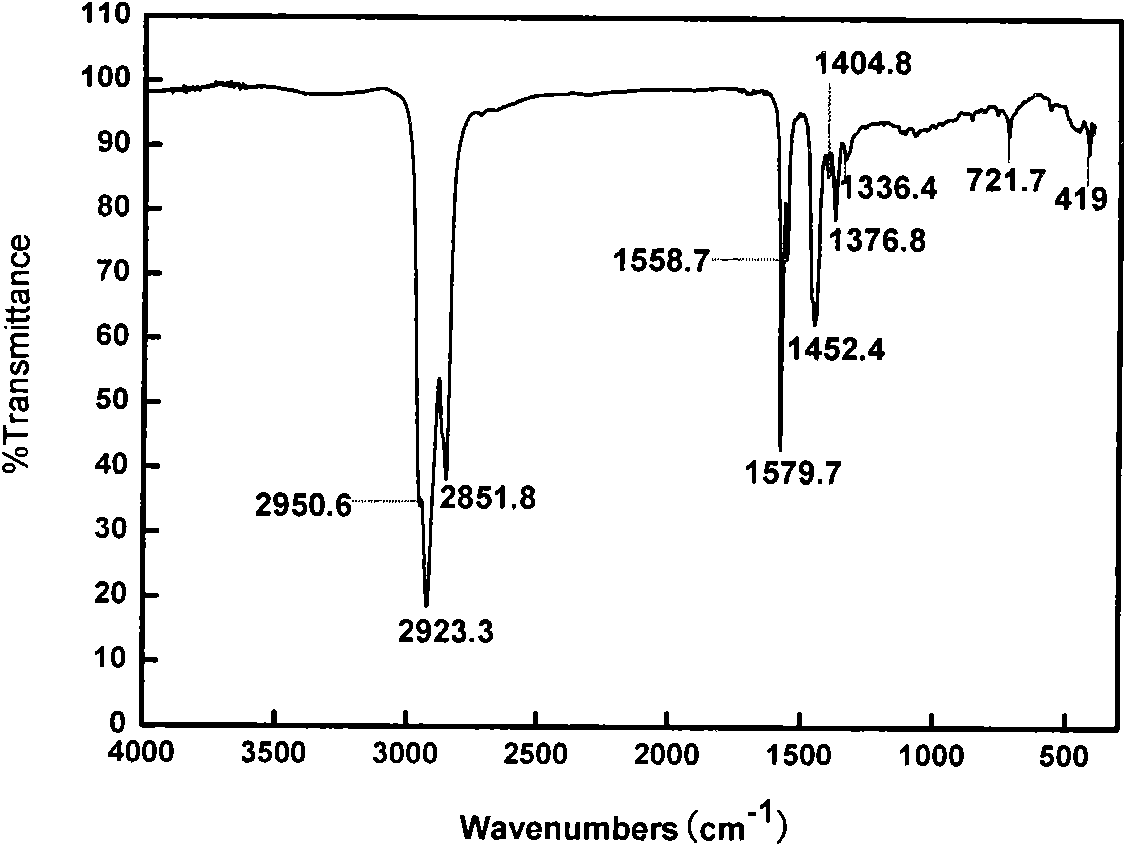

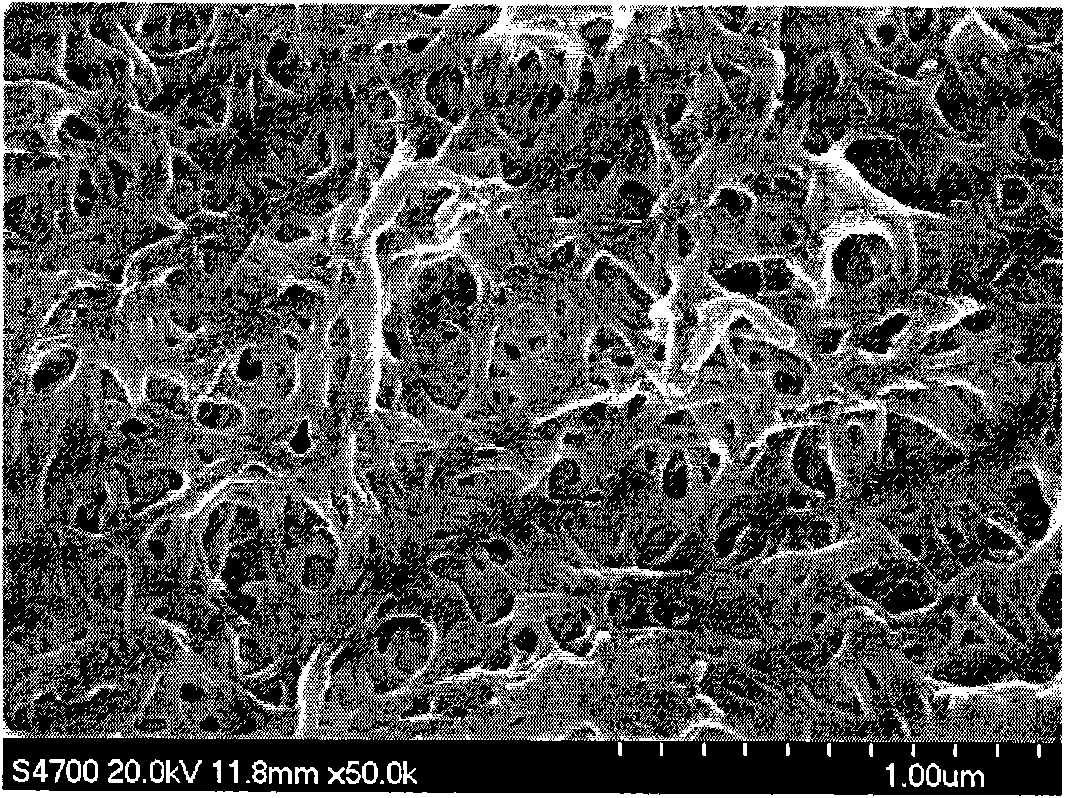

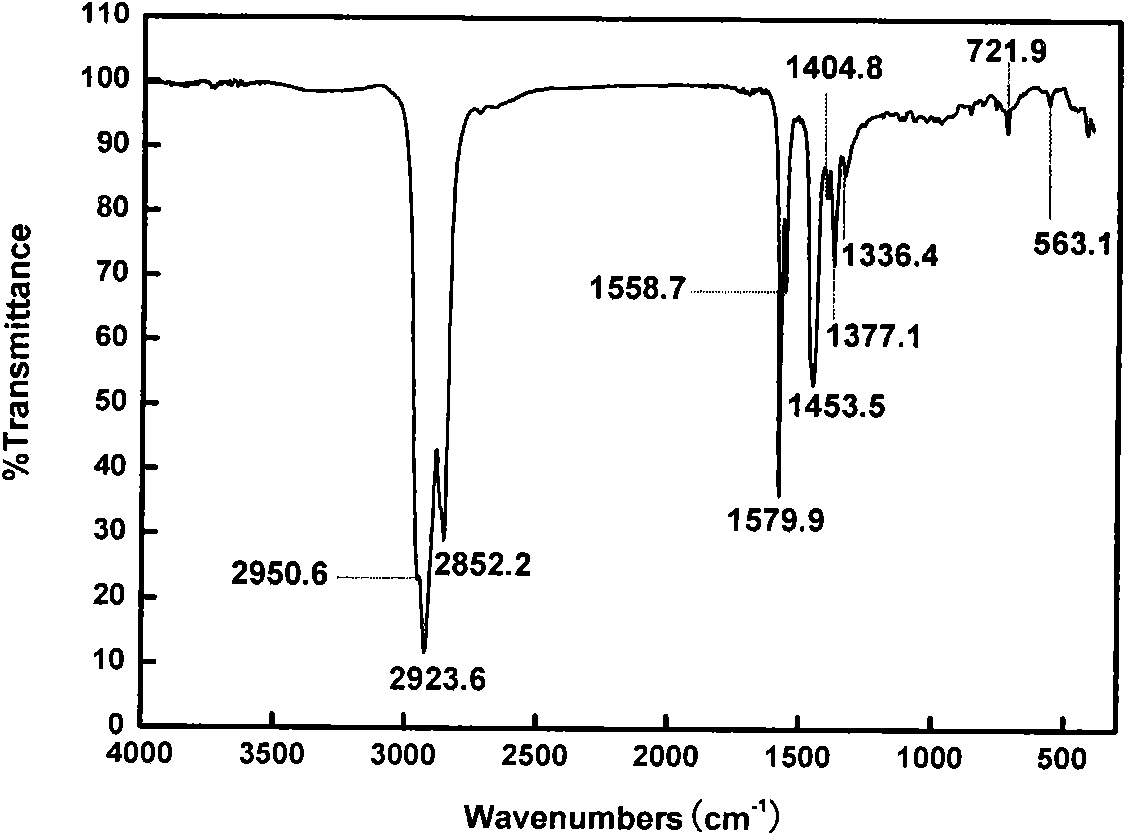

Ion liquid catalyst of esterification reaction, preparation method and usage

InactiveCN101049573AEasy to synthesizeLow costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical reactionAlcohol

A liquid catalyst containing N-alkylpyrrolidone-yl Bronsted acid ions for esterifying reaction has high transform rate, selectivity and cyclic life (more than 20). Said esterifying process includes such steps as providing fatty acid or aromatic acid and straight- or branch-chain alcohol, mixing while adding said catalyst used also as solvent, stirring, heating, laying aside, gravitational depositing, and separating liquid to obtain the esterified product.

Owner:WUHAN UNIV

Floor stripper/cleaner containing organic acid-base pair

InactiveUS20070095003A1High pHAvoid easy removalOther chemical processesChemical paints/ink removersOrganic acidSulfate

Floor finishes are stripped or deep scrubbed using a floor stripper / cleaner composition containing sparingly water-soluble floor finish solvent; water; sulfonic acid, sulfate acid, phosphonic acid, phosphate acid or aromatic acid coupler in an amount sufficient to provide a homogenous aqueous liquid phase and no or low foaming during shaking; and sufficient organic amine so that the composition pH is about 2 to about 11.

Owner:ECOLAB USA INC

Complex lithium grease and preparation method thereof

The invention provides complex lithium grease and a preparation method thereof. The complex lithium grease comprises grease base oil, complex lithium thickening agents and surfactants with mass part ratio of (290-1450):(50.4-251.3):(2-10), wherein the grease base oil is at least one of vacuum second line base oil, vacuum third line base oil and vacuum fourth line base oil; the complex lithium thickening agents are formed by C12-C24 fatty acid lithium and auxiliary acid lithium with mass part ratio of (34-70):(16.4-81.3); and the auxiliary acid lithium is any two of C1-C22 fatty acid lithium, lithium borate, lithium phosphate, aromatic acid lithium, lithium naphthenate, dicarboxylic acid lithium and polybasic acid lithium. The invention also provides the preparation method of the complex lithium grease. The surfactants are added to the complex lithium grease to have synergistic effect with soap molecules of the complex lithium grease and further improve the arrangement of the soap molecules and the capability of curing the base oil, thus increasing the dropping point of the grease.

