Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

845 results about "Titanic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanic acid is a general name for a family of chemical compounds of the elements titanium, hydrogen, and oxygen, with the general formula [TiOₓ(OH)₄₋₂ₓ]ₙ. Various simple titanic acids have been claimed, mainly in the older literature. No crystallographic and little spectroscopic support exists for these materials. Some older literature including Brauer's Handbook refers to TiO₂ as titanic acid.

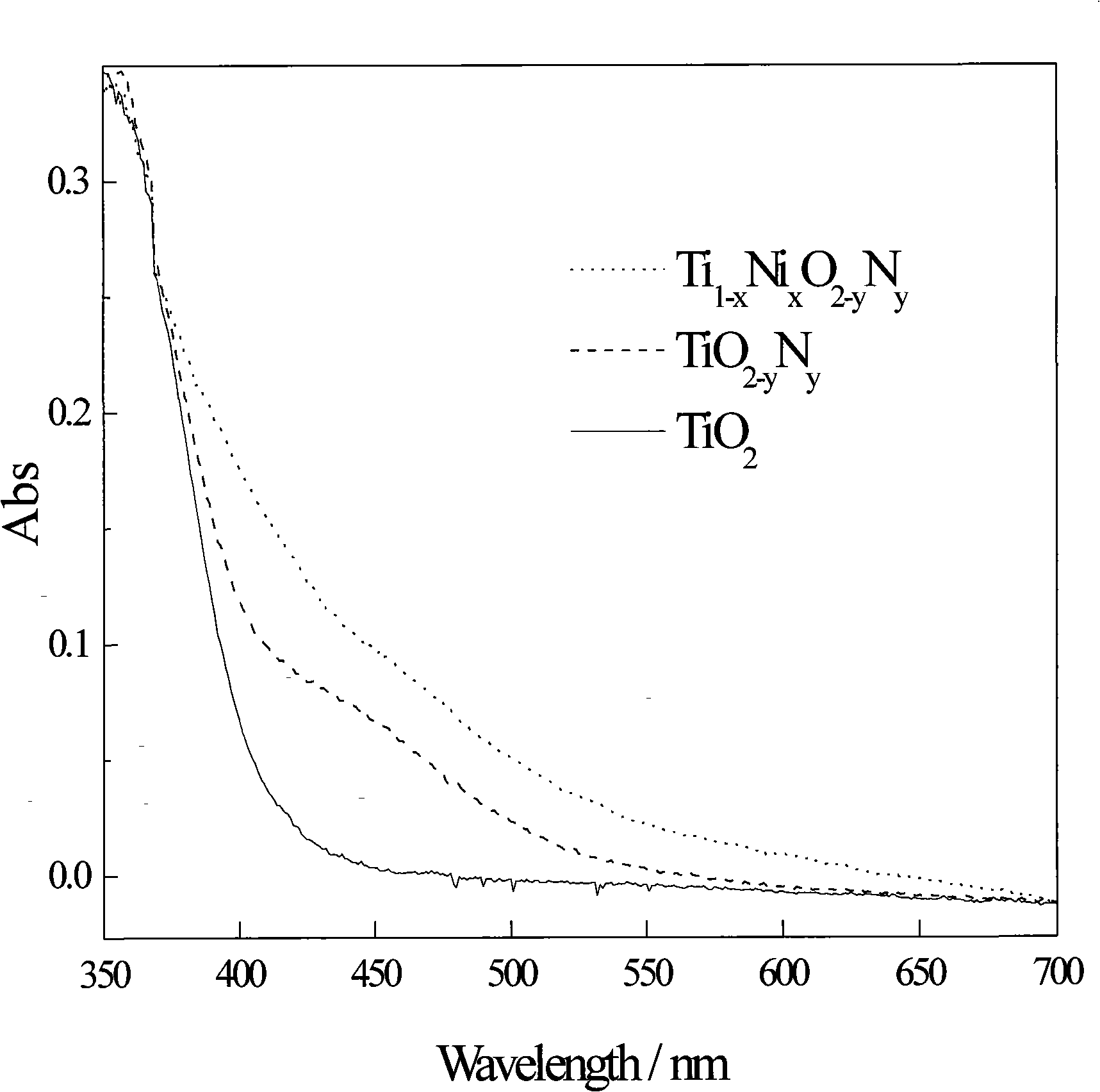

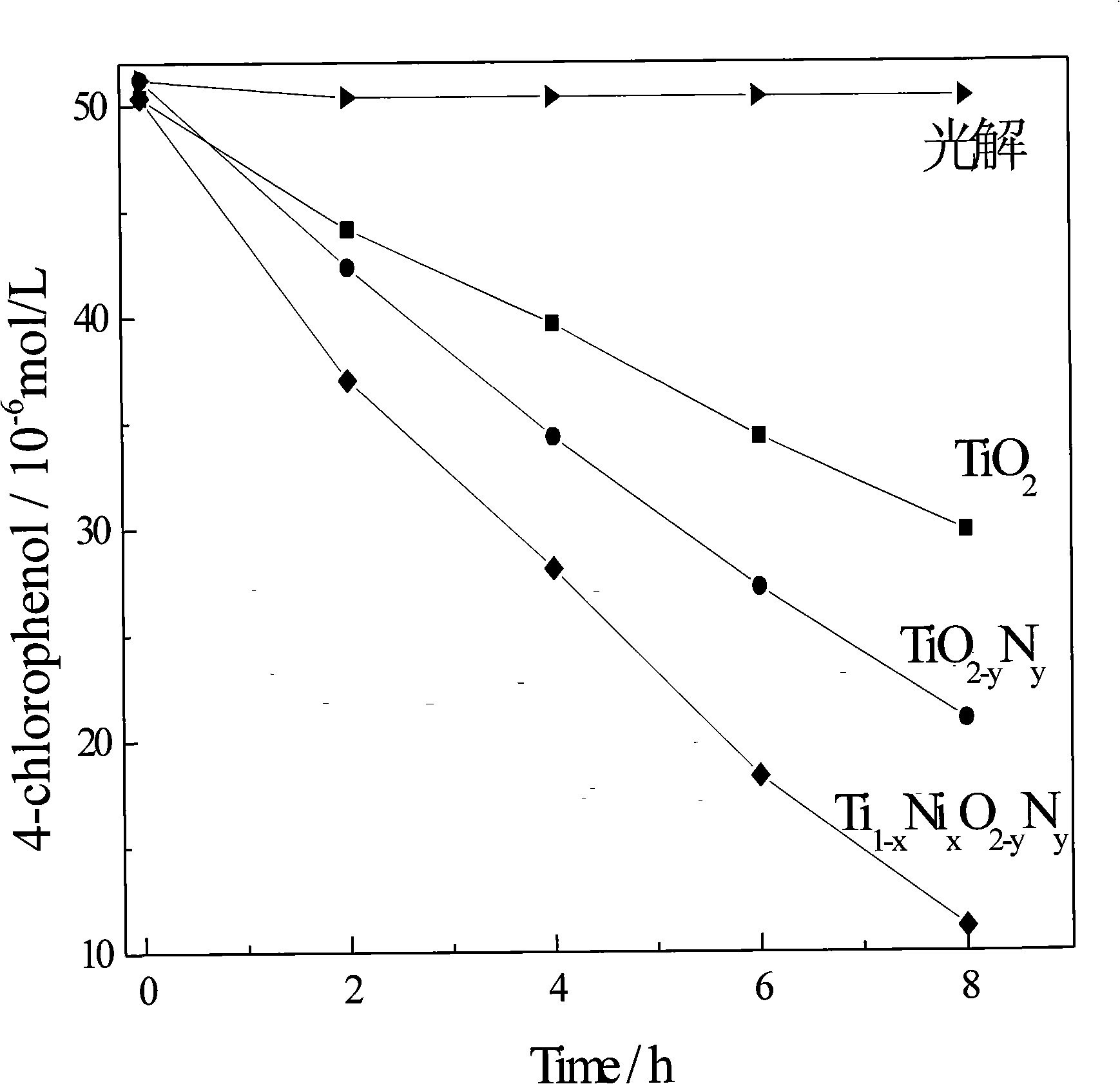

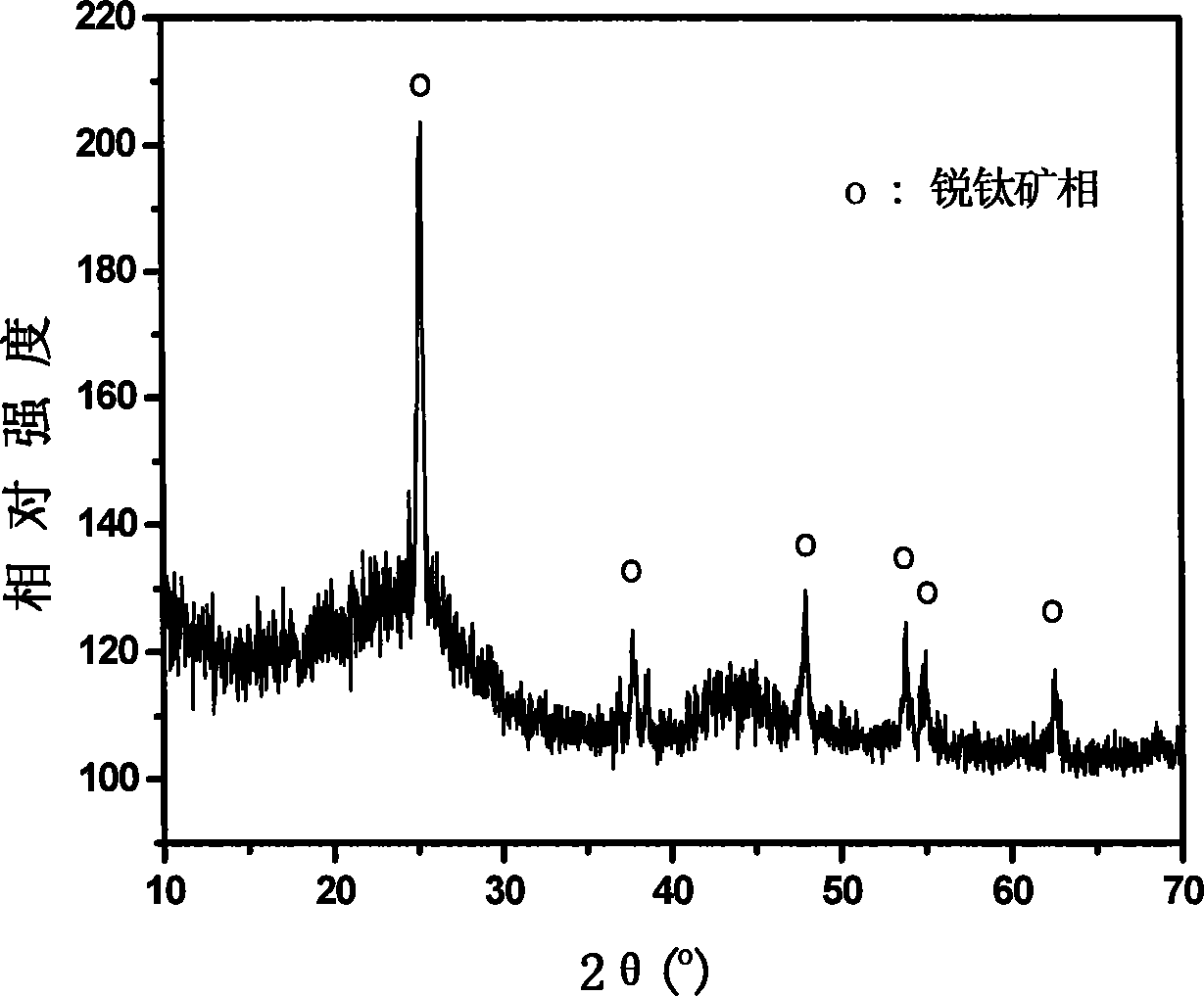

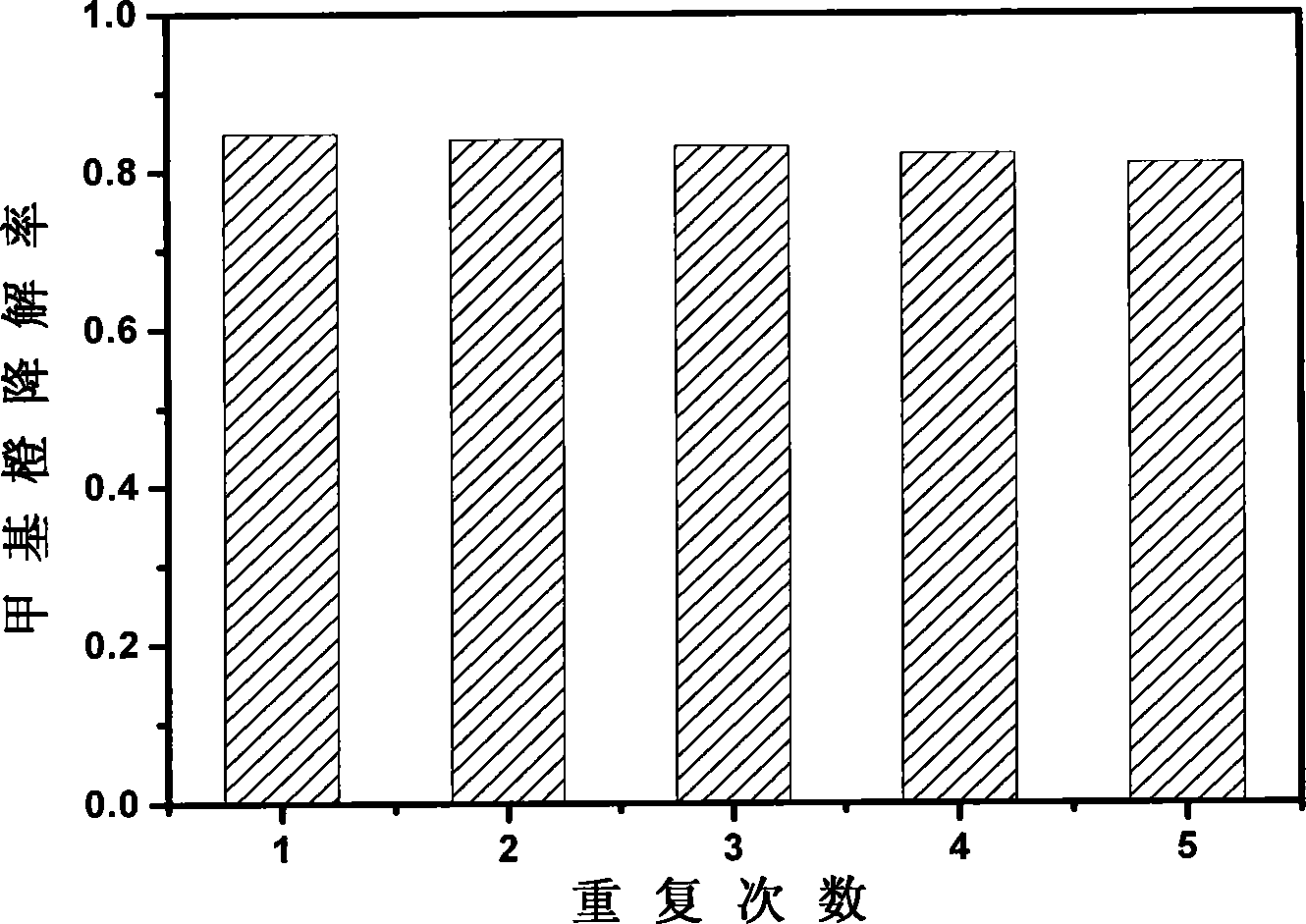

Method for preparing high efficiency metallic, non-metallic ion co-doped nano-TiO2 visible-light responsive photocatalyst

InactiveCN101301619AVisible light catalytic activity is highEnhanced inhibitory effectWater/sewage treatment by irradiationCatalyst activation/preparationPhotocatalytic reactionLight responsive

The invention discloses a process for preparing a high efficiency nanometer Tio2 visible light catalyst codoped with metal and non metallic ion, belonging to the photocatalysis technology field. The invention adopts titanic acid ester as precursor, uses metal salt and non-metallic compound as dopant, in accordance with sol-gel method, prepares the nanometer TiO2-based photocatalyst with codoping, high efficiency and visible light catalytic activity, wherein the catalytic activity is greatly higher than that of single-doped TiO2-based catalyst. The invention is characterized by the following: 1. due to codoping of the metal and non metallic ion, discrete localized doping level is formed respectively on the lower part of the conduction band energy level and the upper part of the valence band energy level of the TiO2-based catalyst, thus increasing the absorption of visible light and greatly improving the catalytic activity; 2. the doping level can inhibit the recombination of photogenerated carrier, promote the probability of the photogenerated carrier entering into the photocatalytic reaction and efficiently degrade pollutant molecules.

