Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

962 results about "Phosphotungstic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphotungstic acid (PTA), tungstophosphoric acid (TPA), is a heteropoly acid with the chemical formula H₃PW₁₂O₄₀. It is normally present as a hydrate. EPTA is the name of ethanolic phosphotungstic acid, its alcohol solution used in biology. It has the appearance of small, colorless-grayish or slightly yellow-green crystals, with melting point 89 °C (24 H₂O hydrate). It is odorless and soluble in water (200 g/100 ml). It is not especially toxic, but is a mild acidic irritant. The compound is known by a variety of different names and acronyms (see 'other names' section of infobox).

Aqueous dispersion for chemical mechanical polishing

InactiveUS6527818B2Pigmenting treatmentOther chemical processesColloidal silicaOXALIC ACID DIHYDRATE

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

Removal of prions from blood, plasma and other liquids

InactiveUS6221614B1High affinityHigh affinity bindingImmobilised enzymesHaemofiltrationBlood plasmaProteinaceous infectious particle

Devices such as flow through columns, substrates such as spherical polymer beads, and methods of using such to remove prions from any liquid sample are disclosed. A surface of a substrate is coated with a prion complexing agent, such as a salt of phosphotungstic acid. Blood or plasma passing through a column containing beads coated with prion complexing agent are rendered prion free.

Owner:RGT UNIV OF CALIFORNIA

Preparation of components for transportation fuels

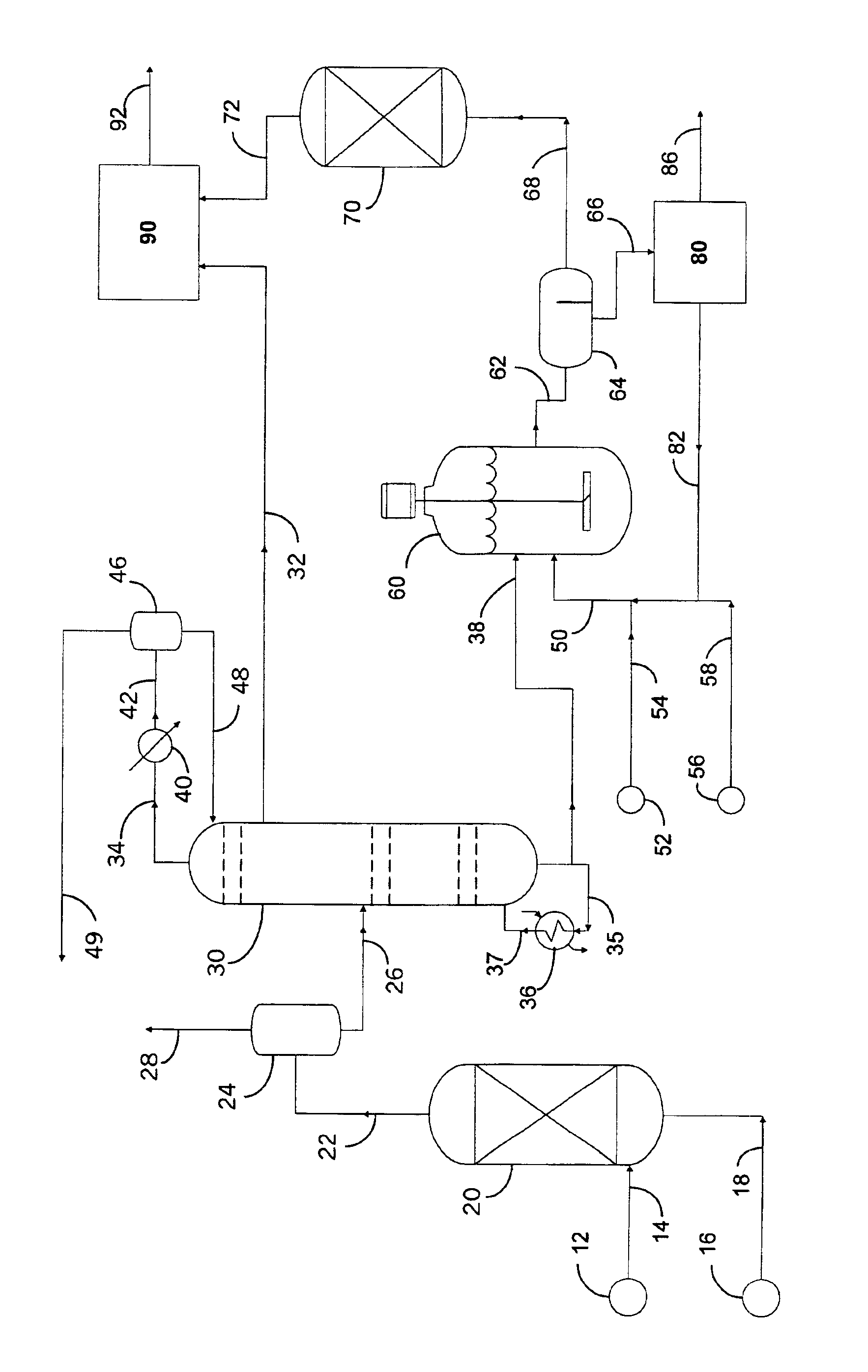

InactiveUS6881325B2Environmentally friendlyRefining with oxygen compoundsRefining with acid-containing liquidsPhosphomolybdic acidComponents of crude oil

Economical processes are disclosed for the production of components for refinery blending of transportation fuels by selective oxidation of feedstocks comprising a mixture of hydrocarbons, sulfur-containing and nitrogen-containing organic compounds. Oxidation feedstock is contacted with a soluble quaternary ammonium salt containing halogen, sulfate, or bisulfate anion, and an immiscible aqueous phase comprising a source of hydrogen peroxide, and at least one member of the group consisting of phosphomolybdic acid and phosphotungstic acid, in a liquid reaction mixture under conditions suitable for reaction of one or more of the sulfur-containing and / or nitrogen-containing organic compounds. Blending components containing less sulfur and / or less nitrogen than the oxidation feedstock are recovered from the reaction mixture. Advantageously, at least a portion of the immiscible acid-containing phase is recycled to the oxidation.

Owner:BP CORP NORTH AMERICA INC

Method for reclaiming carbon fiber reinforced epoxy resin composite material

ActiveCN102181071ARelieve stressImprove degradation efficiencyPlastic recyclingBulk chemical productionEpoxyPhosphomolybdic acid

The invention relates to a method for reclaiming a carbon fiber reinforced epoxy resin composite material. The conventional method is high in equipment requirement and high in reclamation cost. The method comprises the following steps of: adding a catalyst into an organic reagent to prepare supercritical CO2 composite solution; putting the carbon fiber reinforced epoxy resin composite material tobe decomposed into a reaction kettle, and adding the supercritical CO2 composite solution; and reacting for 1 to 24 hours at the temperature of between 100 and 250 DEG C under the pressure of 7.5 to 25.0MPa, cooling the product to normal temperature, washing and drying the solid product in the product to obtain carbon fibers, and performing reduced pressure distillation on the liquid product in the product to obtain phenol and derivatives thereof. The catalyst is one or two of liquid super acid, solid super acid, phosphotungstic acid, phosphomolybdic acid, acetic acid, formic acid, hydrochloric acid, sulfuric acid and nitric acid. The method has the advantages of high degradation efficiency, environmental friendliness, low cost and the like, and is a green method for reclaiming the waste and old carbon fiber reinforced epoxy resin composite material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of improved 4,4-dichlorodiphenylsulfone

InactiveCN102351756AReduce manufacturing costImprove product qualityOrganic chemistryOrganic compound preparationDichloropropaneOrganic solvent

The invention discloses a preparation method of improved 4,4-dichlorodiphenylsulfone. The method comprises steps that: (1) Al2Cl3 is adopted as a catalyst; chlorobenzene, thionyl chloride are adopted as reaction materials; the materials are subject to a Friedel-Crafts reaction; a mother liquor obtained after the reaction is hydrolyzed; the hydrolyzed mother liquor is refluxed for 45 to 60min under a temperature of 95 to 100 DEG C; after refluxing, the mother liquor is cooled to below 20 DEG C, such that the liquor is divided into an organic phase and a water phase; the organic phase is processed through reduced-pressure distillation and centrifugal washing until the organic phase turns neutral, and the organic phase is preserved as a product M for later use, wherein a main component in the product M is 4,4-dichlorodiphenylsulfone; (2) the product M and an oxidizing agent of hydrogen peroxide are adopted as raw materials, and 1,2-dichloropropane is adopted as an organic solvent; an oxidizing reaction is carried out upon the main component 4,4-dichlorodiphenylsulfone in the product M under the effect of a composite catalyst, such that a 4,4-dichlorodiphenylsulfone crude product is synthesized, wherein the composite catalyst is phosphotungstic acid or silicotungstic acid loaded on active carbon. Therefore, the method provided by the invention has advantages of high yield and good product quality. With the method, wastewater can be circulated and reused.