Owner:CHINA NAT OFFSHORE OIL CORP +2

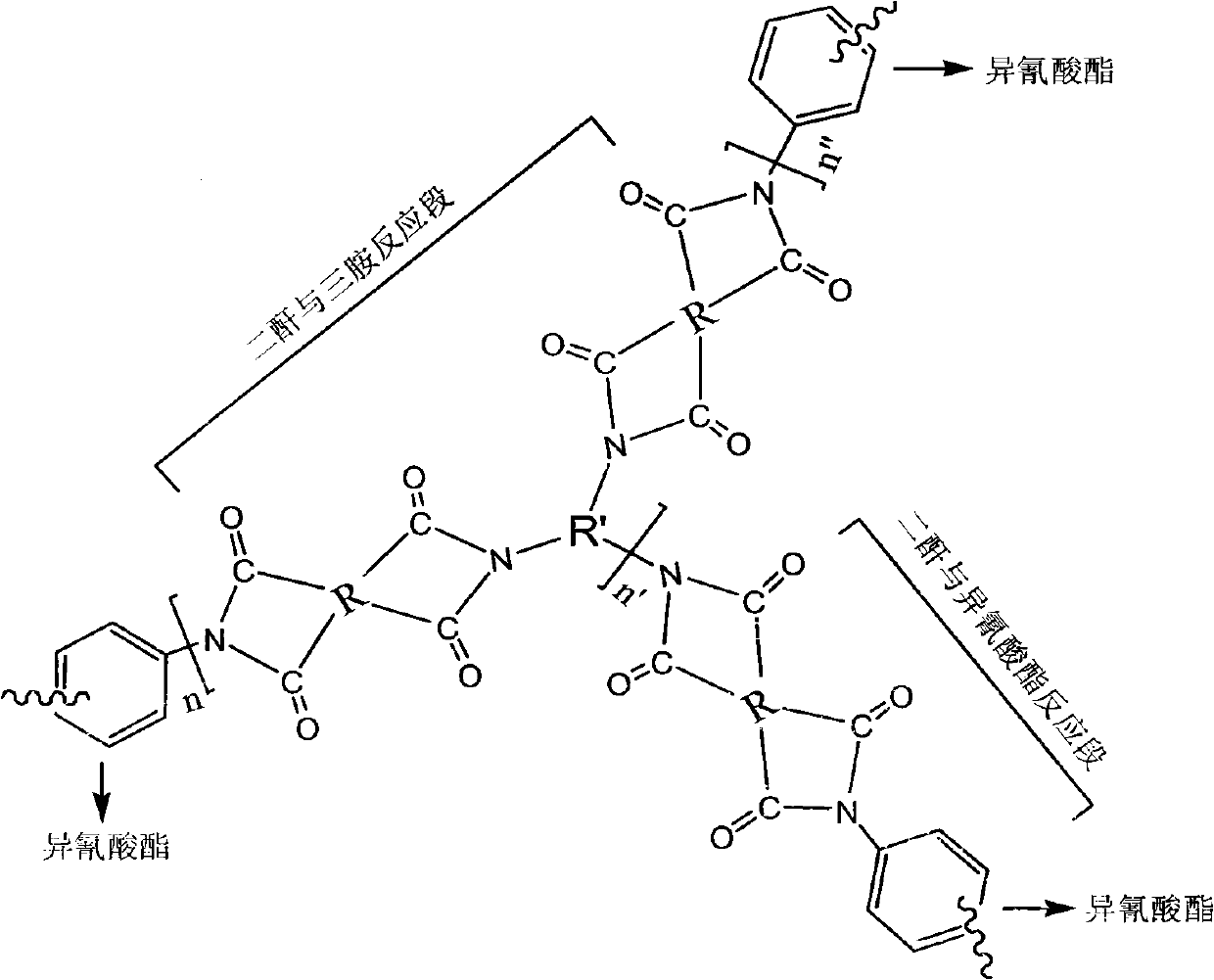

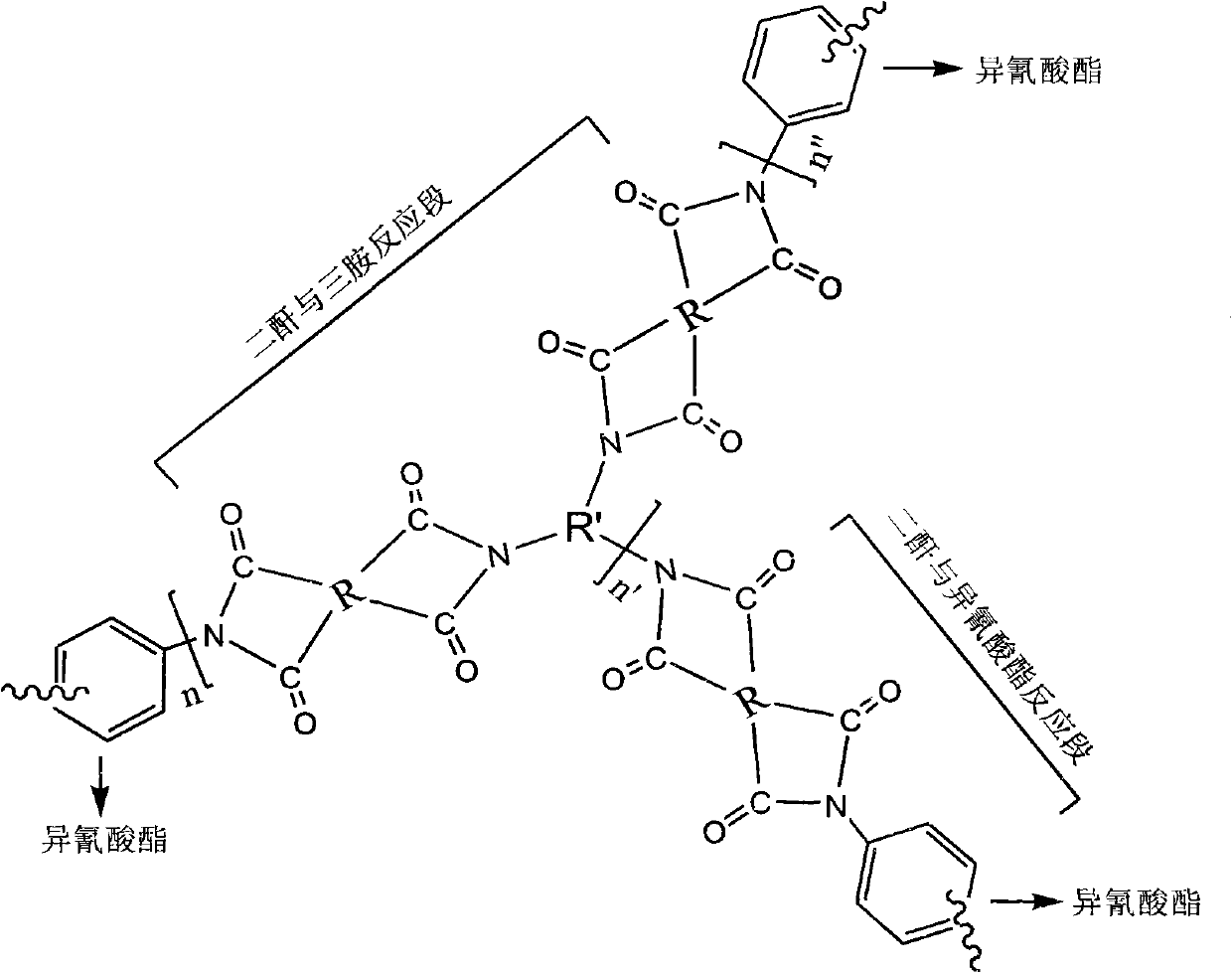

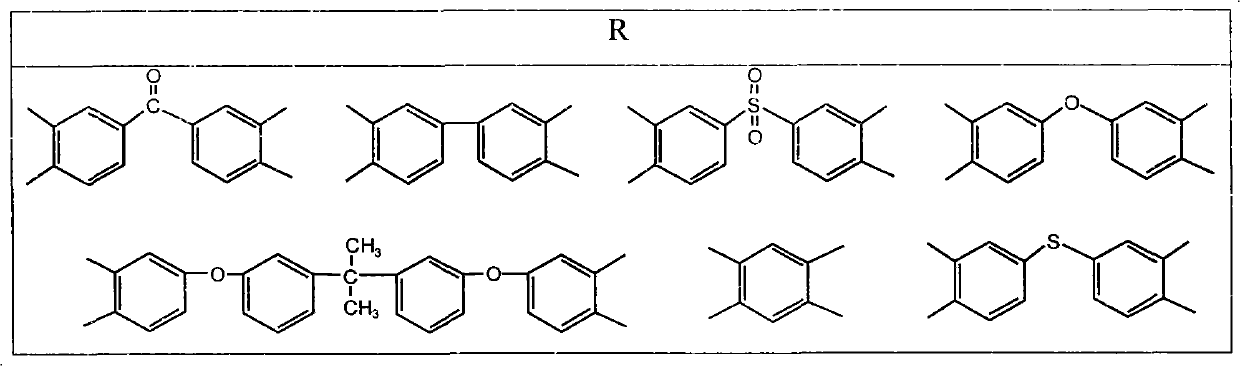

Light flexible polymide foam material and preparation method thereof

The invention discloses a light flexible polymide foam material and a preparation method thereof. The light flexible polymide foam material is obtained by reaction and solidification of hyperbranched aromatic polyamide, a catalyst, a surface active agent, an accessory ingredient and isocyanate, wherein the hyperbranched aromatic polyamide is formed by aromatic triamine together with aromatic dianhydride and / or aromatic acid ester. The intermediate section of the molecular structure is a hyperbranched section formed by the aromatic triamine together with the aromatic dianhydride and / or the aromatic acid ester, the side chain of the molecular structure is a cross-linking or / and linear section formed by aromatic dianhydride and / or aromatic acid ester together with isocyanate. The polymide foam material is simple in preparation process, the shrinkage percentage of the polymide foam material is minus 35.34%-21.75%, the density of the polymide foam material is 6.0 kg / m<3>-31.0 kg / m<3>, and the glass-transition temperature of the polymide foam material is 235 DEG C-320 DEG C; and the polymide foam material is a flexible sound-absorbing noise-reducing polymer foam material and is mainly suitable for the fields of aerospace, ships and electronic industry.

