Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1560results about "Tungsten compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

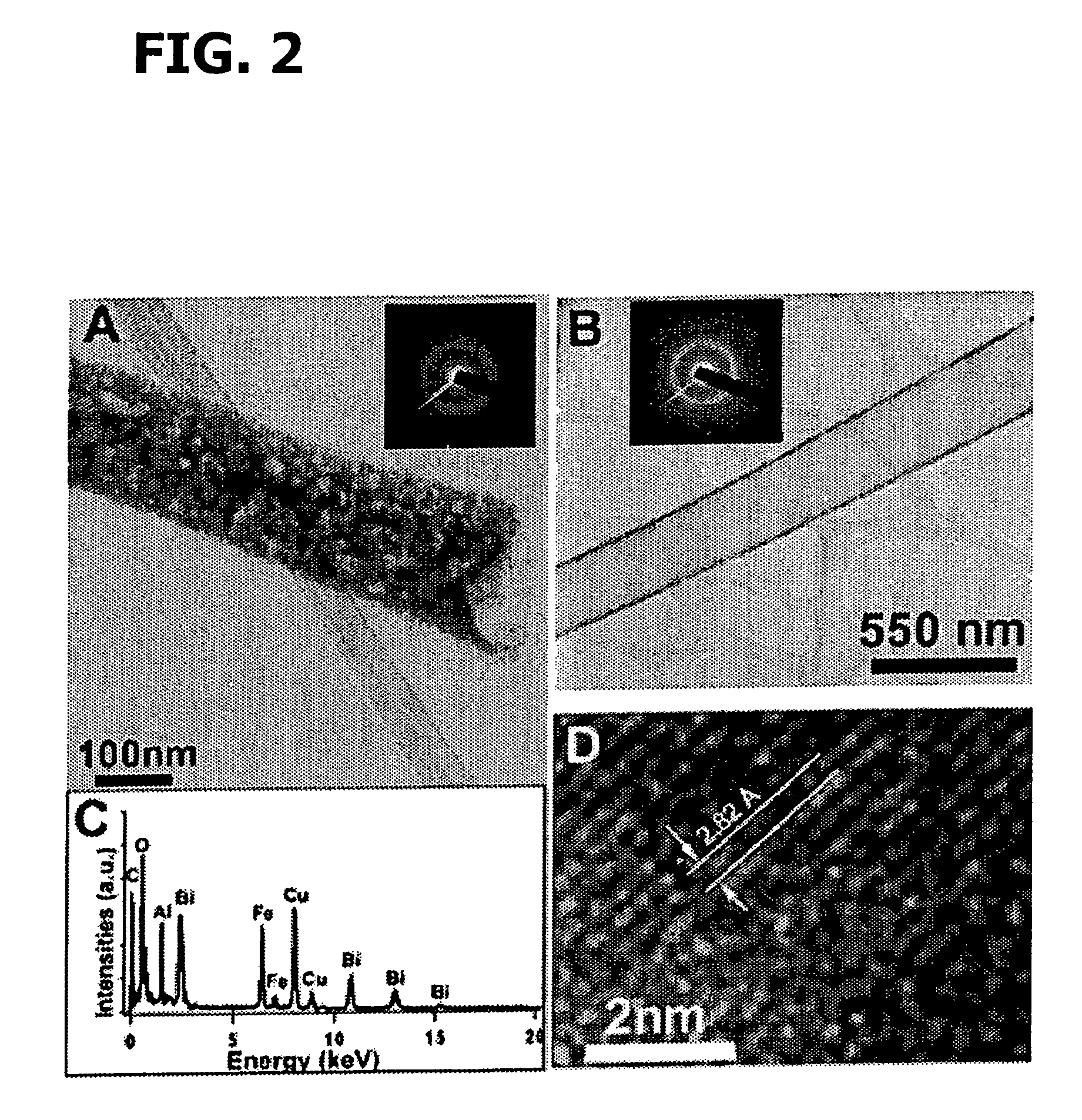

Ternary oxide nanostructures and methods of making same

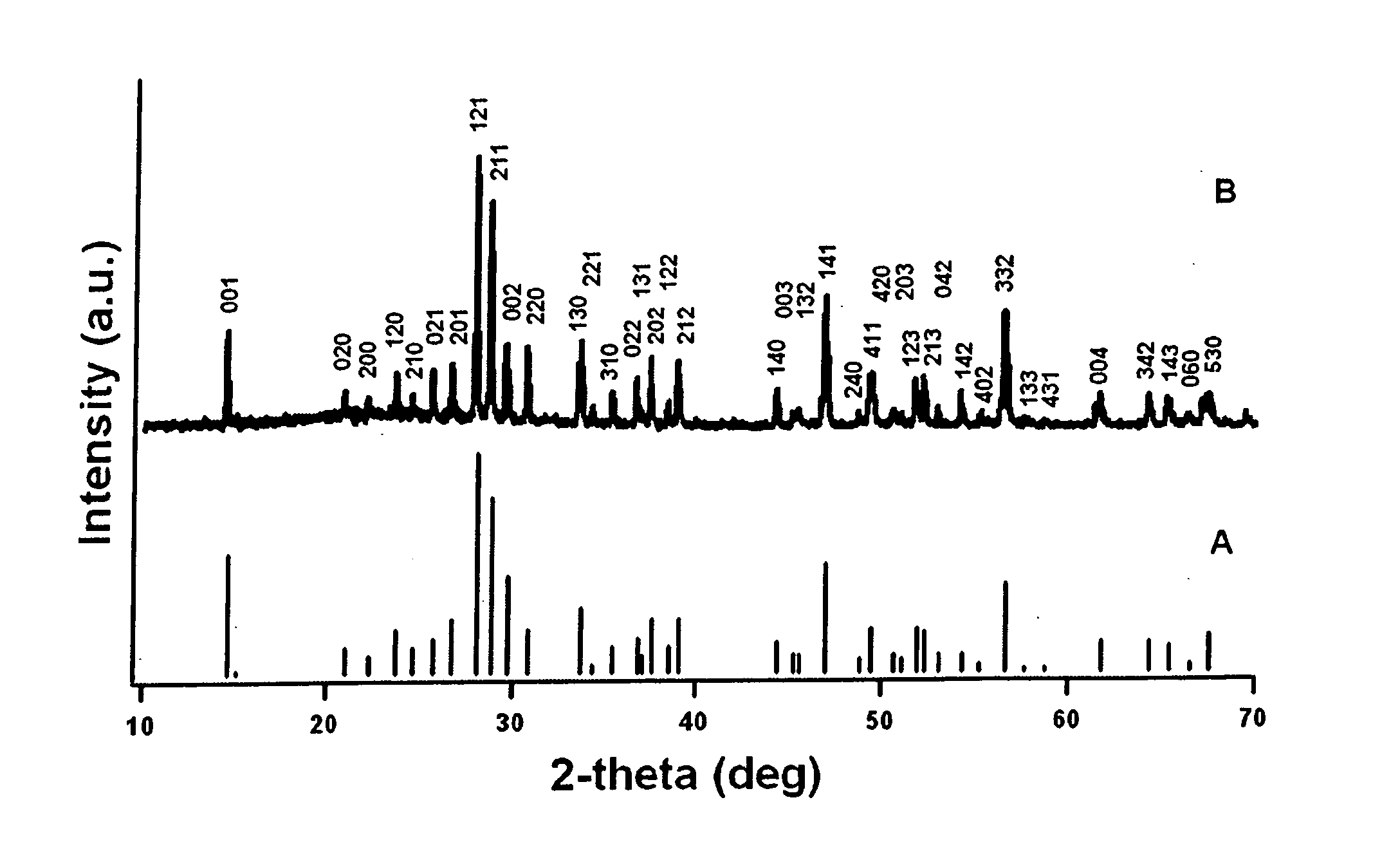

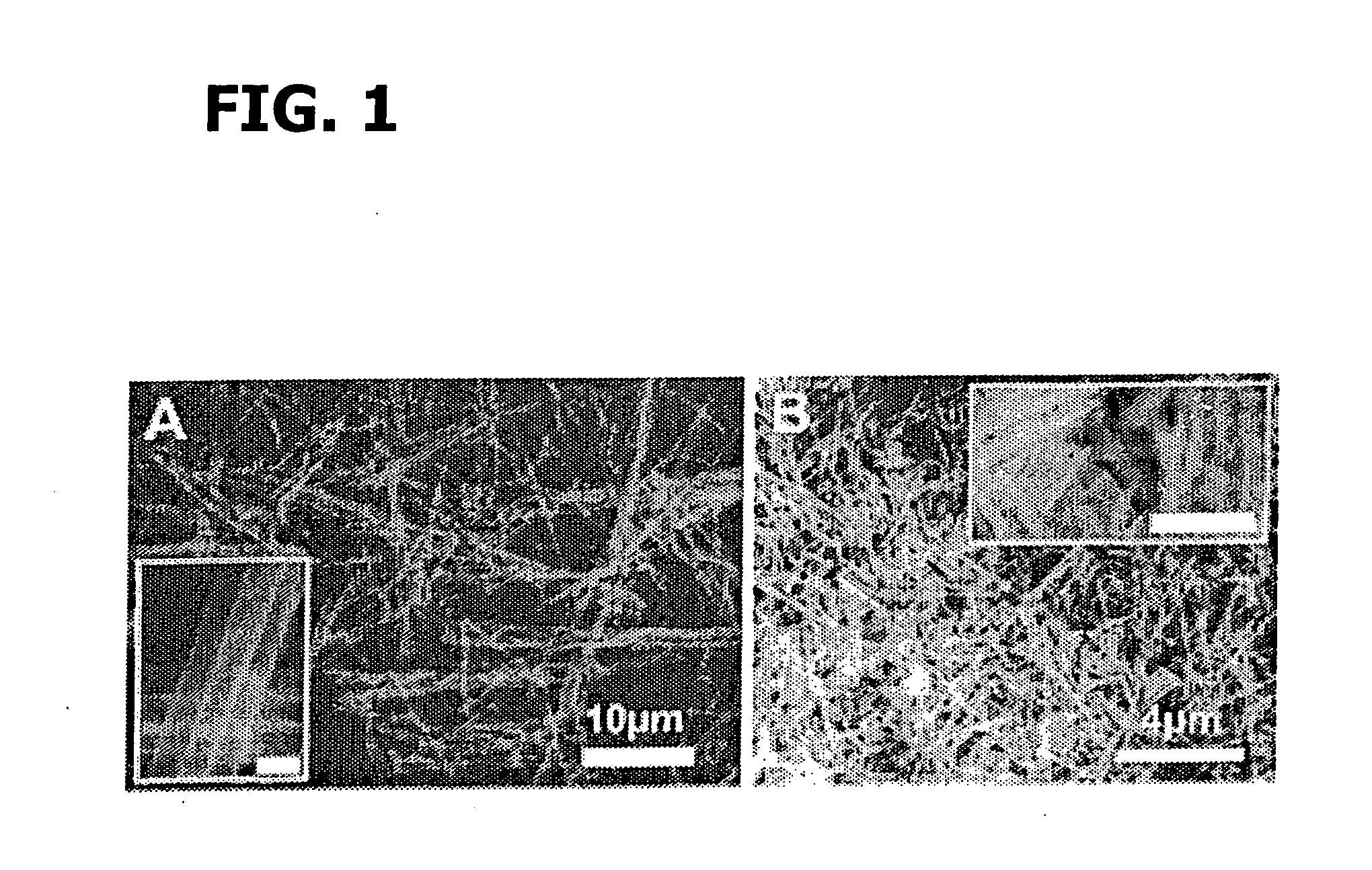

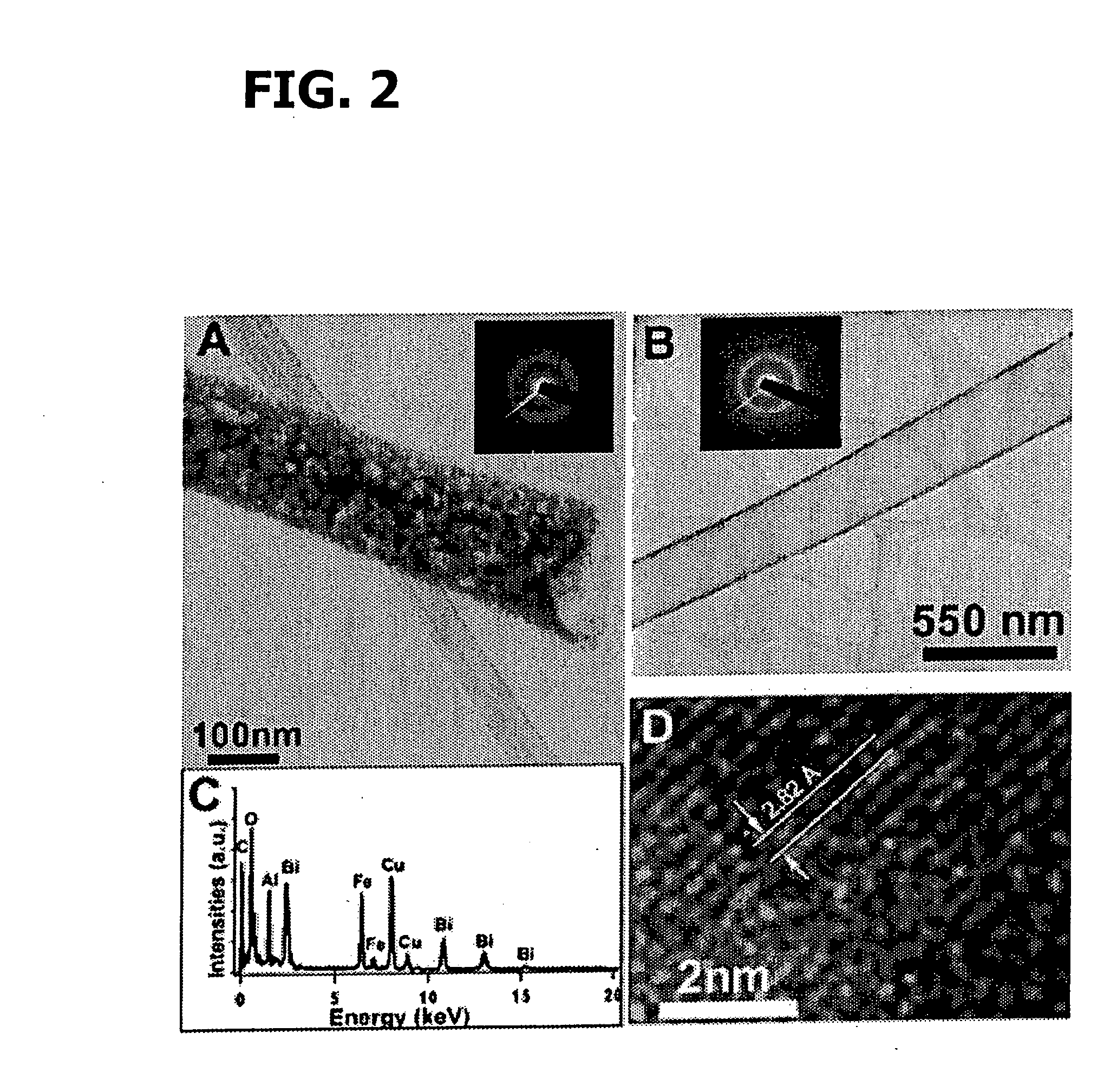

InactiveUS20070138459A1Suitable for preparationFrom gel stateAlkaline earth titanatesNanostructureDislocation

A single crystalline ternary nanostructure having the formula AxByOz, wherein x ranges from 0.25 to 24, and y ranges from 1.5 to 40, and wherein A and B are independently selected from the group consisting of Ag, Al, As, Au, B, Ba, Br, Ca, Cd, Ce, Cl, Cm, Co, Cr, Cs, Cu, Dy, Er, Eu, F, Fe, Ga, Gd, Ge, Hf, Ho, I, In, Ir, K, La, Li, Lu, Mg, Mn, Mo, Na, Nb, Nd, Ni, Os, P, Pb, Pd, Pr, Pt, Rb, Re, Rh, Ru, S, Sb, Sc, Se, Si, Sm, Sn, Sr, Ta, Tb, Tc, Te, Ti, Ti, Tm, U, V, W, Y, Yb, and Zn, wherein the nanostructure is at least 95% free of defects and / or dislocations.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

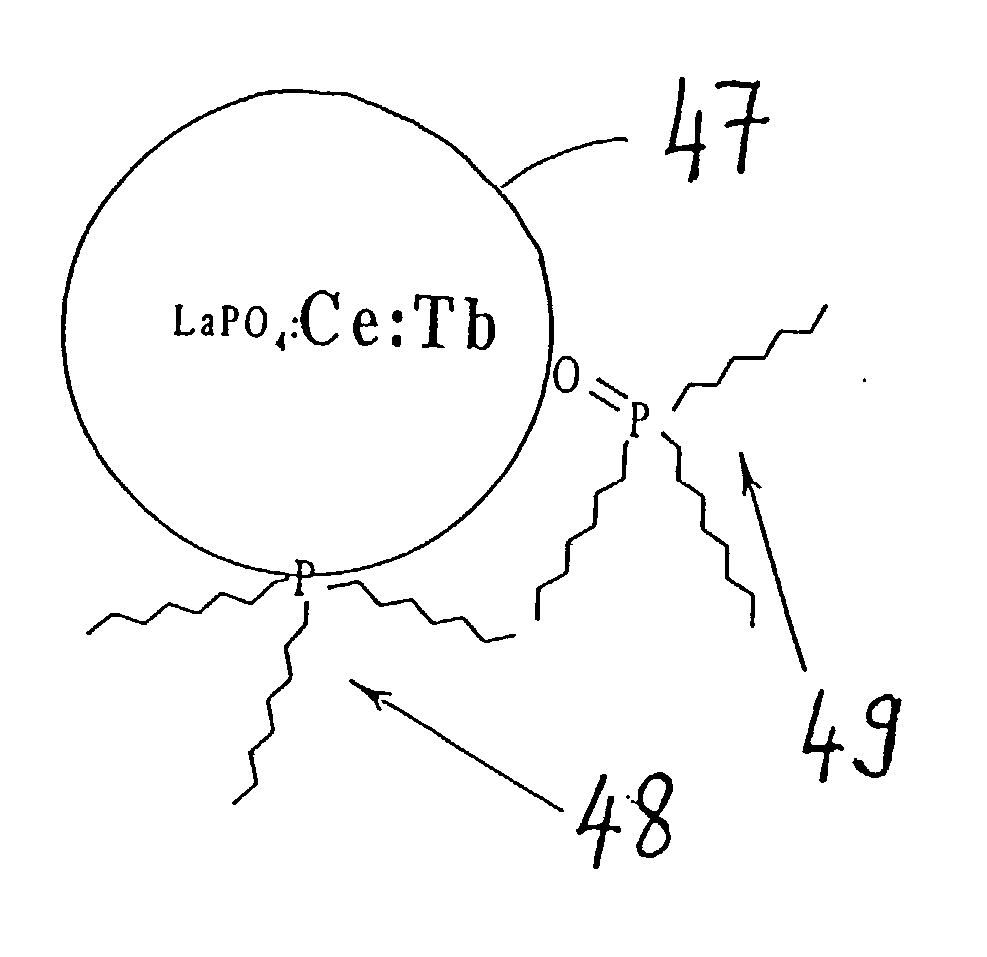

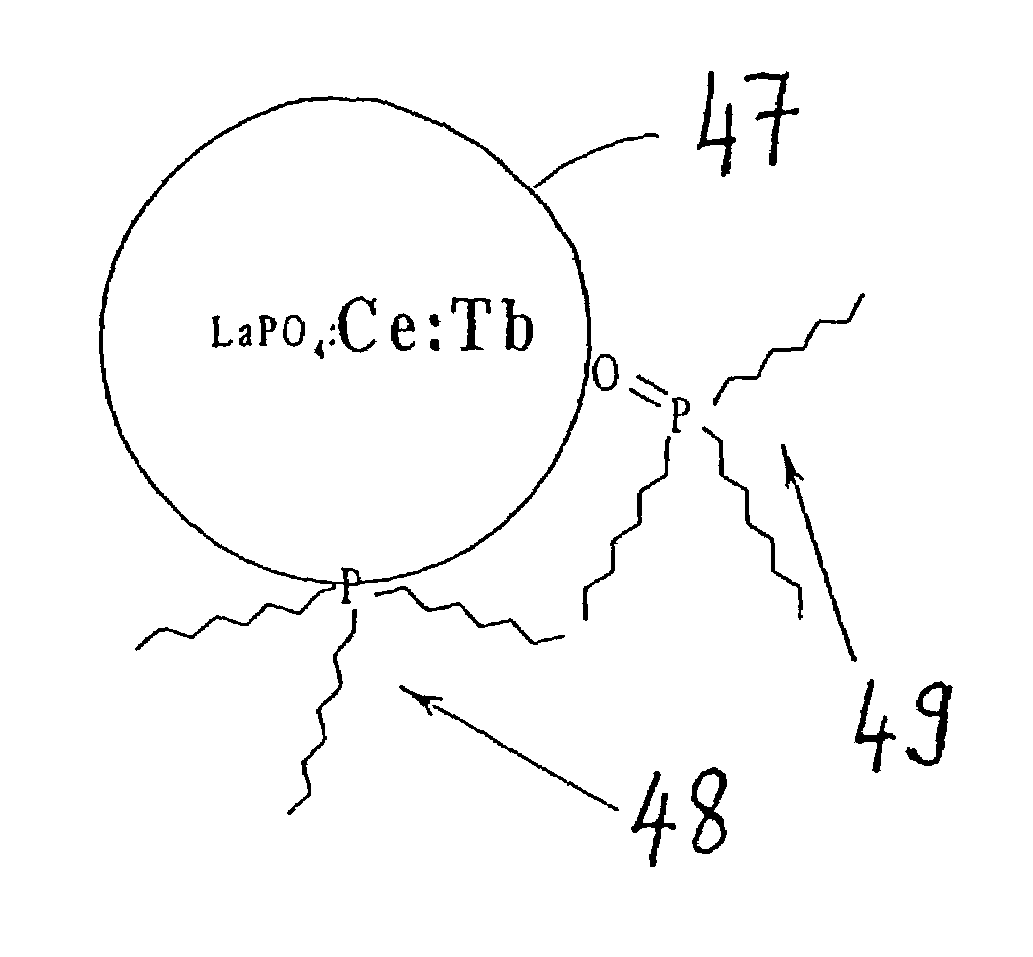

Synthesis of nanoparticles

InactiveUS20030032192A1High sensitivityIncreasing efficiency of collectorOptical radiation measurementMaterial nanotechnologyDopantOrganic solvent

The present invention relates to methods for the preparation of inorganic nanoparticles capable of fluorescence, wherein the nanoparticles consist of a host material that comprises at least one dopant. The synthesis of the invention in organic solvents allows to gain a considerably higher yield compared to the prior art synthesis in water. All kinds of objects can advantageously be marked and reliably authenticated by using an automated method on the basis of a characteristic emission. Further, the size distribution of the prepared nanoparticles is narrower which renders a subsequent size-selected separation process superfluous.