Owner:WUJIANG BEISHE SHENGYUAN TEXTILE PROD AUXILIARIES PLANT

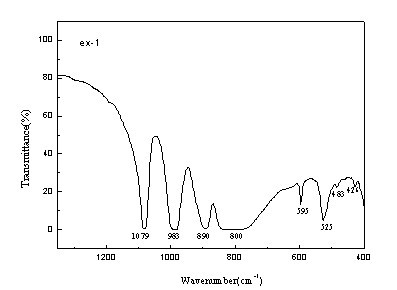

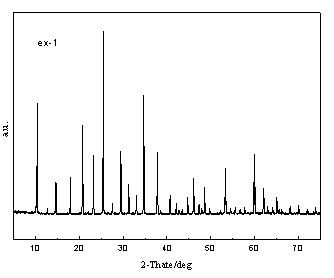

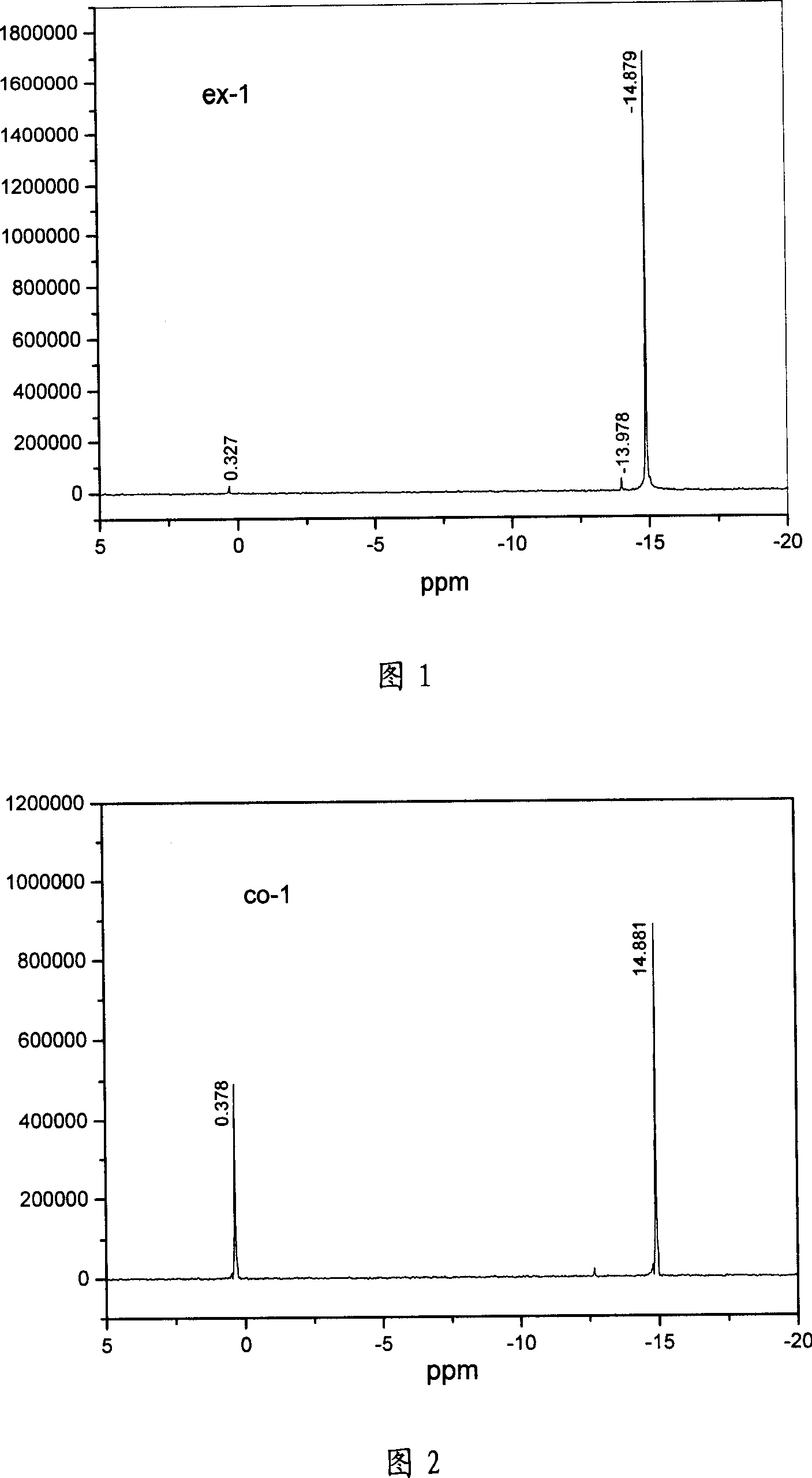

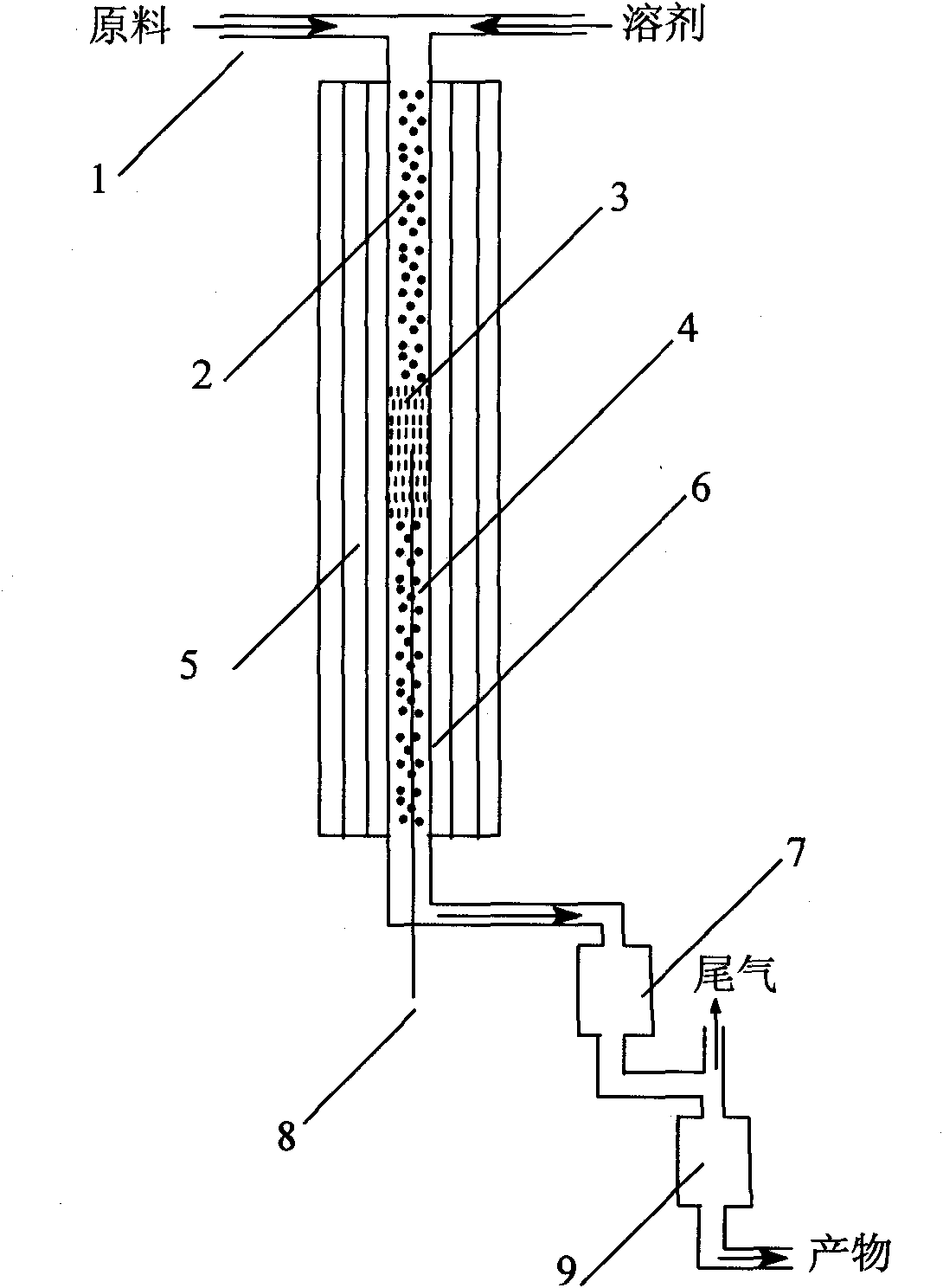

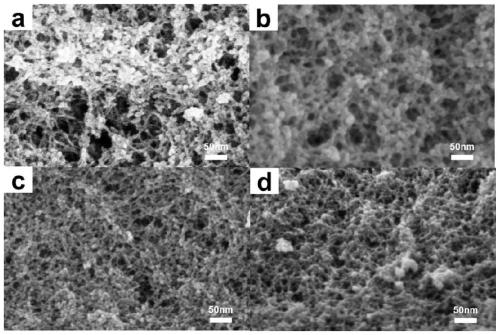

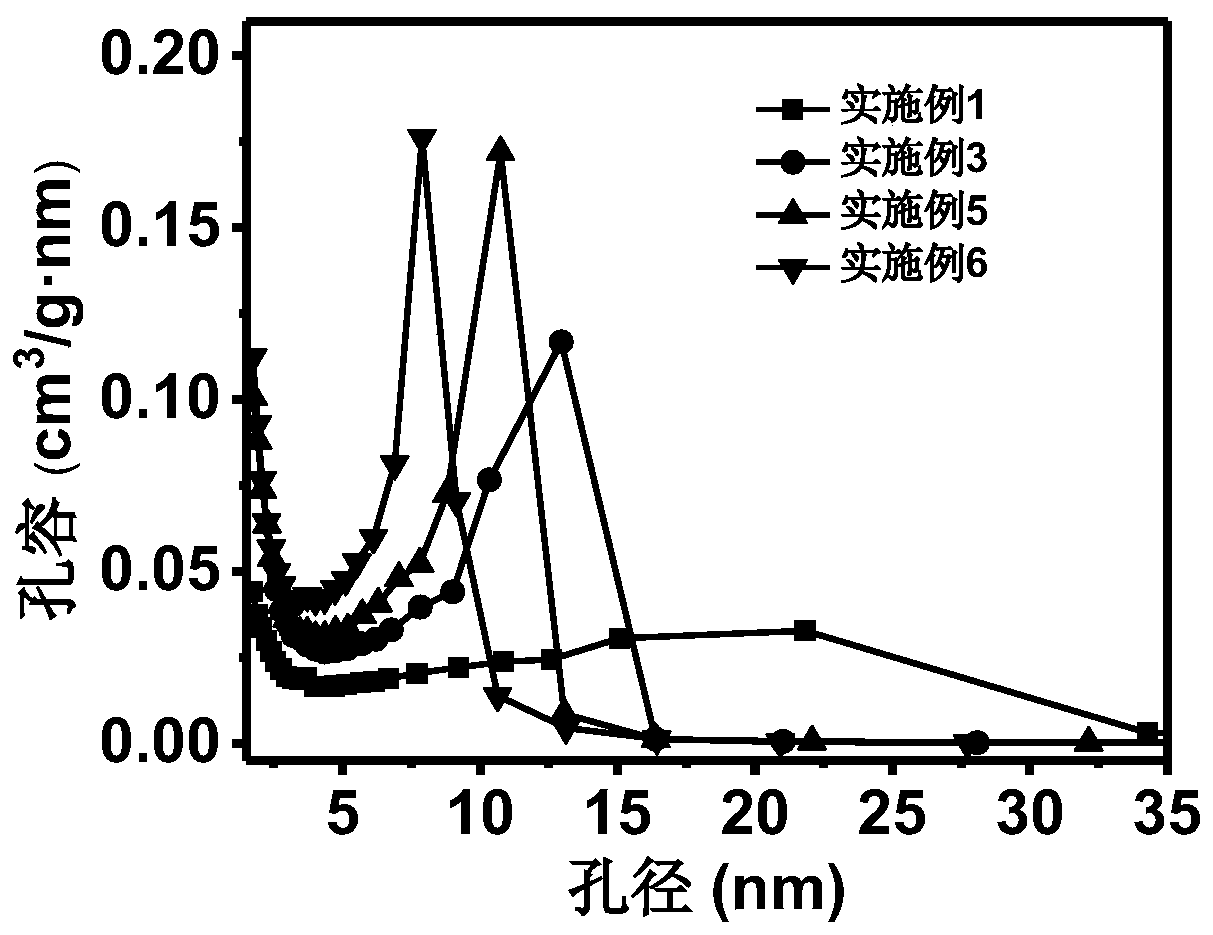

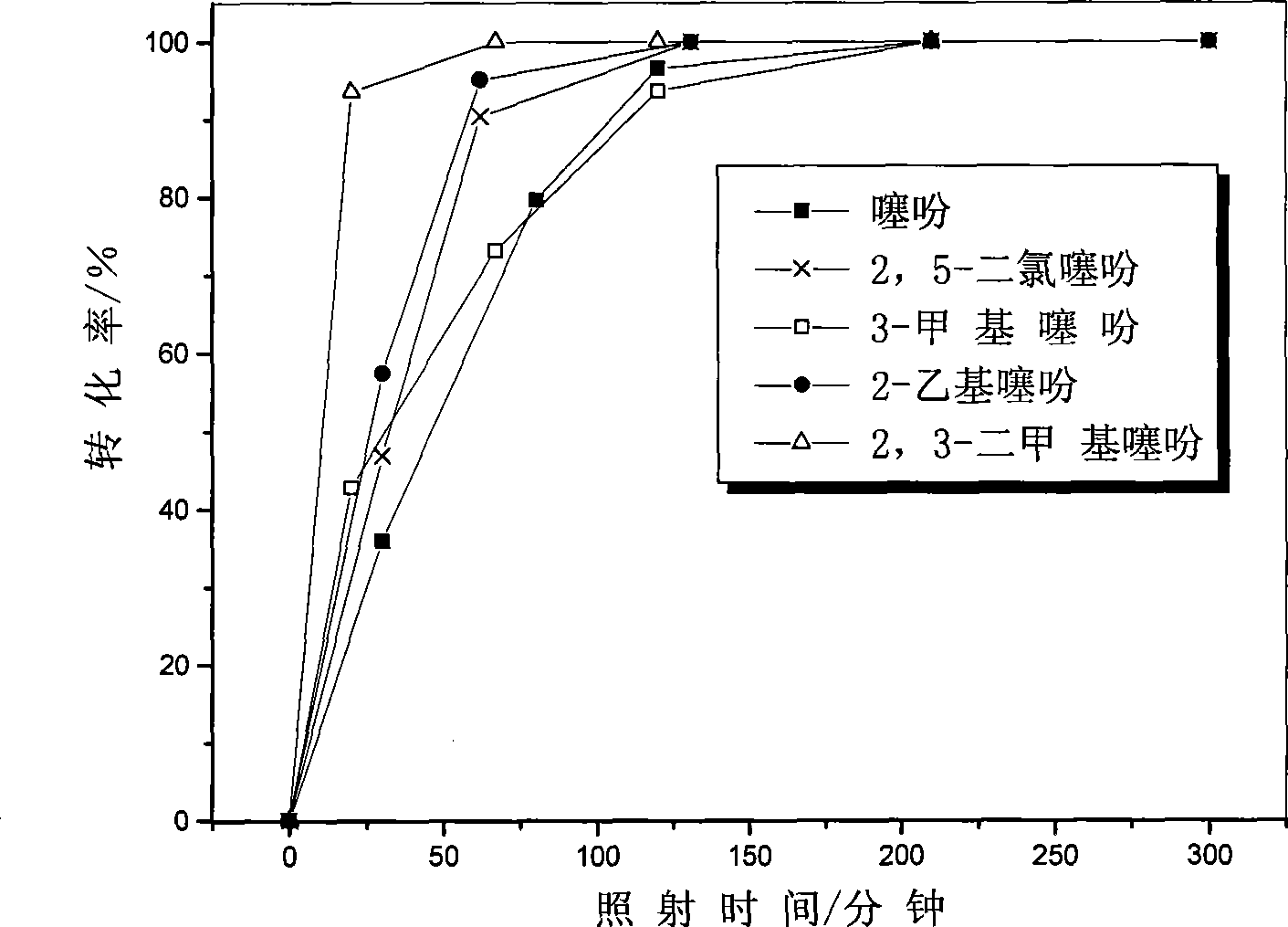

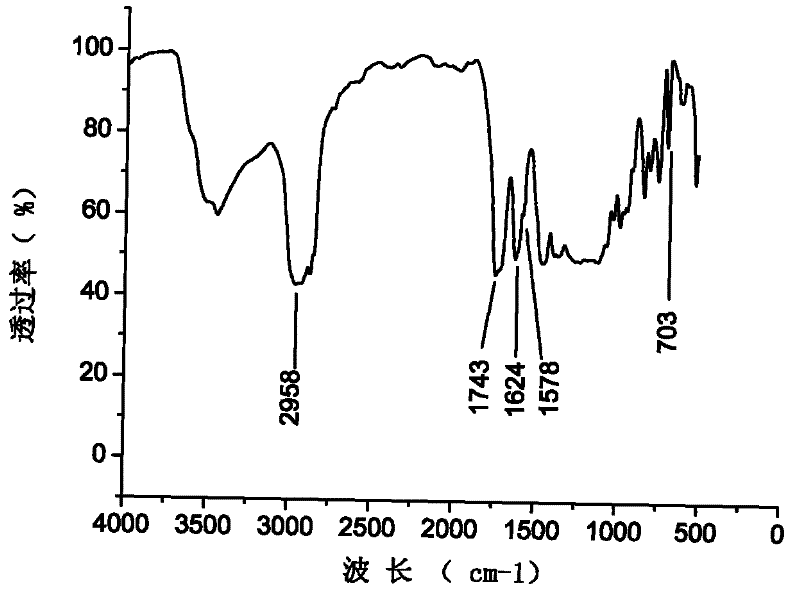

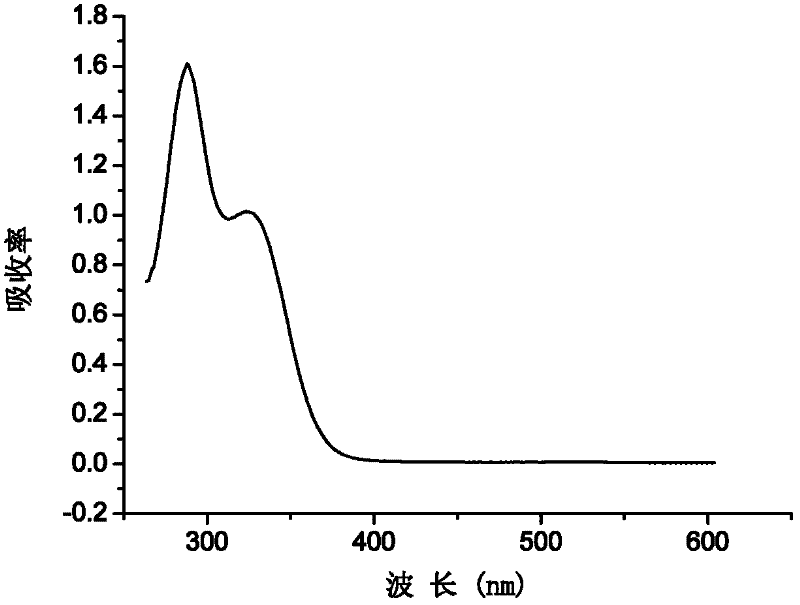

Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof

InactiveCN104874389AEasy to adjustEfficient use ofMetal/metal-oxides/metal-hydroxide catalystsOxygen vacancyMesoporous silica

The invention discloses a mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy and a preparation method thereof. The method comprises the following steps: calcinating at a controlled temperature of 350-600 DEG C in air so as to obtain a mesoporous silica molecular sieve KIT-6 loaded with tungsten trioxide by taking mesoporous silica molecular sieve KIT-6 as a hard template and a silicotungstic acid or phosphotungstic acid hydrate as a tungsten trioxide precursor; then calcinating at a controlled temperature of 450-550 DEG C so as to obtain a mesoporous silica molecular sieve KIT-6 provided with oxygen vacancy and loaded with tungsten trioxide by utilizing H2 as a reducing agent; and finally, removing the mesoporous silica molecular sieve KIT-6 by use of a 10wt% HF aqueous solution, thereby obtaining the mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy and relatively large specific surface area and pore diameter. The mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy is capable of effectively utilizing lights to rapidly catalyze CO2 so as to generate methane, and is high in catalysis efficiency, simple in preparation process and needed equipment, environmentally friendly in preparation process and free from pollution.

Owner:SHANGHAI INST OF TECH

Process for preparing 5-hydroxymethyl-furfural

The invention relates to a preparation method for 5-hydroxymethyl furfural, which belongs to production technology of chemicals, in particular to a method for synthesizing 5-hydroxymethyl furfural (HMF) from carbohydrates by adopting a catalytic way. The method for preparing the 5-hydroxymethyl furfural uses heteropolyacid or heteropolyacid salt as a catalyst, and the 5-hydroxymethyl furfural with high purity can be obtained at a high yield by modulating the catalyst activity, choosing proper solvents, adding additives, optimizing the reaction temperature and time and improving the post treatment technologies, and the corrosion to devices and the environmental pollution can be avoided when using liquid super acids. In the system of saturated sodium chloride solution-positive butanol, the yield of the HMF can reach 70 percent under the catalysis reaction of phosphotungstic acid for 4 minutes at 175 DEG C.

Owner:DALIAN UNIV OF TECH

Solution composition and method for electroless deposition of coatings free of alkali metals

InactiveUS6911067B2Low costImprove anti-corrosion performanceAnti-corrosive paintsLiquid/solution decomposition chemical coatingElectroless depositionMaterials science

An electroless deposition solution of the invention for forming an alkali-metal-free coating on a substrate comprises a first-metal ion source for producing first-metal ions, a pH adjuster in the form of a hydroxide for adjusting the pH of the solution, a reducing agent, which reduces the first-metal ions into the first metal on the substrate, a complexing agent for keeping the first-metal ions in the solution, and a source of ions of a second element for generation of second-metal ions that improve the corrosion resistance of the aforementioned coating. The method of the invention consists of the following steps: preparing hydroxides of a metal such as Ni and