Owner:BEIHANG UNIV

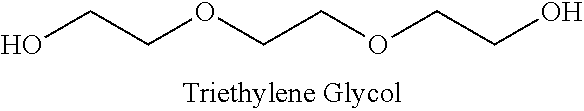

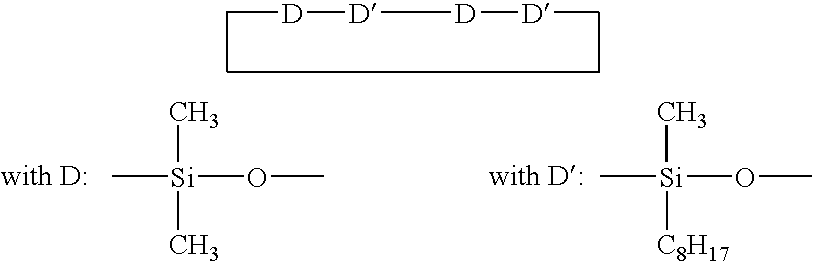

Polymeric Plasticizer Compositions

ActiveUS20160122471A1Organic compound preparationCarboxylic acid esters preparationPolymer sciencePolyethylene terephthalate glycol

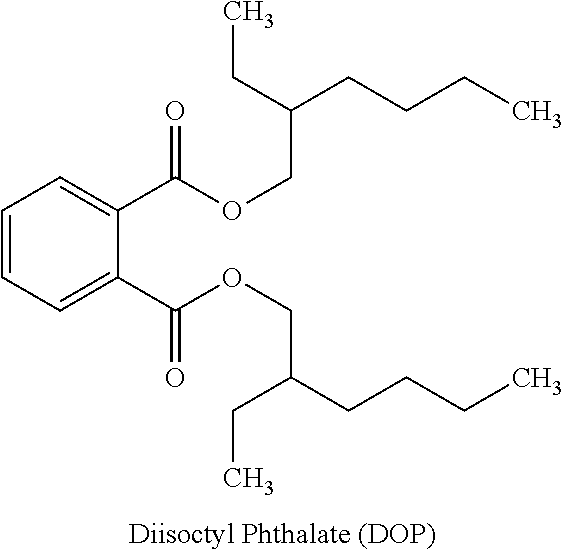

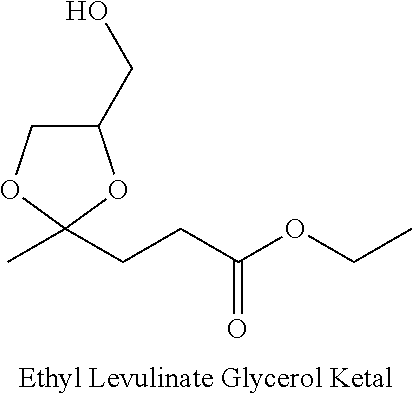

The present invention relates to polymeric plasticizer compositions made from an aromatic acid source, a glycol, and a C4-C36 monocarboxylic acid, or ester or anhydride thereof. The aromatic acid source can include polymeric materials such as recycled polyethylene terephthalate (PET). The present invention also relates to methods for making the polymeric plasticizer compositions, to methods of plasticizing polymeric materials, and to plasticized polymeric compositions. The polymeric plasticizers are useful for plasticizing various polymers, such as thermoplastic polymers, including, for example, polyvinyl chloride (PVC). The polymeric plasticizers provide a sustainable alternative to conventional phthalate ester plasticizers, such as diisooctyl phthalate (DOP).