Owner:NANKAI UNIV

Method for extracting tungsten, titanium and vanadium from waste SCR (selective catalytic reduction) catalyst

InactiveCN102936049ASolve the pollution of the environmentLow equipment requirementsTungsten oxides/hydroxidesTitanium dioxideSlagStrong acids

The invention discloses a method for extracting tungsten, titanium and vanadium from a waste SCR (selective catalytic reduction) catalyst, which comprises the following steps: crushing the waste SCR catalyst, adding a strongly alkaline solution, and reacting; filtering, separating, then adding strong acid into the sodium tungstate and sodium vanadate mixed solution, and reacting to obtain tungstic acid and a sodium salt and vanadic acid mixed solution; regulating the pH value of the sodium salt and vanadic acid mixed solution until precipitate is separated out, thus obtaining ammonium vanadate; then adding sulfuric acid into the tungsten-and-vanadium-removed SCR catalyst, and reacting to obtain a titanyl sulfate solution and solids such as aluminum slag and the like; then adding water into the titanyl sulfate solution, and hydrolyzing to obtain titanic acid and a waste acid solution; and finally, respectively calcining the obtained ammonium vanadate, tungstic acid and titanic acid to obtain vanadium pentoxide, tungsten trioxide and titanium dioxide. According to the invention, tungsten, titanium and vanadium can be extracted from the SCR catalyst through the reaction with strong alkali and strong acid at a low temperature, the equipment requirement is low, the energy consumption is low, some products having added values can be coproduced, and no secondary pollution is generated, thereby facilitating popularization and application.