Co by means of a complexing reaction, in which solutions of hydroxides of Ni and Co are obtained by displacing hydroxyl ions OH− beyond the external boundary of ligands of mono- or polydental complexants; preparing a complex composition based on a tungsten oxide WO3 or a phosphorous tungstic acid, such as H3[P(W3O10)4], as well as on the use of tungsten compounds for improving anti-corrosive properties of the deposited films; mixing the aforementioned solutions of salts of Co, Ni, or W and maintaining under a temperatures within the range of 20° C. to 100° C.; and carrying out deposition from the obtained mixed solution.

Owner:LAM RES CORP

Method for comprehensively recovering tungsten and phosphorus from high phosphorus white tungsten ores

ActiveCN102080161ARealize comprehensive utilizationEasy to separate by filtrationProcess efficiency improvementPhosphorus compoundsWater dischargeDecomposition

The invention discloses a method for receiving tungsten and phosphorus from high phosphorus white tungsten ores, which comprises: decomposing the ores by using mixed acid of phosphoric acid and sulfuric acid, wherein phosphorus-containing ore are converted into phosphoric acid, tungsten-containing ore are converted into phosphotungstic acid, and both the phosphorus and the tungsten enter solution; when the total P2O5 mass content in circular leaching filtrate surpasses 30 percent, extracting tungsten from the circular leaching filtrate, extracting phosphoric acid by using a solvent extraction method, reducing P2O5 mass content in the circular leaching filtrate by controlling the extraction rate of phosphoric acid, resupplying sulfuric acid, and returning to newly leached high phosphorus white tungsten ores; and thus, recovering tungsten and phosphoric acid from the leaching filtrate respectively. The method has the advantages of comprehensively recovering tungsten and phosphorus from ores, lowering requirements on tungsten ore raw material, reducing pressure in ore dressing step, ensuring over 98 percent decomposition rate of the white tungsten ore, recycling leaching agent, greatly reducing leaching cost and waste water discharge, along with simple leaching equipment, convenient operation and easy industrialization implementation.

Owner:CENT SOUTH UNIV

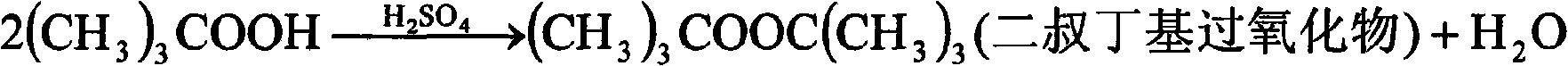

Preparation of tert-butyl hydrogen peroxide and di-tert-butyl peroxide

ActiveCN101298429AMild reaction conditionsHigh yieldOrganic chemistryDi-tert-butyl peroxideOil phase

The invention discloses a preparation method of tert-butyl hydroperoxide and di-t-butyl peroxide which includes the following steps: after mixing vitriol, oxyful and phosphotungstic acid with certain concentration, adding tertiary butyl alcohol into a mixed liquor or adding the mixed liquor into the tertiary butyl alcohol; reacting for 0.5 to 5 hours under 20 to 60 DEG C; obtaining an oil phase after carrying out liquid separation on the crude product of the reaction; obtaining the tert-butyl hydroperoxide and di-t-butyl peroxide products by carrying out decompressing and rectifying on the oil phase; the method has the advantages of simple and convenient operation, low manufacture cost, safety, high efficiency and high yield; in addition, the method of the invention can adjust the relative content of the two reaction products by changing the reaction conditions. The reaction products of tert-butyl hydroperoxide and di-t-butyl peroxide are separated by decompressing and rectifying, thus avoiding the working procedures of acid cleaning and caustic wash in the traditional technique, solving the defect of overlarge waste water amount in the traditional technique, being beneficial to protecting the environment, reducing the manufacture cost and being capable of greatly increasing the enterprise benefits.