Owner:CENT FUR ANGEWANDTE NANOTECH

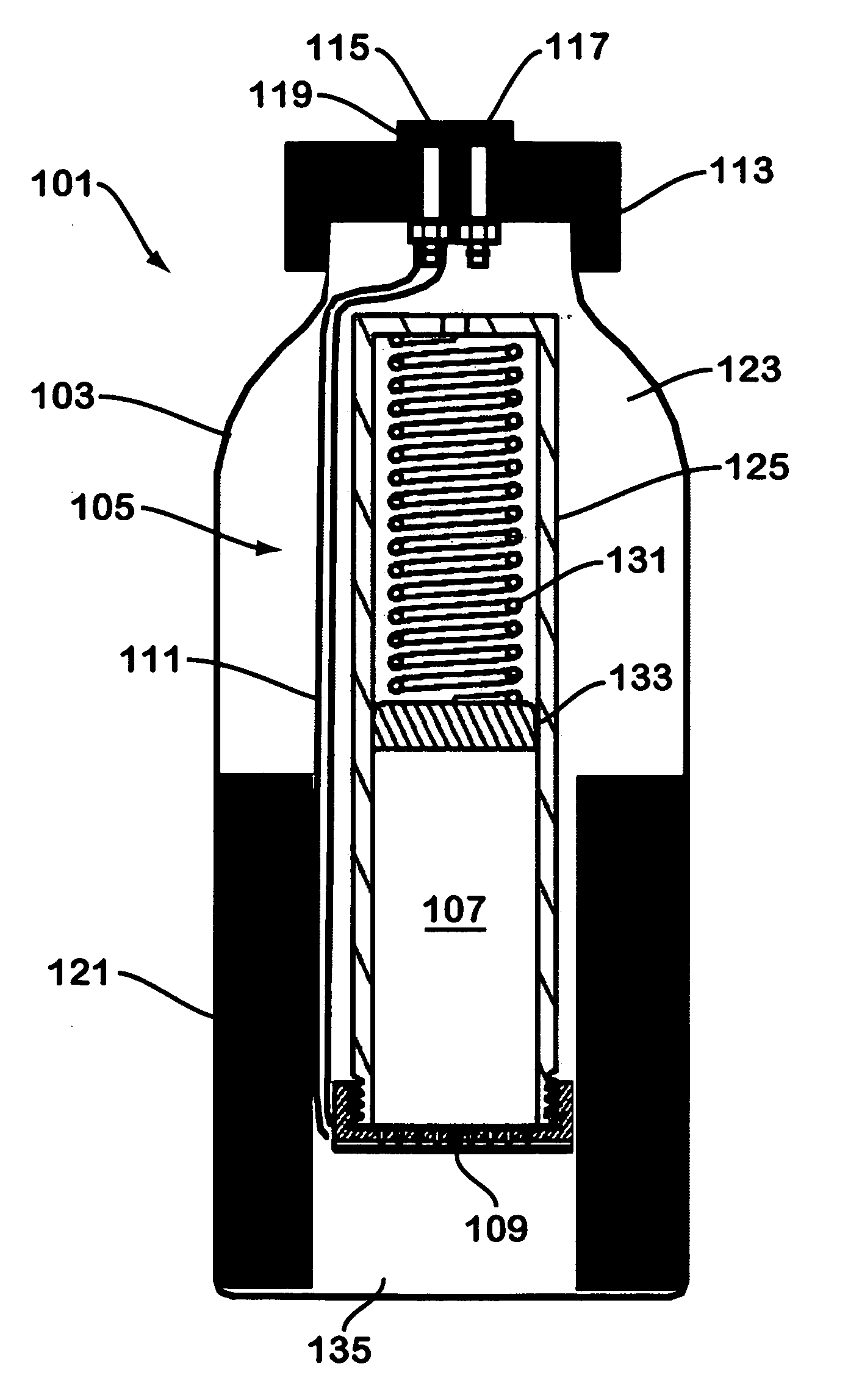

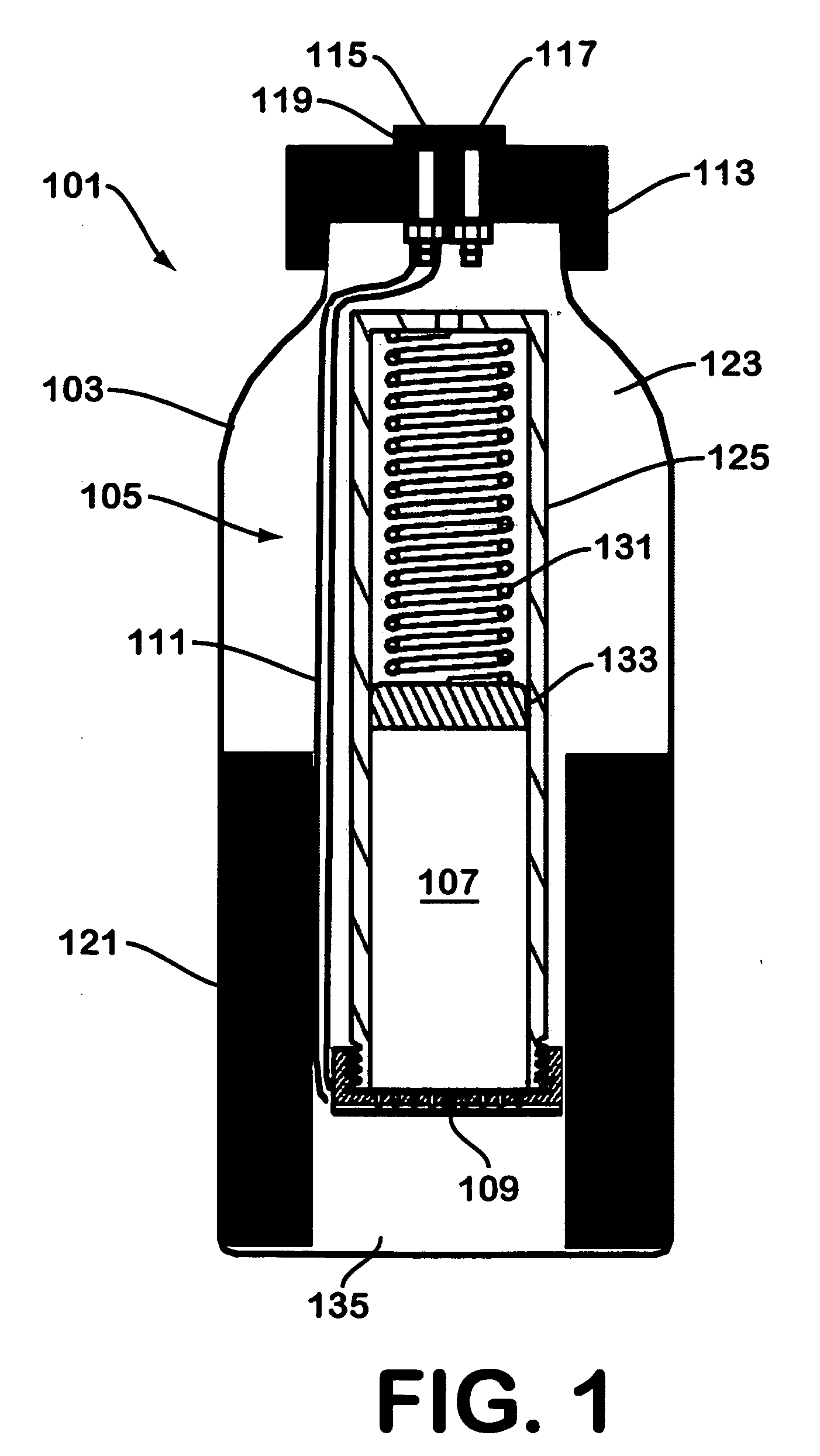

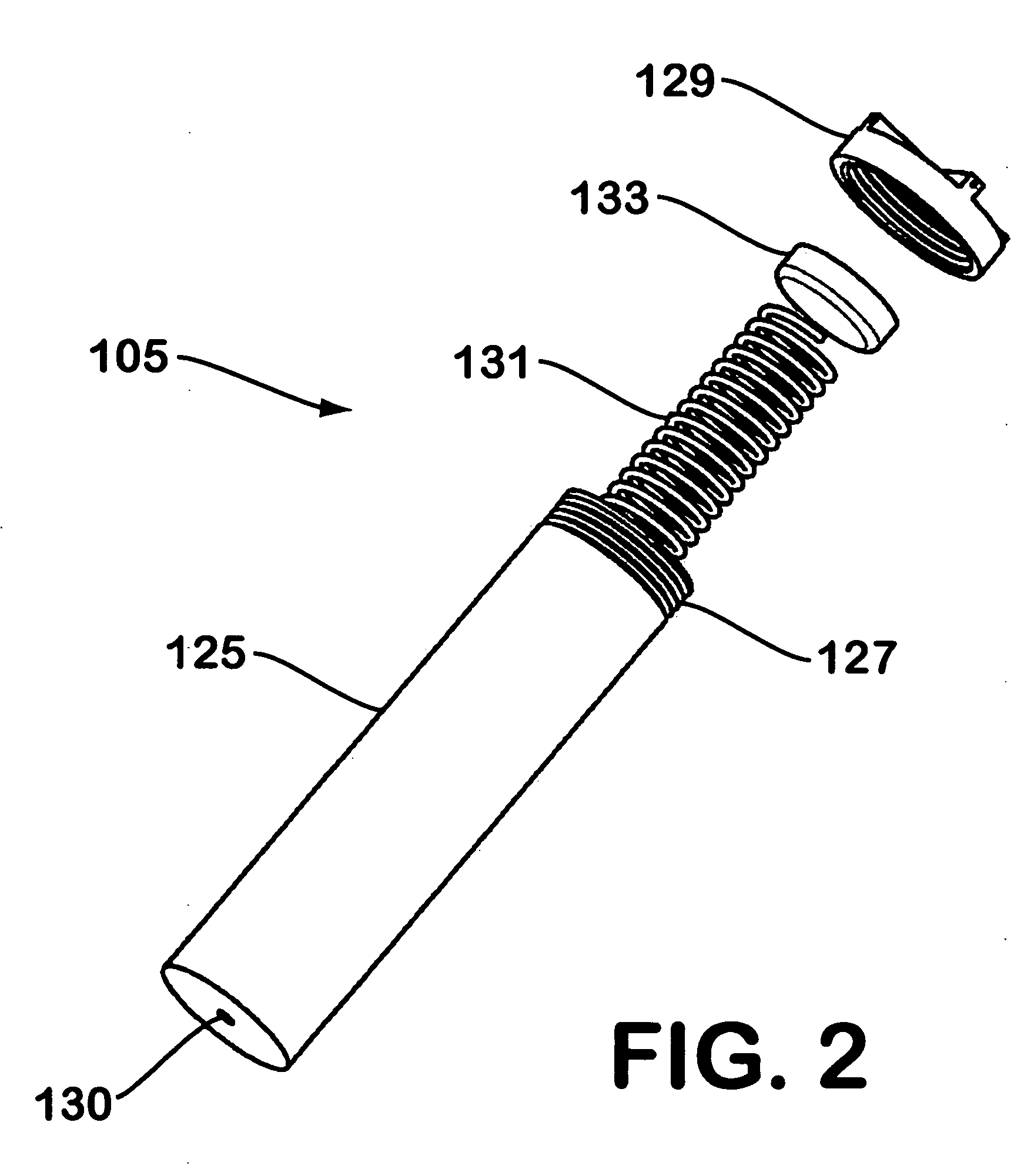

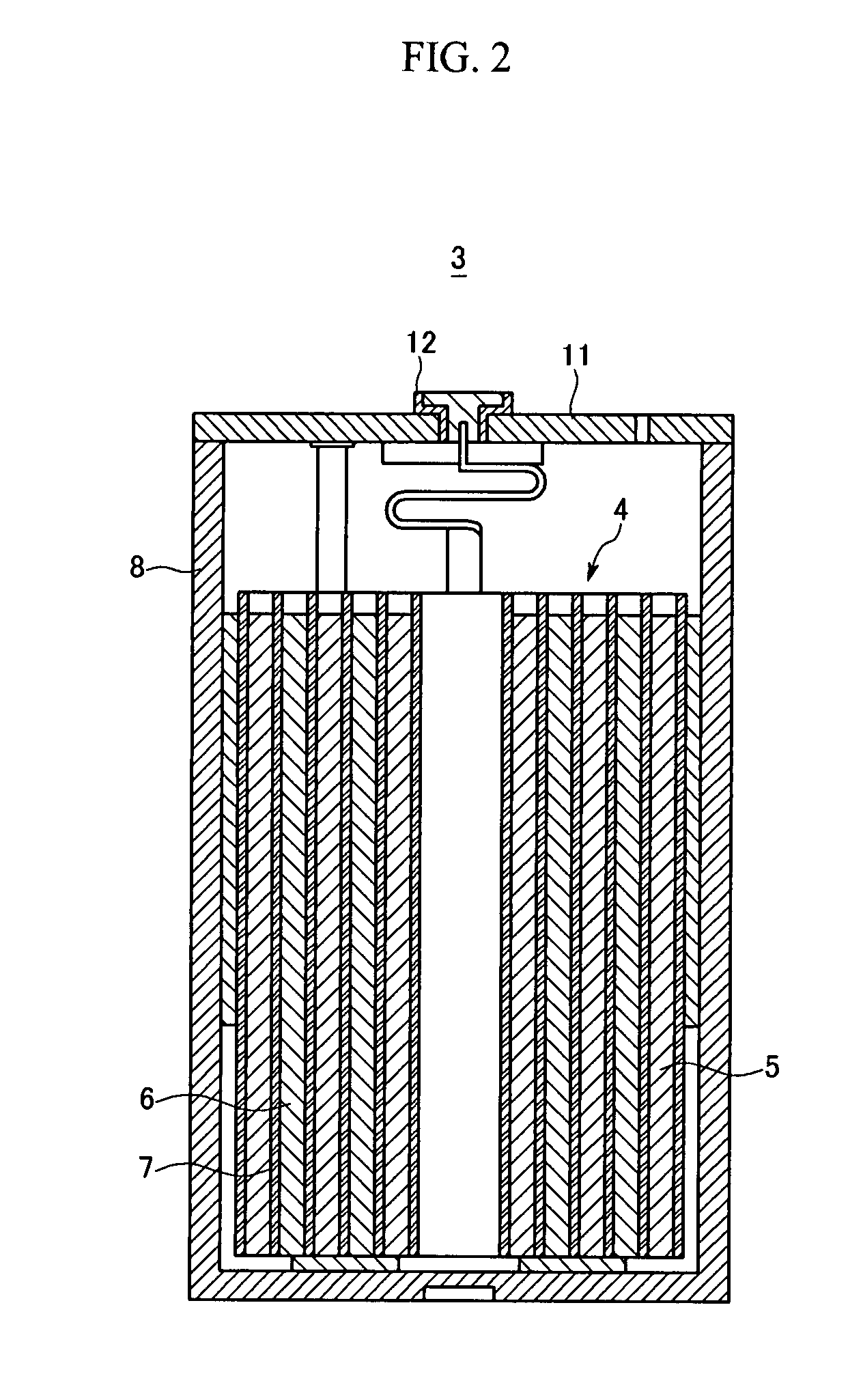

Solid chemical hydride dispenser for generating hydrogen gas

InactiveUS20070020172A1Molybdeum compoundsSynthetic resin layered productsCompound (substance)Hydrogen evolution

A device for generating hydrogen gas is provided. The device (101) comprises a first hydrogen-containing composition (107) that reacts with a second composition to evolve hydrogen gas; a dispenser (105) adapted to apply the first composition to a first porous member (109); and a conduit (111) adapted to supply the second composition to the first porous member. In a preferred embodiment, the first composition is selected from the group consisting of hydrides, borohydrides and boranes, the second composition is water, and the dispenser is spring-loaded and is charged with the first composition. As the first composition reacts with water at the interface to evolve hydrogen gas, the dispenser forces the reaction product across the interface and out of the dispenser, where it will not interfere with the progress of the hydrogen evolution reaction.

Owner:LYNNTECH POWER SYST

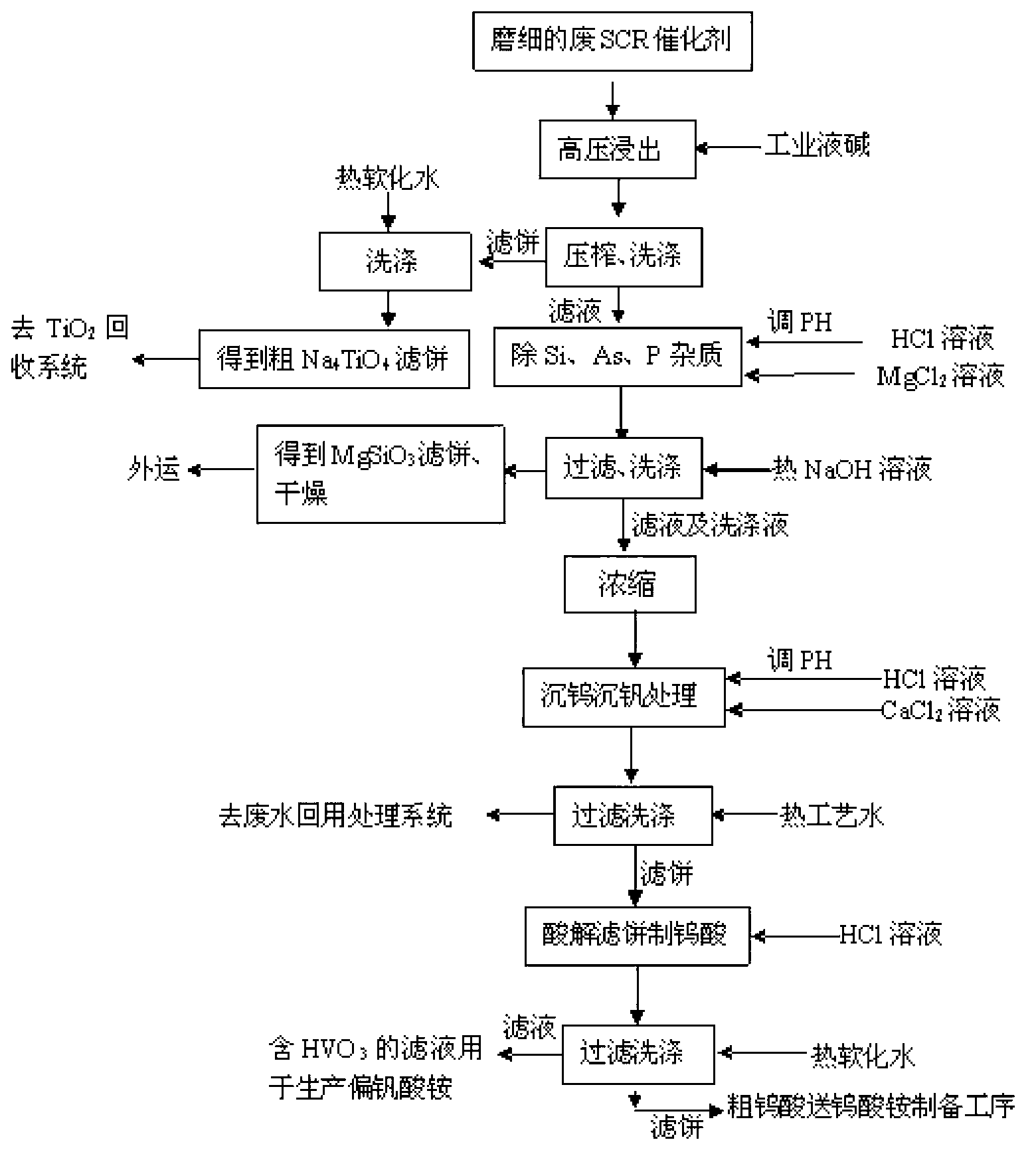

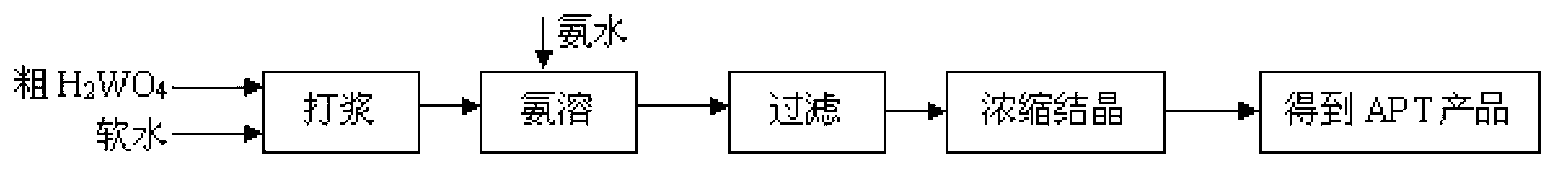

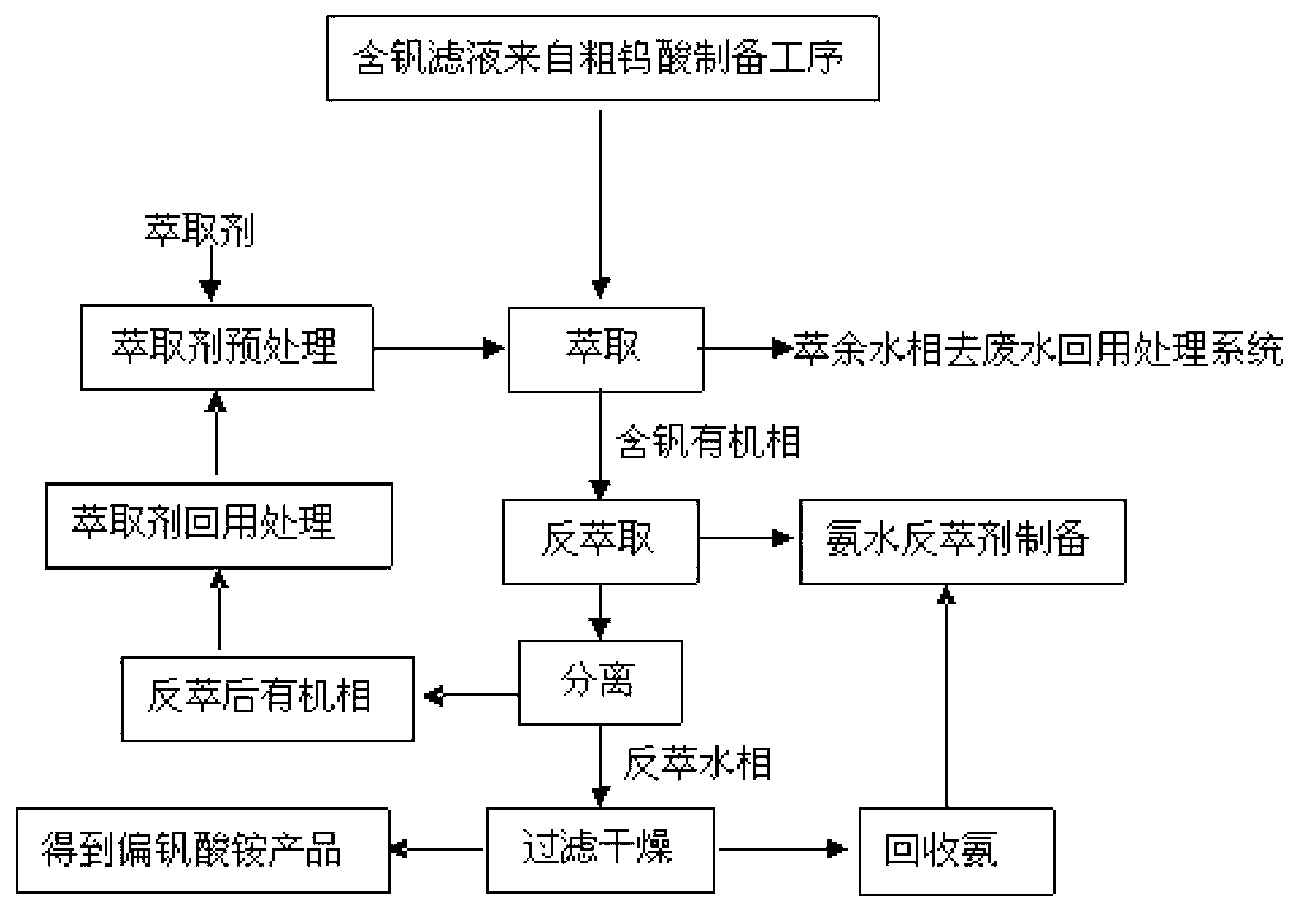

Recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst containing tungsten, vanadium and titanium

InactiveCN102936039AHigh purityHigh recovery rateTitanium dioxideVanadium compoundsHigh concentrationAmmonium paratungstate

The invention discloses recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst. The process includes the following steps: a, preprocessing the SCR waste catalyst and leaching at the high temperature and under high pressure; b, adding hydrochloric acid into leaching liquid, adjusting pH, and removing impurities; c, adding hydrochloric acid into the leaching liquid, reacting, calcining and preparing rutile titanium dioxide; d, preparing ammonium paratungstate; e, preparing ammonium metavanadate; and f, recycling and treating waste water. Main products of ammonium paratungstate, ammonium metavanadate and rutile titanium dioxide obtained in the process are high in purity and recovery rate. By-products of silicon magnesium slags, salty mud, high-concentration sodium chloride liquid and barium sulfate dregs are high-purity harmless useful goods. The process is free of harmful secondary pollutant emission, environment-friendly and capable of circulating, has high economical and social benefit and is practicable.

