Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

295 results about "STANNOUS OXIDE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

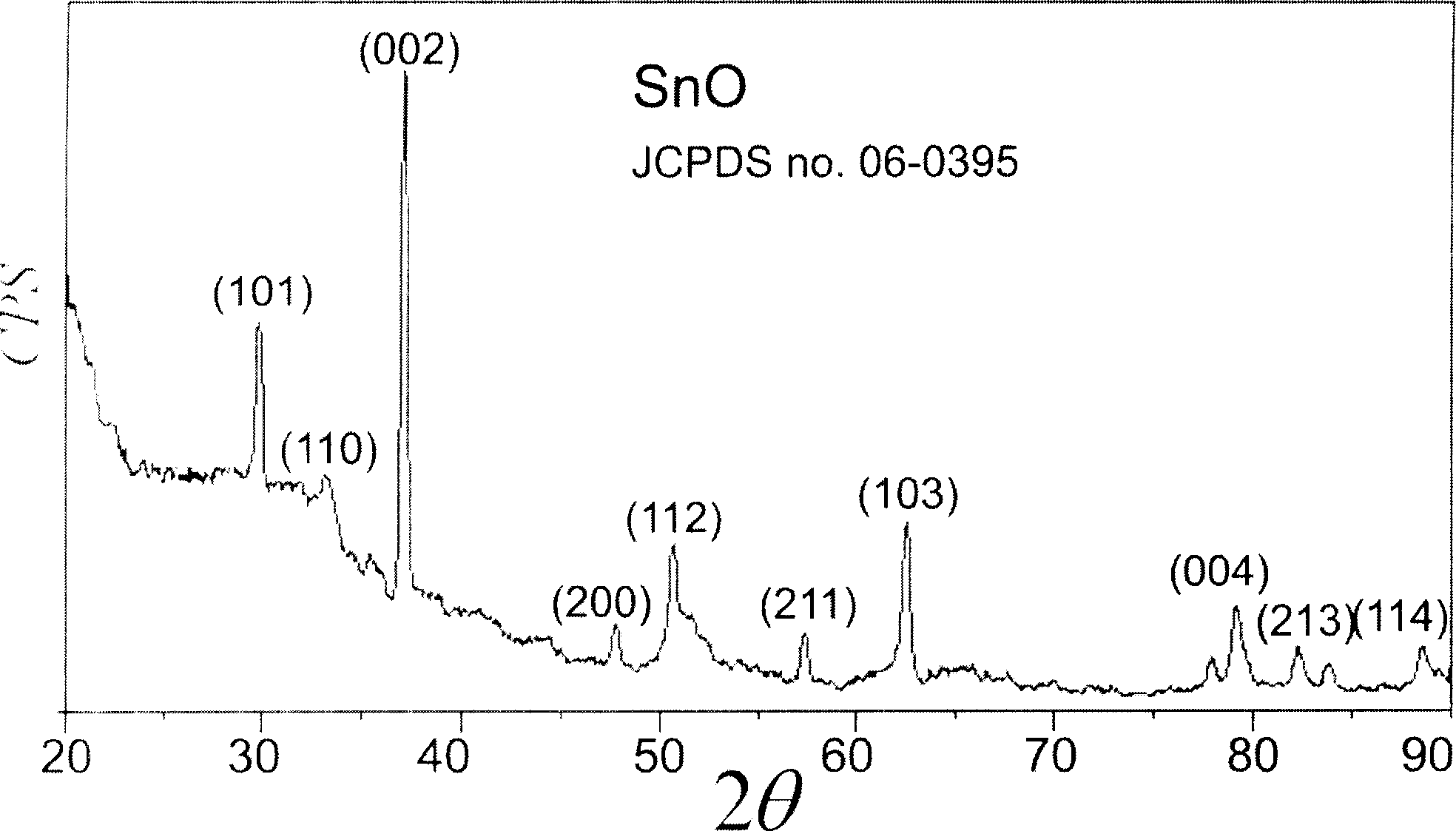

Tin(II) oxide (stannous oxide) is a compound with the formula SnO. It is composed of tin and oxygen where tin has the oxidation state of +2. There are two forms, a stable blue-black form and a metastable red form.

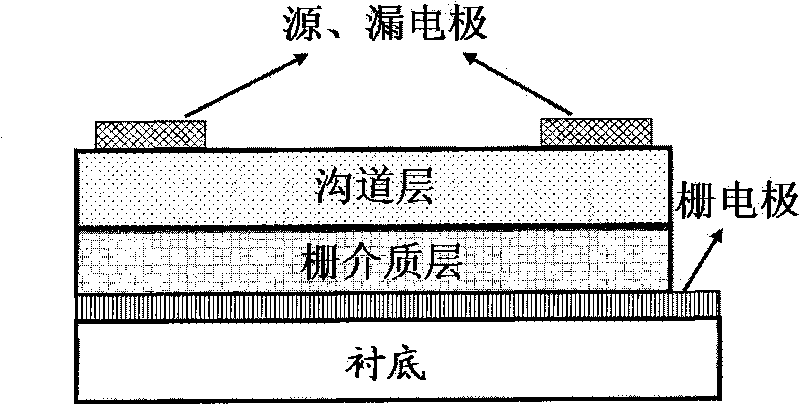

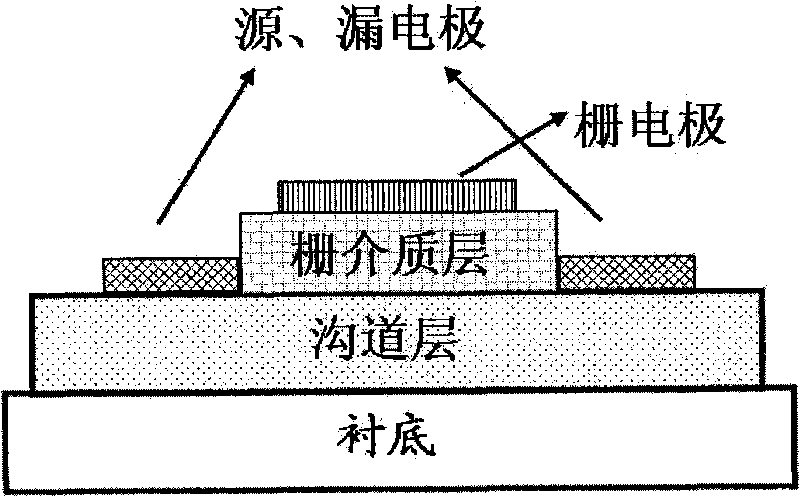

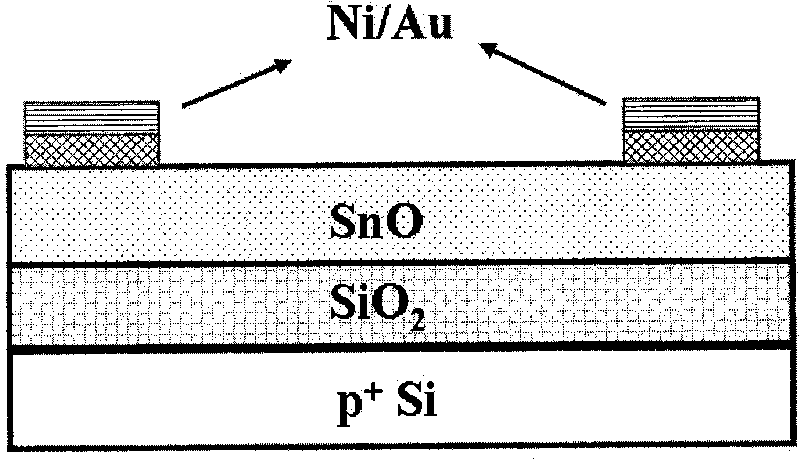

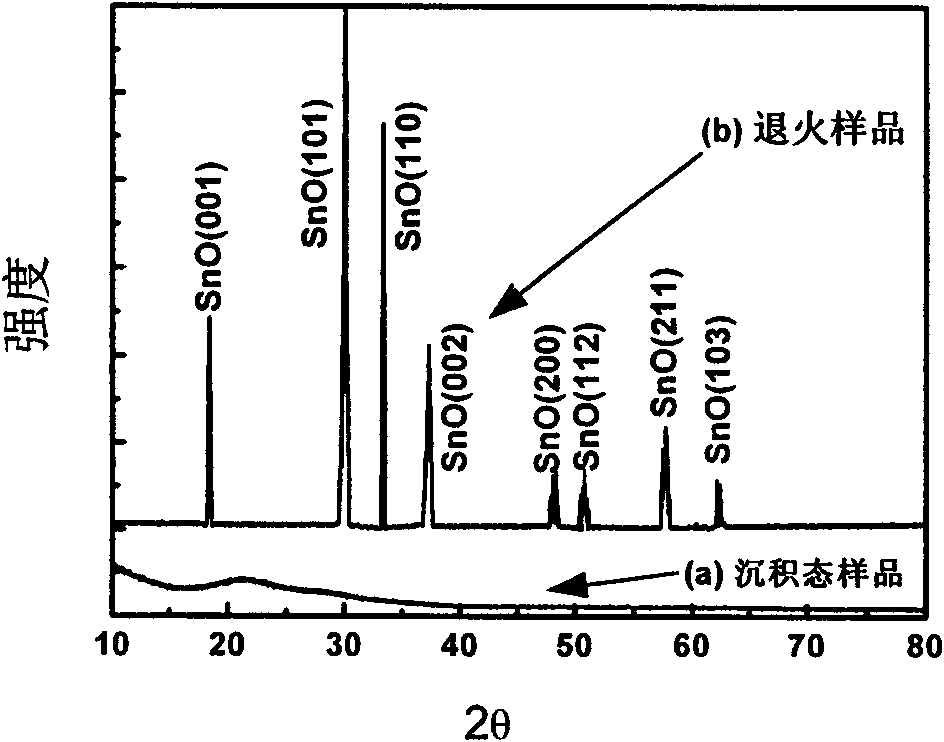

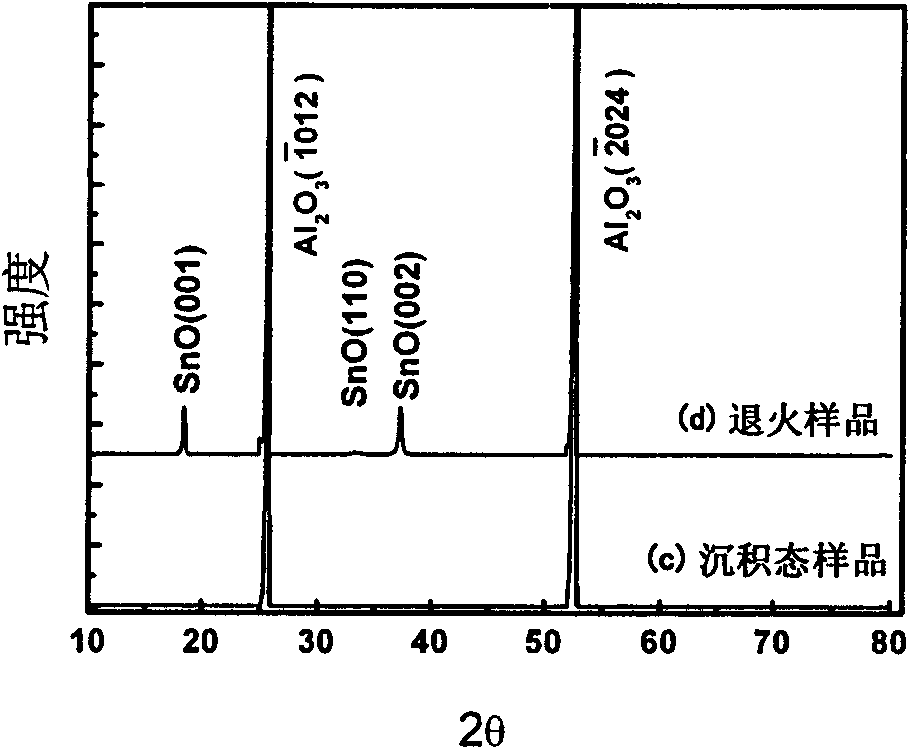

Preparing method of p-type stannous oxide ditch film transistors

InactiveCN101764065AEasy to operateUniform film formationVacuum evaporation coatingSemiconductor/solid-state device manufacturingSTANNOUS OXIDEEvaporation

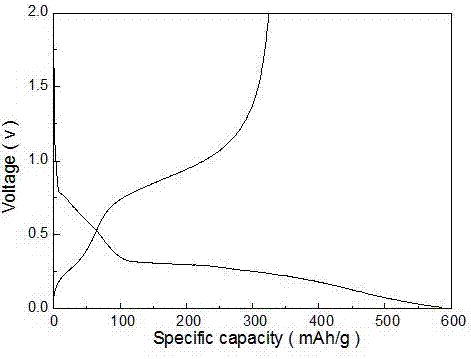

The present invention discloses a preparing method of p-type stannous oxide ditch film transistors, and p-type conducting stannous oxide ditch layers are prepared by using electron beam evaporation technology and rapid thermal annealing technology. The preparing method is simple and controllable, and can realize low-temperature preparation. The p-type stannous oxide ditch film transistors have high field effect mobility, can be used for organic light-emitting diodes and development of oxide based compensating and logic circuits with low loss and the like, and have wide application prospects in the technical field of displays.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