Owner:成都新智金森环保科技有限公司

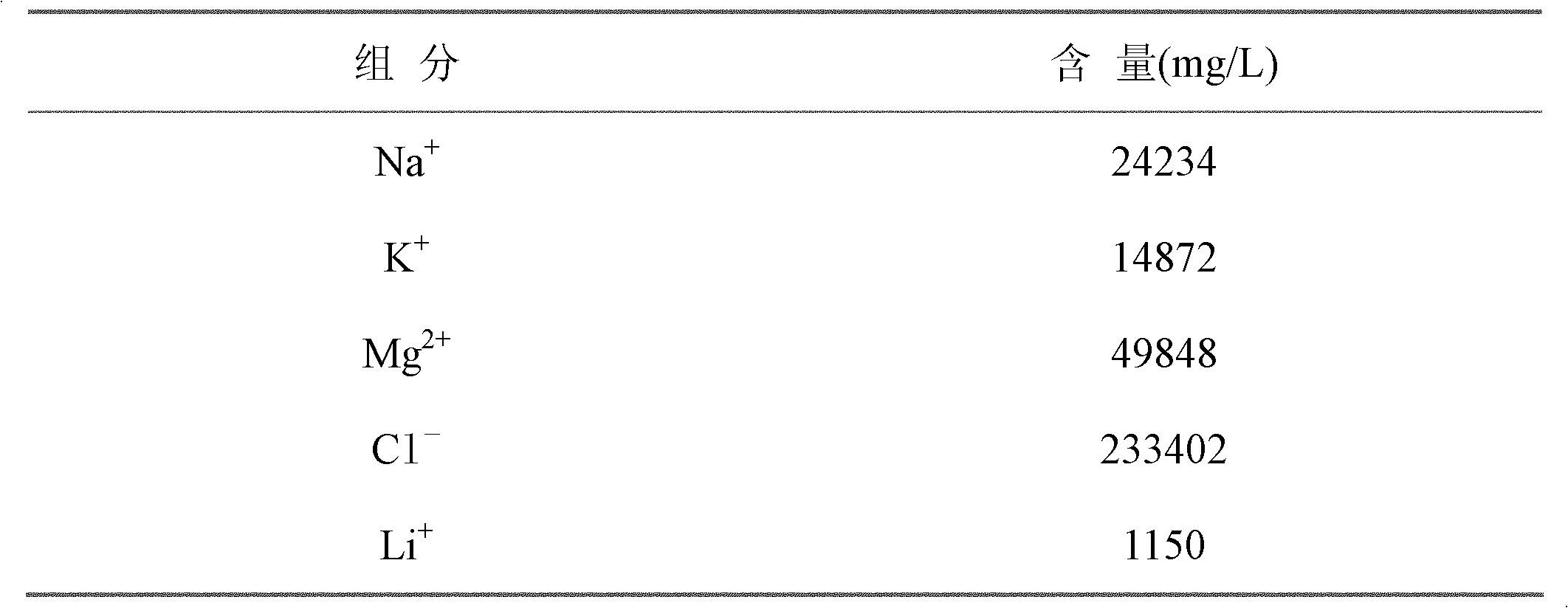

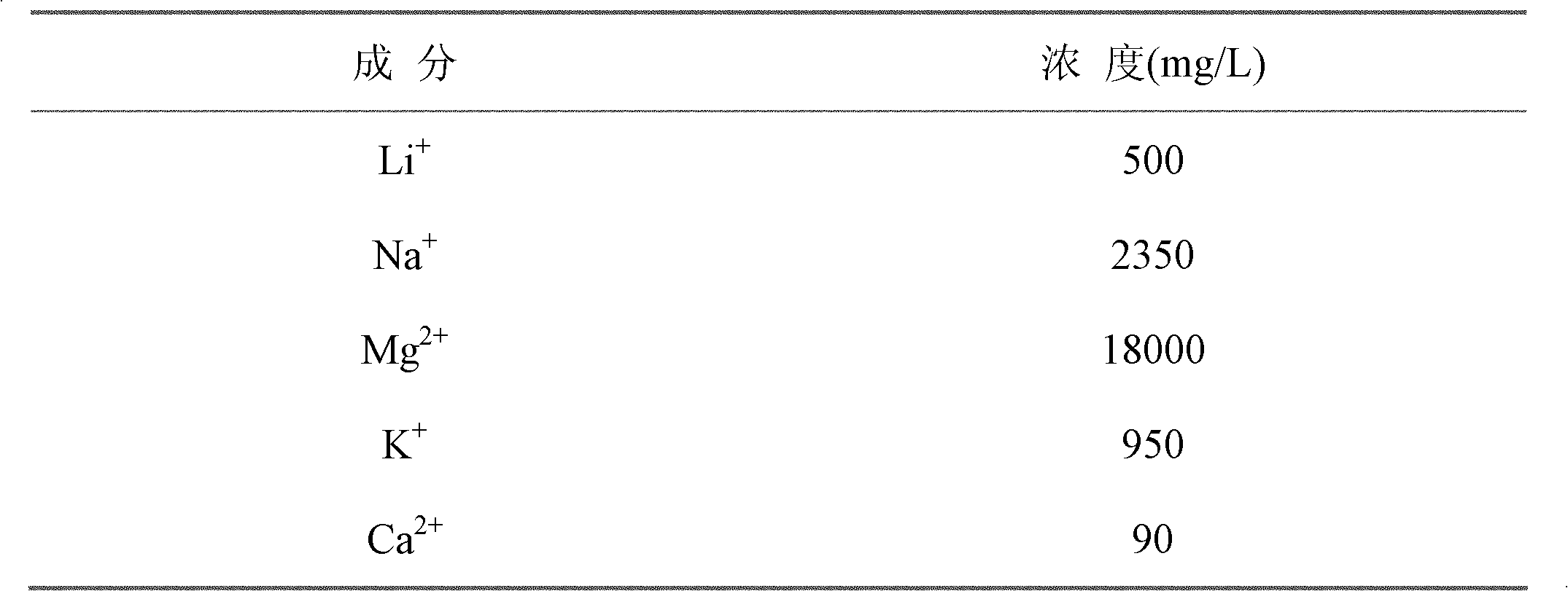

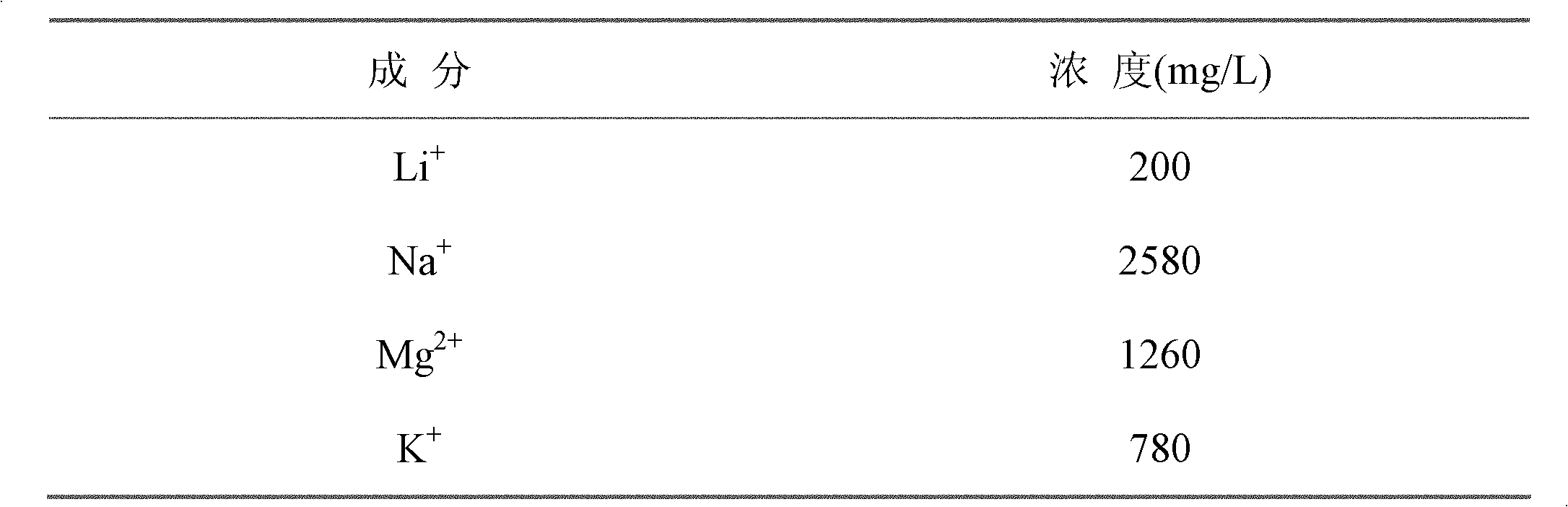

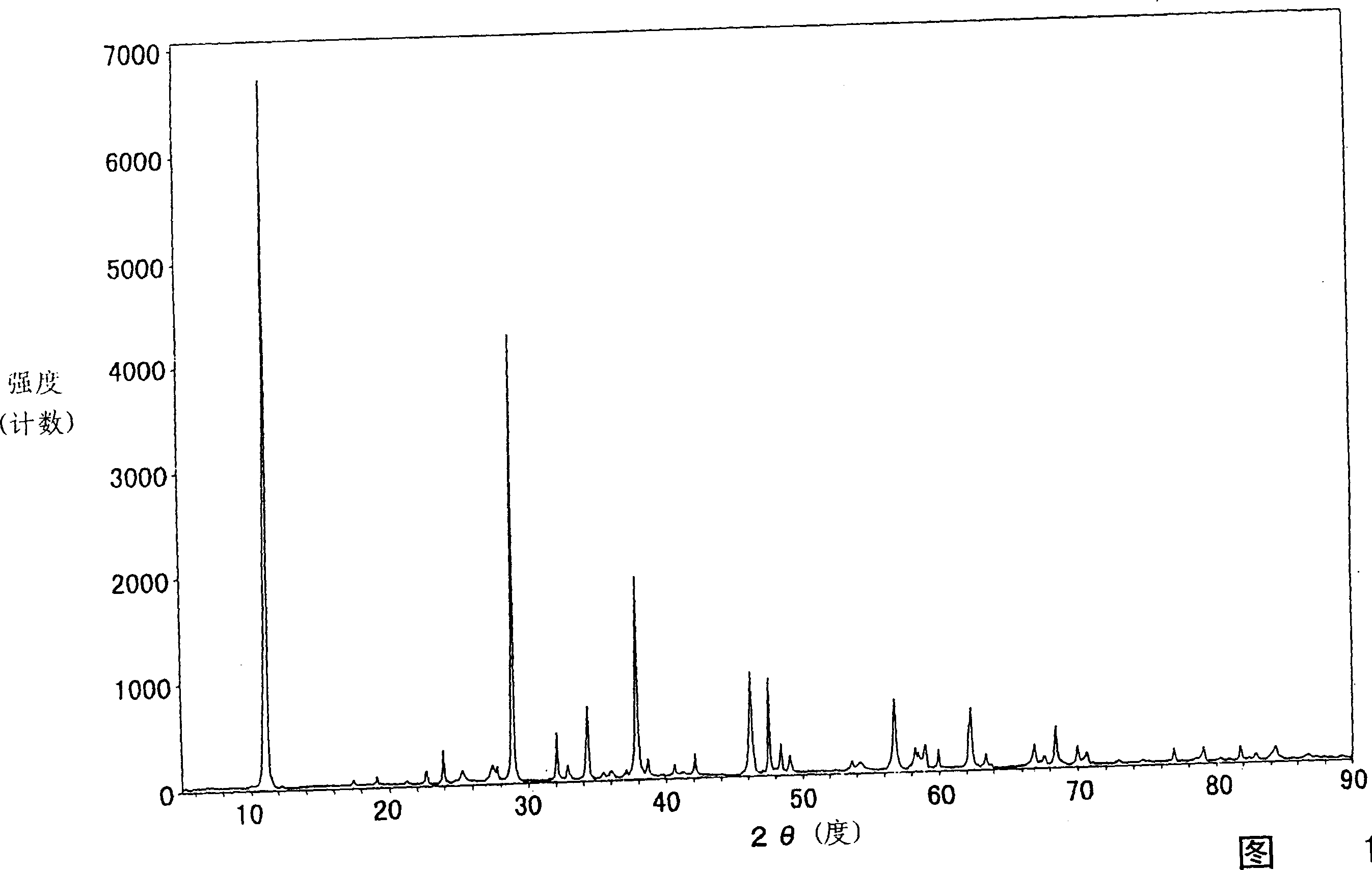

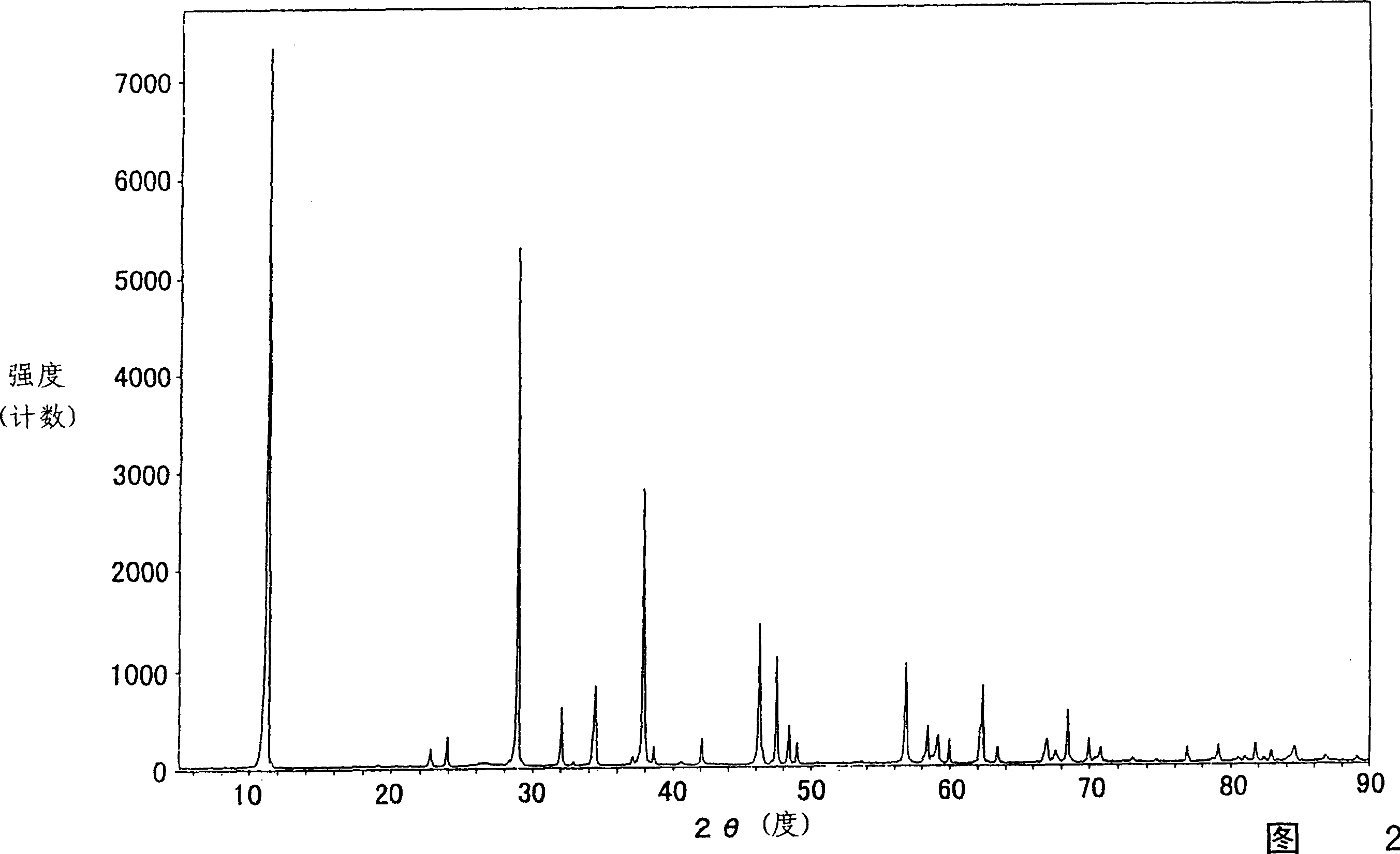

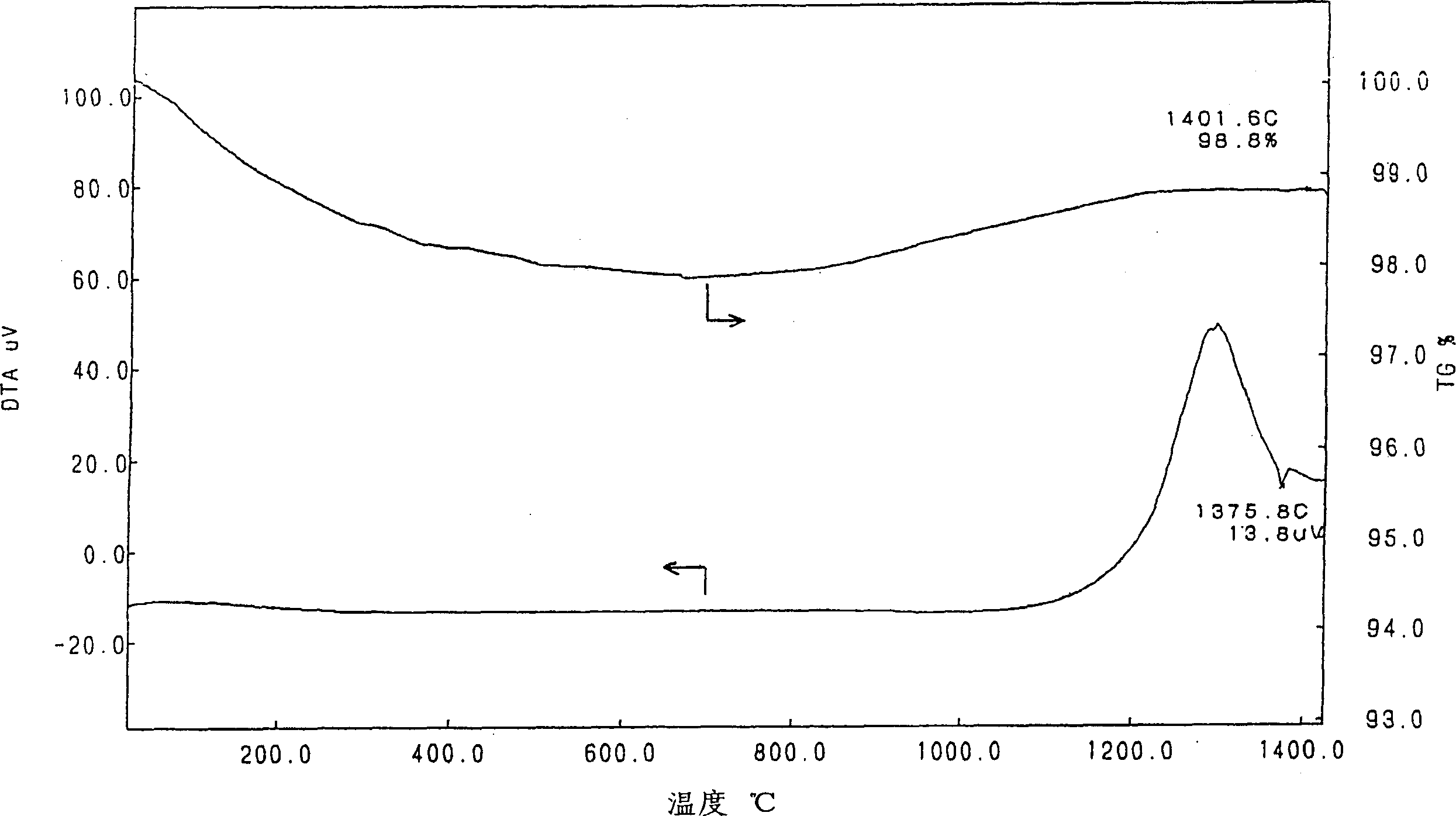

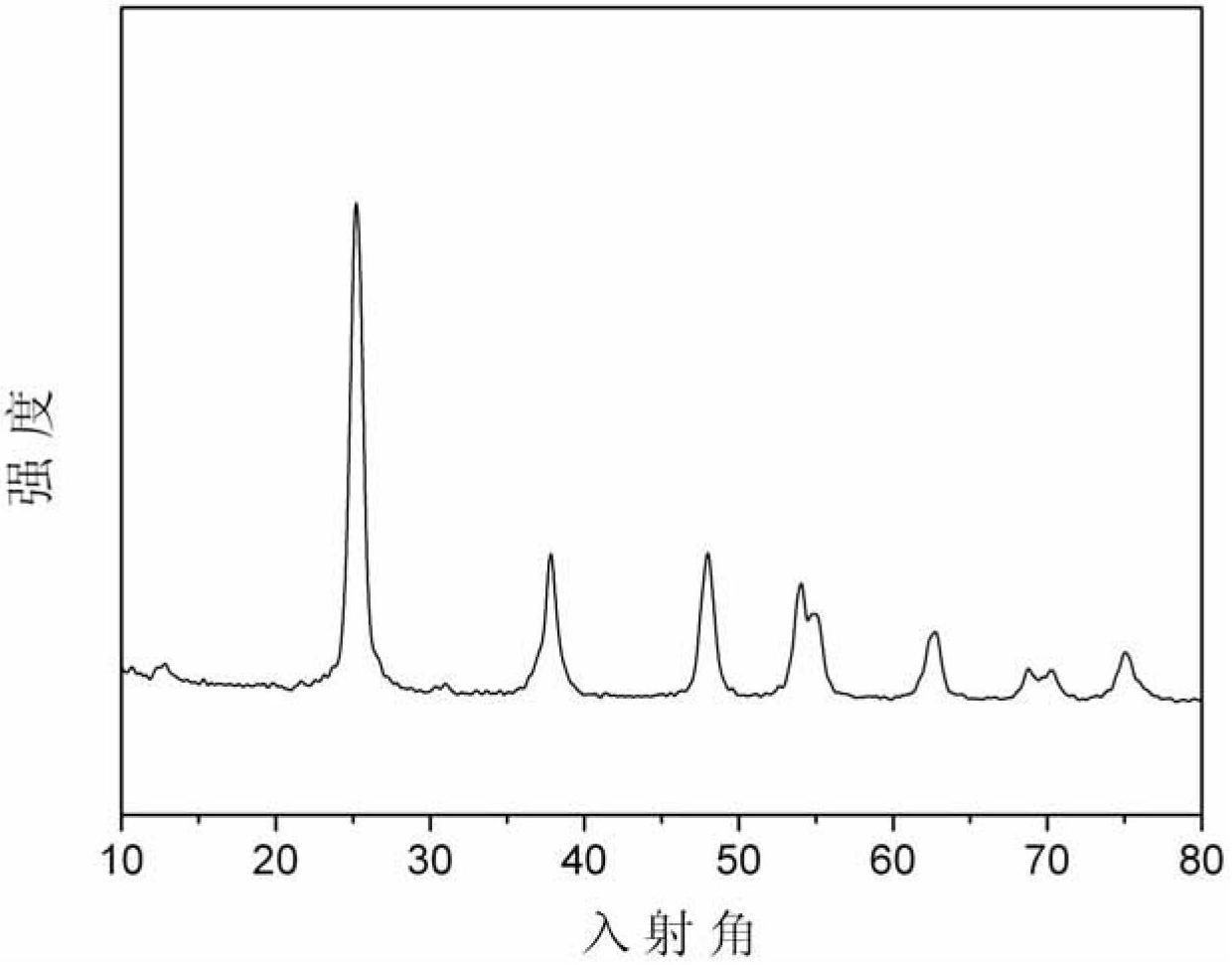

Ion sieve for selectively extracting lithium and application thereof

The invention relates to an ion sieve for selectively extracting lithium and the application thereof. The ion sieve adopts one or the compound of more than one of the following components: Li4Ti5O12, LixMeyTi5O12, and Li4MemTinO12, wherein Me is one or the compound of more than one of the following components: V, Fe, Co, Mn, Al, Ba, Ag, Zr, and Nb, x is greater than 3 and smaller than 4, y is greater than 0 and smaller than 1, m is greater than 0 and smaller than 1, and n is greater than 4 and smaller than 5. The ion sieve is particularly applicable to magnesium and lithium separation in brine with a high magnesium / lithium ratio, and has favorable intercalation and deintercalation performances to Li ions. The material for the titanic acid lithium ion sieve provided by the invention is easy to get and low in cost, the ion sieve has high selectivity and higher adsorptive capacity to the Li ions, as well as long circulating life. The process adopting the titanic acid lithium ion sieve to perform magnesium and lithium separation has the advantages of short procedure, simplicity in operation, low manufacturing cost, and easiness in industrial application.

Owner:CENT SOUTH UNIV

Method for preparing silver-carrying nano titanic oxide

InactiveCN101300982AEnhance photocatalytic antibacterial effectPlay antibacterial functionBiocideDisinfectantsPhosphoric acidSlurry

The present invention provides a method for preparing a nano silver-carrying titanium dioxide antiseptic. The aqueous ammonia solution and silver nitrate solution are dropped into the titanium sulfate solution simultaneously with continuous stirring. The final reaction pH is controlled by ammonia water. The titanium and silver are leaded to coprecipitate. The solution is filtered and washed after maturing. Afterwards the powder of nano silver-carrying titanium dioxide antiseptic is prepared by drying and calcining. The titanic acid or metatitanic can also be taken as precursor. The slurry containing 15-25% of recursor is added with silver nitrate solution with a concentration of 20-30gL<-1>, and the phosphoric acid, sulfuric acid or hydrochloric acid is added with a concentration of 10-15mgL<-1>. The solution is reacted, filtered and washed under the temperature of 50-60 DEG C. The solid object is dried, crushed, calcined and cooled, and the power of nano silver-carrying titanium dioxide antiseptic is obtained. The invention uses generating an indissoluble silver salt with a preparing technique of titanium dioxide to obtain the sustained-releasing of silver and color changing prevention. Furthermore the complex of the electron pair and the cavity is avoided. The photocatalysis antimicrobial effect of titanium dioxide is reinforced. The color, luster, granularity and dispersibility of the product can be well controlled.

Owner:CENT SOUTH UNIV

Method for recovering vanadium, tungsten and titanium from waste vanadium-tungsten-titanium-based denitration catalyst

ActiveCN103484678ASimultaneous recoveryLow recovery rateTitanium compoundsVanadium compoundsTungstateAmmonium metavanadate

The invention relates to a method for recovering non-ferrous metals from waste denitration catalysts, particularly relates to a method for recovering vanadium, tungsten and titanium from a waste vanadium-tungsten-titanium-based denitration catalyst, belonging to the field of non-ferrous metal recovery technologies. The method mainly comprises the steps of preparing the catalyst into powder with the grain size being smaller than 100 meshes, and adding concentrated alkali liquor; heating to react vanadium, tungsten and titanium with alkali, so as to produce slightly-soluble titanate, water-soluble vanadate and tungstate; filtrating to obtain a titanate filter cake, wherein titanate or titanic acid can be prepared from the filter cake; adding ammonium salt into a filtrate so as to precipitate ammonium metavanadate, and filtrating to obtain ammonium metavanadate and a new filtrate; adding concentrated acid into the new filtrate, thereby preparing solid tungstic acid. The method has the advantages of simple process, low energy consumption, good solid-liquid reaction contact, high vanadium, tungsten and titanium recovery rate, and the like.