Owner:ZHEJIANG JINKE CHEM

Method for comprehensively recovering tungsten and fluorine from minerals

InactiveCN102586632AHigh recovery rateImprove solubilitySilicaProcess efficiency improvementDecompositionApatite

The invention provides a method for comprehensively recovering tungsten and fluorine from minerals, namely a mixed acid of phosphoric acid and sulfuric acid is adopted for decomposing complex calcium-containing minerals containing fluorite, scheelite, apatite, and calcite, wherein the fluorite is decomposed to fluorine hydride or silicon tetrafluoride to escape, and absorption treatment is performed for preparing hydrofluoric acid or a fluoride salt; and the scheelite is transformed to phosphotungstic acid to enter into a solution, and filtrate after filtration is supplemented into the consumed sulfuric acid and the phosphoric acid after extraction of the tungsten and returned to the new-round mineral leaching. The method disclosed by the invention has the advantages of comprehensively recovering the fluorine and the tungsten from the minerals, reducing the requirements on the fluorite or the tungsten ore raw material, reducing the pressure on a mineral dressing link, improving the comprehensive recovery rate and simultaneously ensuring the decomposition rate of the fluorite and the scheelite, wherein the decomposition rate of the fluorite is above 98%, and WO3 contained in decomposition slag is reduced to below 0.5%; furthermore, a leaching agent can be recycled, so that leaching cost and wastewater emission are greatly reduced; and the method also has the advantages of simple leaching equipment, convenience in operation and easiness in realization of industrialization.

Owner:CENT SOUTH UNIV

Method for preparing phosphotungstic heteropoly acid with Keggin structure

InactiveCN102659181ASimple preparation processIncrease productivityTungsten compoundsHigh concentrationInorganic salts

The invention discloses a method for preparing phosphotungstic heteropoly acid with a Keggin structure. The method comprises the following steps of: (1) contacting a tungstate solution and an inorganic acid solution; (2) transferring the solution to a high-pressure reaction kettle, and activating at high temperature under high pressure to obtain an active intermediate; (3) contacting the obtained substance and phosphoric acid to obtain a phosphotungstic acid solution; and (4) adding an inorganic salt precipitator into the phosphotungstic acid solution, precipitating phosphotungstic acid by salting-out and crystallization, filtering, purifying and drying to obtain the Keggin phosphotungstic heteropoly acid. By the method, a process flow is simple, the yield of the heteropoly acid is high, and the preparation cost is reduced obviously; high-concentration strong acid in the conventional method is not used in the preparation process, so that the corrosivity to equipment is reduced greatly; and an inflammable low-boiling point organic extractant is not used, and the safety of preparation is improved greatly.

Owner:CENT SOUTH UNIV

Synthesis and purification method of medium chain triglycerides

InactiveCN1594274AHigh purityHigh activityOrganic compound preparationCarboxylic acid esters preparationPurification methodsDistillation

The invention provides a synthesis and purification method of medium chain triglycerides by using solidified phosphotungstic acid as catalyst, medium carbon chain C6-C12 fatty acid and glycerol as raw material for etherification reaction to synthesize the medium carbon chain glyceride, and a three stage molecule distillation purification is employed to obtain the high purity medium carbon chain triglycerides product.

Owner:JIANGNAN UNIV

Method for preparing high-purity phosphotungsticacid

ActiveCN1978327ALow in phosphateHigh purityPhysical/chemical process catalystsTungsten compoundsPhosphoric acidSodium tungstate dihydrate

This invention introduces a method for preparing pure PTA with sodium wolframate as the raw material including : 1, contacting sodium wolframate solution with inorganic acid solution till depositing active tungstenic acid, 2, contacting the deposition with phosphoric acid till dissolving the active tungstenic completely to get PTA solution, 3, adding an inorganic acid precipitator to the solution to deposit, filter and crystallize the deposition to get pure PTA, in which, the mol concentration of the precipitator in the system is 0.1-6mol / 1.

Owner:CHINA PETROLEUM & CHEM CORP +1

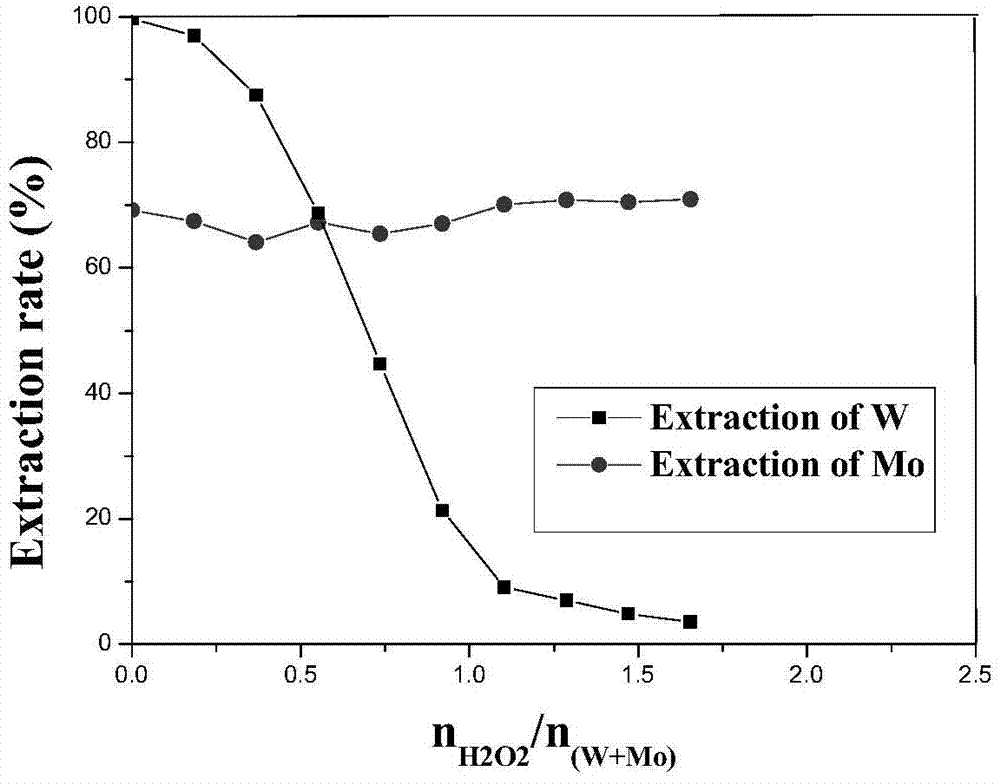

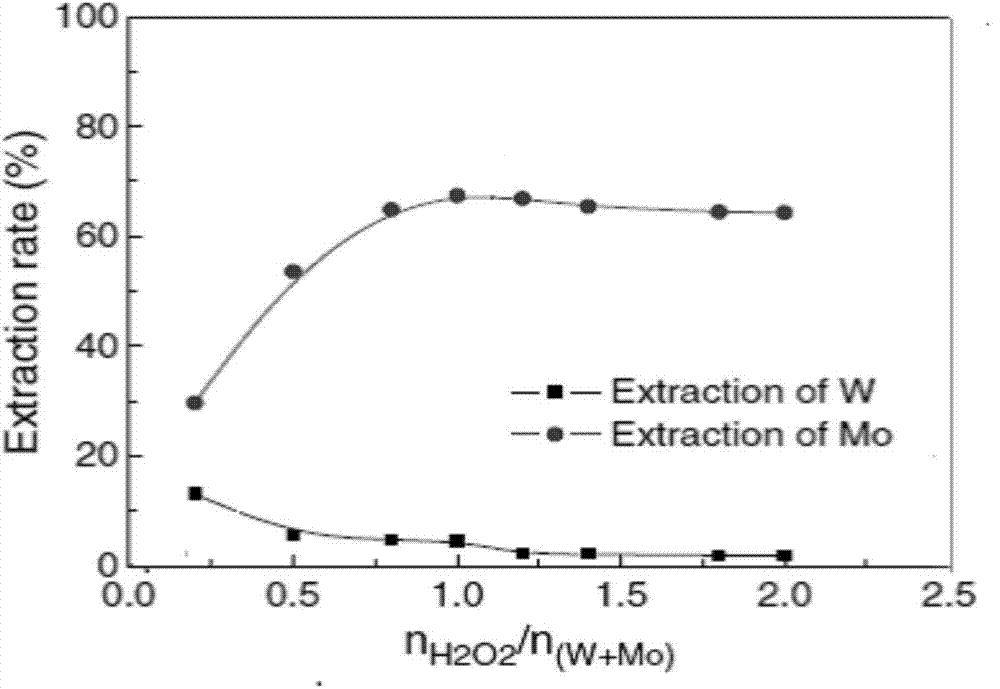

Method for extracting and separating tungsten and molybdenum in high-phosphorus mixed solution containing tungsten and molybdenum

ActiveCN104711422ARealize extraction and separationSimple methodProcess efficiency improvementPhosphomolybdic acidPhosphate

The invention relates to a method for extracting and separating tungsten and molybdenum in a high-phosphorus mixed solution containing tungsten and molybdenum. The method comprises the following steps: adding hydrogen peroxide in the high-phosphorus mixed solution containing tungsten and molybdenum for acidity adjustment and control, and converting phosphotungstic acid and phosphomolybdic acid into peroxy-phosphotungstic acid and peroxy-phosphomolybdic acid; then, taking a mixture of tributyl phosphate (TBP) and methyl phosphate dimethyl heptyl ester (P350) as an extracting agent, extracting the peroxy-phosphomolybdic acid into an organic phase, and leaving the peroxy-phosphotungstic acid in an aqueous phase; from now on, after decomposing the peroxy-phosphotungstic acid in extraction raffinate in the way of heating or ultraviolet irradiation or introduction of sulfur dioxide, extracting tungsten in the solution again with a fresh mixed extracting agent, and finally realizing extraction and separation of tungsten and molybdenum from complex material liquid. The method is small in tungsten co-extraction loss, can effectively solve the extraction and separation problem of tungsten and molybdenum in the high-phosphorus mixed solution containing tungsten and molybdenum, and is easy to realize industrialization.

Owner:CENT SOUTH UNIV

Composite catalyst for preparing sec-butyl acetate with direct esterification of ethyl ester and butylene

InactiveCN101293210ASolve the problem of reduced catalytic efficiencyCatalyst carriersOrganic compound preparationHeteropoly acidCordierite

The present invention relates to a composite catalyst for preparing sec-butyl acetate by direct esterification of ethyl ester and butylene, which takes heteropoly acid as the catalyst active component and porous carrier as the dispersant; the weight proportion of the heteropoly acid and the porous carrier is 0.01:1 to 10:1. The heteropoly acid is one with Keggin structure, which consists of phosphotungstic acid, silicotungstic acid, germanium tungstic acid, arsenowolframic acid, phosphomolybdate, germanomolybdate or arsenicomolybdate. The porous carrier comprises porous SiO2, Al2O3, SBA-15, MCM-41, white carbon black, porous SiC, corallite, andalusite, cordierite, meerschaum, Attapulgite or kaolin. The composite catalyst of the present invention solves the problem that the catalysis efficiency is low if the heteropoly acid is separated out from the reaction system.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Method for decomposing thermosetting epoxy resin or composite material thereof by high-temperature water phase

InactiveCN101519505AHigh catalytic activityNo pollution in the processPlastic recyclingEpoxySingle substance

The invention relates to a method for decomposing a thermosetting epoxy resin or a composite material thereof by high-temperature water phases, which belongs to the technical field of regenerative utilization of waste resin materials or treatment of industrial wastes. The method is characterized by comprising the following steps: putting certain amount of thermosetting epoxy resin sheets or granules, and deionization and catalyst heteropolyacid into a high-temperature high-pressure stainless steel reaction kettle; heating the reaction kettle to raise the temperature to a temperature of 250 and 370 DEG C for 30 to 120 hours; and decomposing the water diversion phase so that the decomposed product becomes an oligomer or a single substance which cannot be dissolved in liquid phase and is easy to separate. The method mainly adopts heteropoly acid, phosphotungstic acid, tungstosilicic acid, or molybdenum phosphoric acid as a catalyst, the addition of the catalyst is 0.1 to 3.0 percent of that of deionized water, and a higher decomposition rate of the epoxy resin can be obtained finally. The method does not need to use an organic solvent as a decomposing liquid, but uses water as the decomposing liquid, thus the method has low cost and is pollution-free to the environment; and the method can achieve the aims of waste regeneration and utilization as well as environmental protection.