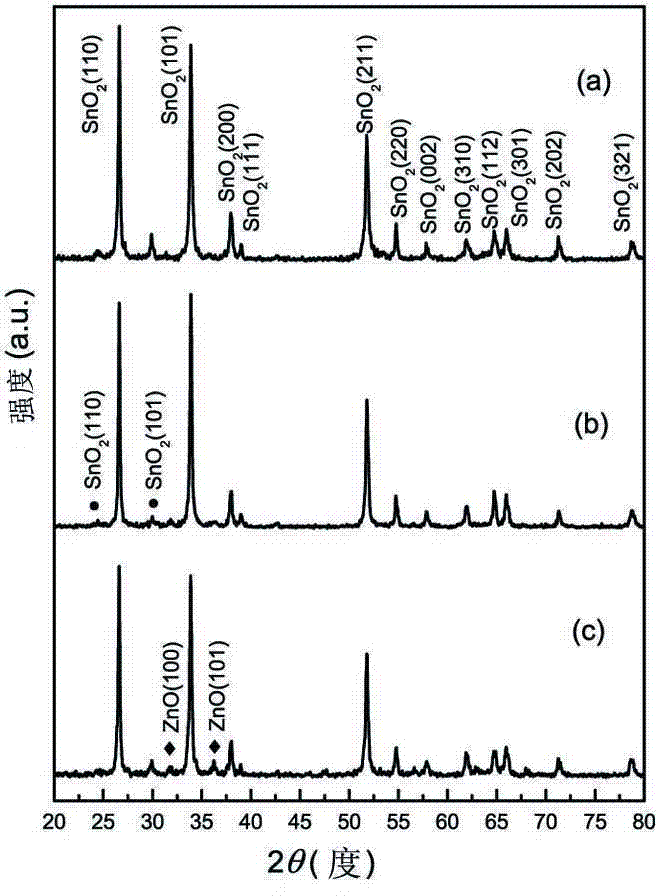

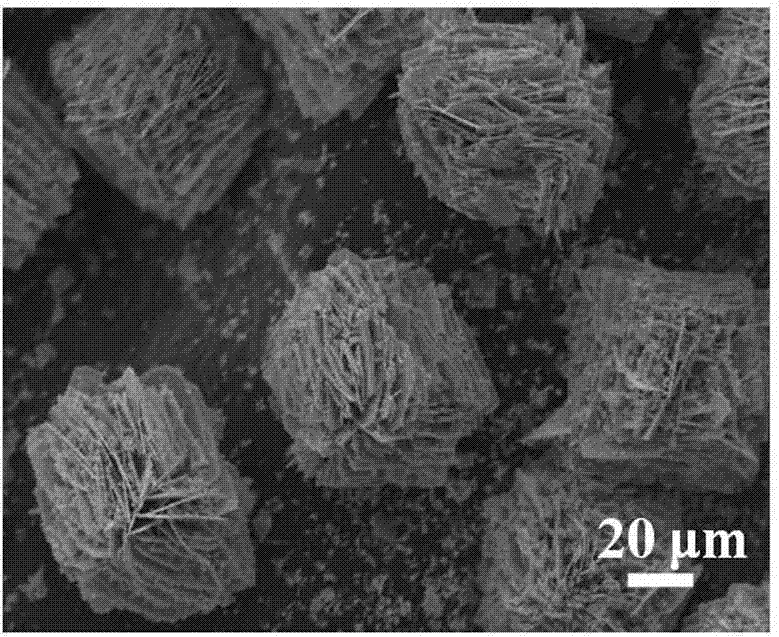

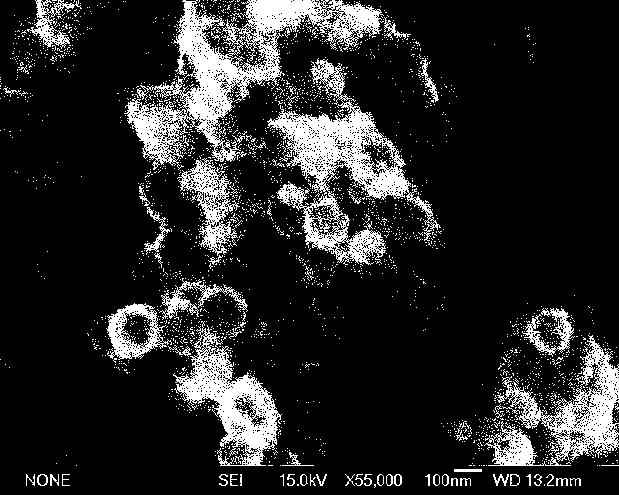

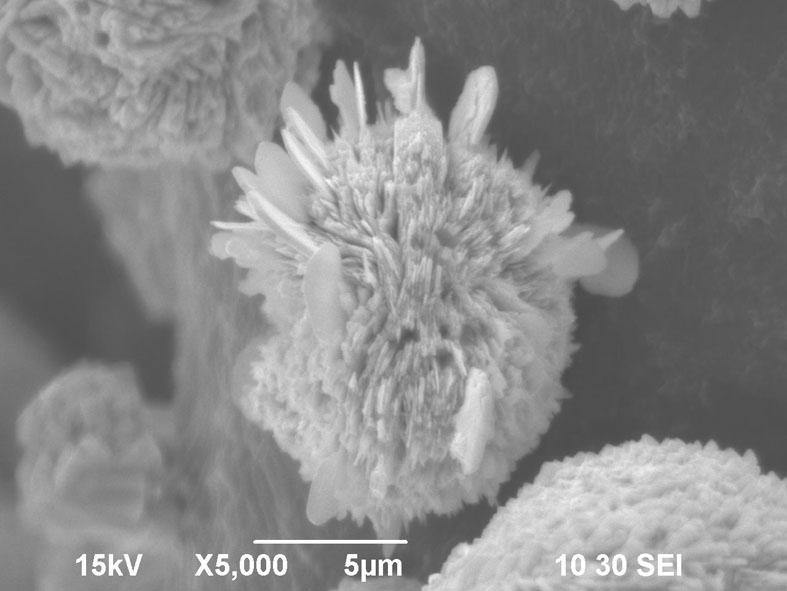

ZnO/SnO2 nano composite gas-sensitive material with flower-shaped grading structure and preparation method of material

InactiveCN103776870AReduced ethanol gas sensitivity performanceGood dispersionMaterial nanotechnologyMaterial analysis by electric/magnetic meansAir atmosphereSTANNOUS OXIDE

The invention provides a ZnO / SnO2 nano composite gas-sensitive material with a flower-shaped grading structure. The ZnO / SnO2 nano composite gas-sensitive material is prepared by the following steps: dripping a sodium hydroxide water solution into an ethanol solution of cetyl trimethyl ammonium bromide and stannous chloride dihydrate under electromagnetic stirring; after dripping, preparing a precursor solution by the continuous electromagnetic stirring; adding the precursor solution into a reaction kettle, reacting at 130 DEG C; carrying out centrifuging on a reactant, washing and drying to obtain a flower-shaped stannous oxide sacrifice template; adding the flower-shaped stannous oxide sacrifice template into a zinc acetate solution; agitating and carrying out ultrasonic treatment; removing a solvent to obtain a ZnO / SnO2 precursor; and carrying out heat preservation on the ZnO / SnO2 precursor for 2-4 hours in an air atmosphere of 700 DEG to obtain the composite gas-sensitive material. According to the ZnO / SnO2 nano composite gas-sensitive material with the flower-shaped grading structure, the controllable preparation of the composite gas-sensitive material on the appearance and components can be realized; the mass percent content of zinc oxide in the composite gas-sensitive material is 5%-15%; a flower shape is assembled by sheet-shaped tin dioxide and zinc oxide nano particles; the ZnO / SnO2 nano composite gas-sensitive material has a good gas sensitive performance and has a wide application prospect in the aspect of manufacturing a novel high-efficient gas sensor.