Owner:曾瑞

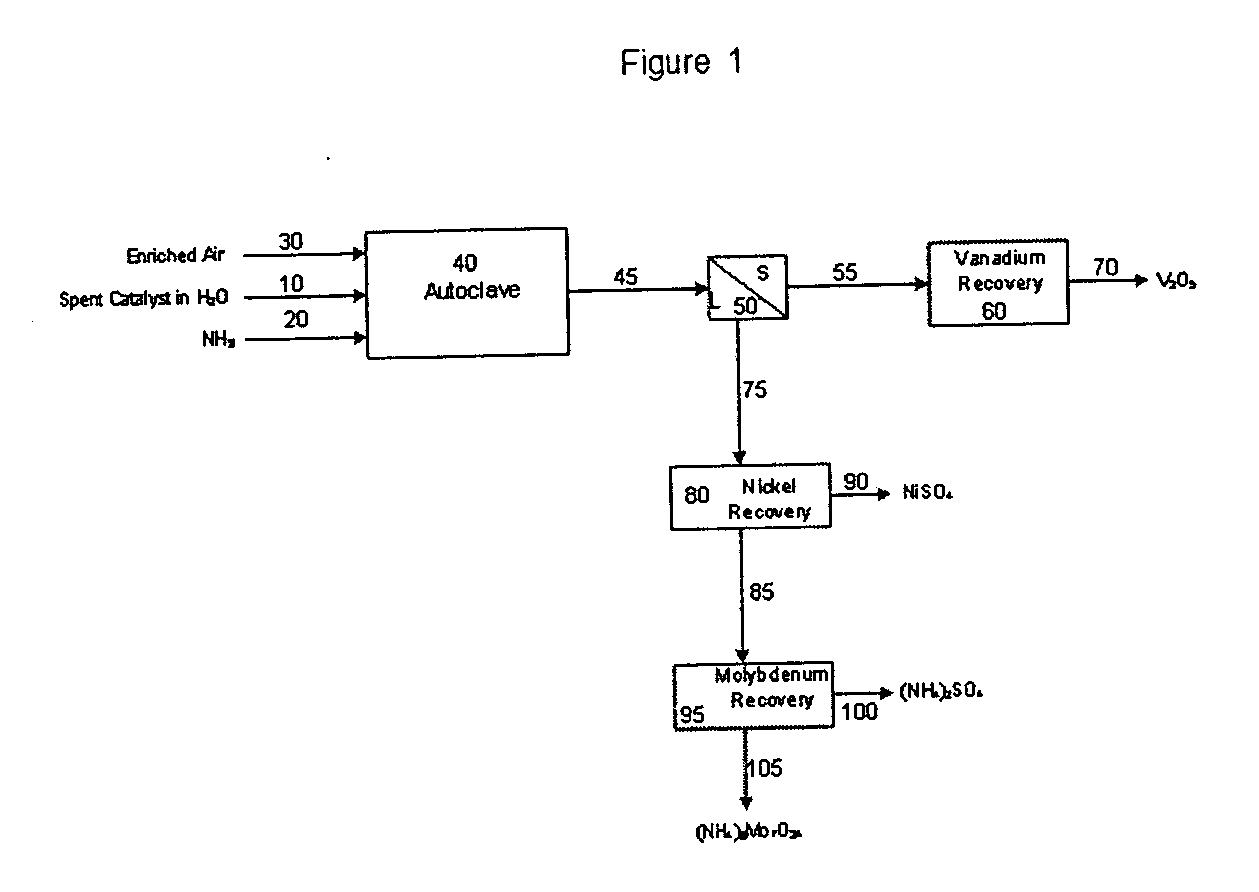

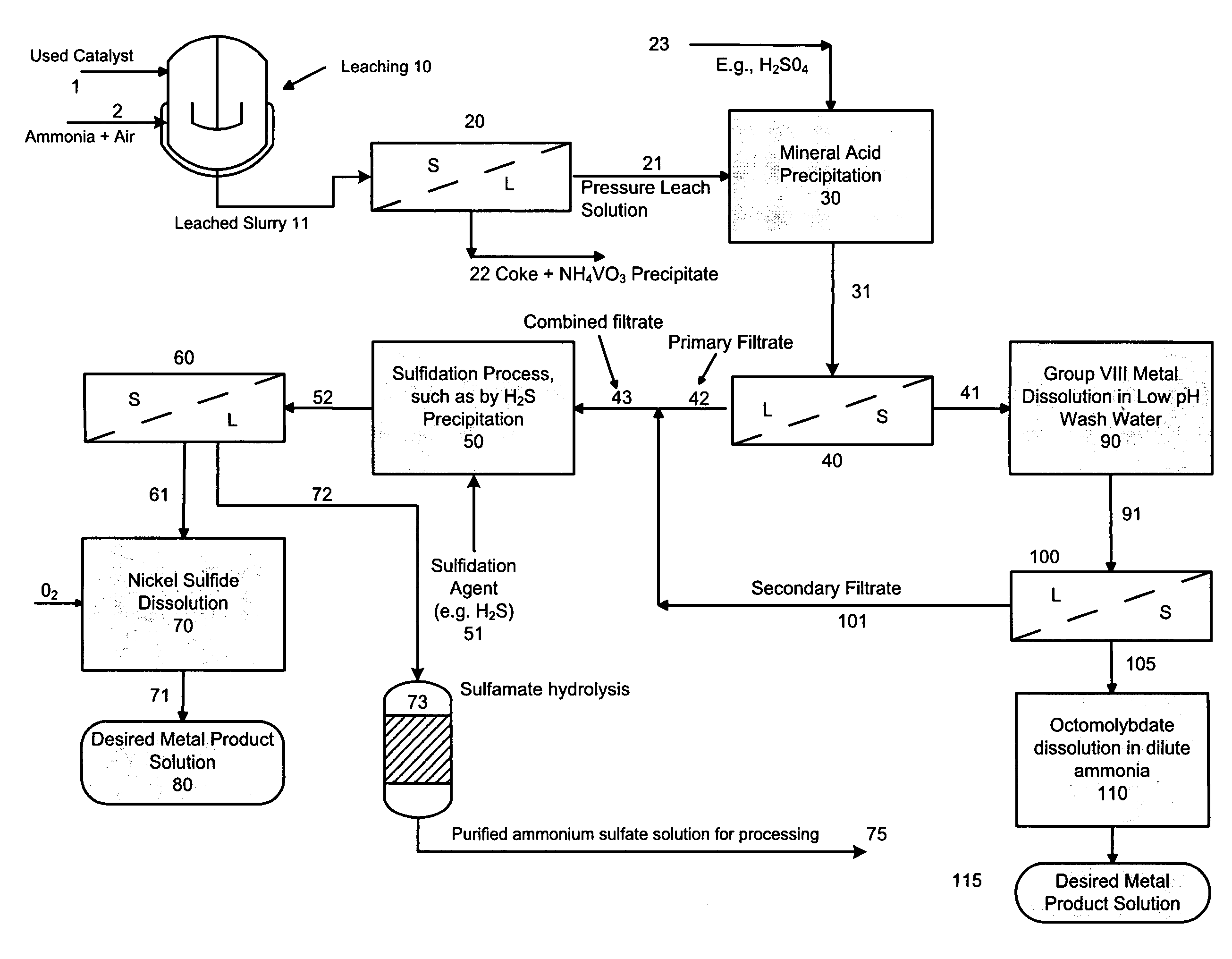

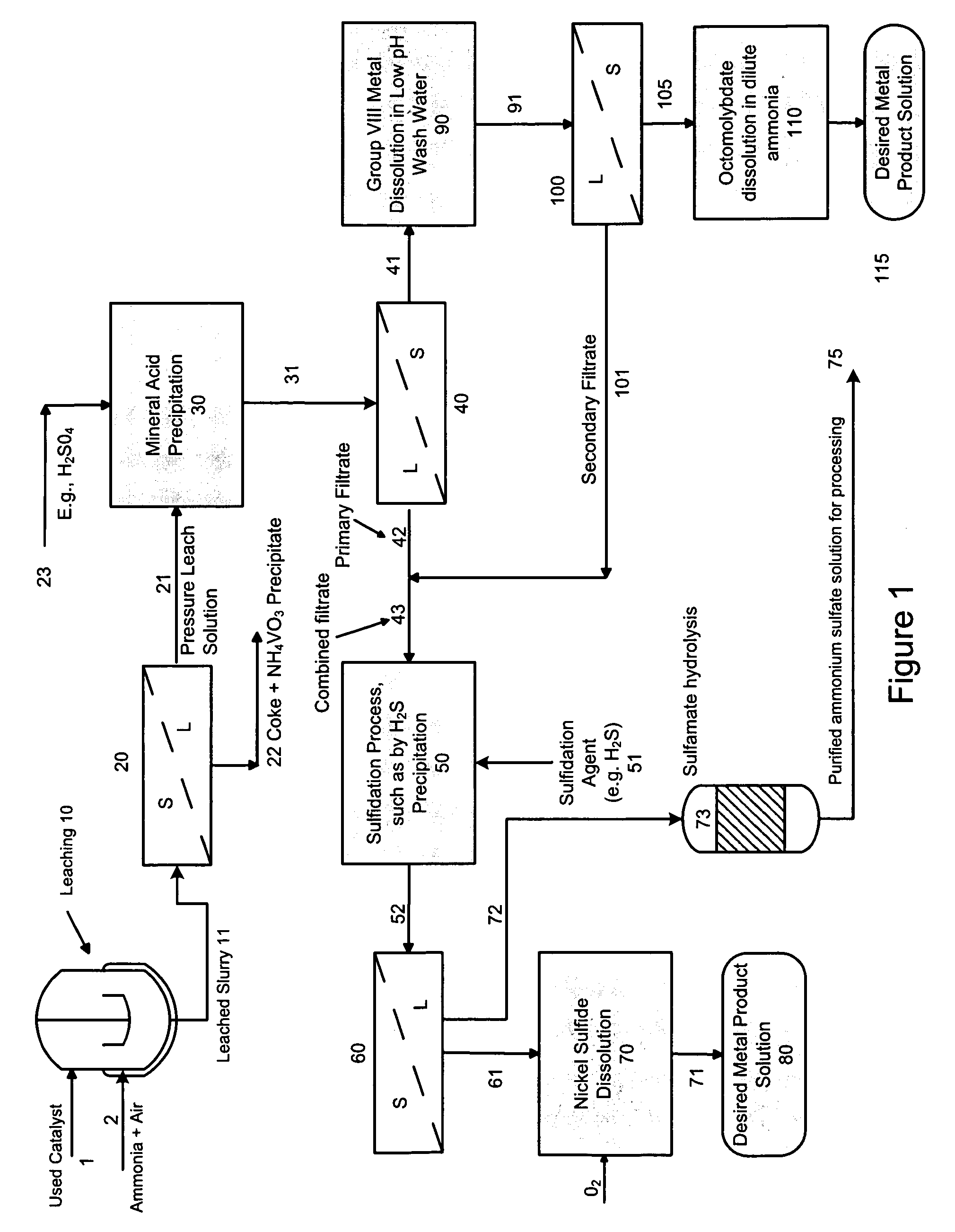

Process for metals recovery from spent catalyst

The process of this invention is directed to the removal of metals from an unsupported spent catalyst. The catalyst is subjected to leaching reactions. Vanadium is removed as a precipitate, while a solution comprising molybdenum and nickel is subjected to further extraction steps for the removal of these metals. Molybdenum may alternately be removed through precipitation.

Owner:CHEVROU USA INC

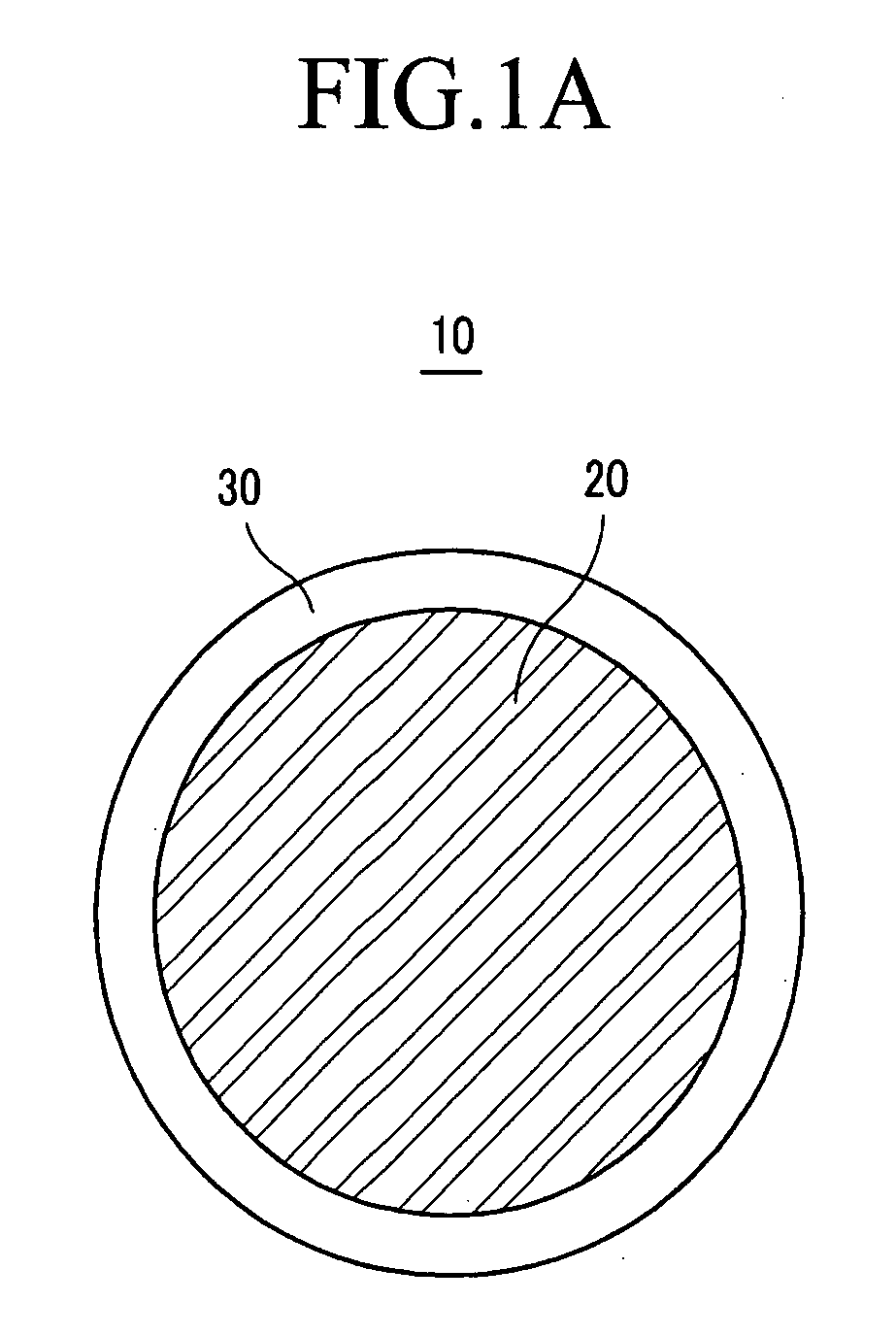

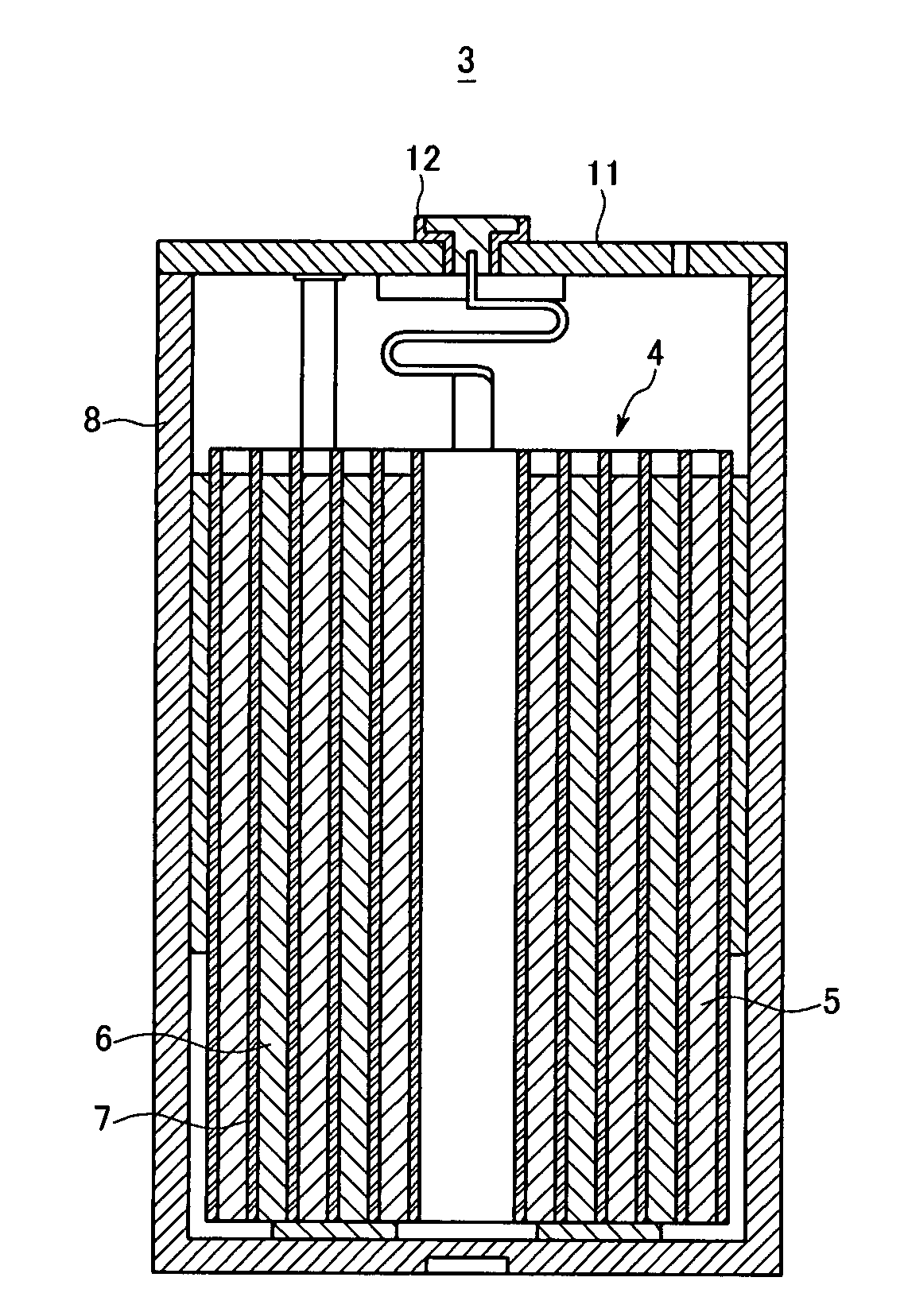

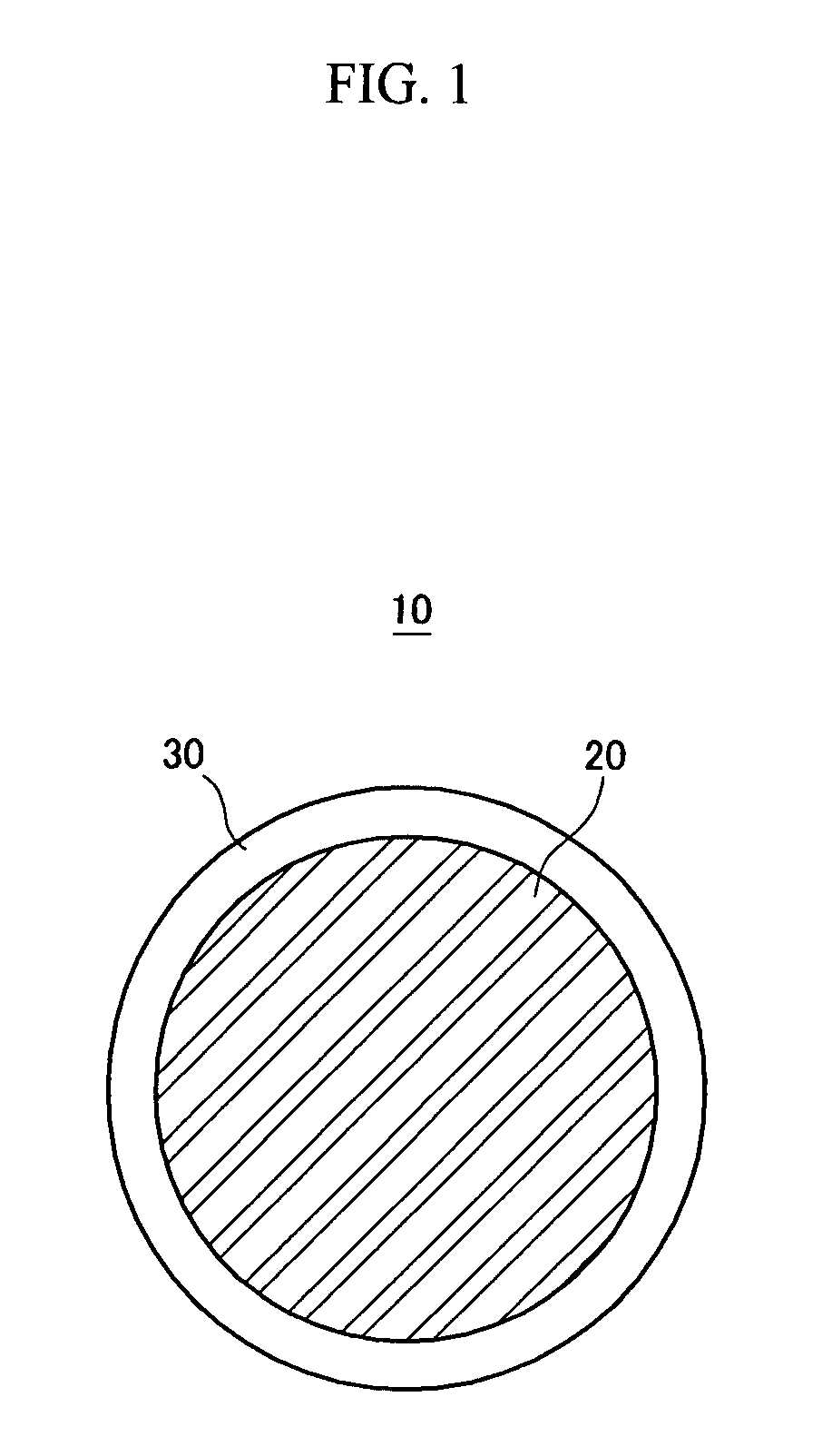

Negative active material for a rechargeable lithium battery,a method of preparing the same, and a rechargeable lithium battery including the same

ActiveUS20080118834A1Improve stabilityImprove cycle lifeElectrode manufacturing processesMolybdeum compoundsArylHigh rate

A negative active material for a rechargeable lithium battery includes a core including an active material being capable of performing reversible electrochemical oxidation and reduction, and a coating layer on the surface of the core. The coating layer includes a reticular structure including —O-M-O— wherein M is selected Si, Ti, Zr, Al, or combinations thereof and an organic functional group linked to the M as a side chain. The organic functional group is selected from the group consisting of an alkyl group, a haloalkyl group, a substituted or unsubstituted aryl group, and combinations thereof. The negative active material for a rechargeable lithium battery according to the present invention can be applied along with an aqueous binder, and improve high capacity, good cycle-life, and particularly high capacity during charge and discharge at a high rate.

Owner:SAMSUNG SDI CO LTD

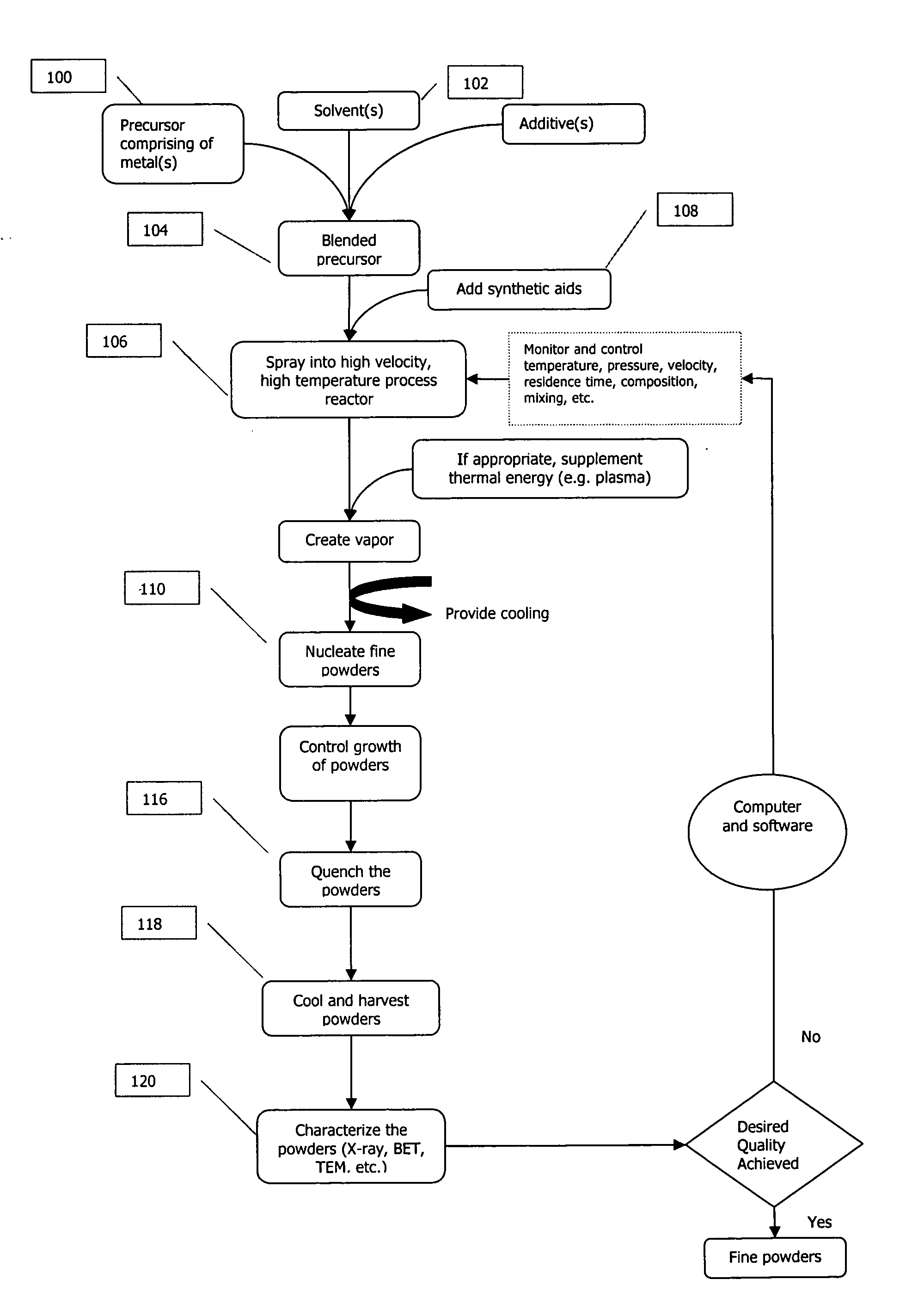

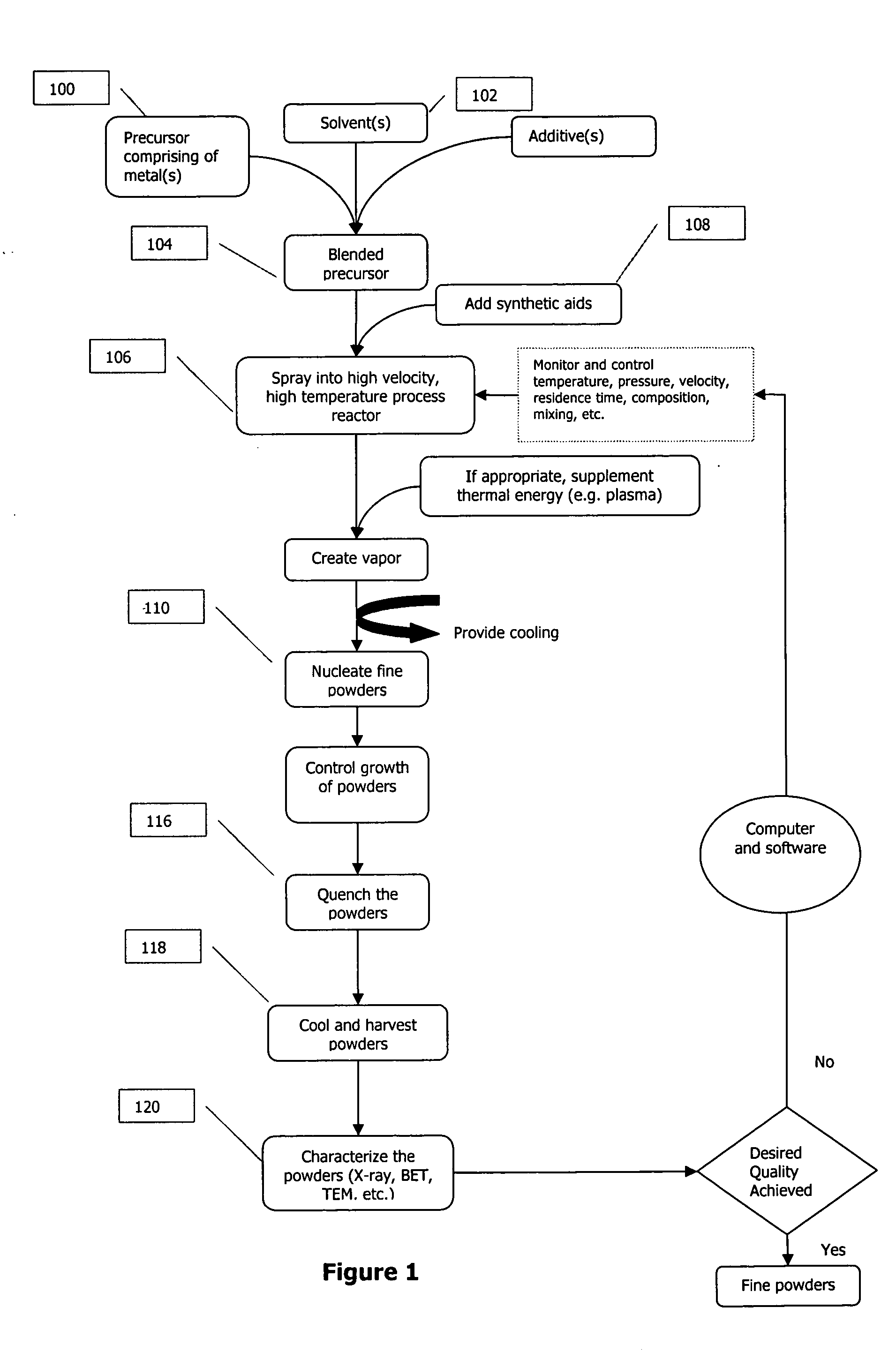

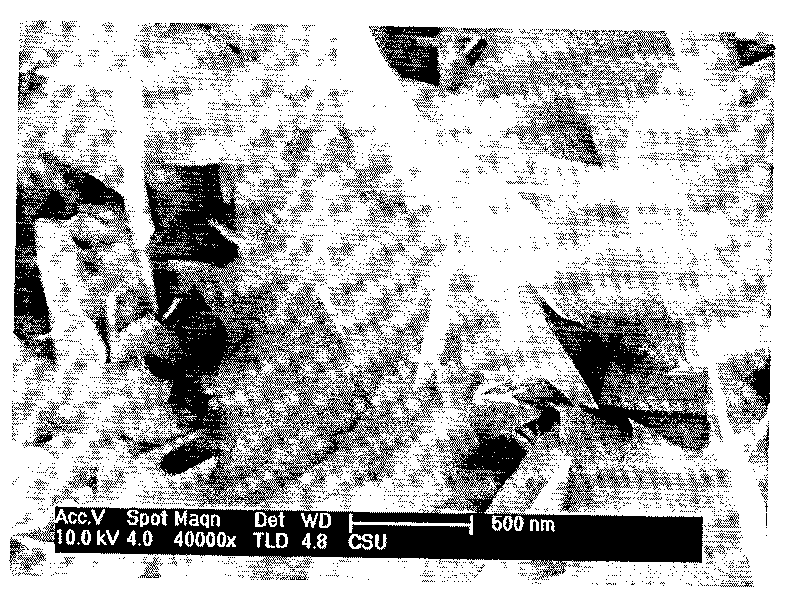

Tungsten comprising nanomaterials and related nanotechnology

InactiveUS20050271566A1High volumeIncrease volumeNanostructure manufactureCell electrodesManufactured nanoparticlesTungsten

Nanoparticles comprising tungsten, methods of manufacturing nanoparticles comprising tungsten, and applications of nanoparticles comprising tungsten, such as electronics, optical devices, photonics, reagents for fine chemical synthesis, pigments, and catalysts are provided.