Owner:BEIJING UNIV OF CHEM TECH

Wood-plastic composite material and method of preparing the same

The invention discloses a wood-plastic composite material and a preparation method thereof. The composite material includes the following materials by the weight portion: 100 portions of reclaimed plastic particles, 80-100 portions of bamboo powder, 80-100 portions of inorganic filler, 1-2.5 portions of titanic acid ester, 1-5 portions of compatibilizing agent, 8-10 portions of lubricant and 1-2 portions of functional auxiliary agent. Compared with the prior art, the invention integrates the advantages of inorganic filler and bamboo fiber, reduces the dosage of vegetable fiber in the traditional wood-plastic formula, and increases the dosage of inorganic filler; the composite material prepared by the method has higher toughness and rigidity, lower water absorption rate and smaller molding shrinkage; and the pollution of waste plastics and vegetable fibers to the environment is reduced.

Owner:HUANGSHAN HUASU NEW MATERIAL SCI & TECH CO LTD +1

Lepidocrosite type potassium magnesium titanate and method for production thereof, and friction material

Lepidocrocite potassium magnesium titanate having a composition represented by the formula K0.2-0.7Mg0.4Ti1.6O3.7-4 and obtainable by subjecting an aqueous slurry of lepidocrocite potassium magnesium titanate having a composition represented by the formula K0.8Mg0.4Ti1.6O4 to an acid treatment and subsequent calcination. <IMAGE>

Owner:OTSUKA CHEM CO LTD

Low temperature crystallized nano titanium dioxide powder and sol synthesizing method

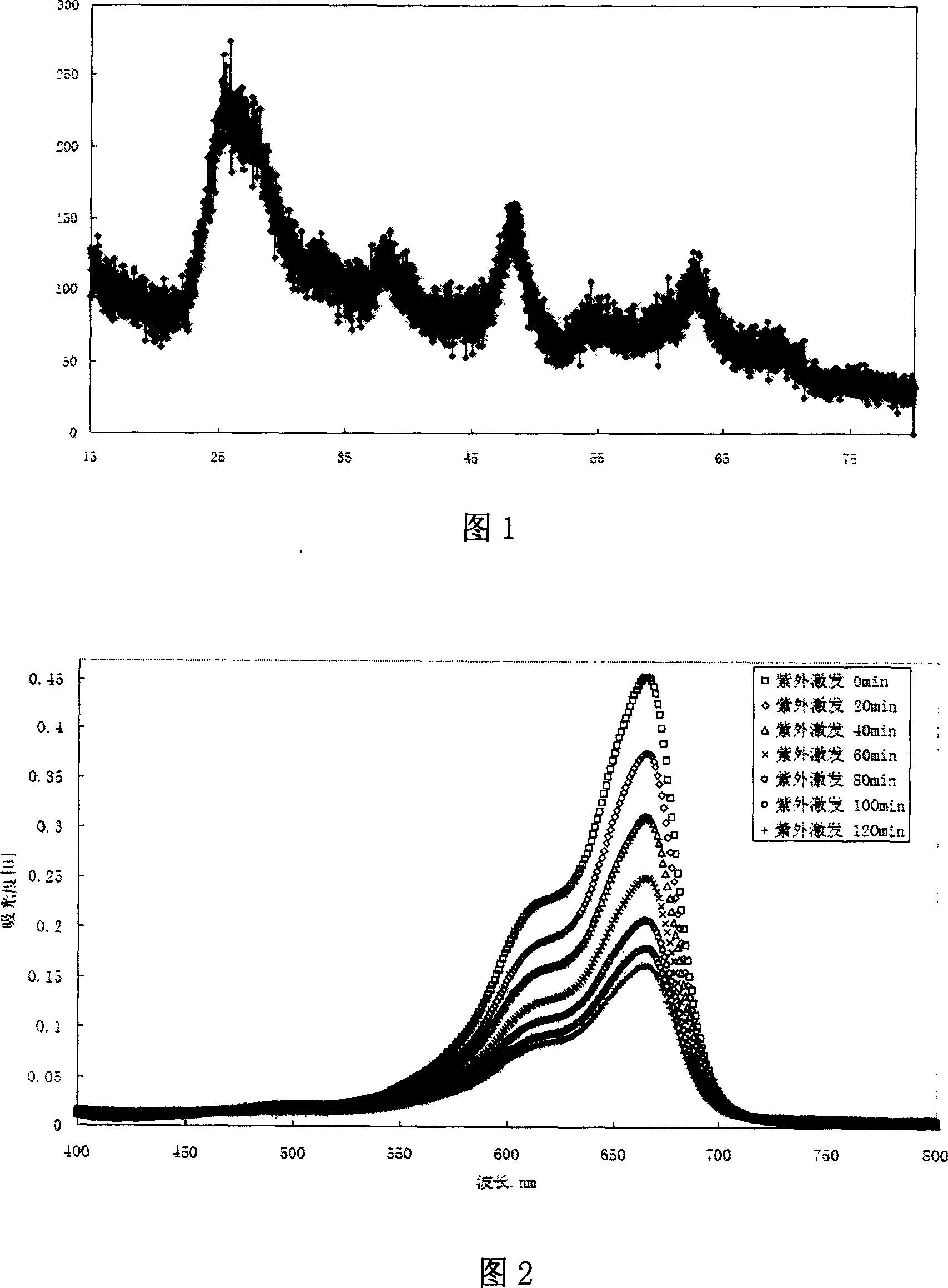

InactiveCN1935669AImprove photocatalytic activityStable storageTitanium dioxideNanocrystalTitanic acid

The invention belongs to an organic metal oxide-TiO2 photocatalyst preparing process, especially relating a synthesizing method of low temperature-crystallizing nanometer TiO powder and sol with high catalytic activity. And it obtains n-titanic acid deposit by making alkali neutralization and dilution hydrolyzation or heating hydrolyzation on titanic solution, and implements synthesizing related system nano crystal materials with normal-pressure and low-temperature liquid phases by such a processing process of re-dispersing the deposit by oxydol. And it largely reduces the cost of raw materials and avoids using titanium tetrachloride with strong corrosivity, reducing equipment requirements.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method and solution for forming anatase titanium dioxide, and titanium dioxide particles, colloidal dispersion and film