Owner:HENAN POLYTECHNIC UNIV

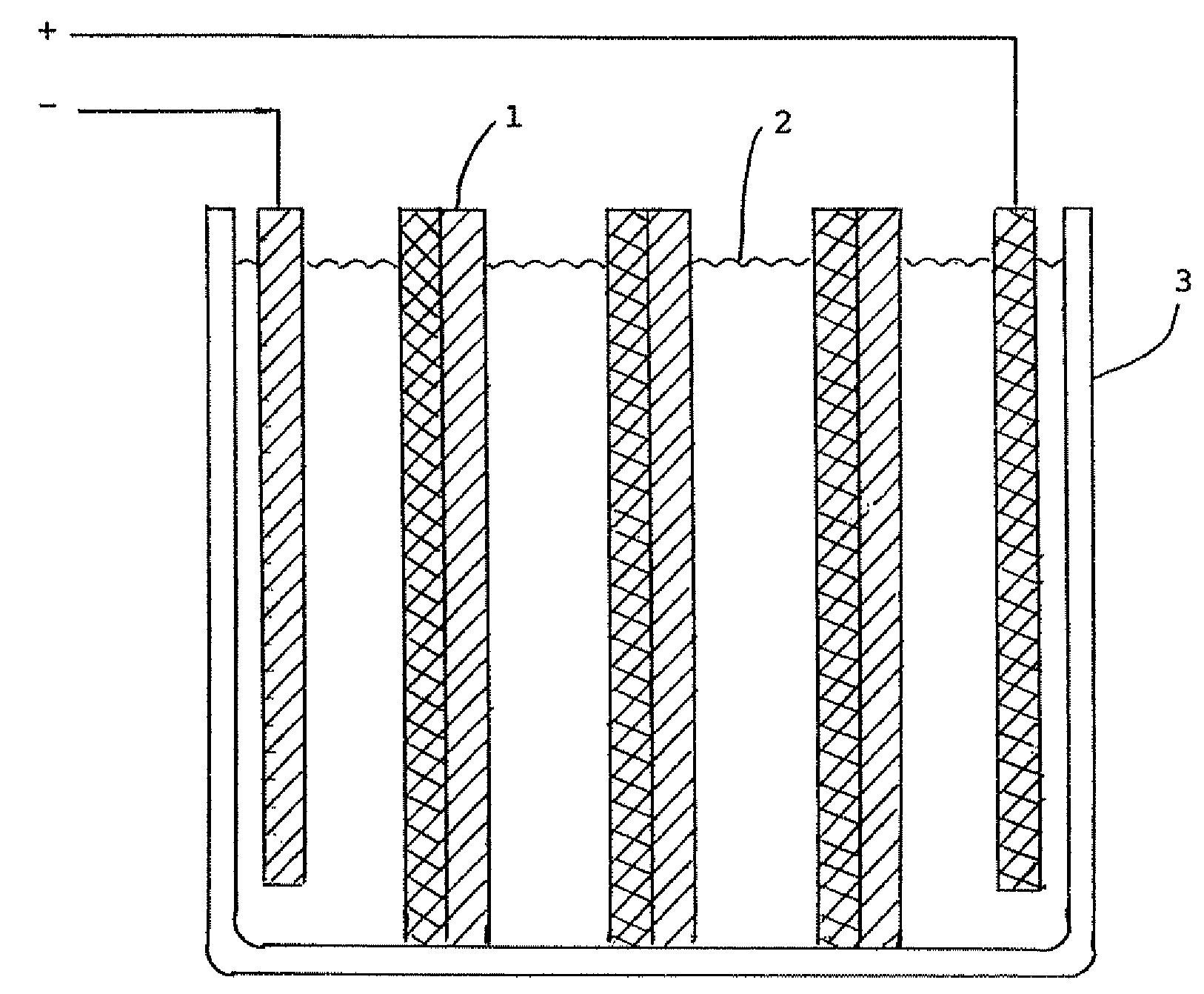

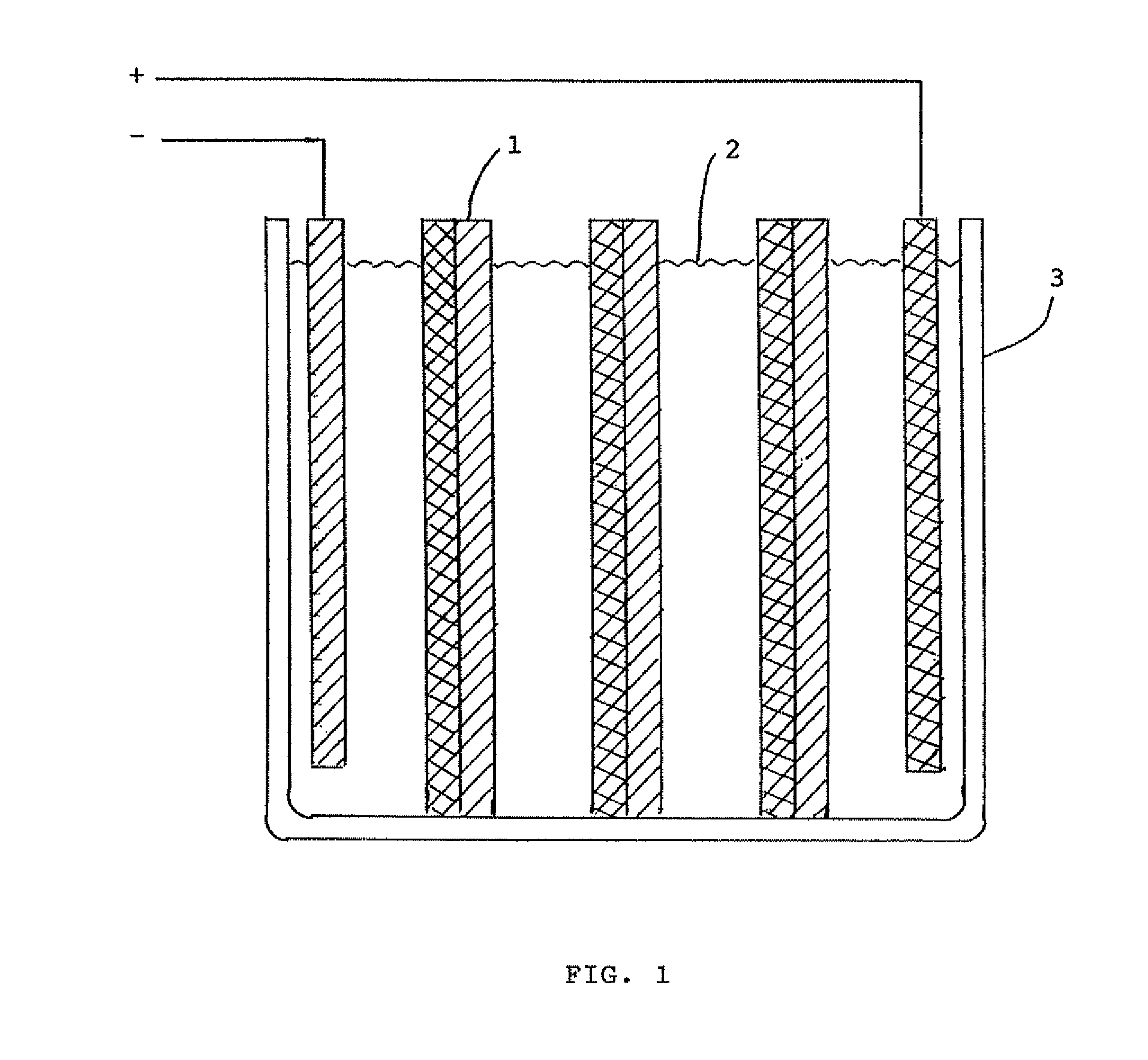

Tin-zinc secondary battery

ActiveUS7550231B2Maximum versatilityAlkaline accumulatorsActive material electrodesSTANNOUS OXIDERechargeable cell

A rechargeable battery is provided with a positive electrode of tin, a negative electrode of zinc and an alkaline electrolyte. Upon charging, some tin is converted to stannic oxide, and zinc oxide is reduced to zinc. When the battery is discharged, stannic oxide is reduced to stannous oxide and zinc is oxidized to zinc oxide.

Owner:JES TECH LLC

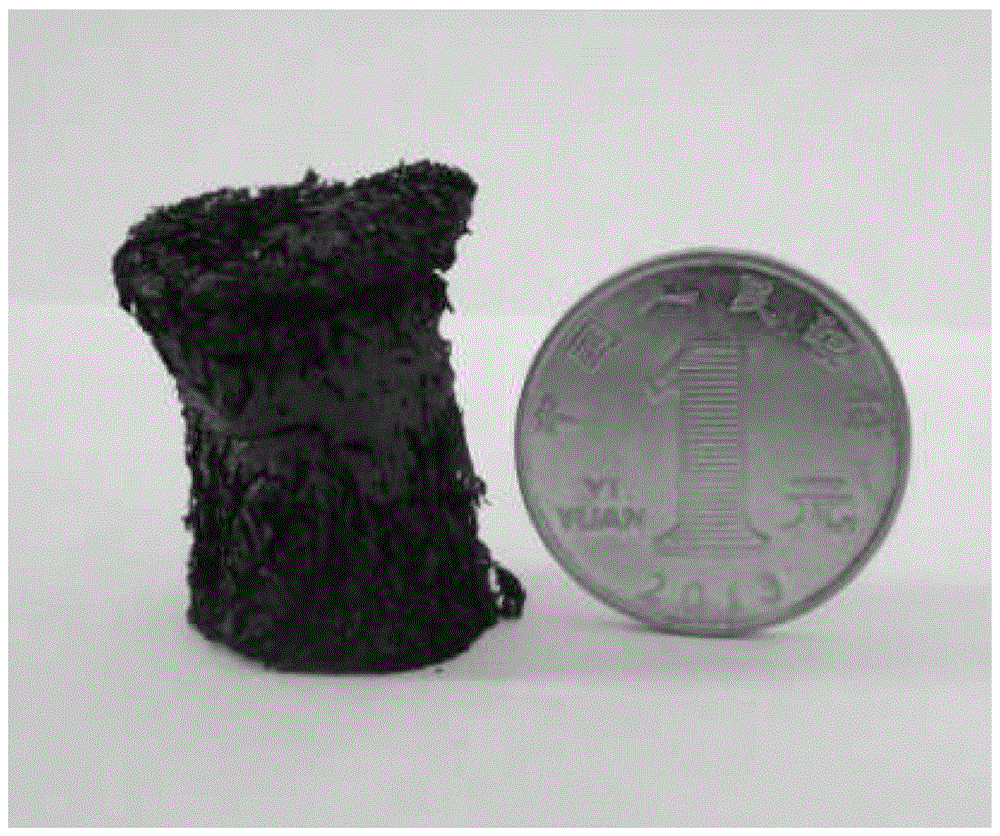

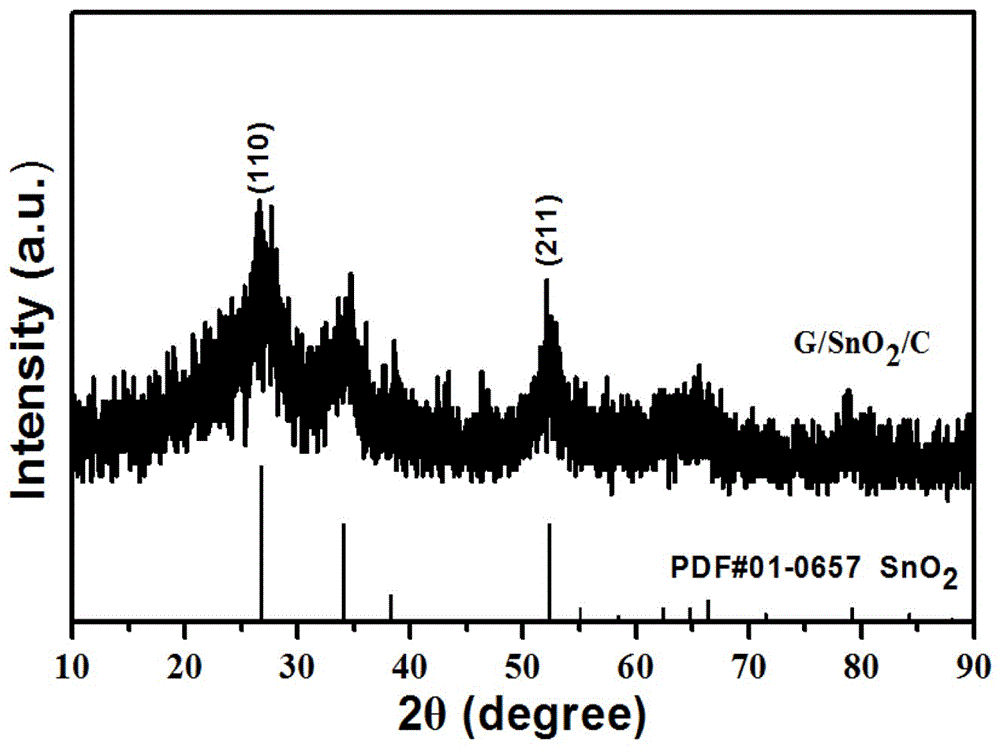

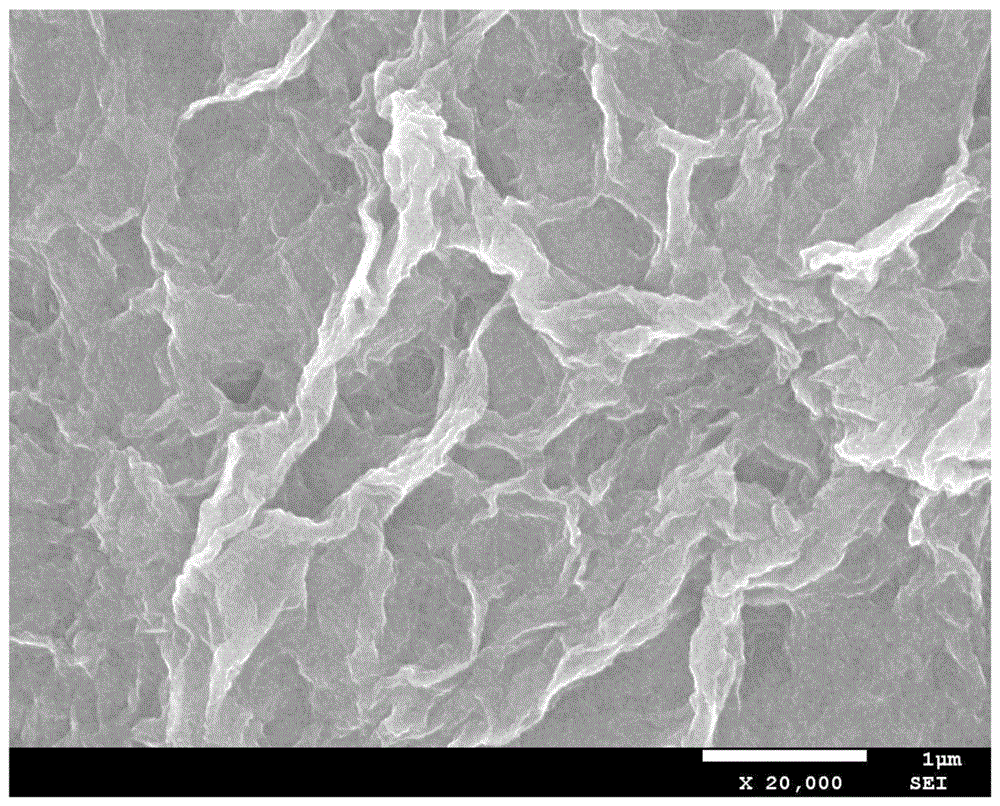

Stannic oxide/graphene/carbon composite material and preparation method thereof

ActiveCN105742635AEnsure structural stabilityImprove bindingCell electrodesSecondary cellsCarbon compositesTin dioxide

The invention discloses a stannic oxide / graphene / carbon composite material and a preparation method thereof, and belongs to the fields of electrochemistry and new energy materials. The method comprises the following steps: oxidizing graphite into a graphite oxide with an oxidant in preparation and then ultrasonically stripping the graphite oxide into a graphite oxide material; mixing a tin source and an organic carbon source with a graphite oxide solution evenly according to different ratios, and preparing a stannic oxide / graphene / carbon liquid gel composite material from the mixed solution through hydrothermal reaction, wherein the hydrothermal reaction temperature is 120-250 DEG C; and the hydrothermal reaction time is 1-48 hours; and carrying out freeze drying and heating treatment on the prepared stannic oxide / graphene / carbon liquid gel composite material to obtain a three-dimensional stannic oxide / graphene / carbon foam composite material. The material disclosed by the invention has good flexibility, is suitable for manufacturing of a flexible electrode, does not need to be added with any assistant when taken as an anode material for a lithium-ion battery, does not need to utilize a metal substrate and demonstrates good cycling stability and relatively high specific capacity.

Owner:CHINA THREE GORGES UNIV

Preparation method for high purity stannous oxide

ActiveCN101367543AReduce manufacturing costThe process steps are simpleTin oxidesForeign matterFiltration

The invention provides a method for preparing high-purity stannous oxide that is applicable to the electronic industry, which comprises the following steps: tin powder, chlorine gas and water are synthesized to be stannic chloride in the environment that is provided with hydrochloric acid; the stannic chloride is reduced with equal or more tin powder to be stannous chloride; after the filtration, the concentration of the stannous chloride solution is adjusted, and antioxidant is added into the stannous chloride solution; finally the stannous chloride solution is slowly dropped into sodium hydroxide solution; the pH value at the reaction termination is controlled; the filtered precipitate is centrifuged, washed and dried to get stannous oxide. The stannic chloride is prepared by oxidation and restoration, so that the copper, arsenic and stibium contained in the tin powder can be removed; the ions such as zinc, iron, lead, and the like are separated from the precipitate of the stannous oxide through controlling the pH value at the reaction termination of the stannous chloride and the sodium hydroxide. The method is simple to be operated, and the process parameters are easy to be controlled. The purity of the stannous oxide that is obtained in the method can reach more than 99 percent, and the content of each foreign matter is less than 0.001 percent, thereby being applicable to the electronic industry.