Owner:PPG IND OHIO INC

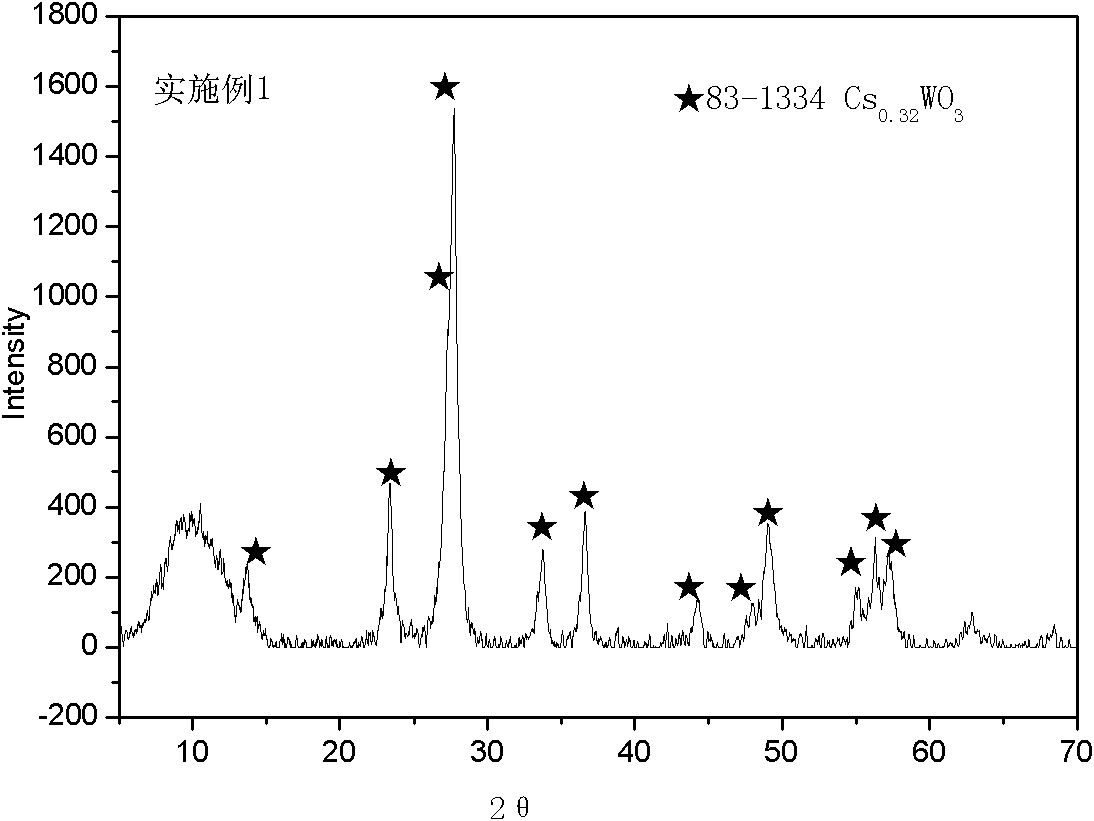

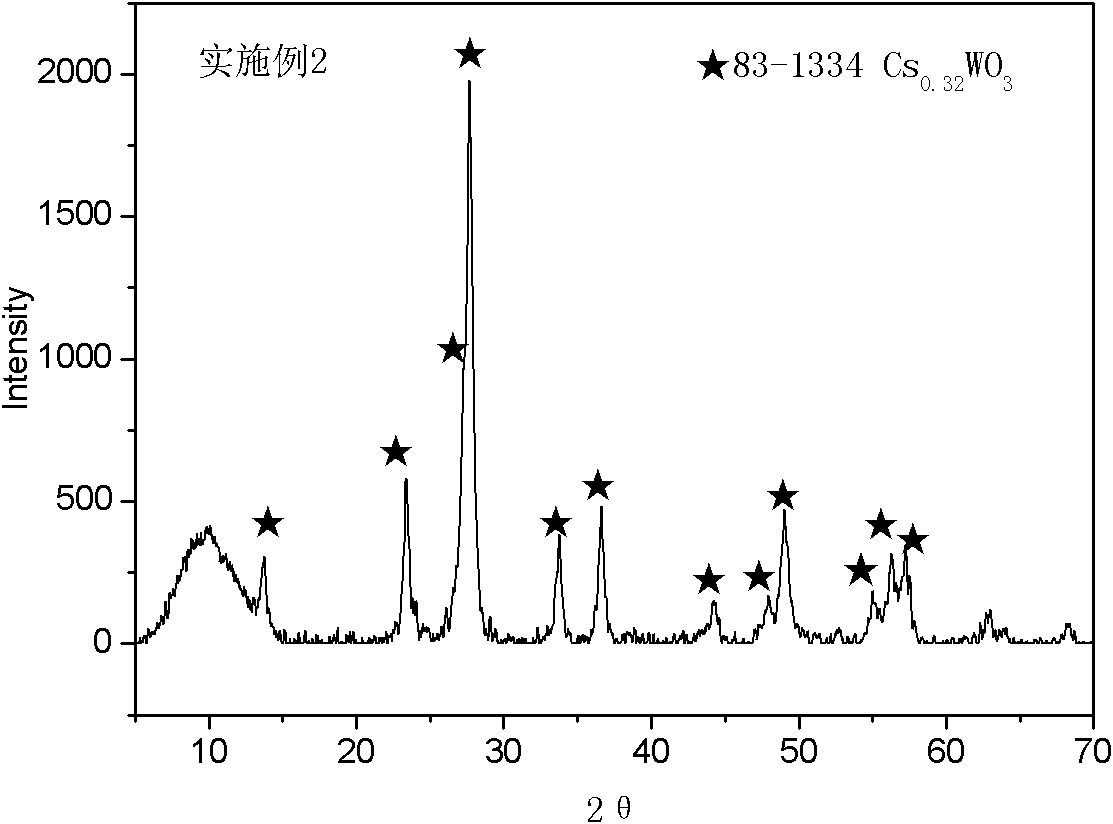

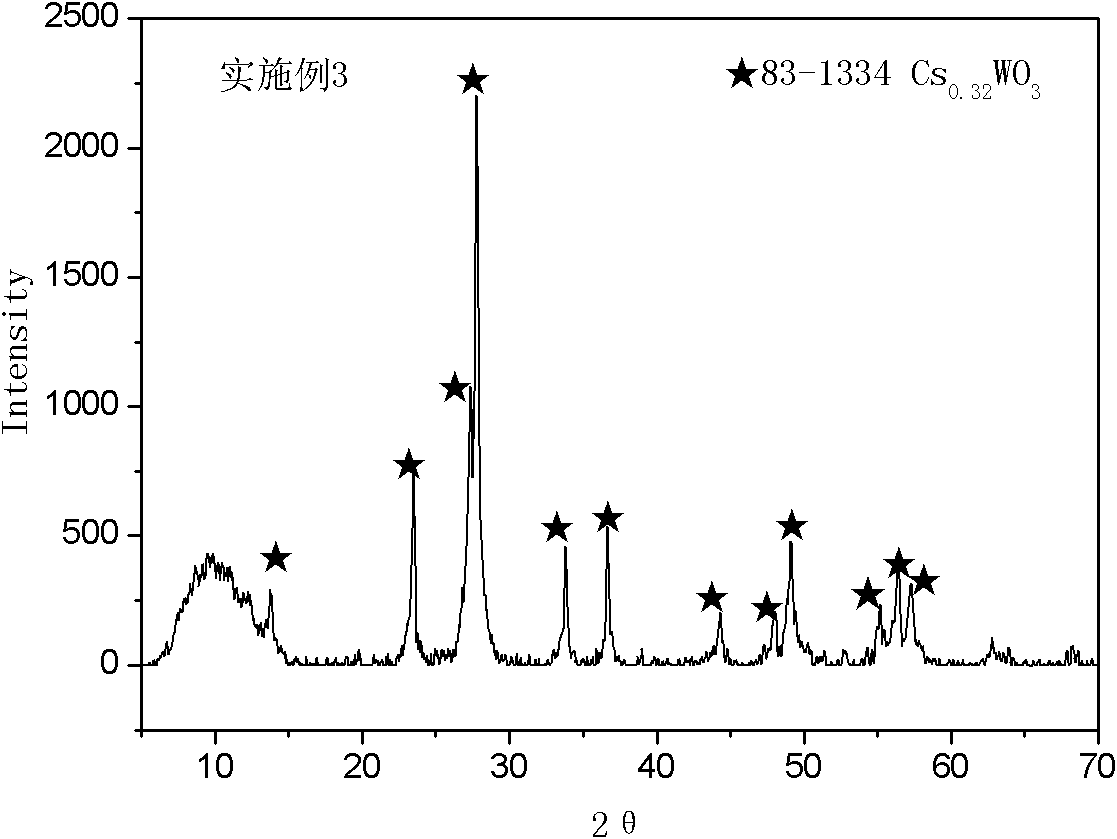

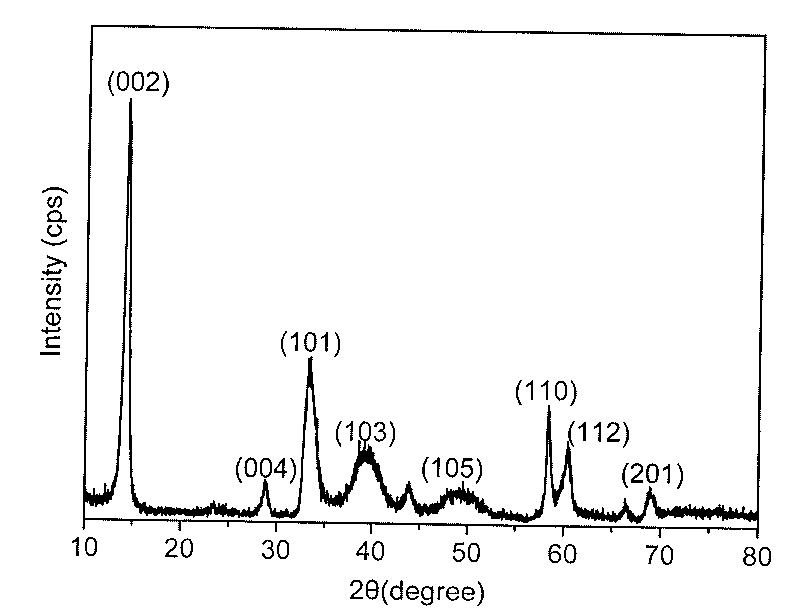

Cesium tungsten bronze powder and preparation method thereof

InactiveCN102320662AOptimal Control StructureReduce manufacturing costTungsten compoundsGranularitySolvent

The invention relates to cesium tungsten bronze powder and a preparation method thereof. The method comprises the following steps that: 1, precursor solution with tungstic acid, cesium carbonate and reducing substances is prepared according to a Cs / W mole ratio of 0.01 to 0.35 / 1, and the solvents are water or a mixture formed by ethanol and the water according to a volume ratio of 1 / 4 to 4 / 1; and 2, the precursor solution takes reaction for 1 to 3d under the condition of 180 to 200 DEG C in an autoclave, and the cesium tungsten bronze powder is obtained after the obtained precipitates are treated. The powder has the crystalline phase composition of Cs0.2WO3 or Cs0.32WO3, the size of the powder particle is 100 to 1300nm, and the specific surface area is 7 to 50m<2> / g. The synthetic process has the advantages that raw materials are cheap and mild, the operation is easy, the production cost can be reduced, in addition, the low-temperature (lower than or equal to 20 DEG C) synthesis is adopted, and the process is suitable for production and practical application. In addition, the product purposes are wide.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Support ink for three dimensional (3D) printing

An ink composition for use as a support ink in three dimensional (3D) printing processes comprises a dispersion of solid particles in liquid carrier, compatible with an inkjet print head, wherein after removing the liquid carrier, the solid particles serve as support material for a Three Dimensional (3D) printed object, wherein the support material is separable from the 3D printed object.

Owner:XJET

Thermoelectric material and thermoelectric converting element using the same

Compounds are expressed by general formula of AxBC2-y where 0<=x<=2 and 0<=y<1, and have CdI2 analogous layer structures; A-site is occupied by at least one element selected from the group consisting of Li, Na, K, Rb, Cs, Mg, Ca, Sr, Ba, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Zr, Nb, Mo, Ru, Rh, Pd, Ag, Cd, Hf, Ta, W, Re, Ir, Pt, Au, Sc, rare earth elements containing Y, B, Al, Ga, In, Tl, Sn, Pb and Bi; B-site is occupied by at least one element selected from the group consisting of Ti, V, Cr, Zr, Nb, Mo, Hf, Ta, W, Ir, and Sn; C-site is occupied by at least one element selected from the group consisting of S, Se and Te; the compounds exhibit large figure of merit so as to be preferable for thermoelectric generator / refrigerator.