Owner:SHANGHAI UNIV

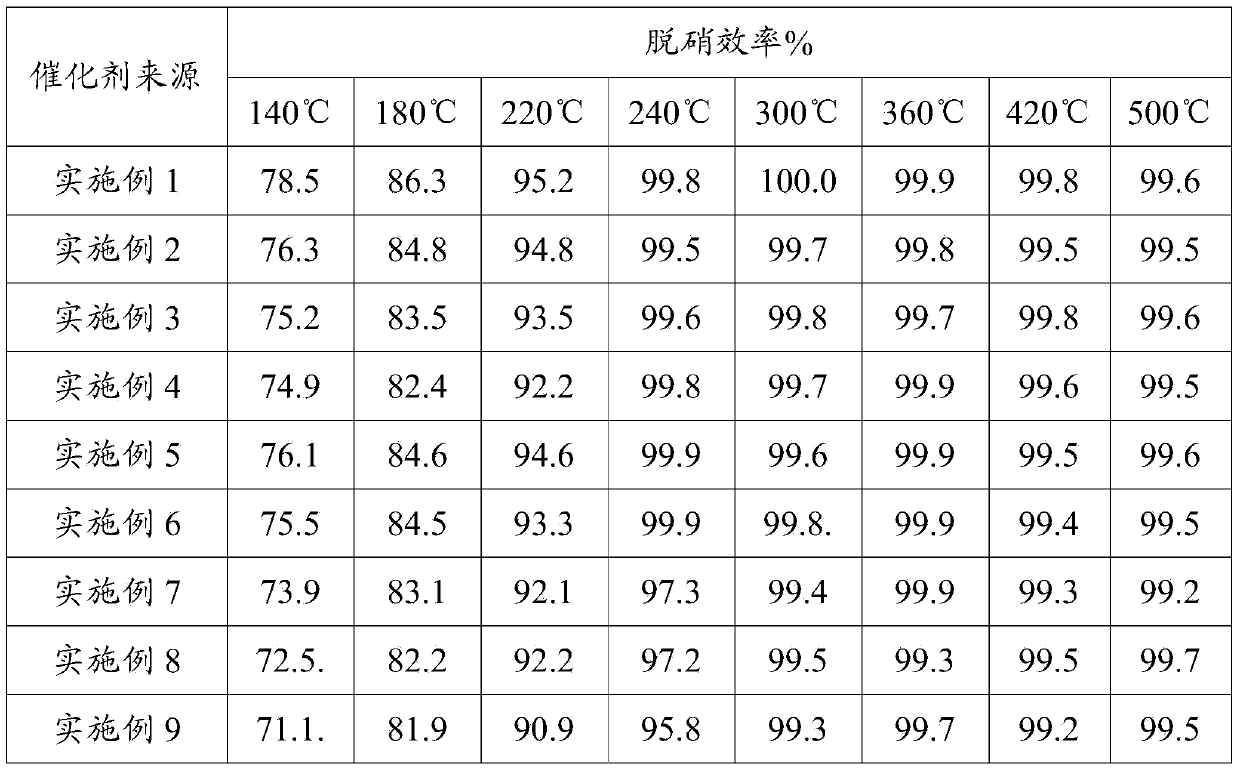

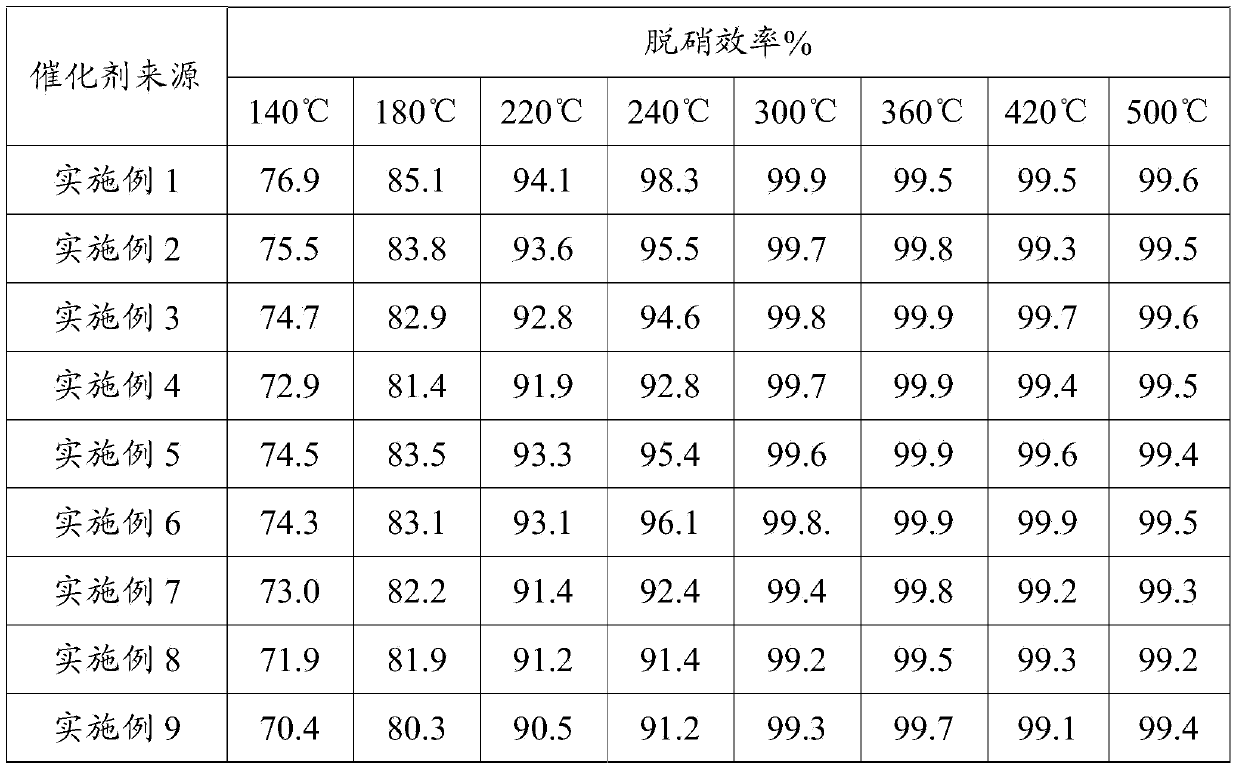

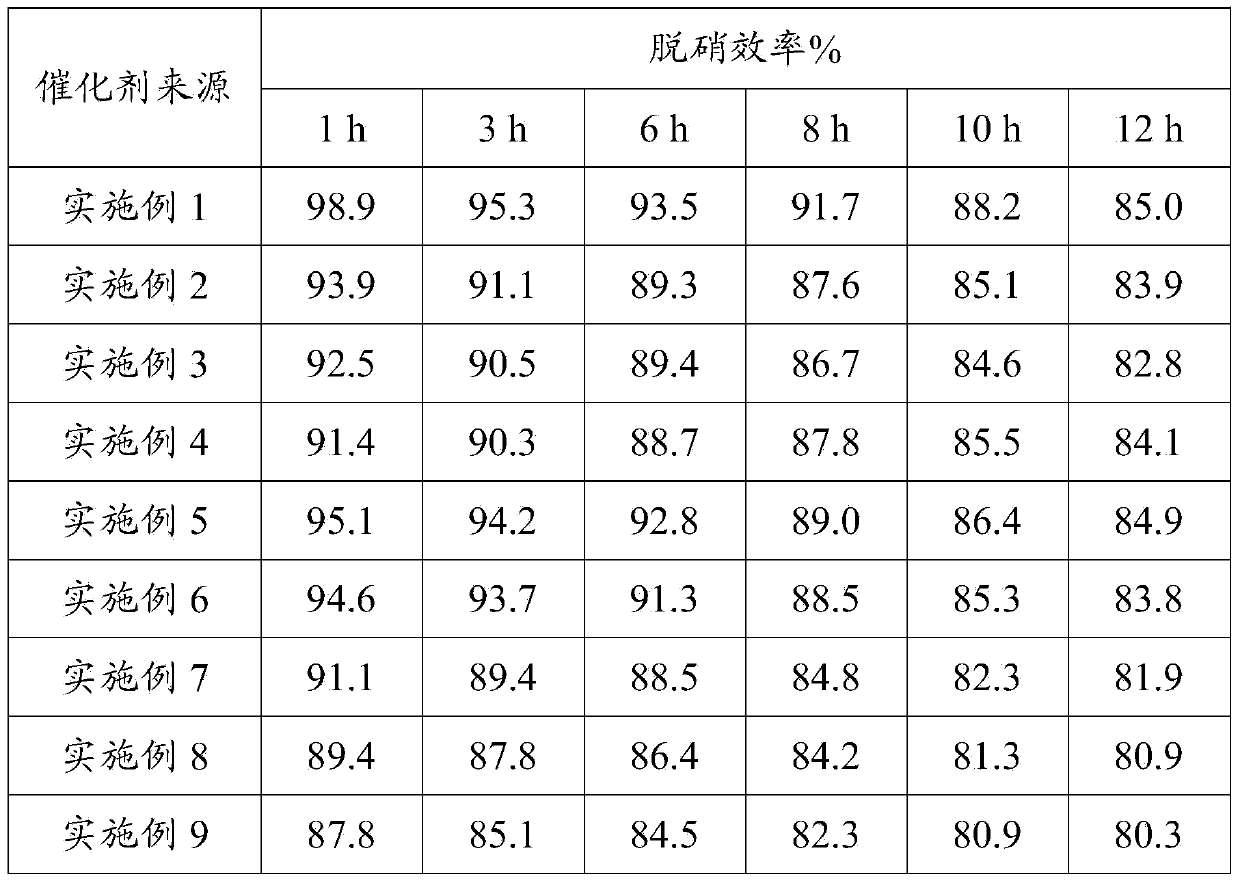

Middle and low temperature SCR denitration catalyst with anti-poisoning performance, and preparation method thereof

ActiveCN103990496AHigh activityEasy to placeOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationPhosphomolybdic acidAlkaline earth metal

The invention discloses a middle and low temperature SCR denitration catalyst with an anti-poisoning performance. The invention also discloses a preparation method of the middle and low temperature SCR denitration catalyst with an anti-poisoning performance. The preparation method comprises the following steps: 1, calcining a transition metal salt at 400-700DEG C for 1-10h to obtain a transition metal oxide; 2, mixing heteropoly acid or heteropoly salt with the prepared transition metal oxide according to a mass ratio of 1:(0.1-1), and carrying out dry mixing grinding to obtain an intermediate, wherein the heteropoly acid is phosphotungstic acid or phosphomolybdic acid, and the heteropoly salt is corresponding B salt of phosphotungstic acid or phosphomolybdic acid; and 3, calcining the intermediate obtained in step 2 at 80-500DEG C to obtain a finished product. The catalyst has an excellent middle and low temperature denitration performance, has a very excellent anti-poisoning ability on SO2, alkali metals and alkaline earth metals, and has unique advantages in the treatment of exhaust gases with high content of the alkali metals or alkaline earth metals, comprising cement kiln tail gas, biomass fuel boiler flue gas and the like.