Owner:GUANGDONG GUANGHUA SCI TECH

High-efficiency catalyst for synthesizing di(2-ethylhexyl) terephthalate

InactiveCN101234355AQuick responseImprove product qualityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaneTitanium metal

The invention discloses a high efficiency catalyst used for compounding dioctyl phthalate which comprises titanium metal compounds, tin metal compounds, and other metal compounds; among which, the titanium metal compounds are titanic acid four phenyl ester, titanic acid four ethyl ester, silicic acid four alkane ester modified titanate or compound silicon dioxide carrier titanate; the tin metal compounds are stannous oxide, stannous oxalate, acetate diethyl tin, or dibutyl didodectyl acid tin; other metal compounds are ethylene glycol antimony, sodium aluminate, aluminum oxide, aluminum hydrous oxide plus sodium hydroxide, manganese oxide, cobalt oxide, antimony trioxide or zinc oxide. The catalyst used for compounding dioctyl phthalate of the invention has the advantages of improving reaction speed (Reaction time is improved within 3 hours from more than 8 hours in original technology), having a thorough esterification, and improving the quality of the product.

Owner:郭立耀

Compound clarifying agent for high-aluminum alkali-free borosilicate glass

The invention discloses a compound clarifying agent for high-aluminum alkali-free borosilicate glass and belongs to the field of glass manufacturing. The compound clarifying agent comprises the following components by weight percent: 80-89% of thinning agents, 3-6% of sulfates, 4-6% of chlorine alkaline earth salts and 4-10% of stannous oxides. The invention provides a better clarifying agent for a fusing process of the high-aluminum alkali-free borosilicate glass, so as to facilitate the discharging of air bubbles during the glass fusing process and increase the yield.

Owner:成都中光电科技有限公司 +1

Preparation process of 2,2,4-trimethyl-1,3-pentanediol mono-sio butyrate

InactiveCN1429809AUnderstand the pros and cons of the step-up processOrganic compound preparationCarboxylic acid esters preparationChemistrySTANNOUS OXIDE

A process for preparing 2,2,4-trimethyl-1,3-pentadiol monoisobutyrate includes such steps as condensation reaction of isobutyraldehyde at 10-60 deg.c under action of catalyst, dirct heating to 60-150deg.c, further reaction, recovering the unreacted isobutyraldehyde, and vacuum rectifying. The said catalyst is chosen from alkali or alkali-earth metal hydroxide, alkali-earth metal oxide, alkali oralkali-earth metal salt, organotion and stannous oxide. Its advantages are high purity (98%) and less generation of by-product.

Owner:CHINA PETROLEUM & CHEM CORP

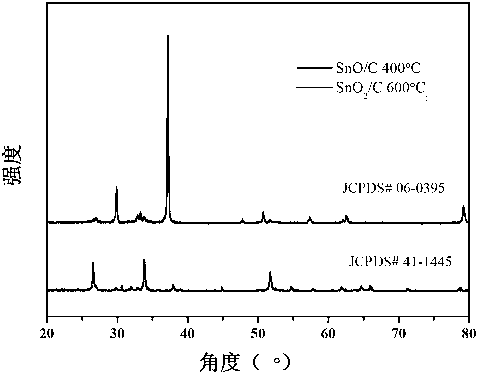

In-situ etching method for preparing hollow tin-based oxide/carbon composite nano-material

InactiveCN103346299AEfficient removalPromote crystallizationCell electrodesCarbon compositesTin dioxide

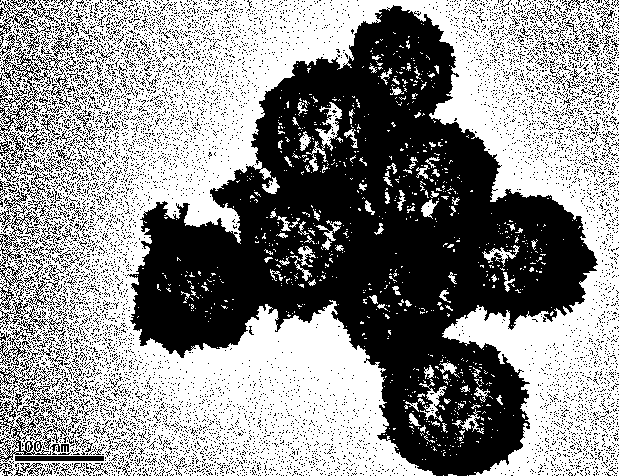

The invention relates to a preparation method of a hollow tin-based oxide / carbon composite nano-material, and belongs to the technical field of material synthesis and electrochemistry. The method comprises: taking a carbon coated silica composite material as a template, stannous chloride (SnCl2-H2O(1 / 2)) as a tin source, urea as an alkali source, and water as a solvent, adopting a simple in-situ etching hydrothermal crystallization method for generation of a stannic oxide based nano-material and successful removing of the silica template at the same time, to obtain the tin-based oxide / carbon composite nano-material with a hollow spherical structure and homogeneous morphology. In the method, the raw material ratio of the tin source and urea is the key of the method. And more important, by simple control of the subsequent heat treatment temperature, the carbon composite nano-materials of stannous oxide (SnO) and of tin oxide (SnO2) with two totally different crystal phases can be obtained.

Owner:SHANGHAI UNIV

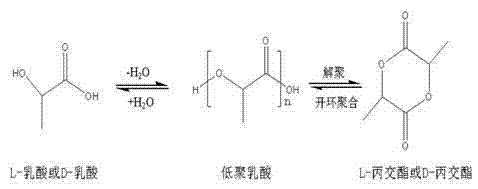

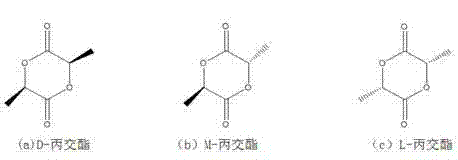

High-purity lactide and preparation method thereof

The invention discloses high-purity lactide and a preparation method thereof. The preparation method comprises the steps of raw material addition, free water removal, polycondensation, depolymerization, distillation and secondary distillation. The raw material addition step refers to that a catalyst is added into L-lactic acid or D-lactic acid, wherein the catalyst is one or more of zinc oxide, stannous oxide and stannous octoate. In the preparation process, the use of an organic solvent, N2 and inert gas and environmental pollution are avoided, the vacuum degree is moderate, purification loss is reduced, the production cost is reduced, and the method is suitable for industrial production. The L-lactide or D-lactide product prepared by the method is high in yield, optical purity and quality, the yield is more than or equal to 97 percent, and the optical purity of the purified lactide is 99.45 percent or above.

Owner:SHANDONG SHOUGUANG JUNENG GOLDEN CORN CO LTD

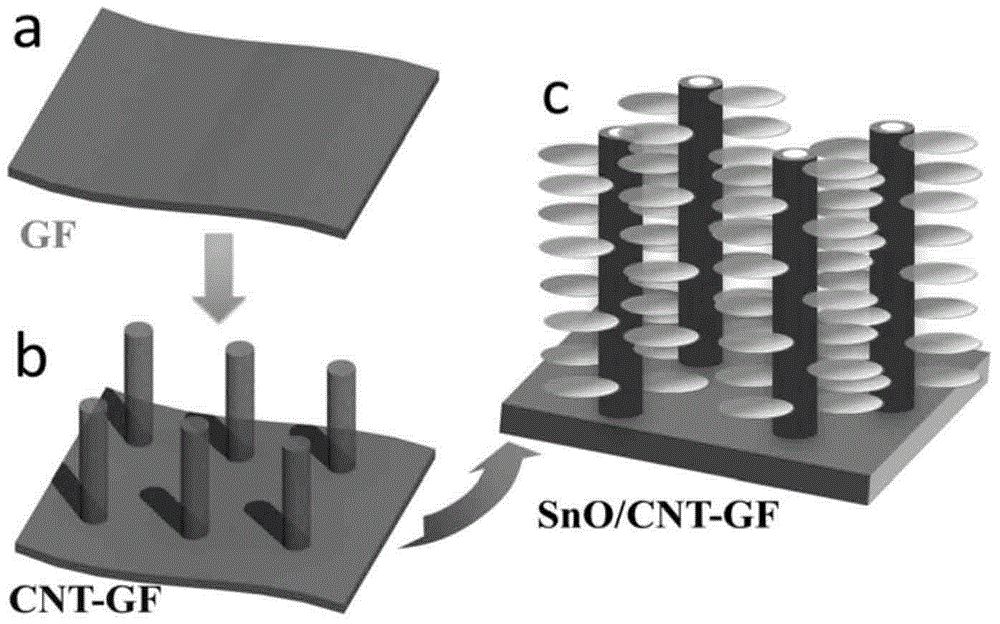

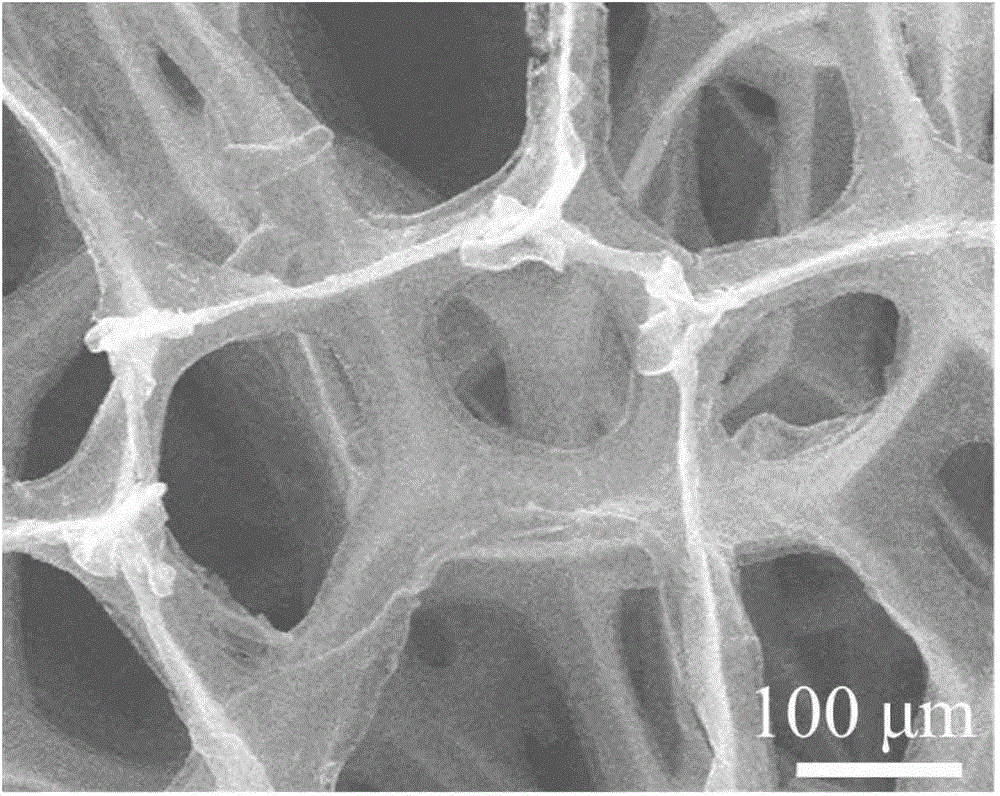

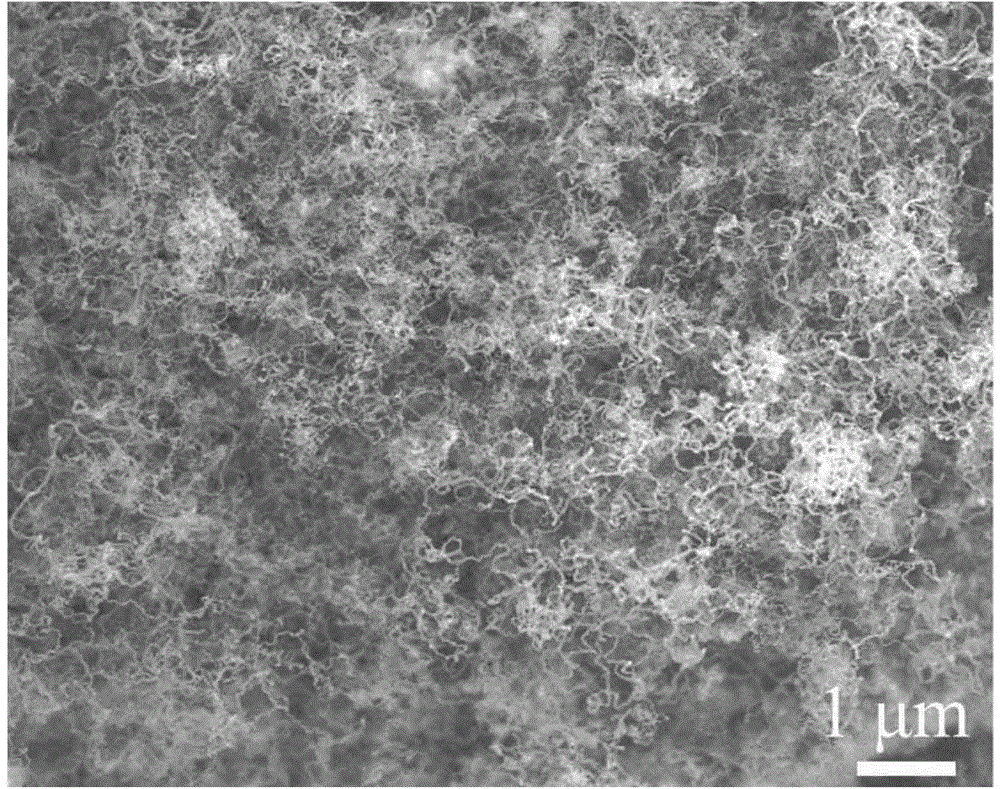

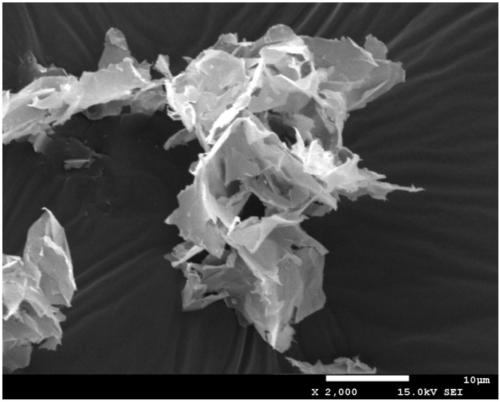

Method for preparing flexible stannous oxide nano sheet/carbon nanotube-graphene three-dimensional composite material