Owner:NEC CORP

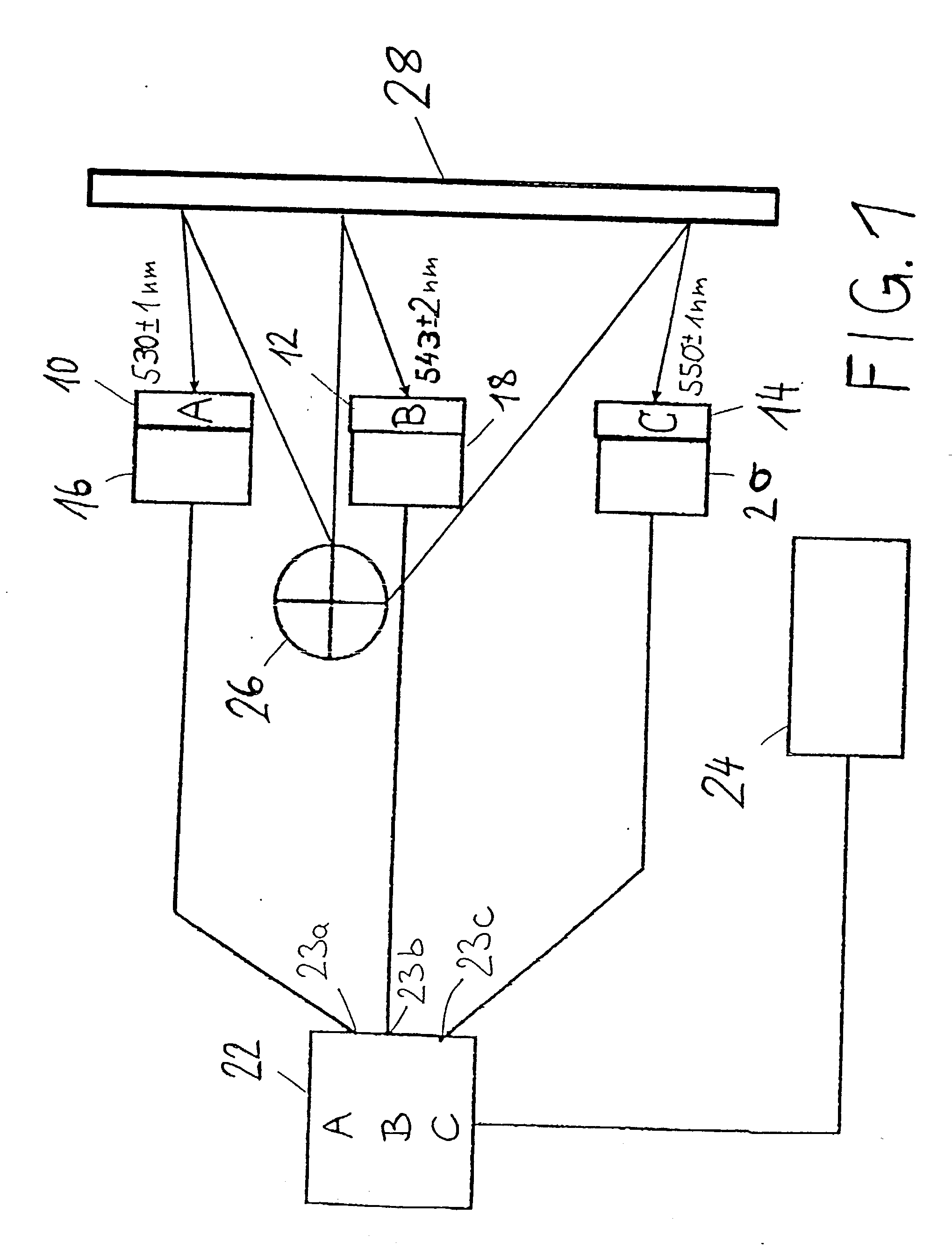

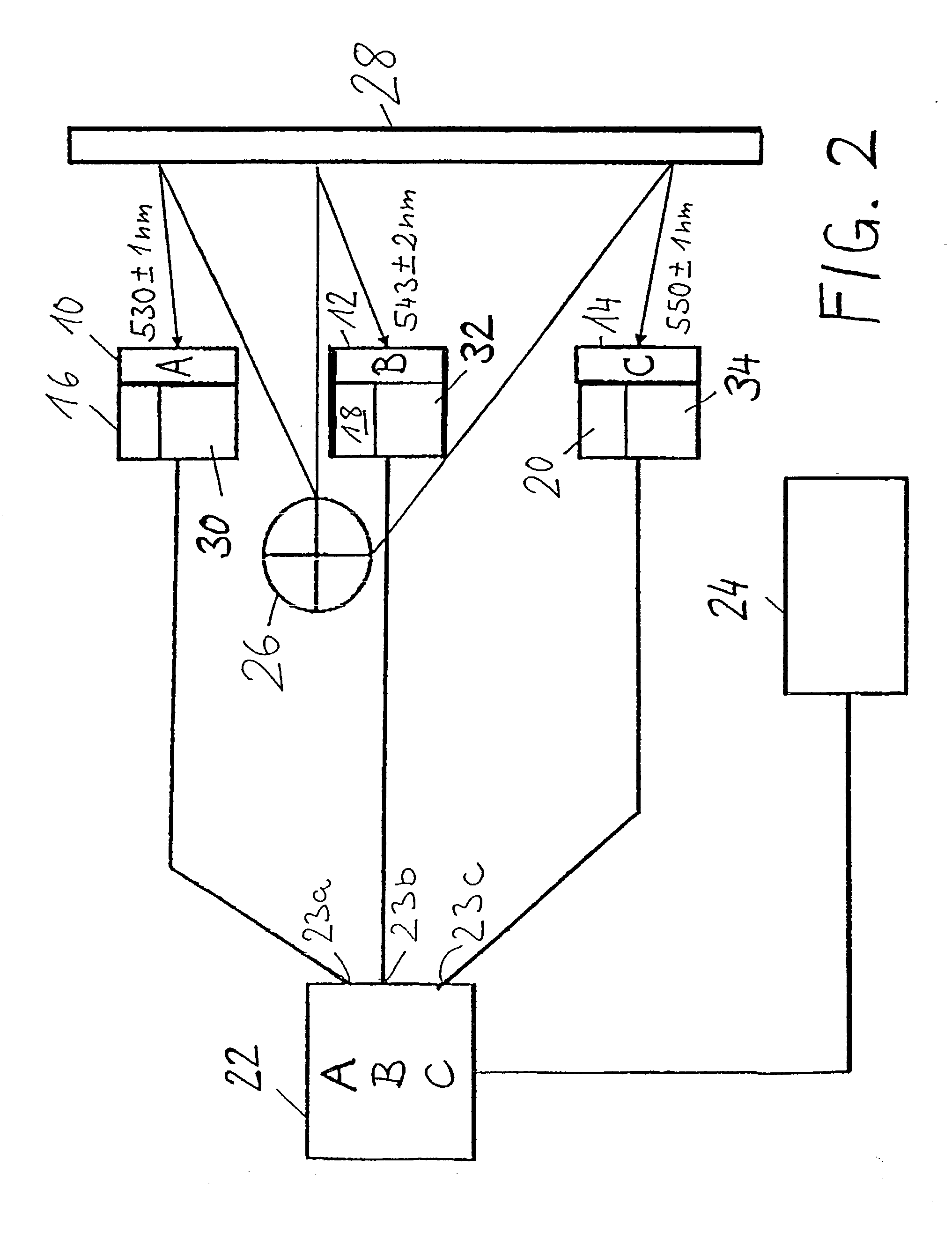

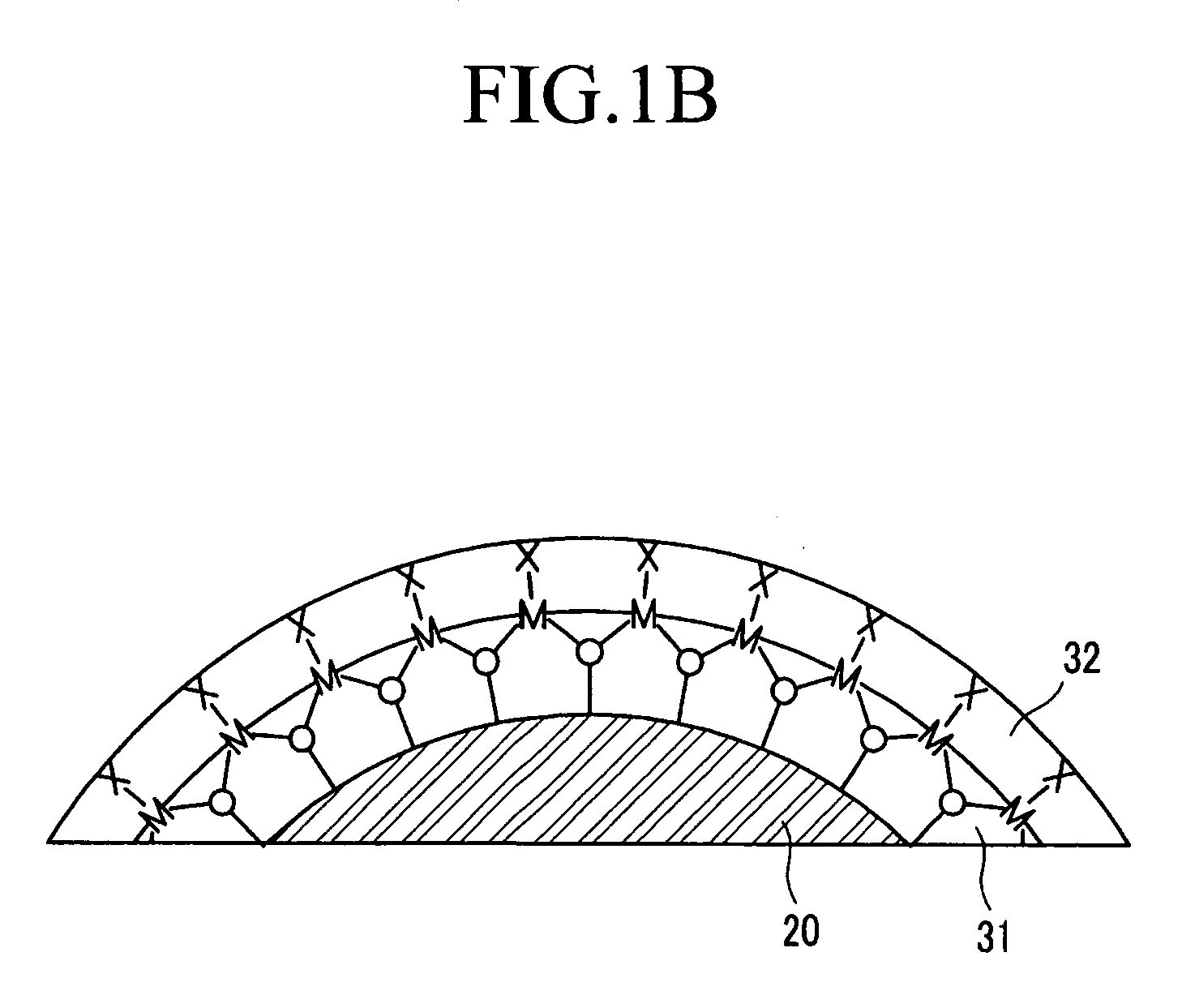

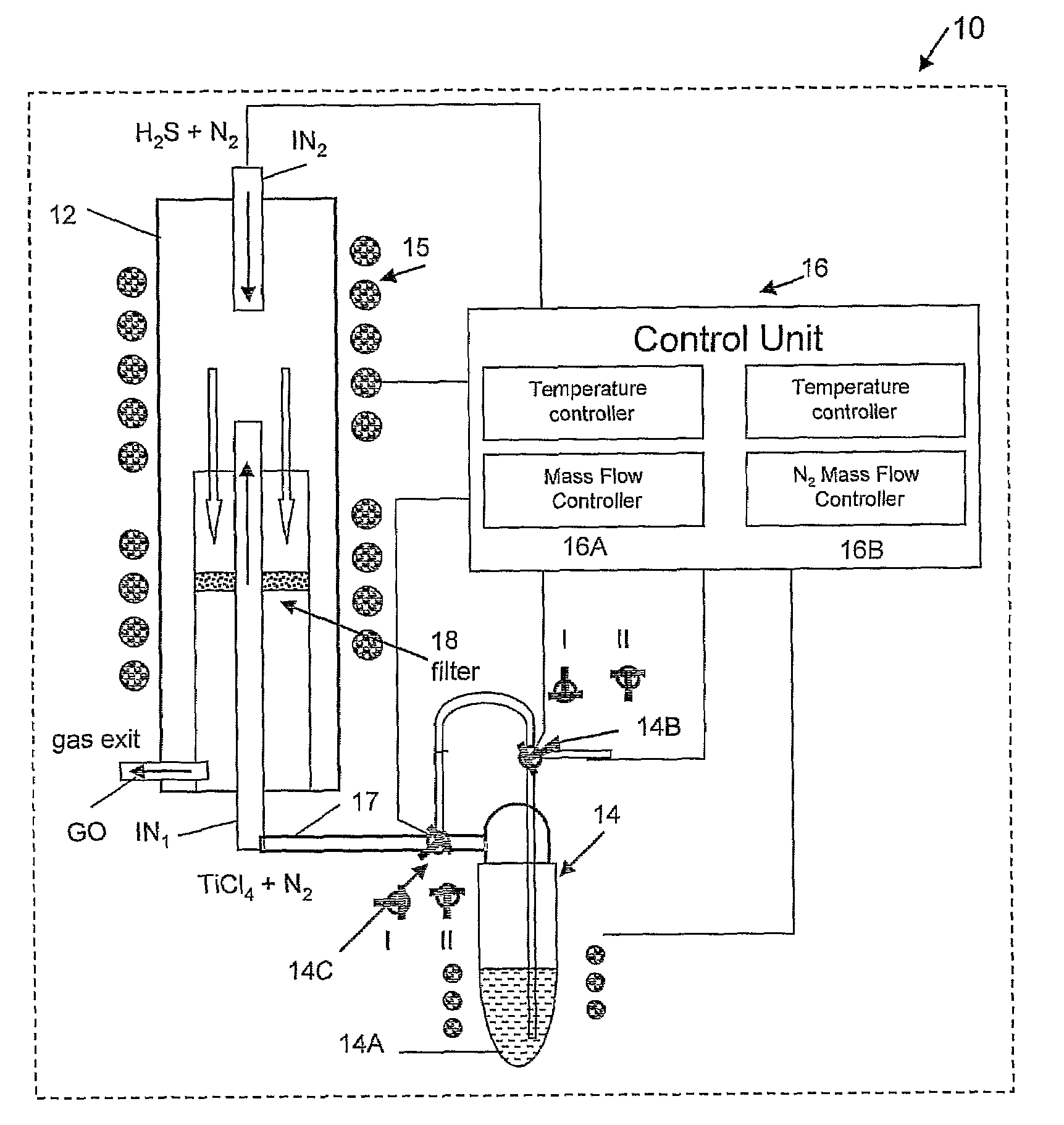

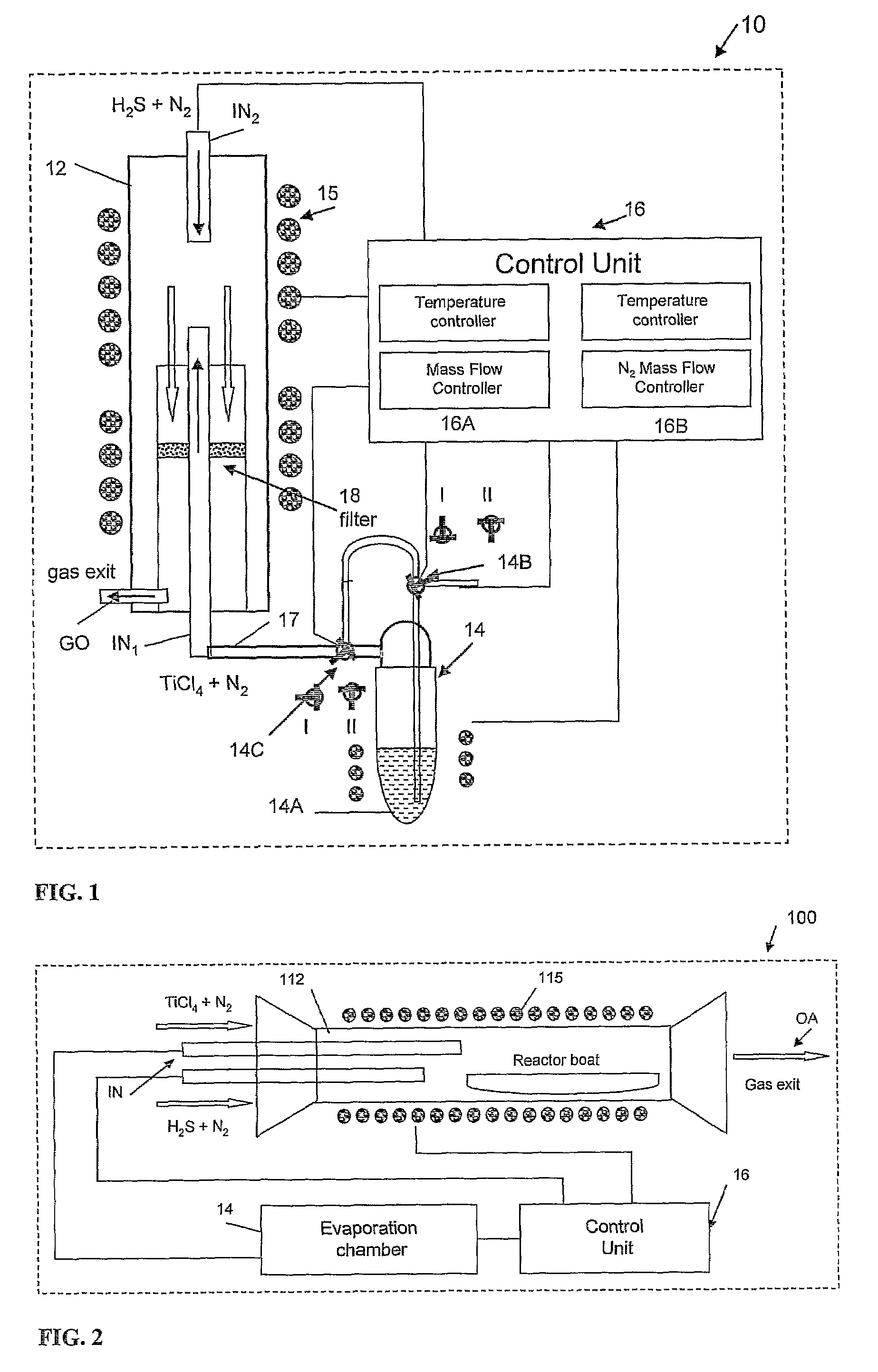

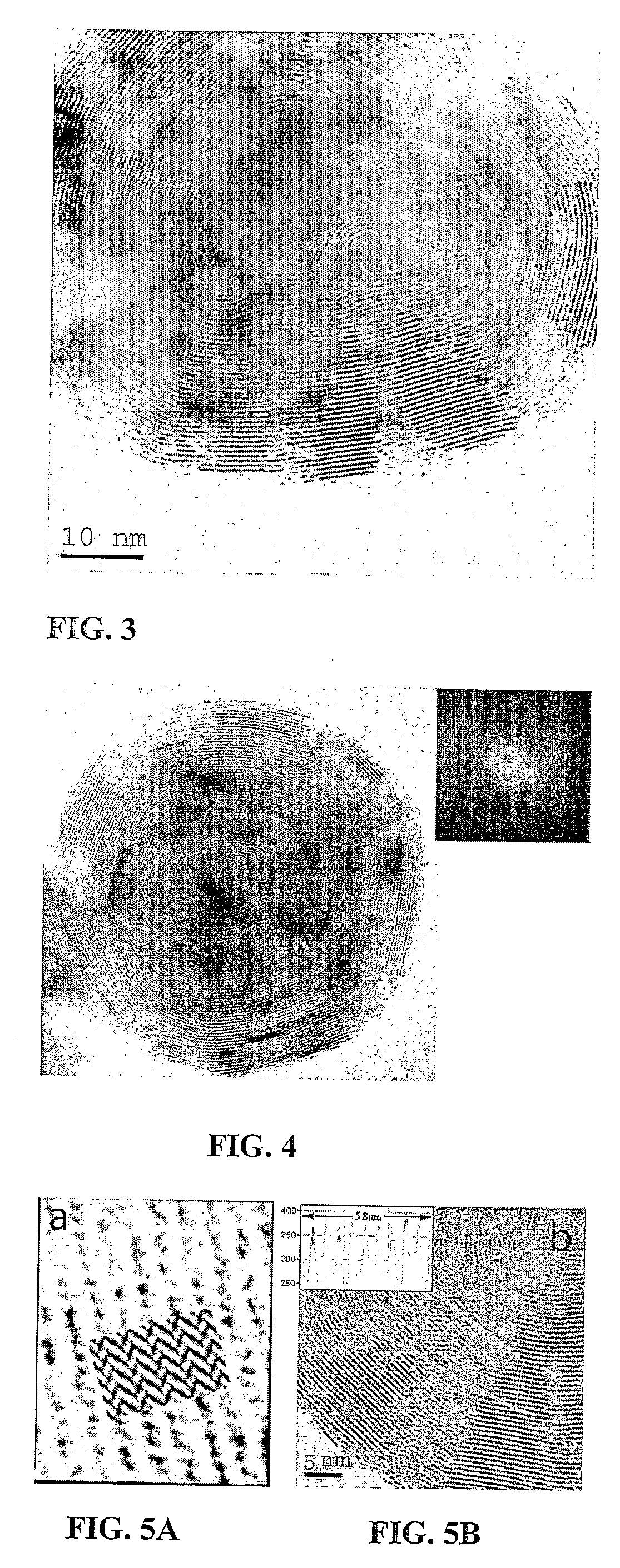

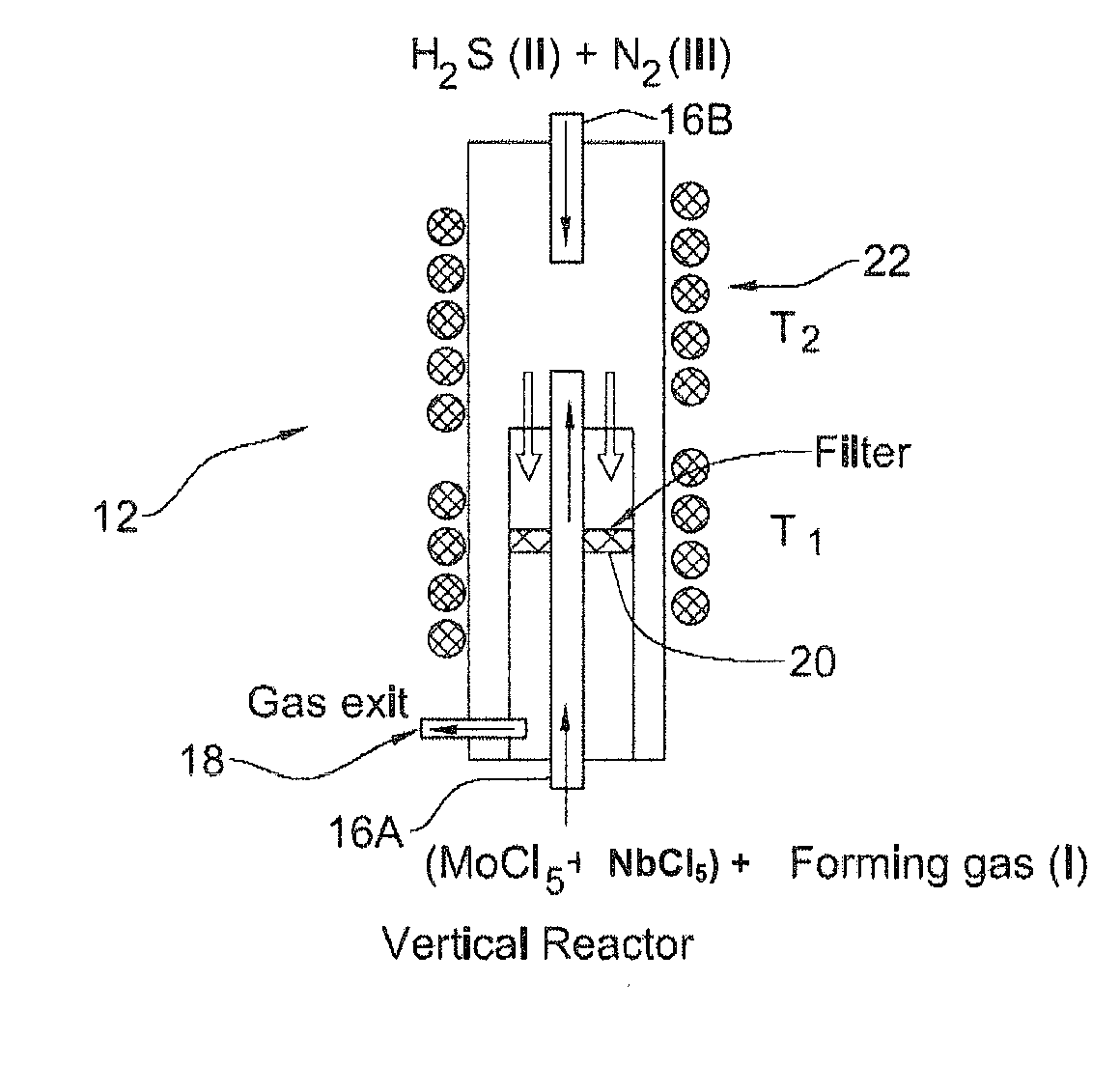

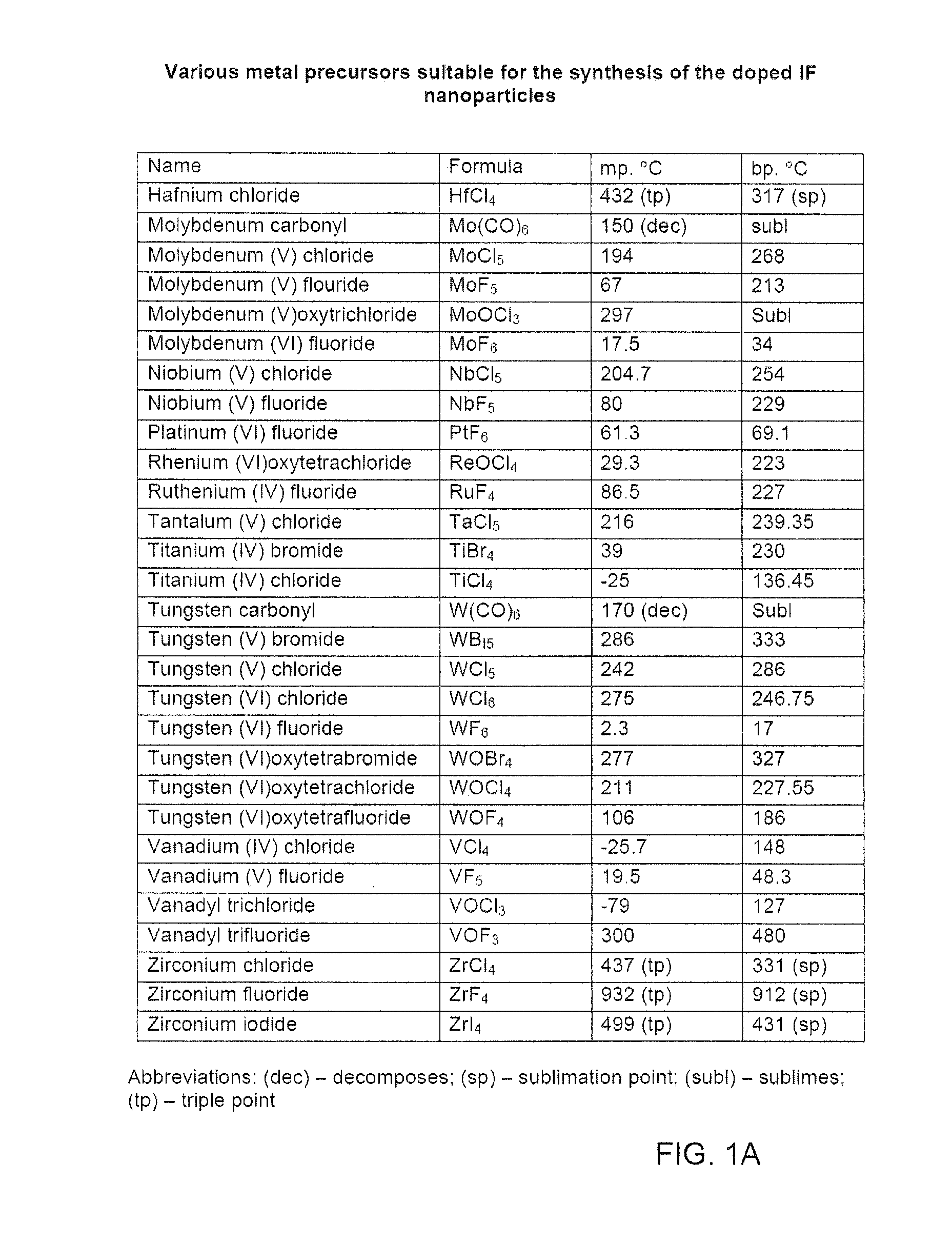

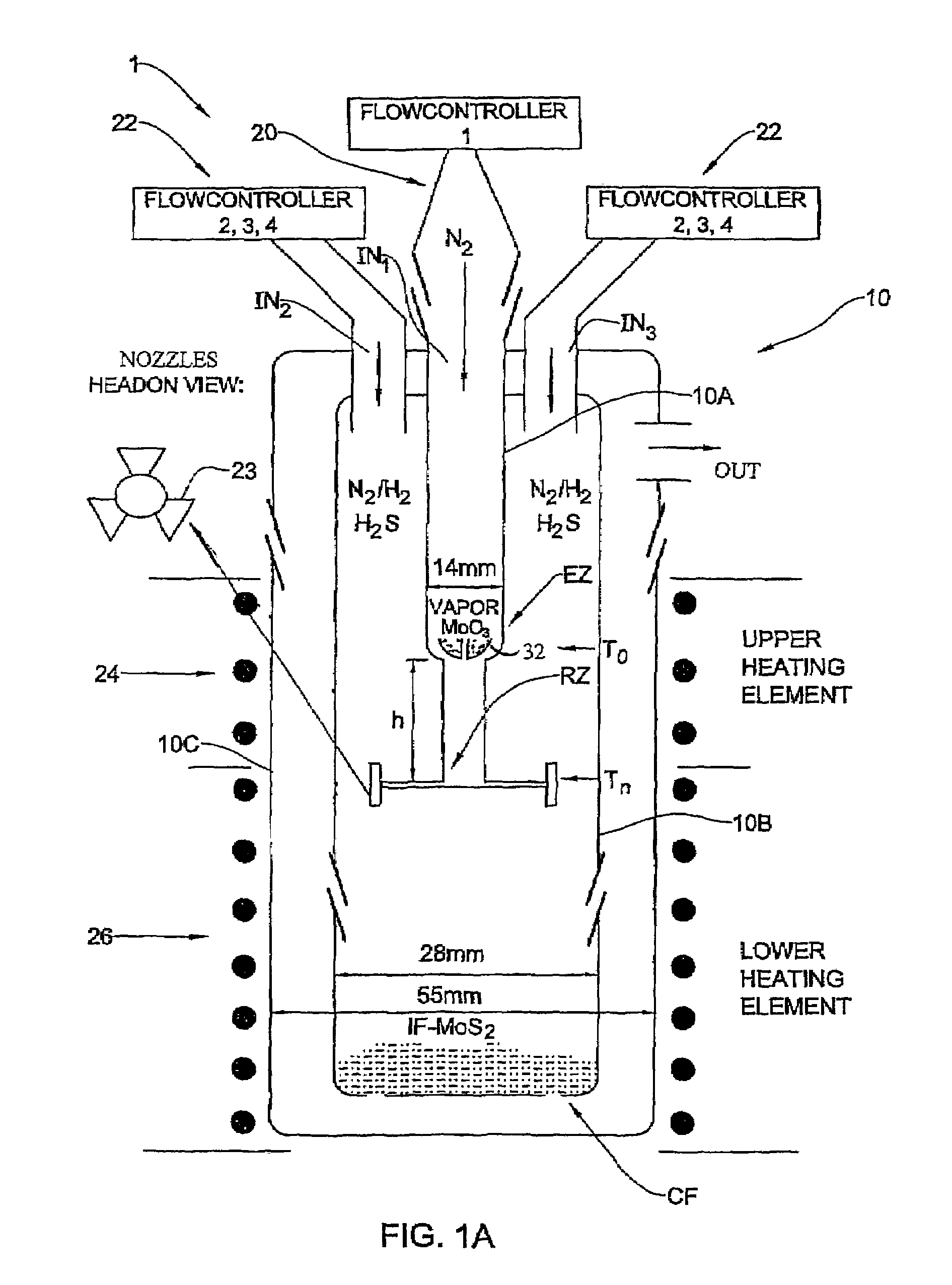

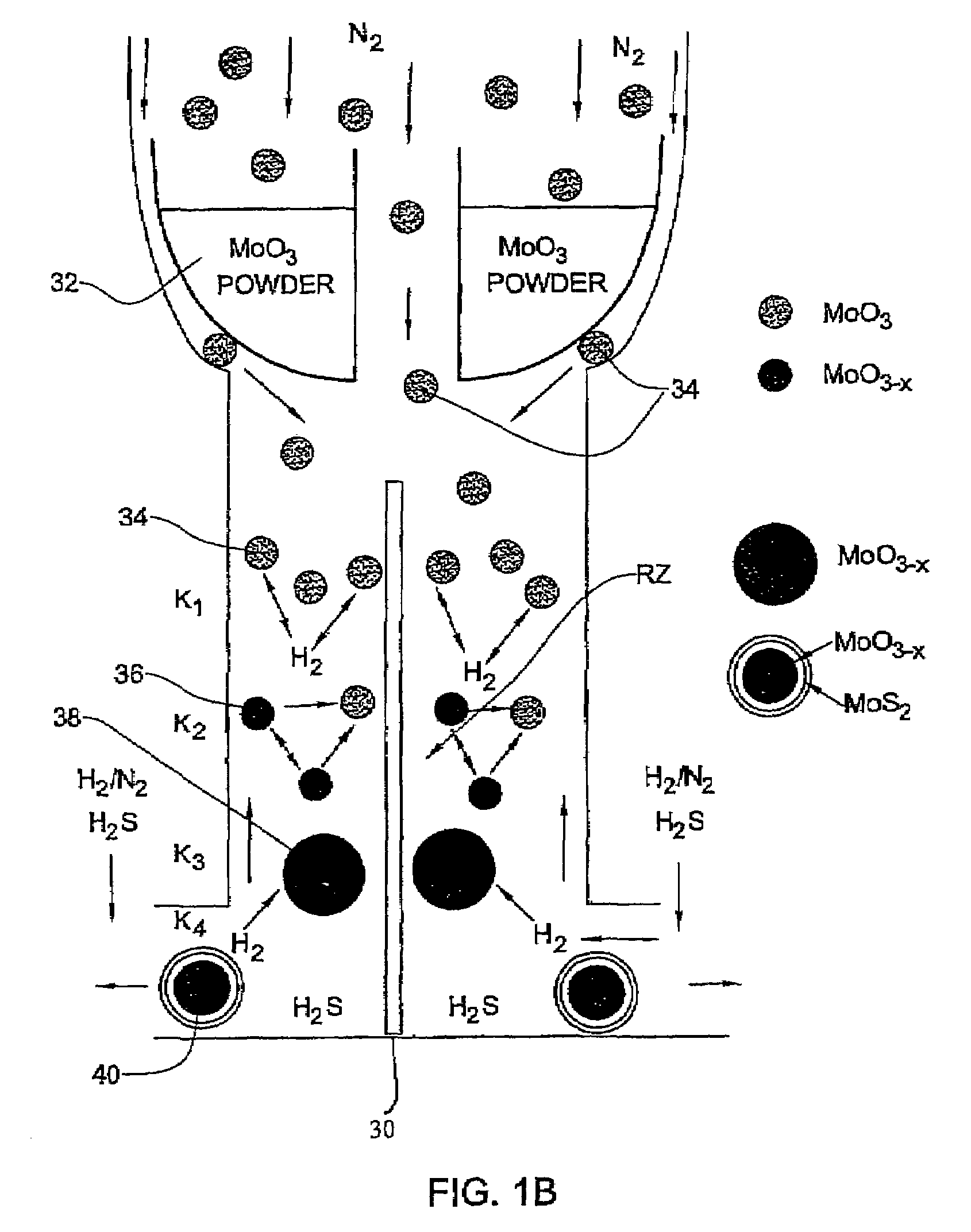

Process and apparatus for producing inorganic fullerene-like nanoparticles

ActiveUS7641886B2Easy to produceImproved propertyMaterial nanotechnologyNanostructure manufactureGas phaseMetal chalcogenides

The present invention provides a process for obtaining fullerene-like metal chalcogenide nanoparticles, comprising feeding a metal precursor (INi) selected from metal halide, metal carbonyl, organo-metallic compound and metal oxyhalide vapor into a reaction chamber (12) towards a reaction zone to interact with a flow of at least one chalcogen material (IN2) in gas phase, the temperature conditions in said reaction zone being such to enable the formation of the fullerene-like metal chalcogenide nanoparticles product. The present invention further provides novel IF metal chalcogenides nanoparticles with spherical shape and optionally having a very small or no hollow core and also exhibiting excellent tribological behavior. The present invention further provides an apparatus for preparing various IF nanostructures.

Owner:A Y Y T TECHCAL APPL & DATA UPDATE +1

Method for recovering vanadium, tungsten and titanium from waste vanadium-tungsten-titanium-based denitration catalyst

ActiveCN103484678ASimultaneous recoveryLow recovery rateTitanium compoundsVanadium compoundsTungstateAmmonium metavanadate

The invention relates to a method for recovering non-ferrous metals from waste denitration catalysts, particularly relates to a method for recovering vanadium, tungsten and titanium from a waste vanadium-tungsten-titanium-based denitration catalyst, belonging to the field of non-ferrous metal recovery technologies. The method mainly comprises the steps of preparing the catalyst into powder with the grain size being smaller than 100 meshes, and adding concentrated alkali liquor; heating to react vanadium, tungsten and titanium with alkali, so as to produce slightly-soluble titanate, water-soluble vanadate and tungstate; filtrating to obtain a titanate filter cake, wherein titanate or titanic acid can be prepared from the filter cake; adding ammonium salt into a filtrate so as to precipitate ammonium metavanadate, and filtrating to obtain ammonium metavanadate and a new filtrate; adding concentrated acid into the new filtrate, thereby preparing solid tungstic acid. The method has the advantages of simple process, low energy consumption, good solid-liquid reaction contact, high vanadium, tungsten and titanium recovery rate, and the like.