Owner:RESINATE MATERIALS GRP

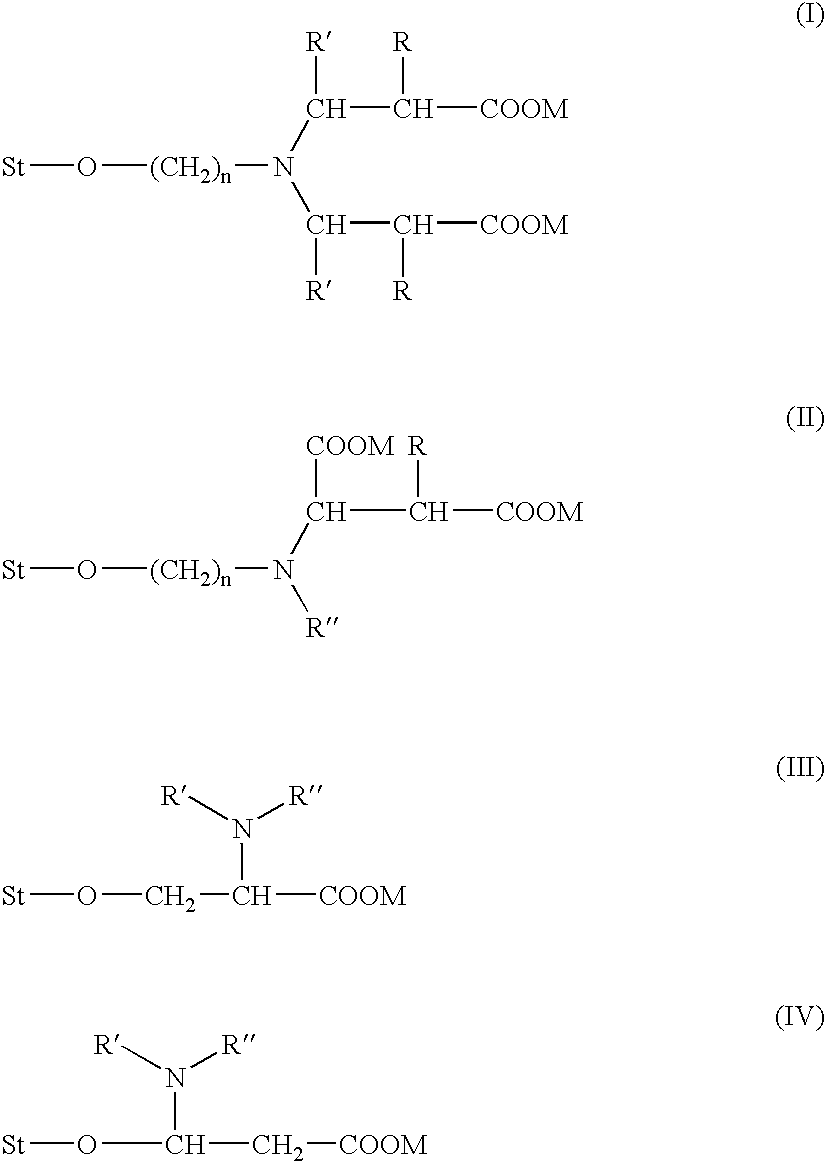

Cosmetic compositions containing a starch and an ester and the use thereof

InactiveUS20050069511A1Easy to disentangleIncrease holdingsCosmetic preparationsHair cosmeticsAlcoholCarboxylic acid

The present invention relates to a cosmetic composition comprising: a cosmetically acceptable medium, at least one starch and at least one ester selected from (1) liquid esters from a C3-C30 carboxylic acid and a C1-C30 alcohol, with at least one from the acid or the alcohol is branched or possesses at least one carbon-carbon double bond; and (2) esters from a C7-C30 aromatic acid having a carboxylic group that is directly linked to the aromatic ring, and a C1-C30 alcohol. The inventive composition is substantially free of soap. This composition has a “melting” texture and can be easily rinsed off. Hair treated with this composition has a soft feel with no residues. The inventive composition is preferably suitable for washing and / or conditioning keratinous materials, such as hair or skin.

Owner:LOREAL SA

Method to accelerate biodegradation of aliphatic-aromatic co-polyesters by enzymatic treatment

Provided is a method for accelerating the biodegradation of aliphatic-aromatic co-polyesters comprising greater than 60 mol percent aromatic acid, based on total diacid in the co-polyester. The method involves contacting at least one hydrolytic enzyme in aqueous solution to the co-polyester.