ActiveCN104617274AImprove conductivityExcellent rate performanceMaterial nanotechnologyElectrode manufacturing processesSTANNOUS OXIDEMechanical stability

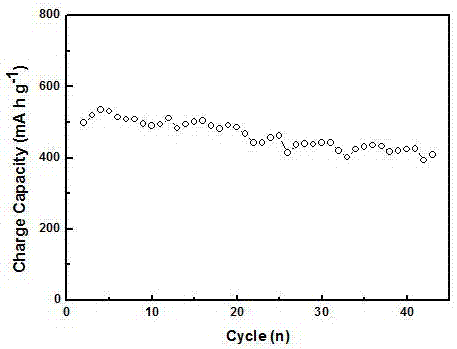

The invention discloses a method for preparing a flexible stannous oxide nano sheet / carbon nanotube-graphene three-dimensional composite material, relates to a method for preparing a three-dimensional composite material, and aims at solving the problems that a lithium battery cathode material prepared by using a conventional method is low in specific capacity, low in multiplying power and poor in recycling property. The method comprises the following steps: I, preparing three-dimensional graphene foam; II, preparing a carbon nanotube-graphene foamed three-dimensional composite material; III, growing stannous oxide nano sheets. The flexible stannous oxide nano sheet / carbon nanotube-graphene three-dimensional composite material prepared by using the method keeps high specific capacity of greater than 900mAh / g at 100mA / g, the capacity is not remarkably attenuated after the material is recycled for 100 times; the material is good in mechanical stability and good in flexibility, and is free of breakage or peeling when being repeatedly bent. The flexible stannous oxide nano sheet / carbon nanotube-graphene three-dimensional composite material can be prepared by using the method disclosed by the invention.

Owner:天津北方焦耳新能源科技有限公司

Stannic oxide based nanometer rod air-sensitive material and process for preparing the same

InactiveCN1737558AHigh sensitivitySimple processMaterial electrochemical variablesTin oxidesSTANNOUS OXIDEUrea

This invention relates to one electro element materials by use of chemical or physical property analysis technique, which relates to one SnO2 nanometer bar sensitive material and its process method. The nanometer bar materials is composed by following weighted as mole: tin tetrachloride for one share; aquacare for 1.5 to 3 shares; bismuth nitrate for 0.08 to 0.12 shares for formulating, mixing, drying, pressing and pre-firing.

Owner:GUANGZHOU UNIVERSITY

Method for producing unsaturated polyester resin by utilizing refuse of biatomic acid such as terephthalic acid and catalyst used thereof

The invention discloses a method to use binary ester wastes like P-phthalic acid to prepare unsaturated polyester resin, substituting fully or partly industrial waste residue containing binary acid for the binary acid to produce the unsaturated resin. It adopts stannous oxide, stannous salt or other stannous compound as catalyzer, added in effective quantity of catalyst. It largely reduces production cost and helps protect environment; besides, the new-type catalyzer can accelerate reaction velocity, able to be applied to the production of similar unsaturated resin.

Owner:陈少岳 +3

Method for preparing babbitt alloy from residue containing silver of copper anode slime

InactiveCN102312097AEasy to separateLow costProcess efficiency improvementElectrolytic agentAntimony potassium tartrate

The invention relates to a method for preparing a babbitt alloy from residue containing silver of copper anode slime. The method comprises the following steps:1, adding sodium carbonate, powdered carbon and borax according to the mass of the residue containing silver, and uniformly mixing; 2, melting to obtain a crude alloy containing lead; 3, preparing an electrolyte from fluosilicic acid, lead fluorosilicate, stannous oxide and potassium antimonyl tartrate, and adding with gelatin and ethyl naphthol; 4, treating the crude alloy as an anode and a stainless steel plate as a cathode, and taking the cathode plate (the stainless steel plate) and peeling cathode products each 12h; and 5, adding lead, antimony and copper or tin, antimony and copper to the cathode products, and melting to obtain the lead-based or tin-based babbitt alloy. The method which has the advantages of short flow, low cost, and strong practicality and allows the lead-based or tin-based babbitt alloy to be prepared from the residue containing silver of the copper anode slime is especially suitable for anode slime processing in electrolyzing electronic wastes with regenerated copper, and has the characteristics of simple and feasible operation, and high recovery rate of valuable metals.

Owner:广东省资源综合利用研究所

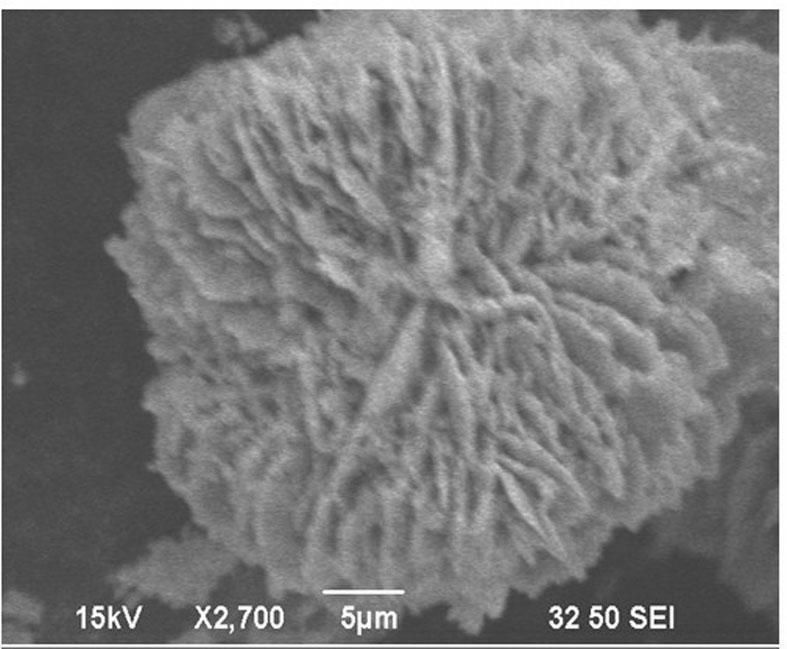

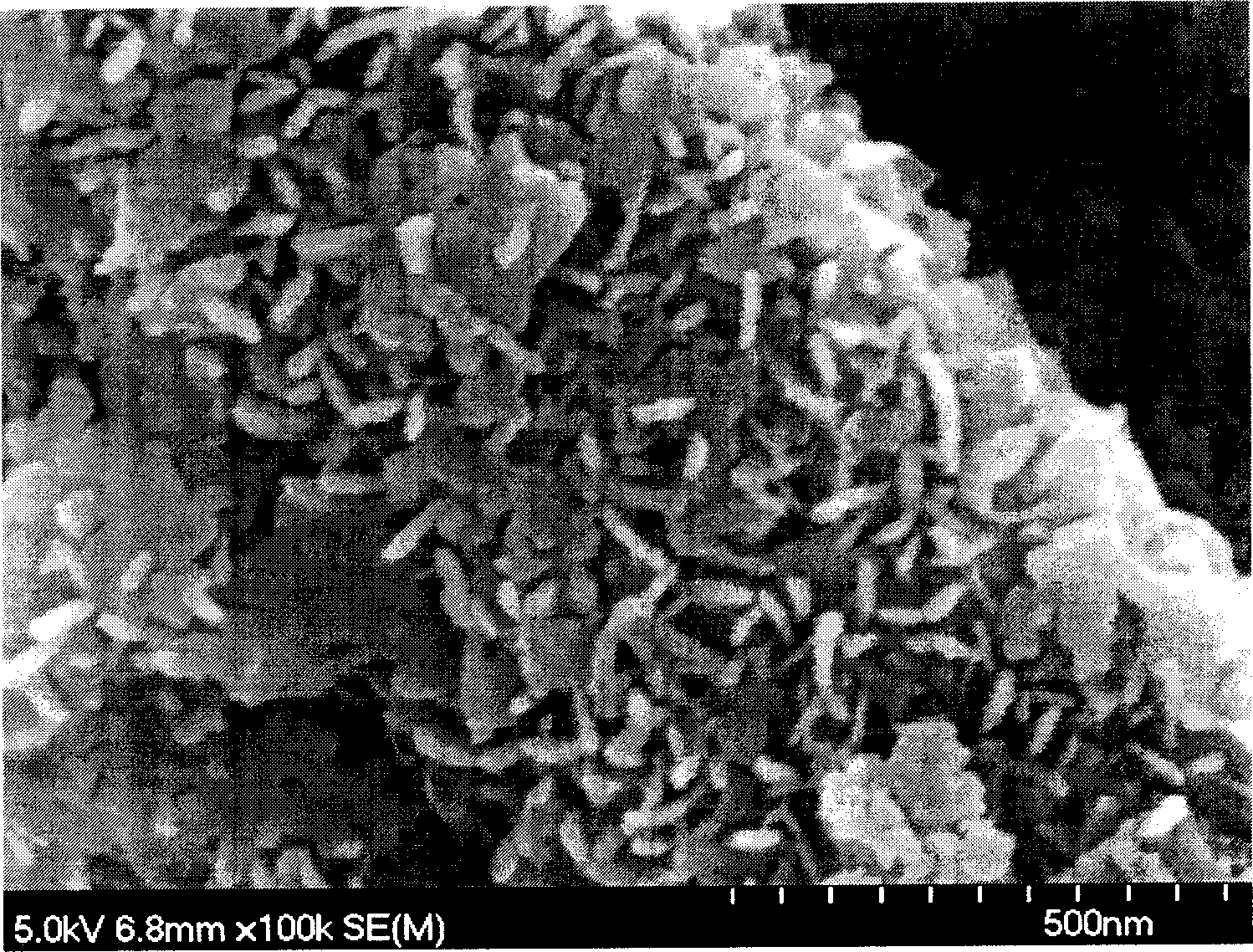

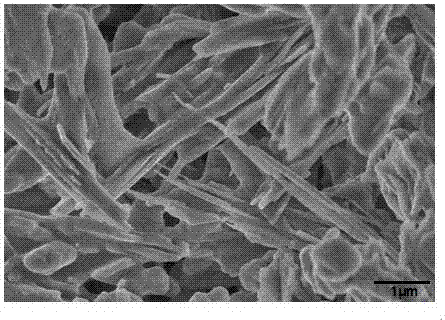

Method for preparing comby stannous oxide nanometer material

InactiveCN102659176AEasy to operateMild and easy to controlNanotechnologyTin oxidesChemical synthesisHydration reaction

The invention discloses a method for preparing a comby stannous oxide nanometer material. The method comprises the following steps of: putting stannous chloride dehydrate in a hexadecyl trimethyl ammonium bromide aqueous solution under the condition of stirring by adopting a hydro-thermal synthesis method to obtain a mixed solution; then, dropwise adding a sodium hydroxide aqueous solution to the mixed solution; stirring to obtain a final mixed solution, wherein in the final mixed solution, the molar concentration of the stannous chloride dehydrate is controlled to be between 0.10mol / L and 0.15mol / L, and the molar ratio of the stannous chloride dehydrate to hexadecyl trimethyl ammonium bromide to sodium hydroxide is 1:1:(2-4); putting the final mixed solution in a reaction kettle, wherein the degree of filling is 80-90 percent, and performing a hydrothermal reaction for 12-15h at the temperature of 120-160 DEG C; and performing centrifugation, washing and drying on the obtained product to prepare the comby stannous oxide nanometer material. The prepared comby stannous oxide nanometer material has an even porous structure and can be applied in the aspects of lithium ion battery anode materials, chemical synthesis catalysts and the like. The method disclosed by the invention has the characteristics that the operation is simple, the cost is low, the pollution is low and industrial large-scale production can be easily realized.