Owner:BEIJING UNIV OF CHEM TECH

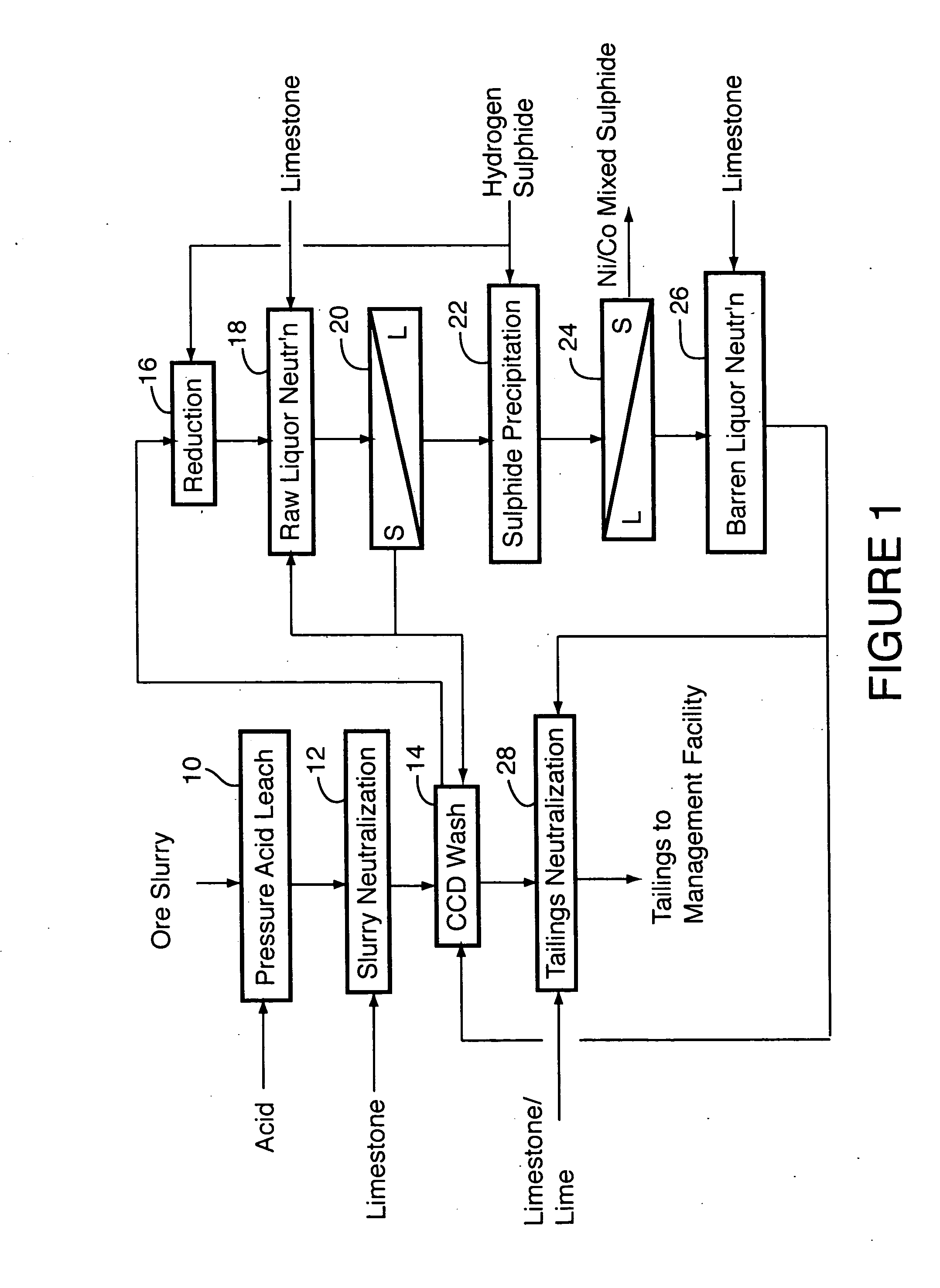

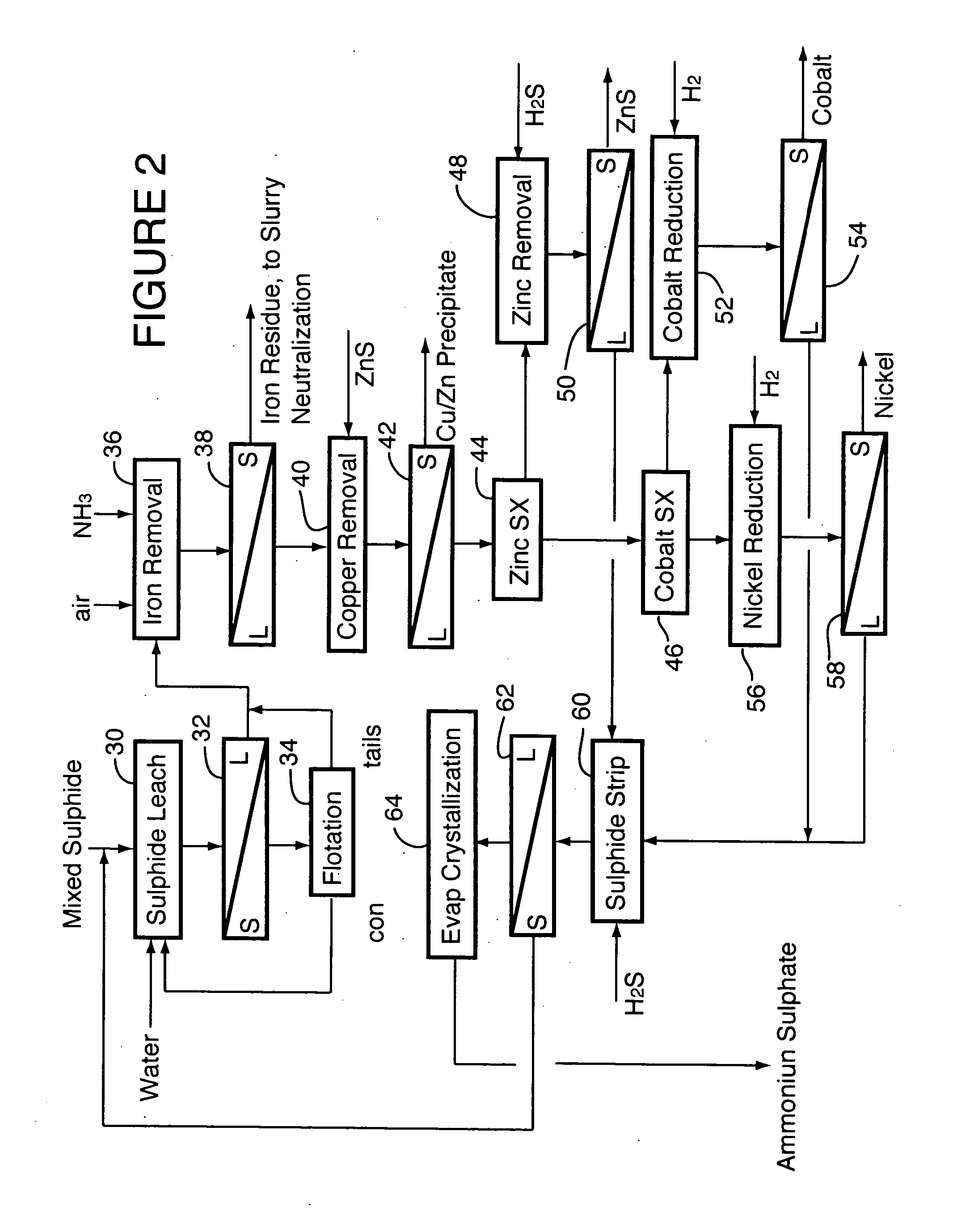

Process for recovery of nickel and cobalt from laterite ore

ActiveUS20060228279A1Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INTERNATIONAL

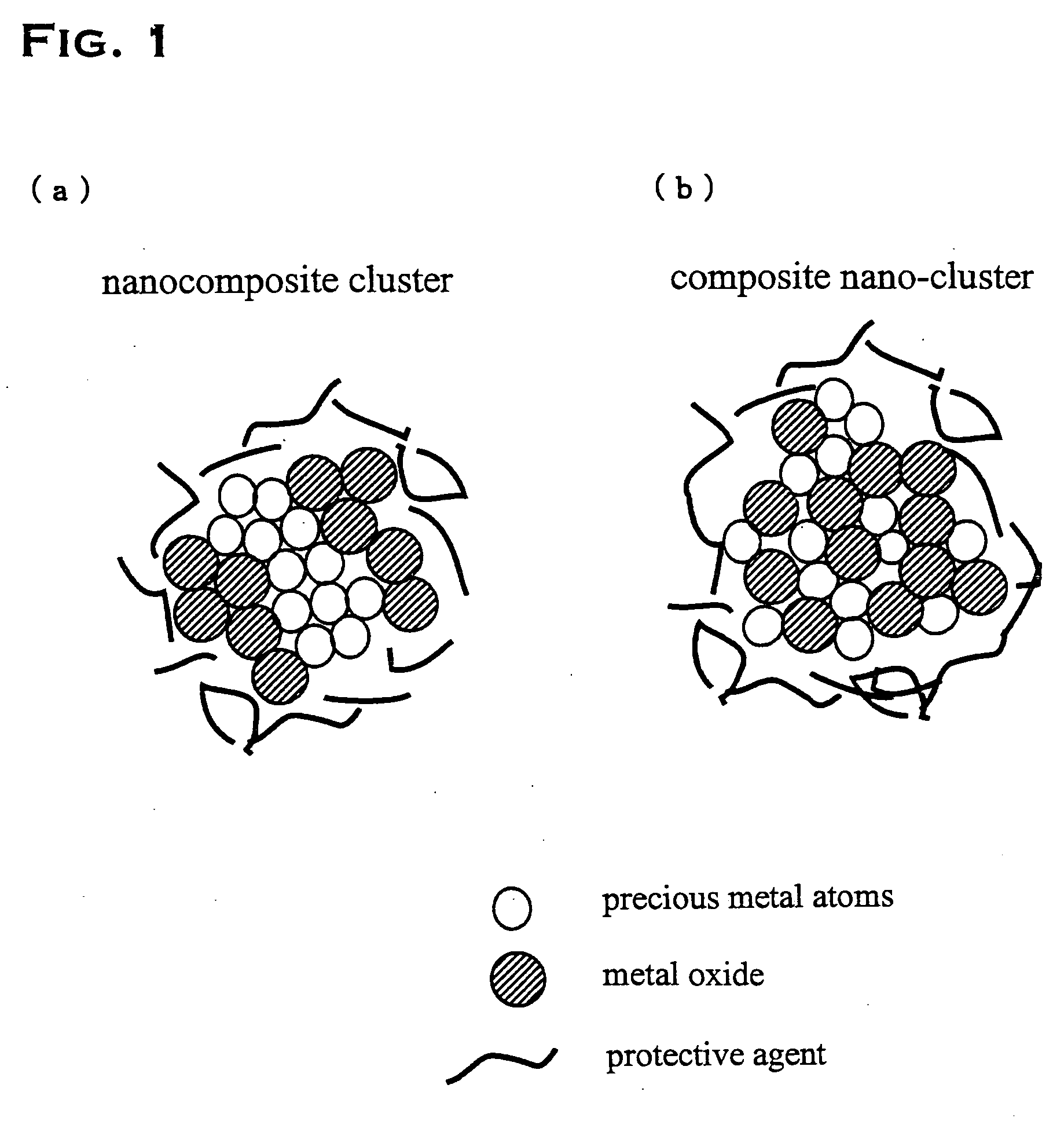

Precious metal - metal oxide composite cluster

InactiveUS20050065026A1Increase the effective surface areaSmall granularityMaterial nanotechnologyTransportation and packagingOxide compositeMaterials science

The present invention provides a precious metal—metal oxide composite cluster, wherein said cluster is formed as a single particle by combining a precious metal portion comprising a single atom or an aggregate of a plurality of atoms consisting of one or more precious metals, and a metal oxide portion comprising a single molecule or an aggregate of a plurality of molecules consisting of one or more metal oxides, and wherein said particle has a particle size between 1 and 100 nm.

Owner:TANAKA PRECIOUS METAL IND

Ternary oxide nanostructures and methods of making same

InactiveUS7585474B2Suitable for preparationFrom gel stateAlkaline earth titanatesSingle crystalNanostructure

A single crystalline ternary nanostructure having the formula AxByOz, wherein x ranges from 0.25 to 24, and y ranges from 1.5 to 40, and wherein A and B are independently selected from the group consisting of Ag, Al, As, Au, B, Ba, Br, Ca, Cd, Ce, Cl, Cm, Co, Cr, Cs, Cu, Dy, Er, Eu, F, Fe, Ga, Gd, Ge, Hf, Ho, I, In, Ir, K, La, Li, Lu, Mg, Mn, Mo, Na, Nb, Nd, Ni, Os, P, Pb, Pd, Pr, Pt, Rb, Re, Rh, Ru, S, Sb, Sc, Se, Si, Sm, Sn, Sr, Ta, Tb, Tc, Te, Ti, Tl, Tm, U, V, W, Y, Yb, and Zn, wherein the nanostructure is at least 95% free of defects and / or dislocations.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

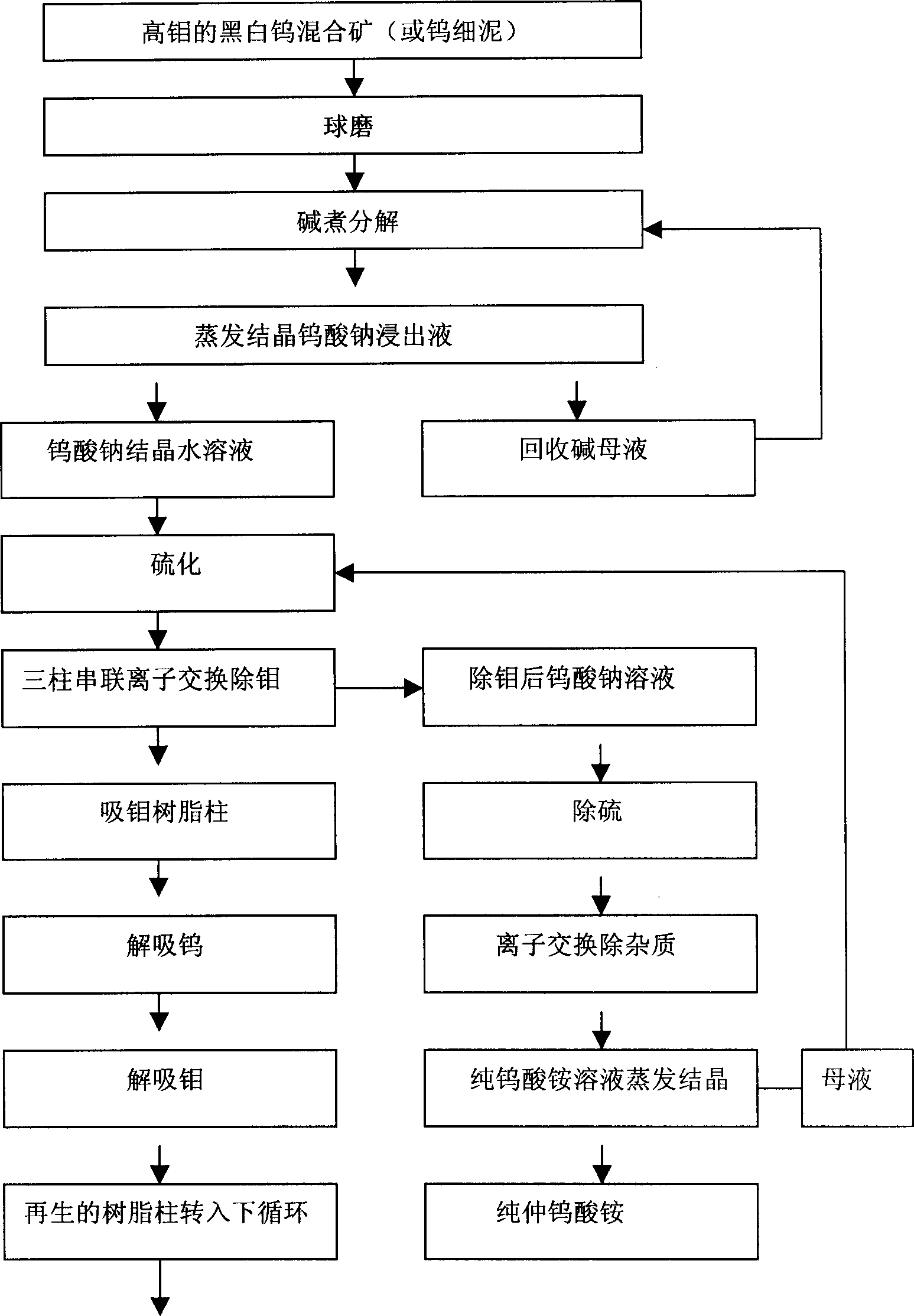

Process for preparing high purity ammonium para-tungstate using hihg-molybdenum tungsten ore

The present invention provides a method of treating high-molybdenum tungsten mineral or tungsten slime by means of three-ion column exchange molybdenum-eliminating technology so as to obtain ammoniumpara-tungstate with high purity at low cost. The treating process includes grinding, alkali leaching, filtering and concentration to obtain sodium tungstate crystal; water dissolving, filtering and sulfurizing sodium tungstate; ion exchange to eliminate molybdenum; desulfurizing sodium tungstate liquid; ion exchange to elimiante impurity and desorbing tungsten with ammonia water and ammonium chloride solution to prepare ammonium tungstate solution; and evaporation to obtain ammonium para-tungstate crystal. The present invention has low cost.

Owner:王旭升 +1

Negative active material for rechargeable lithium battery, method of preparing thereof, and rechargeable lithium battery including the same

ActiveUS20080118840A1Improve stabilityExcellent charge and discharge efficiency and cycle-lifeMaterial nanotechnologyMolybdeum compoundsDischarge efficiencyVanadium oxide

A negative active material for a rechargeable lithium battery of the present invention includes a lithium-vanadium oxide core material being capable of performing reversible electrochemical oxidation and reduction, and an inorganic oxide coating layer disposed on the surface of the core material. The negative active material can improve stability at the interface between a negative electrode and an electrolyte, charge and discharge efficiency, and cycle-life, and can be applied along with all kinds of aqueous and non-aqueous binders.

Owner:SAMSUNG SDI CO LTD

Synthesis of nanoparticles

Owner:CENT FUR ANGEWANDTE NANOTECH

Very low thermal expansion composite

InactiveUS20050191515A1Low thermal expansionPigmenting treatmentMaterial nanotechnologyNegative coefficientOpto electronic

Disclosed are composites having very low coefficients of thermal expansion and methods of preparing the composites. Also disclosed are composites having negative coefficients of thermal expansion. Applications of the composites to a wide variety of uses, such as electronic and optoelectronic devices are also disclosed.

Owner:SHIPLEY CO LLC

Method for preparing mono-disperse tungsten disulfide nano slices

InactiveCN101723464ASimple processLow costNanostructure manufactureTungsten compoundsChemical synthesisSulfur

The invention discloses a method for preparing mono-disperse tungsten disulfide nano slices. The method comprises the following steps: ball-milling, mixing and activating tungsten oxide and sulfur serving as raw materials, and annealing for 30 to 120 minutes at the constant temperature of between 600 and 700 DEG C in a protective atmosphere; during annealing at the constant temperature, preposing a part of sulfur powder as a complementary sulfur source, wherein the mass ratio of the complementary sulfur powder to the reaction mixture is between 0.05 and 10; and then, cooling a reaction product to below 250 DEG C along with a furnace in the protective atmosphere to obtain the mono-disperse tungsten disulfide nano slices. The method prepares a large amount of mono-disperse slice tungsten disulfide material by a simple and effective chemical synthesis method; and the method is simple and quick, has low production cost, and can be widely used in the aspects of lubrication and catalysis.

Owner:CENT SOUTH UNIV

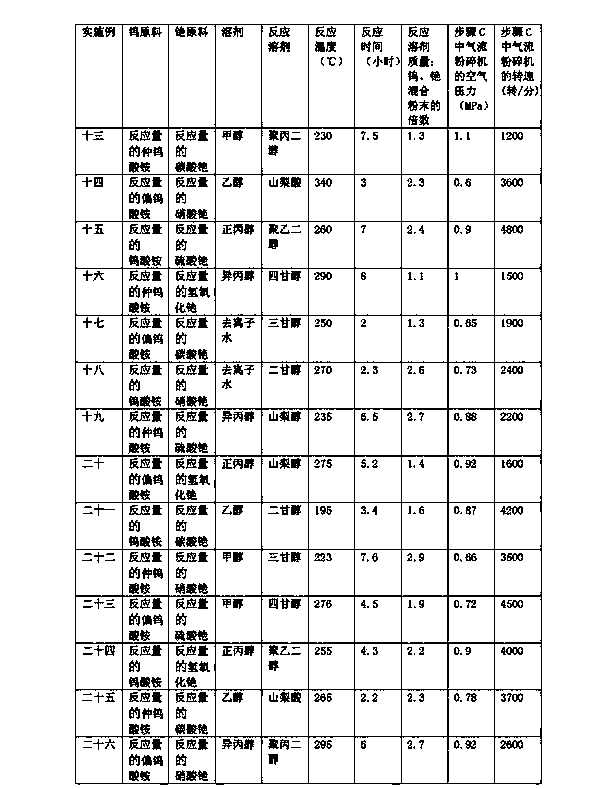

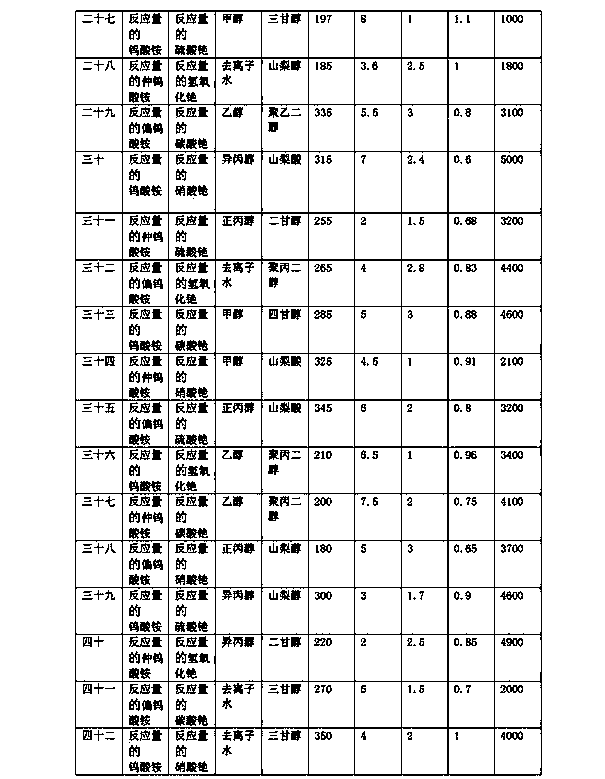

Preparation method of cesium tungstate nanopowder

ActiveCN104192910ALow degree of reunionIncrease productivityMaterial nanotechnologyTungsten compoundsTungstatePhysical chemistry

The invention discloses a preparation method of cesium tungstate nanopowder. The preparation method comprises the following steps of A, dissolving reacting doses of tungsten raw materials and cesium carbonate raw materials into a solvent, drying the solution to obtain particles, and further smashing the obtained particles to obtain tungsten and cesium mixed powder; B, placing the tungsten and cesium mixed powder into a sealed reaction kettle with a stirring function, adding a reaction solvent in the sealed reaction kettle, and reacting at the temperature of 180-350 DEG C for 2-8h while stirring, wherein the mass of the reaction solvent is 1-3 times as mush as that of the tungsten and cesium mixed powder; and C, separating the reaction product obtained in the step B, washing by using deionized water or ethanol, then, drying, and milling by using a jet mill to obtain a target product, namely the cesium tungstate nanopowder. The cesium tungstate nanopowder prepared by using the preparation method is low in agglomeration degree; and the preparation method is high in production efficiency and low in cost.

Owner:宁波今心新材料科技有限公司

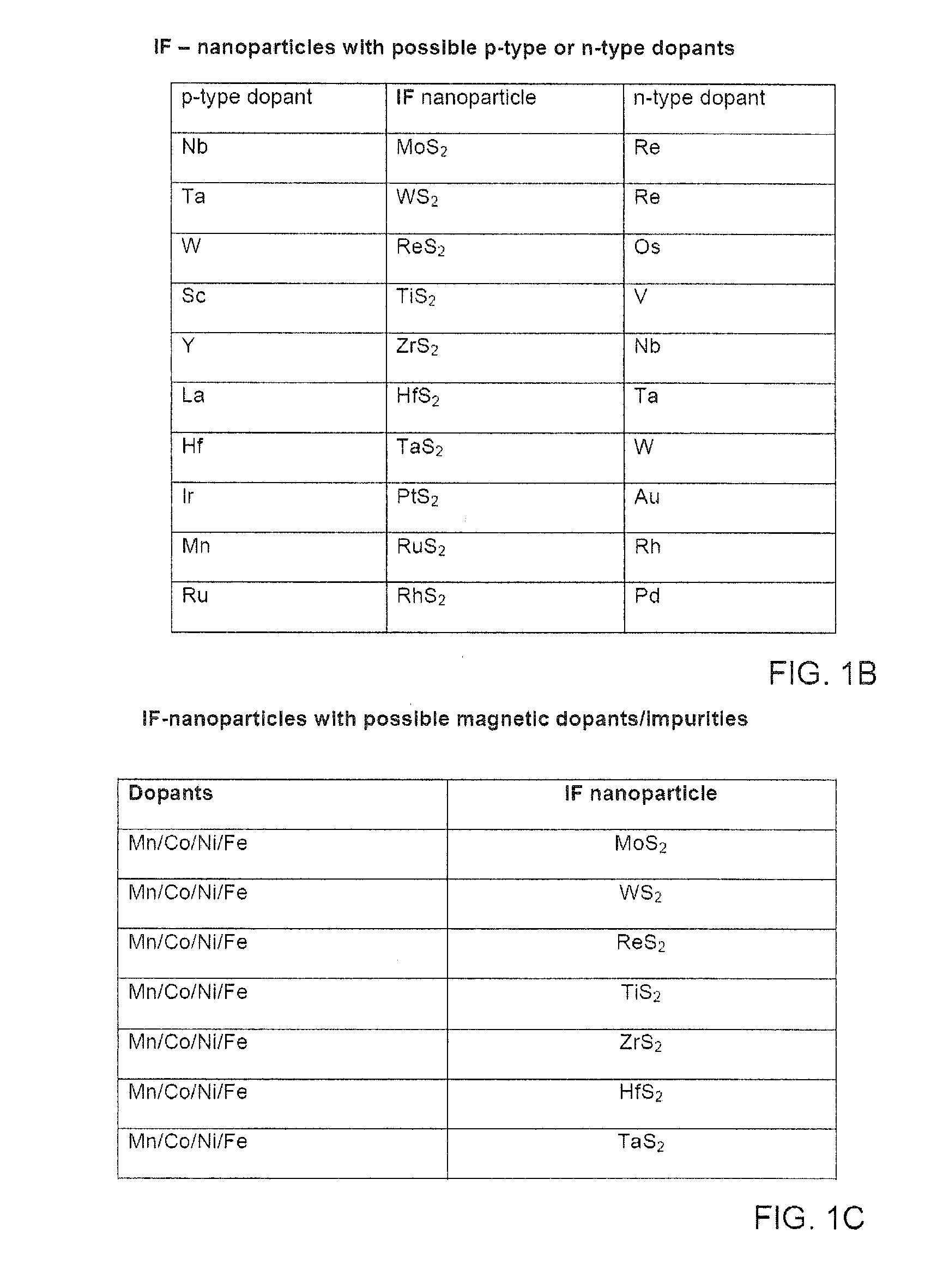

Fullerene-like nanostructures, their use and process for their production

ActiveUS20100227782A1Improve conductivityMaterial nanotechnologyConductive materialAlloyElectronic properties

A nanostructure, being either an Inorganic Fullerene-like (IF) nanostructure or an Inorganic Nanotube (INT), having the formula A1−x-Bx-chalcognide are described. A being a metal or transition metal or an alloy of metals and / or transition metals, B being a metal or transition metal B different from that of A and x being ≦0.3. A process for their manufacture and their use for modifying the electronic character of A-chalcognide are described.

Owner:YEDA RES & DEV CO LTD

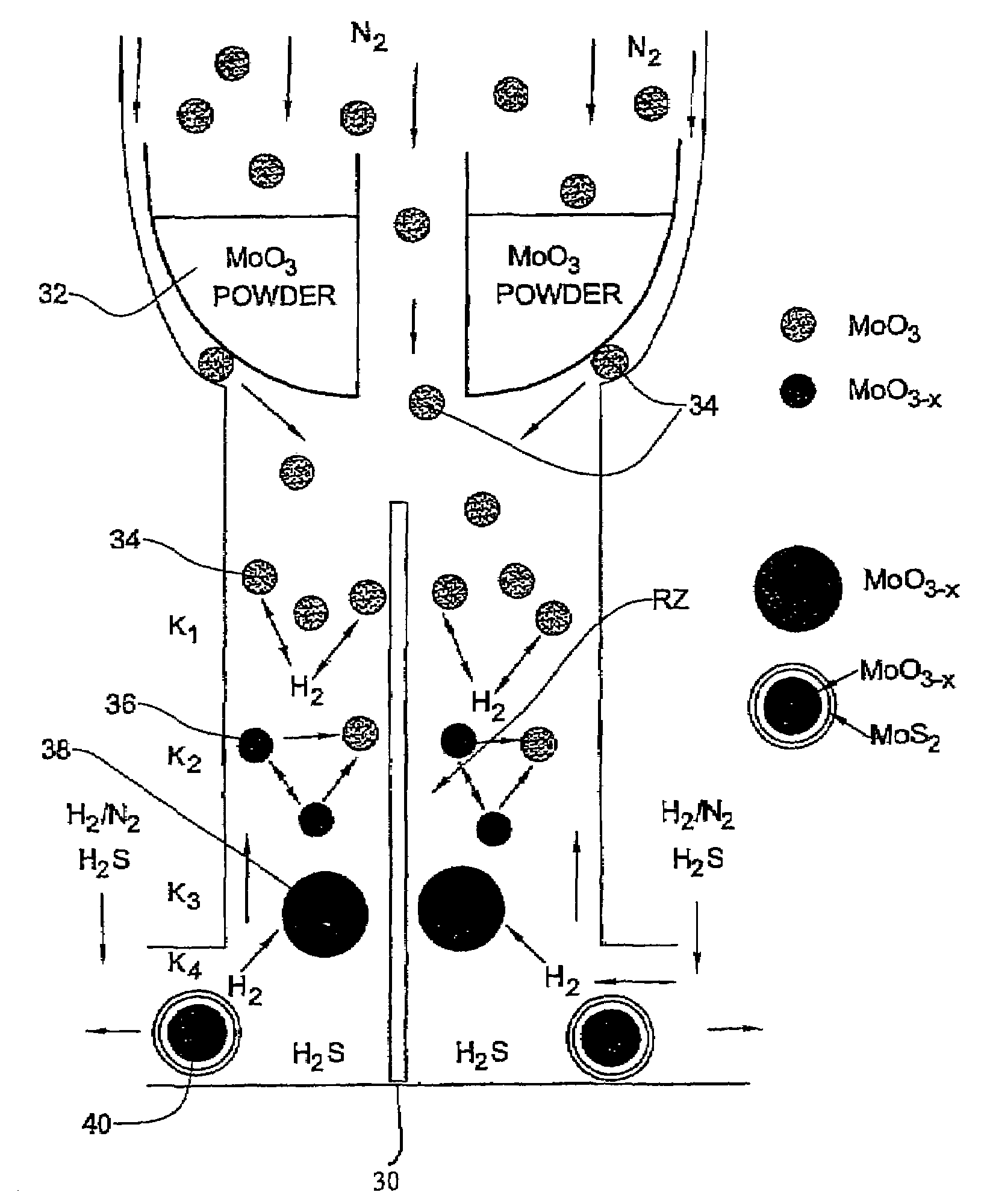

Method and apparatus for producing inorganic fullerene-like nanoparticles

InactiveUS7018606B2Easy to produceMaterial nanotechnologyNanostructure manufactureNanoparticleGas phase

A process and apparatus are presented for obtaining inorganic fullerene-like nanostructures. A metal oxide is evaporated at predetermined temperature conditions, and is swept towards a reacting zone, to which first and second gas phase reacting agents are concurrently swept. The evaporated metal oxide thus interacts with the first reacting agent and is converted into metal suboxide nanoparticles in the gas phase. The condensing metal suboxide nanoparticles interact with the second reacting agent in the gas phase resulting in substantially pure phase of the inorganic fullerene-like nanoparticles.