Owner:EI DU PONT DE NEMOURS & CO

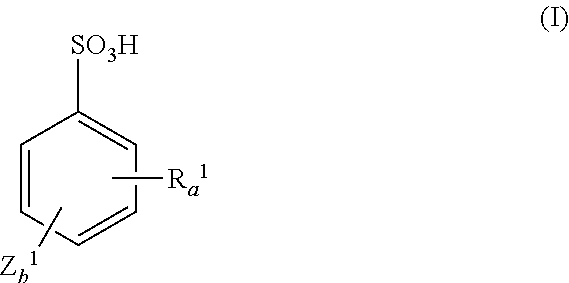

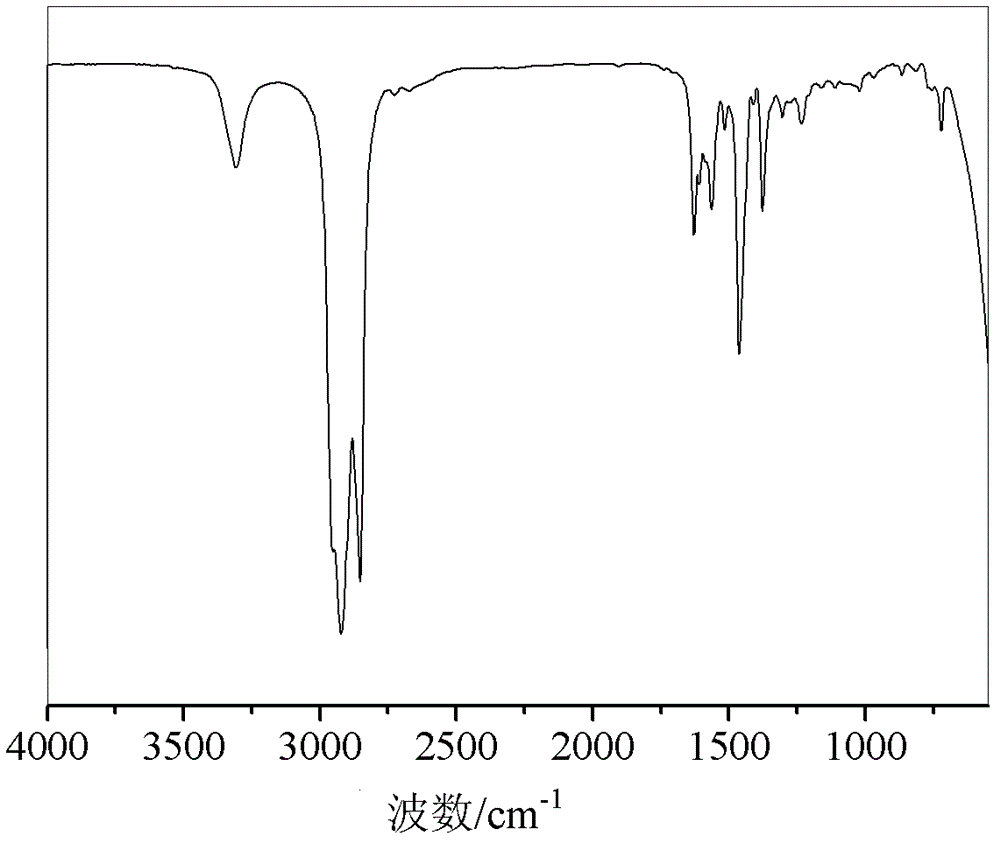

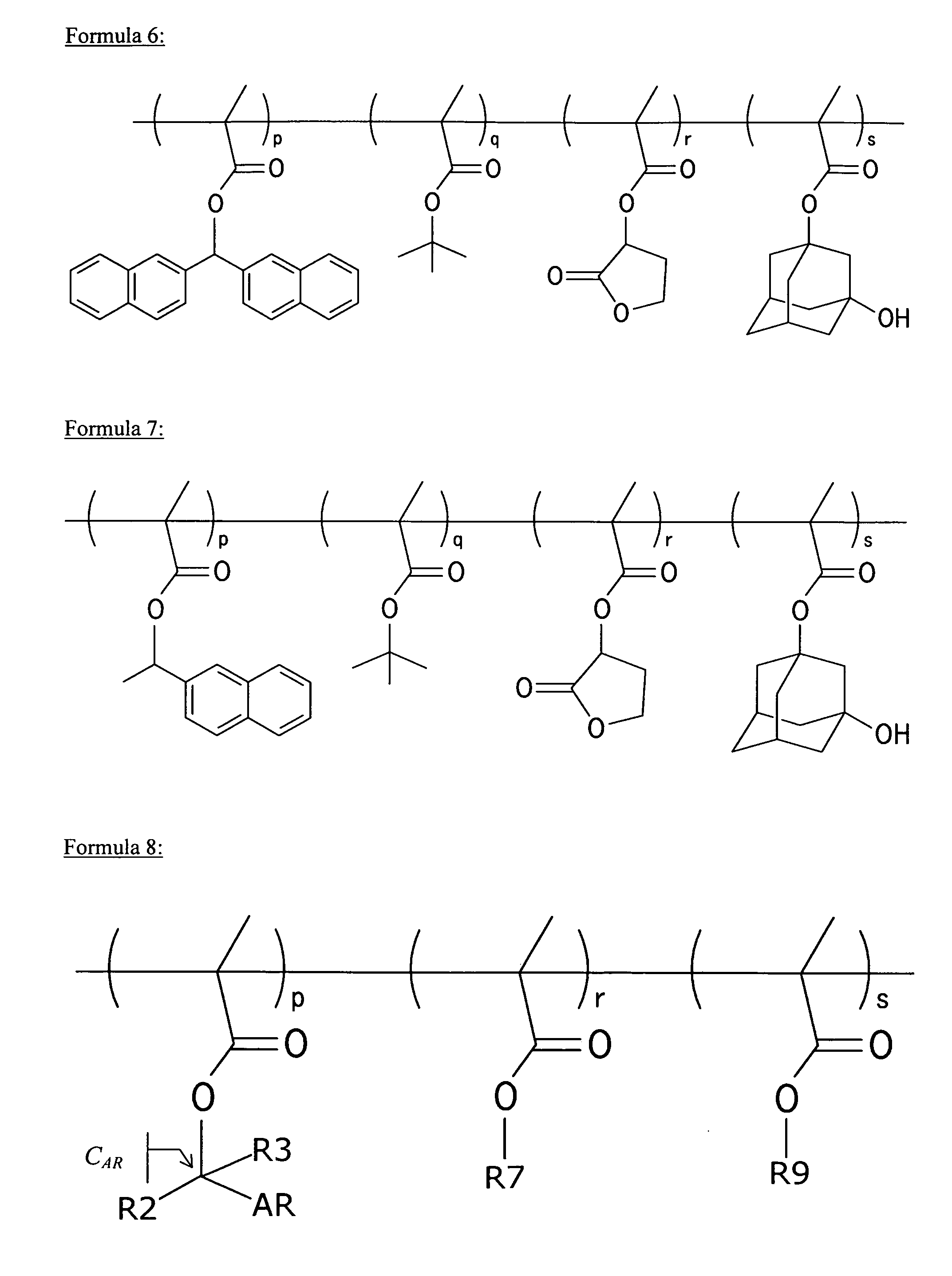

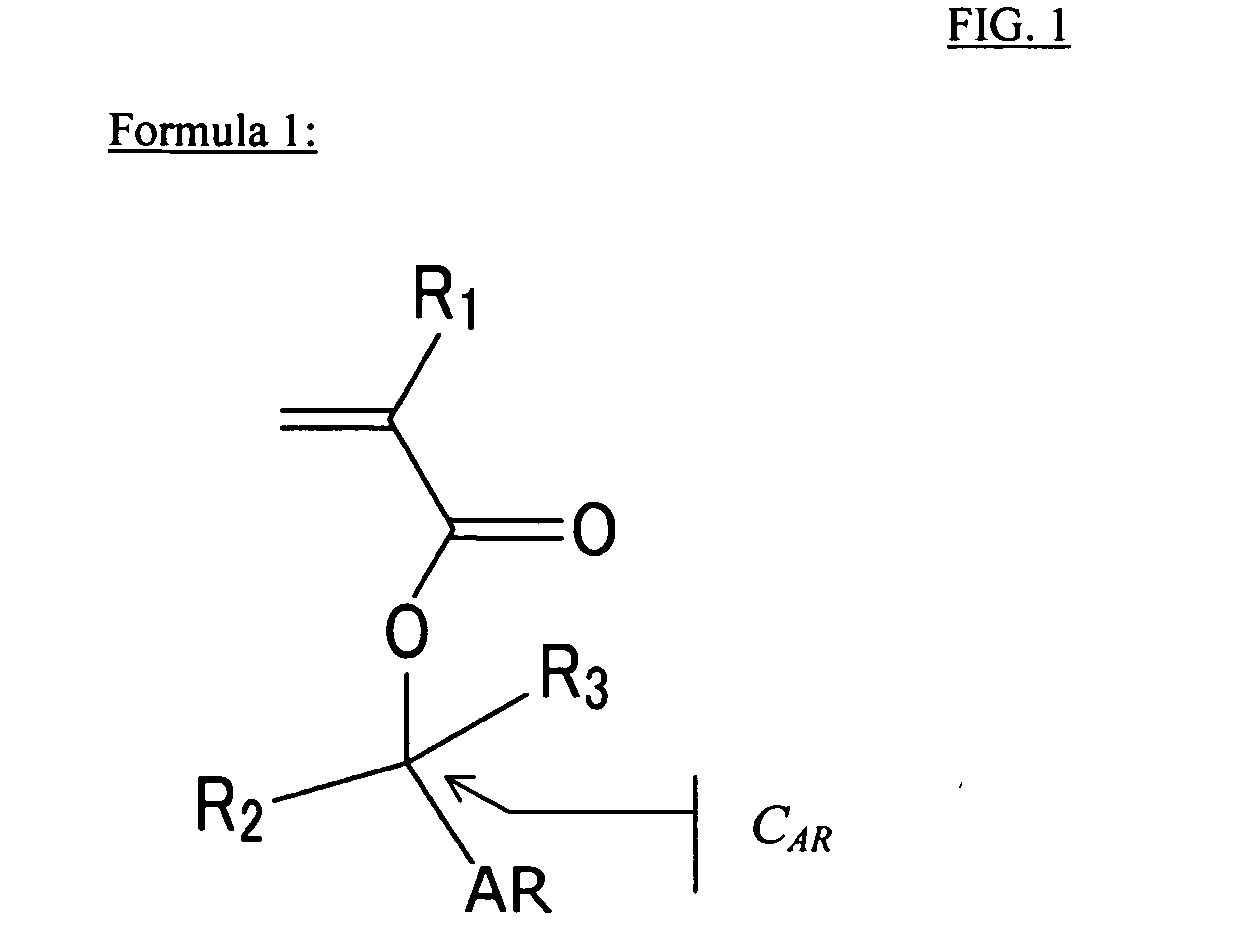

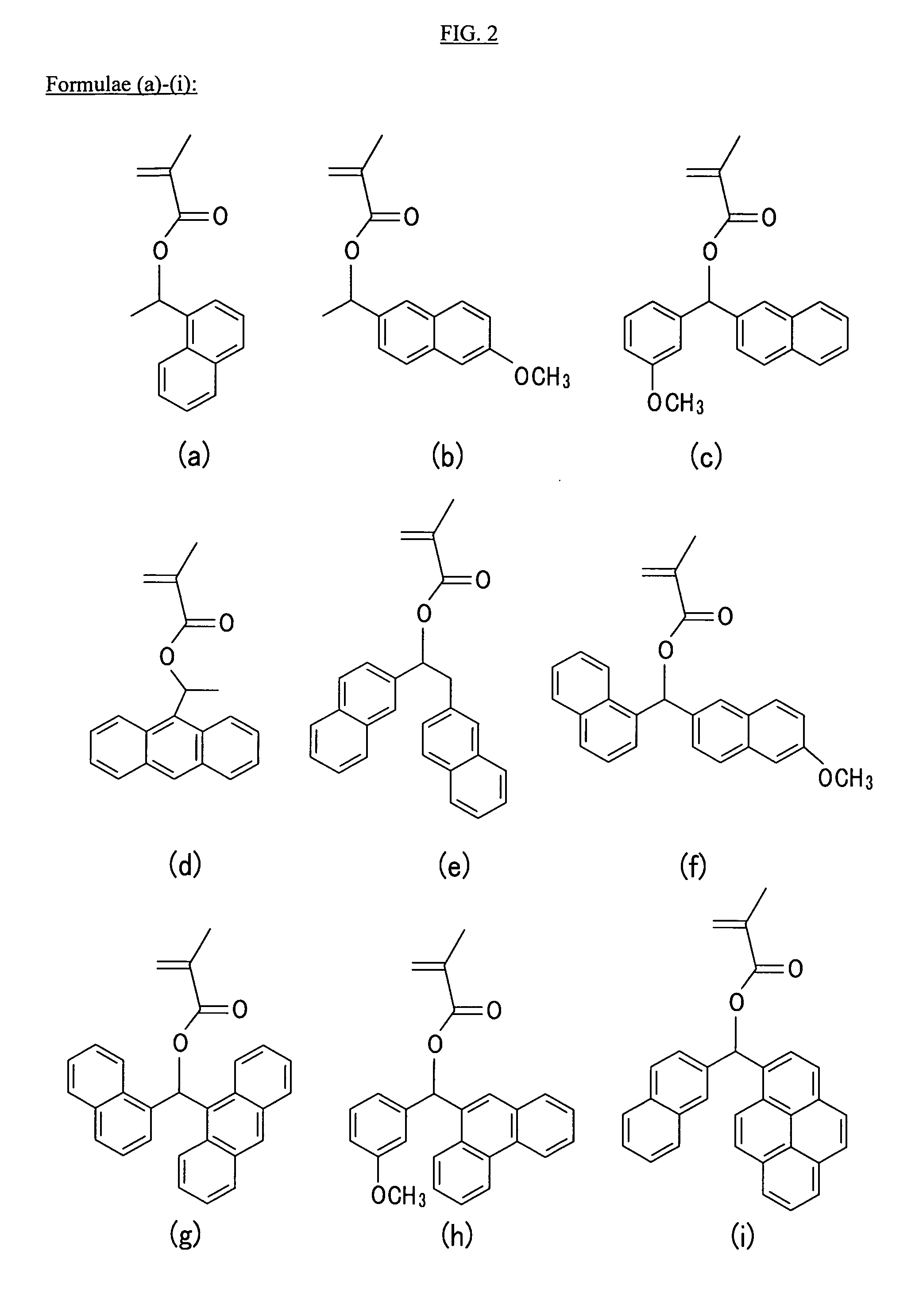

(Meth)acrylate compound having aromatic acid labile group, photosensitive polymer, resist composition, and associated methods

A (meth)acrylate compound having an aromatic acid-labile group, the (meth)acrylate compound being represented by the following Formula 1:In Formula 1, R1 is hydrogen or methyl, R2 is hydrogen, a substituted or unsubstituted alkyl, or a substituted or unsubstituted aryl, R3 is hydrogen, a substituted or unsubstituted alkyl, or a substituted or unsubstituted aryl, AR is a substituted or unsubstituted phenyl, or a substituted or unsubstituted aryl having from two to four fused aromatic rings, and carbon CAR is bonded directly to an aromatic ring of AR.

Owner:CHEIL IND INC

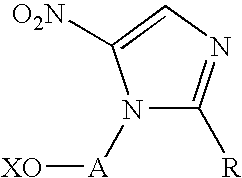

Composition that consists of alkanedicarboxylic acids and a pharmaceutical active ingredient

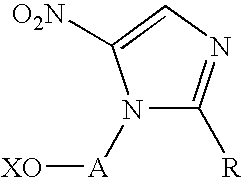

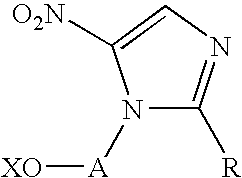

The invention consists of a composition that an alpha, omega-n-alkanedicarboxylic acid and an imidazole derivative with general formula whereby R is a hydrogen atom or an alkyl group, A is a saturated chain of an aliphatic hydrocarbon group, X is a hydrogen atom or an alkyl radical of a monocarboxylic or dicarboxylic aliphatic or aromatic acid. The composition is used as a pharmaceutical active ingredient, whereby the composition is used for treating psoriasis, atopic dermatitis, common acne or rosacea.