Owner:HENAN POLYTECHNIC UNIV

Tin dioxide based nano gas sensitive material and preparation method thereof

InactiveCN1769881AImprove adsorption capacityHigh sensitivityMaterial electrochemical variablesElemental selenium/telluriumTin dioxidePotassium borohydride

The invention relates to a stannic oxide (SnO2) base nano air-sensitive material and method for making the same which comprises steps of: calculating and getting stannous chloride as mole ratio, proportioning with sodium dodecylbenzene sulfonate, potassium borohydride, antimony oxide and ethyl silicate; grinding, drying, prefiring to get stannic oxide nano powder; according to the mole proportion, doping carbon nano tube with the produced stannic oxide nano powder. The inventive method has the advantages of being lower cost than doping noble metallic elements in the stannic oxide (SnO2) base nano air-sensitive material, and of having high sensitivity.

Owner:GUANGZHOU UNIVERSITY

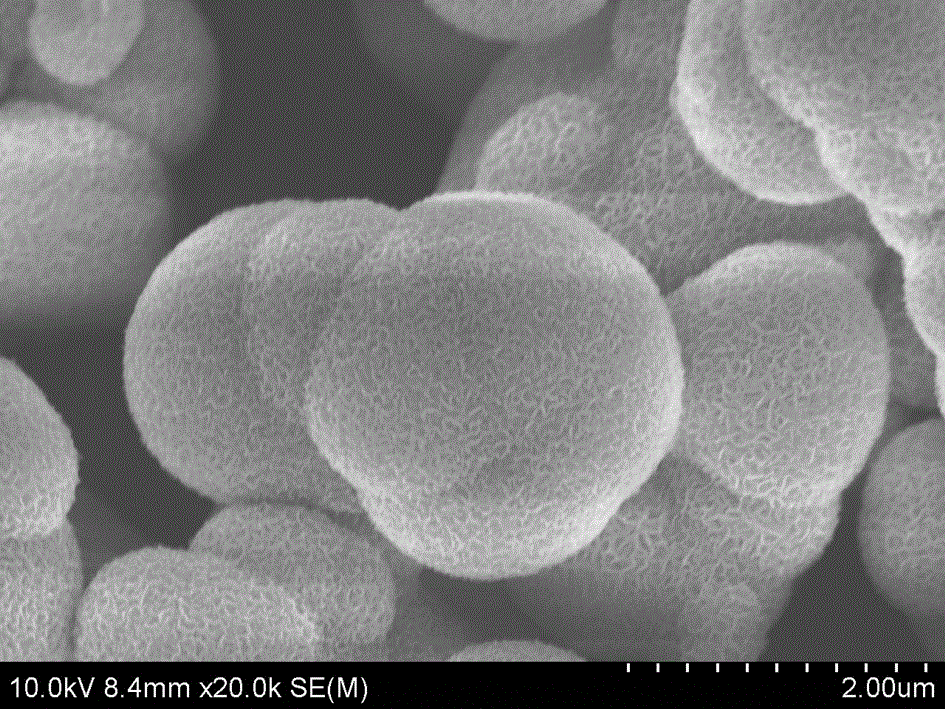

Method for preparing porous spherical stannous oxide nano material

InactiveCN102659177AReduce or avoid generatingHigh purityNanotechnologyTin oxidesHydration reactionSTANNOUS OXIDE

The invention relates to a method for preparing porous spherical stannous oxide nano material. The method comprises the steps of: slowly dripping a certain amount of prepared sodium hydroxide anhydrous ethanol solution into stannous chloride anhydrous ethanol solution, and stirring while dripping; after dripping, continuously stirring for 10-20min to obtain stannous oxide precursor liquid, wherein in the obtained stannous oxide precursor liquid, the molar concentration of dihydrated stannous chloride is controlled to be 0.125-0.25mol / L and the molar ratio between the dihydrated stannous chloride and sodium hydroxide is controlled to be 1: 2-1: 3.5; putting the prepared stannous oxide precursor liquid into a reaction kettle, wherein the filling degree is 80-90%; sealing the reaction kettle, and carrying out heat preservation on the reaction kettle in an electric constant temperature drying oven for 6-15h at the temperature of 130-170 DEG C; then naturally cooling the reaction kettle to room temperature; and carrying out centrifugation, washing and drying on the product to obtain gray black nano stannous oxide material. The method is simple in operation, mild in condition, easy in control of the condition, low in cost, less in pollution and easy for industrial production; and the prepared porous spherical stannous oxide nano material has the advantages of being even in morphology, high in component purity and the like.

Owner:HENAN POLYTECHNIC UNIV

Method for preparing ITO nanometer line and gas sensor thereof

The invention discloses a method to prepare ITO nanometer lines and a method to prepare ITO gas sensors. The method to prepare ITO nanometer lines is as follows: a layer of gold film deposits on an underlayer; powdered indium oxide, stannous oxide and plumbago are mixed pro rata, and are arranged in a boat; the underlayer is also arranged on the boat to be heated and thermally insulated together with the mixture. The air pressure inside a silica tube in a heater is kept to be about 300 Pa, and gaseous mixture containing little oxygen is admitted in the silica tube; after the heater is cooled to the room temperature, yellowish products are generated on the underlayer. The method to prepare the sensors is that the nanameter lines are dispersed in the solution for about two hours with ultrasonic wave, and are dried; the sizing agent formed is applied on the ceramic tubes of two electrodes, and needs covering on the electrodes; then the sizing agent is dried or sintered, and is connected with a leading wire. The method to prepare the ITO nanometer lines has the advantages of simplicity, controllability, low cost, and that the materials have excellent gas sensitivity. The method to prepare the gas sensor has the advantages of short response time, short recovery time, stable nature, low noise, and high sensitivity; and the method is applicable for large-scale industrial production.

Owner:HUNAN UNIV

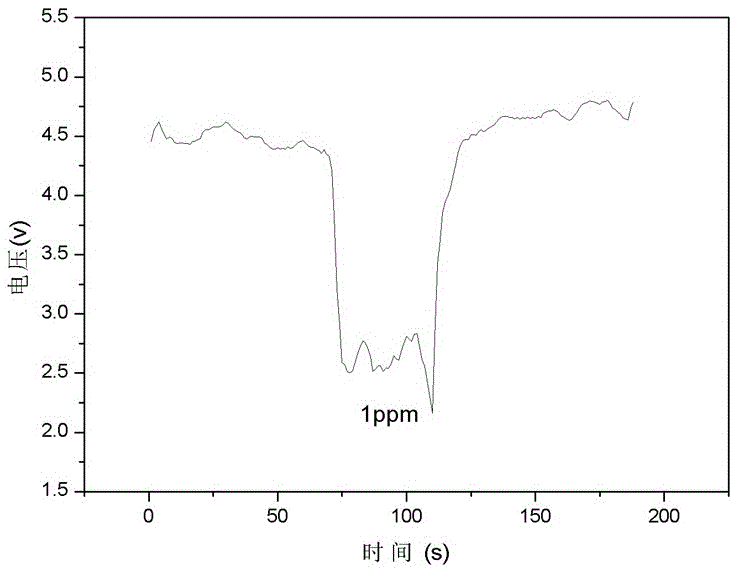

Stannic oxide-loaded porous nickel oxide gas sensor material as well as preparation and application thereof

The invention relates to a stannic oxide-loaded porous nickel oxide gas sensor material as well as preparation and application thereof. Alkali and an inorganic salt containing nickel are added into a hydrothermal reaction kettle to carry out a thermostatic reaction; porous nickel oxide ball particles are obtained from the an obtained product through cleaning, acidizing, washing and drying; the obtained porous nickel oxide ball particles are dispersed into an aqueous solution of water soluble stannate, n-butyl alcohol is added, and water in hydroxide is removed at the azeotropy point, so that the stannic oxide-loaded porous nickel oxide gas sensor material is obtained. The raw materials are cheap, well crystalized stannic hydroxide is evenly modified and loaded on nickel hydroxide at the normal temperature, dehydration is performed with the azeotropy technique, the structure and the morphology of the material can be stably controlled, and the limit of detection of gas is 1ppm or lower. Besides the field of gas sensors, the stannic oxide-loaded porous nickel oxide gas sensor material can also be applied to the fields of solar cells, photocatalysts and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method for the preparation of high purity stannous oxide

Provided herein are methods for the preparation of high purity stannous oxide comprising: (a) reacting a Sn salt with a C2-12 dicarboxylic acid in the aqueous phase to form a suspension comprising a Sn-dicarboxylate complex; (b) washing the Sn-dicarboxylate complex with water to obtain a wash solution comprising a washed Sn-dicarboxylate complex essentially free of the anion of the Sn salt; and (c) reacting the washed Sn-dicarboxylate complex with a base to form high purity SnO, wherein the high purity SnO has an alpha radiation count of less than about 0.002 cph / cm2.

Owner:HONEYWELL INT INC

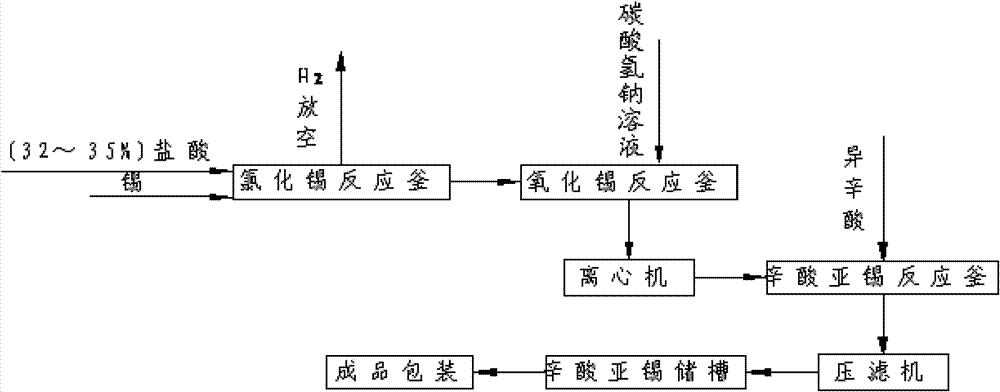

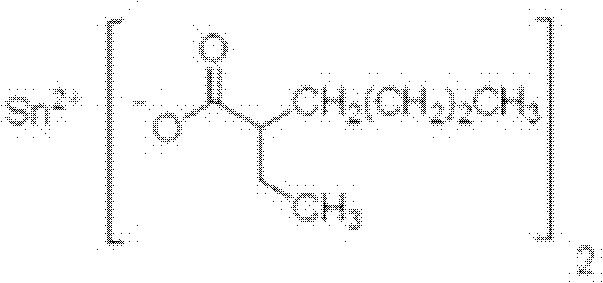

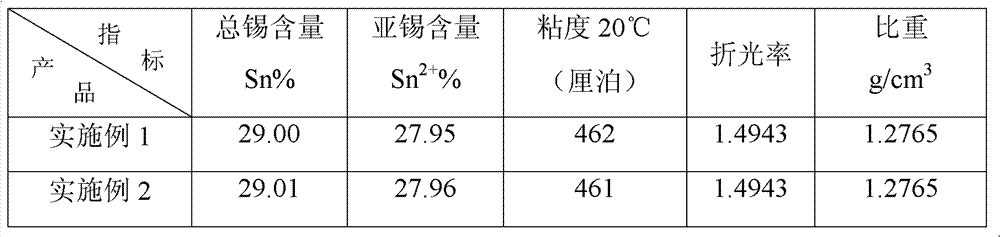

Preparation process of stannous octanoate

InactiveCN102775293ASimple processLower reaction conditionsCarboxylic acid salt preparationSTANNOUS OXIDEChemical industry

Belonging to the field of chemical industry, the invention particularly relates to a preparation process of stannous octanoate. The process consists of: putting stannous oxide and isooctanoic acid into a reaction kettle in proportion, actuating stirring and a vacuum pump, carrying out a dehydration reaction at a temperature of 115-130DEG C until no fraction generation, further conducting the reaction for 2-3 hours, then performing cooling and filtering so as to obtain a stannous octanoate end product. The process provided in the invention simply and directly adopts stannous oxide and isooctanoic acid as raw materials for preparation. The used stannous oxide can be obtained through self-preparation and can also be purchased on the market. By using the new process, the prepared product not only has good quality and high purity, but also has low energy consumption and stable quality. Meanwhile, in the whole production process, less waste gas and waste water are generated compared with other preparation methods.