Owner:YEDA RES & DEV CO LTD

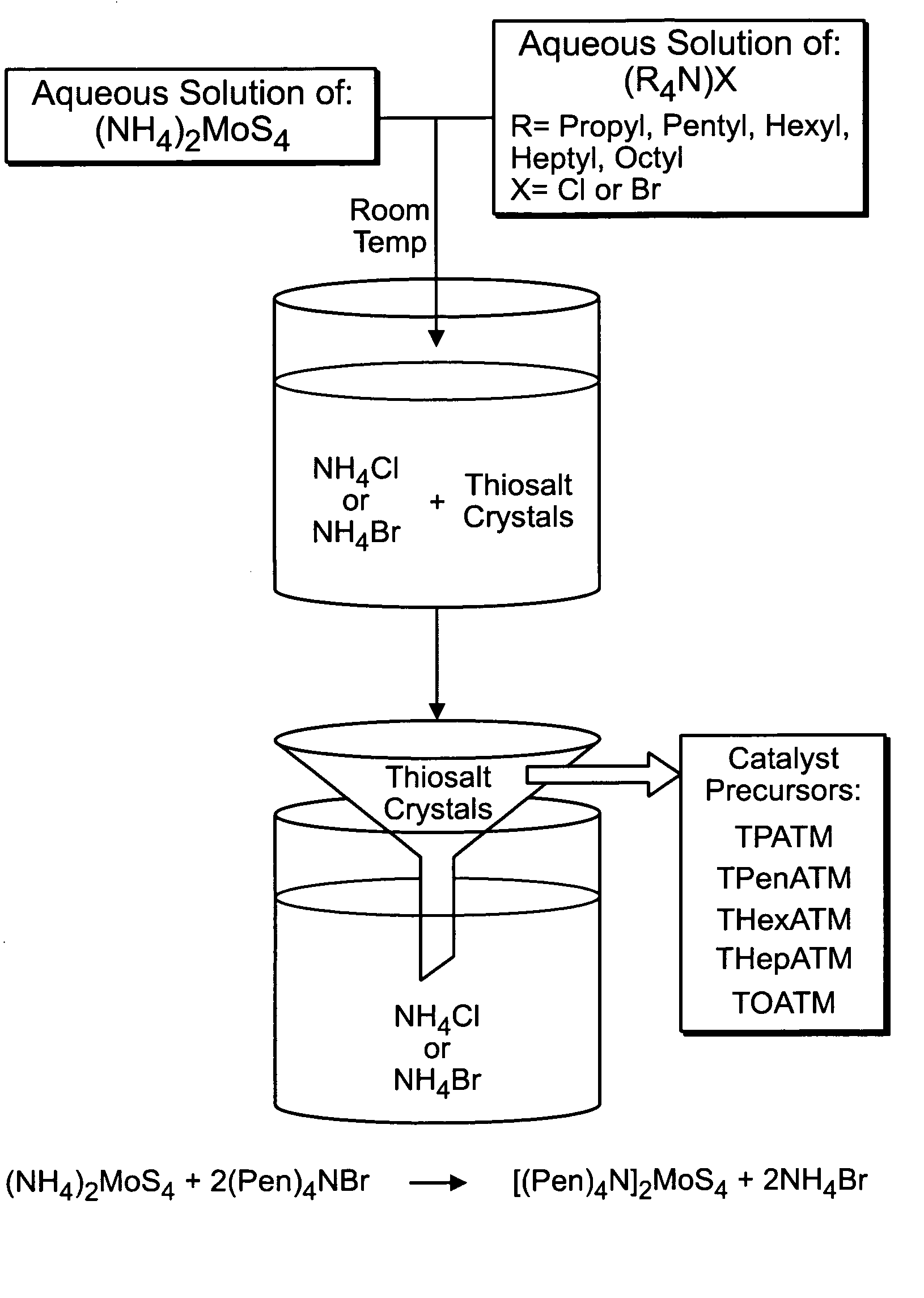

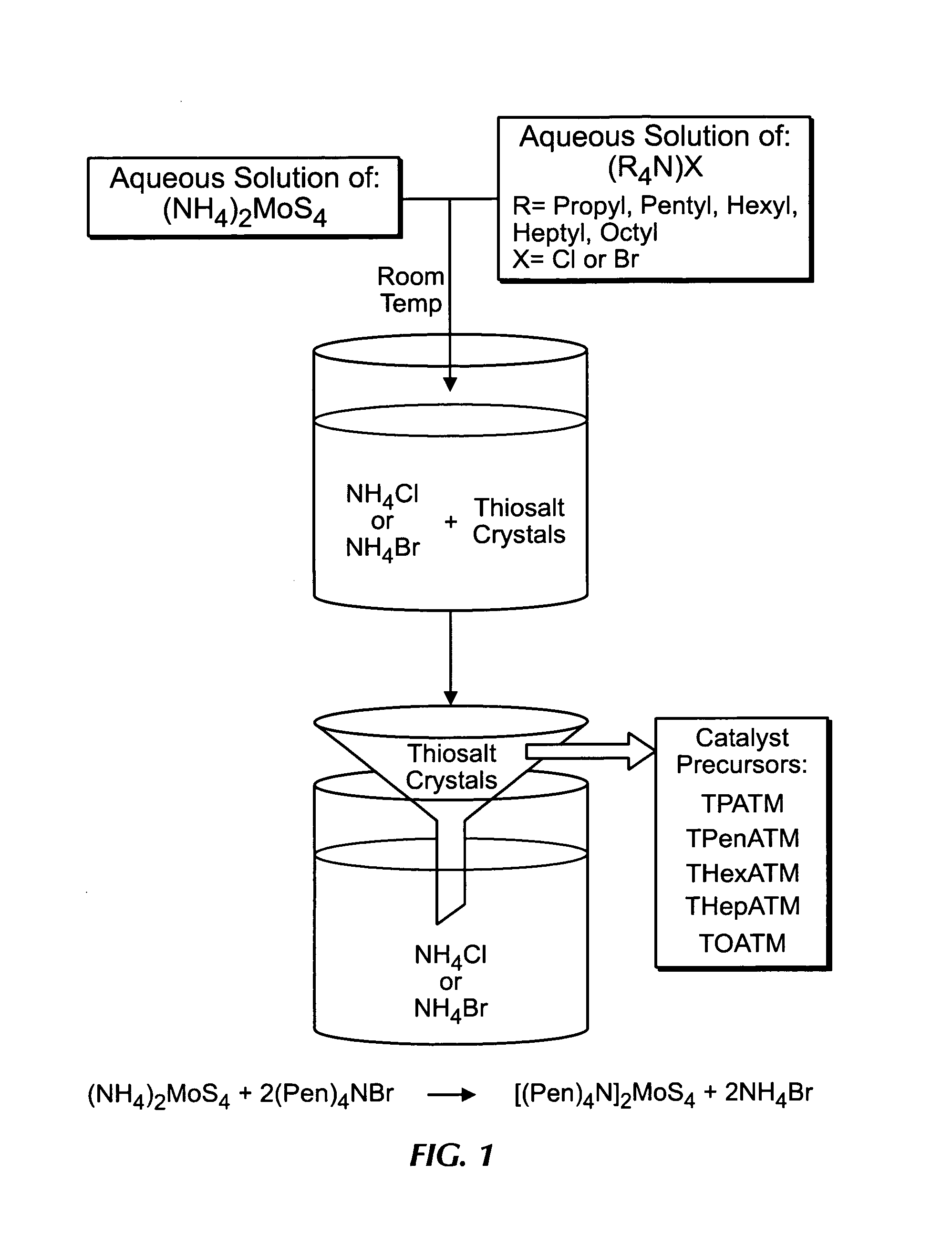

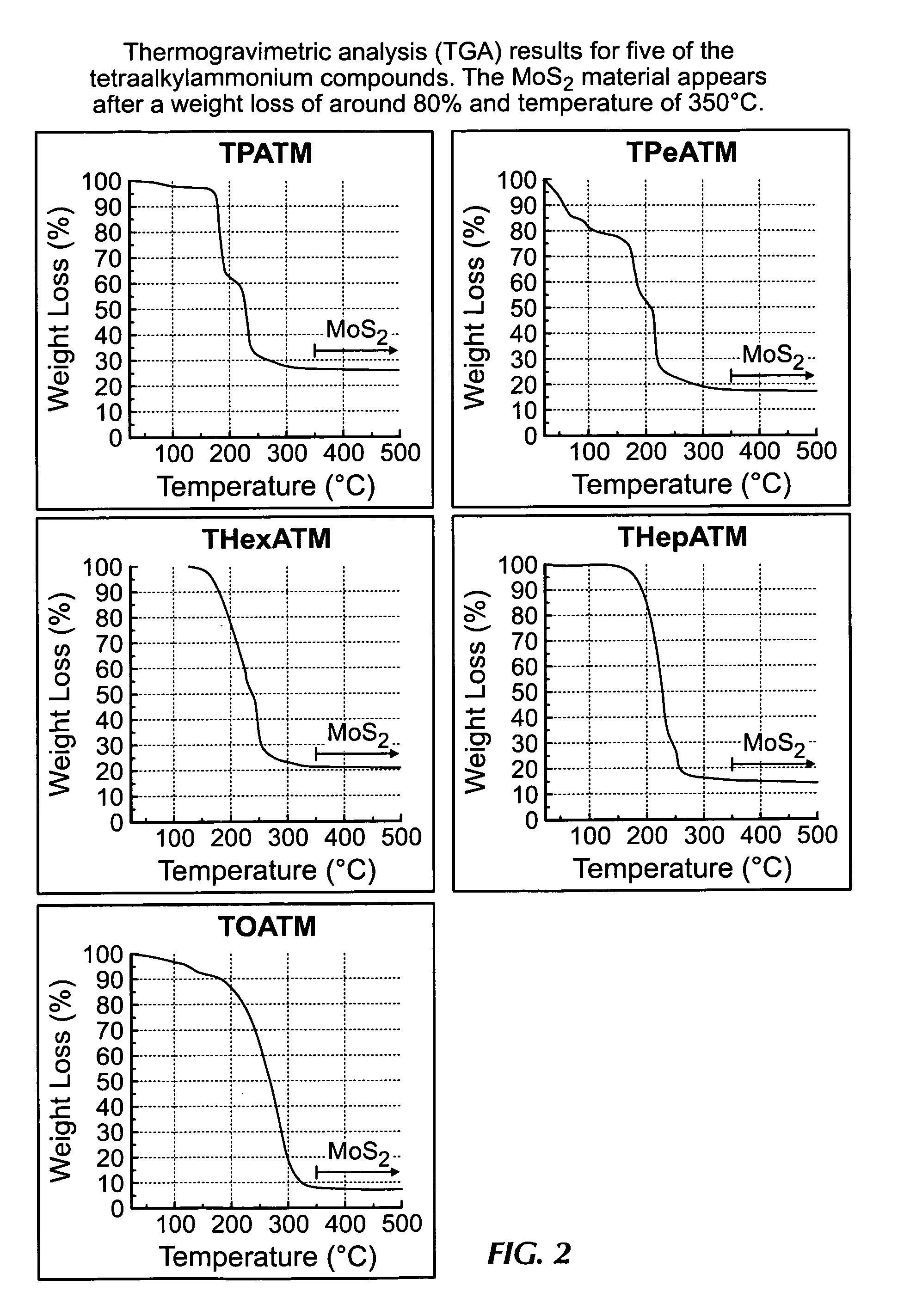

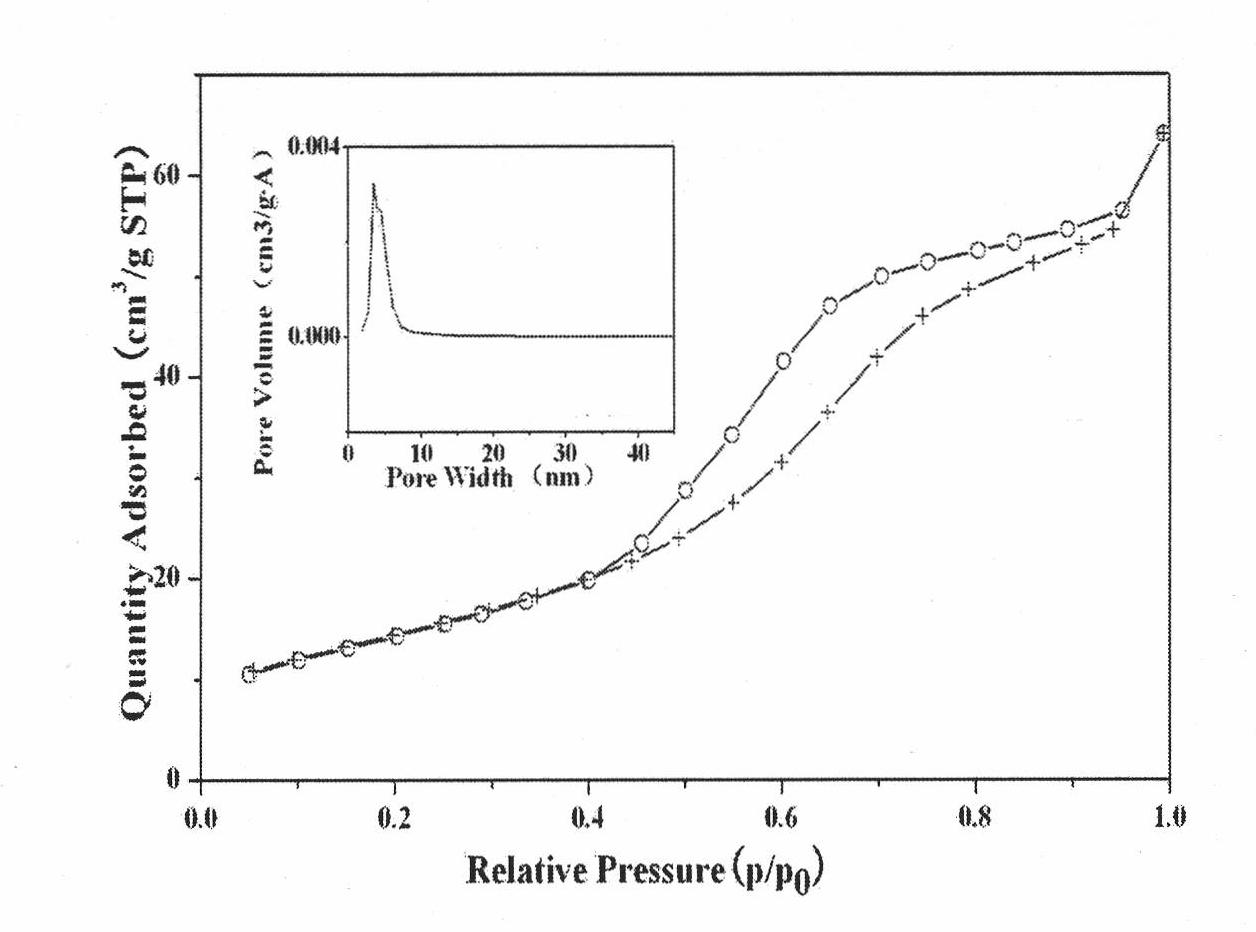

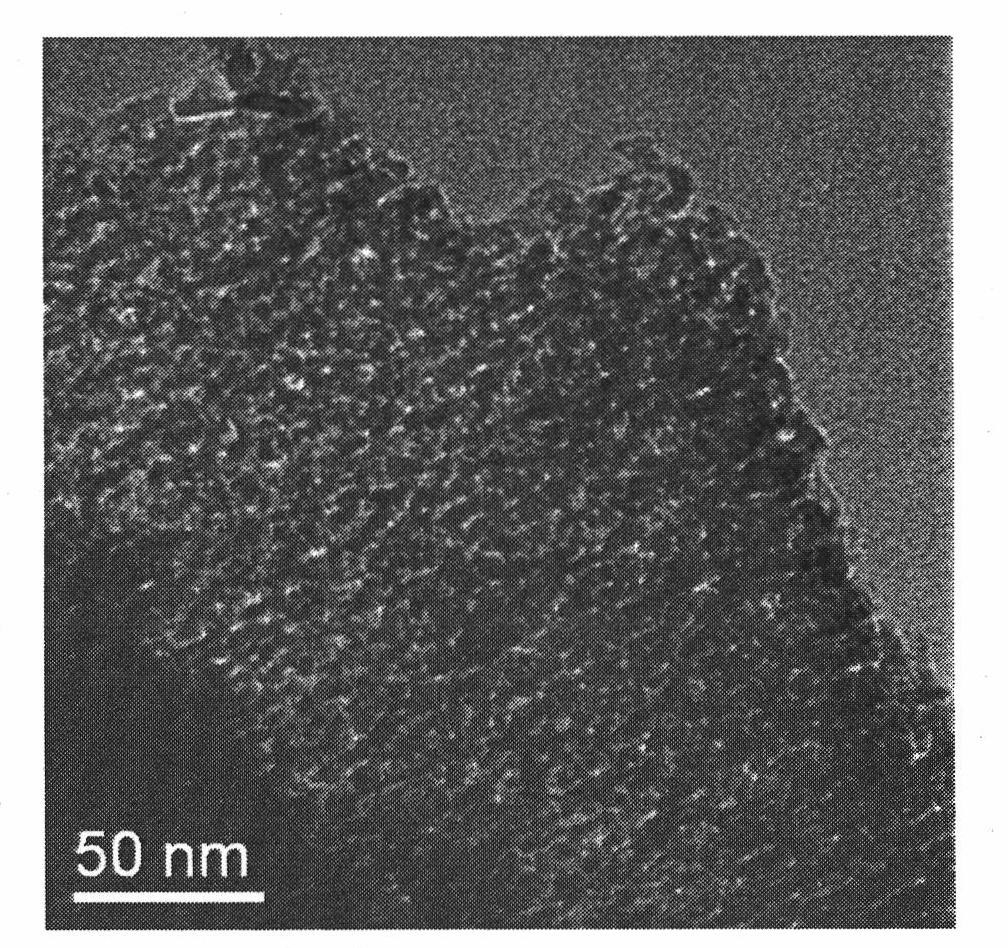

Preparation of amorphous sulfide sieves

Owner:CENT DE INVESTIGACIION & MATERIALES AVANZADOS SC +1

Mesoporous tungstate photocatalysis material and preparation method thereof

InactiveCN102372305AAvoid fusion growthImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsTungsten compoundsInorganic saltsTungstate

The invention provides a mesoporous tungstate photocatalysis material and a preparation method thereof. According to the invention, metal inorganic salt and alkoxide are used as precursors, and molecular level mixing of metallic elements in a precursor solution is realized through addition of a chelating agent so as to avoid phase separation during evaporation of solvents; the method of an inorganic pore forming agent is used to allow a certain metallic element to be excessive in the process of synthesis and to exceed stoichiometric proportion, a part of the excessive metallic element participates in a reaction in the process of roasting to produce tungstate, and the rest part of the excessive metallic element is precipitated to form metal oxide or salt, functioning as a pore forming agent and stabilizing a meso-structure; the inorganic pore forming agent is removed by using treating methods of acid, alkali, dissolving and the like to obtain the mesoporous tungstate material. The invention has the advantages of a simple synthesis process, no harsh conditions and practicable operation. When applied in indoor air purification, the mesoporous tungstate photocatalysis material obtained in the invention has an obvious effect in removing formaldehyde, with a removal rate up to 92%.

Owner:范晓星

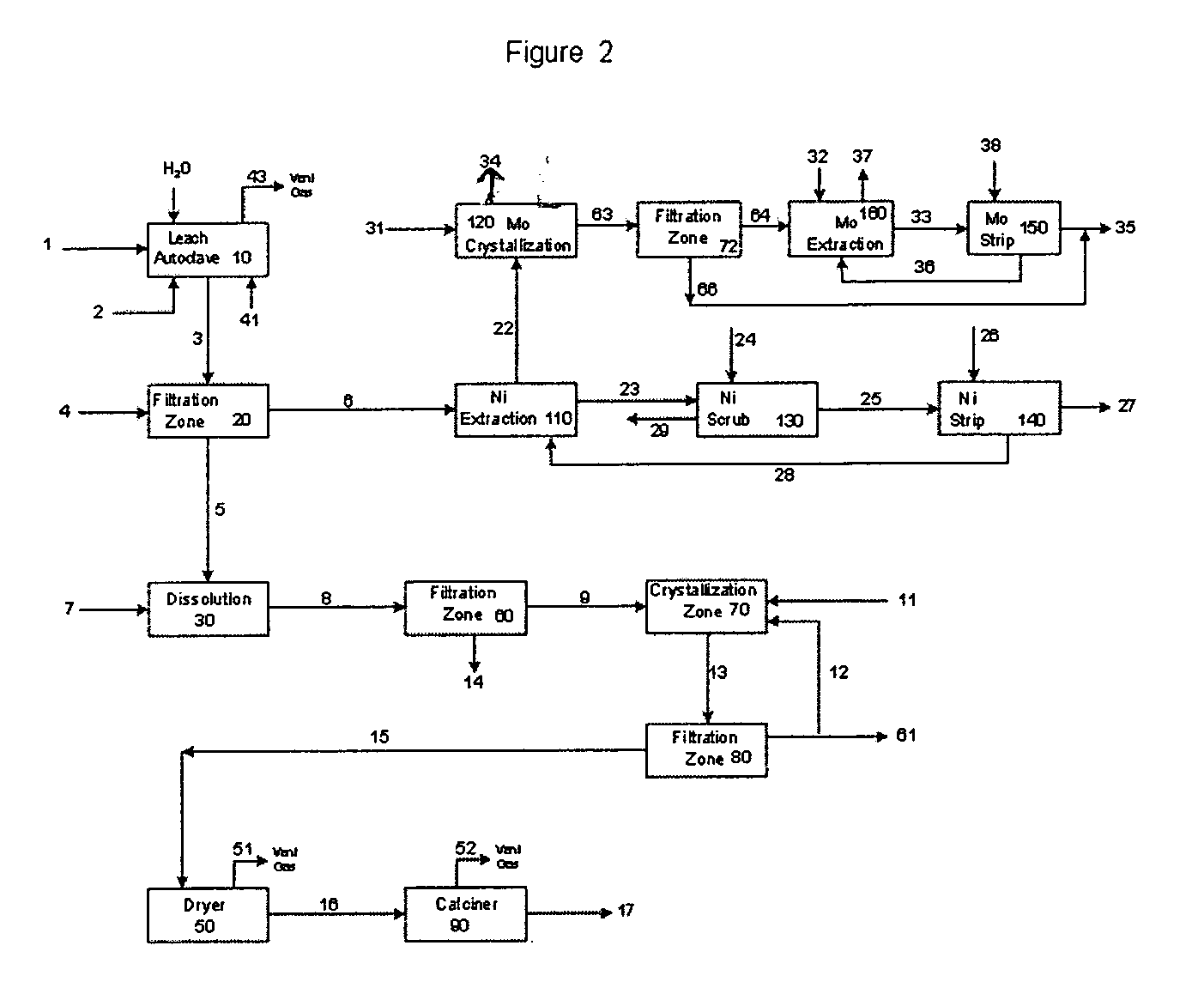

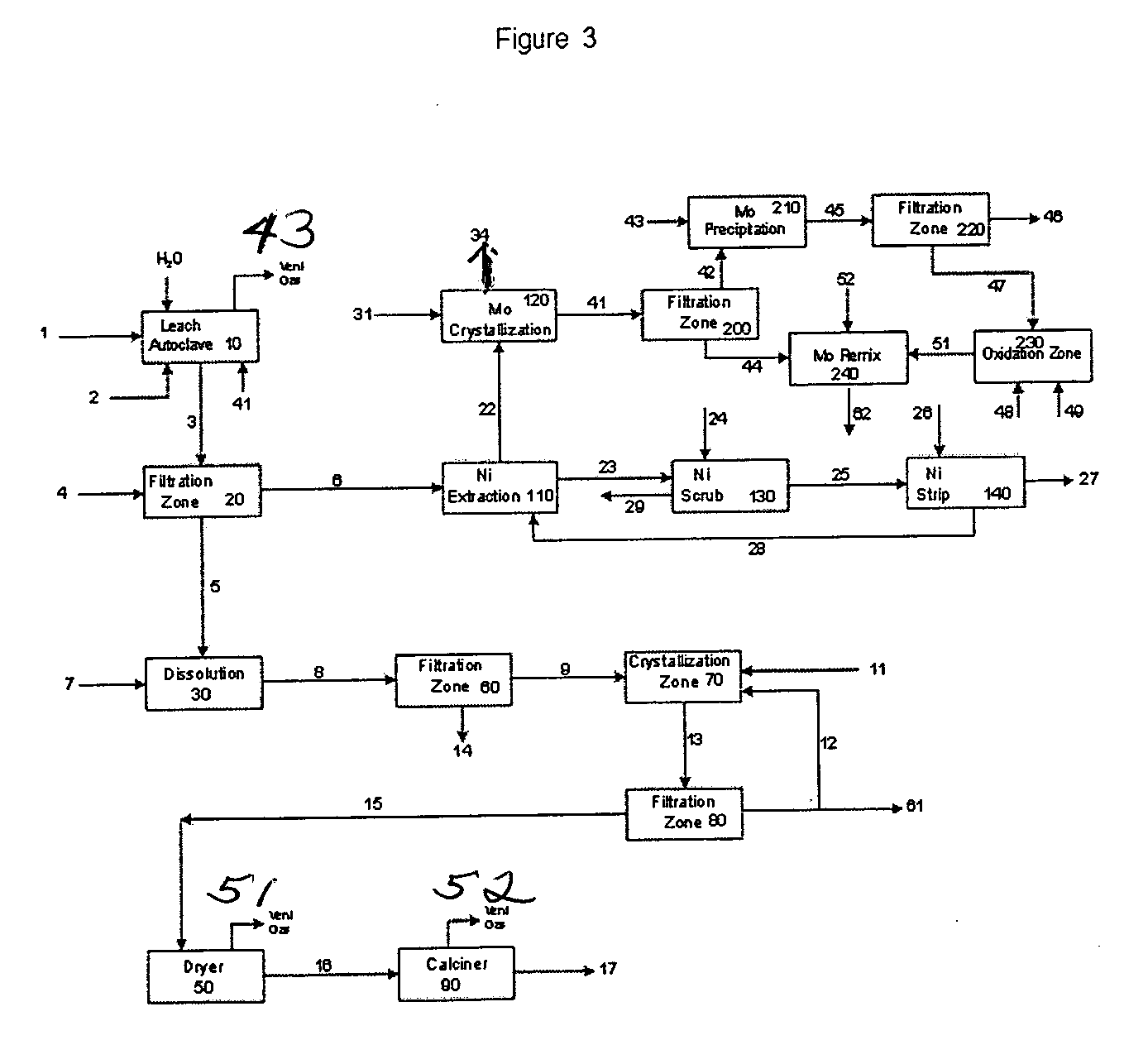

Process for separating and recovering base metals from used hydroprocessing catalyst

A method is disclosed for separating and recovering base metals from a used hydroprocessing catalyst originating from Group VIB and Group VIII metals and containing at least a Group VB metal. In one embodiment, the method comprises the steps of: contacting the used catalyst with an ammonia leaching solution under conditions sufficient to dissolve the group VIB metal and the Group VIII metal into the leaching solution; forming a leached slurry containing at least a group VIB metal complex and at least a group VIII metal complex, ammonium sulfate and a solid residue containing at least a Group VB metal complex and coke; separating and removing from the leached slurry the solid residue and coke; precipitating from the remaining solution at least a portion of the Group VIB metal complex and at least a portion of the Group VIII metal complex by controlling the pH to form a liquid material substantially free of Group VB, Group VIB and Group VIII metals and another solid material comprising substantially Group VIB and Group VIII metal complexes. Said solid material is further processed by dissolution, means of separation, further means of precipitation and oxidative dissolution to produce, separately, a Group VIB metal product solution, a Group VIII metal product solution and a purified ammonium sulfate product solution.