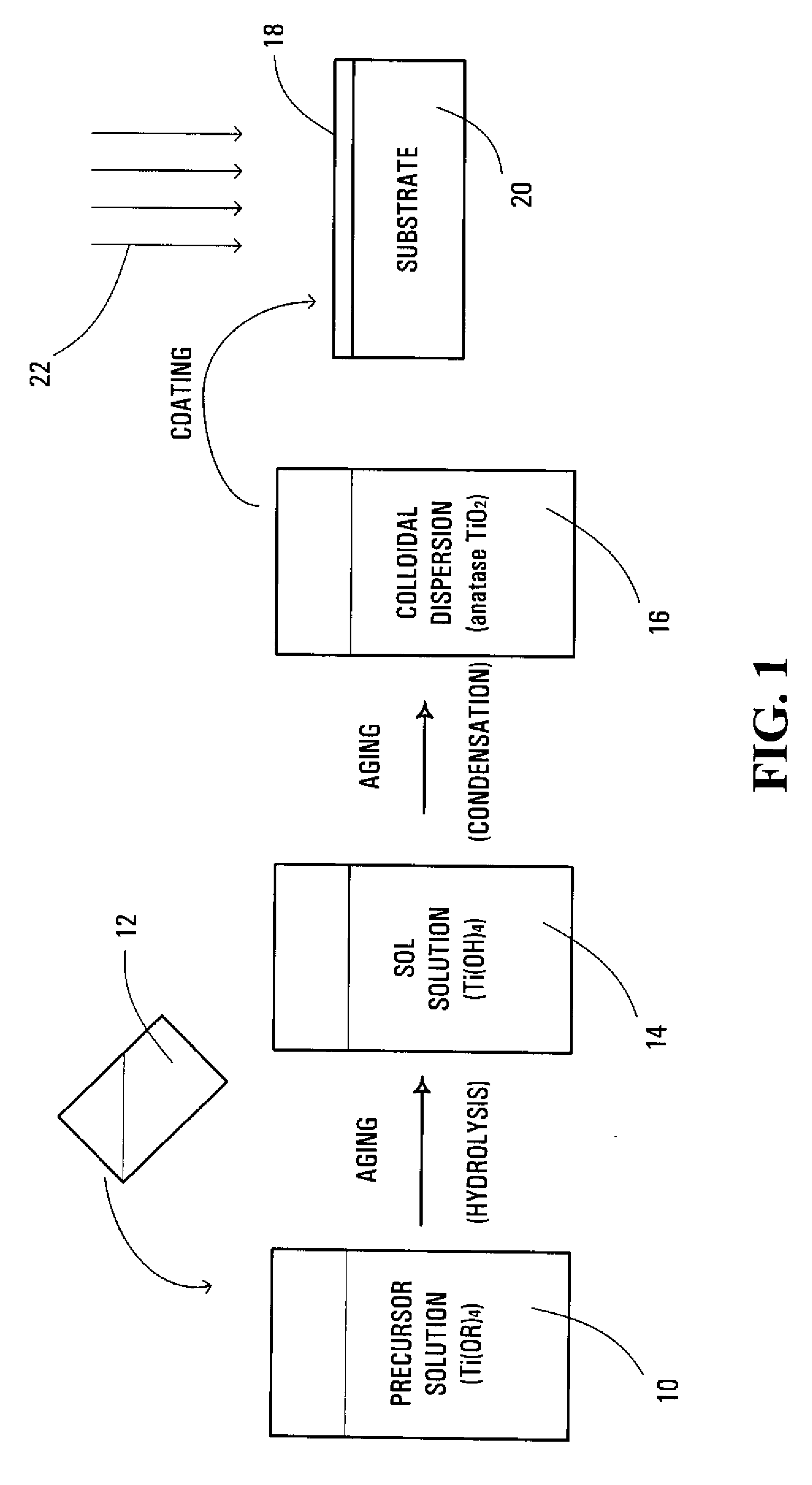

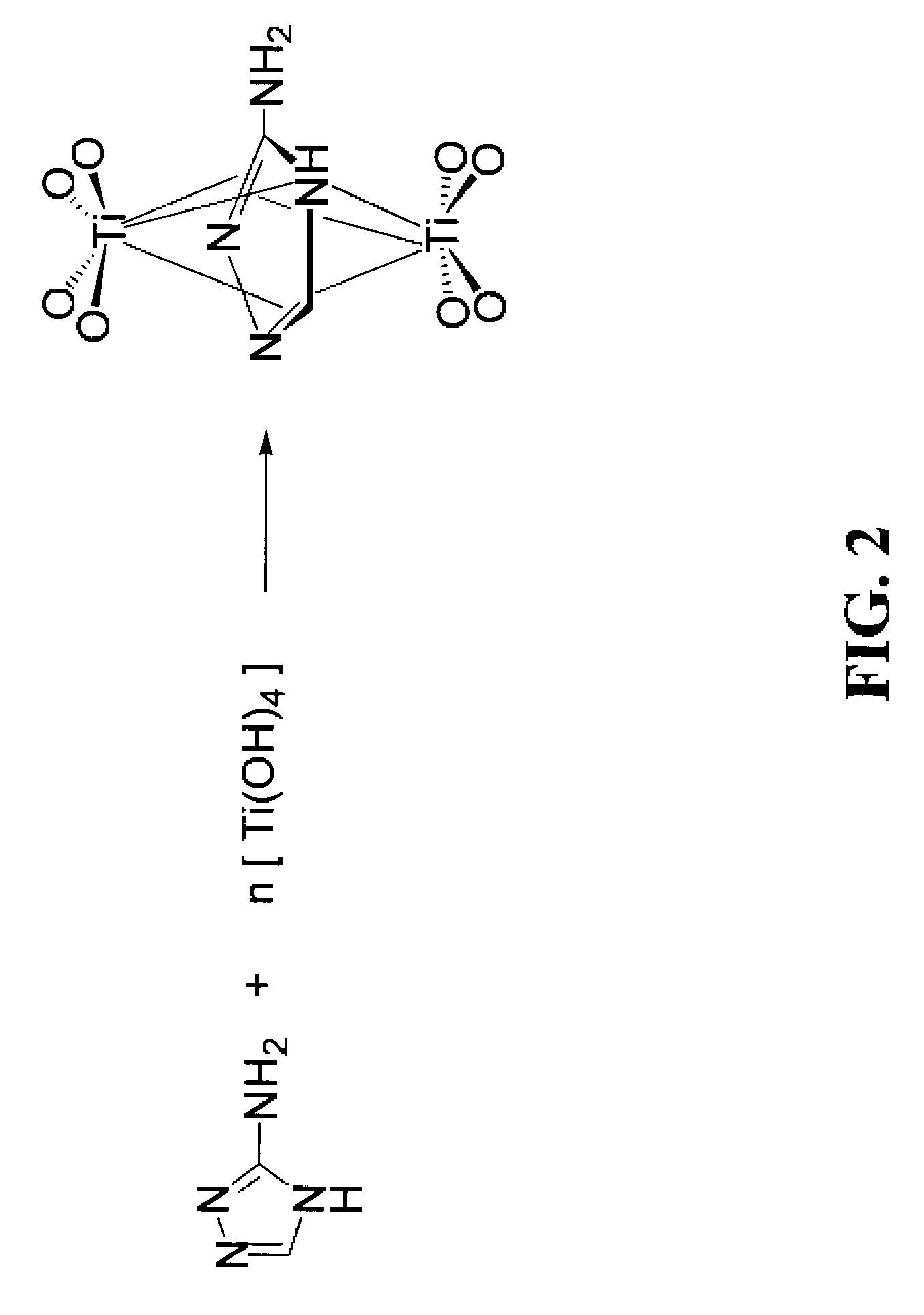

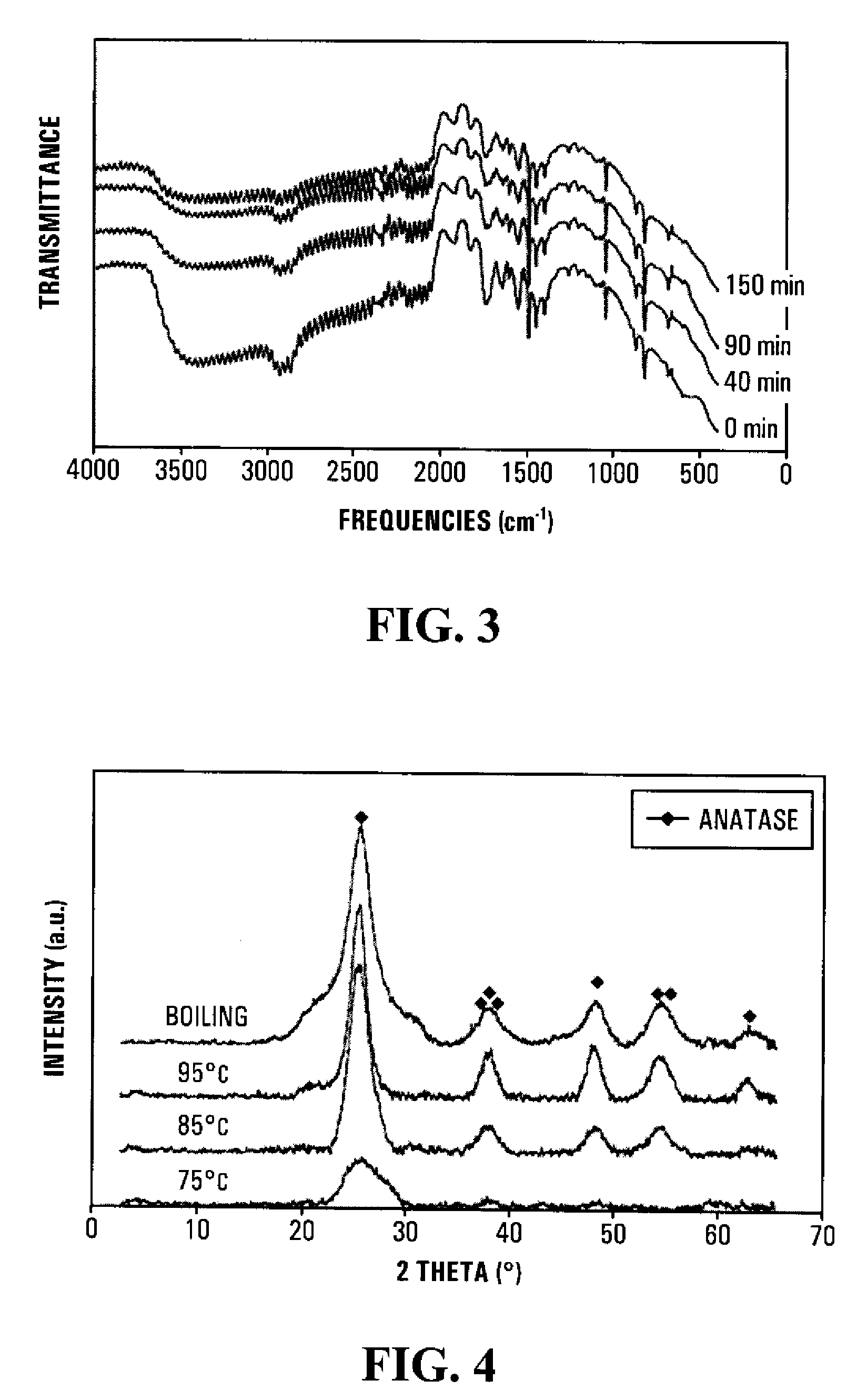

InactiveUS20060254461A1Accelerated agingImprove propertiesPigmenting treatmentOther chemical processesTitanium chlorideTetrazole

A sol solution containing poly(titanic acid) and a planar heterocyclic ligand is provided. Titanium dioxide (TiO2) particles are formed by aging the sol solution at a temperature below about 140° C. The particles have metallocene-like Ti-complexes comprising the heterocyclic ligand and can be substantially in the anatase phase. The heterocyclic ligands can be triazole, tetrazole, or thiadiazole. The sol solution may be prepared by aging a precursor solution. The precursor solution may contain the heterocyclic ligands and a precursor for poly(titanic acid). The precursor may be titanium alkoxide or titanium chloride. The sol solution may also contain at least one of an organic acid, a base, and a surfactant. The aged sol solution may form a colloidal dispersion of the TiO2 particles. A photo-catalytic and transparent film may be formed from the TiO2 particles by depositing a layer of the colloidal dispersion on a support.

Owner:AGENCY FOR SCI TECH & RES

Process for producing absorbent charcoal loading titanium dioxide photocatalyst

InactiveCN101244383ASimple processSave raw materialsPhysical/chemical process catalystsIce waterTitanic acid

The invention relates to a preparation method of activated carbon supported titanium dioxide photocatalyst, belonging to the preparation technical field of titanium dioxide photocatalyst, comprising a plurality of steps as followings: pretreating, washing and drying the activated carbon; at the condition of ice-water bath, adding meta-titanic acid and ammonia according to a molar ratio of 1:2 into 20 to 40 milliliter hydrogen peroxide with a concentration of 30%, and agitating for 50 to 70 minutes to obtain a yellowish green sol; then adding the pretreated activated carbon into the yellowish green sol and agitating for 3 to 5 hours, filtering the activated carbon after standing for 12 to 24 hours, then calcining with the protection of inert gas to obtain the activated carbon supported titanium dioxide photocatalyst. The weight ratio of the pretreated activated carbon and the meta-titanic acid is 1:1 to 3:1. The preparation method has the advantages of simple technology, cheap raw material, mild preparation conditions, easy operation, granular shape, good organic pollutant degradation effect, easy separation, regeneration and long service life of the supported photocatalyst prepared by the preparation method, nonuse of organic solvent, non-pollution in the whole production process, accordance with the requirement of sustainable development and environment-friendly integrated technology.

Owner:TONGJI UNIV

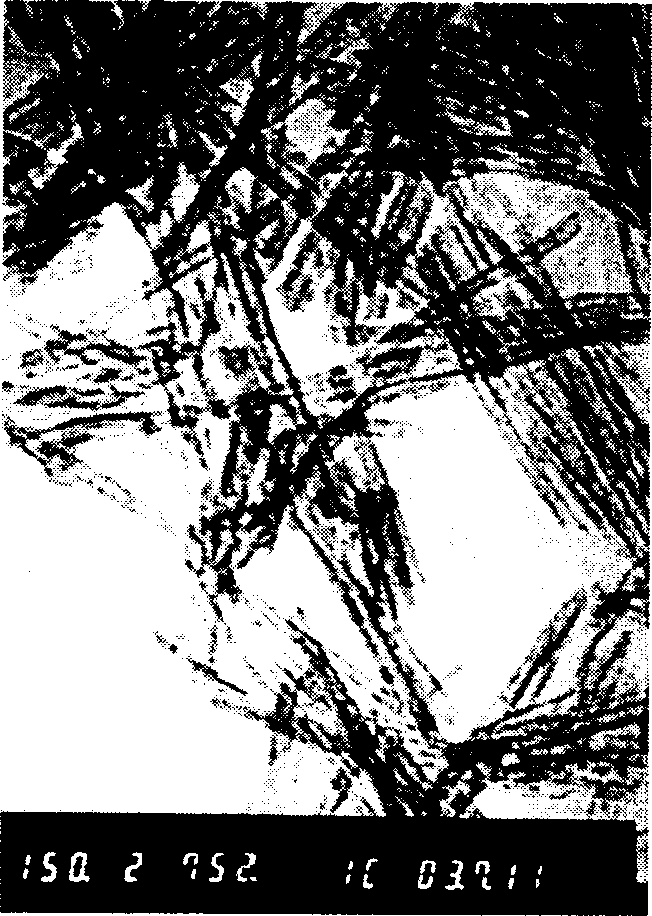

Titanium oxide nano tube and preparing method thereof

The invention relates to a Ti oxide nano tube and preparing method. Its character: using TiO2 of various crystal shapes as raw material, and making ultrasonic processing, hydrothermal reaction and after treatment in NaOH solution to obtain titanic acid nano tube, and then baking to form TiO2 nano tube with anatase structure. The TiO2 nano tube has uniform appearance, small tube diameter and large specific surface area. It has wide applied prospect in the fields of photocatalysis, environmental purification, solar cell, gas and wet sensitive materials, etc. It has low energy consumption, simple device, and easy controlled condition, easy to realize large-scale industrial production.

Owner:TSINGHUA UNIV

Rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and using method of rare-earth modified Ti-Zr chemical passivation solution

ActiveCN103103512AImprove compactnessImprove performanceMetallic material coating processesCerium nitratePotassium fluoride

The invention discloses a rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and a using method of the rare-earth modified Ti-Zr chemical passivation solution. The rare-earth modified Ti-Zr chemical passivation solution is characterized in that the passivation solution is a main salt for auxiliary film-formation, which takes rare-earth compounds as a Ti-Zr passivation treatment solution, and a passivation film is light yellow in appearance and has field judgement property on the quality of a formed film. A formula of the rare-earth modified Ti-Zr chemical passivation solution is as follows: each litre of solution contains 0.5g.L<-1>-10g.L<-1> of potassium fluotitanate (hexafluorotitanic acid), 0.5g.L<-1>-10g.L<-1> of potassium fluozirconate (fluozirconic acid), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (ceric sulfate and ammonium ceric nitrate), 2g.L<-1>-10g.L<-1> of potassium nitrate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (potassium fluoride), 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate or OP-10, 0.2mL-5mL.L<-1> of nitric acid and 1g.L<-1>-5g.L<-1> of boric acid. The using method of the rare-earth modified Ti-Zr chemical passivation solution comprises the following steps of: (1) clearing dirt, such as dirt attached to an aluminium alloy; (2) pretreating the surface of the aluminium alloy; (3) carrying out passivating treatment on the surface of the aluminium alloy by using the rare-earth modified Ti-Zr chemical passivation solution; and (4) washing the aluminium alloy by using water and drying the aluminium alloy. The rare-earth modified Ti-Zr chemical passivation solution disclosed by the invention has the advantages of light yellow appearance, high film formation speed, simple process, uniformity in film layer, strong corrosion resistance, low environment pollution and the like.

Owner:GUANGDONG XINGFA ALUMINUM

Thermoforming plastic printing ink adopting ultraviolet-infra red drying technology

The invention discloses a heat moulding plastic printing ink based on ultraviolet-infrared drying technique, which comprises the following parts: 100-300g prepolymer-ultraviolet solidified resin, 50-200g activated monomer, 20-200g optical initiator, 10-150g infrared solidified resin, 79-150g dye, 10-30% titanic acid ester coupling agent 401, defoamer, levelling agent and inhibitor.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

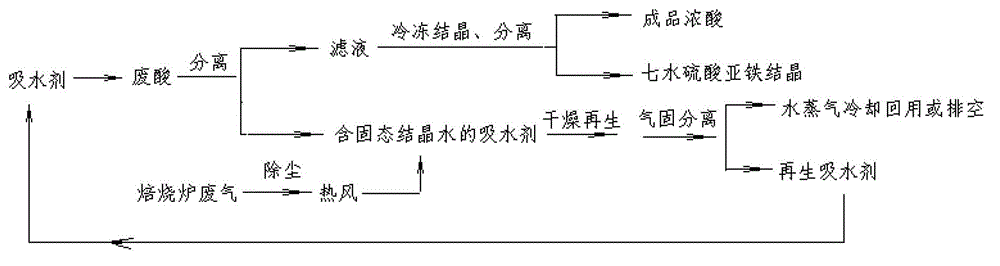

Method for concentrating waste sulfuric acid by utilizing waste heat of titanium dioxide calcinator

InactiveCN102910594ASolve manySolve process problemsSulfur compoundsEnergy inputLiquid waterOperability

The invention discloses a method for concentrating waste sulfuric acid by utilizing waste heat of a titanium dioxide calcinator, comprising the following steps: at normal temperature and pressure, proper amount of water absorbent is added to titanium dioxide waste acid, liquid water is dissolved out in the form of solid crystal water through the water absorbent, filtrate after solid-liquid separation is cooled, iron vitriol in the solution is crystallized and dissolved out, and the acid liquid is further concentrated; the two steps are repeatedly carried out until the concentration of sulfuric acid in the final filtrate reaches more than 60%, and then the final filtrate is utilized in the acid hydrolysis procedure; and the water absorbent is dehydrated and dried to be regenerated by taking dustproof tail gas of the calcinator, and the steam generated in the drying and regeneration is cooled and flows back to technological process as washing water in titanic acid rinsing or is drained. The method provided by the invention solves the problems of more equipment, long flow and easy blockage in the existing technology, and the equipment investment and operating cost are reduced; and the water absorbent is recycled after being regenerated, so that the energy is saved, the consumption is reduced, and the efficiency is obvious; no wastewater, waste gases and residues are generated in the whole technology, the operability is strong, the productivity of equipment is high, the flow is simple, the investment is less, the cost is low, energy is saved, emission is reduced, and the benefit is obvious.