Owner:ZHEJIANG UNIV

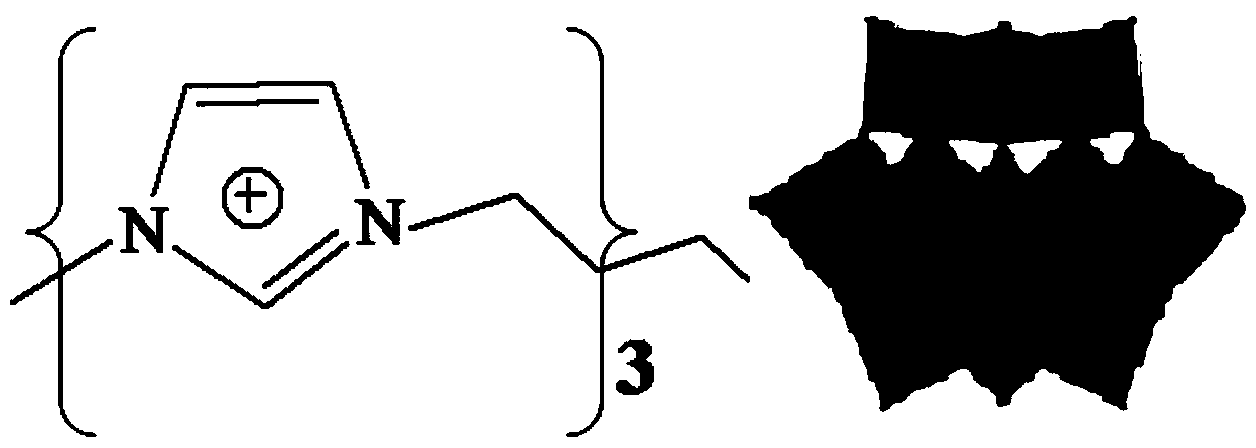

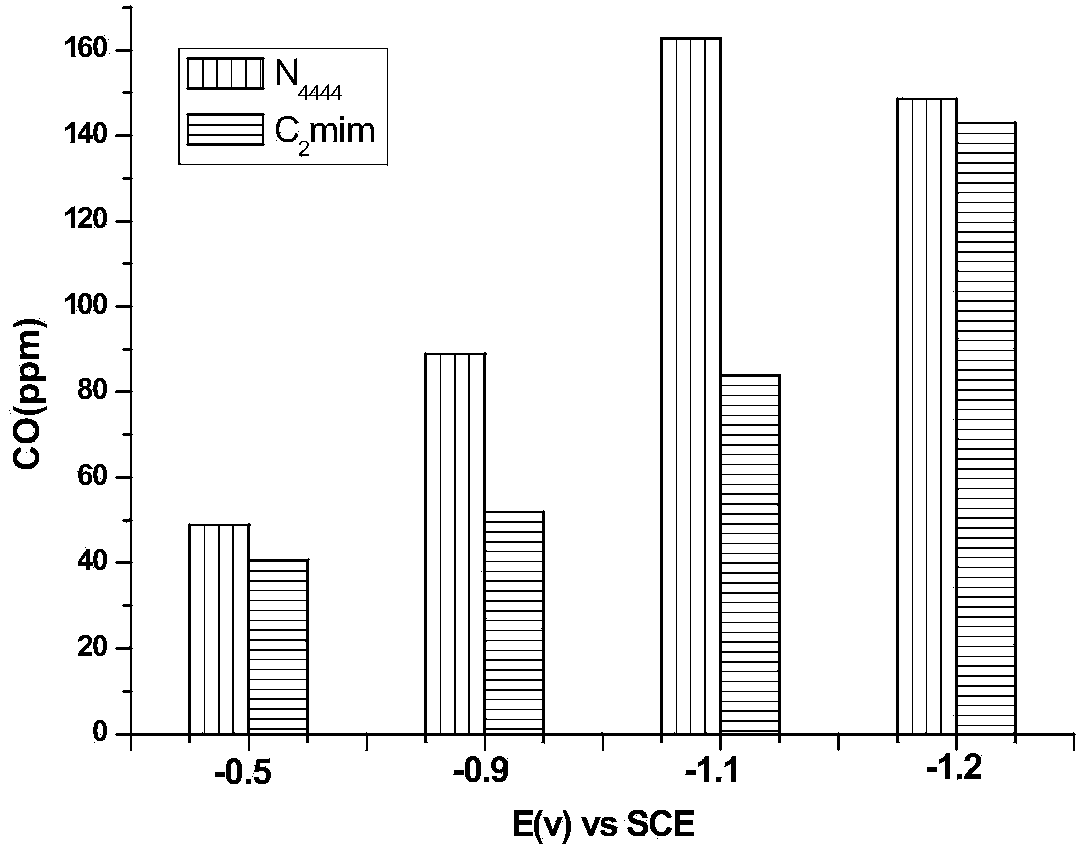

Method for electrocatalytic reduction of carbon dioxide using multi-metal oxygen cluster ionic liquid as electrocatalyst

ActiveCN104032324AEasy to synthesizeRaw materials are easy to getElectrolysis componentsOrganic-compounds/hydrides/coordination-complexes catalystsPhosphomolybdic acidResource utilization

The invention relates to a method for electrocatalytic reduction of CO2 using multi-metal oxygen cluster ionic liquid as electrocatalyst. The method is characterized in that positive ions of the multi-metal oxygen cluster ionic liquid are imidazoles [Cnmim]+(n=2, 4, 6, 8), pyridines [Cnpyr]+(n=2, 4) and quaternary ammonium salts [N4444]+, and negative ions of the multi-metal oxygen cluster ionic liquid are phosphotungstic acid negative ions (PW12O403-) and phosphomolybdic acid negative ions (PMo12O403-); and the electrocatalytic reduction reaction is a three-electrode system, wherein a glassy carbon electrode is a working electrode, a platinum sheet electrode is a counter electrode, and a saturated calomel electrode is a reference electrode. The method is simple in process and convenient in operation, performs the electrocatalytic reduction for the CO2 to form such fuels as methane and carbon monoxide, realizes the resource utilization of the CO2, reduces the atmospheric pollution, and has important significance on the environmental protection.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

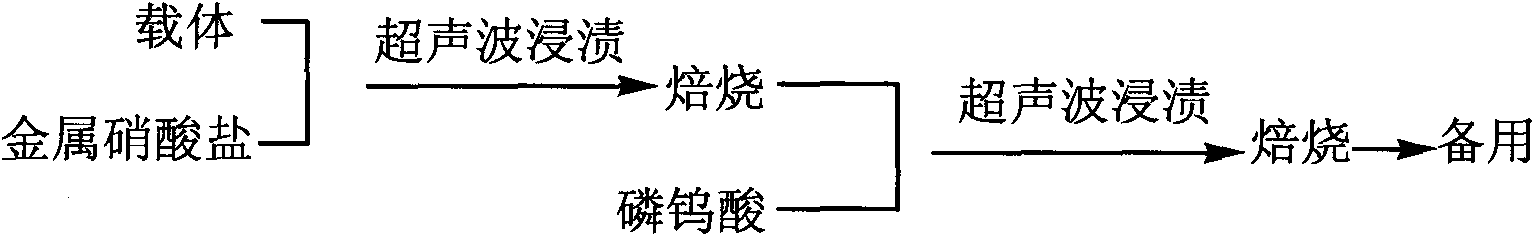

Phosphotungstic acid modified catalyst, preparation method and application in acrolein preparation thereof

InactiveCN101786020AWide variety of sourcesReduce manufacturing costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsFixed bedRare earth

The invention provides a phosphotungstic acid modified catalyst, and a preparation method thereof. In the catalyst, Al2O3, SiO2 or a zeolite molecular sieve is used as a vector; the vector is modified by using metal oxide, and then, glycerol is dehydrated by using supported phosphotungstic acid as the catalyst to prepare acrolein, wherein the metal oxide is alkaline-earth metal oxide, rare-earth metal oxide or transition metal oxide; the supported metal oxide accounts for 1 to 10 mass percent of the vector; and the capacity of the phosphotungstic acid is 30 percent. When the phosphotungstic acid modified catalyst is applied in the acrolein preparation, the reaction temperature is 300 DEG C, the concentration of the glycerol aqueous solution is 30 percent, inert solvent is added in the ratio of 20 to 200 percent of the glycerol solution, and space velocity of the volume of a fixed bed is 1 to 10 h-1. The precursor of the catalyst has wide sources, low price and low production cost. After the catalyst is modified by the metal oxide, the passivating speed of the catalyst is slowed down, the service life of the catalyst is prolonged, and catalytic activity is high. The catalyst can be recycled, has small corrosion to equipment, and reduces pollution to environment.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Environmental protection and high efficiency corrosion inhibitor for inhibiting salt water corrosion on carbon steel, preparation method and use method thereof

ActiveCN103508570AEffective corrosion inhibitionAvoid corrosionScale removal and water softeningPhosphomolybdic acidBenzoic acid

The present invention provides an environmental protection and high efficiency corrosion inhibitor for inhibiting salt water corrosion on carbon steel, a preparation method and a use method thereof, and relates to the field of chemistry. The corrosion inhibitor has characteristics of high efficiency, low cost, low toxicity and environmental protection, and is prepared through carrying out mixing stirring dissolving on 5-50% of a benzotriazole substance, 1-10% of benzoic acid and a salt thereof, 1-10% of molybdate, tungstate, phosphomolybdic acid and a salt thereof, and phosphotungstic acid and a salt thereof, 2-20% of an alcohol amine substance, 1-10% of an acid phosphate, 1-10% of a gluconate, 1-10% of an alkaline regulator, 1-10% of an oxygen scavenging agent and the balance of water. According to the present invention, the potassium dichromate or the sodium nitrite with high toxicity, and the non-environmental protection high phosphorus and high zinc can be replaced, and corrosion of calcium chloride salt water on carbon steel and copper can be significantly inhibited when the concentration of the corrosion inhibitor is 0.3-0.5%.