Owner:CHEVROU USA INC

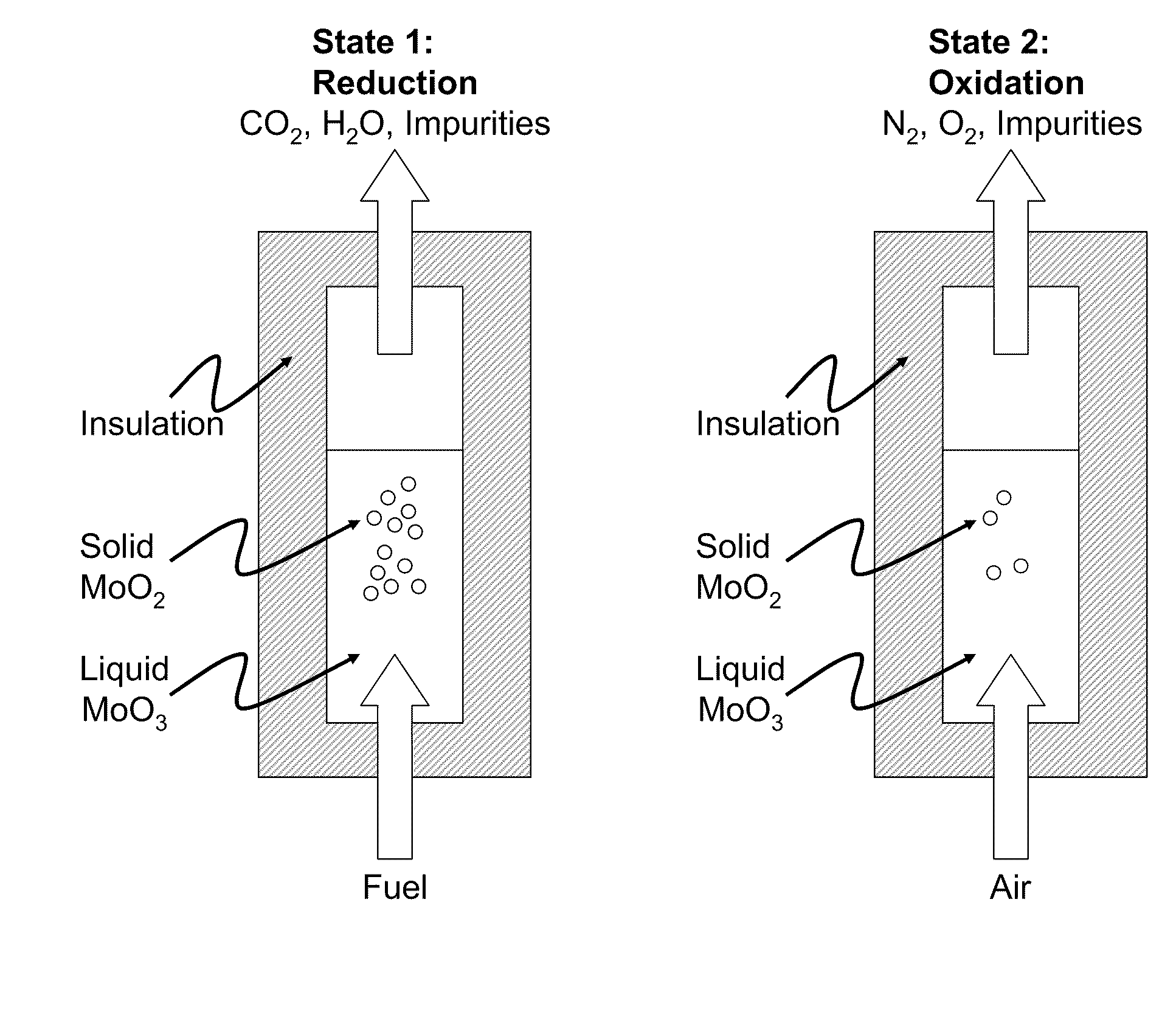

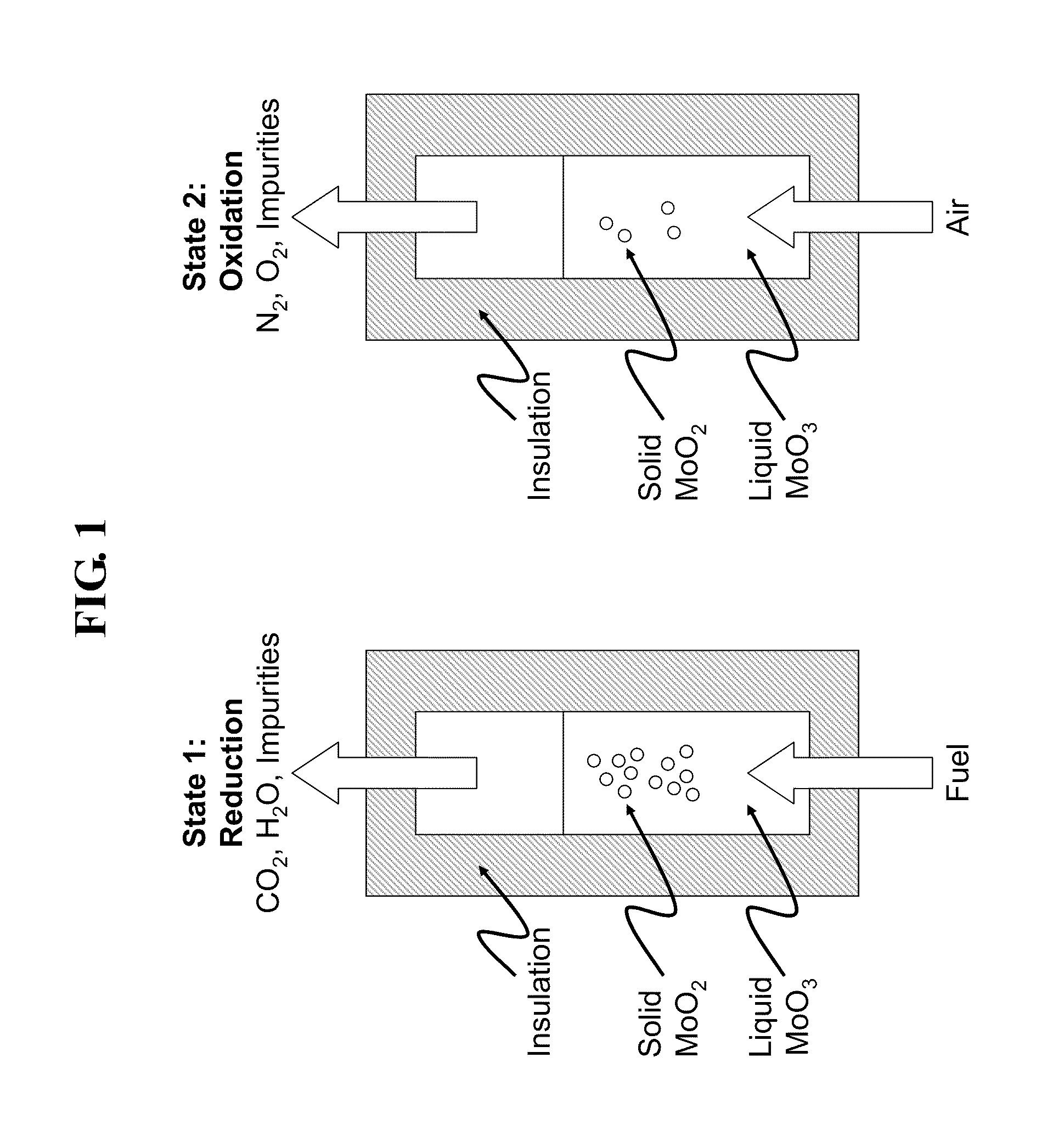

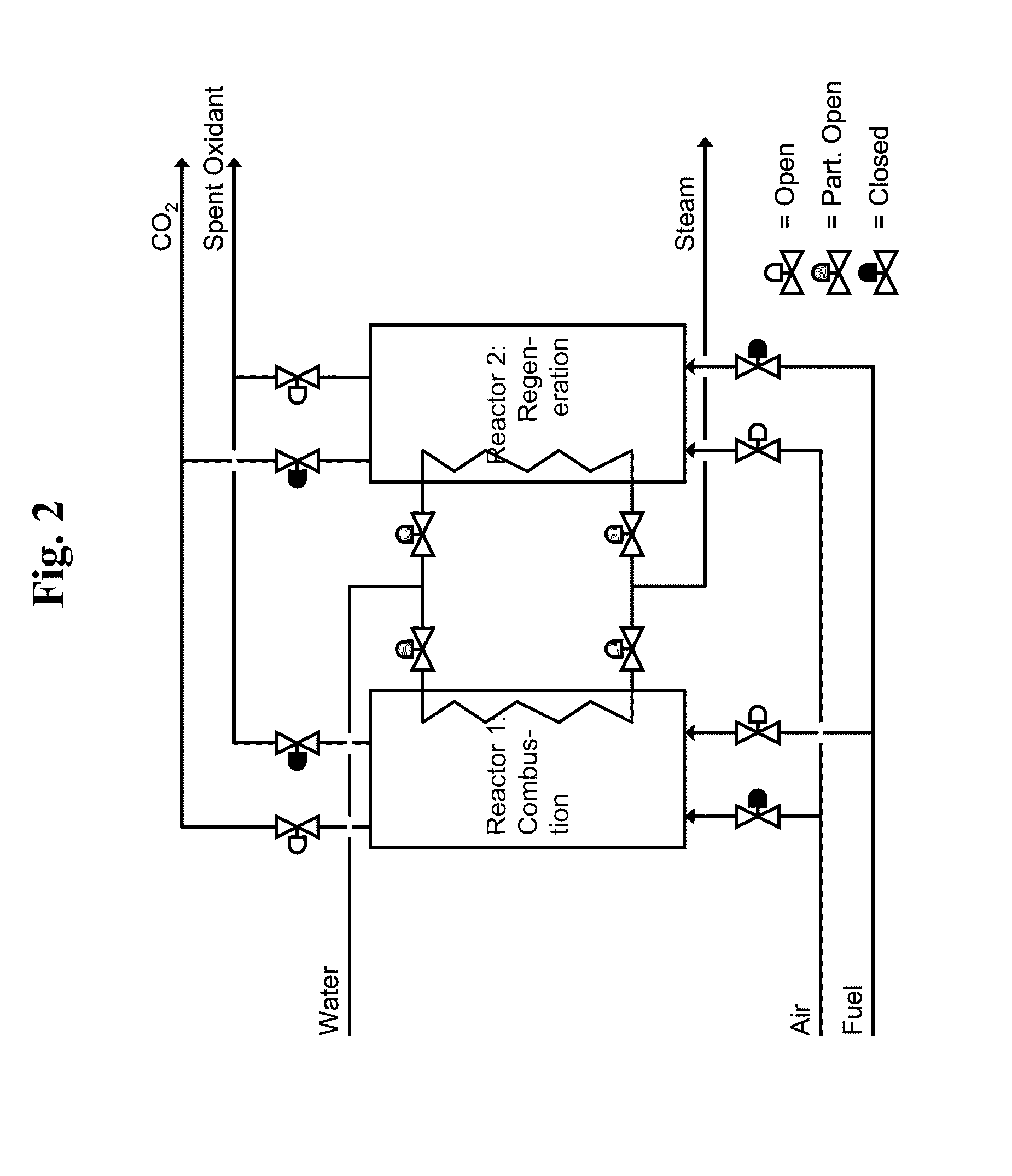

Liquid-phase chemical looping energy generator

Owner:PHILLIPS 66 CO

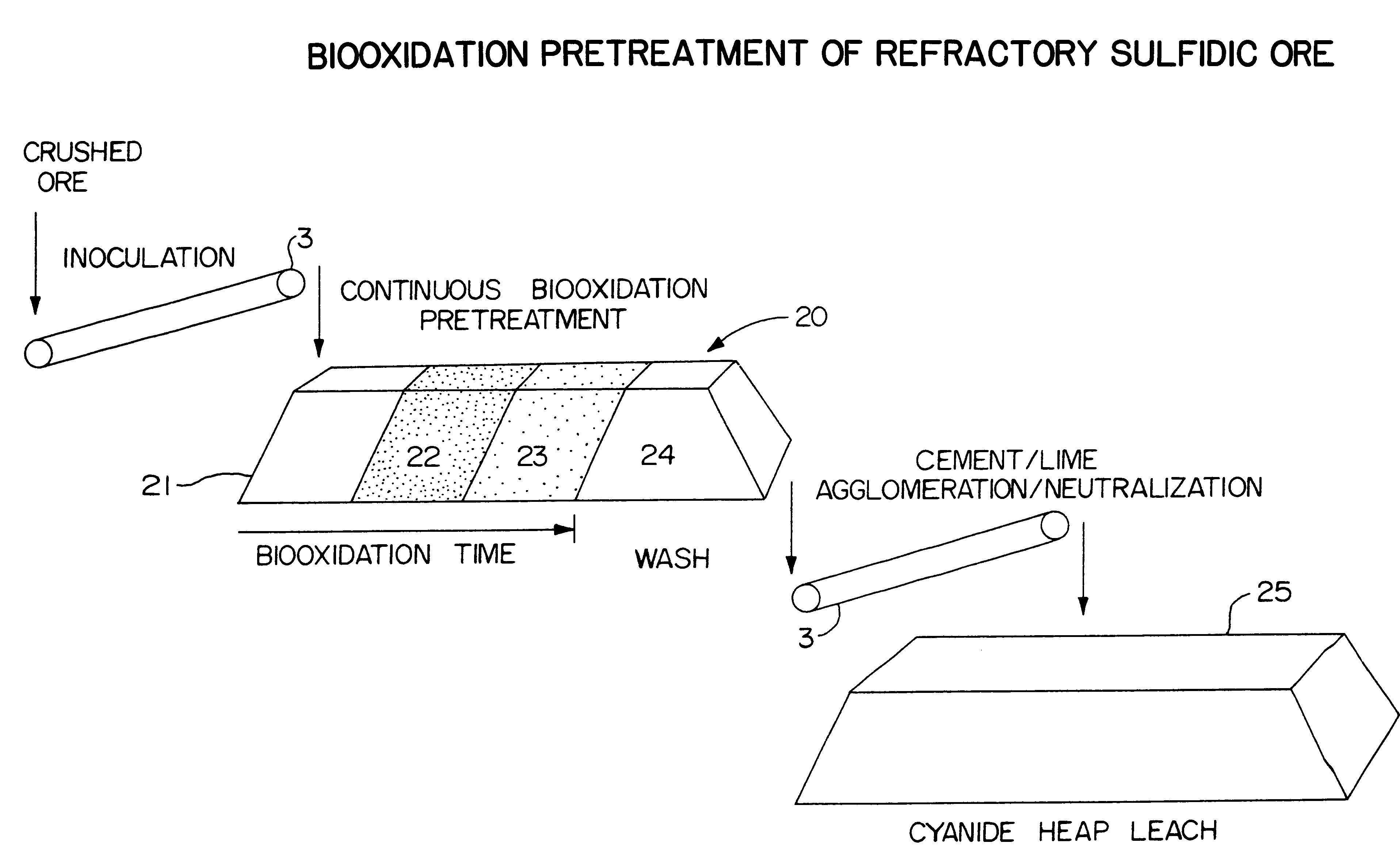

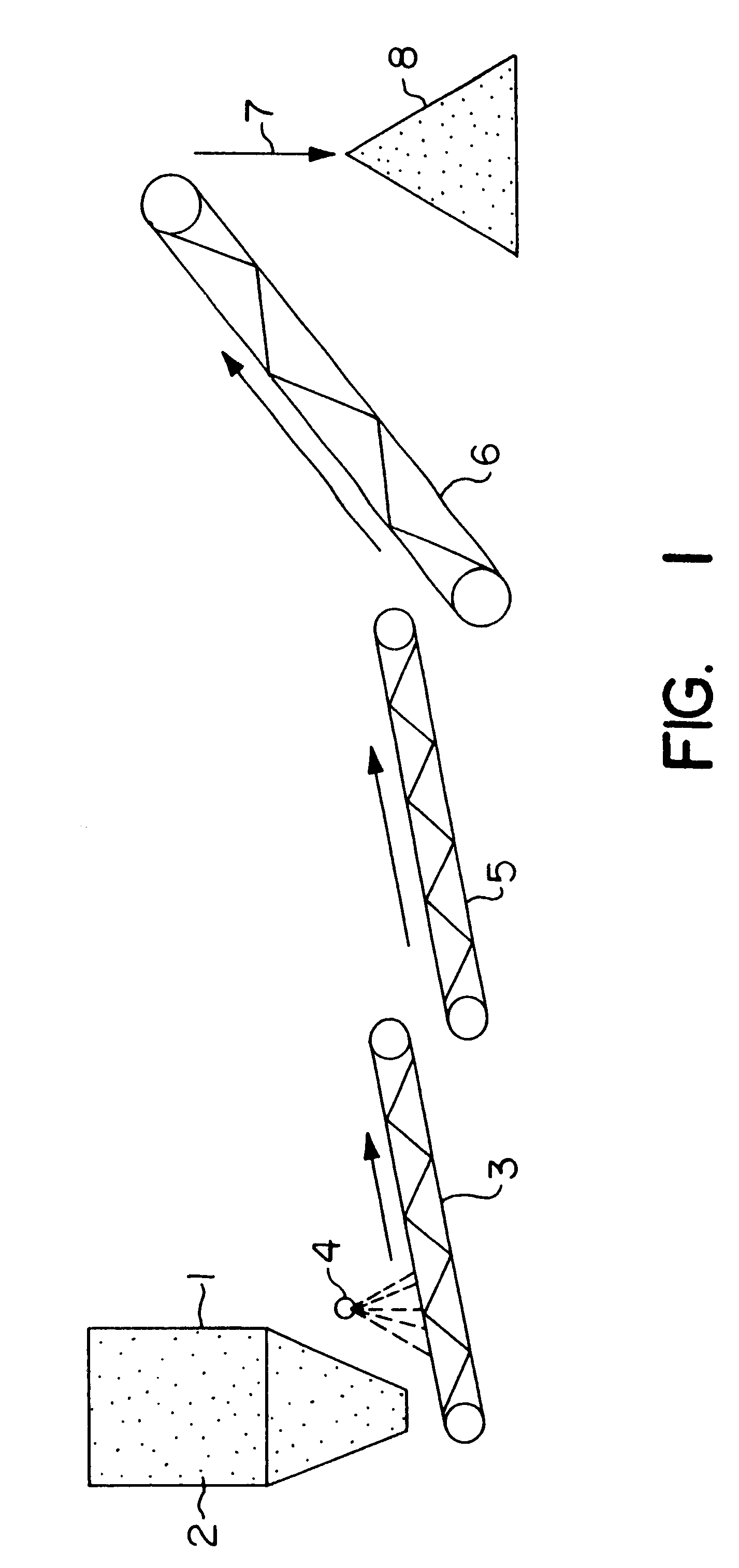

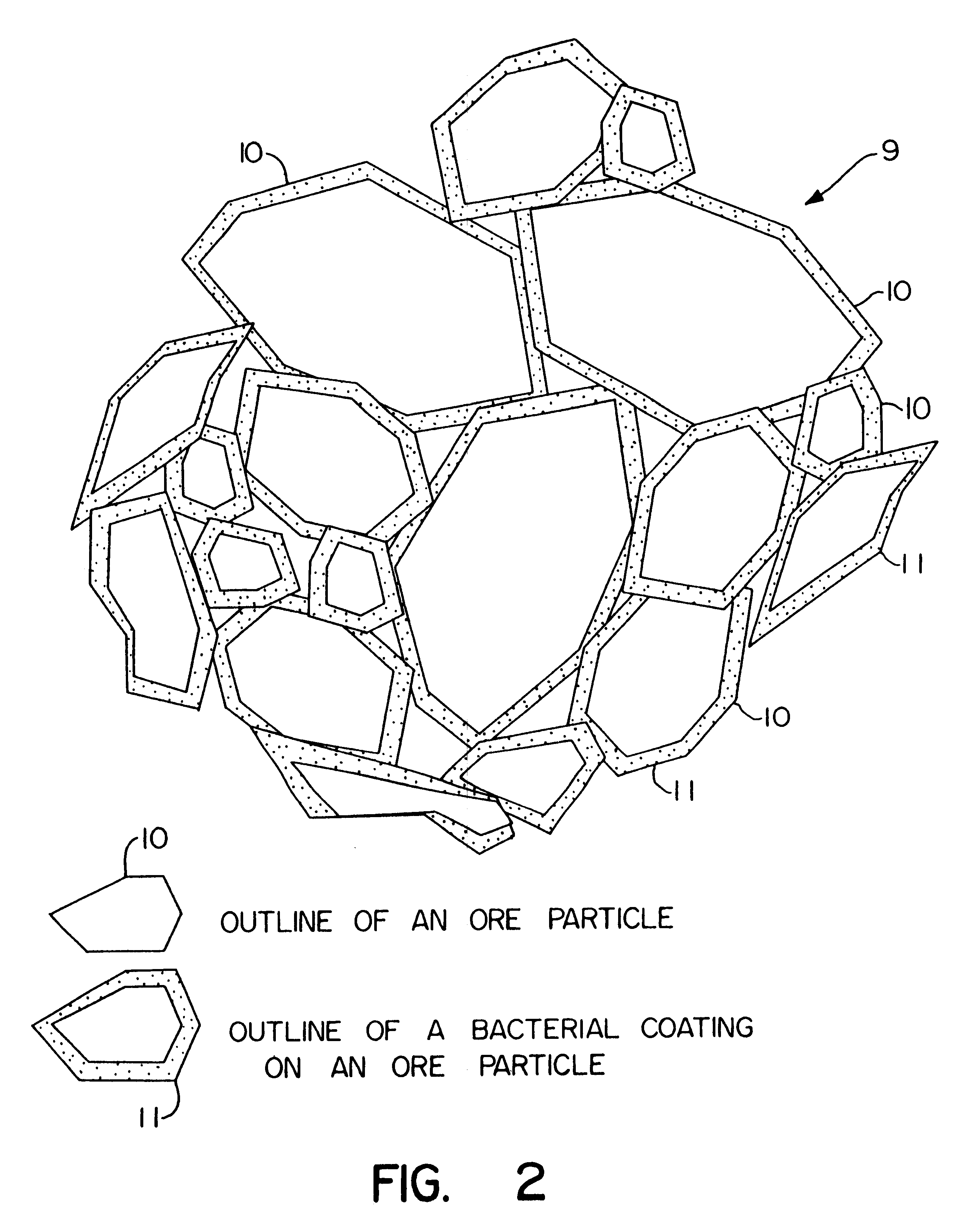

Biooxidation process for recovery of metal values from sulfur-containing ore materials

InactiveUS6383458B1Increase ratingsIncrease attractivenessTransuranic element compoundsSolvent extractionParticulatesPartial oxidation

A process for the recovery of one or more metal values from a metal ore material comprising those of one or more values and a matrix material having a sulfur content wherein the sulfur is present in an oxidation-reduction state of zero or less comprisinga. forming particulates from particles of said ore and an inoculate comprising bacteria capable of at least partially oxidizing the sulfur content;b. forming a heap of said particulates;c. biooxidizing the sulfur content andd. recovering those one or more metal values.

Owner:NEWMONT USA LTD

Solid chemical hydride dispenser for generating hydrogen gas

InactiveUS7666386B2Molybdeum compoundsSynthetic resin layered productsCompound (substance)Hydrogen evolution

A device for generating hydrogen gas is provided. The device (101) comprises a first hydrogen-containing composition (107) that reacts with a second composition to evolve hydrogen gas; a dispenser (105) adapted to apply the first composition to a first porous member (109); and a conduit (111) adapted to supply the second composition to the first porous member. In a preferred embodiment, the first composition is selected from the group consisting of hydrides, borohydrides and boranes, the second composition is water, and the dispenser is spring-loaded and is charged with the first composition. As the first composition reacts with water at the interface to evolve hydrogen gas, the dispenser forces the reaction product across the interface and out of the dispenser, where it will not interfere with the progress of the hydrogen evolution reaction.

Owner:LYNNTECH POWER SYST

Process for separating and recovering base metals from used hydroprocessing catalyst

A method is disclosed for separating and recovering base metals from a used hydroprocessing catalyst originating from Group VIB and Group VIII metals and containing at least a Group VB metal. In one embodiment, the used catalyst is contacted with an ammonia leaching solution to dissolve and separate the Group VIB and VIII metals from the Group VB metal complex and coke associated with the used catalyst. The resulting Group VIB and VIII metal containing solution is processed through at least two additional precipitation and liquid / solid separation steps to produce, in separate processing streams, a Group VIB metal product solution (such as ammonium molybdate) and a Group VIII metal product solution (such as nickel sulfate). Additionally, two separate filtrate streams are generated from liquid-solid separation steps, which filtrate streams are combined and subjected to hydrolysis and oxidation (oxydrolysis) to generate a purified ammonium sulfate solution for further processing, such as for fertilizer.

Owner:CHEVROU USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com