Owner:黄正源

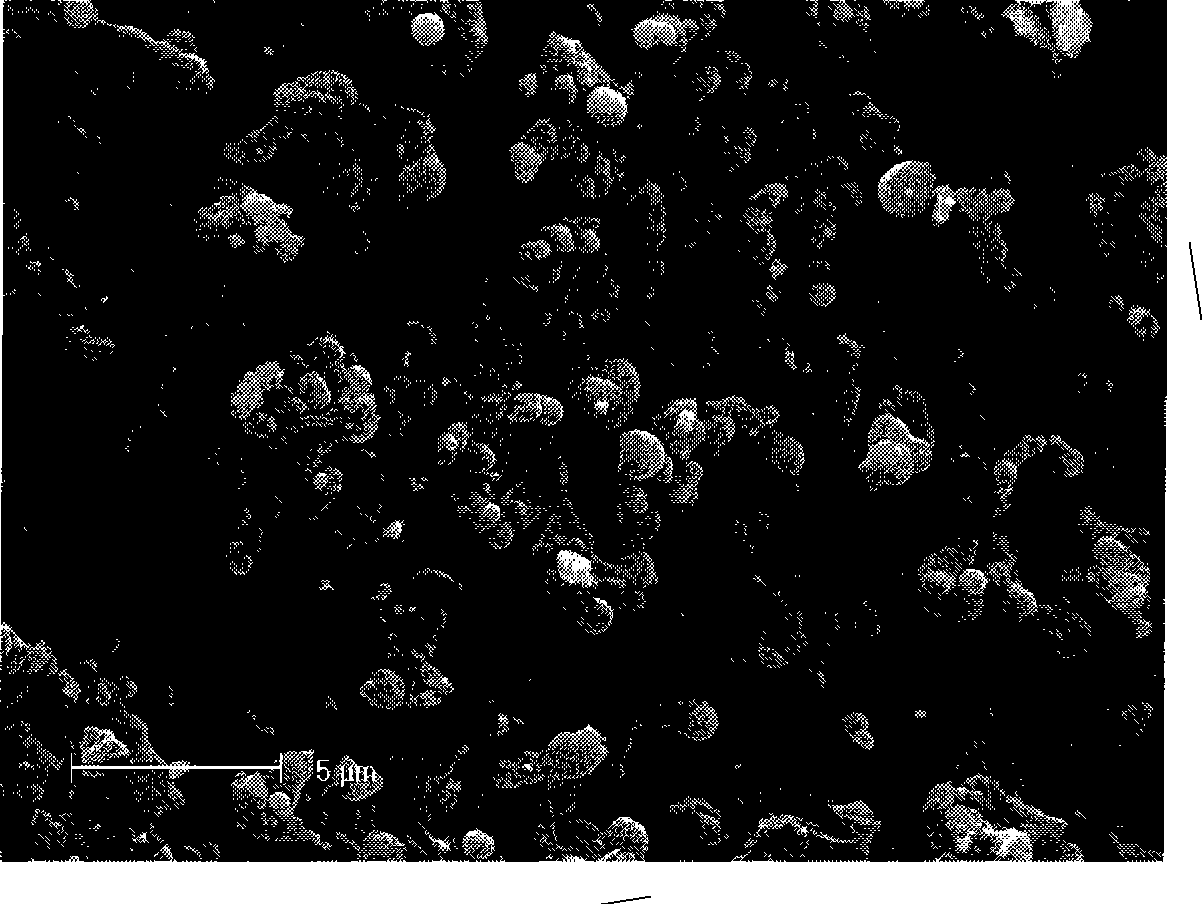

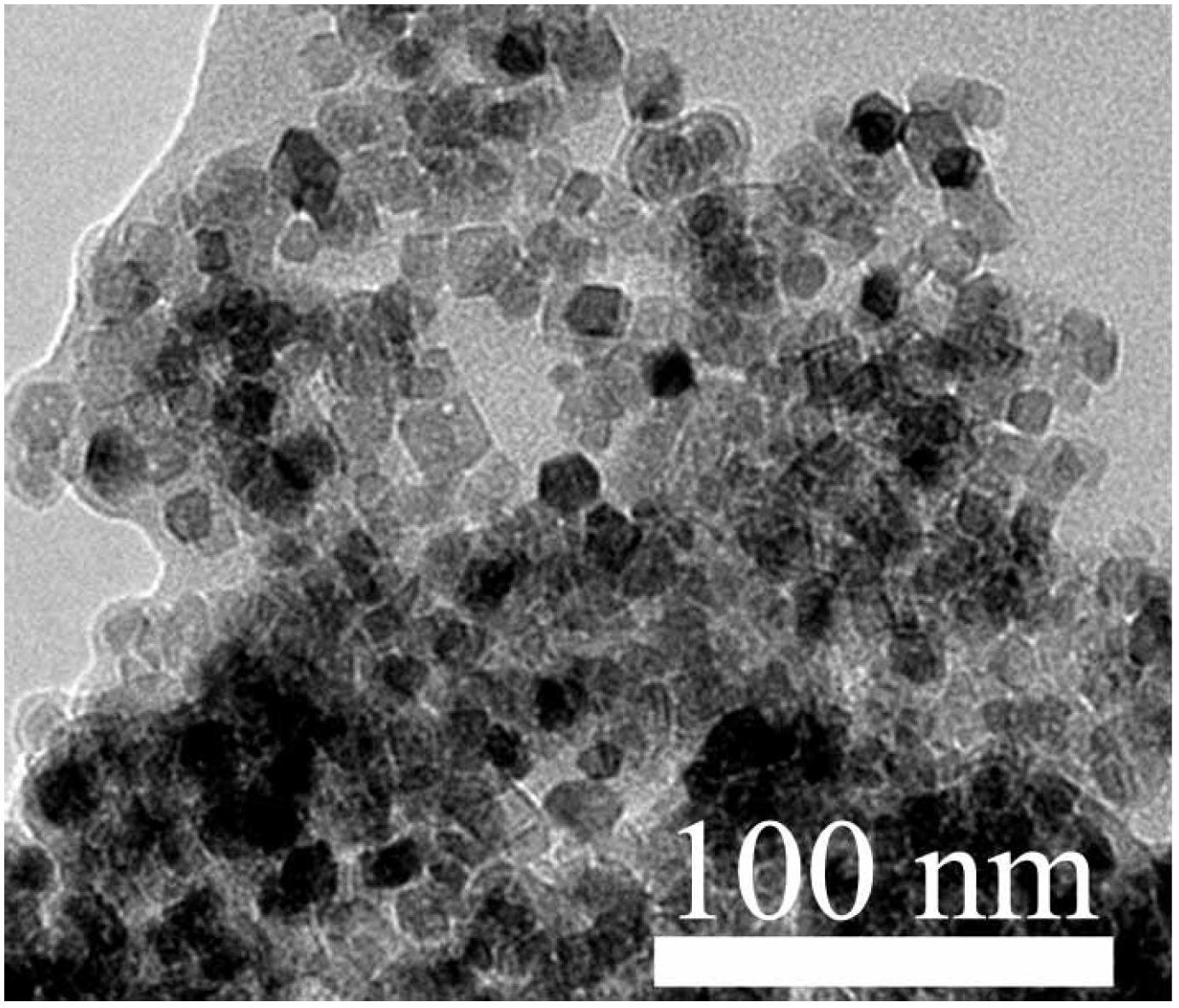

Method for preparing metal doped TiO2 nanocrystal particles

InactiveCN104190416AHas visible light catalytic activityGood suspensionMetal/metal-oxides/metal-hydroxide catalystsLight ActivityAqueous solution

The invention discloses a method for preparing metal doped TiO2 nanocrystal particles. The method comprises the following steps: dispersing a titanium source in a metal ion aqueous solution, hydrolyzing to obtain metal ion doped hydrated titanic acid precipitation, dispersing the metal ion doped hydrated titanic acid precipitation in a hydrogen peroxide aqueous solution, and hydrothermally reacting to obtain the metal doped TiO2 nanocrystal particles. The method for preparing the metal doped TiO2 nanocrystal particles, which is disclosed by the invention, can be used for preparing metal doped monodisperse and suspended TiO2 nanocrystal particles with visible-light activity, and the method has a good application prospect in the fields of photocatalytic air purification, photocatalytic water treatment and the like.

Owner:李建明

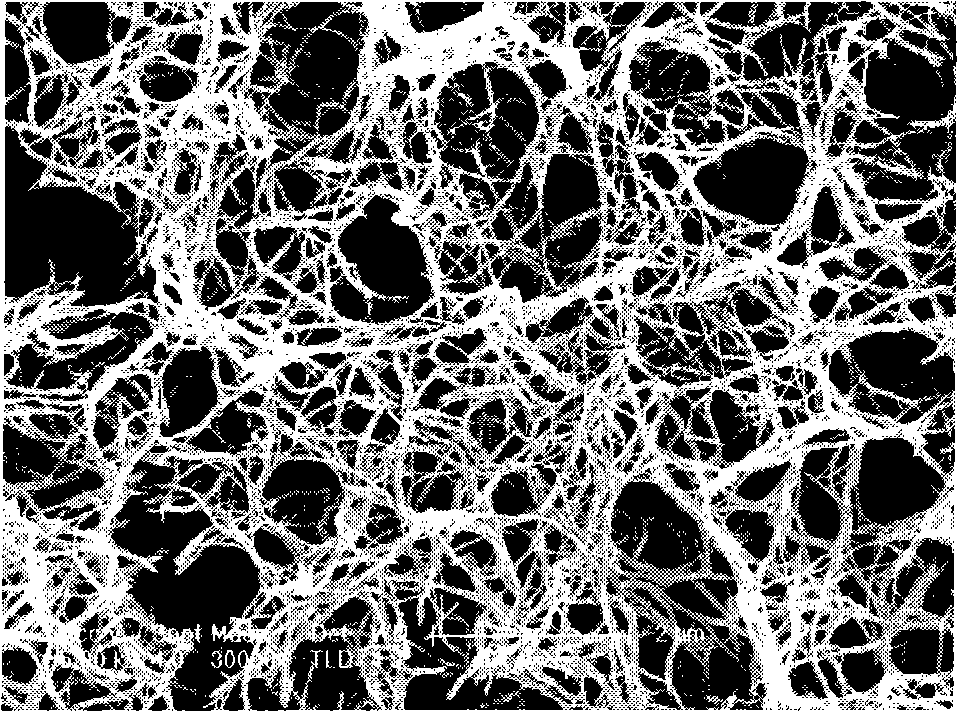

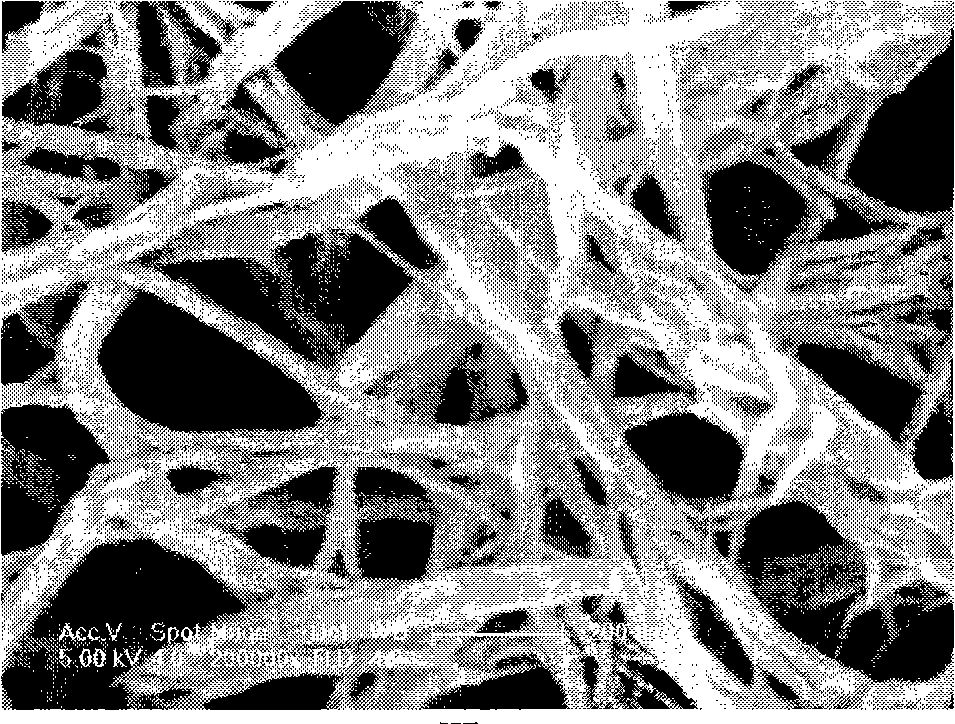

Titanium oxide nano wire film on metallic titanium surface and manufacture method thereof

InactiveCN101343746ALarge specific surface areaImprove bindingMetallic material coating processesTitanium surfaceNanowire

The invention relates to a metal titanium surface titanium oxide nanowire film and the preparation method. The component of the prepared film can be titanate, titanic acid or titanium dioxide, the diameter of the nanowire is between 10nm to 100nm, the nanowires are interlaced and winded to form a great amount of large holes and mesopore networks, and the pore space is between 20nm to 500nm. The main procedures of the preparation method are: firstly, pickling cleaning of the metal titanium surface; secondly, mixed oxidizing solution of strong alkali and oxydol is used to oxidize the metal titanium surface and to form the titanate nanowire film; thirdly, acid soaking is adopted to exchange alkaline metal ions to form the titanic acid nanowire film; fourthly, the titanium dioxide nanowire film is formed through high temperature torrefying. The preparation method of the metal titanium surface titanium oxide nanowire film of the invention is simple, the cost is low, the method is suitable for large-scale industrial production, and the prepared titanium oxide has the application prospect in photochemical catalysis related field and the electrochemistry sensing related field.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of titanium series catalyst for polyester

The invention discloses a preparing method of titanium-system catalyst of polyester, which is characterized by the following: reacting titanic acid ester and 2-hydroxy carboxylic compound and organic phosphonic acid compound; making the product react with at least one phosphorus compound of phosphoric acid, phosphorous acid, hypophosphorous acid, phosphate ester or phosphite ester; fitting for polyester industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing loaded nano titanium dioxide photocatalysis film

InactiveCN1634653AHigh catalytic activityImprove photocatalytic activityCatalyst activation/preparationChemical reactionTitanic acid

This invention relates to a sol to gel method to process load nanometer titania effective light catalyzer thin film process method, which belongs to light catalyzer materials chemical technique field and comprises the following steps: using the pure titanic acid butonate and absolute ethyl alcohol, aminoethyl alcohol, water, poly-glycol 600 as materials; getting transparent stable light yellow titania sol through common temperature chemical reaction; then adopting the dipping and lifting method to load titania thin film on metal wire surface; finally burning in Muffle furnace under temperature of 450íµ to 550íµ to get the light catalyzer thin film.

Owner:SHANGHAI UNIV

Methods for preparing and using crystal seeds of rutile in high activity

This invention relates to a process for producing rutile-type titanium dioxide powder, especially a method for preparing high-activity rutile seed crystal for titanium dioxide powder production. The method comprises: (1) adding 50-70 deg.C metatitanic acid into 80-100 deg.C NaOH solution at a ratio of 1:(1.2-2.5), and dissolving; (2) cooling, washing with water, preparing into 100-250 g / L slurry, and adding HCl to adjust the pH value to 2.0-3.1; (3) hydrolyzing under stirring for 2-24 h; (4) controlling the electric conductivity of the washing solution less than or equal to 400 mu.S / cm, or pNa greater than or equal to 2.5 for washing during titanic acid hydrolysis process; (5) adding HCl at an acid / titanium ratio of (0.19-0.35):1 for dissolution at 50-70 deg.C; (6) adding water to dilute, and cooling to a seed crystal concentration of 90-110 g / L. This invention has such advantages as high rutile seed crystal activity, high titanium dioxide powder rotary kiln productivity, high titanium dioxide powder quality, and high titanium dioxide powder production efficiency.

Owner:朱贤荣 +2

Method for preparing nano silicon dioxide coated by nano titanium dioxide

InactiveCN101613537AUniform particle size distributionHigh purityInorganic pigment treatmentUltrasound - actionSilicic acid

The invention discloses a method for preparing nano silicon dioxide coated by nano titanium dioxide, which is implemented by firstly dripping inorganic acid in silicate solution under the conditions of stirring and ultrasonic, controlling pH, reaction temperature and time of a reaction system to obtain white silicic acid collosol, drying to obtain silicic acid gel, then mixing the silicic acid gel with water followed by bal milling, rinsing and filtering to obtain gel, hot decomposing the silicic acid gel to obtain silicon dioxide powder; secondly, mixing the silicon dioxide powder with a mixed solution of glacial acetic acid, water and absolute alcohol under the conditions of stirring and ultrasonic; and thirdly, adding mixed solution of Tetrabutyl orthotita and absolute alcohol to the mixture, standing, drying and ball milling the mixture to obtain silicon dioxide powder coated by titanic acid gel, then heating for decomposition to obtain composite material powder. The grain diameter of the composite material of silicon dioxide coated by nano titanium dioxide is 1-100nm and the purity thereof is over 99.8%.