Owner:INTENDIS GMBH

Hydrolysis method of esters

InactiveCN1541991AImprove the conversion rate of hydrolysisEasy to separateOxygen-containing compound preparationOrganic compound preparationPhosphomolybdic acidHeteropoly acid

The ester hydrolyzing method includes hydrolyzing ester in water to produce C1-C10 fatty acid or aromatic acid and C1-C4 fatty alcohol under the presence of ammonium salt of heteropoly acid as catalyst. The ammonium salt of heteropoly acid is obtained through the reaction between heteropoly acid in Keggin structure and inorganic ammonium salt or organic amine, the heteropoly acid is selected from phosphotungstic acid, silicotungstic acid, silicomolybdic acid and phosphomolybdic acid; the inorganic ammonium salt is selected from ammonium carbonate, ammonium nitrate, ammonium sulfate, ammonium phosphate and diammonium hydrochloride; and the organic amine is selected from fatty amine, alicyclic amine and arylamine. The said ester hydrolyzing method can obtain high conversion rate in relatively lower water / ester ratio and relatively short time, and the catalyst is cheap and easy to separate from the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified light flexible polyimide foam material and preparation method thereof

The invention discloses a modified light flexible polyimide foam material and a preparation method thereof. The modified light flexible polyimide foam material is obtained by the reaction of a hyper branched / linear polyamide acid prepolymer formed by aromatic diamine, aromatic triamine, aromatic dianhydride and / or aromatic ester, a catalyst, a surfactant, an additive and an isocyanate, and