Owner:CHAOYANG GUANGDA CHEM

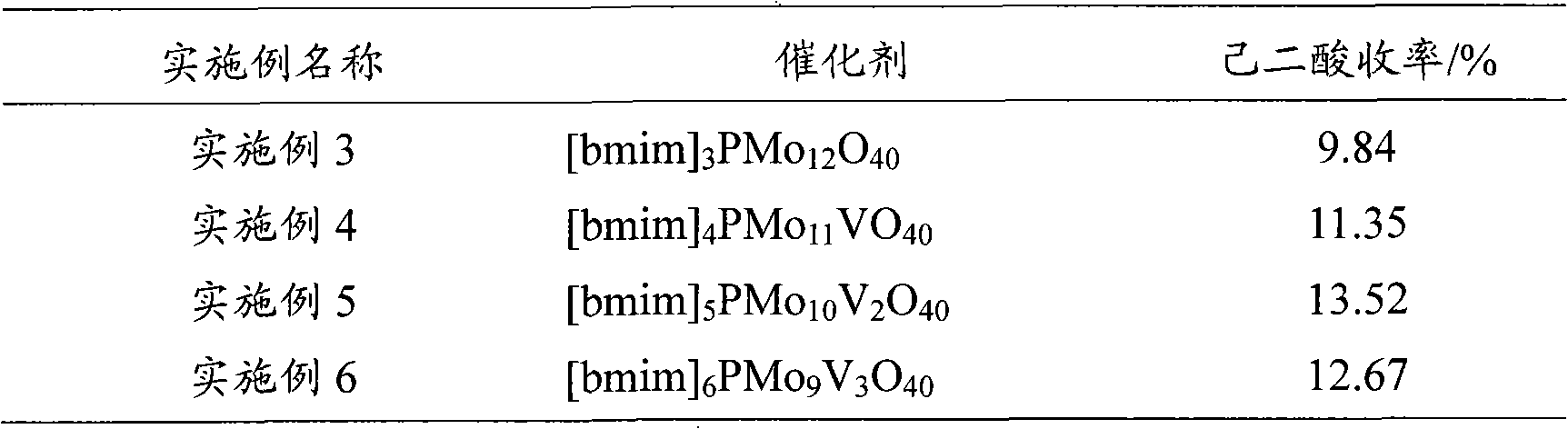

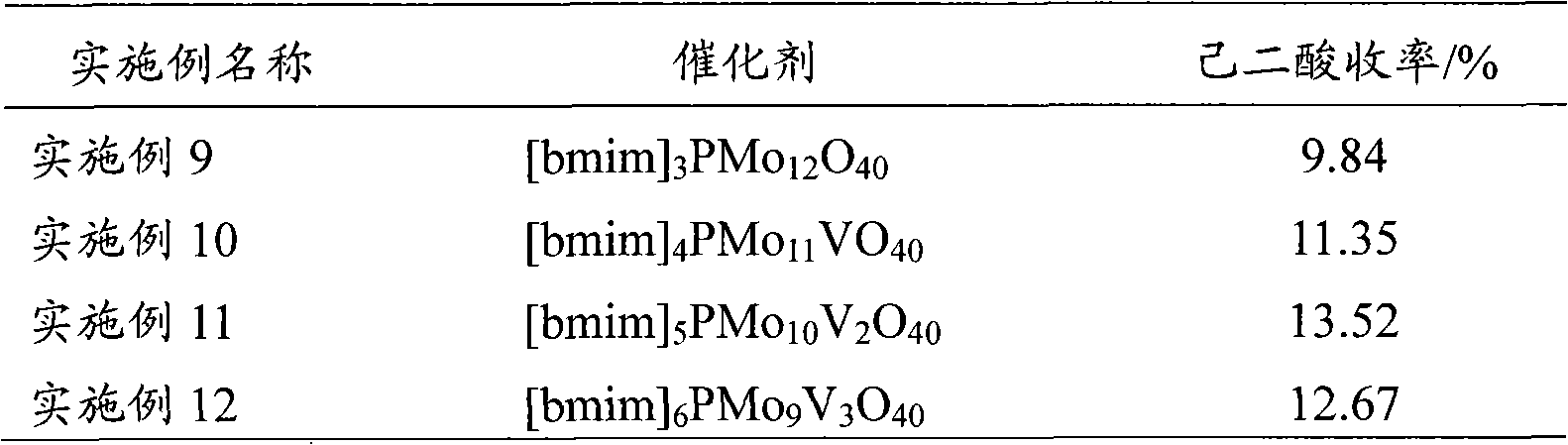

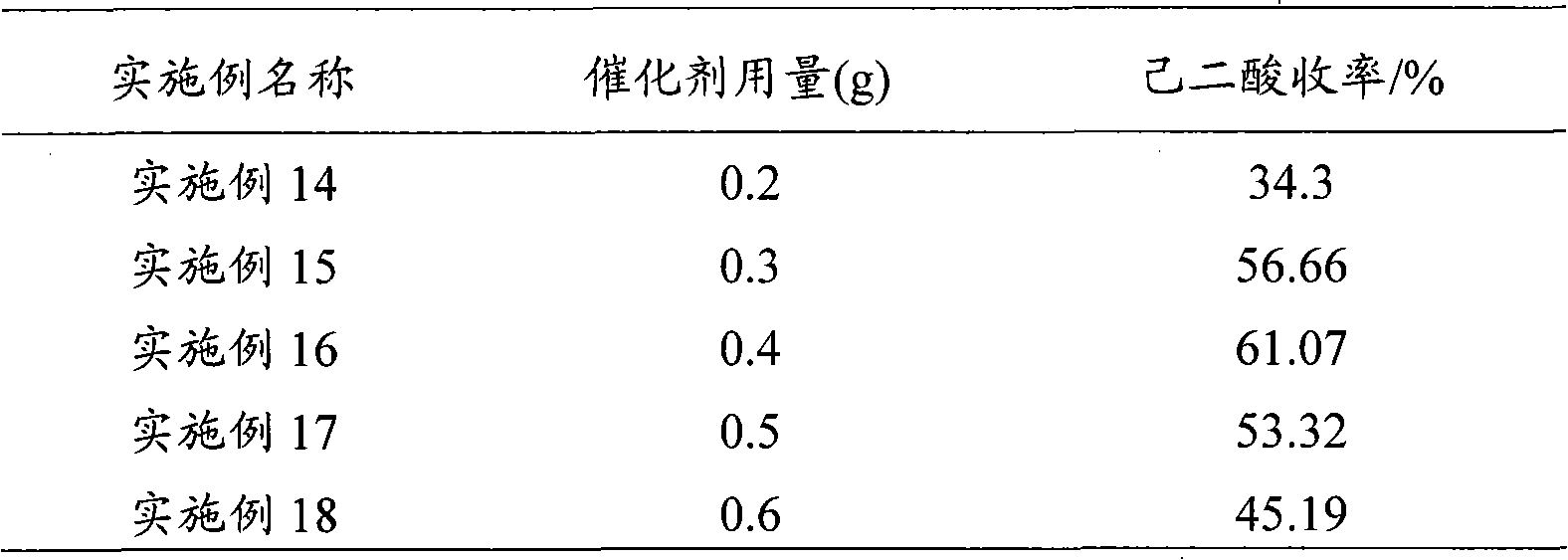

Method for preparing hexane diacid by liquid-phase catalytic oxidation of cyclohexanol

InactiveCN101302147AAvoid it happening againReduce usageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPhosphomolybdic acidHeteropoly acid

The invention provides a method for preparing adipic acid through liquid-phase catalytic oxidation of cyclohexanol. H2O2 is taken as oxidant, a heteropoly acid imidazole salt is taken as catalyst, the cyclohexanol undergoes the catalytic oxidation to prepare the adipic acid, the catalyst can be phosphotungstic acid 1-butyl-3-methylimidazolium bmim3PW12O40, phosphomolybdic acid 1-butyl-3-methylimidazolium bmim3PMo12O40, and molybdovanadophosphoric heteropolyacid 1-butyl-3-methylimidazolium bmim3+xPMo12-xVxO40 (x is equal to between 1 and 3) and so on, and the bmim represents a 1-butyl-3-methyl-imidazolium cation. Compared with the method of preparing the adipic acid by industrially using nitric acid (nitrate) to oxidize the cyclohexanol, the method can not produce poisonous oxynitride N2O, and avoids the harm to the environment; and in a reaction system, phase shift catalyst and addition agent are not used, which avoids the potential environmental pollution and has apparent economic and social significance.

Owner:ZHEJIANG UNIV OF TECH

Preparation method and applications of multi-level pore structure metal organic framework material

ActiveCN110256683AAdvantages of preparation methodAperture controllableOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation from oxiranesN dimethylformamideSynthesis methods

The invention provides a preparation method and applications of a multi-level pore structure metal organic framework material. The preparation method comprises: mixing a metal salt, an organic ligand, N,N-dimethylformamide, water and carboxylic acid, uniformly stirring, carrying out a hydrothermal reaction, cooling to a room temperature after completing the hydrothermal reaction, carrying out centrifugation, and purifying to prepare the multi-level pore structure metal organic framework material. According to the present invention, the prepared multi-level pore structure metal organic framework material has characteristics of stable performance and controlled and uniform pore size; and phosphotungstic acid is loaded in the mesoporous channel of the metal organic framework material through an in-situ synthesis method, the original framework structure can be remained after the loading, and the presence of the mesopores allows the contact between the large substrate molecule and the active site so as to extend the application range of the multi-level pore structure metal organic framework material.

Owner:WUHAN UNIV OF TECH

Method for preparing epoxy chloropropane

The invention discloses a method for preparing epoxy chloropropane. The method comprises the following step of: oxidizing chloropropene by using a phosphotungstic acid quaternary ammonium salt, a phosphoric acid quaternary ammonium salt and hydrogen peroxide under a solvent-free condition to generate the epoxy chloropropane.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrolysis method of esters

InactiveCN1541991AImprove the conversion rate of hydrolysisEasy to separateOxygen-containing compound preparationOrganic compound preparationPhosphomolybdic acidHeteropoly acid

The ester hydrolyzing method includes hydrolyzing ester in water to produce C1-C10 fatty acid or aromatic acid and C1-C4 fatty alcohol under the presence of ammonium salt of heteropoly acid as catalyst. The ammonium salt of heteropoly acid is obtained through the reaction between heteropoly acid in Keggin structure and inorganic ammonium salt or organic amine, the heteropoly acid is selected from phosphotungstic acid, silicotungstic acid, silicomolybdic acid and phosphomolybdic acid; the inorganic ammonium salt is selected from ammonium carbonate, ammonium nitrate, ammonium sulfate, ammonium phosphate and diammonium hydrochloride; and the organic amine is selected from fatty amine, alicyclic amine and arylamine. The said ester hydrolyzing method can obtain high conversion rate in relatively lower water / ester ratio and relatively short time, and the catalyst is cheap and easy to separate from the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for removing sulfur in diesel by photo catalytic oxidation

The invention relates to a method for removing the sulfur in gasoline and diesel oil through photocatalytic oxidation; a catalyst is dissolved into an accessory ingredient and then is added into an oil product; under the irradiation of light, the sulfur-compounds in the oil product are selectively oxidized by molecular oxygen and generated into sulfur dioxide which escapes from a reaction liquid; the accessory ingredient is methanol, ethanol or acetonitrile; the catalyst is phosphotungstic acid, phosphotungstate, phosphomolybdate, phosphomolybdate or any mixture thereof or a derivative thereof; the light refers to artificial light or sunshine which can inspire the catalyst or a complex compound thereof; the molecular oxygen refers to the molecular oxygen or pure compressed oxygen in the air; the dosage of the catalyst is 0.01 to 5g for each L of fuel; the dosage of the accessory ingredient is 1 to 500g for each L of fuel; the pressure of the oxygen is 0.02 to 1.0 MPa; the method is carried out under normal temperature and pressure and does not need the treatment of extraction and concentration; the sulfur is separated in the mode of SO2 without products of organic sulfur like sulfone, sulphoxide, thioether, and the like, thereby having no loss of organic carbon; the yield of the oil product can achieve more than 99 percent.

Owner:PETROCHINA CO LTD +1

Polyacrylate elastomer with core-shell structure and its preparation method

The invention discloses polyacrylate elastomer with a core-shell structure and its preparation method. The polyacrylate elastomer with the core-shell structure is obtained by using acrylic acid ester, metacrylic acid ester and a reactive type ultraviolet ray absorber according to a certain ratio through a method of the polymerization of seed emulsion in a semicontinuous feeding mode, wherein the color of the appearance is white, light yellow or yellow, and the weight average molecular weight is 2 to 10xe<5>g / mol. Polymer latex particles appear as a microsphere state before the demulsificationof the elastomer, a three-layer structure of the latex particles microsphere can be observed after dyeing by phosphor-tungstic acid, the three layers comprise a core layer, a transition layer and a shell layer sequentially from the inside to the outside. According to the invention, polyacrylate elastomer with the core-shell structure reacts the polymer material by a melt blending process so that the ultraviolet light stability of the high-molecular material can be enhanced and the polymer material can be effectively is toughened, and the emulsion polymerisation method has the advantages of environmental protection without pollution, mature technology and easy realization of industrialization.