Owner:STATE GRID CORP OF CHINA +1

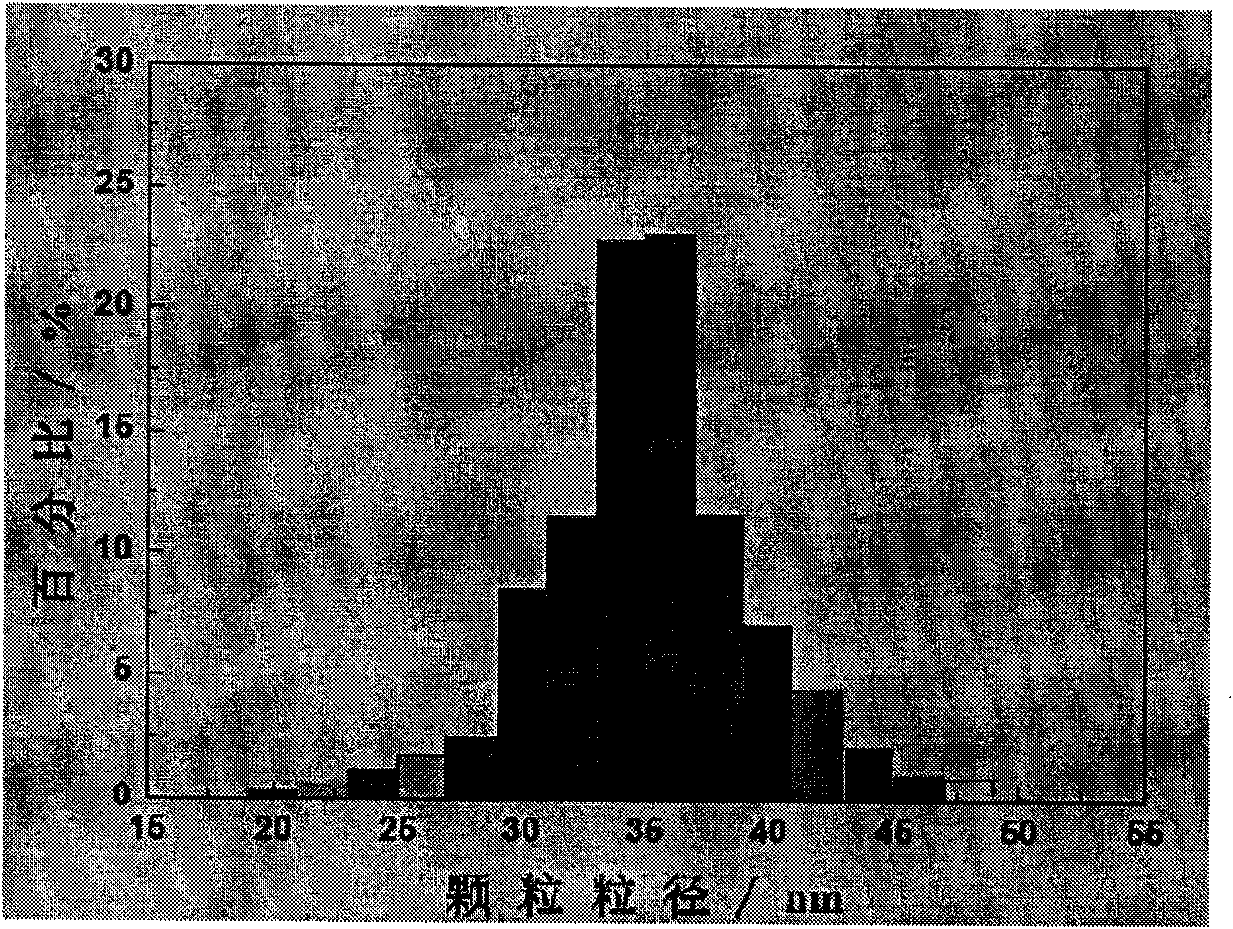

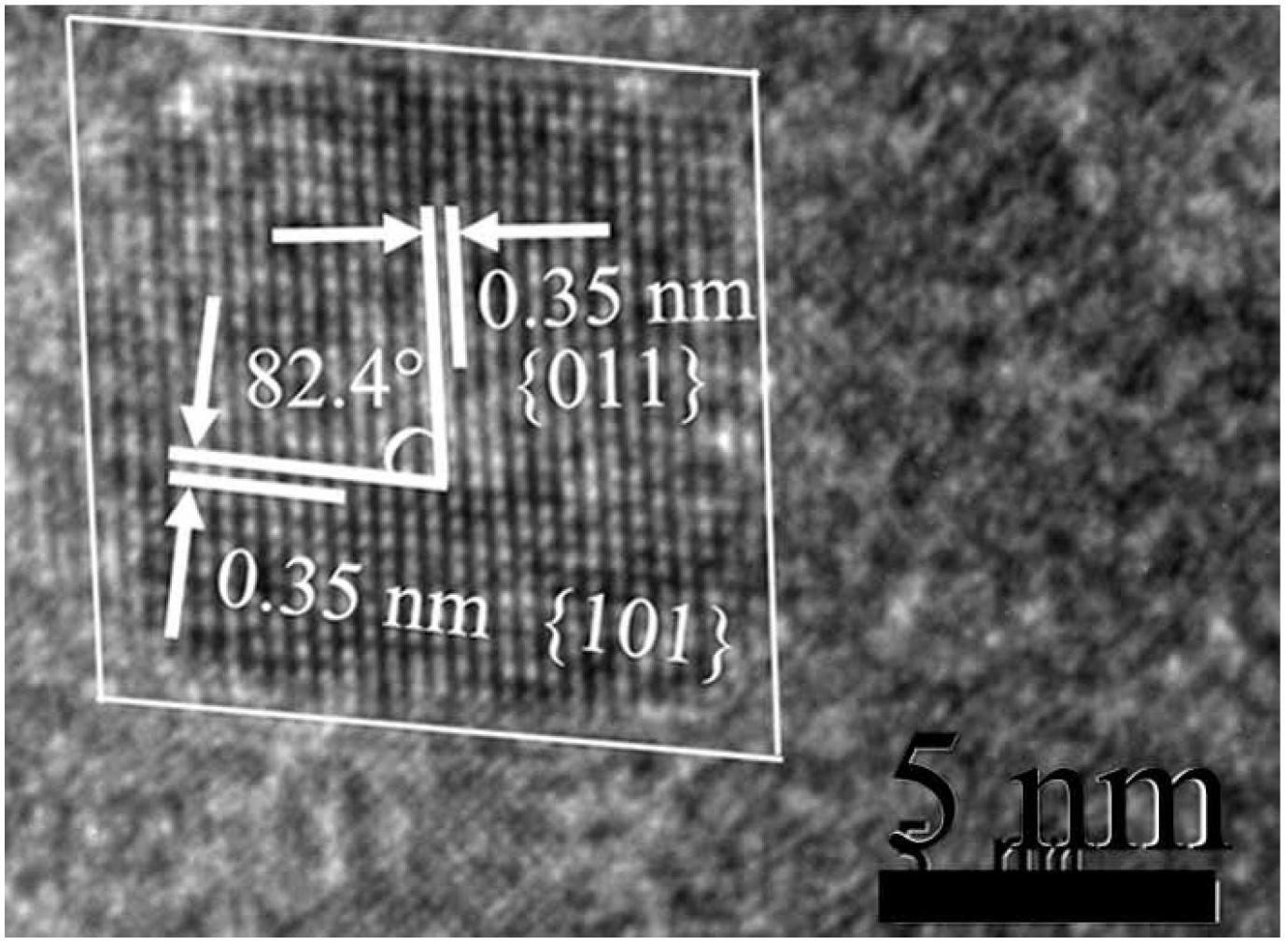

Preparation method of {001} face exposed titanium dioxide nanocrystals

InactiveCN102674451AImprove photocatalytic efficiencySimple and fast operationNanotechnologyTitanium dioxideProtonationTitanic acid

The invention relates to a preparation method of nanocrystals, particularly a preparation method of {001} face exposed titanium dioxide nanocrystals. The invention solves the technical problems of large particle size and small specific areas in the {001} face exposed titanium dioxide nanocrystals prepared by the existing method. The method comprises the following steps: 1. preparing protonized titanic acid hydrate; 2. washing the protonized titanic acid hydrate with alcohol, transferring into a polytetrafluoroethylene hydrothermal kettle, adding alcohol and a hydrofluoric acid water solution, keeping the temperature, carrying out centrifugal separation to obtain a precipitate, washing with water, washing with alcohol, drying, and grinding to obtain the {001} face exposed titanium dioxide nanocrystals. The titanium dioxide product obtained by the method is a pure anatase phase, the exposure rate of the {001} face is 26-66%, the maximum specific area is 155m<2>g<-1>, and the minimum average particle size of the crystals is 11nm.

Owner:HARBIN INST OF TECH

Method for subjecting TiO2 photocatalyst to be supported on honeycomb ceramics surface

InactiveCN1962061ALarge specific surface areaGood light transmissionWater/sewage treatment by irradiationCatalyst activation/preparationOrthogonal methodHoneycomb

The invention relates to a method for preparing TiO2 catalyst on the surface carrier of three-dimension beehive ceramic network, wherein it uses orthogonal method to prepare the titanic acid gel and the titanic acid gel with silver, iron, or lanthanum ion; uses dichroite beehive cermai and beehive ceramic as carrier; using gel-sol method to carry the titanic acid gel on the carrier. The load amount of optical catalyst film on the ceramic carrier is 0.21mg / cm2; the TiO2 diameter is 15-20nm; the thickness of load film is 300-400nm; when using it to purify the formaldehyde, and the initial density is 0.42-0.49mg / m3, the formaldehyde density will be lower than 72.2-74% after seven hours; when using it to disinfect, and the initial virus density is 554-924cfu / m3, the virus number is reduced 67.0-75.9% after 14.5h.

Owner:JIANGSU GAOCHUN CERAMICS

Preparation method of high dispersing rutile product

ActiveCN102391689AReduce dosageLow costTitanium dioxidePigment treatment with macromolecular organic compoundsPhysical chemistryWater soluble

The invention discloses a preparation method of a high dispersing rutile product; the preparation method comprises the following steps of: adopting a sulfuric acid process which sequentially comprises steps of acidolysis reaction, hydrolyzing generation of metatitanic acid, salt treatment, calcining, wet grinding, then sanding, coating and aerating powder to obtain titanium white, washing rutile titanium dioxide crude product obtained by calcining so as to reduce the content of water-soluble sale thereinto, and then adding a dispersing agent to the washed rutile titanium dioxide for wet grinding; the alkyd resin series of a rutile product prepared by the method has the dispersiveness of 20 degrees and gloss of more than 120; if the rutile crude product is not washed, the alkyd resin series of the rutile product prepared by the same after-treatment method has the dispersiveness of 20 degrees and gloss of up to 120; and the usage quantity of the dispersing agent is greatly reduced in the wet grinding process, thereby saving the cost and greatly increasing the dispersion performance of the product.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Preparation method and application of nitrogen-doped titanium dioxide heterojunction structure

InactiveCN102327779ASimple preparation techniqueLow costPhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionOrganic dye

The invention relates to a preparation method and application of a nitrogen-doped titanium dioxide heterojunction structure with a visible light catalytic performance, which belongs to the technical field of photocatalysis materials. The method comprises the following steps of: a. preparing analytically pure titanic acid ester or titanium tetrachloride and analytically pure isopropanol into a mixed solution, continuously stirring, dropping the mixed solution in distilled water and stirring for 6-24h to obtain titanium oxide sol; b. mixing the titanium oxide sol with 40-80 percent by weight ofhydrazine hydrate or 60-80 percent of quadrol water solution, then carrying out ultrasonic dispersion on the mixed solution, transferring the mixed solution to an airtight and corrosion-resistant reaction kettle and preserving heat and reacting for 36-72h to obtain a solid product; and c. washing, suction filtering and drying the mixed solution for 6-12h to obtain powder of the nitrogen-doped titanium dioxide heterojunction structure. The preparation technology used by the invention is simple and low in energy consumption; and the prepared nitrogen-doped titanium dioxide heterojunction structure has high efficiency for photocatalytic degradation of organic dye.