the curing of the product. The intermediate section of the molecular structure is a hyper branched / linear section formed by aromatic diamine, aromatic triamine, aromatic dianhydride and / or aromatic ester, and the side chain is a crosslinked or / and linear section formed by aromatic dianhydride and / or aromatic ester; the polyimide foam material of the invention has simple process, has a shrinkage of -50.75% to 23.67%, a density of 4.0 kg / m3-31.0 kg / m3, and a glass transition temperature of 230 DEG C-320 DEG C, is a flexible sound-absorbing and noise-reducing polymer foam material, and is applicable tothe fields of aviation and aerospace, ship, and electronic industries.

Owner:BEIHANG UNIV

Composite polyol for producing hard polyurethane foam

The present invention relates to chemical material. The material for producing hard polyurethane foam includes: polyol based on cane sugar 30-50 wt%, polyepoxy ethane / polyepoxy propane polyether polyol with molecular weight of 500-800 and based on sorbic alcohol 14-30 wt%, polyepoxy ethane / polyepoxy propane polyether polyol with molecualr weight of 100-300 and based on amines 0-10 wt%, linear polyepoxy ethane / polyepoxy propane polyether polyol with 500-1000 molecular weight 5-15 wt%, polyester polyol with 200-700 molecular weight and based on aromatic acid anhydride 0-10 wt%, other compound with 60-500 molecular weight and with at least one hydrogen atom capable of reacting with isocyanate 1-5 wt%, water 1-7 wt%, amine catalyst 0.5-5.0 wt% and optional supplementary material and / or additive 1-15 wt%.

Owner:COVESTRO DEUTSCHLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com