Owner:SICHUAN UNIV

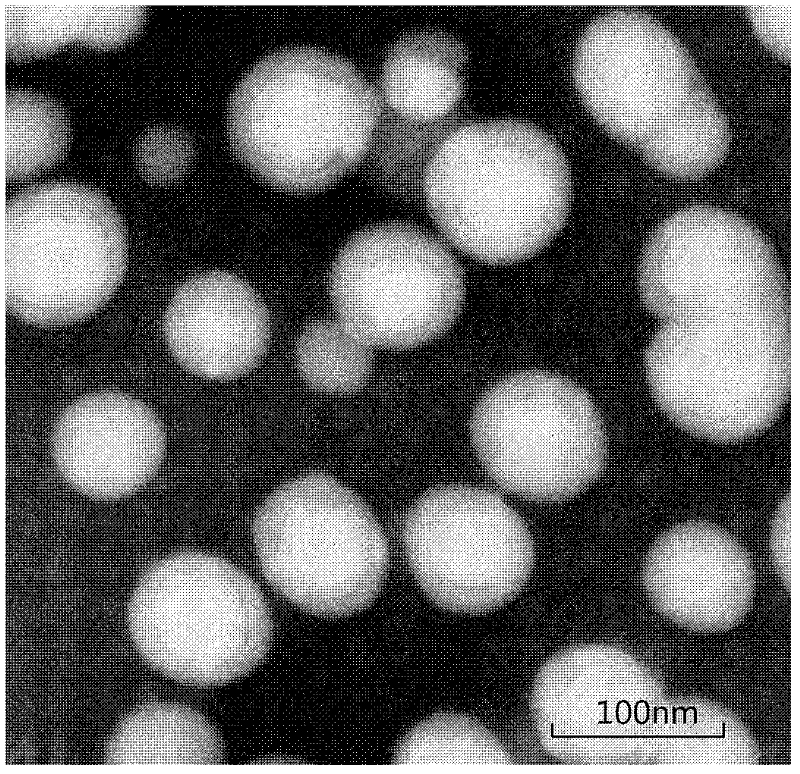

Supported phosphotungstic acid catalyst and preparation thereof, and preparation method of methyl acetate

ActiveCN102962084AWith repeated useLess side effectsPhysical/chemical process catalystsOrganic compound preparationMethyl acetateMesoporous silica

The invention provides a supported phosphotungstic acid catalyst which comprises a spherical mesoporous silica carrier and phosphotungstic acid supported on the spherical mesoporous silica carrier; on a basis of total weight of the catalyst, the catalyst comprises 10-50 wt% of the phosphotungstic acid, and 50-90 wt% of the spherical mesoporous silica carrier. The invention also provides a preparation method of the supported phosphotungstic acid catalyst. In addition, the invention also provides a preparation method of methyl acetate by using the supported phosphotungstic acid catalyst. The supported phosphotungstic acid catalyst of the invention can be recovered for recycle; when compared with a homogeneous catalyst-concentrated sulfuric acid, the supported phosphotungstic acid catalyst has better catalytic performance, and cause no corrosion to equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of attapulgite-based solid acid catalyst for vegetable fat epoxidation

ActiveCN103657696AImprove thermal stabilityHigh catalytic activityPhysical/chemical process catalystsFatty acid chemical modificationSolid acidAdditional values

The invention discloses a preparation method of an attapulgite-based solid acid catalyst for vegetable fat epoxidation. The preparation method comprises the steps of synthesizing phosphotungstic acid peroxide serving as a catalyst for fat epoxidation; then performing purification, acid modification and organic modification on attapulgite; and finally, loading the phosphotungstic acid peroxide on the organically modified attapulgite serving as a carrier to obtain the load type solid acid catalyst. According to the preparation method, the performance of the phosphotungstic acid peroxide is improved, the repeated use of the phosphotungstic acid peroxide is realized, the application range of the attapulgite is expanded, and the additional value of the attapulgite is increased; the attapulgite-based solid acid catalyst has the characteristics of easiness in separation of the catalyst from products, zero pollution, no corrosion to equipment, simplicity in post-treatment of the products, reutilization, simple regeneration process and the like.

Owner:盱眙凹土能源环保材料研发中心 +1

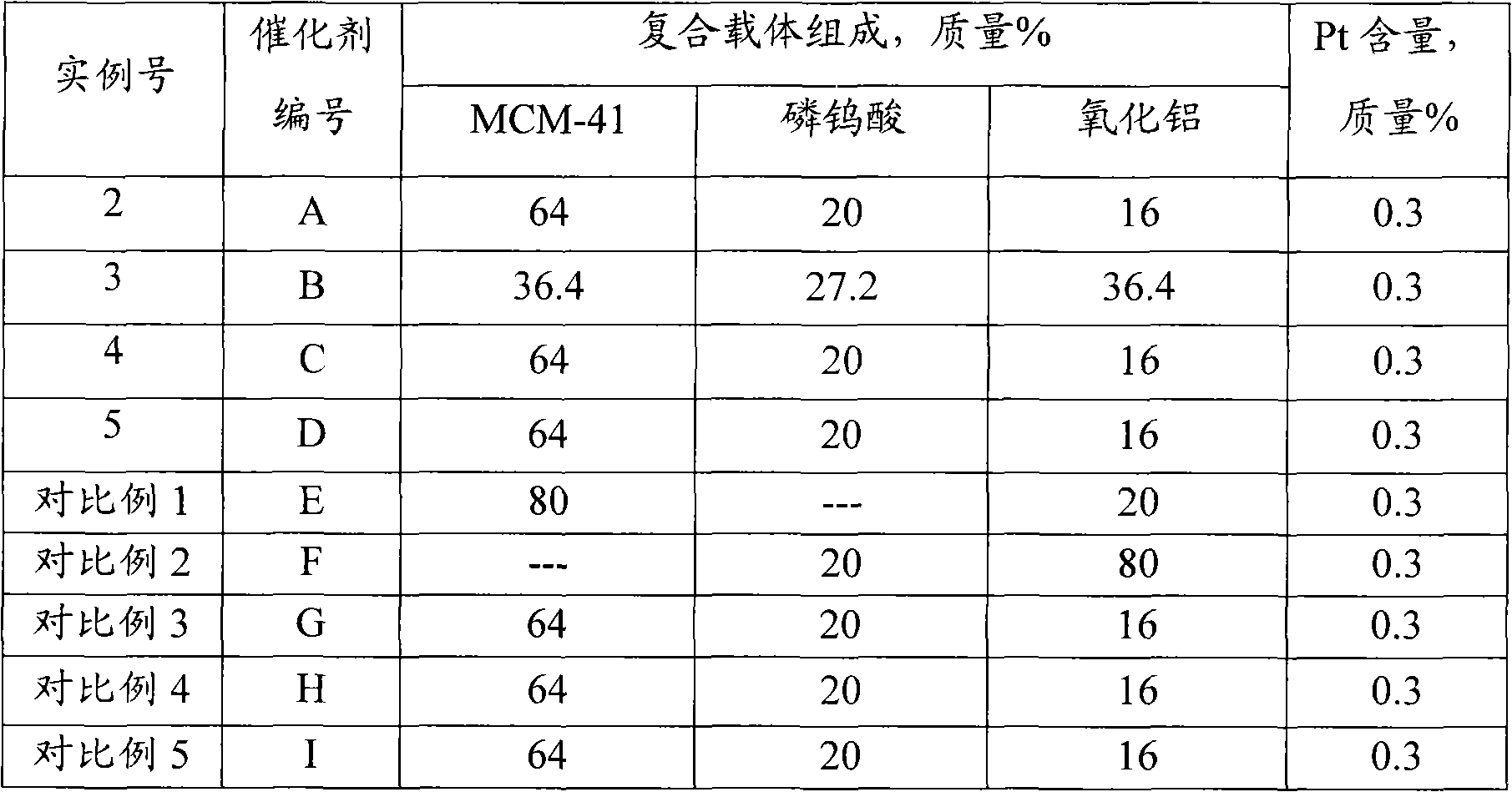

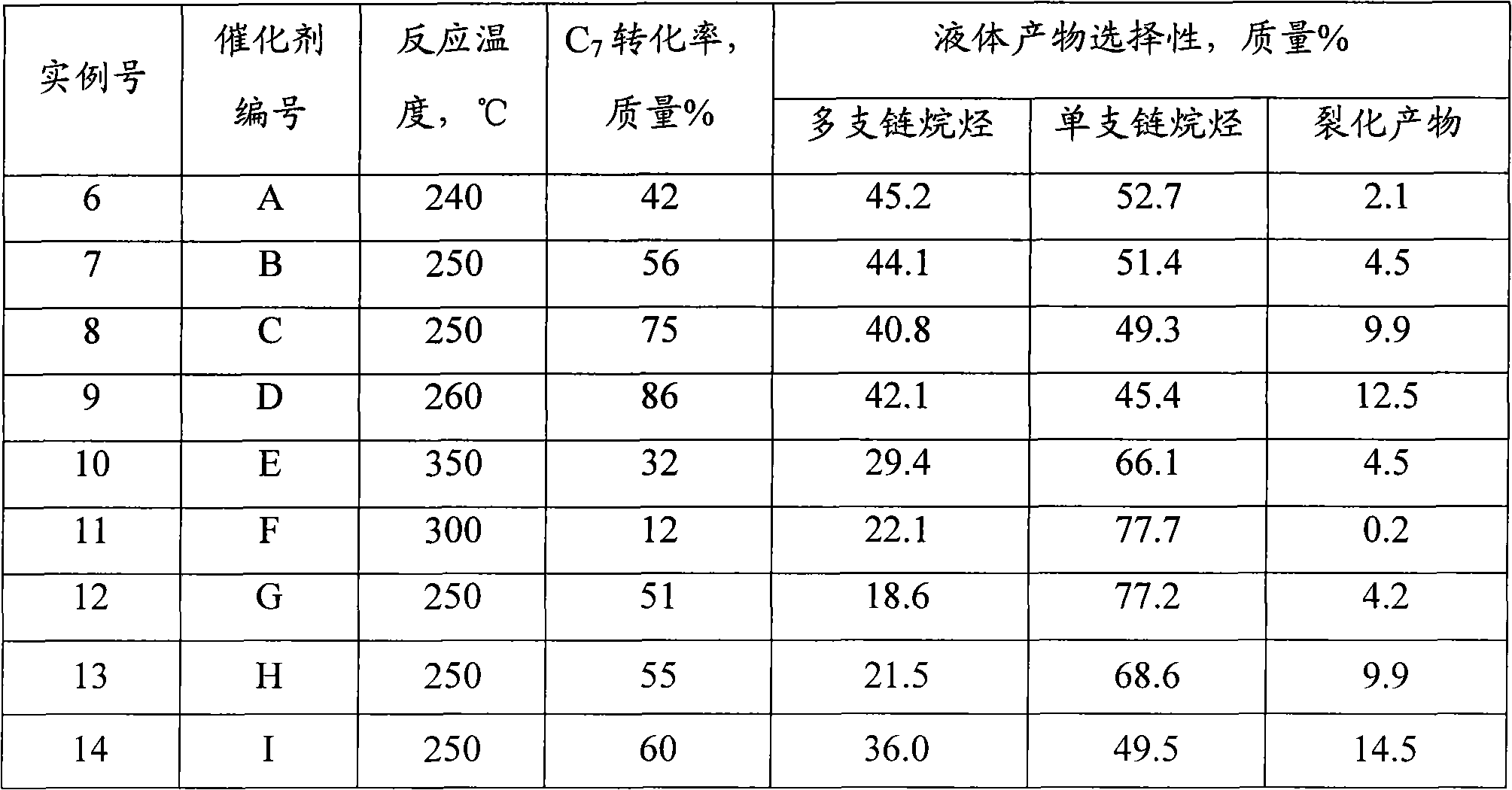

C7-C10 n-alkane isomerization catalyst and preparation method thereof

ActiveCN102107142AImprove liquid yieldHigh activityHydrocarbon by isomerisationMolecular sieve catalystsPlatinumIsomerization

The invention discloses a C7-C10 n-alkane isomerization catalyst which comprises a composite carrier and 0.05-3.0% of platinum by mass based on carrier, wherein the composite carrier comprises 20-70% of MCM-41 molecular sieve by mass, 10-35% of phosphotungstic acid by mass and 10-50% of aluminum oxide by mass. The catalyst is used for the isomerization reaction of the C7-C10 n-alkane, and has relatively high isomerization activity, high product liquid yield and relatively high selectivity of highly branched alkane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/371f3b02-68c7-41ef-a7cd-a4dfbefe86ed/1505051449421.PNG)

![Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/371f3b02-68c7-41ef-a7cd-a4dfbefe86ed/1505051449422.PNG)

![Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/371f3b02-68c7-41ef-a7cd-a4dfbefe86ed/1505051449423.PNG)