Owner:JIANGSU DAMING TECH

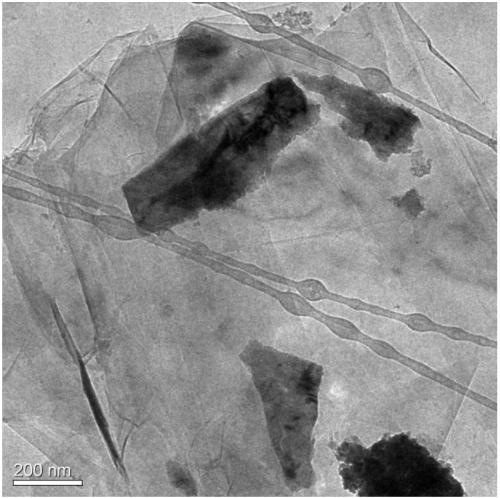

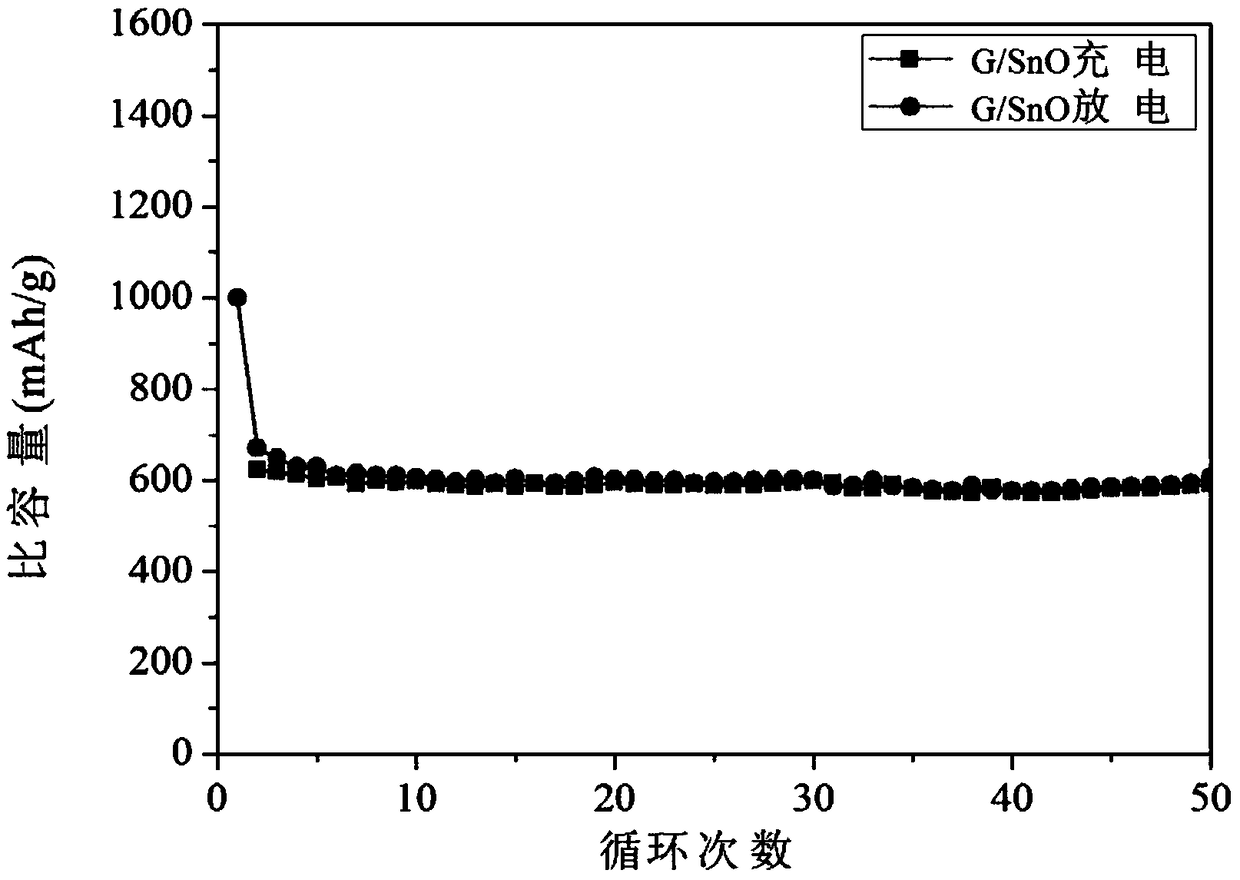

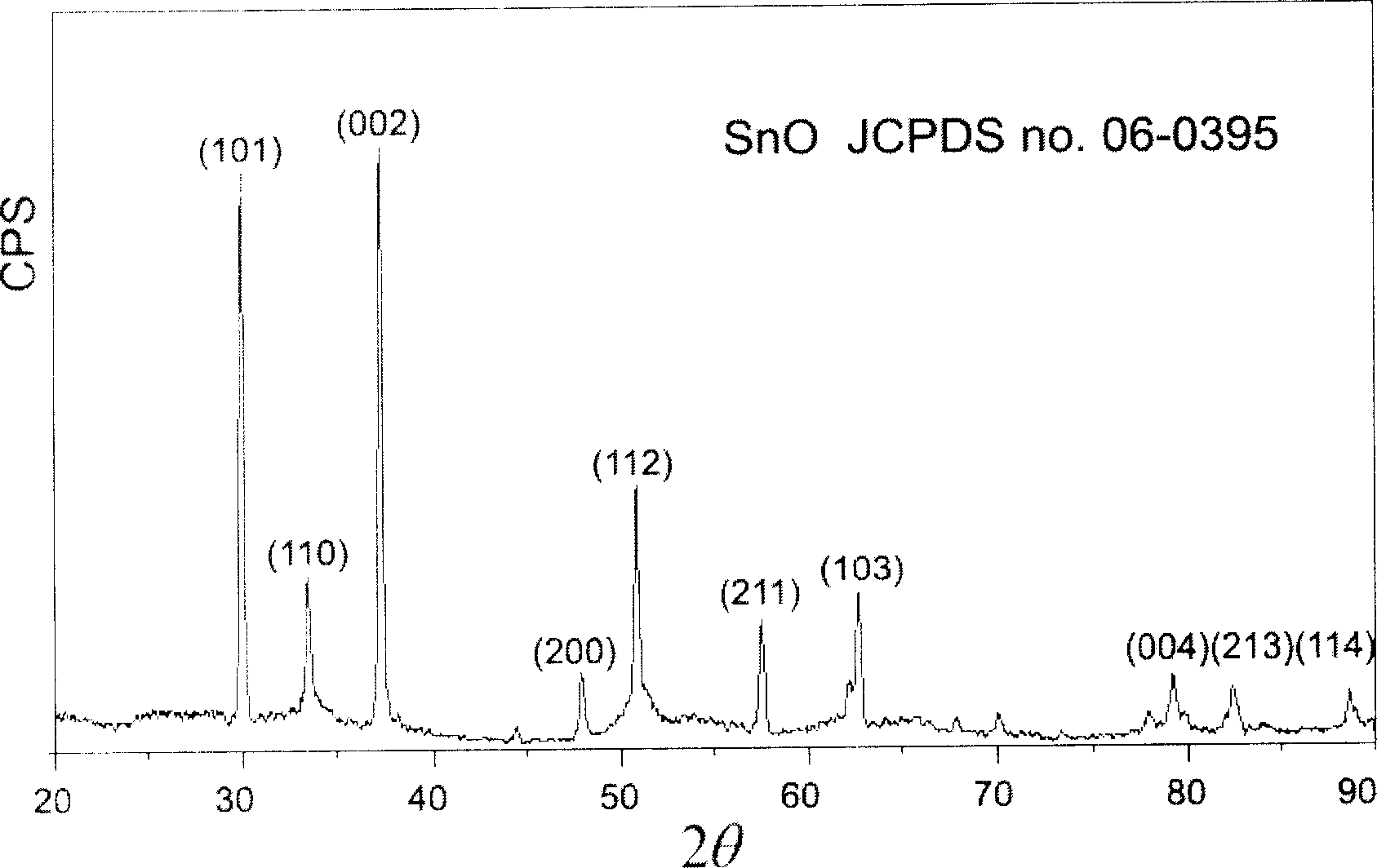

Graphene/stannous oxide two-dimensional heterojunction composite material and preparation method thereof

ActiveCN109273694AEasy to operateEnable mass manufacturingCell electrodesGrapheneHeterojunctionElectron Transport Pathway

The invention discloses a graphene / stannous oxide two-dimensional heterojunction composite material, a preparation method and a use thereof, belonging to the technical field of lithium ion battery materials, wherein the composite material is composed of graphene nanosheets and stannous oxide nanosheets through layer-by-layer assembly and composite; 20 to 95 percent of graphene nano sheet and 80 to5 percent of stannous oxide nano sheet in that composite material. The invention aims at peeling off graphene and SnO nanosheets from cheap and easily available graphite and stannous oxide minerals,constructing two-dimensional synergistic action between graphene and stannous oxide nanosheets, and preparing graphene / SnO two-dimensional nanoheterojunction composite material; A novel cathode material for lithium ion batteries with high capacity and long lifetime was obtained by enhancing the electron transport pathway in the electrode reaction and buffering the volume expansion of the materialduring the charge-discharge process of lithium ion batteries.

Owner:深圳市普利司德高分子材料有限公司

Method for synthesis of polylactide polyol by lactide and polyol

InactiveCN103396535ALow viscosity average molecular weightHigh viscosity average molecular weightTin dioxidePropanoic acid

The invention relates to a method for obtaining polylactide polyol by a way of ring-opening polymerization of lactide with lactide and a polyol as direct raw materials. The method includes the following steps: A, lactide purification: a crude product lactide is purified, and lactide with the content of more than 99.5% and the optical purity of more than 99% is obtained; B, synthesis of polylactide polyol: the purified lactide and the polyol are added into a reaction kettle, then a catalyst is added according to a lactide weight ratio of 0.5 / 1000-1 / 1000 into the reaction kettle for polymerization, and polylactide polyol with the viscosity average molecular weight of 100-5000 is obtained, wherein the catalyst is a composite catalyst comprising one or more of zinc lactate, zinc oxide, zinc powder, diethyl zinc, tin lactate, tin oxide, tin dioxide, stannous oxide, stannous lactate, stannous octoate, stannous chloride, tin powder, propionic acid or tetrabutyl titanate. The method has simple process and easy operation, is suitable for industrialized production applications, and has no 'three wastes' emissions.

Owner:SHENZHEN ESUN IND

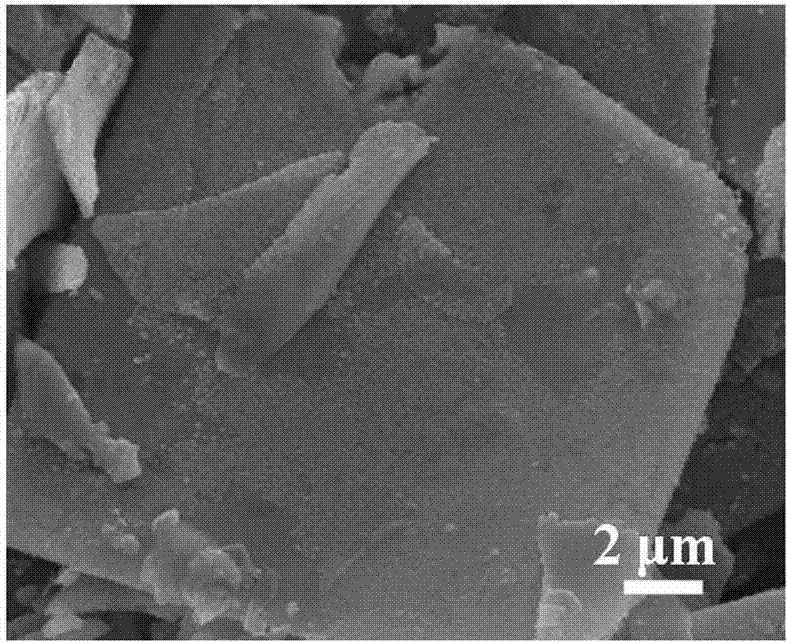

Hydrothermal synthesis method for producing Nano sheet material of stannous oxide

This invention discloses a hydrothermal method for synthesizing stannous oxide nanomaterial. The method comprises: (1) dissolving stannous chloride in citric acid or polyethylene glycol, controlling the mol concentration of stannous chloride, and stirring; (2) adding 4-10 mol times of hydrazine hydrate, and continuing stirring; (3) filling 80-90% of a pressure kettle with the solution, and treating at 120-150 deg.C for 10-24 h; (4) centrifuging the treated solution, and drying to obtain stannous oxide sheets. Hydrazine hydrate is adopted, by replacing sodium hydroxide or ammonia solution, as an alkali mineralizing agent. Meanwhile, the metastable stannous oxide product cannot be oxidized due to the reducibility of hydrazine hydrate.

Owner:ZHEJIANG SCI-TECH UNIV

Synthetic method of trimethylolpropane tricaprylate

ActiveCN101445453AHigh selectivityAdvanced and reasonable technologyPreparation by caroxylic acid/anhydride-hydrocarbon reactionMetal/metal-oxides/metal-hydroxide catalystsSTANNOUS OXIDEFiltration

The invention relates to a synthetic method of trimethylolpropane tricaprylate, which belongs to the technical field of esters compound synthesizing in organic chemistry. Taking trimethylolpropane and isocaprylic acid as material, an esterification reaction is preformed in nitrogen gas under the action of metallic oxide catalyst, the trimethylolpropane tricaprylate is obtained after depickle and filtration; the mass ratio of the trimethylolpropane and the isocaprylic acid is 1:3.15-3.95; the metallic oxide catalyst is stannous oxide or ferric oxide or magnesia, and the like, and the adding amount of the catalyst accounts for 0.03 to 0.10 percent by weight of the total weight of the trimethylolpropane and the isocaprylic acid. The invention reasonably selects metal oxide as the catalyst, and the metal oxide does not erode equipment, can be removed by filtration after the reaction is finished and can be recovered for recycle use; and the invention has advanced and reasonable process and less equipment investment through reasonable regulation of the adding amount of the trimethylolpropane and the isocaprylic acid and the proportion of the metal oxide catalyst and the optimal selection of reaction temperature and reaction time.