Owner:QILU UNIV OF TECH

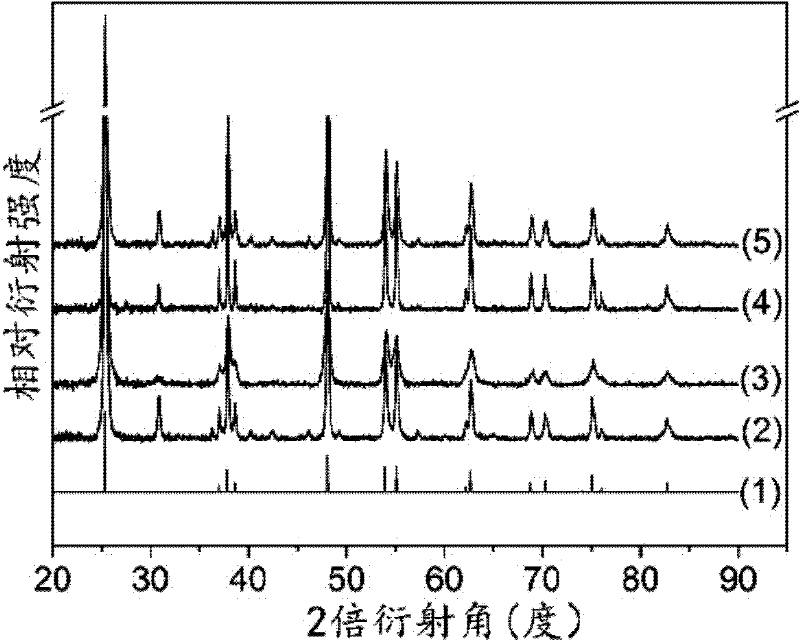

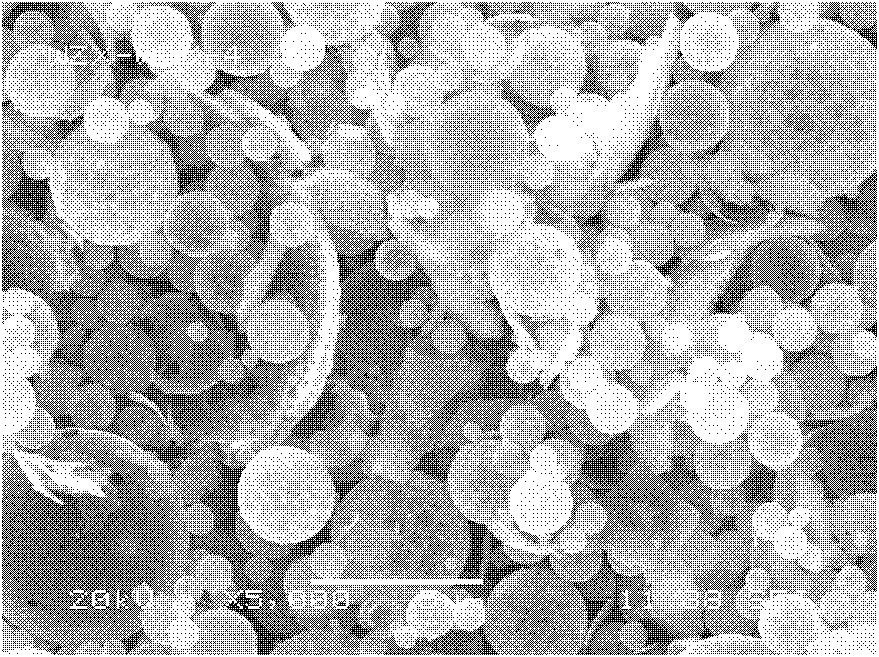

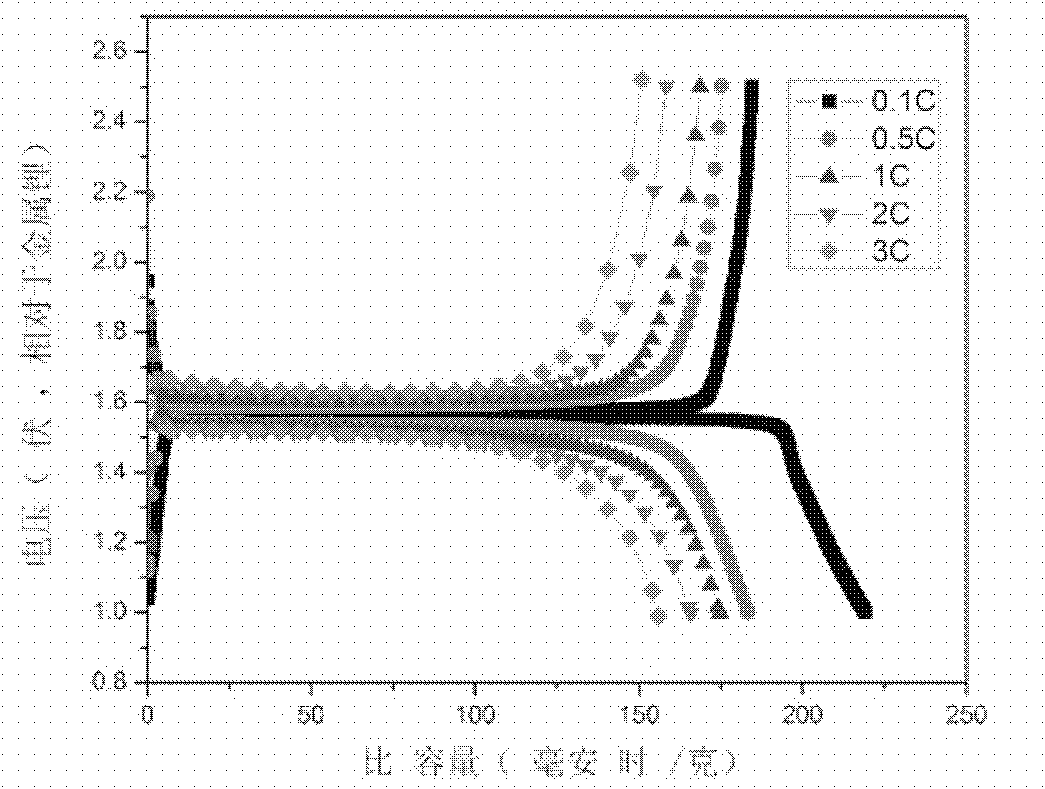

Method for preparing spherical lithium titanate from inorganic titanium sources

The invention discloses a method for preparing spherical lithium titanate from inorganic titanium sources. The method comprises the following steps: pulping the titanium precipitate prepared from titanic acid or ilmenite and industrial titanic solution with water, adding a coordinating agent to the pulp according to the molar ratio of the coordinating agent to titanium being (1.0:1)-(20:1), adjusting the pH value to be 7-14 with alkali, then carrying out reaction in a stirred reactor at the temperature of 10-80 DEG C for 5-720min and filtering the reactant to obtain titanium solution; adding lithium sources to the solution according to the molar ratio of lithium to titanium being 4:5; and then carrying out spray drying on the mixed solution to obtain a lithium titanate precursor and calcining the precursor in the inert atmosphere at the temperature of 550-900 DEG C for 1-72 hours to obtain lithium titanate, the cathode material of lithium ion batteries. The method has the characteristics of wide raw material range, simple process flows, low energy consumption, low cost, good product particle size and morphology, high purity and excellent electrochemical property.

Owner:CENT SOUTH UNIV

Composite hydrosol color fixing finishing agent, synthesizing method and use thereof

InactiveCN1546781AReduce pollutionReduce washing waste waterFibre treatmentDyeing processFiberPolymer science

The invention refers to a kind of compound lyosol fixing arrangement agent, a synthesizing method and the usage. The arrangement agent is made up of following products: (1) the silicon sol is made up of gamma-glycidol ether oxygen propyl trimethoxy-silane, water and hydrochloric acid, whose mol proportion is: 1:5-100:1í‡10 -5-1í‡10 -1; (2) the titanium sol is made up of titanic acid butyl ester, water and hydrochloric acid whose proportion is 1:0.1-10:10-200: 1í‡10 -4-1í‡10 -1; (3) the product is produced by mixing above mentioned silicon sol and titanium sol, the mol proportion of silicon and titanium is 1:0.05-1.0. The arrangement agent may form a mesh particle film on the surface of the fiber, realizes the color fixing aim.

Owner:DONGHUA UNIV

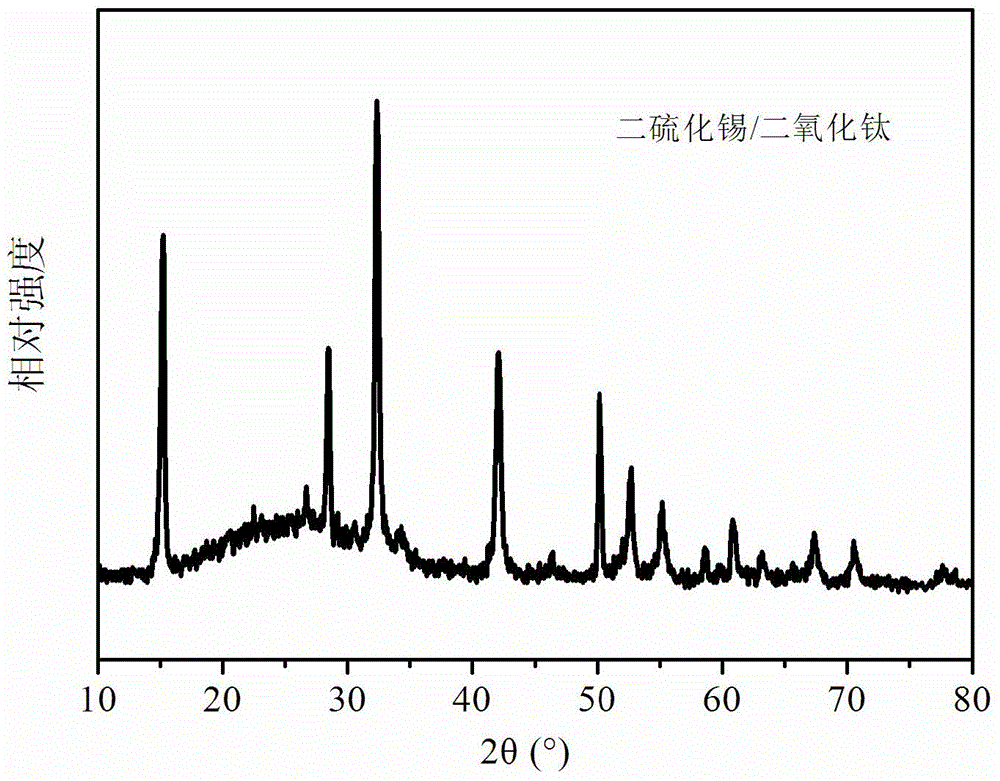

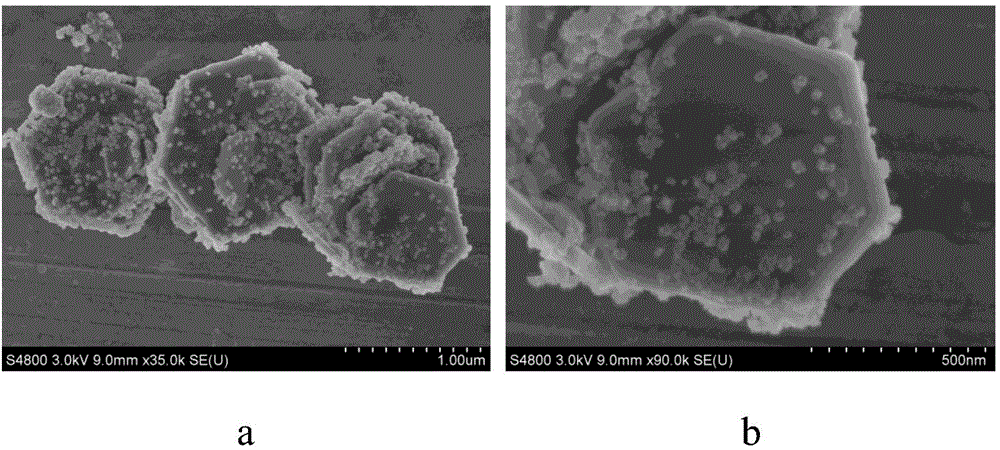

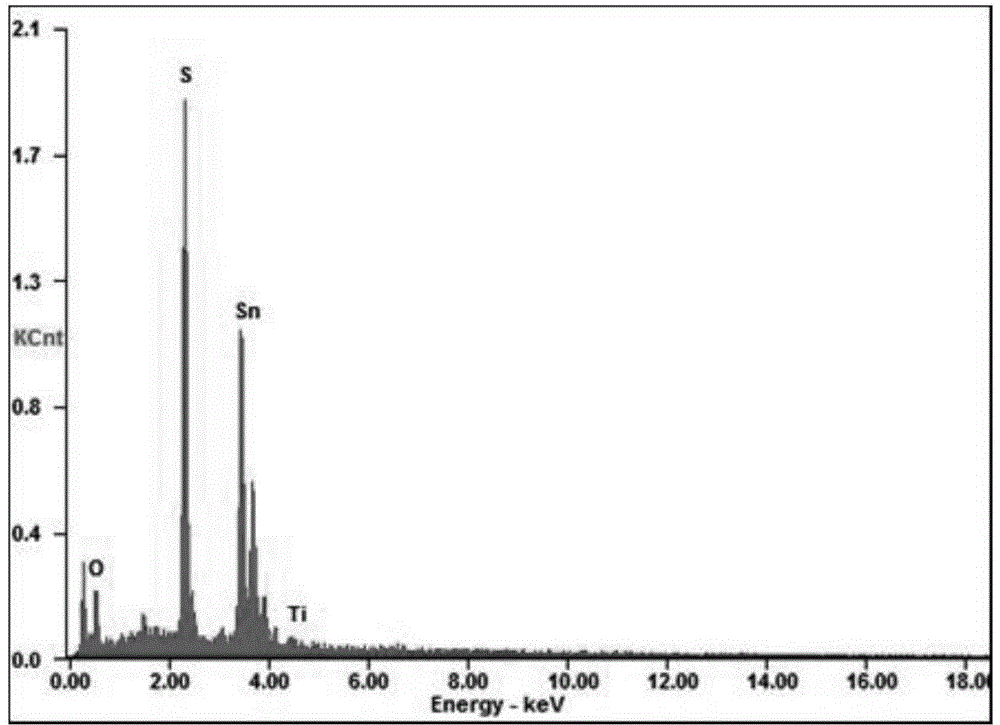

Tin disulfide/titanium dioxide compound photocatalyst and preparation method thereof

ActiveCN104888753AUniform sizeRegular shapeMaterial nanotechnologyWater/sewage treatment by irradiationThioureaPotassium dichromate

The invention discloses a tin disulfide / titanium dioxide compound photocatalyst which is prepared from a precursor solution through hydrothermal reaction, wherein the precursor solution is prepared from tin disulfide powder and butyl titanate in the mass ratio of 1:(20-100). The compound photocatalyst has controllable size, tin disulfide is of a hexagonal nanoscale flake shape, titanium dioxide nano-particles are uniformly loaded on tin disulfide, and the photocatalyst material has high photocatalytic reduction efficiency on potassium dichromate in a water body. The invention also discloses a preparation method of the compound photocatalyst. The preparation method comprises the following steps: a. preparing tin disulfide powder from tin chloride pentahydrate and thiourea; b. mixing the tin disulfide powder and butyl titanate to prepare the precursor solution; and c. hydrothermally heating the prepared precursor solution to prepare the compound photocatalyst. The preparation steps are simplified greatly, the control difficulty of technological parameters is lowered, and the large-scale preparation of the tin disulfide / titanium dioxide compound photocatalyst is realized.

Owner:澄城县海泰电子材料有限责任公司

High-efficiency catalyst for synthesizing di(2-ethylhexyl) terephthalate

InactiveCN101234355AQuick responseImprove product qualityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaneTitanium metal

The invention discloses a high efficiency catalyst used for compounding dioctyl phthalate which comprises titanium metal compounds, tin metal compounds, and other metal compounds; among which, the titanium metal compounds are titanic acid four phenyl ester, titanic acid four ethyl ester, silicic acid four alkane ester modified titanate or compound silicon dioxide carrier titanate; the tin metal compounds are stannous oxide, stannous oxalate, acetate diethyl tin, or dibutyl didodectyl acid tin; other metal compounds are ethylene glycol antimony, sodium aluminate, aluminum oxide, aluminum hydrous oxide plus sodium hydroxide, manganese oxide, cobalt oxide, antimony trioxide or zinc oxide. The catalyst used for compounding dioctyl phthalate of the invention has the advantages of improving reaction speed (Reaction time is improved within 3 hours from more than 8 hours in original technology), having a thorough esterification, and improving the quality of the product.

Owner:郭立耀

Codoping titanium dioxide nano sol and preparation method thereof

InactiveCN101054202AAchieve UV red shiftPhysical/chemical process catalystsWater/sewage treatment by irradiationUltravioletPolyethylene glycol

The invention discloses a method for preparing co-doped TiO2 nano-sol, which comprises the following steps: 1) dripping butyl titanate into absolute ethyl alcohol followed by continuous stir till the end of drip; then adding in concentrated hydrochloric acid followed by continuous stir, and then still stirring for 25-35min at the end of addition to produce blended solution; 2) dripping the above blended solution into de-ionized water with continuous stir, stirring for further 70-80min after dripping and then vibrating for 13-18min in ultrasonic wave to produce sol; 3) adding polyethylene glycol, urotropine and AgNO3 into the above sol and stirring for 55-65min to produce nano-sol. The co-doped TiO2 nano-sol prepared in the invention has the functions of Einstein shift of ultraviolet ray, photocatalysis after absorption of visible light and light source free antisepsis etc.

Owner:ZHEJIANG UNIV

Preparation method of kieselguhr load type compound photocatalyst with iron ions doped titanium dioxide

InactiveCN101628236ASignificant purification and decolorizationAbundant resourcesWater/sewage treatment by irradiationOther chemical processesWater bathsIron salts

The invention discloses a preparation method of a kieselguhr load type compound photocatalyst with iron ions doped with titanium dioxide, comprising the following steps: (1) mixing titanic acid esters or titanium salt with an alcoholic solvent, and then adding kieselguhr into the alcoholic solvent and stirring so as to form slurry; (2) dissolving iron salt into water to form an iron salt solution, and in a water bath with the temperature of 10-95 DEG C, dropping the iron salt solution into the slurry and stirring so that the titanic acid esters or the titanium salt inside the slurry is hydrolyzed to obtain colloidal sols; (3) aging the colloidal sols under room temperature to obtain dried gel; and (4) baking the dried gel for 0.5-5 hours under the temperature of 200-800 DEG C to obtain the kieselguhr load type compound photocatalyst with the iron ions doped with the titanium dioxide. The compound photocatalyst prepared by the method can effectively process waste water.

Owner:ZHEJIANG SCI-TECH UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com