Owner:ZHEJIANG HUANGMA TECH

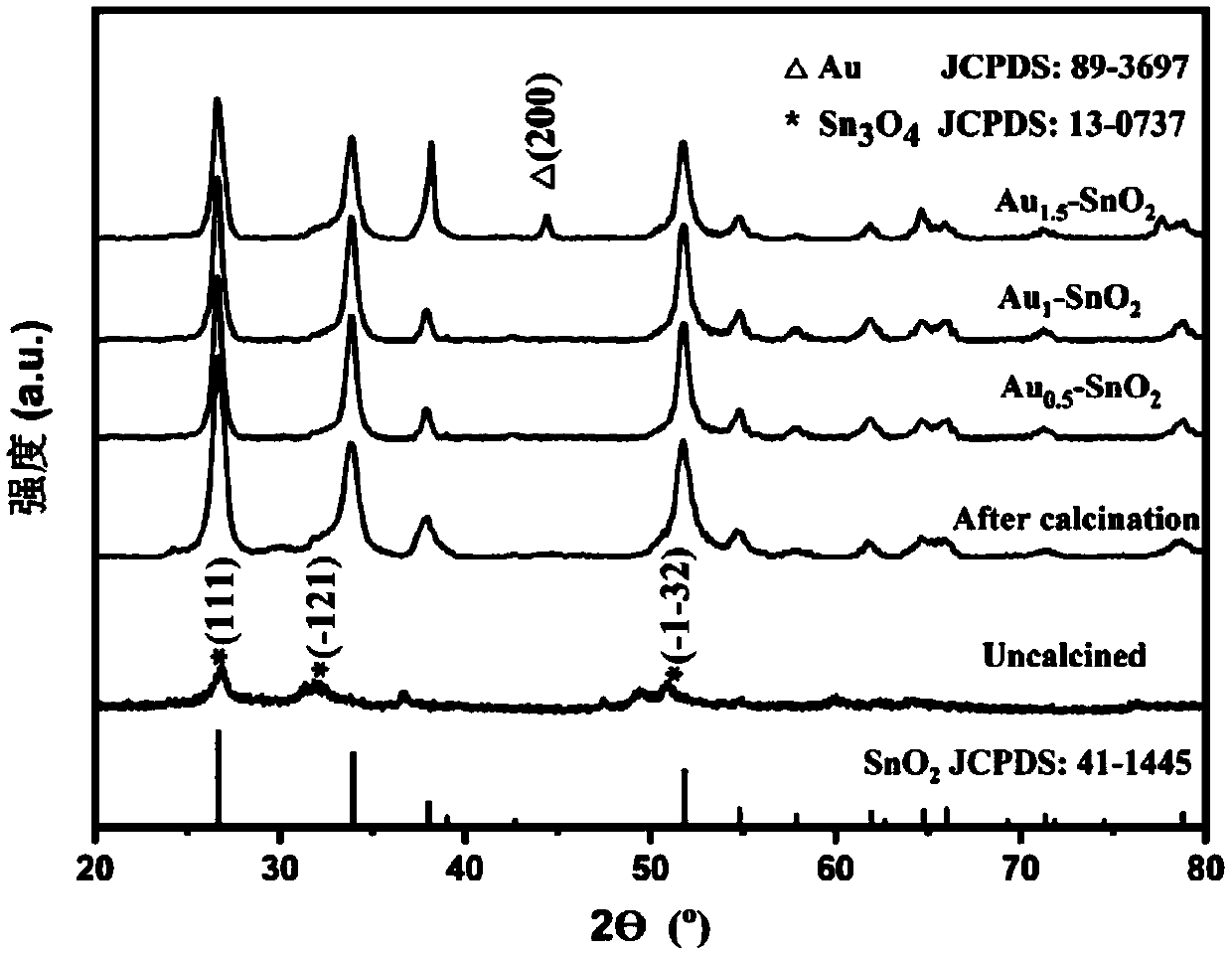

Self-reduction preparation method of gold nanoparticle loaded tin dioxide nanoflower gas-sensing material

ActiveCN109682865AHigh catalytic activityImprove adsorption capacityOther chemical processesNanotechnologyTin dioxideGold particles

The invention discloses a self-reduction preparation method of gold nanoparticle loaded tin dioxide nanoflower gas-sensing material. The method comprises the steps that a citrate sodium aqueous alkaline solution is mixed with a stannous chloride ethanol solution and placed in a reaction kettle to be heated to reach 180 DEG C, reaction is conducted for 12 hours, and floral stannic oxide powder is obtained after a product is washed and dried. The powder is dispersed in deionized water, a chloroauric acid solution is added, the reduction of the stannous oxide is used for reducing the chloroauricacid solution into gold nanoparticles, and the product is washed and dried after being stirred. Finally the gold nanoparticle loaded tin dioxide nanoflower gas-sensing material is obtained after calcination processing is conducted. The method has the advantages that the method is simple, the reaction conditions are mild, the method can be industrialized, prepared tin dioxide nanoflowers have the advantages of uniform size and large specific surface area, the experimental steps are simplified and the cost is reduced compared with a traditional method, the loaded gold nanoparticles have the advantages that the size is uniform, the distribution is uniform and nanoparticles do not aggregate, and more excellent gas-sensing performance on ethanol is shown by the gold particle loaded tin oxide nanoflowers.

Owner:BEIJING UNIV OF TECH

Method for synthesizing trimethylolpropane fatty acid ester

InactiveCN101229998AHigh selectivitySimple production processOrganic compound preparationCarboxylic acid esters preparationNitrogen gasHydrolysis

The invention relates to a method for synthesizing trimethylolpropane fatty acid ester, belonging to a technical field of synthesizing ester compounds in organic chemistry. Taking the trimethylolpropane and fatty acid are taken as the material, the invention is characterized in that: under the effect of solid catalyst and nitrogen atmosphere, dehydration-condensation reaction is caused and the obtained substances are filtered to prepare the trimethylolpropane fatty acid ester; the solid catalyst refers to stannous oxide or mixed oxide of Al2O3-SiO2, ferric chloride and so on and the adding amount of the solid catalyst is 0.02 to 0.11 percent of total weight percentage of the trimethylolpropane and the fatty acid; the weight ratio of the trimethylolpropane and the fatty acid is 1:2.85 to 3.05. In the invention, the novel solid catalyst is reasonably selected and the catalyst has high selectivity and by-products are hardly produced; the novel solid catalyst does not decay devices and the invention has the advantages of simple production processes, feasible recirculation and reutilization, stable product quality as well as favorable stability of hydrolysis, favorable biological degradation and low volatility.

Owner:浙江皇马控股集团有限公司

Caron-coated stannous oxide compound and preparation method and application thereof

InactiveCN107359329AImprove cycle performancePromote circulationCell electrodesSecondary cellsCyclic processSodium-ion battery

The invention discloses a carbon-coated stannous oxide compound. The carbon-coated stannous oxide compound is prepared by the steps of dissolving trihydroxymethyl aminomethane into water, stirring and preparing into a buffer solution; weighing the buffer solution, adding stannous oxide, stirring to form a black turbid solution; adding dopamine and continuously stirring; performing washing, centrifuging and drying; and performing calcining in nitrogen atmosphere to obtain the carbon-coated stannous oxide composite material. Dopamine is used as the carbon source for coating the surface of SnO, so that volume expansion of SnO in a circulation process is relieved, thereby improving the cycling performance in the application when SnO is used as a negative electrode material of a sodium ion battery; in the synthesis process, the solvent is non-toxic and harmless, the cost is relatively low and the operation is simple; the carbon-coated stannous oxide composite material has the most major advantage of excellent cycling performance; the initial-circle charging specific capacity can be close to 500mAh / g and the capacity is barely attenuated after 300 cycles, so that possibility is provided for the actual application of the composite material in the sodium ion battery material in the future.

Owner:NORTHEAST NORMAL UNIVERSITY

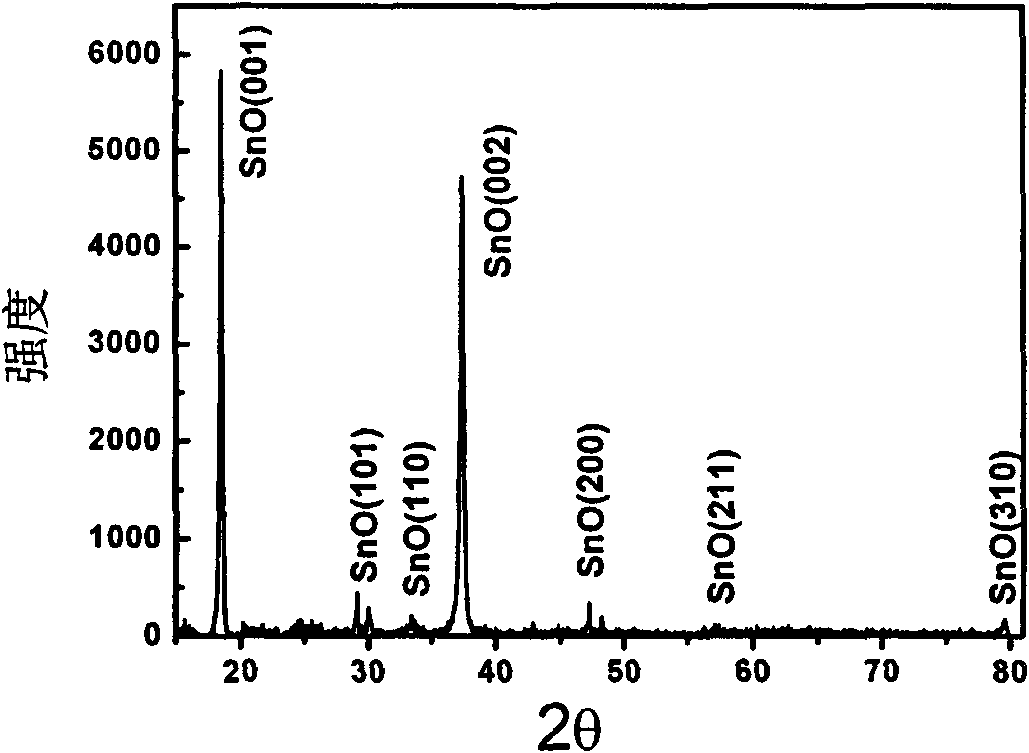

Preparation method of stannous oxide polycrystalline film

InactiveCN102021519ASimple preparation processReduce manufacturing difficultyVacuum evaporation coatingSemiconductor/solid-state device manufacturingSTANNOUS OXIDEEvaporation

The invention relates to a preparation method of polycrystalline stannous oxide film. The invention utilizes stannic oxide (SnO2) as the evaporation material and electron beam evaporation equipment. The preparation method comprises the following steps: preparing SnOx (x is bigger than 1 and smaller than 2) amorphous film at a low temperature firstly, conducting vacuum annealing treatment at high temperatures, therefore obtaining stannous oxide (SnO) polycrystalline film. The invention is advantageous in that: the preparation method is simple and controllable, in addition a large-area uniform film can be formed on a substrate such as quartz glass, and the film-forming repeatability is good. Stannous oxide is p-type electric conductive oxide and can be used to prepare oxide-based photoelectron and electron device.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

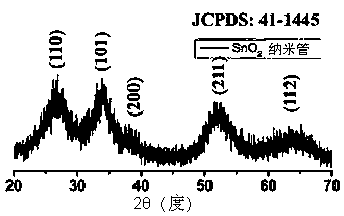

Stannic oxide nanotubes with high electrical properties and preparation method therefor

ActiveCN105481004AEasy to prepareSimple manufacturing methodMaterial nanotechnologyTin oxidesTin dioxideSTANNOUS OXIDE

The invention relates to stannic oxide nanotubes with high electrical properties and a preparation method therefor. The method comprises the steps: (1) preparing a first mixed solution containing silicon dioxide nanotubes and / or titanium dioxide nanotubes, an alcoholic solution, a tin salt and urea; (2) subjecting the first mixed solution to a reaction in a hydrothermal reactor; (3) carrying out centrifugal separation on the reacted first mixed solution, so as to obtain a first sediment; (4) calcining the first sediment; (5) putting the calcined first sediment in a strongly alkaline solution, so as to obtain a second mixed solution; and (6) carrying out centrifugal separation on the second mixed solution so as to obtain a second sediment, washing the second sediment, and carrying out drying, thereby obtaining the stannic oxide nanotubes with high electrical properties.

Owner:江苏先进无机材料研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com